Patents

Literature

101results about How to "Improve delivery capabilities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Telecommunication networks

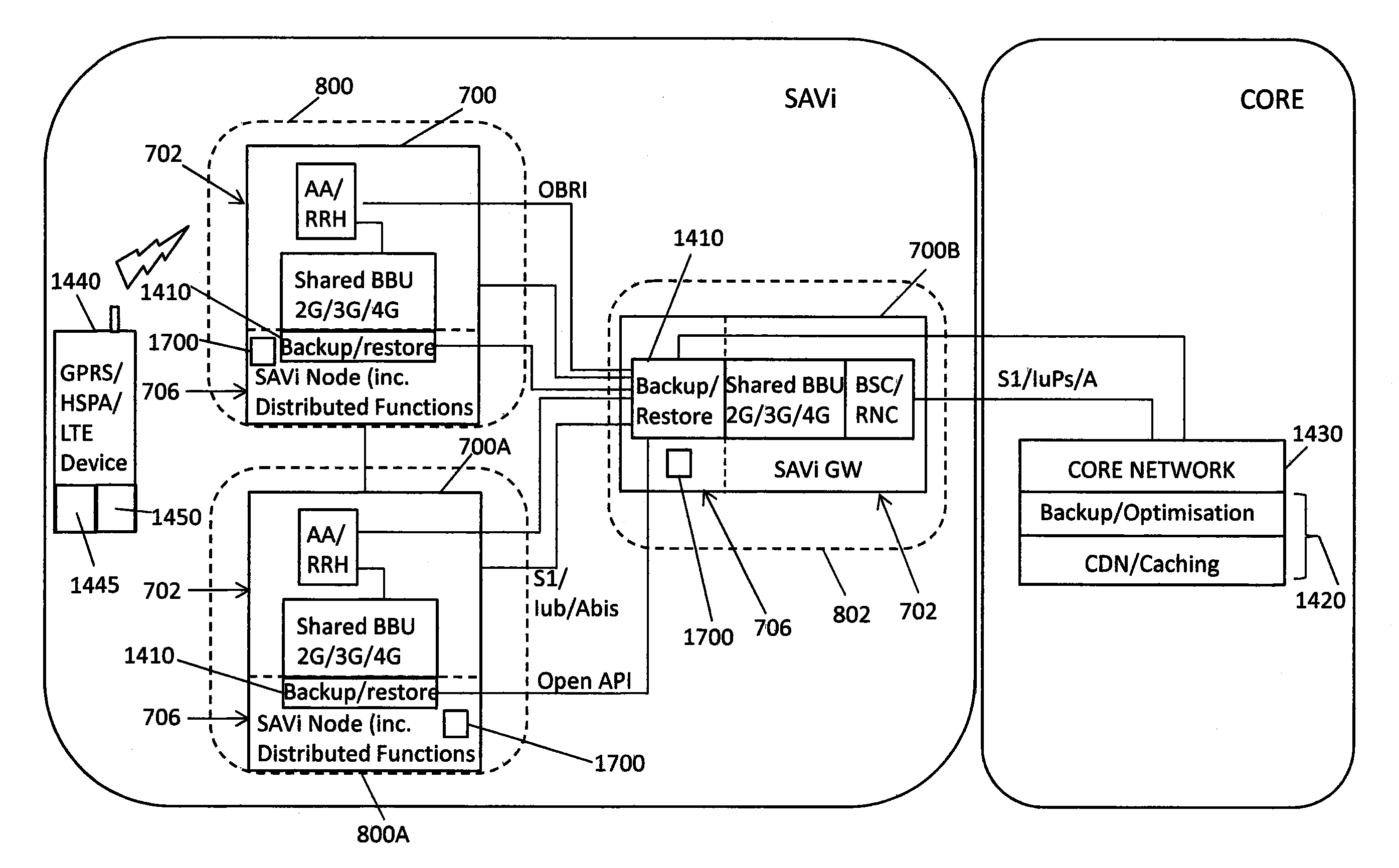

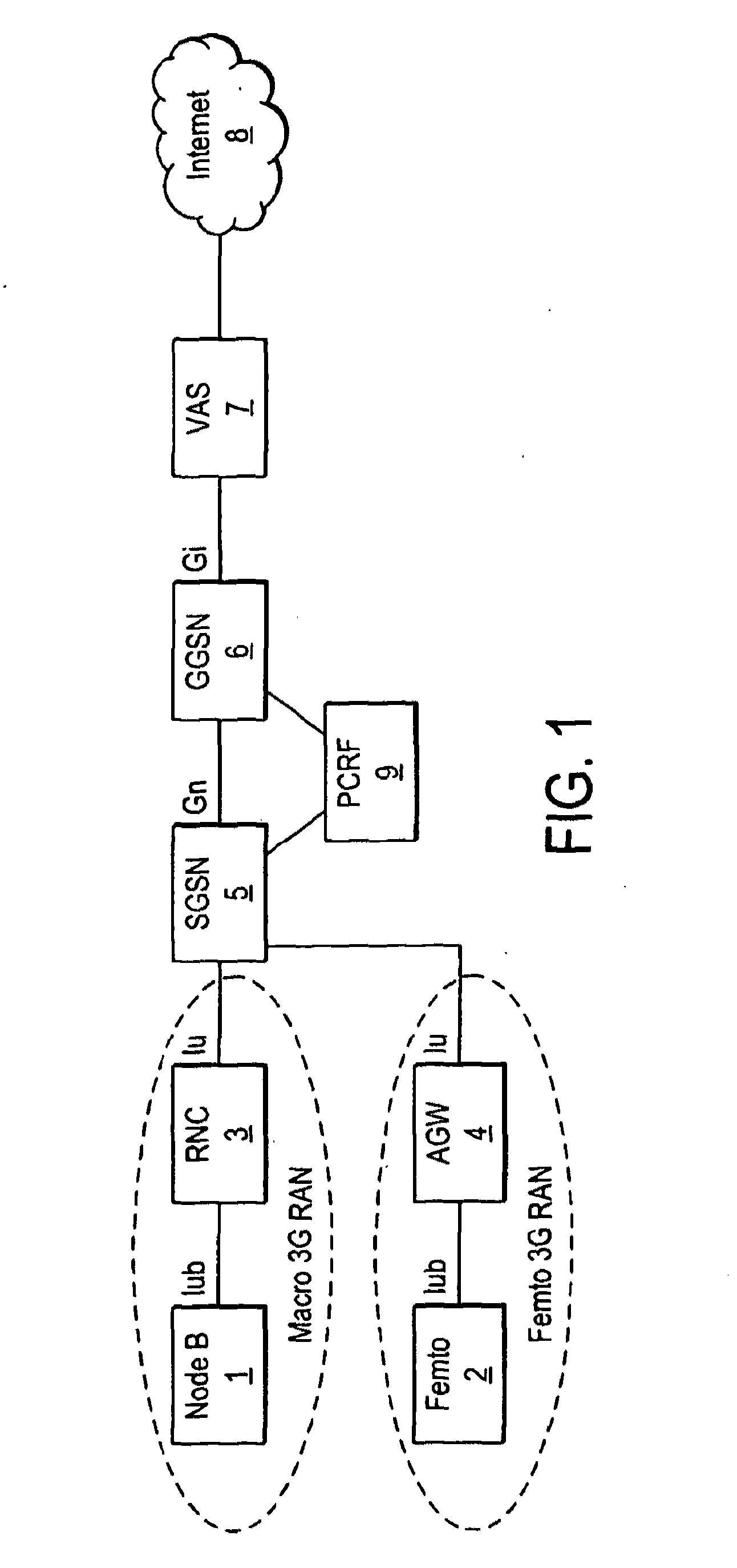

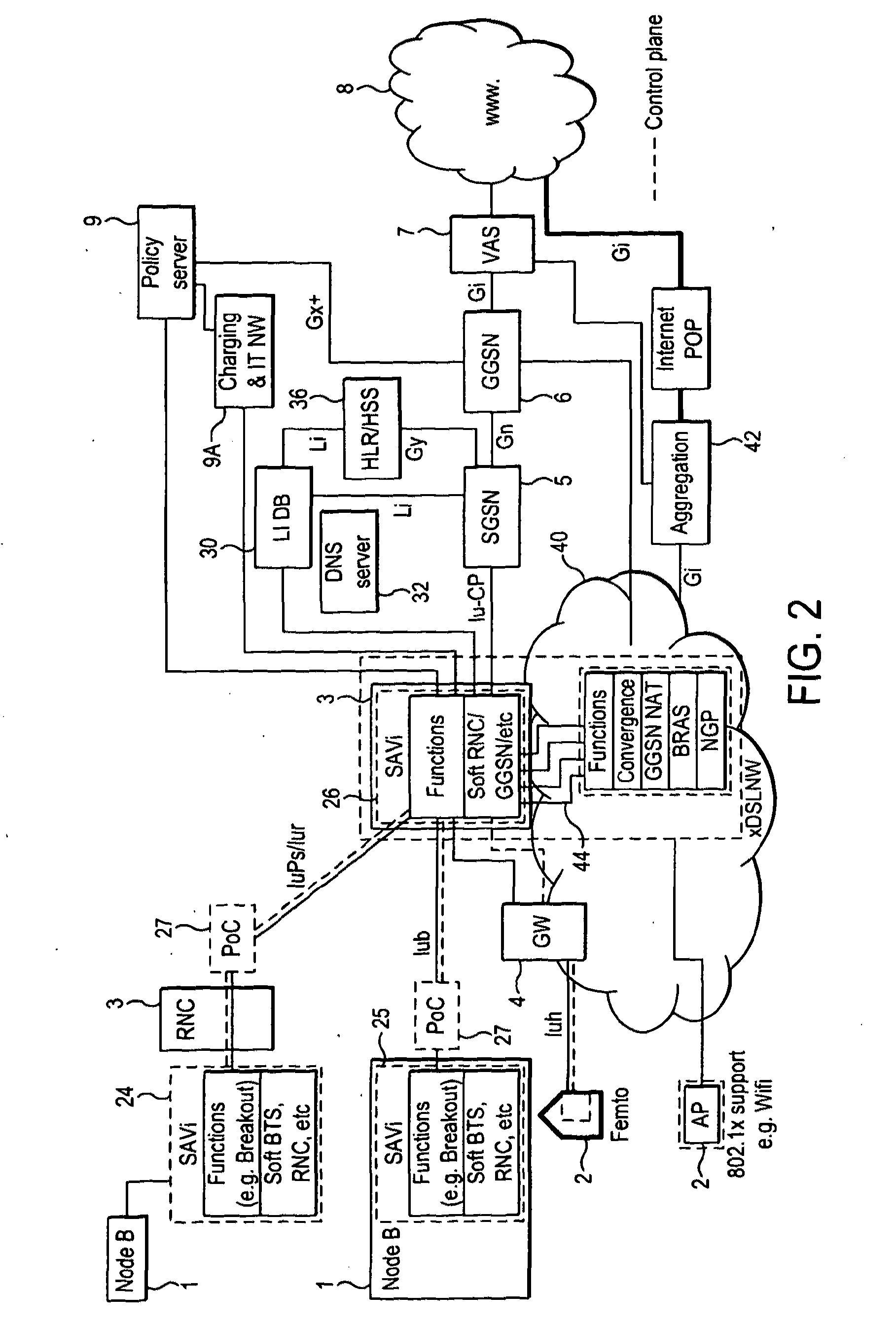

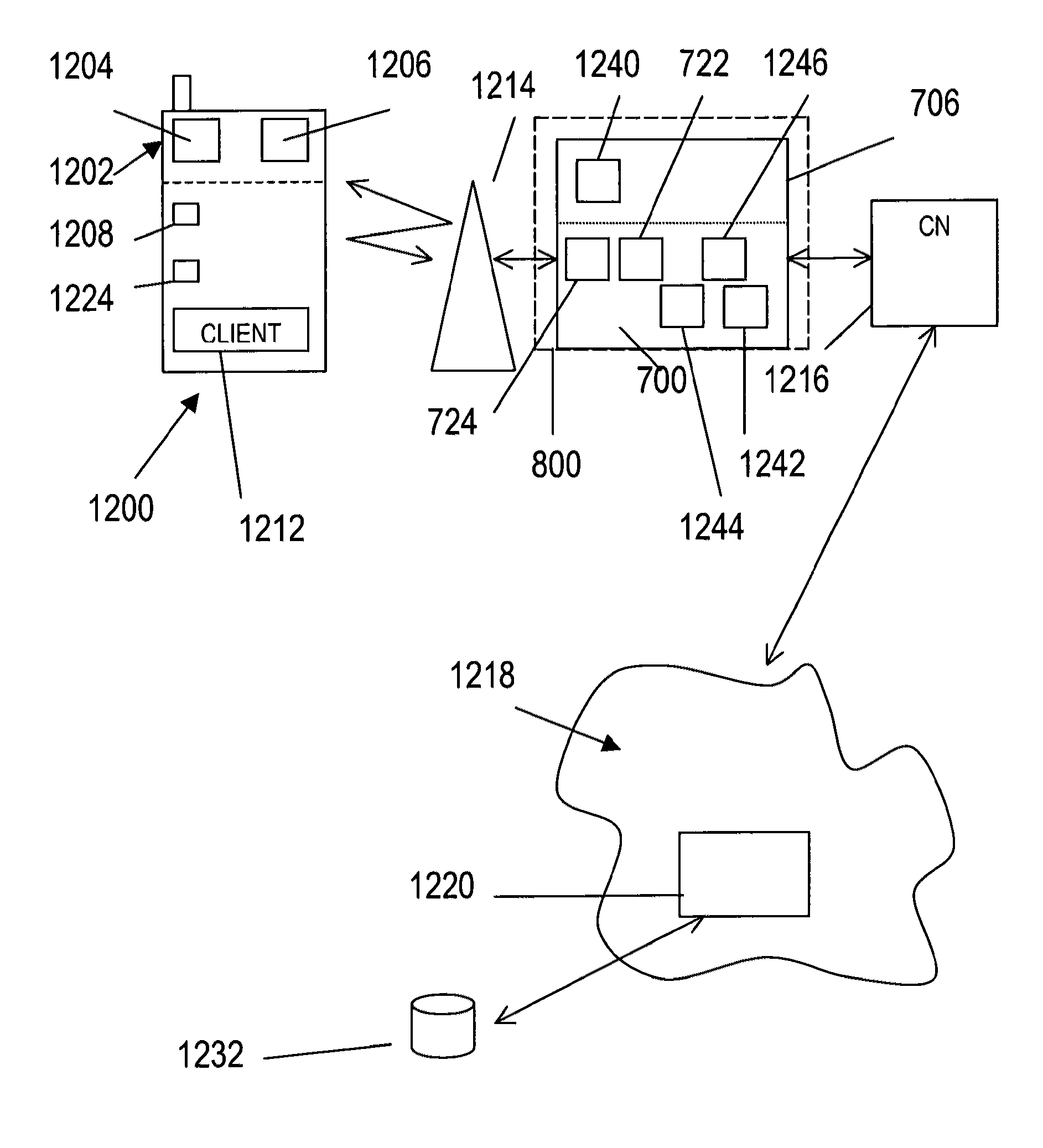

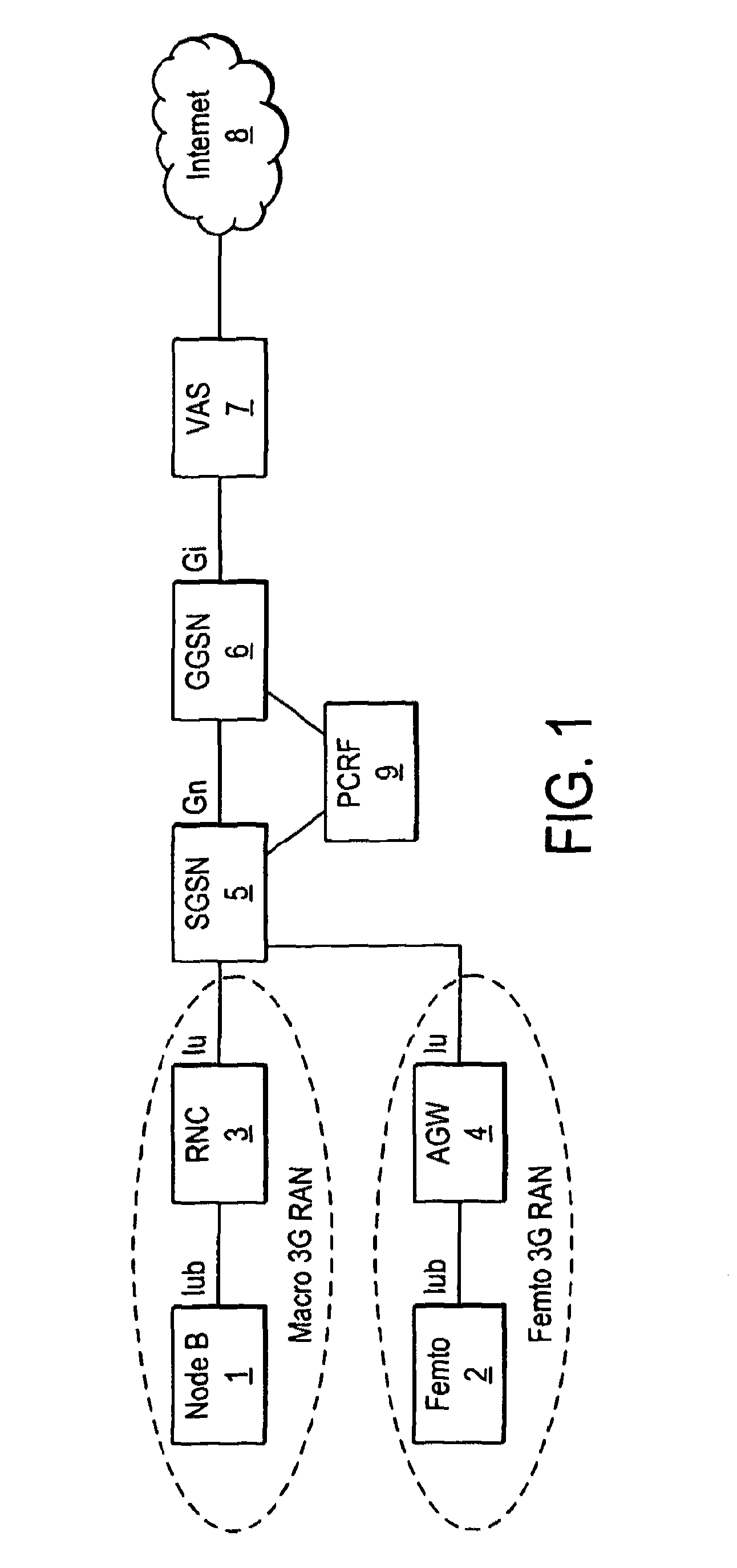

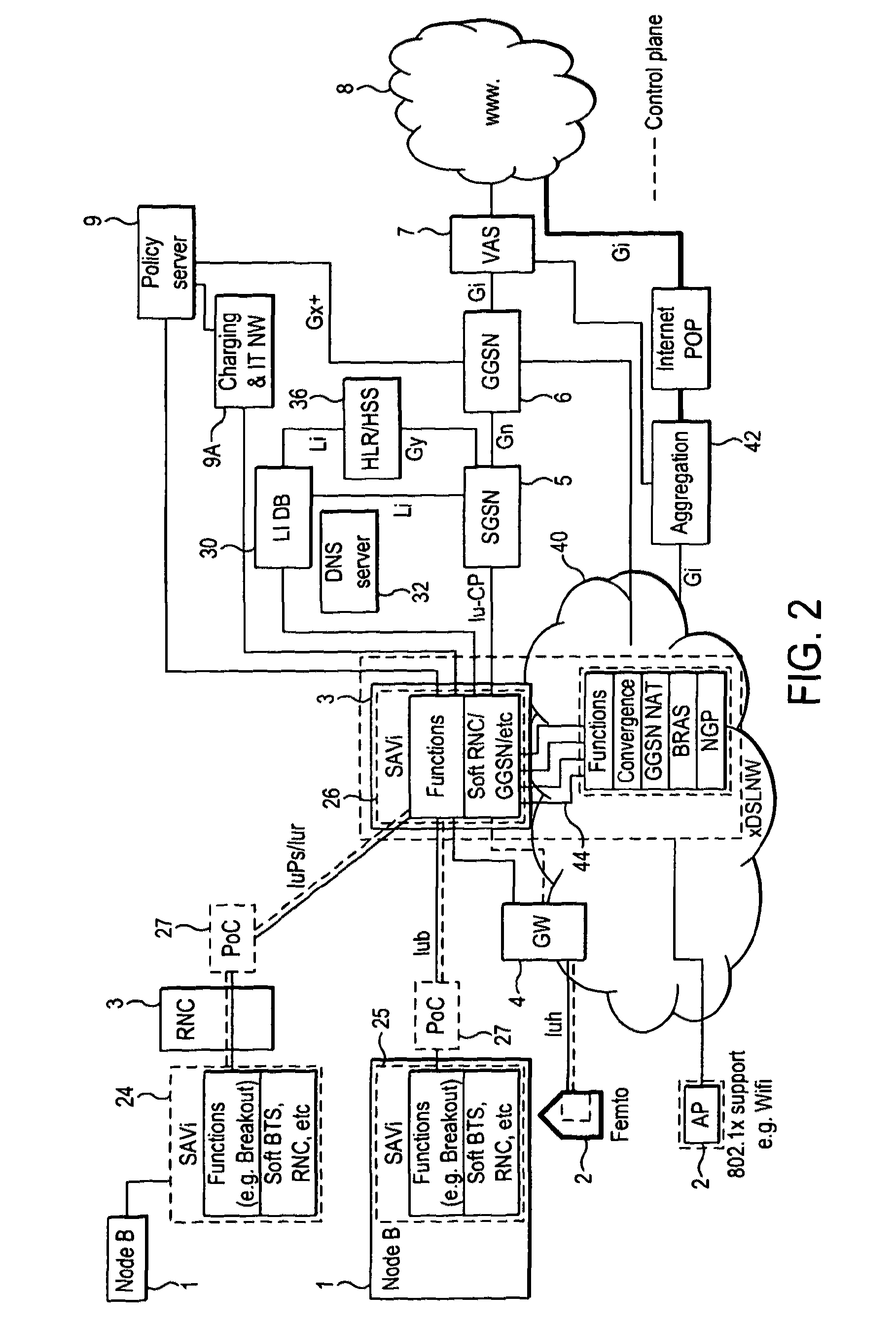

ActiveUS20120064908A1High resolutionIncrease volumeAccounting/billing servicesNetwork traffic/resource managementAccess networkTelecommunications network

A mobile telecommunications network includes a core and a radio access network having a radio for wireless communication with mobile terminals registered with the network, wherein the radio access network includes a controller operable to control the use of network resources by the mobile terminals. The controller may include an application programming interface, API, which provides a consistent interface to a multiplicity of applications hosted on the control mean. The controller may be provided at an access node site and / or a gateway site.

Owner:VODAFONE IP LICENSING

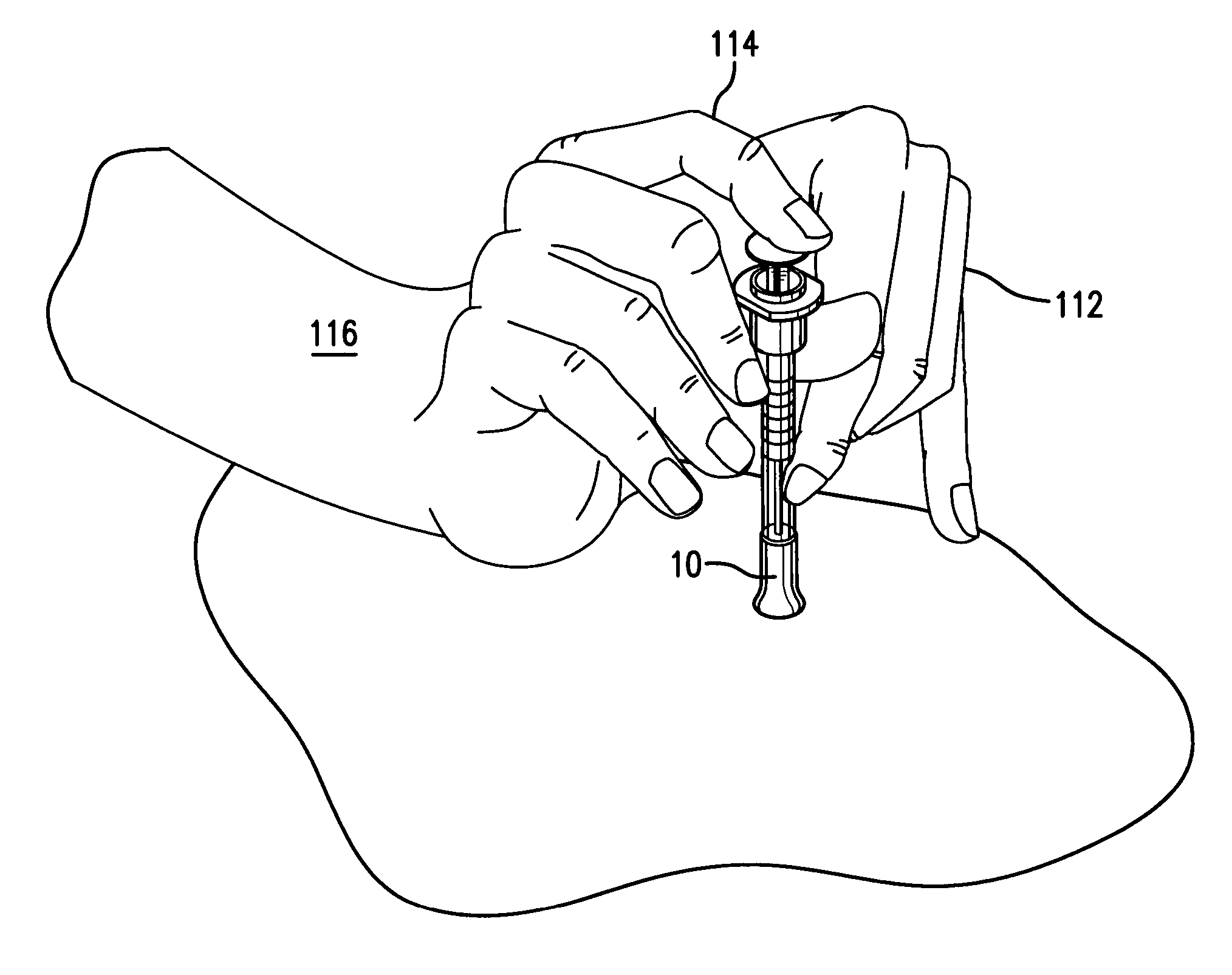

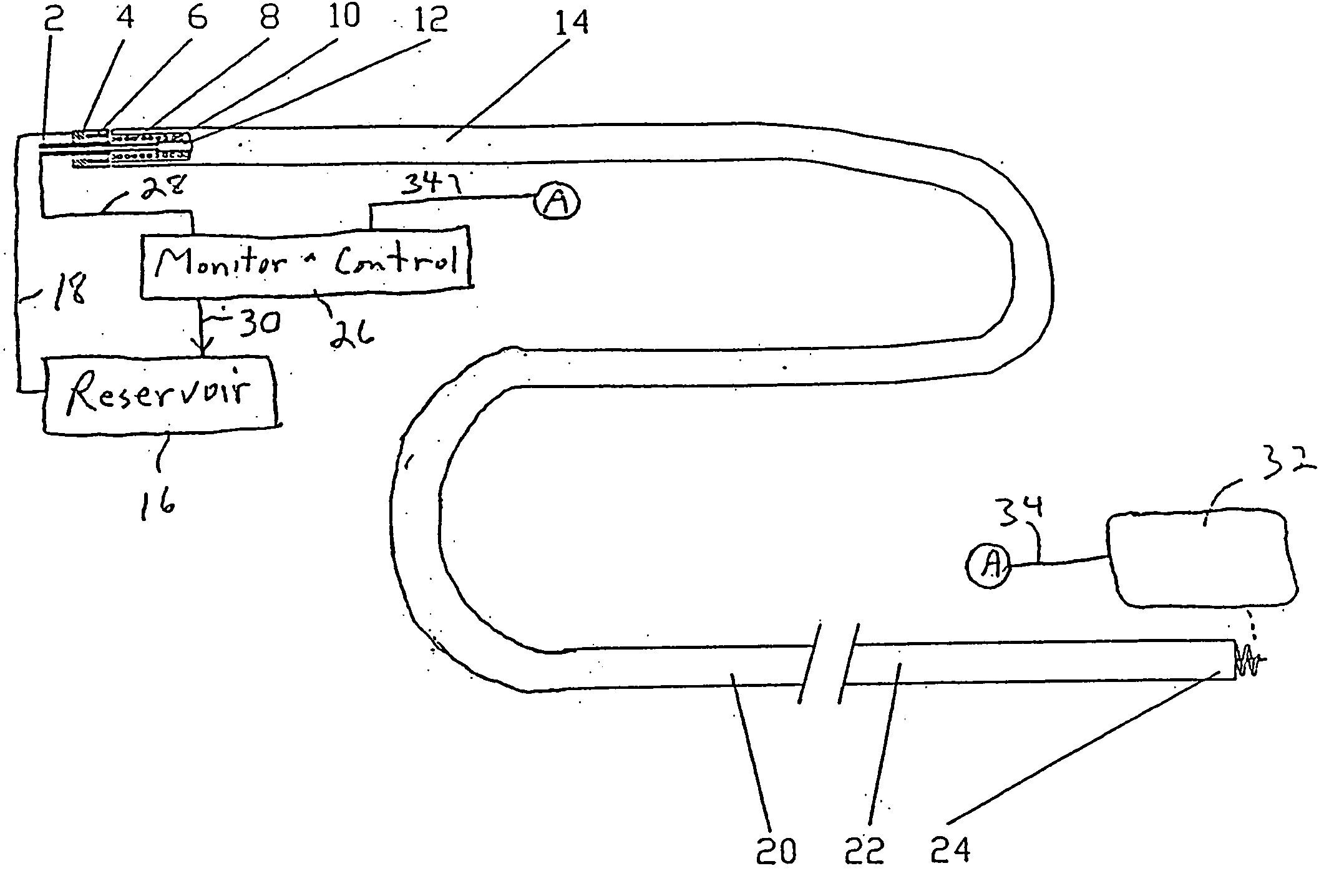

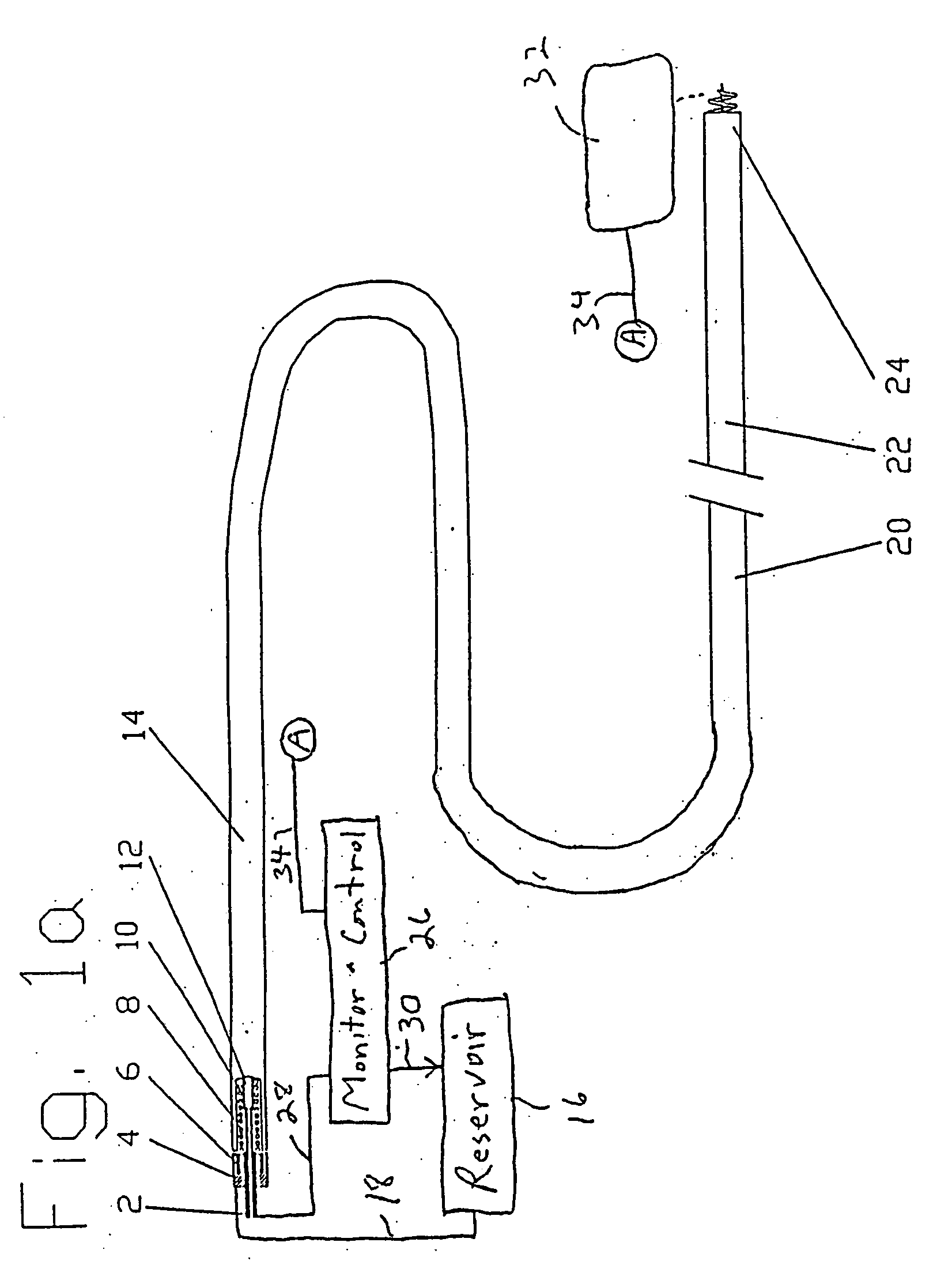

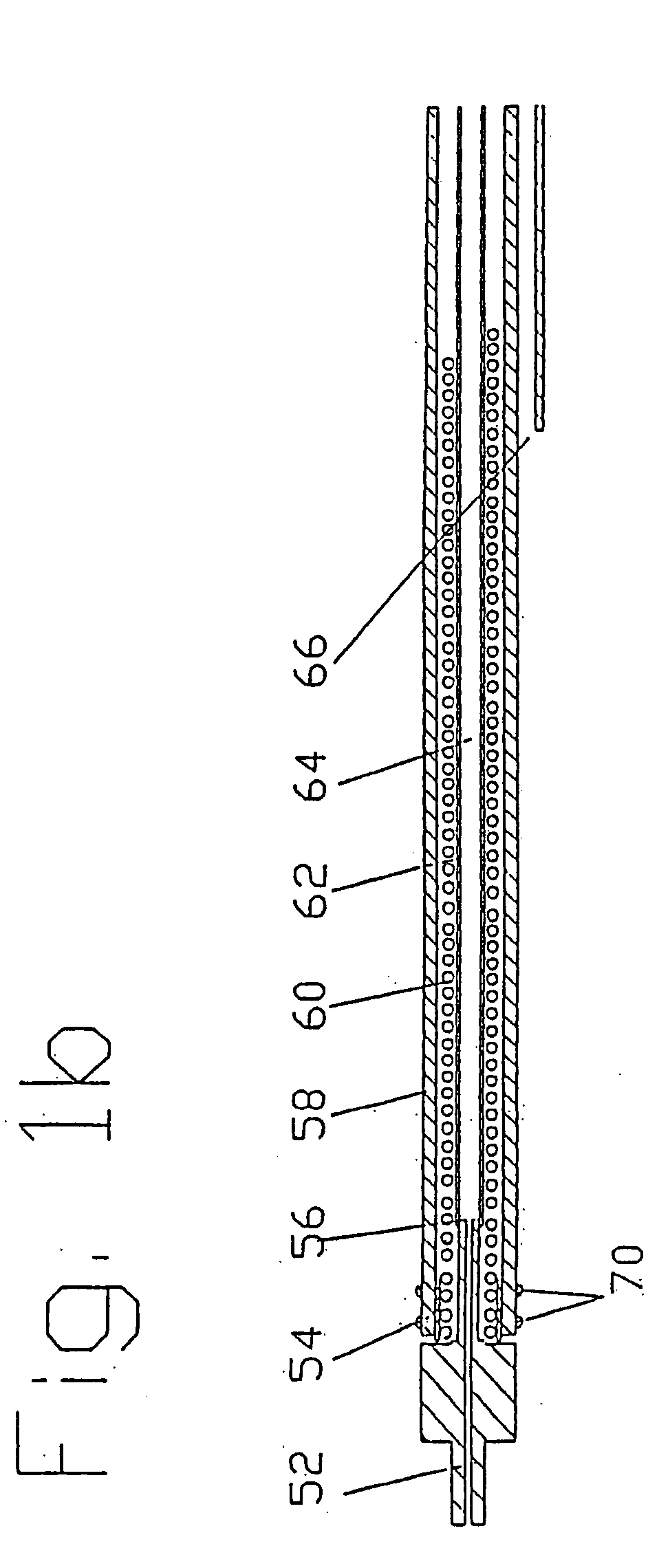

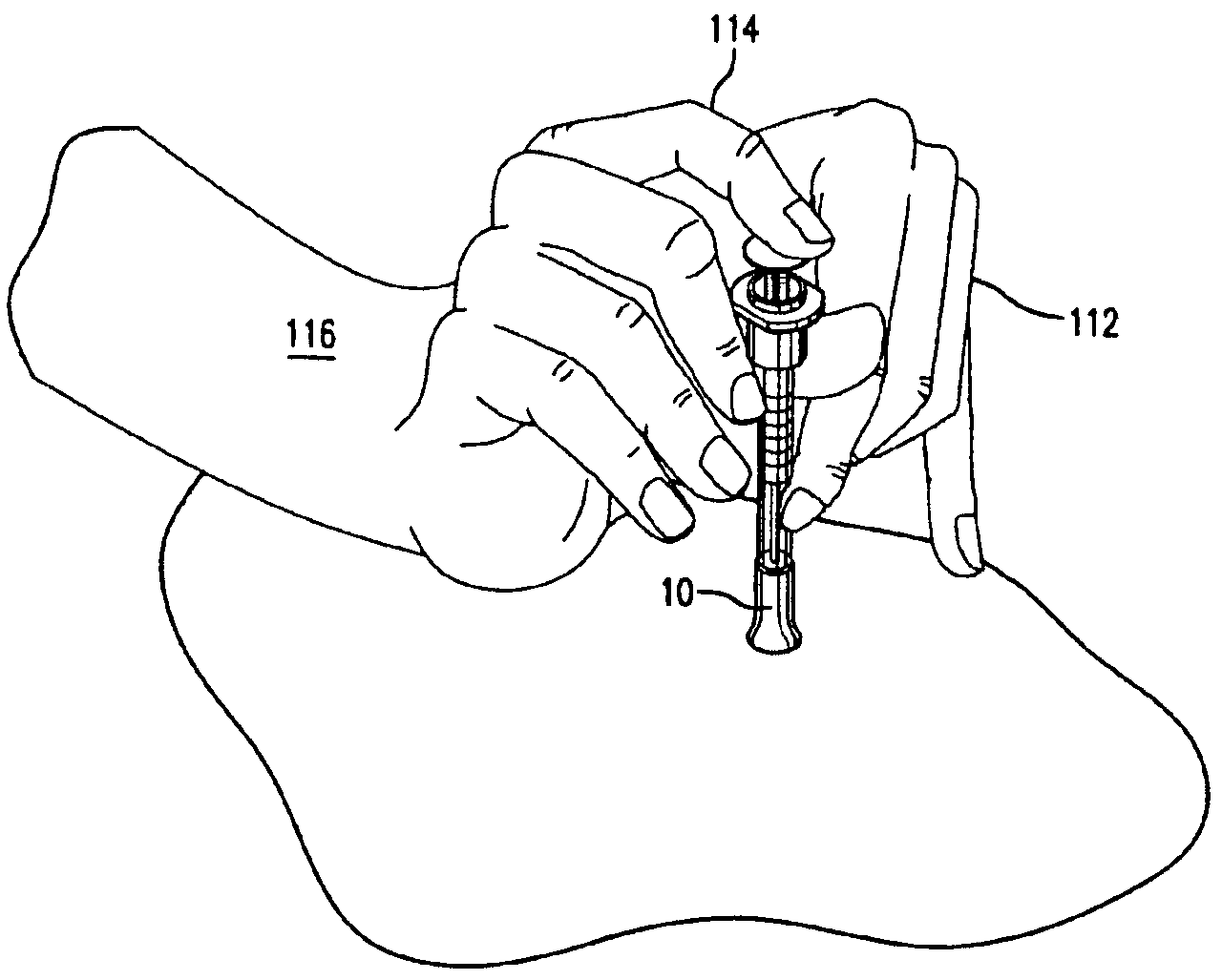

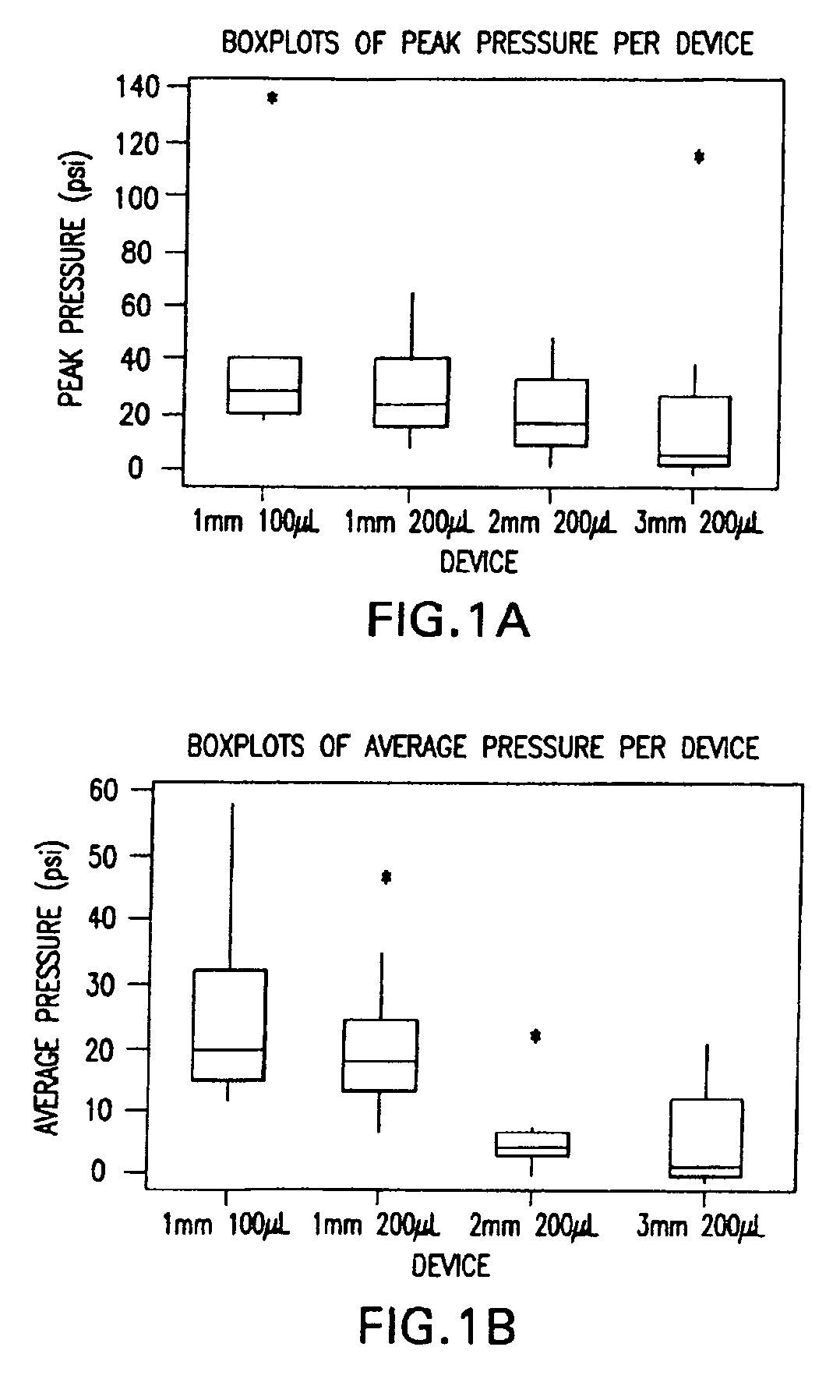

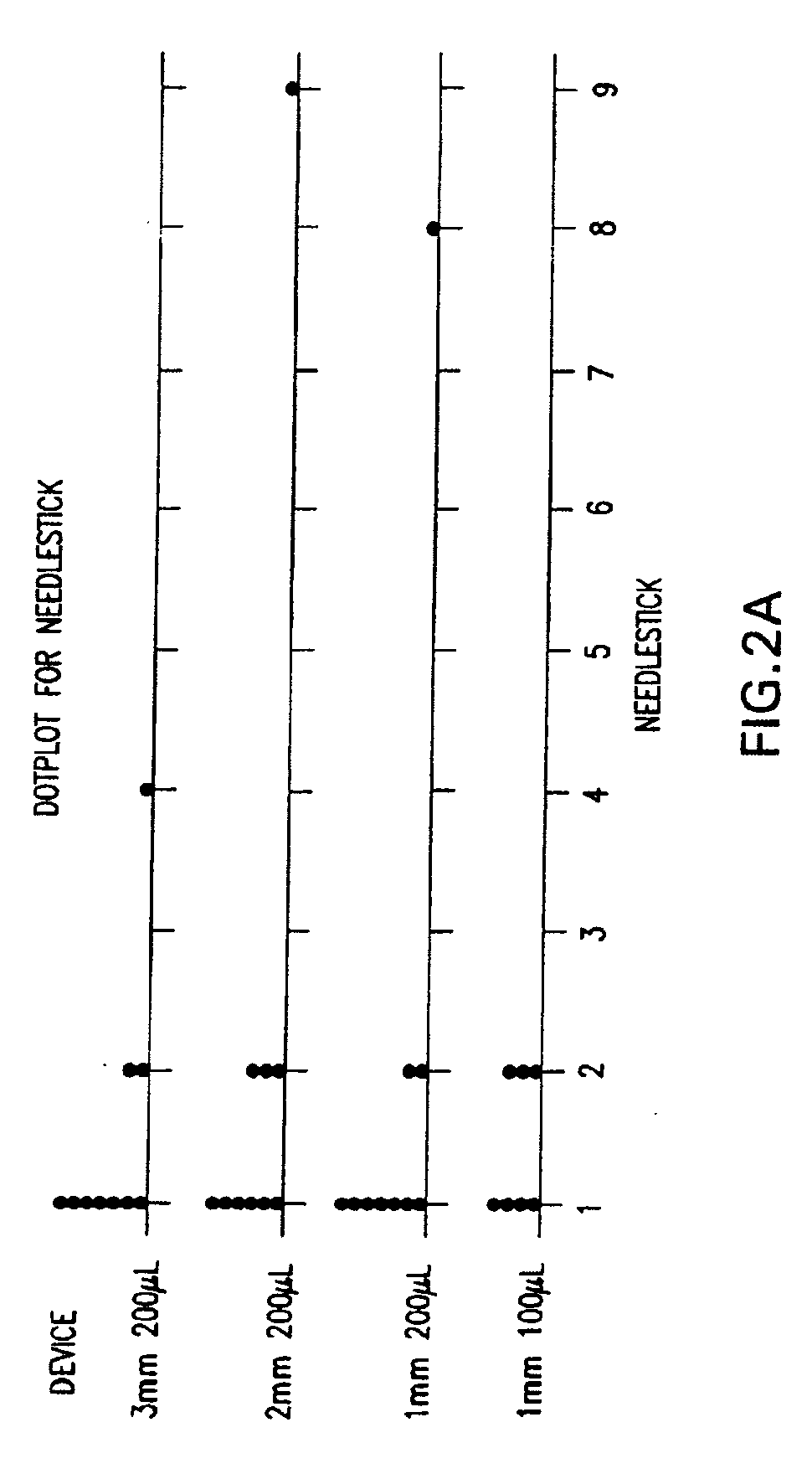

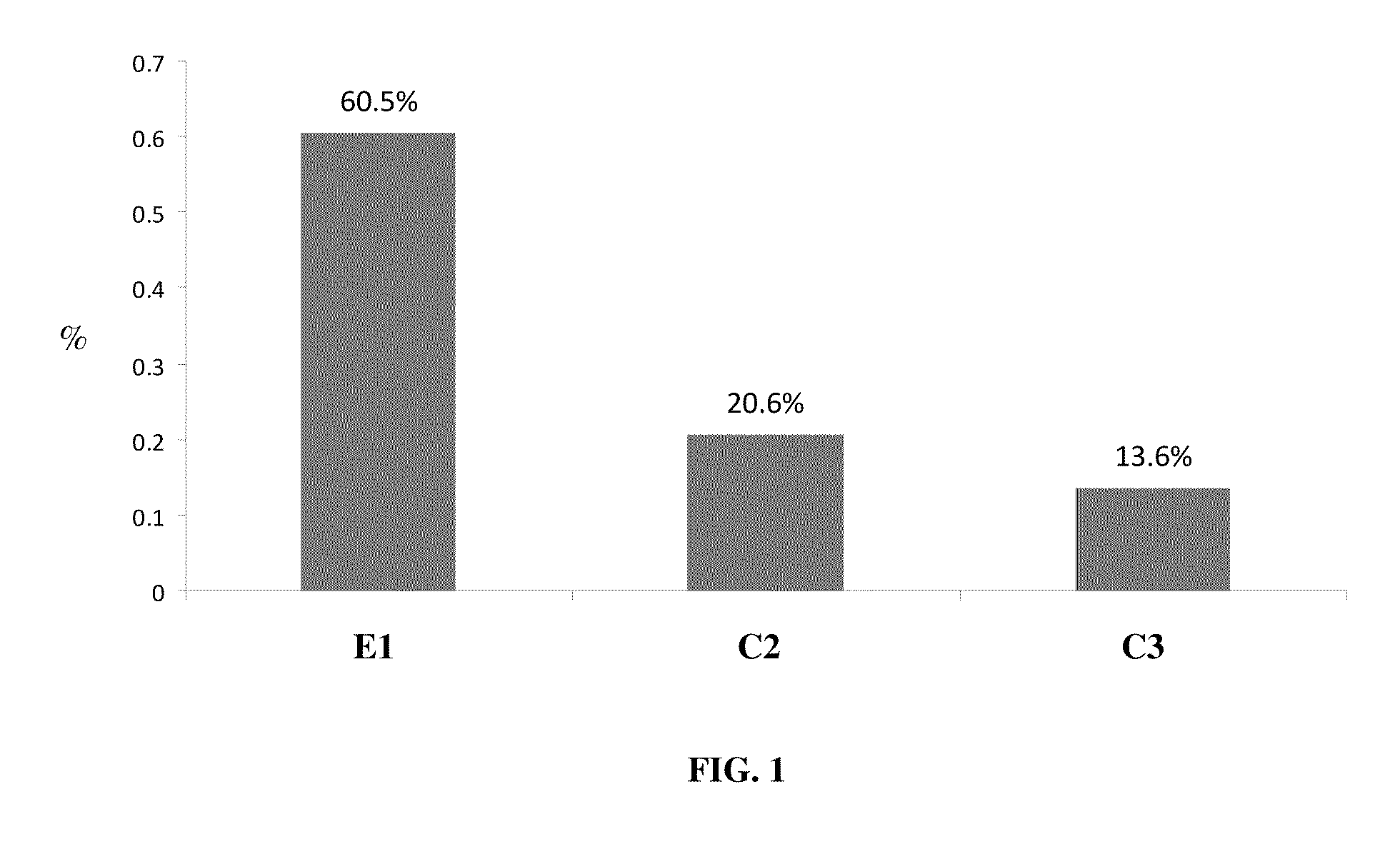

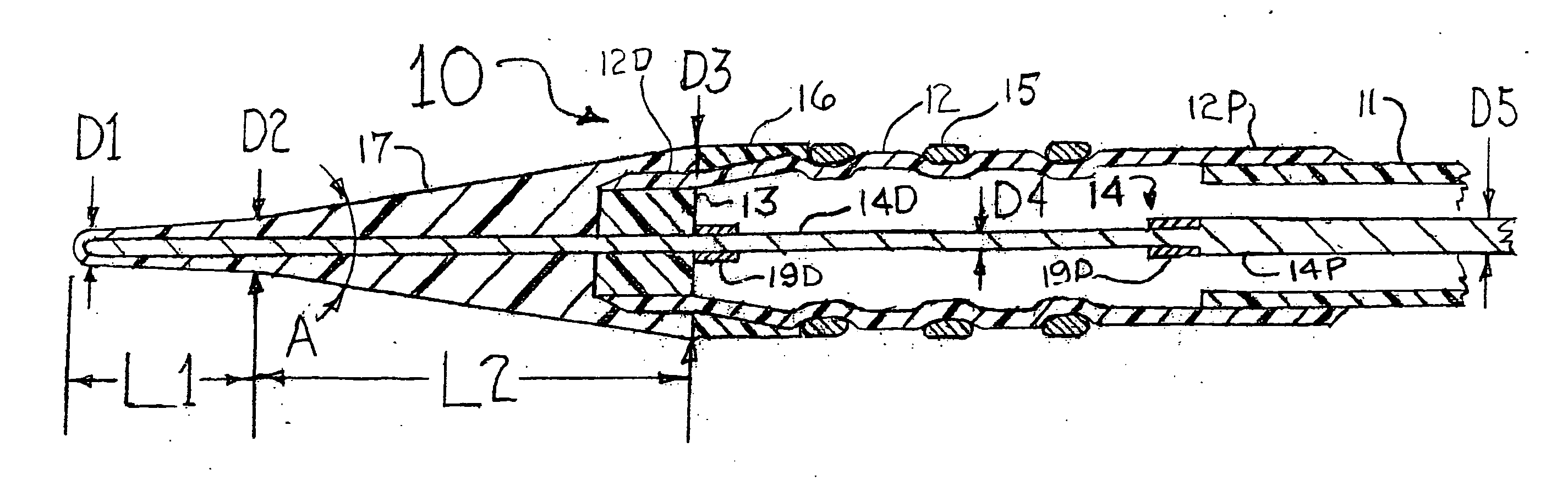

Methods and devices for improving delivery of a substance to skin

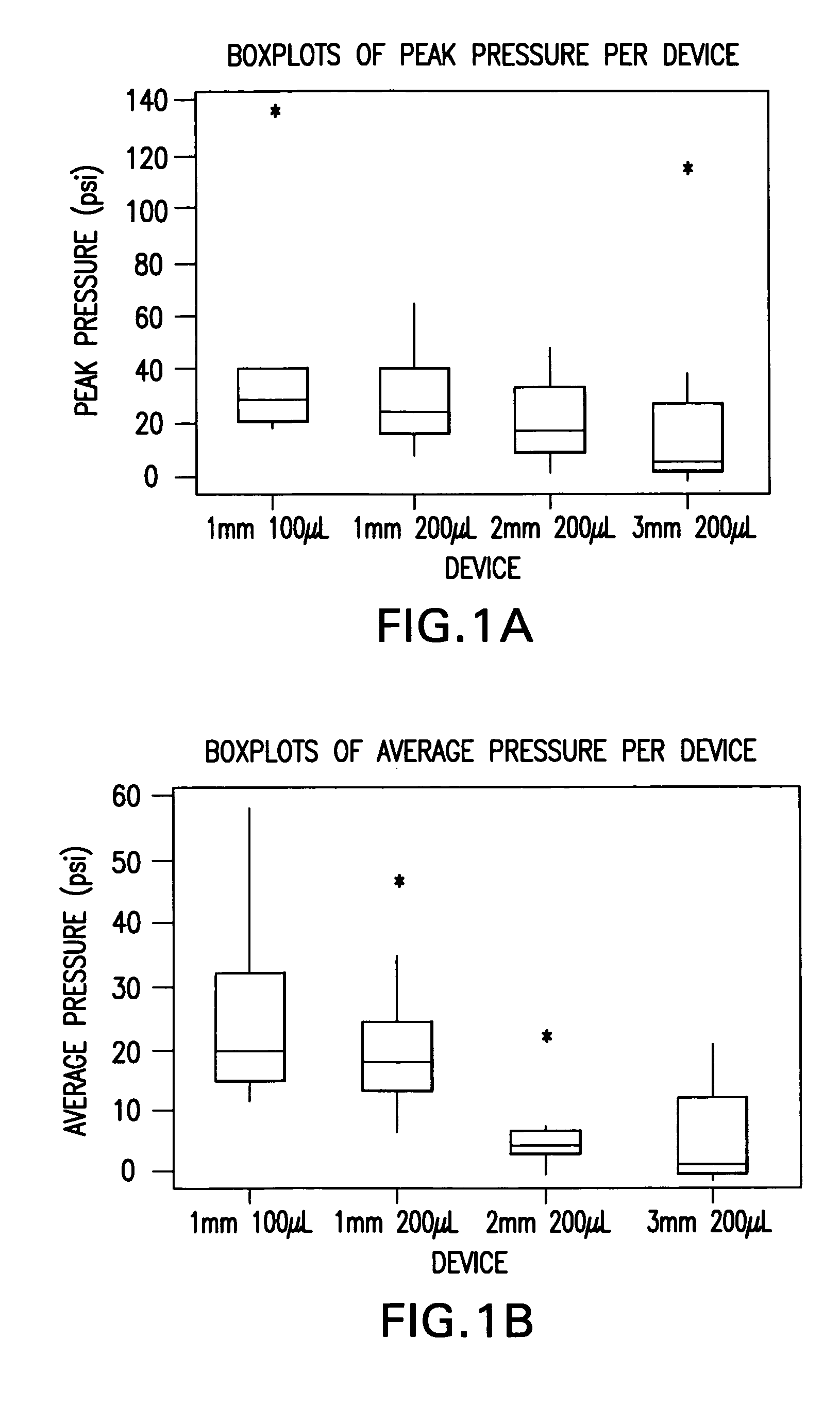

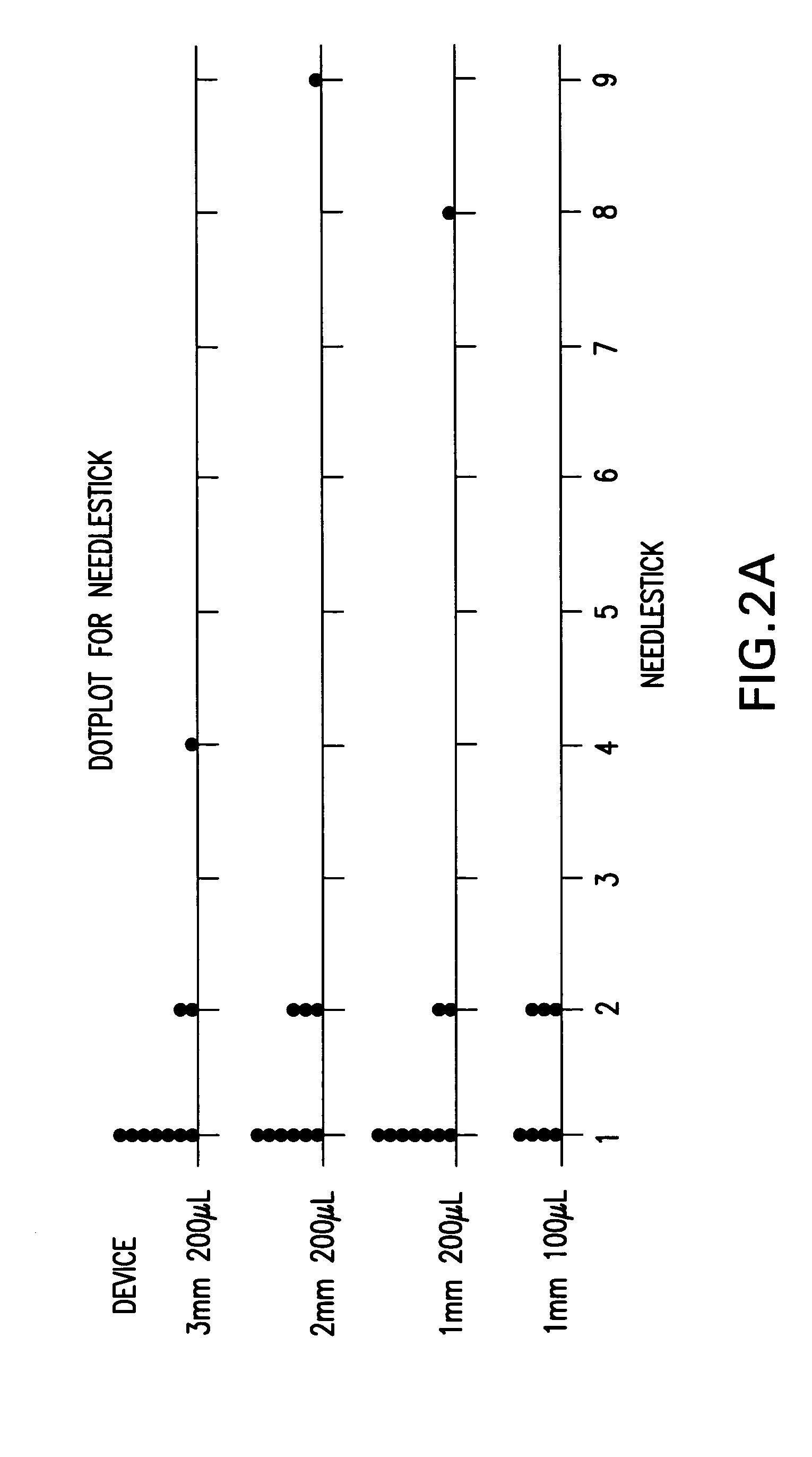

InactiveUS20050256499A1Efficacy is alteredImprove delivery capabilitiesMedical devicesPressure infusionDelivery PerformanceInjection site

A method of delivery of a substance to a human subject's skin comprising deposition into a specific compartment of the skin, wherein the delivery occurs at a controlled rate and pressure. The methods of the invention provide accurate deposition of s pre-selected volume of the substance, e.g., greater than 90% of the pre-selected volume. The methods of the invention encompass varying one or more parameters including but not limited to configurations of the delivery device, volume, pressure, and flow rate of delivery, to enhance the efficacy of delivery of the substance to the human skin. Substances delivered in accordance with the methods of the invention result in a more efficacious deposition of the substance into the targeted compartment, improved delivery performance, i.e., completeness of delivery as measured by quantification of the substance not delivered or the amount of the substance leaked out from the injection site, and enhanced safety as measured by the occurrence of minimal adverse cutaneous events at the site of injection.

Owner:BECTON DICKINSON & CO

Telecommunication networks

ActiveUS8639260B2Increase volumeReduce the amount requiredAccounting/billing servicesNetwork traffic/resource managementAccess networkTelecommunications network

A mobile telecommunications network includes a core and a radio access network having a radio for wireless communication with mobile terminals registered with the network, wherein the radio access network includes a controller operable to control the use of network resources by the mobile terminals. The controller may include an application programming interface, API, which provides a consistent interface to a multiplicity of applications hosted on the control mean. The controller may be provided at an access node site and / or a gateway site.

Owner:VODAFONE IP LICENSING

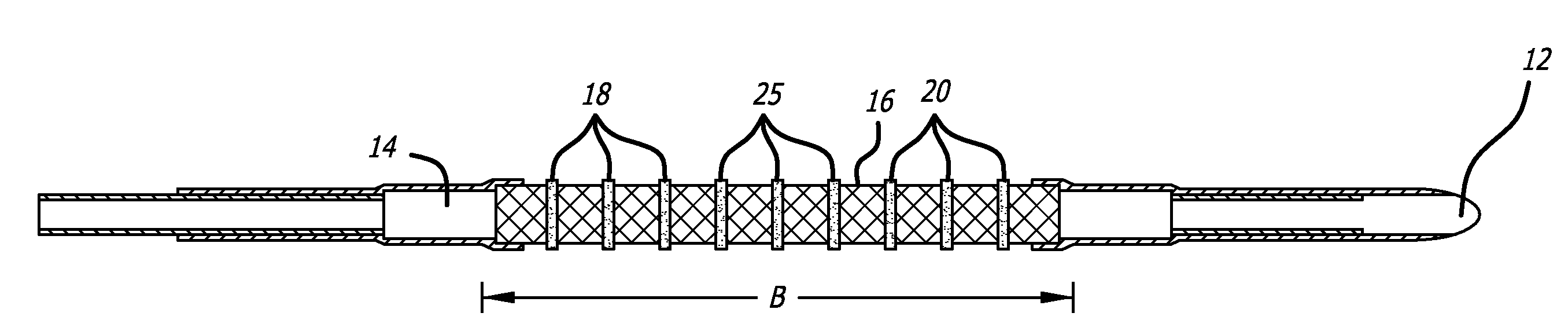

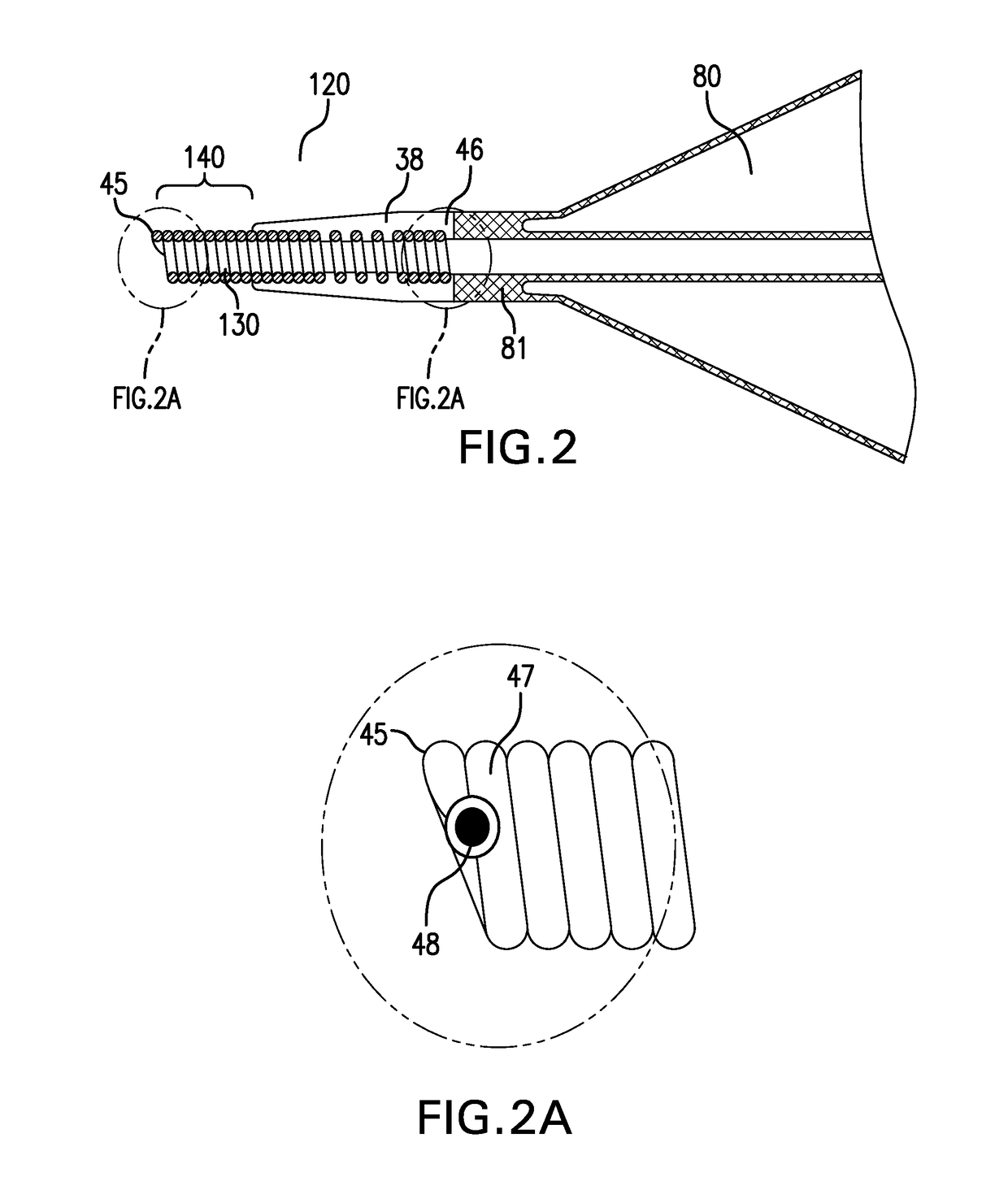

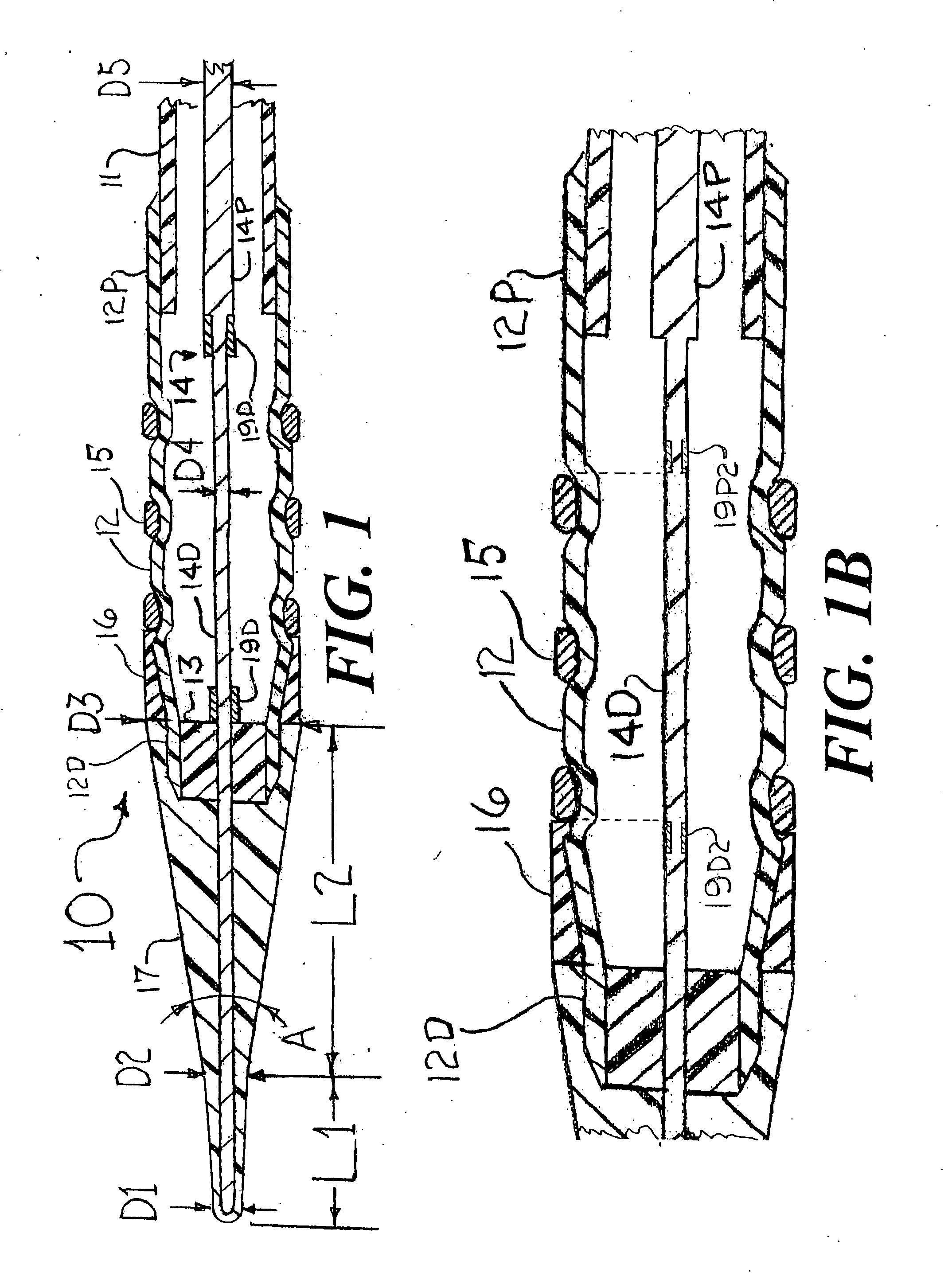

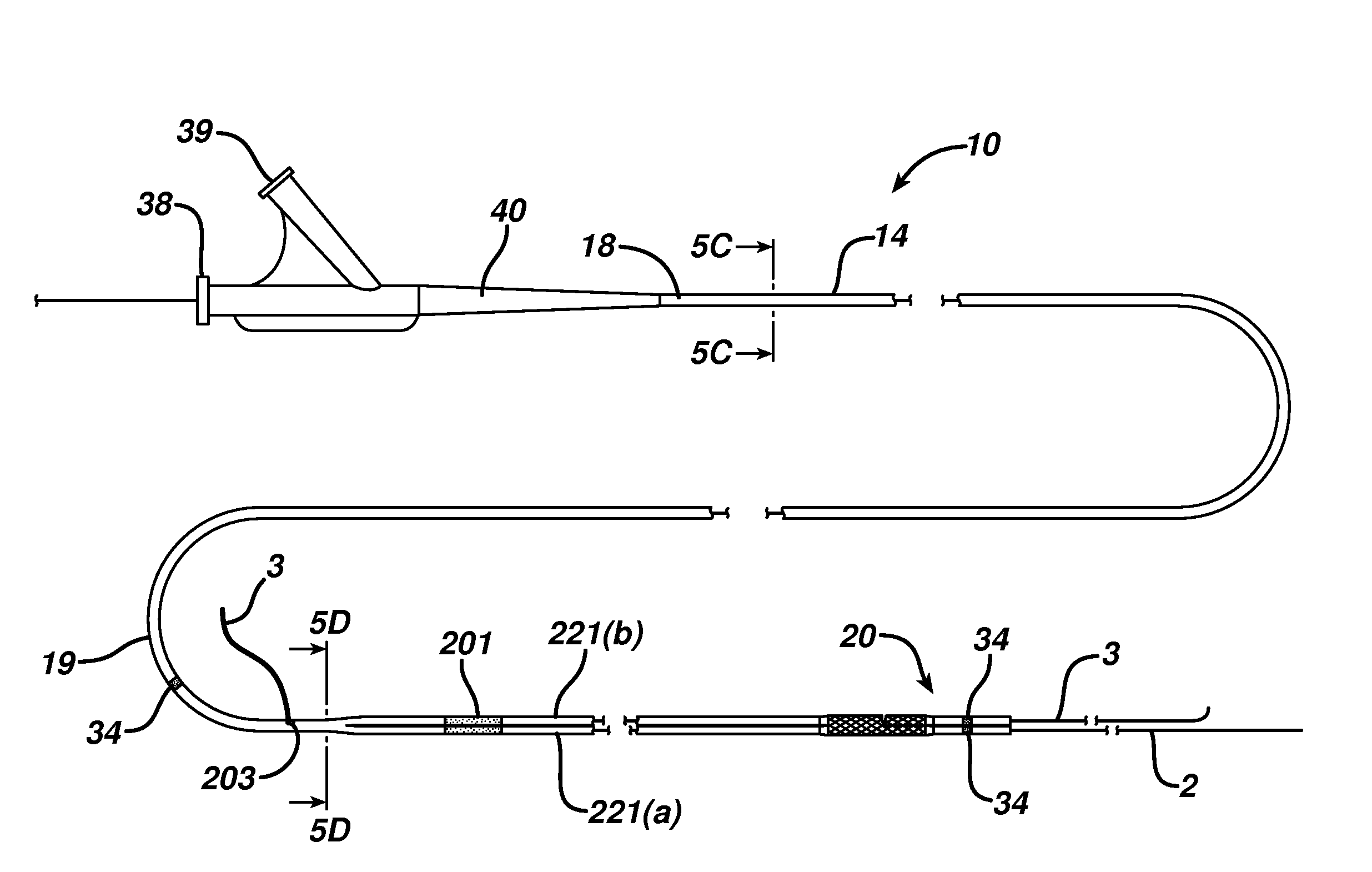

Cardiac drug delivery system and method of use

InactiveUS20050215991A1Improve delivery capabilitiesIncrease collateral flowInfusion syringesInternal electrodesControlled deliveryBiomedical engineering

A system is disclosed, for administering a therapeutic agent locally and to a depth within cardiac tissue. An elongate, flexible catheter contains a flexible electric conductor and supports at its distal end an implantable electrode incorporating a penetrating element, typically a fixation helix or a linear needle that penetrates cardiac tissue as the electrode is implanted. A therapeutic agent is delivered through the electrode, to the cardiac tissue surrounding the penetrating element. The electrode can act as a sensor to monitor an electrical condition of the surrounding cardiac tissue and to control delivery of the agent responsive to the sensed electrical condition. Several embodiments feature a distal reservoir adjacent the electrode, for effecting transient deliveries of the therapeutic agent in minute quantities. Other embodiments are disclosed for providing sustained deliveries of agents.

Owner:BIOCARDIA

Methods and devices for improving delivery of a substance to skin

InactiveUS20090124997A1Efficacy is alteredImprove delivery capabilitiesMedical devicesPressure infusionDelivery PerformanceHuman skin

A method of delivery of a substance to a human subject's skin comprising deposition into a specific compartment of the skin, wherein the delivery occurs at a controlled rate and pressure. The methods of the invention provide accurate deposition of s pre-selected volume of the substance, e.g., greater than 90% of the pre-selected volume. The methods of the invention encompass varying one or more parameters including but not limited to configurations of the delivery device, volume, pressure, and flow rate of delivery, to enhance the efficacy of delivery of the substance to the human skin. Substances delivered in accordance with the methods of the invention result in a more efficacious deposition of the substance into the targeted compartment, improved delivery performance, i.e., completeness of delivery as measured by quantification of the substance not delivered or the amount of the substance leaked out from the injection site, and enhanced safety as measured by the occurrence of minimal adverse cutaneous events at the site of injection.

Owner:BECTON DICKINSON & CO

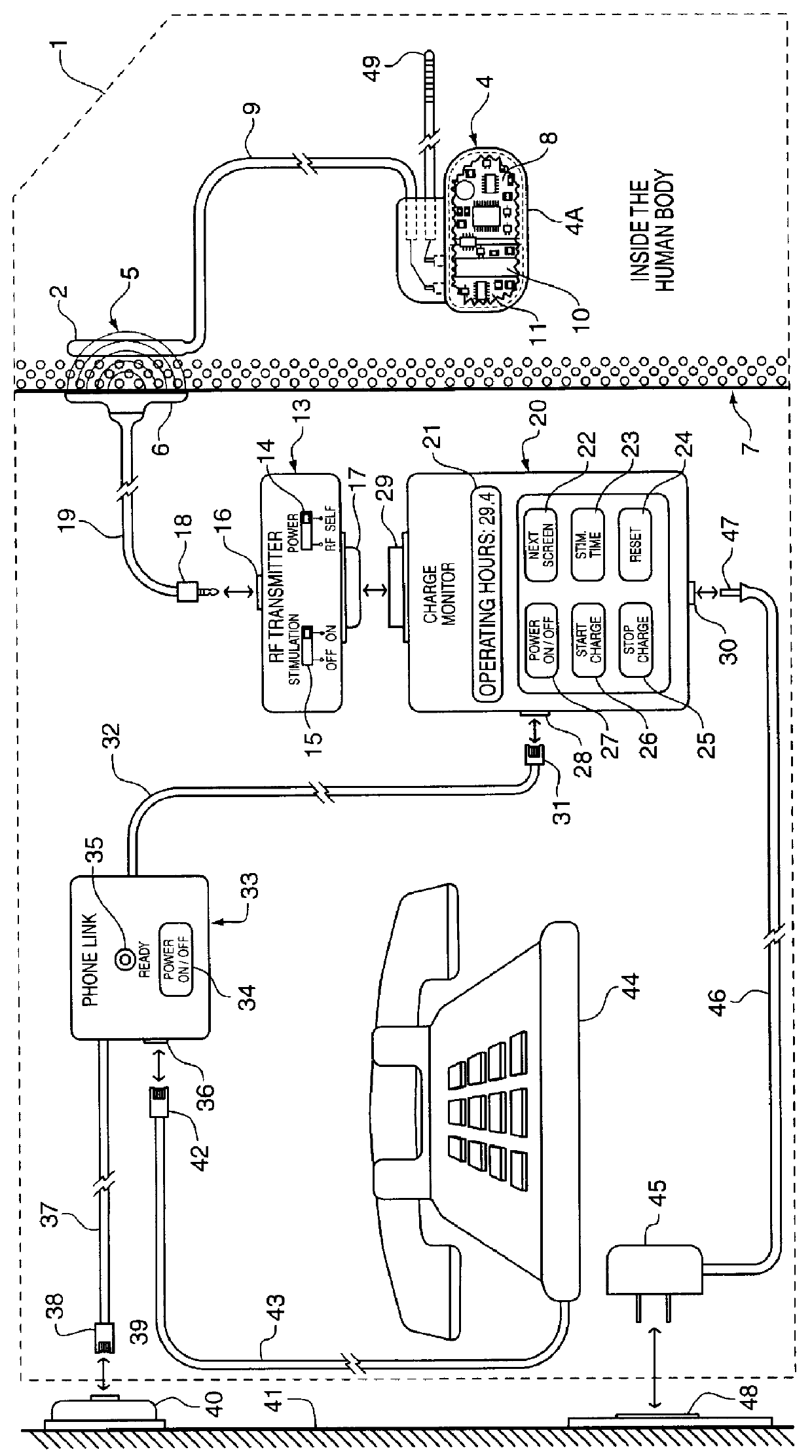

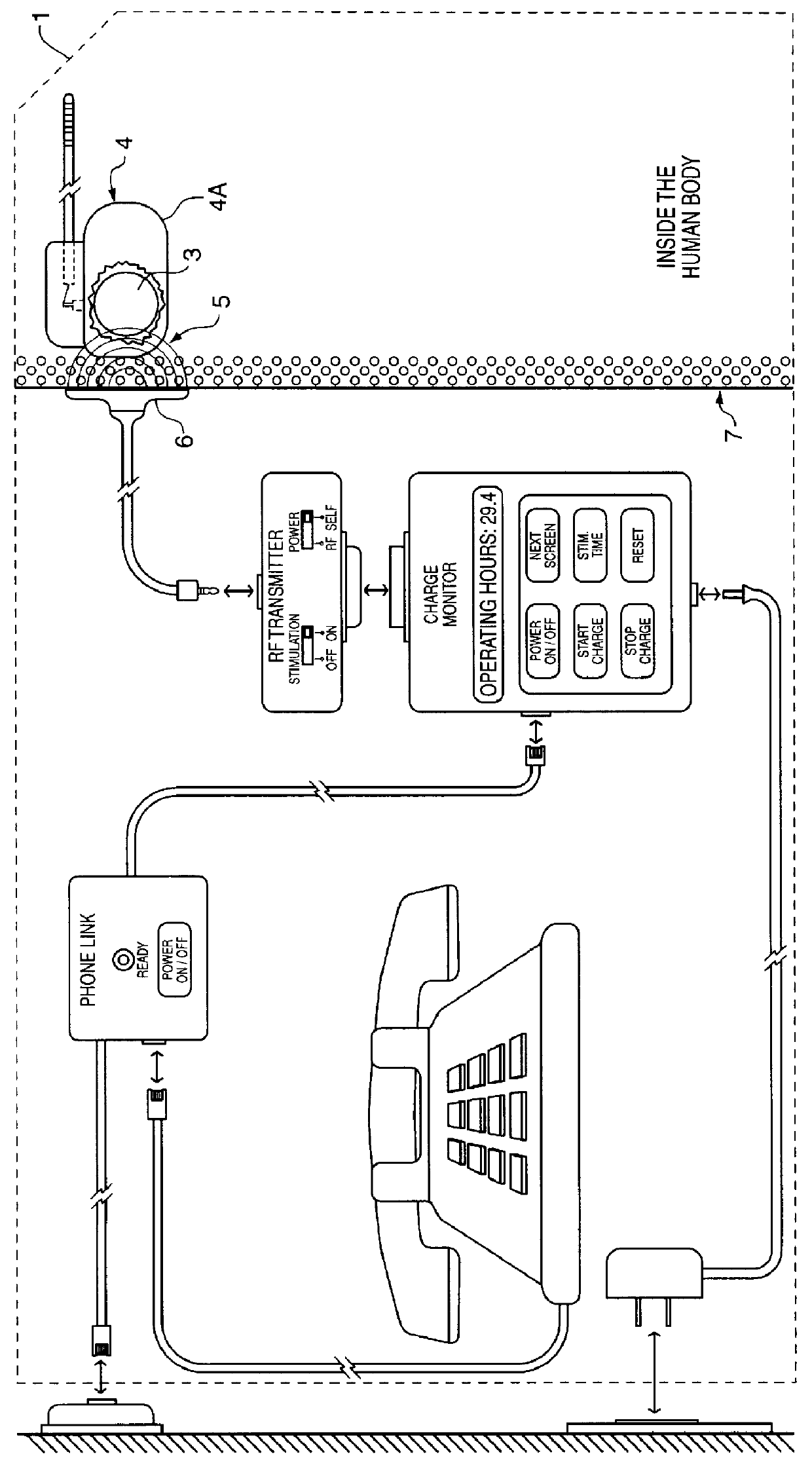

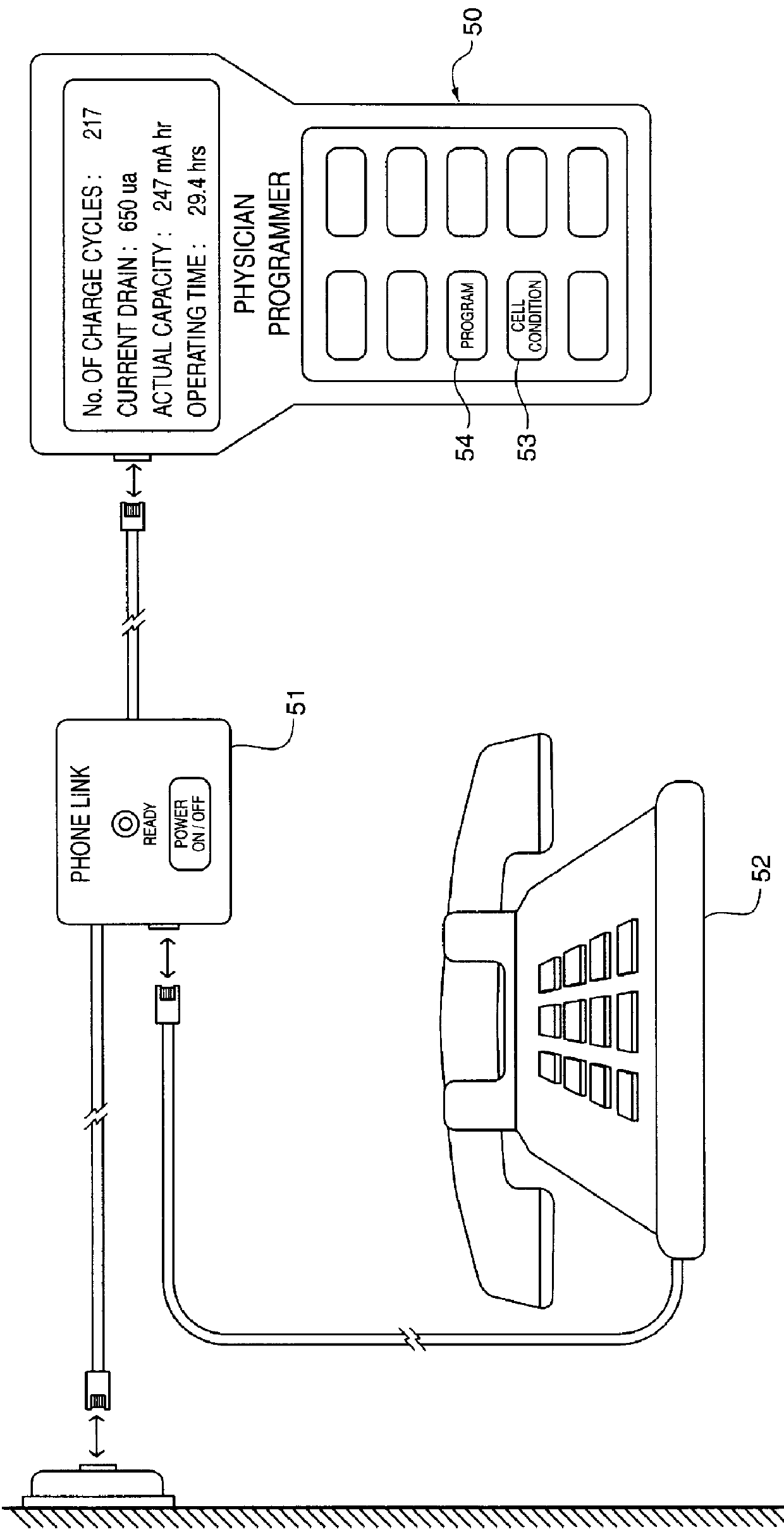

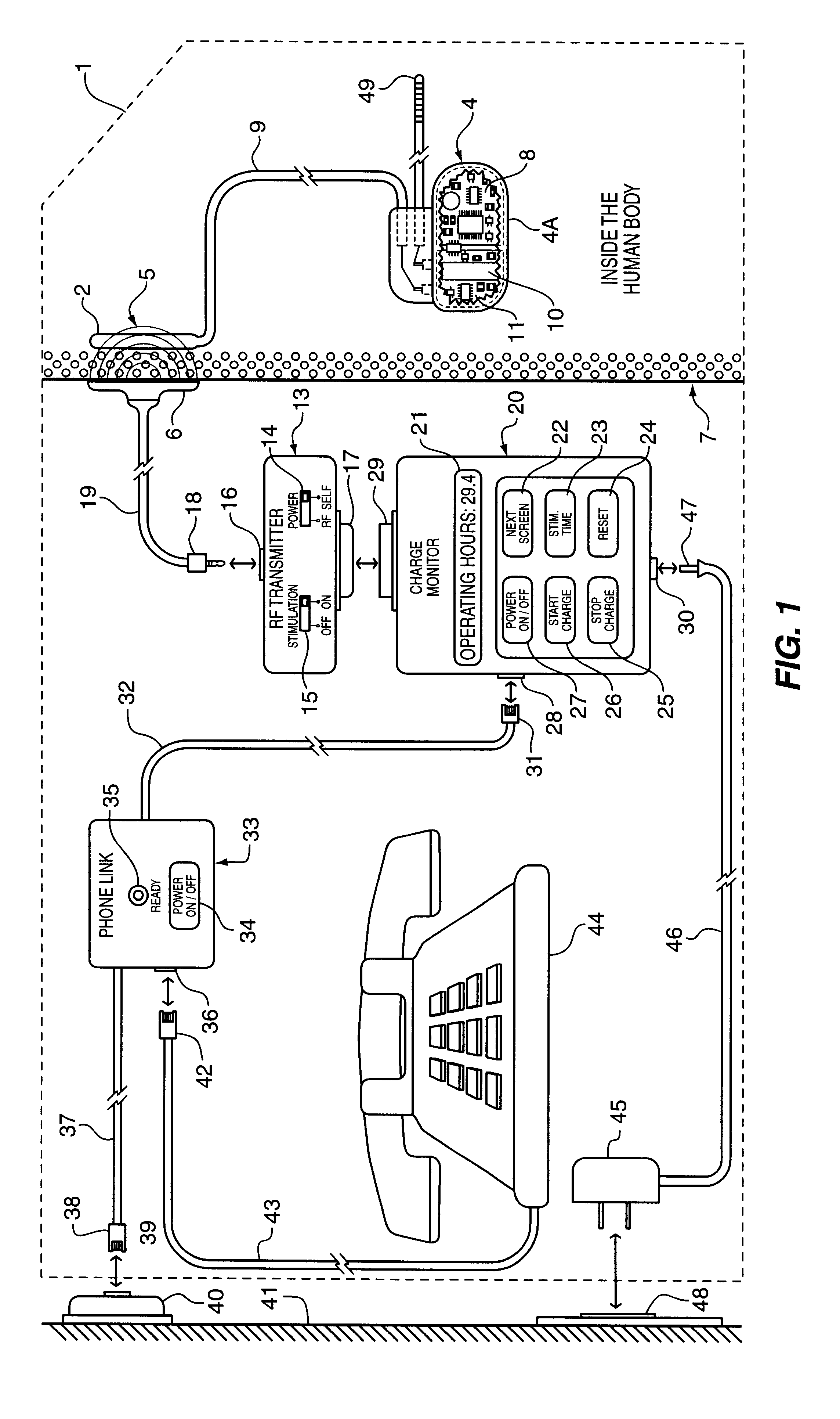

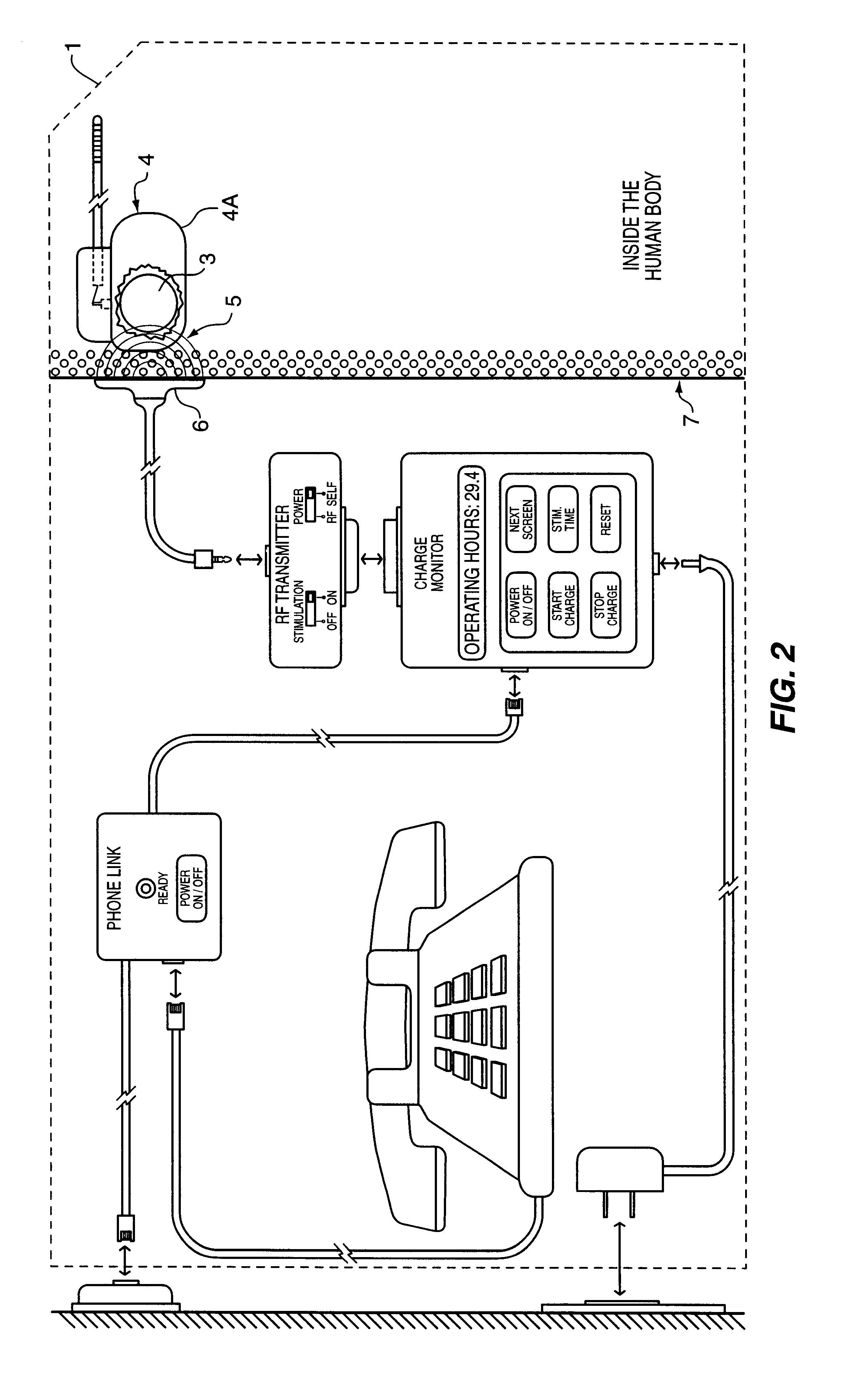

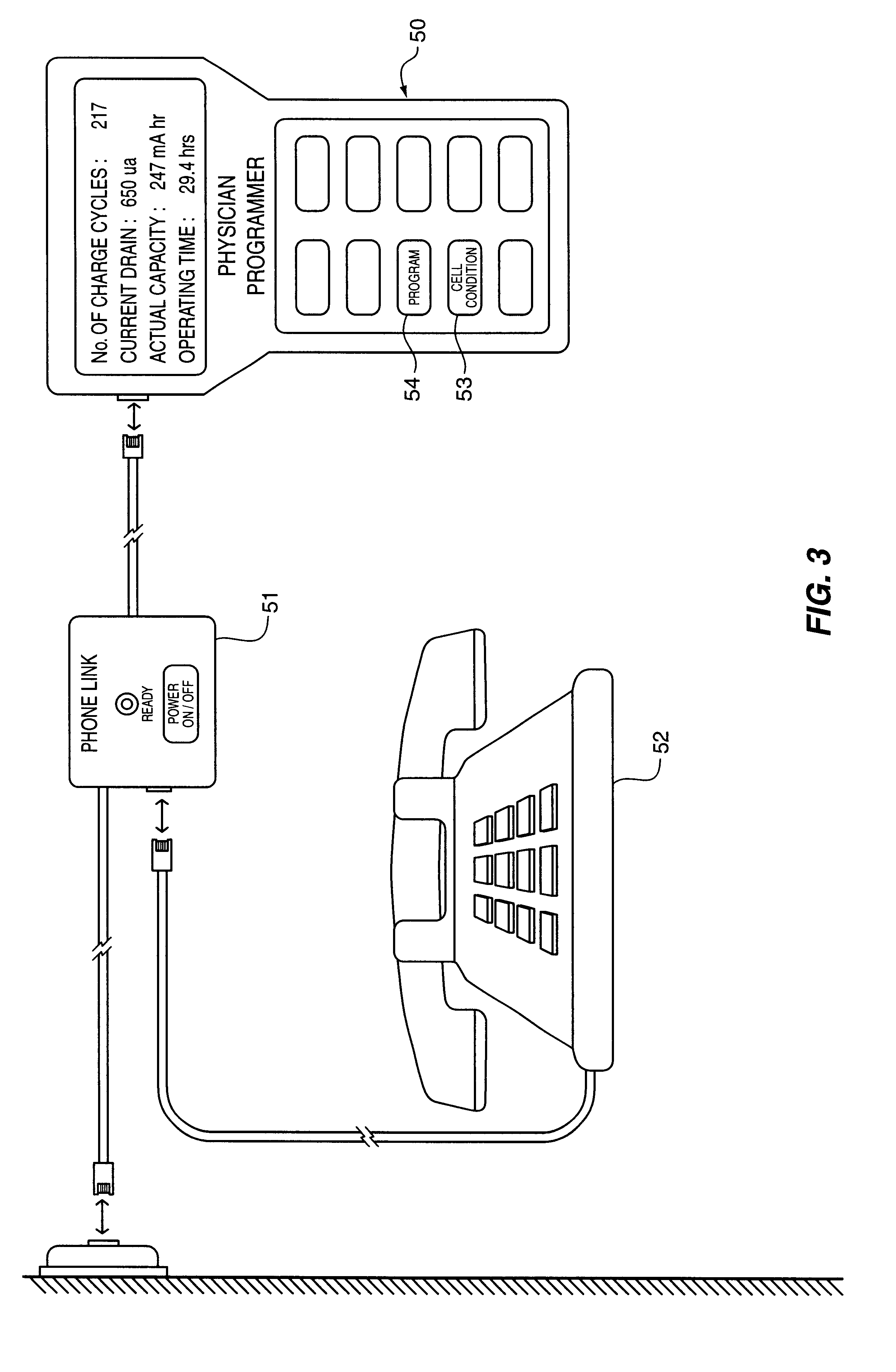

Implantable power management system

InactiveUS6166518AAccurately calculate and displayIncrease energy densityElectromagnetic wave systemHeart stimulatorsLow voltageElectric power

The method and system for managing power supplied from a charging circuit to a power source in an implantable medical device comprises the steps of and circuitry for: measuring the current drain of the medical device; measuring the elapsed time since the last full charge of a power source of the device; calculating the actual capacity of the power source (corrected for fade) based on the variable of current drain and the variable of elapsed time; calculating the operating time based on the variable of current drain and the variable of the actual capacity of the power source; measuring the voltage of the power source; signaling the medical device when the power source voltage has reached a certain low value which requires disconnection from the power source; disconnecting, during discharging, the power source from the medical device upon the power source reaching a certain low voltage in order to prevent deep discharging of the power source and subsequent damage; precisely limiting the charging voltage to the power source in order to prevent overcharging beyond safe limits; disconnecting, during charging, the power source from the charging circuit upon the power source reaching a certain high voltage in order to prevent overcharging of the power source and subsequent damage; sensing when the electromagnetic waves being transmitted by an RF transmitter / charger induce a voltage level above a certain value at an RF receiver of the implanted power management system; reconnecting power supply inputs of the medical device to the power source upon sensing this induced high voltage level; monitoring the temperature of the power source during charging and discharging; disconnecting the charging circuitry from the power source if the temperature of the power source raises above a certain level during charging; reconnecting the charging circuitry to the power source when the temperature of the power source drops below a certain low value during charging; disconnecting the implanted medical device from the power source if the temperature of the power source raises above a certain level during discharging; and, reconnecting the medical device to the power source when the temperature of the power source drops below a certain low value during discharging.

Owner:EXONIX

Implantable power management system

InactiveUS6278258B1Accurately calculate and displayIncrease energy densityElectromagnetic wave systemSecondary cellsLow voltageElectric power

The method and system for managing power supplied from a charging circuit to a power source in an implantable medical device comprises the steps of and circuitry for: measuring the current drain of the medical device; measuring the elapsed time since the last full charge of a power source of the device; calculating the actual capacity of the power source (corrected for fade) based on the variable of current drain and the variable of elapsed time; calculating the operating time based on the variable of current drain and the variable of the actual capacity of the power source; measuring the voltage of the power source; signaling the medical device when the power source voltage has reached a certain low value which requires disconnection from the power source; disconnecting, during discharging, the power source from the medical device upon the power source reaching a certain low voltage in order to prevent deep discharging of the power source and subsequent damage; precisely limiting the charging voltage to the power source in order to prevent overcharging beyond safe limits; disconnecting, during charging, the power source from the charging circuit upon the power source reaching a certain high voltage in order to prevent overcharging of the power source and subsequent damage; sensing when the electromagnetic waves being transmitted by an RF transmitter / charger induce a voltage level above a certain value at an RF receiver of the implanted power management system; reconnecting power supply inputs of the medical device to the power source upon sensing this induced high voltage level; monitoring the temperature of the power source during charging and discharging; disconnecting the charging circuitry from the power source if the temperature of the power source raises above a certain level during charging; reconnecting the charging circuitry to the power source when the temperature of the power source drops below a certain low value during charging; disconnecting the implanted medical device from the power source if the temperature of the power source raises above a certain level during discharging; and, reconnecting the medical device to the power source when the temperature of the power source drops below a certain low value during discharging.

Owner:EXONIX

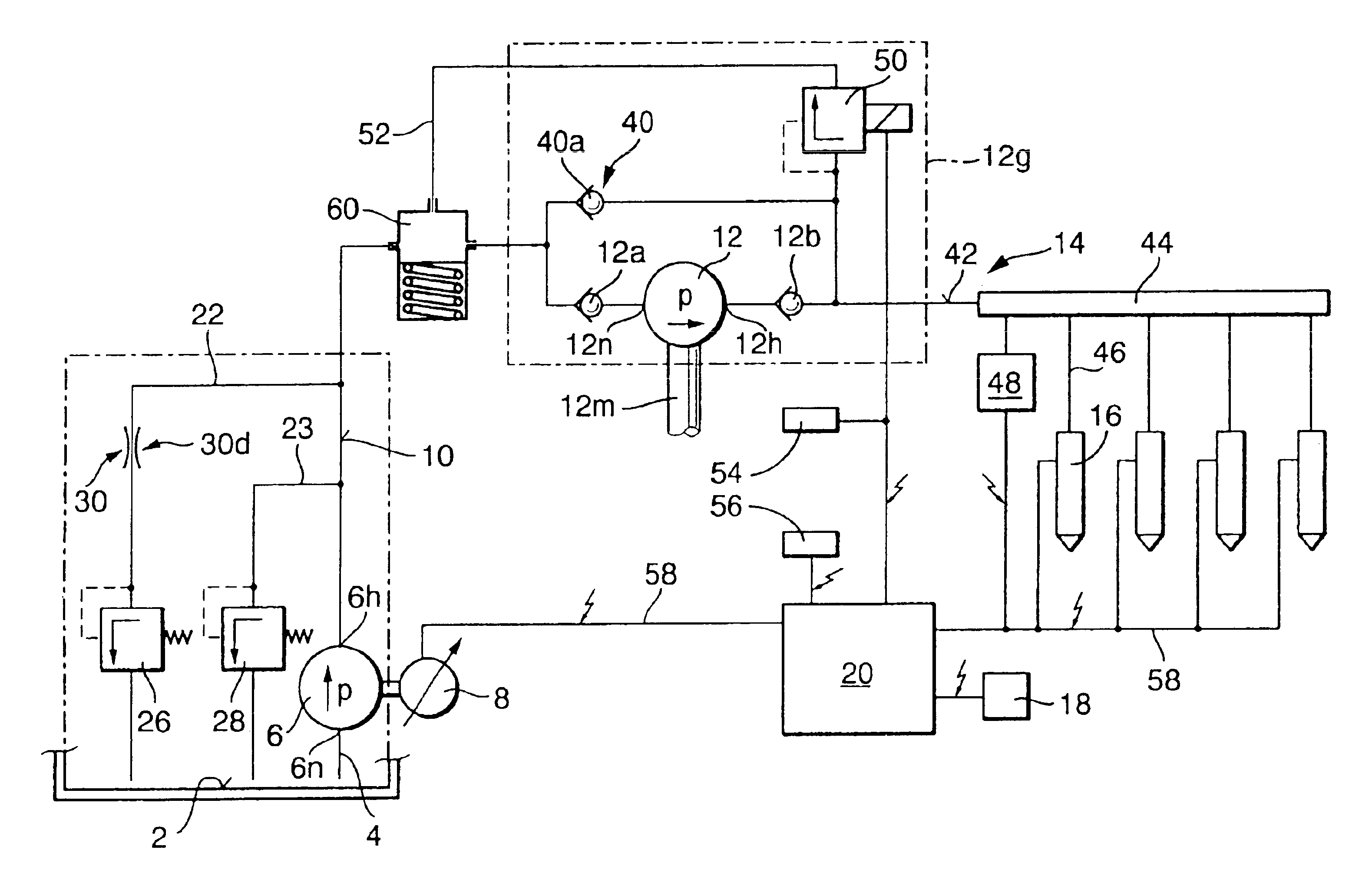

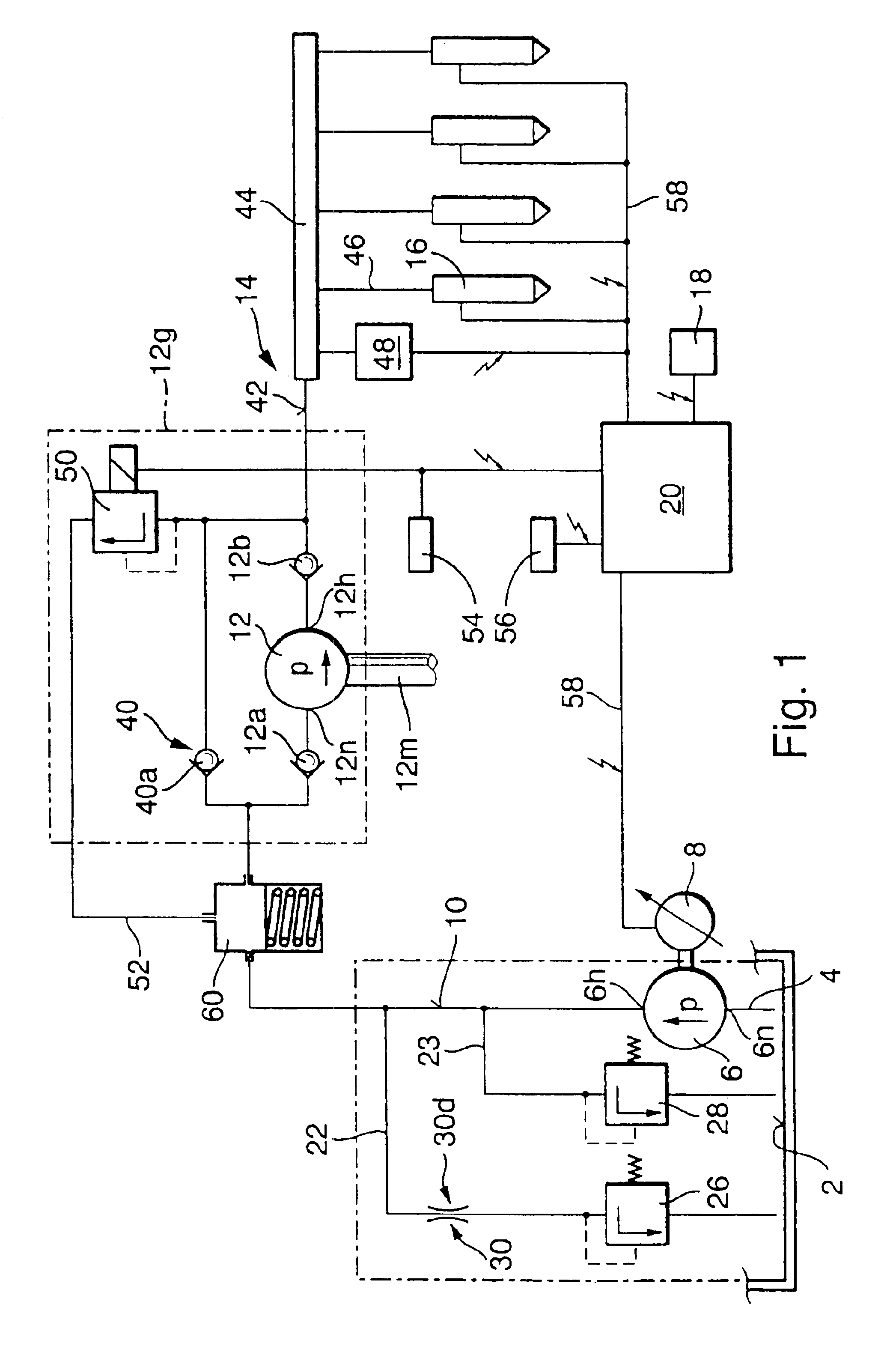

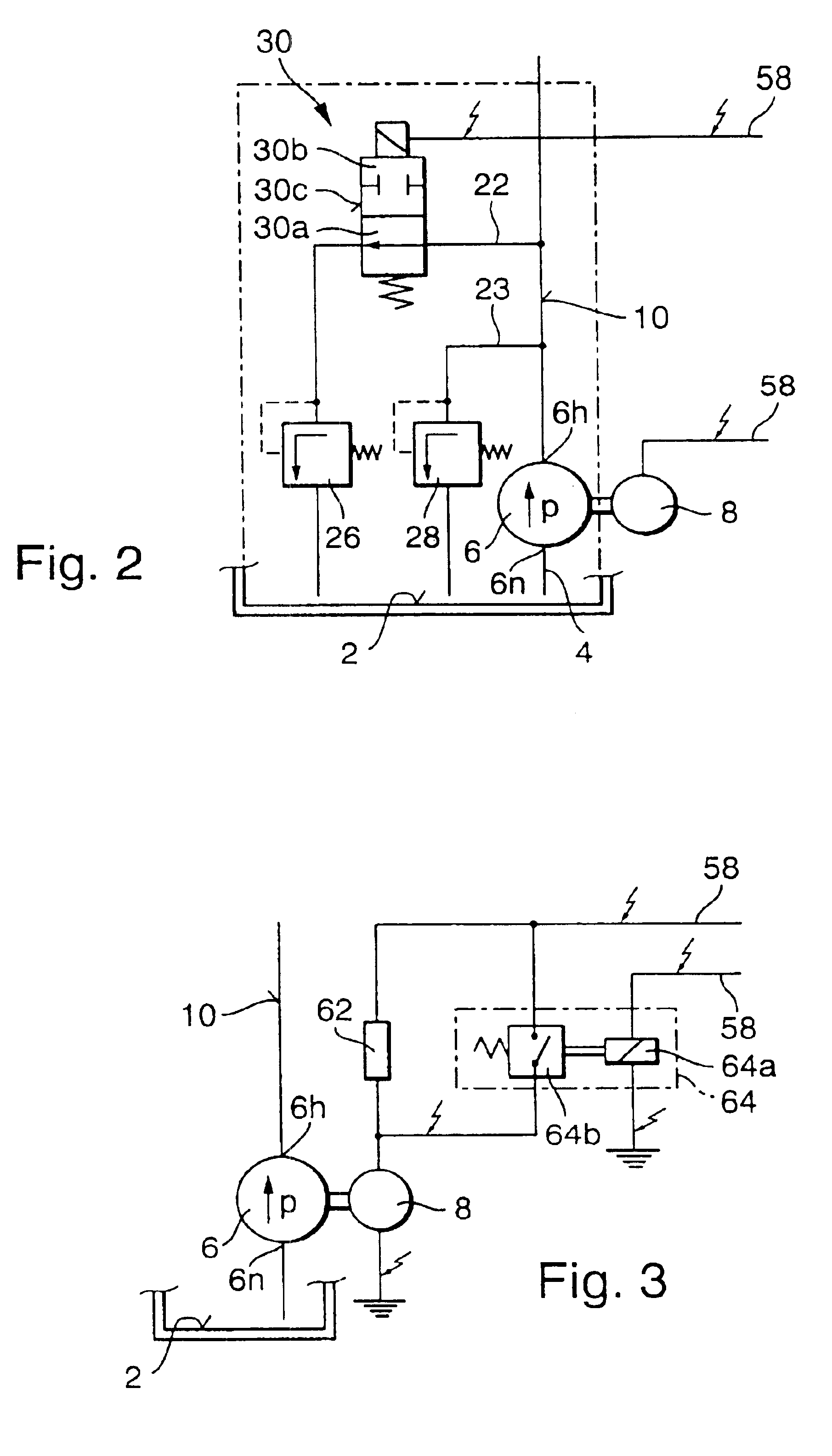

Fuel supply system of an internal combustion engine

InactiveUS6889656B1Reduce startup timeImprove delivery capabilitiesElectrical controlLighting support devicesExternal combustion engineInternal combustion engine

In fuel supply systems with two fuel pumps connected in series and fuel valves that inject directly into the combustion chamber, there have been occasional problems. The proposal is made that in order to eliminate these problems, the first fuel pump operates with increased delivery capacity, particularly during the startup process and in the event of high fuel temperature. The fuel supply system is provided for an internal combustion engine of a vehicle.

Owner:ROBERT BOSCH GMBH

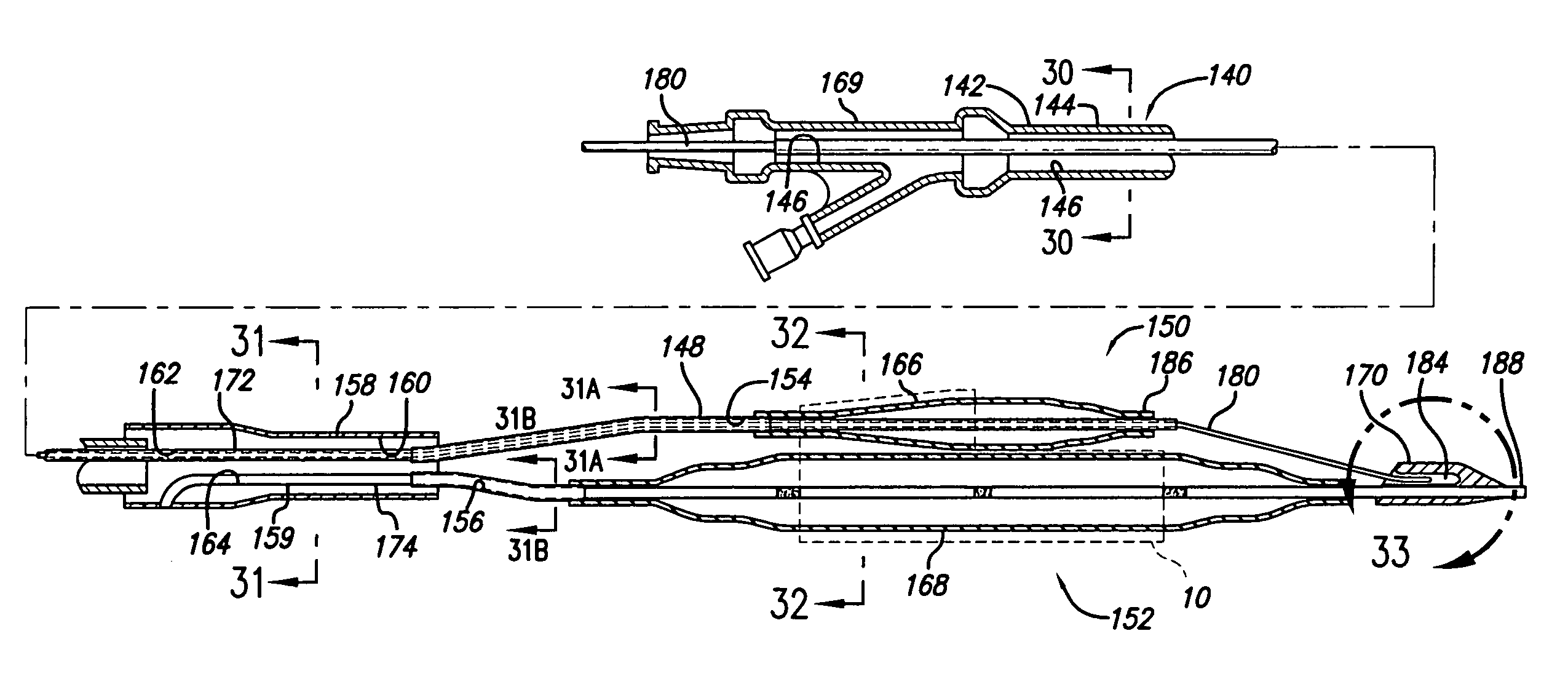

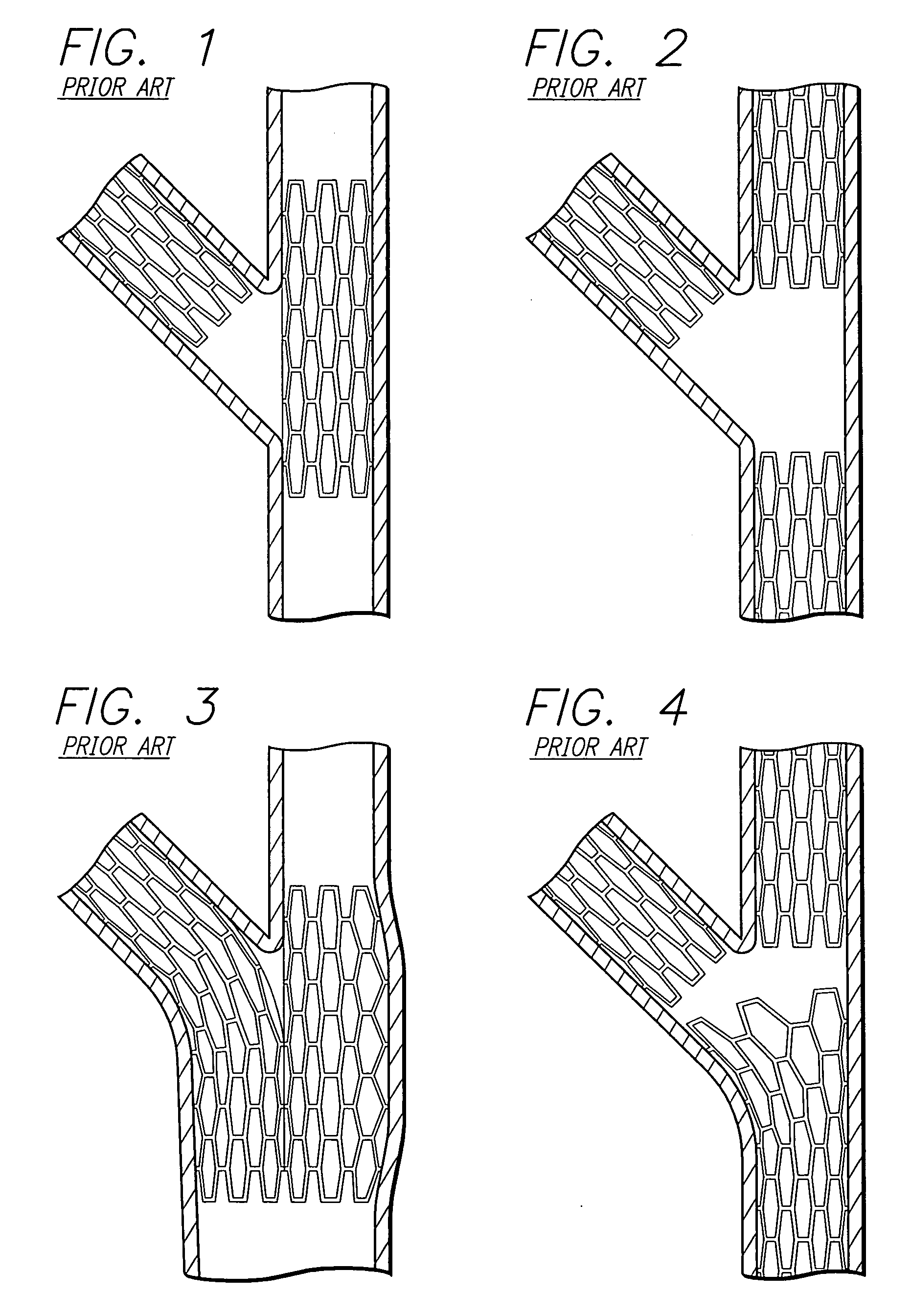

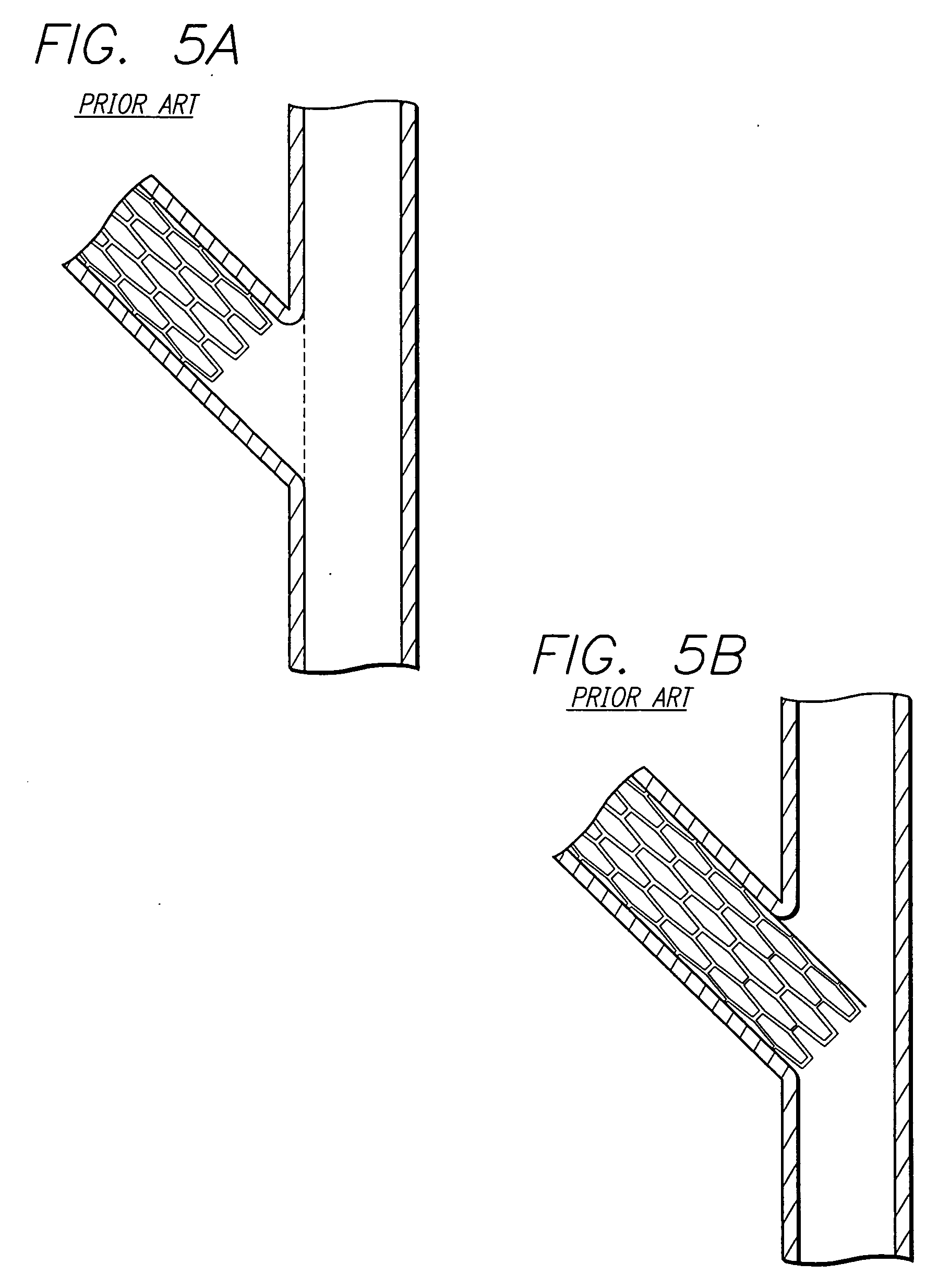

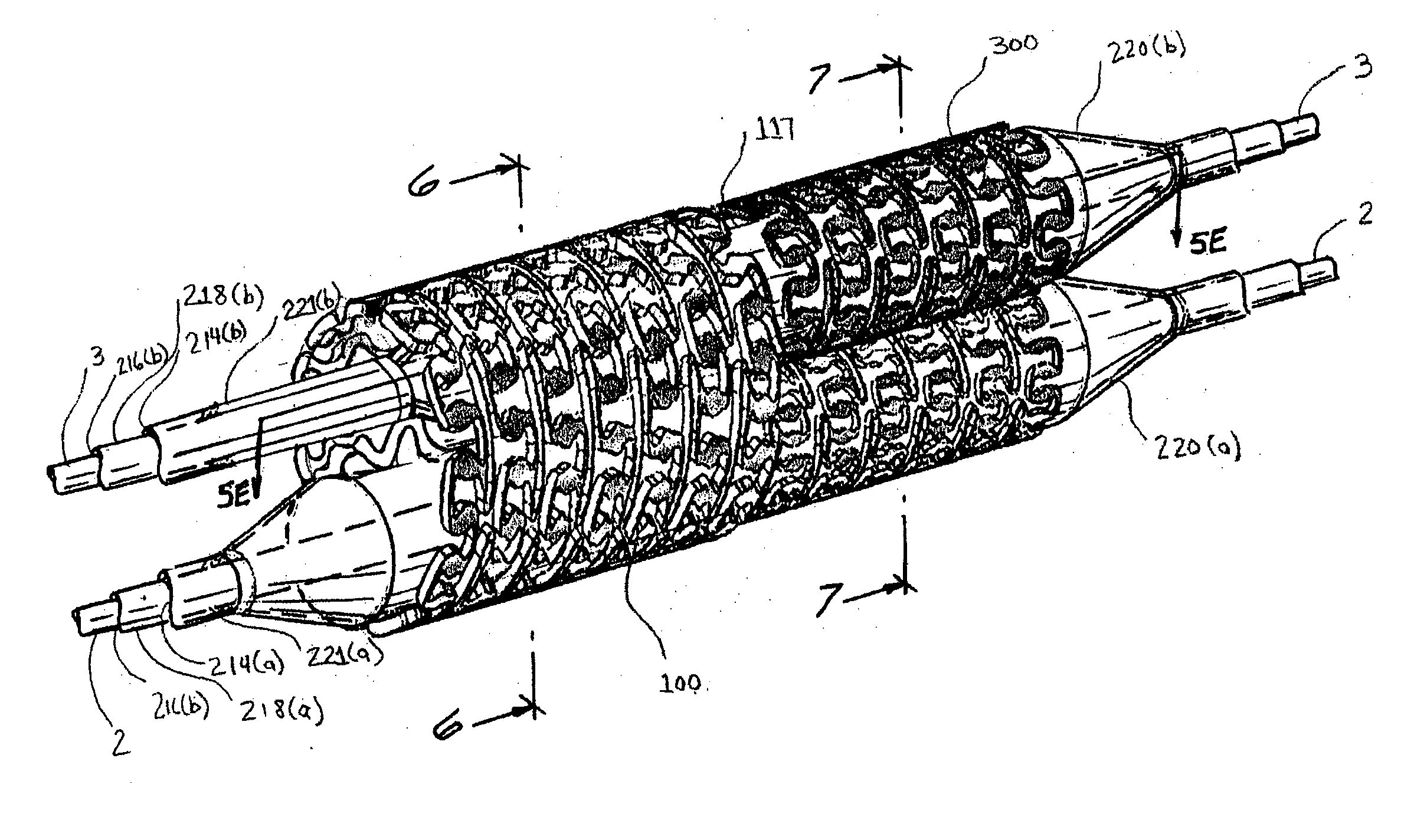

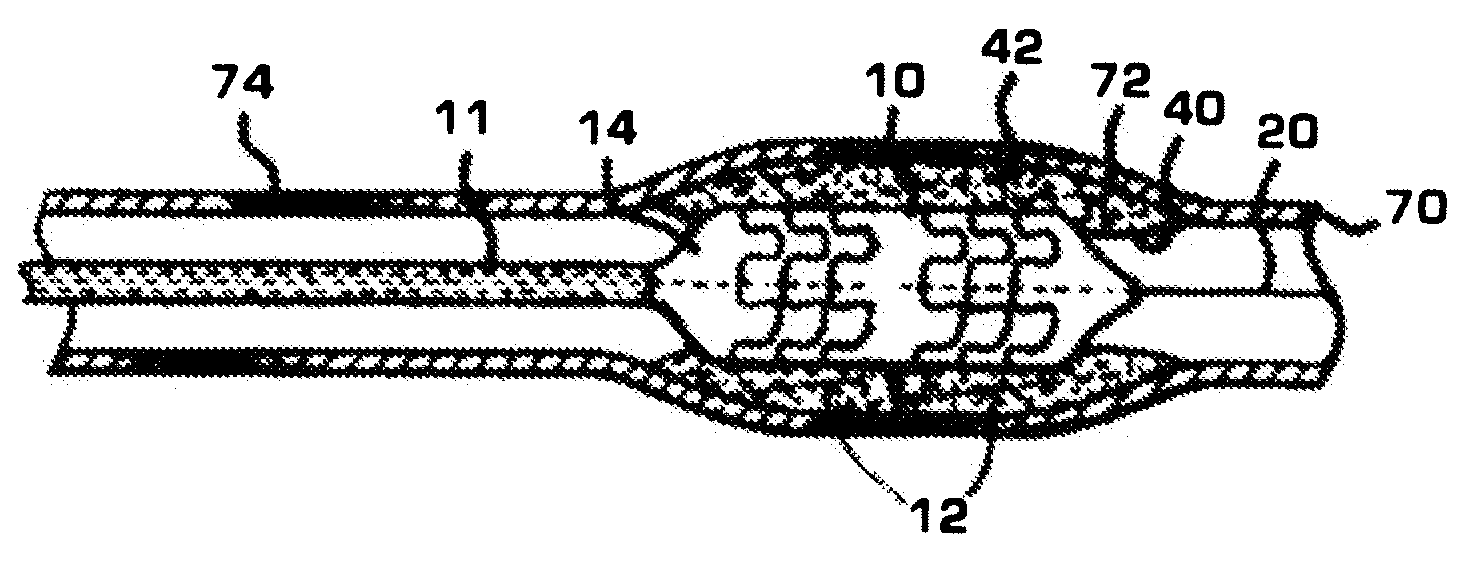

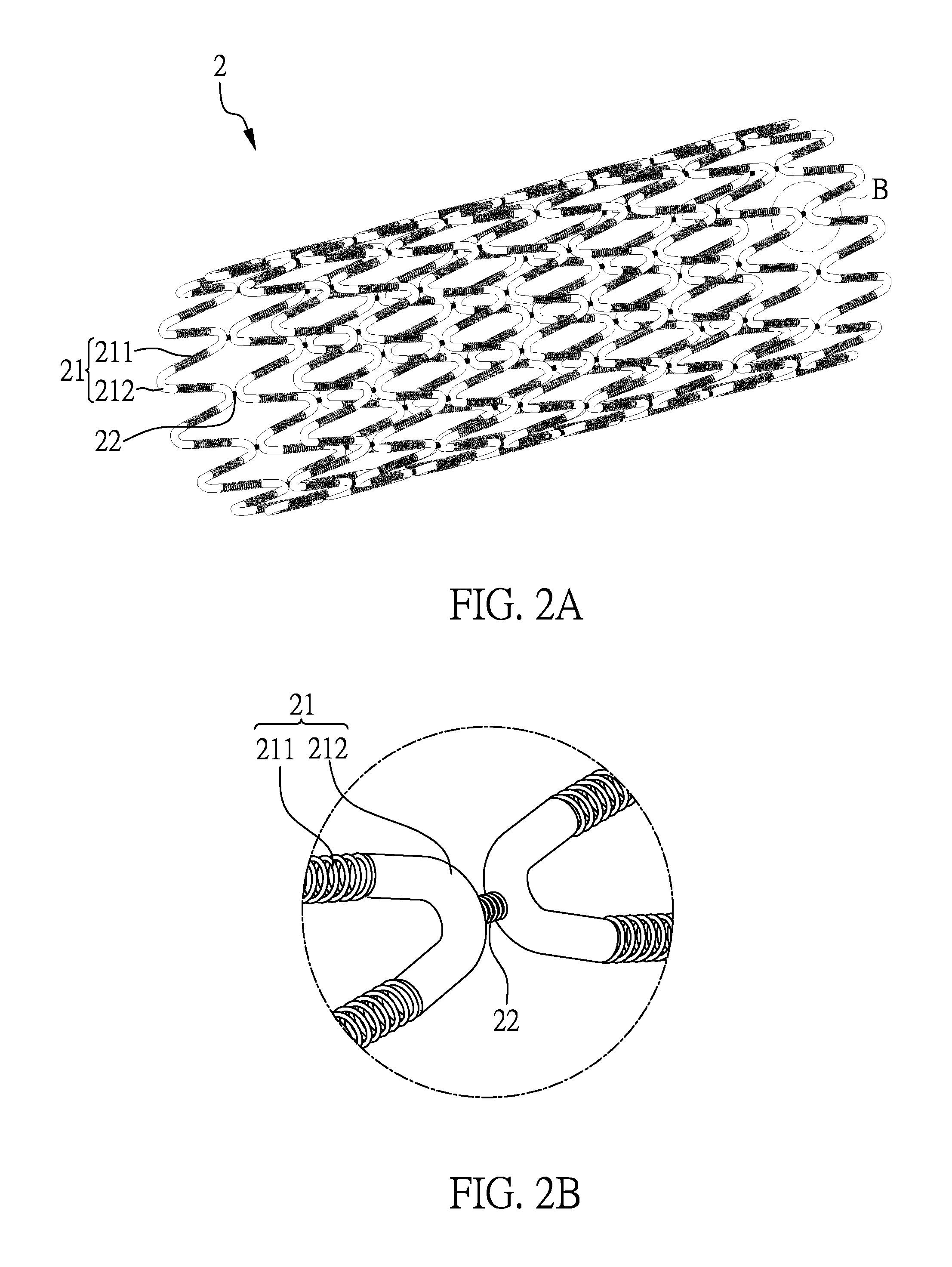

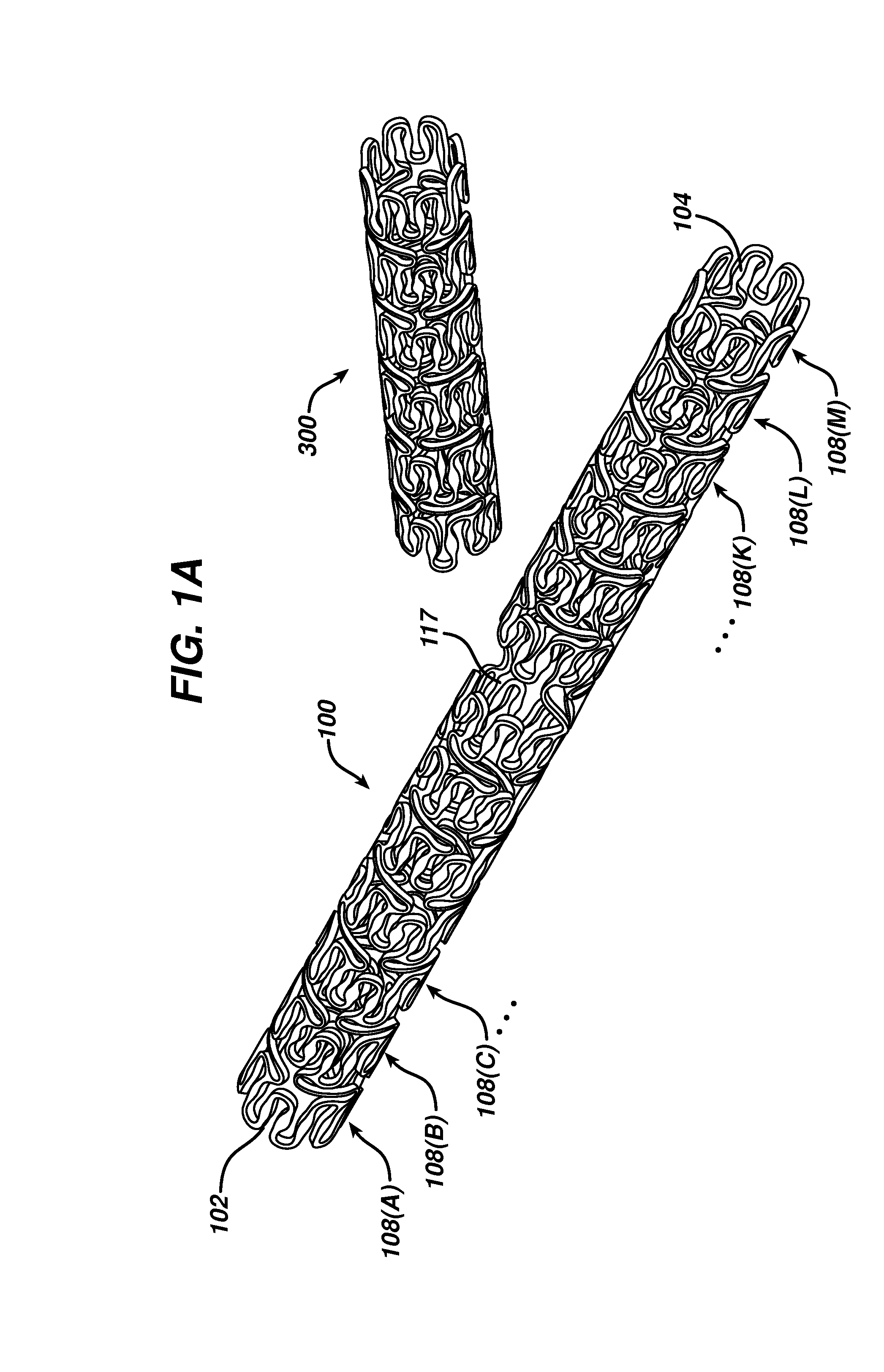

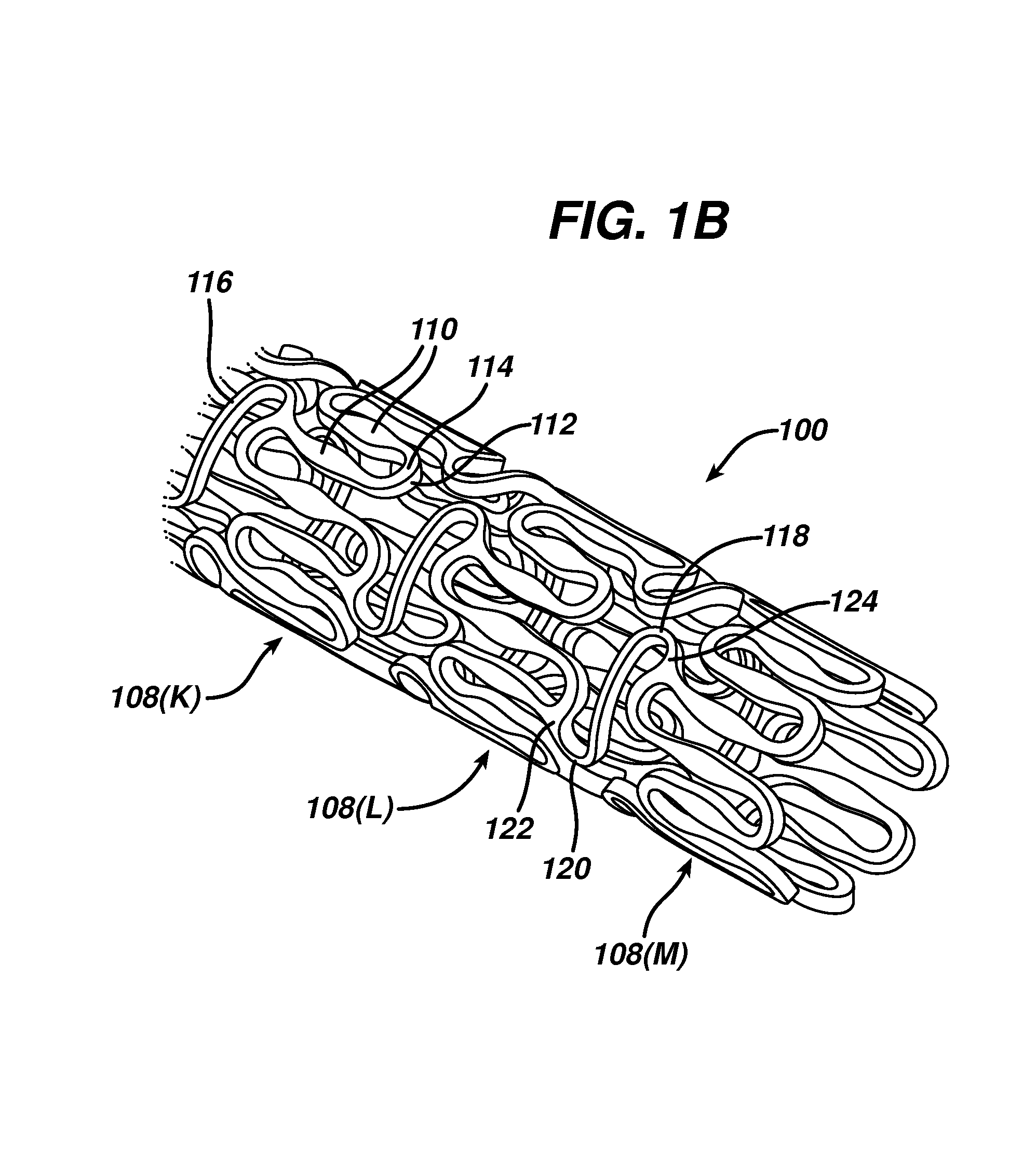

Catheter assembly and method for treating bifurcations

InactiveUS20080009933A1Improve delivery capabilitiesSave effortStentsBlood vesselsInsertion stentBlood vessel

An improved stent design and stent delivery catheter assembly for repairing a main vessel and a side branch vessel forming a bifurcation. The stent includes rings aligned along a common longitudinal axis and connected by links, where the stent has one or more portals for aligning with and partially expanding into the opening to the side branch vessel. The stent is implanted at a bifurcation so that the main stent section is in the main vessel, and the portal section covers at least a portion of the opening to the side branch vessel. A second stent can be implanted in the side branch vessel and abut the expanded central section to provide full coverage of the bifurcated area in the main vessel and the side branch vessel. Radiopaque markers on the stent and on the tip of the delivery catheter assist in aligning the portal section with the opening to the side branch vessel.

Owner:ABBOTT CARDIOVASCULAR

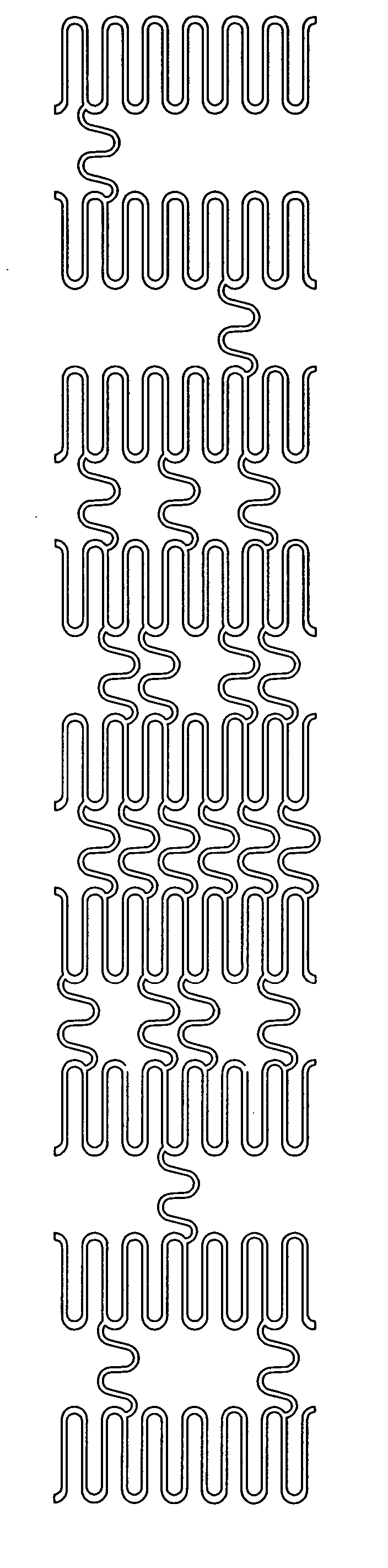

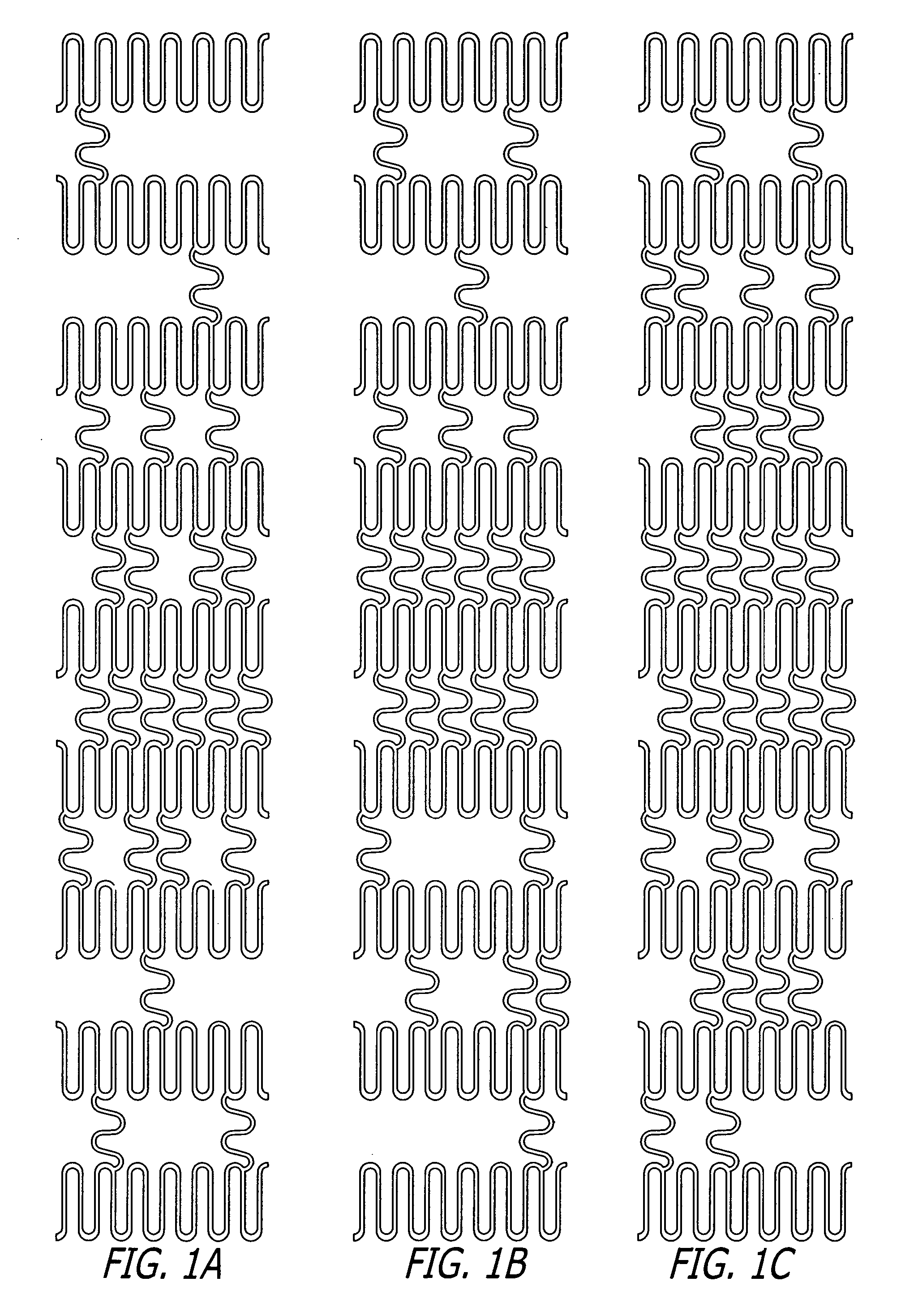

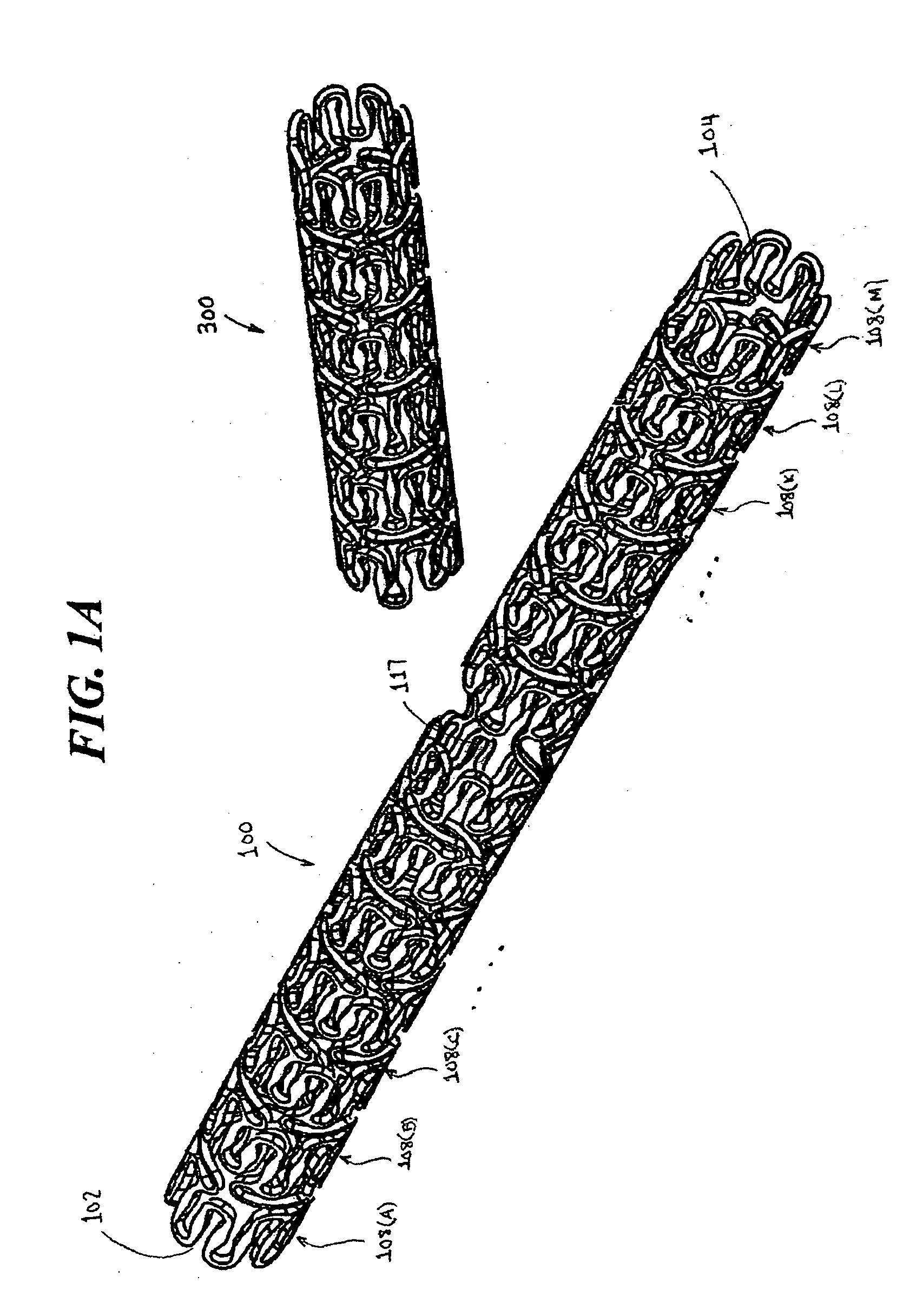

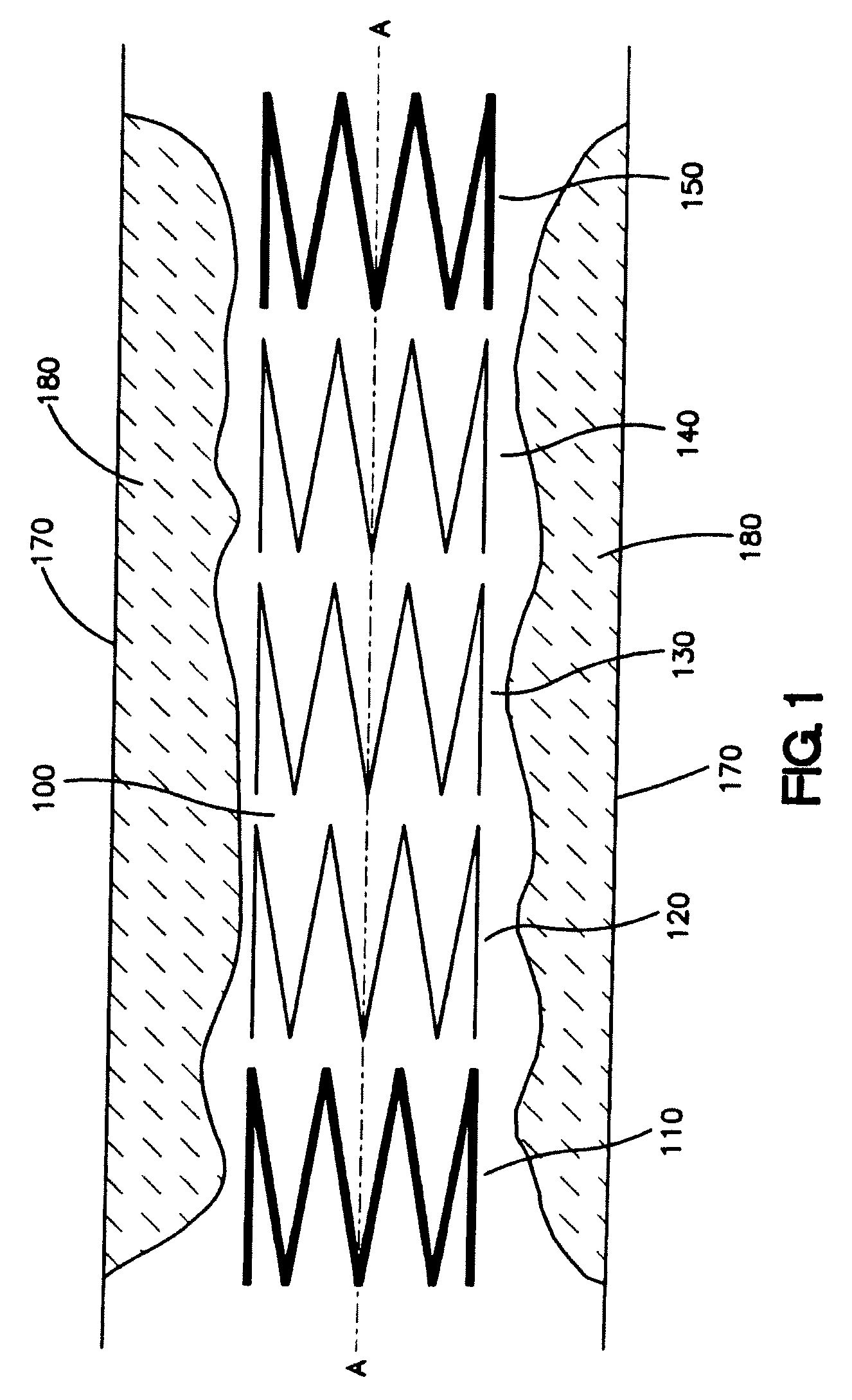

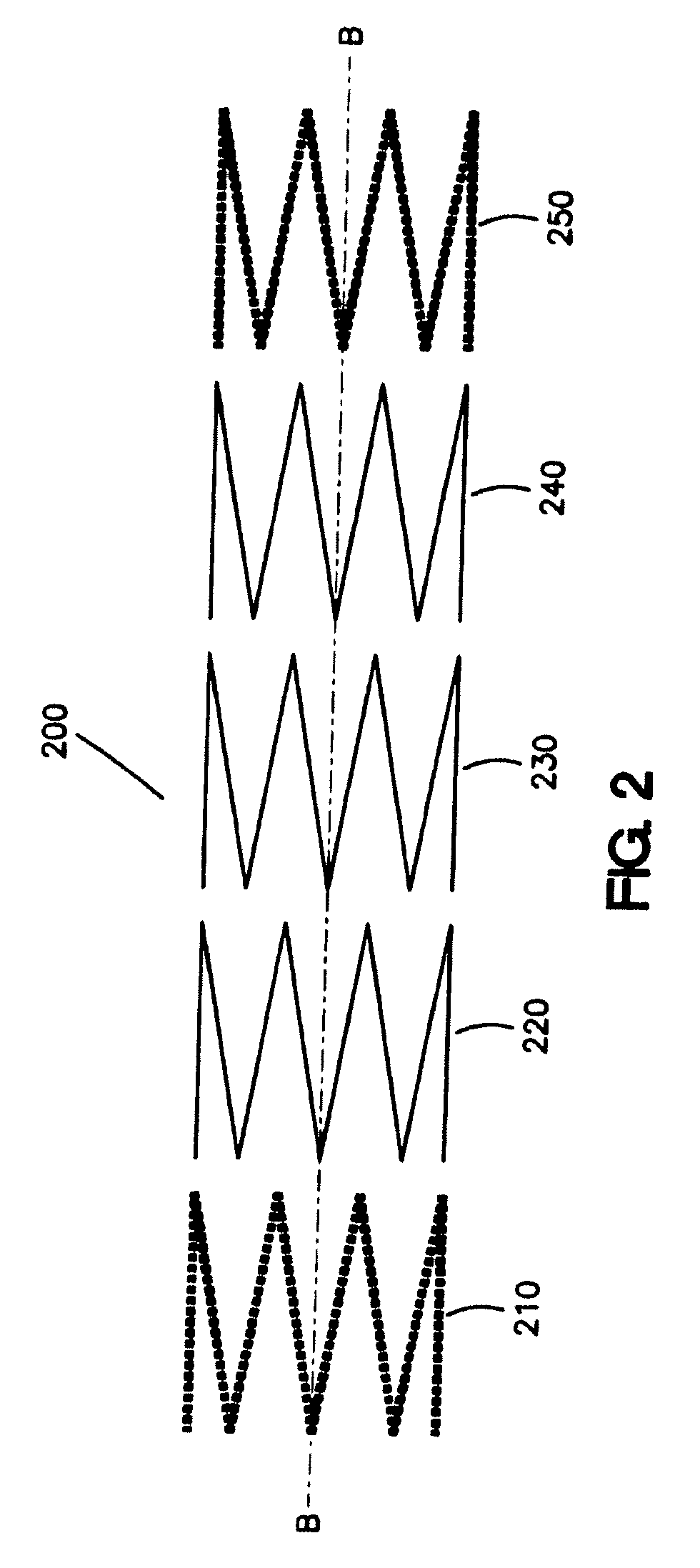

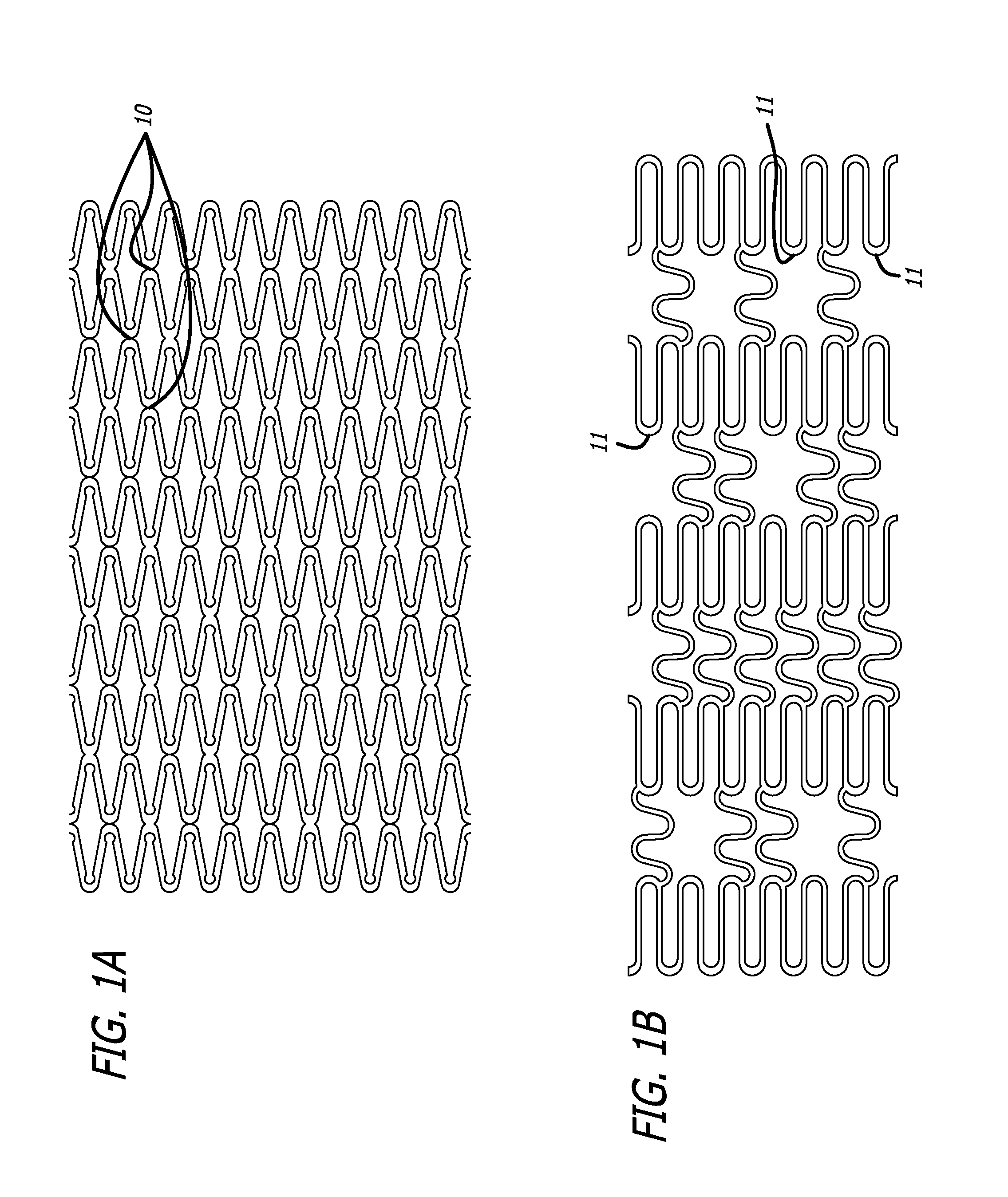

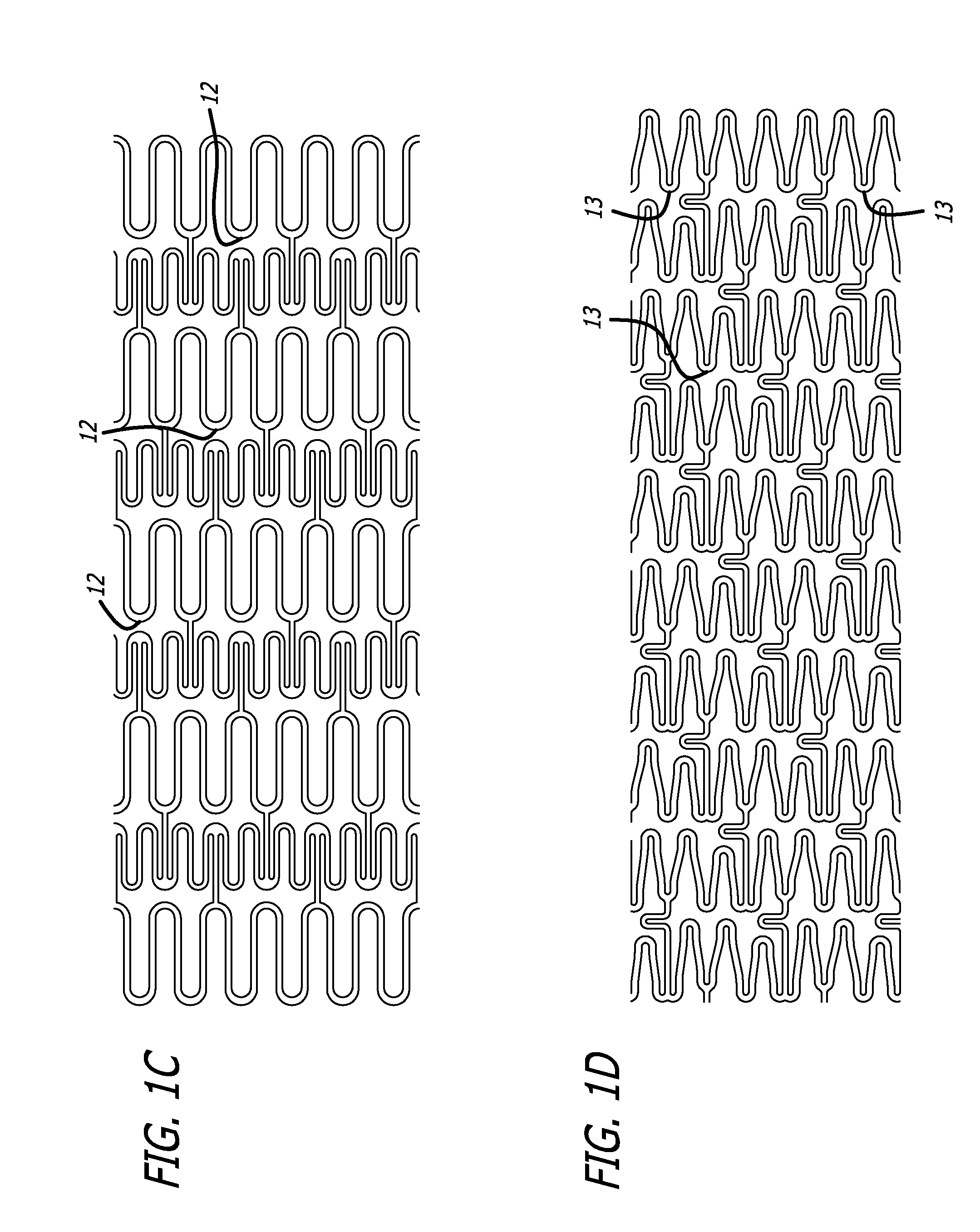

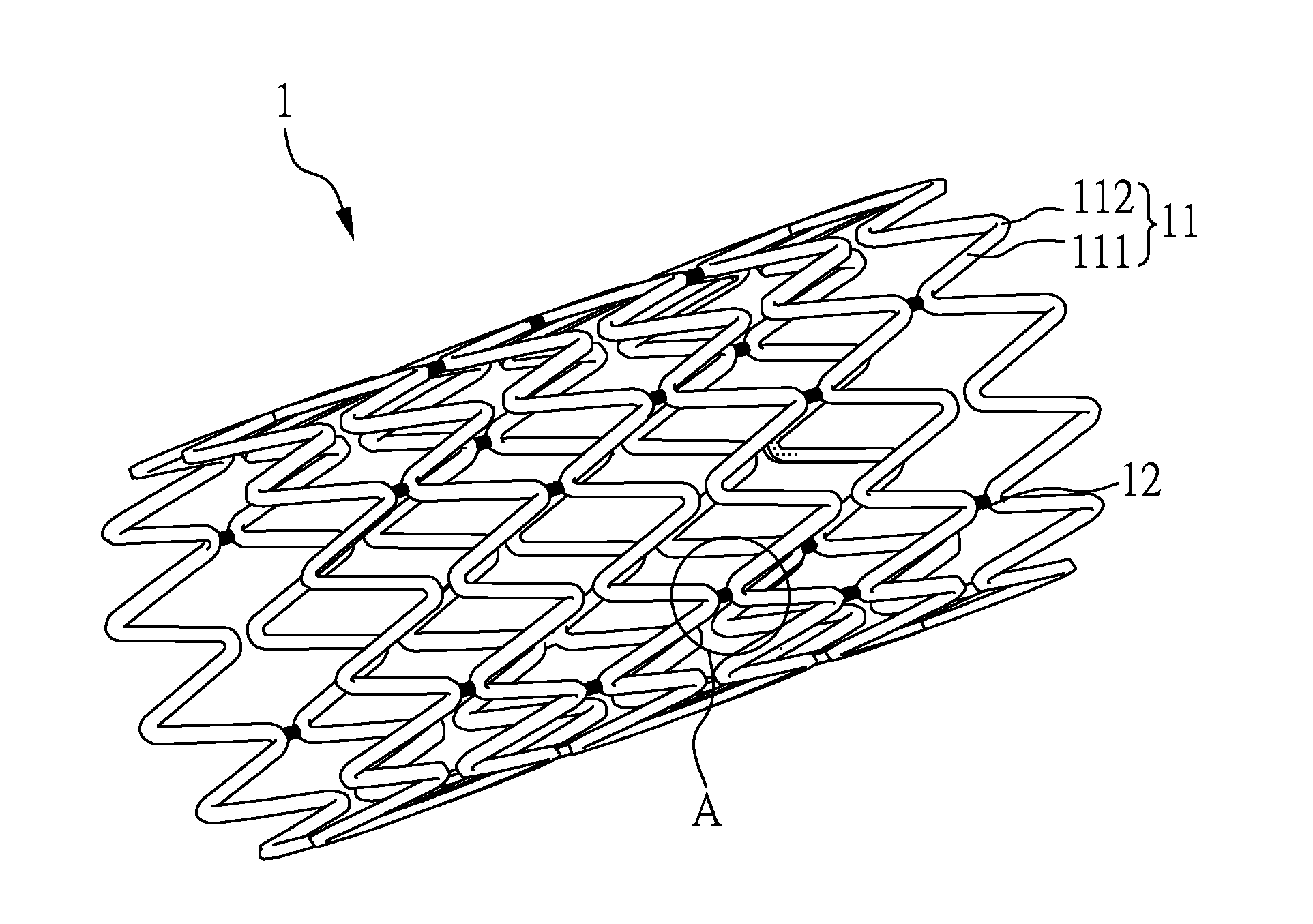

Lumen-supporting stents and methods for creating lumen-supporting stents with various open/closed designs

InactiveUS20070050011A1Great flexibilityImprove deliverabilityStentsBlood vesselsTreatment goalsStent design

Disclosed herein are various open / closed stent designs and methods for creating the same that can be individually adopted depending on particular treatment objectives. Specifically, the stents of the present invention are manufactured to include different open / closed configurations along their length by varying the number of crossovers, connectors or weld points between sections of the stent. Open portions contain less crossovers, connectors or weld points and are more flexible than closed portions which contain more crossovers, connectors or weld points.

Owner:MEDLOGICS DEVICE CORP

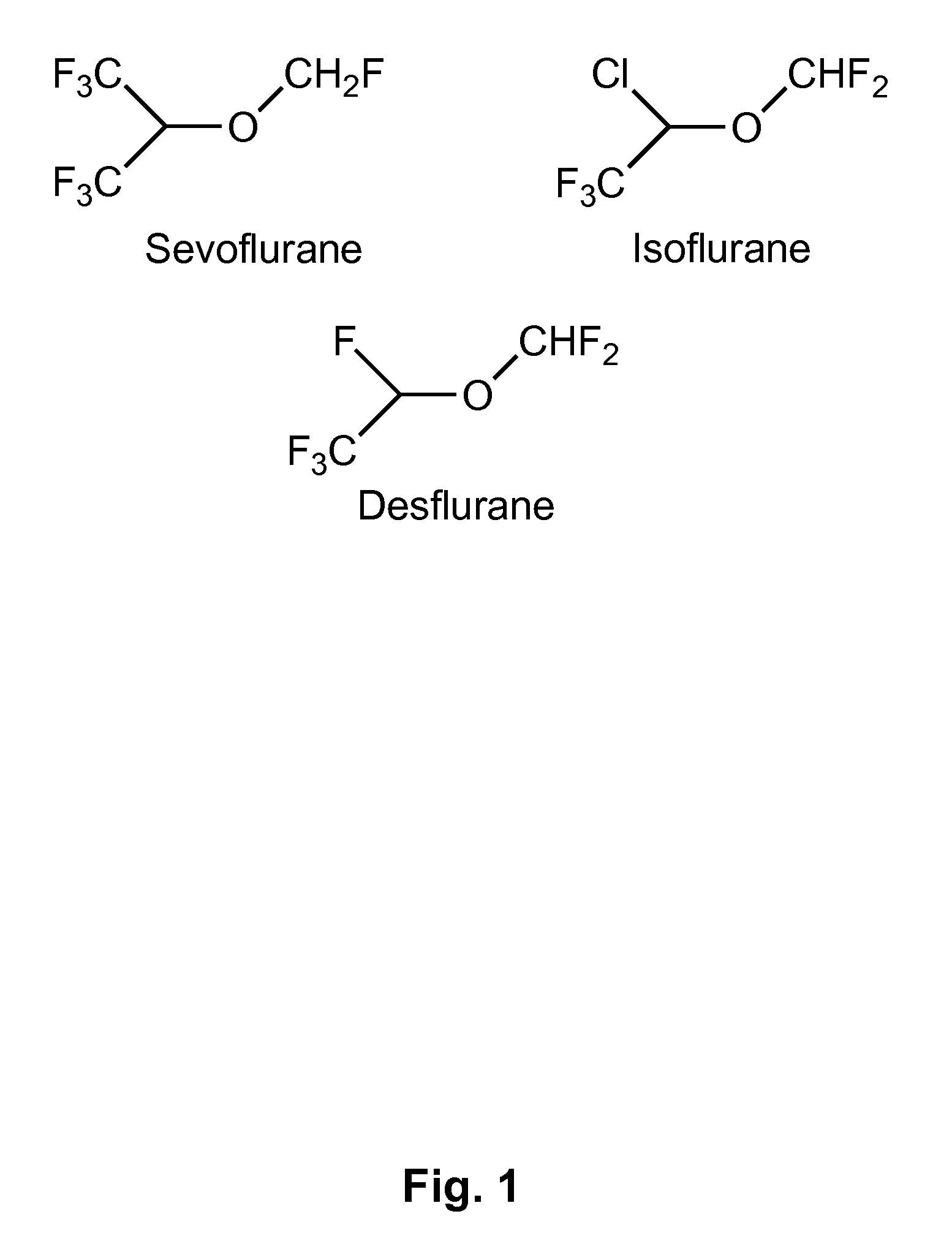

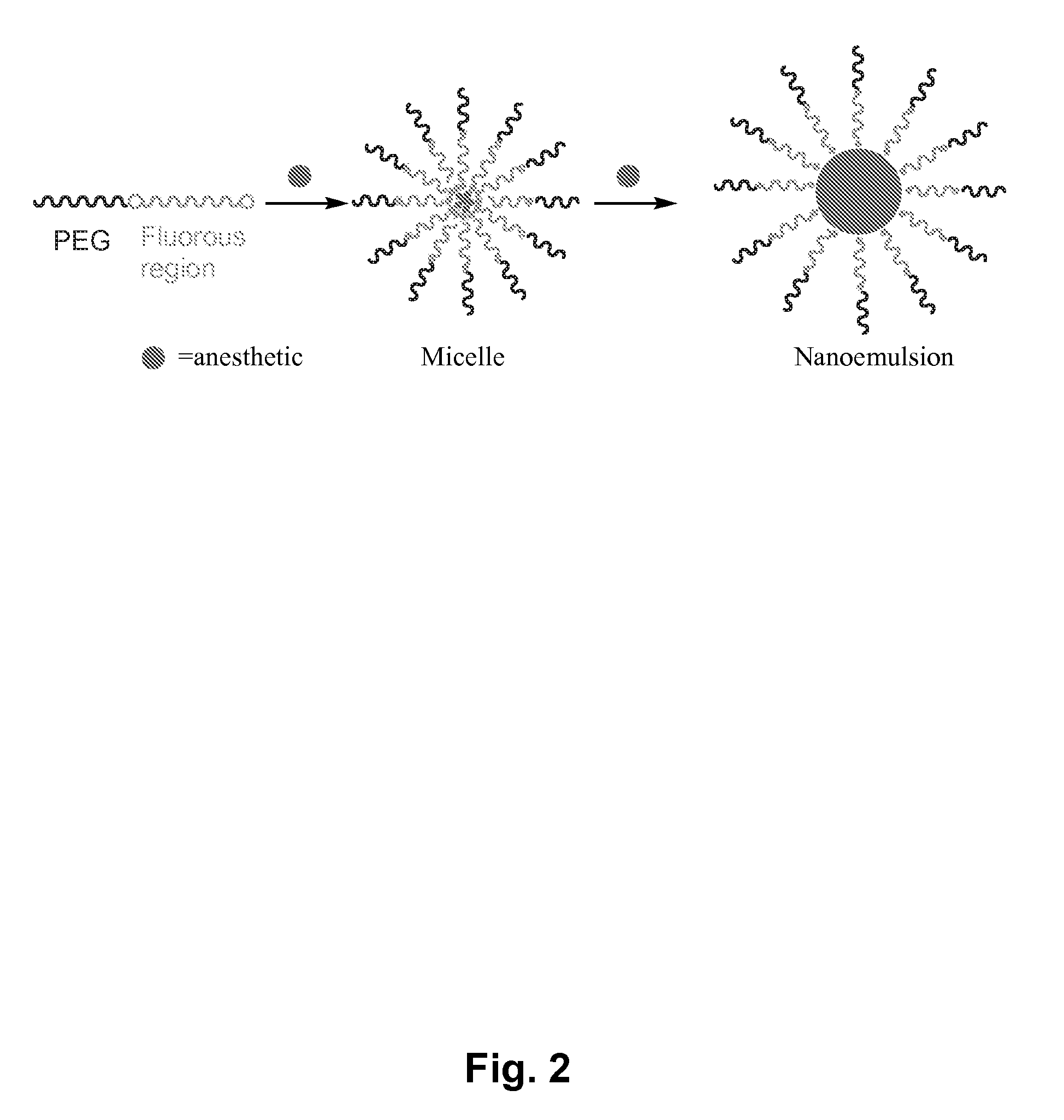

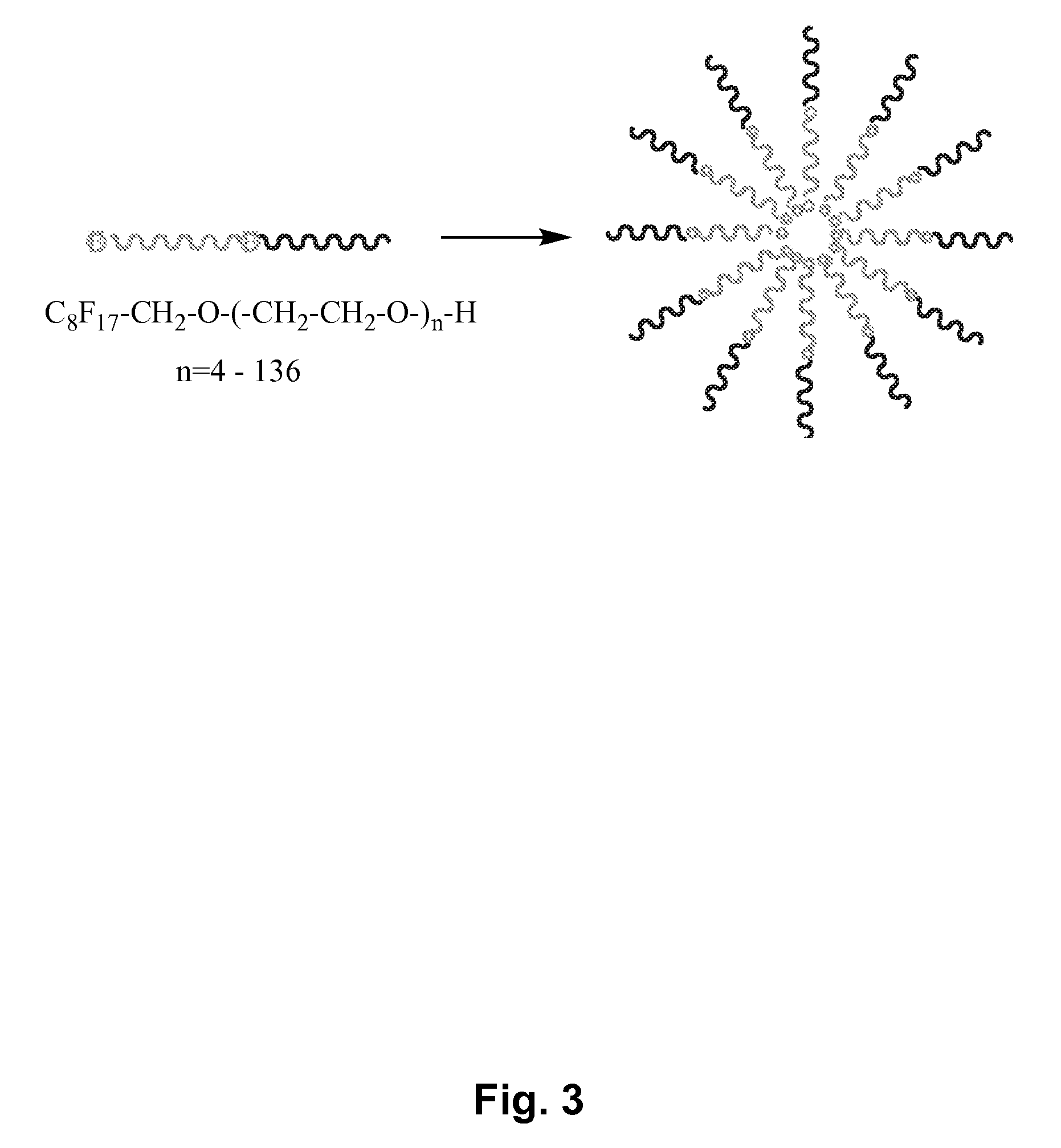

Fluoropolymer-based emulsions for the intravenous delivery of fluorinated volatile anesthetics

InactiveUS20080234389A1Maintenance can be inducedReduce interfacial tensionBiocideNervous disorderAnesthetic AgentEmulsion

The present invention provides therapeutic formulations, including therapeutic emulsions and nanoemulsions, and related methods for the delivery of fluorinated therapeutic compounds, including an important class of low boiling point perfluorinated and / or perhalogenated volatile anesthetics. Emulsion-based fluorinated volatile anesthetic formulations compatible with intravenous administration are provided that are capable of delivering and releasing amounts of fluorinated volatile anesthetic compounds effective for inducing and maintaining anesthesia in patients. Intravenous delivery of the present emulsion-based fluorinated volatile anesthetic formulations permits anesthetic levels in a patient to be selectively adjusted very rapidly and accurately without the need to hyperventilate patients and without the use of irritating agents.

Owner:WISCONSIN ALUMNI RES FOUND

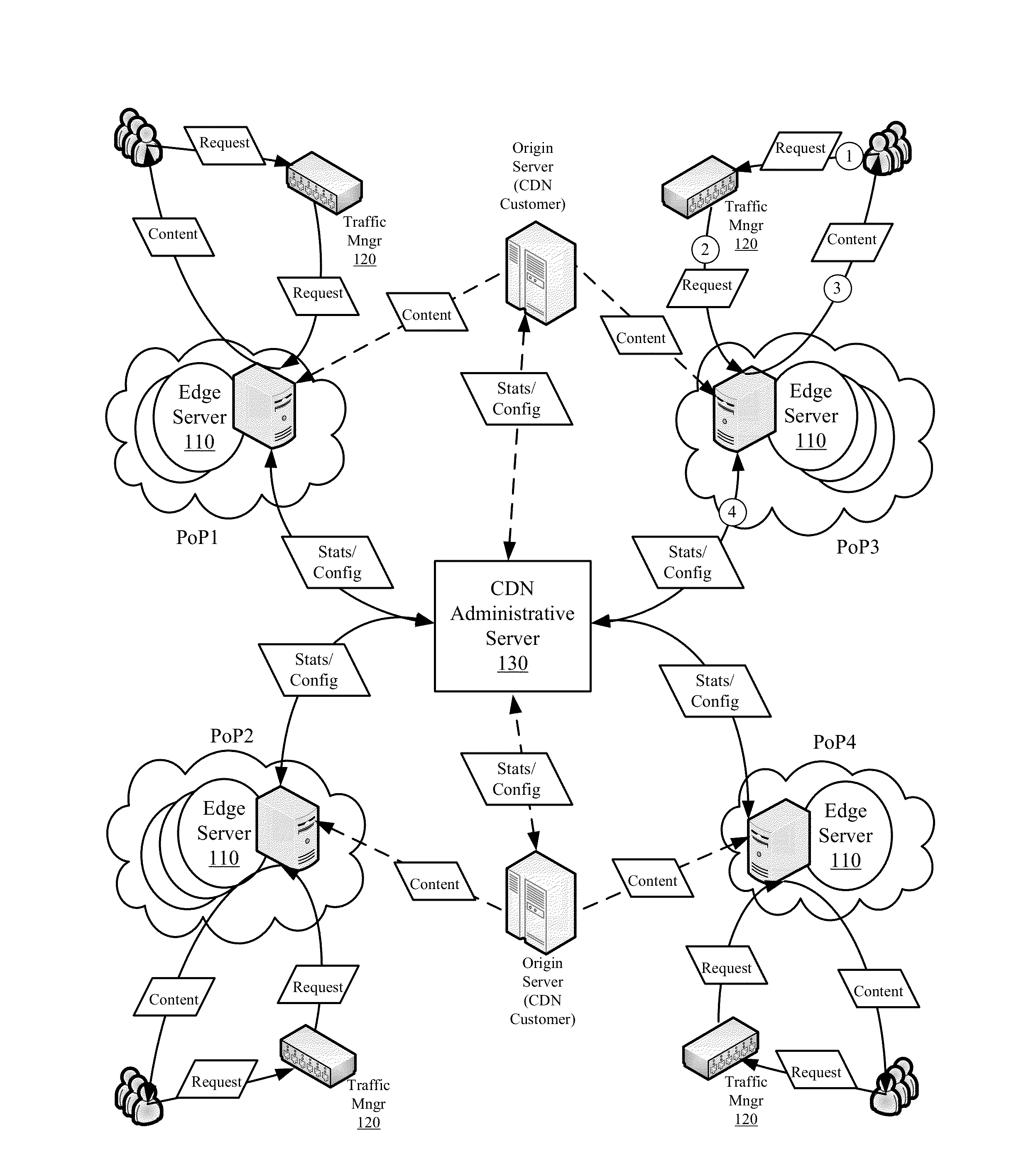

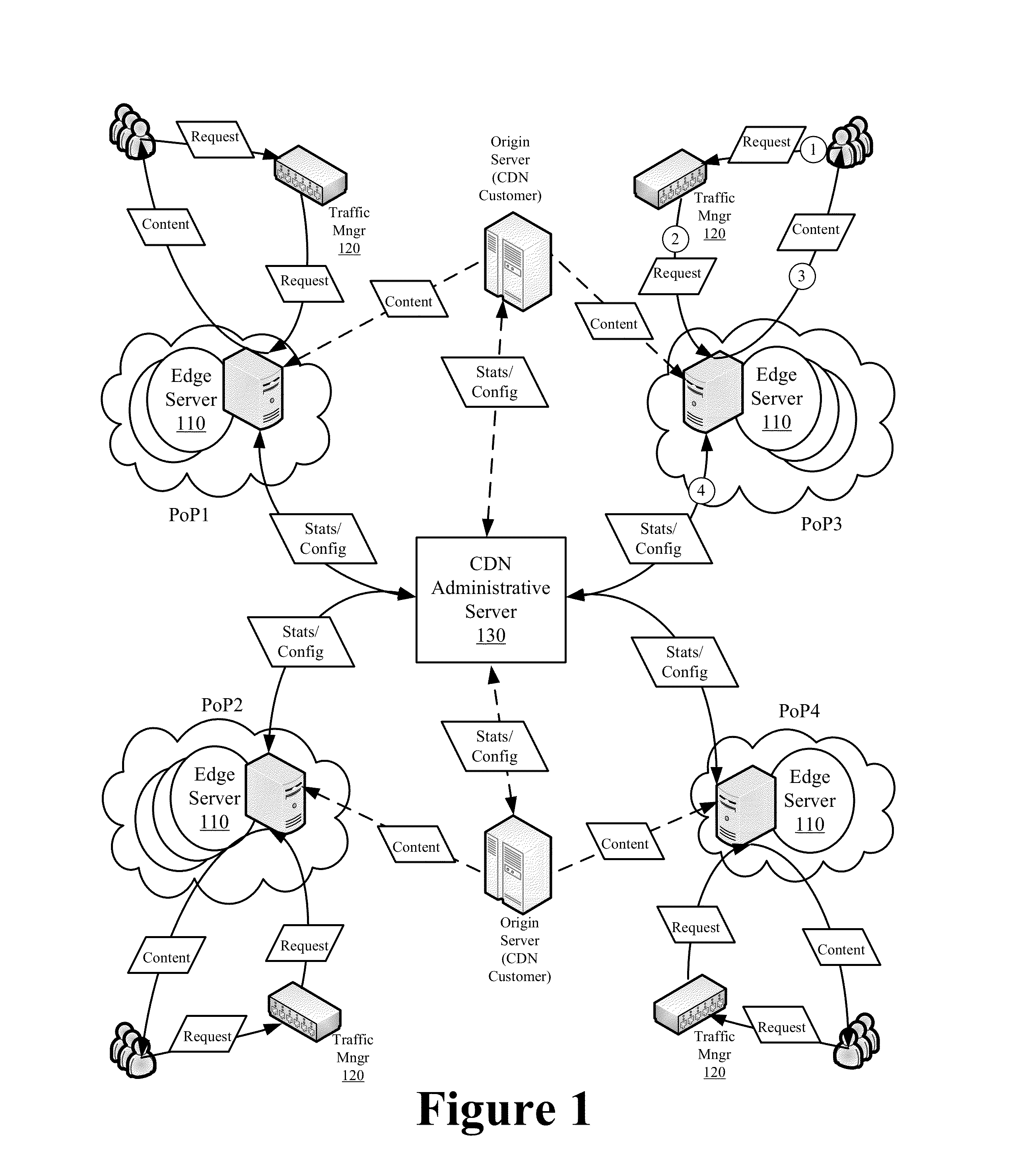

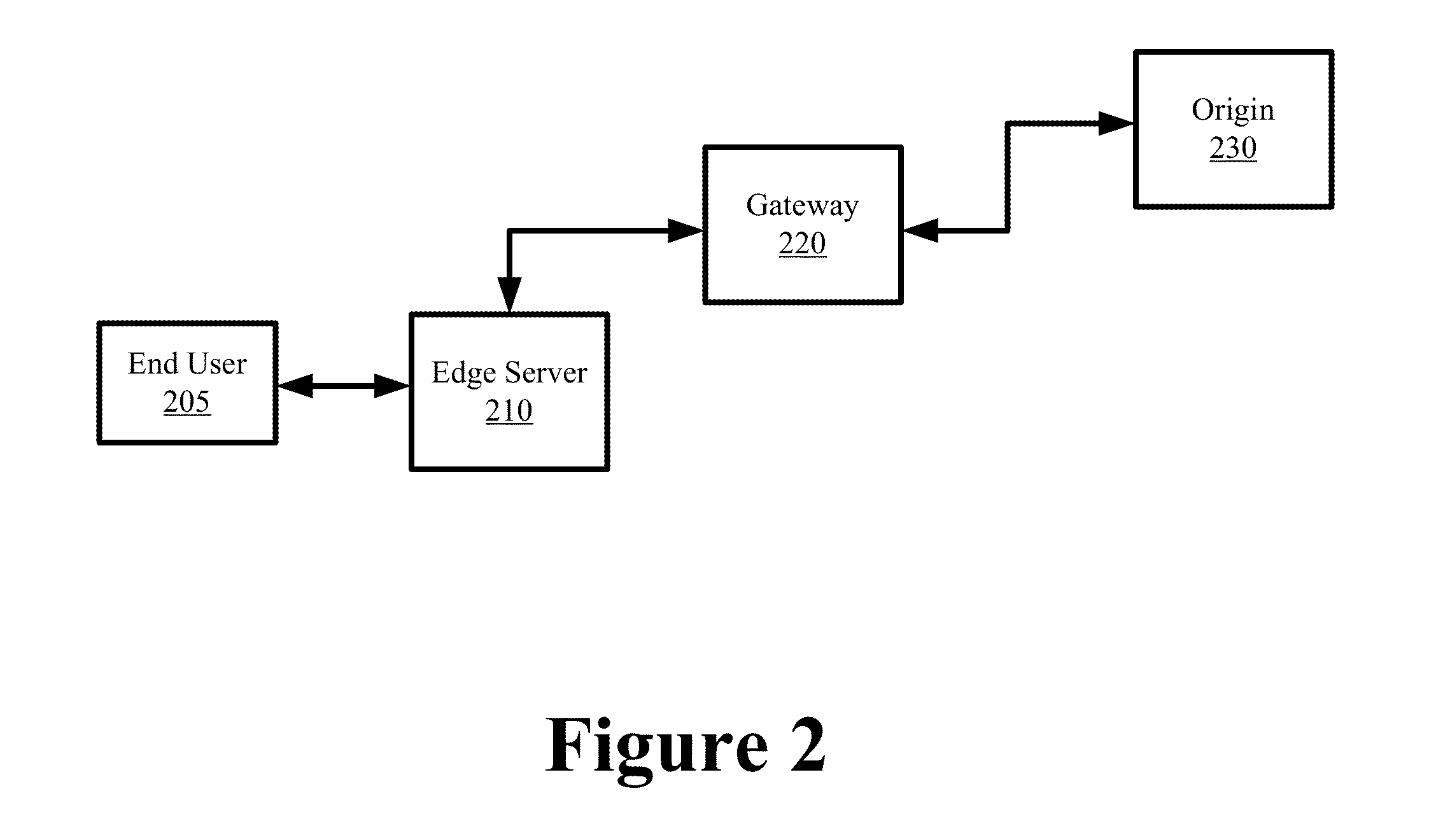

Efficient Cache Validation and Content Retrieval in a Content Delivery Network

ActiveUS20140095804A1Enhanced content deliveryIncrease contentError detection/correctionMemory adressing/allocation/relocationContent retrievalChecksum

Some embodiments provide systems and methods for validating cached content based on changes in the content instead of an expiration interval. One method involves caching content and a first checksum in response to a first request for that content. The caching produces a cached instance of the content representative of a form of the content at the time of caching. The first checksum identifies the cached instance. In response to receiving a second request for the content, the method submits a request for a second checksum representing a current instance of the content and a request for the current instance. Upon receiving the second checksum, the method serves the cached instance of the content when the first checksum matches the second checksum and serves the current instance of the content upon completion of the transfer of the current instance when the first checksum does not match the second checksum.

Owner:EDGIO INC

Apparatus for treating a bifurcated region of a conduit

ActiveUS20070219611A1Improved deliverabilityMinimizing effectStentsBlood vesselsProsthesisBiomedical engineering

A system for treating a diseased body conduit bifurcation that is readily deliverable into a region of a body conduit having typically asymmetric anatomy, such as a vessel bifurcation is provided. The system comprises a delivery device such as a catheter having a shaft with varying torsional properties along its length and a delivery apparatus mounted at its distal end. A distal end of the device can be inserted into the main branch and at least one side branch of a vessel bifurcation. The distal end includes at least two expansion members having expandable scaffolds or prostheses mounted thereon. One scaffold is configured such that one expansion member extends through the length of the scaffold while the other expansion member extends through the side-structure of the scaffold. A second scaffold is mounted on the expansion member extending through the side-structure of the first scaffold.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

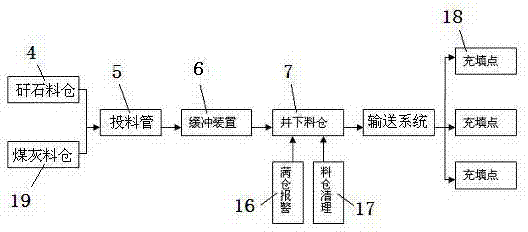

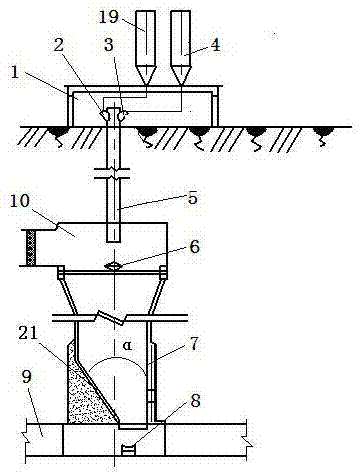

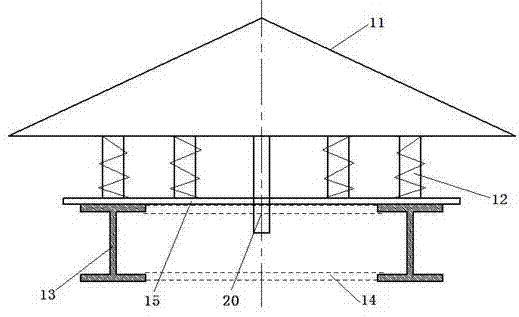

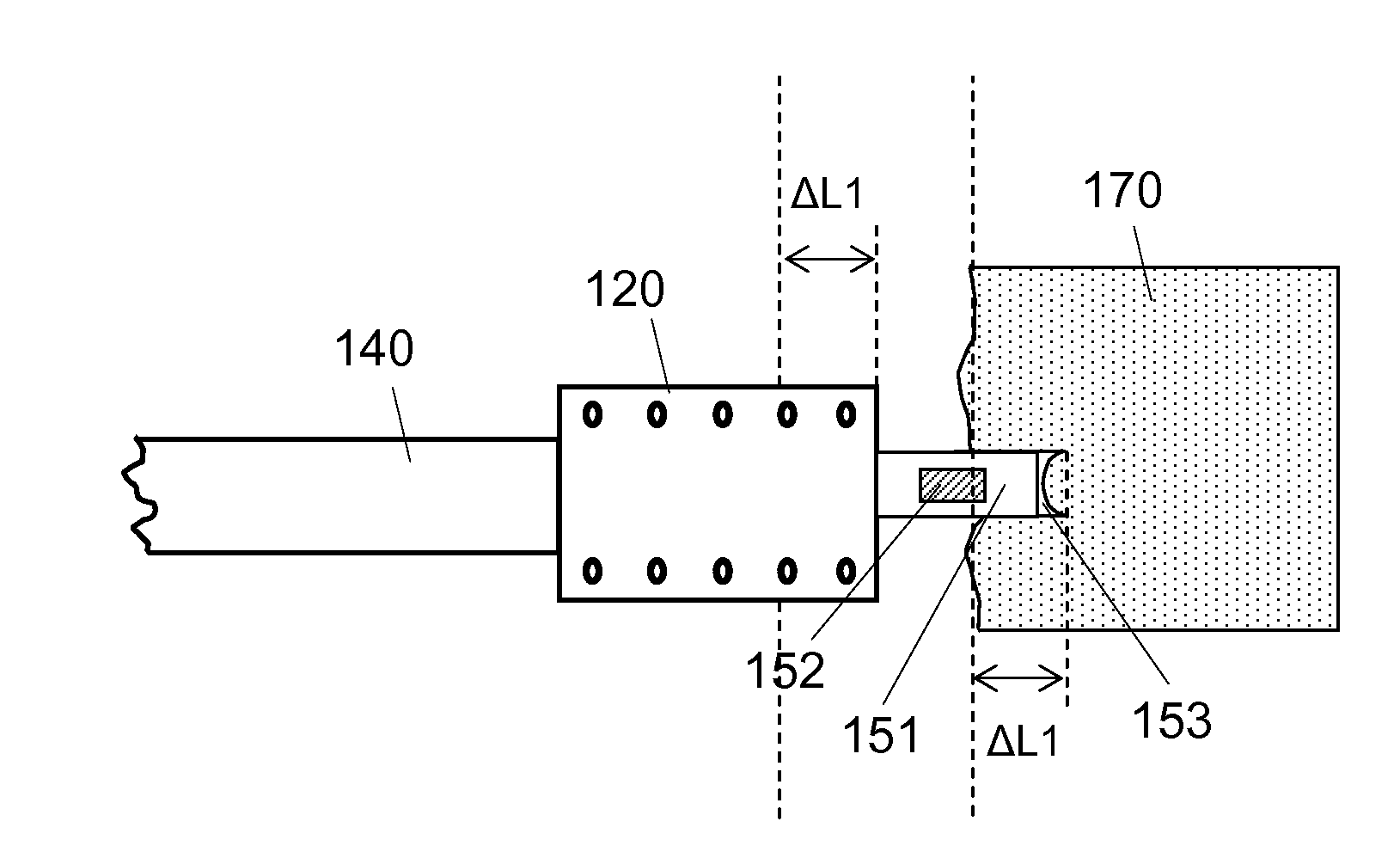

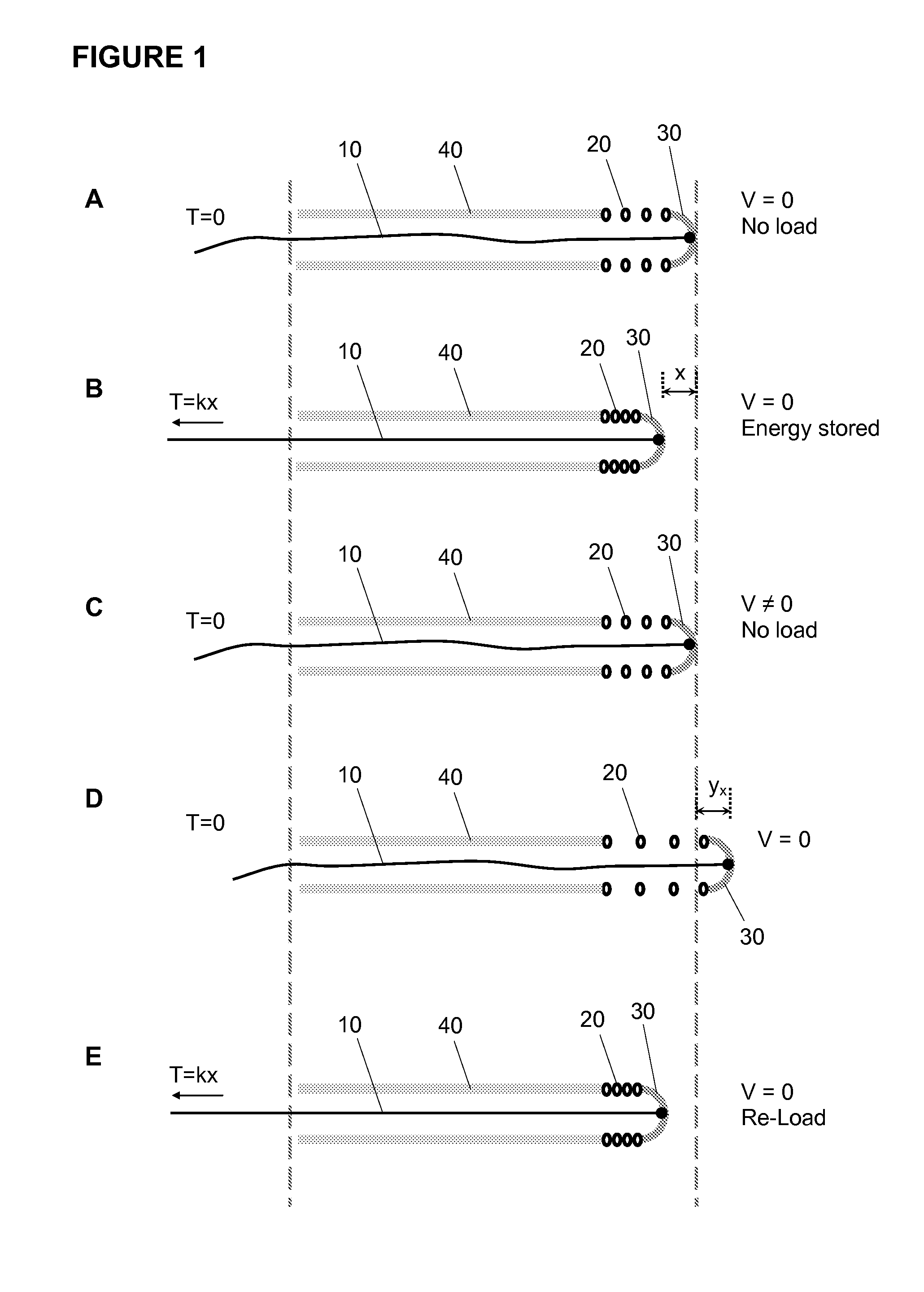

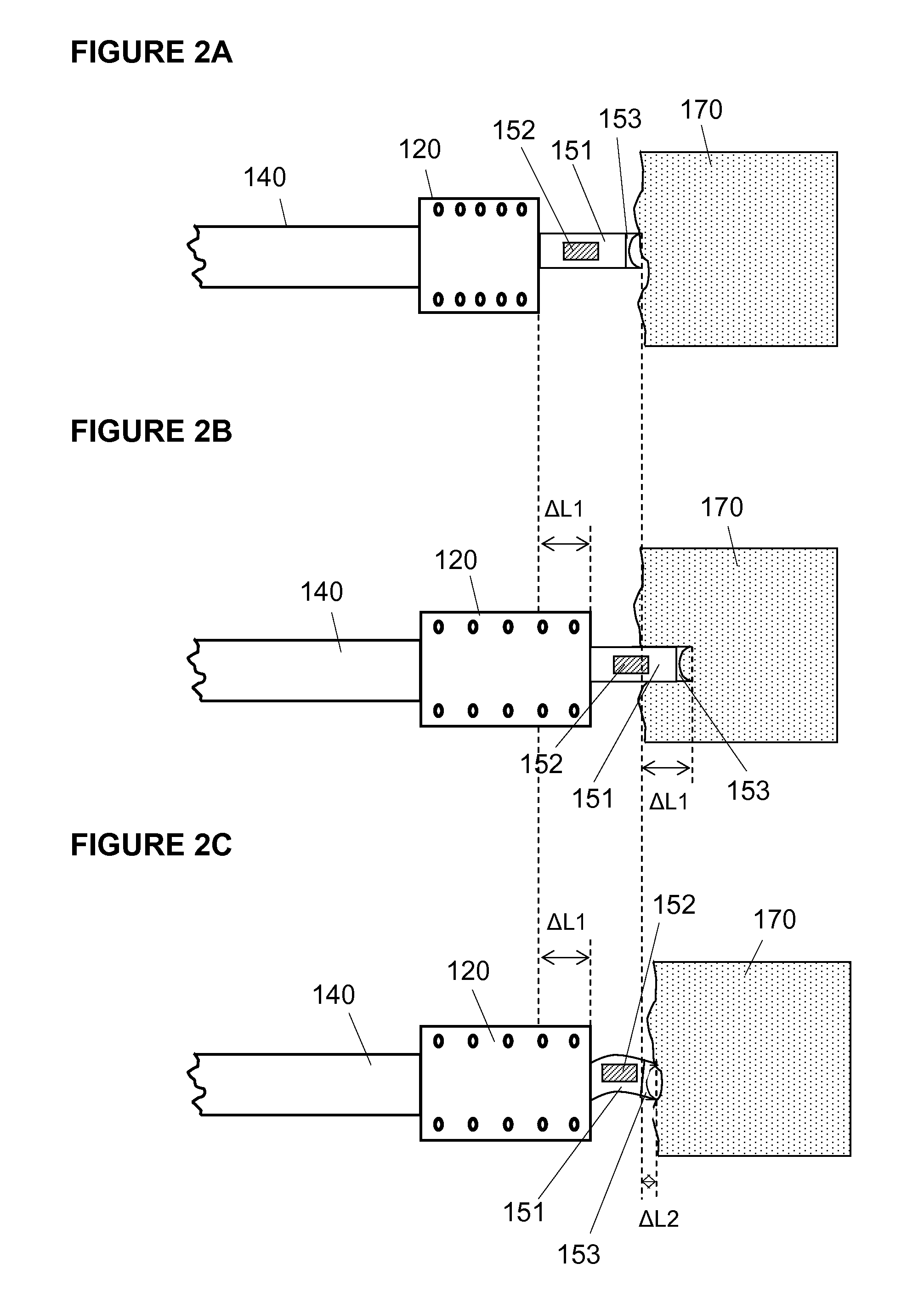

System for feeding coal mine solid filling material

InactiveCN102889097AImprove delivery capabilitiesAvoid cloggingMaterial fill-upFilling materialsClosed chamber

The invention relates to a system for feeding a coal mine solid filling material. The system comprises a filling control chamber, a gangue material bin, a coal ash material bin, a feeding pipe, an underground closed chamber, an impact resistance buffering device, an underground material bin and an underground conveying system, wherein the impact resistance buffering device is positioned at the bottom of the underground closed chamber; the feeding pipe is connected with the underground material bin through the underground closed chamber; the underground material bin is connected with the underground conveying system; the underground conveying system comprises a conveying passage and a conveyer; the conveyer is connected to a filling point; the feeding pipe consists of a protection hole wall steel pipe and a double-layer anti-abrasion pipe; a ceramic anti-abrasion pipe is sleeved on a shrinkage wall at the bottom of the underground material bin; and an outwards discharging type air guide hose is arranged at the upper opening of the underground material bin. According to the system, a large-aperture perpendicular feeding pipe is used for feeding the material, so that the feeding capacity of the filling material is improved, and a filling effect and the safety are improved; by the umbrella-shaped impact resistance buffering device, falling impact force of the filling material can be relieved; the compactness of the filling material in the bin can be reduced; and the bins can be prevented from being plugged.

Owner:HEBEI COAL SCI RES INST

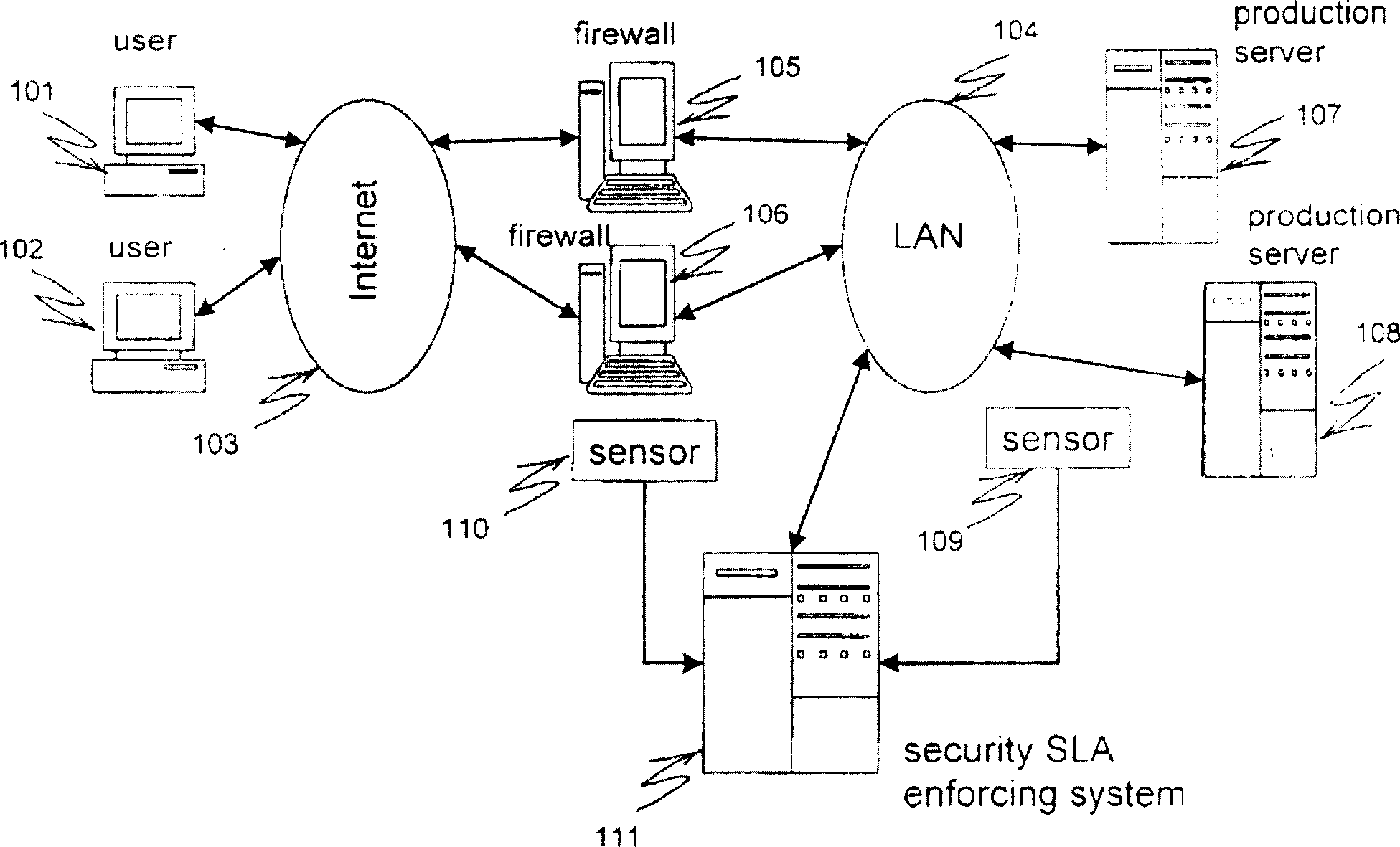

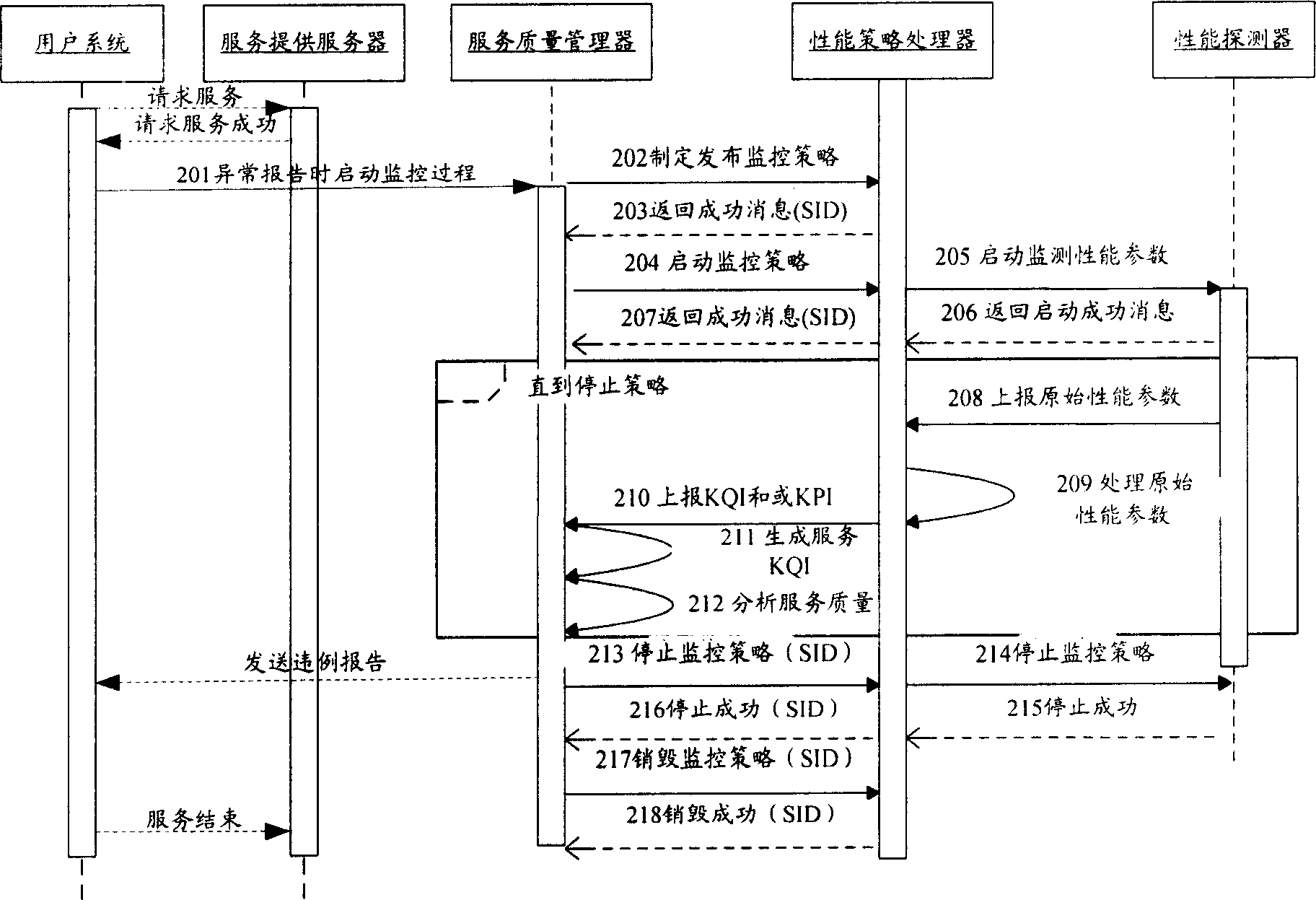

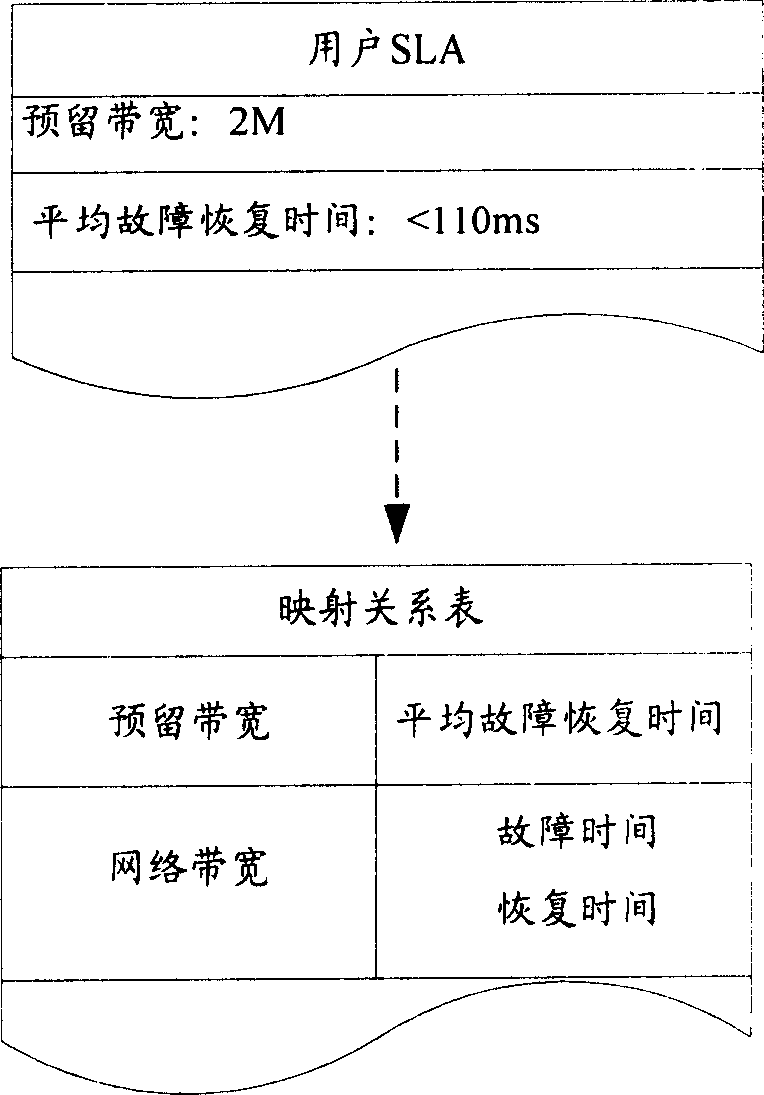

Method and system for monitoring service quality according to service level protocol

InactiveCN1859227AReal-time monitoring of operating conditionsImprove satisfactionData switching networksService-level agreementDistributed computing

The present invention discloses method and system to make monitoring to communication service quality according to service level agreement SLA. It contains configuring service quality manager in service provider SP network, configuring performance strategy processor in service transmission network; said service quality manager according to need insured SLA to establish monitoring strategy and issuing to performance strategy processor in service transmission network; performance strategy processor according to said monitoring strategy to make monitoring collection to performance parameter in service transmission network, and reporting said monitoring collected information to service quality manager; service quality manager according to reported performance parameter determining SLA corresponded service quality. The present invention can realize monitoring service transmission network service quality according to SLA in wide area network environment, thereby effectively ensuring SLA.

Owner:HUAWEI TECH CO LTD

Stent with unconnected stent segments

InactiveUS20080255657A1Improved deliverabilityEasily variedStentsBlood vesselsBlood vesselIntravascular stent

Owner:BOSTON SCI SCIMED INC

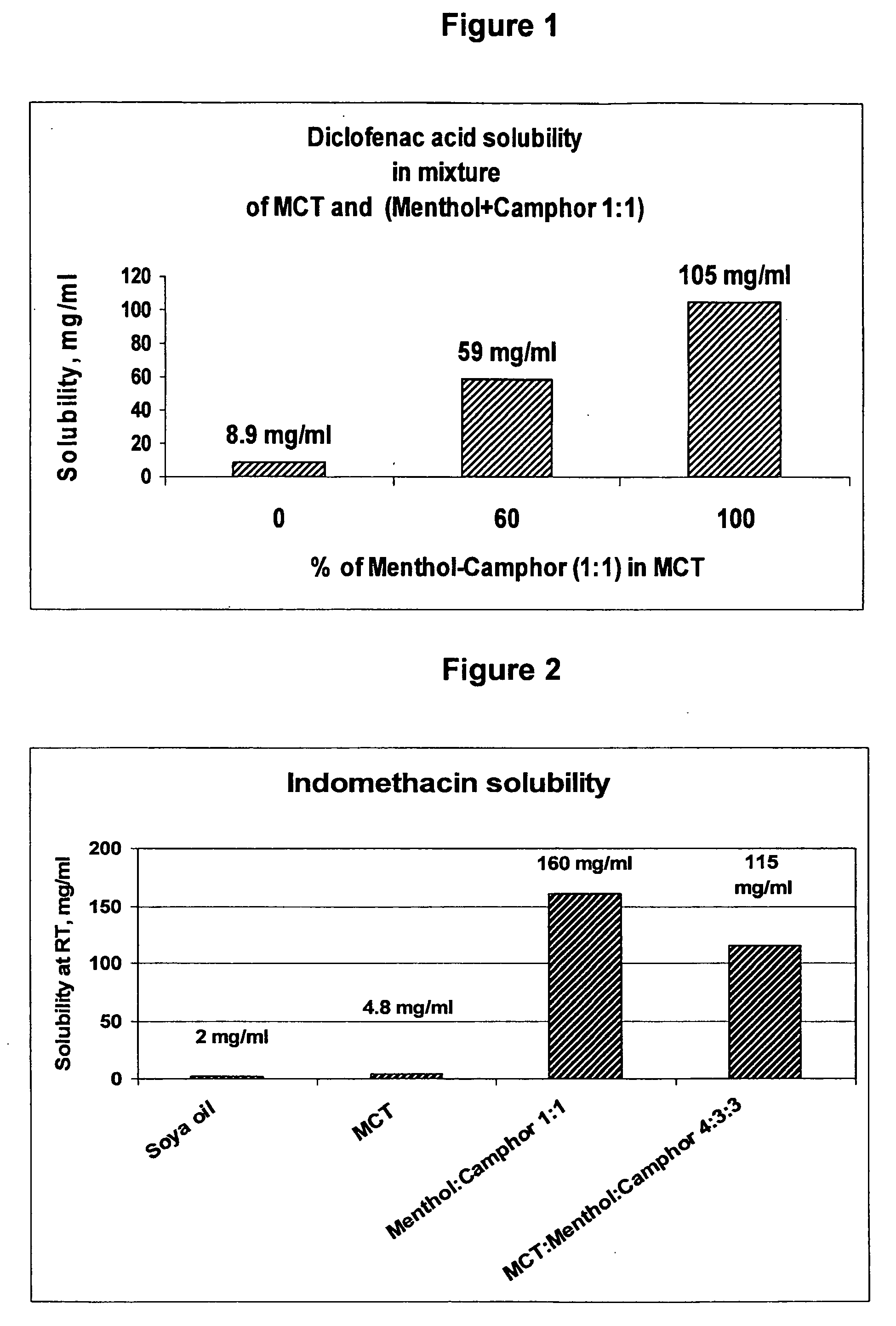

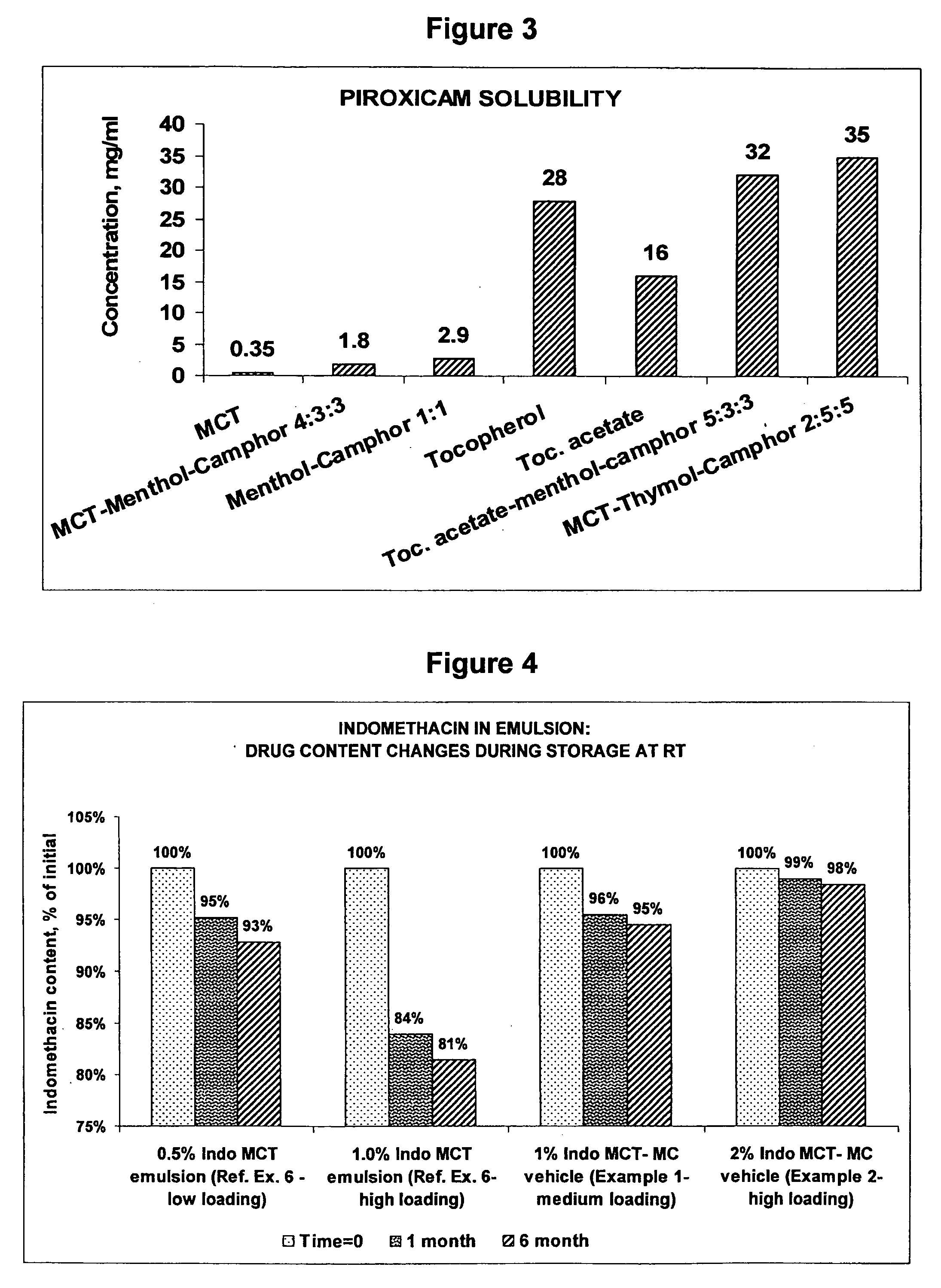

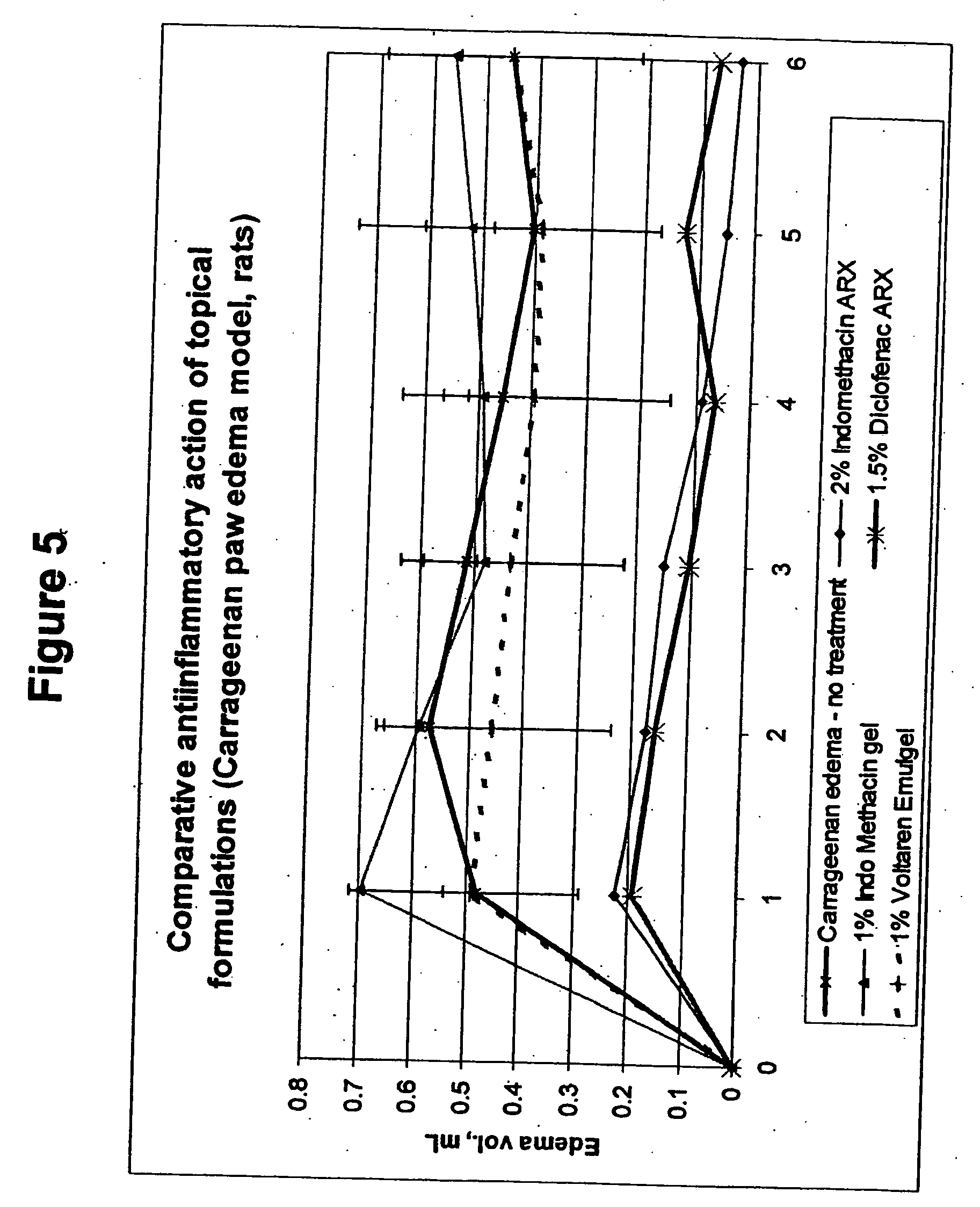

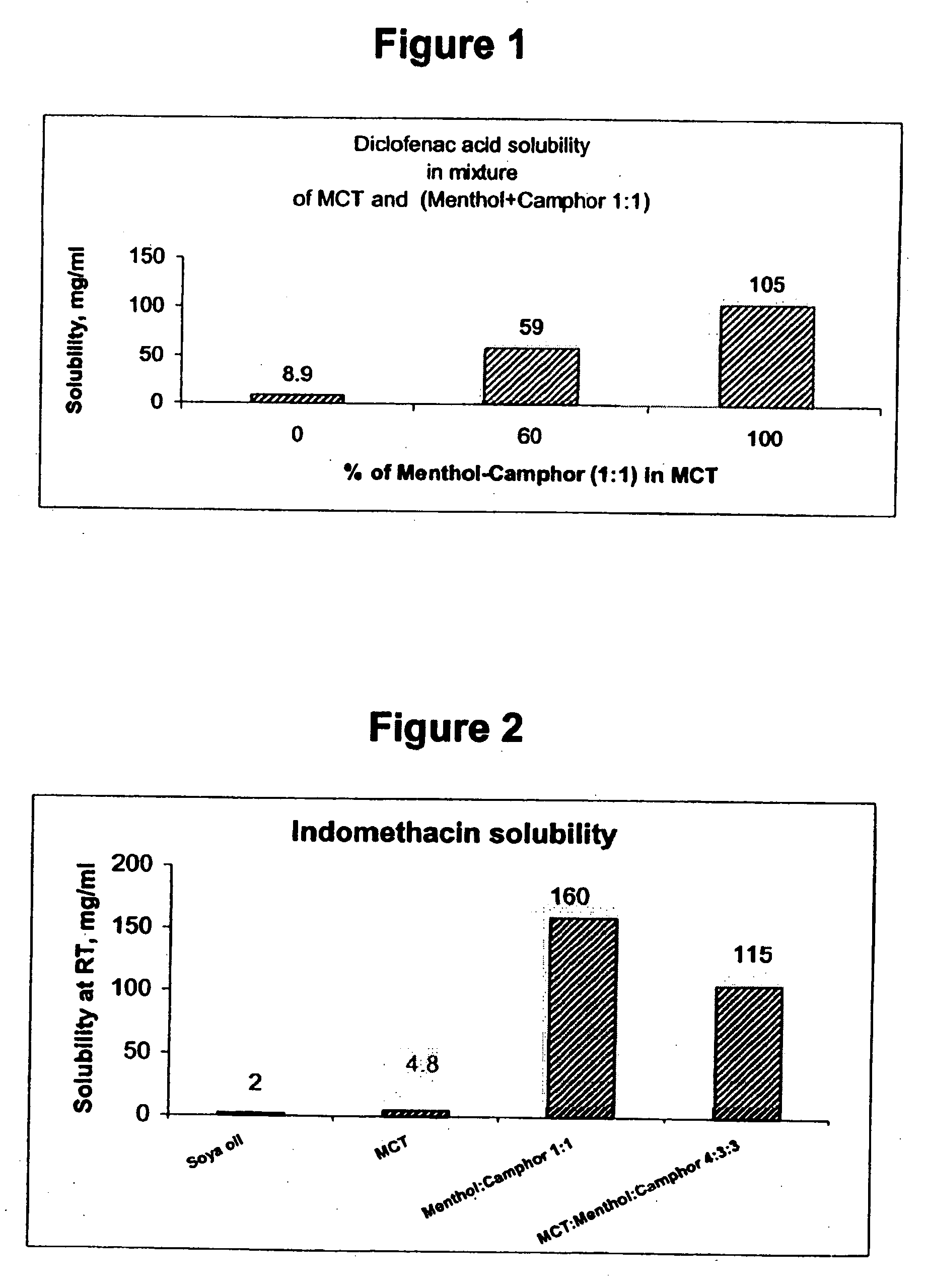

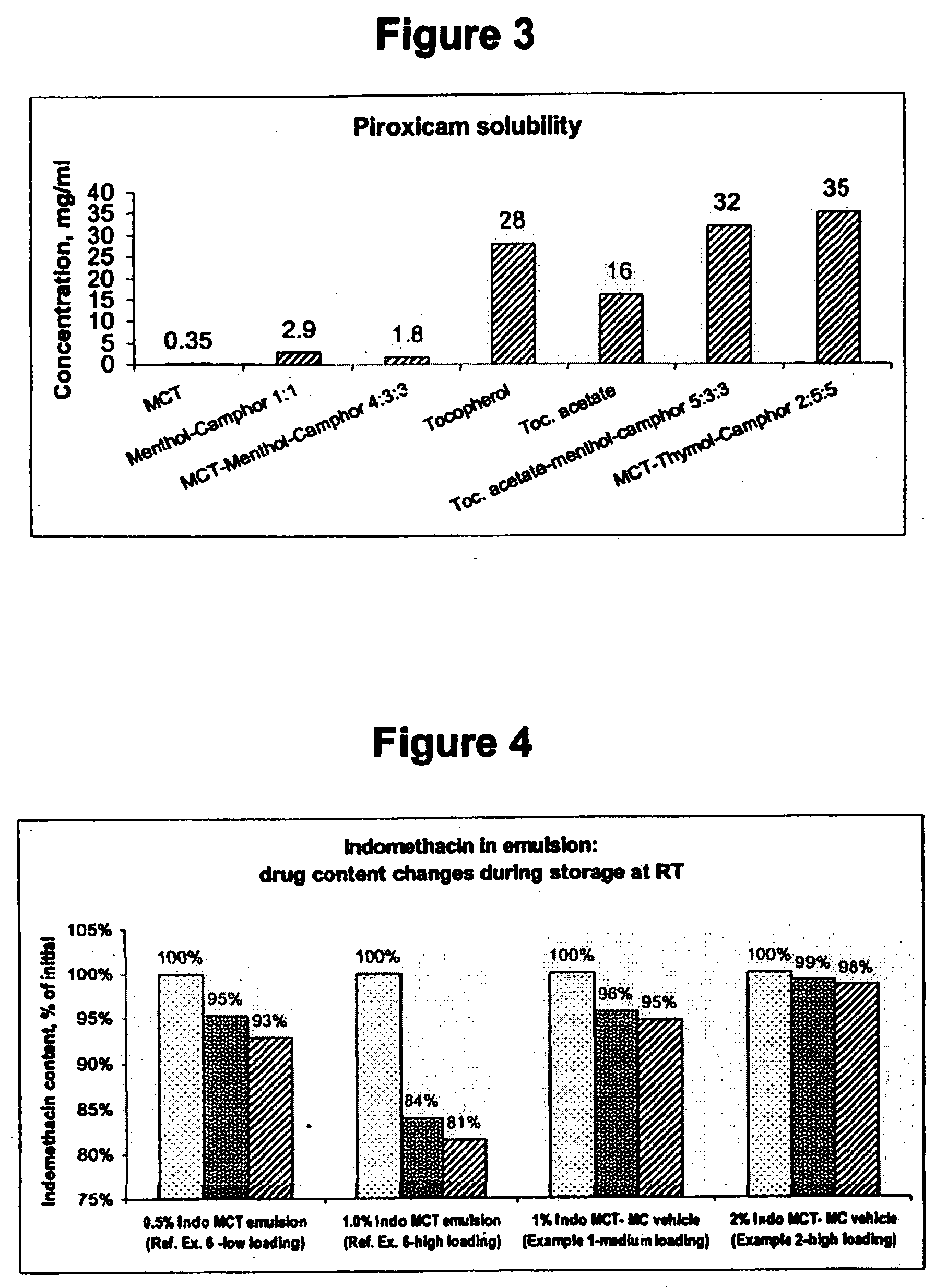

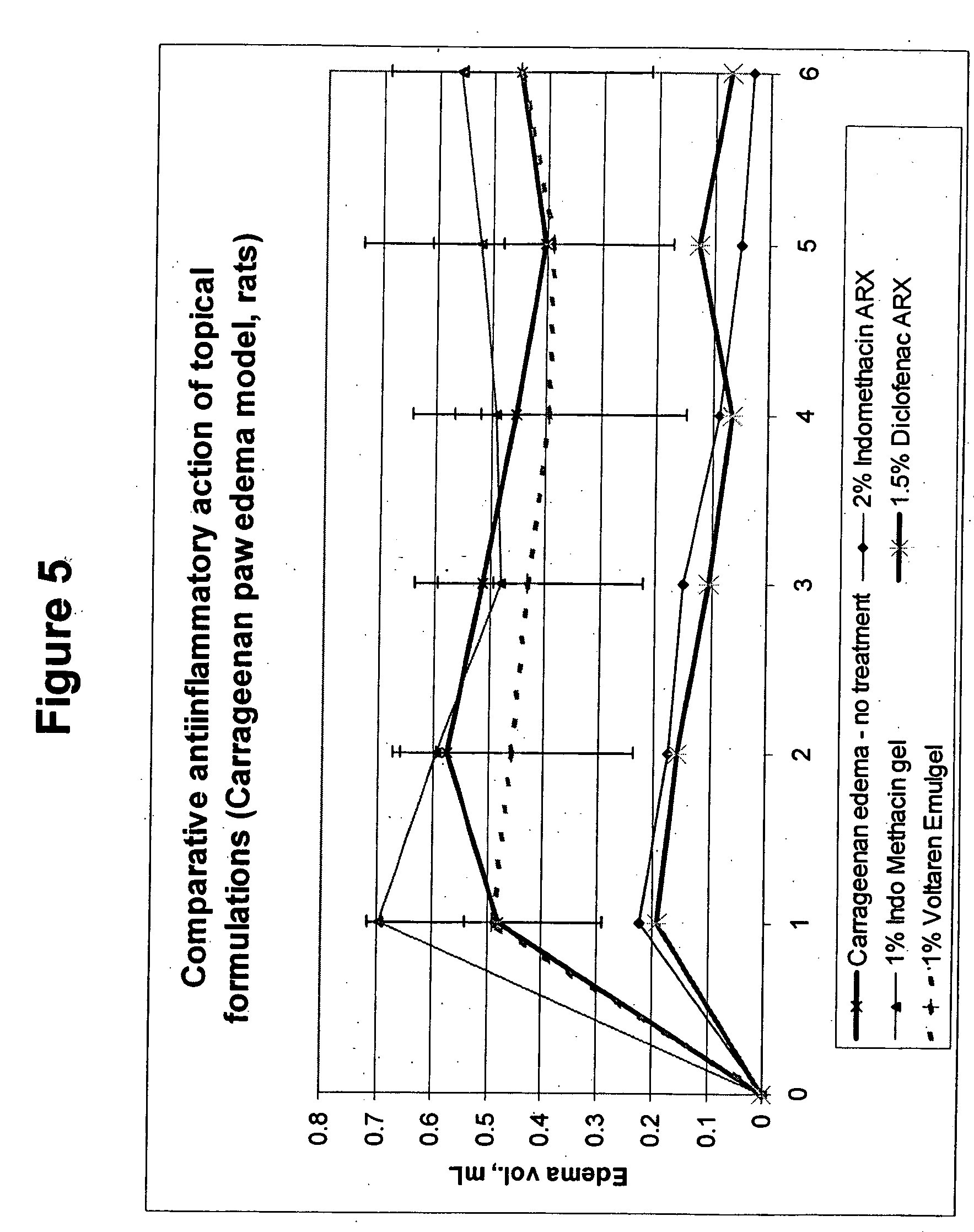

Vehicle for topical delivery of anti-inflammatory compounds

InactiveUS20060241175A1SolubilityPresent synergistic behavior in anti-inflammatory actionBiocideHydroxy compound active ingredientsCompound aMedicine

Owner:ALPHARX

Vehicle for topical delivery of anti-inflammatory compounds

InactiveUS20050158348A1SolubilityImprove delivery capabilitiesSalicyclic acid active ingredientsNervous disorderCompound aSolubility

A vehicle for topical application which contains a liquid eutectic mixture of hydrophobic compounds to improve solubility of pharmaceutically active component and enhance topical and transdermal delivery.

Owner:ALPHARX

Tethered Self-Expanding Stent Delivery System

InactiveUS20080039920A1Minimize stent movementPrecise positioningStentsBlood vesselsDelivery systemTreating Site

The present invention relates to devices, systems and methods to maintain self-expanding stents in a compressed form during delivery to and positioning at a treatment site. The devices, systems and methods of the present invention can provide for more accurate stent positioning and can improve the deliverability of self-expanding stents. Designs of the devices, systems and methods of the present invention include slotted designs, tethered designs and encapsulating flexible sheath designs.

Owner:MEDLOGICS DEVICE CORP

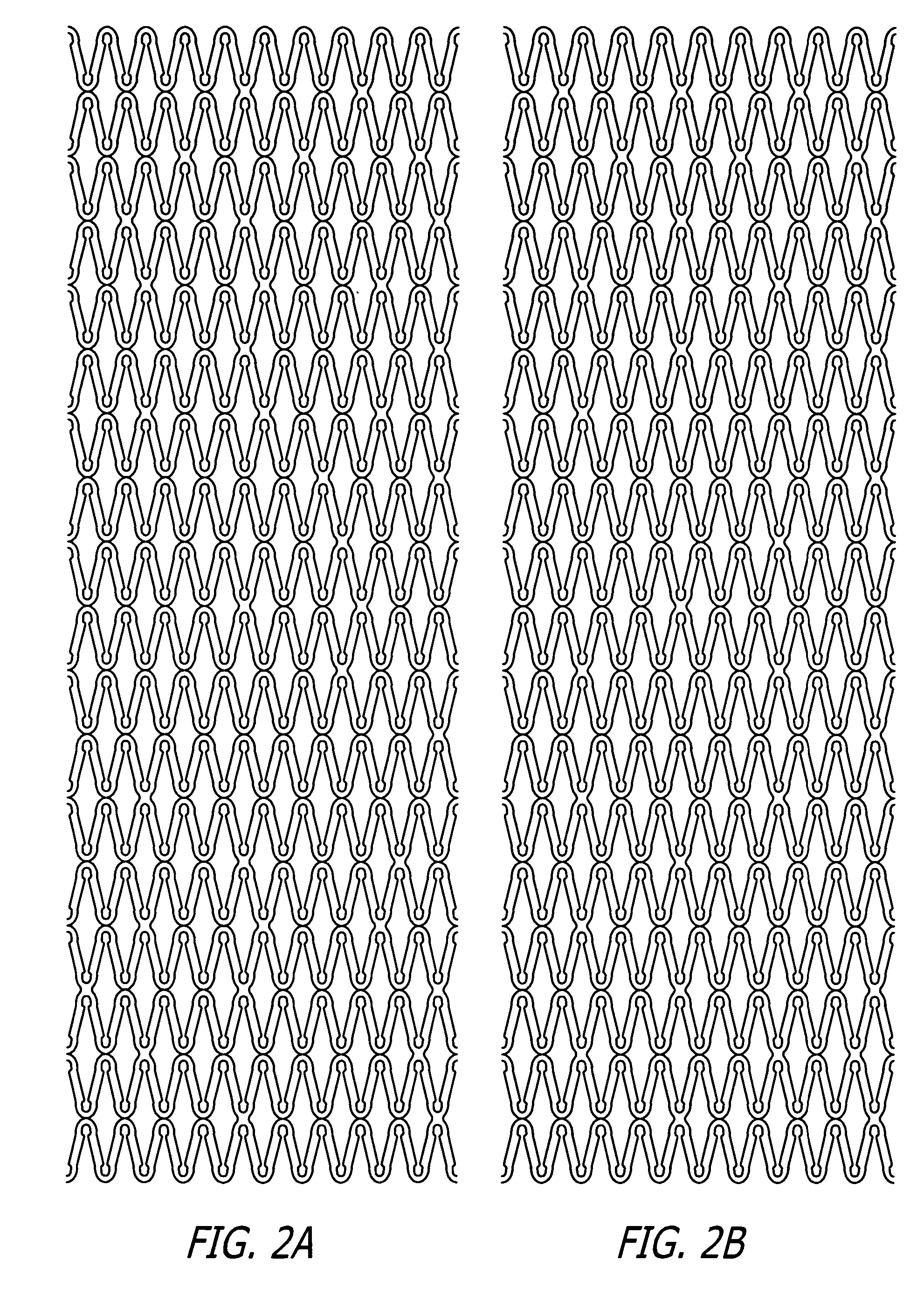

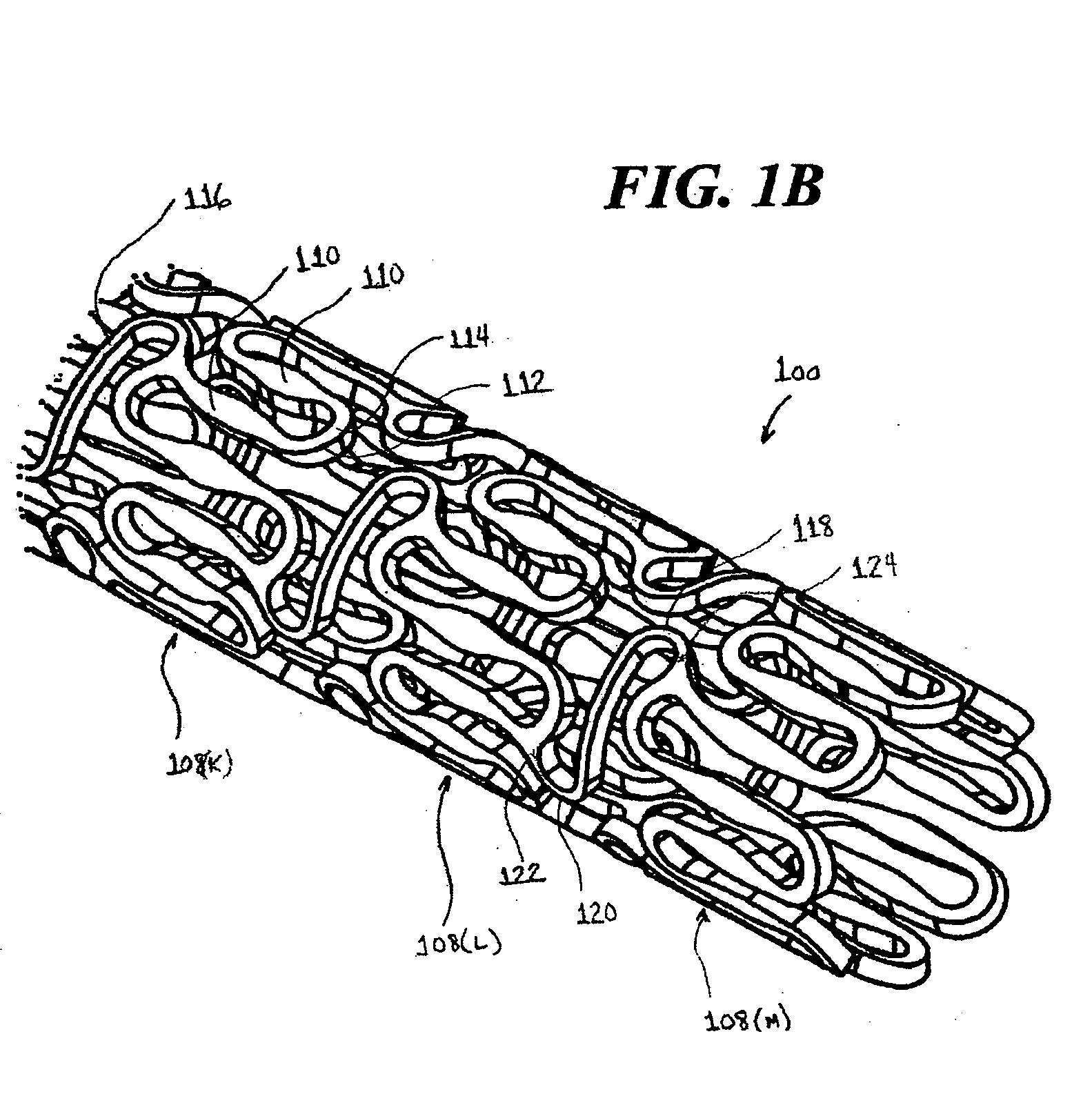

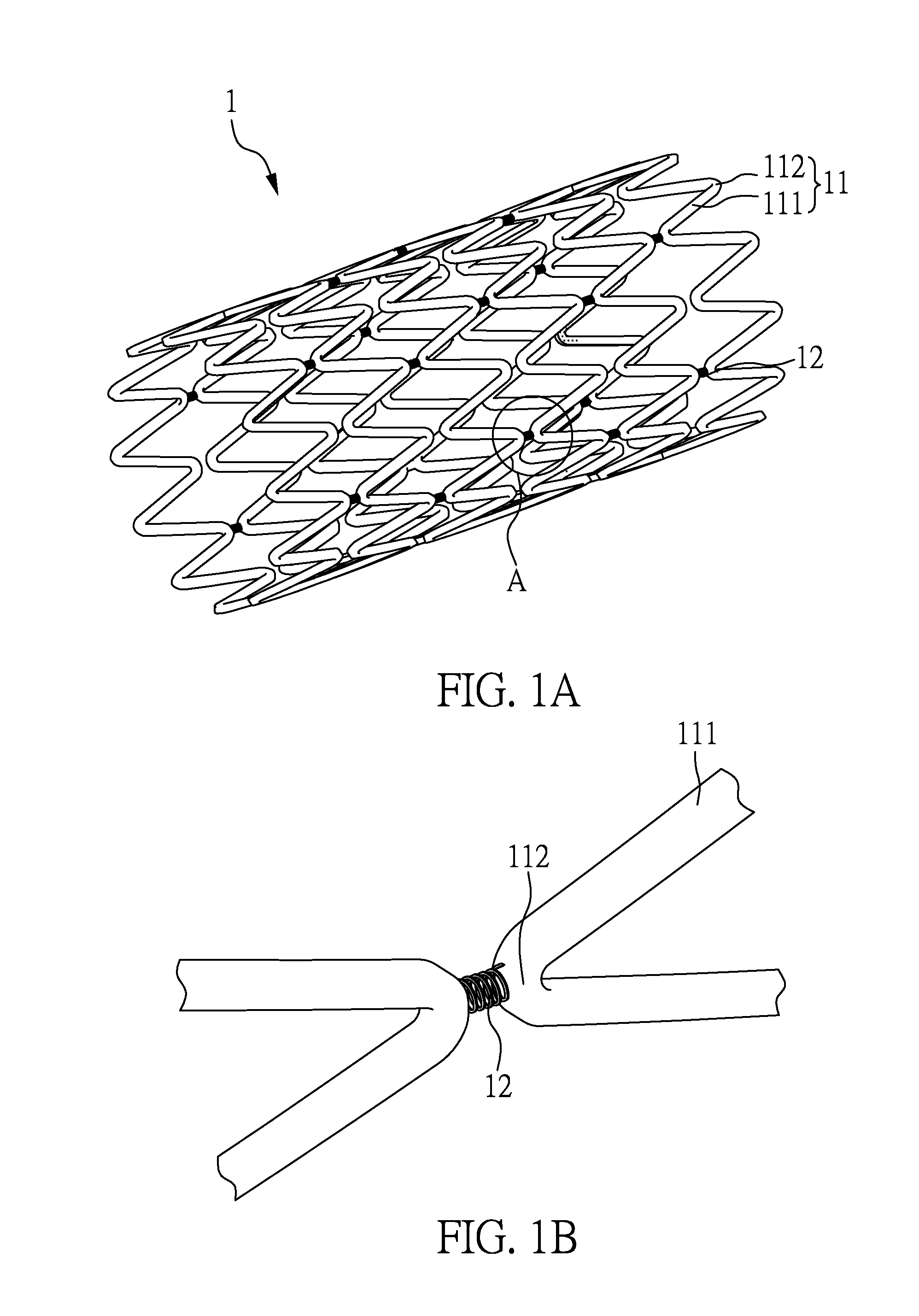

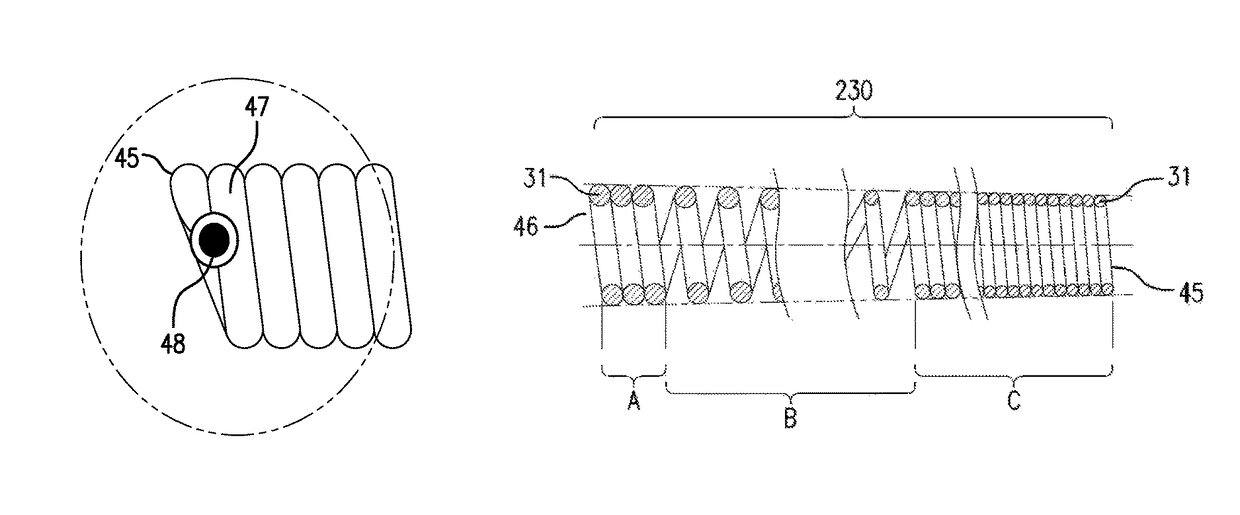

Intravascular stent with helical struts and specific cross-sectional shapes

InactiveUS20160008149A1Improve stent propertyImprove delivery rateStentsAdditive manufacturing apparatusInsertion stentEngineering

The present invention relates to a stent, comprising: a plurality of radially-expandable rings arranged along a longitudinal axis, wherein each radially-expandable ring may comprise a plurality of bar arms and a plurality of crowns, and adjacent crowns are connected by the bar arms therebetween; and a plurality of connectors between the radially-expandable rings for connecting such radially-expandable rings; wherein a cross-sectional shape of the bar arms, the crowns or the connectors may comprise helical structures, specific cross-sectional shapes, or a combination thereof. New stent manufacturing techniques, such as the 3D additive printing, could be used for making these proposed stents feasible.

Owner:NAT TAIWAN UNIV

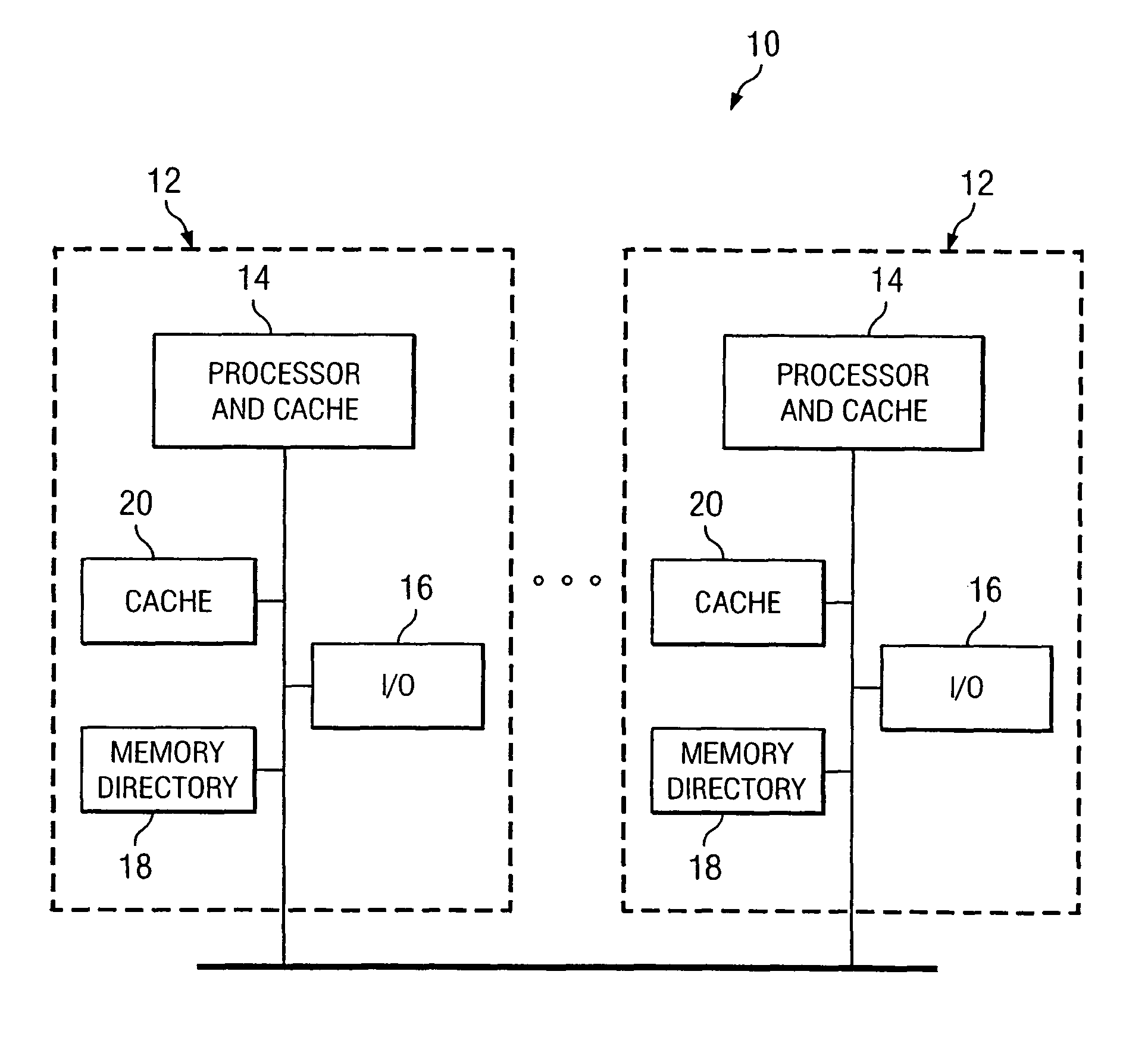

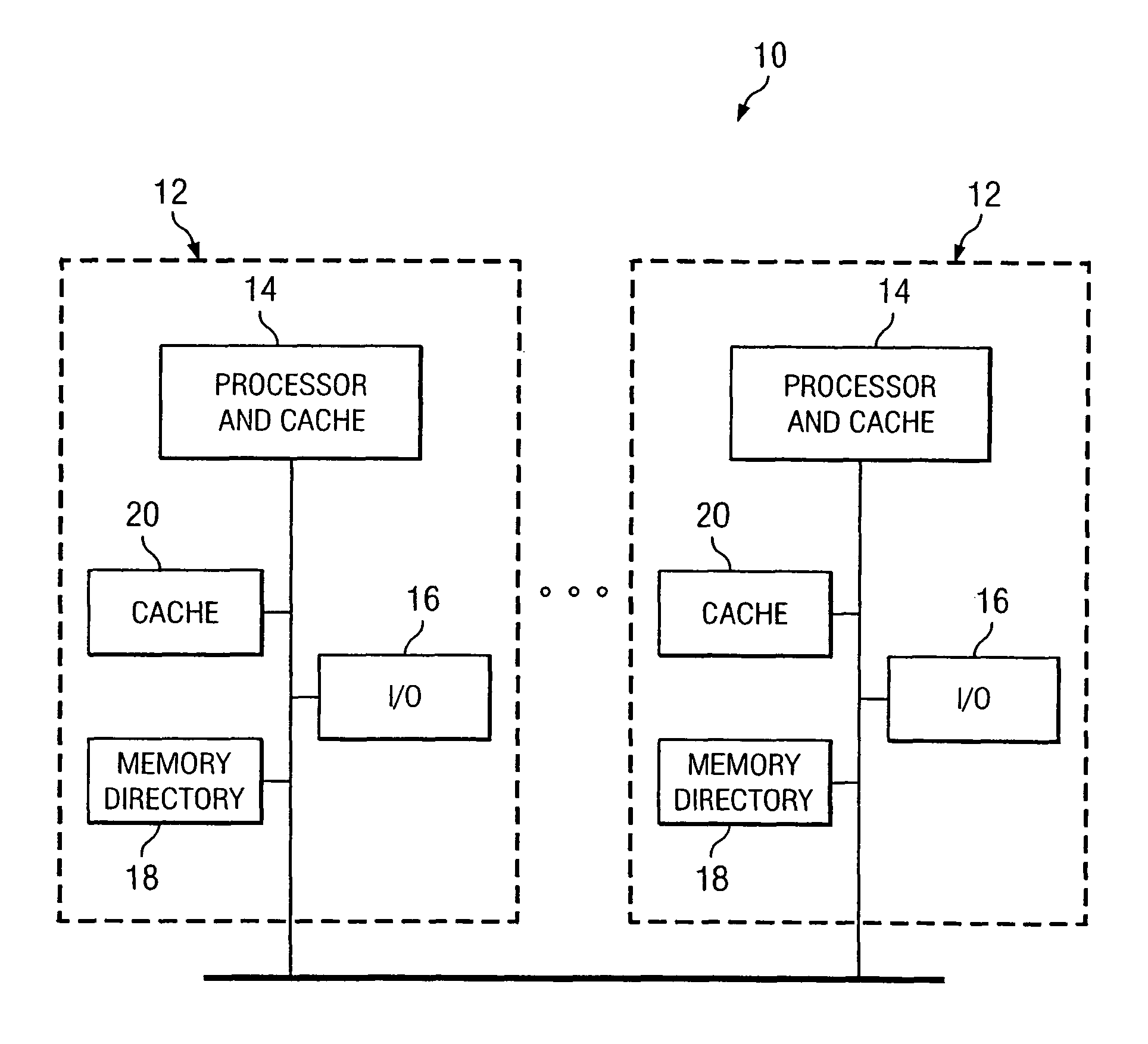

Method for performing cache coherency in a computer system

ActiveUS7802058B1Improve delivery capabilitiesSelectively usedMemory adressing/allocation/relocationComputerized systemParallel computing

In a computing system, cache coherency is performed by selecting one of a plurality of coherency protocols for a first memory transaction. Cache coherency is performed on appropriate caches in the computing system in accordance with the selected one of the plurality of coherency protocols. For a second memory transaction, another selection is made of the plurality of coherency protocols. The selected one of the coherency protocols for the second memory transaction may be the same as or different from the selected one of the plurality of coherency protocols for the first memory transaction.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

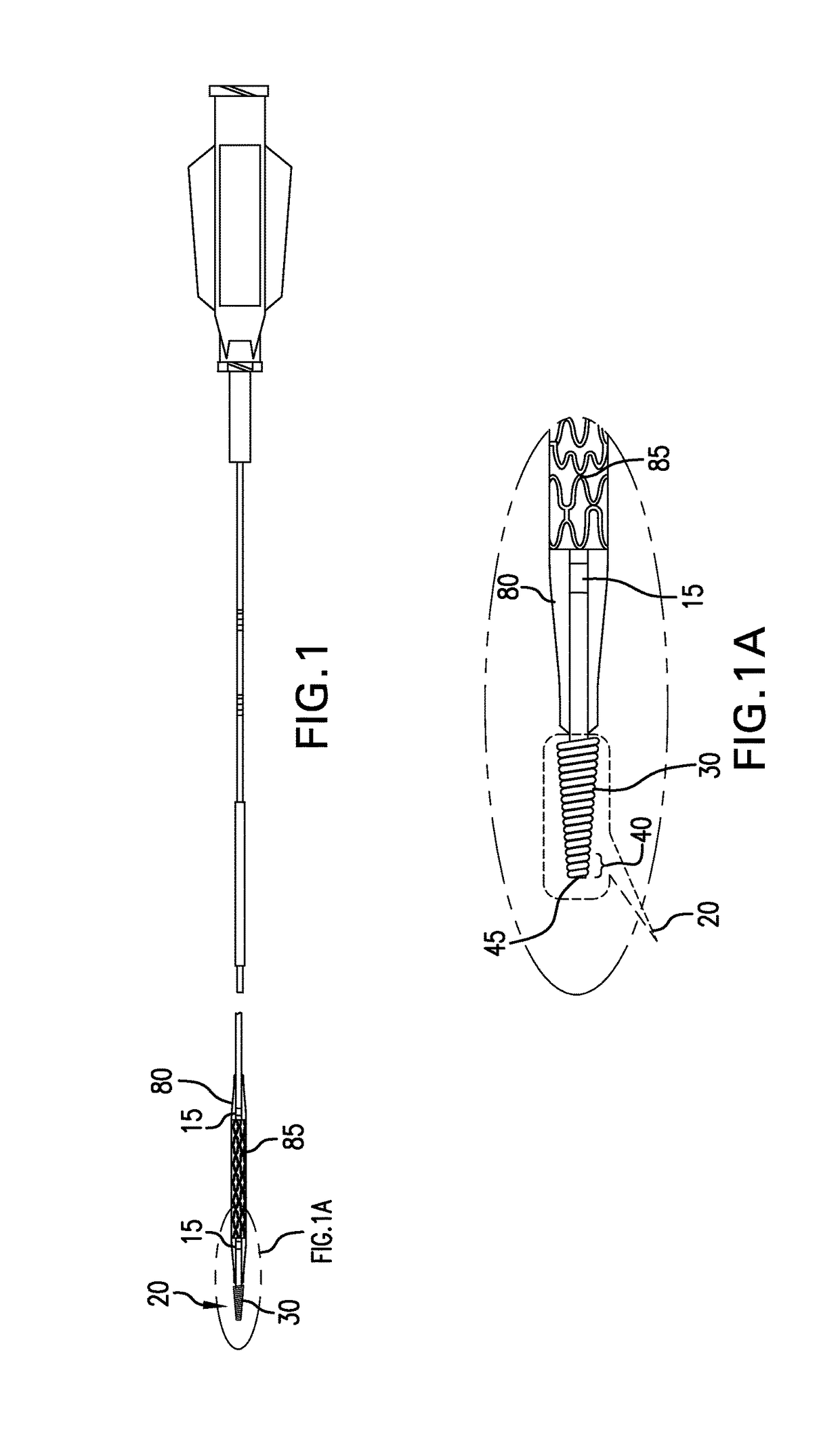

Catheter tip assembled with a spring

Owner:MEDINOL LTD

Personal-care composition comprising a cationic active

InactiveUS20100305169A1Improve delivery capabilitiesCosmetic preparationsBiocidePersonal careOil phase

A personal-care composition in the form of an oil-in-water emulsion comprises a water phase, an oil phase, an anionic pairing agent, a cationic active, and an anionic thickener. In one embodiment, the anionic pairing agent is pre-formed from the neutralization of an acid with a base. In another embodiment, the anionic pairing agent is formed in situ from the neutralization of an acid with a base. At least 25% by weight of the cationic active is present in the oil phase. In certain embodiments, a method for regulating keratinous tissue condition and a method for improving deliverability of a cationic active in the presence of an anionic thickener comprise the steps of: providing the aforementioned personal-care composition, and applying the composition to keratinous tissue in need of treatment. The personal-care composition allows for previously unattainable levels of the cationic active to locate within the oil phase of the emulsion.

Owner:THE PROCTER & GAMBLE COMPANY

Device for traversing vessel occlusions and method of use

InactiveUS20110196384A1Less sensitiveEfficient energy transferCatheterOsteosynthesis devicesBlood vesselBiomedical engineering

An apparatus, system and method for re-canalization or opening a passage through an occlusion in a blood vessel is provided. The apparatus and method, which are appropriate for both cardiovascular as well as peripheral vessels, use a pulling member and a spring element, for example a compression spring, to oscillate a vibratable member, and the system of the invention includes the apparatus and a control unit to permit the frequency or amplitude of oscillation of the vibratable member to be adjusted. Also provided is a method for oscillating a vibratable member using a pulling member and a spring element. The apparatus and system are useful not only for penetrating a total or partial occlusion, but also to improve deliverability of a catheter through a partially occluded vessel or a tortuous vessel.

Owner:MEDINOL LTD

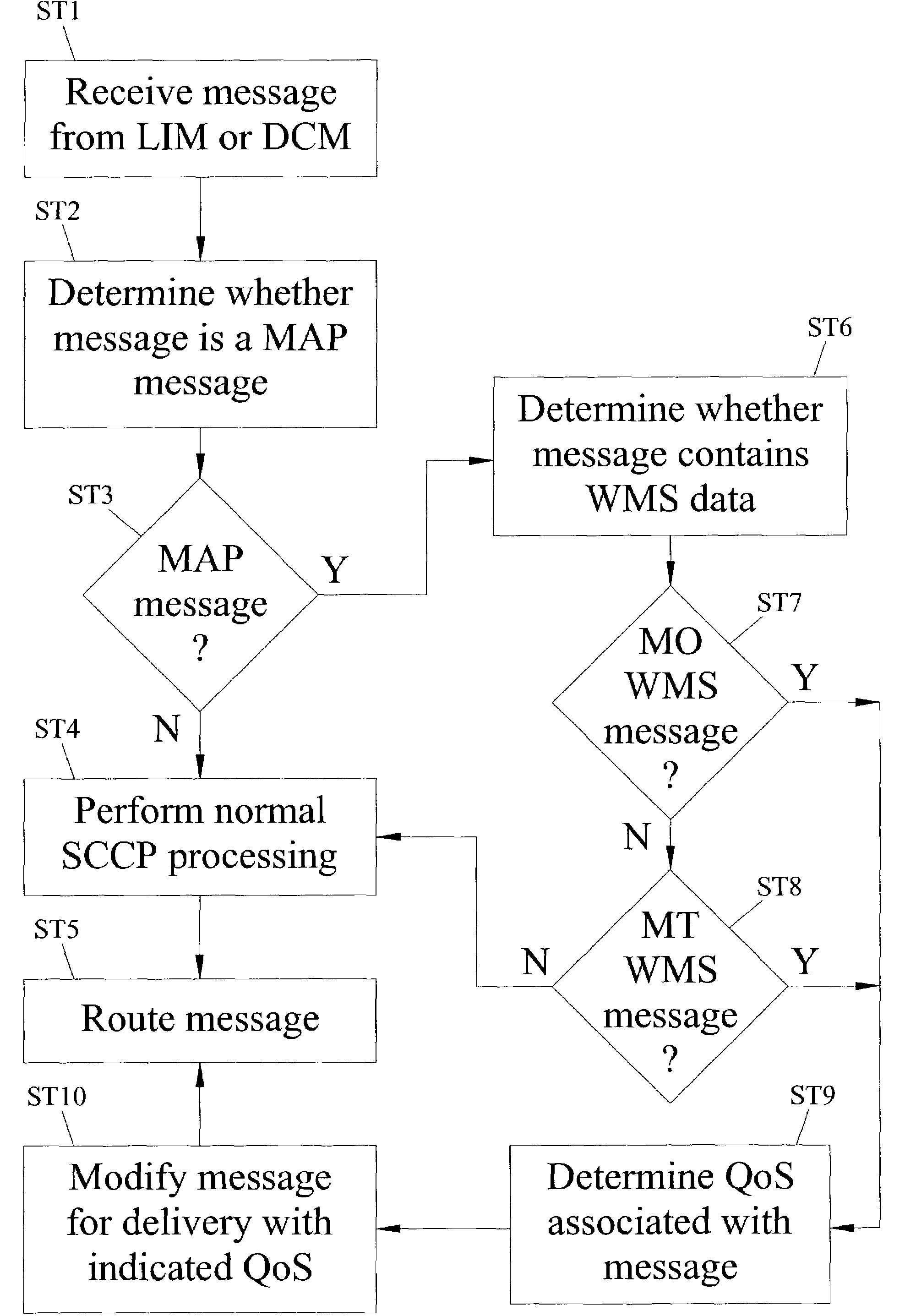

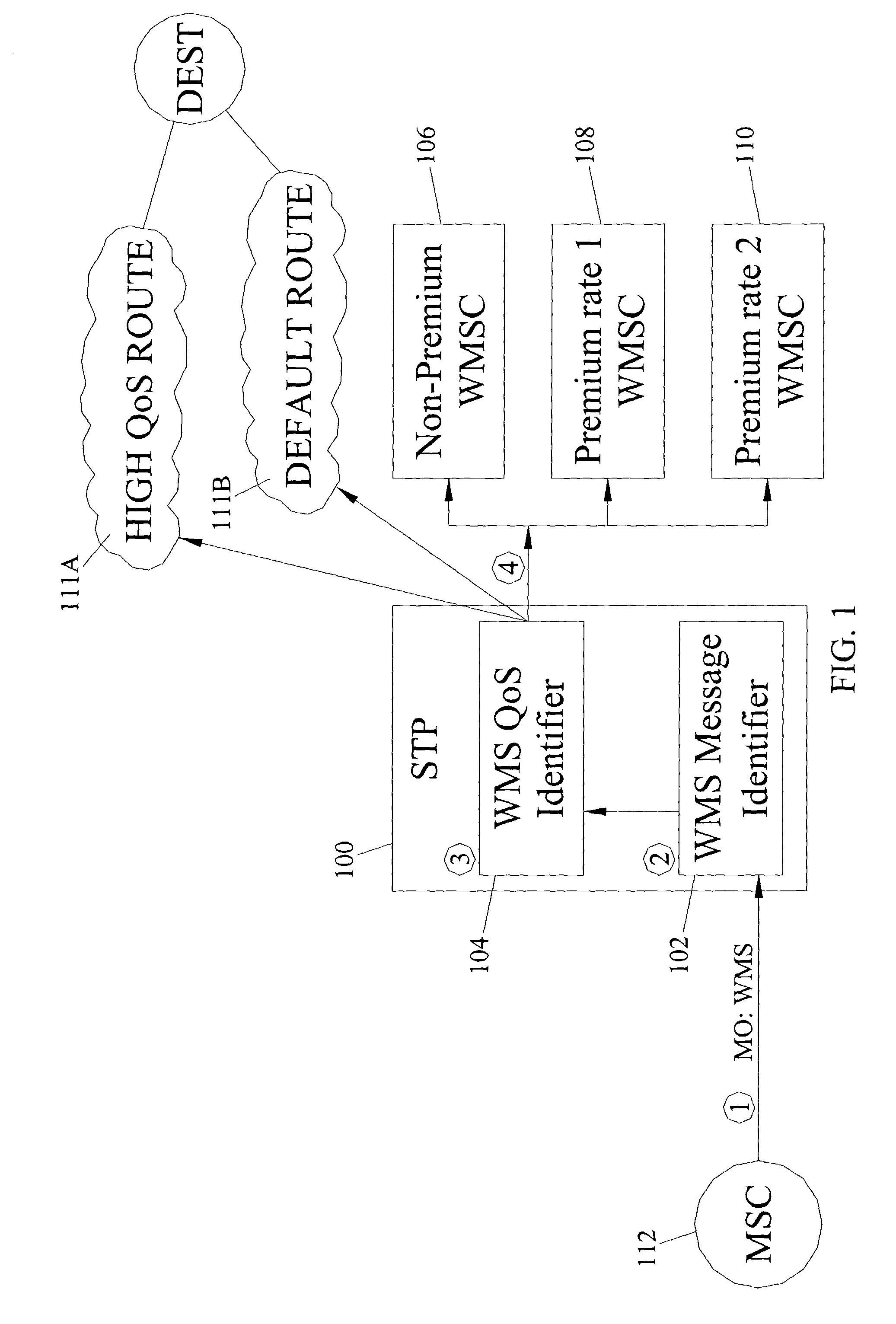

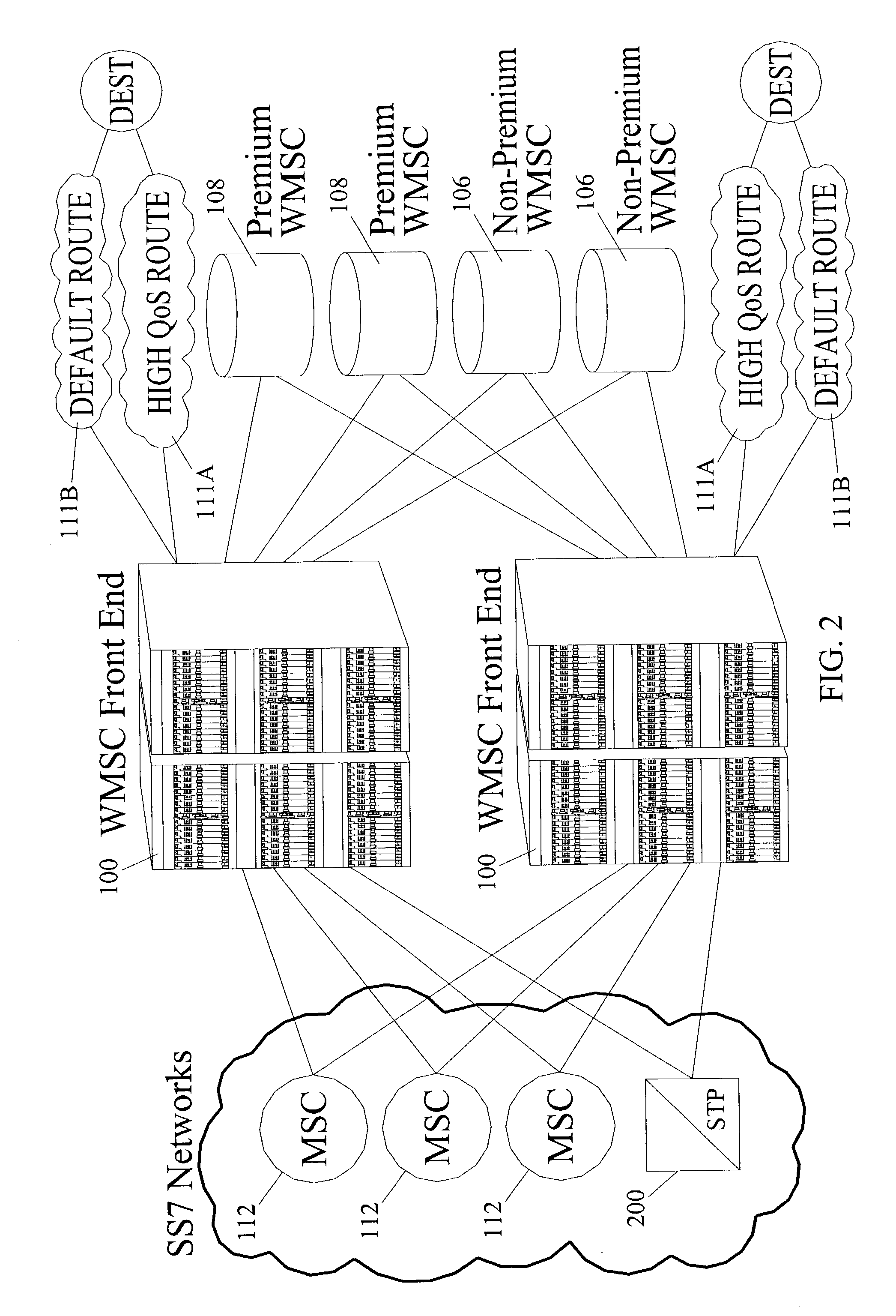

Methods and systems for triggerless screening of wireless message service messages for delivery with differential quality of service

ActiveUS7133420B2Enhanced and guaranteed QoSQuality of serviceError preventionNetwork traffic/resource managementQuality of serviceDifferential quality

Methods and systems for triggerless screening of WMS messages for delivery with differential quality of service (QoS) are disclosed. Signaling messages are screened to determine whether they contain WMS content. In response to determining that a message contains WMS content, origination and / or destination party information is extracted from the WMS message to determine the QoS associated with the WMS message. The WMS message is then modified to include routing information for delivering the SMS messages to their intended destinations with different qualities of service.

Owner:TEKELEC GLOBAL INC

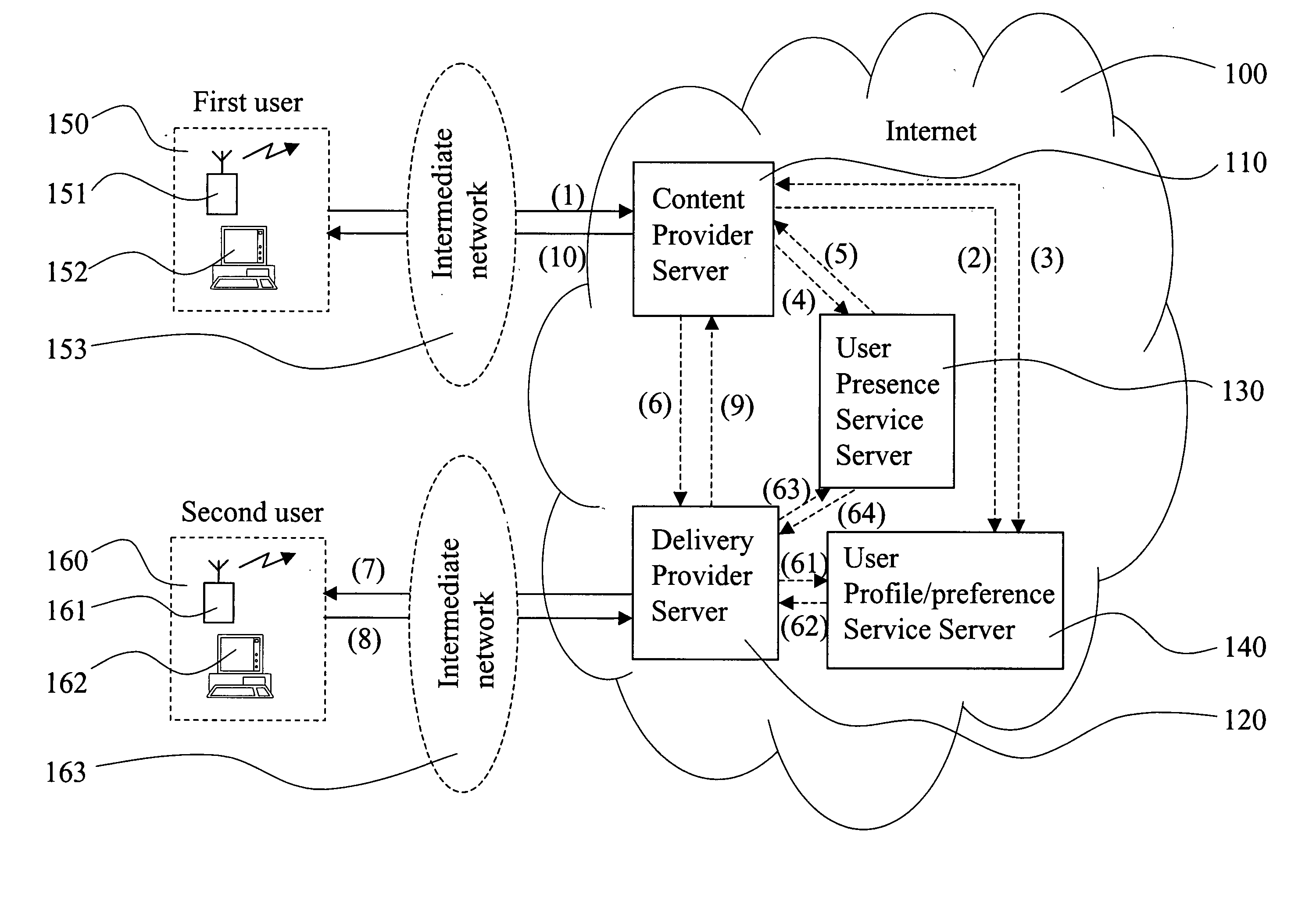

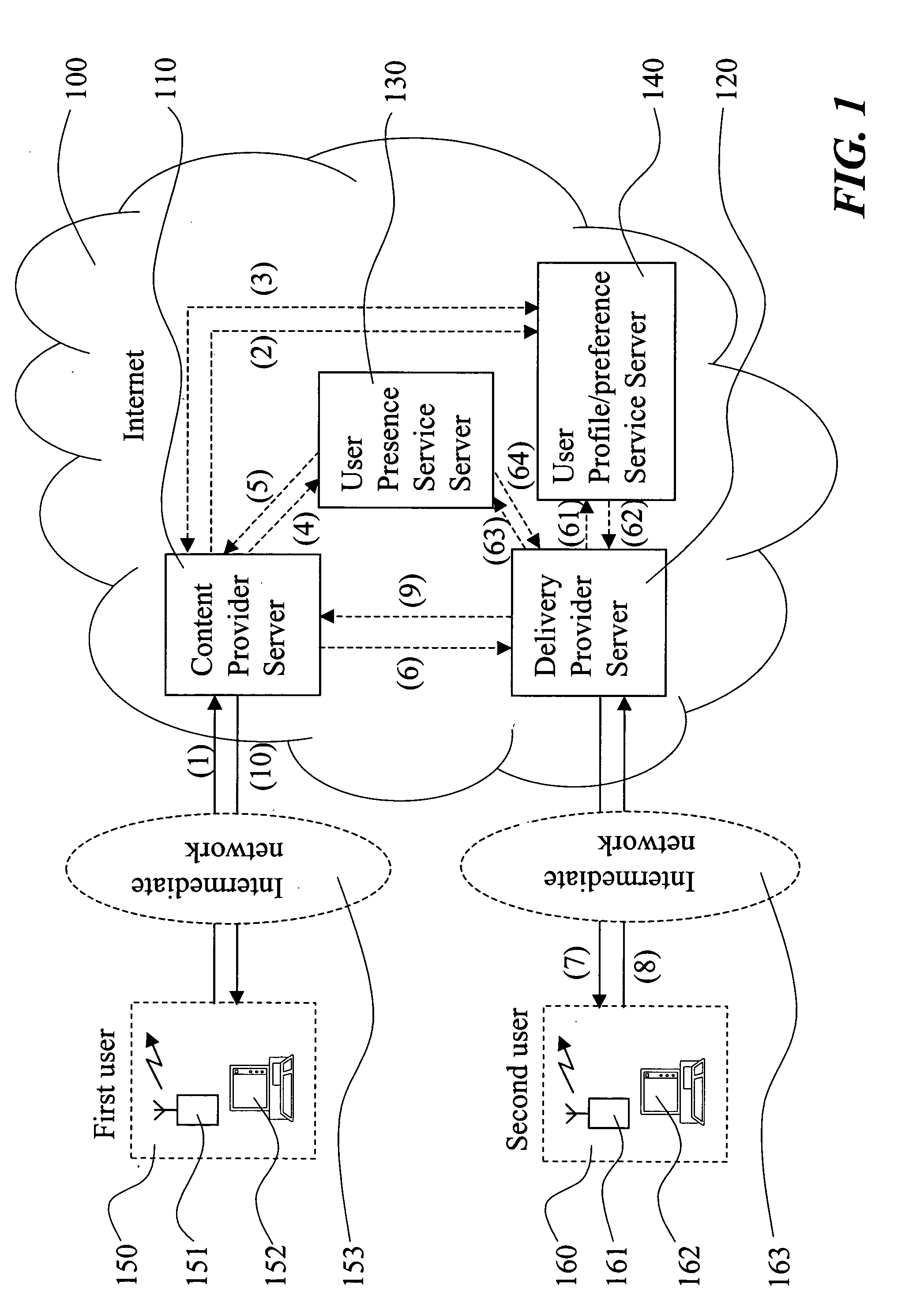

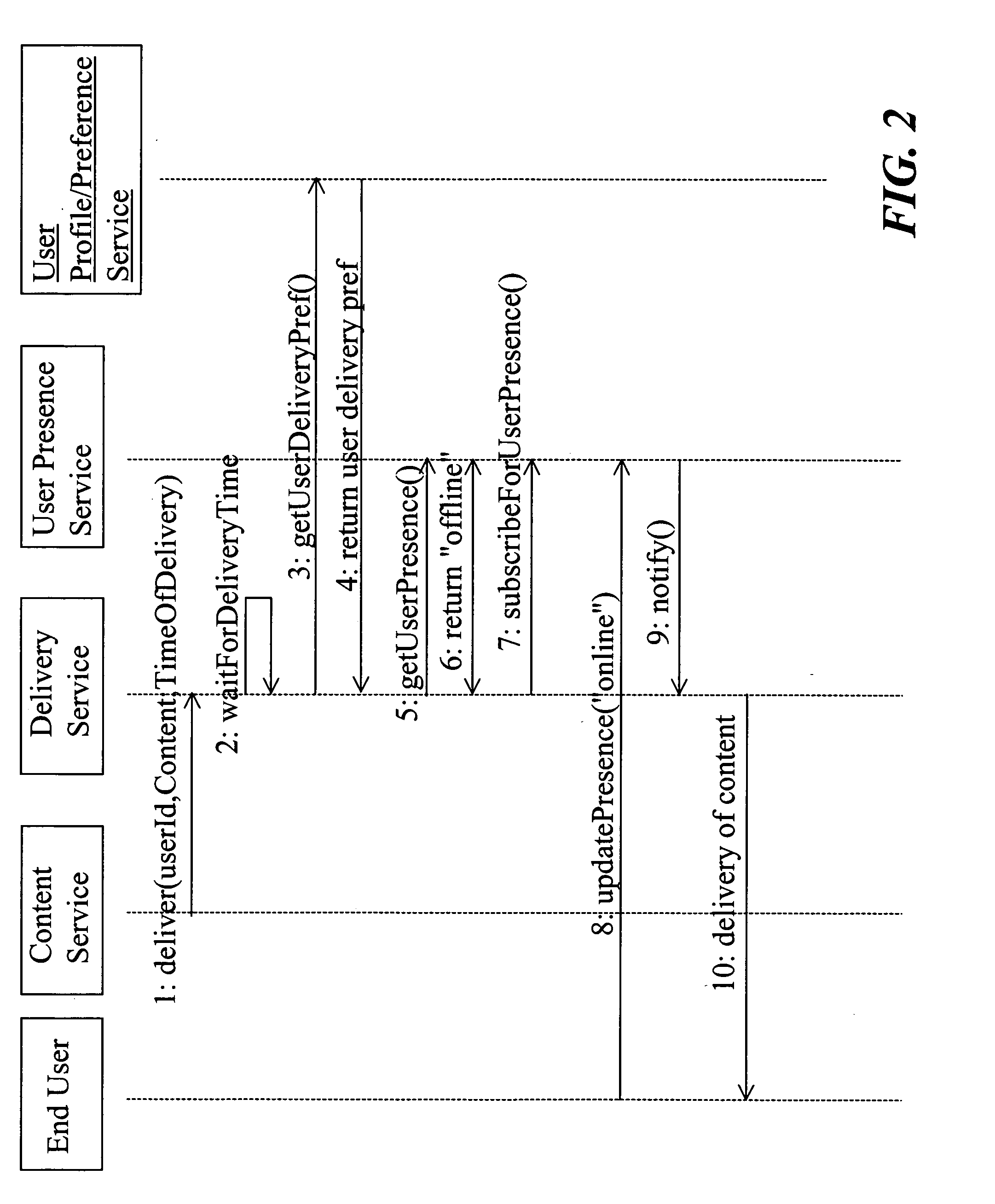

Method, system and web service for delivering digital content to a user

InactiveUS20050044082A1Improve delivery capabilitiesIncrease the likelihood of successDigital data information retrievalTransmissionComputer networkWeb service

The present invention relates to delivery of digital content of a content provider 110 to a user 160. The invention is based on the idea to utilize user presence information of a user in the delivery mechanism of digital content to the user. The operation of delivering digital content is separated in two co-operating services, a content service of a content provider 110 and a delivery service of a delivery provider 120. The content service utilizes the delivery service for accomplishing delivery of the digital content to a specific receiving user. Either the request to the delivery service to deliver the digital content, or the attempt by the delivery service to deliver the content, is made in dependence on user presence information indicating the availability of the user for receiving the digital content.

Owner:NOKIA CORP

Stent delivery system with improved deliverabilty features

InactiveUS20080077223A1Improved deliverabilitySave time and costStentsBlood vesselsStent placementDistal portion

A stent delivery system for placing a stent within a vessel of a human body. The stent delivery system includes an elongated tube that extends for most of the length of the stent delivery system and is attached to a distal end of a proximal section of an inflatable balloon. A stent is then co-axially mounted on the inflatable balloon. A front section of the stent delivery system includes a small angle cone having a lubricious outer surface. The front section is then attached to a cylindrical distal portion of the balloon and has an outside diameter at the proximal end of the small angled cone which is approximately the same diameter as the outer diameter of the stent. A core wire extends within the inflatable balloon and further into the front section of the stent delivery system.

Owner:FISCHELL ROBERT E +4

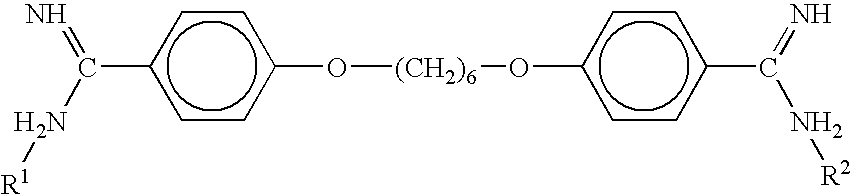

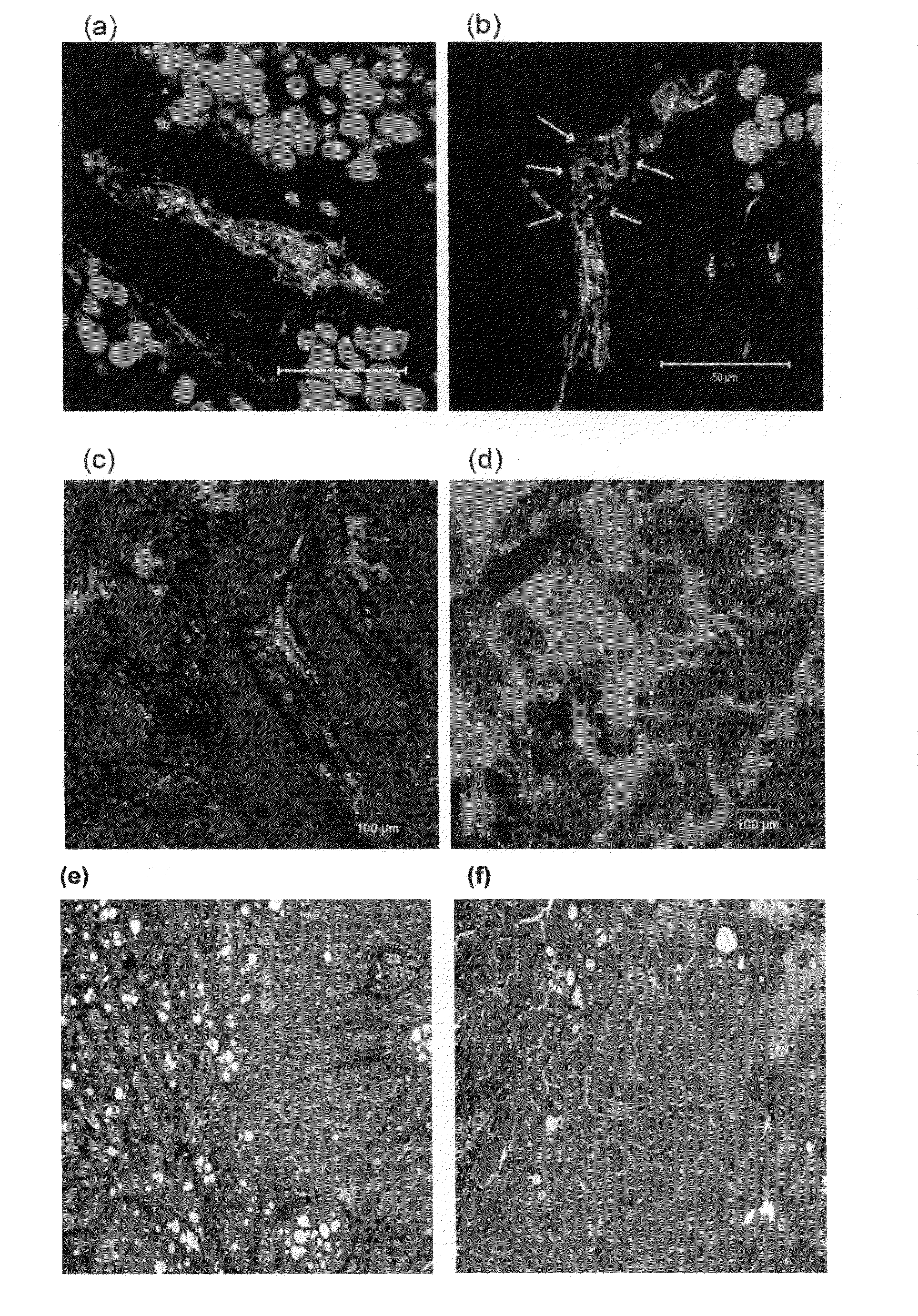

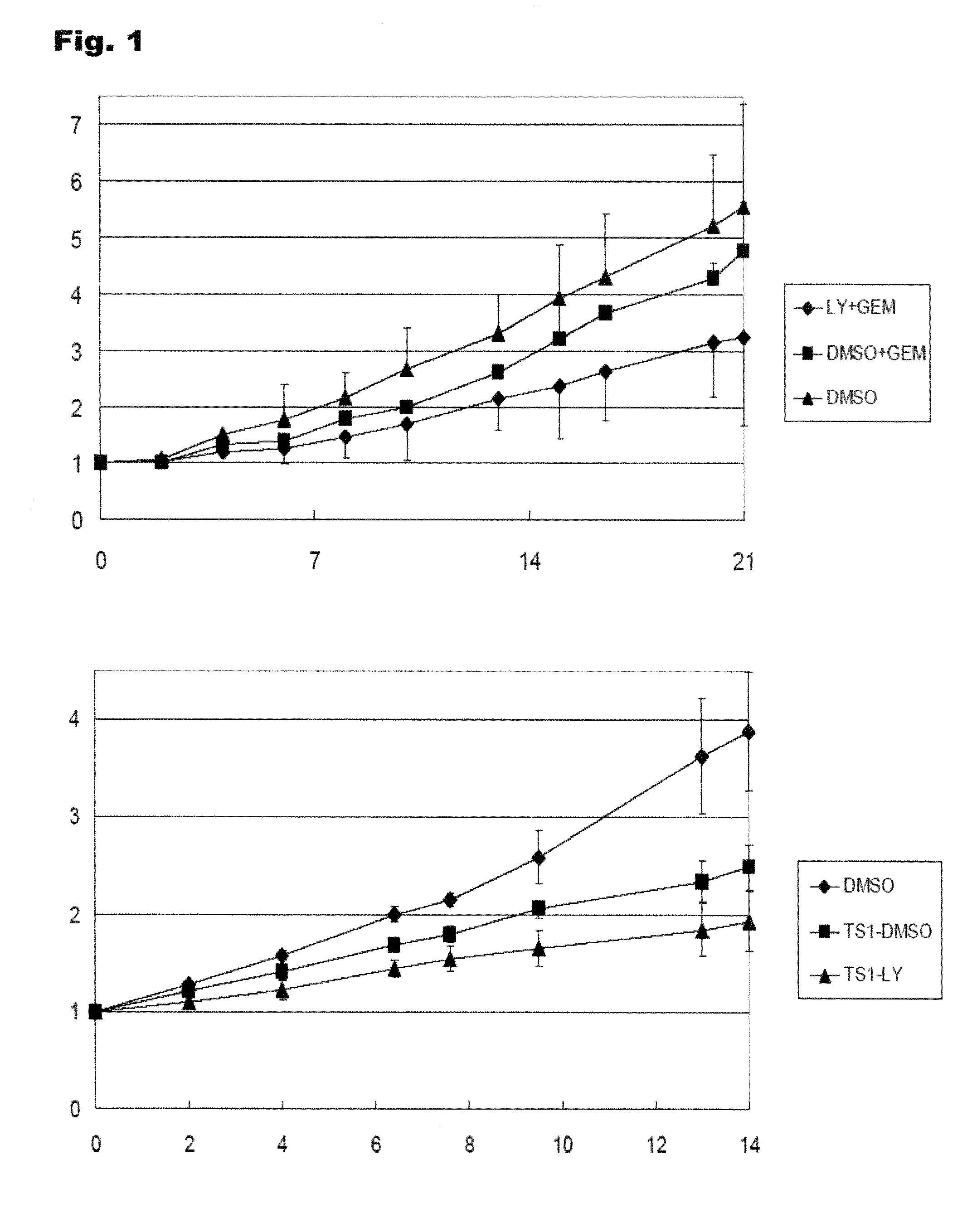

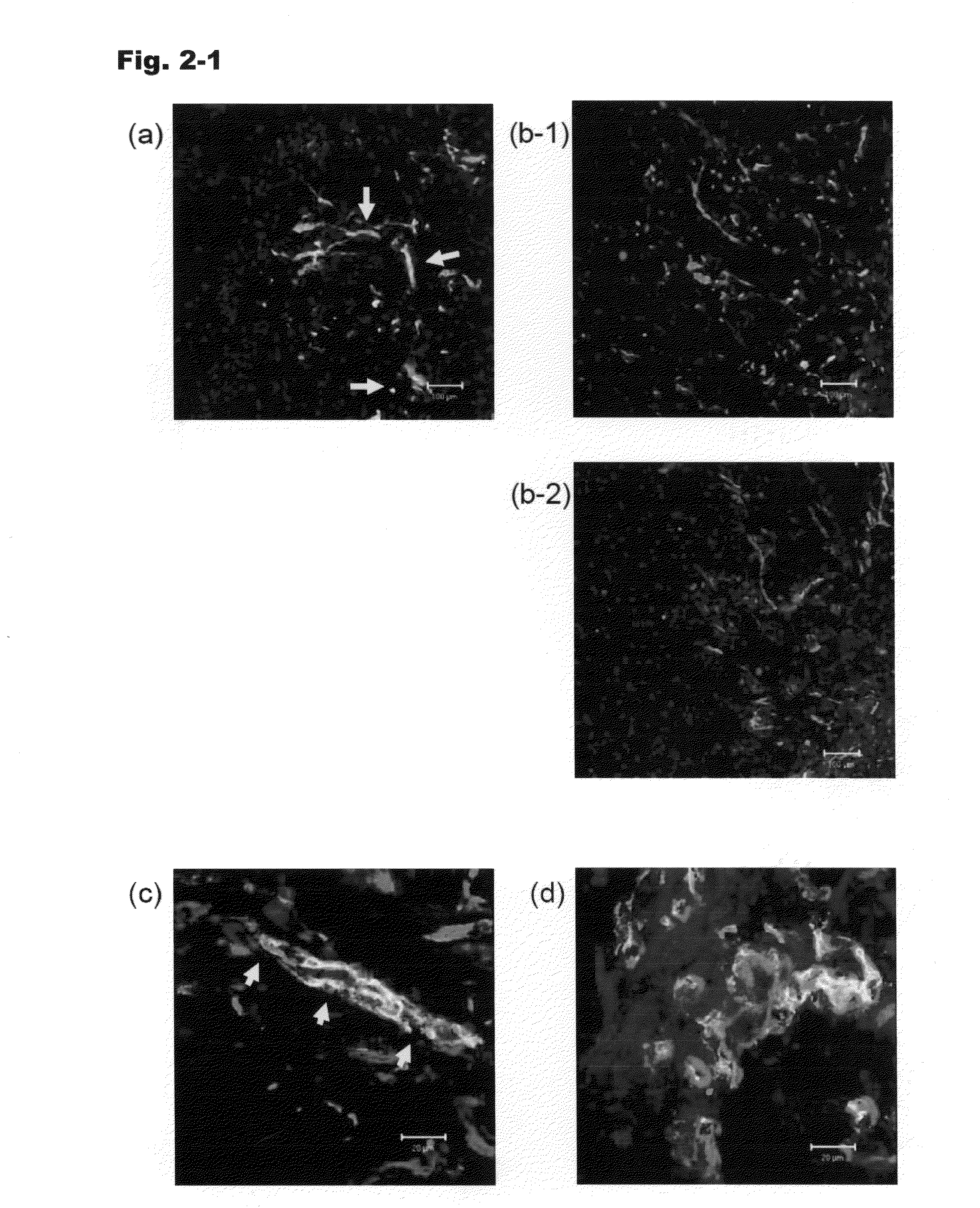

Combined Use of TGF-Beta Signaling Inhibitor and Antitumor Agent

InactiveUS20090186076A1Increased leakinessReduce fibrosisOrganic active ingredientsIn-vivo radioactive preparationsTgf β signallingDepressant

The combined use of a TGF-β signaling inhibitor and an antitumor active substance or an imaging agent modified by a drug-encapsulating macromolecular micelle, or the like, is provided. The selective delivery capability of the antitumor active substance or the imaging agent to the target is improved, increasing the antitumoral activity in the target.

Owner:THE UNIV OF TOKYO

Method for placing a medical device at a bifurcated conduit

ActiveUS20080125847A1Prevent kinkingImprove delivery capabilitiesStentsBlood vesselsMain branchMedicine

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

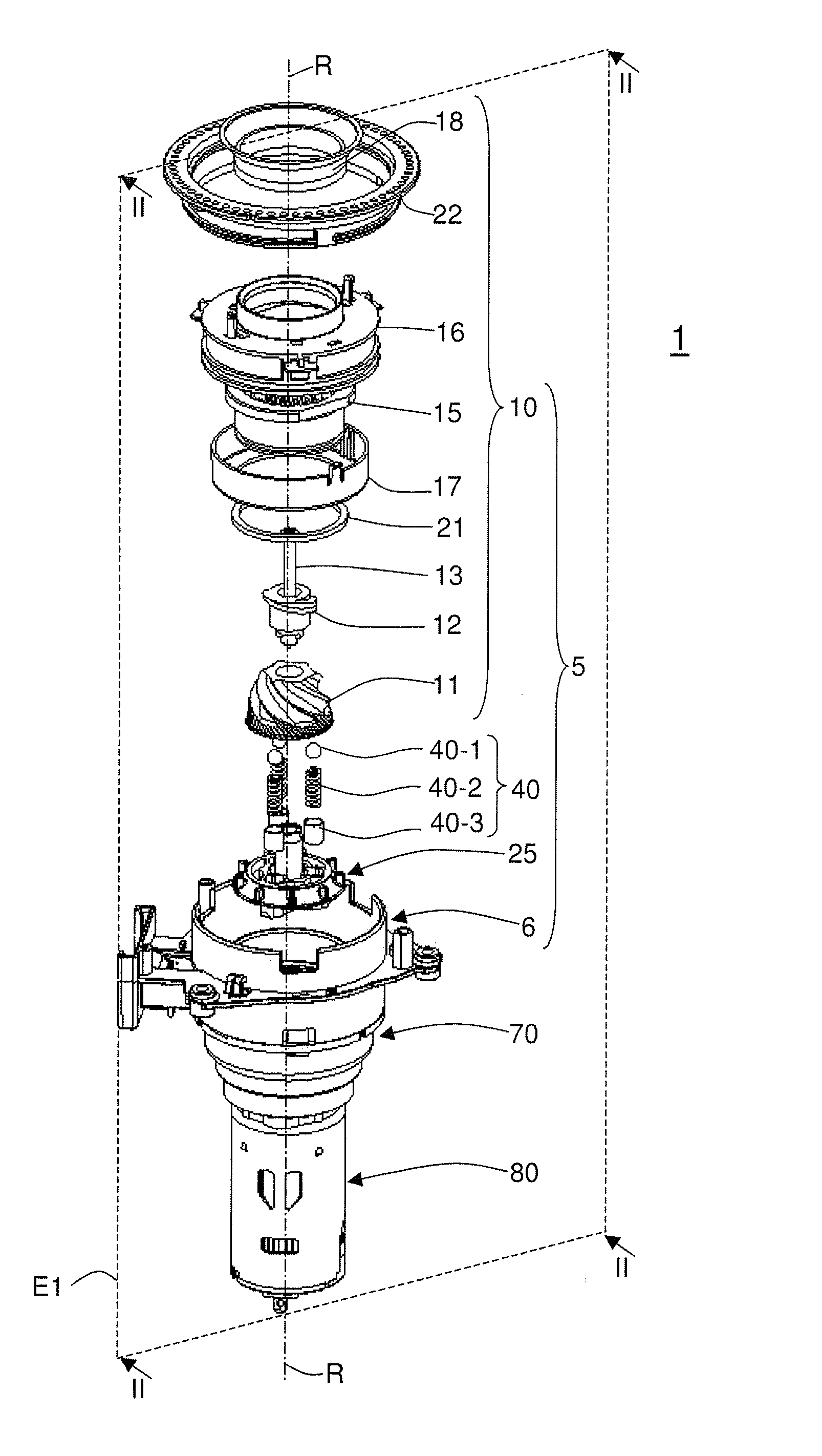

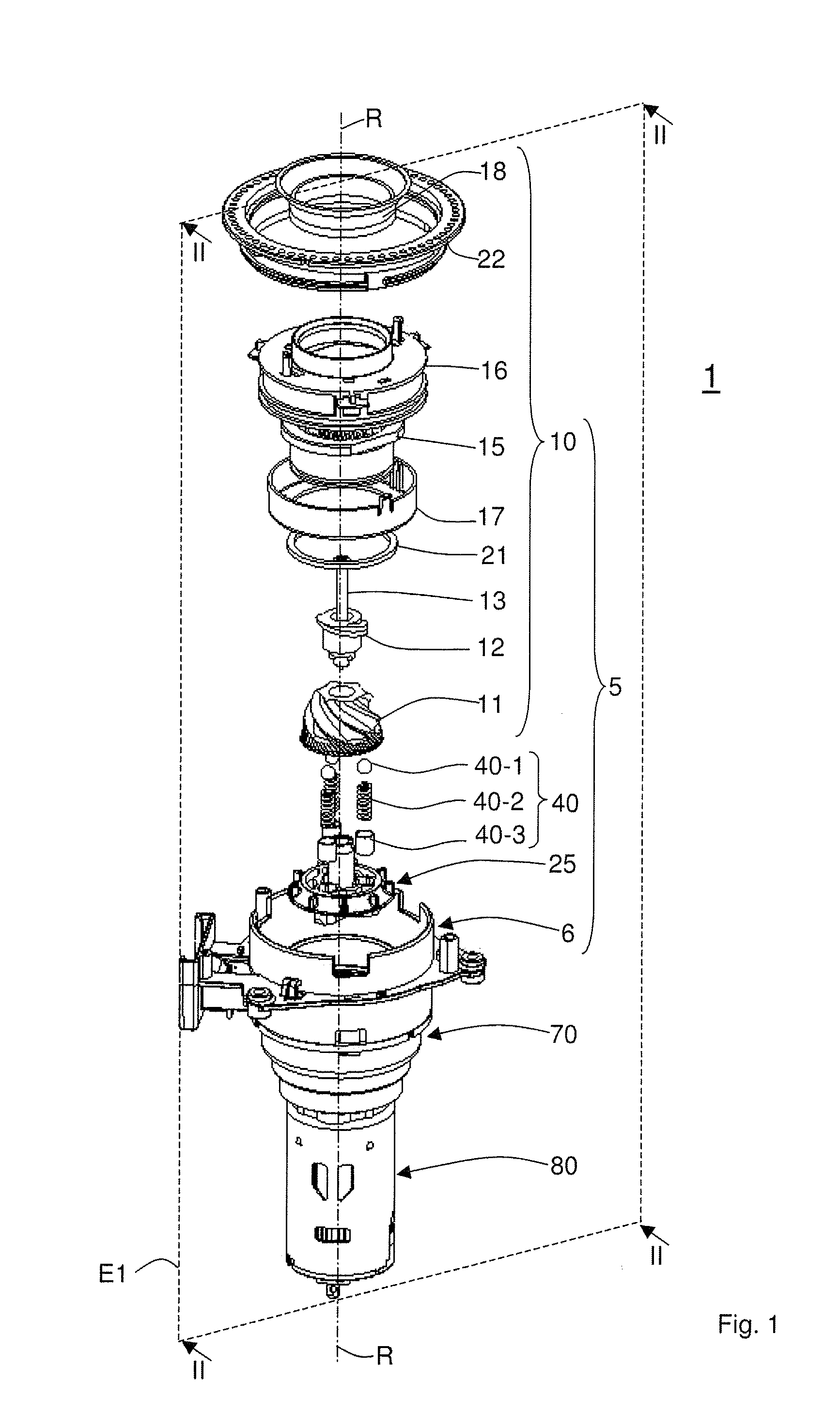

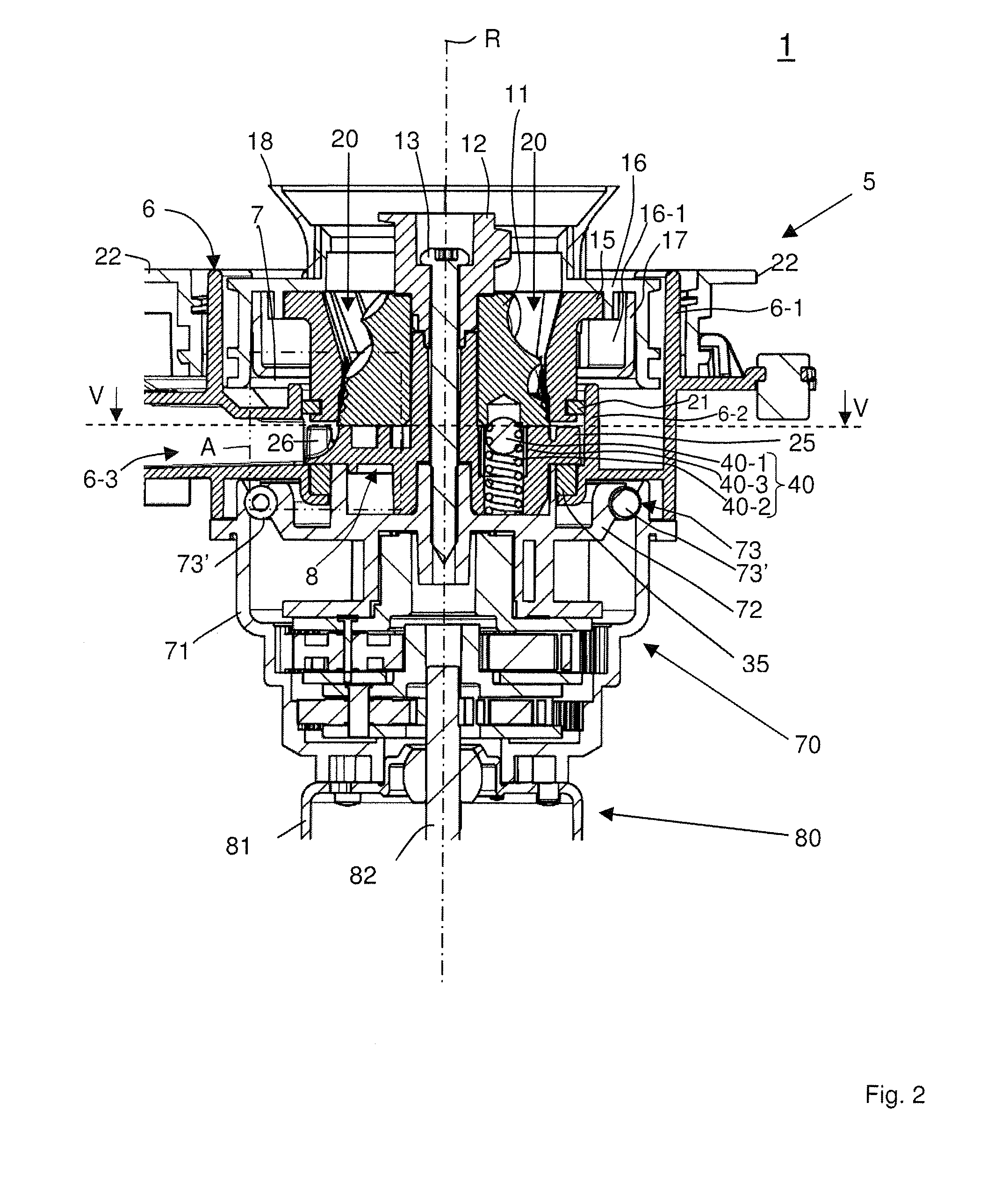

Grinder

ActiveUS20140224910A1Improve delivery capabilitiesFast shippingCoffee millsSpice millsEngineeringMechanical engineering

A new grinder is described which is used to grind coffee beans, with a first grinding element and a second grinding element, wherein the two grinding elements are rotatable relative to one another, in such a way that coffee beans are ground by the grinding elements into a coffee powder, and with an entrainer wheel rotatable with the first grinding element, said entrainer wheel being used to convey, on its edge region, the ground coffee powder out of the grinding elements via an exit channel. The edge region of the entrainer wheel is constituted tapered towards the grinding elements with a concave profile, in such a way that an inner high edge (Ri) and an outer low edge (Ra) are formed, and the entrainer wheel comprises a plurality of entrainer vanes distributed in the edge region over the periphery.

Owner:JURA ELEKTROAPPARATE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com