Patents

Literature

66results about How to "Friction loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

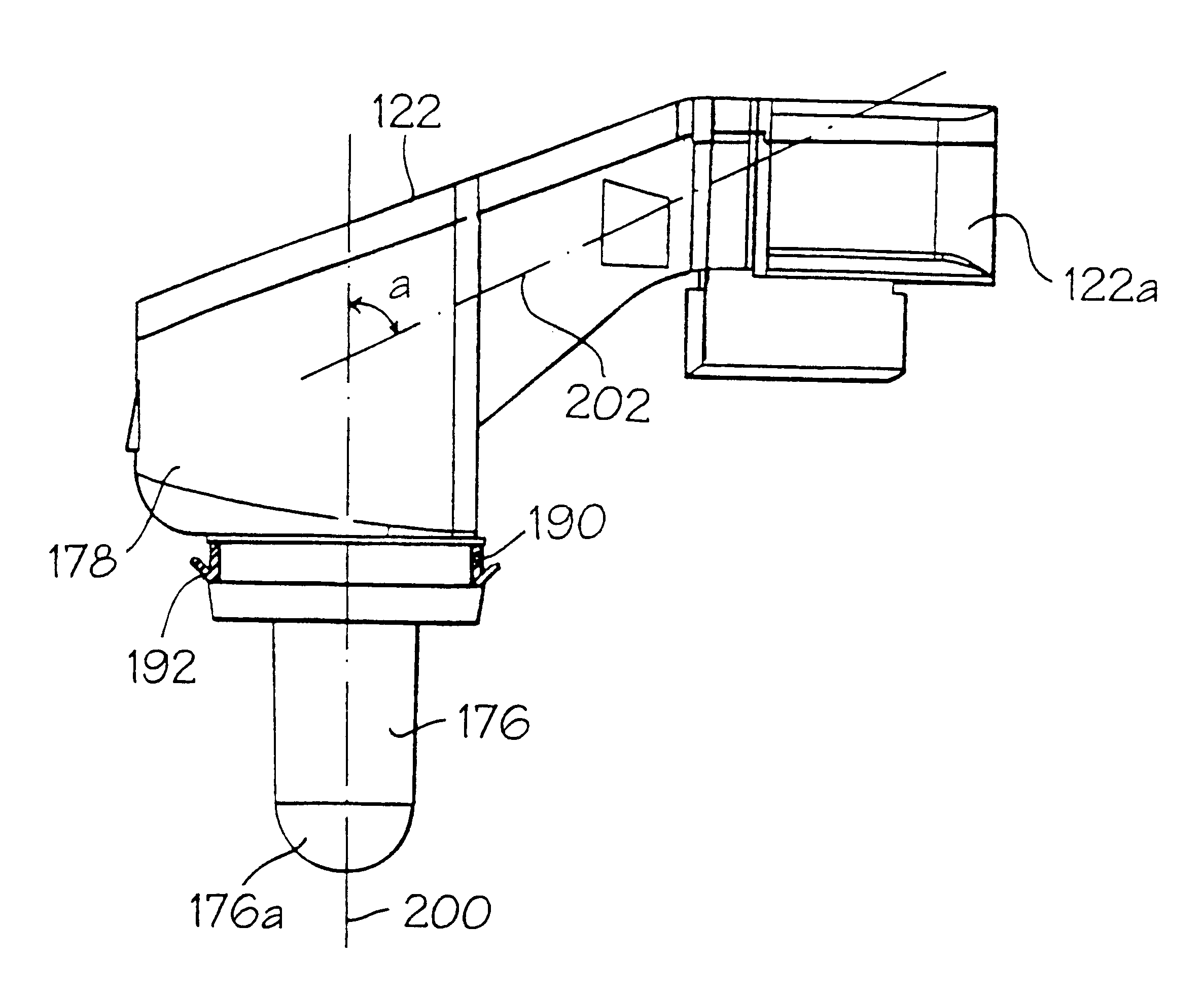

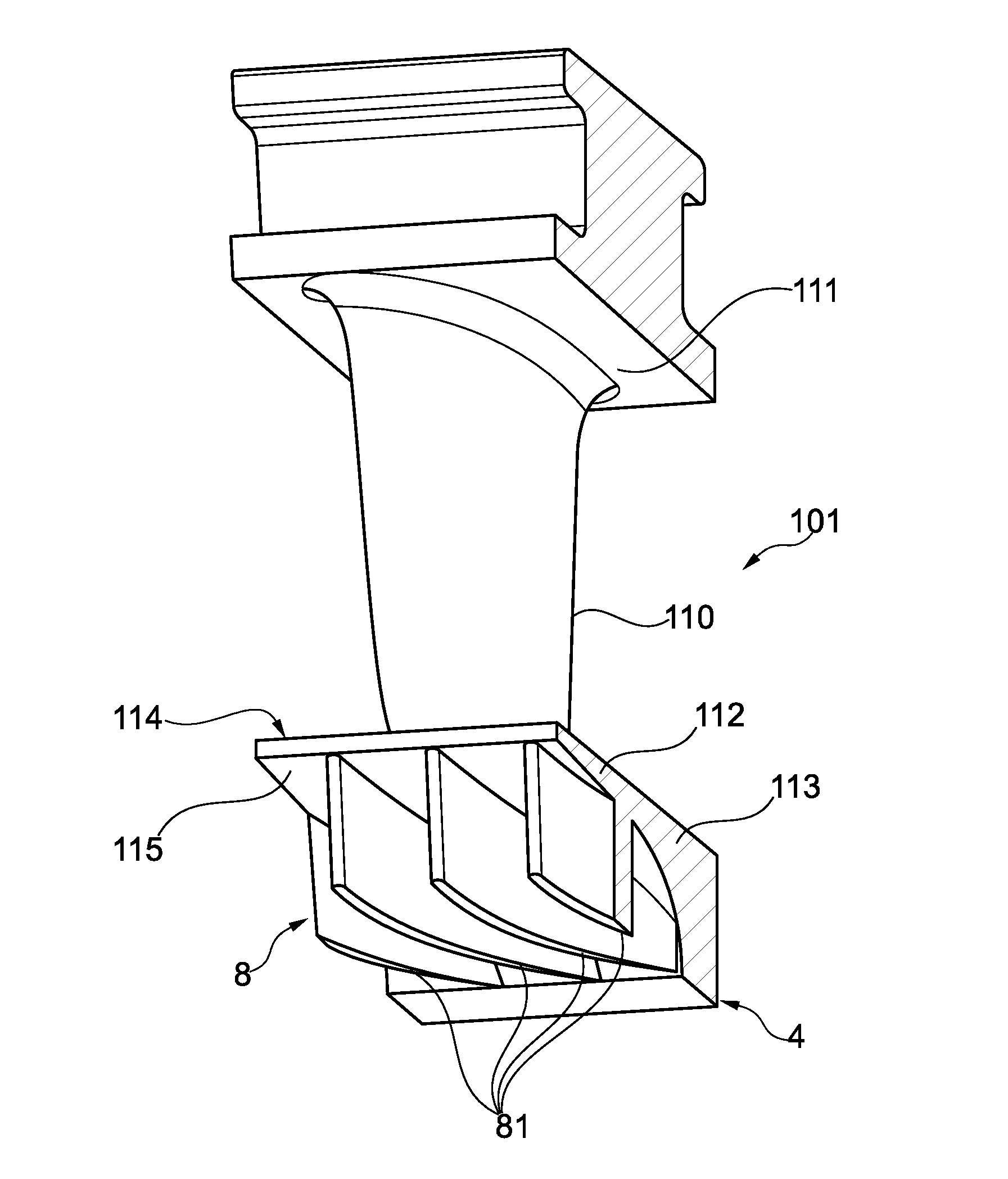

Cyclonic separating apparatus with tangential offtake conduit

InactiveUS6482246B1High efficiency performanceImprove good performanceSuction filtersReversed direction vortexCycloneEngineering

The invention provides cyclonic separating apparatus comprising a tapering cyclone having a larger end a smaller end, a fluid outlet located at the larger end of the cyclone, the fluid outlet becoming located coaxially with the cyclone, and a tangential offtake conduit communicating with the fluid outlet, wherein the distance between the tangential offtake conduit and the smaller end of the cyclone increases in the downstream direction of the tangential offtake conduit. Preferably, the tengential offtake conduit follows a substantially helical path. This reduces the turbulence created in the tangential offtake conduit and allows kinetic energy of the exiting fluid to be recovered as pressure energy.

Owner:DYSON TECH LTD

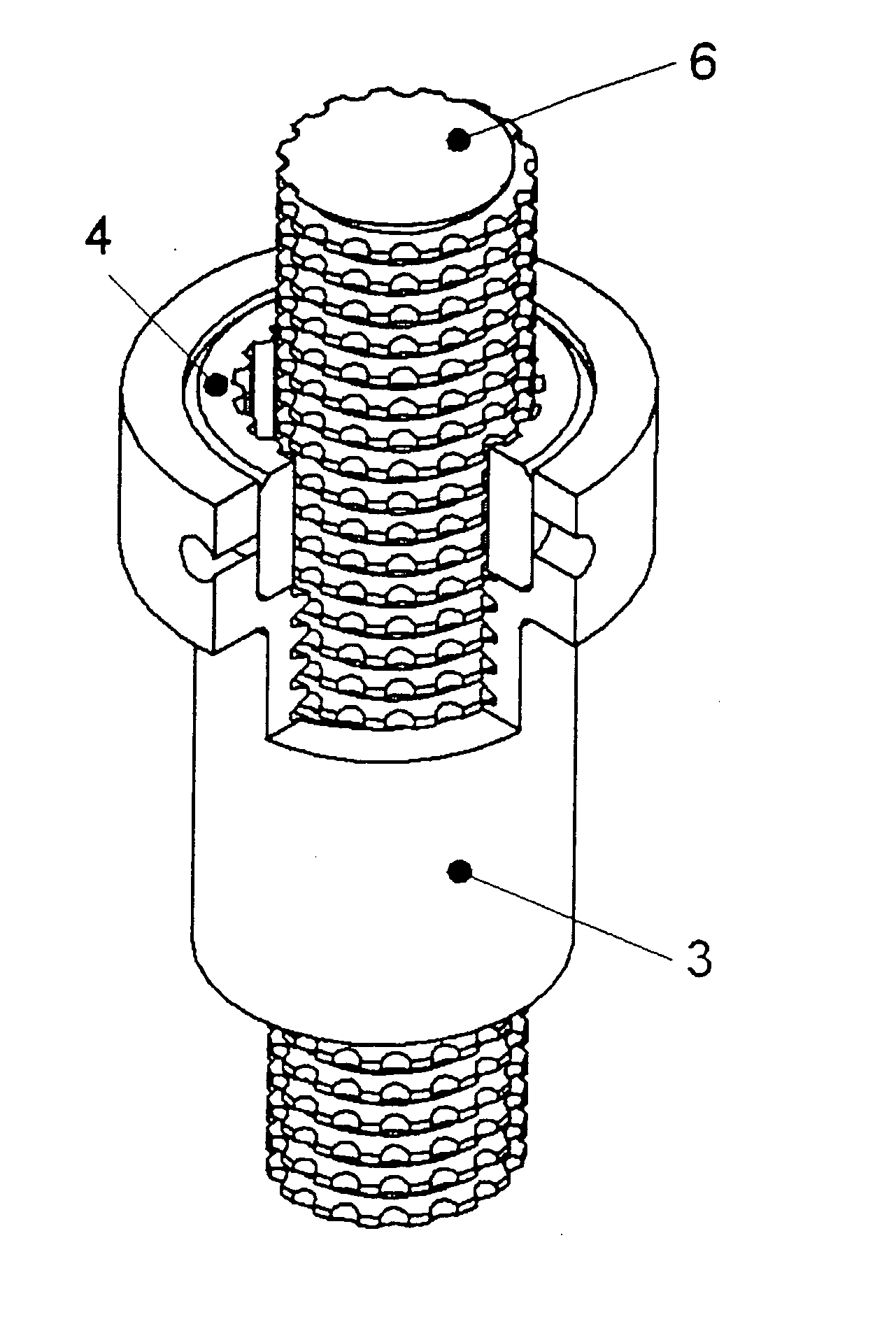

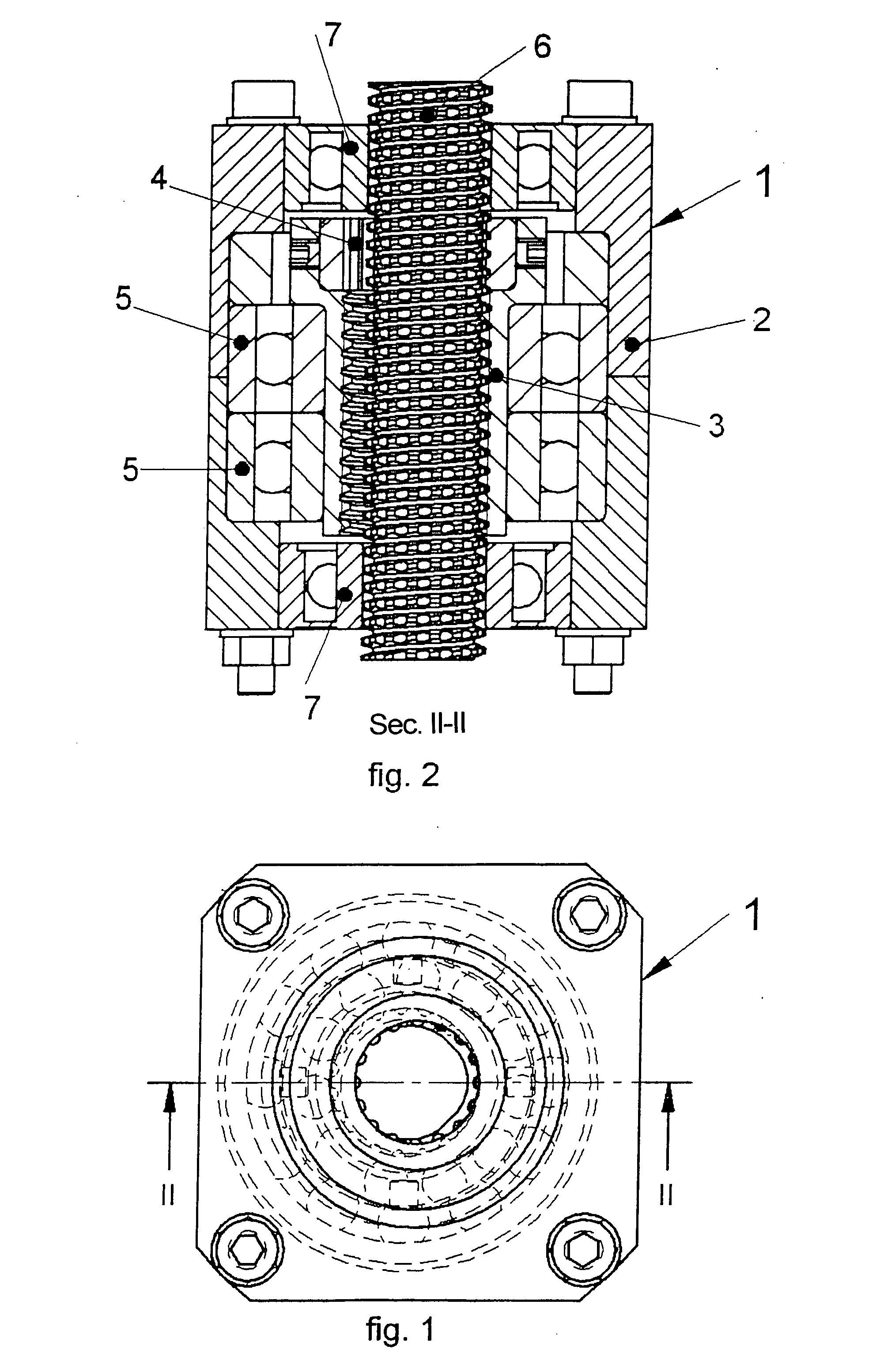

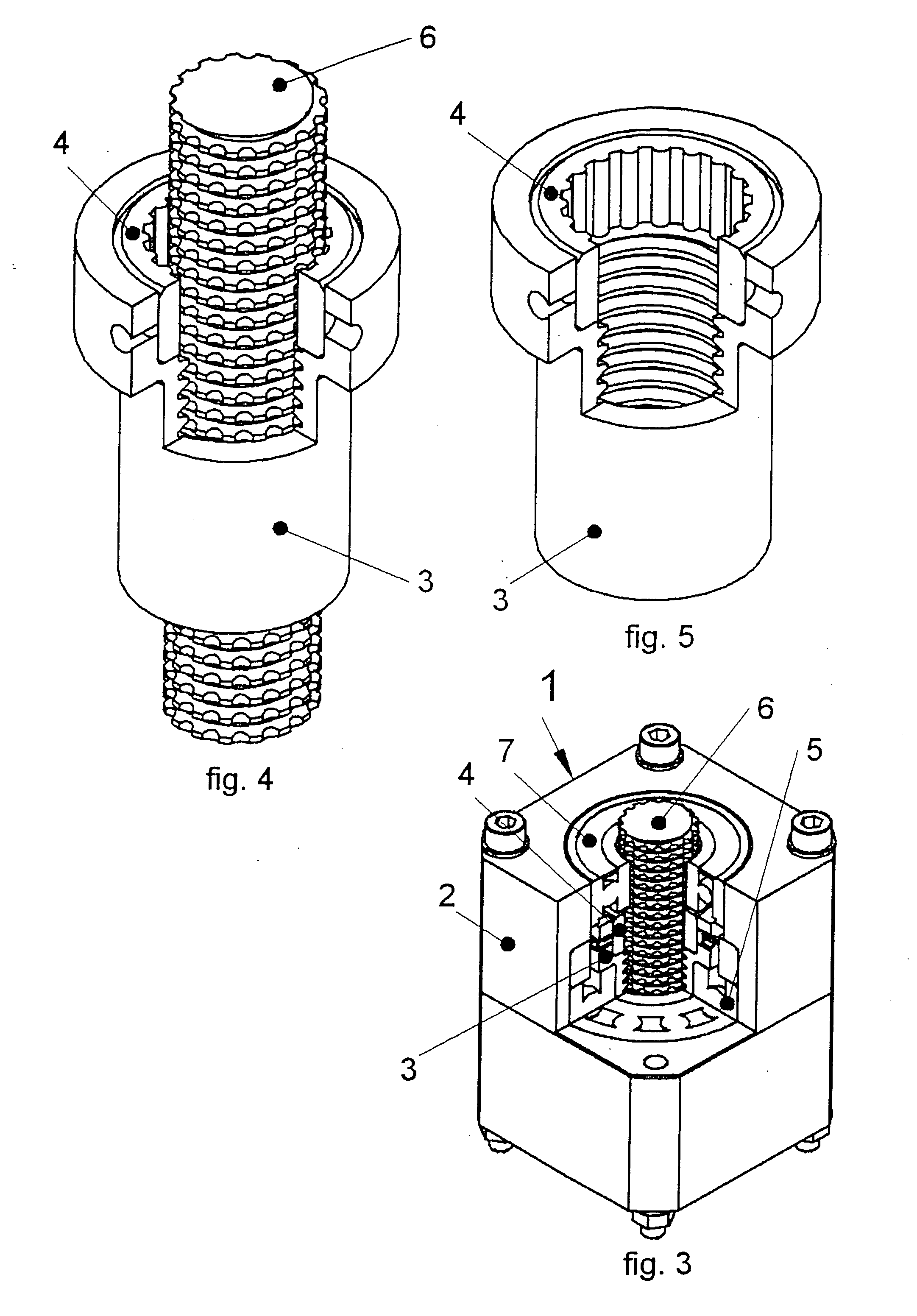

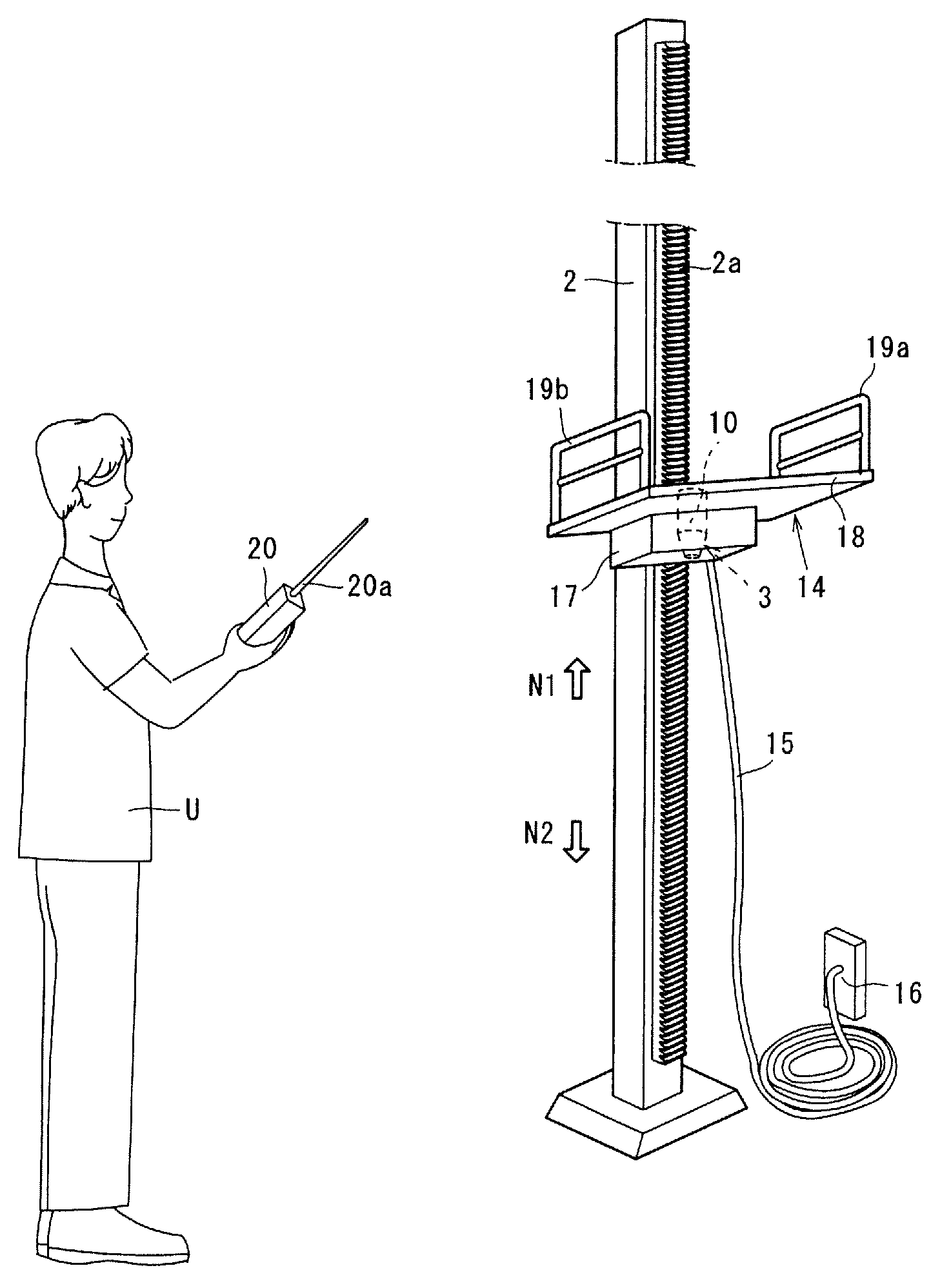

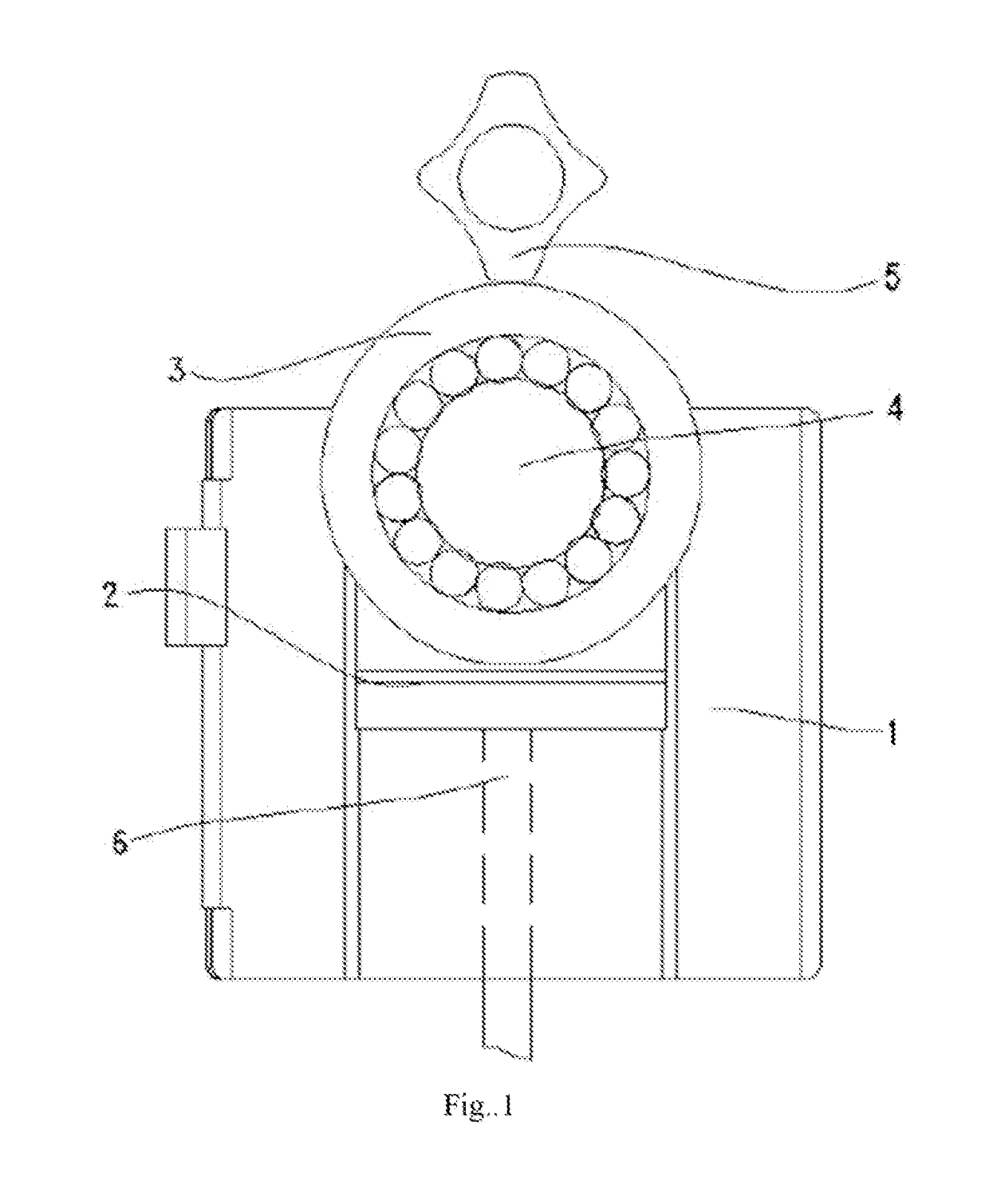

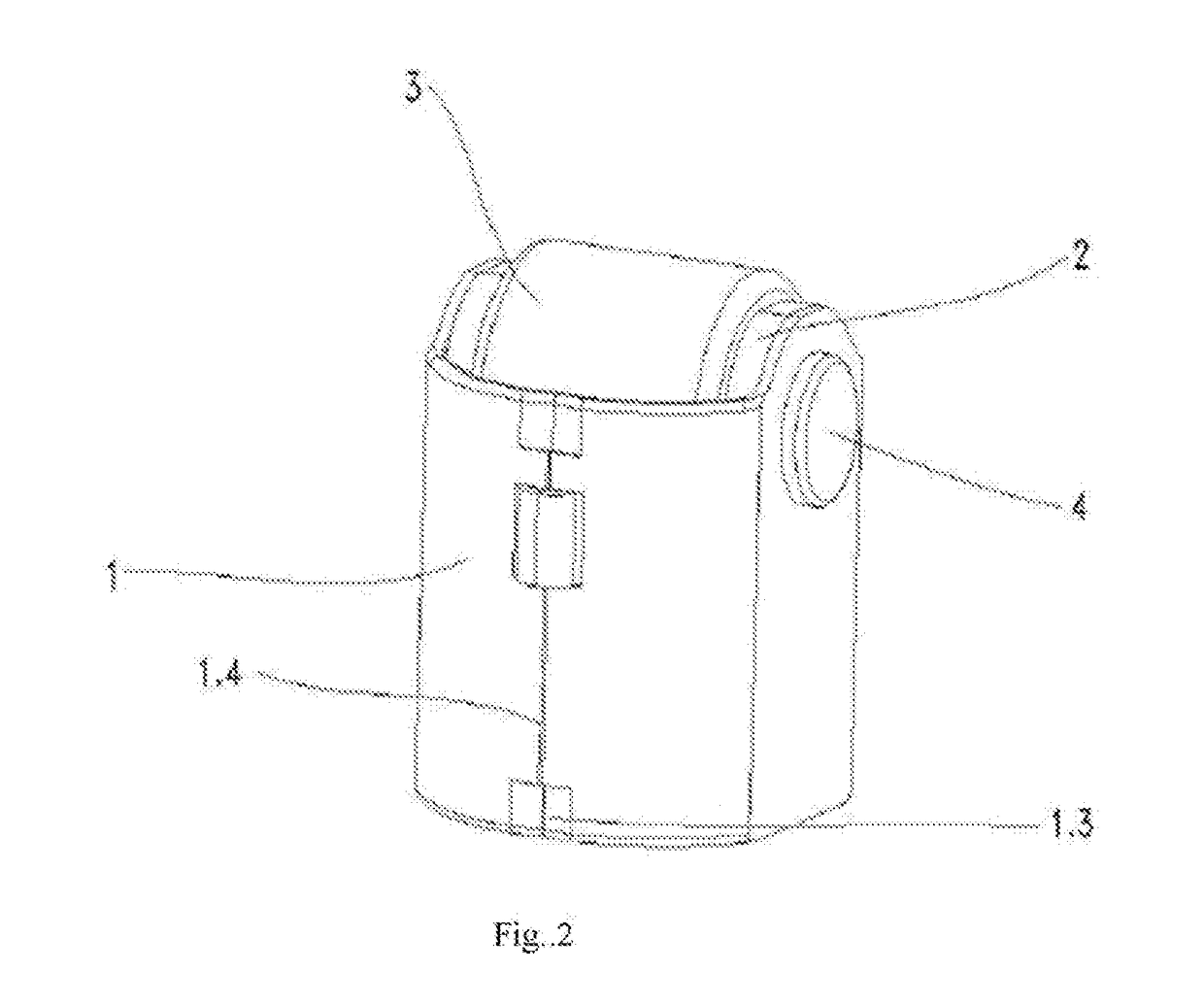

Rolling Screw

InactiveUS20080210039A1Simple and economical and reliableFriction lossToothed gearingsPortable liftingFree rotationEngineering

Owner:ARES ENG SRL

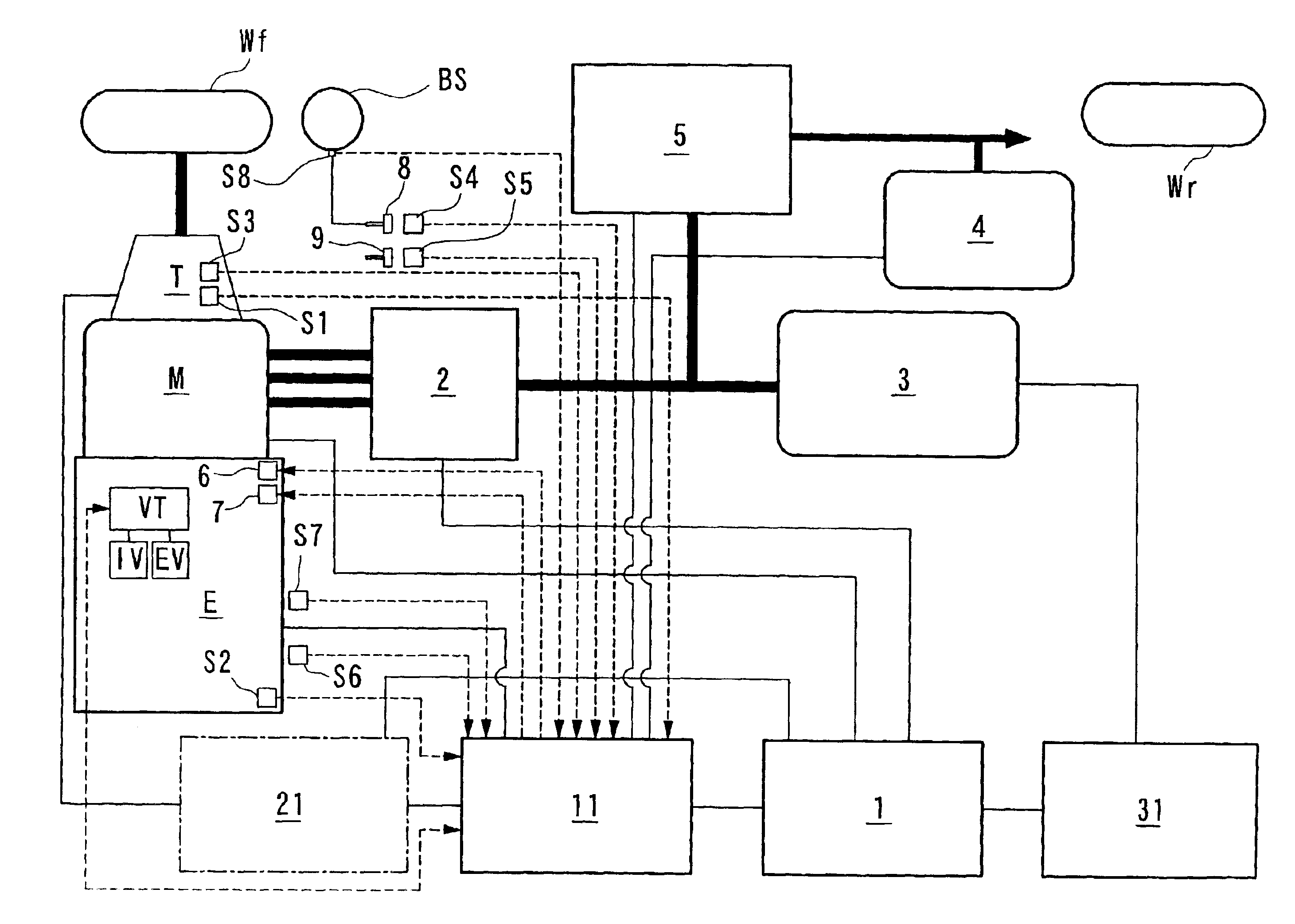

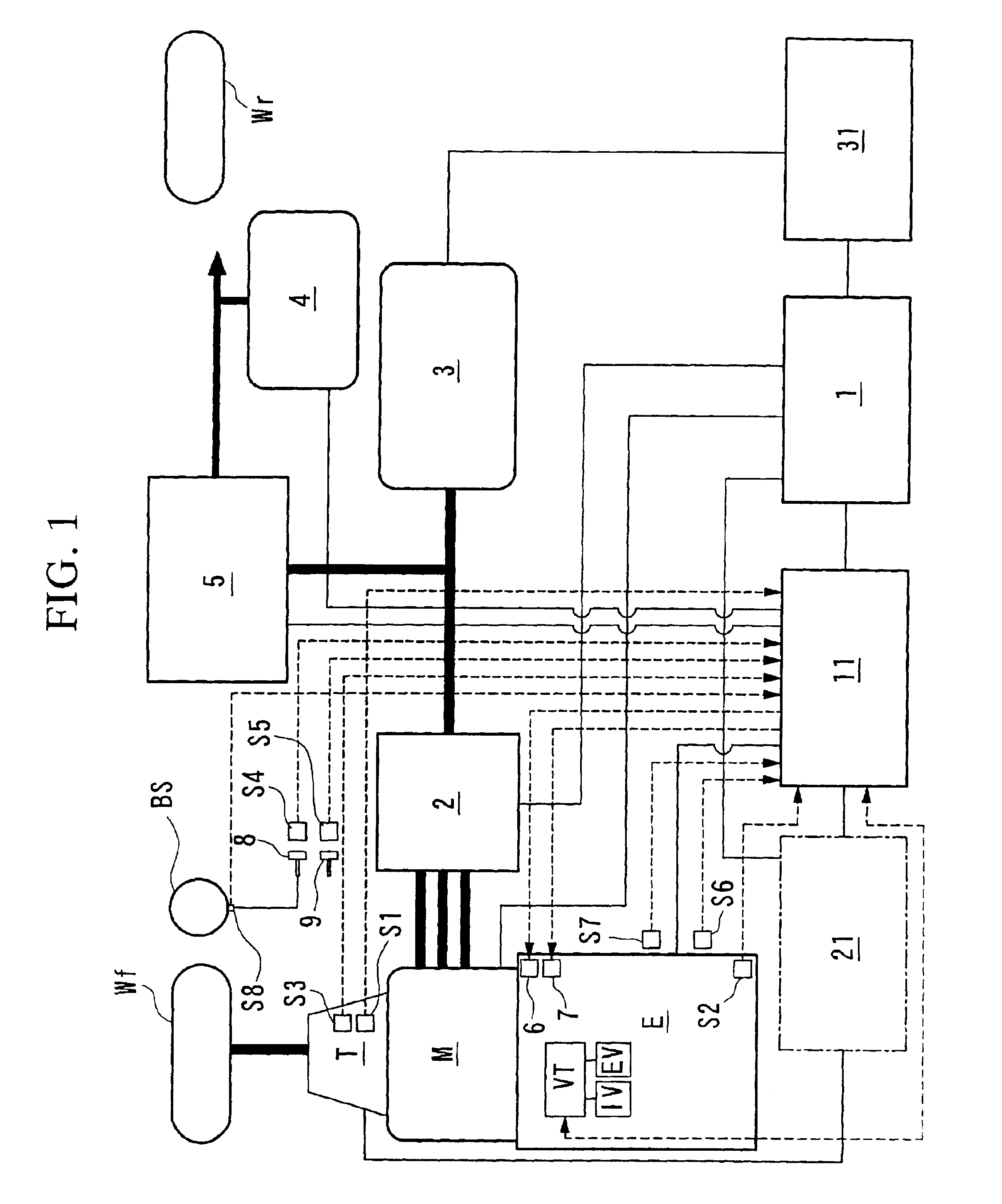

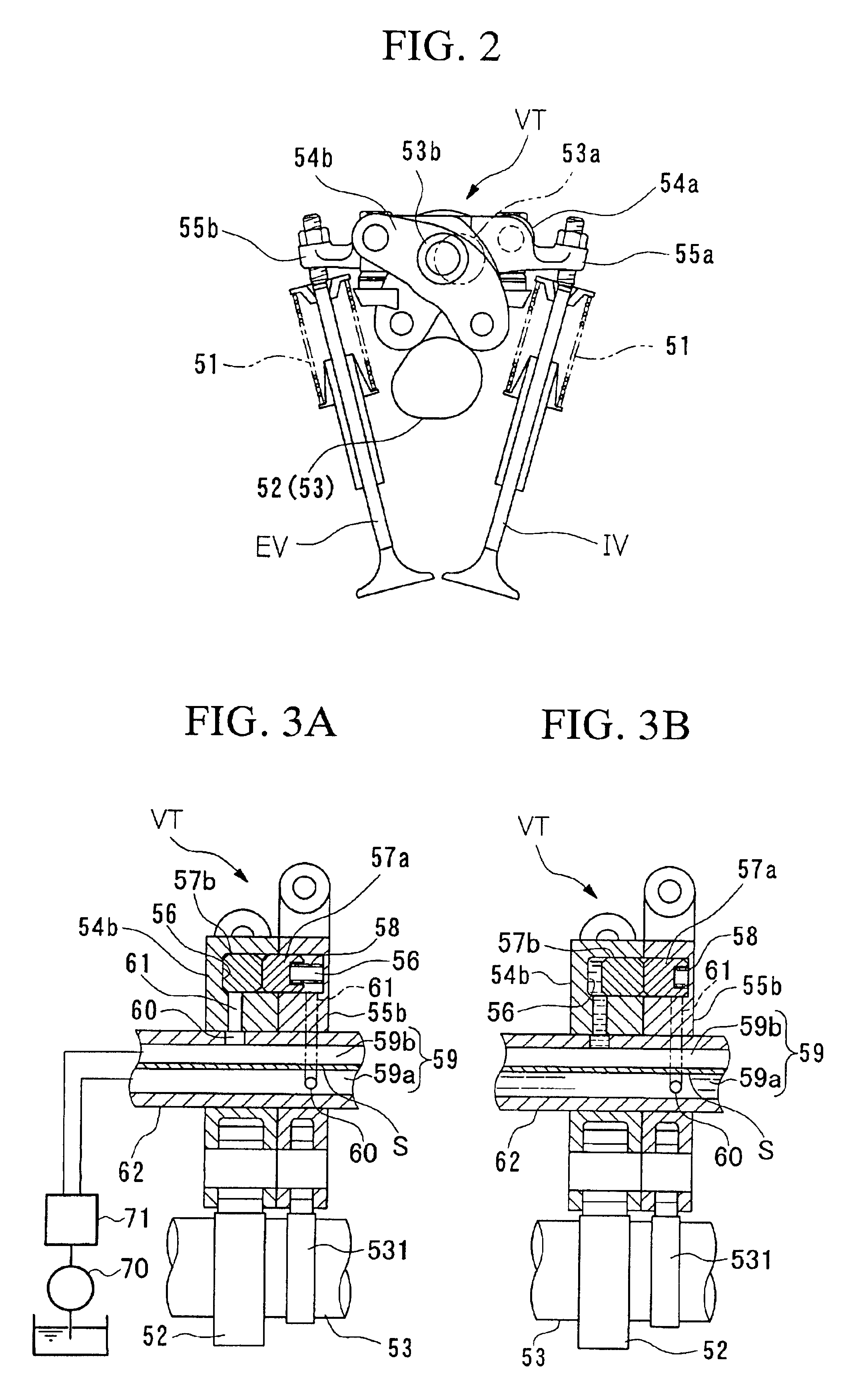

Control apparatus for hybrid vehicle

InactiveUS6857491B2Reduce the amount of solutionIncrease fuel consumptionValve arrangementsElectrical controlVariable valve timingStops device

In a control apparatus for a hybrid vehicle having an engine and a motor as a driving source, the control apparatus stops fuel supply to the engine by a fuel supply stop device during deceleration, and performs regenerative braking by the motor depending on the deceleration state, wherein the engine is a type of engine capable of executing cylinders deactivated operation for at least one cylinder, and the control apparatus comprises the cylinders deactivated operation execution flag F_ALCS for determining whether it is appropriate for cylinders to enters into the deactivated operation based on the traveling conditions of a vehicle and a variable valve timing mechanism for deactivating the operation of the cylinders of the engine when the cylinders deactivated operation is determined. Furthermore, when the fuel supply to the engine is stopped during deceleration, the cylinder deactivated operation is performed based on the all cylinders deactivated operation execution flag F_ALCS and the variable valve timing system.

Owner:HONDA MOTOR CO LTD

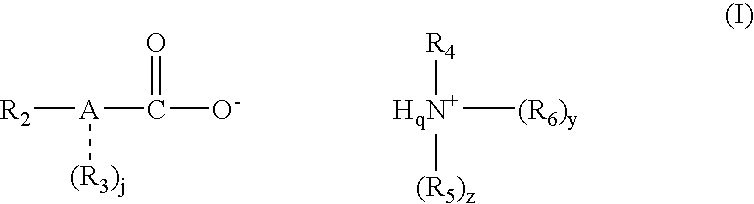

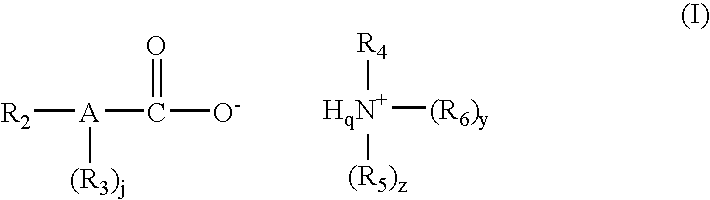

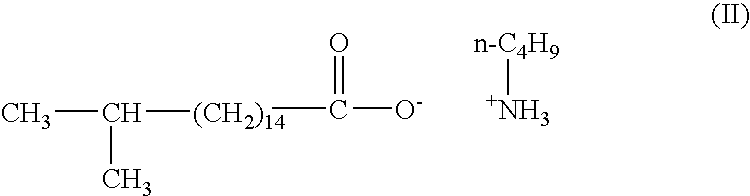

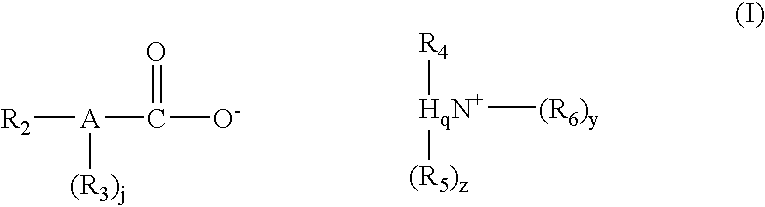

Friction modifier additives for fuel compositions and methods of use thereof

InactiveUS6866690B2Improve fuel economyFriction lossLiquid carbonaceous fuelsAdditivesCombustionFriction loss

A friction modifier for combustible fuels is provided that is prepared by combining a saturated carboxylic acid and an alkylated amine. Furthermore, there also is an additive concentrate for use in fuels, especially in gasoline for internal combustion engines, comprising (a) a friction modifier comprising of a branched saturated carboxylic acid salt of an alkylated amine, such as n-butylamine isostearate; (b) a detergent package, as well as the combustible fuels containing this additive concentrate. The particular selection of friction modifier (a) enables a stable additive concentrate to be formulated providing a significant benefit in friction loss when incorporated in gasoline used to fuel an internal combustion engine, and hence an improvement in fuel economy. Moreover, the use of the friction modifier (a) in combination with a detergent package permits increased fuel efficiency to be obtained without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

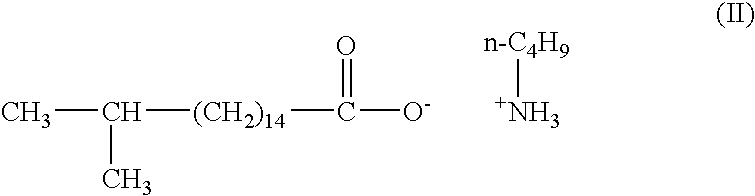

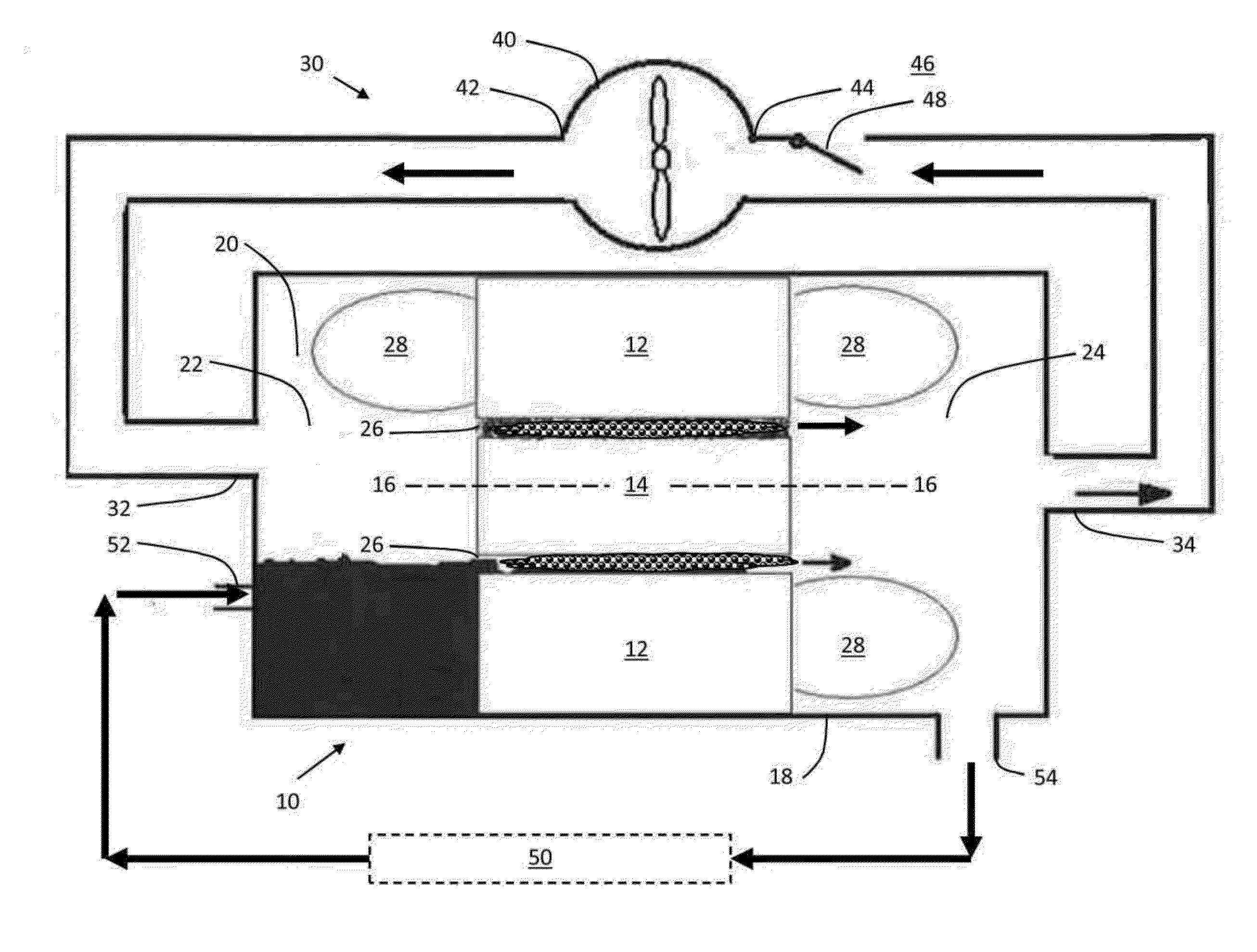

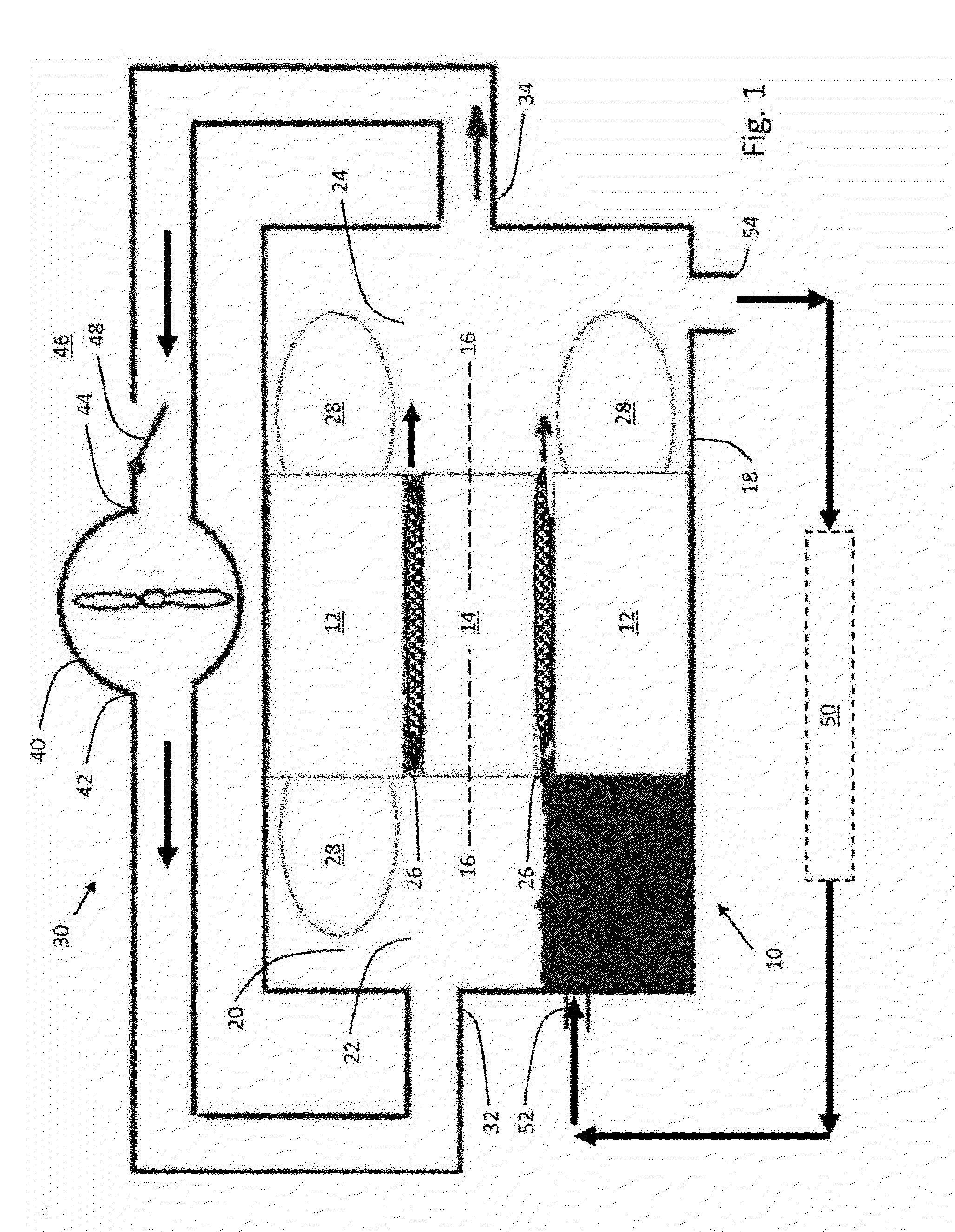

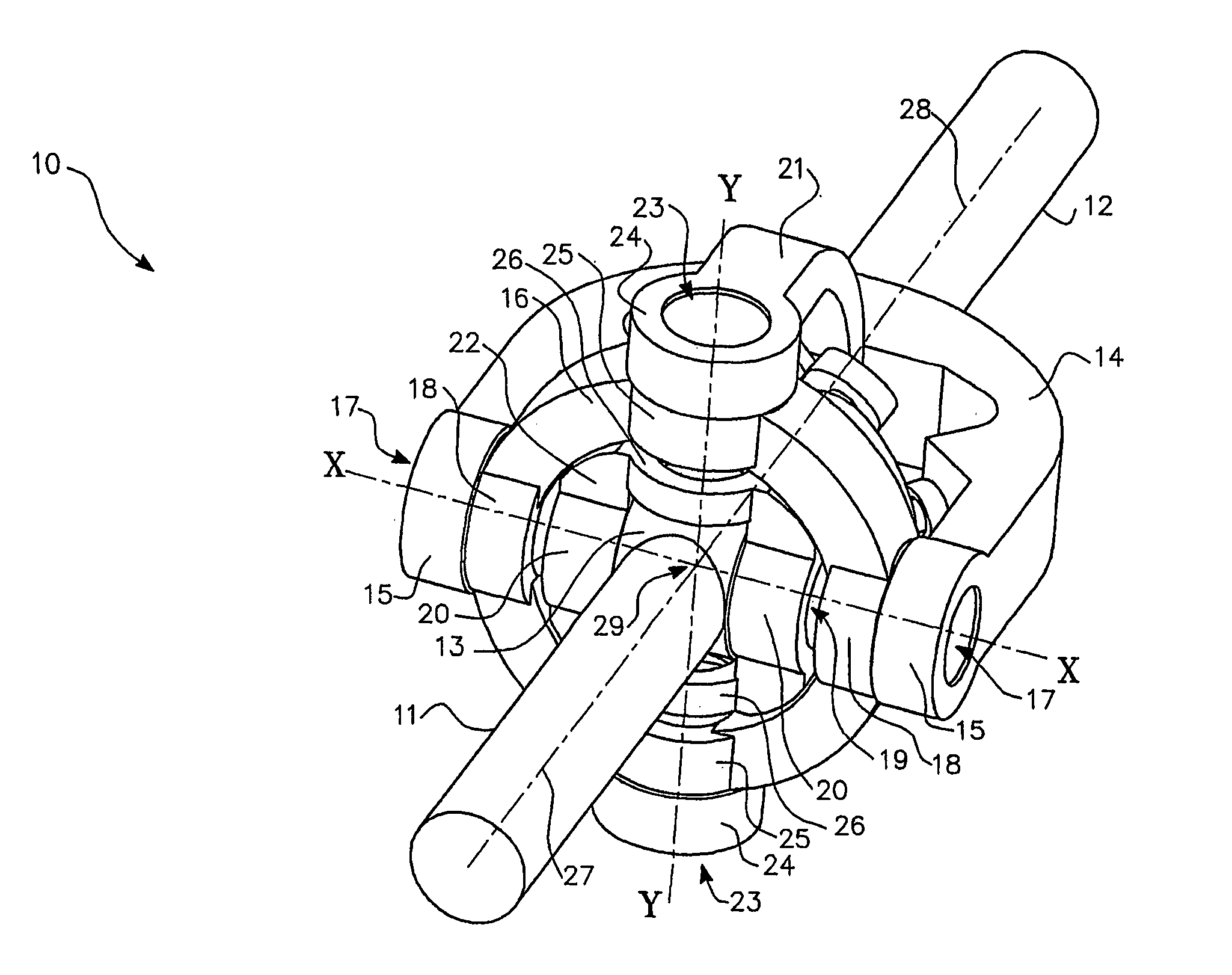

Two-phase-flow, panel-cooled, battery apparatus and method

InactiveUS20100252238A1Eliminate needEnhancing free convectionSemiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

Two-phase, boiling heat transfer in confined channels close to a source of heat, such as an electrical component or device, carries the latent heat of vapors away to remote locations where “real estate” demands of air convection are tolerable operationally, economically, and technologically. Liquid-to-vapor, phase-change, heat transfer in a narrow channel (e.g., typically less than 0.200 inches total thickness, and often less than 0.150 in the channel itself) improves by several hundred percent the heat extraction from modest temperature (e.g., about 120 degree F.) devices, when compared to heat fluxes in pool boiling. Saturated working fluids provide nearly isothermal conditions in the working fluid. Minimal conduction paths provide minimal temperature gradients, and capillary action may maintain nearly constant temperature conditions about a surface of a heat source, while carrying heat of vaporization away to a condensation location.

Owner:BATTY J CLAIR +1

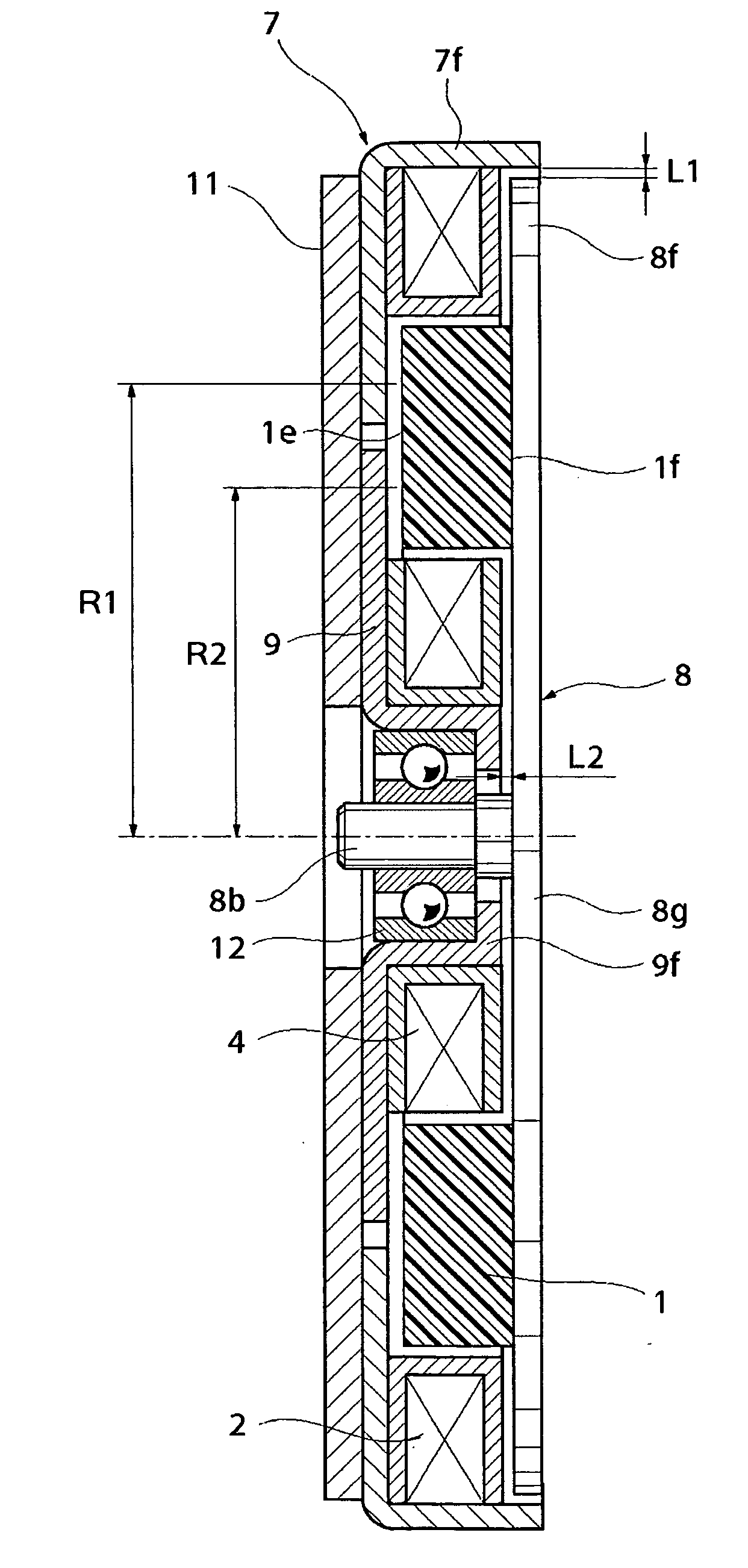

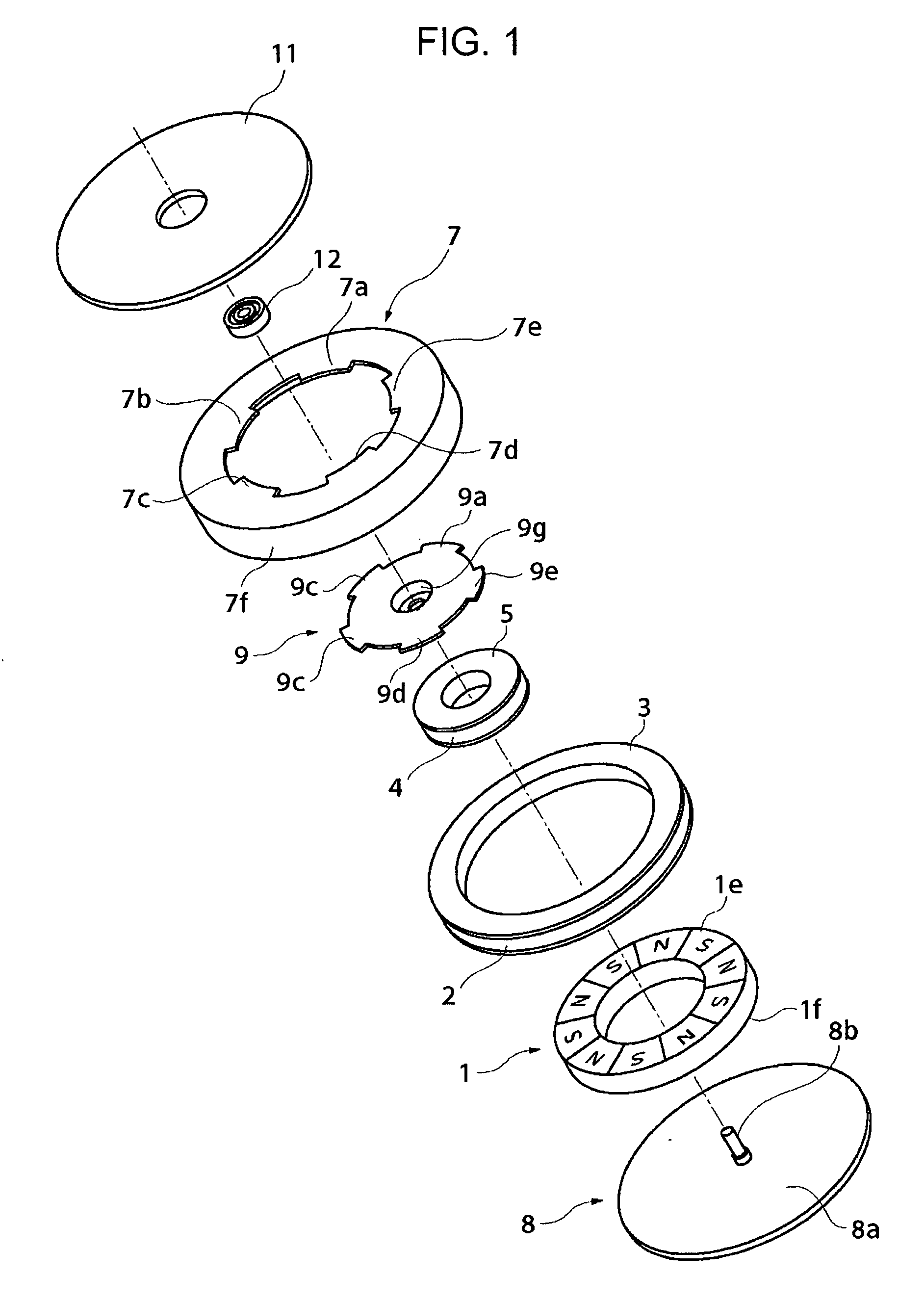

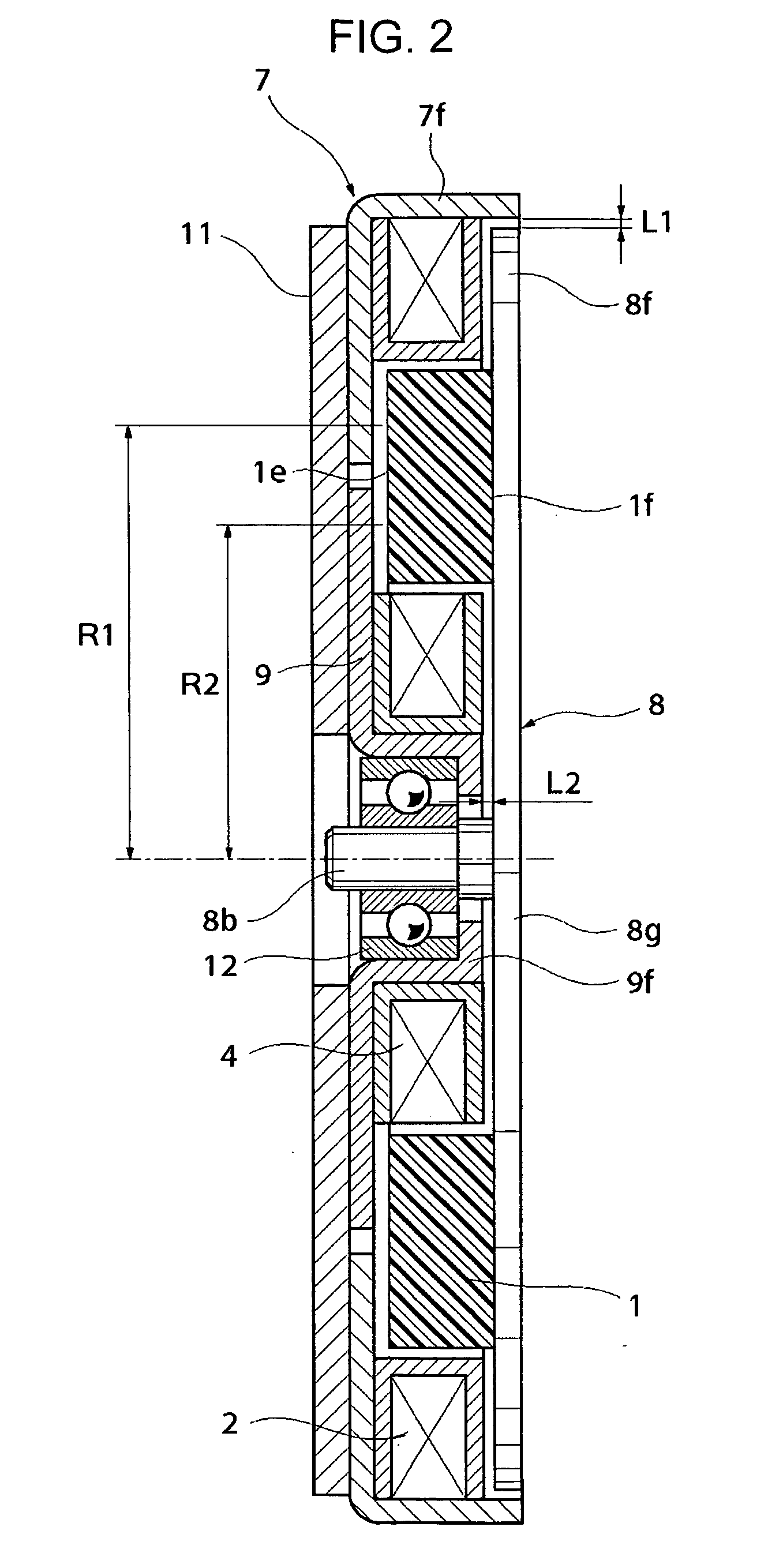

Driving device

InactiveUS20060267421A1Easy-to-assemble low-costIncrease productionMagnetic circuit rotating partsMaster clocksMagnetic polesEngineering

A stepping motor includes a magnet having a magnetized portion, first and second coils, a first yoke having a first-magnetic-pole portion, a second yoke having a second-magnetic-pole portion, and a rotating yoke having a third-magnetic-pole portion fixed to the single surface of the magnet. The first coil is disposed outside of the outer-circumferential surface of the magnet, and the second coil is disposed inside of the inner-circumferential surface of the magnet so as to have the same concentricity as the magnet. The first and second magnetic-pole portions and the magnetized portion face each other across a certain gap. The cylindrical portion of the first yoke and the outermost-diameter portion of the rotating yoke face each other across a gap in the radial direction, and the cylindrical portion of the second yoke and the flat surface portion of the rotating yoke face each other across a gap in the shaft direction. Thus, an easy-to-assemble low-cost driving device having a thin shape in the shaft direction, and high output with small torque loss is provided.

Owner:CANON KK

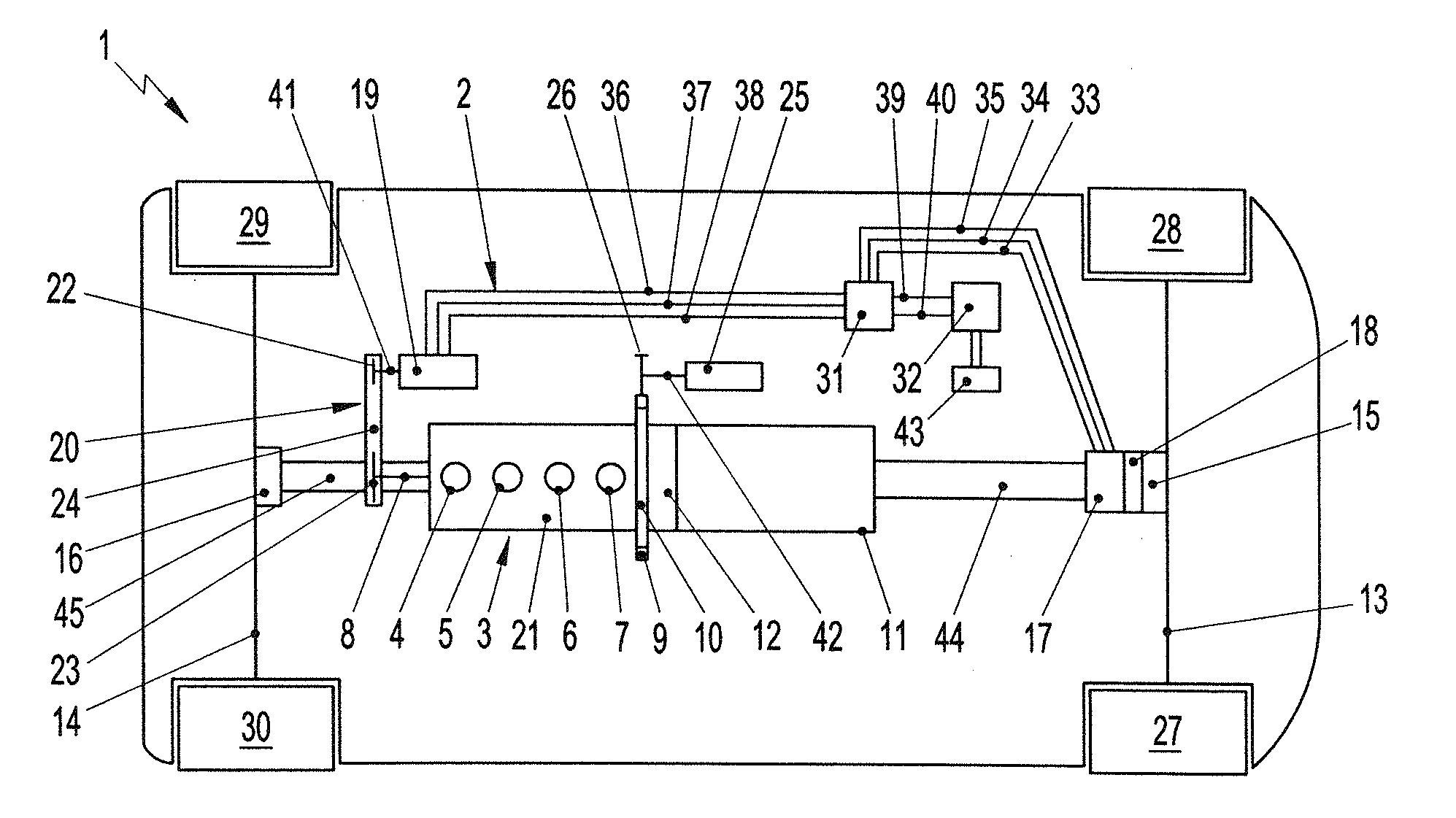

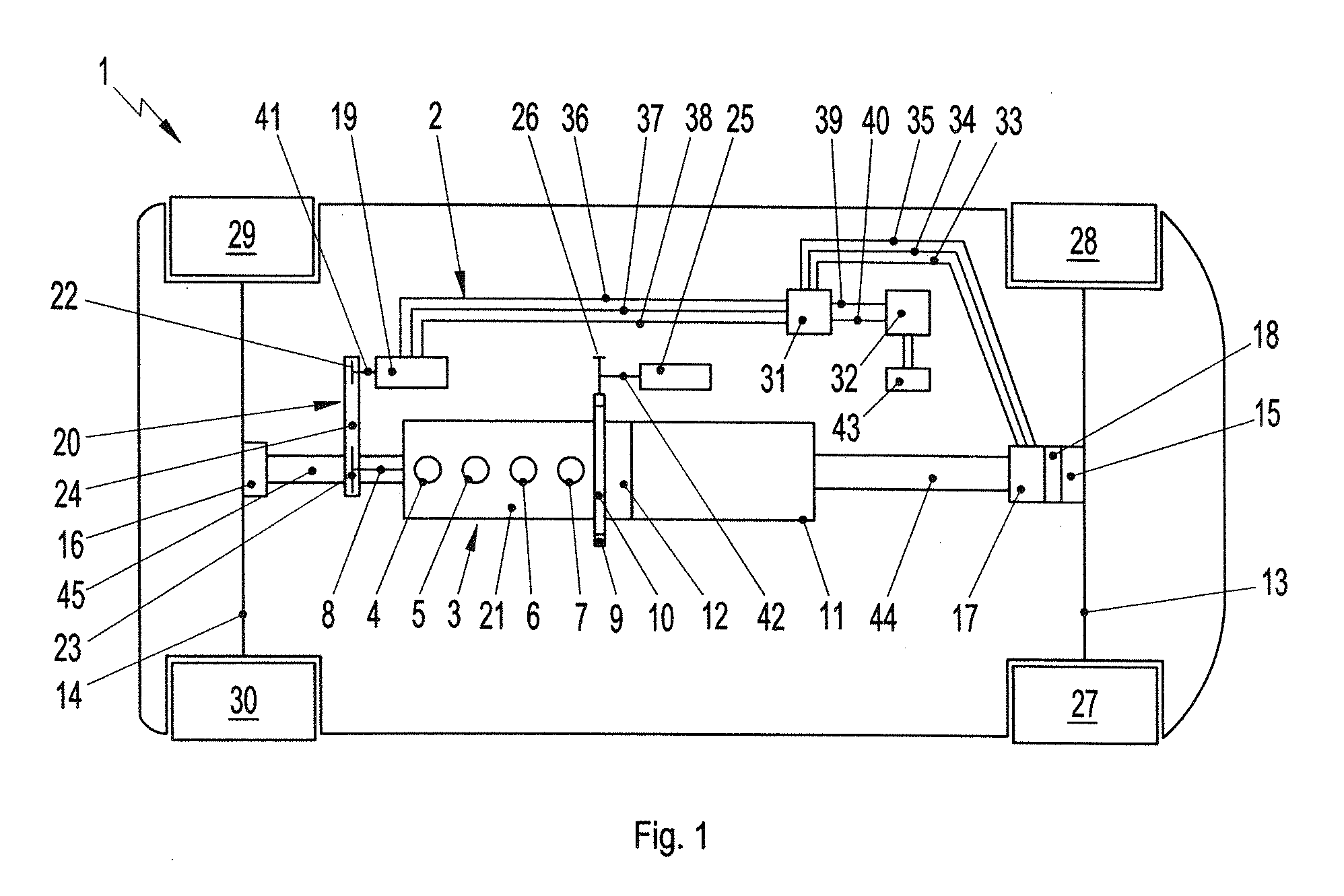

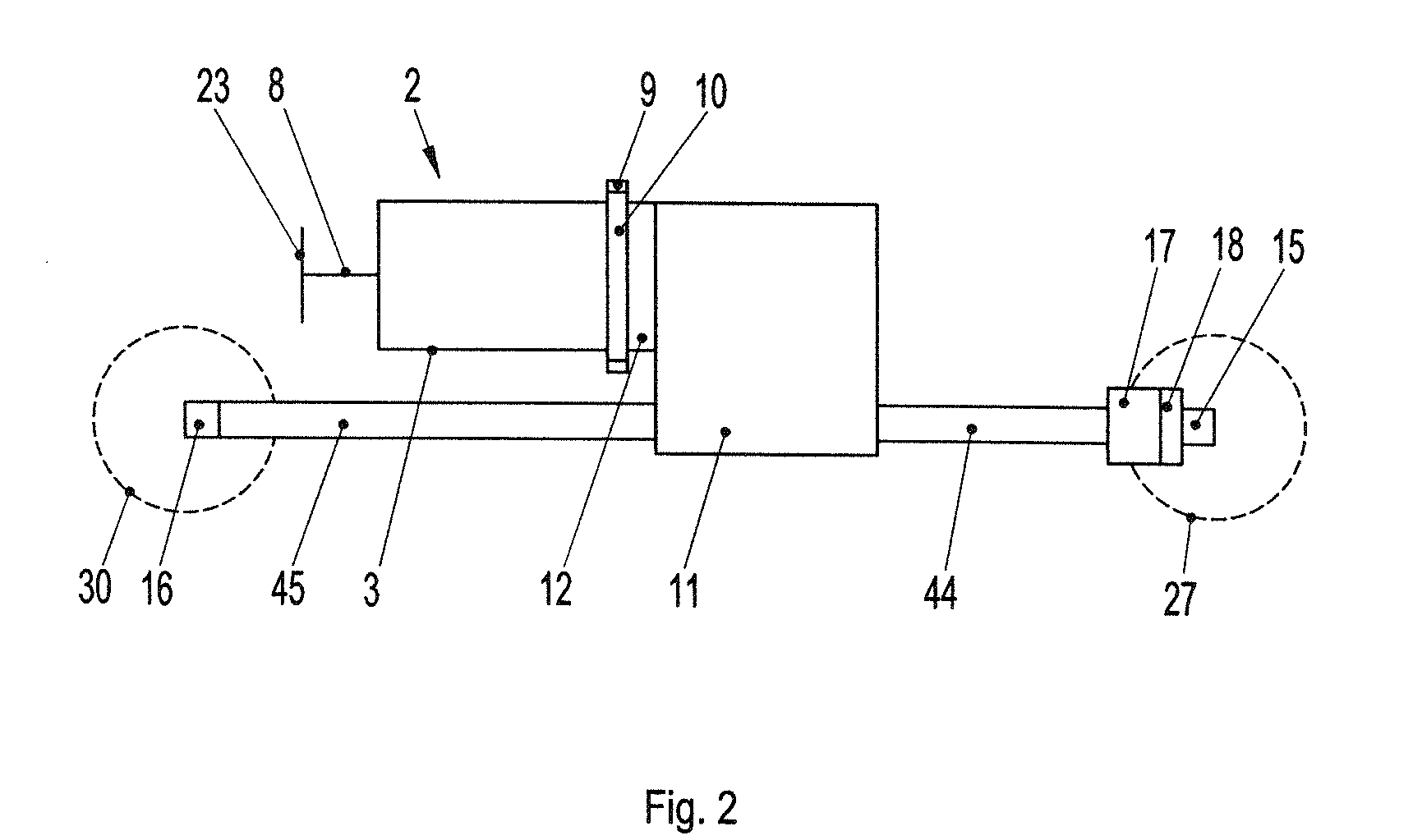

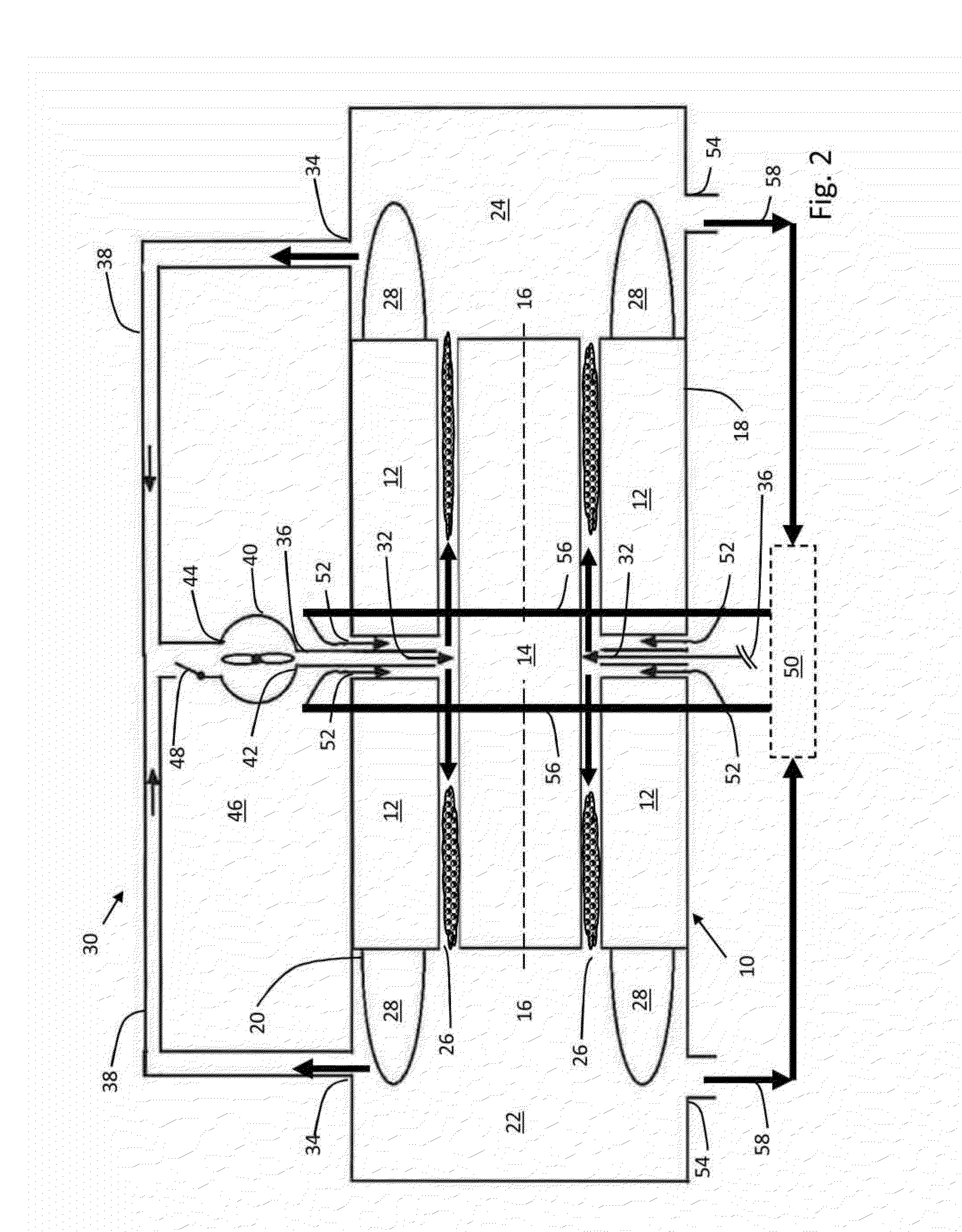

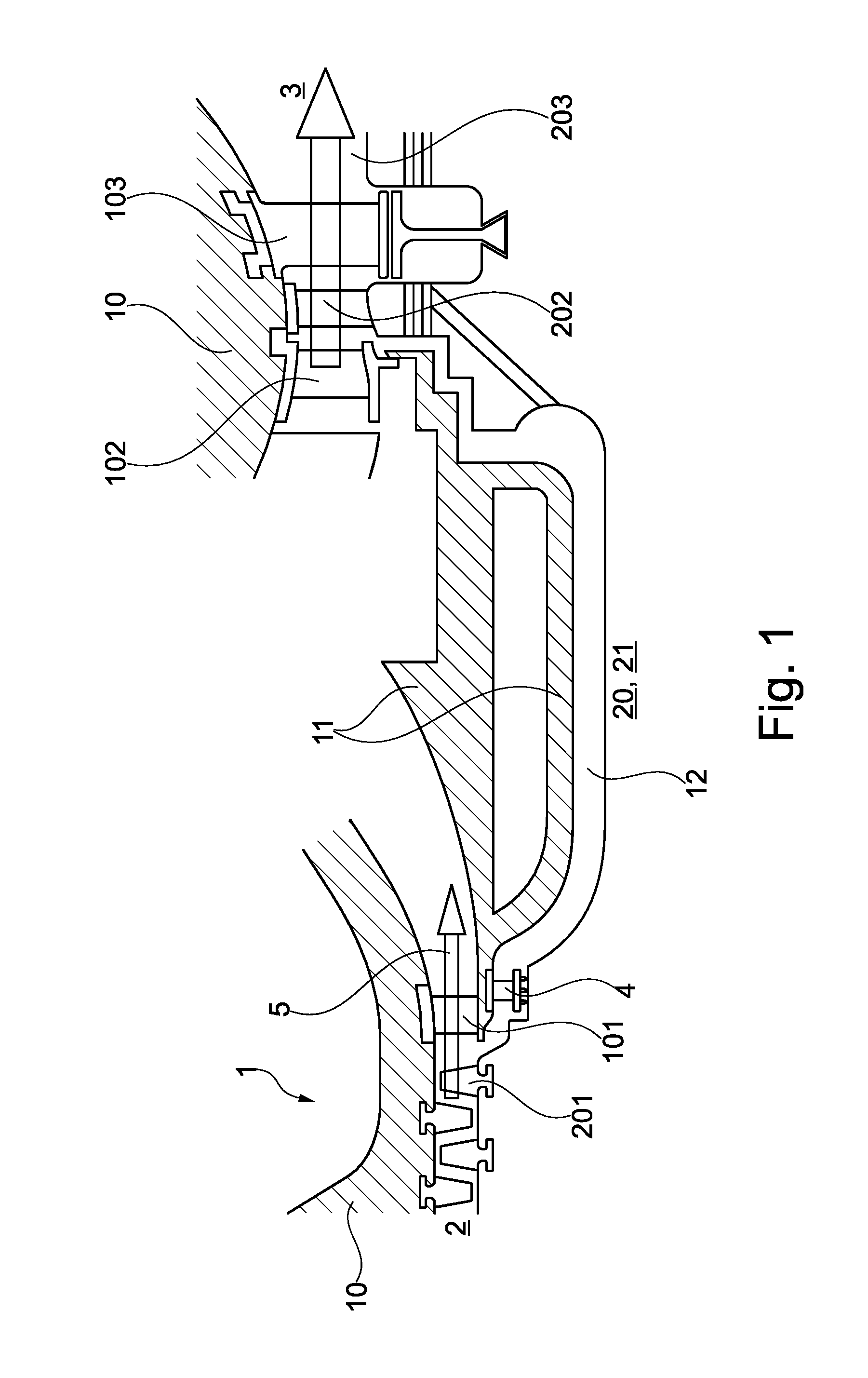

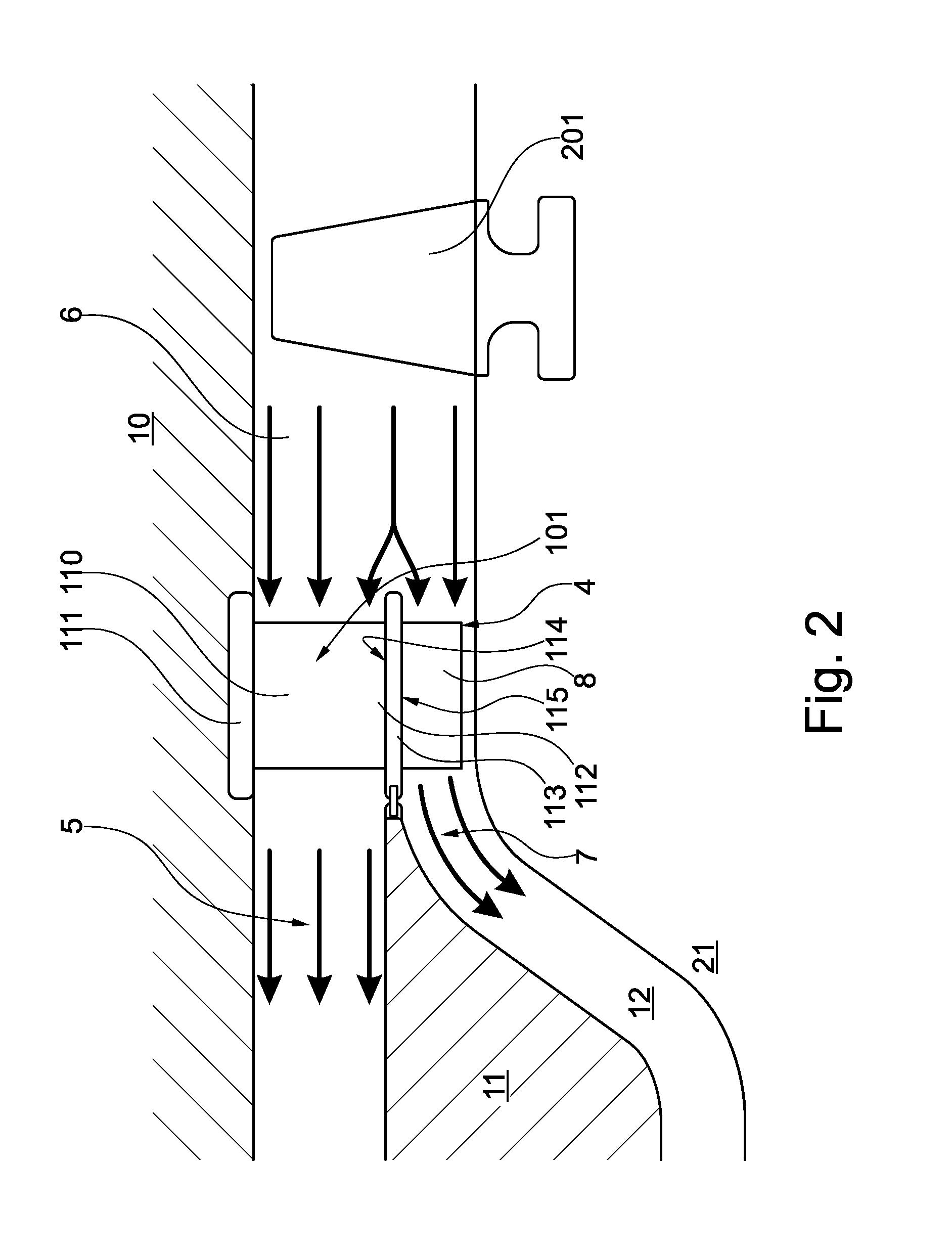

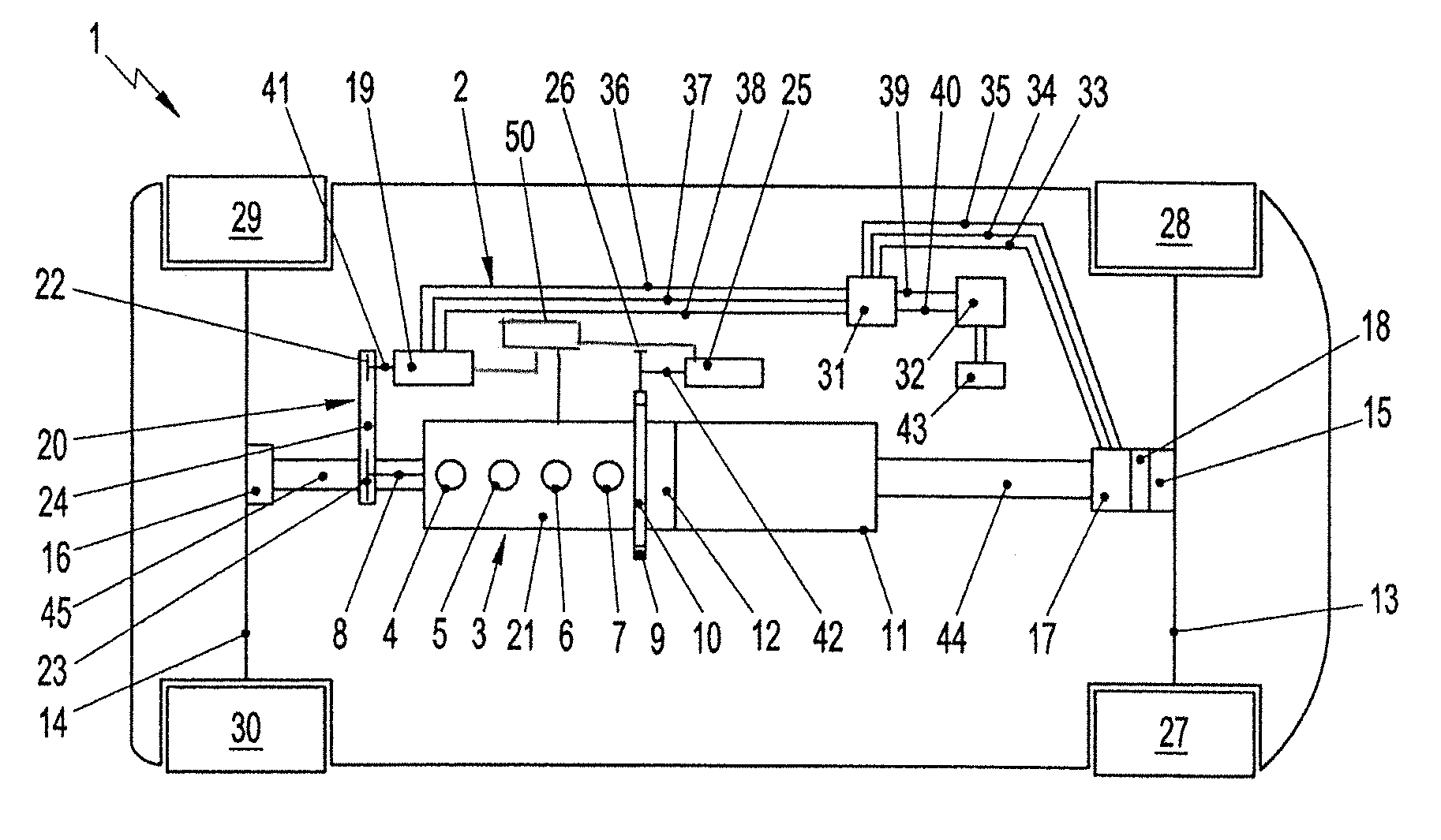

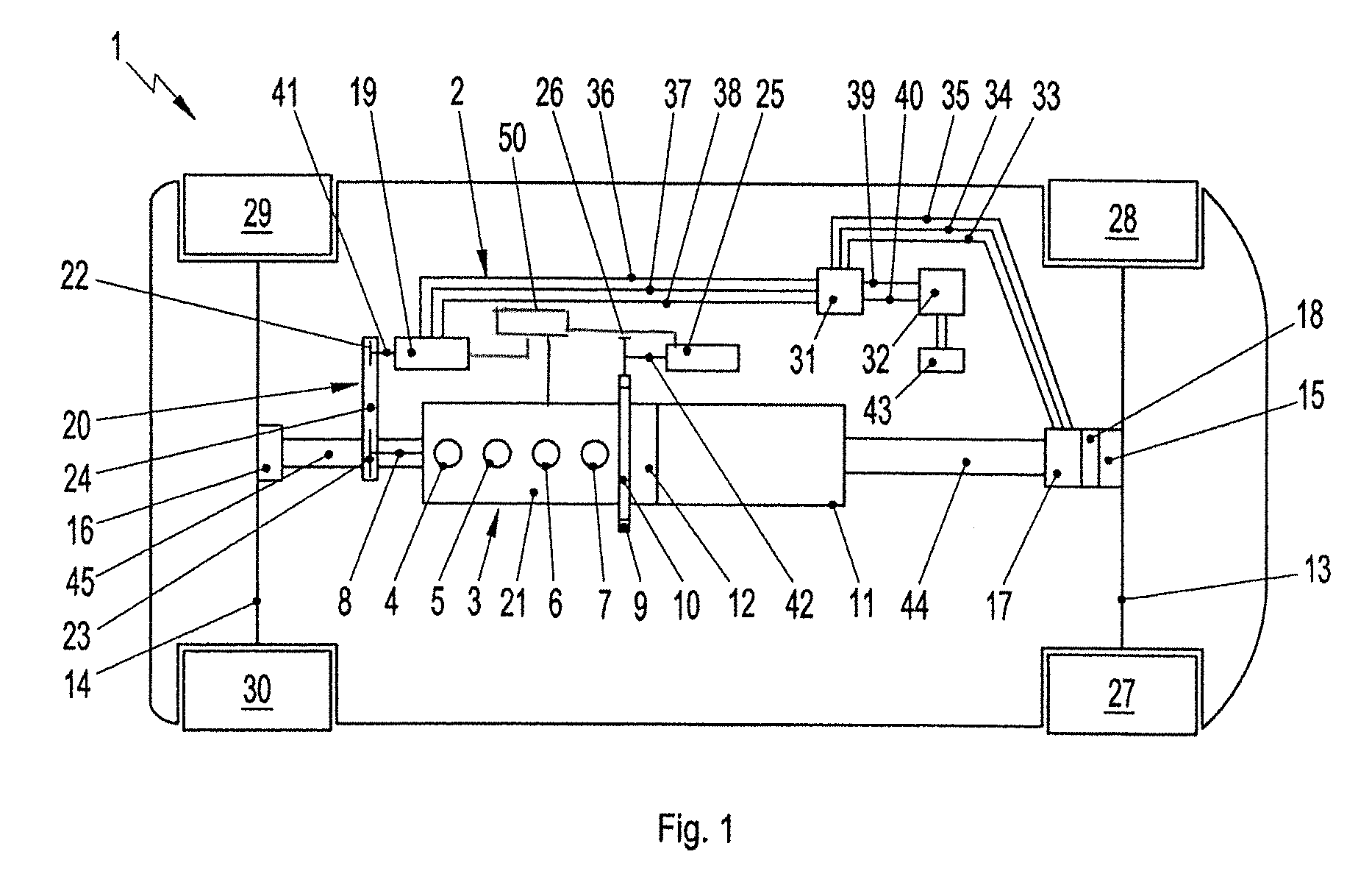

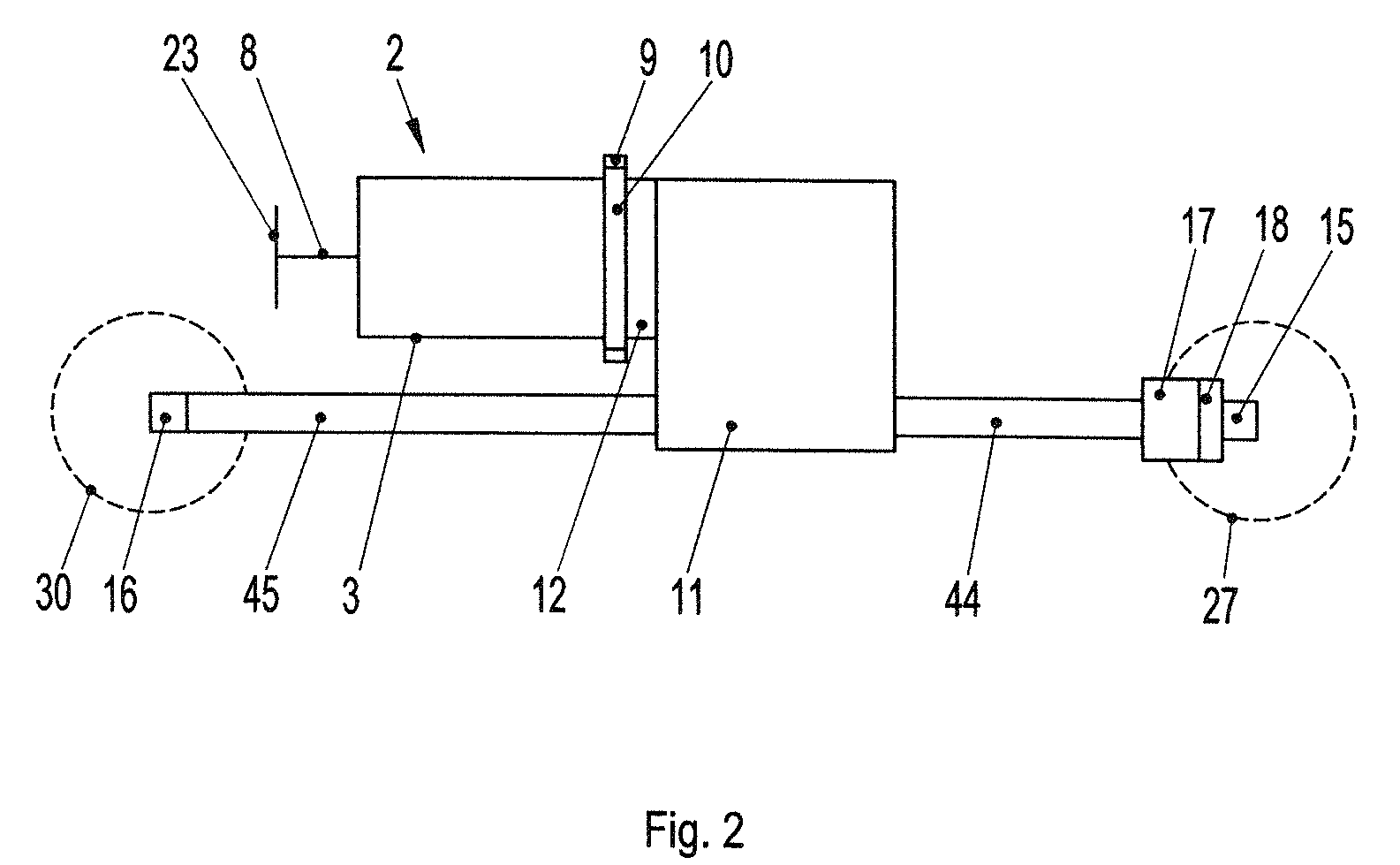

Drive system for a motor vehicle and motor vehicle having such a drive system

ActiveUS20120006152A1Reduced space requirementsAvoid friction lossGearingGas pressure propulsion mountingInternal combustion engineMotorized vehicle

A drive system (2) for a motor vehicle (1) has a transmission (11) for driving at least one drive axle (13, 14) of the motor vehicle (1). An internal combustion engine (3) optionally is connected operatively to the transmission (11) or decoupled therefrom. A first electric machine (17) optionally is connected operatively to the at least one drive axle (13, 14) or to an output shaft (39) of the transmission (11) or decoupled therefrom. A second electric machine (19) is connected operatively to the internal combustion engine (3).

Owner:DR ING H C F PORSCHE AG

Additives for fuel compositions to reduce formation of combustion chamber deposits

InactiveUS7402185B2Reduce formationLow melting pointNon-fuel substance addition to fuelLiquid carbonaceous fuelsCombustion chamberEngineering

A method for reducing the formation of combustion chamber deposits in an engine using a friction modifier for combustible fuels is provided. The friction modifier is prepared by combining a saturated carboxylic acid and an alkylated or alkoxylated amine. The particular selection of friction modifier enables a stable additive concentrate to be formulated providing a significant decrease in CCD without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

Two Phase Gap Cooling of an Electrical Machine

ActiveUS20150171707A1Improve cooling effectFriction lossCooling/ventillation arrangementGas passingEngineering

An electro-dynamic machine has a rotor and stator with a gap therebetween. The machine has a frame defining a hollow interior with end cavities on axially opposite ends of the frame. A gas circulating system has an inlet that supplies high pressure gas to the frame interior and an outlet to collect gas passing therethrough. A liquid coolant circulating system has an inlet that supplies coolant to the frame interior and an outlet that collects coolant passing therethrough. The coolant inlet and gas inlet are generally located on the frame in a manner to allow coolant from the coolant inlet to flow with gas from the gas inlet to the gap. The coolant outlet and gas outlet are generally located on the frame in a manner to allow the coolant to be separated from the gas with the separated coolant and gas collected for circulation through their respective circulating systems.

Owner:BALDOR ELECTRIC COMPANY

Friction modifier alkoxyamine salts of carboxylic acids as additives for fuel compositions and methods of use thereof

InactiveUS7435272B2Improve fuel economyIncrease in IVDOrganic chemistryLiquid carbonaceous fuelsCombustionFriction loss

A friction modifier for combustible fuels is provided that is prepared by combining a saturated carboxylic acid and an alkoxylated amine or etheramine. Furthermore, there also is an additive concentrate for use in fuels, especially in gasoline for internal combustion engines, comprising (a) a friction modifier comprising of a branched saturated carboxylic acid salt of an alkoxylated amine, such as isohexyloxypropylamine isostearate; (b) a detergent package, as well as the combustible fuels containing this additive concentrate. The particular selection of friction modifier (a) enables a stable additive concentrate to be formulated providing a significant benefit in friction loss when incorporated in gasoline used to fuel an internal combustion engine, and hence an improvement in fuel economy. Moreover, the use of the friction modifier (a) in combination with a detergent package permits increased fuel efficiency to be obtained without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

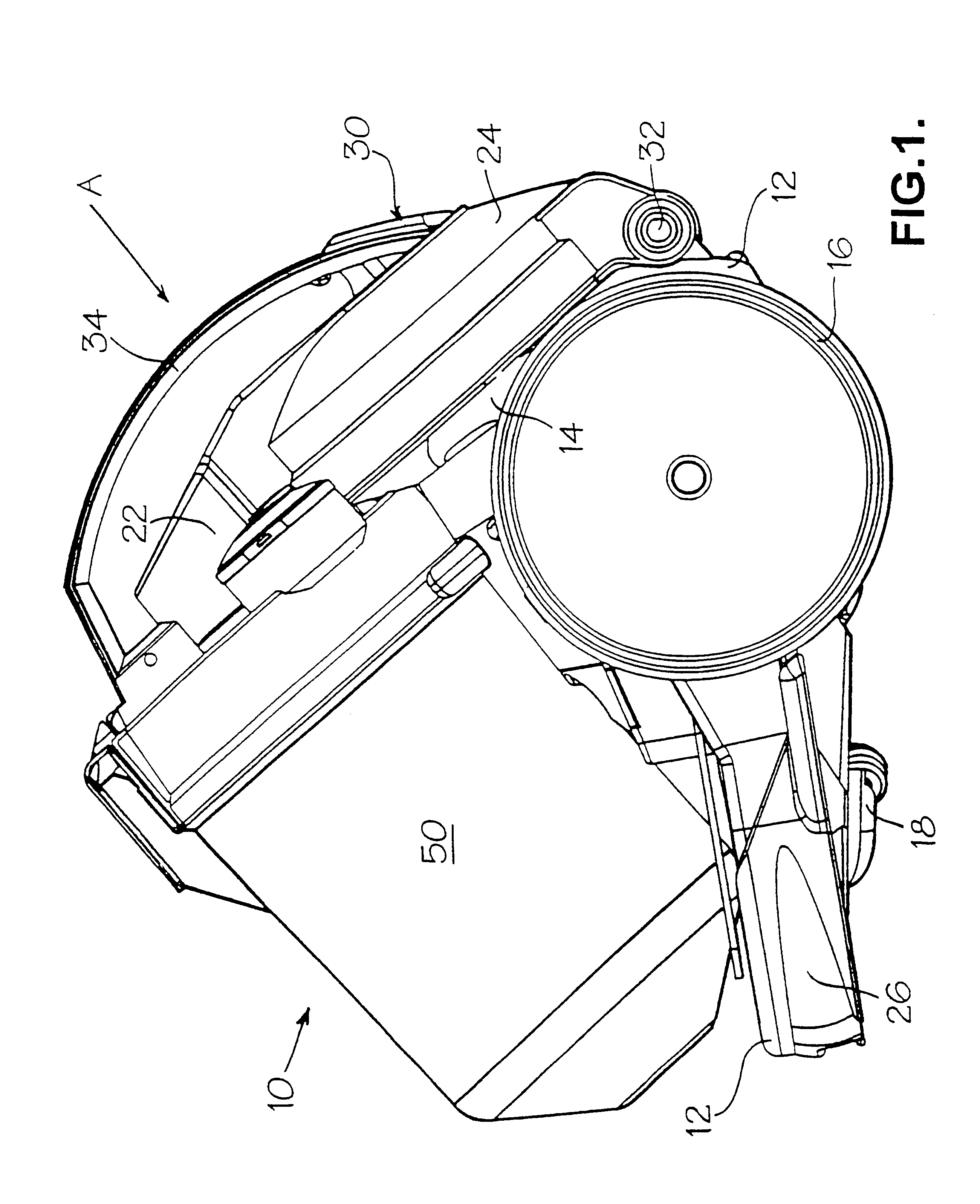

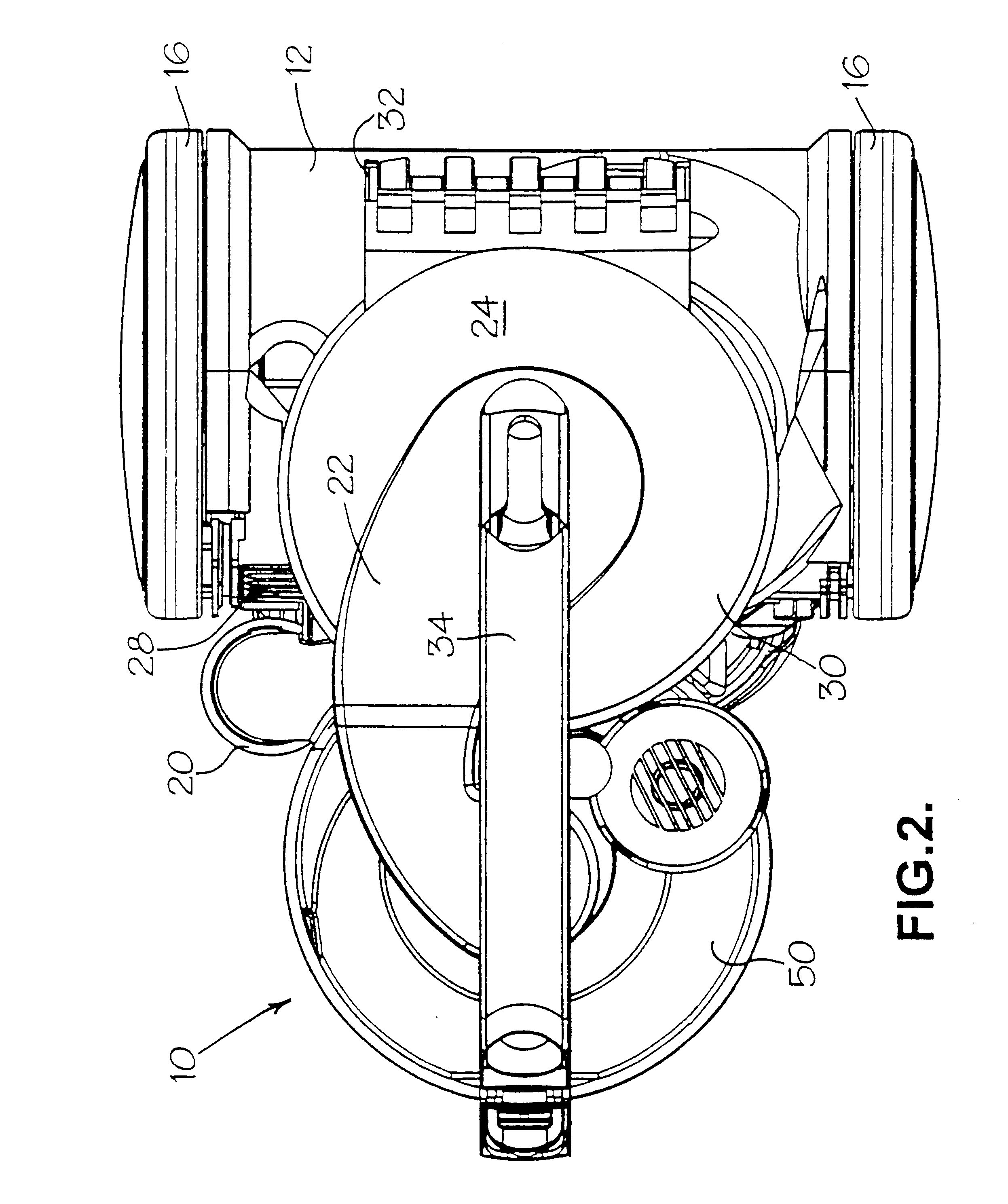

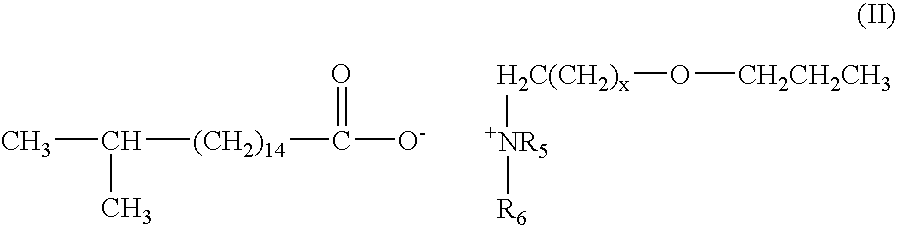

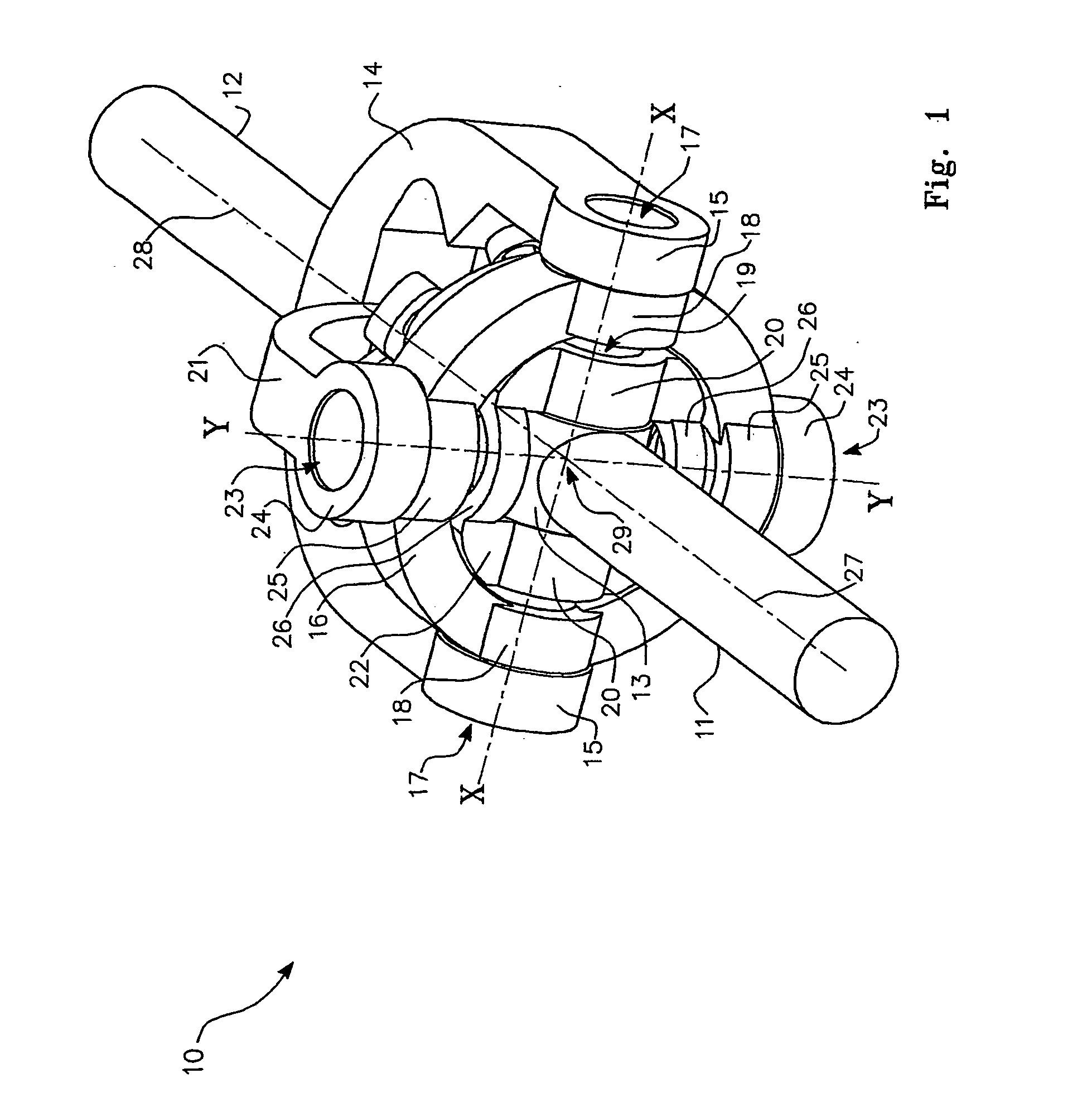

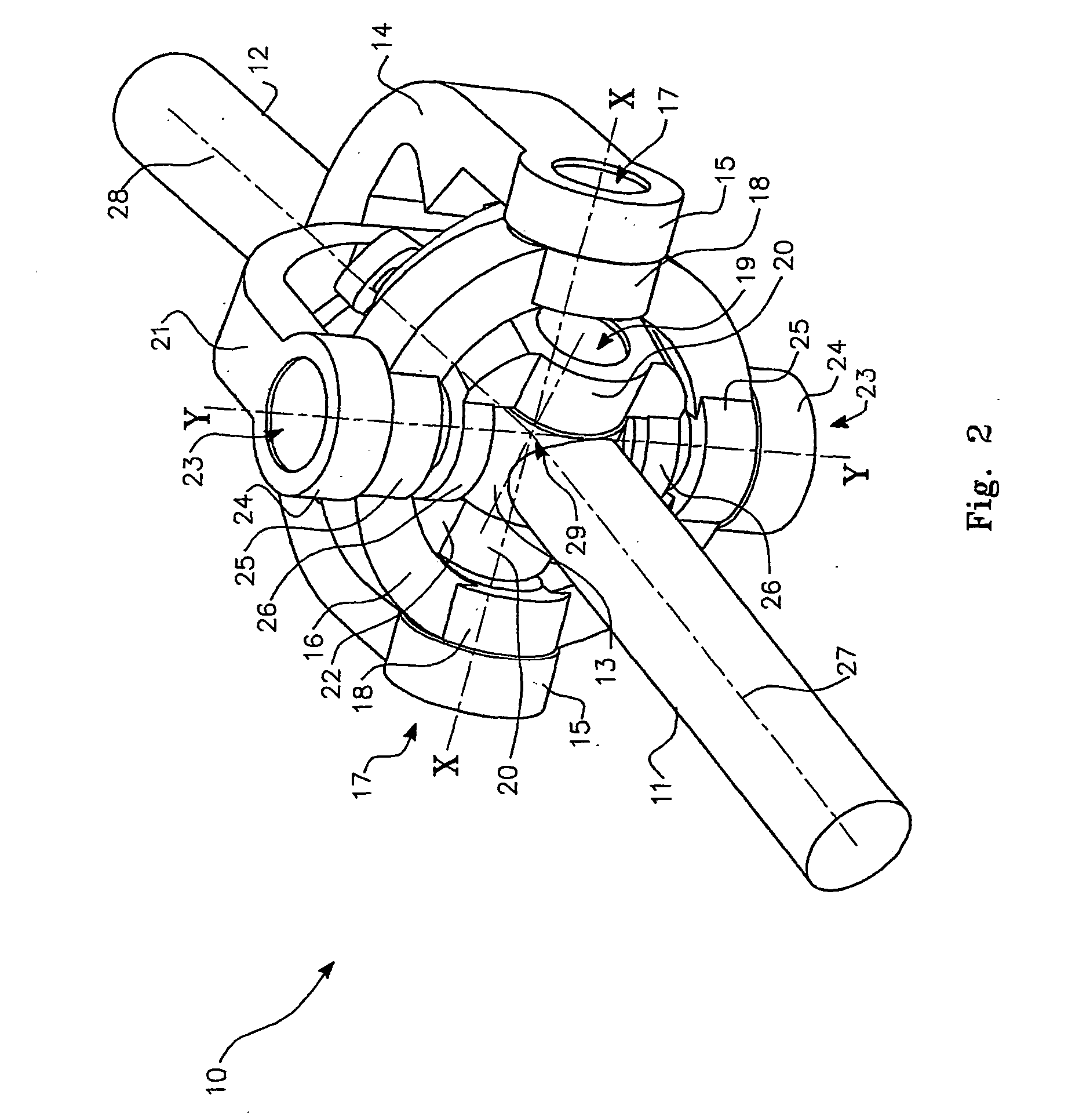

Constant velocity coupling and control system therefor

InactiveUS20040106458A1Friction lossEasy to useYielding couplingRotary machine partsCouplingControl system

A constant velocity coupling 10, 305 which rotatably connects an input shaft 11 to an output shaft 12 by means of a control mechanism or control system 21, 309 which, in particular forms, includes a gimbal arrangement comprised of an inner yoke 22 rotatably connected to an outer yoke 16. The control mechanism including control yoke 21 constrains at least portions of the coupling to lie on or in association with a homokinetic plane 300 of the coupling. In particular forms the control mechanism operates symmetrically about supplementary angle bisector 308.

Owner:THOMPSON COUPLINGS

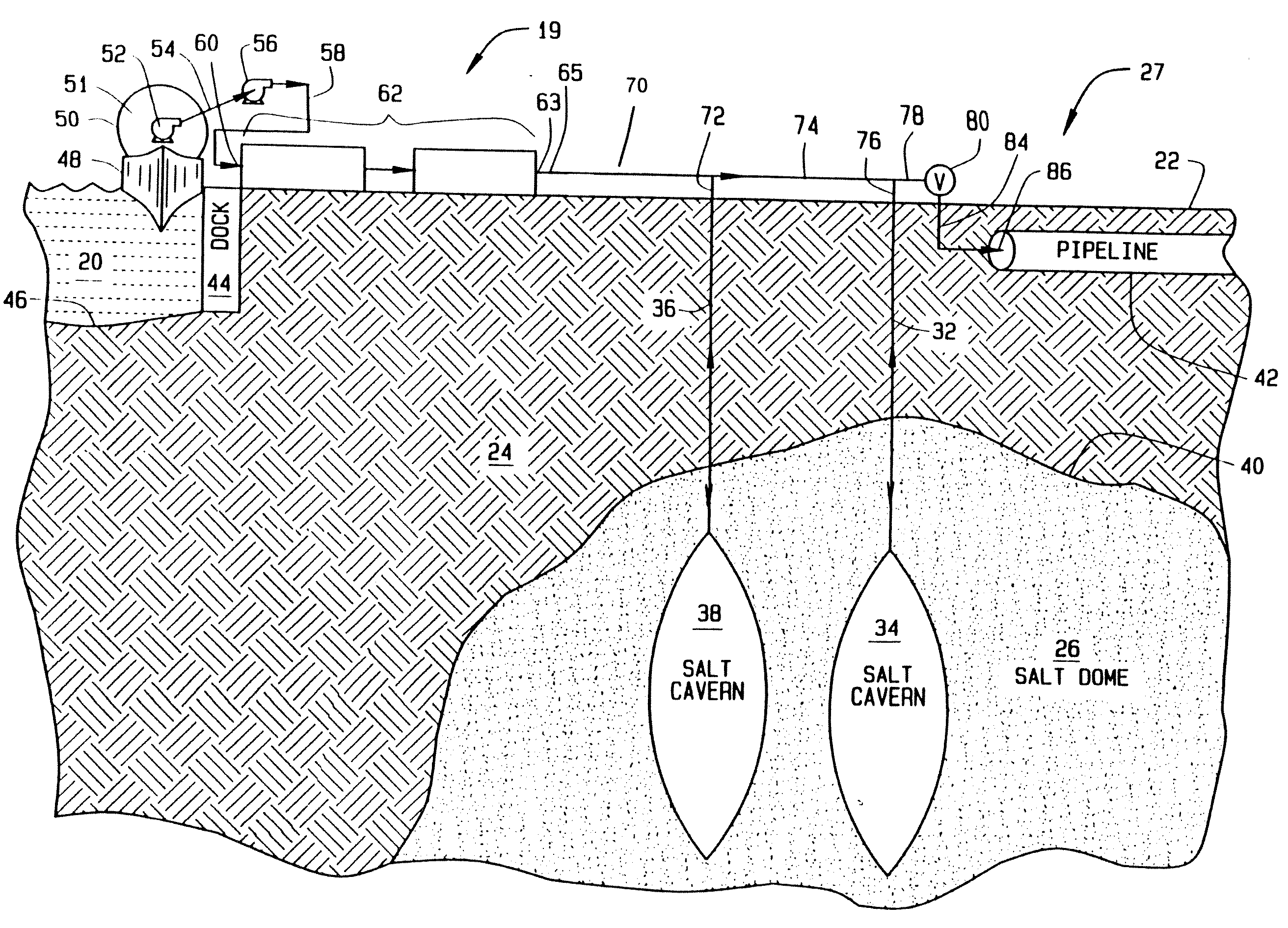

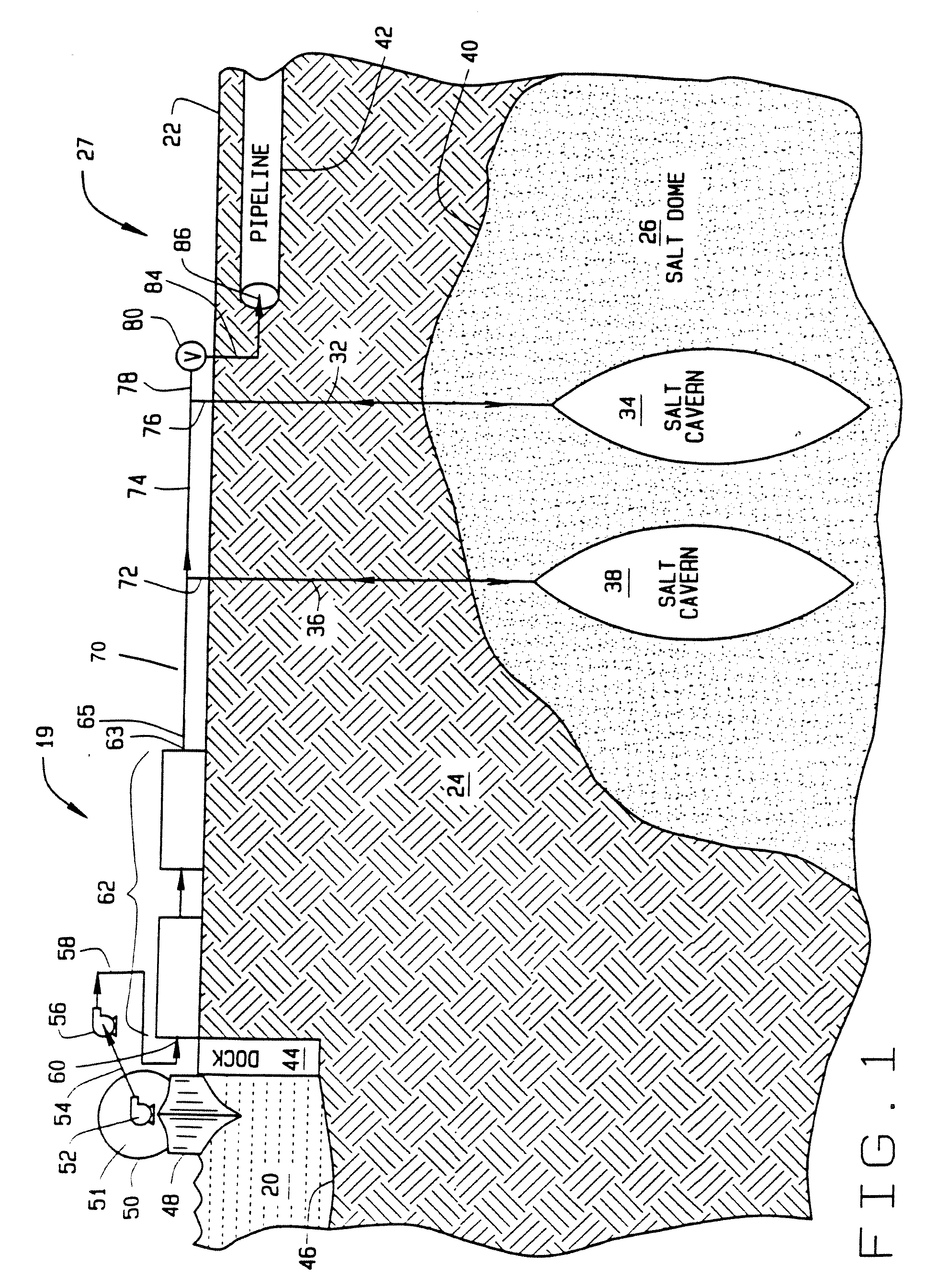

Dual gas facility

InactiveUS20040194476A1Reduce and eliminate icingIncrease wall thicknessGas handling applicationsGas handling/storage effectsNatural gas storageSalt dome

The Dual Gas Facility stores natural gas in one or more man-made salt caverns typically located in a single salt dome or in bedded salt. The Dual Gas Facility can access different sources of natural gas. A first gas source is from a natural gas pipeline(s) and a second gas source is from LNG. Depending on economic conditions, supply conditions and other factors, the Dual Gas Facility can receive gas from the natural gas pipeline(s) and / or from LNG to fill the salt caverns. Of course, the LNG must be warmed before being stored in a salt cavern.

Owner:CONVERSION GAS IMPORTS

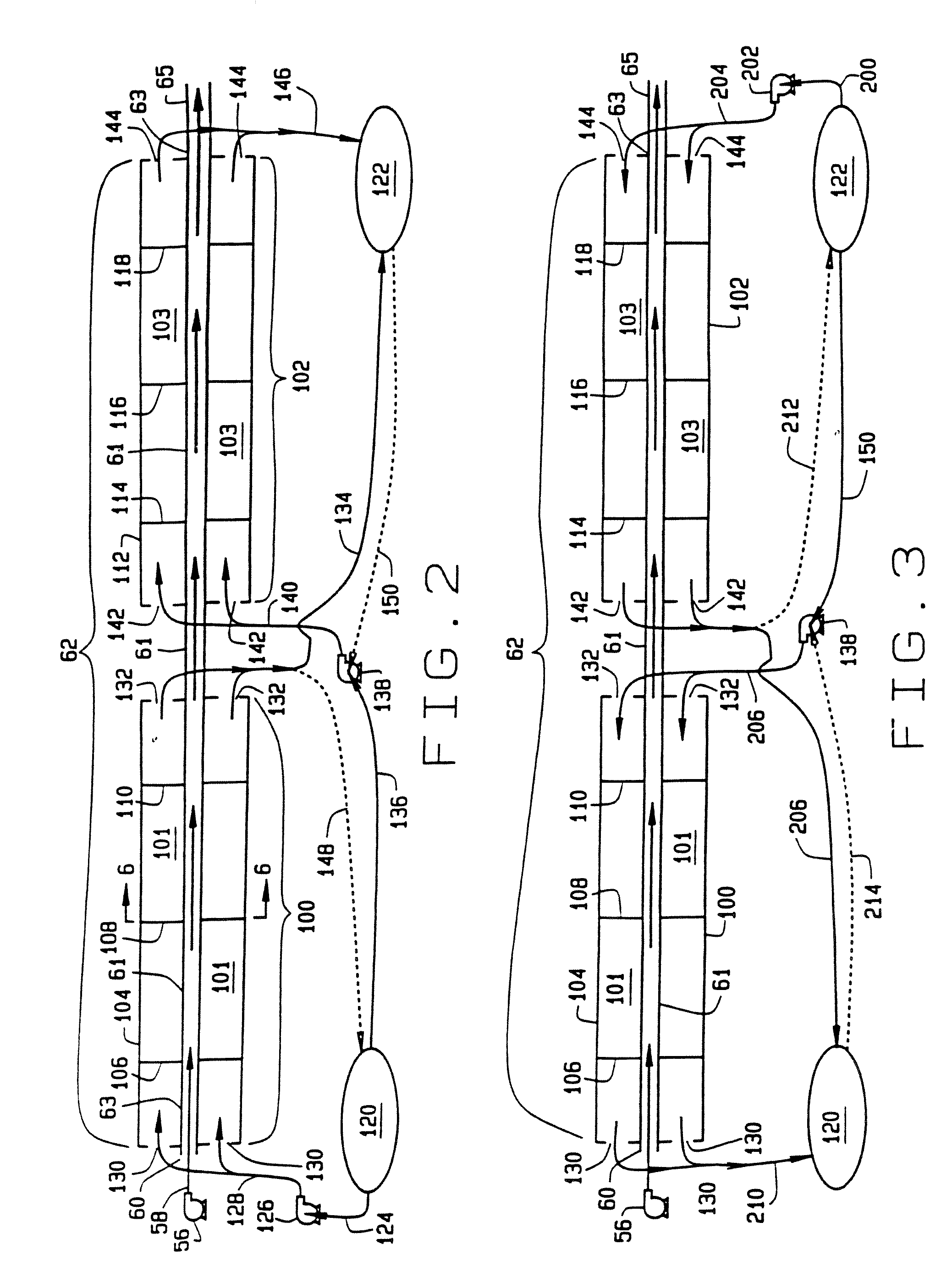

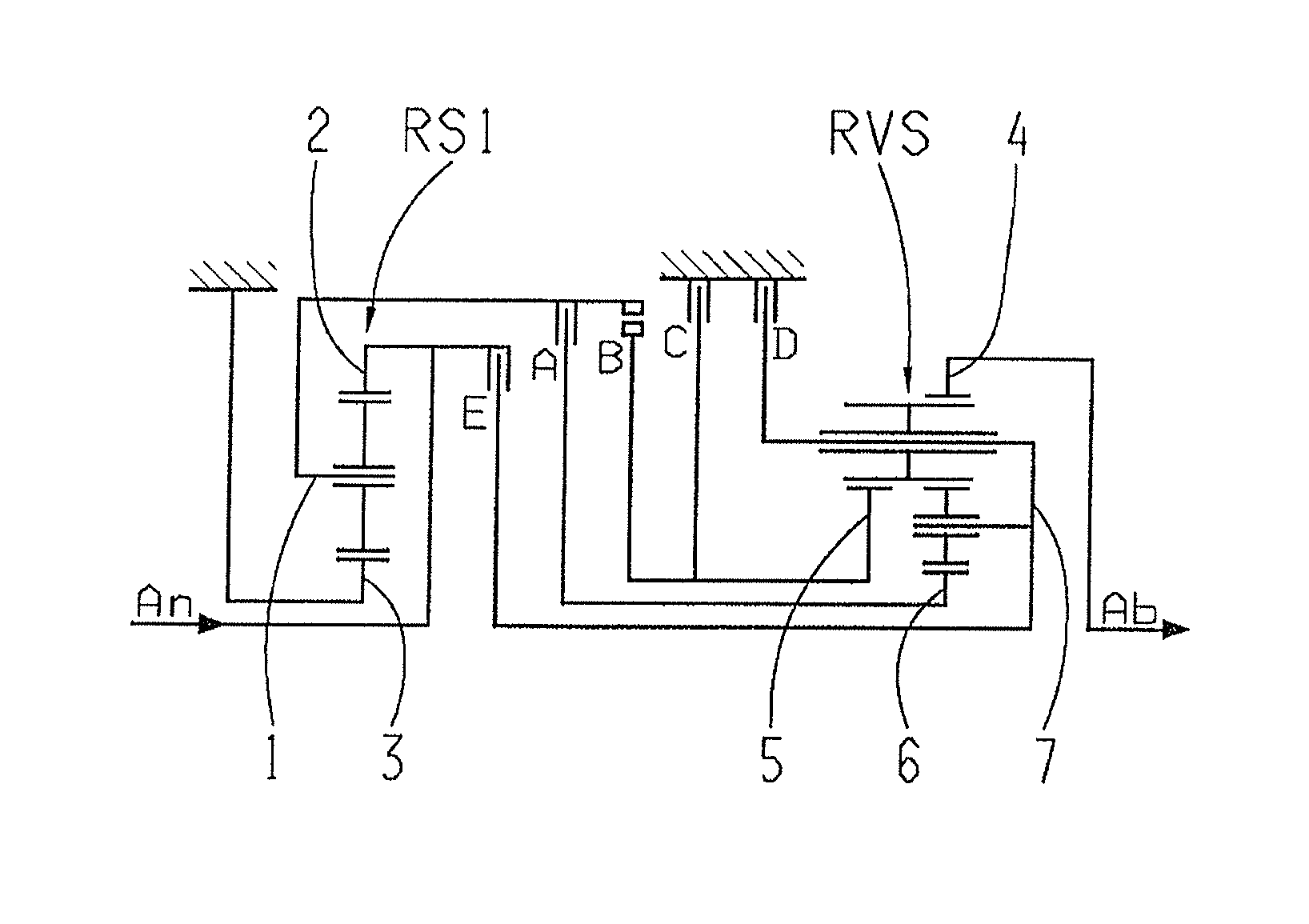

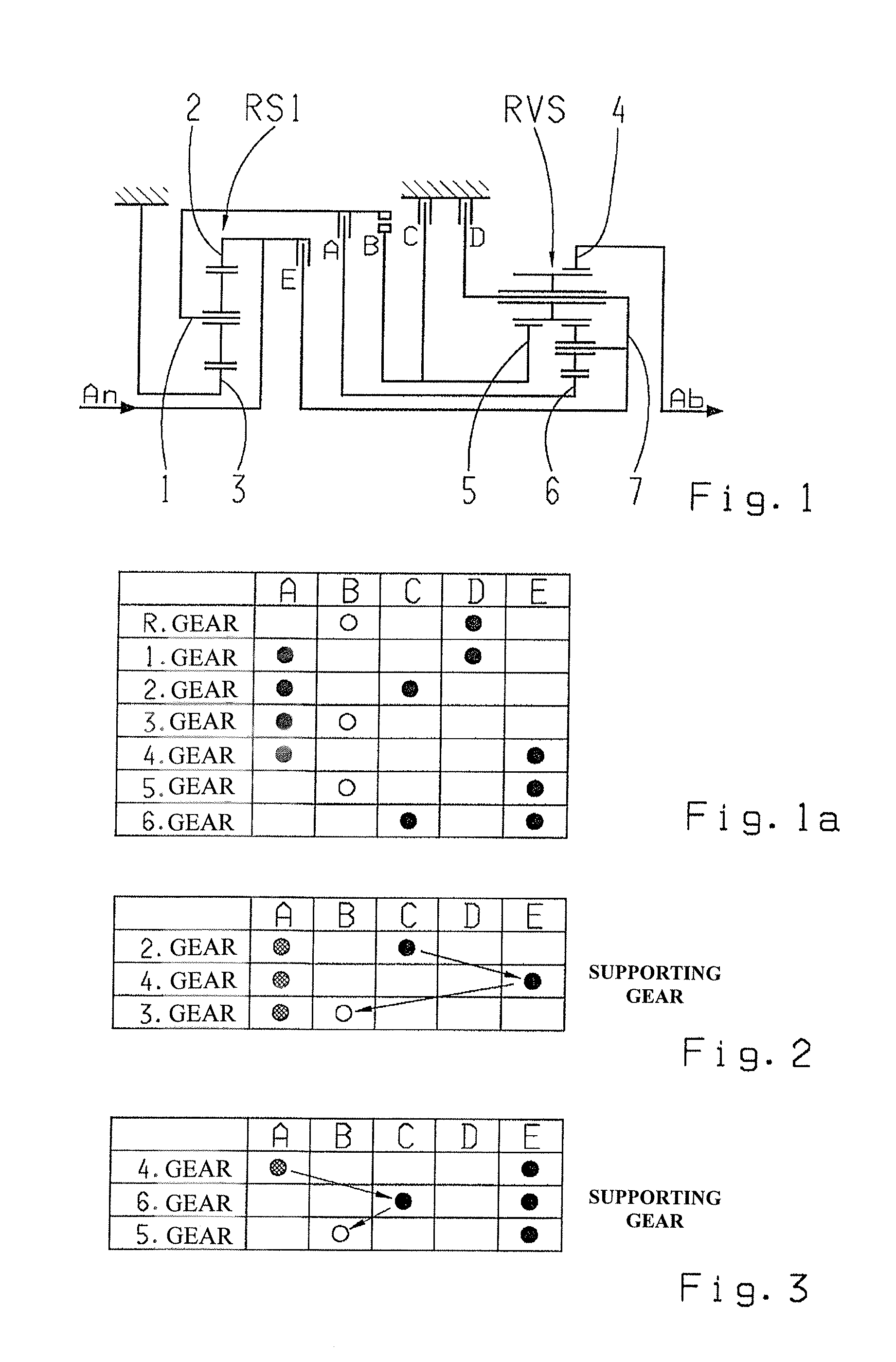

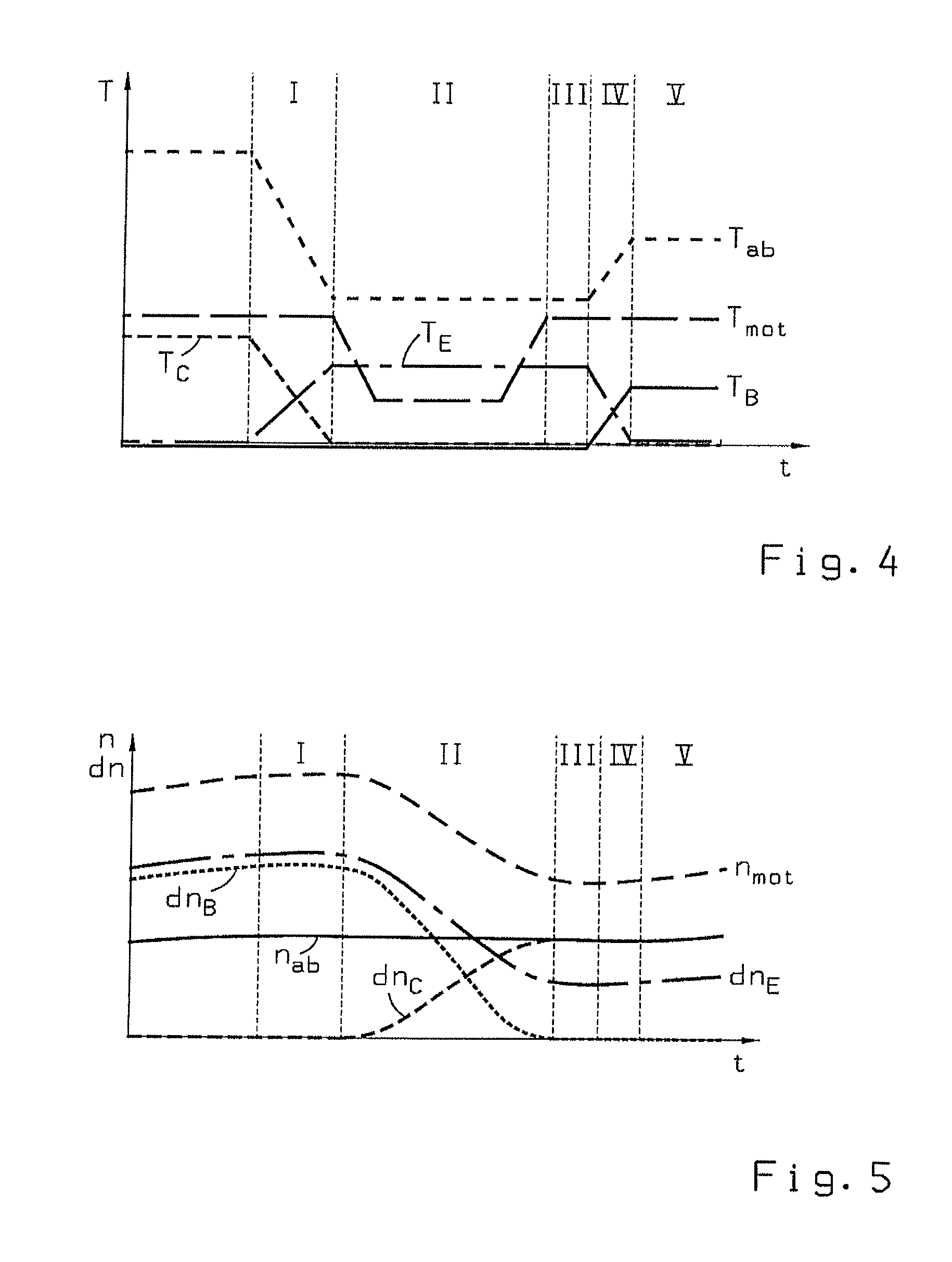

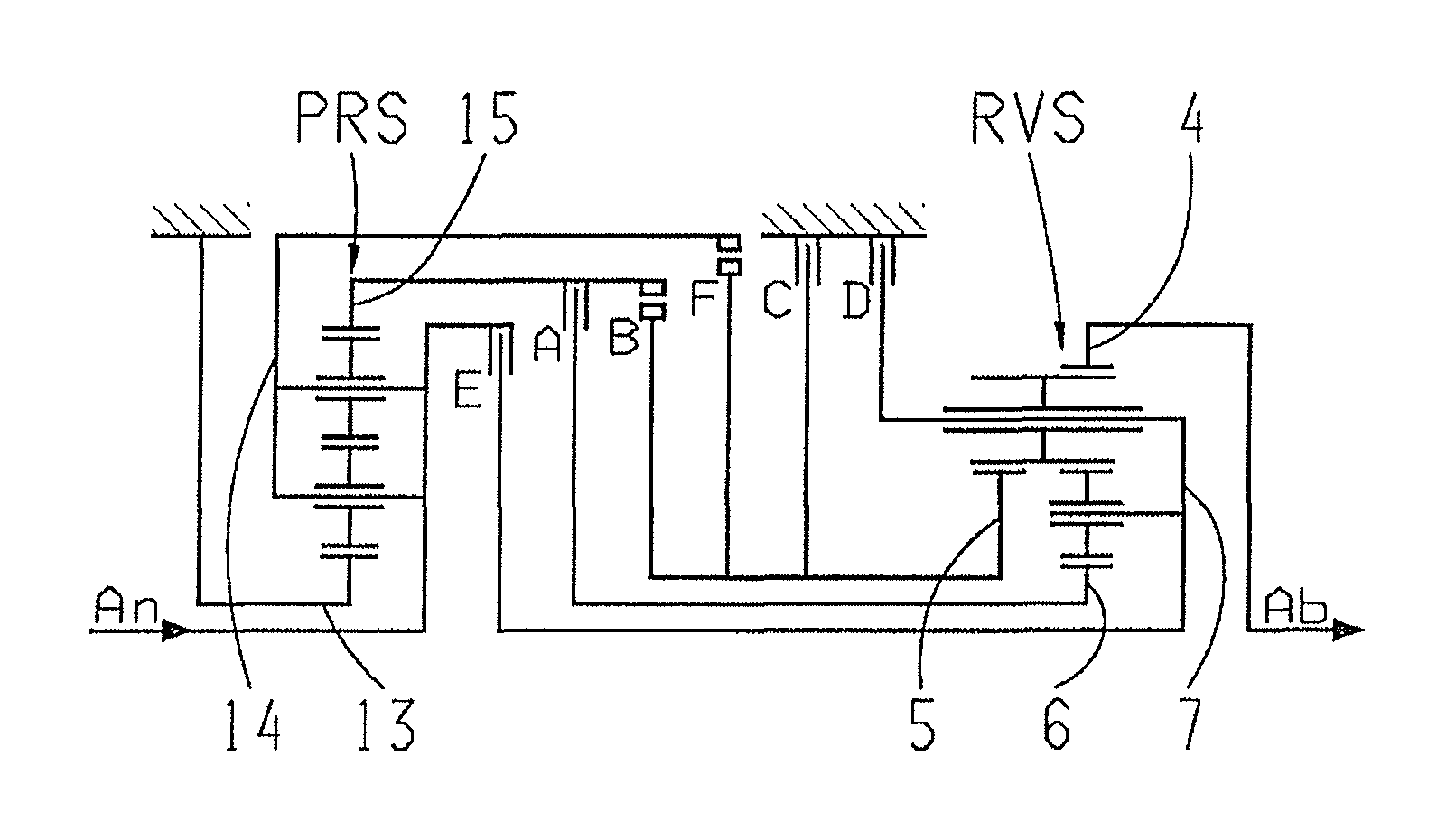

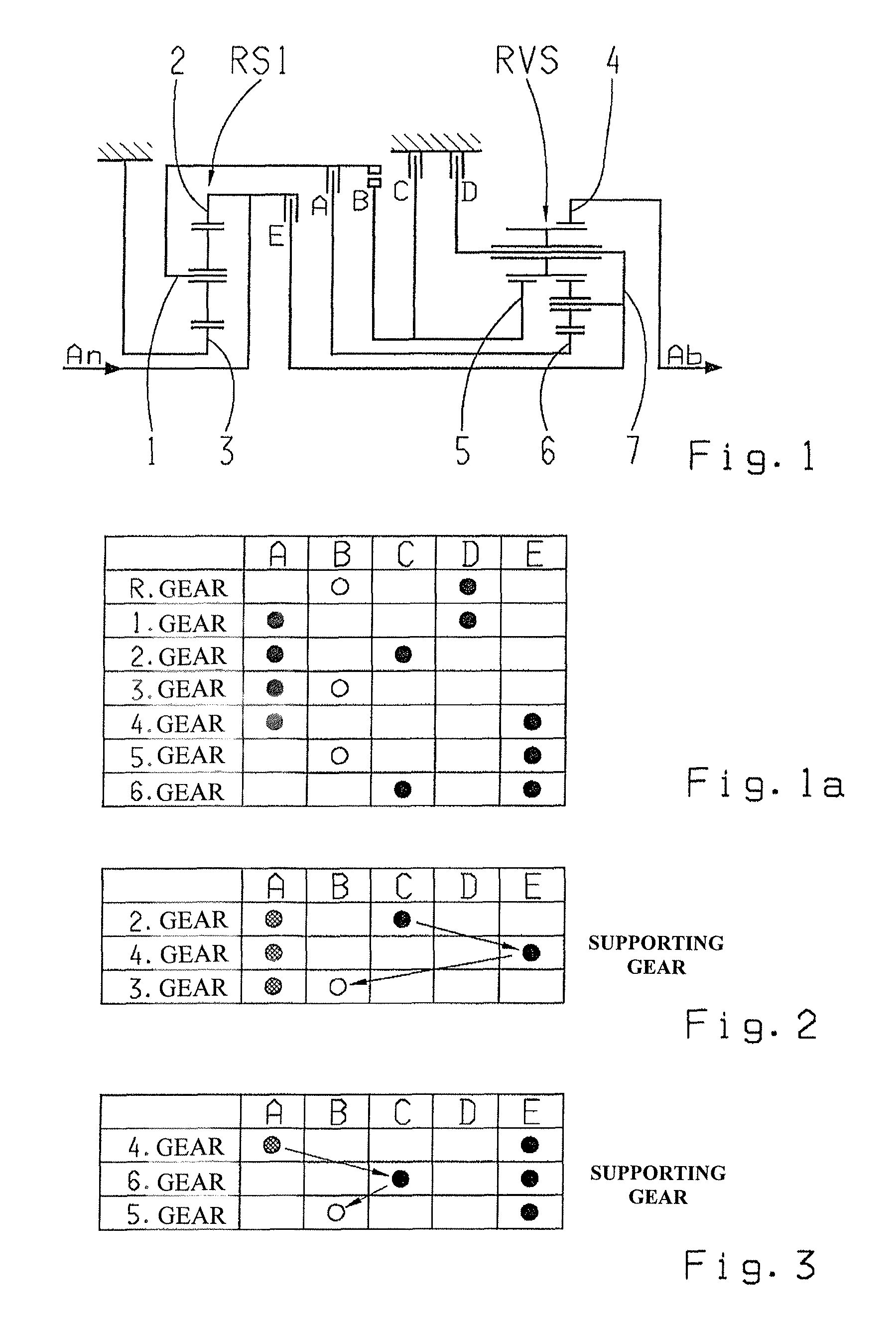

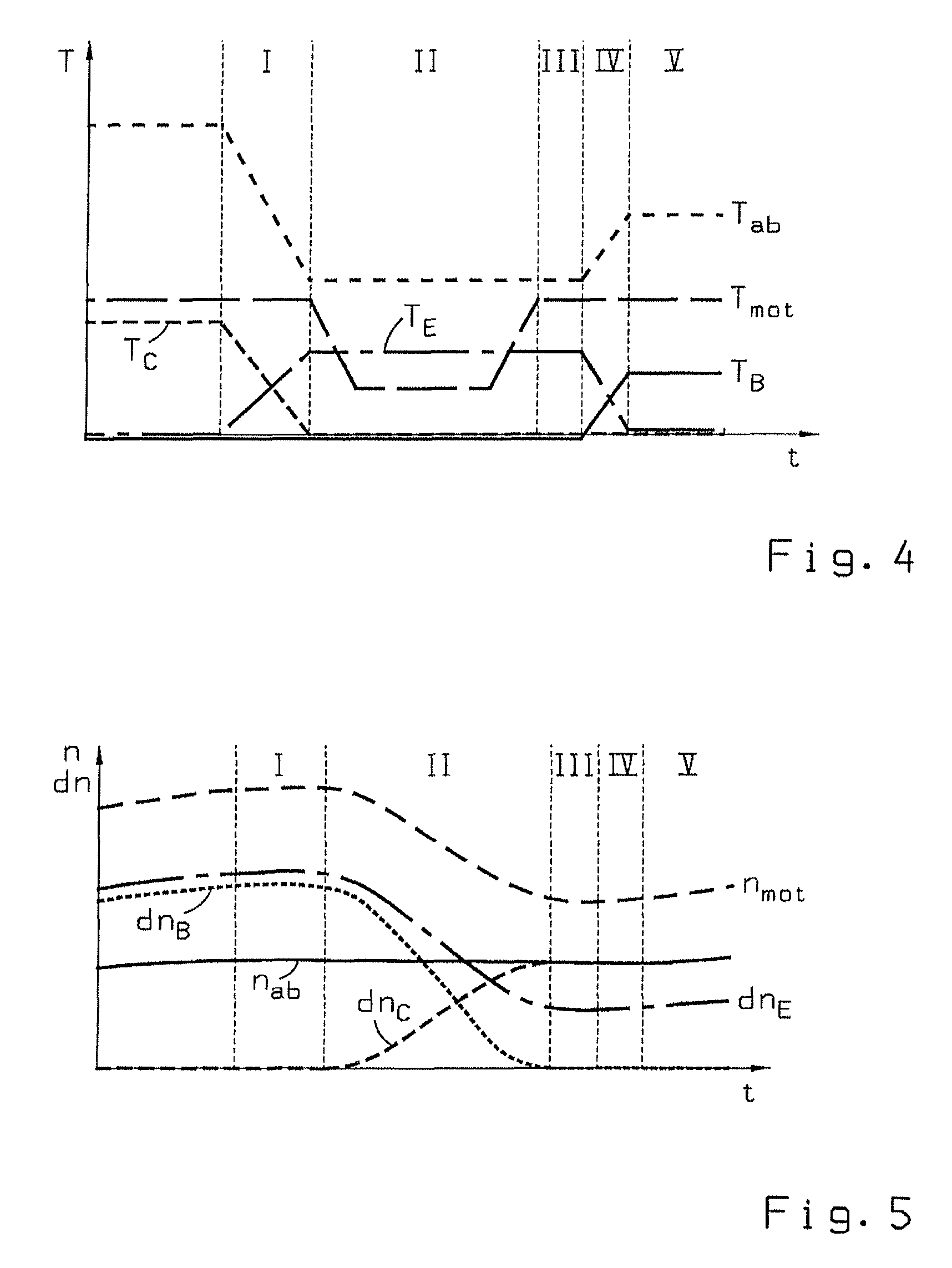

Power-shiftable transmission

ActiveUS20130196814A1Transmission lossFriction lossToothed gearingsGearing controlPower flowAutomatic transmission

A power-shiftable transmission, in particular an automatic transmission for a vehicle, which comprises a plurality of frictional shifting elements and at least one interlocking shifting element (A, B, C, D, E) and a plurality of gearwheels which can be engaged in a power flow by the shifting elements (A, B, C, D, E). In order to engage a gear step, at least two associated shifting elements (A, B, C, D, E) are engaged and at least one interlocking shifting element (B), as a shifting element (B) to be engaged, is associated with a gear step to be engaged with a supporting gear.

Owner:ZF FRIEDRICHSHAFEN AG

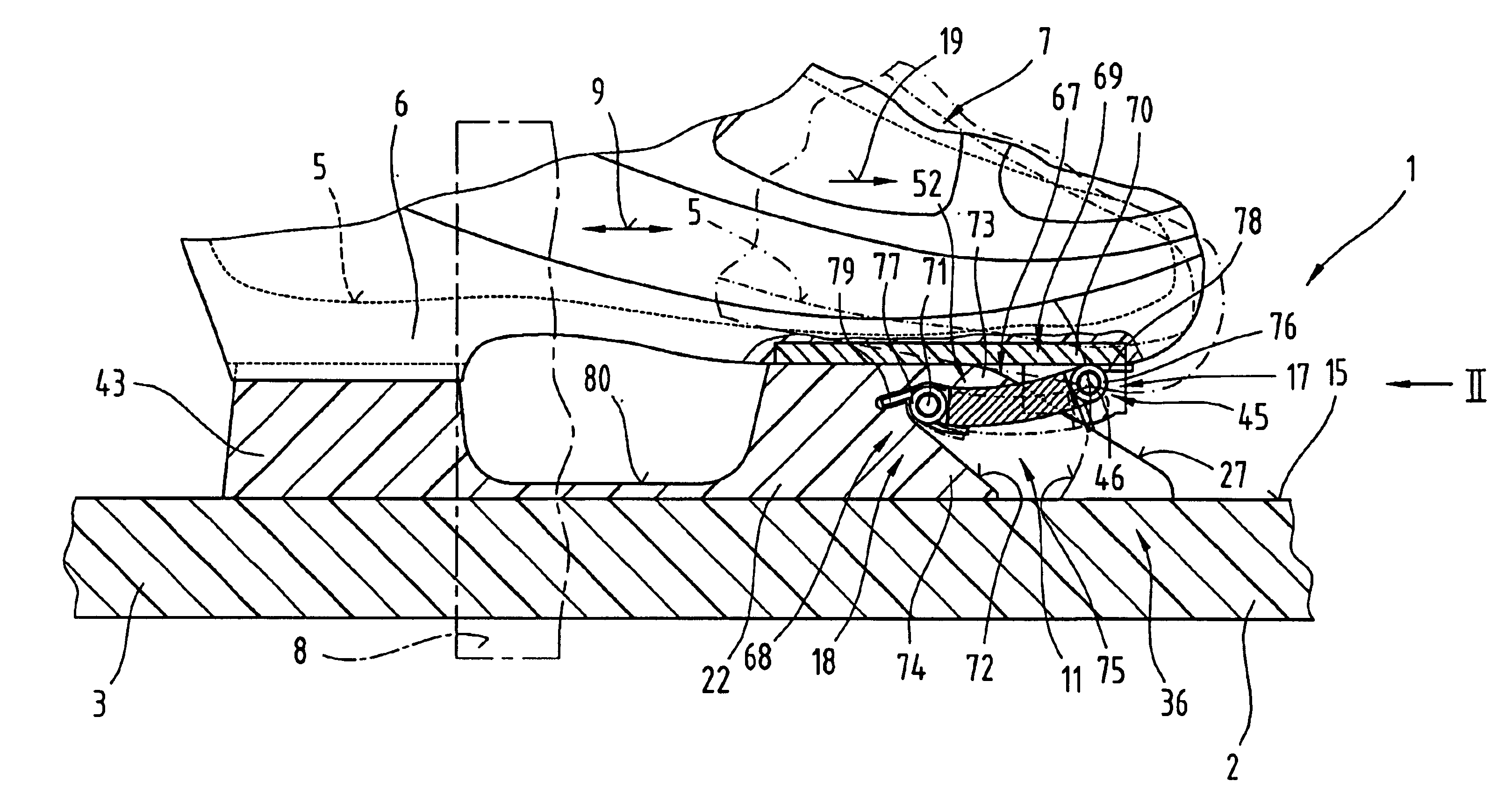

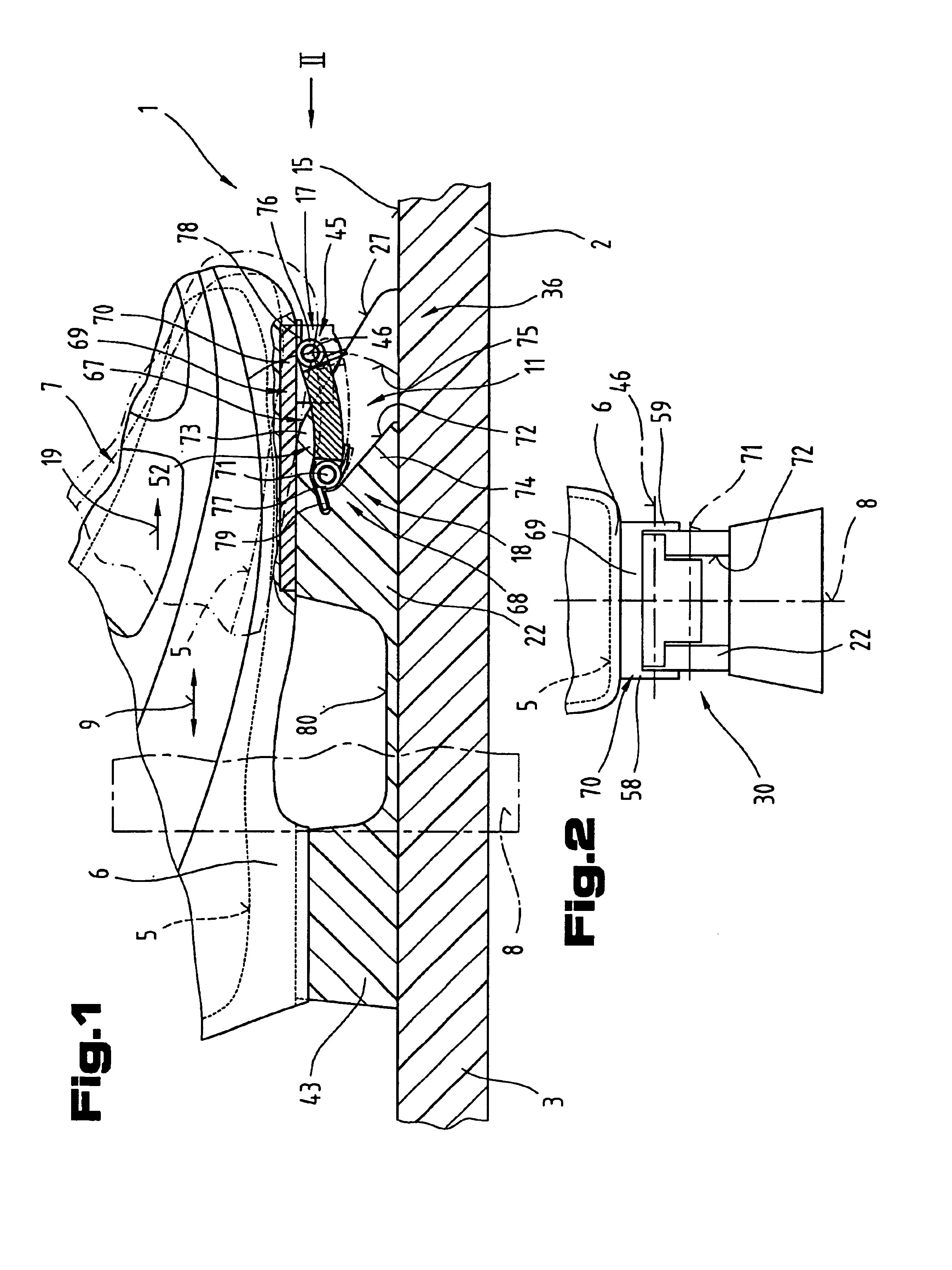

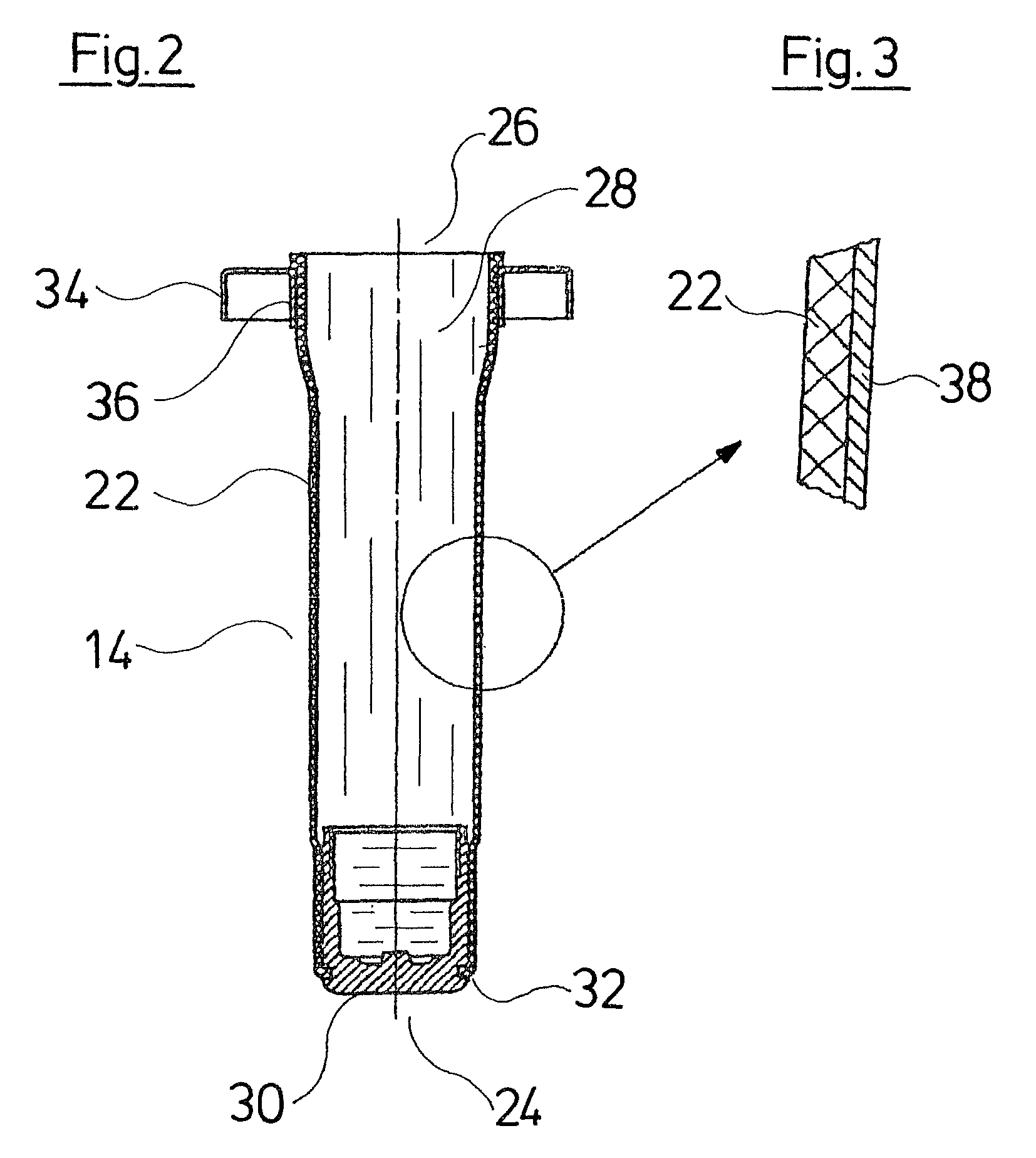

Flexible connection between sports device and shoe

InactiveUS6843497B1Improve user performanceIncrease resistanceSki bindingsSkatesVertical planeEngineering

The invention describes a pivotable binding system (1) for mounting between a sports device (2) and a tread surface (5) for a user's foot, in which the tread surface (5) is pivotable about an axis extending more or less parallel with the ankle joint of the foot and is displaceable, at least in a part region assigned to the toes, to a position closer to the sports device (2), and can be joined to the sports device by at least one binding element (11). The binding element (11) is flexible and is resiliently deformable in a vertical plane (8).

Owner:ATOMIC AUSTRIA

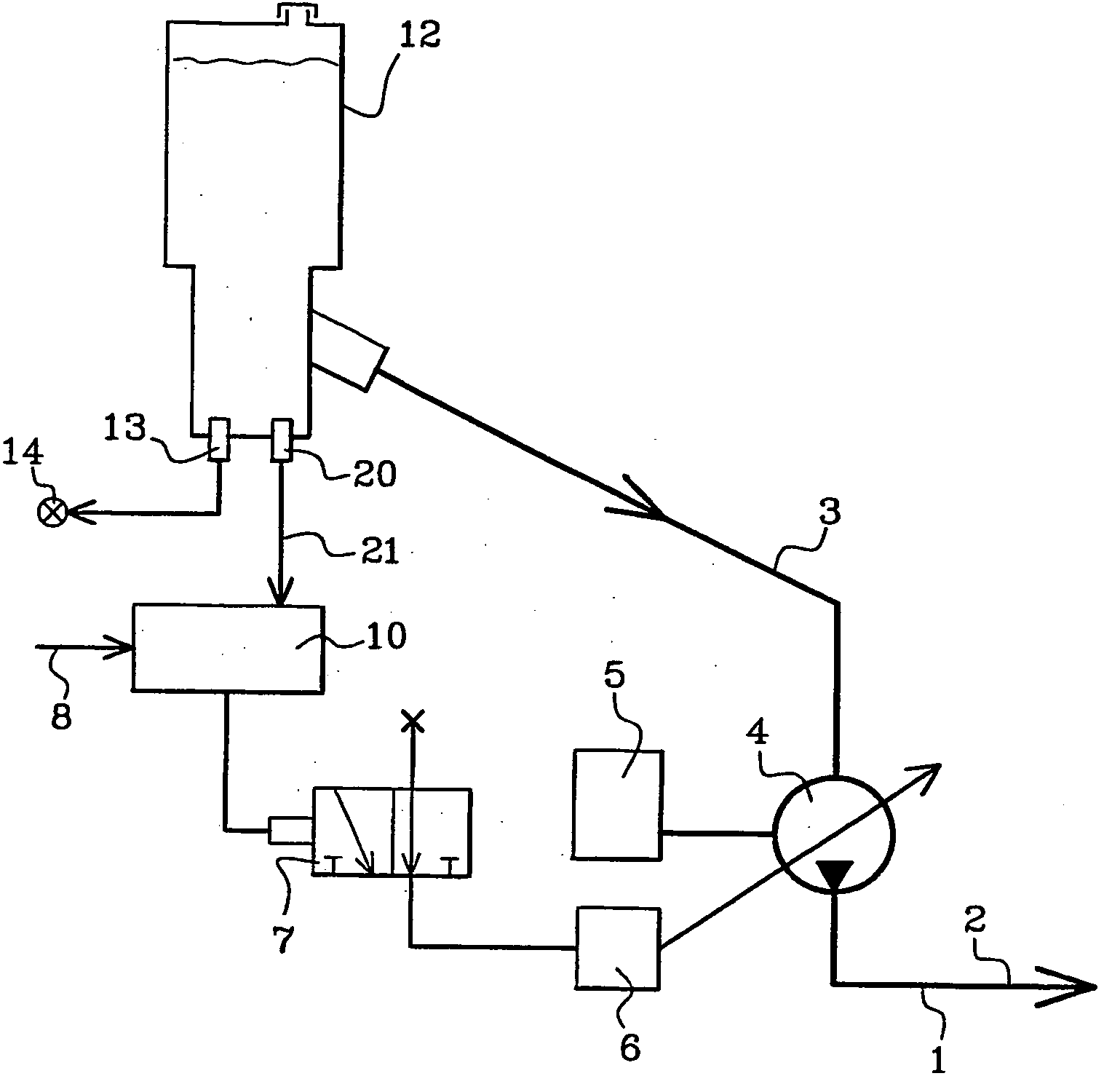

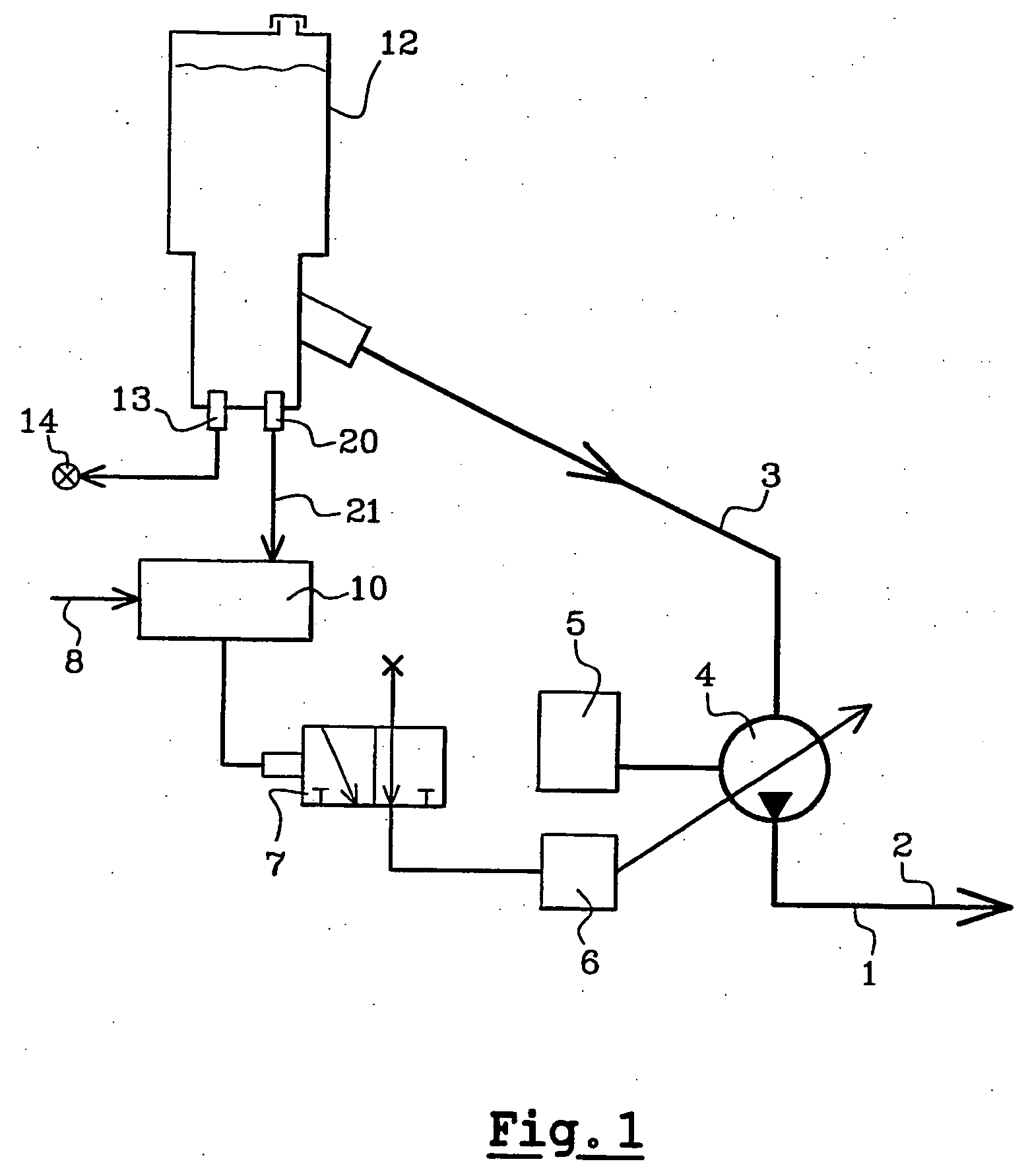

Loader/excavator-type heavy construction machine and method of controlling the operation of one such machine

The invention relates to a loader / excavator-type heavy-construction machine comprising a hydraulic system which powers one or more hydraulic actuators. The aforementioned hydraulic system is equipped with a variable-delivery pump which can operate in two different modes, namely full power mode for use as an excavator and reduced power mode for use as a loader. The invention is characterized in that it also comprises a temperature sensor which is used to determine the temperature of the oil in the hydraulic system and means of automatically switching the operation of the pump from full power mode to reduced power mode when the oil temperature exceeds a pre-determined threshold.

Owner:VOLVO CONSTR EQUIP

Power transmission mechanism and exhaust heat recovery apparatus

InactiveUS20100043427A1Frictional loss causedMinimize frictional lossDynamo-electric brakes/clutchesGas pressure propulsion mountingDrive shaftEngineering

A power transmission mechanism that transfers power from an output shaft disposed in sealed-off space within a power generation unit includes: a drive shaft to which the power from the output shaft is transmitted; a first magnet that is fitted to the drive shaft and that rotates together with the drive shaft; a second magnet that is fitted to a driven shaft, which is arranged concentrically with the drive shaft, that is disposed outside the sealed-off space, and that faces the first magnet; and a partition wall that is interposed between the first magnet and the second magnet, and that separates a drive shaft side space and a driven shaft side space from each other.

Owner:TOYOTA JIDOSHA KK

Power-shiftable transmission

ActiveUS9182013B2Transmission lossFriction lossToothed gearingsGearing controlAutomatic transmissionPower flow

A power-shiftable transmission, in particular an automatic transmission for a vehicle, which comprises a plurality of frictional shifting elements and at least one interlocking shifting element (A, B, C, D, E) and a plurality of gearwheels which can be engaged in a power flow by the shifting elements (A, B, C, D, E). In order to engage a gear step, at least two associated shifting elements (A, B, C, D, E) are engaged and at least one interlocking shifting element (B), as a shifting element (B) to be engaged, is associated with a gear step to be engaged with a supporting gear.

Owner:ZF FRIEDRICHSHAFEN AG

Engine and method for operating said engine

InactiveUS20160177833A1Improve cooling efficiencyRotor cooling is improvedPump componentsWind motor controlCompressed fluidEngineering

Disclosed is an engine, the engine having a compressor, an expansion machine, and a shaft, the shaft having a direction of rotation. The engine includes a compressed fluid main flow path, a flow divider arranged at and fluidly connected to the compressed fluid main flow path, and a duct fluidly connecting the flow divider and components of the expansion machine. The duct is arranged such that, when the engine is operated, a fluid is guided through the duct from the flow divider towards the expansion machine components. A flow deflector device is arranged within a flow path and configured to deflect and thereby accelerate a flow therethrough directed form the flow divider towards the expansion machine components in a tangential direction, wherein the deflection can be effected into the shaft direction of rotation.

Owner:ANSALDO ENERGIA SWITZERLAND AG

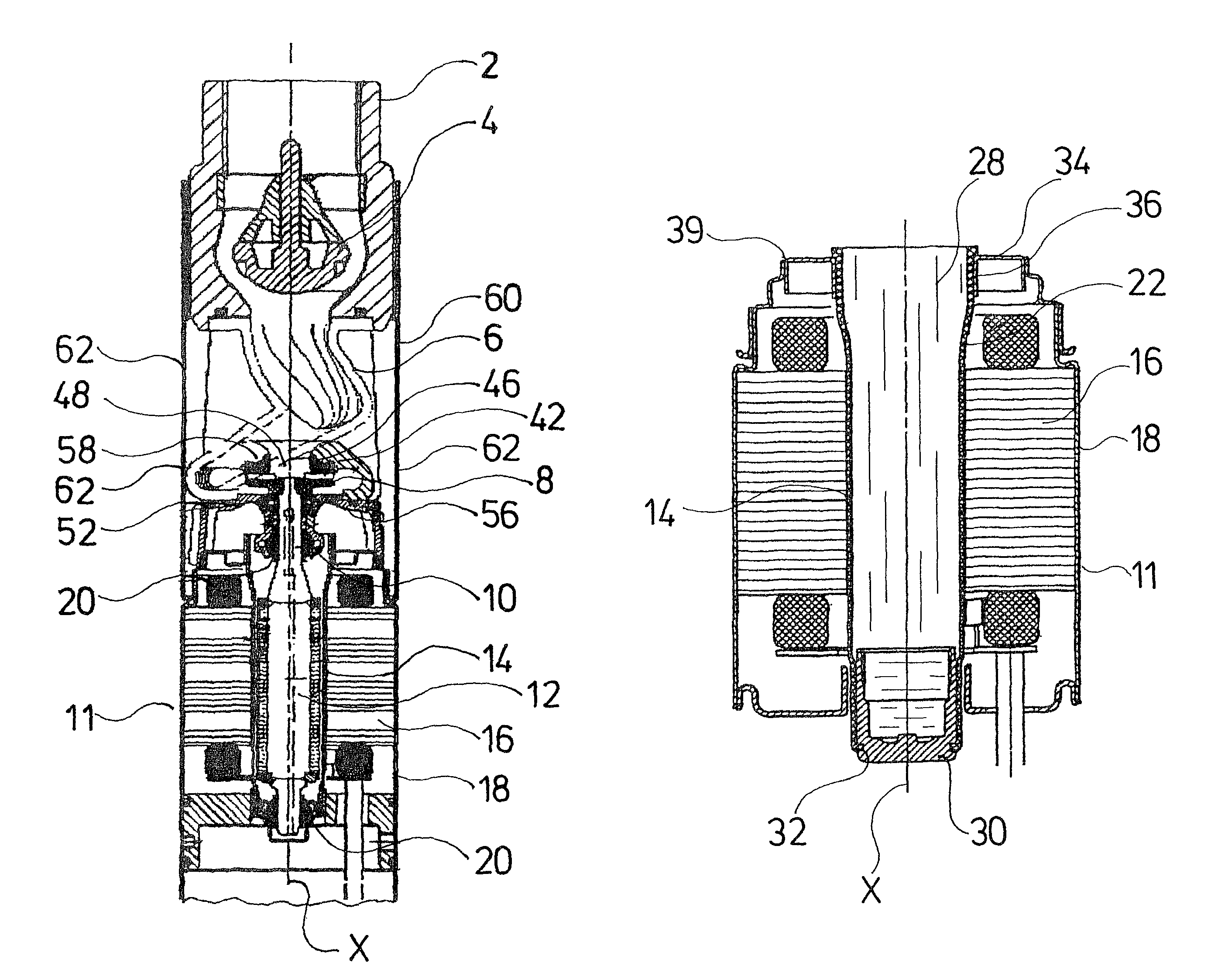

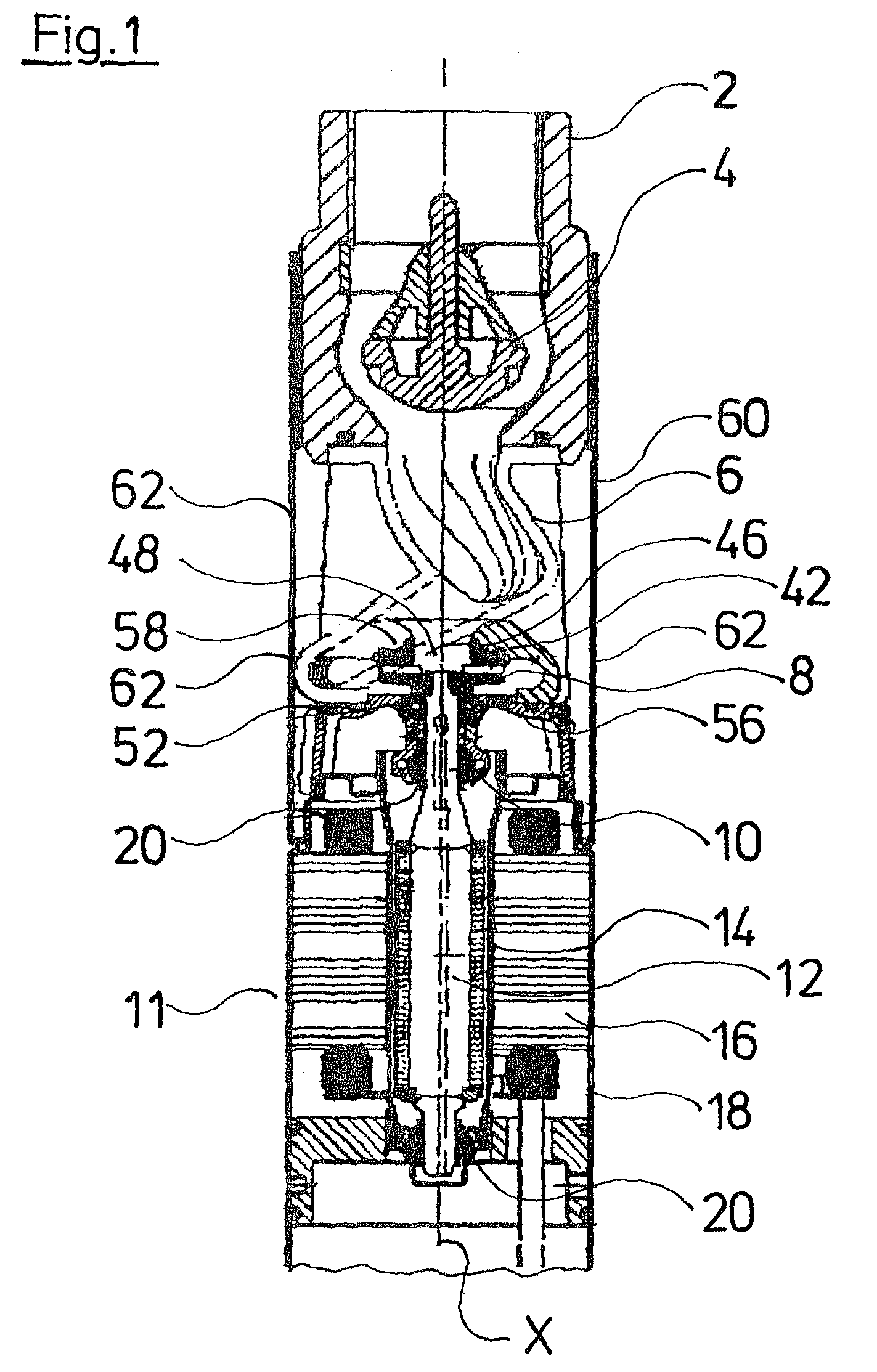

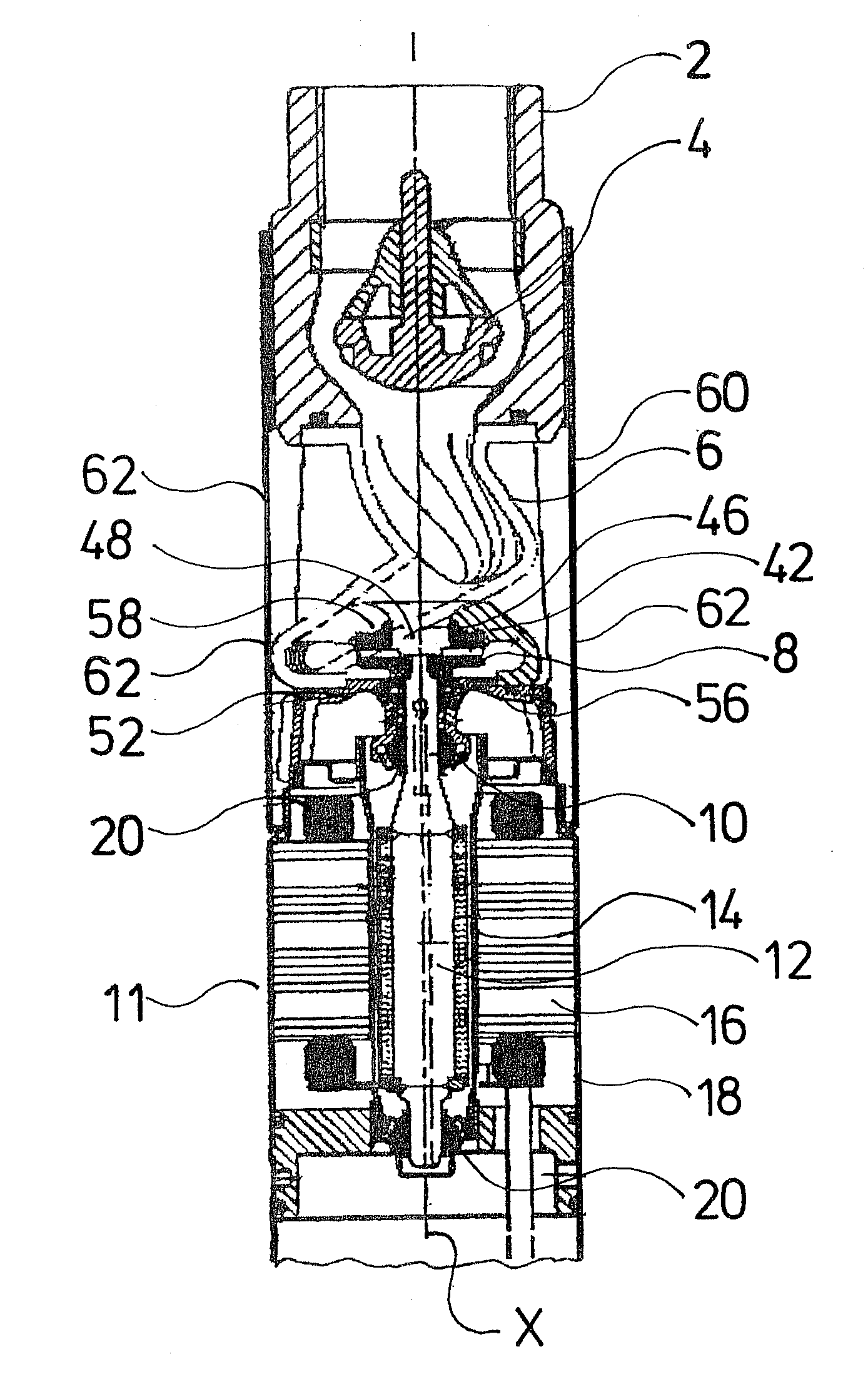

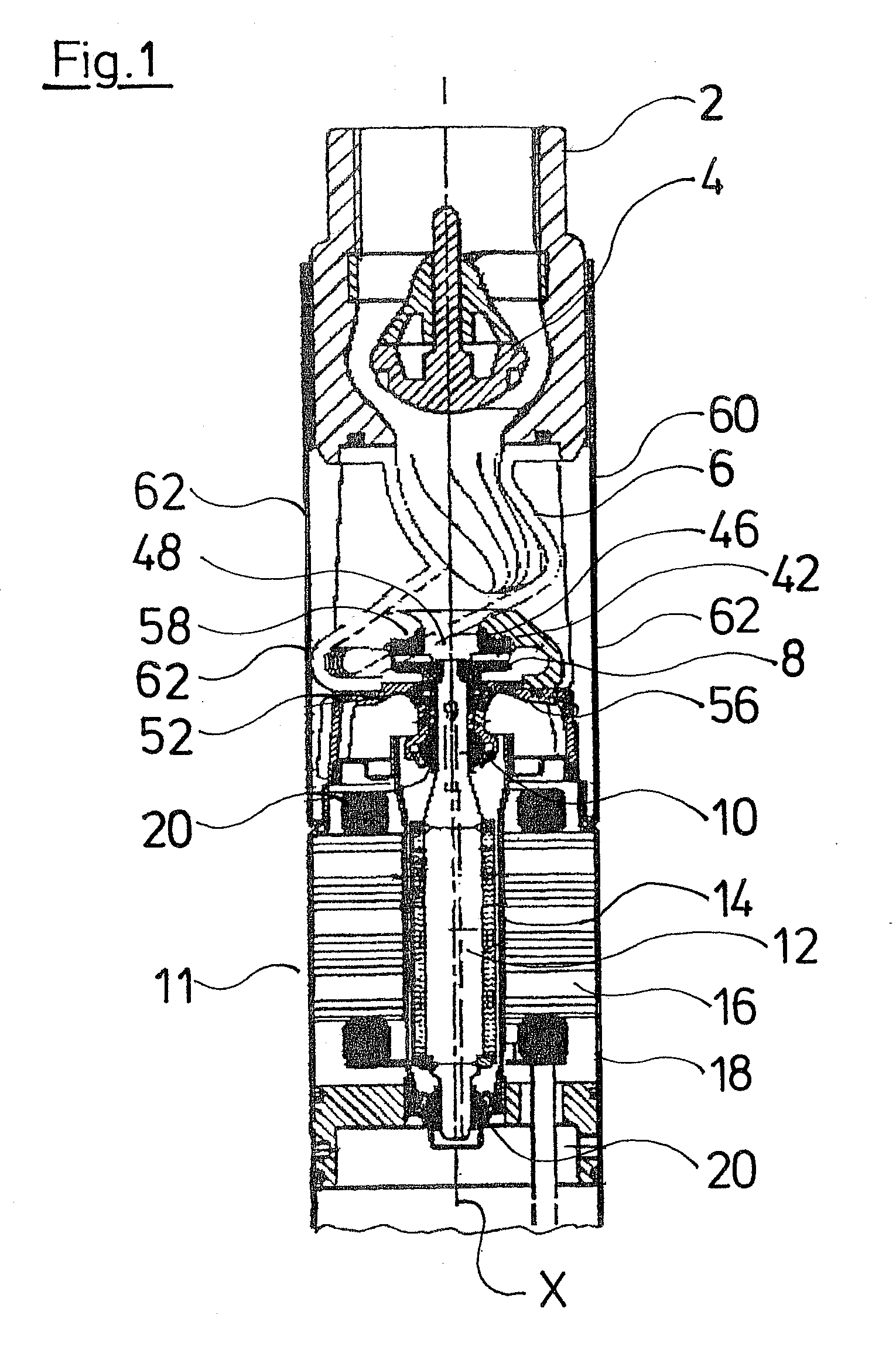

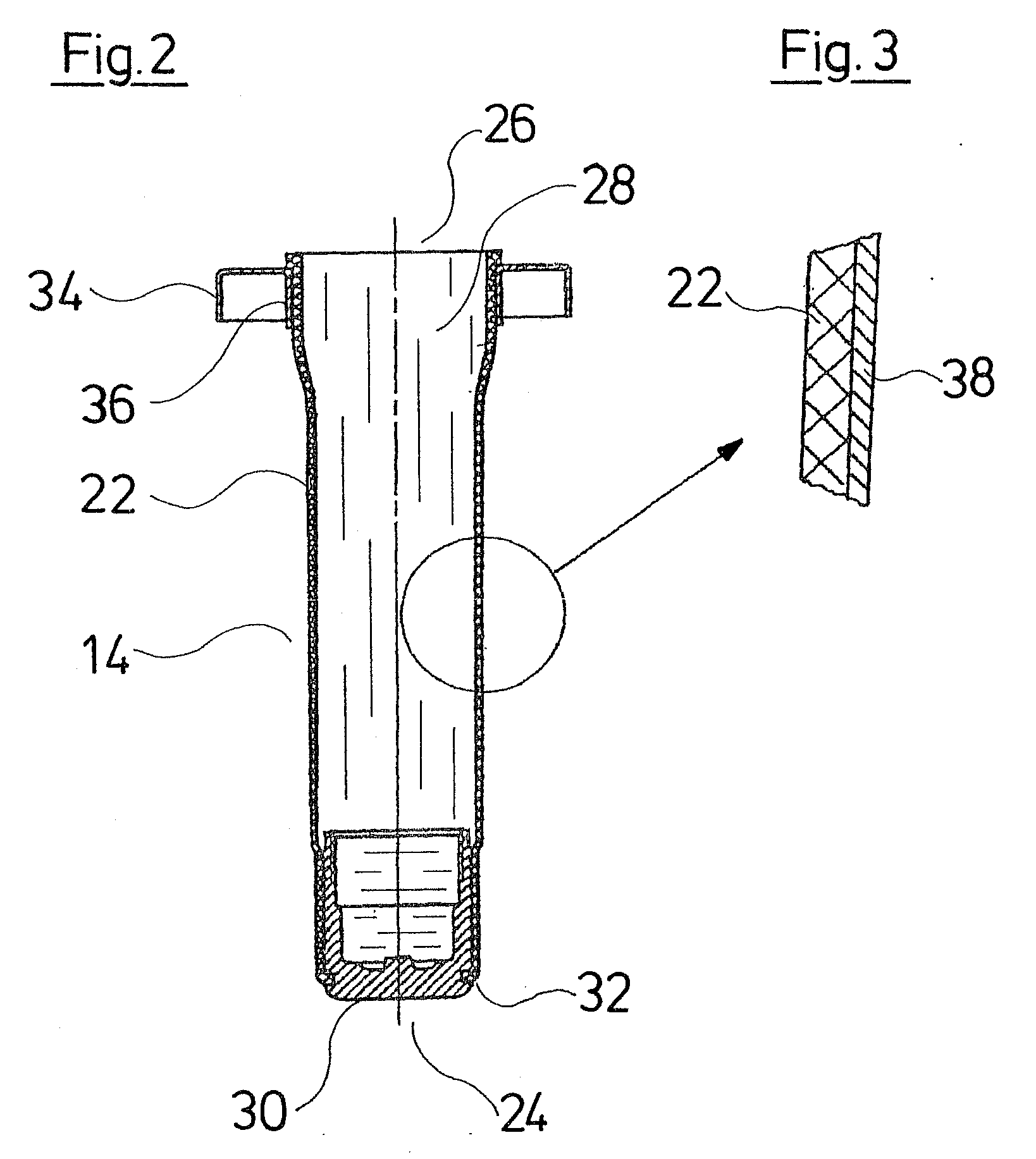

Pump assembly

ActiveUS8333575B2Improve delivery capabilitiesReduction of friction and of lossPump componentsPiston pumpsElectric motor

A pump unit is provided having a wet-running electric motor, wherein a rotor of the pump unit can be driven by the electric motor at a maximum speed of greater than 20,000 rev / min, and the rotor is sealed off axially in the region of a suction port.

Owner:GRUNDFOS MANAGEMENT AS

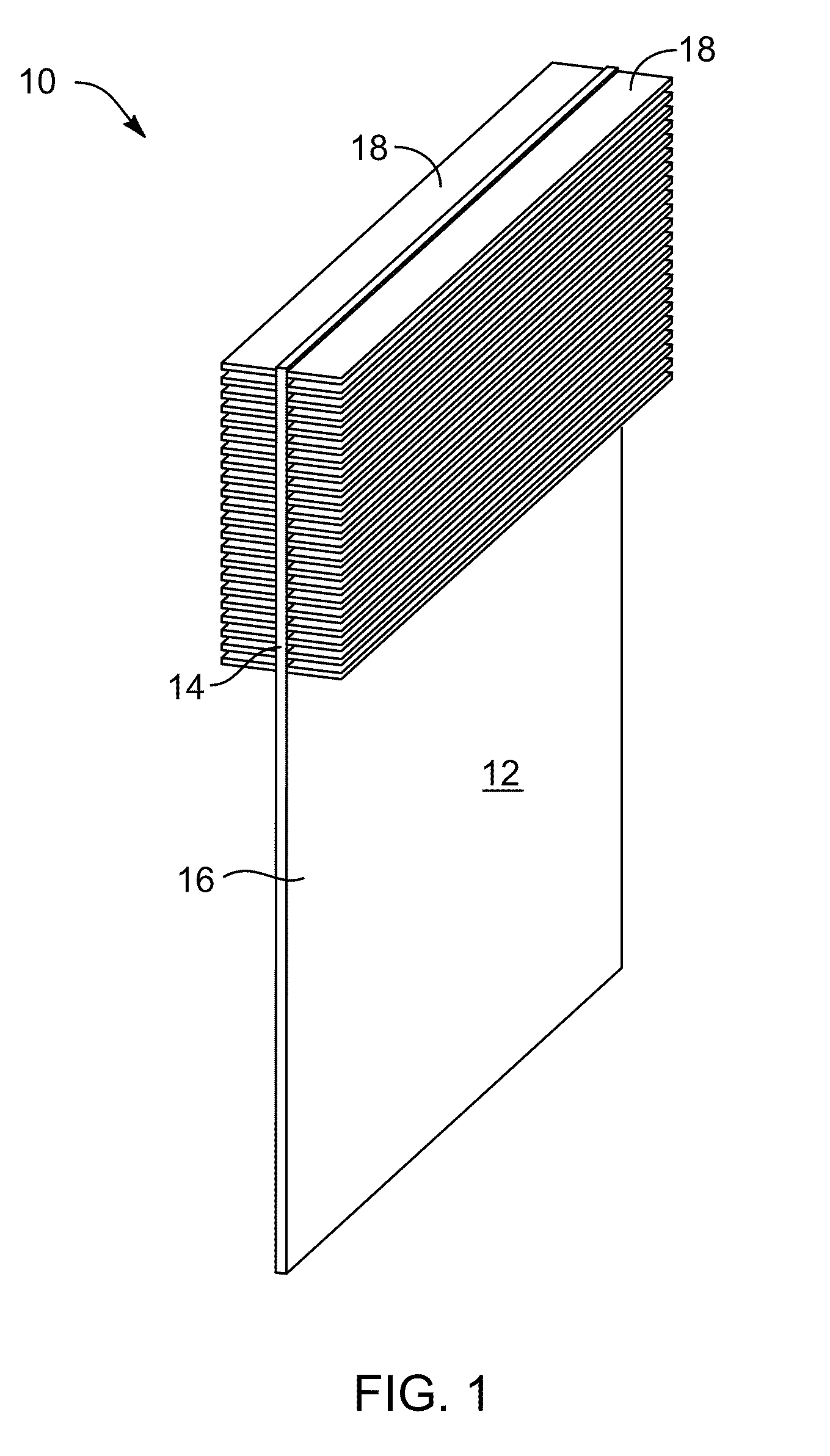

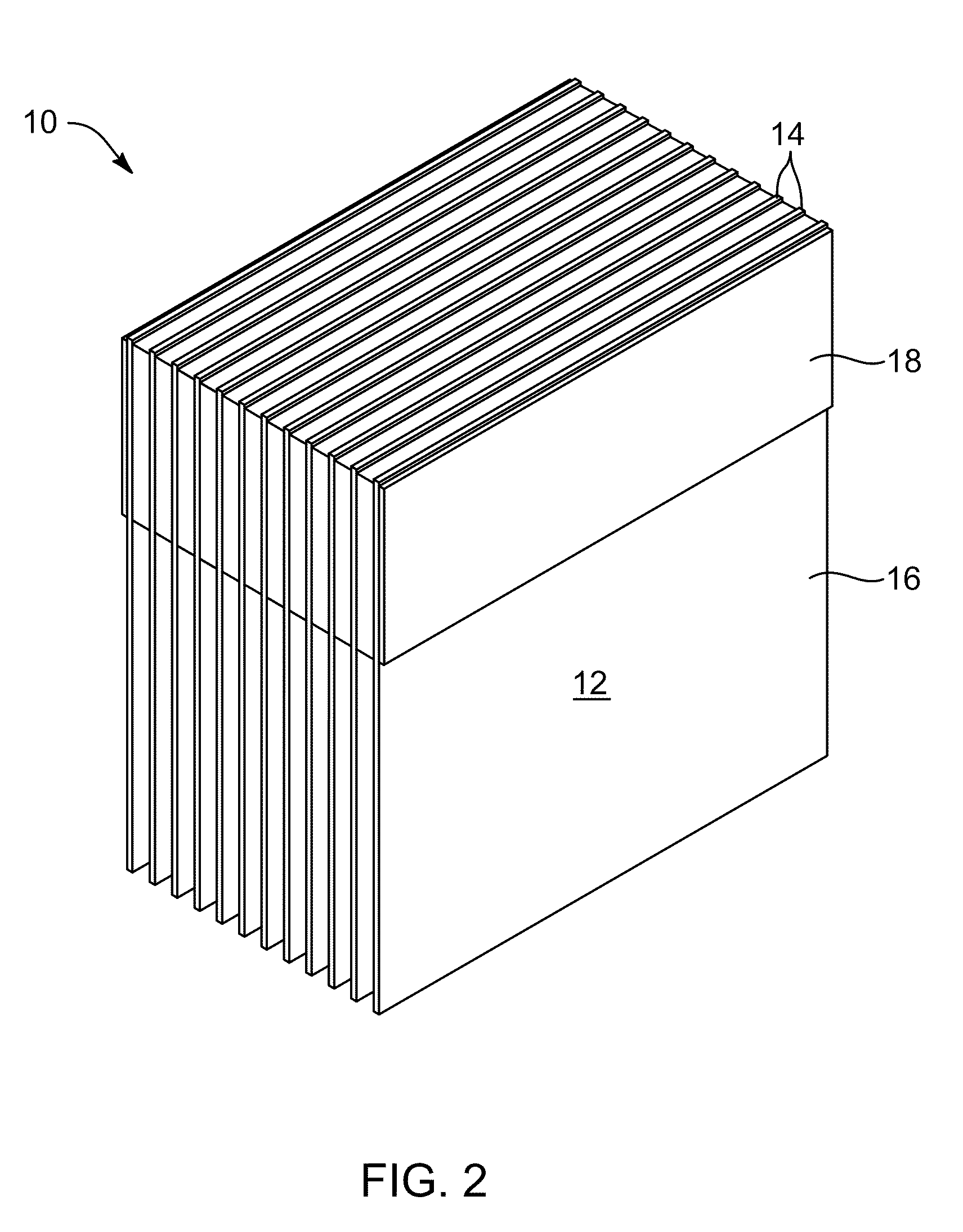

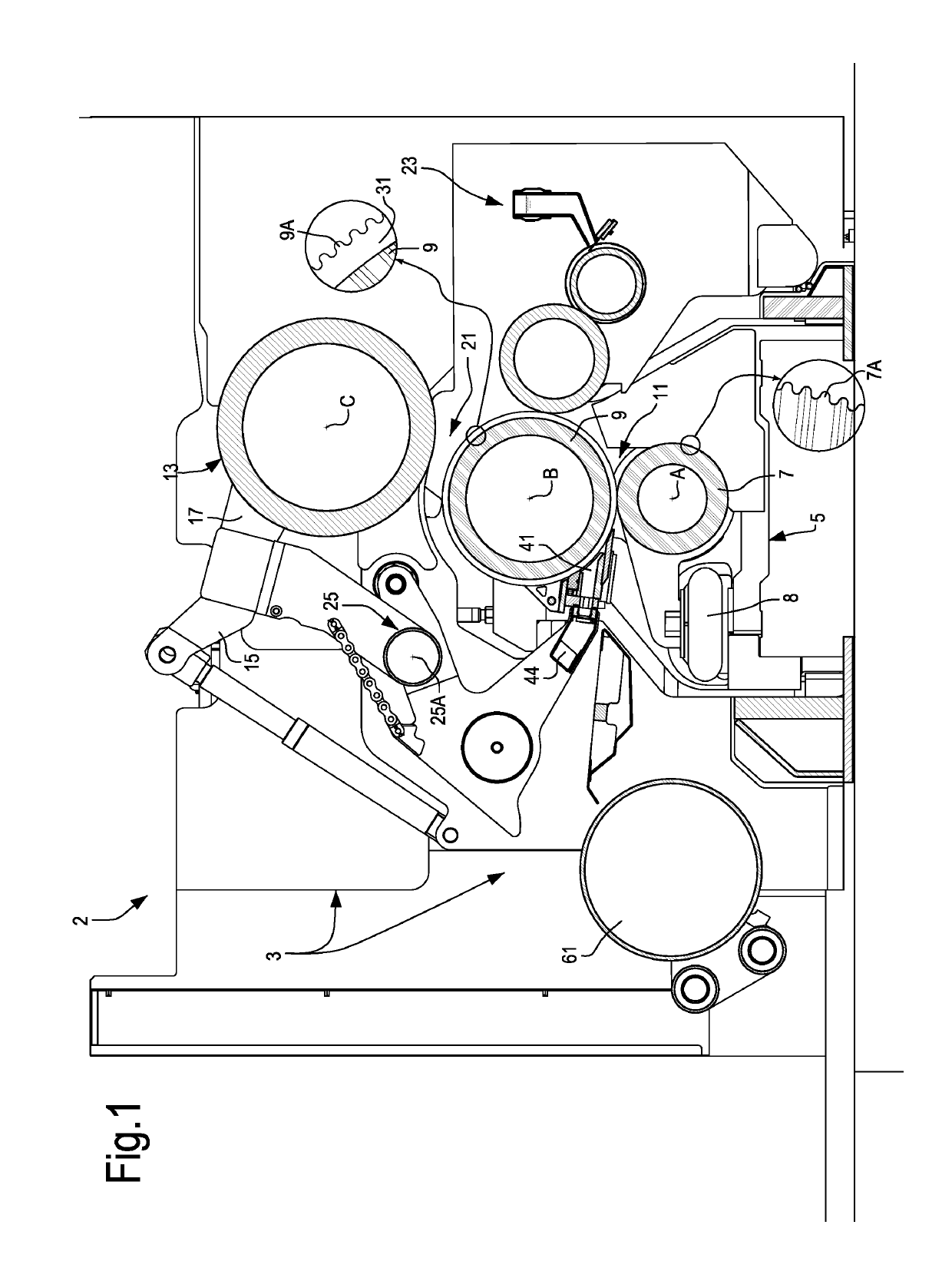

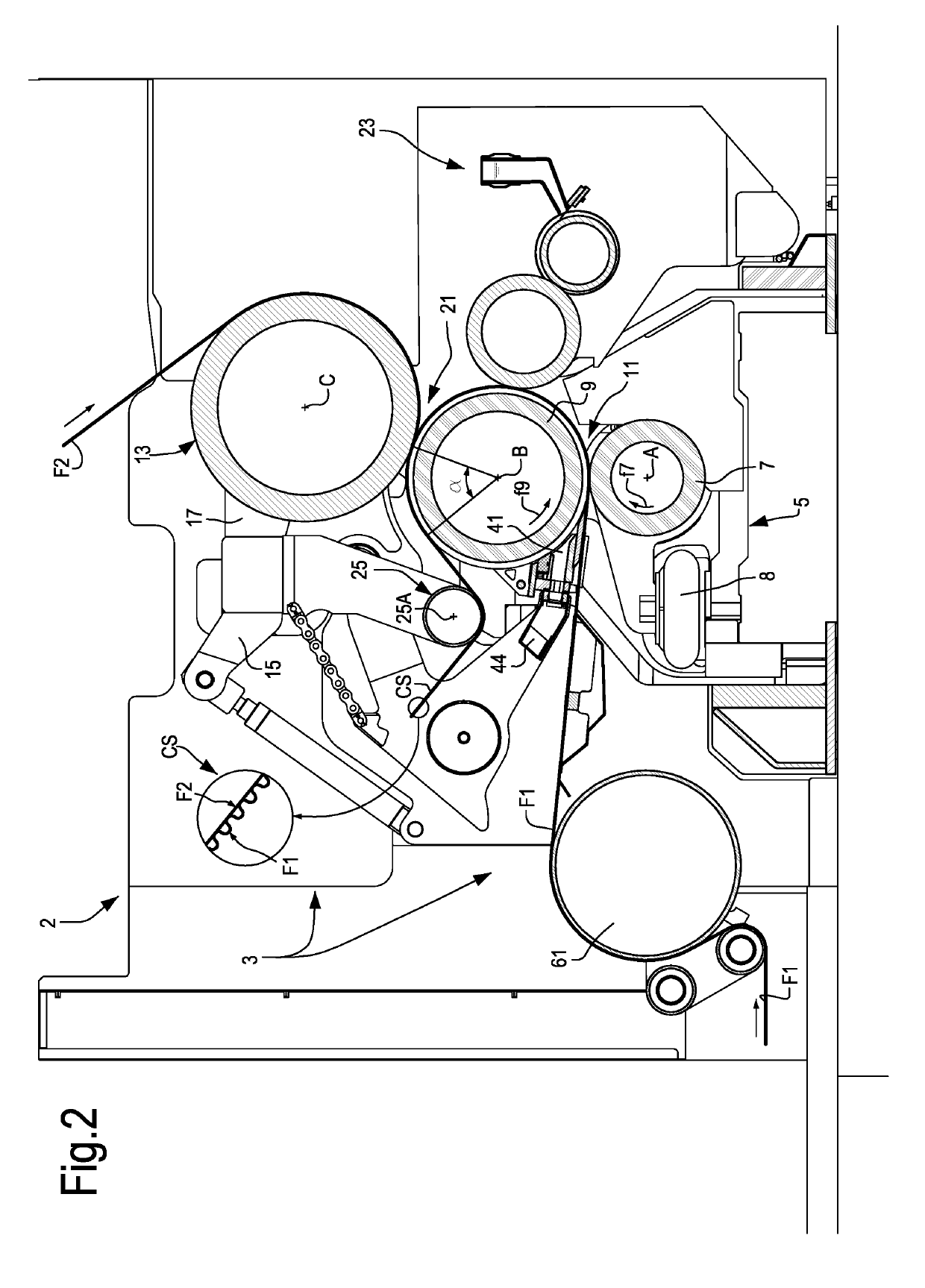

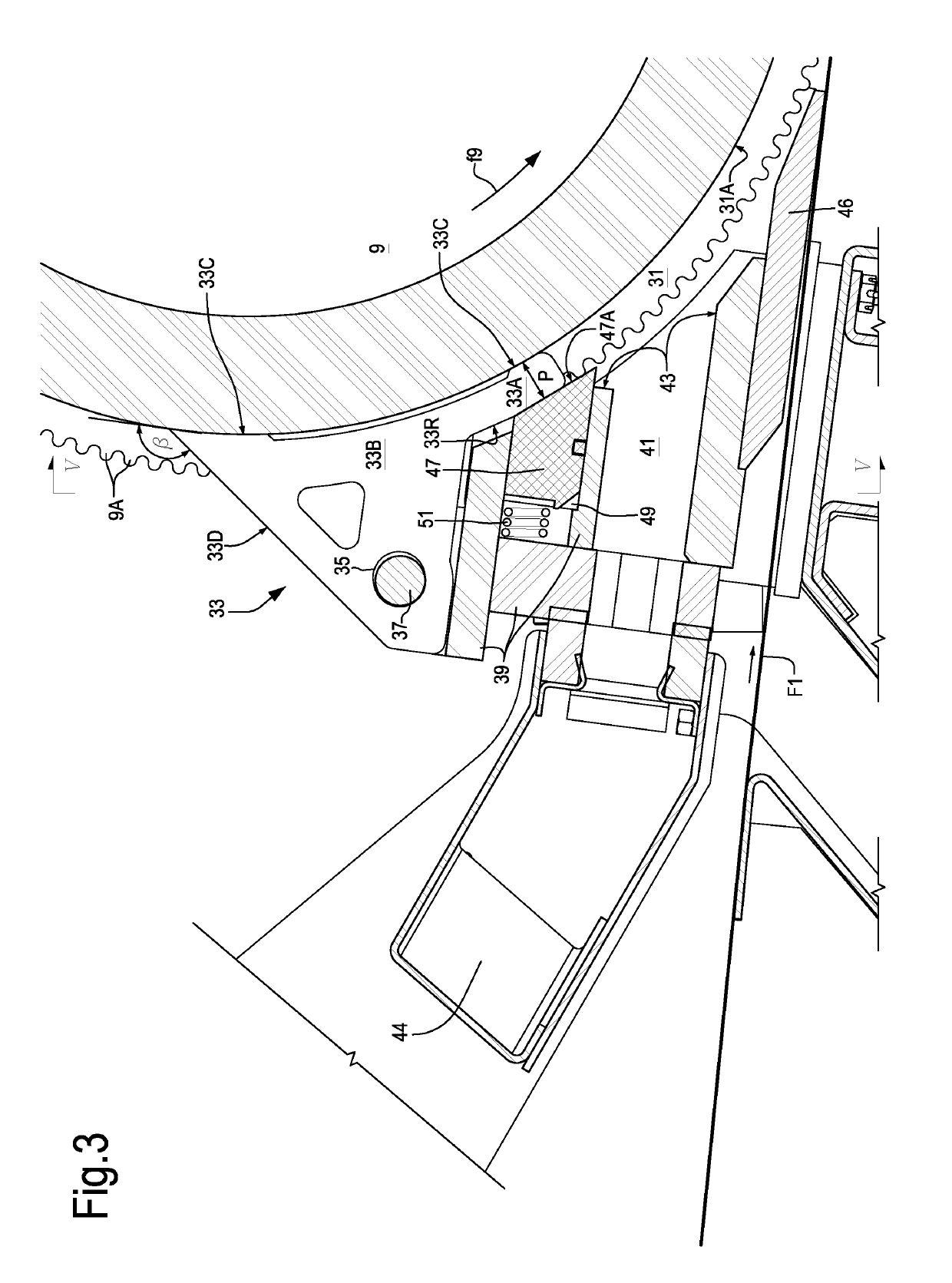

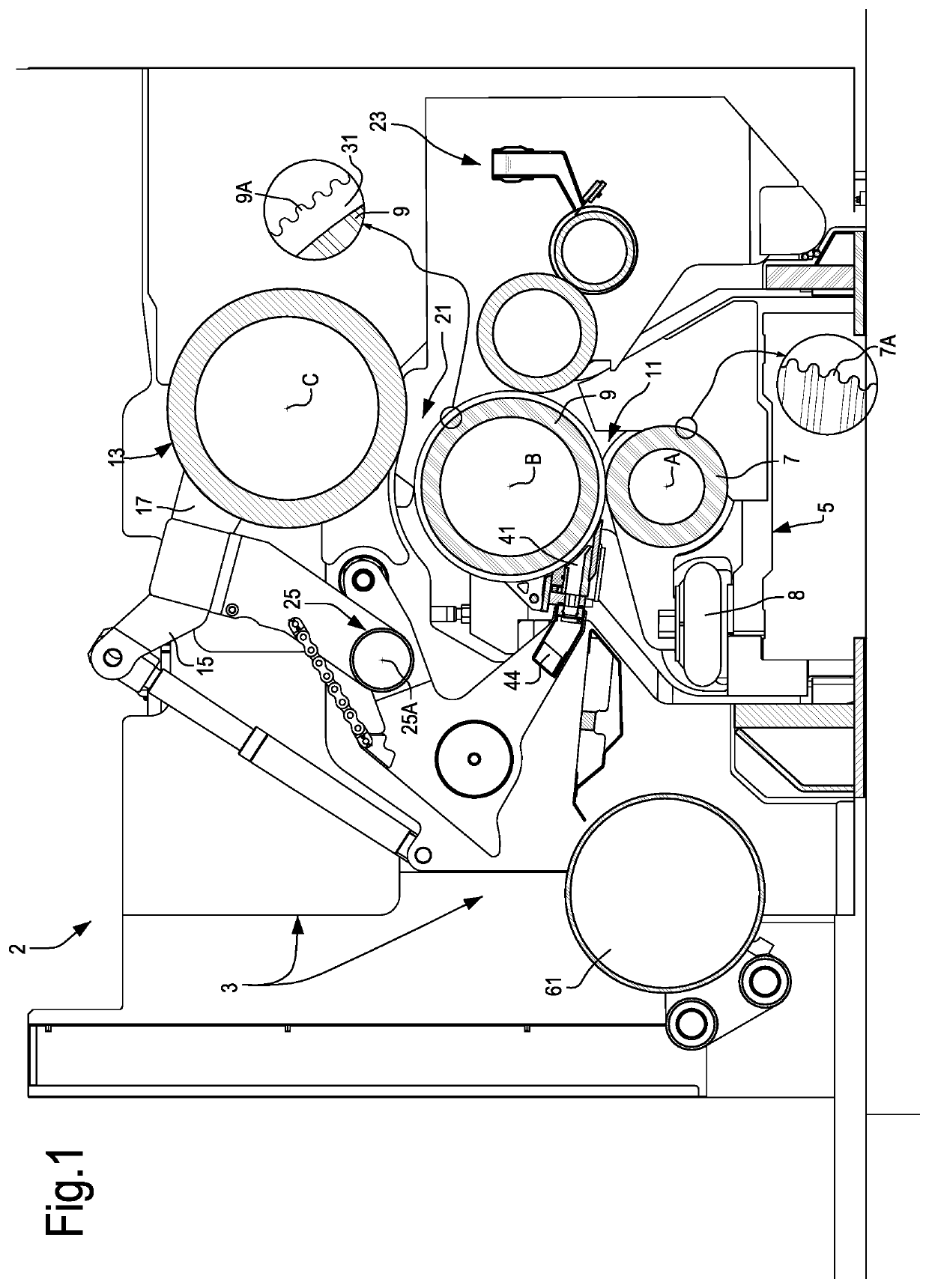

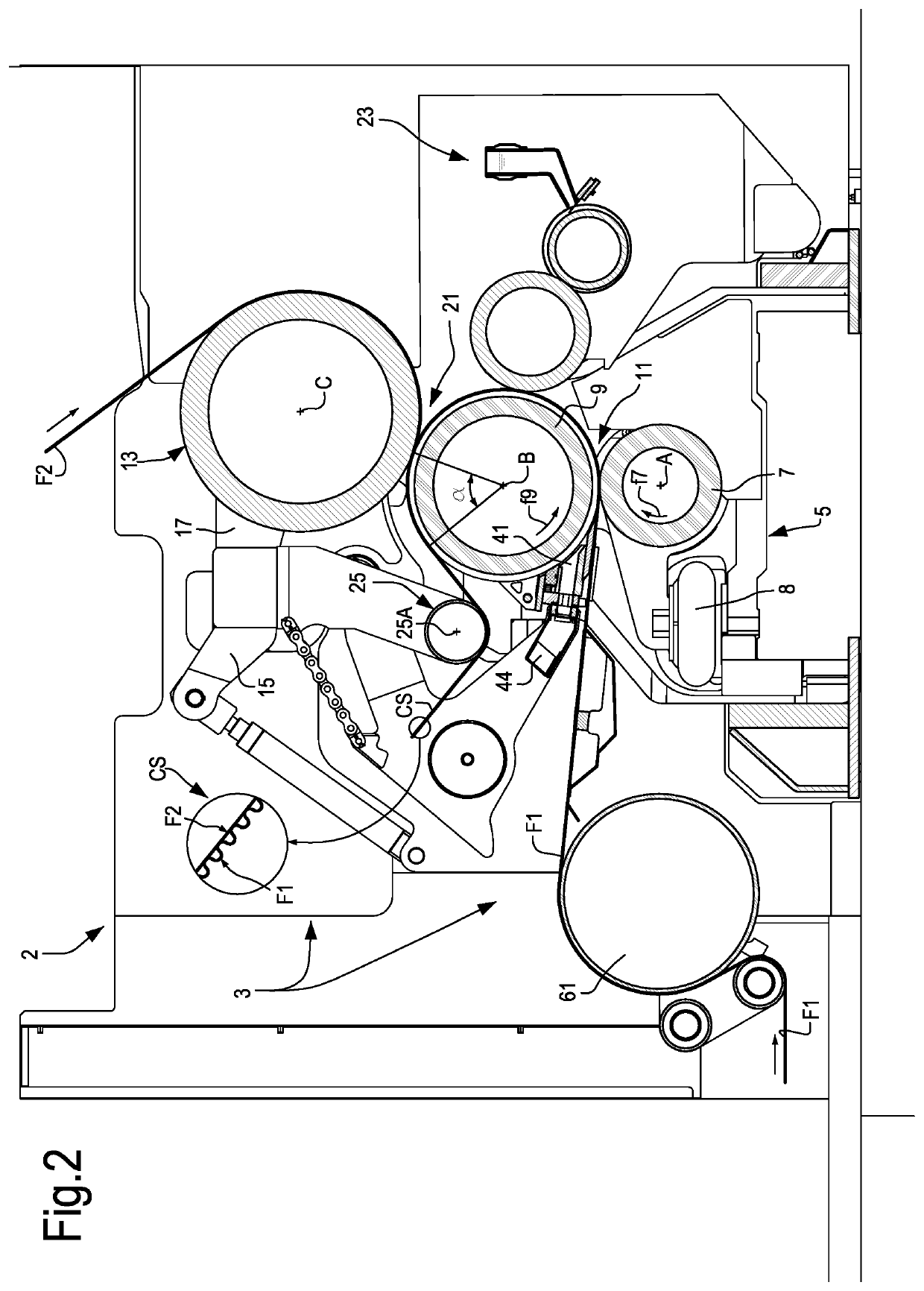

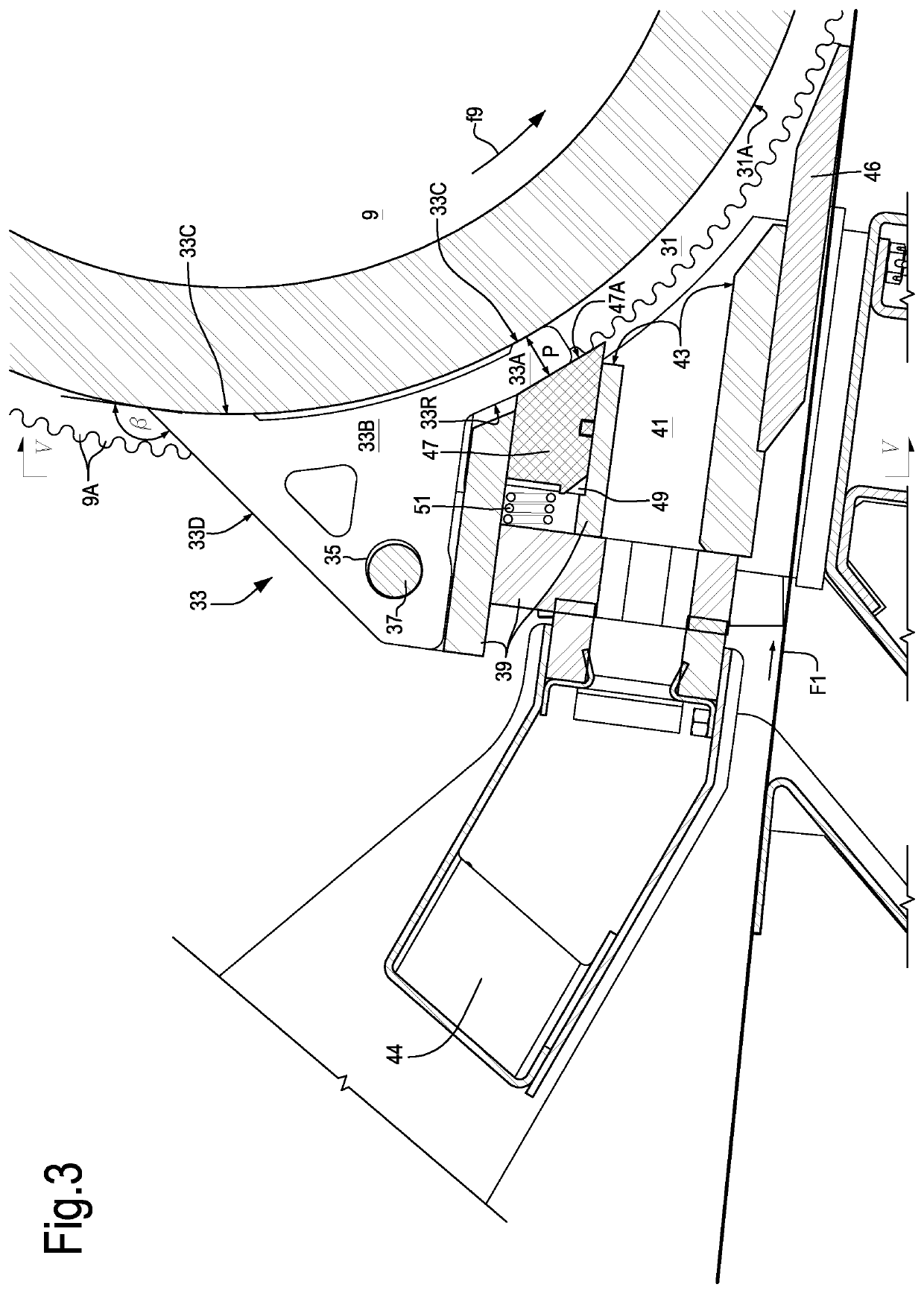

Single facer for producing single face corrugated paperboard, and related method

ActiveUS20190105866A1Reduce consumptionReduce thermal power lossMechanical working/deformationPaper/cardboard layered productsPaperboardEngineering

A single facer including a first corrugating roller with a first rotation axis and a second corrugating roller with a second rotation axis. The two corrugating rollers form a corrugating nip, through which a paper sheet passes. The single facer also includes a pressing member, co-acting with the second corrugating roller and forming a pressure nip therewith, as well as a glue applicator co-acting with the second corrugating roller. With the second corrugating roller a suction box is associated, extending approximately parallel to the second rotation axis of the second corrugating roller and defining a suction area around the second corrugating roller. A series of laminar members, each of which is inserted in a respective one of the annular grooves of the second corrugating roller, are arranged between the pressing member and the first corrugating roller and extend in the respective annular grooves towards the suction box.

Owner:GUANGDONG FOSBER INTELLIGENT EQUIP CO LTD

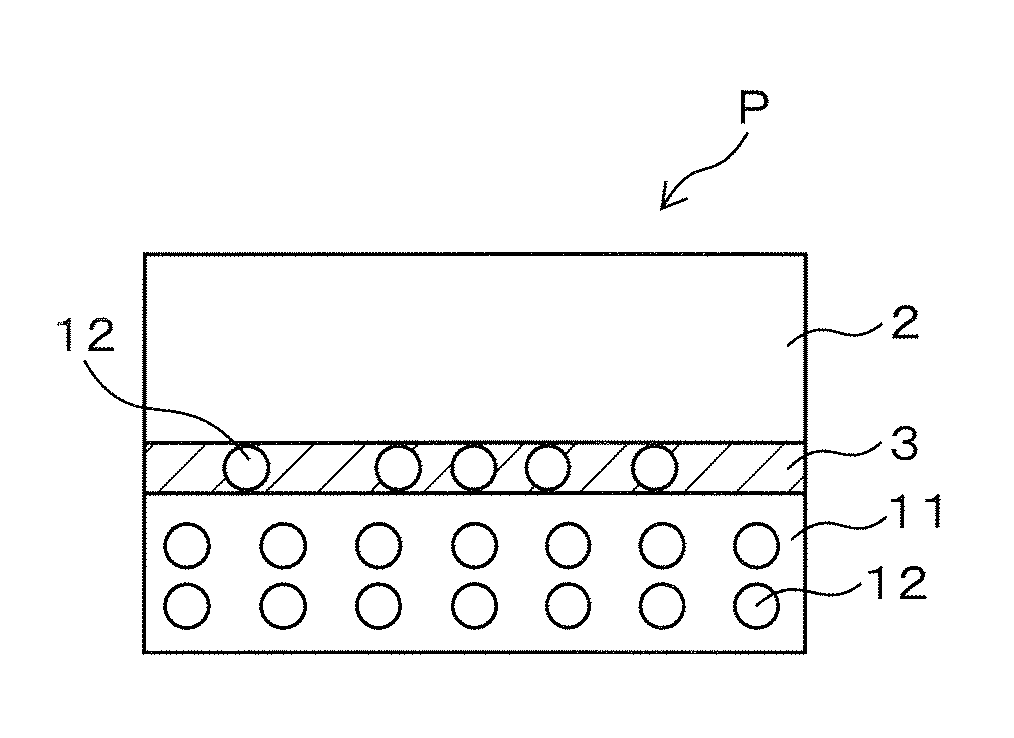

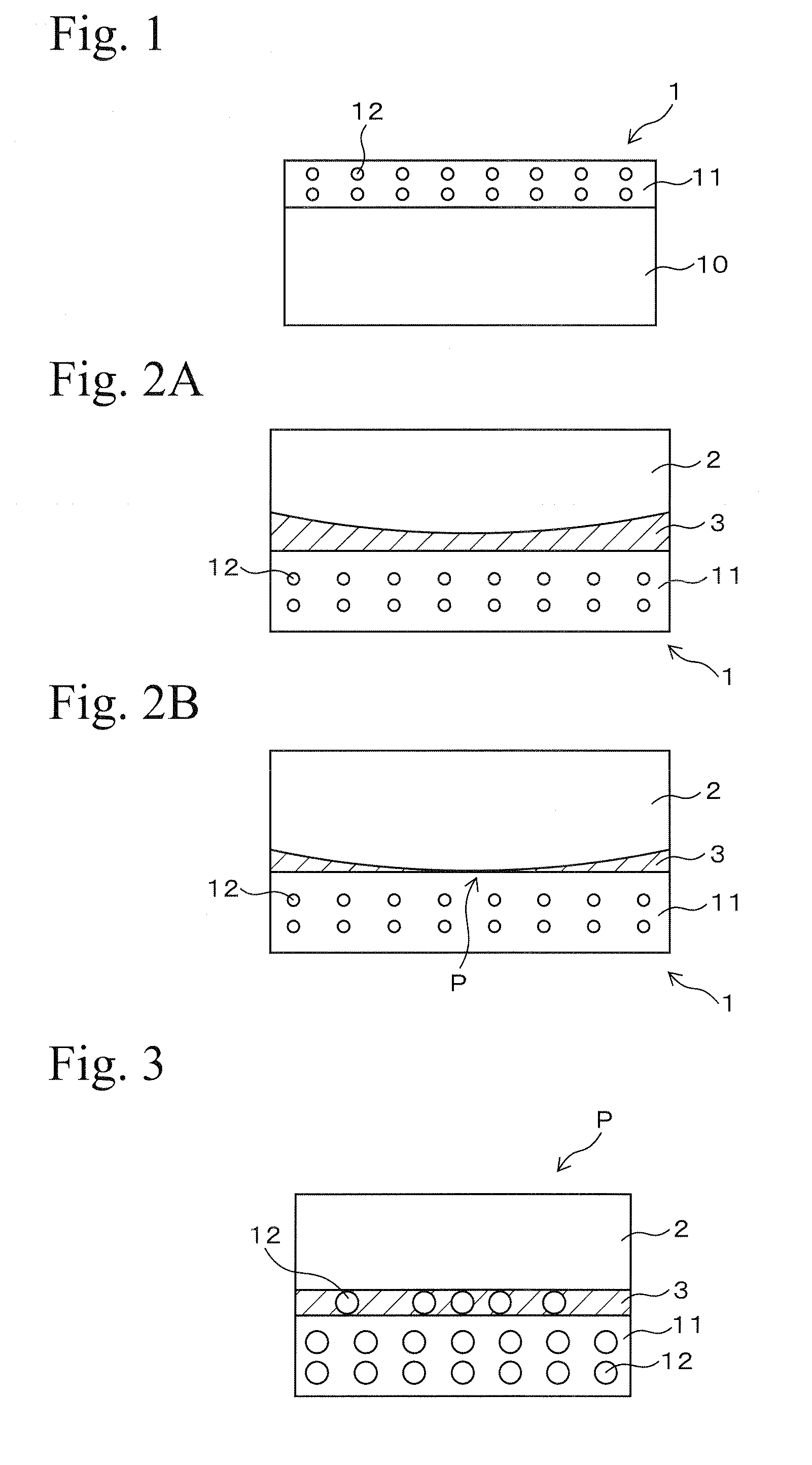

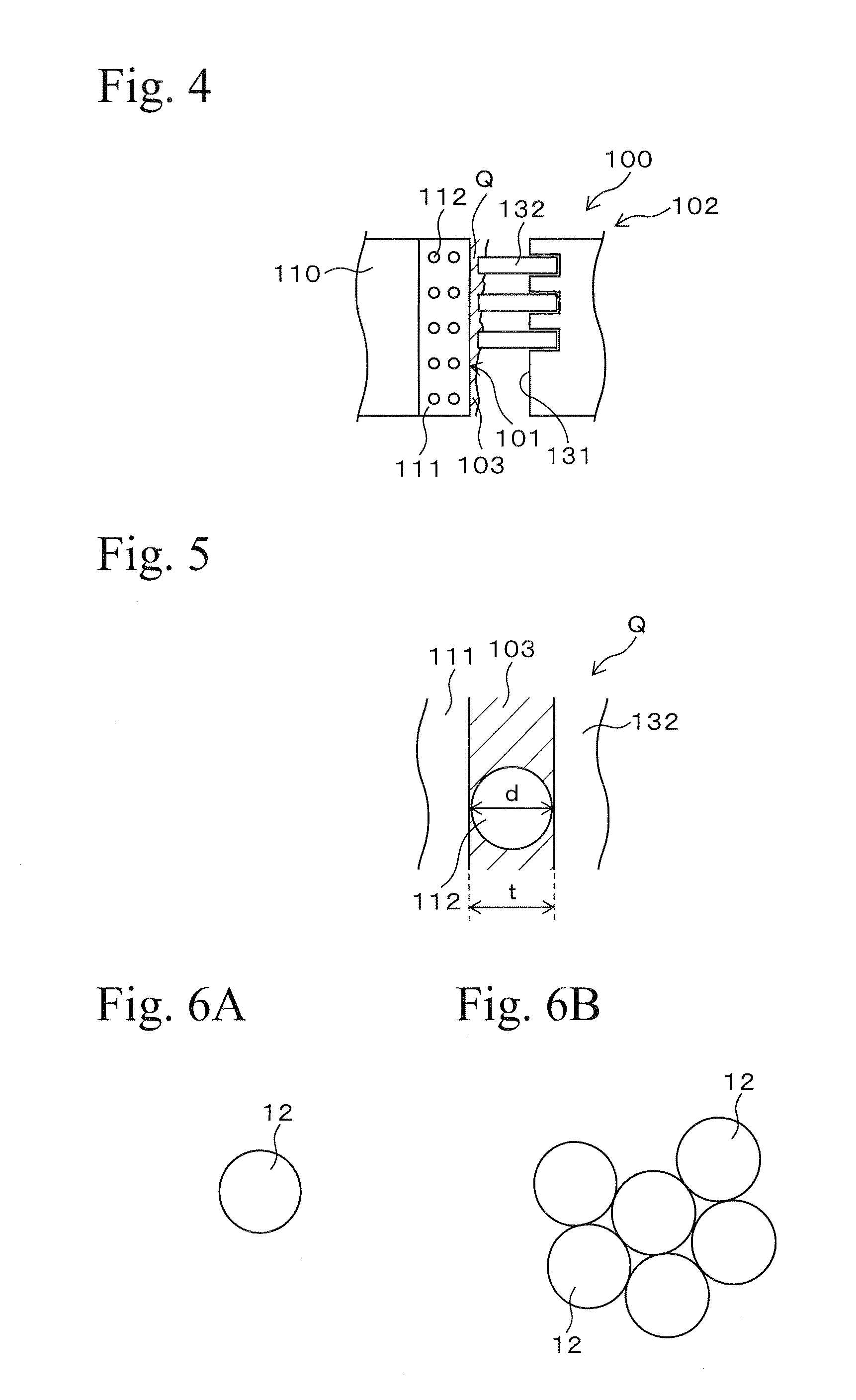

Sliding member and process for producing the same

InactiveUS20110249920A1Reduce frictionLow production costMaterial nanotechnologyVacuum evaporation coatingBall bearingStructure function

High surface pressure is applied to the sliding surfaces such that local solid contact occurs on sliding interfaces. Microscopic wear occurs on the sliding surfaces. Carbon-based molecules 12, having rollable hollow structures, are included as separate molecules or aggregates of molecules in the lubricating film 11. The molecules 12 are exposed from the lubricating film 11 by the microscopic wear. A portion of the carbon-based molecules 12 is separated from the lubricating film 11, and supplied to the sliding surfaces. The carbon-based molecules 12 having rollable hollow structures function as ball bearings on the molecular level on the sliding interfaces. When at least one separated carbon-based molecule 12 exist between the sliding interfaces, local friction can be reduced in comparison to when separated carbon-based molecule 12 does not exist.

Owner:HONDA MOTOR CO LTD

Drive system for a motor vehicle and motor vehicle having such a drive system

ActiveUS8991283B2Friction lossReliable cold startingGearingGas pressure propulsion mountingElectric machineInternal combustion engine

A drive system (2) for a motor vehicle (1) has a transmission (11) for driving at least one drive axle (13, 14) of the motor vehicle (1). An internal combustion engine (3) optionally is connected operatively to the transmission (11) or decoupled therefrom. A first electric machine (17) optionally is connected operatively to the at least one drive axle (13, 14) or to an output shaft (39) of the transmission (11) or decoupled therefrom. A second electric machine (19) is connected operatively to the internal combustion engine (3).

Owner:DR ING H C F PORSCHE AG

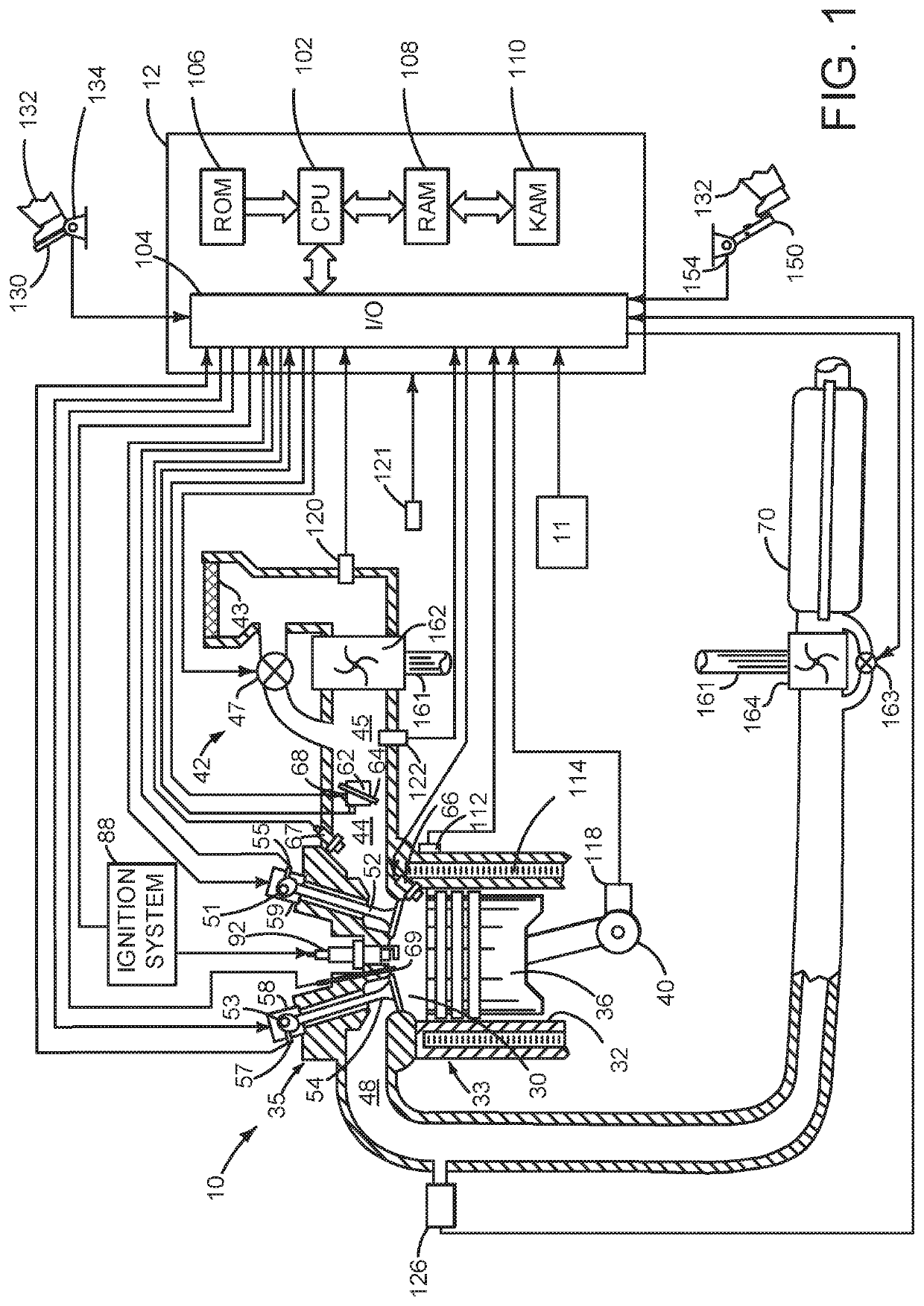

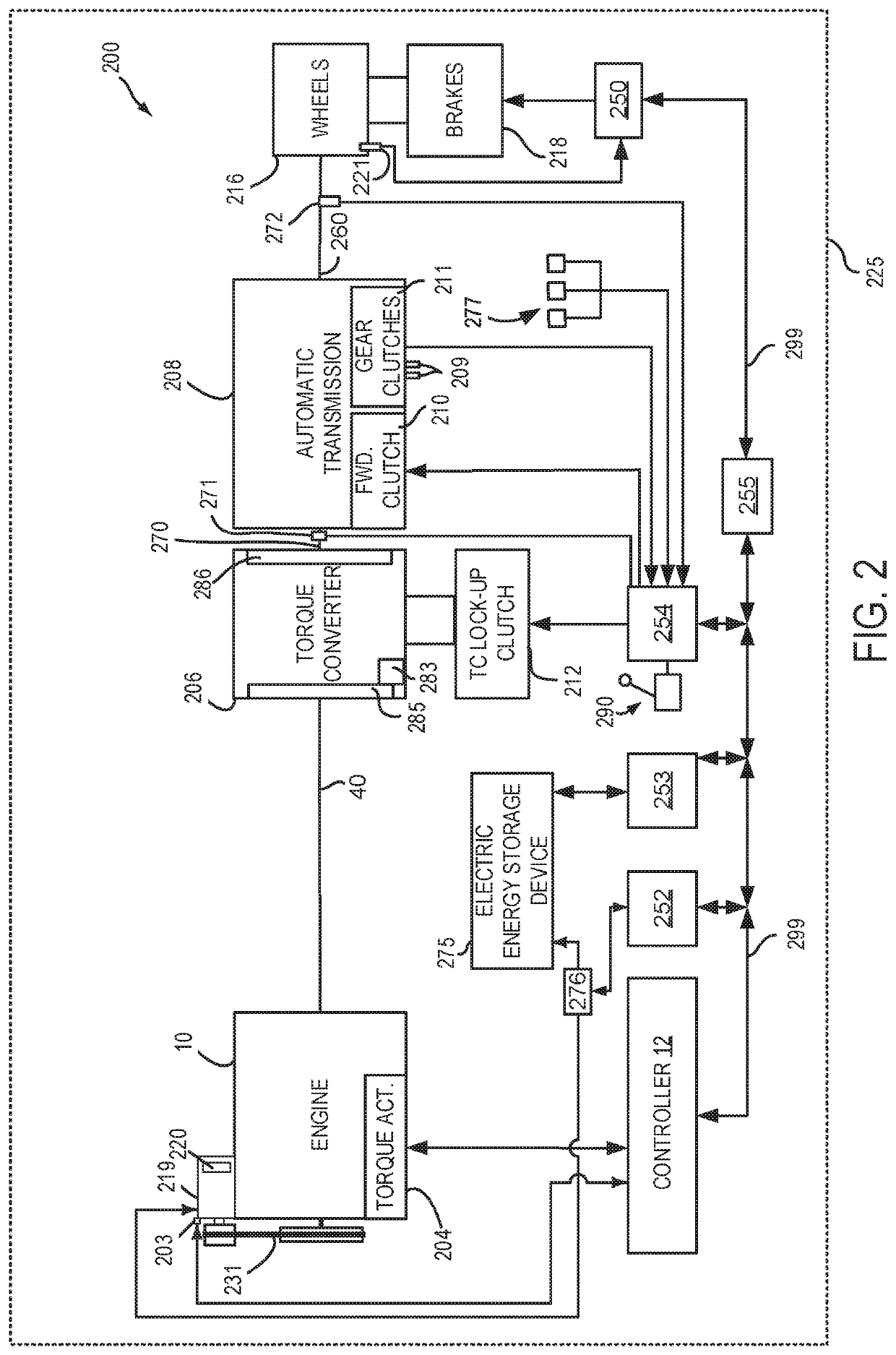

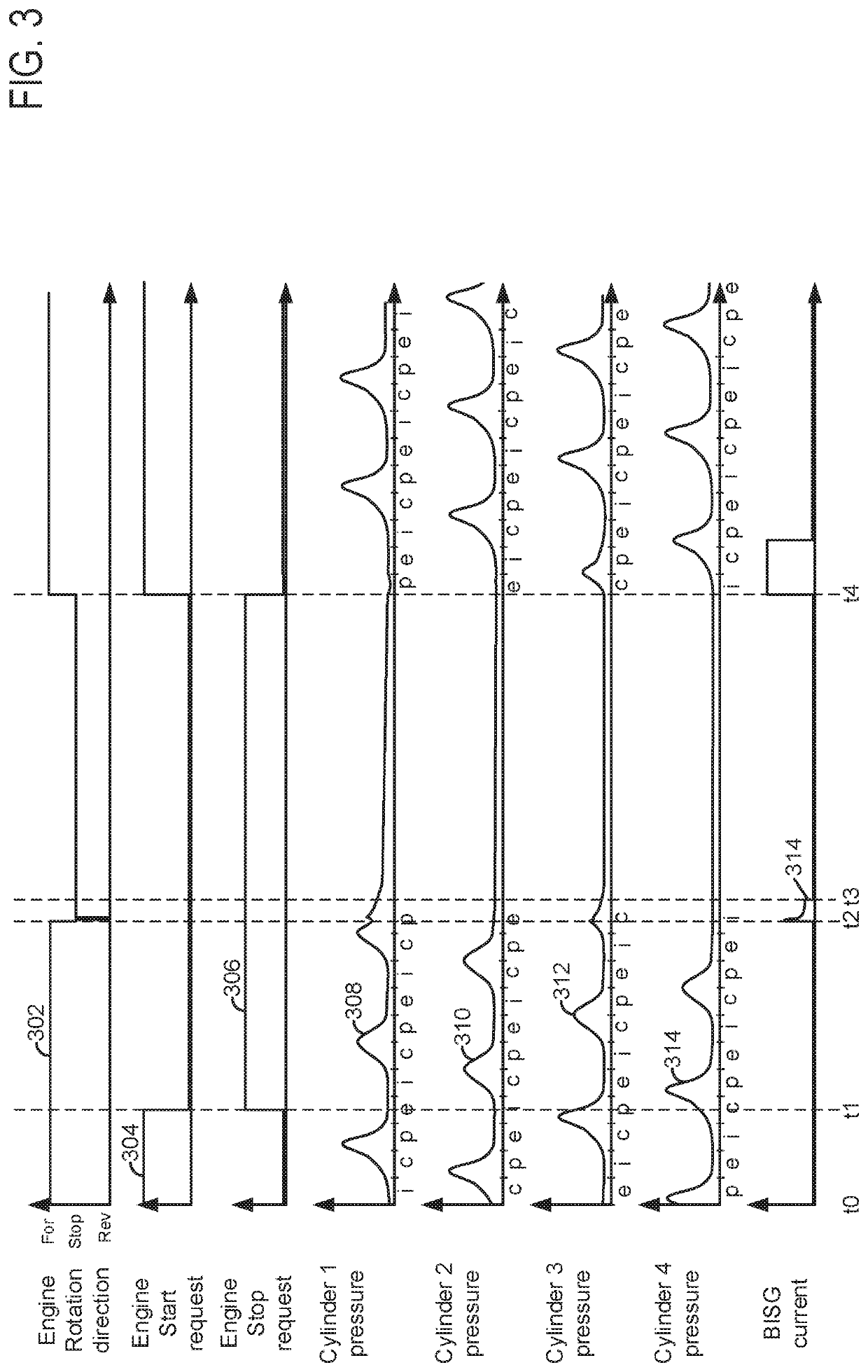

Methods and system for starting a vehicle

ActiveUS20200240382A1Reliably start engineLarge excess torque capacityElectric motor startersMachines/enginesTop dead centerInternal combustion engine

Systems and methods for operating an internal combustion engine that may be automatically stopped and started are described. In one example, an engine is rotated in a reverse direction after an engine stop so that a belt integrated starter / generator may rotate the engine in a forward direction and utilize the inertia of the engine to rotate trough top-dead-center compression stroke, thereby starting the engine.

Owner:FORD GLOBAL TECH LLC

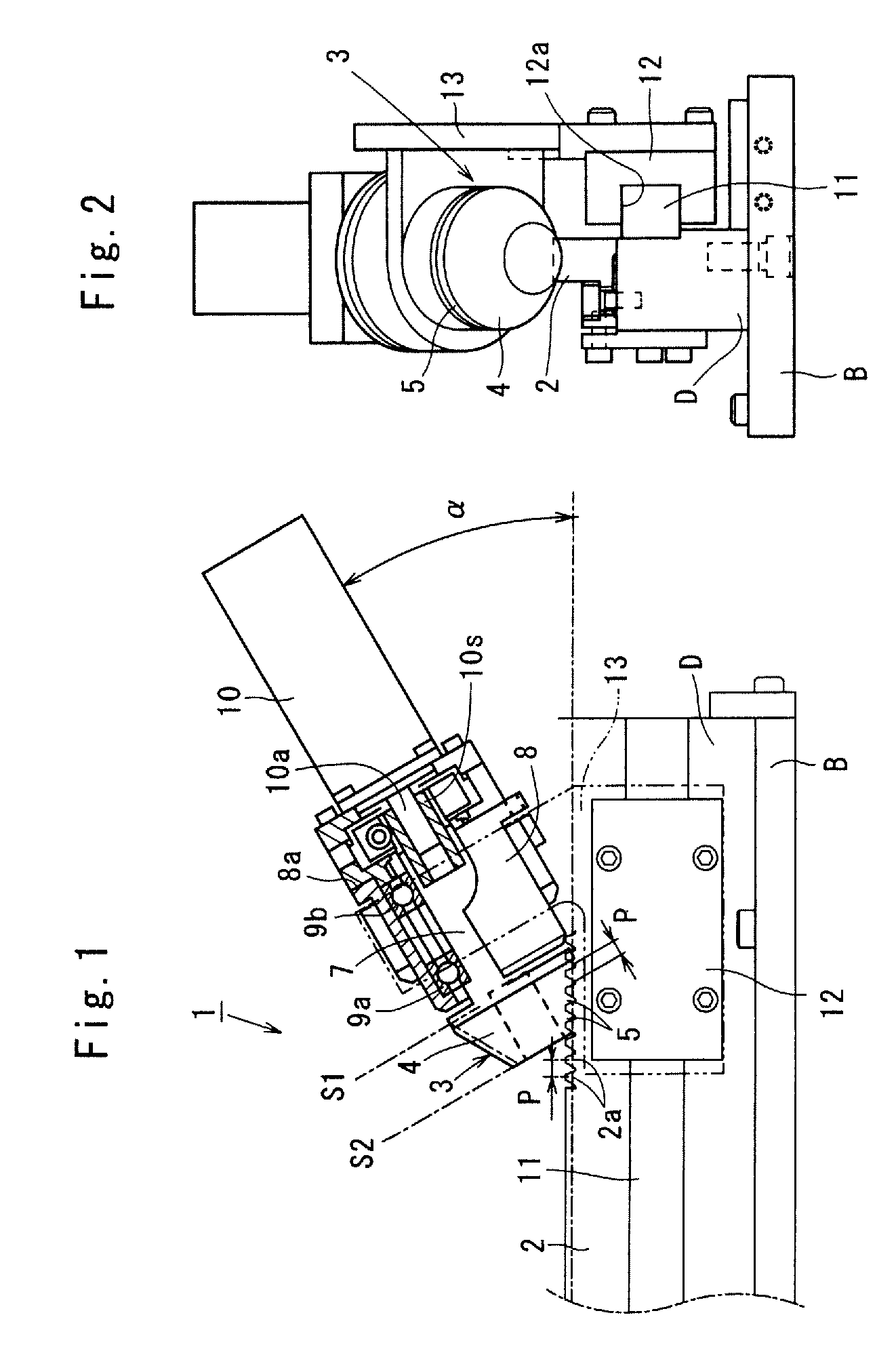

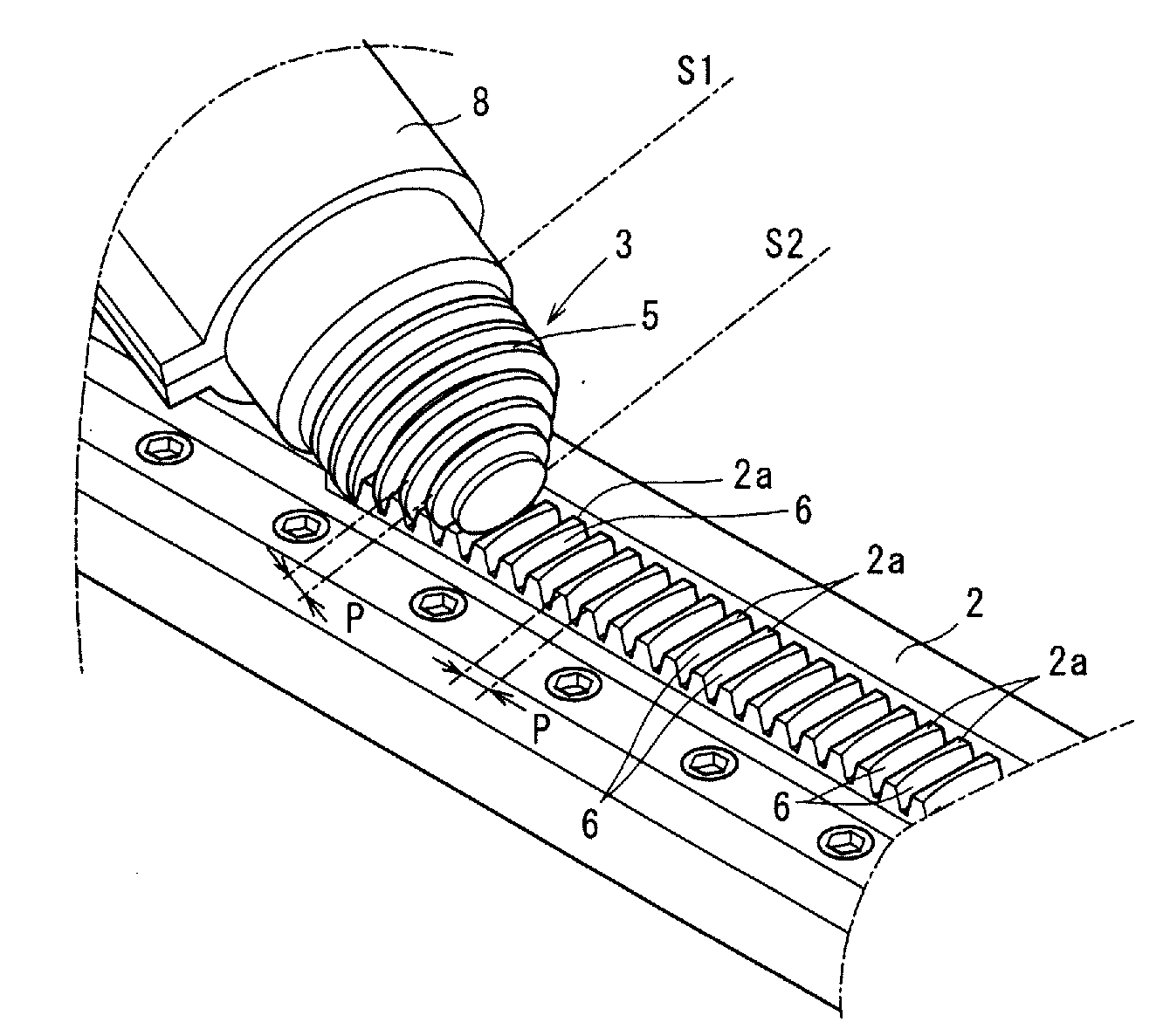

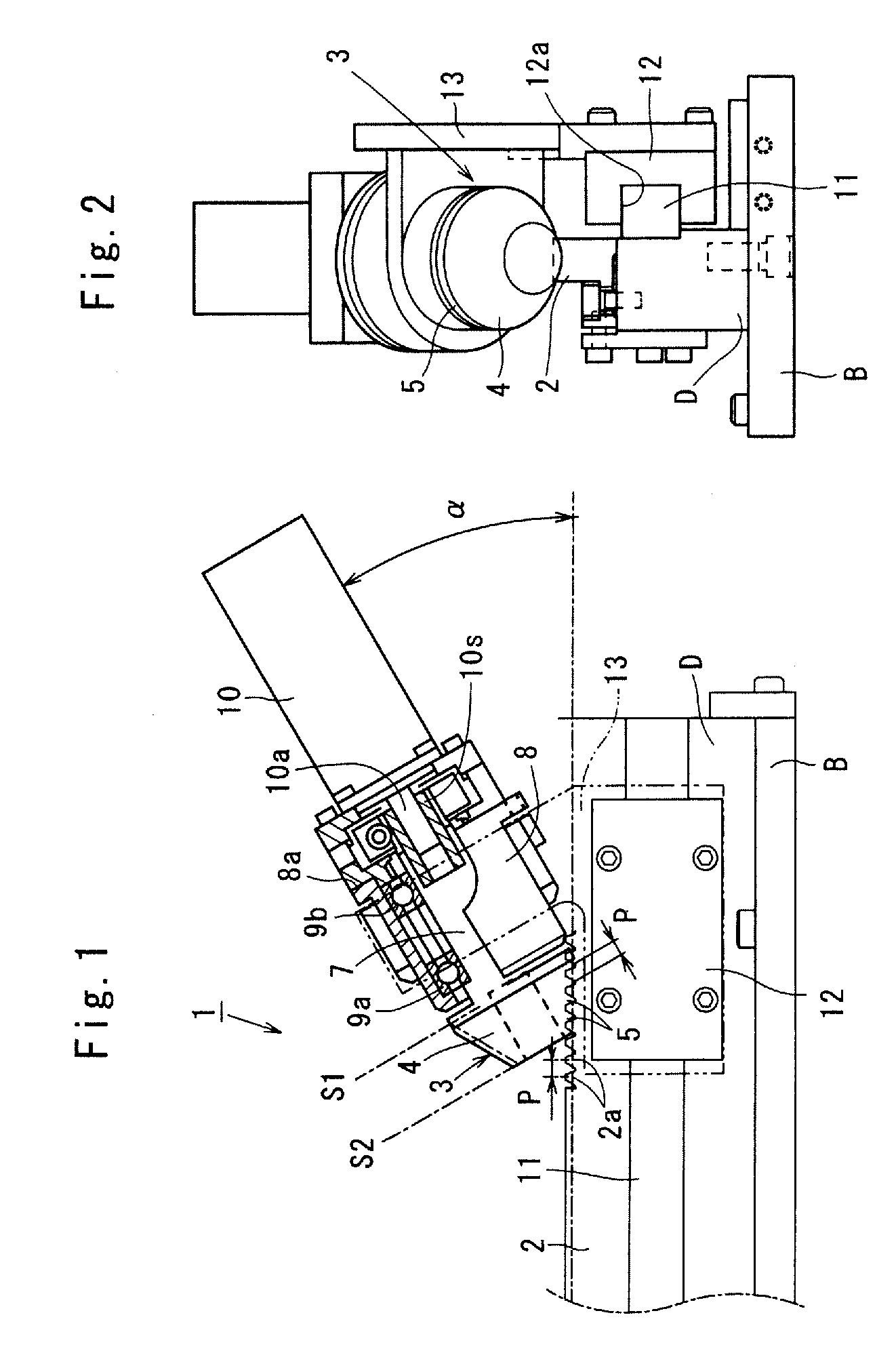

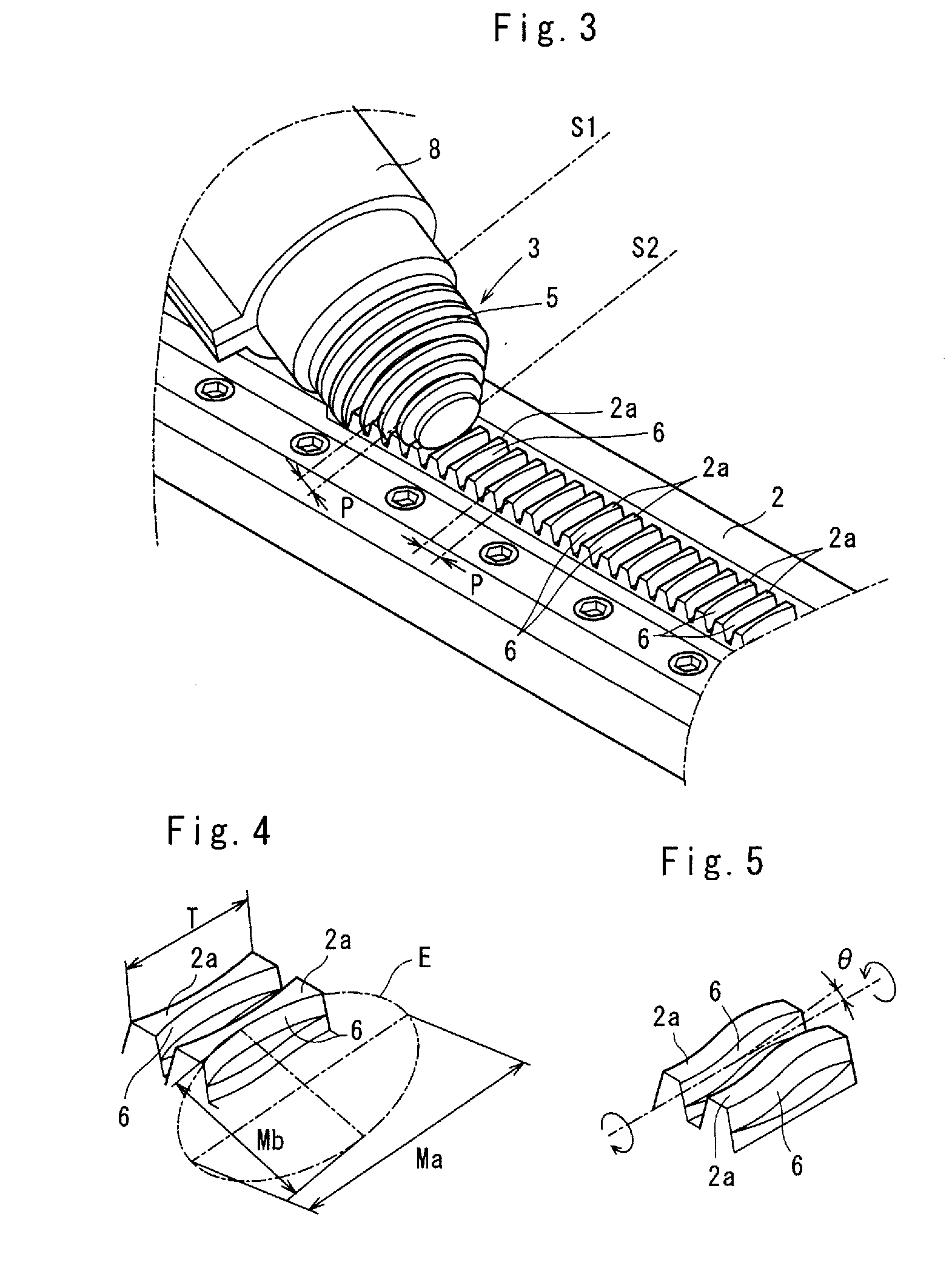

Worm-rack type transmission device

InactiveUS7900890B2Improve transmission efficiencyFriction lossLifting devicesFriction gearingsFriction lossSelf locking

In a worm-rack type transmission device (1), a curved side portion (6) is provided on rack teeth (2a) of a linear rack (2) in a manner to form a part of an ellipsoidal surface (E) and twisted by a changing rate (θ) of a torsional manner a toothed streak (5) of a worm wheel (3). The worm wheel (3) brings the toothed streak (5) into engagement with the curved side portion (6) in a line-to-line contact, enabling to a self-locking property and strengthening a transmission power to insure a high transmission efficiency with a least friction loss so as effectuate a linear drive for an extended distance travel with a high precision.

Owner:KAMOSEIKO

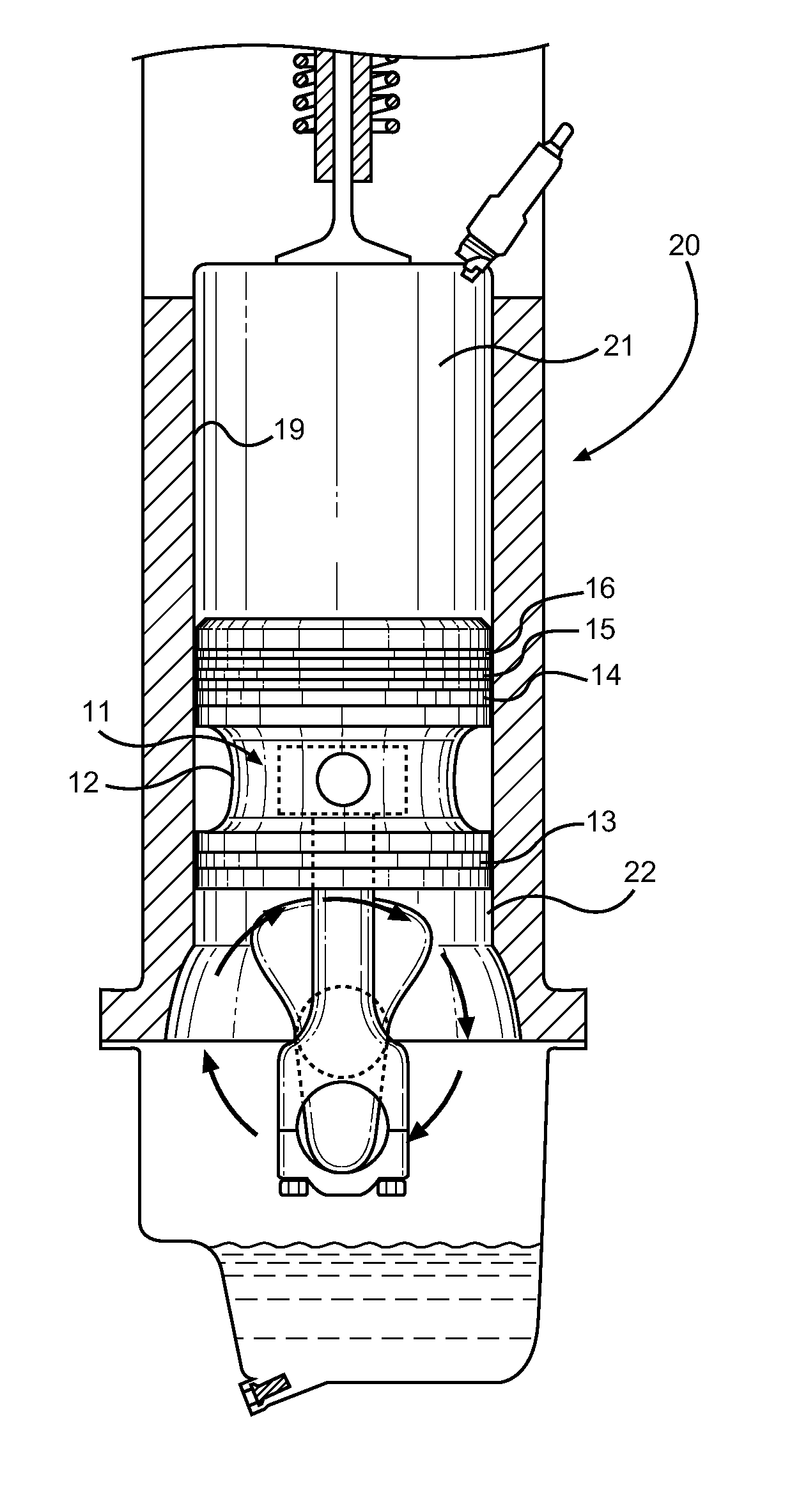

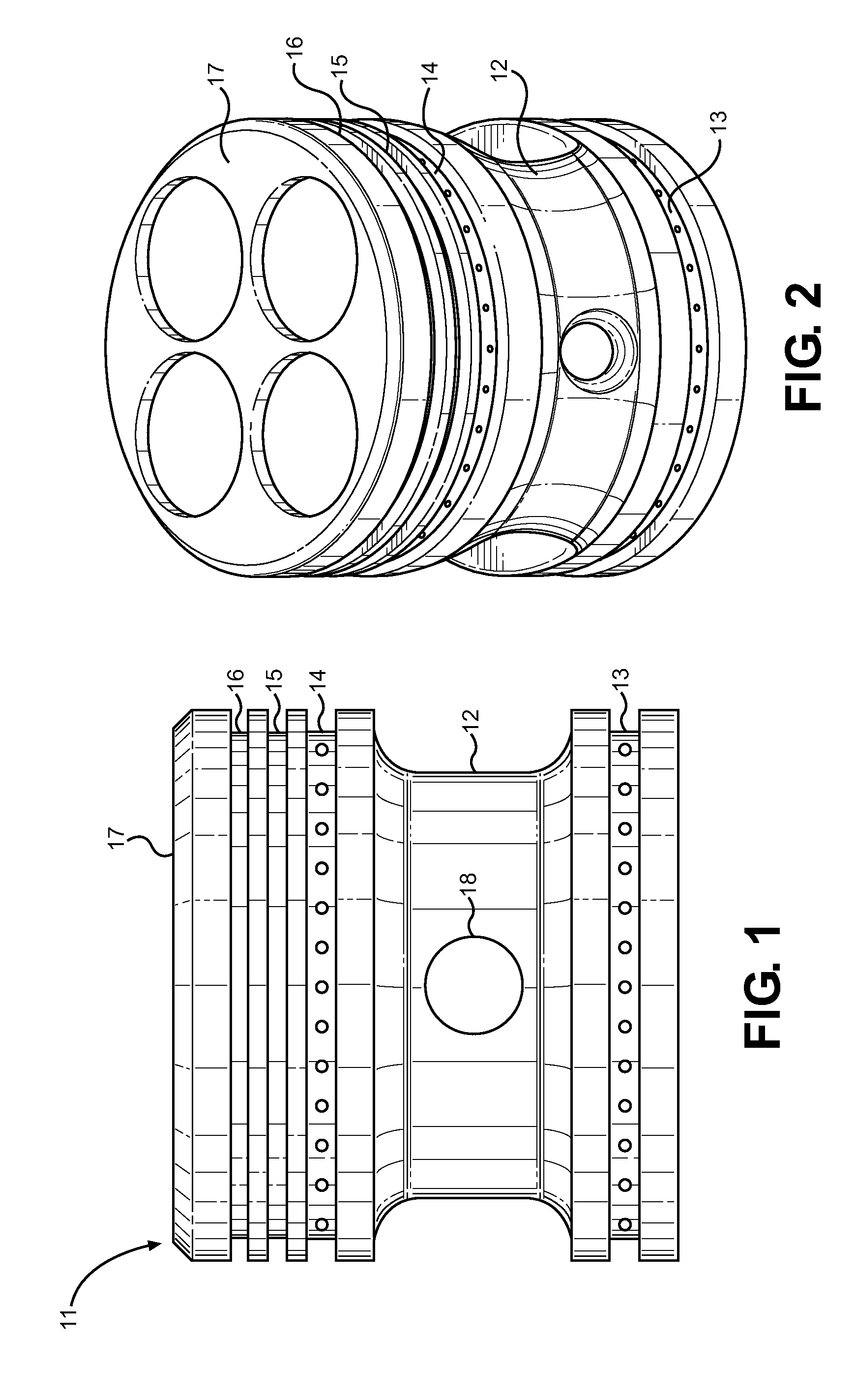

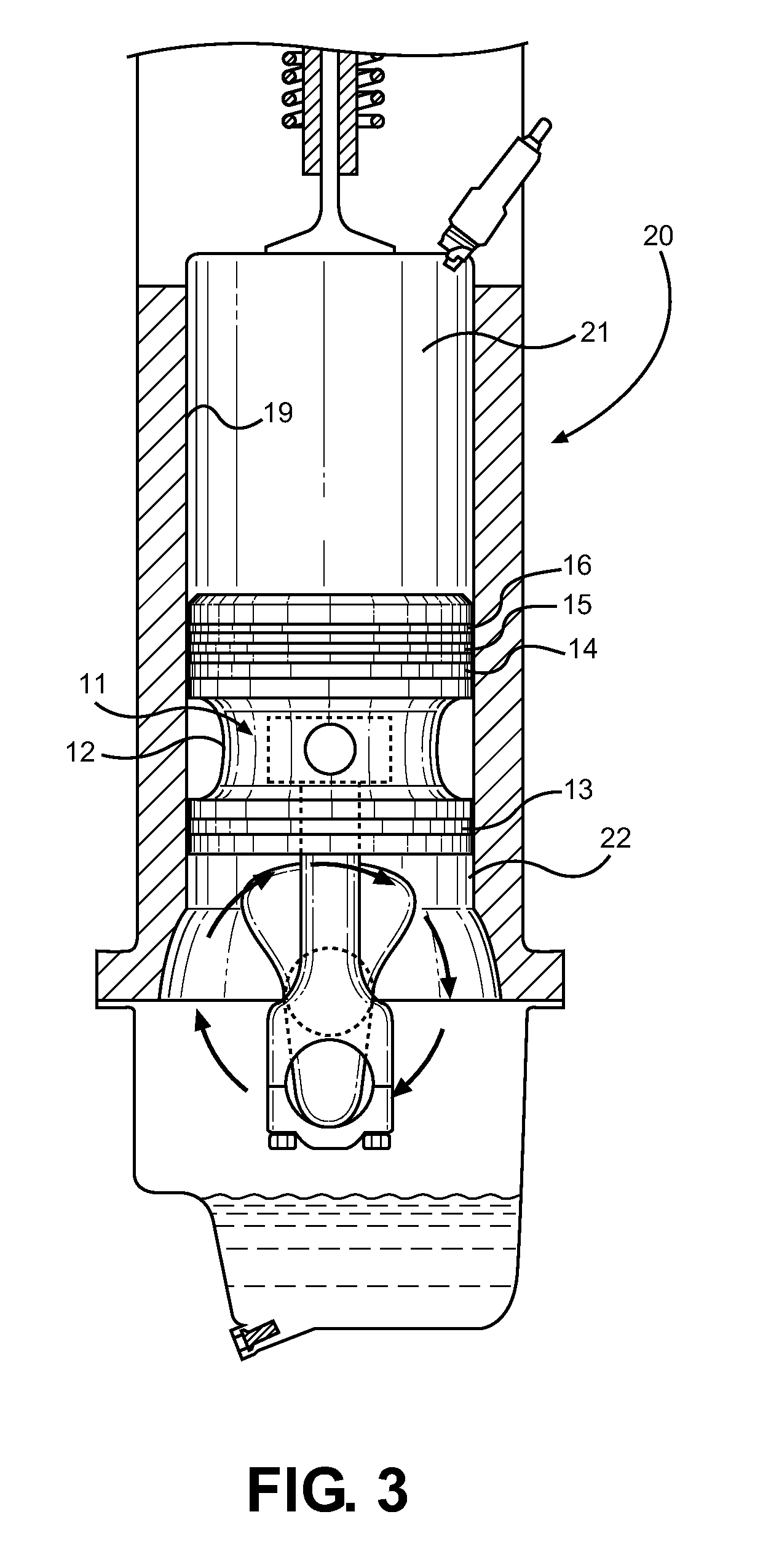

Low Drag Piston

ActiveUS20120227700A1Reducing mechanical lossReduce frictionMachines/enginesPistonsFriction reductionPiston ring

Disclosed is a low drag piston for a reciprocating engine that comprises a piston head that reduces mechanical and viscous friction while improving oil lubrication and thermal load dissipation throughout the piston stroke. The piston comprises a cylindrical crown and lower skirt area such that these elements are the only surfaces in contact with the cylinder walls and support a plurality of piston rings, while the interior skirt region is recessed inward in a concave shape to reduce drag, friction and thermal expansion interferences. An additional oil control ring increases oil outflow to further reduce friction and drag, while the pin boss that holds the connection between the piston head and the connecting rods is recessed inward within the inwardly concave central portion.

Owner:GUNNING ROHAN

High pressure oil pump roller tappet

InactiveUS20170342951A1Easy to assembleSimple structureValve arrangementsFuel injecting pumpsEngine efficiencyCam

A high-pressure oil pump roller tappet, used for automobile fuel injection system, mounted between the driving cam and the tappet. The roller tappet includes a shell, a holder, a roller, and a pin. Planes A are arranged on both sides of the seam on lateral sides of the shell. Holes I are arranged at symmetrical positions on two planes A. Holes II are arranged on symmetrical positions on vertical plates. The roller is located in the middle of the pin. Welding has no requirement on the thickness of the plate. The weight can be controlled effectively, reducing inertia force, friction, and wear, improving engine efficiency. The shell and holder are designed as being separate, ensuring that the shell subjects to lateral force as little as possible when the holder subjects to a force, such that the shell is less likely to vibrate. Thus, the shell avoids the abrasion.

Owner:HANGZHOU XZB TECH

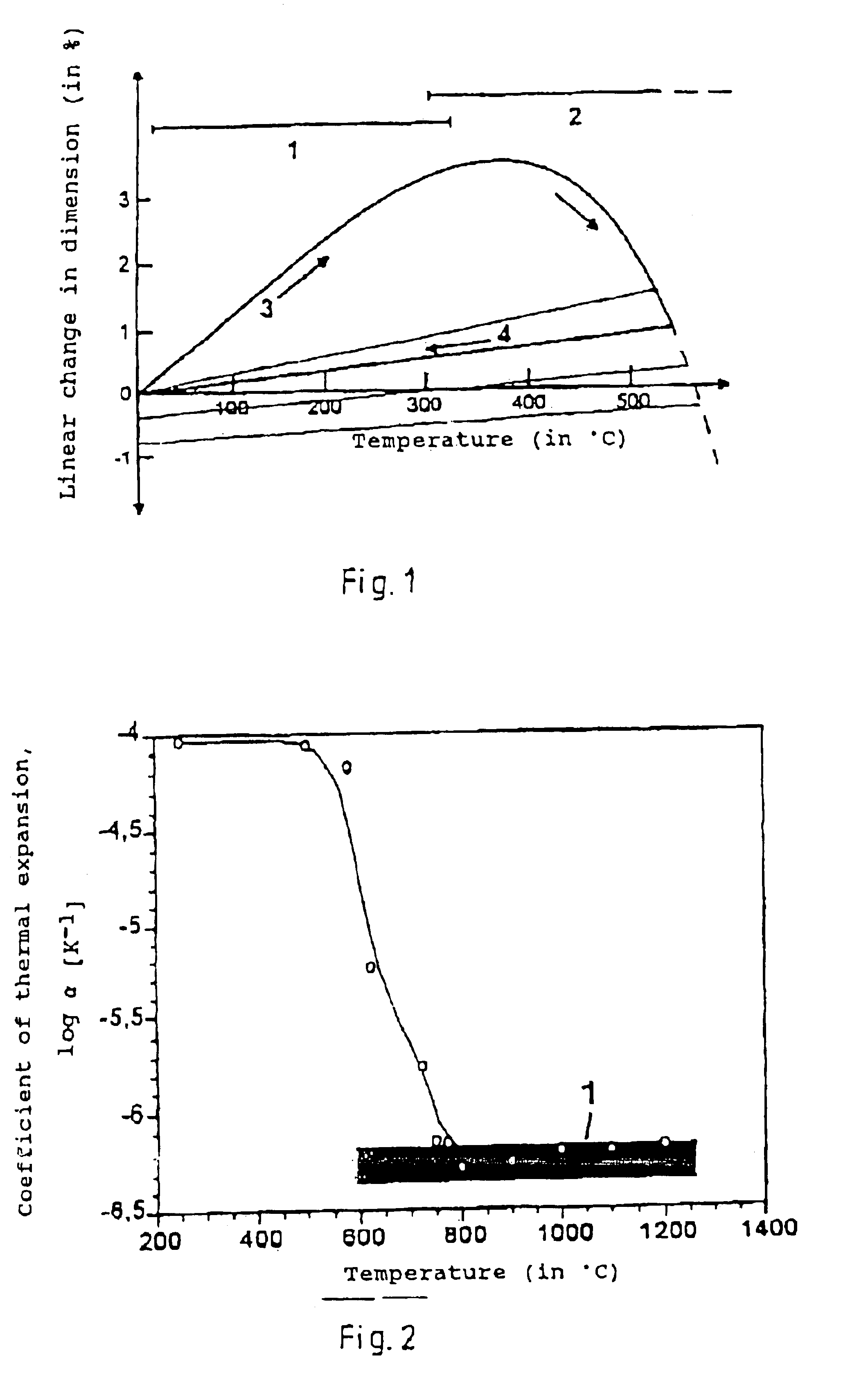

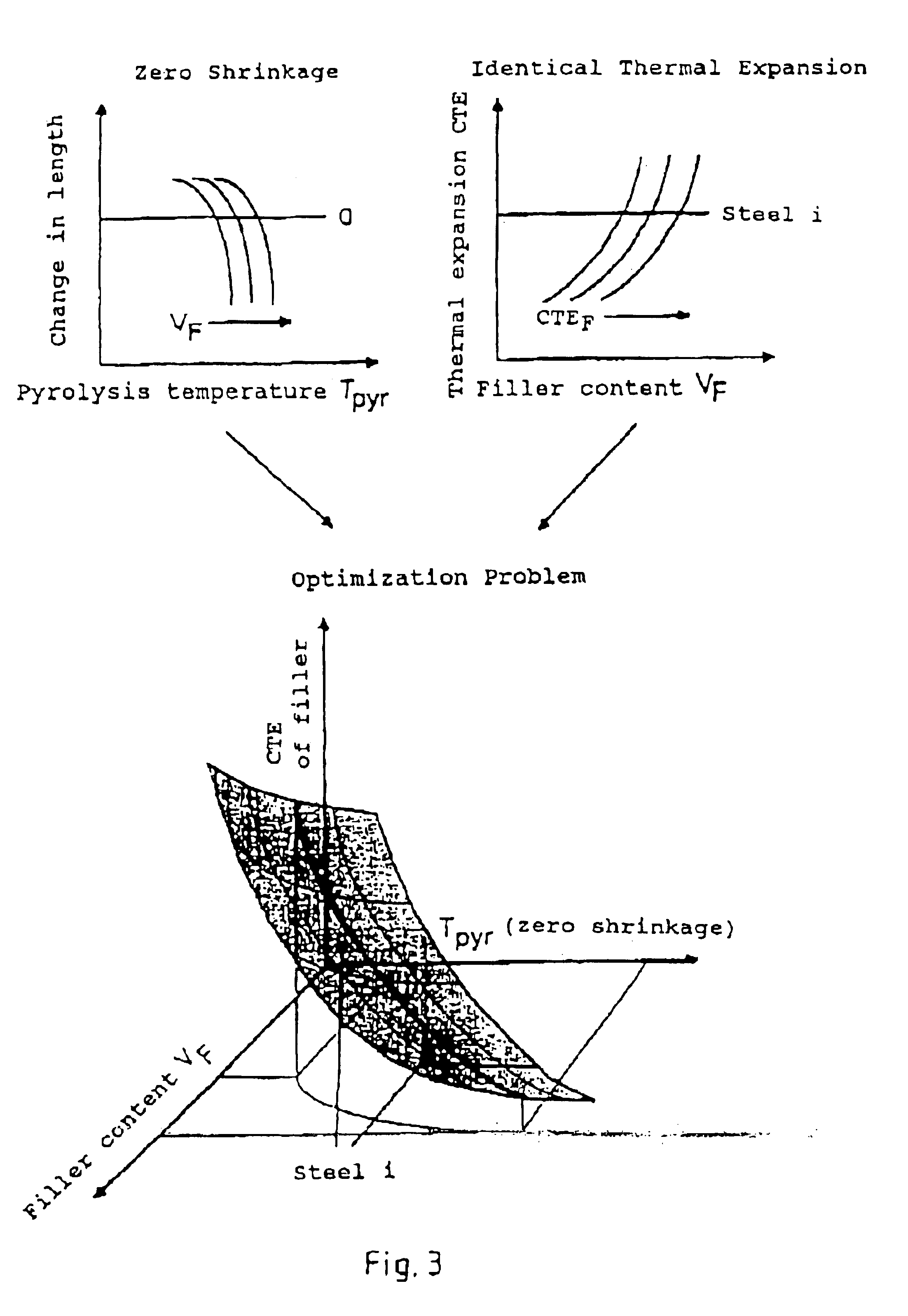

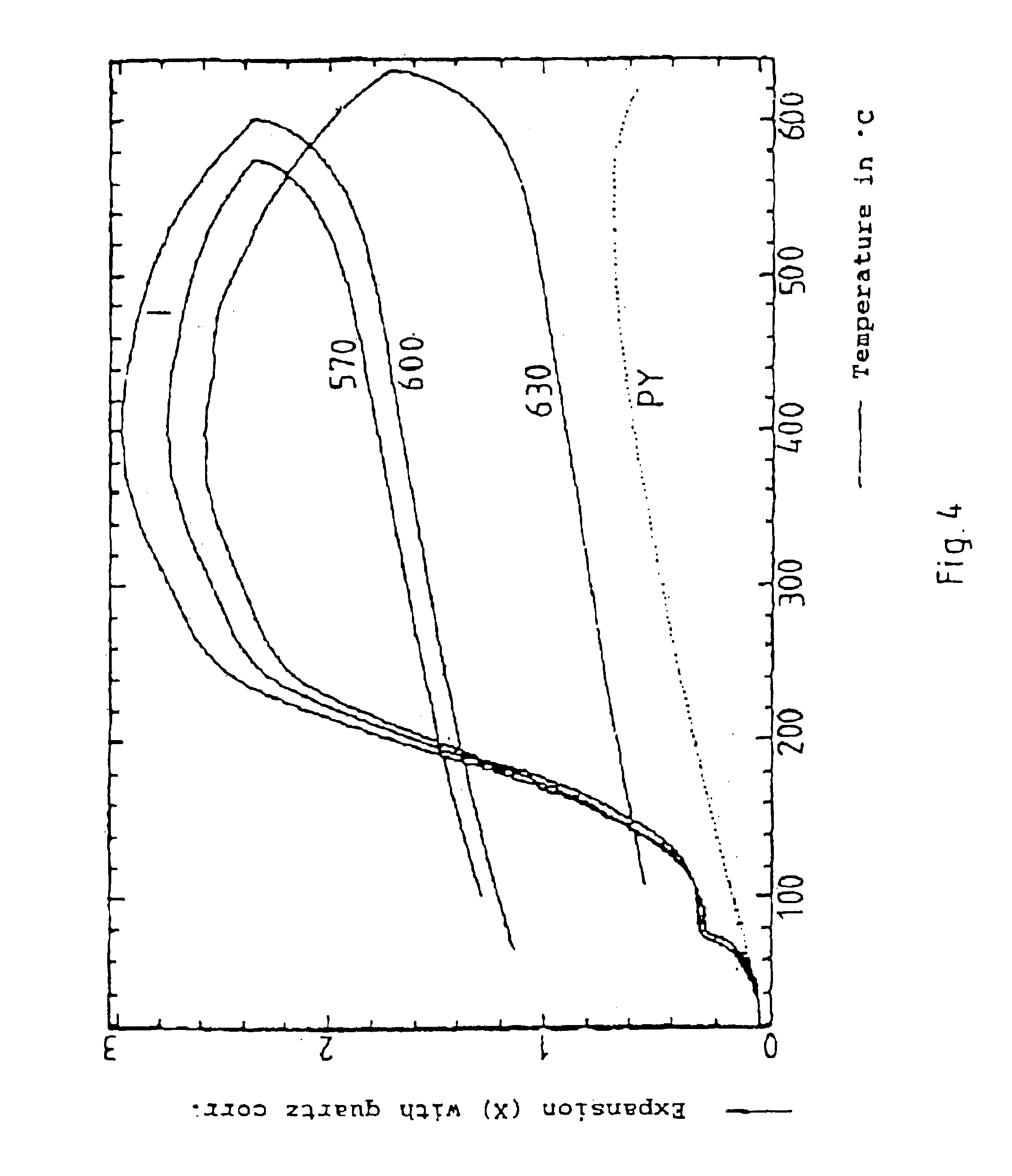

Polymerceramic materials with thermal expansion characteristics similar to those of metals

InactiveUS6783866B1Zero shrinkageLow costPretreated surfacesRecord information storageComposite constructionCeramic composite

The invention relates to polymer ceramic composite materials with a virtually zero shrinkage compared to the original model after concluding partial pyrolysis and with a comparable thermal expansion behavior (preferably in an application range of 400° C. or less) to metal construction materials, in particular gray cast iron or steel, which are obtainable by methods described below; corresponding composite constructions and molded parts; and methods for producing and using these materials, composite constructions and molded parts. The polymer ceramic composite materials can for instance be used instead of or in contact with steel or gray cast iron temperature-proof molded parts, predominantly in mechanical engineering, without postmachining after the creative forming.

Owner:RAUSCHERT

Pump assembly

ActiveUS20090035161A1Smooth connectionFirmly connectedPump componentsPiston pumpsElectric motorEngineering

A pump unit is provided having a wet-running electric motor, wherein a rotor of the pump unit can be driven by the electric motor at a maximum speed of greater than 20,000 rev / min, and the rotor is sealed off axially in the region of a suction port.

Owner:GRUNDFOS MANAGEMENT AS

Worm-rack type transmission device

InactiveUS20100044656A1Increase engagementTransmission powerLifting devicesFriction gearingsFriction lossEngineering

In a worm-rack type transmission device (1) a curved side portion (6) is provided on rack teeth (2a) of a linear rack (2) in a manner to form a part of an ellipsoidal surface (E) and twisted by a changing rate (θ) of a torsional manner a toothed streak (5) of a worm wheel (3). The worm wheel (3) brings the toothed streak (5) into engagement with the curved side portion (6) in a line-to-line contact, enabling to a self-locking property and strengthening a transmission power to insure a high transmission efficiency with a least friction loss so as effectuate a linear drive for an extended distance travel with a high precision.

Owner:KAMOSEIKO

Single facer for producing single face corrugated paperboard, and related method

ActiveUS10618242B2Reduce consumptionReduce thermal power lossMechanical working/deformationPaper/cardboard layered productsRotational axisPaperboard

Owner:GUANGDONG FOSBER INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com