Method for welding Q500qE ultralow-carbon bainite steel for bridge

A carbon bainitic steel, welding method technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problem of no technical solution, achieve promotion of upgrading, strong practicability, full objectivity and rationality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

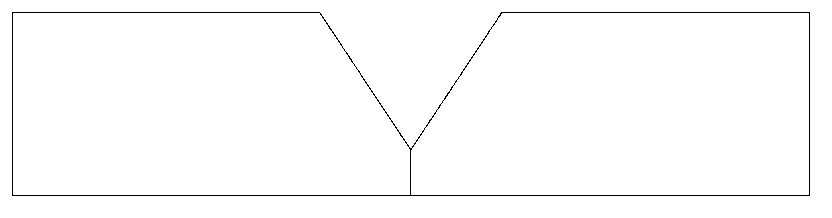

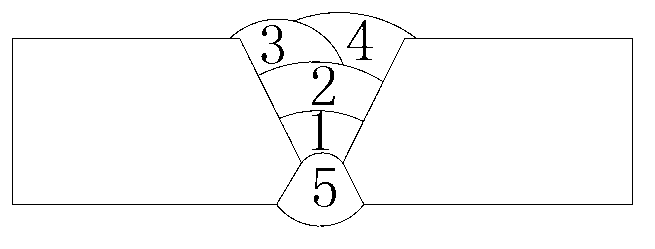

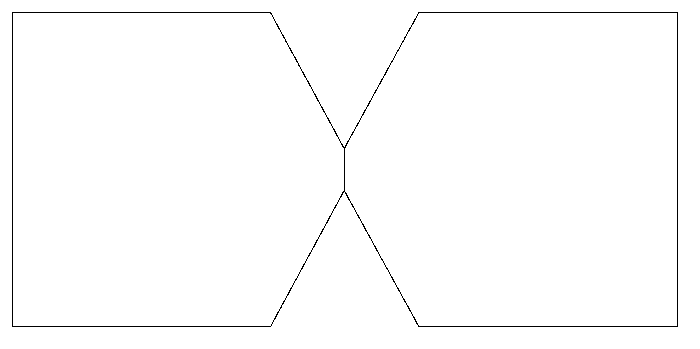

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0075] The chemical composition of the Q500qE ultra-low carbon bainitic steel for bridges involved in the present invention is listed in Table 1, and the mechanical properties are listed in Table 2.

[0076] Table 1: Chemical Composition of Steel (wt%)

[0077]

[0078] Table 2: Mechanical properties of steel

[0079]

[0080] According to the different plate thicknesses B of Q500qE ultra-low carbon bainitic steel for bridges, the present invention determines the preheating temperature before welding as follows: when the plate thickness B≤32mm, no preheating is required before welding; when the plate thickness B>32~44mm , the preheating temperature before welding is 80 °C; when the thickness of the plate B> 44 ~ 60mm, it needs to be preheated at 100 °C.

[0081] The invention aims at the welding heat input of Q500qE ultra-low ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com