Heat-conducting nylon composite material, preparation method and application thereof

A nylon composite material and thermally conductive filler technology are applied in the field of thermally conductive nylon composite materials and their preparation, which can solve the problems of restricting the replacement of LED products, high PPS price, and high processing temperature, and achieve increased mechanical properties, processability, and good mechanics. performance, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

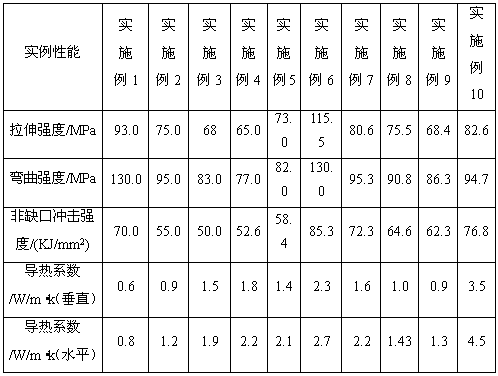

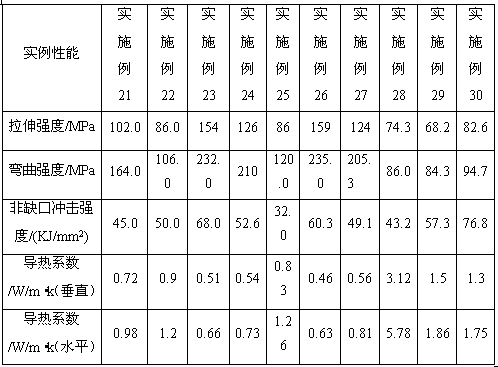

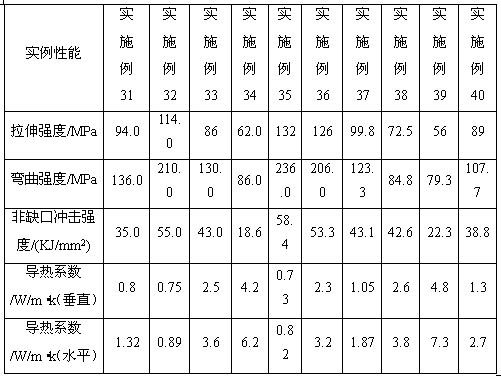

Examples

Embodiment 1

[0048] Put 900g of alumina with a D50 of 0.5um into a blast oven, set the temperature at 100°C, dry for 5 hours, take it out and put it in an aluminum-plastic bag, vacuumize it and pack it for later use.

[0049] Put 1800g of nylon 66 (EPR27) into a dehumidification drying oven, set the temperature at 120°C, and after drying for 4 hours, take it out and put it into a high-speed mixer, add 15g of coupling agent KH550 (commercially available), 9g of lubricant calcium stearate ( Commercially available), low speed 500 r / min, stirring for 1 min, adding alumina, high speed stirring 1500 r / min, discharging after 2 min, adding 300g flame retardant XDP (commercially available) at the main feeding port of the extruder It is added in weight loss metering at the side feeding port, extruded, pelletized and set aside. Temperature settings for each zone of the extruder: Zone 1: 260 °C, Zone 2: 260 °C, Zone 3: 260 °C, Zone 4: 260 °C, Zone 5: 250 °C, Zone 6: 220 °C, Zone 7: 220 °C, Zone 8 Zon...

Embodiment 2

[0051] Put 300 g and 1200 g of alumina with a D50 of 0.5um and 15um respectively into a blast oven, set the temperature at 100 °C, and after drying for 5 hours, take it out and put it in an aluminum-plastic packaging bag, and vacuumize and seal it for later use.

[0052] Put 1200 g of nylon 66 (EPR27) into a vacuum oven, set the temperature at 120 °C, and after drying for 4 h, take it out and put it into a high-speed mixer, add 15 g of titanate coupling agent NDZ-105 (commercially available), and lubricate Calcium stearate 9g (commercially available), low speed 500 r / min, stirring for 1 min, adding alumina filler, high speed stirring 1500 r / min, discharging after 2 min, adding at the main feeding port of the extruder, 300 g resistance The fuel OP (commercially available) is added in weight loss metering at the side feeding port, and then extruded, pelletized and ready for use. Temperature settings in each zone of the extruder: Zone 1: Zone 1: 260°C, Zone 2: 260°C, Zone 3: 260°...

Embodiment 3

[0054] Put 2191.6 g of aluminum nitride with a D50 of 5um into a blast oven, set the temperature at 100 °C, dry for 5 hours, take it out and put it in an aluminum-plastic packaging bag, and vacuumize it for later use.

[0055] Put 300g of nylon 66 and 308.4g of nylon 6 (M2400) into a blast oven, set the temperature at 100°C, dry for 4 hours, take them out and put them in a high-speed mixer, add 15g of aluminate coupling agent DL-411-A, 15g lubricant PETS, low speed 500 r / min, stirring for 0.5min, then change to high speed stirring 1500 r / min, discharge after 2min, add in the main feeding port of the extruder, filler aluminum nitride, 200g flame retardant MCA (Commercially available) Add in weight loss metering at the side feeding port, extrude, pelletize, and set aside. Temperature settings for each zone of the extruder: Zone 1: 260 °C, Zone 2: 260 °C, Zone 3: 260 °C, Zone 4: 260 °C, Zone 5: 250 °C, Zone 6: 220 °C, Zone 7: 220 °C, Zone 8 Zone: 220°C, Zone 9: 220°C, Machine he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com