Patents

Literature

37results about How to "Avoid grain coarsening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

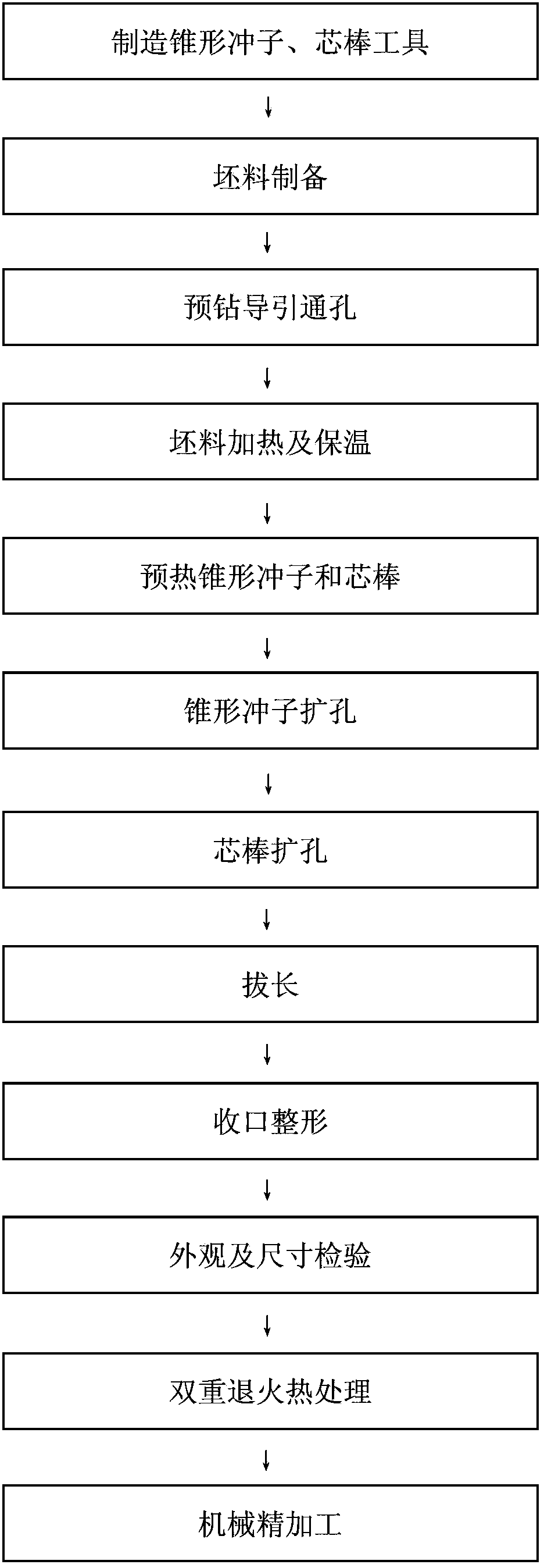

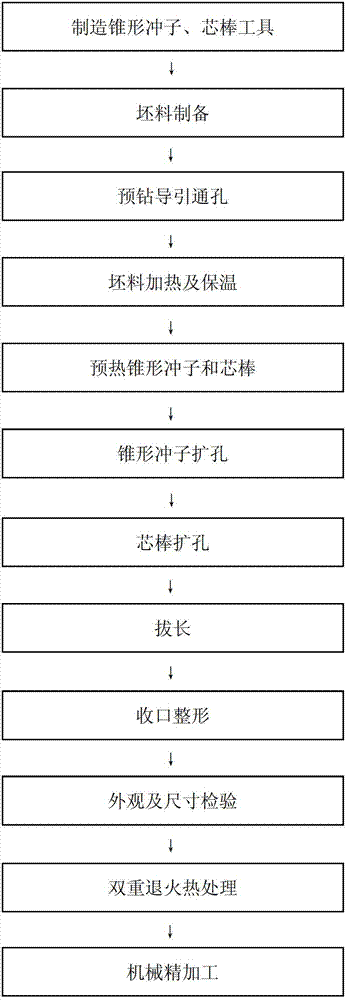

Forging and molding process method for titanium alloy tubular piece

ActiveCN103358100AReduce consumptionAvoid folding wrinkles or even cracksMetal-working apparatusFurnace typesTitanium alloyHeating temperature

The invention discloses a forging and molding process method for a titanium alloy tubular piece, which belongs to the technical field of forging and pressing, and is particularly suitable for tubular forging and molding of TC9 and TC11 titanium alloy materials. The method is mainly technically characterized in that methods such as pre-boring of guide through holes, hole expanding, drawing, binding and reshaping, and the like are adopted, and meanwhile, the heating temperature and heat preserving time of a TC9 or TC11 titanium alloy are controlled, so that crystal grains of the TC9 or TC11 titanium alloy can be prevented from being coarsened, the metallographic structure and mechanical performance of the TC9 or TC11 titanium alloy are prevented from being influenced, the consumption of the titanium alloy materials are lowered effectively, and the cost is saved; meanwhile, folding, corrugation and even cracks of inner holes are avoided; and the process method has the characteristics of easiness, high practicability, high product yield, and the like.

Owner:江南工业集团有限公司

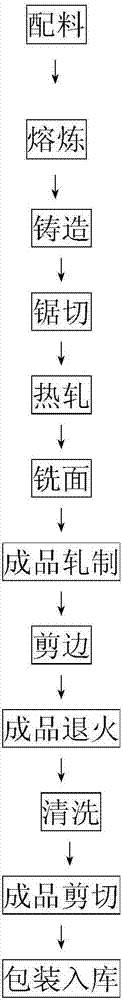

Preparation process of copper strip for framework material

ActiveCN107385270AIncreased strength and softening resistanceAvoid grain coarseningCorrosionScratching

Provided is a preparation process of a copper strip for a framework material. The preparation process comprises the technological steps of proportioning, smelting, casting, saw cutting, hot rolling, face milling, finished product milling, edge shearing, finished product annealing, washing, finished product shearing and packaging and putting into a storage. Compared with a special-shaped framework material manufactured by an original process, the copper strip produced by the preparation process has the remarkable advantages of high strength, good electrical conductivity, good subsequent machining performance and the like, chemical components of the material are stable, the surface is clean, smooth, free of oxidation discoloration, and free of defects like peeling, burrs, bubbles, cracks, layering, inclusion, holes, black points, folding, verdigris, scratching and corrosion, the copper strip can adapt to the more severe use environment, and the service life of a profiled bar is prolonged.

Owner:中铝洛阳铜加工有限公司

Method for producing lithium ion cells positive electrode material and equipment thereof

InactiveCN1610149AOvercomes the inherent disadvantages when used aloneUniform temperatureElectrode manufacturing processesLithium compoundsLithiumElectric arc furnace

The preparation process of positive pole material for lithium ion cell includes the following steps: setting the mixture of hydroxide, oxide or salt of lithium and hydroxide, oxide or salt of transition metal in certain ratio in crucible; setting the crucible in microwave oven to calcine the mixture; setting the crucible in electric furnace to sinter the calcined matter; cooling the crucible with sintered matter in cooling cavity; crushing and sieving the sintered matter to obtain the positive pole material product for lithium ion cell. The apparatus for preparing positive pole material for lithium ion cell, combined microwave-electric heating furnace, is also disclosed. The present invention is suitable for continuous large-scale production of positive pole material for lithium ion cell.

Owner:广州鸿森材料有限公司

Low-chromium wear-resisting steel ball

InactiveCN105331902AImprove temper stabilityAvoid grain coarseningFurnace typesHeat treatment furnacesChromiumCorrosion

The invention discloses a low-chromium wear-resisting steel ball. The low-chromium wear-resisting steel ball comprises, by weight, 0.7%-0.9% of C, 0.3%-0.5% of S, 0.8%-1% of Mn, 0.9%-1.1% of Cr, 0.07%-0.09% of Ni, 0.07%-0.09% of Mo, 0.03%-0.04% of Al, 0.3%-0.5% of Cu, 0.0005%-0.002% of B, 0.19%-0.21% of V, 0.01%-0.014% of P, 0.001%-0.0012% of S and the balance Fe. The low-chromium wear-resisting steel ball is high in wear resistance, good in toughness, high in impact resistance, resistant to corrosion and low in cost.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

Low-alloy steel high in strength and toughness performance and preparing method of low-alloy steel

The invention discloses low-alloy steel high in strength and toughness performance and a preparing method of the low-alloy steel. The preparing method is a reasonable matching method for improving the strength and toughness performance in the manner that the aspects of component improvement, short-procedure design in which casting blank reheating is omitted, casting blank core part quality improvement, structure micronization control and rolling schedule optimization are taken into comprehensive consideration, the technical skill potential of modern material machining is fully reflected, and the actions of grain refinement, controlled rolling, rapid cooling and other technology means on steel strengthening and toughening are brought into play. It is ensured that brittle phase crack initiation of products of moderate-thickness plates is reduced and a new structure form is obtained so as to prevent crack expanding, and the breakthrough of the short-procedure technology of direct hot rolling of the ultrahigh strength and toughness steel casting blank is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

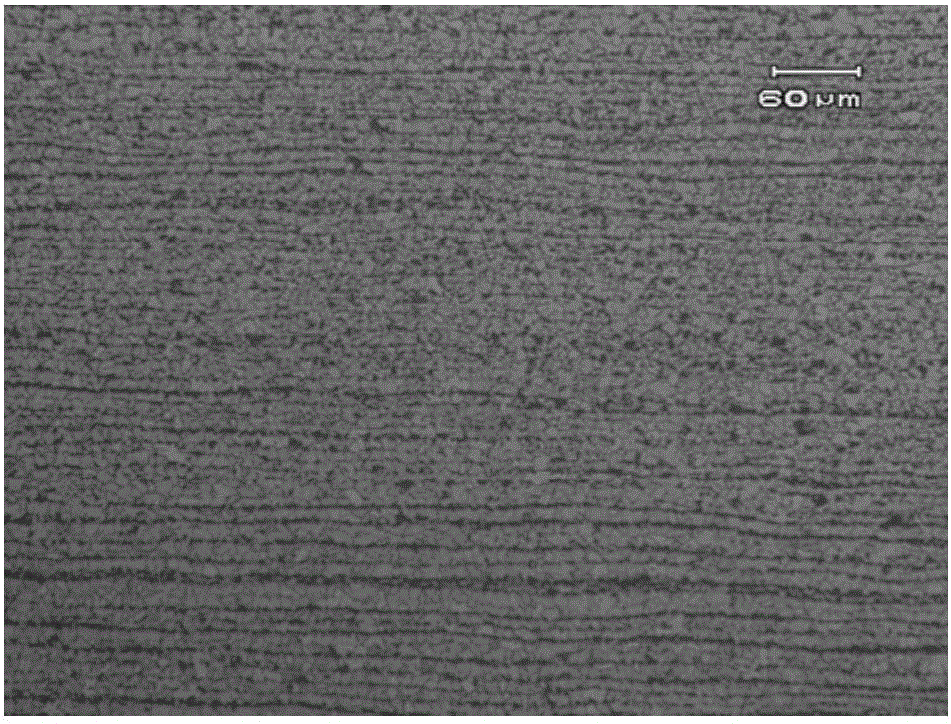

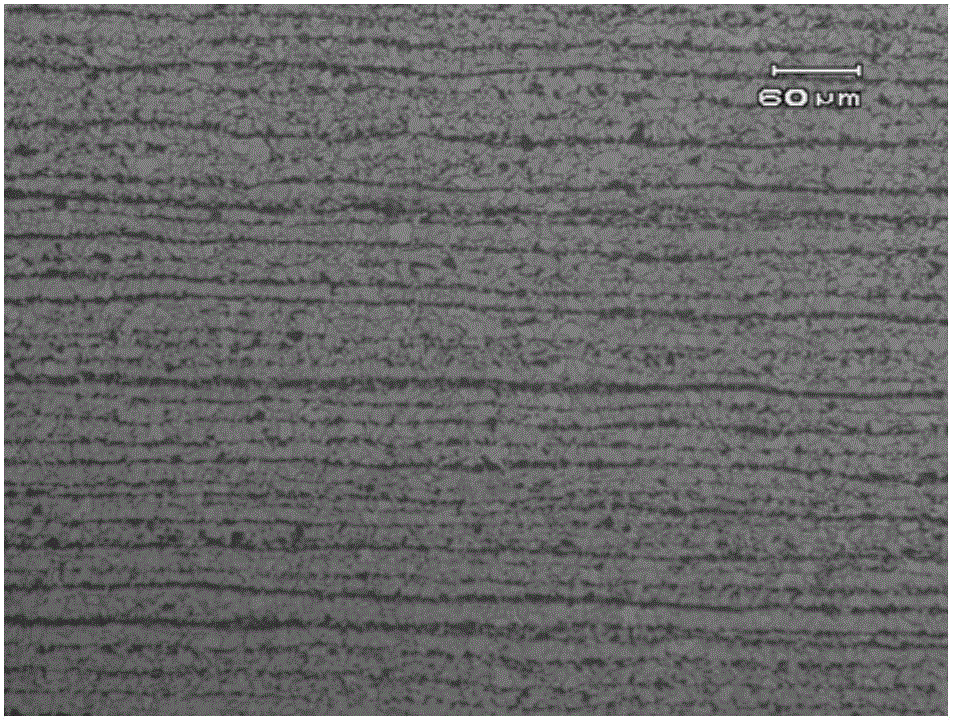

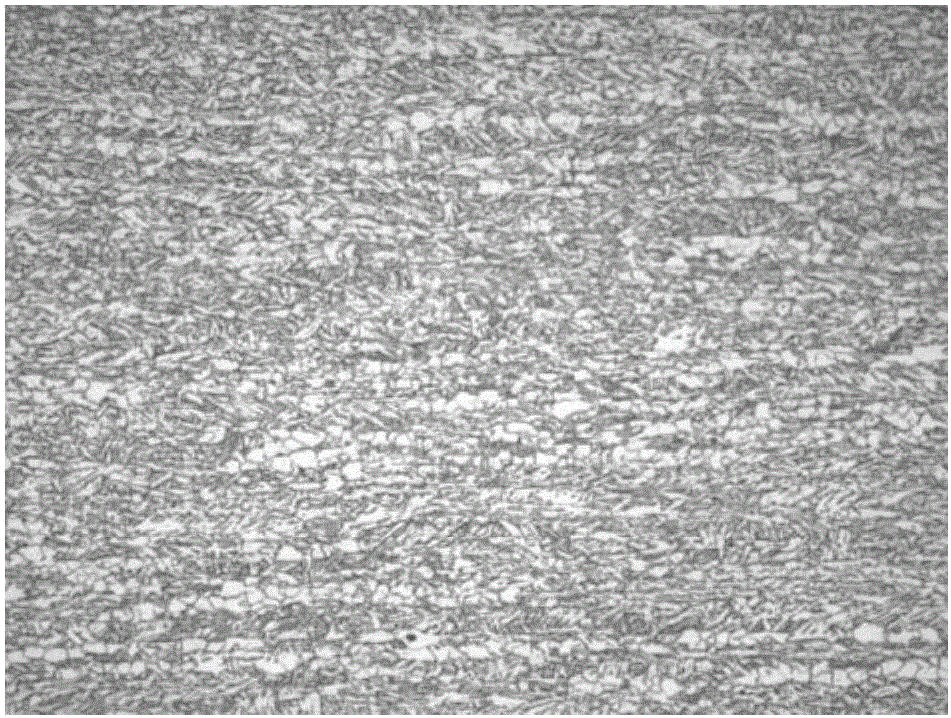

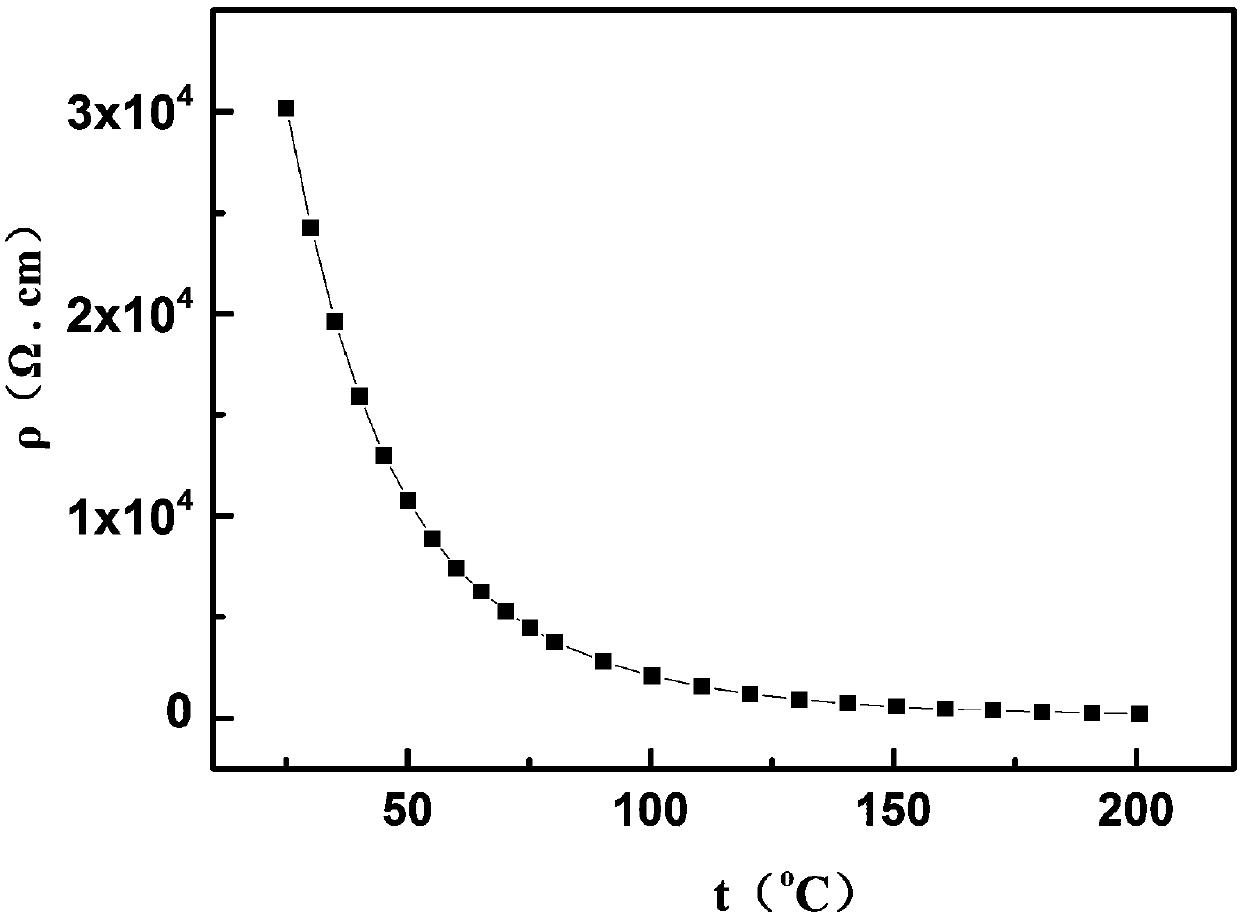

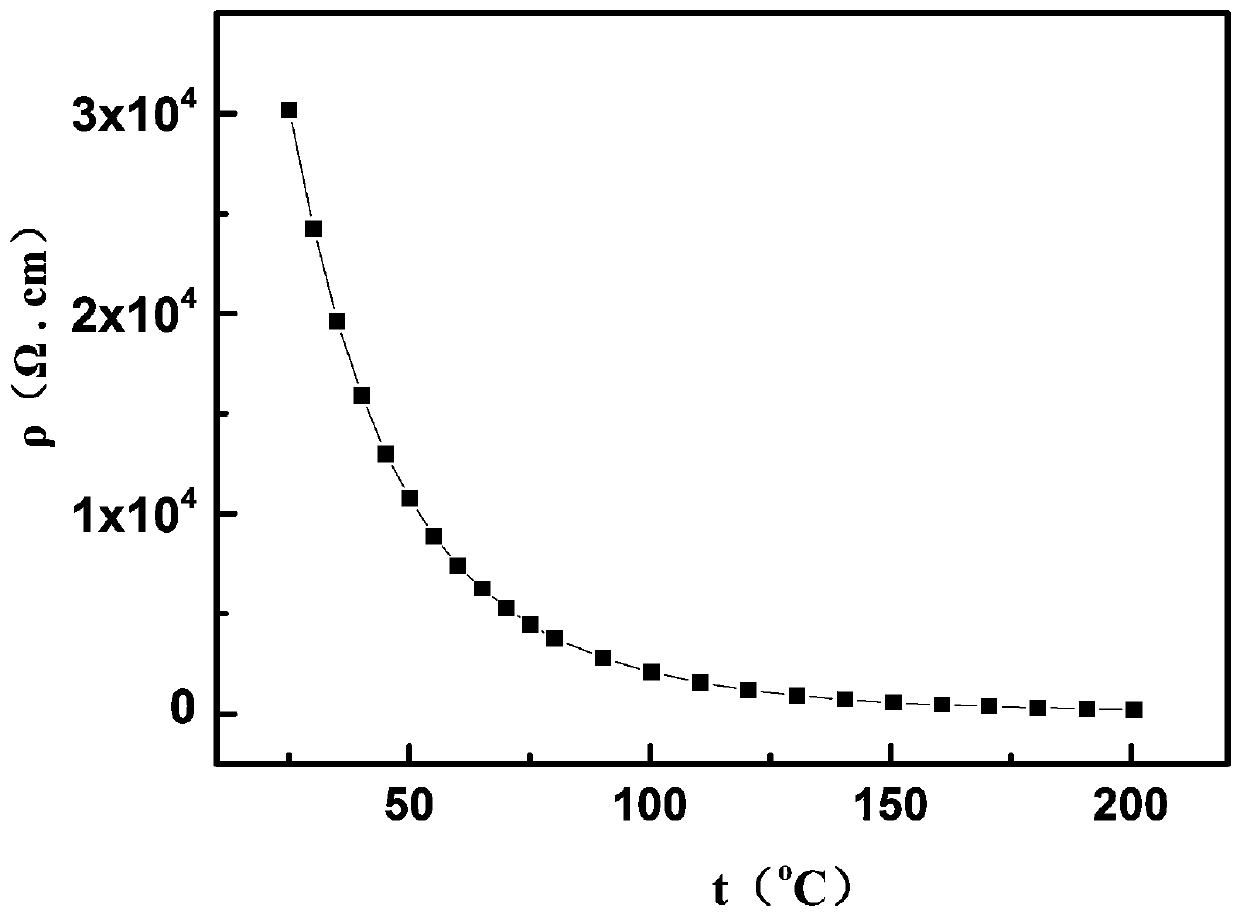

Method for preparing nano NTC (Negative Temperature Coefficient) thermal-sensitive material

ActiveCN108033774AImprove compactnessAvoid the disadvantage of losing a larger activityHigh resistanceNegative temperature

The invention discloses a novel method for preparing a nano NTC (Negative Temperature Coefficient) thermal-sensitive material. The novel method comprises the following steps: firstly, preparing nickel-manganese spinel powder of which the particle size is 50nm by using a sol-gel method; treating nano powder by using modes of tabletting and isostatic pressing so as to obtain a raw blank; sintering the raw blank for 0-60 seconds in a super-fast sintering furnace at 1000-1040 DEG C; further sintering for 5-20 hours in an air furnace at 850-950 DEG C, thereby finally obtaining the thermal-sensitiveNTC material of which the particle size is smaller than 500nm. The thermal-sensitive material has relatively high resistance and material constants.

Owner:NINGXIA UNIVERSITY

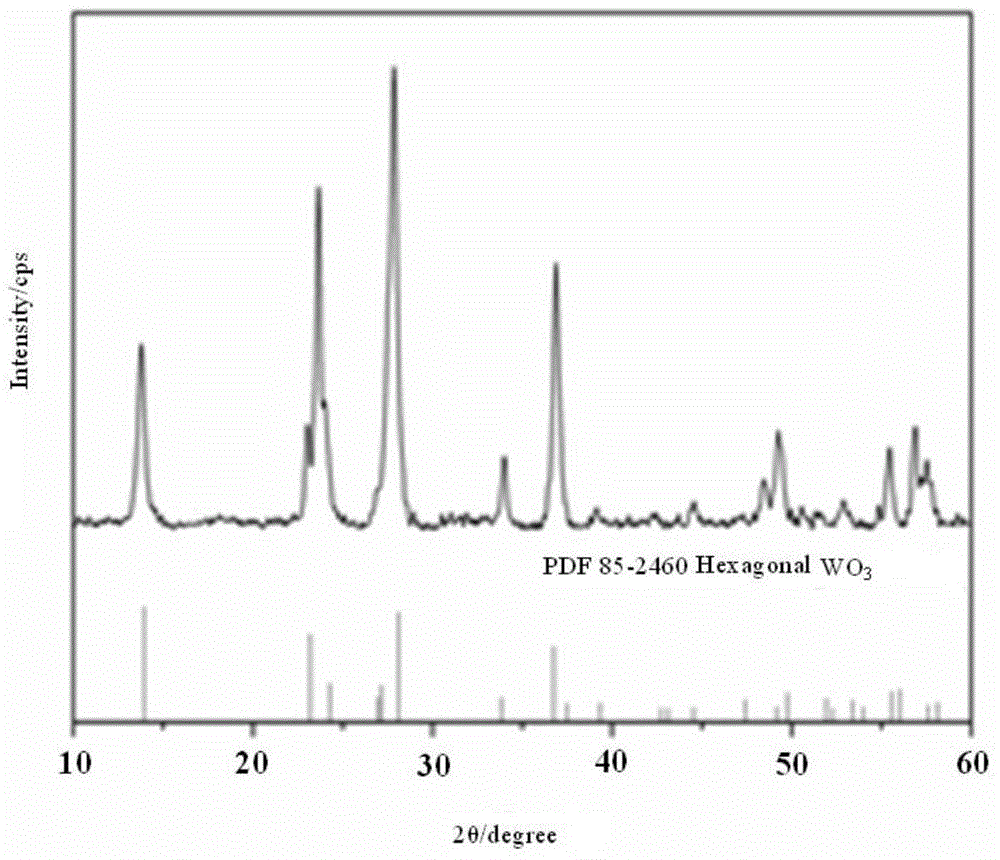

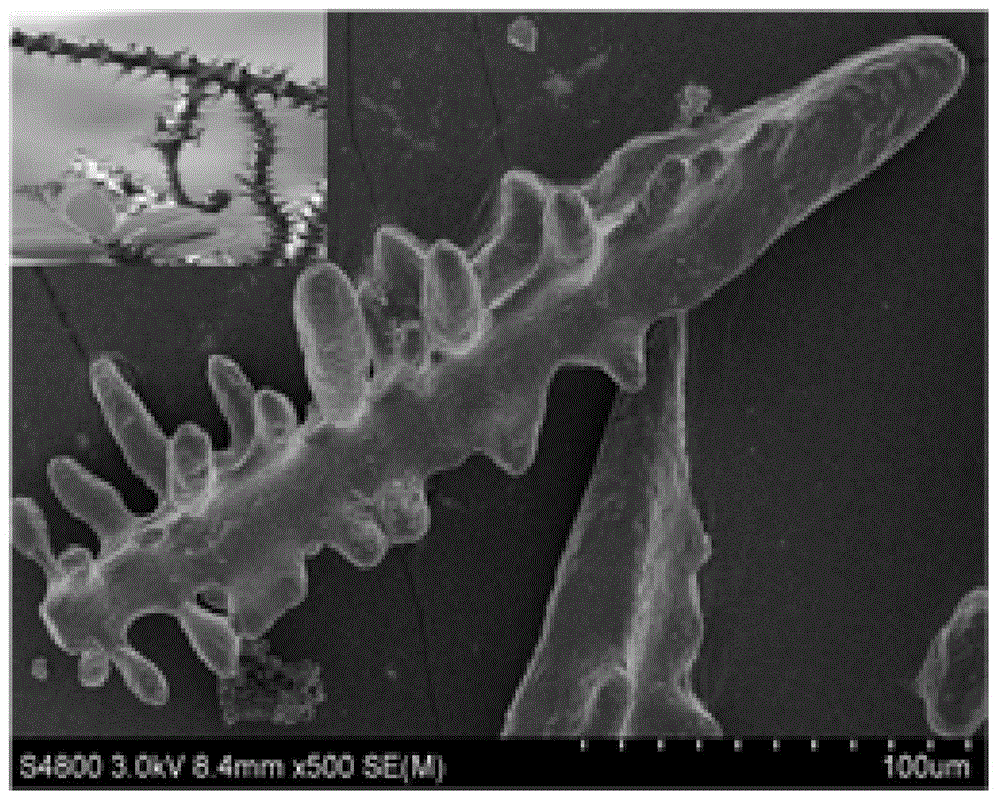

Preparation method of one-dimensional Euphorbia-milii-shaped WO3 microcrystal

ActiveCN104909409AAchieving controllable synthesisUniform shapeTungsten oxides/hydroxidesDispersityDistilled water

The invention provides a preparation method of a one-dimensional Euphorbia-milii-shaped WO3 microcrystal, which comprises the following steps: adding WCl6 into an isopropanol-distilled water mixed solvent, adding a polyoxyethylene-polyoxypropylene block copolymer into the solution to obtain a precursor solution, pouring the precursor solution into a hydrothermal kettle, and reacting while controlling the temperature at 80-240 DEG C under the pressure of 2-16 MPa for 4-36 hours, wherein the hydrothermal kettle is fixed in an homogeneous reaction instrument, and rotates around a fixed axis at the rate of 20-70 r / min in the insulating process; and taking out the product, washing and drying. The prepared one-dimensional Euphorbia-milii-shaped WO3 microcrystal has the advantages of high purity, favorable crystallinity, favorable dispersity, uniform size, uniform shape and obvious oriented growth.

Owner:安徽翰邦科技咨询有限公司

Microwave hydrothermal preparation method of NiTiO3 nano film

InactiveCN101775656AHigh purityImprove uniformityPolycrystalline material growthFrom normal temperature solutionsProcess equipmentTemperature control mode

The invention discloses a microwave hydrothermal preparation method of a NiTiO3 nano film, comprising the following steps: adding analytically pure nickel nitrate hexahydrate in ethanol to obtain a solution A; adding analytically pure tetrabutyl titanate, citric acid, water and acetylacetone in the solution A to obtain a solution B; placing a silicon substrate in hydrogen peroxide for ultrasonic oscillation and drying; pouring the solution B in a hydro-thermal reaction kettle, placing the silicon substrate in the hydro-thermal reaction kettle and immersing in film-coating liquid; sealing the hydro-thermal reaction kettle and placing in an MDS-8 type warm-pressing double control microwave hydro-thermal reactor; selecting a temperature controlling mode or a pressure controlling mode to react, and cooling naturally to the room temperature after reaction; and opening the hydro-thermal reaction kettle, taking the silicon substrate, respectively washing with deionized water, absolute ethyl alcohol or isopropanol, and drying to obtain the final product NiTiO3 nano film. The reaction can be finished in liquid phase in one time, post-treatment is avoided, the process equipment is simple, and the obtained film has high purity and favorable uniformity.

Owner:SHAANXI UNIV OF SCI & TECH

Anti-corrosive anti-impact wearable steel ball and preparation method thereof

The invention discloses an anti-corrosive anti-impact wearable steel ball. The anti-corrosive anti-impact wearable steel ball comprises, by weight, 0.7-0.75% of C, 11-13% of Cr, 1-1.2% of Si, 1.5-1.6% of Mn, 0.05-0.06% of B, 1-2% of Ni, 2.1-2.15% of Y, 0.04-0.06% of Ti, 0.03-0.05% of Cu, 0.01-0.03% of Co, 0.3-0.4% of Zr, 0.03-0.04% of Nb, less than or equal to 0.012% of P, less than or equal to 0.002% of S, and the balance Fe. The invention further discloses a preparation method of the anti-corrosive anti-impact wearable steel ball. The anti-corrosive anti-impact wearable steel ball is good in corrosion resistance, high in impact resistance and good in wear resistance.

Owner:ANHUI RUITAI NEW MATERIALS TECH

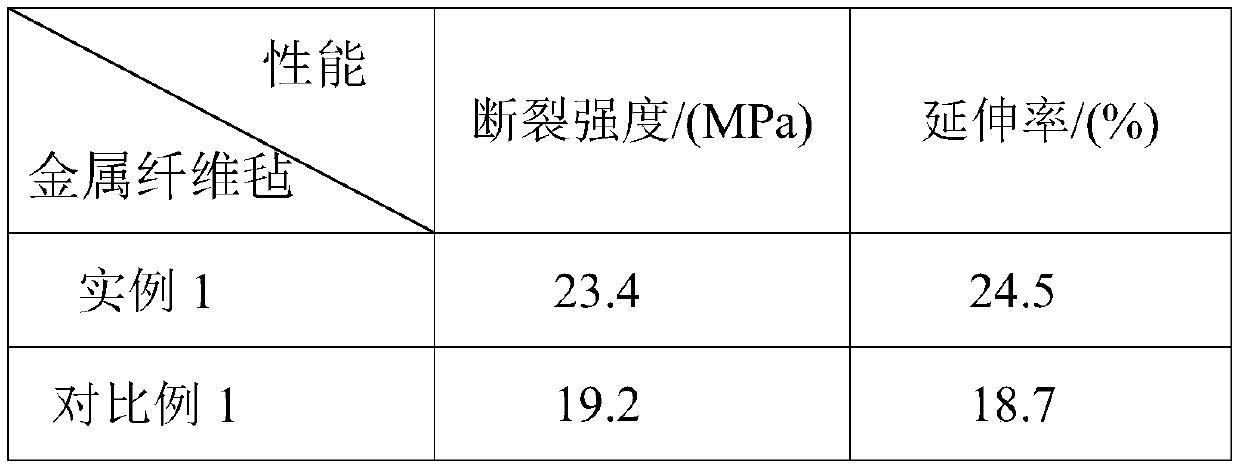

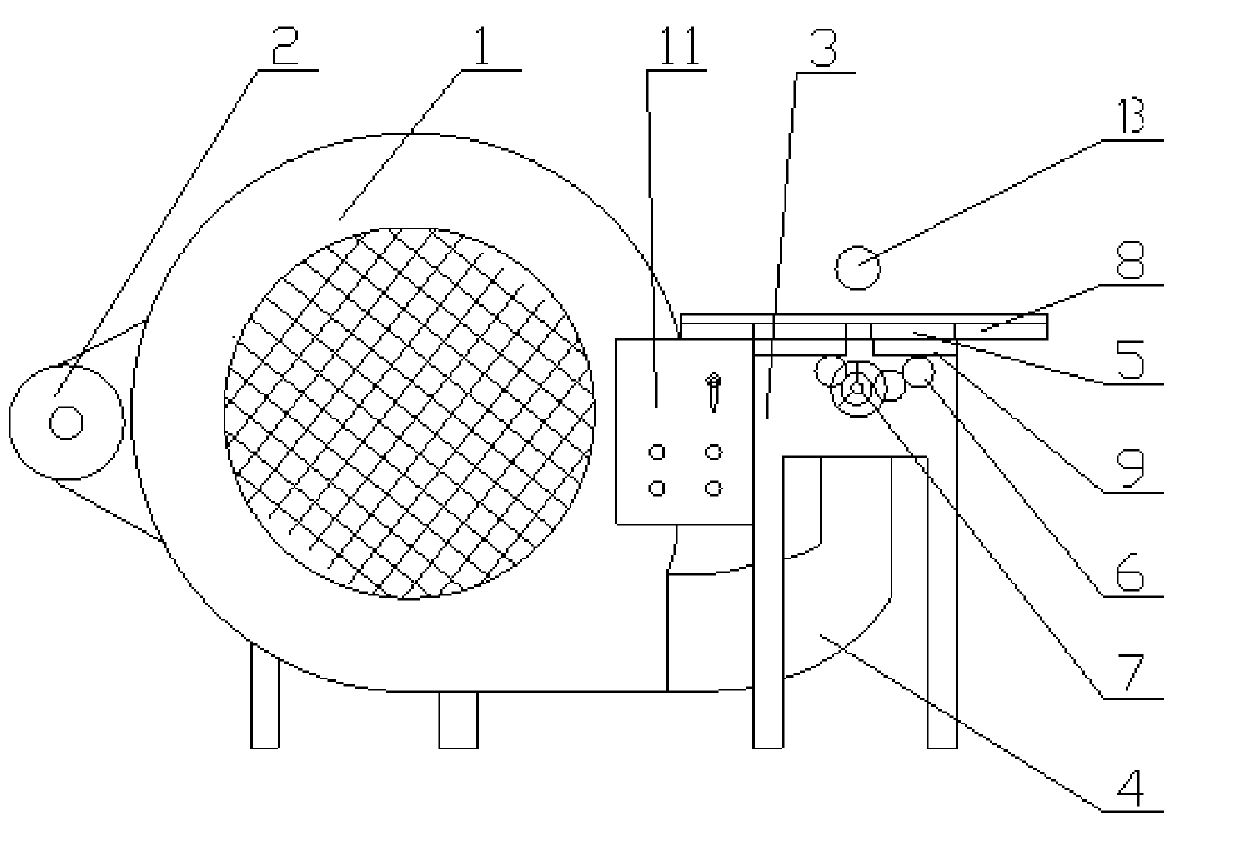

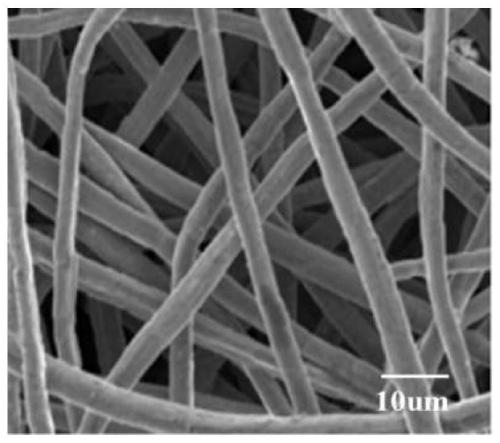

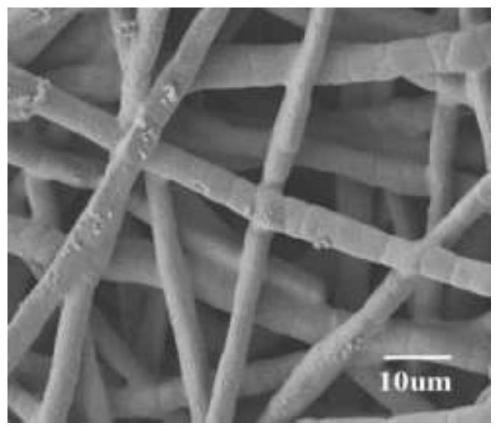

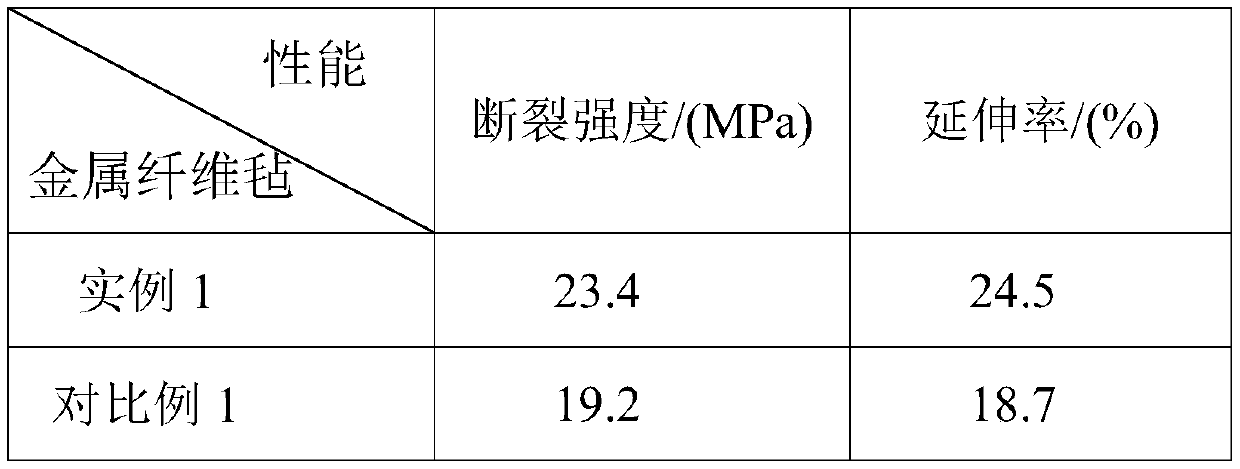

Preparation method of high-precision metal fibrofelt for high-temperature gas dust removal

ActiveCN110787534AImprove mechanical propertiesImprove folding resistanceFiltration separationMetal fiberCrude fibre

The invention discloses a preparation method of a high-precision metal fibrofelt for high-temperature gas dust removal. The preparation method comprises the following steps: firstly, paving crude fibers into a crude fibrofelt blank by adopting felt paving equipment; performing vacuum high-temperature sintering treatment on the crude fibrofelt blank by adopting a high-temperature vacuum furnace, and cooling to obtain a crude fiber sintered felt; paving superfine fibers into a superfine fibrofelt blank by adopting the felt paving equipment, and then flattening the superfine fibrofelt blank by adopting a flattening machine so as to obtain a flat superfine fibrofelt blank; stacking the flat superfine fibrofelt blank and the crude fiber sintered felt, covering the surface of an obtained felt with a non-metal high-temperature-resistant material, then feeding an obtained felt blank into a high-temperature vacuum furnace for vacuum high-temperature sintering treatment, taking out the felt blank after cooling, and flattening the felt blank to obtain the high-precision metal fibrofelt. The high-precision metal fibrofelt prepared by the method is good in mechanical property, folding resistance and binding force of felt layers.

Owner:西安菲尔特金属过滤材料股份有限公司

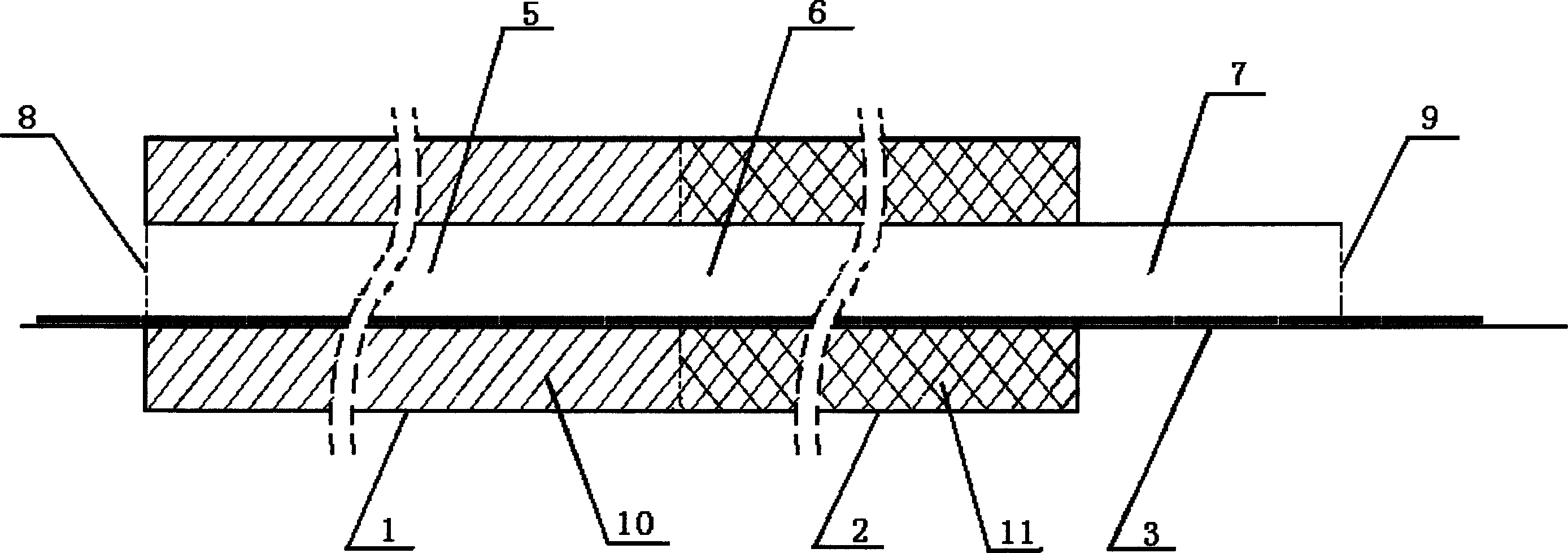

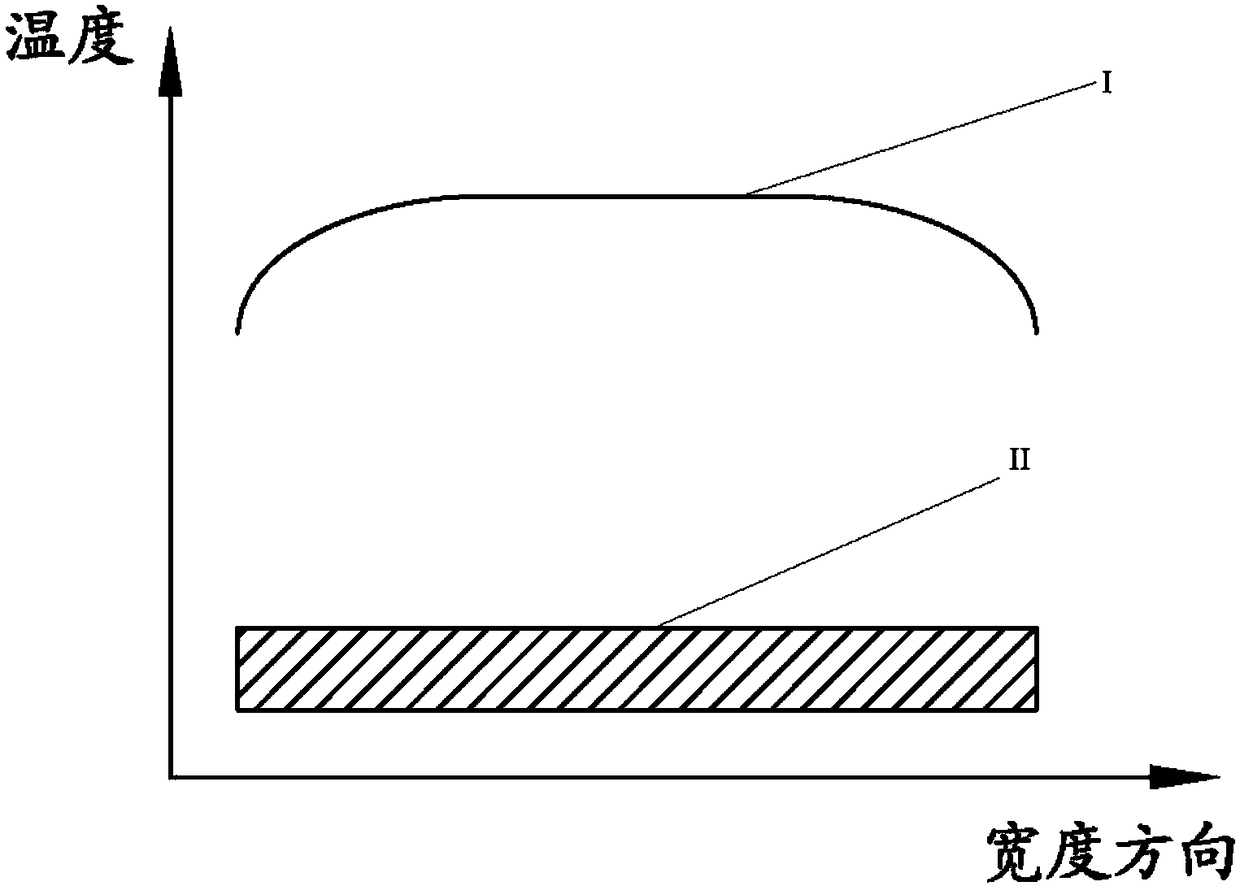

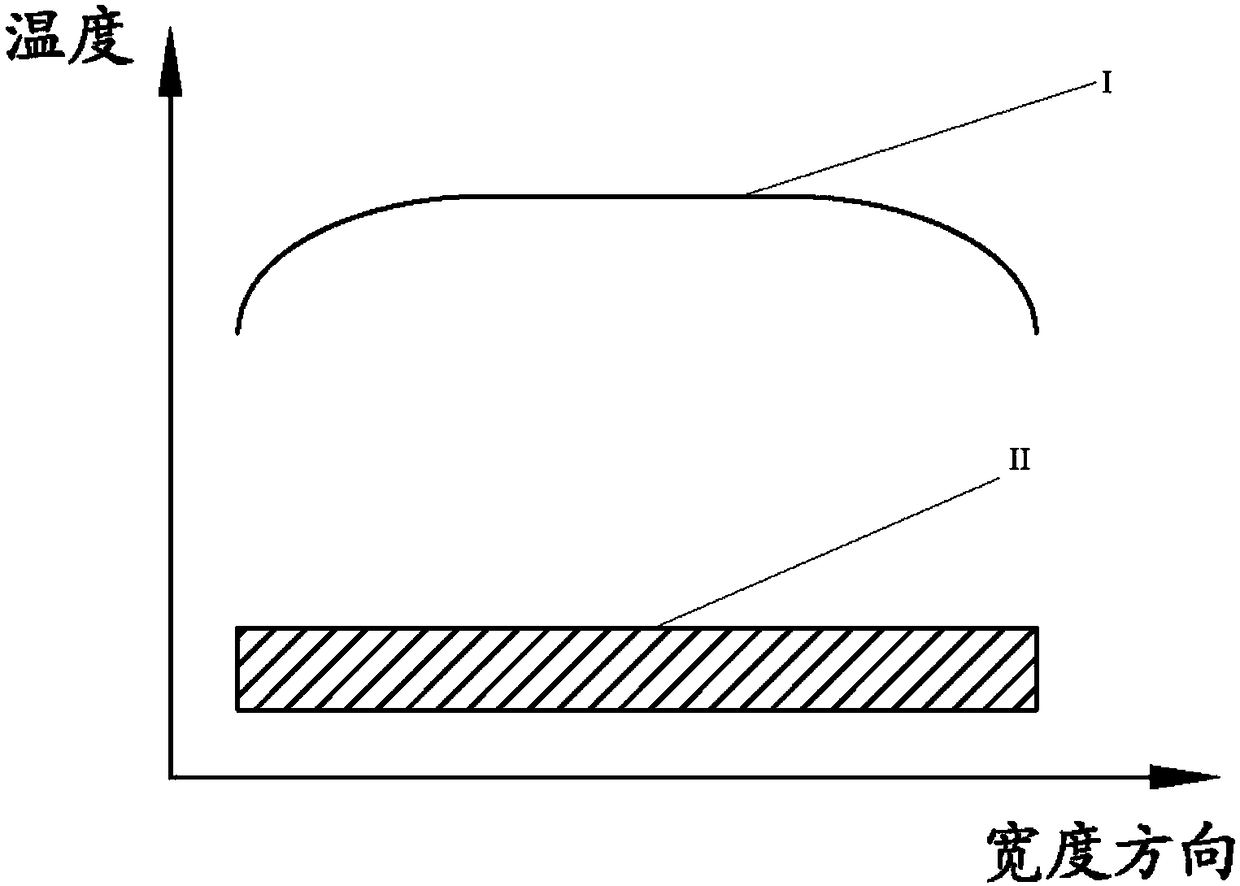

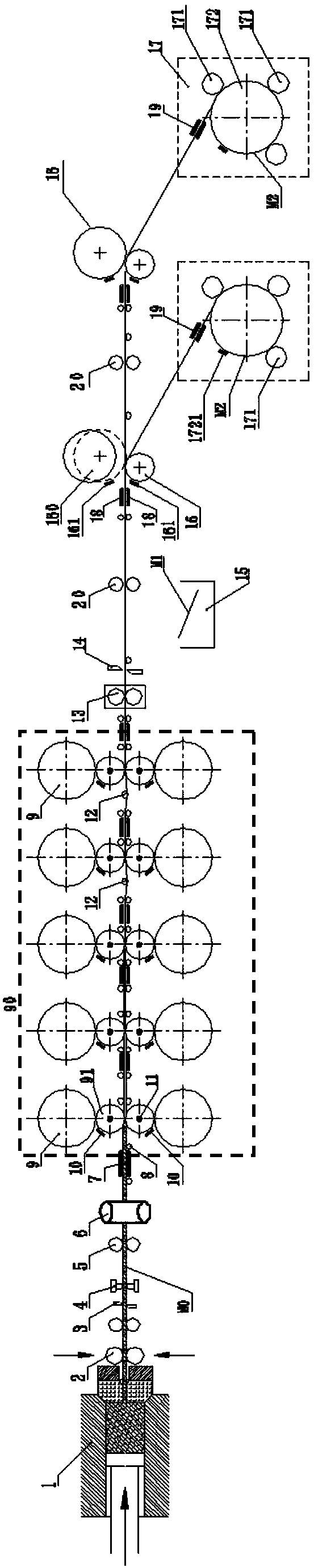

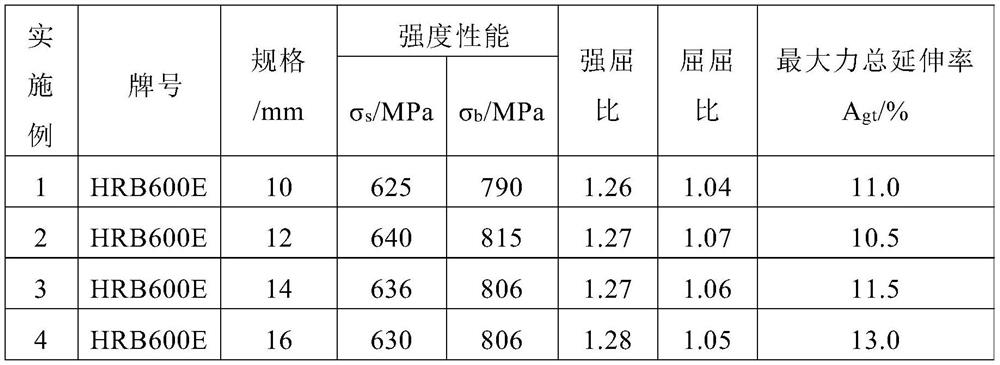

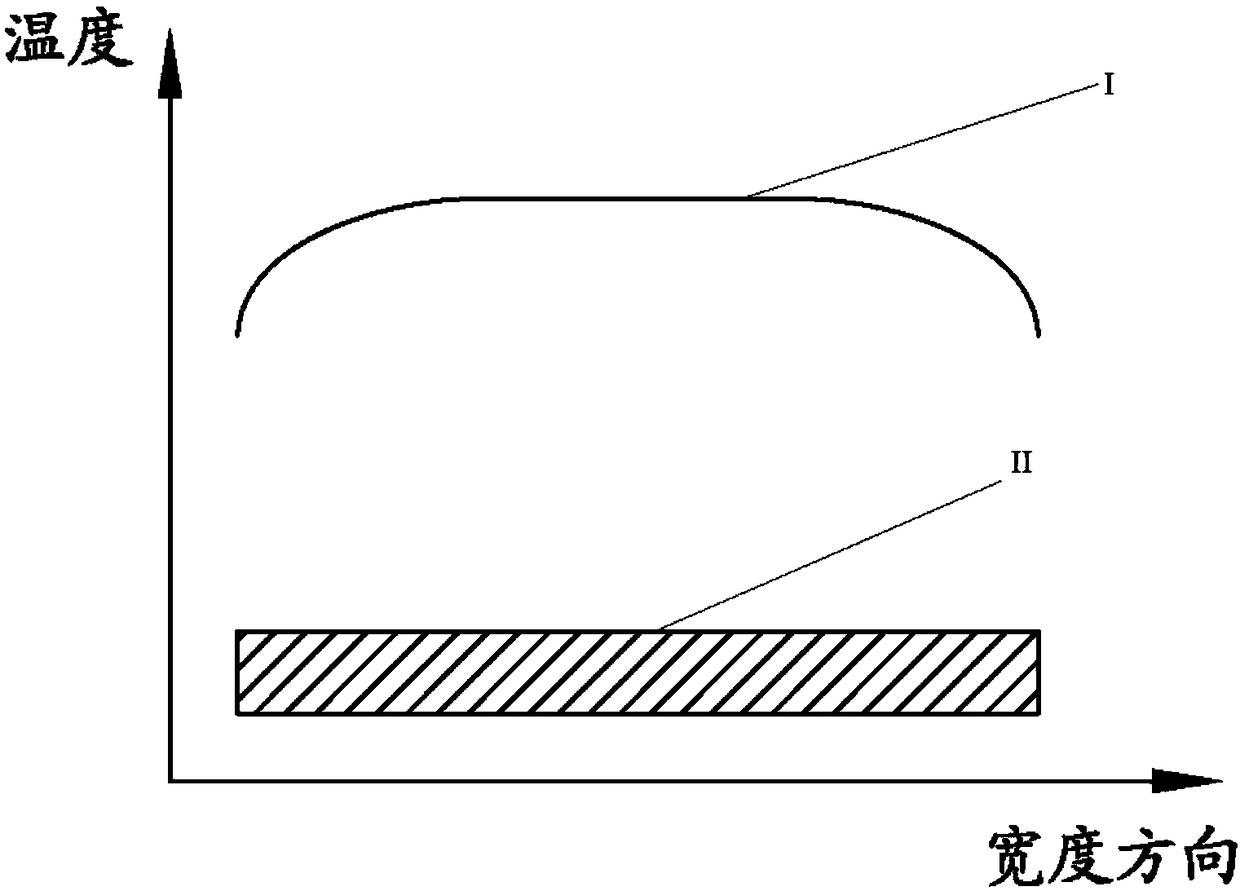

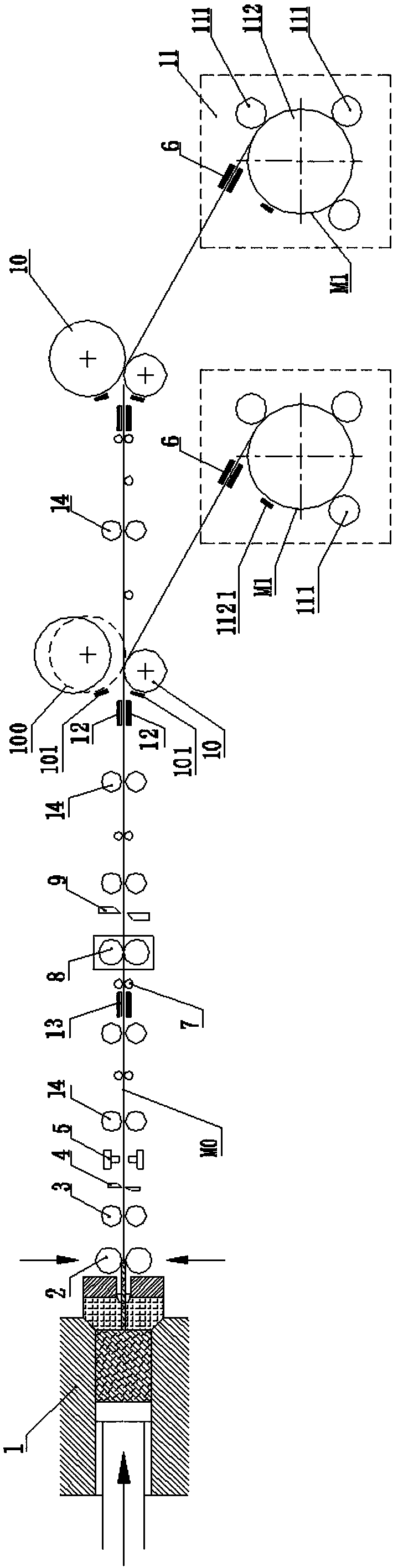

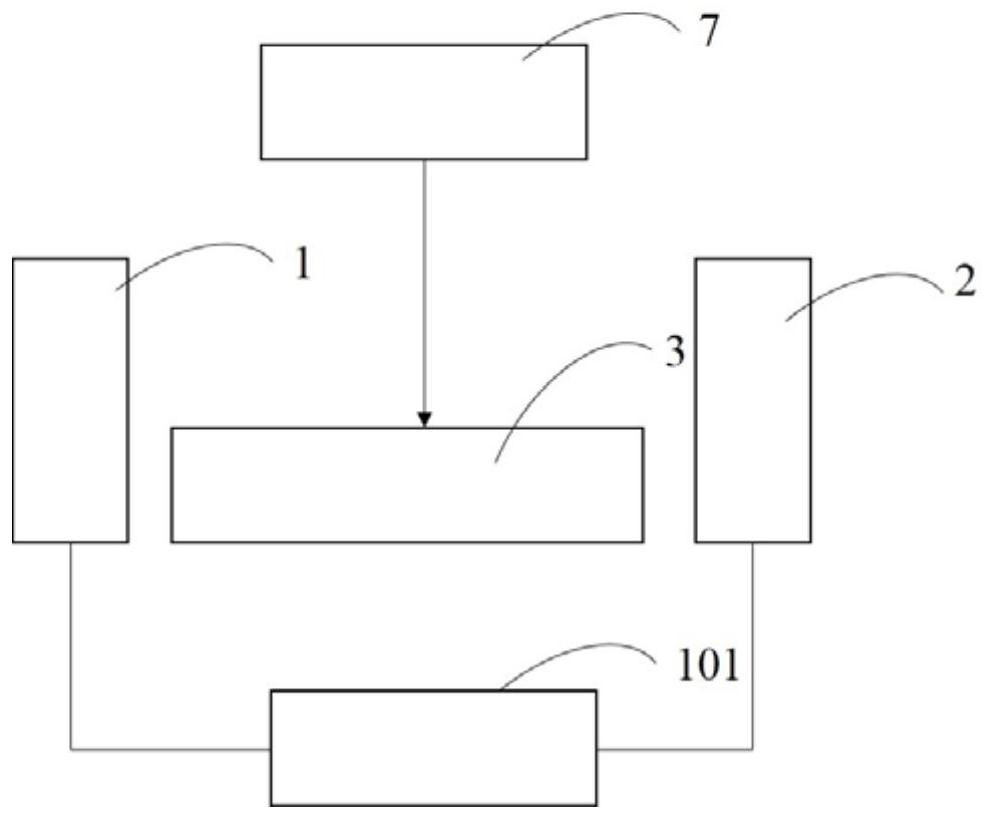

Production line for producing magnesium alloy products by temperature-control continuous rolling

InactiveCN108787745APrecise temperature controlImprove product qualityTemperature control deviceMetal rolling arrangementsProduction lineTemperature control

The invention discloses a production line for producing magnesium alloy products by temperature-control continuous rolling. The production line comprises a multi-frame temperature control continuous rolling machine, roller surface heating devices, heat conveying rollers, plate strip heating devices and a control unit, wherein the multi-frame temperature control continuous rolling machine is provided with multiple frames; rollers are correspondingly arranged on all the frames; the roller surface heating devices are arranged corresponding to all the rollers for heating all the rollers; the heatconveying rollers are arranged at the upstream parts of the frames corresponding to the frames; the plate strip heating devices are arranged at the upstream parts of the frames corresponding to the frames; and the control unit is connected with the roller surface heating devices, the heat conveying rollers and the plate strip heating devices for controlling the heating process. The production lineproduce rolled magnesium alloy products by adopting a whole-process temperature control continuous rolling mode, in particular thin magnesium plates, pieces or magnesium rolls; the continuous precisetemperature control rolling is performed aiming at plastic deformation characteristics of magnesium alloy materials in the whole production process; and through whole-process temperature control continuous rolling, the mode of repeated low-temperature heat feeding of the magnesium alloy materials in traditional intermittent multi-pass rolling is prevented, so that the energy consumption is saved.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

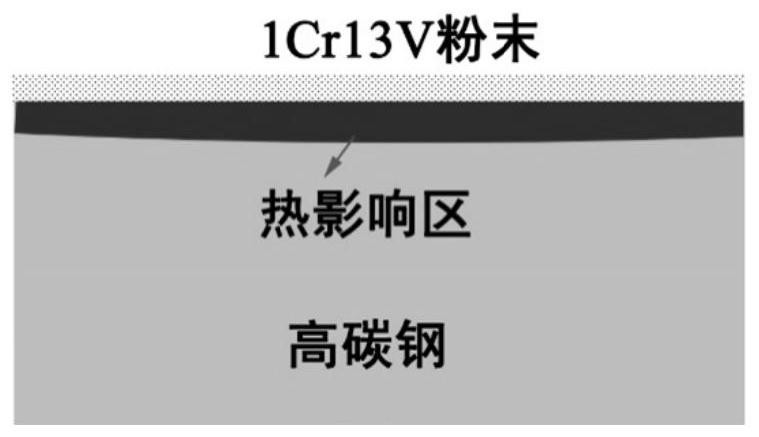

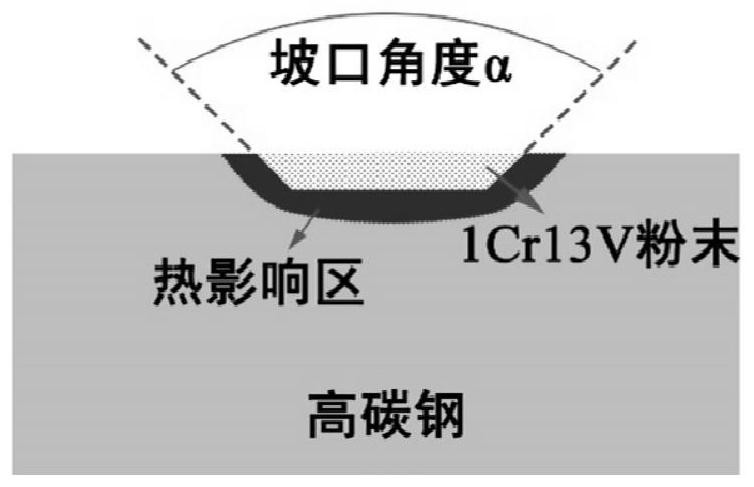

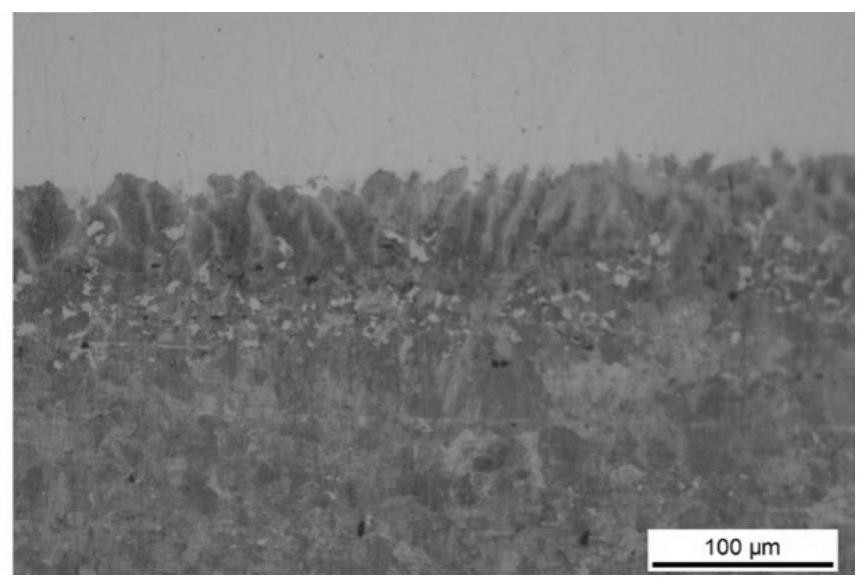

Laser surface strengthening method for improving surface quality and performance of high-carbon steel component

InactiveCN111996525AAvoid grain coarseningReduced tendency to overheatMetallic material coating processesCarbon steelSurface processing

The invention relates to the field of laser surface processing and manufacturing, in particular to a laser surface strengthening method for improving the surface quality and performance of a high-carbon steel component, which comprises the following steps of: integrally paving a layer of 1Cr13V stainless steel powder on the high-carbon steel component, and compacting the powder; carrying out preheating treatment on the high-carbon steel component, and after the preheating treatment is finished, melting the pre-laid powder by adopting a laser cladding process to obtain a deposition layer; and repeating the steps until the preset height requirement is met. The 1Cr13V stainless steel powder has the obvious cost advantage, the cladding forming performance of the powder can be improved by adjusting the element content, namely reducing the C element content and adding a small amount of V element, cracking of a cladding area is effectively prevented, and good metallurgical bonding can be formed between the cladding area and the high-carbon steel component through the laser cladding technology.

Owner:BEIHANG UNIV

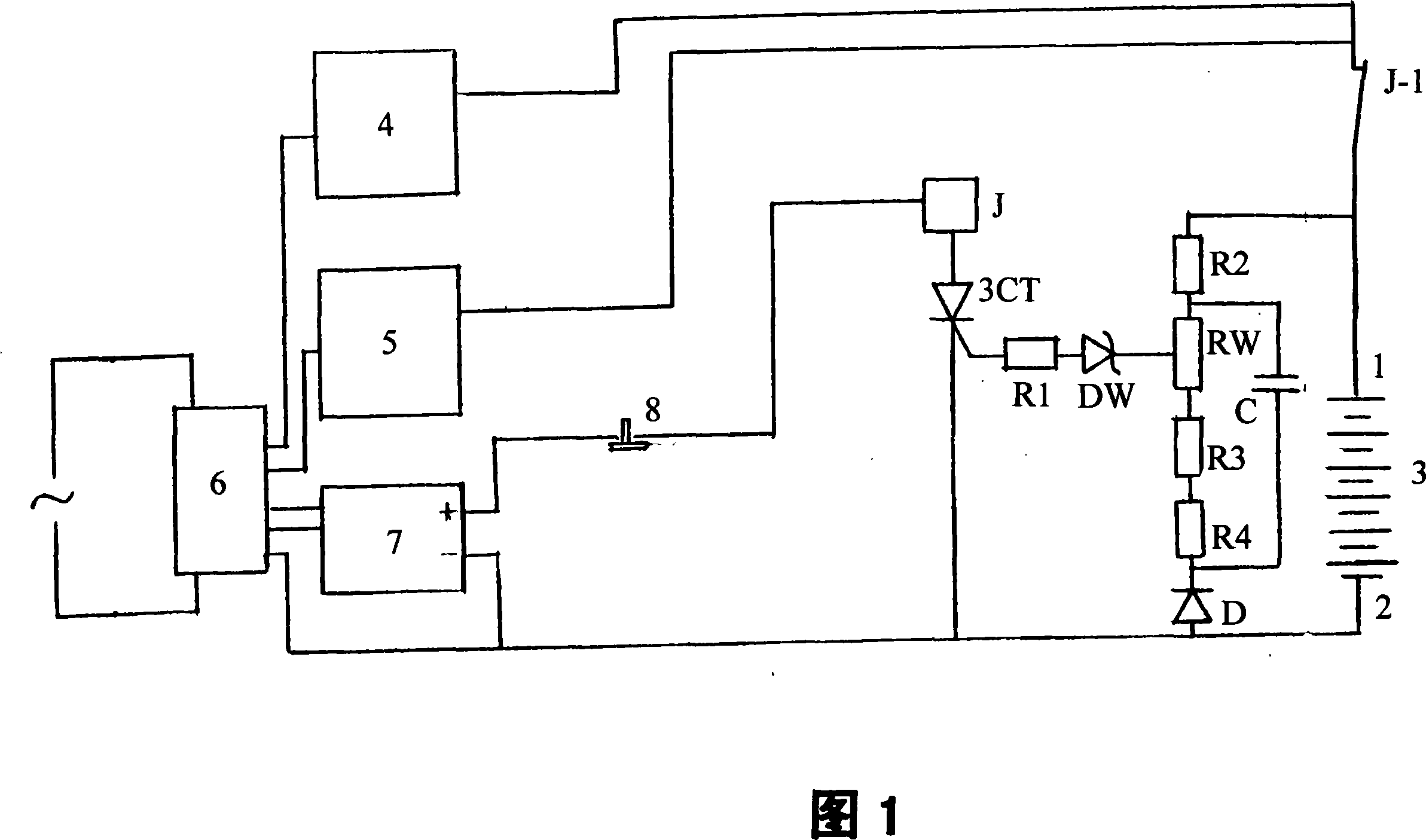

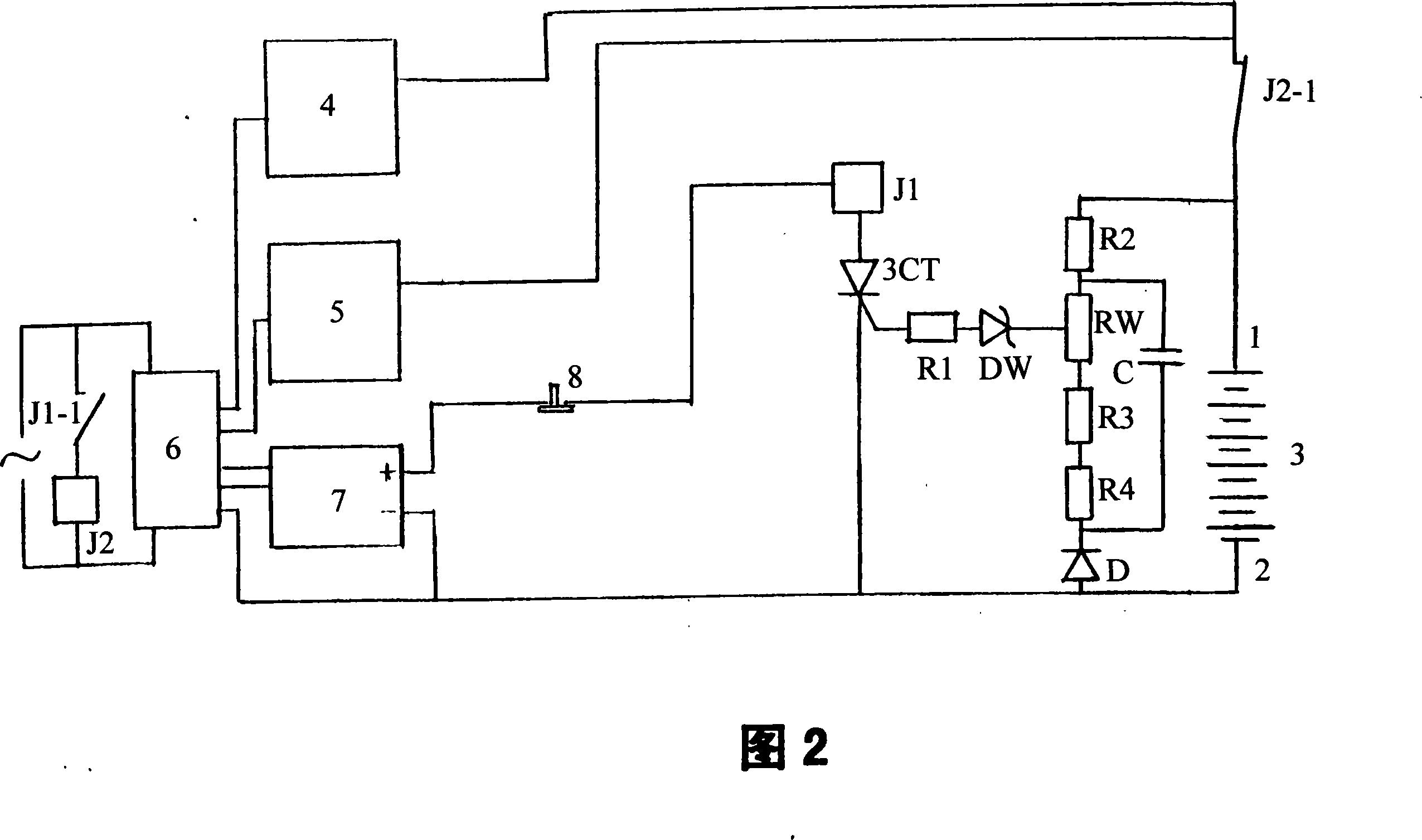

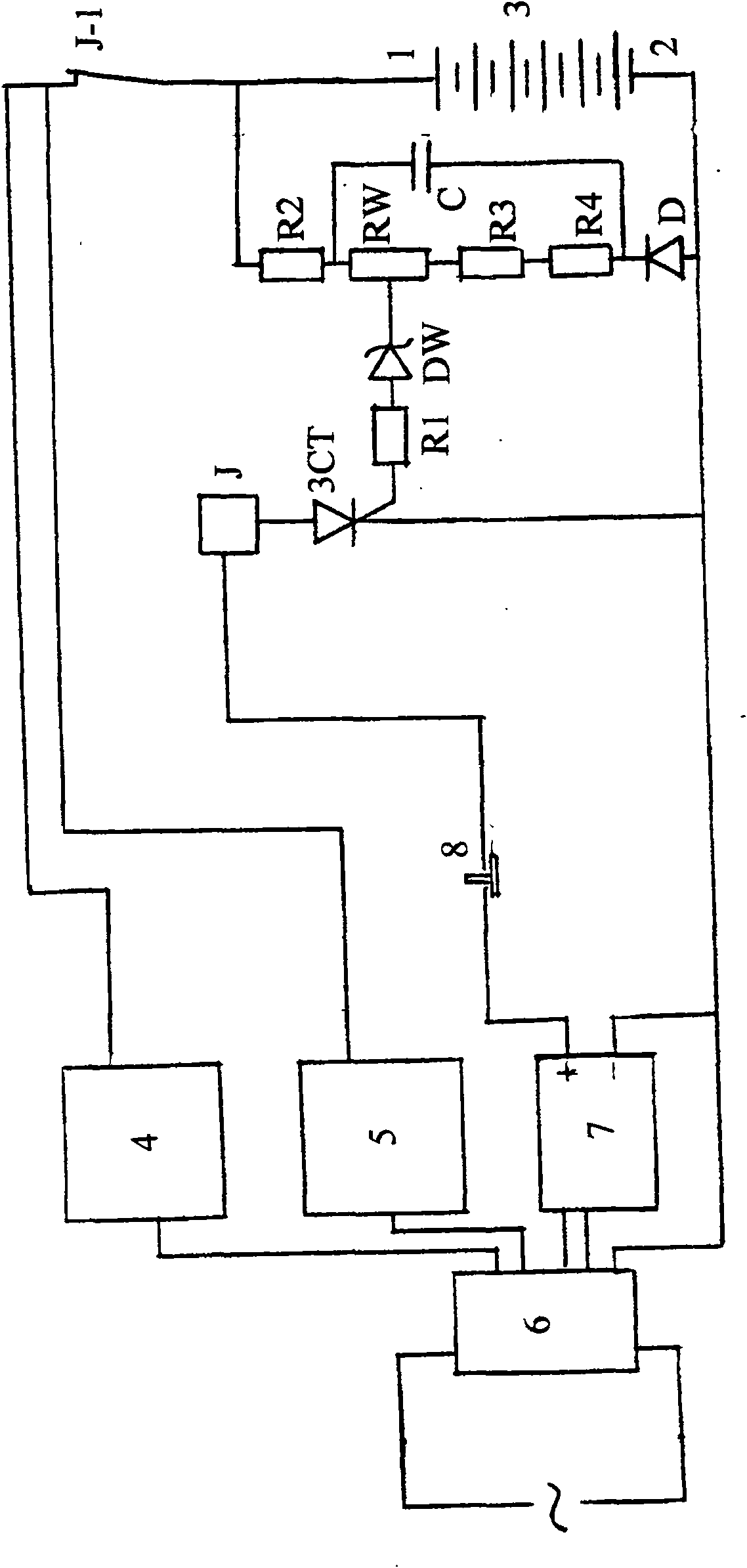

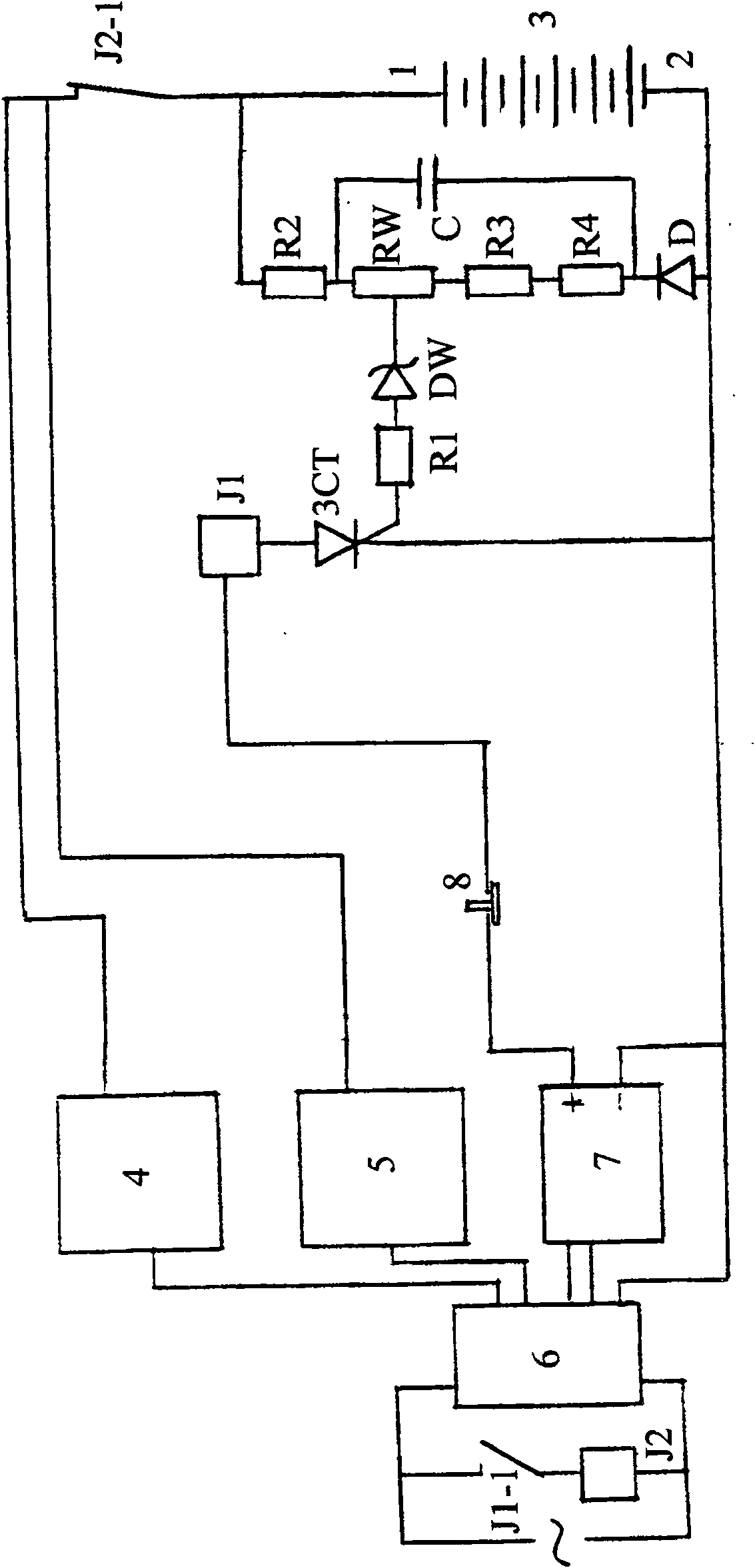

Automatic stop charging control circuit of positive and negative combination pulse charge machine

InactiveCN101227093APrevent overchargingExtended service lifeBatteries circuit arrangementsEmergency protective circuit arrangementsCapacitanceSilicon-controlled rectifier

The invention belongs to the accumulator charging controlling field, wherein a diode D anode of an automatic charging stopping controlling circuit of a positive and negative combination impulse charging device is connected with a charging negative electrode, a second electric resistance R2, a variable resistance RW, a third electric resistance R3 and a fourth electric resistance R4 are connected in series in turn between a charging positive electrode and the diode D cathode, one end of a relay J or a first relay J1 is connected with a positive pole of a constant voltage power supply, the other end is connected with an anode of a silicon controlled rectifier 3CT, a cathode of the silicon controlled rectifier 3CT is respectively connected with a negative pole of the constant voltage power supply and the charging negative electrode, a controlling electrode is connected with the middle end of the variable resistance RW through the first electric resistance R1 and a constant voltage diode DW in turn, one end of a capacitance C is connected between the second resistance R2 and the variable resistance RW, the other end is connected between the fourth electric resistance R4 and the diode D cathode, a normally-closed contact J-1 or J-2 of the relay J or a second relay J2 is connected in series on the circuit that the charging anode is connected with one input end of the positive and negative impulse charging circuit, and a normally-closed contact J1-1 of the first relay J1 is connected with the second relay J2 on two input circuits of an alternating current power supply. The invention solves the technical problem that an accumulator is prevented from over charging.

Owner:陈荣森 +1

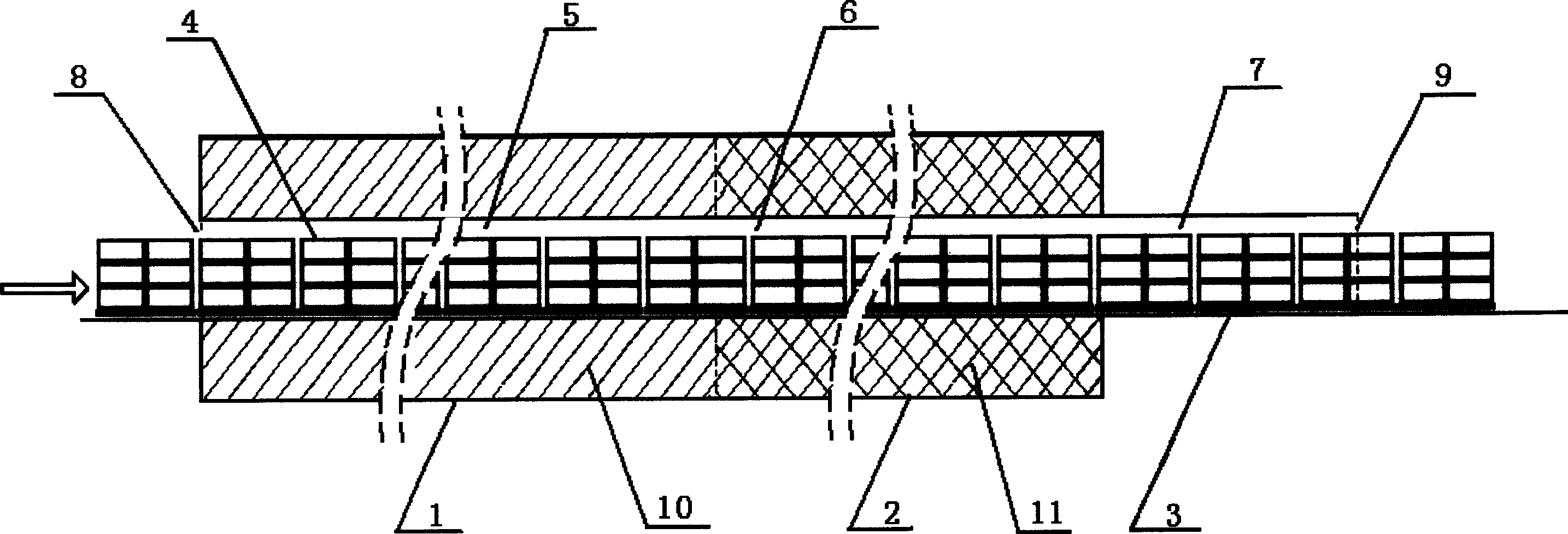

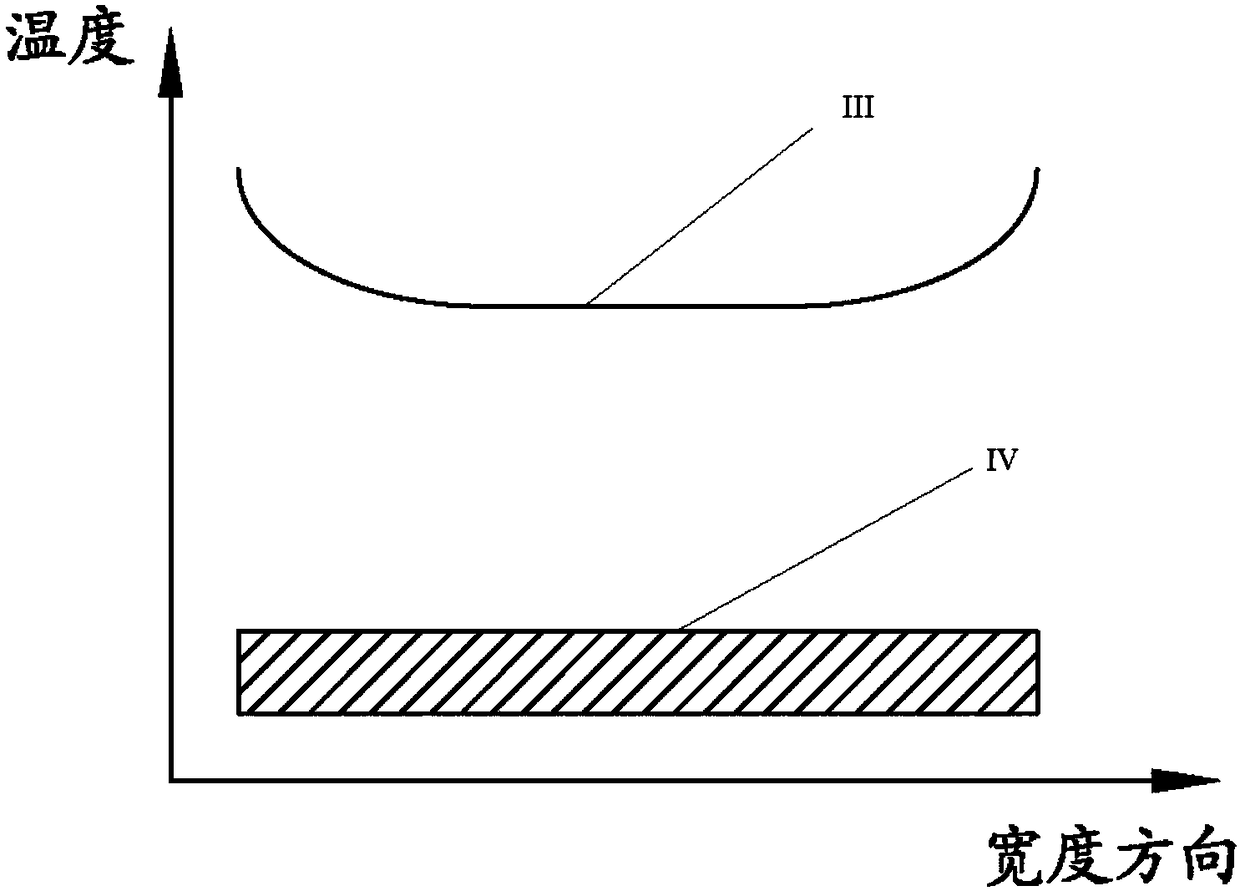

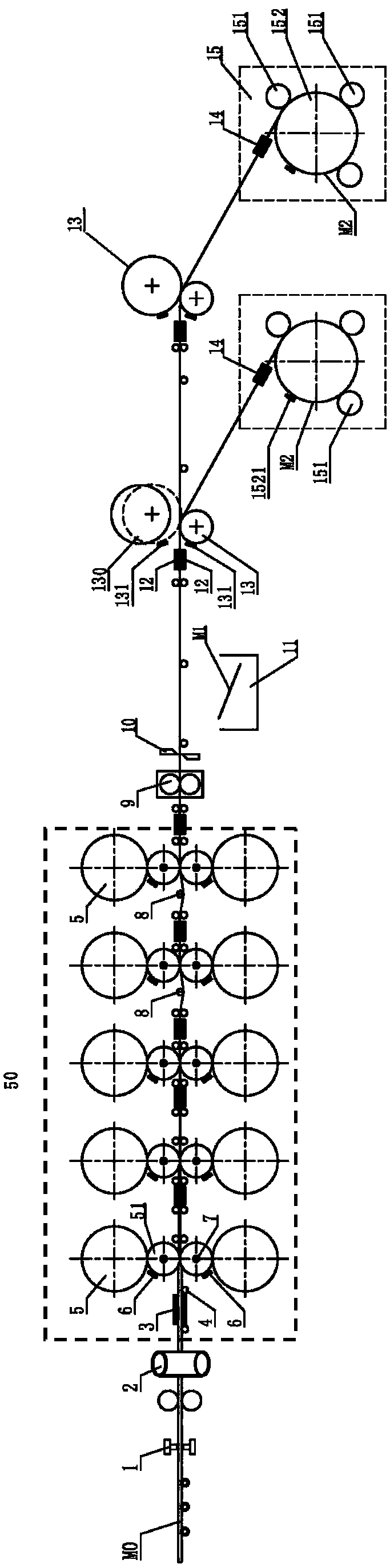

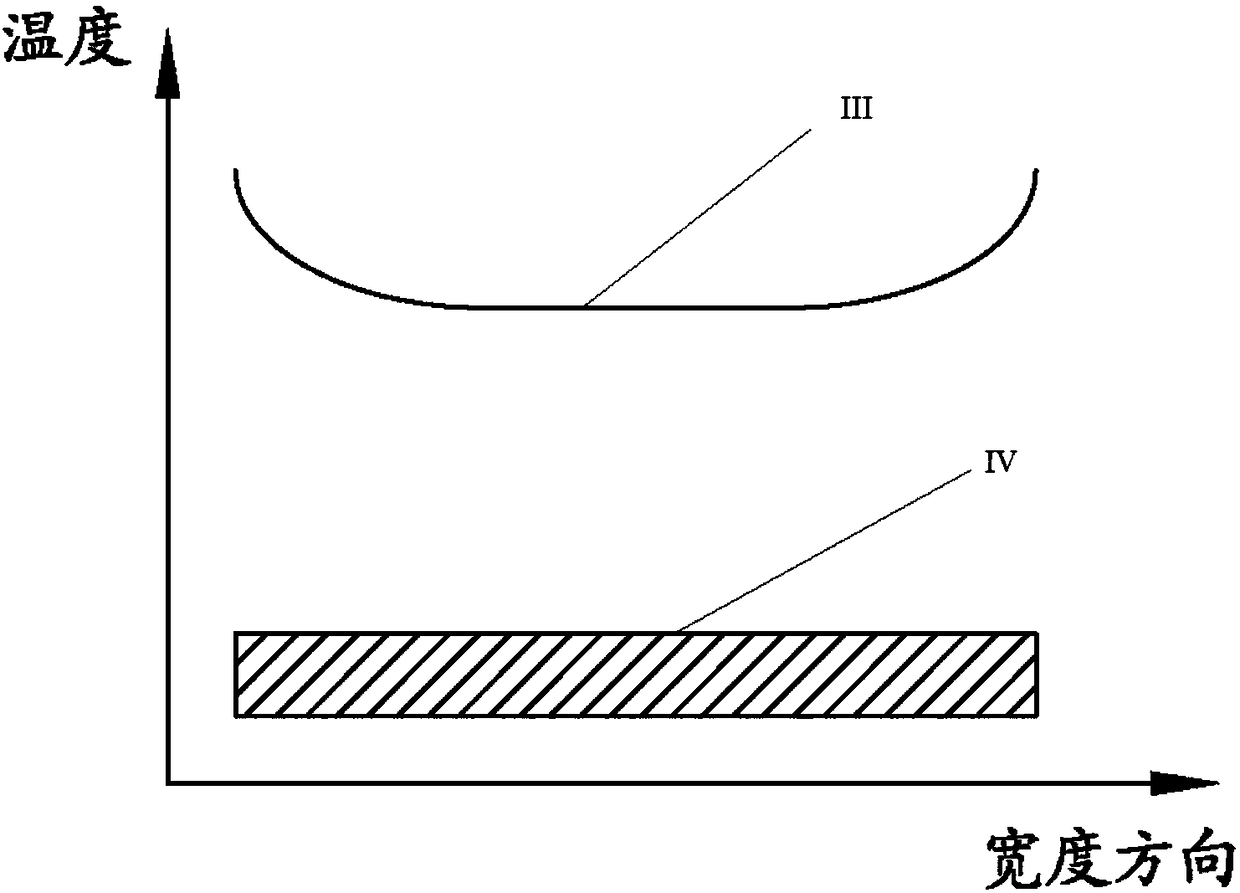

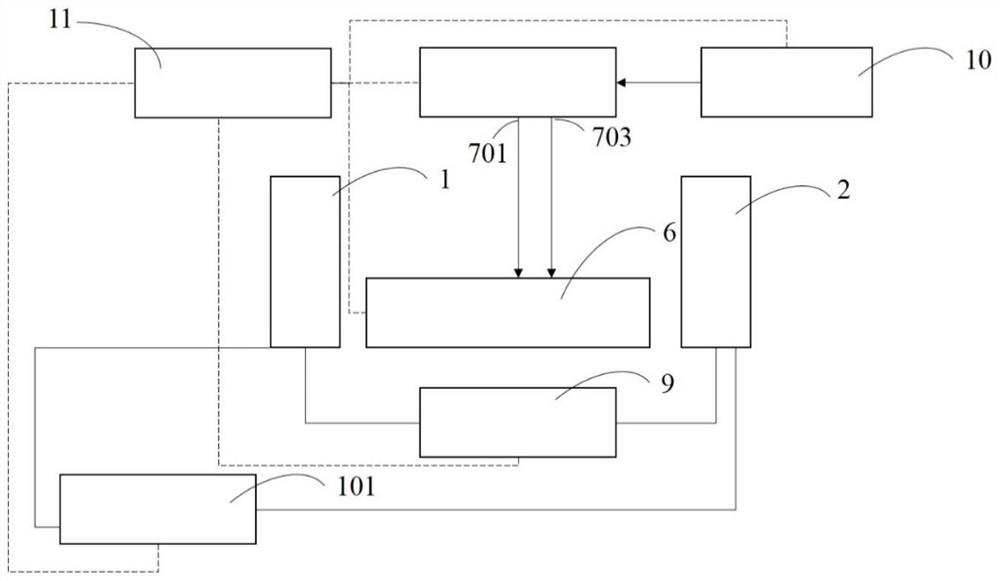

Production line for continuous-extrusion, continuous-rolling and temperature-control production of magnesium alloy products

ActiveCN108787746APrecise temperature controlSmall footprintTemperature control deviceMetal rolling arrangementsTemperature controlProduction line

The invention discloses a production line for continuous-extrusion, continuous-rolling and temperature-control production of magnesium alloy products. The production line comprises an extruder, an alignment pinch roll arranged at the outlet position of the extruder, an alignment pinch roll face heating device heating the roll face of the alignment pinch roll, a tension pinch roll arranged at the downstream position of the alignment pinch roll, a tension pinch roll face heating device heating the roll face of the tension pinch roll, a multi-rack temperature control continuous rolling mill, roller face heating devices, heat conveying rollers, plate strip heating devices and a control unit, wherein the multi-rack temperature control continuous rolling mill is provided with multiple racks, andthe racks are correspondingly provided with rollers; the roller face heating devices correspond to the rollers so as to heat the rollers; the heat conveying rollers correspond to the racks and are arranged at the upstream positions of the racks; the plate strip heating devices correspond to the racks and are arranged at the upstream positions of the racks; and the control unit is connected with the alignment pinch roll face heating device, the tension pinch roll face heating device, the roller face heating devices, the heat conveying rollers and the plate strip heating devices so as to control the heating process of the alignment pinch roll face heating device, the tension pinch roll face heating device, the roller face heating devices, the heat conveying rollers and the plate strip heating devices.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

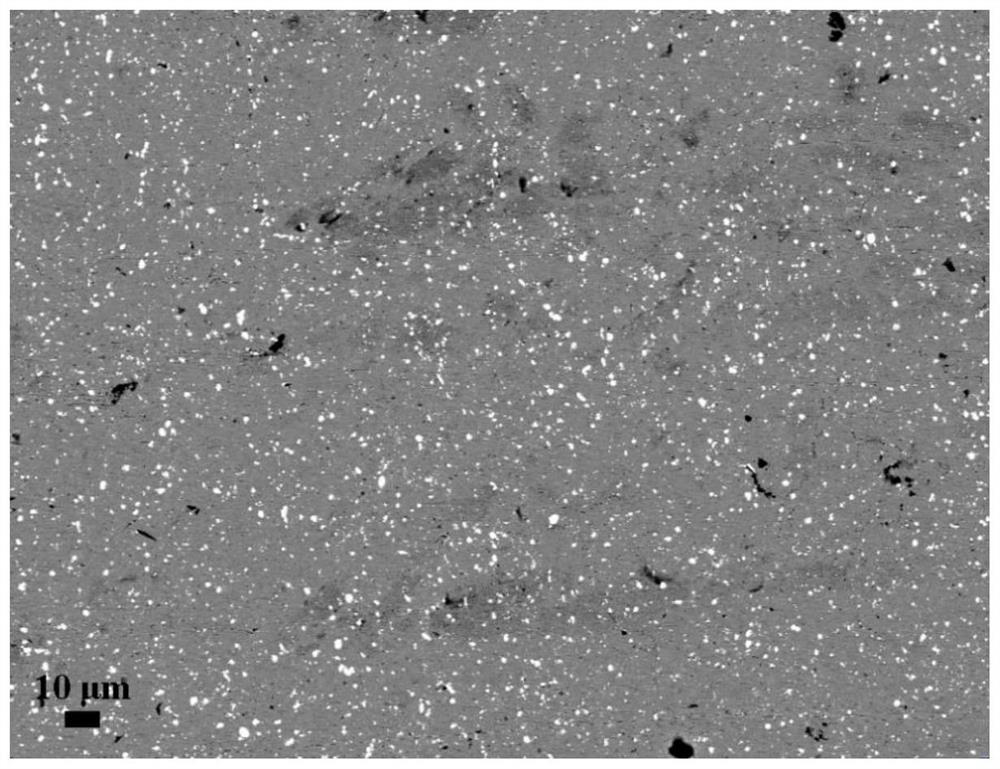

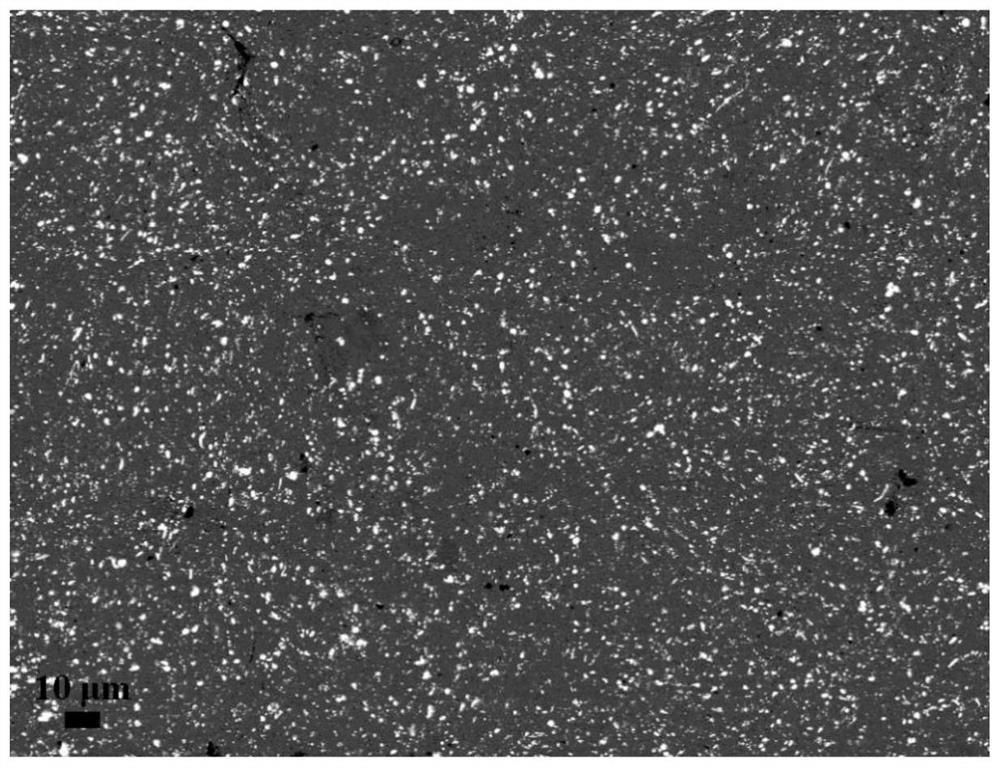

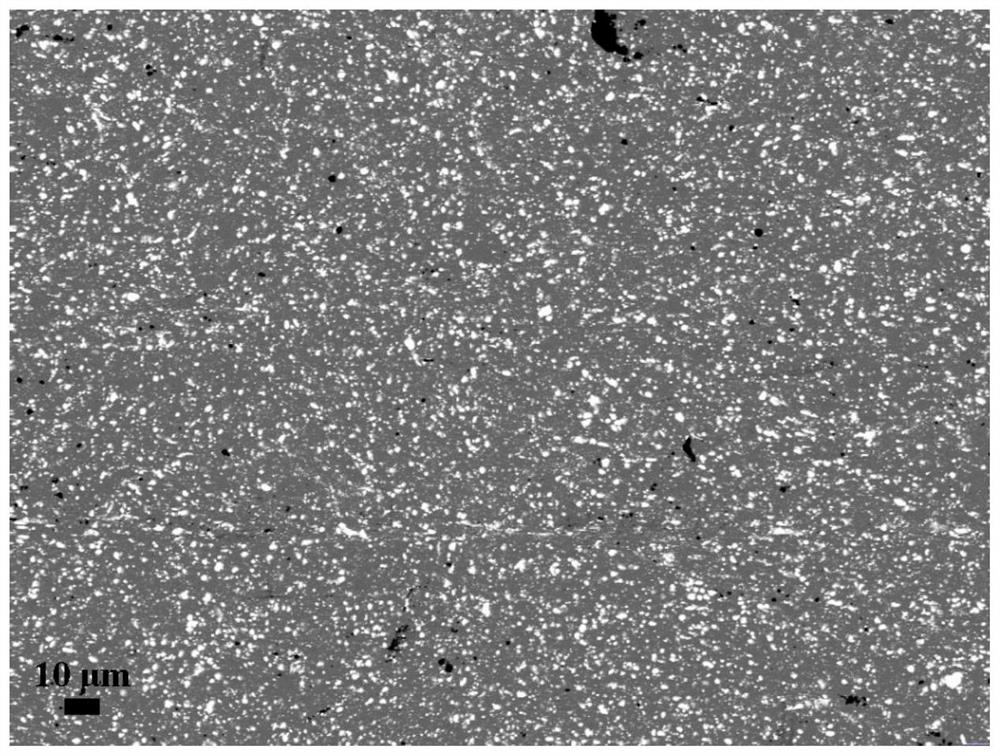

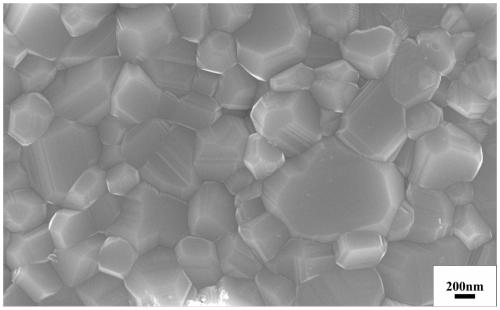

Method for preparing tungsten dispersion strengthened copper composite material through electroforming

ActiveCN114293232ACo-electrodepositionCo-electrodeposition achievesElectroforming processesElectroformingElectric contact

The invention provides a method for preparing a tungsten dispersion strengthened copper composite material through electroforming, and belongs to the field of copper-based composite material preparation. The process comprises the following steps: preparing a plating solution containing copper and tungsten, treating an electrode plate, then adjusting proper electroforming process parameters, depositing ions containing copper and tungsten on a cathode plate subjected to specific treatment, and finally separating a casting layer to obtain the block copper-tungsten composite material with uniformly distributed tungsten particles and small size. The composition proportion, microstructure, mechanical properties and the like of the composite material can be controlled by adjusting electroforming parameters and plating solution components. The preparation method has the characteristics of short preparation process, continuous and controllable components and fine and uniform particles, the nano tungsten particles can greatly improve the mechanical property of the copper alloy, excellent electric and heat conduction performance is kept, and the preparation method has wide prospects in application of electronic packaging materials, electrode materials, electric contact materials and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of nano-ntc thermosensitive material

ActiveCN108033774BImprove compactnessAvoid the disadvantage of losing a larger activityManganeseTableting

The invention discloses a novel method for preparing a nano NTC (Negative Temperature Coefficient) thermal-sensitive material. The novel method comprises the following steps: firstly, preparing nickel-manganese spinel powder of which the particle size is 50nm by using a sol-gel method; treating nano powder by using modes of tabletting and isostatic pressing so as to obtain a raw blank; sintering the raw blank for 0-60 seconds in a super-fast sintering furnace at 1000-1040 DEG C; further sintering for 5-20 hours in an air furnace at 850-950 DEG C, thereby finally obtaining the thermal-sensitiveNTC material of which the particle size is smaller than 500nm. The thermal-sensitive material has relatively high resistance and material constants.

Owner:NINGXIA UNIVERSITY

Low-alloy-content corrosion-resistant high-performance magnesium alloy and preparation method thereof

ActiveCN114525437ALow content of eutectic phaseImprove corrosion resistanceRare-earth elementMg alloys

The invention belongs to the technical field of metal materials, and discloses a low-alloy-content corrosion-resistant high-performance magnesium alloy and a preparation method thereof. The magnesium alloy comprises, by mass, 0.15%-0.55% of aluminum, 0.01%-0.5% of manganese, 0.03%-0.1% of calcium and the balance magnesium, additive elements and inevitable impurities, the additive elements are one or combination of tin, zinc, gadolinium and yttrium, and the adding amount of the additive elements is as follows: 0%-0.4% of tin, 0%-0.5% of zinc, 0%-0.35% of gadolinium and 0%-0.35% of yttrium. The preparation method comprises the steps of alloy smelting, pouring, homogenizing heat treatment and rapid extrusion. After the process, an atomic scale microstructure is formed in the magnesium alloy. The rare earth elements can change the components of the second-phase particles, reduce the micro galvanic corrosion of the microstructure and the magnesium matrix and remarkably improve the corrosion resistance, and can also interact with the zinc element to reduce the grain size; the tin element is dissolved in the magnesium matrix, the strength of weakening micro galvanic corrosion can be achieved, the corrosion resistance is improved, and meanwhile the deformation capacity of the magnesium alloy can be improved through the trace tin element.

Owner:JILIN UNIV

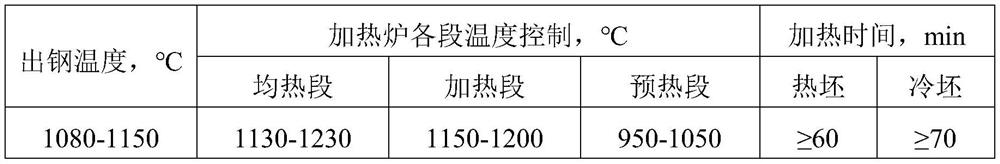

Anti-seismic reinforcing steel bar and preparation method thereof

The invention relates to the technical field of ferrous metallurgy, in particular to an anti-seismic reinforcing steel bar and a preparation method thereof.The anti-seismic reinforcing steel bar comprises, by weight, 0.20%-0.25% of C, 0.65%-0.80% of Si, 1.35%-1.60% of Mn, 0.090%-0.110% of V, 0.20%-0.30% of Cr, larger than or equal to 0.0180% of N, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.55% of Ceq and the balance Fe and inevitable impurities. The beneficial influence of the specification effect of the small-specification HRB600E anti-seismic steel bar on the strength performance is fully considered, the C content is properly reduced and controlled to be 0.20%-0.25%, Ceq is smaller than or equal to 0.55%, the requirements for the C content and the carbon equivalent of the 500 MPa-grade steel bar in the GB / T 1499.2-2018 standard are met, the continuous casting rejudgment of the 500 MPa-grade steel bar can be achieved on a production organization, the production efficiency is not affected, the production organization is facilitated, and waste judgment loss is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Production line for producing magnesium alloy plate and strip coils by continuous extrusion and coiling

InactiveCN108787780ASmooth rollSolve the problem of difficult production and access to magnesium coilsTemperature control deviceMetal rolling arrangementsProduction lineTemperature control

The invention discloses a production line for producing magnesium alloy plate and strip coils by continuous extrusion and coiling. The production line includes an extruder, a centering pinch roll arranged at the outlet of the extruder, a roll surface heating device of the centering pinch roll heating the roll surface of the centering pinch roll, a tension pinch roll arranged downstream of the centering pinch roll, a roll surface heating device of the tension pinch roll heating the roll surface of the tension pinch roll, a heat transfer roll arranged in order along the conveying direction of the production line, a temperature-controlled coiler including a coiling drum, a coiling drum surface heating device heating the surface of the coiling drum, an auxiliary coiling roll and a roll surfaceheating device of the auxiliary coiling roll, a first plate and strip heating device arranged upstream of the temperature-controlled coiler relative to the temperature-controlled coiler and heating magnesium alloy plates and strips which are about to enter the temperature-controlled coiler, and a control unit used for controlling heating temperature of the magnesium plates and contact rolls in the whole production line so as to ensure that the magnesium plates undergo predetermined bending deformation in an optimum plastic deformation temperature range.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

Oxide-reinforced low-activation steel and manufacturing method thereof

ActiveCN113322407AStrong pinning dislocation strengthening effectImprove high temperature mechanical propertiesAdditive manufacturing apparatusFurnace typesWire rodMetallurgy

The invention discloses oxide-reinforced low-activation steel and a manufacturing method thereof. The manufacturing method comprises the following steps of in the smelting process of the low-activation steel, after the components of the low-activation steel reach the standard, adding Ti, Zr or Hf into the low-activation steel, after melting down, adding Y, uniformly stirring, and tapping and casting into a steel ingot; conducting homogenizing annealing and rolling on the steel ingot to obtain a wire rod; drawing the wire rod into a wire material; and conducting electric arc fuse forming on the wire material to obtain the oxide-reinforced low-activation steel, wherein ion gas and shielding gas adopted in the electric arc fuse forming process are both mixed gas of CO2 and Ar gas, and the cooling mode is natural cooling and solidification under the Ar protection atmosphere. According to the oxide-reinforced low-activation steel, the structure of the oxide reinforcement phase is more complex, and compared with existing oxide-reinforced low-activation steel, the oxide-reinforced low-activation steel has better high-temperature mechanical performance, and meanwhile, the processing method can rapidly achieve processing of the oxide-reinforced low-activation steel, and the yield of the oxide-reinforced low-activation steel can be increased.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

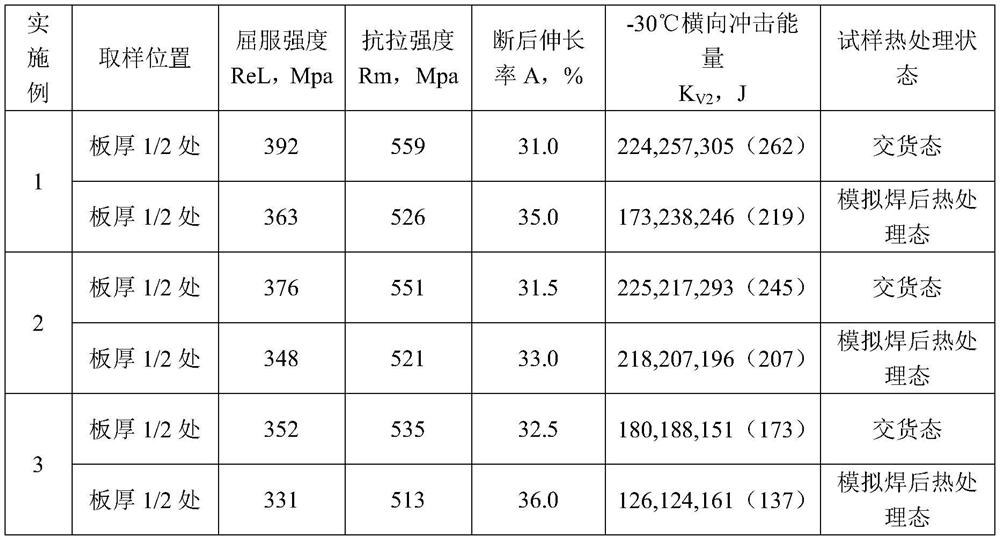

A kind of q345r steel plate with excellent performance under high temperature simulated post-weld heat treatment conditions and its manufacturing method

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Forging and molding process method for titanium alloy tubular piece

ActiveCN103358100BReduce consumptionAvoid folding wrinkles or even cracksMetal-working apparatusFurnace typesTitanium alloyHeating temperature

The invention discloses a forging and molding process method for a titanium alloy tubular piece, which belongs to the technical field of forging and pressing, and is particularly suitable for tubular forging and molding of TC9 and TC11 titanium alloy materials. The method is mainly technically characterized in that methods such as pre-boring of guide through holes, hole expanding, drawing, binding and reshaping, and the like are adopted, and meanwhile, the heating temperature and heat preserving time of a TC9 or TC11 titanium alloy are controlled, so that crystal grains of the TC9 or TC11 titanium alloy can be prevented from being coarsened, the metallographic structure and mechanical performance of the TC9 or TC11 titanium alloy are prevented from being influenced, the consumption of the titanium alloy materials are lowered effectively, and the cost is saved; meanwhile, folding, corrugation and even cracks of inner holes are avoided; and the process method has the characteristics of easiness, high practicability, high product yield, and the like.

Owner:江南工业集团有限公司

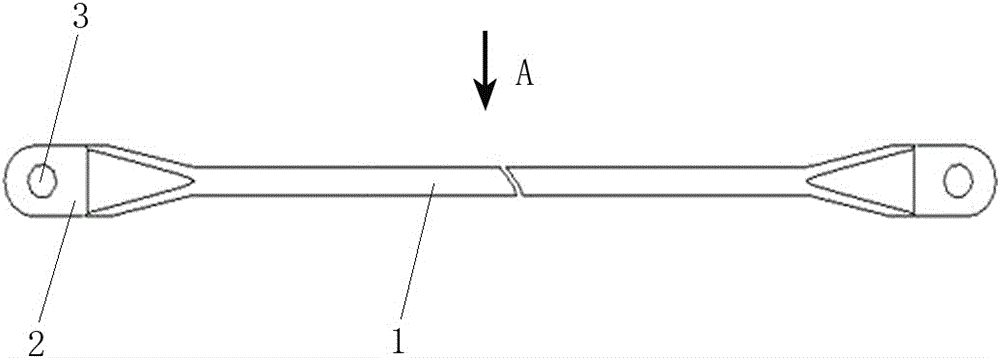

Forged type pull plate and manufacturing method thereof

InactiveCN105800481AIncrease profitImprove securityMetal-working apparatusCranesManufactured materialStructural engineering

The invention discloses a forged type pull plate. The forged type pull plate comprises a round steel body; the two ends of the round steel body are each provided with a pull plate connector in a forged manner; and connector holes are formed in the pull plate connectors. The invention further discloses a manufacturing method of the forged type pull plate. Round steel serves as raw materials, and blanking is performed till the needed size is achieved; molds are adopted at the two ends of the round steel for forging so that the pull plate connectors can be formed; and the connector holes are formed in the two pull plate connectors in a machined manner. By means of the forged type pull plate and the manufacturing method of the forged type pull plate, the rolled steel utilizing rate of the pull plate can be remarkably increased, the anti-fatigue performance of the pull plate is enhanced, good corrosion resistant performance is achieved through attachment of oil paint, the pull plate is applied to a truss arm type crane, and the safety performance of the truss arm type crane can be obviously improved.

Owner:XCMG CONSTR MACHINERY

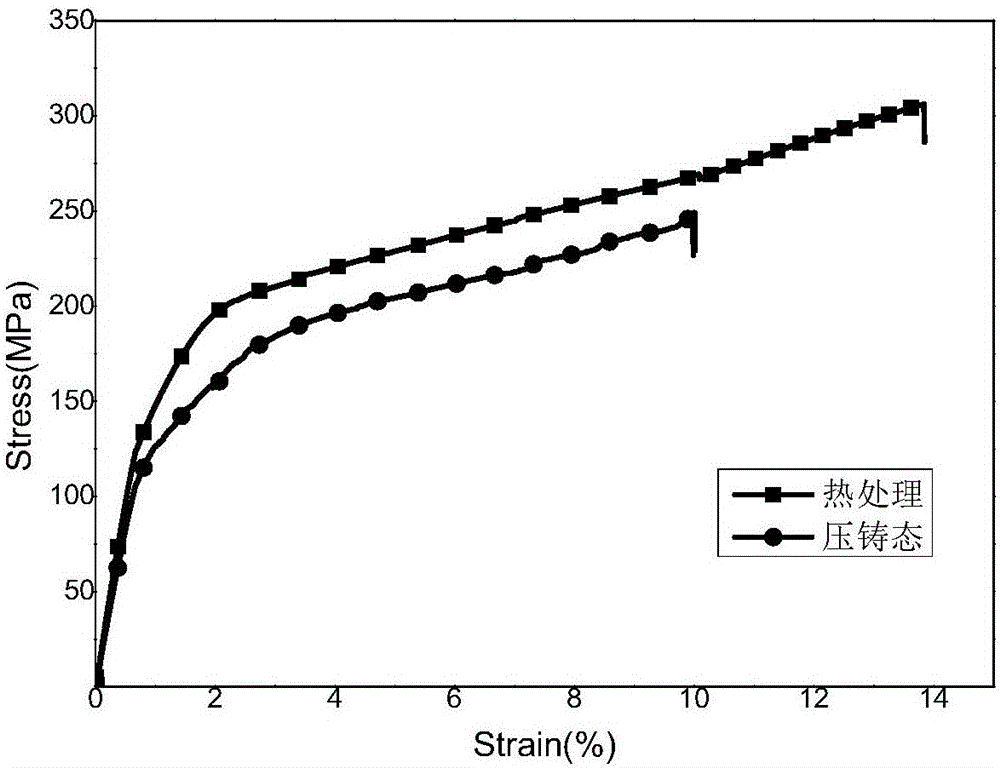

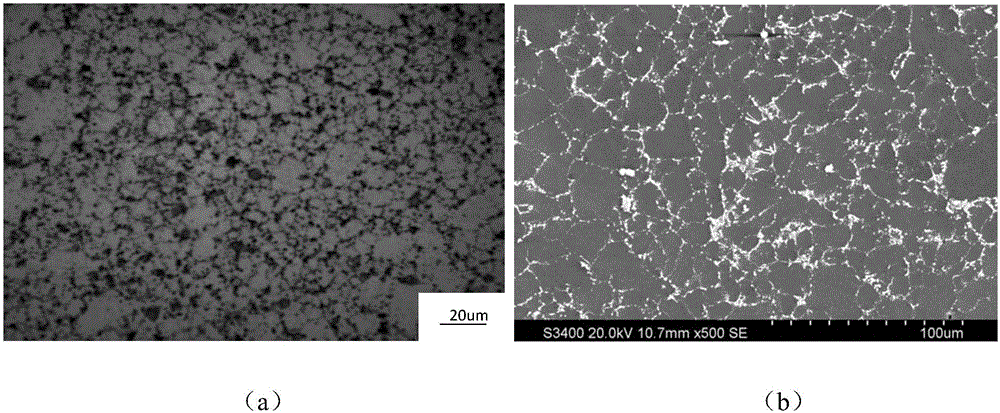

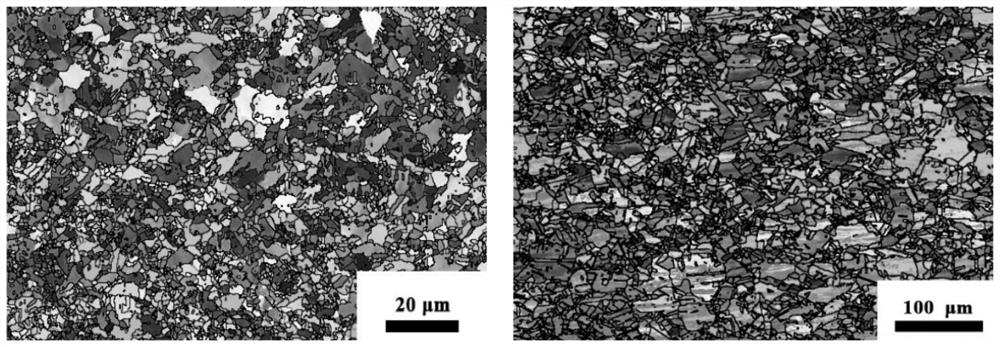

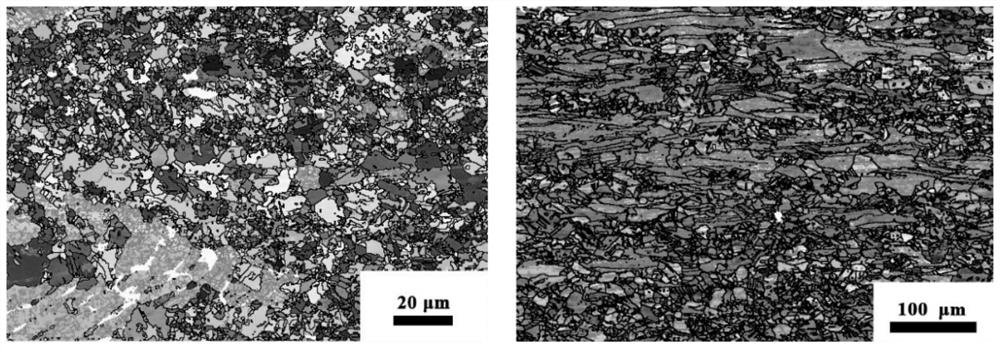

Heat treatment method for improving toughness of die-casting magnesium alloy

Aiming at the disadvantage of poor toughness of die-casting Mg-Al alloy, the invention provides a heat treatment method for improving the toughness of vacuum die-casting Mg-7Al-1Ca-0.5Sn alloy. Through primary heat treatment and secondary heat treatment performed on the vacuum die-casting Mg-7Al-1Ca-0.5Sn alloy, alloy components can be more uniform, the tissue and shape are obviously improved, the quantity of precipitated phases is increased, the precipitated phases are diffused on a base body, obvious growing of crystalline grains does not exist, and the mechanical property of the alloy is obviously improved. After the vacuum die-casting Mg-7Al-1Ca-0.5Sn alloy is subjected to the primary heat treatment and secondary heat treatment, the room temperature tensile strength is 288.9 to 306.8MPa, the yield strength is 148.5 to 178.2MPa, and the elongation percentage is 12.5 to 13.8 percent. The performance index of the alloy is obviously better than that of commercial AZ91 alloy and AM60 alloy.

Owner:SHENYANG POLYTECHNIC UNIV

Automatic stop charging control circuit of positive and negative combination pulse charge machine

InactiveCN100547877CPrevent overchargingExtended service lifeBatteries circuit arrangementsEmergency protective circuit arrangementsCapacitanceSilicon-controlled rectifier

Owner:陈荣森 +1

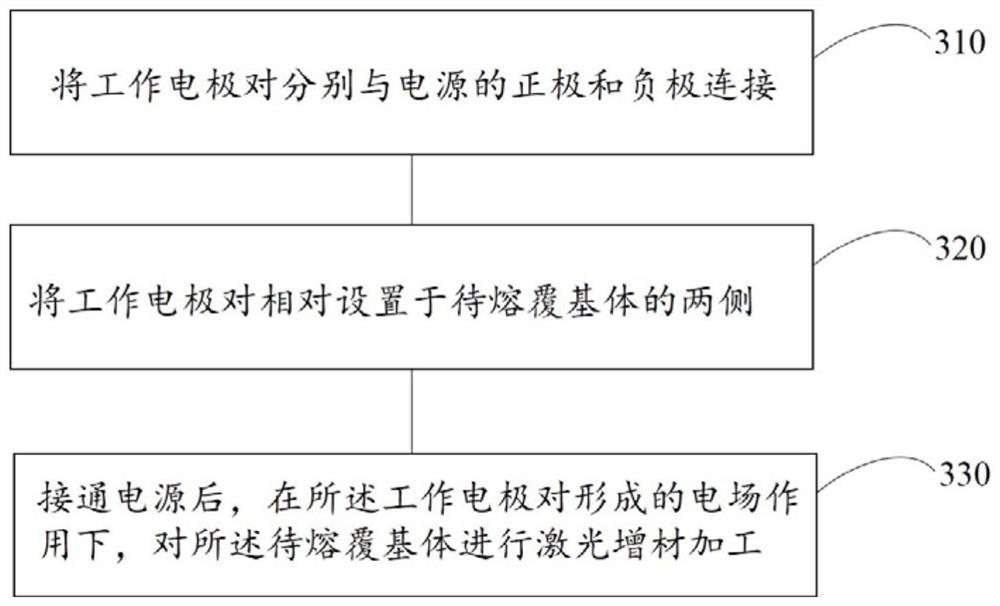

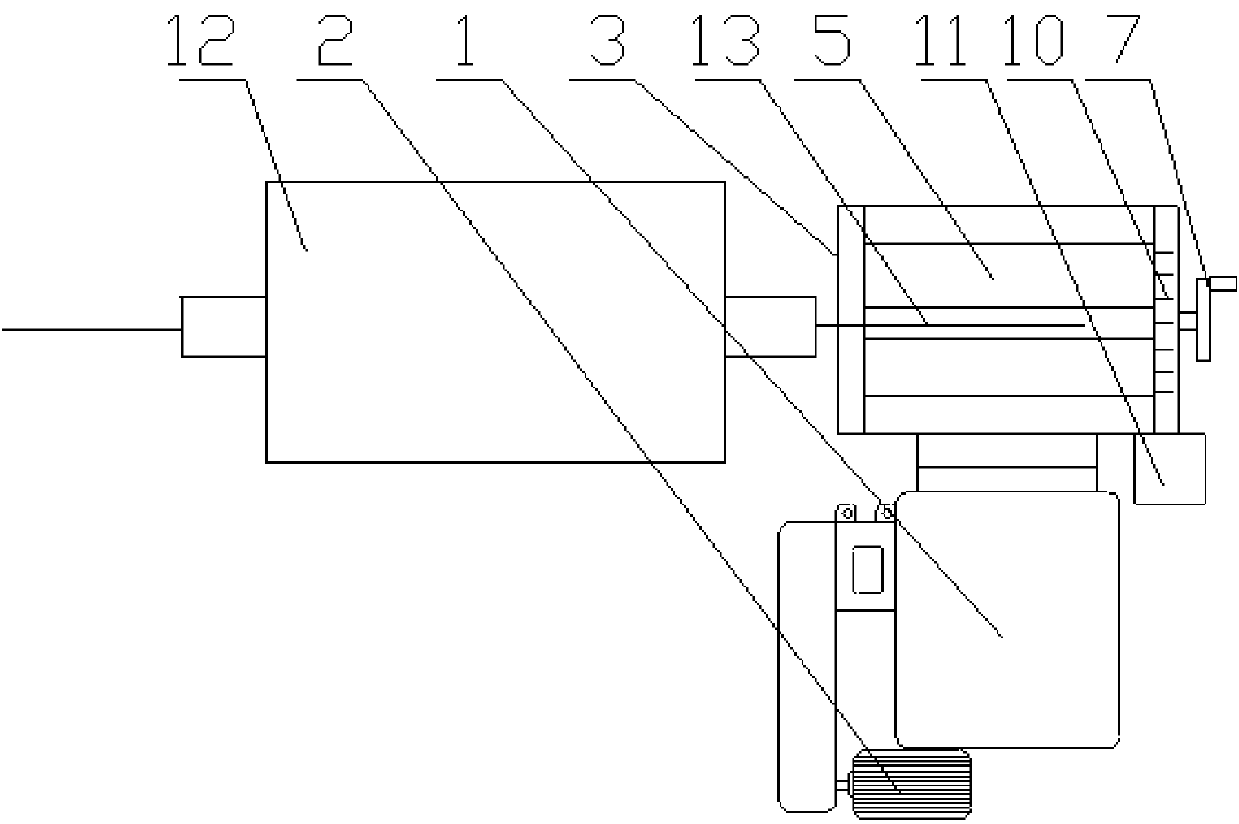

Electrostatic field assisted laser additive manufacturing device and method

PendingCN113351865ARealize regulationImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringErbium lasers

The invention discloses an electrostatic field assisted laser additive manufacturing device and method. The electrostatic field assisted laser additive manufacturing device at least comprises a power source, working electrode pairs and a laser. The working electrode pairs are correspondingly connected with the positive electrode and the negative electrode of the power source; and the laser is used for performing laser additive machining on a to-be-cladded base body between the working electrode pairs under the action of an electrostatic field formed by the working electrode pairs. According to the electrostatic field assisted laser additive manufacturing device, in the laser additive machining process, the working electrode pairs can provide the electrostatic field for the to-be-cladded base body located between the working electrode pairs, and under the action of the electrostatic field, elimination of holes in a workpiece in the manufacturing process and regulation and control of the trend of the internal structure of the workpiece can be achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Experimental method for performing air cooling and heating process on heating wire rod and air cooling device

InactiveCN101629883BAvoid one-sidednessAvoid grain coarseningPreparing sample for investigationMeasuring instrumentEngineering

The invention discloses an experimental method for performing air cooling and heating process on a heating wire rod and an air cooling device. The experimental method adopts the technical scheme that the wire rod is heated to a prescribed temperature by a tubular heating furnace in a laboratory; the wire rod with the prescribed temperature is conveyed out through a heating pipe of the tubular heating furnace; the air cooling device with adjustable wind speed and blast volume is arranged at a delivery outlet of the heating pipe for conveying the wire rod so ensure that the wire rod conveyed bythe heating pipe passes through the air outlet of the air cooling device; thermocouples are inserted in different positions of the wire rod and connected with a digital temperature measuring instrument to reflect the temperature change of the wire rod, and the temperature change signal of the digital temperature measuring instrument is fed back to a variable-frequency controller of the air cooling device so as to control the cooling speed of the wire rod. The invention has the advantages of precisely controllable and adjustable wind speed, blast volume and wire rod cooling speed, as well as simple and compact structure, convenient operation and control, low cost and the like, and can provide the practical and effective experimental data for the enterprise production.

Owner:GUIZHOU UNIV

Preparation method of high-precision metal fiber felt for high-temperature gas dust removal

Owner:西安菲尔特金属过滤材料股份有限公司

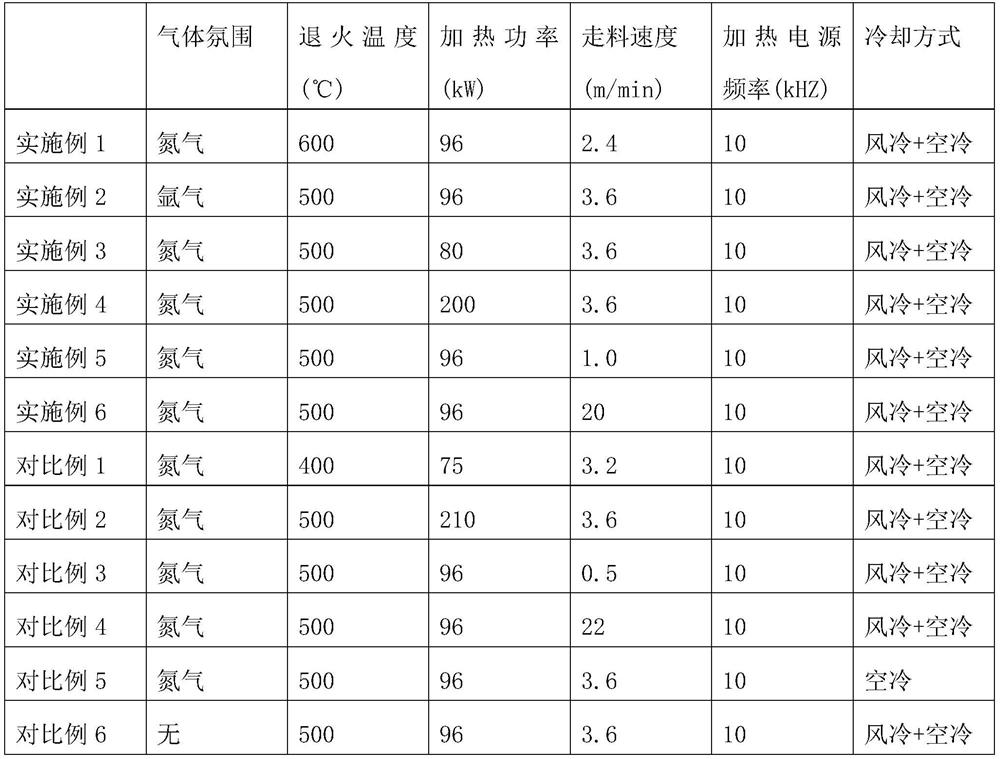

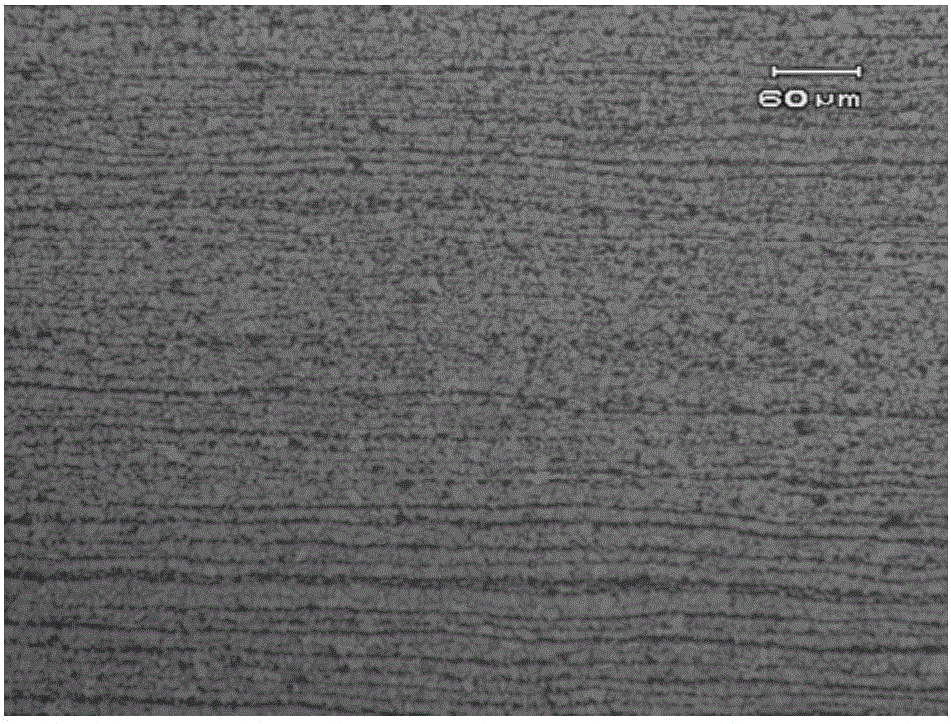

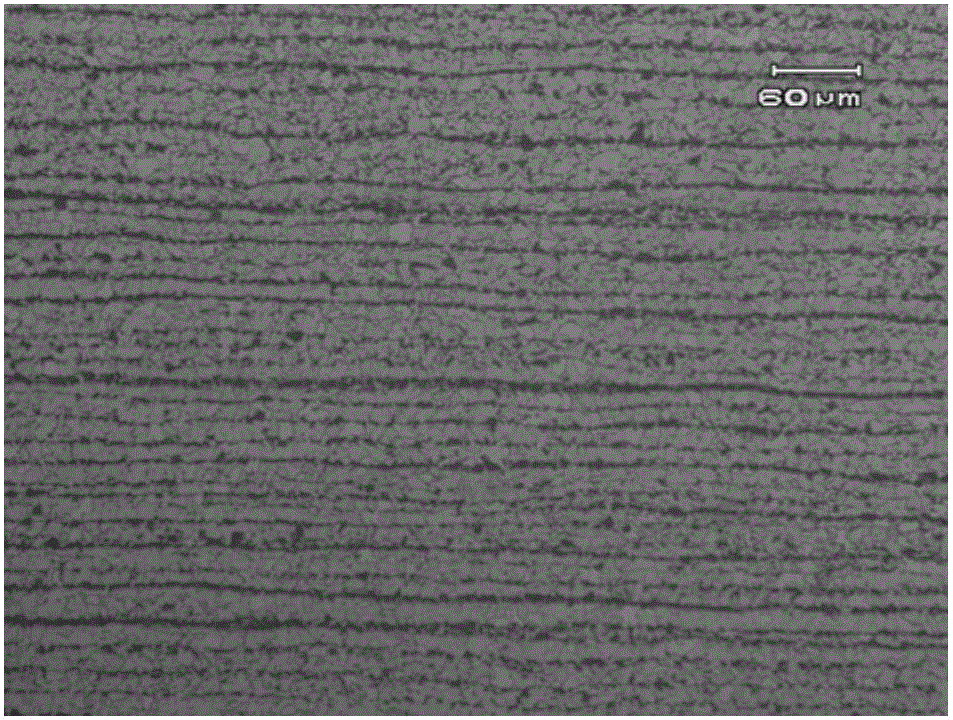

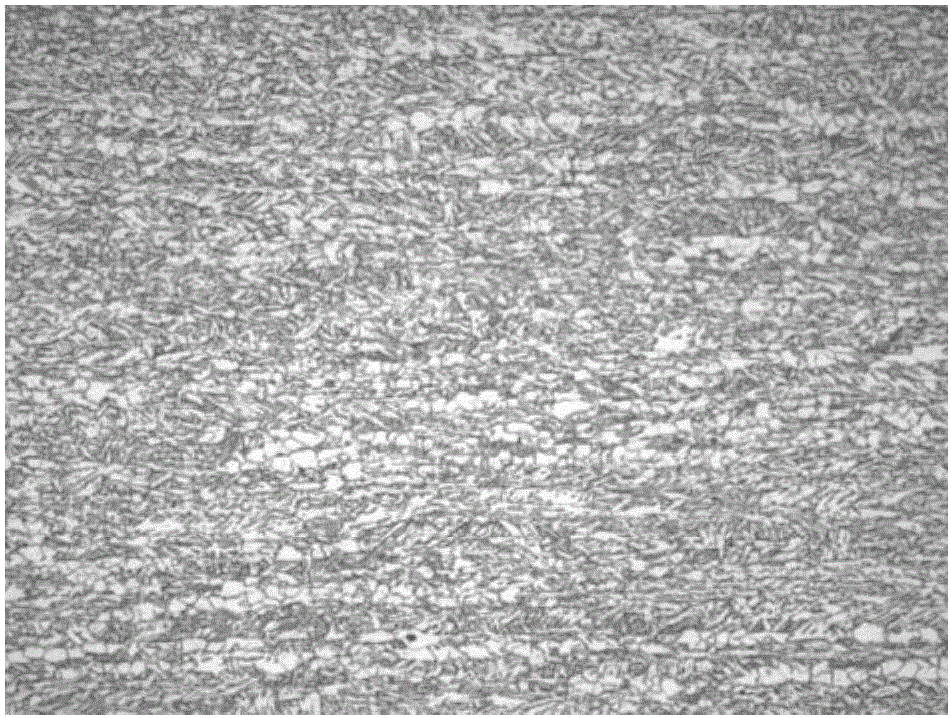

Continuous rapid annealing process for brass-coated pure copper stranded wire high-speed rail through ground wire

PendingCN114381594AAvoid grain coarseningImprove consistencyFurnace typesIncreasing energy efficiencyHeating powerMaterials processing

The invention relates to the field of metal layered composite material processing, and discloses a continuous rapid annealing process for a brass-coated pure copper stranded wire high-speed rail through ground wire, which adopts rapid induction annealing under the conditions that the annealing temperature is 500-600 DEG C, the heating power is 80-200kW, the feeding speed is 1-20m / min, and air cooling is performed after forced air cooling is performed to be below 150 DEG C after heating. The medium-frequency induction heating power supply is adopted to improve the heating rate, the brass coating layer and the pure copper stranded wire are completely recrystallized at a high temperature within a short time, on one hand, grain coarsening of pure copper caused by a low recrystallization temperature is avoided, and on the other hand, the consistency of the annealing temperature of the wire is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

A kind of low alloy steel with high strength and toughness and preparation method thereof

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com