Patents

Literature

47results about How to "Suitable for connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

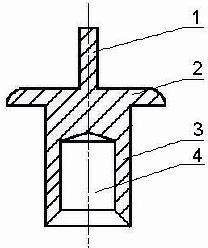

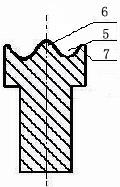

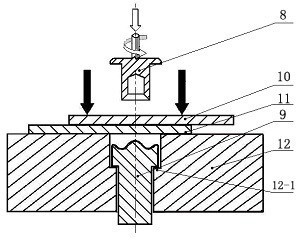

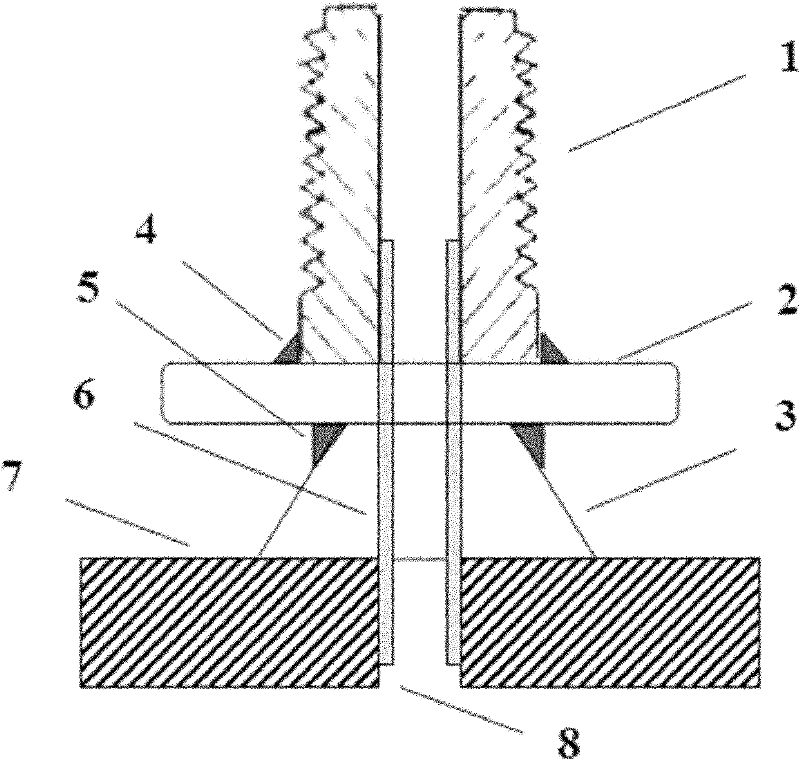

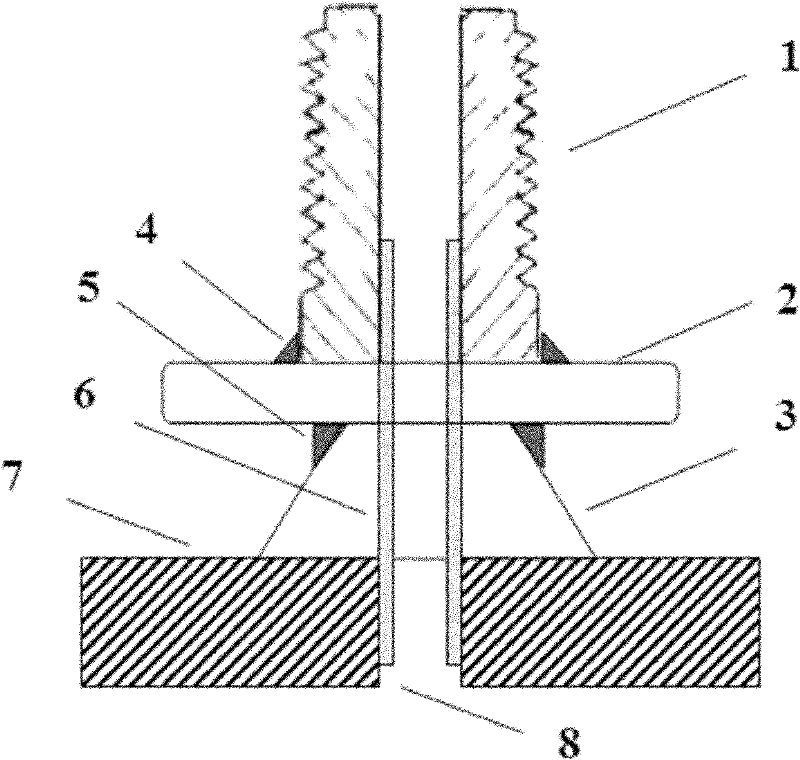

Metal plate rotating friction riveting method

InactiveCN102615508AEasy to useSimple structureOther manufacturing equipments/toolsNon-electric welding apparatusPunchingInterlock

The invention relates to a metal plate rotating friction riveting method which adopts a semitubular rivet, a cylindrical punching lever and a die, wherein the semitubular rivet comprises an integrally arranged clamping lever, a rivet cap and a semitubular rivet shank, the head of the cylindrical punching lever is provided with a rotary circular pit, and the middle part of the pit is provided with a protruding plug; the cylindrical punching lever is vertically positioned in the die and supported by the die; and the shape of the circular piston hole in the die is matched with that of the cylindrical punching lever. The invention provides a riveting technology for metal plate connection in a wider application range, and also provides a new metal plate riveting method aiming at the defects in the existing riveting technology. The invention uses the plug-free semitubular rivet, and the mechanical interlock between the plate and the rivet is formed by the extrusion of the punching lever with a tapered plug at the head; and thus, the rivet structure is simplified, and the rivet can rotate into the metal plate more easily, so that the extrusion pressure required by the rivet swelling strain for forming the mechanical interlock is reduced.

Owner:ZHENGZHOU UNIV +1

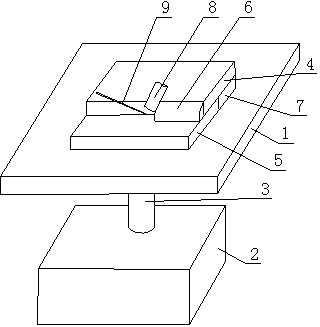

Method for brazing copper aluminum tubes without aid of brazing flux

InactiveCN102581414AReduce porosityImprove air tightnessSoldering apparatusWelding/soldering/cutting articlesSlag (welding)Weld seam

The invention discloses a method for brazing copper aluminum tubes without the aid of brazing flux. The method includes the steps: firstly, expanding one end of optional one of the copper aluminum tubes into a socket by a thermal expansion method, manufacturing a brazing alloy plate into a brazing thin tube by a stamping method, and placing the brazing thin tube into the socket; secondly, inserting one end of another welded tube into the brazing thin tube, and tightly abutting the end opening of the welded tube to the bottom of the socket to form close fit; and thirdly, assembling the brazing thin tube and the welded tube on a welding fixture, performing local induction heating for joints, and applying proper welding pressure and ultrasonic vibration. The method can be used for brazing the thin-wall copper aluminum tubes without the brazing flux, fusion lines are long, welding seams are compact, slag inclusion is avoided, the air tightness and the bonding strength of the joints are greatly improved, reliability is high, welding time is short, and great production and use values are achieved.

Owner:李明雨 +1

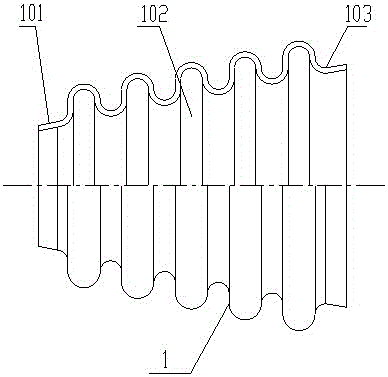

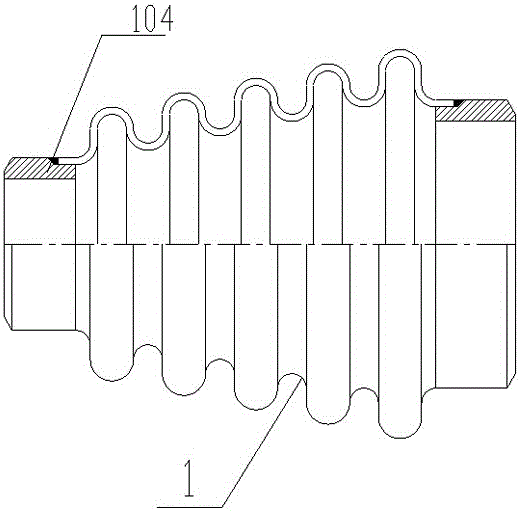

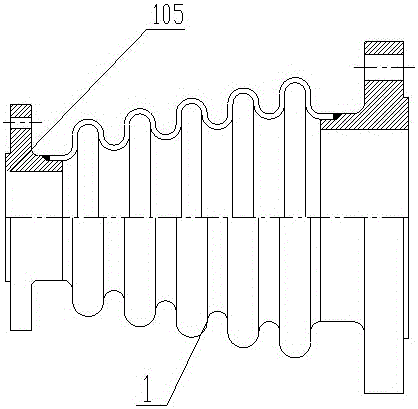

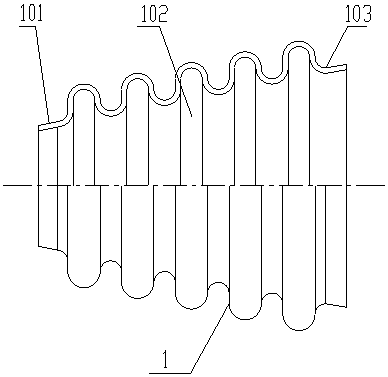

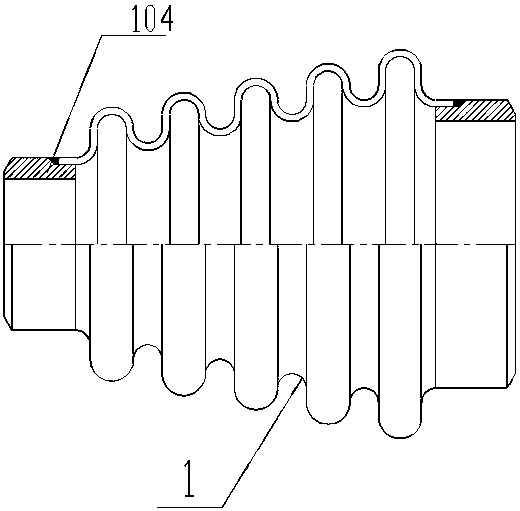

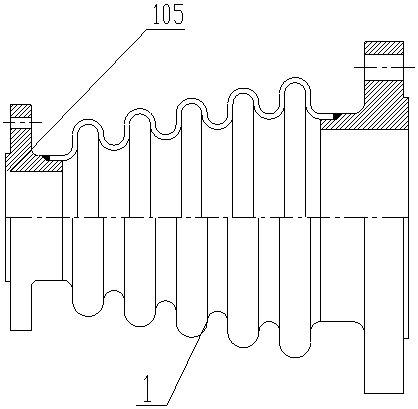

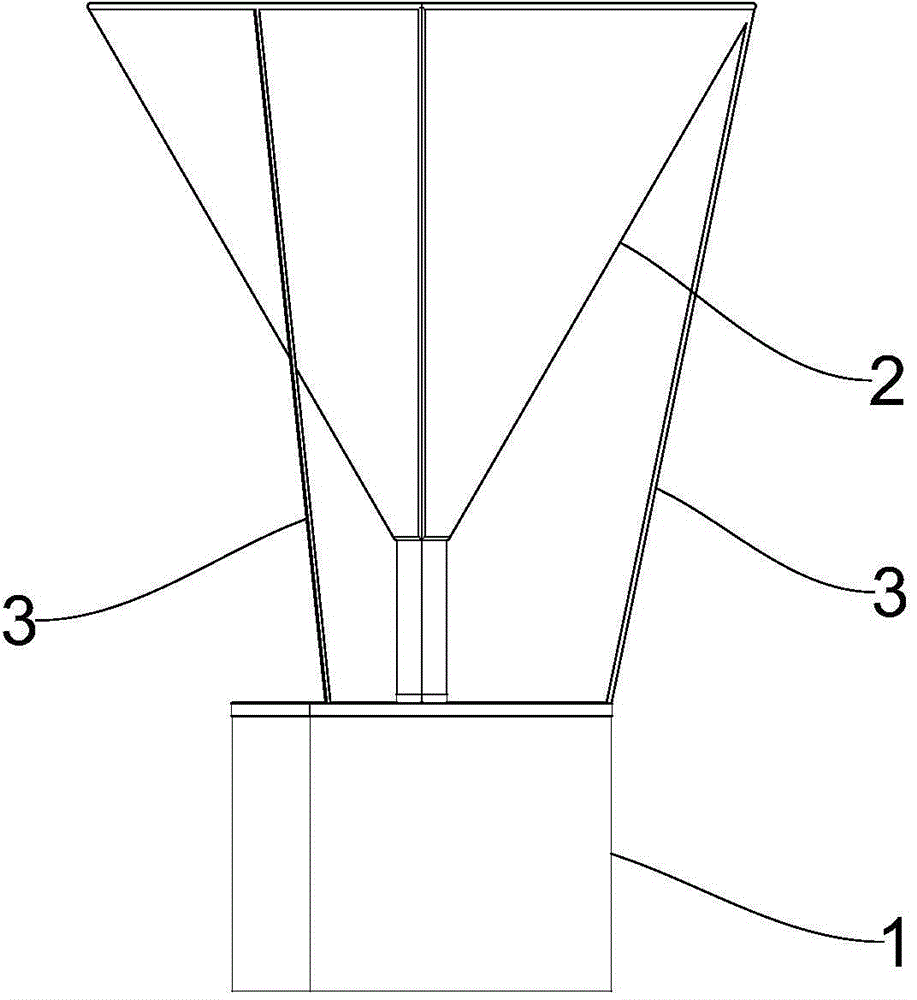

Variable-diameter corrugated pipe and shaping method for same

ActiveCN106090453ASuitable for connectionReduce usagePipeline expansion-compensationRigid pipesPipe fittingEngineering

The invention provides a variable-diameter corrugated pipe and a shaping method for the same. The variable-diameter corrugated pipe comprises a small-diameter straight edge conical pipe section, a large-diameter straight edge conical pipe section and a conical corrugated section disposed between the small-diameter straight edge conical pipe section and the large-diameter straight edge conical pipe section, wherein wave crests and wave troughs of the conical corrugated section gradually increase from the small-diameter straight edge conical pipe section to the large-diameter straight edge conical pipe section, and the whole conical corrugated section is conical; a small end of the conical corrugated section located at the corresponding wave trough is connected to a large end of the small-diameter straight edge conical pipe section; a large end of the conical corrugated section located at the corresponding wave trough is connected to a small end of the large-diameter straight edge conical pipe section; and the small-diameter straight edge conical pipe section, the large-diameter straight edge conical pipe section and the conical corrugated section are fabricated through integral shaping, wherein a dual-layer sealing structure is adopted in the shaping method to ensure a success rate of the shaping and shaping quality. According to the invention, workloads required for onsite installation of variable-diameter pipe fittings can be reduced, and safe pipeline running can be ensured.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

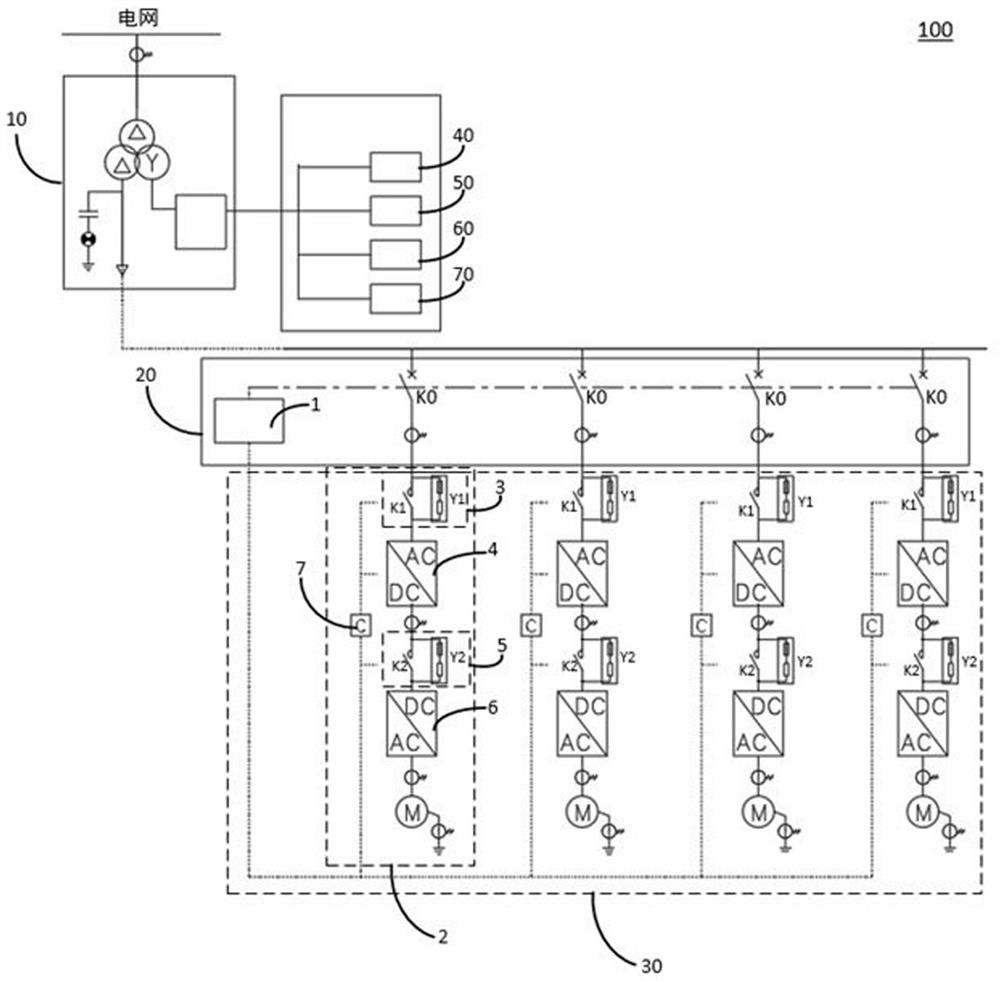

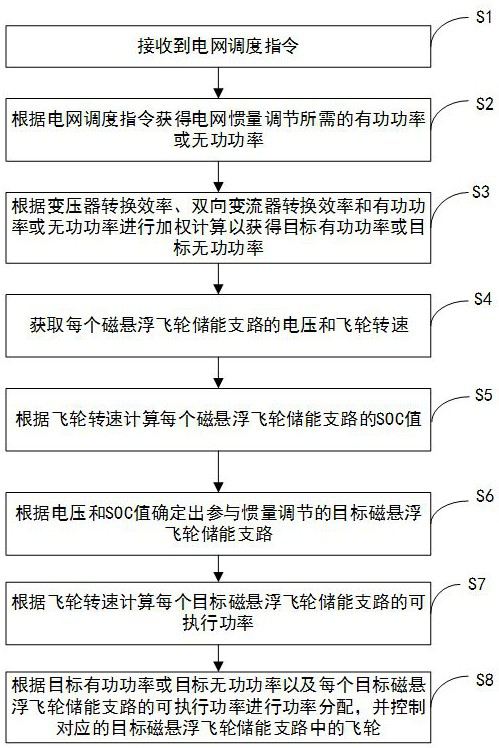

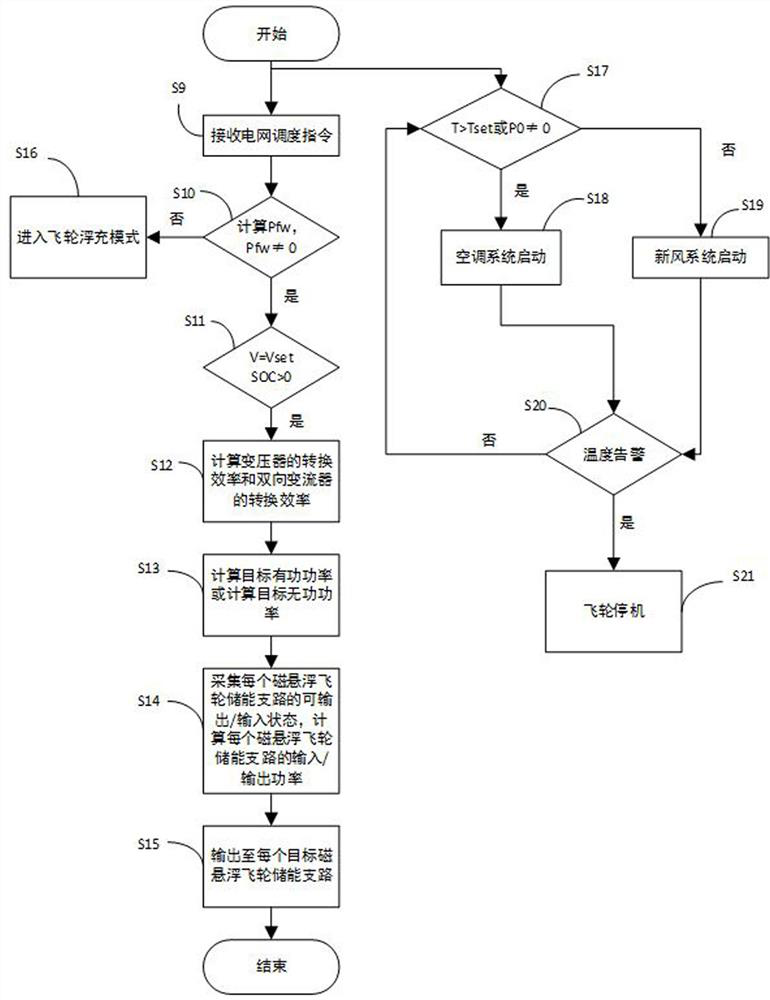

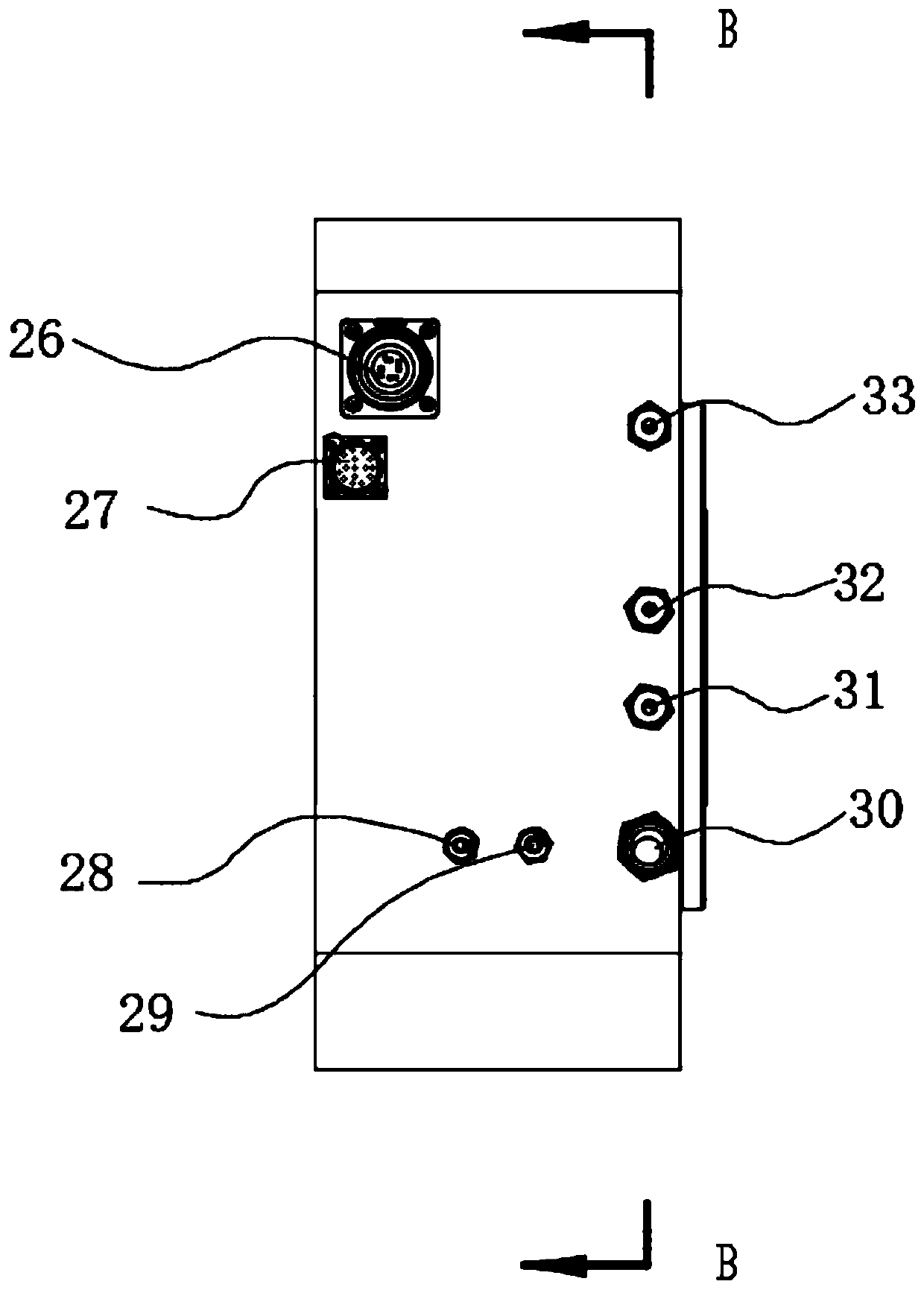

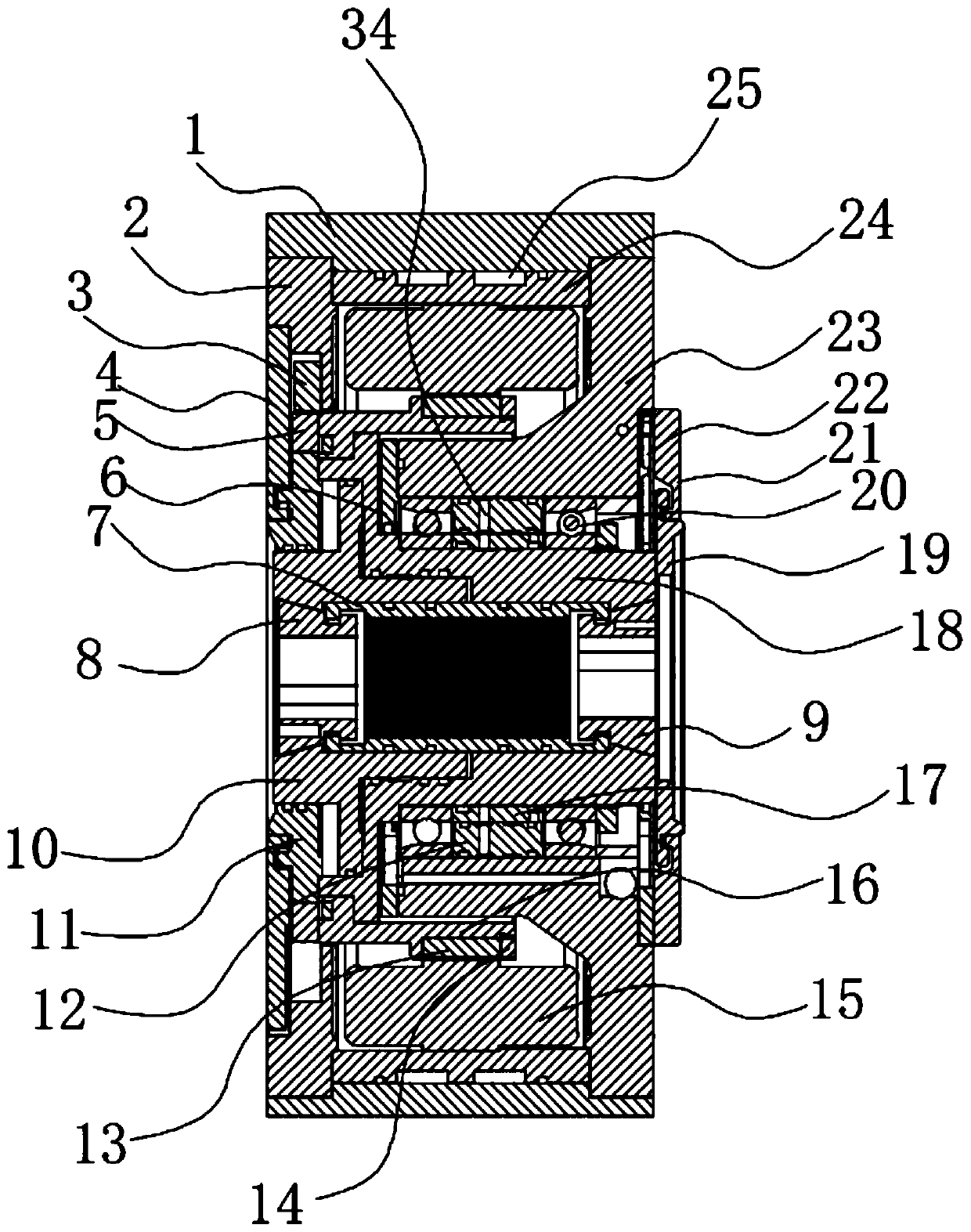

Flywheel energy storage system, control method of flywheel energy storage system and storage medium

ActiveCN112803453AReduce the risk of full load warrantyRealize chargingSingle network parallel feeding arrangementsEnergy storageWind drivenFlywheel energy storage

The invention discloses a flywheel energy storage system, a control method of the flywheel energy storage system and a storage medium. The flywheel energy storage system used for assisting in power grid inertia adjustment of a wind driven generator comprises: a transformer; master control equipment, which comprises a master controller and N master control relays, wherein the first end of each master control relay is connected with the transformer, and the master controller is connected with each master control relay; a magnetic suspension flywheel energy storage device, which comprises N magnetic suspension flywheel energy storage branches arranged corresponding to the N master control relays. wherein each magnetic suspension flywheel energy storage branch comprises a first pre-charging loop, a first bidirectional converter, a second pre-charging loop, a second bidirectional converter, a motor and a flywheel controller. According to the flywheel energy storage system for assisting in power grid inertia adjustment of the wind driven generator, frequent and deep charging and discharging can be achieved, the risk of full-load power protection of the power grid is reduced, and the economic adjustment mode of smooth adjustment of the wind driven generator is met.

Owner:沈阳微控新能源技术有限公司

Universal joint for submarine optical cable connector box

InactiveCN102147516ASimple structureImprove flexibilityFibre mechanical structuresPivotal connectionsUniversal jointSacroiliac joint

The invention provides a universal joint for a submarine optical cable connector box relating to a connecting device for protecting optical cable conductors. The universal joint for a submarine optical cable connector box comprises a joint, a lining and a connecting sleeve, wherein the joint is provided with a ball joint; the lining is sleeved on the ball joint of the joint; and the connecting sleeve is sleeved on the lining. By the transition of the lining, the joint and the connecting sleeve can rotate optionally along a central axis, and the optical cable is not pulled by the generation of excessive bending. The universal joint for a submarine optical cable connector box is reasonably designed and simply structured; and the optical cables in the universal joint can be curved optionally without being bended and pulled. The structure is more suitable for the connection of rigid parts in the optical cable joint and the bending restrictor. The structure of the universal joint for a connector box provided by the invention is simple, the bending performance is good, and a whole length component of the original connector box is divided into three parts which are a bending restrictor part, a connector box steel straight part and a bending restrictor part at another end, so that the construction and maintenance are convenient.

Owner:JIANGDONG FITTINGS EQUIP

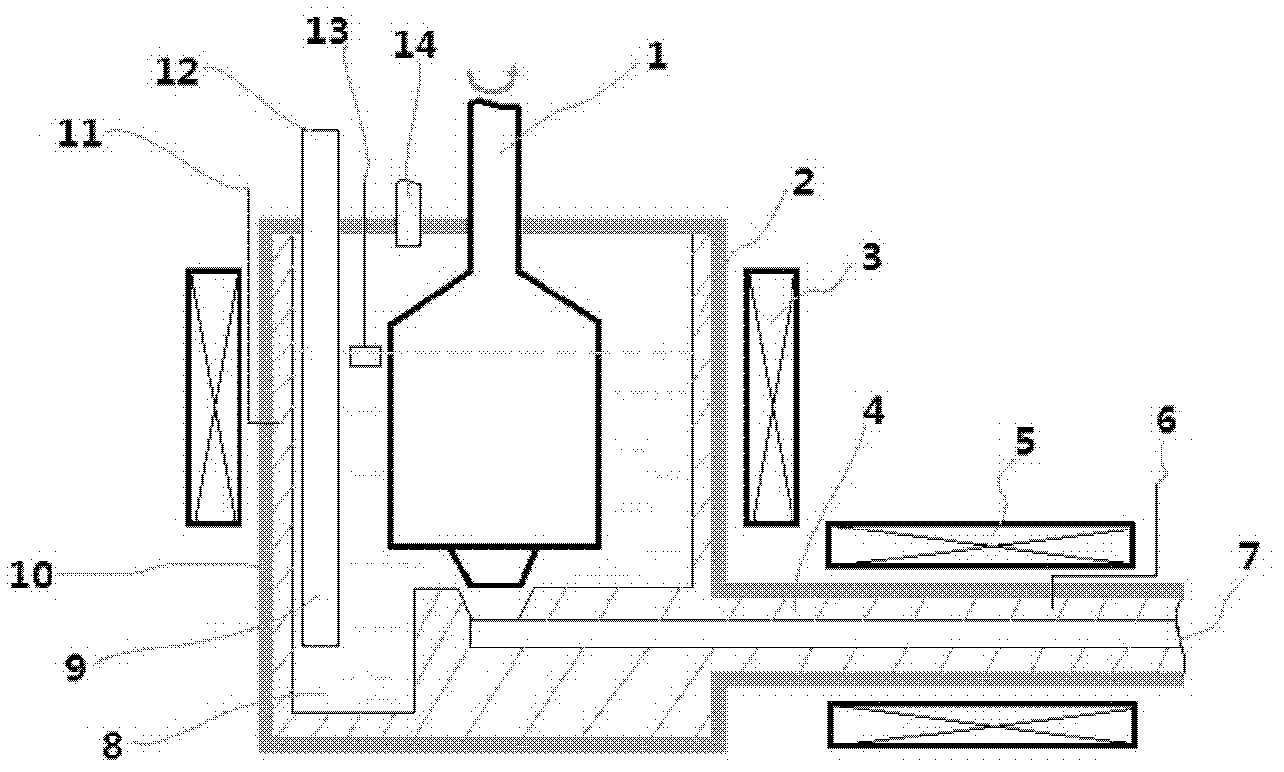

Device for manufacturing metal paste in double forcing and homogenizing mode and machining forming method thereof

The invention relates to a device for manufacturing metal paste in a double forcing and homogenizing mode and a manufacturing forming method of the device. The device comprises a control rod, a pre-fabricating cavity, a main coil, a material discharging pipe, an auxiliary coil, a thermocouple, a paste outlet, a slag collecting groove, a liquid inlet pipe, heating and warm-keeping layers, a thermocouple, an alloy inlet, a liquid level sensor, an air pressure pipe and the like. The control rod is a radial symmetrical body and located right in the center of the pre-fabricating cavity, and the liquid inlet pipe, the liquid level sensor, the air pressure pipe and the like are distributed around the control rod. The material discharging pipe is located on the lower portion of the pre-fabricating cavity and is horizontally arranged. The main coil and the auxiliary coil are respectively distributed on the outer portion of the warm-keeping layer of the pre-fabricating layer and the outer portion of the warm-keeping layer of the material discharging pipe, and metal molten bodies bear the electro-magnetic stirring effect produced by the main coil and / or the mechanical stirring effect of self-rotation of the control rod inside the pre-fabricating cavity. Moreover, the metal molten bodies bear the enhancing stirring effect of the auxiliary coil in a secondary mode in the material discharging pipe. The device and the method are simple and easy to achieve, the metal molten bodies are obvious in homogenizing effect after being compounded and stirred in a secondary and enhancing mode, and therefore superior casting pieces which are even in alloy component and thin and small in crystal particle can be obtained.

Owner:有研金属复材技术有限公司

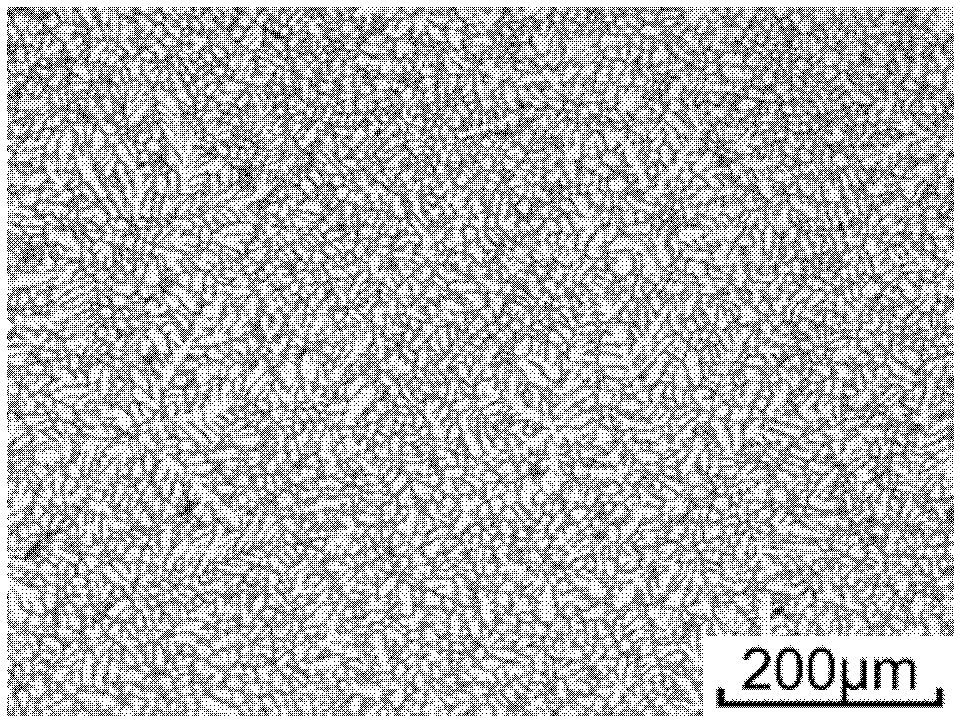

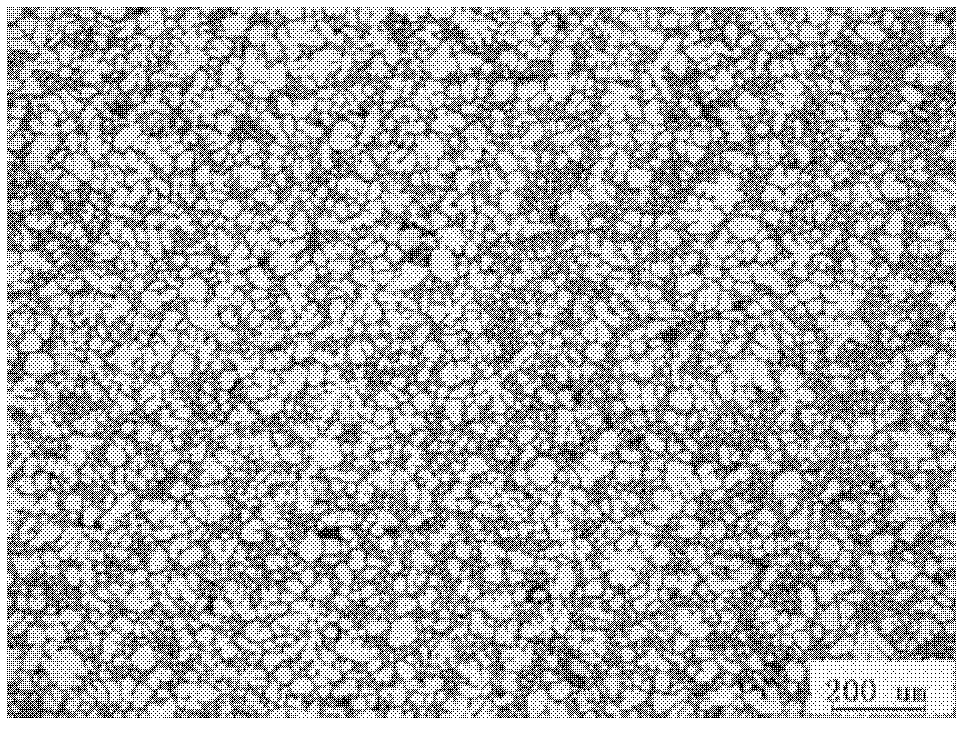

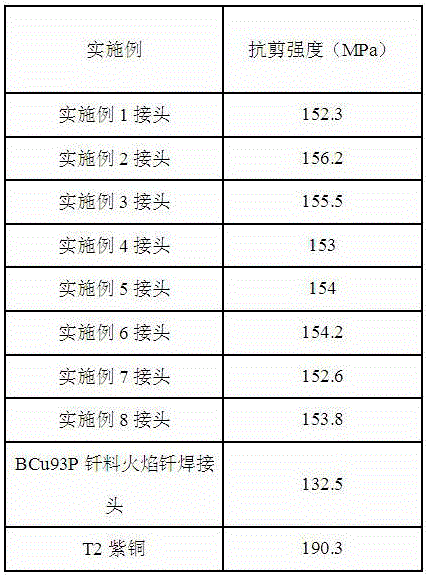

Copper alloy contact reaction brazing method and used active connecting agent

InactiveCN106270869AHigh densityLow soldering temperatureWelding/cutting media/materialsWelding/soldering/cutting articlesBoronVacuum chamber

The invention relates to a copper alloy contact reaction brazing method and a used active connecting agent. The active connecting agent comprises the following components in percentage by weight: 78-85 percent of red phosphorus powder, 5-12 percent of boron powder and 10 percent of a bonding agent. The copper alloy contact reaction brazing method comprises the following steps: (1) coating the joint surface of copper blocks to be welded with the active connecting agent; (2) combining the copper blocks to form a butt brazing joint, fixing and compressing on a welding fixture and putting into a vacuum chamber of a hot isothermal furnace; (3) applying the welding pressure of 0.085-0.02 MPa and pumping to a certain vacuum degree; (4) introducing high-purity argon gas with the purity of 99.999 percent, performing heating and heat preservation on a workpiece when the pressure intensity in the furnace is not lower than 4,357 KPa and completing brazing. As the active connecting agent provided by the invention is utilized for copper alloy contact reaction brazing, the copper alloy in-situ synthesis brazing joint is realized, and a solder flux is not required; the brazing temperature is low, so that the influence on base materials is less; the compactness of the brazing joint is high, and the shearing strength of the brazing joint achieves is 80 percent or above of the strength of the copper alloy base materials.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Surface mechanical attrition treatment and ultrasonic wave collaborative assistance dissimilar metal TIG melting and brazing method

InactiveCN103934551AEasy to spreadImprove wettabilitySoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedMetal

The invention discloses a surface mechanical attrition treatment and ultrasonic wave collaborative assistance dissimilar metal TIG melting and brazing method. The method includes the step B that TIG melting and brazing is achieved through assistance of ultrasonic waves in the welding process. The method is characterized by further including the step A that surface mechanical attrition treatment is performed on low-melting-point parent metal. The method has the advantages that operation is easy to perform, the welding quality can be improved, it is prevented that welded joint structures are thick and large, brittle intermetallic compounds are prevented from being generated, the welding performance is improved, and the method is particularly applicable to connection of dissimilar metal under the condition that metal oxide can be easily generated on the surface of the low-melting-point parent metal in two types of parent metal.

Owner:CHONGQING UNIV

Cable connecting terminal and cable

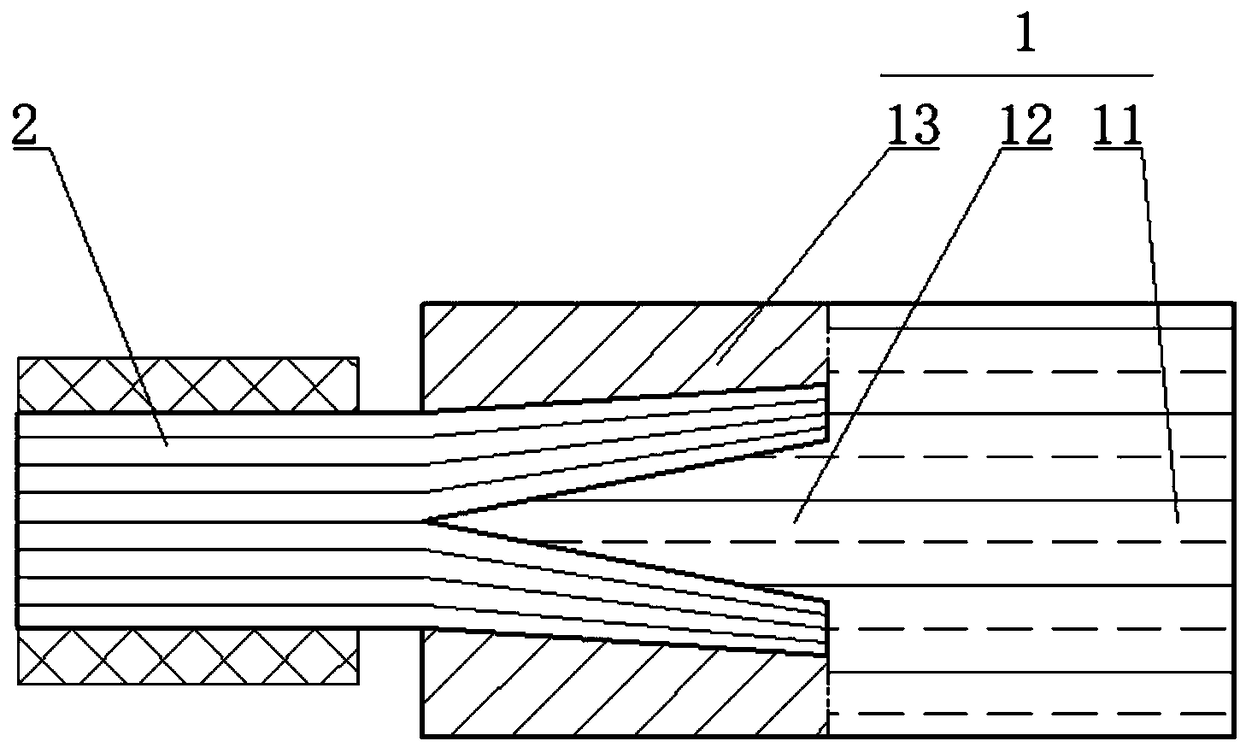

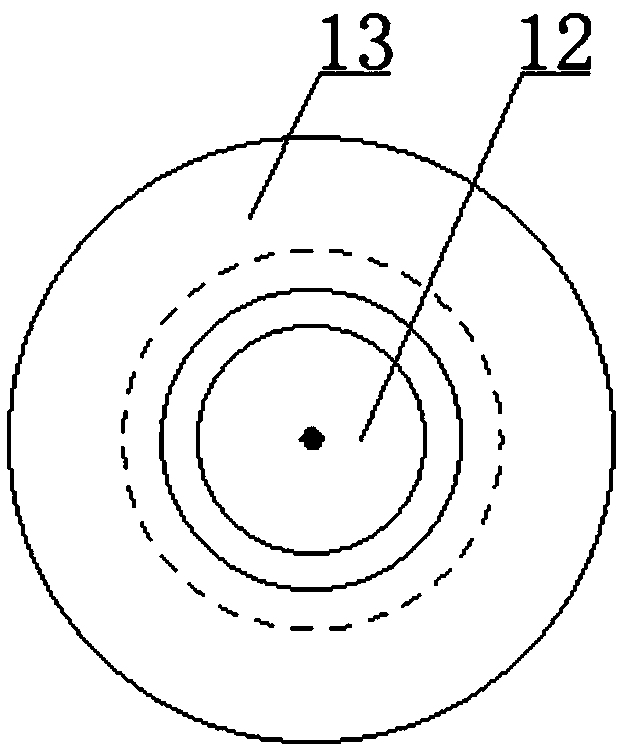

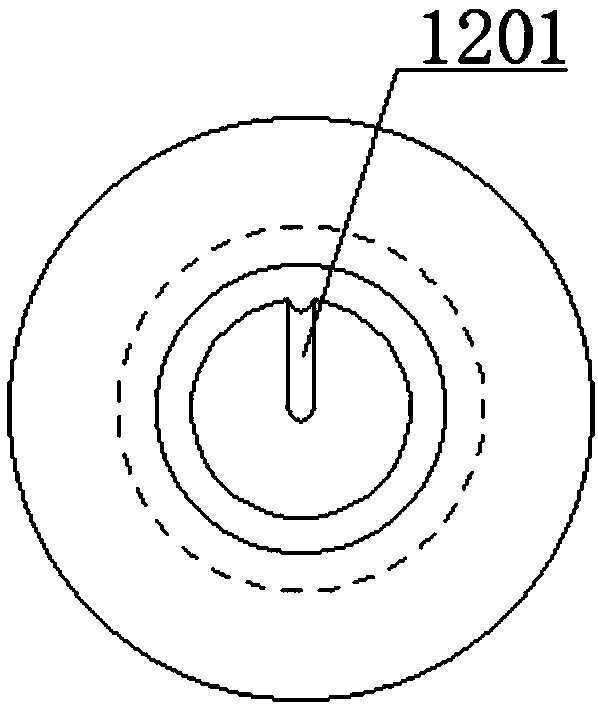

PendingCN109494498AQuality improvementHigh strengthVehicle connectorsClamped/spring connectionsEngineeringUltimate tensile strength

The invention relates to a cable connecting terminal comprising a working end and a clamping end that are fixedly connected. The clamping end includes a mandrel and a sleeve that are arranged coaxially; the head of the clamping end points to the root direction; and the outer diameter of the mandrel is gradually increased and the inner diameter of the sleeve is gradually increased. Accommodation space is formed between the mandrel and the sleeve; and the random radial cross-sectional area of the accommodation space is not less than the cross-sectional area of a conductive wire bundle. Accordingto the cable connecting terminal, the contact area with the conductive wire bundle of the cable is increased and the resistance is low; and compared with the existing cable terminal, the provided cable connecting terminal is shorter. The connection is done closely and the connection strength is enhanced.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

Improved type Sn-Ag-Zn lead-free solder for inhibiting solid state interface reaction

InactiveCN101053932AImprove reliabilityGrowth inhibitionWelding/cutting media/materialsSoldering mediaInterfacial reactionSolid-state

The present invention relates to an improved Sn-Ag-Zn solder free of lead used for inhibiting the solid state interfacial reaction, which belongs to the technical field of electronic material. The mass percentage of each component is 0.05~3.02 % of Zn, 3.43~3.52% of Ag, balance Sn. The diffusion barrier layer formed on the reaction interface can inhibit the diffusion of Cu atom, so that the growing of the intermetallic compounds on the reaction interface can be inhibited. The problem of that the solder is easy to react with the base metal to bring about the mass dissolution of the base metal and the mass intermetallic compounds formed on the interface, which can seriously affect the interface reliability, is solved. The solder free of lead of the present invention has a simple technology and is easy to realize mass production.

Owner:SHANGHAI JIAO TONG UNIV

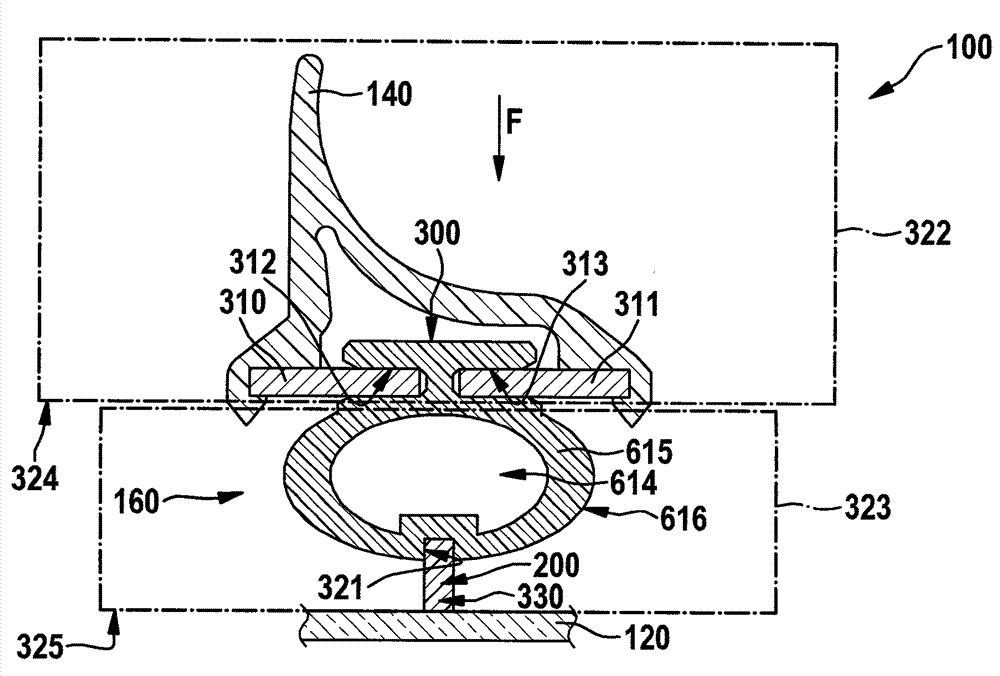

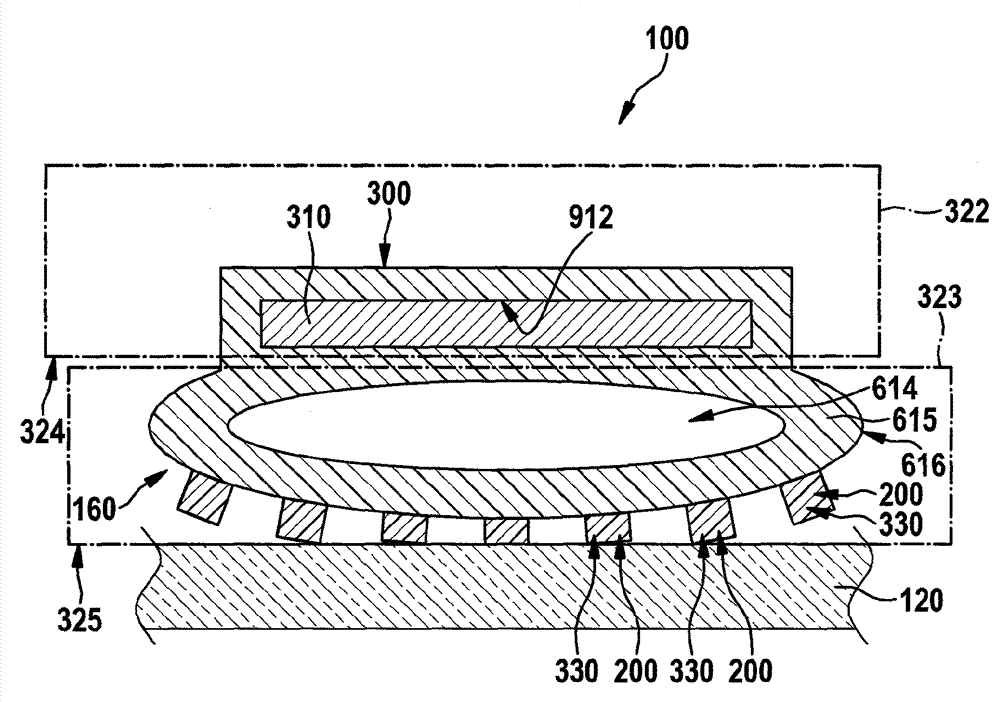

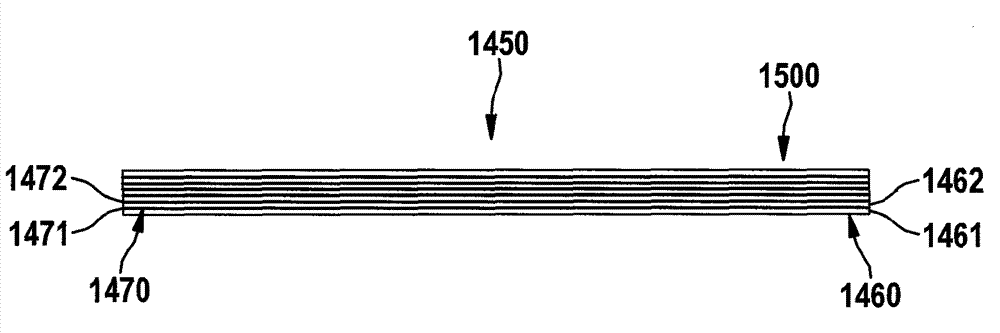

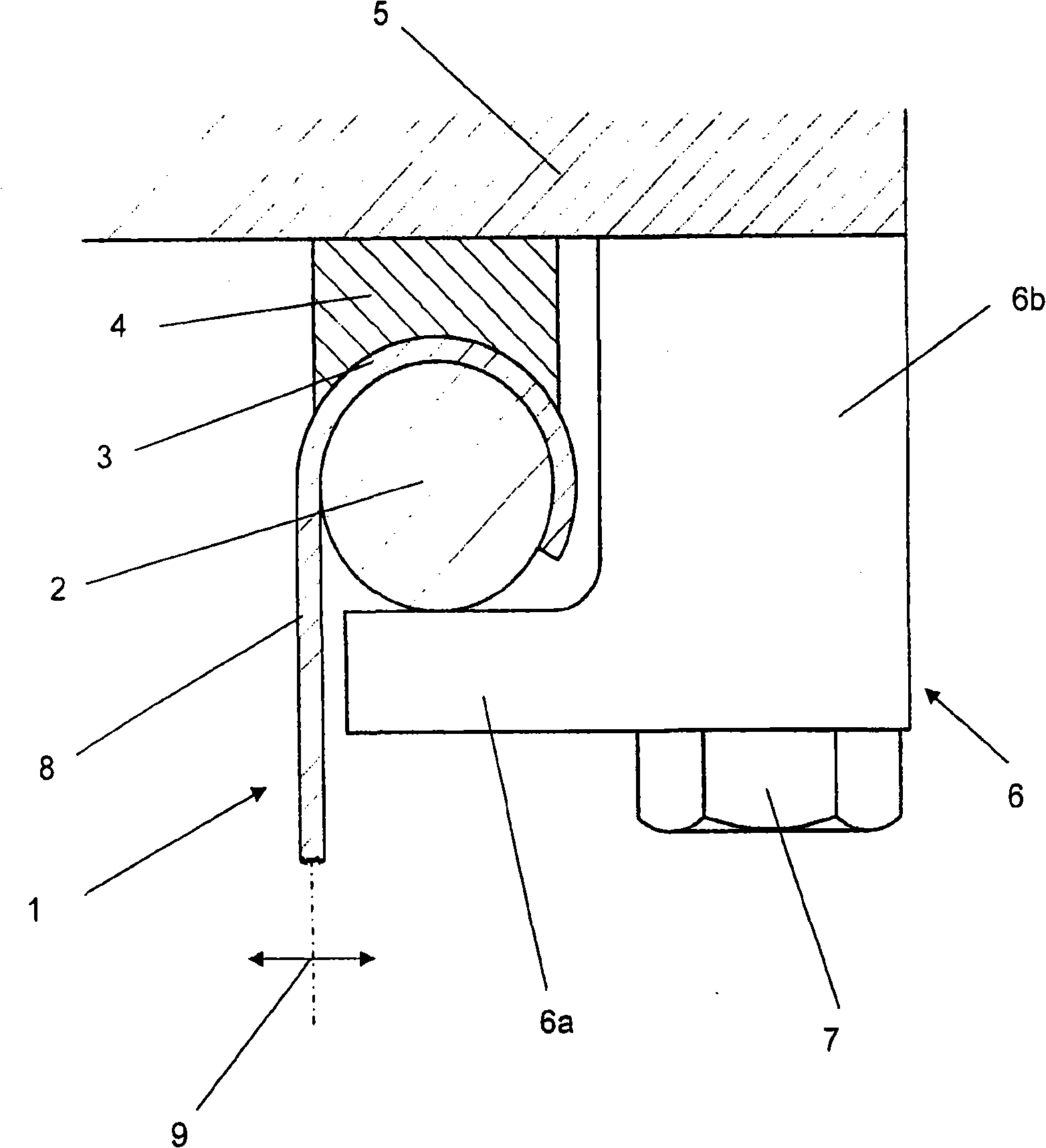

Wiper blade

The invention relates to a wiper blade (100) which is provided with a bearing segment (322) and a wiping and cleaning segment (323) connected with the with the bearing segment (322). The bearing segment (322) is fixed on a wiping arm, and the wiping and cleaning segment (323) is provided with at least one wiping and cleaning element (160) which is used for wiping and / or cleaning process. The wiping and cleaning element (160) is provided with a fiber system (200) which comprises at least one fiber unit (330), especially a miniature fiber system comprising at least one miniature fiber.

Owner:ROBERT BOSCH GMBH

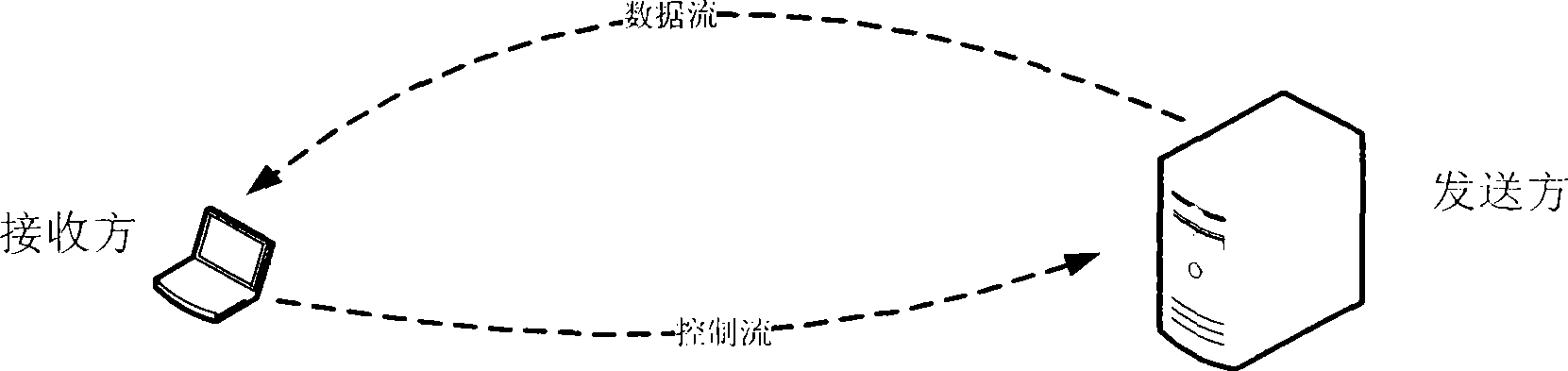

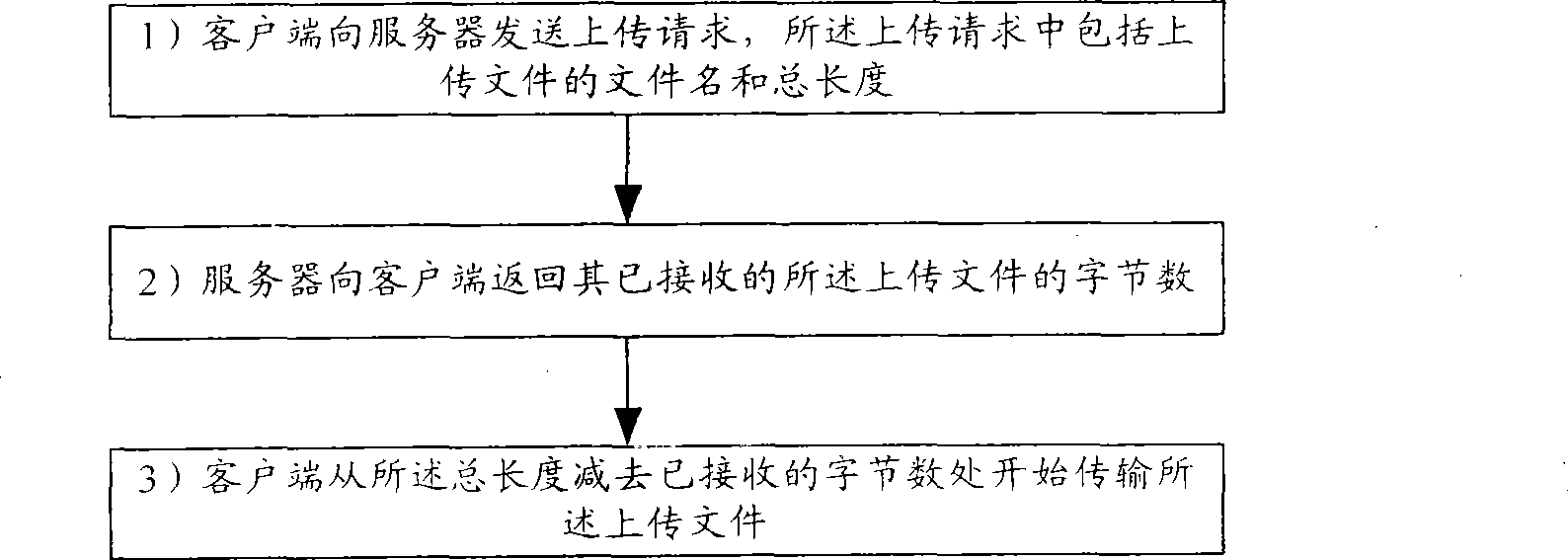

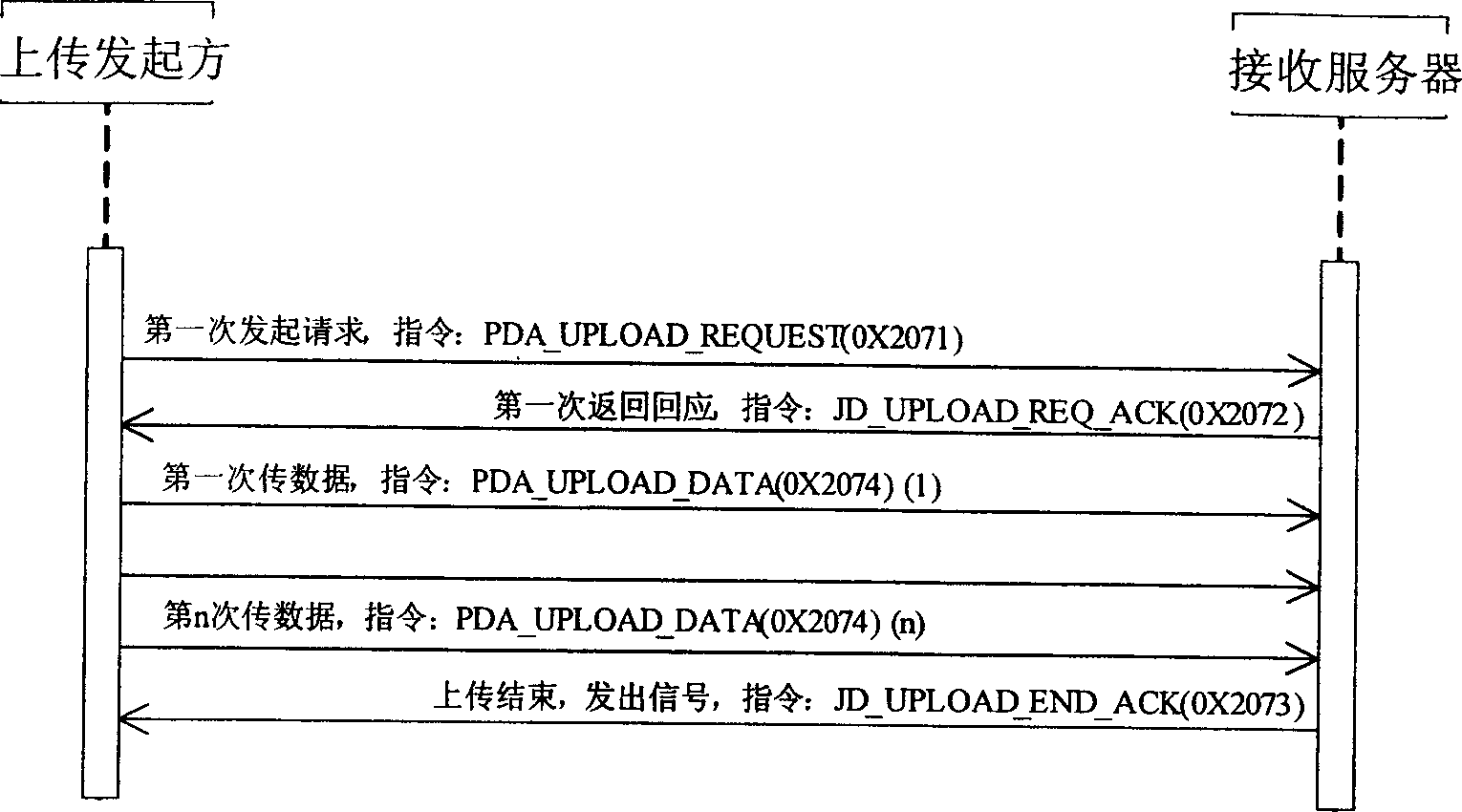

File uploading method

InactiveCN101483661ASave resourcesSuitable for connectionError prevention/detection by using return channelSpecial data processing applicationsClient-sideByte

The invention discloses a file uploading method comprising that a client sends an uploading request to a server, and the uploading request comprises file name and total length of the uploading file; the server returns the number of bytes of the received uploaded file to the client; the client subtracts the number of bytes of the loaded file from the whole length, and starts to uploading the rest file at the point. Resources can be saved by using the method.

Owner:AUTONAVI

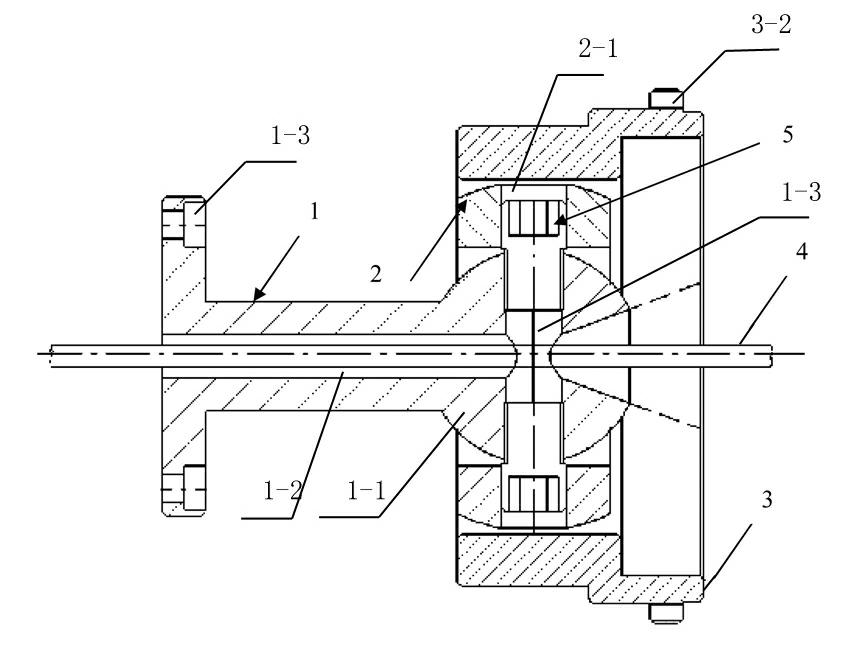

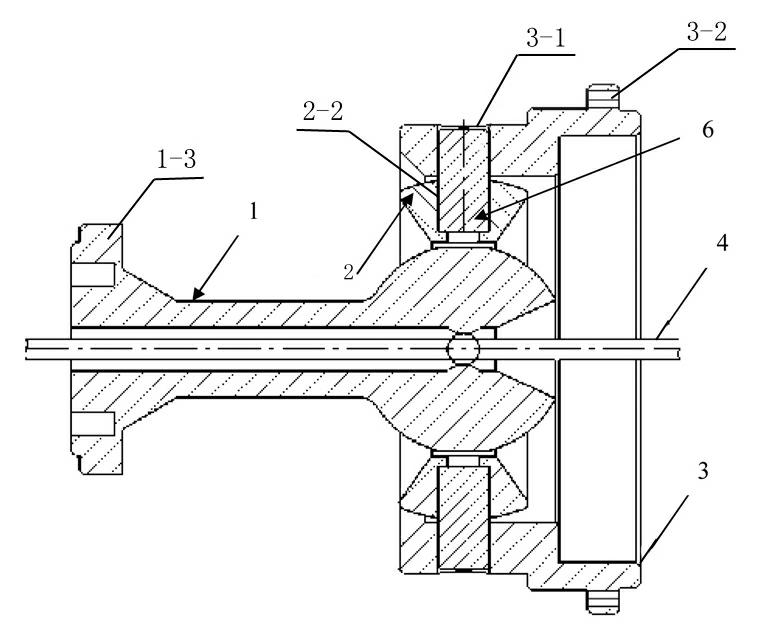

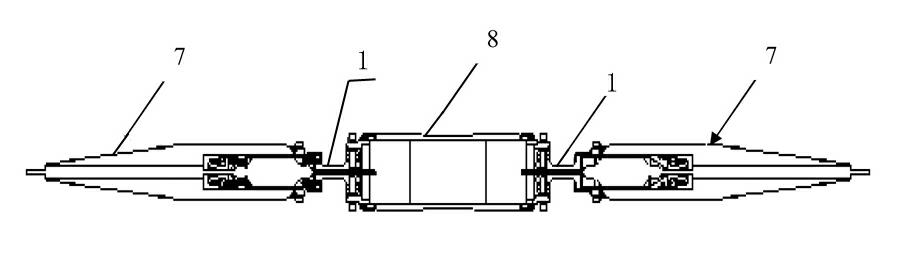

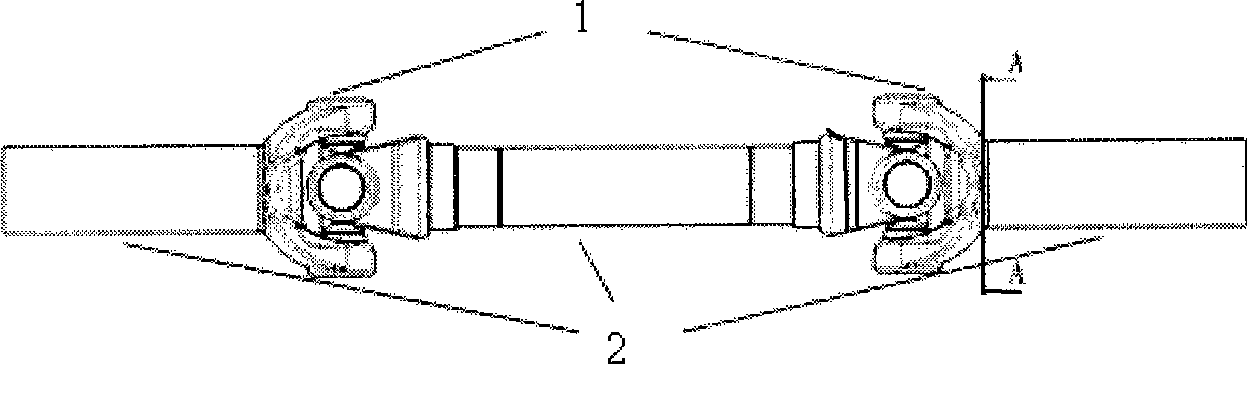

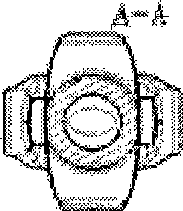

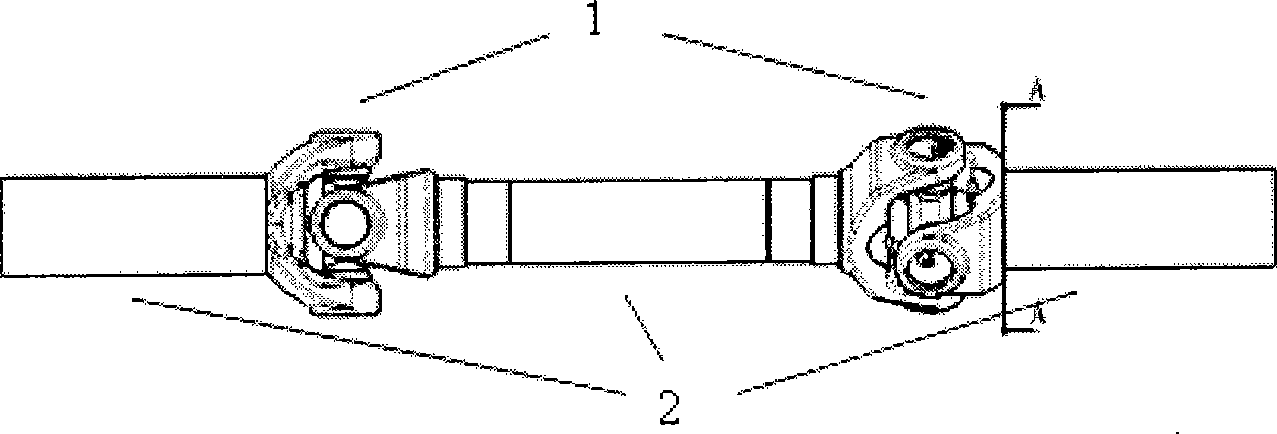

Composite structure of transmission shaft end cross coupling

ActiveCN101440844AReduce vibration amplitudeDo not change angleYielding couplingVibration amplitudeUniversal joint

The invention discloses a combined structure of a transmission shaft end crossed shaft coupling. The combined structure comprises a transmission shaft, wherein both ends of the transmission shaft are connected with crossed shaft type universal joint shaft couplings; and the phase angle theta between the crossed shaft type universal joint shaft couplings is more than 0 degree and less than 90 degrees. The combined structure breaks through the connection mode of the prior crossed shaft type universal joint shaft coupling and solves the vibration problem of the transmission shaft; meanwhile, the combined structure does not change the included angle between transmission shafts and the operating rotating speed of the transmission shafts, thereby reducing the operating vibration amplitude of the transmission shafts substantially; vibration reduction in the structure is more than three fourths of that of the prior proposal; moreover, the proposal is simple and easy to carry out and is suitable for the connection of a plurality of shafts.

Owner:DONGFENG MOTOR CORP HUBEI

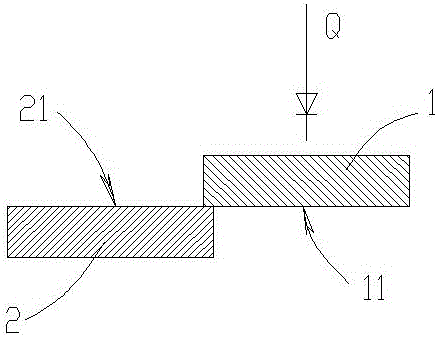

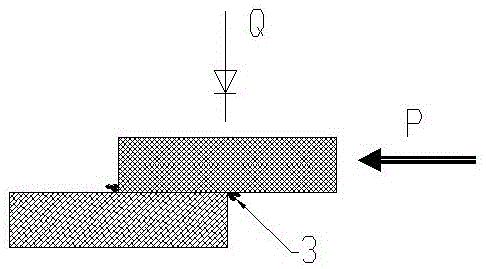

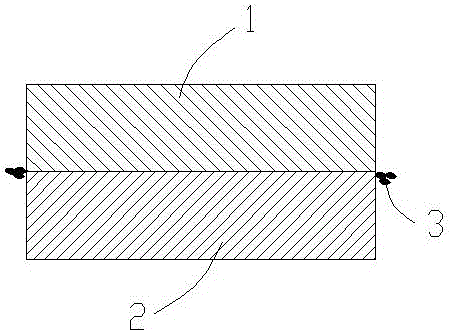

Copper-aluminum connecting piece face-face penetrating fusion welding technique and preparation method

ActiveCN106583914ADoes not change physical propertiesAvoid problemsWelding/soldering/cutting articlesNon-electric welding apparatusVolumetric Mass DensityEngineering

The invention discloses a copper-aluminum connecting piece face-face penetrating fusion welding technique and a preparation method. The problems that in the prior art, firm joint surfaces of copper-aluminum joint surfaces cannot be continuously generated, or base material crystal grains become thick and big, so that the physical property, the mechanical property and the electrical and chemical index of base materials and the joint surfaces are influenced are solved. The copper-aluminum connecting piece face-face penetrating fusion welding technology is characterized in that the main microstructures of the copper-aluminum connecting piece joint surfaces are dissolved solid matter organizations generated in the physical preparing process in a connecting mode; after the base materials are preheated, energy is supplied through low-temperature friction and extra-high voltage, so that atoms or molecules of solid phase aluminum materials and solid phase copper materials deviate from the equilibrium position to conduct long-distance migration, and a solid phase connecting face with physical connecting characteristics is formed; the total quantity of the dissolved solid matter in the joint surfaces is more than 95%, or the total quantity of compounds, oxides and mixtures in the firm joint surfaces is equal to or less than 5%, so that the mechanical properties of original base materials are basically retained, and the original base materials have the characteristic that the physical properties are higher than the physical properties of parent materials of the base materials; and density and mechanical strength are higher than those of base materials.

Owner:ZHEJIANG KANGSHENG CO LTD +1

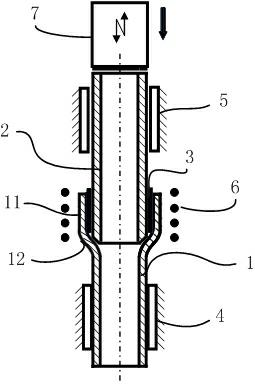

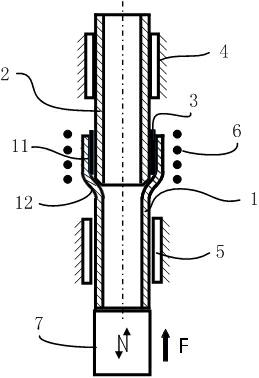

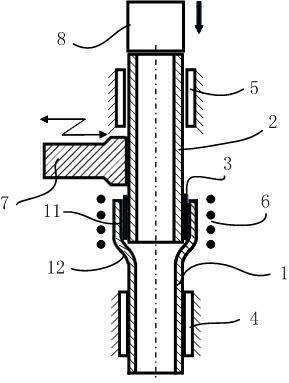

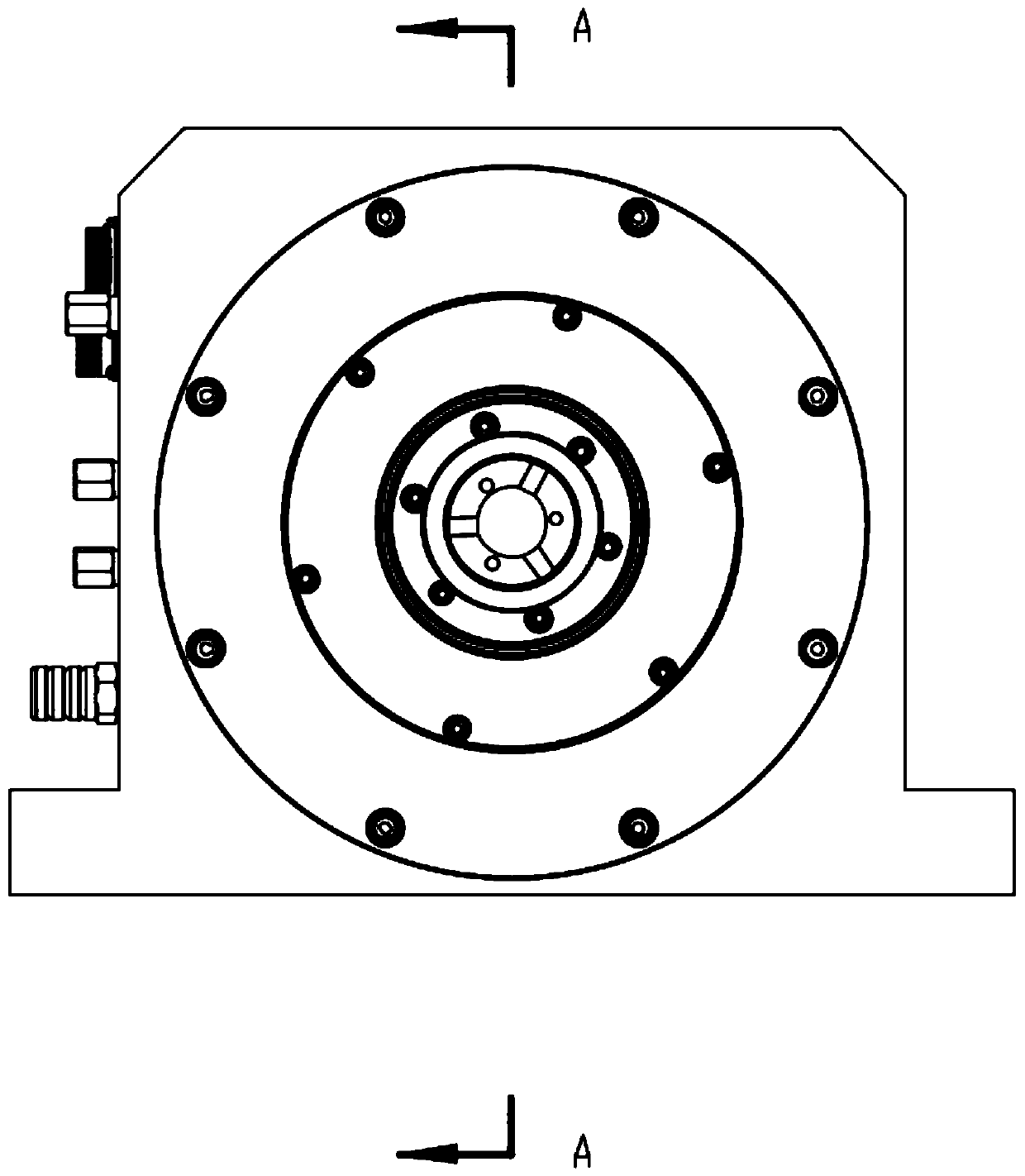

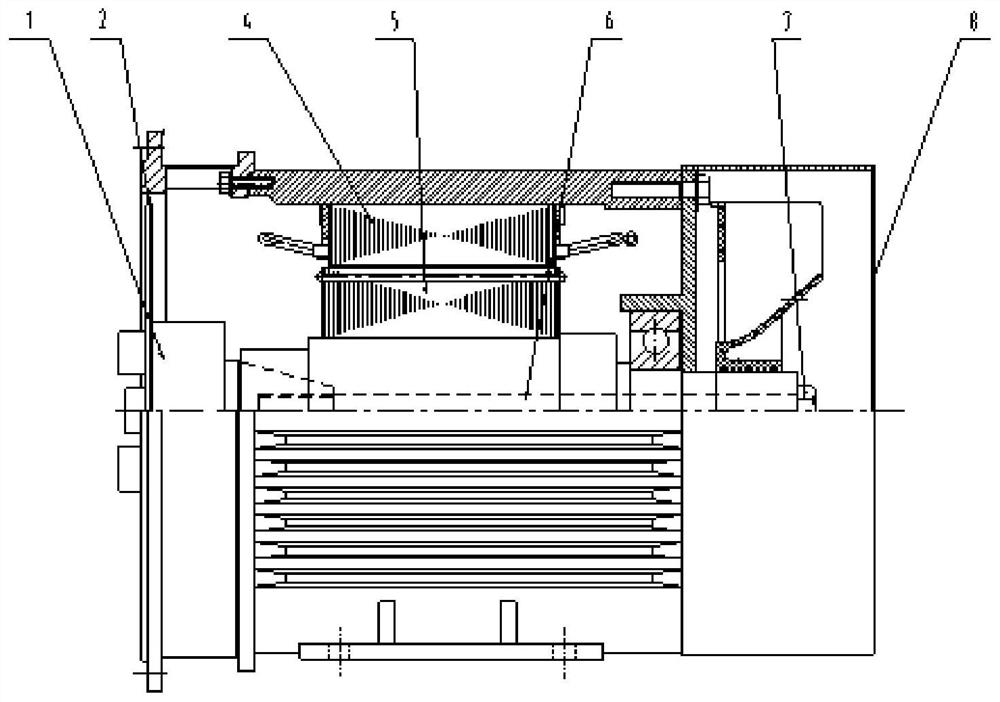

Integrated water-cooled permanent magnet servo two-way clamping electric spindle structure

PendingCN109940175AFix issues affecting accuracyRealize "zero transmissionMaintainance and safety accessoriesElectricityEngineering

The invention relates to an integrated water-cooled permanent magnet servo two-way clamping electric spindle structure. The integrated water-cooled permanent magnet servo two-way clamping electric spindle structure comprises a clamping base shell and a right bearing block. The right bearing block is embedded into one side in the clamping base shell, a spindle is coaxially mounted in the right bearing base, a spindle bearing is arranged between the right bearing base and the spindle, a rotor sleeve connected with the spindle is arranged on the outer side of the right bearing base, a stator is arranged on the portion, located on the outer side of the rotor sleeve, in the clamping base shell, an oil cylinder piston is axially mounted at one end of the spindle, a left rubber chuck and a rightrubber chuck are mounted in the oil cylinder piston and the spindle, and the left side of the oil cylinder piston is sleeved with an oil cylinder sealing cover. A hydraulic clamping oil inlet and a hydraulic loosening oil inlet are formed in the right bearing block, and a left bearing block sealing cover and a right bearing block sealing cover are mounted on the left side and the right side of theright bearing block. The brand-new structure is adopted, and the problems in the prior art are effectively solved.

Owner:宁波市鄞州华本电主轴科技有限公司

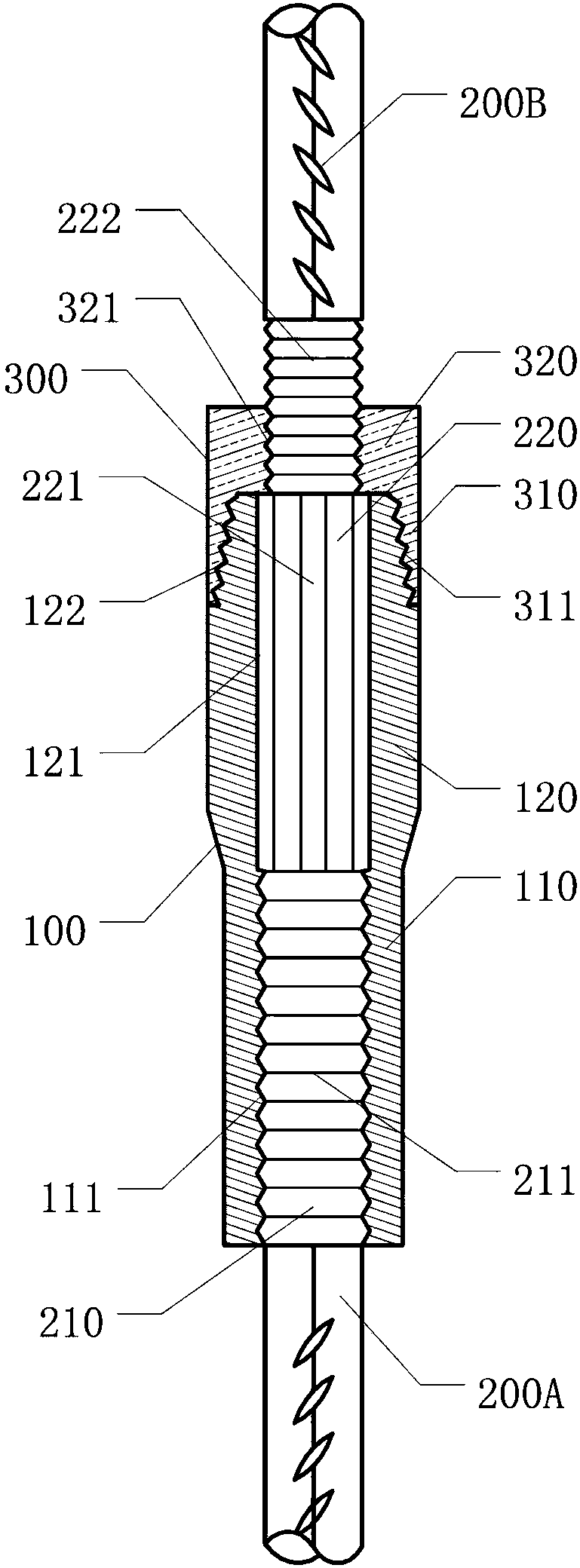

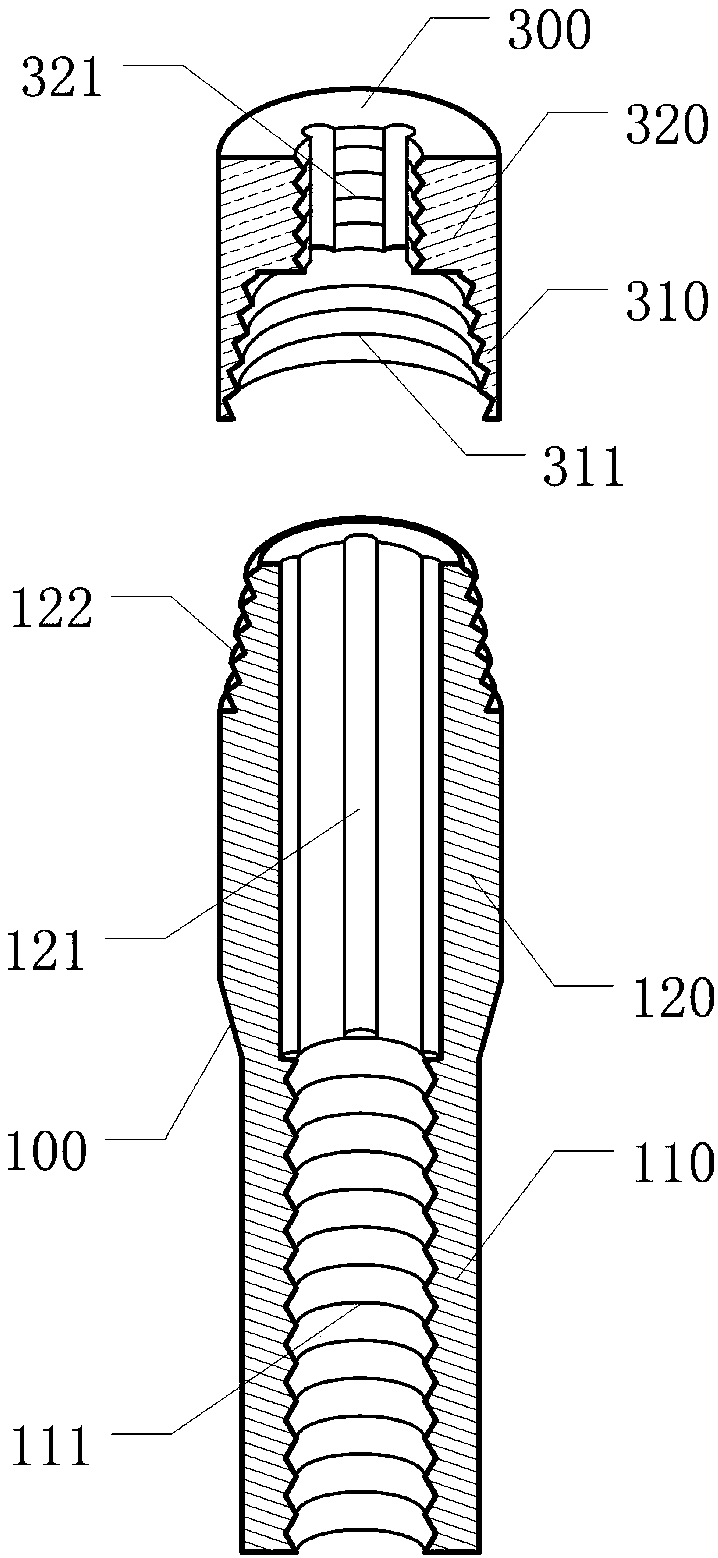

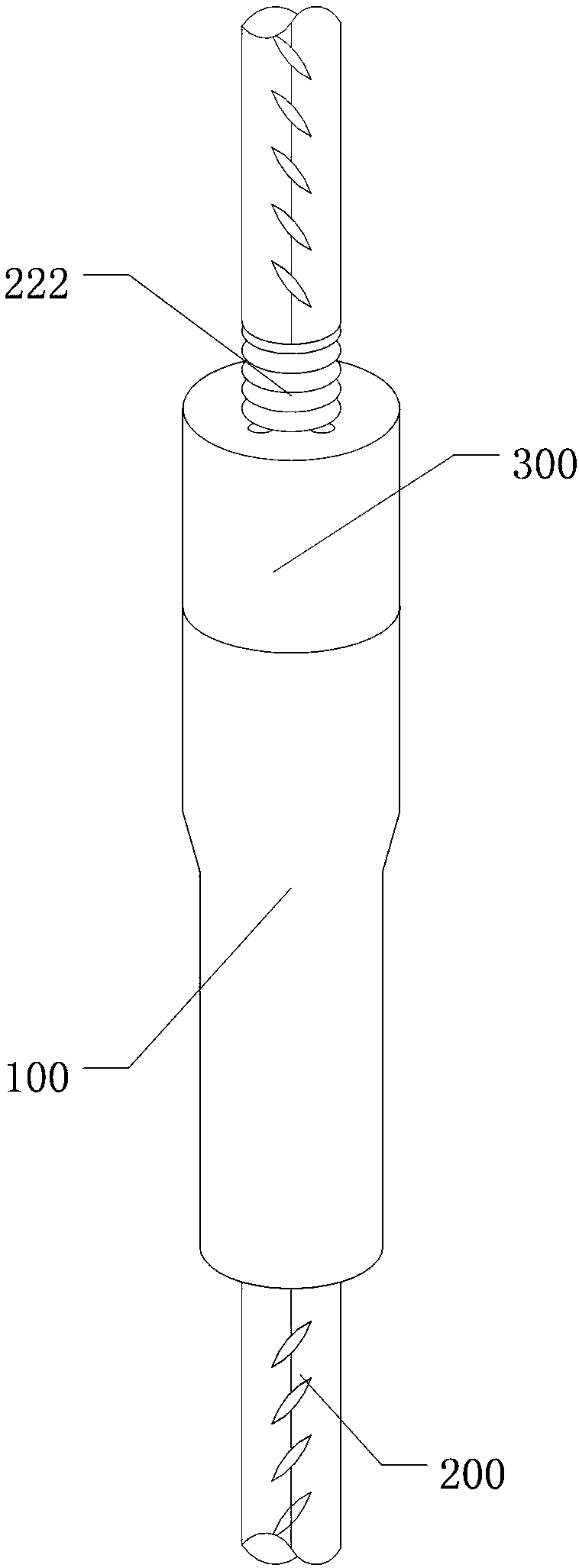

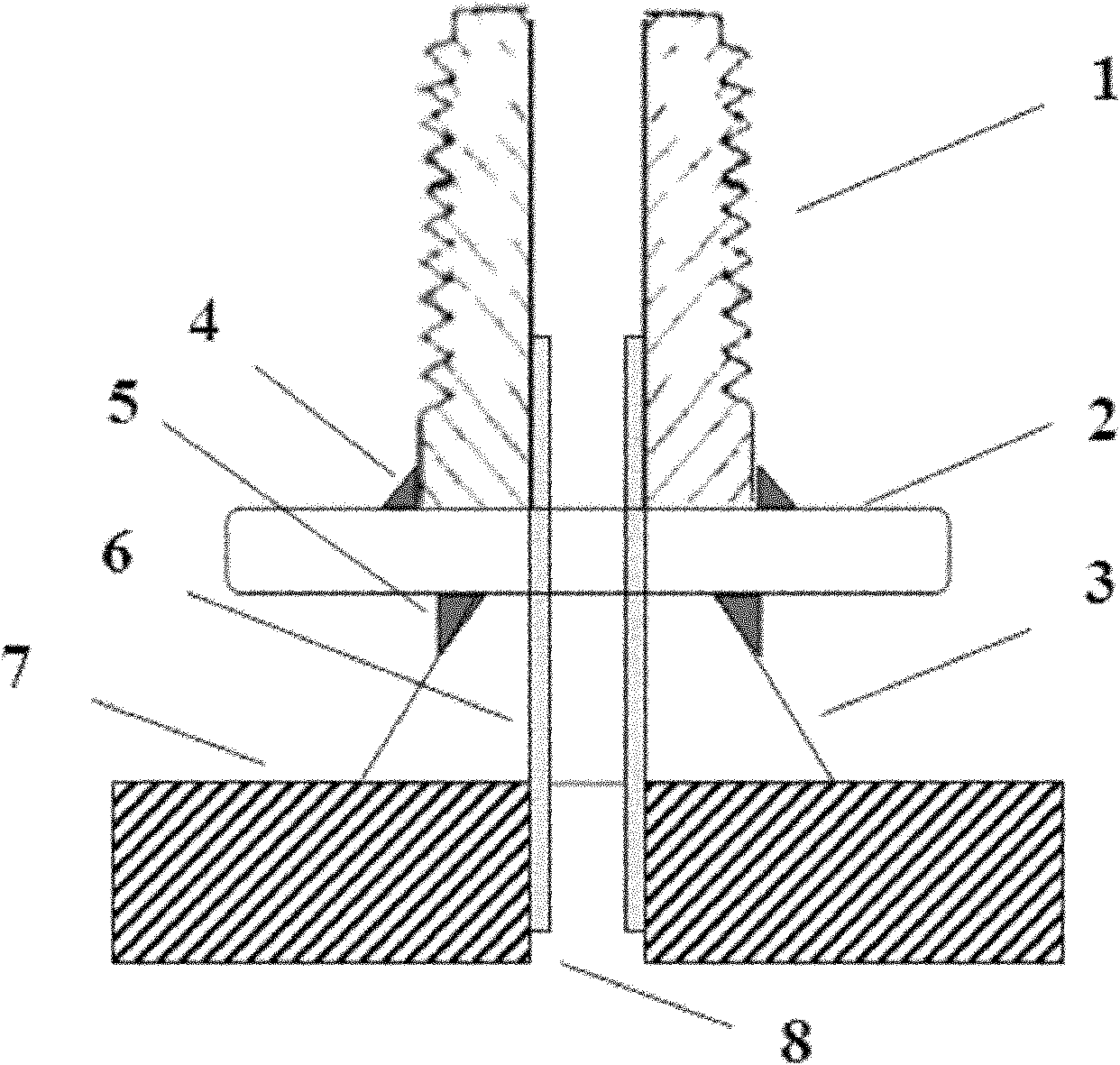

Mechanical connection assembly for pile foundation reinforcing steel bars for highway bridge engineering, and connecting method of mechanical connection assembly

ActiveCN107829526AHigh strengthFast connectionBuilding reinforcementsBulkheads/pilesBridge engineeringMaterial resources

The invention discloses a mechanical connection assembly for pile foundation reinforcing steel bars for highway bridge engineering. The mechanical connection assembly comprises a sleeve, a reinforcingsteel bar and a fixing sleeve, wherein one end of the sleeve is arranged as a threaded connecting end, and another end opposite to the threaded connecting end is arranged as a guide connecting end; one end of the reinforcing steel bar is matched with the threaded connecting end of the sleeve, and the other end of the reinforcing steel bar is matched with the guide connecting end; the outer diameter, at the guide connecting end, of the reinforcing steel bar is larger than that of a reinforcing steel bar body; the fixing sleeve comprises a sleeve fixing end matched with the sleeve, and a reinforcing steel bar fixing end matched with the reinforcing steel bar, thus rapidly connecting and fixing the sleeve and the reinforcing steel bar; furthermore, the fixing sleeve is high in joint strength, stable in structure and suitable for operation in a vertical direction. The invention also discloses a connecting method of the mechanical connection assembly for the pile foundation reinforcing steel bars for the highway bridge engineering. The connecting method has the advantages of simple steps, convenient construction, wide application scope, and capabilities of realizing rapid connection and fixation between the reinforcing steel bars, accelerating the project progress, and saving manpower and material resources.

Owner:GUANGXI CHANGCHANG ROAD & BRIDGE CONSTR

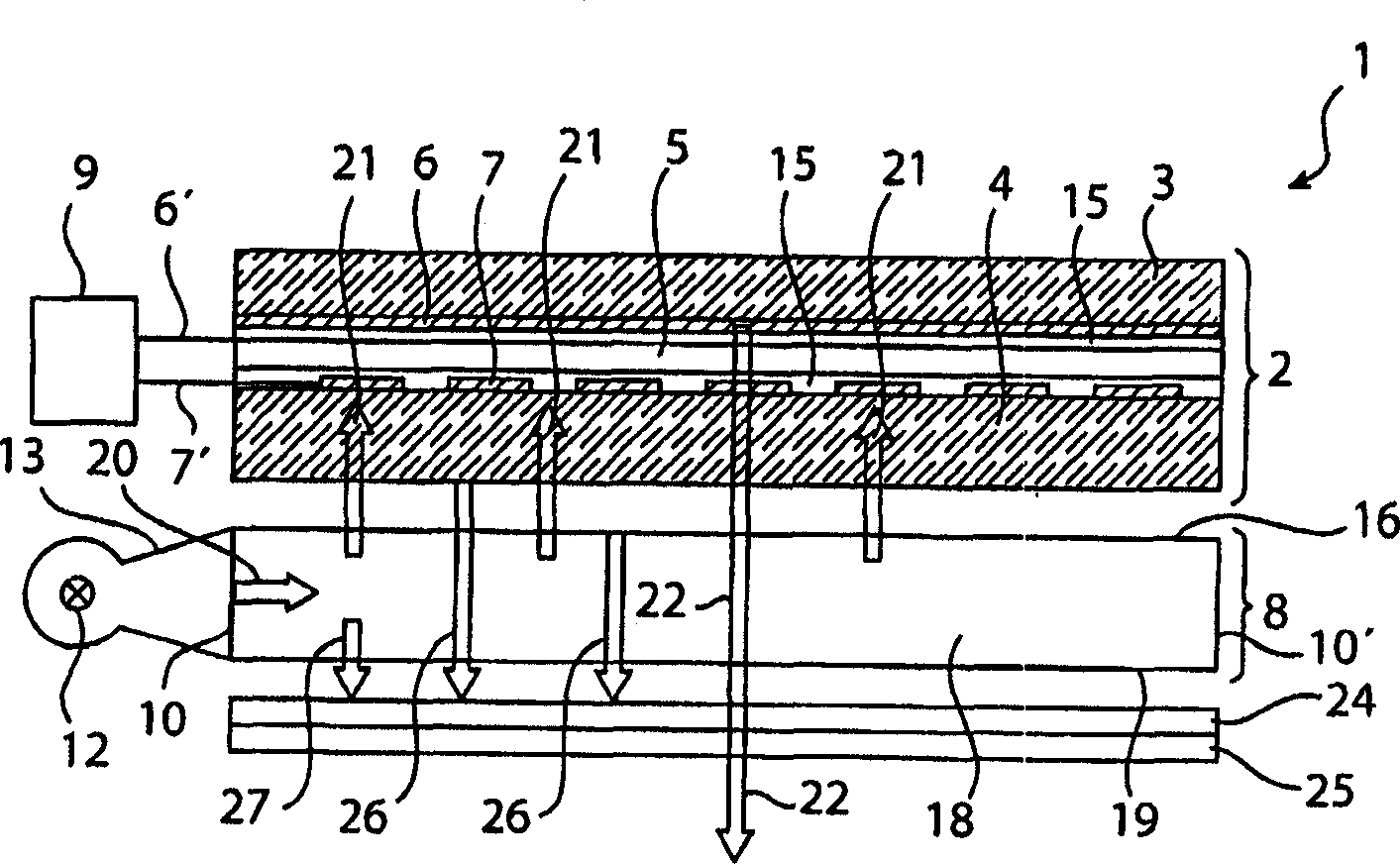

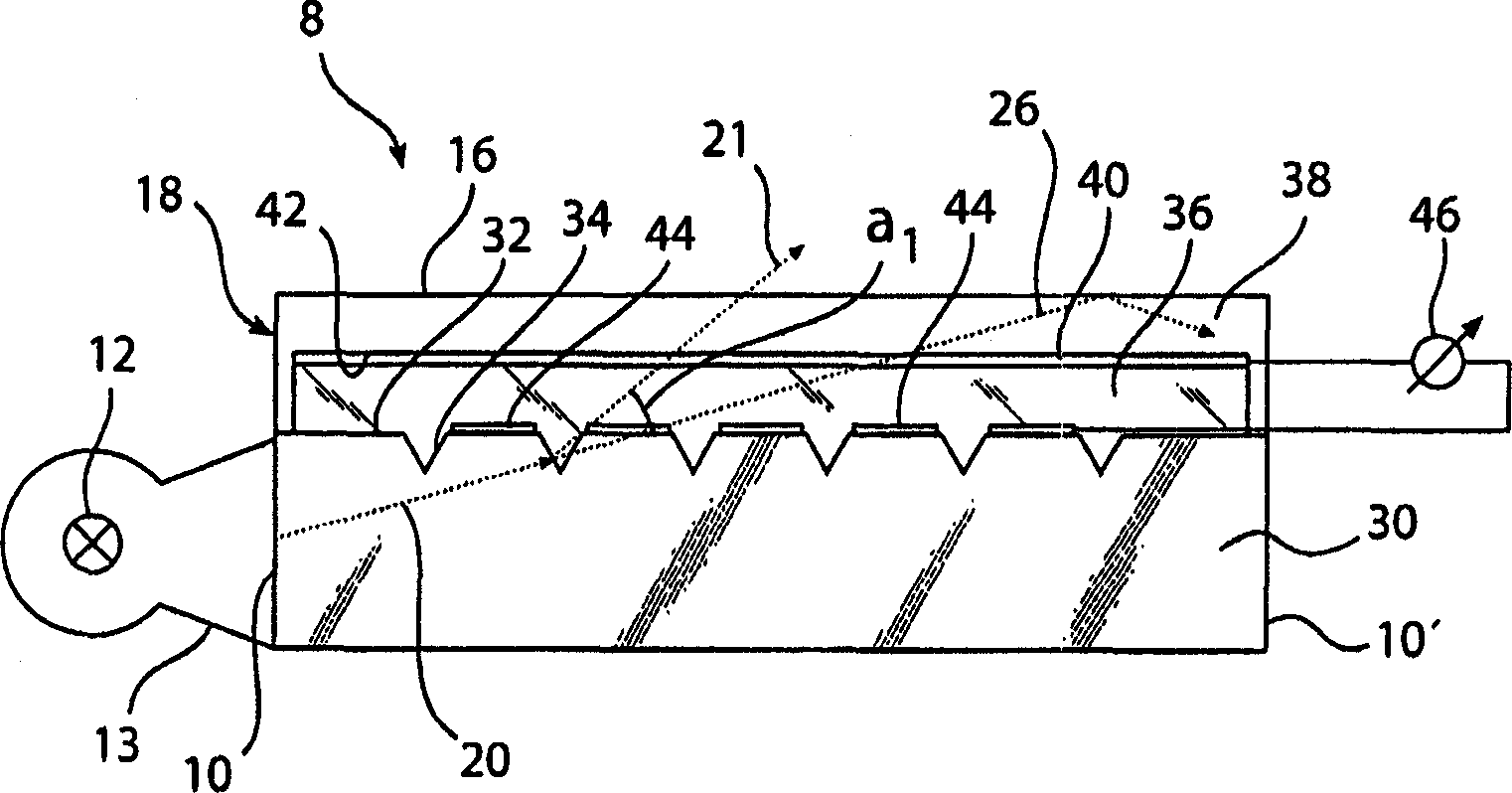

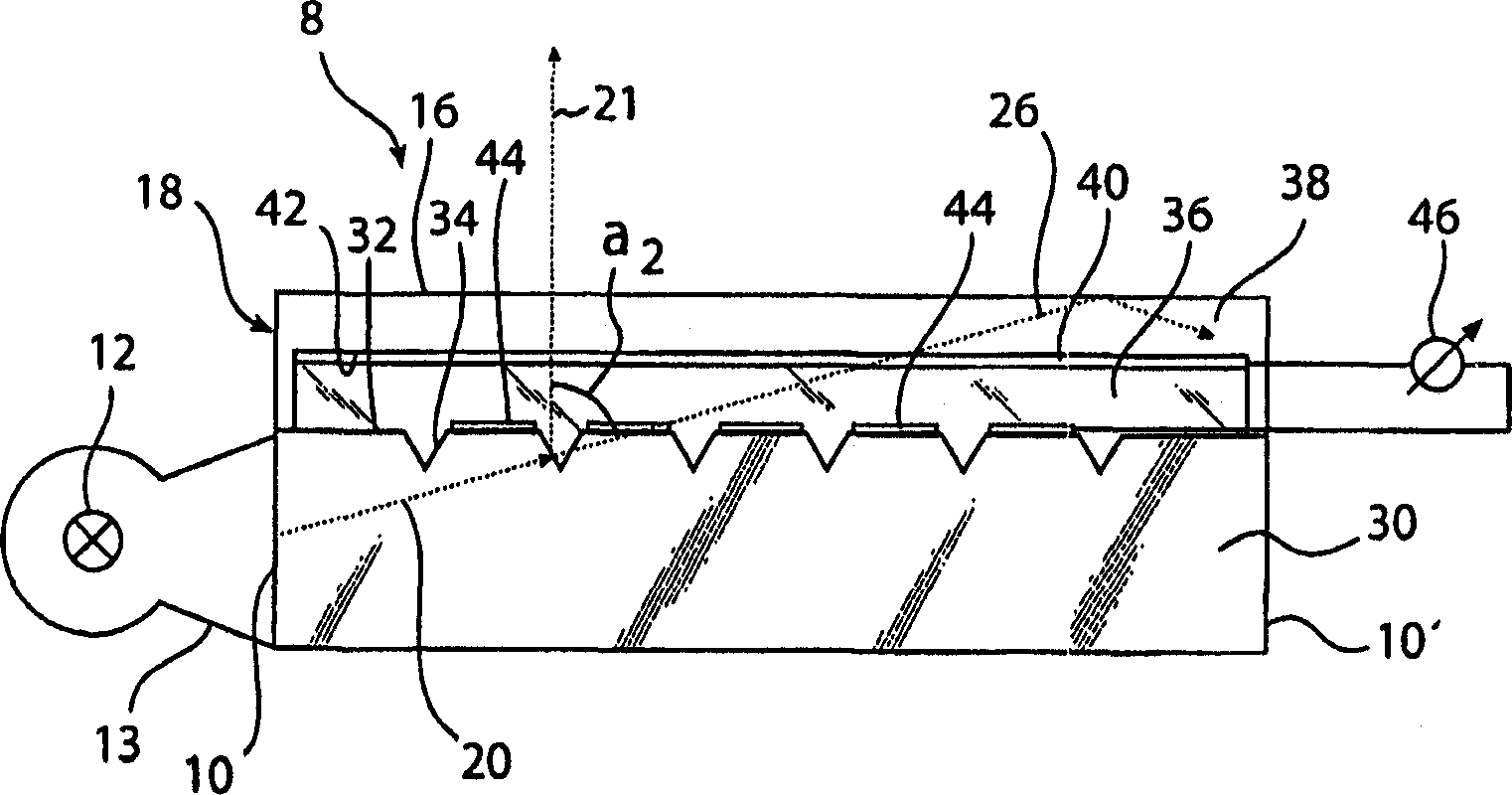

Illumination system

InactiveCN1816769AReduce manufacturing costEasy maintenanceVehicle headlampsVehicle lighting systemsVoltage generatorLight guide

An illumination system (8) comprises an optical waveguide (18) which is made from optically transparent components and has four end faces (10, 10'). A light source (12) whose light is coupled into the optical waveguide (18) via one of the end faces (10) is situated opposite this end face (10). The optical waveguide (18) has a light guide (30). A birefringent layer (36) comprising liquid crystals is provided on the light guide (30) at an exit surface side thereof. A first electrode (40) and a second electrode (44) both have electrical contact with the birefringent layer (36) and are connected to a voltage generator (46). By varying the voltage applied between the electrodes (40, 44), the birefringent properties of the birefringent layer (36) comprising the liquid crystals may be varied to control the direction of light coupled out via the exit surface (16).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

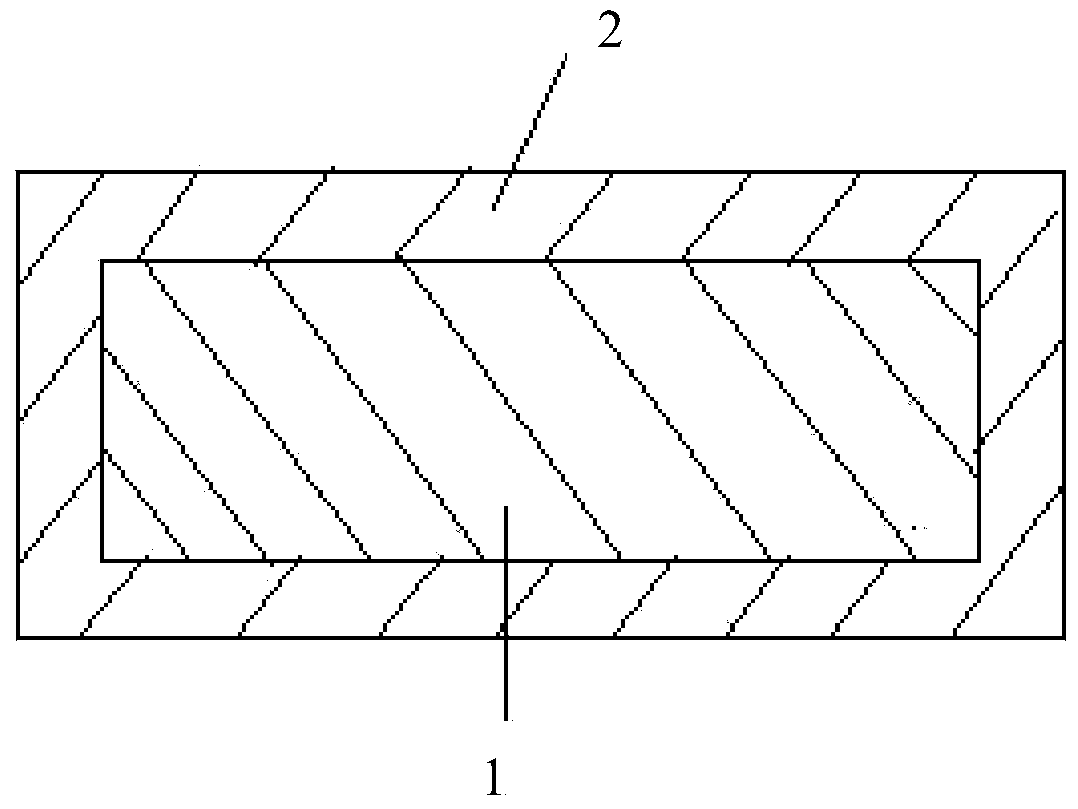

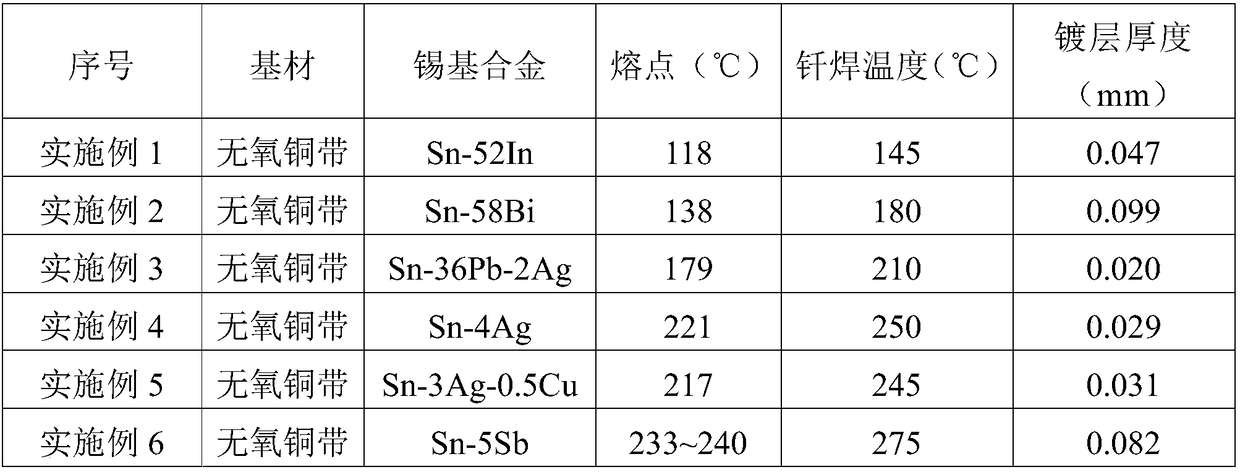

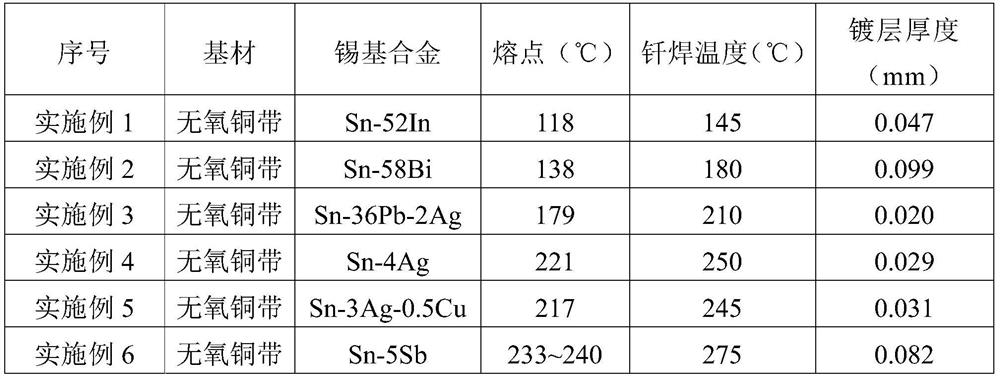

Tin-based alloy and copper strip composite material and preparation method thereof

ActiveCN109509571AInhibition of dissolutionIncrease profitSingle bars/rods/wires/strips conductorsSoldering apparatusHybrid integrated circuitCopper tape

The invention relates to a tin-based alloy and copper strip composite material and a preparation method thereof, and belongs to the field of non-ferrous metal high-frequency brazing machining. The tin-based alloy and copper strip composite material is composed of a core material and a coating wrapping the surface of the core material; the core material is a copper strip, the coating is a tin-basedalloy, and the thickness of the single-side coating ranges from 20 [mu]m to 100 [mu]m. According to the preparation method, a high-frequency brazing principle is adopted, and a compact tin-based alloy material plating layer is formed on the surface of a copper strip; the method comprises the steps of copper base strip material surface soldering flux presetting, copper strip and brazing filler metal compounding, high-frequency induction rapid brazing, air cooling solidification, strip material axis-winding packaging and the like, and the method is simple in process and suitable for batch production. The tin-based alloy and copper strip composite material prepared through the method has the advantages of being free of solder skip and tin nodule defects, good in conductivity, high in weldability, good in corrosion resistance, good in oxidation resistance, firm in coating and the like, is mainly applied to the electronic industrial fields of electronic components, hybrid integrated circuits, solar photovoltaic modules and the like, and has wide market prospects.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

A kind of reducing bellows and its forming method

ActiveCN106090453BSuitable for connectionReduce usagePipeline expansion-compensationRigid pipesPipe fittingPetroleum engineering

Owner:LUOYANG SUNRUI SPECIAL EQUIP

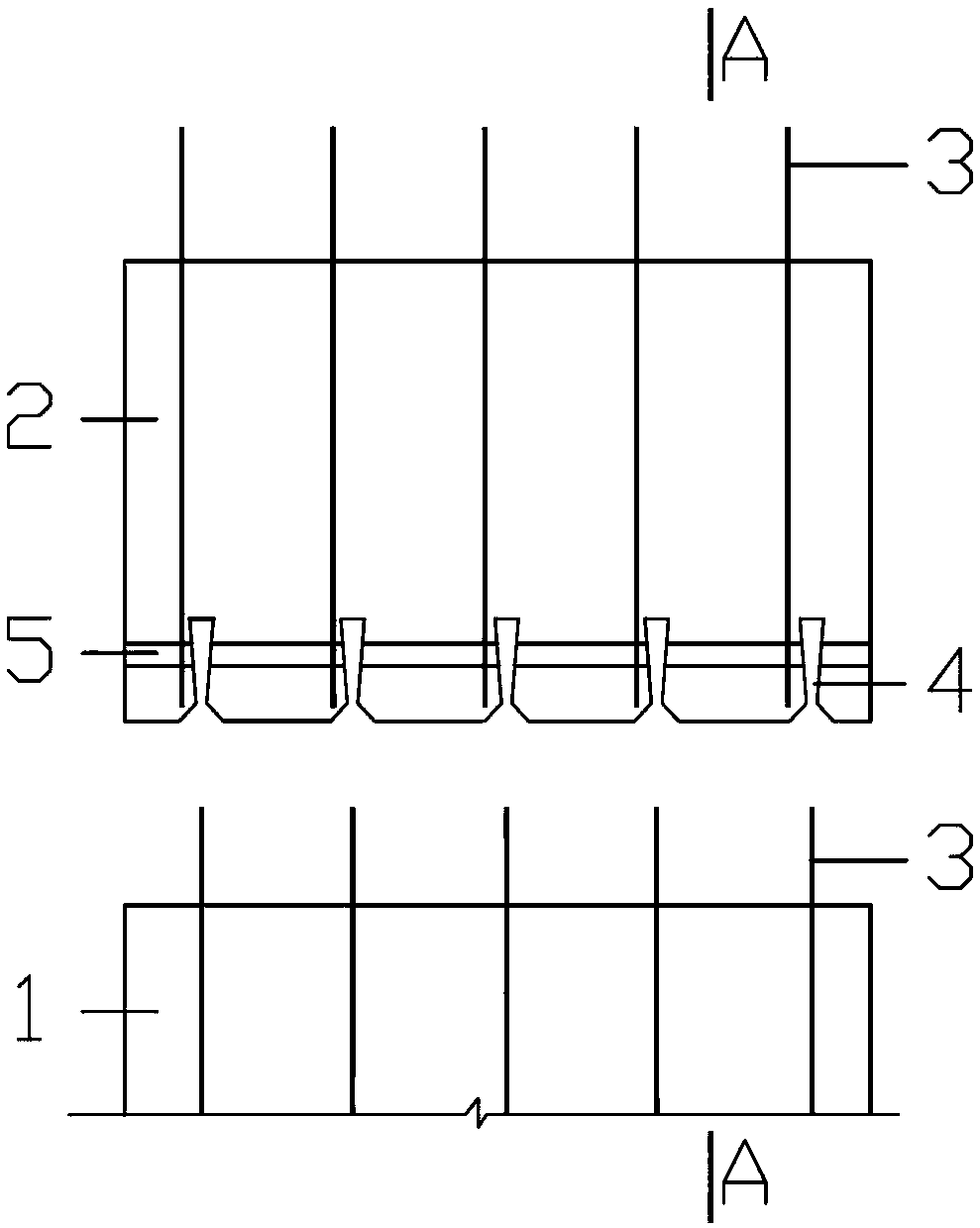

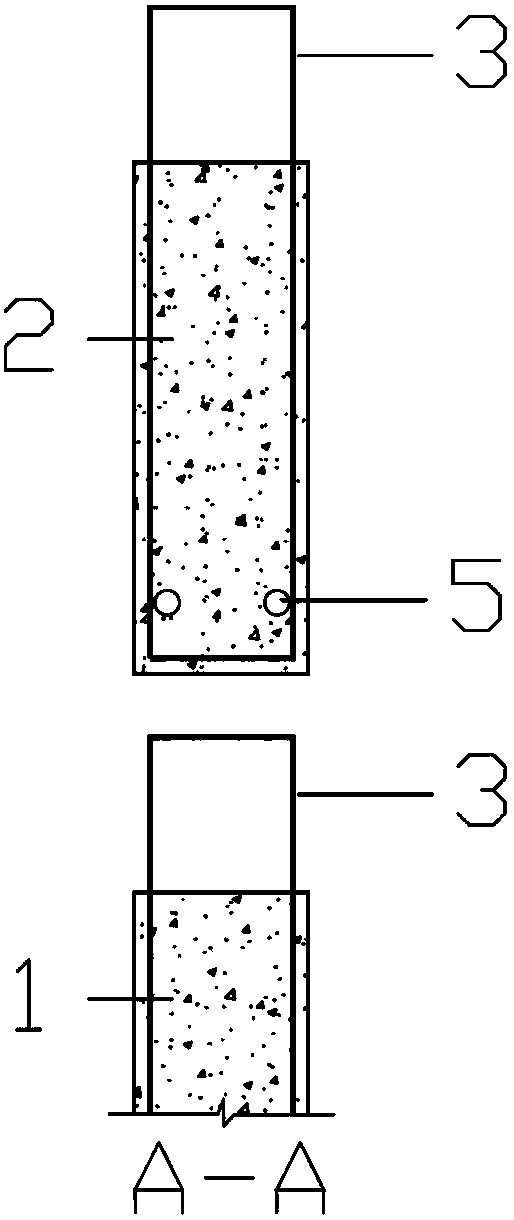

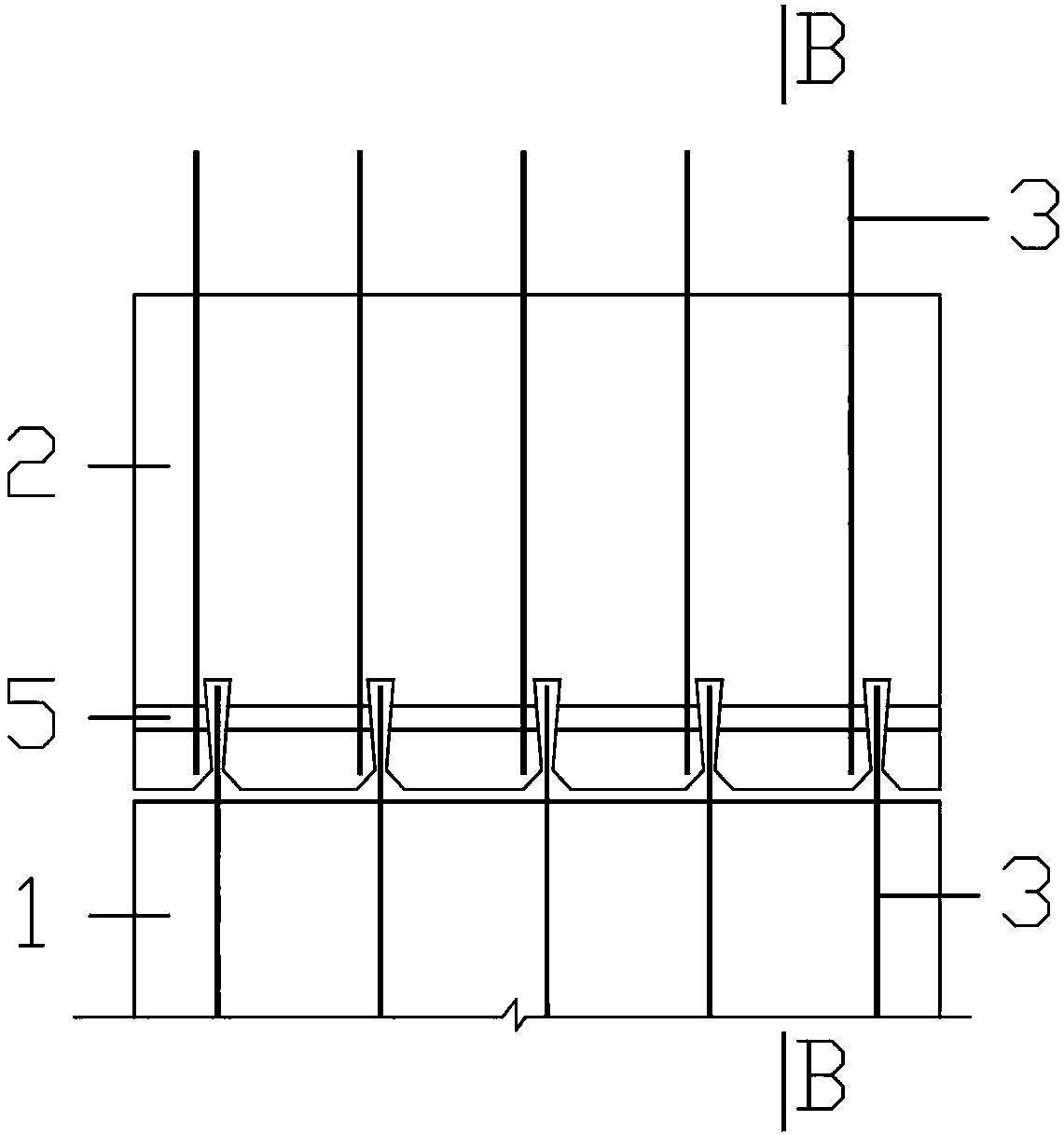

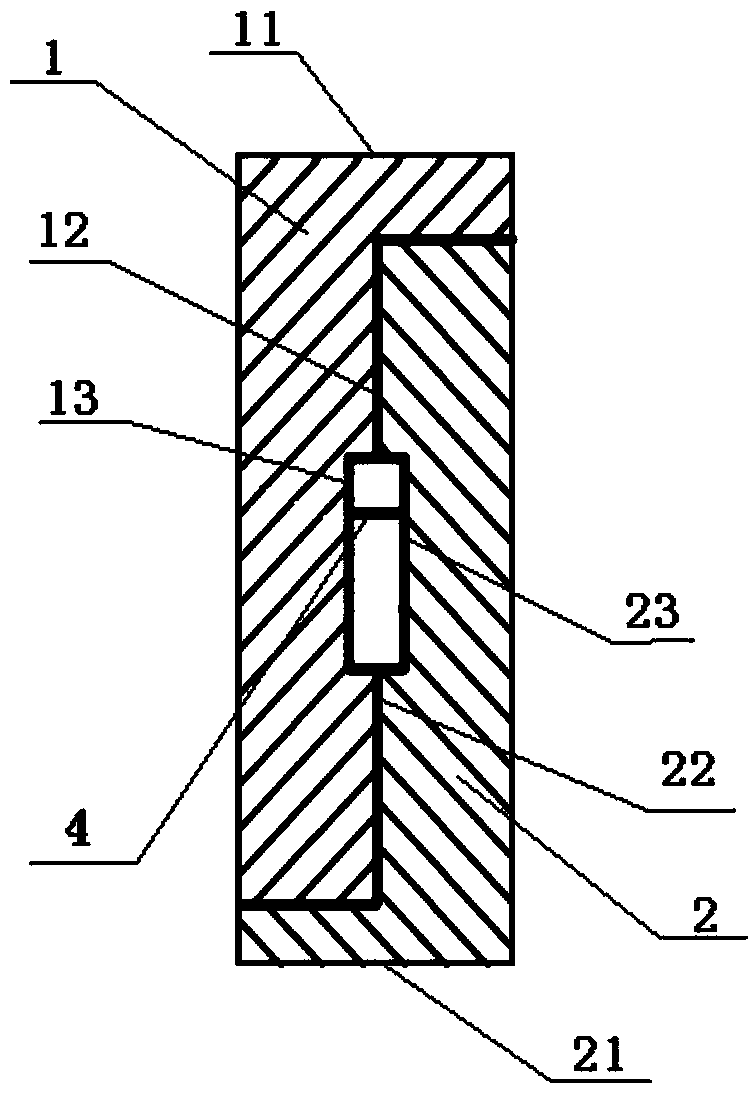

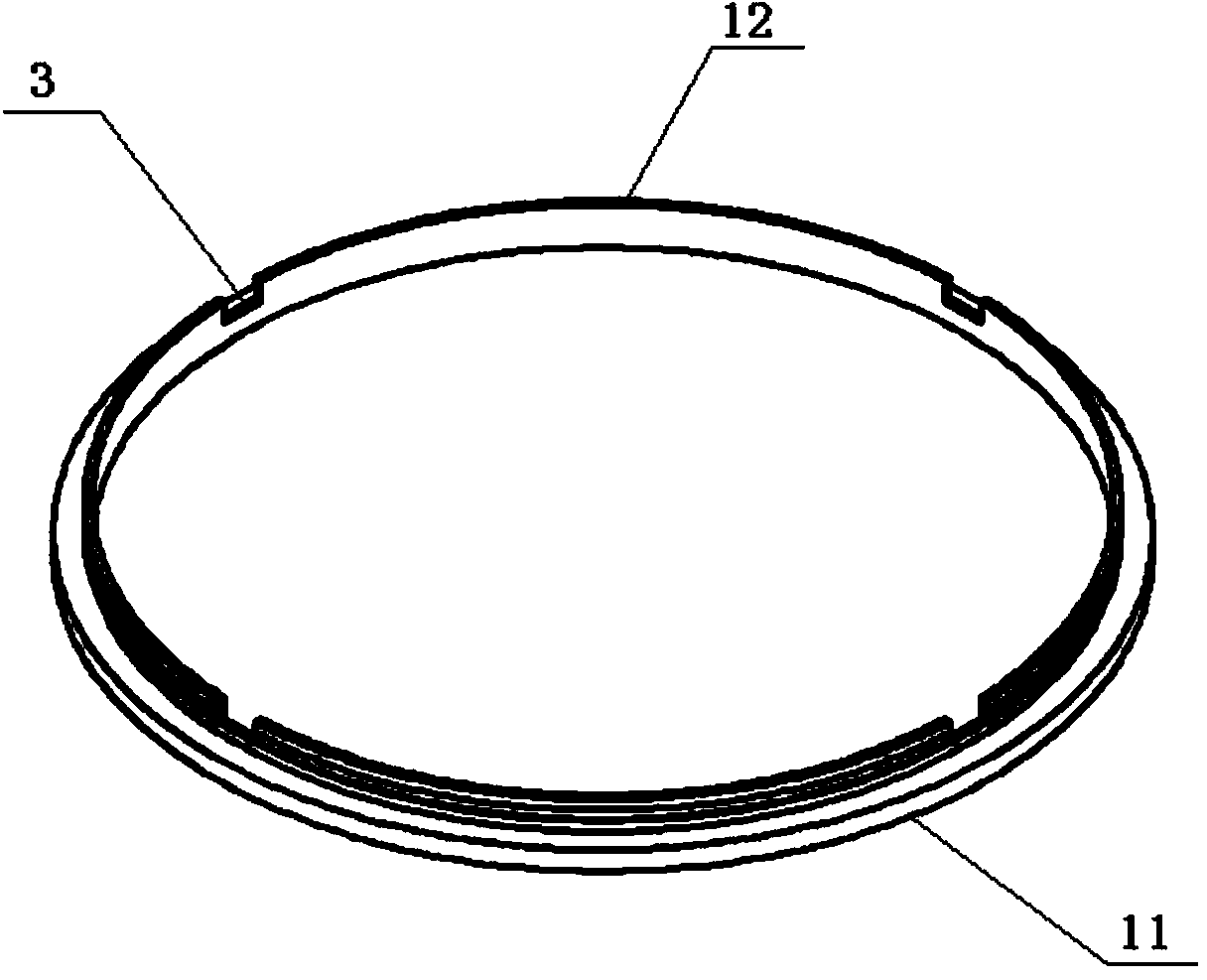

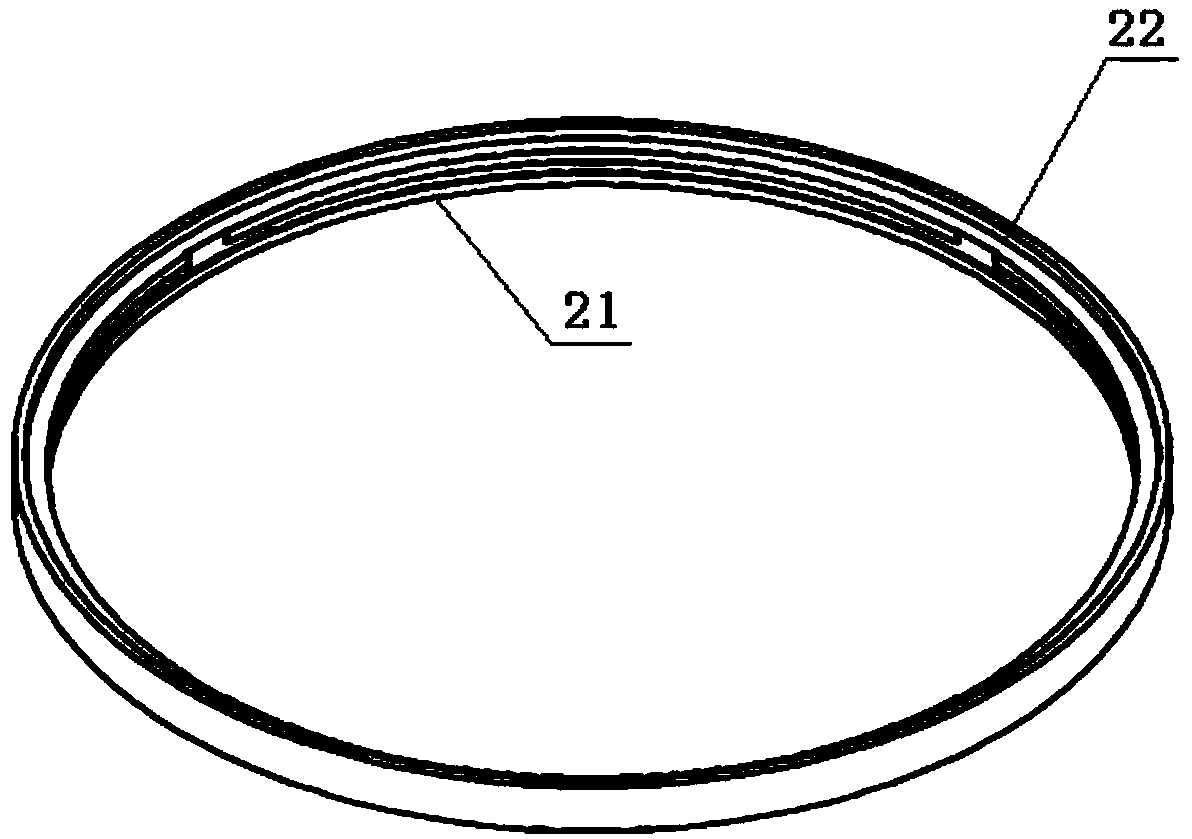

Ring rib pin tenon connection structure of concrete member and construction method thereof

The invention relates to a ring rib pin tenon connection structure of concrete members with pin bolt connection used in combination with tenon connection. The ring rib pin tenon connection structure of the concrete members is characterized in that the ring rib pin tenon connection structure consists of pre-embedded ring ribs, reserved tenon grooves, reserved pin holes, pins and grouting slurry ofthe concrete members; connection ends of two concrete members connected to each other are provided, wherein one ends are the pre-embedded ring ribs, and the others are the reserved tenon grooves and pin holes; the pre-embedded ring ribs of one member or tenons pre-embedded with ring ribs are inserted into the tenon grooves of another member; the pins are then inserted into the reserved pin holes;bonding slurry is filled or injected into the gaps inside the tenon grooves and pin holes of the members; after the slurry solidifies, the slurry becomes grouting slurry, and the two concrete membersare connected together. A construction method of the ring rib pin tenon connection structure is also related to. The ring rib pin tenon connection structure and the construction method thereof have the advantages of not only reducing costs but also improving safety of the structure, facilitating construction and inspection, and having broad application prospects.

Owner:SHANGHAI CITI RAISE CONSTR GRP

Small-sized device for connecting plane micropore for single-pore vacuum encapsulation and pipeline

InactiveCN102136375AReduce air leakageReduce leakageLight-sensitive devicesFinal product manufacturePore diameterEngineering

The invention relates to a small-sized device for connecting a plane micropore for single-pore vacuum encapsulation and a pipeline. The small-size device comprises four parts, namely a connecting rod, a handle, a suction disc and a pore-entrance needle head; the connecting rod is connected with an outer-end pipeline through an outside screw thread; the outer diameter of the pore-entrance needle head is a little smaller than the inner diameter of the connecting rod and the aperture of the plane micropore; the upper end of the pore-entrance needle head is inserted into the connecting rod; the connecting rod, the handle, the suction disc and the pore-entrance needle head are sealed by using sealing glue; and the lower end of the pore-entrance needle head is inserted into the pore-entrance needle head. By the small-sized device for connecting the plane micropore for single-pore vacuum encapsulation and the pipeline, the single-pore vacuum encapsulation of the small-size device can be realized.

Owner:NANJING UNIV

Oil sump and method of its production

ActiveCN101358551AAvoid size deviationAvoid crackingGear lubrication/coolingOilsumpsCombustionReduction drive

The invention relates to an oil sump and a processing method. The oil sump is used in internal combustion engines or transmissions, where the oil sump consists of sheet metal shaped by deep drawing and has a reinforced edge, by means of which it rests, in its mounted state, in the internal combustion engine or the transmission with a seal positioned between them. The reinforcement consists of at least one separate metal part, which is mounted on the edge of the oil sump by positive locking and / or nonpositive locking with deformation of the edge of the oil sump.

Owner:MAN TRUCK & BUS AG

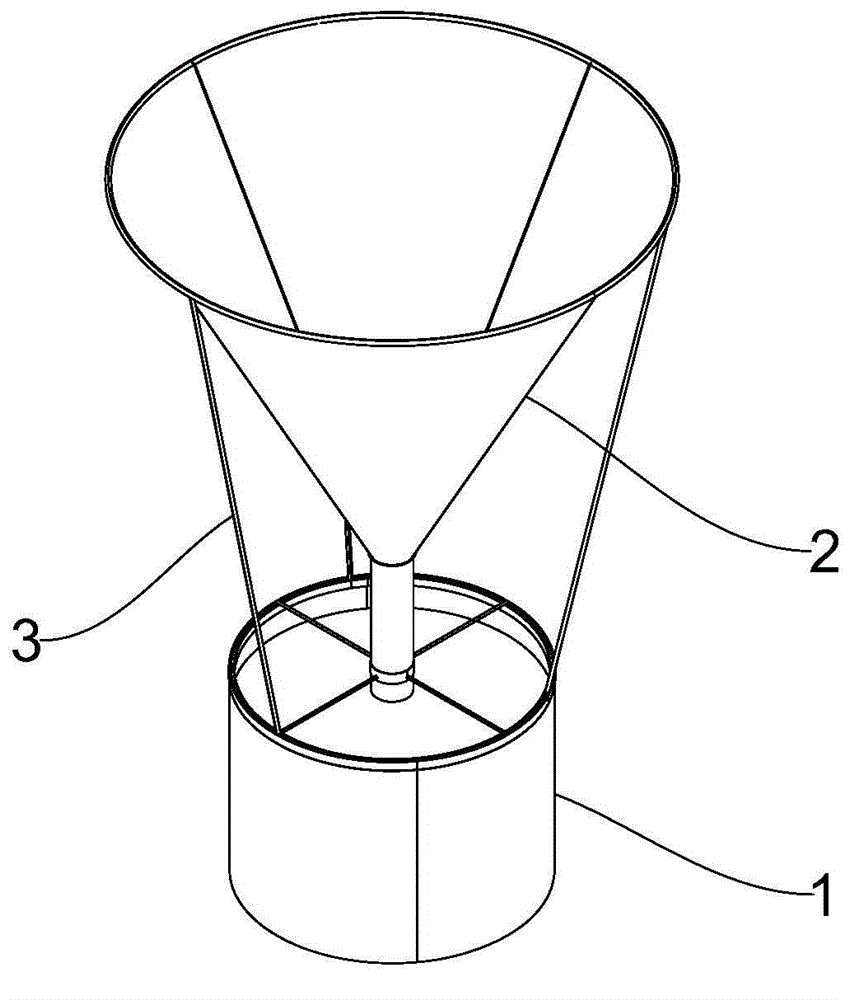

Indoor dehumidifier

The invention discloses an indoor dehumidifier, which comprises a water receiving barrel, and further comprises a water vapor collector, wherein the water vapor collector has a funnel-shaped structure, the lower end is connected to the water receiving barrel, and the water vapor collector is prepared from a hydrophilic material. According to the present invention, the indoor dehumidifier has the following advantages that the funnel-shaped water vapor collector prepared from the hydrophilic material is arranged so as to well collect the water vapor in the air and reduce the indoor air humidity, the price is low, the electric energy is not required to be consumed, no noise is generated, and the indoor dehumidifier is suitable for connection use, and has the long service life.

Owner:常娟

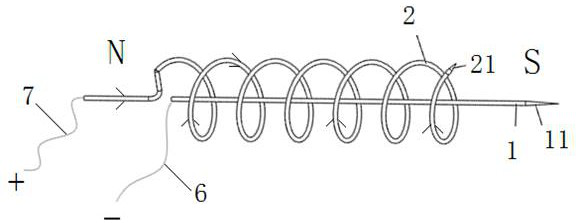

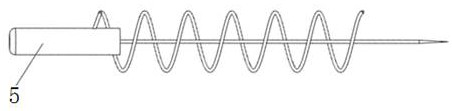

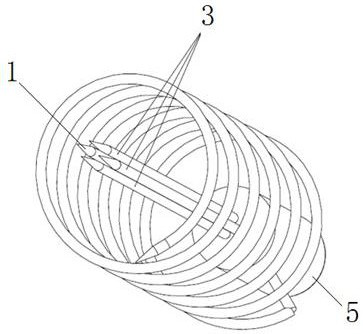

Irreversible electroporation ablation needle, needle passage ablation device and ablation device

ActiveCN114376723AConnection suitable forSuitable for connectionSurgical instruments for heatingCell membraneElectromagnetic induction

The invention provides an irreversible electroporation ablation needle, a needle passage ablation device and an ablation device.The irreversible electroporation ablation needle comprises a first needle, a second needle, a third needle and a fourth needle, a second needle head is arranged on the second needle, the second needle is wound on the outer side of the first needle, at least one part of the second needle is arranged in a bent shape, the second needle is connected with a second electrode, the polarity of the first electrode is opposite to that of the second electrode, the first electrode is suitable for being connected with an alternating-current power supply, and when a loop is formed between the first needle and the second needle, the loop is closed. At least one part of the second needle is bent, so that a magnetic field can be generated in the second needle according to the law of electromagnetic induction. The formed magnetic field can influence the ion transport capacity of tumor cell membranes, programmed cell death can be caused, and damage to tumors is achieved. Therefore, a finite element simulation method and the like do not need to be additionally adopted to carry out simulation operation on the to-be-ablated area, and the tumor ablation effect can be effectively achieved.

Owner:北京微刀医疗科技有限公司

Flanged connection structure and anti-thunder segmented combined tower comprising same

ActiveCN104019003AWith lightning protection functionOvercome the shortcomings of easy fatigue fracture, large amount of operation and maintenance, etc.Final product manufactureWind energy generationInterference fitEngineering

The invention discloses a flanged connection structure. The flanged connection structure comprises an inner flange plate and an outer flange plate, and the horizontal circular plate face of the inner flange plate and the horizontal circular plate face of the outer flange plate are respectively used for being connected with a cylinder. The inner flange plate is inserted into the outer flange plate, the outer side wall of the inner flange plate and the inner side wall of the outer flange plate on the insertion portion intersect, a rectangular groove is formed in the intersection position, the rectangular groove is divided into multiple segments, and a wedge-shaped strip inserting opening is formed in the segment, between every two adjacent segments, of the inner flange plate; the flanged connection structure further comprises a plurality of sets of wedge-shaped strips, the number of the sets is equal to the number of the segments of the rectangular groove, each set of wedge-shaped strips is composed of one upper wedge-shaped strip and one lower wedge-shaped strip, the two wedge-shaped strips in each set are inserted into the rectangular groove from the two ends of the same segment of the rectangular groove respectively to form interference fit, and positioning plugs are fixed to the segments of the rectangular groove. The connection structure is simple, high in production efficiency, small in maintenance workload and low in cost. The invention further discloses an anti-thunder segmented combined tower comprising the flanged connection structure, reliability of tower connection is improved, and lightning current conduction performance of the tower is improved.

Owner:GUODIAN UNITED POWER TECH

Single-support permanent magnet motor

InactiveCN112003415ASolve the problem of inconvenient installation of fully enclosed connectionSolve the swap problemMechanical energy handlingCentering/balancing rotorsCouplingElectric machinery

The invention discloses a single-support permanent magnet motor, which relates to the technical field of motors, and comprises a stator and a rotor, and further comprises a detachable coupling piece fixing device, wherein the coupling piece fixing device is spliced with a motor rotating shaft to complete the horizontal correction of the rotor, and the motor rotating shaft is connected with the coupling piece fixing device through a long screw rod; the coupling sheet fixing device is connected with driven equipment through an interface. A conical shaft is arranged at one end of the coupling piece fixing device, a rotating shaft conical hole is formed in one end of the motor rotating shaft, and the conical shaft is in taper fit with the rotating shaft conical hole. According to the single-support permanent magnet motor, the detachable coupling piece fixing device is arranged, and horizontal correction of the motor rotor is completed through taper design in the process that the taper holein the rotor is matched with the taper shaft on the coupling piece fixing device; the problem that the permanent magnet motor and the driven equipment are inconvenient to connect and install in a full-closed manner is solved by fixing the permanent magnet motor through long screws.

Owner:KUNGFU SCI TECH CO LTD

Small-sized device for connecting plane micropore for single-pore vacuum encapsulation and pipeline

InactiveCN102136375BAchieve connectionSolve the problem of fillingLight-sensitive devicesFinal product manufacturePore diameterEngineering

Owner:NANJING UNIV

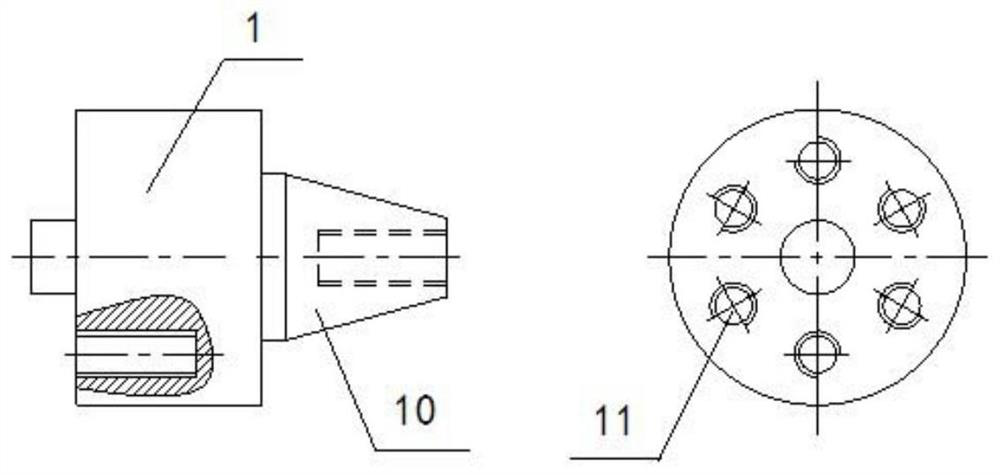

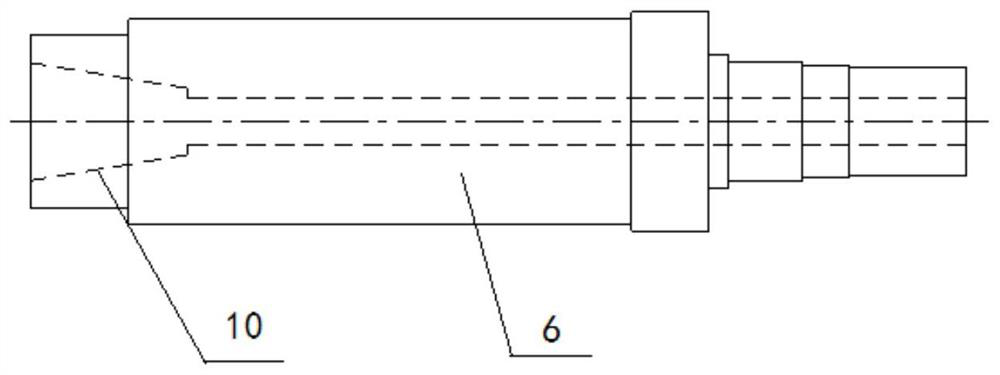

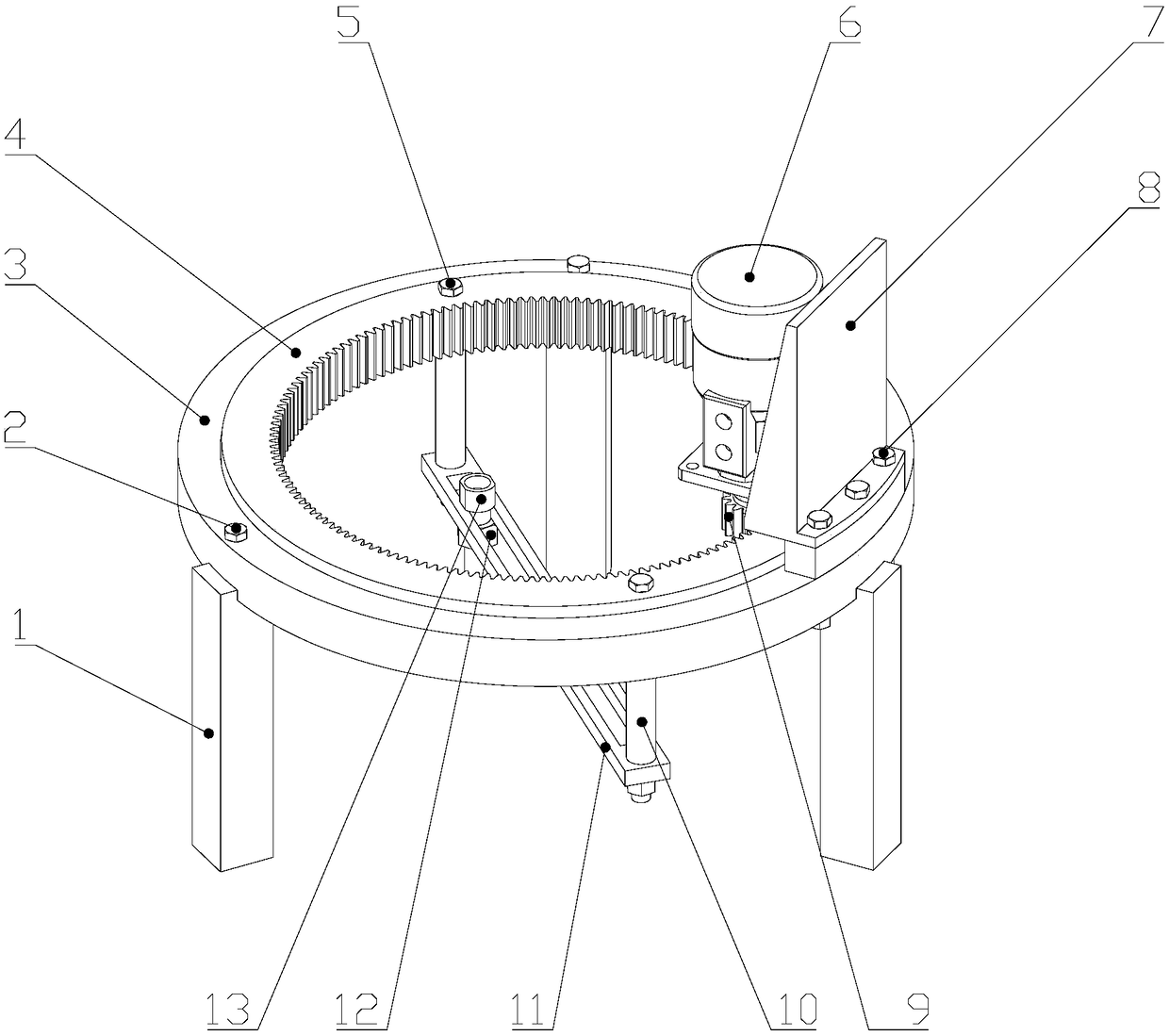

Holing machine of cold cutting non-contact type

InactiveCN108747835AAvoid entanglementReduce weightBlast gunsAbrasive machine appurtenancesSpray nozzleWater jet

The invention provides a holing machine of a cold cutting non-contact type, and relates to the field of holing machines, in particular to a cold cutting non-contact type holing device based on water jet. The holing machine of the cold cutting non-contact type comprises supporting legs, a slewing device, a motor fixing frame, a power device, a nozzle installing device, a nozzle and a clamping device. At least three supporting legs are installed on the lower portion of the slewing device through fixing bolts. The motor fixing frame is installed on the slewing device. The power device is installed on the motor fixing frame. The output end of the power device is meshed with inner ring teeth of the slewing device. The nozzle installing device is installed on the lower portion of the slewing device and can rotate along with the slewing device. The nozzle and the clamping device are installed on the nozzle installing device, and the cutting diameter can be adjusted on the nozzle installing device. The holing machine of the cold cutting non-contact type has the beneficial effects that the structure is novel, machining is convenient, use is convenient, winding is avoided, the cutting radiusis adjustable, and the holing machine is suitable for connecting and fixing various plate faces. The novel holing machine of the cold cutting non-contact type integrates economy and practicality.

Owner:DALIAN MARITIME UNIVERSITY

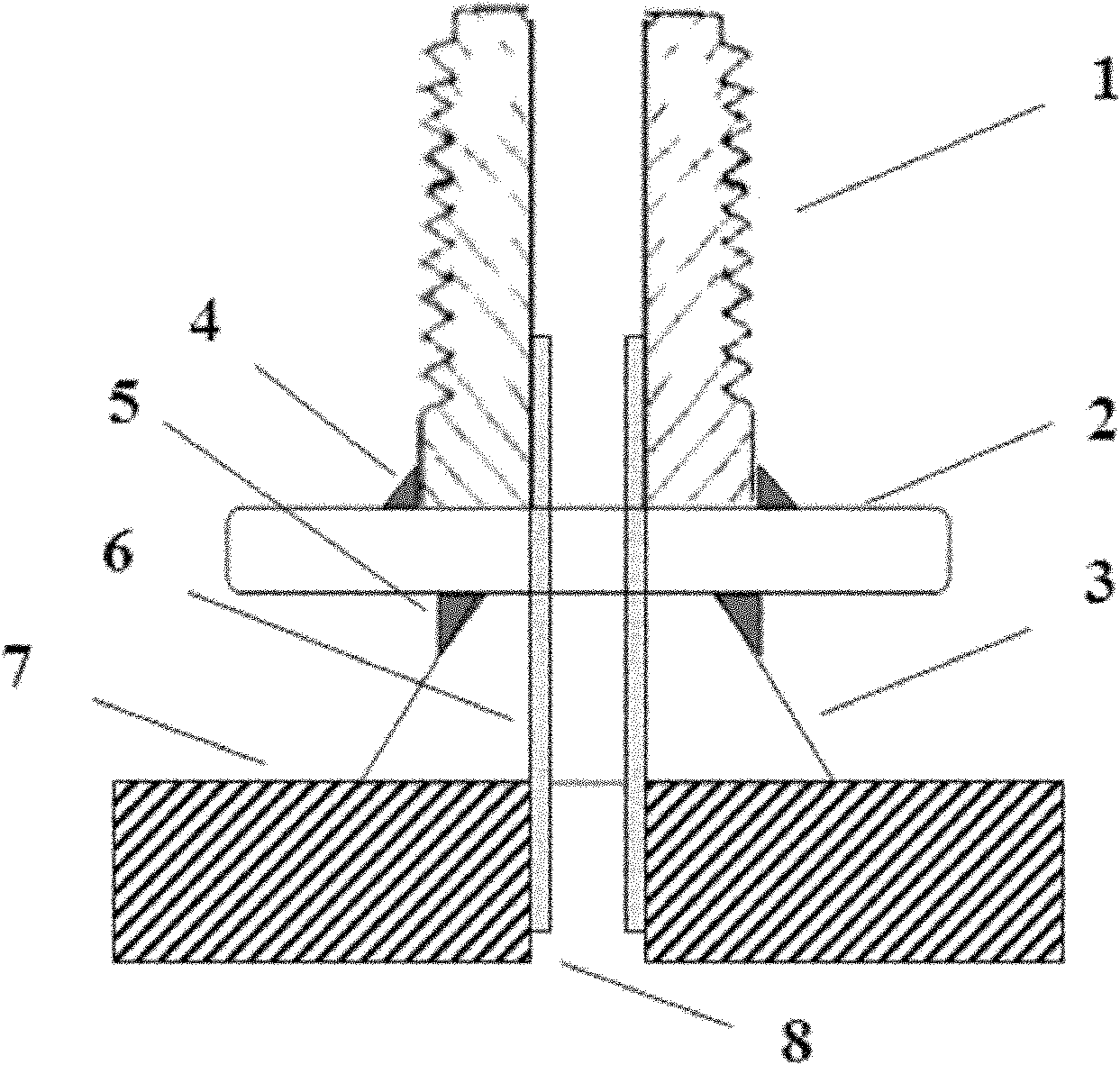

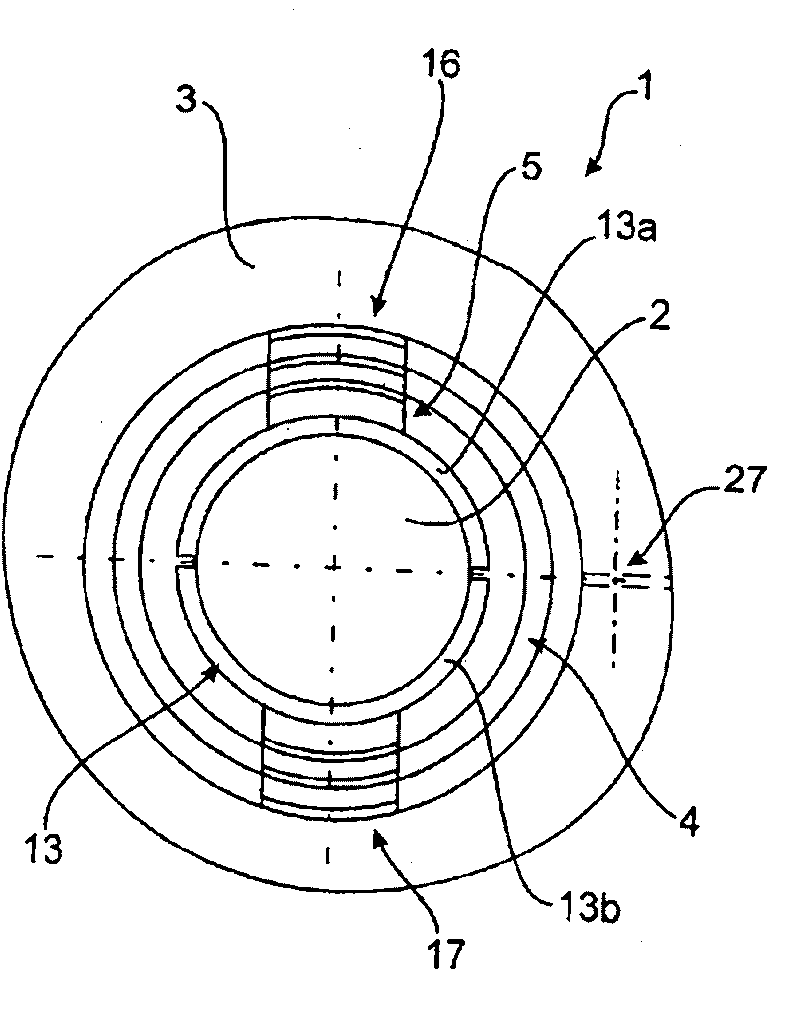

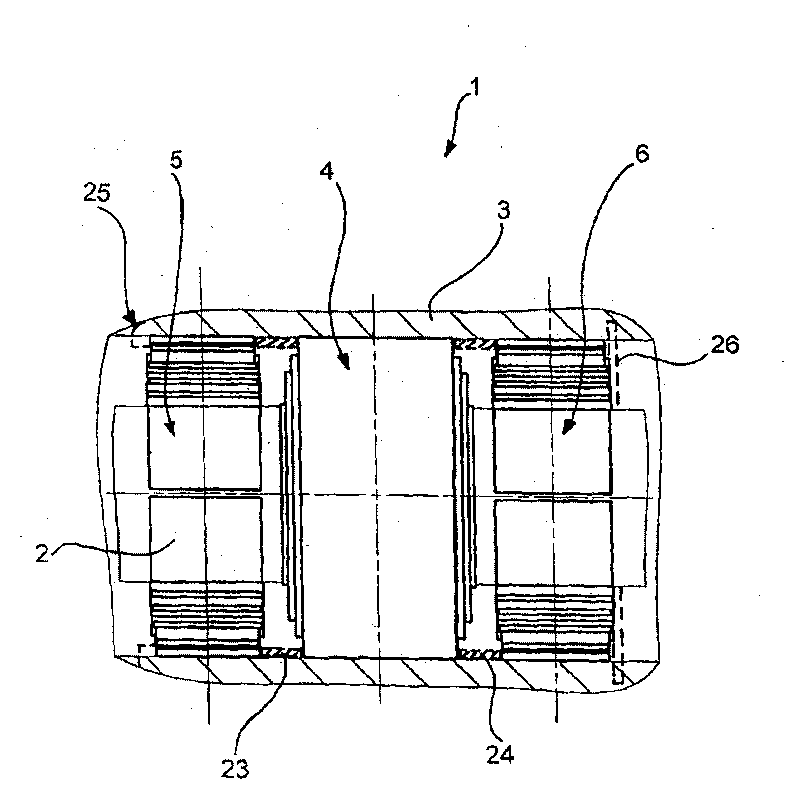

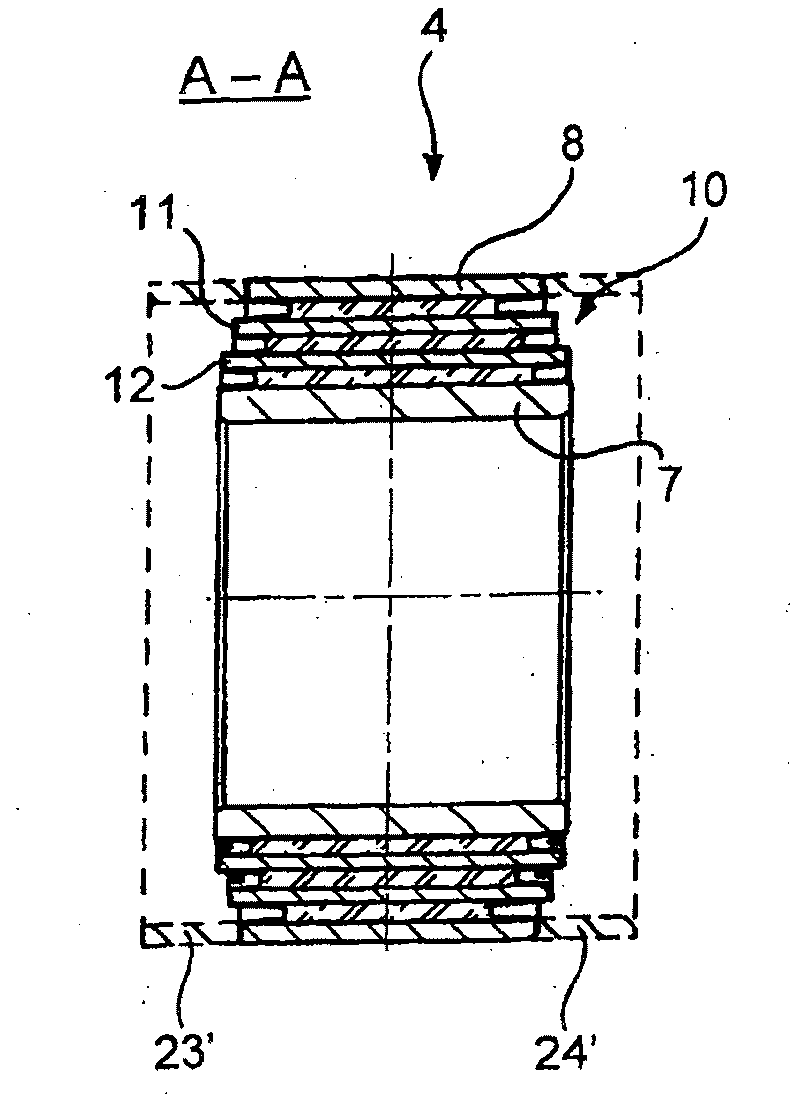

Pivot bearing and an articulated bus

InactiveCN101280816BReduce rigiditySuitable for connectionMultiple spring combinationsOther connectionsElastomerClassical mechanics

The present invention relates to a pivot bearing, in particular on a swivel joint between a front wheel and a rear wheel of an articulated bus, which includes a cylindrical articulated bus (4) composed of a inner pipe (7), a outer pipe (8), a composition rubber layer (10) between them and a contain cover (3), the inner pipe mounted on the a bearing pin (2) with anti-torsion function, the outer pipe provided with a longitudinal seam (9).The pre-tightening articulated bus (4) inserts in the contain cover (3).According to the invention, an elastomer metal bushings (5, 6) are arranged at both endof the pre-tightening articulated bus (4) and are spaced slightly from it.The elastomer metal bushings includes a inner pipe (13) which has a interrupted elastomer layer case (16, 17) clinging and crossing the free-space (14, 15) at individual radial direction relative place, and inserting into the contain cover (3) with pre-tightening inside of the elastomer layer case (16, 17) under assembling condition, wherein the inner pipe (13) is mounted on the a bearing pin (2) with anti-torsion function, and the elastomer layer shells lies in a common longitudinal plane.

Owner:JORN +1

A kind of tin-based alloy and copper strip composite material and preparation method thereof

ActiveCN109509571BSuitable for connectionImprove solderabilitySingle bars/rods/wires/strips conductorsSoldering apparatusNon-ferrous metalIntegrated circuit

The invention relates to a tin-based alloy and copper strip composite material and a preparation method thereof, belonging to the field of high-frequency brazing processing of non-ferrous metals. The tin-based alloy and copper tape composite material is composed of a core material and a coating layer wrapped on the surface of the core material. The preparation method adopts the principle of high-frequency brazing to realize the formation of a dense tin-based alloy material coating on the surface of the copper strip, including presetting flux on the surface of the copper-based strip, compounding the copper strip and the brazing material, high-frequency induction rapid brazing, and air-cooling solidification. , tape wrapping around the shaft, etc. This method has a simple process and is suitable for mass production. The composite material of tin-based alloy and copper tape prepared by this method has no leakage welding, no tin nodules defect, and has the characteristics of good electrical conductivity, strong solderability, good corrosion resistance, good oxidation resistance and firm coating, etc. It is mainly used for Electronic components, hybrid integrated circuits, solar photovoltaic modules and other electronic industry fields have broad market prospects.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com