Patents

Literature

9713results about How to "Guaranteed performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

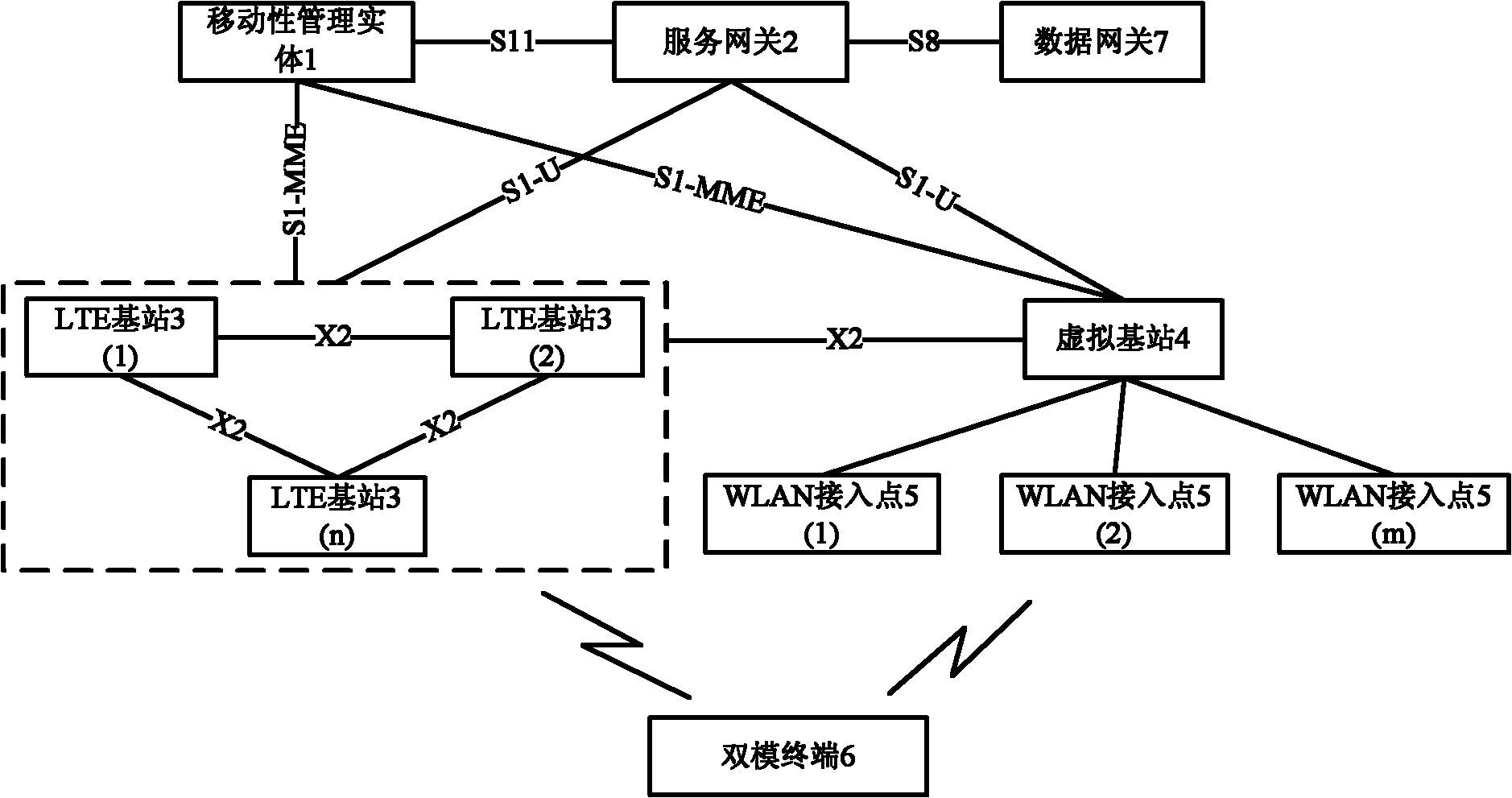

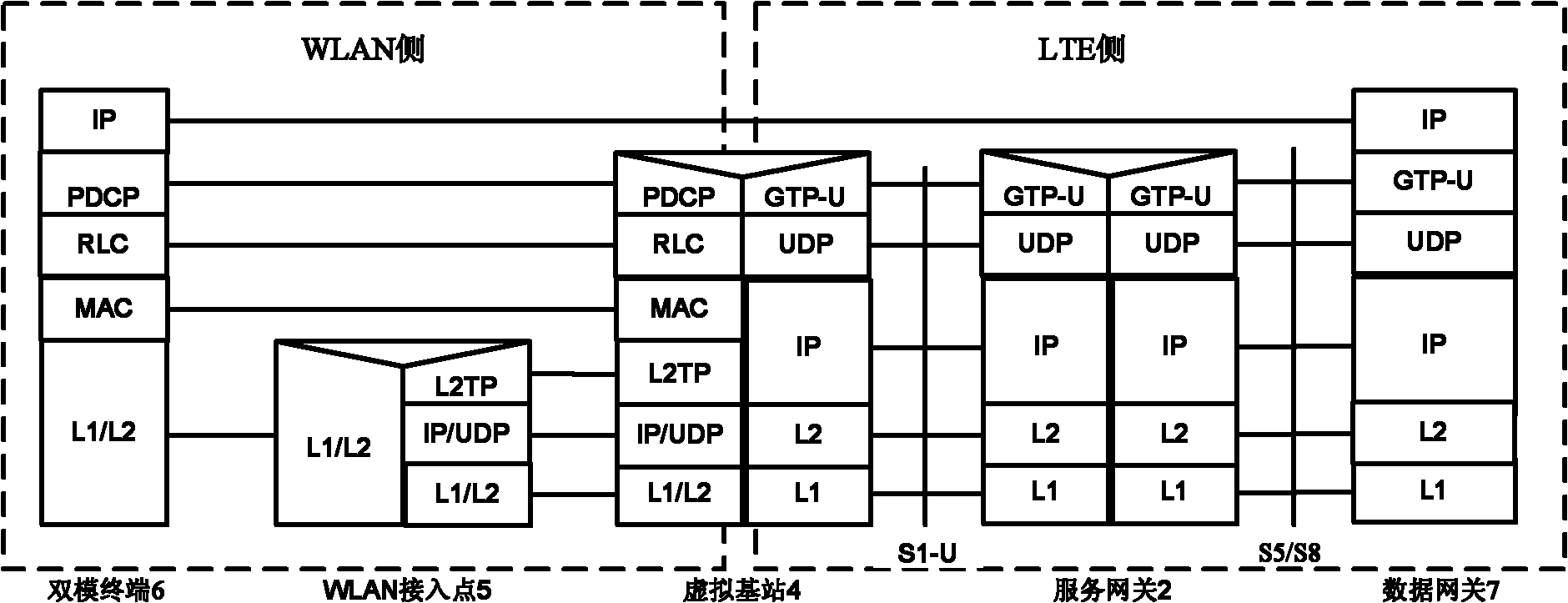

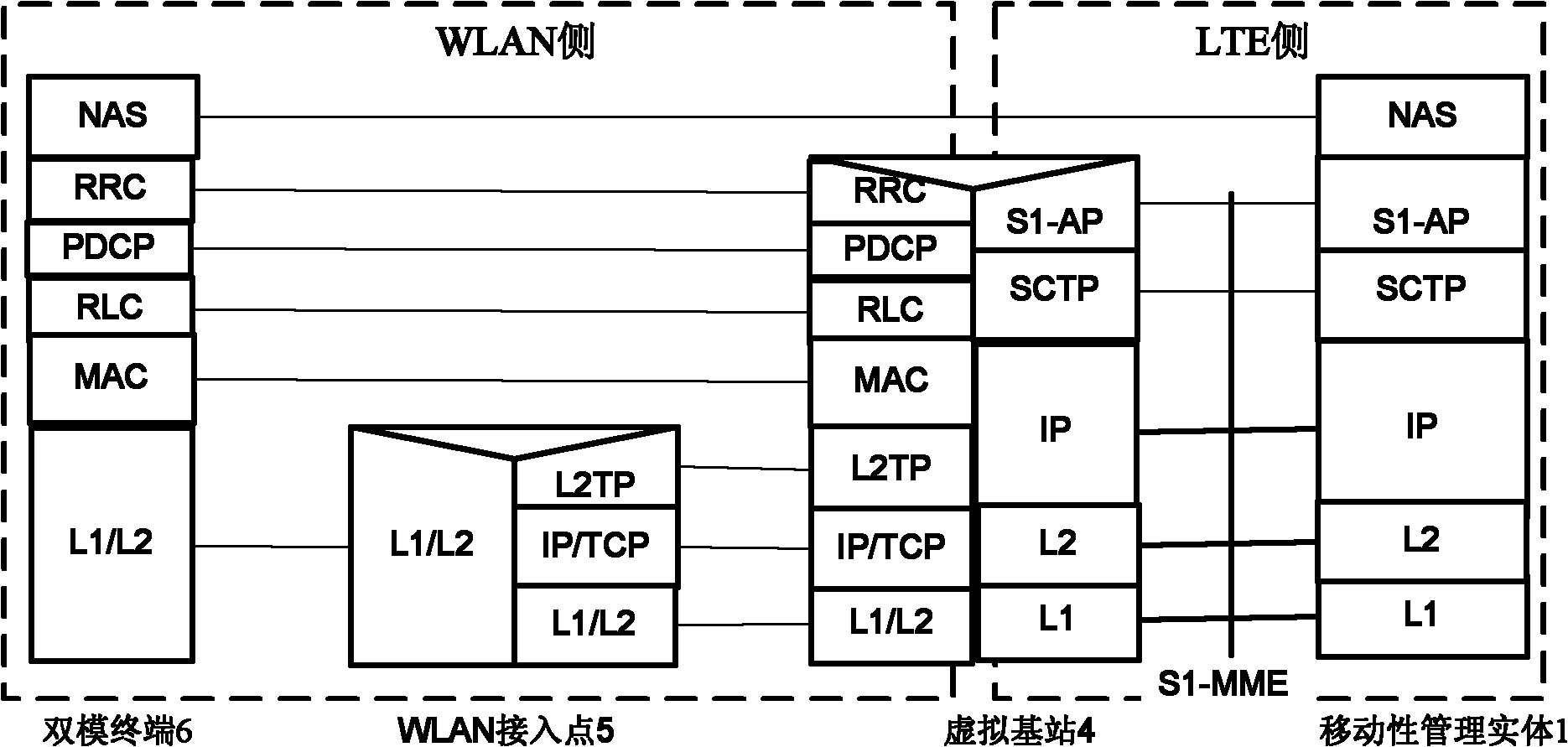

LTE and WLAN interconnecting system and switching method

InactiveCN101841880AMeet business quality requirementsReduce latencyWireless communicationTime delaysCoupling

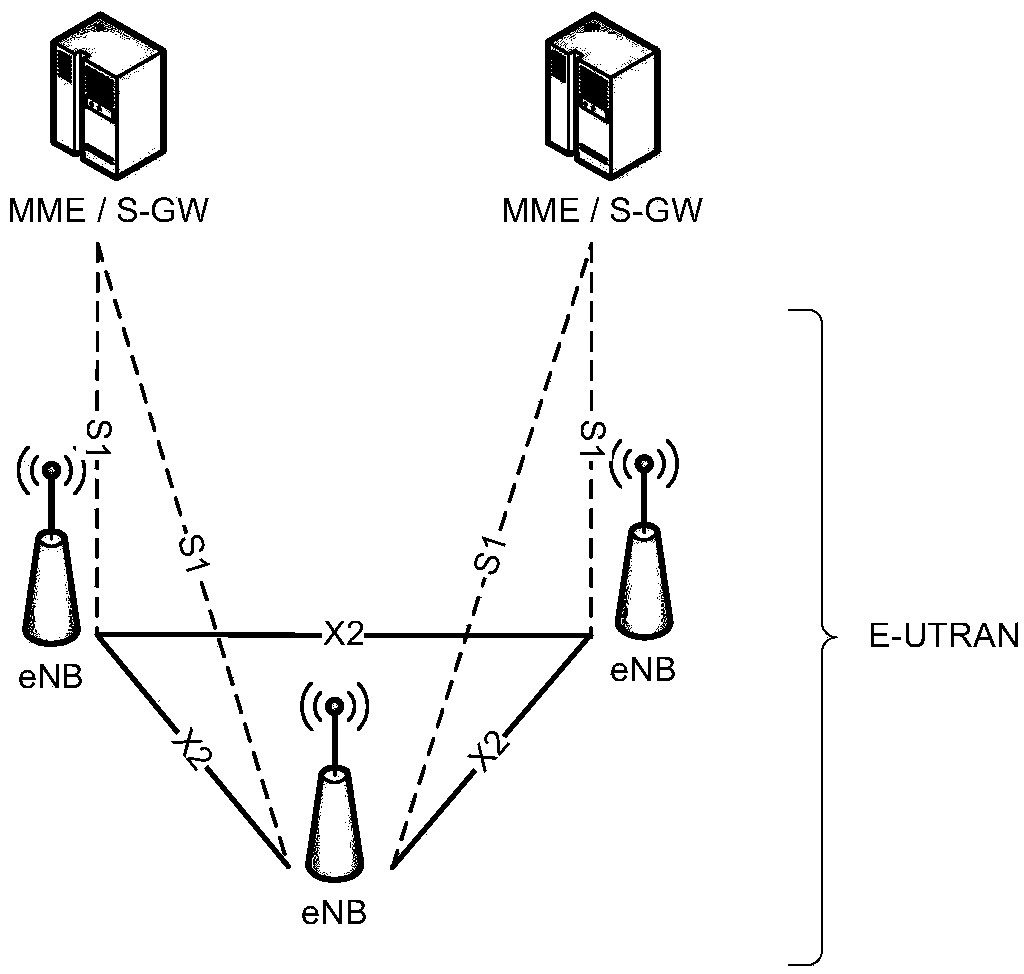

The invention provides an LTE and WLAN interconnecting system and a switching method; and the system introduces the entity of a virtual base station under an LTE architecture, and accesses the entity into the interface of the LTE as WLAN. On the LTE side, the virtual base station remains transparent relative to the LTE side, and is provided with the functions of a general LTE base station. On the WLAN side, the virtual base station can control the WLAN access point. The switching between the LTE and the WLAN is realized through the virtual base station through a standard X2 interface. A second layer tunneling protocol or an Ethernet tunneling protocol is adopted between the virtual base station and the WLAN access point to realize the transmission and the receiving of data and signaling during the switching process, and the WLAN serves as the bottom layered transmission channel of the data and the signaling of an LTE system. The method has the advantage that for the LTE, the switching process is kept consistent with the LTE switching process, which has very small impact on the traditional LTE. The WLAN is connected with the LTE in a tight coupling way, thereby greatly meeting the business requirement requirements, reducing the time delay caused by system switching, and ensuring the system performance.

Owner:HUAZHONG UNIV OF SCI & TECH

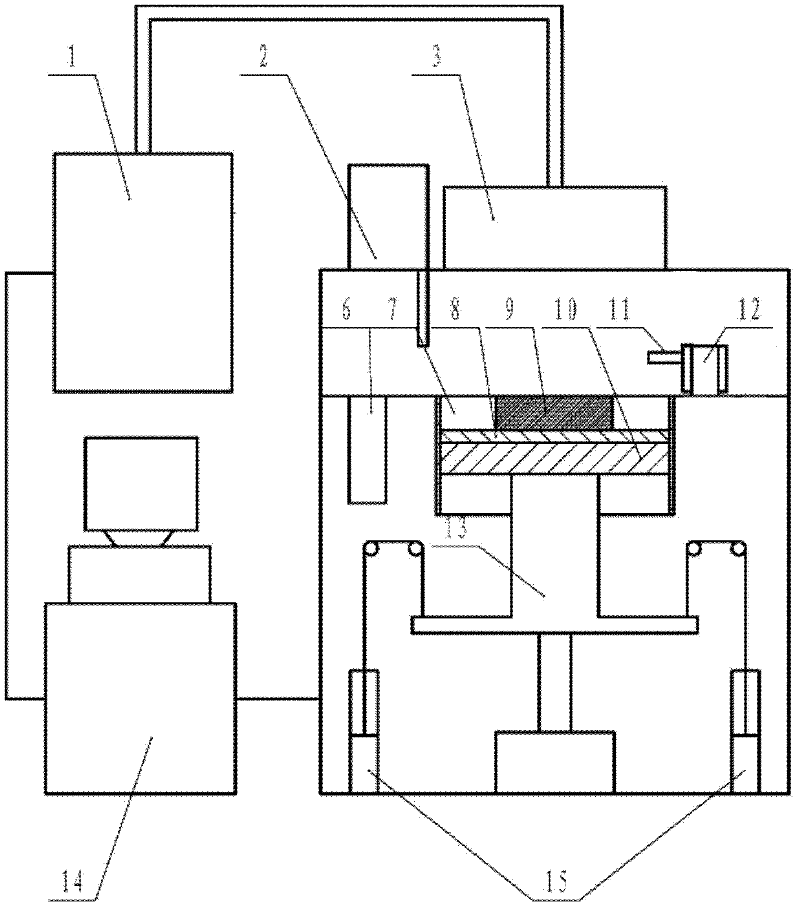

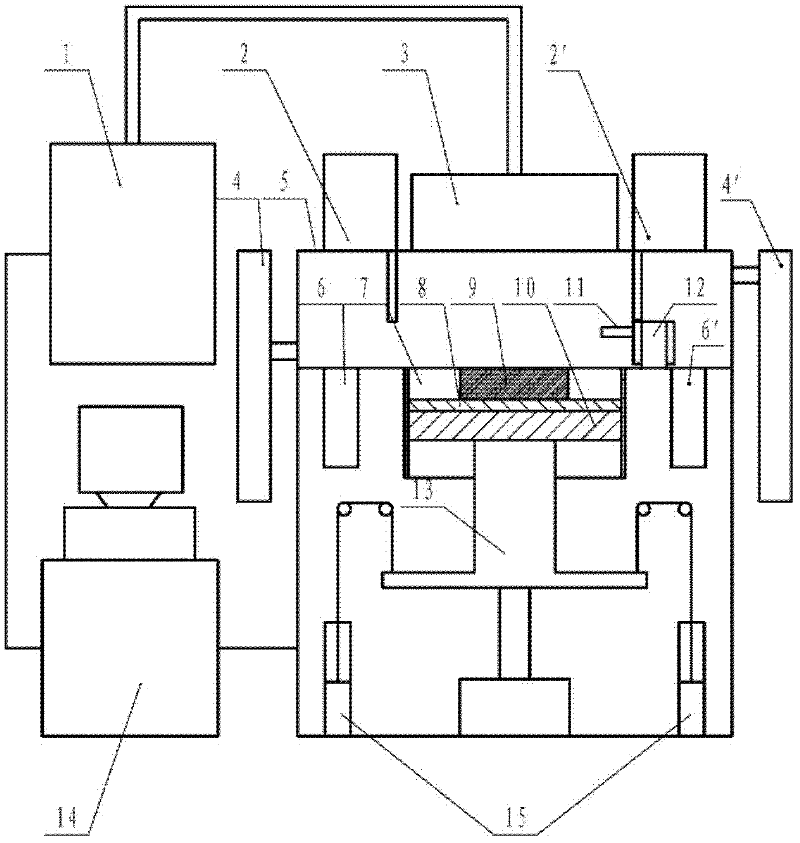

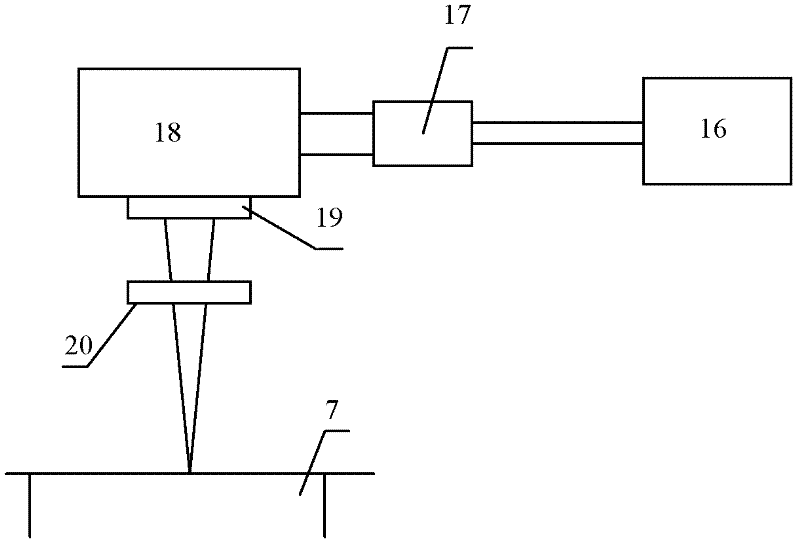

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

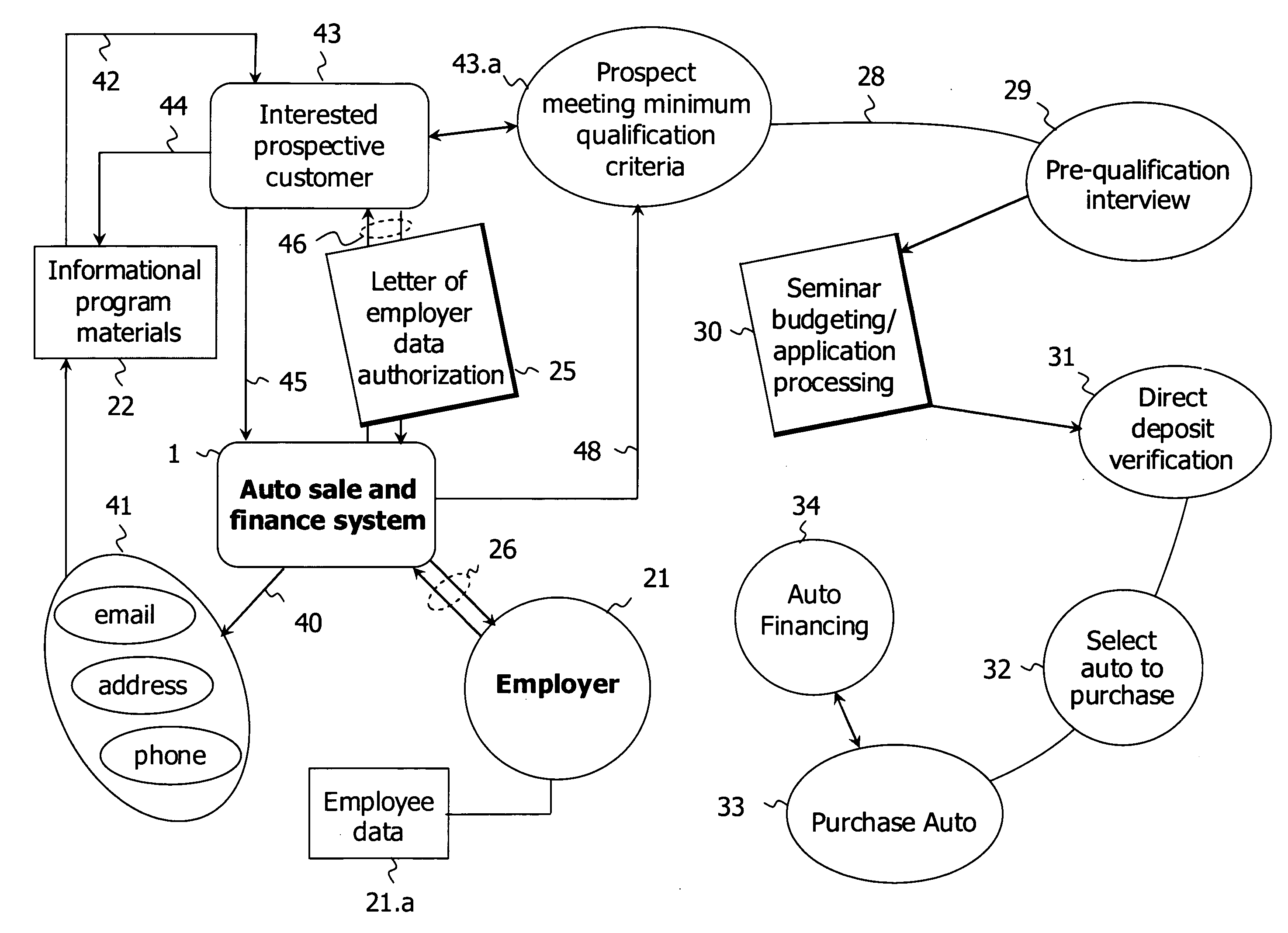

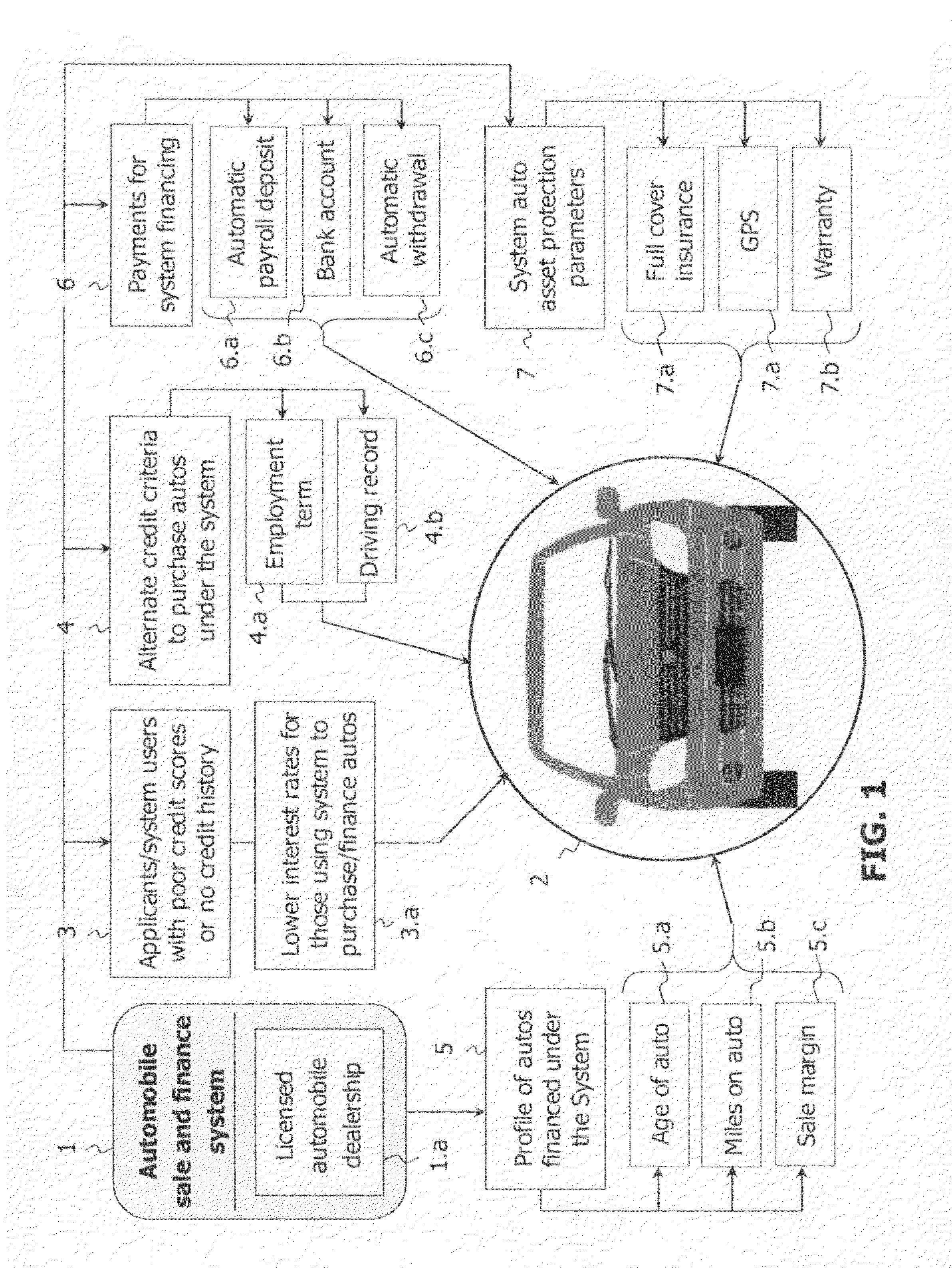

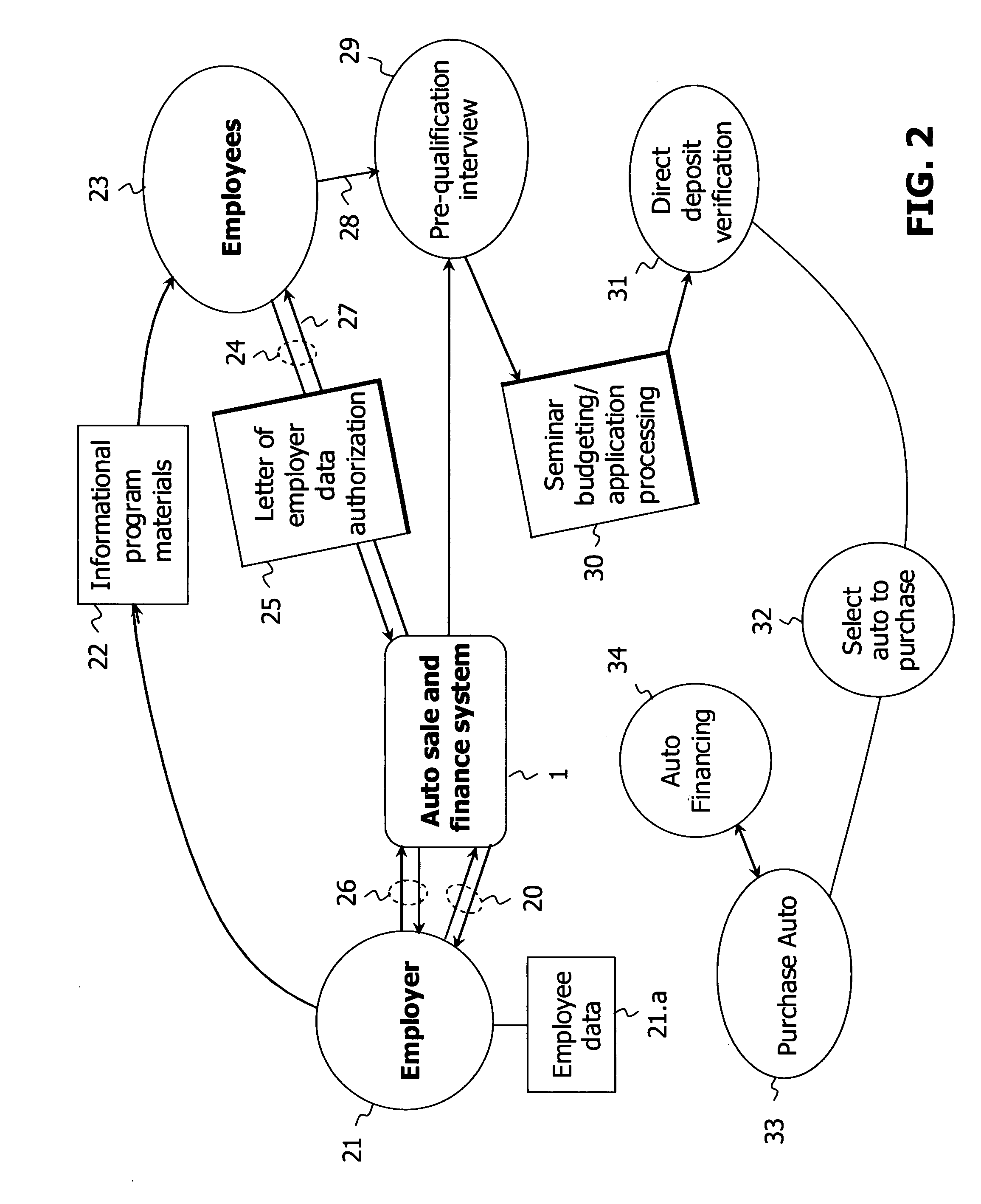

Sub-prime automobile sale and finance system

InactiveUS20070288271A1Raise interest ratesHigh riskFinancePosition fixationSystem structureProgram planning

A system to provide automobile financing to individuals with relatively lower credit scores or ratings, or no credit rating, due to lack of credit or lending purchases, that would otherwise only qualify for sub-prime, higher interest loans. Due to the overall system structure, lower rate interest loans can be extended to participants. The system utilizes the auto financing loan applicant's term of employment and / or other employment performance data as the principal credit criteria to qualify the creditworthiness of an applicant versus the applicant's credit score or credit rating. Applicant's driving records are also reviewed as system automobile loan approval credit criteria. Loan applicants provide employment related information and execute a letter of authorization providing the system with authority / rights to contact the applicant's employer to verify said employment information. In order to provide participants with lower interest rates than would otherwise be available through conventional channels, automobiles financed under the system must meet minimum profile criteria, including the year of the auto, the mileage, retail value relative to the wholesale value, and autos financed under the system are covered by extended warranties and have GPS systems installed for asset protection purposes. In utilizing employment term as the principal creditworthiness criteria, the system can to be offered through employers as an employee loyalty reward program.

Owner:KLINKHAMMER KIRK WILLIAM

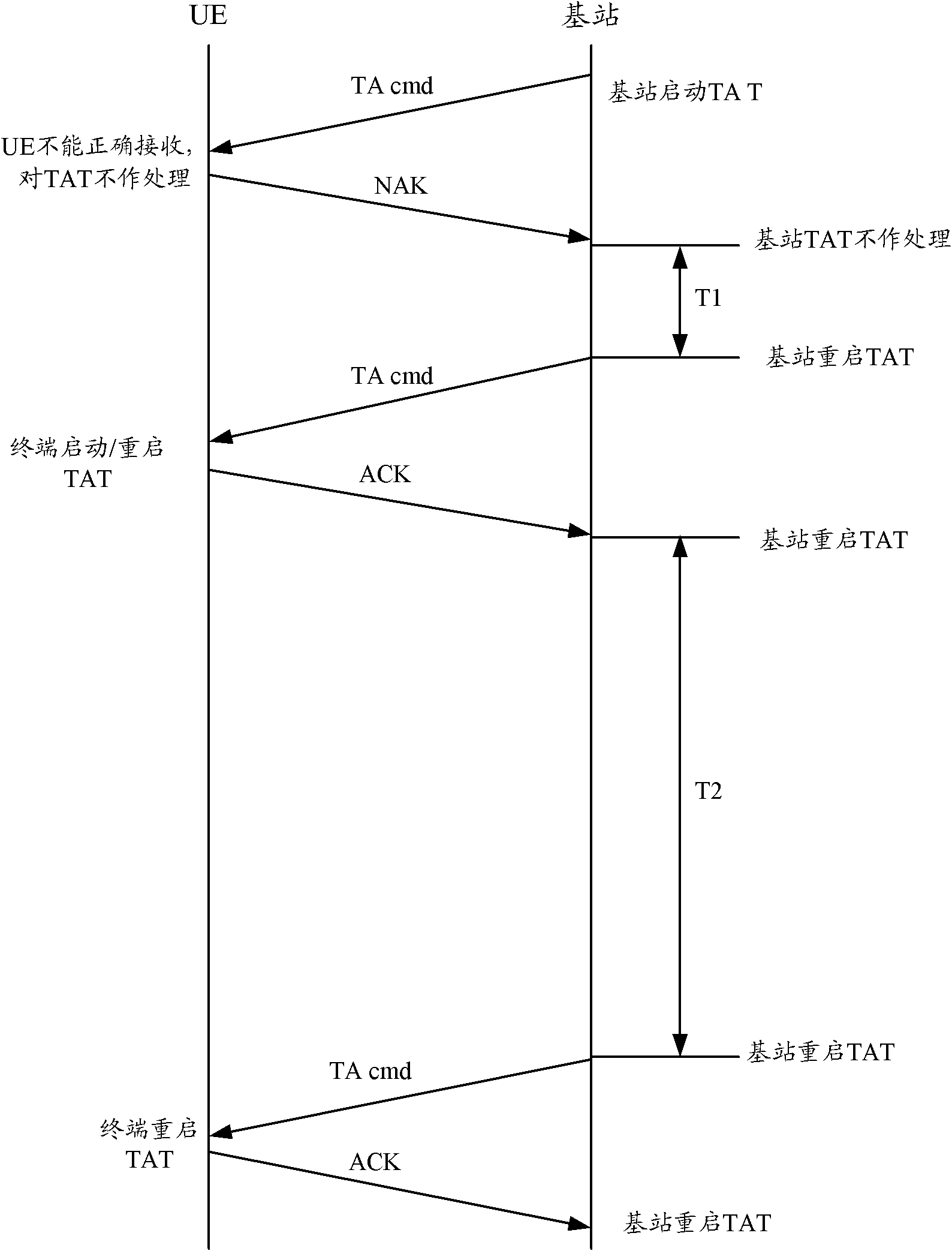

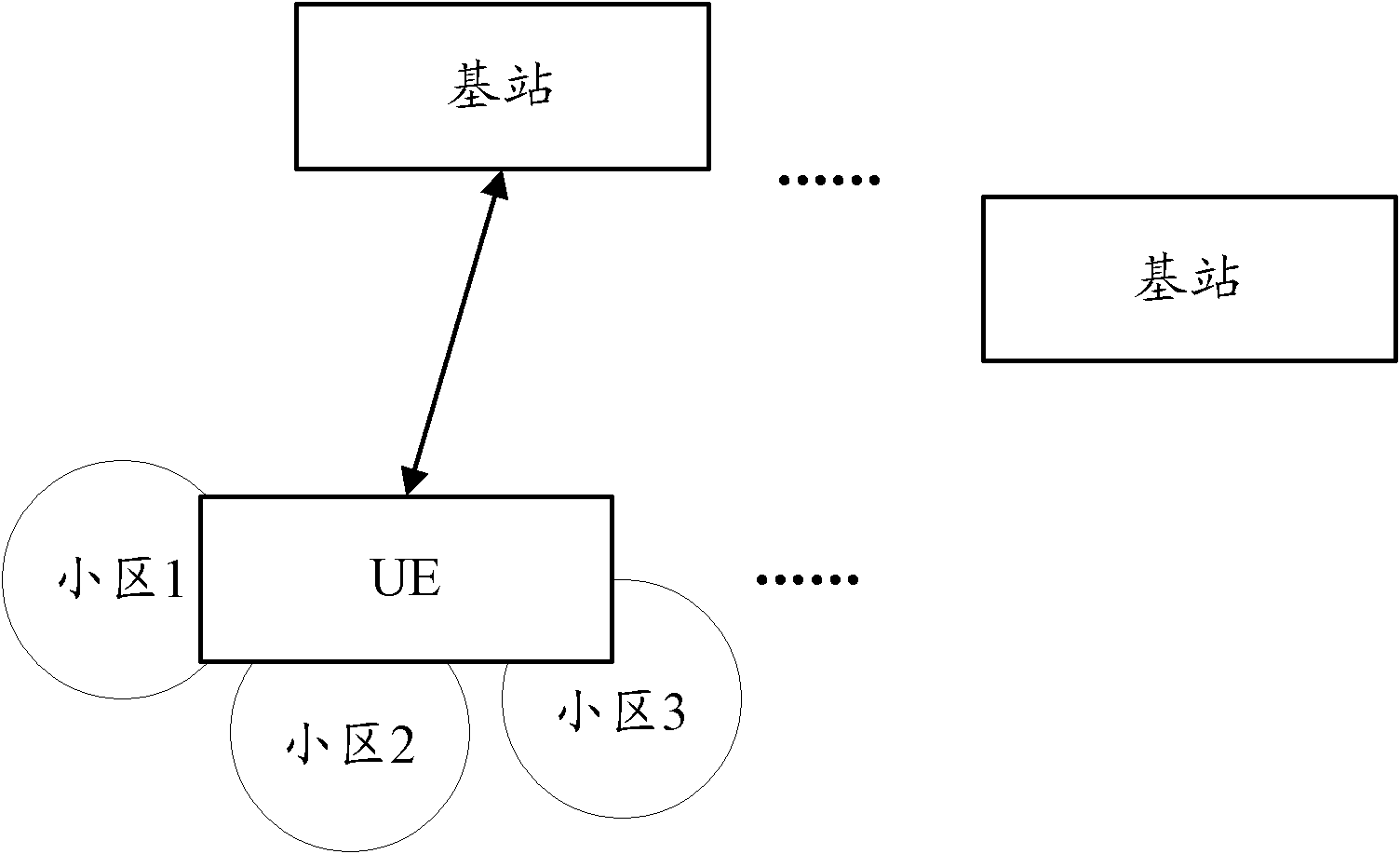

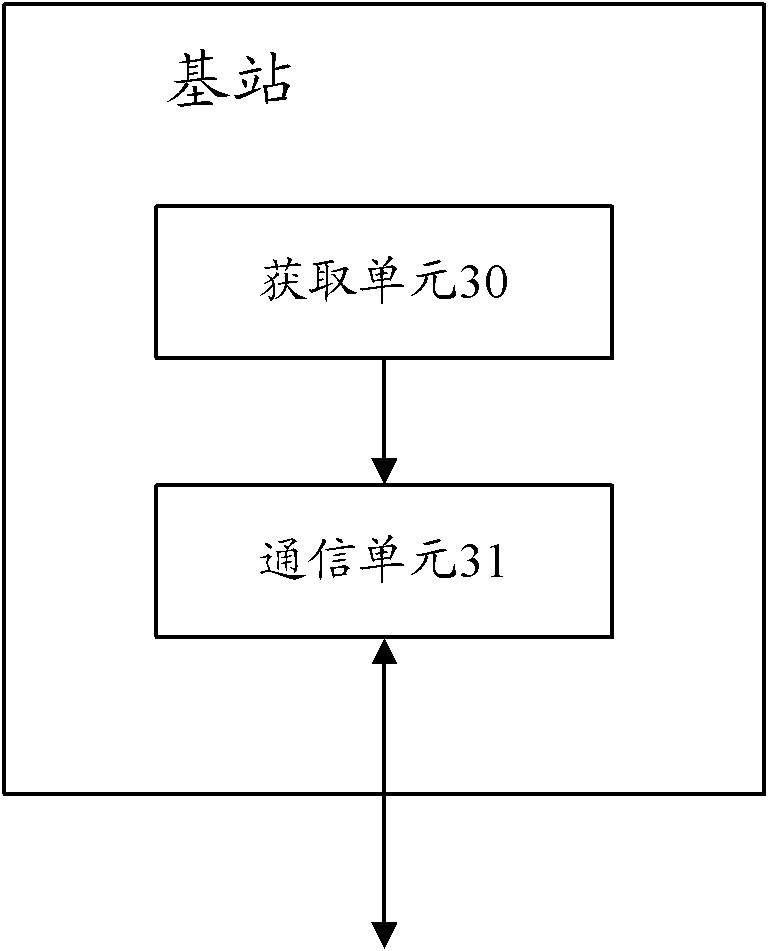

Method and device for random access

ActiveCN102036411AImprove the implementation mechanismGuaranteed performanceWireless communicationUser equipmentSynchronism

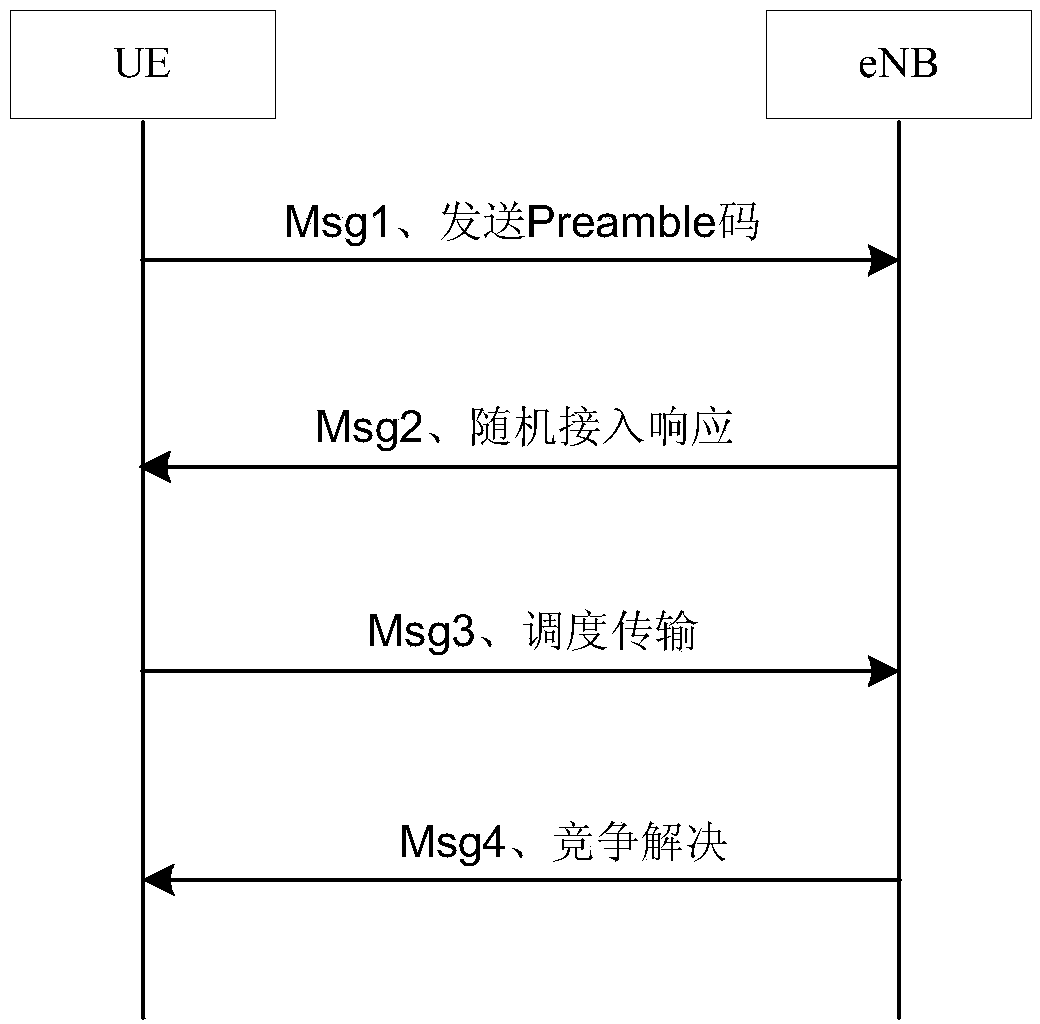

The invention discloses a method and a device for random access (RA), which are used in an LTE (long term evolution)-A system employing carrier aggregation technology and realize random access for user equipment (UE) gathering a plurality of cells. The method comprises that: a base station acquires an RA related parameter set for an auxiliary cell of terminal configuration, and sends the RA related parameter to a terminal; the terminal receives an RA related parameter set for an auxiliary cell of local configuration and sent by a network side, and selects the auxiliary cell corresponding to the RA related parameter from various auxiliary cells of the local configuration according to the RA related parameter to initiate a random access flow. Therefore, the aim that the UE is synchronous with the network side in a specific auxiliary cell through the random access is fulfilled, so that the UE keeps uplink synchronism with the network side in the configured scell, and the overall performance of the system is ensured.

Owner:DATANG MOBILE COMM EQUIP CO LTD

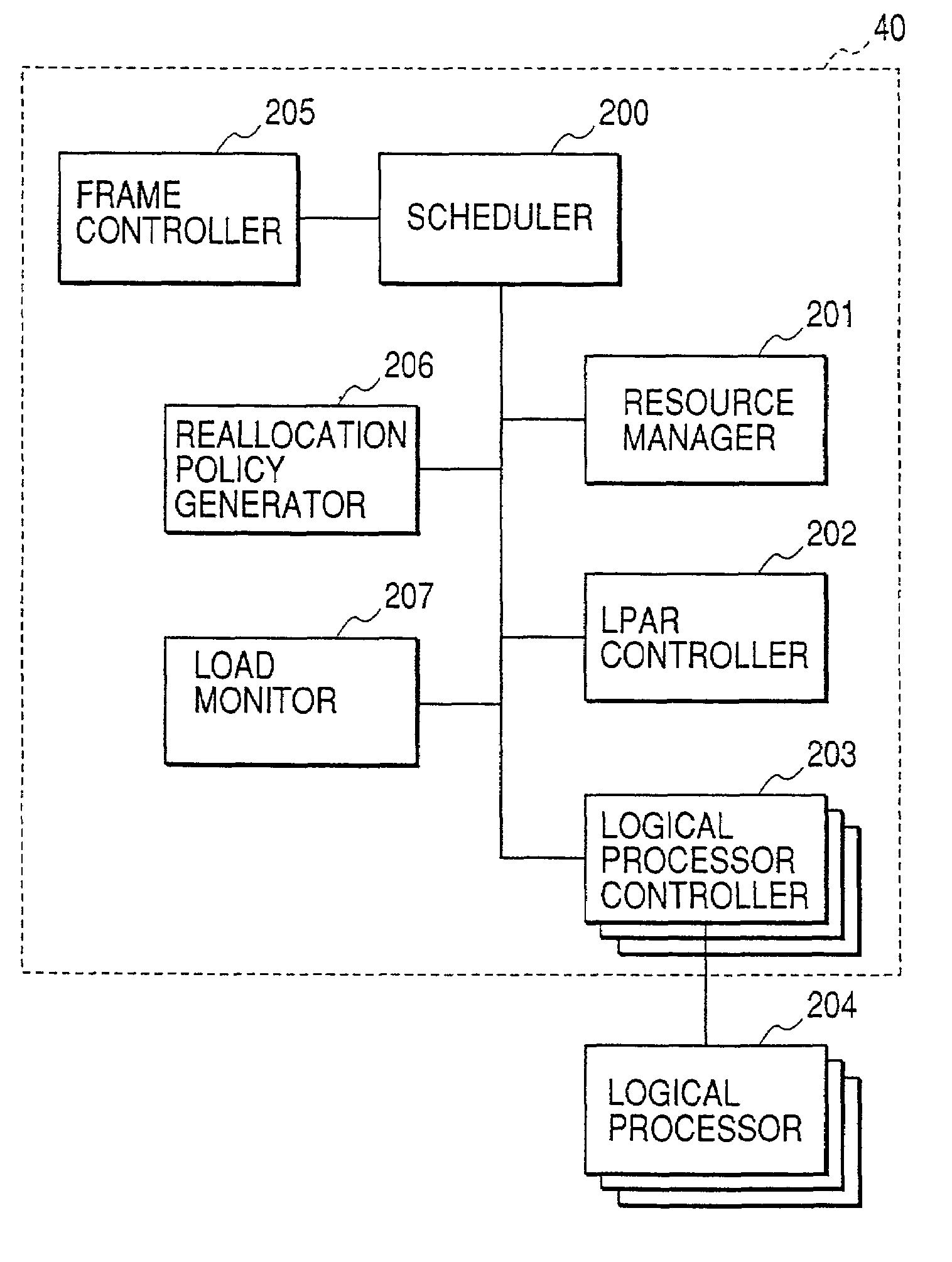

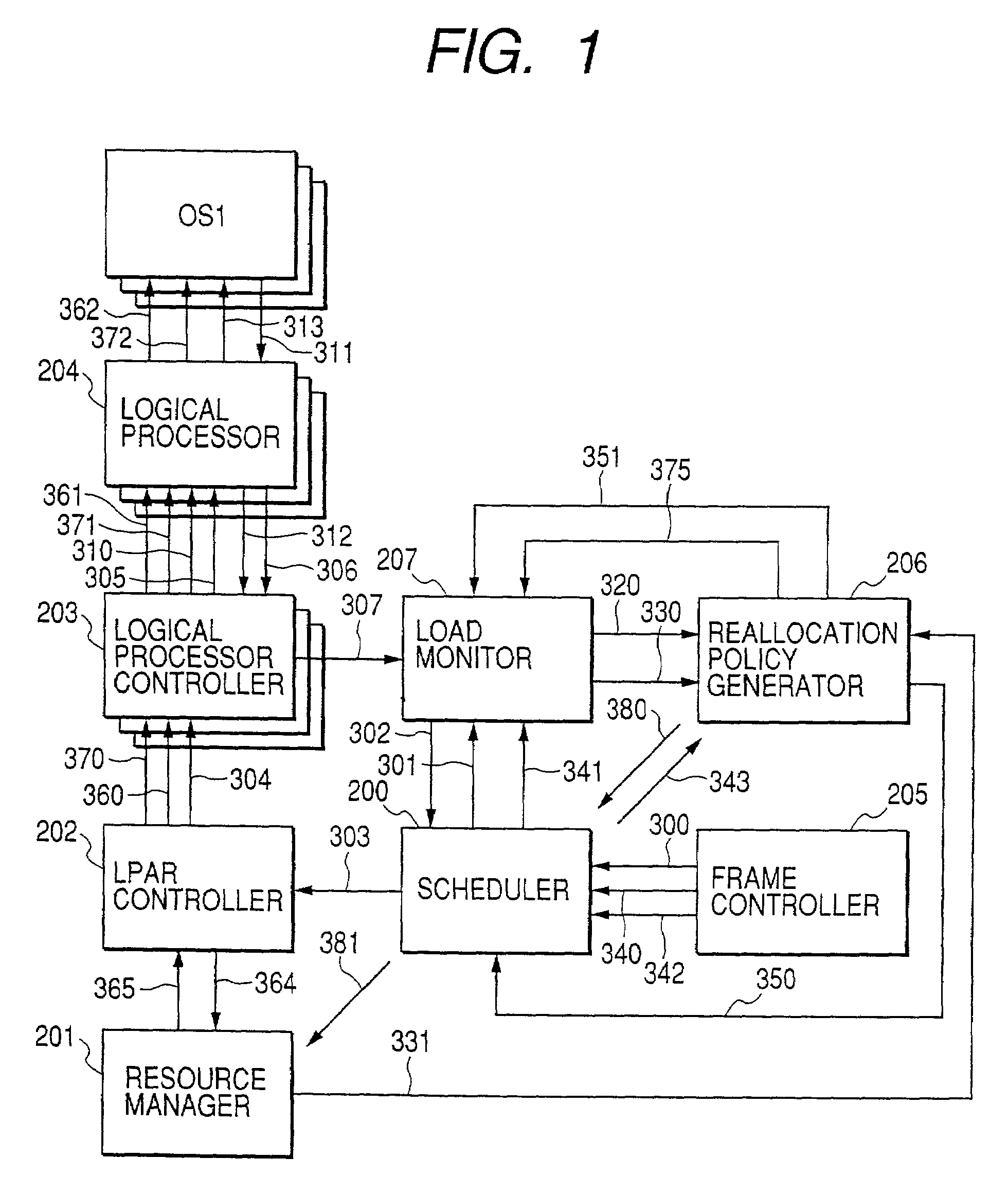

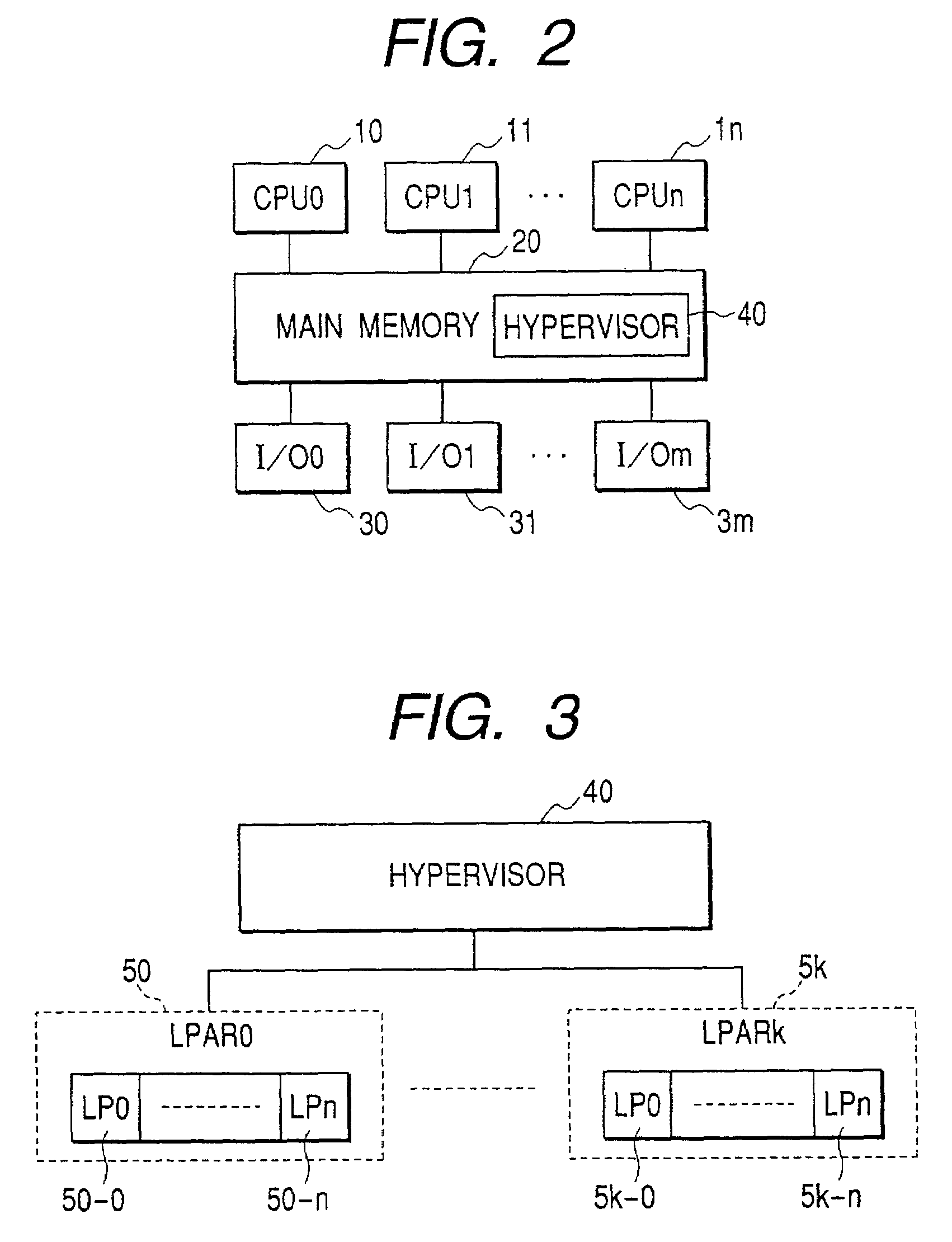

Virtual computer system with dynamic resource reallocation

InactiveUS7290259B2Increase the number ofGuaranteed performanceResource allocationError detection/correctionDynamic resourceVirtual computing

A virtual computer system including a reallocation means, in which a plurality of LPAR are operated by logically dividing physical resources composing a physical computer exclusively or in time dividing manner so as to dynamically change reallocation of physical resources among each of LPARs. Based on load conditions measured by an application or an OS of each LPAR, physical resource allocation to each LPAR is determined, thereby conducting reallocation of LPAR.

Owner:HITACHI LTD

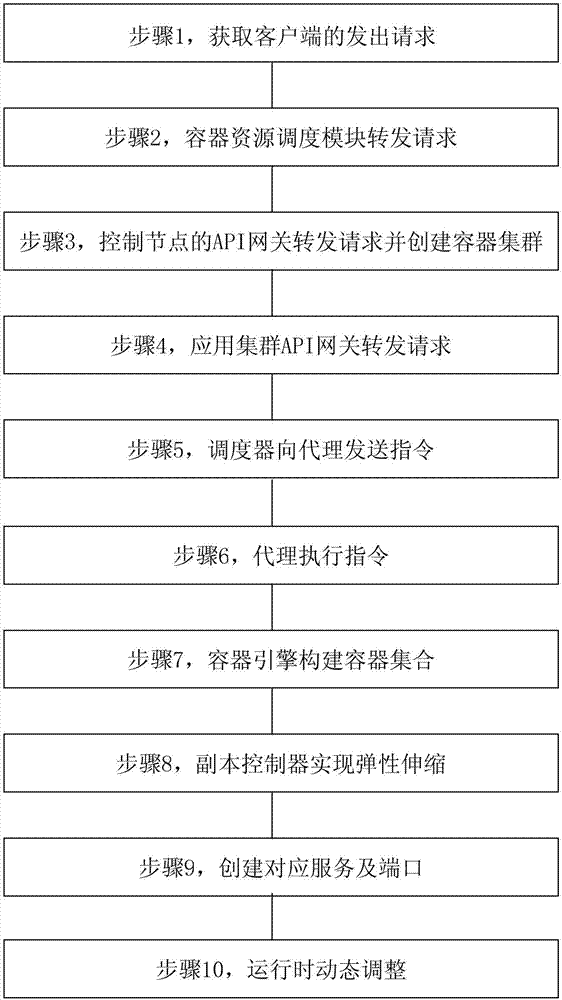

Large-scale container scheduling system and method based on cloud platform

ActiveCN107426034AImplement two-level schedulingGuaranteed concurrencyData switching networksSoftware simulation/interpretation/emulationVirtualizationClosed platform

The invention discloses a large-scale container scheduling system and method based on a cloud platform. The system comprises a control node for receiving and analyzing a request sent from a client and then sending the analyzed request to the cloud platform; the cloud platform for managing the container and creating underlying resource used by the container, and providing the virtual resource of the underlying cloud platform for the container. The method comprises the following steps: acquiring a sending request of the client; forwarding the request by the container resource scheduling module; forwarding the request through an API gateway of the control node and creating a container cluster; forwarding the request through an application cluster API gateway; sending an instruction to a proxy through a scheduler; executing the instruction by the proxy; and constructing a container set through a container engine, and realizing the elastic telescopic through a transcript controller; creating a corresponding server and port; and dynamically adjusting in running. The system disclosed by the invention not only can manage the container, but also can automatically provide the virtual resource of the underlying cloud platform.

Owner:INFORMATION COMM COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

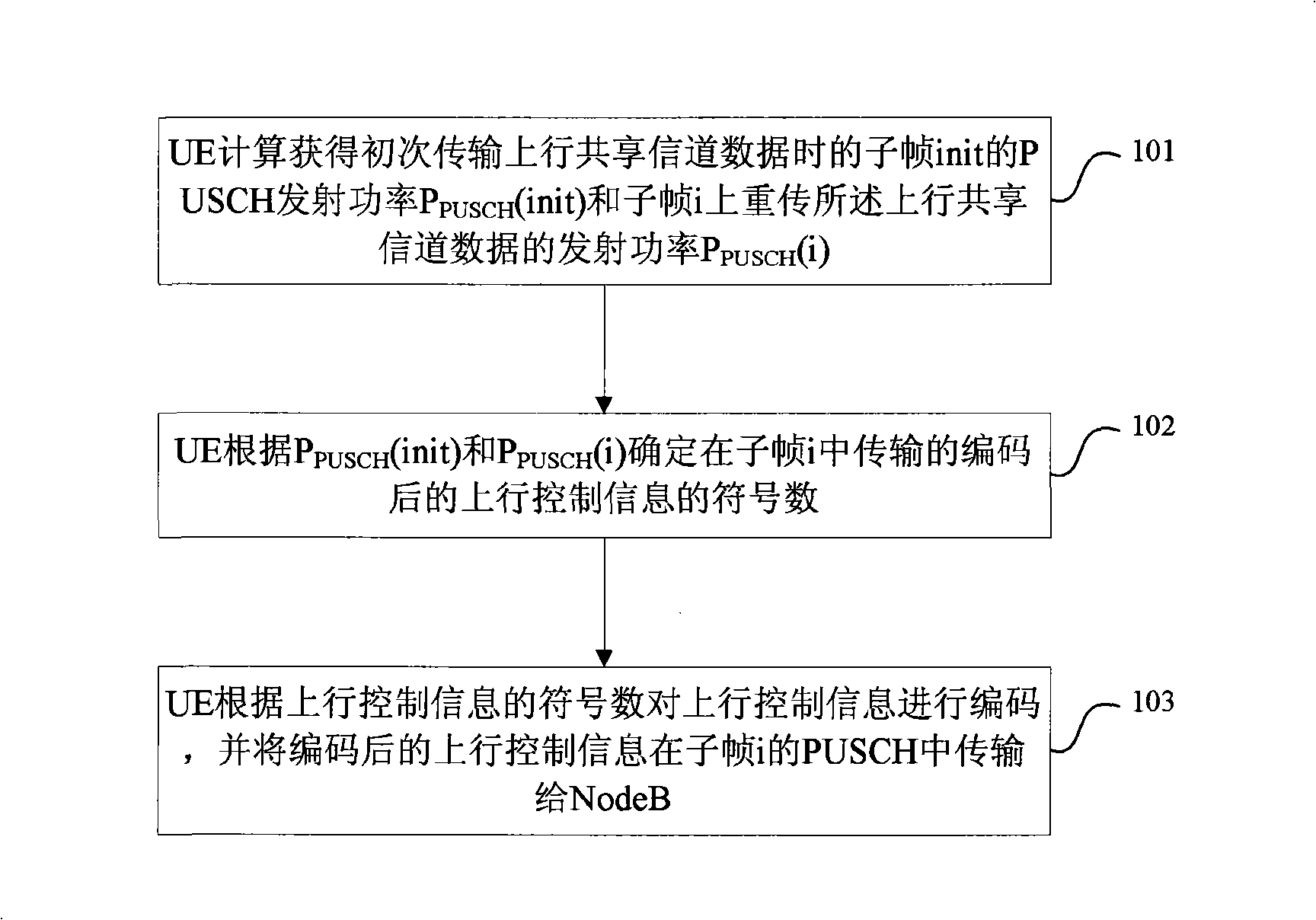

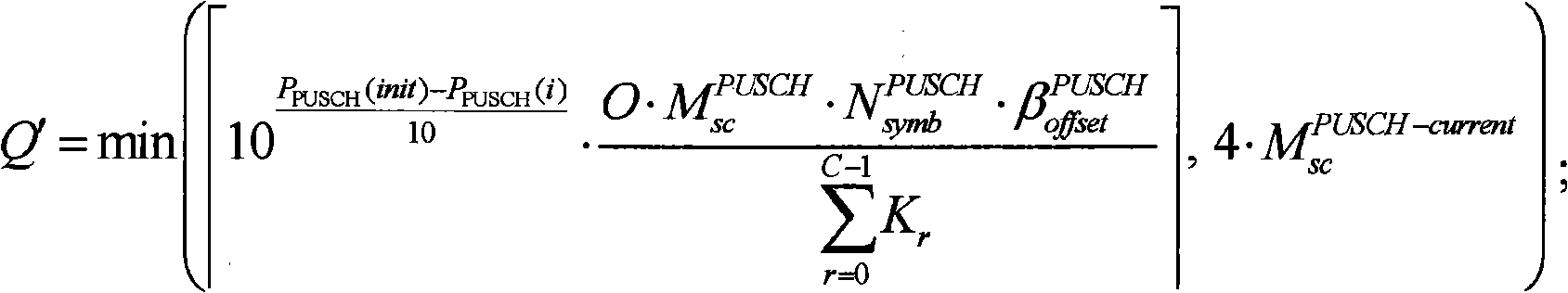

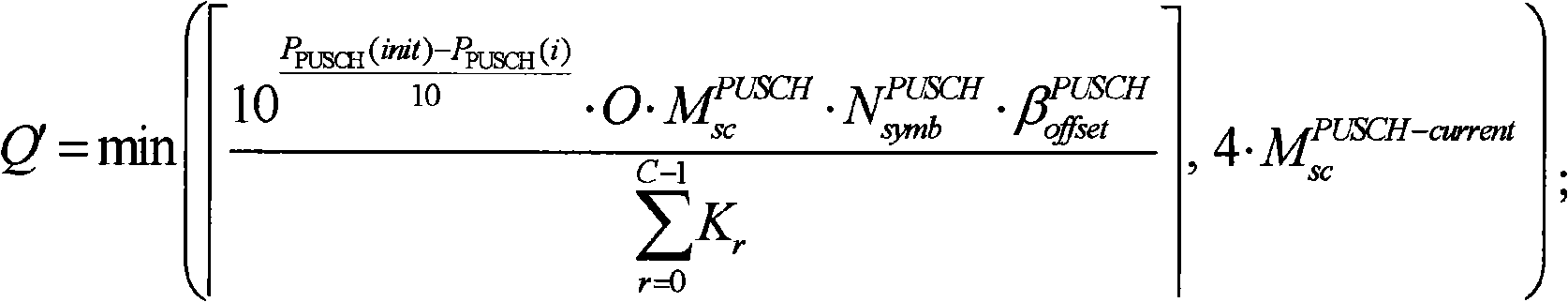

Method for transmitting ascending control information and method for calculating transmission parameter

ActiveCN101409894AGuaranteed performanceSystem performance guarantee caused by performance mismatchPower managementNetwork traffic/resource managementChannel dataInit

The invention provides a method for transferring uplink control information. The method comprises the steps as follows: when uplink shared channel data and the uplink control information are required to be transferred in an uplink shared channel PUSCH of a subframe i simultaneously, a user terminal obtains the transmission power P<PUSCH> (init) of primarily transferred uplink shared channel data and the transmission power P<PUSCH> (i) of the uplink shared channel data transferred in the subframe i; the user terminal confirms the symbol quantity of the uplink control information after being coded in the subframe i according to the comparison relation between P<PUSCH> (init) and P<PUSCH> (i) and the size and the bandwidth of a transmission block when the uplink shared channel data is transferred primarily; the user terminal codes the uplink control information according to the symbol quantity of the uplink control information after being coded and transfers the coded uplink control information to a base station in the PUSCH of the subframe i.

Owner:ZTE CORP

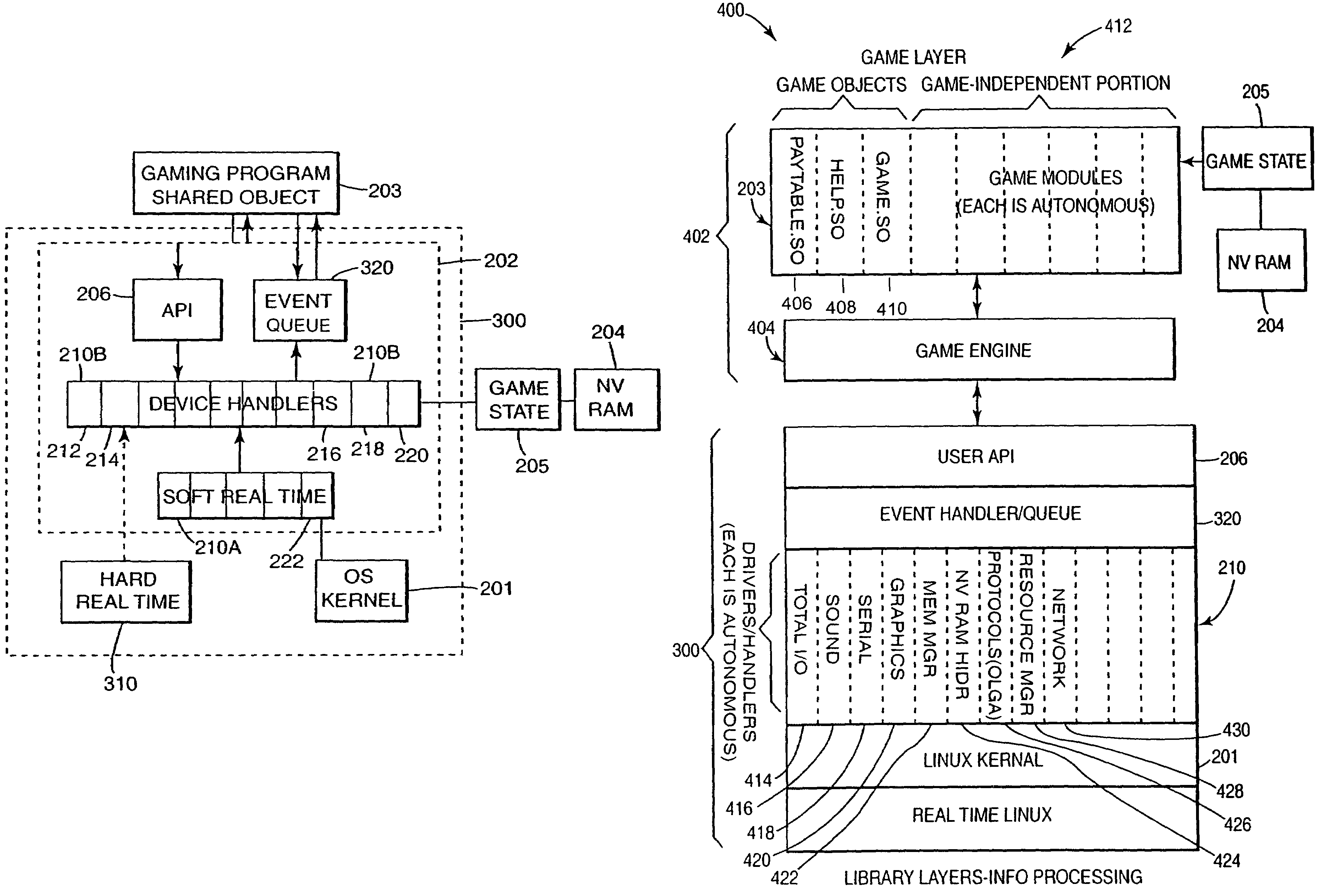

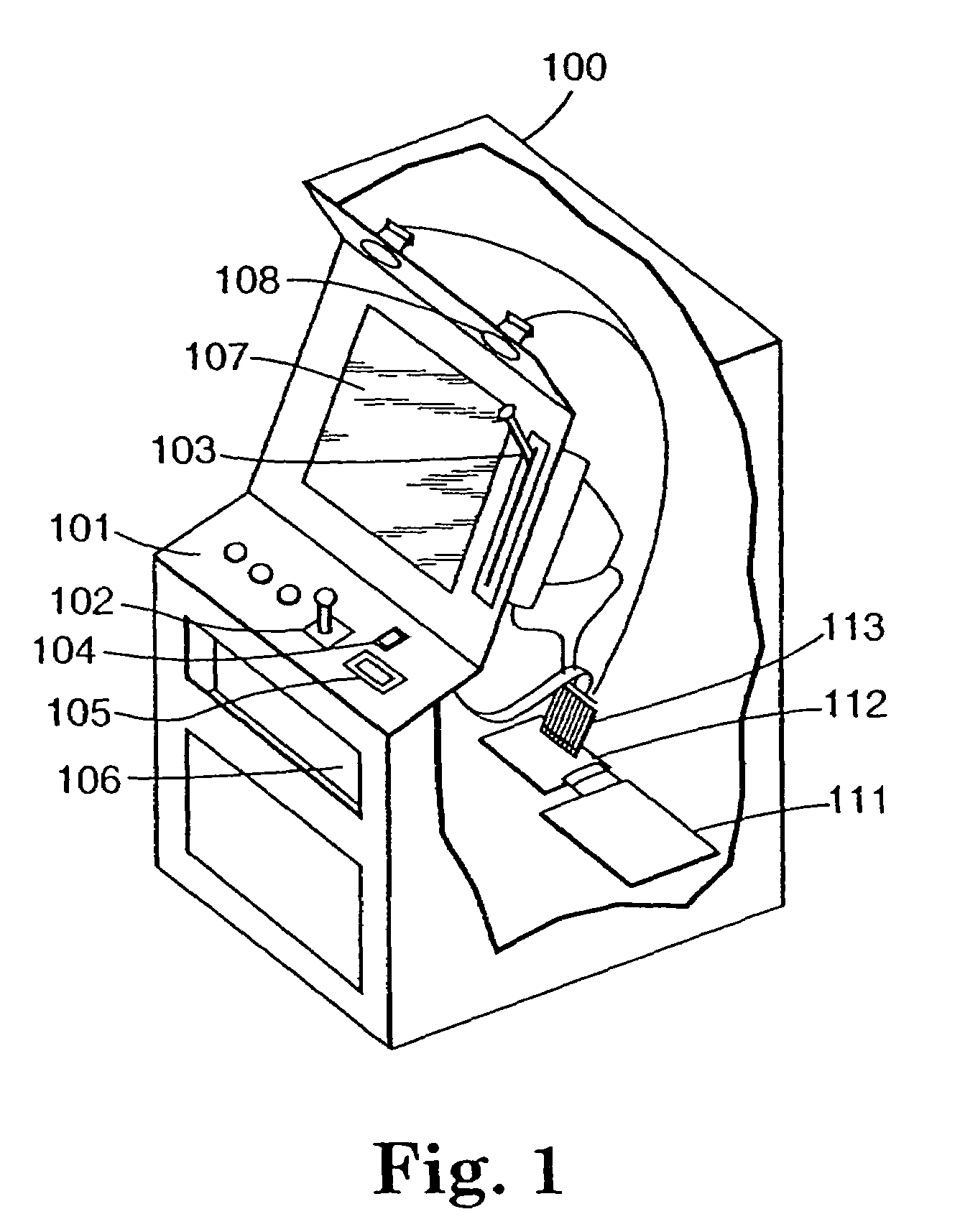

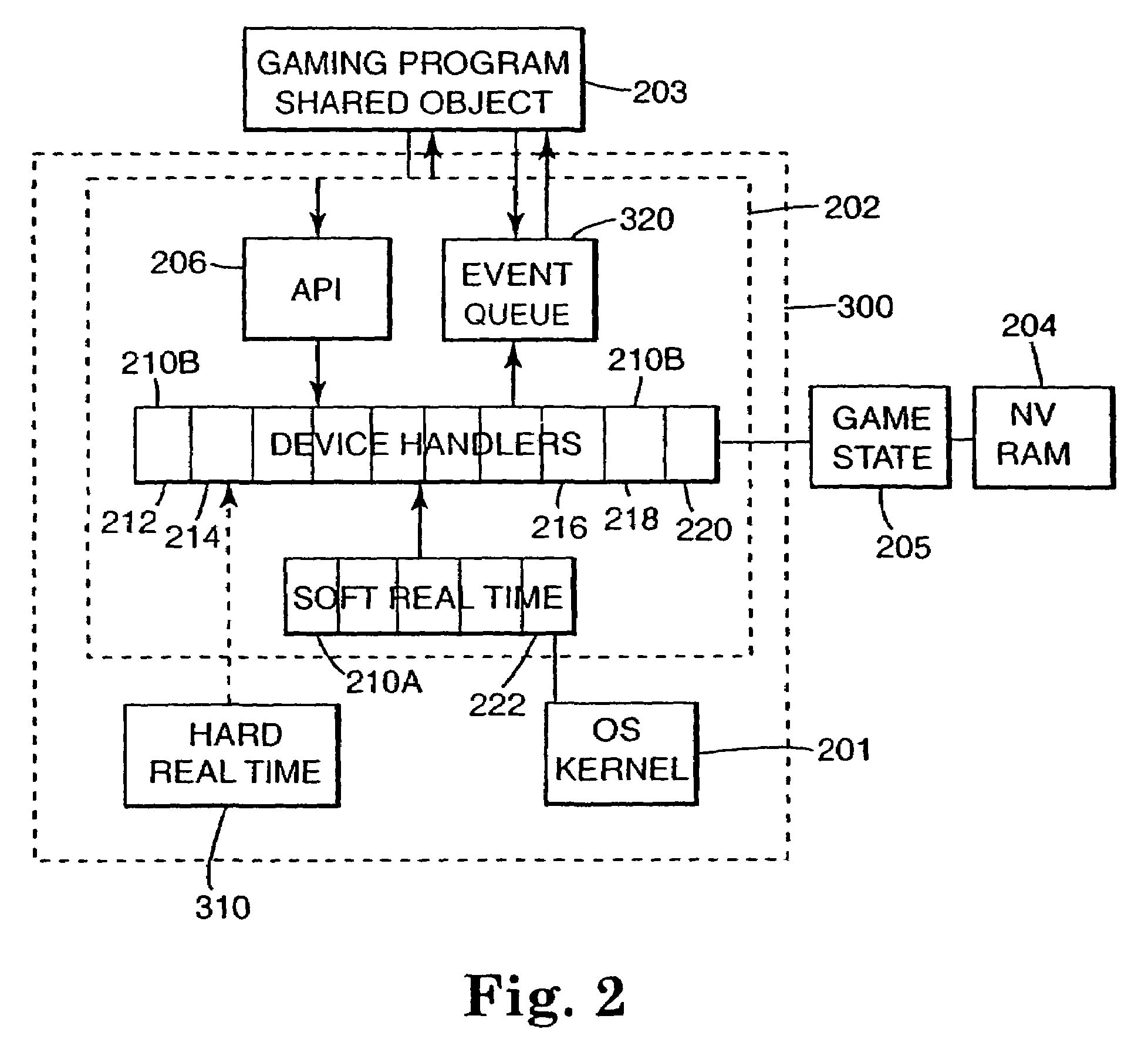

Method for developing gaming programs compatible with a computerized gaming operating system and apparatus

InactiveUS7618317B2Assured of performanceReduce approval timeMemory loss protectionComputer security arrangementsOperational systemApplication software

The present invention in various embodiments provides a computerized wagering game method and apparatus that features an operating system kernel, a system handler application that loads and executes gaming program shared objects and features nonvolatile storage that facilitates sharing of information between gaming program objects. The system handler of some embodiments further provides an API library of functions callable from the gaming program objects, and facilitates the use of callback functions on change of data stored in nonvolatile storage. The nonvolatile storage also provides a nonvolatile record of the state of the computerized wagering game, providing protection against loss of the game state due to power loss. The system handler application in various embodiments includes a plurality of device handlers, providing an interface to selected hardware and the ability to monitor hardware-related events.

Owner:IGT

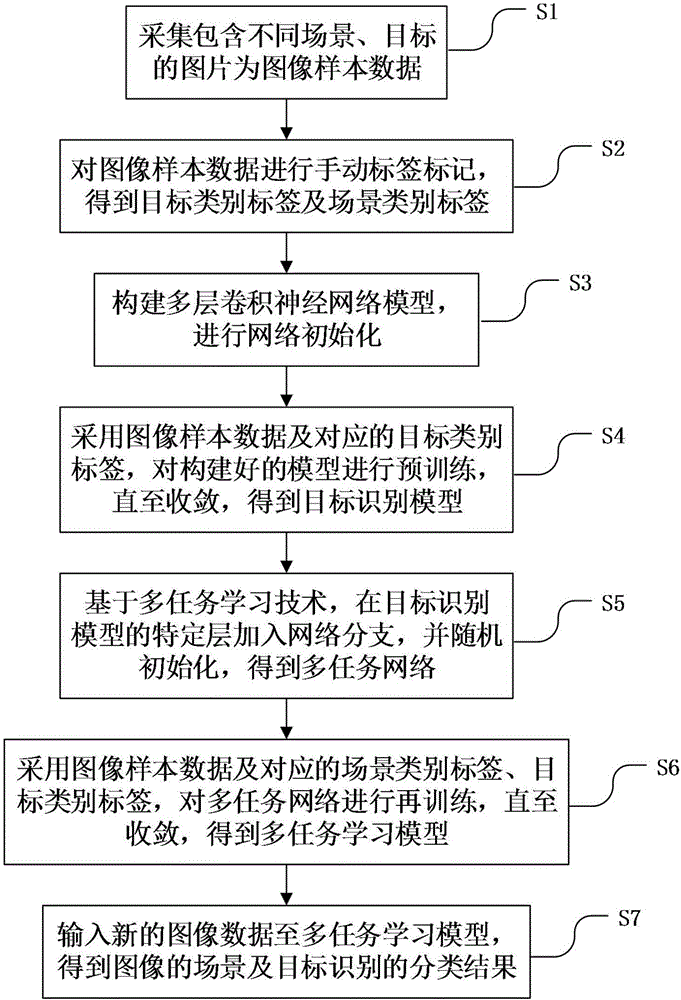

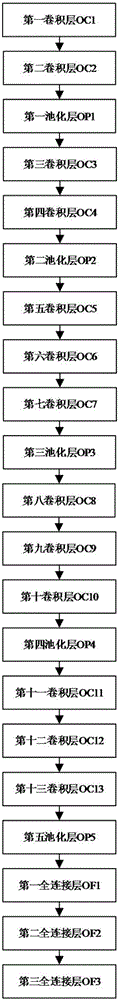

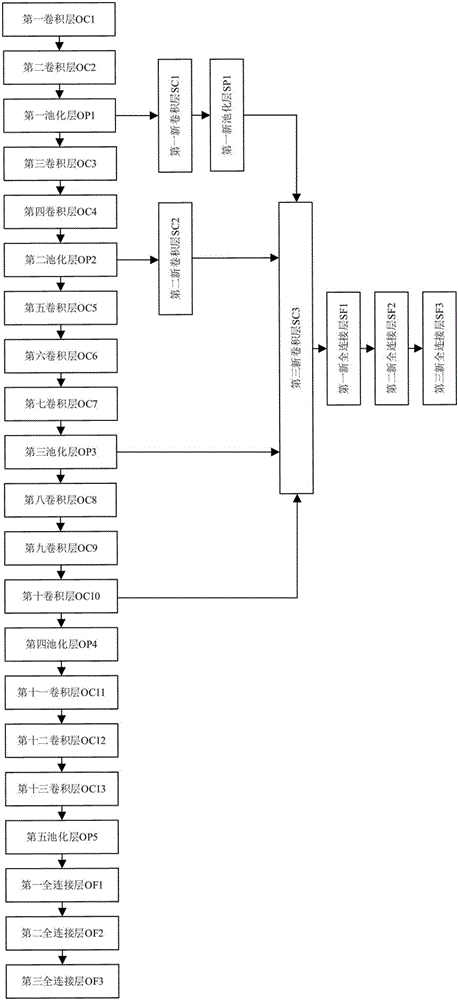

Scene and target identification method and device based on multi-task learning

InactiveCN106845549ARealize integrated identificationImprove single-task recognition accuracyCharacter and pattern recognitionNeural architecturesTask networkGoal recognition

The invention relates to a scene and target identification method and device based on multi-task learning. The method comprises the steps that pictures containing different scenes and targets are collected as image sample data; the image sample data is subjected to manual label marking, and target class labels and scene class labels are obtained; a multi-layer convolutional neural network model is built, and network initialization is conducted; the image sample data and the corresponding target class labels are adopted for pre-training the built model till convergence, and a target identification model is obtained; based on a multi-task learning technology, network branches are added into a specific layer of the target identification model, random initialization is conducted, and a multi-task network is obtained; the image sample data and the corresponding scene class labels and target class labels are adopted for e-training the multi-task network till convergence, and a multi-task learning model is obtained; new image data is input to the multi-task learning model, and classification results of scene and target identification of images are obtained. Accordingly, the single task identification precision is improved.

Owner:珠海习悦信息技术有限公司

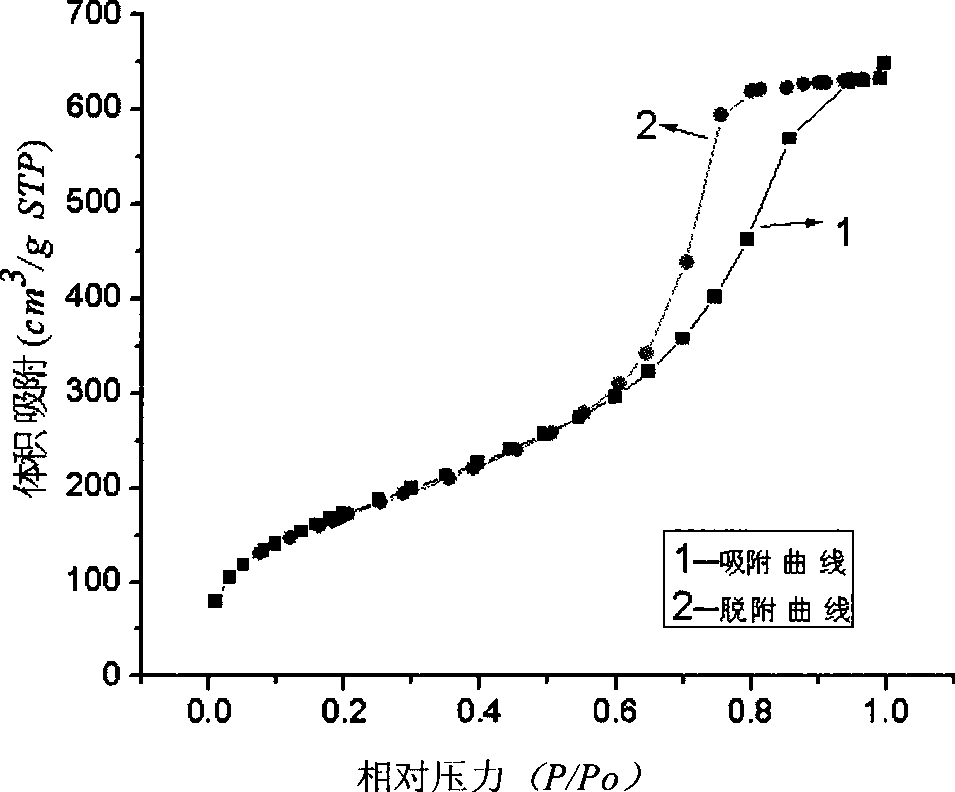

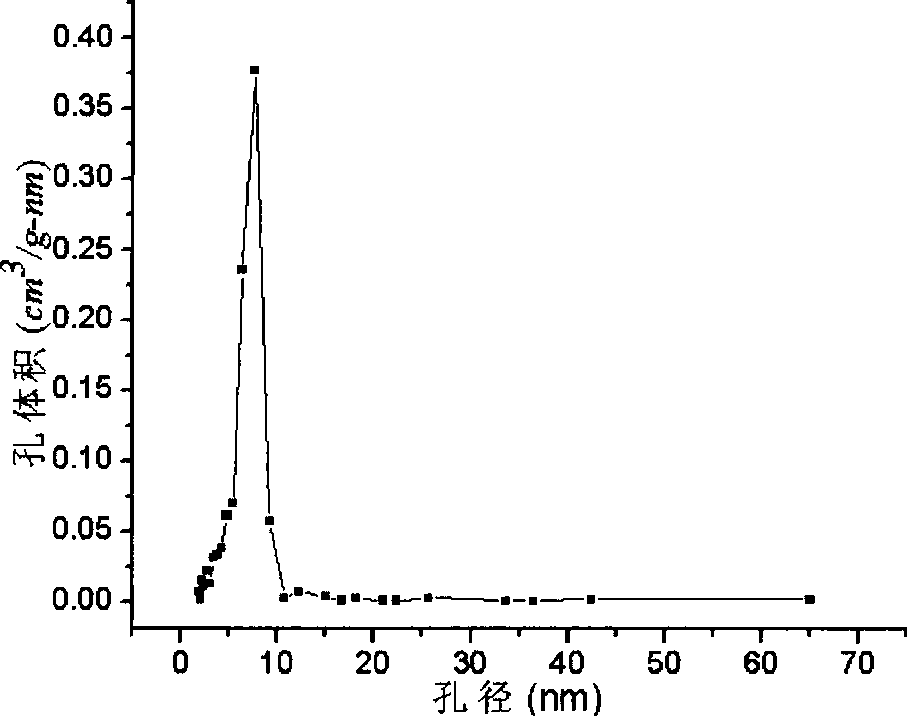

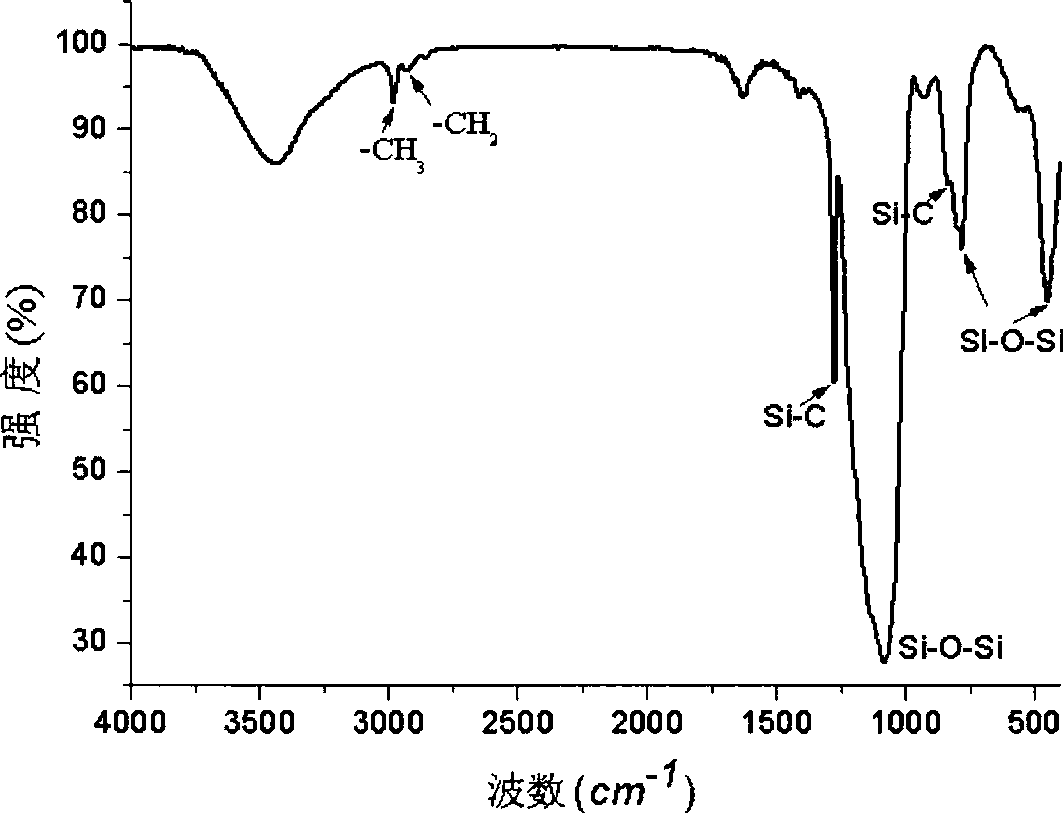

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

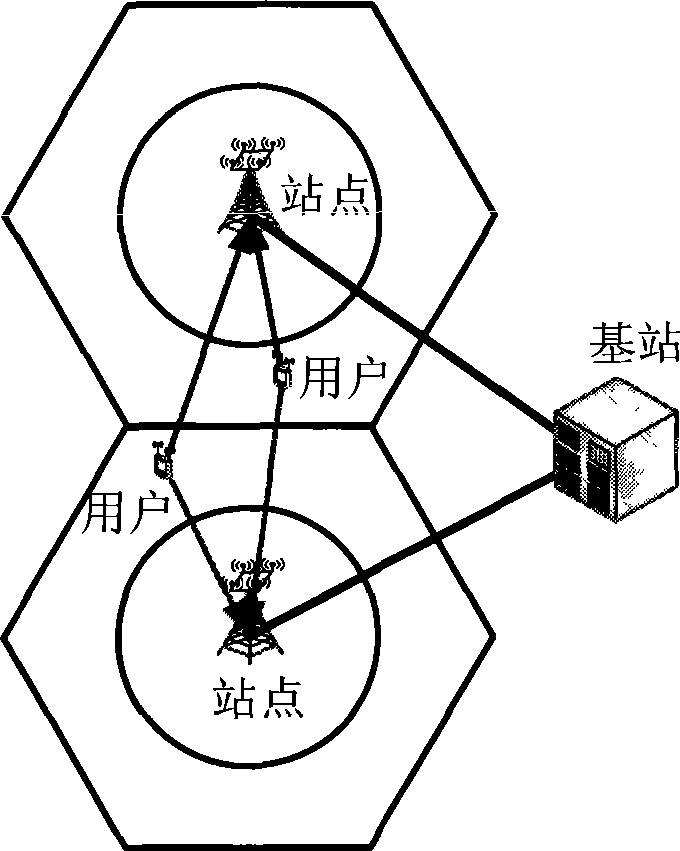

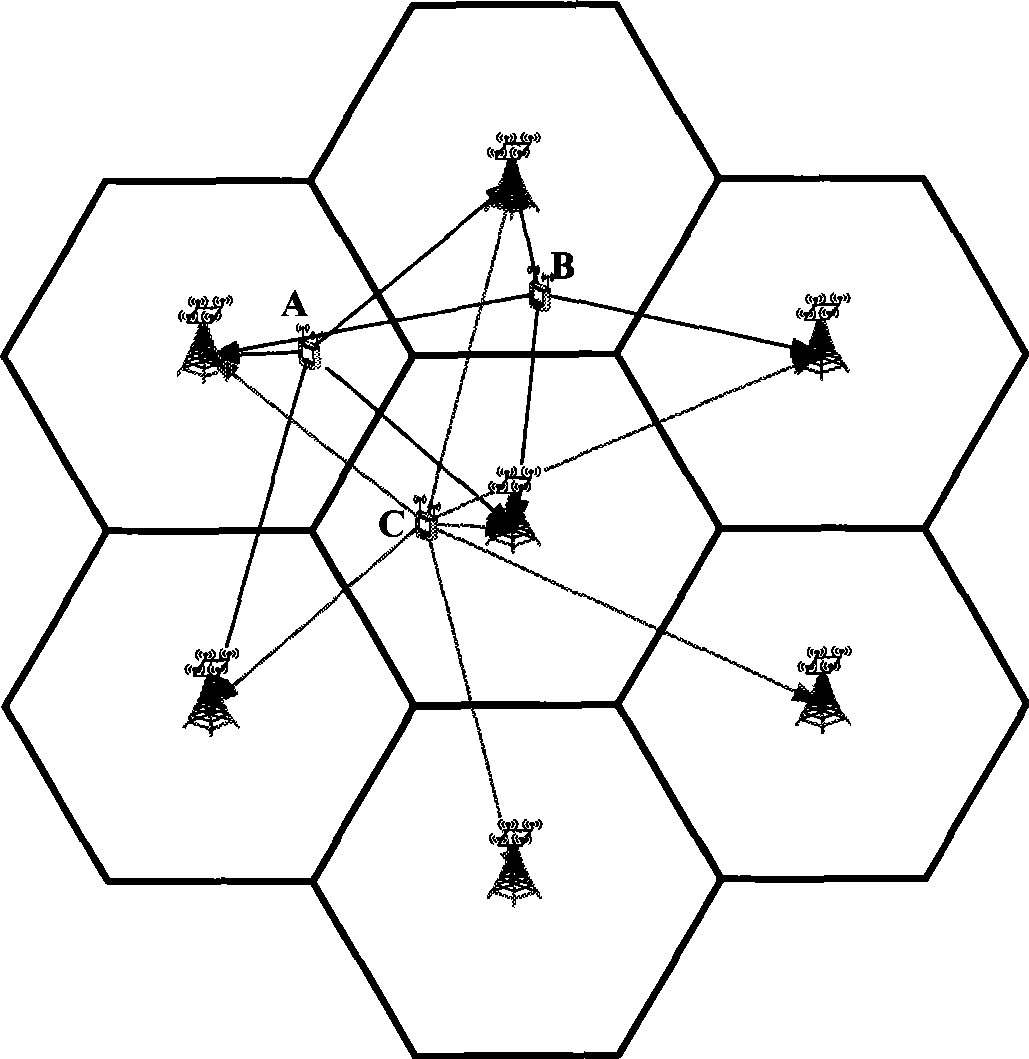

Uplink multipoint collaboration implementing method combining inter-cell interference coordination

InactiveCN101483873ASimplify the division processGuaranteed CompatibilitySite diversityNetwork planningNonlinear methodsClassification methods

The invention relates to a realization method for the uplink multipoint cooperation (CoMP) combining with inter-cell interference coordination (ICIC), which comprises the following steps: 1) a site measures the SINR of the user to judge whether the user is a marginal user or a central user and distributes the working frequency band of the user based on ICIC frequency band classification method; 2) the user sends data to the cell according to the distributed working frequency band; 3) the site judges whether the site or the business of the user supports CoMP; if CoMP is not supported, the data is extracted by a linear or nonlinear method; if CoMP is supported, step 4) is followed; 4) the cell receives the sent data and processes the data. The method ensures the compatibility of CoMP and ICIC proposals, which can improve the marginal throughput of the cell and the average throughput of the system.

Owner:XIDIAN UNIV

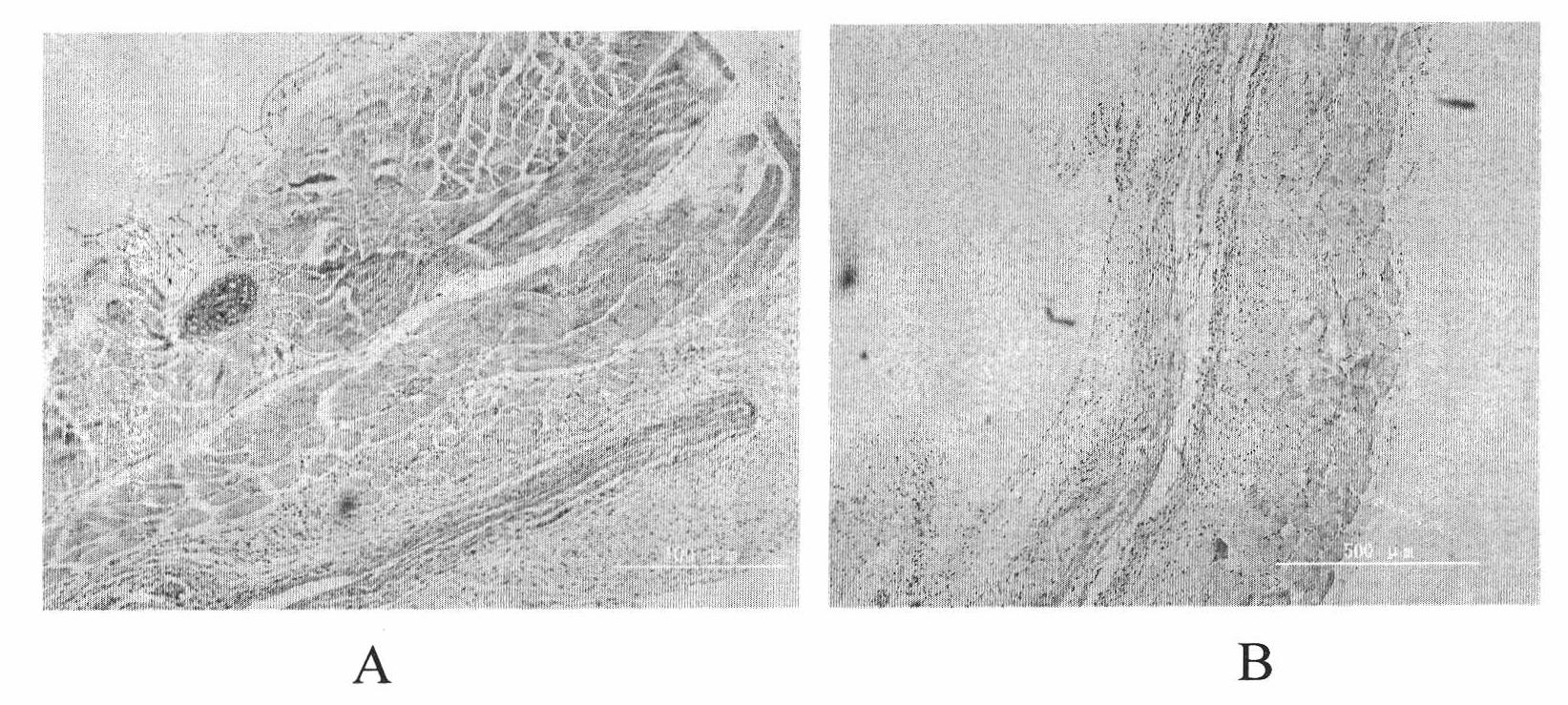

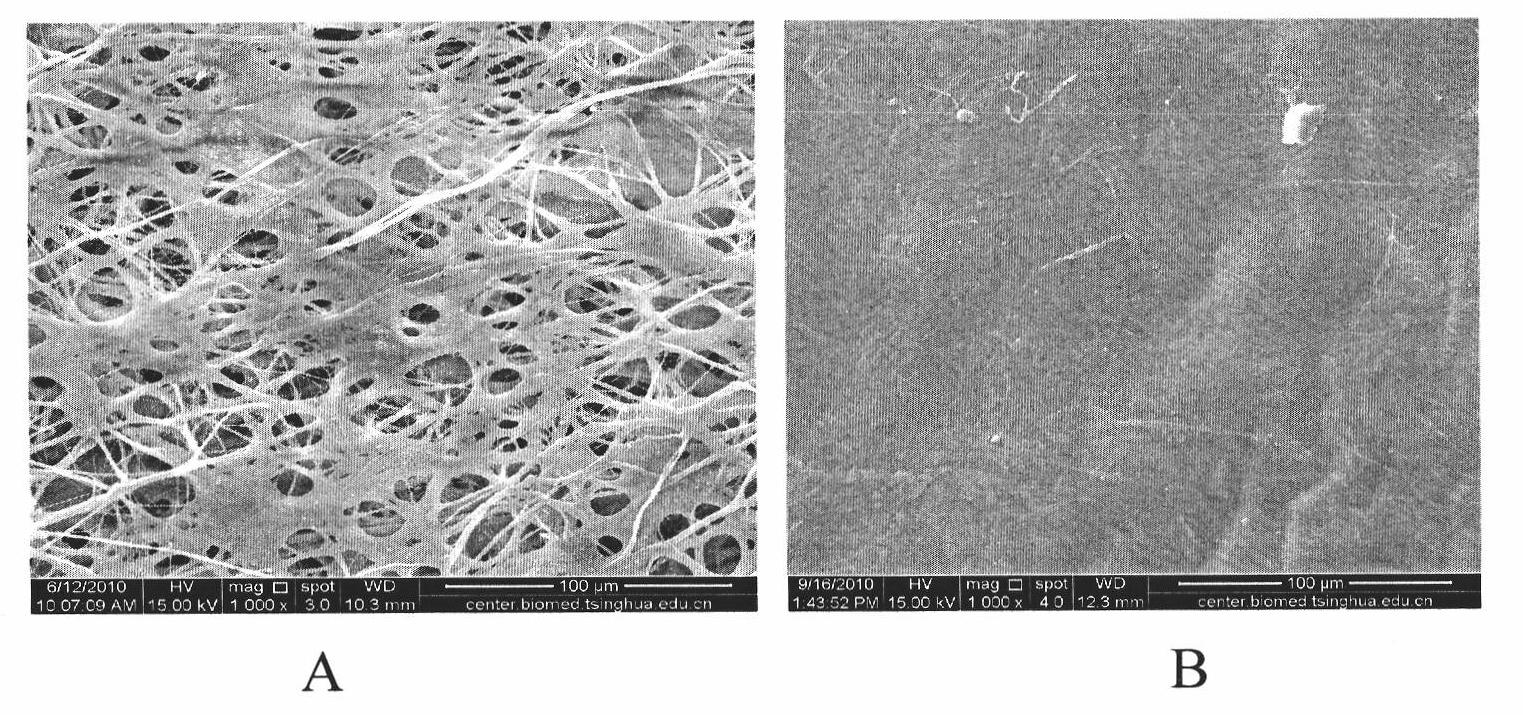

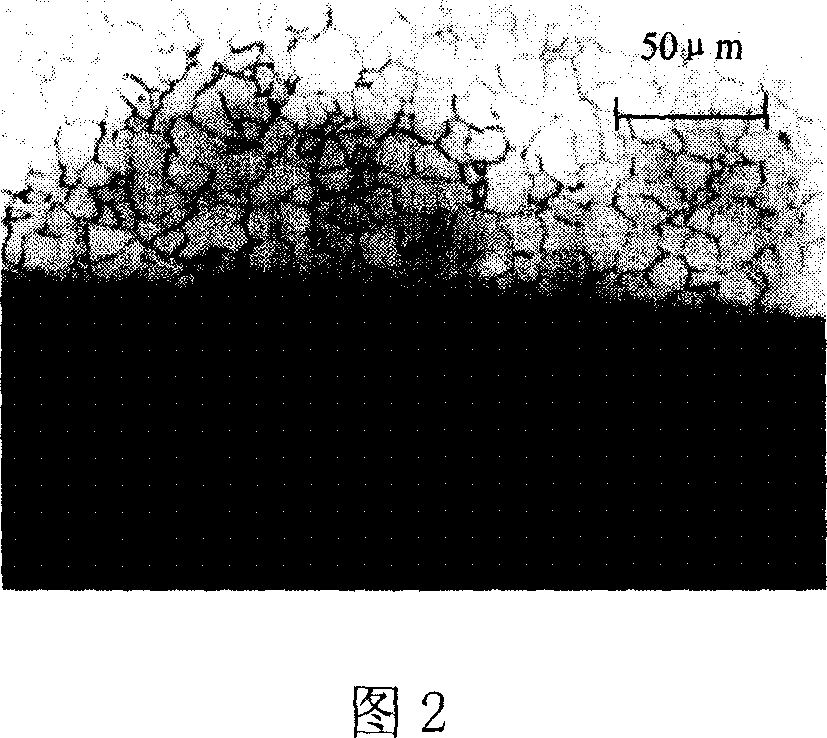

Small intestinal submucosa (SIS) soft tissue repair patch and preparation method thereof

InactiveCN102462561AImprove surface porosityImprove biological activityProsthesisTissue repairSoft tissue.FNA

The invention relates to a method for preparing a small intestinal submucosa (SIS) soft tissue repair patch, and the soft tissue repair patch prepared by the method. The invention also relates to application of the soft tissue repair path to tissue repair.

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

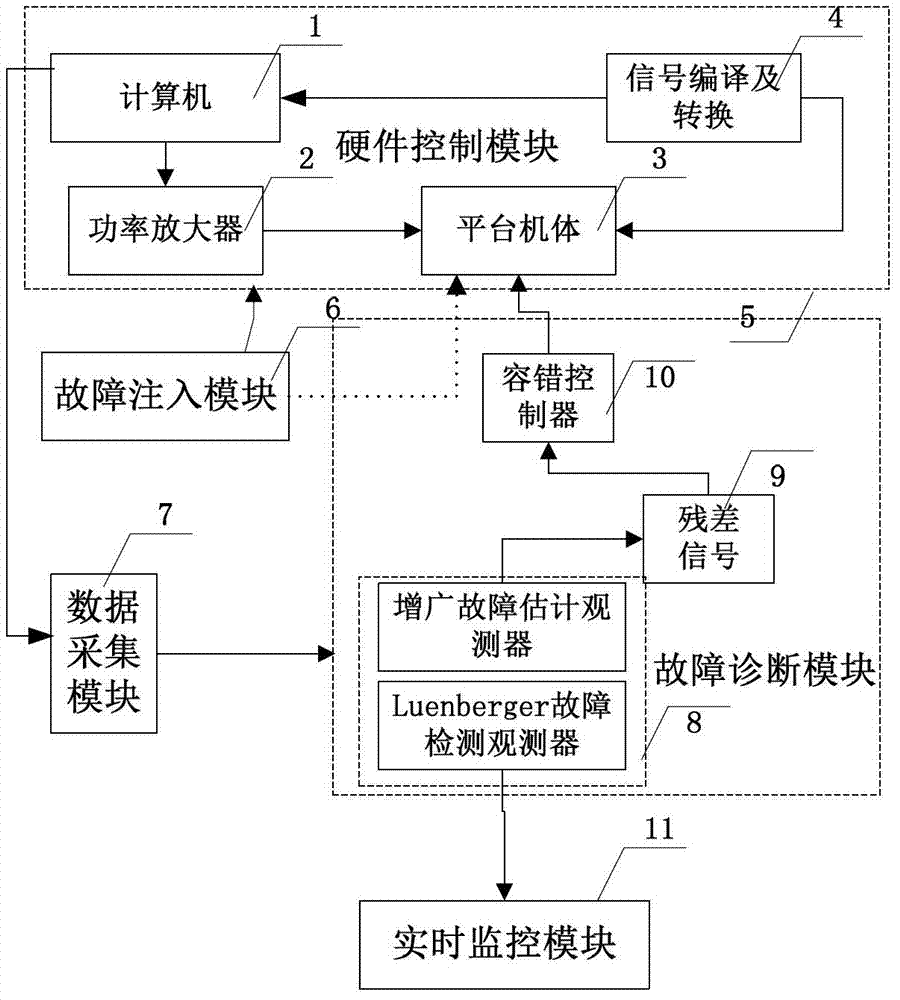

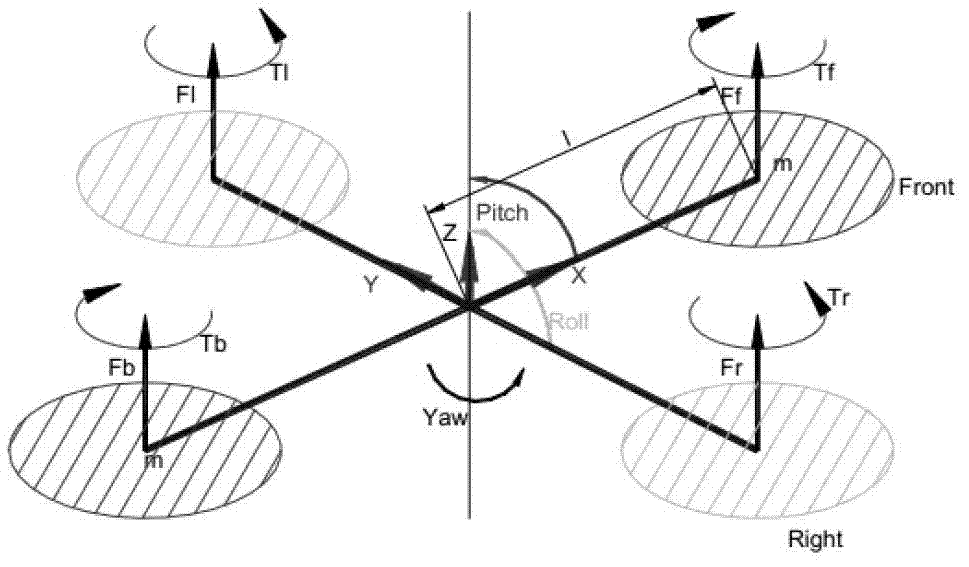

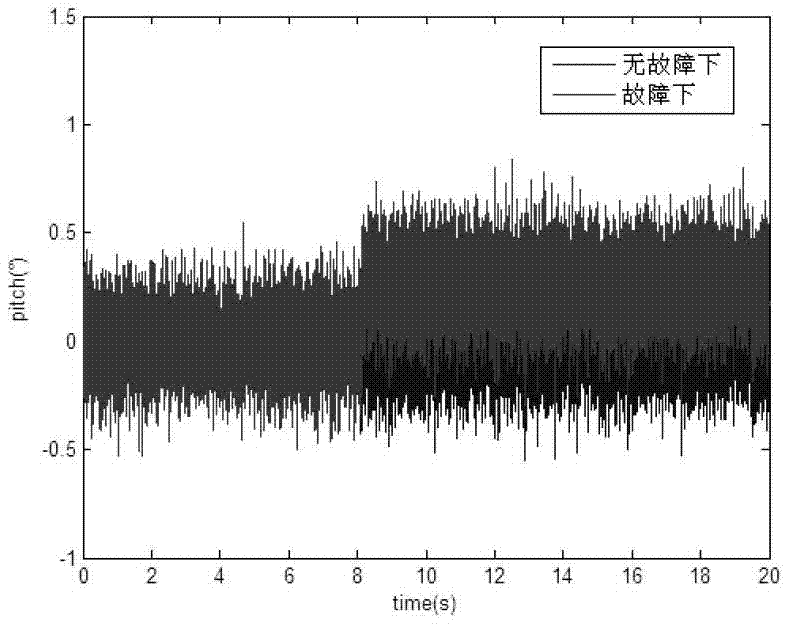

A plurality of united observer based fault diagnosis and fault-tolerant control device and method

ActiveCN102854874AAvoid serious coupling problemsAvoid errorsElectric testing/monitoringAviationDiagnosis methods

The invention discloses a plurality of united observer based fault diagnosis and fault-tolerant control device and a method and belongs to the field of aerospace. The plurality of united observer based fault diagnosis and fault-tolerant control device comprises following modules of a fault injection module, a fault diagnosis module, a real time monitoring module and a hardware control module. According to the method, the problem that traditional observer based fault diagnosis methods are limited by conditions is mainly solved, the operation is simple, the implementability is high, and the method can be used for diagnosing faults of actuating mechanisms of a four rotor wing helicopter and verifying feasibility of state monitoring.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

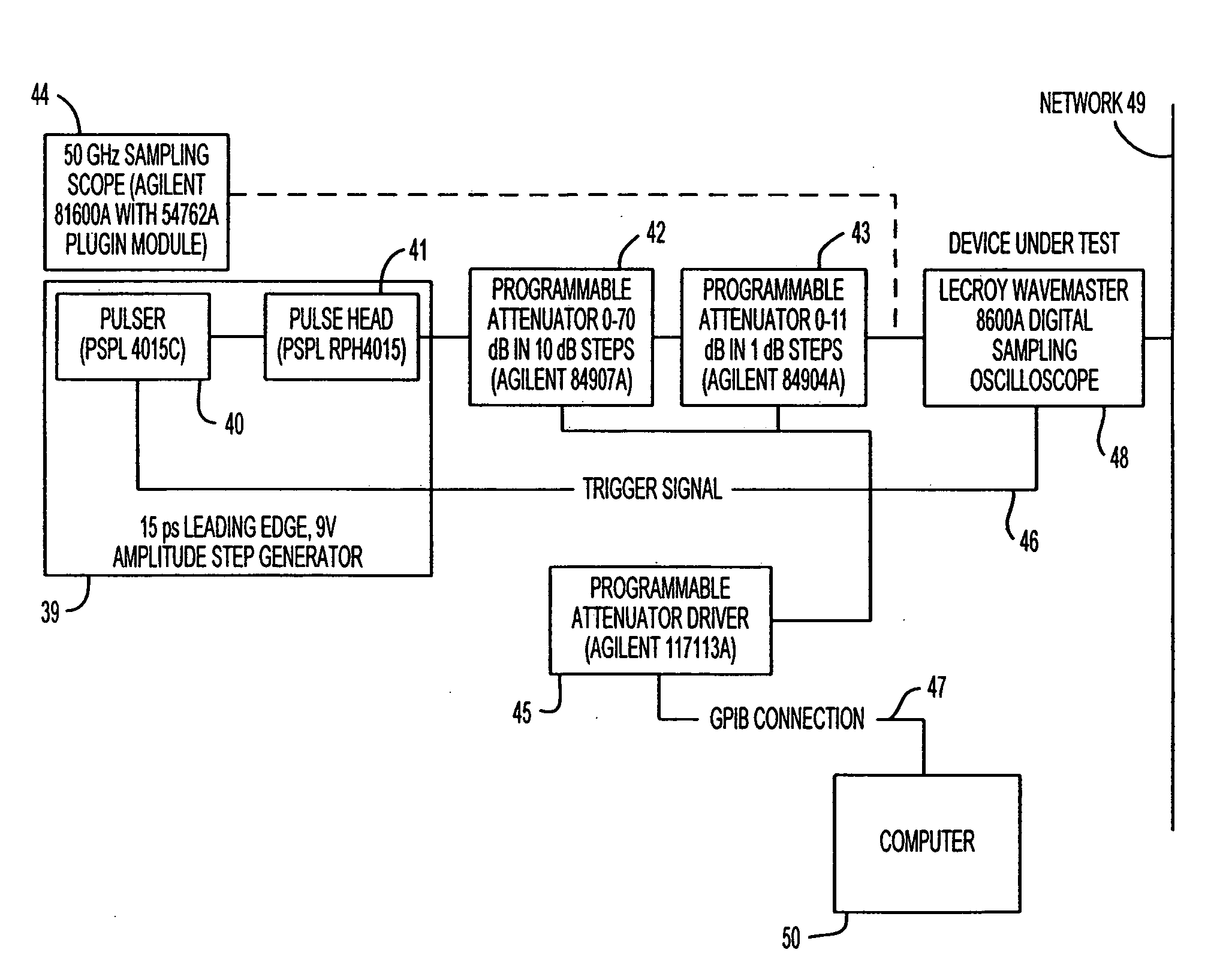

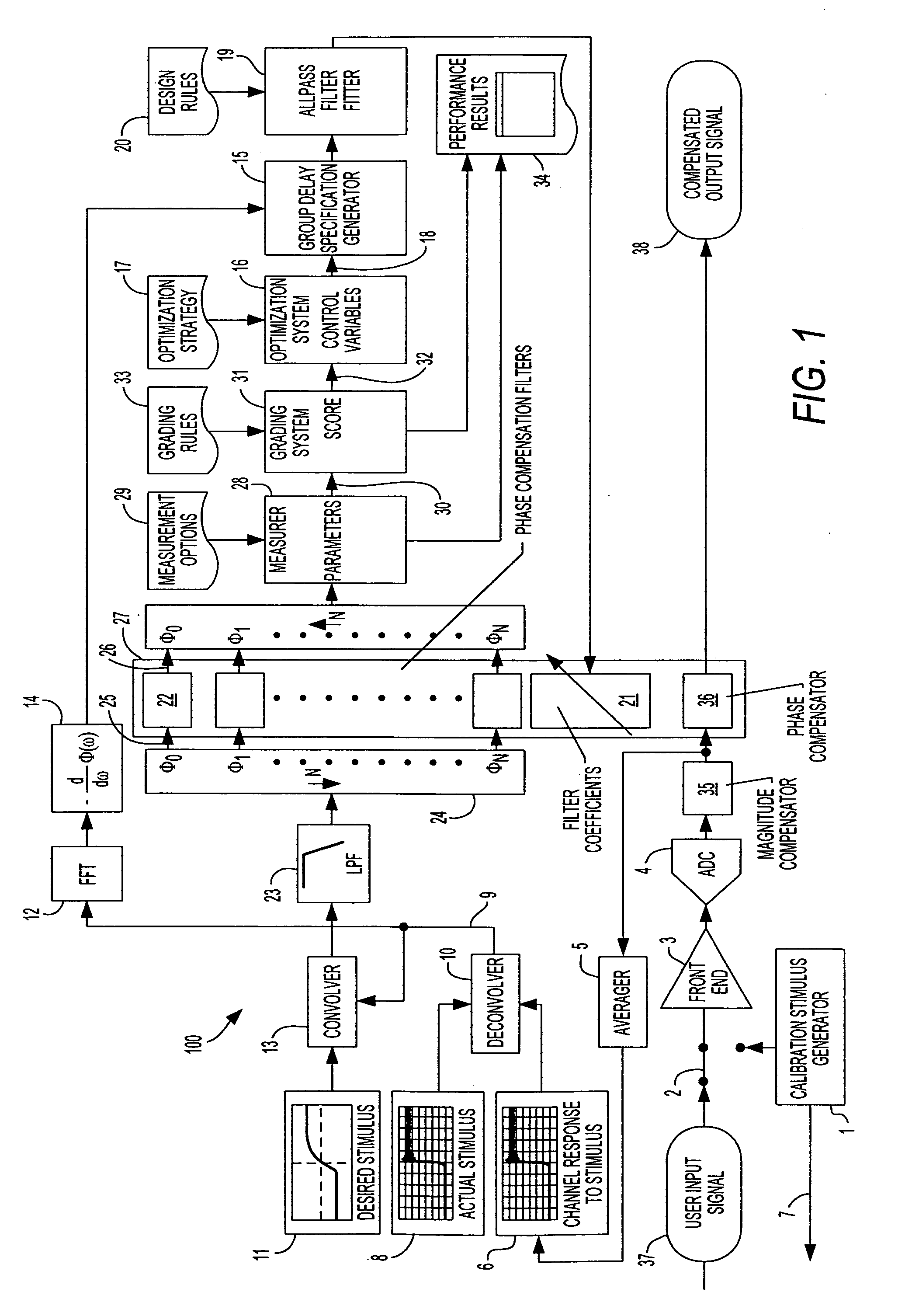

Digital group delay compensator

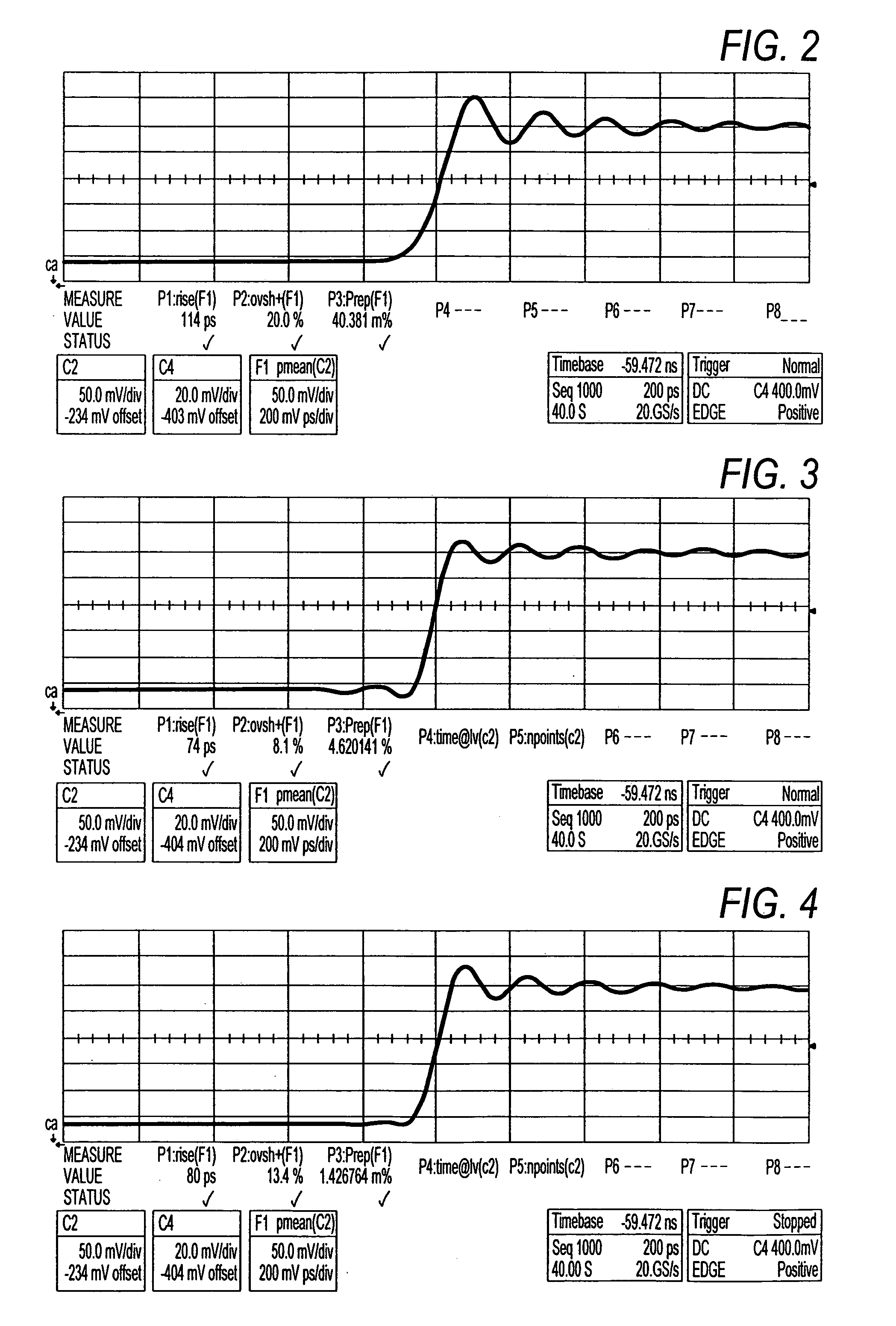

ActiveUS7050918B2Reliable compensationGuaranteed performanceMultiple-port networksDigital variable displayElectrical and Electronics engineeringAll-pass filter

A digital group delay compensation system comprising a digital allpass filter that is utilized in an implementation phase; and a system that generates coefficients for the allpass filter used in the implementation phase such that the overall performance of a system is measured and optimized in a calibration phase.

Owner:TELEDYNE LECROY

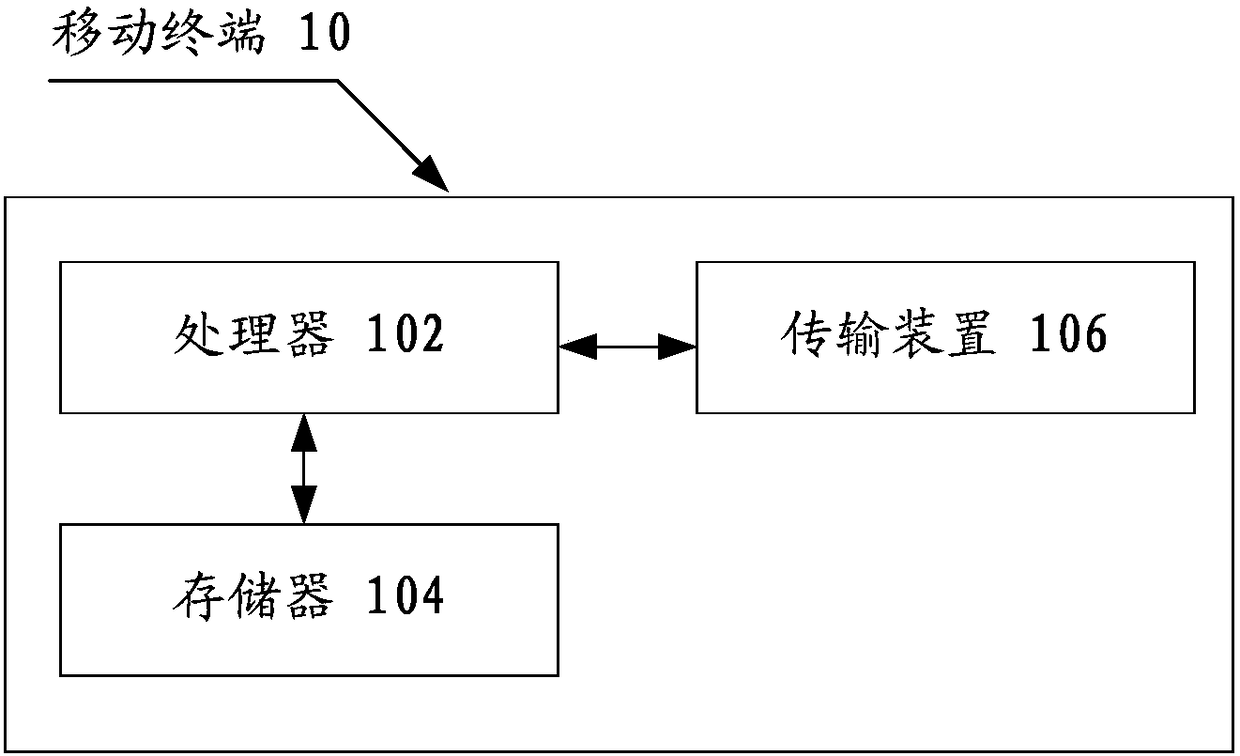

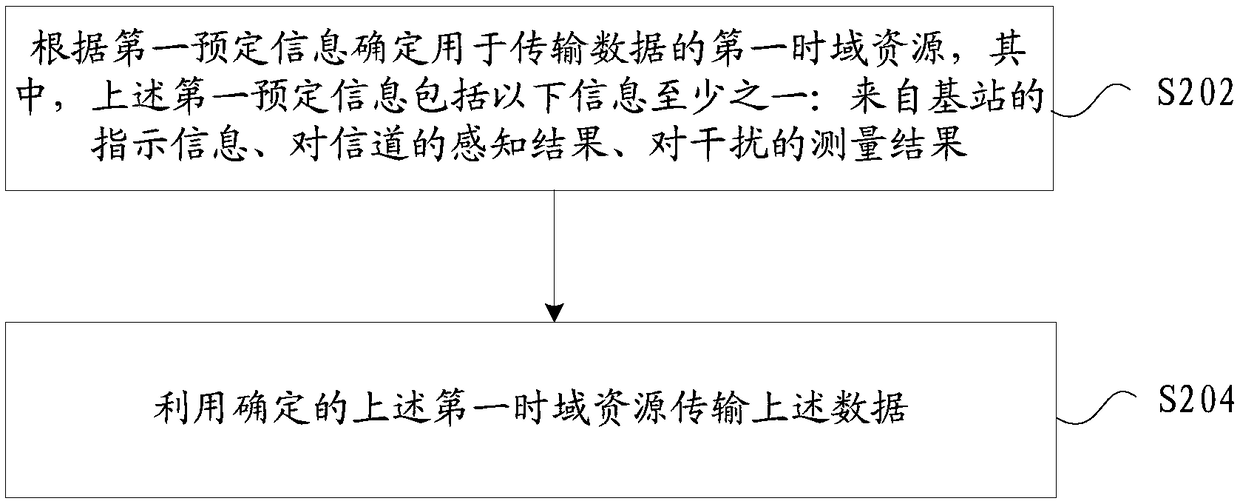

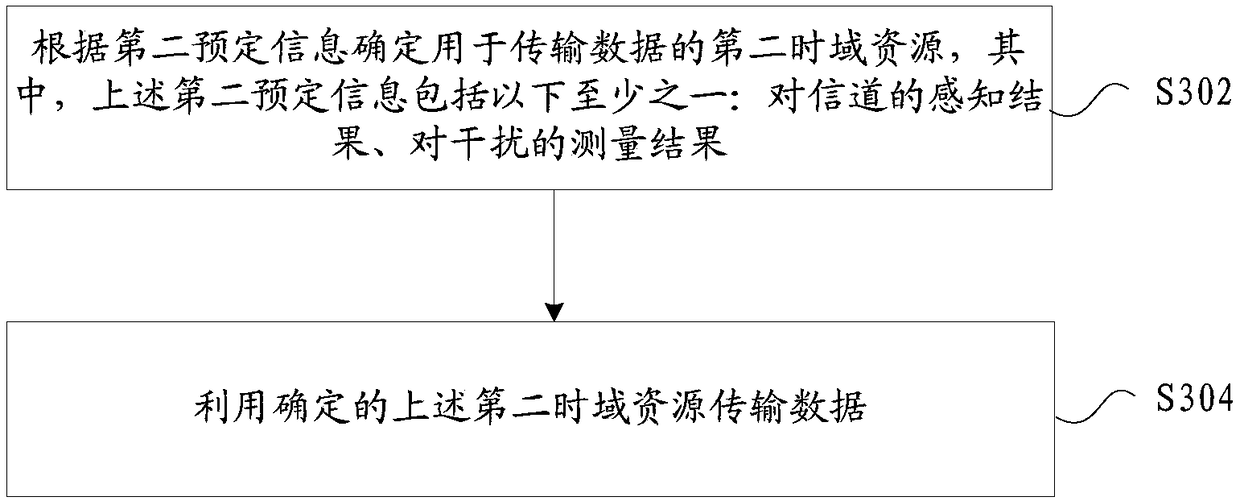

Data transmission method and device

ActiveCN108282879AReduce distractionsGuaranteed performanceTransmission path divisionCriteria allocationData transmissionBase station

The invention provides a data transmission method and device. The method comprises the steps of determining a first time domain resource for transmitting data according to first preset information, wherein the first preset information comprises a piece of the following information: indication information from a base station, a sensing result for a channel and an interference measurement result; and transmitting the data through utilization of the determined first time domain resource. Through application of the method and the device, the problem that in related technologies, dynamic uplink anddownlink data sending cannot be realized according to business demands is solved, and the effect that the data transmission interference is reduced, the data transmission probability is improved andthe system performance is ensured is achieved.

Owner:ZTE CORP

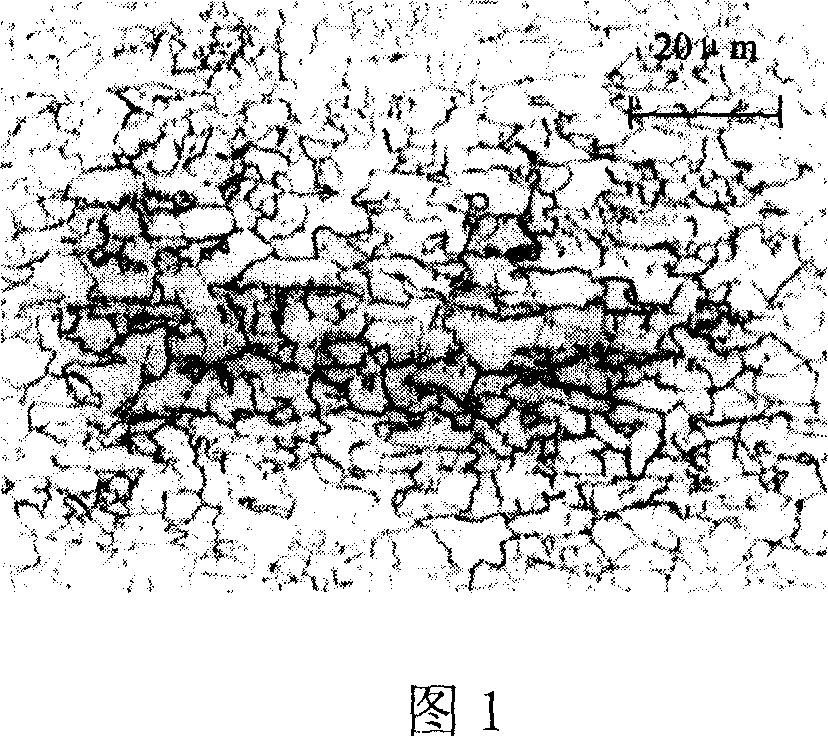

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

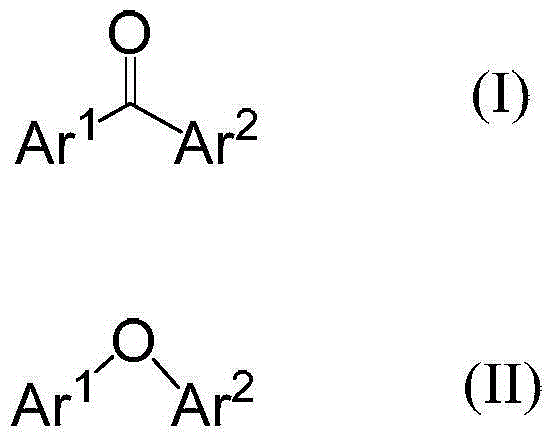

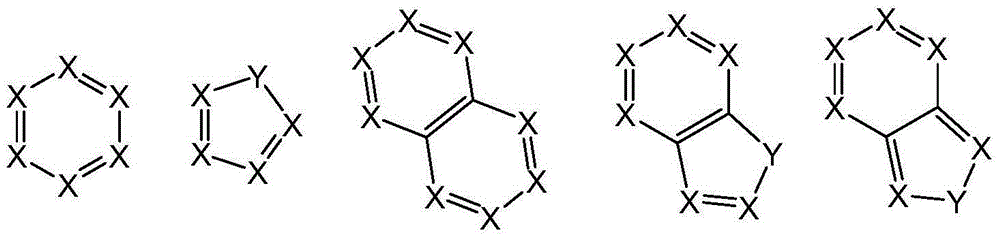

Printing ink and electronic device printed by applying printing ink

ActiveCN105038408AGuaranteed performanceEasy to printFrom normal temperature solutionsInksOrganic solventEther

The invention discloses printing ink containing inorganic nano-materials; the provided printing ink contains at least one inorganic nano-material, especially quantum dots, and at least one aromatic ketone or aromatic ether-based organic solvent. The invention also relates to an electronic device printed by applying the printing ink, especially an electroluminescent device.

Owner:GUANGZHOU CHINARAY OPTOELECTRONICS MATERIALS

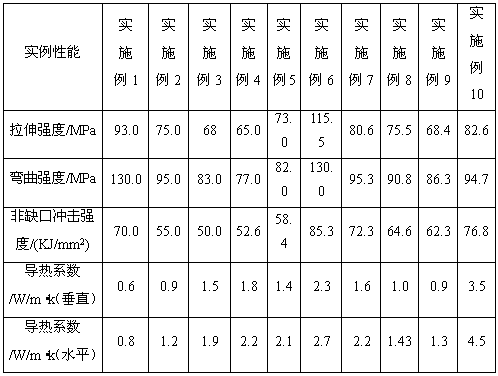

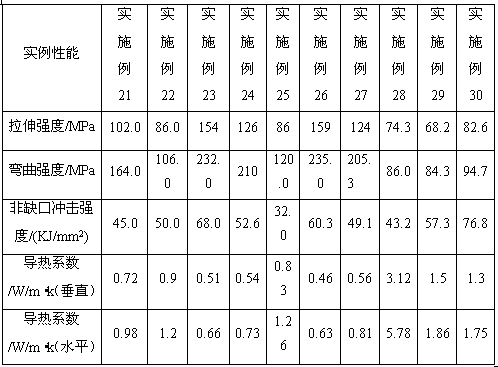

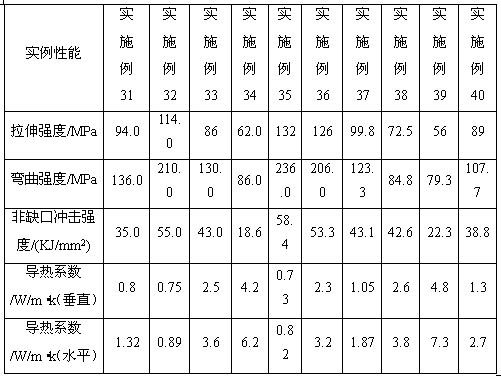

Heat-conducting nylon composite material, preparation method and application thereof

The invention provides a heat-conducting nylon composite material, a preparation method and application thereof. The formula comprises the components in parts by weight of 20.0-80.0 parts of PA66 and / or PA6, and 15.0-75.0 parts of thermal conductive filler, wherein the heat-conducting coefficient of the thermal conductive filler is 5W / m.k-900W / m.k. The preparation method comprises the steps of a) stirring and mixing the thermal conductive filler and carrying out surface modification; b) mixing and extruding the mixed material on an extruder, wherein the temperature is 220-265 DEG C; and c) obtaining the heat-conducting nylon composite material from the material by extruding, pelletizing and drying. The material is applied to the fields of a radiating material of a light-emitting diode (LED) lamp housing, or a low-voltage apparatus and an electronic radiating element.

Owner:BENSONG ENG PLASTICS HANGZHOU

Grading method for cascade utilization of power battery of electric vehicle

ActiveCN102437385AGuaranteed performanceImprove performanceElectrical testingSecondary cells manufactureEvaluation resultPower battery

The invention provides a grading method for the cascade utilization of a power battery of an electric vehicle. The grading method comprises the following steps of: (1) performing external characteristic analysis on the cascade-utilized power battery, and judging whether the cascade utilization of the power battery can be realized or not; (2) primarily grading the battery on which the cascade utilization can be performed according to external characteristic parameters of the battery, and performing sampled internal characteristic analysis on the battery of each grade; (3) establishing incidence relations between internal and external characteristic parameters based on the internal and external characteristic analysis, and evaluating the health status of the battery; and (4) grading the cascade-utilized power battery by combining a health status evaluation result of the battery and the using conditions of the battery. By the grading method for the cascade utilization of the power battery of the electric vehicle, the performance of the battery not only can be ensured to meet the requirements of application occasions, but also can be fully utilized.

Owner:CHINA ELECTRIC POWER RES INST +1

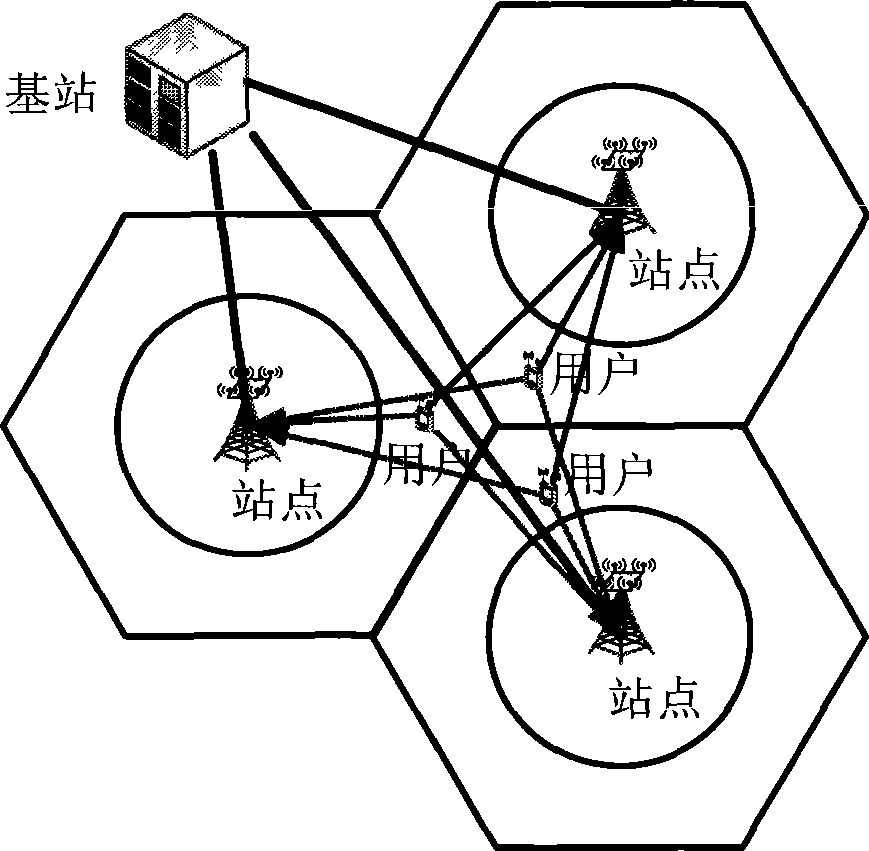

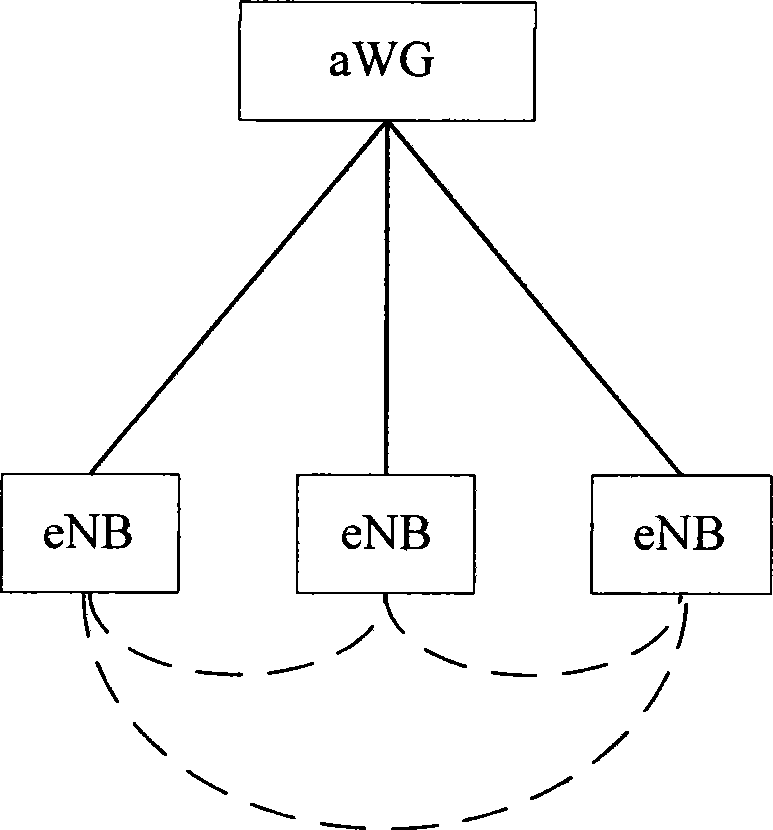

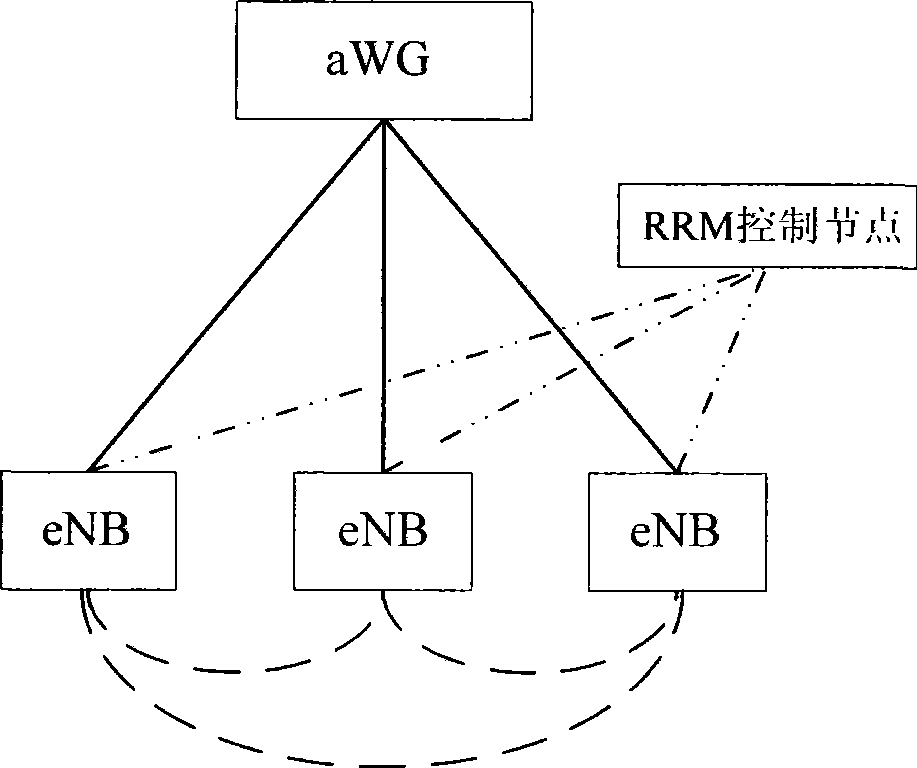

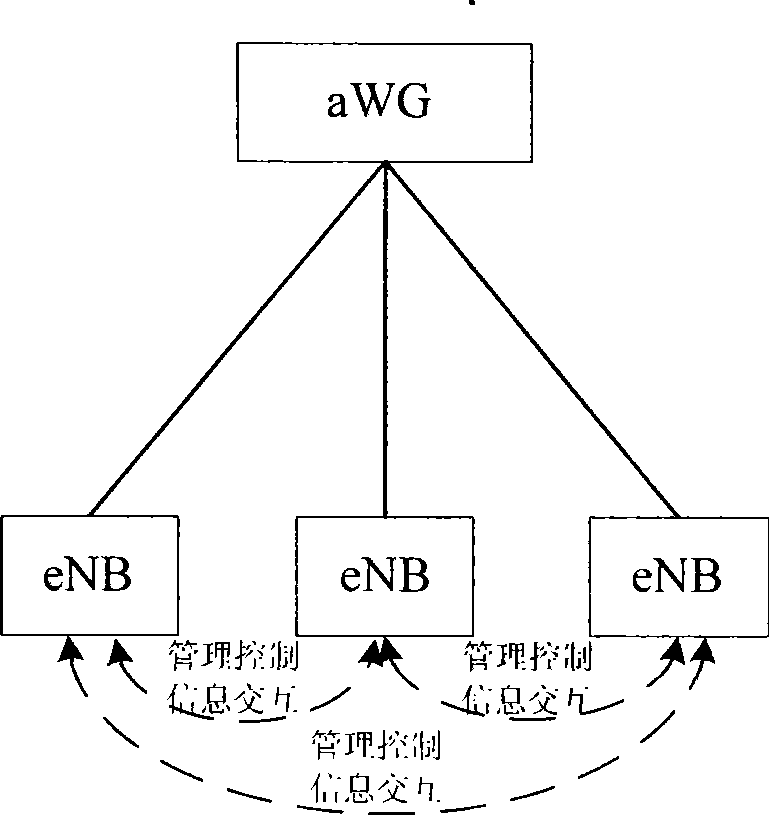

Staged wireless resource management method based on dynamic cell group in cellular system

InactiveCN101400135AGuaranteed performanceReduce distractionsNetwork planningTime domainWireless resource management

The invention discloses a classification wireless resource management method based on a dynamic district group, suitable for cellular communication system. Adjacent districts constitute a district group according to interference relationships between adjacent districts, a plurality of districts belonging to the same district group are joined up to perform wireless resource management, reducing interference between the districts and increasing performance of the edge users, ensuring requirement of service quality. Structure of the district group is updated periodically according to the interference change between the districts. The wireless resource management method in the invention is a classification method. The district group may unifiedly manage the resource distribution of a plurality of districts inwards, also manage the resource distribution of the edge of the district. The districts in the district group are joined up in a centralized mode, also in a distributing mode. The wireless resources distributed in the district group comprise time, frequency and space, the joining mode includes combining time domain and frequency domain, combining beam direction and power.

Owner:BEIJING UNIV OF POSTS & TELECOMM

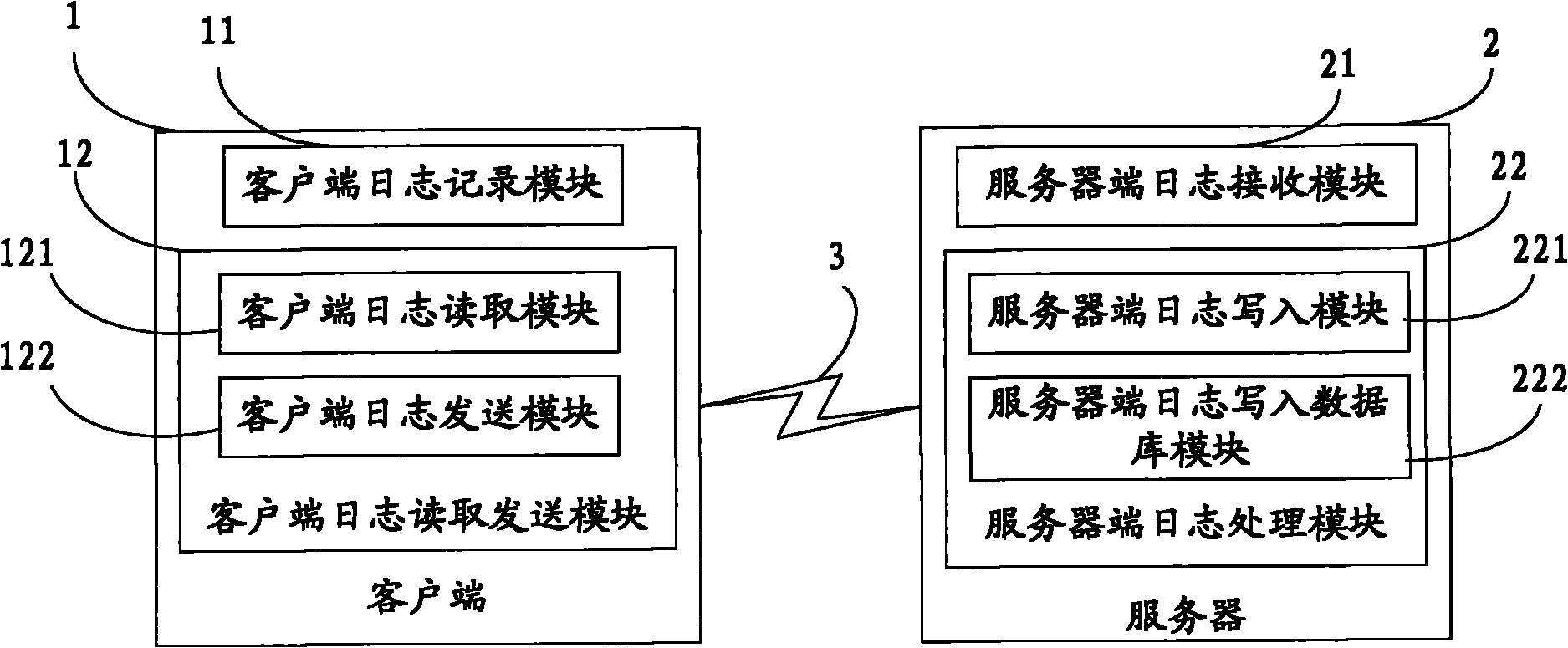

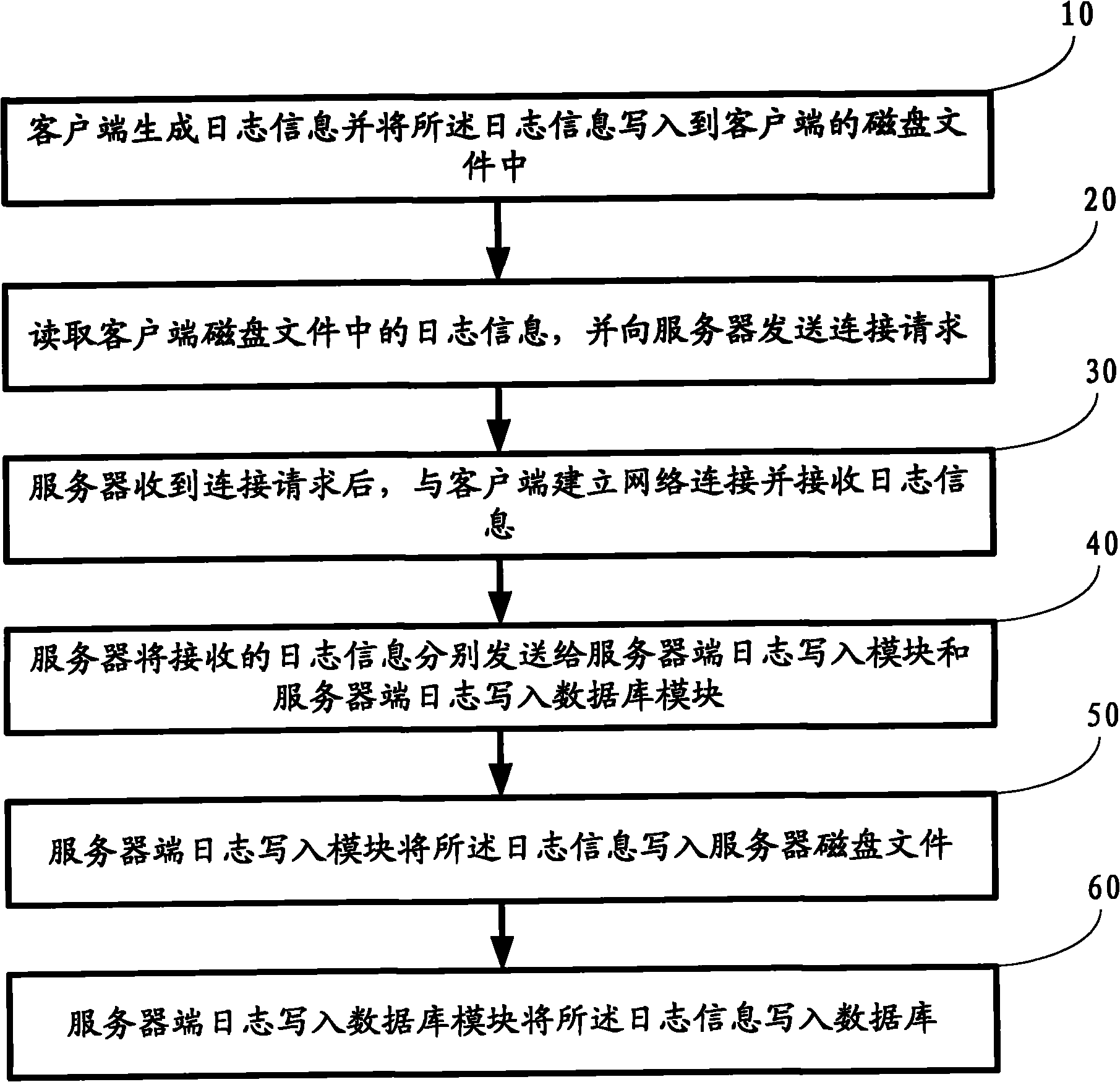

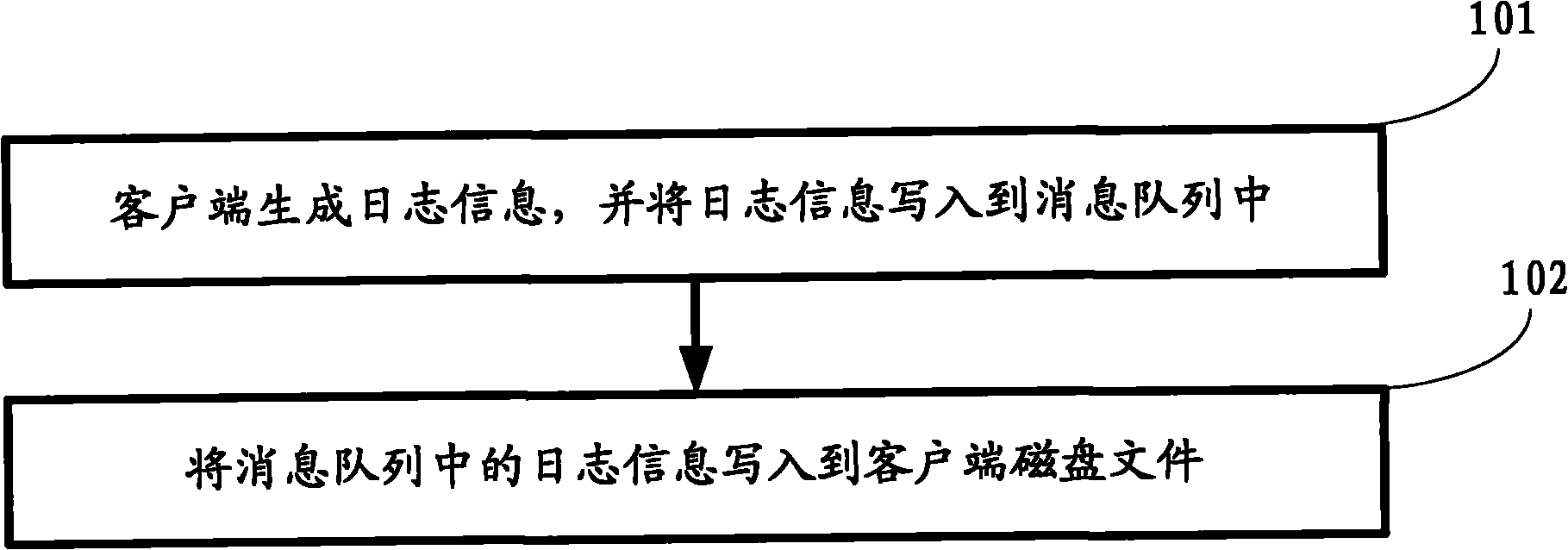

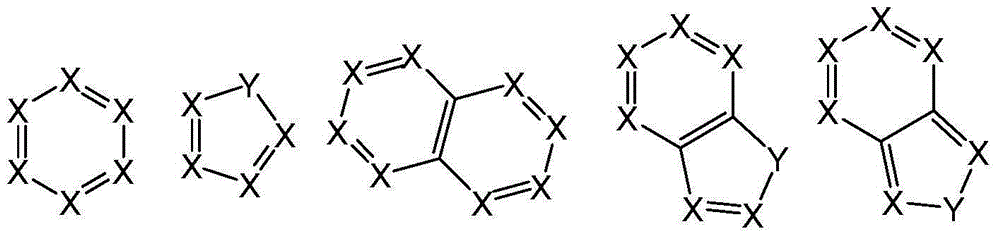

Log acquisition device and log acquisition method

InactiveCN101969386AReal-time deliveryRealize distributed collectionData switching networksServer logNetwork connection

The invention relates to a log acquisition device and a log acquisition method. The device comprises at least one client for collecting logs and at least one server for recording the logs, wherein log information is transmitted between the client and the server through a network in real time. The method comprises that: the client generates the log information, writes the log information into a disk file of the client, reads the log information from the disk file of the client, and sends a connection request to the server; after receiving the request, the server establishes network connection with the client and receives the log information; the server sends the received log information to a server log writing module and a server log writing database module; the server log writing module writes the log information into the disk file of the server; and the server log writing database module writes the log information into the database. When the device and the method of the invention are used, the data analysis is more real-time, and the distributed acquisition of the logs is realized.

Owner:道有道科技集团股份公司 +1

Printing ink composition and electronic device

ActiveCN105062193AGuaranteed performanceEasy to printInksPhotovoltaic energy generationOrganic solventQuantum dot

The invention discloses a printing ink composition comprising one or more inorganic nano-materials. The printing ink composition comprises the inorganic nano-materials, particularly quantum dots, and one or more organic solvents based on substituted aromatics or heteroaromatics. The invention further relates to an electronic device printed with the printing ink, particularly an electroluminescent device.

Owner:GUANGZHOU CHINARAY OPTOELECTRONICS MATERIALS

Method and device for predictive control of agricultural vehicle systems

ActiveUS9008918B2Better field modelEasy to predictAnalogue computers for trafficMowersEngineeringMoisture

A method for controlling an agricultural vehicle system when moving along a course of travel over a fieldproviding a field model correlating a field characteristic, e.g. a farmland condition such as farmland slope, or a crop condition such as crop density or moisture, to a specific location in the field,from the field model and at least one previously obtained value for the field characteristic, predicting a value for the field characteristic in front of the agricultural vehicle system thus obtaining an anticipated field characteristic, and;controlling the agricultural vehicle system at least partly in response to the anticipated field characteristic.

Owner:BLUE LEAF I P INC

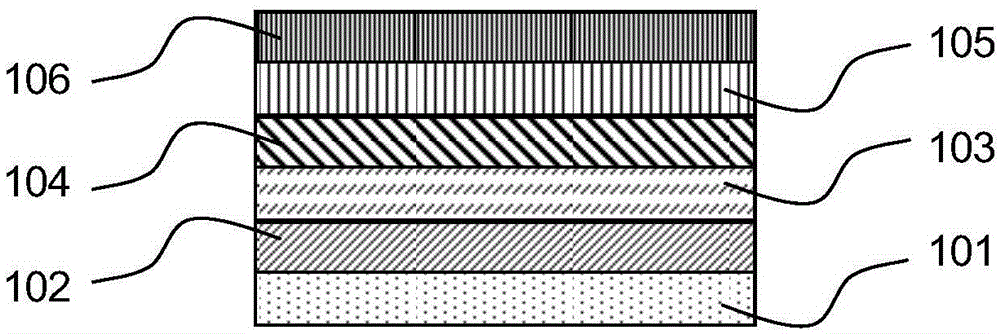

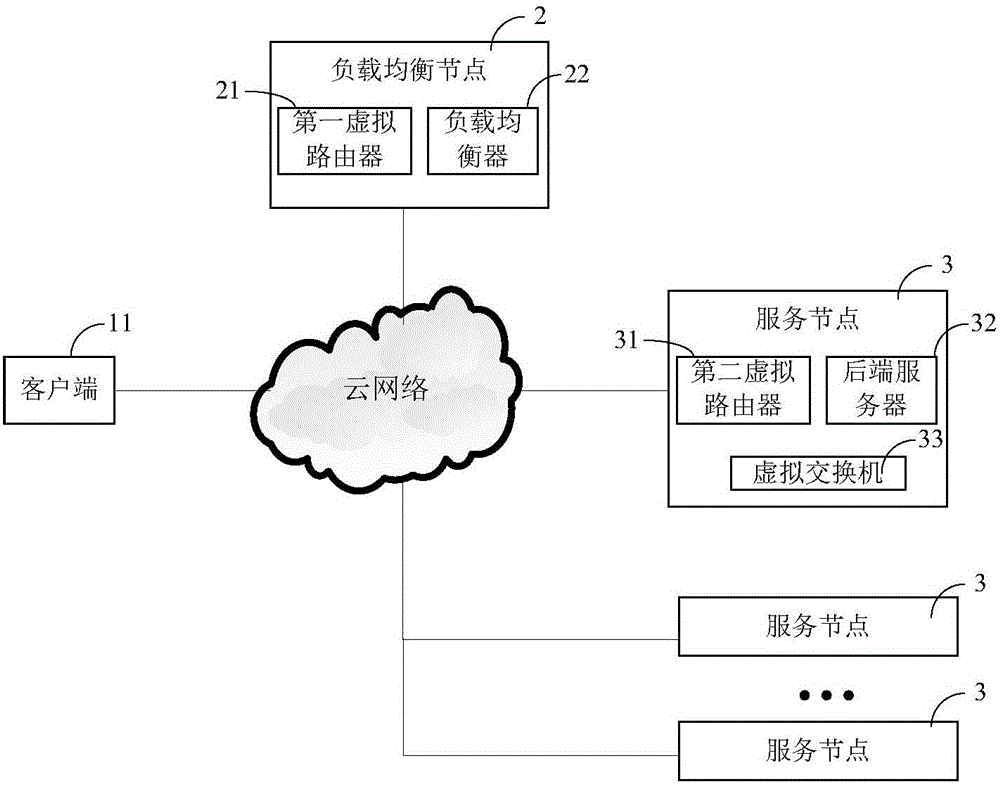

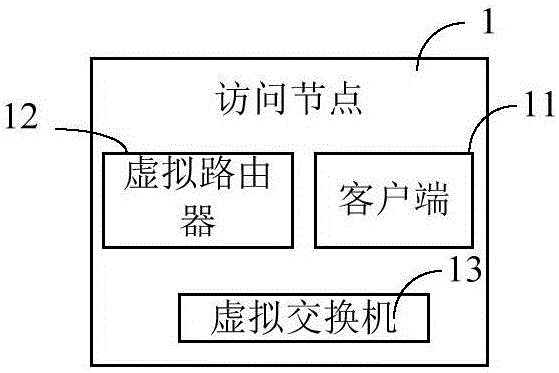

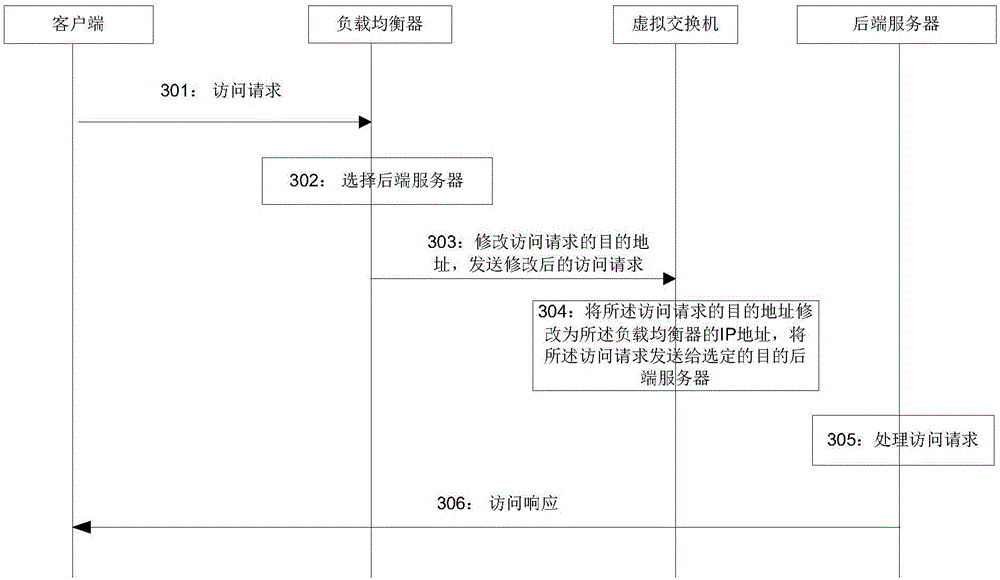

Load balancing method, apparatus and system

ActiveCN106686085AGuaranteed network performanceGuaranteed performanceTransmissionClient-sideCloud computing

The invention relates to a load balancing system, a load balancing method and a service node, aiming at realizing network-segment-crossing disposition of a back end server and a load equalizer in a DR mode in a cloud computing network. The load balancing system includes a load equalizer and at least one service node, wherein the a virtual switch and at least one back end server are run on the server node; the IP address of a logic interface of the back end server is the IP address of the load equalizer; the load equalizer receives an access request of a client, and modifies the destination address of the access request into the IP address of a virtual network interface card of a destination back end server; and when the virtual switch of the service node receives the access request, the destination address of the access request is modified into the IP address of the load equalizer, so that when the destination back end server returns the access response, the source address of the access response is the address of the load equalizer.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

Uplink scheduling requesting method, uplink scheduling method and equipment

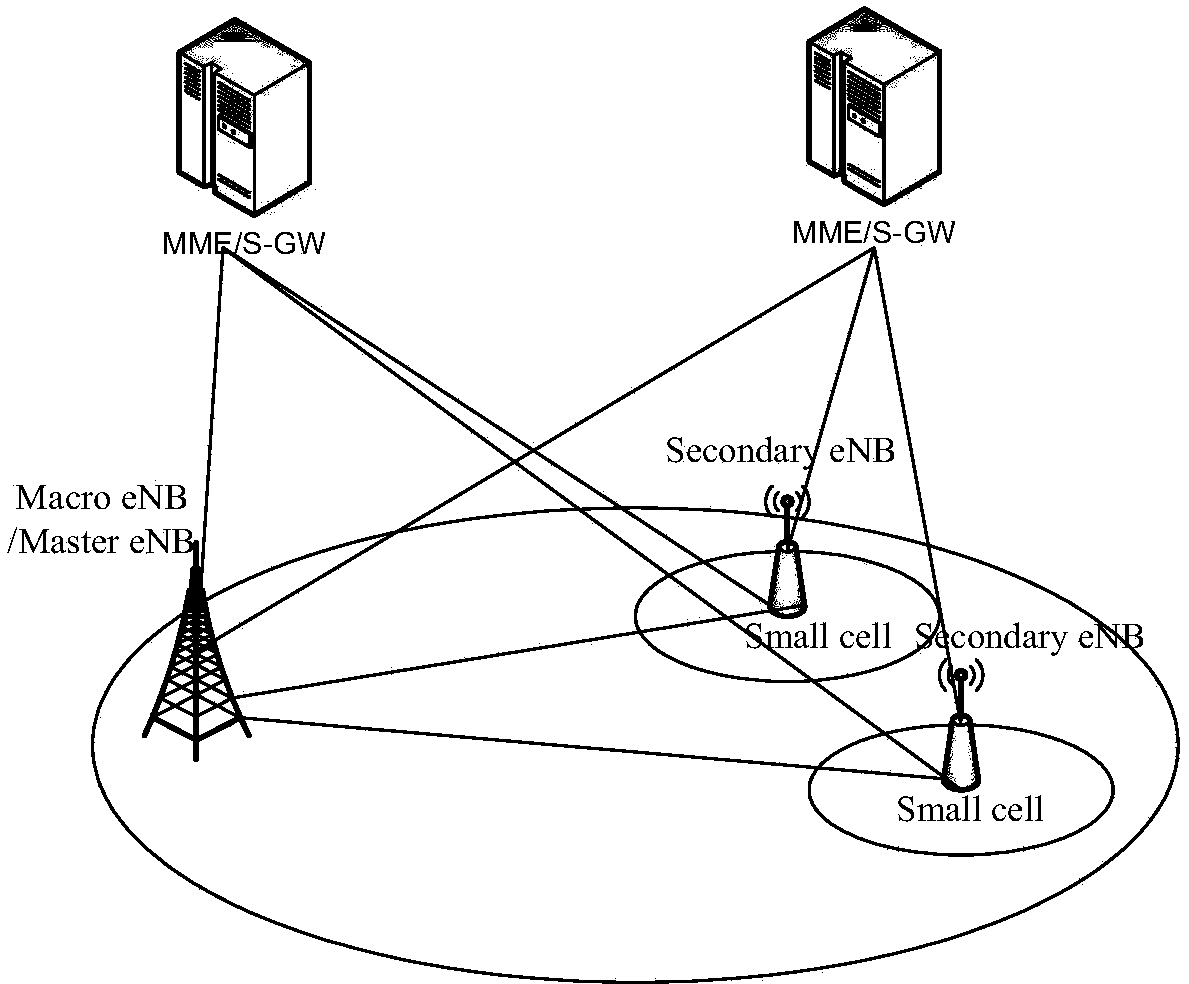

The invention discloses an uplink scheduling requesting method, an uplink scheduling method and equipment. According to the uplink scheduling requesting method, the uplink scheduling method and the equipment, in a scene of multi-evolved NodeB (eNB) aggregation, particularly bearing separation, user equipment (UE) informs a secondary eNB (SeNB) cell of an uplink data transmission request in a direct manner or in an indirect master eNB (MeNB) manner to enable the SeNB cell to schedule uplink transmission of the UE on the SeNB cell according to the uplink data transmission request of the UE. The problem about scheduling of uplink data transmission through the uplink data transmission request and an uplink resource request of a network or the UE is solved, and the performances of a system and a user are ensured.

Owner:DATANG MOBILE COMM EQUIP CO LTD

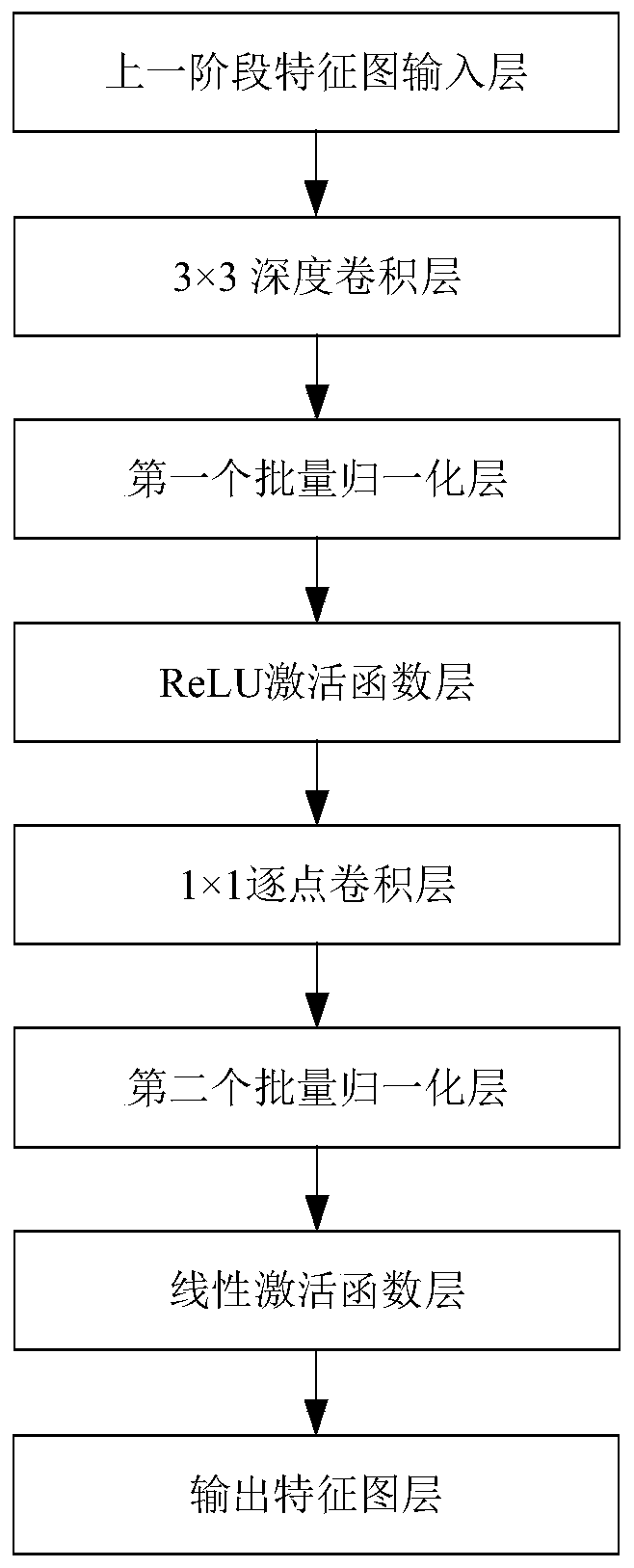

Remote sensing image target detection method based on deep evolution pruning convolutional network

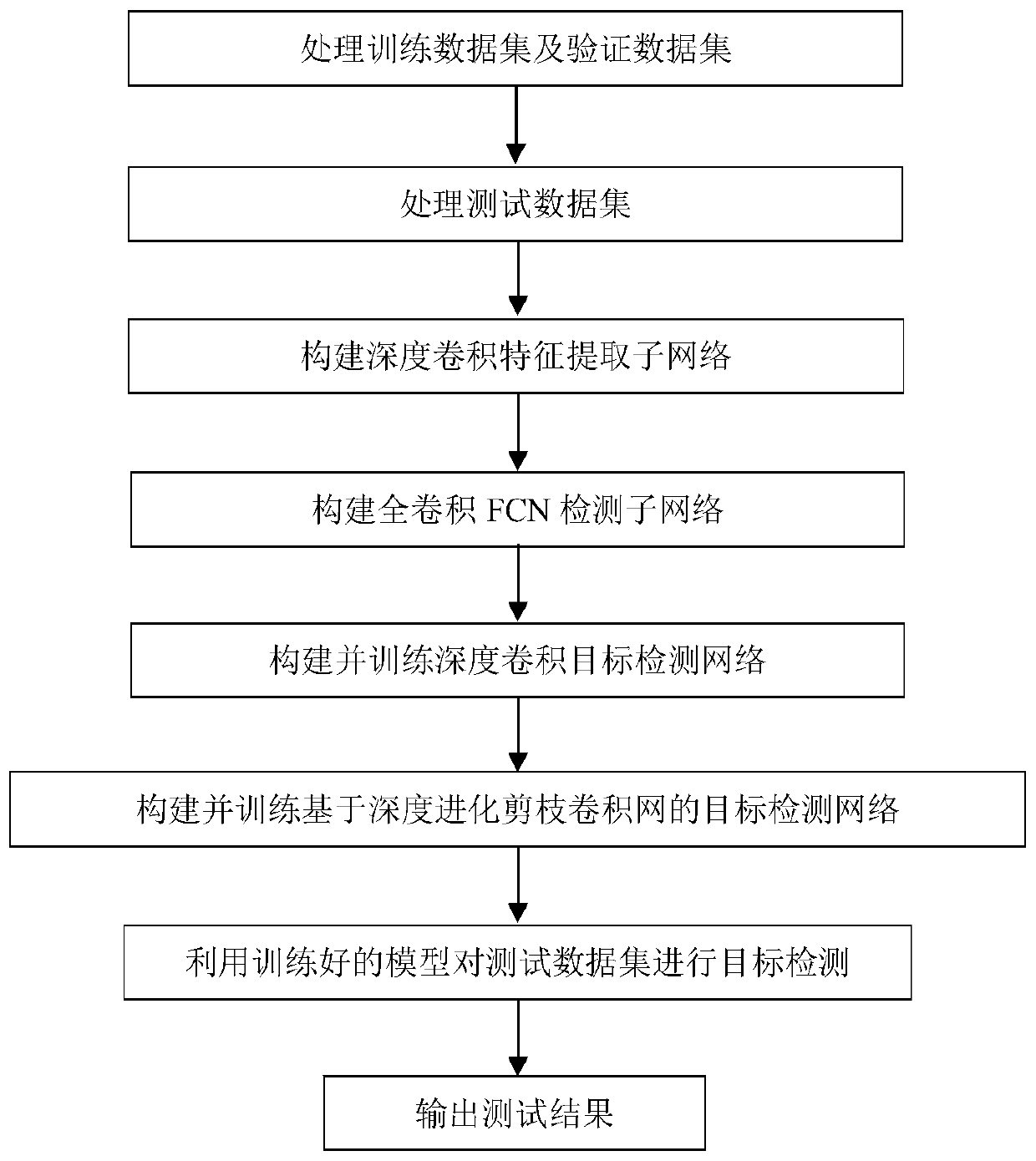

ActiveCN110532859AGuaranteed detection accuracyAvoid destructionScene recognitionNeural architecturesFeature extractionData set

The invention discloses a remote sensing image target detection method based on a deep evolution pruning convolutional network. The problem that the detection speed and the detection precision are notglobally and effectively optimized at the same time in existing remote sensing image target detection is solved. The method comprises the specific steps of processing a data set; constructing a deepconvolution feature extraction subnet; constructing a full convolution FCN detection subnet; constructing and training a deep convolution target detection network; constructing and training a target detection network based on a deep evolution pruning convolutional network; performing target detection on the test data set by using the trained model; and outputting test results. According to the method, a reverse residual structure is constructed by using depth separable convolution, so that the model parameter quantity is greatly reduced while the detection precision is high; the target detection network is combined with evolutionary pruning to realize global acceleration. The method greatly reduces the calculation amount, remarkably improves the target detection speed, is high in detectionprecision, and is used for the quick and accurate detection of small targets in a remote sensing image, such as an airplane and a ship.

Owner:XIDIAN UNIV

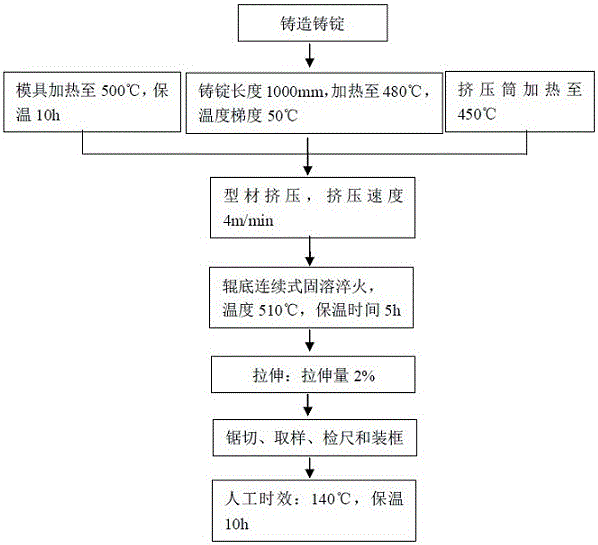

Preparing method for 6-series aluminum alloy sectional bar

InactiveCN105838938APrecise control of heating temperatureGuaranteed performanceAluminium alloyArtificial aging

Owner:广西南南铝加工有限公司

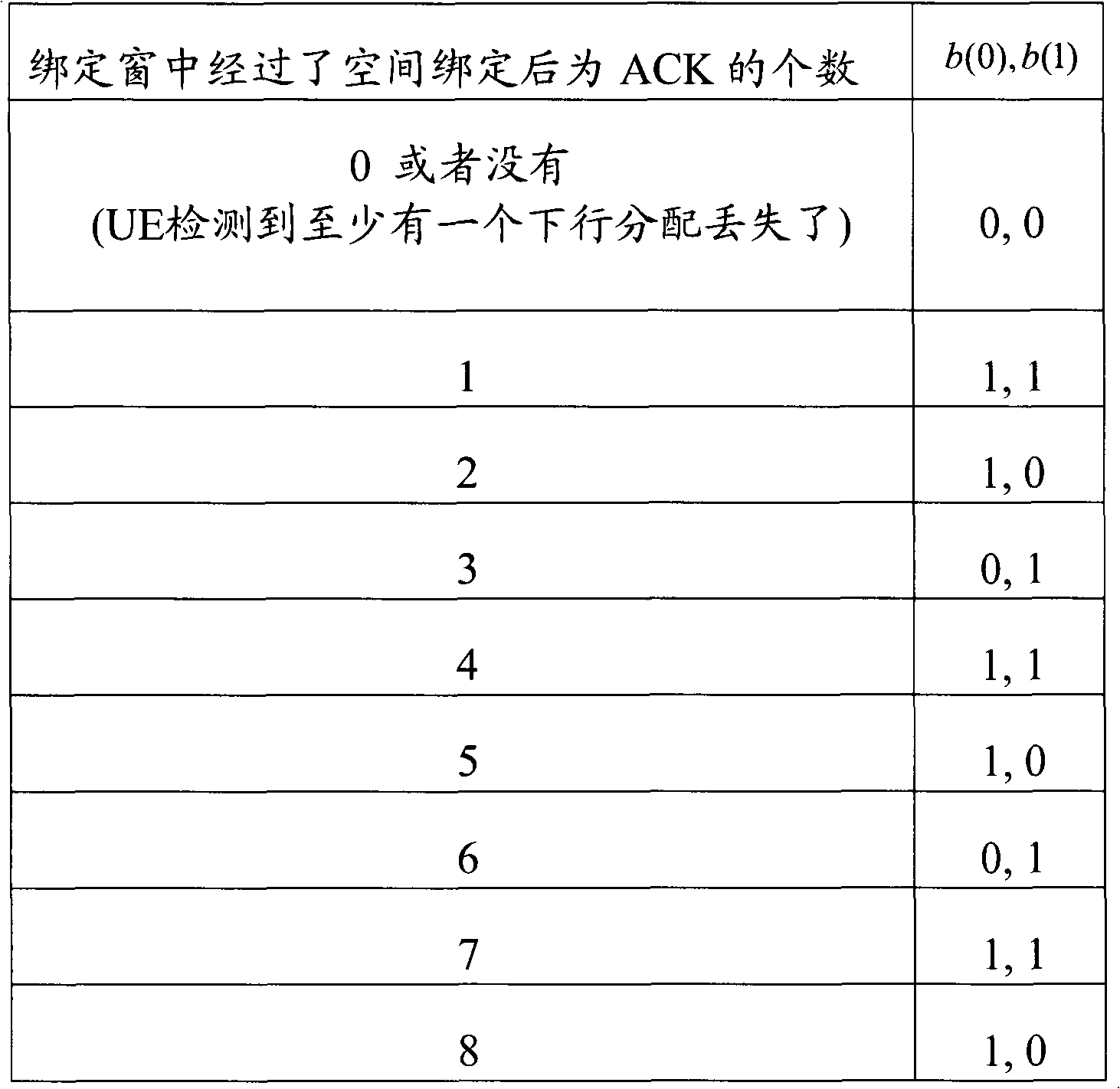

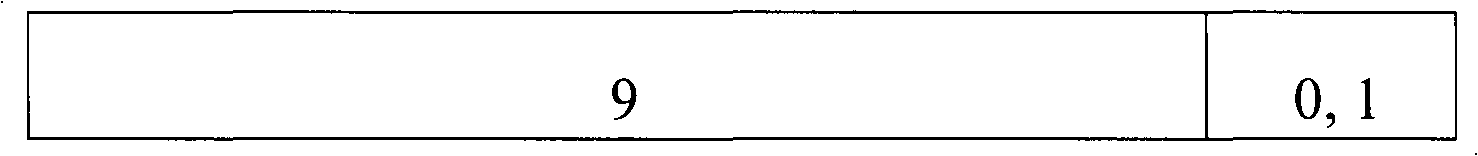

Transmission method of uplink control signaling and terminal

ActiveCN102098146ASolve the problem of sending at the same timeGuaranteed performanceError prevention/detection by using return channelSignal allocationChannel state informationControl signal

The invention discloses a transmission method of uplink control signaling and a terminal, a base station, relating to the digital communication field. The transmission method of the uplink control signaling comprises the step: in a time division duplex (TDD) system, the terminal maps ACK / NACK (Acknowledgement / Negative Acknowledgement) response messages as M bit information according to the right / wrong ACK / NACK response messages of the to-be-fed back N physical downlink shared channels (PDSCH) and other uplink control information, and the mapping relationship, wherein the M bit information and the other uplink control information are sent on the physical downlink shared channel which is in convention with the base station, wherein the mode of the ACK / NACK response message fed back by the terminal is the channel selection mode. By using the transmission method of the uplink control signaling and the terminal provided by the invention, the problems of simultaneously sending the response messages, scheduling requests, channel state information of a plurality of download component carriers can be effectively solved, and the performance of the system can be ensured.

Owner:ZTE CORP

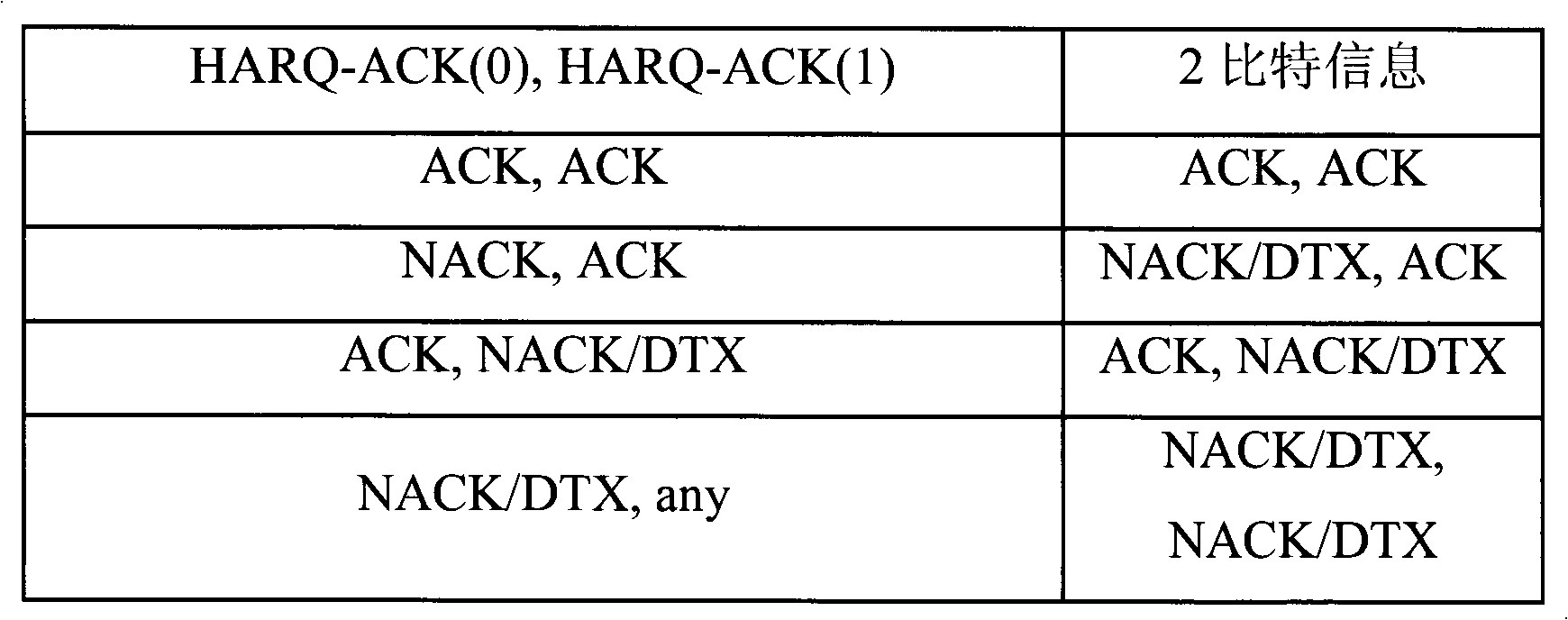

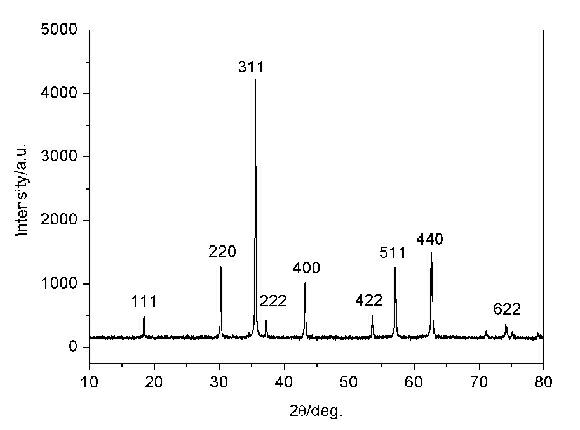

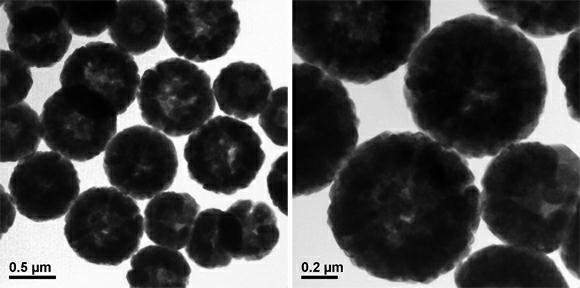

Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

The invention discloses a preparation method of a lithium-stored composite material Fe3O4 / C with a hollow sphere structure and an application of the lithium-stored composite material Fe3O4 / C with a hollow sphere structure in a lithium ion battery, belonging to the technical fields of material synthesis and high-energy lithium-ion storage batteries. The preparation method is characterized in that a solvothermal method or hydrothermal method is utilized to prepare the Fe3O4 / C composite material with a hollow sphere and narrower particle size distribution, wherein the Fe3O4 / C composite material is high in purity; and the mean particle size of the Fe3O4 / C composite material is 750 nanometers and the wall thickness of the Fe3O4 / C composite material is 250 nanometers. An electrochemical test proves that the first discharging specific capacity of the Fe3O4 / C composite material prepared by the method can be 1157mAh / g, and the discharging specific capacity of the Fe3O4 / C composite material can be 900mAh / g after being circulated for 65 times, thus showing the perfect cyclical stability. The Fe3O4 / C composite material has good rate performance; and the charging specific capacity of the Fe3O4 / C composite material is 620mAh / g and 460mAh / g respectively under 2C and 5C charge-discharge rates, thus the rate performance is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The Fe3O4 / C lithium ion battery cathode material is low in cost, simple in process and easy to industrialize, and has wide application prospects in the high-energy lithium ion battery field.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

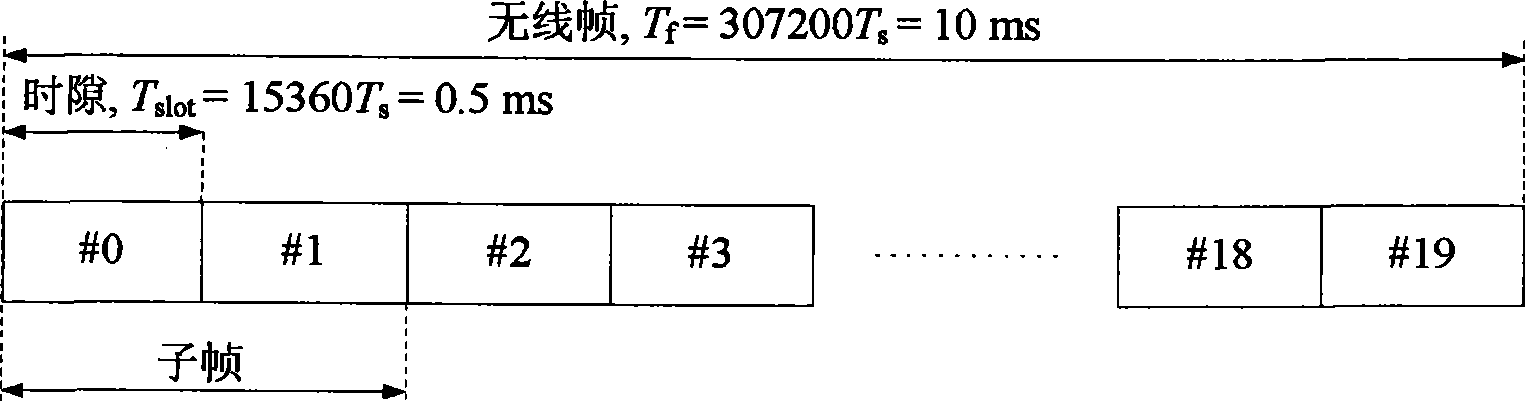

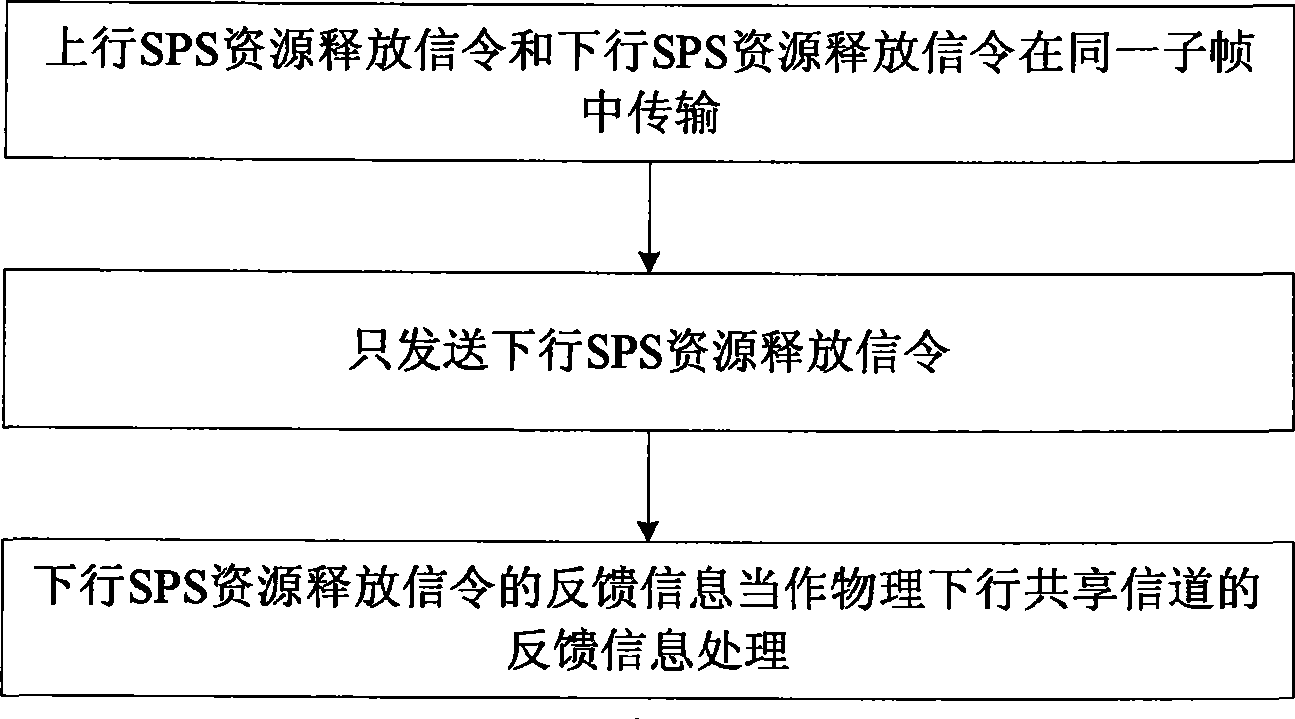

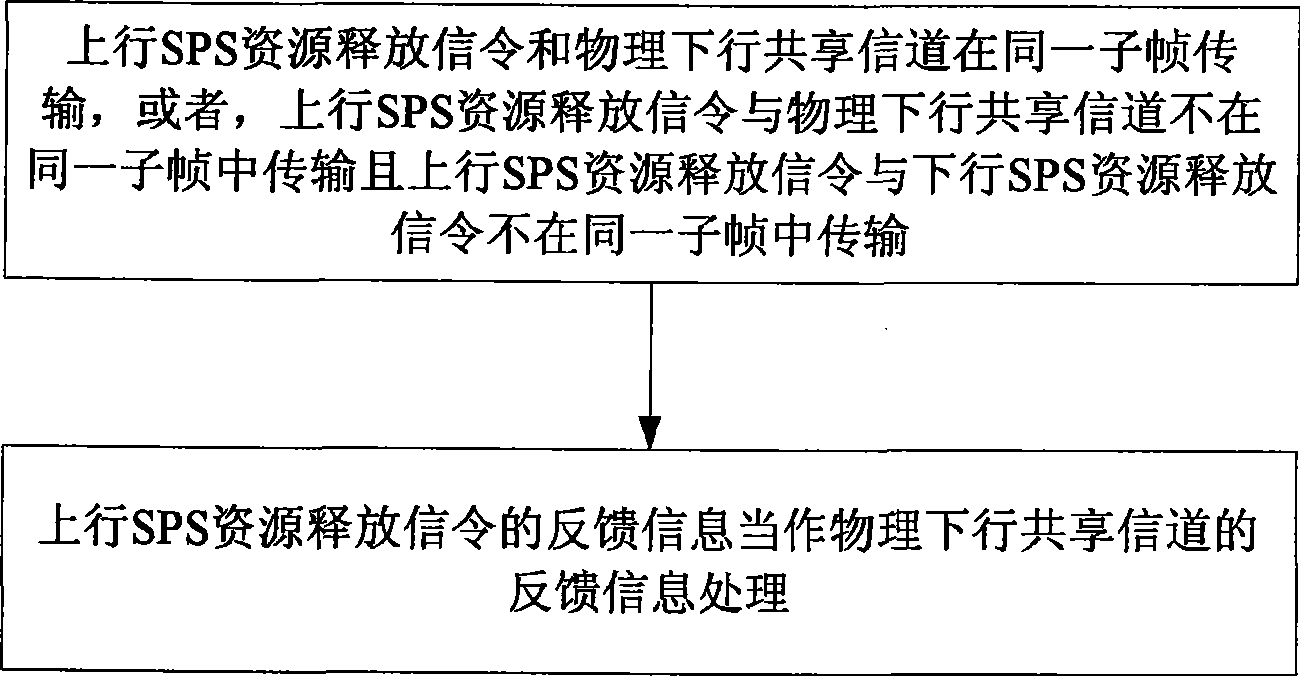

Uplink semi-persistent scheduling released feedback information sending method

InactiveCN101478371ATroubleshoot sending issuesMake sure to accept the statusError preventionWireless network protocolsTelecommunications

The invention provides a method for transmitting feedback information released by uplink semi-persistent scheduling (SPS), wherein the feedback information of resource release signaling of the uplink SPS, as the feedback information of the physical downlink shared channel, is processed. The invention also provides a method for transmitting feedback information released by SPS, wherein for the same one user terminal, when the resource release signaling of the uplink SPS and the resource release signaling of the downlink SPS are transmitted on the same sub-frame, the sub-frame transmits the resource release signaling of only one type of SPS, and the feedback information of the resource release signaling of the transmitted SPS, as the feedback information of the physical downlink shared channel, is processed. The method for transmitting feedback information released by uplink SPS solves the transmission problem of the feedback information released by uplink SPS and solves the problem of compatibility with the acknowledgement / negative acknowledgement (ACK / NACK) feedback information of existing downlink data, thereby ensuring the receiving stat of the resource release signaling of the uplink SPS, preventing the extra interference and unnecessary decoding error, and further ensuring the system performance.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com