Patents

Literature

692results about How to "Speed up the mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

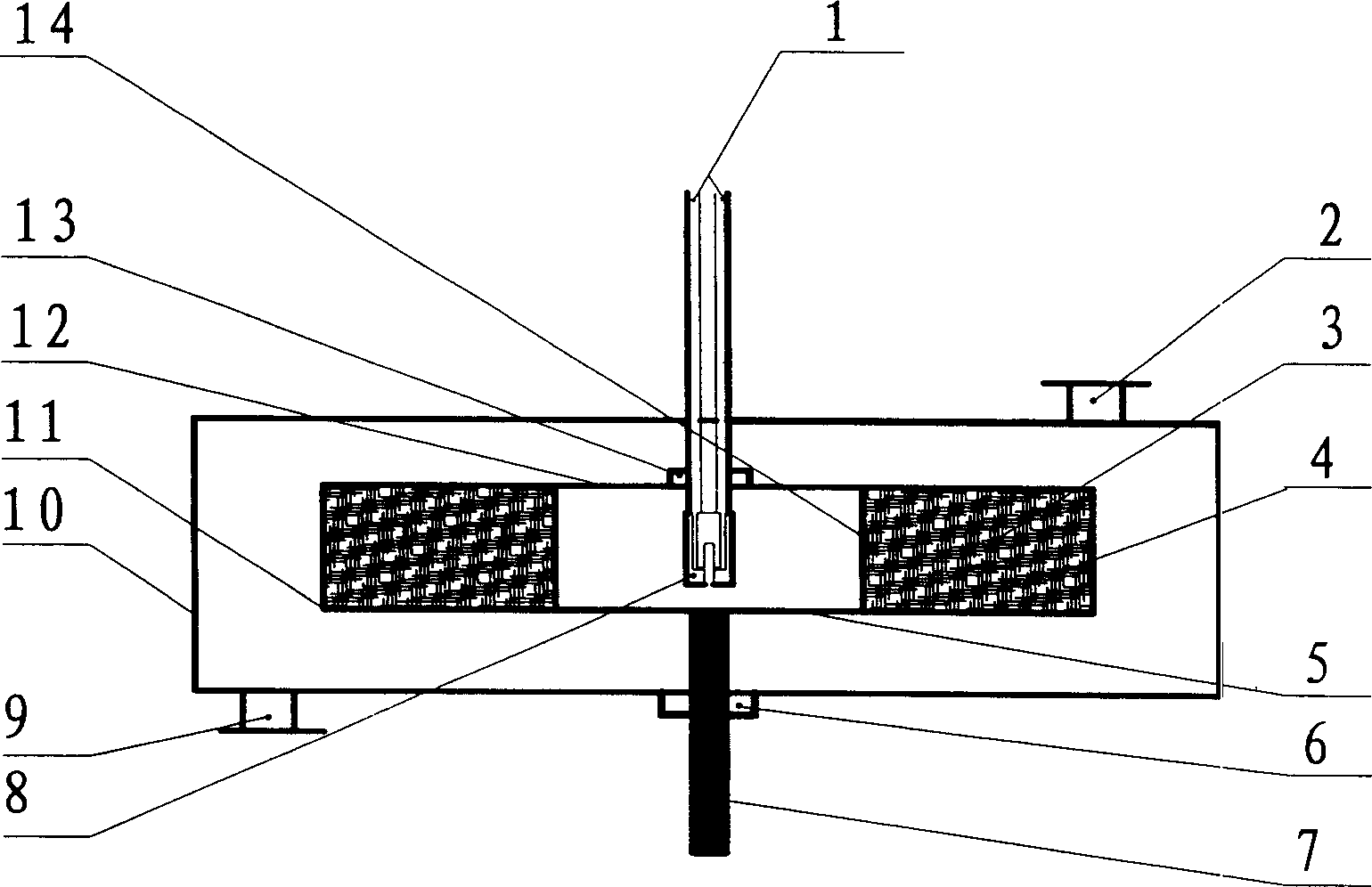

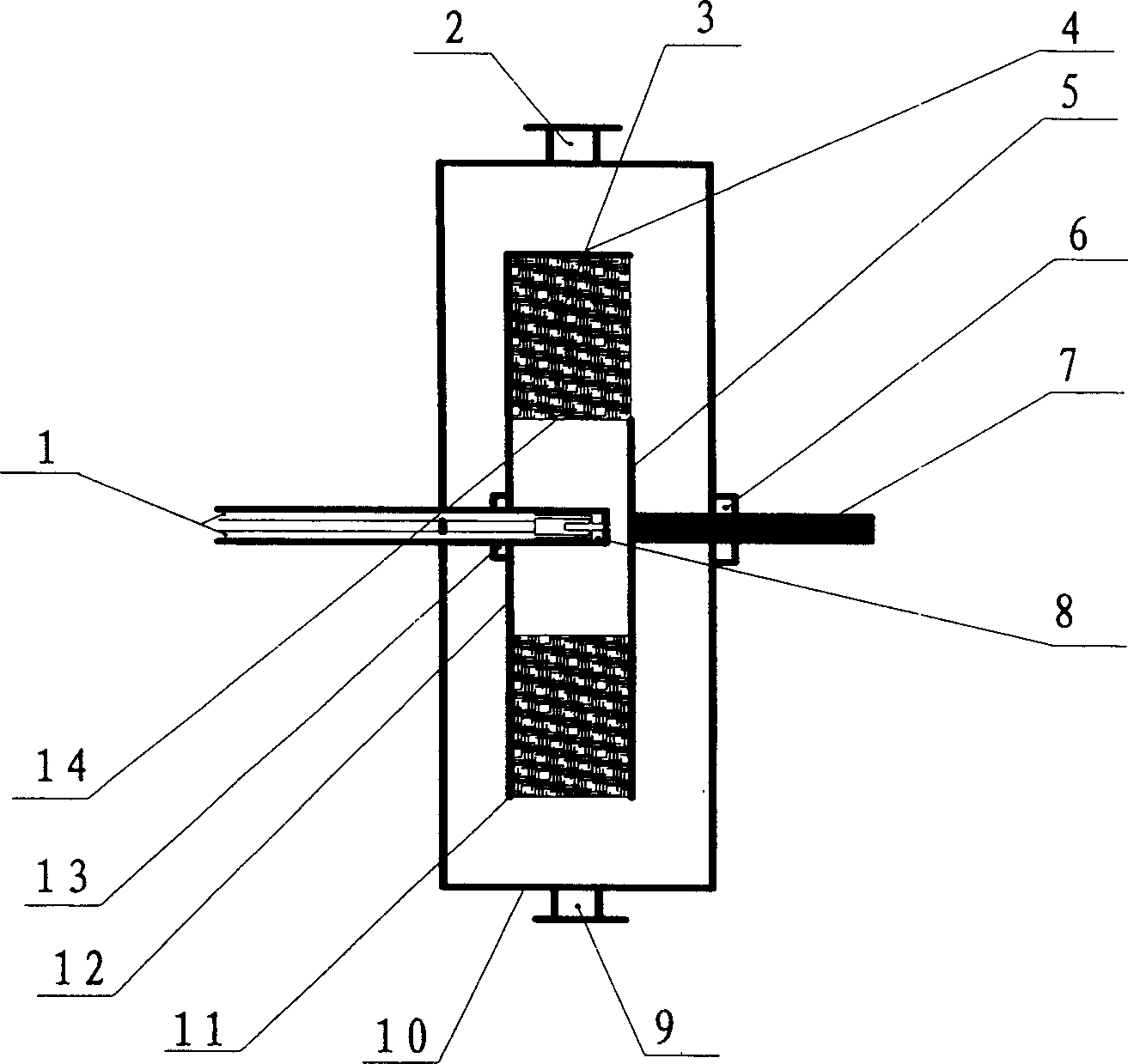

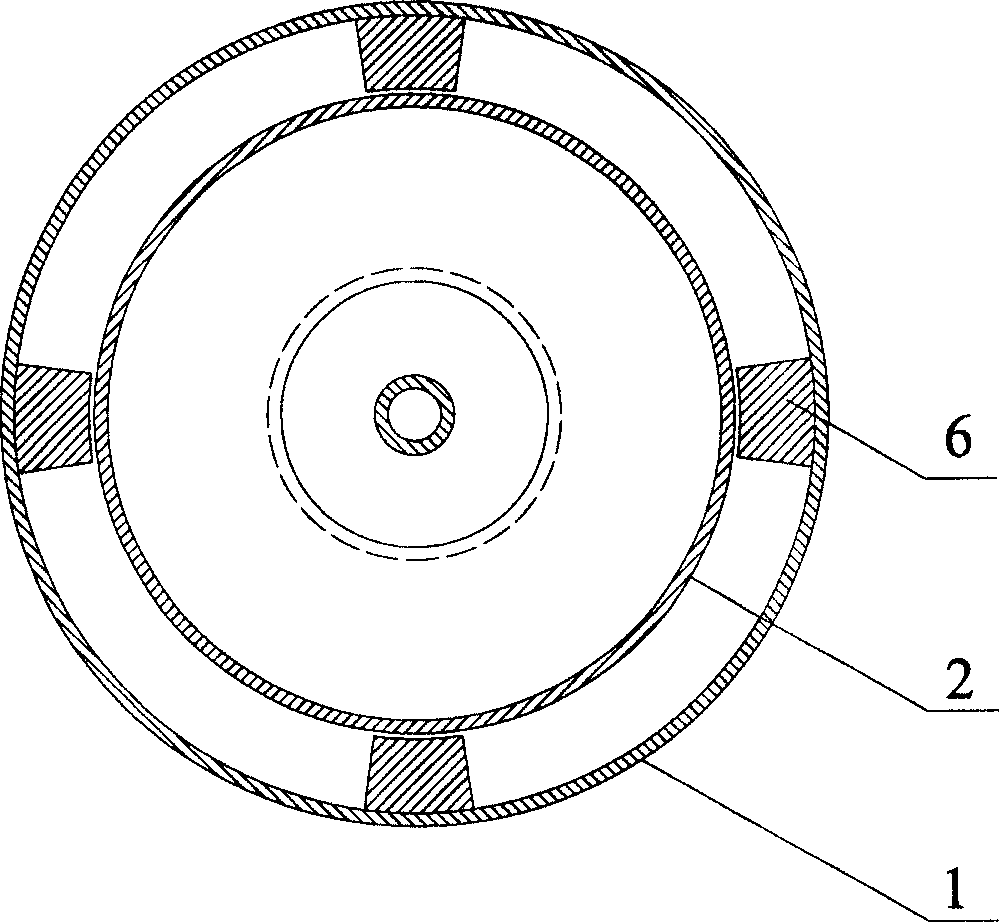

Impact flow-rotary filler bed device and using method

InactiveCN1425493AEfficient, fast and even mixingGood micro-mixing environmentRotating receptacle mixersTransportation and packagingSolventEngineering

The present invention relates to one multiple-fluid reinforced mass transferring equipment and method, and aims at solvent the problem of mixing materials homogeneously and fast. The technological scheme of the present invention is one impact flow-rotary packed bed equipment including ring inner baffle, circular outer baffle, hollow ring drum, stuffing, rotating shaft and casing; one impact flow unit comprising material feeding pipes and nozzles, ga soutlet and liquid material outlet. The present invention is used mainly in fast mixing and reaction of different phases.

Owner:ZHONGBEI UNIV

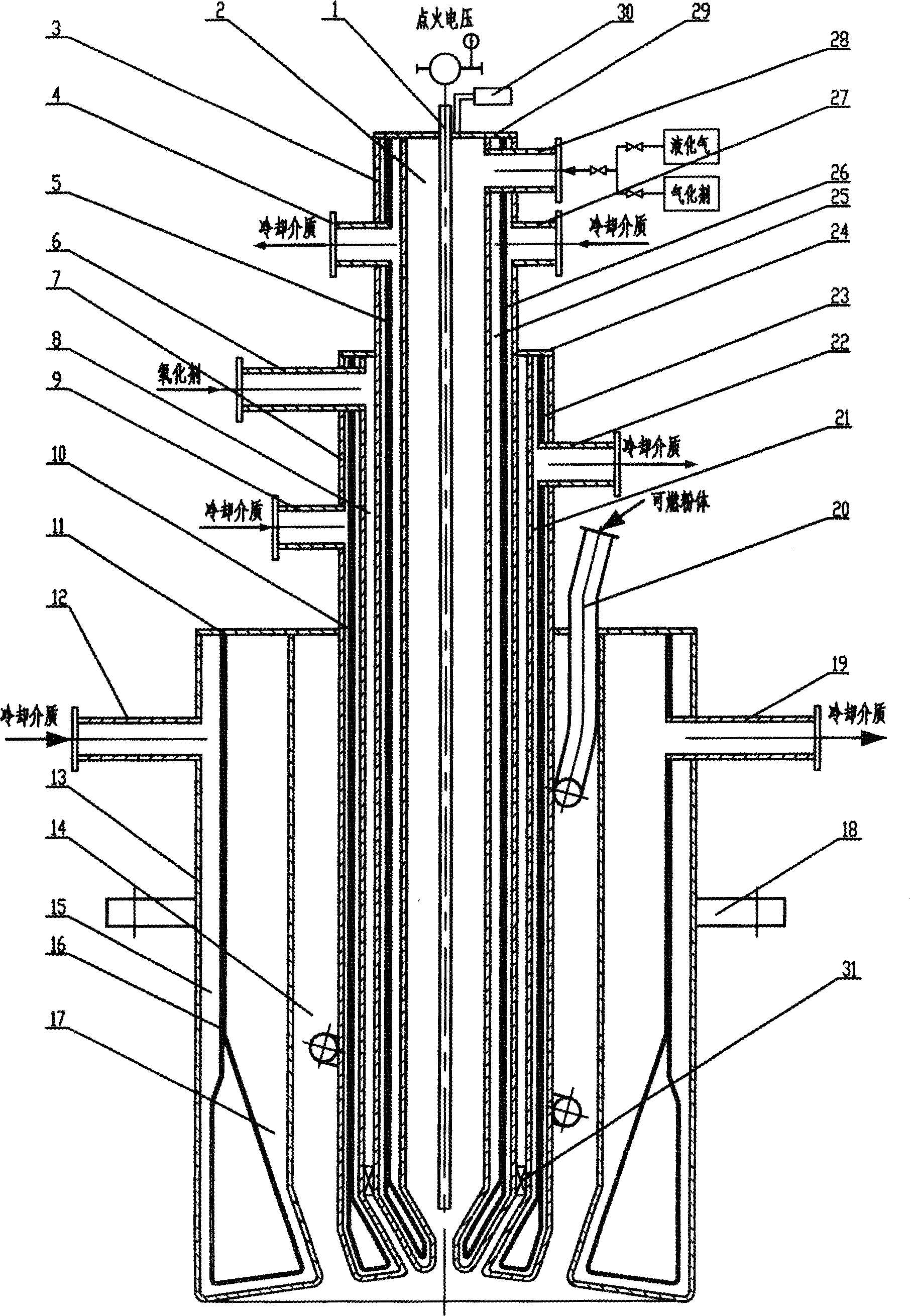

Powder-combustible vortex burner

ActiveCN1710333AAvoid ablationExtended service lifePulverulent fuel combustion burnersFlame detectionCooling channel

A vortex burner of combustible micropowder i.e pulverized coal is prepared by setting primary cooling jacket with an ignition device at the centre of it and a flame detection device at jacket top cover ; arranging primary , secondary and tertiary cooling jackets in sequence coaxially as radial outwards to form primary and secondary air channel and cooling channel , tertiary micropowder channel and tertiary channel ; connecting primary air-channel to fuel gas inlet tube and gasifying agent inlet tube after they are combined for switching over two gases by valve ; setting spiral - flow device at secondary air-channel outlet and jetting out pulverized coal in spiral - flow way at its conveying tube outlet.

Owner:CHANGZHENG ENG

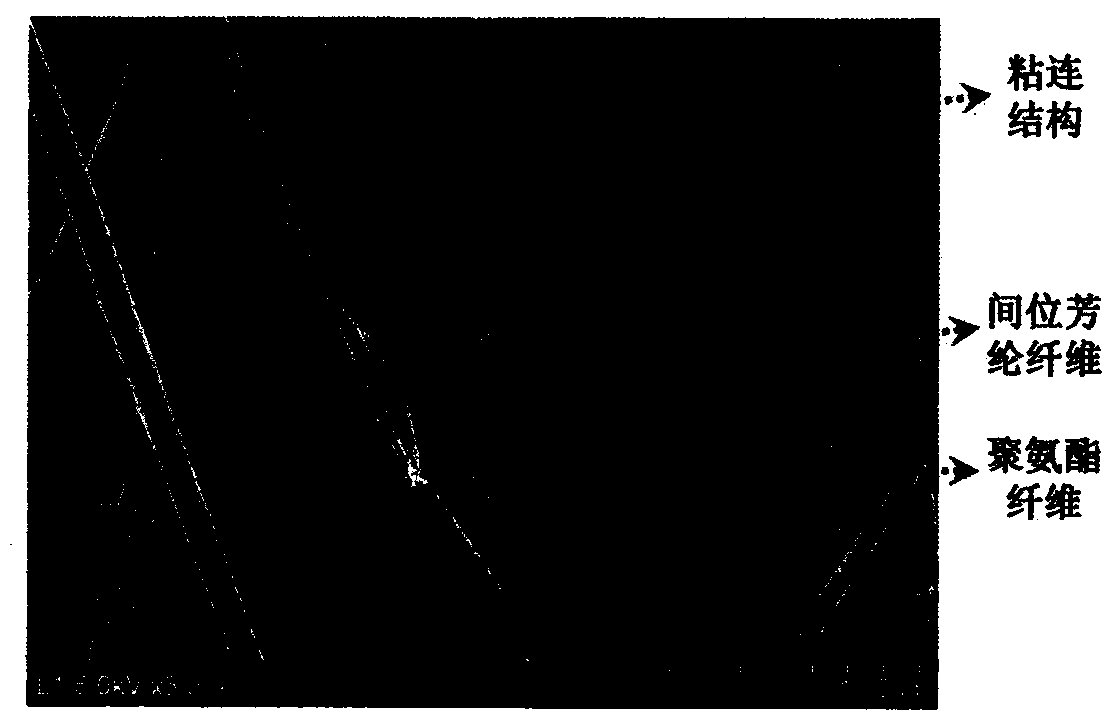

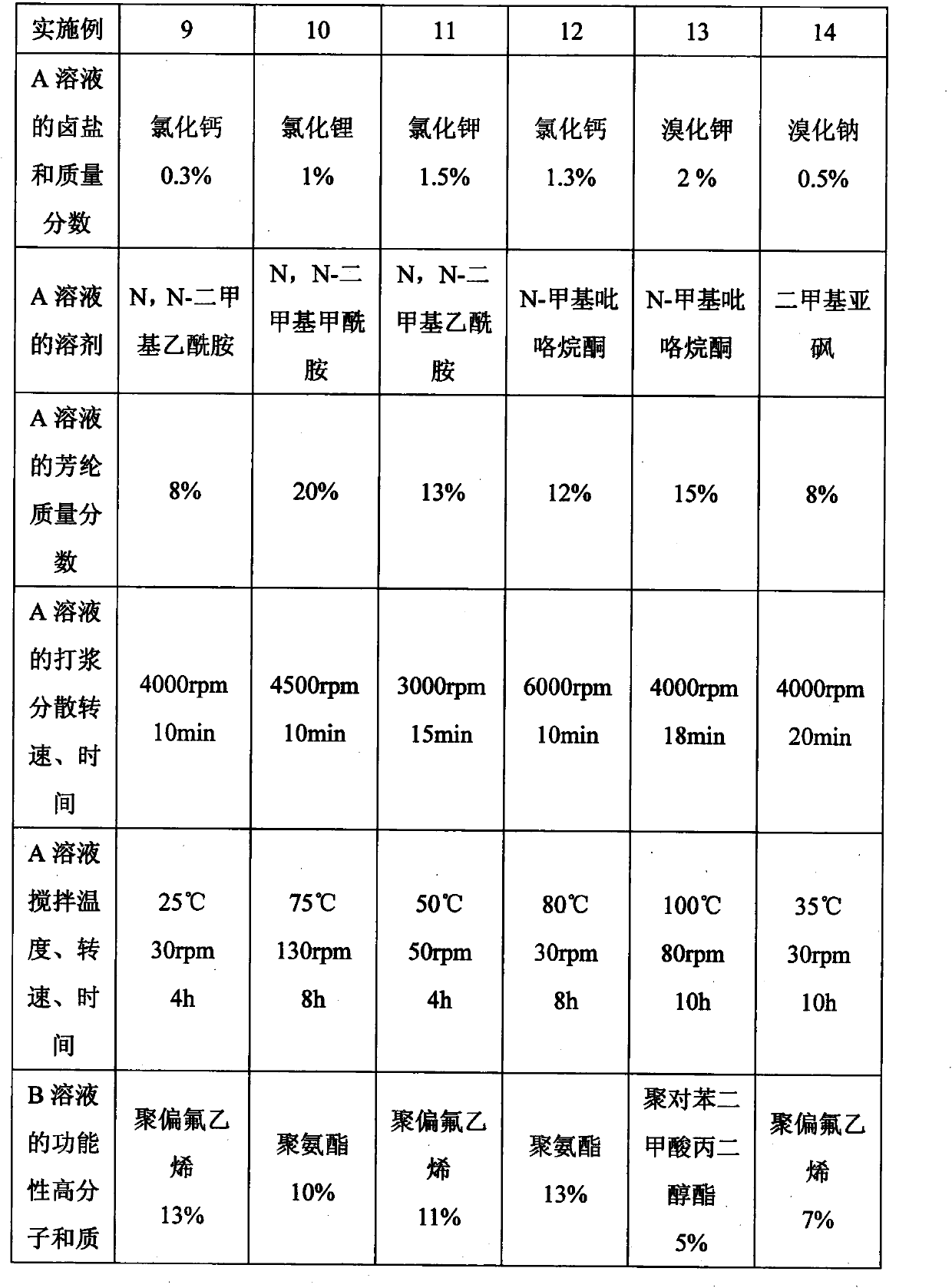

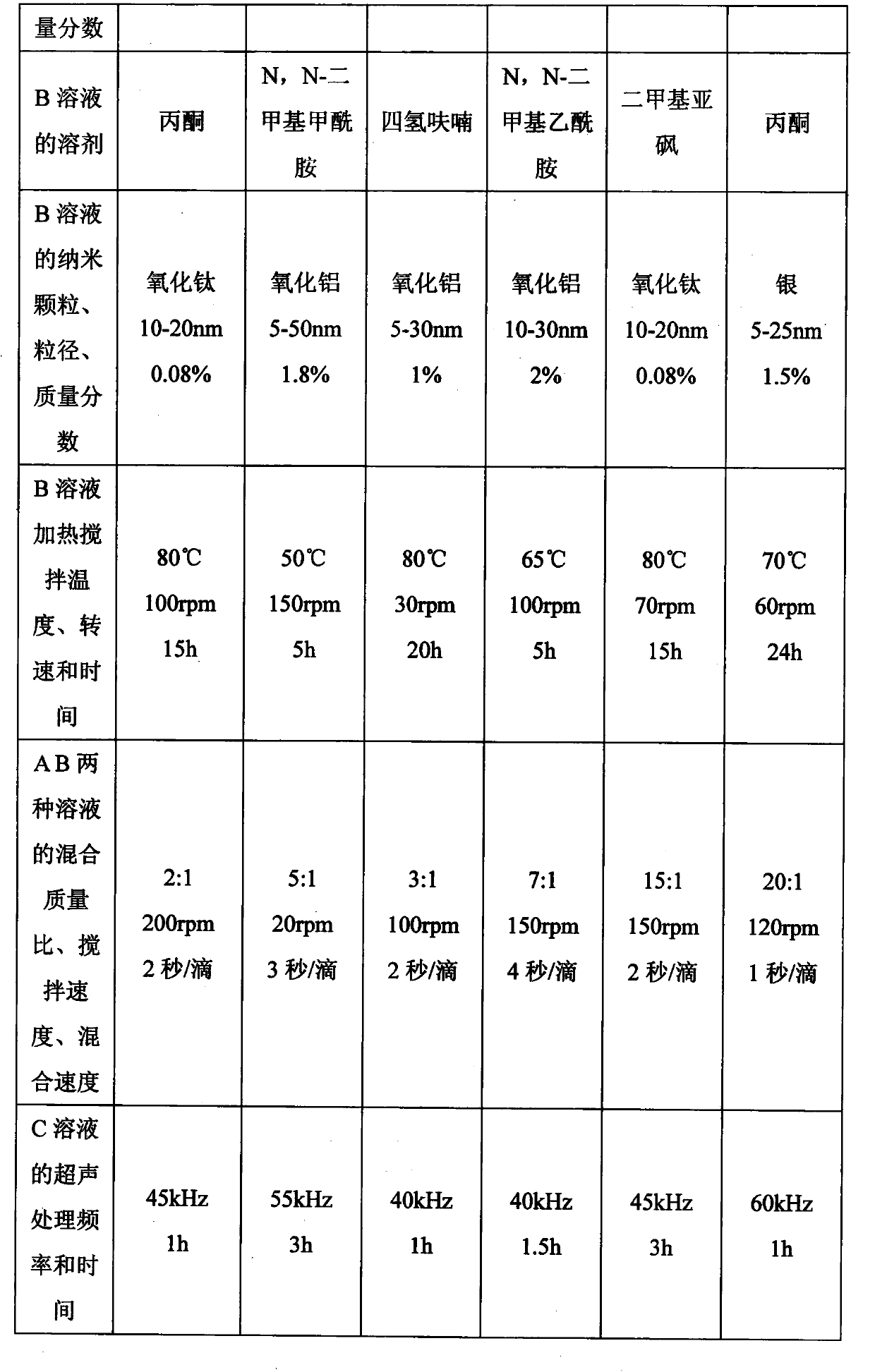

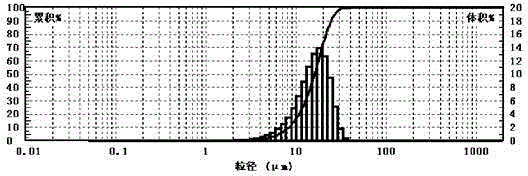

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

L-polylactide filler for injection and preparation method thereof

ActiveCN105879124AExtended shelf lifeGood stabilityPharmaceutical delivery mechanismProsthesisSodium hyaluronateAloin

The invention discloses an L-polylactide filler for injection and a preparation method thereof. Active ingredients of the filler are L-polylactide particles, honeycomb HA and a synergist, the honeycomb HA is obtained by alcohol precipitation and drying of a water solution formed by mixing sodium hyaluronate high in molecular weight and sodium hyaluronate low in molecular weight in an alkaline condition, and the synergist is mannitol or a mixture of mannitol and aloe polysaccharide with a mass ratio of 1:0.05-0.12. The filler is simple to prepare, shorter in re-suspension time, long in validity period and more convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

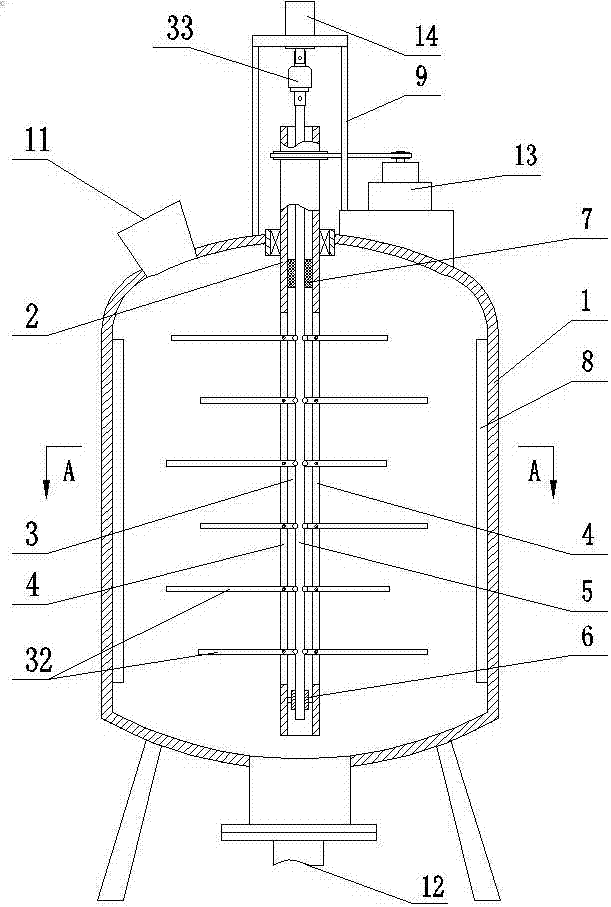

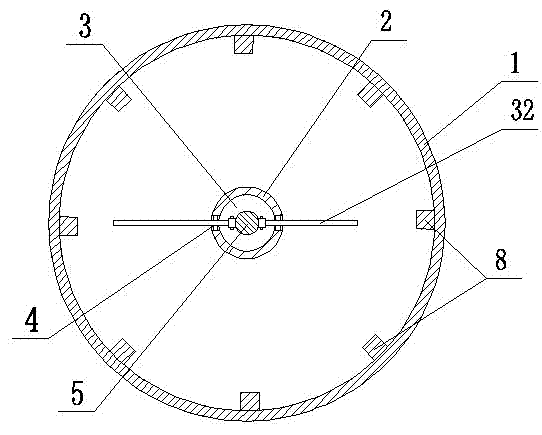

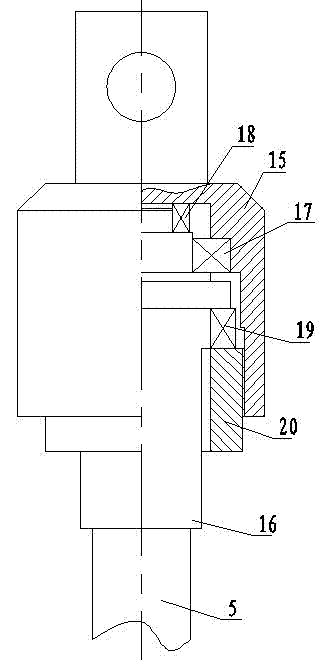

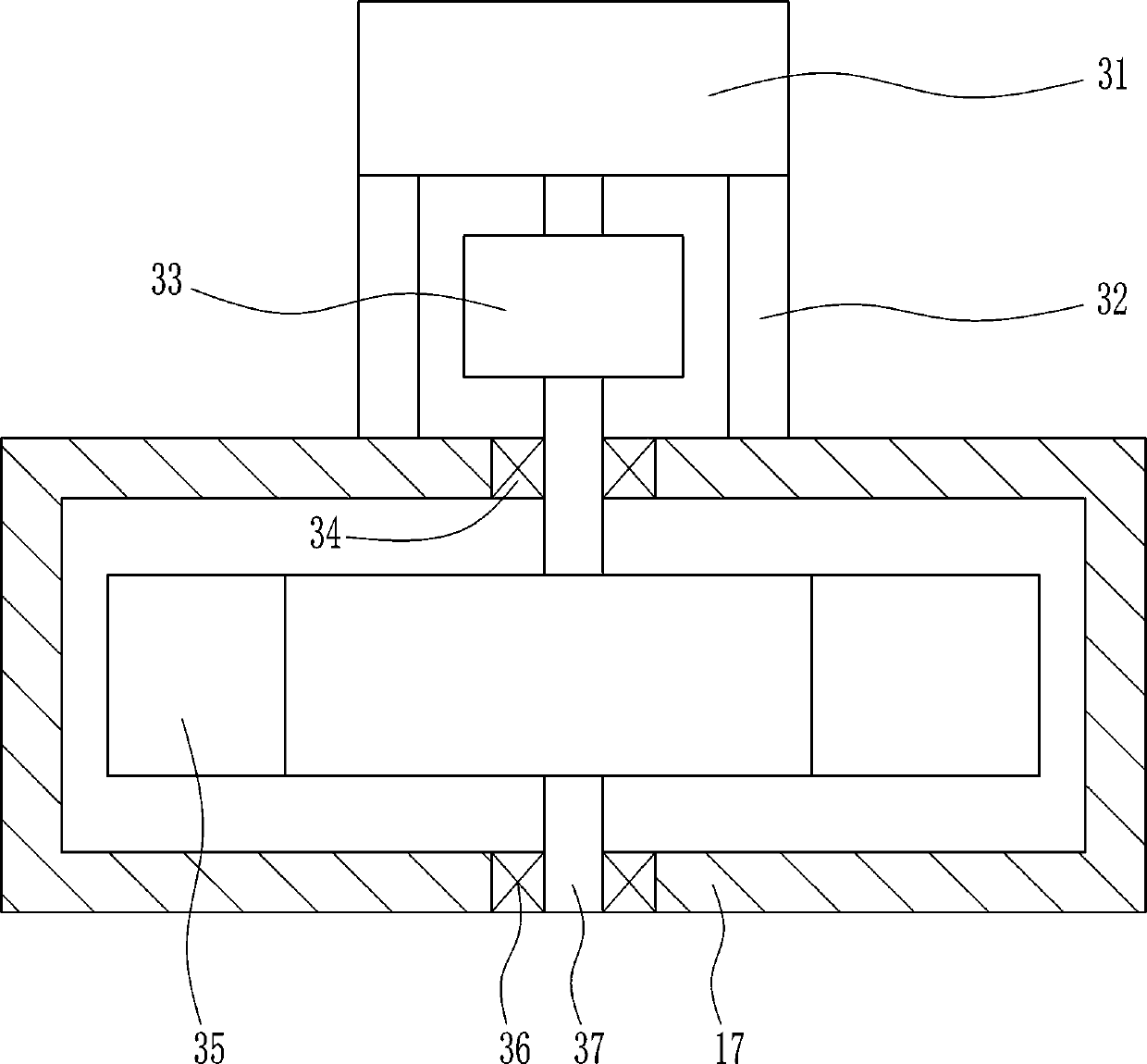

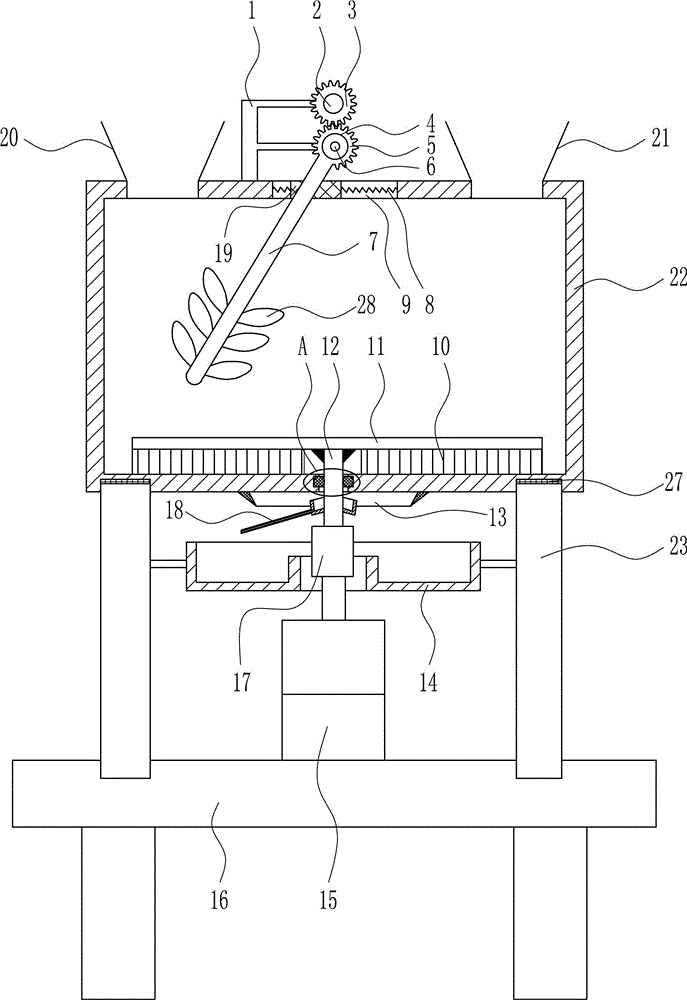

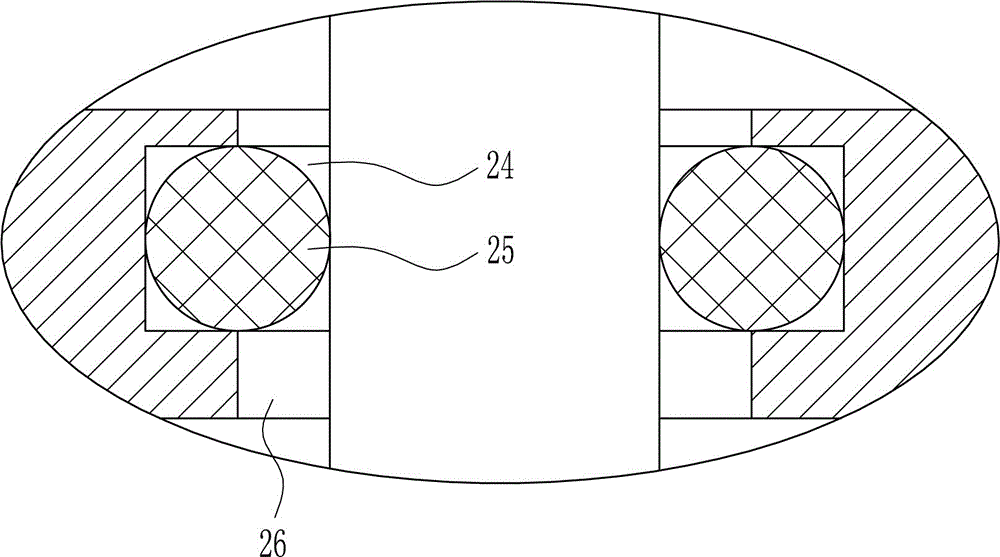

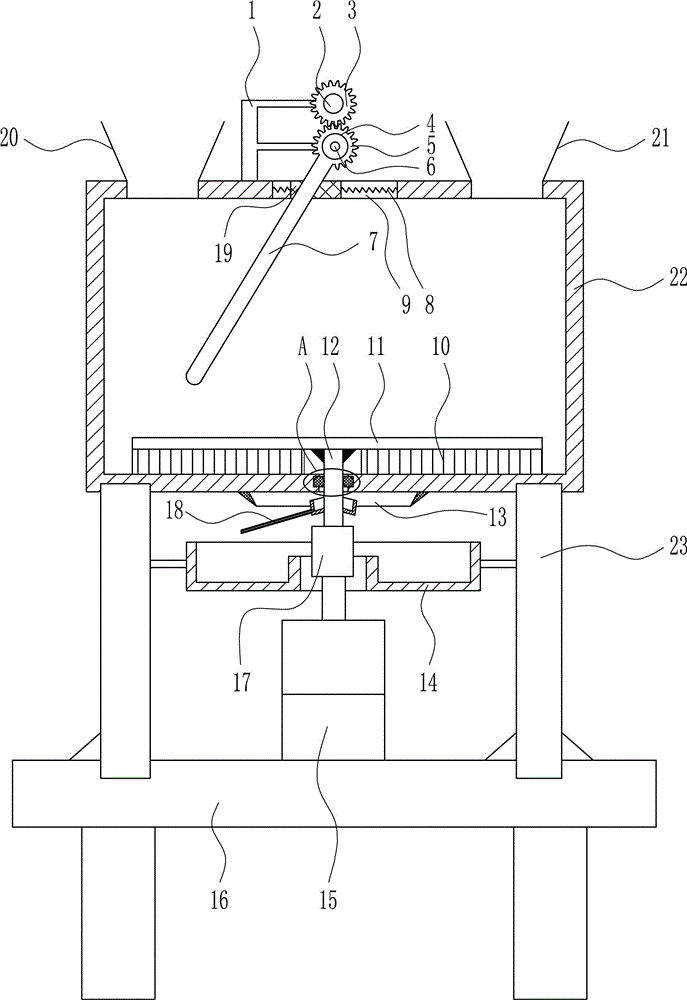

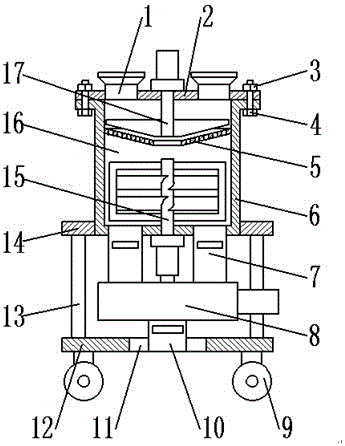

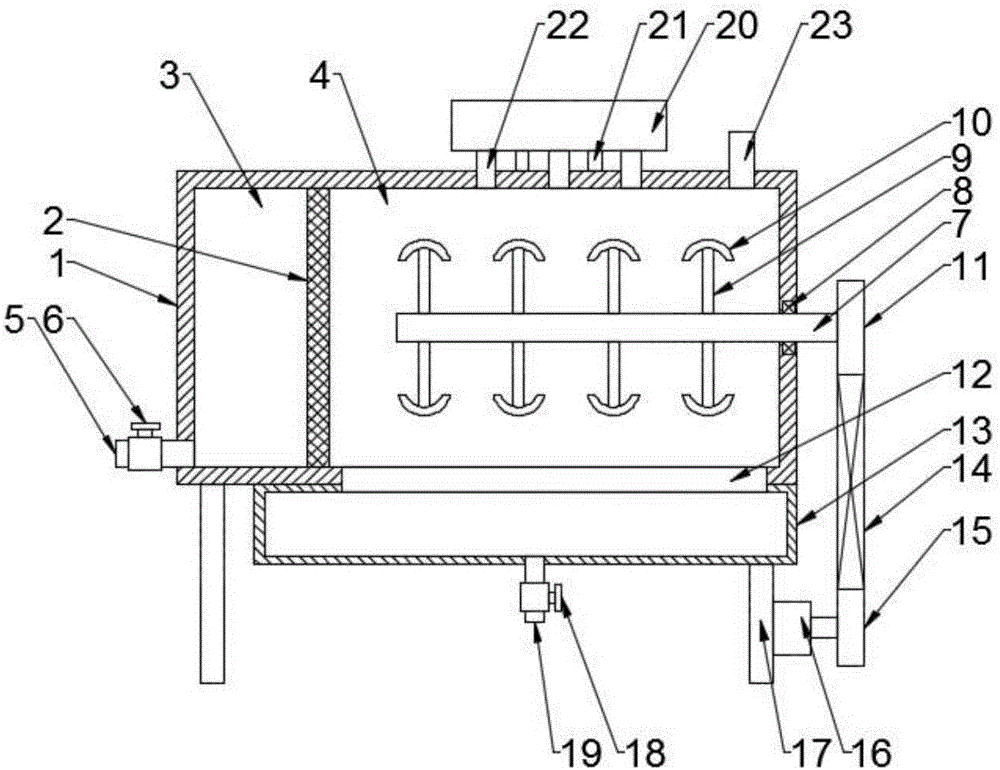

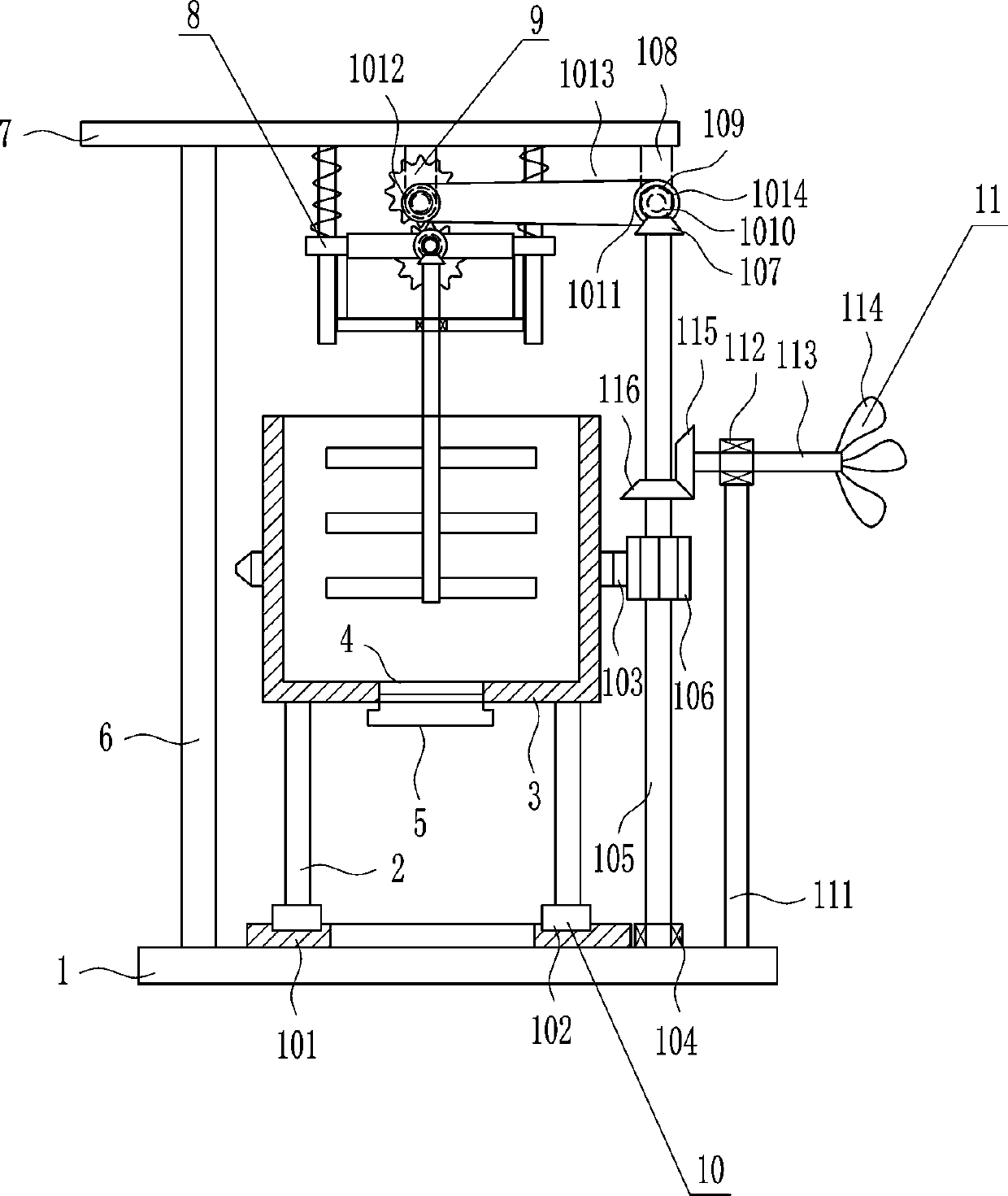

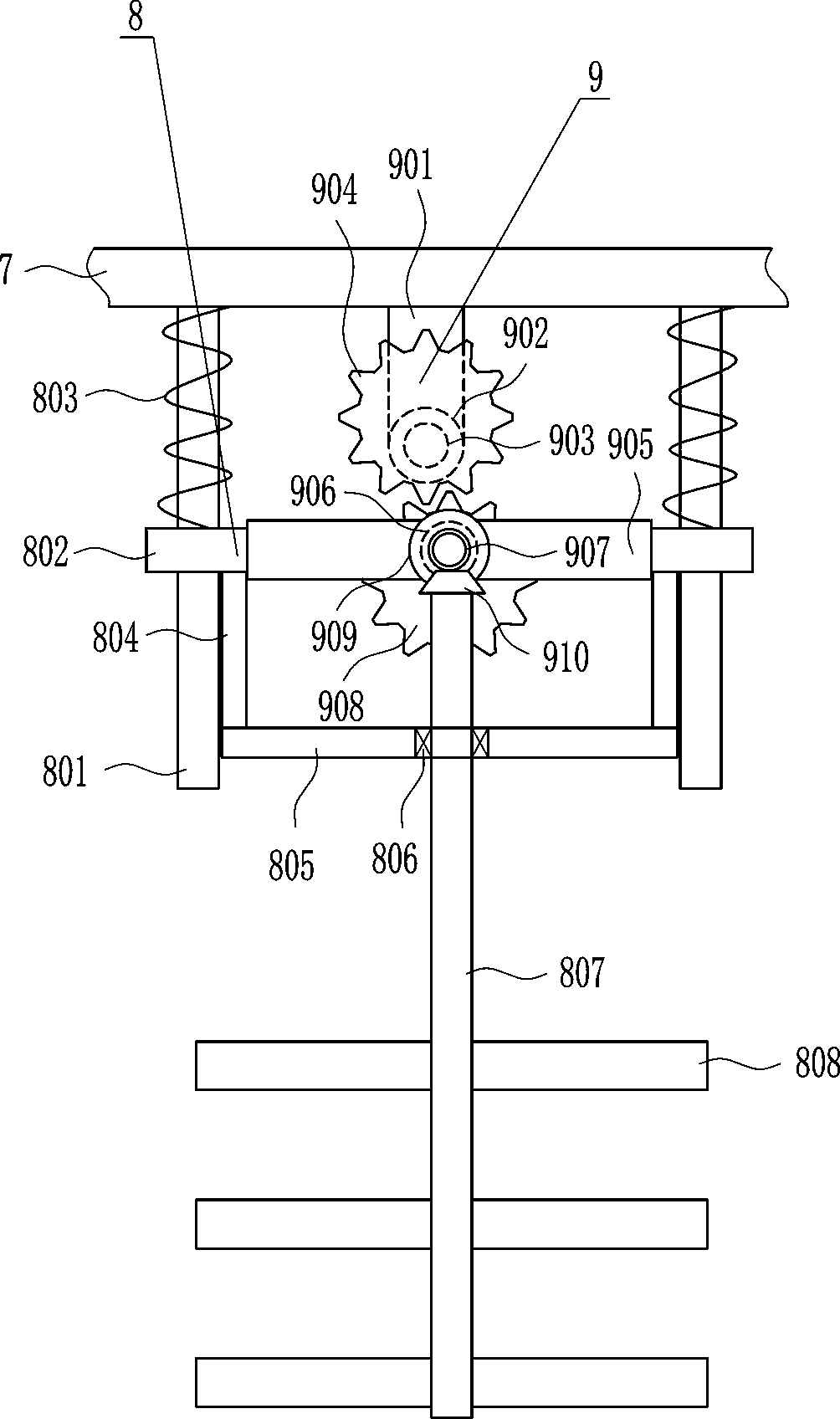

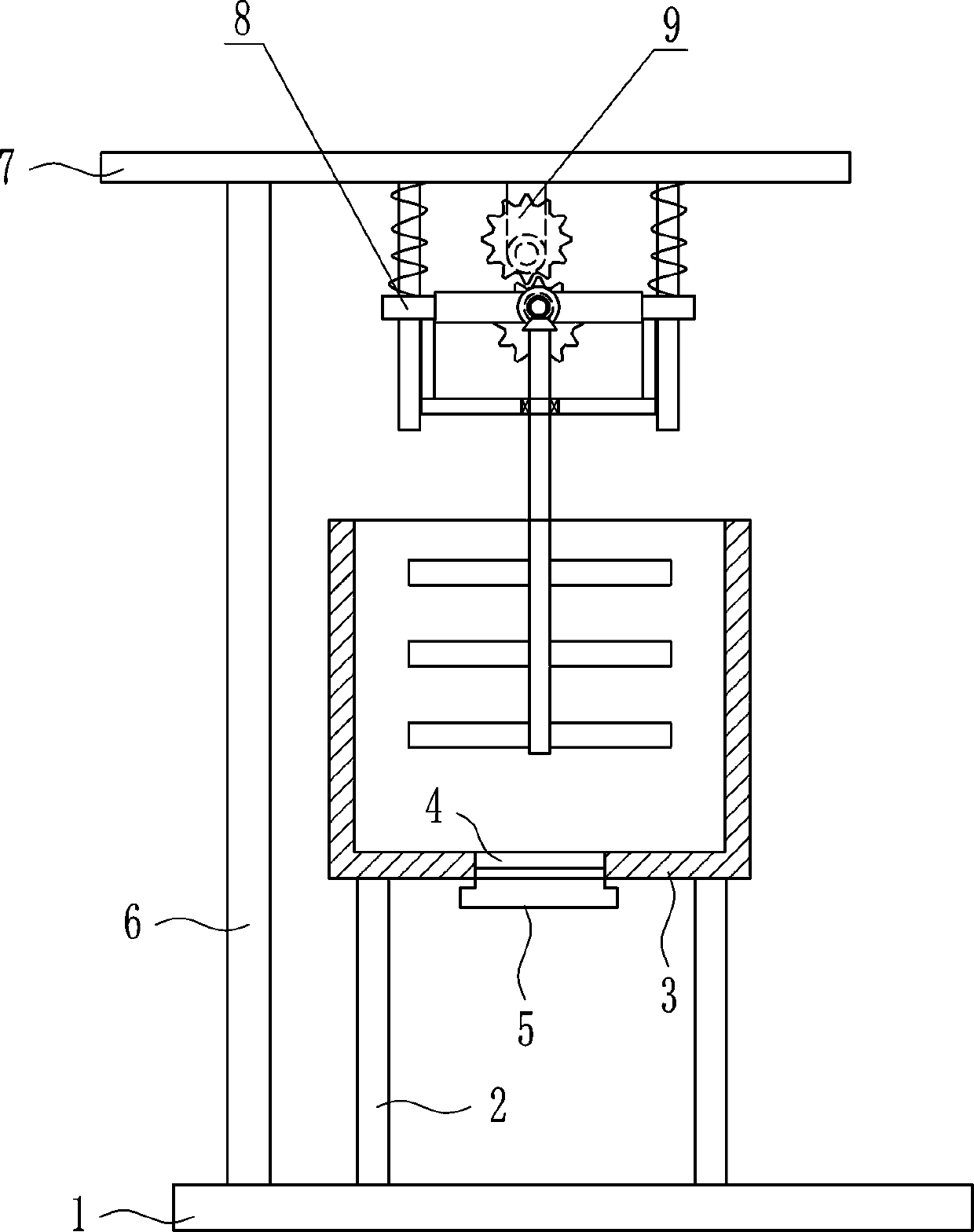

Reaction kettle with stirring arms capable of swinging

InactiveCN102962024ASpeed up the mixingLarge stirring rangeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsPush pullMixing effect

The invention discloses a reaction kettle with stirring arms capable of swinging. The reaction kettle comprises a kettle body and a stirring shaft, wherein the top of the kettle body is provided with a material inlet; the bottom of the kettle body is provided with a material outlet; the stirring shaft is rotatably connected on the top wall of the kettle body and divided into a kettle inside section and a kettle outside section; the kettle outside section of the stirring shaft is in power connection with a power device arranged at the top of the kettle body; the stirring shaft is provided with an axial through cavity; the kettle inside section of the stirring shaft is provided with an installation groove; the wall of the installation groove is hinged with a plurality of stirring arms which are arranged at intervals from top to bottom; the outer end of each stirring arm extends to the side wall of the kettle body and the inner end of each stirring arm is hinged with a pull rod which is slidably connected in the through cavity; the upper end of the pull rod extends out of the through cavity; and the extending end of the pull rod is in power connection with a push-pull device arranged at the top of the kettle body so as to realize up and down swinging of the stirring arms. The reaction kettle has the advantages of high speed of mixing liquid to uniform and excellent mixing effect and brings about the benefits of shortening the reaction time and improving the production efficiency.

Owner:SHANDONG TIANWEI MEMBRANE TECH

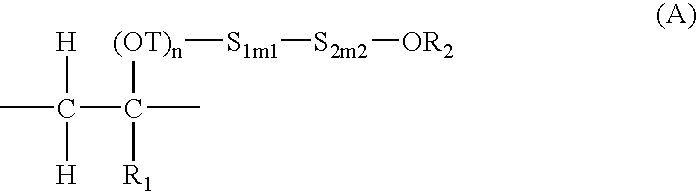

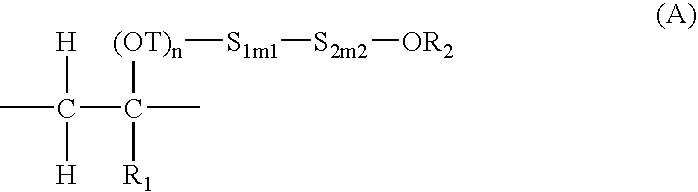

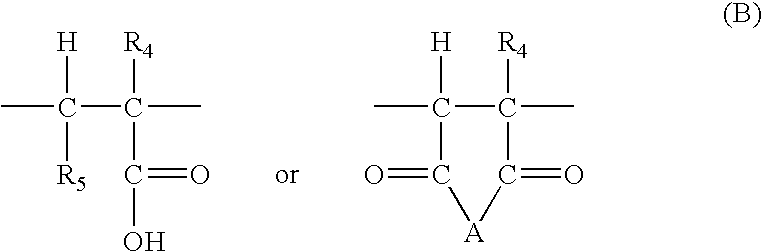

Cement additive

InactiveUS20060247402A1Excellent working property and workabilityImprove the level ofOrganic dyesGranular deliveryHydrogenCopolymer

The present invention concerns a cement additive containing copolymers comprising one or more constitutional units represented by formula A: (A) R1 is hydrogen, an alkyl group having 1 to 4 carbon atoms, an alkenyl group having 1 to 4 carbon atoms or an aryl group having 6 to 9 carbon atoms; R2 is hydrogen or an alkyl group having 1 to 9 carbon atoms, an alkenyl group having 1 to 9 carbon atoms or an aryl group having 6 to 9 carbon atoms; T is alkylene (including straight-chain and branched alkylene) having 1 to 4 carbon atoms or arylene having 6 to 9 carbon atoms; n is 0 or 1; S1 and S2 are, independently of one another, —OCkH2k— or —OCH2CHR3—, with the proviso that k is 2 or 3, R3 is an alkyl group having 1 to 9 carbon atoms, an aryl group having 6 to 9 carbon atoms; and 6<_m1+m2<_25.

Owner:CONSTR RES & TECH GMBH

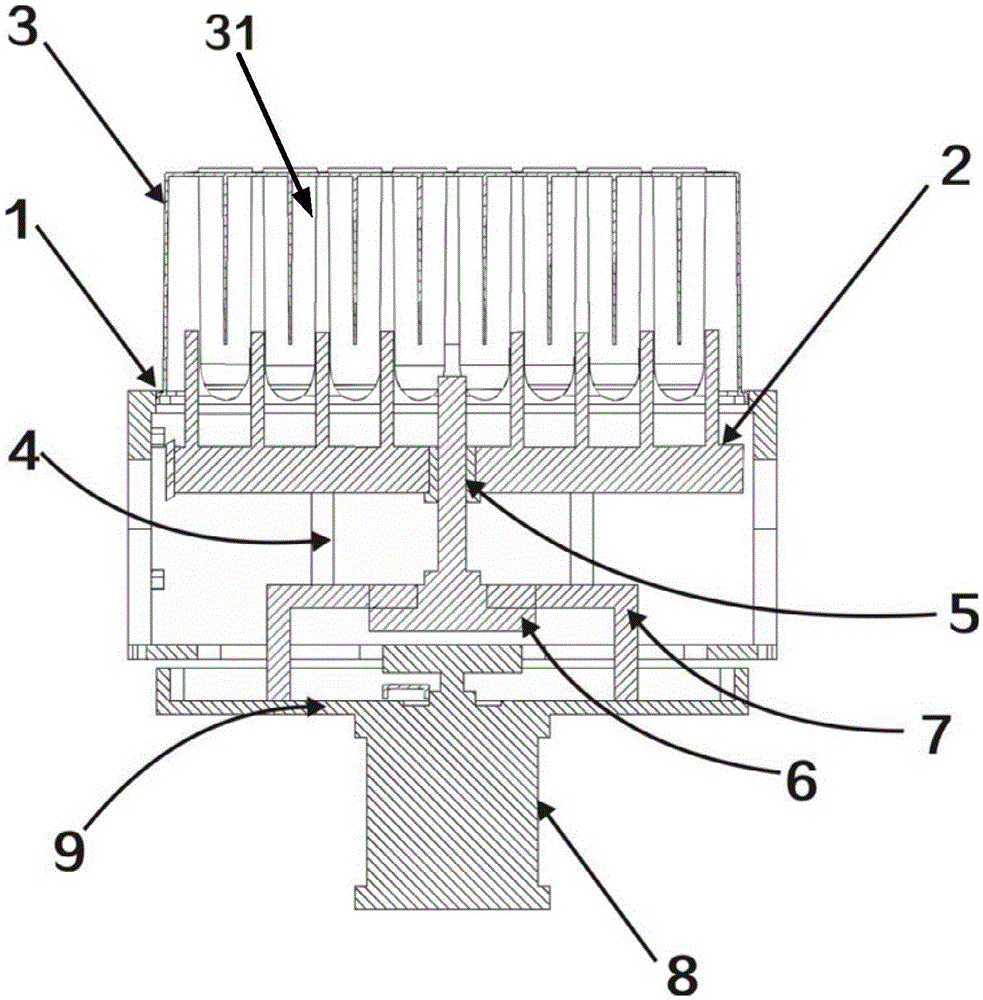

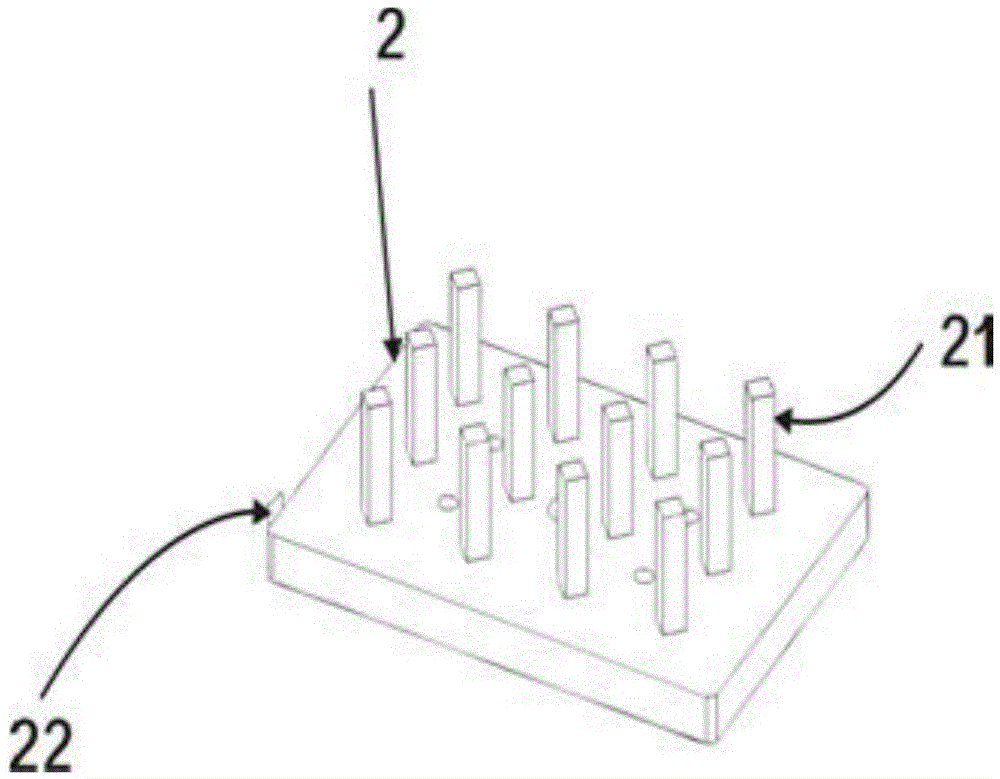

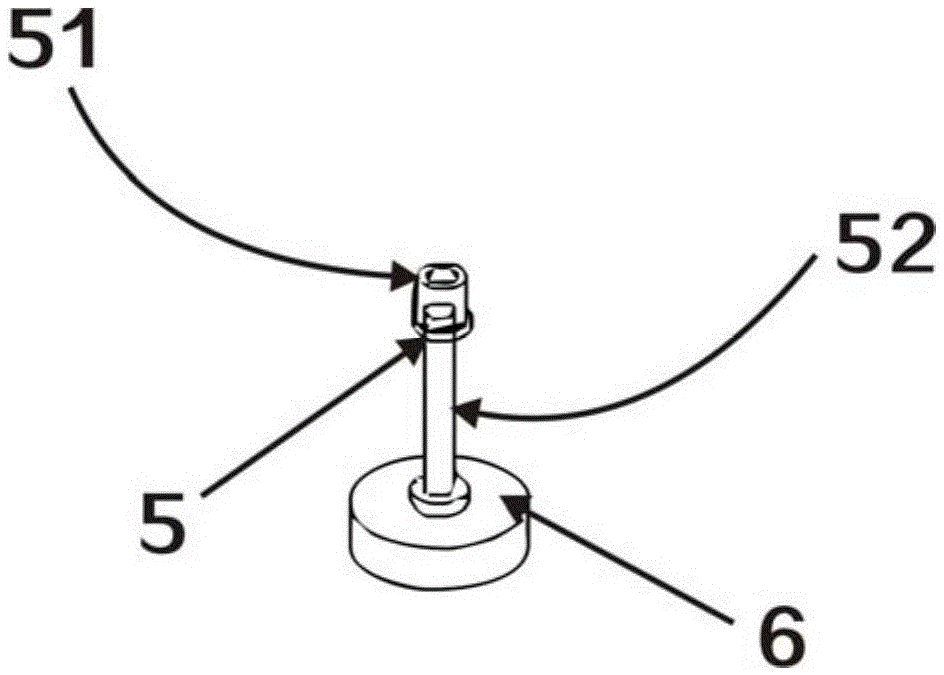

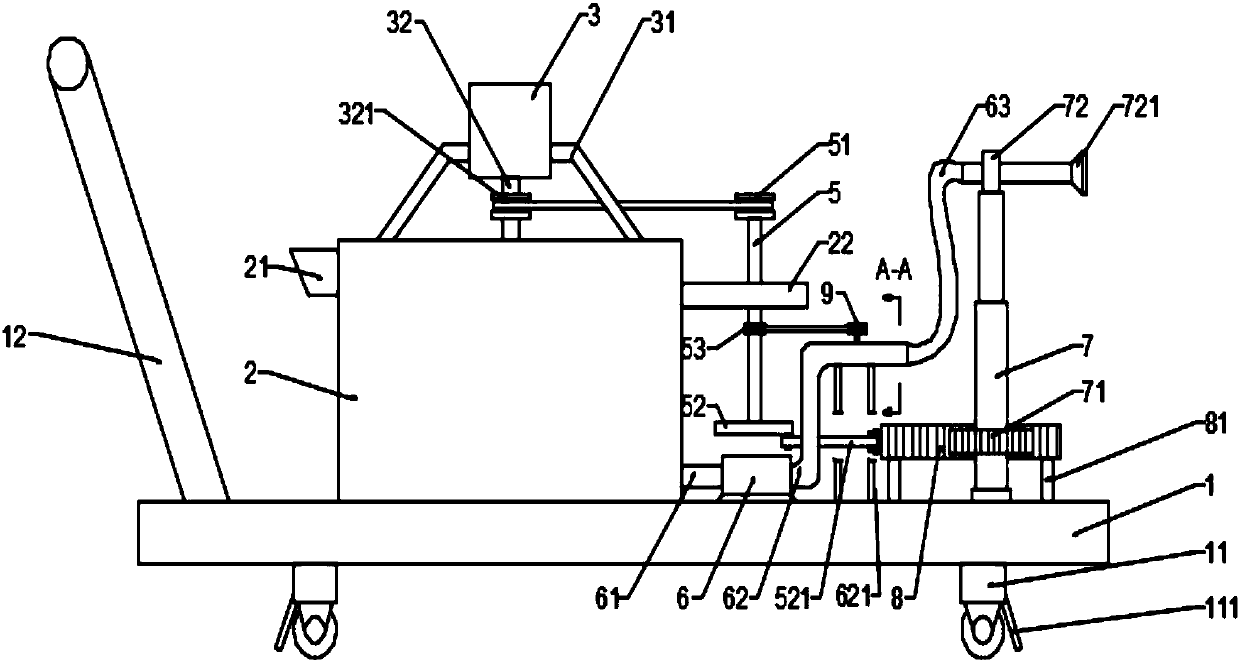

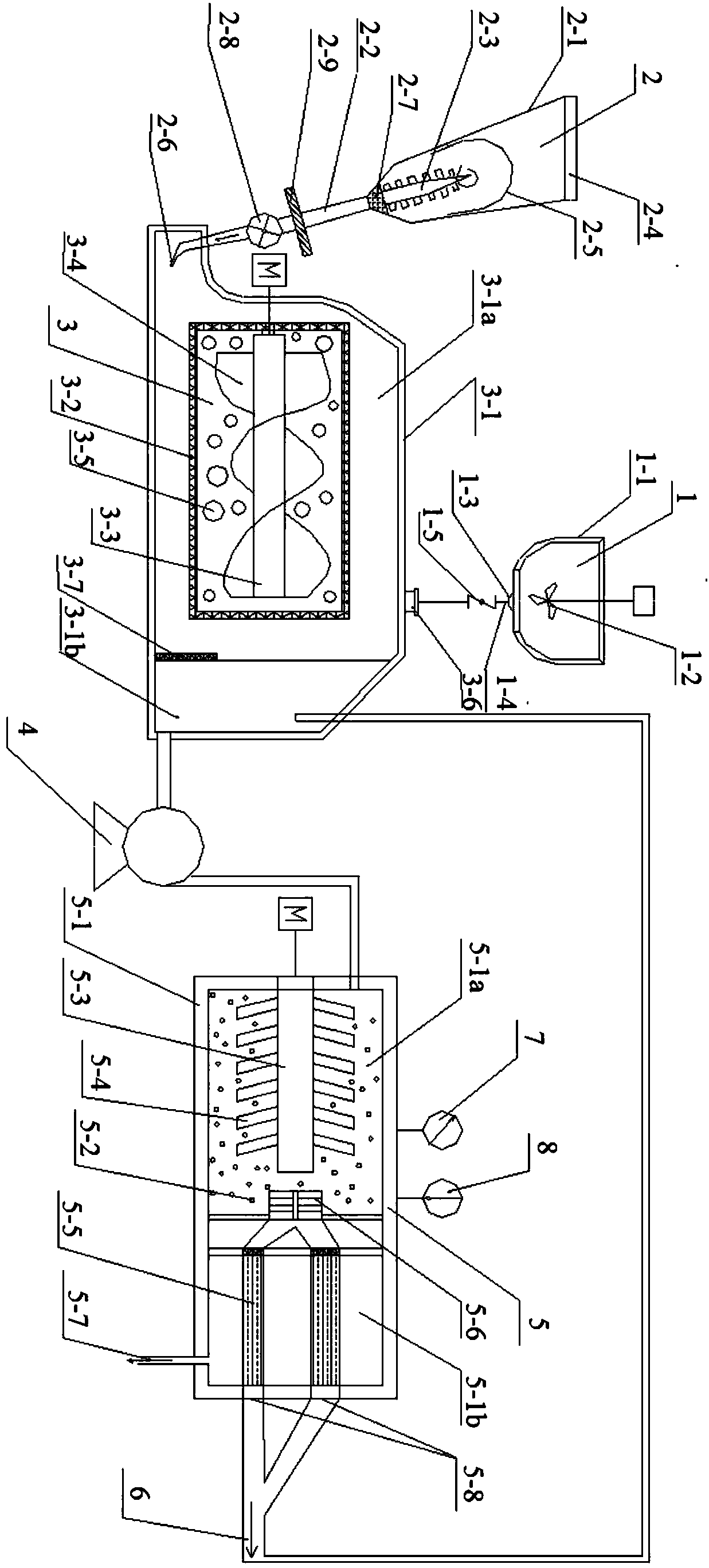

Magnetic bead based nucleic acid extraction device and method

InactiveCN105543089AEasy to remove layer by layerAvoid diversionBioreactor/fermenter combinationsBiological substance pretreatmentsSolution treatmentMagnetic bead

The invention provides a magnetic bead based nucleic acid extraction device. The magnetic bead based nucleic acid extraction device comprises a deep-well multi-well plate, a magnetic adsorption mechanism, a position moving mechanism and an oscillation mechanism, wherein the magnetic adsorption mechanism comprises a magnetic bar fixing base and a magnetic bar movably arranged on the magnetic bar fixing base; the position moving mechanism comprises a ball screw and a driving motor, and two ends of the ball screw are connected with the magnetic bar fixing base and the driving motor respectively; the oscillation mechanism comprises a carrier and a main oscillation unit connected with the carrier; the magnetic bar fixing base, the ball screw and the driving motor are all located in the carrier; the deep-well multi-well plate is detachably arranged on the upper surface of the carrier. According to the magnetic bead based nucleic acid extraction device, layer-by-layer solution treatment can be realized through the position moving mechanism, magnetic separation time is shortened, magnetic adsorption is thorough, and magnetic beads are not carried away; meanwhile, solution transfer, magnetic adsorption and oscillation can be performed in the same position, so that transfer between deep-well multi-well plates through a manipulator is avoided, and magnetic adsorption time and cost are reduced.

Owner:SANSURE BIOTECH

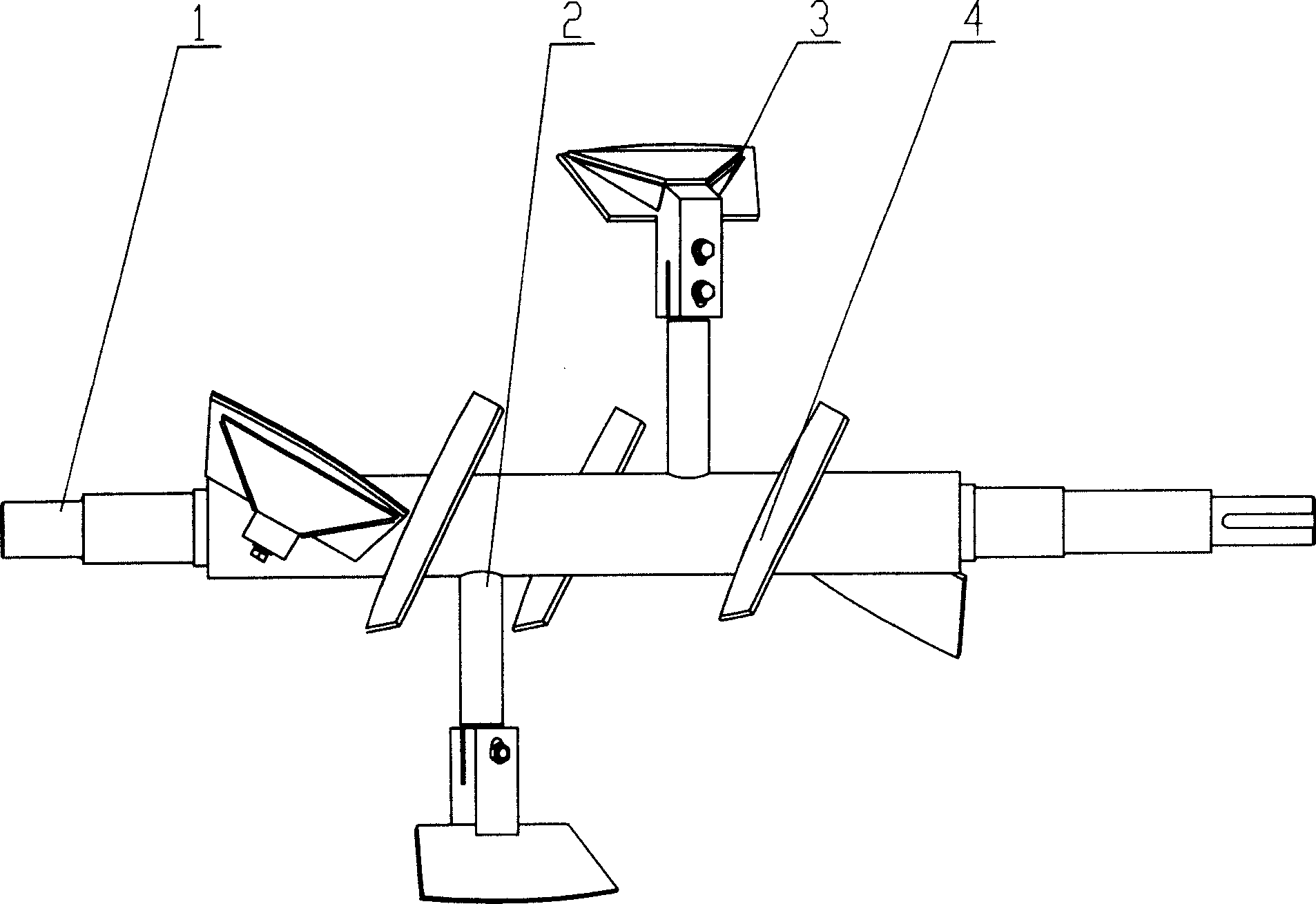

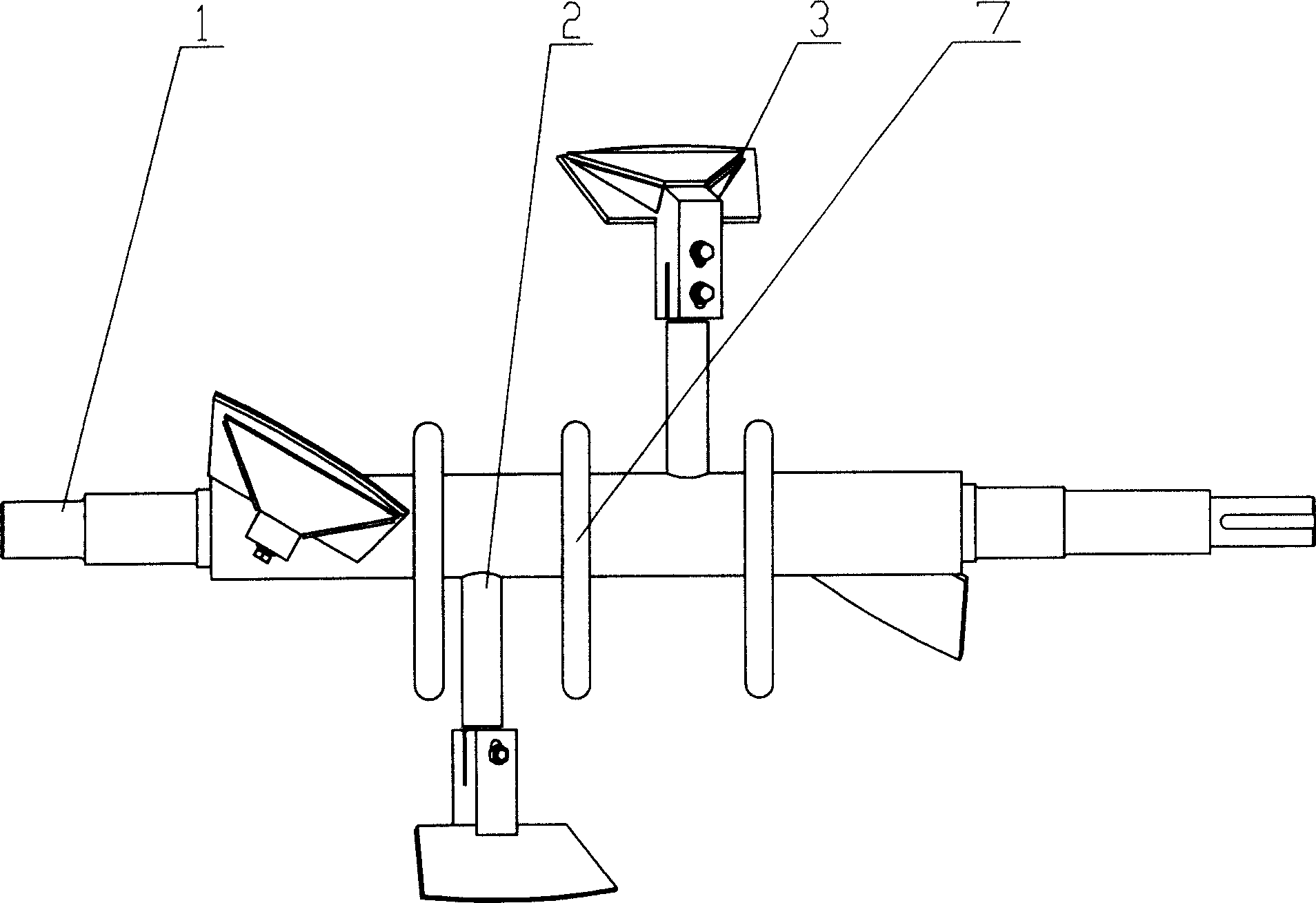

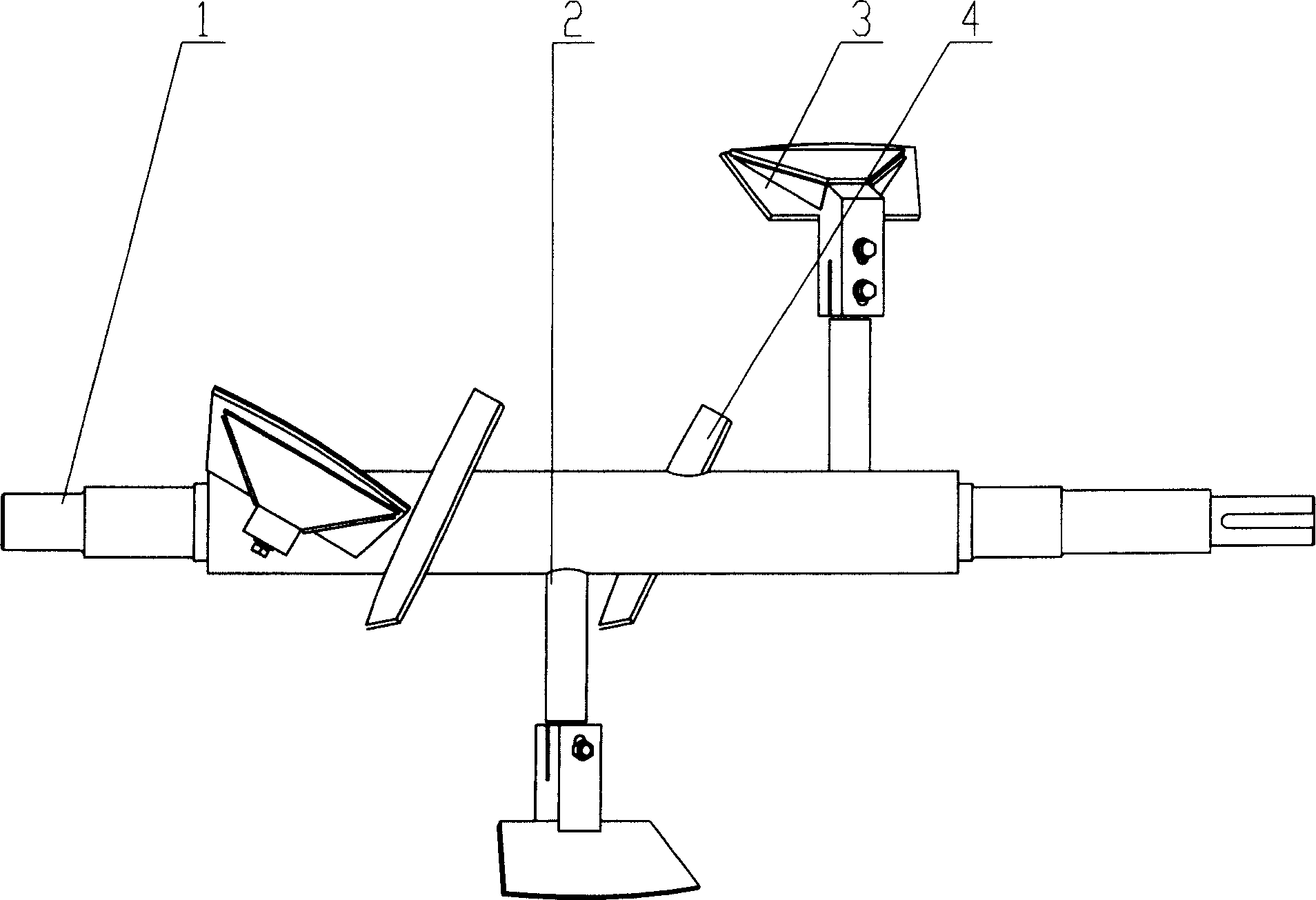

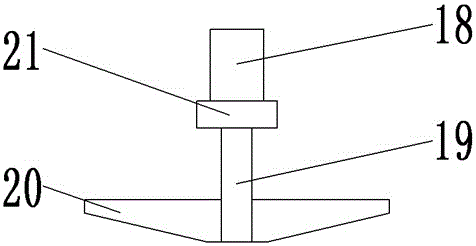

Swinging spraying water fertilizer irrigation vehicle

InactiveCN107593075ASpeed up the mixingAchieving Secondary StirringPressurised distribution of liquid fertiliserDrive shaftAgricultural engineering

The invention discloses a swinging spraying water fertilizer irrigation vehicle which comprises a bottom plate, a water tank, a pump machine and support rods, wherein a motor is arranged above the topof the water tank; the output end of the motor is connected with a transmission shaft; the transmission shaft stretches into the water tank and extends further; a plurality of stirring rods are connected with the body, inside the water tank, of the transmission shaft; a water outlet tube is connected with the water outlet of the pump machine; spraying tubes are arranged at the tops of the supportrods; the spraying tubes are connected with the water outlet tube through telescopic hoses; a transverse plate is fixed on the right side of the water tank; a vertical shaft is arranged on the transverse plate in a penetration manner; the vertical shaft is rotationally connected with the transverse plate; a third belt pulley is fixed at the periphery of the middle shaft body of the vertical shaft; the third belt pulley is connected with a fourth belt pulley through a belt; the fourth belt pulley is positioned above a horizontal section of the water outlet tube; a rotating shaft is connected with the bottom of the fourth belt pulley; the rotating shaft extends into the water outlet tube and is connected with a baffle plate; and the rotating shaft is rotationally connected with the wall ofthe water outlet tube in a sealed manner. The swinging spraying water fertilizer irrigation vehicle disclosed by the invention has the advantages of being wide in irrigation range and uniform in irrigation.

Owner:郑州晨昱硕电子科技有限公司

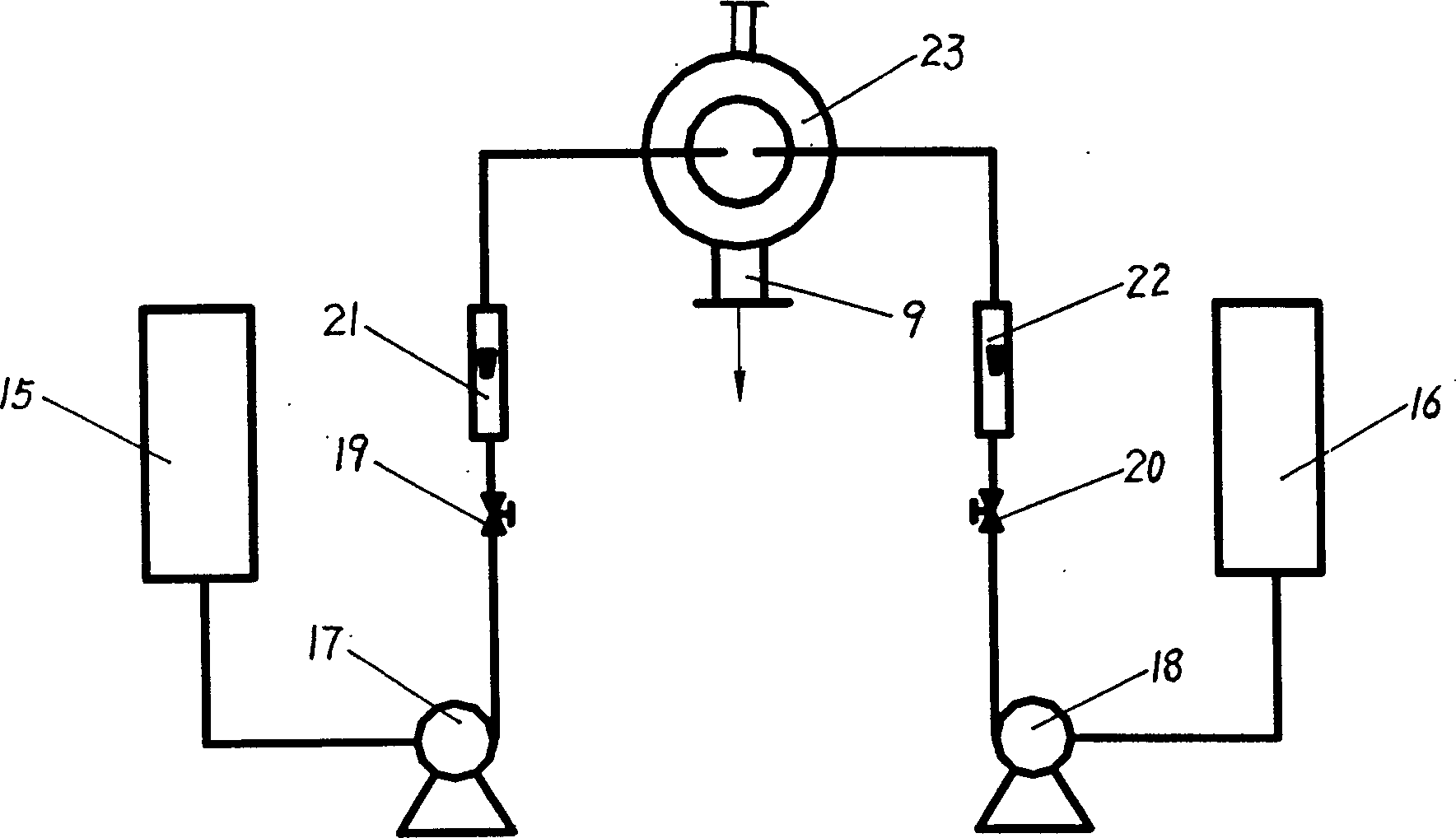

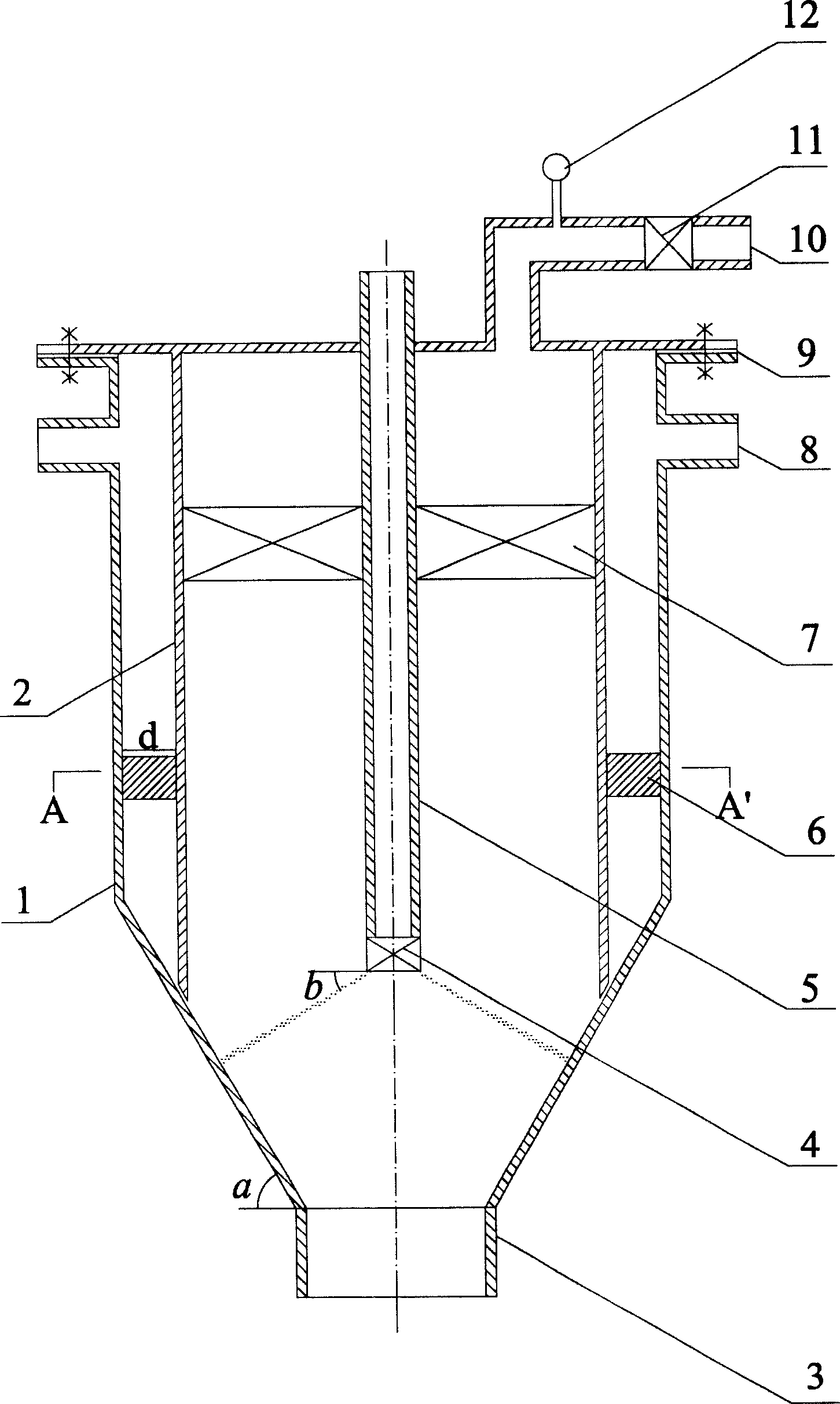

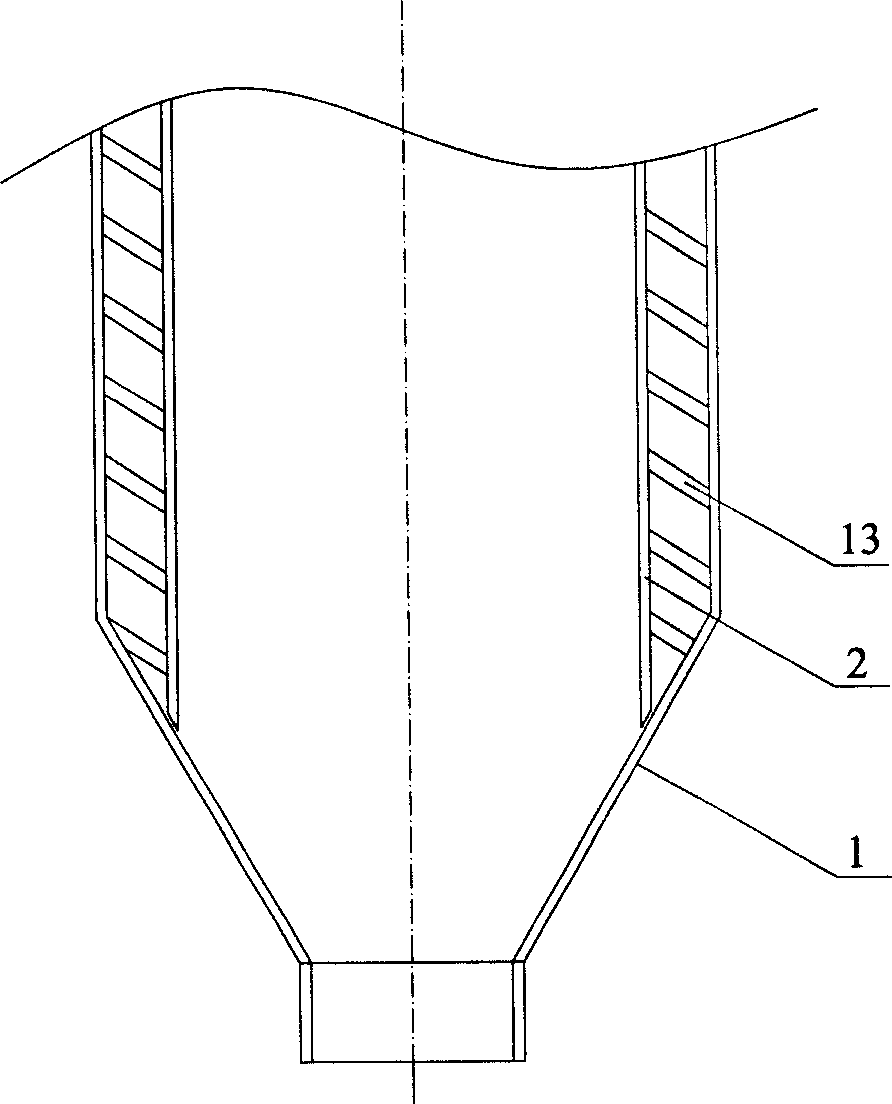

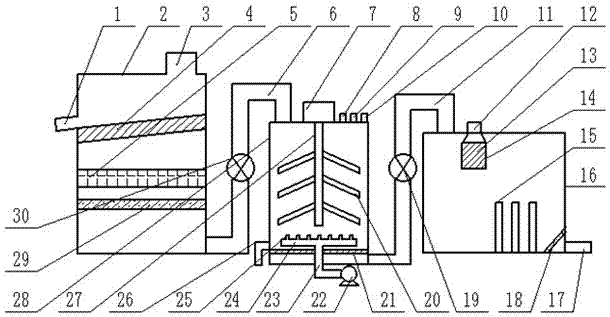

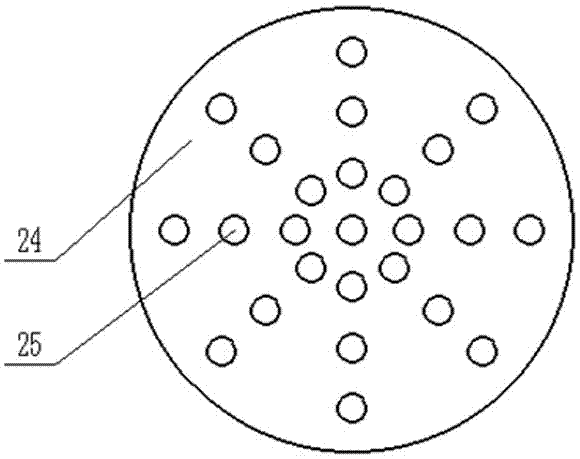

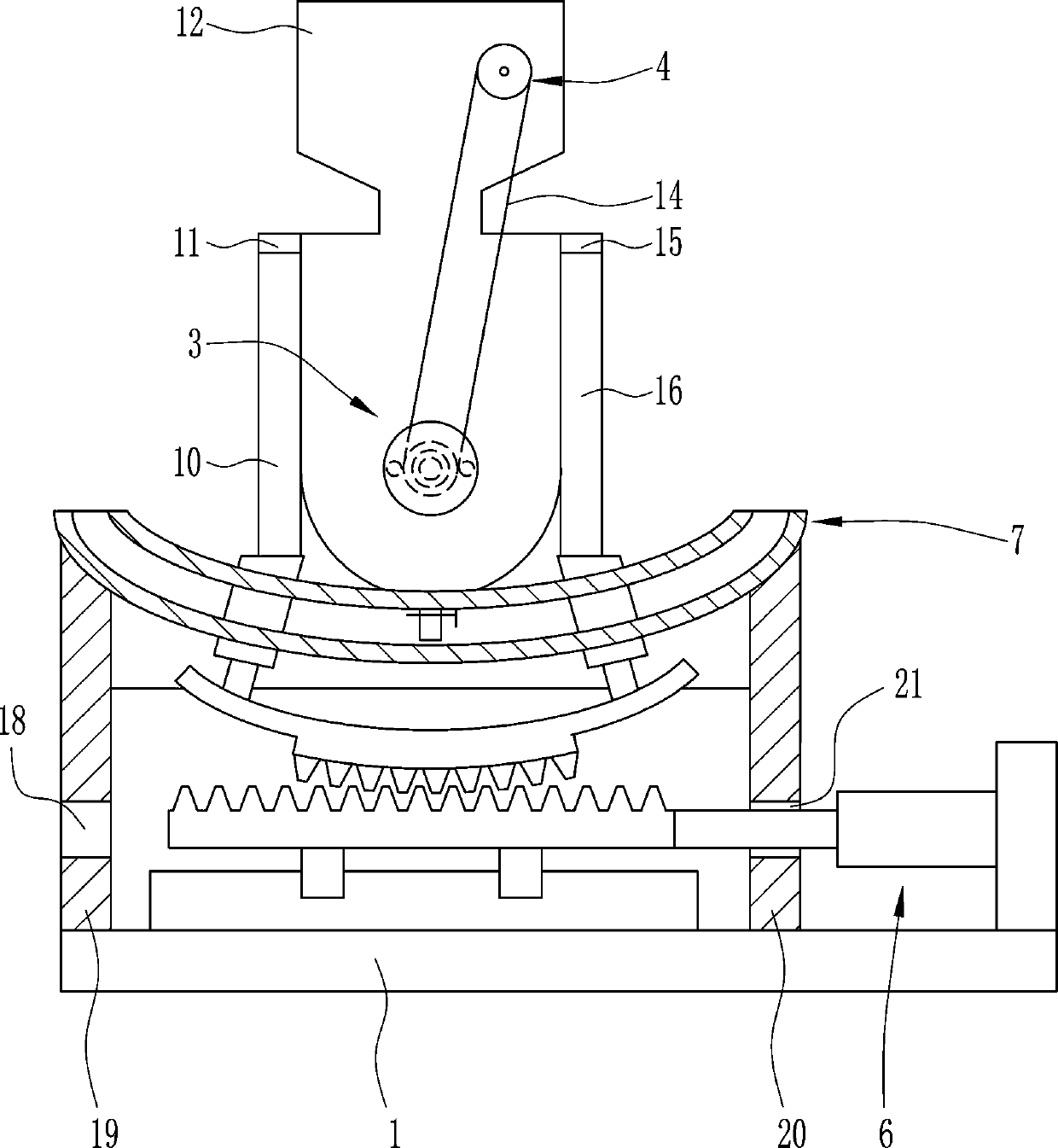

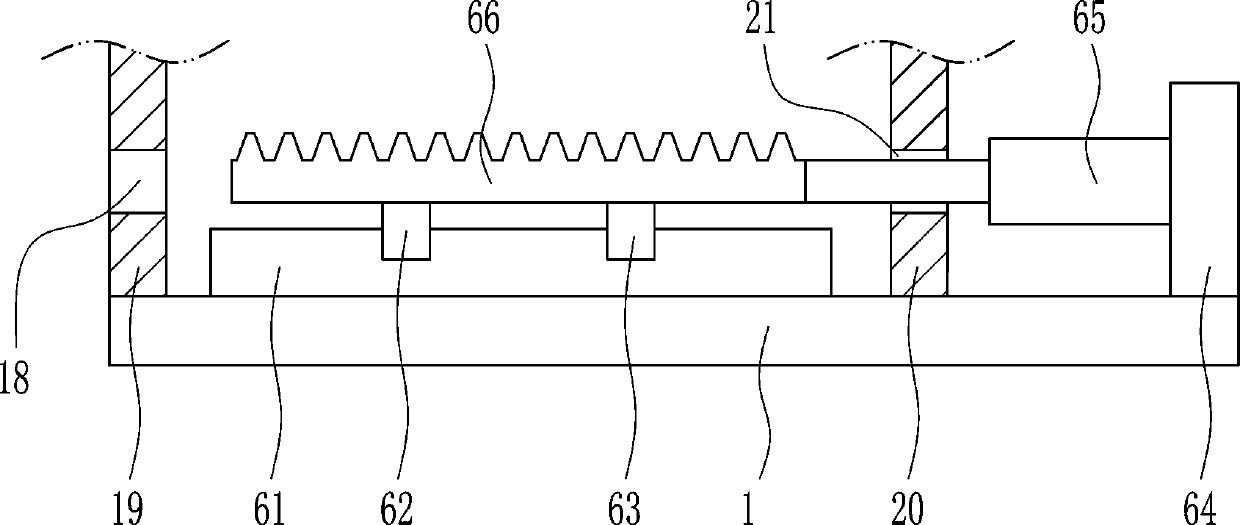

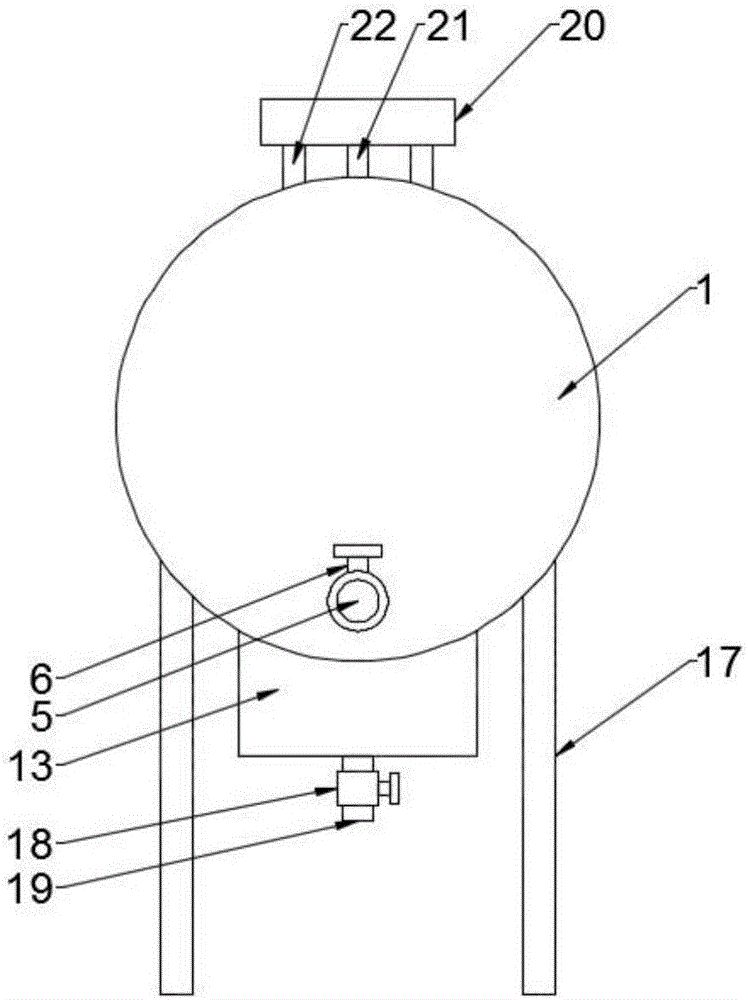

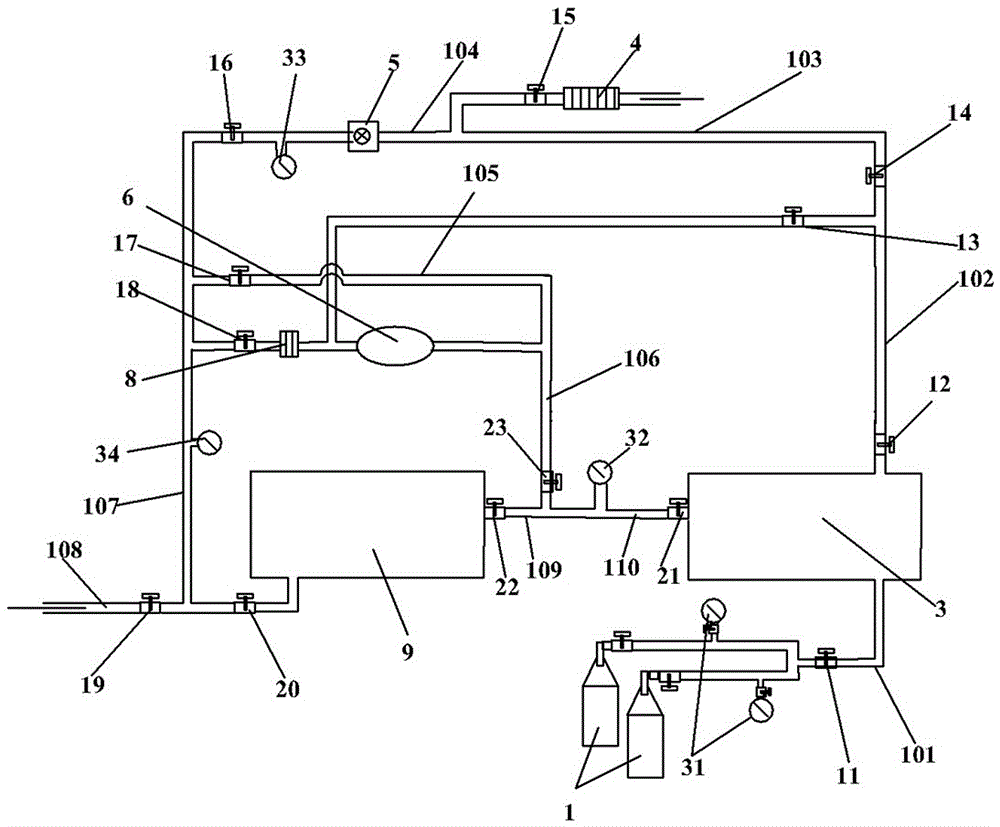

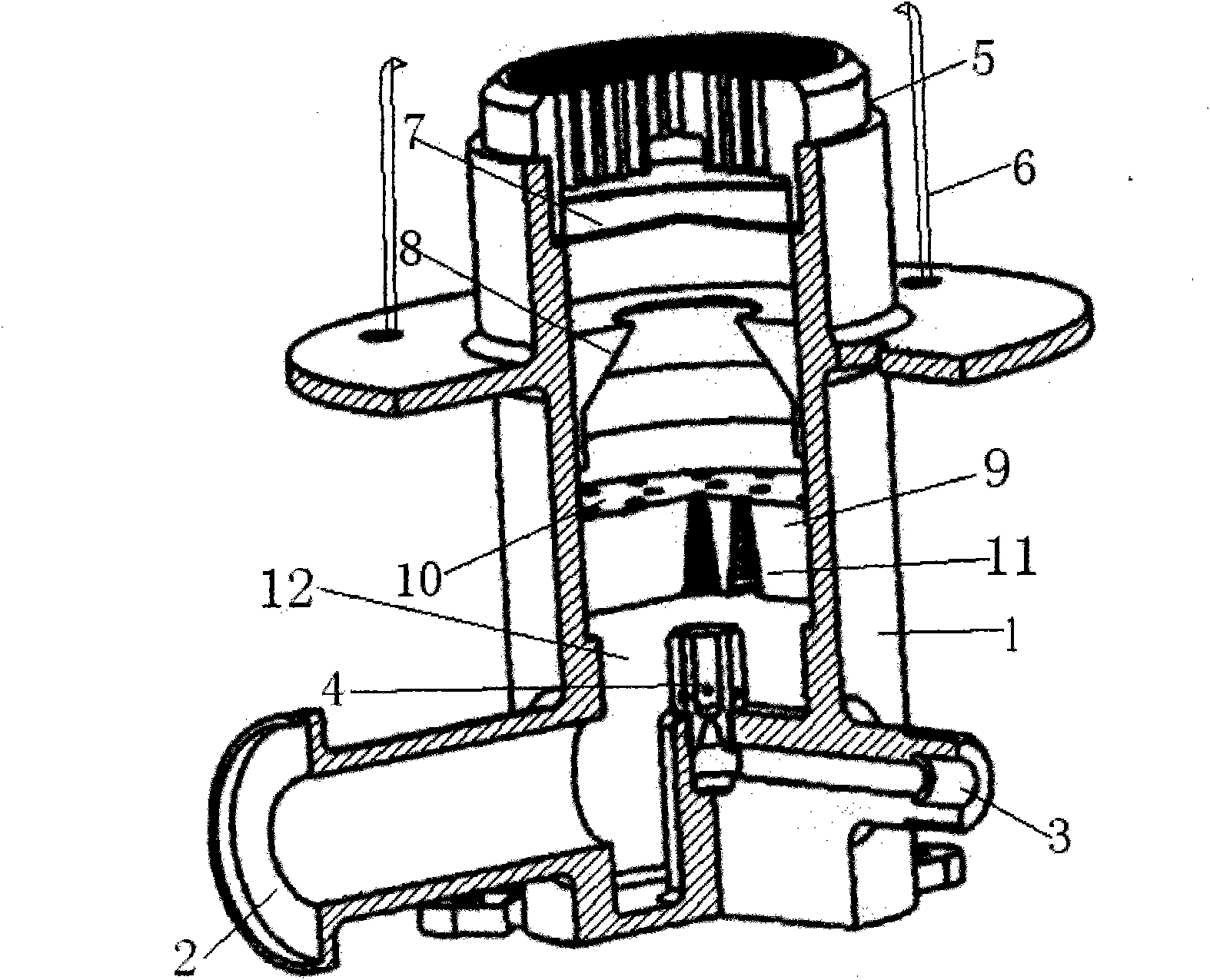

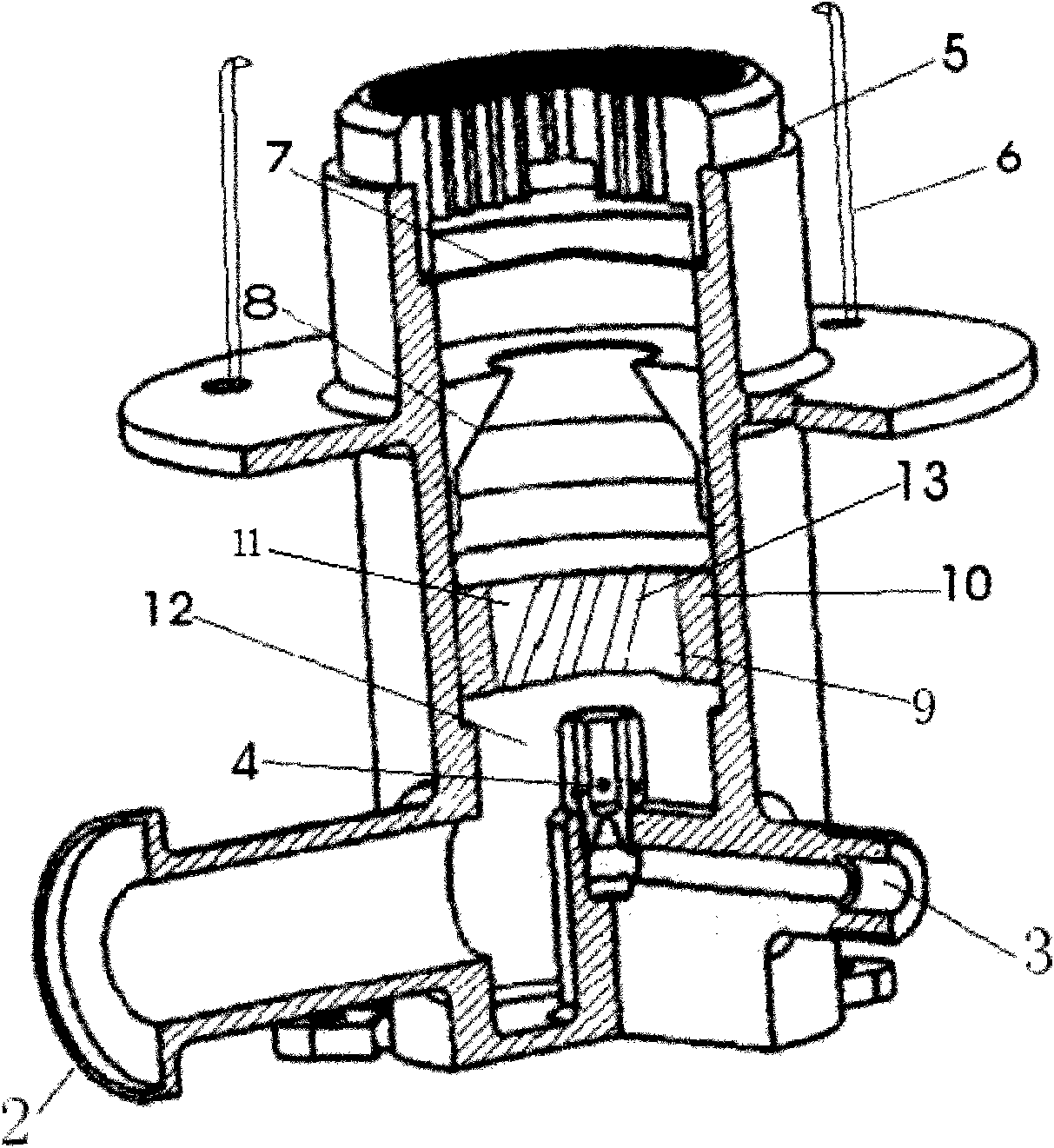

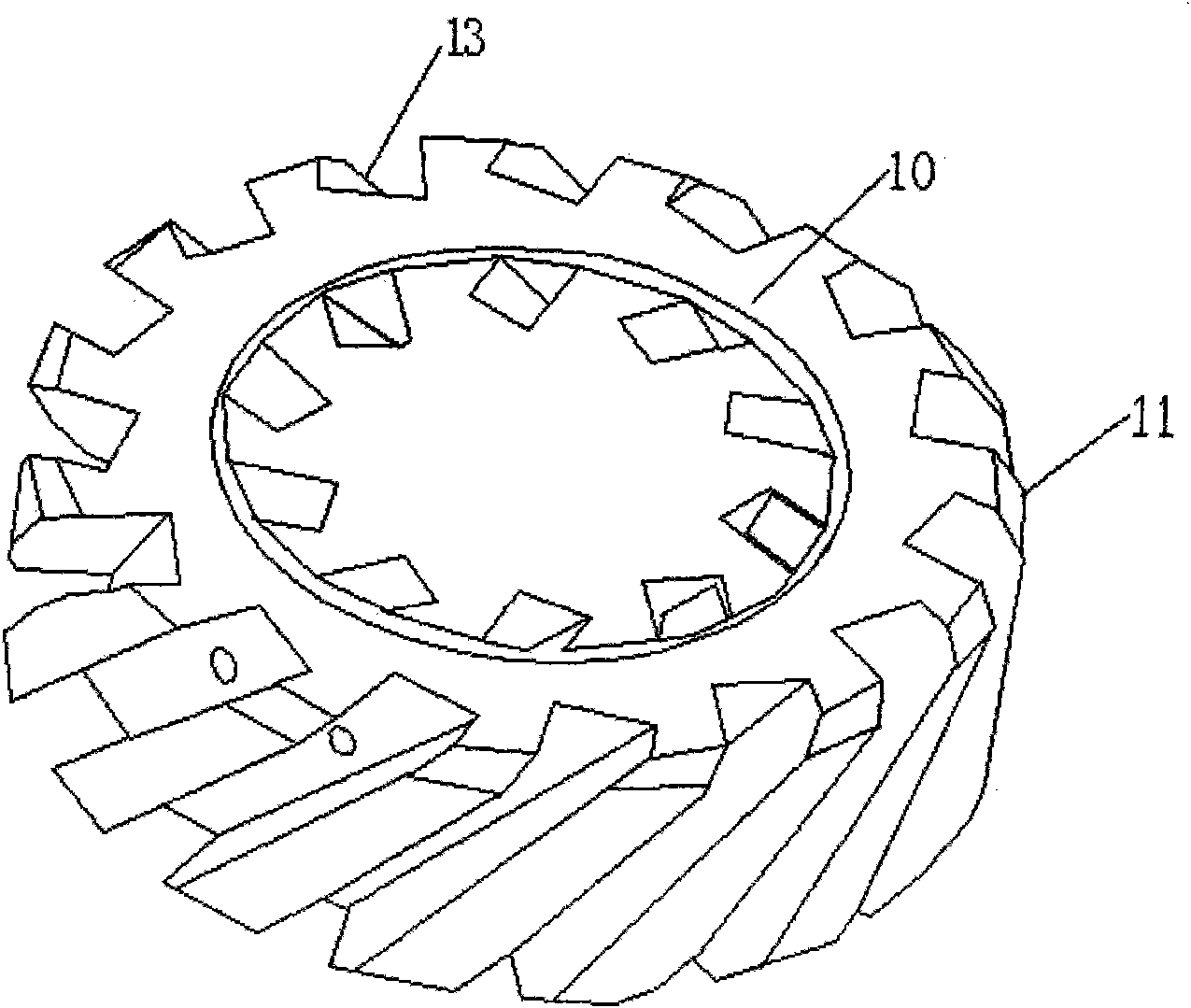

Liquid-liquid fast-mixing reactor

InactiveCN1669631AGuaranteed to proceed normallyEfficient mixingChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesCycloneSpray nozzle

The invention relates to a liquid-liquid fast-mixing reactor, which comprises a housing, an inner casing, a liquid conducting tube, an injector, a demister, a backing sheet, a pad, an adjusting valve, a manometer, wherein the housing (1) has a liquid feed inlet (8), the necked-in parts, and a liquid outlet (3); the inner casing (2) has the liquid conducting tube (5), the injector (4), the air outlet (10), the adjusting valve (11) and the manometer (12) inside. The space between the inwall of the housing (1) and the inner casing (2) forms a channel cyclone or non-cyclone through which a fold of liquid inlets, and another liquid passes the liquid conducting tube and the injector and forms the droplet distributed circlewise, the droplet connects with the film formed when the first fold of liquid passing the chine, and the two folds of liquid mix in the meeting point rapidly, then the product will be discharged from the liquid outlet (3).

Owner:TSINGHUA UNIV

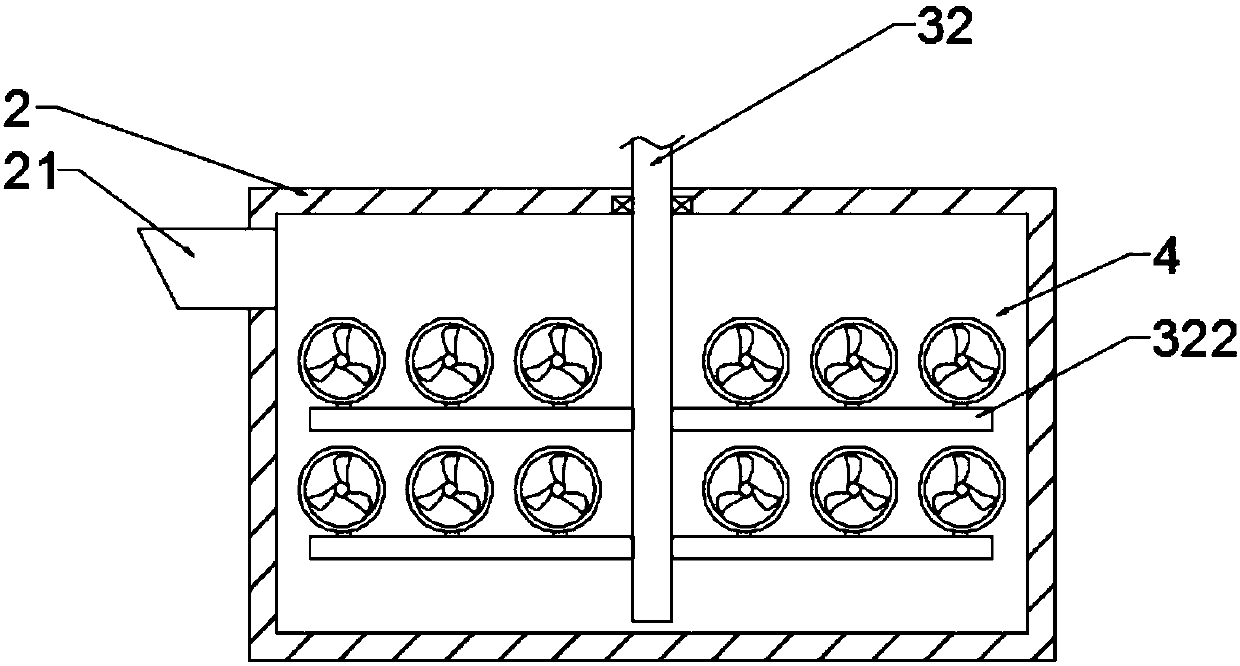

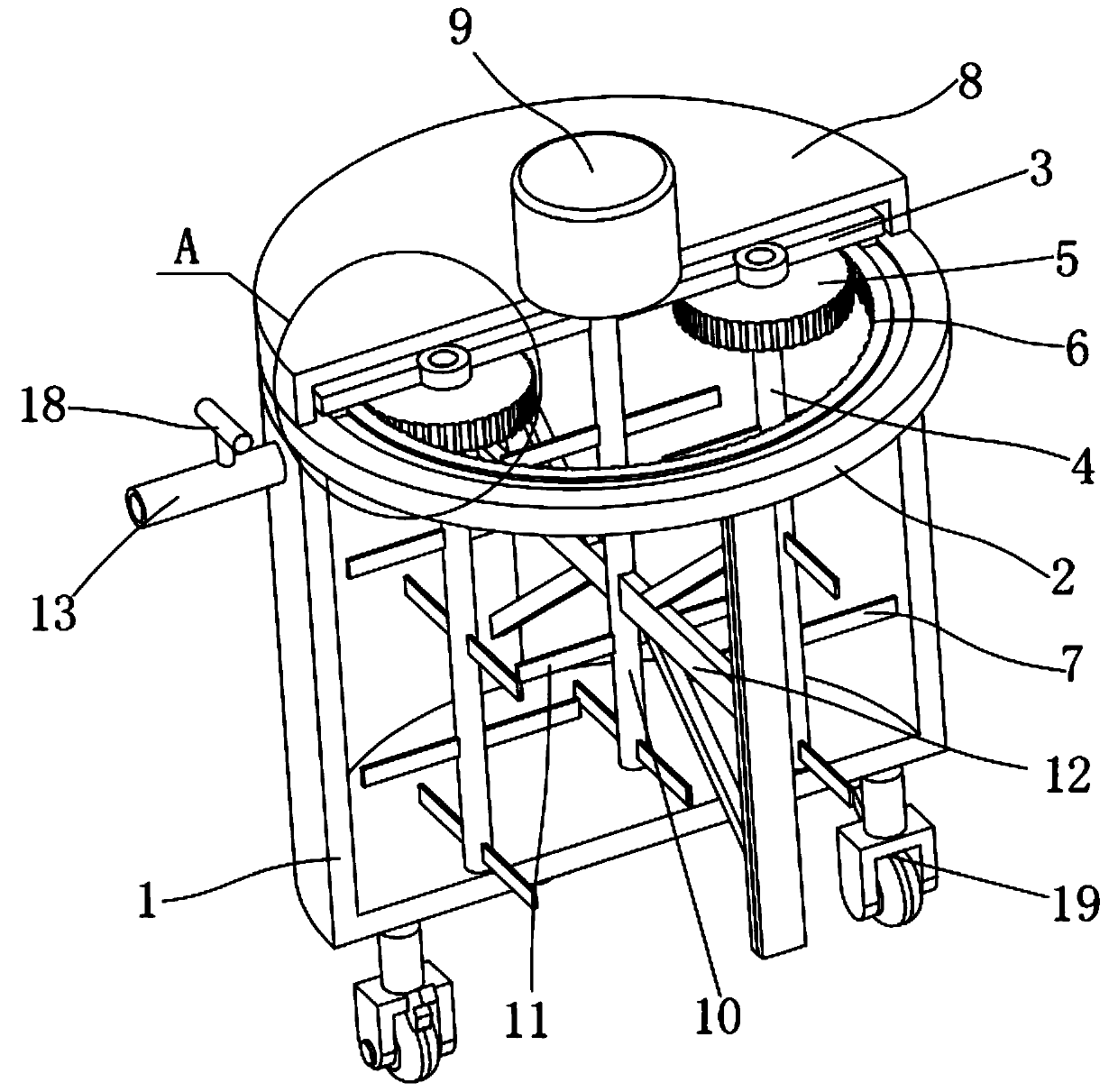

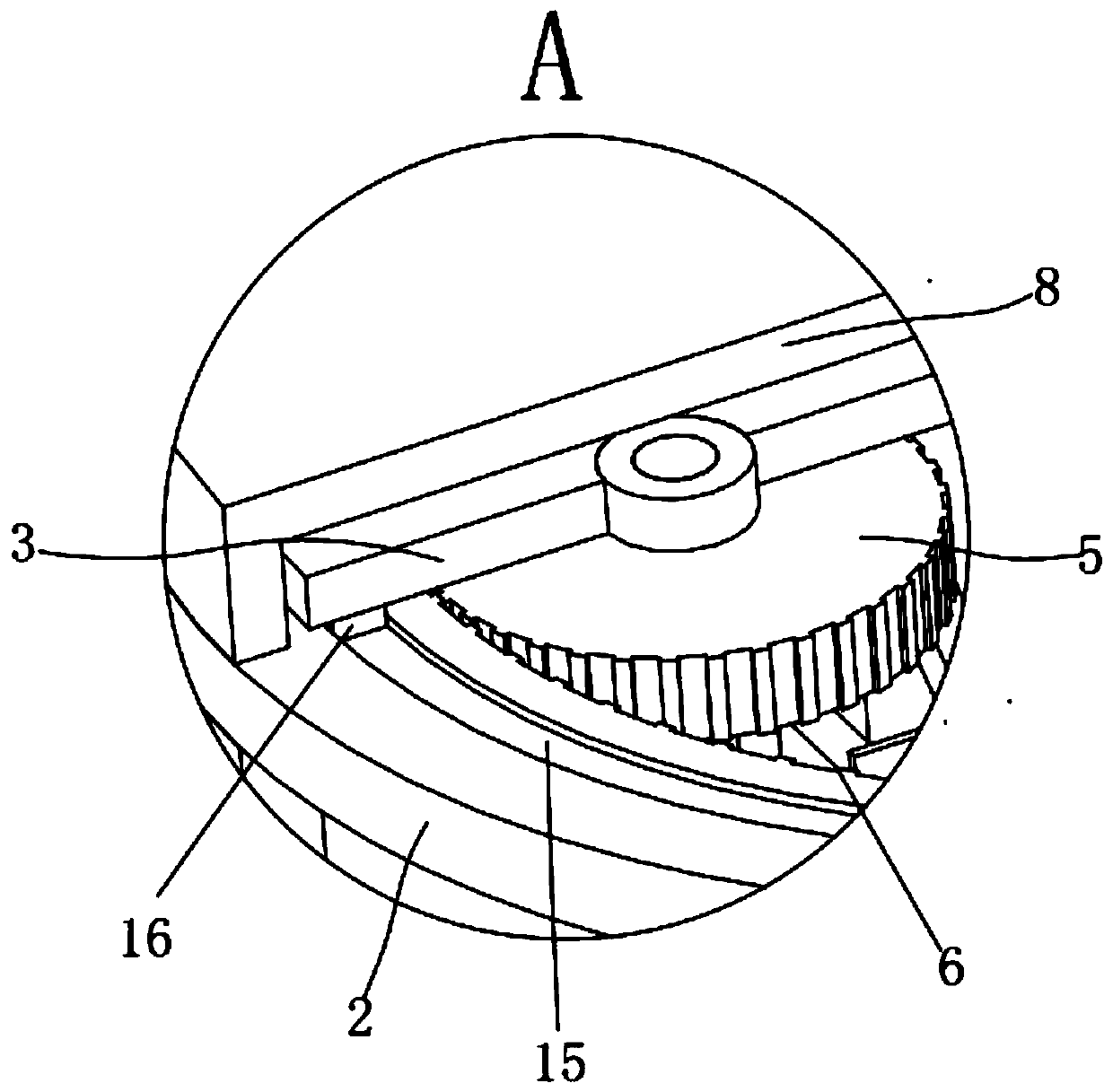

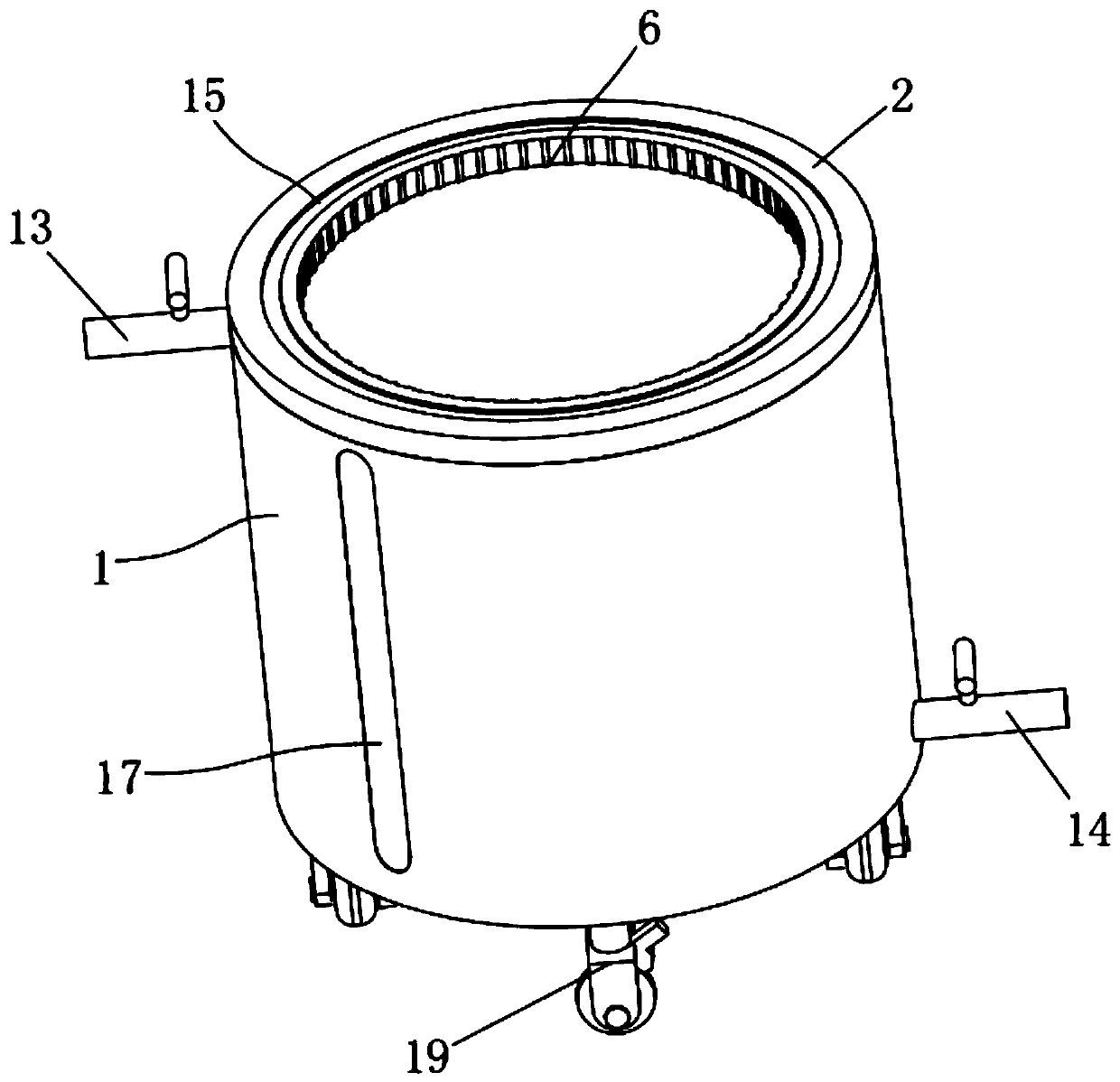

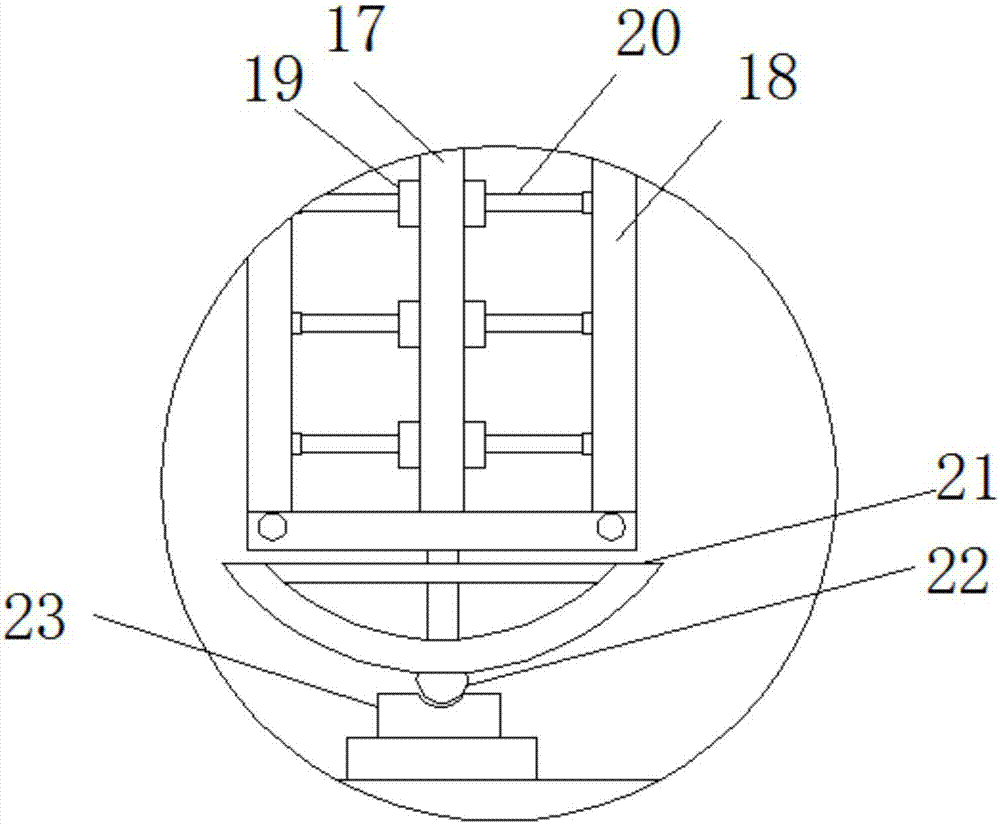

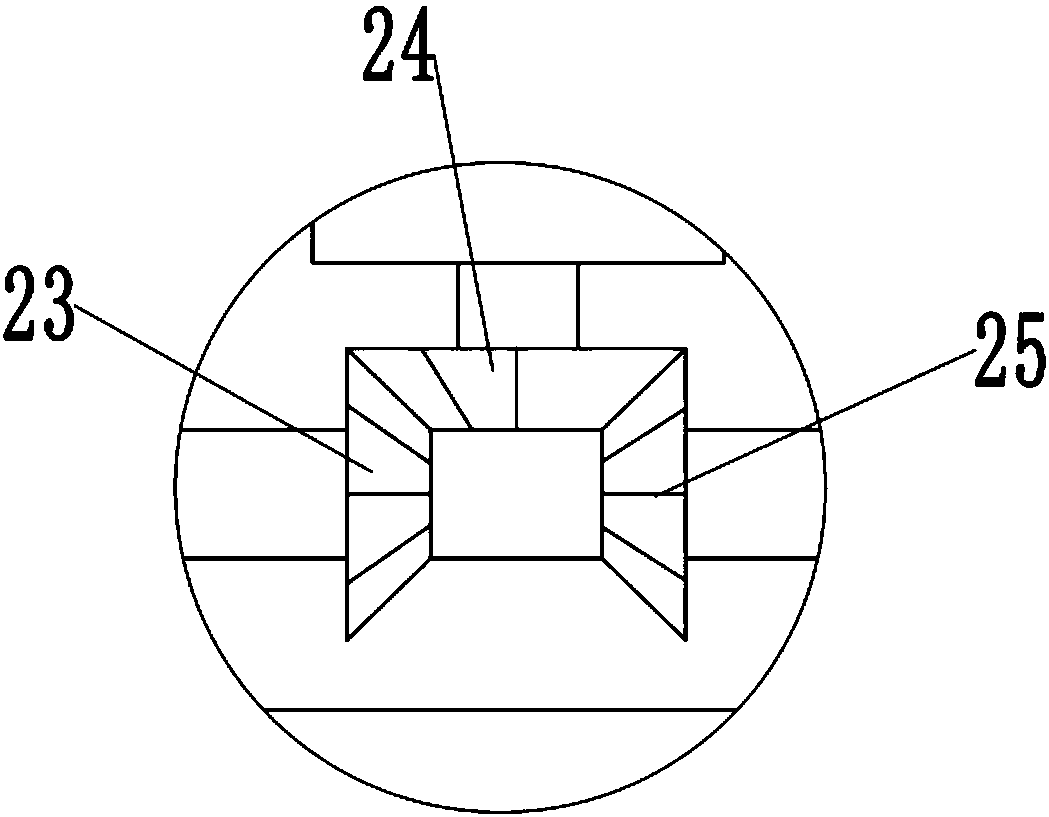

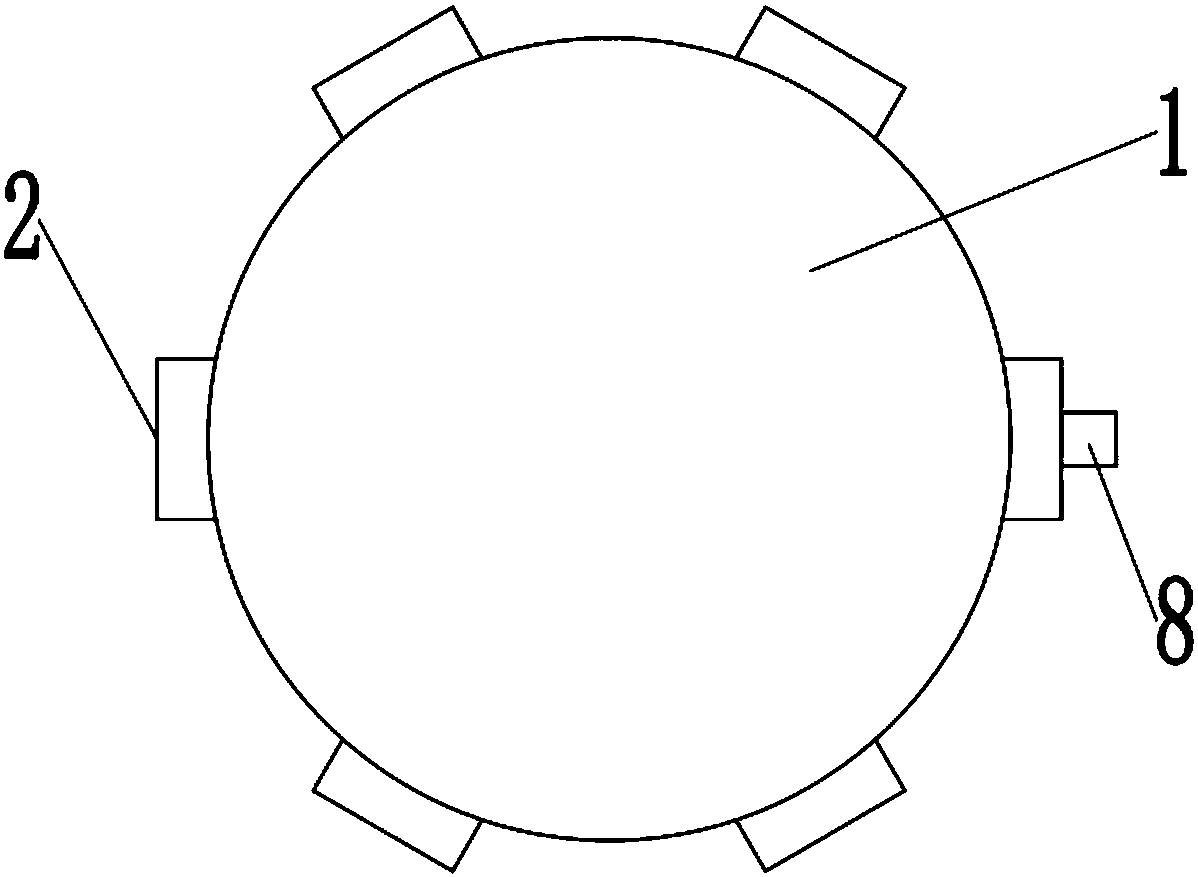

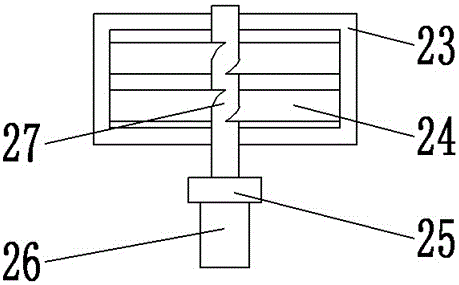

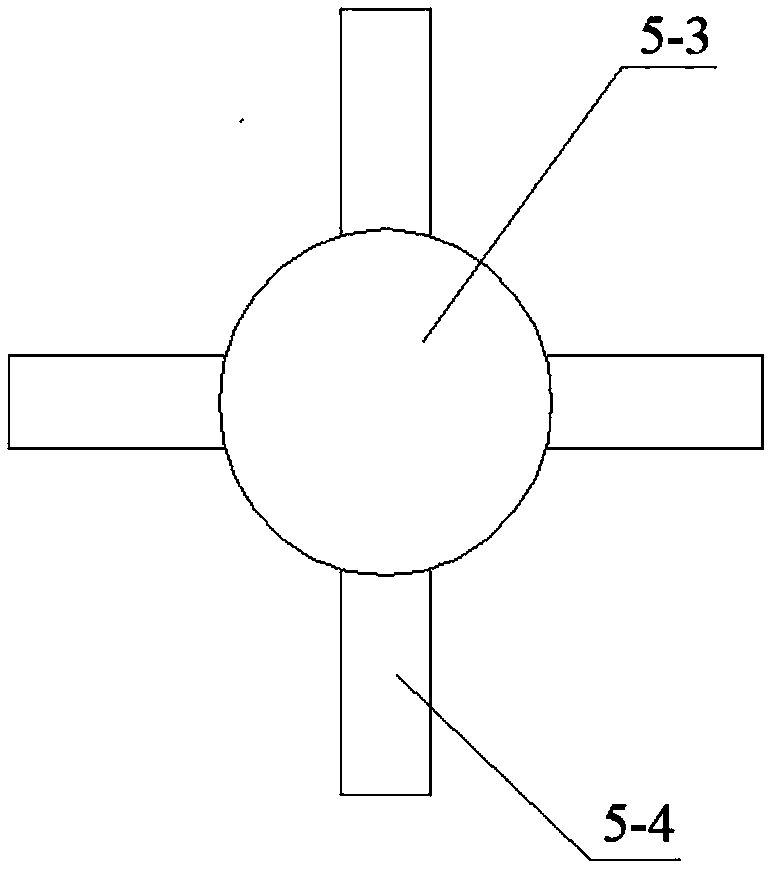

Mixing device for polymer gel raw material production

InactiveCN110681291ASpeed up the mixingImprove mix qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a mixing device for polymer gel raw material production. The device comprises a mixing barrel, wherein a fixed ring is fixed at the upper end of the mixing barrel; a turntableslides at the upper end of the fixed ring; first rotating shafts are mounted on two sides of the turntable; the upper ends of the first rotating shafts are in key connection with an outer gear; the outer side of the outer gear is engaged with an inner gear; the inner gear is embedded in the fixed ring; first stirring blades are welded on the first rotating shafts; a mounting base is fixed at the upper end of the fixed ring; a servo motor is fixedly connected to the upper end of the mounting base; a second rotating shaft is fixed to an output shaft of the servo motor; second stirring blades arewelded to the upper side and the lower side of the second rotating shaft; an inner wall wiping mechanism is fixedly connected to the middle part of the second rotating shaft; a feeding pipe communicates with the upper end of the mixing barrel; and discharging pipes symmetrically communicate with the lower end of the mixing barrel. The stirring directions of the stirring blades in the mixing barrel are different, so different vortexes are generated; and thus, the mixing speed of raw materials is increased, mixing quality is good, working efficiency is high, and the wall of the barrel can be automatically cleaned.

Owner:江山市永安消防材料有限公司 +1

Chemical wastewater treatment equipment

InactiveCN106946384ASettling fastSpeed up the mixingTreatment involving filtrationMultistage water/sewage treatmentFiltrationWastewater

The invention discloses a chemical sewage treatment equipment, which comprises a filter box, a sedimentation box and an oxidation adsorption box. The inside of the filter box is fixedly connected with a first filter net, a primary filter layer and a secondary filter layer in sequence from top to bottom. The right side of the filter box is provided with a settling box, and the middle part of the upper end of the settling box is fixedly installed with a driving motor. An oxidation adsorption box is installed on the right side of the sedimentation box, and a conical blower is fixedly installed on the left side of the upper end of the oxidation adsorption box. Adsorption rods are arranged on the right side of the cage. The present invention is simple in structure and reasonable in design. The impurities in the water are thoroughly removed through multiple filtrations. The coagulant is mixed with the sewage very quickly and the sedimentation speed is fast. After adjusting the pH, the impurities in the water are further removed by oxidation adsorption. pollutants.

Owner:江苏德利泰电气有限公司

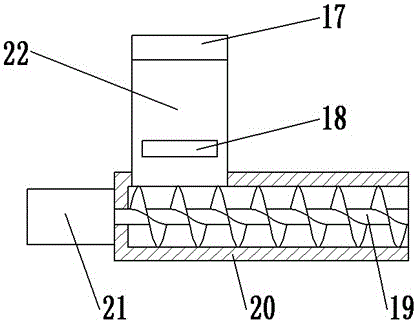

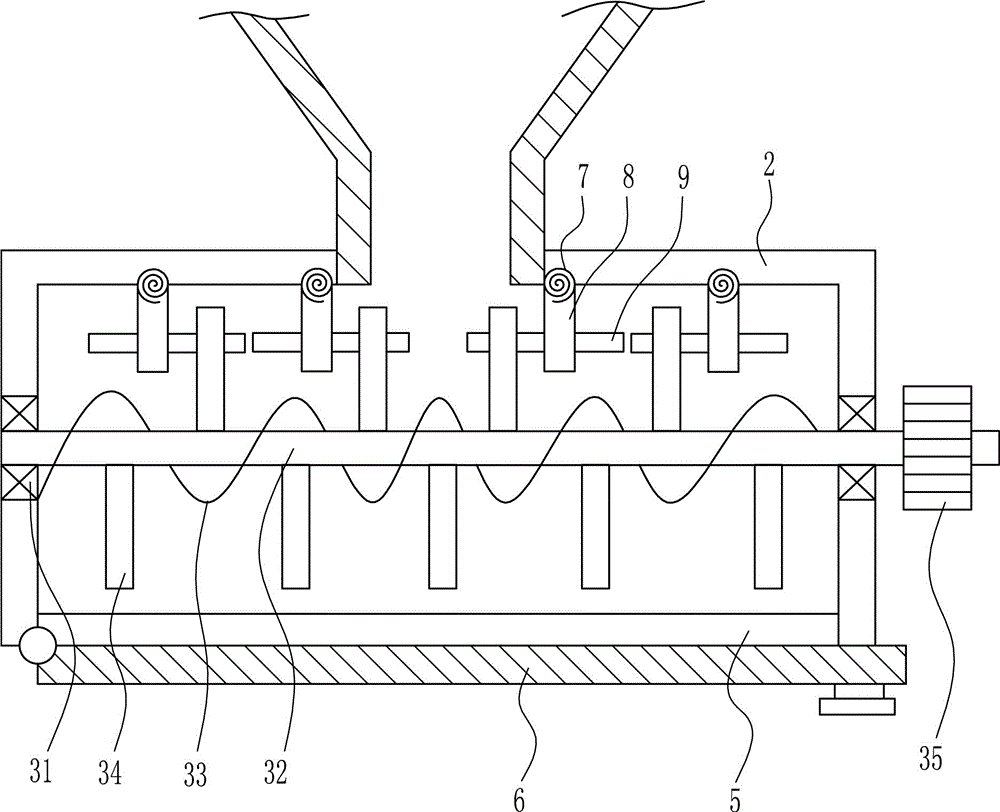

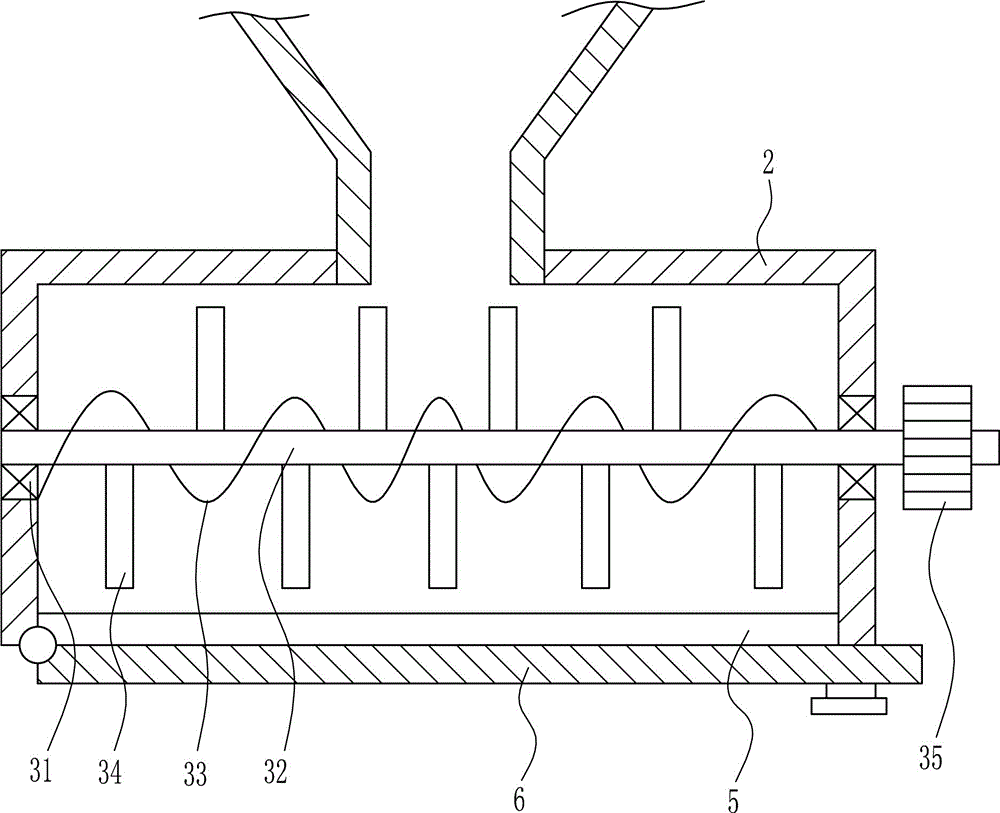

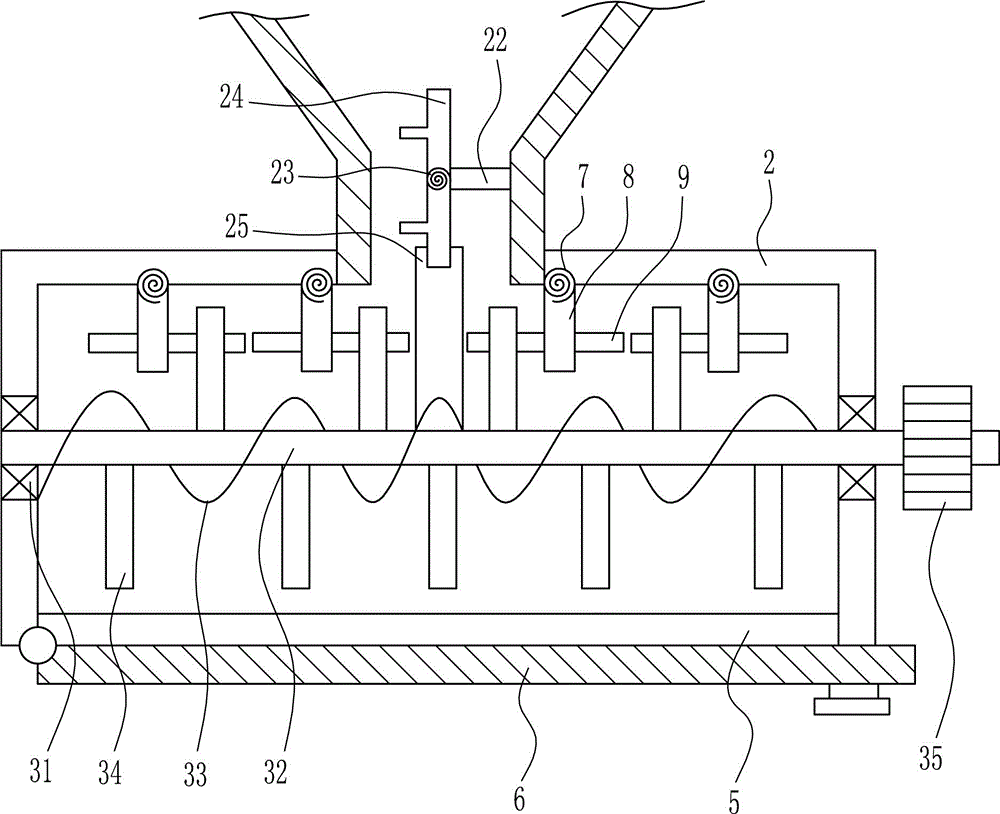

Printing and dyeing raw material mixing apparatus

InactiveCN107376751ASpeed up the mixingAdjustable rotation speedRotary stirring mixersTransportation and packagingFilling materialsUniversal joint

The invention relates to the technical field of mechanical equipment, and discloses a printing and dyeing raw material mixing apparatus. The apparatus comprises a casing, two sides of the top part of the casing are fixedly connected to bearers, the top parts of the bearers are fixedly connected to a supporting plate, and the top of the supporting plate is fixedly connected to a water tank; double sides of the water tank are fixedly connected to water pipes, and interface parts of the water tank and the water pipes are fixedly connected to sealing gaskets; one end of the two water pipes is respectively inserted with a buffering box, the buffering boxes are at double sides of the top part of a casing cavity, double sides of the bottom parts of the buffering boxes are fixedly connected to universal joints, and the bottom parts of the universal joints are movably connected to nozzles. The printing and dyeing raw material mixing apparatus employs a servo motor in the casing to drive connecting rods and stirring paddles at the bottom of the connecting rod, so that frame type mixing blades and mixing arms at double sides of the connecting rods run simultaneously, filled materials are comprehensively and uniformly stirred, stirring and mixing speed is improved, the servo motor can adjust the rotation speed and control speed of stirring, and the stirring effects are better.

Owner:梁留伟

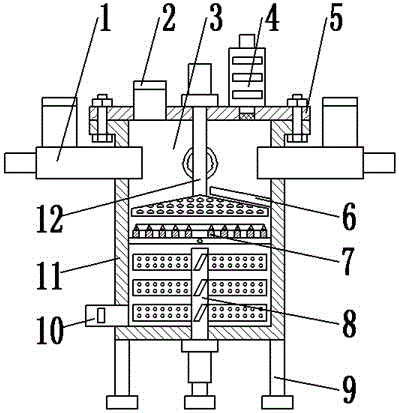

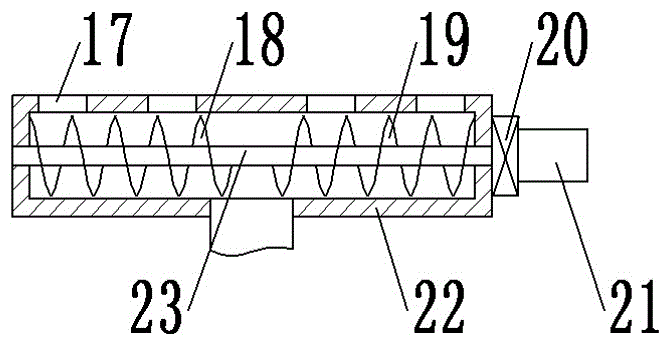

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

Paddle type mixing machine

InactiveCN1608723AImprove clippingThe structure is novel, reasonable and simpleRotary stirring mixersAgricultural engineeringFast flow

The present invention discloses one kind of paddle type mixing machine in the field of mixing machinery. There are machine body; stirring barrel set on the machine body; rotor comprising rotating shaft inside the stirring barrel, brace bar on the shaft and paddles fixed in the fast flow area; and characterized transition area stirring part set on the shaft and in the slow flow area. The transition area stirring part may be installed directly on the rotating shaft, on the middle section of the brace bar, or on the support column on the rotating shaft. The present invention has novel structure, simple manufacture process and low cost, and is suitable for both single shaft paddle mixing machine and double shaft paddle mixing machine.

Owner:JIANGSU MUYANG GRP CO LTD

Efficient fertilizer mixing machine for gardens

InactiveCN107551914AEnergy savingStir wellShaking/oscillating/vibrating mixersMixer accessoriesFertilizerAgricultural engineering

The invention relates to a mixing machine and especially relates to an efficient fertilizer mixing machine for gardens. The technical problem to be solved by the invention is to provide the efficientfertilizer mixing machine for gardens, that is capable of uniformly and fully mixing. In order to solve the technical problem, the efficient fertilizer mixing machine for gardens, provided by the invention, comprises a first mounting plate, a collecting box, a stirring mechanism, a linking mechanism, a crushing mechanism, a driving mechanism, a swinging mechanism, a valve, a discharging pipe, a first fixing rod, a second fixing rod, a feeding hopper, a sieving plate, a flat belt, a third fixing rod, a fourth fixing rod, a mixing tank, a first support plate and a second support plate; the collecting box is arranged at the top of the first mounting plate; the driving mechanism is fixedly arranged at the top of the first mounting plate. The efficient fertilizer mixing machine for gardens canachieve the effect of uniformly and fully mixing.

Owner:刘治国

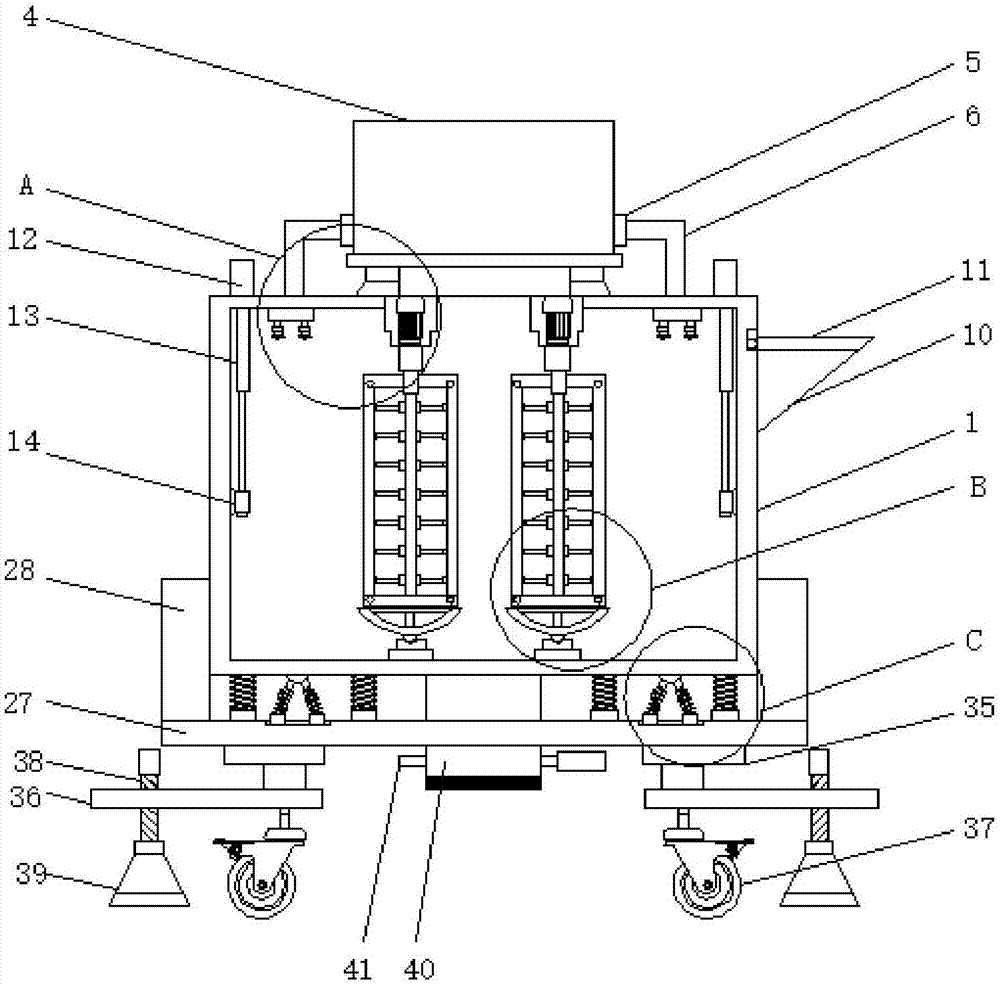

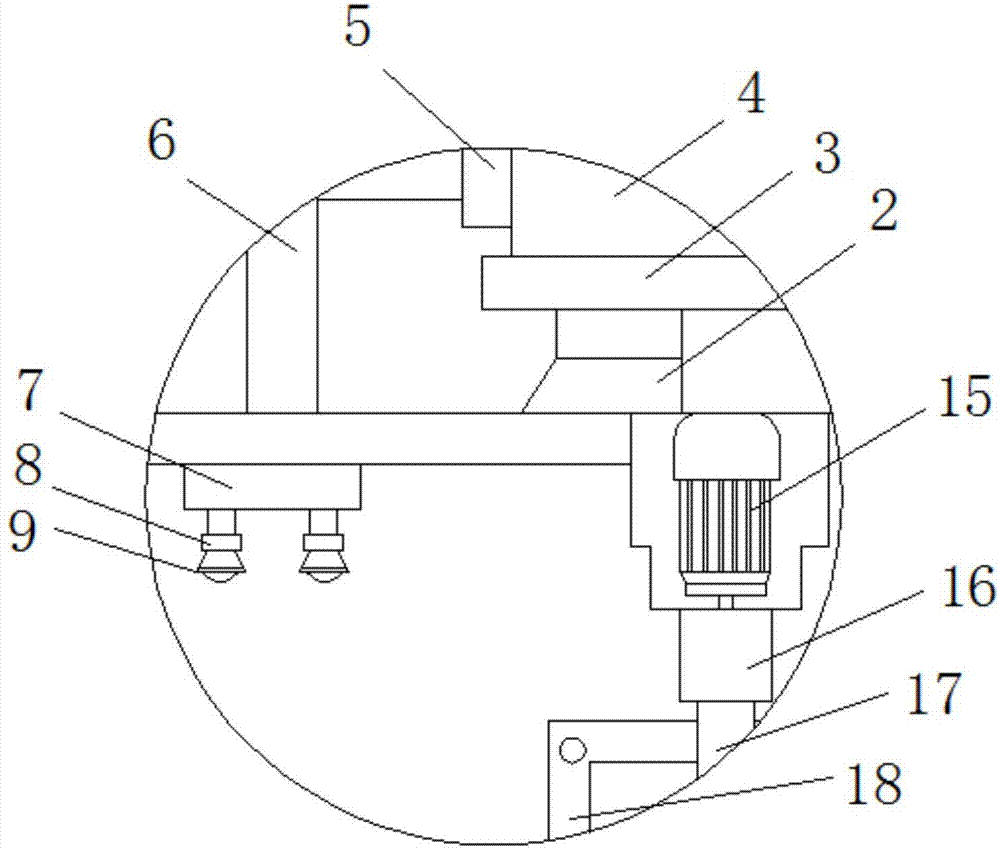

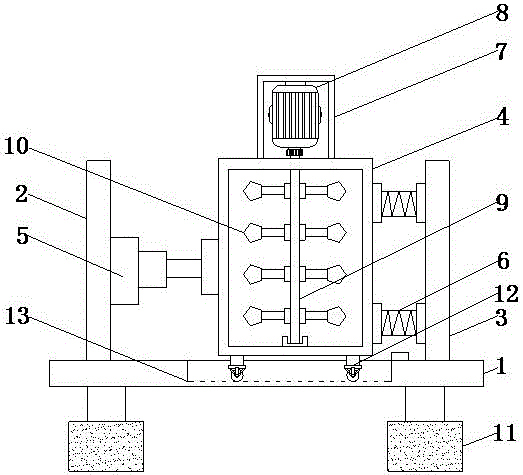

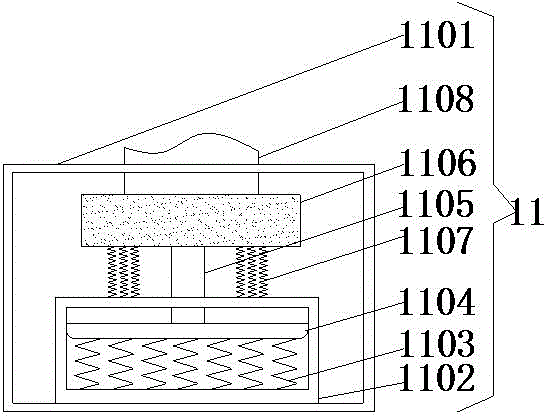

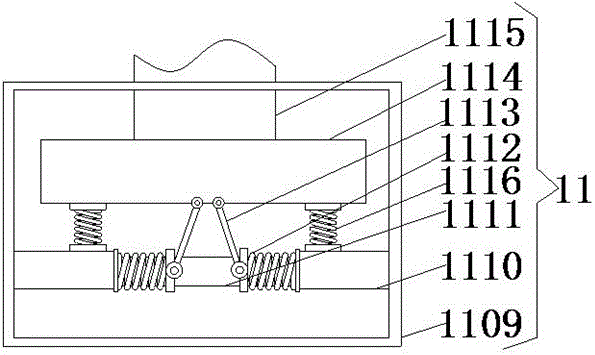

Chemical material mixing machine with damping function

InactiveCN106311049AWith shock absorption functionAddressed issues with damage, increased mixer overhaul frequencyShaking/oscillating/vibrating mixersTransportation and packagingDamping functionEngineering

The invention discloses a chemical material mixing machine with a damping function. The chemical material mixing machine comprises a bottom plate, wherein two sides of the bottom plate are respectively fixedly connected with a first support pillar and a second support pillar, a barrel is in sliding connection to the top of the bottom plate and is located between the first support pillar and the second support pillar, and one side, close to the barrel, of the first support pillar is fixedly connected with the barrel by an electric expansion link. The chemical material mixing machine with the damping function can effectively solve the problems of conventional mixing machines that severe vibration is generated in operation, the mixing machine is damaged due to excessive vibration, and the mixing machine overhauling frequency is increased, and therefore, the service life of the mixing machine is prolonged, and the working efficiency is improved while the cost is lowered; and the barrel can be moved back and forth during operation, so that the chemical material can be further mixed, and the mixing speed is promoted, and therefore, the working efficiency is improved, and the working cost is saved.

Owner:WUXI RISHENG CHEM CO LTD

Formula and smelting key technique for high-strength and high-tenacity aluminum alloy

InactiveCN108300910AImprove thermal conductivityGood castabilityTransportation and packagingMixersThermal treatmentAluminium alloy

The invention discloses a formula and a smelting key technique for a high-strength and high-tenacity aluminum alloy. The high-strength and high-tenacity die-casting aluminum alloy has good casting performance, mechanical performance and thermal treatment performance, and also has high strength and tenacity, so that the mechanical performance of the aluminum alloy is good; recording of cicada chirping is placed in a metal fluid in the smelting key technique, so that characteristic sound vibration of cicada chirping can spread in the metal fluid; according to observation, sound vibration of cicada chirping can generate more scattering and dissipating in a spreading medium compared with sound vibration with more low-frequency components; and more ripples can be motivated on the surface of themetal fluid.

Owner:深圳市博锐专利新技术服务有限公司

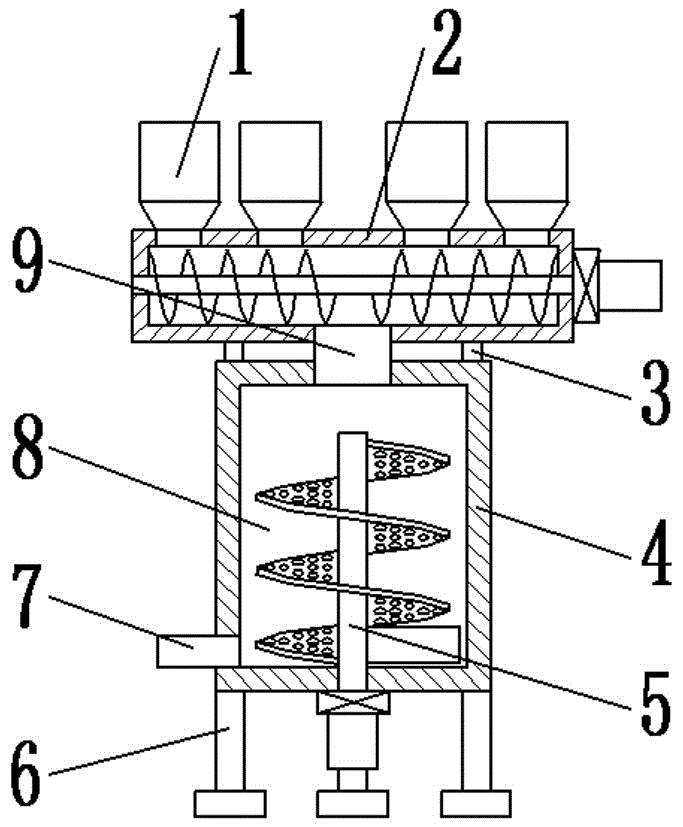

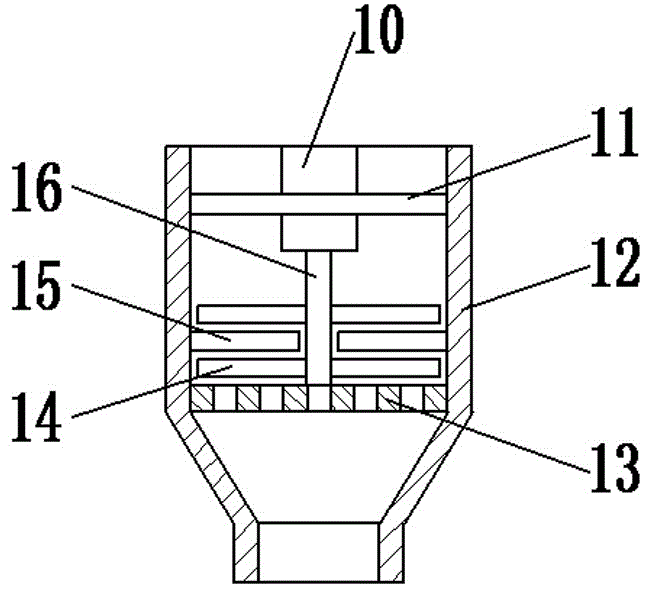

Feed mixing device for animal husbandry

The invention relates to a feed mixing device, in particular to a feed mixing device for animal husbandry. The feed mixing device for animal husbandry can conveniently stir and mix food and feed. In order to achieve the technical purpose, the feed mixing device for animal husbandry comprises a feeding box and the like. A stirring box is connected to the bottom of the feeding box, a stirring mechanism is connected into the stirring box, the right side of the stirring box is connected with a driving mechanism, a first through hole is formed in the bottom of the stirring box, the bottom of the stirring box is rotationally connected with a baffle, the baffle is located on the lower side of the first through hole, and the right side of the bottom of the baffle is connected with the bottom of the stirring box in a bolt connection mode. Firstly, the driving mechanism is arranged, it is achieved that the stirring mechanism is driven by the driving mechanism to stir and mix the food and the feed, and the effect of evenly stirring and mixing the food and the feed effectively and rapidly is achieved.

Owner:盐城市同俊精密机械制造有限公司

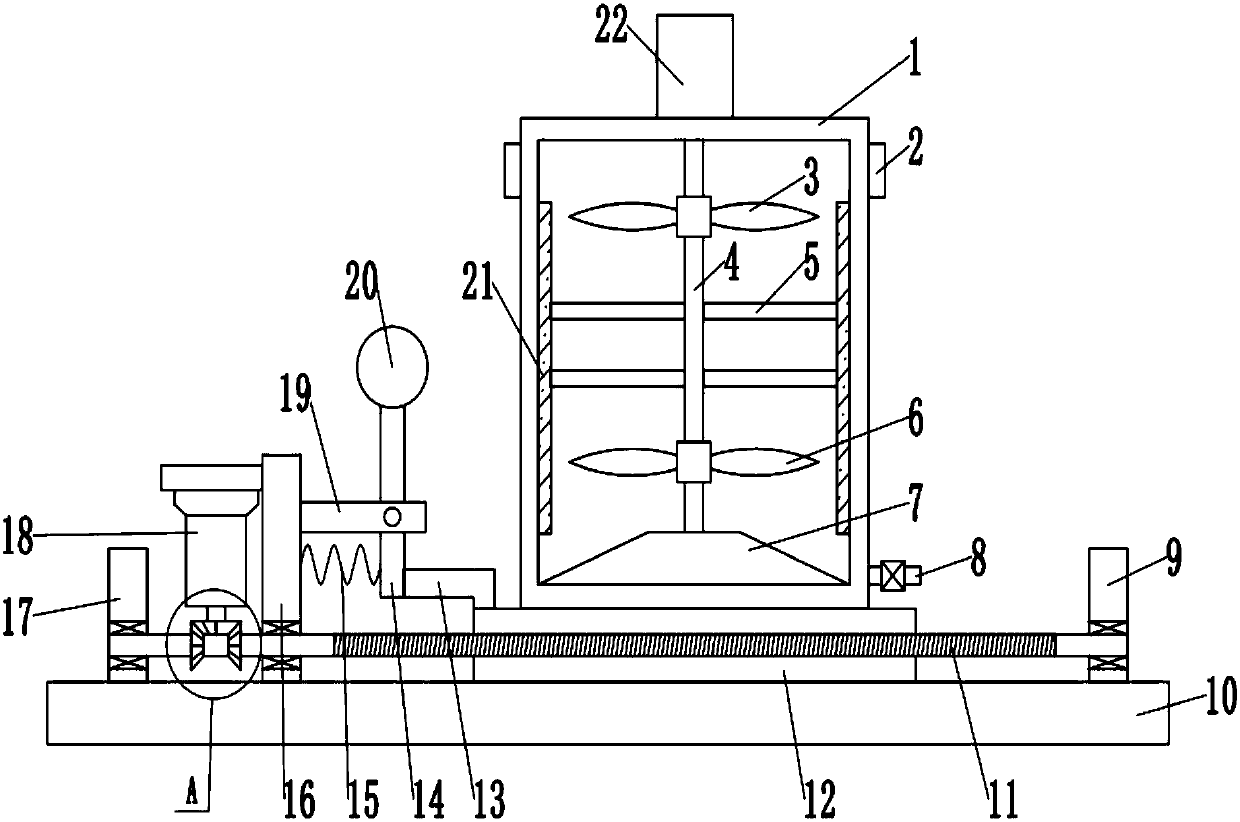

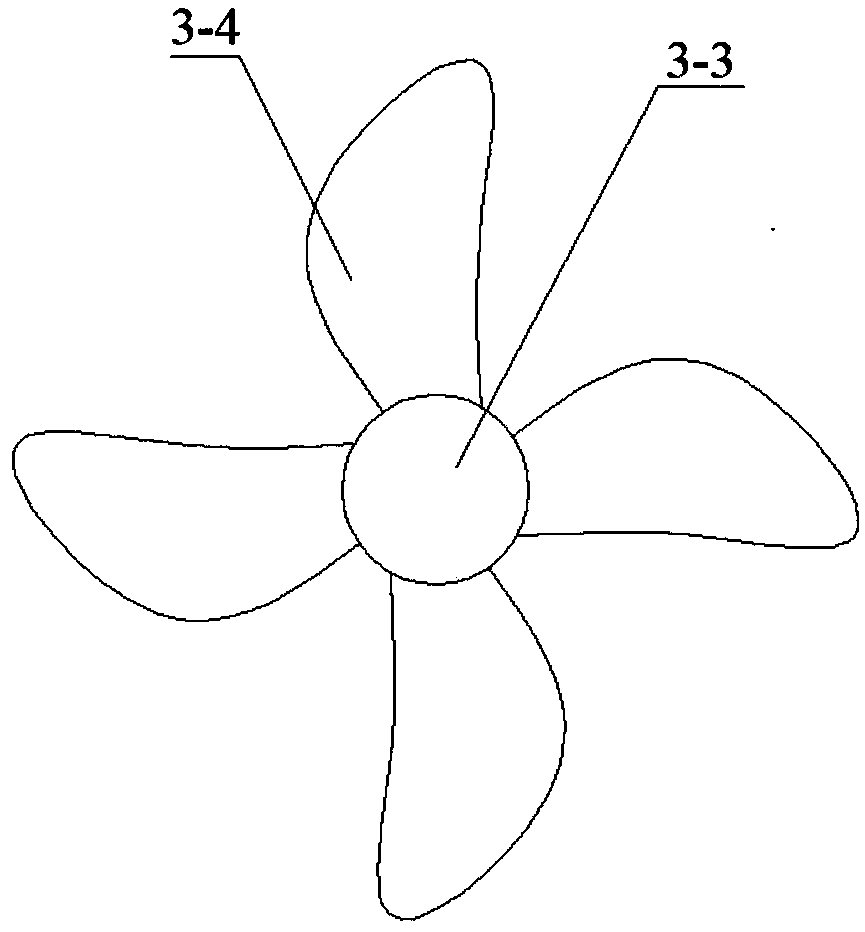

High-efficiency medicine mixing device provided with premixing device

InactiveCN106732125AImprove mix qualitySpeed up the mixingRotary stirring mixersTransportation and packagingRotational axisPropeller

The invention provides a high-efficiency medicine mixing device provided with a premixing device. The high-efficiency medicine mixing device comprises a mixing tank and the premixing device, wherein the mixing tank is internally provided with a mixing cavity; the top of the mixing tank is communicated with the premixing device by a connecting pipe; the bottom of the premixing device is fixedly connected with the mixing tank by a connecting column, and the premixing device consists of a premixing tank, a first motor and a rotating shaft; a plurality of mounting grooves are formed in the top of the premixing tank; the rotating shaft is provided with a first spiral propeller blade and a second spiral propeller blade; feeding devices are respectively arranged in the mounting grooves; the plurality of feeding devices are available, and each feeding device consists of a crushing tank, a crushing motor, a crushing rotary shaft, a fixed blade and a rotary blade; a stirring device is arranged in the mixing tank. According to the high-efficiency medicine mixing device, the first spiral propeller blade and the second spiral propeller blade are used for premixing medicines, and the premixed medicines are mixed again by using the stirring device, so that a subsequent production technology is smoothly carried out.

Owner:卿琦

Left-right-movement efficient mixing device for building coating

InactiveCN108031321AAvoid stickingSpeed up the mixingTransportation and packagingRotary stirring mixersArchitectural engineeringMixing effect

The invention discloses a left-right-movement efficient mixing device for a building coating. The left-right-movement efficient mixing device comprises a mixing barrel and a base, wherein the bottom of the mixing barrel is arranged on the upper surface of the base by a sliding block in a sliding manner; a rotating shaft is rotationally arranged inside the mixing barrel; first screw blades are fixedly arranged at the upper part of the rotating shaft; second screw blades are fixedly arranged at the lower part of the rotating shaft; stirring rods are fixedly arranged at the middle position of therotating shaft; a support is fixedly arranged on the left side of the base; the lower side of the support is rotationally connected with a screw; a rotating motor is fixedly arranged on the upper-left side of the support; a driving bevel gear is fixedly connected to the output end of the rotating motor and is of a semi-bevel gear structure; a first bevel gear and a second bevel gear are also symmetrically arranged on the screw. According to the left-right-movement efficient mixing device disclosed by the invention, by arranging the mixing barrel which can move leftwards and rightwards, the first screw blade, the second screw blade and the stirring rod, the coating in the barrel is quickly mixed, the mixing speed is increased and the mixing effect is improved.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

High-environment-friendliness industrial material mixing equipment

InactiveCN106621963AIncrease mixing speedReduce vibration effectsShaking/oscillating/vibrating mixersTransportation and packagingMixing tankPetroleum engineering

The invention relates to mixing equipment, in particular to high-environment-friendliness industrial material mixing equipment and aims to realize high mixing speed and mixing thoroughness of the high-environment-friendliness industrial material mixing equipment. The equipment comprises a first supporting frame, a rotating motor, a first gear, a bearing seat, a second gear, a first rotating shaft, an oscillating rod, an elastic part, a brush, a fixing plate, a second rotating shaft and the like. A left supporting rod and a right supporting rod are connected with a liquid receiving basin by means of adhesive connection, a mixing tank is connected to upper ends of the supporting rods by means of mortise joint, the bottom middle of the mixing tank is provided with a second through hole and an arc groove, and the diameter of the second through hole is smaller than that of the arc groove. The high-environment-friendliness industrial material mixing equipment has advantages of high mixing speed, thoroughness in mixing, simplicity in operation and simple structure.

Owner:刘德平

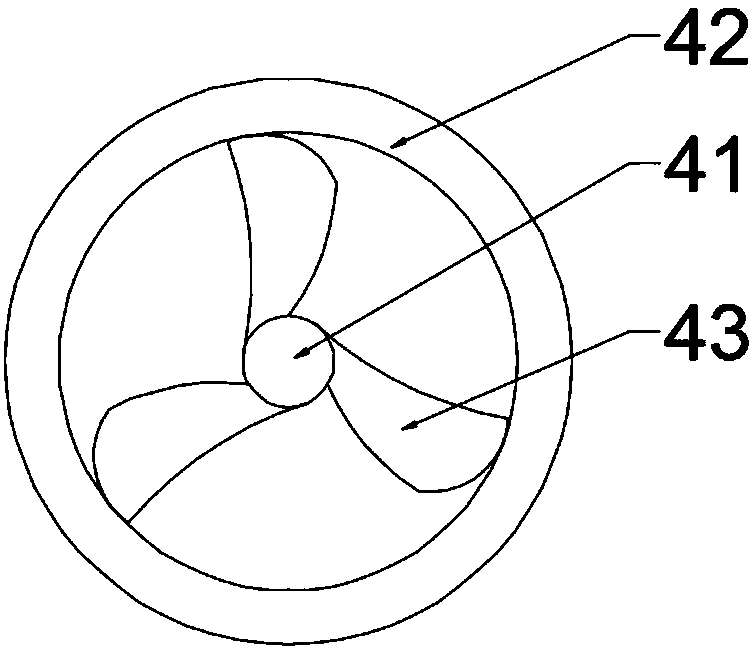

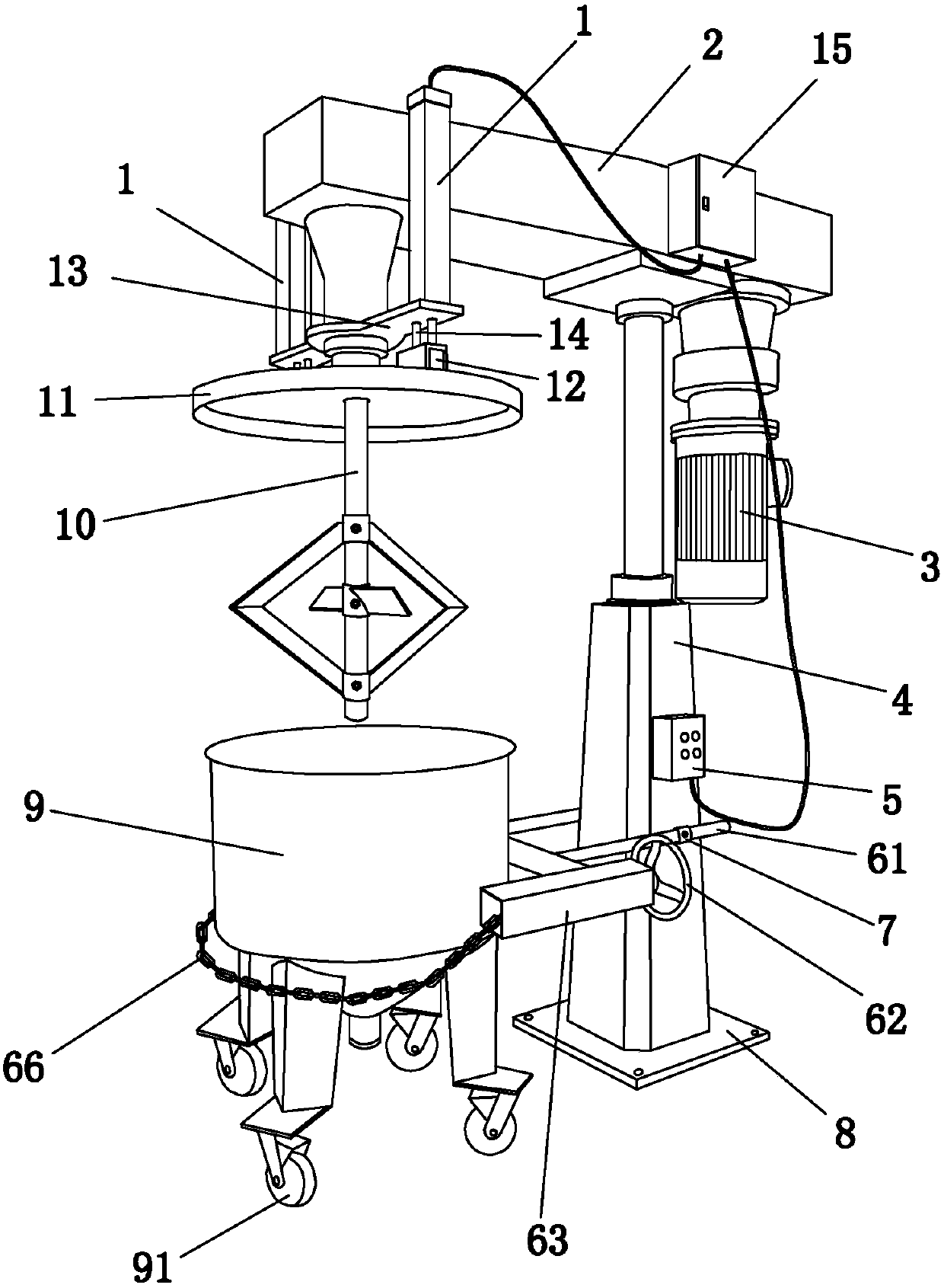

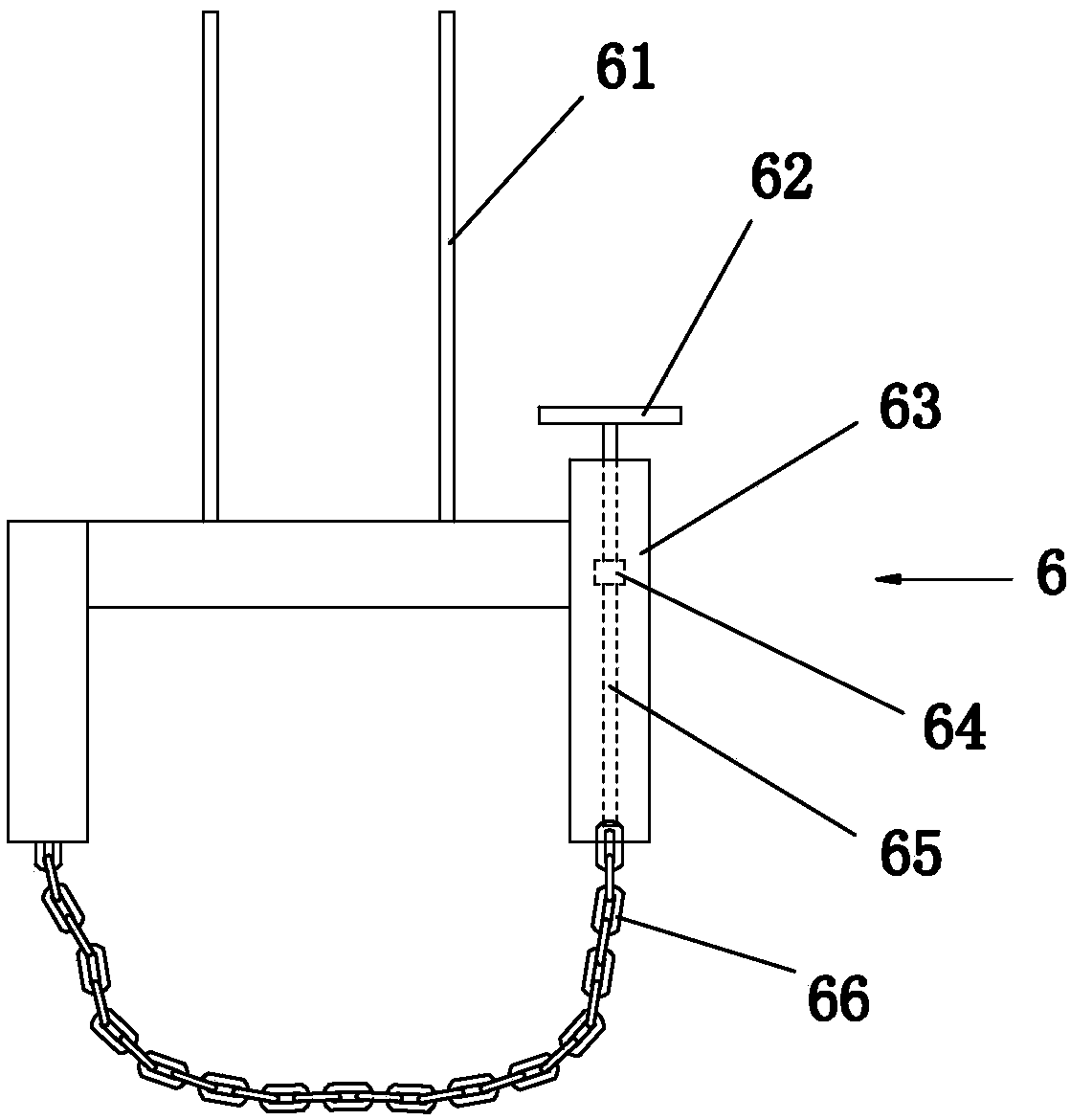

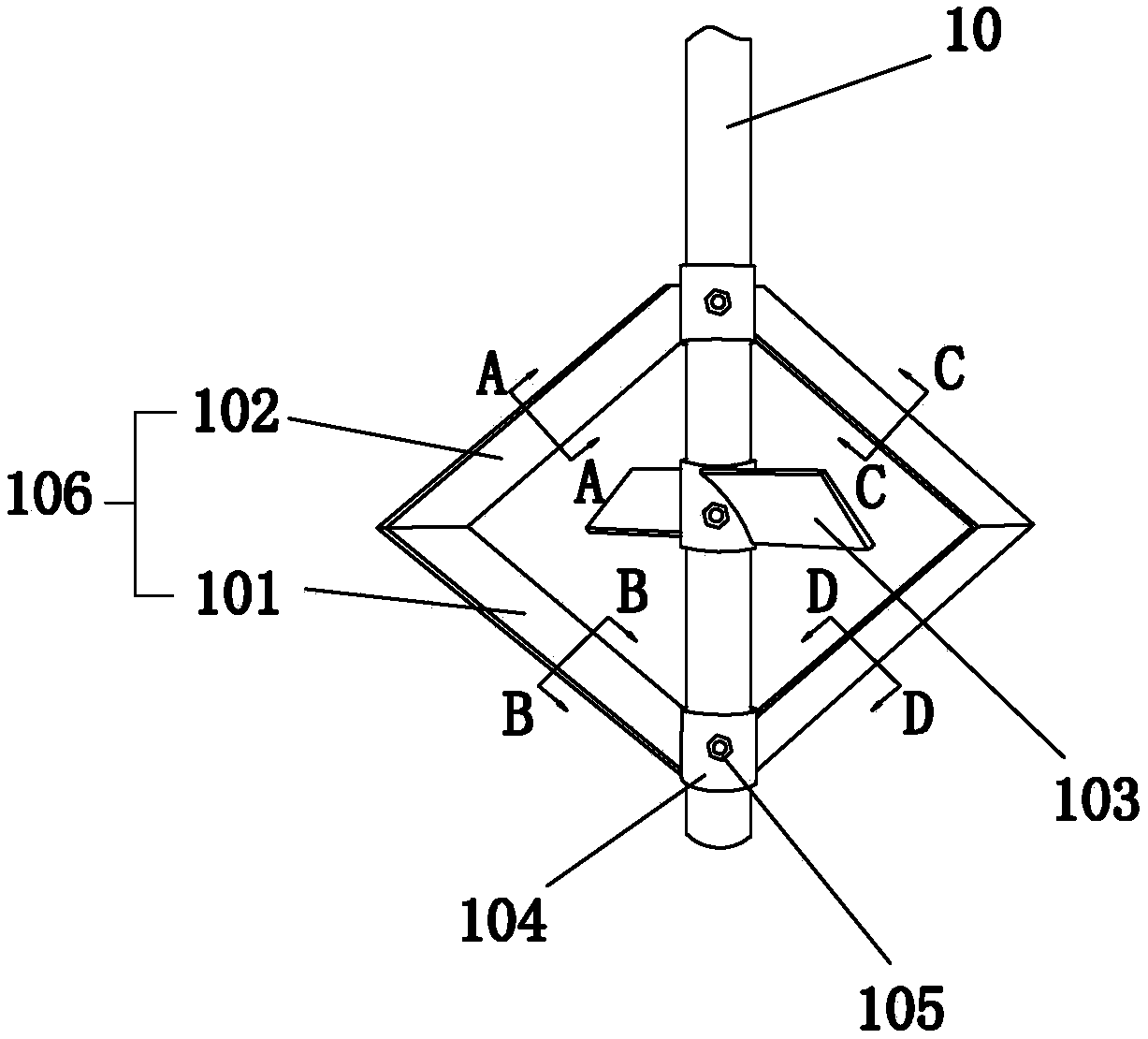

Efficient mixer

ActiveCN108014682ASpeed up the mixingEfficient mixingTransportation and packagingRotary stirring mixersPropellerPulp and paper industry

The invention discloses an efficient mixer. The efficient mixer comprises a mixer body, a stirring rod and a motor, wherein the stirring rod is installed on the mixer body vertically and downwards, the stirring rod is driven to rotate through the motor, and the motor is installed on the mixer body; the lower end, which is used for stirring, of the stirring rod is provided with at least two propeller blades and at least two bending-angle blades, each bending-angle blade includes an upper stirring plate and a lower stirring plate, and the upper stirring plates and lower stirring plates are correspondingly fixed on the outer wall of the stirring rod; outer ends of each upper stirring plate and the corresponding lower stirring plate are connected and form a bending angle, the propeller bladesare used for pressing a powdery material downwards, and the bending-angle blades are used for driving slurry to rotate. Through the efficient mixer, the material can be stirred better and faster.

Owner:GUANGZHOU RUXING TECH DEV +2

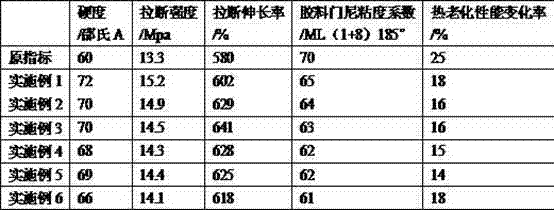

Radial tyre bladder and preparation method thereof

ActiveCN102731918AExtended service lifeImprove heat resistanceSpecial tyresPolymer scienceVulcanization

The invention discloses a radial tyre bladder and a preparation method of the radial tyre bladder, belonging to the technical fields of compositions of macromolecular compound and preparation methods. The radial tyre bladder comprises the following raw materials by weight: 90-110 parts of butyl rubber, 5-6 parts of chloroprene rubber, 4-6 parts of castor oil, 48-55 parts of carbon black, 0.7-1.5 parts of stearic acid, 0.4-0.8 parts of paraffin, 7-10 parts of resin, and 4-6 parts of zinc oxide. The method comprises the following steps: (a) preparing ingredients, mixing and filtering: mixing the semi-finished rubber and zinc oxide at 50-60 DEG C for 40-50 seconds, adding the resin and mixing for 60-70 seconds, adding other additives, raising the temperature to 150-160 DEG C, mixing for 7-8 minutes to obtain a mixture, and standing for 12-24 hours; (b) extruding to obtain slices and forming rubber strips; (c) vulcanizing and polishing, wherein the vulcanization temperature is 160-170 DEG C and a pressure-maintaining and temperature-preservation process is performed for 3-5 minutes. According to the technical scheme of the invention, the production efficiency is improved, the heat resistance of the rubber is increased, and the service life of the tyre bladder is prolonged.

Owner:浙江华和塑胶科技有限公司

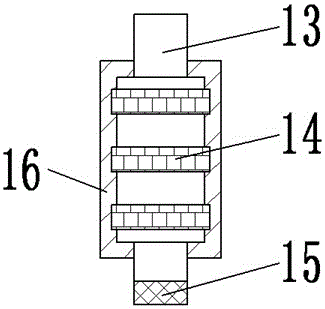

Lithium battery negative pole material stirring and mixing apparatus

InactiveCN106693822AEasy to pre-mixReduce falling speedTransportation and packagingMixer accessoriesEngineeringLithium battery

The invention provides a lithium battery negative pole material stirring and mixing apparatus. The lithium battery negative pole material stirring and mixing apparatus comprises a tank body, an upper cover, a material guide device, a first mixing device and a second mixing device, wherein a first mixing cavity is arranged in the tank body, and the upper cover is arranged at the opening on the top; a material guide tray, the material guide device and the first mixing device are arranged in the first mixing cavity; the material guide device is composed of a first motor, a material guide rotation shaft and a material guide plate; the first mixing device is composed of a second motor, a first mixing rotation shaft, a stirring blade and a stirring frame; two communicating pipes are symmetrically arranged on the bottom surface of the tank body; each communicating pipe is provided with a baffle plate, and the other end of the communicating pipe communicates with the second mixing device; and the second mixing device is composed of a material mixing pipe, a third motor, a second mixing rotation shaft, a first spiral material mixing plate and a second spiral material mixing plate. By arranging the two mixing devices, raw materials can be sufficiently mixed, thereby being beneficial to improving the mixing speed.

Owner:SHENZHEN JUOCAN TECH CO LTD

Flocculent precipitate treatment device for chemical engineering wastewater

InactiveCN106823891ASpeed up the mixingWell mixedTransportation and packagingRotary stirring mixersDrive wheelCompound (substance)

The invention discloses a flocculent precipitate treatment device for chemical engineering wastewater. The device comprises a stirring box. A filter screen divides an inner cavity of the stirring box into a purified water cavity and a precipitate cavity; a drain pipe is connected with the bottom end of the purified water cavity in a running-through manner; a stirring shaft is arranged in the precipitate cavity; a plurality of stirring rods are uniformly arranged on the stirring shaft; the bottom end of the stirring box is fixedly connected to a dirt box; a plurality of supporting legs are uniformly arranged at the bottom end of the stirring box; a motor is arranged on one of the supporting legs; a motor shaft of the motor is fixedly connected to a driving wheel; a flocculant box and a water inlet pipe are arranged on the top end of the precipitate cavity; and a plurality of communicating tubes are connected with the bottom end of the flocculant box in a running-through manner. According to the invention, the arranged stirring shaft stirs sewage to improve the mixing speed of the sewage and the flocculant, and the flocculant is uniformly scattered in the precipitate cavity everywhere through the plurality of communicating tubes, so that the flocculant is uniformly mixed with the sewage, and therefore, impurities in the sewage are fully coagulated to form blocks; the filter screen can effectively filter the coagulated blocks, so that the discharged sewage does not affect follow-up steps.

Owner:惠安县长智电子科技有限公司

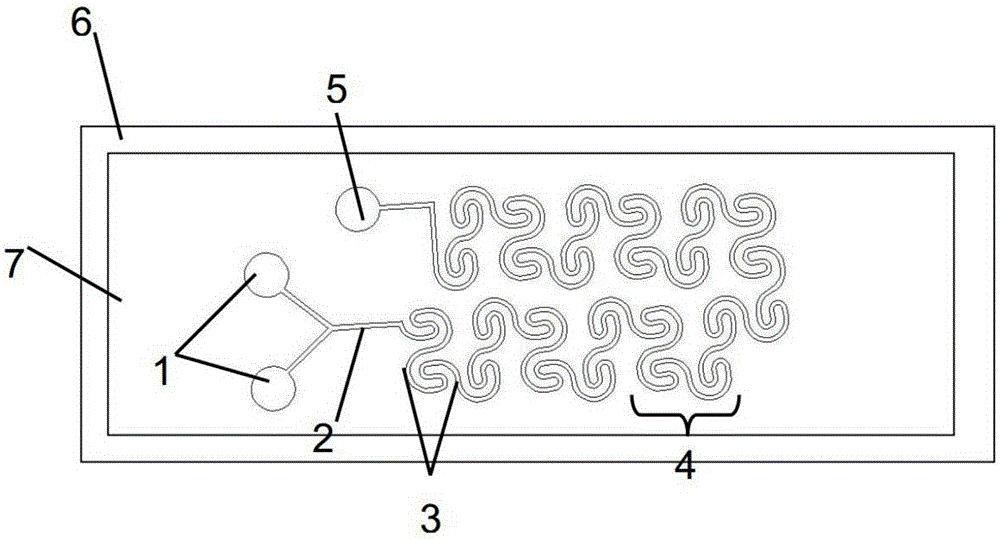

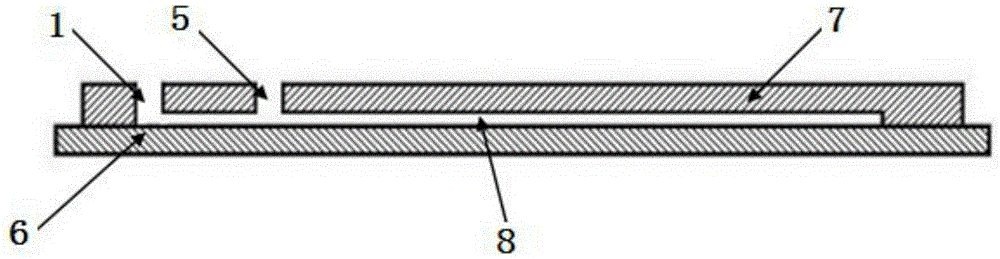

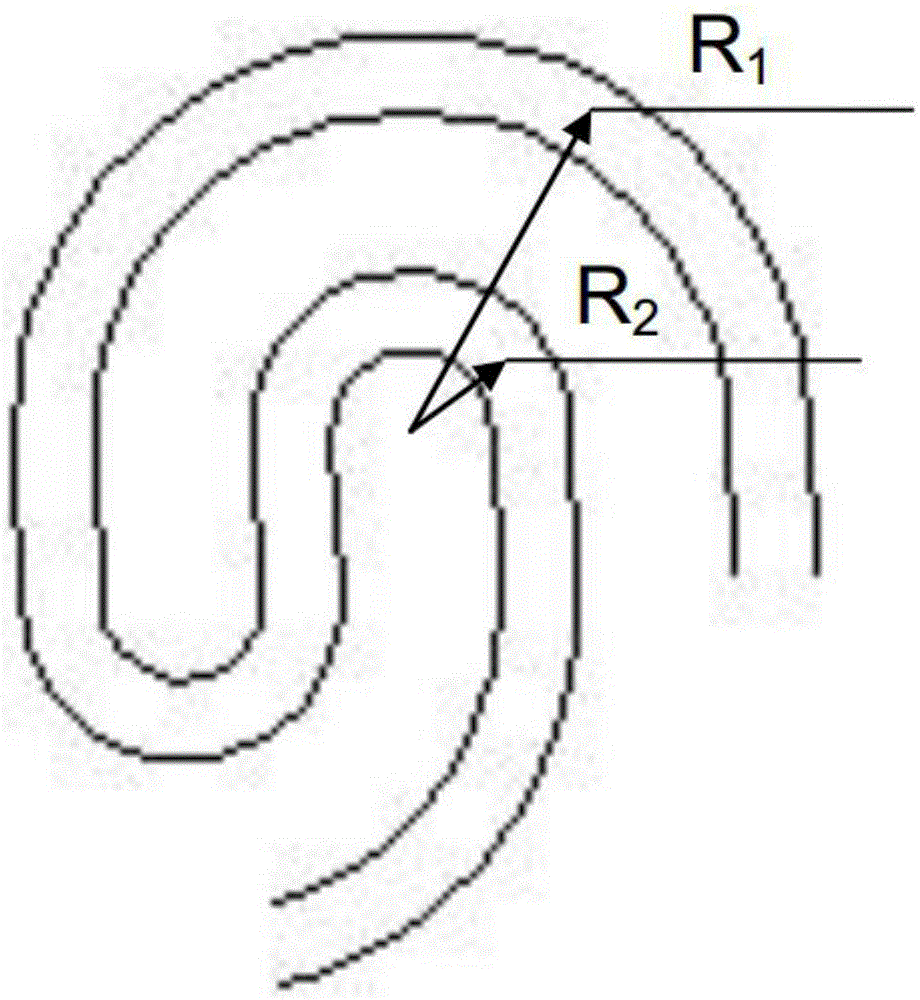

Distorted arc-shaped micro mixer based on enhanced secondary flow effect

The invention provides a distorted arc-shaped micro mixer based on an enhanced secondary flow effect. The micro mixer comprises a plurality of inlets, a mixing pipeline, an arc-shaped bend hybrid matrix and an outlet, wherein the inlets are communicated with one end of the arc-shaped bend hybrid matrix through the mixing pipeline, the other end of the arc-shaped bend hybrid matrix is communicated with the outlet, and the arc-shaped bend hybrid matrix comprises a plurality of arc-shaped bend mixing units which are sequentially communicated. Compared with a common S-type mixing pipeline, the mixing speed of the mixer is increased in a nonlinear mode along with mixing length increase.

Owner:SHANGHAI JIAO TONG UNIV

Fertilizer mixing machine for agriculture

InactiveCN107774177ASpeed up the mixingEasy to useRotating receptacle mixersTransportation and packagingAgricultural engineeringAgriculture

The invention relates to a mixing machine, and particularly relates to a fertilizer mixing machine for agriculture. The technical problem to be solved by the invention is to provide an agricultural fertilizer mixing machine which can save time and labor, can increase the mixing speed, is convenient to use, and is simple to operate. In order to solve the technical problem, the invention provides the fertilizer mixing machine for agriculture. The mixing machine comprises a base; the middle of the top of the base is vertically connected with two supporting rods through bolts, wherein the two supporting rods are symmetrically arranged on the left side and the right side; a mixing box is connected between the top ends of the two supporting rods; the top of the mixing box is opened; a discharging opening is formed in the bottom of the mixing box; a blocking block is arranged at the discharging opening; a supporting plate is vertically connected to the top of the base on the left side of themixing box; a top plate is horizontally connected to the top of the supporting plate; and a mixing device and a driving device are arranged at the bottom of the top plate. According to the invention,the driving device can drive the mixing device, a rotating device and a cooling device to work at the same time, so that the effect of improving the mixing speed can be achieved.

Owner:深圳诺智研机械研究设计有限公司

Gas mixing device

InactiveCN106568638AWell mixedSpeed up the mixingFlow mixersTransportation and packagingProcess engineeringAir compressor

The invention relates to a gas mixing device including an air compressor having a gas inlet and a gas outlet; the gas mixing device also includes a first gas storage tank and a second gas storage tank for storing mixed gas; the first gas storage tank is connected with the gas inlet of the air compressor through a first pipeline; the second gas storage tank is connected with the gas inlet of the air compressor through a second pipeline; the first gas storage tank communicates with the gas outlet of the air compressor through a third pipeline; the second gas storage tank communicates with the gas outlet of the air compressor through a fourth pipeline; a first control valve, a second control valve, a third control valve and a fourth control valve for controlling on-off of the corresponding pipelines are correspondingly arranged on the first pipeline, the second pipeline, the third pipeline and the fourth pipeline; the air compressor pumps gas in the first gas storage tank into the second gas storage tank through the first pipeline and the fourth pipeline and pumps gas in the second gas storage tank into the first gas storage tank through the second pipeline and the third pipeline. The gases in the two gas storage tanks are circulated by the air compressor, the mixing speed of the mixed gas can be effectively accelerated, and the mixing requirement is achieved in a short time without long-term standing.

Owner:PINGGAO GRP +4

Blast-injecting forced-advancing full pre-mixing energy-saving combustor

The invention provides a blast-injecting forced-advancing full pre-mixing energy-saving combustor which comprises a main cavity, a blast pipe, a fuel gas pipe, a nozzle, a fire distributor and a firing needle, wherein the blast pipe and the fuel gas pipe are connected with the main cavity; the nozzle is connected with the fuel gas pipe; and the fire distributor and the firing needle are arranged at the top of the main cavity. The blast-injecting forced-advancing full pre-mixing energy-saving combustor is characterized in that a screen, a flow fixer and a gas flow mixer are sequentially arranged between the fire distributor and the nozzle in the main cavity; the caliber of the gas outlet end of the flow fixer is smaller than the caliber of a gas inlet end of the flow fixer; the flow mixer is a cylinder of which the diameter corresponds to the internal diameter of the main cavity; and a plurality of gas mixing holes are arranged vertically along the cylinder and the calibers of all gas outlet ends of the gas mixing holes are smaller than the calibers of all gas inlet ends of the gas mixing holes. By adopting the structure, the effects of the high efficiency, the energy conservation and the environment protection are achieved.

Owner:何梅顺

Solid liquid mixing device for preparing superfine slurry

PendingCN108355569APrevent flutteringEasy to flyTransportation and packagingMixer accessoriesSlurrySolid particle

The invention discloses a solid liquid mixing device for preparing superfine slurry. The solid liquid mixing device comprises a liquid mixing feeding device, a solid pulverizing feeding device, a primary solid liquid mixing device, a conveying pump, a secondary solid liquid mixing device, a material return pipe and the like, wherein a pulverizing device performs primary pulverizing on solid particles, so that the mixing speed is accelerated; through the arrangement of a baffle plate and a blast blower, the solid particles are prevented from flying into air; a stirring paddle is arranged into aspiral paddle shape, so that mixed materials can be easily driven to rotate in an advancing way; a screen mesh type framework is arranged at the periphery of a tube body, so that the solid particlescan conveniently go in or out; the mixing speed is accelerated; an included angle of a stirring blade and a stirring shaft forms a certain angle, so that the pulverizing and mixing effects are reinforced. The solid liquid mixing device disclosed by the invention has the advantages that the air dust pollution cannot be caused; the mixing efficiency is high; the mixing speed is high; the continuousoperation can be realized; the goal of preparing the superfine slurry through solid liquid mixing can be fast and efficiently achieved.

Owner:SUZHOU SUNMUN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com