Preparation method of powdered oil feed

A technology of powdered oil and feed, applied in animal feed, animal feed, applications, etc., can solve the problems of powdered oil easy to melt, low in other content, not easy to store, etc., to increase the nutrition needed for growth, improve egg production rate and egg production Heavy, palatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of a kind of powder oil feed of this example, its steps are:

[0034] a. Add animal fats and vegetable fats into 20kg emulsifier in proportion, and send them into the emulsifier to emulsify at a high speed of 18000 rpm for 2 hours, of which animal fats are 200kg, vegetable fats are 300kg, animal fats are lard and chicken and duck oil Vegetable oil consists of 150kg of soybean oil, 50kg of palm oil, 25kg of corn oil, 25kg of coconut oil, and 50kg of rapeseed oil;

[0035] b. Send the emulsified mixture to a homogenizer for two homogenization treatments;

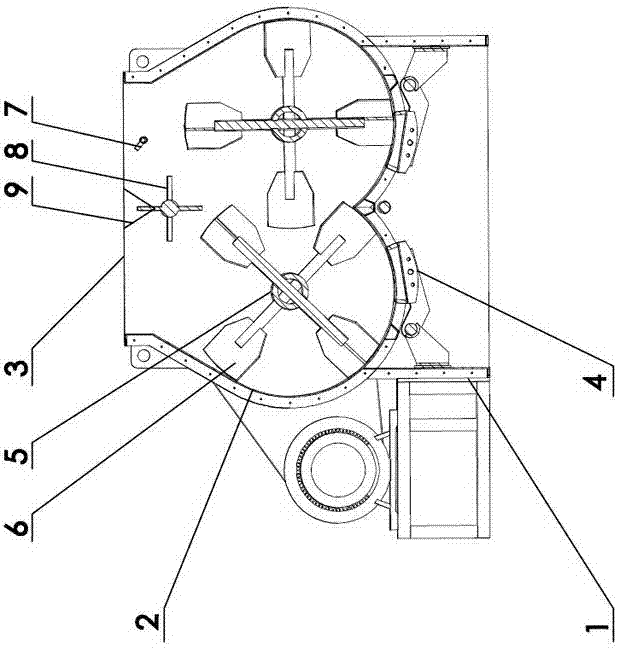

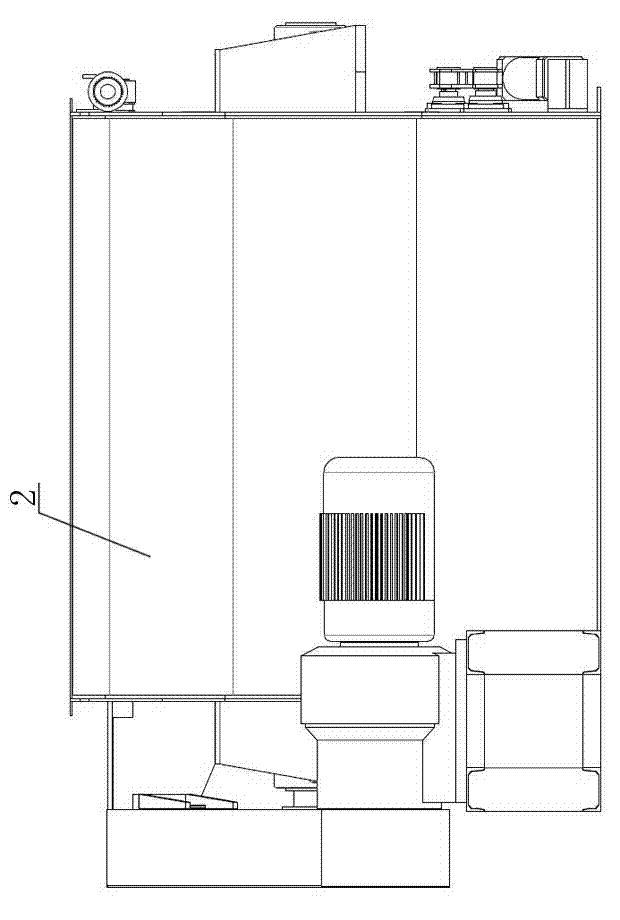

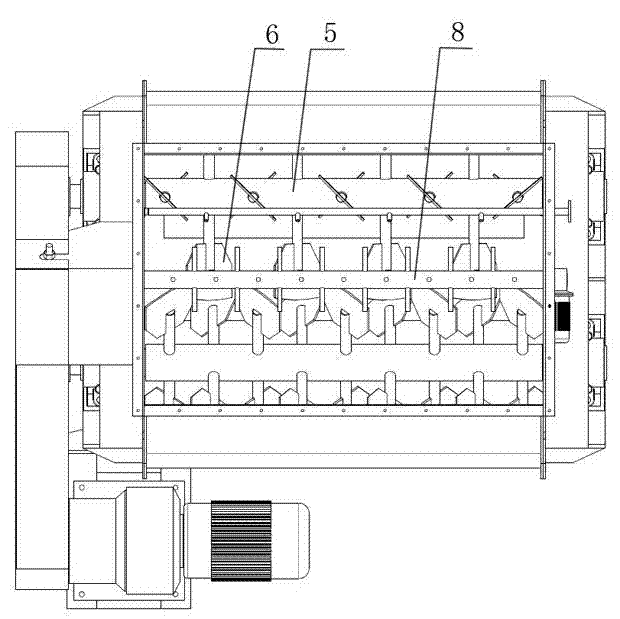

[0036] c. Add animal protein, vegetable protein, minerals, trace elements, and vitamins to the homogenized mixture in proportion and mix them in a gravity-free twin-shaft paddle mixer, such as figure 1 , figure 2 , image 3 , the gravity-free twin-shaft paddle mixer includes a frame 1, a cylinder 2 is arranged on the frame, a feed inlet 3 is arranged on the upper part of the c...

Embodiment 2

[0037]Embodiment 2: the preparation method of a kind of powder oil feed of this example, its steps are:

[0038] a. Add animal fats and vegetable fats into 20kg emulsifier in proportion, and send them into the emulsifier to emulsify at a high speed of 18000 rpm for 2 hours, wherein the animal fats are 150kg, the vegetable fats are 350kg, and the animal fats are lard and chicken and duck oil; Vegetable oil consists of 150kg of soybean oil, 75kg of palm oil, 25kg of corn oil, 25kg of coconut oil, and 75kg of rapeseed oil;

[0039] b. Send the emulsified mixture to a homogenizer for two homogenization treatments;

[0040] c. Add animal protein, vegetable protein, minerals, trace elements, and vitamins to the homogenized mixture in proportion and mix them in a gravity-free twin-shaft paddle mixer, such as figure 1 , figure 2 , image 3 , the gravity-free twin-shaft paddle mixer includes a frame 1, a cylinder 2 is arranged on the frame, a feed inlet 3 is arranged on the uppe...

Embodiment 3

[0041] Embodiment 3: the preparation method of a kind of powder oil feed of this example, its steps are:

[0042] a. Add animal fats and vegetable fats into 20kg emulsifier in proportion, and send them into the emulsifier to emulsify at a high speed of 18000 rpm for 2 hours, of which animal fats are 250kg, vegetable fats are 250kg, animal fats are lard and chicken and duck oil Vegetable oil consists of 150kg of soybean oil, 25kg of palm oil, 25kg of corn oil, 25kg of coconut oil, and 25kg of rapeseed oil;

[0043] b. Send the emulsified mixture to a homogenizer for homogenization;

[0044] c. Add animal protein, vegetable protein, minerals, trace elements, and vitamins to the homogenized mixture in proportion and mix them in a gravity-free twin-shaft paddle mixer, such as figure 1 , figure 2 , image 3 , the gravity-free twin-shaft paddle mixer includes a frame 1, a cylinder 2 is arranged on the frame, a feed inlet 3 is arranged on the upper part of the cylinder, and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com