A welding method of a tin ball welding device

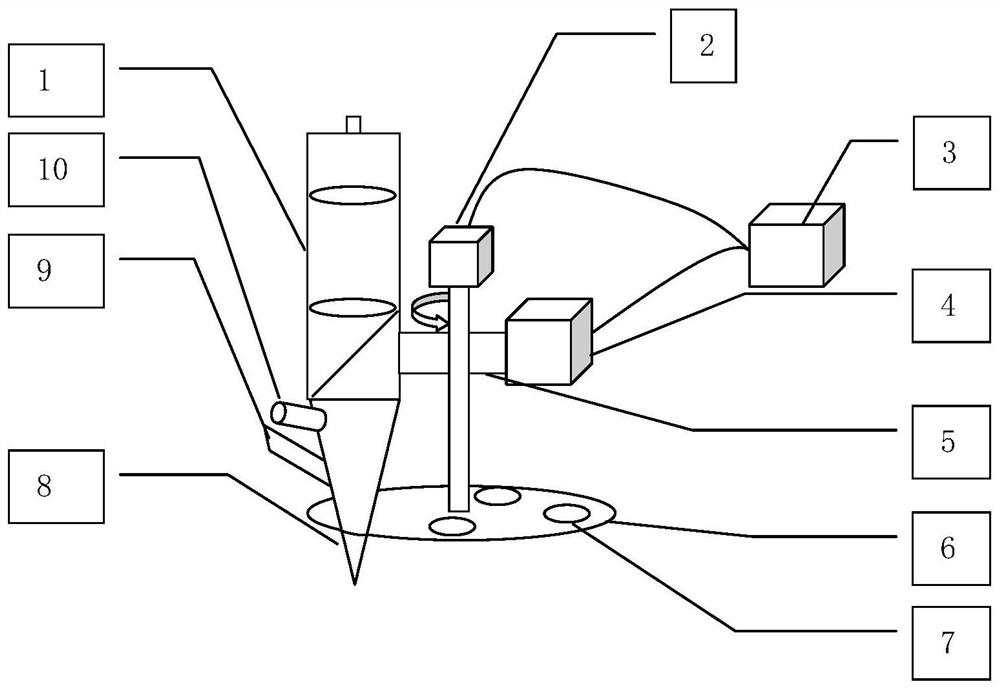

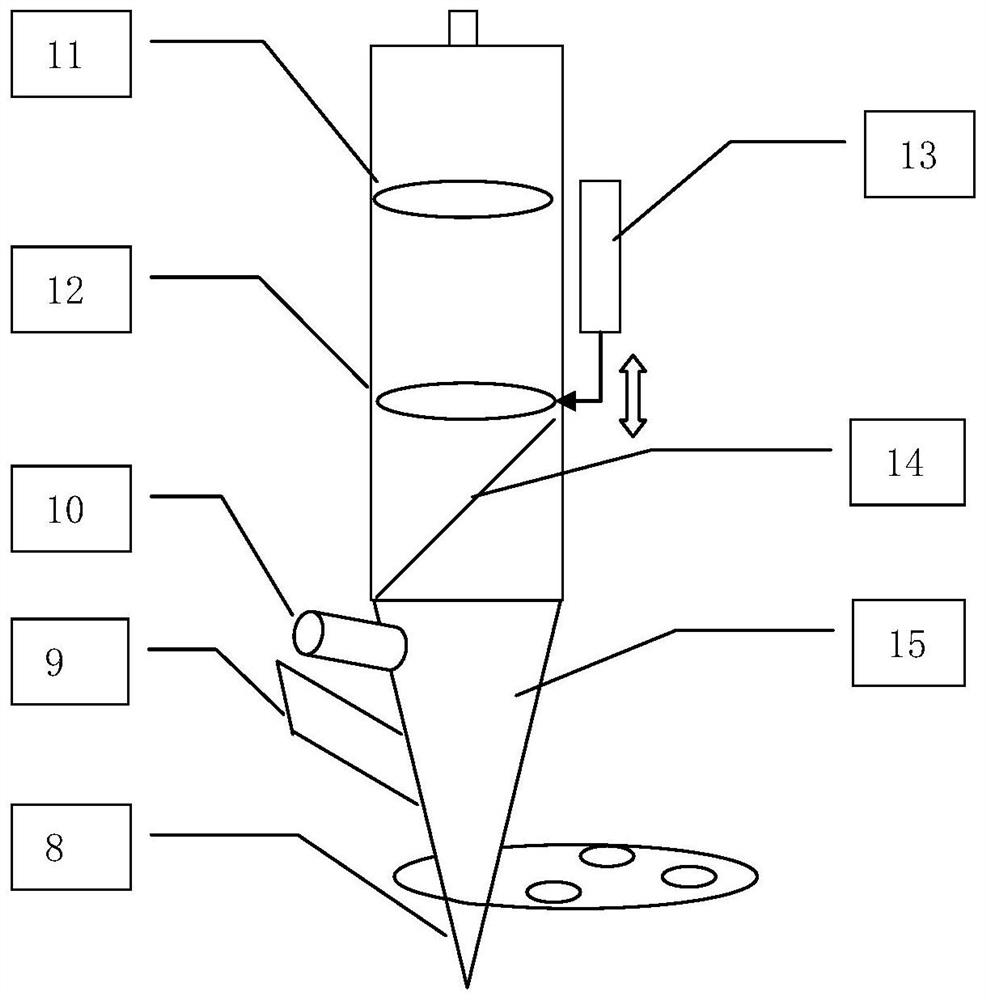

A technology of welding device and welding method, which is applied in the welding of solder ball welding device and the laser welding field of laser welding device, which can solve the problems of inability to select nozzles, lack of coaxial vision, and inability to continuously replenish solder balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] refer to Figure 4 , is a flow chart of the solder ball soldering process for solder pads with a pad size less than or equal to 3.04mm. When soldering such pads, it is necessary to ensure that the solder balls are accurately melted at the specified position. The solder ball welding method based on this device includes four stages: visual positioning, laser preheating, solder ball implantation, and solder joint formation. specific:

[0066] ⑴Visual positioning stage, image channel, detect the position of the product to be welded and perform correction.

[0067] ⑵In the laser preheating stage, the laser channel blows protective gas into the transition chamber, and the light is directly irradiated on the pad and kept, so that the pad is fully preheated.

[0068] (3) In the solder ball implantation stage, the laser channel implants single or multiple solder balls, and the solder balls melt quickly and drop on the pad.

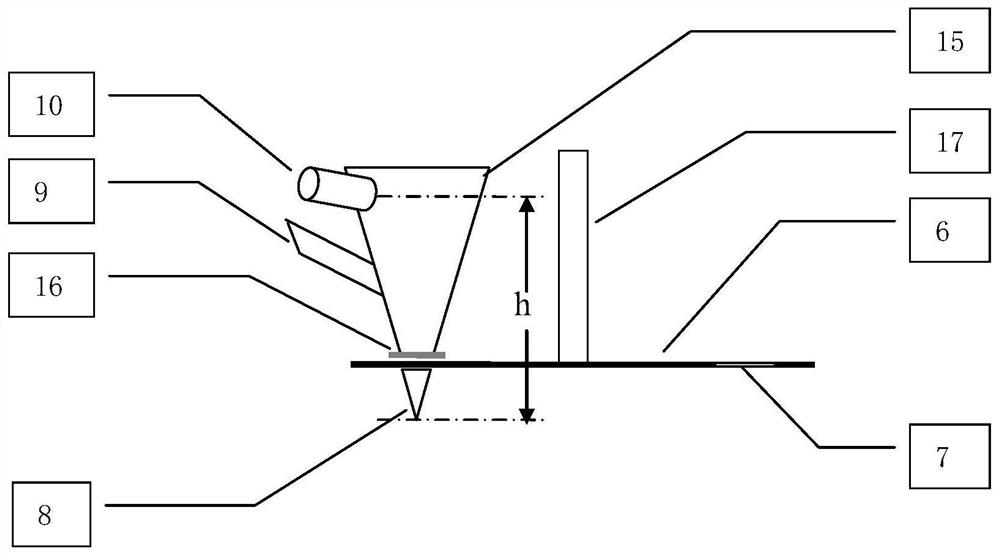

[0069] ⑷In the solder joint forming stage, the lase...

Embodiment 2

[0071] refer to Figure 5, is a flow chart of the solder ball welding process for pads larger than 3.04mm in size. When soldering this pad, it is only necessary to ensure that the solder balls melt within a certain area. The process includes: visual positioning, laser preheating, solder ball planting There are four stages of entry and solder joint formation.

[0072] ⑴Visual positioning stage, image channel, detect the position of the product to be welded and perform correction.

[0073] ⑵In the laser preheating stage, the laser channel blows protective gas into the transition chamber, and the light is directly irradiated on the pad and kept, so that the pad is fully preheated.

[0074] (3) In the solder ball implantation stage, the laser channel implants single or multiple solder balls, and the solder balls melt quickly and drop on the pad.

[0075] ⑷ Solder joint forming stage, image channel, adjust the focusing mirror, increase the pad spot and keep the laser irradiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com