Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

A technology of negative electrode material and mixing equipment, applied in mixers with rotary stirring devices, mixers, dispersing particle filtration, etc., can solve the problems of destroying the production environment, adversely affecting high-quality products, affecting the ratio of raw materials, and achieving uniform mixing of raw materials , improve quality, improve the effect of mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

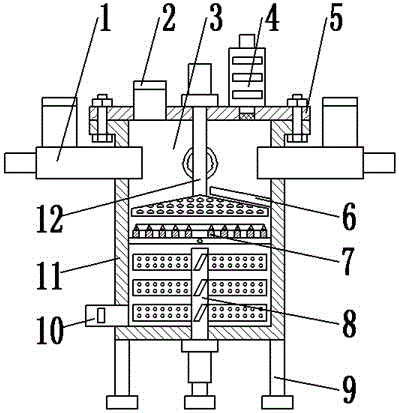

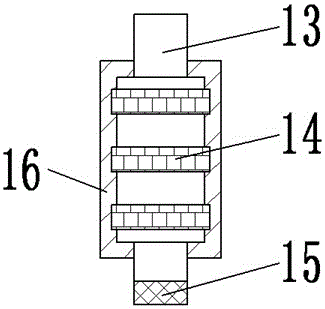

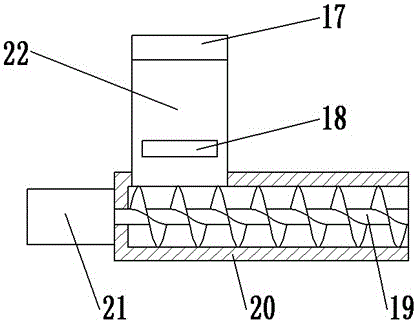

[0022] see Figure 1-6 , a lithium battery negative electrode material mixing device that prevents dust and can remove impurities, including a tank body 11 and a top cover 5; the tank body 11 is set as a hollow cylinder, and the inside is set as a mixing chamber 3, and a top cover is set at the top opening 5; the upper cover 5 is fixedly connected with the tank body 11 through the mutual screwing of bolts and nuts, and the joint is provided with a sealing gasket; the upper cover 5 and the tank body 11 are both made of stainless steel; the upper cover 5 is provided with auxiliary Feeding pipe 2 and filtering device 4; the auxiliary feeding pipe 2 is arranged on the left side of the upper cover 5, and the opening of the auxiliary feeding pipe 2 is provided with a cover plate; the filtering device 4 is arranged on the right side of the upper cover 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com