Patents

Literature

819 results about "Copper tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper tape refers to a thin strip of copper, often backed with adhesive. Copper tape can be found at most hardware and gardening stores and sometimes electronic stores. Copper tape is used to keep slugs and snails out of certain areas in gardens, potted plants, and trunks of fruit trees, and other trees and shrubs. It is also used for other applications, such as electromagnetic shielding or low-profile surface mount transmission line in electronics and in the production of tiffany lamps. It comes in two forms; conductive adhesive and non-conductive adhesive (which is more common).

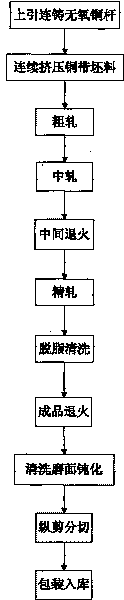

Production technique of copper strips for solar modules

InactiveCN101719527AHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLiquid surfaces

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

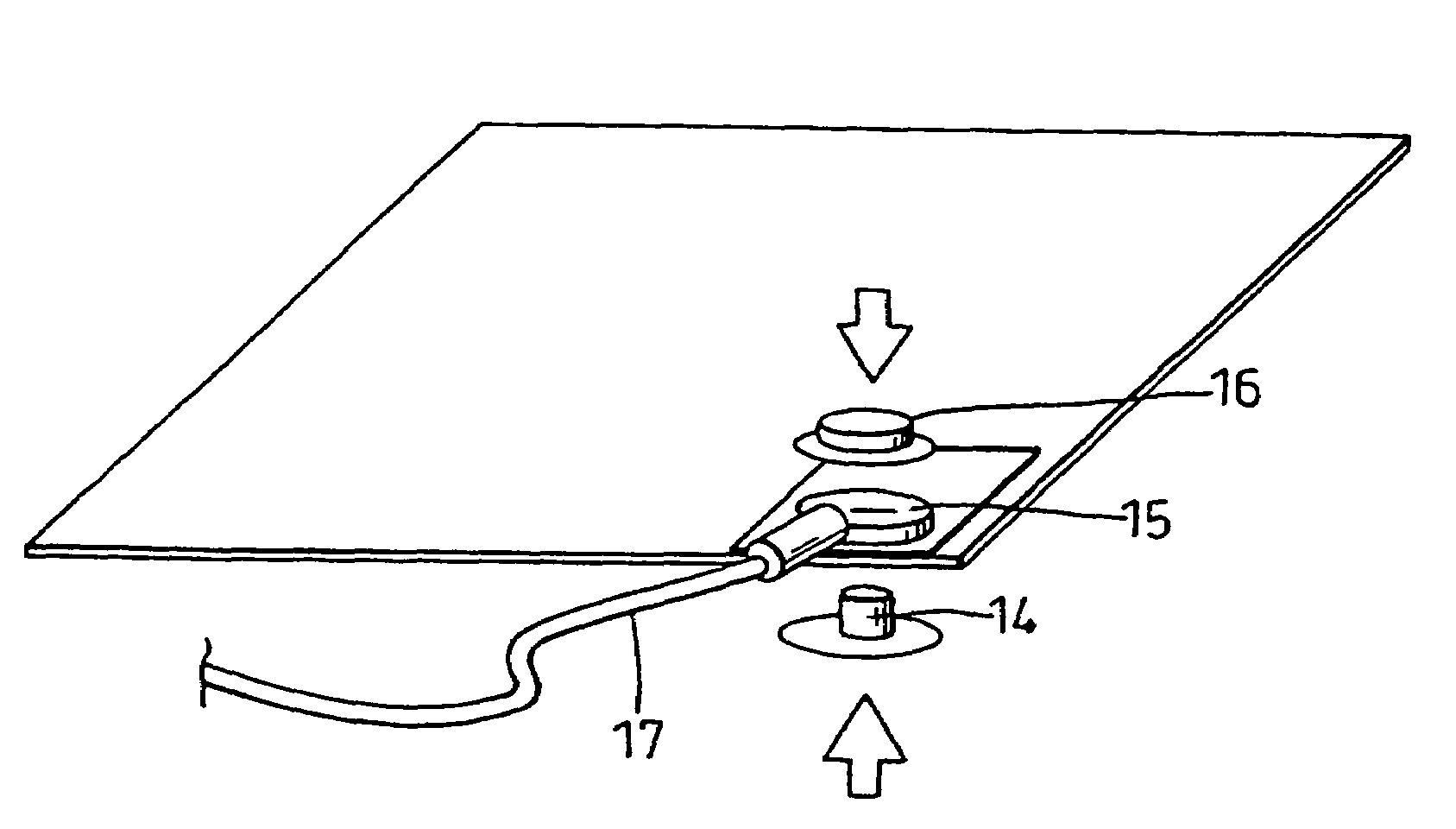

Electrical connection

InactiveUS6974935B2Low viscosityNon-metal conductorsElectrically conductive connectionsCold spotAdhesive

A device for connecting a source of electrical power to a coating or film incorporating carbon particles, an objective met by providing a coating of a nickel compound to the coating or film of carbon particles, and applying to the nickel coating a tin-copper tape coated with a silver-loaded conductive adhesive. What results is a uniform heating effect over a relatively wide area, substantially free from hot and cold spots or areas.

Owner:INSPIRATION HEALTHCARE GRP PLC

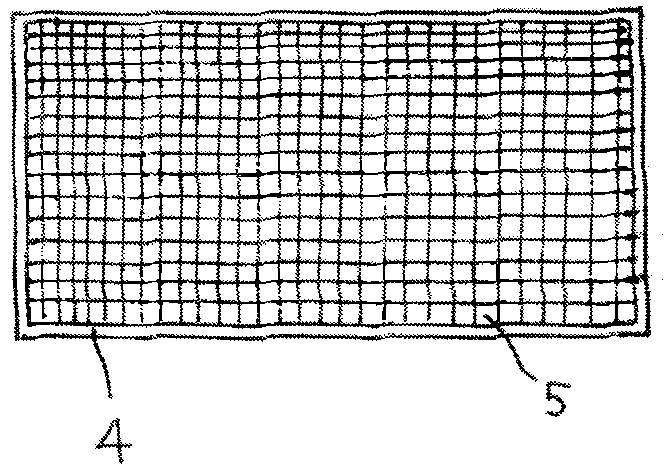

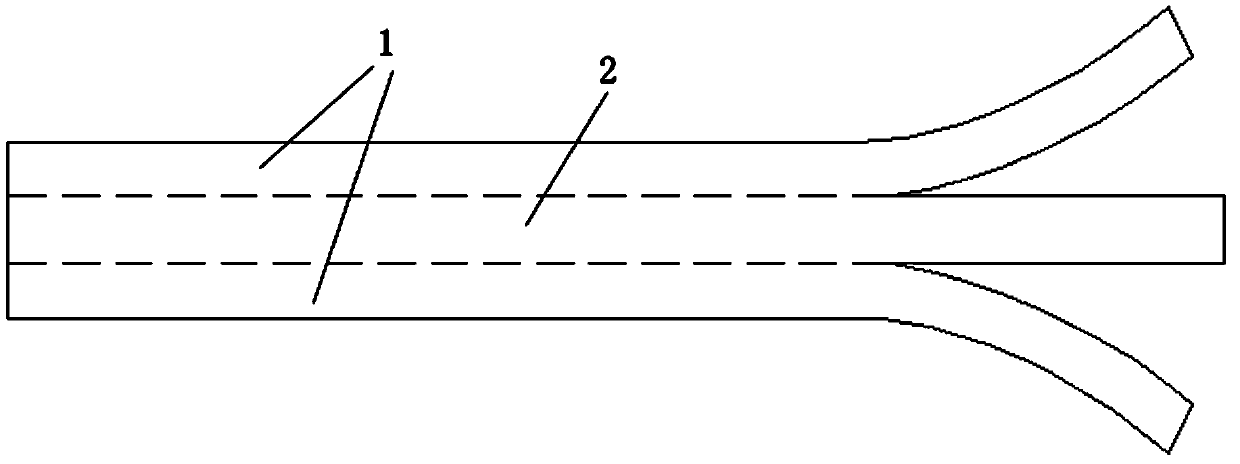

Diffuse reflection type tin-coated welding strip and method for producing same

ActiveCN101789452AIncrease power consumptionLower the immersion temperatureFinal product manufacturePhotovoltaic energy generationDiffuse reflectionAir blower

The invention discloses a diffuse reflection type tin-coated welding strip and a method for producing the same. The diffuse reflection type tin-coated welding strip comprises a copper strip and a tin coating on the copper strip, wherein the surface of the tin coating is provided with distributed pit-shaped bodies. The production method comprises the following steps of: raising the temperature in a tin furnace to between 230 and 250 DEG C, and putting the copper strip in metallic alloy coating solution in the tin furnace for immersion tin-coating, wherein the speed of the immersion tin-coating is controlled to be 1 to 2m / min; and taking the tin-coated welding strip subjected to the immersion coating out, and cooling the tin coating on the surface of the copper strip by an air blower and a screen arranged on the air blower to obtain the distributed pit-shaped bodies. Because the surface of the tin coating is provided with the distributed pit-shaped bodies, the physical indexes of the diffuse reflection type tin-coated welding strip are stable, and the diffuse reflection type tin-coated welding strip can diffuse sunlight, so that more sunlight can be reflected to a battery plate, and the received solar energy is increased.

Owner:QINHUANGDAO DONGWU ELECTRONICS

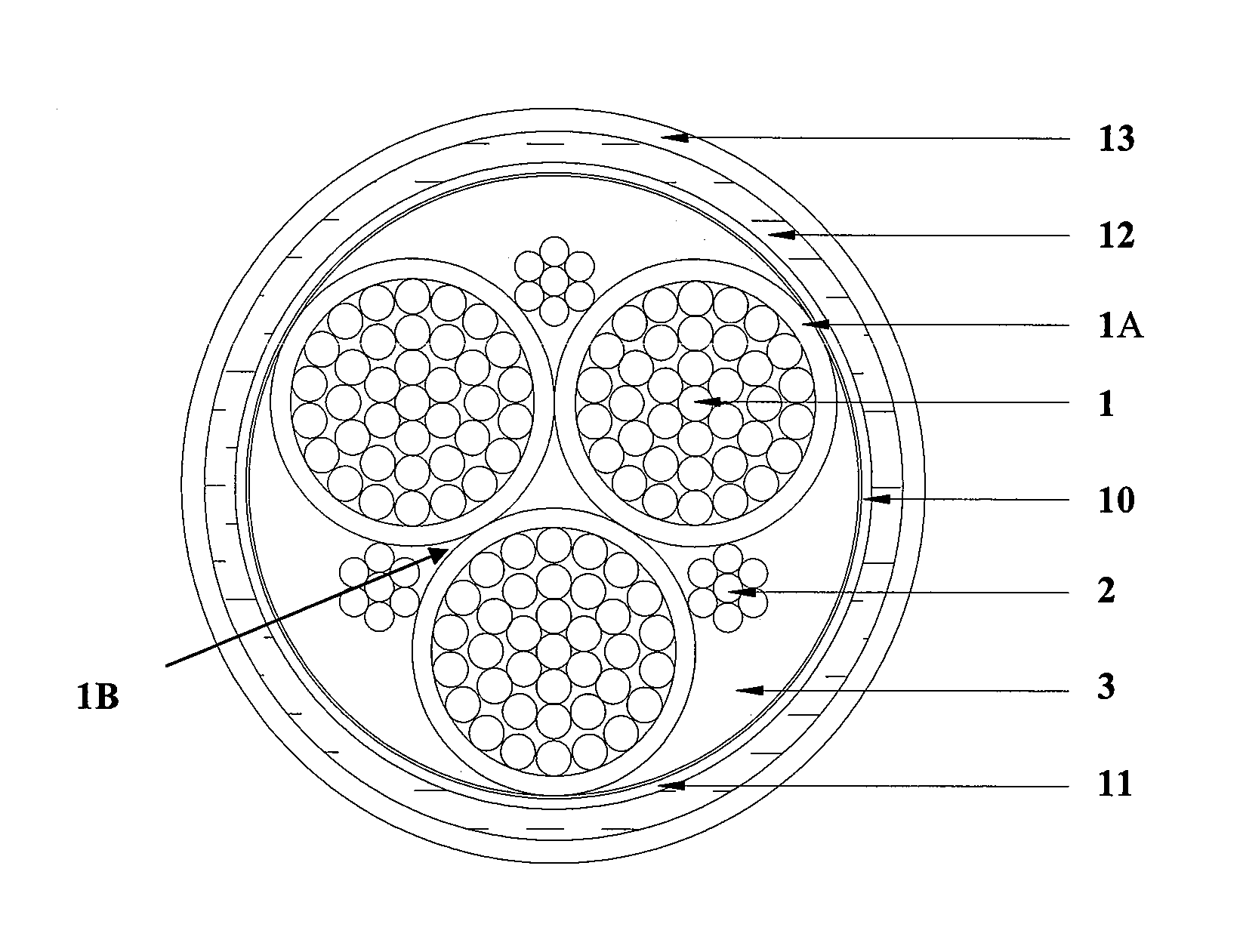

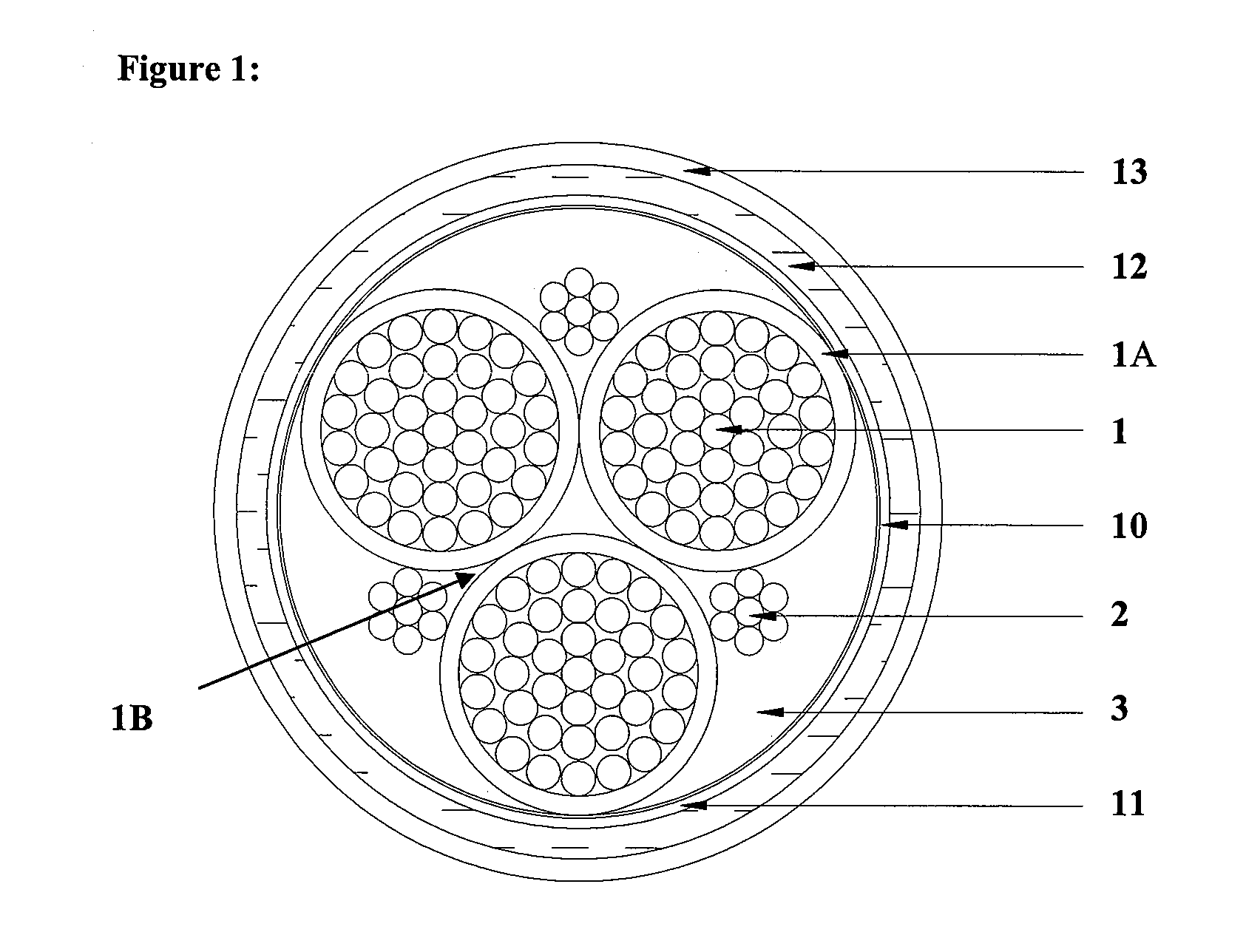

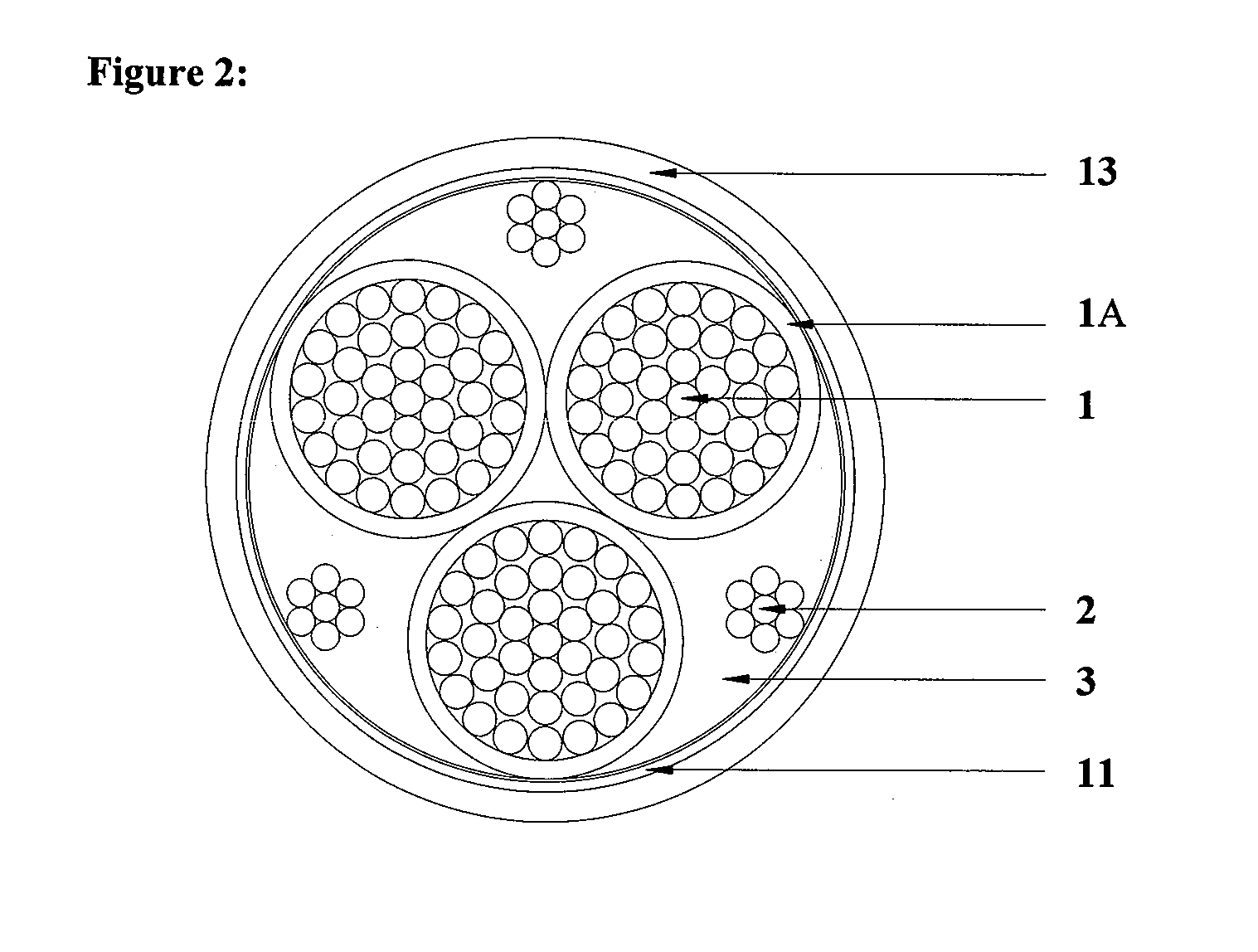

Adjustable speed drive/variable frequency drive cable, connector and termination system

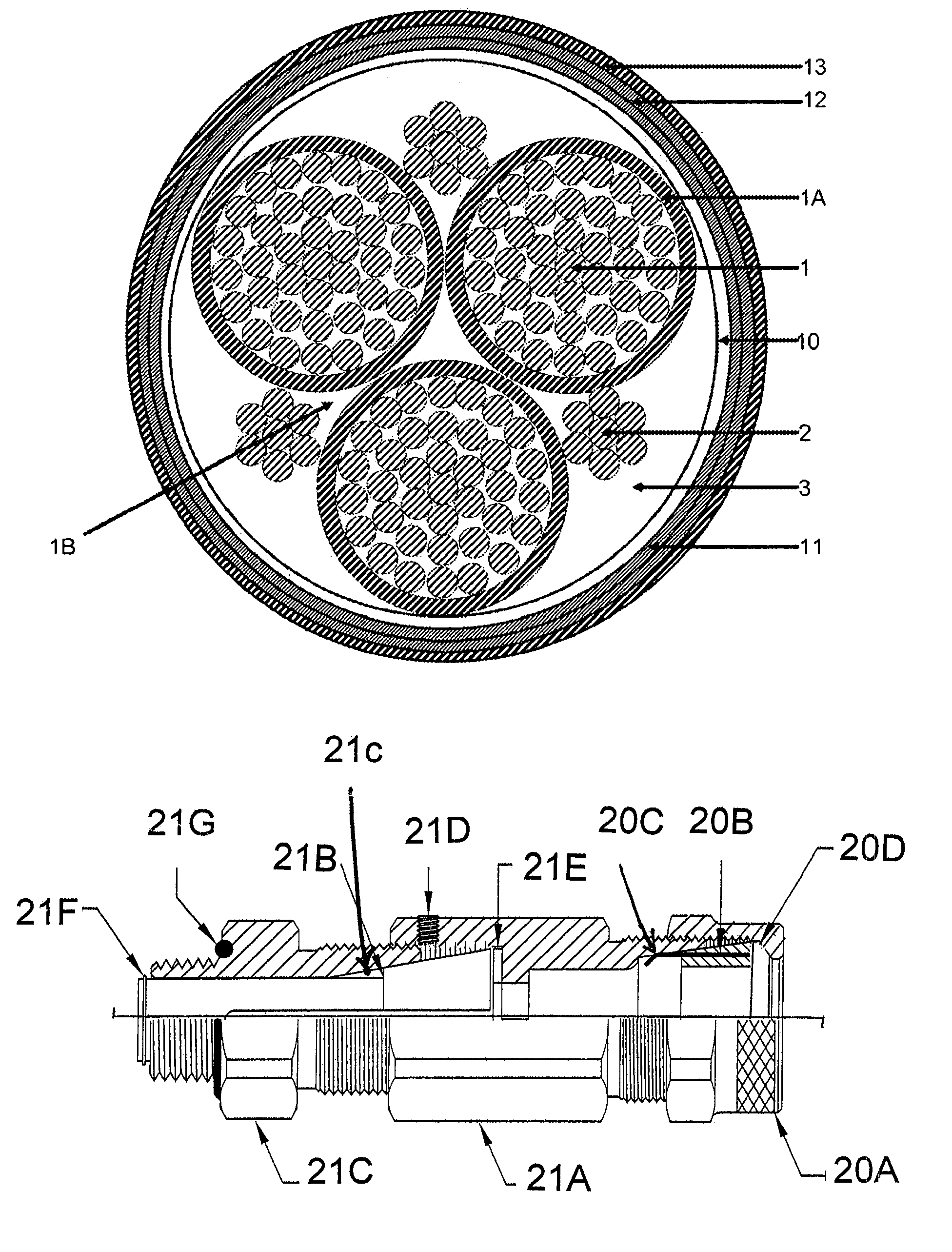

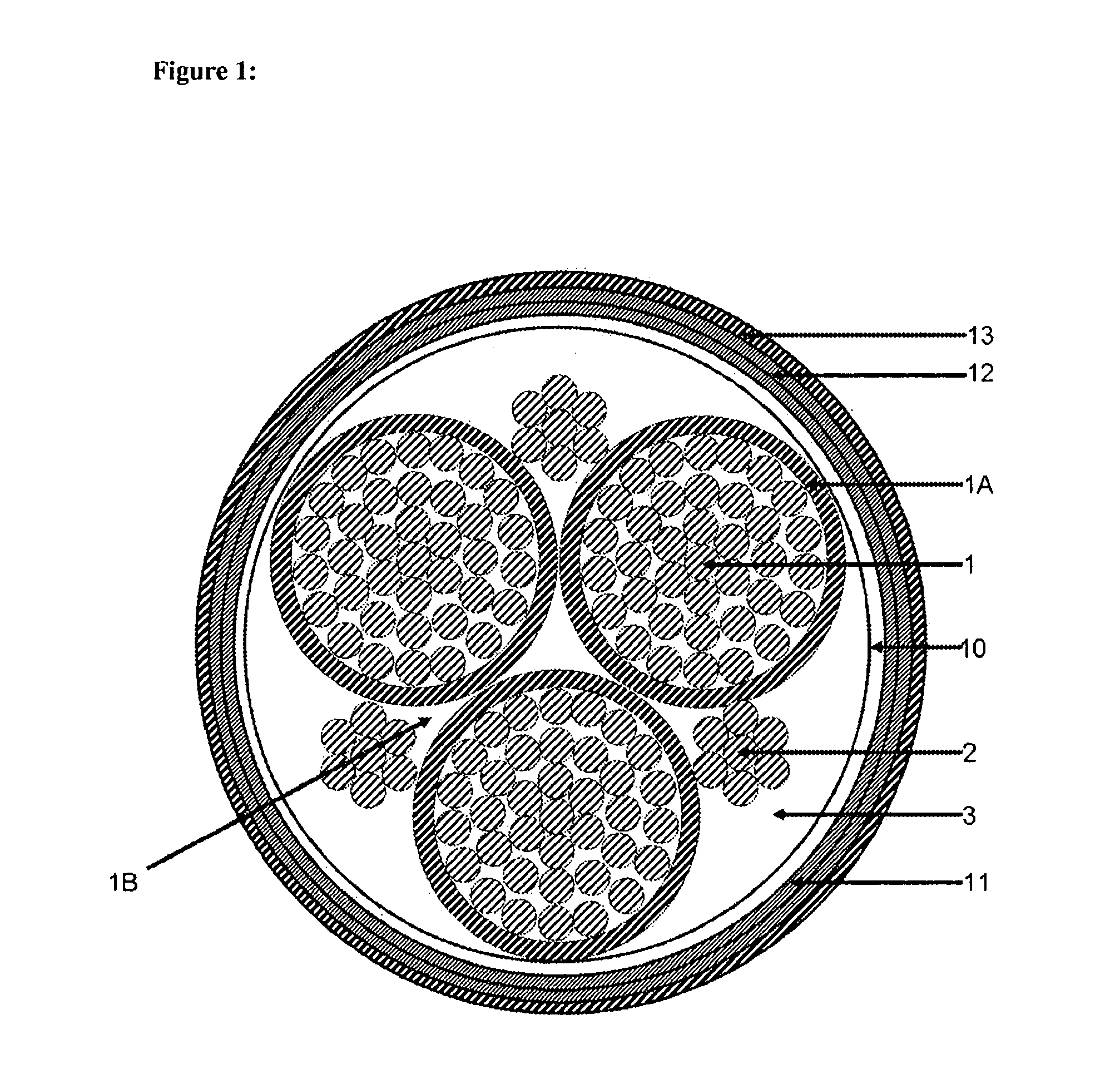

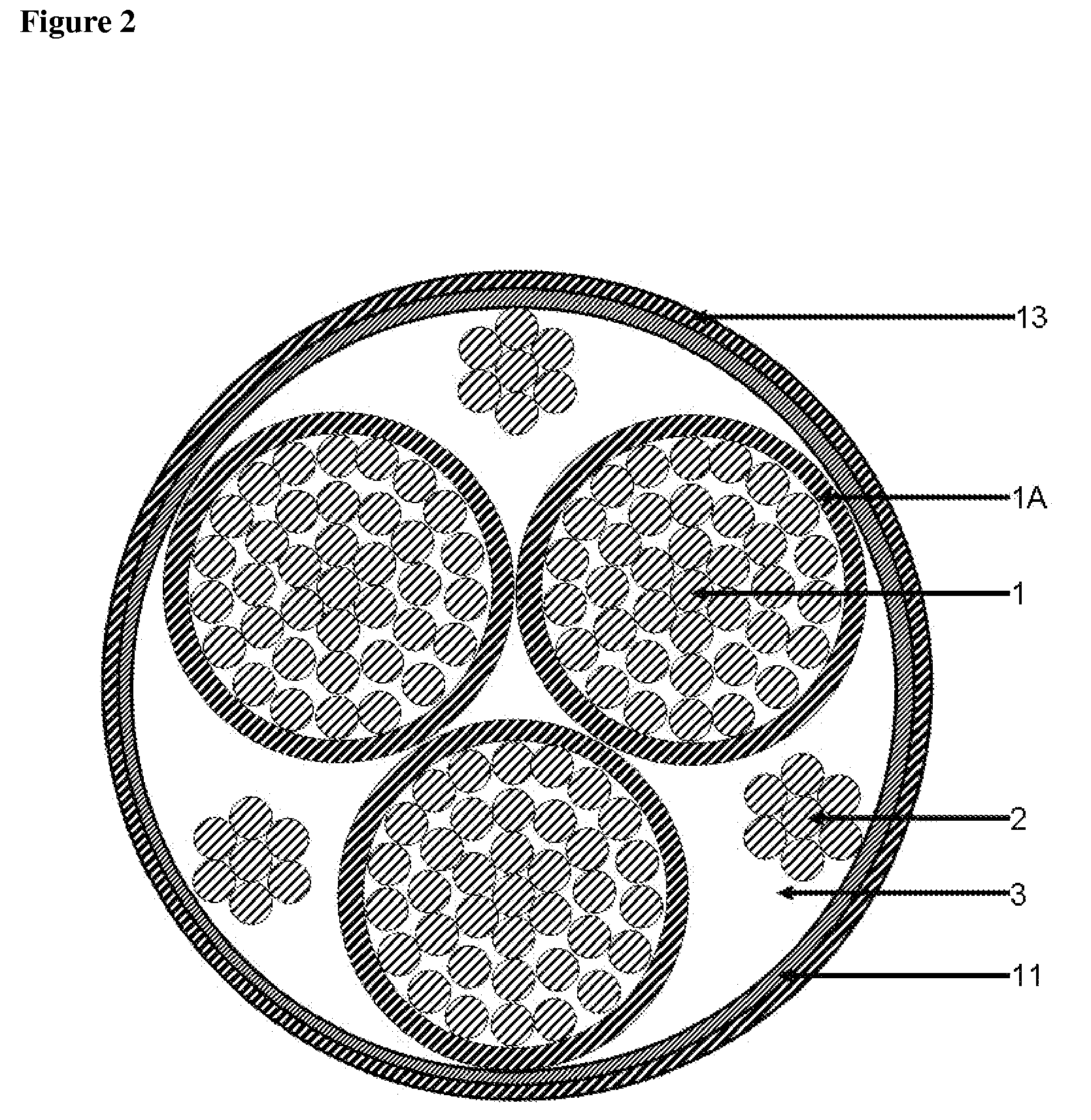

A cable and termination system for use with adjustable speed drives, including flexible tray cables and metal-clad cables, and terminations coupled therewith. The cables generally include three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations coupled with the cables include a plurality of connectors and flexible, tinned-copper braids which act as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

Production method of high-power precision alloy SMD (surface mount device) resistor

InactiveCN104051099AImprove cooling effectHigh precisionResistors adapted for applying terminalsAlloyThermal transmittance

The invention provides a production method of a high-power precision alloy SMD (surface mount device) resistor. The production method comprises the steps: respectively combining two oxygen-free copper strips with two sides of a resistor alloy strip to form an integrated strip-shaped resistor strip, and wrapping a high-heat-conductivity substrate with the integrated strip-shaped resistor strip; etching a basic resistor structure on a wrapping body; precisely adjusting the resistance value of the basic resistance structure; coating, terminal electroplating and printing a resistor body to form a high-power precision alloy SMD resistor. The material with high heat radiation capability and high heat conductivity such as a metal substrate, a high-heat-conductivity ceramic substrate is used as the substrate, so that the actual load capacity of the resistor is greatly increased; the oxygen-free copper strip is partially arranged on the side surface and below the substrate and used as an electrode lead, so that the contact area is increased, and the heat conductivity of the resistor body is also increased on the other hand.

Owner:SHENZHEN YEZHAN ELECTRONICS

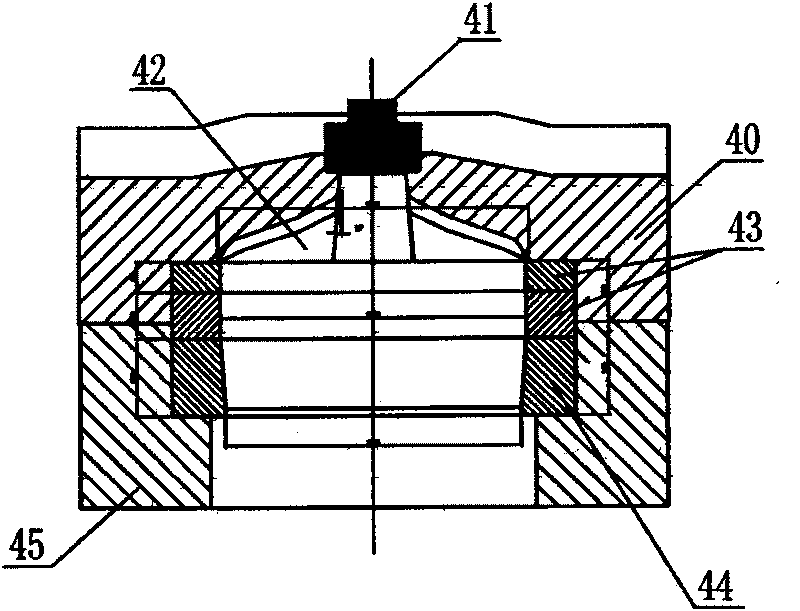

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

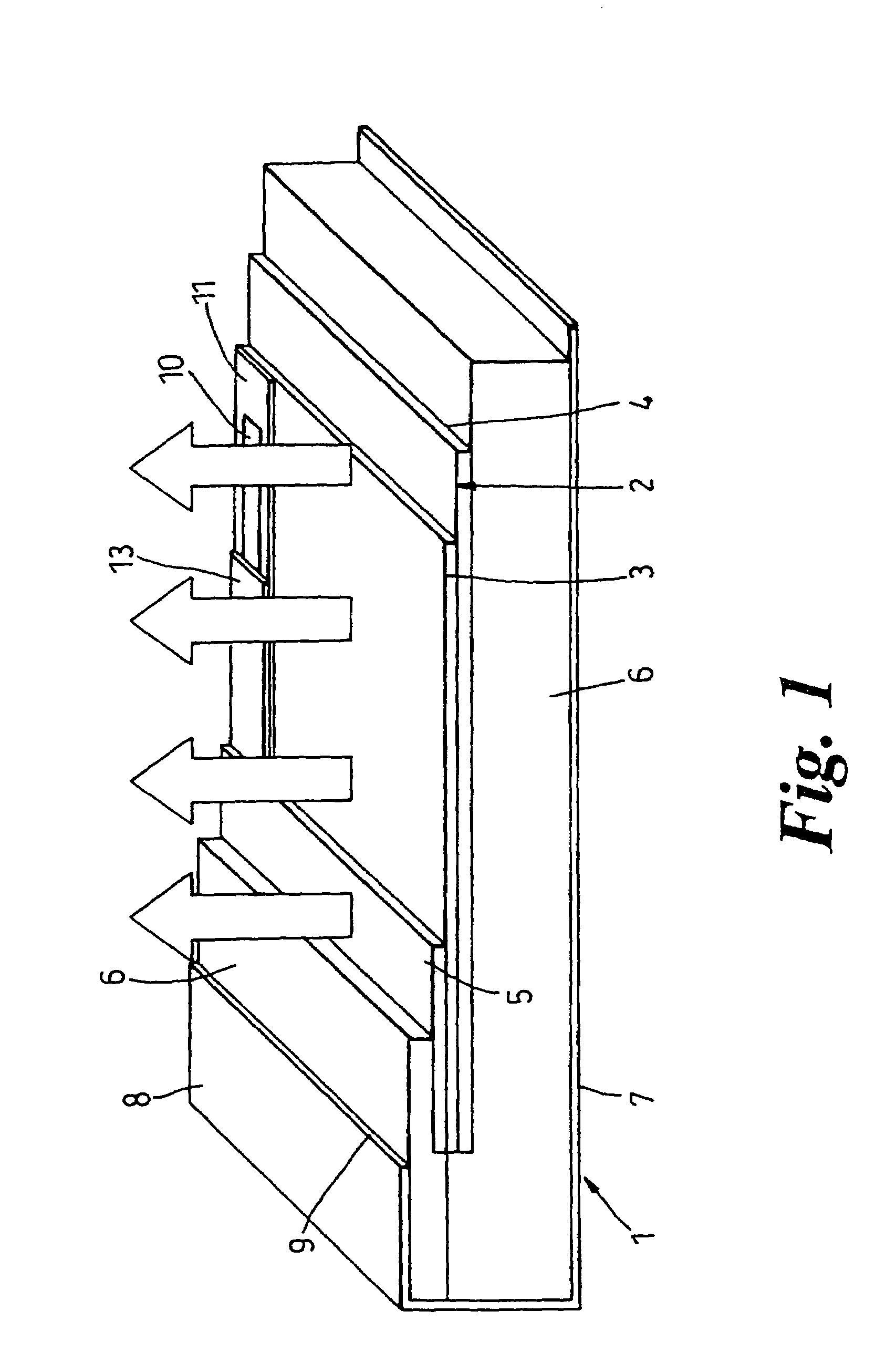

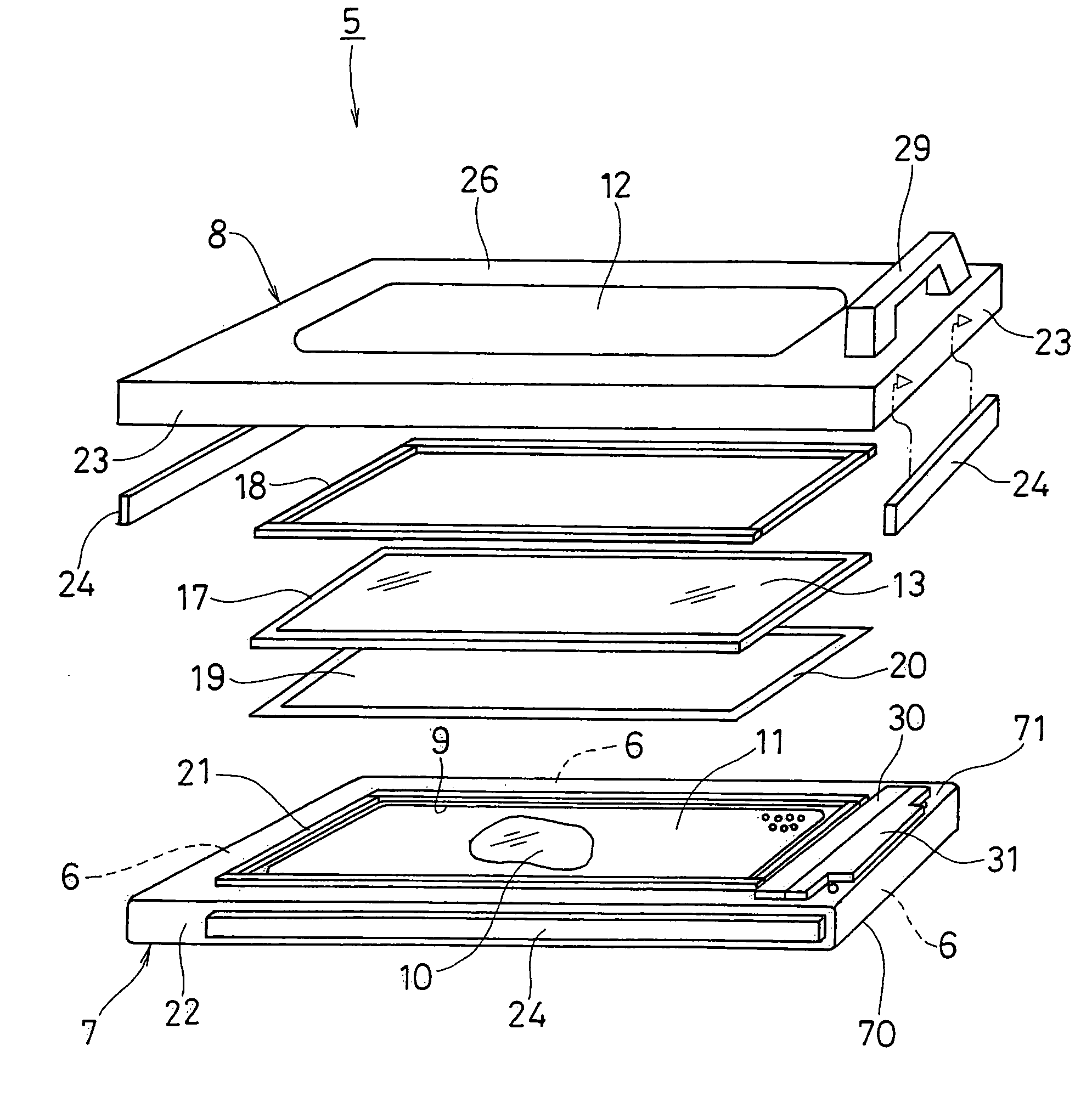

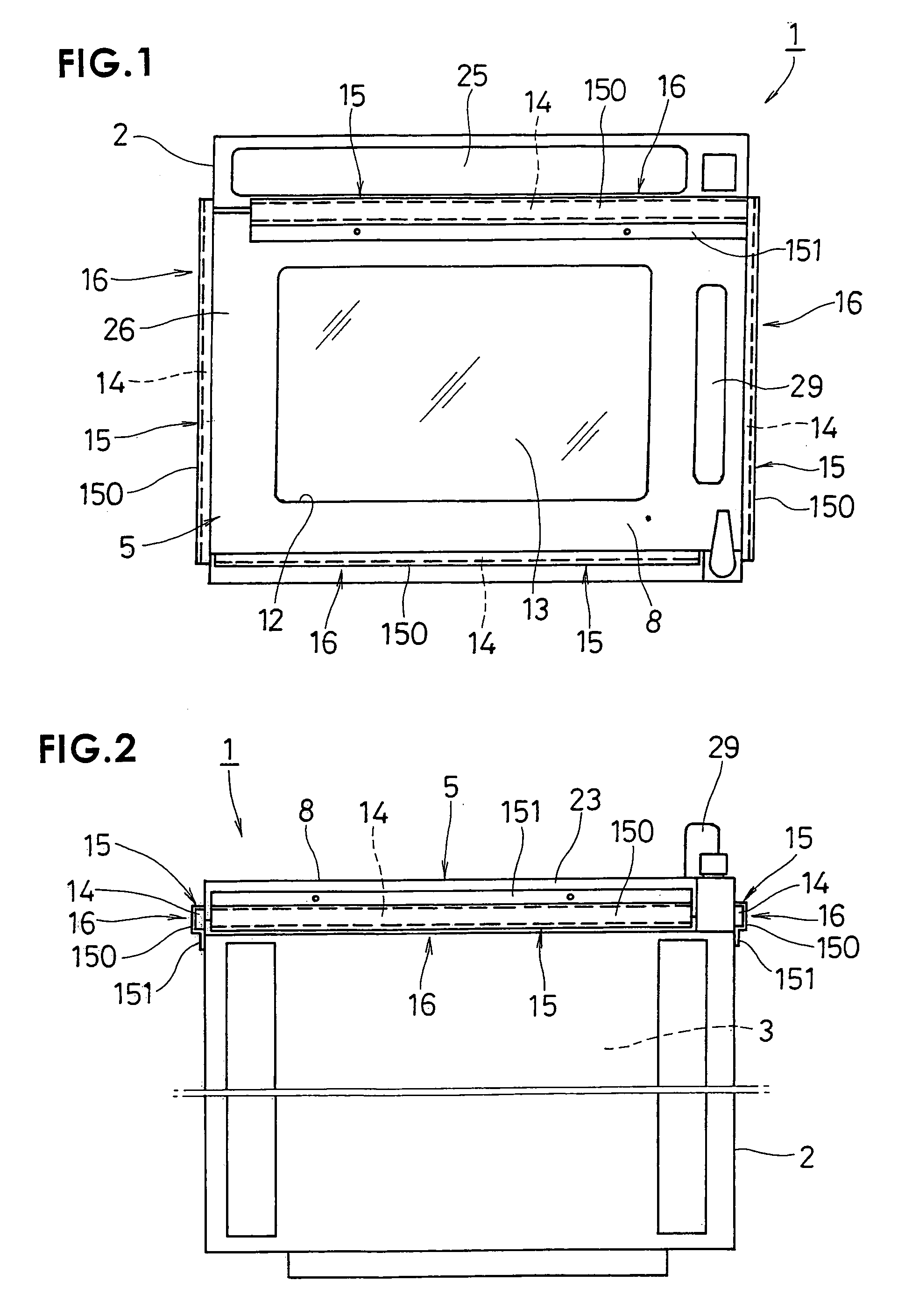

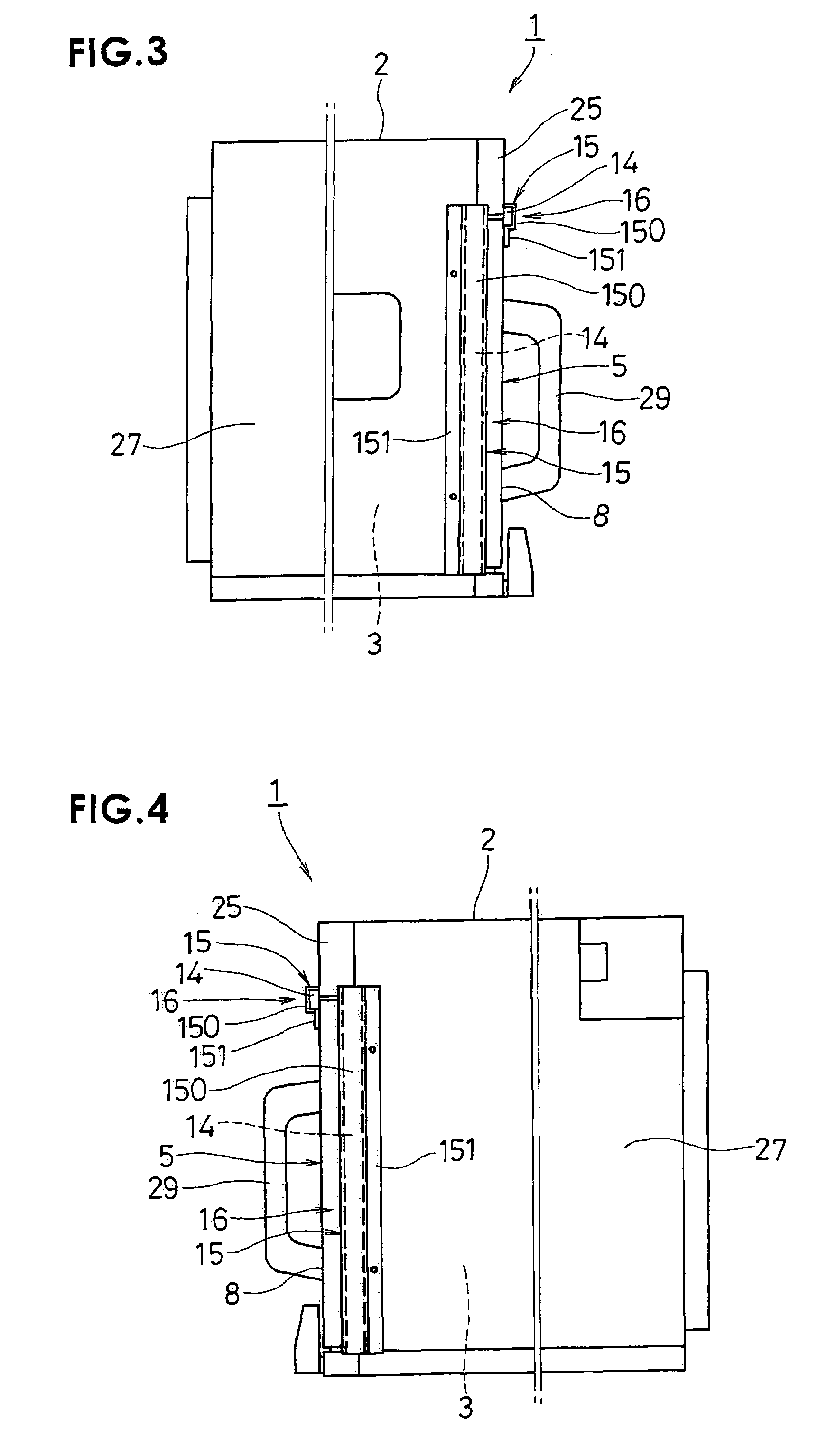

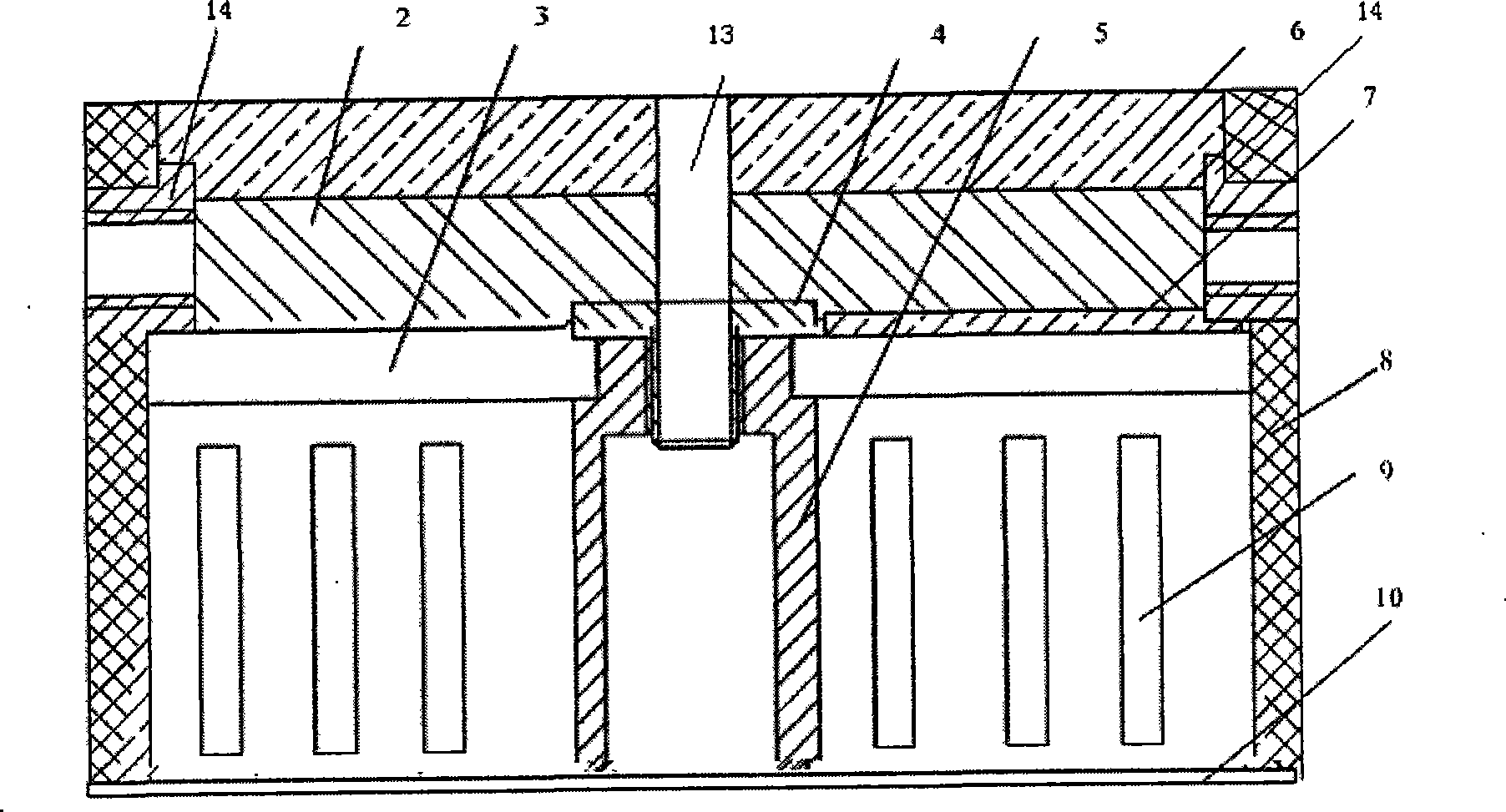

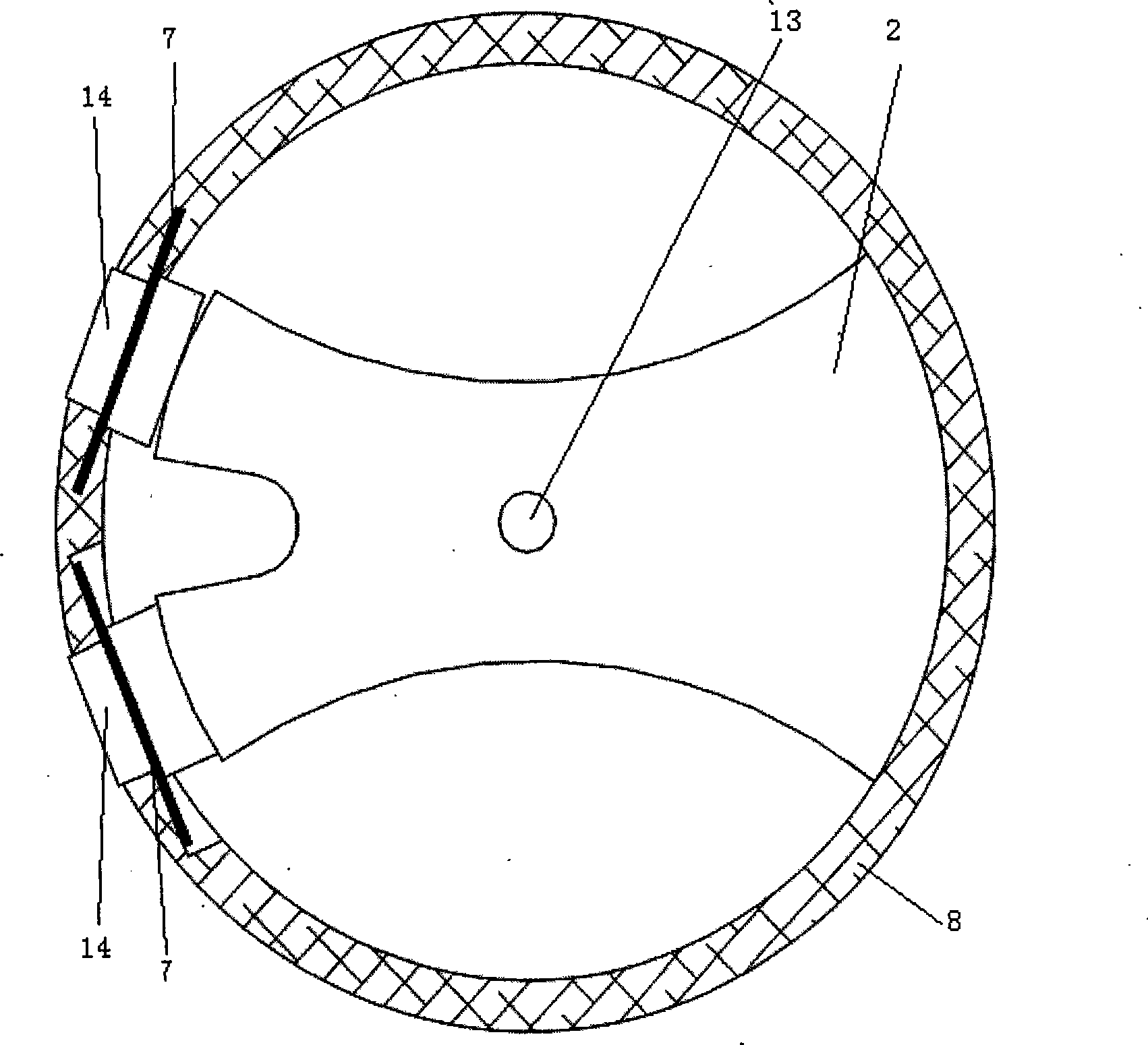

Microwave oven

ActiveUS7053348B1Reduce outputReduce errorsDoors for stoves/rangesDomestic stoves or rangesPunchingMicrowave oven

The invention provides a microwave oven capable of reducing the electromagnetic noises in the 2.45 GHz band generated during operation of the microwave oven. A microwave oven 1 including a microwave oven main body 2 having a heating chamber 3, and a door attached thereto. A ferrite sheet 14 disposed to cover the gap formed between the microwave oven main body 2 and the door 5 reduces the electric waves leaking through a choke groove 6 formed to a door panel 7. A punching metal plate 11 disposed on an outer side of a rear window film 10 and a wire mesh sheet 19 disposed on an inner side of a front window glass 13 shields the electric waves leaking through the window of the door 5, and the shielded electric waves are flown via a copper tape 20, an aluminum tape 17 and an EMI gasket 18 to a door case 8. Ferrite sheets 21 and 24 reduce the electric waves leaking through the gap of the door 5.

Owner:JAMCO

Production technology for bimetal coating copper strip

The invention discloses a production technology for a bimetal coating copper strip, which comprises the following steps: 1, smelting casting: preheating and drying electrolytic copper and placing in a smelting device for melting, adopting wood coal and graphite flakes to cover the surface of copper liquid, and after performing degasification and deoxidation on line by a degasification device, using a traction machine set to guide a copper rod upwards in a vacuum clutch type way to enable the copper rod to enter a wire taking-up device; 2, continuous extruding: enabling the oxygen-free copper rod obtained in step 1 to pass through a continuous extrusion machine set to produce a copper strip plate, and quickly using a cooling medium to cool to 20-30 DEG C to obtain the fine grain structured copper strip plate with the grain size of 0.005 mm to 0.010 mm; 3, rolling; 4, intermediate annealing; 5, fine rolling; 6, annealing; 7, cleaning and inactivating; 8, cutting; and 9, packaging and storing into a warehouse. According to the invention, the production technology has the advantages of excellent welding performance, high plastic processing performance, high electric conductivity, high surface quality and the like, and the technological process is short, and the technology is efficient and energy-saving.

Owner:NANTONG JIUWUBA TECH ENTERPRISE INCUBATOR CO LTD

Adjustable Speed Drive Cable and Shield Termination

ActiveUS20070107921A1Power cables with screens/conductive layersInsulated cablesThree-phaseAdjustable-speed drive

The product of the present invention comprises flexible tray cables and metal-clad cables designed for use with adjustable speed drives, and terminations coupled therewith. The cables comprise, generally, three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations comprise a plurality of connectors and a plurality of flexible, tinned-copper braids acting as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

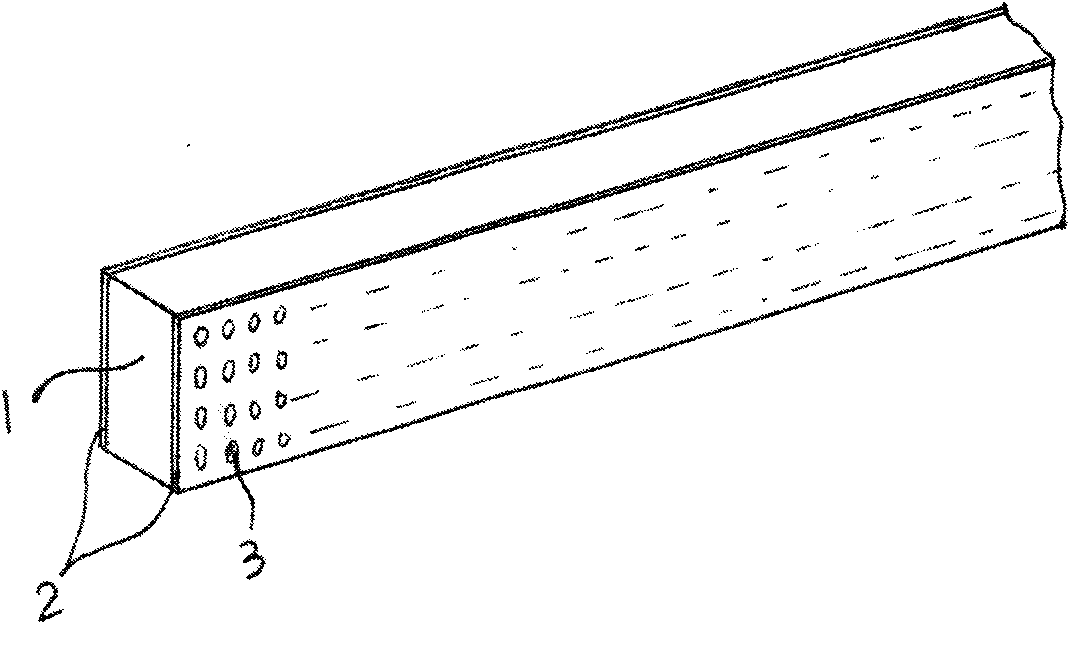

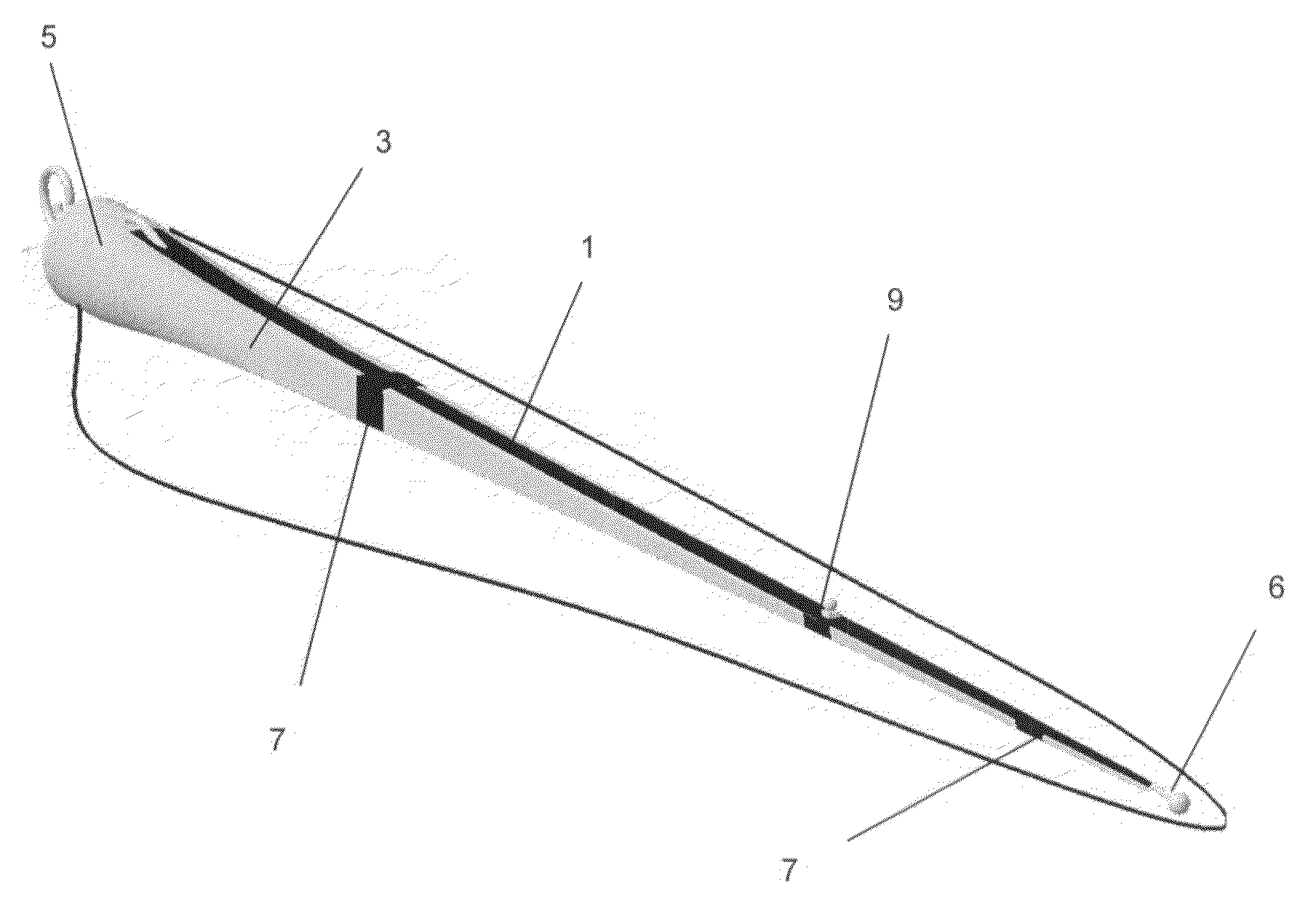

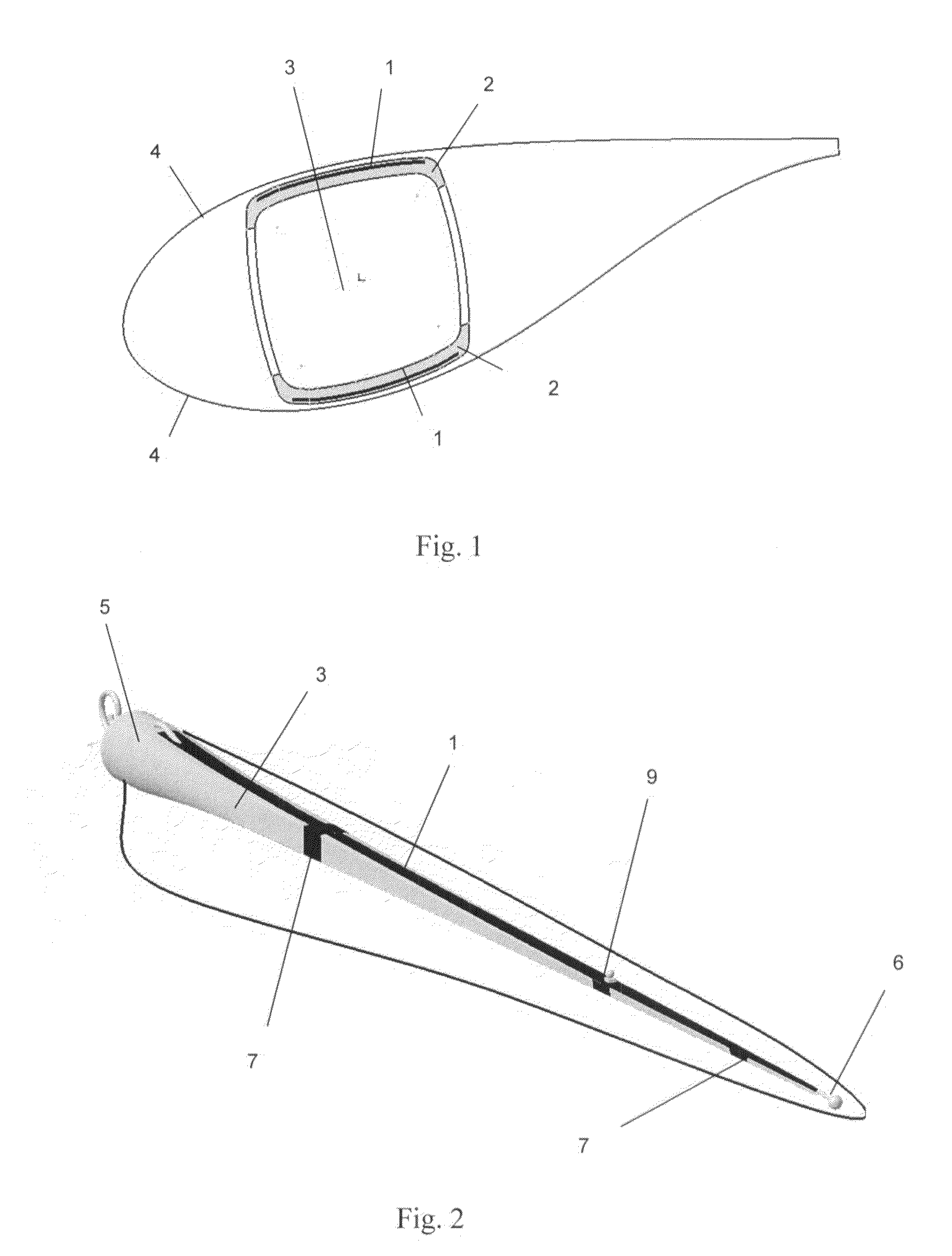

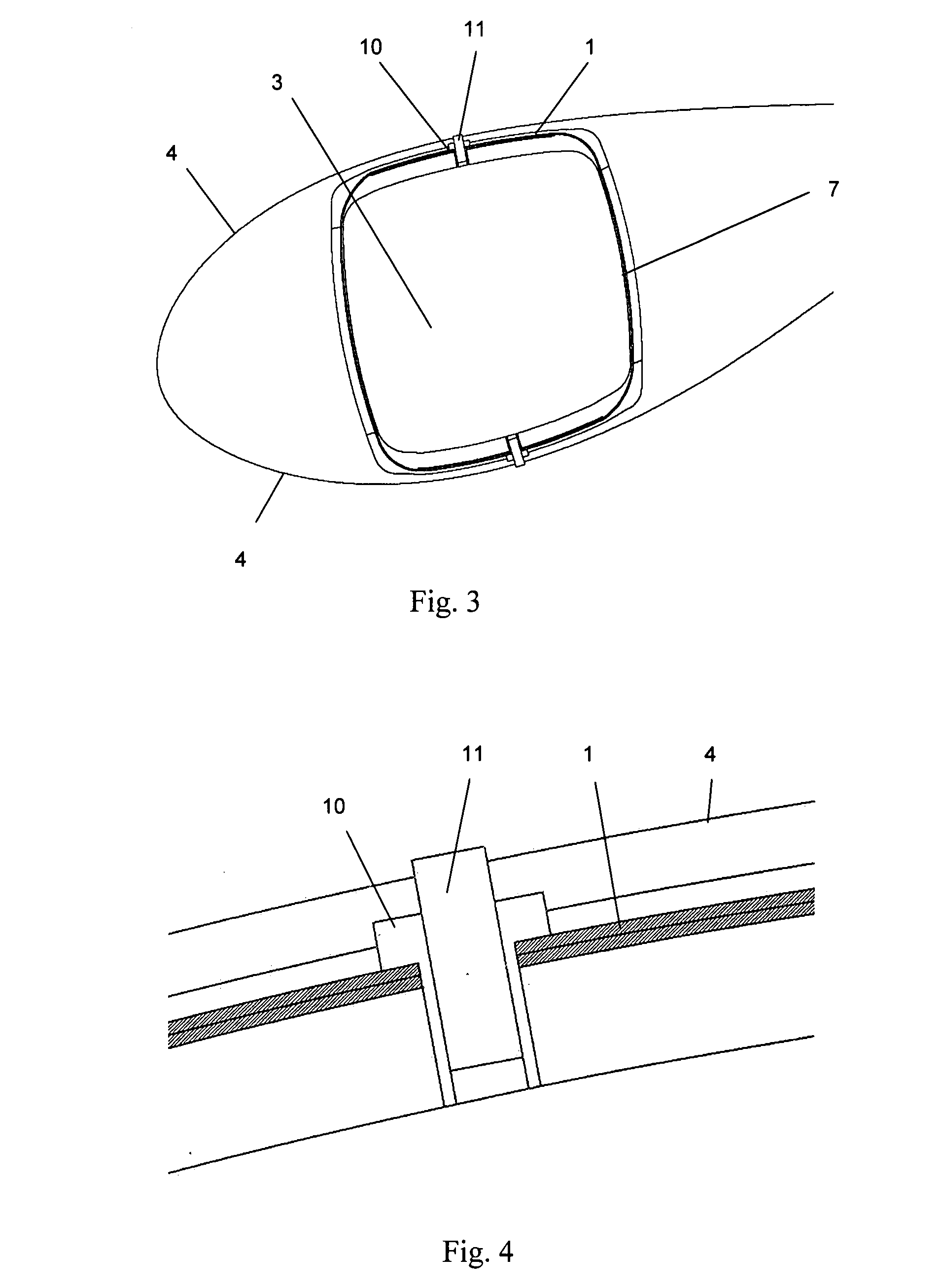

Lightning Arrester System for a Wind Generator Blade

ActiveUS20080145229A1Reduce usageDesign innovationInstallation of lighting conductorsBlade accessoriesPower flowCarbon fibers

The invention relates to a lightning arrester system for wind generator blade, which replaces the standard main copper cable and which employs two strips of copper that extend along the entire length of the beam such as to be in direct contact with the carbon fibre. In this way, the carbon fibre laminate and the copper strip are always at the same potential, thereby preventing any possible arc-over between the two elements. The carbon fibre laminate is barely affected by the passage of current owing both to the electrical characteristics of the two components and to the selected configuration which conveys most of the current through the copper strips. In addition, with said novel system it is possible to position intermediate receivers on the actual laminates and in direct contact with the copper strip.

Owner:GAMESA INNOVATION & TECH SA

Tin-lead welding strip for solar photovoltaic assembly and manufacturing method thereof

InactiveCN102254978AImprove adhesionImprove conductivityFinal product manufacturePhotovoltaic energy generationMicrometerDross

The invention discloses a tin-lead welding strip for a solar photovoltaic assembly, which comprises a copper strip base material, wherein a compact tin-lead alloy layer with a thickness of 3-20 micrometers covers the surface of the copper strip base material. A manufacturing method of the tin-lead welding strip for the solar photovoltaic assembly comprises the step of: covering the compact tin-lead alloy layer on the copper strip base material by adopting an electroplating method, wherein the thickness of the tin-lead alloy layer is 3-20 micrometers. Because the electroplating method is adopted, a cladding material has a crystal lattice characteristic and capacities of enhancing adhesive force of the welding strip and improving the conductivity of the photovoltaic welding strip. The welding strip has a volume resistivity of 0.0185-0.021omega mm<2> / m which is lower than that of the welding strip manufactured through thermal tin immersion and a melting point of 183-190 DEG C lower than that of a lead-free welding strip, and has no abnormal phenomena such as tin knobs, tin dross, copper cuttings, discoloration and the like. A process capability index (CPK) value is effectively increased.

Owner:SHANGHAI WELNEW MICRO ELECTRONICS

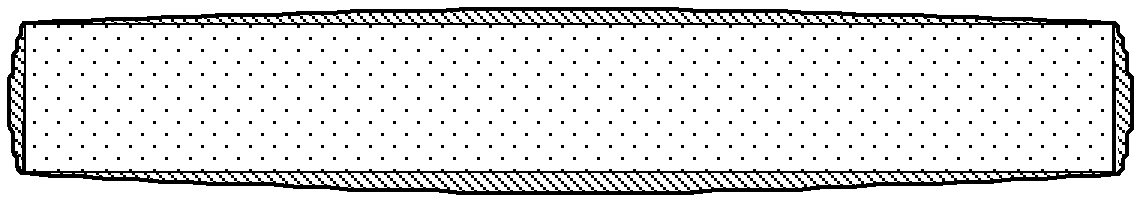

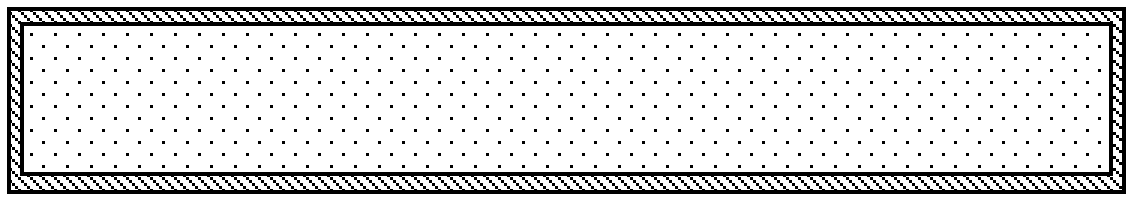

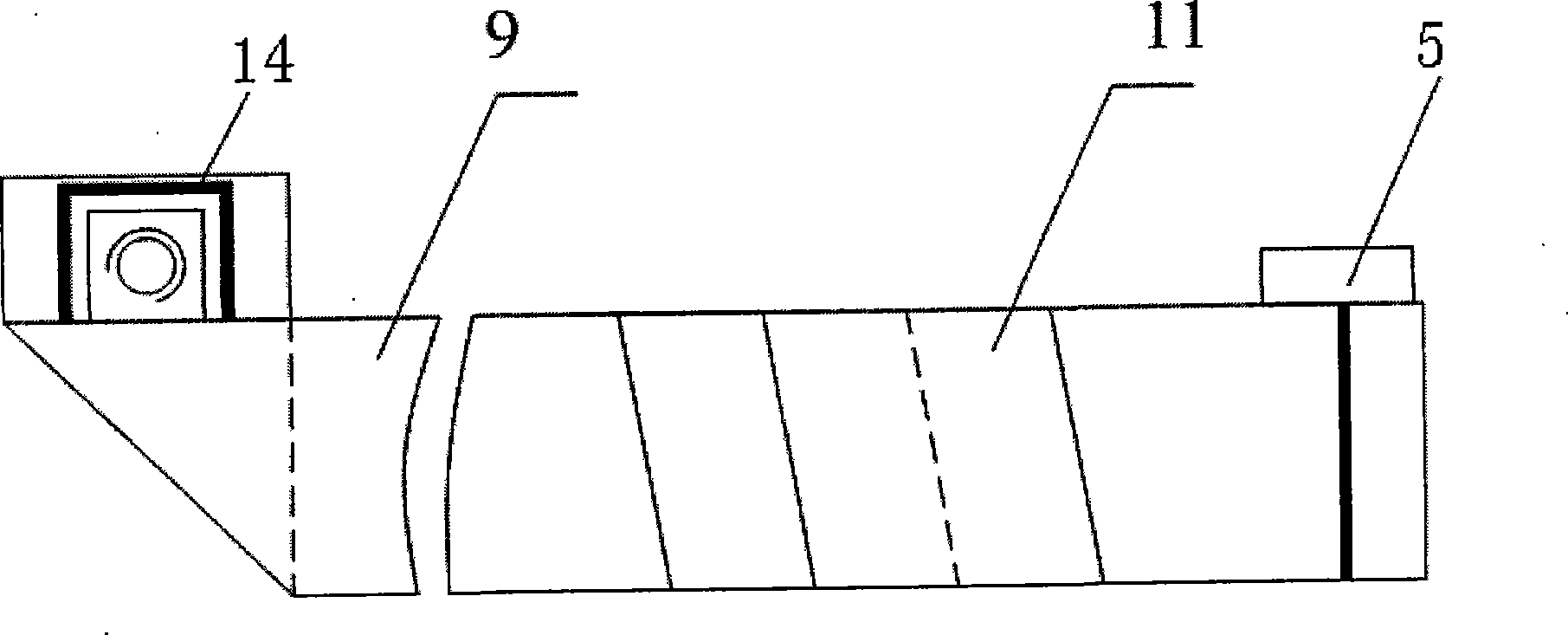

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350AUniformly foamed poresUniform field strengthCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

The invention relates to a broadband radial pattern leaky coaxial cable used for subway and a manufacturing method thereof, and the leaky coaxial cable has the double functions of transmission line of information and duplexer. The structure of the leaky coaxial cable consists of an inner conductor, an insulation layer, an outer conductor and a jacket, wherein, the inner conductor is externally covered with the insulation layer which is externally covered with the outer conductor that is externally sheathed with the jacket, and the insulation layer that covers on the surface of the inner conductor adopts nitrogen or carbon dioxide physical foam to form a foamed polyethylene insulation layer; cambered slotted holes are opened on a clutch gold belt of the outer conductor covered outside the insulation layer. The manufacturing method comprises the steps: (1) a spiral wrinkle inner conductor is manufactured by longitudinal covering welding and embossing by using a copper strip; (2) the nitrogen or the carbon dioxide are adopted to be injected into the smelted polyvinyl plastics, and then the physical foamed polyethylene insulation layer is formed on the surface of the inner conductor by extrusion and cladding; (3) the slotted holes broken out by the clutch gold belt of the outer conductor are the cambered slotted holes; (4) the clutch gold belt of the outer conductor is covered on the insulation layer longitudinally, and the surface of the clutch gold belt of the outer conductor is crowded and covered with the jacket.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

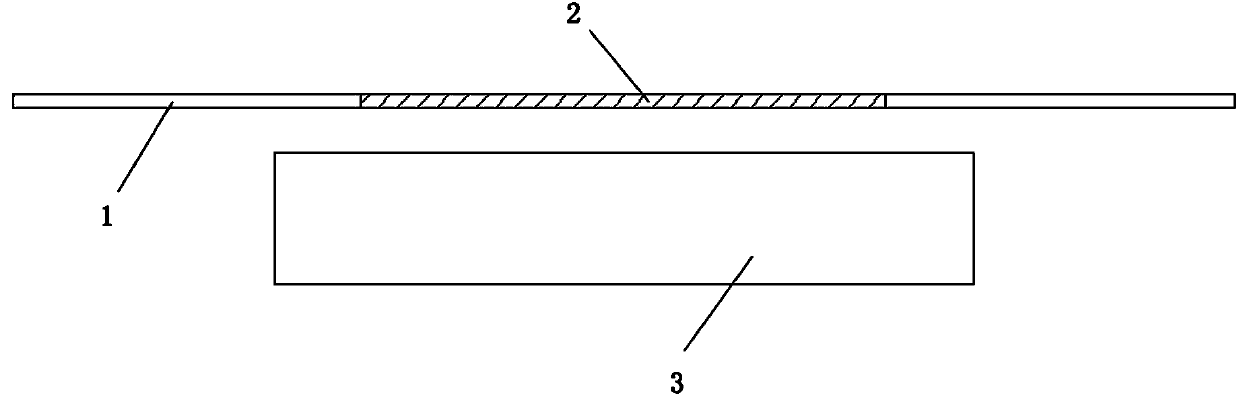

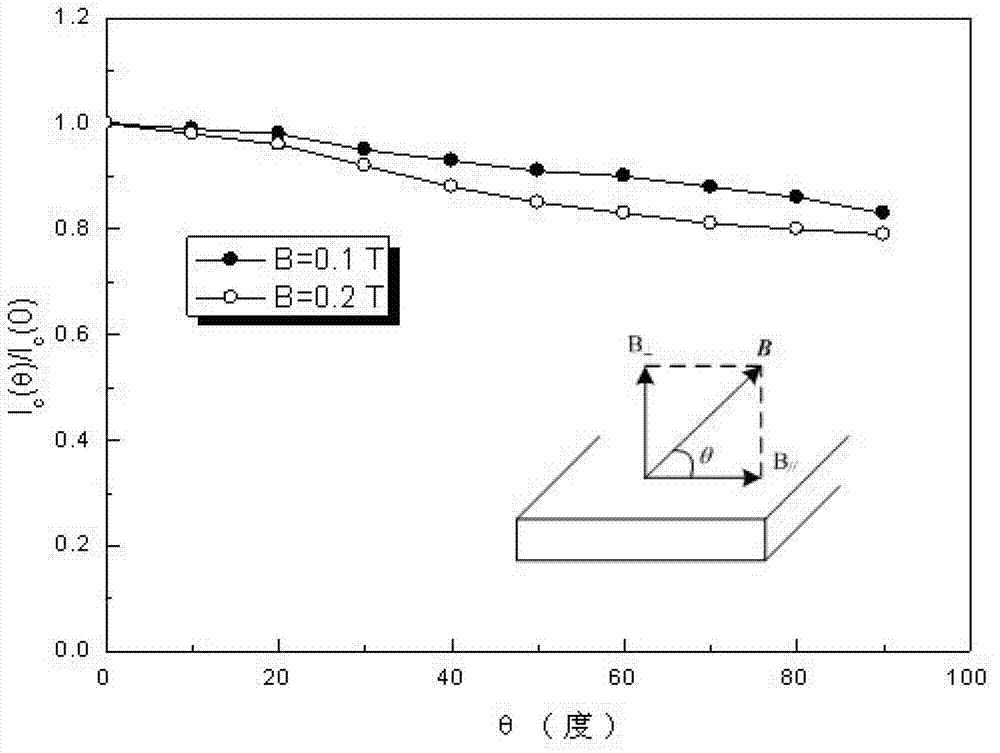

Superconducting strand based on ReBCO high-temperature superconducting tape

InactiveCN102779581AImprove engineering current densityImprove toughness and strengthSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingSeam welding

The invention belongs to the field of superconducting material and relates to a superconducting strand based on a ReBCO high-temperature superconducting tape. The superconducting strand comprises a superconducting strand core and a coating layer. The ReBCO high-temperature superconducting tape is cut into tapes which are arranged and stacked to be the superconducting strand core with circular, square or rectangular cross section; the coating layer is made of copper tapes, aluminum tapes, aluminum alloy tapes, stainless steel tapes or ReBCO coating superconducting tapes; the coating layer is rolled and coated on the superconducting strand core. A laser Ag welding technology is used for carrying out butt-seam welding on the coating tapes. The superconducting strand provided by the invention expands the application range of the coating superconductor, improves engineering current density, flexibility and mechanical strength of the superconducting wire, and is applicable to a superconducting cable, a current guide wire, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

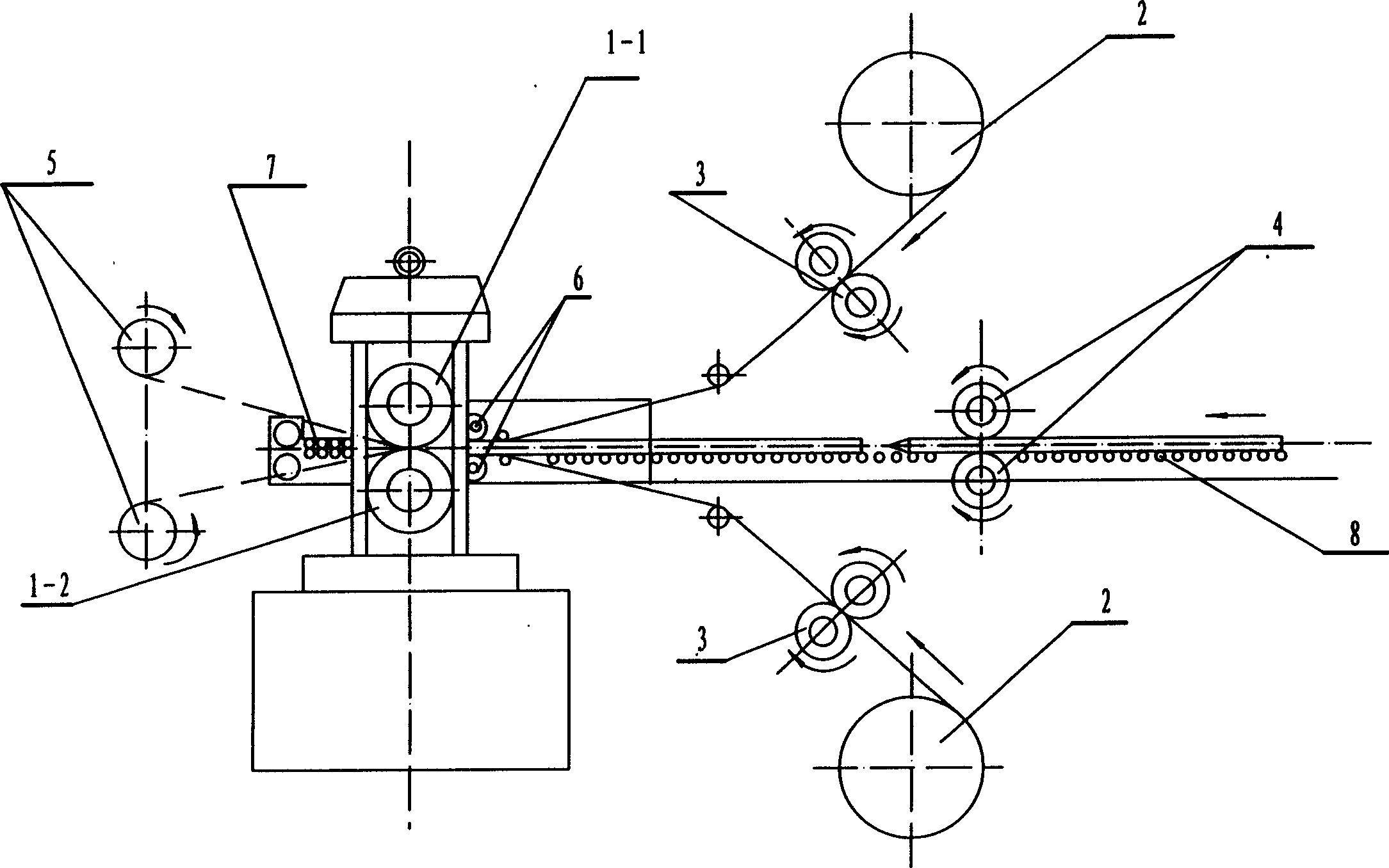

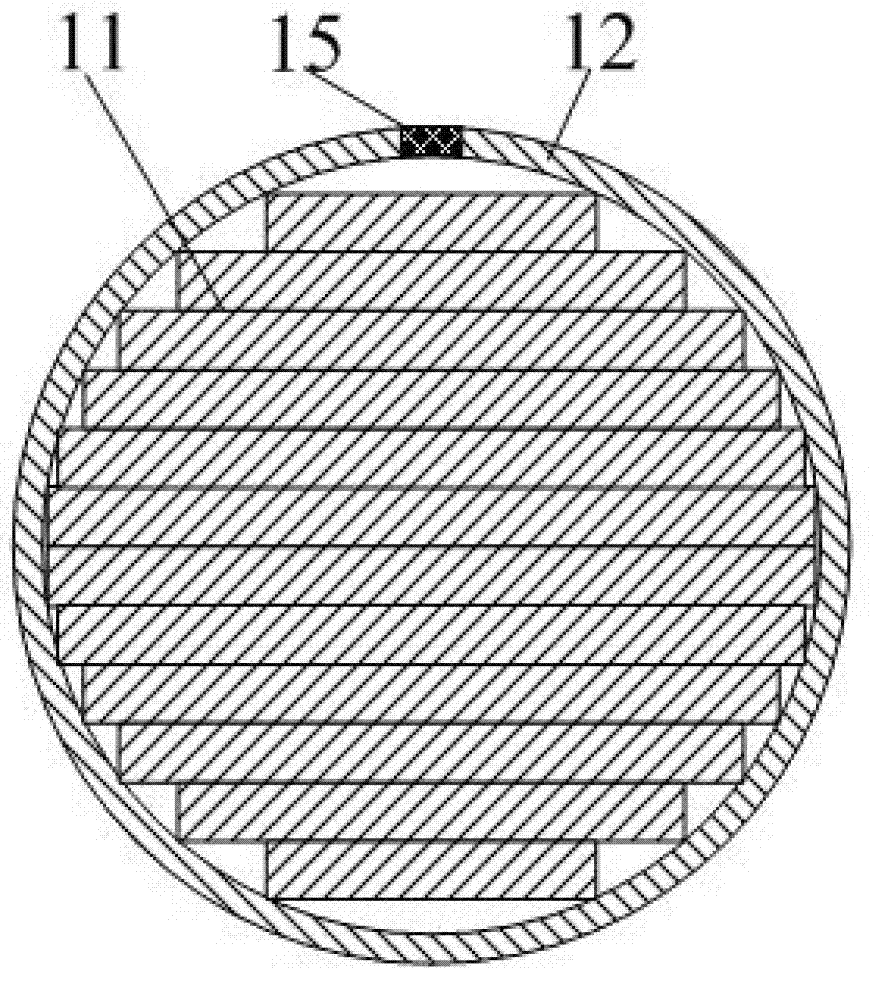

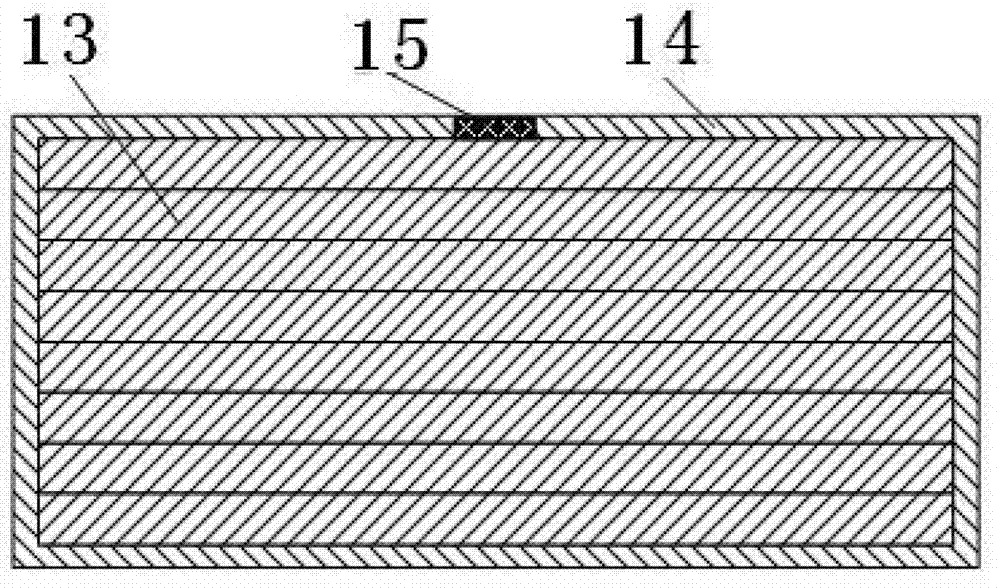

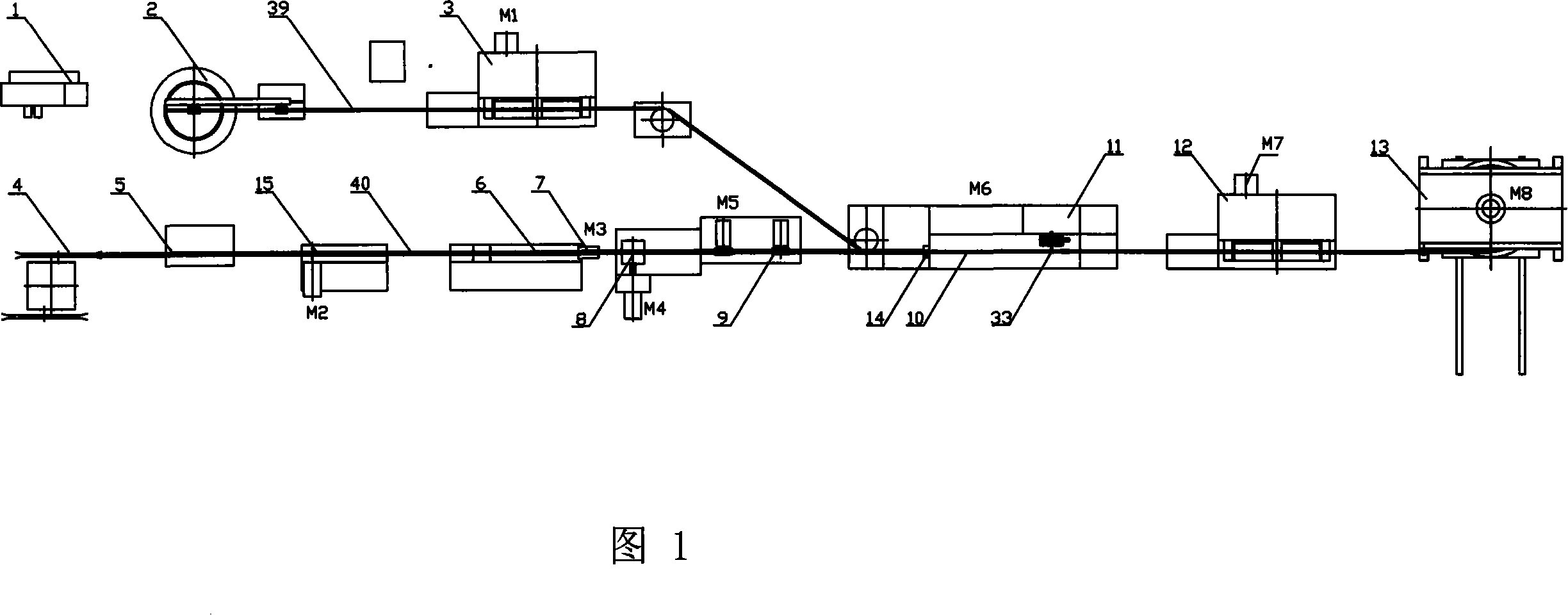

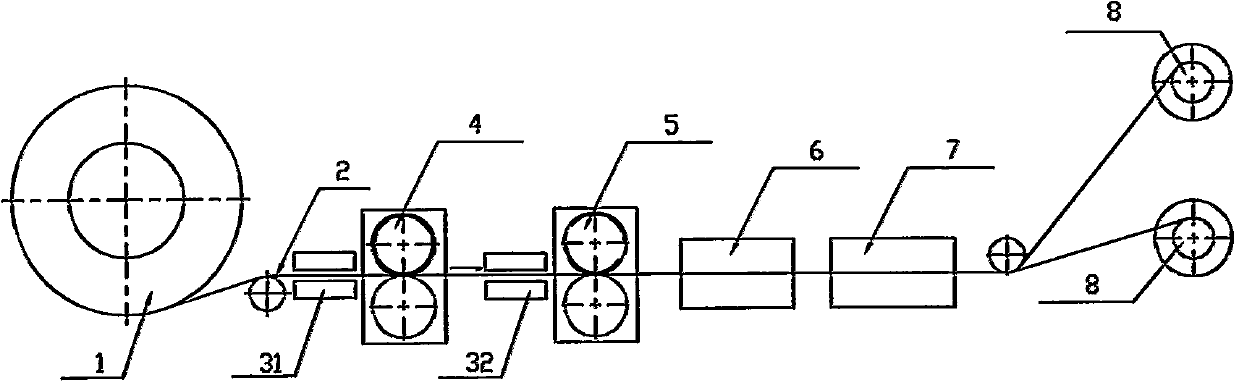

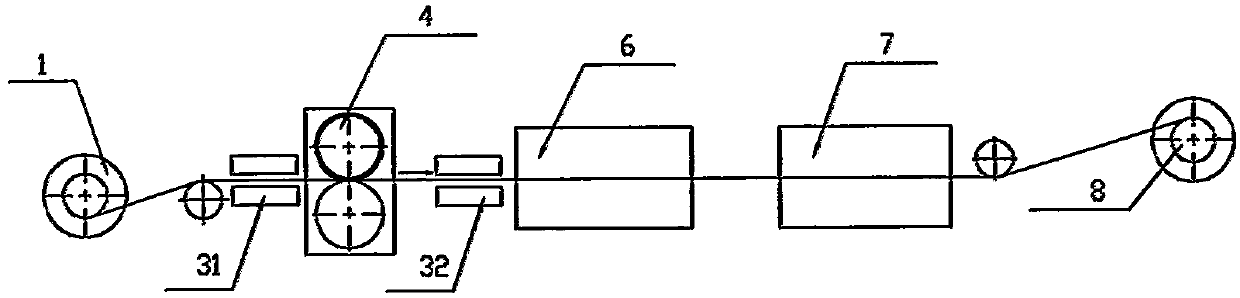

Bimetallic composite wire rod high-efficient production line

InactiveCN101121228AIncrease productivityGuaranteed uptimeProgramme controlComputer controlWinding machineProduction line

The invention discloses a high-efficiency production line for bimetallic composite wires, which comprises an aluminum rod butt welding machine (1), an aluminum rod discharging rack (2), and an aluminum rod drawing machine (3) arranged in sequence; and a copper strip discharging machine arranged in sequence frame (4), copper strip butt joint machine (5), copper strip cleaning tank (6), copper strip drying machine (7), copper strip grinding machine (9) and overmolding machine (10) arranged in sequence, welding device (11), composite wire billet drawing machine (12), wire take-up machine (13); an aluminum bar peeling device ( 14), a copper strip warehouse (15) is provided between the copper strip butt joint machine (5) and the copper strip cleaning tank (6), which can reduce the labor intensity of workers, ensure continuous production and increase the yield of finished products.

Owner:费兰英 +2

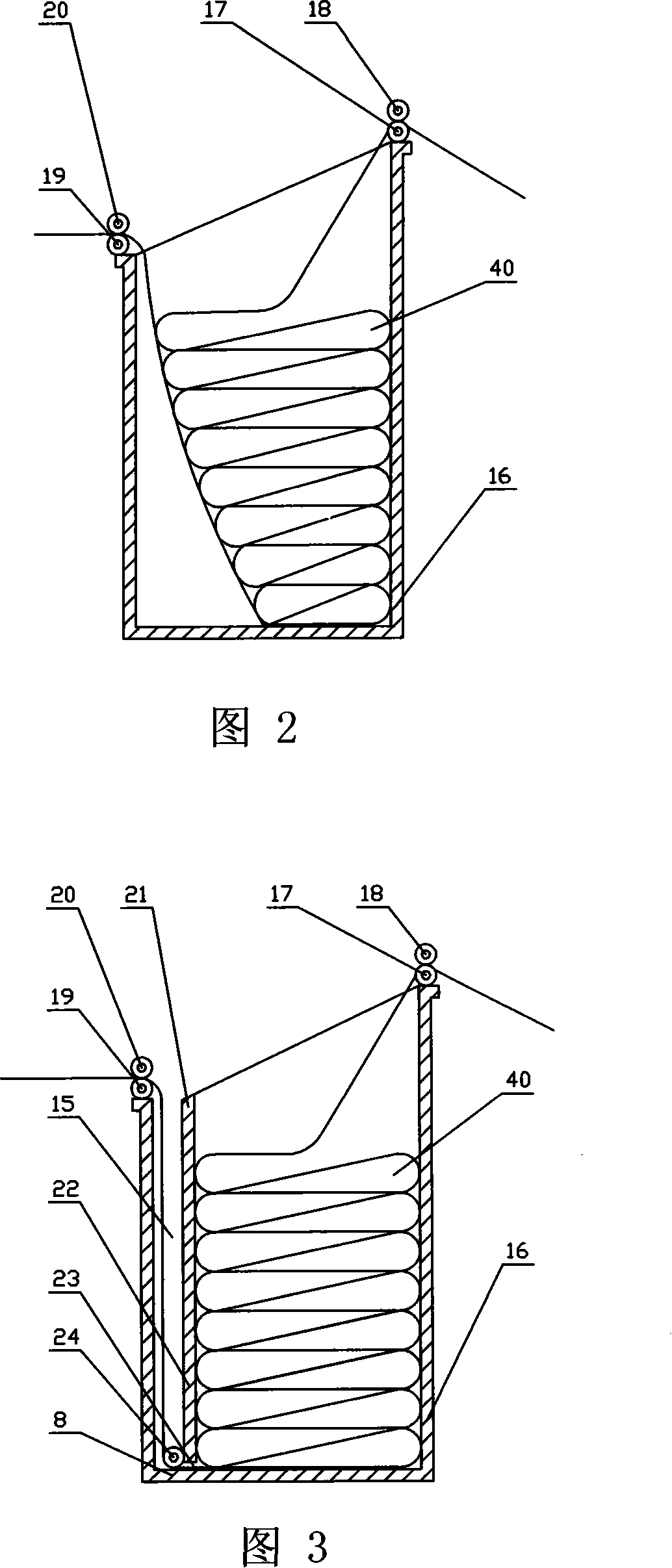

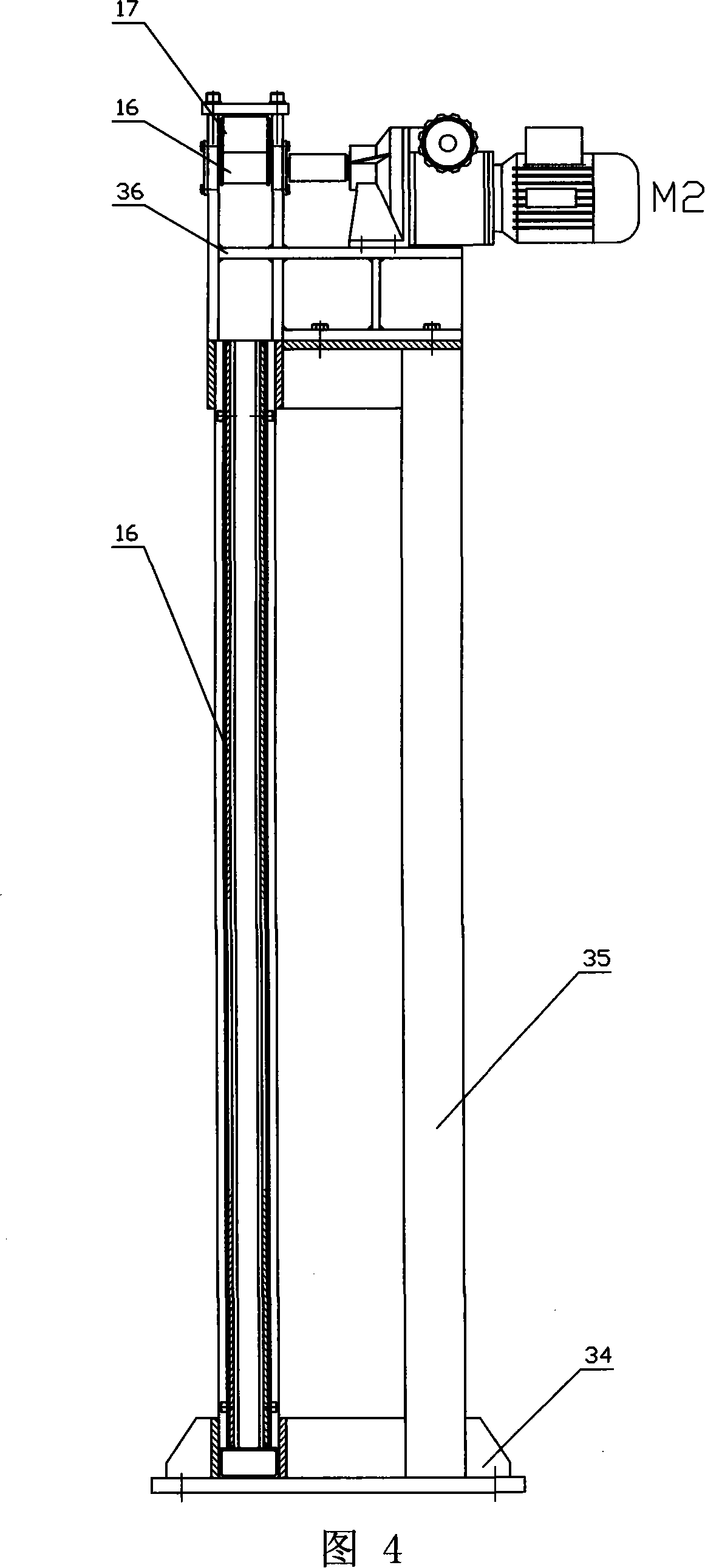

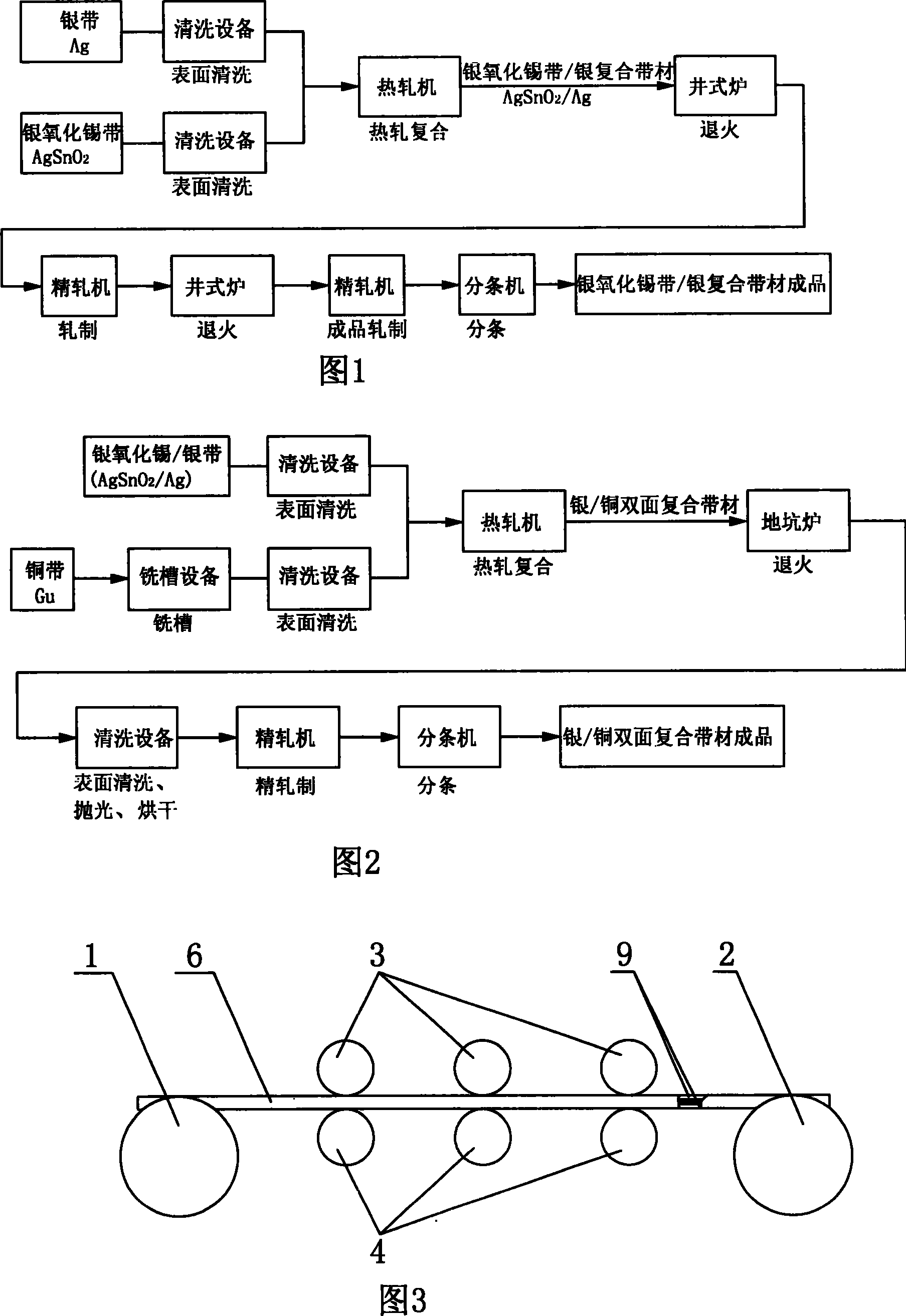

Machining technique of silver/copper double composite strip material

This invention relates to electricity materials technique field and to one silve to copper double compound band process method, which comprises the following steps: firstly grinding the silver metal oxidation with one thin siver band to form silver metal oxidation or silver compound materials; grinding silver metal oxidation and silver compound band through its top silver band layer and copper band heat grinding through heat compound band for annealing.

Owner:东莞市中一合金科技有限公司

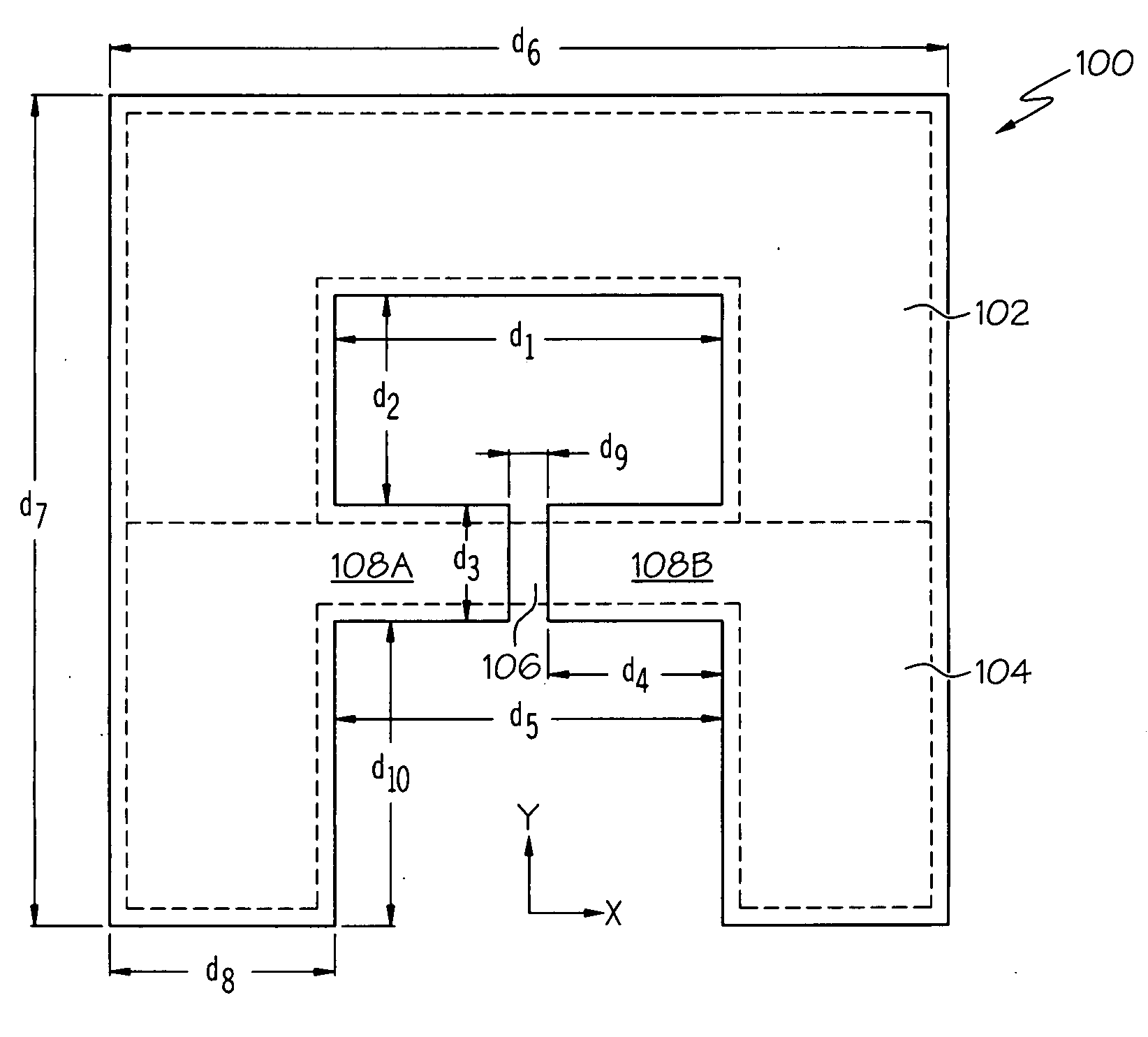

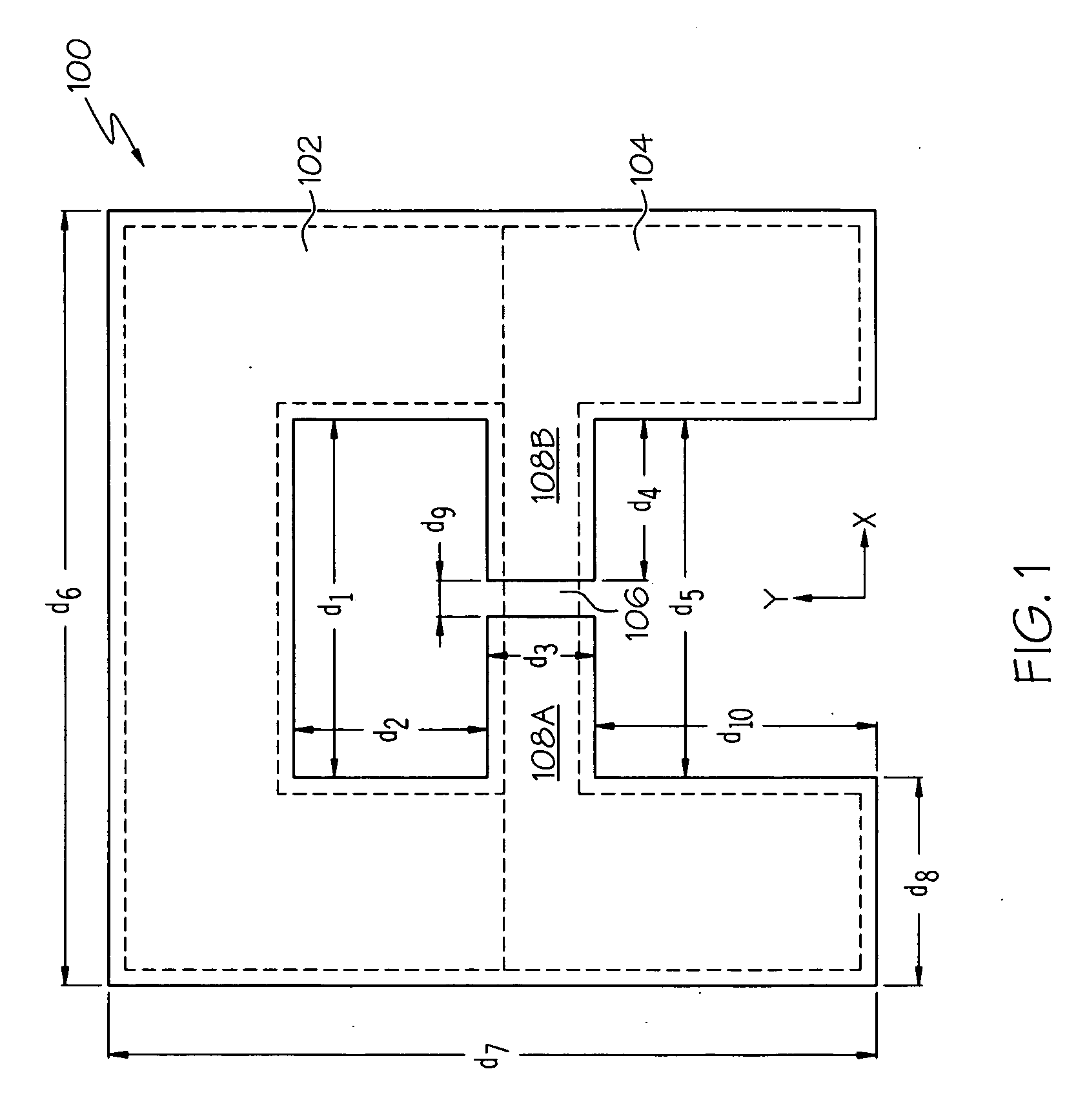

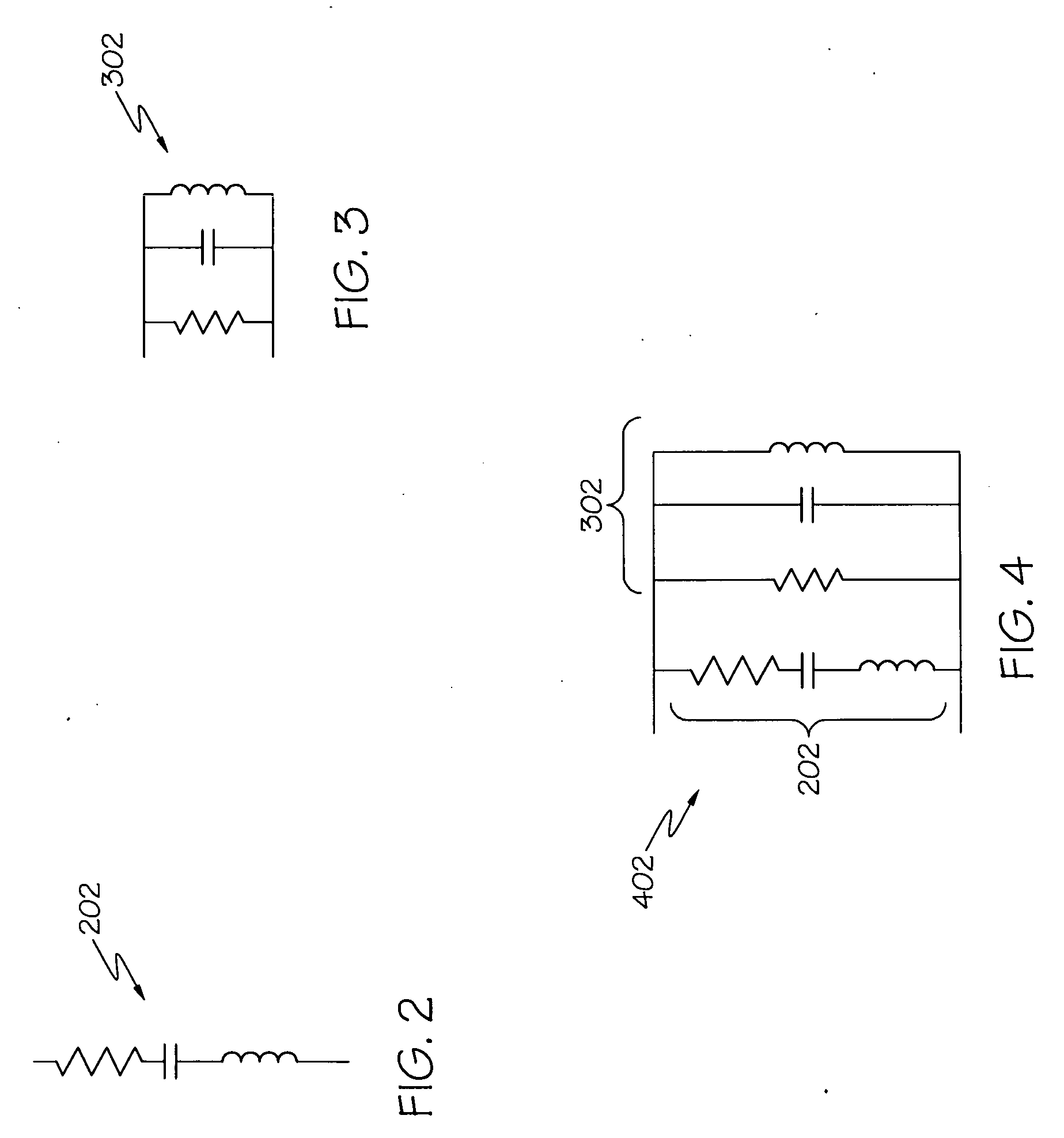

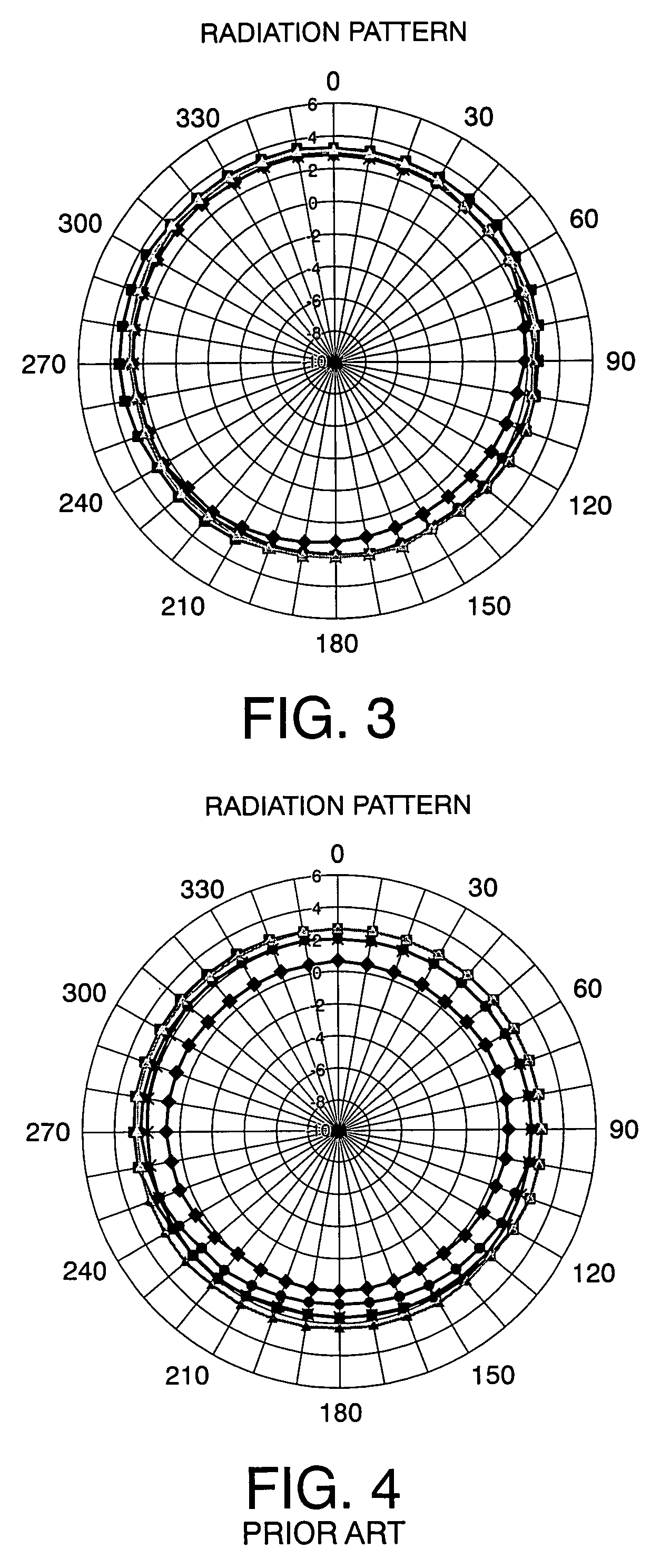

Methods and apparatus for a low reflectivity compensated antenna

ActiveUS20100309068A1Simultaneous aerial operationsRadiating elements structural formsEngineeringReflectivity

An antenna includes a dipole radiator region forming a series resonant tank having a first quality factor value Q1, and a loop compensator / radiator region integral with the dipole region and forming a parallel resonant tank having a second quality factor value Q2 that is substantially equal to Q2. The antenna may be a conductive sheet antenna (e.g., comprising copper tape) having a generally “A” shaped structure with a discontinuity in a middle segment.

Owner:SYMBOL TECH LLC

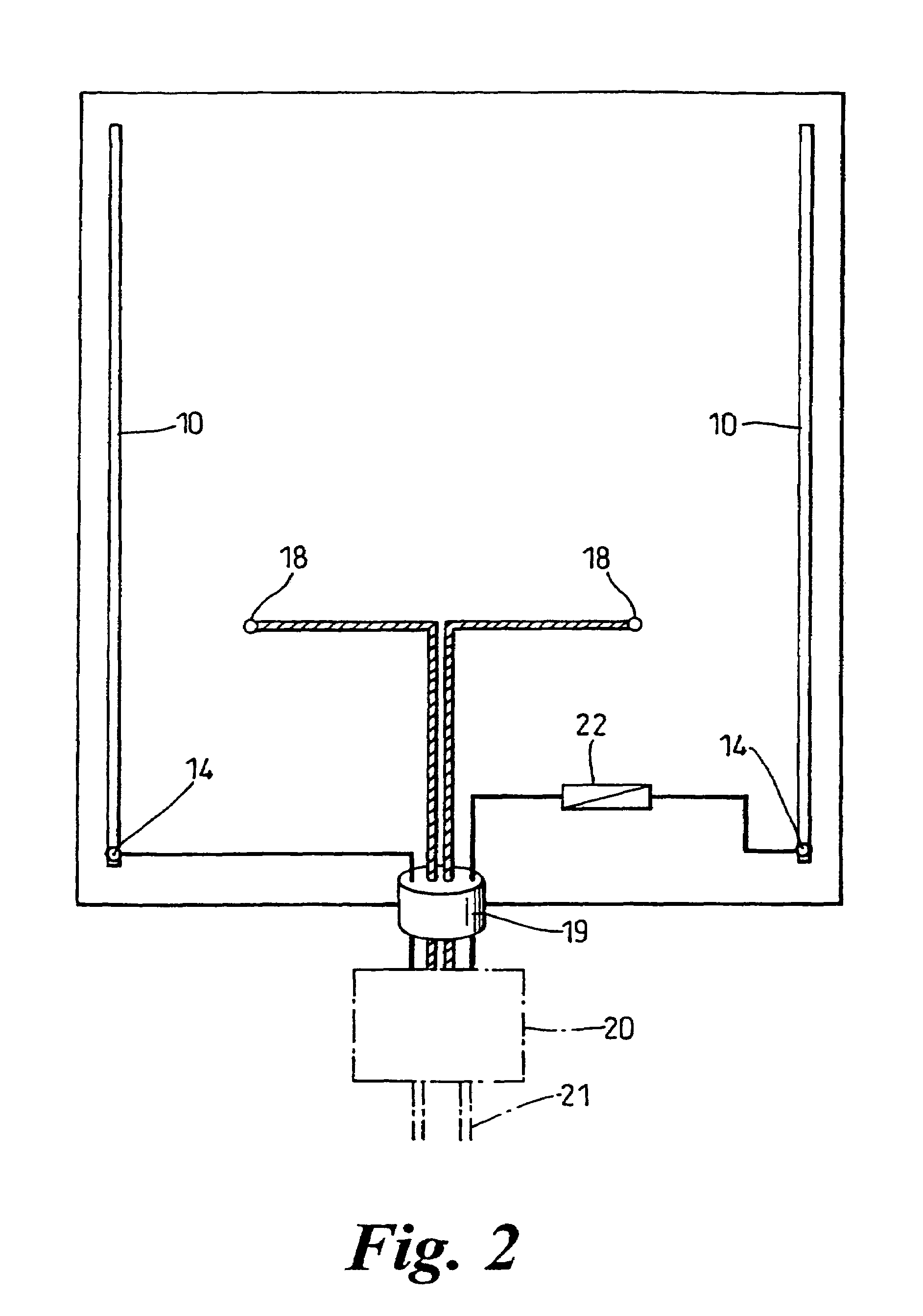

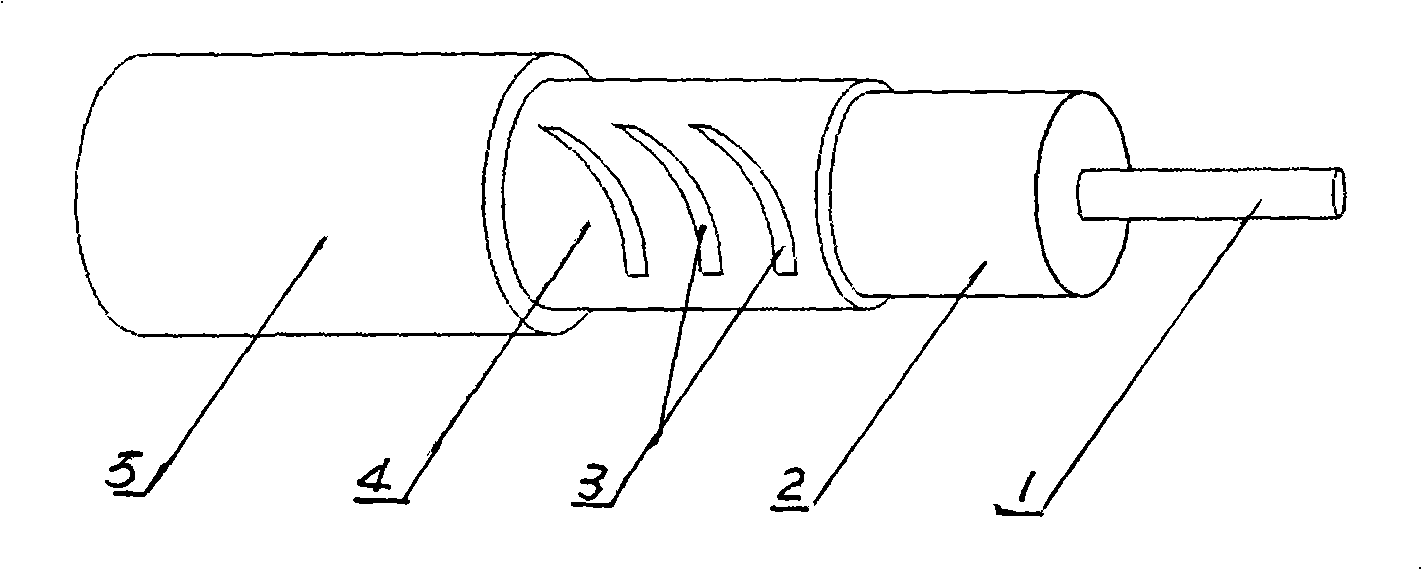

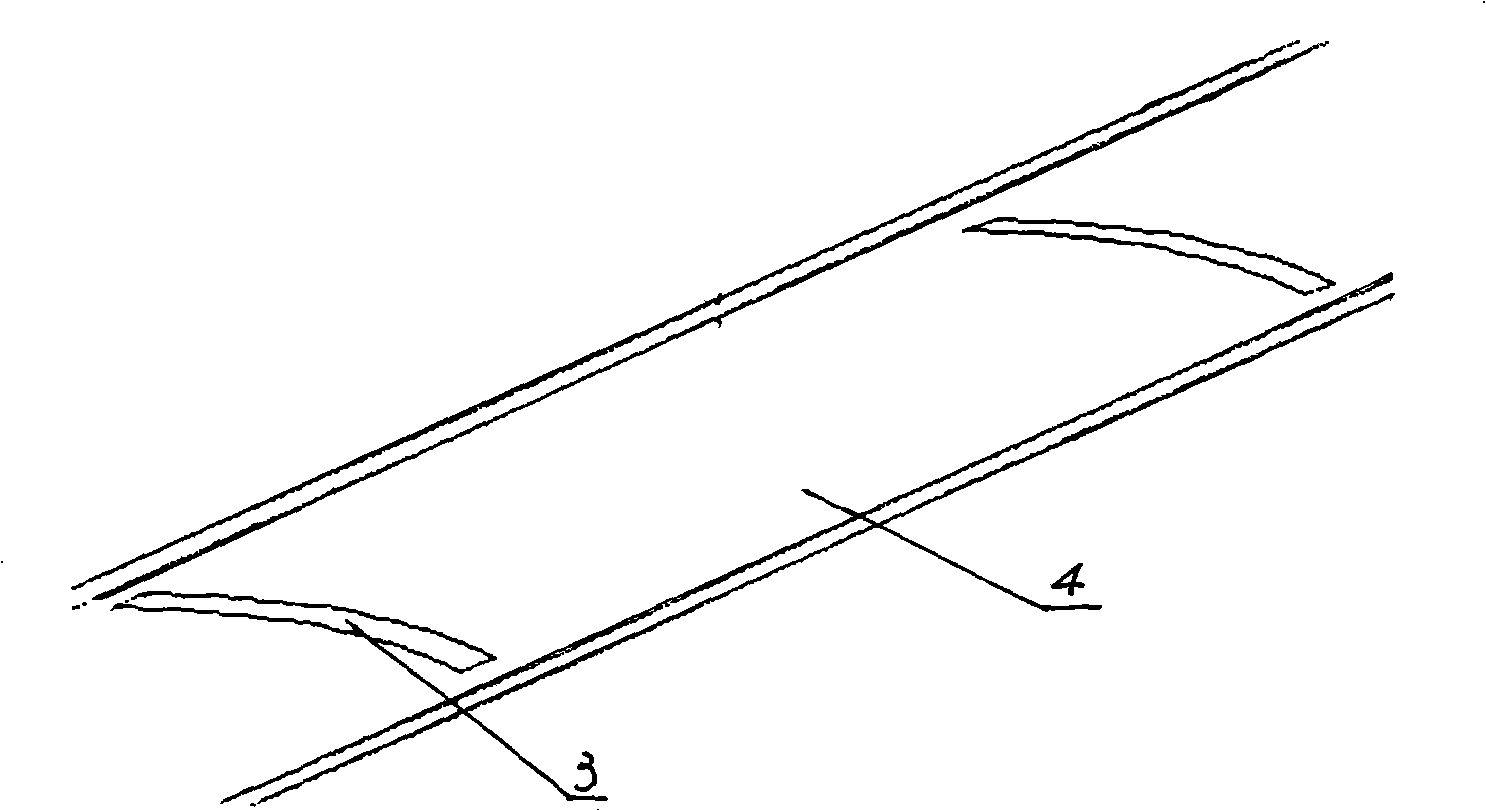

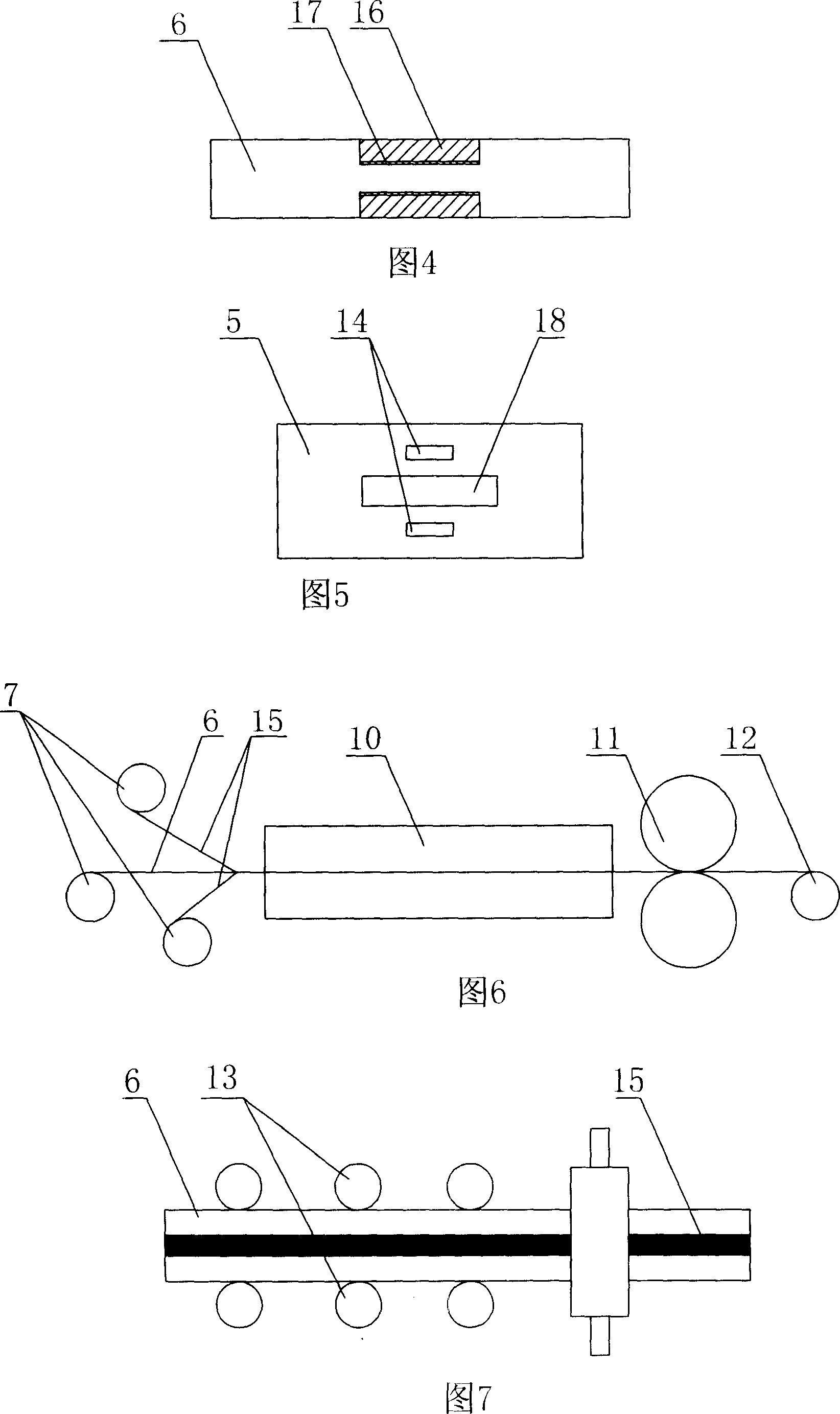

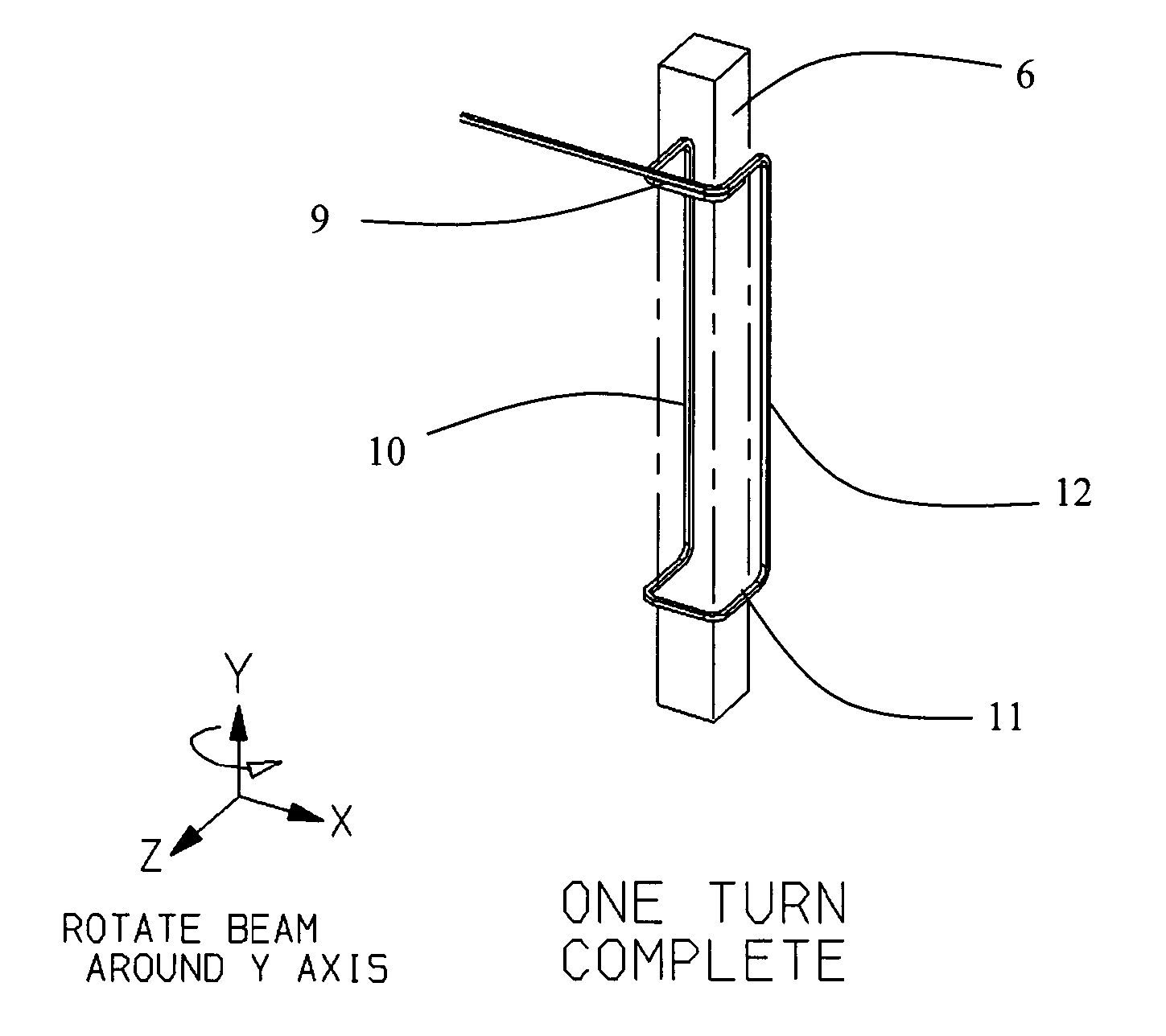

Method of forming single-layer coils

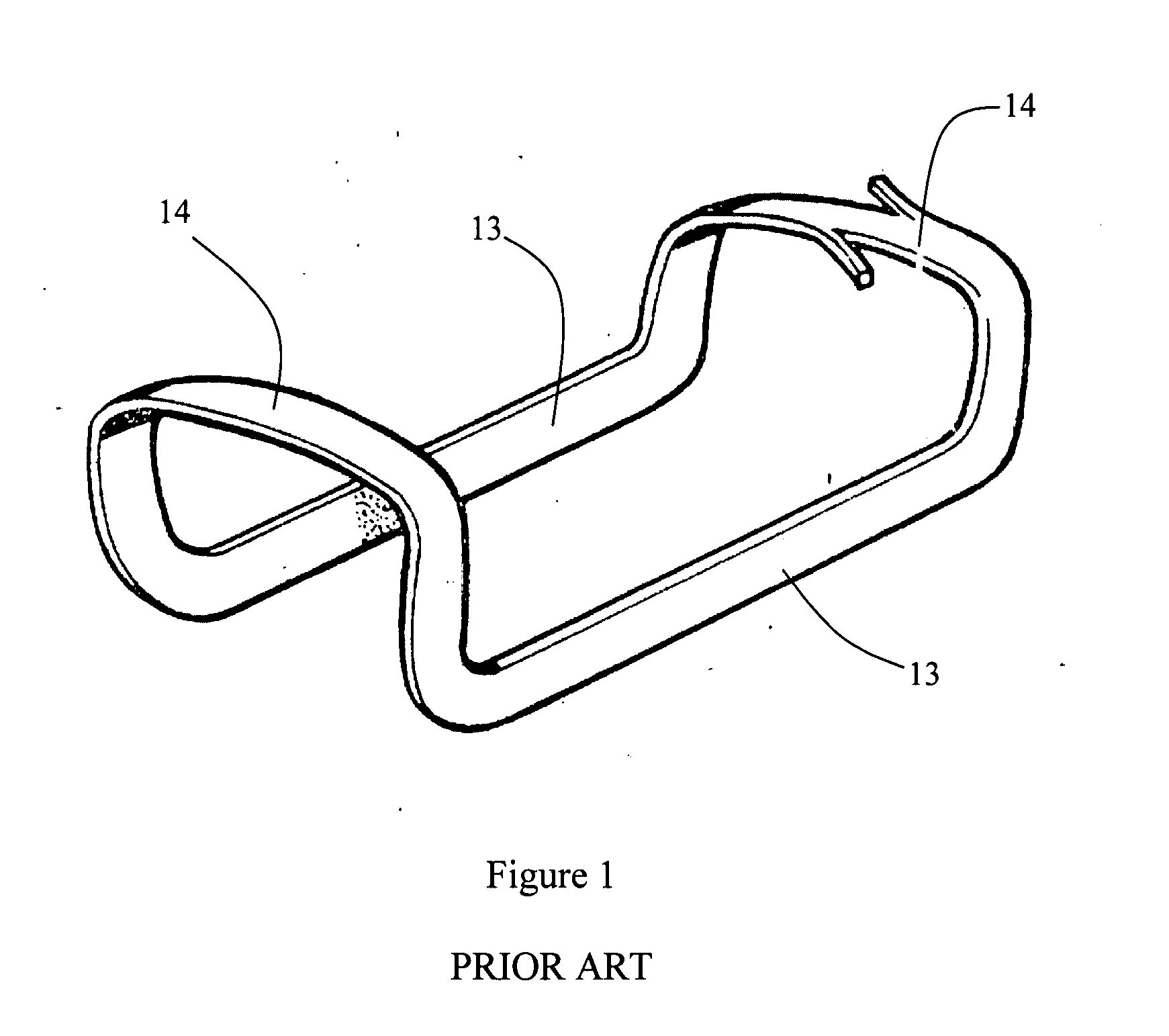

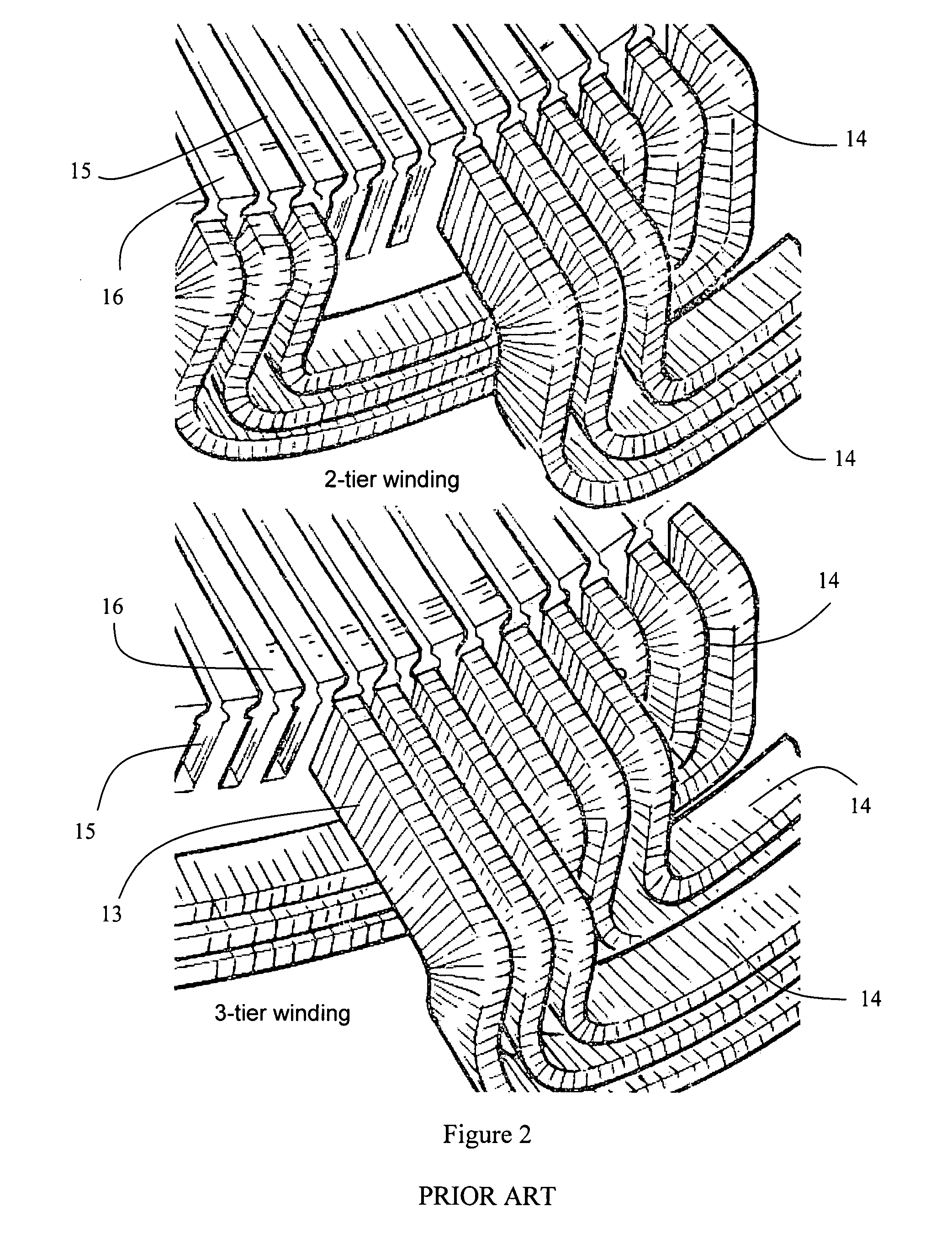

InactiveUS20080010812A1Quicker and easy and cheapFilament handlingManufacturing dynamo-electric machinesSingle processEngineering

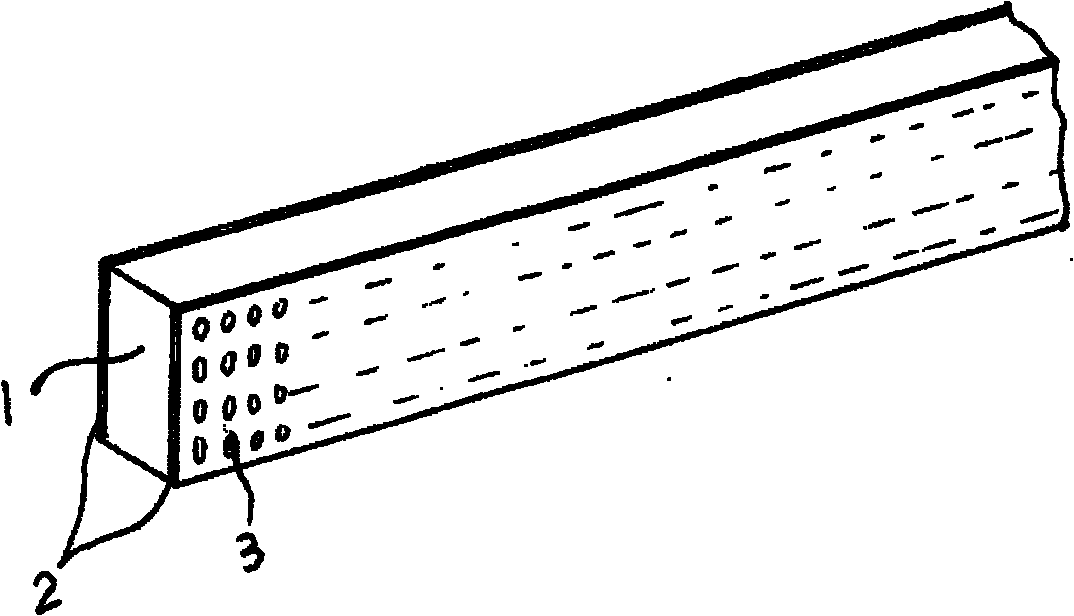

The present invention provides a method of forming a single-layer coil for an electrical machine in a single process from a length of insulated rectangular conductor such as copper tape, for example. The coil is formed by winding the conductor around first and second coil-forming members 5 and 7 provided on a beam 6 having a longitudinal axis and which is capable of being rotated about a first axis of rotation that is substantially parallel to the longitudinal axis of the beam and a second axis of rotation that is substantially at right angles to the longitudinal axis of the beam.

Owner:GE POWER CONVERSION

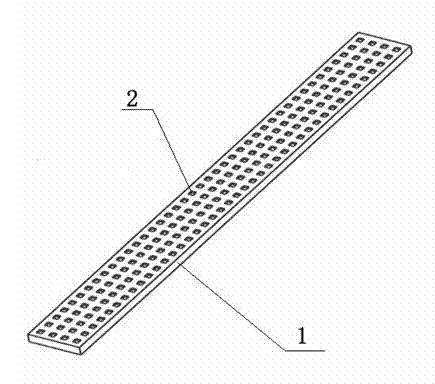

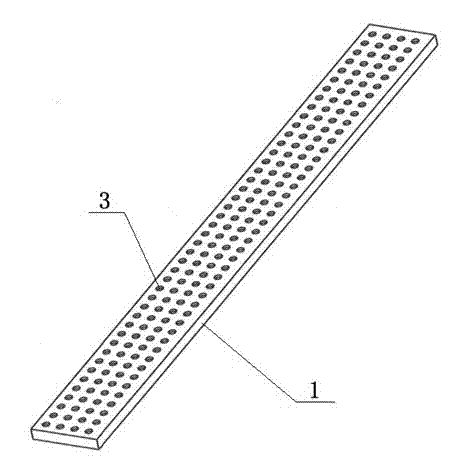

Surface irregular high-power tin-plate copper strip of photovoltaic subassembly and manufacture method of surface irregular high-power tin-plate copper strip

ActiveCN102737754AImprove conductivityImprove qualitySingle bars/rods/wires/strips conductorsPhotovoltaic energy generationSolar batteryOxygen

The invention discloses a surface irregular high-power tin-plate cooper strip of a photovoltaic subassembly and a manufacture method of the surface irregular high-power tin-plate copper strip. The tin-plate copper strip comprises an oxygen-free cooper strip which serves as a base material, and a tin-plate layer covered on the external surface of the oxygen-free cooper strip, wherein irregular structures are also uniformly distributed on the positive surface and the negative surface of the oxygen-free cooper strip; and the irregular structures are in regular geometrical shapes in the form of a groove. The stability of the physical performance of a product can be ensured by the irregular structures, simultaneously the irregular structure at the negative surface can enlarge the contact area with a battery piece, and can improve the welding performance while combining with the battery piece; while being used in combination with the common solar battery piece, the irregular structure on the positive surface can reflect more sunshine on the battery piece due to the irregular structure, and therefore, the power of a whole solar photovoltaic subassembly can be improved; while being used in combination of a photothermal-photovolatic battery piece subassembly, the irregular structure on the positive surface can enlarge the heating area due to the enlarged surface area of the irregular structure, besides the reflection of the sunshine is improved, and thus, the power of the whole solar photovoltaic subassembly can be improved to a greater extent.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS

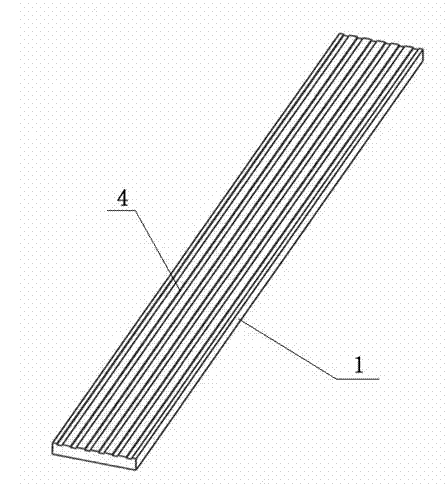

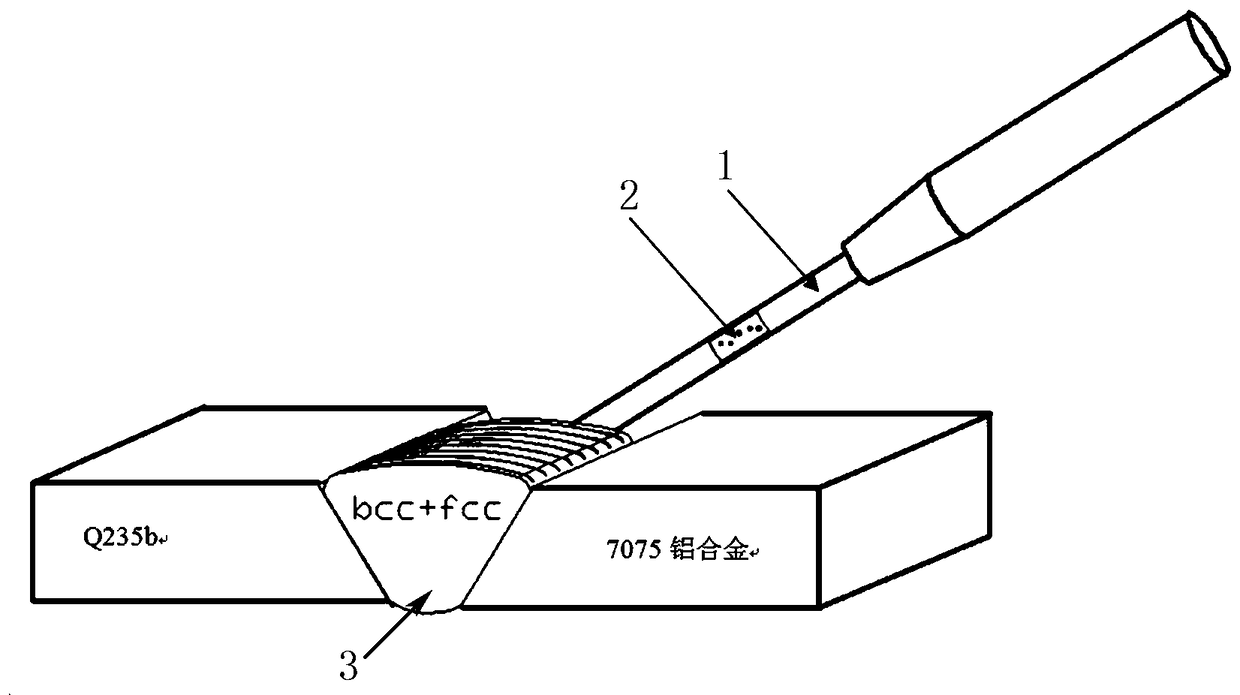

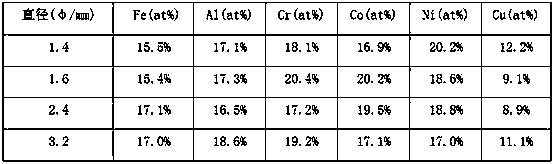

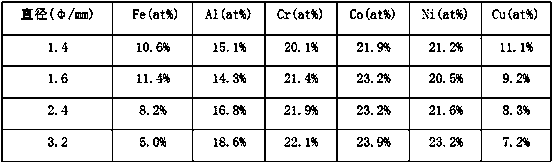

High-entropy flux cored wire for aluminum-steel MIG welding and preparation method of high-entropy flux cored wire

InactiveCN108161278AGood compatibilityAvoid it happening againWelding/cutting media/materialsSoldering mediaEntropy fluxHigh entropy alloys

The invention discloses a high-entropy flux cored wire for aluminum-steel MIG welding. Powder is prepared from, by atomic percentage, 5%-15% of Fe, 10%-20% of Al, 20%-30% of Co, 18%-35% of Cr, 20%-35%of Ni and 5%-13% of Cu, and the total percentage is 100%. Industrial high-purity copper tape is adopted for an outer skin material. A preparation method comprises the steps that firstly, a mother alloy is melted; secondly, atomized power is prepared by applying a vacuum gas atomization powdering technology; and thirdly, the high-entropy flux cored wire is prepared by the adoption of flux cored wire forming unit equipment. The high-entropy flux cored welding wire is used for aluminum-steel MIG welding, a high-quality aluminum-steel welded joint is obtained, the chemical compositions of weld metal are within a principal element range of a high-entropy alloy, and the high entropy of a weld is achieved. The weld has excellent strength and toughness, brittle intermetallic compound phases are eliminated effectively, and the good synthesized mechanical properties are provided.

Owner:TAIYUAN UNIV OF TECH

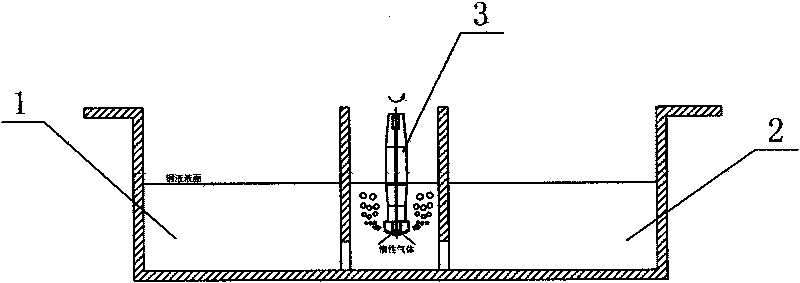

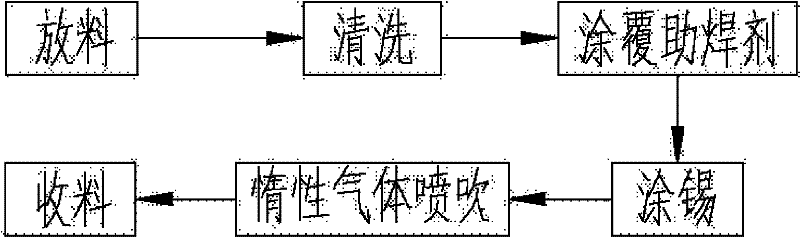

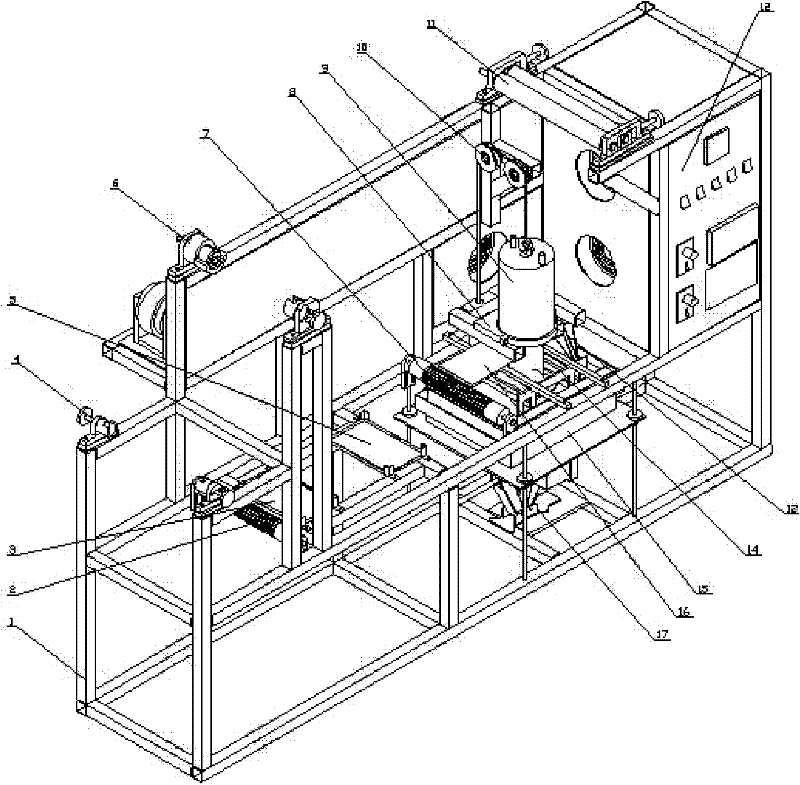

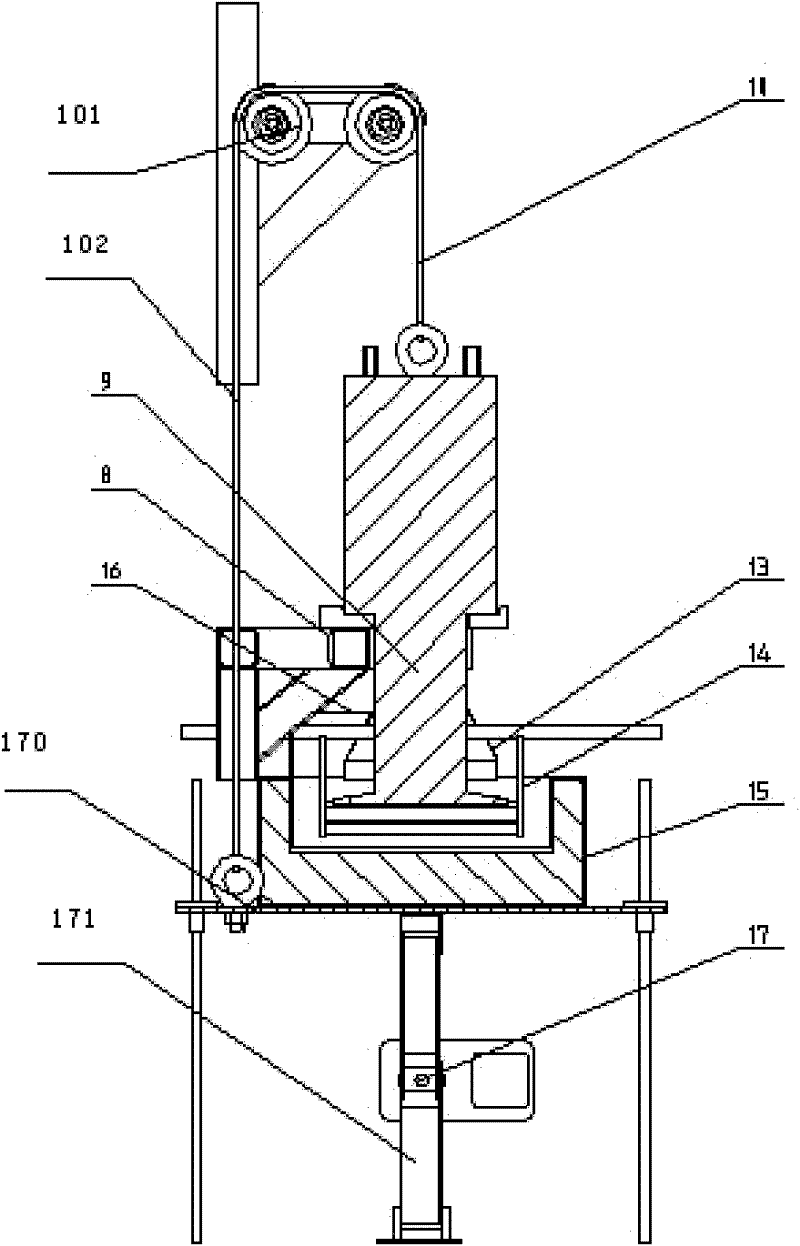

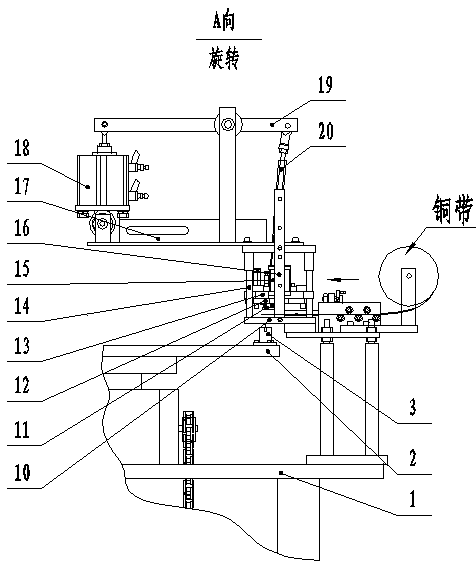

Manufacturing method of photovoltaic welding strip and tin coating machine thereof

ActiveCN102226259AAvoid pinholesQuality improvementHot-dipping/immersion processesFinal product manufactureSlagTransducer

The invention provides a manufacturing method of a photovoltaic welding strip and a tin coating machine thereof. The method comprises the following steps: A, carrying out a simple pretreatment on a copper strip; B, sending the pretreated copper strip into a plating solution of a tin furnace for tin coating, when tin coating, carrying out an ultrasonication to the copper strip with ultrasonic waveemitted by an ultrasonic wave transducer arranged above the tin furnace; C, blowing tin with inert gases, and D, receiving materials. According to the invention, by adding ultrasonic wave in the tin coating process, tin liquor can rapidly form an alloy layer of copper and tin on the surface of the copper strip by the sound pressure effect of the ultrasonic wave, the production efficiency of the photovoltaic welding strip is increased, the transporting speed of the copper strip reaches to 10-80m / min; by removing grease and oxide layer on the copper strip surface, reducing the usage of chemicalreagents, simplifying the pretreatment before coating, and utilizing the ultrasonic wave to crush clusters of tin oxide, the defects of pinhole and tin slag of the welding strip is prevented, the quality of the welding strip is improved, and the production efficiency is raised greatly.

Owner:江苏威腾新材料科技有限公司

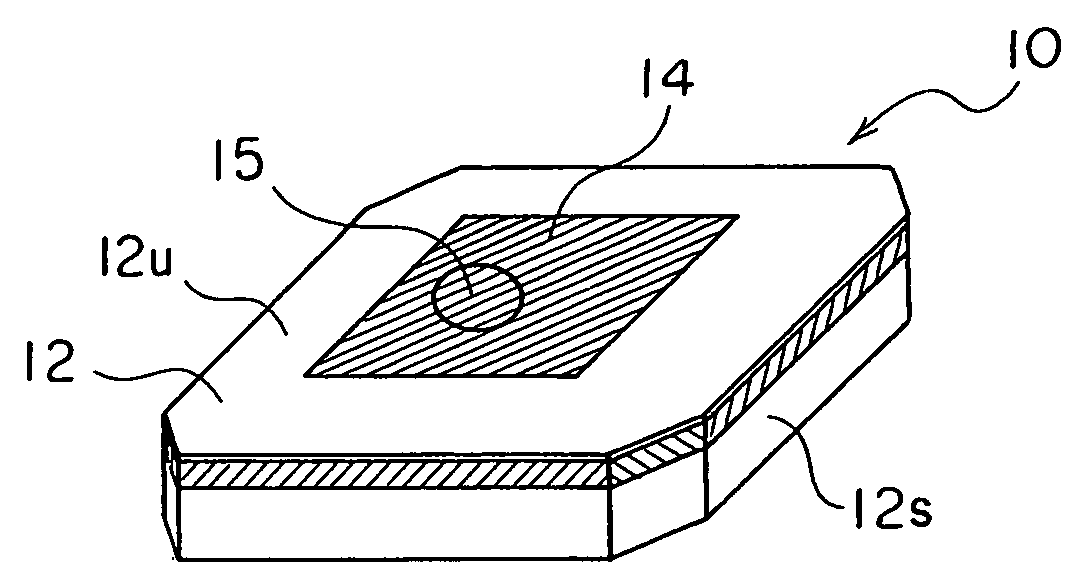

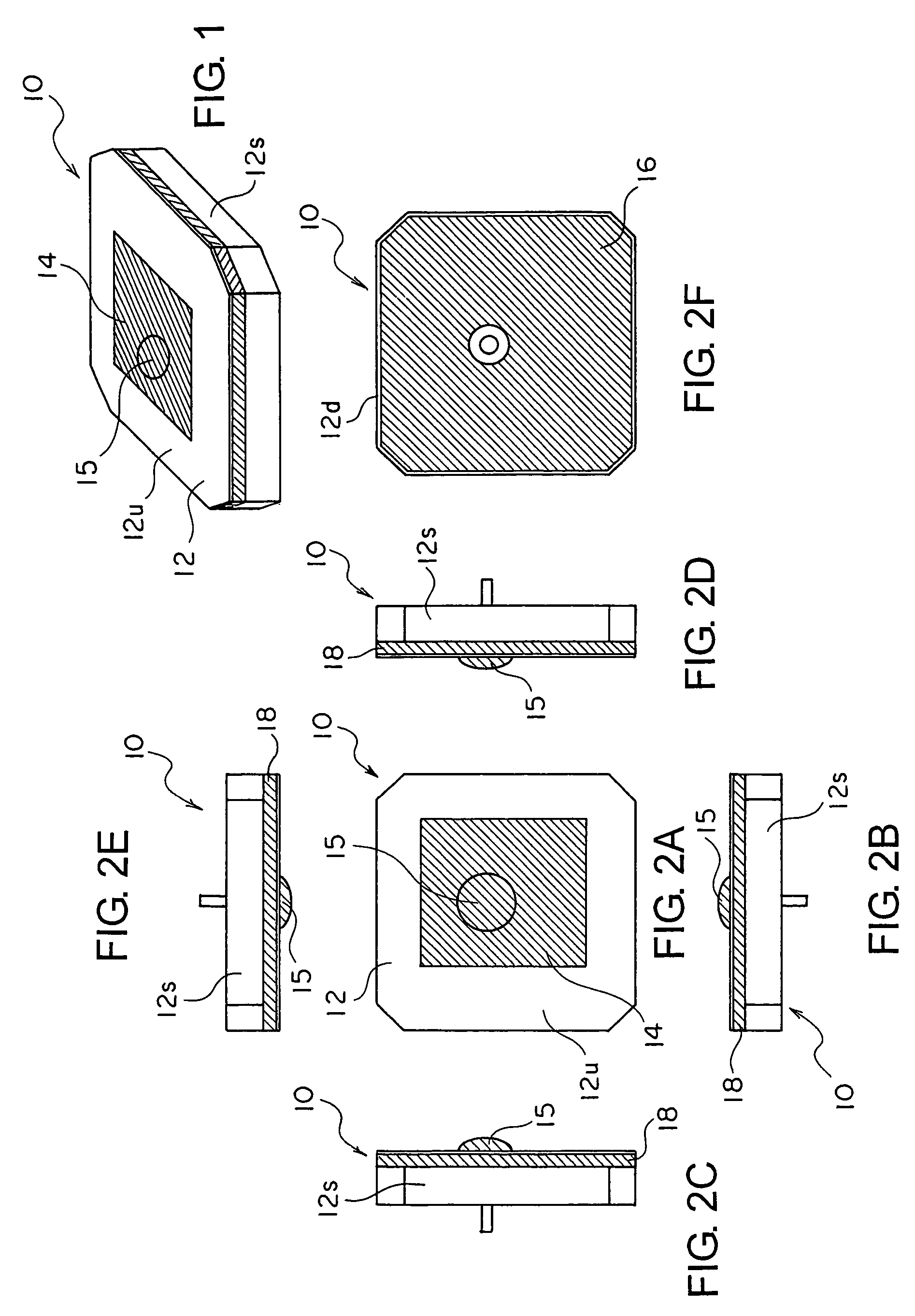

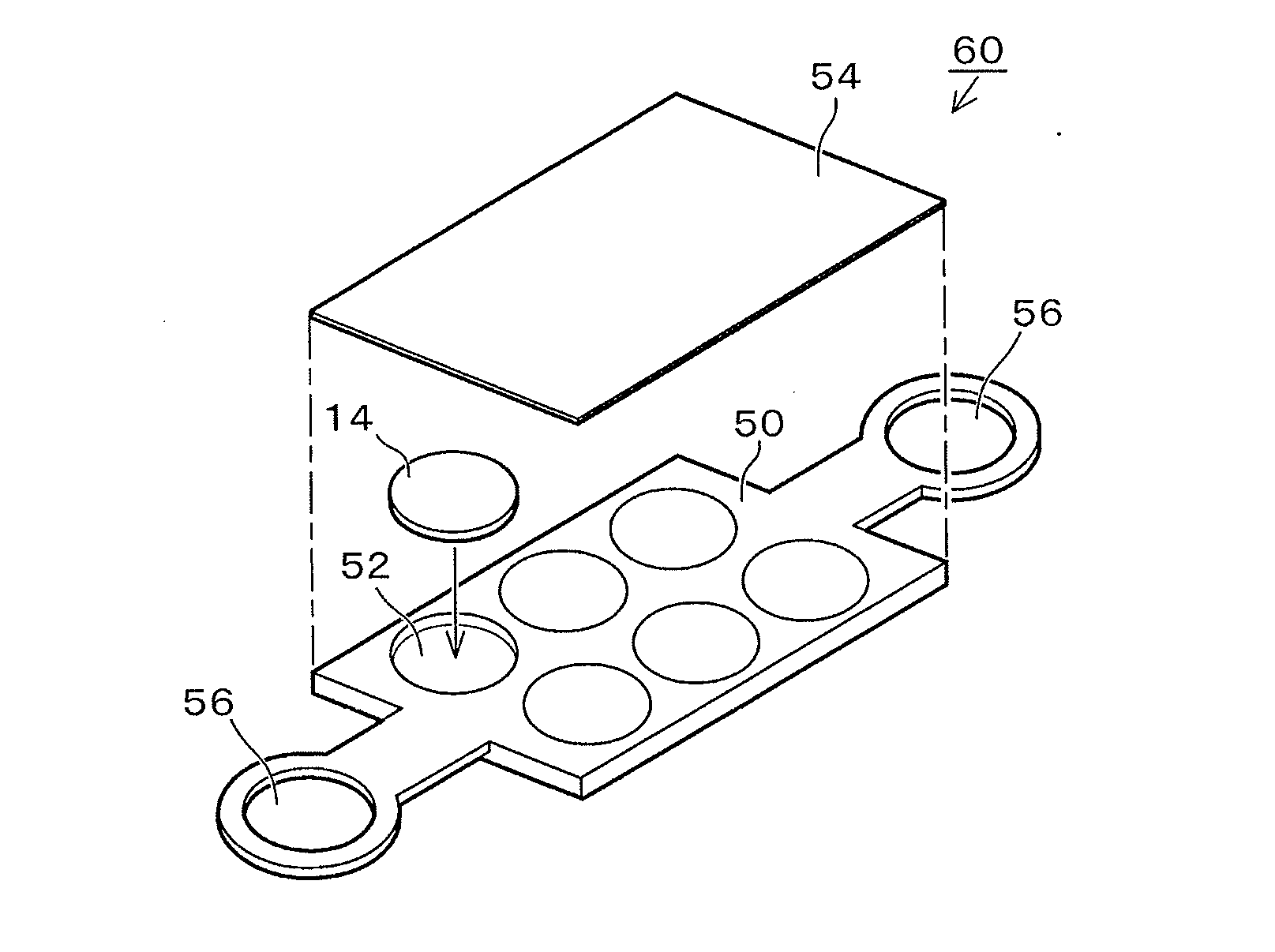

Patch antenna having a non-feeding element formed on a side surface of a dielectric

InactiveUS7042399B2Reduce distractionsEasy to adjustSimultaneous aerial operationsRadiating elements structural formsDielectricRadiating element

In a patch antenna including a dielectric having a top surface, a bottom surface, and a side surface, a radiation element formed on the top surface of the dielectric, and a ground conductor formed on the bottom surface of the dielectric, a ring-shaped non-feeding element is formed on the side surface of the dielectric. The non-feeding element preferably may be formed on the side surface of the dielectric in the vicinity of the top surface of the dielectric. In addition, the non-feeding element may be formed by pasting a copper tape or by thick film printing.

Owner:MITSUMI ELECTRIC CO LTD

Hot rolling production technology of copper-aluminum composite board

InactiveCN107552564AReduce processIncrease productivityAuxillary arrangementsMetal rolling arrangementsBonding processHeating furnace

The invention discloses a hot rolling production technology of a copper-aluminum composite board. The hot rolling production technology comprises the following technological steps of raw material preparation, surface treatment, heating, rolling bonding, annealing and slitting, specifically, the thickness and the width of an aluminum strip and a copper strip are selected according to needs; surfacepolishing treatment is conducted on the aluminum strip and the copper strip respectively; the aluminum strip and the copper strip are heated in an upper layer heating furnace and a lower layer heating furnace correspondingly; the heated aluminum strip and the heated copper strip enter a rolling mill synchronously to be rolled and bonded, and the copper-aluminum composite board is obtained; annealing is conducted on the copper-aluminum composite board which is subjected to rolling and bonding by adopting a bell type heating technology; the annealed copper-aluminum composite board is cooled tobe at the normal temperature, and slit into flat boards. According to the hot rolling production technology, hot rolling bonding of the copper-aluminum composite board can be achieved by controlling the heating temperatures of the copper strip and the aluminum strip respectively, bonding can be achieved through one-time rolling, the problems that the rolling force is large and rolling needs to beconducted for many times in the cold rolling bonding process are solved, the utilization property of the composite board is improved, the production efficiency is increased and the cost is lowered.

Owner:无锡银荣板业有限公司

A copper-clad aluminum complex cable copper strip composition and machining process

InactiveCN101060023AImprove welding effectImprove the lubrication effectOther manufacturing equipments/toolsMetal/alloy conductorsHigh intensityMachining process

The disclosed copper strip for Cu-covered-Al composite cable comprises: 59. 9705-99. 9805% cathode copper, <40% waste red copper, 0. 002-0. 012% P, <0. 002% O, and <0. 0155% other impurity. The preparation method comprises: mixing, smelting, covering, deoxidizing, revolving furnace, covering, holding, detecting, casting, sawing, ingotting and heating, hot-rolling, milling surface, coarse rolling, end shearing, intermediate annealing, fine rolling, product annealing, surface passivating, and packaging. This product has high conductivity, strength, extensibility, and welding feature. The tension processing ratio can come up to 99. 99%.

Owner:LUOYANG COPPER PROCESSING GROUP

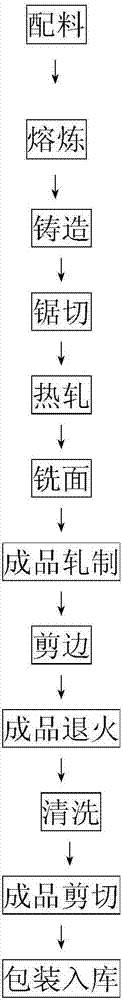

Preparation process of copper strip for framework material

ActiveCN107385270AIncreased strength and softening resistanceAvoid grain coarseningCorrosionScratching

Provided is a preparation process of a copper strip for a framework material. The preparation process comprises the technological steps of proportioning, smelting, casting, saw cutting, hot rolling, face milling, finished product milling, edge shearing, finished product annealing, washing, finished product shearing and packaging and putting into a storage. Compared with a special-shaped framework material manufactured by an original process, the copper strip produced by the preparation process has the remarkable advantages of high strength, good electrical conductivity, good subsequent machining performance and the like, chemical components of the material are stable, the surface is clean, smooth, free of oxidation discoloration, and free of defects like peeling, burrs, bubbles, cracks, layering, inclusion, holes, black points, folding, verdigris, scratching and corrosion, the copper strip can adapt to the more severe use environment, and the service life of a profiled bar is prolonged.

Owner:中铝洛阳铜加工有限公司

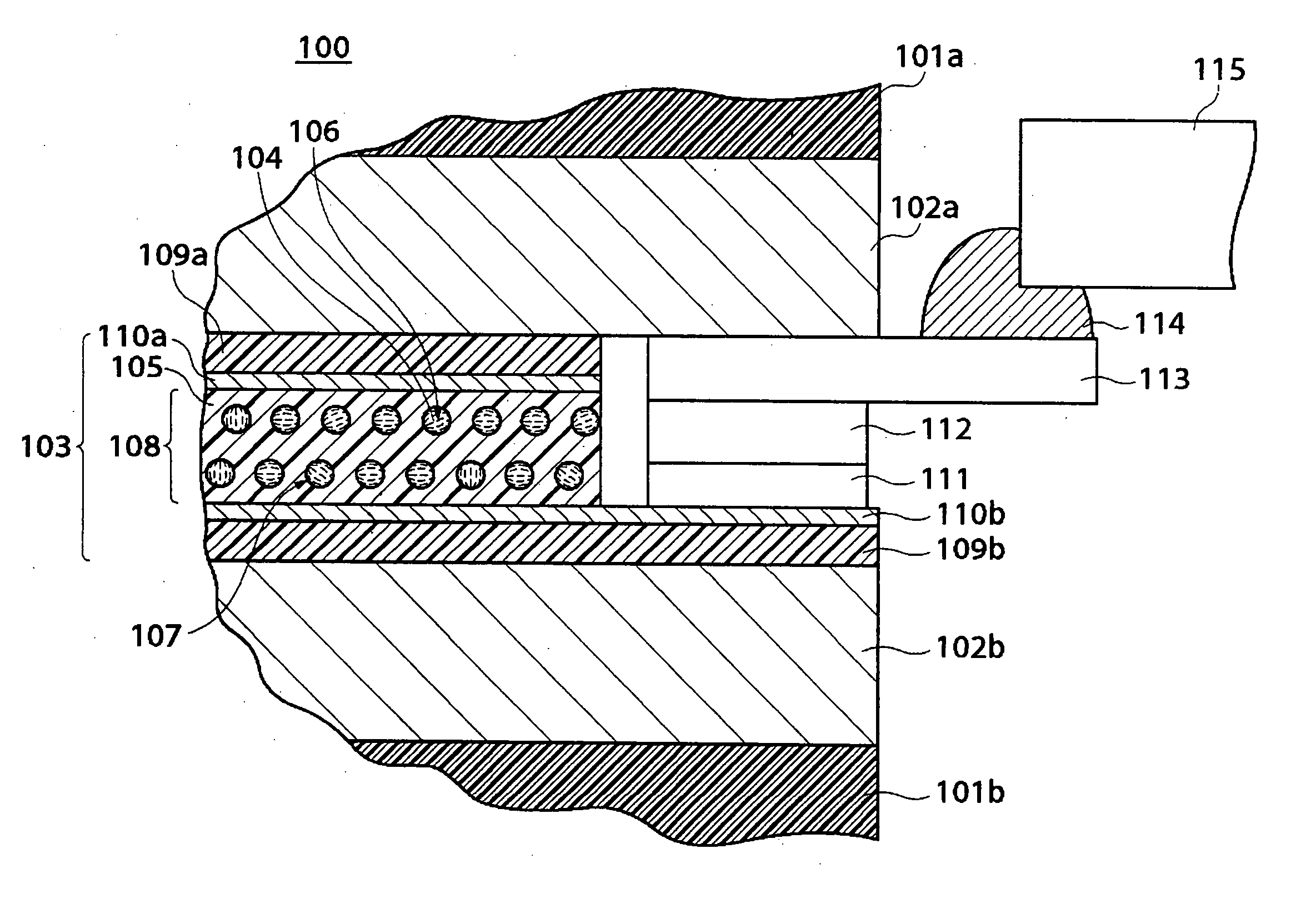

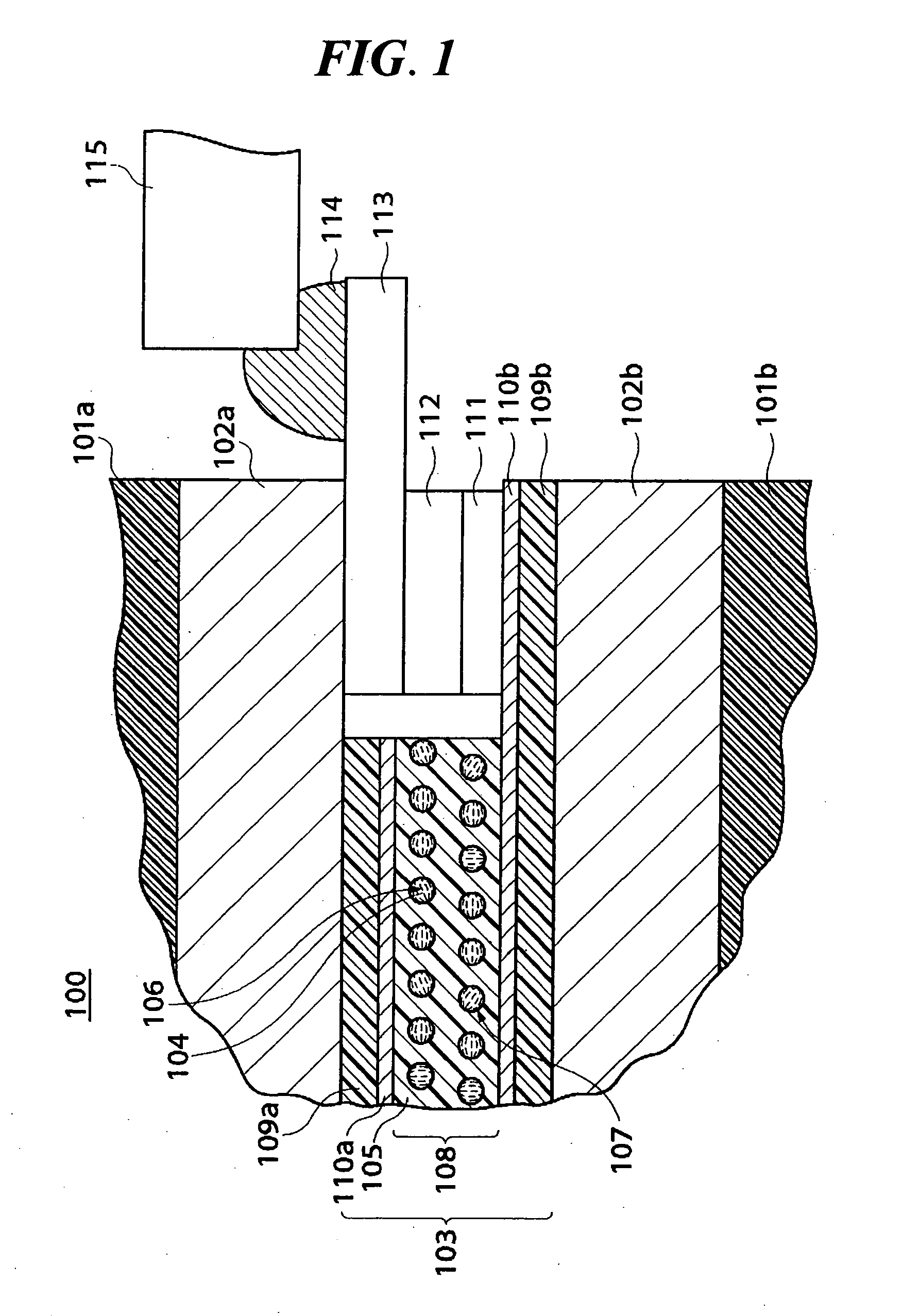

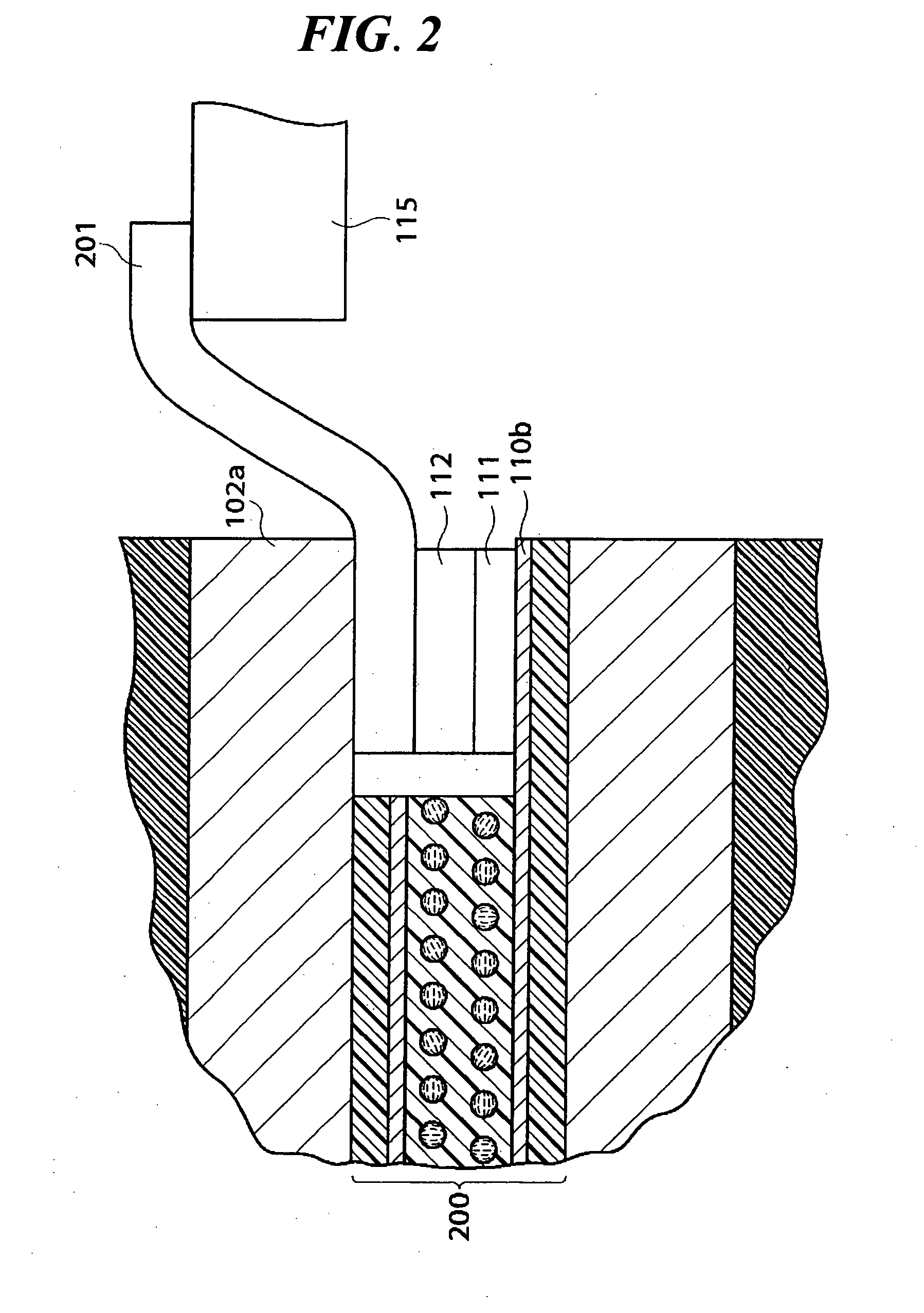

Light adjuster and laminated glass

InactiveUS20050190332A1Reduce stepsOperation failureLight protection screensGlass/slag layered productsLiquid-crystal displayEngineering

There is provided a light adjuster which is capable of improving handleability thereof and preventing the occurrence of operation failure. A light adjuster 103 is comprised of a pair of PET films 109a and 109b that sandwich a liquid crystal layer 108 therebetween, transparent electrically conductive films 110a and 110b that are provided on respective facing surfaces of the pair of PET films 109a and 109b, and an electrode structure provided at one end of the light adjuster 103. The electrode structure is comprised of a connecting base formed of a silver paste 111 that is applied to an exposed part of the transparent electrically conductive film 110b, a copper tape 112 that is stuck on the upper surface of the silver paste 111, and a tabular connector 113 made of a metal that is pressed onto the copper tape 112 at one end thereof. A lead line 115 is secured to the other end of the connector 113 by solder 114 to supply power from an external power source. The thickness of the electrode structure is not less than the value of the combined thickness of the liquid crystal layer 108, the transparent electrically conductive film 110a, and the PET film 109a.

Owner:NIPPON SHEET GLASS CO LTD

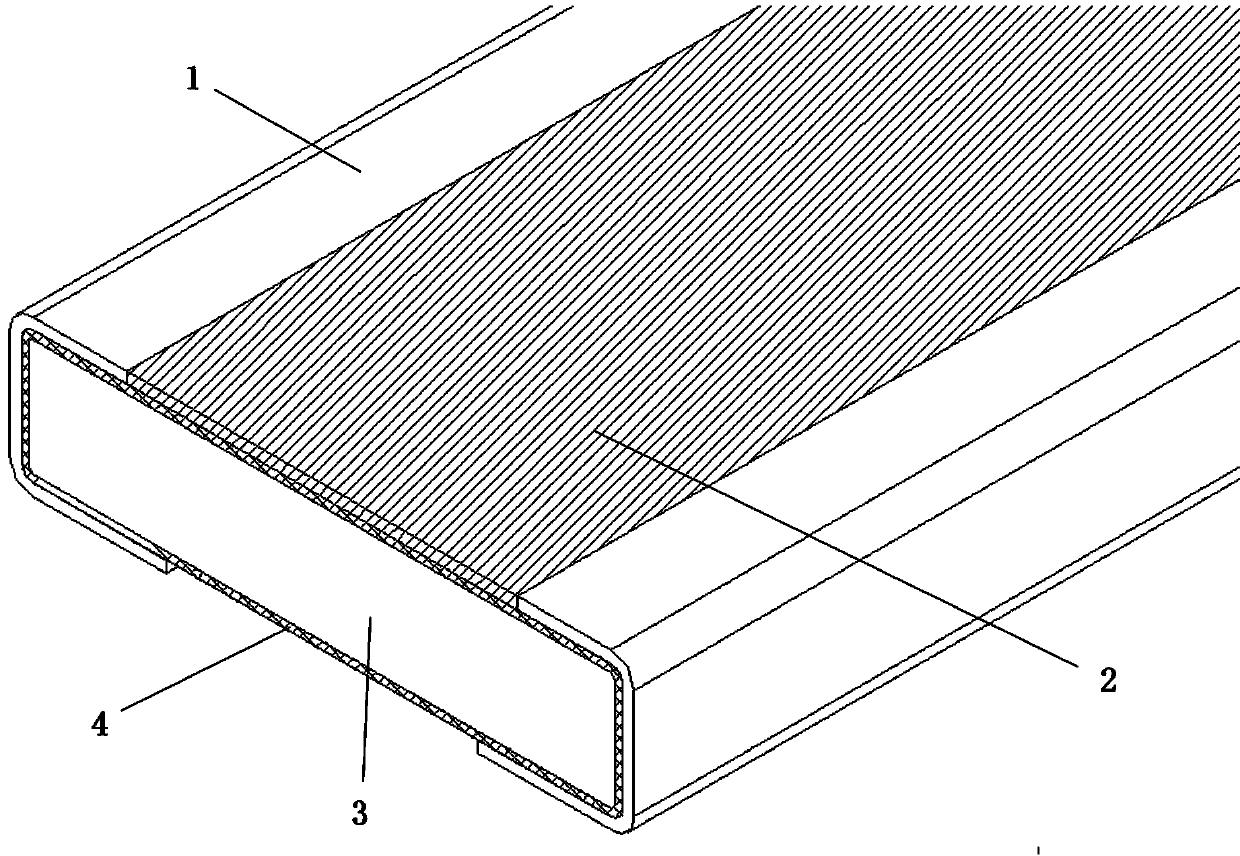

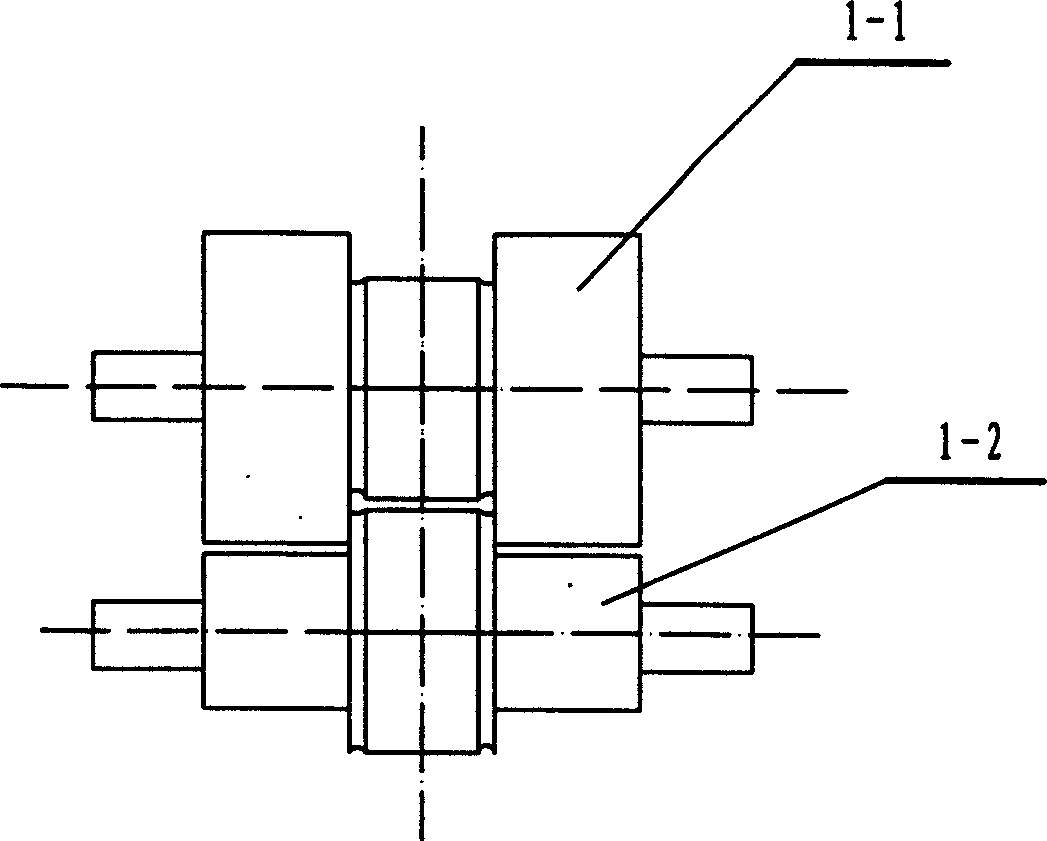

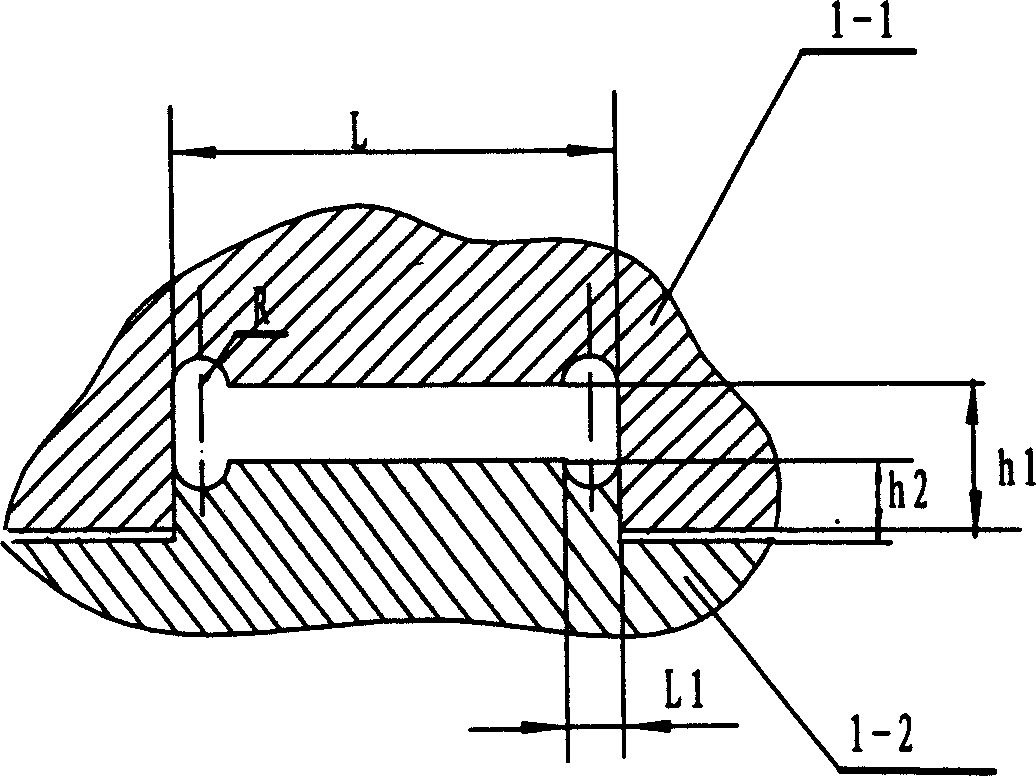

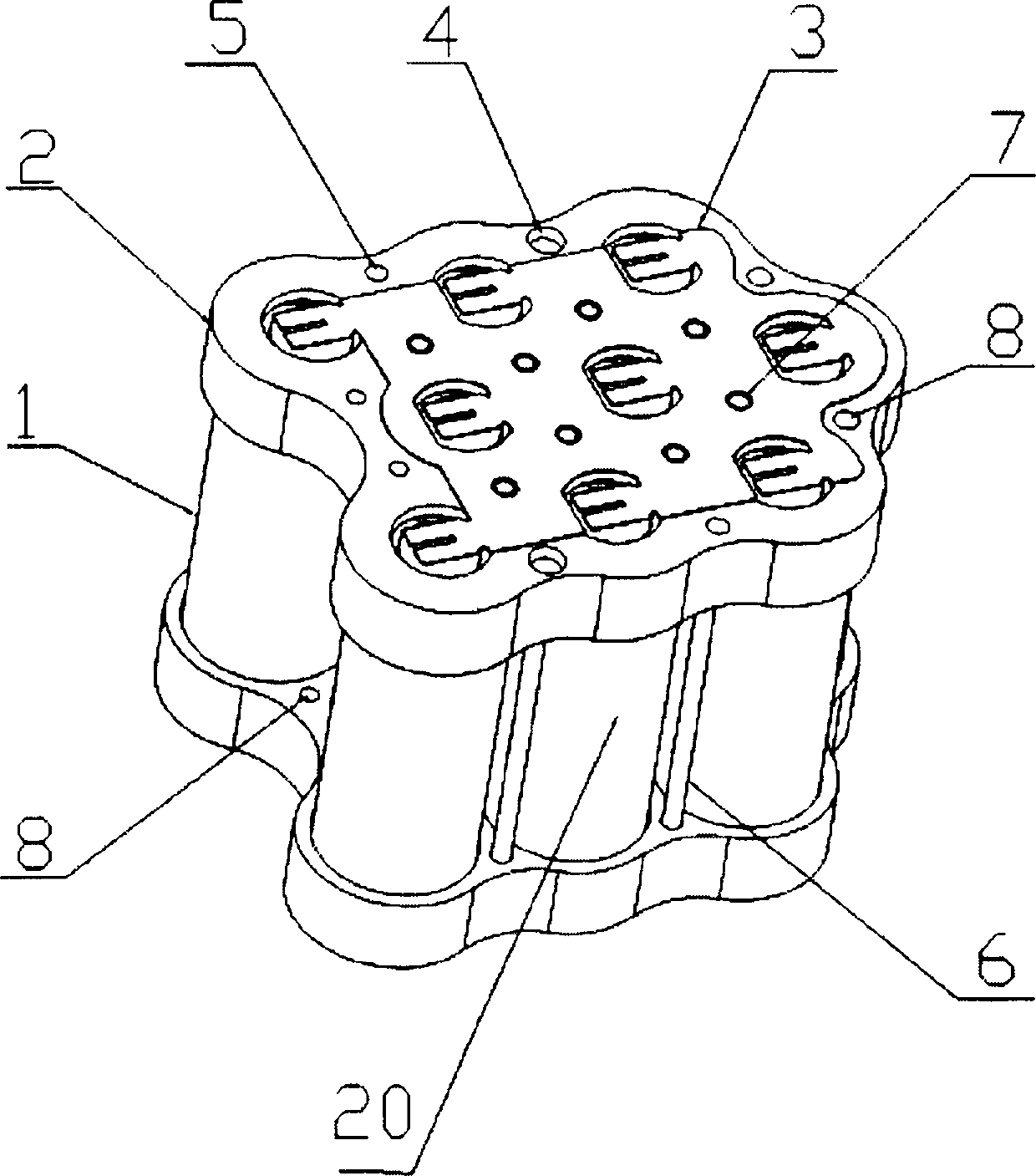

Discharge coil for electromagnetic riveter and production method thereof

The invention discloses a discharge coil for an electromagnetic riveter, wherein the center of the coil is a core tube, an initial end of a copper strip is welded with the core tube, the core tube is surrounded by layers of the copper strip wrapped by glass fabric, the continuous copper strip forms a cake-shaped disc in a shell, a round insulating board is arranged on the cake-shaped disc, the center of the insulating board is a through hole matched with the upper end of the core tube, a supporting plate is arranged on the insulating board, an insulating layer is arranged on the supporting plate, a connecting line is fixedly connected with a countersunk nut on the shell, and the supporting plate is supported against two countersunk square nuts. The invention also discloses a method for producing the discharge coil. The countersunk nuts are adopted, so the external dimension of the coil is reduced and the coil can be conveniently arranged into a small-scale electromagnetic riveter; a radiating hole at the center of the coil improves heat dissipation conditions of the coil and reduces the temperature rise speed of the coil; the whole coil is packaged in the shell so as to ensure that the coil can bear larger impact load; and the design of a partition improves the insulating property of the coil.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

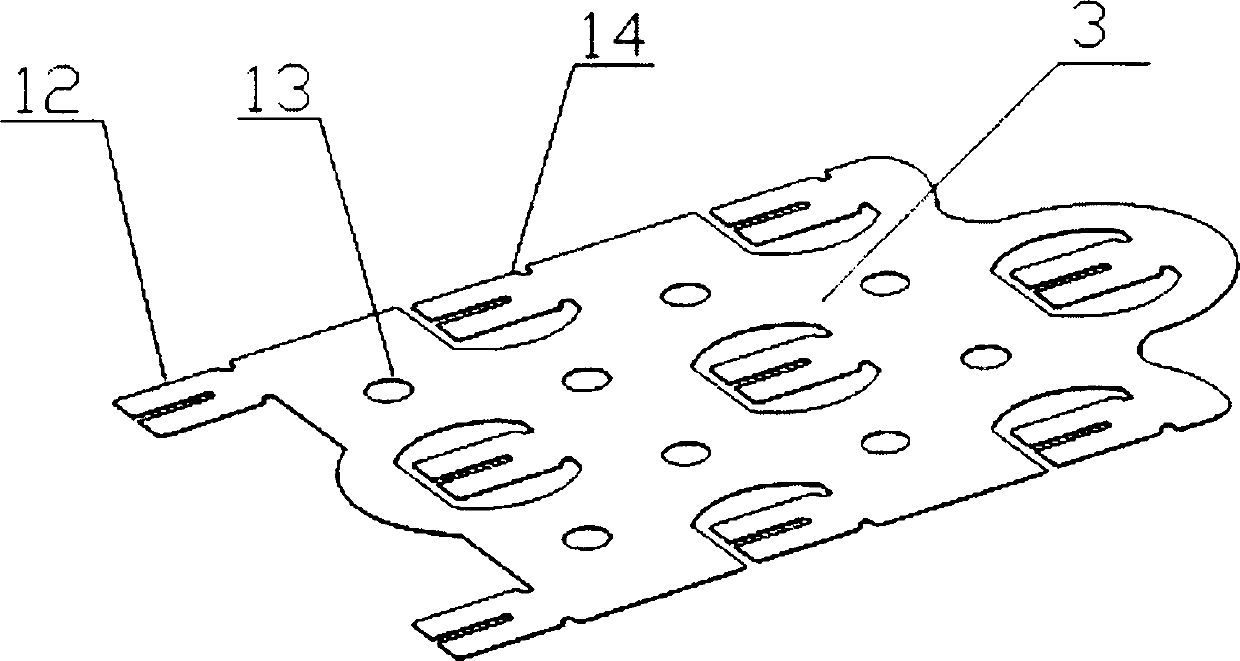

Method for manufacturing photovoltaic solder strip

InactiveCN103341703AIncrease productivityLower yield strengthWelding/cutting media/materialsSoldering mediaMicrometerWork in process

The invention discloses a method for manufacturing a photovoltaic solder strip. The method for manufacturing the photovoltaic solder strip includes the flowing steps: a, embossing a raw material, namely a copper strip, with a metal embossing process, forming a reflective groove structure on the surface of the copper strip, obtaining a first semi-finished product, b, conducting an annealing treatment on the first semi-finished product with an annealing process, forming a second semi-finished product, c, selecting proper coated metal, conducting electroplating on the second semi-finished product with an electroplating process, controlling the plating thickness and making the plating thickness to be ranged from 1 micrometer to 30 micrometers, and obtaining the needed photovoltaic solder strip. By means of the photovoltaic solder strip manufactured through the above method, the optical use ratio of a solar cell module can be improved, the manufacturing cost of the photovoltaic solder strip is reduced, the work efficiency of the photovoltaic solder strip is improved, and industrialized production is achieved.

Owner:TRINA SOLAR CO LTD

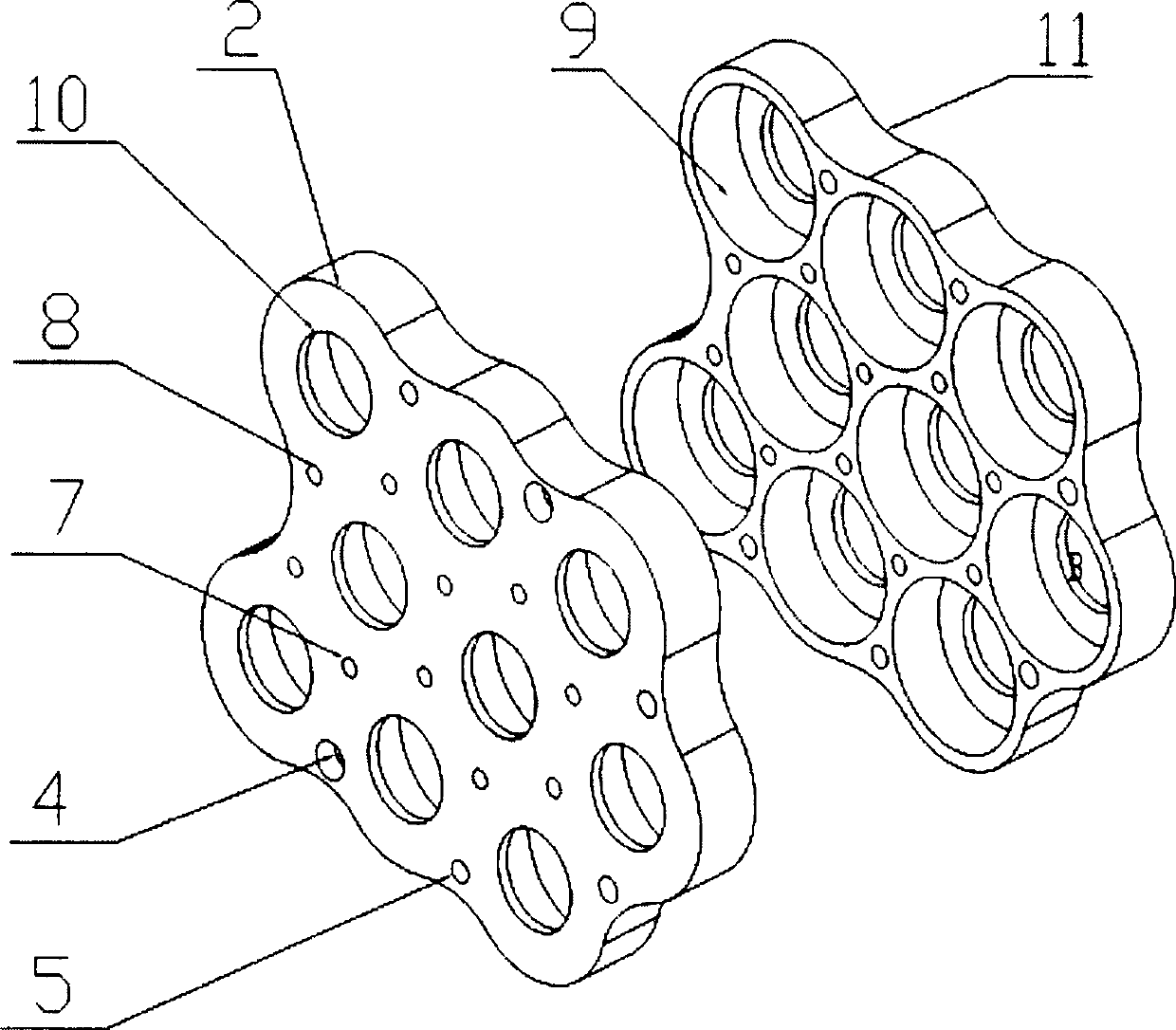

Universal battery module unit

ActiveCN103682479AEasy to replaceImprove versatilityAssembling battery machinesCell component detailsWhole bodyDrive motor

The invention relates to a cylindrical lithium ion battery module combination unit. The cylindrical lithium ion battery module combination unit comprises a plurality of single cylindrical lithium ion batteries which are fixed by screws through a bracket; the bracket ensures that a safe spacing distance exists between the batteries and the single batteries are welded with welding and connecting sheets to form a parallel body. A plurality of screw holes in the bracket and a positive electrode (negative electrode) bus-bar form tight plane contact to be connected into a whole body when the screw holes are used for assembling a battery module. The welding and connecting sheets are formed by punching nickel-plated steel belts, nickel belts, copper belts and nickel-plated copper belts; the section area is determined by the maximum safe current value of the batteries. A plurality of battery module units are combined into various battery modules with different capacities and voltage grades through different arraying combinations. The modules are convenient to detach, maintain and replace; the module units are applicable to an application field of large-capacity battery modules for driving motors or energy-storage power stations.

Owner:江苏海四达电源有限公司 +1

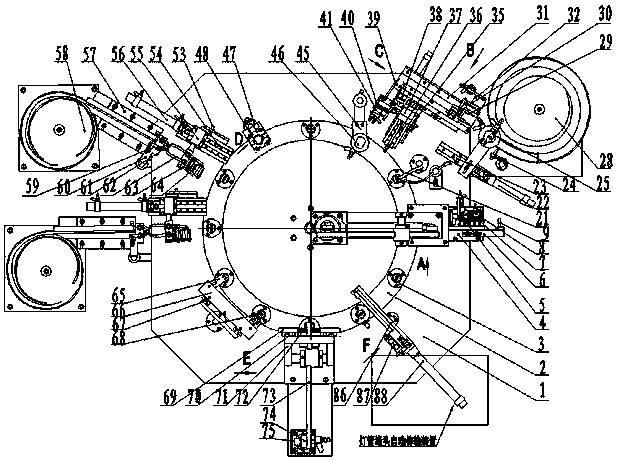

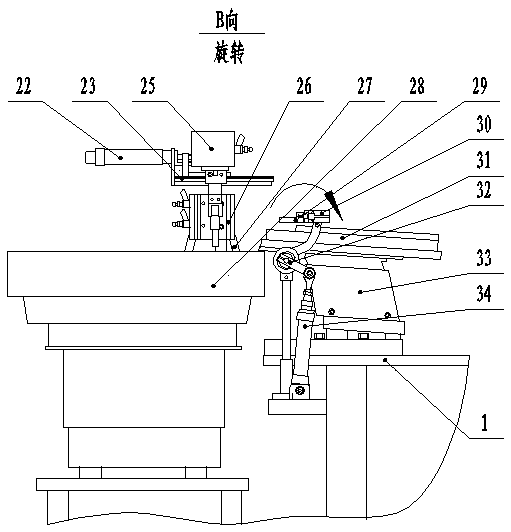

Full automatic assembling machine for T8LED lamp tube plugs

The invention relates to a full automatic assembling machine for T8LED lamp tube plugs. The full automatic assembling machine comprises a machine frame. A station dividing plate is arranged on the machine frame. A plurality of plug bases are evenly distributed on the station dividing plate. The plastic plugs can be mounted on the plug bases. The plug bases are provided with stamping connecting sheet fixing cavities. The machine frame is provided with a stamping connecting sheet copper tape conveying device, a plastic plug charging device, a plastic plug feeding device and a plastic plug mounting device. A plug lamp pin hole perforating fixing device and a lamp pin hole perforating control cylinder are mounted on the machine frame. An automatic lamp pin charging device and a lamp pin mounting device are mounted on the machine frame. The machine frame is provided with an automatic lamp pin, connecting sheet and plug pressing device. The machine frame is provided with an automatic plug discharging device. The production rate of the full automatic assembling machine is 1500 lamp tube plugs / hour, the full automatic assembling machine can assemble 12000 lamp tube plugs every day if working eight hours every day, and the efficiency is improved by 40 times.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

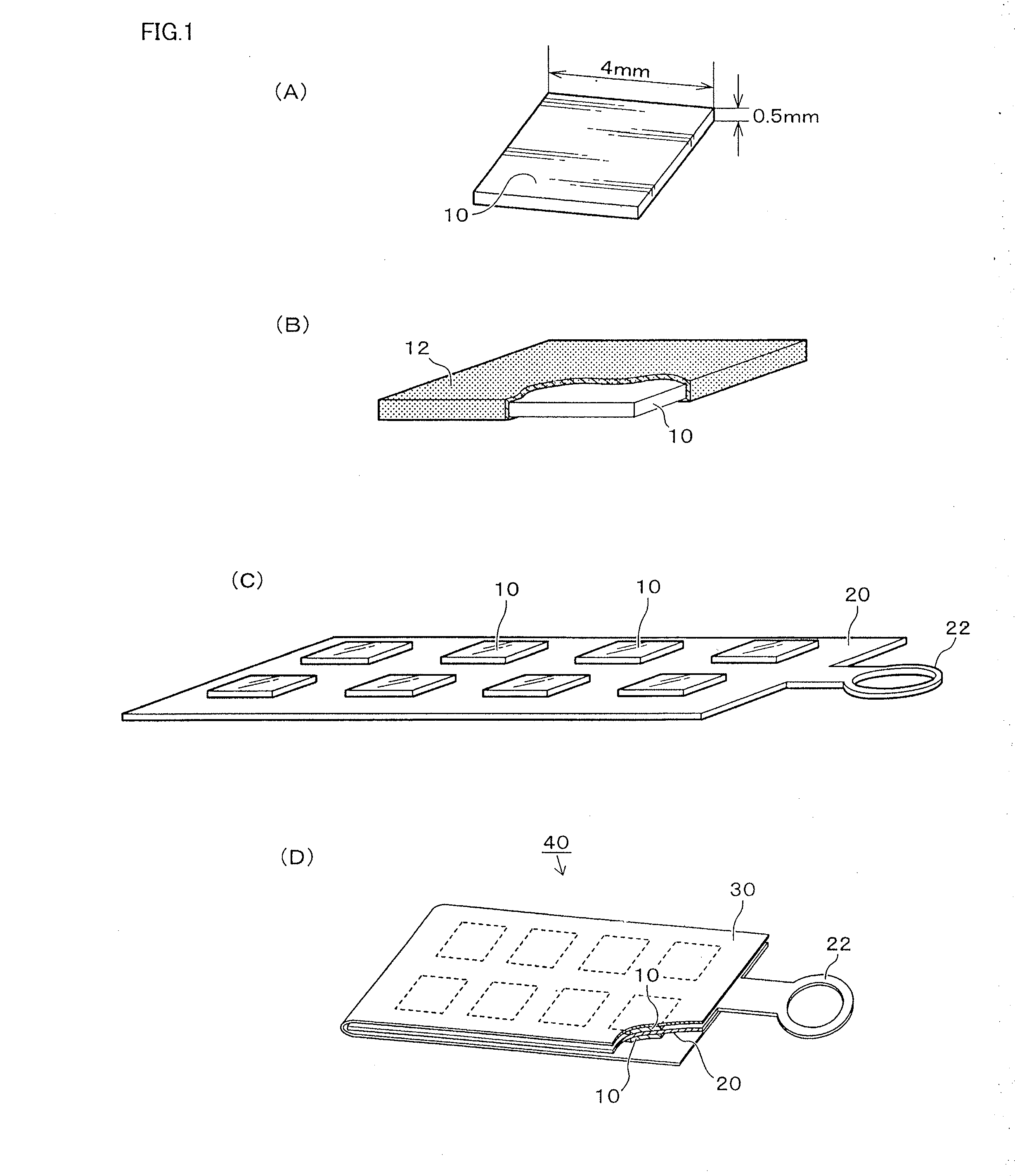

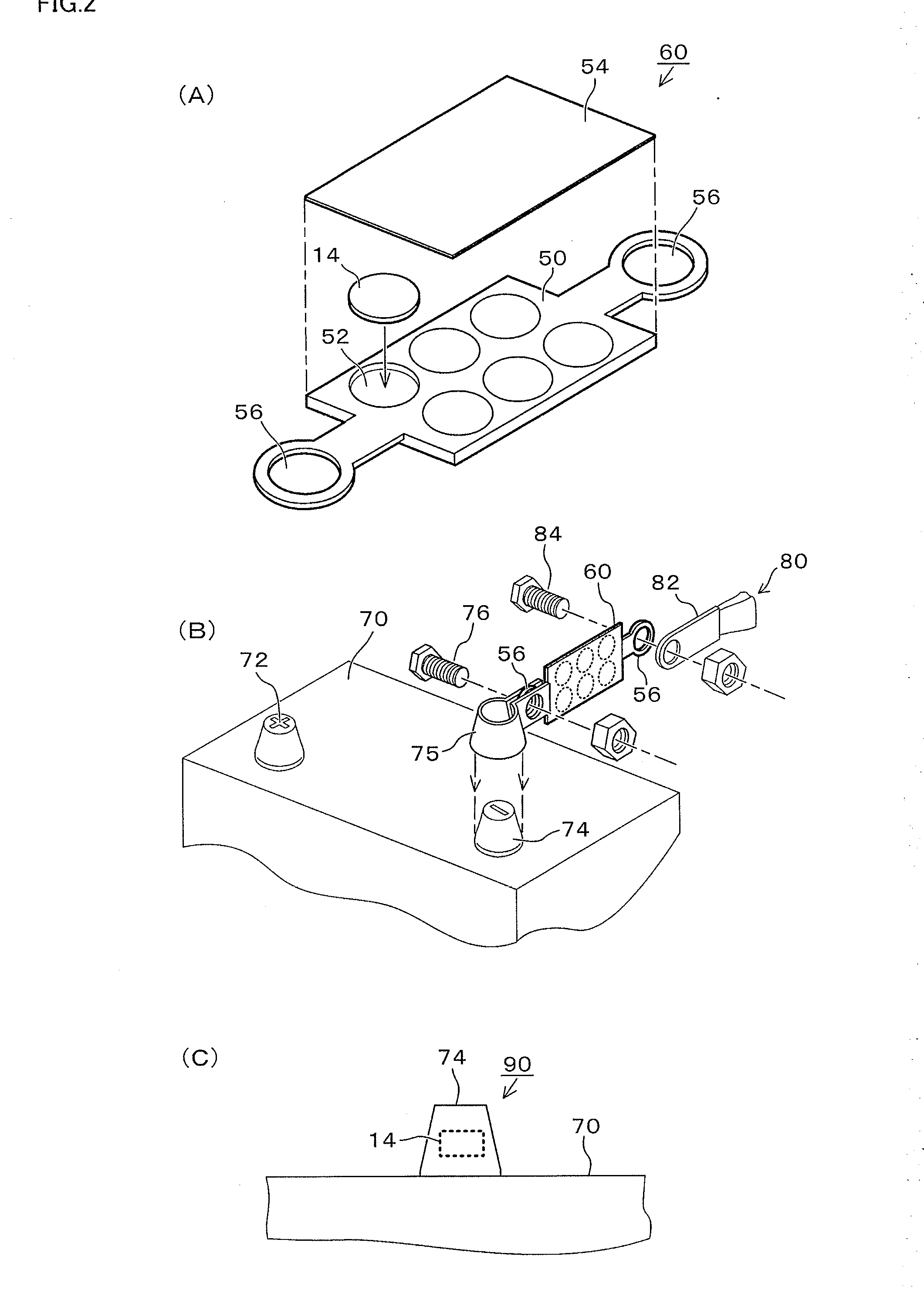

Charge supplier

ActiveUS20120039012A1Reduce charge-causing malfunctionGuaranteed uptimeSpraying power supplyElectric/fluid circuitAdhesiveEngineering

A charge supplier improves an electrically charged state of a vehicle or the like by allowing any part of the vehicle, such as an engine and electrical equipments, to maintain its movements. A charge supplier includes a plurality of rectangular tablet-like germanium chips bonded to a copper plate using a conductive adhesive, and a copper tape folded to sandwich the copper plate, so that the germanium chips are provided between the copper plate and the copper tape. The copper tape may be secured to the copper plate by pressing the copper tape toward the copper plate to deform the copper tape, or by using a conductive adhesive. An attaching terminal is provided in the copper plate on the side of the opening of the copper tape which is folded in a shape of “U”.

Owner:NAKAI TOORU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com