Patents

Literature

189results about How to "Short welding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for brazing copper aluminum tubes without aid of brazing flux

InactiveCN102581414AReduce porosityImprove air tightnessSoldering apparatusWelding/soldering/cutting articlesSlag (welding)Weld seam

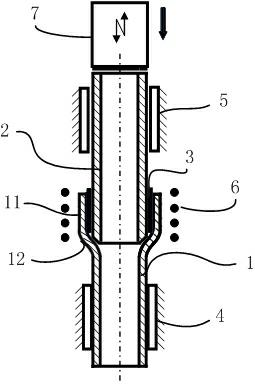

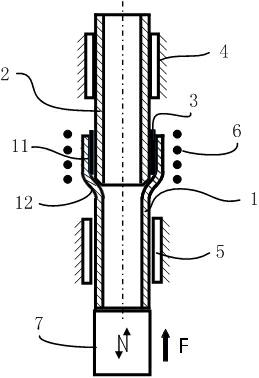

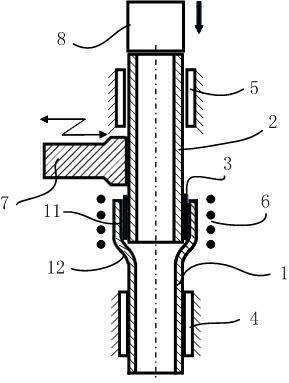

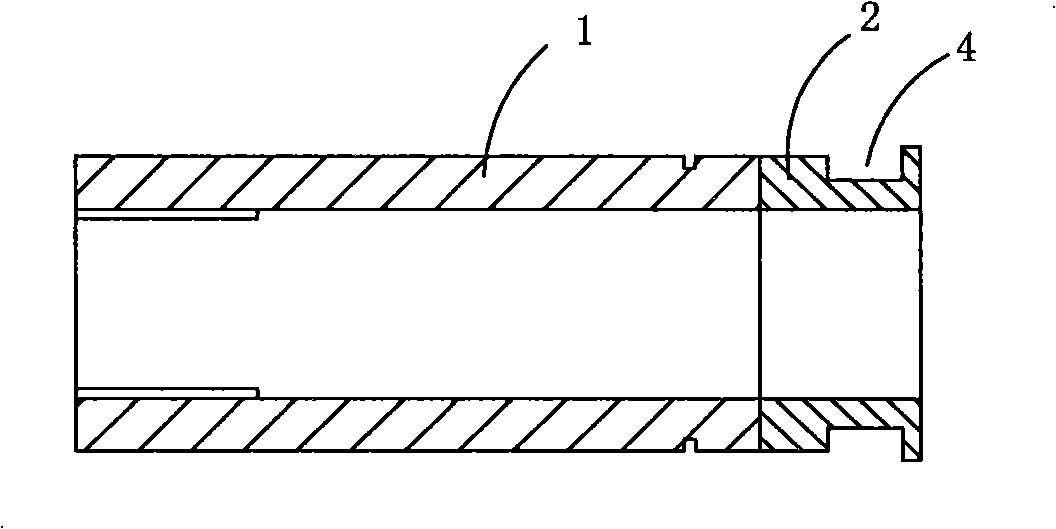

The invention discloses a method for brazing copper aluminum tubes without the aid of brazing flux. The method includes the steps: firstly, expanding one end of optional one of the copper aluminum tubes into a socket by a thermal expansion method, manufacturing a brazing alloy plate into a brazing thin tube by a stamping method, and placing the brazing thin tube into the socket; secondly, inserting one end of another welded tube into the brazing thin tube, and tightly abutting the end opening of the welded tube to the bottom of the socket to form close fit; and thirdly, assembling the brazing thin tube and the welded tube on a welding fixture, performing local induction heating for joints, and applying proper welding pressure and ultrasonic vibration. The method can be used for brazing the thin-wall copper aluminum tubes without the brazing flux, fusion lines are long, welding seams are compact, slag inclusion is avoided, the air tightness and the bonding strength of the joints are greatly improved, reliability is high, welding time is short, and great production and use values are achieved.

Owner:李明雨 +1

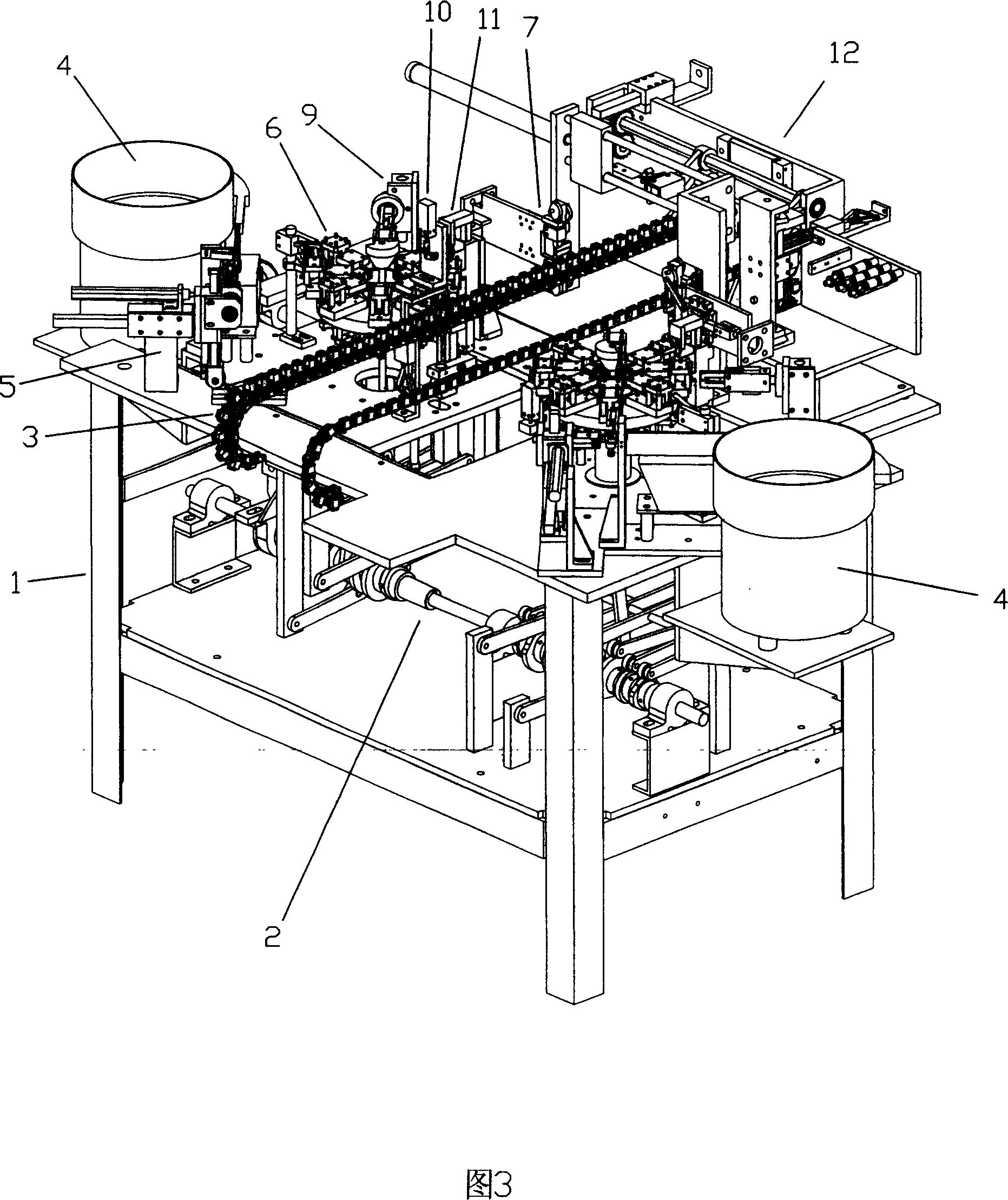

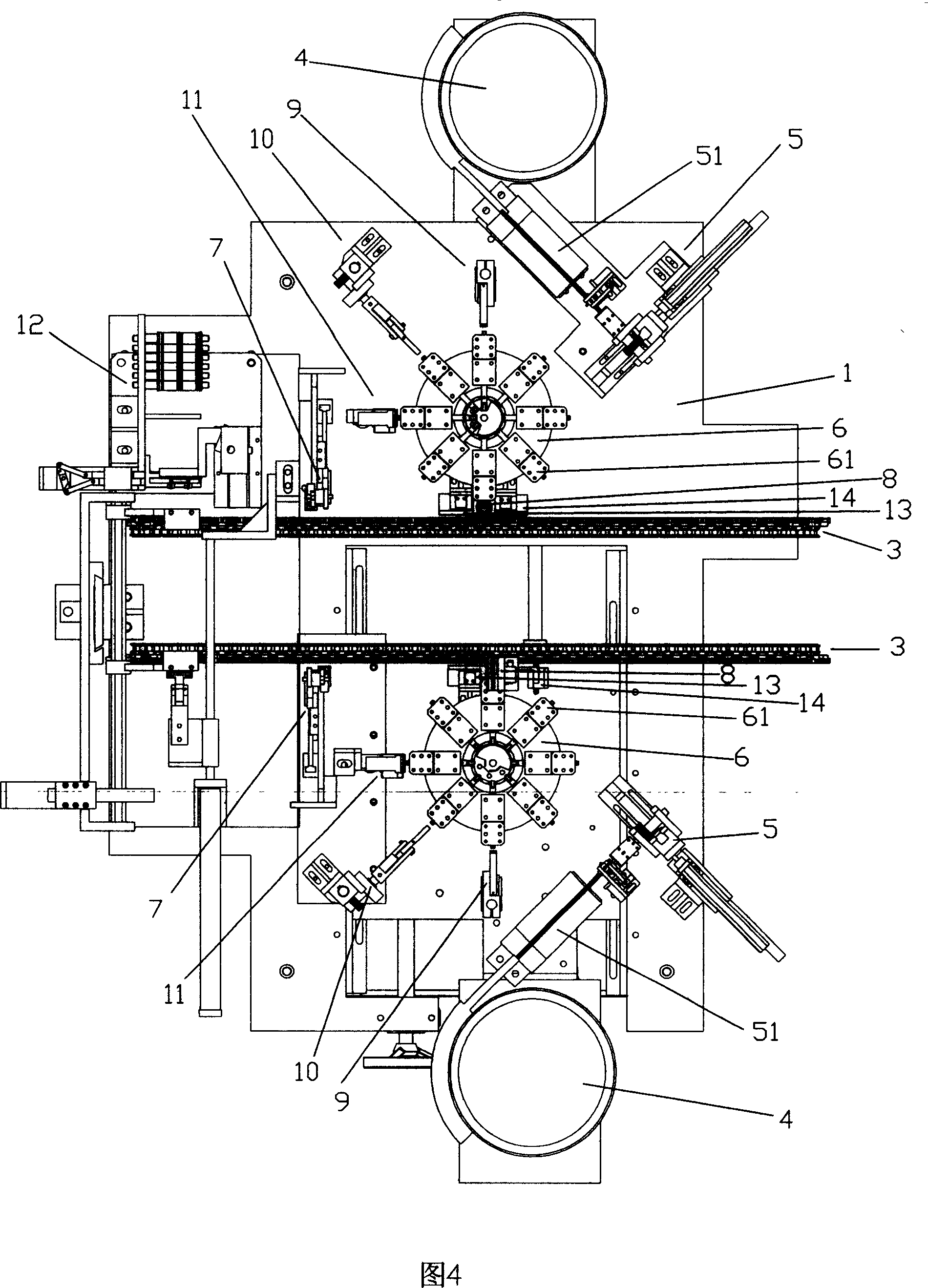

LED lamp pin welding method and equipment

InactiveCN101021298AIncrease productivityShort welding timeLine/current collector detailsPoint-like light sourceWire cuttingLED lamp

The present invention relates to a LED lamp pin welding equipment. It includes machine frame, transmission mechanism positioned under the machine frame, conveying chain positioned on the machine frame, vibration plate, LED-placing device, clamping device, stripping and wire-cutting device and welding device. It is characterized by that on the above-mentioned machine frame it has two vibration plates, two LED-placing devices, two clamping devices, two stripping and wire-cutting devices and two welding devices which are respectively positioned at two sides of conveying chain. Besides, said invention also provides the welding method matched with said LED lamp pin welding equipment.

Owner:HE SHAN NEO NEON LIGHTING DECORATION LTD

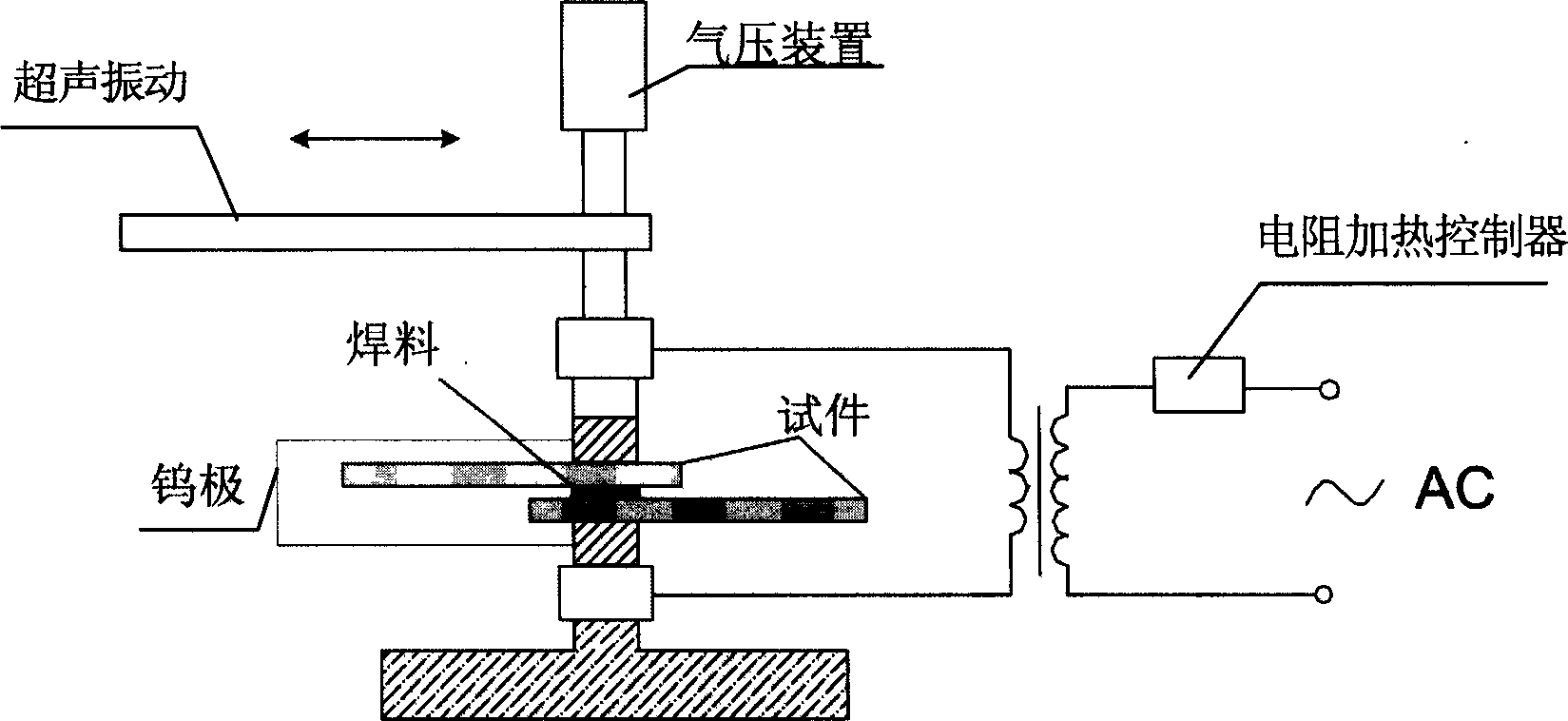

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

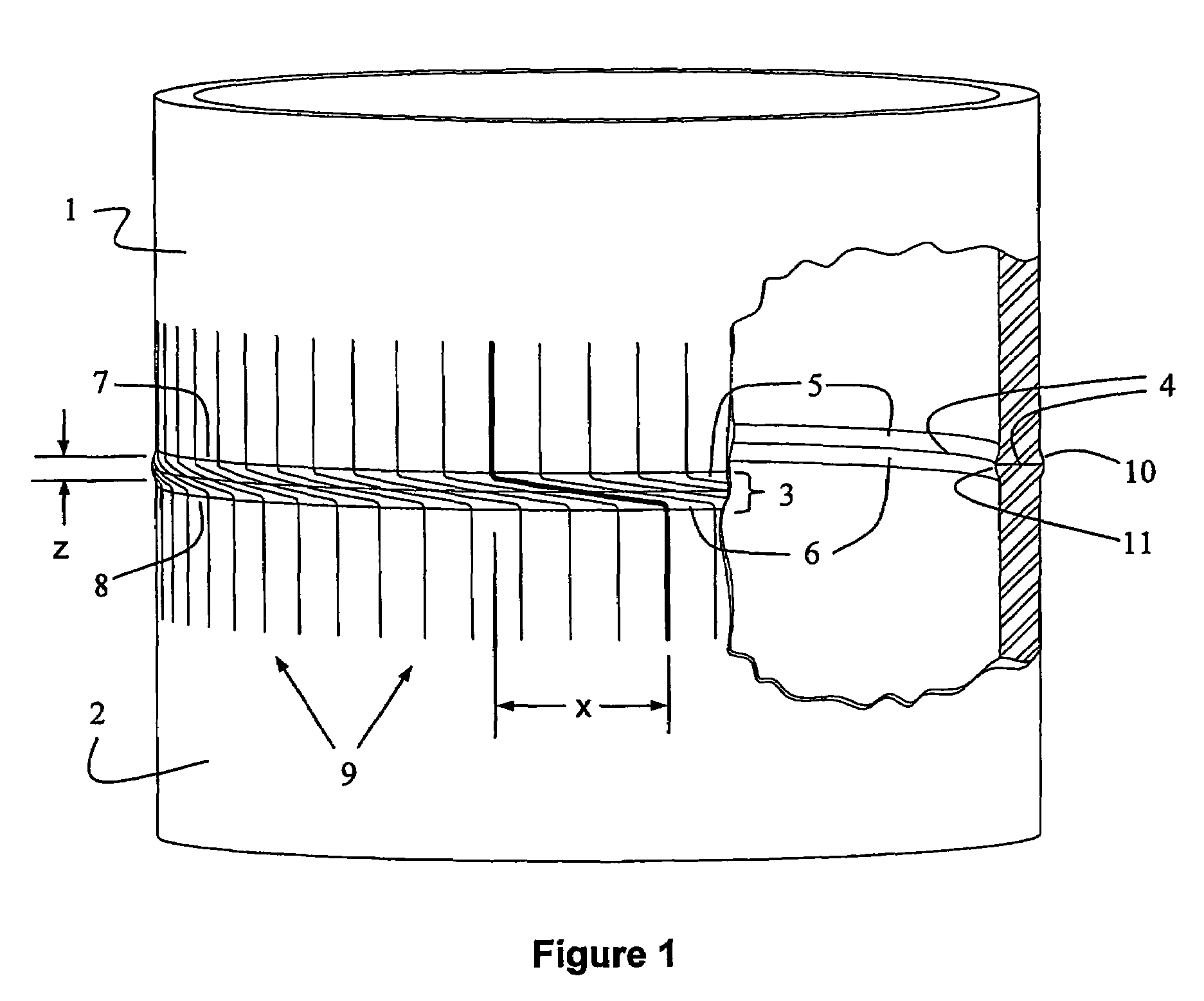

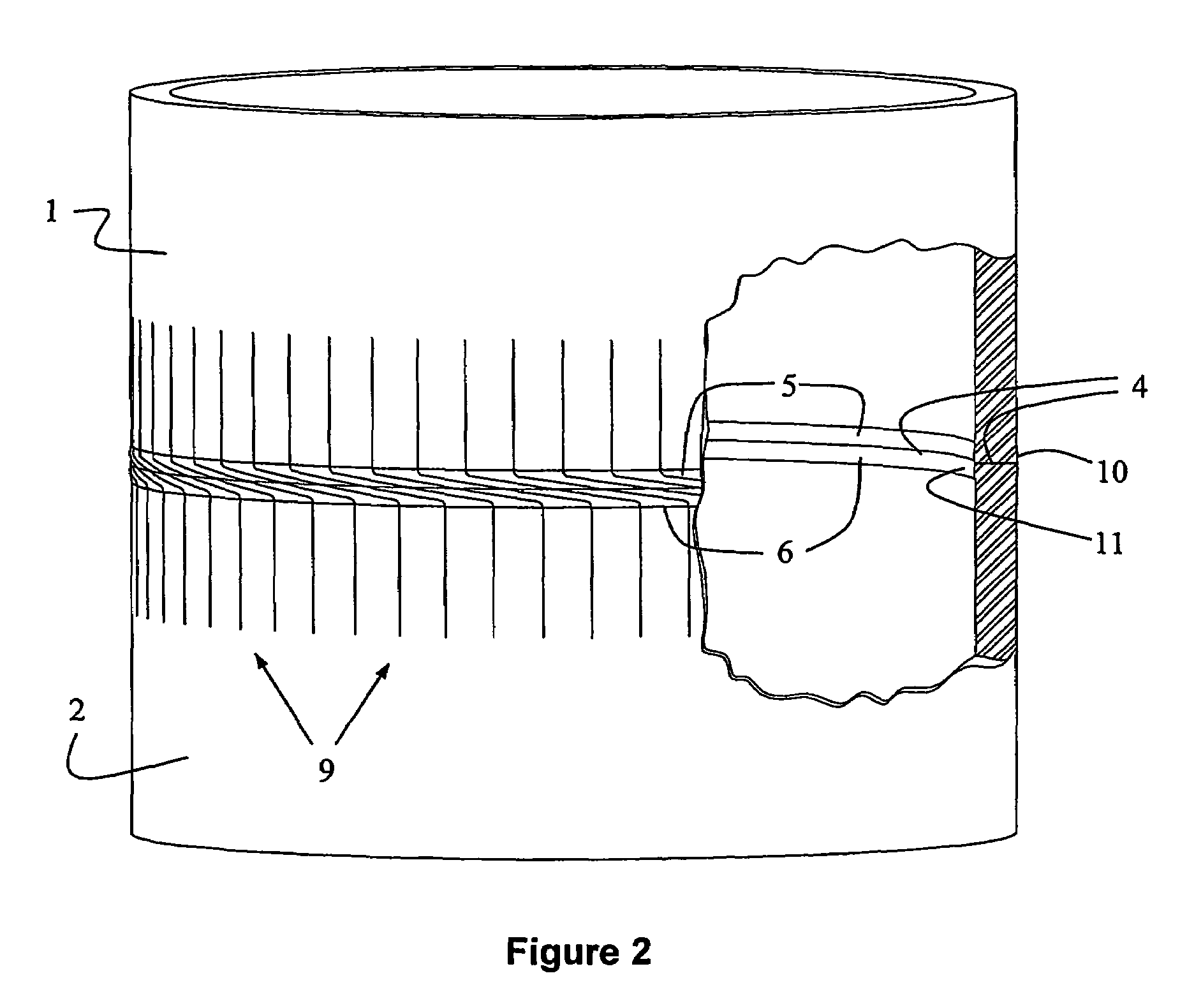

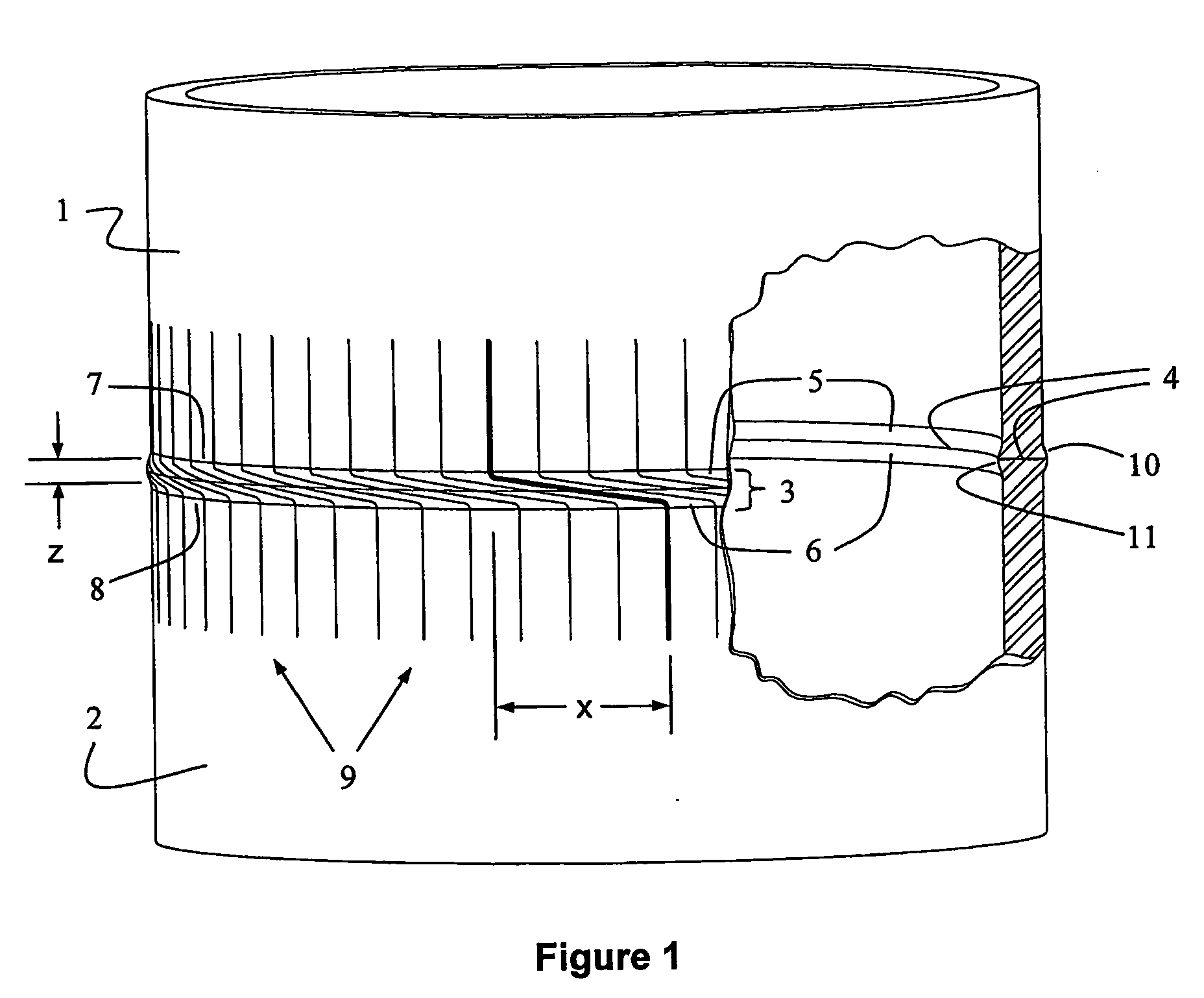

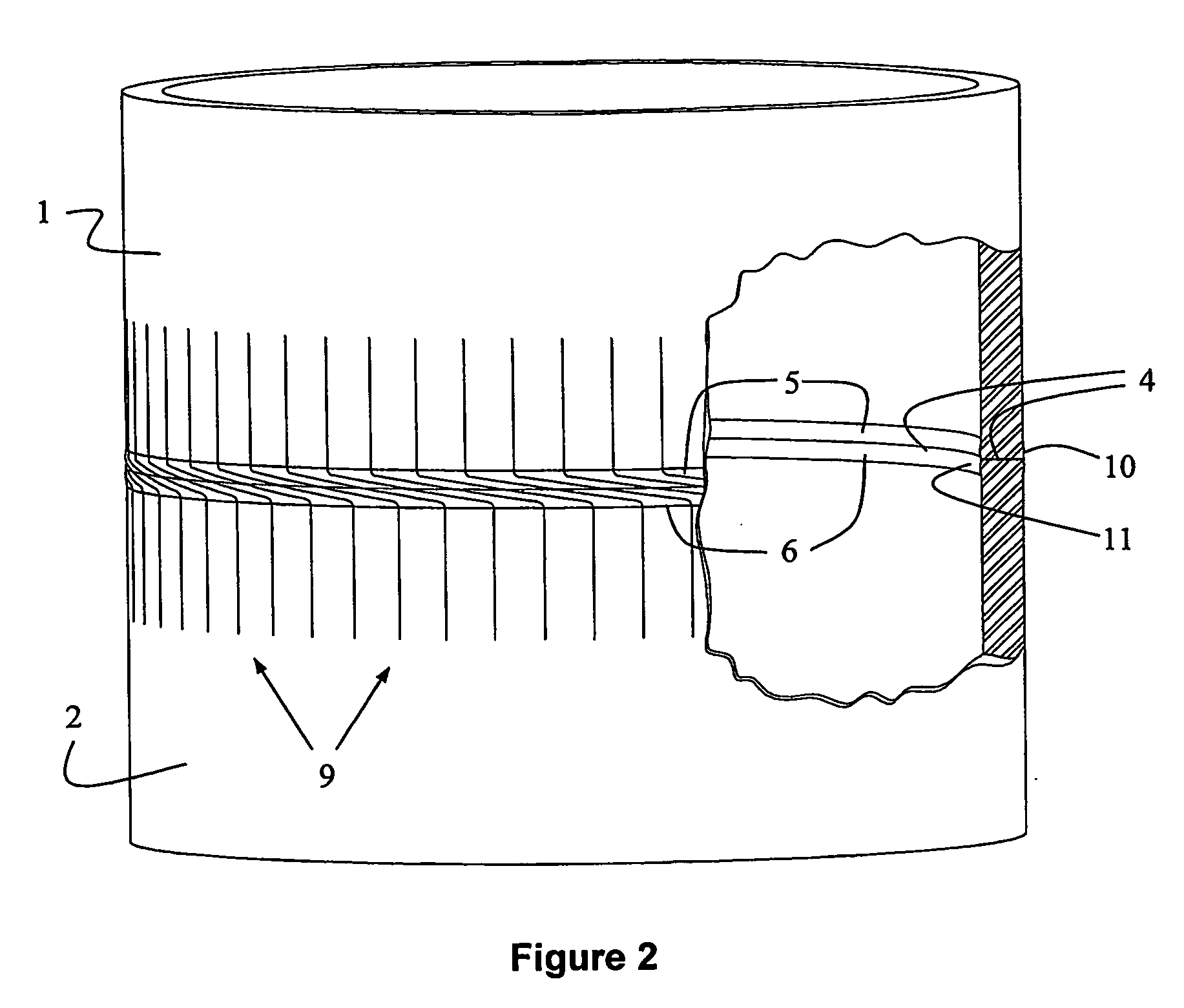

Method of induction weld forming with shear displacement step

ActiveUS7348523B2Increase ratingsFast formingFurnaces without endless coreArc welding apparatusOperating temperature rangeEngineering

A shear-assisted solid state welding method for joining of metal parts, involves a first step of heating opposing surfaces in a non-passivating environment to a temperature in the hot working temperature range of the metal. A second step involves bringing the opposing surfaces into contact while still in the hot working temperature range, and applying compressive stress sufficient to substantially prevent sliding in response to shear displacement, causing plastic flow in the hot layers. A third step involves imposing relative shear displacement of the metal work pieces without disengaging the opposing surfaces. The shear displacement induces plastic shear strain within the hot layers to progressively induce bonding.

Owner:NOETIC TECH INC

Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

InactiveCN101330174AHigh strengthImprove wear resistanceContact materialsContact member manufacturingElectrical resistance and conductanceLow voltage

The invention discloses a copper-aluminum socket connector for the electric conduction, the preparation method thereof and the application thereof. The socket connector comprises an aluminum body and a copper plug integrated into a whole by welding. The preparation method comprises the following steps: (1) manufacturing the molded aluminum body and the copper plug, and cleaning the welding surfaces of both the aluminum body and the copper plug; and (2) welding the aluminum body and the copper plug into an integrated part by adopting a flash welder or a spin friction welder to obtain the copper-aluminum socket connector semi-product for the electric conduction. The socket connector is mainly applied to a moving contact, a static contact or a conductive contact arm in a high and low voltage switch cabinet or a vacuum circuit breaker. The socket connector has the advantages of non-contact resistance, no galvanic corrosion, smaller resistance, less current conveyance loss, improved current transmission efficiency and reduced power transmission and transformation loss.

Owner:梁楚欣

Temperature-equalizing plate and device and method for manufacturing temperature-equalizing plate

InactiveCN102494550ALow metal surface requirements for weldingShort welding timeIndirect heat exchangersNon-electric welding apparatusWorking fluidEngineering

Owner:SICHUAN WUXIN ENERGY TECH

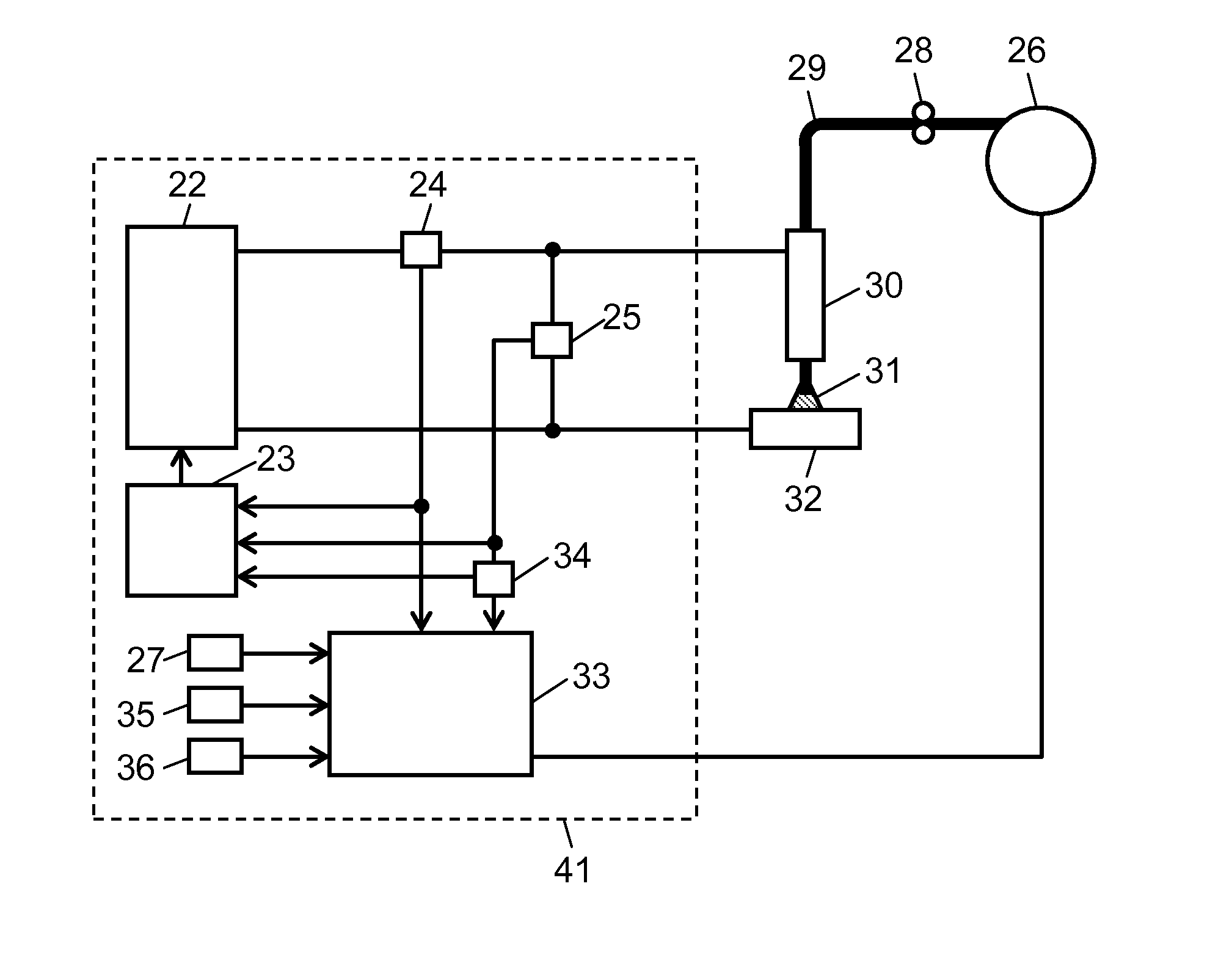

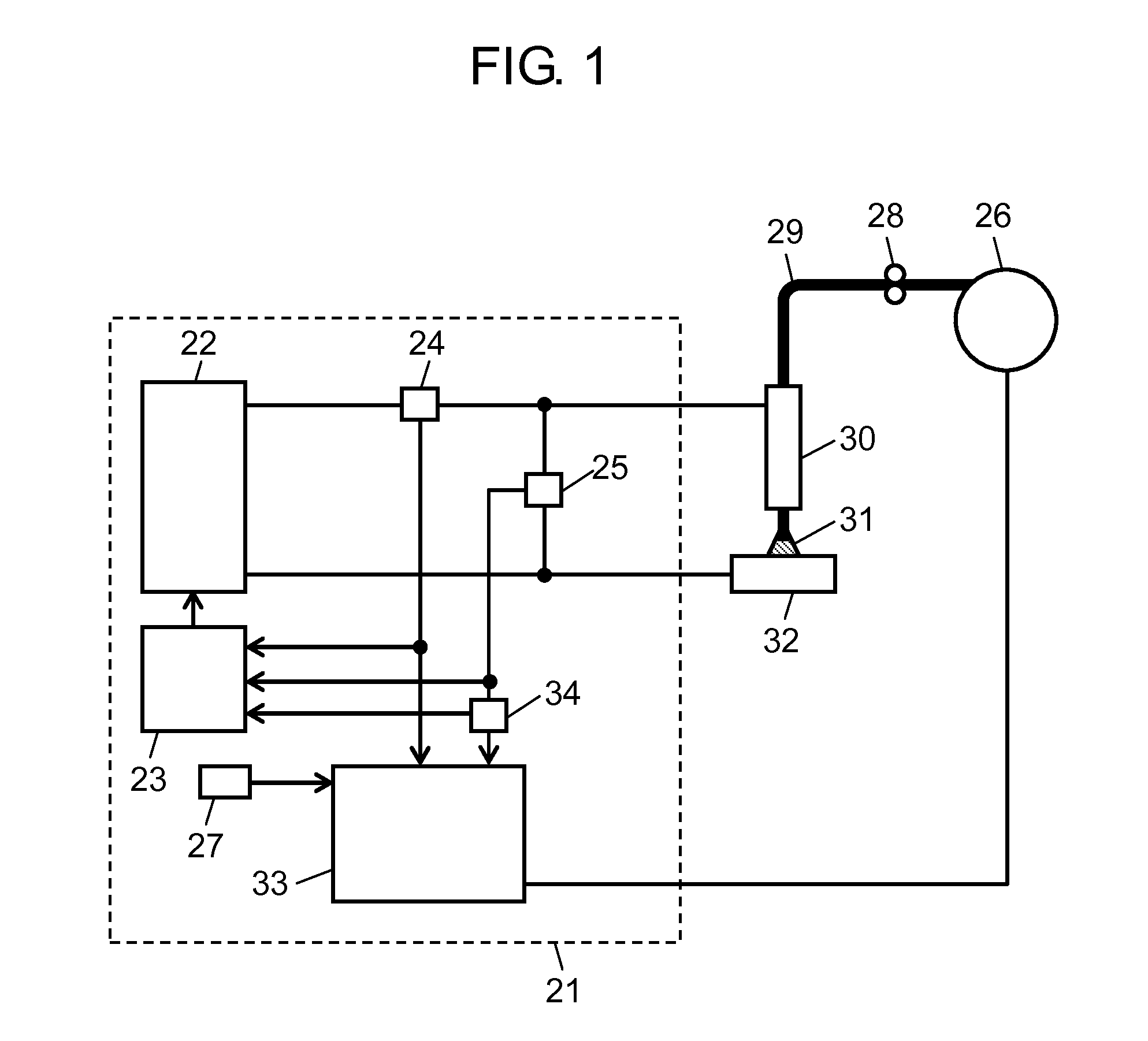

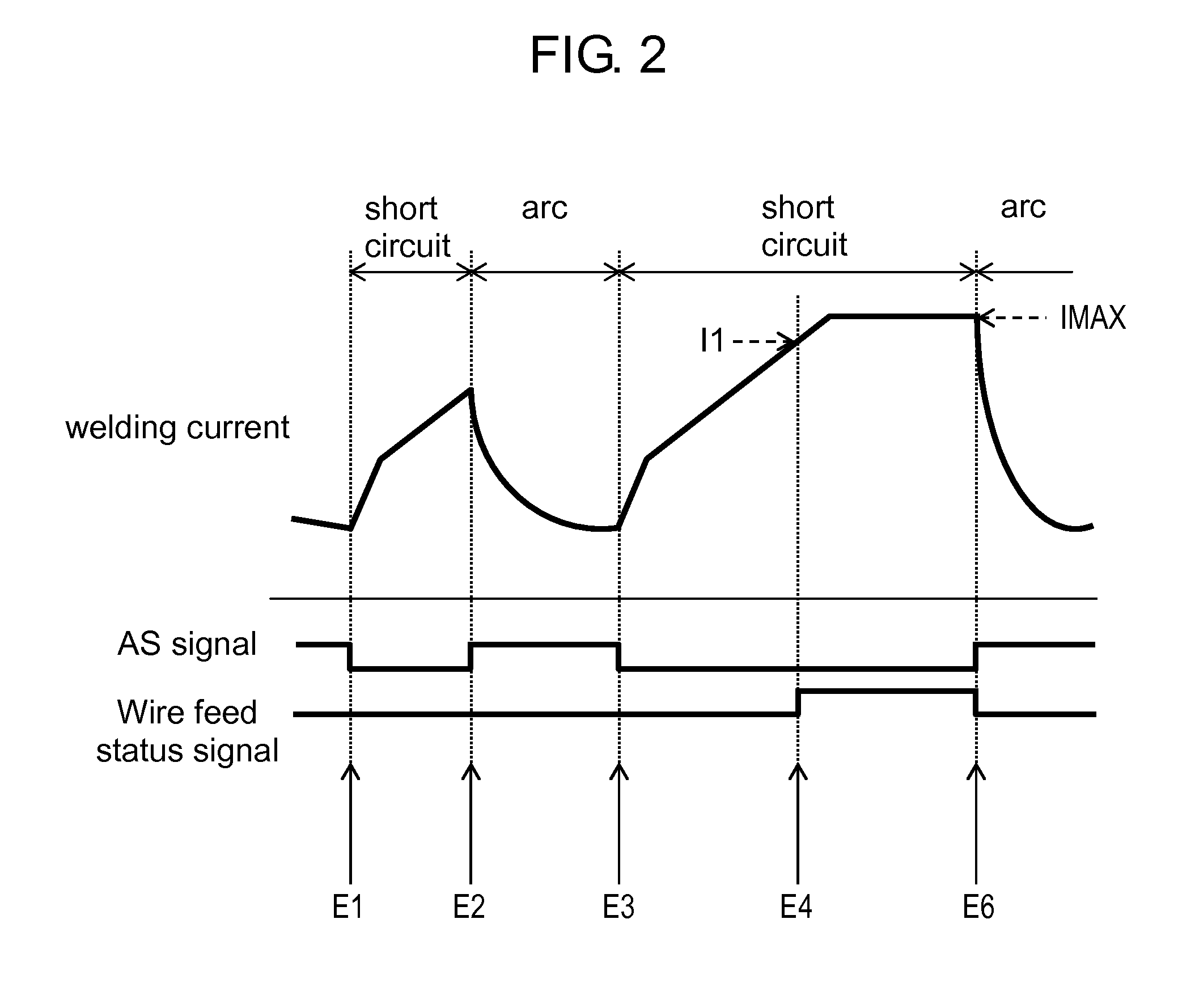

Welding method and welding device

ActiveUS20120223063A1High welding qualityHigh efficiencyArc welding apparatusWelding defectEngineering

In a method and device for performing welding, after the welding current reaches a first current value during a short circuit, the feeding of the welding wire is stopped, slowed down, or moved backward. As a result, the opening of a short circuit is urged to reduce the frequency at which welding is unnecessarily interrupted by an overcurrent protection function. This achieves high weld quality such as the absence of welding defects, and high production efficiency.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

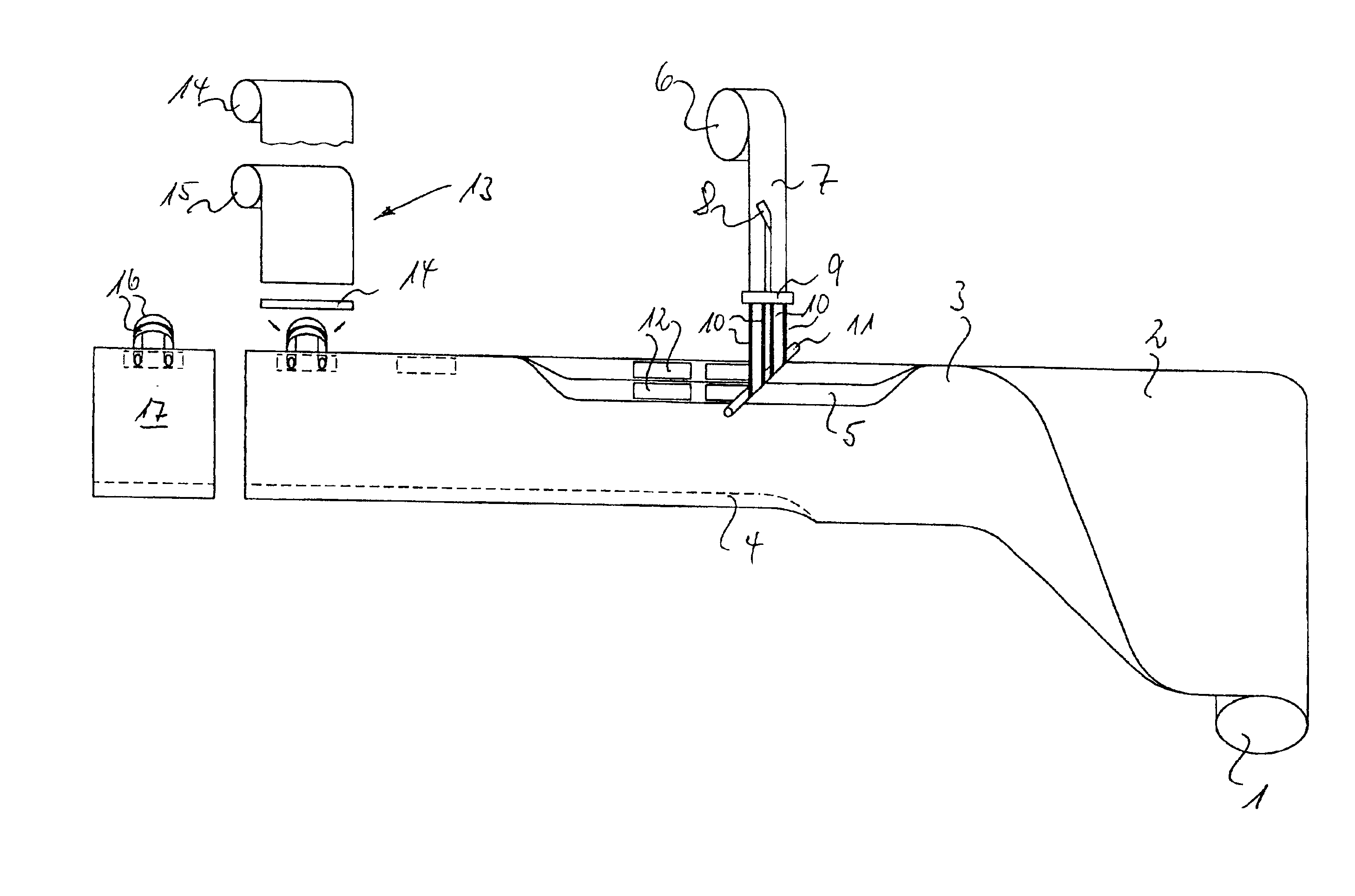

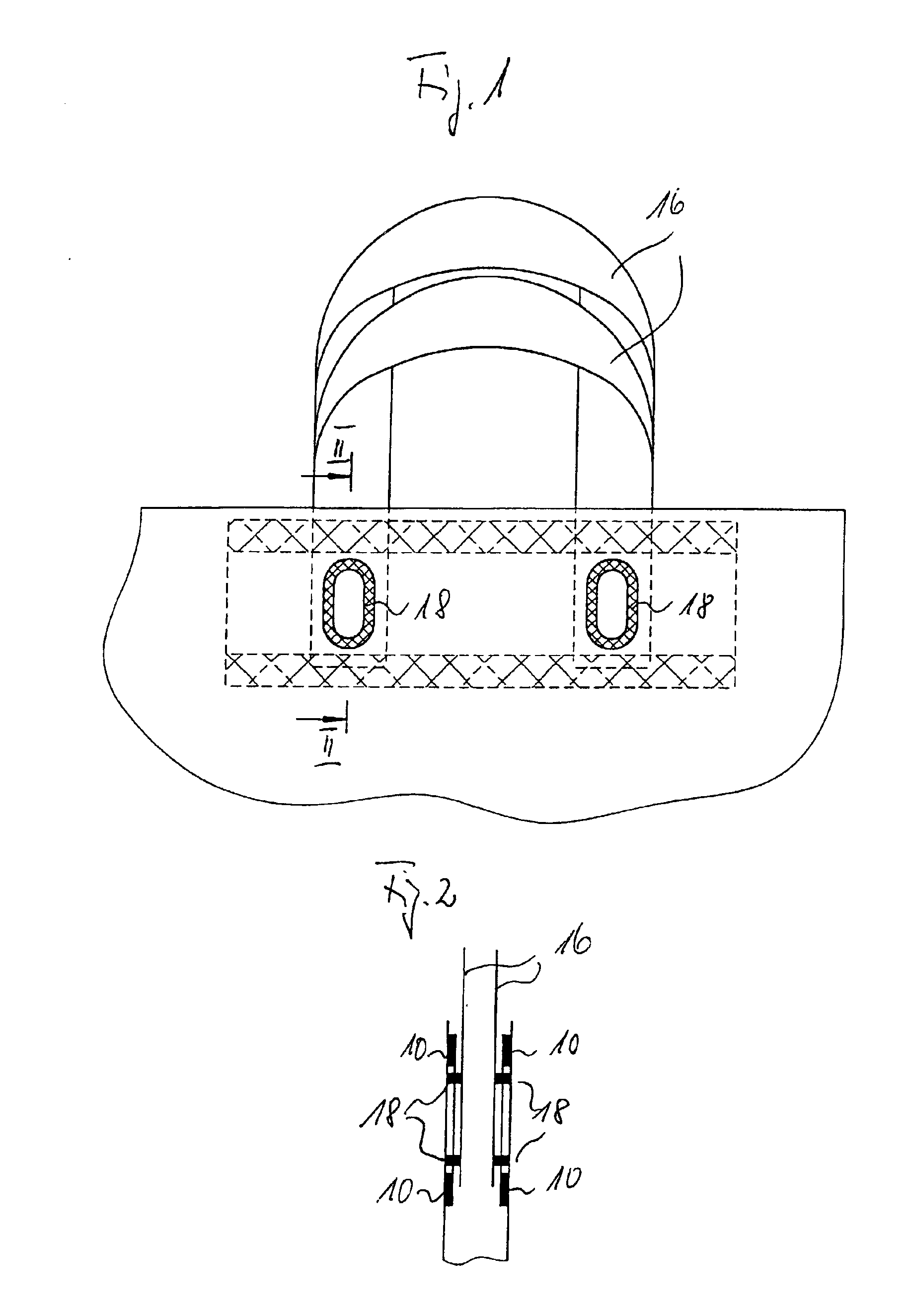

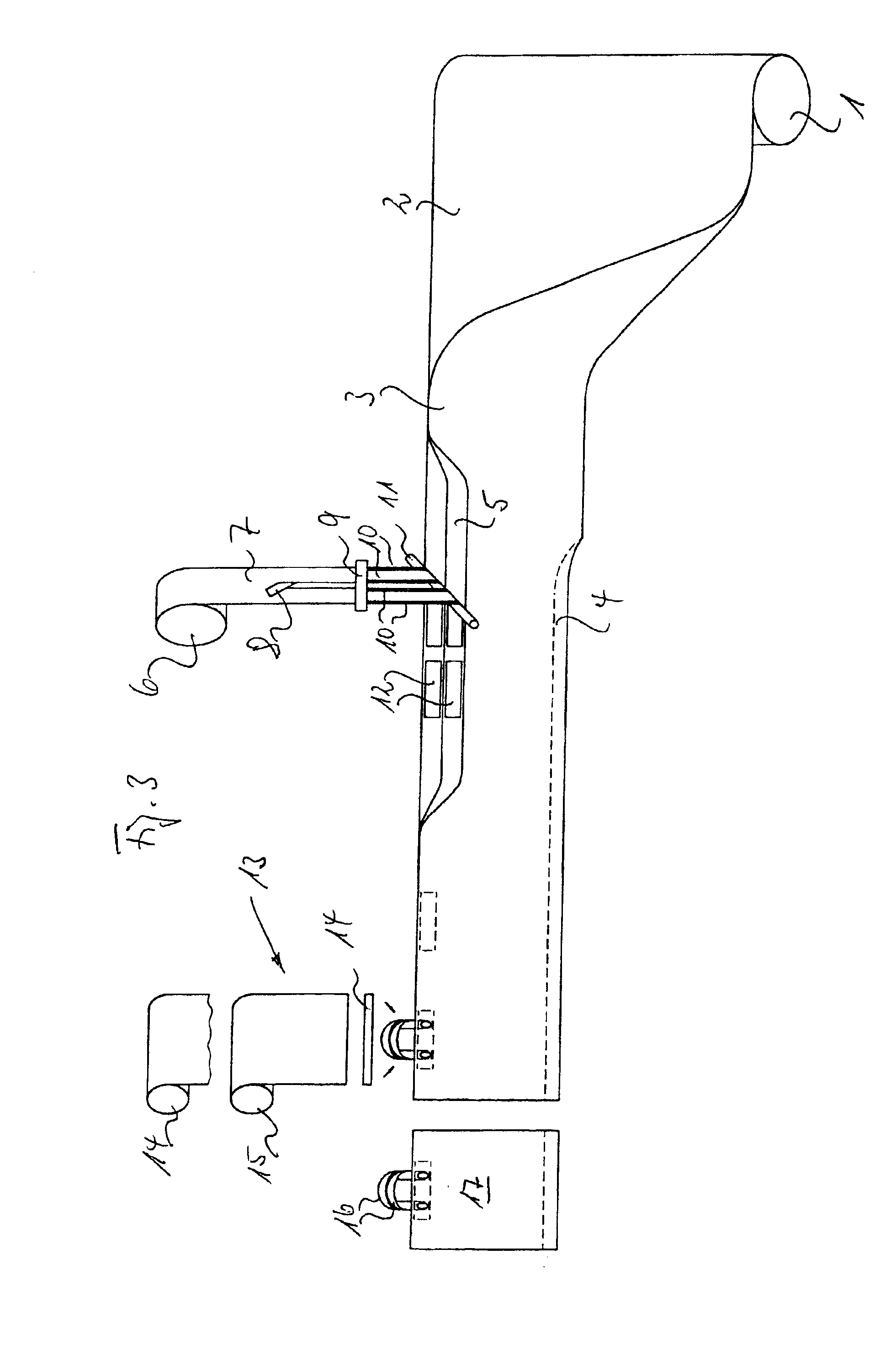

Method for producing loop handle shopping bags

InactiveUS6899663B2Simple and cost-effectiveShort welding timeEnvelopes/bags making machineryBag making operationsThermoplasticWeld seam

For the production of loop handle shopping bags based on semi-tube sheeting consisting of thermoplastic plastic, an edge strip of the semi-tube sheeting is folded onto itself and reinforcement warps, consisting of a weld-friendly thermoplastic plastic that provides a good weld, are attached on the interior sides of the edge areas by means of glueing or welding at a distance corresponding to the width of the shopping bags to be produced.Subsequently, the edge strip is folded back so that the added reinforcement warps are positioned back-to-back. Double-layer handle strips are positioned in a U-shape and placed between the reinforcement warps with their end areas of the free shanks, and welded together with the edge areas through the reinforcement warps between welding devices. The shopping bags are then separated from the semi-tube sheeting by means of separating weld seams.

Owner:WINDMOELLER & HOELSCHER GMBH

Method for welding carbon steel heads

The invention discloses a method for welding carbon steel heads, which comprises the following concrete steps of: firstly, carrying out punch forming on a mould; then, manufacturing a welding groove and determining the width of the welding groove; welding a top circular middle plate and a top circular side plate by electric slag pressure welding; splicing the top circular middle plate and the top circular side plate through welding; splicing peripheral plate pieces through welding, and carrying out air gouging and back gouging on the backs of welds under the condition of CO2 protection by using a carbon arc air gouging machine; and finally, carrying out grouped welding on the welded top circular plate and the plate pieces by using sectional skip welding. The method disclosed by the invention is implemented mainly by using an electric slag pressure welding process; and the method is high in machining efficiency, reliable in weld quality, short in welding time, high in qualified rate, low in rejection rate, beautiful in appearance and low in cost, and has a broad application prospect.

Owner:JIANGSU TIANCHENG END SOCKET

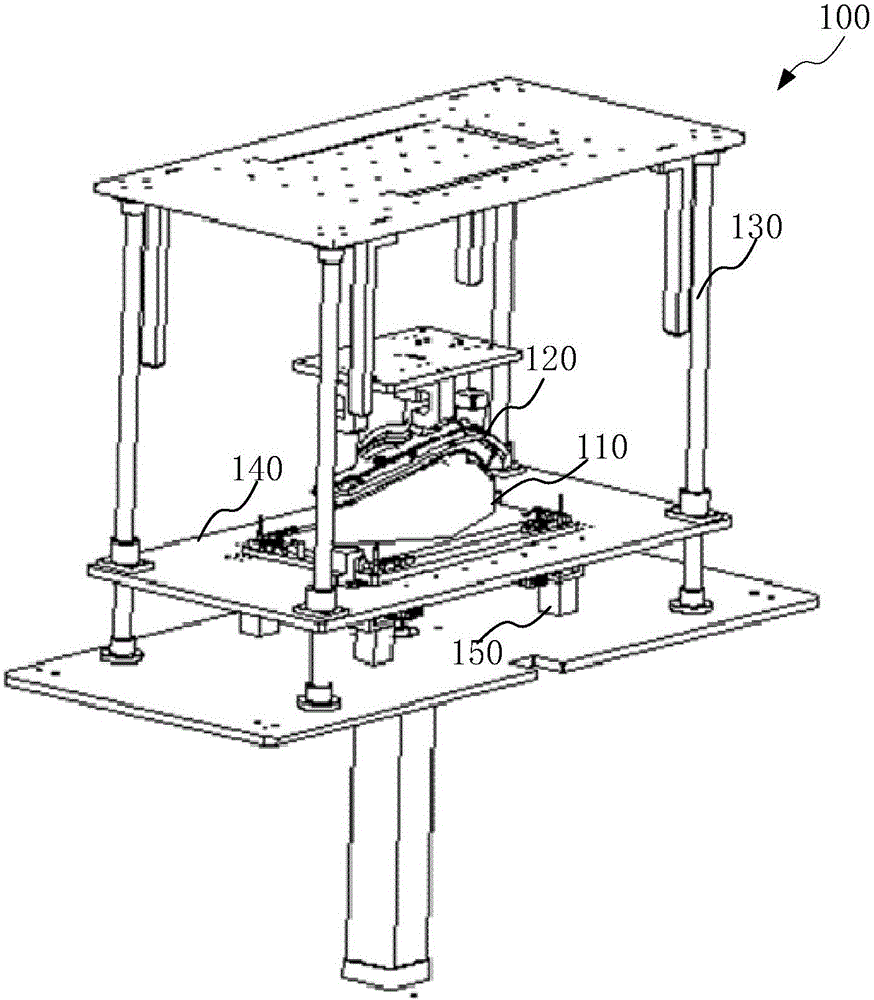

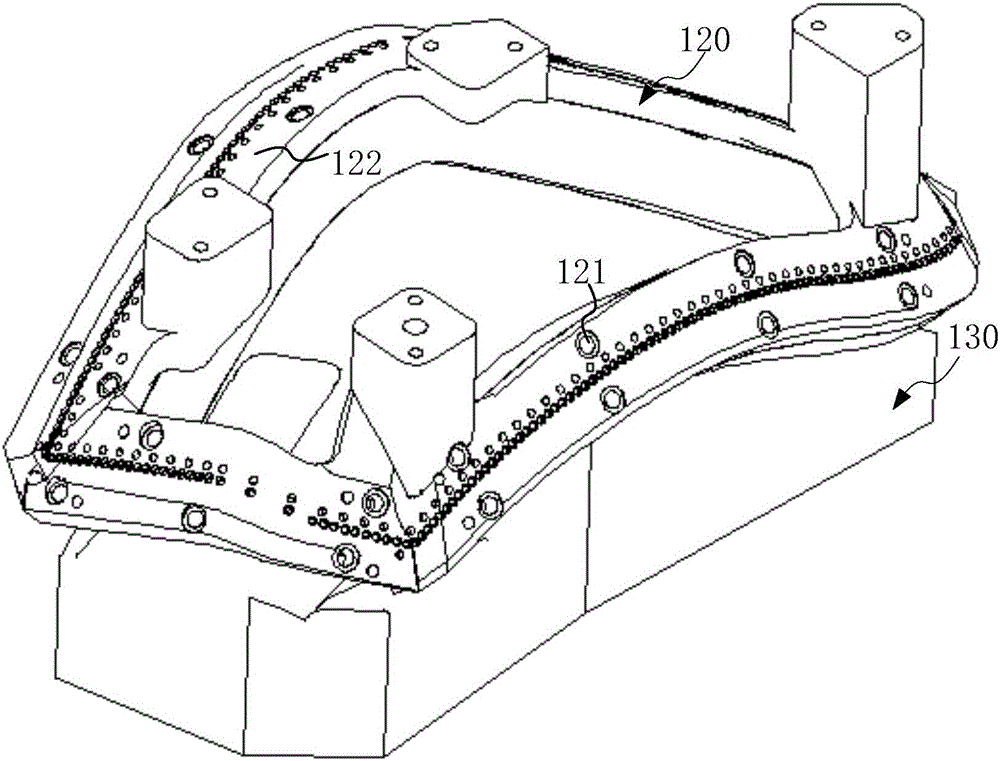

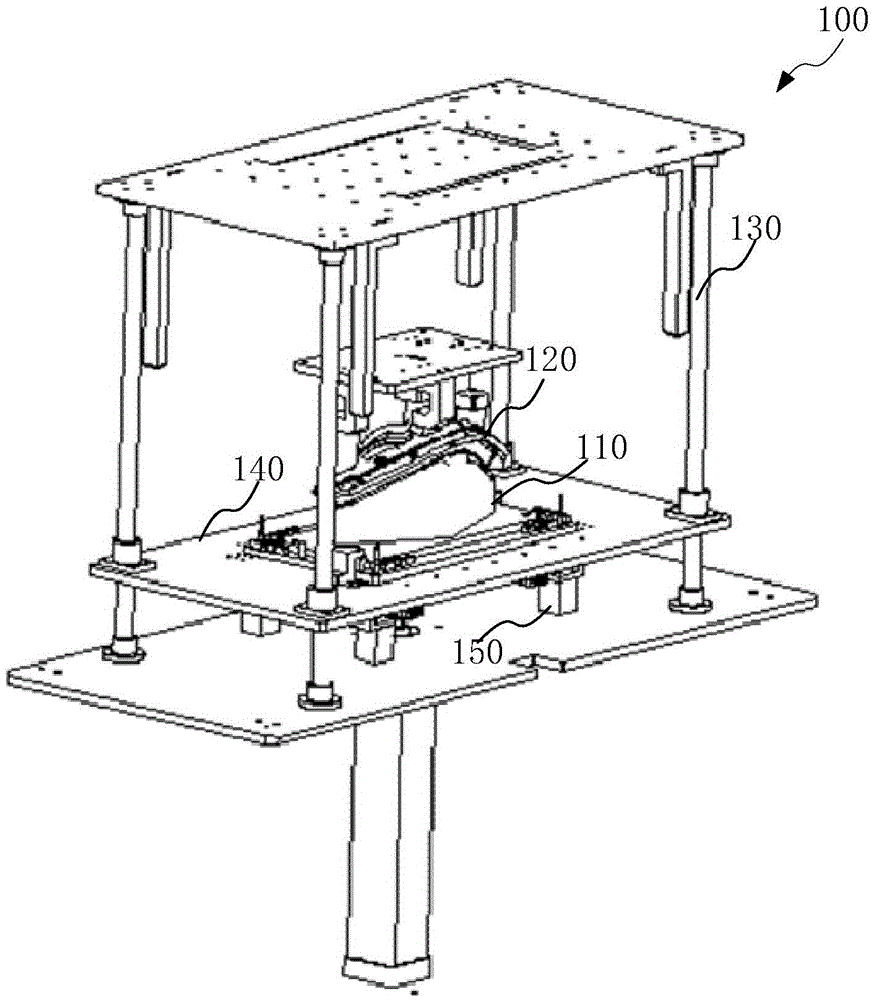

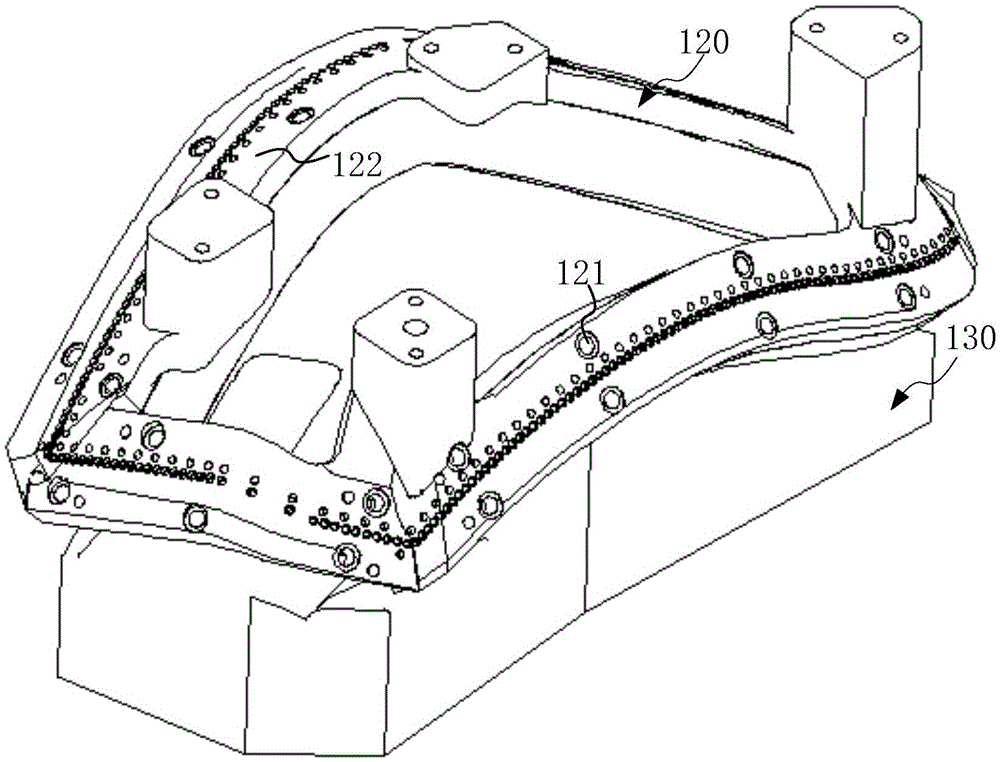

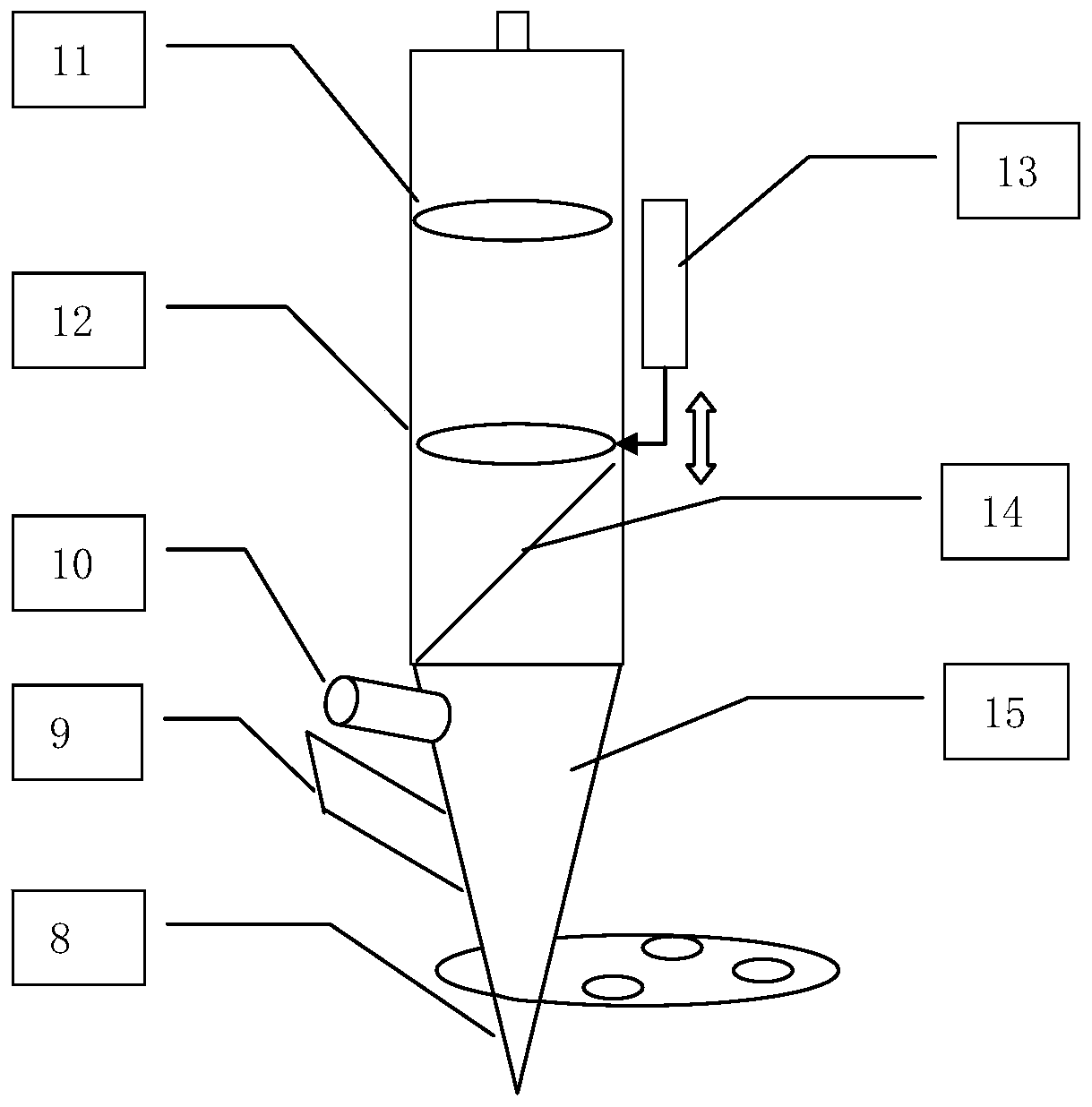

Laser synchronous welding device

ActiveCN104985324AShort welding timeHigh speedDomestic articlesLaser beam welding apparatusLaser transmitterLight guide

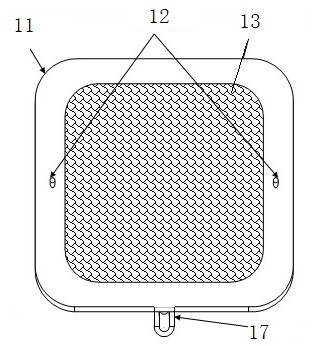

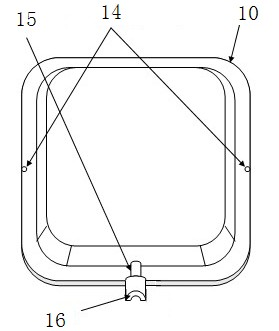

The invention provides a laser synchronous welding device which is used for welding an automobile lamp body and a lens. The laser synchronous welding device comprises a laser emitter, a first mold, a second mold and a light guiding pipe. The laser emitter is connected with an optical fiber set and meanwhile provides a plurality of beams of lasers. The first mold is used for containing the lamp body and suitable for moving up and down relative to the second mold. The second mold is used for containing the lens and evenly provided with a plurality of optical fiber fixing holes at the position corresponding to the welding position of the lens. Each optical fiber of the optical fiber set is connected to the corresponding optical fiber fixing hole. The light guiding pipe is used for shaping and focusing the lasers and located in the second mold. The light guiding pipe transversely penetrates the optical fiber fixing holes, and therefore the lasers can irradiate the light guiding pipe after being transmitted through the optical fibers. When the first mold moves to coincide with the second mold, the lasers shaped by the light guiding pipe penetrate the lens and are focused on welding ribs of the lamp body. The welding ribs of the lamp body are molten, and therefore the lamp body and the lens can be welded together. The device finishes welding the whole automobile lamp synchronously at a time and is high in efficiency and low in cost.

Owner:SHANGHAI SEEYAO ELECTRONICS CO LTD

Brazing powder for ultrasonic assisted brazing and brazing method

ActiveCN109759741AEnable low-temperature interconnectsSave heating energyWelding/cutting media/materialsSoldering mediaBiological activationCobalt

The invention provides brazing powder for ultrasonic assisted brazing and a brazing method. The brazing powder is prepared by uniformly mixing tin copper powder or tin silver copper powder, or powderof the tin copper powder mixed with the tin silver copper powder with any one kind, or any two kinds, or any three kinds, or any four kinds, or any five kinds of nickel powder, cobalt powder, copper powder, tin powder and titanium powder of active nanoparticles with the diameters being 1-1000nm according to the mass ratio being at most 20%. According to the brazing powder for ultrasonic assisted brazing and the brazing method, the temperature is low during welding, and the active nanoparticles are adopted; by oscillation heating of an ultrasonic generator, the metallurgical reaction between solder or the nanoparticles and a base material is promoted, the full-solid phase or semisolid state low-temperature interconnection of lead-free solder is realized, and the welding temperature is morethan 30% lower than conventional liquid phase interconnection; oscillating activation and friction generated by the ultrasonic generator can cause an oxidation film on the surface of the welding basematerial to be broken to achieve the effect of film removal, thus gas pollution from a welding flux is reduced, the welding pollution is less, and the joint quality is high.

Owner:CHONGQING UNIV OF TECH

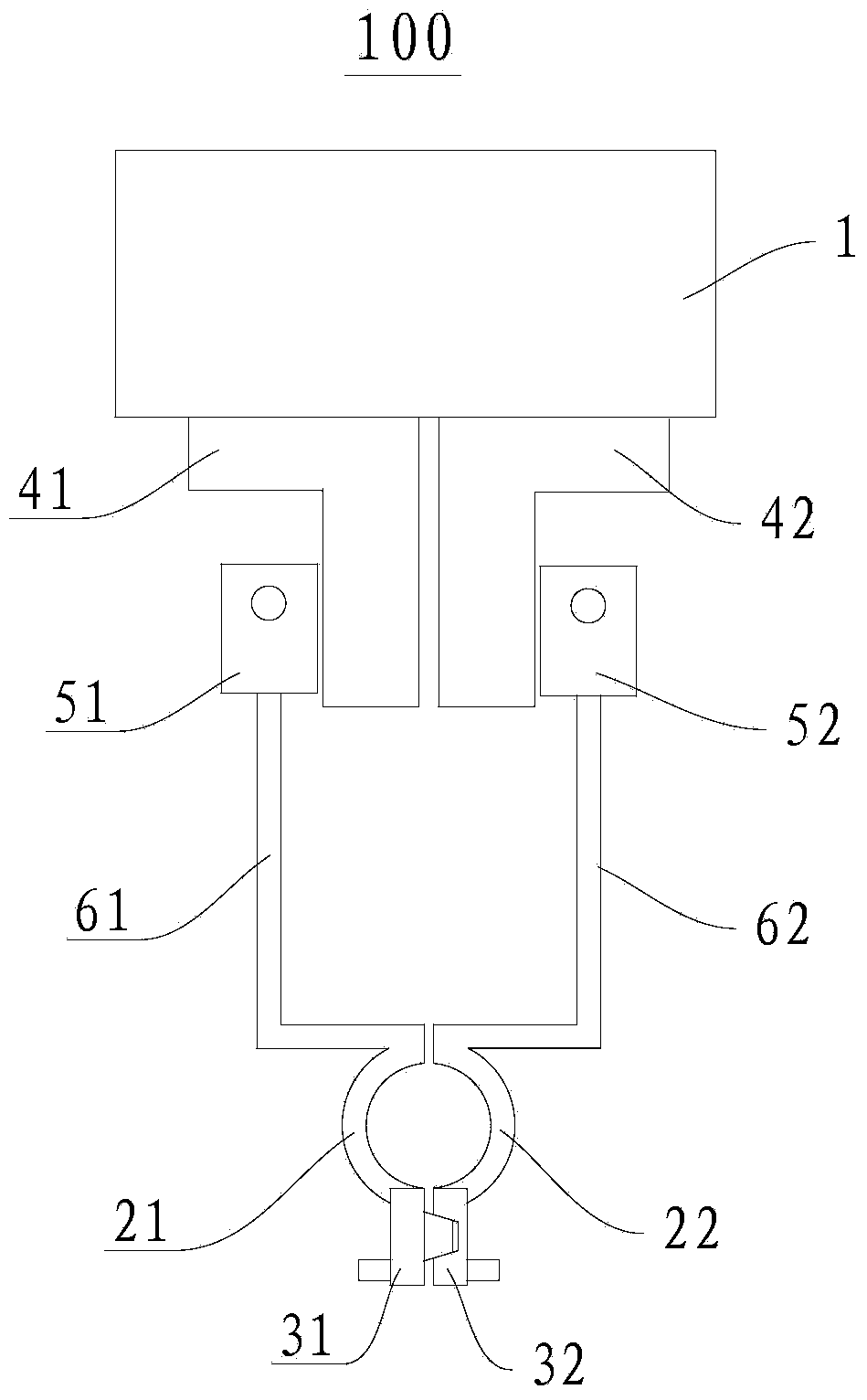

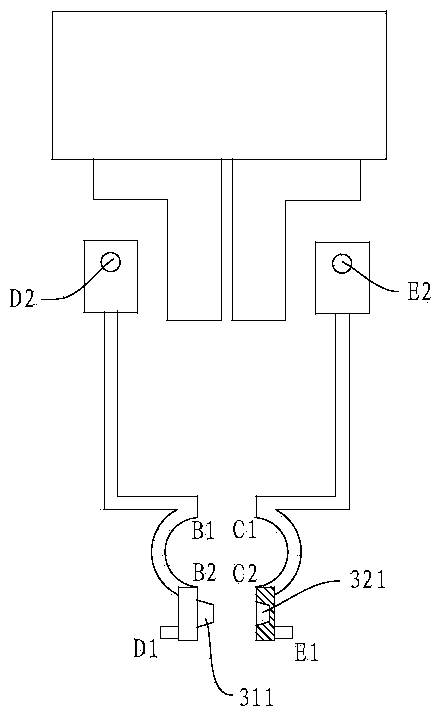

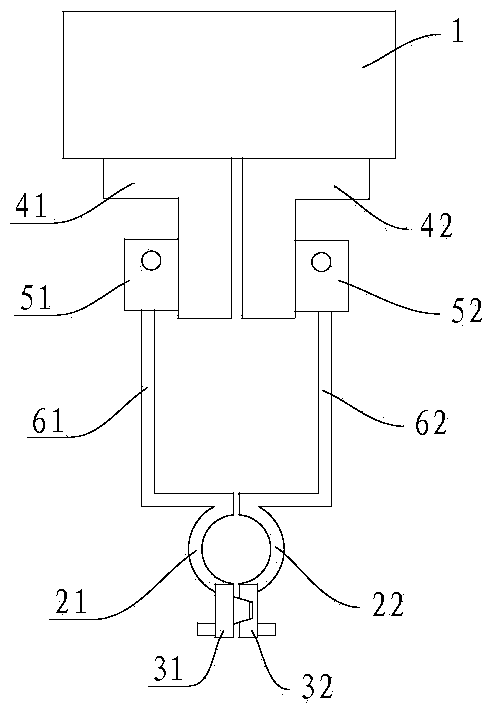

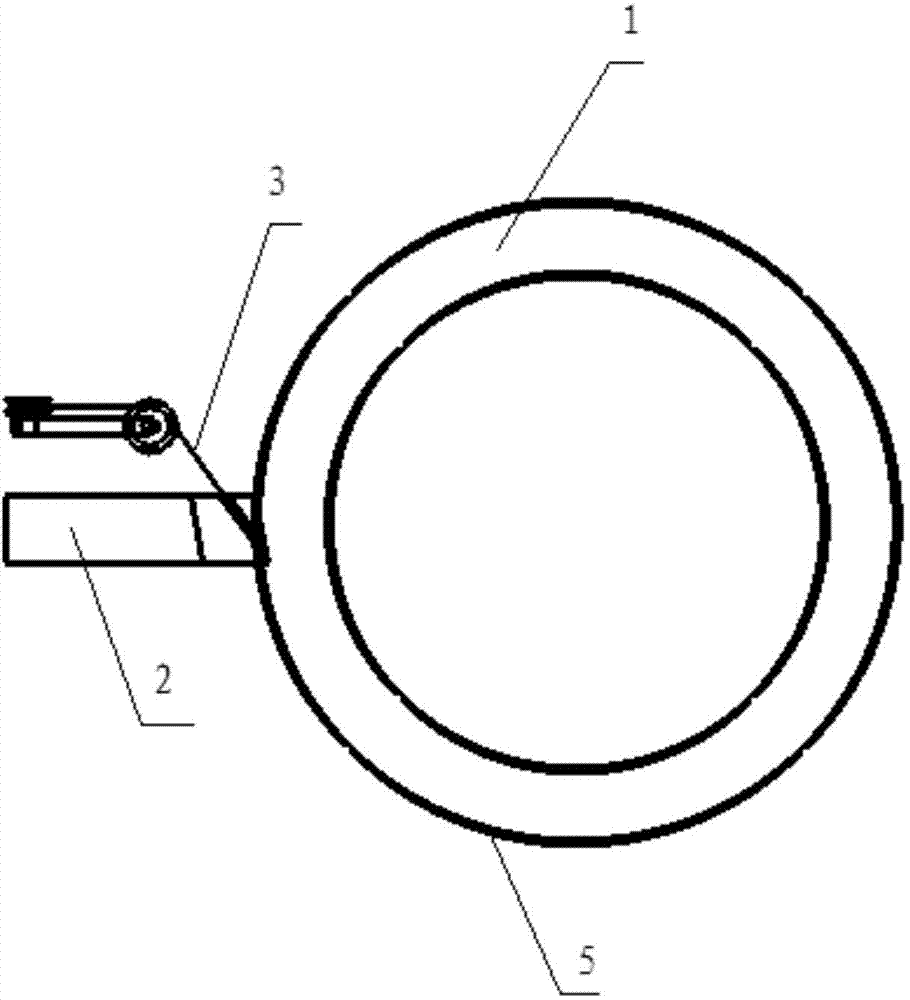

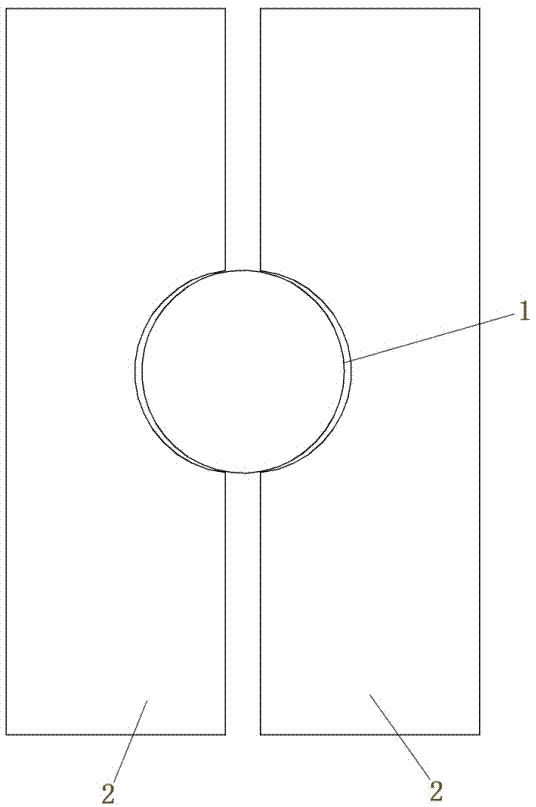

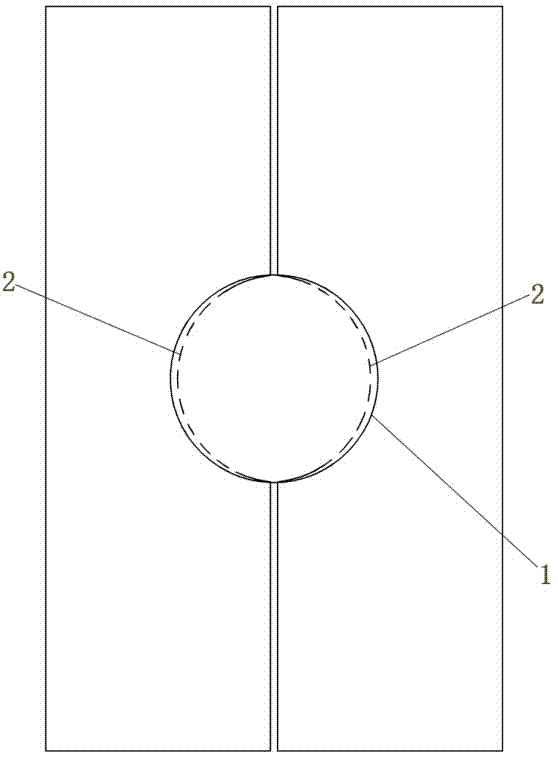

Welding device

ActiveCN103706909AAchieving hoop heatingFully automatedHeating appliancesMetal working apparatusEngineeringElectrical and Electronics engineering

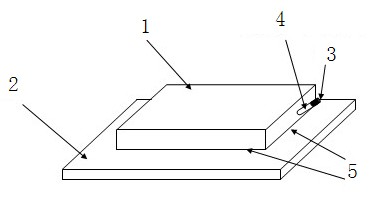

The invention discloses a welding device. The welding device comprises a high-frequency device, a first coil segment and a second coil segment. The first coil segment and the second coil segment are oppositely arranged, and the relative position of the first coil segment and the second coil segment can be adjusted so that a matching state of the first coil segment and the second coil segment and a separating state of the first coil segment and the second coil segment can be switched. When the first coil segment and the second coil segment are in the matching state, a first end of the first coil segment and a first end of the second coil segment are electrically connected with the high-frequency device respectively; the first end of the first coil segment is close to the first end of the second coil segment, a second end of the first coil segment makes contact with a second end of the second coil segment, so that an annular coil is formed by the first coil segment and the second coil segment. When the first coil segment and second coil segment are in the separating state, the second end of the first coil segment is separated from the second end of the second coil segment. The welding device can be used for welding air suction pipes, air cylinder connecting pipes and liquid accumulator elbows, and is short in welding time and high in welding efficiency.

Owner:GUANGDONG MEIZHI PRECISION MFG

Method of induction weld forming with shear displacement step

ActiveUS20060289480A1Increase ratingsFast formingFurnaces without endless coreArc welding apparatusMetal workingSolid-state

A shear-assisted solid state welding method for joining of metal parts, involves a first step of heating opposing surfaces in a non-passivating environment to a temperature in the hot working temperature range of the metal. A second step involves bringing the opposing surfaces into contact while still in the hot working temperature range, and applying compressive stress sufficient to substantially prevent sliding in response to shear displacement, causing plastic flow in the hot layers. A third step involves imposing relative shear displacement of the metal work pieces without disengaging the opposing surfaces. The shear displacement induces plastic shear strain within the hot layers to progressively induce bonding.

Owner:NOETIC TECH INC

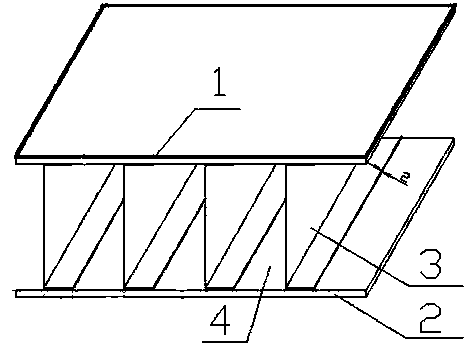

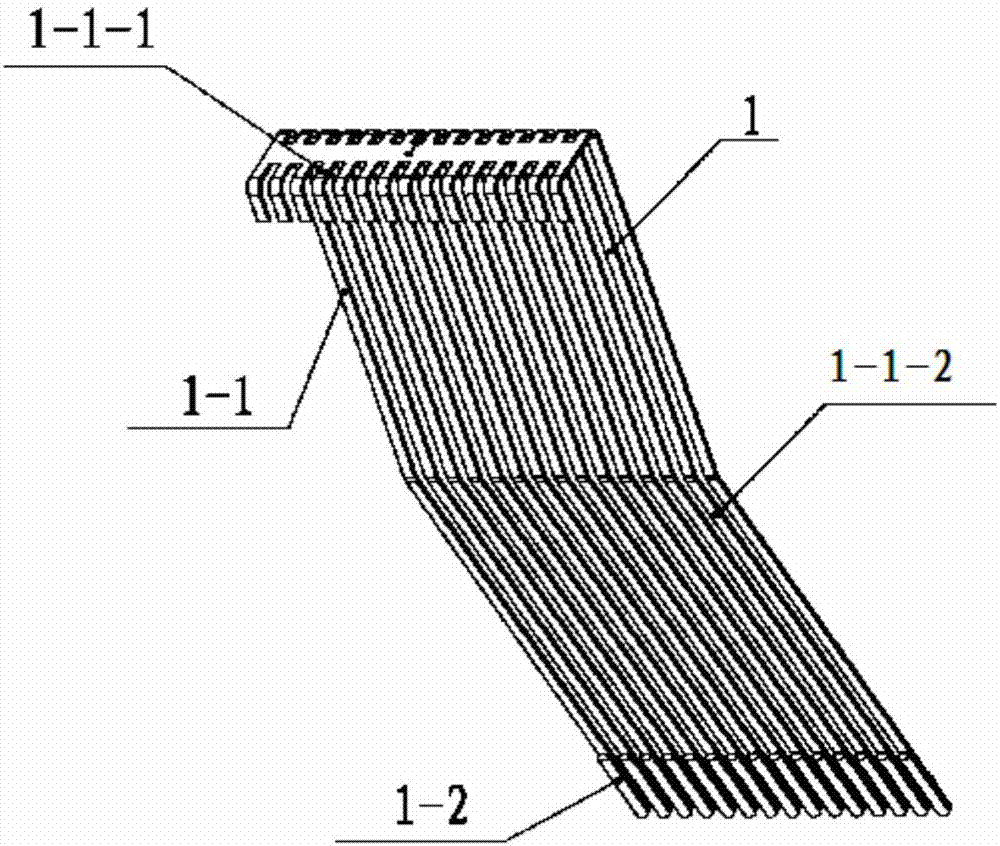

Anti-detonation, fireproof, insulating and noise reduction ocean platform bulkhead structure

InactiveCN103803028ANo structureHigh specific strengthArtificial islandsUnderwater structuresDetonationEngineering

The invention provides an anti-detonation, fireproof, insulating and noise reduction ocean platform bulkhead structure which comprises a pair of sandwich plates which are arranged in parallel in an up-and-down mode and a shock resistance structure. The shock resistance structure comprises upper trapezoid sets and lower trapezoid sets which are respectively composed of three leaf springs. Damping materials are arranged between the upper trapezoid sets and the lower trapezoid sets. The adjacent upper trapezoid sets and the lower trapezoid sets are connected through damping springs. The upper trapezoid sets and the lower trapezoid sets are filled with first stuffing. Each sandwich plate comprises a pair of upper skin plate and lower plate which are arranged in parallel, and the outer surfaces of the skin plates are coated with insulating layers, wherein a laminboard is arranged between the two skin plates, and the gaps between the laminboard and the skin plates are filled with second stuffing. The anti-detonation, fireproof, insulating and noise reduction ocean platform bulkhead structure has the advantages of being capable of resisting detonation and fire, insulating, capable of reducing noise, simple in structure, capable of facilitating coating construction and quality inspection, short in construction time, suitable for rush repair and the like.

Owner:JIANGSU MARITIME INST +1

Chip and carrier self-contrapositioning soft soldering method under gas protection

ActiveCN1666839ASimple structureReduce manufacturing costSoldering auxillary devicesShielding gasEngineering

The invention relates to the self-contraposition soldering of the chip and the carrier under gas protection. It uses the gas protection, the minimum surface energy principle, the precise control of carrier size to realize the self-contraposition. It is characterized in that the method put the carrier, the chip the soldering sheets and the operational tools in the glove-operation box with protective gas, the heating table and the worktable to implement the process. The invention has high soldering efficiency and low damaging rate of the chip.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Air conditioner liquid storage device welding protection device and application method thereof

ActiveCN106270915AAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

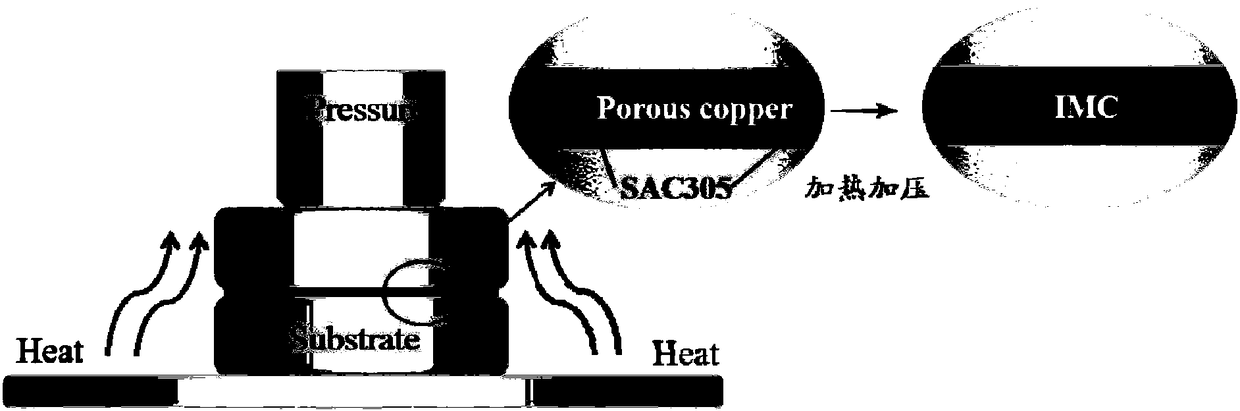

Preparation method of high-temperature serving welding point based on tin-filled foamy copper

InactiveCN108581109AEasy to getLow costSoldering apparatusWelding/soldering/cutting articlesAlloyCopper

The invention provides a preparation method of a high-temperature serving welding point based on tin-filled foamy copper, wherein the foamy copper has a three-dimensional porous structure and is prepared by adopting a dealloying corrosion method; brazing filler metal is bought; and the overall process is a heating and pressurizing welding process. Each welding point can be obtained in a welding way within a short time (5 min) under a low-temperature (230 DEG C) and low-pressure (3-5 MPa) condition; moreover the obtained mutually-connected welding points serve under a high temperature and can keep relatively good reliability; and each welding point is good in mechanical properties, good in electric conductivity and heat conductivity and widely applied to various high-temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Pipeline hot melting wire arrangement method

InactiveCN103672276AWill not cause difficultyEasy to operatePipe connection arrangementsSurface layerEngineering

The invention relates to a pipeline hot melting wire arrangement method. The method includes the following steps of embedding metal wires under plastic surface layers in the inner diameter direction or the outer diameter direction of the two ends of a plastic tube and distributing the metal wires in an area to be welded according to the corresponding wire arrangement screw pitch through a wire arrangement knife in the area to be welded of the plastic tube, reserving one section of each end of each metal wire to be exposed out of the corresponding plastic surface layer, and conducting welding after the metal wires are well distributed, and cutting off the sections, exposed out of the plastic surface layers of the plastic tube, of the two ends of each metal wire after the welding is completed. The method is easy and rapid to operate, short in welding time, low in construction cost, level and smooth in appearance after welding and good in welding effect. Even when broken wires exist in the wire arrangement process, the metal wires which have been already embedded can be easily drawn out through the reserved wire heads, the wires can be arranged again, and the difficulty of recovering and separating the metal wires can not occur.

Owner:TIANJIN QINGTAI HOISTING EQUIP

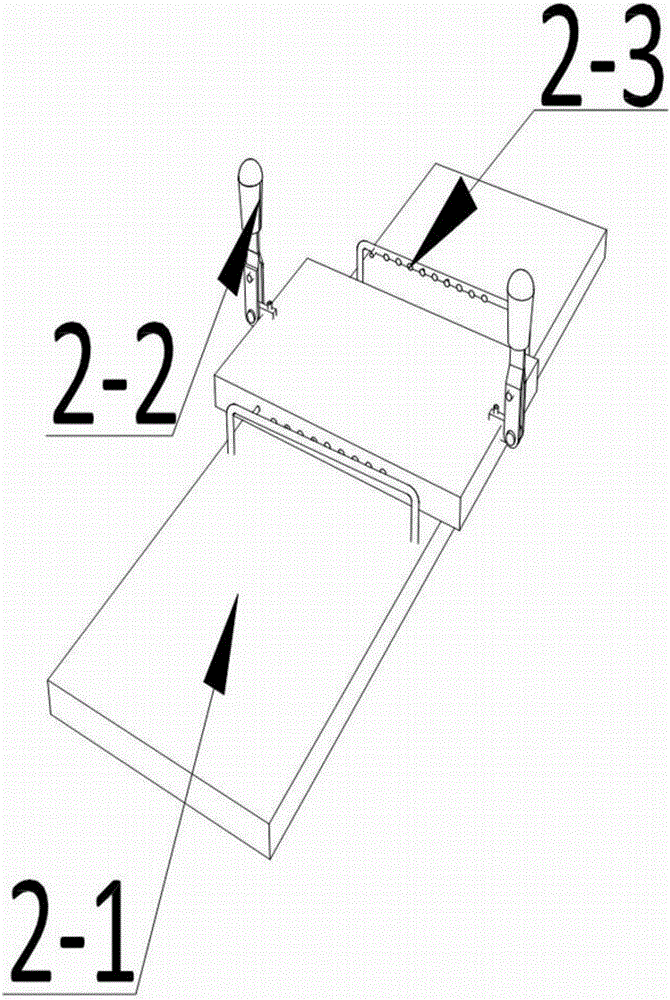

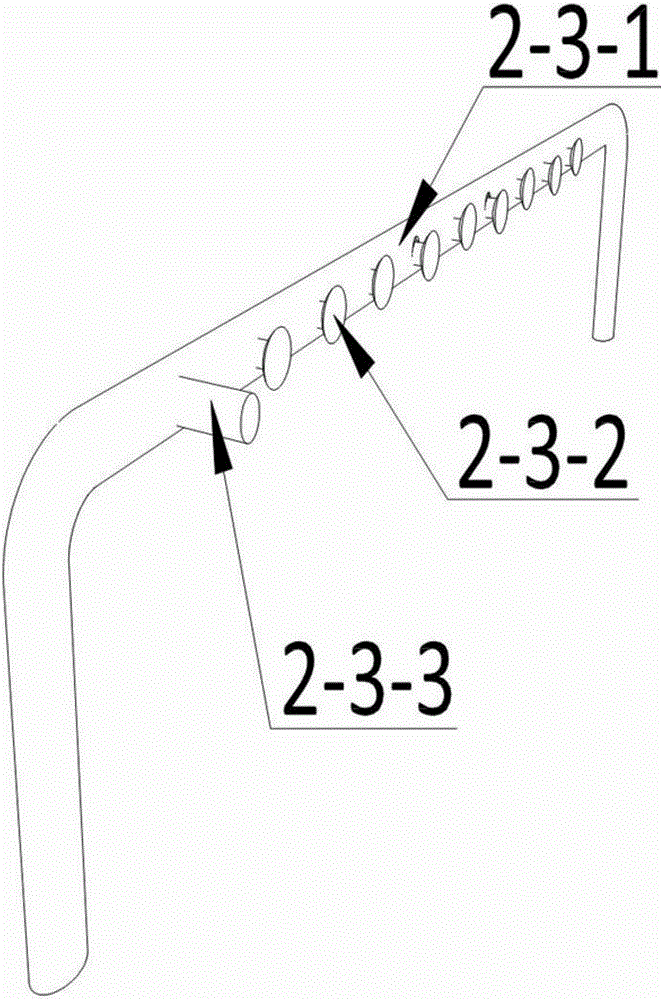

Horizontal sliding rail-type pose self-adjusting welding machine and control method thereof

InactiveCN106238984ACompact structureHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingAutomation

The invention discloses a horizontal sliding rail-type pose self-adjusting welding machine and a control method thereof. The horizontal sliding rail-type pose self-adjusting welding machine is composed of a pedestal, a workpiece fixing base, a welding wire storage box, a welding head, a horizontal sliding rail, a horizontal driving cylinder, a horizontal sliding block, a vertical driving cylinder and an electric cabinet. The welding head moves on the horizontal sliding rail through the horizontal sliding block and is driven by the vertical driving cylinder to arrive at a designated position of the system. Spot welding can be performed on workpieces under the action with a welding wire, and the welding wire can be replaced automatically in the welding process. According to the horizontal sliding rail-type pose self-adjusting welding machine, the degree of automation of the device is high, the welding wire can be replaced automatically, and working efficiency is greatly improved; and welding time of the workpieces is short, welding spots are smooth and plump, and welding quality is good.

Owner:XUZHOU UNIV OF TECH

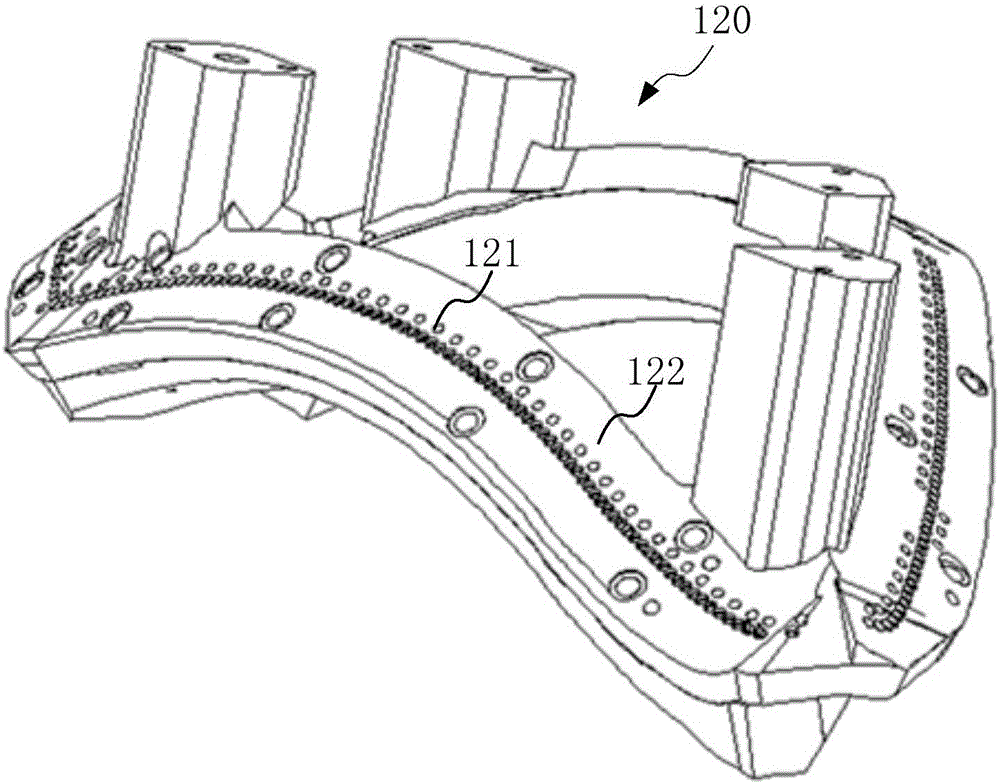

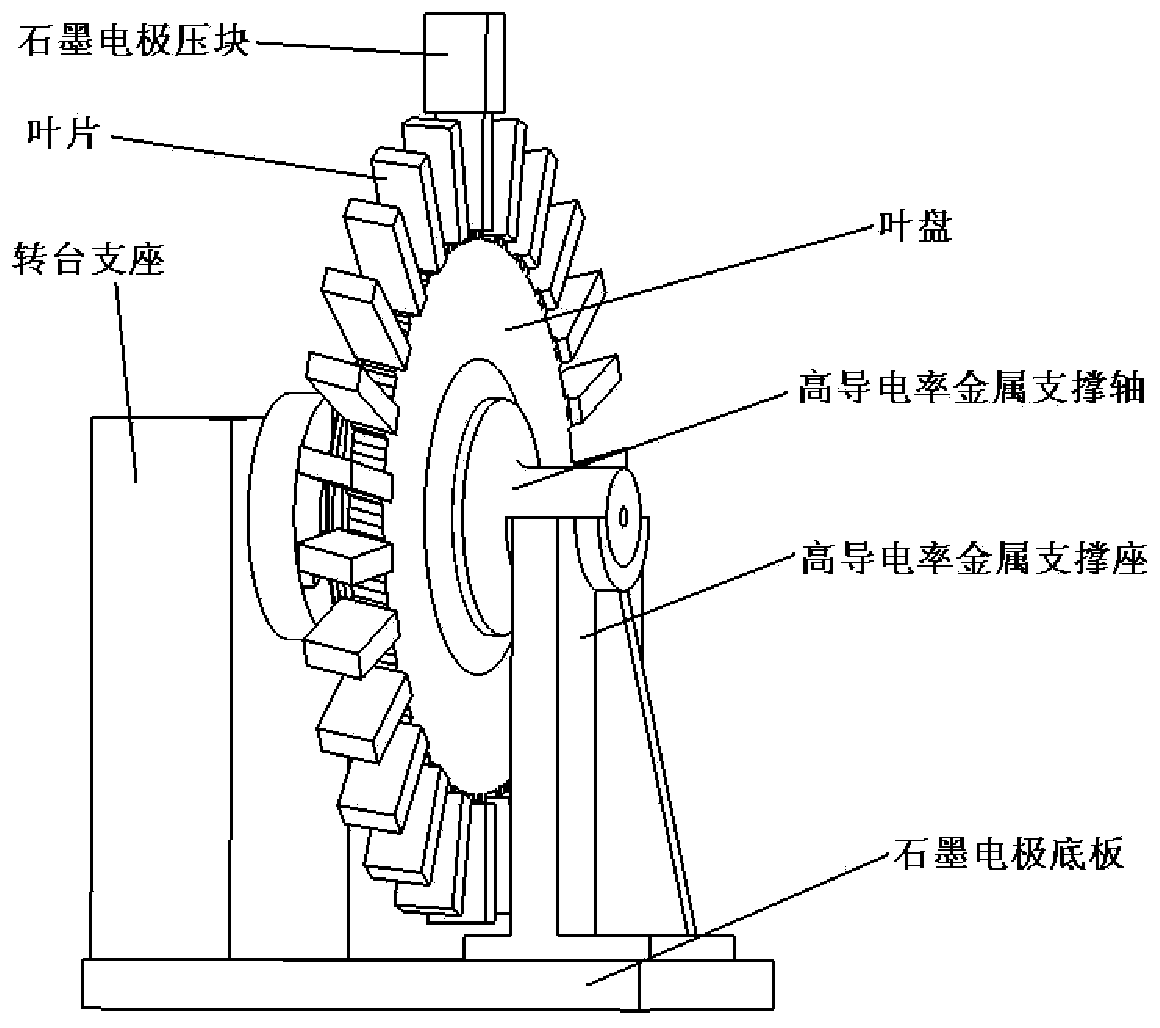

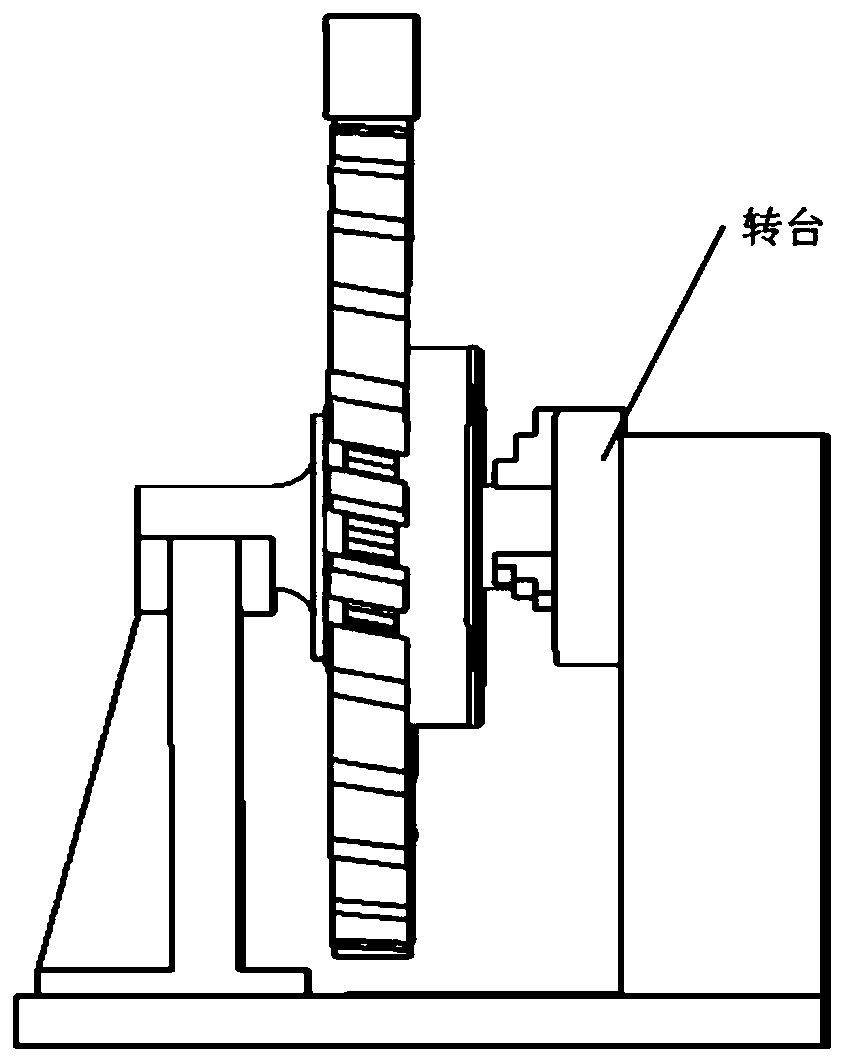

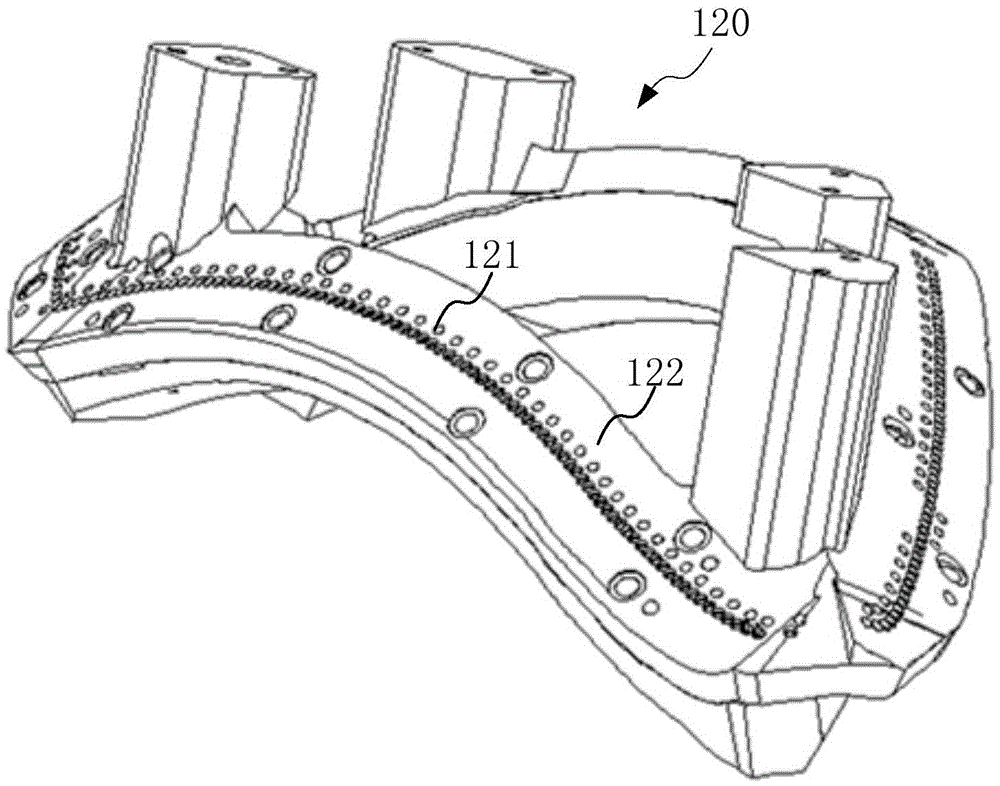

Manufacturing method for dissimilar alloy integral blade disc structure

ActiveCN110303259ASolve difficultyMeet the needs of high-performance blisksWelding apparatusPlasma diffusionAlloy

The invention relates to a manufacturing method for a dissimilar alloy integral blade disc structure. The method comprises the steps that a blade disc is rotationally and axially mounted on a high-conductivity metal support base through a high-conductivity metal support shaft, and the support base is mounted on a graphite electrode bottom plate; and after blades and the blade disc are assembled, discharge plasma diffusion welding is adopted for welding, during welding, the upper portions of the blades are pressed through a graphite electrode pressing block, direct current pulse current is connected between the graphite electrode pressing block and the graphite electrode bottom plate, discharge plasma is generated, diffusion welding of the blades and the blade disc is rapidly achieved underthe action of impact pressure, joule heat and an electric field, all the blades are welded to the blade disc, and the integral blade disc is obtained, wherein the blades and the blade disc are prepared from different alloys. Through the discharge plasma diffusion welding method, the problems of high manufacturing difficulty and high scrap rate of integral blade discs are solved, the performance and economic complementarity advantages of the dissimilar alloys are fully achieved, and the demand for the high performance integral blade disc of aeroengines is met.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A laser synchronous welding equipment

ActiveCN104985324BShort welding timeHigh speedDomestic articlesLaser beam welding apparatusLaser transmitterLight guide

The invention provides a laser synchronous welding device which is used for welding an automobile lamp body and a lens. The laser synchronous welding device comprises a laser emitter, a first mold, a second mold and a light guiding pipe. The laser emitter is connected with an optical fiber set and meanwhile provides a plurality of beams of lasers. The first mold is used for containing the lamp body and suitable for moving up and down relative to the second mold. The second mold is used for containing the lens and evenly provided with a plurality of optical fiber fixing holes at the position corresponding to the welding position of the lens. Each optical fiber of the optical fiber set is connected to the corresponding optical fiber fixing hole. The light guiding pipe is used for shaping and focusing the lasers and located in the second mold. The light guiding pipe transversely penetrates the optical fiber fixing holes, and therefore the lasers can irradiate the light guiding pipe after being transmitted through the optical fibers. When the first mold moves to coincide with the second mold, the lasers shaped by the light guiding pipe penetrate the lens and are focused on welding ribs of the lamp body. The welding ribs of the lamp body are molten, and therefore the lamp body and the lens can be welded together. The device finishes welding the whole automobile lamp synchronously at a time and is high in efficiency and low in cost.

Owner:SHANGHAI SEEYAO ELECTRONICS CO LTD

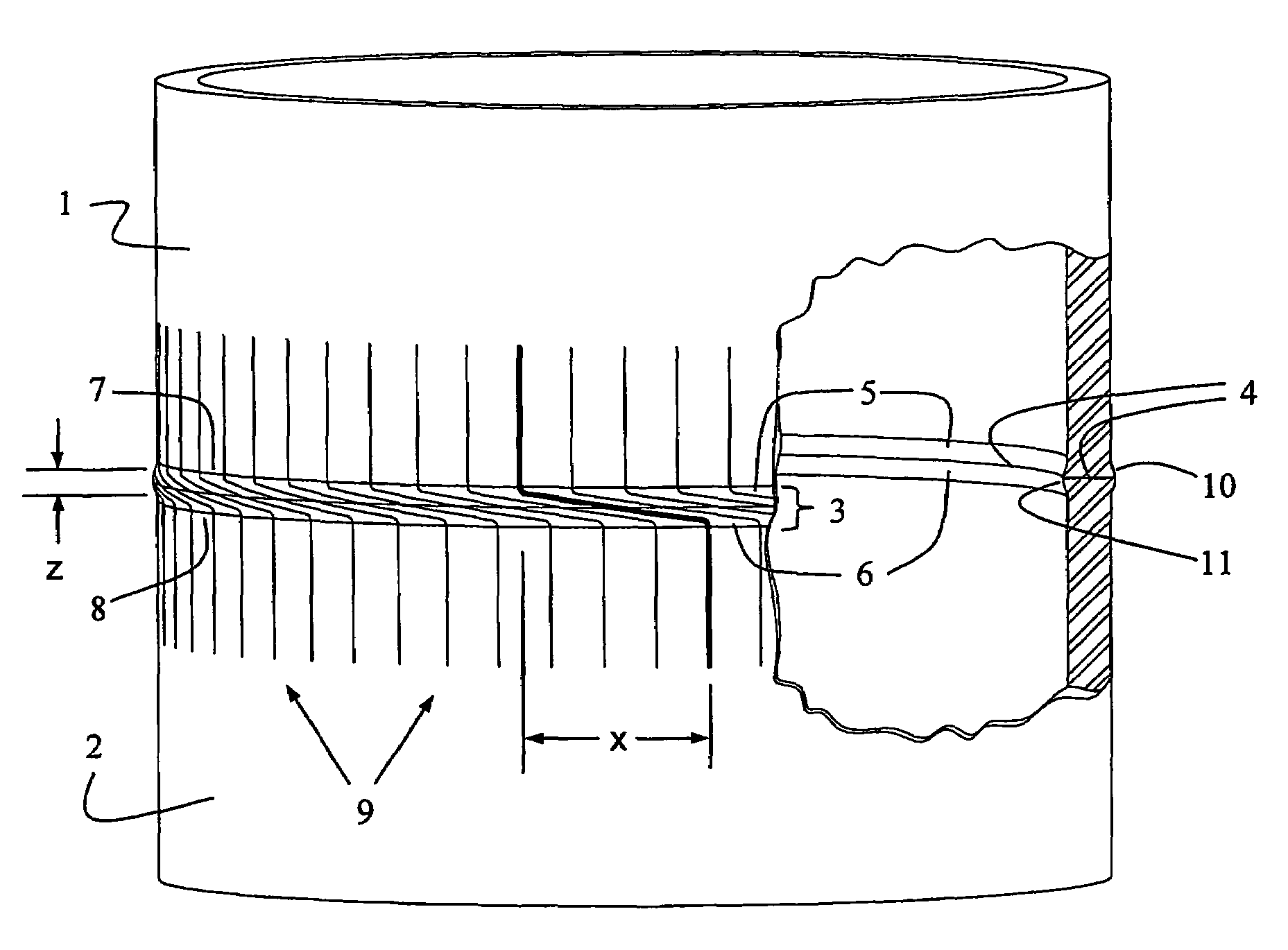

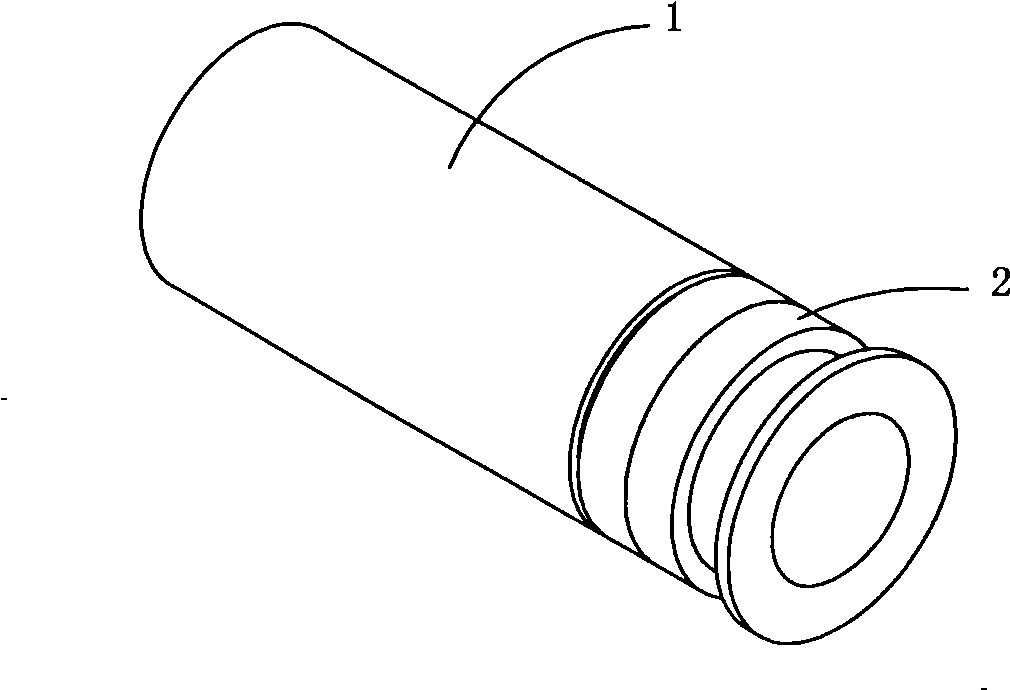

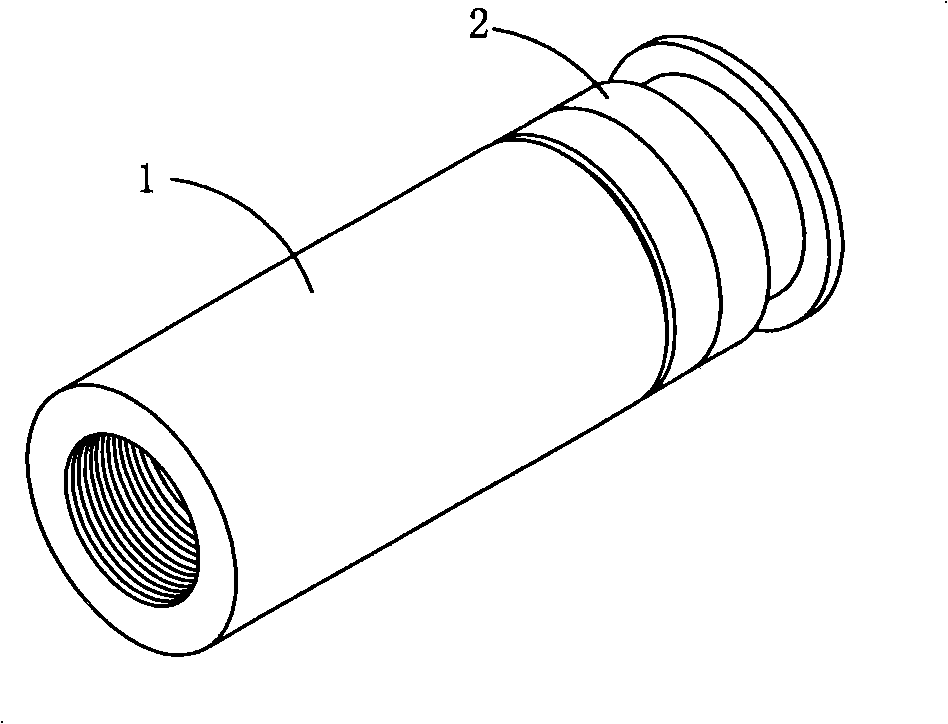

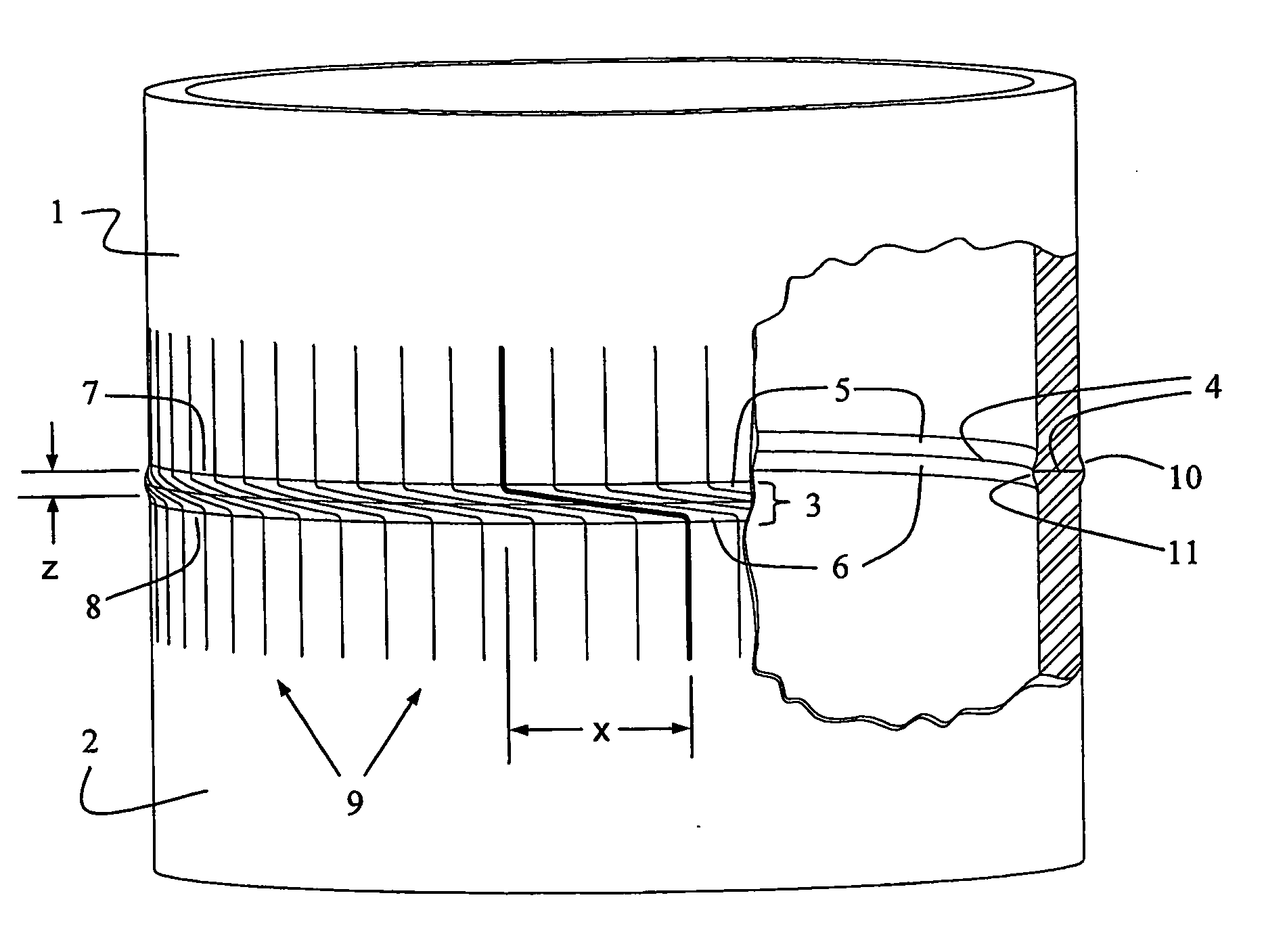

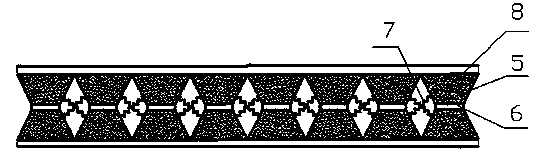

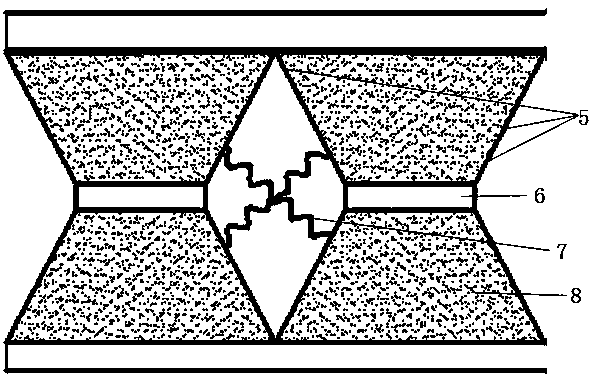

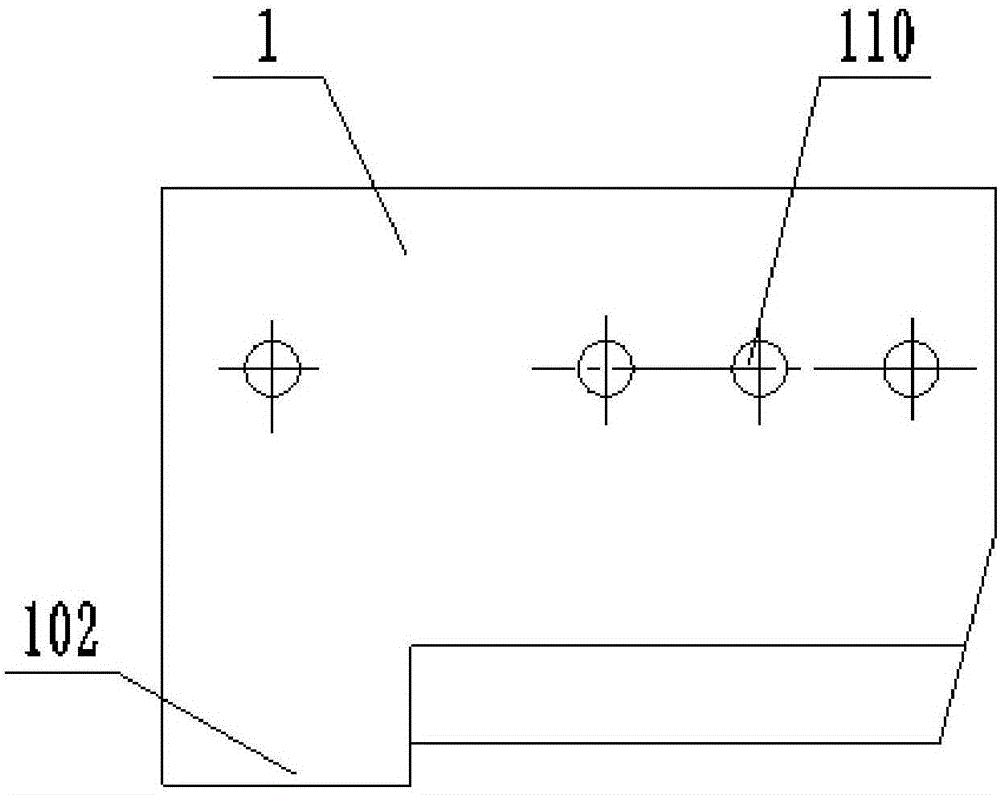

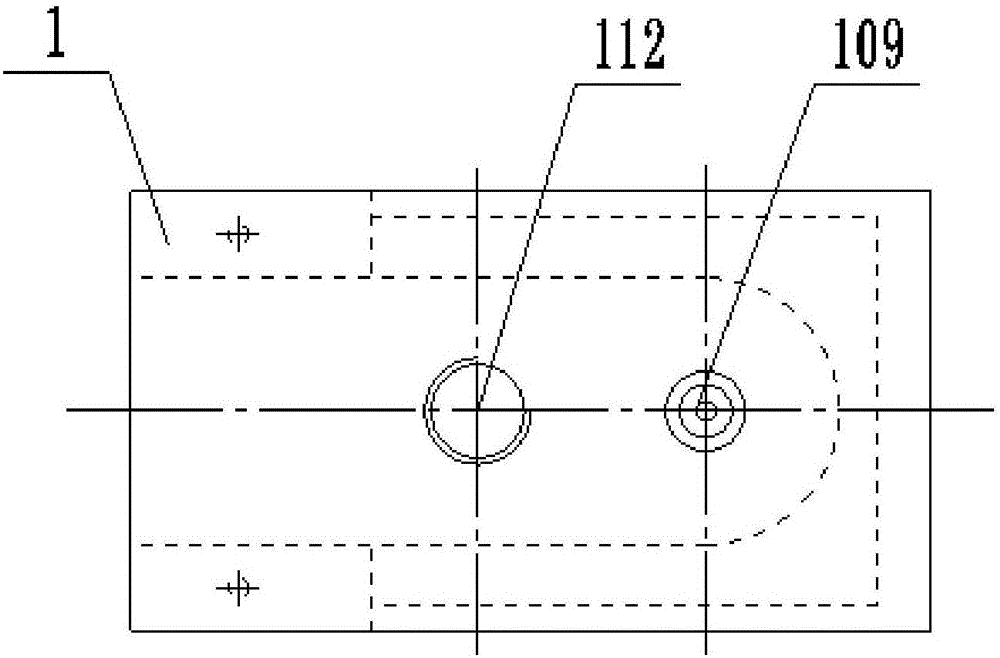

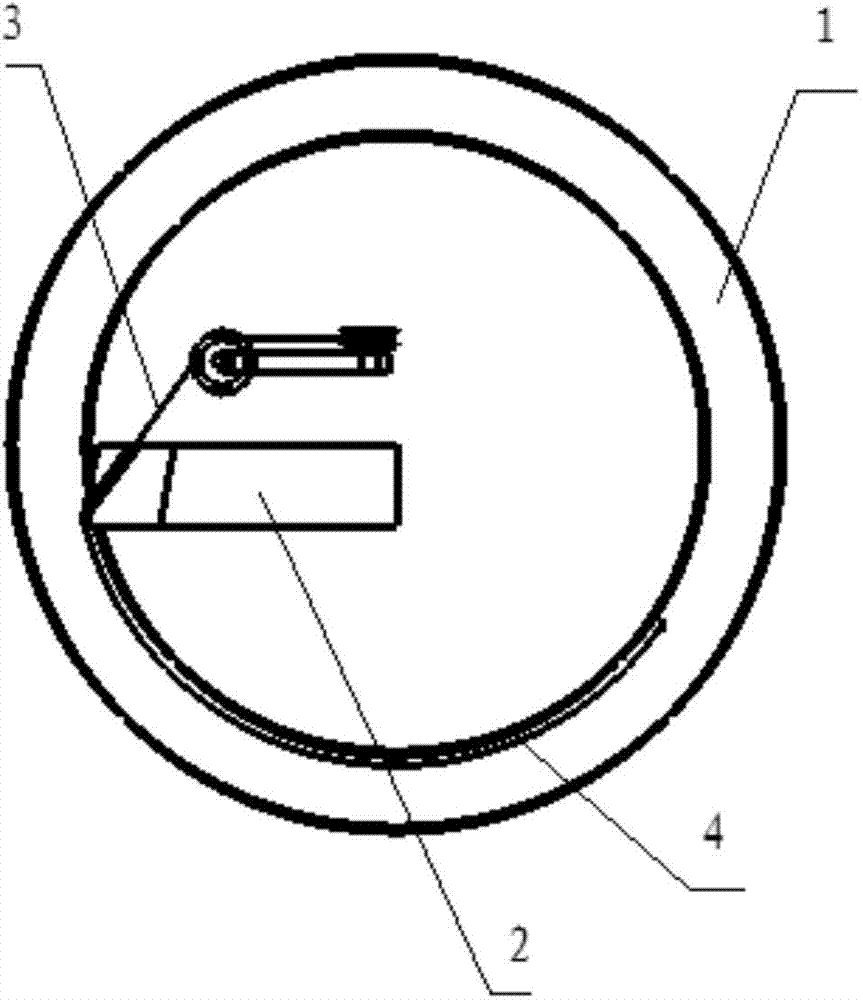

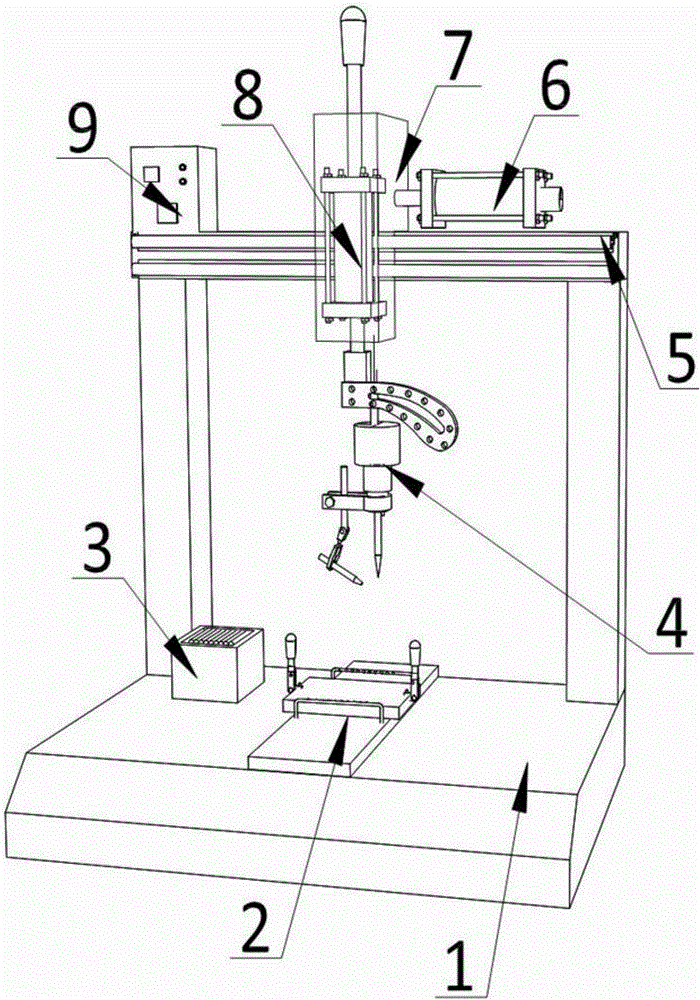

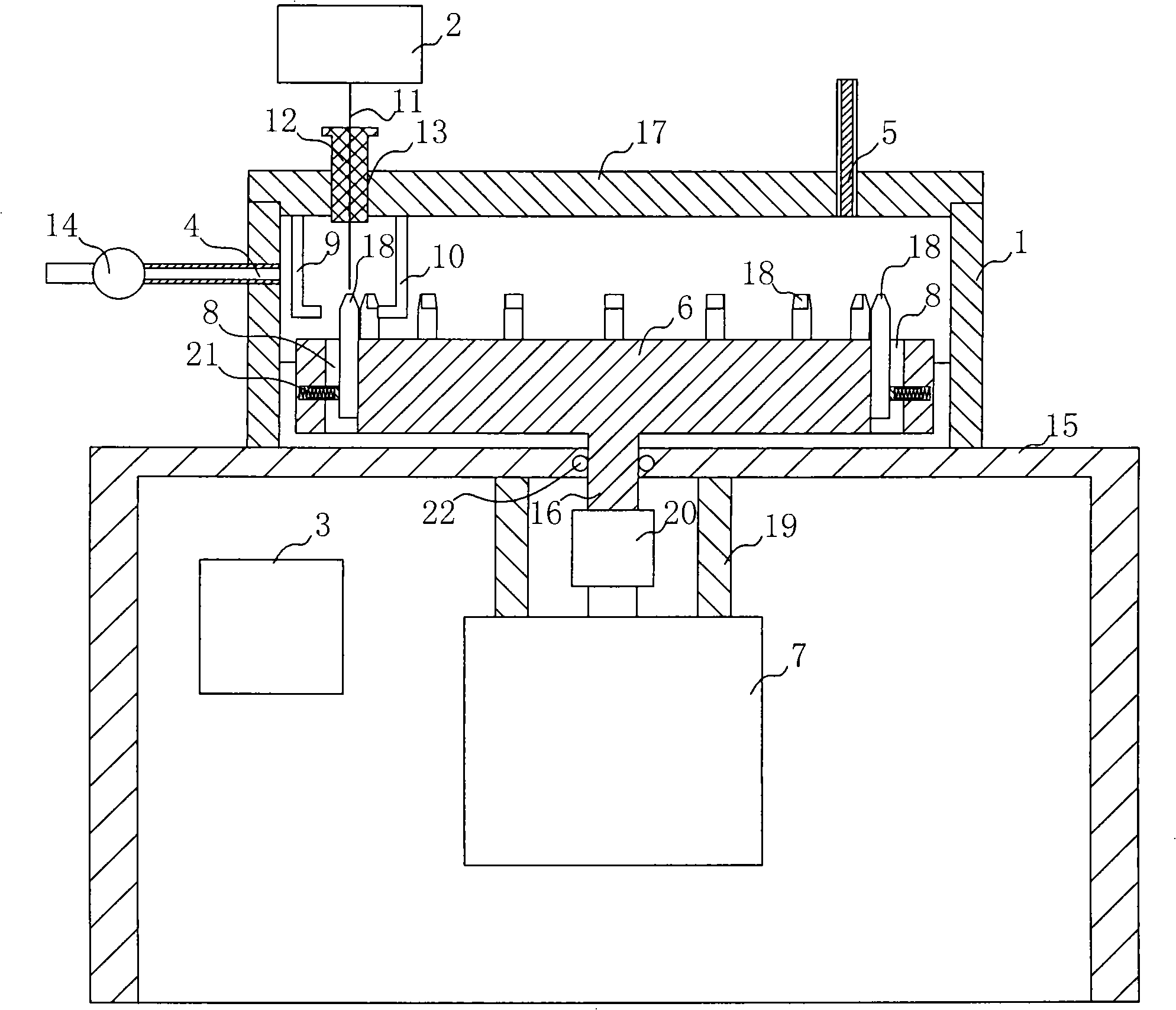

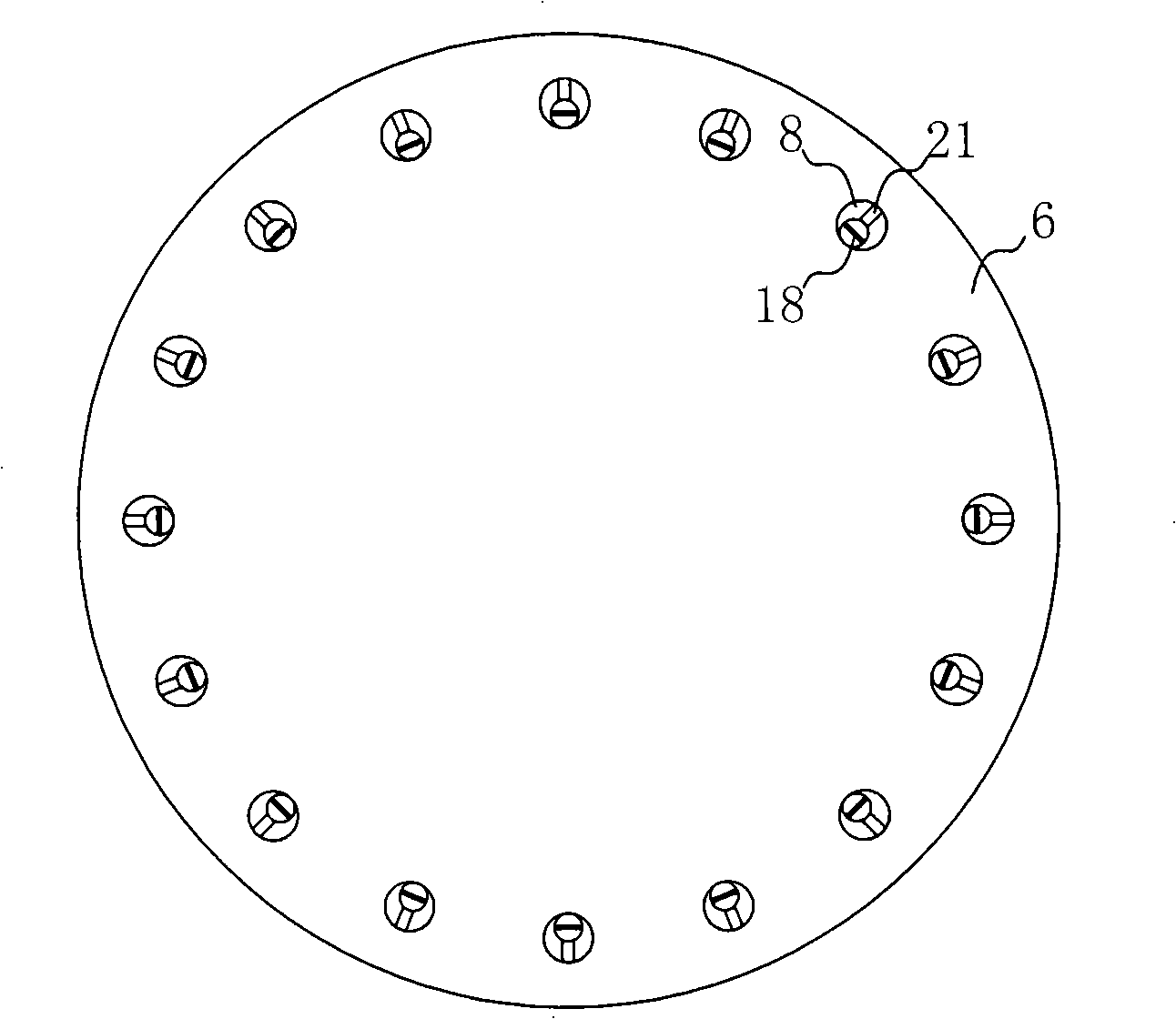

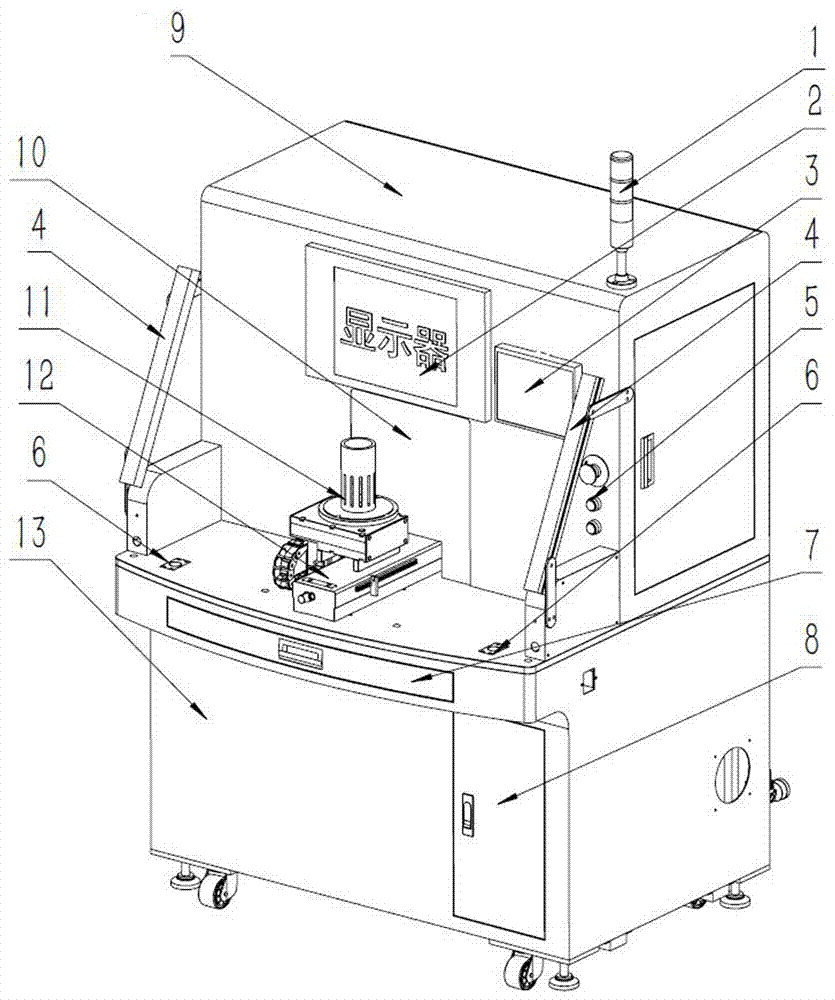

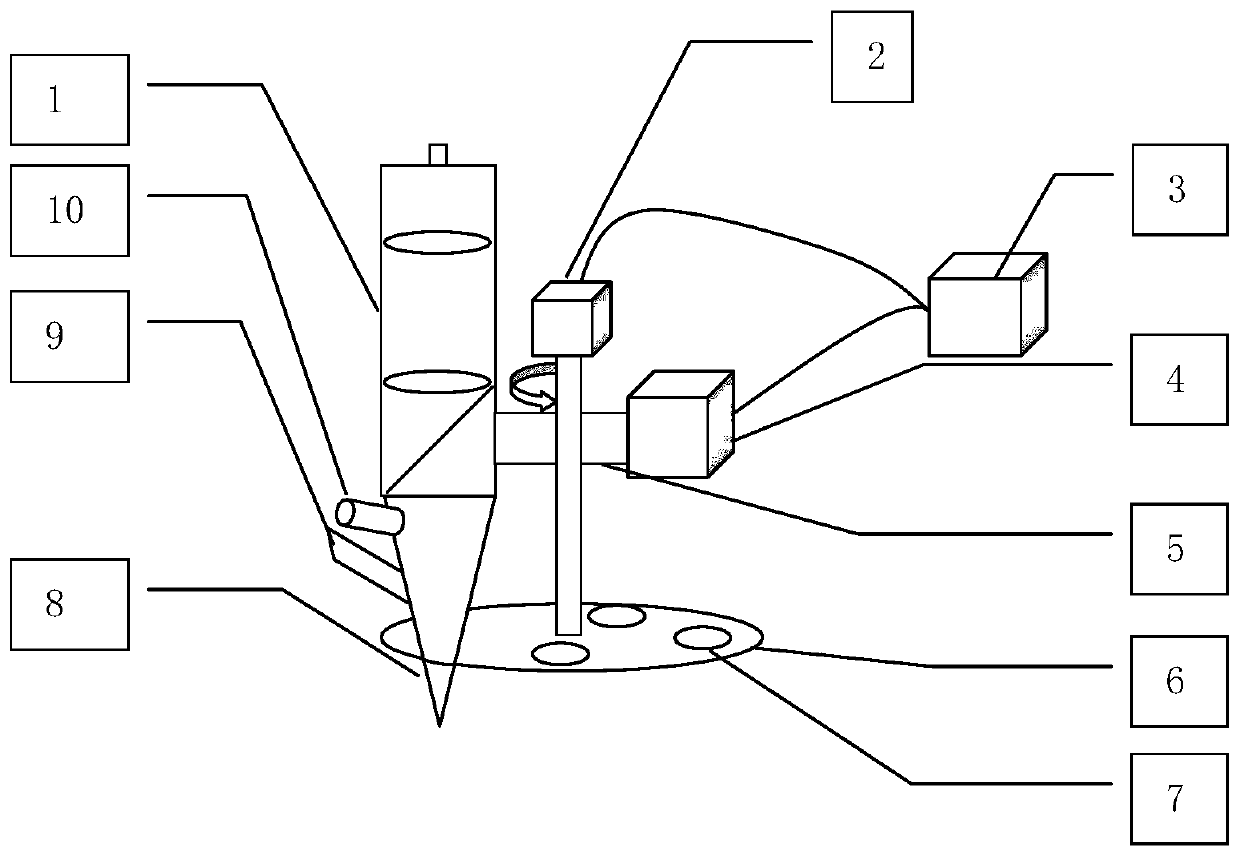

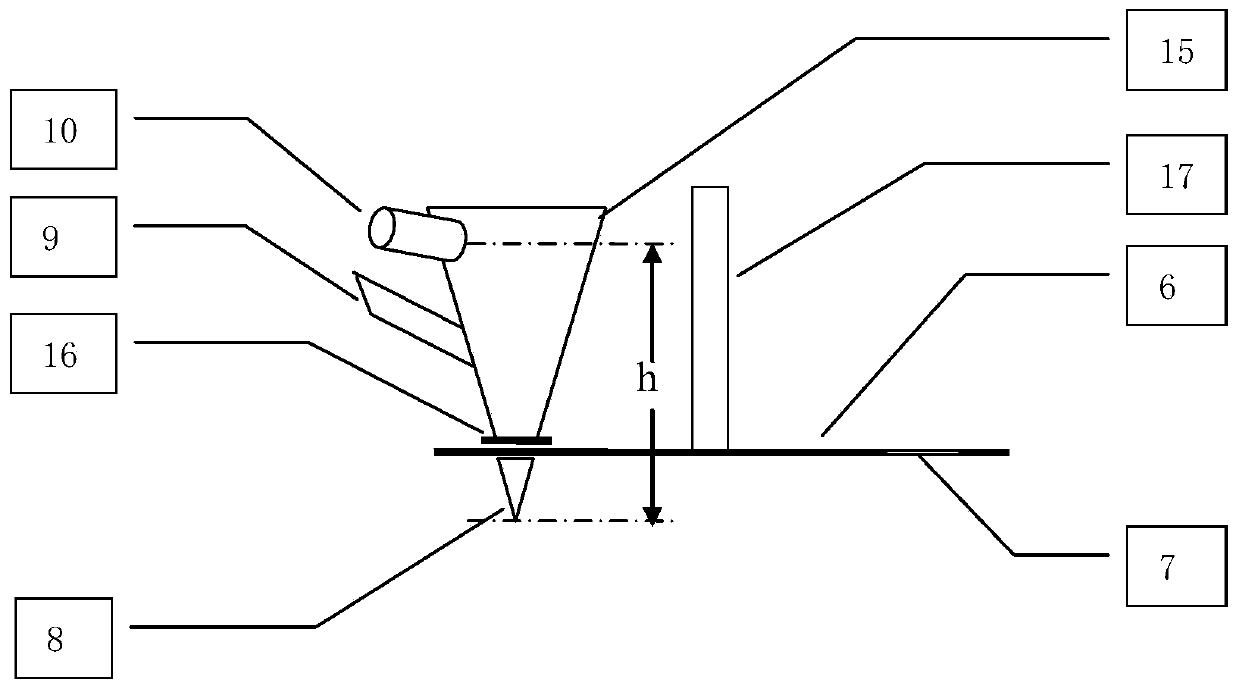

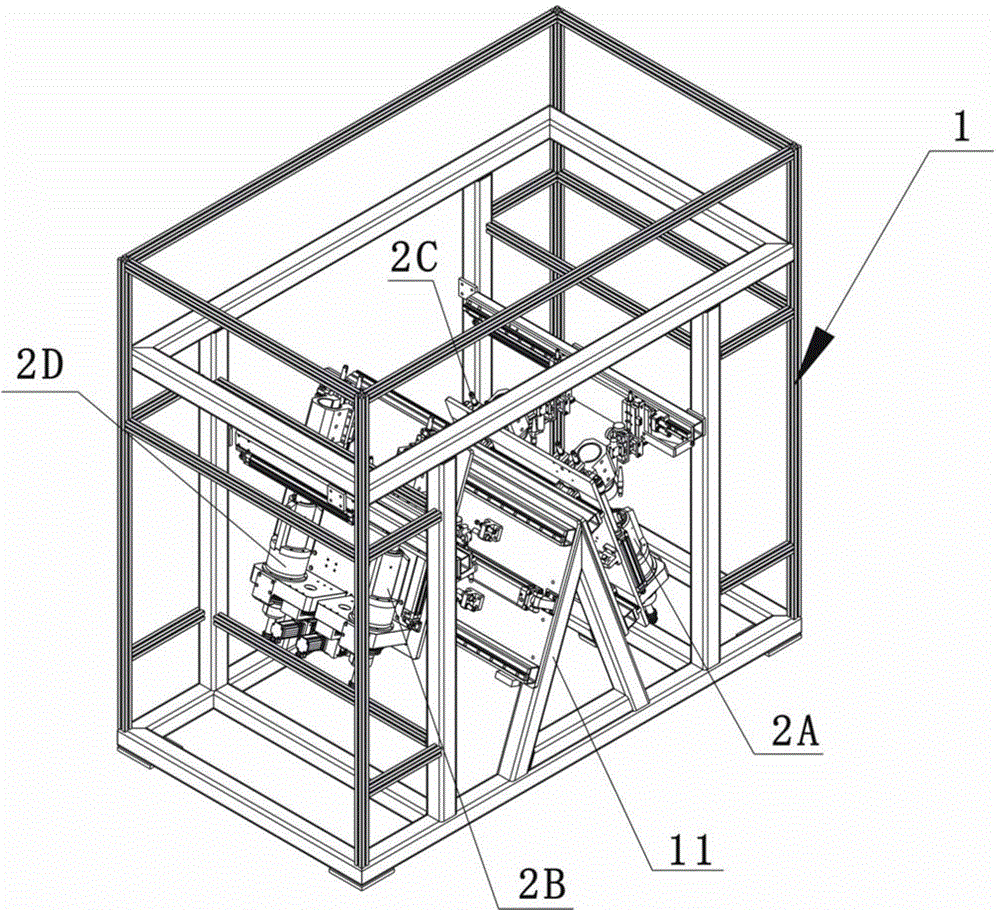

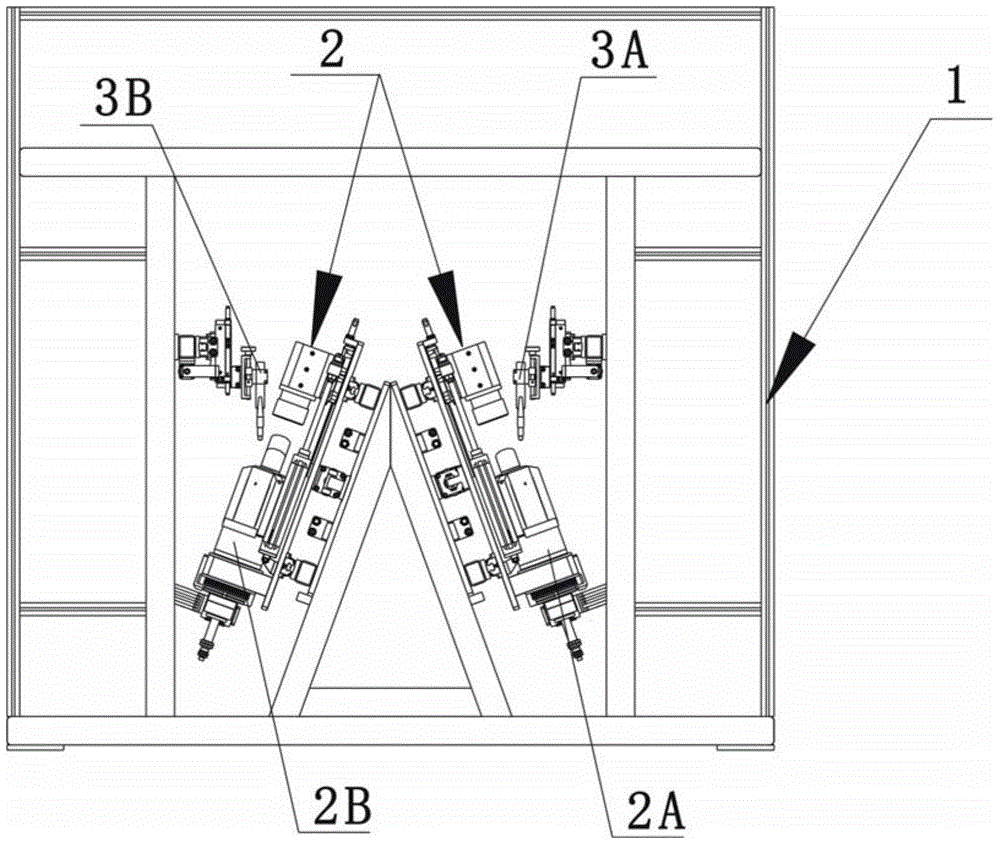

Automatic welding machine of gold sample tube

InactiveCN101337300AImprove welding efficiencyWeld smoothWelding/cutting auxillary devicesArc welding apparatusEngineeringDrive motor

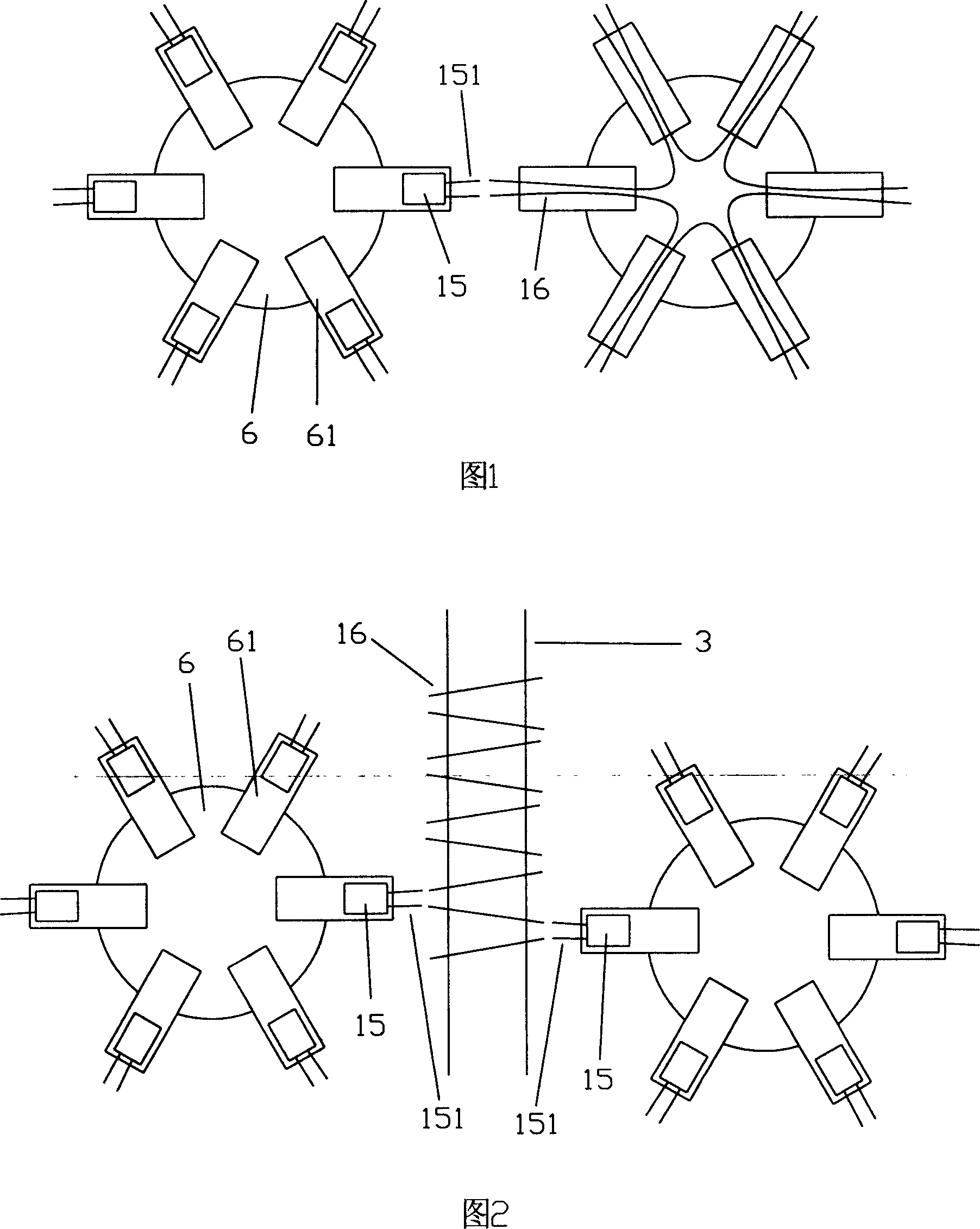

The invention discloses an automatic welding machine for a gold sample cell, which comprises an argon chamber (1), an argon arc welding machine (2), a program controller (3); an admitting port (4) and a vent port (5) are arranged in the argon chamber; a turnplate (6) is arranged in the argon chamber; the turnplate is connected with a driving motor (7); a plurality of gold tube locating holes (8) are formed on the turnplate; each gold tube locating hole is positioned on a circumference which takes the rotating center of the turnplate as the center thereof; an infrared emitter (9) and an infrared receiver (10) are respectively arranged in the argon chamber on the two sides right above the gold tube locating holes; the tungsten welding pin (11) of the argon arc welding machine is arranged in the argon chamber; the end part of the tungsten welding pin is arranged right above the gold tube locating holes; and the program controller is connected with the argon arc welding machine, the driving motor, the infrared emitter and the infrared receiver. The method adopts automatic welding, so that the welding efficiency is high, the success rate of welding is 100%, the welding line is even and smooth, the welding time is short, and the maximum heating temperature of the sample does not exceed 40 DEG C.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

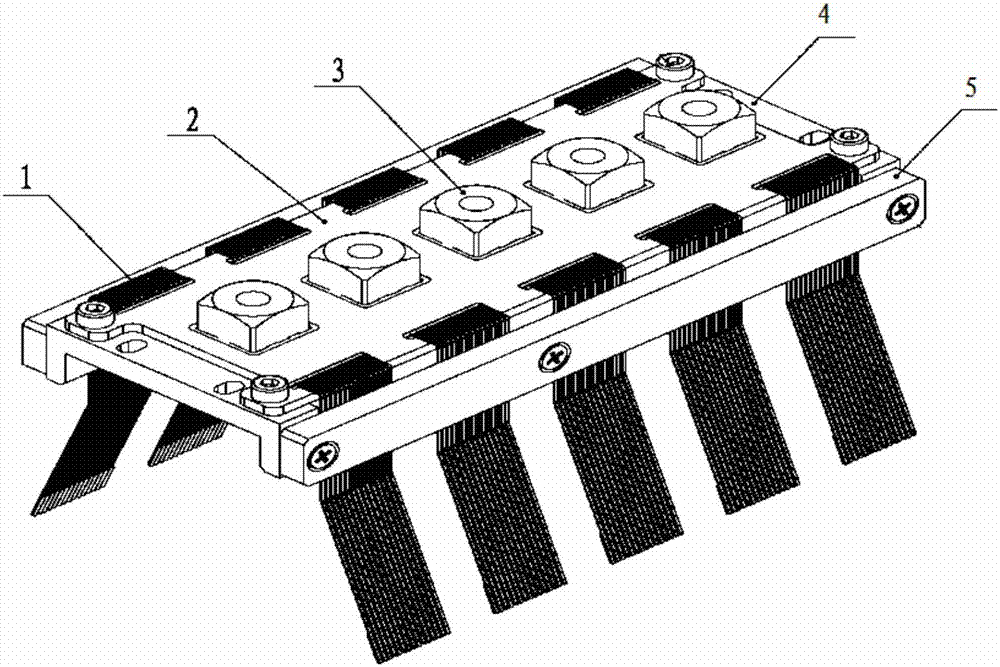

Combined brush assembly for wind power sliding ring

ActiveCN107104340AImprove electrical performanceImprove contact effectRotary current collectorElectricityMiddle line

A combined brush assembly for a wind power sliding ring relates to the technical field of a power transmission device for wind power generation. The combined brush assembly comprises brushes, a printed circuit board, winding terminals, a support plate and side press plates, wherein the support plate is of a horizontally-placed rectangular structure, a groove is formed in a middle part of a lower surface of the support plate along a direction of a long edge, the printed circuit board is of a horizontally-placed rectangular structure and is fixedly arranged on an upper surface of the support plate, the n brushes are stacked and fixedly arranged at two sides of the printed circuit board along the direction of the long edge at equal distance, the m wiring terminals are uniformly arranged at a middle line of an upper surface of the printed circuit board along the direction of the long edge, the side press plates are symmetrically arranged at two sides of the long edge of the support plate, n is a positive integer, and m is a positive integer. The invention proposes the combined brush assembly for the wind power sliding ring, the fabrication process of brush assembly for the wind power sliding ring is simplified, the usage amount of a gold-based brush wire is reduced, and the cost is reduced.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

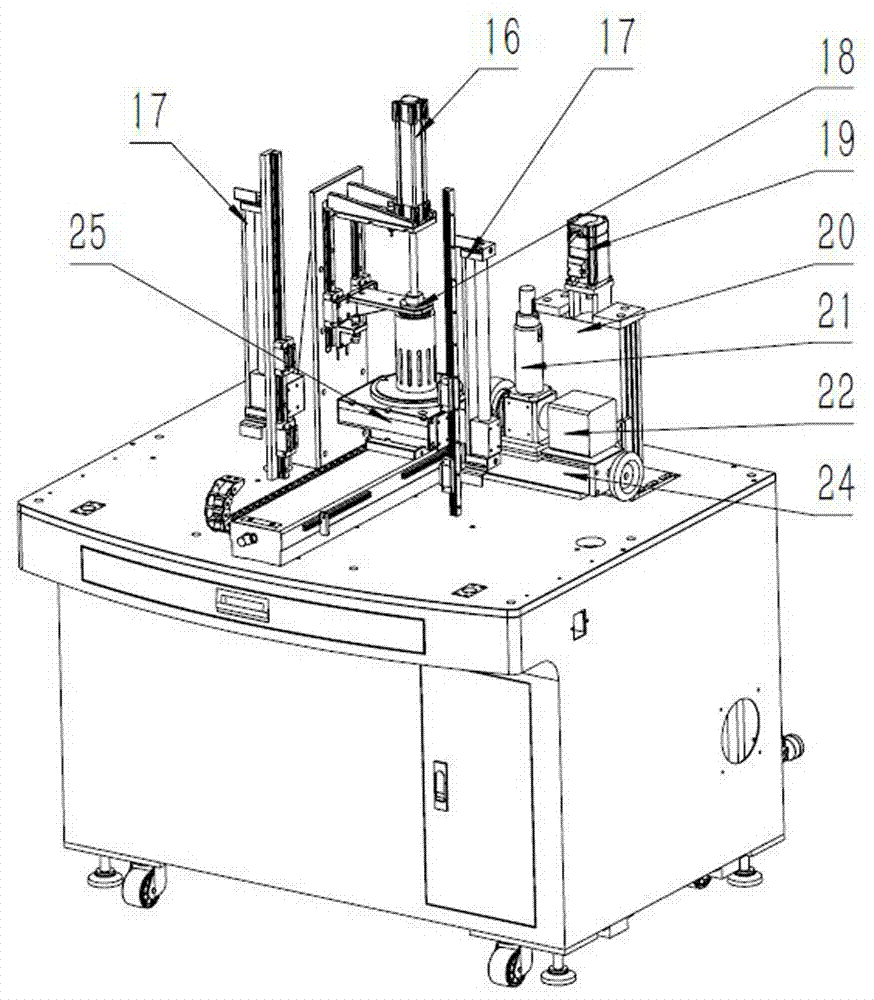

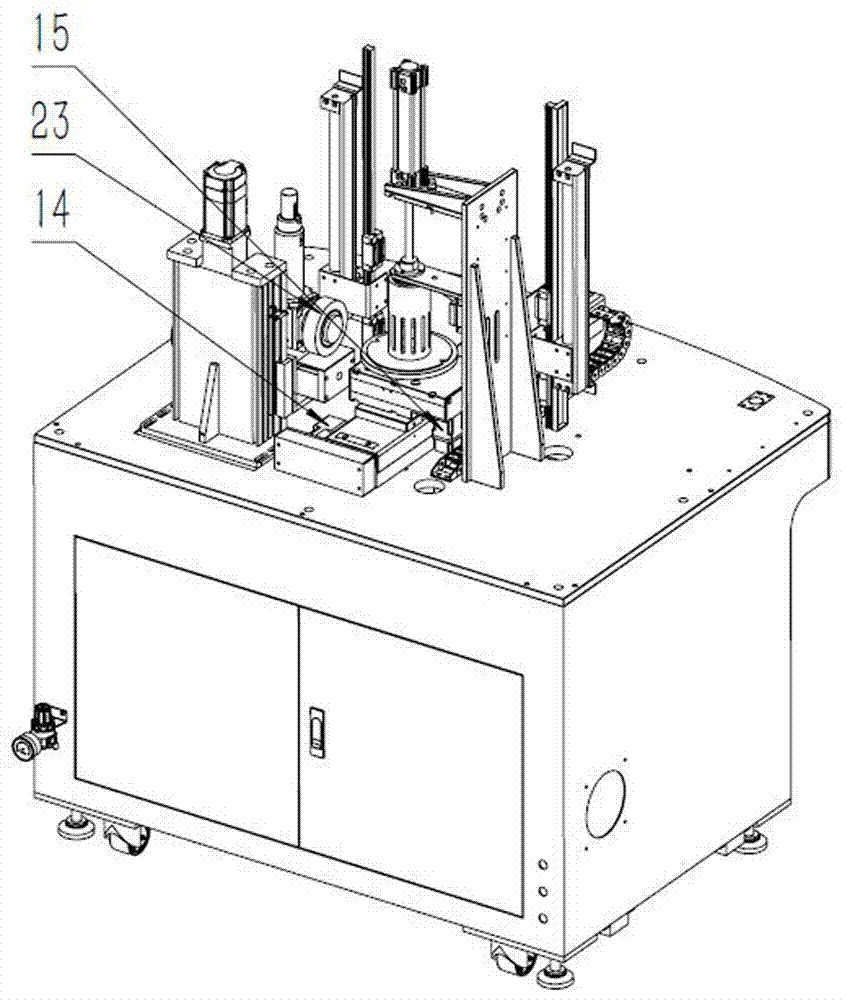

Motor stator core laser automatic welding equipment

ActiveCN106862764AEasy to makeObserve the welding effect in real timeWelding/soldering/cutting articlesMetal working apparatusElectric machineryDisplay device

The invention discloses motor stator core laser automatic welding equipment which comprises an industrial personal computer chassis, an automatic feeding mechanism, a pressing rotary mechanism and a laser welding mechanism; the feeding mechanism is composed of a Y-axis module, an R-axis rotating mechanism and a welding carrier, and the welding carrier rotates along with the R-axis rotating mechanism; the pressing rotary mechanism is composed of a pressing air cylinder and a follow-up rotating mechanism, and the follow-up rotating mechanism rotates along with the welding carrier; the laser welding mechanism is composed of a collimation welding head, an industrial camera, a light source, an X-axis manual module, a Z-axis module and a Z-axis servo motor; and different welding focal lengths can be adjusted according to different product specifications, an operation displayer and a monitor are installed in front of an equipment protective cover, operational program calling and welding effect monitoring are facilitated, operability and the product yield are improved, the welding time is short, the welding carrier is easily manufactured, the production efficiency can be effectively improved, the structure is simple and stable, and equipment faults are effectively reduced.

Owner:SUZHOU SHOLASER TECH CO LTD

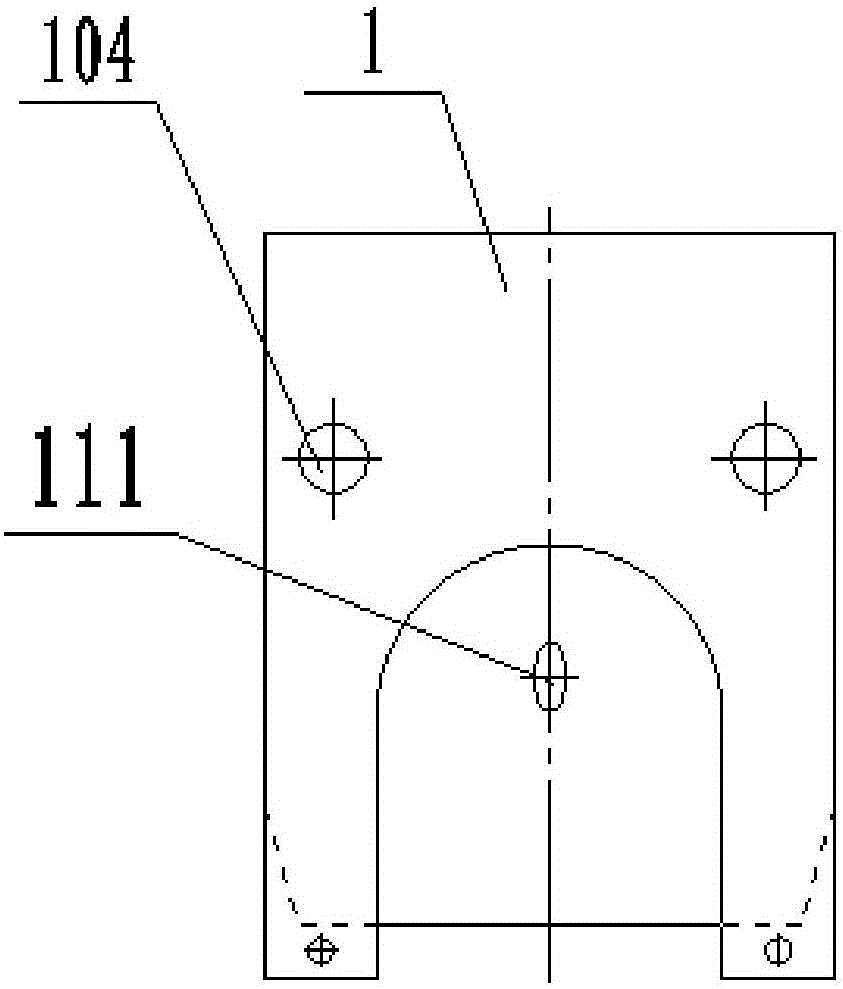

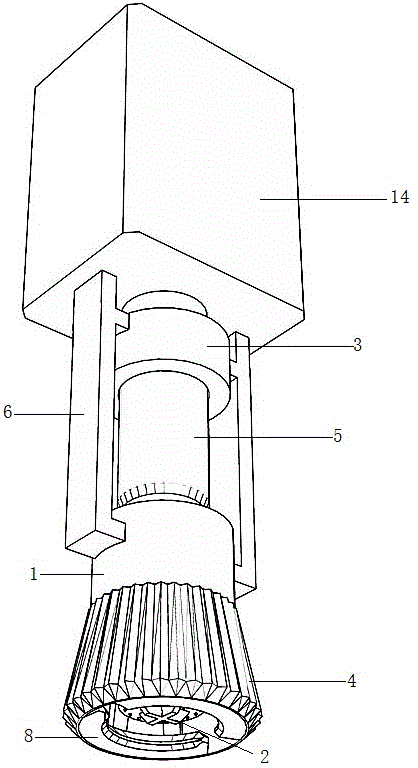

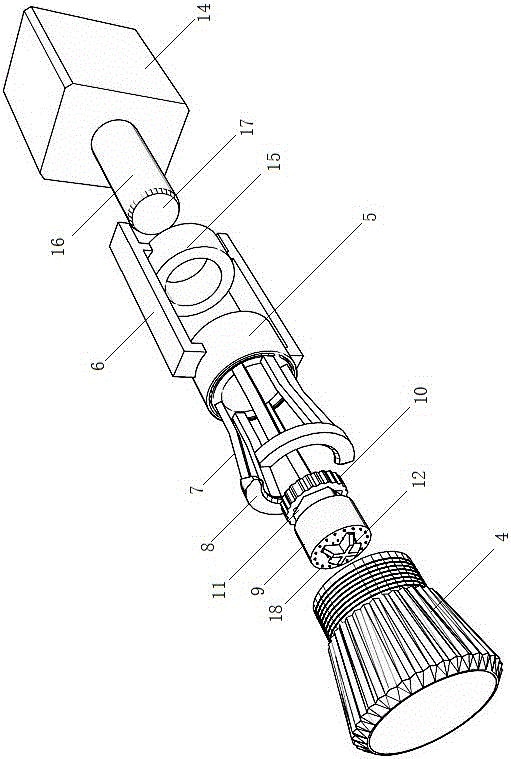

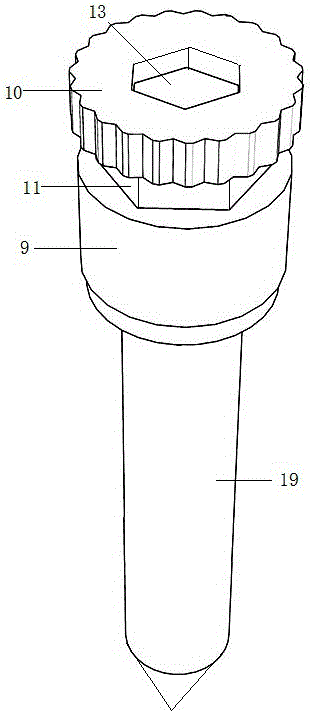

Orthopedics nail taking device

InactiveCN105877835AShort welding timeImprove welding strengthFastenersLocking mechanismUltrasonic welding

The invention discloses an orthopedics nail taking device, and relates to the technical field of orthopedics medical equipment. The orthopedics nail taking device comprises a nail locking mechanism, a transition core wire mechanism and an ultrasonic welding mechanism, wherein the nail locking mechanism comprises a truncated cone-shaped sleeve positioned at the lower part and a guide tube positioned at the upper part; antiskid stripes are uniformly arranged on the outer wall of the truncated cone-shaped sleeve in the circumferential direction; the upper end of the truncated cone-shaped sleeve is in screw-thread fit with the guide tube; the lower end of the guide tube is connected with two symmetrically arranged elastic hoop semi-bodies; the transition core wire mechanism comprises a cylindrical welding block positioned at the lower end, a transmission screw cap positioned at the upper end and a hexagonal double-screw bolt connected between the cylindrical welding block and the transmission screw cap; a crossed bulge is arranged at the lower end of the cylindrical welding block; an internal hexagonal screw hole is formed in the top surface of the transmission screw cap; the ultrasonic welding mechanism comprises a support arranged on two sides of the guide tube and an ultrasonic welding machine arranged at the upper end of the support. The orthopedics nail taking device is convenient to use and simple to operate, and can be firmly connected with nails, so that the nails are unlikely to slip off and be broken in the nail taking process.

Owner:RIZHAO HOSPITAL OF TCM

Welding method of solder ball welding device

ActiveCN111014868AAchieve visual effectsQuick switchSolder feeding devicesSoldering auxillary devicesLight spotSolder ball

The invention designs a welding method of a solder ball welding device. According to the solder ball welding method, a solder ball welding device with a coaxial vision system is adopted, a laser focusing head, a controller, a CCD camera and a rotating disc are arranged in the solder ball welding device, part of a laser light path coincides with a vision imaging light path, and coaxial and same-focus laser and vision are achieved. During welding, welding nozzles of different sizes can be switched by rotation, rapid switching between solder ball welding of different sizes and visual imaging is achieved, the sizes of light spots are rapidly adjusted to adapt to the nozzles of different hole diameters, and the requirements of welding spots of multiple specifications are met. Through the processes of preheating before welding, continuous ball spraying and light supplementing after welding, sound welding of welding spots with different sizes and high heat dissipation speed are achieved. During welding, random solder balls can be supplemented in real time, and after entering the transition bin, the solder balls are directly melted in the falling process and then drop on a bonding pad without staying at a nozzle opening, so that the welding time is shortened, and the production efficiency is improved.

Owner:WUHAN BESKYS TECH CO LTD

Welding method of arc-shaped welding seam

The invention discloses a welding method of an arc-shaped welding seam, comprising the following steps of: selecting a submerged-arc welding machine; selecting a round steel according to the width of a guide wheel of the welding machine; bending the round steel into a shape of a welding seam radian; fixing the round steel on a steel plate to be welded in a spot-welding mode; clearing a position needing welding by positioning, and clearing away impurities such as oxide skin, rust, water, oil stains, and the like; preheating; carrying out positioned welding; welding; and finally inspecting: carrying out appearance inspection and magnetic powder inspection. The invention has the advantages of attractive welding seam formation, high welding speed, working efficiency improvement, labor strength reduction and less welding deformation.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD

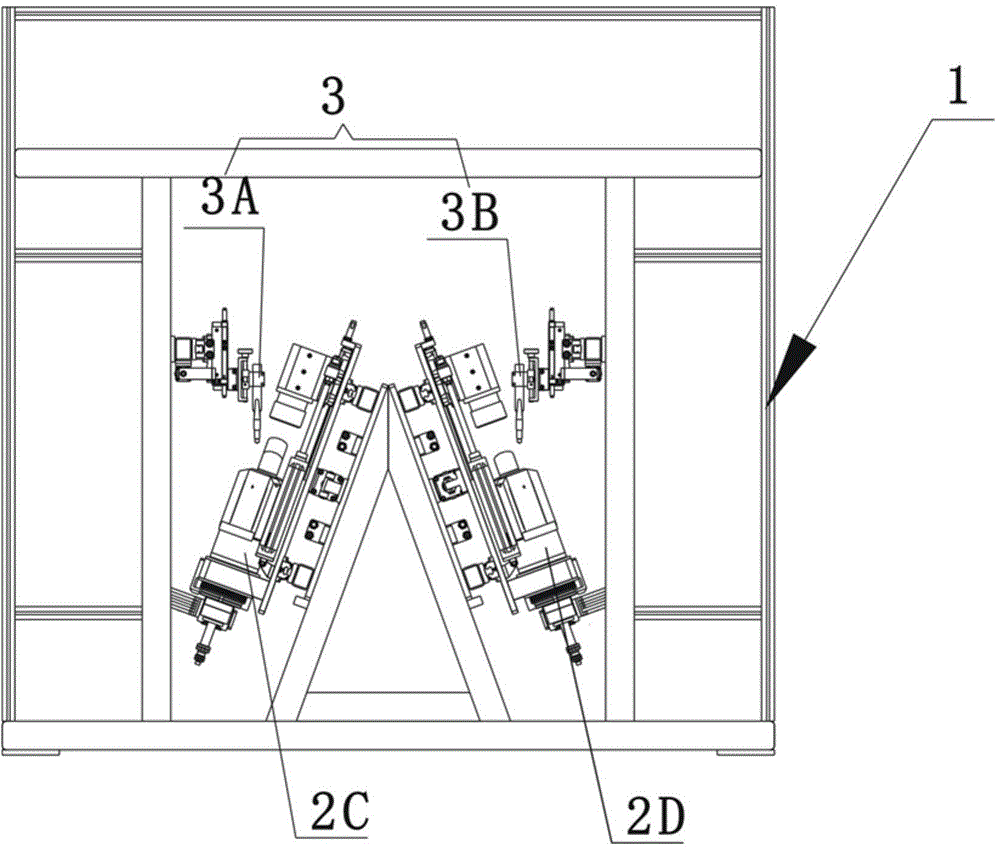

Welding device and application

InactiveCN104889545ANo splashAchieve circular seam weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringArc welding

The invention provides a welding device and application. The welding device adopts non-consumable-electrode arc welding for welding and comprises a frame, at least one positioning and clamping mechanism, at least one welding mechanism and at least one rotary mechanism. The positioning and clamping mechanisms are arranged on the frame and used for positioning and clamping welding workpieces, and an included angle between the axis of the clamped welding workpieces and the horizontal plane is 2-178 degrees. Each welding mechanism comprises at least one welding gun which is used for welding the clamped welding workpieces. The rotary mechanisms drive the welding workpieces or the welding guns to rotate around the axes of the welding workpieces during welding.

Owner:斯培淦

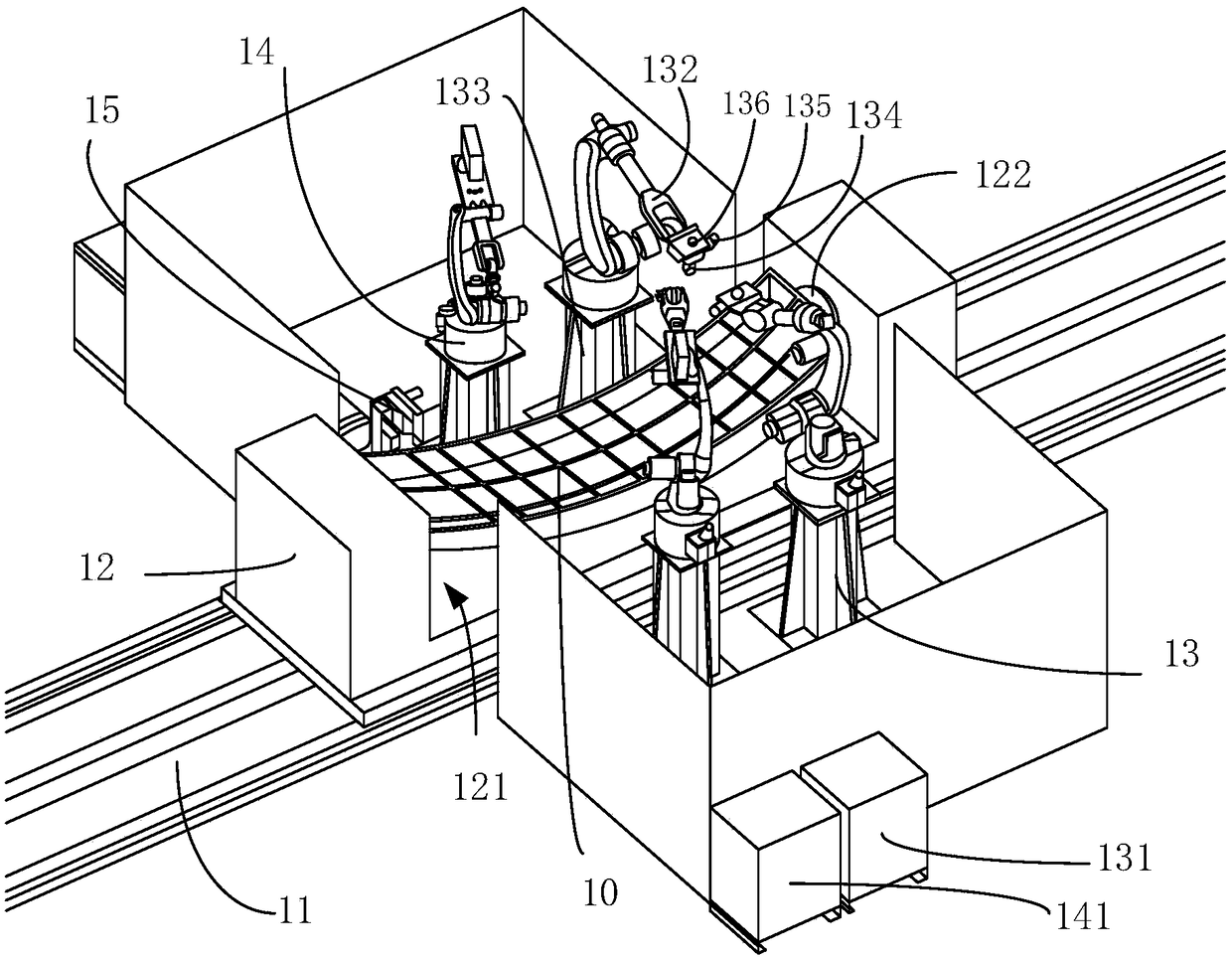

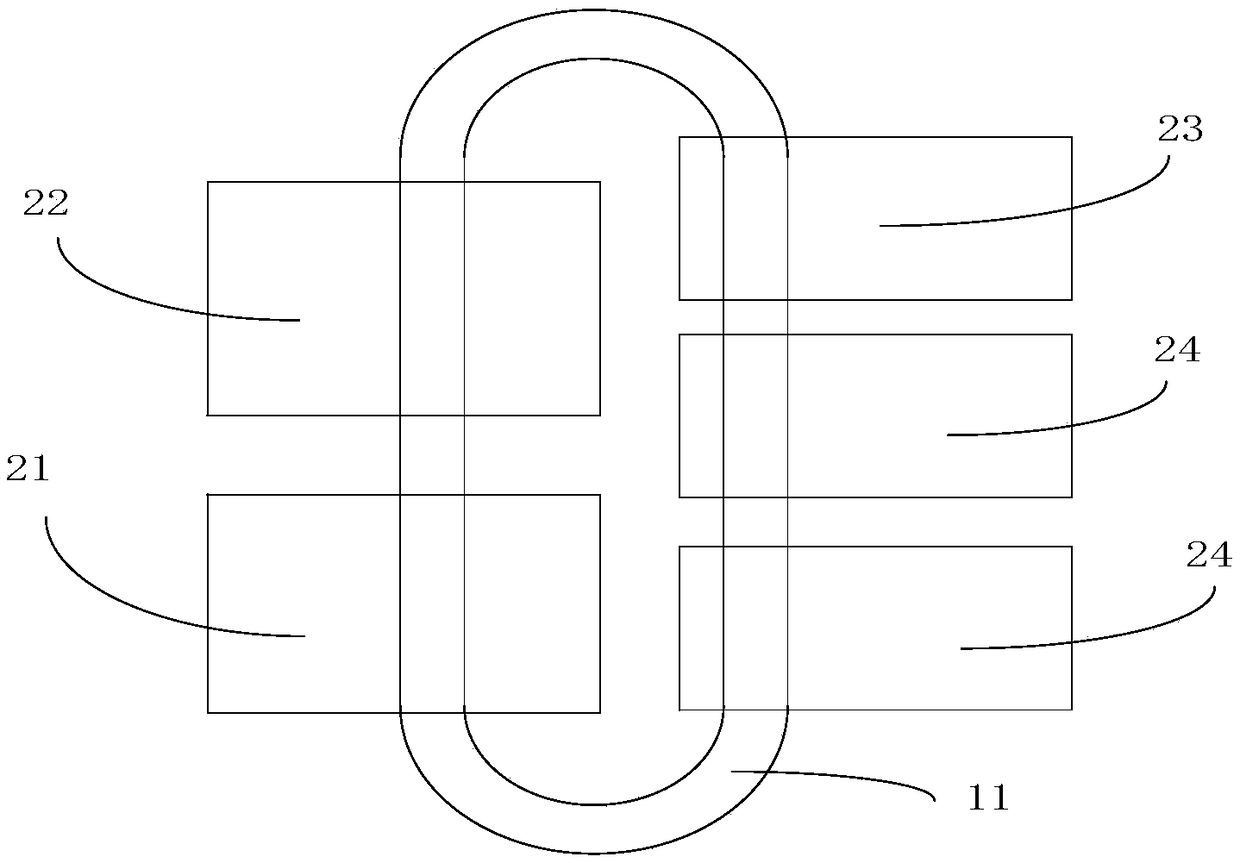

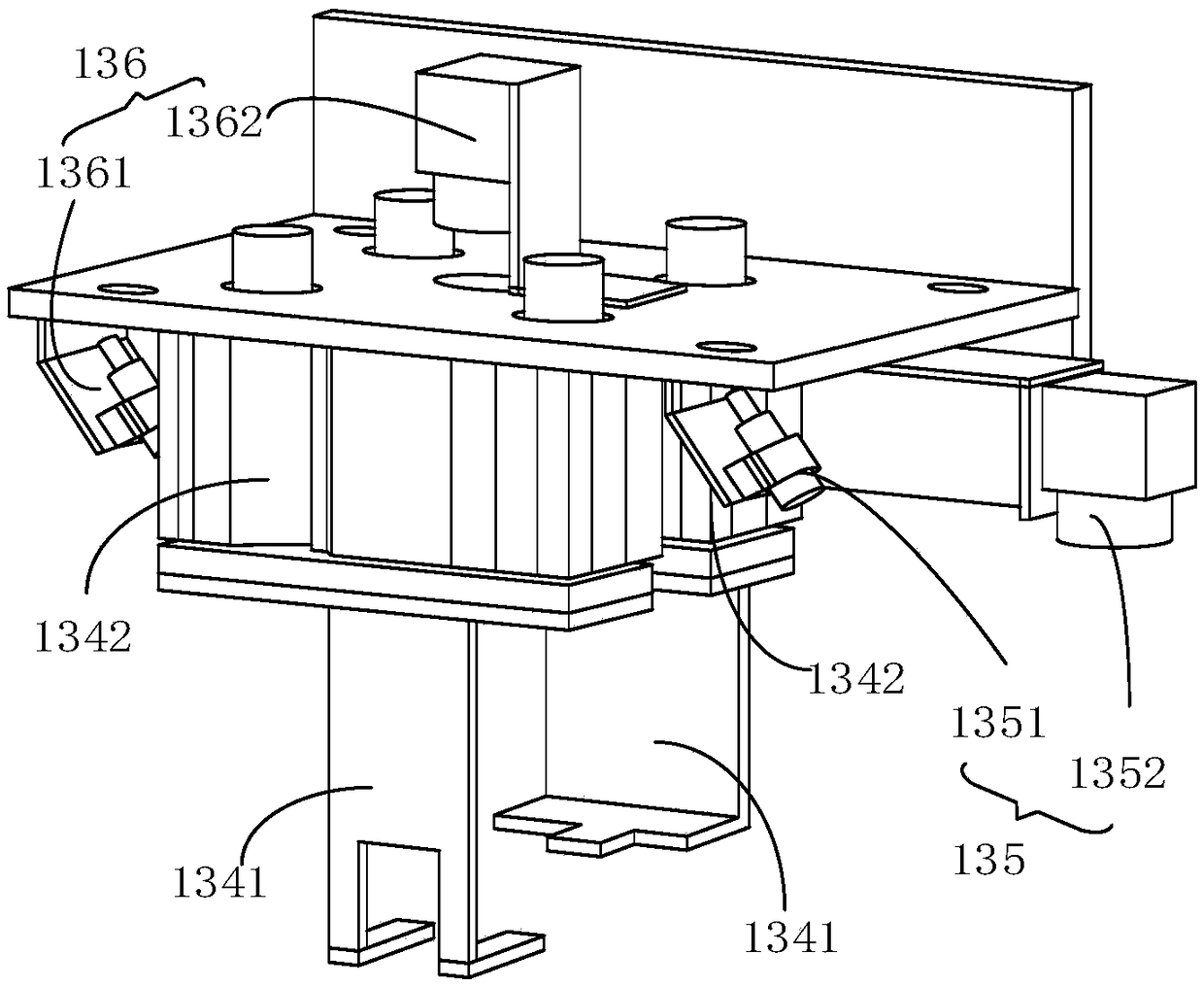

Automatic welding device, clamping robot and automatic welding method

ActiveCN109496173AReduce work intensityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesRebarClose contact

The invention relates to an automatic welding device, a clamping robot and an automatic welding method. The automatic welding device comprises: a code material tire (12), which is used for placing cross-shaped transverse steel bars and longitudinal steel bars to be welded materials, wherein the transverse steel bars and longitudinal steel bars form a a reinforcing mesh (10), a clamping robot (13)for judging whether there is a gap between the transverse reinforcing bars and the longitudinal reinforcing bars, and clamping the transverse reinforcing bars and the longitudinal reinforcing bars having the gap so as to be in close contact with each other, and a welding robot ( 14) for welding the transverse reinforcing bars and longitudinal reinforcing bars that are close to each other.

Owner:SHENZHEN A&E INTELLIGENT TECH INST CO LTD

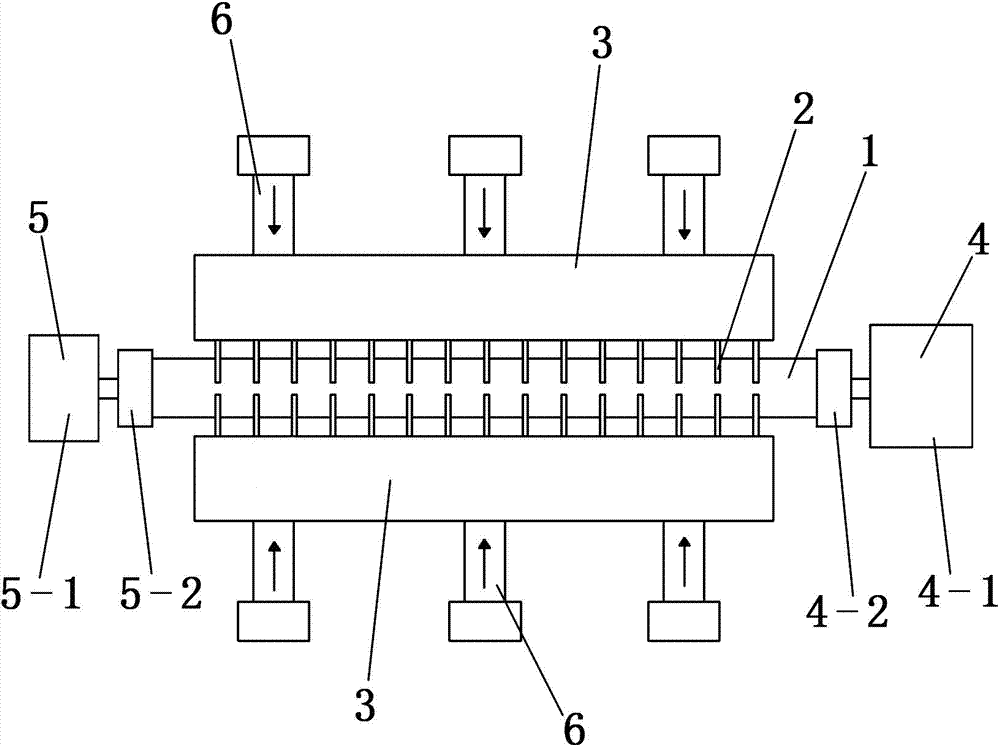

Method and equipment for welding steel pipe and fins of H-type coal economizer used for boiler

ActiveCN104759823AUnlimited spacingLow machining accuracy requirementsWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingElectric machine

The invention provides a method and equipment for welding a steel pipe and fins of an H-type coal economizer used for a boiler, belongs to the technical field of boiler manufacturing and solves the current problems existing in the welding of the steel pipe and the fins. The method for welding the steel pipe and the fins of the H-type economizer used for the boiler comprises the step of conducting friction welding to the multiple fins with the steel pipe simultaneously; the equipment for welding the steel pipe and the fins of the H-type economizer used for the boiler comprises two fin fixing dies, hydraulic telescopic devices, a motor driving system and a supporting device; the two fin fixing dies are arranged symmetrically, multiple grooves used for the fins to be inserted therein are formed in the inner surfaces of the two fin fixing dies correspondingly, the hydraulic telescopic devices are arranged at the outer sides of the two fin fixing dies respectively, the motor driving system is arranged at the outer side of one end of the two fin fixing dies, and the supporting device is arranged at the outer side of the other end of the two fin fixing dies. The method and equipment are used for welding of the H-type coal economizer.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com