Patents

Literature

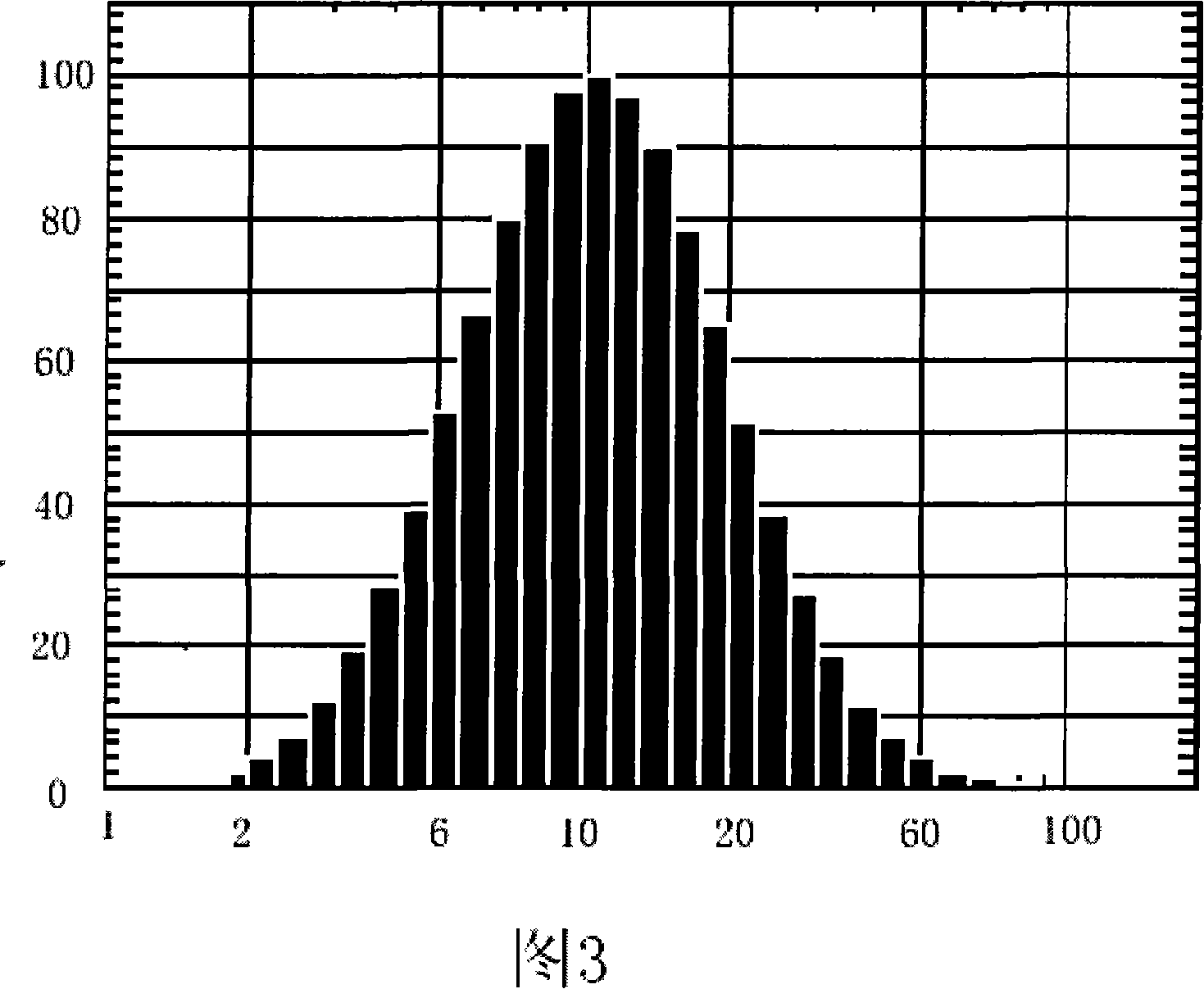

6574 results about "Stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stearates are the salts and esters of stearic acid. The conjugate base of stearic acid, C₁₇H₃₅COO⁻, is also known as the stearate anion.

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives , phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

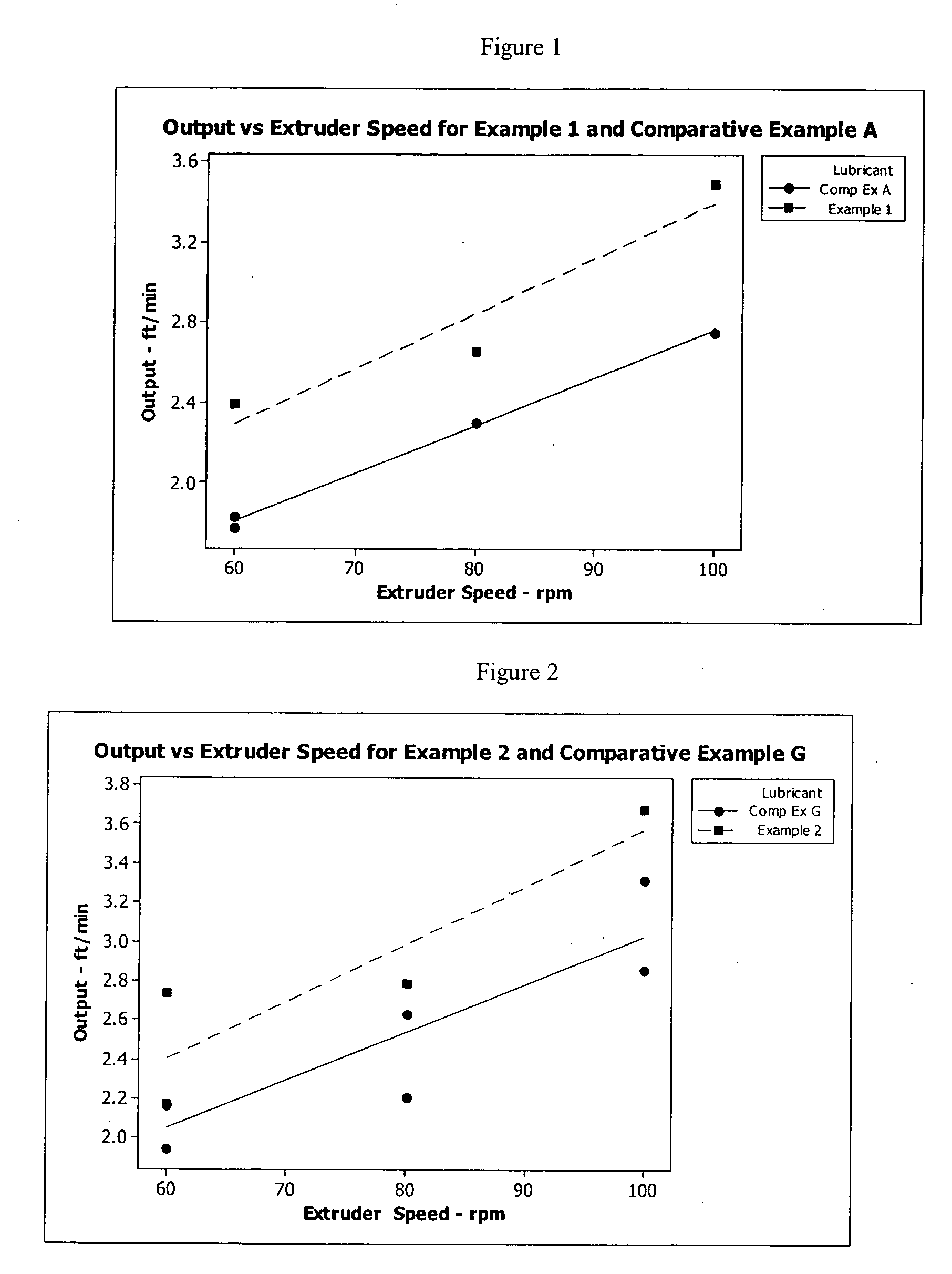

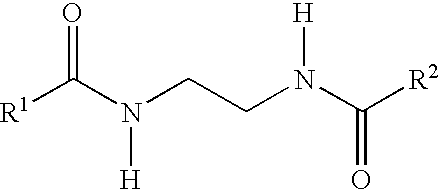

Cellulosic-thermoplastic composite and method of making the same

Provided is a composition comprising fatty acid bis-amide, inorganic particulate such as pumice, cellulosic particulate, thermoplastic and maleic anhydride grafted polyolefin. The combination of an ethylene bis-amide and a minor amount of pumice produces cellulosic-thermoplastic composite that has superior extrusion properties over conventional metal stearate / ethylene bis-stearamide (EBS) compositions such as improved flex strength and resistance to water absorption.

Owner:ADDIVANT USA

Topical skin care formulations

InactiveUS20110044920A1Improve visual appearanceExtended maintenance periodCosmetic preparationsBiocideCaprylyl GlycolStearic acid

Disclosed is a topical skin care composition that includes water, silymarin, hydrolyzed algin, palmitoyl tripeptide 8, ceramide 2, pomegranate extract comprising pomegranate sterols, glycerin, disodium EDTA, caprylic / capric triglyceride, shea butter, C12-15 alcohols benzoate, dimethicone, glyceryl stearate and PEG 100 stearate, cetyl alcohol, stearyl alcohol, stearic acid, butylene glycol, caprylyl glycol, and (s) a mixture of acrylamide / sodium acryloyldimethyl taurate copolymer, isohexadecane, and polysorbate 80.

Owner:MARY KAY INC

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:PNC BANK NAT ASSOC

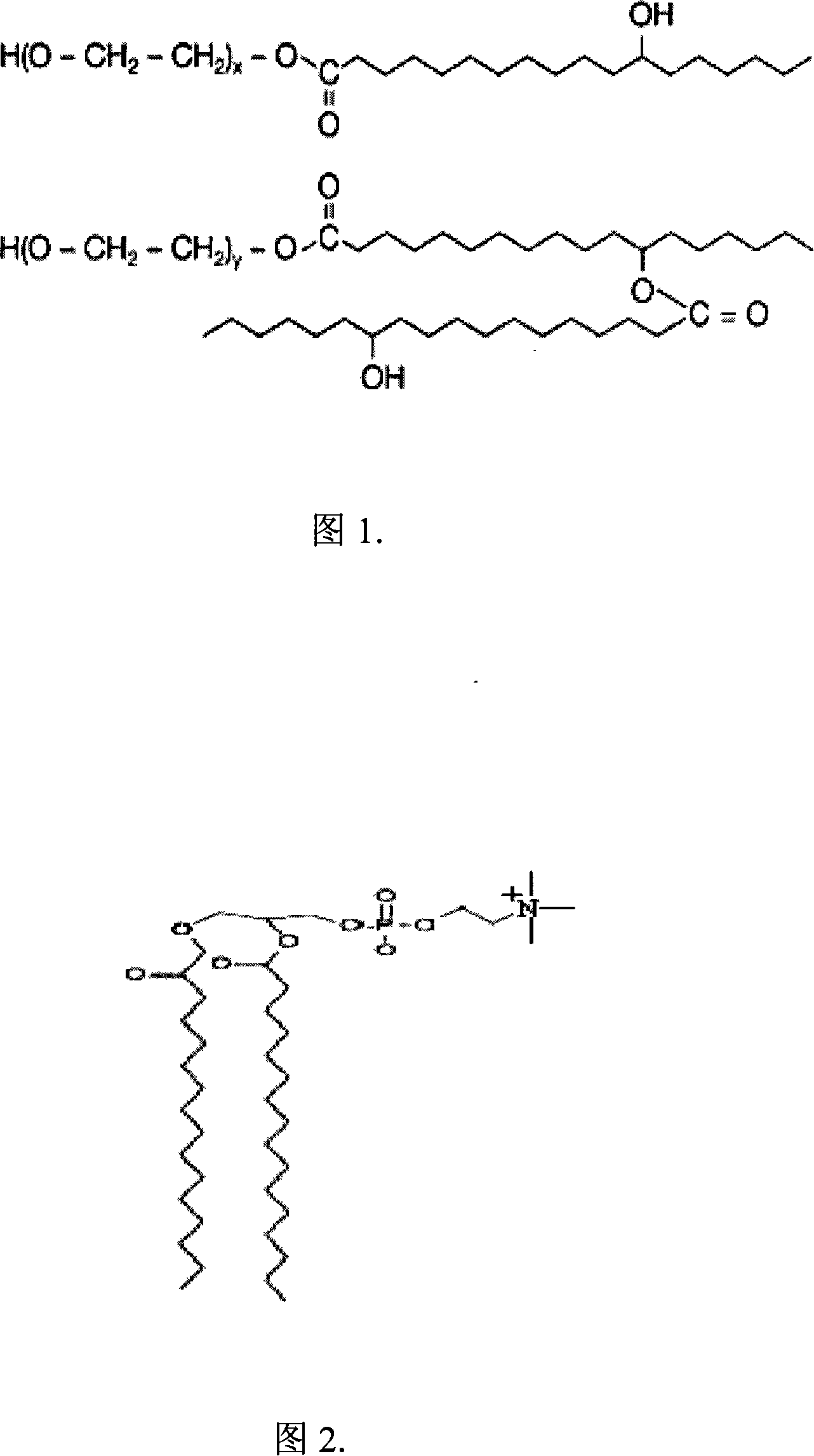

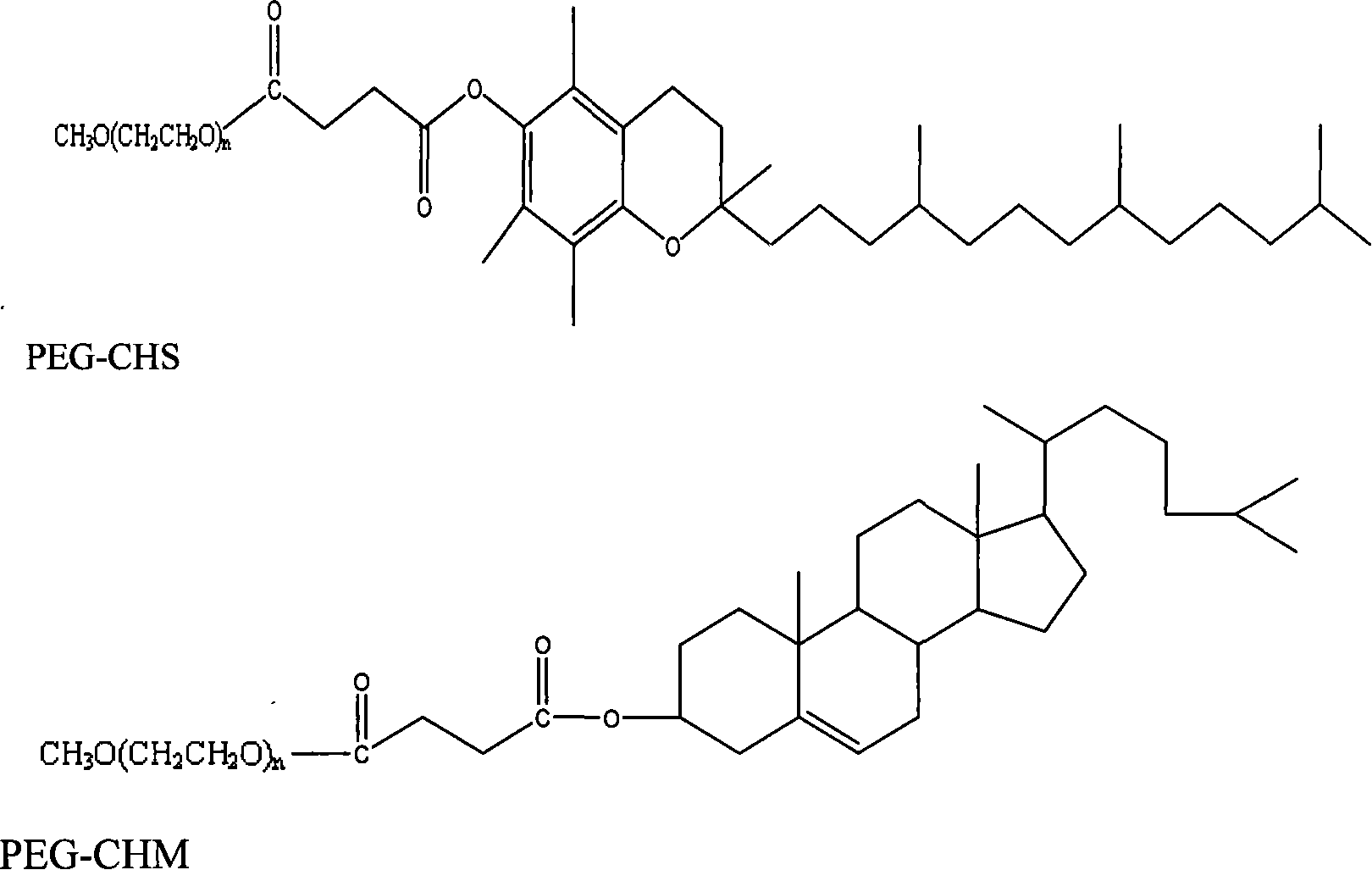

Mixed glue bundle pharmaceutical preparations produced in combination use of multiple surfactant and processes for their preparation

InactiveCN101138550AStrong dilution stabilityReduce viscosityPharmaceutical non-active ingredientsLiposomal deliverySolubilityMixed micelle

The present invention relates to a mixed micelle medicine preparation and a preparation method, which is prepared by the combination of various kinds of surface acting agents. The mixed micelle consists of the polyethylene glycol-12-hydroxy stearate and the other surface acting agents of one kind or various kinds. The other surface acting agents comprise phospholipid, VE Macrogol succinate, Macrogol-VE-carbonate and Macrogol-VE-succinate. In addition, the mixed micelle also comprises drugs, solvent, a stabilizer with or without other components and a PH conditioner. The amount of the polyethylene glycol-12-hydroxy stearate in the prescription is 4 percentage to 40 percentage, W / V: the amount of the phospholipid is 0 percentage to 30 percentage, W / V: the amount of the activator is 0 percentage to 30 percentage, W / V: the amount of the drug is 0.001 percentage to 10 percentage, W / V: the amount of the solvent is 0 percentage to 90 percentage, W / V. The medicine comprises the hydrophobicity drug and the lip solubility drug, but the medicine is not restricted by the both kinds of drugs. The present invention has the following advantages. Firstly, the preparation has good dilution stability, which can improve the defect in the present preparation and can meet the demanding for clinical drug administration. Secondly, the toxicity is low and the chemical stability is excellent.

Owner:SHENYANG PHARMA UNIVERSITY

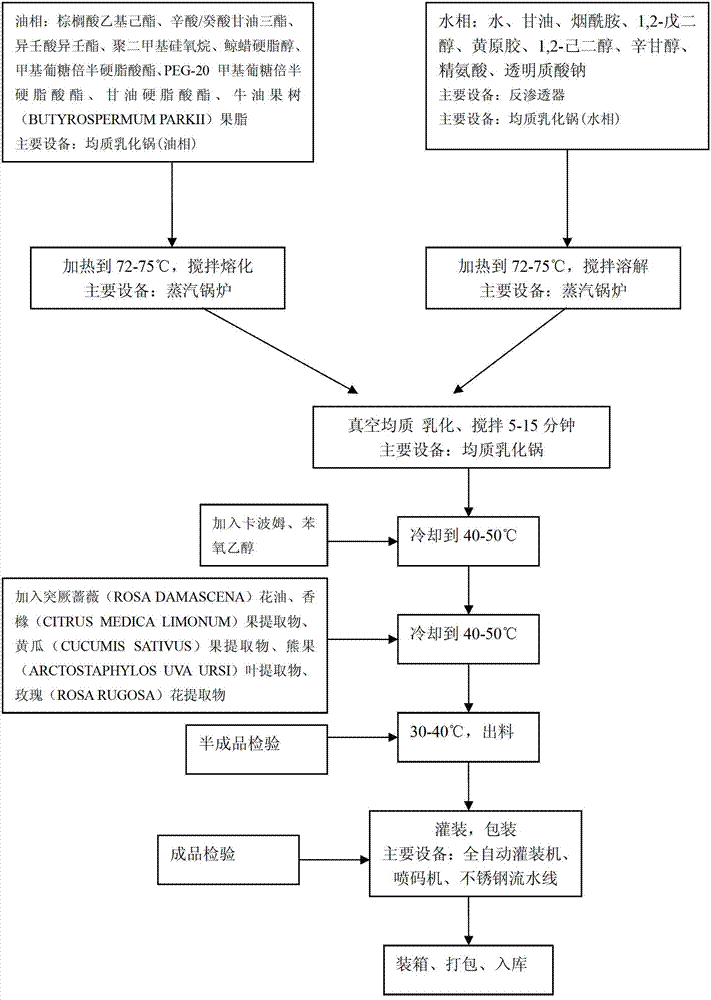

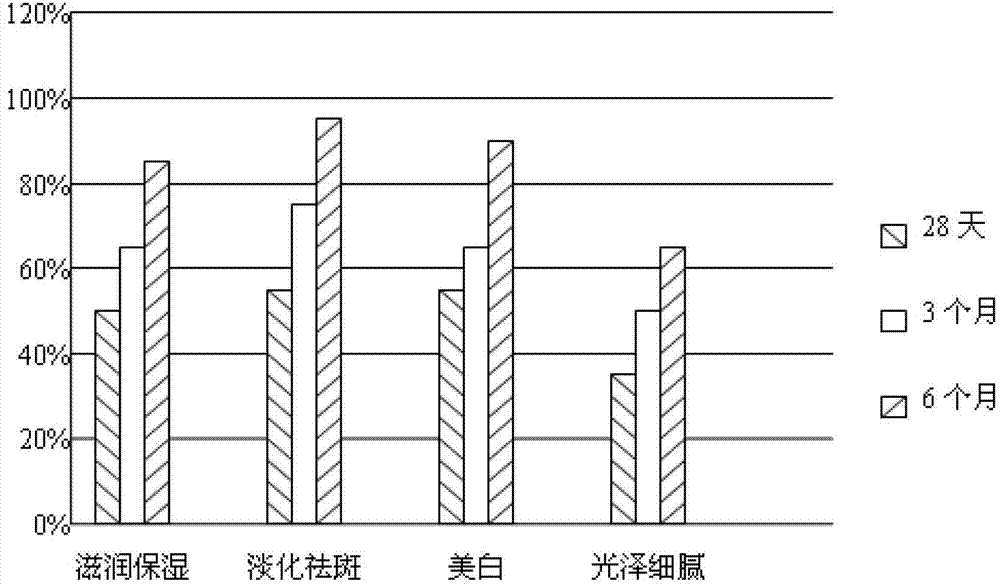

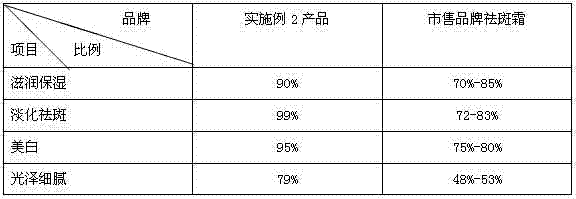

Whitening and freckle-removing cream

ActiveCN103393568AFine lusterActivated cellsCosmetic preparationsToilet preparationsEthylhexyl palmitateAdditive ingredient

The invention discloses whitening and freckle-removing cream. The cream is mainly prepared from glycerin, ethylhexyl palmitate, caprylic / capric triglyceride, isononyl isononanoate, polydimethylsiloxane, 1,2-pentanediol, butyrospermum parkii butter, 1,2-hexanediol, caprylyl glycol, cetostearyl alcohol, carbomer, xanthan gum, nicotinamide, arginine, rosa damascena flower oil, citrus medica L. extract, cucumis sativus fruit extract, bearberry leaf extract, rose extract, sodium hyaluronate, methyl glucose sesqui-stearate, PEG-20 methyl glucose sesqui-stearate, glyceryl stearate, phenoxyethanol and water. A natural cosmetic is prepared from whitening components of natural plants and directly acts on the facial skin, so that the effective ingredients permeate into the basal layer of the skin to reduce and decompose existing melanin, activate cells and diminish facial freckles; and the natural cosmetic is reasonable in compatibility, so that the skin is whitened and moistened and has delicate sheen.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

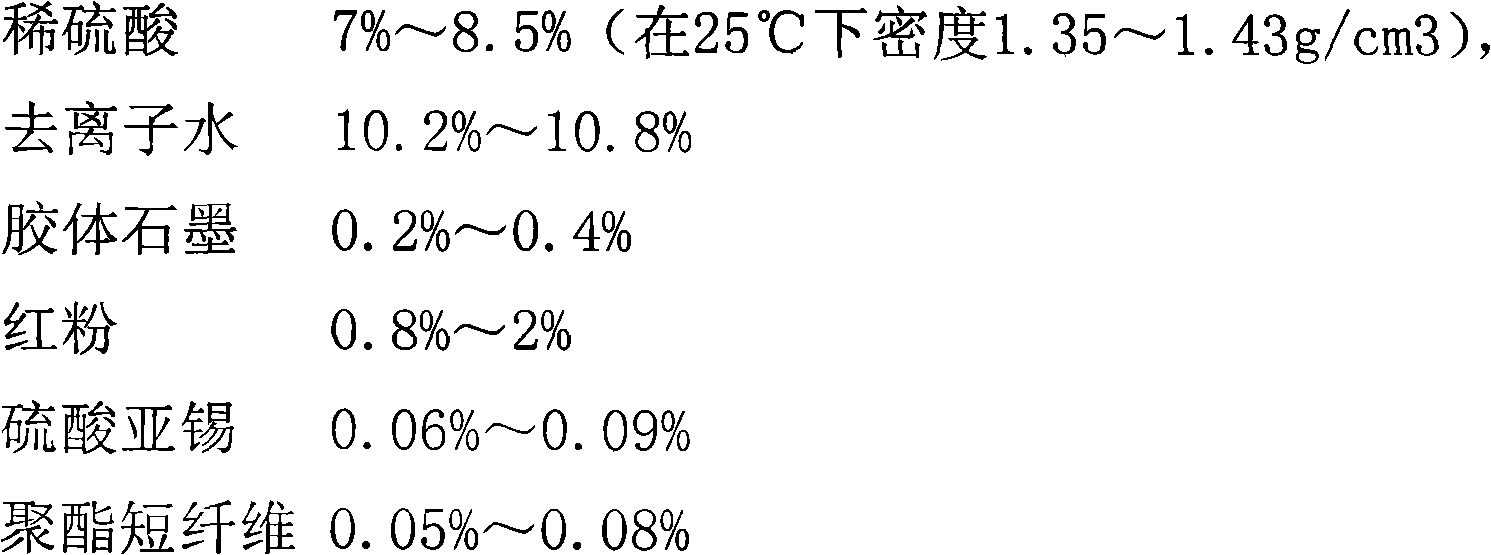

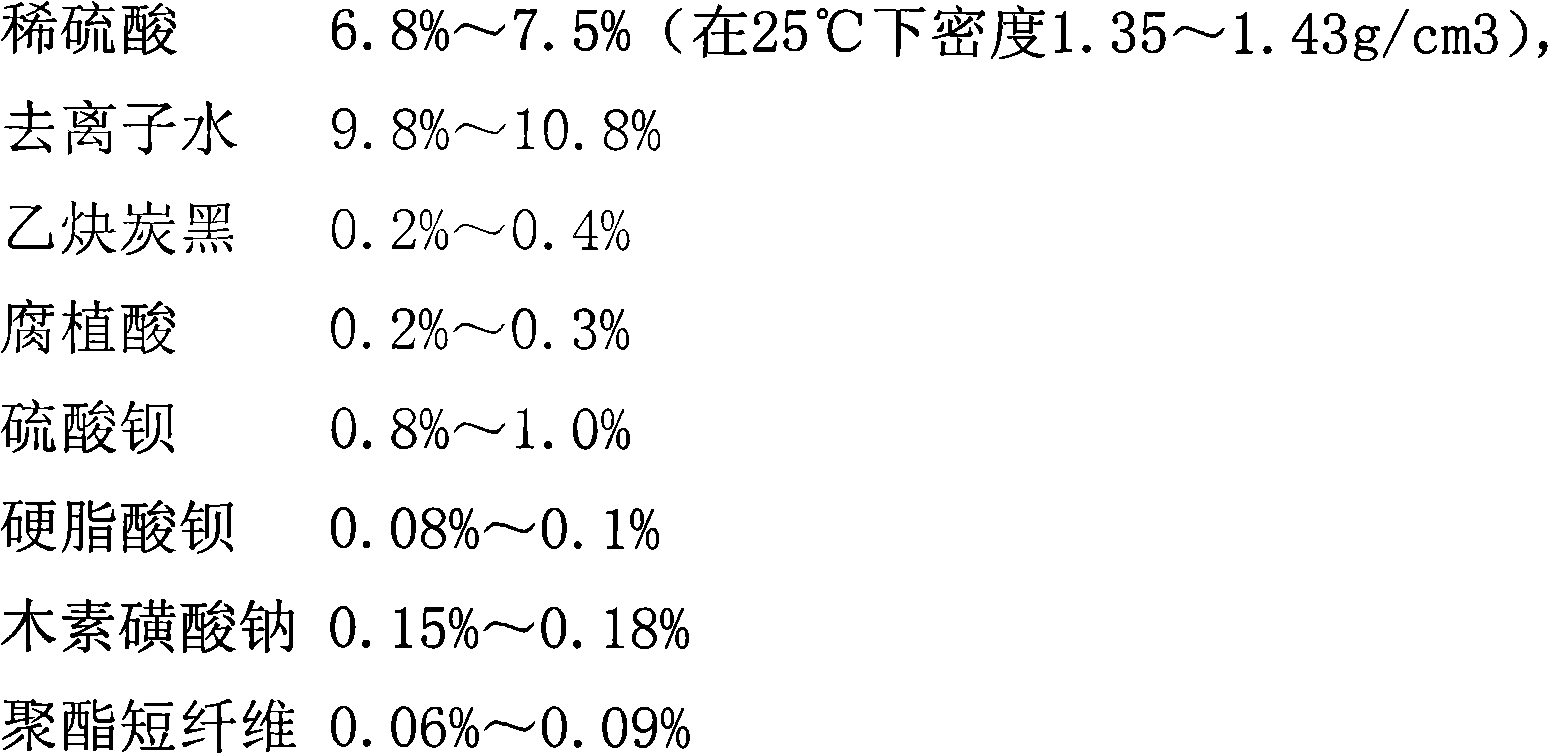

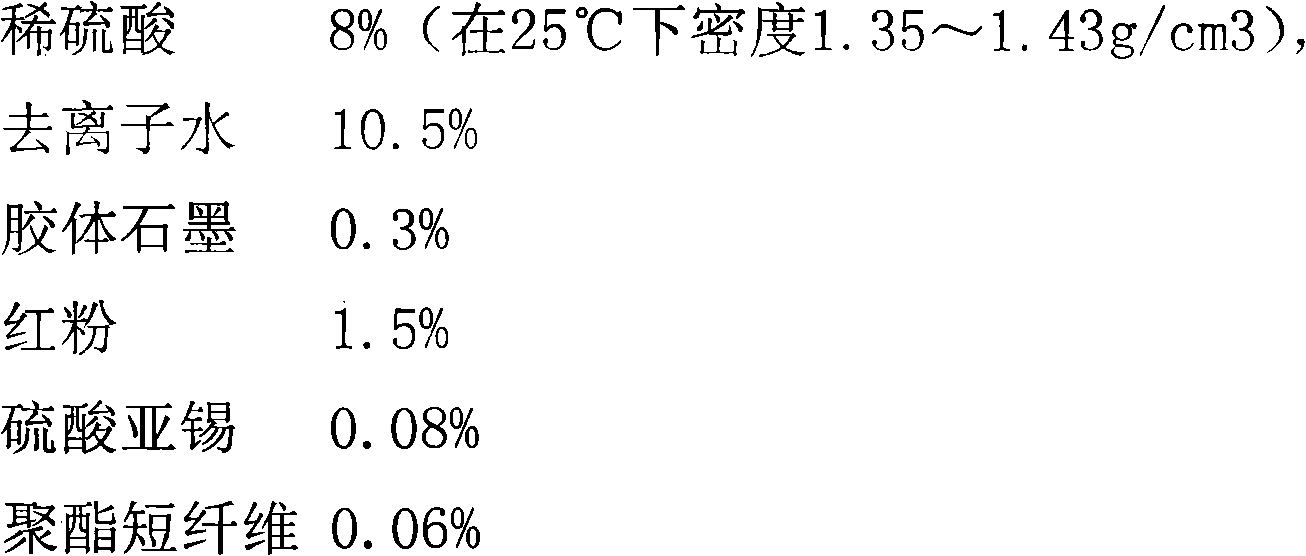

Formula and preparation method of high energy storage lead-acid battery lead paste

ActiveCN102354751AImprove charging efficiencyHigh initial capacityLead-acid accumulator electrodesFiberPolyester

The invention provides a formula and preparation method of a high energy storage lead-acid battery lead paste and relates to the technical field of lead-acid batteries. The formula of a positive plate lead paste comprises the following raw materials: 7-8.5% of dilute sulphuric acid, 10.2-10.8% of deionized water, 0.2-0.4% of colloidal graphite, 0.8-2% of red powder, 0.06-0.09% of stannous sulfate, 0.05-0.08% of polyester staple fiber and the balance of lead powder; the formula of a negative plate lead paste comprises the following raw materials: 6.8-7.5% of dilute sulphuric acid, 9.8-10.8% of deionized water, 0.2-0.4% of acetylene black, 0.2-0.3% of humic acid, 0.8-1.0% of barium sulfate, 0.08-0.1% of barium stearate, 0.15-0.18% of sodium lignosulphonate, 0.06-0.09% of polyester staple fiber and the balance of lead powder. The battery prepared by the lead paste has the advantages of high initial capacity and long cycle life; and the overdischarge resistance and charge acceptance of the battery are higher than the standard requirements.

Owner:TIANNENG BATTERY GROUP +4

Highland barley noodle

ActiveCN1969666AHigh nutritional valueImprove immunityDough treatmentMetabolism disorderManihotCholesterol

The invention discloses a barley noodle, which comprises the following parts: one or more component from barley noodle, wheat flour, maize starch, manihot starch, sweet potato starch, potato starch and glutelin powder, one or more of glutamine transaminase, xylanase and cellulose enzyme, one or more of guar gum, xanthan gum, sodium polyacrylate, sodium alginate and konjaku flour, one or more of monosodium calcium lactate stearate, diacetyl tartaric acid monoester, soya phosphatide and monoaliphatic acid glyceride, water, salt and egg.

Owner:青海大垚生态农业科技发展有限公司

Agronomic crop stalk medium density fiberboard using natural rubber and manufacturing method therefor

InactiveCN101367227AIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The invention provides a crop straw medium density fiberboard by natural gum. Raw materials of the medium density fiberboard comprise crop straw fiber, a bonding agent, a waterproof and lubricating agent and a flame retardant, wherein the bonding agent is natural gum and comprises plant gum and animal gum; the waterproof and lubricating agent is natural wax, stearic acid or stearate; and the flame retardant is non-toxic and harmless flame retardant. The mixture ratio for all the raw materials by weight percent is: 75 to 93 percent of the crop straw fiber, 1 to 8 percent of the bonding agent (dried), 0.5 to 8 percent of the waterproof and lubricating agent, and 5.5 to 23.5 percent of the flame retardant. All the raw materials are produced into a finished product through mixing, sizing, spreading, prepressing, hot pressing and edge cutting; and microwave is used for auxiliary heating in the hot pressing phase. The crop straw medium density fiberboard by the natural gum can realize complete degradation under natural condition after the medium density fiberboard is abandoned or destroyed without any nonreversible destruction to the environment, so the production and application of the crop straw medium density fiberboard realize complete sustainability and recyclability, and have significant realistic and historic significance.

Owner:张东旭

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives, phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

Drilling fluid lubricating agent

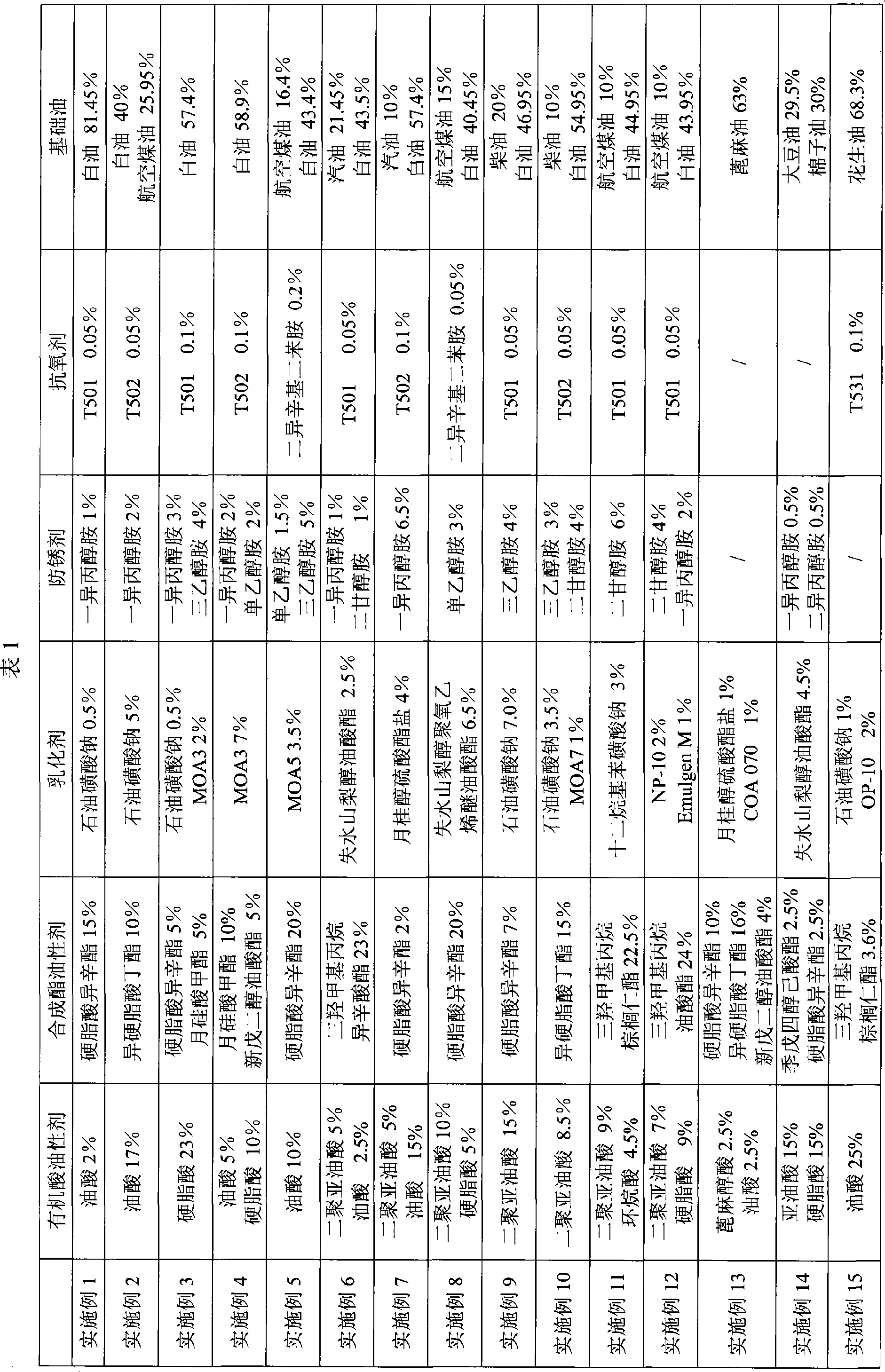

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

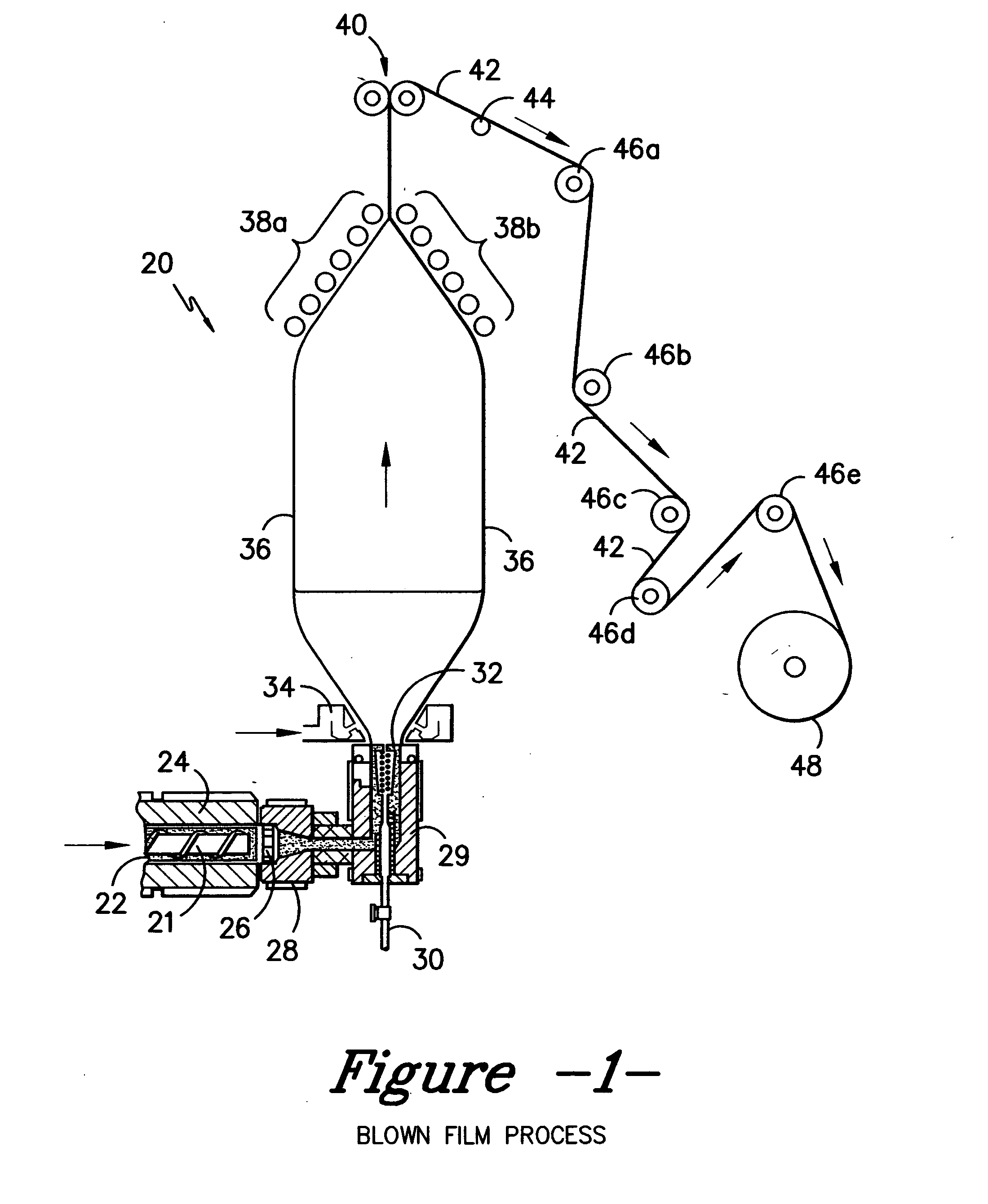

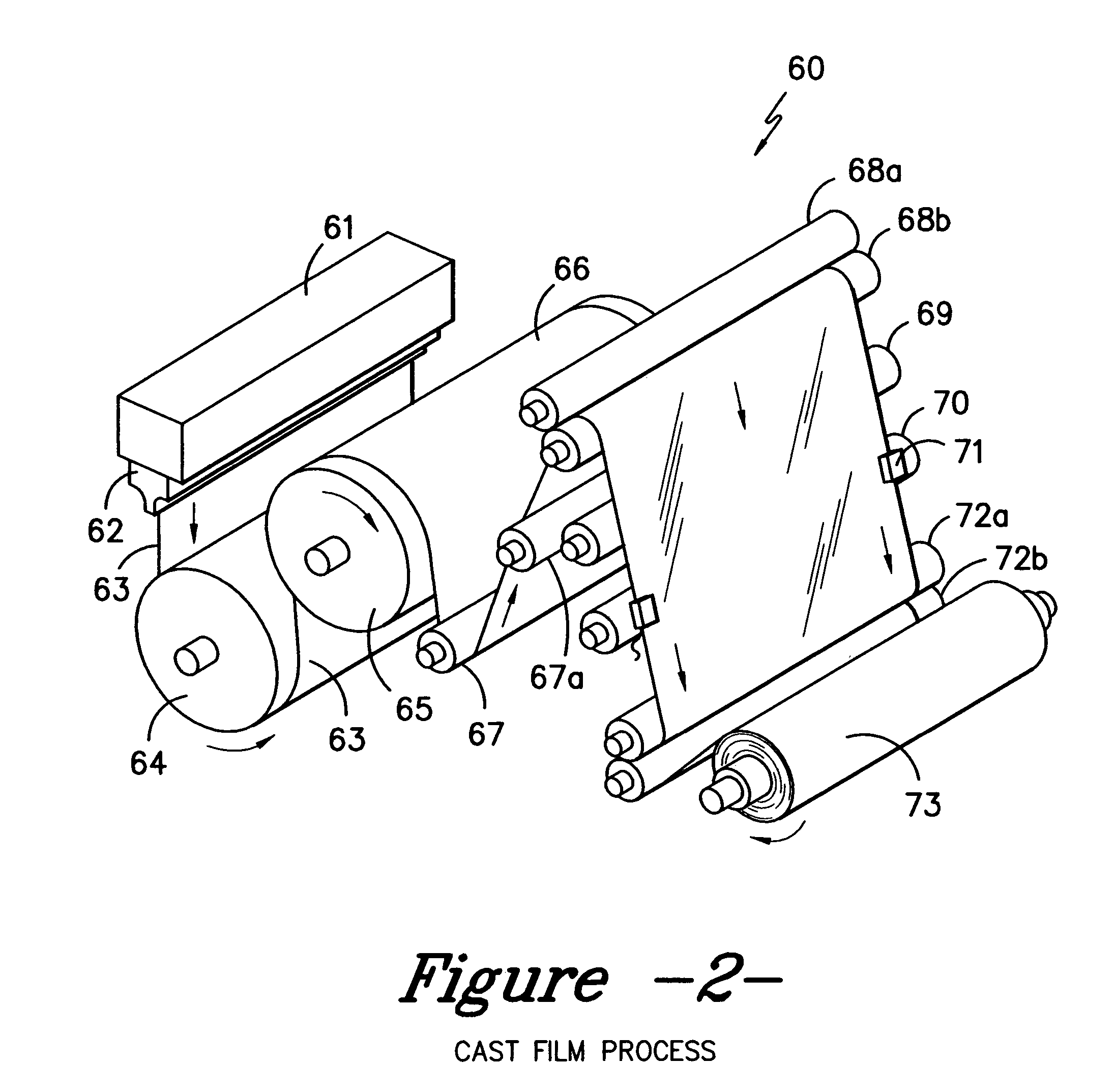

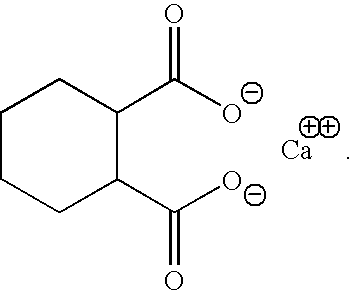

Film and methods of making film

A film article comprising a polyethylene polymer or copolymer and a cycloaliphatic metal salt is disclosed. A method of making a blown and a cast polyethylene film is shown. The film may also include various additives that are employed to improve the properties of the film, including stearate-containing compounds. Additives employed in one embodiment of the invention may reduce the percent haze of film formed in the process, thereby providing desirably low levels of haze. Zinc stearate is one additive that can be employed in making a low haze polyethylene film.

Owner:MILLIKEN & CO

Polyvinyl chloride heat stabilizer and preparation method thereof

ActiveCN102898741ASimple preparation processApplication productivity is reliablePolyvinyl chlorideStearic acid

The invention discloses a novel environment-friendly type PVC heat stabilizer comprising 1,3-dimethyl-6-Aminouracil as a main stabilizing agent. The novel environment-friendly type PVC heat stabilizer comprises the following ingredients: 1-5weight parts of 1,3-dimethyl-6-Aminouracil, 10-100 weight parts of epoxy soybean oil, 3-10 weight parts of calcium stearate, 3-10 weight parts of zine stearate, and 2-15 weight parts of organic auxiliary agent. According to the invention, the heat stabilizer disclosed herein significantly raises the stability of PVC materials in the processing process; and compared with traditional stabilizing agents, the heat stabilizer disclosed herein contains no heavy metal, and is an environment-friendly efficient novel heat stabilizer.

Owner:太原市塑料研究所

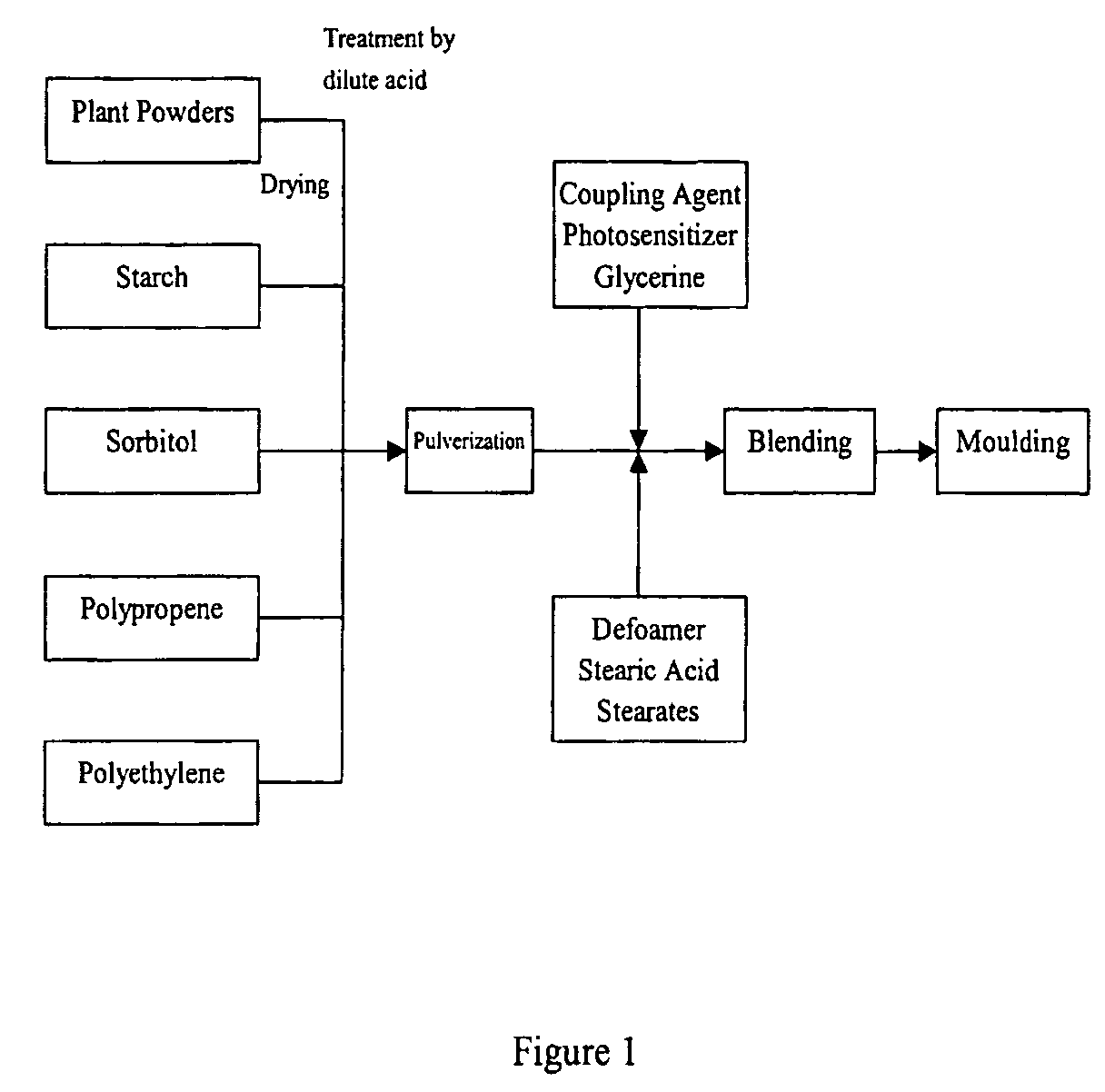

Biodegradable composition for the preparation of tableware, drink container, mulching film and package and method for preparing the same

The present invention relates to a biodegradable composition for the preparation of table-ware, mulching film and package, which comprises: 2-6% by weight of starch; 35-45% by weight of plant powders; 20-30% by weight of calcium carbonate; 2-7% by weight of sorbitol; 7-13% by weight of polypropylene; 2-5% by weight of polyethylene; 2-6% by weight of coupling agent; 1-2% by weight of defoamer; 2-5% by weight of stearic acid; 2-6% by weight of stearate; 3-6% by weight of glycerine or epoxidized soybean oil; and 60-100 ppm photosensitizer. The present invention also relates to a method for preparing the composition, which comprises: treating a plant waste with a diluent acid, drying and pulverizing, then mixing it with starch, polypropylene, and polyethylene, sorbitol, defoamer, coupling agent, stearic acid, stearate, glycerine and photosensitizer homogeneously; and blending the mixture obtained in a double-screw extruder at a temperature of 160-180° C. to obtain the composition of the present invention.

Owner:XU HAO

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

Construction garbage concrete segment and method for producing the same

InactiveCN101508544AGuaranteed StrengthGuaranteed durabilitySolid waste managementMixing operation control apparatusBrickAdditive ingredient

The invention discloses a building waste concrete brick and a manufacturing method thereof. The brick is manufactured by mixing, molding, maintaining and drying regenerative raw materials of the building waste, cement, fly ash, a tackifier, a waterproof agent, an excitant and water. The regenerative raw materials of the building waste is obtained by processing waste concrete and such inorganic hard ingredients as manufactured products, waste tiles, waste stones and the like, with the maximum grain size of 8mm; the tackifier is the carbide slag, high-viscosity attapulgite clay powder, cellulose ether and the like; the waterproof agent is the products of stearate series; the excitant is quicklime powder, calcium chloride, sodium sulfate and the like. The brick of the invention prepared through the steps of raw material stirring, molding, maintaining and drying has simple technique, easy operation, low cost and stable product quality; the wall bodies built with the brick have good impermeability and anti-cracking performance. A large amount of building wastes which are low in price are utilized for the brick, thus reducing the consumption of natural resources, conforming to the strategy of sustainable development and witnessing obvious social and environmental benefits.

Owner:CHINA BUILDING MATERIALS ACAD

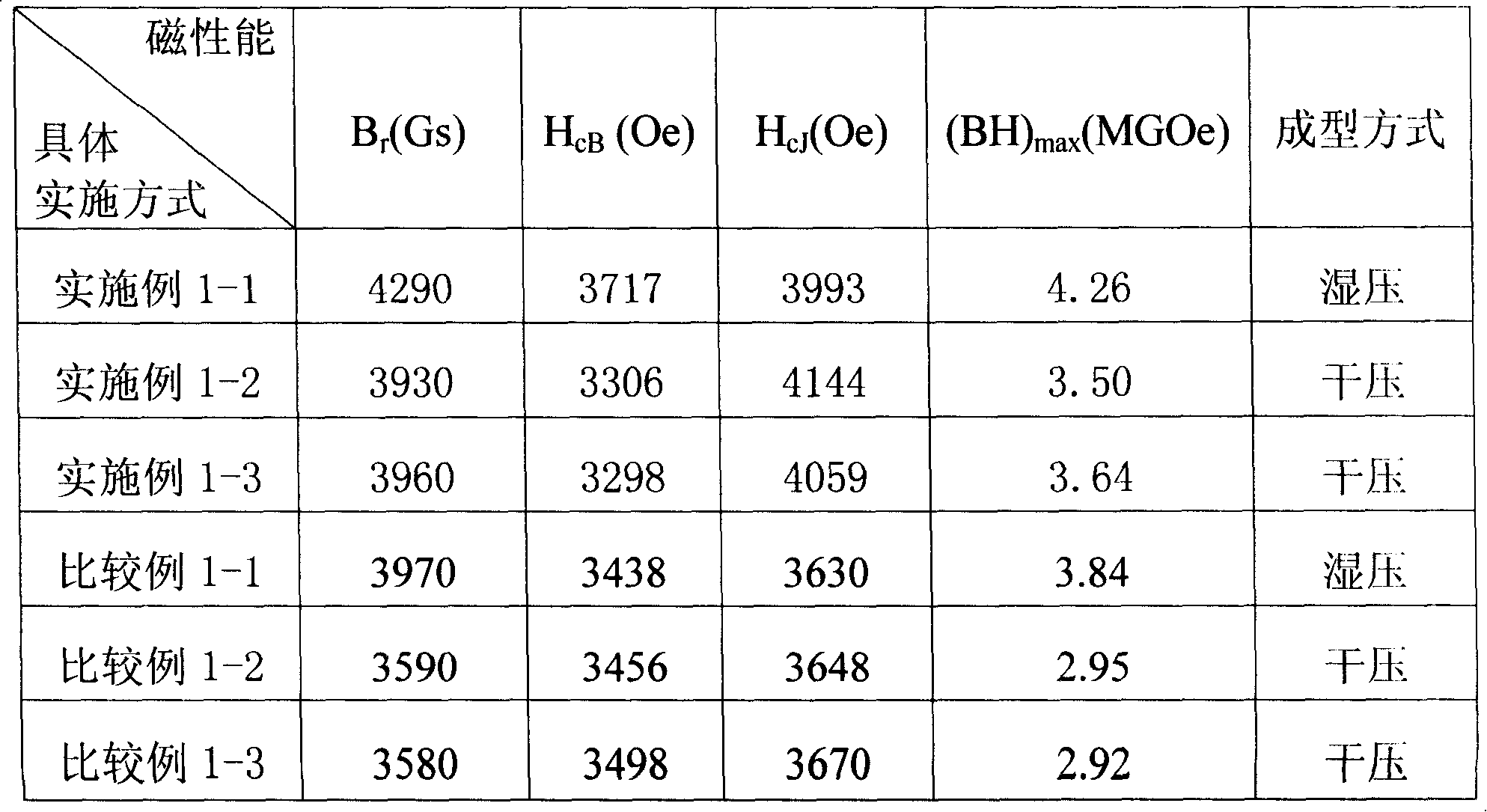

Method for manufacturing dry-pressing formed sintered permanent ferrite

InactiveCN101205137AIncrease productivityEasy to realize automatic moldingMetallurgyPolyethylene glycol

The invention relates to a manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding. The method comprises following working procedures: crushing process, the preparation process of dry pressing the magnetic powder, dry pressing process and sinter process. The organic dispersant added in the crushing process is one or a plurality among polyethylene glycol, calcium stearate and calcium gluconate, and the content of the organic dispersant is 0.1wtpercent-1.5wtpercent; the bond added in the he preparation process of dry pressing the magnetic powder is one or a plurality among PVA, polyethylene glycol, camphor and stearate, and the content of the bond is 0.1wtpercent-1.5wtpercent. 1. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention has the advantages of that the productivity effect is high, the molding mould is simple and the automation molding is easy to be realized; the surface of the molded finished product is lubricous and even, the fettling is not needed, and the workload of the post processing is decreased greatly; 2. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the unique preparation technique of dry pressing the magnetic powder, and the orientation in the process of magnetic field press is relatively good, and the high Br and high HCJ dry-pressing sintering permanent magnetism ferrite is easy to be gained; 3. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the pre-sintering material with a better performance of ion substitutional main prescription, and a dry-pressing anisotropic sintering permanent magnetism ferrite with a better magnetism performance can be achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Herbal skin care formulation and a process for the preparation thereof

InactiveUS6368639B1Avoid disadvantagesEffective and easy to useBiocideCosmetic preparationsSandalwood oilStearic acid

The invention relates to a herbal skin care formulation comprising of beeswax, stearic acid, glycerol monostearate, olive oil, aloe gel, glycerine, triethanolamine, parabens, propylene glycol, essential oils, sandalwood oil, and the balance comprising rose water. The invention also relates to a process for the preparation of the formulation.

Owner:COUNCIL OF SCI & IND RES

Method for clearing up nanometer uvioresistant antibacterial self-cleaning fabric

The invention relates to a method for clearing up a nanometer uvioresistant antibacterial self-cleaning fabric. The method comprises the steps of: (1) mixing a titanium slat with an organic acid in a mass ratio of 10:(1-3), stirring the mixed solution uniformly, then adding the mixed solution into an inorganic acid solution to react at 50-60 DEG C for 30-60 minutes, so as to obtain nanometer TiO2clearing up liquid; (2) soaking and rolling the fabric twice in the nanometer TiO2 clearing up liquid; (3) mixing stearate, hydrolyst, water and alcohol at room temperature to react for 0.5-2 hour toobtain a water repellent; and (4) padding or soaking the fabric mentioned in step (2) in the water repellent, pre-drying and baking the fabric cleared up in a manner of water repellence, thus obtaining a nanometer uvioresistant antibacterial self-cleaning fabric. The method disclosed by the invention is simple and easy to industrialize, and the treated fabric has good self-cleaning performance and also has good uvioresistant and antibacterial performances, so the nanometer uvioresistant antibacterial self-cleaning fabric has good application prospect.

Owner:DONGHUA UNIV

Fragrant environment protection polyvinyl chloride granules

The invention discloses aromatic environment protective PVC granules which includes the components with the following weight portions: 100 weight portions of PVC resin; 8 weight portions to 40 weight portions of DOTP plasticizer; 10 weight portions to 40 weight portions of TOTM plasticizer; 2 weight portions to 12 weight portions of environment protective Ca / Zn thermal stabilizer; 0.1 weight portion to 1.5 weight portions of antioxidizer; 0 weight portion to 2.5 weight portions of polyethlene wax; 2 weight portions to 12 weight portions of plastic deodorant; 2 weight portions to 12 weight portions of aromatic essence, 0.5 weight portion to 3 weight portions of barium stearate; 0.1 weight portion to 3 weight portions of stearic acid; 3 weight portions to 20 weight portions of highly activated calcium bicarbonate filler; 0 weight portion to 10 weight portions of environment protective non-toxic flame retardant. The invention has the advantages that because all the raw materials in the prescription are safe and environment protective, the granulate is non-toxic, harmless and aromatic, has excellent performance, is environment protective, has no pollution and meets relevant provisions of the ROHS directive issued by European Union and the ''Management Method on Control of Electronic Information Product Pollution'' issued by China. The granule has wide scope of application, and is suitable to serve as the insulating material of wires and cables, floor leather material, sole material, toys for children and daily plastic products.

Owner:TBEA DEYANG CABLE CO LTD

Three-layer noise reduction drainage pipe and manufacture method thereof

InactiveCN102313084AHigh strengthReduce impact noiseDomestic plumbingRigid pipesManufacturing cost reductionPolyvinyl chloride

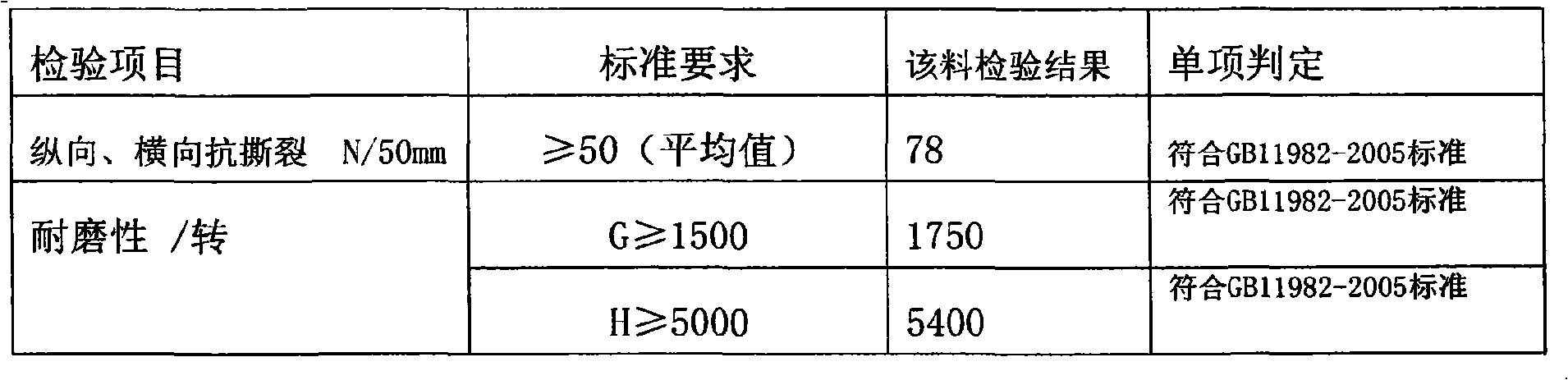

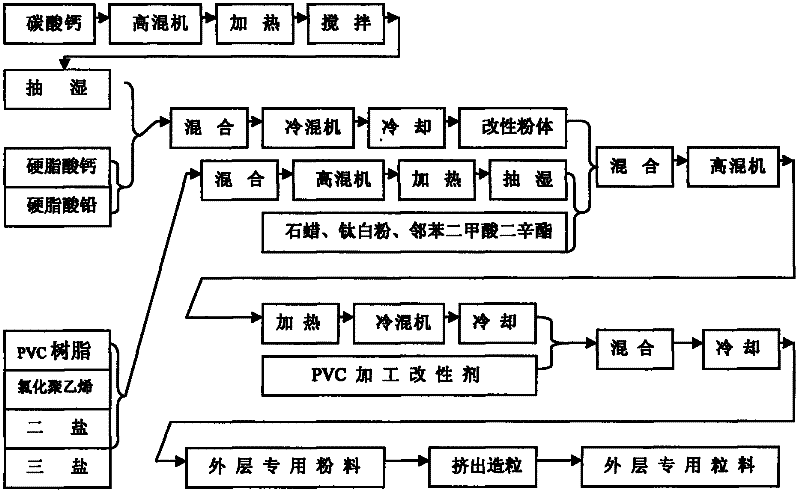

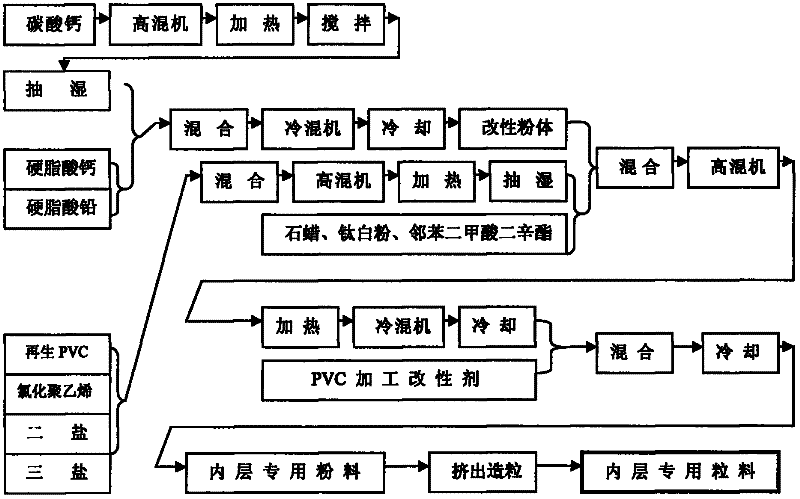

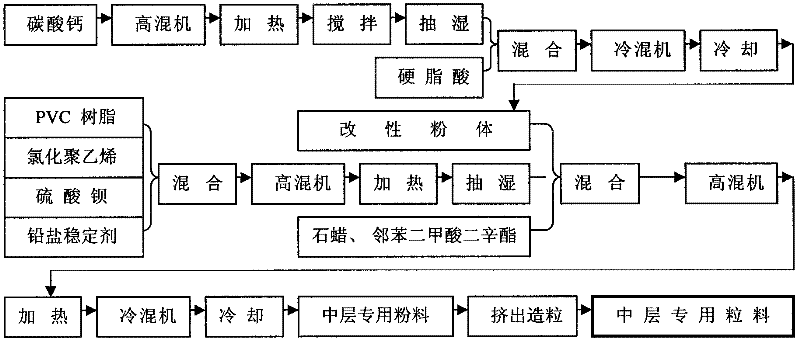

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. The noise reduction middle layer is a sound-absorbing middle layer or a sound insulation middle layer made of expandable polyvinyl chloride composition materials. The above layers are prepared with the following materials. The impact-resistance outer layer is made of polyvinyl chloride resin, chlorinated polyethylene, dibasic lead phosphite, tribasic lead sulfate, calcium stearate, lead stearate, paraffin, PVC processing and modifying agent, active light calcium carbonate, titanium dioxide and dioctyl phthalate. The sound-absorbing middle layer is made of polyvinyl chloride resin, chlorinated polyethylene, lead salt stabilizer, calcium stearate, stearic acid, paraffin, dioctyl phthalate, active light calcium carbonate and barium sulfate. The sound insulation middle layer is made of polyvinyl chloride resin, methacrylic ester polymer and inorganic foaming agent. Compared with the outer layer, the impact-resistance inner layer comprises the same components with the outer layer, except that PVC is adopted instead of polyvinyl chloride resin. The noise of the drainage pipe can be effectively reduced and the intensity of the drainage pipe is enhanced.

Owner:ZHEJIANG SANLENG PLASTIC

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Antiallergic microemulsion

InactiveCN105708757AImprove stabilityLong term storageCosmetic preparationsToilet preparationsVegetable oilStearate

The invention discloses an antiallergic microemulsion, which contains: sorbitan sesquioleate and PEG‑60 sorbitan stearate; one or more oily components, Selected from hydrocarbon oils, synthetic oils, animal and vegetable oils, silicone oils and mixtures thereof; polyhydric alcohols and water; one or more water-soluble antiallergic raw materials. The microemulsion is a water-in-oil system, has good stability, can be stored for a long time, has a good solubilizing effect on water-soluble anti-allergic raw materials, and can be made into products with higher functional components.

Owner:江西登云健康美业互联有限公司 +1

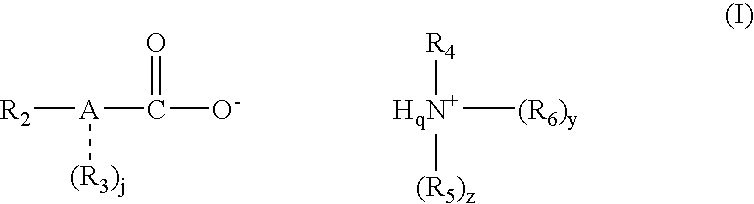

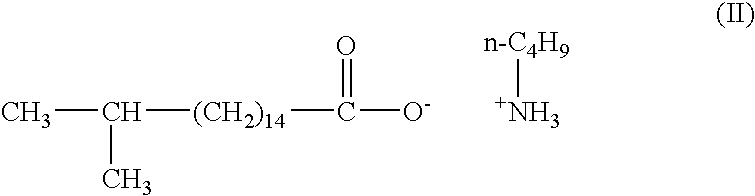

Friction modifier additives for fuel compositions and methods of use thereof

InactiveUS6866690B2Improve fuel economyFriction lossLiquid carbonaceous fuelsAdditivesCombustionFriction loss

A friction modifier for combustible fuels is provided that is prepared by combining a saturated carboxylic acid and an alkylated amine. Furthermore, there also is an additive concentrate for use in fuels, especially in gasoline for internal combustion engines, comprising (a) a friction modifier comprising of a branched saturated carboxylic acid salt of an alkylated amine, such as n-butylamine isostearate; (b) a detergent package, as well as the combustible fuels containing this additive concentrate. The particular selection of friction modifier (a) enables a stable additive concentrate to be formulated providing a significant benefit in friction loss when incorporated in gasoline used to fuel an internal combustion engine, and hence an improvement in fuel economy. Moreover, the use of the friction modifier (a) in combination with a detergent package permits increased fuel efficiency to be obtained without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic adds / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives, phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

Bamboo-plastic composite section bar

A bamboo plastic composite sectional material consists of PVC 100 proportion, bamboo-sand optical powder 100-200 proportion, barium stearate 0.6-1.0 proportion, CPE 4-6 proportion, lead stearate 0.6-1.0 proportion, industrial stearic acid 1-1.5 proportion, n-octyl ester phthalate 2-3.5 proportion, light calcium carbonate 15-45 proportion, stabilizer 3-6 proportion, ACR 2-6 proportion, foaming regulator 5-10 proportion, ADC foaming agent 1-2 proportion and polyvinyl wax 0.2-1.0 proportion. It costs low and is simple. It has better quality, strength and toughness and various uses. It can be used for door, window, decorative line and floor.

Owner:重庆星星套装门(集团)有限责任公司

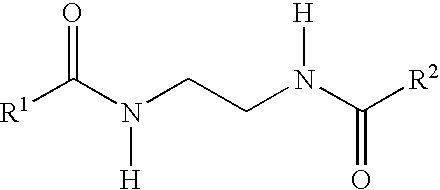

Fluorinated ester melt additives for thermoplastic fibers

InactiveUS6063474AImparting alcohol repellencyIncreased repellencyWoven fabricsNon-woven fabricsFiberPolyester

A composition having repellency to low surface tension fluids comprising a material prepared by forming a mixture of a polymer selected from the group consisting of polyolefin, polyamide, polyester, polyacrylate, and blends and copolymers thereof, and a fluorochemical compound comprising a fluorocarbon / hydrocarbon ester of the formulae: wherein Rf is selected from the group consisting of: 1) F(CF.sub.2).sub.x --(CH.sub.2).sub.m wherein x is from about 4 to about 20 and m is from about 0 to about 6; and 2) F(CF.sub.2).sub.x --SO.sub.2 N(R.sub.2)--R.sub.3 where x is a positive integer from about 4 to about 20, R.sub.2 is an alkyl radical of from about 1 to about 4 carbon atoms, R.sub.3 is an alkylene radical of from about 1 to about 12 carbon atoms; and R.sub.1 is an aliphatic hydrocarbon having from about 12 to about 76 carbon atoms; and provided that said fluorochemical compound is other than perfluoroalkylethyl stearate; and melt extruding the mixture.

Owner:EI DU PONT DE NEMOURS & CO

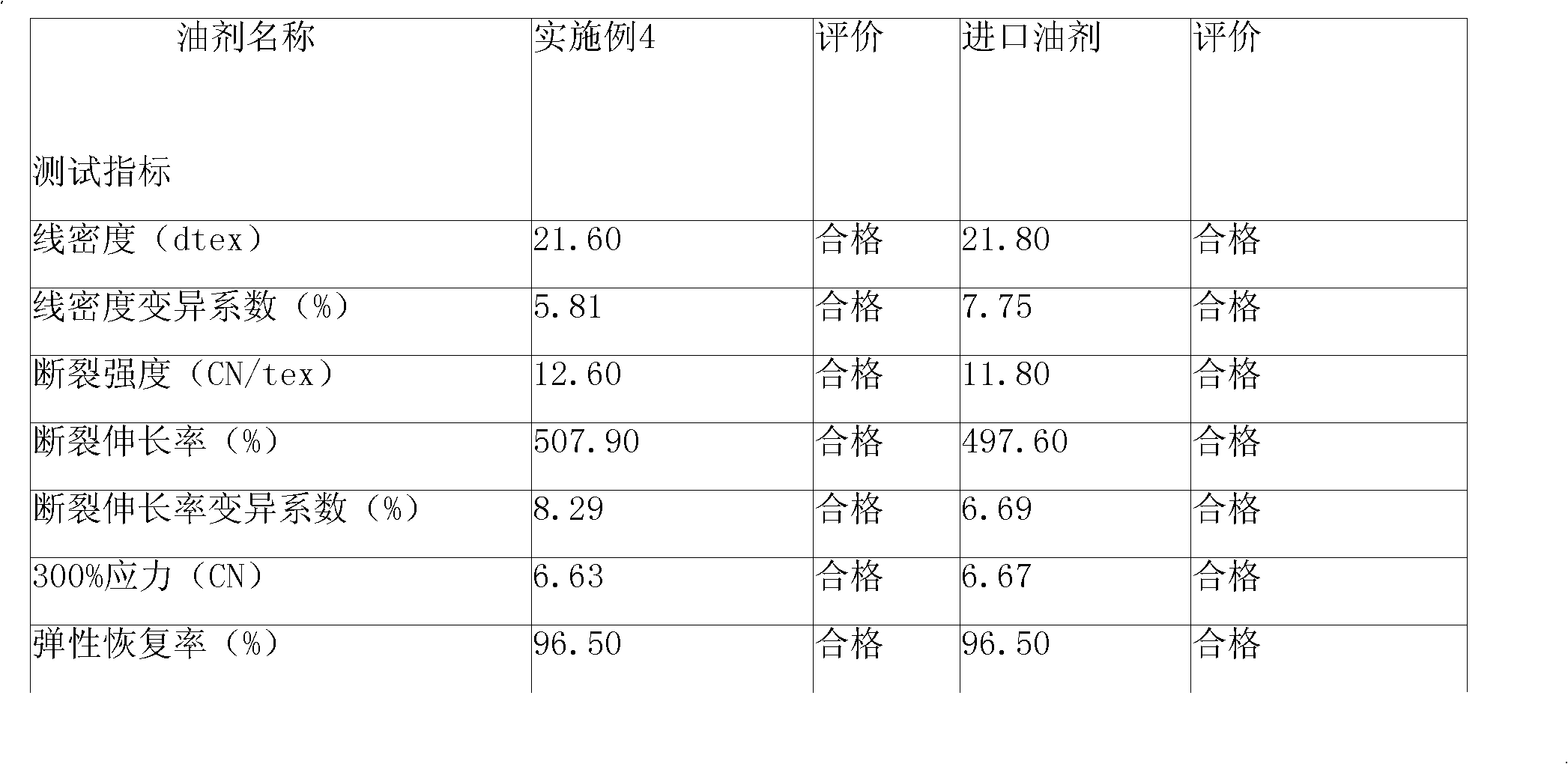

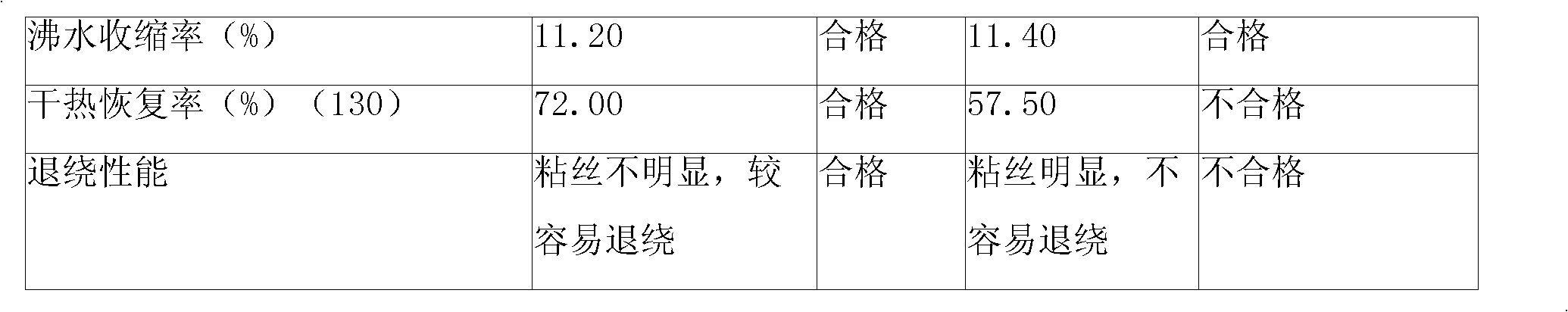

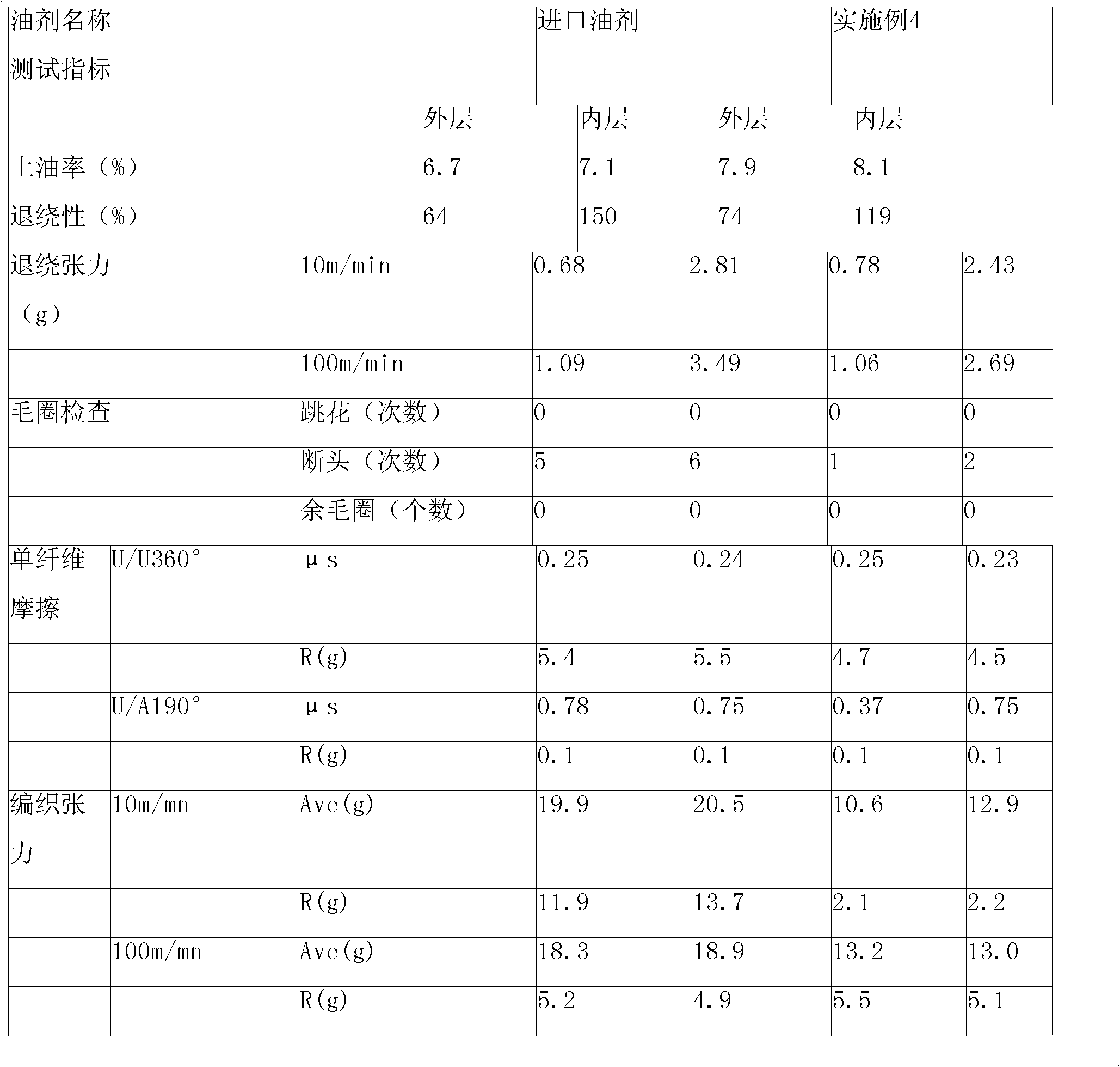

Polyurethane fiber dry spinning oil agent and preparation method thereof

The invention discloses a polyurethane fiber dry spinning oil agent, which comprises 30 to 80 weight percent of dimethyl silicon oil, 10 to 50 weight percent of mineral oil, 1 to 7.5 weight percent of high-carbon isomeric fatty alcohol or acid, 1 to 5 weight percent of dispersed component, 0.1 to 1.5 weight percent of stearate and 2 to 20 weight percent of antistatic component. The dispersed component is a mixture of an organic silicon surfactant and acrylic acid-maleic acid copolymer, and the weight ratio of the organic silicon surfactant to the crylic acid-maleic acid copolymer is 1:0.5-2; and the antistatic component is a mixture of polyether silicon oil and nonionic isomeric alcohol polyethenoxy ether, and the weight ratio of the polyether silicon oil to the nonionic isomeric alcohol polyethenoxy ether is 1:0.5-2. The polyurethane fiber dry spinning oil agent has excellent smoothness, softness, antistatic property, stable performance and excellent anti-adherent performance; polyurethane fiber treated by the oil agent has good unreeling property and forming property; and in the subsequent processing flow, polyurethane filaments are easy to unreel, not drop edge and has few broken filaments.

Owner:BEIJING GUANGHUA TEXTILE GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com