Patents

Literature

105results about How to "Raw material stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

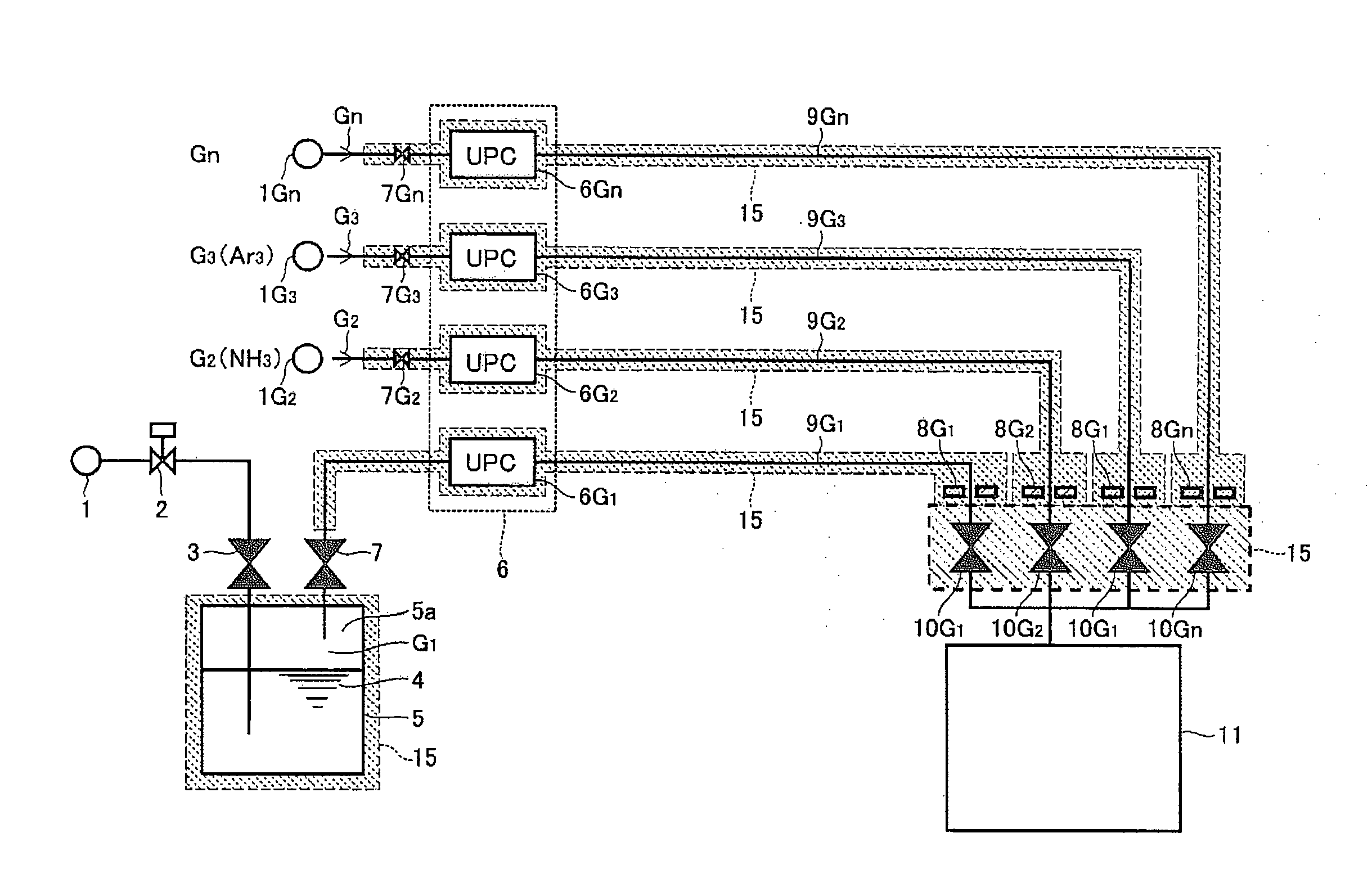

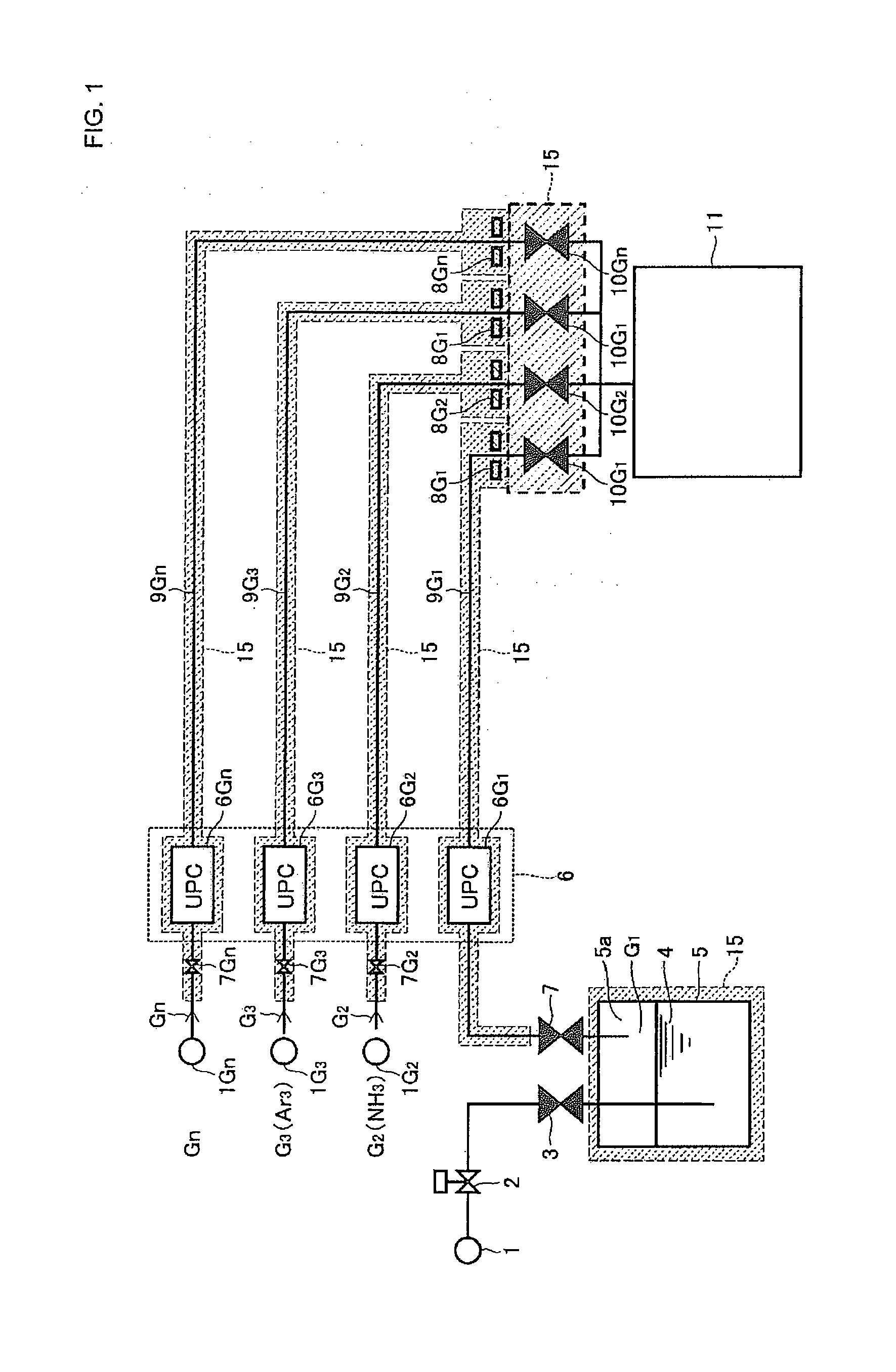

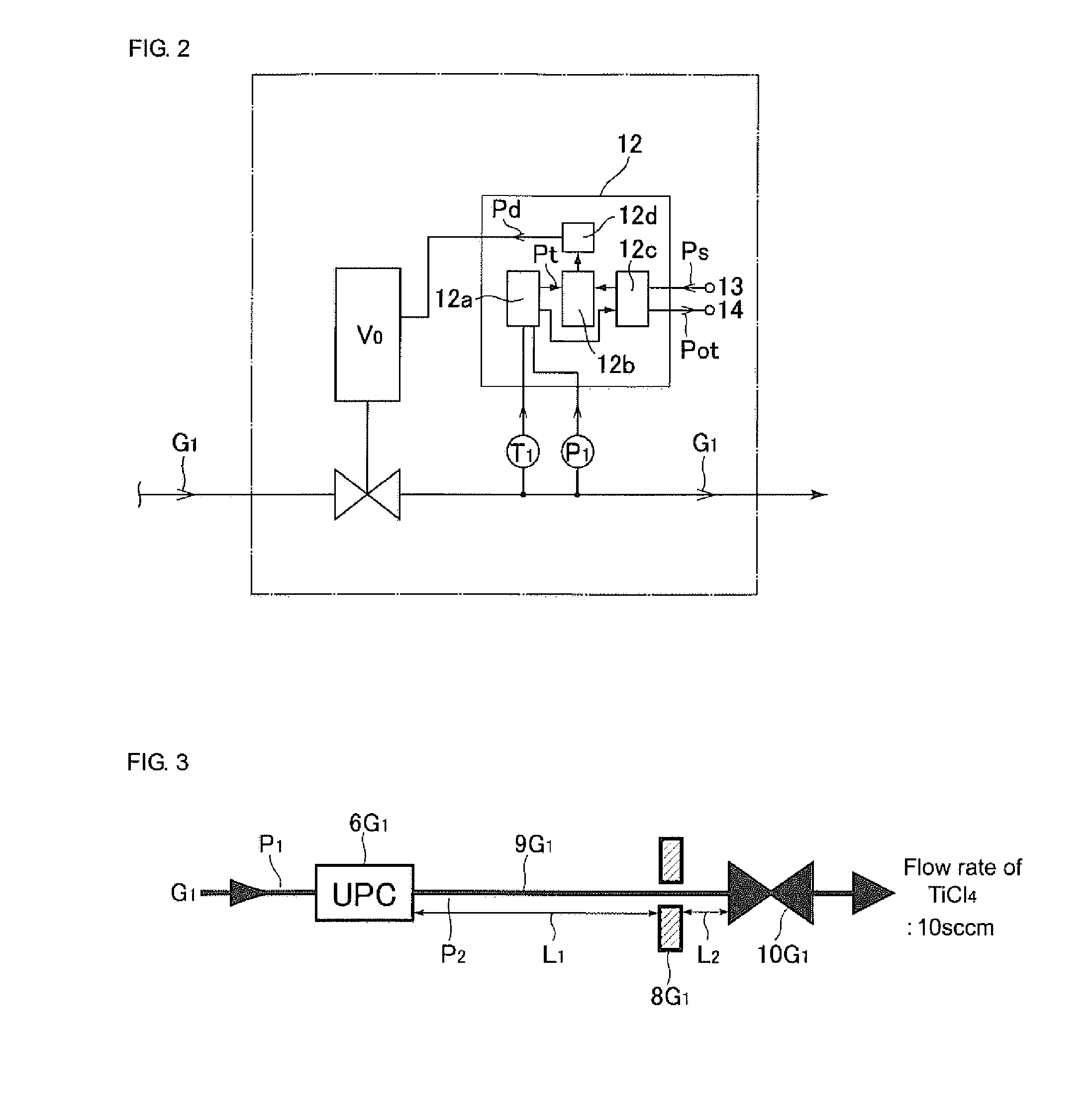

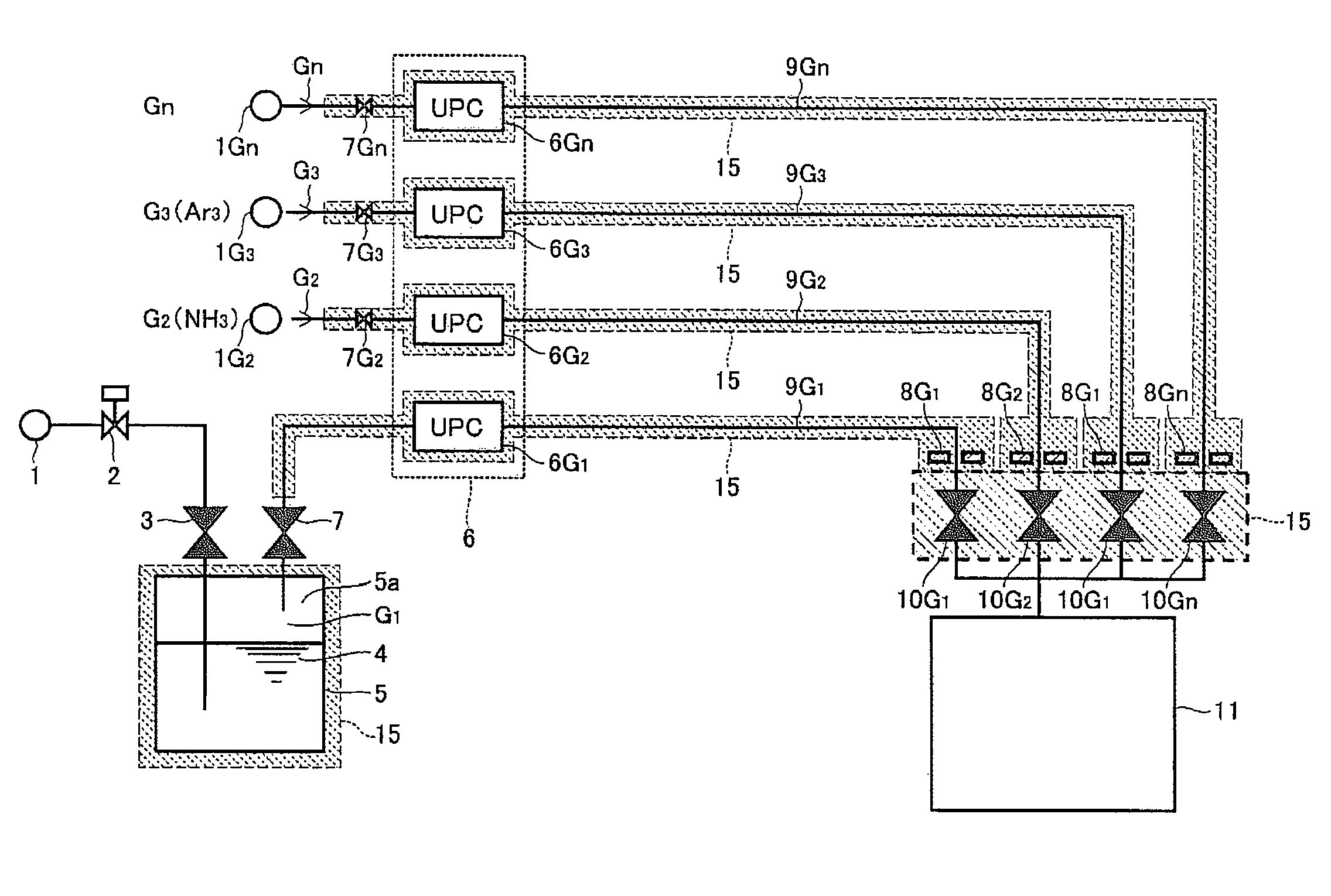

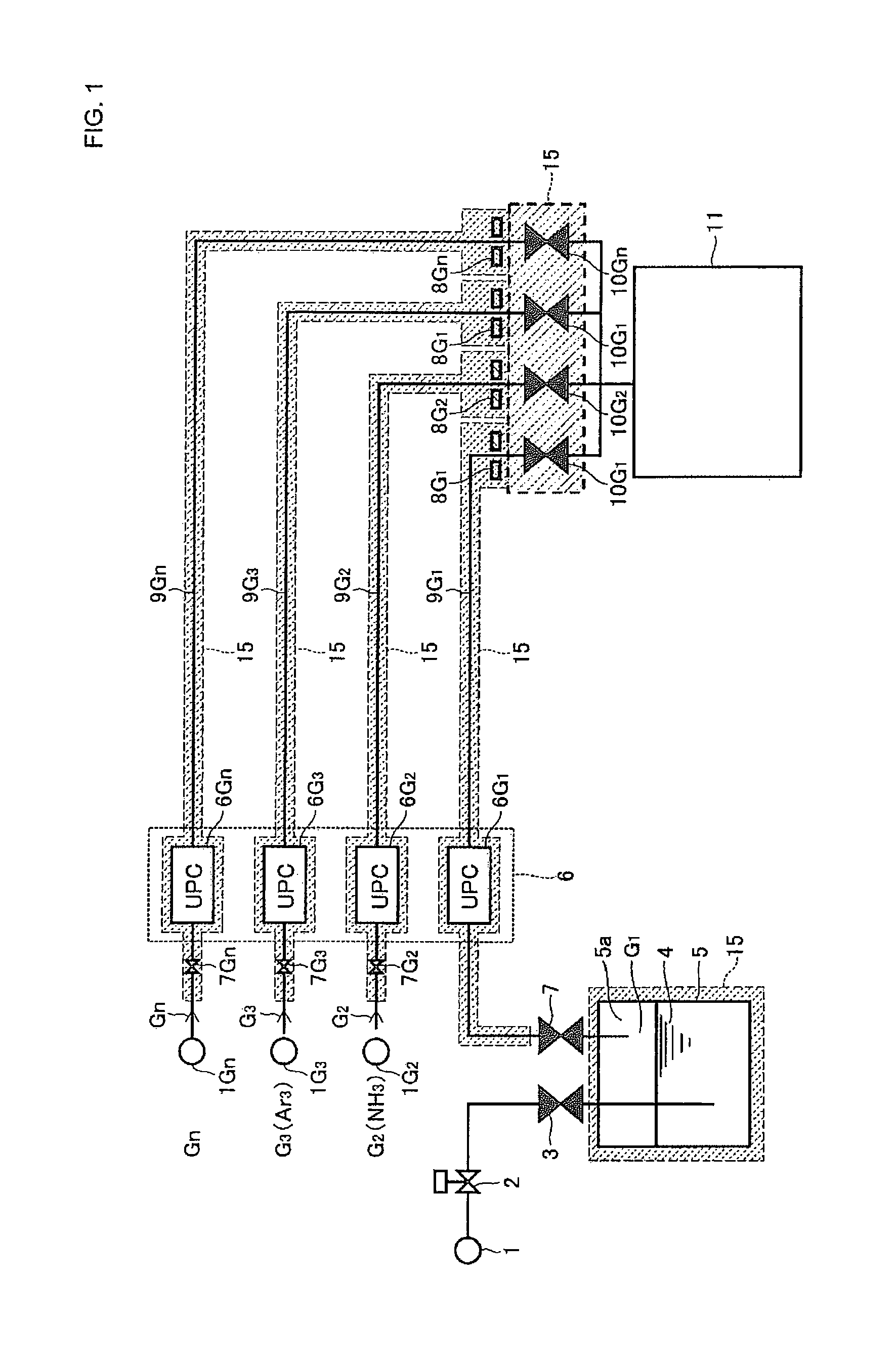

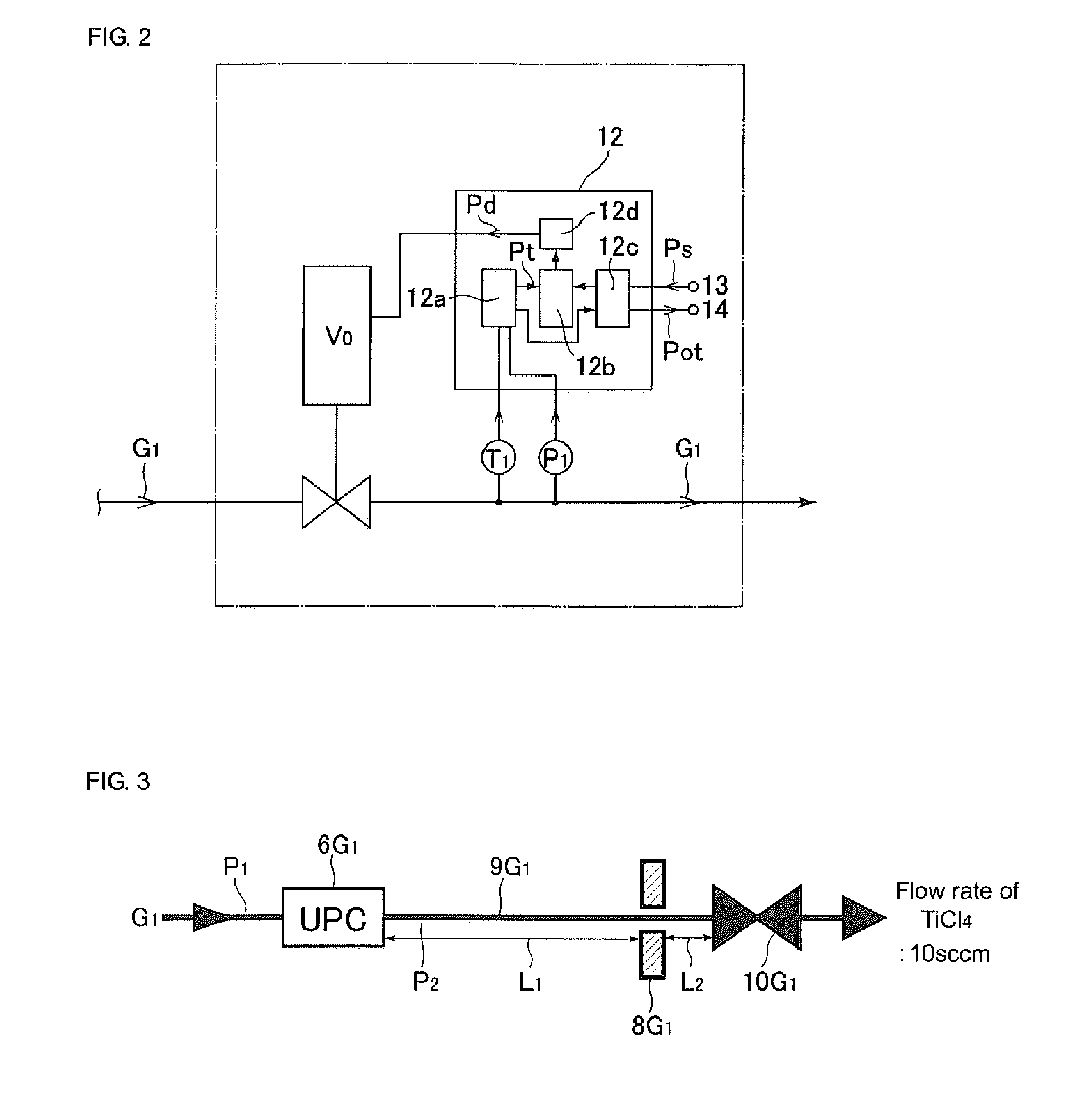

Raw material gas supply apparatus for semiconductor manufacturing equipment

ActiveUS20140190581A1Improve precision controlStable supplyOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingProduct gasProcess engineering

A raw material gas supply apparatus includes a liquid raw material gas supply source, a source tank storing liquid raw material, a gas distribution passage through which raw material gas comprising steam of the liquid raw material is supplied to a process chamber from the source tank, an automatic pressure regulator installed on an upstream side of the gas passage, wherein the automatic pressure regulator keeps supply pressure of the raw material gas at a set value, a supply gas switching valve installed on a downstream side of the gas passage, wherein this valve opens and closes the gas passage, an orifice provided on at least one of an inlet side or outlet side of the valve, wherein the orifice regulates flow rate of the raw material gas, and a constant temperature heating device heats the source tank, the gas passage, the valve and the orifice to a set temperature.

Owner:FUJIKIN INC

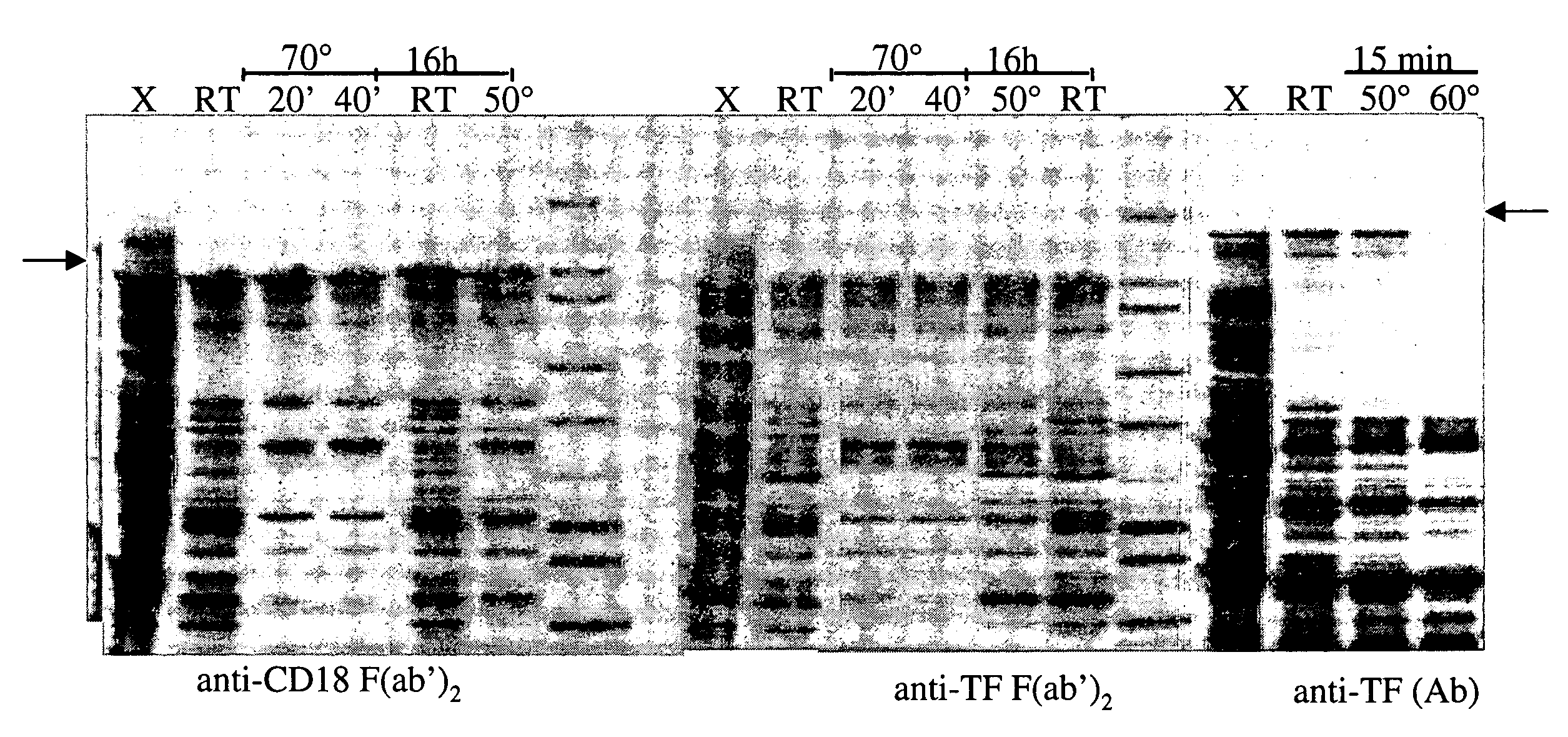

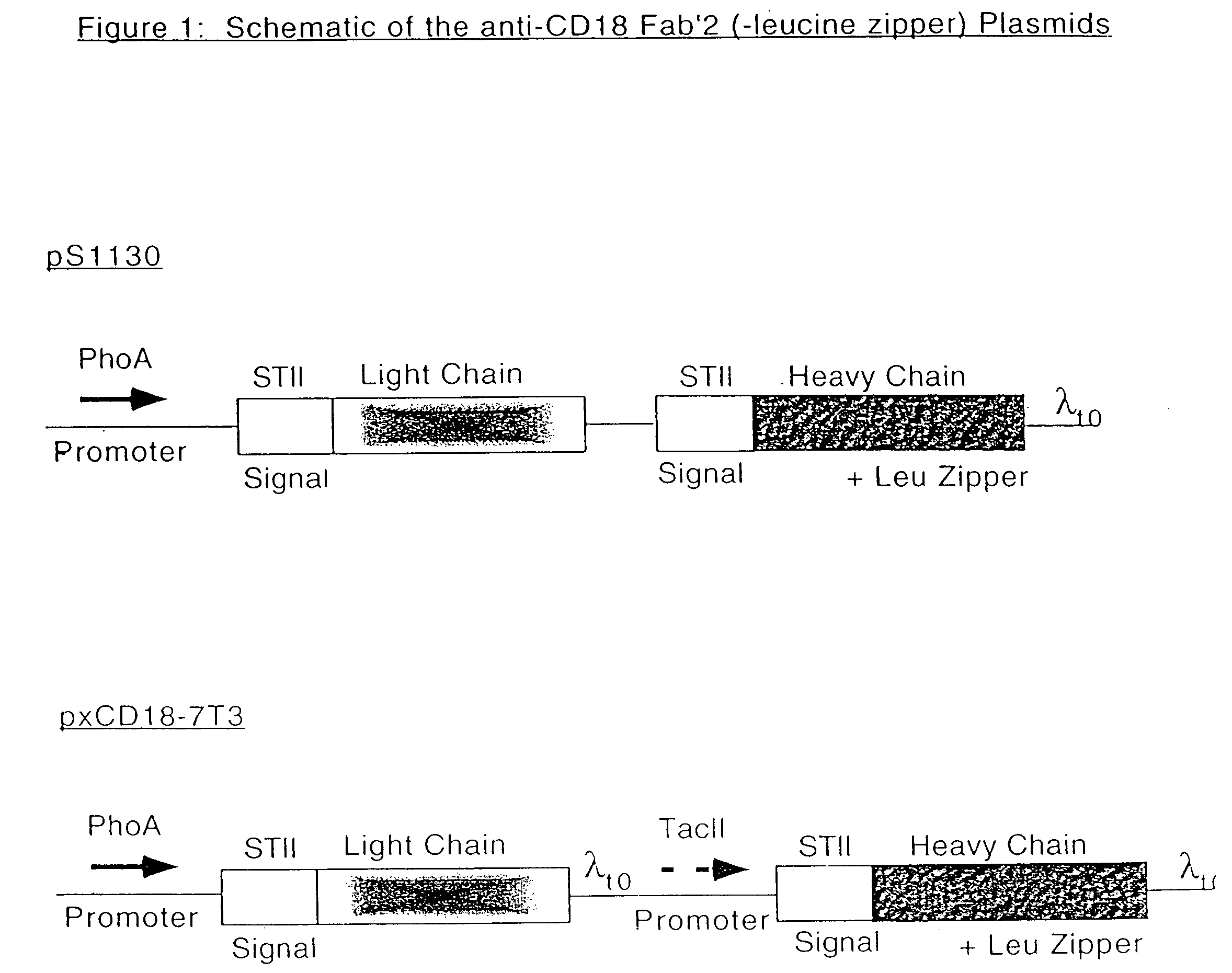

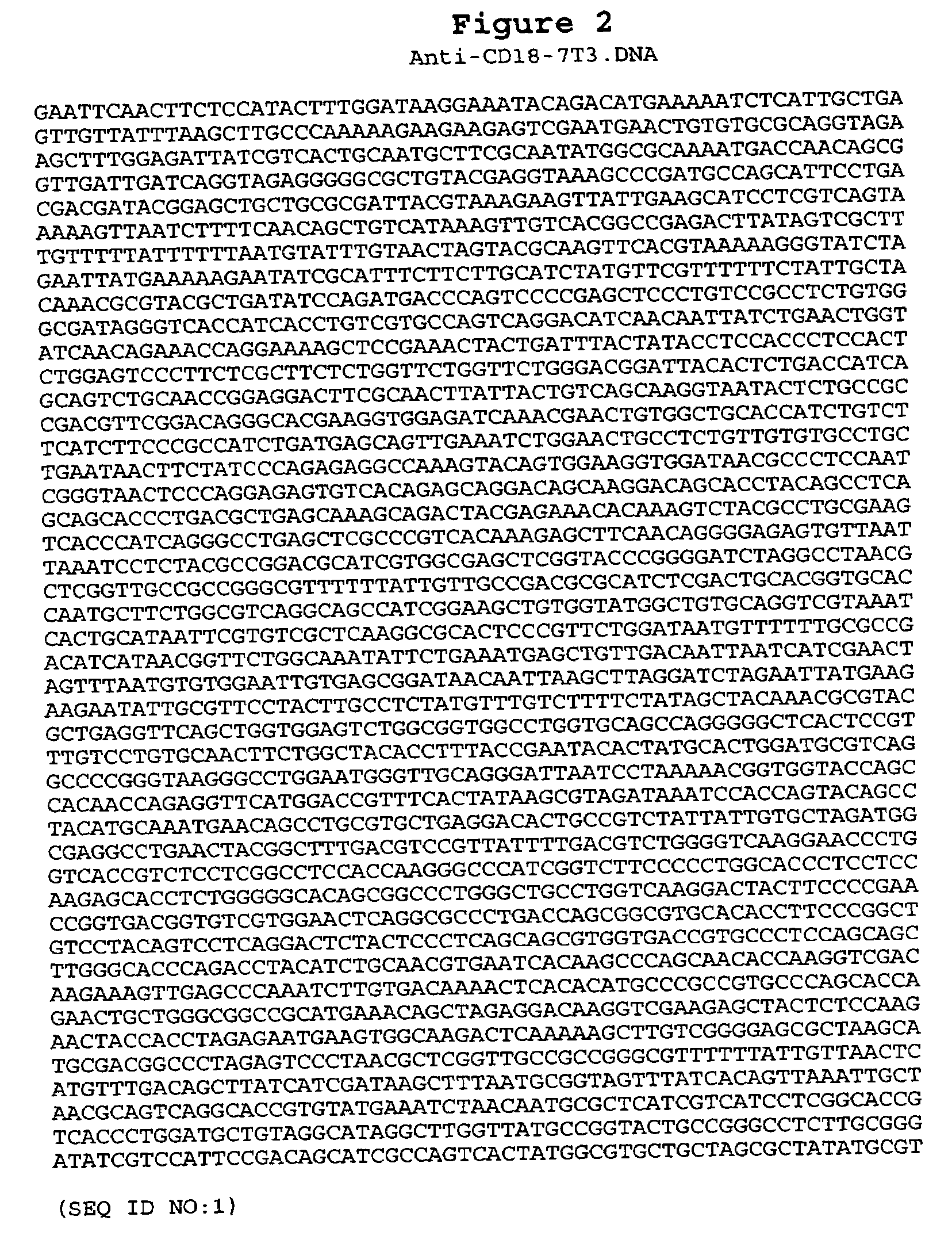

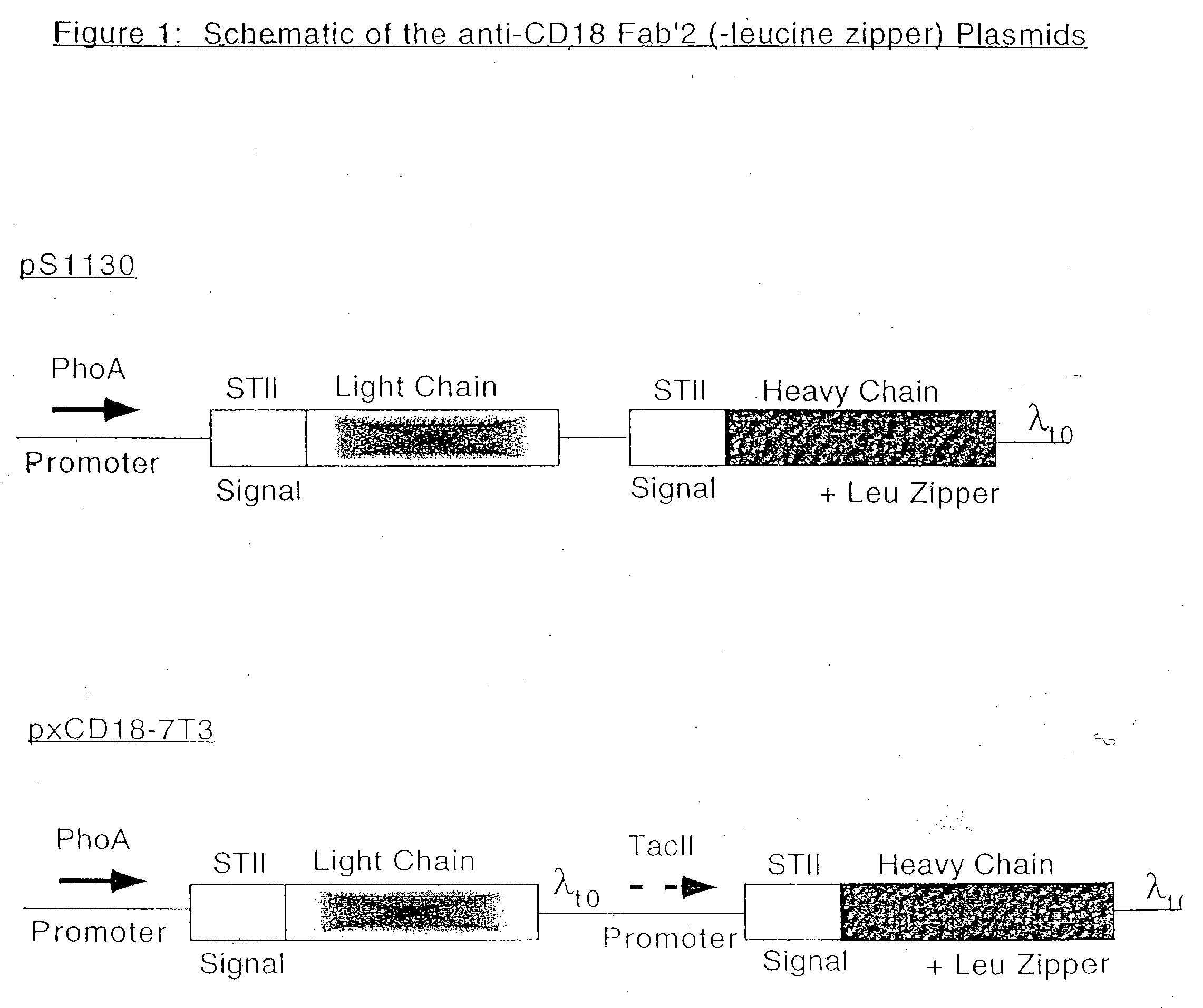

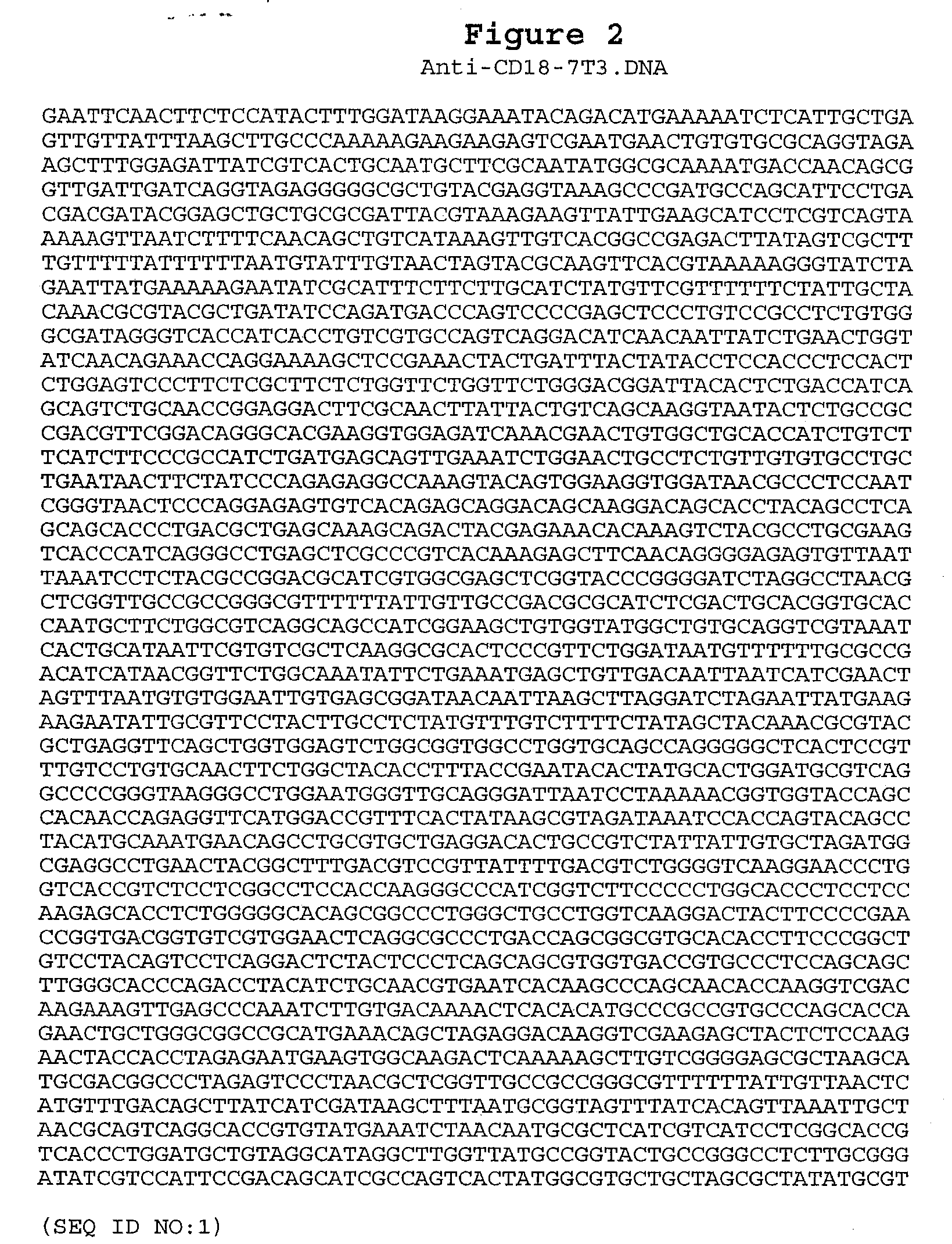

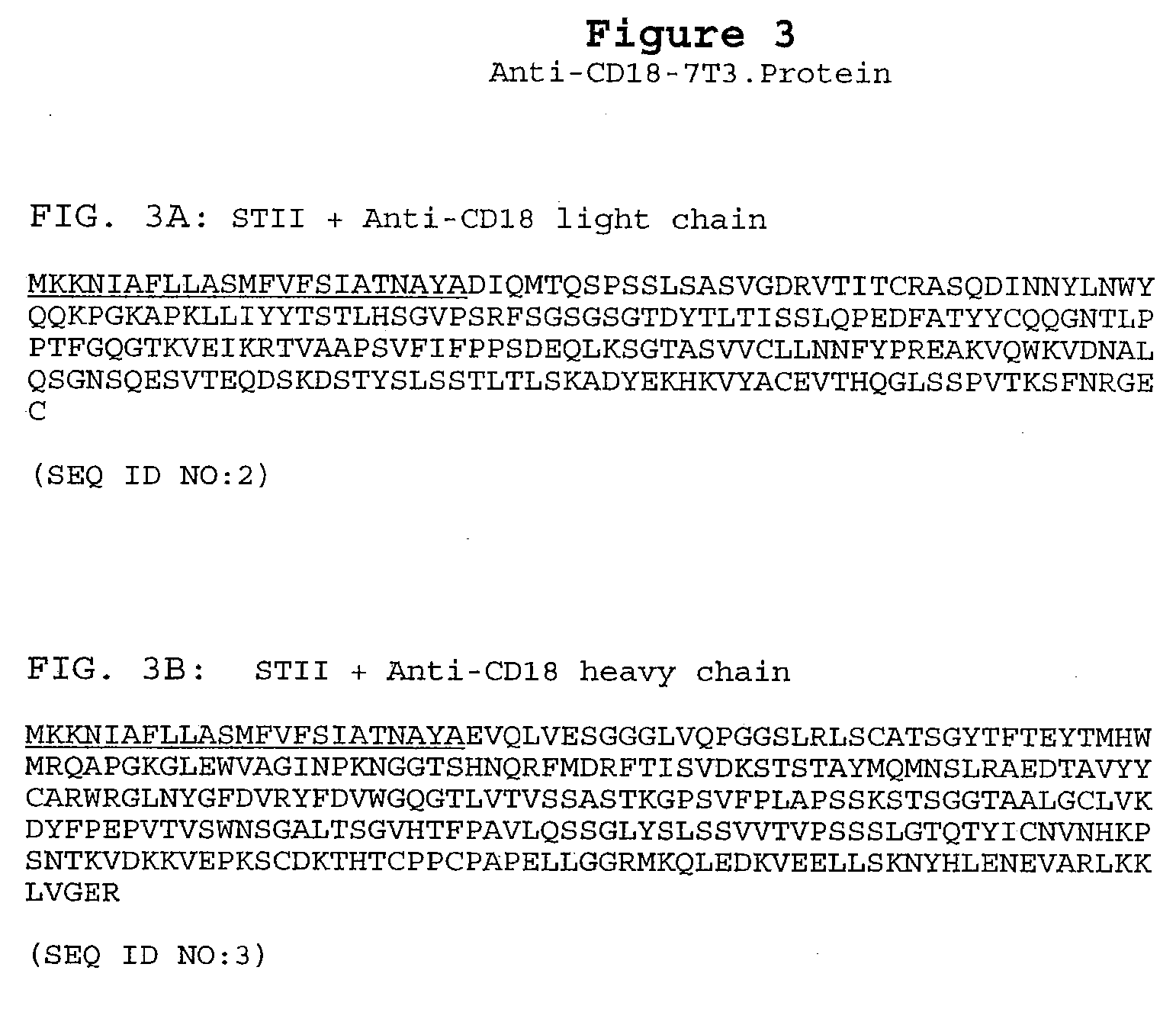

Purification of polypeptides

A method for purifying a desired heterologous polypeptide from microbial fermentation broth or homogenate in which it is produced and solubilized is described. This method involves adding to the broth or homogenate an effective amount of a solution of 6,9-diamino-2-ethoxyacridine lactate (ethacridine lactate) to precipitate host cell impurities under conditions wherein the majority of polypeptide remains soluble, and separating the desired polypeptide from the broth or homogenate. The broth or homogenate containing the ethacridine lactate and polypeptide is also disclosed.

Owner:GENENTECH INC

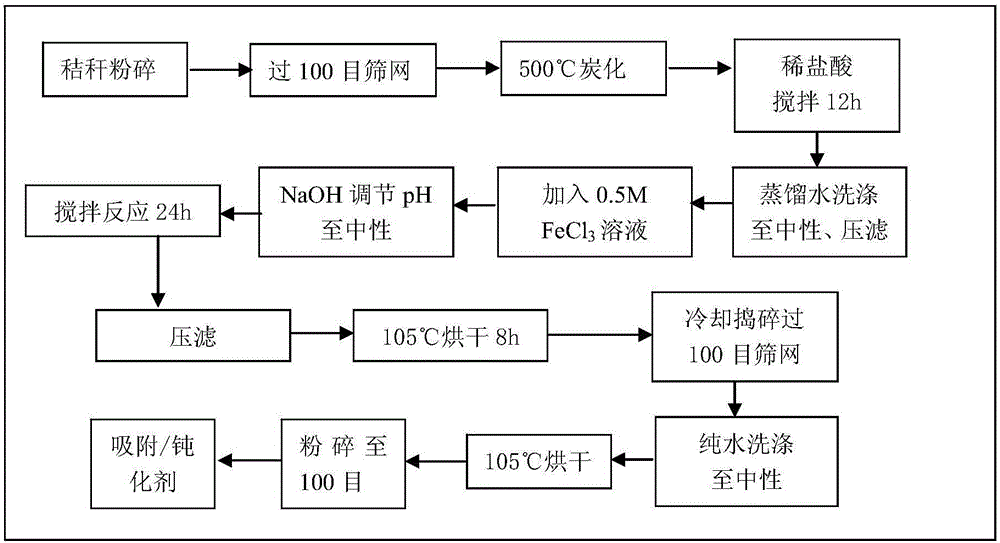

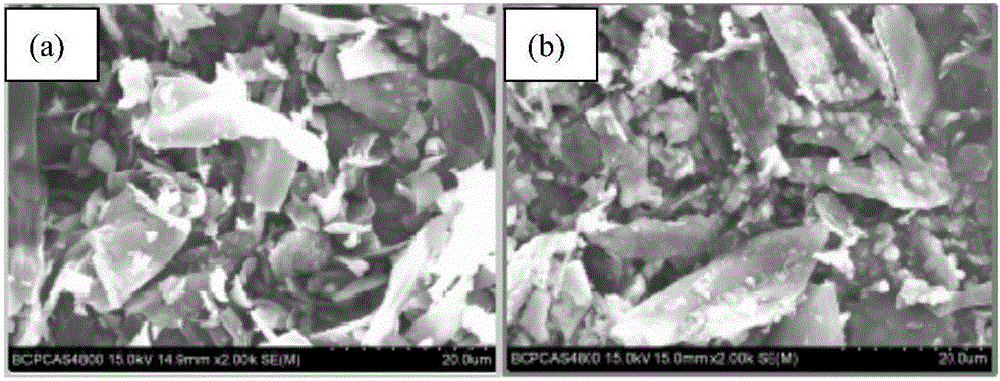

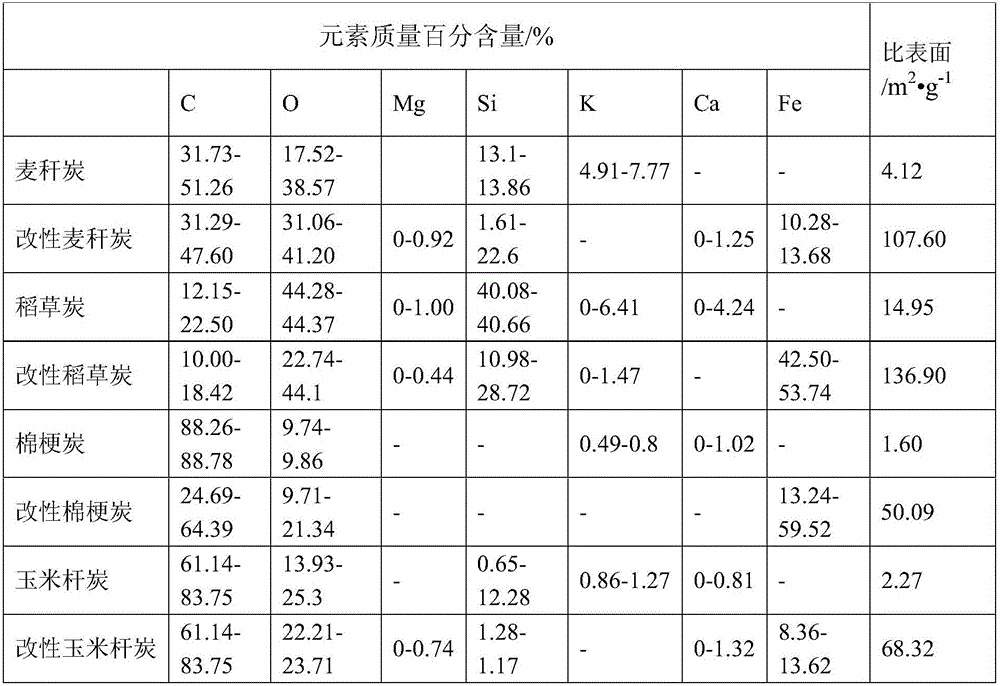

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

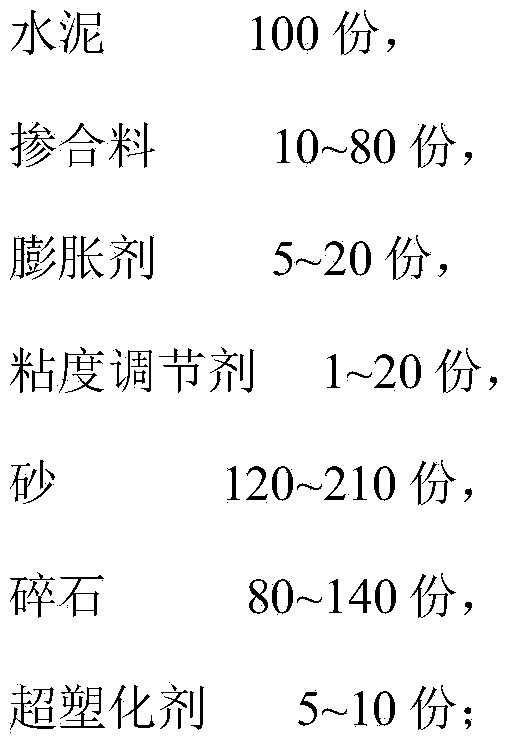

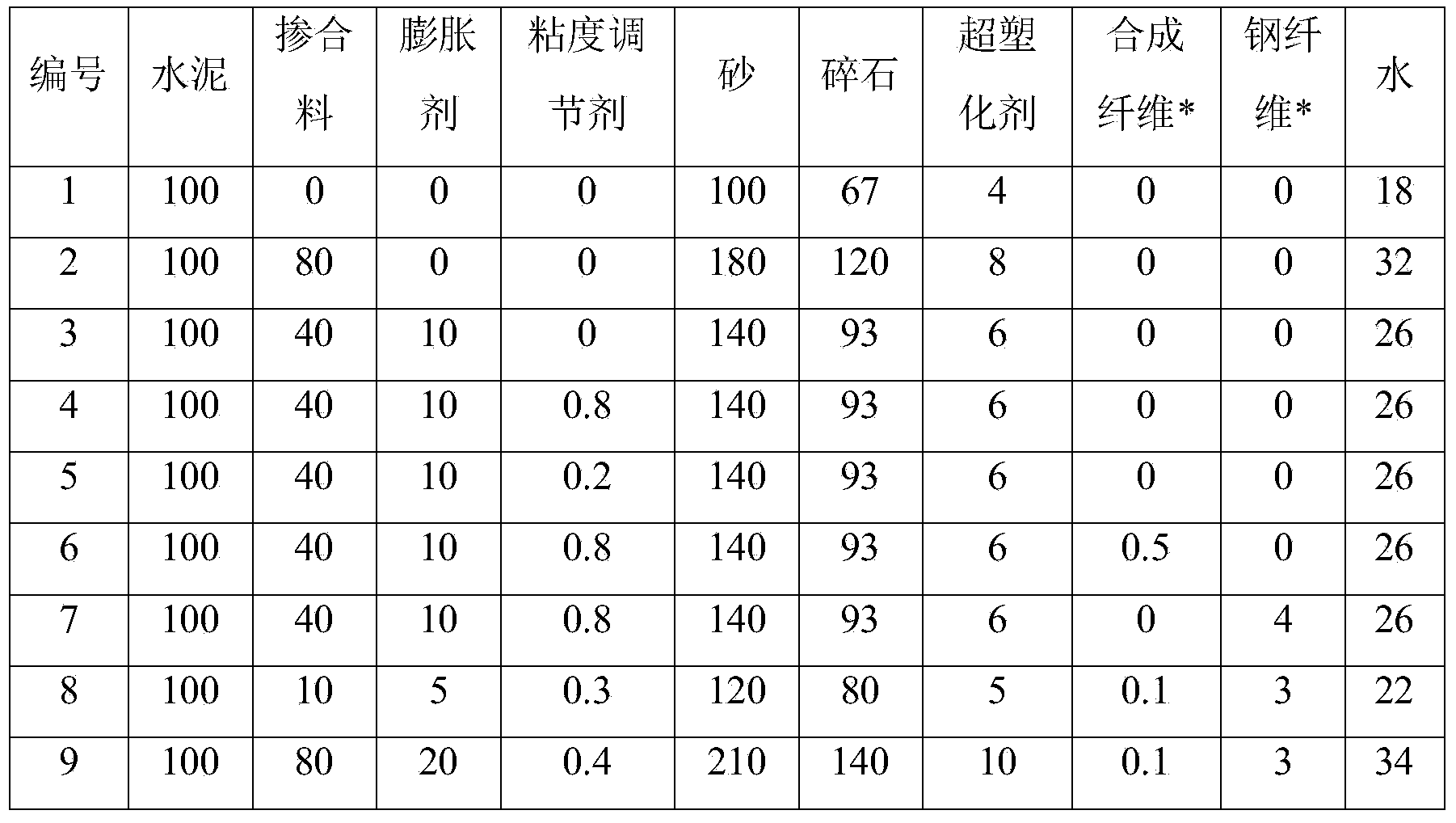

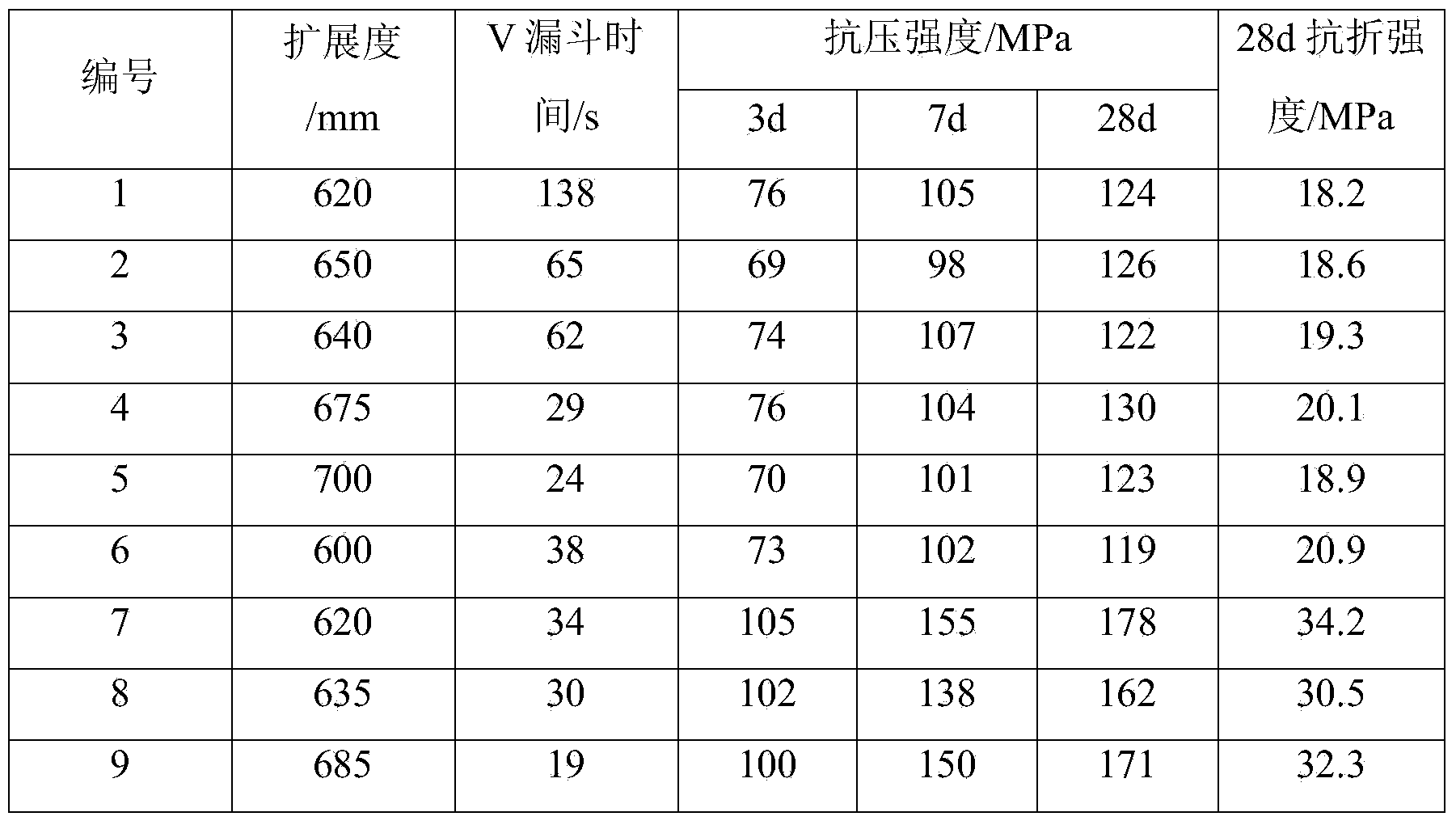

Full-particle size ultrahigh-performance concrete composition

The invention discloses a full-particle size ultrahigh-performance concrete composition which is prepared from the following components: 100 parts of cement, 10-80 parts of admixture, 5-20 parts of expanding agent, 1-20 parts of viscosity regulator, 120-210 parts of sand, 80-140 parts of rubble and 5-10 parts of super plasticizer while certain volume dosage of fiber is added. The full-particle size ultrahigh-performance concrete composition disclosed by the invention has controllable rheological property and shrinkage strain property and ultrahigh mechanical property and durability. Water is directly added on the site according to a proportion, and the full-particle size ultrahigh-performance concrete can be obtained through forced stirring.

Owner:JIANGSU SOBUTE NEW MATERIALS

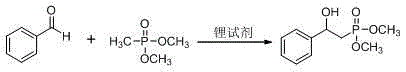

Preparation method of beta-hydroxyphosphonate derivatives

InactiveCN104370960ARich typeRaw materials are easy to getGroup 5/15 element organic compoundsMANGANESE ACETATEEthylic acid

The invention discloses a preparation method of beta-hydroxyphosphonate derivatives. The preparation method comprises that an arylethene derivative, a phosphorus reagent and manganese acetate are dissolved in a solvent and the solution undergoes a reaction at a temperature of 20-60 DEG C to produce the beta-hydroxyphosphonate derivative. Under the action of ammonia water, a beta-aminophosphonate derivative is prepared from the beta-hydroxyphosphonate derivative. The preparation method utilizes the arylethene derivative as an initiator and utilizes multiple easily available raw materials. The beta-hydroxyphosphonate derivatives belong to multiple types and can be directly used and can be used for other further reactions. The preparation method has a short synthesis route, mild reaction conditions, simple reaction and aftertreatment processes and a high yield and is suitable for large-scale production.

Owner:翁后科

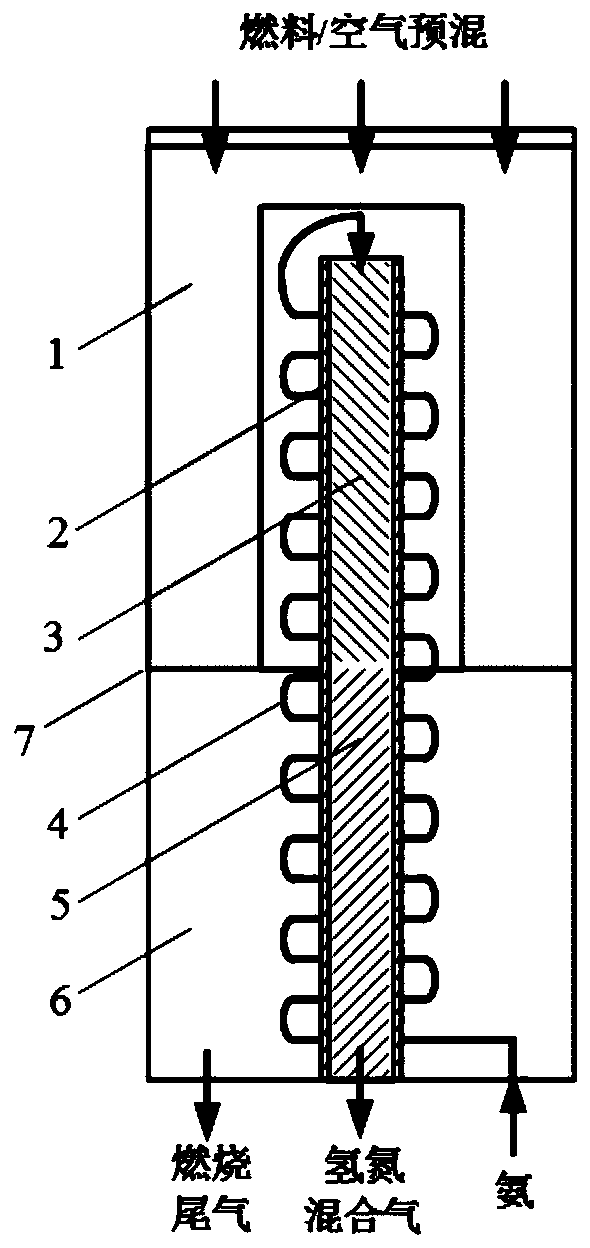

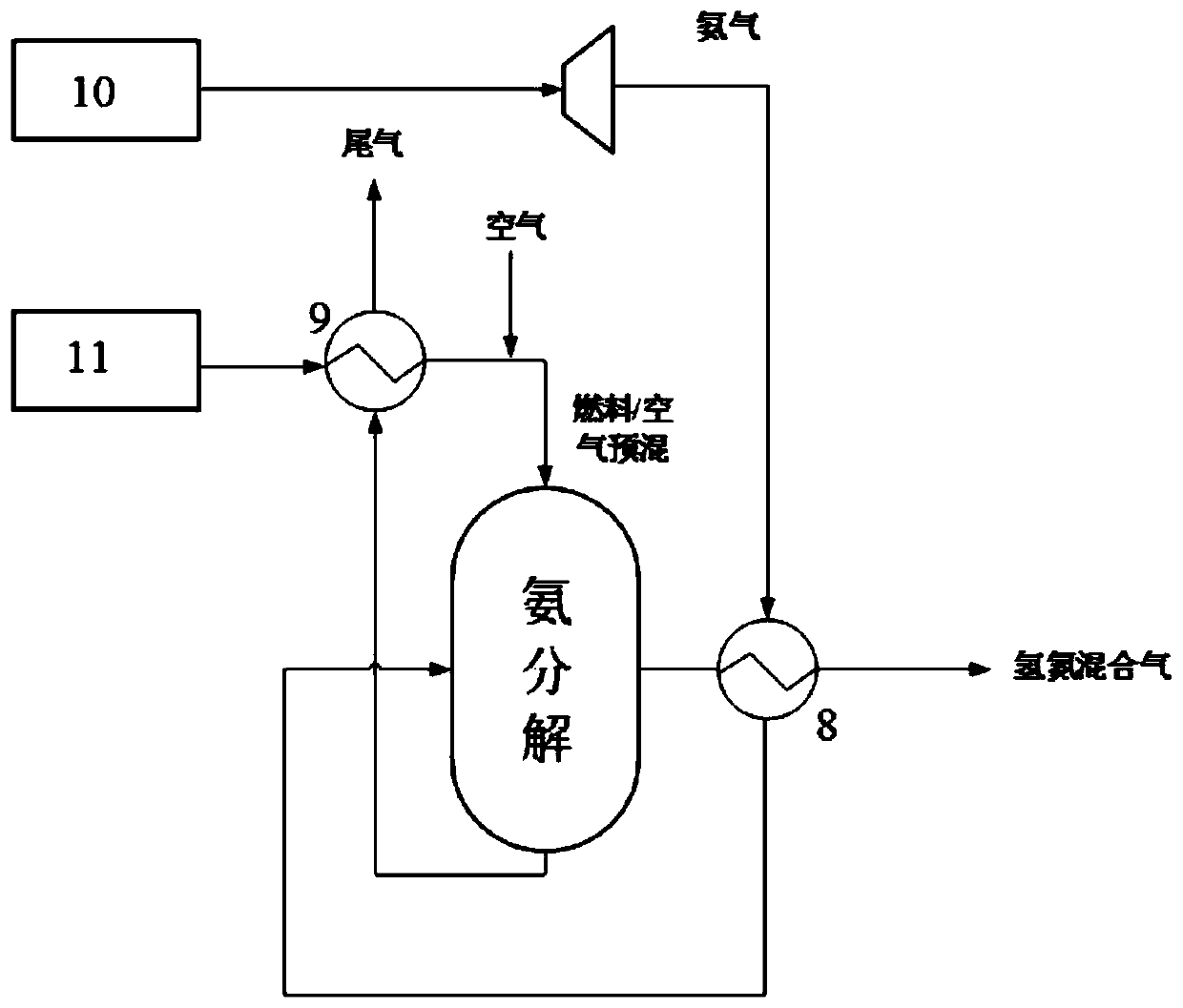

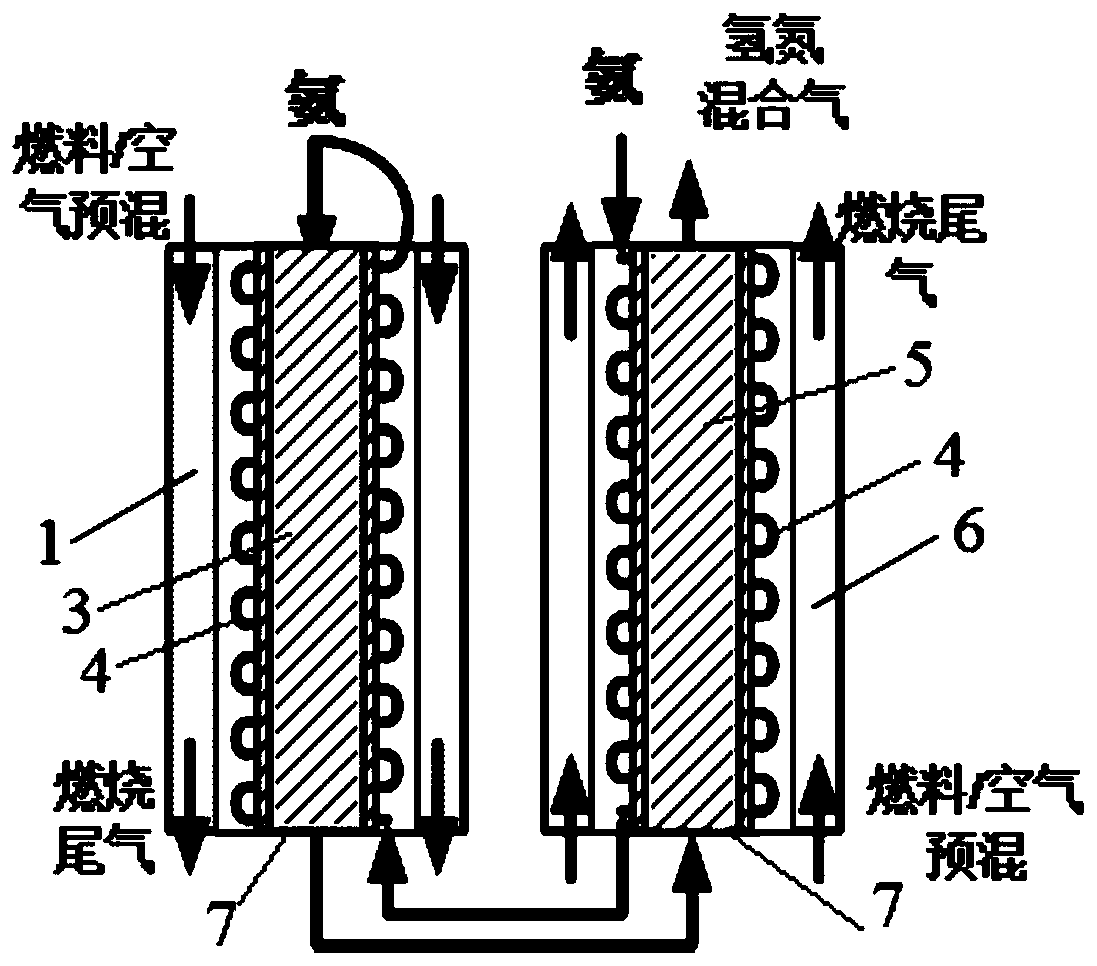

Ammonia decomposition device, ammonia decomposition system and hydrogen production method

ActiveCN110203882ADecompose thoroughlyImprove decomposition efficiencyGas treatmentHydrogen separation using solid contactDecompositionNitrogen

The invention belongs to the technical field of hydrogen production, and concretely relates to an ammonia decomposition device, an ammonia decomposition system and a hydrogen production method. The ammonia decomposition device comprises a shell, a heating zone, a heat exchange zone, a reaction section and a heat exchange coil. The heat exchange coil is spirally wound around the outer wall of the reaction section to sufficiently heat ammonia gas, so the heating efficiency of ammonia gas is increased; a first reaction section and a second reaction section which are sequentially communicated arearranged in the reaction section to ensure that the ammonia gas is decomposed after entering the first reaction section in order to generate a nitrogen and hydrogen mixture, so the decomposition efficiency of the ammonia gas is increased; and the second reaction section can perform secondary decomposition on the residual ammonia gas in the nitrogen and hydrogen mixture produced in the first reaction section, so the residual amount of ammonia gas in the nitrogen and hydrogen mixture in the second reaction section is reduced, thereby the ammonia gas is decomposed more thoroughly. The device makes the conversion rate of ammonia gas reach 99.9% or more and the residual amount of ammonia gas in the nitrogen and hydrogen mixture less than 1000 ppm.

Owner:福大紫金氢能科技股份有限公司

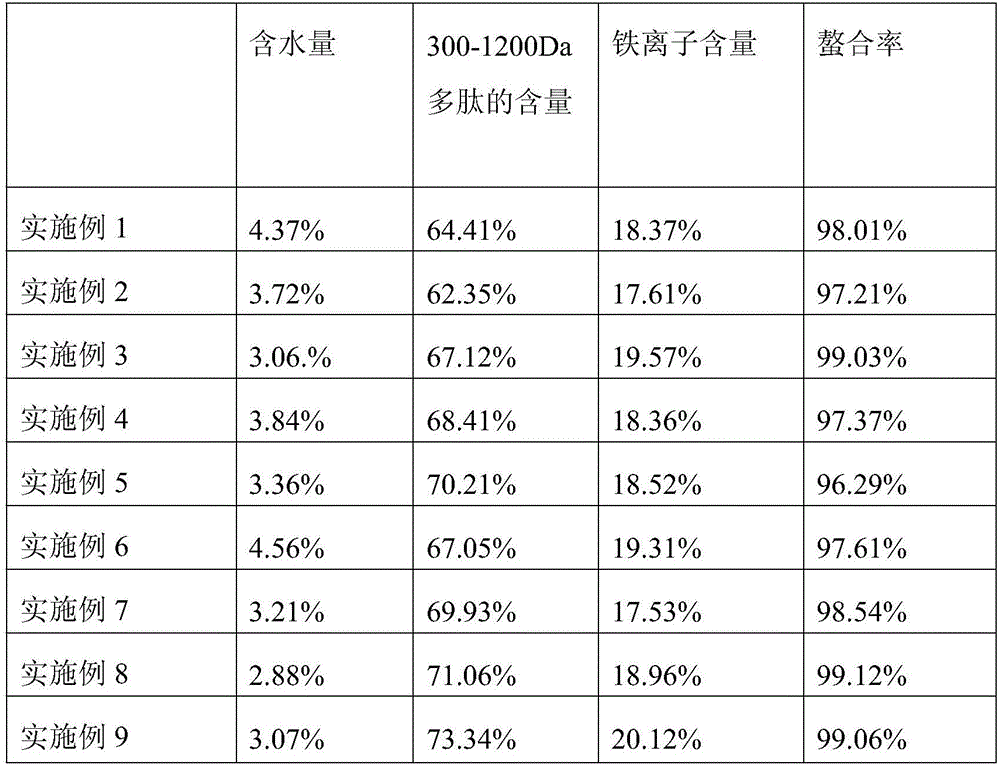

Polypeptide iron chelate prepared from soy isolate protein serving as substrate and preparation method

InactiveCN105746907AImprove content and purityRaw material stabilityAnimal feeding stuffAccessory food factorsProtein servingsChemistry

The invention discloses a polypeptide iron chelate prepared from soy isolate protein serving as a substrate and a preparation method of the polypeptide iron chelate. The polypeptide iron chelate is prepared from the soy isolate protein serving as a base material which is subjected to fermentation, enzymolysis, nanofiltration, chelation and drying, and polypeptide produced after fermentation, enzymolysis and filtration of the soy isolate protein is taken as a chelating agent for preparation of the polypeptide iron chelate. Compared with like polypeptide iron chelated iron, the purity of the polypeptide iron chelate is greatly improved and the content of the polypeptide iron chelate is greatly increased, the polypeptide iron chelate can completely replace pure microelement additives to be directly added to feed, and the application effect is good; the feed attractant effect is good; the product is stable and contains a large number of multifunctional polypeptide substances.

Owner:SHANGHAI YUANYAO BIOLOGICAL SHARES

Preparation method of powdered oil feed

The invention relates to a feed, in particular to a preparation method of a powdered oil feed. The preparation method mainly solves the technical problems that the powdered oil feed in the prior art is easy to melt, oxided and deteriorated and is difficult to preserve, a carrier of the traditional oil powder is a non-nutritive substance such as furfur, corn (cob) flour, modified starch, powder fiber and the like, only fat is provided, other nutritional ingredients are low, and the powdered oil feed can only serve as energy feed on an aspect of animal demand. By a special method, the carrier in the oil powder is replaced to animal and vegetable protein from the non-nutritive substance. The method comprises the following steps of: adding and mixing animal fat and vegetable fat according to proportion; adding an emulsifier into a mixture according to proportion, and performing high-speed emulsification; homogenizing the emulsified mixture by a homogenizing machine; and adding animal protein, vegetable protein, vitamin, mineral substances and trace elements into the homogenized mixture according to proportion, mixing in a solid-liquid stirring and mixing machine; and packaging.

Owner:HANGZHOU XIANGBAO FEED

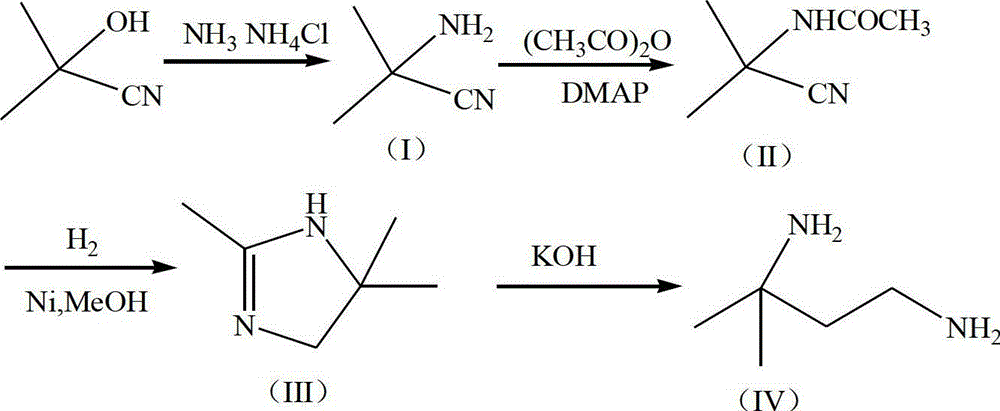

Preparation method of 2-methyl-1,2-propane diamine

InactiveCN102976951ARaw material stabilityLow costOrganic compound preparationAmino compound preparationDiamineSolvent

The invention discloses a preparation method of 2-methyl-1,2-propane diamine. The method comprises the following preparation steps of: 1) preparing alpha-amino isobutyronitrile (I); 2) preparing alpha-acetamido isobutyronitrile (II); 3) preparing 2,4,4-trimethyl-2-imidazoline (III); and 4) preparing 2-methyl-1,2-propane diamine (IV). The preparation method disclosed by the invention has the advantages of stable raw materials, low cost, mild reaction conditions and high reaction yield and is easy to industrialize. The solvent in the reaction process can be recycled by distilling.

Owner:张家港市大伟助剂有限公司

Healthcare animal growth promoter containing soybean oligosaccharides and clostridium butyricum

InactiveCN103719559ARaw material safetyRaw material stabilityAnimal feeding stuffAnimal scienceAdditive ingredient

The invention provides a healthcare animal growth promoter containing soybean oligosaccharides and clostridium butyricum. The healthcare growth promoter is characterized by being prepared by taking the soybean oligosaccharides and the clostridium butyricum as main active ingredients and attapulgite as a carrier and compounding, wherein the soybean oligosaccharides account for 15%-40% of the total weight, the clostridium butyricum accounts for 30%-55% of the total weight, and the attapulgite accounts for 5%-55% of the total weight; the purity of the soybean oligosaccharides is equal to or higher than 95%; the total viable count of the clostridium butyricum is equal to or higher than 1.0*1010 CFU / g; the additive amount of the healthcare growth promoter in a feed is 0.05%-2%. The healthcare growth promoter has the benefits as follows: (1) the growth speed of domestic animals can be remarkably increased; (2) the immunity and the breeding safety of the domestic animals can be improved and the survival rate of the domestic animals can be increased; (3) the raw materials are safe, stable, nontoxic, pollution-free and residue-free, and the novel healthcare animal growth promoter is safe, efficient and green.

Owner:天津天隆农业科技有限公司

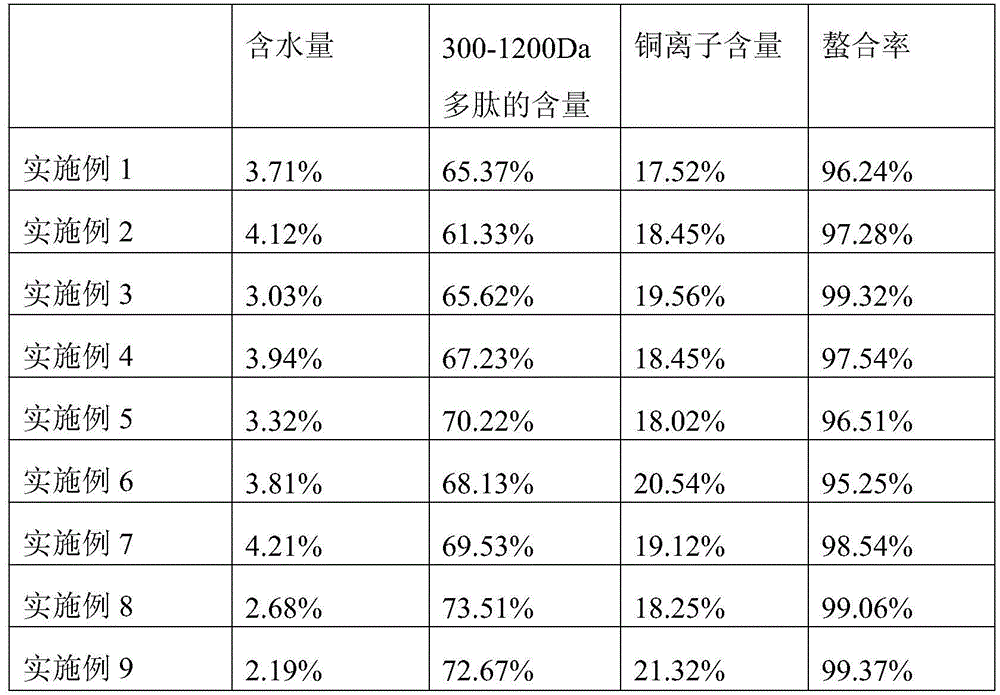

Polypeptide copper chelate prepared by using soybean protein isolate as substrate and preparation method

InactiveCN105661049AImprove immune functionHigh purityAnimal feeding stuffAccessory food factorsFiltrationCopper

The invention discloses a polypeptide copper chelate prepared by using soybean protein isolate as a substrate and a preparation method thereof. The soybean protein isolate is used as a basic material and is subjected to fermentation, enzymolysis, nanofiltration, chelation and drying, and the polypeptide copper chelate is prepared by using the polypeptide produced after fermentation, enzymolysis and filtration conducted on the soybean protein isolate as the a chelating agent. The polypeptide copper chelate is remarkably improved compared with like polypeptide chelated copper in purity and content, the mode that a pure microelement additive is directly added to a feed can be completely replaced, and an application effect is good. A food calling effect is good. A product is stable and contains a large amount of multifunctional polypeptide substances.

Owner:SHANGHAI YUANYAO BIOLOGICAL SHARES

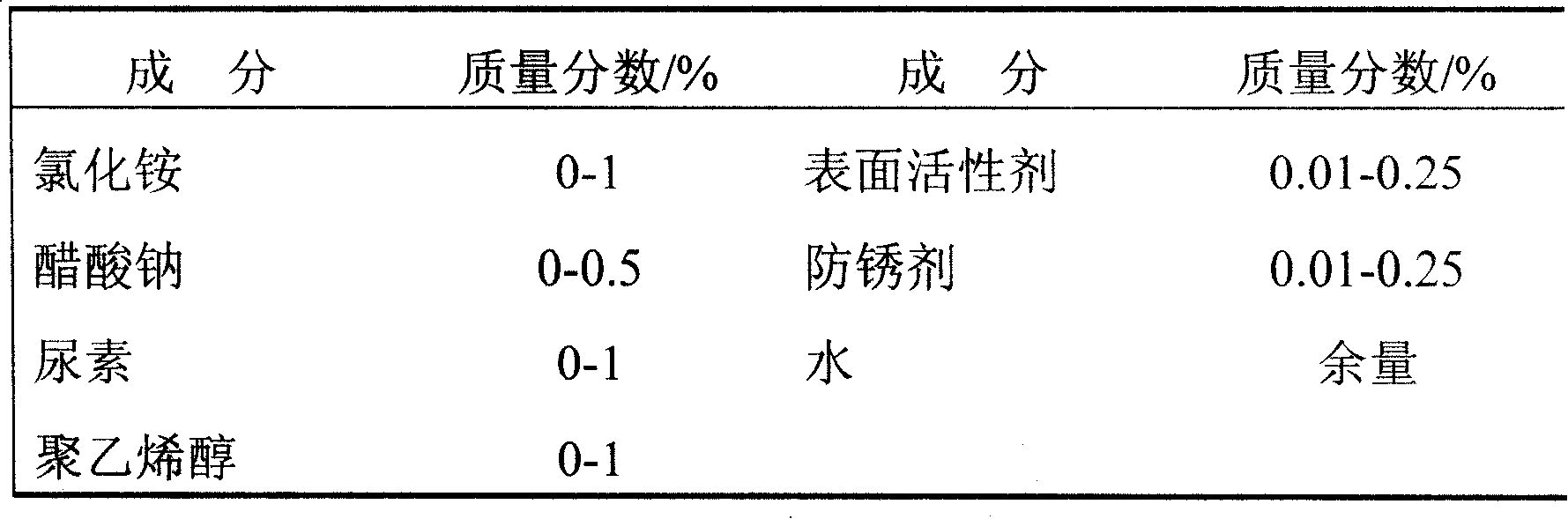

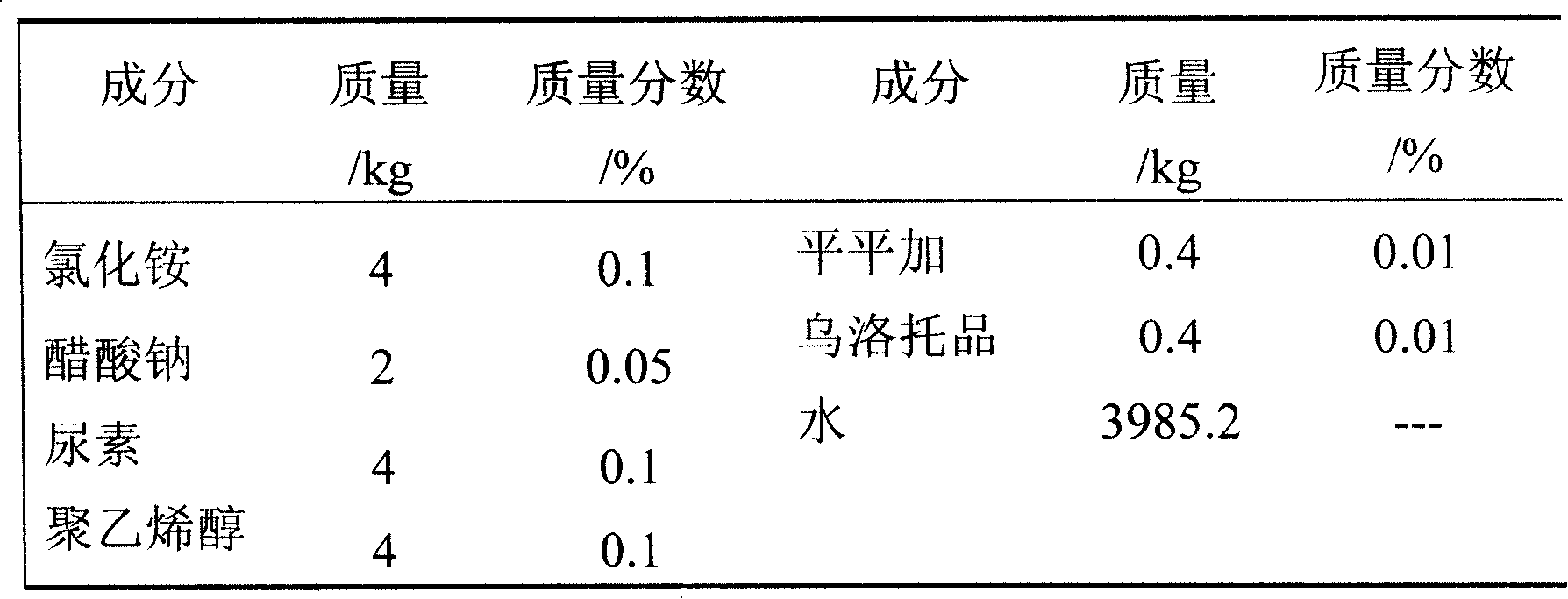

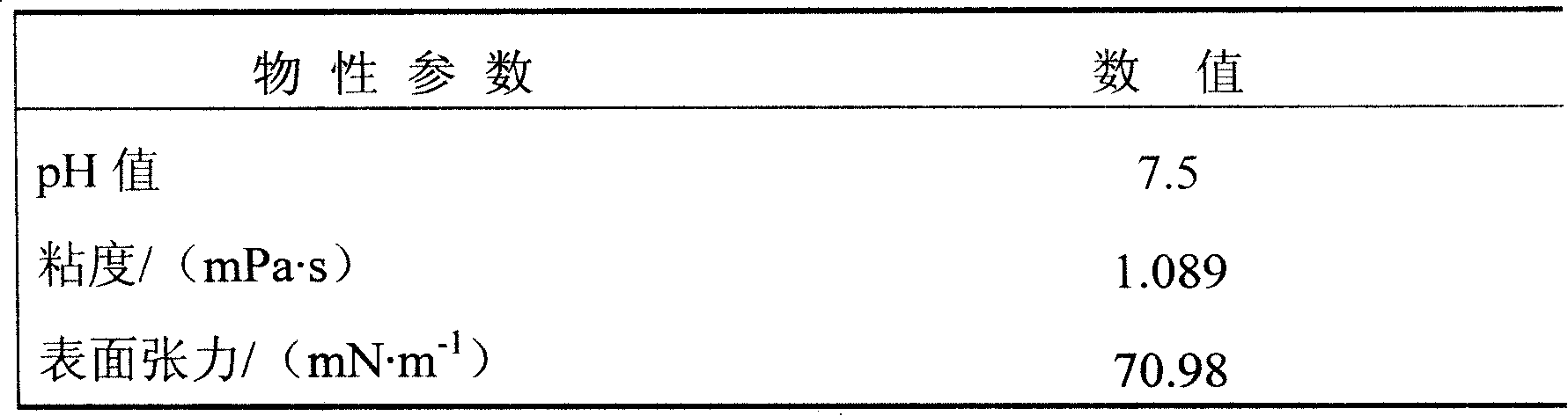

Water solution containing fine spray extinguishment additive agent and preparation and application

InactiveCN101214411AReduce the temperatureStrong penetrating powerFire rescueFire extinguisherSodium acetateCombustion

The invention relates to aqueous solution with fine water mist fire extinguishment additive, with the quality percentage of all components as below: ammonium chloride 0 percent to 1 percent, polyvinyl alcohol 0 percent to 1 percent, sodium acetate 0 percent to 0.5 percent, surface active agent 0.01 percent to 0.25 percent, urea 0 percent to 1 percent, rust preventive 0.01 percent to 0.25 percent, and the rest is water. The aqueous solution can improve the fire extinguishing efficiency of the fine water mist and effectively prevent after-combustion of inflamers; has little corrosion to equipments and instruments; basically has no pollution to fire scenes; is high-efficiency, stable and clean; the raw materials of all components are easy to be obtained; has stable performance; is basically nontoxic and low in cost; and has low consumption.

Owner:HENAN POLYTECHNIC UNIV

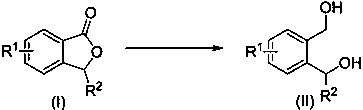

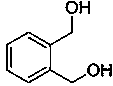

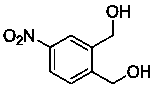

Method for synthesizing o-benzenedicarbinol derivative

ActiveCN108610237AHigh yield preparationSimple processCarboxylic acid nitrile preparationOrganic compound preparationSilane compoundsPhthalide

The invention belongs to the technical field of chemical engineering and particularly relates to a method for synthesizing an o-benzenedicarbinol derivative. Phthalide as a raw material is subjected to a reduction ring-opening reaction under the action of alkali and silane compounds, and o-benzenedicarbinol is prepared. According to the method, raw materials are easy to obtain, the method is simple and convenient to operate, the reaction selectivity is high, the product yield is high, and the reaction condition is mild; the synthesized monosubstituted or polysubstituted o-benzenedicarbinol derivative has high quality and good functional group compatibility.

Owner:FUDAN UNIV

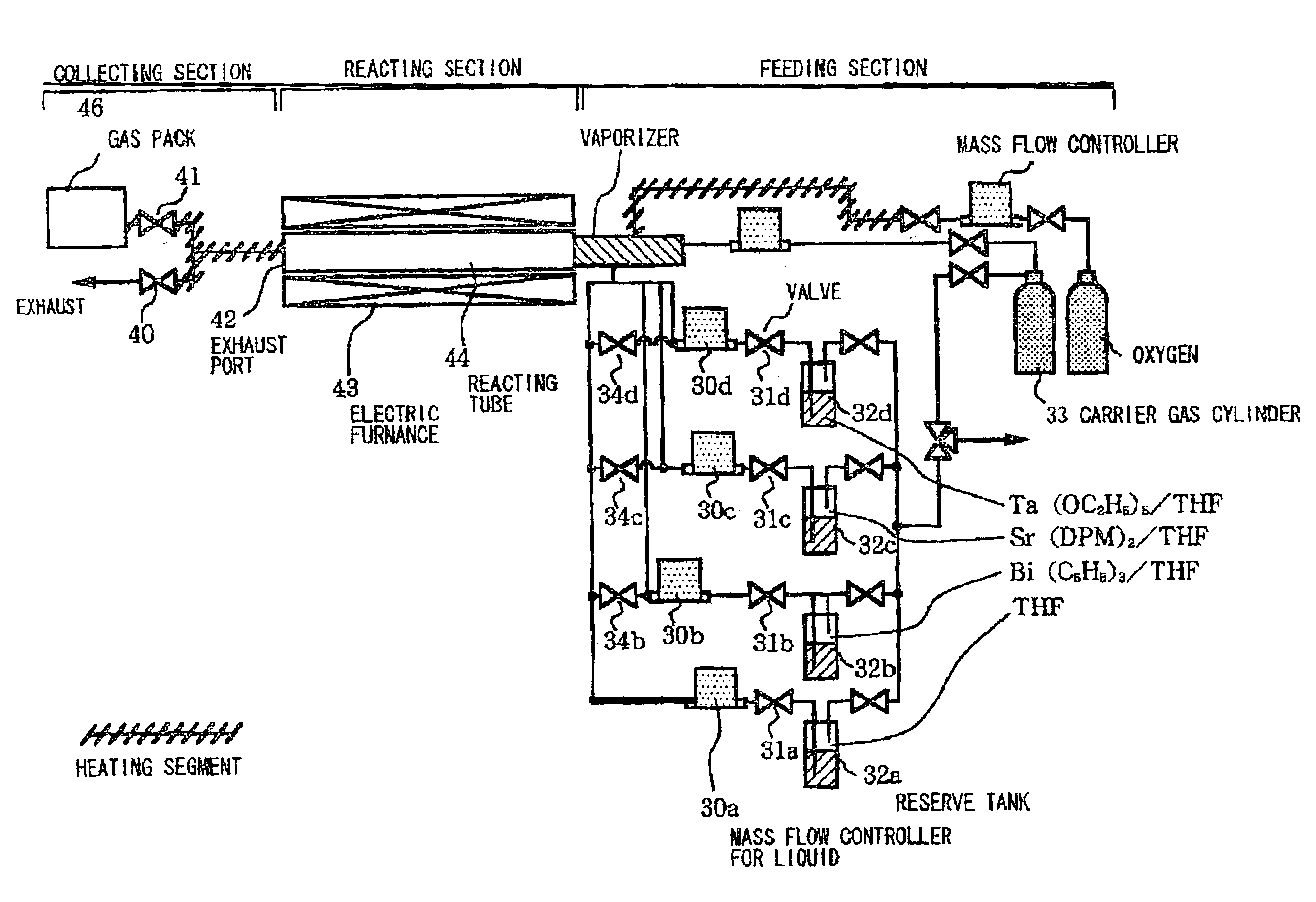

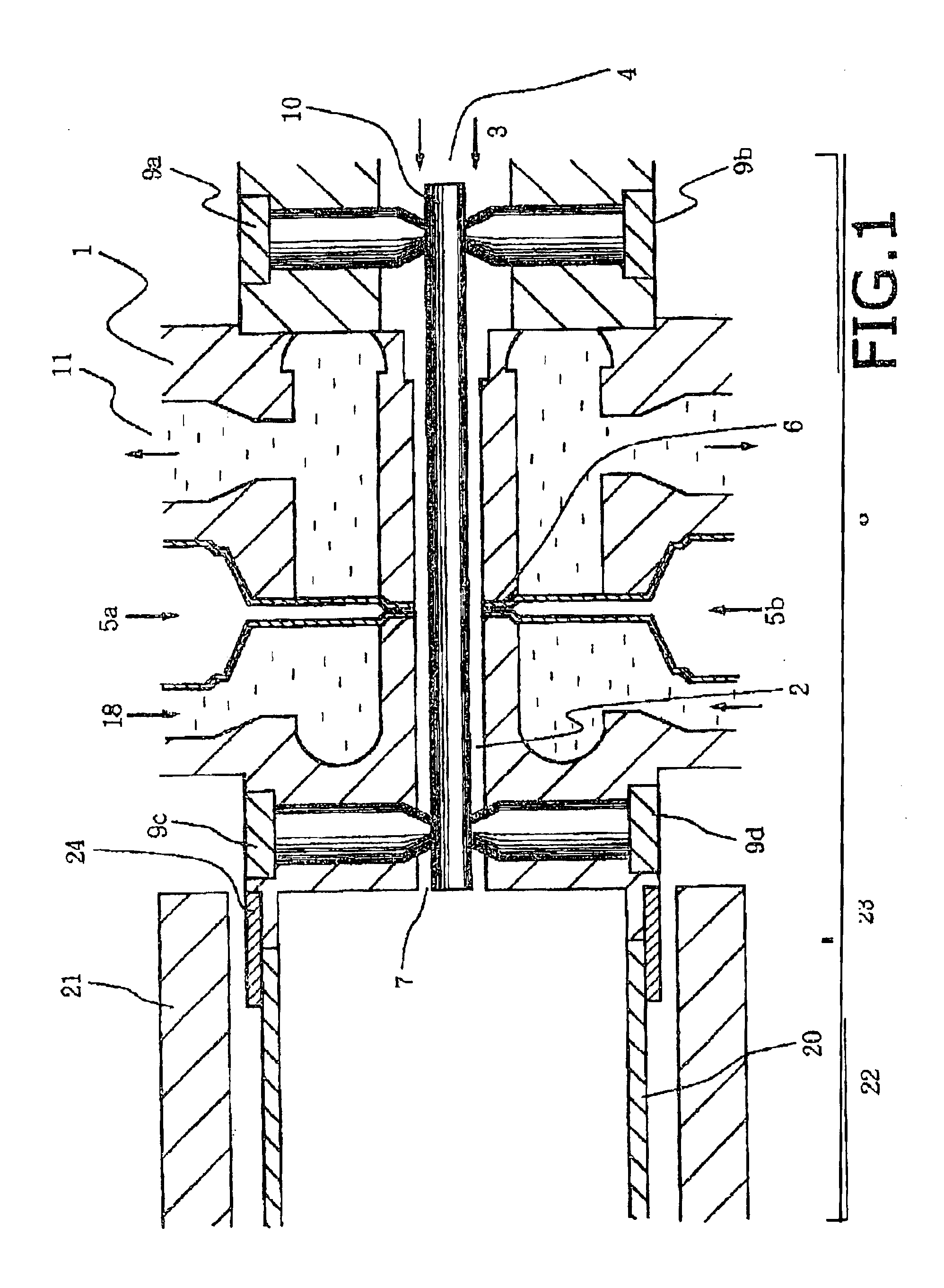

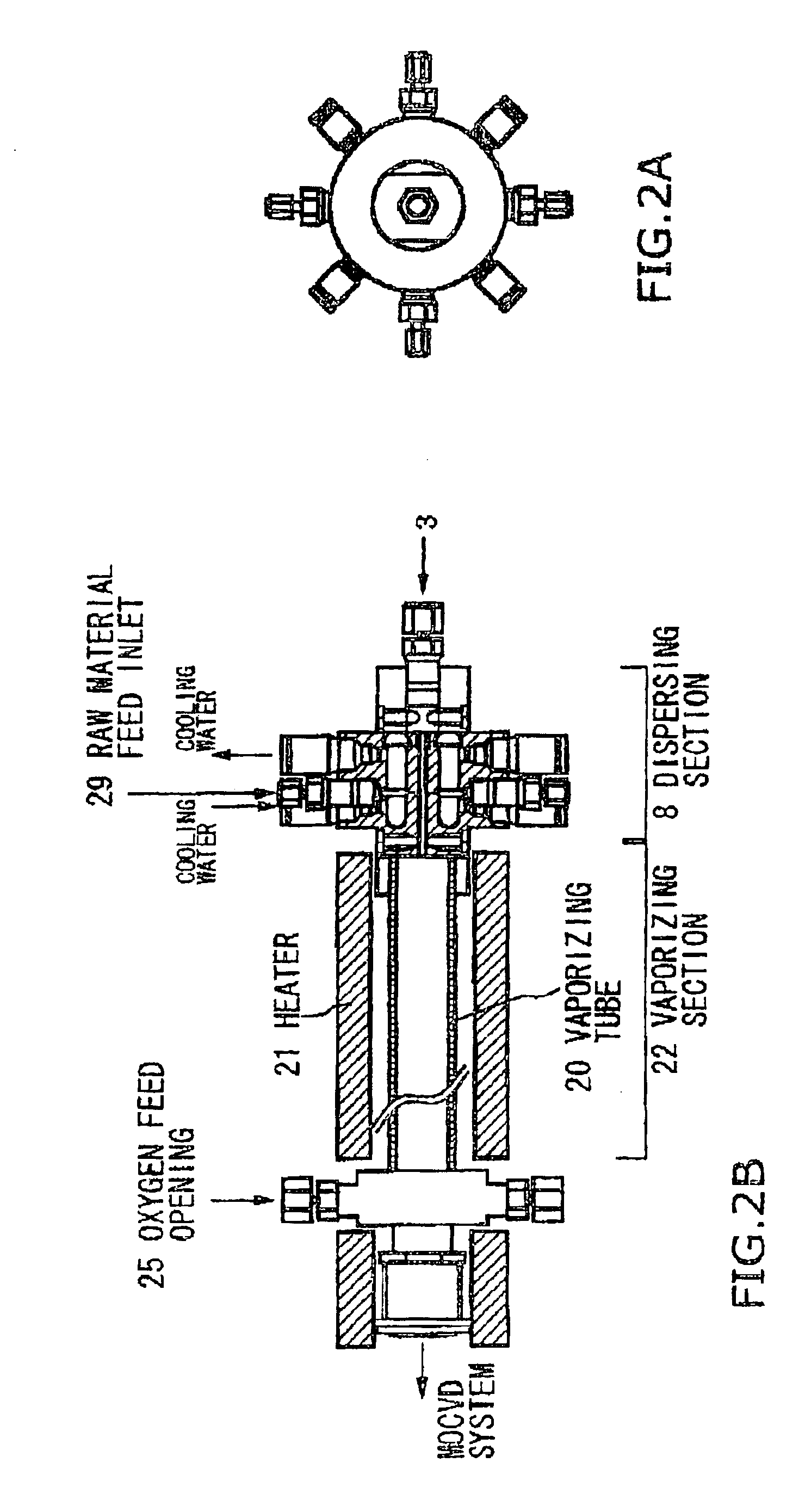

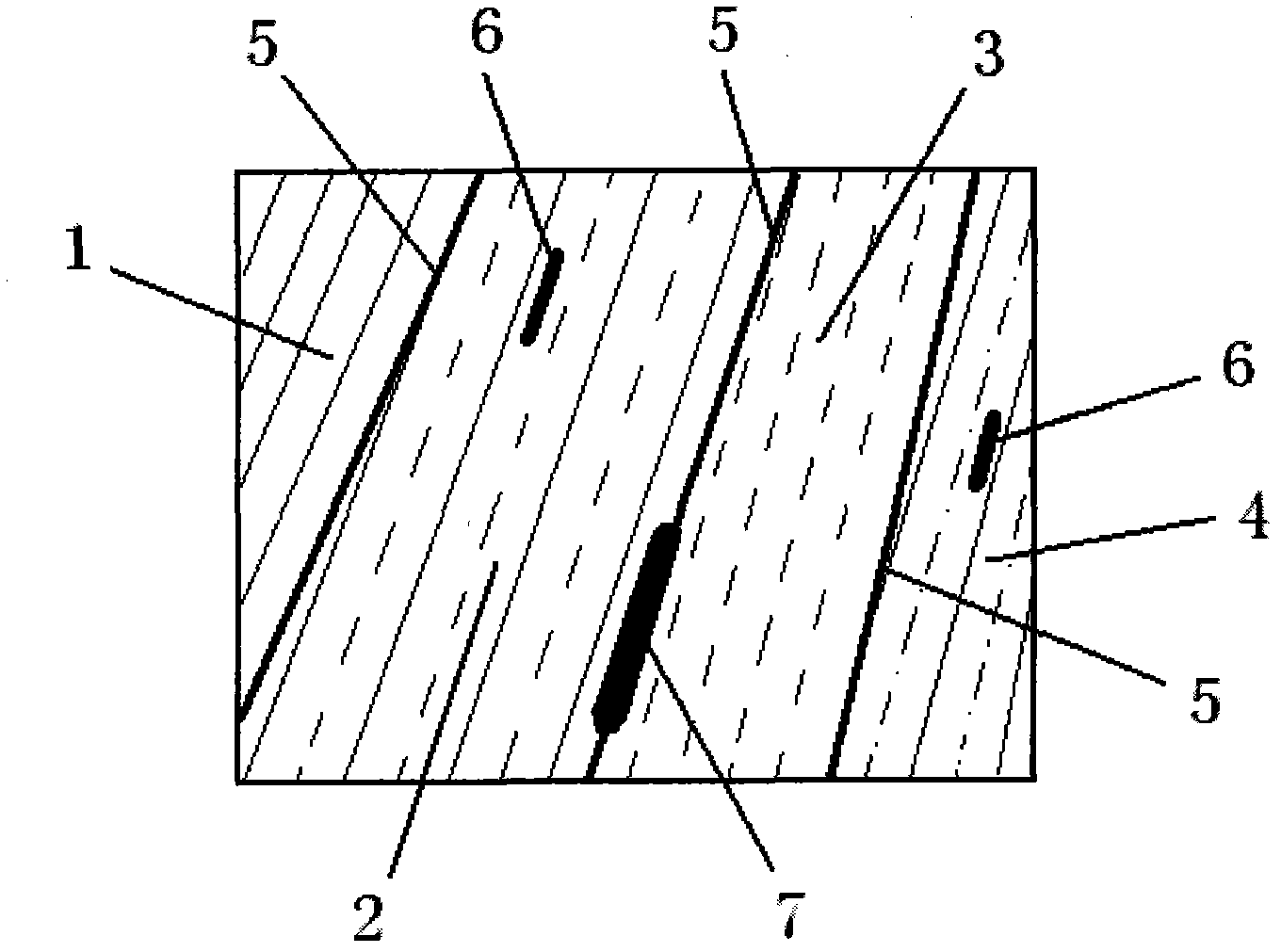

Vaporizer for MOCVD and method of vaporizing raw material solutions for MOCVD

InactiveUS6931203B2Raw material stabilityLong-term useSpace heating and ventilationFlash steam boilersReaction tubeRaw material

Disclosed is a vaporizer constituted of a dispersing section 8 and a vaporizing section 22. The dispersing section 8 comprises a gas introduction port 4 for introducing a carrier gas 3 under pressure into a gas passage, means for feeding raw material solutions 5a and 5b to the gas passage, and a gas outlet 7 for delivering the carrier gas containing the raw material solutions to the vaporizing section 22. The vaporizing section 22 comprises a vaporizing tube 20 having one end connected to a reaction tube of the MOCVD system and having the other end connected to the gas outlet 7 of the dispersing section 8, and heating means for heating the vaporizing tube 20. The vaporizing section 22 serves to heat and vaporize the raw material solution containing carrier gas 3 delivered from the dispersing section 8. The dispersing section 8 includes a dispersing section body 1 having a cylindrical hollow portion, and a rod 10 having an outer diameter smaller than the inner diameter of the cylindrical hollow portion. The rod 10 has a spiral groove 60 formed in the external periphery closer to the vaporizing section 22, the rod 10 being inserted into the cylindrical hollow portion.

Owner:KANUSHIKI KAISHA WATANABE SHOKO +2

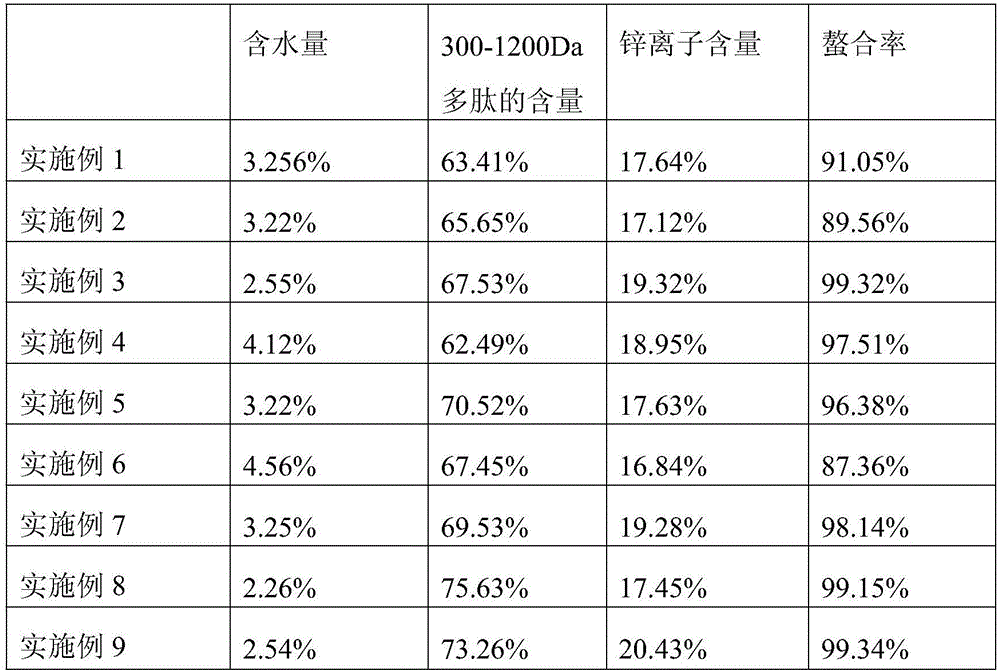

Polypeptide zinc chelate prepared with soy protein isolate as base and preparation method

InactiveCN105724784AImprove content and purityRaw material stabilityAccessory food factorsEnzymeSoy protein

The invention discloses polypeptide zinc chelate prepared with soy protein isolate as base and a preparation method. The polypeptide zinc chelate is prepared by soy protein isolate as base through fermenting, enzymolysis, nanofiltering, chelating and drying. After fermenting, enzymolysis and filtering of the soy protein isolate, polypeptide is generated as chelate to obtain polypeptide zinc chelate.Purity and content of the polypeptide zinc chelate are higher than those of the like polypeptide chelate zinc, and the polypeptide zinc chelate can be directly added into fodder completely instead of pure microelement additive and is excellent in application effect. The polypeptide zinc chelate is good in food calling effect, stable and contains much multifunctional polypeptide.

Owner:SHANGHAI YUANYAO BIOLOGICAL SHARES

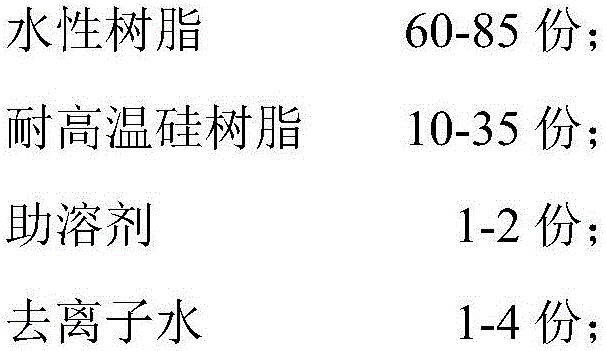

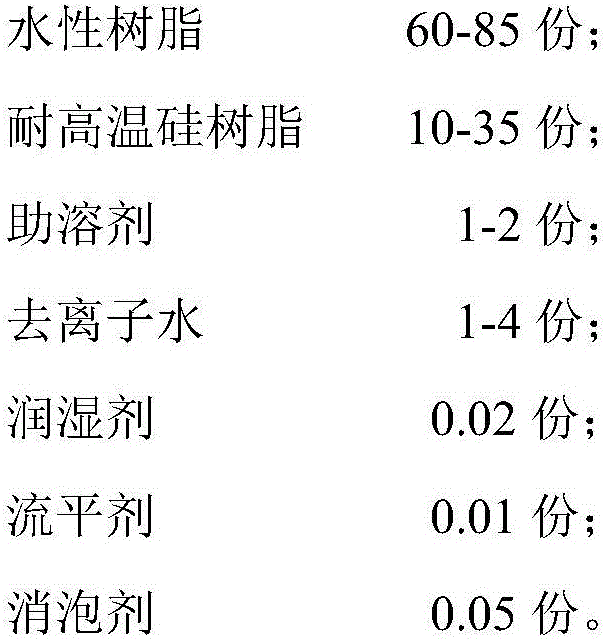

High-temperature-resisting aqueous aluminum-plating transferring paint composition and preparation method thereof

InactiveCN106147451AHigh temperature resistanceImprove temperature resistanceFireproof paintsPolyurea/polyurethane coatingsFoaming agentSolvent

The invention provides a high-temperature-resistant water-based aluminized transfer coating composition and a preparation method thereof; the coating composition comprises the following components in parts by weight: 60-85 parts of water-based resin, 10-35 parts of high-temperature-resistant silicone resin , 1-2 parts of co-solvent; 1-4 parts of deionized water; 0.02 parts of wetting agent; 0.01 parts of leveling agent; 0.05 parts of defoaming agent. The invention can be applied to the improvement of the temperature resistance of multi-system water-based coatings. By adding an appropriate amount of modified silicone resin, the temperature resistance value tested by the molding method is significantly improved by 10-30°C compared with the coating without adding it, and the The added amount will not cause compatibility problems.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Coal blending method for blast furnace coal injection

ActiveCN103255247ASolve the problem of sprayingLow costBlast furnace detailsProcess engineeringAnthracite

The invention relates to a coal blending method for blast furnace coal injection, which comprises the step of mixing the following coal varieties in percentage by weight: 20-25% of first blind coal, 15-20% of second blind coal, 0-15% of third blind coal, 25-30% of soft coal and 25-30% of powder coal, wherein the sum of weight percents of all the coal varieties is 100%; the first blind coal is one comprising 9.0% of Vdaf, 10.50% of Ad, 0.47% of Std and 81% of fixed carbon; the second blind coal is one comprising 9.6% of Vdaf, 10.45% of Ad, 0.52% of Std and 80% of fixed carbon; and the third blind coal is one comprising 9.1% of Vdaf, 11.63% of Ad, 0.50% of Std and 80% of fixed carbon. According to the invention, the blockage of equipment such as a chute, screen or the like of a coal injection system can be reduced, the coal injection quality can be stabilized, and the coal injection cost can be lowered.

Owner:NANJING IRON & STEEL CO LTD

Synthesizing method of tetrahydroquinoline derivative

The invention relates to a synthesizing method of a tetrahydroquinoline derivative. Specifically, a Lewis acid SnCl2 and an oxidant are subjected to an oxidation reduction reaction; a produced oxidation product SnCl4 assists in in-situ promotion of an aza-Diels-Alder cycloaddition reaction of aniline, aldehyde and olefin, such that a 1,2,3,4-tetrahydroquinoline derivative is obtained. With the method, aliphatic aldehyde successfully participates in the reaction, and a range of aldehyde substrates in Povarov reactions is expanded. An accelerant is the combination of SnCl2 and the oxidant. Compared with a method for directly using SnCl4 or other Lewis acid accelerant, with the method provided by the invention, the synthesis of the 1,2,3,4-tetrahydroquinoline derivative has the advantages of cheap price, simple operation, mild reaction conditions, low corrosion, and high yield of prepared 1,2,3,4-tetrahydroquinoline derivative.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Environment-friendly waterborne coating for buildings and preparation method of environment-friendly waterborne coating

InactiveCN106752559AEasy to prepareRaw materials are easy to getAnti-corrosive paintsEpoxy resin coatingsSodium silicateDefoaming Agents

The invention discloses an environment-friendly waterborne coating for buildings and a preparation method of the environment-friendly waterborne coating. The environment-friendly waterborne coating is prepared from 25-35 parts of a water-soluble acrylate polymer, 20-30 parts of light calcium carbonate, 18-25 parts of talcum powder, 10-15 parts of sodium silicate, 15-20 parts of heavy calcium carbonate powder, 10-15 parts of titanium dioxide, 15-25 parts of emulsified epoxy resin, 2-4 parts of a plasticizer, 5-8 parts of auxiliaries, 3-6 parts of a curing agent, 4-6 parts of a defoaming agent, 2-5 parts of a leveling agent and 15-25 parts of water. The obtained waterborne coating is non-toxic, pollution-free and environment-friendly; the adhesive force is 0-level, and the environment-friendly waterborne coating is not prone to falling off, is high in corrosion resistance and shock strength and has good covering power and good comprehensive performance; the production technology is simple, the use range is wide, the cost is low, and industrial production is facilitated.

Owner:芜湖浩权建筑工程有限公司

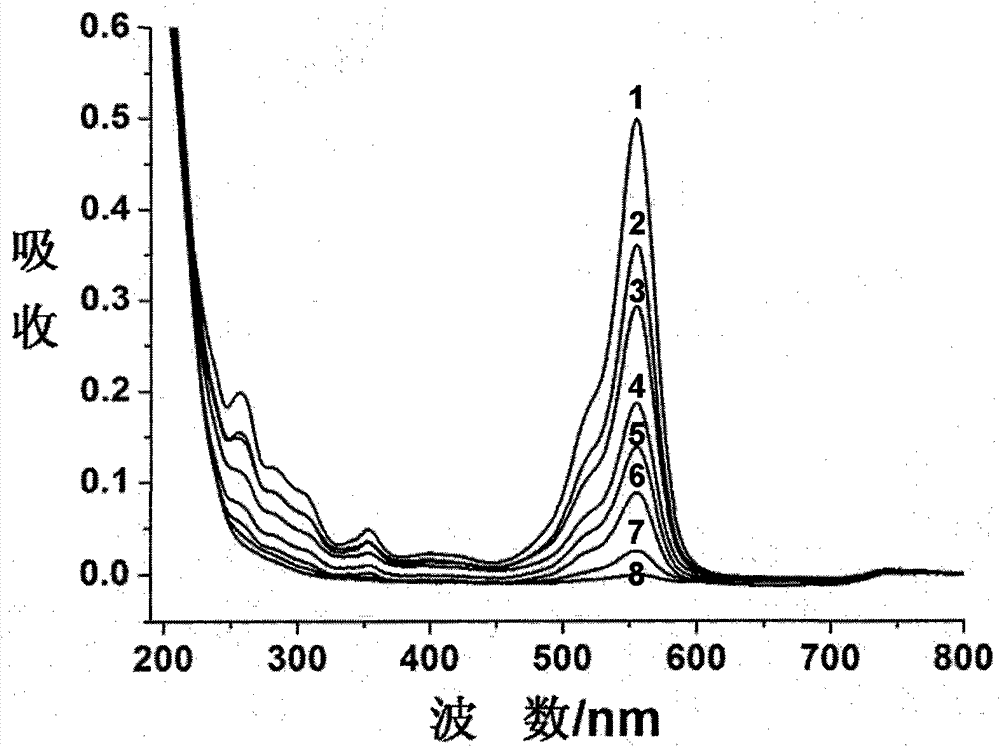

Application of polyoxometallate containing Keplerate in carrying out heterogeneous photocatalytic degradation on rhodamine B

InactiveCN102210917BRaw material stabilityHigh catalytic efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenWater soluble

Owner:BEIJING UNIV OF CHEM TECH

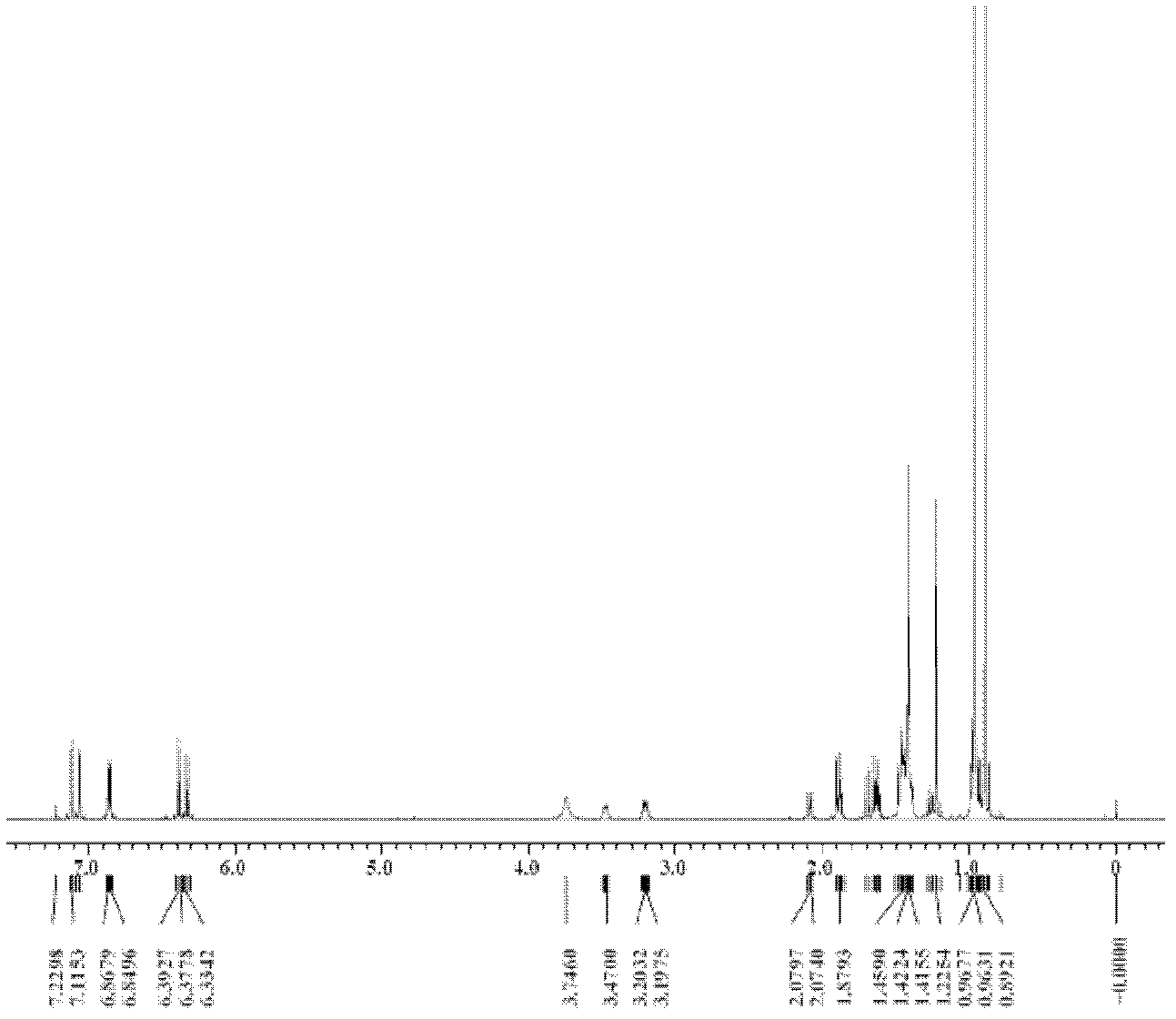

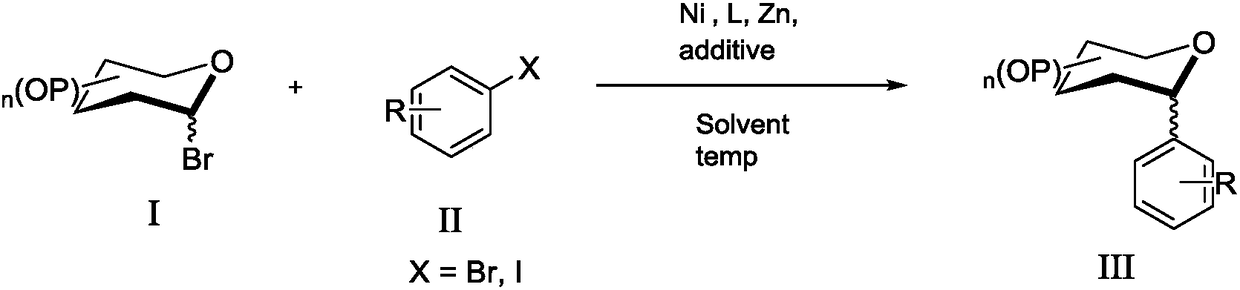

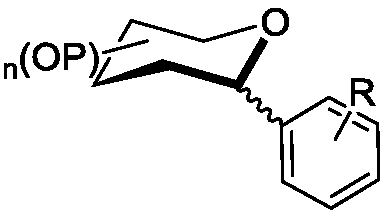

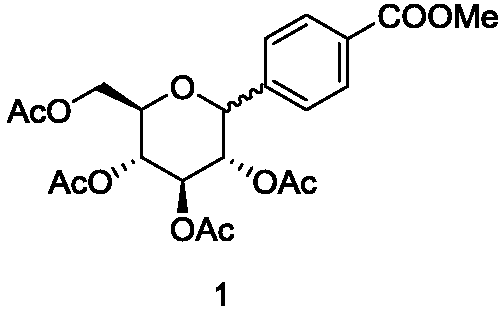

C- aryl glycoside compound and synthesis method thereof

InactiveCN108530409AMild responseSimple post-processingOrganic chemistryWater bathsSynthesis methods

The invention relates to a C-aryl glycoside compound and a synthesis method thereof. A structural formula of the compound is shown in the description, wherein R is H, acetyl, methyl formate group, NHBoc or 4-methoxy; basic reaction takes glycosyl bromide and aryl iodine (bromine) as a substrate, and reaction is gently performed for 6-12 hours under icy-water bath or normal temperature under actions of a catalyst, a ligand, a reducer and an additive, so that the C-aryl glycoside compound is obtained. The catalyst metal is relatively cheap, raw materials are simple and easily available, the reaction is moderate, one-step reaction is performed, steps are simple, operations are safe, and the yield is relatively high, so that stereoselectivity is relatively good.

Owner:SHANGHAI UNIV

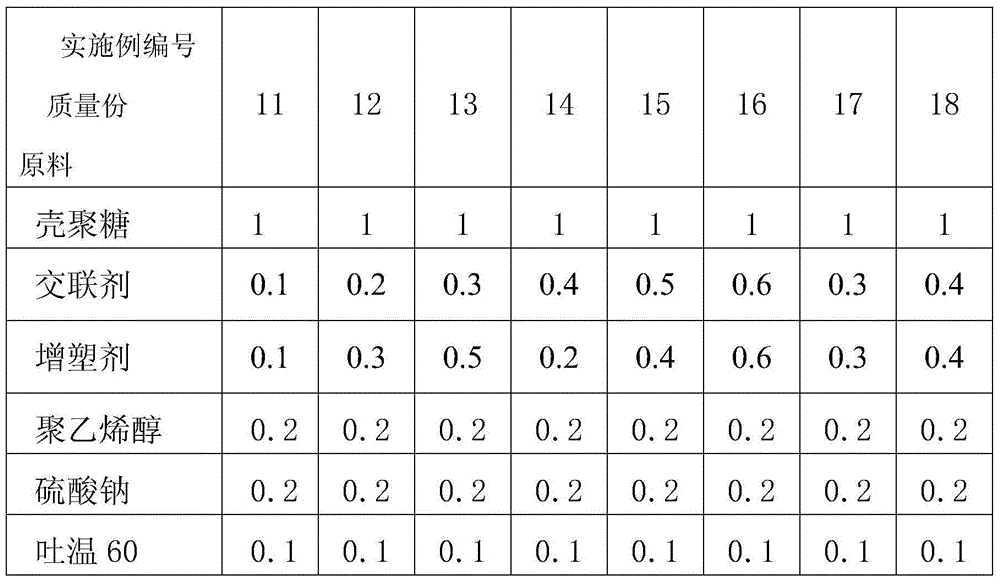

Preparation method of chitosan modified starch impregnating compound

The invention discloses a preparation method of chitosan modified starch impregnating compound. The preparation method is characterized in that the preparation method comprises the following steps: taking 9-18 parts by mass of raw starch to a reaction container, and adding 300 parts by mass of water; stirring and raising temperature to 90 DEG C; pasting for 1 hour and obtaining starch paste; taking 1-3 parts by mass of chitosan in the starch paste, and orderly adding 0.1-0.6 parts by mass of cross-linking agent, 0.1-0.6 parts by weight of plasticizer, 0.2 parts by weight of polyving akohol, 0.2 parts by weight of sodium sulfate and 0.1 parts by weight of Twain 60 under the condition of stirring, and obtaining a mixture; reacting the mixture at 90 DEG C for 1-5 hours, cooling to room temperature, and placing for 2 hours; defoaming, and obtaining the chitosan modified starch impregnating compound. By adopting the preparation method of the chitosan modified starch impregnating compound, the technique is simple and cost is low; the product can be directly applied to wiredrawing production of glass fiber tank furnace, glass fiber textile processing, and other domains; the using effect is good.

Owner:SOUTHWEAT UNIV OF SCI & TECH

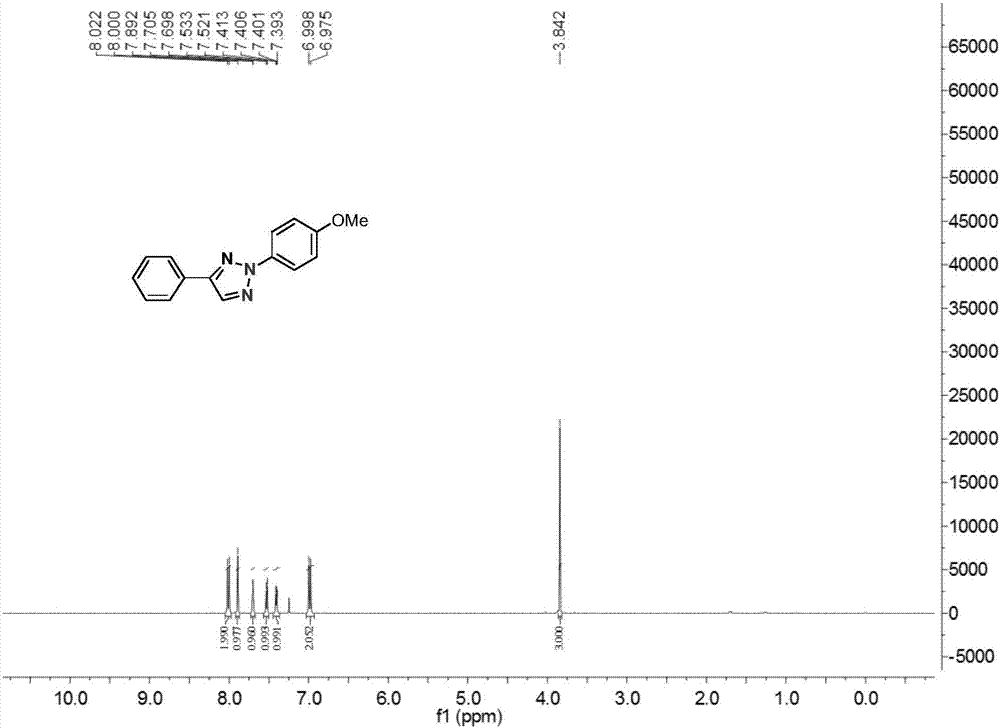

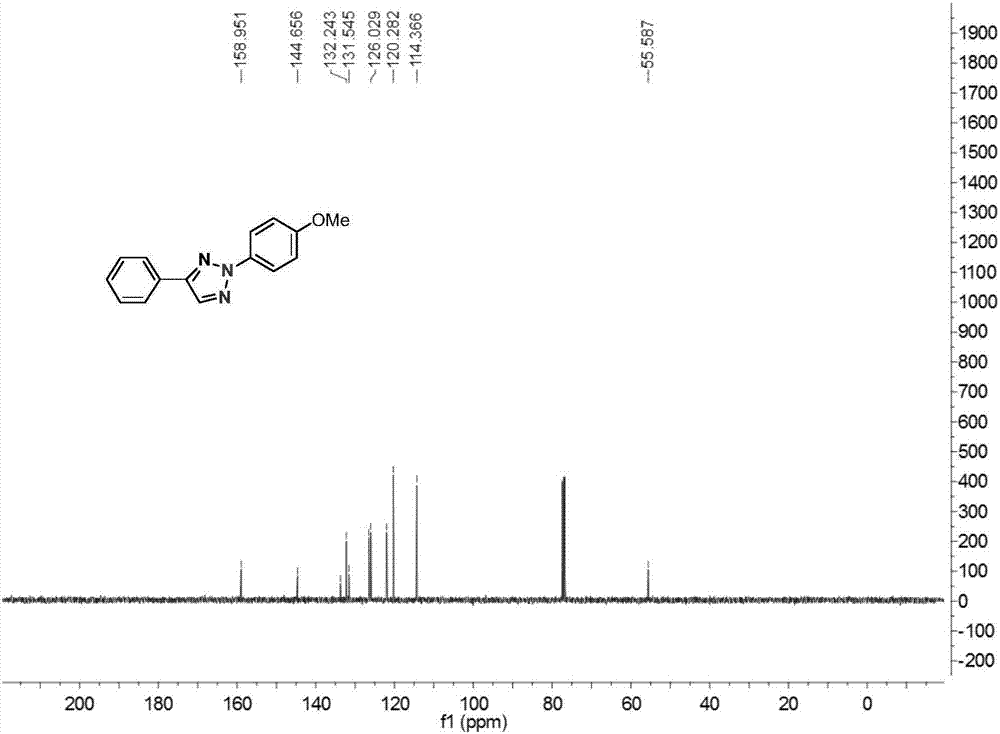

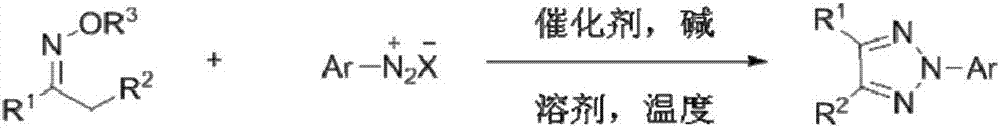

Method for constructing N-2-aryl-substituted-1,2,3-triazole

The invention discloses a method for constructing N-2-aryl-substituted-1,2,3-triazole and belongs to the field of synthesis of pharmaceutical and chemical materials. The method comprises steps as follows: ketoxime ester, aryl diazonium salt, alkali, a copper salt catalyst and a solvent are added to a reactor and are stirred and react for 12-24 h at the temperature of 70-90 DEG C, a product is cooled to the room temperature after the reaction, water and ethyl acetate are added for extraction of a reaction liquid, the solvent is removed through reduced-pressure evaporation, a crude product is obtained and subjected to column chromatography purification, and a N-2-aryl-substituted-1,2,3-triazole compound is obtained. According to the method, the used raw materials are non-toxic, air-stable, cheap and available, and unstable, easily explosive and dangerous azides are not used; the N-2-aryl-substituted-1,2,3-triazole compound is high in reaction selectivity, good in functional group adaptability, wide in substrate adaption range and high in product yield. The synthesis method is simple to operate and safe, adopts mild reaction conditions, is insensitive to water and air and has good industrial application prospect, and enlarged production to gram scale can be realized.

Owner:SOUTH CHINA UNIV OF TECH

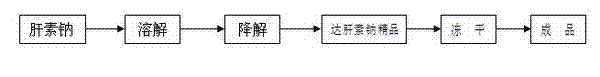

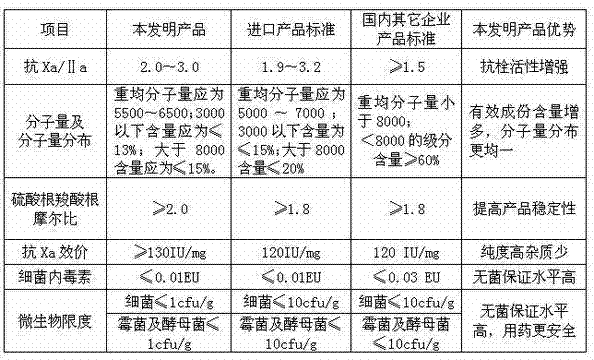

Preparation process of dalteparin sodium

ActiveCN102558393BPrevent embolismPrevent venous thromboembolismOrganic active ingredientsMetabolism disorderExtracorporeal circulationFreeze-drying

Owner:HEBEI CHANGSHAN BIOCHEM PHARMA

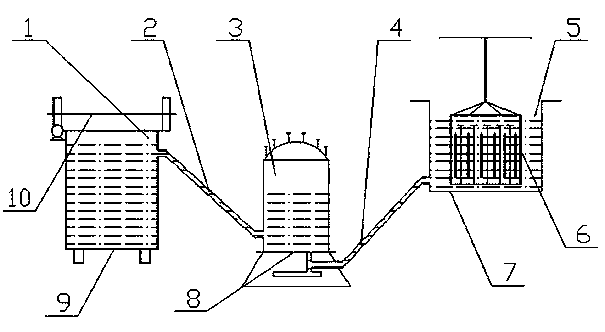

Electroplating device for galvanization of alkaline solution

The invention discloses an electroplating device for galvanization of alkaline solution. The device comprises an electroplating tank (1), a filtering machine (3) and a dissolving tank (5), wherein the electroplating tank (1) is communicated with the filtering machine (3) by virtue of a pipeline A (2); the filtering machine (3) is communicated with the dissolving tank (5) by virtue of a pipeline B (4); the electroplating tank (1) comprises an electroplating tank body (9) and an anode (10); a filter plate (8) is arranged inside the filtering machine (3). The device is characterized in that a joint of the pipeline A (2) is positioned above the filter plate (8); a joint of the pipeline B (4) is positioned below the filter plate (8); the dissolving tank (5) consists of a dissolving tank body (7) and a frame body (6); the frame body (6) is arranged inside the dissolving tank body (7); an electronic monitoring system is connected with the electroplating tank (1), the filtering machine (3) and the dissolving tank (5). The device has a simple structure, and is stable in performance, and efficient and practical; the raw materials are reduced.

Owner:AVIC STANDARD PARTS MFG

Raw material gas supply apparatus for semiconductor manufacturing equipment

ActiveUS9556518B2Improve precision controlRaw material stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

A raw material gas supply apparatus includes a liquid raw material gas supply source, a source tank storing liquid raw material, a gas distribution passage through which raw material gas comprising steam of the liquid raw material is supplied to a process chamber from the source tank, an automatic pressure regulator installed on an upstream side of the gas passage, wherein the automatic pressure regulator keeps supply pressure of the raw material gas at a set value, a supply gas switching valve installed on a downstream side of the gas passage, wherein this valve opens and closes the gas passage, an orifice provided on at least one of an inlet side or outlet side of the valve, wherein the orifice regulates flow rate of the raw material gas, and a constant temperature heating device heats the source tank, the gas passage, the valve and the orifice to a set temperature.

Owner:FUJIKIN INC

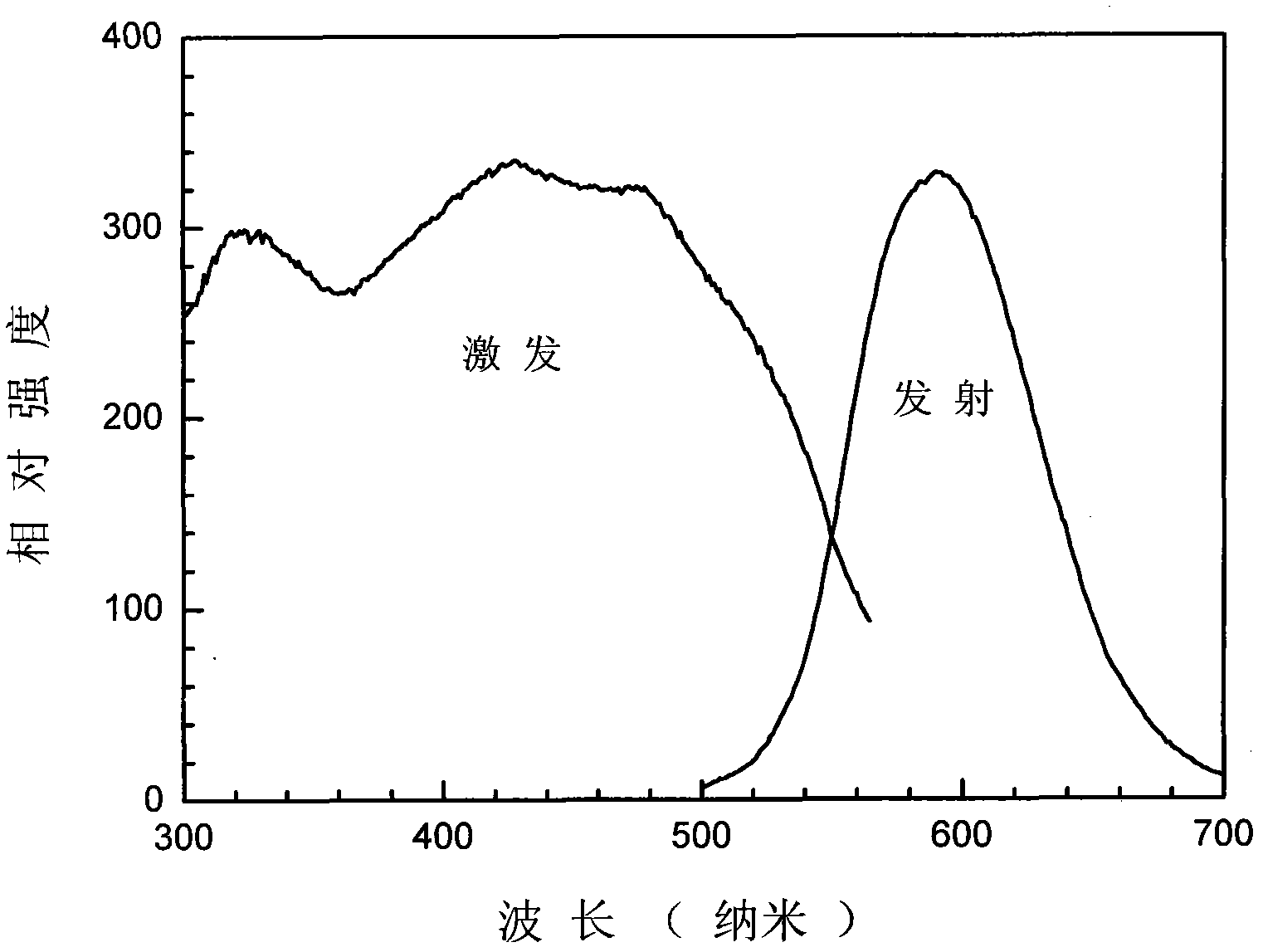

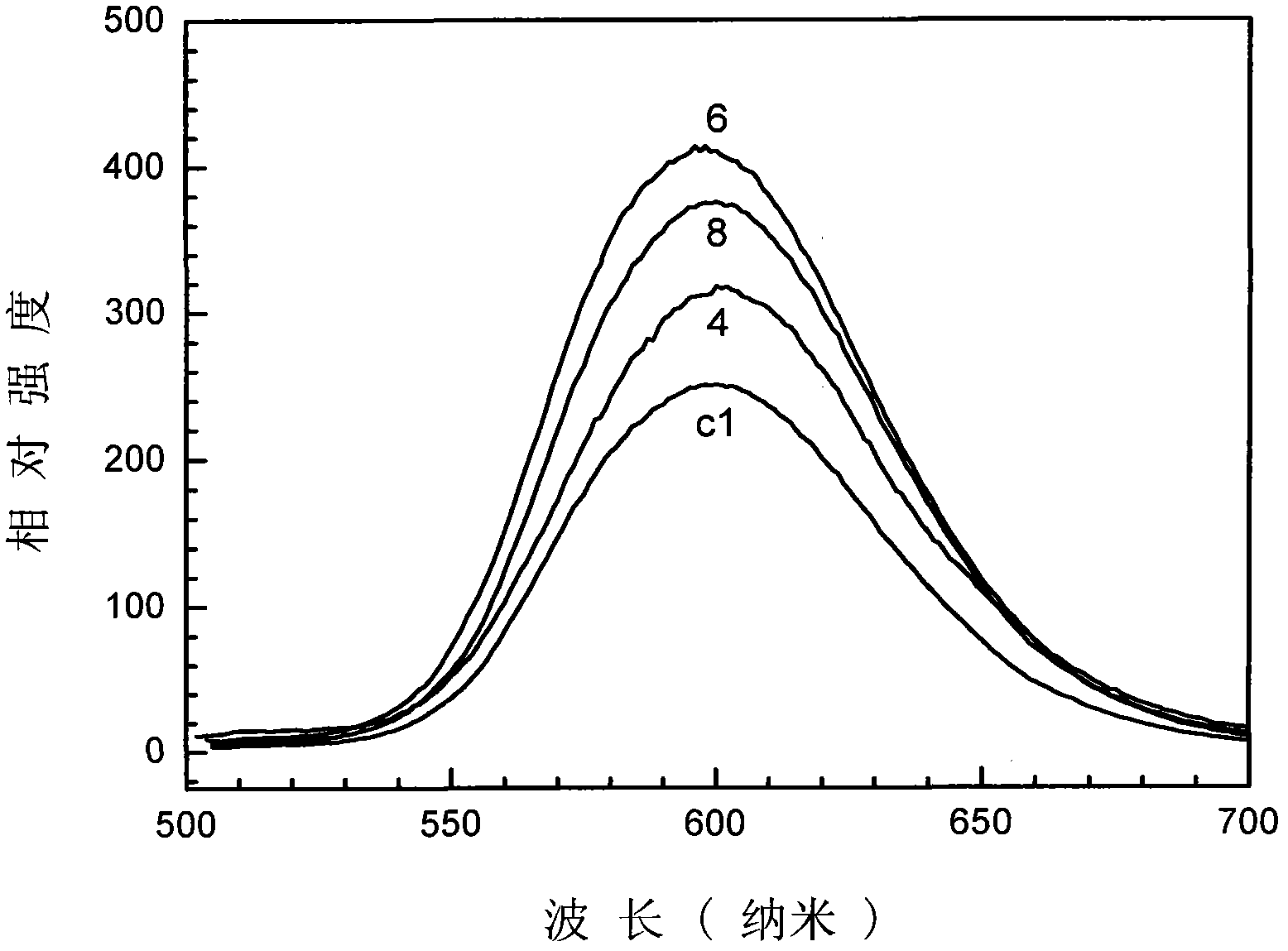

A group of compound fluorescent materials and a preparation method thereof

ActiveCN103184047AHigh luminous intensityEnhanced resistance to thermal decayLuminescent compositionsSemiconductor devicesLuminous intensityRare earth

The invention provides a group of novel compound fluorescent materials and a preparation method thereof. Each compound fluorescent material is composed of a main phase and a second phase, wherein the main phase is coordinated by taking nitrogen as an anion and takes rare earth as an active ion, and the second phase is of nitrogen inert metal simple substances such as Co, Rh, Ir, Cu, Au, Ag, Ni, Pd, Pt, Ru, Os and Zn. Low phonon energy nitrogen inert metal simple substance is distributed in a main phase crystal domain or on a crystal domain boundary in a fluorescence main phase crystal domain structure in the form of a second phase micro crystal domain, so that the luminescent intensity and the heat decay resistance of the fluorescent phase are improved. The compound fluorescent material is prepared by using the calcium cyanamide thermal reduction nitridation reaction process which takes the particles of the nitrogen inert metal simple substances as seed crystals, can be excited by UV-blue-green light to obtain red light or green-orange light emission, and can be used for manufacturing high-efficiency LED devices.

Owner:邓华

Purification of polypeptides

A method for purifying a desired heterologous polypeptide from microbial fermentation broth or homogenate in which it is produced and solubilized is described. This method involves adding to the broth or homogenate an effective amount of a solution of 6,9-diamino-2-ethoxyacridine lactate (ethacridine lactate) to precipitate host cell impurities under conditions wherein the majority of polypeptide remains soluble, and separating the desired polypeptide from the broth or homogenate. The broth or homogenate containing the ethacridine lactate and polypeptide is also disclosed.

Owner:GENENTECH INC

Preparation method for obtaining high-purity praseodymium oxide and neodymium oxide through single-factor separation of praseodymium-neodymium enriched product

The invention relates to the technical field of rare earth separation, in particular to a preparation method for obtaining high-purity praseodymium oxide and neodymium oxide through single-factor separation of a praseodymium-neodymium enriched product. The preparation method comprises the following steps: dissolving light rare earth of lanthanum, cerium, praseodymium and neodymium into hydrochloric acid; after impurities are removed, mixing and adding a feed liquid and an organic phase into an extraction tank, introducing a water phase into the extraction tank in the opposite direction, carrying out an extraction reaction, collecting a Pr and Nd rare earth organic phase, and obtaining a praseodymium-neodymium organic phase enriched product; adding qualified praseodymium and neodymium products, adjusting the contents of praseodymium and neodymium, and stabilizing the mass ratio of praseodymium; and mixing the adjusted praseodymium-neodymium enriched product serving as a raw material with an organic phase, adding the mixture into an extraction tank, and performing single-factor separation to obtain high-purity praseodymium oxide and neodymium oxide. The method provided by the invention can ensure that the praseodymium and neodymium obtained by single-factor separation are high in purity and contain few impurities. Moreover, large-batch production of praseodymium and neodymium products is facilitated, and the product quality is very stable.

Owner:中稀(常州)稀土新材料有限公司

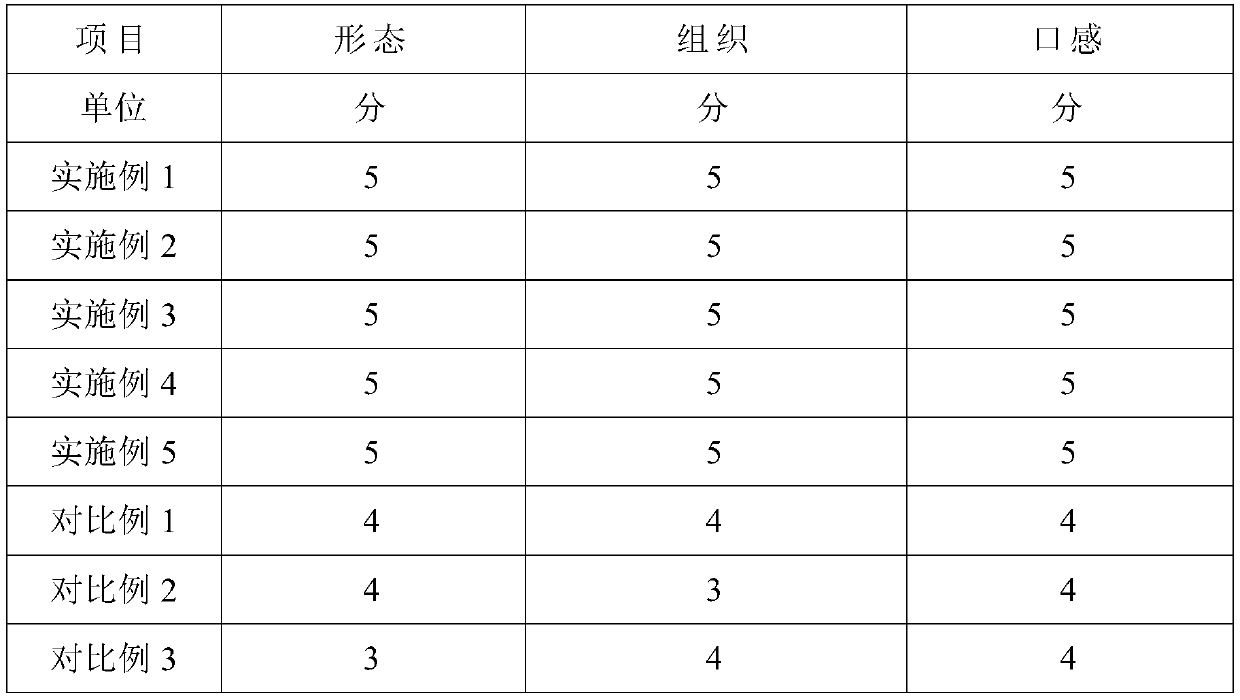

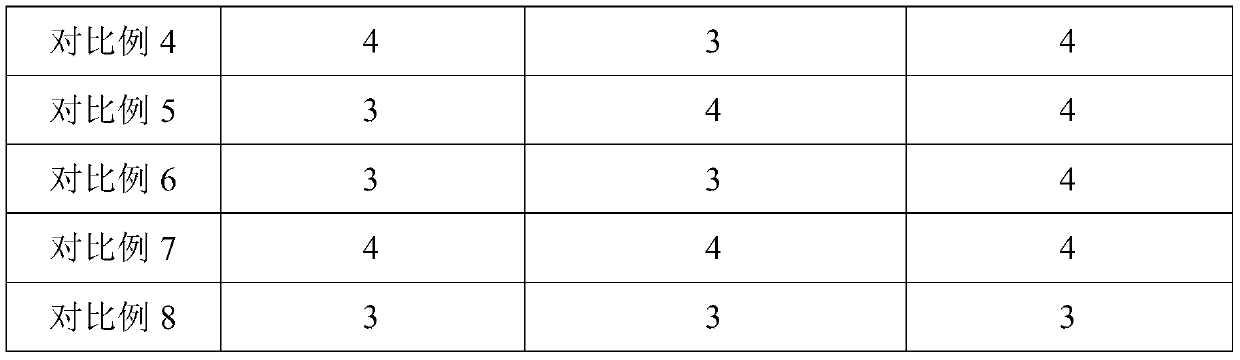

Rice cake premix flour and preparation method thereof

InactiveCN110521744AReduce energy consumptionReduce professionalismDough treatmentDough/pre-mixesChemistryRice flour

The invention discloses rice cake premix flour. The flour is characterized by comprising raw materials in parts by weight as follows: 150-250 parts of rice flour, 100-150 parts of low gluten wheat flour, 10-20 parts of yam flour, 10-15 parts of cyclodextrin, 20-30 parts of sweet potato starch, 5-10 parts of adonitol, 5-10 parts of lactitol, 3-8 parts of hawthorn flour, 5-10 parts of barley grass flour, 5-10 parts of barley leaf flour and 20-40 parts of ingredients. The invention further discloses a preparation method of the rice cake premix flour and rice cake prepared by the rice cake premixflour. The rice cake premix flour is high in nutritive value and good in taste, rice cake premix flour is simple, convenient and safe to prepare the rice cake, success rate is high, and the prepared rice cake has the advantages of soft and delicate taste.

Owner:安徽金太阳食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com