Patents

Literature

723results about How to "Improve precision control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow rate control using mass flow rate control device

ActiveUS20100000608A1Minimizing effectImprove accuracyOperating means/releasing devices for valvesTesting/calibration apparatusData conversionProduct gas

It is possible to respecify the product (mass flow controller) corresponding to multiple types of actual process gases and multiple flow rate ranges, even after the mass flow controller has been shipped. With the mass flow rate control device in an initial state, calibration gas characteristic data is derived by measuring actual flow rate versus a flow rate setting signal using a calibration gas, and this calibration gas characteristic data is then saved to control unit. Meanwhile, actual gas characteristic data is derived by measuring actual flow rate versus a flow rate setting signal for each of a plurality of types of actual gas, and this actual gas characteristic data is then saved to a storage medium. Subsequently, prior to operating the mass flow rate control device, the actual gas characteristic data for an actual process gas is read from the storage medium via a computer, and the calibration gas characteristic data that was saved to the control unit is read out. The calibration gas characteristic data is then converted to controlled flow rate correction data based on the actual gas characteristic data, and the controlled flow rate correction data is saved to the control unit. Actual gas flow rate is corrected based on this controlled flow rate correction data.

Owner:HITACHI METALS LTD

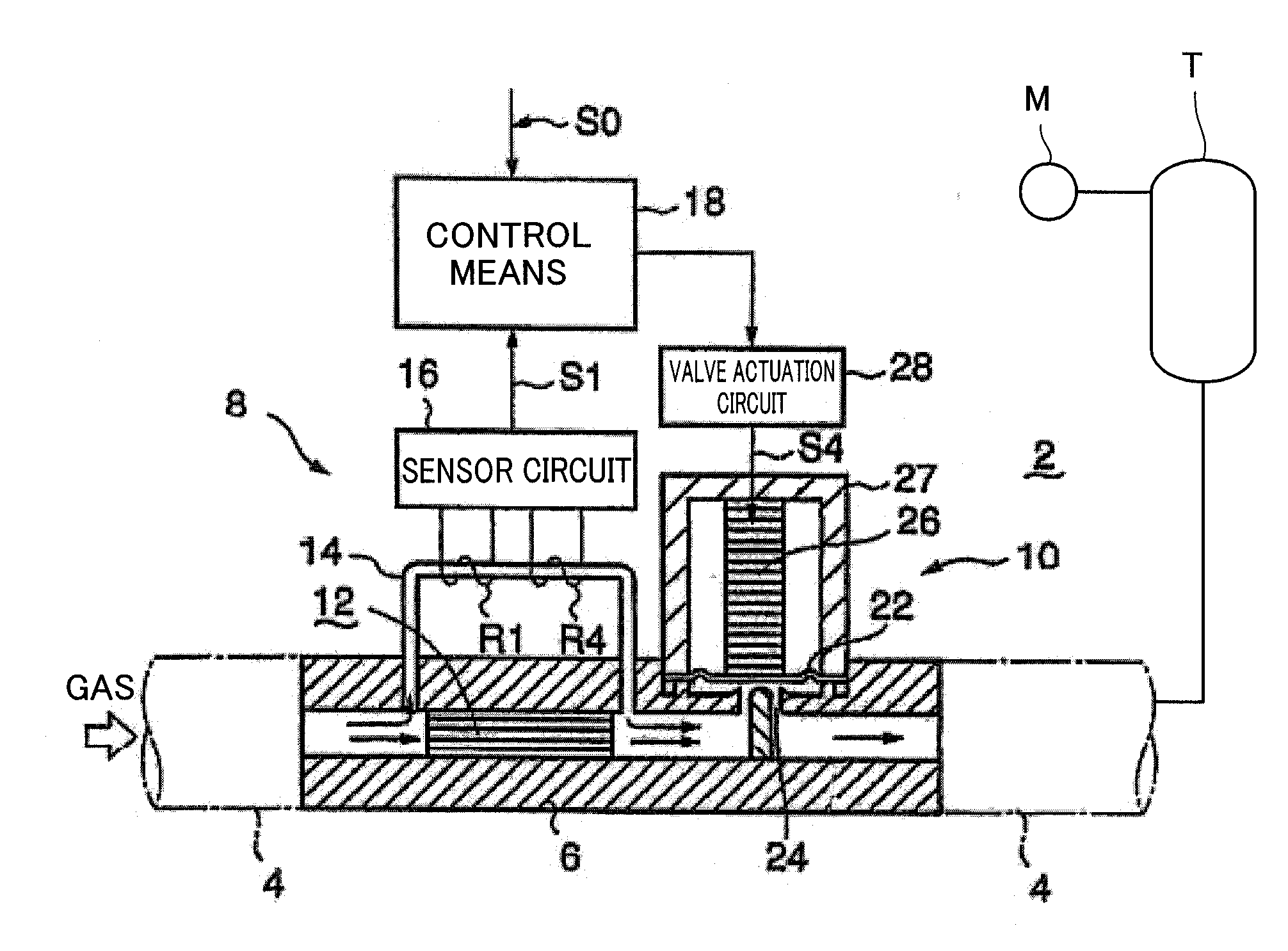

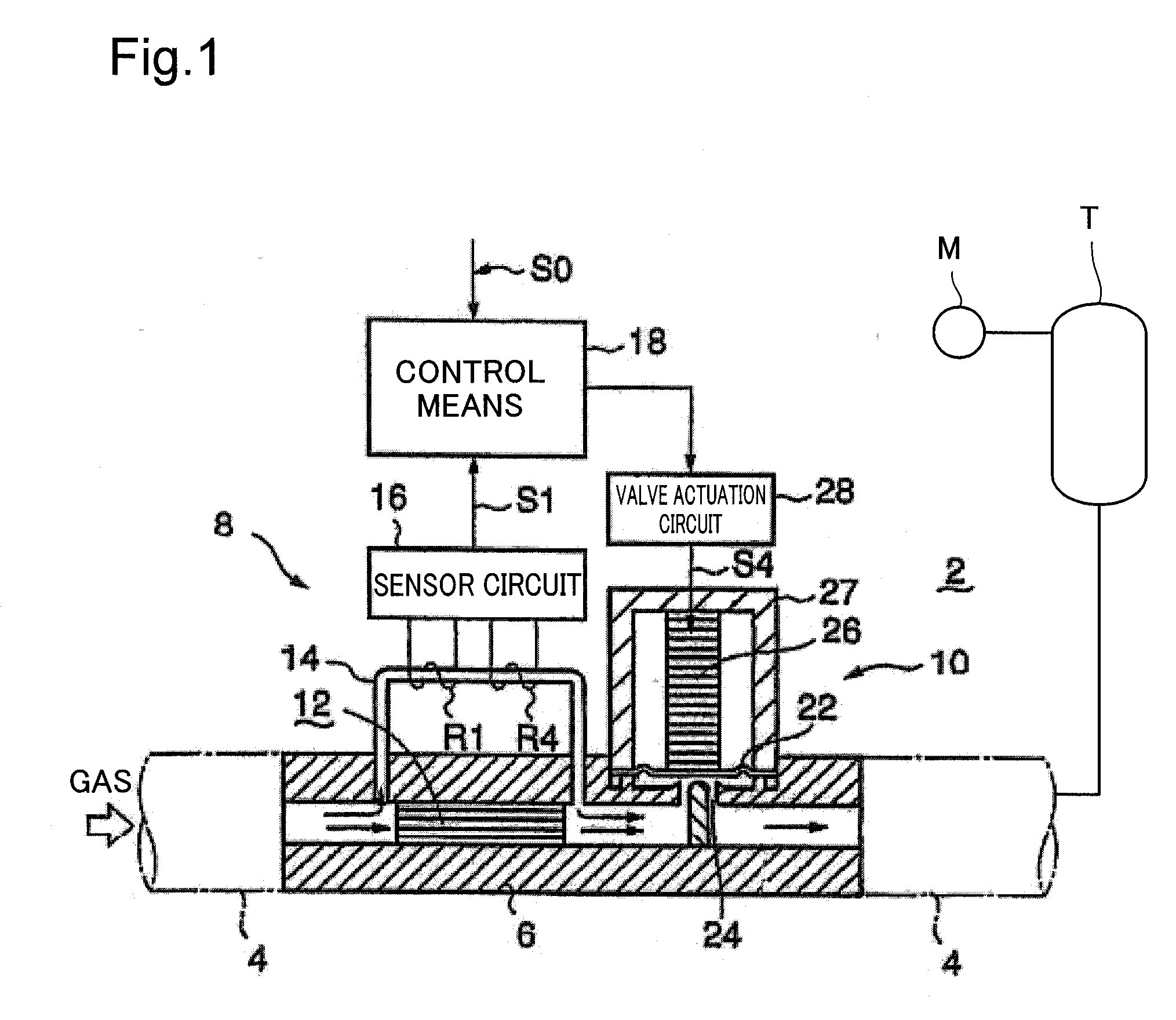

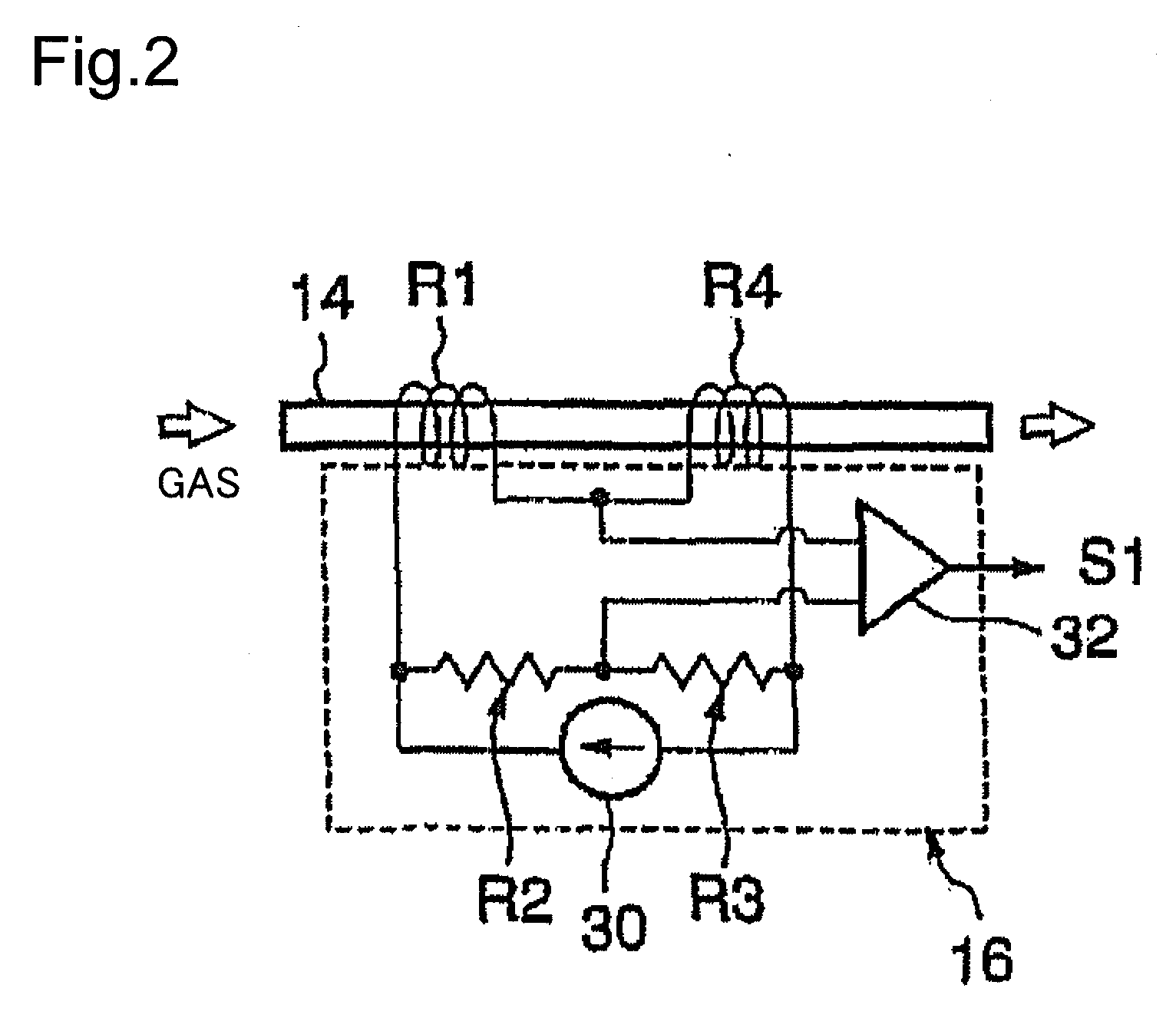

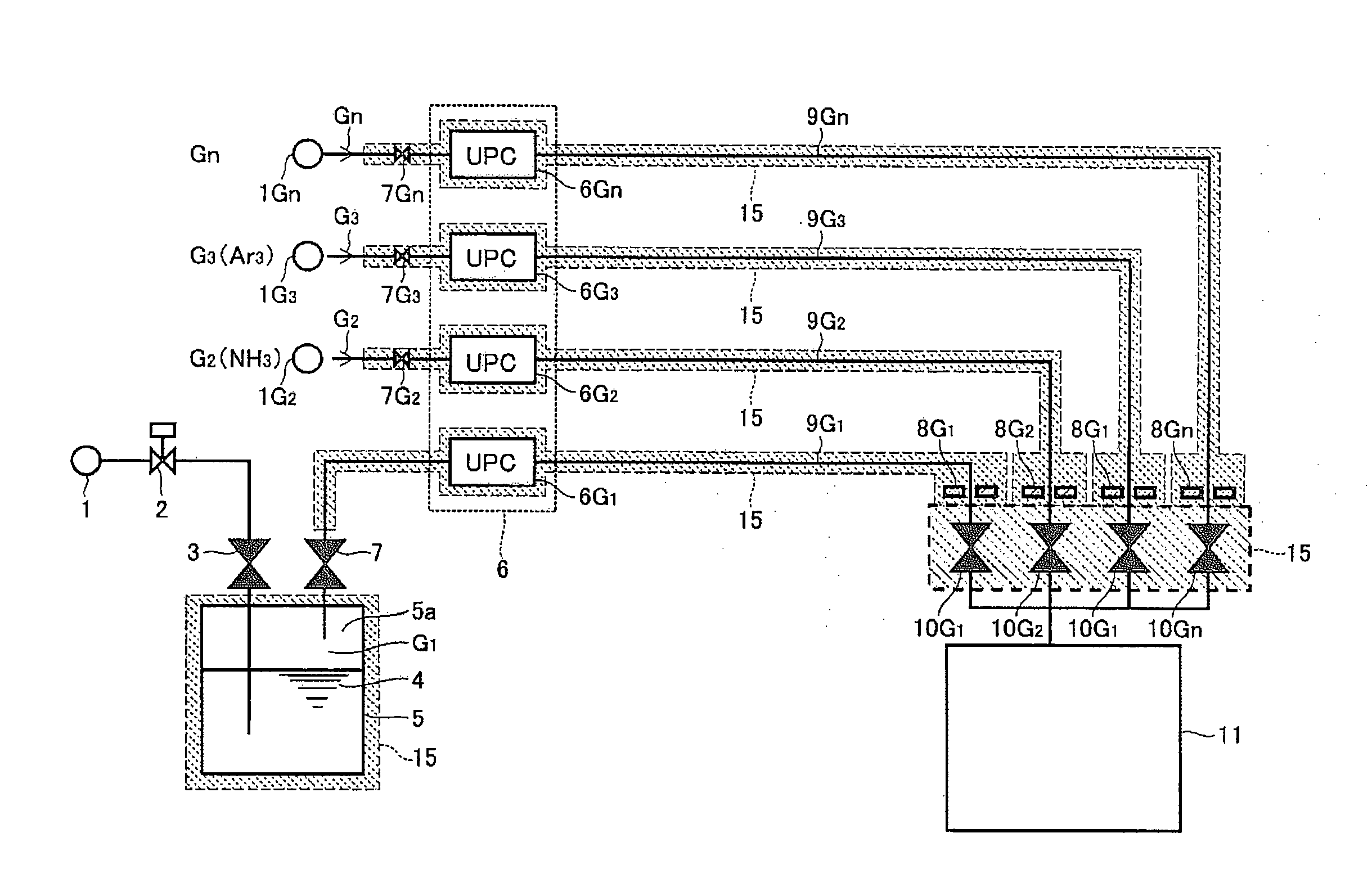

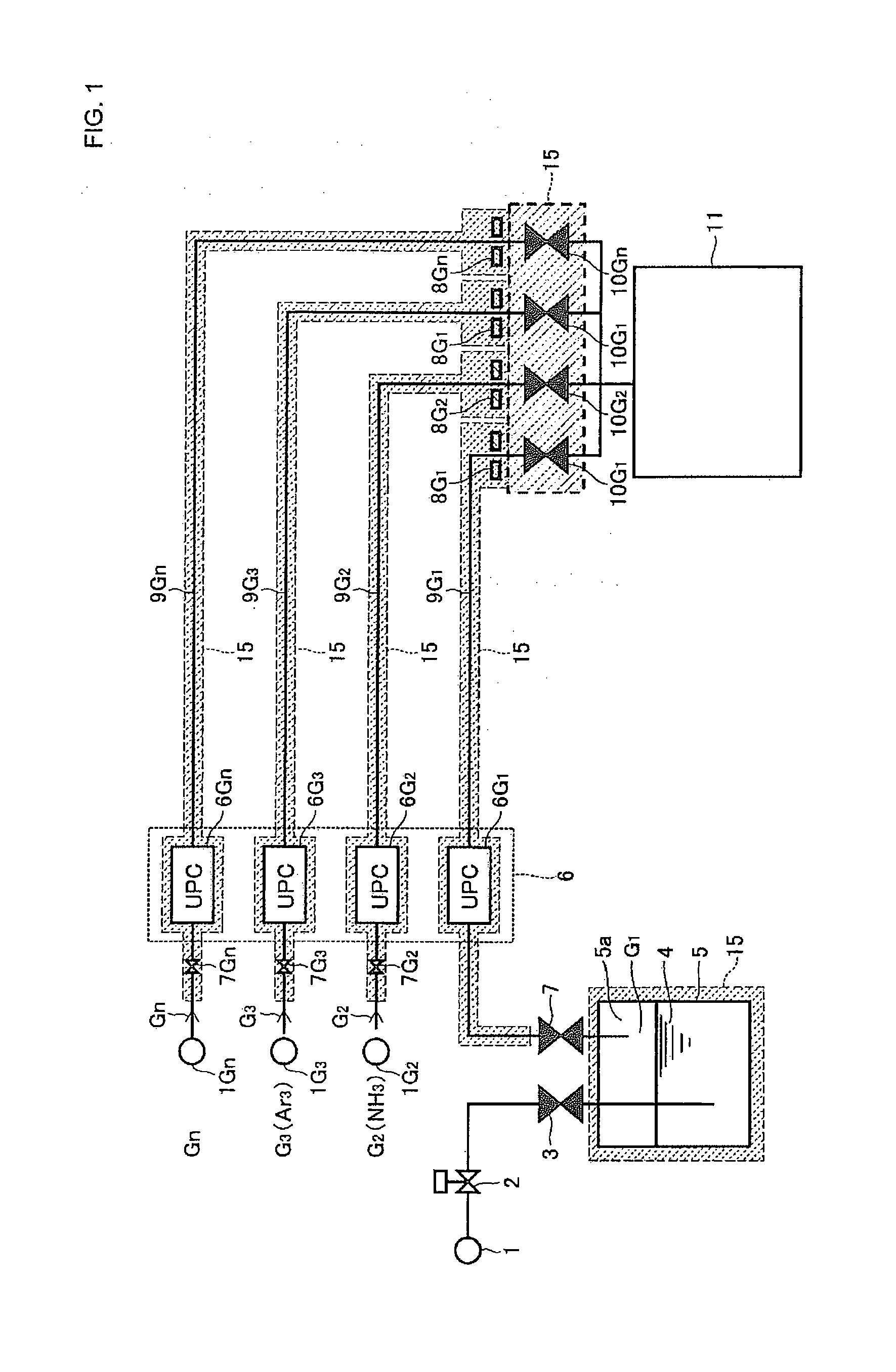

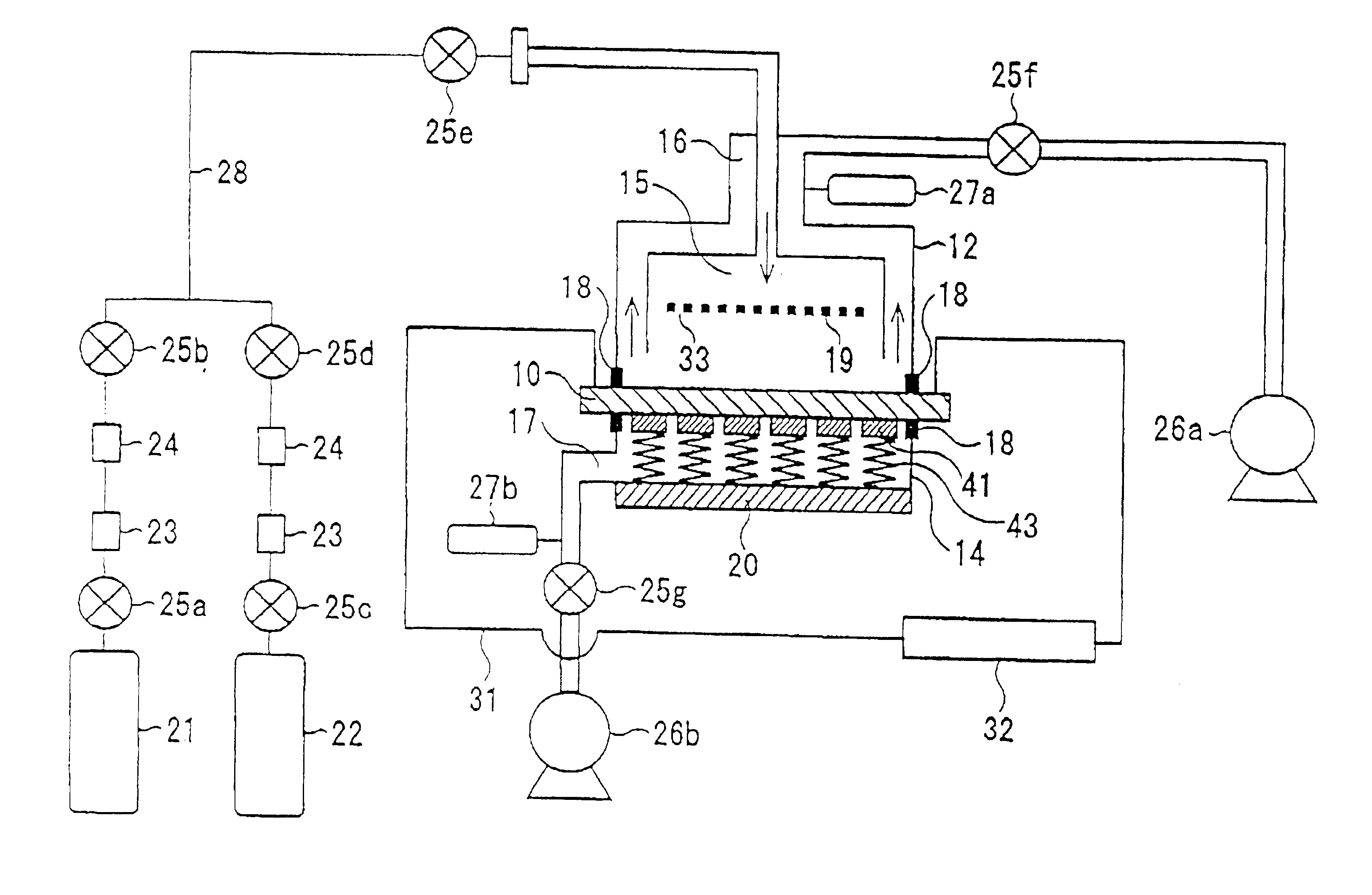

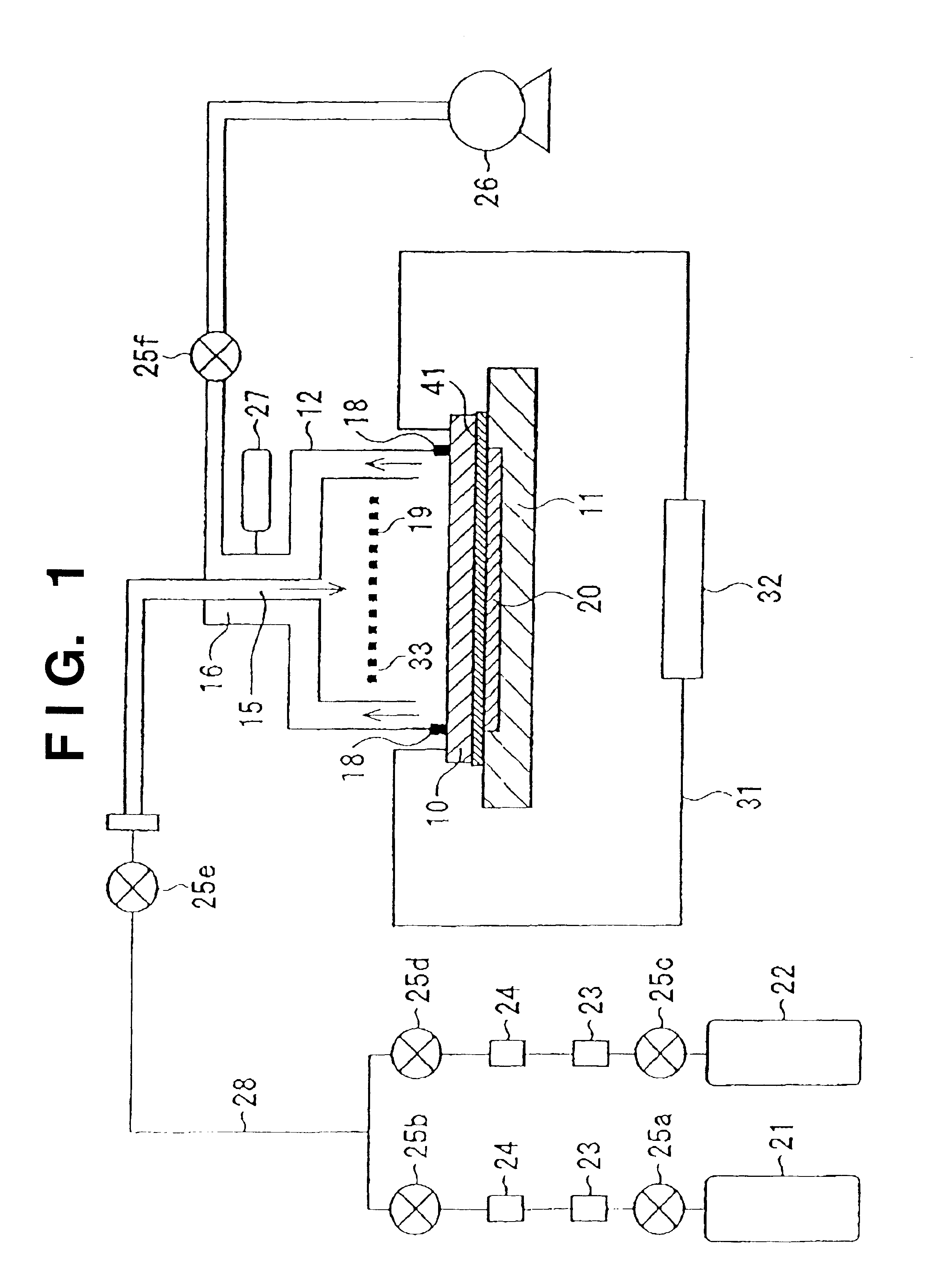

Raw material gas supply apparatus for semiconductor manufacturing equipment

ActiveUS20140190581A1Improve precision controlStable supplyOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingProduct gasProcess engineering

A raw material gas supply apparatus includes a liquid raw material gas supply source, a source tank storing liquid raw material, a gas distribution passage through which raw material gas comprising steam of the liquid raw material is supplied to a process chamber from the source tank, an automatic pressure regulator installed on an upstream side of the gas passage, wherein the automatic pressure regulator keeps supply pressure of the raw material gas at a set value, a supply gas switching valve installed on a downstream side of the gas passage, wherein this valve opens and closes the gas passage, an orifice provided on at least one of an inlet side or outlet side of the valve, wherein the orifice regulates flow rate of the raw material gas, and a constant temperature heating device heats the source tank, the gas passage, the valve and the orifice to a set temperature.

Owner:FUJIKIN INC

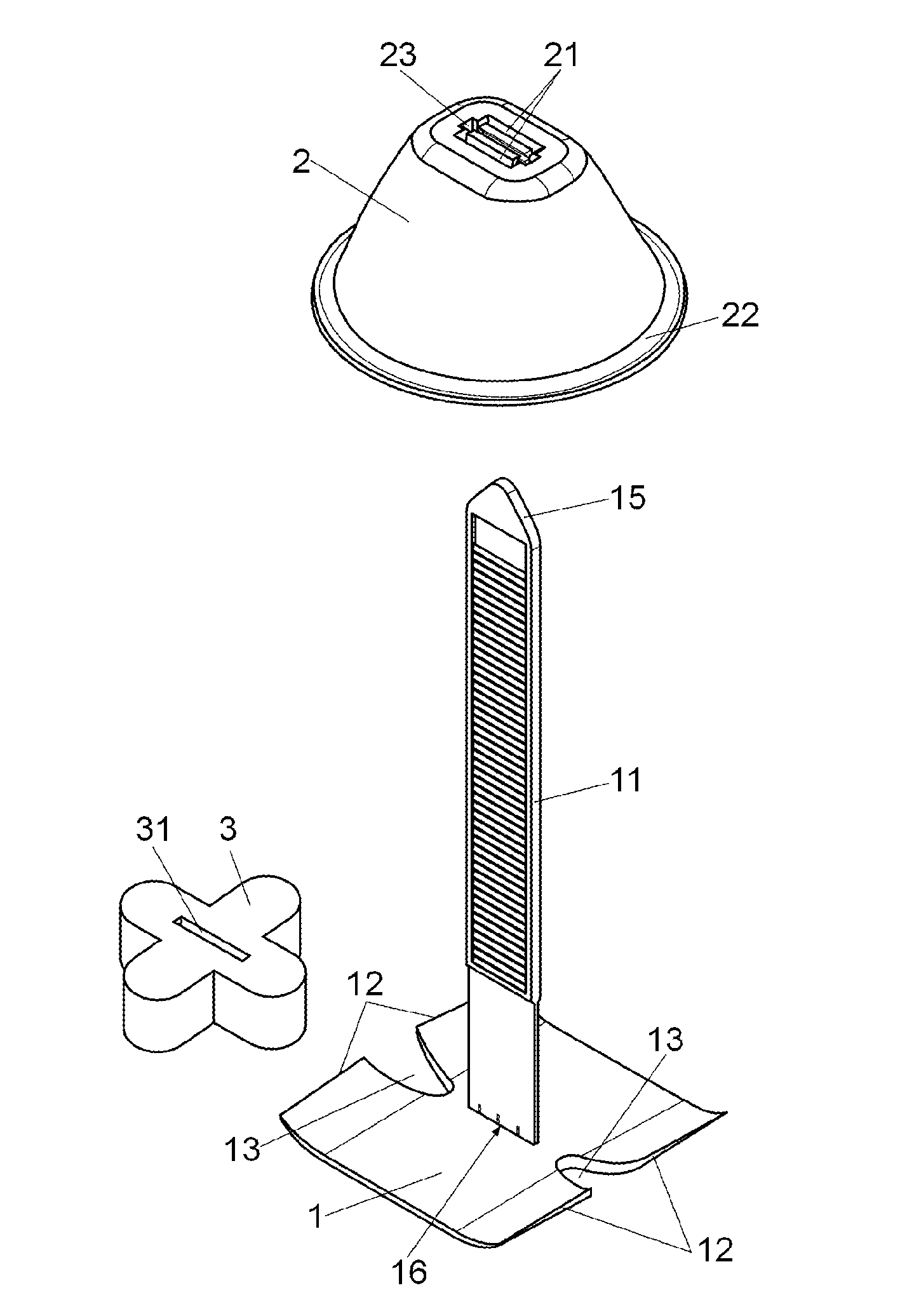

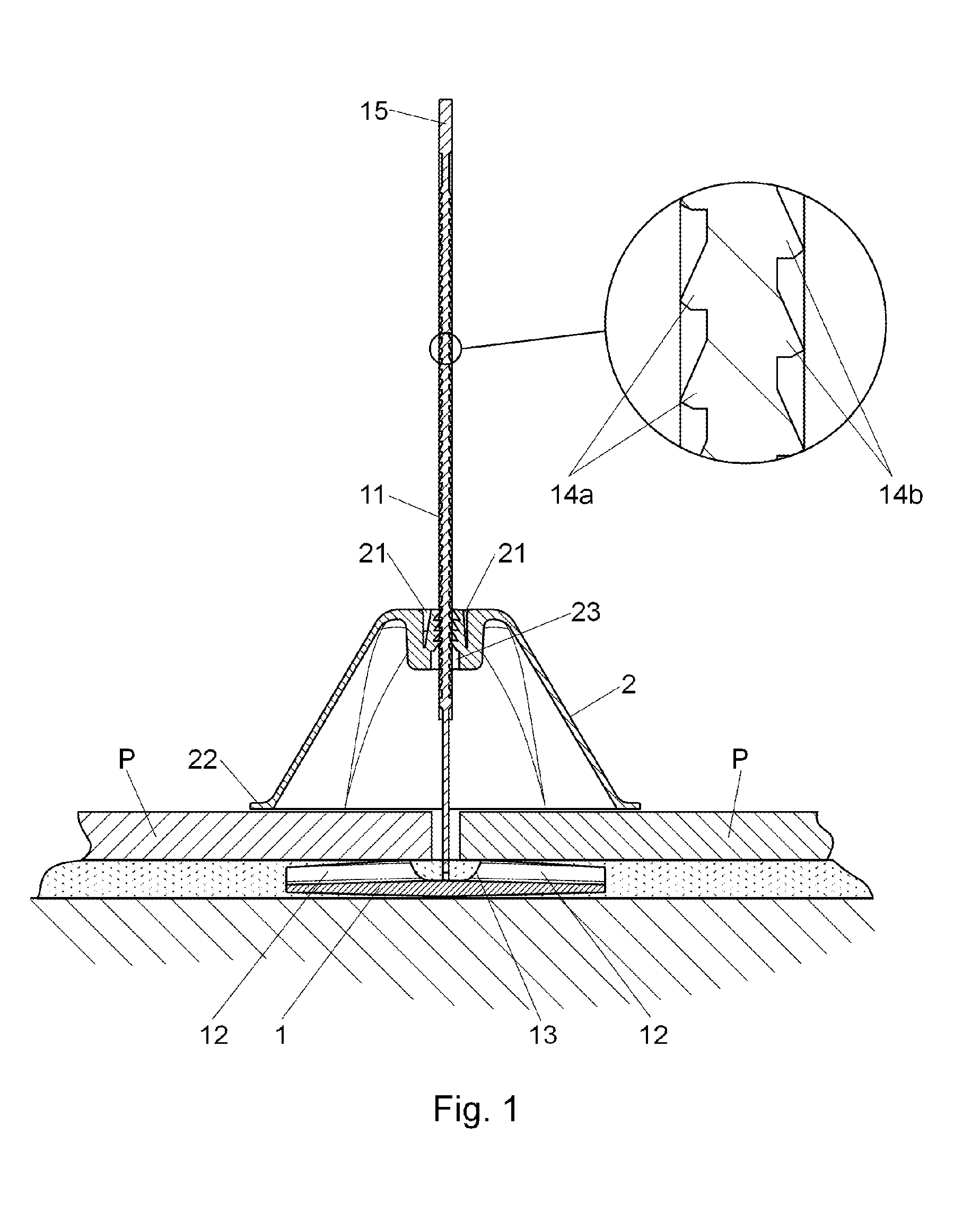

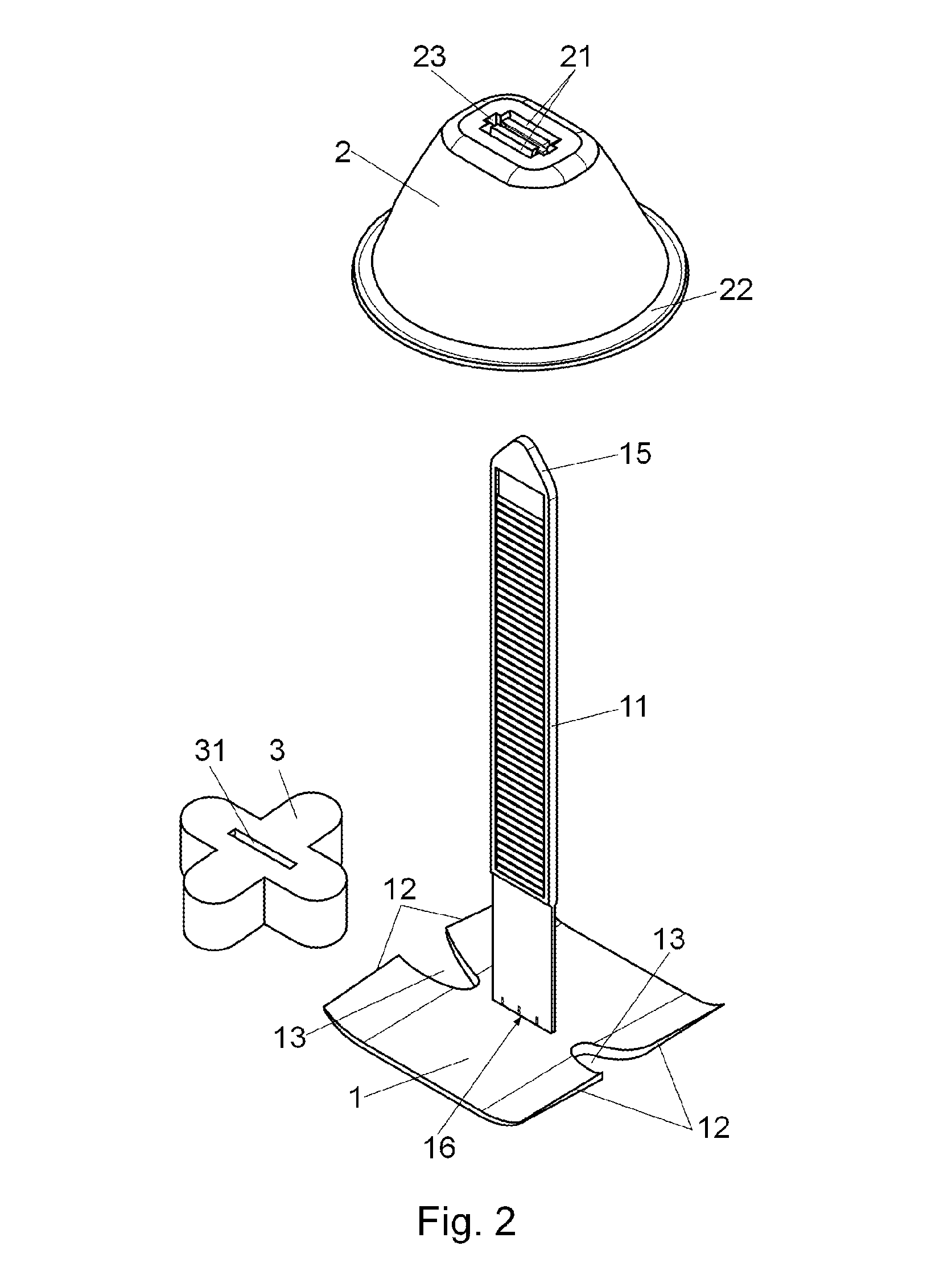

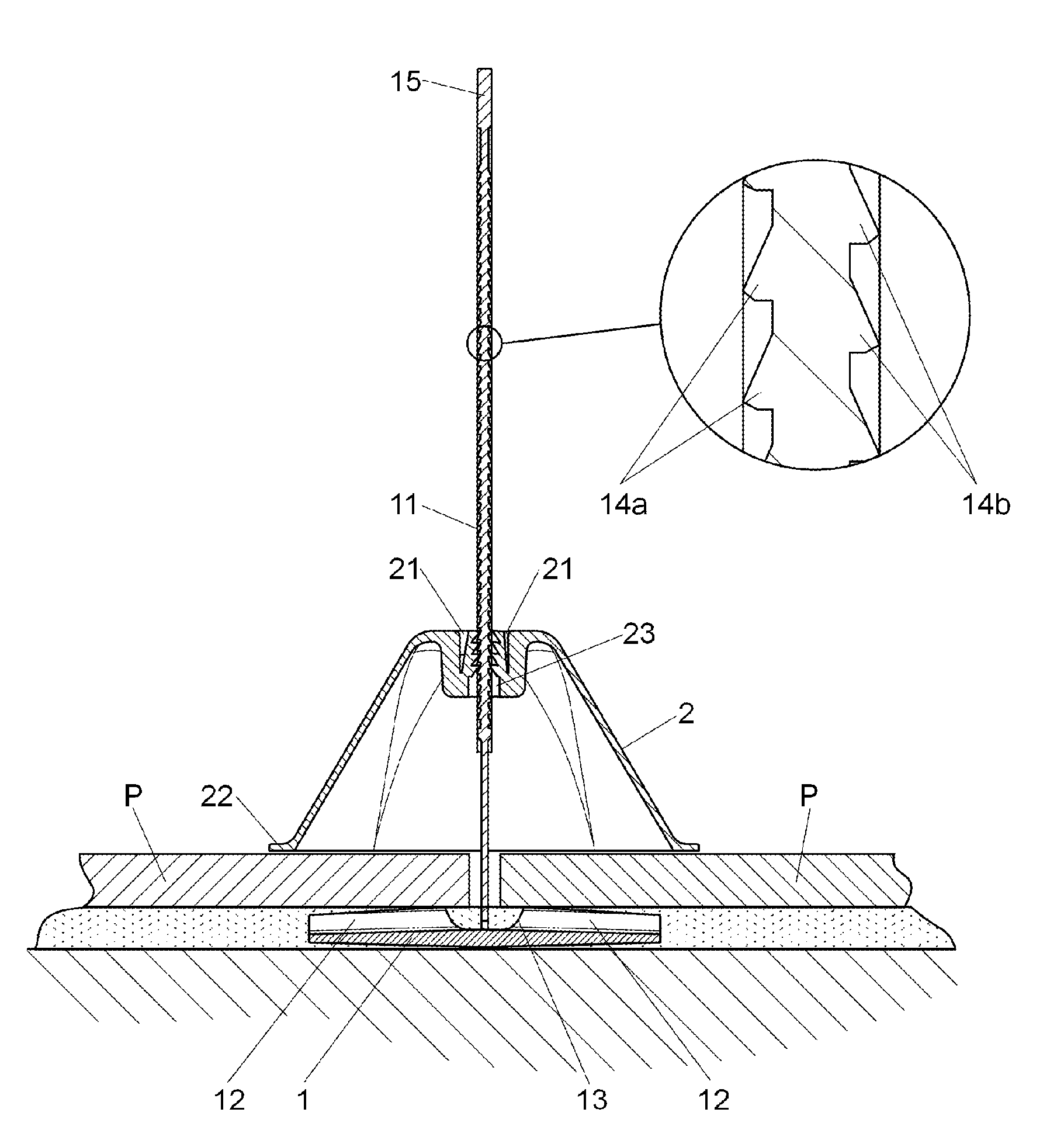

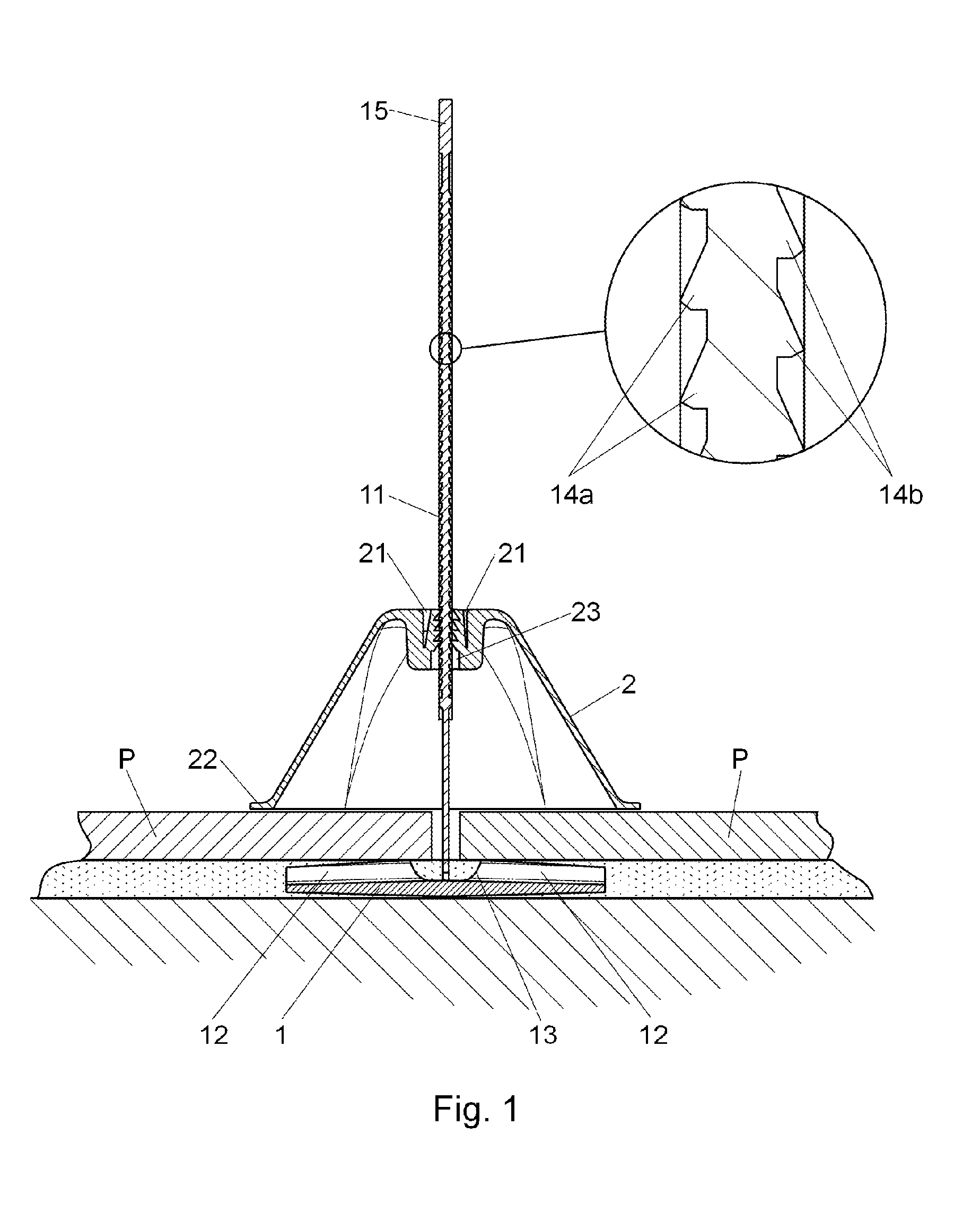

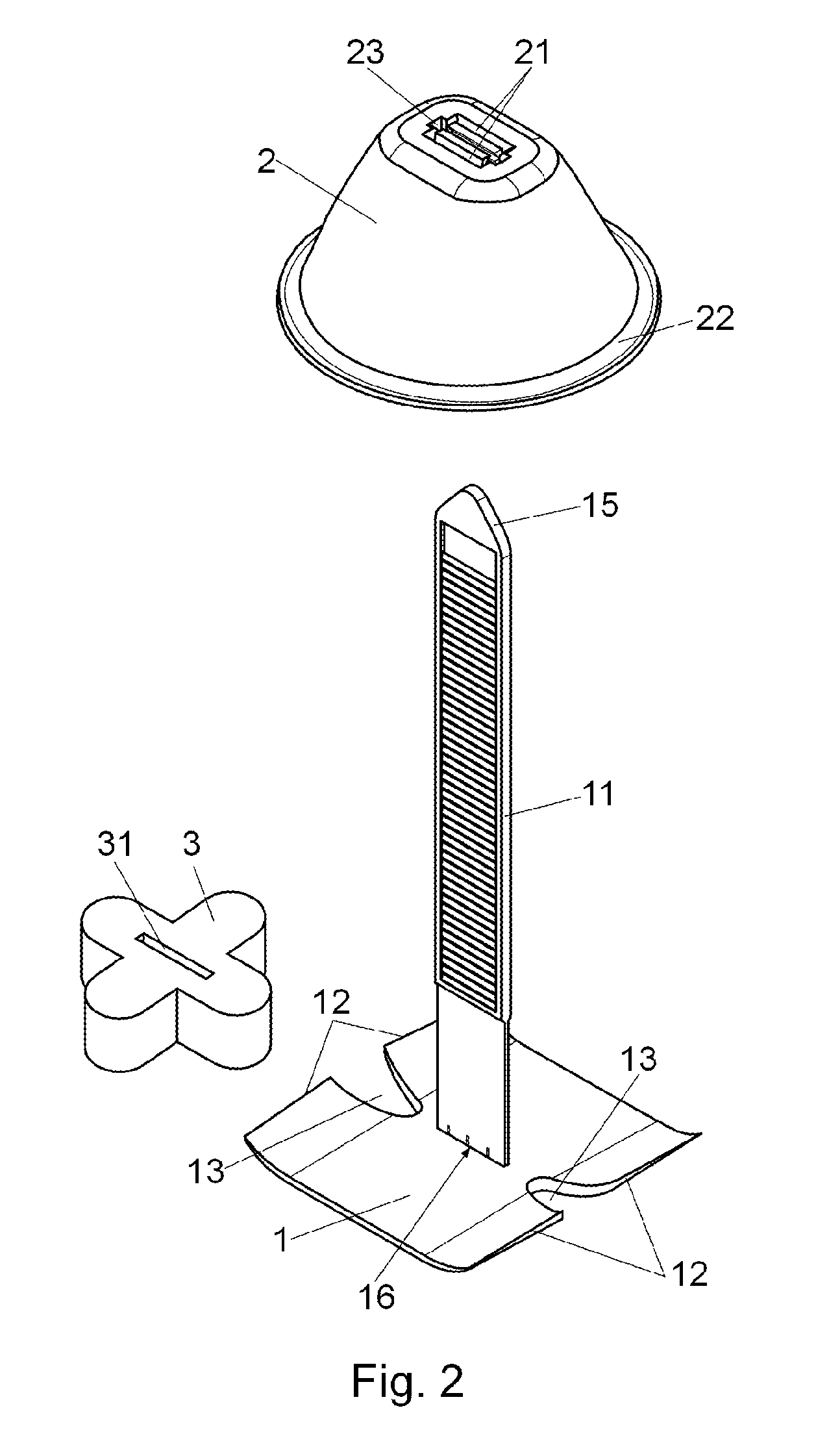

Levelling device for the placing of pieces for covering floors and similar

ActiveUS20100263304A1Shorten the timeImprove working conditionsCeilingsRoof toolsEngineeringHollow form

The device has a first lower substantially flat body, which has in its upper part a flexible post with a narrowed or weakened portion and a second upper body with the passage for receiving and securing said post. The flexible post, which has a rectangular cross section, has in its main surfaces respective mutually opposed toothings, which teeth are offset in the lengthwise direction and the passage of the second body has two latching pawls mutually opposed, so that in the operative position of the devices, the teeth of the flexible post engage in an alternate form with said latching pawls. The second body has a bell like hollow form with a lower widened contact mouth or border.

Owner:GERMANS BOADA SA

Levelling device for the placing of pieces for covering floors and similar

Owner:GERMANS BOADA SA

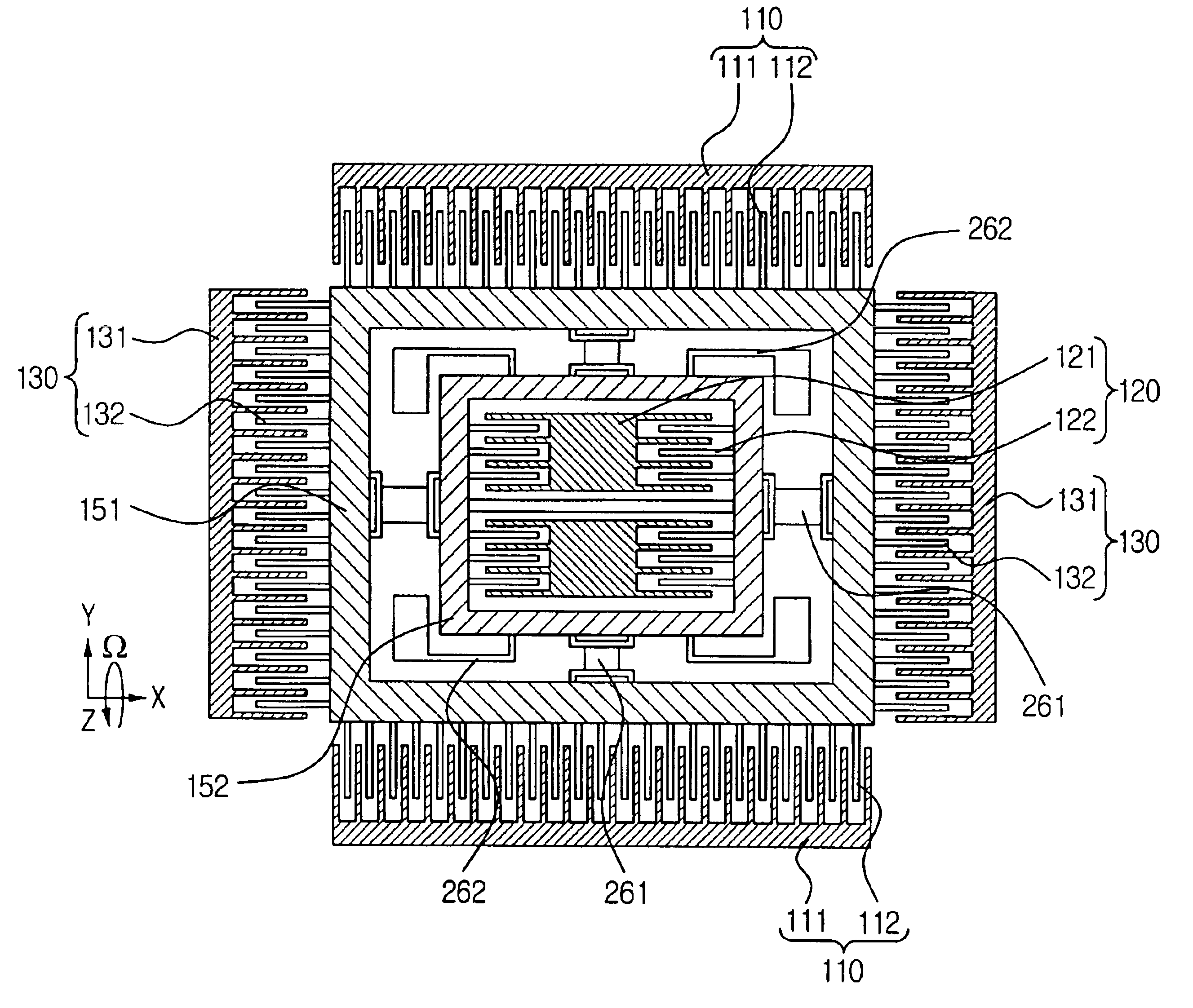

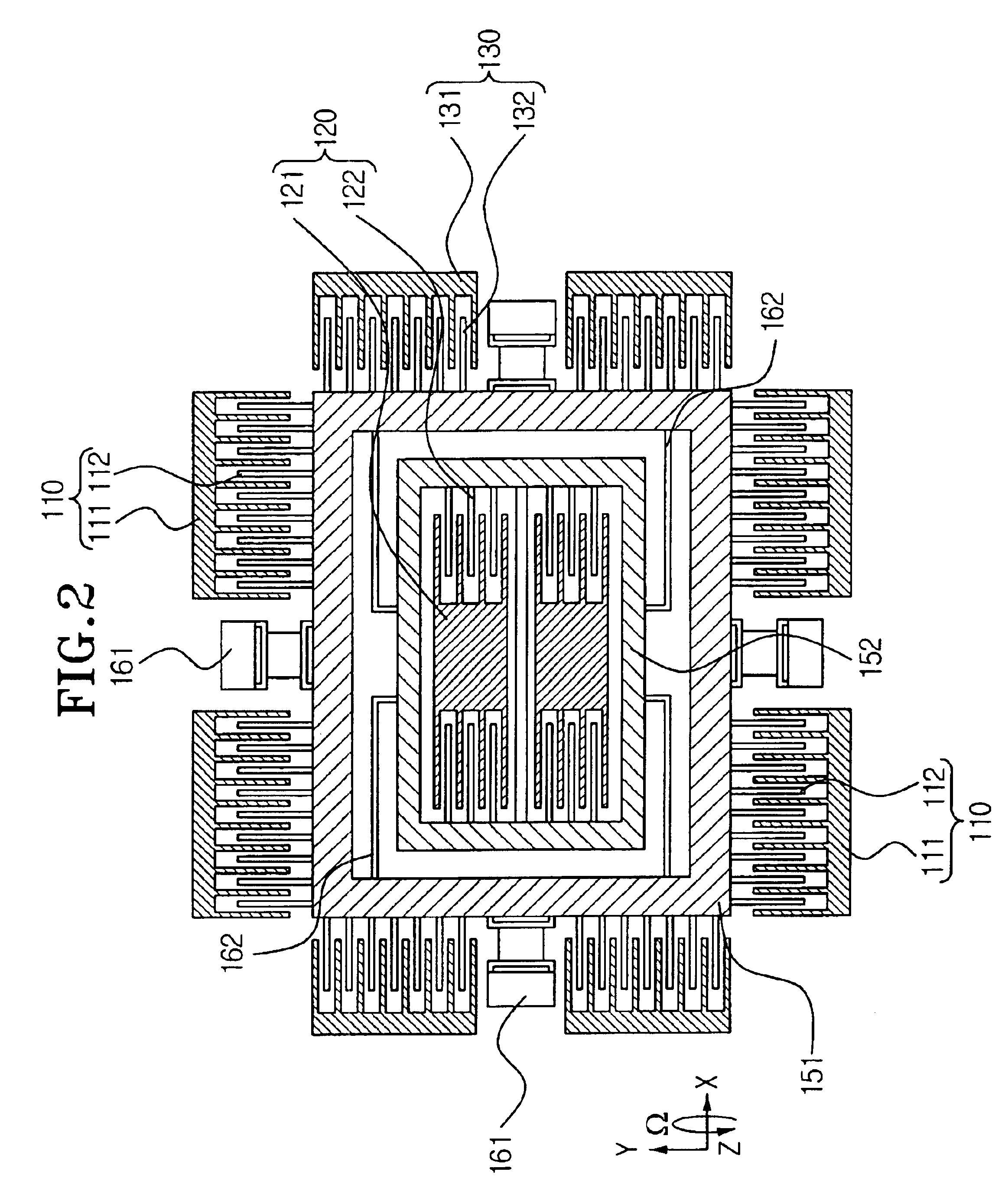

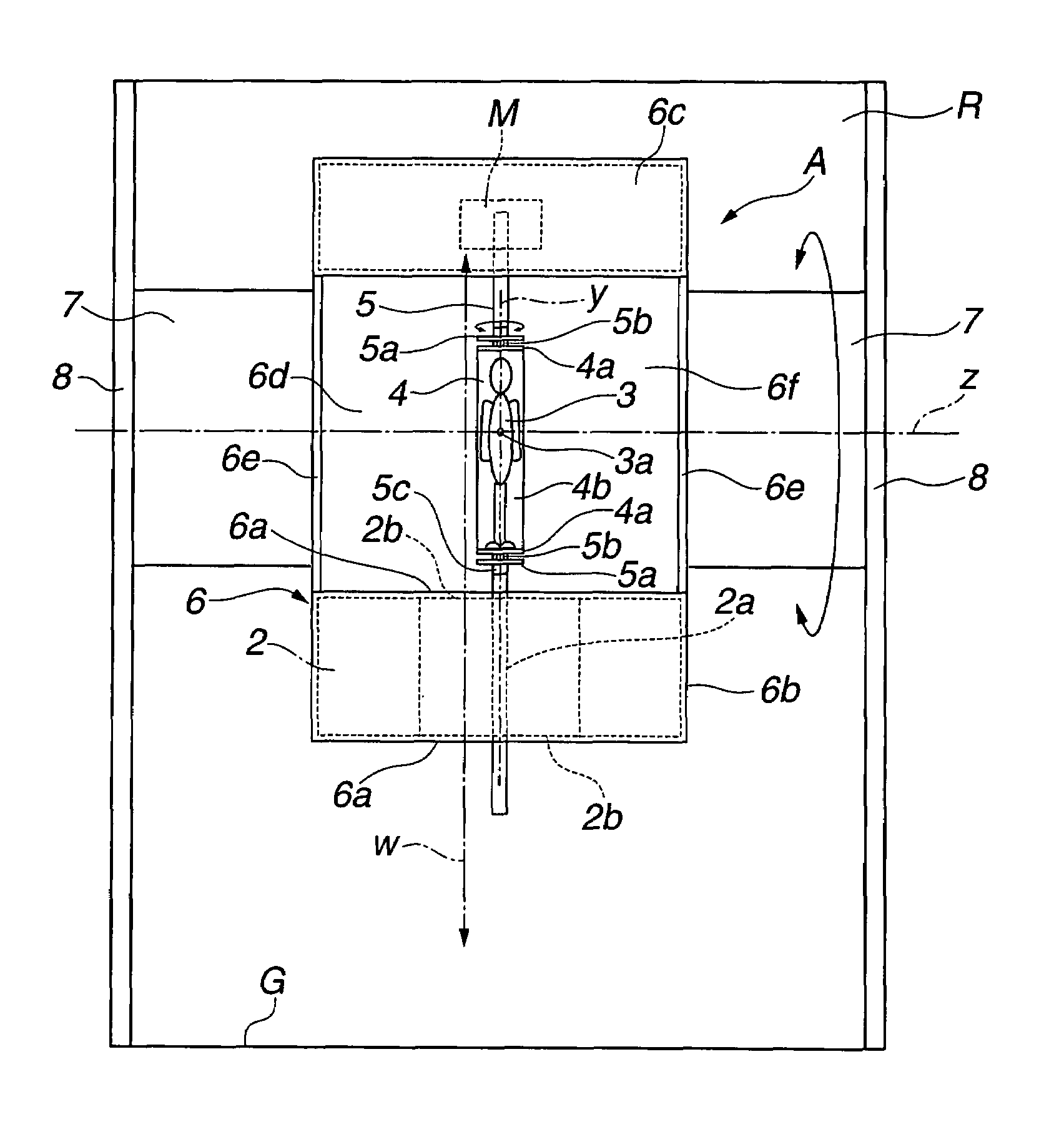

MEMS gyroscope having mass vibrating vertically on substrate

InactiveUS6915693B2Easy to manufactureLess malfunction probabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAngular velocity

X type MEMS gyroscope has a first mass vertically vibrating on a substrate and a second mass horizontally vibrating on the substrate. A driving electrode is disposed on the same surface with the first mass. The first mass can move in relation to the second mass in the vertical direction, and is fixed in relation to the second mass in the horizontal direction. The second mass is operative to be moved in a horizontal direction in relation to the substrate by a Coriolis force, which is generated by an angular velocity applied while the first mass is being vibrated. A sensing electrode measures displacement of the second mass in the horizontal direction. All moving electrodes and stationary electrodes are disposed on the same surface, and all elements are manufactured by using one mask. Therefore, adhesion between the moving and stationary electrodes is prevented and the manufacturing process is simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

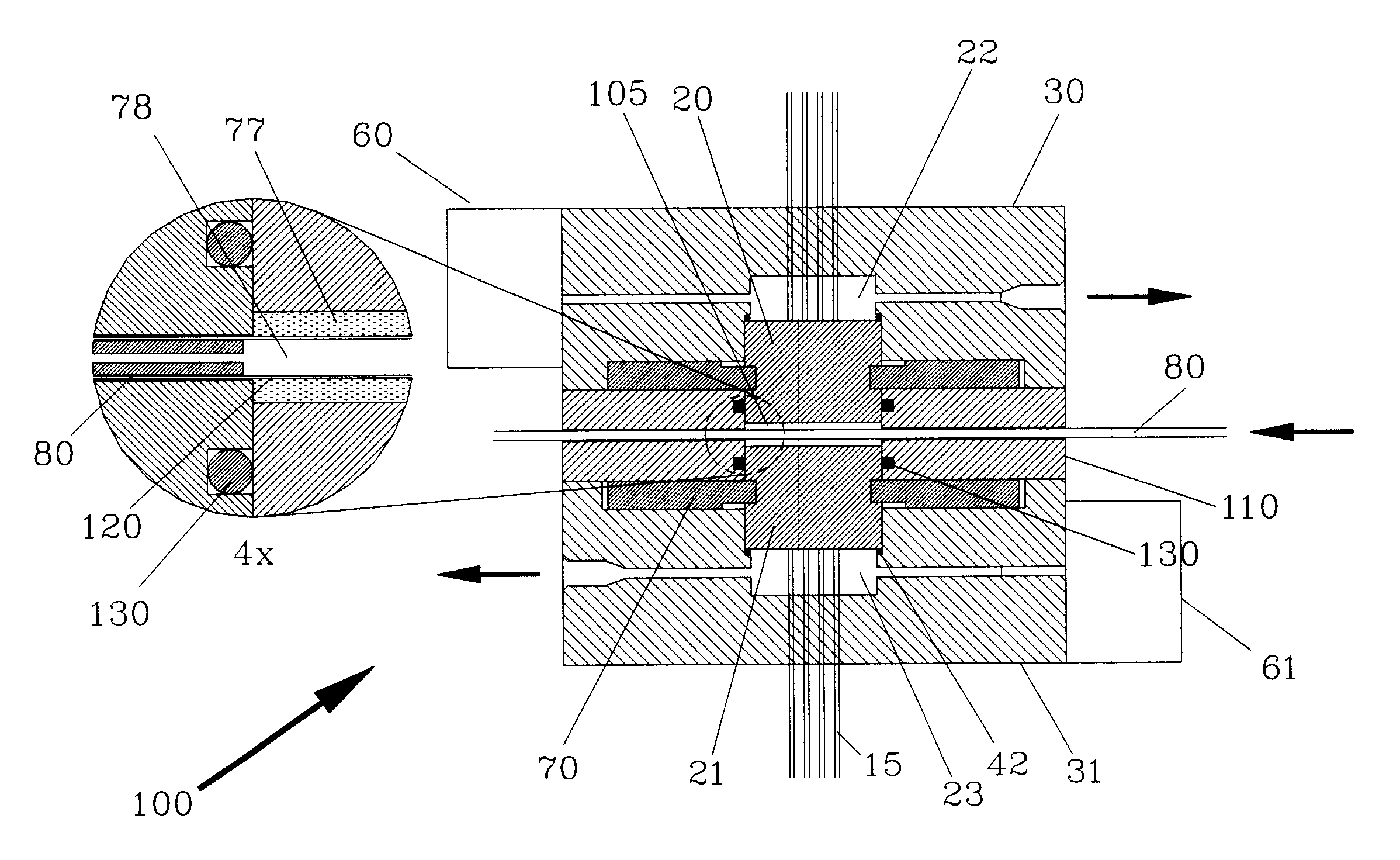

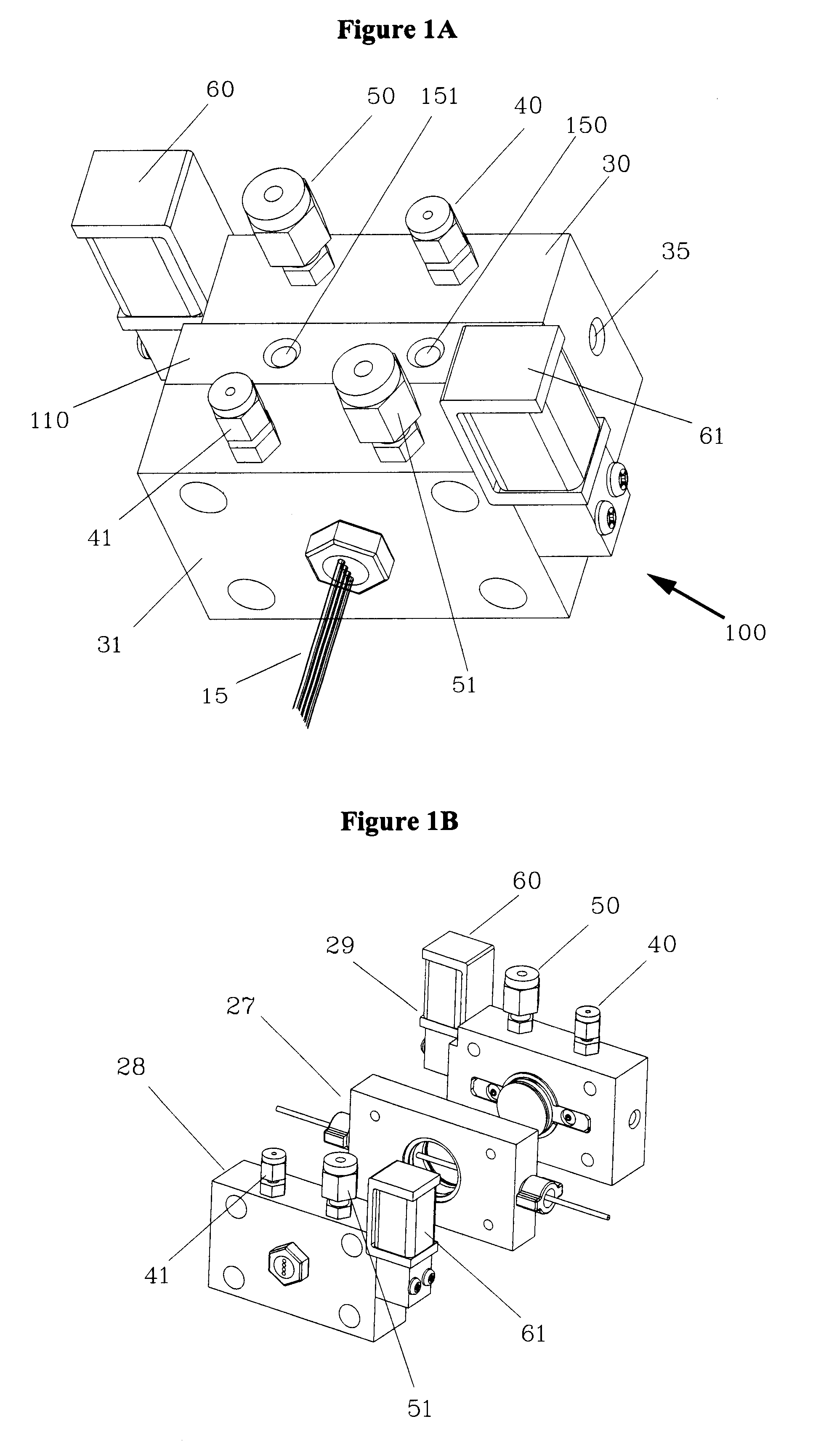

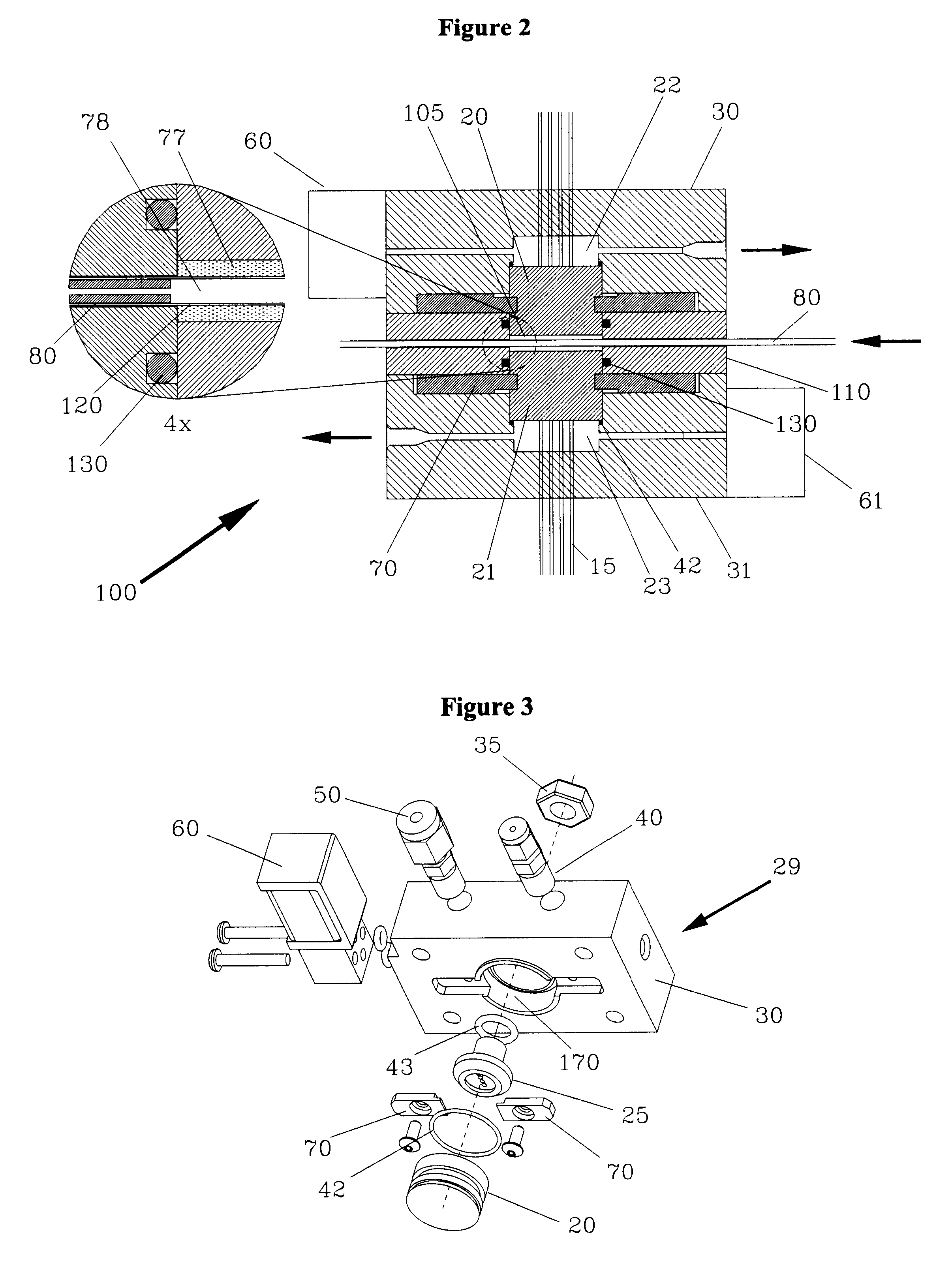

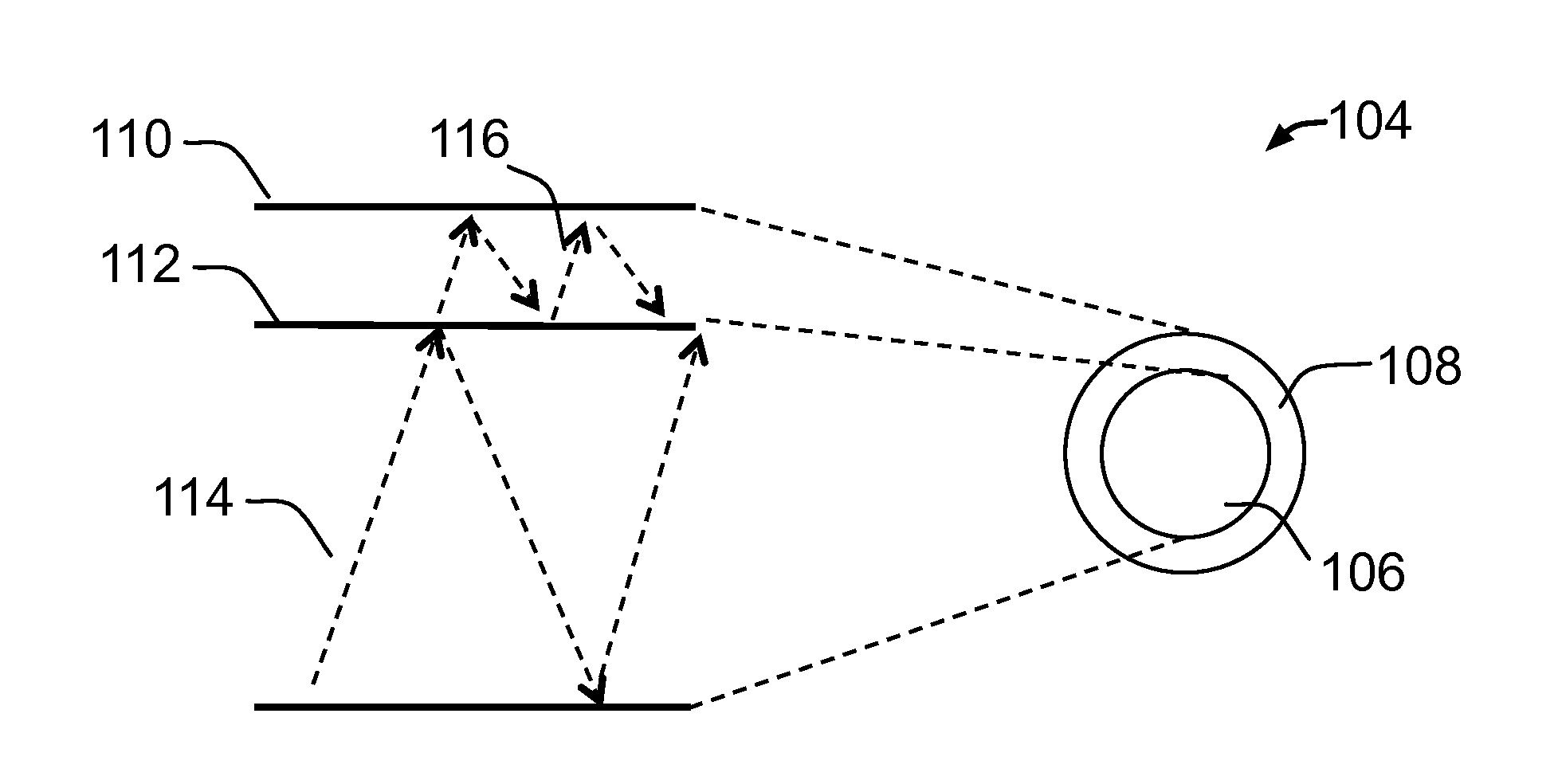

Programmable tracking pressure regulator for control of higher pressures in microfluidic circuits

InactiveUS6662818B2Low costImprove precision controlValve arrangementsControlling ratio of multiple fluid flowsCapillary networkEngineering

Regulator for precision control of pressure based on a means of measuring pressure differentials. More specifically, the present invention provides a pressure control that tracks a relatively high background pressure, and applies a positive or negative offset to create the small pressure differentials that can be utilized to transport fluids within a capillary network. The present invention is also directed to a method of controlling microfluidic elements (such as donut cavities) with a high degree of precision. In high performance liquid chromatography applications, this is accomplished using tracking pressure regulators to measure and respond to the difference between the liquid pump pressure and the regulated pneumatic pressure.

Owner:PERSPECTIVE BIOSYST

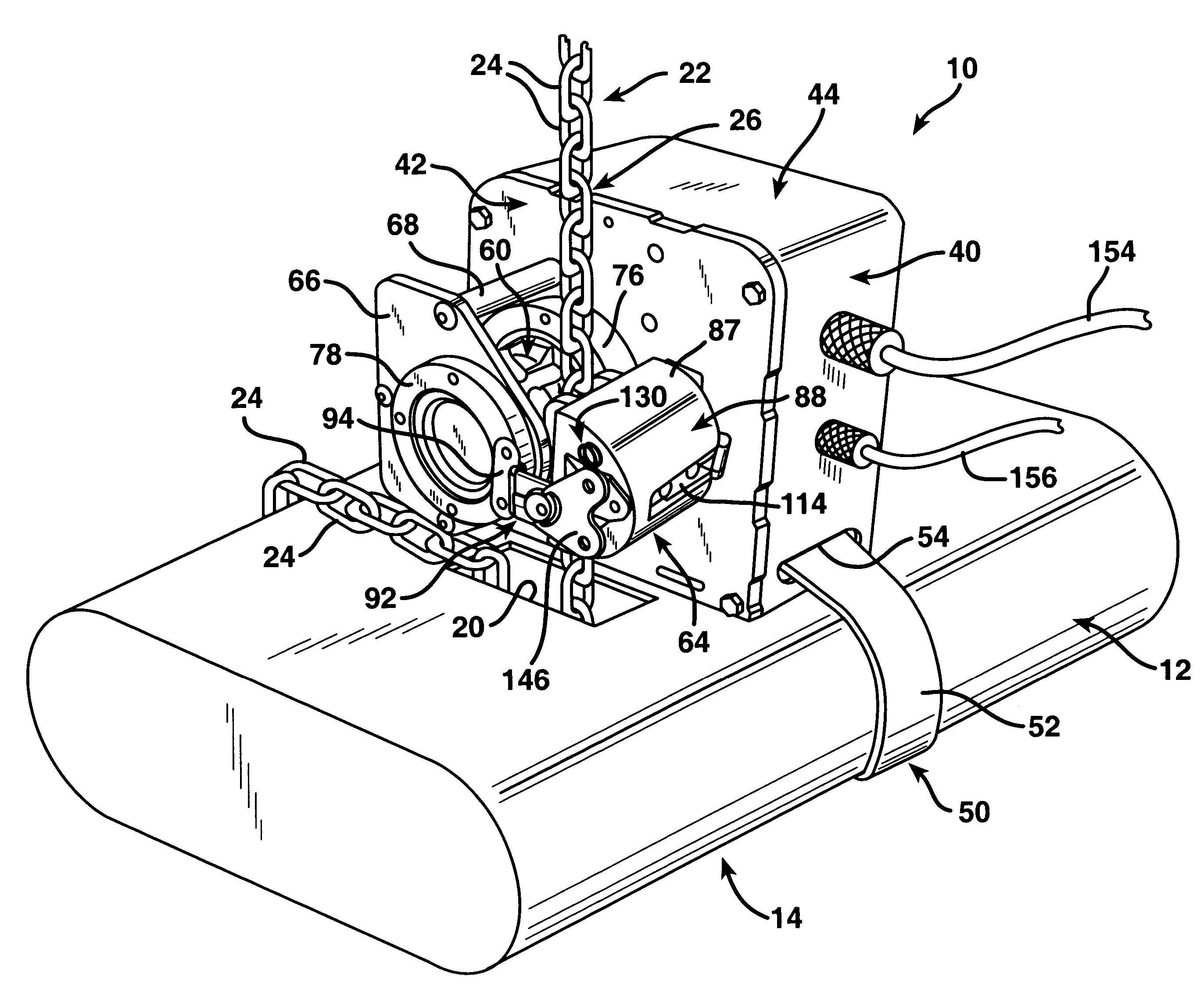

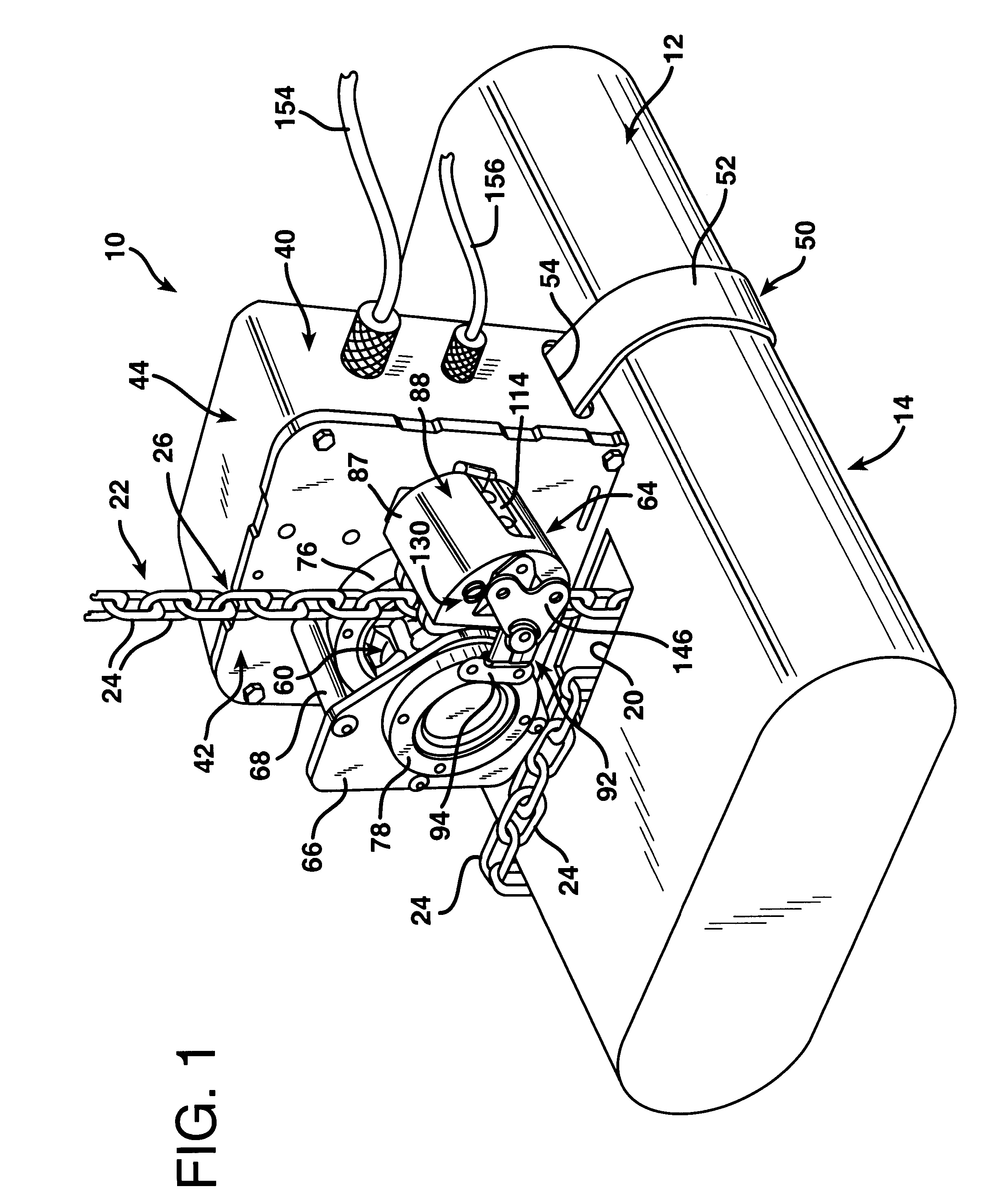

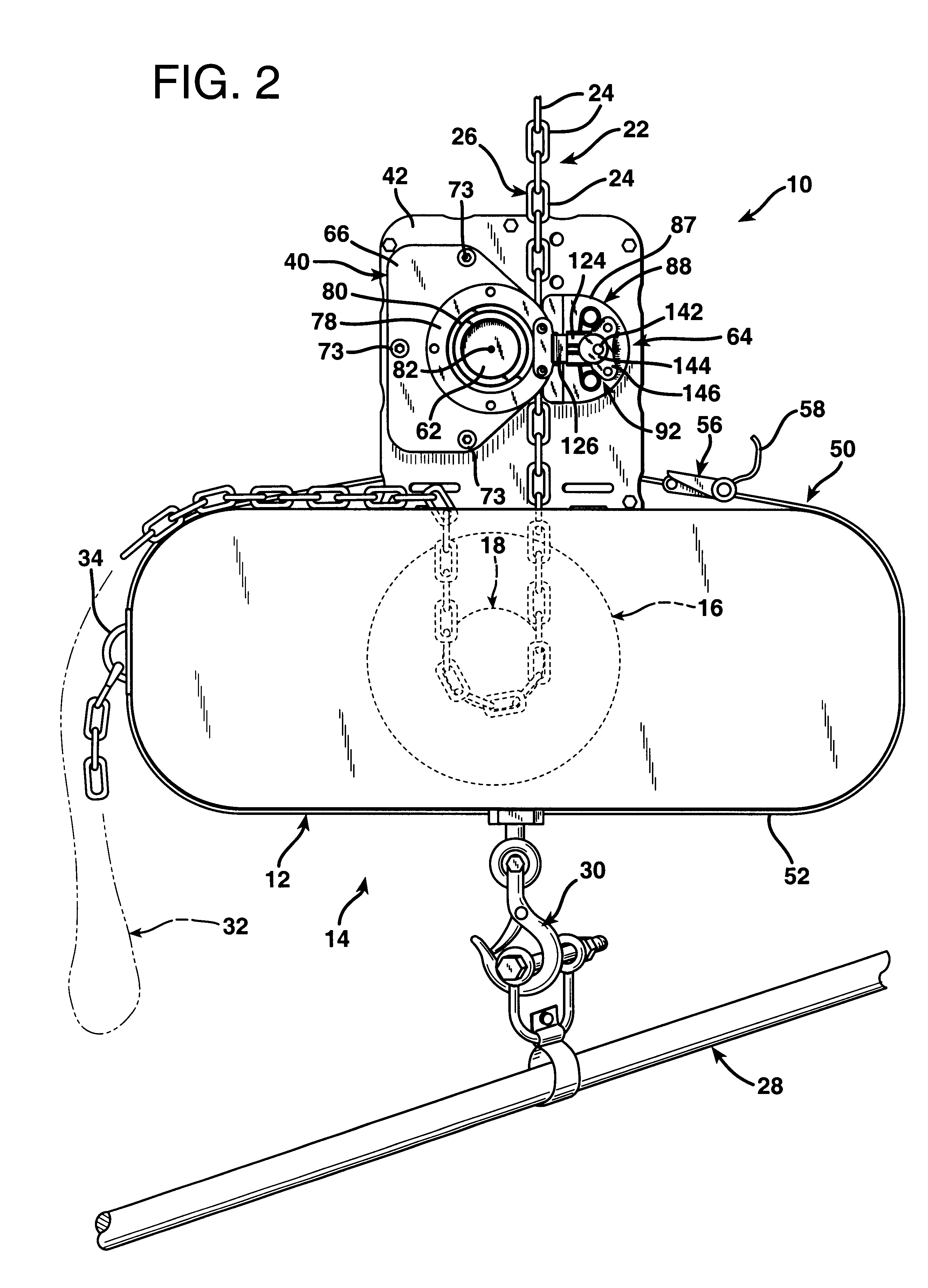

Removable chain hoist position encoder assembly

InactiveUS6209852B1Not easy to damageImprove precision controlMeasuring wheelsPortable liftingEngineeringSprocket

A chain hoist having a casing into which and with respect to which a chain travels is provided with an externally mounted position encoder assembly. A releasable connector, such as a ratchet strap, is employed to firmly but removably couple the position encoder assembly housing externally on the chain hoist casing. The releasable connector holds the position encoder assembly housing in a fixed position relative to the chain hoist casing. The position encoder assembly has a chain gear that is rotatably mounted relative to the position encoder assembly housing proximate to the chain access opening in the chain hoist casing. The precision encoder assembly chain gear engages the portion of the chain that is maintained under tension at a location externally of the chain hoist casing and rotates as the chain travels relative to the chain hoist casing. A releasable clamp is anchored relative to the position encoder assembly housing and is engageable to maintain engagement of the position encoder assembly chain gear with the chain. An encoder is mounted with respect to the position encoder assembly housing and detects rotational movement of the position encoder assembly chain gear. The sensor provides electrical output signals indicative of the extent and direction of rotational movement of the position encoder assembly chain gear. The position encoder assembly provides precise, reliable output signals indicative of the position of the chain relative to the chain hoist. The position encoder assembly may be readily removed from the chain hoist, and just as easily attached thereto.

Owner:GEORGE & GOLDBERG DESIGN ASSOC

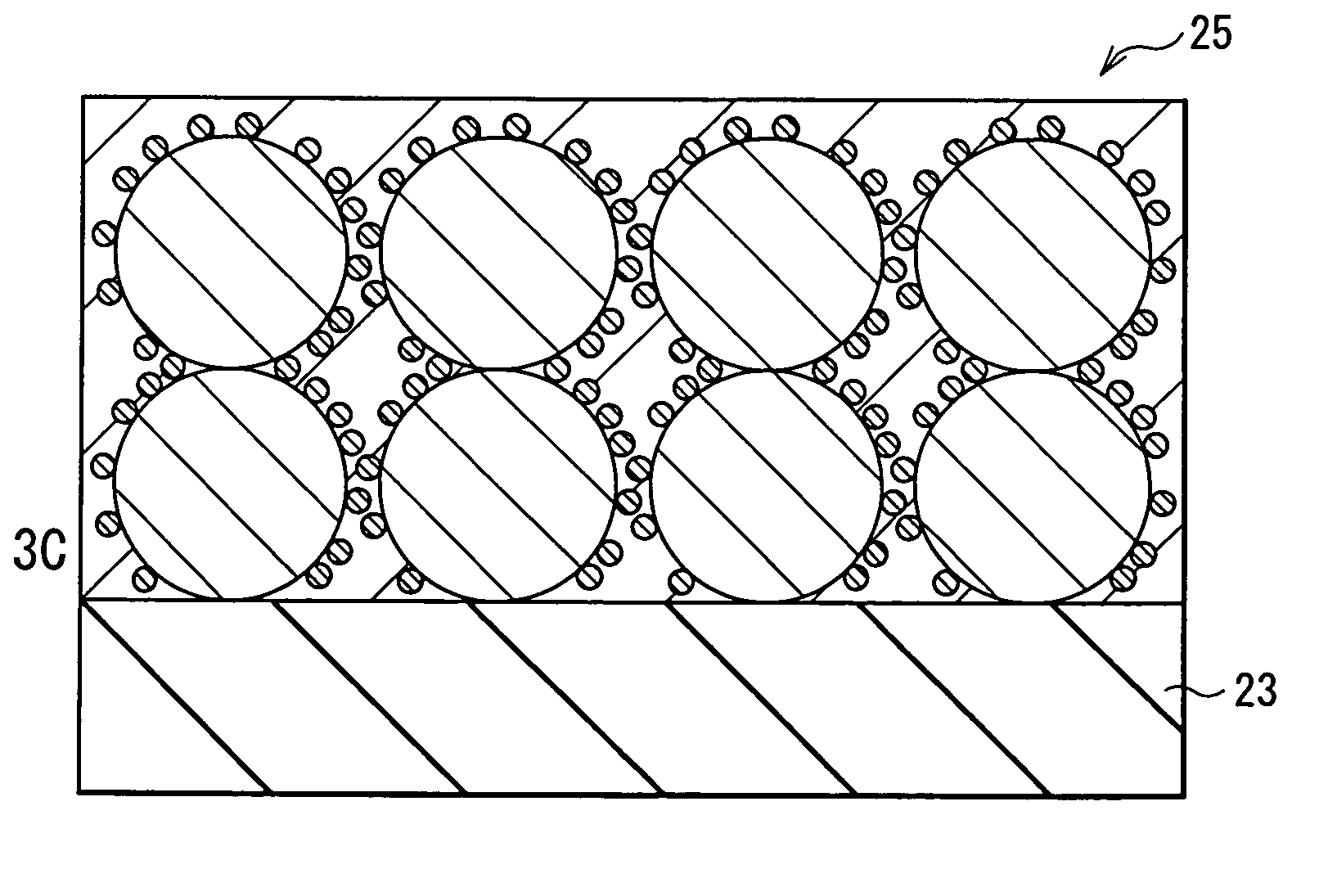

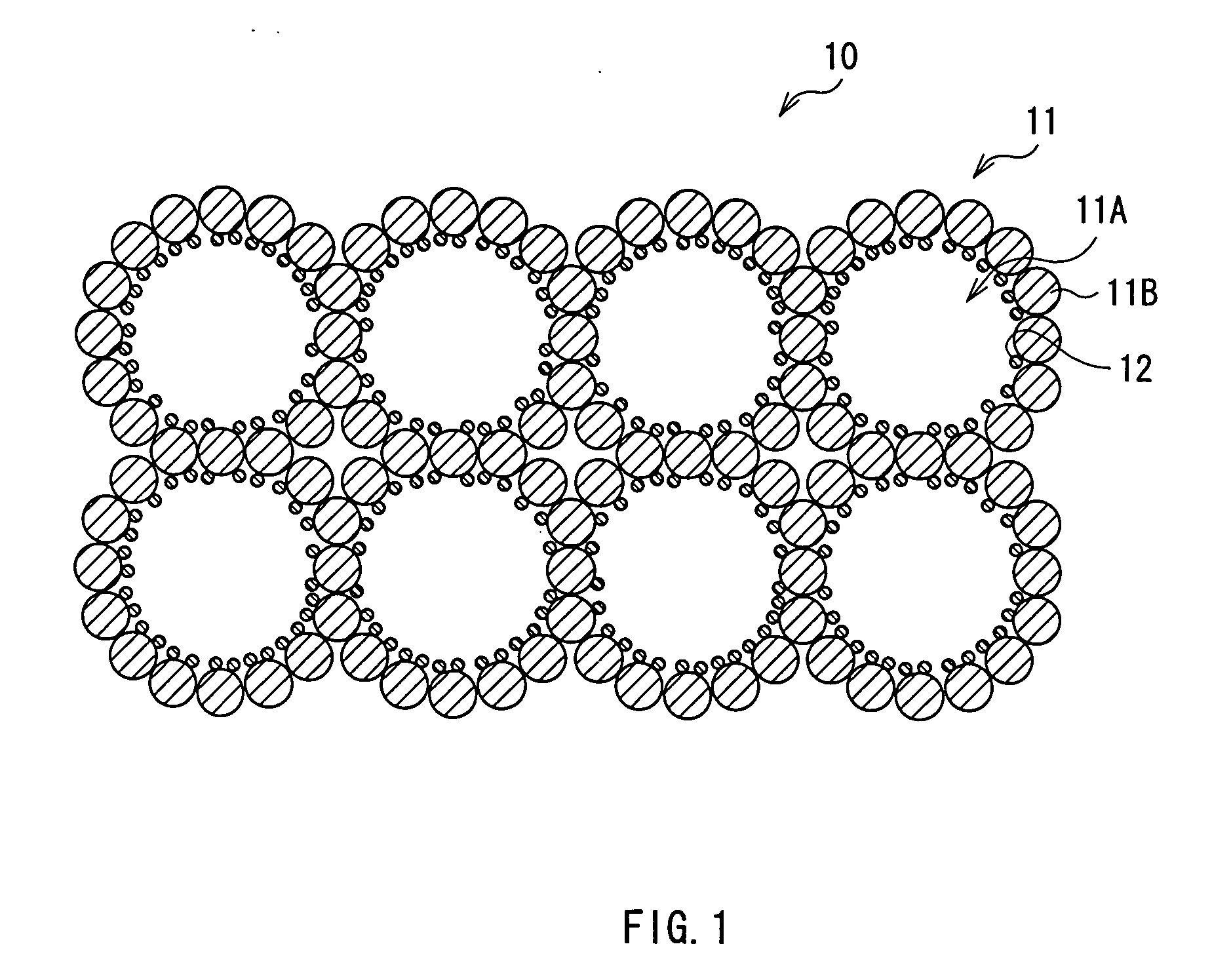

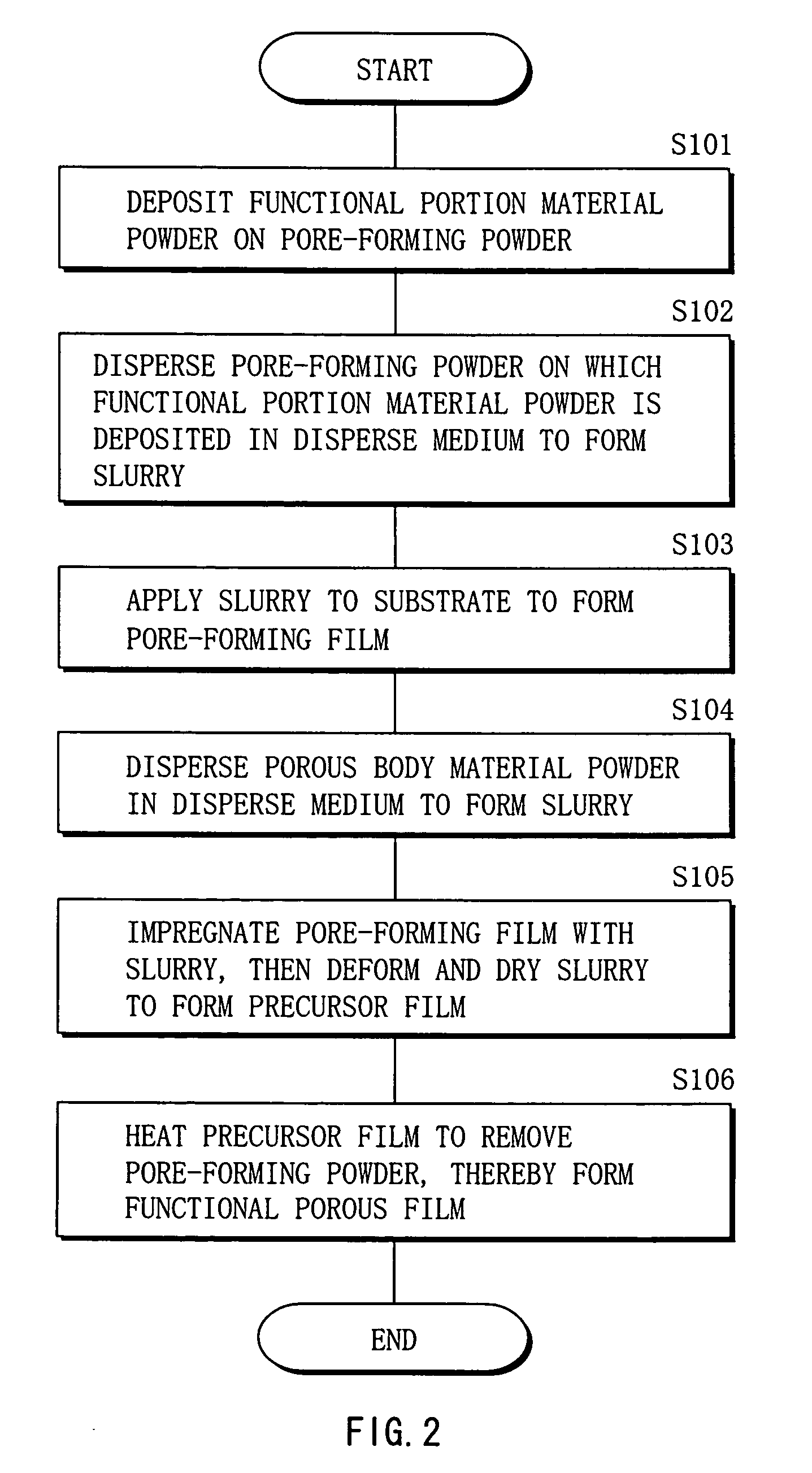

Functional porous film, sensor, method of manufacturing functional porous film, method of manufacturing porous metal film, and method of manufacturing sensor

InactiveUS20050109617A1Improve accuracyImprove precision controlCell electrodesMaterial electrochemical variablesMetallurgyPorous film

Provided are a functional porous film having a plurality of functions, a method of manufacturing the same, and a sensor using the same. In the functional porous film, a functional portion having a different function from a porous body is disposed on the inner wall of a pore of the porous body. The functional porous film is formed through forming a precursor film including a pore-forming powder such as an organic powder on which a material powder of the functional portion is deposited and a material powder of the porous body, and then heating the precursor film to remove the pore-forming powder and sinter the material powder of the porous body.

Owner:TDK CORPARATION

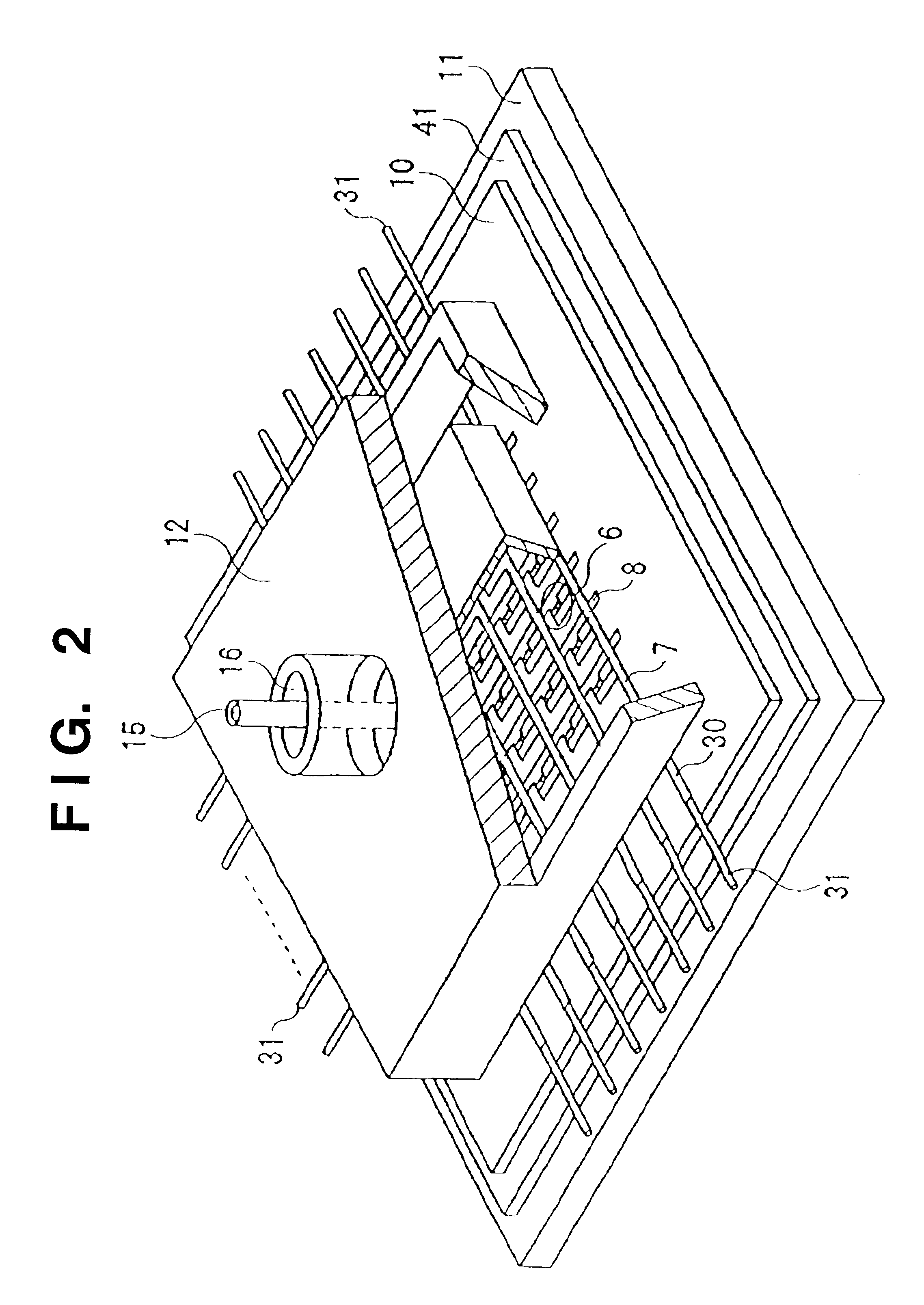

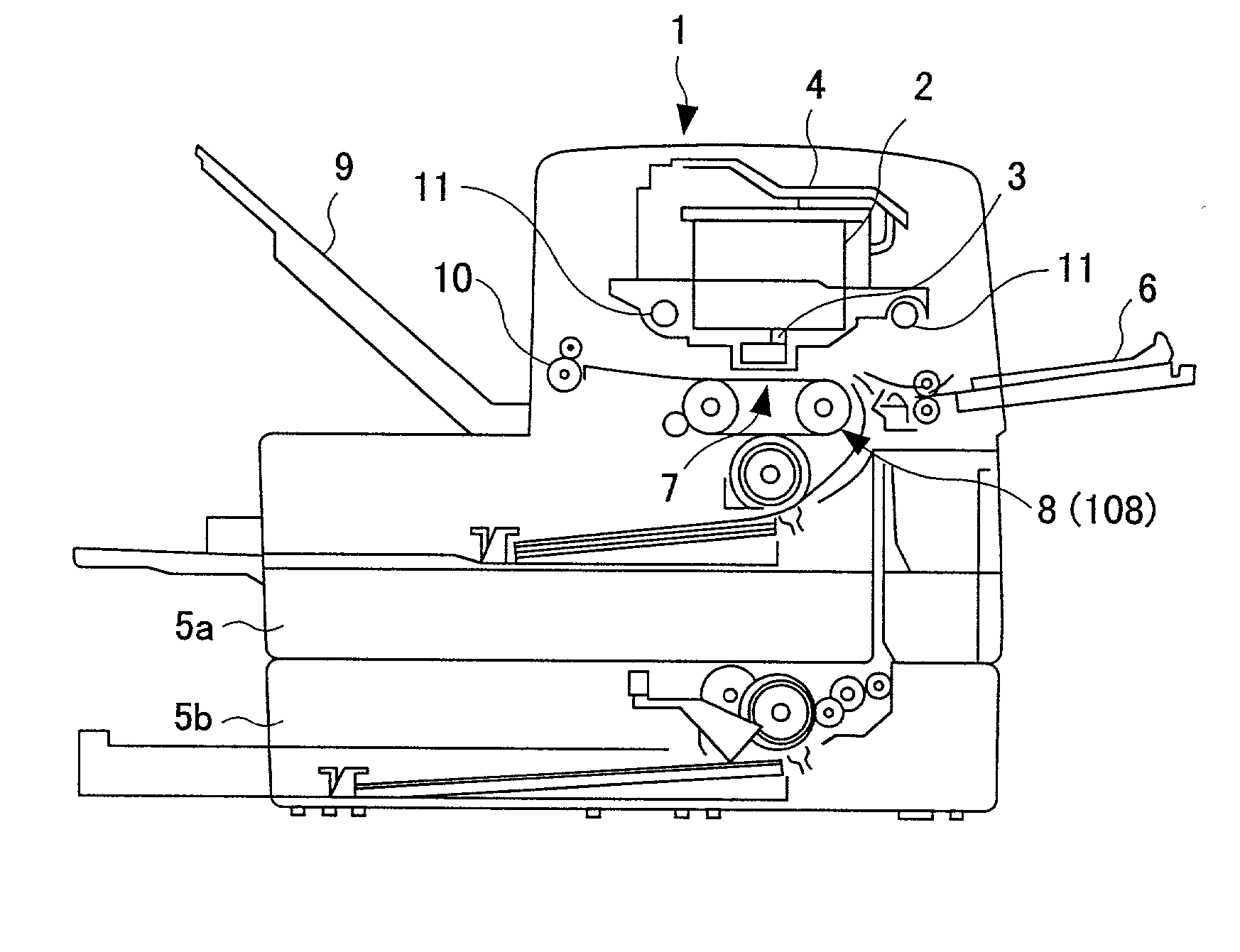

Apparatus for producing electron source

InactiveUS6726520B2Easy to operateAvoid damageElectroluminescent light sourcesSolid-state devicesElectrical conductorElectron source

This invention provides an electron source manufacturing apparatus which can be easily downsized and operated. The electron source manufacturing apparatus includes a support member for supporting a substrate (10) having a conductor (11), a vessel (12) which has a gas inlet port (15) and a gas exhaust port (16) and covers a partial region of the surface of the substrate (10); a gas inlet unit (24) connected to the gas inlet port (15) to introduce gas into the vessel, an exhaust unit (26) connected to the gas exhaust port to evacuate the interior of the vessel, and a voltage application unit (32) for applying a voltage to the conductor.

Owner:CANON KK

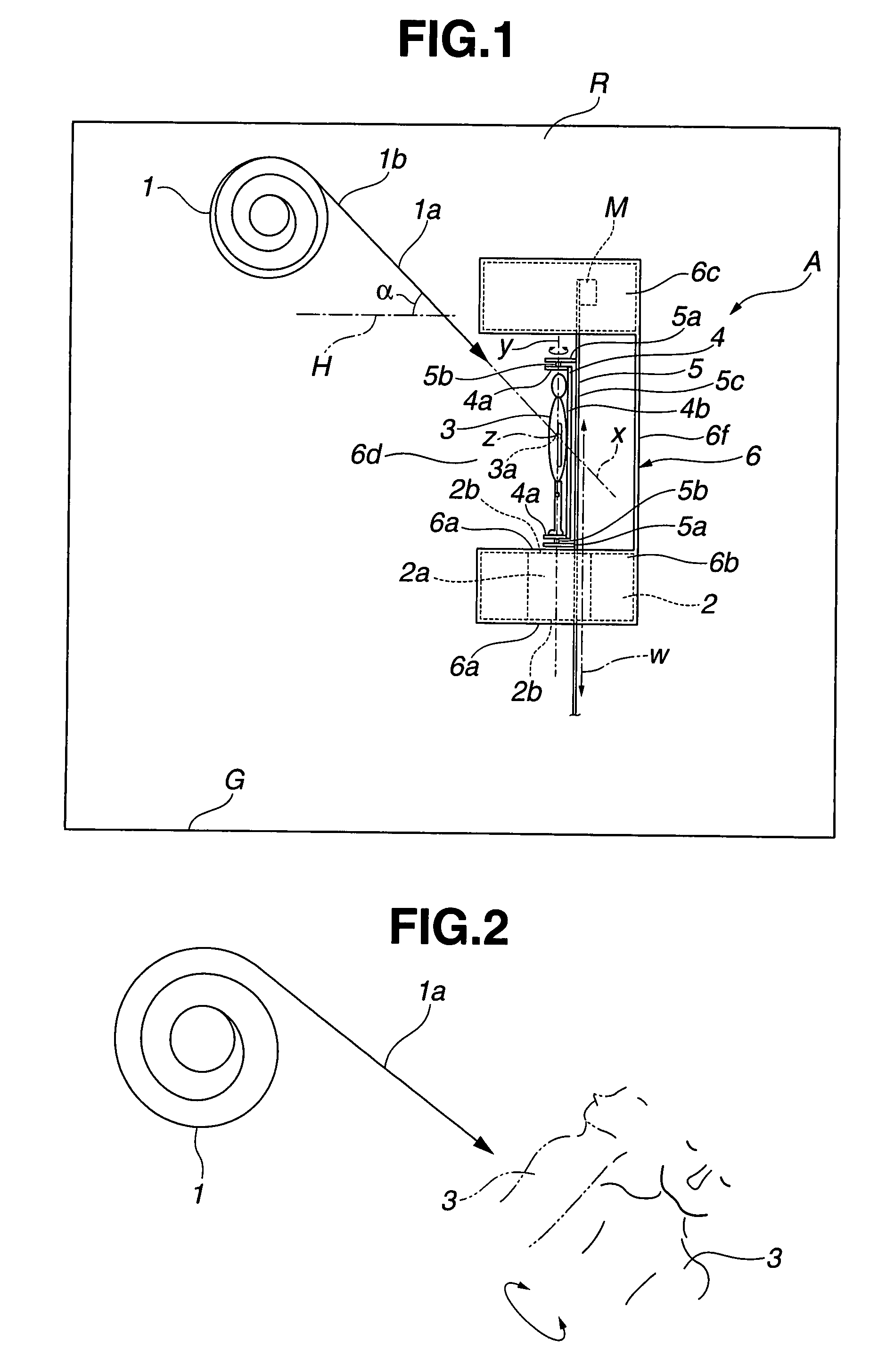

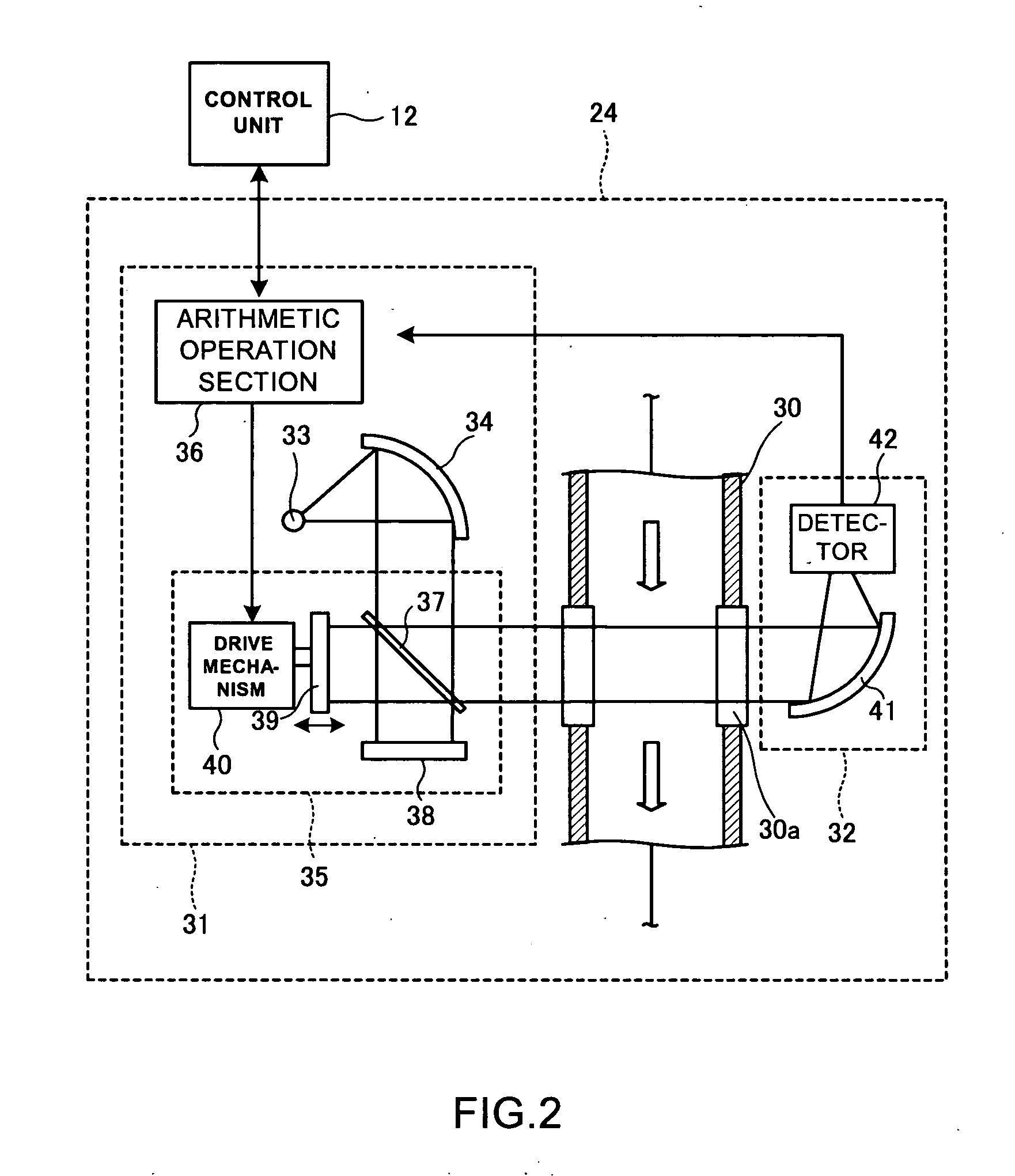

Particle beam irradiation system

InactiveUS7659528B2Simple structureImprove precision controlPhotometryDiagnostic recording/measuringParticle beamCt scanners

A particle beam irradiation system includes a particle beam irradiation apparatus, which is free of a gantry structure, having a particle beam irradiator for irradiating an affected area of a patient with a particle beam, the particle beam irradiator being housed in a chamber, a CT scanner installed in the chamber, for positionally confirming the affected area of the patient, a drive unit for moving the patient from a detection range to an irradiation range, a patient fixing device for fixing the patient in position, the device being mounted on the drive unit for rotation, and a housing unit having a structure housing the drive unit with the patient fixing device mounted and the CT scanner, the housing unit being rotatable about an axis perpendicular to a plane including a direction in which the particle beam is applied and a direction in which the drive unit moves.

Owner:UEMATSU MINORU +2

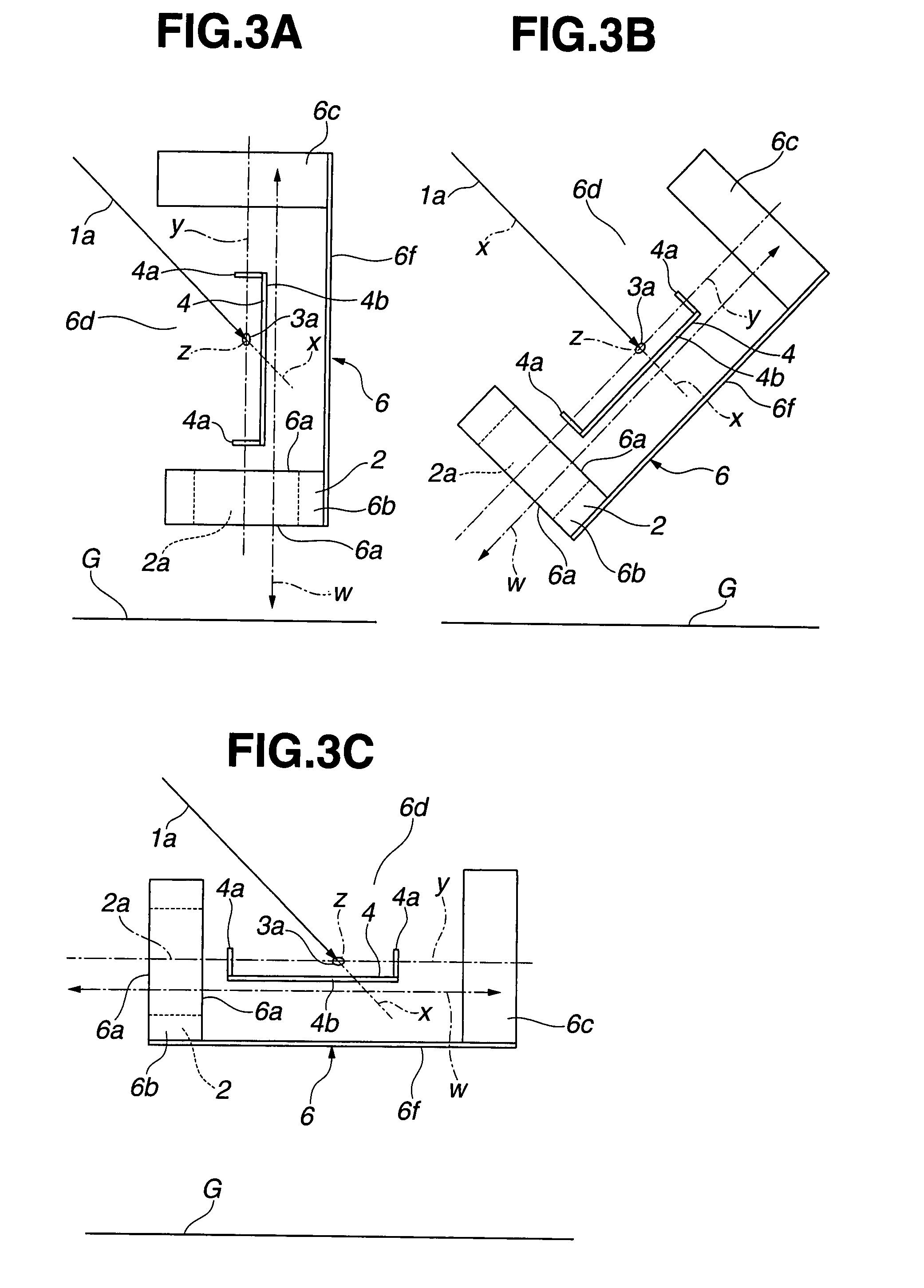

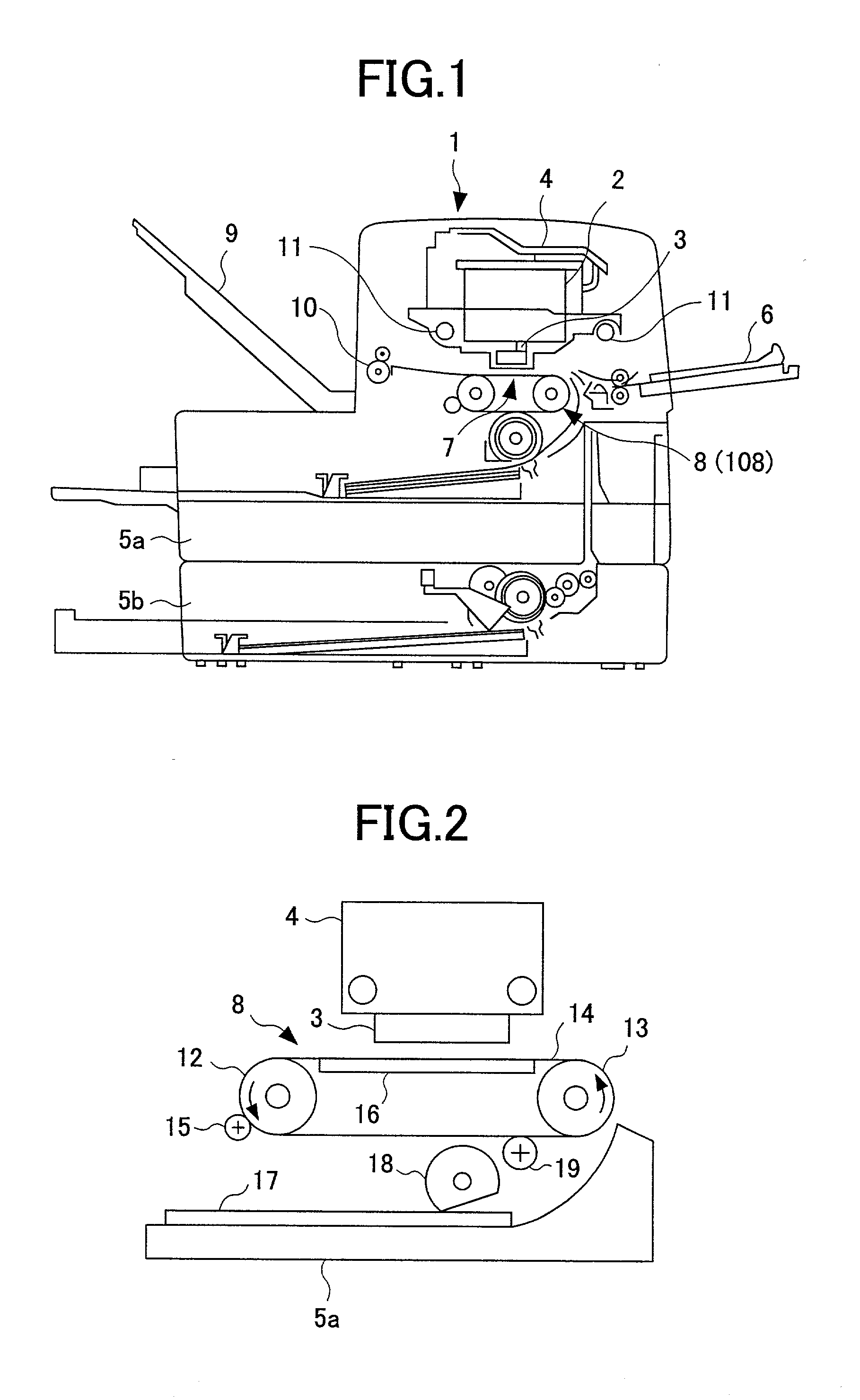

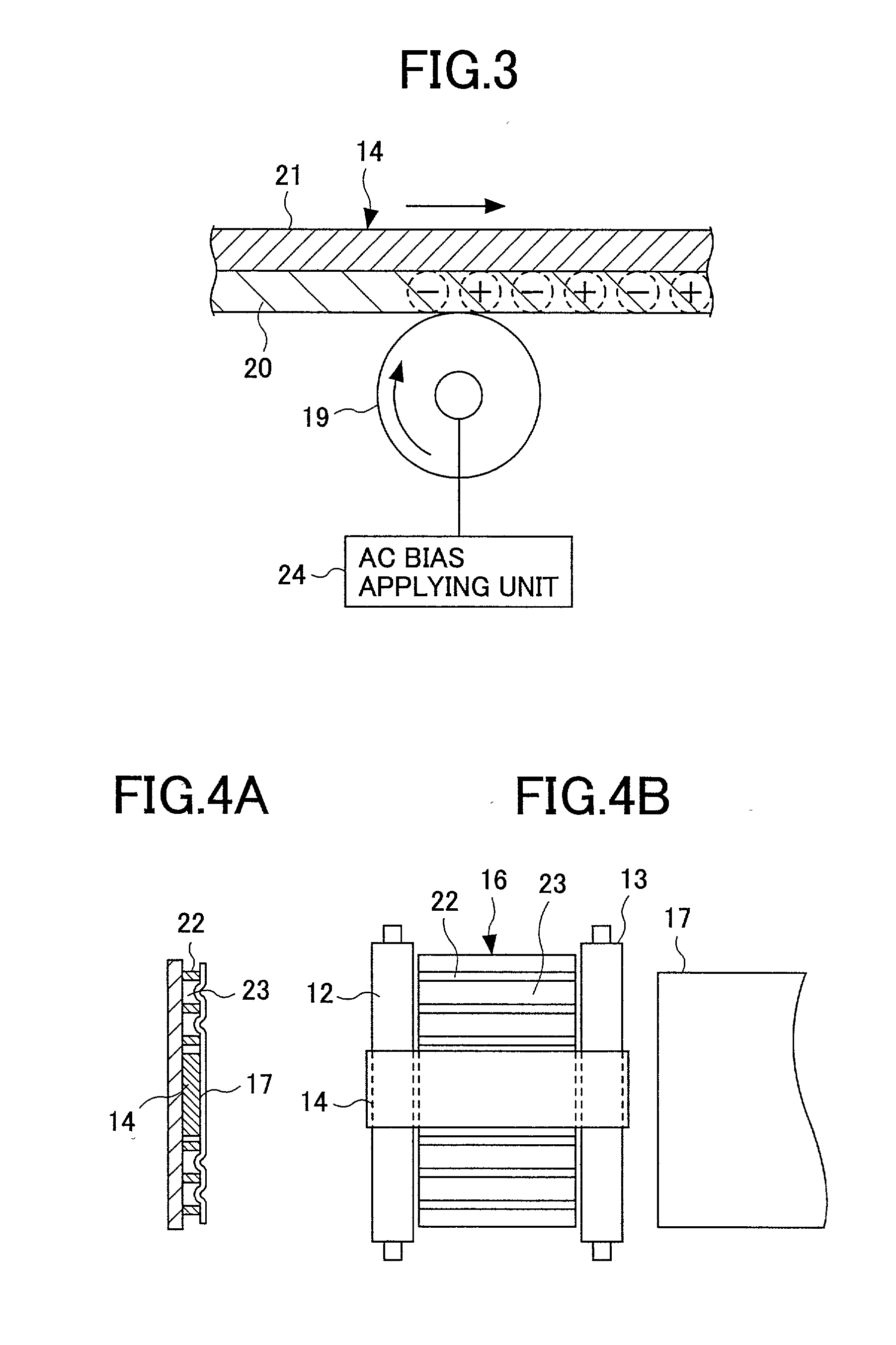

Recording-medium conveying device conveying a recording medium on a conveying belt charged with a positive charge and a negative charge alternately

InactiveUS20020126193A1Eliminate the problemHigh precisionOther printing apparatusArticle feedersImage recordingEngineering

This recording-medium conveying device comprises a conveying belt, the conveying belt, a belt charging unit, and a pressing roller. The conveying belt is wound around a driving roller and a driven roller so as to convey a recording medium to an image recording part. The conveying belt includes an insulating layer formed at one side contacting the recording medium. The belt charging unit is provided in contact with the insulating layer so as to charge the insulating layer with a positive charge and a negative charge alternately in a moving direction of the conveying belt by applying an AC bias to the conveying belt. The pressing roller presses the conveying belt against the driving roller so as to prevent the conveying belt from slipping on the driving roller.

Owner:RICOH KK

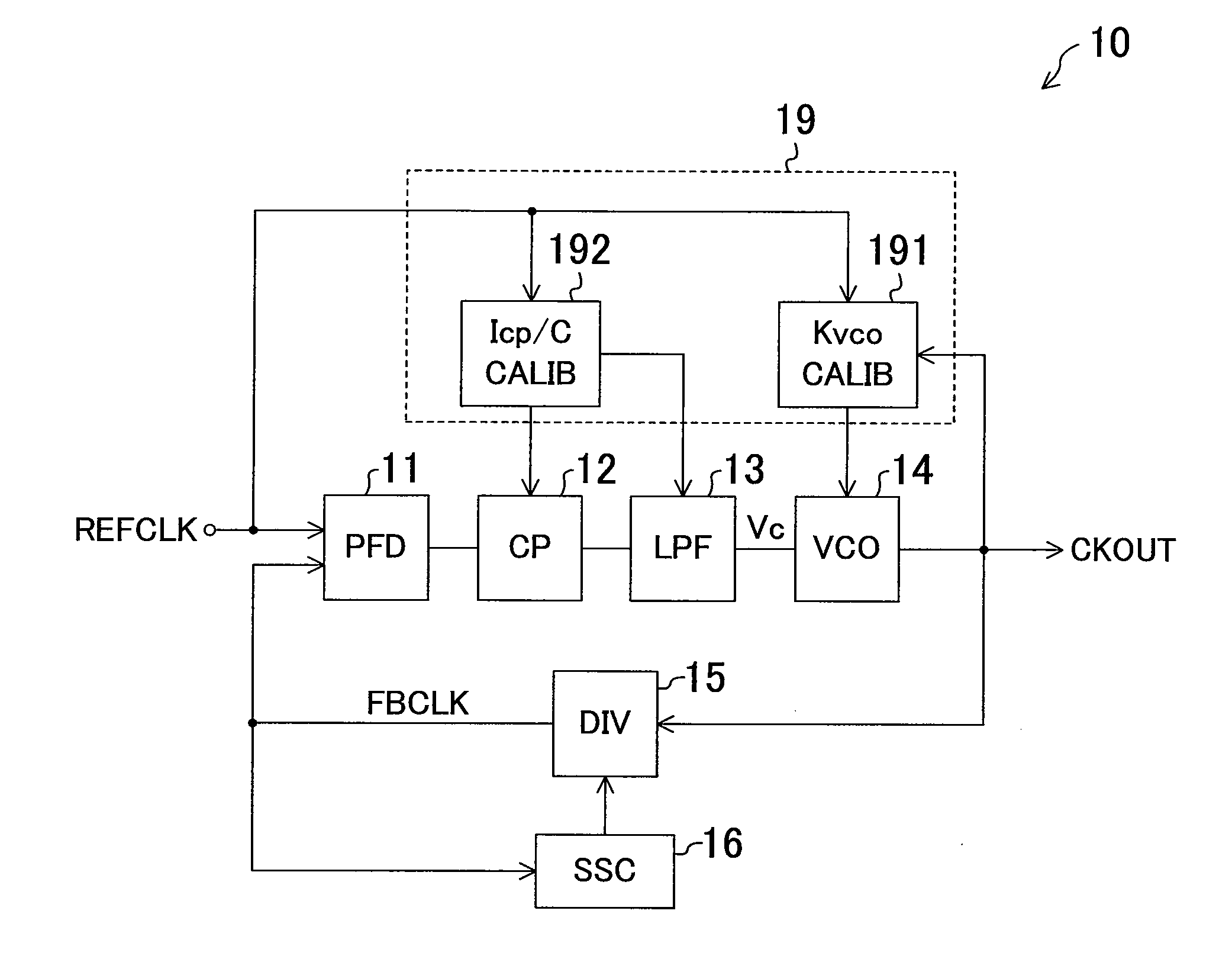

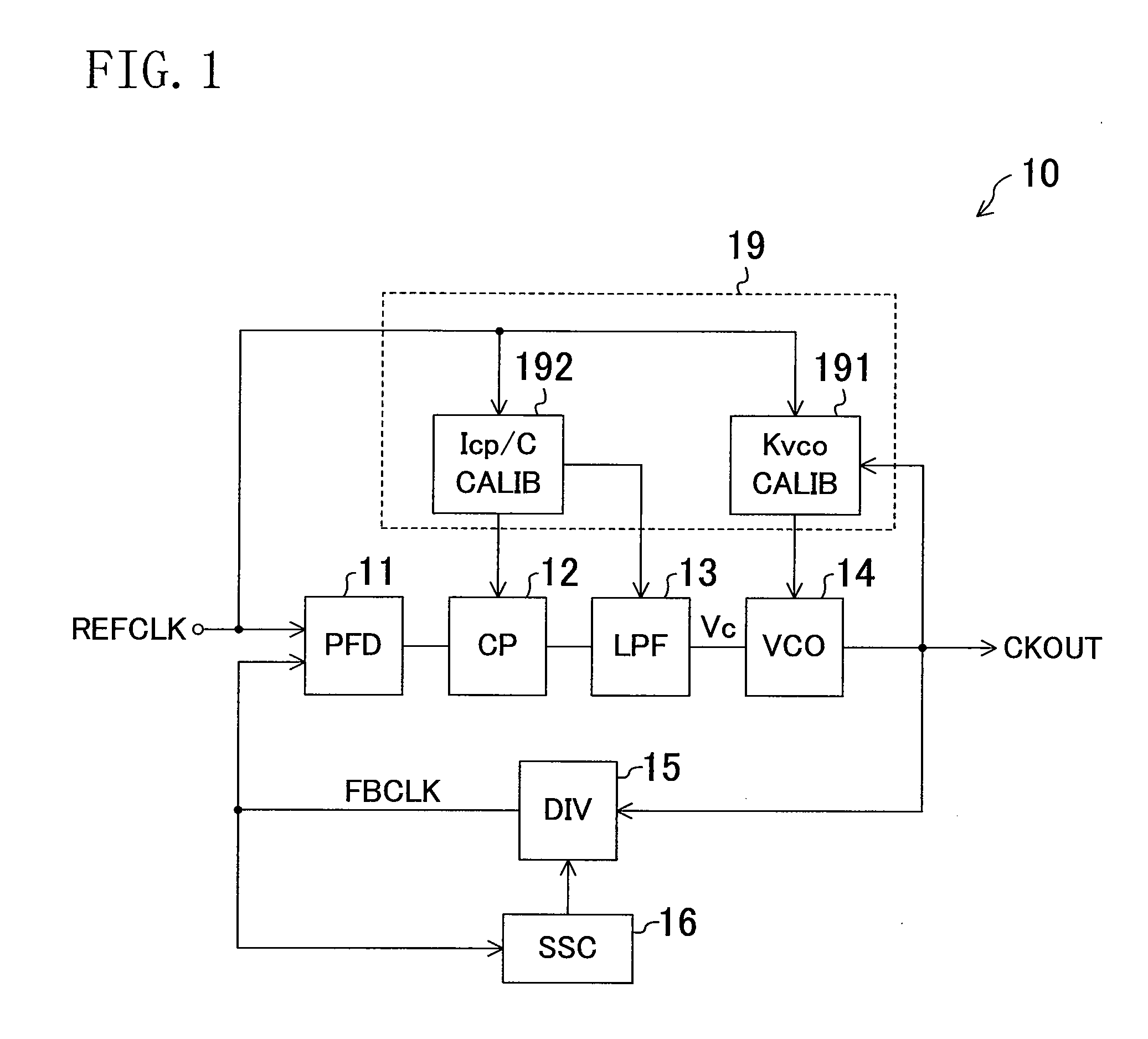

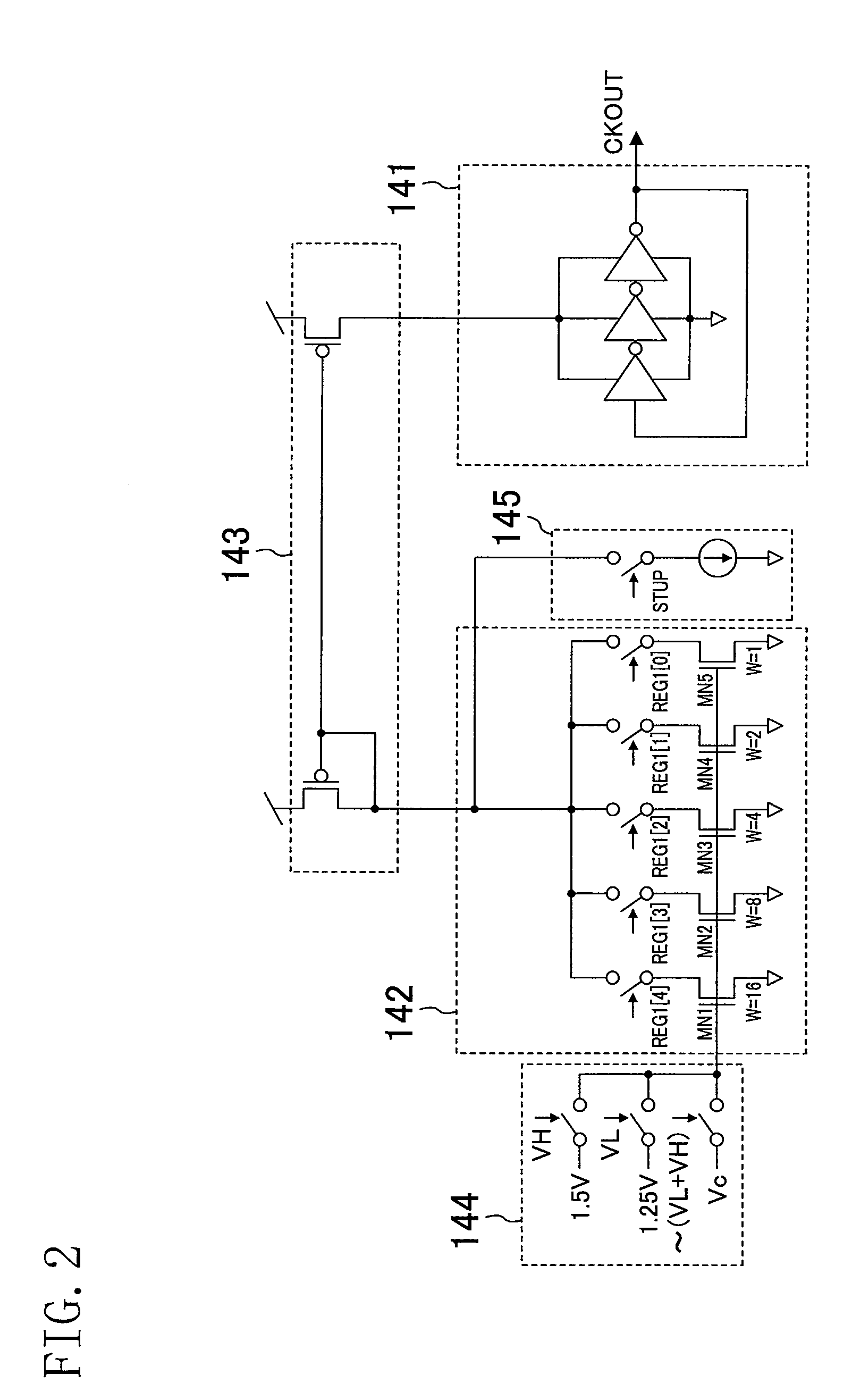

Spread spectrum control pll circuit and its start-up method

ActiveUS20100127739A1Simple configurationLimiting loop bandwidthPulse automatic controlLoop filterCapacitance

A calibration circuit (19) adjusts at least one of one of a charging current of a charge pump circuit (12) and a capacitance value of a filter capacitor in a loop filter circuit (13) and a gain of a voltage controlled oscillator (14), depending on a frequency of a reference clock signal input to a calibration circuit (10).

Owner:PANASONIC CORP

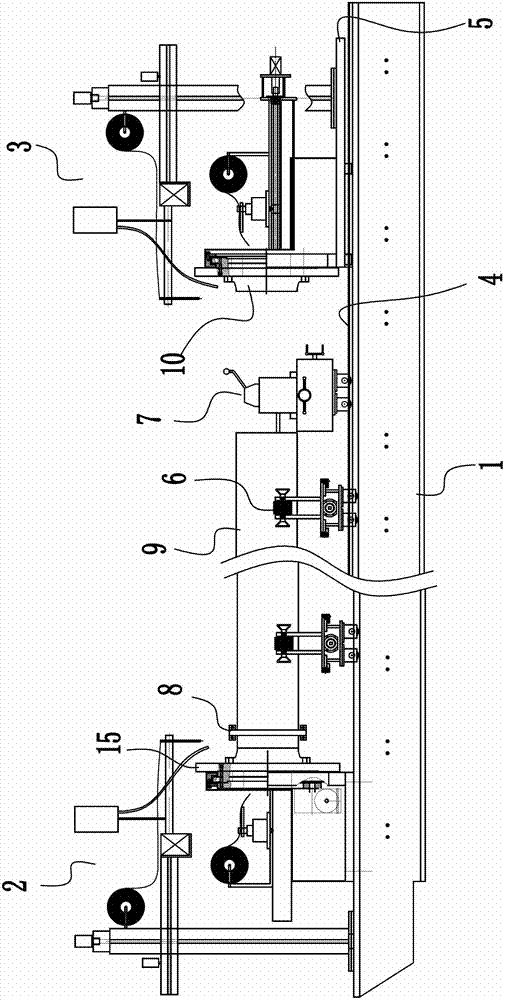

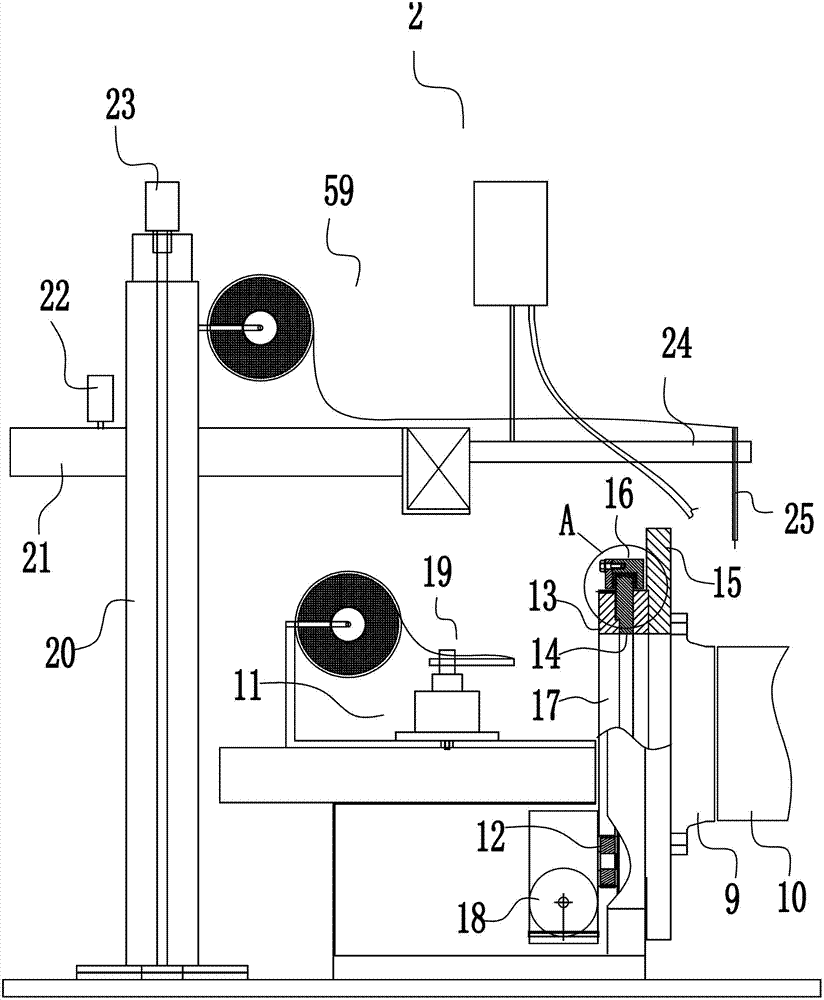

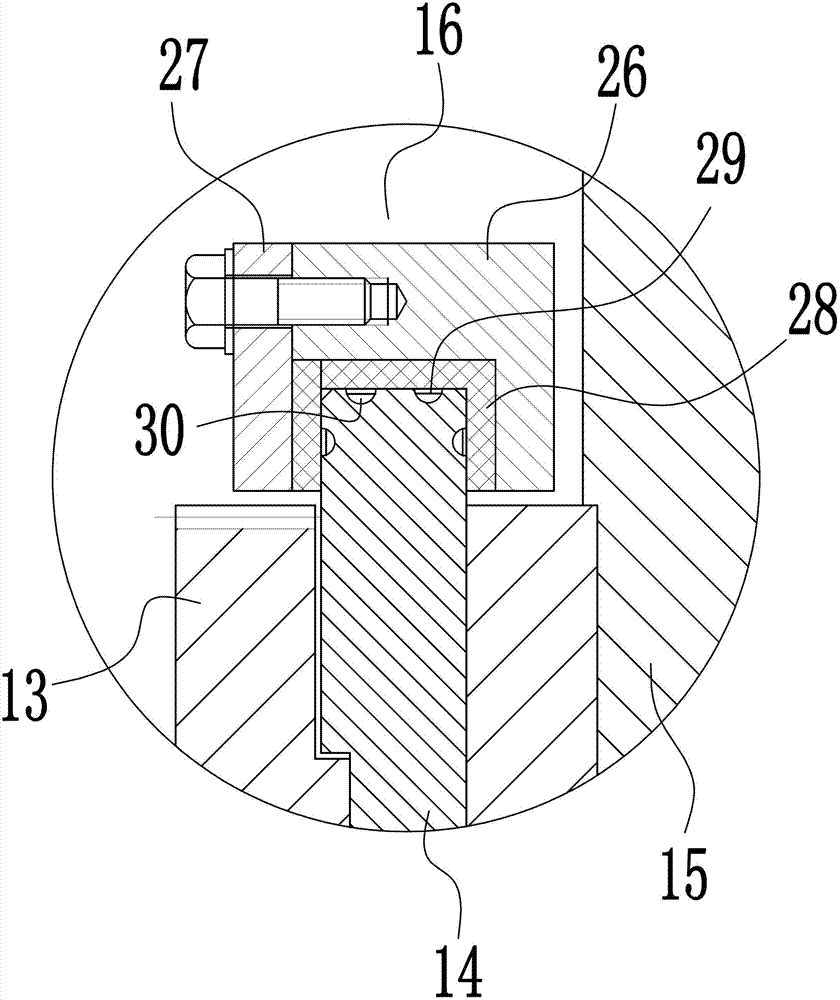

Integrated steel pipe and flange splicing and machining machine and machining process thereof

InactiveCN102729045ALarge amount of welding depositionImprove welding speed and qualityArc welding apparatusOther manufacturing equipments/toolsSteel tubeMachining process

The invention discloses an integrated steel pipe and flange splicing and machining machine and a machining process thereof and aims to provide an integrated steel pipe and flange splicing and machining machine which can improve the manufacturing precision and the production efficiency and reduce the labor intensity and is high in steel pipe and flange welding quality and a machining process of the machine. The integrated steel pipe and flange splicing and machining machine comprises a working platform, and a supporting bracket which is arranged on the working platform and is used for supporting a steel pipe, wherein one end of the working platform is provided with a first welding device; a first guide rail which extends to the other end of the working platform is arranged on the top of the working platform; a first mounting plate is arranged on the first guide rail in a sliding mode; a second welding device is arranged on the first mounting plate; and flange fixing templates are arranged on the first welding device and the second welding device. The machining process comprises the following steps of: lifting the steel pipe to the supporting bracket, and fixing the flange to a flange fixing template; and welding annular gaps of the inner and outer side faces of the steel pipe and the flange through the first welding device and the second welding device.

Owner:戴刚平

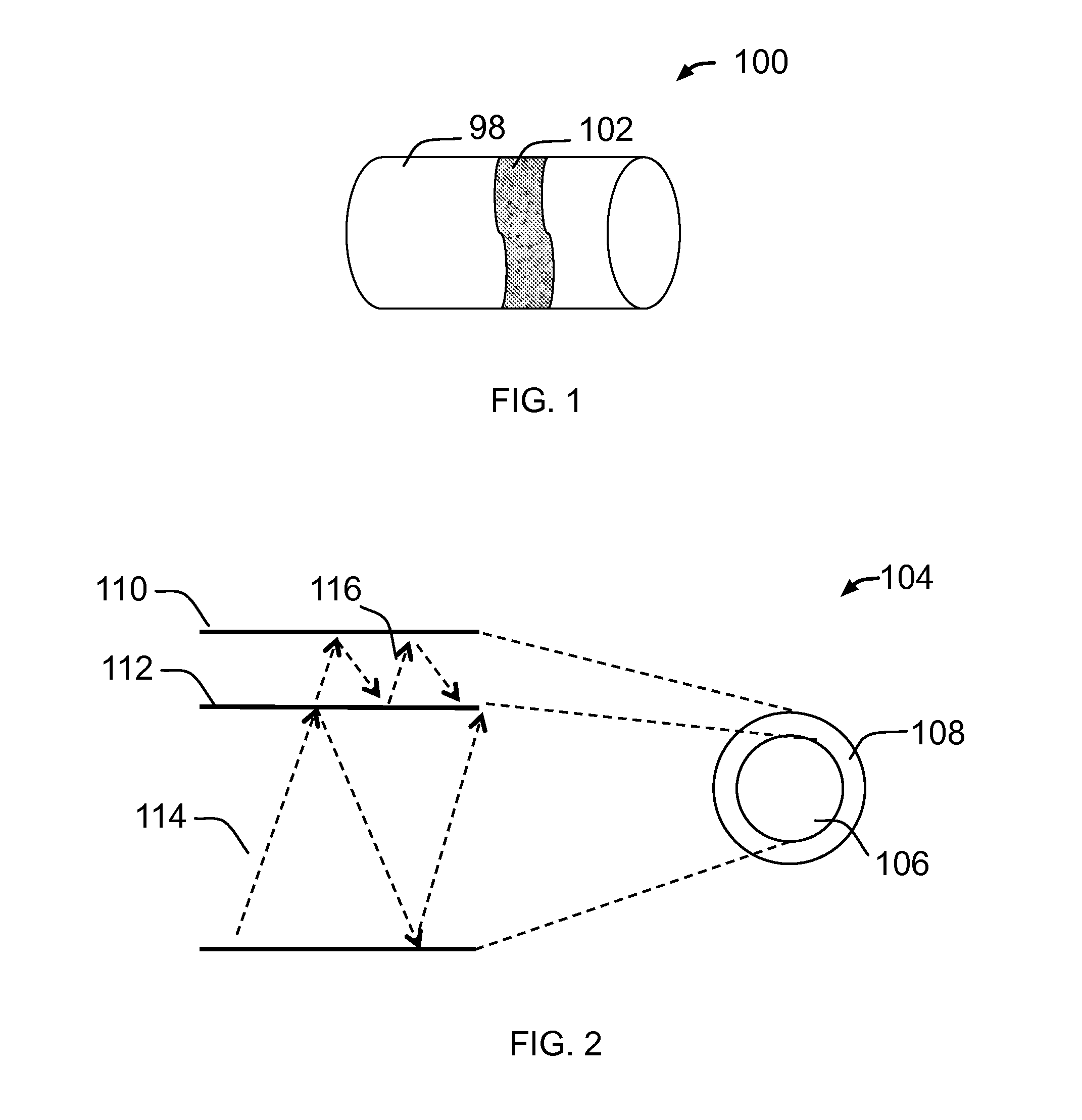

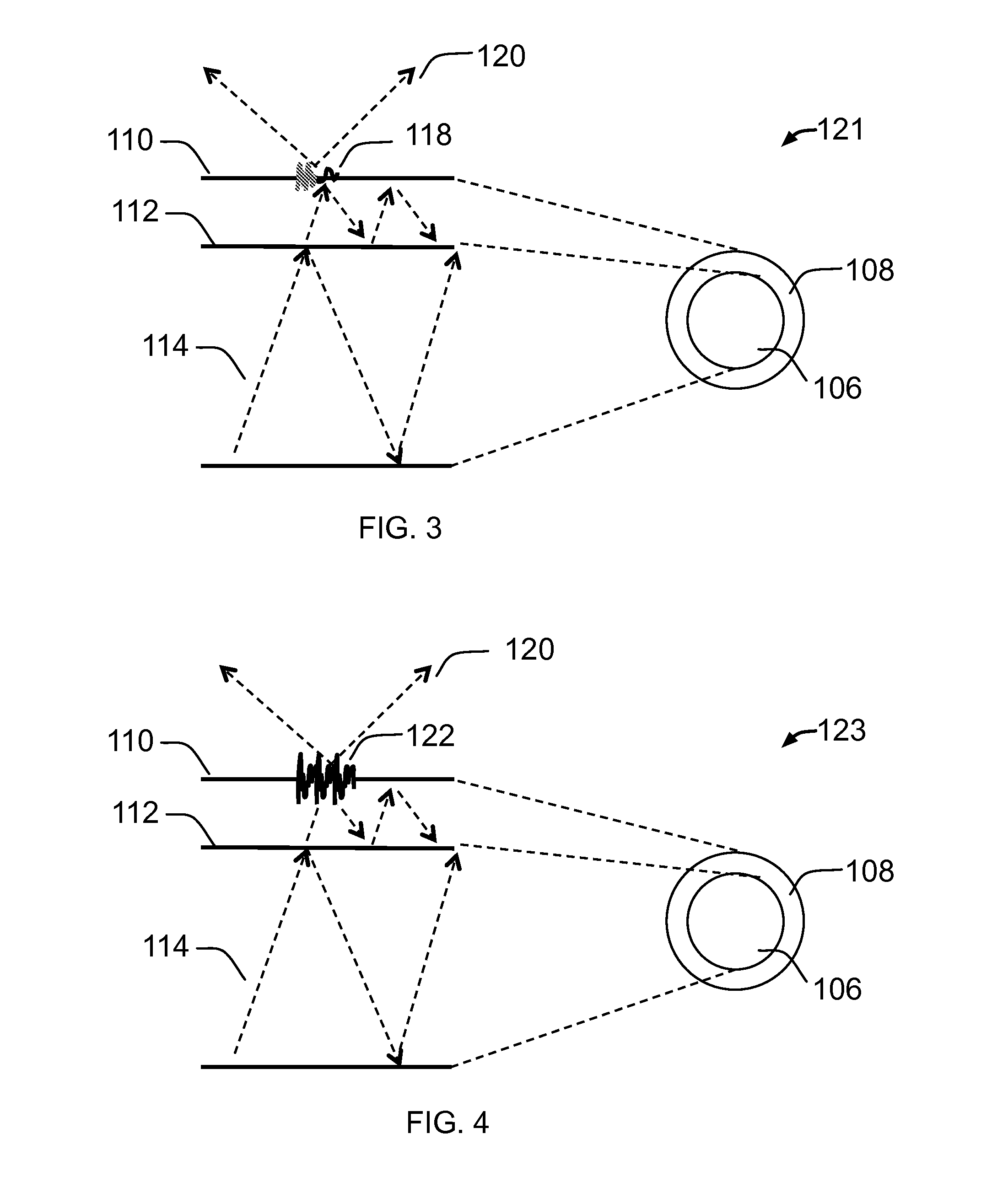

Optical fibers having a Surface Light Field Emulation (s-LiFE) segment and method of making the same

InactiveUS20110188261A1Improve performanceLow costCladded optical fibreOptical articlesFiberDiffusion

A modified optical fiber comprises one Surface Light Field Emulation (s-LiFE) segment, comprising a core; a cladding; and multiple controlled nanoscale diffusion centers to emit light through the side of the optical fibers. Optionally, the modified optical fiber has a coating. The nanoscale diffusion centers are physical geometric patterns or composition patterns in the cladding or the coating. The s-LiFE optical fiber is a member of an illumination system further comprising a light source. The method of making of said s-LiFE optical fiber comprises a fiber spooning step.

Owner:ENLIGHTING

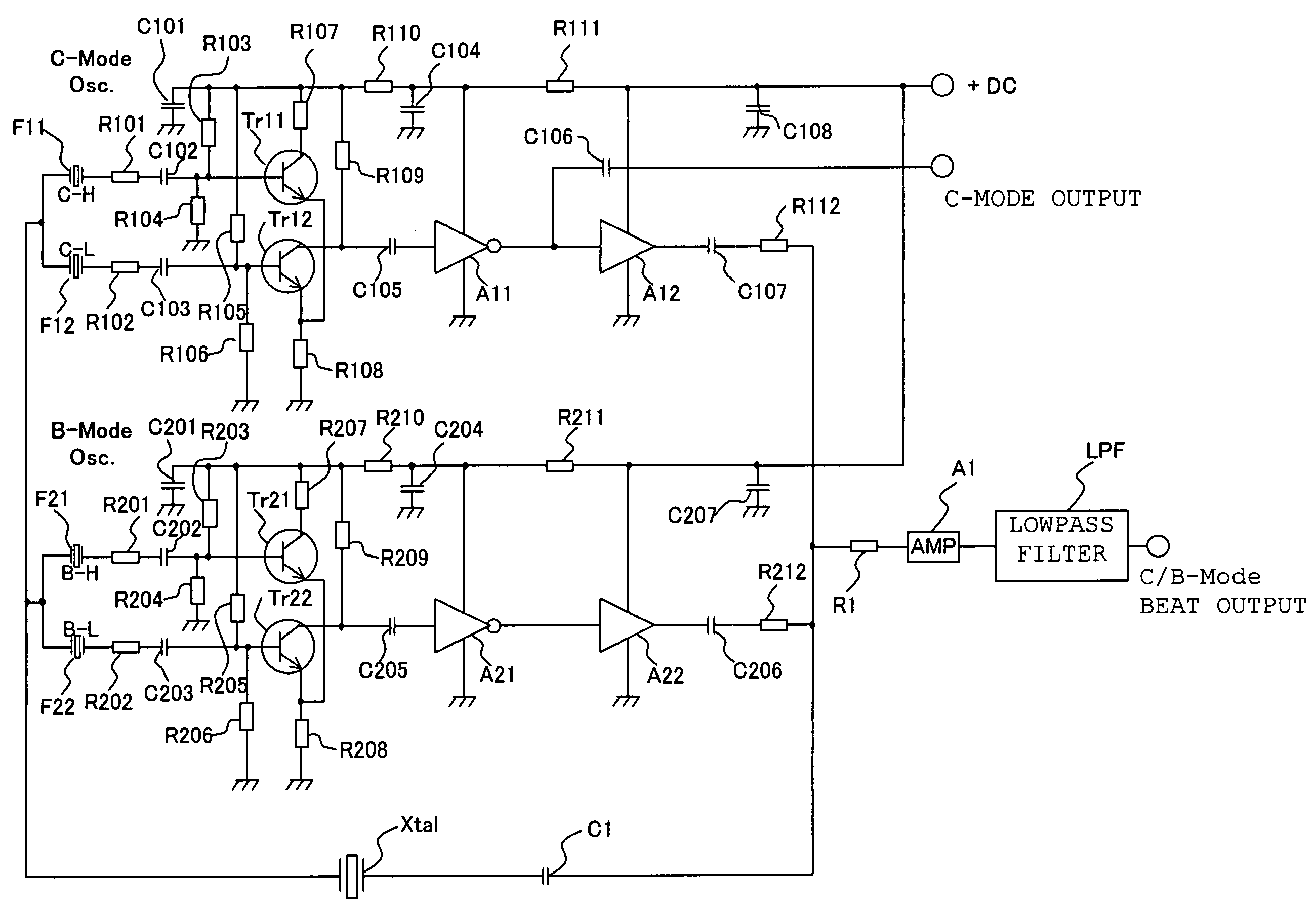

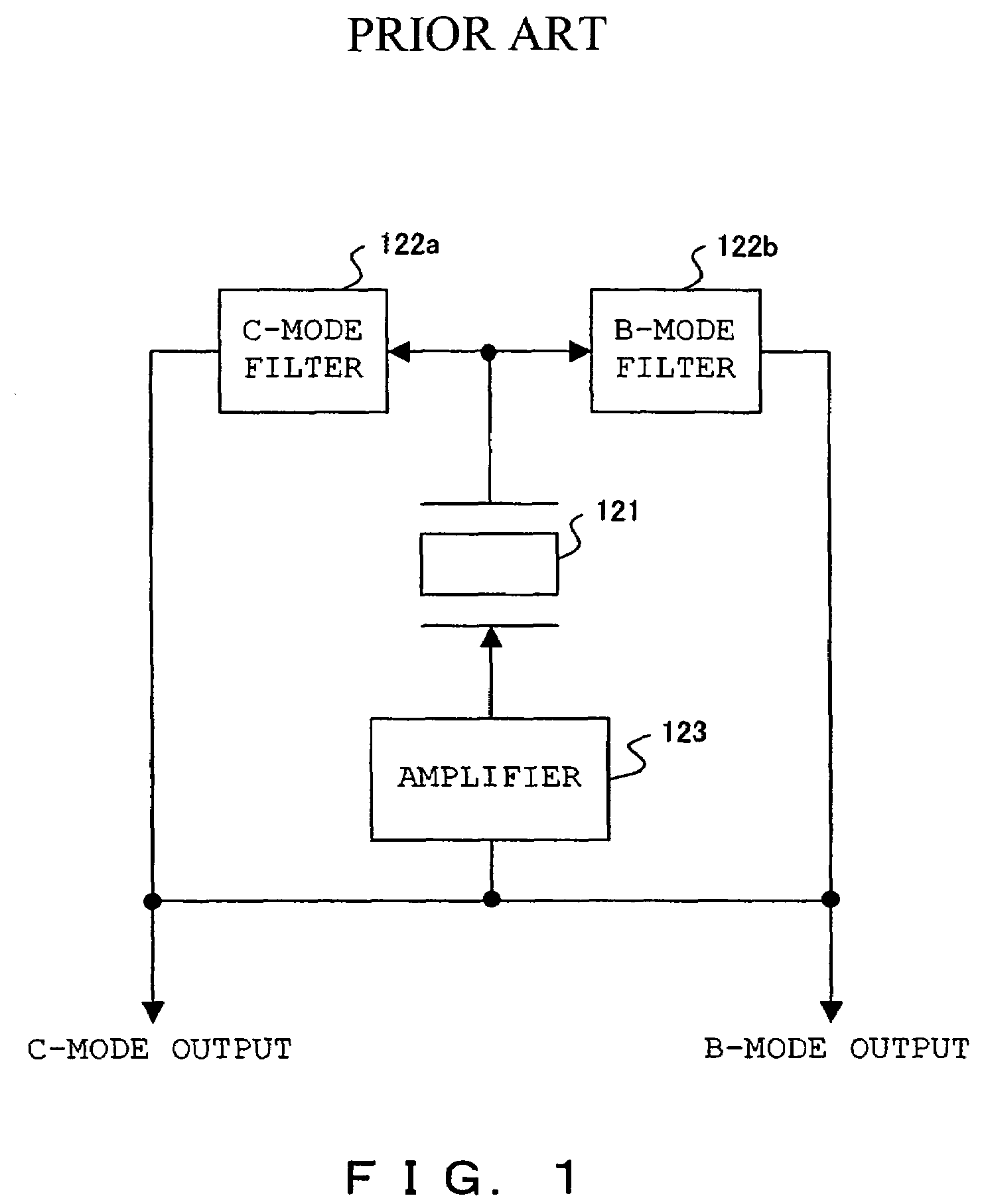

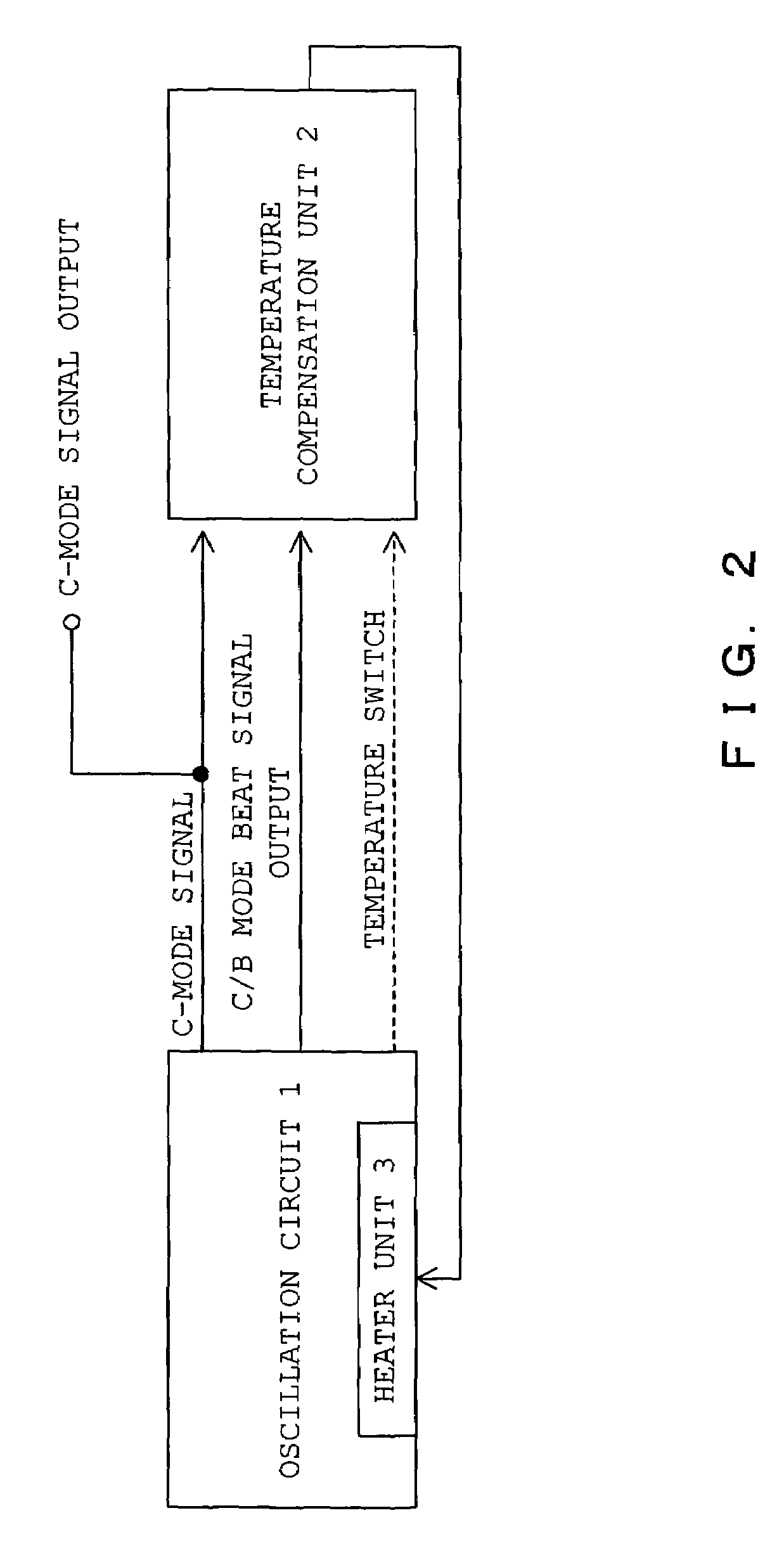

Crystal oscillator device, oscillation method and heater

InactiveUS7378916B2Improve thermal efficiencyImprove precision controlPiezoelectric/electrostriction/magnetostriction machinesOscillations generatorsResonanceQuantum electrodynamics

The crystal oscillator device for simultaneously generating oscillator signals with a plurality of oscillation modes of a crystal unit, comprising: a primary resonator unit filtering the oscillator signal with a primary oscillation mode, which is one of the oscillation modes, from the output of the crystal unit, a secondary resonator unit filtering the oscillation signal, bearing a different resonance frequency from that of the primary resonator unit, with the primary oscillation mode from the output of the crystal unit, a primary phase synthesis unit, synthesizing the phases of the output signal of the primary resonator unit and the output signal of the secondary resonator unit, a tertiary resonator unit, a quaternary resonator unit, and a secondary phase synthesis unit.

Owner:NIHON DEMPA KOGYO CO LTD

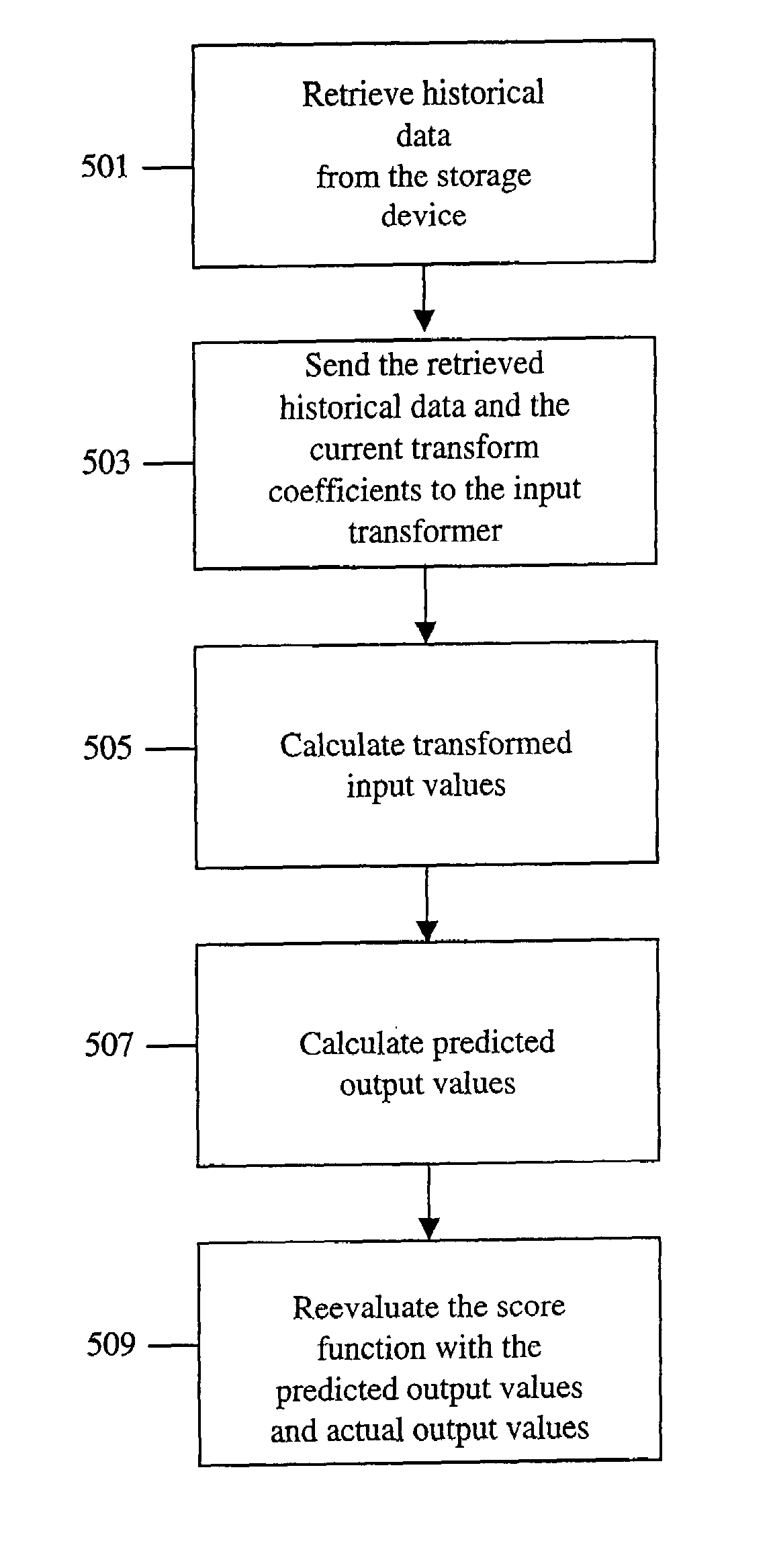

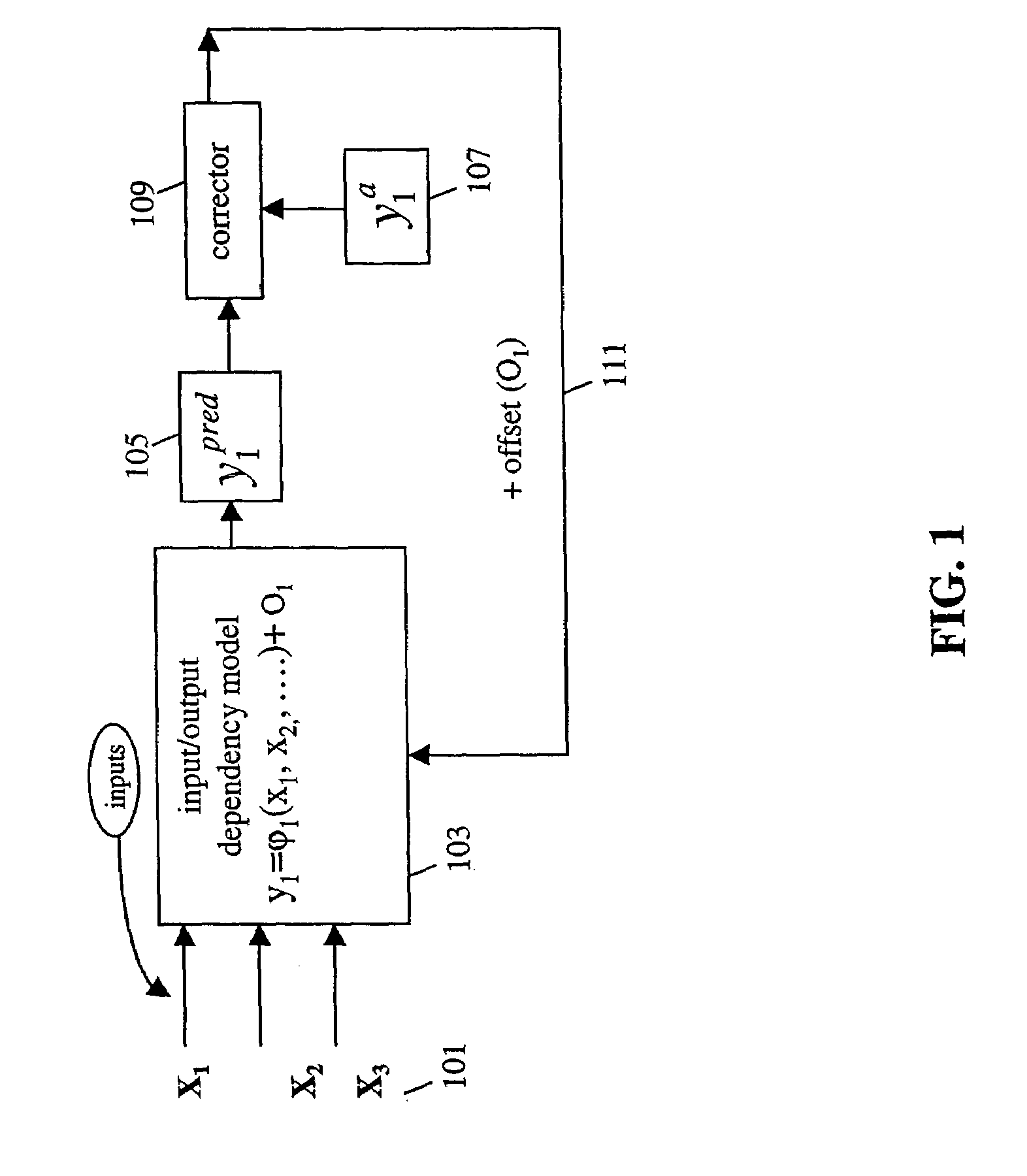

Method, system and medium for controlling manufacture process having multivariate input parameters

InactiveUS7272459B2Minimize effect of outputAccurate modelingComputer controlElectric controllersEngineering

A method, system, and medium of modeling and / or for controlling a manufacturing process is disclosed. In particular, a method according to embodiments of the present invention includes the step of identifying one or more input parameters. Each input parameter causes a change in at least two outputs. The method also includes the step of storing values of the identified inputs and corresponding empirical output values along with predicted output values. The predicted output values are calculated based on, in part, the values of the identified inputs. The method also includes the step of calculating a set of transform coefficients by minimizing a score equation that is a function of differences between one or more of the empirical output values and their corresponding predicted output values. The method further includes the steps of receiving a new set of values for the identified inputs, transforming the new set of values for the identified input using the set of coefficients, and calculating a set of predicted output values using the transformed input values.

Owner:APPL MATERIALS ISRAEL LTD

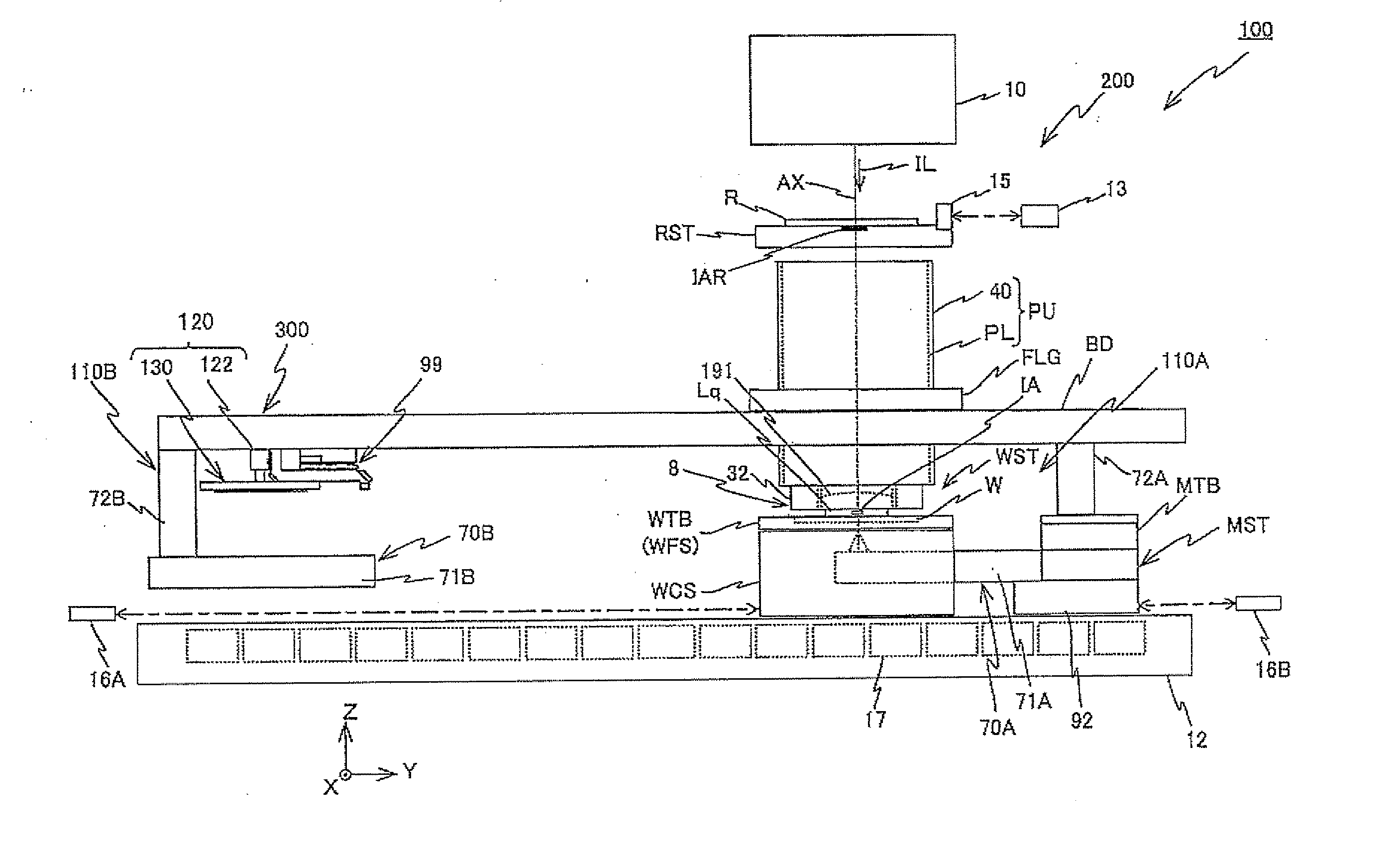

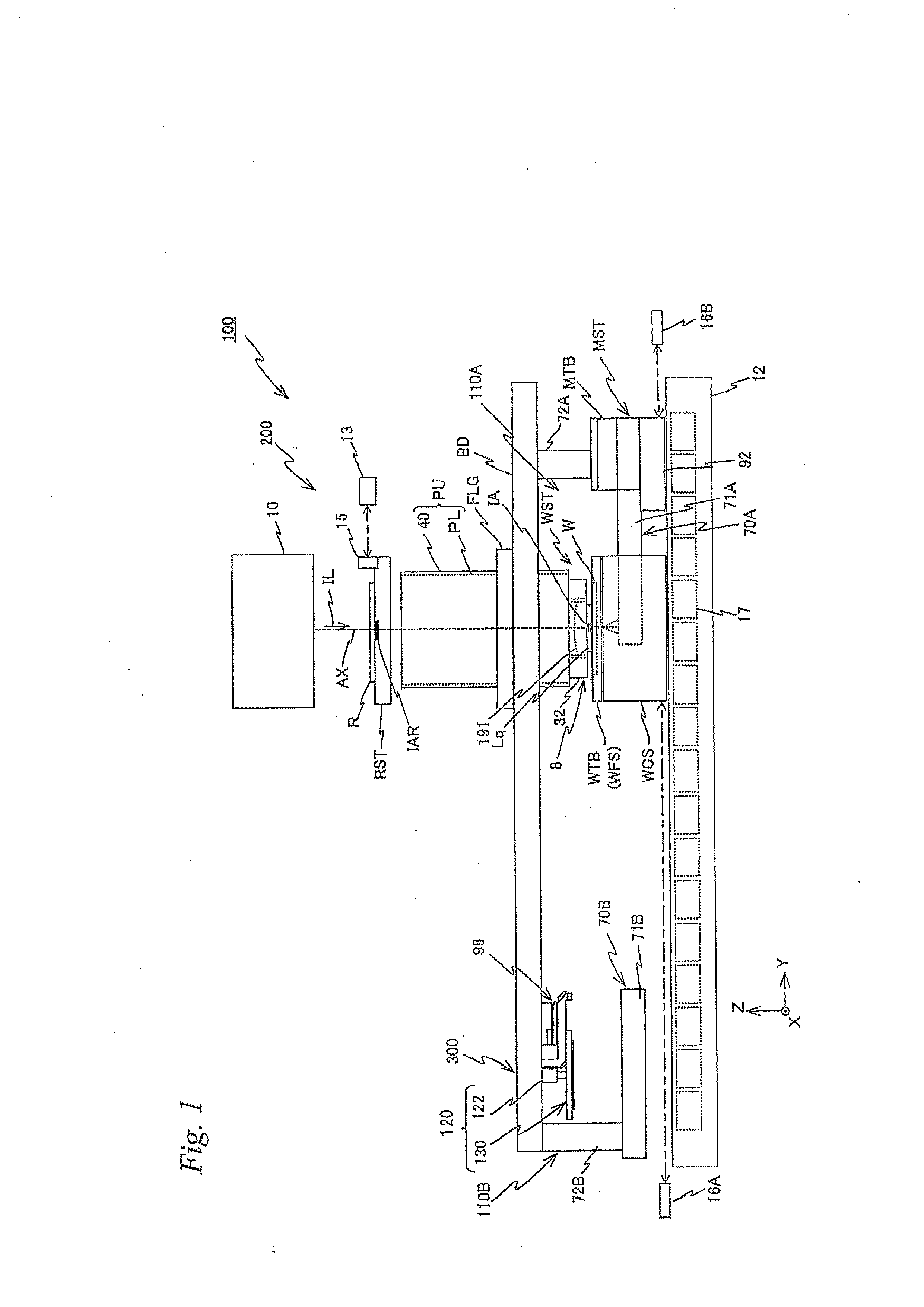

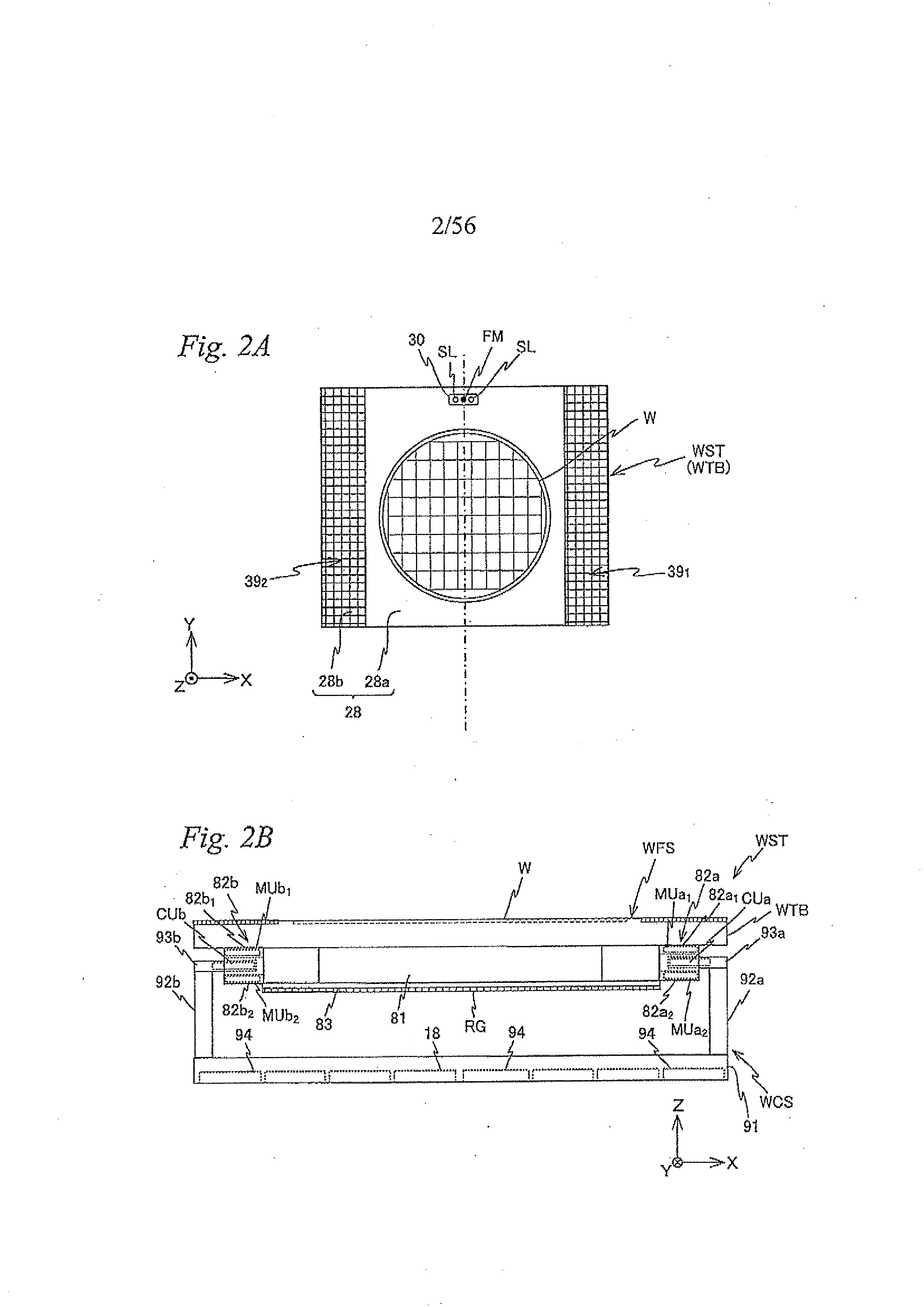

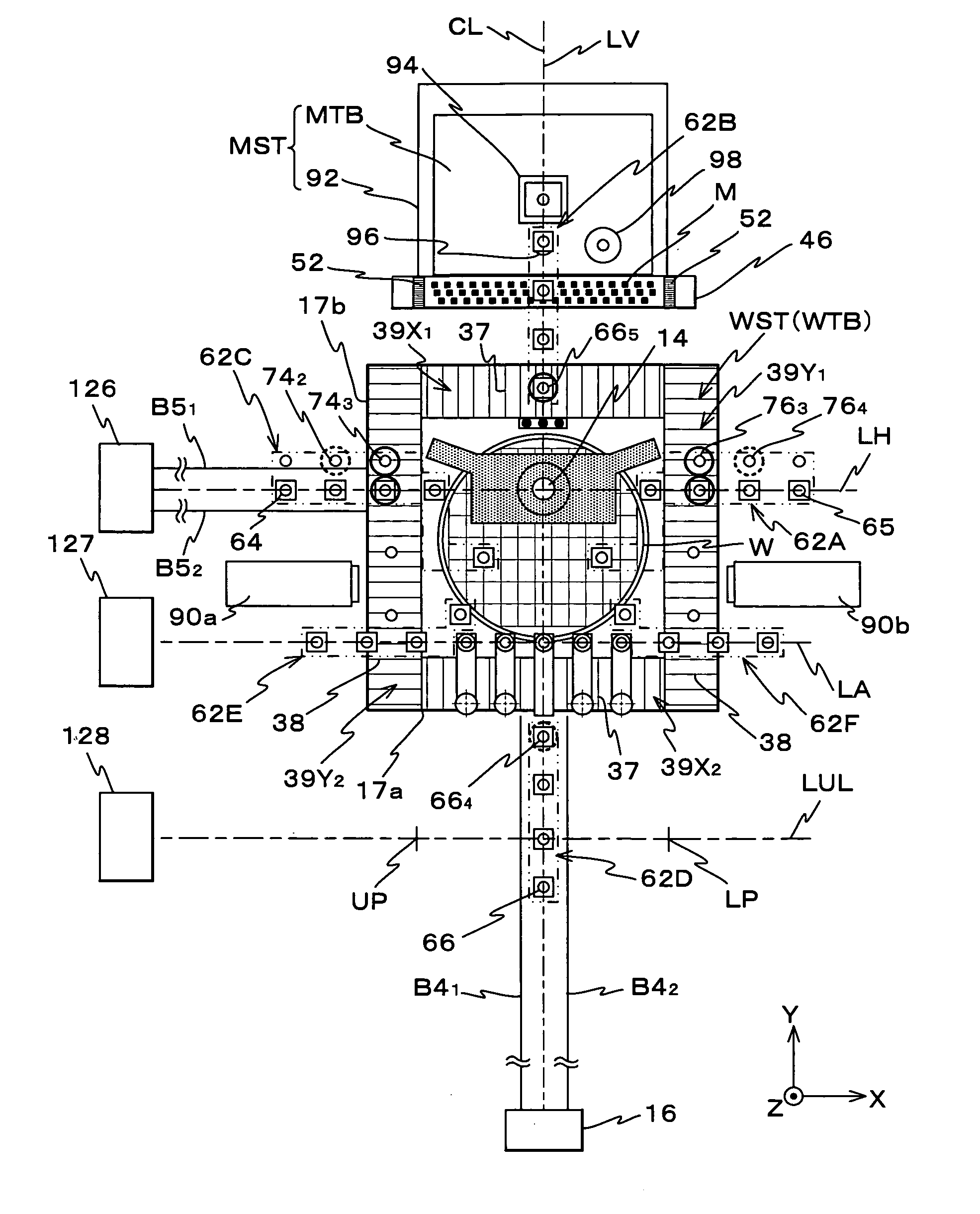

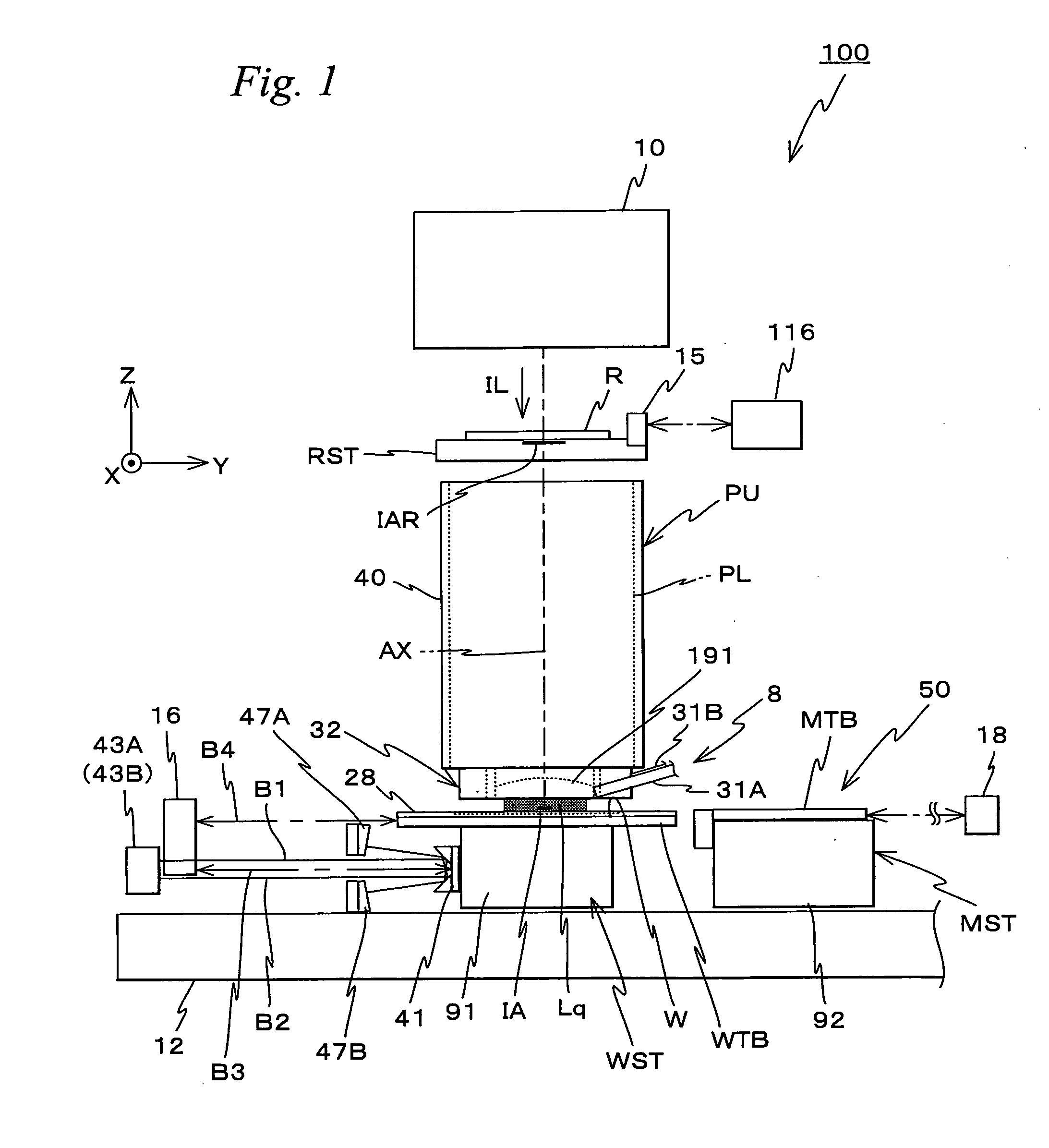

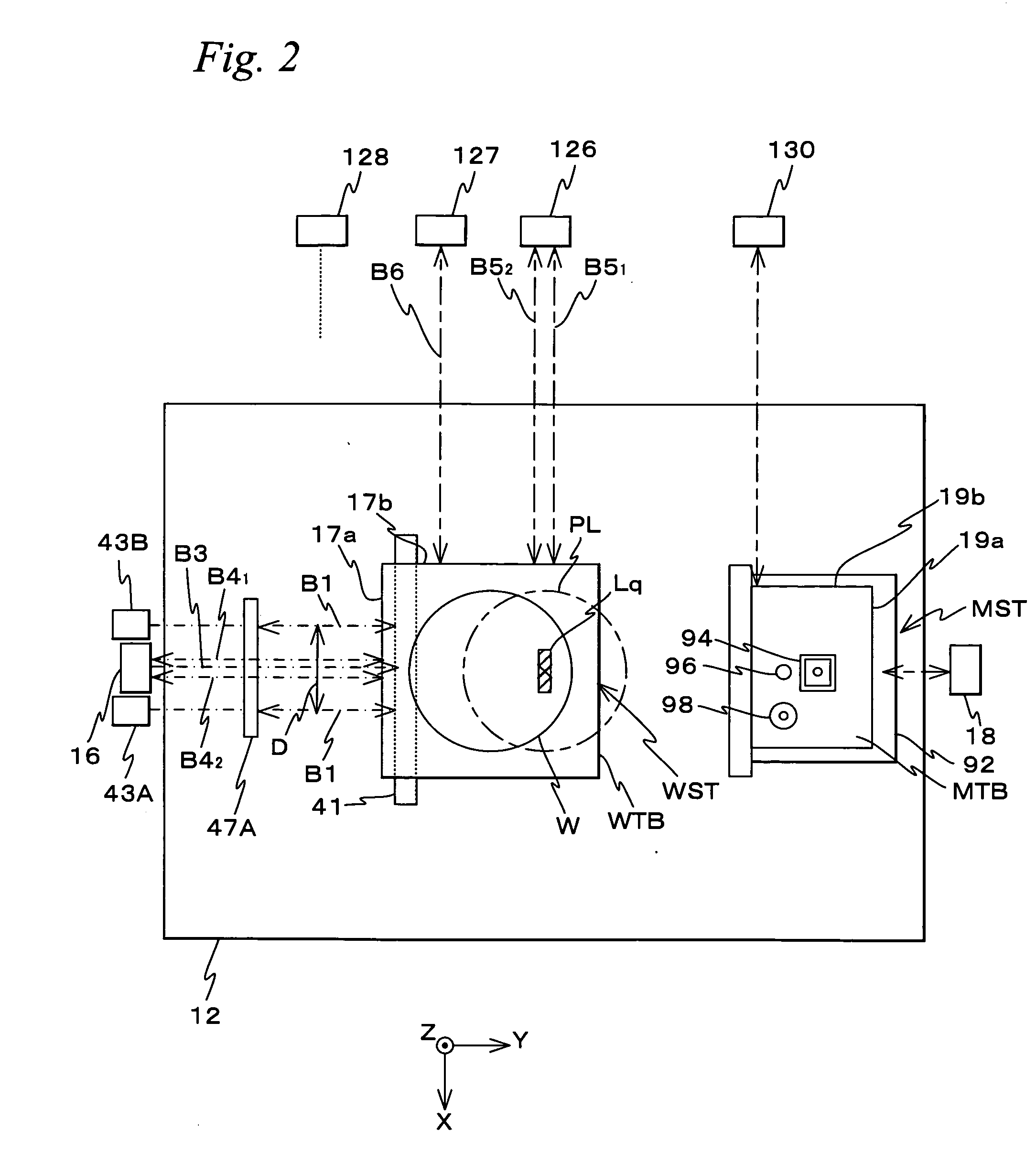

Exposure apparatus and exposure method, and device manufacturing method

ActiveUS20130183623A1Improve reliabilityGood precisionElectric discharge tubesMeasurement/indication equipmentsGratingLight beam

An exposure apparatus is equipped with a table which holds a wafer and is movable along an XY plane and has a grating provided on its rear surface, an encoder which irradiates a first measurement beam on the grating from below, receives a return light, and measures a first position information of the table when the table moves in a predetermined range, and another encoder which has a head section provided in a frame and irradiates a second measurement beam on a different grating on the table from the head section, receives a return light, and can measure a second position information of the table, concurrently with measurement of the first position information by the encoder when the table moves in predetermined range. A controller drives the table, based on position information having a higher reliability of the first and the second position information.

Owner:NIKON CORP

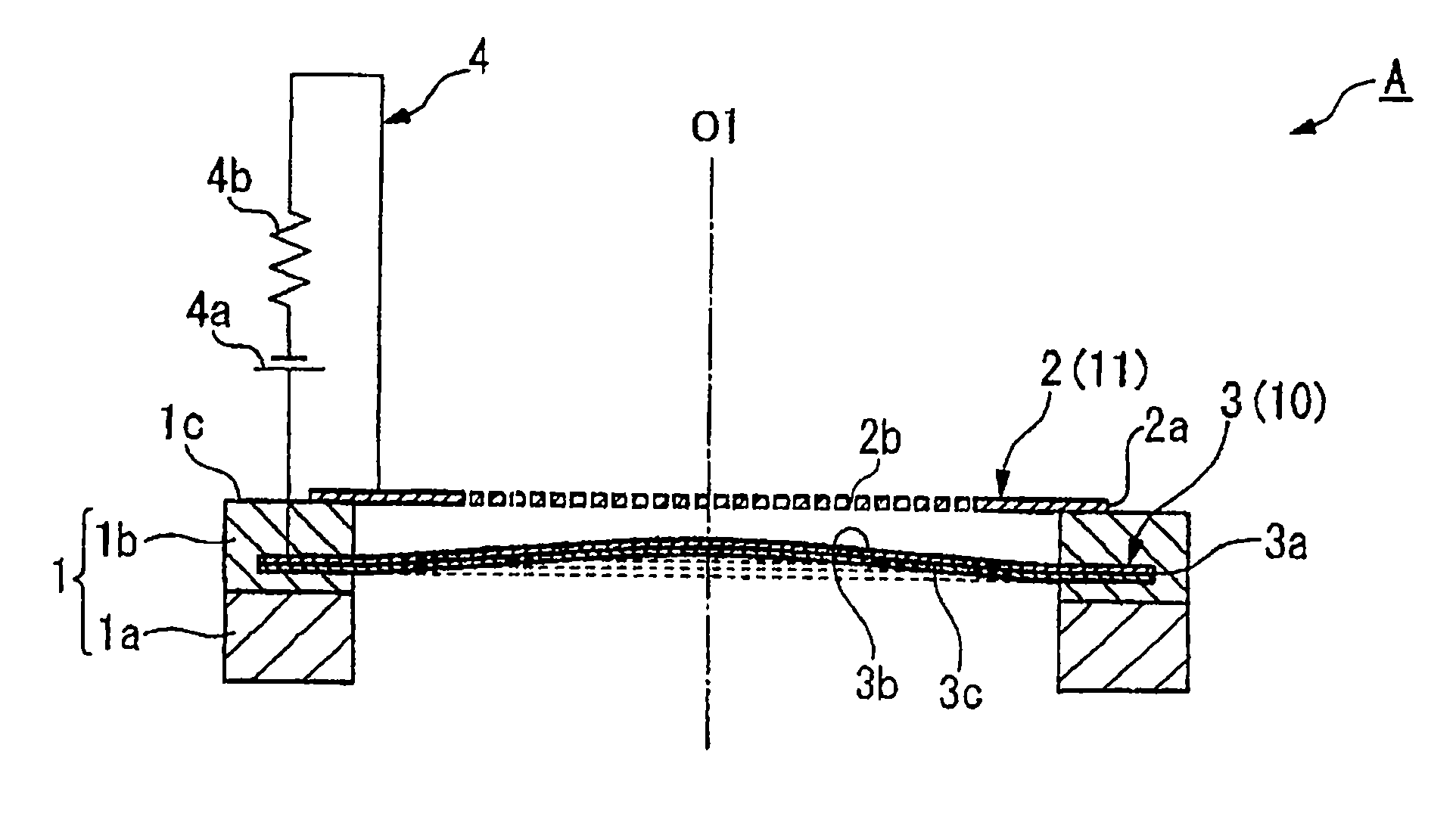

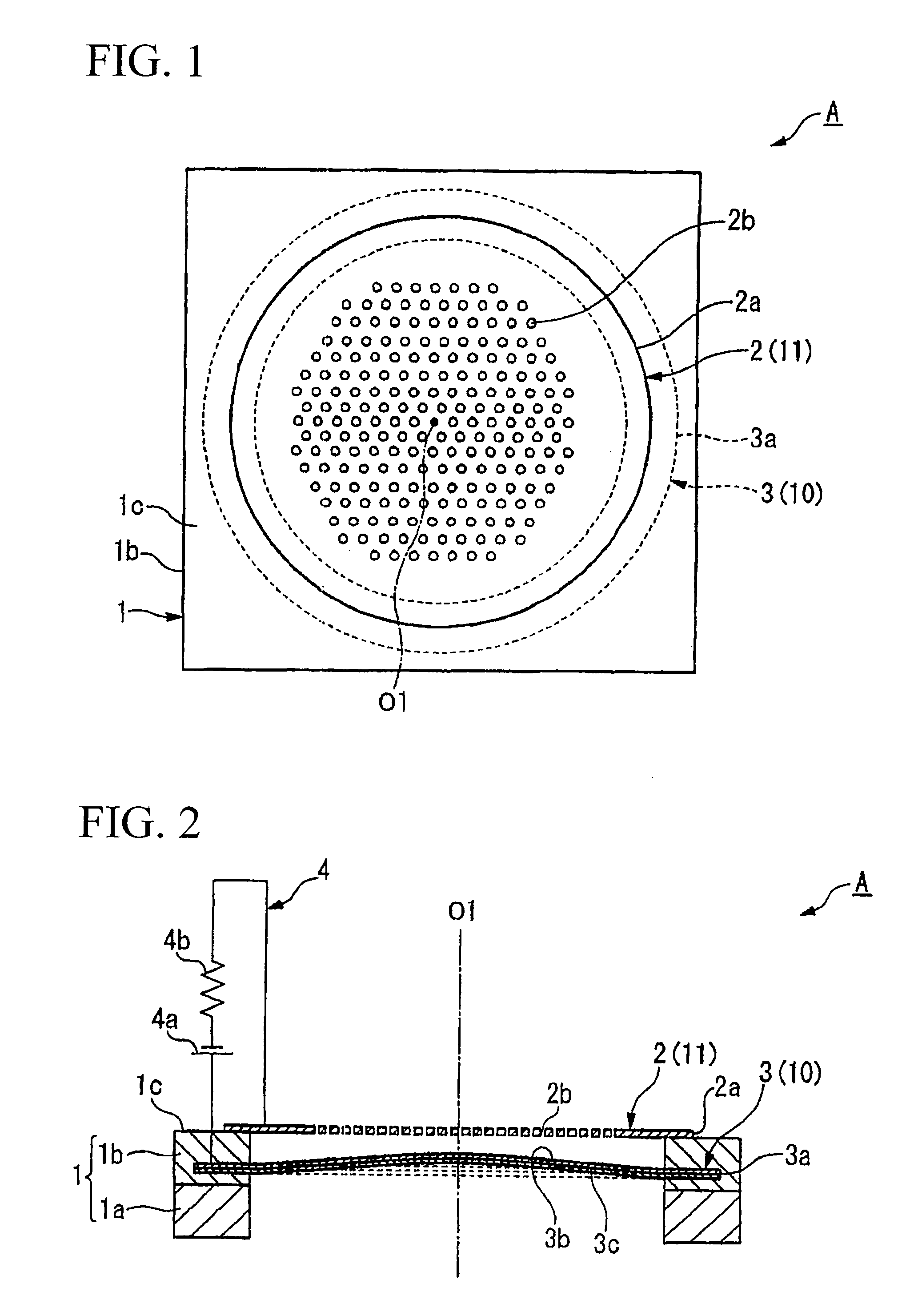

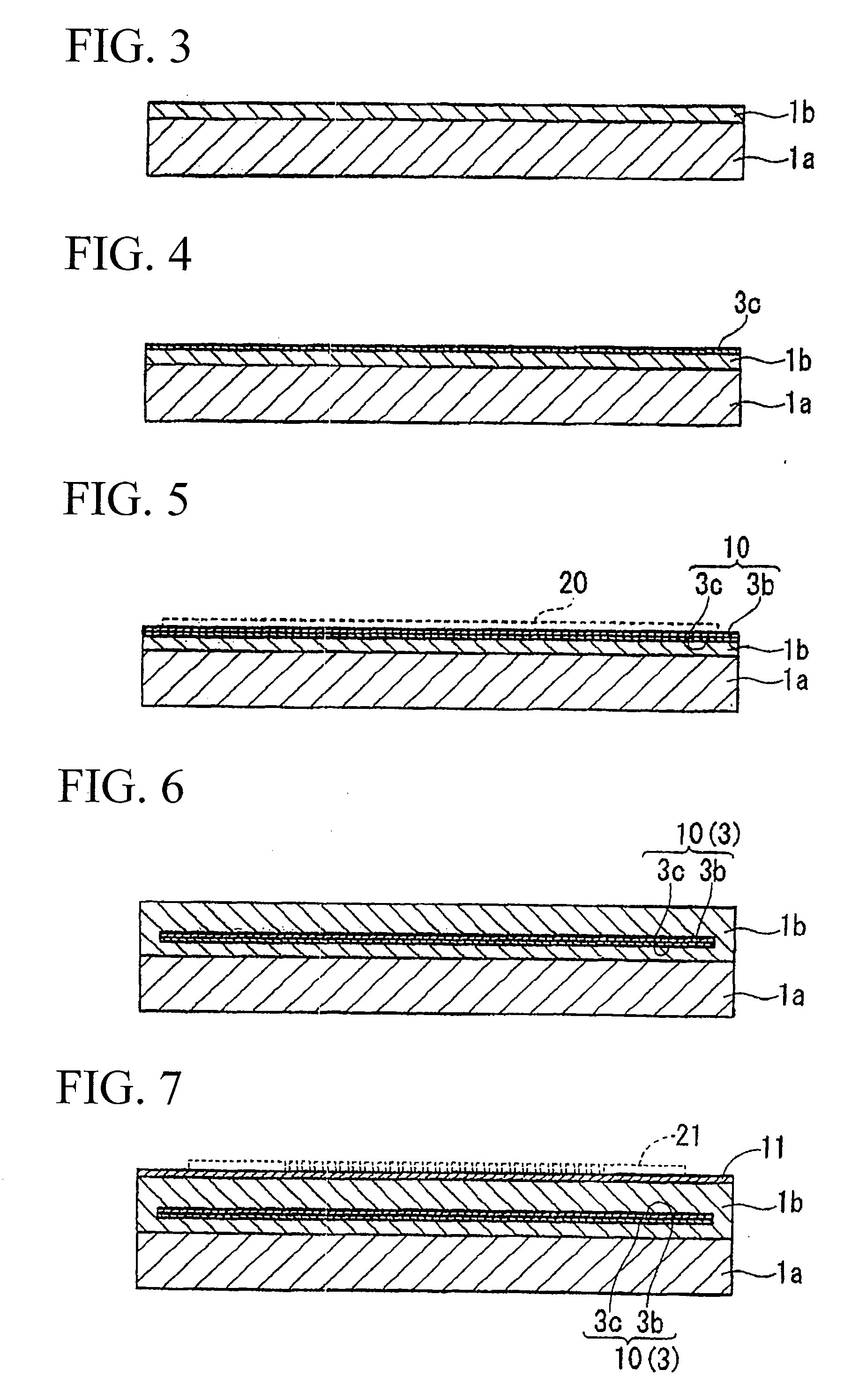

Capacitor microphone and diaphragm therefor

InactiveUS20070121972A1Improved vibration characteristicsHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsHydrofluoric acidEngineering

In a capacitor microphone, a diaphragm is positioned opposite to a fixed electrode for covering inner holes of a ring-shaped support, wherein when the diaphragm is deflected to approach the fixed electrode due to electrostatic attraction upon application of a bias voltage, internal stress that occurs on the diaphragm is canceled by compressive stress that is applied to the diaphragm in advance. The diaphragm is formed using a multilayered structure including a first thin film and a second thin film whose internal stress differs from the internal stress of the first thin film, thus adjusting the total internal stress thereof. The diaphragm can be formed in such a way that a center layer having a single-layered structure is sandwiched between first and second coating layers having controlled residual tensions and resistance against hydrofluoric acid.

Owner:YAMAHA CORP

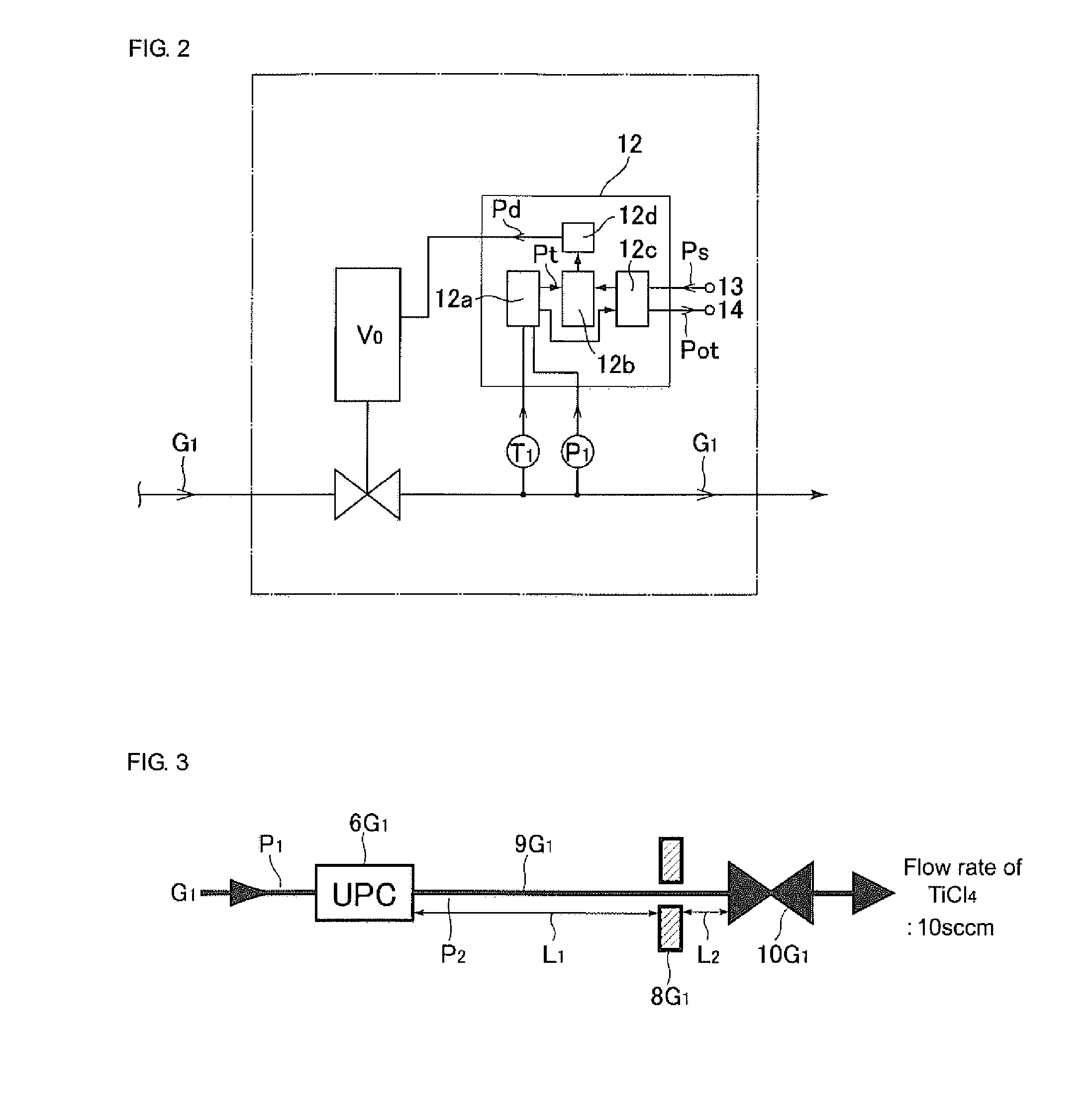

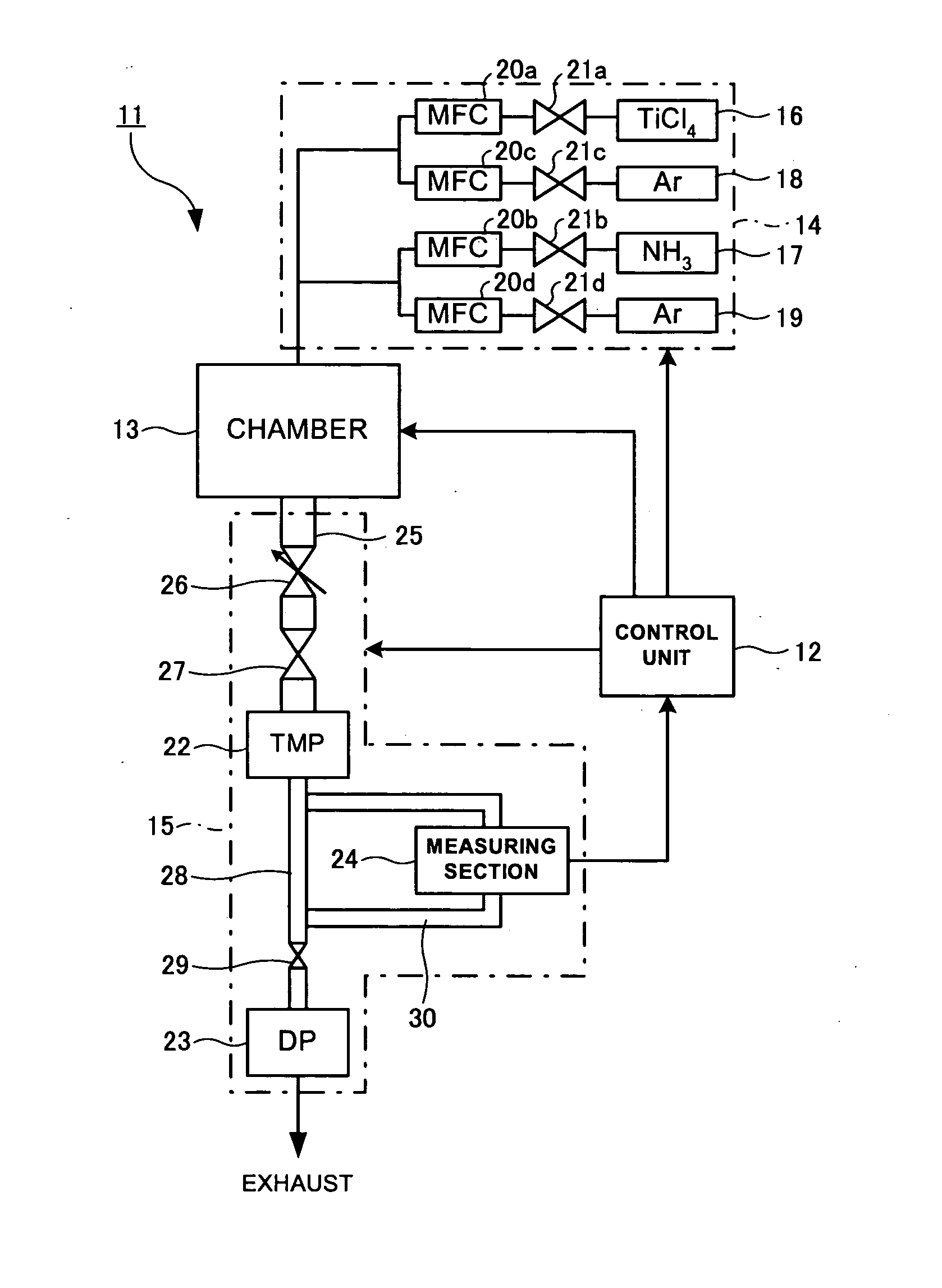

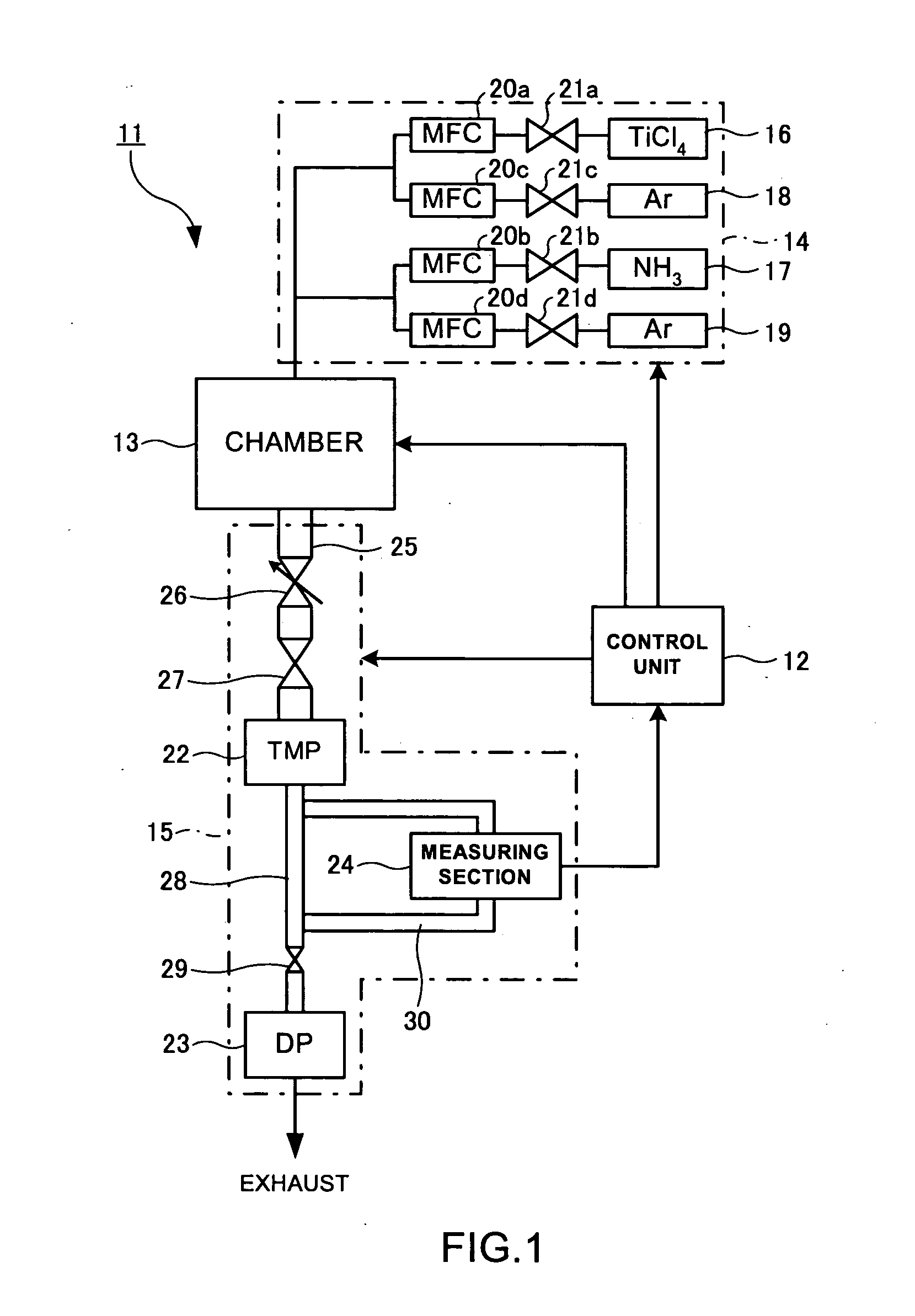

Processing device and processing method

InactiveUS20050145333A1Improve accuracyHigh analytical sensitivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingExhaust gasEngineering

An exhaust line (15) connected to a chamber (13) comprises a TMP (22) and a dry pump (23). The chamber (13) and the TMP (22) are connected by a first exhaust pipe (25), and the TMP (22) and the dry pump (23) are connected by a second exhaust pipe (28). A measuring section (24) monitors a partial pressure of TiCl4 or NH3 in an exhaust gas flowing in the second exhaust pipe (28). Two types of process gases are alternately supplied into the chamber (13) for a predetermined time, and when the partial pressure of one of the supplied process gases in the exhaust gas is reduced to a predetermined value, a control means (12) starts supplying the other process gas.

Owner:TOKYO ELECTRON LTD

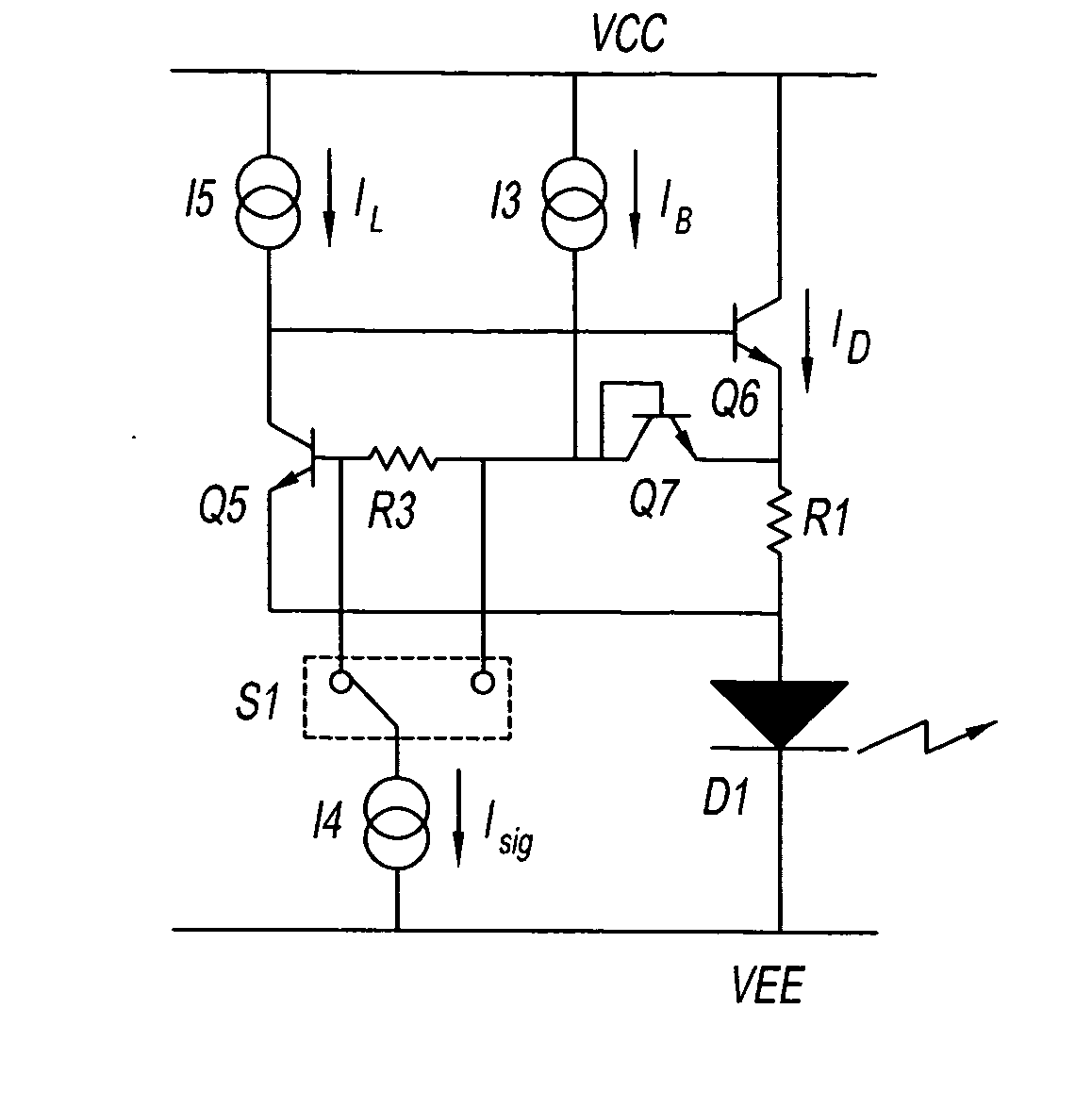

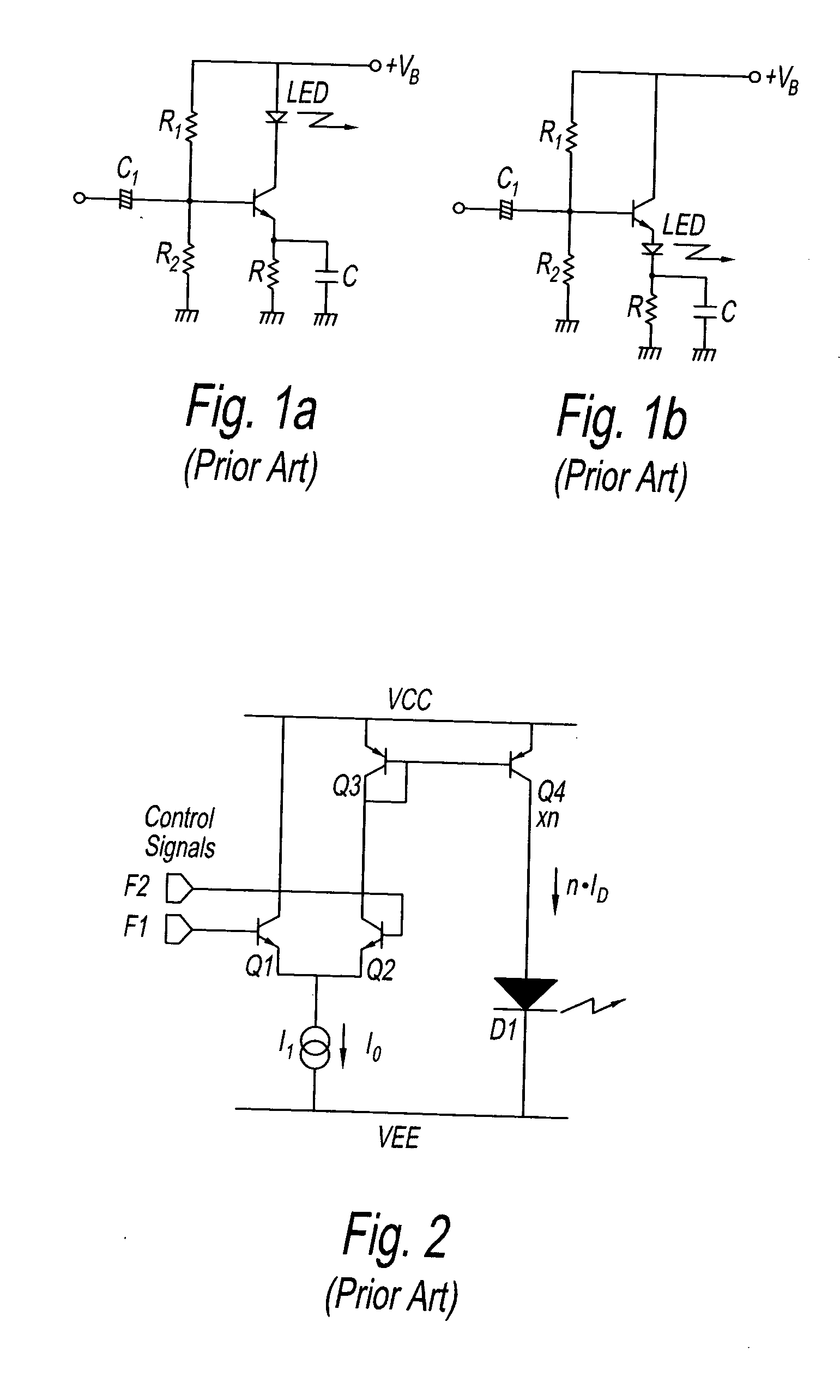

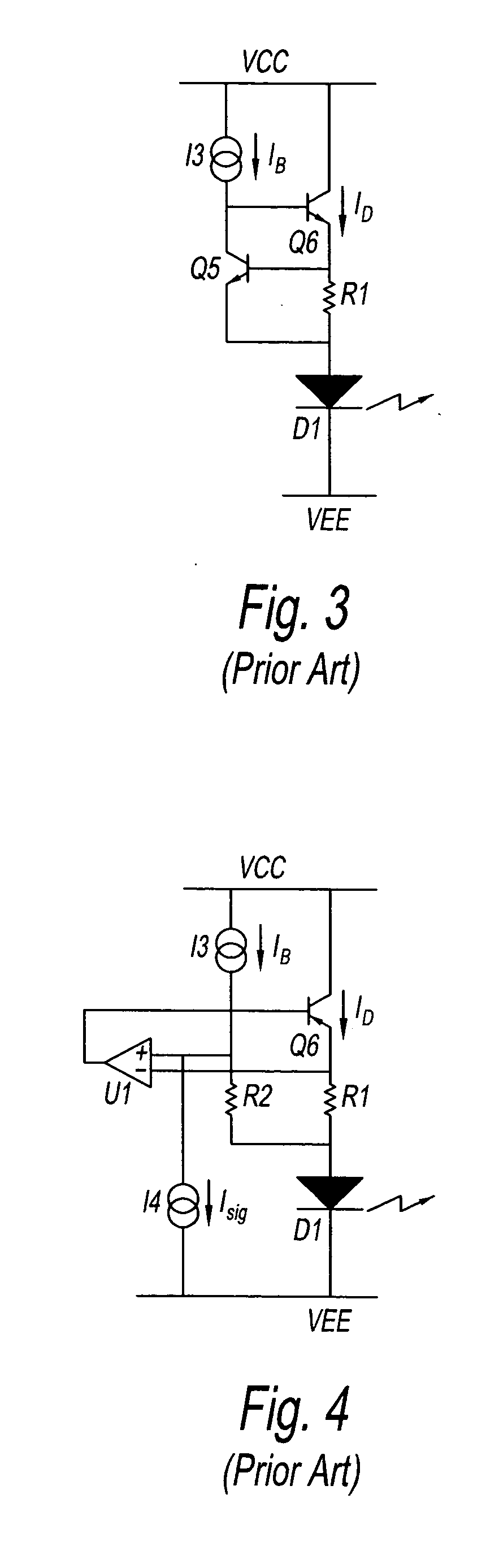

LED drive circuit

ActiveUS20050029527A1Small sizeEasy to integrateElectroluminescent light sourcesSolid-state devicesLED circuitAnode

An LED drive circuit, wherein a circuit that drives light-emitting diode with a common connected cathode has a resistor connected to the anode of the light-emitting diode, an NPN-type transistor connected to the second terminal of the resistor that approximately determines the control current for the emission of light in cooperation with the resistor, an NPN-type transistor positioned in parallel with the resistor and connected to the anode of the light-emitting diode, and a current supply, a level shifter, and a switch for selectively changing the voltage between the base-emitter of the second transistor, which are placed between the base of transistor and resistor.

Owner:LITE ON TECH CORP

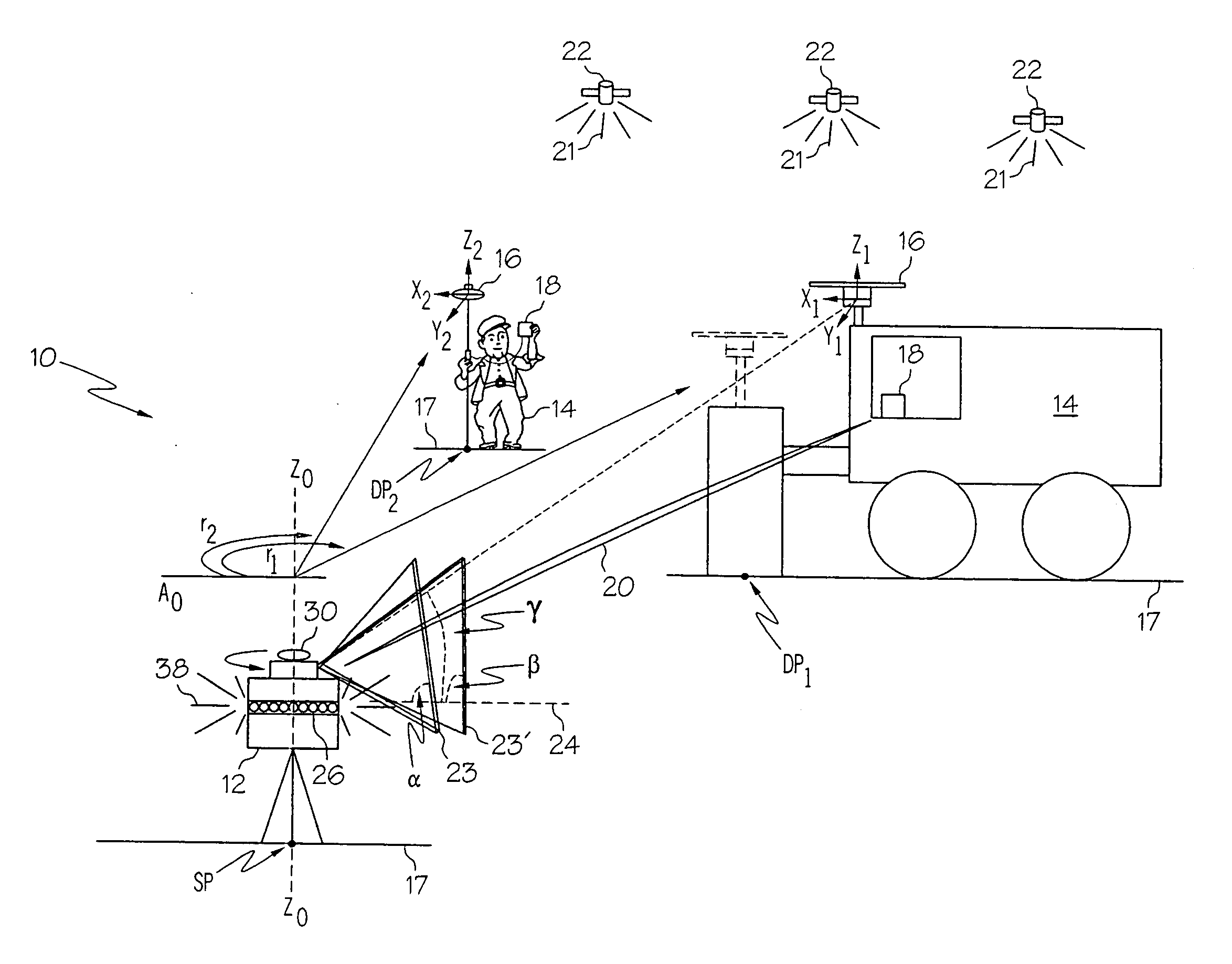

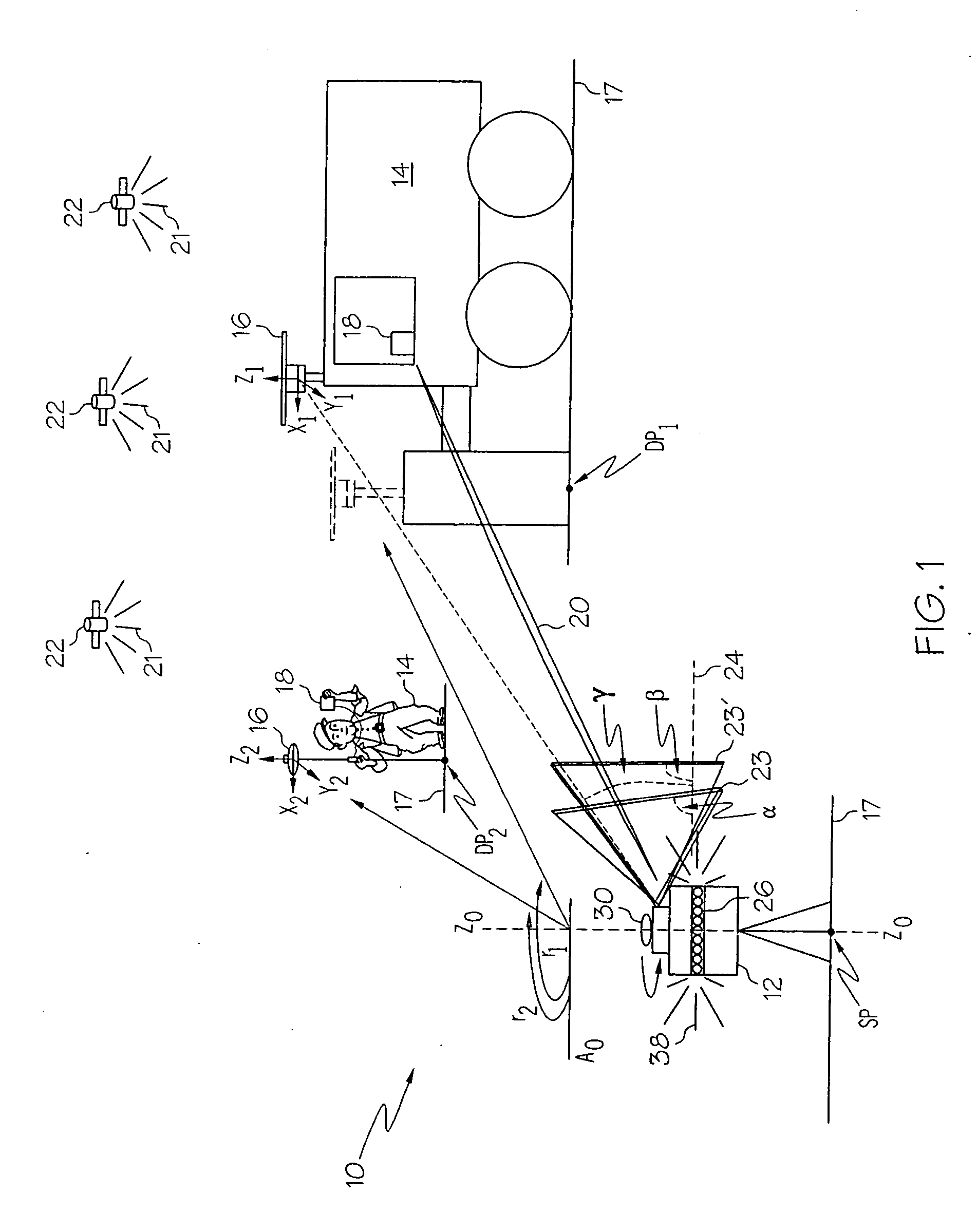

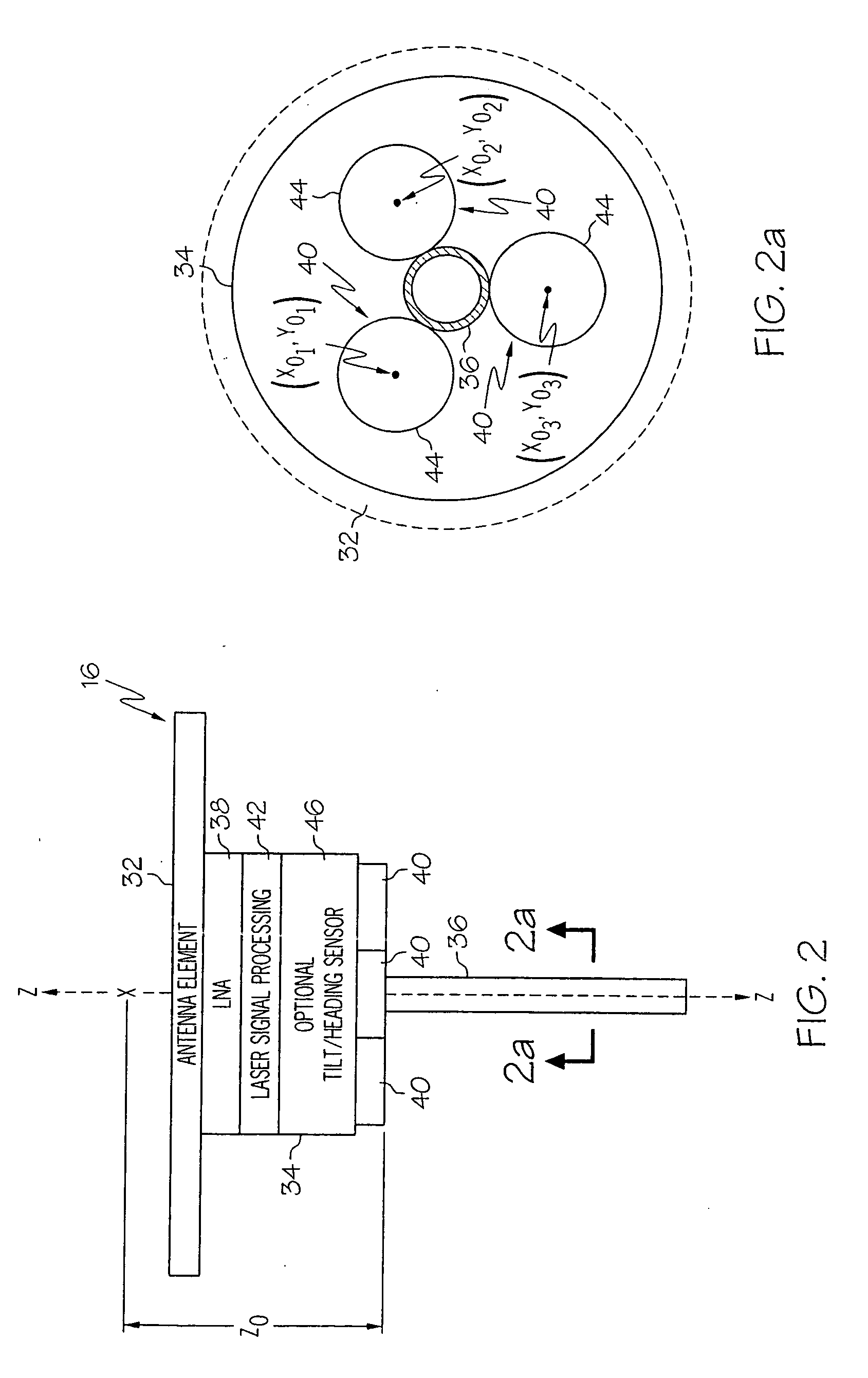

Navigation system using both GPS and laser reference

ActiveUS20070052950A1Slow down operationImprove precision controlAngle measurementPosition fixationLaser transmitterMachine control

A machine control system uses a laser system and global navigation satellite system to determine the position of the machine. The laser system has a laser detector positioned in a known and fixed relationship with the nominal phase center of a global navigation satellite antenna. The laser detector receives laser light transmitted from a laser transmitter. The outputs of the laser system and the global navigation satellite system are used together to determine the position of the transmitter prior to being used to determine the position of the machine.

Owner:TRIMBLE NAVIGATION LTD

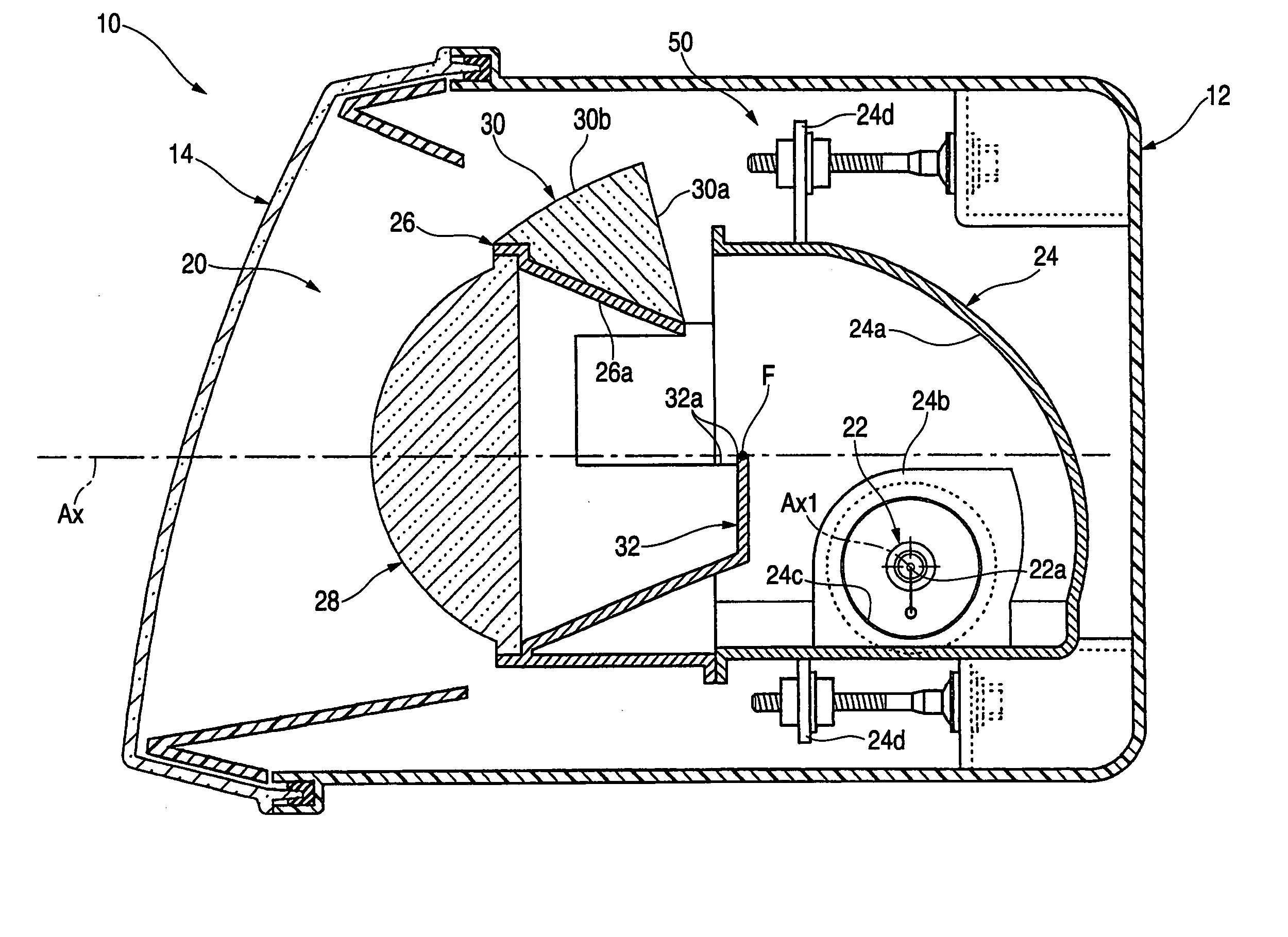

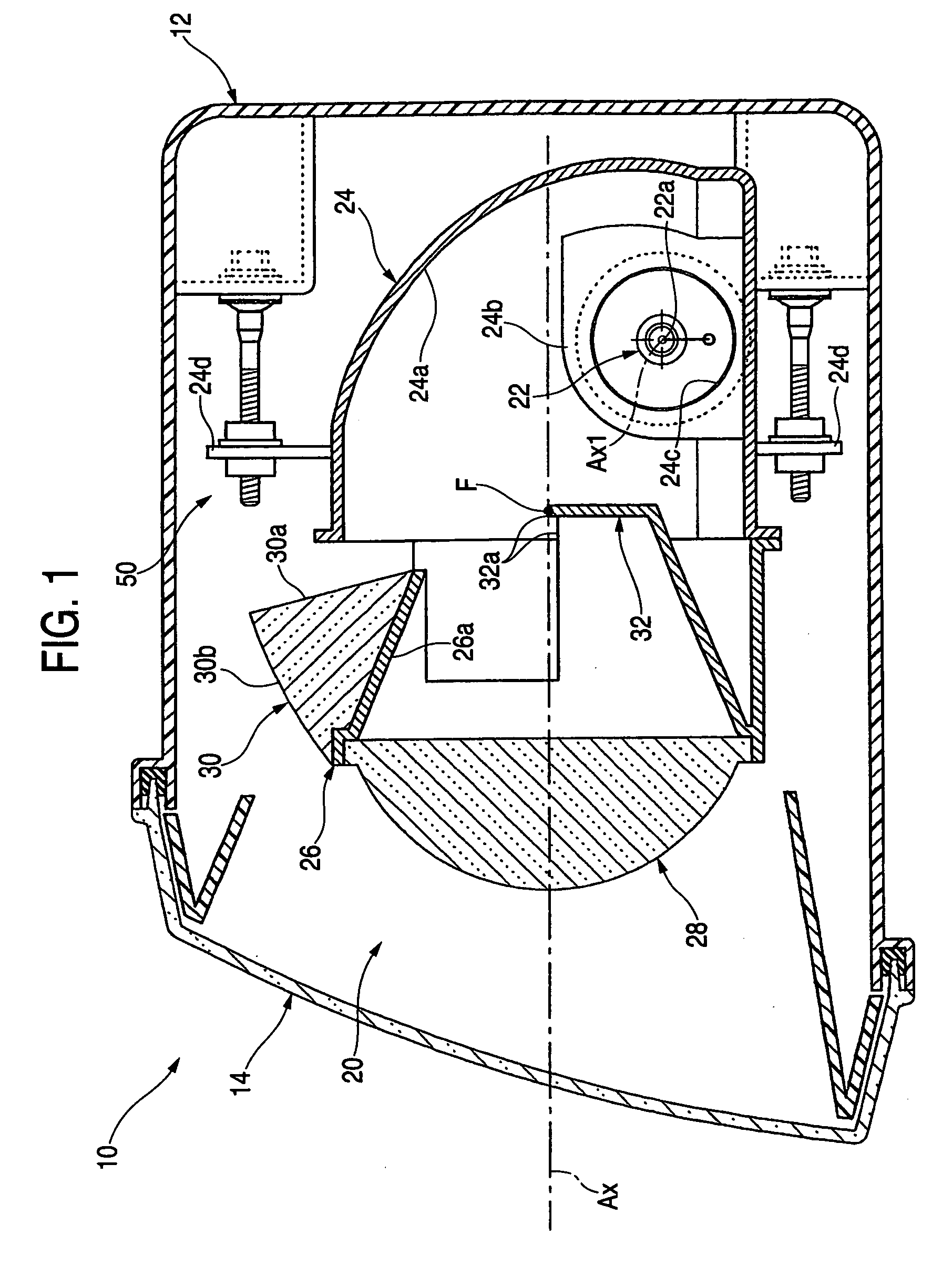

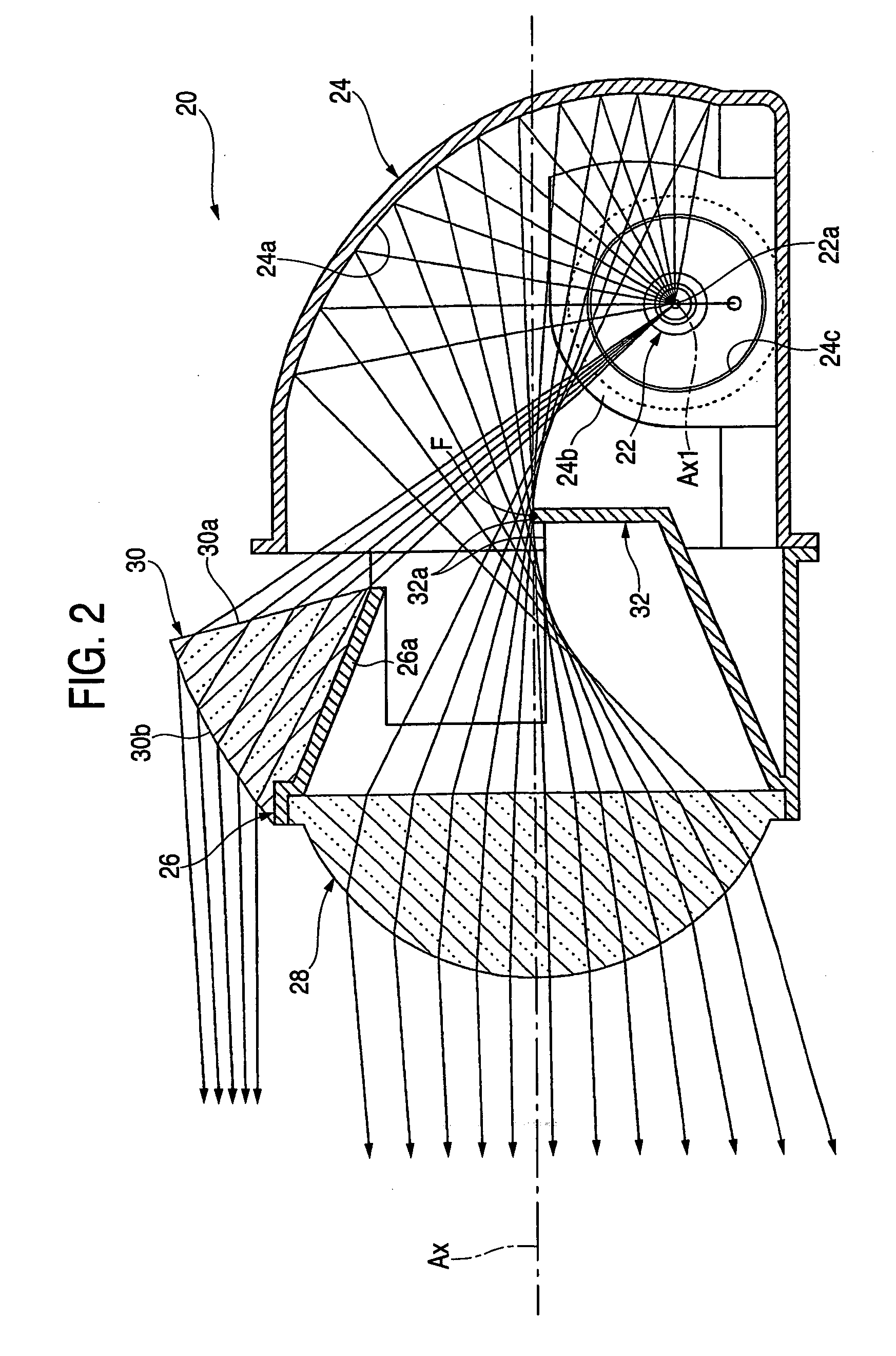

Vehicle headlamp

InactiveUS20050225995A1Increase the amount of lightBright enoughNon-electric lightingVehicle headlampsDistribution controlOptical axis

A light source bulb 22 is inserted and fixed into a reflector 24 from a side in a position placed downward apart from an optical axis Ax. Thus; it is possible to effectively utilize an optical-axis side region in a reflecting plane 24a for a light distribution control. Moreover, an almost prism-shaped light transmitting member 30 is provided in the vicinity of the upper end of the outer peripheral edge portion of a projection lens 28 between the projection lens 28 and the reflector 24, and a direct light from a light source 22a toward the upper space of the projection lens 28 is emitted forward to be deflected downward. Consequently, it is possible to increase the amount of a light to be irradiated on the forward part of a vehicle, and furthermore, to carry out a deflection control for the direct light emitted from the light source 22a with high precision.

Owner:KOITO MFG CO LTD

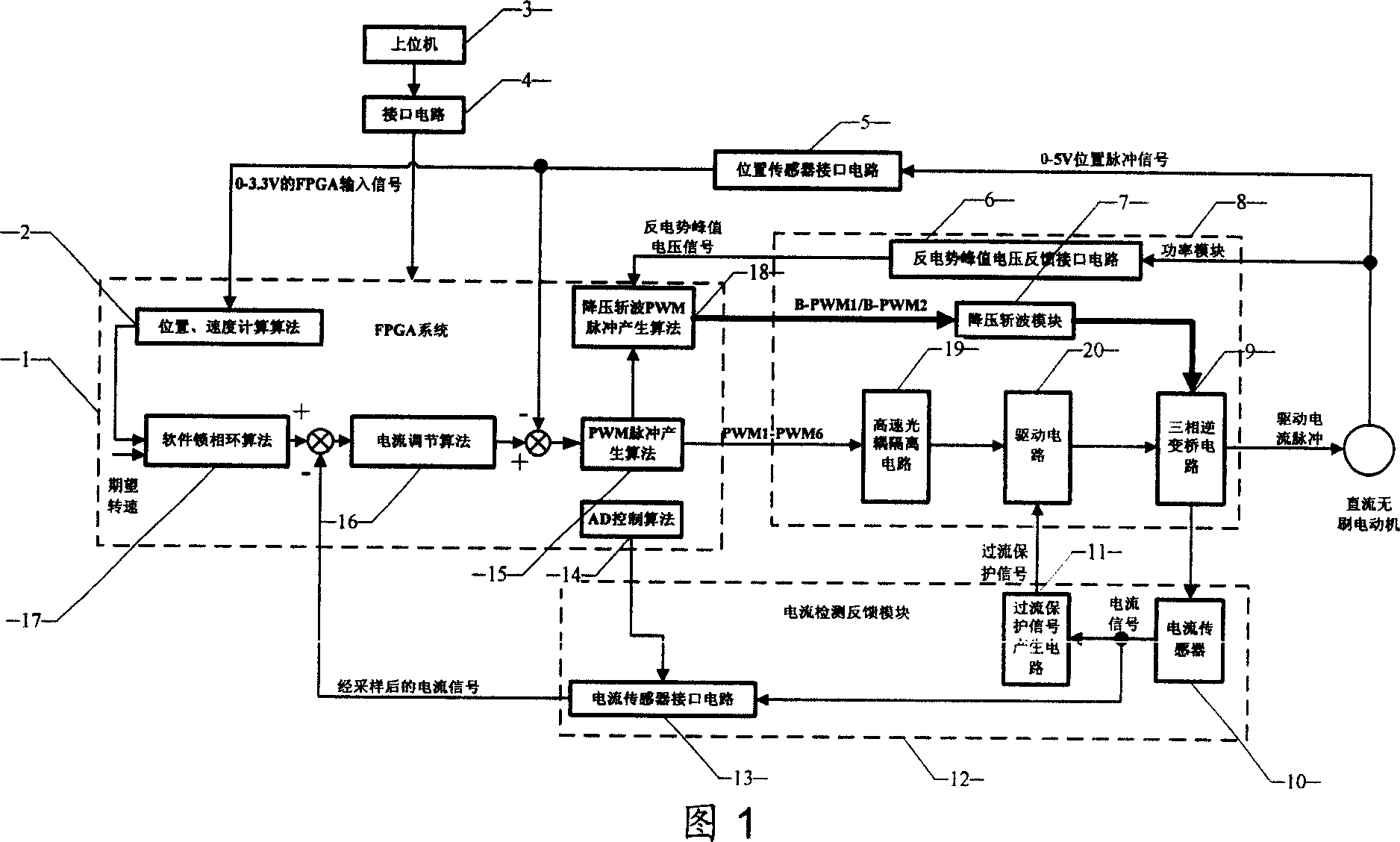

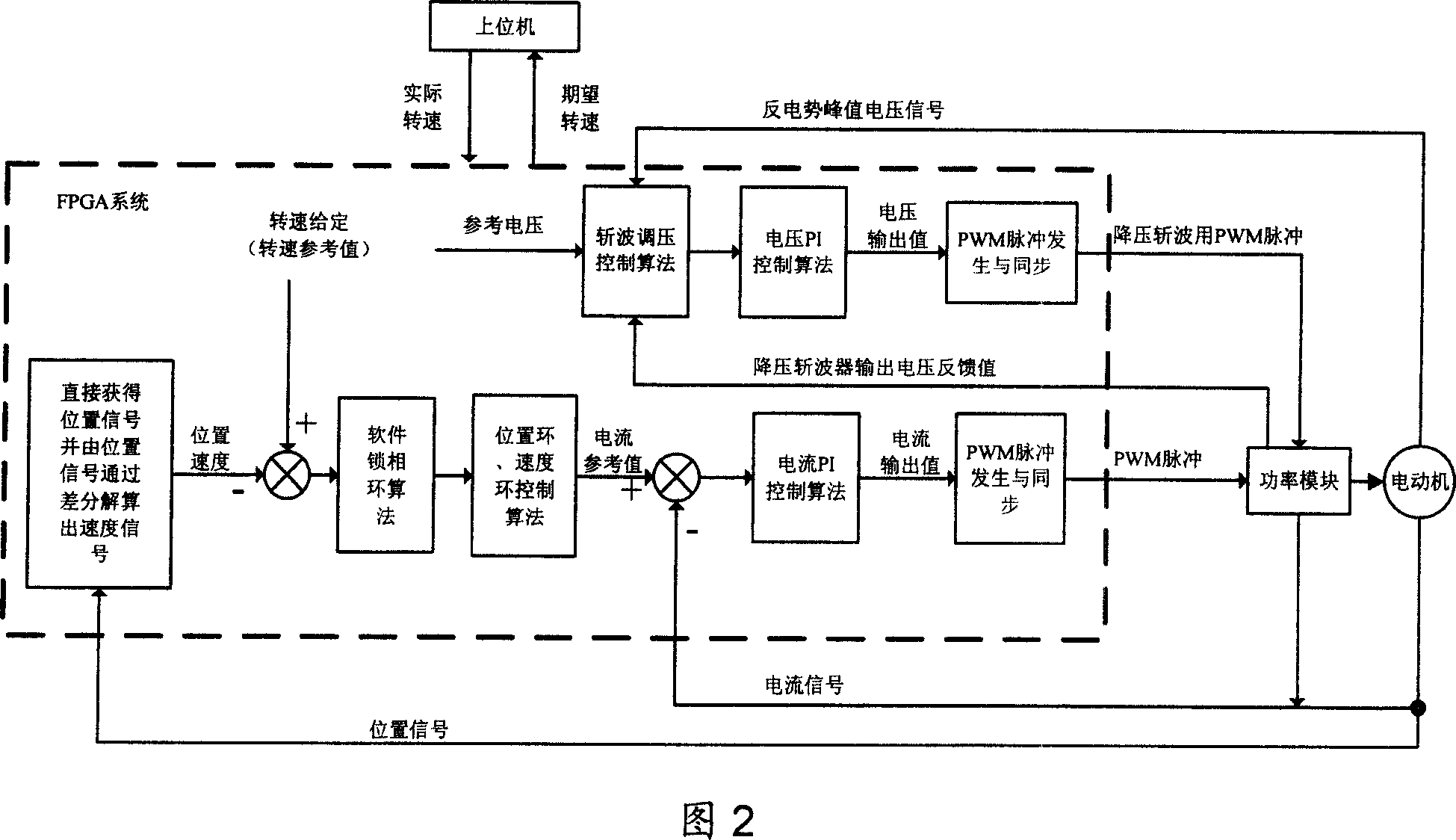

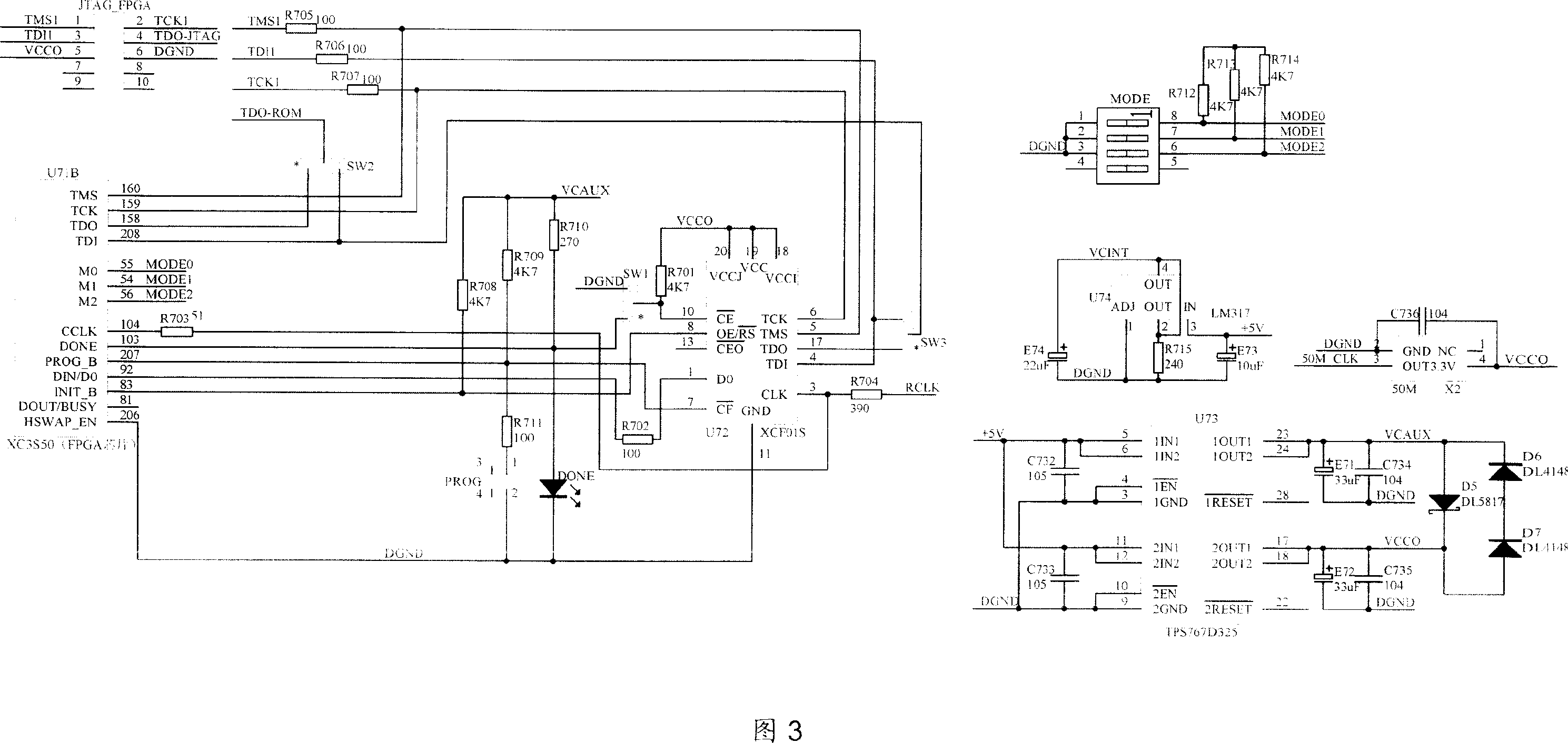

A low-loss, high reliability integration magnetic levitation flywheel DC brushless motor control system

InactiveCN1968003AHigh control precisionHighly integratedField or armature current controlElectronic commutatorsBrushless motorsFpga implementations

The invention relates to a magnetic suspension flywheel direct-current non-brush motor controlling system, wherein it comprises FPGA system, direct-current detecting feedback module, positioning sensor interface circuit, and power module; the FPGA module obtains request rotation speed from super machine, via sensor interface circuit and feedback module to obtain position signal and current signal, and the control algorism of FPGA, to calculate out the control value, and process reduction chopper PWM modulation, and amplify via amplifying module to generate the needed control current, and realize control accurately. The invention has low power consumption and high reliability.

Owner:BEIHANG UNIV

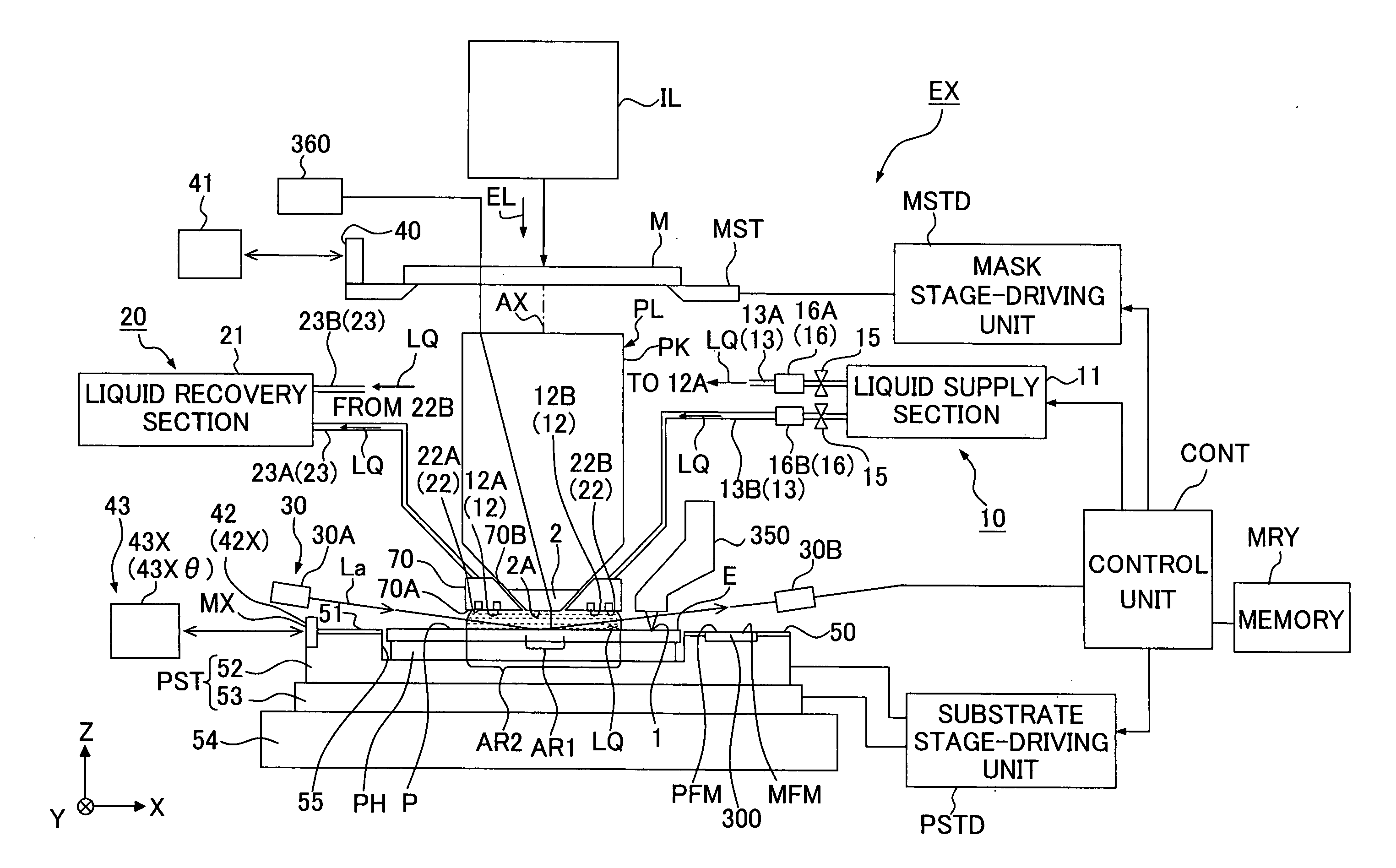

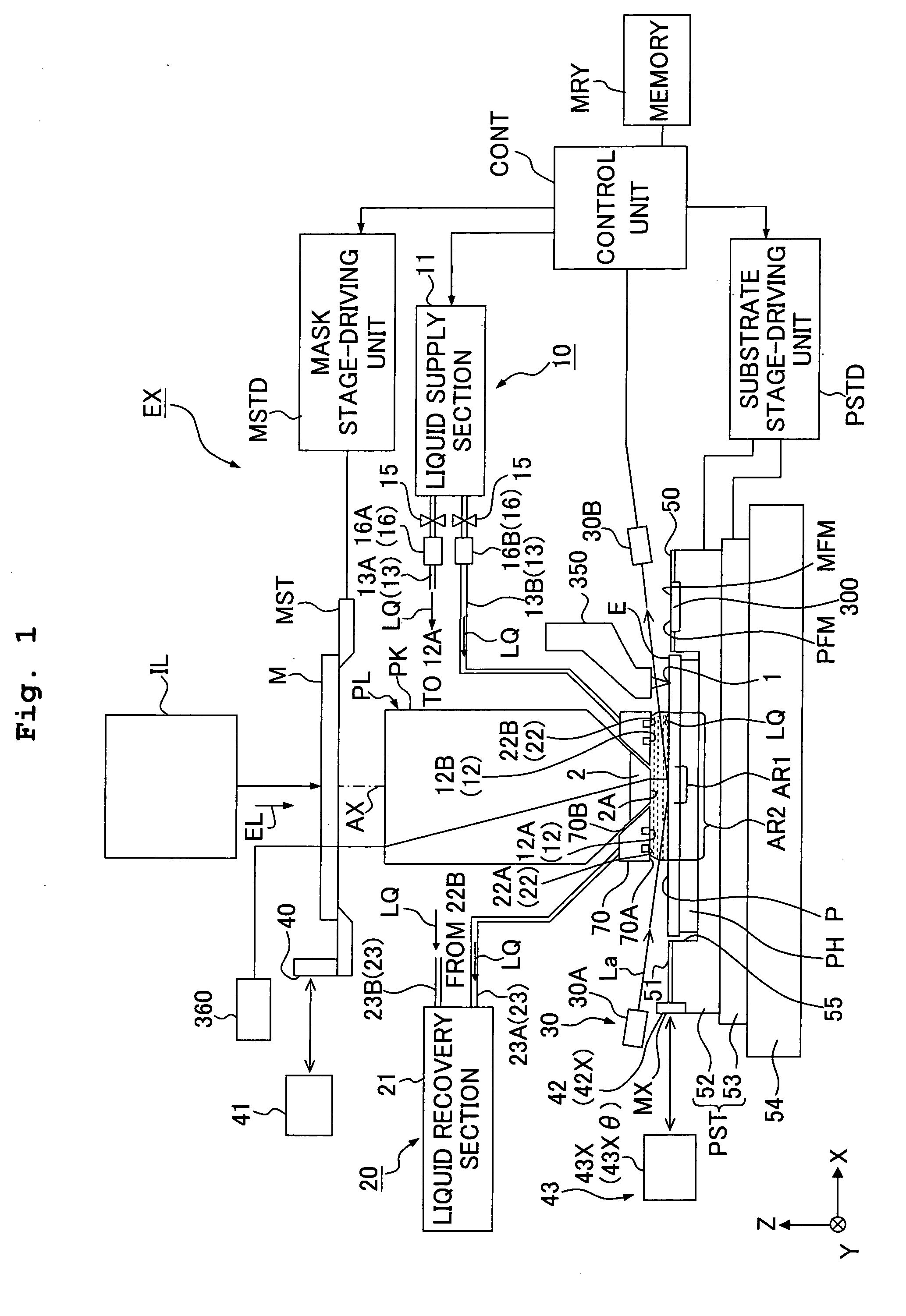

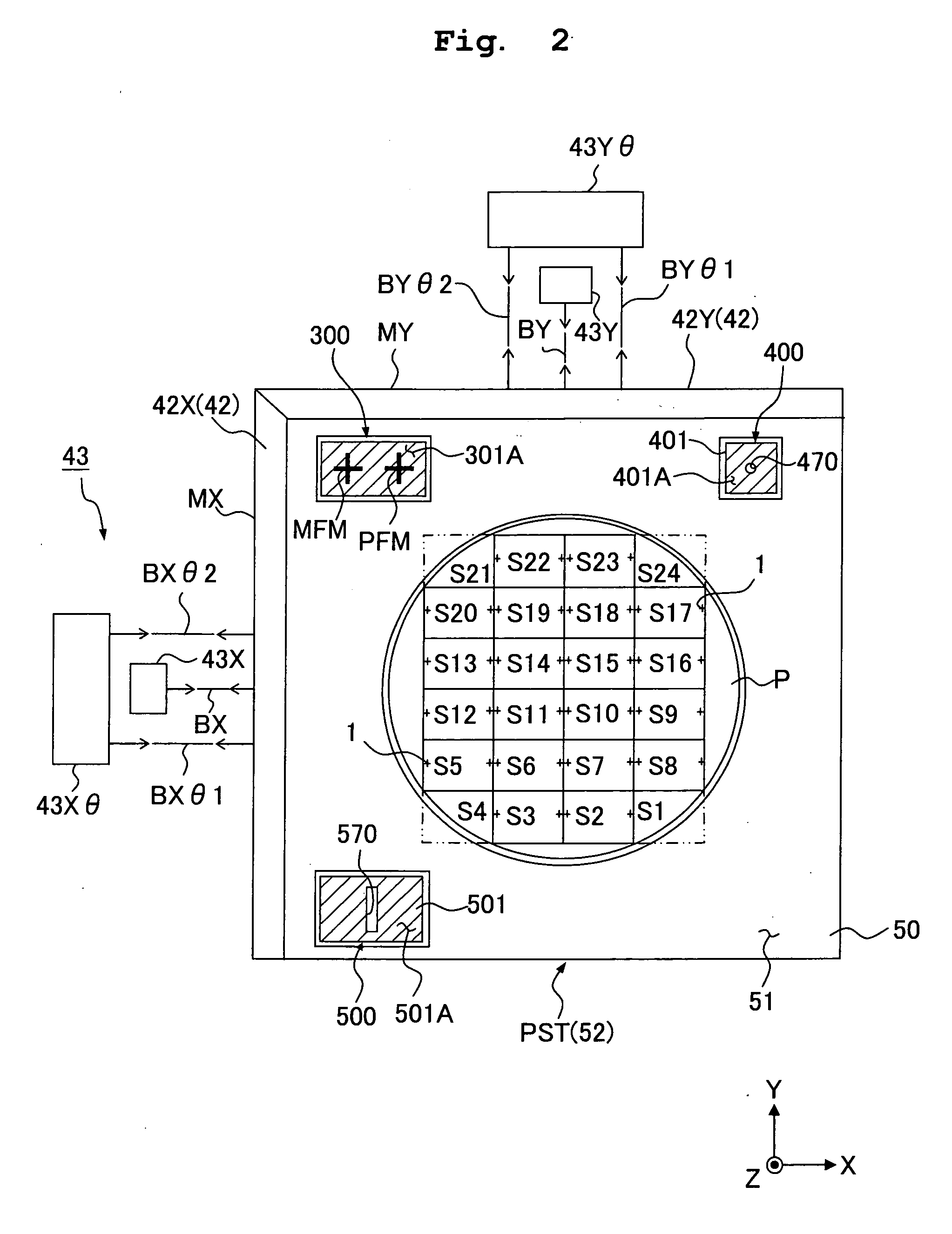

Exposure apparatus, exposure method, position control method, and method for producing device

InactiveUS20070058146A1Improve precision controlImprove accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsPosition control

Exposure apparatus EX exposes a substrate P through a liquid LQ. The exposure apparatus is provided with a substrate stage PST which can hold the substrate P, an interferometer system (43), which projects a measuring light on a reflecting plane formed on a moving mirror on the substrate stage PST, receives the reflected light and measures position information of the substrate stage PST, and a memory MRY, which stores error.

Owner:NIKON CORP

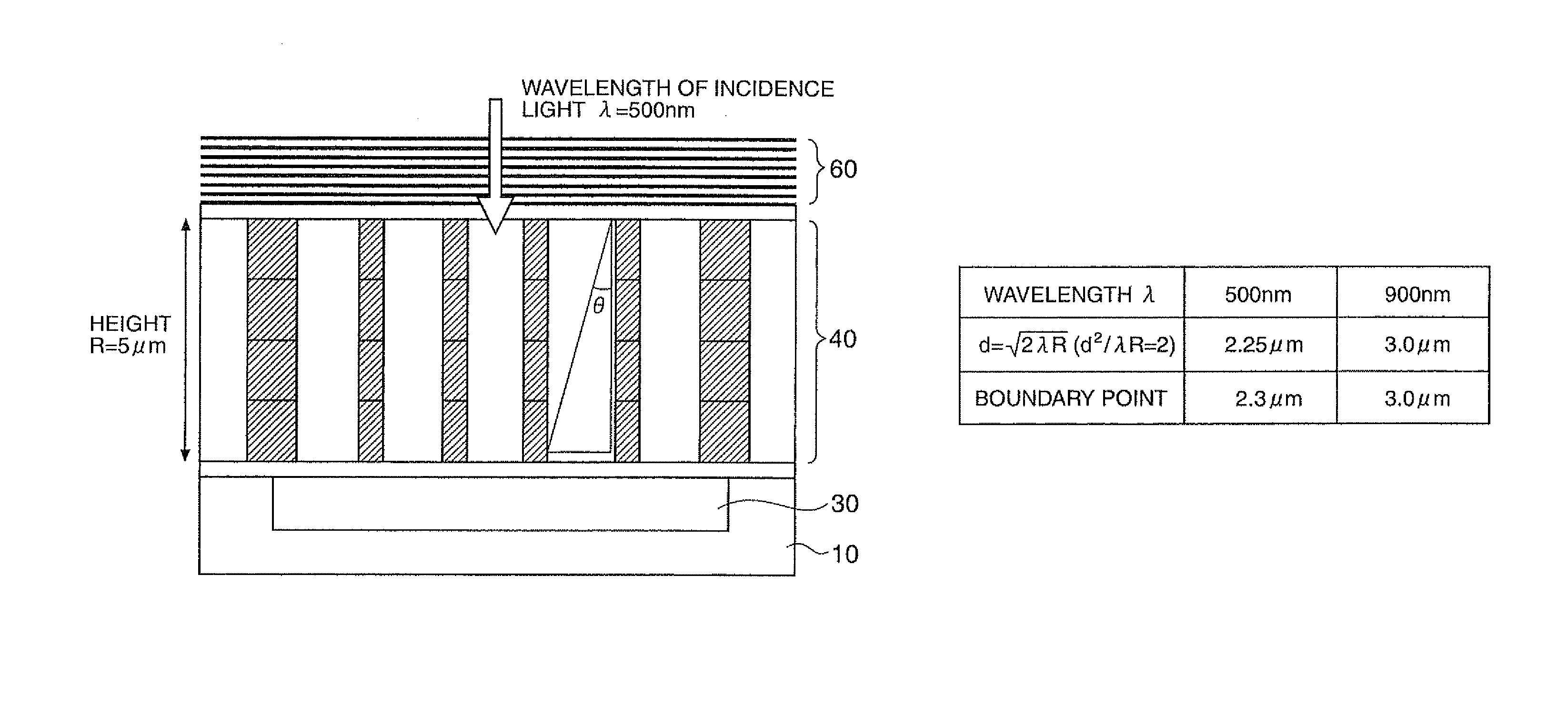

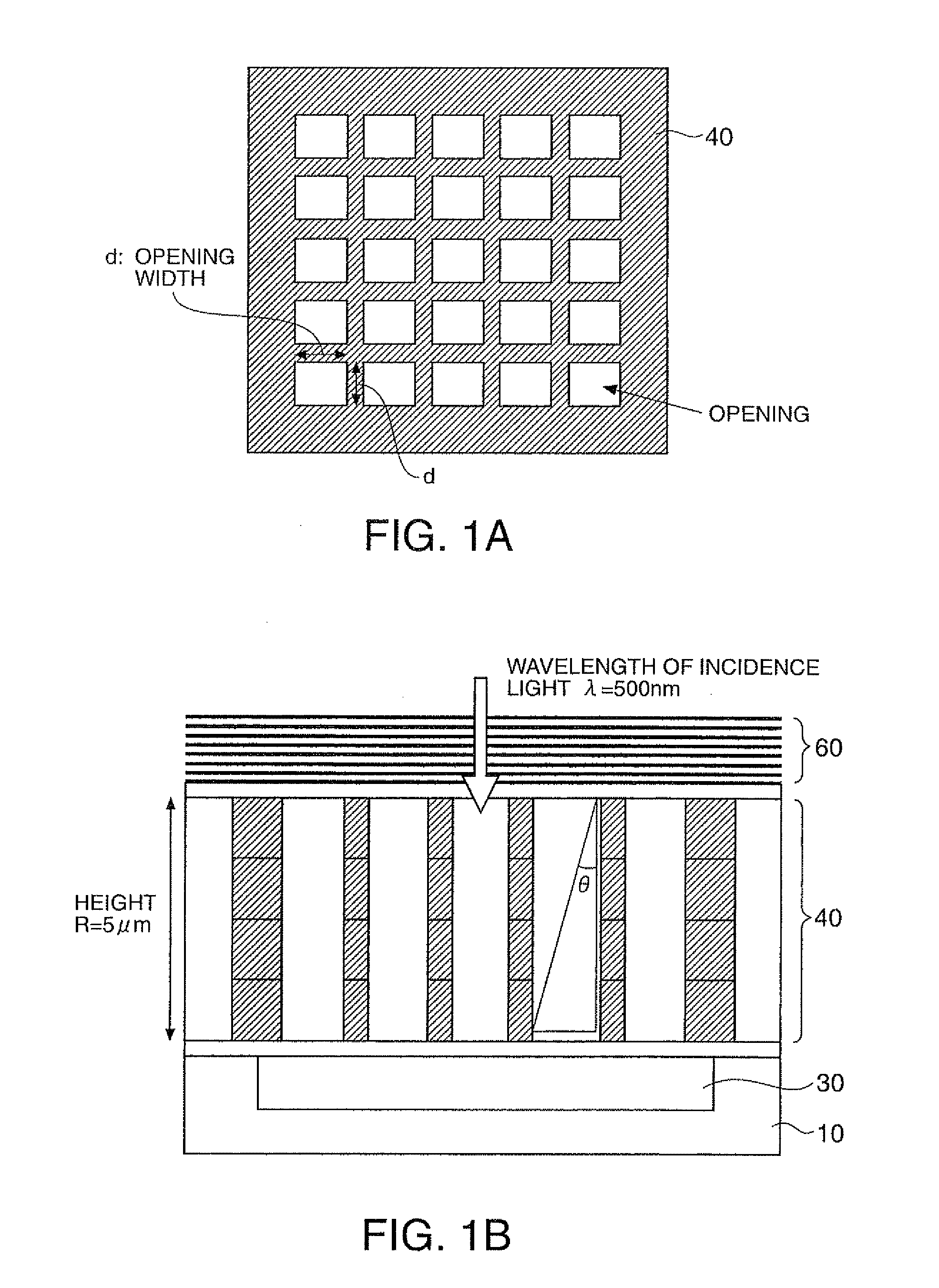

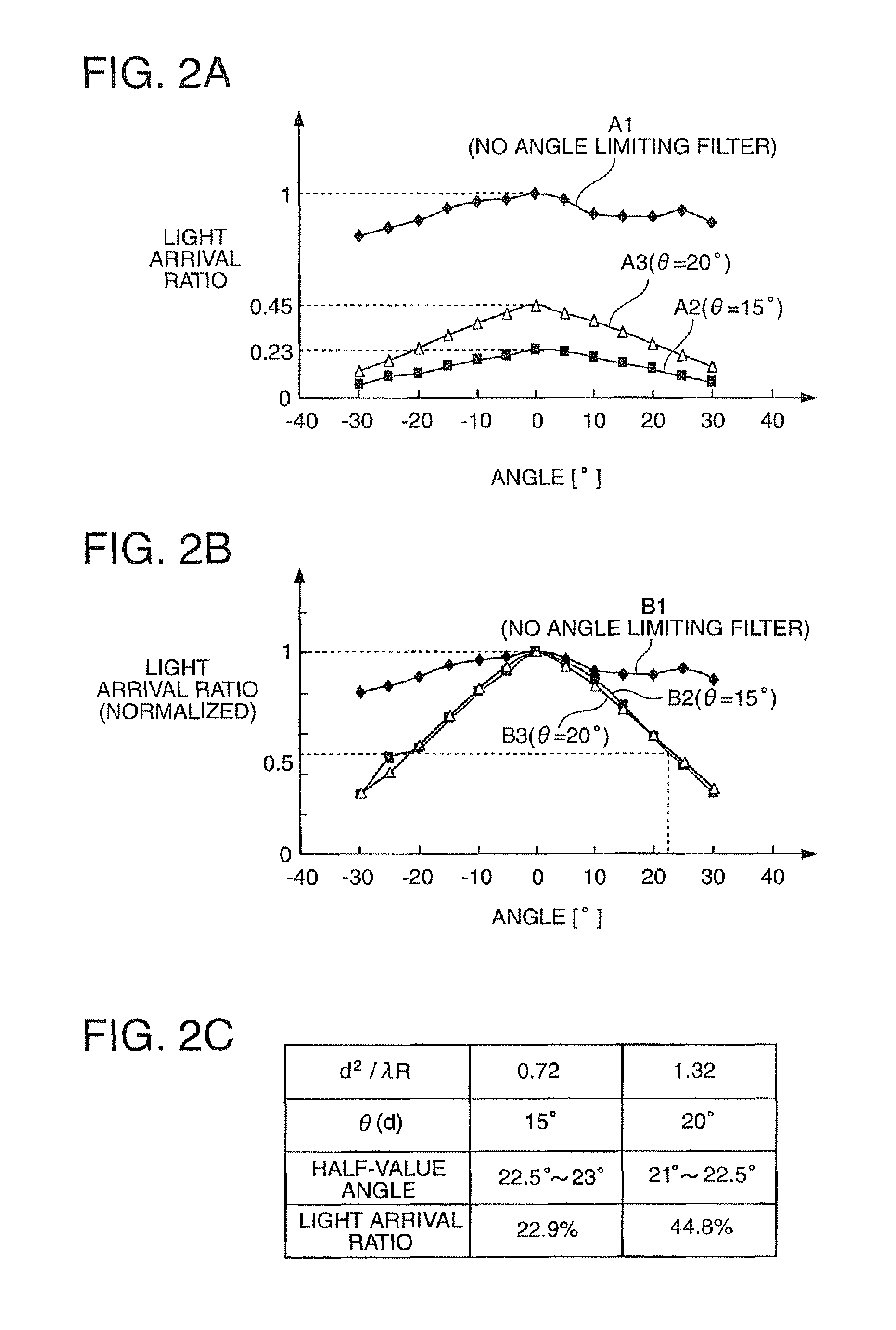

Optical sensor and electronic apparatus utilizing an angle limiting filter

ActiveUS8976357B2Improve accuracyImprove precision controlAngle measurementRadiation pyrometryAngle of incidenceLength wave

An optical sensor includes a light receiving element (for example a photodiode) and an angle limiting filter that limits the incidence angle of incidence light with respect to the light receiving area of the light receiving element. When a wavelength of the incidence light is denoted by λ, a height of the angle limiting filter is denoted by R, and a width of an opening of the angle limiting filter is denoted by d, “d2 / λR≧2” is satisfied.

Owner:SEIKO EPSON CORP

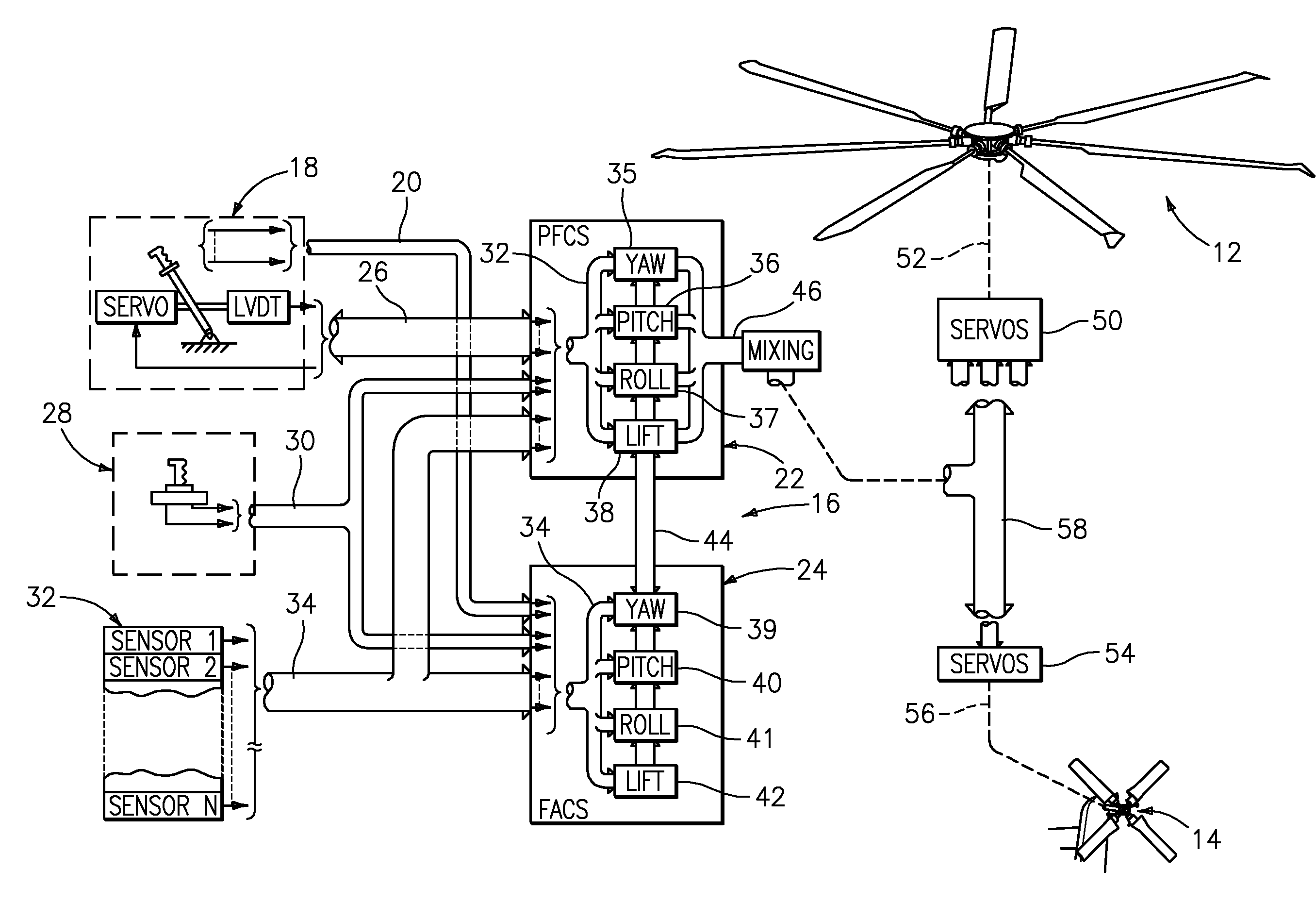

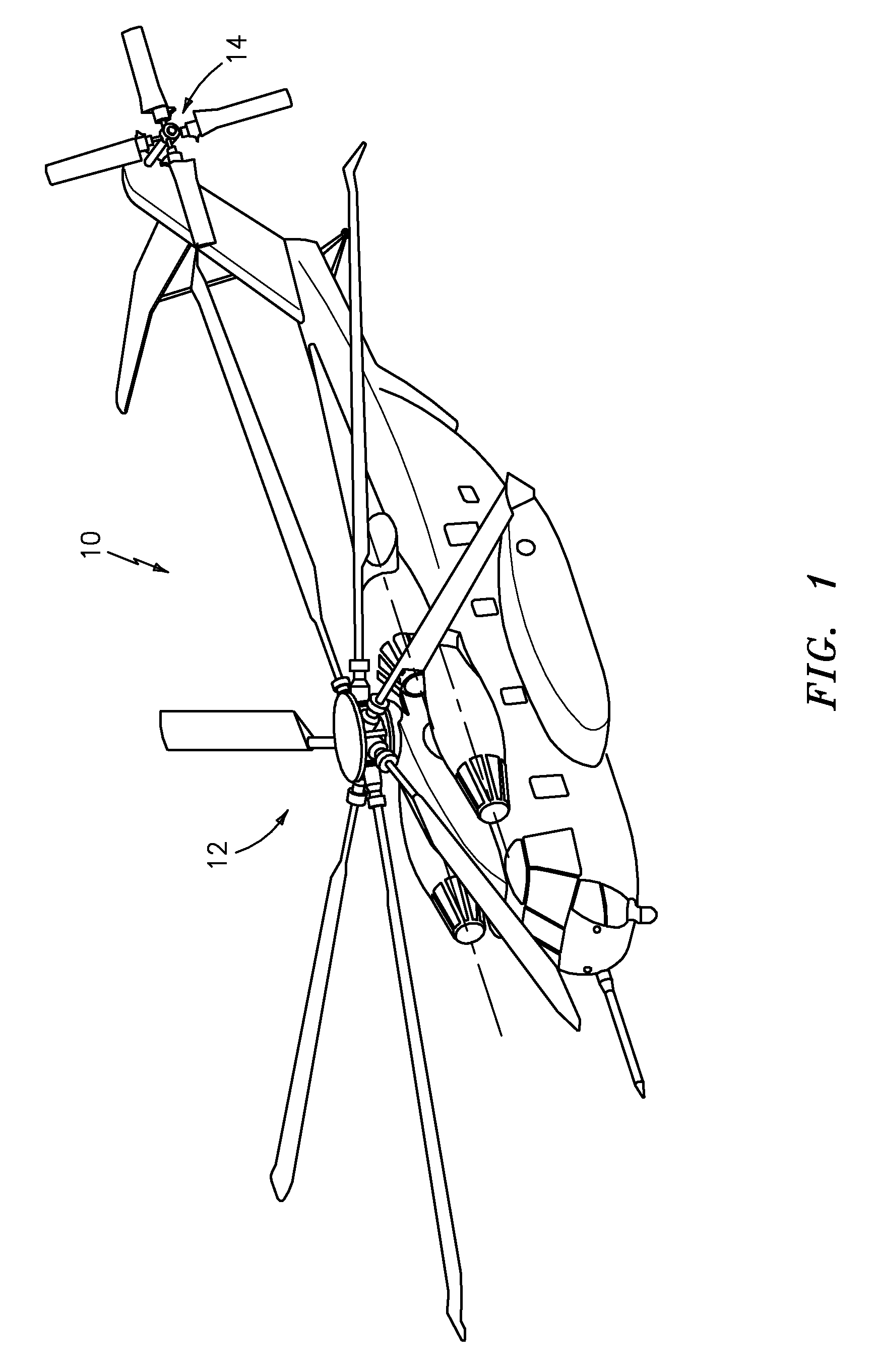

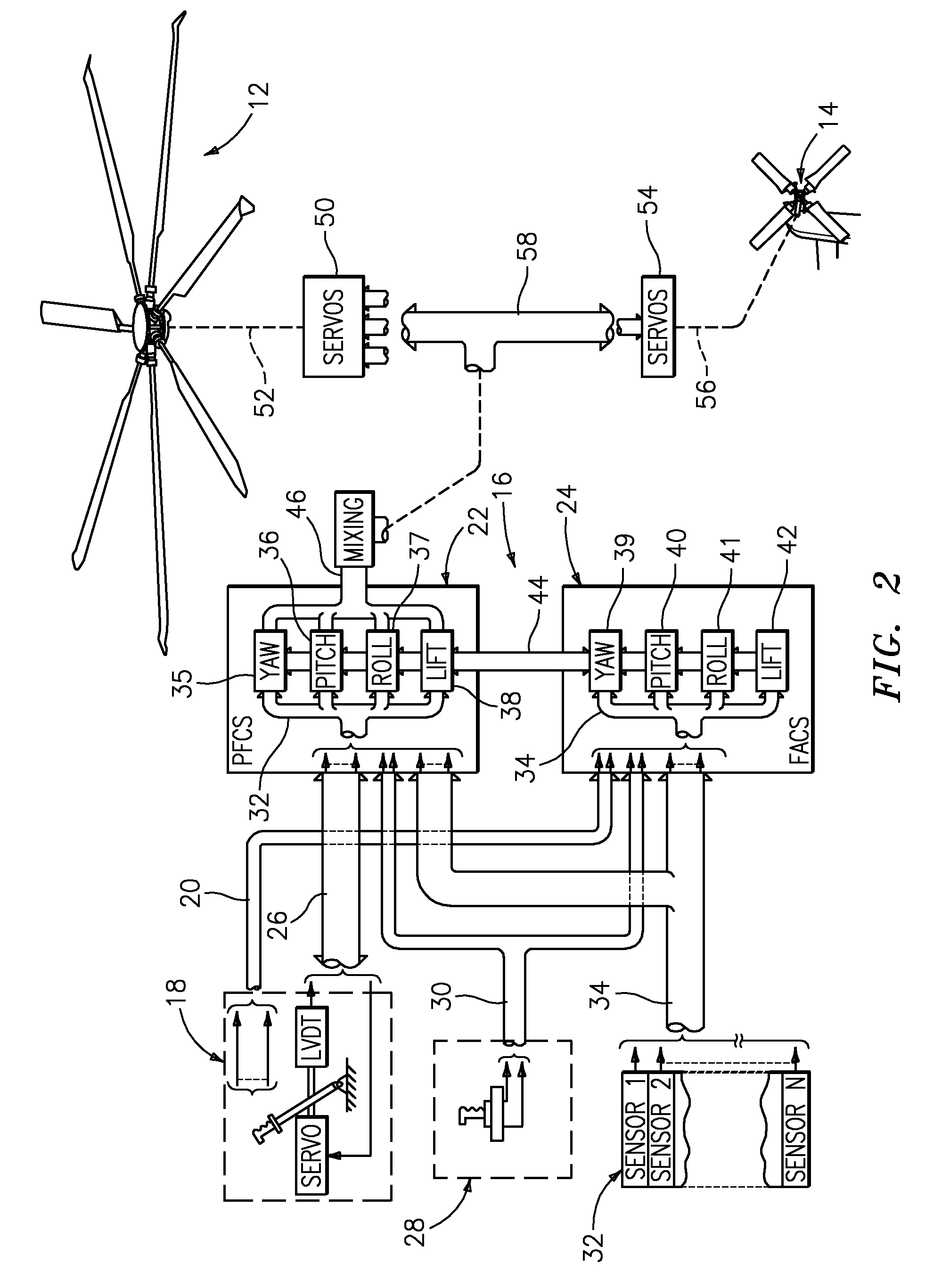

Altitude and acceleration command altitude hold algorithm for rotorcraft with large center of gravity range

ActiveUS20080249672A1Reduced pilot workloadImprove accuracyAircraft controlDigital data processing detailsAerospace engineeringGravitation

A flight control system includes an Acceleration and Attitude Command / Velocity Hold mode (AACVH) algorithm which blends attitude commands with acceleration commands. This blending determines a trim attitude for a given rotorcraft flight condition.

Owner:SIKORSKY AIRCRAFT CORP

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20090040488A1Good precisionImprove accuracyPhotomechanical apparatusPhotographic printingEngineeringEncoder

Positional information of a stage within a movement plane is measured, using three encoders which include at least one each of an X encoder and a Y encoder. Based on position measurement values of the stage, the encoder used in position measurement is switched from an encoder (Enc1, Enc2 and Enc3) to an encoder (Enc4, Enc2 and Enc3). On the switching, a coordinate linkage method or a phase linkage method is applied to set an initial value of an encoder (Enc4) which is to be newly used. Accordingly, position measurement values of the stage before and after the switching are stored even though the encoder used in position measurement of the stage is sequentially switched, and the stage can be driven accurately two-dimensionally.

Owner:NIKON CORP

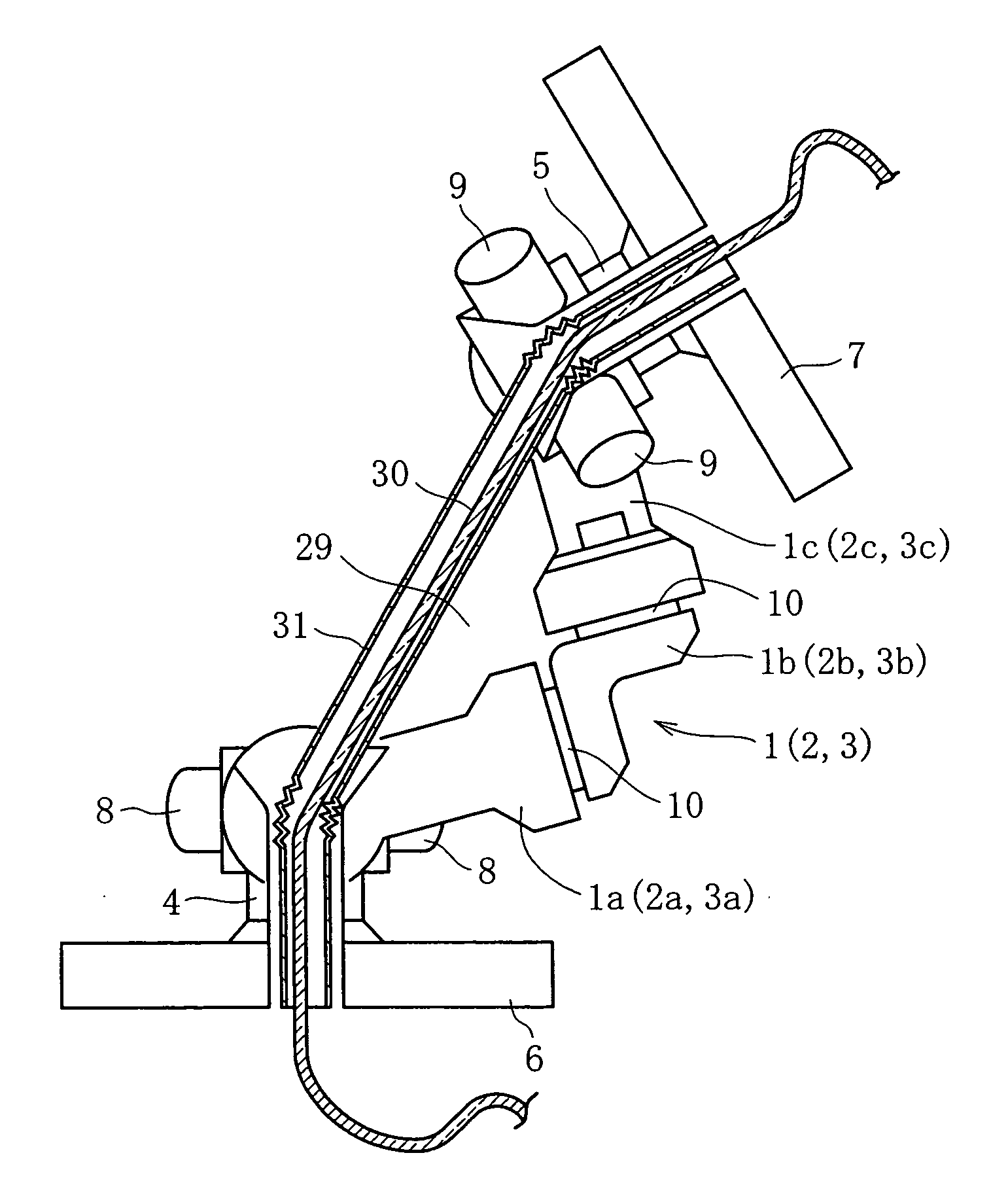

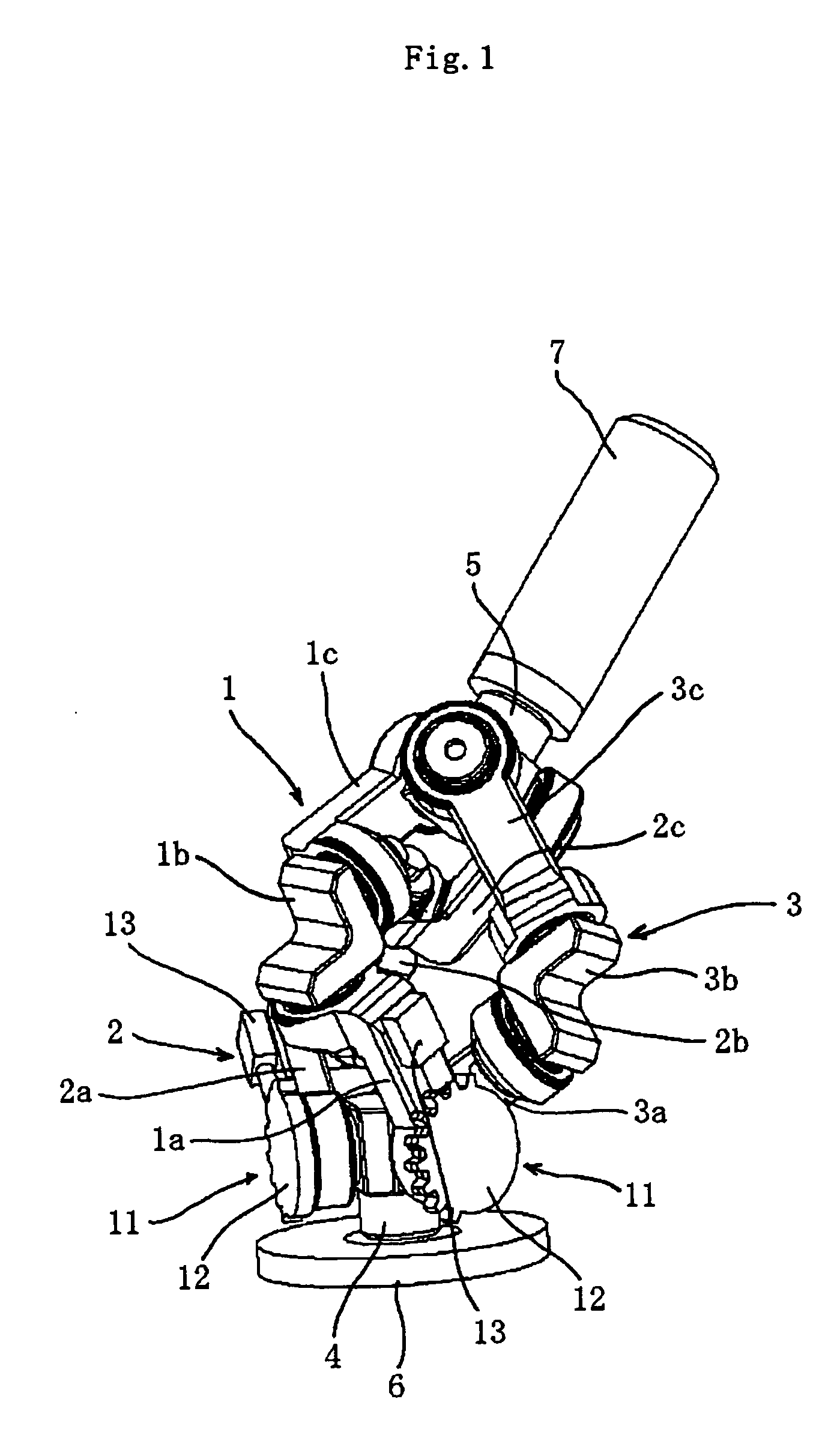

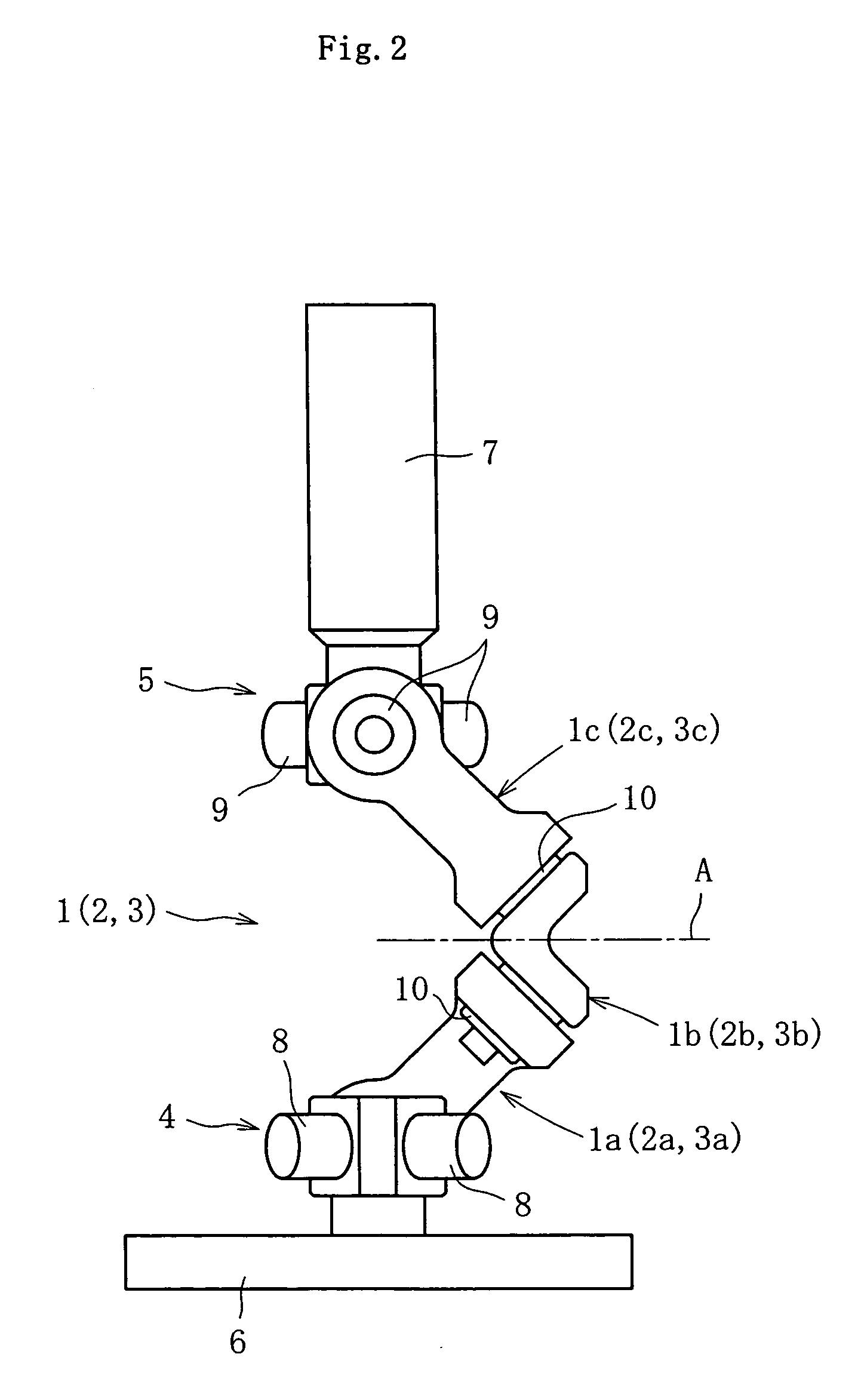

Linkage System

InactiveUS20080028881A1Large loading capacityImprove rigidityManual control with multiple controlled membersProgramme-controlled manipulatorEngineeringLoad capacity

A linkage system is provided which is equipped with a compact and high-rigidity link mechanism with a large load capacity. The linkage system includes three or more link mechanisms. Each link mechanism consists of a center link member and end link members rotatably coupled to the center link member and to link hubs that are provided to an input member and an output member, respectively. An input side and an output side of a center cross-sectional plane of each link mechanism are geometrically identical. One or more of revolute joints of two or more of the link mechanisms that are coupled to the input member are provided with a stopping mechanism for stopping the output member at a given position.

Owner:NTN CORP

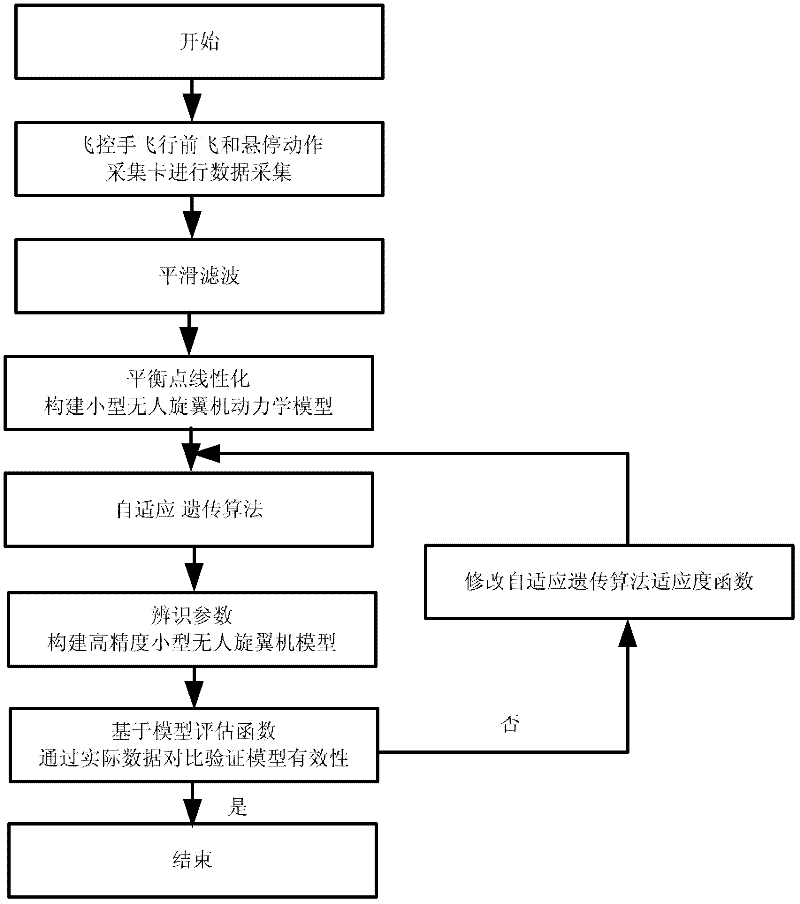

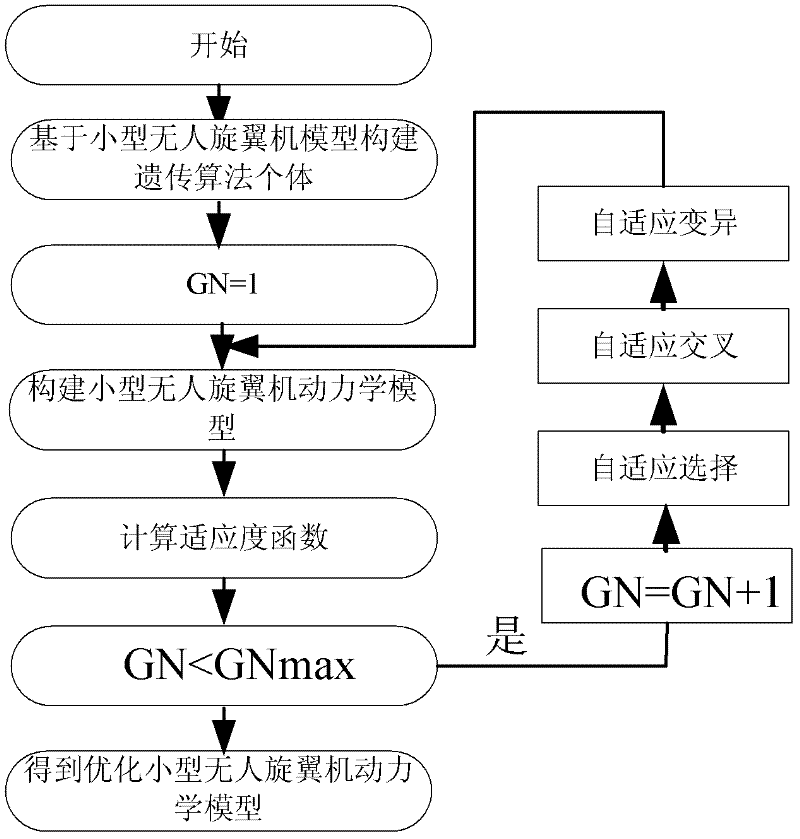

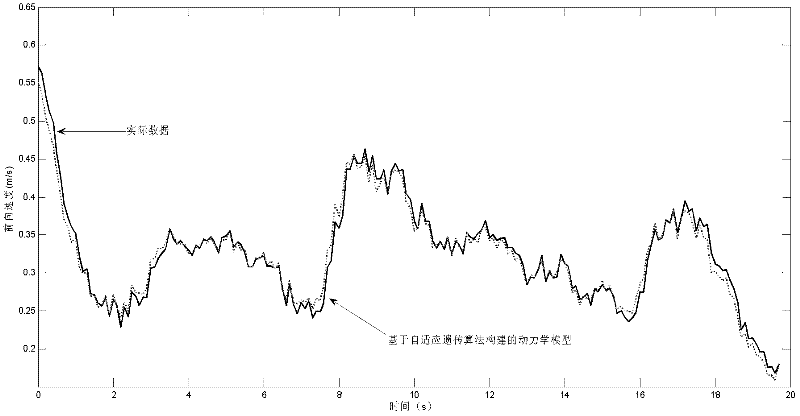

A Dynamic Model Identification Method for Small Unmanned Rotorcraft Based on Adaptive Genetic Algorithm

ActiveCN102298329ASolve the identification problemImprove precision controlGenetic modelsAdaptive controlDynamic modelsFiltration

The invention discloses a small-size unmanned rotary wing aircraft dynamic model identification method based on an adaptive genetic algorithm, which relates to flight status data acquisition and optimization, dynamic model building and parameter identification, and parameter optimization validation. Firstly, status data and control data when a small-size unmanned rotary wing aircraft executes standard actions are acquired through a data acquisition system, and smoothing and filtration are conducted to eliminate wild values; then aiming at the operating characteristics of the small-size unmanned rotary wing aircraft at autonomous takeoff and landing stages, a small-size unmanned rotary wing aircraft dynamic model is built through a balance point linearization method and model parameters are identified through the adaptive genetic algorithm; and finally intelligent parameter evaluation indexes are built and the effectiveness of the model parameters is evaluated and judged through a one-step predication method. The small-size unmanned rotary wing aircraft dynamic model identification method based on the adaptive genetic algorithm solves the problem in the dynamic model identificationof the small-size unmanned rotary wing aircraft, can realize the high-accuracy control of the small-size unmanned rotary wing aircraft, and has the advantages of low testing cost, short cycle, simplecalculation, high dynamic model accuracy and weak dependence on initial values.

Owner:BEIHANG UNIV

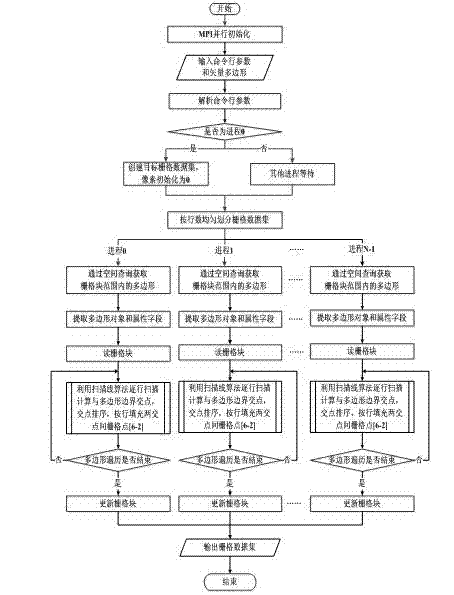

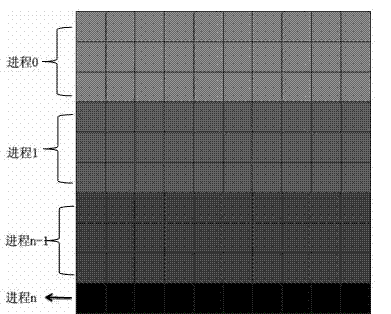

Polygonal rasterisation parallel conversion method based on scanning line method

InactiveCN102542035AImplement parallel processingTroubleshoot rasterization issuesSpecial data processing applicationsComputational scienceAlgorithm

The invention discloses a polygonal rasterisation parallel conversion method based on a scanning line method, belonging to the field of a geographic information system. The polygonal rasterisation parallel conversion method comprises inputting a command line parameter; carrying out MPI (Message Passing Interface) parallel initialization so as to obtain a total progress number and a current progress number; adopting an equal parallel mode, analyzing the command line parameter in each progress respectively, collecting parameter values behind a leading indicator respectively, reading a vector data source by using an OGROpen method, and judging whether the progress is the No.0 progress; adopting a data parallel strategy, dividing a raster data set vector polygon to be distributed to all progresses, and carrying out rasterisation of a polygon in each progress at the same time; writing the raster data, updating a raster block in each progress and outputting the converted raster data. The method is utilized to perform polygonal rasterisation of large amount of data to achieve relatively high efficiency and a satisfying conversion result, the conversion processing speed of a multi-core / multiprocessor of a high performance server to polygonal rasterisation is improved sufficiently, and the conversion time of polygonal rasterisation is shortened greatly.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com