Patents

Literature

46results about How to "Minimizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

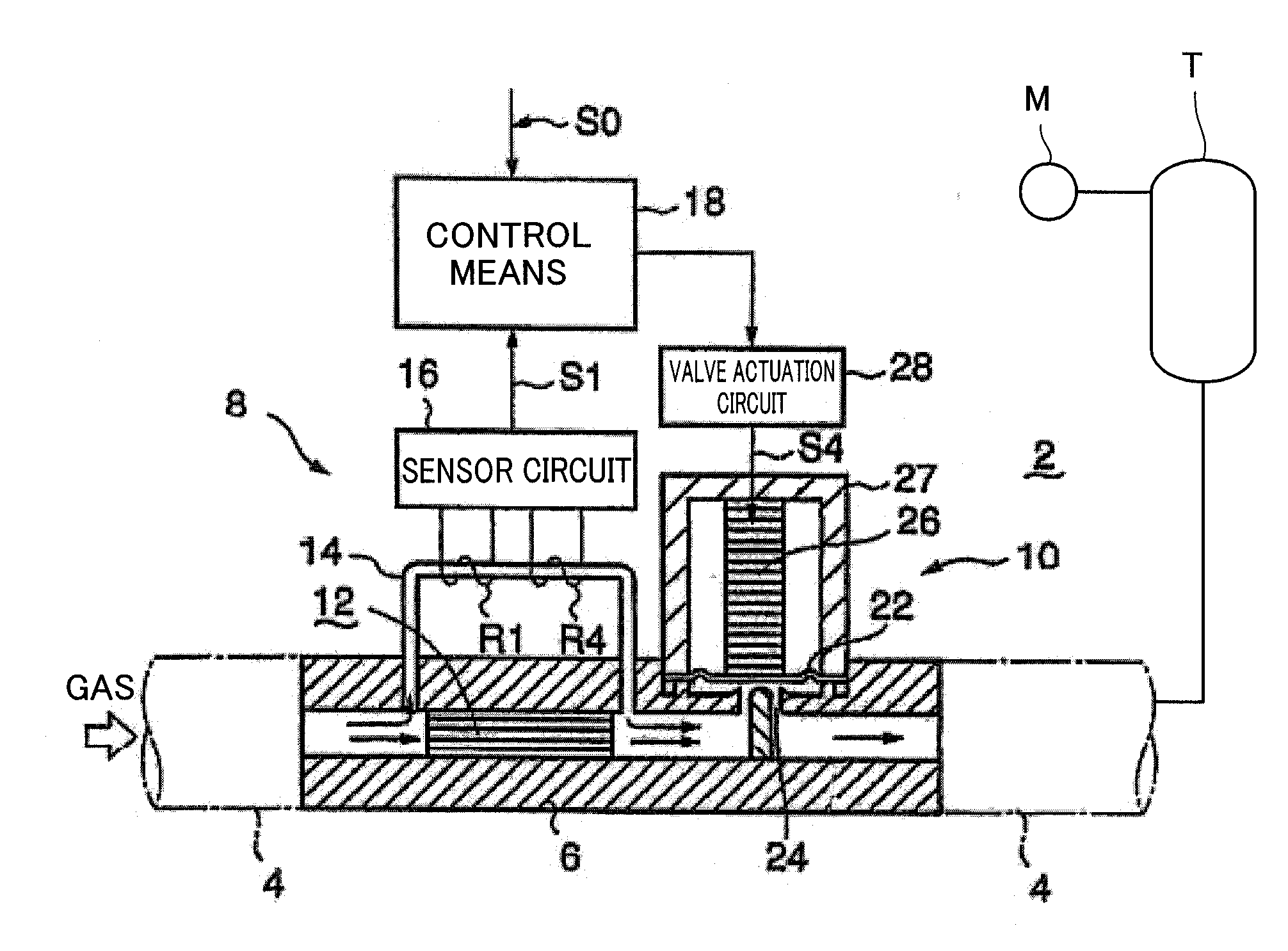

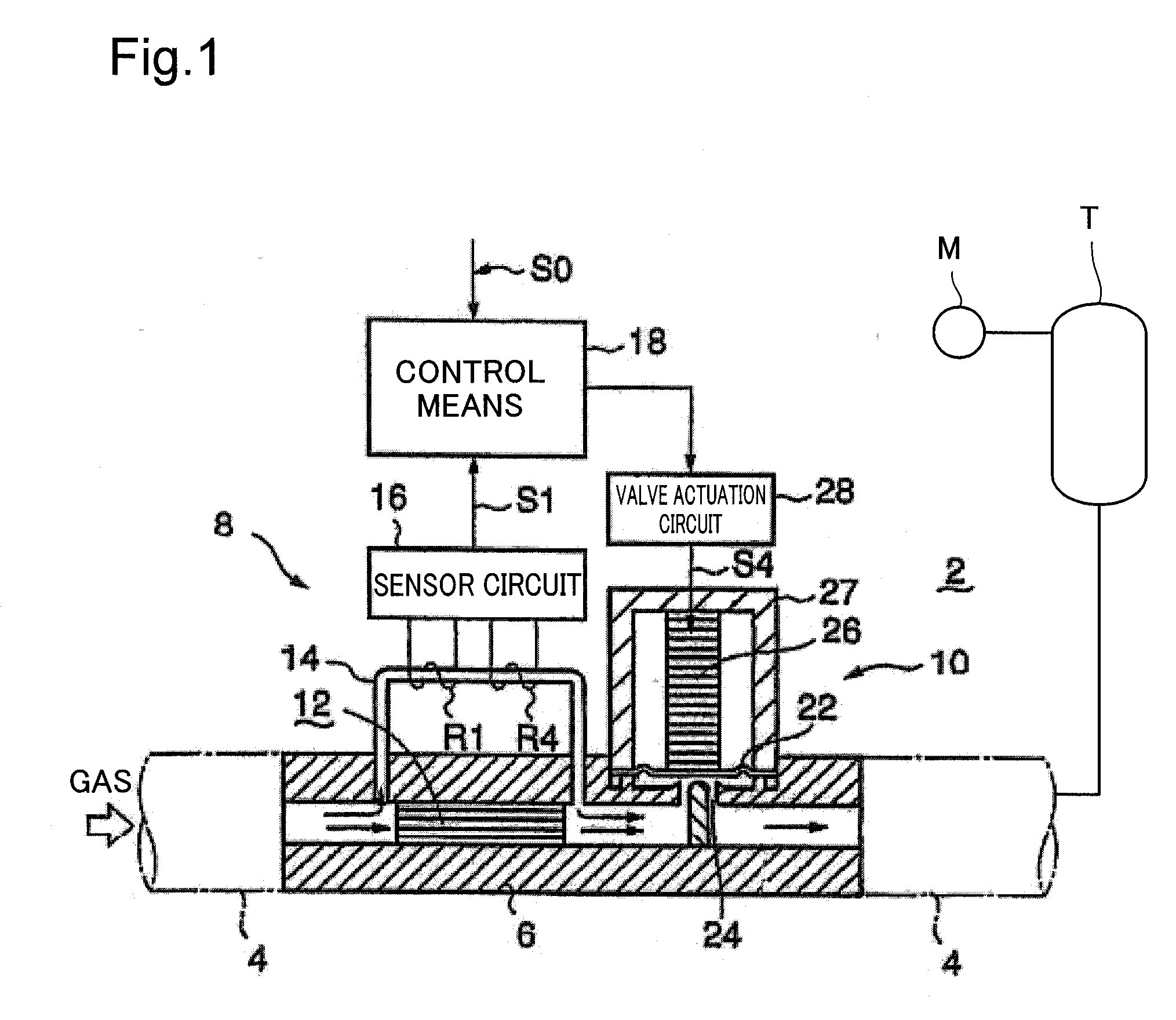

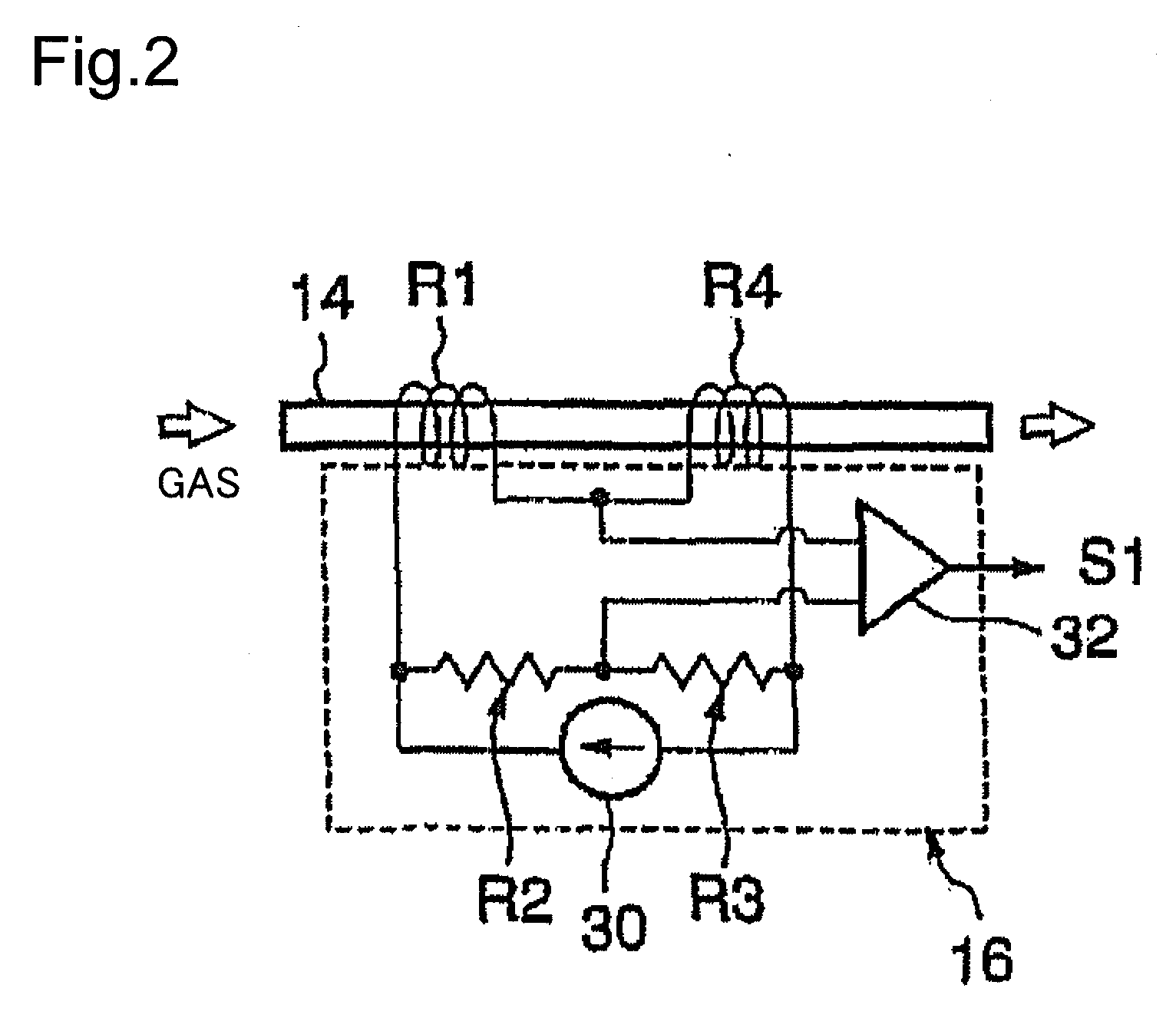

Flow rate control using mass flow rate control device

ActiveUS20100000608A1Minimizing effectImprove accuracyOperating means/releasing devices for valvesTesting/calibration apparatusData conversionProduct gas

It is possible to respecify the product (mass flow controller) corresponding to multiple types of actual process gases and multiple flow rate ranges, even after the mass flow controller has been shipped. With the mass flow rate control device in an initial state, calibration gas characteristic data is derived by measuring actual flow rate versus a flow rate setting signal using a calibration gas, and this calibration gas characteristic data is then saved to control unit. Meanwhile, actual gas characteristic data is derived by measuring actual flow rate versus a flow rate setting signal for each of a plurality of types of actual gas, and this actual gas characteristic data is then saved to a storage medium. Subsequently, prior to operating the mass flow rate control device, the actual gas characteristic data for an actual process gas is read from the storage medium via a computer, and the calibration gas characteristic data that was saved to the control unit is read out. The calibration gas characteristic data is then converted to controlled flow rate correction data based on the actual gas characteristic data, and the controlled flow rate correction data is saved to the control unit. Actual gas flow rate is corrected based on this controlled flow rate correction data.

Owner:HITACHI METALS LTD

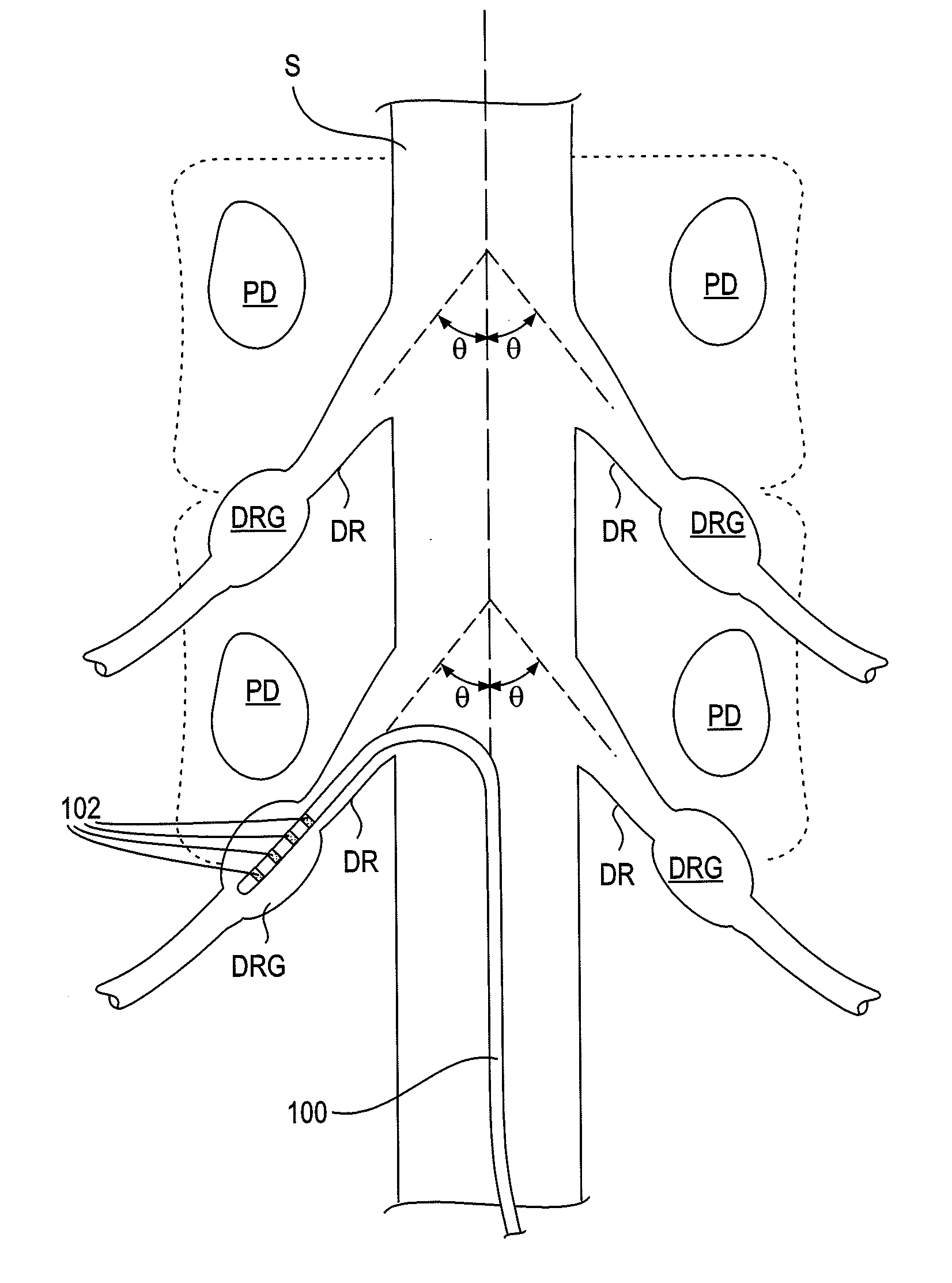

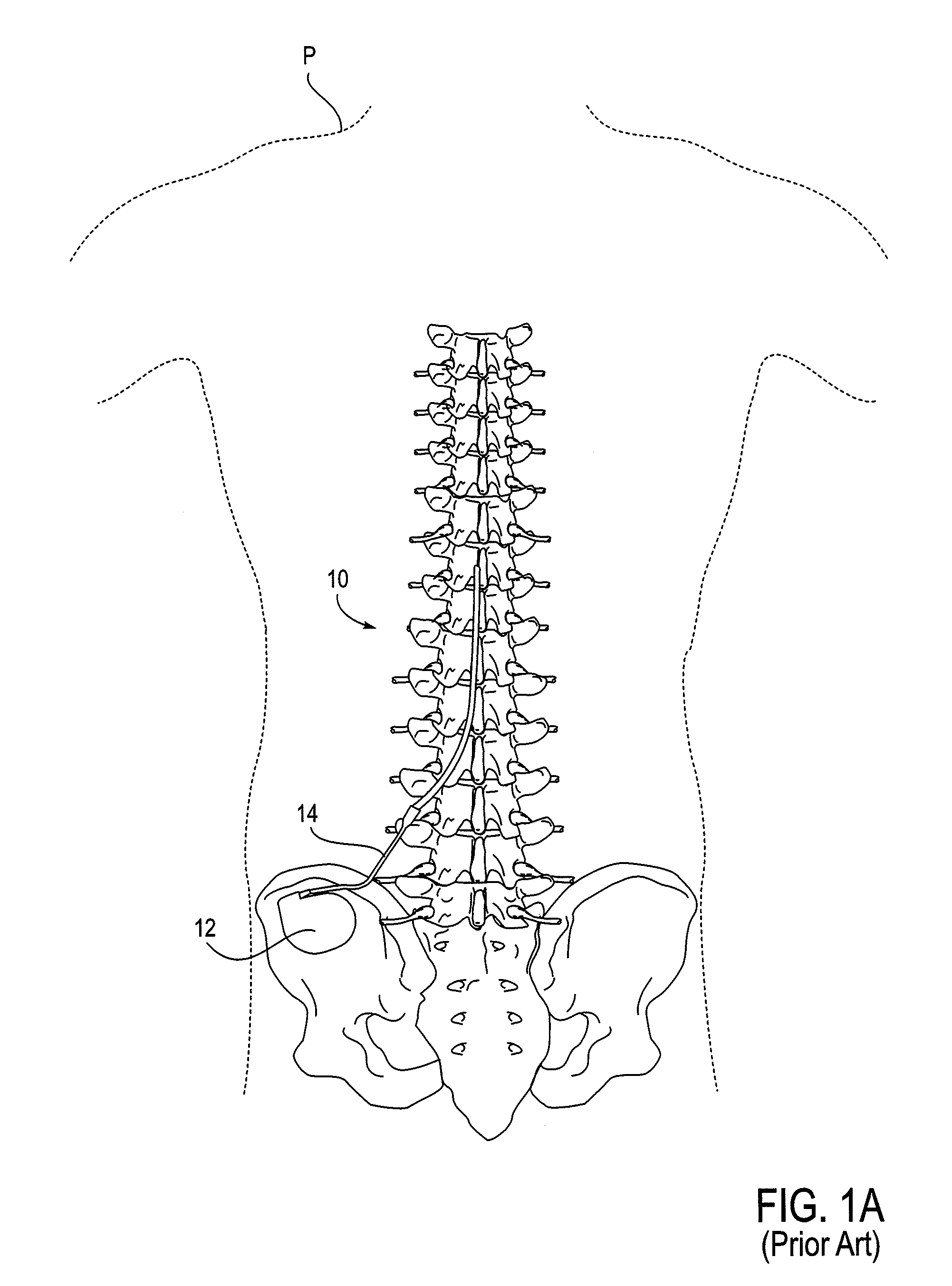

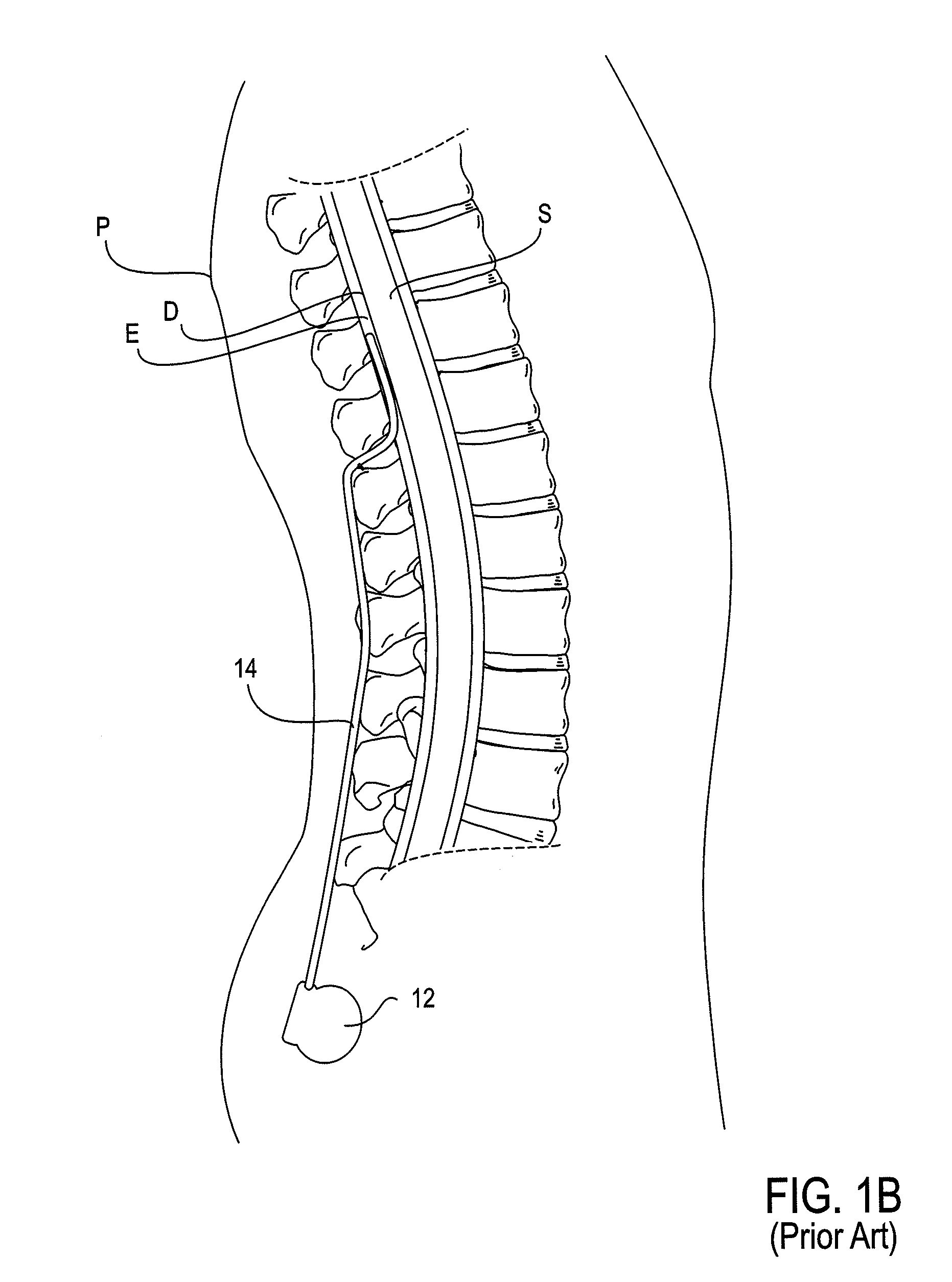

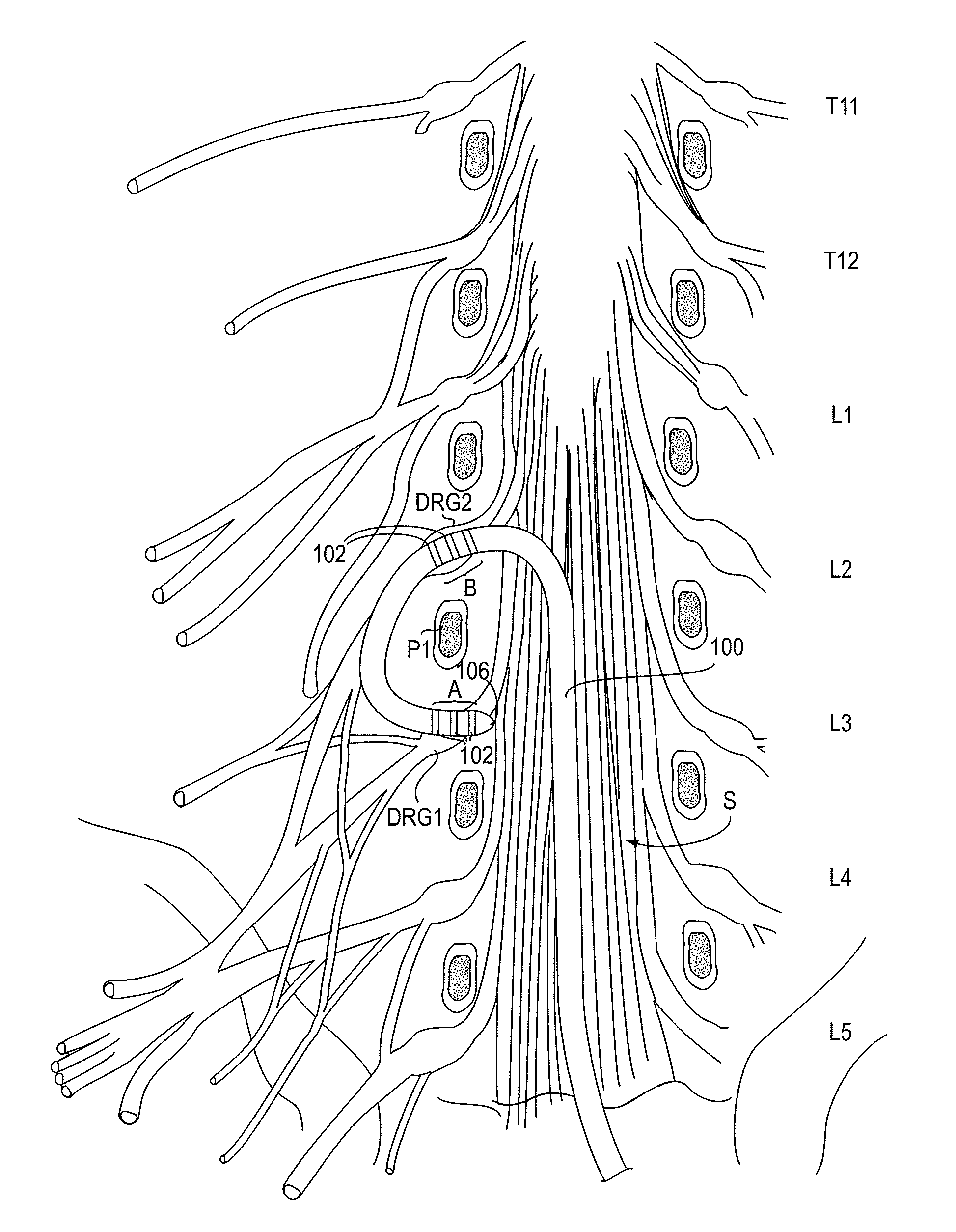

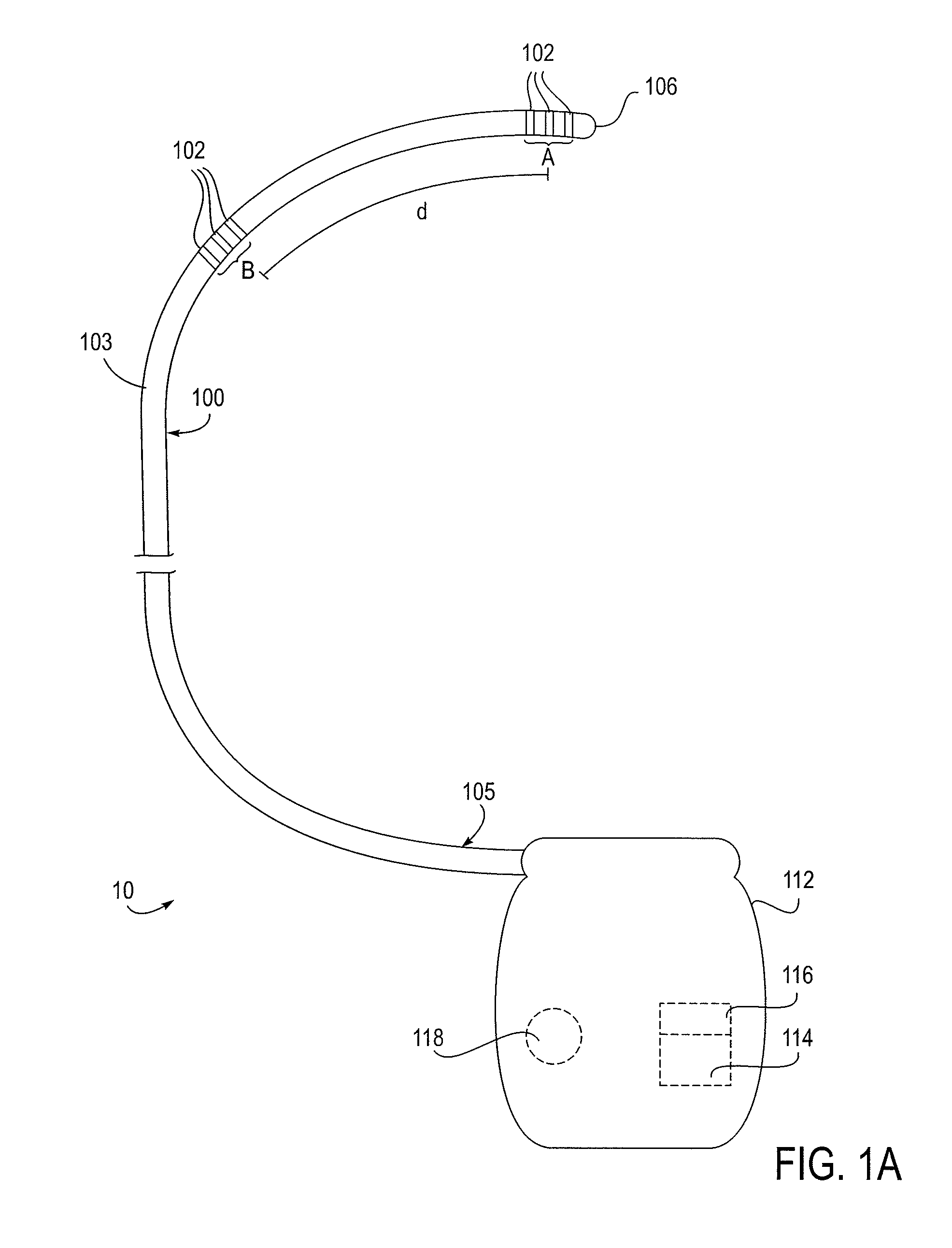

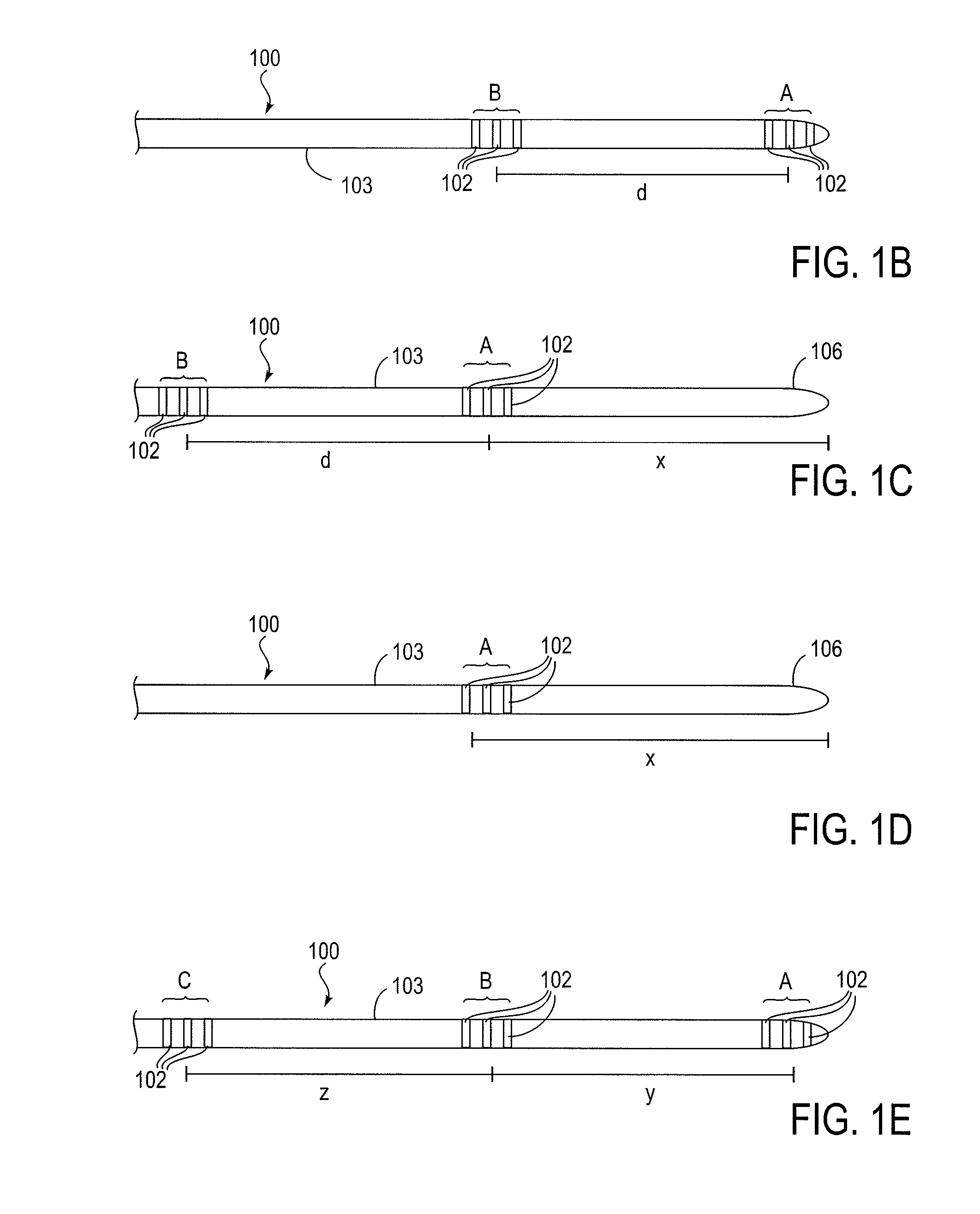

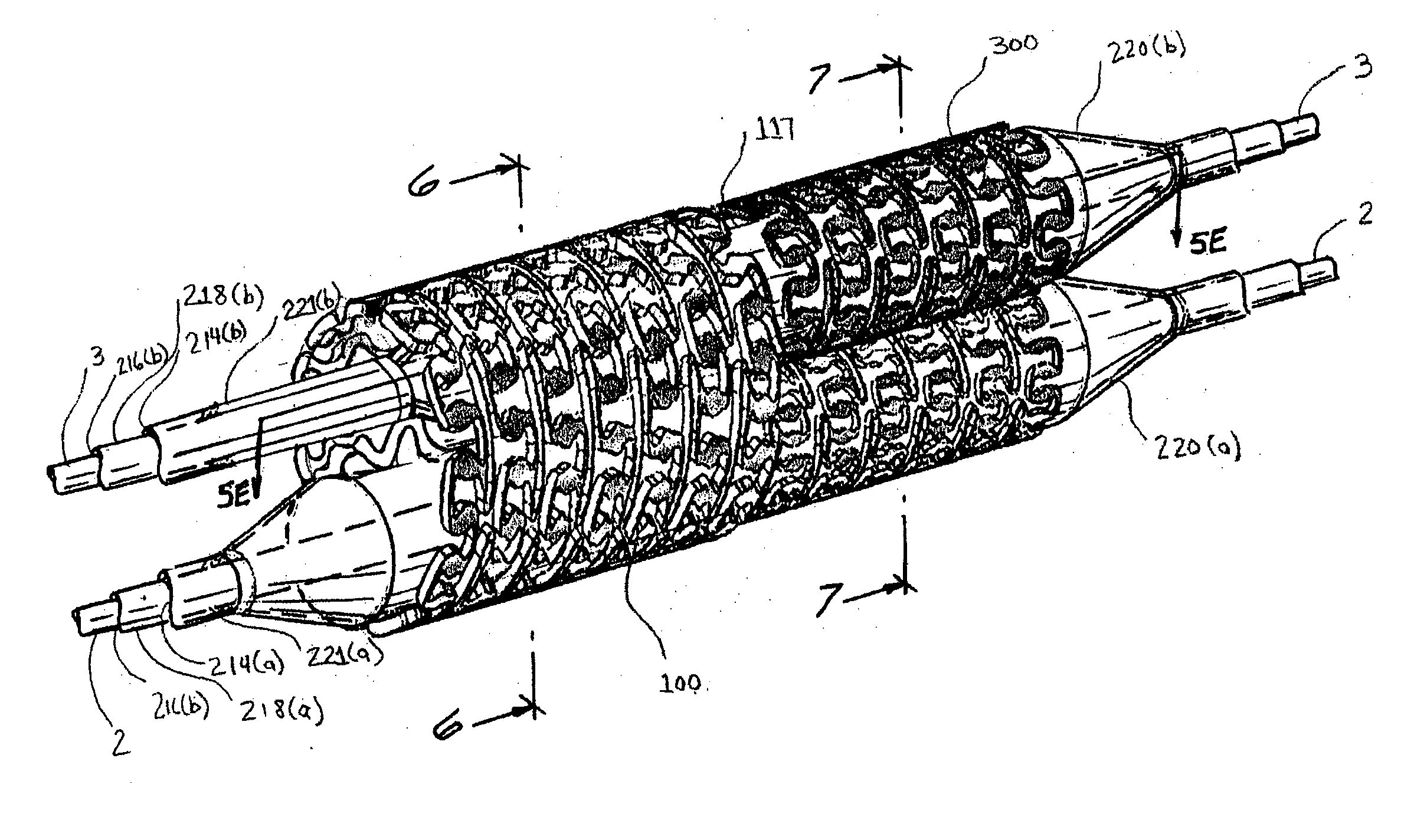

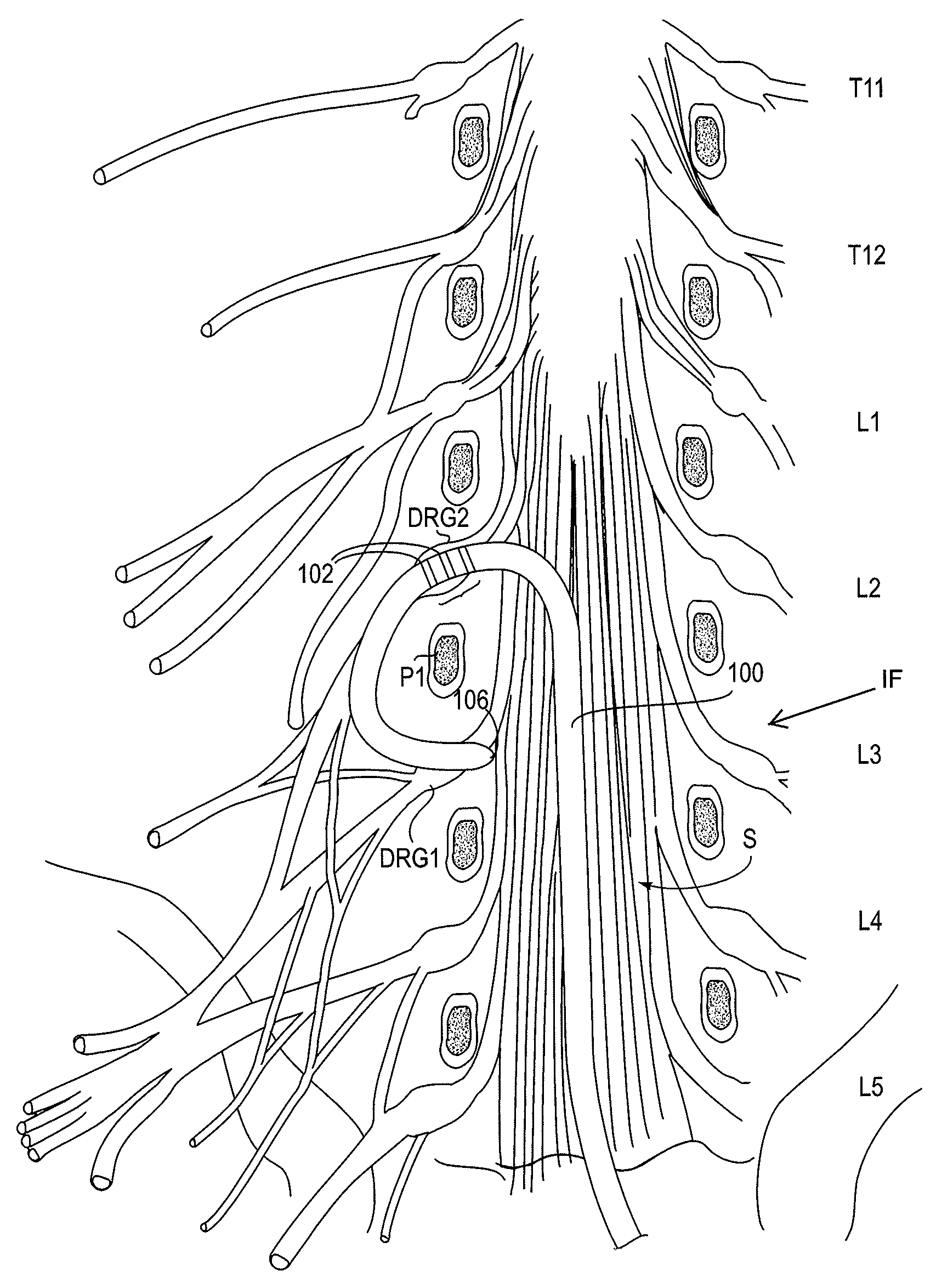

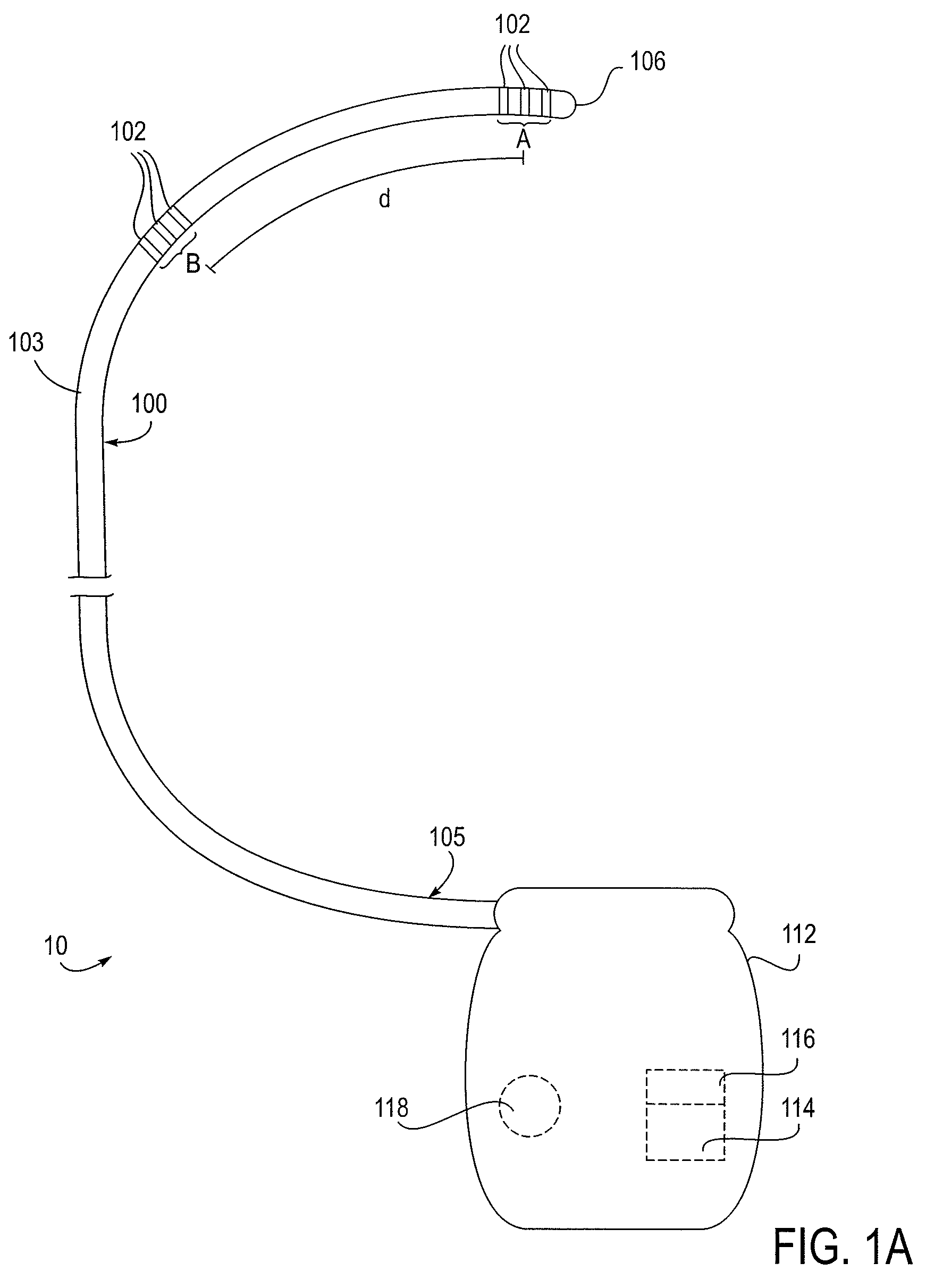

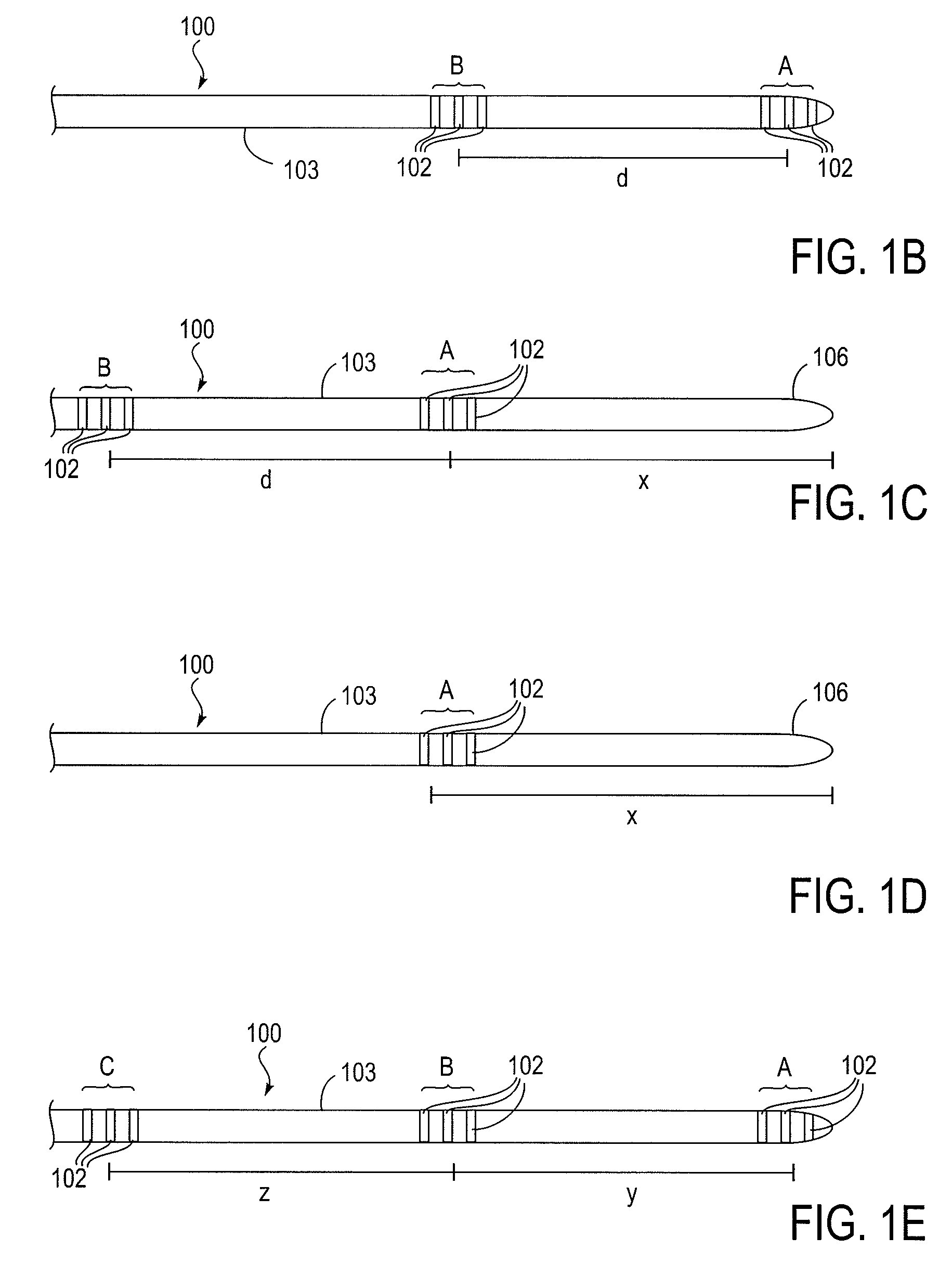

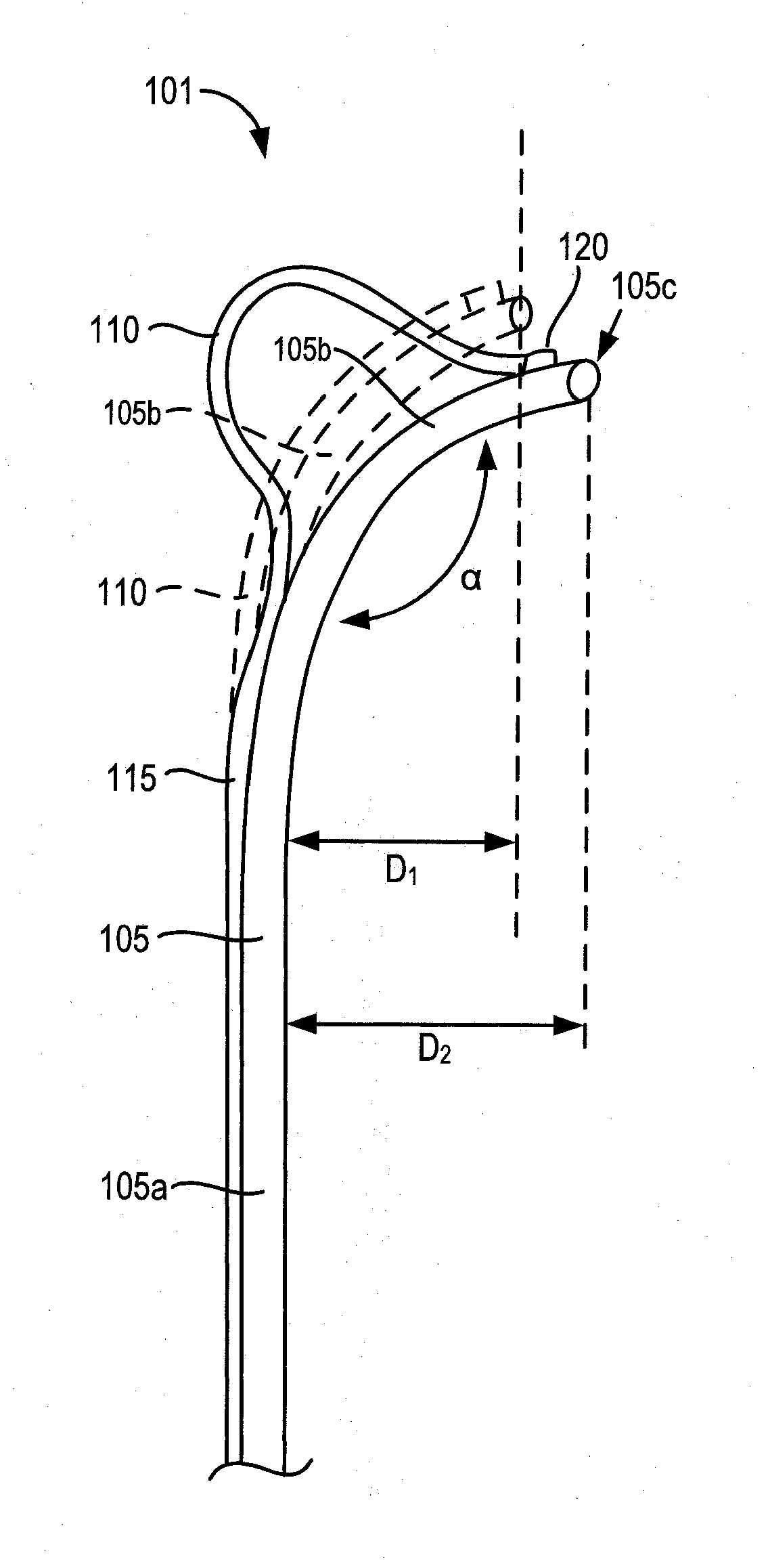

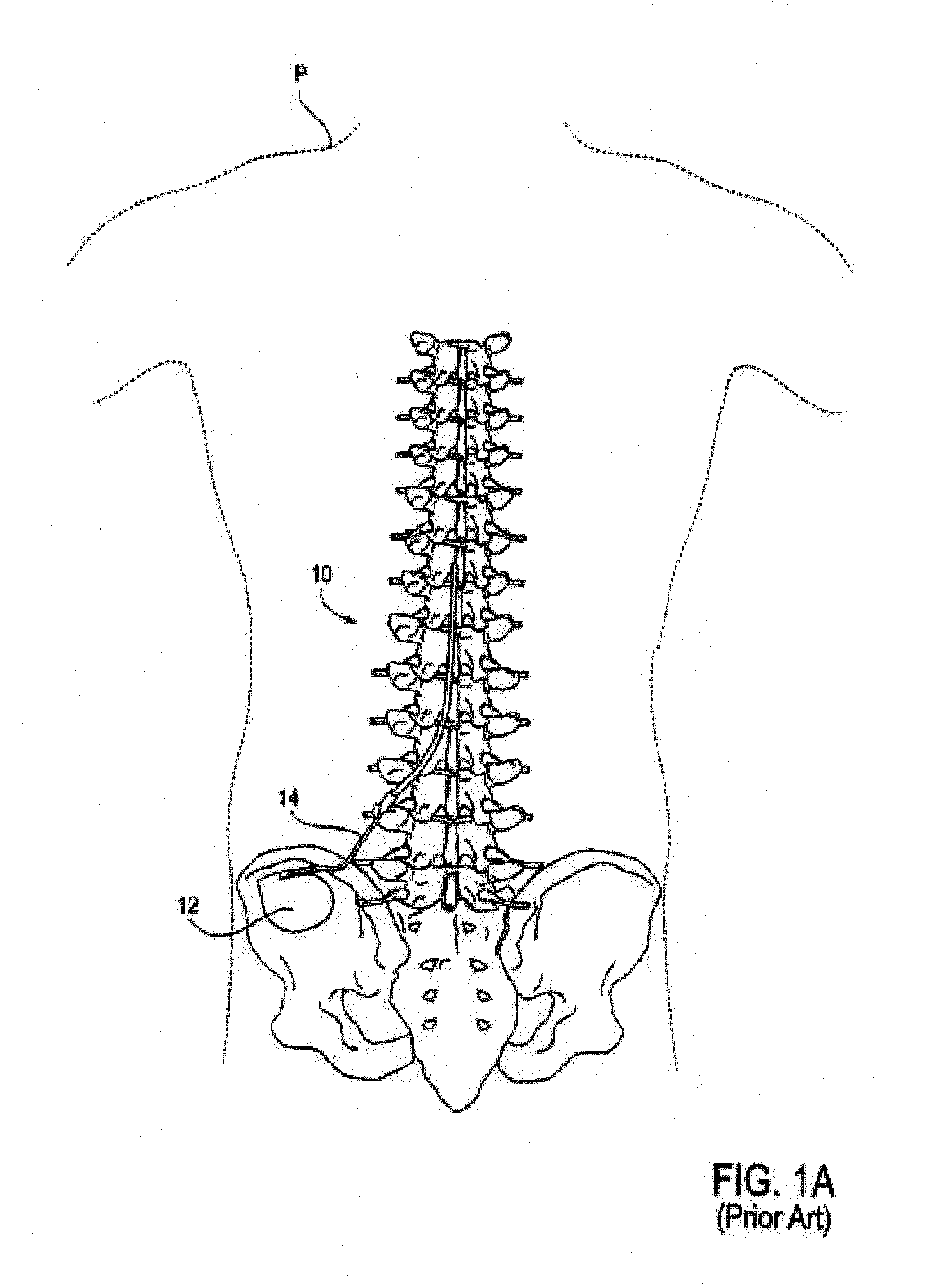

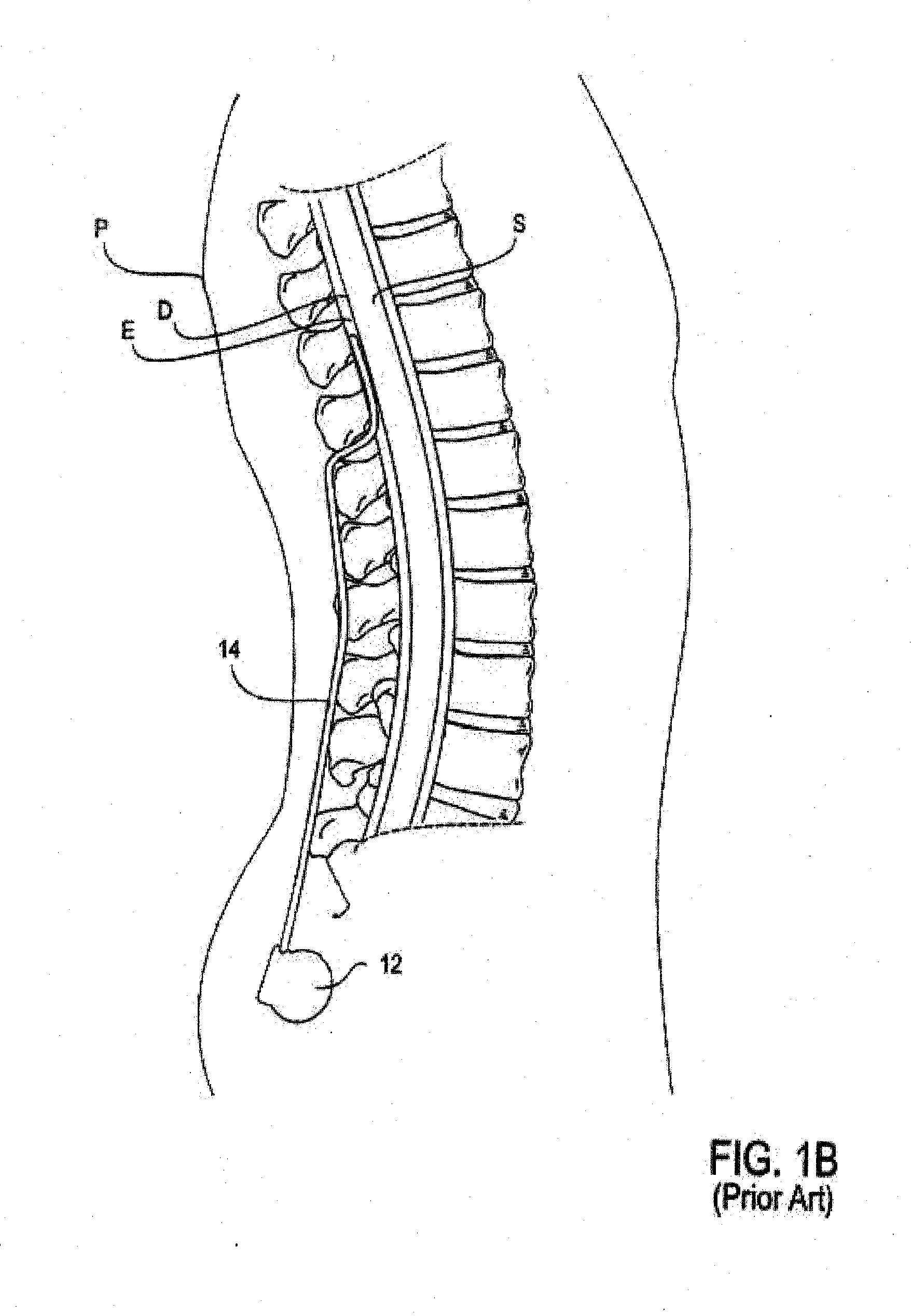

Stimulation leads, delivery systems and methods of use

InactiveUS20100179562A1Minimizing complicationMinimize side effectsSpinal electrodesDiagnosticsSide effectMedicine

Devices, systems and methods are provided for accessing and treating anatomies associated with a variety of conditions while minimizing possible complications and side effects. This is achieved by directly neuromodulating a target anatomy associated with the condition while minimizing or excluding undesired neuromodulation of other anatomies. Typically, this involves stimulating portions of neural tissue of the central nervous system, wherein the central nervous system includes the spinal cord and the pairs of nerves along the spinal cord which are known as spinal nerves. In particular, some embodiments of the present invention are used to selectively stimulate portions of the spinal nerves, particularly one or more dorsal root ganglions (DRGs), to treat chronic pain while causing minimal deleterious side effects such as undesired motor responses.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

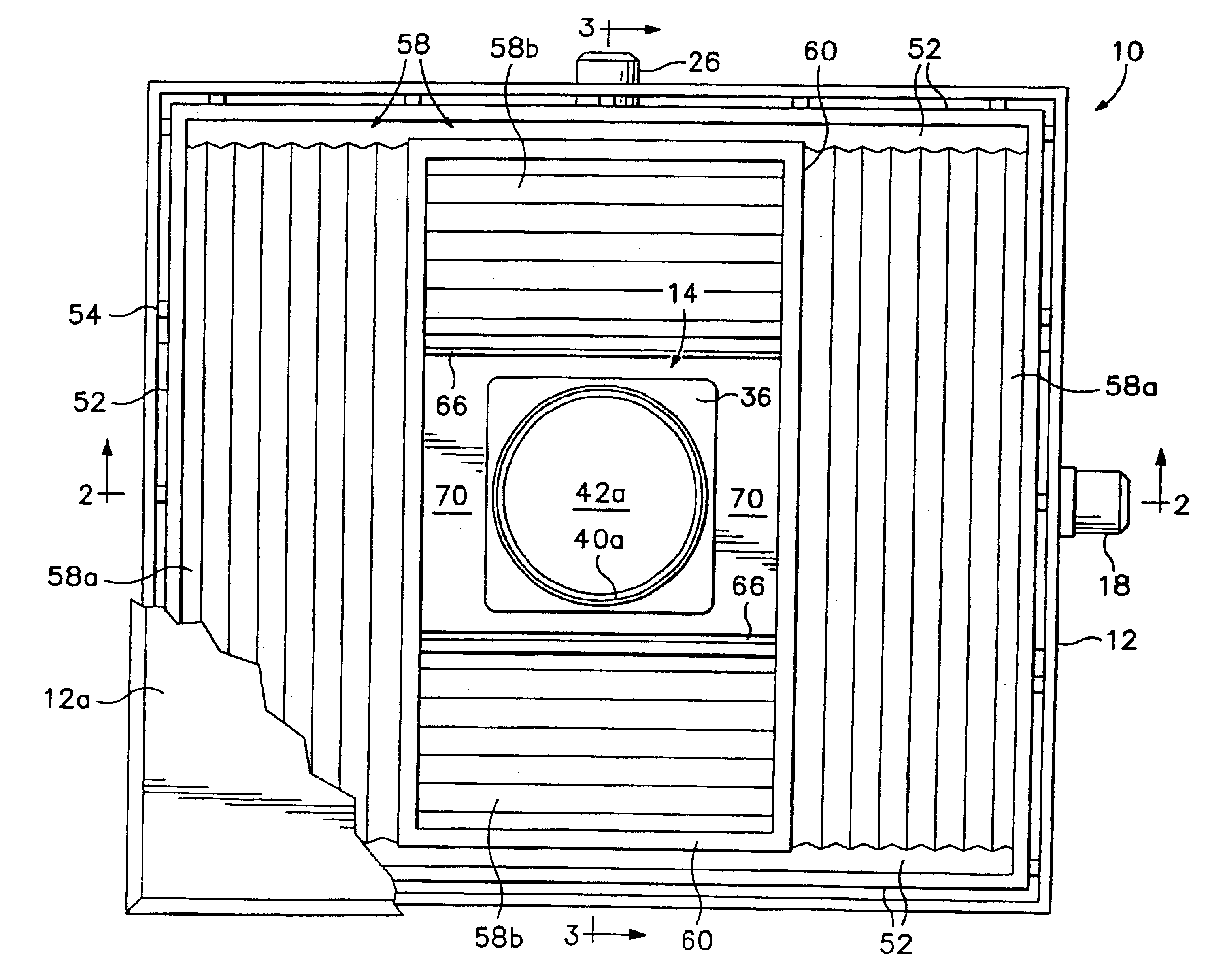

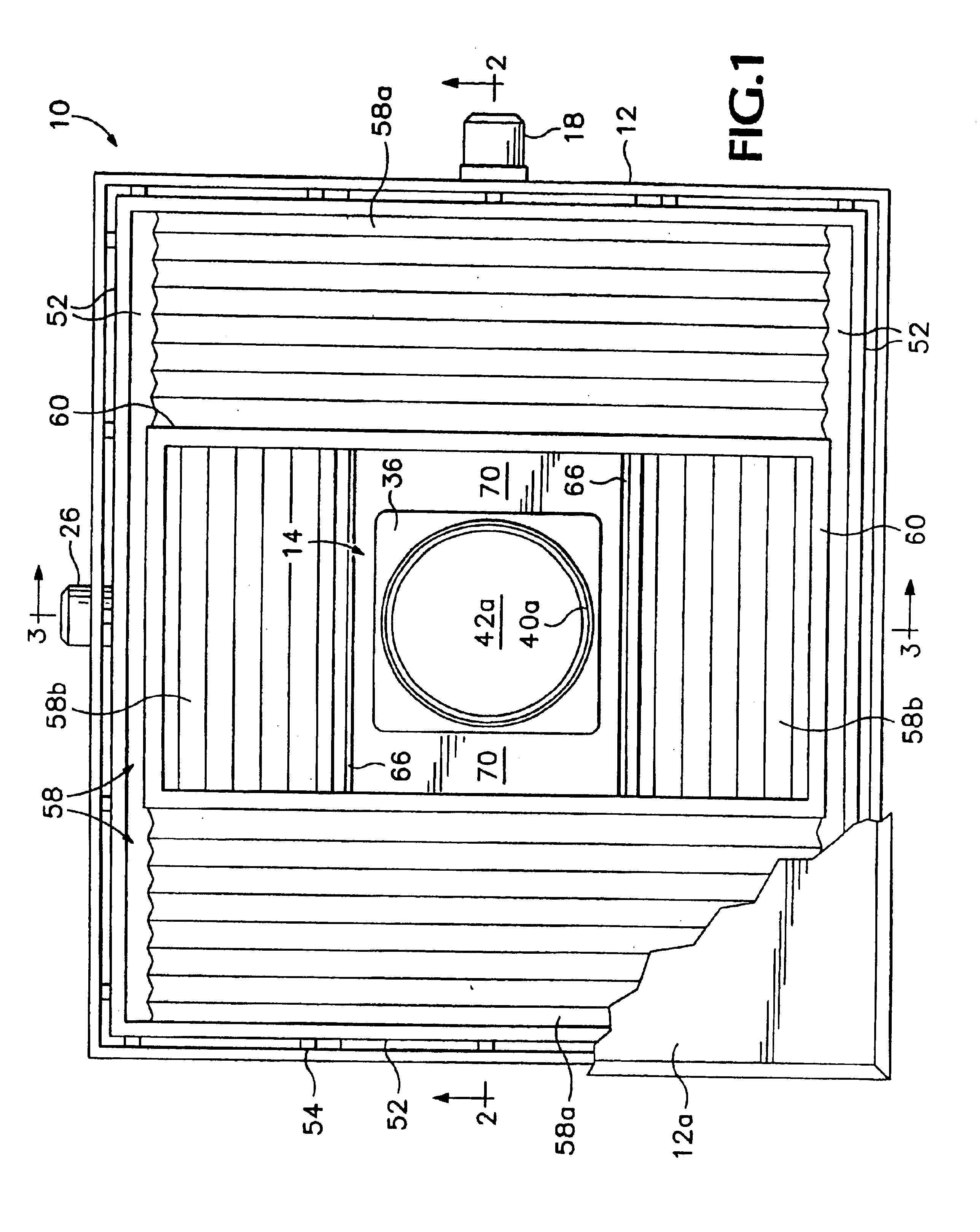

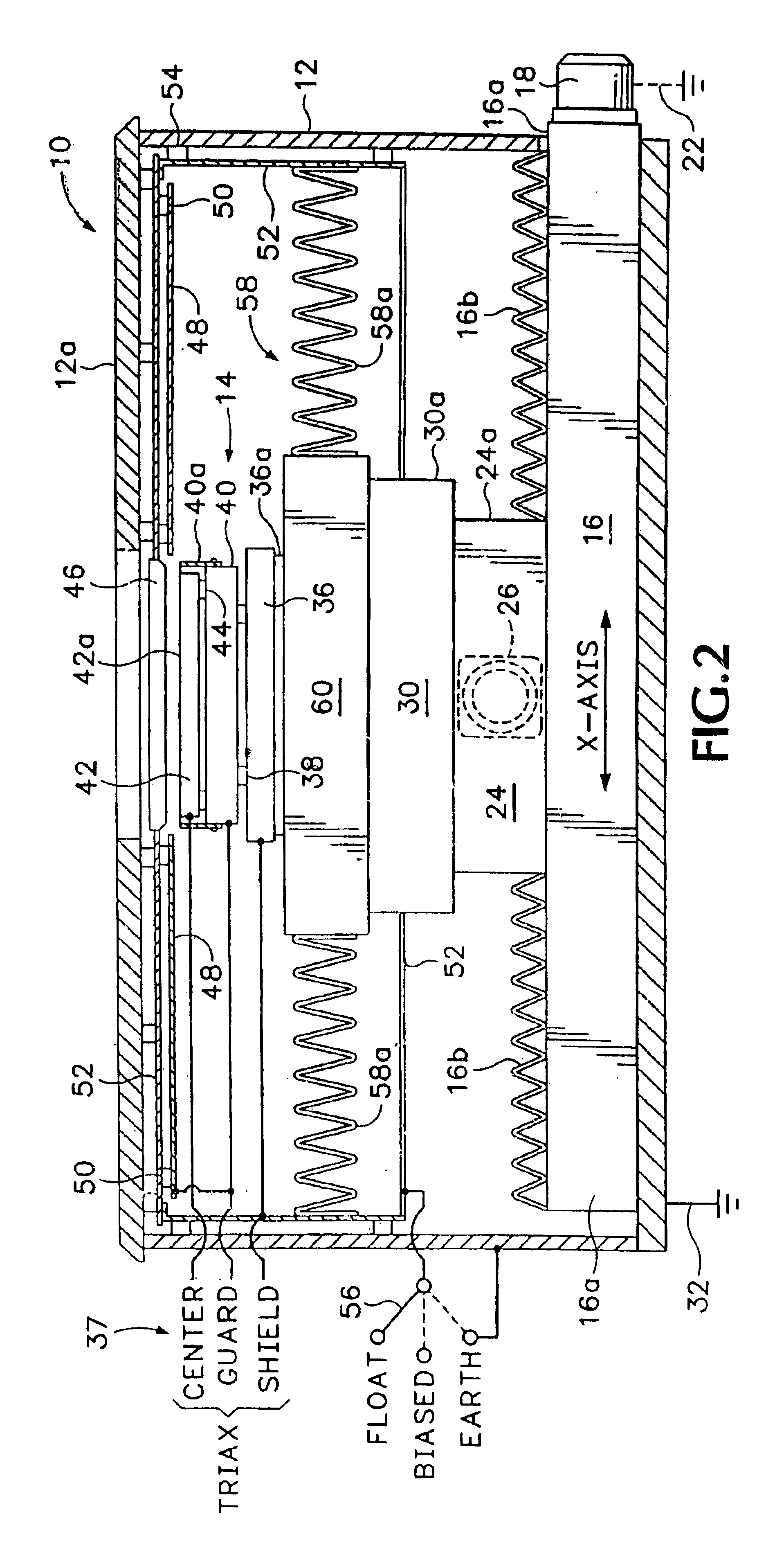

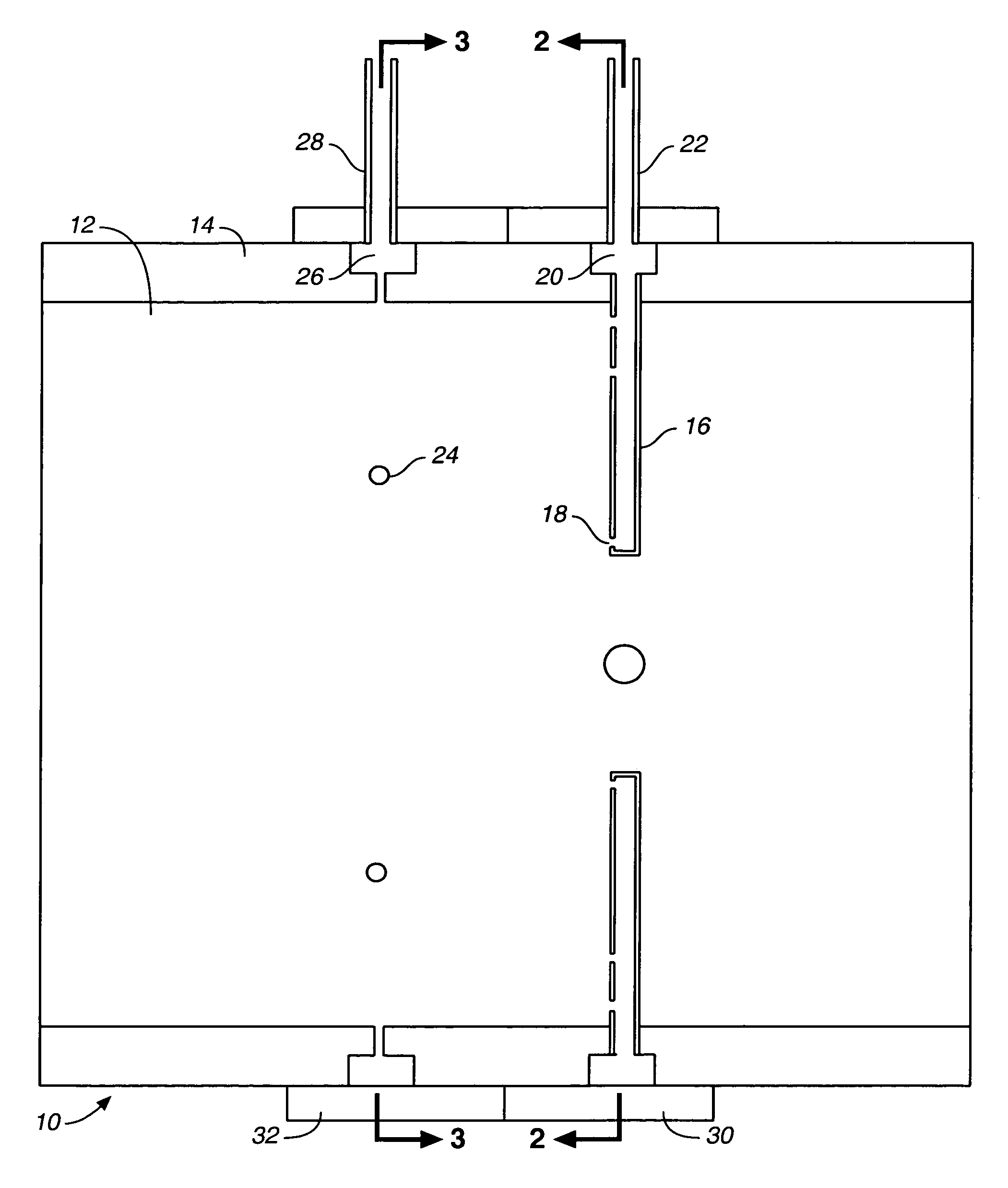

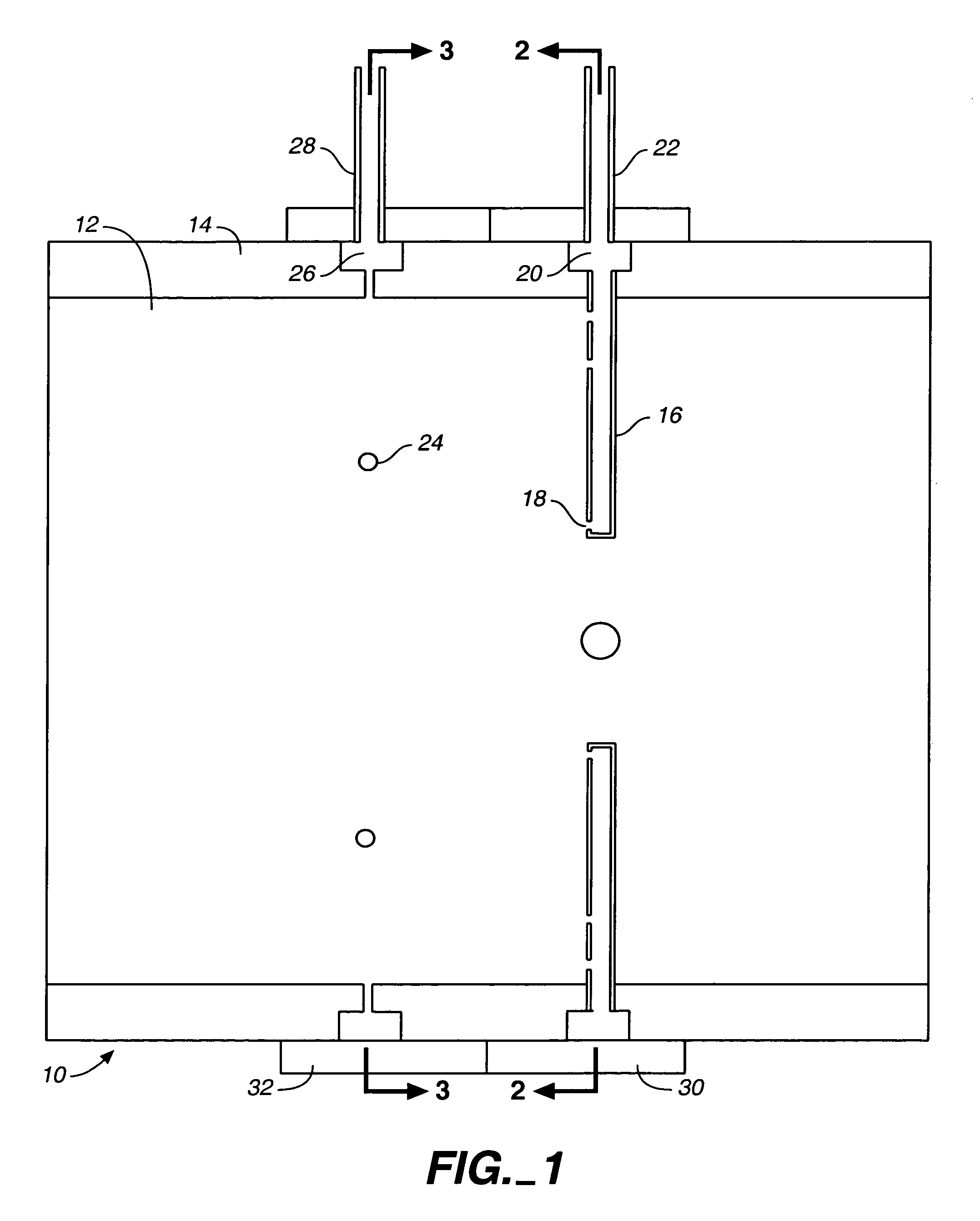

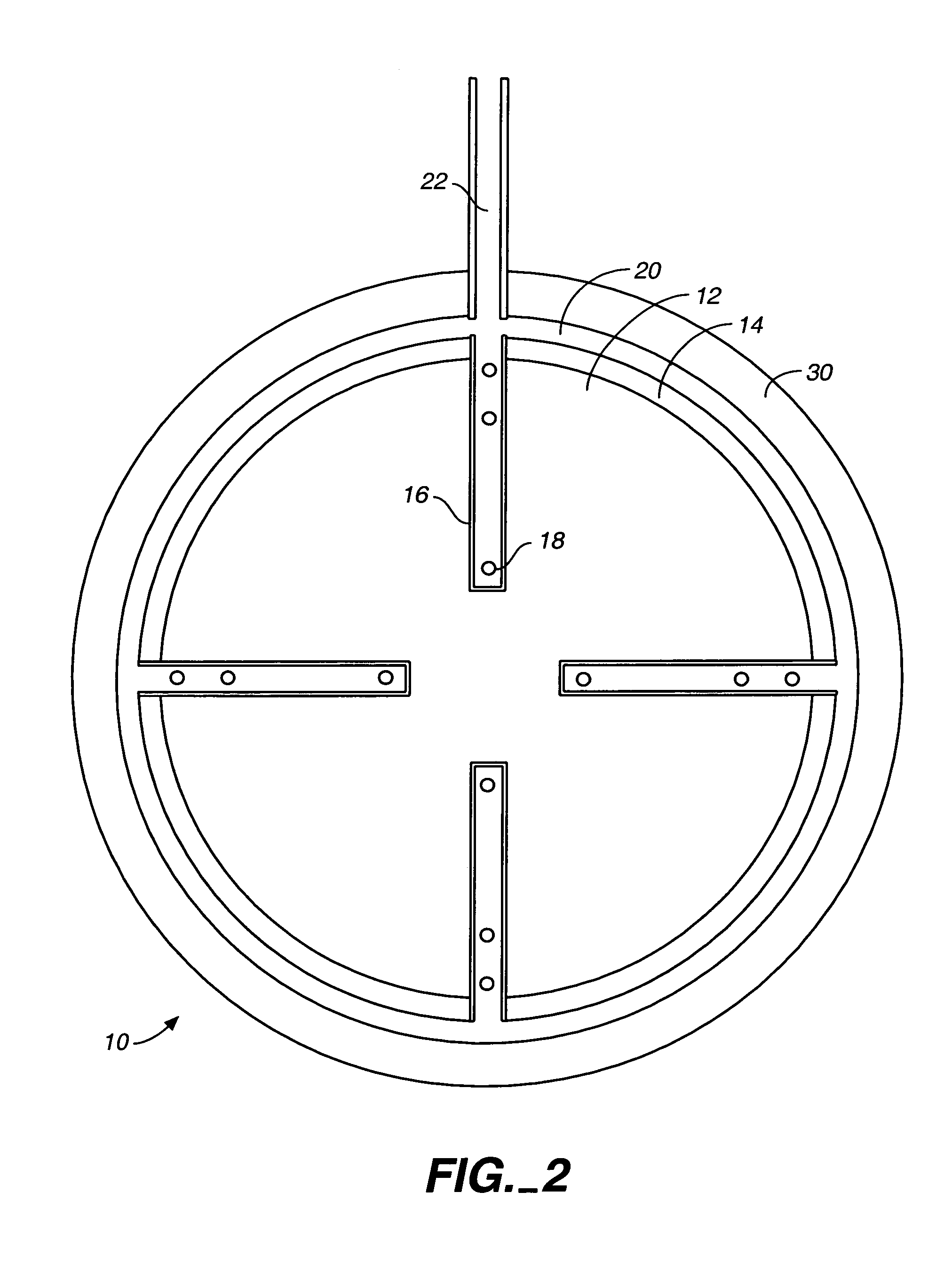

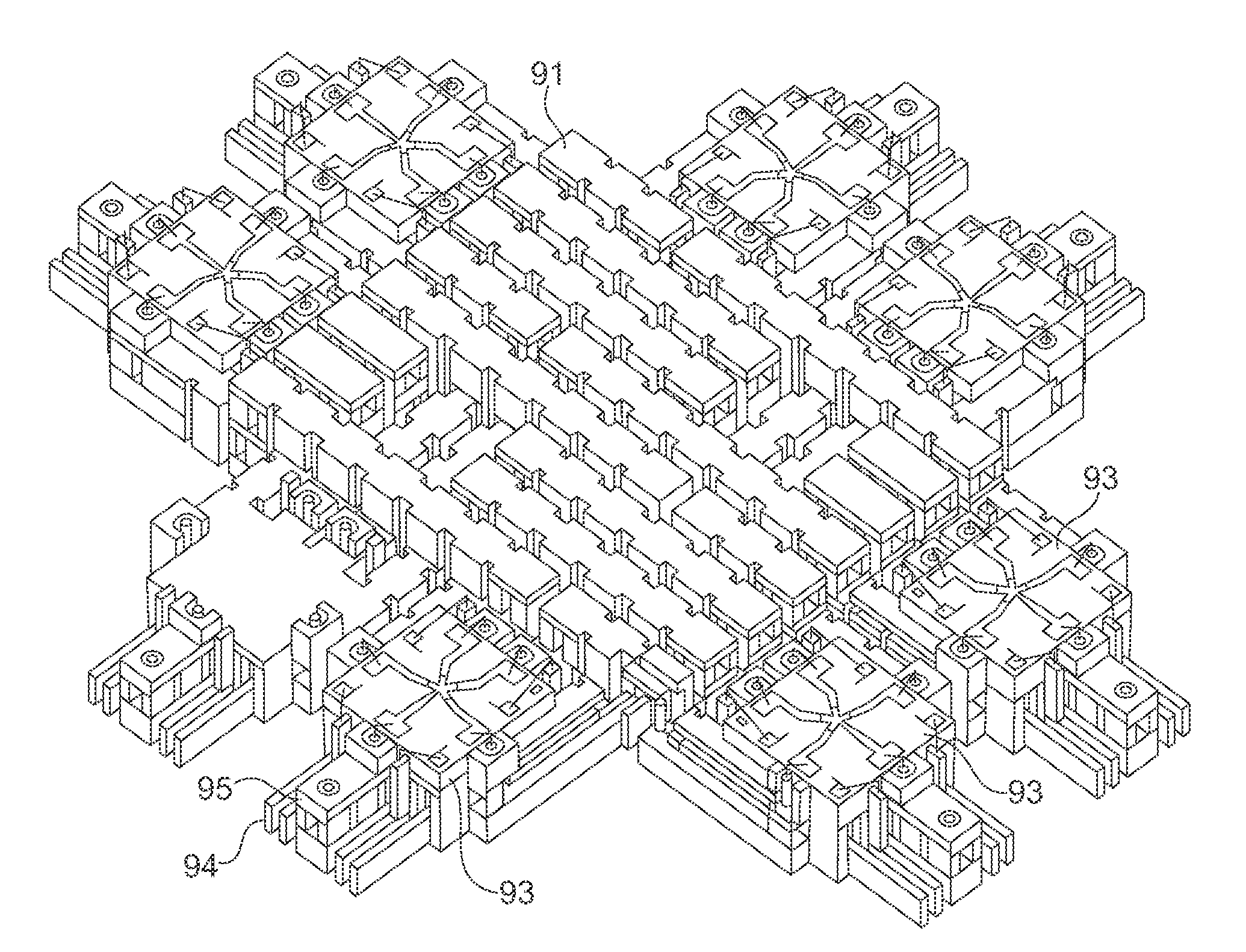

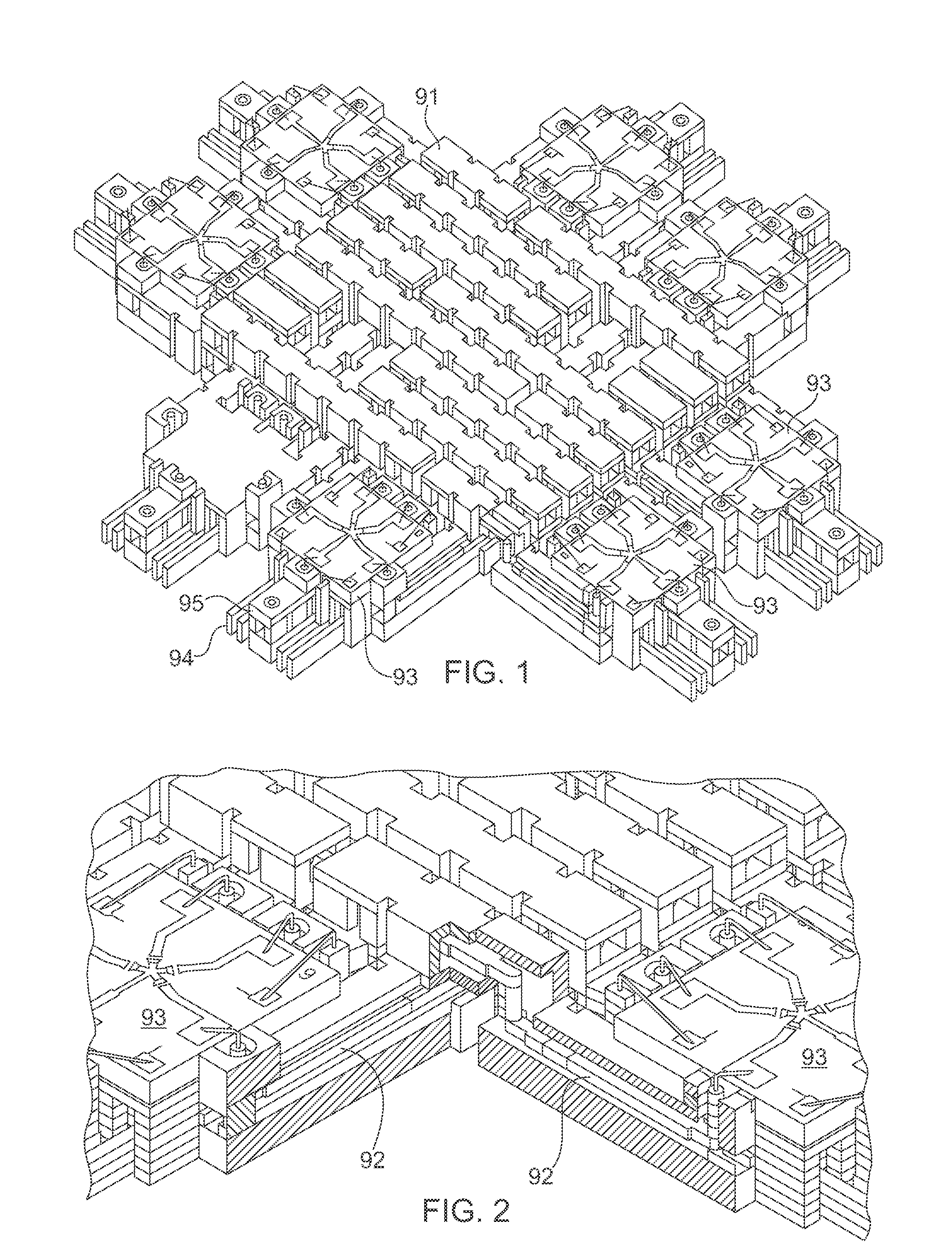

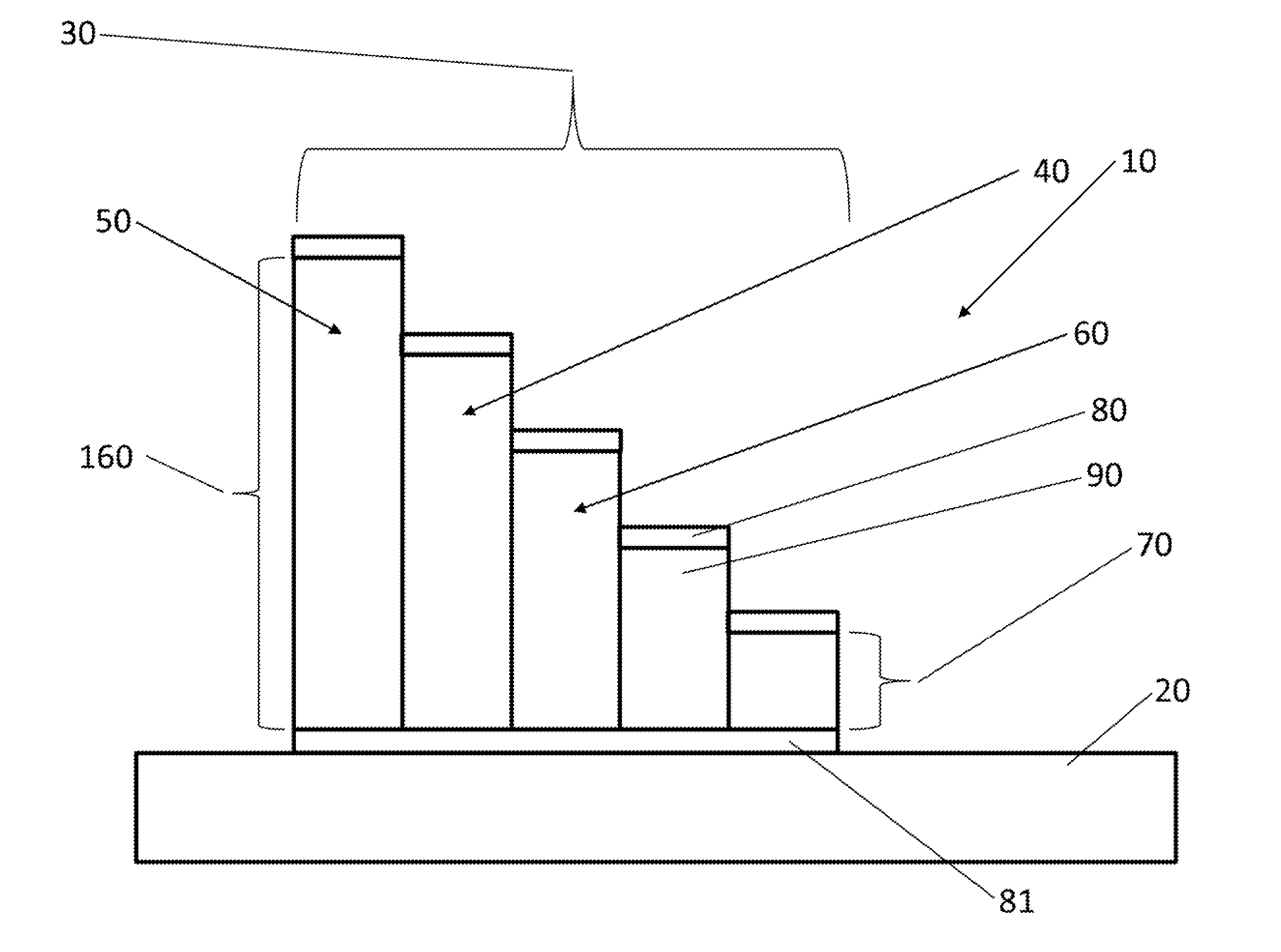

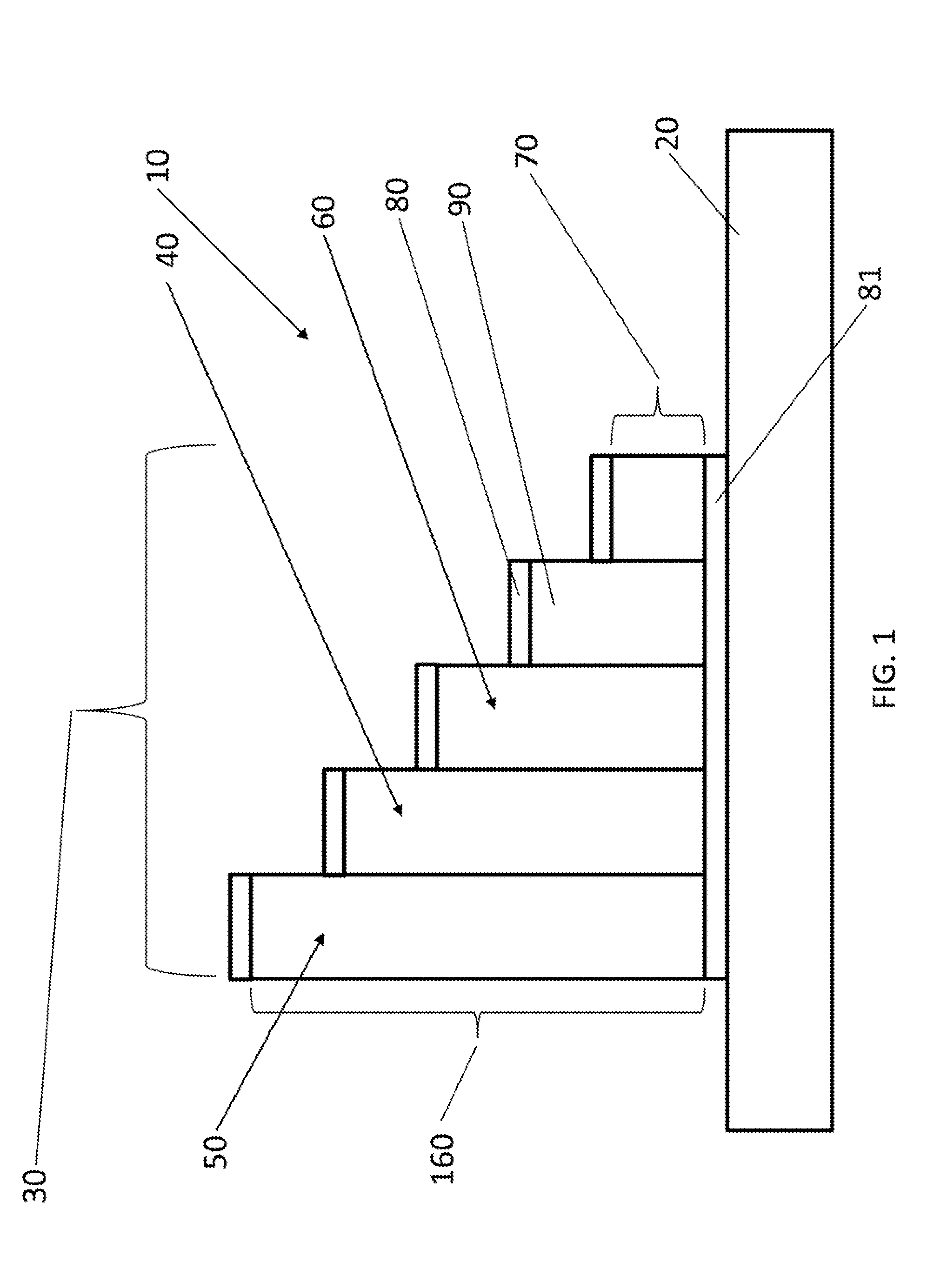

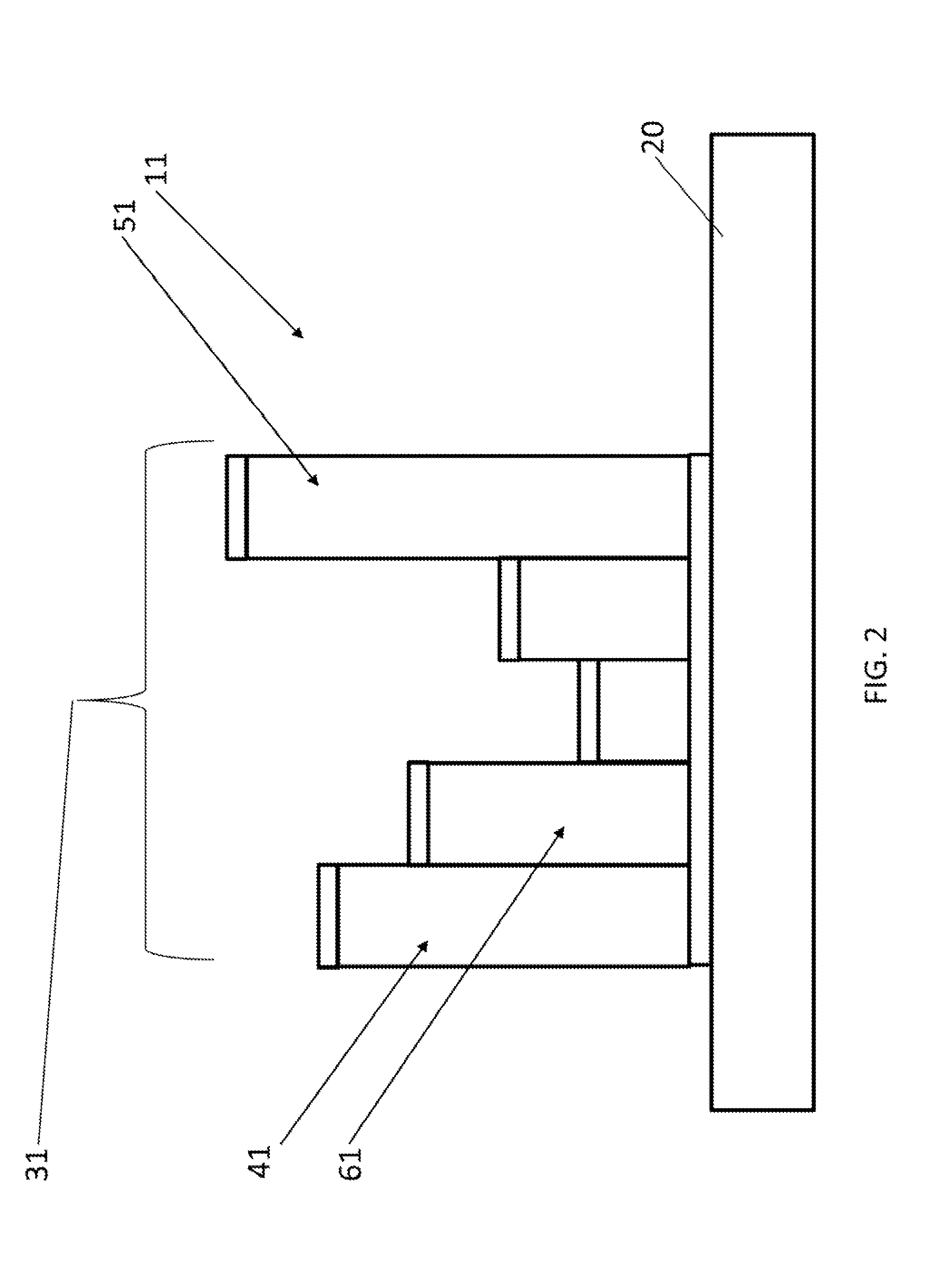

Probe station having multiple enclosures

InactiveUS6842024B2Minimizing effectMinimize impactSemiconductor/solid-state device testing/measurementInstrument screening arrangementsElectrically conductivePower station

A probe station for probing a test device has a chuck element for supporting the test device. An electrically conductive outer shield enclosure at least partially encloses such chuck element to provide EMI shielding therefor. An electrically conductive inner shield enclosure is interposed between and insulated from the outer shield enclosure and the chuck element, and at least partially encloses the chuck element.

Owner:CASCADE MICROTECH

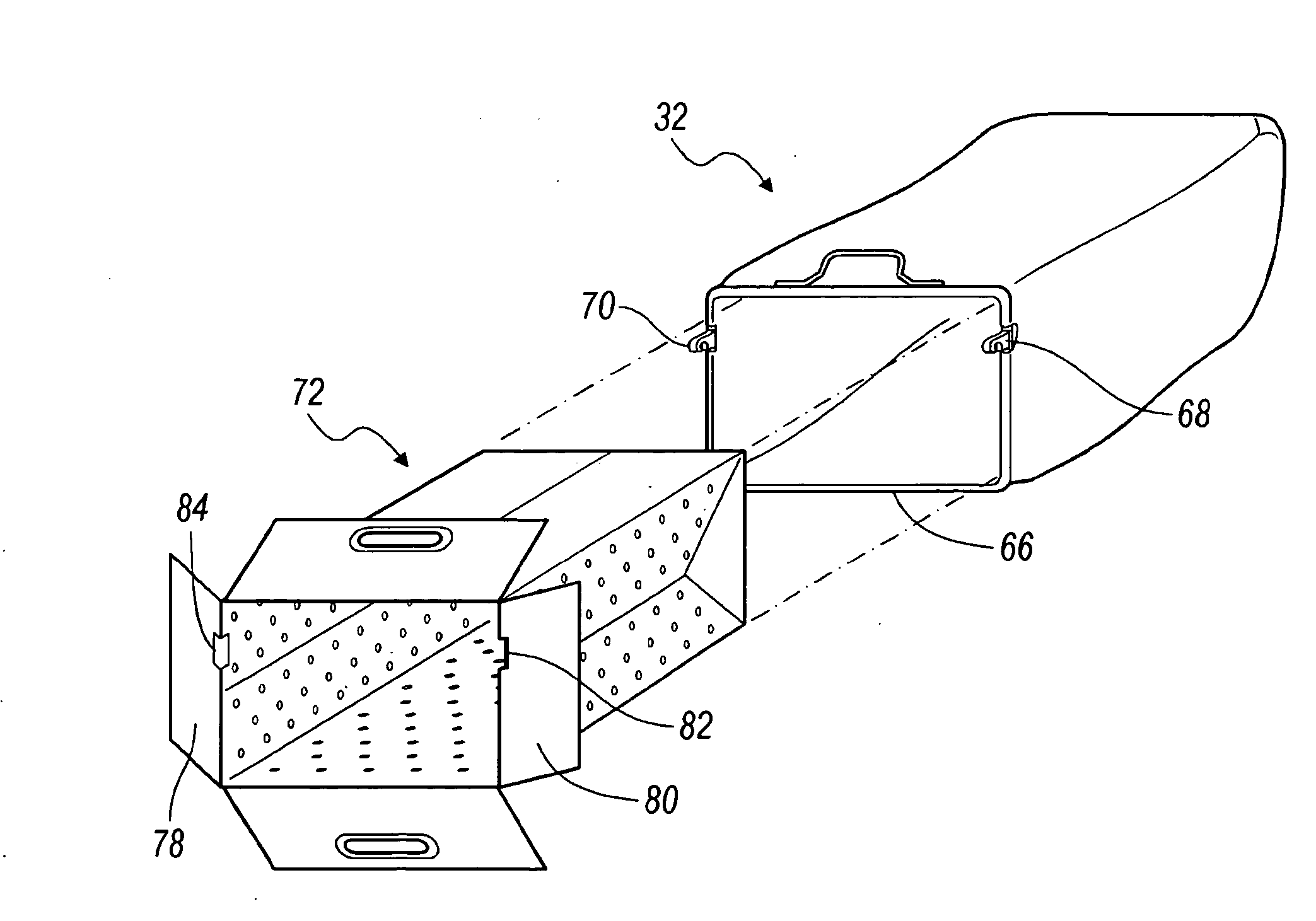

Methods, systems and devices for neuromodulating spinal anatomy

ActiveUS20100292769A1Minimizing complicationMinimize side effectsSpinal electrodesExternal electrodesSide effectSpinal anatomy

Devices, systems and methods for treating pain or other conditions while minimizing possible complications and side effects. Treatment typically includes electrical stimulation and / or delivery of pharmacological or other agents with the use of a lead or catheter. The devices, systems and methods provide improved anchoring which reduces migration of the lead yet allows for easy repositioning or removal of the lead if desired. The devices, systems and methods also provide for simultaneous treatment of multiple targeted anatomies. This shortens procedure time and allows for less access points, such as needle sticks to the epidural space, which in turn reduces complications, such as cerebral spinal fluid leaks, patient soreness and recovery time. Other possible complications related to the placement of multiple devices are also reduced.

Owner:TC1 LLC

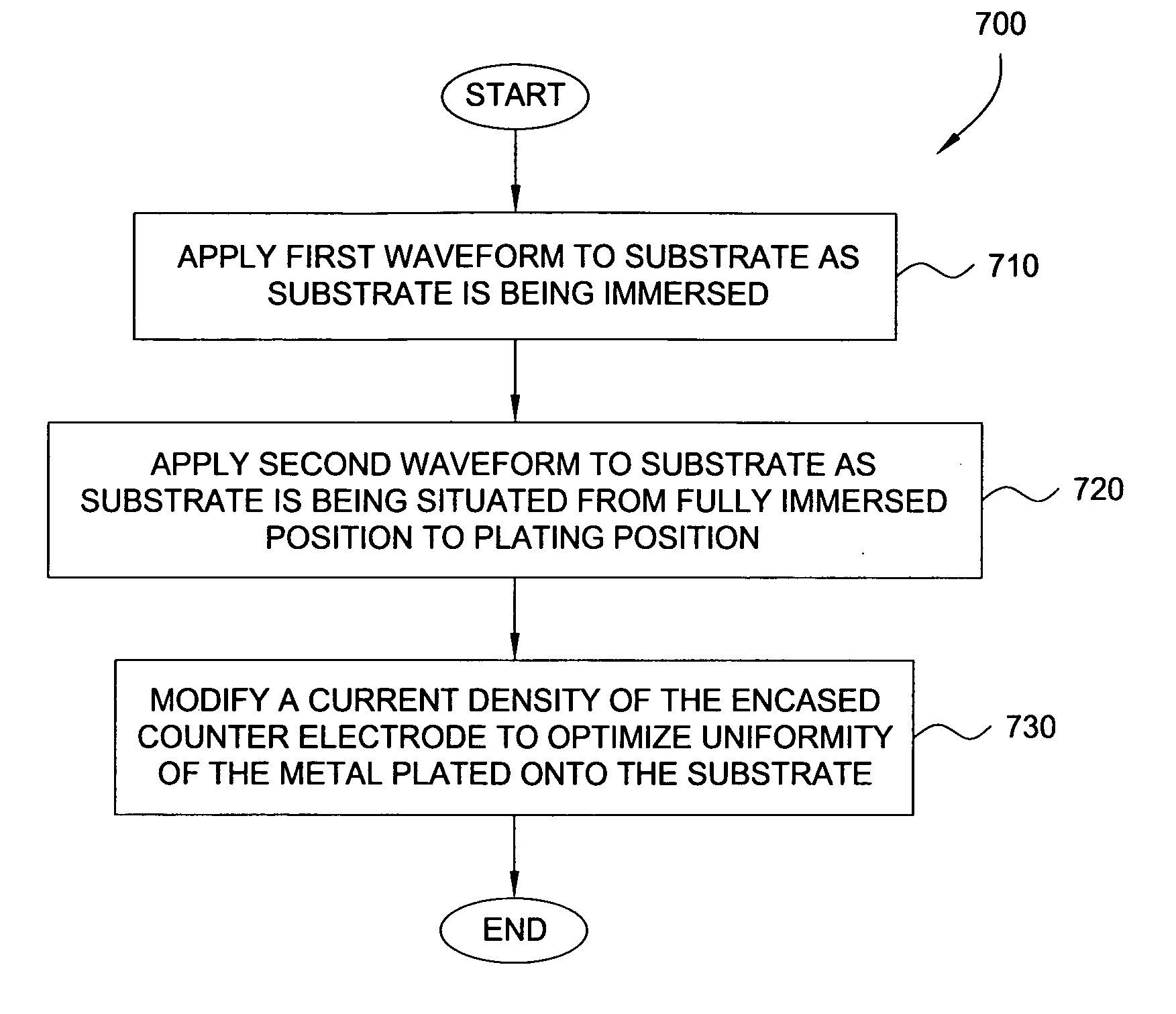

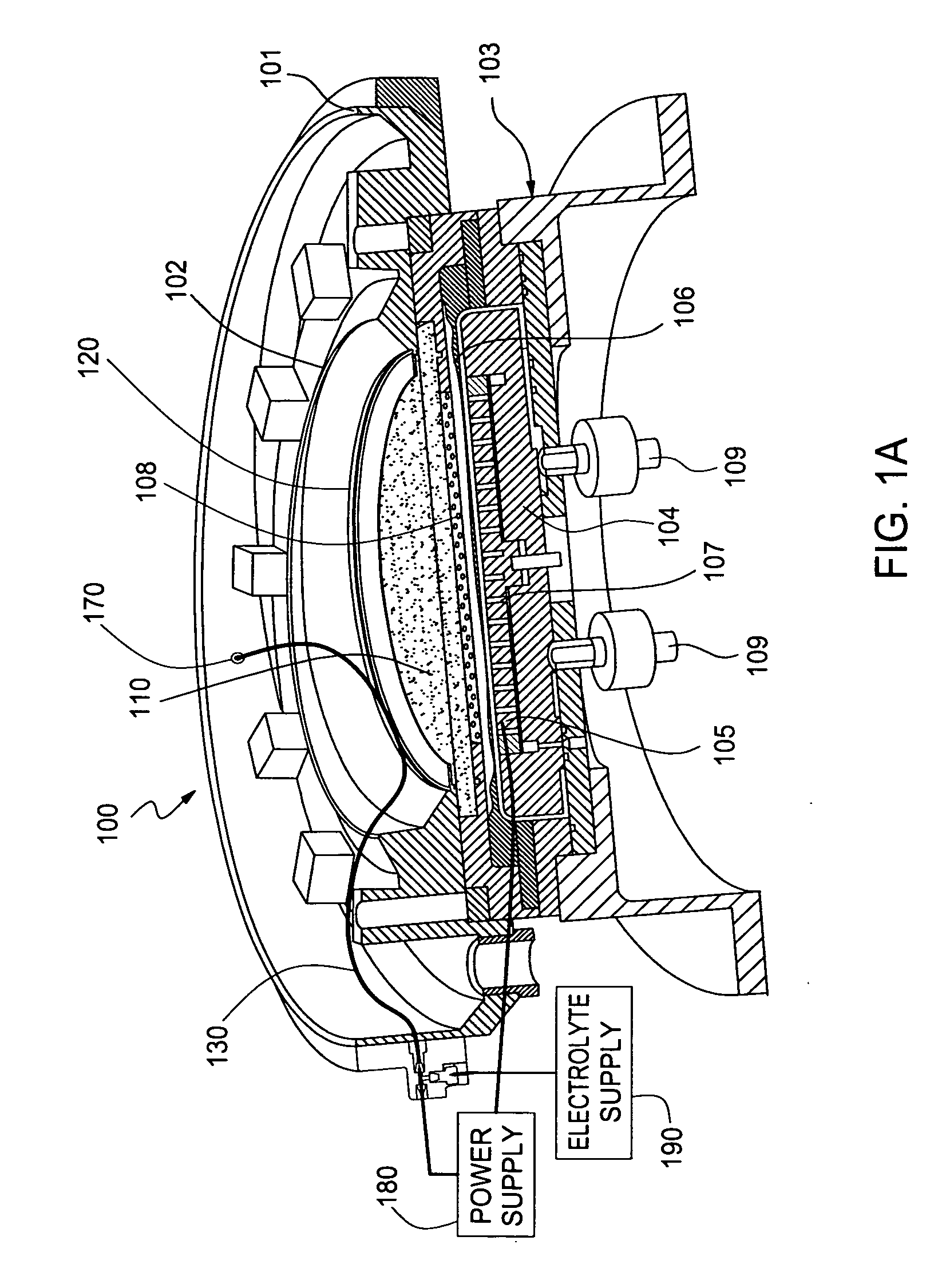

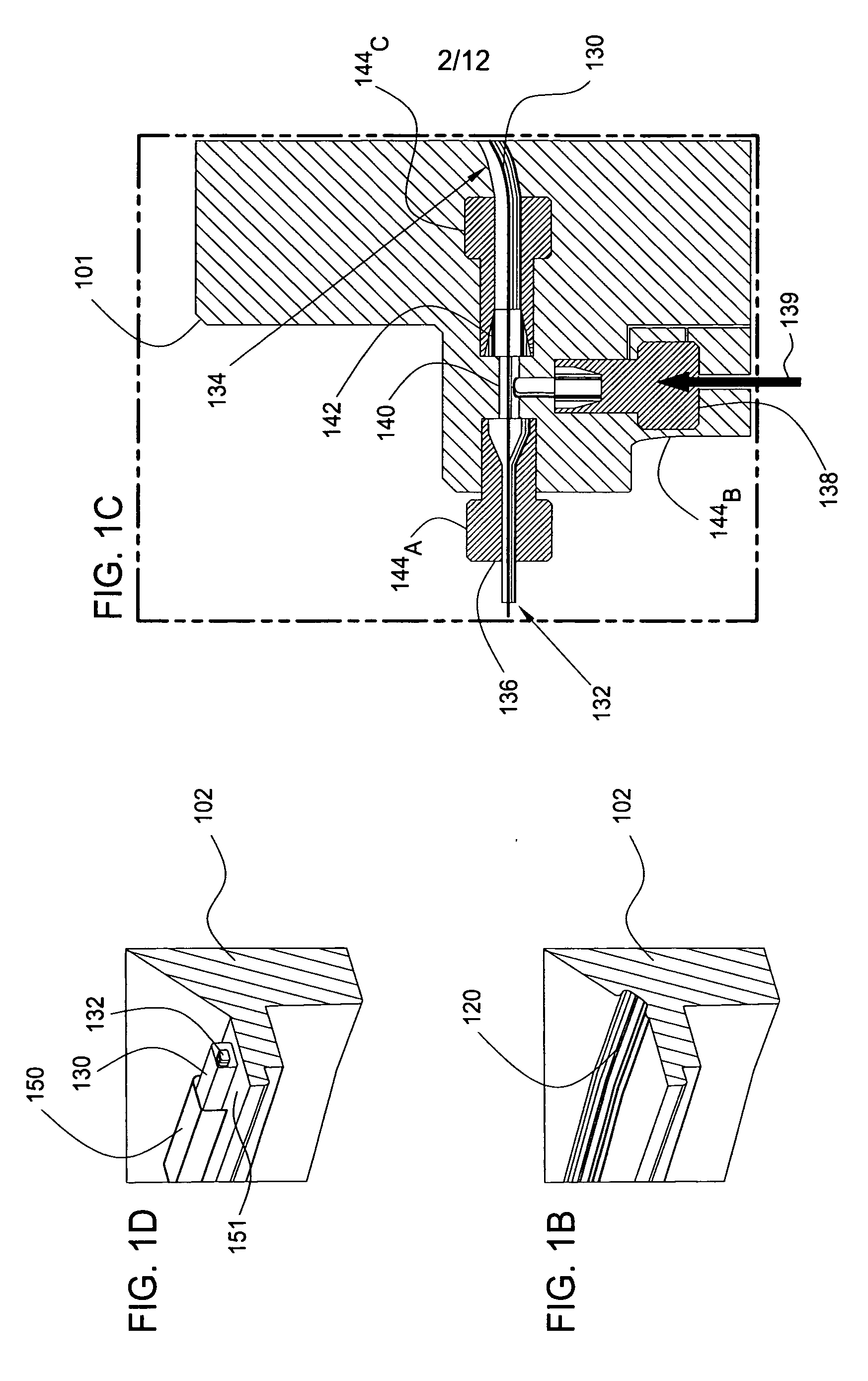

Apparatus and method for improving uniformity in electroplating

A method and apparatus for plating a metal onto a substrate. One embodiment of the present invention provides an apparatus for electroplating a substrate. The apparatus comprises a fluid basin, an anode disposed near a bottom of the fluid basin, a restrictor disposed above the anode, and a substrate support member configured to move the substrate within the fluid basin among different elevations relative to the restrictor. Plating profiles on the substrate may be adjusted by changing the elevation of the substrate during plating.

Owner:APPLIED MATERIALS INC

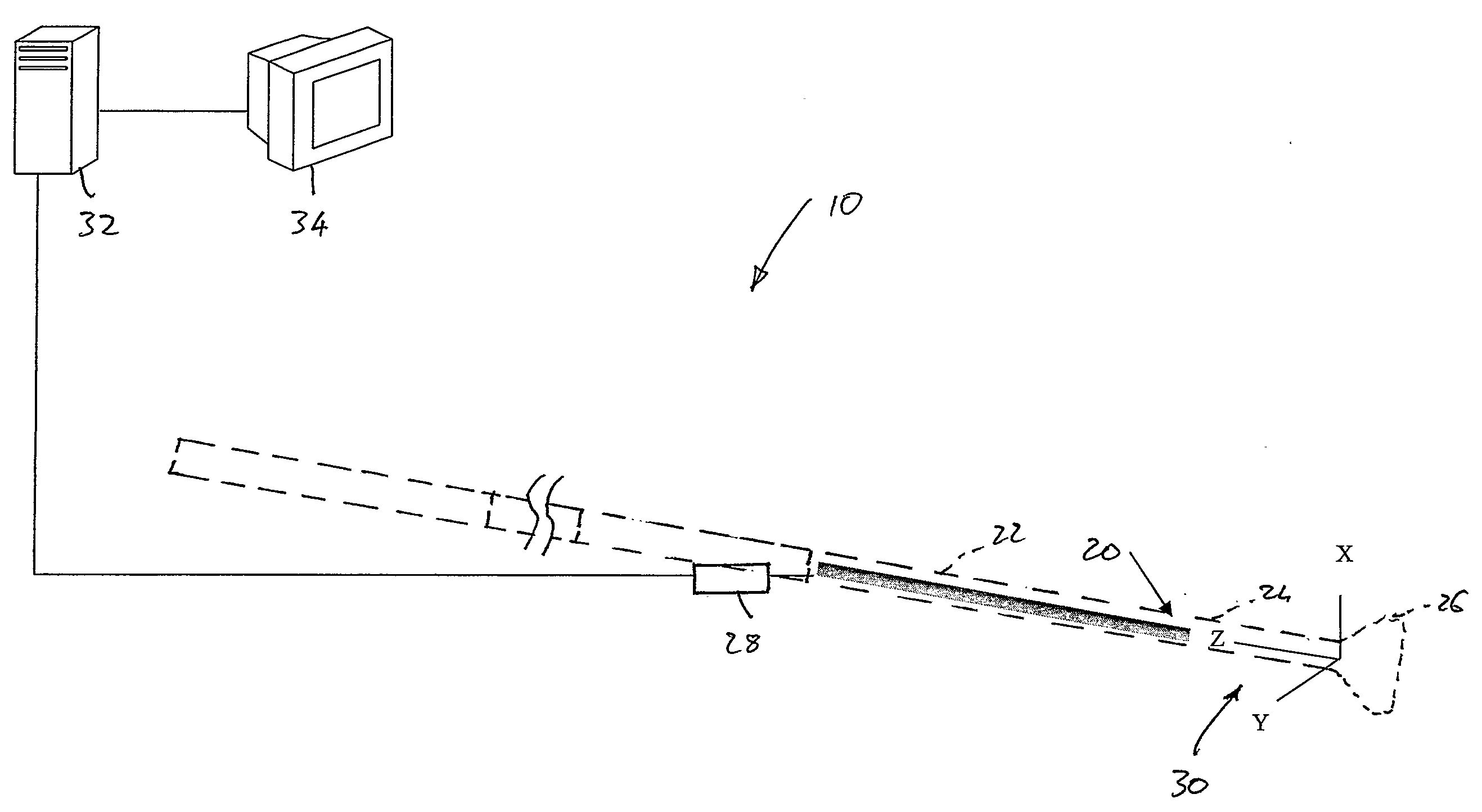

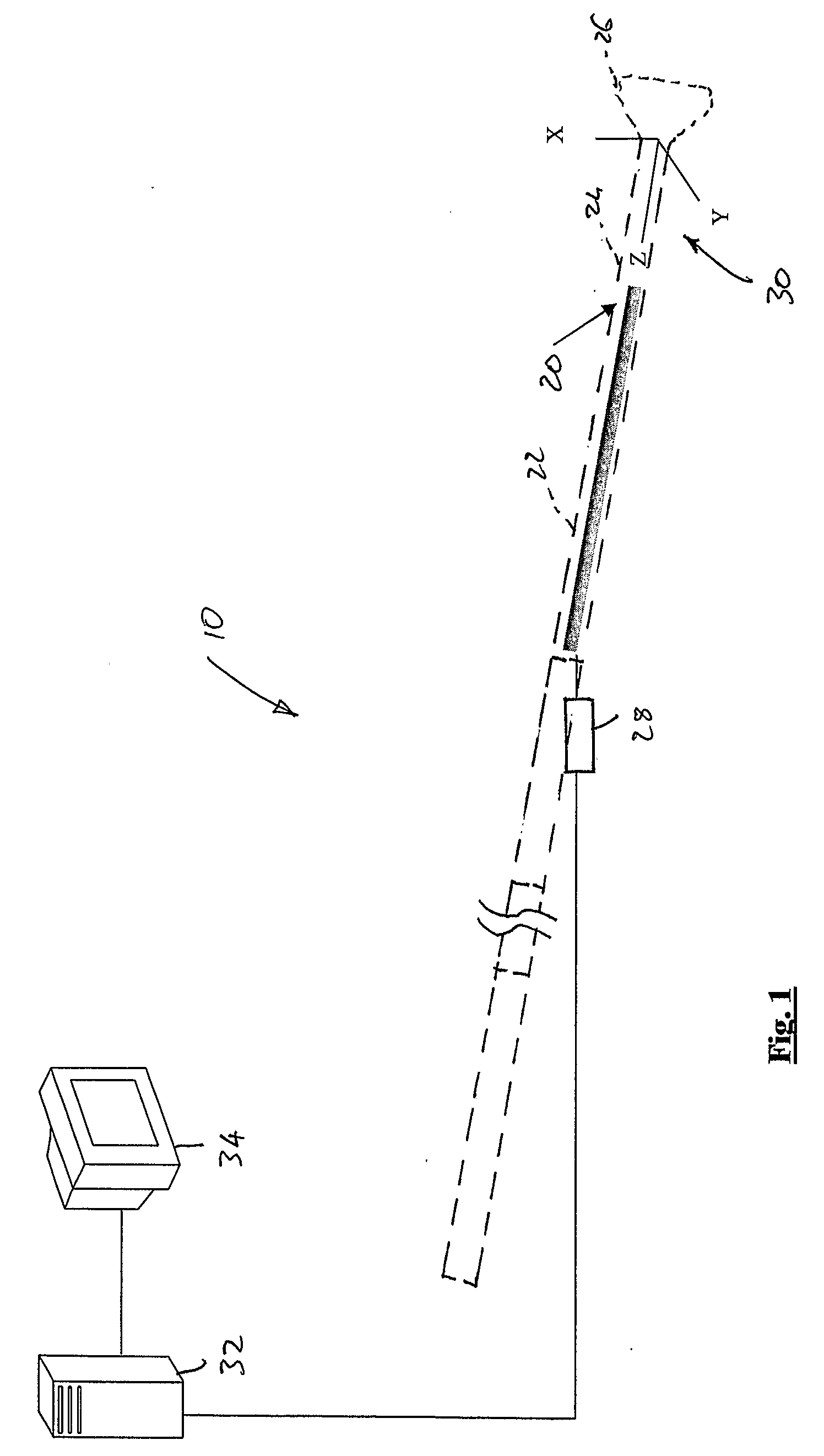

Magnetic Beacon Guidance System

InactiveUS20090222208A1Minimizing effectMinimize impactElectric/magnetic detection for well-loggingSurveyGuidance systemAtomic physics

A method of guiding a probe (20) to a target includes placing a magnetic field generator at the target and guiding the probe (20) to a region of the target. The probe carries a survey sensor pack (28) and the method includes using the survey sensor pack (28), firstly, to obtain a plurality of survey readings and, secondly, to obtain a plurality of magnetic beacon readings using a magnetic field generated by the magnetic field generator. A selected number of the survey readings and the magnetic beacon readings are compared and a difference between the survey readings and the magnetic beacon readings is determined. The method includes compensating for that difference thereafter to guide the probe (20) to the target.

Owner:SPECK NEIL

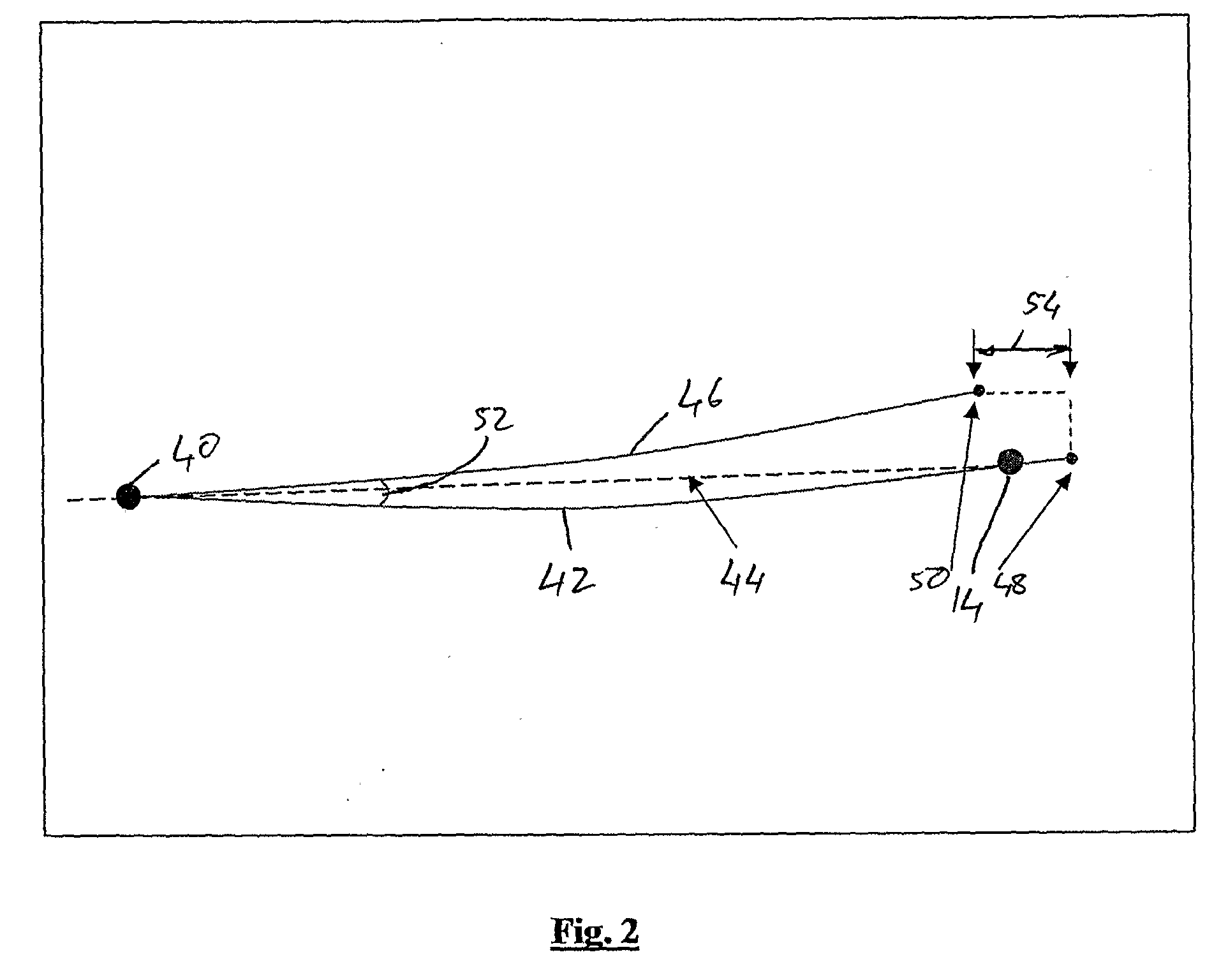

Method and apparatus for measurement of flow rate

InactiveUS6928884B1Minimizing effectEasily customizedVolume/mass flow by differential pressureEngineeringStreamflow

A bi-directional, clean or grey medium, wide temperature range, low intrusion, low turbulence, mass flow meter extends multiple pressure sensing tubes, each containing multiple pressure sensing ports, into a bounded path a distance no more than one half the diameter of the path, or semi-traversing. These sensing tubes sense impact or static pressures to obtain a sensing pressure, and are in fluid communication with a channel located externally of the bounded path which provides a total average sensing pressure for measurement. A series of reference pressure ports are located flush to the wall surface of the bounded path to obtain a reference pressure. These reference ports are in fluid communication with another channel located externally of the bounded path which provides a total average reference pressure for measurement. The difference in total average sensing pressure and total average reference pressure can be measured and used to calculate the average velocity and volume of gas within the bounded path. Alternatively, the difference in total average pressures can produce a measurable sample flow through a channel connecting the two total average pressure plenums, which is proportional to the flow through the bounded path.

Owner:PEARSON JOHN J

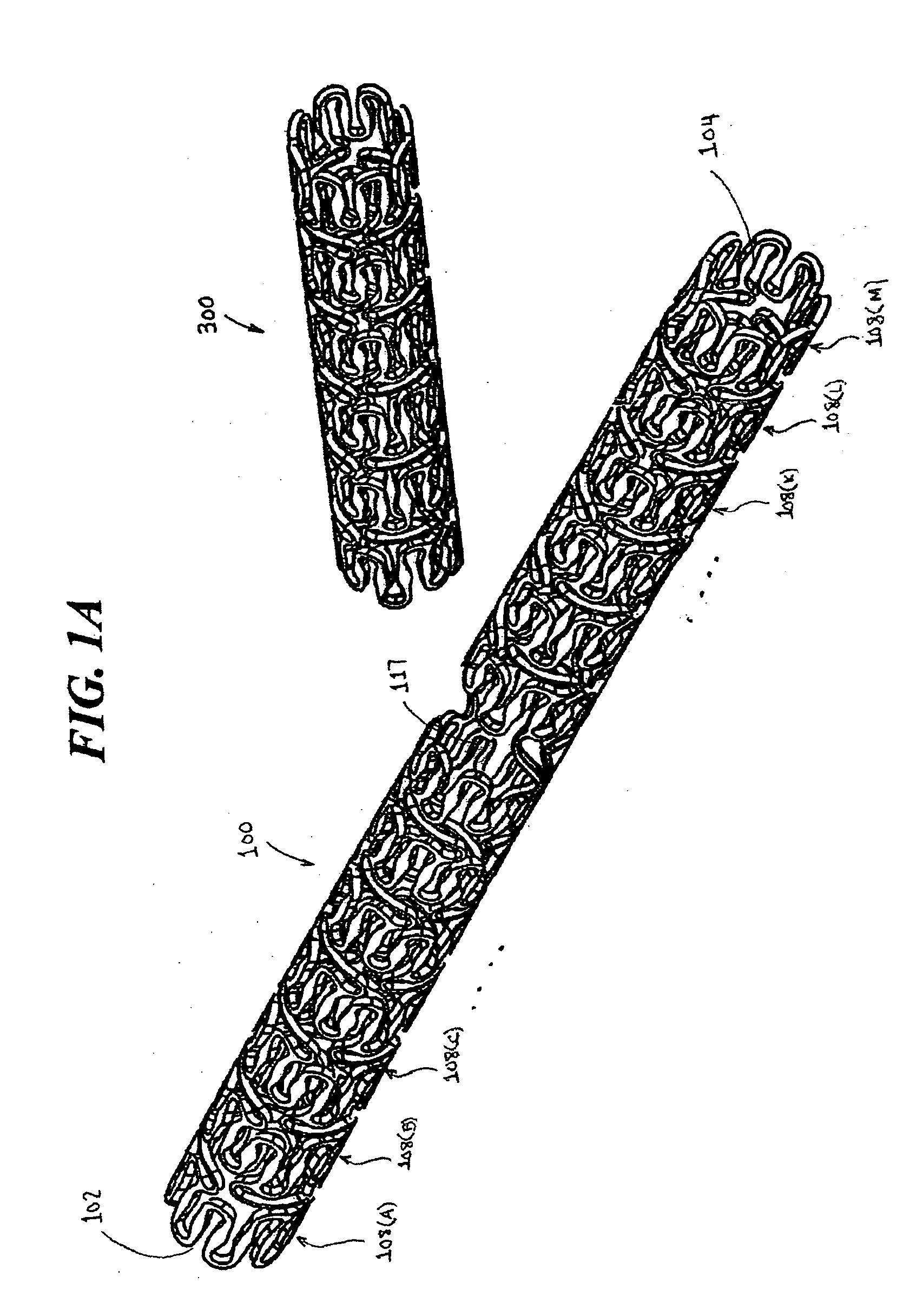

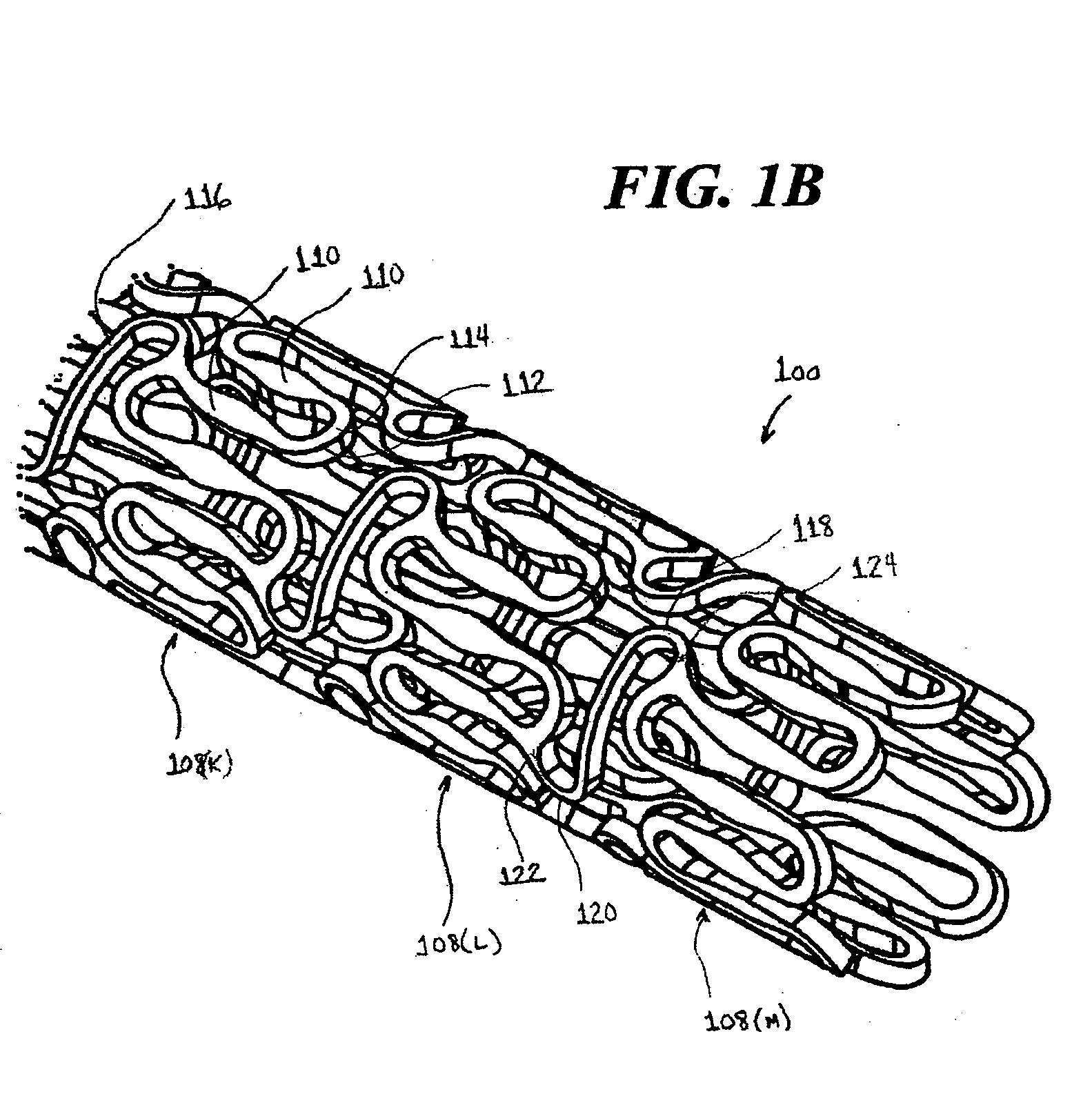

Apparatus for treating a bifurcated region of a conduit

ActiveUS20070219611A1Improved deliverabilityMinimizing effectStentsBlood vesselsProsthesisBiomedical engineering

A system for treating a diseased body conduit bifurcation that is readily deliverable into a region of a body conduit having typically asymmetric anatomy, such as a vessel bifurcation is provided. The system comprises a delivery device such as a catheter having a shaft with varying torsional properties along its length and a delivery apparatus mounted at its distal end. A distal end of the device can be inserted into the main branch and at least one side branch of a vessel bifurcation. The distal end includes at least two expansion members having expandable scaffolds or prostheses mounted thereon. One scaffold is configured such that one expansion member extends through the length of the scaffold while the other expansion member extends through the side-structure of the scaffold. A second scaffold is mounted on the expansion member extending through the side-structure of the first scaffold.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Method and apparatus for load balancing in cellular communication system

ActiveUS8830874B2Easy to useMinimize overheadError preventionTransmission systemsLoad SheddingCellular communication systems

Owner:SAMSUNG ELECTRONICS CO LTD

Methods, systems and devices for neuromodulating spinal anatomy

ActiveUS9259569B2Minimally invasivePromote migrationSpinal electrodesExternal electrodesSide effectSpinal anatomy

Devices, systems and methods for treating pain or other conditions while minimizing possible complications and side effects. Treatment typically includes electrical stimulation and / or delivery of pharmacological or other agents with the use of a lead or catheter. The devices, systems and methods provide improved anchoring which reduces migration of the lead yet allows for easy repositioning or removal of the lead if desired. The devices, systems and methods also provide for simultaneous treatment of multiple targeted anatomies. This shortens procedure time and allows for less access points, such as needle sticks to the epidural space, which in turn reduces complications, such as cerebral spinal fluid leaks, patient soreness and recovery time. Other possible complications related to the placement of multiple devices are also reduced.

Owner:TC1 LLC

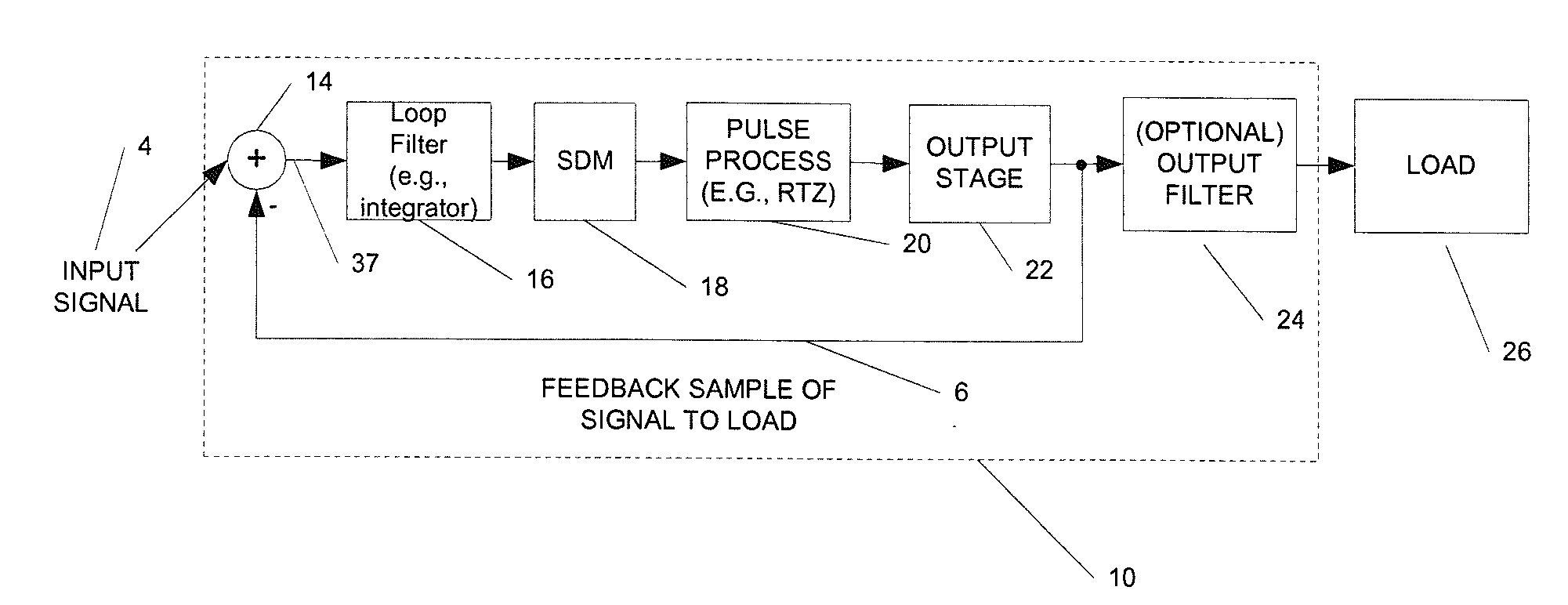

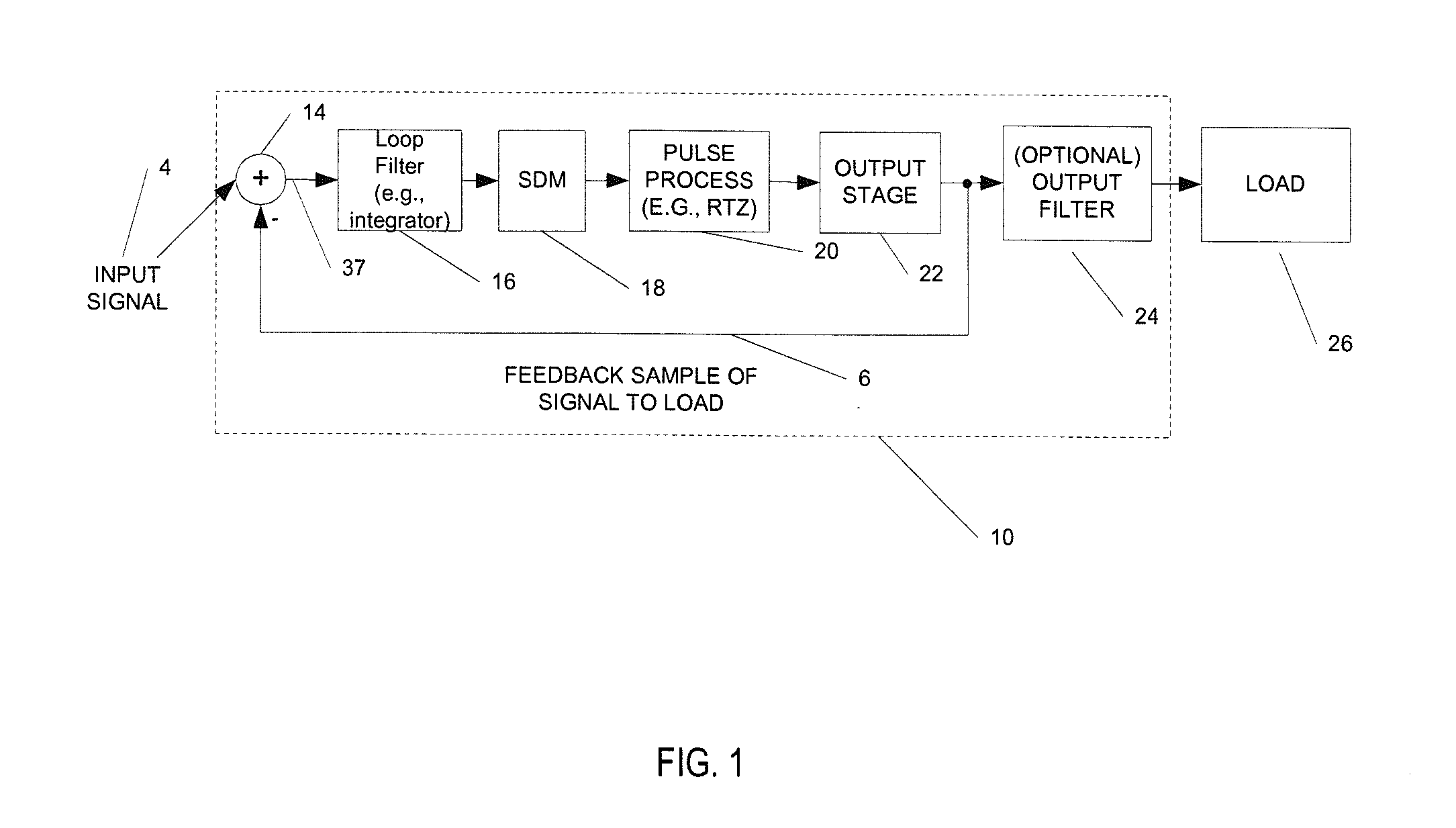

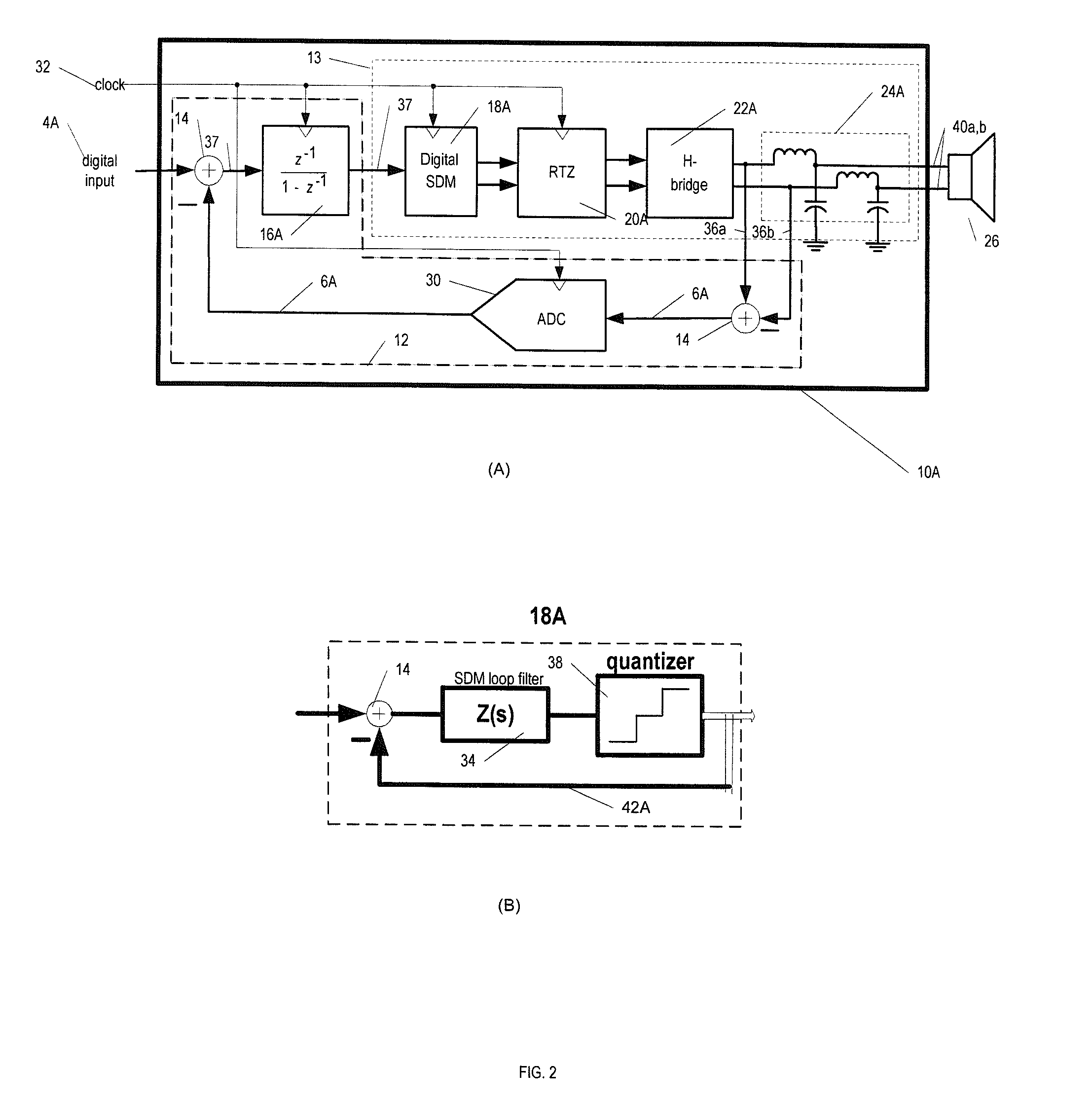

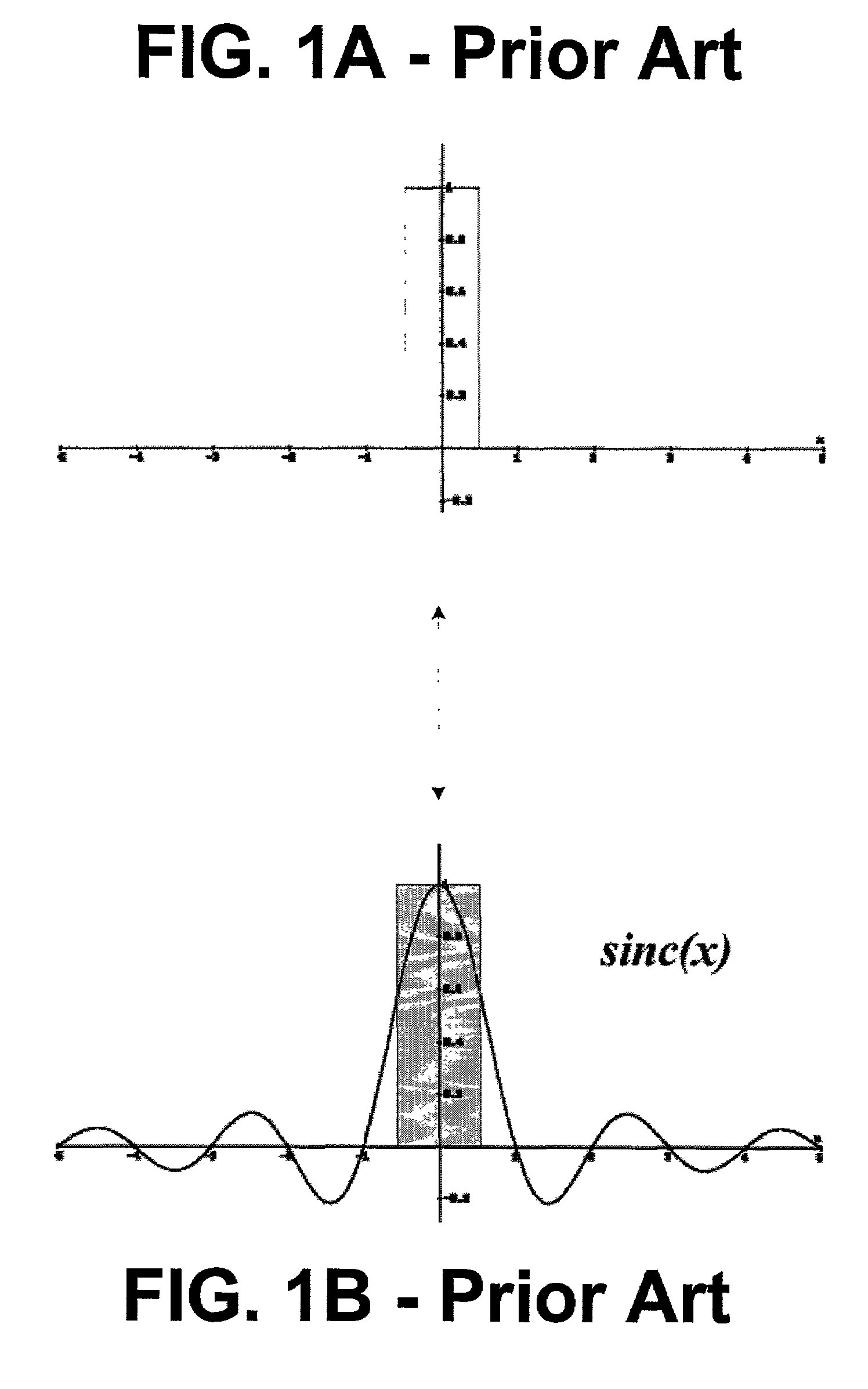

Sigma-delta based class d audio or servo amplifier with load noise shaping

ActiveUS20080042746A1Minimizing effectIncrease numberAmplifier modifications to reduce non-linear distortionAudio amplifierAudio frequencyError signal

An amplifier capable of driving an analog load is provided. The amplifier can be constructed and arranged to operate as at least one circuit selected from the group consisting of a class D amplifier, voltage regulator, audio amplifier, servo amplifier, servo control, digital control, switching power supply, and switching power amplifier. The amplifier comprises a sigma delta modulator (SDM), a pulse processing circuit, an output stage, and a feedback loop. The SDM produces a plurality of noise-shaped output pulses based upon an input signal (e.g., an analog input signal) to the amplifier and an error signal. The pulse processing circuit processes at least a portion of the plurality of noise-shaped output pulses to ensure that each of the noise-shaped output pulses in the portion contains an amount of energy that is as close as possible to the amount of energy in the other pulses. The output stage is coupled to the pulse processing circuit and has first state wherein the output stage provides analog noise-shaped output energy pulses to a load and a second state where the output energy delivered is essentially zero. The feedback loop is coupled between the output stage and the SDM. The feedback loop samples the energy provided to the load during the first state by measuring the load during the second state and generates an error signal based on the difference between the sampled portion of the noise-shaped output pulses and the input signal to the amplifier.

Owner:INTRINSIX

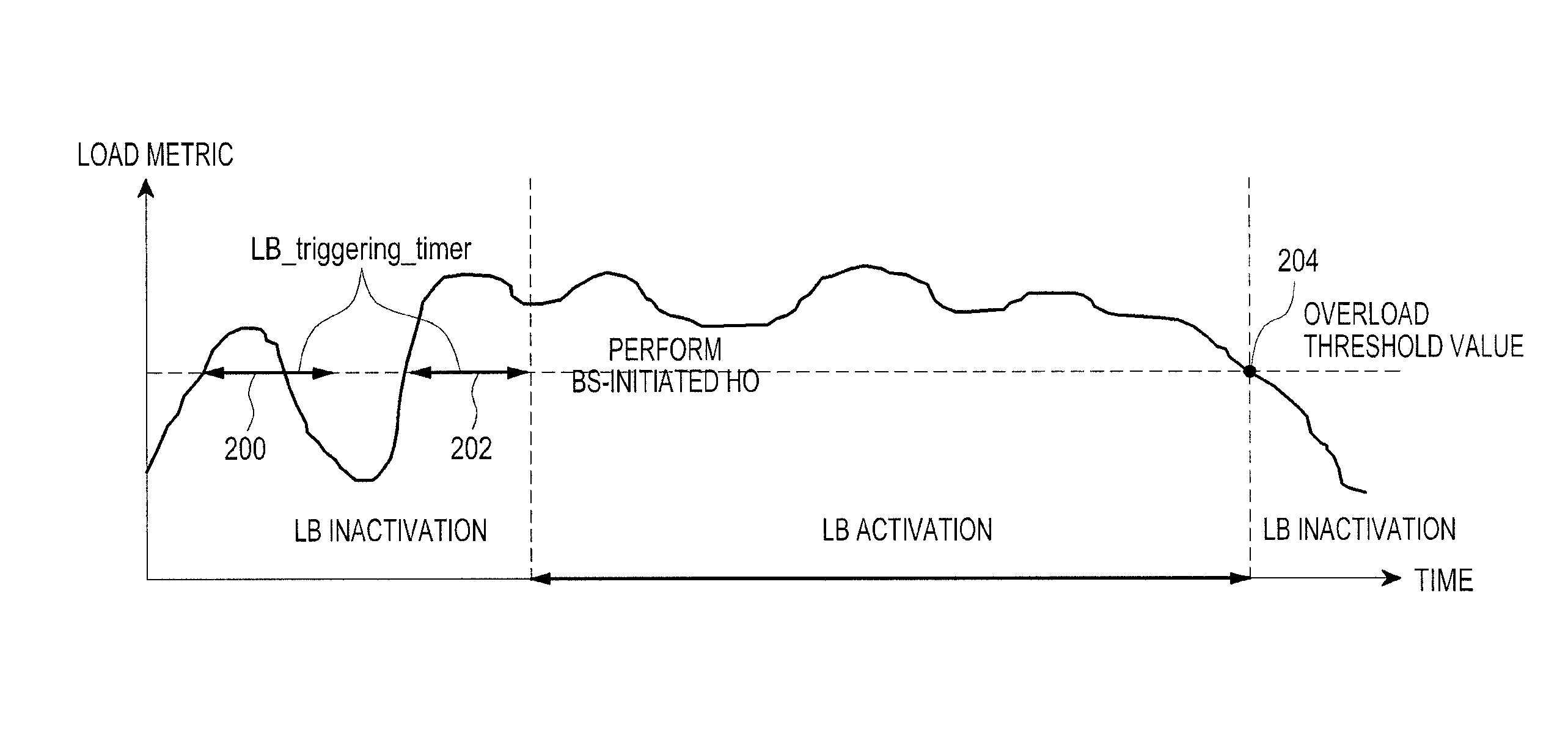

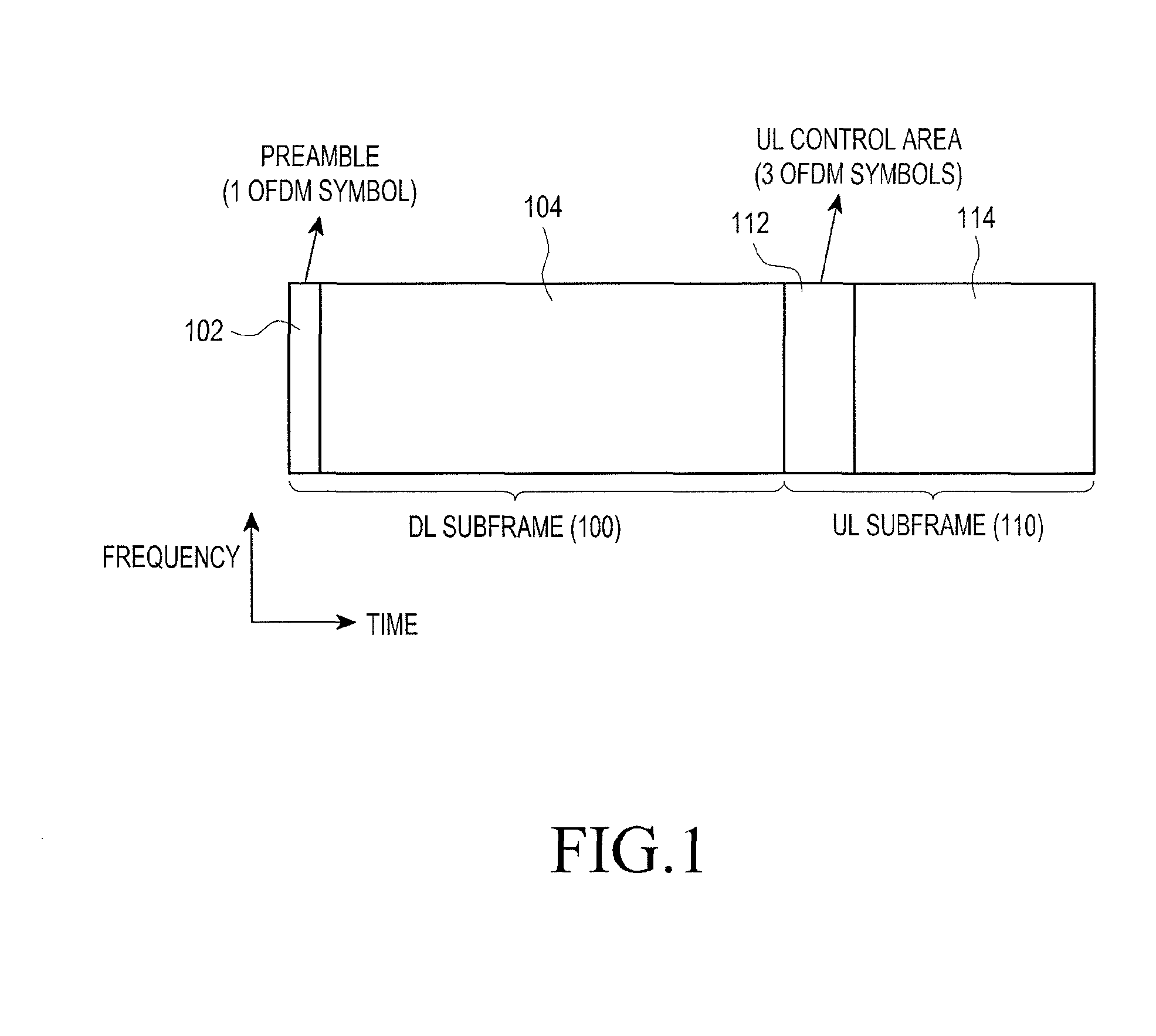

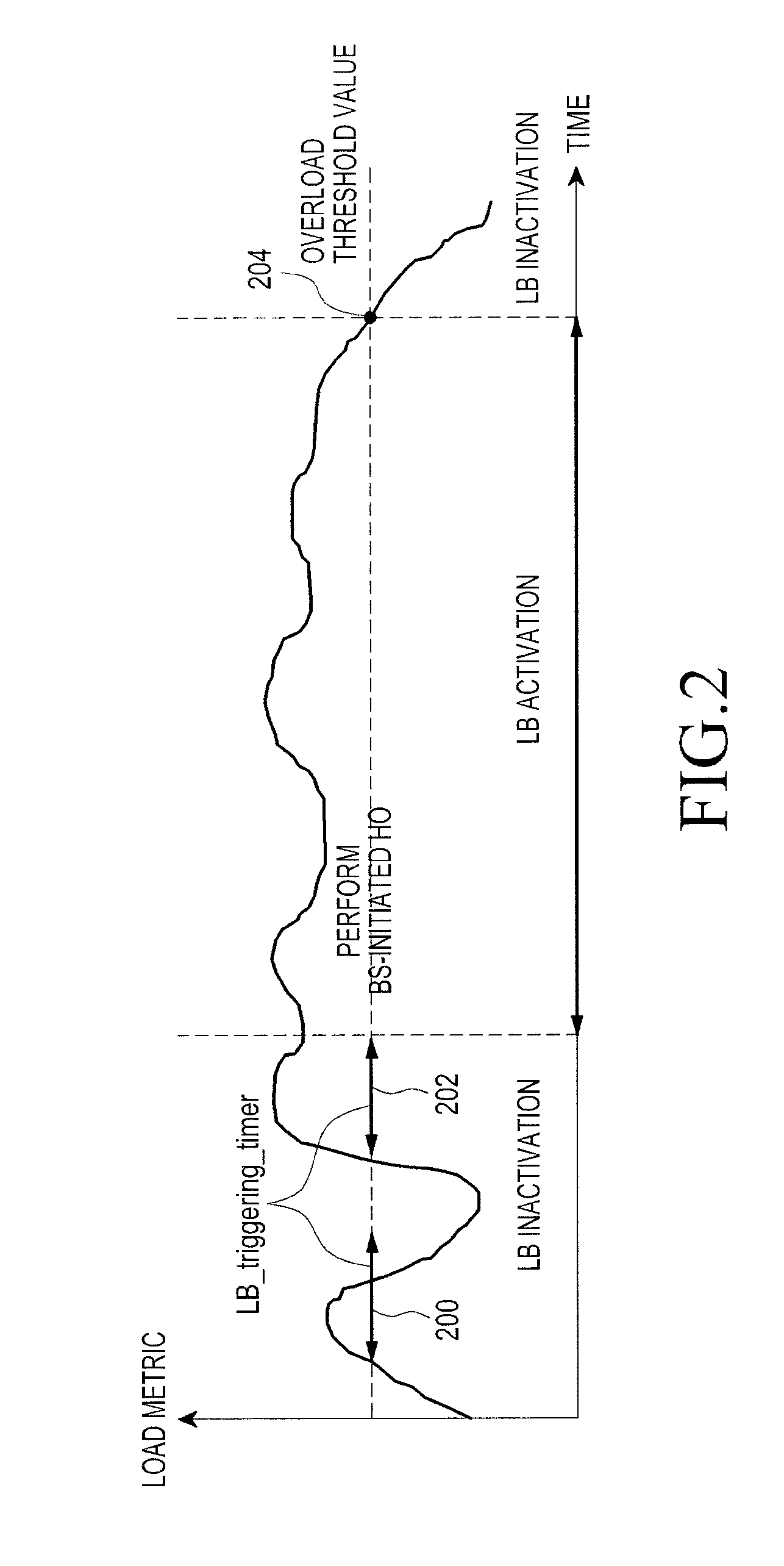

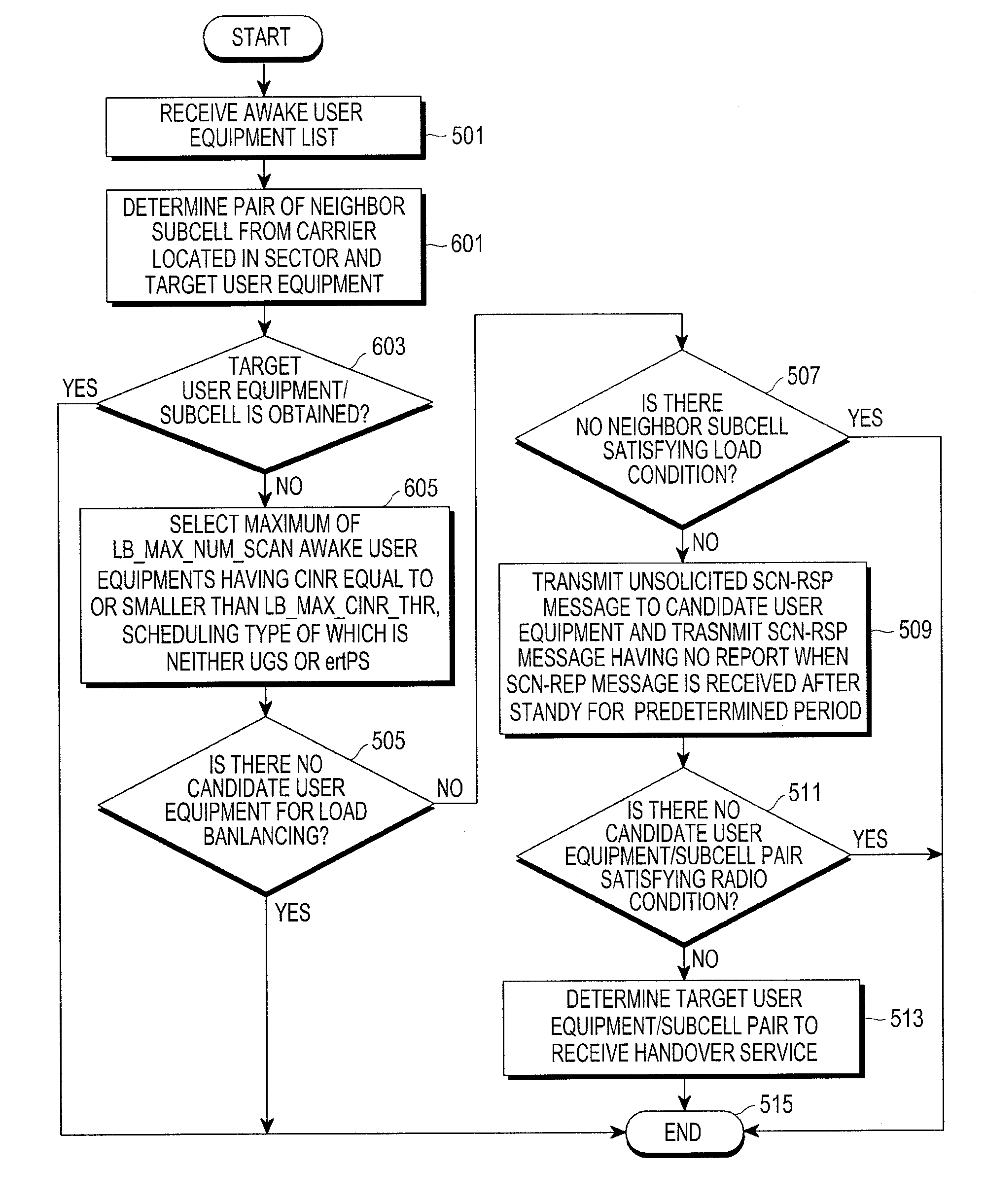

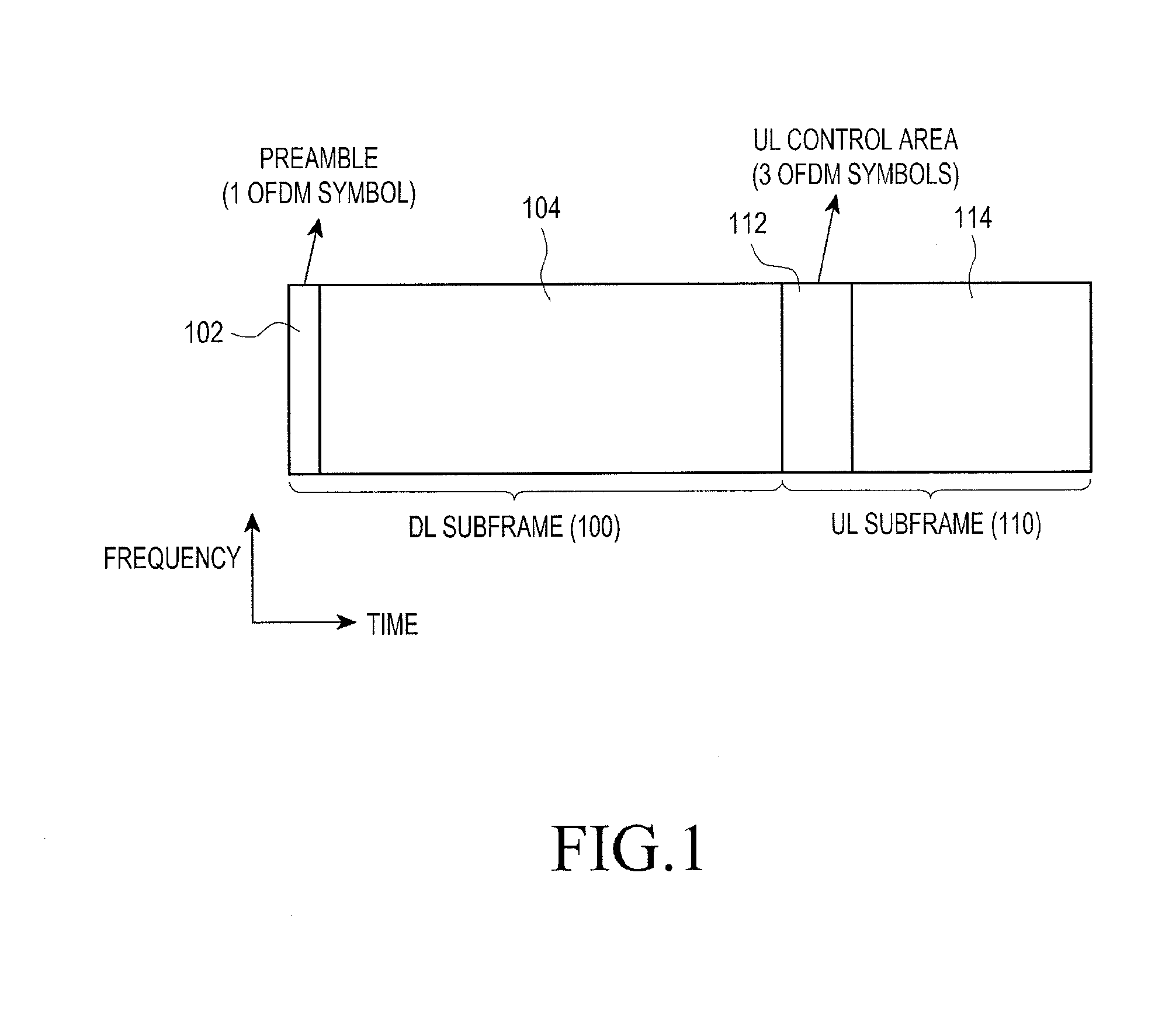

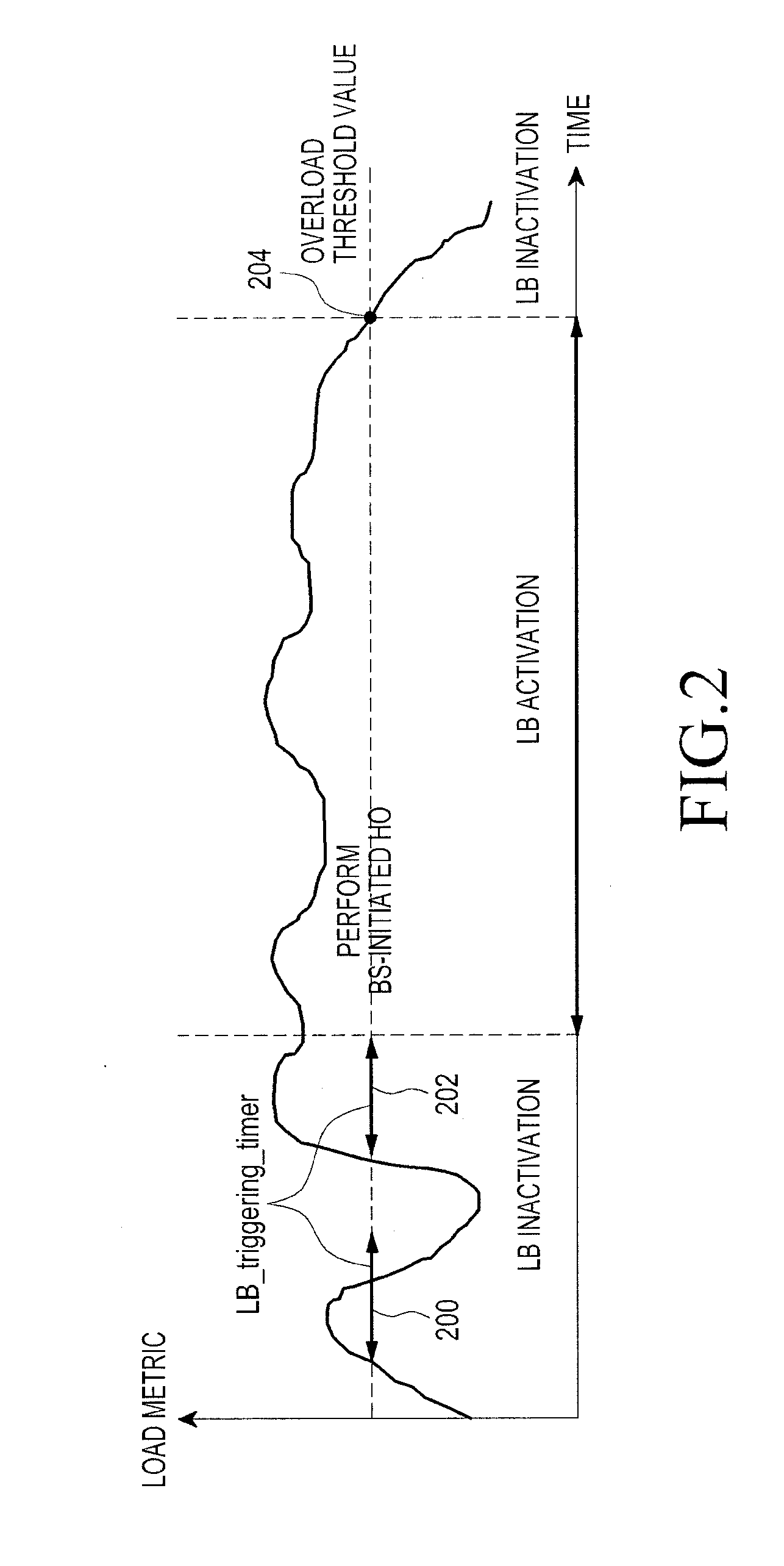

Method and apparatus for load balancing in cellular communication system

ActiveUS20130028093A1Efficient executionReduce management costsError preventionTransmission systemsLoad SheddingCellular communication systems

A method and an apparatus for load balancing a serving subcell providing a data service to one or more user equipments in a cellular communication system are provided. The method includes calculating a load metric by using a radio resource occupation rate of data traffic in one or more scheduling types except for a Best Effort (BE) scheduling type, determining whether the serving subcell is in an overload state by using the load metric, and triggering a load balancing algorithm when it is determined that the serving subcell is in the overload state. Accordingly, the load metric used for load balancing may be defined to have a value closer to an actual free load, and thus the load balancing may be efficiently performed.

Owner:SAMSUNG ELECTRONICS CO LTD

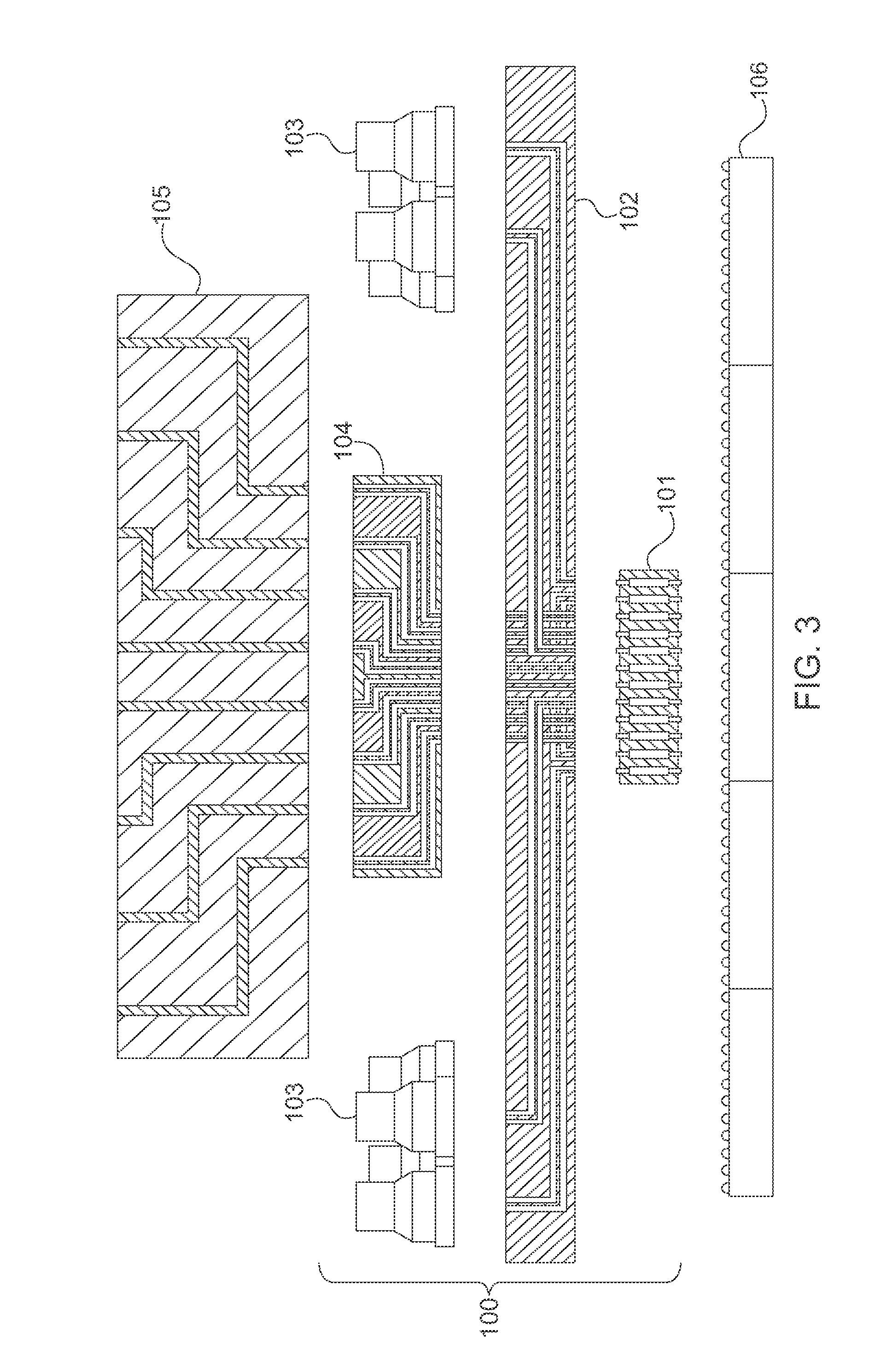

Wafer scale test interfact unit: low loss and high isolation devices and methods for high speed and high density mixed signal interconnects and contactors

InactiveUS20160341790A1Reduce lossGood precisionParticular array feeding systemsElectronic circuit testingHigh densityEngineering

Devices and methods for multilayer packages, antenna array feeds, test interface units, connectors, contactors, and large format substrates. The device comprising a 3D coaxial distribution network structure including a plurality of coaxial transmission lines separated by a first pitch at the input and a second, wider pitch at the output thereof.

Owner:CUBIC CORPORATION

Articulable introducer sheath

InactiveUS20140257240A1Minimizing complicationMinimize side effectsSpinal electrodesInfusion syringesDistal portionSurgical site

Articulable introducer sheaths and related methods and systems for accessing various surgical sites are disclosed. An introducer sheath comprises a tubular body and a filament. The tubular body has a proximal portion, a distal portion, and a central lumen. The filament is constrained on or within at least a portion of the proximal portion and unconstrained over at least a portion of the distal portion. The distal end of the filament is held or attached near a distal end of the tubular body so that advancement of the filament relative to the tubular body causes the unconstrained portion to bow out or extend radially outward, such as to engage a body tissue so as to steer the tubular body when the tubular body has been introduced into a surgical site, such as an epidural space. A surgical tool or medical implant can then be advanced through the sheath.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

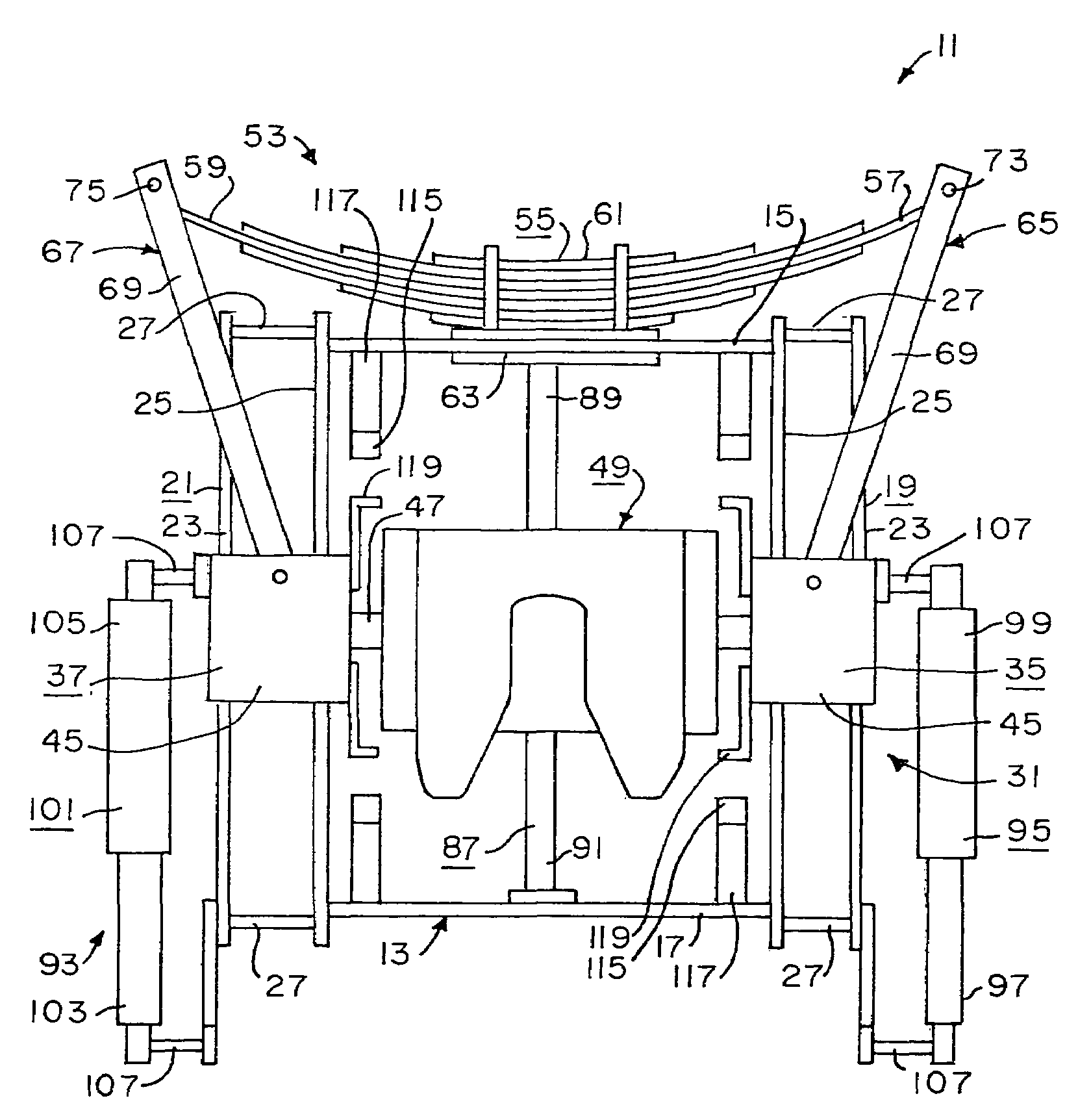

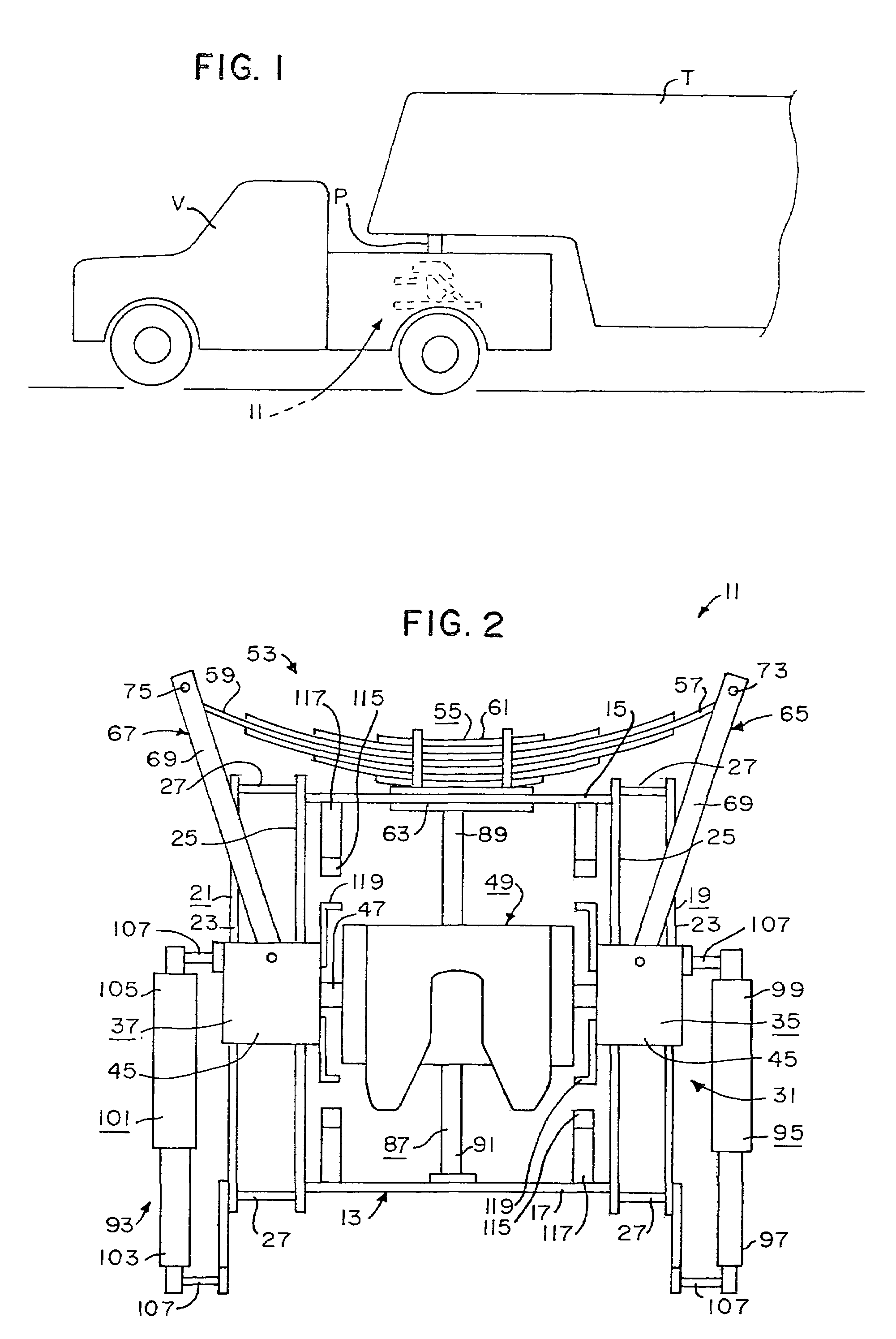

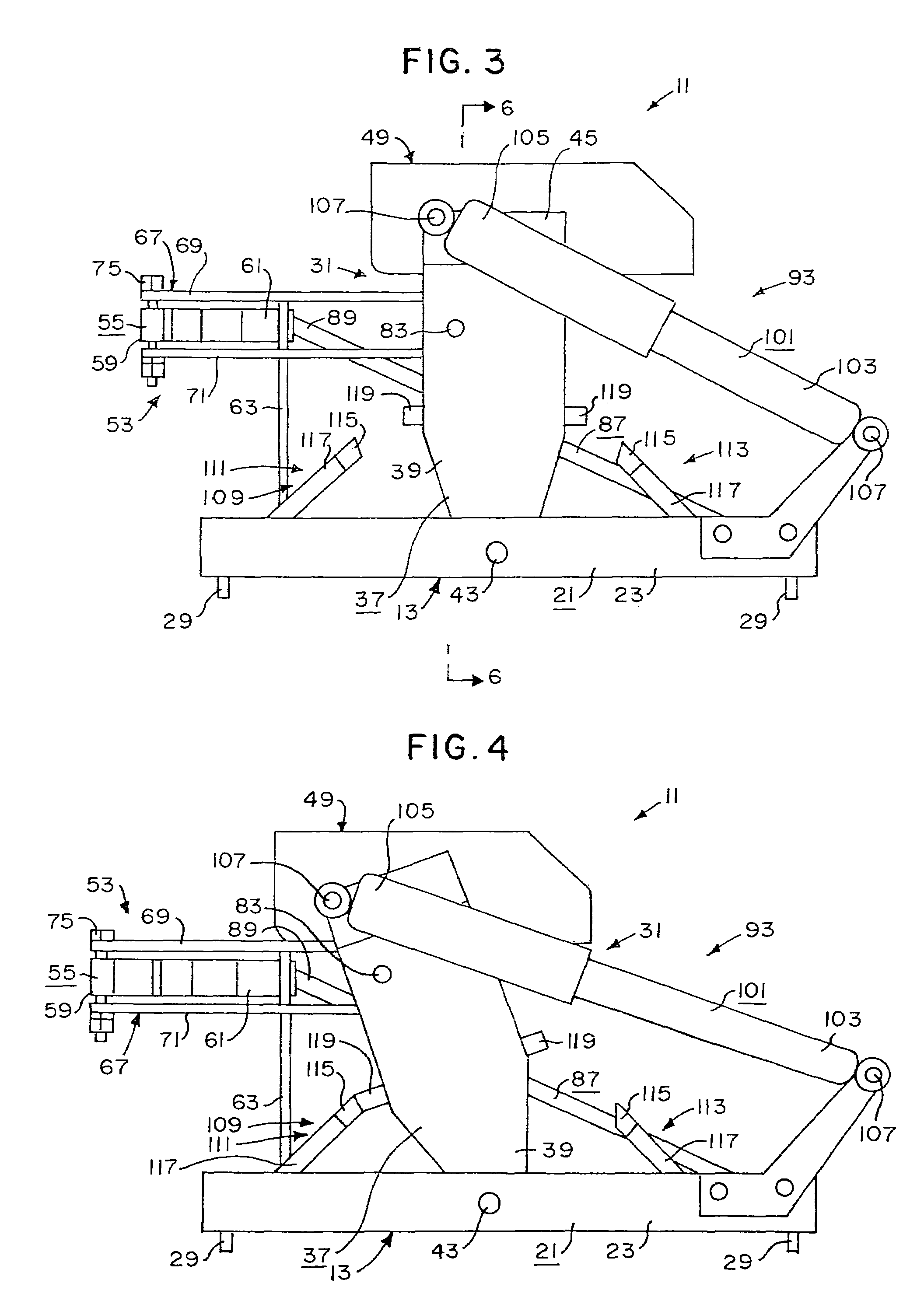

Hitch assembly

InactiveUS6957823B1Minimizing effectReduce possibilityTractor-trailer combinationsEngineeringLeaf spring

A hitch assembly including a frame for being attached to a tow vehicle; a cradle assembly pivotally attached to the frame for pivotal fore and aft movement; a hitch receiver mounted to the cradle assembly for being attached to a trailer; a leaf spring mounted to the cradle assembly and the fore end of the frame for controlling fore and aft movement of the cradle assembly; and shock absorbers mounted to the cradle assembly and the aft end of the frame for dampening fore and aft movement of the cradle assembly.

Owner:ALLEN DAVID E

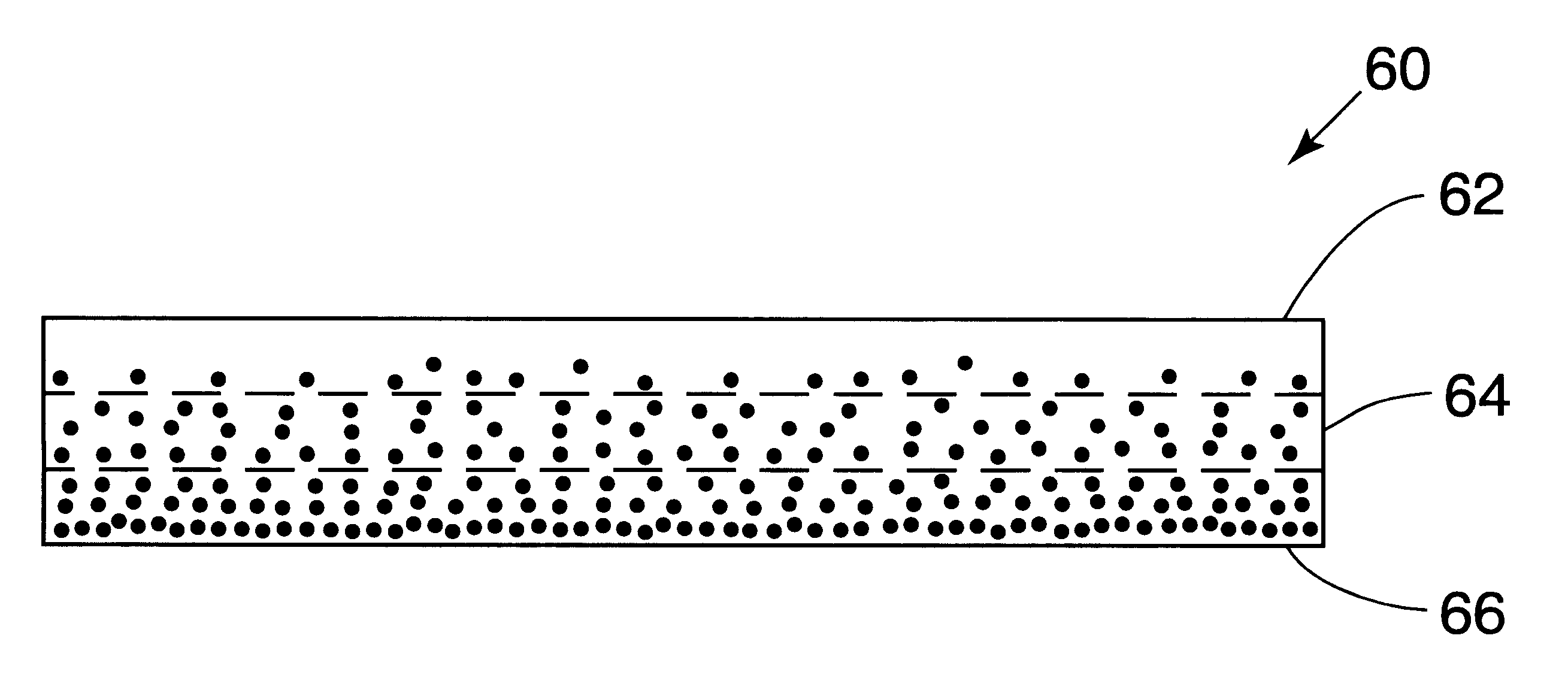

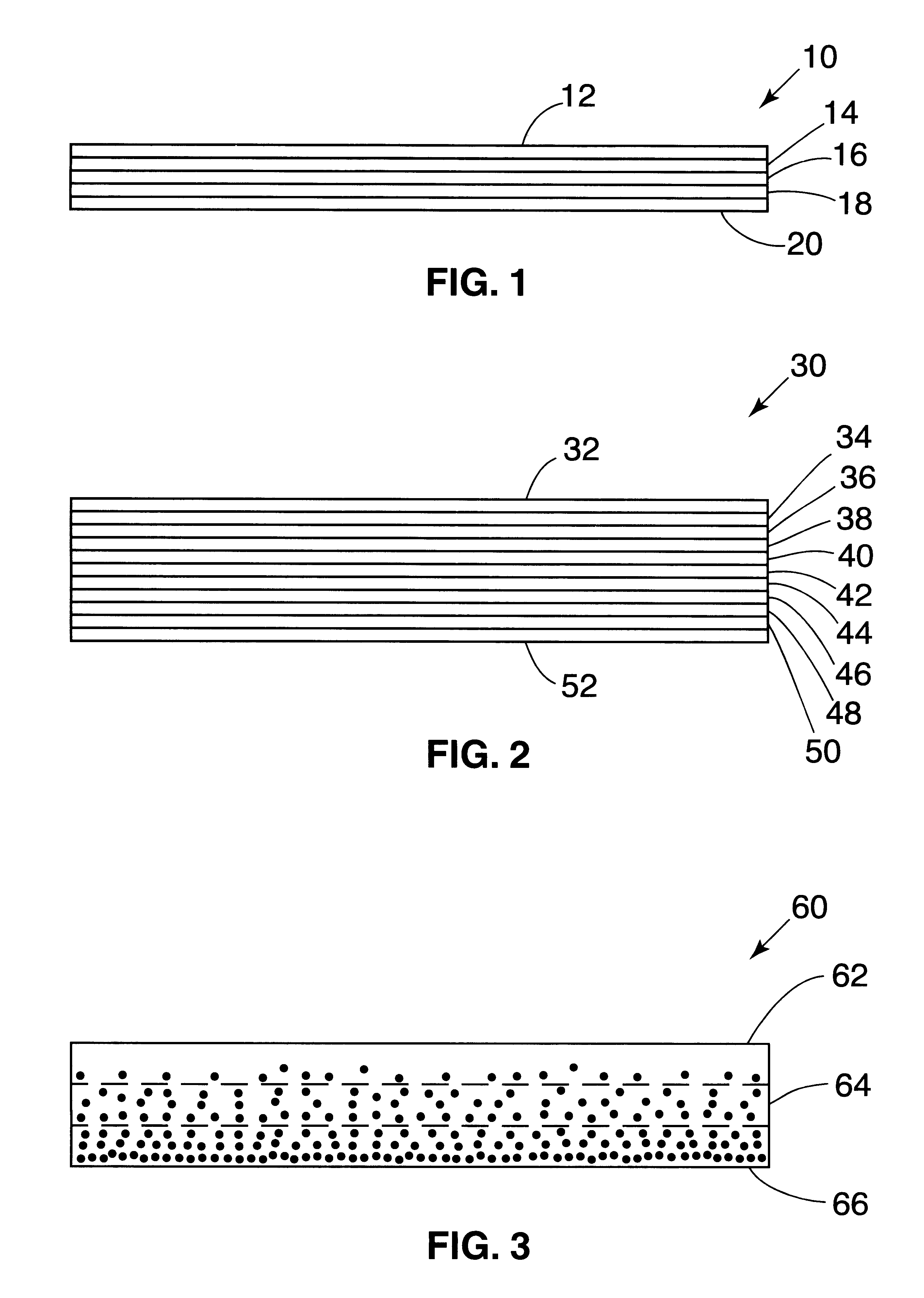

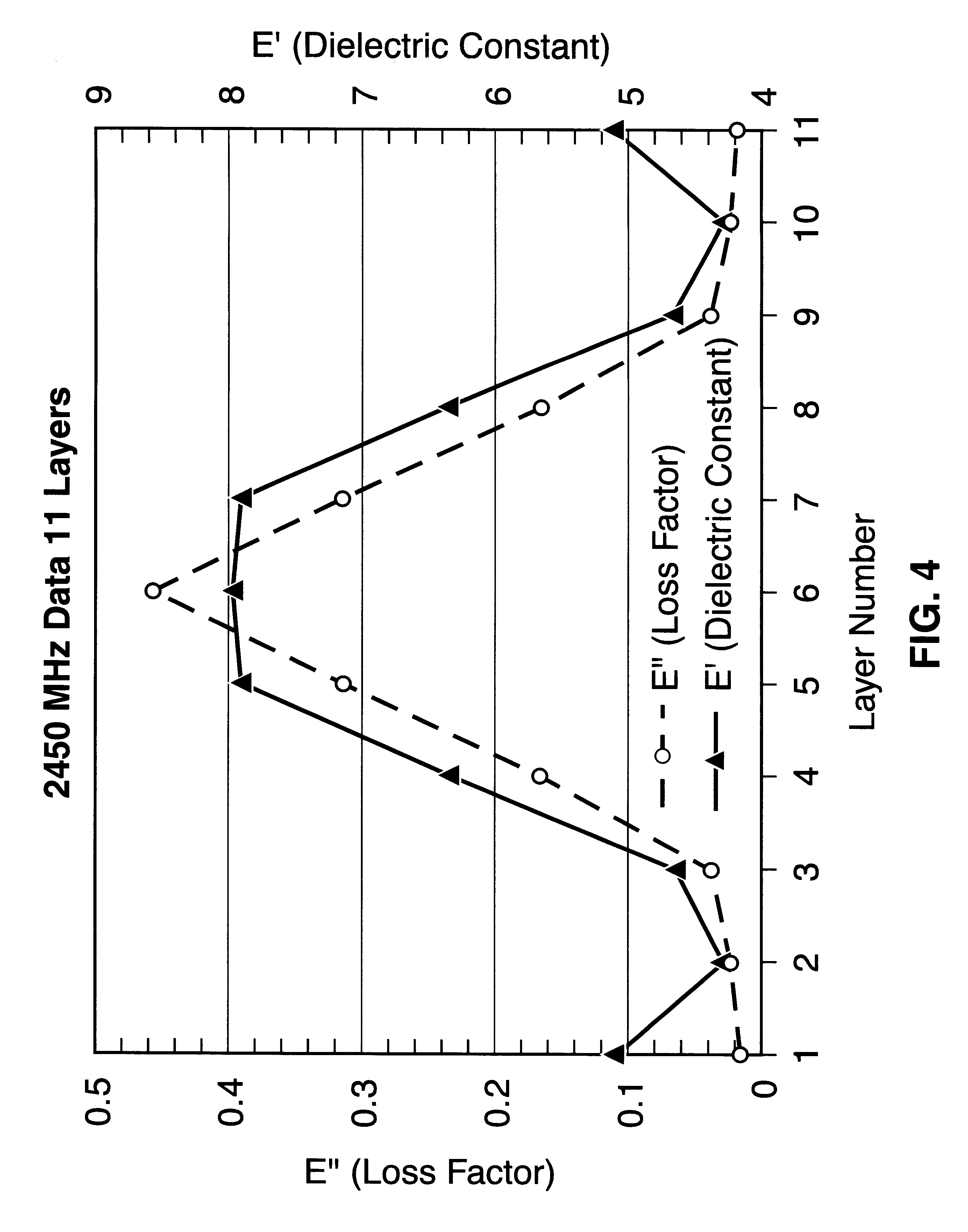

Method of making a functionally graded material

InactiveUS6248286B1Minimizing effectMinimize impactCeramic shaping apparatusClaywaresFunctionally graded materialMetallurgy

A gelcasting method of making an internally graded article includes the steps of: preparing at least two slurries, each of the slurries including a different gelcastable powder suspended in a gelcasting solution, the slurries characterized by having comparable shrinkage upon drying and sintering thereof; casting the slurries into a mold having a selected shape, wherein relative proportions of the slurries is varied in at least one direction within the selected shape; gelling the slurries to form a solid gel while preserving the variation in relative proportions of the slurries; drying the gel to form a dried green body; and sintering the dry green body to form a solid object, at least one property thereof varying because of the variation in relative proportions of the starting slurries. A gelcasting method of making an internally graded article alternatively includes the steps of: preparing a slurry including a least two different phases suspended in a gelcasting solution, the phases characterized by having different settling characteristics; casting the slurry into a mold having a selected shape; allowing the slurry to stand for a sufficient period of time to permit desired gravitational fractionation in order to achieve a vertical compositional gradient in the molded slurry; gelling the slurry to form a solid gel while preserving the vertical compositional gradient in the molded slurry; drying the gel to form a dried green body; and sintering the dry green body to form a solid object, at least one property thereof varying along the vertical direction because of the compositional gradient in the molded slurry.

Owner:LOCKHEED MARTIN ENERGY SYST INC

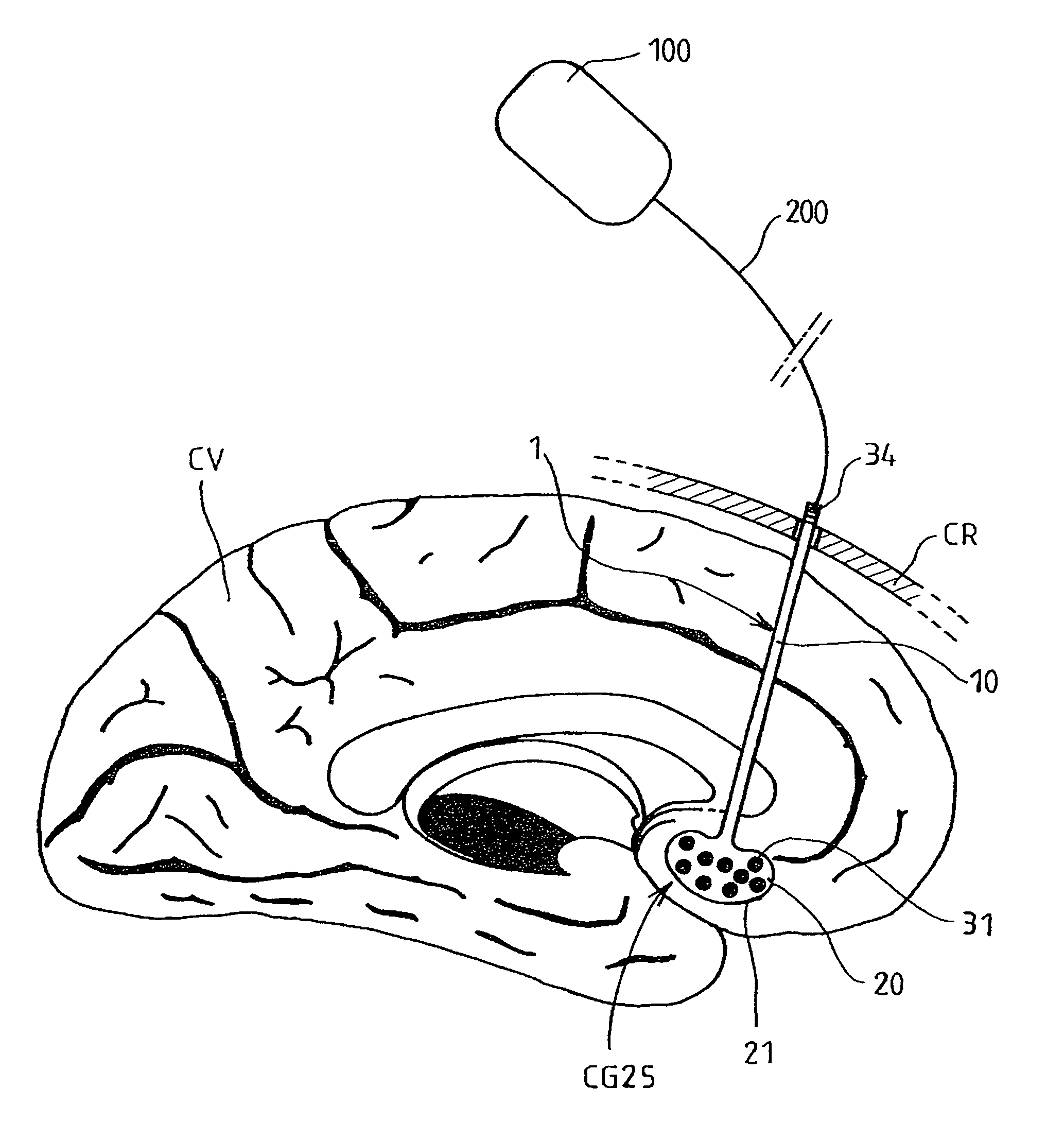

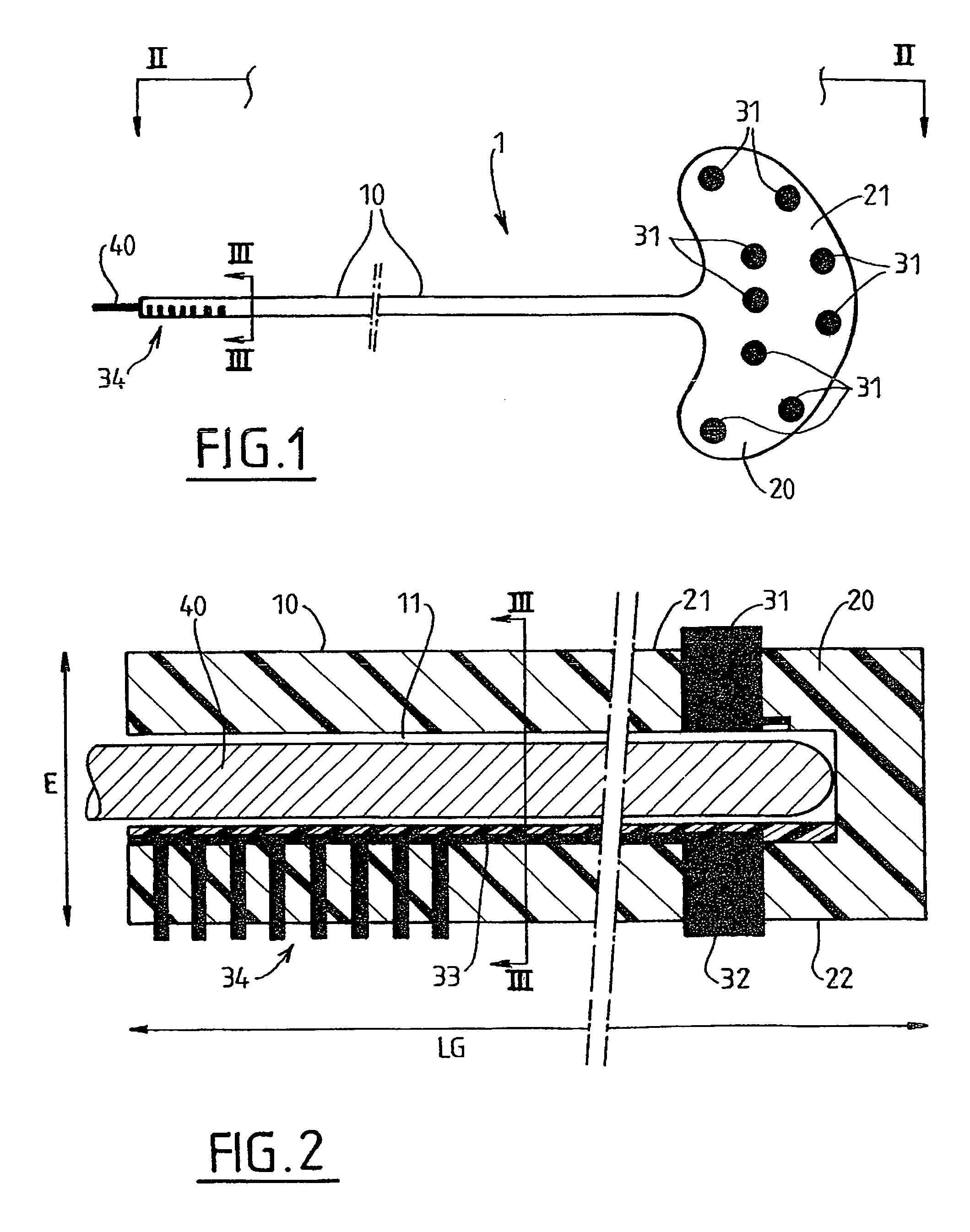

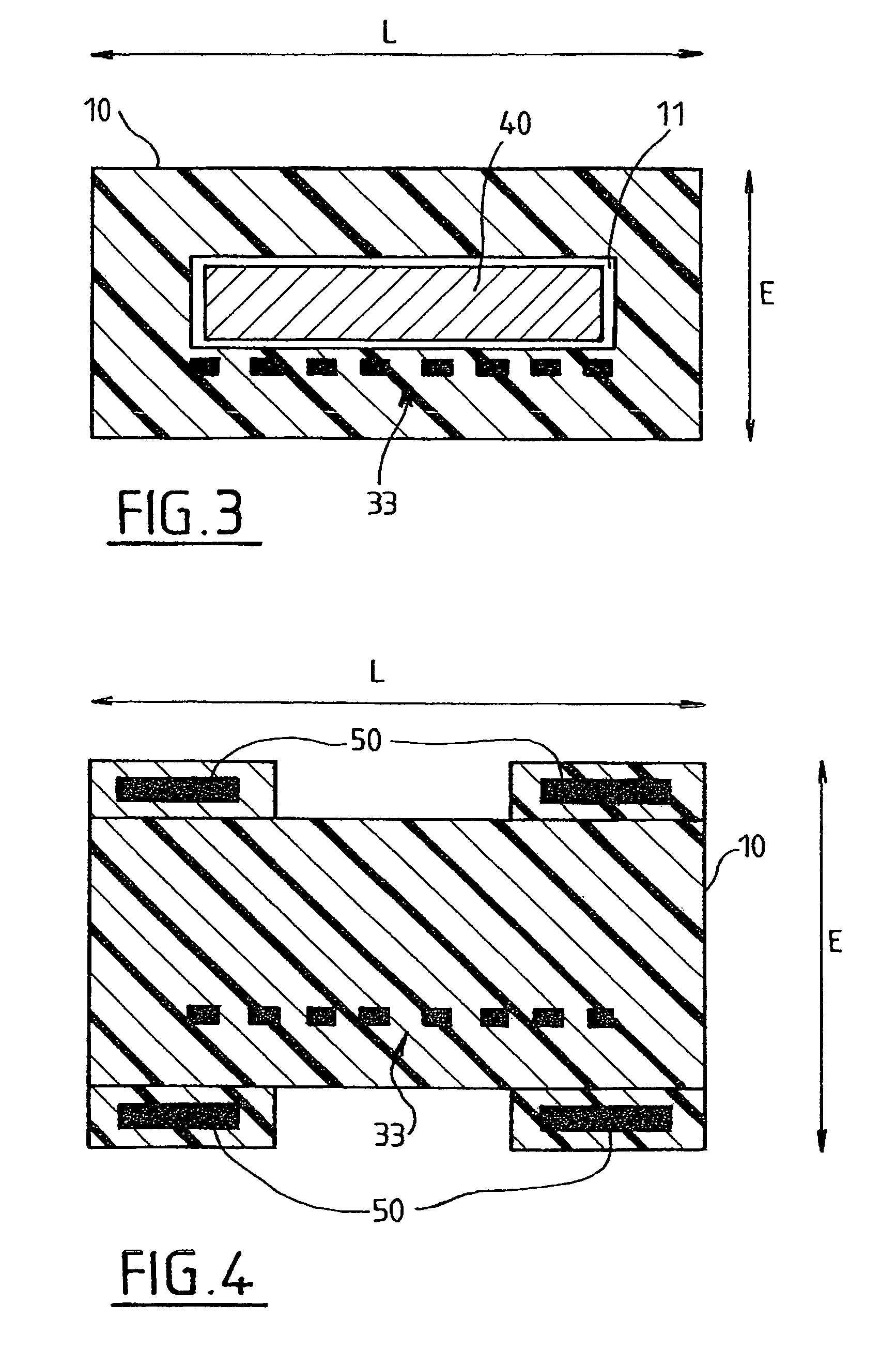

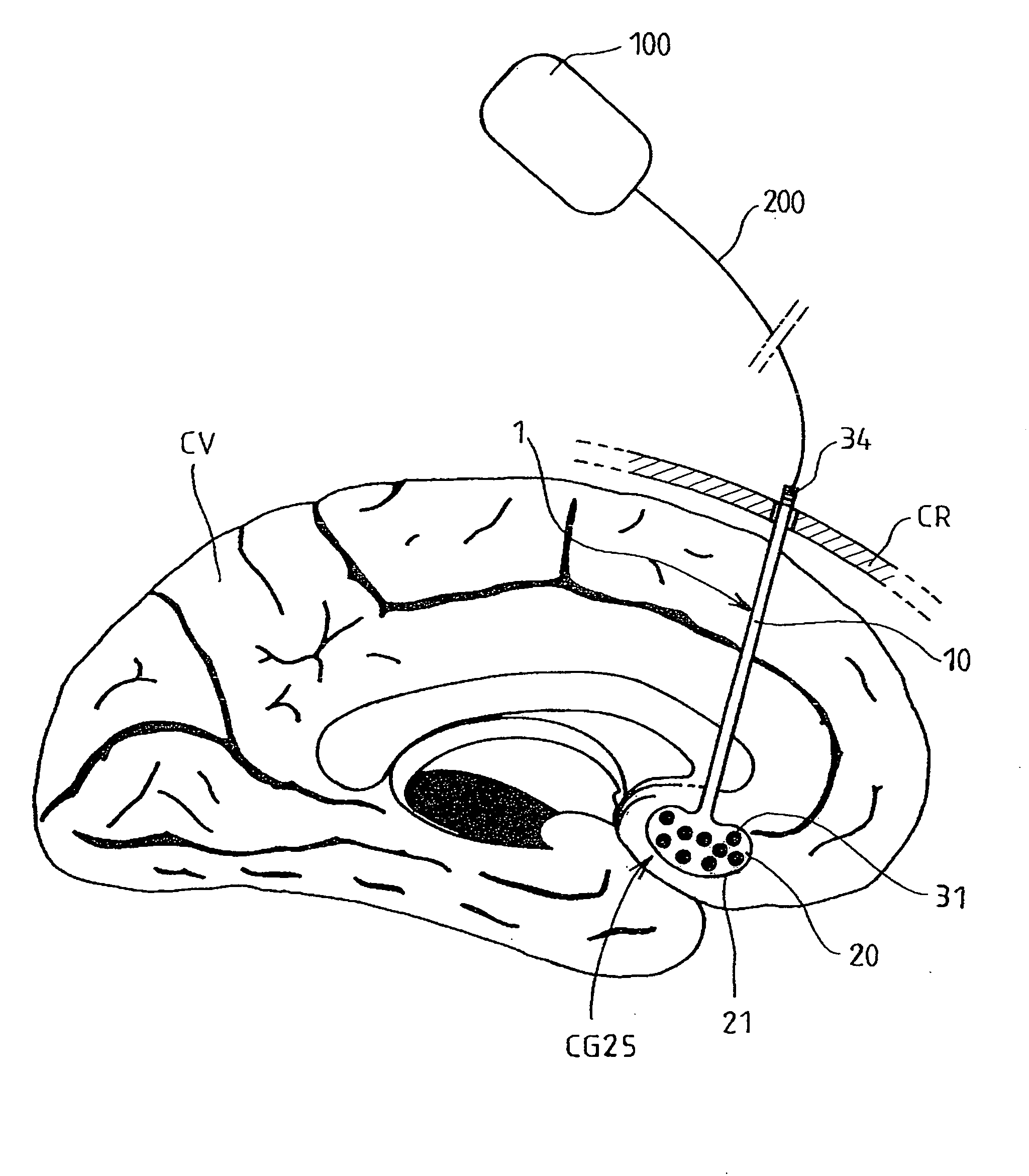

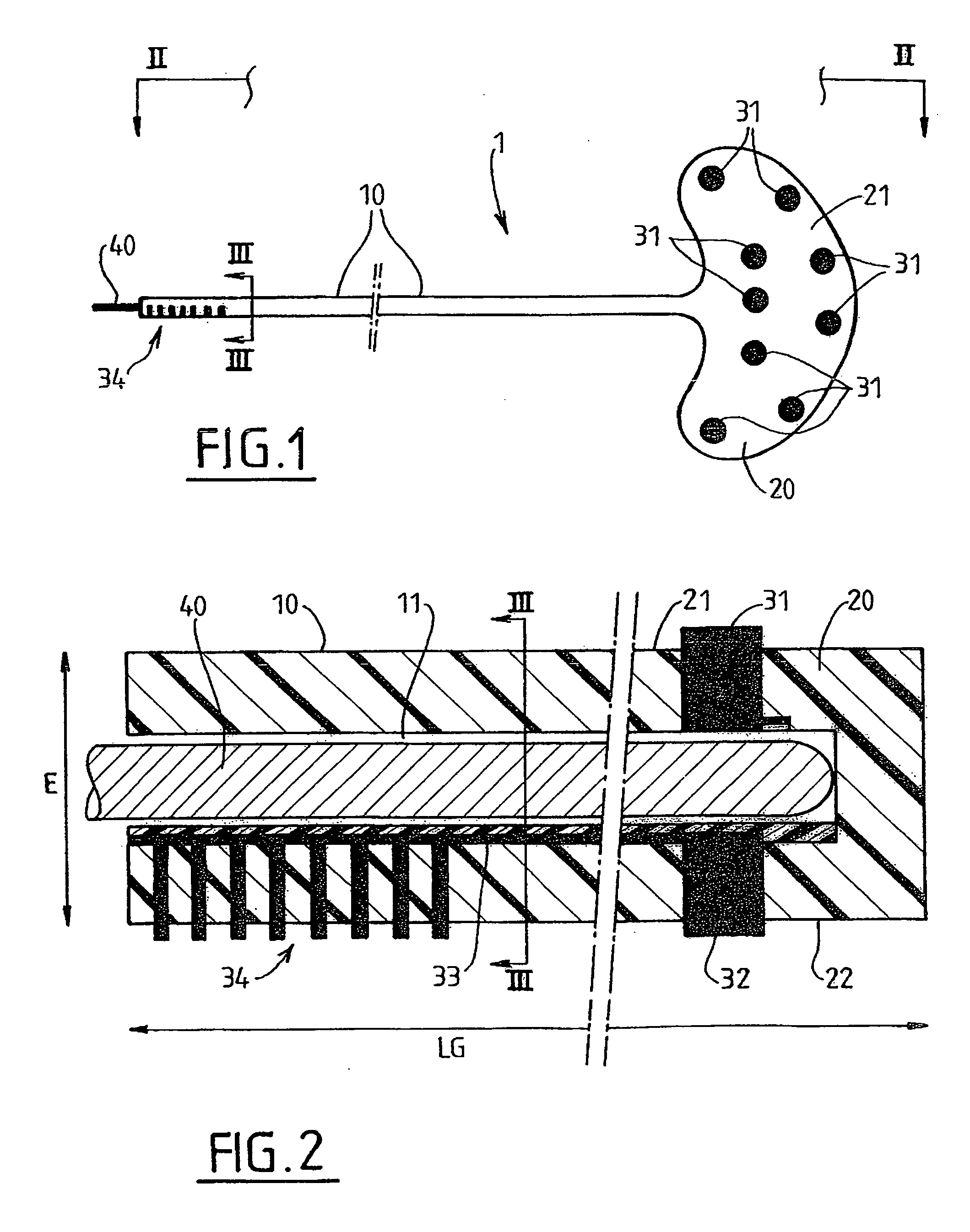

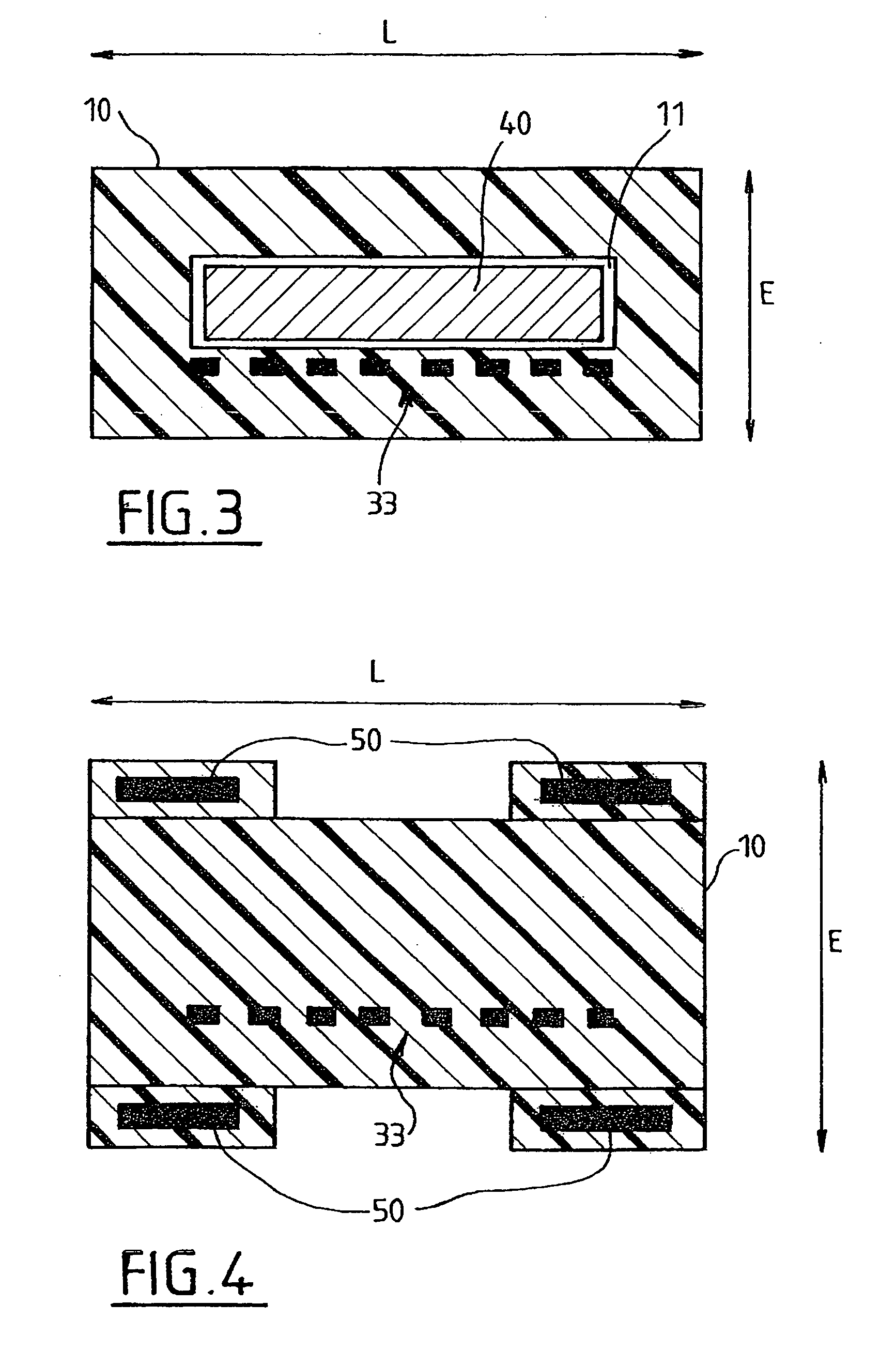

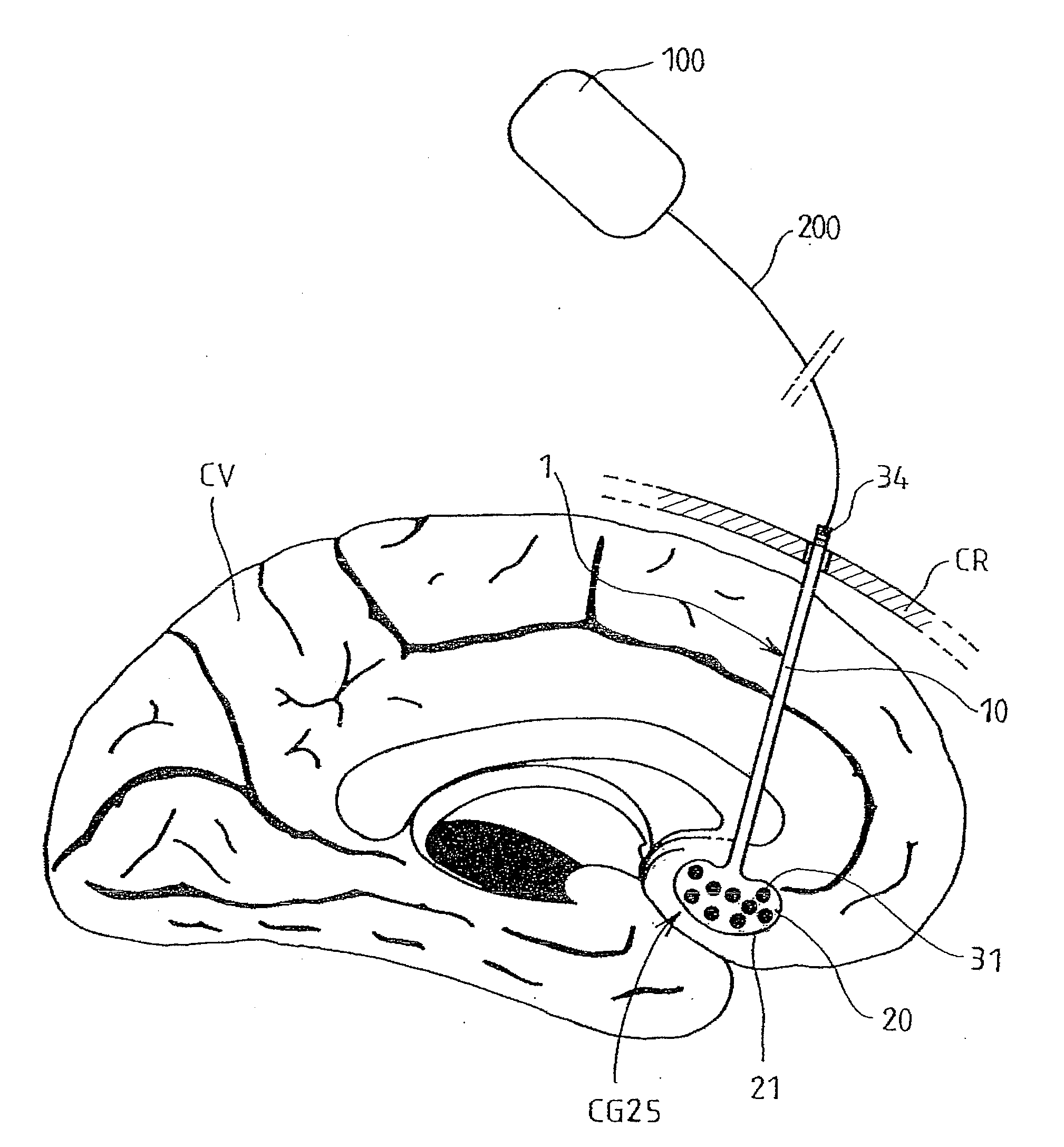

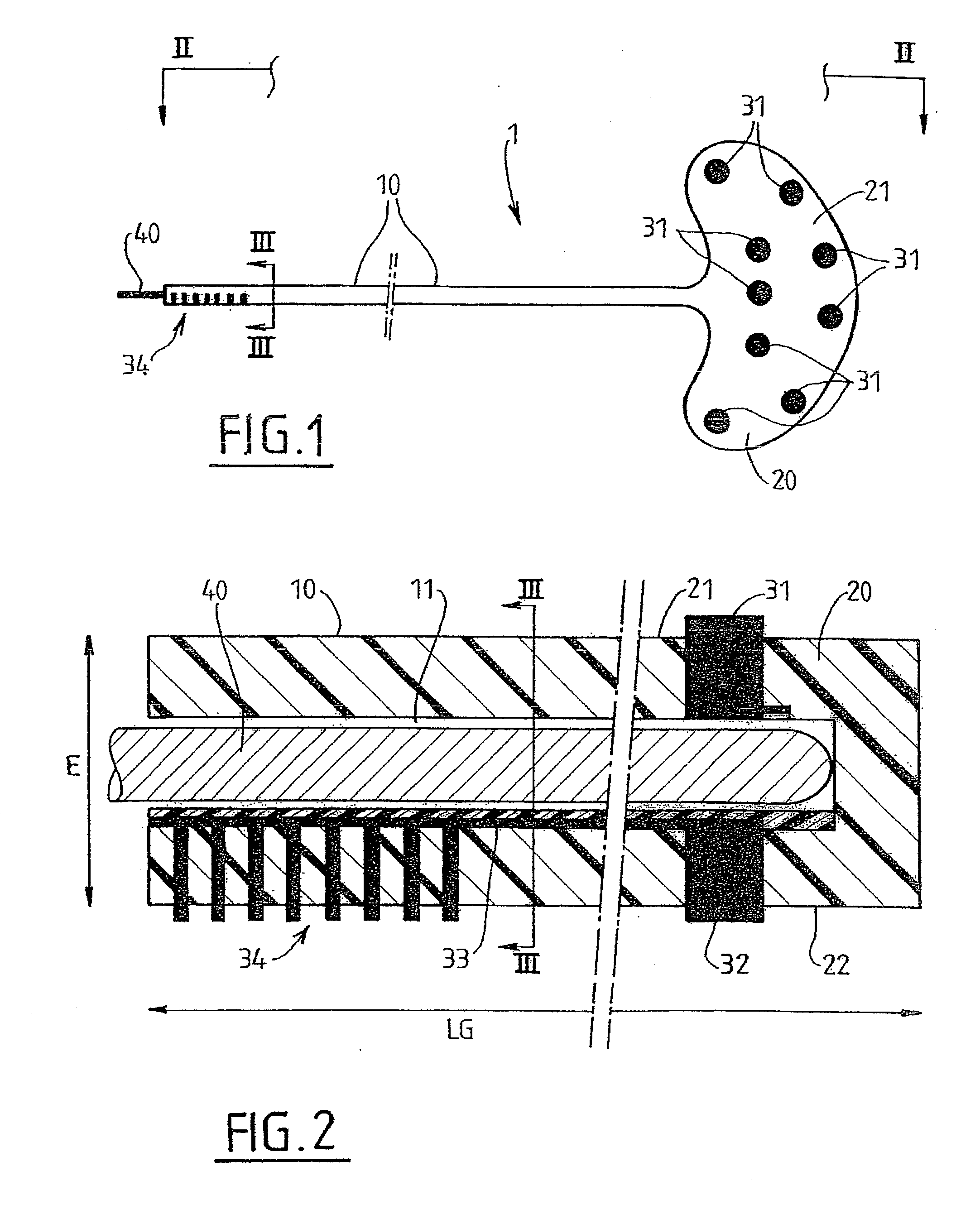

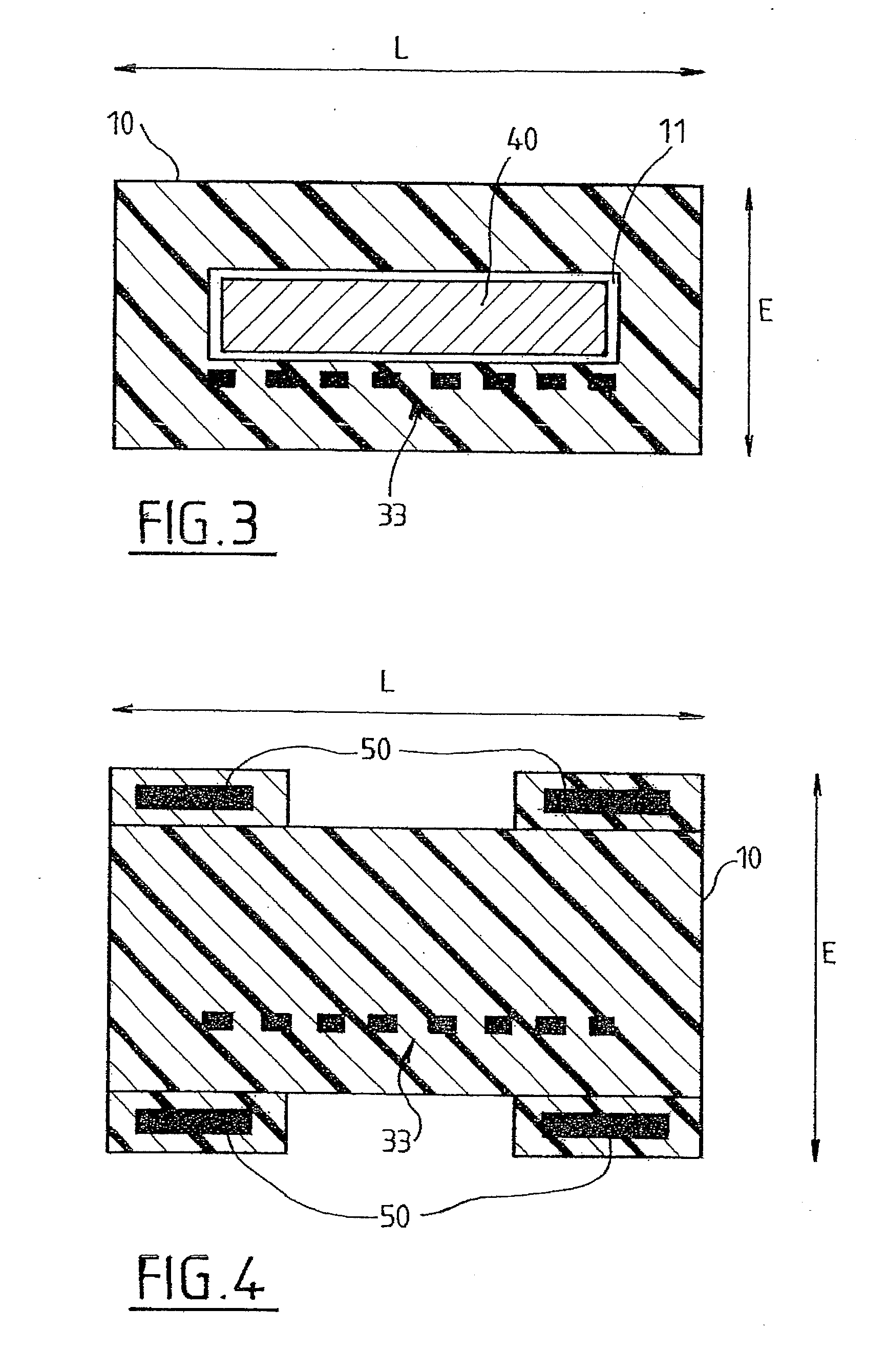

Multiple electrode lead and a system for deep electrical neurostimulation including such a lead

ActiveUS7991481B2Minimizing effectMinimizing riskHead electrodesExternal electrodesElectrical conductorEngineering

A lead for deep electrical neurostimulation comprising a rod of biocompatible material and a blade, also of biocompatible material, secured to one end of the rod and in alignment therewith. The blade presents two main faces and a plurality of electrodes disposed on at least one of the two main faces in a two-dimensional configuration. The electrodes are connected to conductor elements disposed inside or on a surface of said rod. A deep electrical neurostimulation system comprising an electrical pulse generator connected to at least one lead of the above-described type is also disclosed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

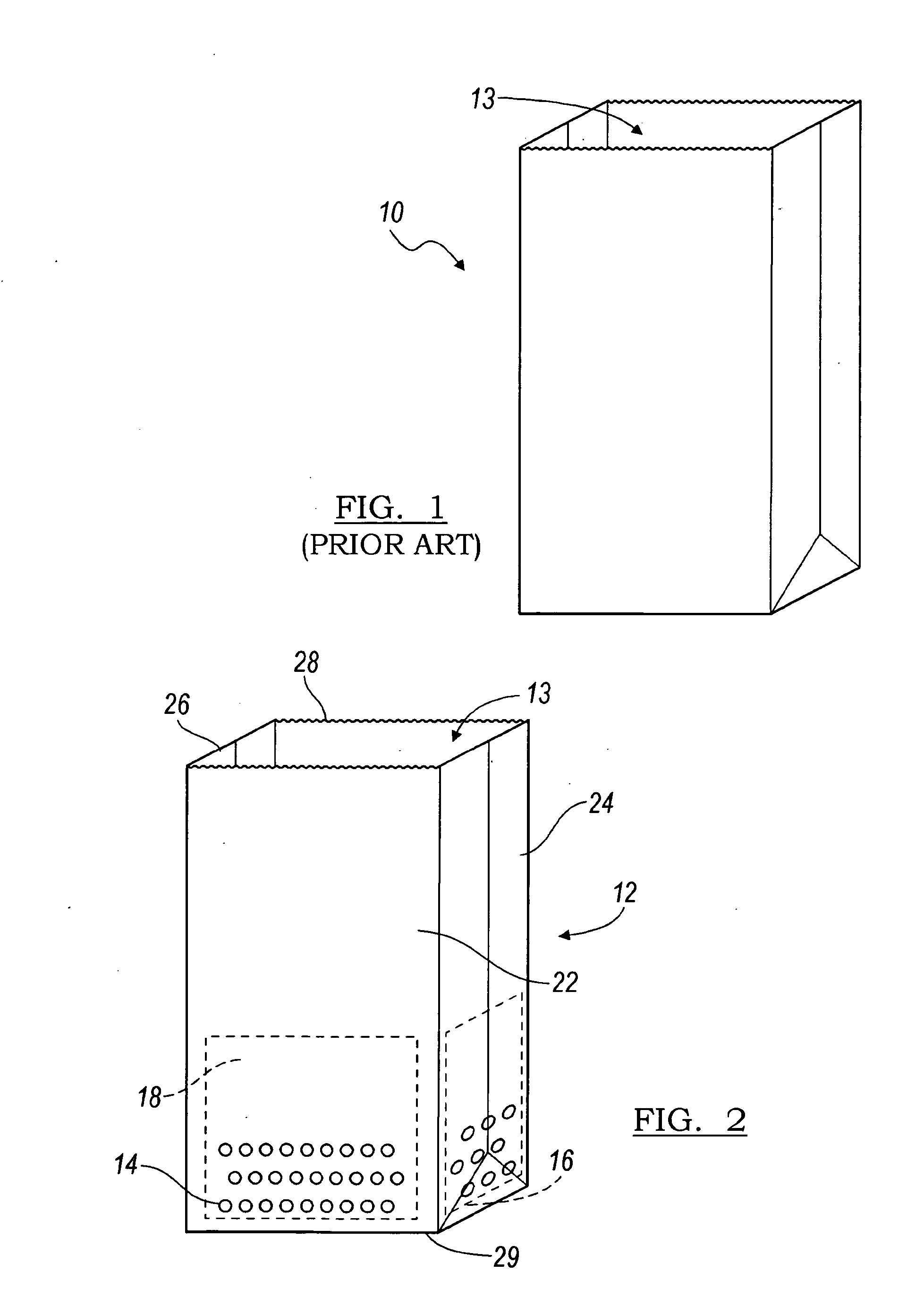

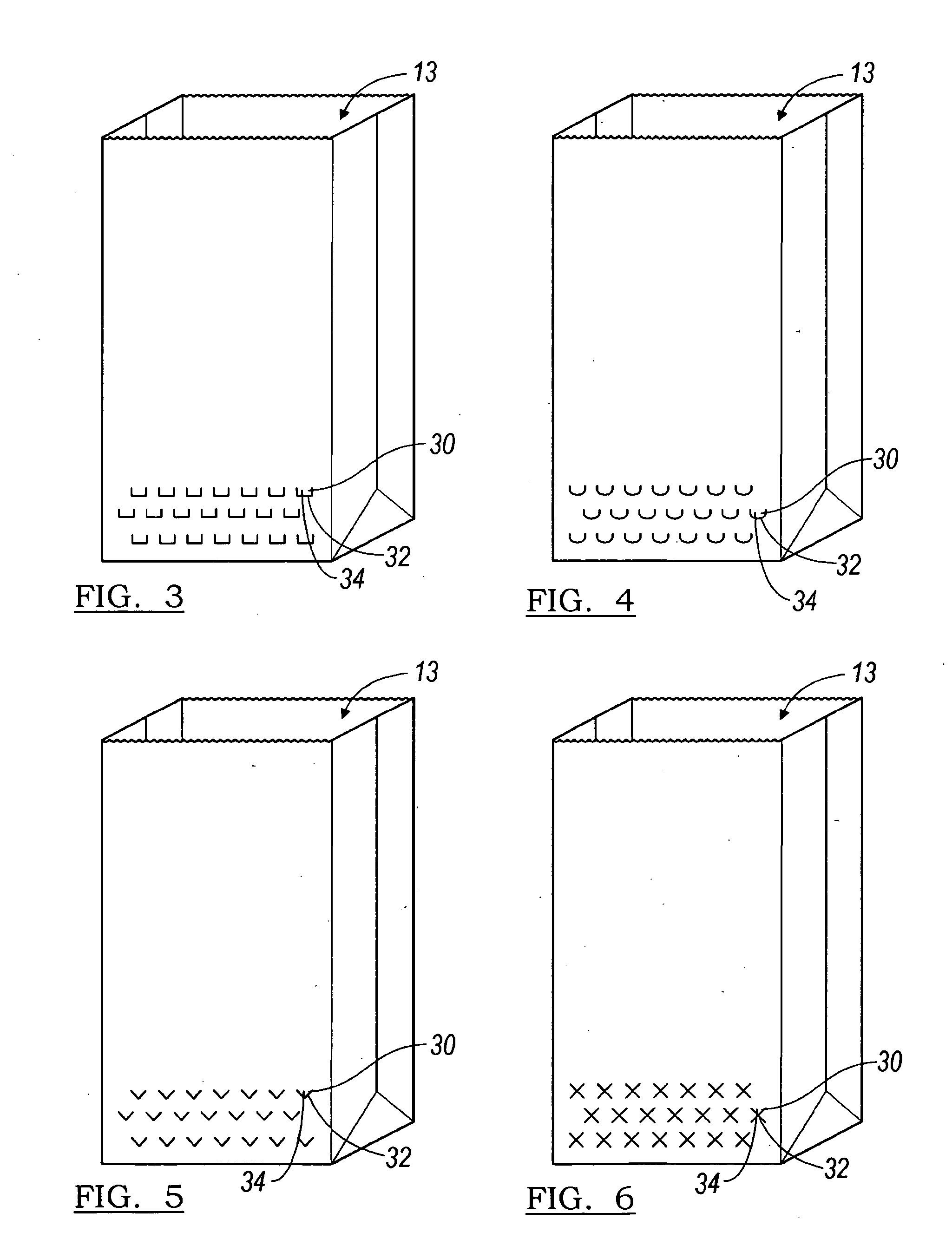

Refuse bag with improved air removal and content compaction

InactiveUS20060168932A1Minimizing effectSignificantly reducing air & possible allergensMowersBagsEngineeringMechanical engineering

A lawn refuse bag is provided that includes a tubular container having a first side surface, a second side surface, a third side surface, a fourth side surface, and a fifth side surface. The tubular container further includes an open end for receiving compressible contents therein. A plurality of perforations are selectively disposed on at least one side surface of the tubular container adapted to discharge air from the tubular container away from a user compressing the contents therein.

Owner:TOPORSKI TODD

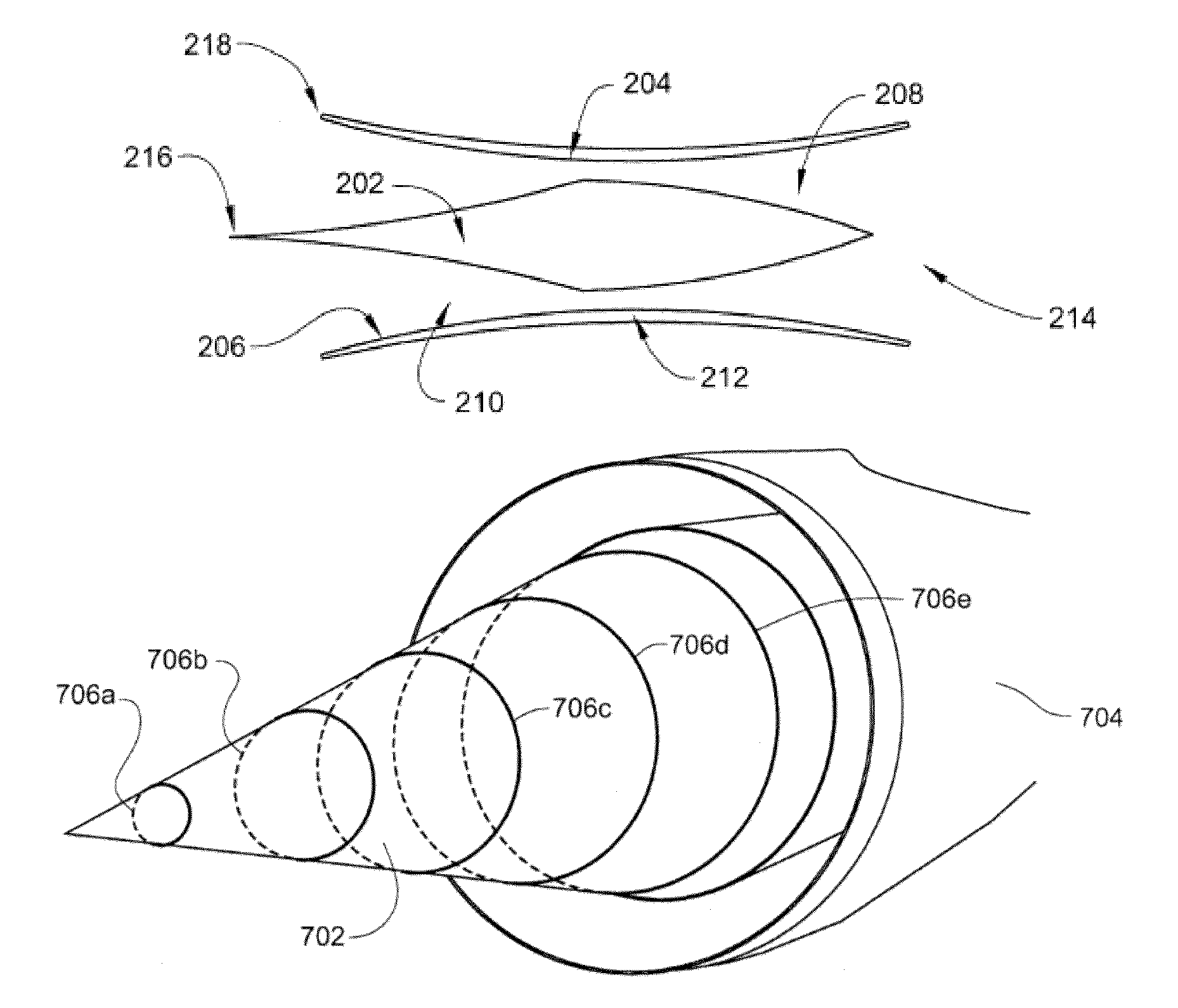

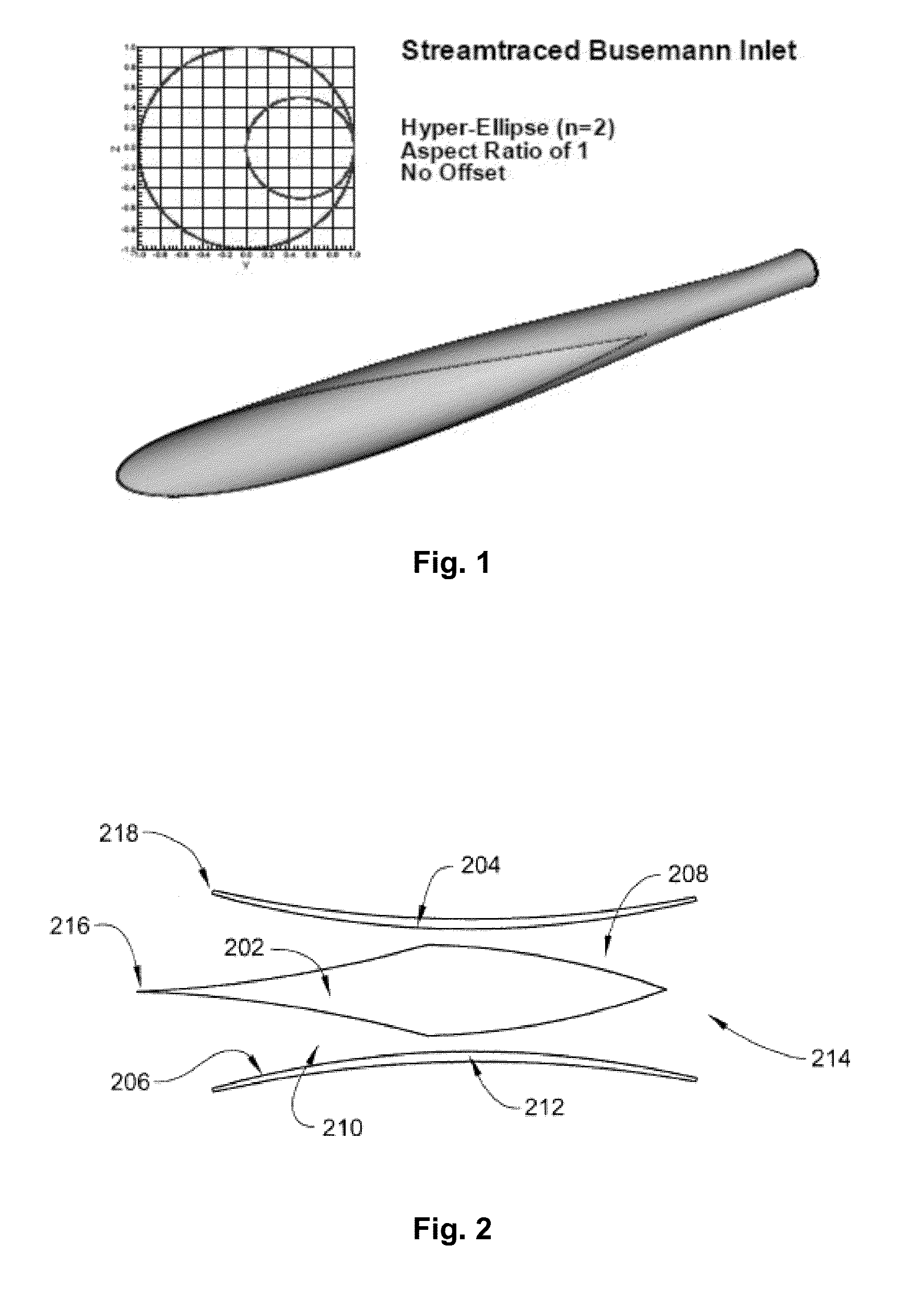

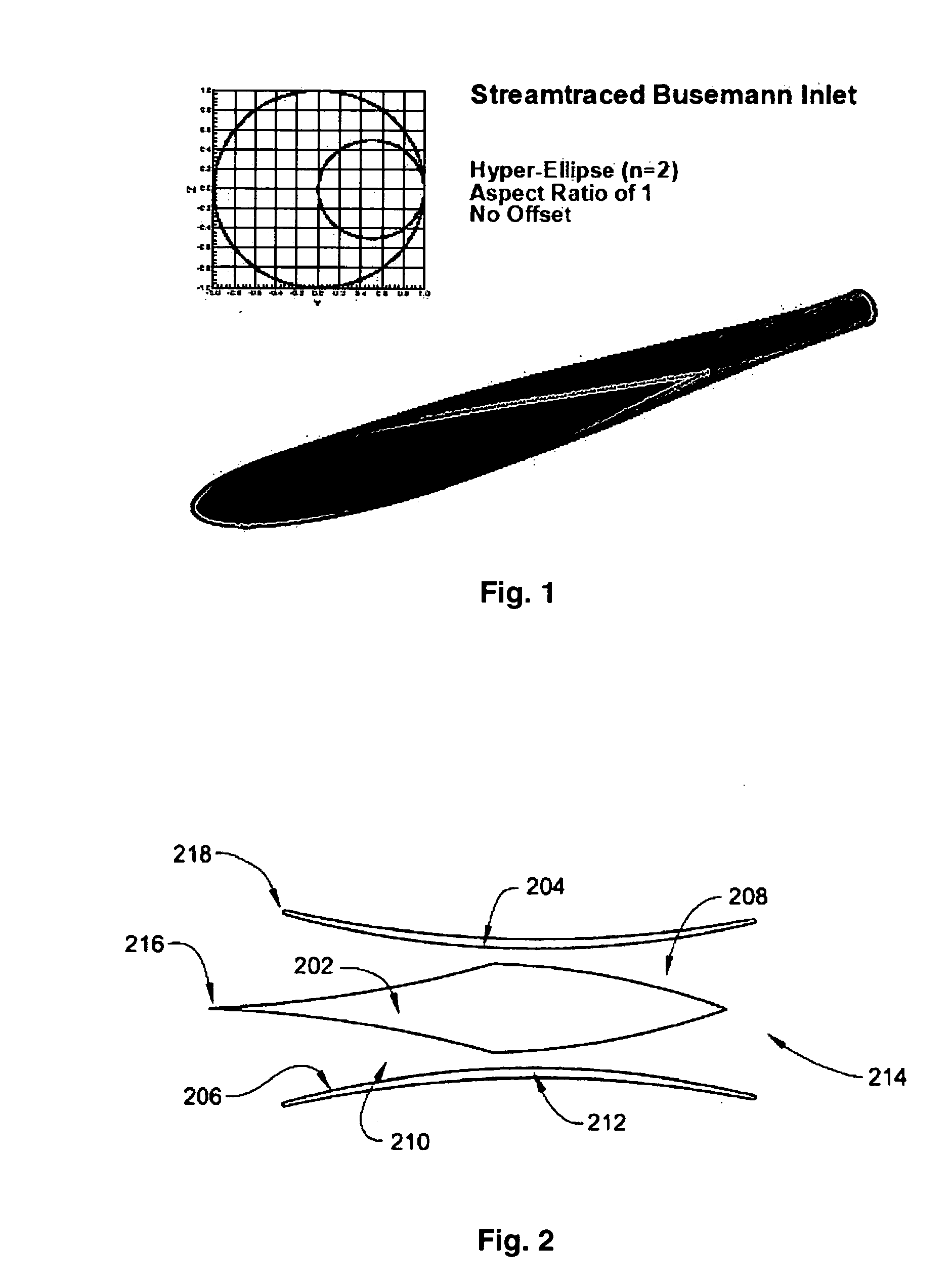

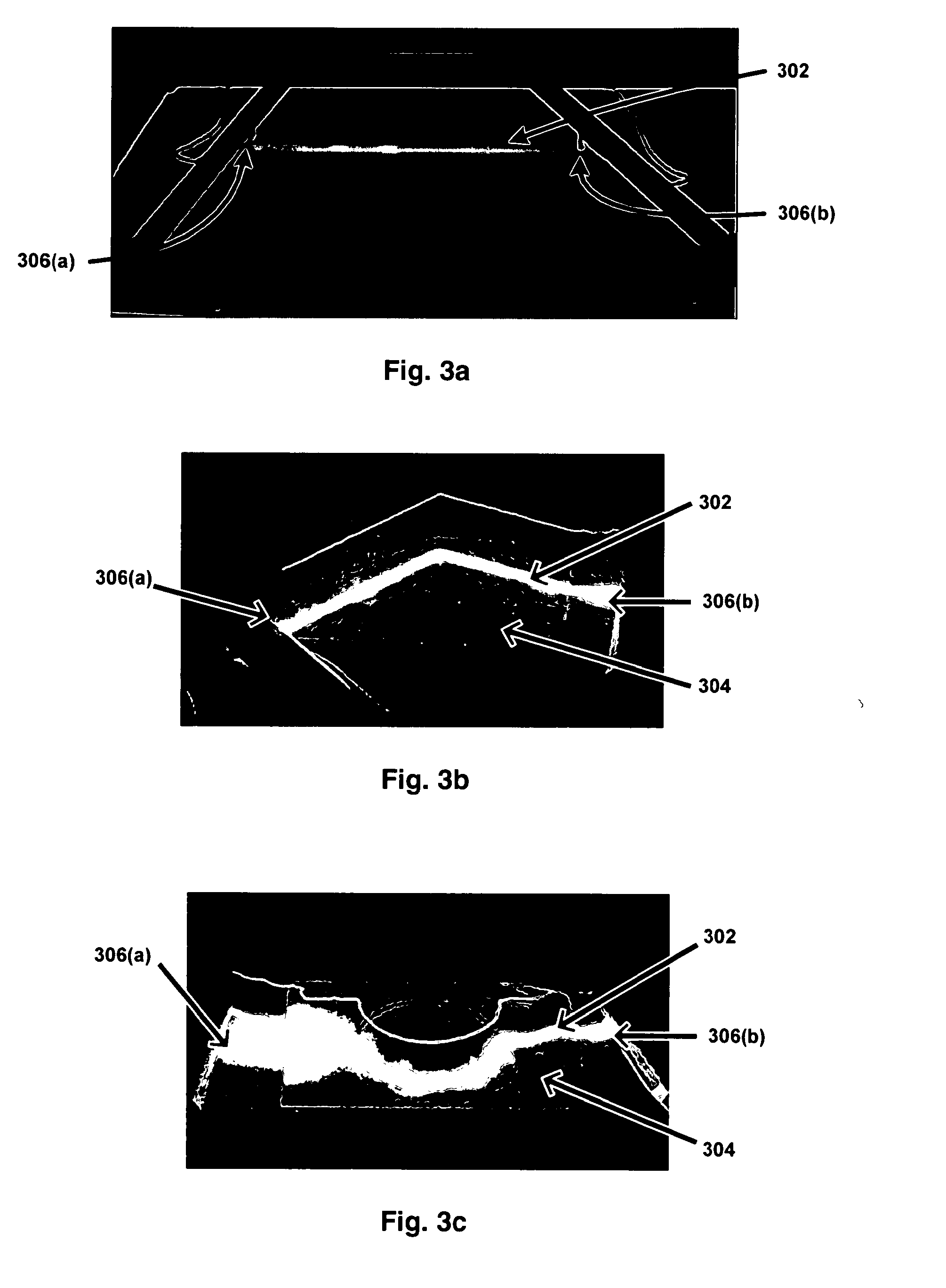

Energy-deposition systems, equipment and method for modifying and controlling shock waves and supersonic flow

ActiveUS8960596B2Minimize impactMinimizing of buildEngine manufactureAerodynamic testingShock waveThroat

Systems, equipment, and methods to deposit energy to modify and control shock waves and hypersonic or supersonic fluid flow, including systems for controlling, mitigating, and / or effecting air flow in relation to air vehicles, wind tunnels, or other assets, or the like, as well as systems, equipment, and methods for disrupting the shock structure at the inlet for the engine of an air vehicle traveling at supersonic or hypersonic speed; mitigating blast effects on vehicles; mitigating heating of throats in supersonic and hypersonic wind tunnels, as well as control the flow parameters and Mach number in their test sections.

Owner:KREMEYER KEVIN

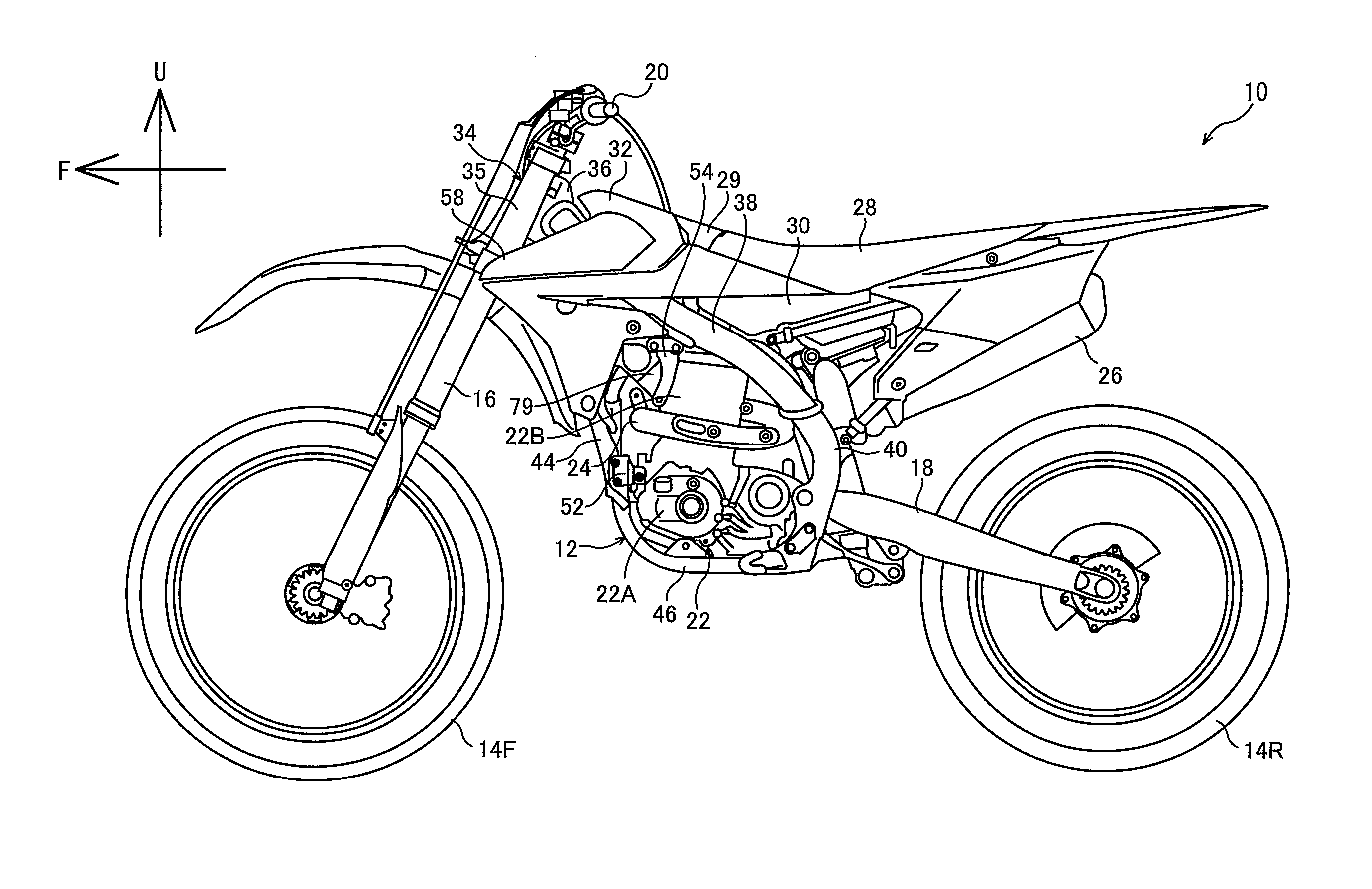

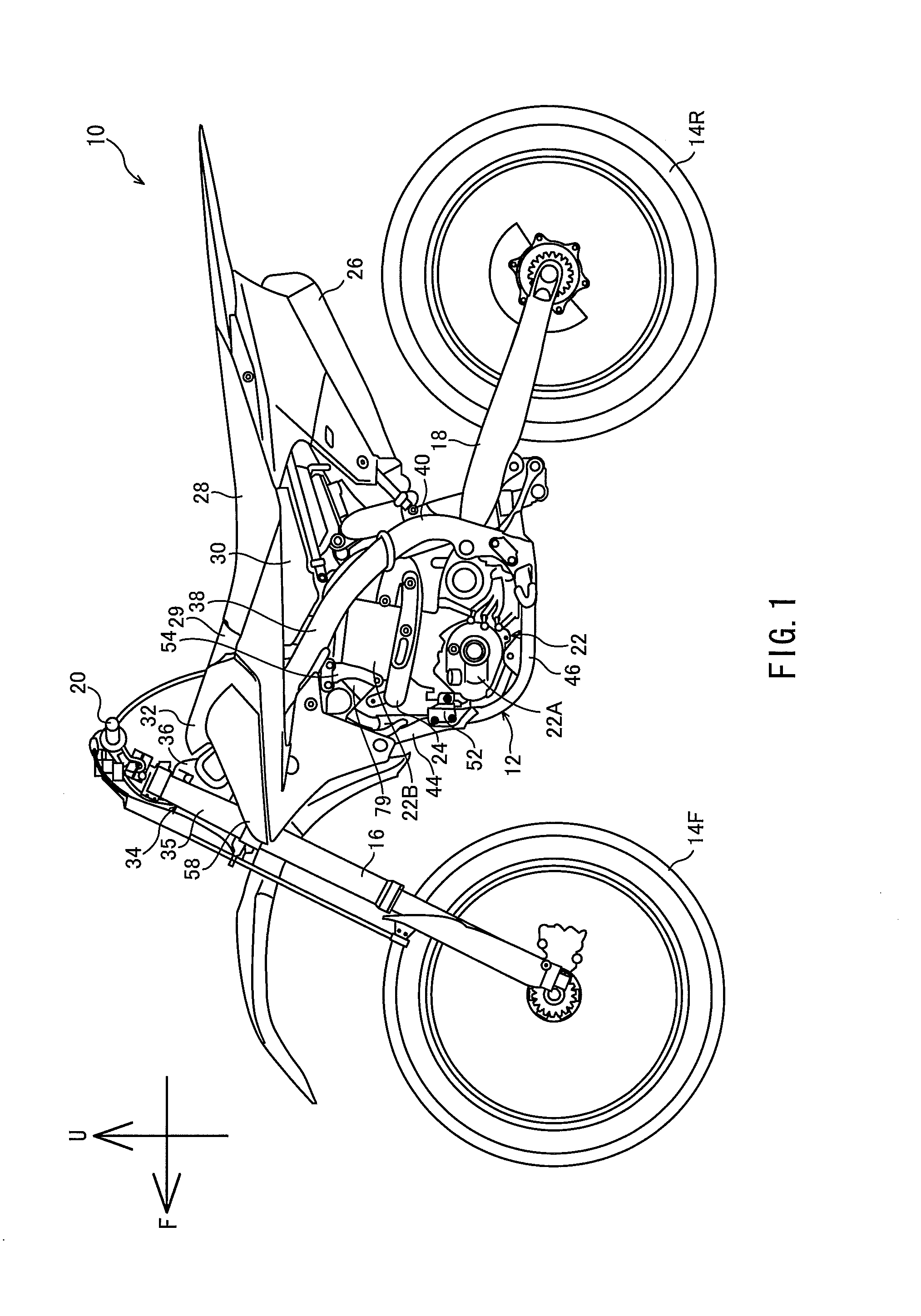

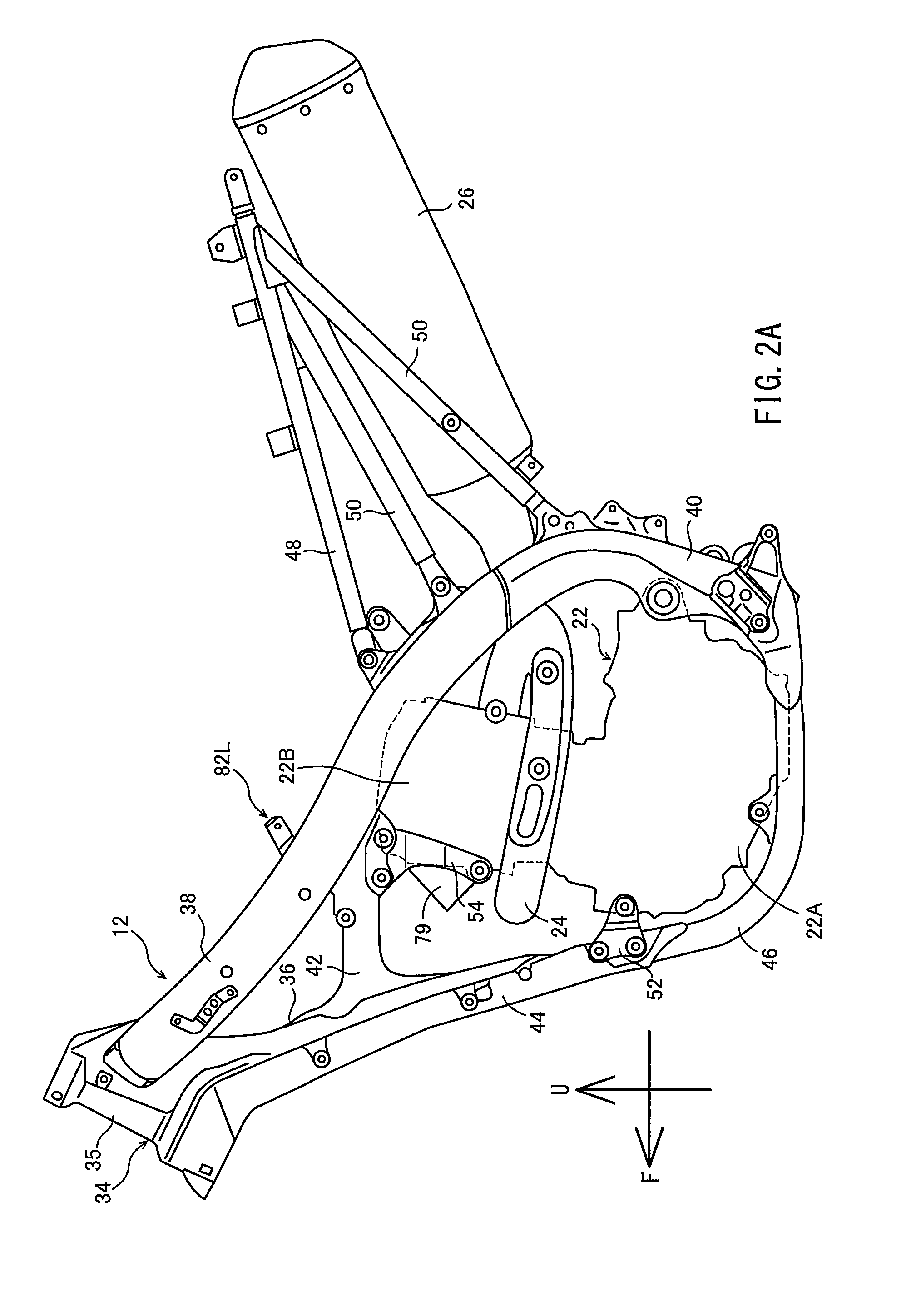

Straddle-type vehicle

A straddle-type vehicle has reduced wiring and a mass of the vehicle as measured in top-to-bottom and front-to-rear directions with respect to the vehicle is concentrated while minimizing the effects of heat from the engine on an engine control unit and ignition coil. An air cleaner is located rearward of a head pipe. A fuel tank is located rearward of the air cleaner. A rear portion of the air cleaner is located above the engine. A front portion of the fuel tank is located above the engine. The engine control unit and the ignition coil are located above the engine and located between the air cleaner and the fuel tank. The ignition coil overlaps the engine control unit as viewed in a side view of the vehicle.

Owner:YAMAHA MOTOR CO LTD

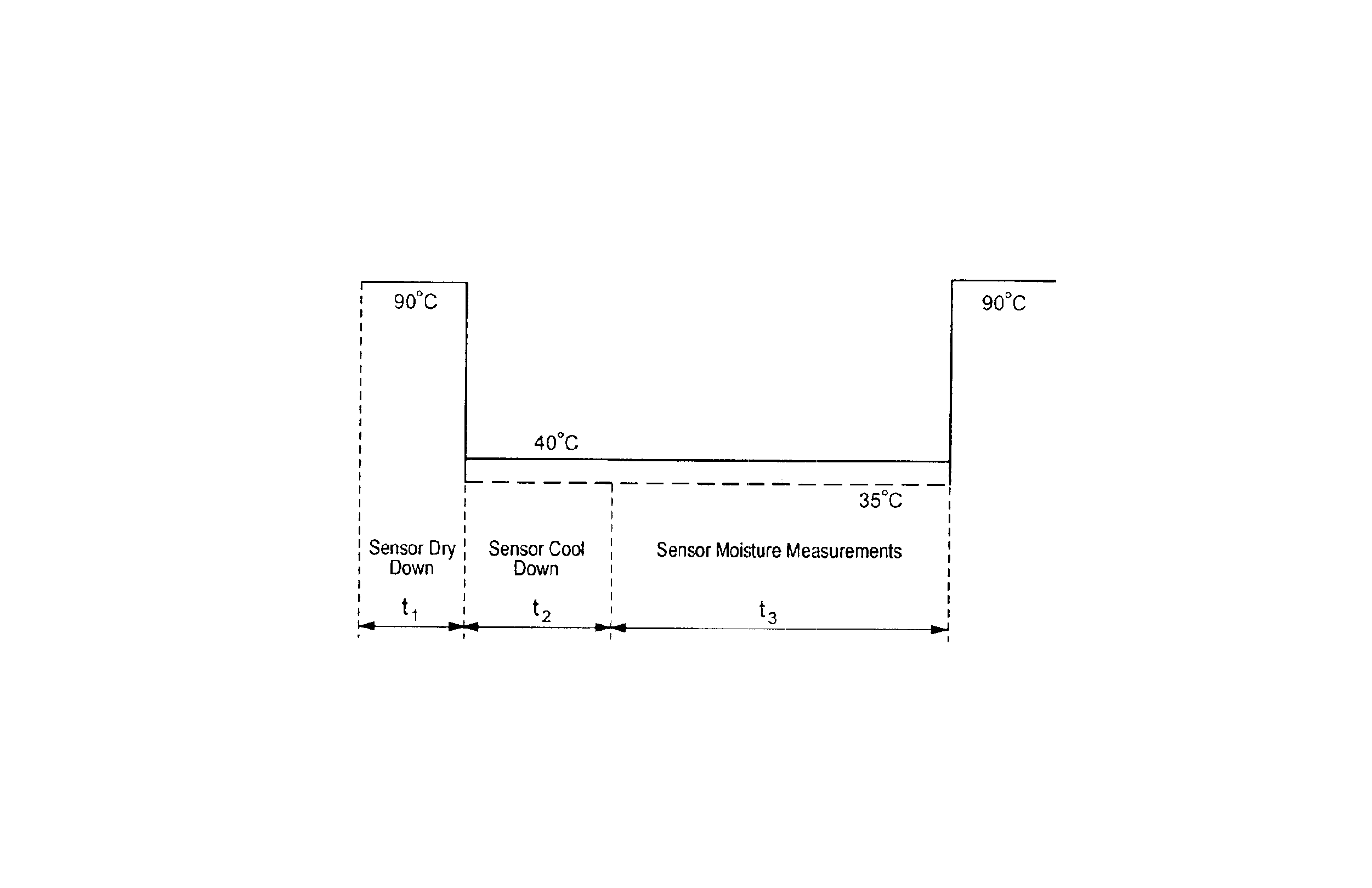

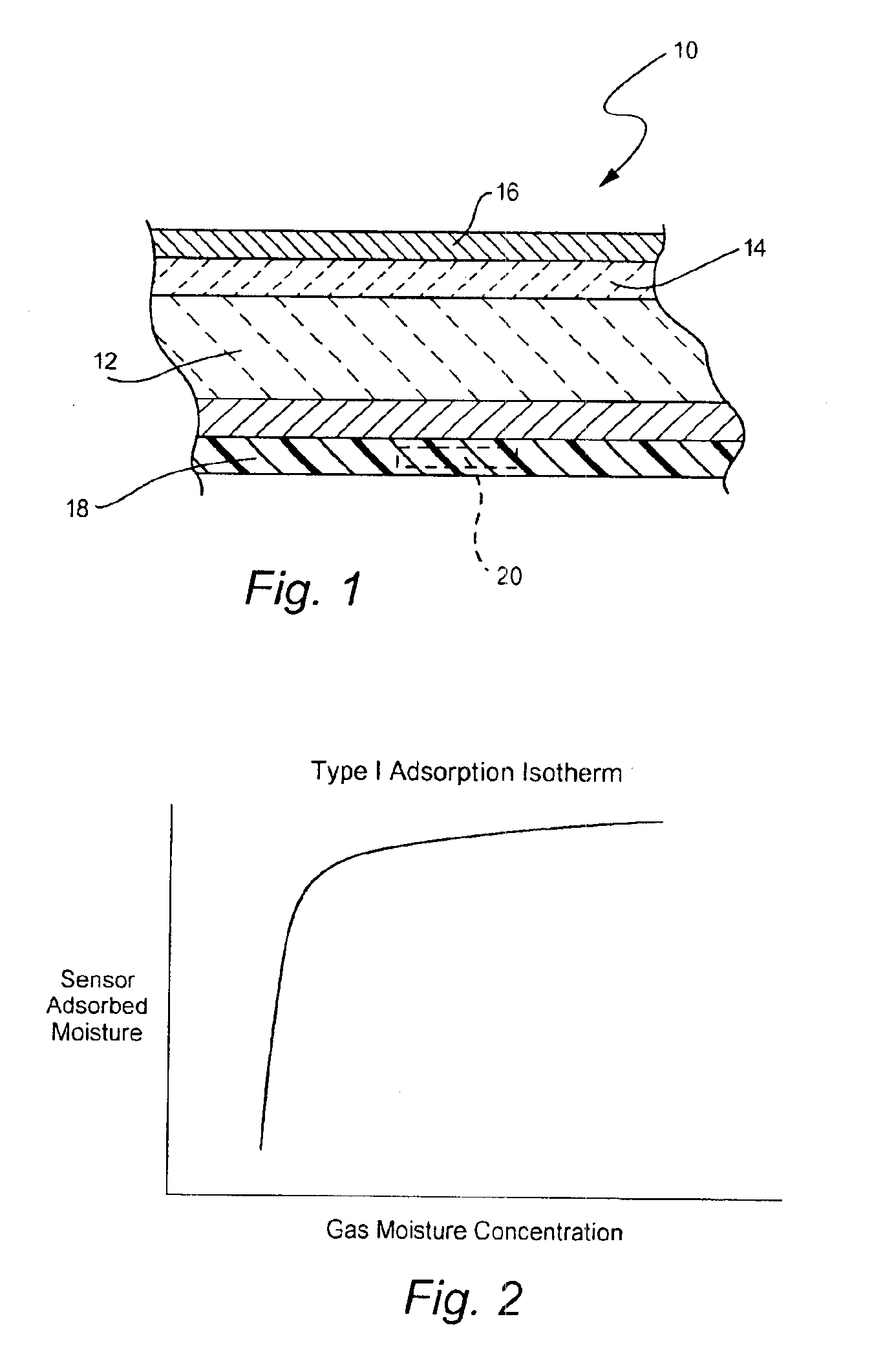

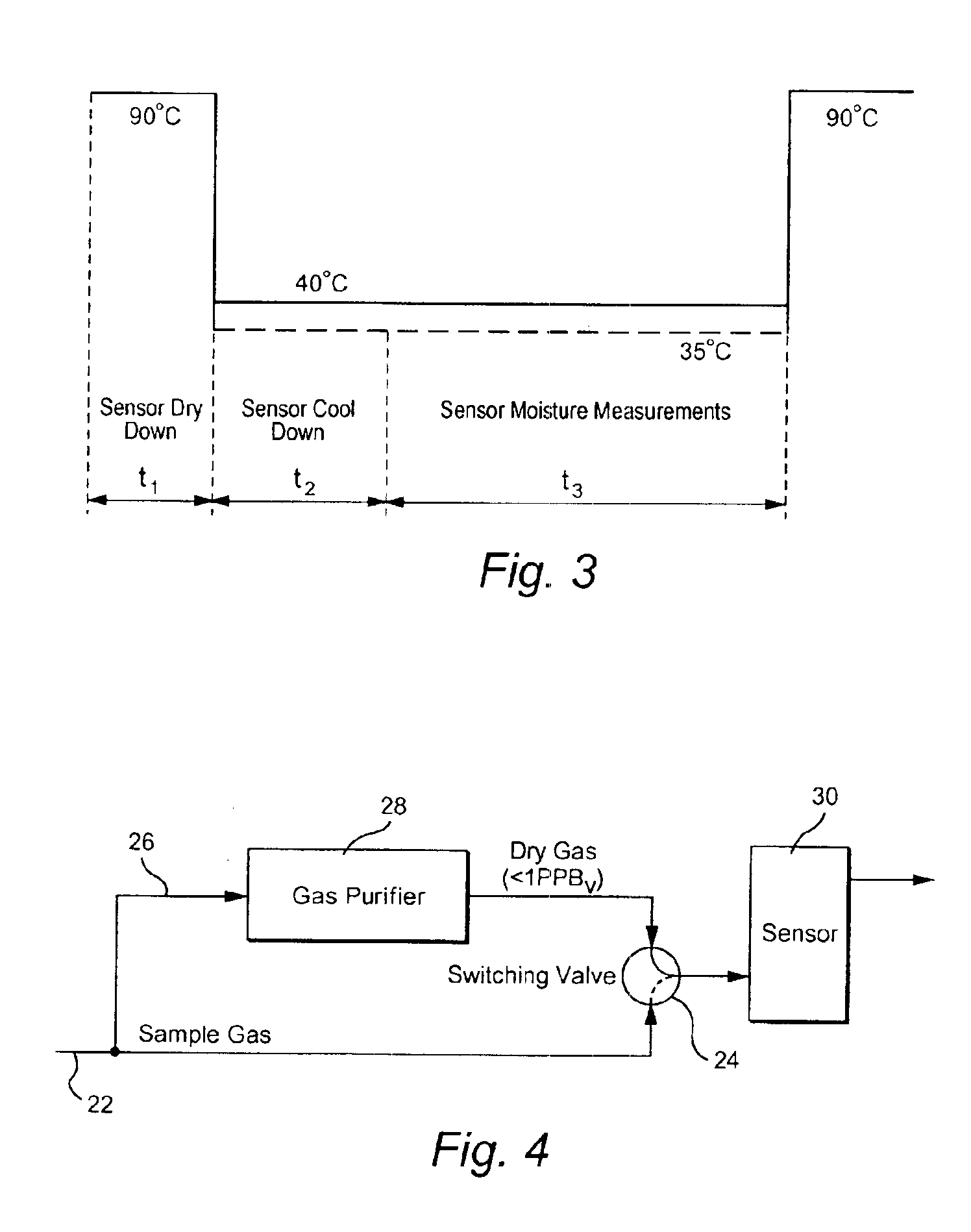

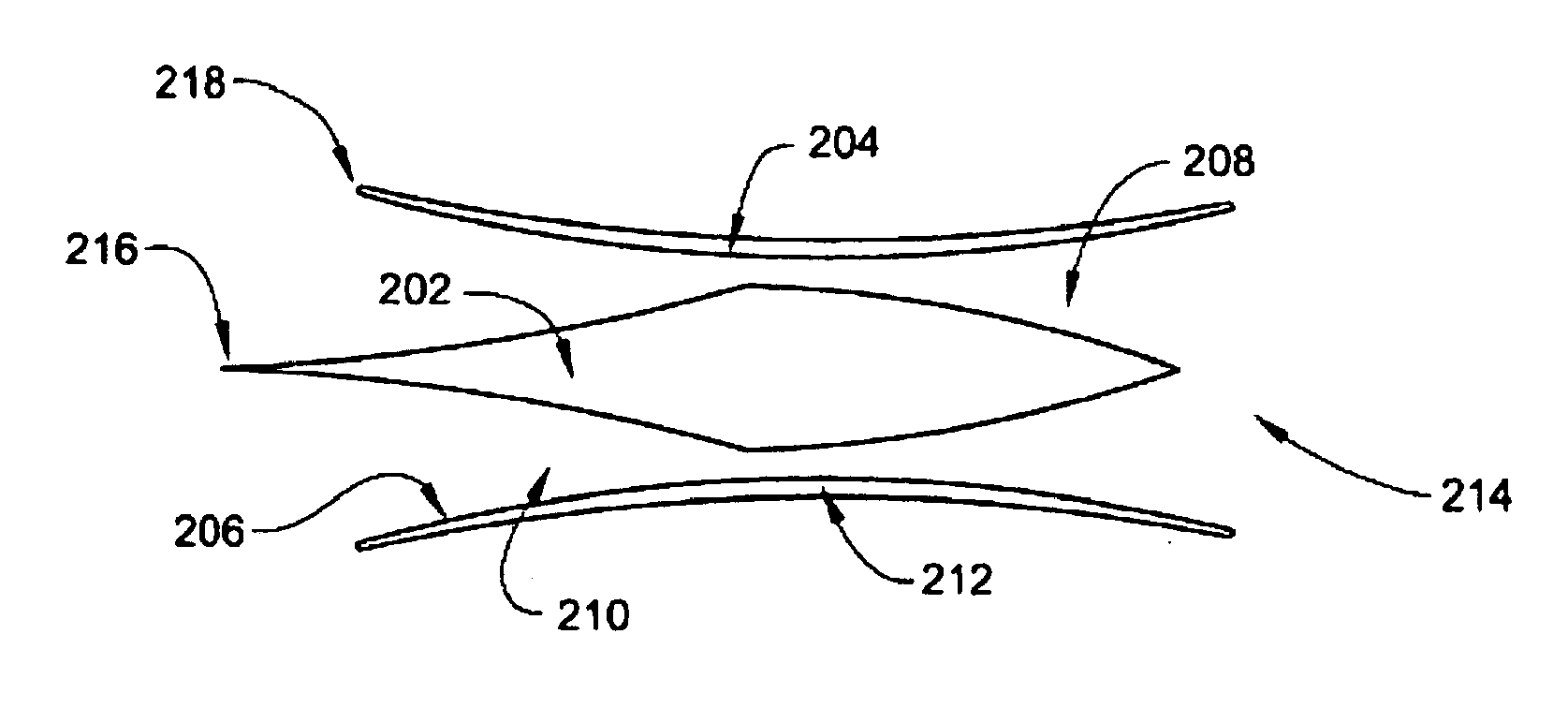

Aluminum oxide moisture sensor and related method

ActiveUS6865940B2Reduce driftResponse speed be increaseUsing mechanical meansMaterial resistanceElectricityEngineering

A method of operating an aluminum oxide moisture sensor to measure moisture in a sample gas, where the sensor comprises a pair of electrodes sandwiched about a dielectric, the method comprising: a) heating the sensor to a first temperature above the sample gas temperature and holding the sensor at said first temperature for a first predetermined period of time; b) cooling down the sensor to a second lower temperature over a second predetermined period of time; c) taking plural samples of sensor conductance over a third predetermined period of time at the lower temperature; and d) determining a rate of adsorption of the moisture and using the rate of adsorption as a measure of moisture in the sample gas.

Owner:BAKER HUGHES INC

Energy- deposition sytems,eguipment and method for modifying and controling shock waves and supersonic flow

ActiveUS20110030379A1Minimizing of abrasionMinimizing effect of heatEngine manufactureAerodynamic testingShock waveBlast effects

Systems, equipment, and methods to deposit energy to modify and control shock waves and hypersonic or supersonic fluid flow, including systems for controlling, mitigating, and / or effecting air flow in relation to air vehicles, wind tunnels, or other assets, or the like, as well as systems, equipment, and methods for disrupting the shock structure at the inlet for the engine of an air vehicle traveling at supersonic or hypersonic speed; mitigating blast effects on vehicles; mitigating heating of throats in supersonic and hypersonic wind tunnels, as well as control the flow parameters and Mach number in their test sections.

Owner:KREMEYER KEVIN

Multiple electrode lead and a system for deep electrical neurostimulation including such a lead

ActiveUS20090012593A1Effective treatmentMinimizing riskHead electrodesExternal electrodesElectrical conductorEngineering

A lead for deep electrical neurostimulation, the lead comprising:a rod of biocompatible material; anda blade, also of biocompatible material, secured to one end of said rod and in alignment therewith;in which said blade presents two main faces and a plurality of electrodes disposed on at least one of said two main faces in a two-dimensional configuration, said electrodes being connected to conductor elements disposed inside or on a surface of said rod.A deep electrical neurostimulation system comprising: an electrical pulse generator for deep electrical neurostimulation; and at least one lead of the above-described type, having its electrodes electrically connected to said electrical pulse generator.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

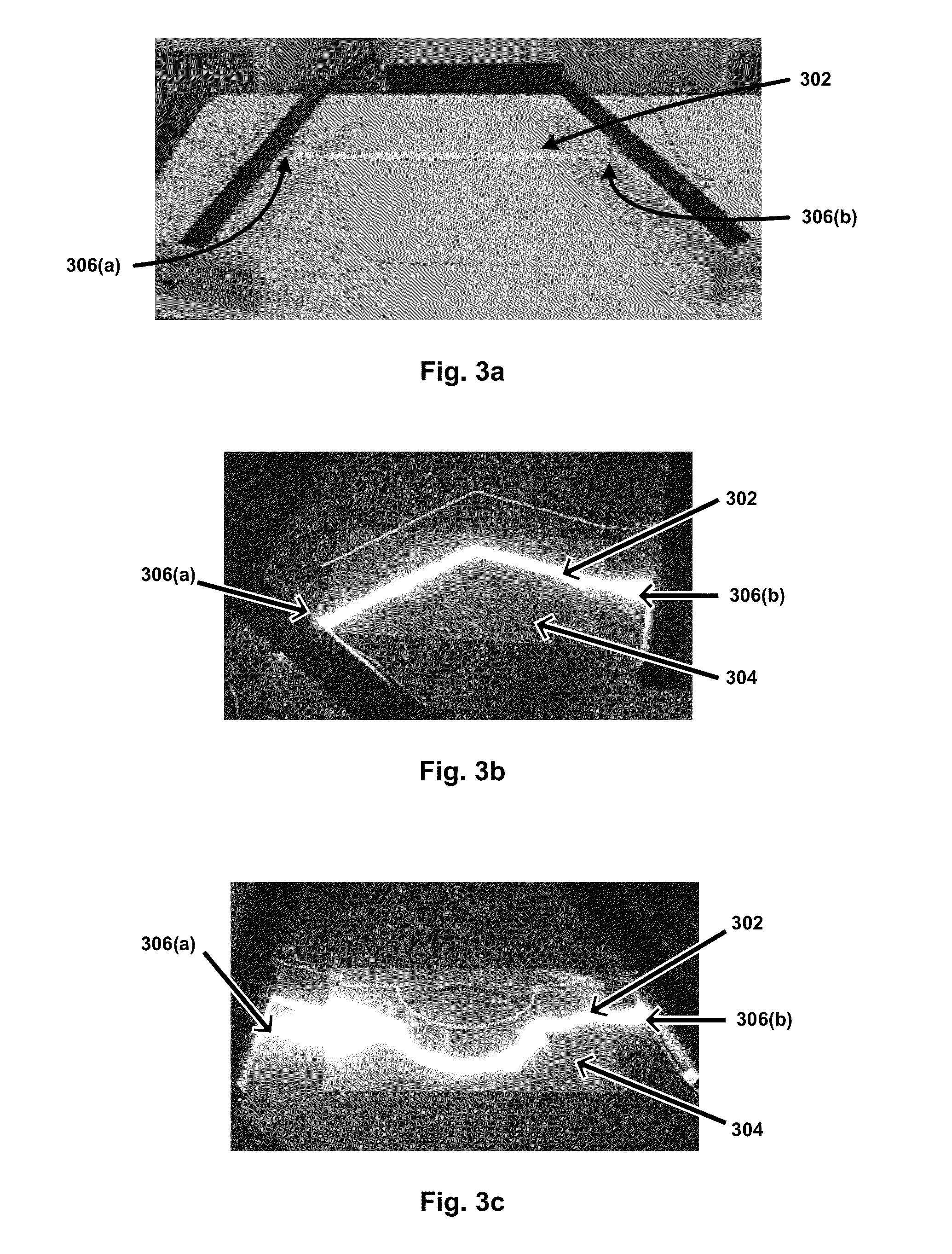

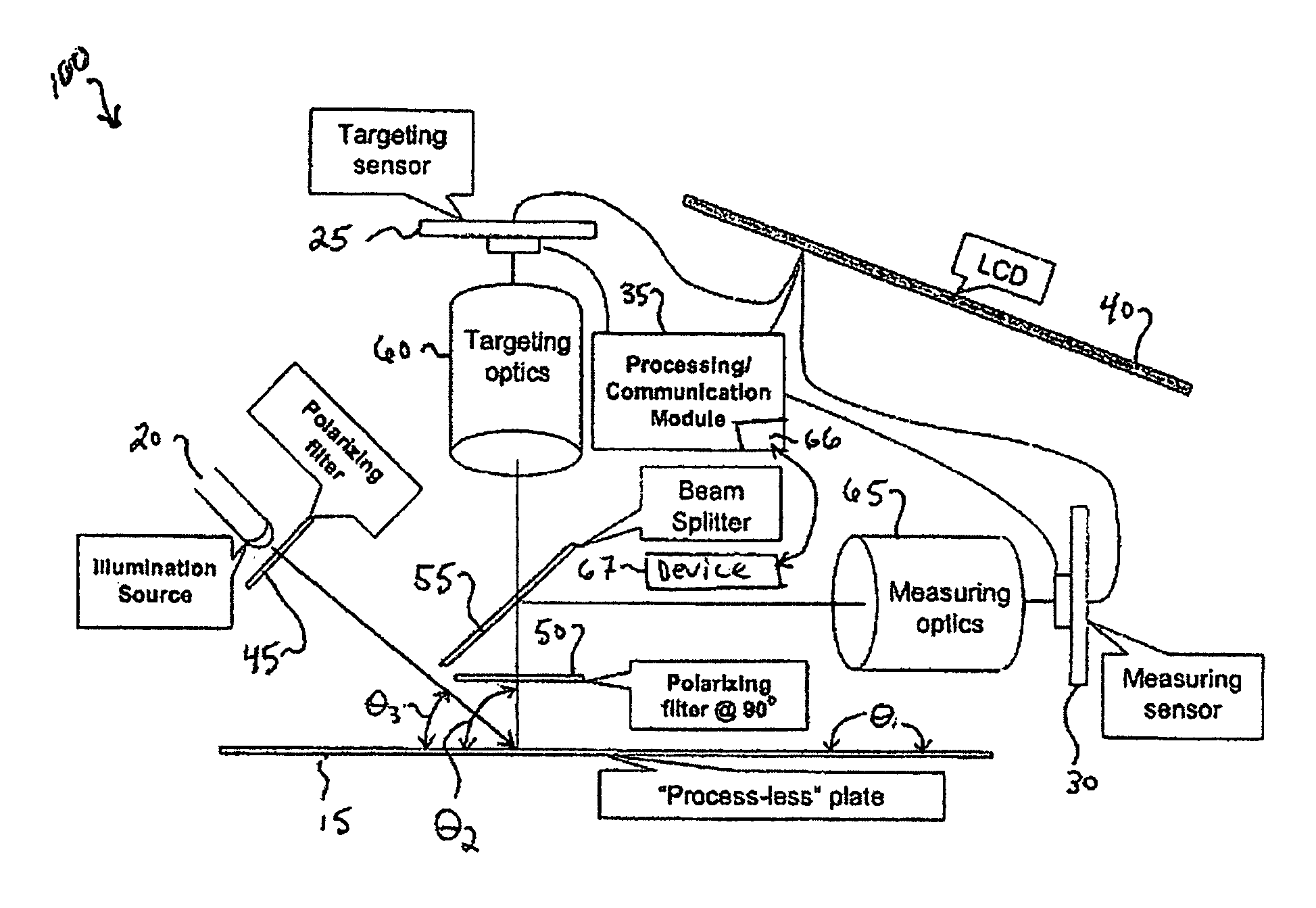

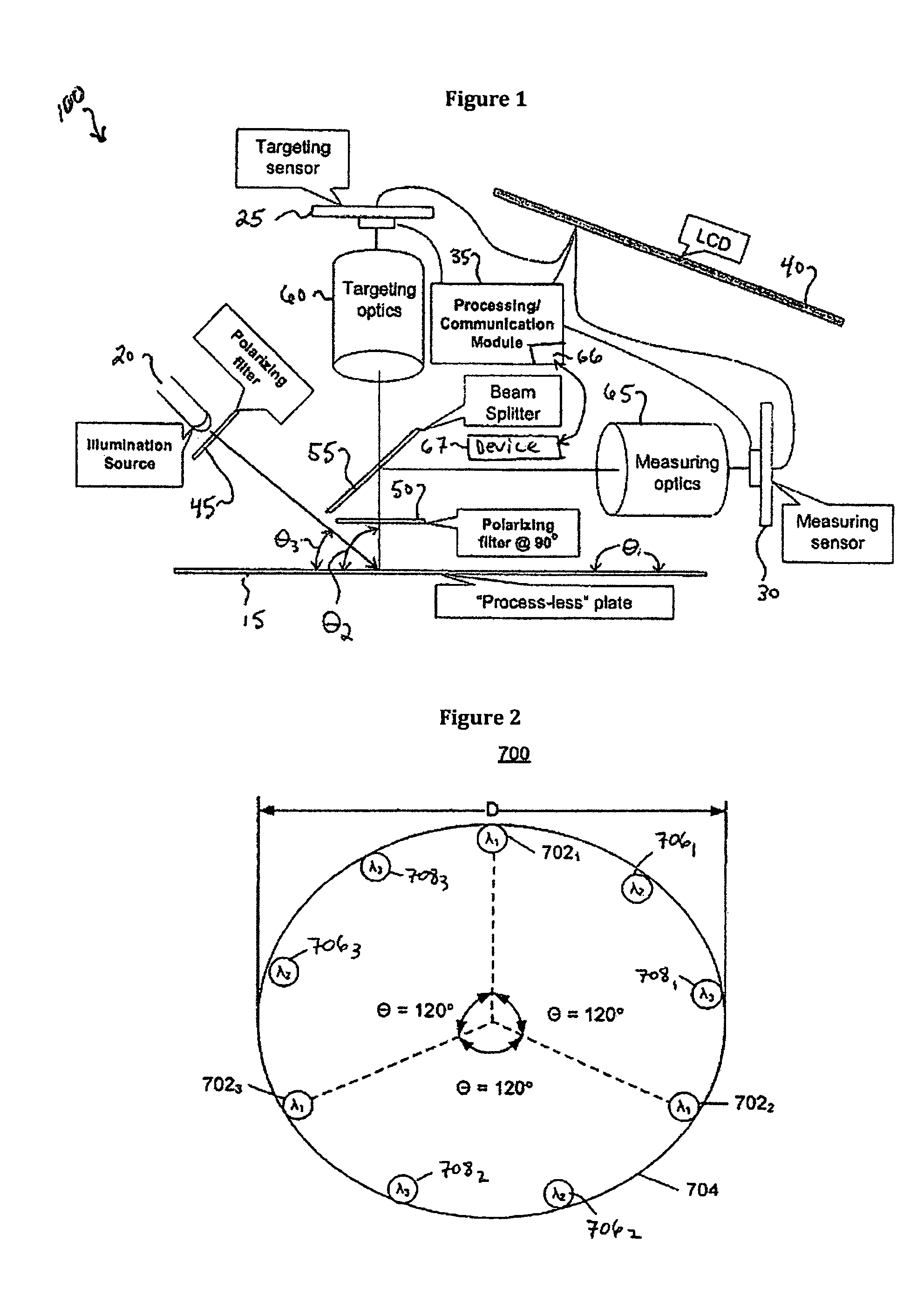

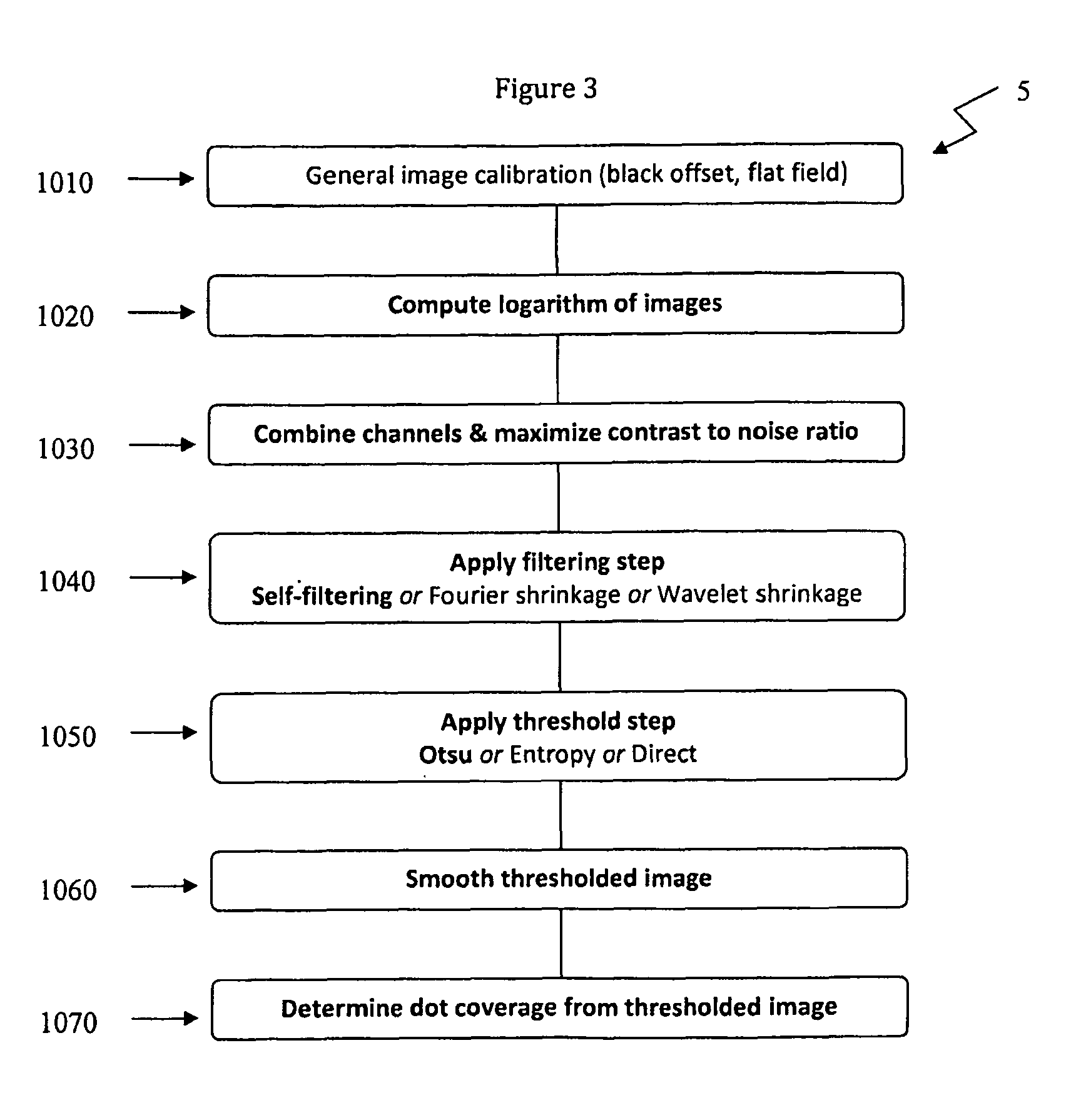

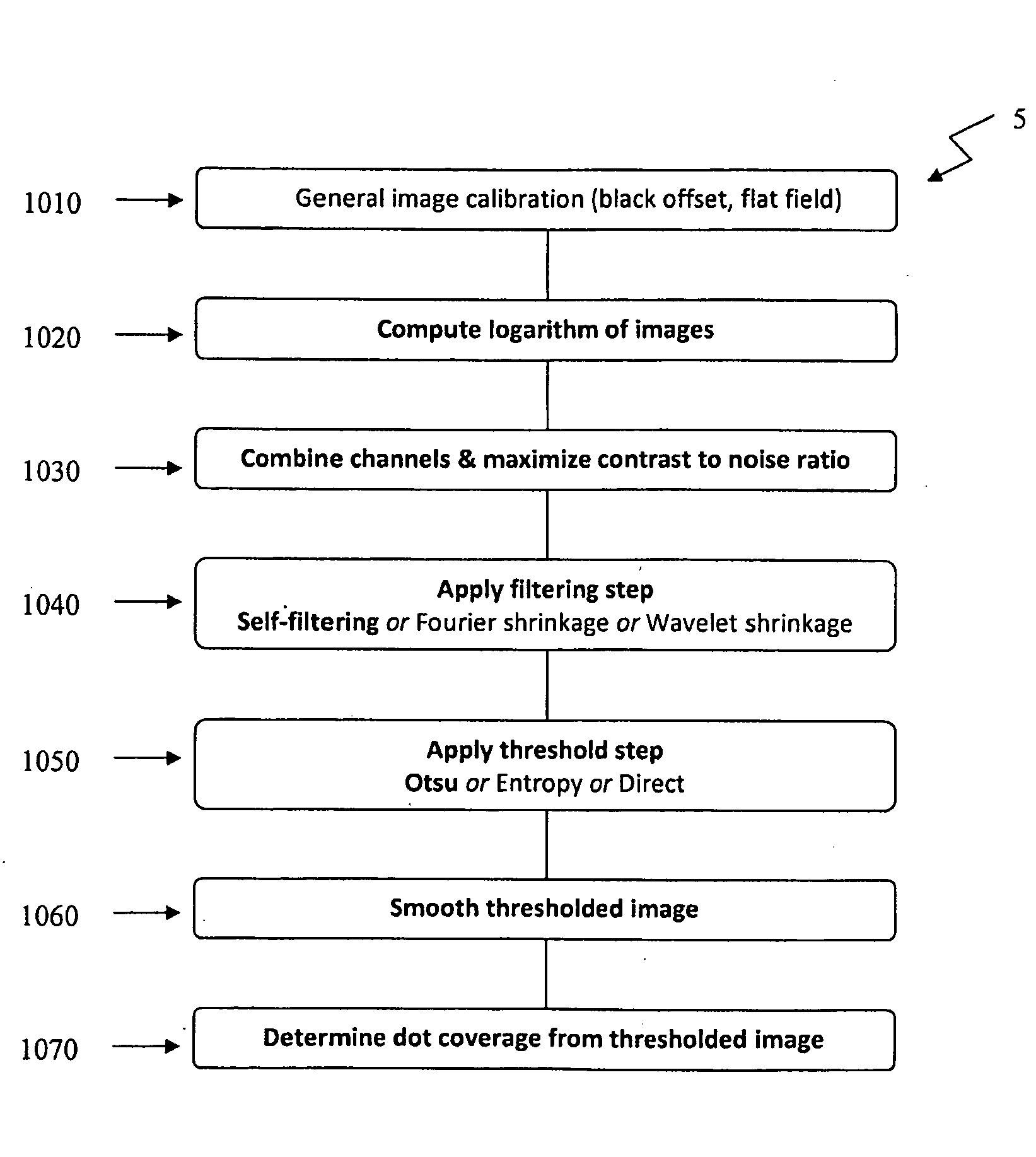

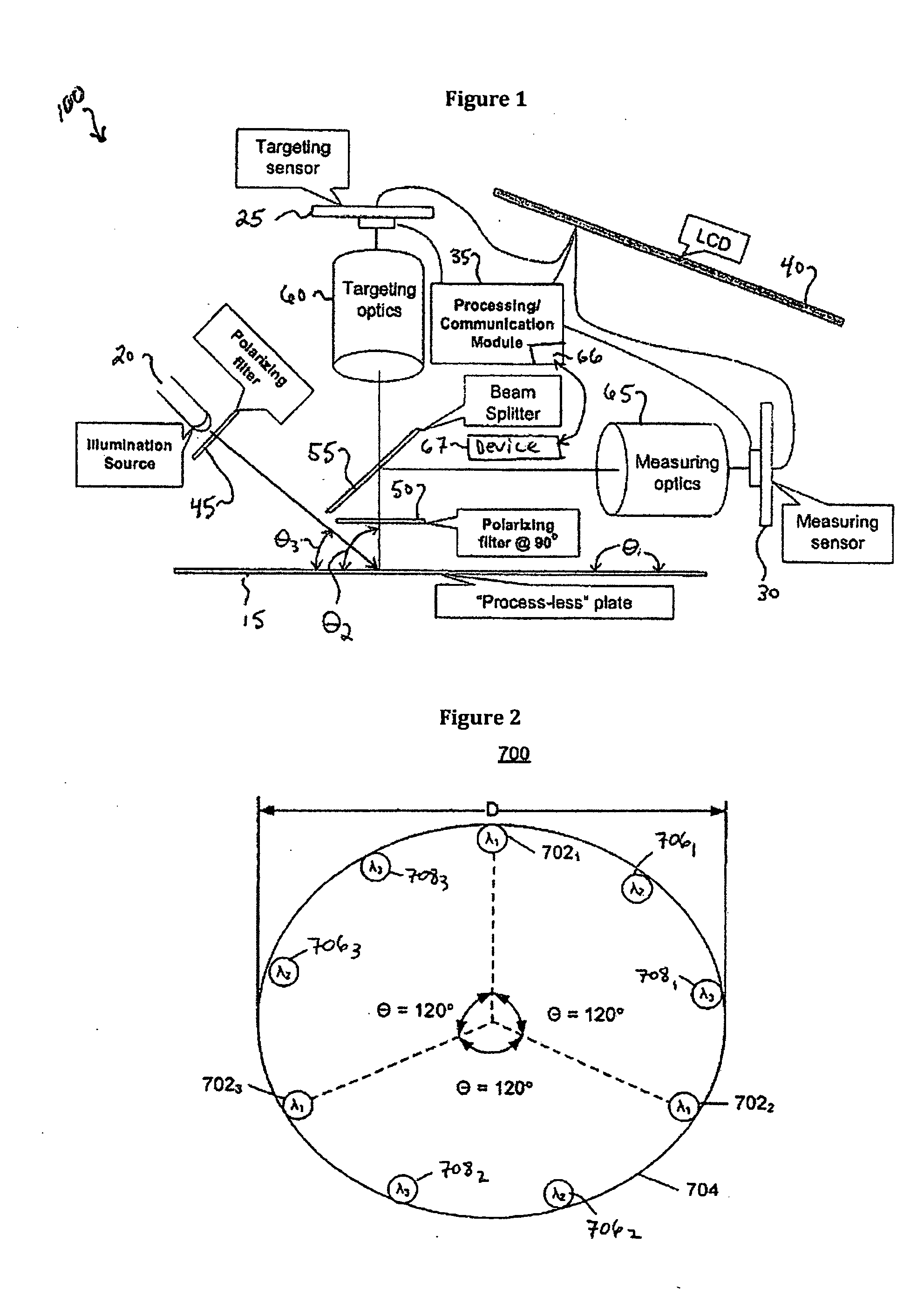

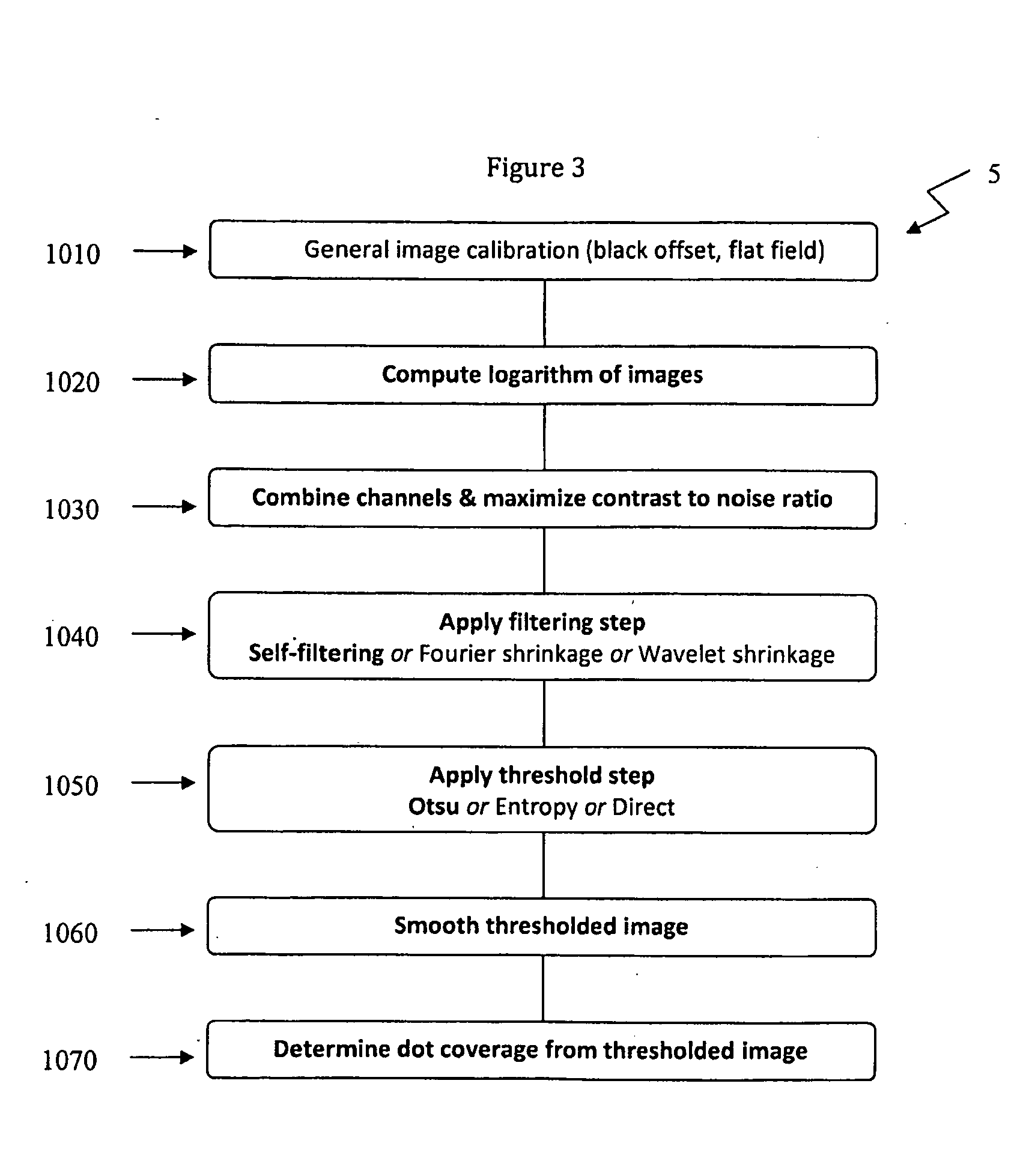

Systems and method for optical scatter imaging of latent image plates

InactiveUS8237138B2Minimize distortionMinimizing effectImage enhancementImage analysisLatent imageData acquisition

Computer-implemented systems and methods for processing image data of a process-free plate are provided according to the present disclosure. The systems and methods may, generally, include a data acquisition step / means for receiving image data using one or more channels of a imaging system, each channel functioning to image the same target region of a process-free plate using a different wavelength of light, and a data processing step / means for filtering the image data using at least one of: (i) self-filtering, (ii) Fourier shrinkage and (iii) Wavelet shrinkage. When the image data is received using a plurality of channels, the received image data may advantageously be combined so as to optimize contrast-to-noise performance. The disclosed systems and methods may advantageously perform the operations of image de-noising, contrast enhancement, and thresholding, and may further involve compensation techniques, e.g., for minimizing distortion and blurring effects.

Owner:X RITE INC

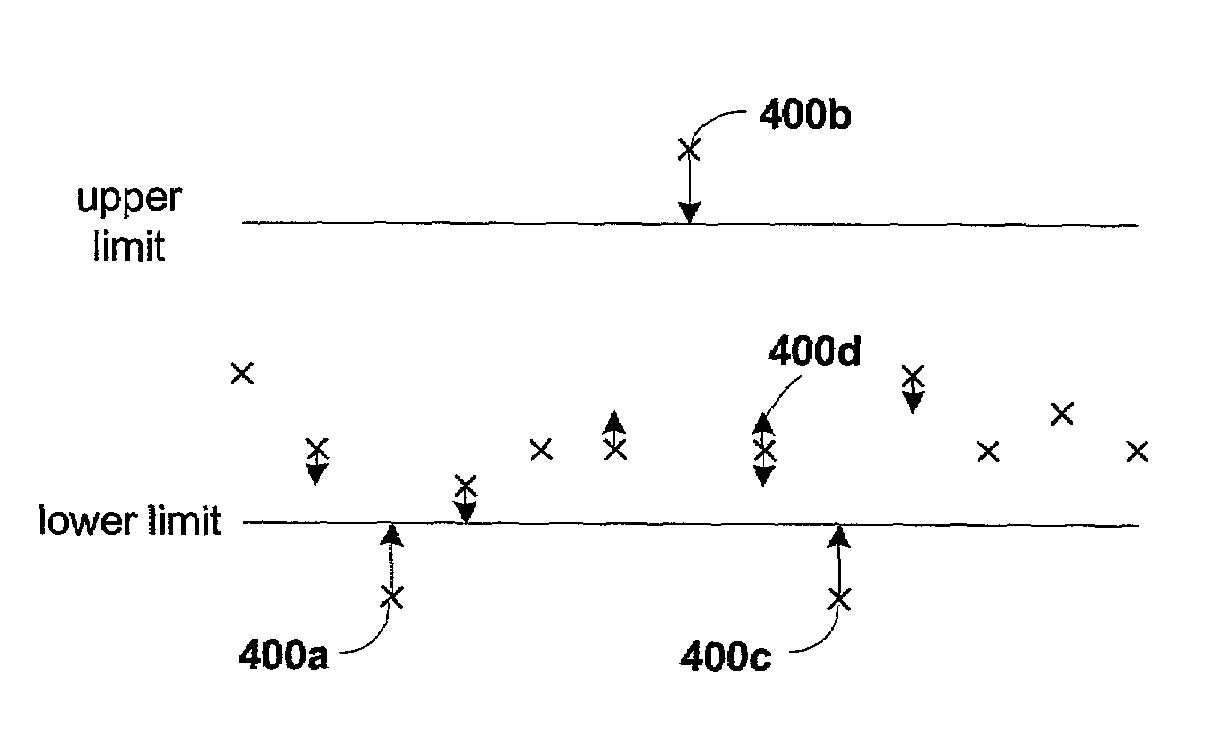

Method and apparatus for multiplexed fabry-perot spectroscopy

ActiveUS20150253189A1Minimizing effectImprovement in spectral resolutionRadiation pyrometryInterferometric spectrometryPhysicsFabry–Pérot interferometer

A method of optical spectroscopy and a device for use in optical spectroscopy. The device includes a substrate, and a plurality of etalon cavities affixed to or coupled to the substrate. A signal is received from a Fabry-Perot interferometer. The signal is sampled using the device according to a generalized Nyquist-Shannon sampling criterion. The signal is sampled using the device according to a phase differential criterion for wave number resolution. An input spectrum for the signal is reconstructed based on the signal sampled according to the generalized Nyquist-Shannon sampling criterion and the signal sampled according to the phase differential criterion for wave number resolution.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Systems and method for optical scatter imaging of latent image plates

InactiveUS20090244636A1Minimize distortionMinimizing effectImage enhancementImage analysisLatent imageData acquisition

Computer-implemented systems and methods for processing image data of a process-free plate are provided according to the present disclosure. The systems and methods may, generally, include a data acquisition step / means for receiving image data using one or more channels of a imaging system, each channel functioning to image the same target region of a process-free plate using a different wavelength of light, and a data processing step / means for filtering the image data using at least one of: (i) self-filtering, (ii) Fourier shrinkage and (iii) Wavelet shrinkage. When the image data is received using a plurality of channels, the received image data may advantageously be combined so as to optimize contrast-to-noise performance. The disclosed systems and methods may advantageously perform the operations of image de-noising, contrast enhancement, and thresholding, and may further involve compensation techniques, e.g., for minimizing distortion and blurring effects.

Owner:X RITE INC

Multiple electrode lead and a system for deep electrical neurostimulation including such a lead

InactiveUS20110264166A1Minimizing effectMinimizing riskHead electrodesNanomedicineElectrical conductorEngineering

A lead for deep electrical neurostimulation, the lead comprising:a rod of biocompatible material; anda blade, also of biocompatible material, secured to one end of said rod and in alignment therewith;in which said blade presents two main faces and a plurality of electrodes disposed on at least one of said two main faces in a two-dimensional configuration, said electrodes being connected to conductor elements disposed inside or on a surface of said rod.A deep electrical neurostimulation system comprising: an electrical pulse generator for deep electrical neurostimulation; and at least one lead of the above-described type, having its electrodes electrically connected to said electrical pulse generator.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Systems and methods for diffusing clipping error

InactiveUS7233963B2Spreading localized errorMinimizing effectDigital computer detailsTelevision systemsData miningData set

Systems and methods are provided for diffusing clipping error in a computing system. When a data set contains values which are to be restricted to a range, and the data set includes one or more values which are beyond the range, the invention provides methodology that is an improvement over clipping extraneous values to the range or squeezing the values to the range. Advantageously, systems and methods are provided for distributing or diffusing error to neighboring samples of the data set, thereby spreading localized error, and minimizing the effects associated with remapping the data set to the restrictive range.

Owner:MICROSOFT TECH LICENSING LLC

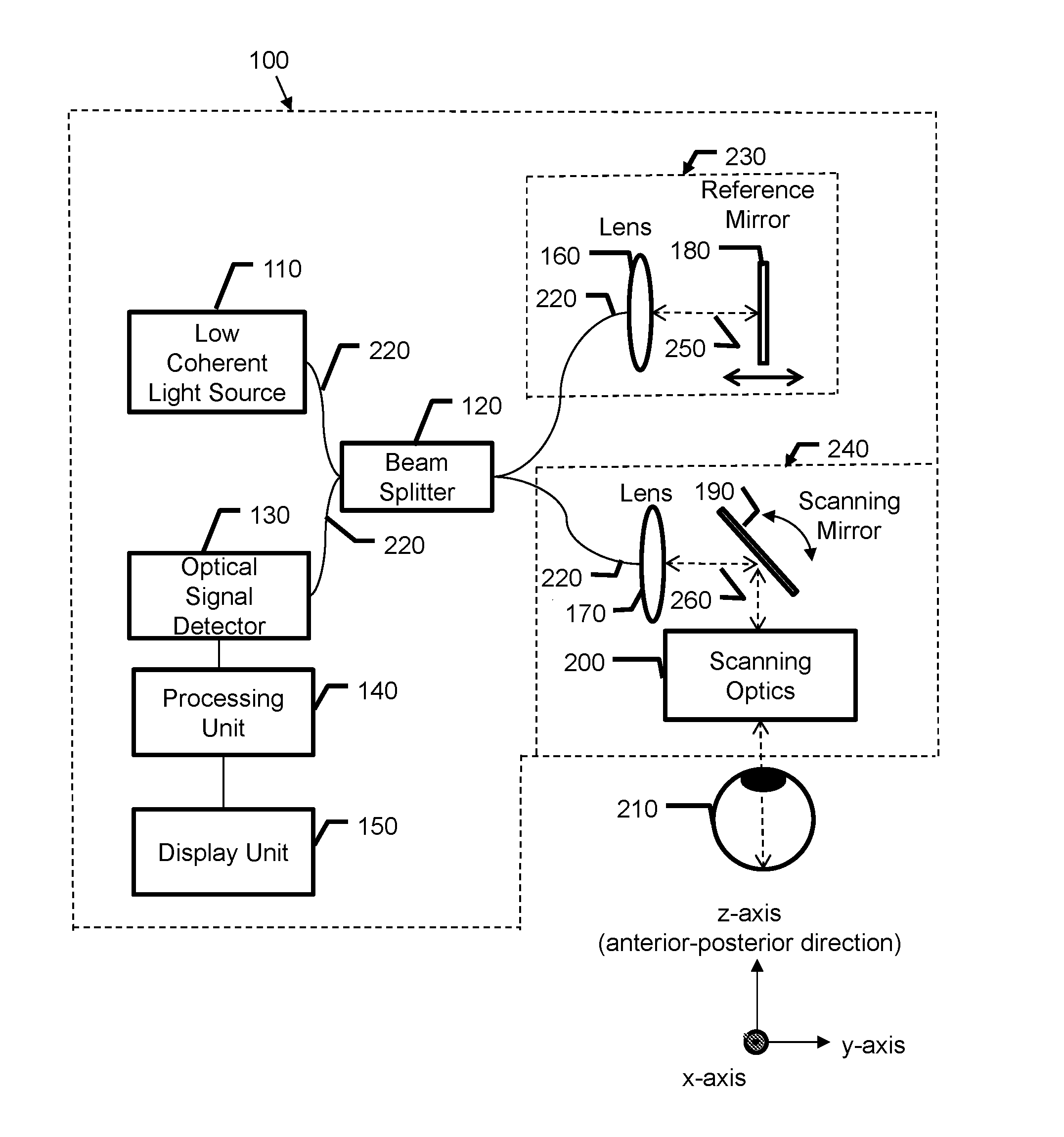

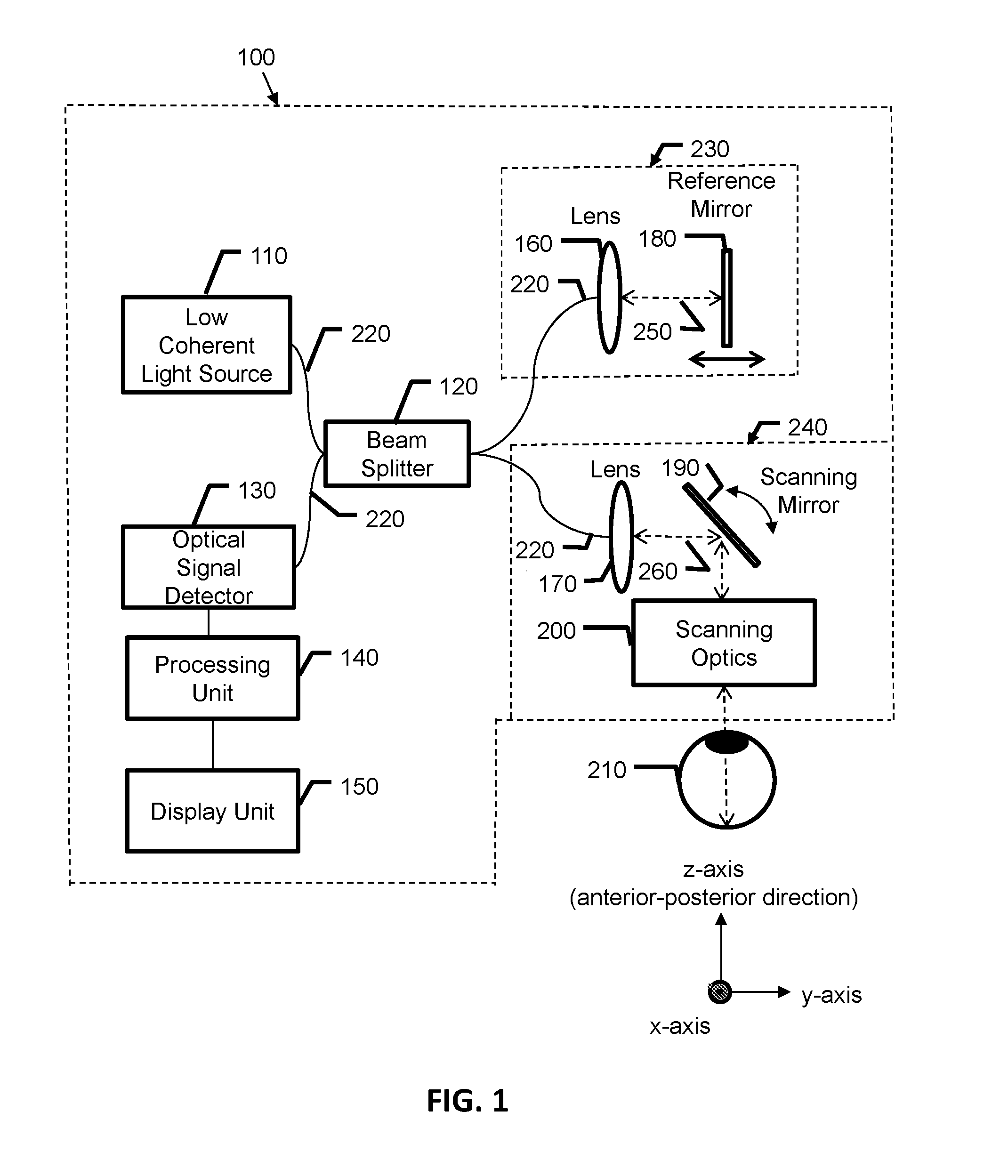

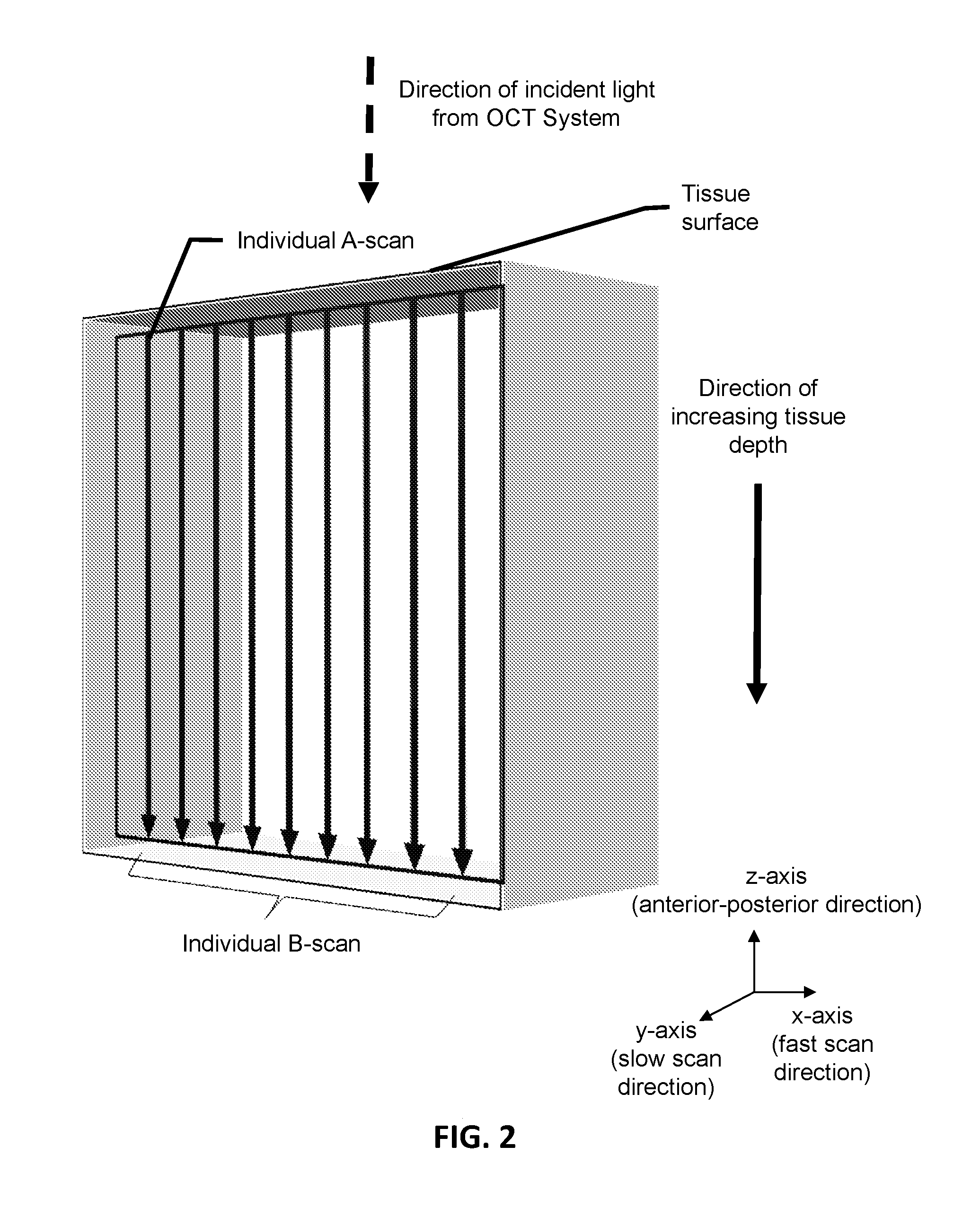

Extended duration optical coherence tomography (OCT) system

InactiveUS20160331227A1Minimizing effectProvide stabilityOthalmoscopesOct angiographyLarge field of view

This disclosure relates to the field of Optical Coherence Tomography (OCT). This disclosure particularly relates to methods and systems for providing larger field of view OCT images. This disclosure also particularly relates to methods and systems for OCT angiography. These systems may allow OCT scanning for an extended duration and generation of large field OCT images suitable for the OCT angiography.

Owner:UNIV OF SOUTHERN CALIFORNIA

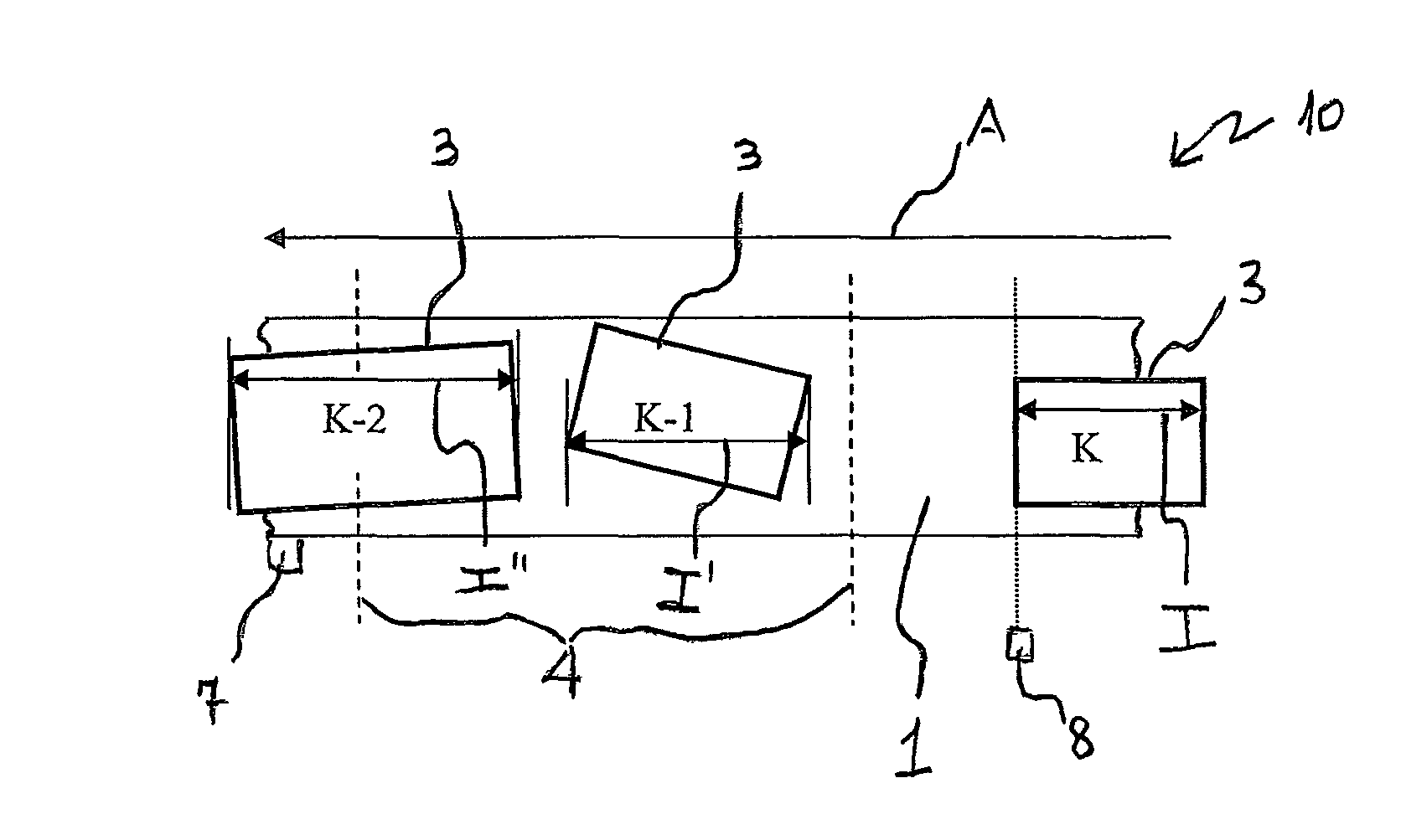

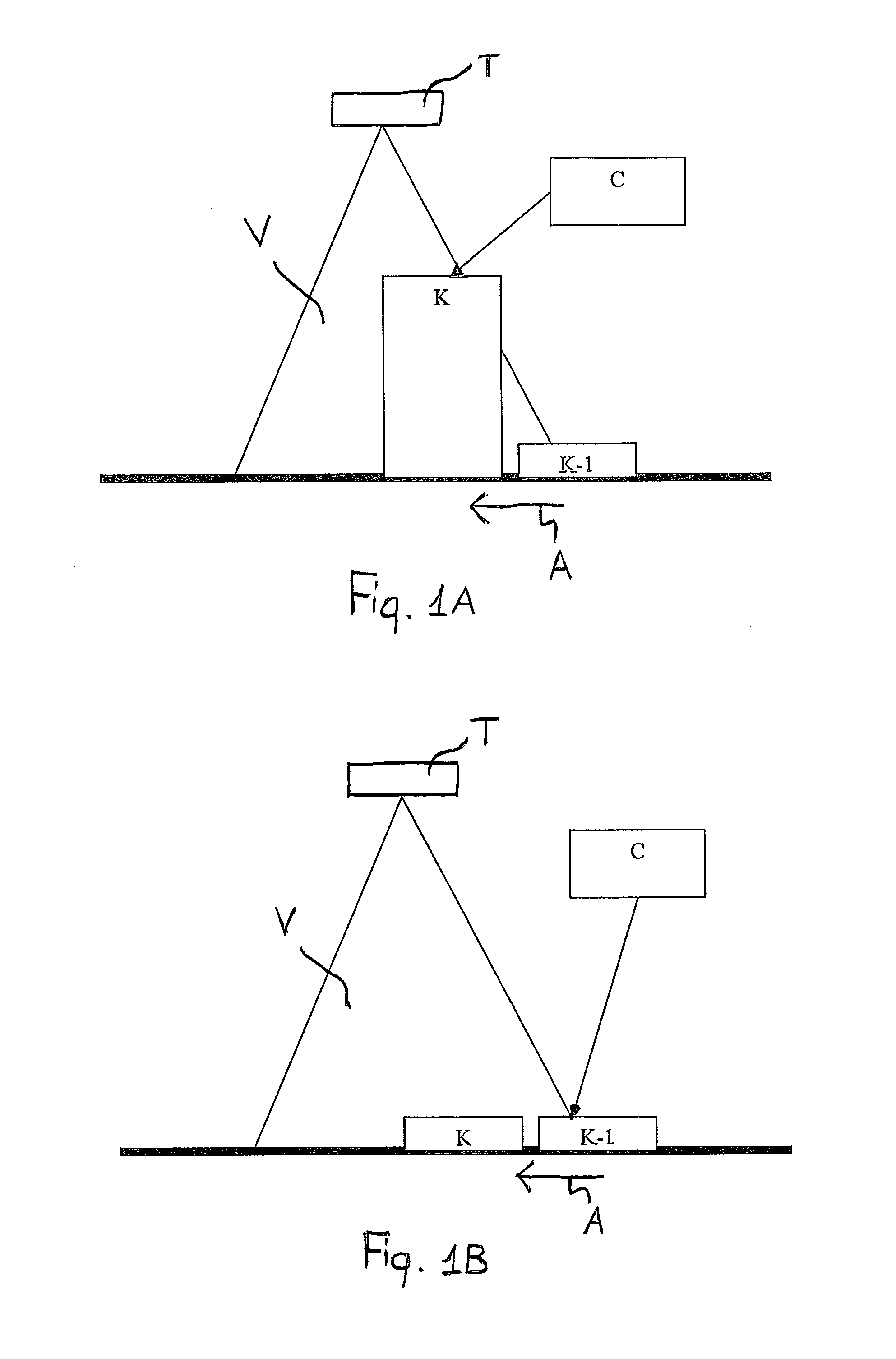

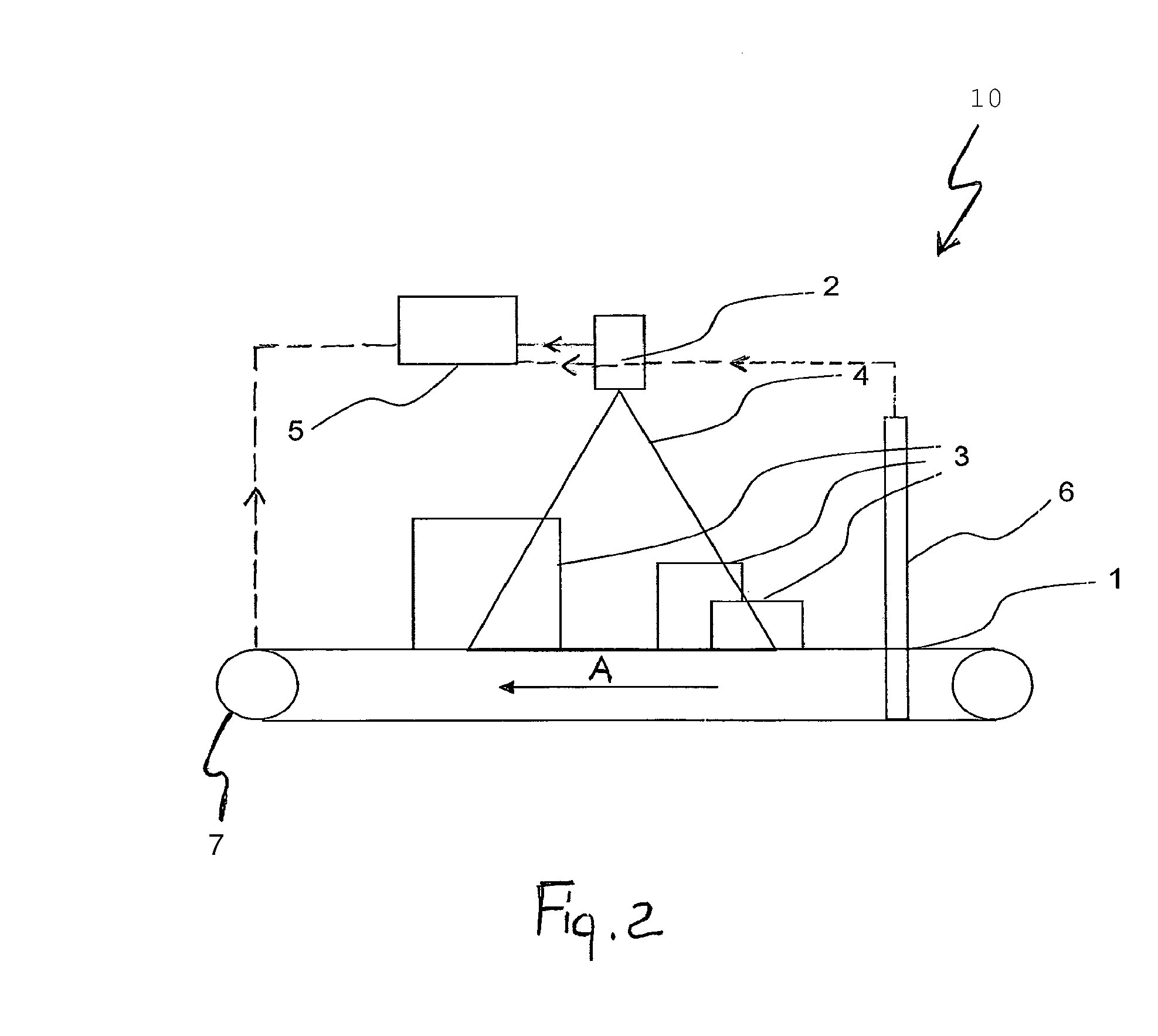

Method for the optical identification of objects in motion

ActiveUS9349047B2Reducing possibility of errorMinimizing effectCharacter and pattern recognitionSensing by electromagnetic radiationStationary Reference FrameComputer graphics (images)

The method includes the steps of acquiring, by at least one camera having a predetermined magnification ratio, at least one image containing at least one coded information and at least one object and properly associating the coded information with the at least one object on the basis of the position of the coded information and of the at least one object along an advancing direction with respect to a fixed reference system. The above-mentioned position of the coded information is determined starting from the position of the coded information within the image acquired by the camera and on the basis of the distance of the coded information from the camera. Such a distance is in turn determined on the basis of the magnification factor of a reference physical dimension detected at a surface of the object or of the coded information.

Owner:DATALOGIC IP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com