Patents

Literature

46916 results about "Lithium battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium batteries are primary batteries that have metallic lithium as an anode. These types of batteries are also referred to as lithium-metal batteries. They stand apart from other batteries in their high charge density (long life) and high cost per unit. Depending on the design and chemical compounds used, lithium cells can produce voltages from 1.5 V (comparable to a zinc–carbon or alkaline battery) to about 3.7 V.

Battery management system for control of lithium power cells

ActiveUS9099877B2Provide reliablyEnhanced and improved operatingCharge equalisation circuitCircuit monitoring/indicationRechargeable cellEngineering

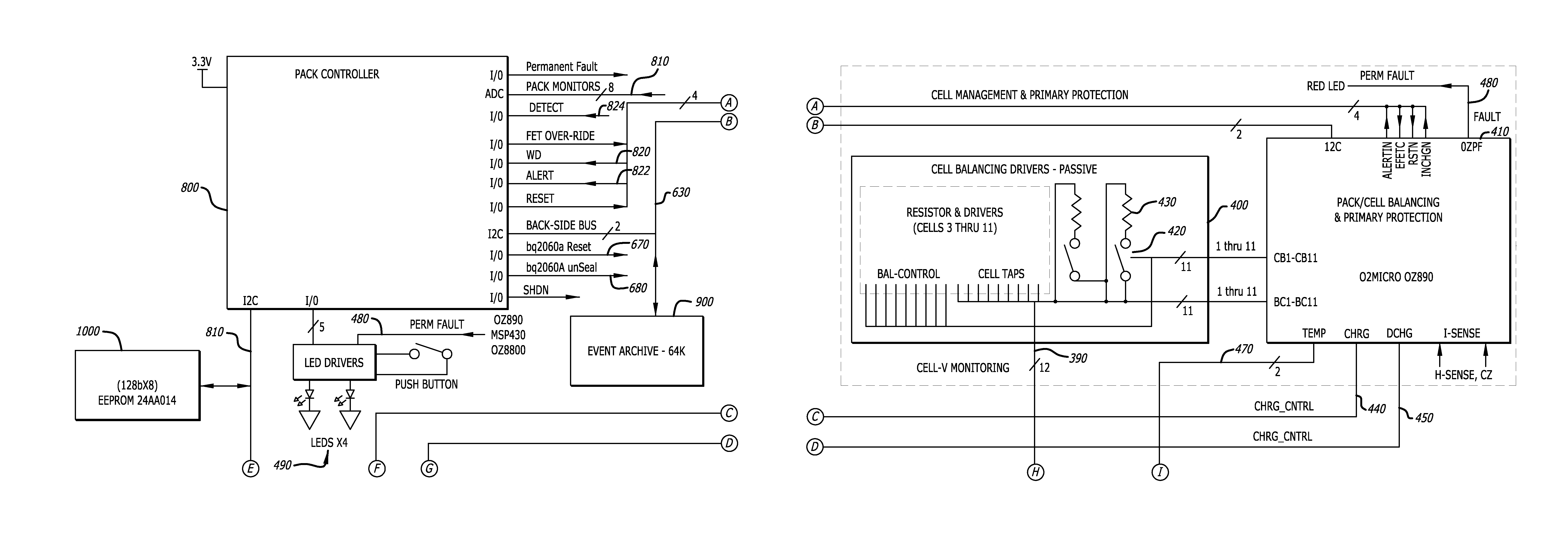

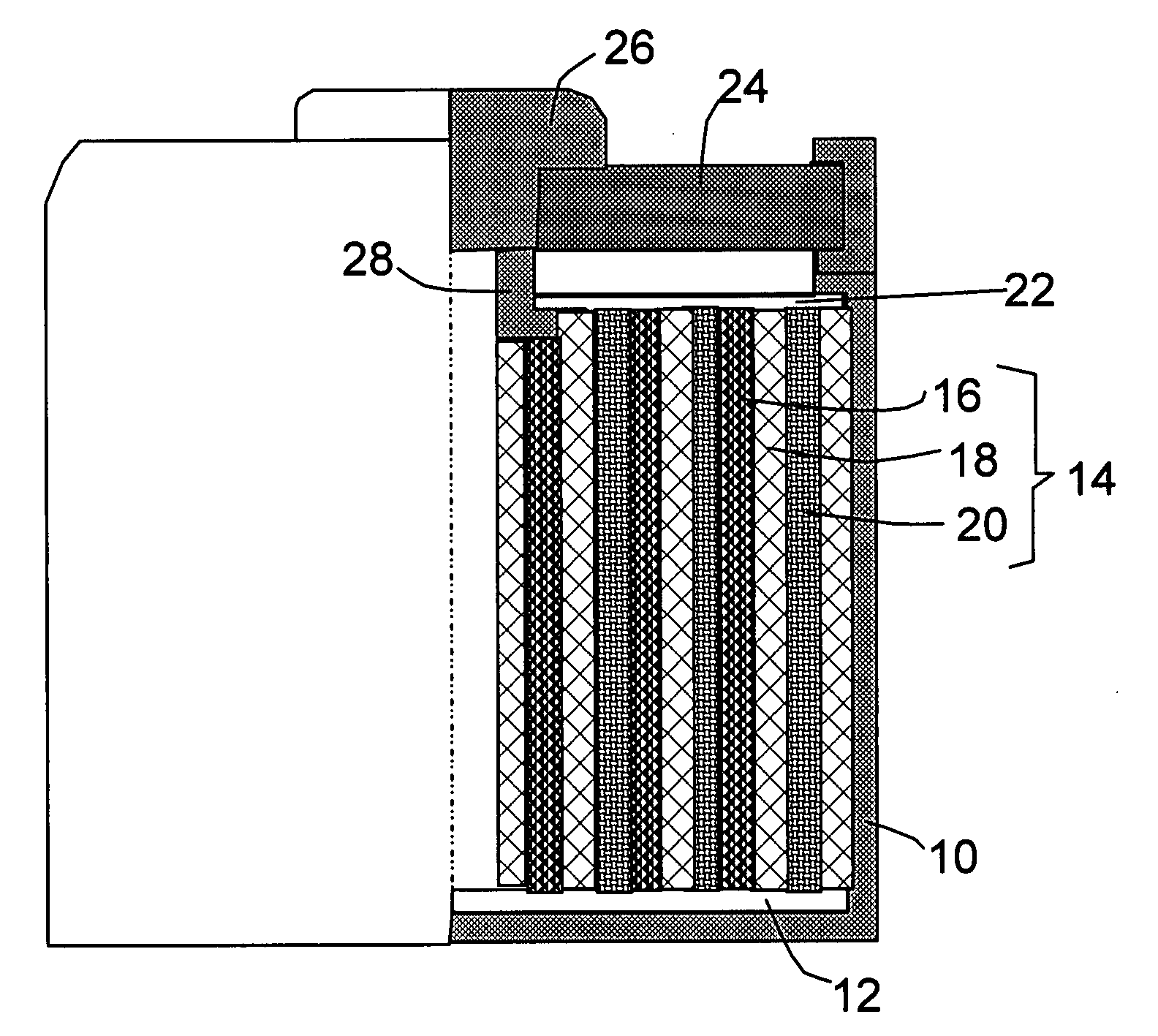

An intelligent rechargeable battery pack having a battery management system for monitoring and controlling the charging and discharging of the battery pack is described. The battery management system includes primary and secondary protection circuits for monitoring the charging and discharging of the battery. Individual battery cells forming the battery pack are connected by a main bus to a connector for connection to a battery charger or a device to be powered, and the main bus may be interrupted by a switch controlled by the battery management system to prevent damage to the battery during charging or discharging of the battery.

Owner:ZOLL CIRCULATION

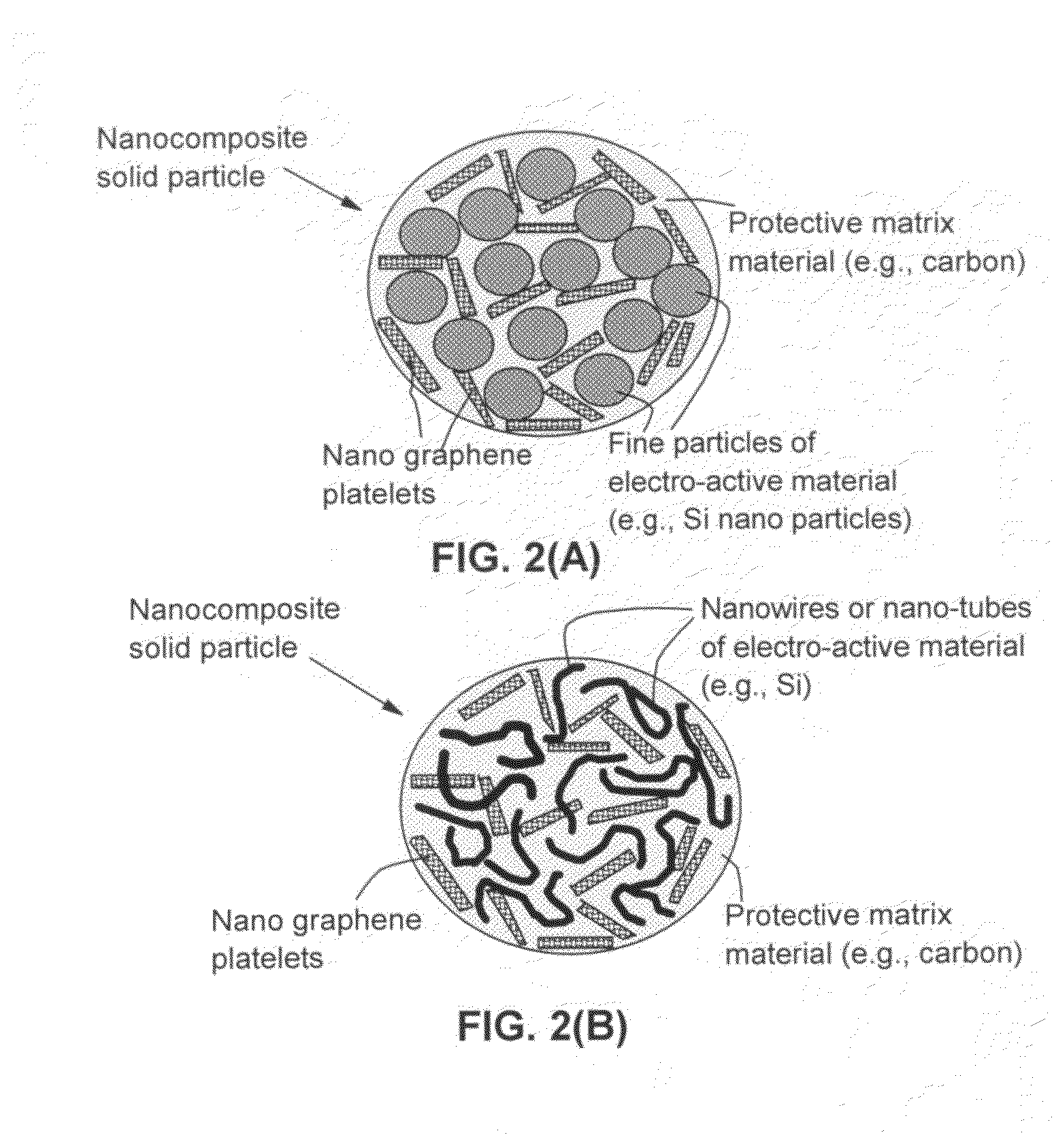

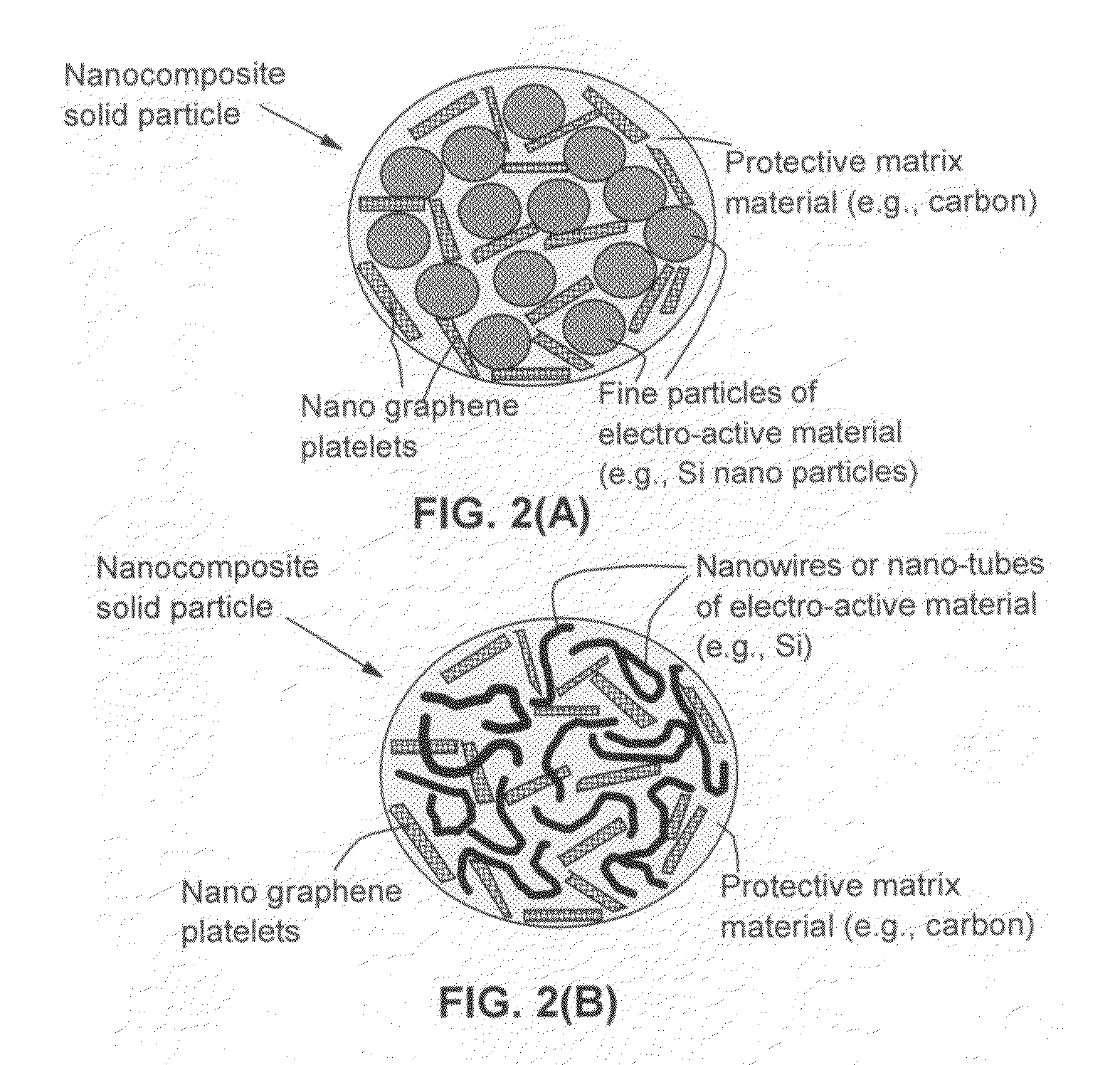

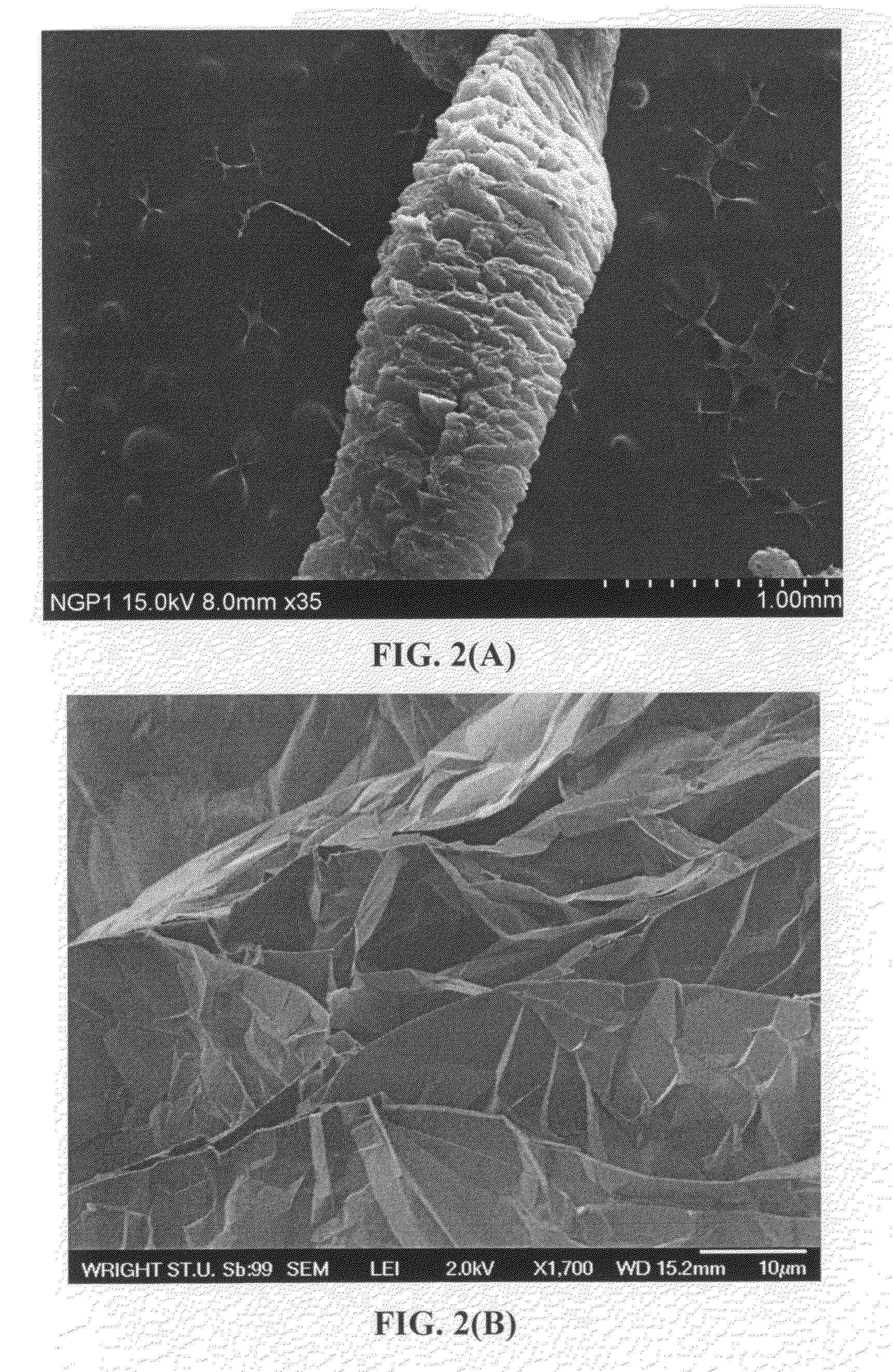

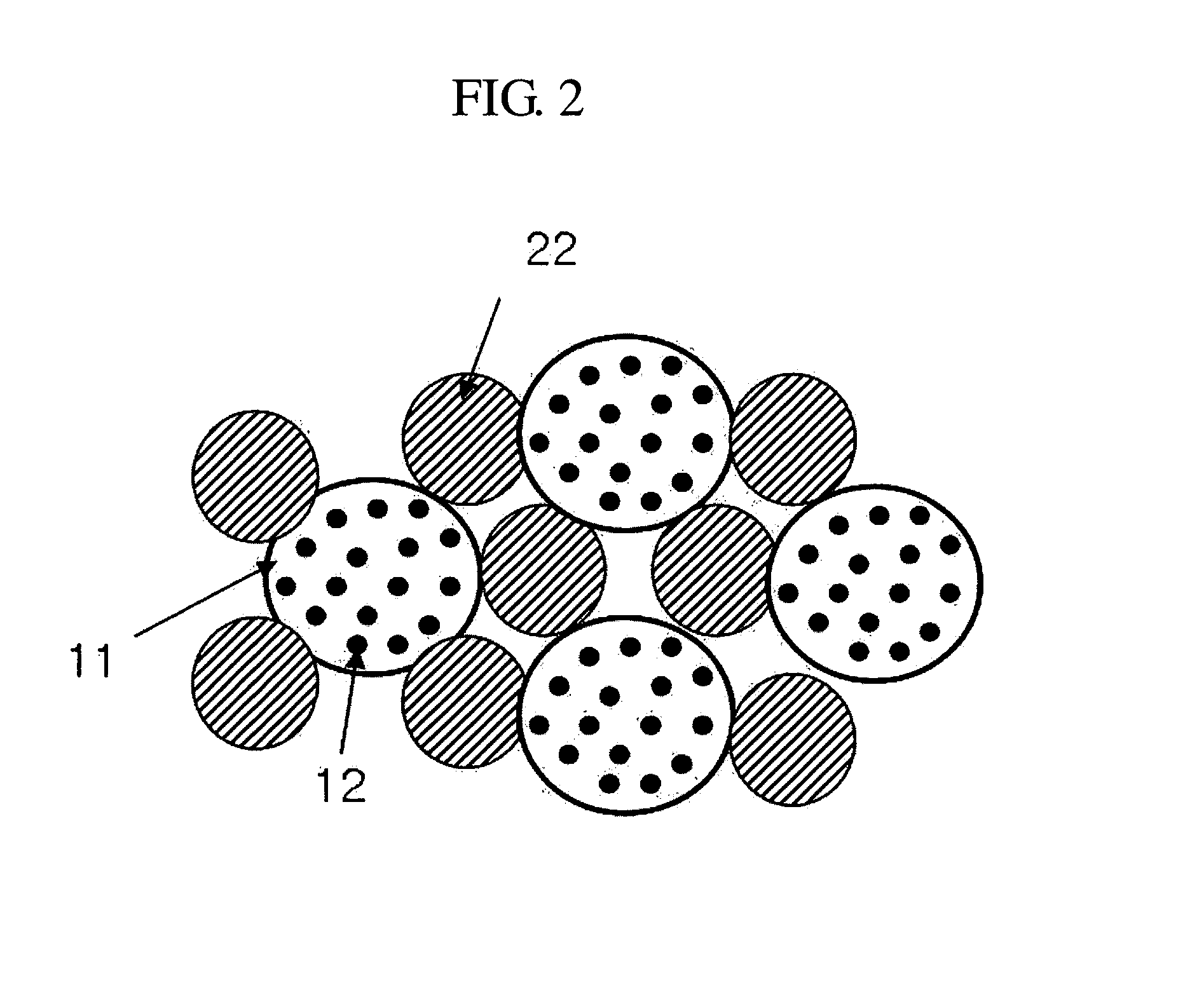

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

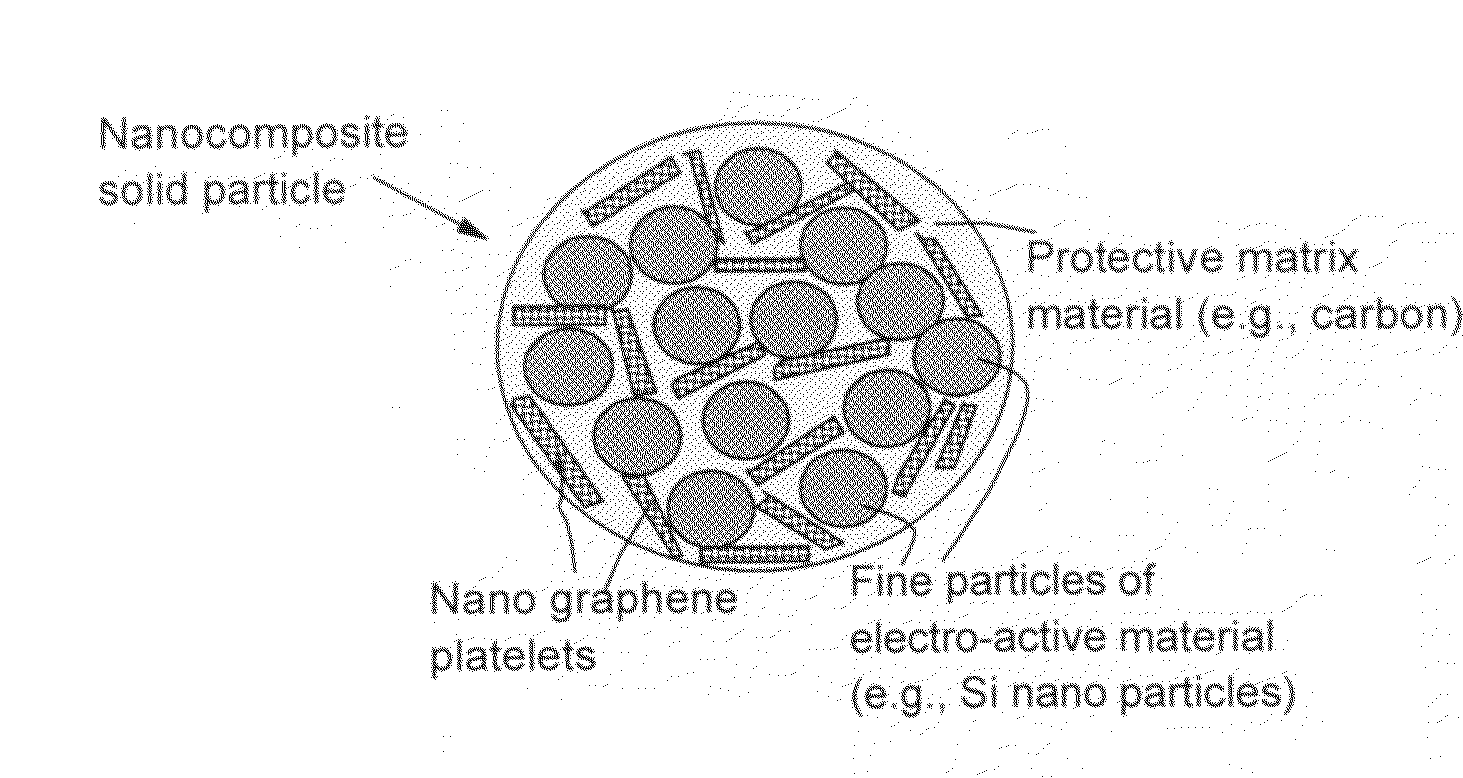

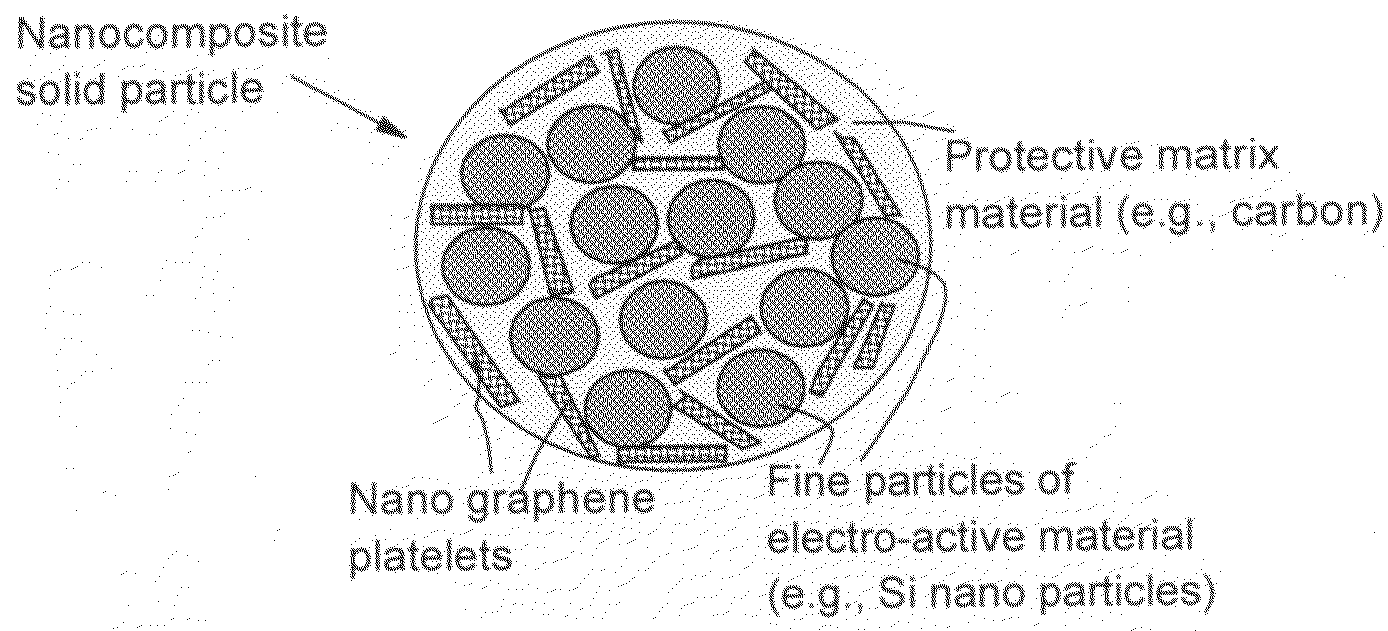

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

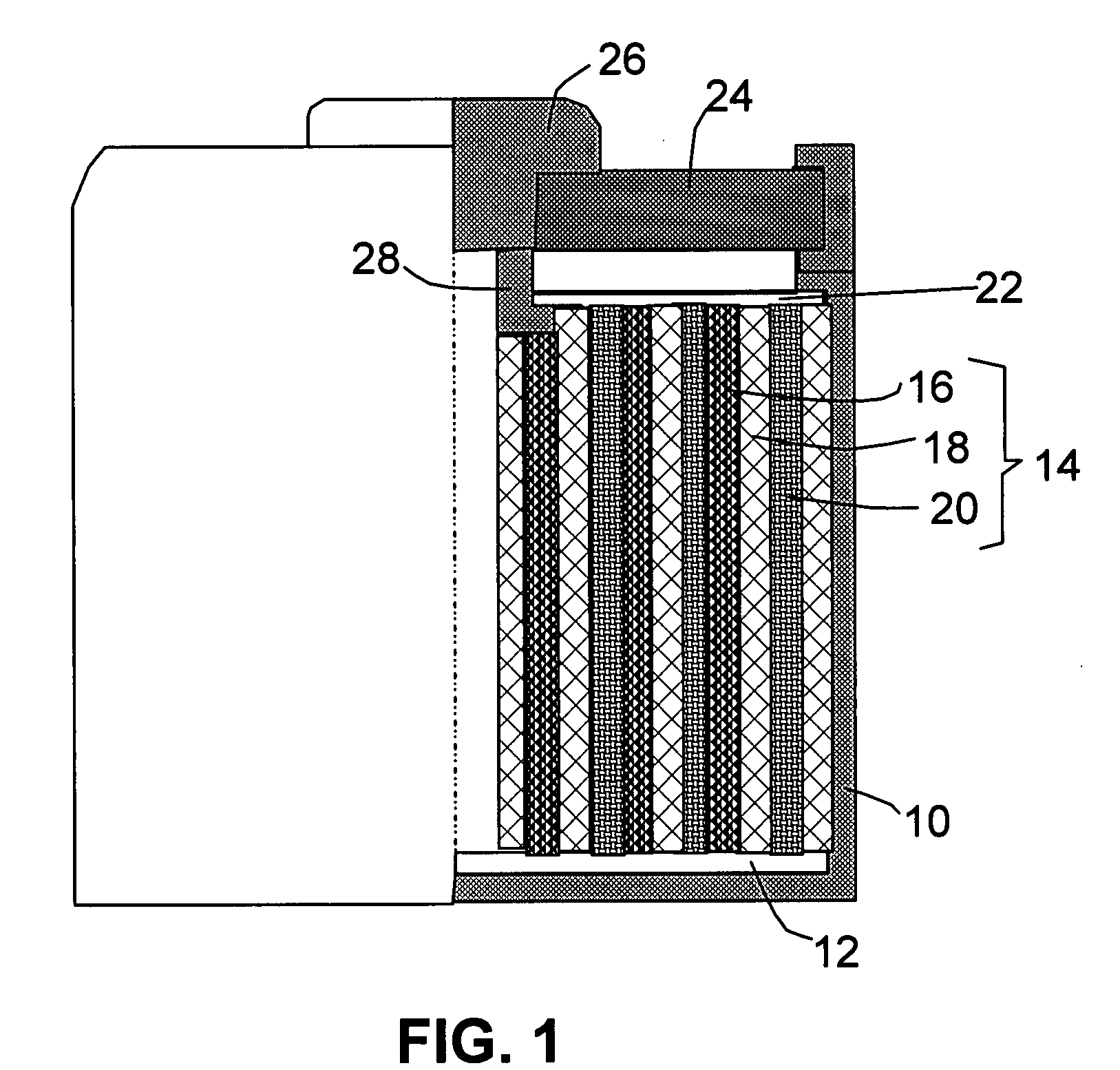

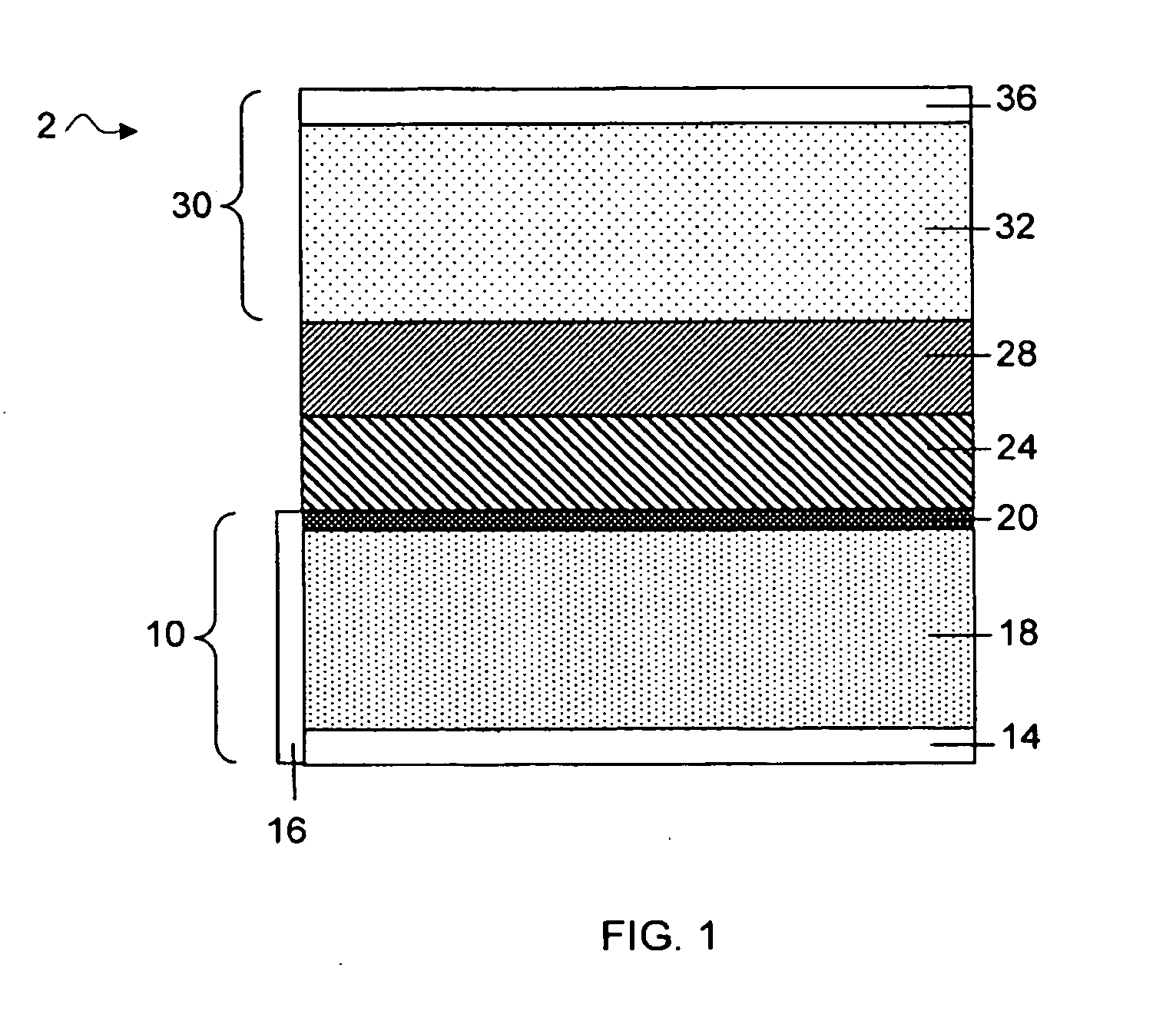

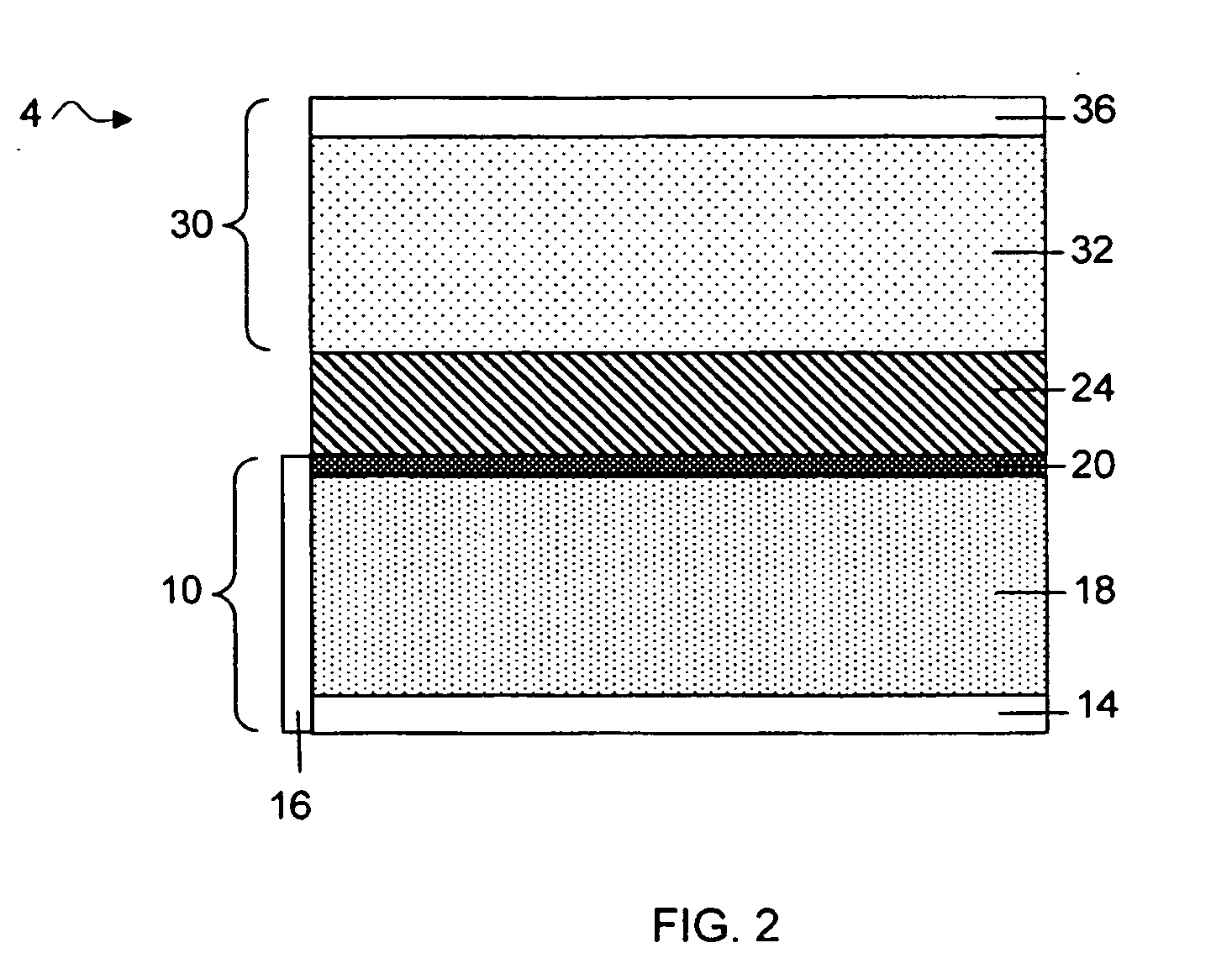

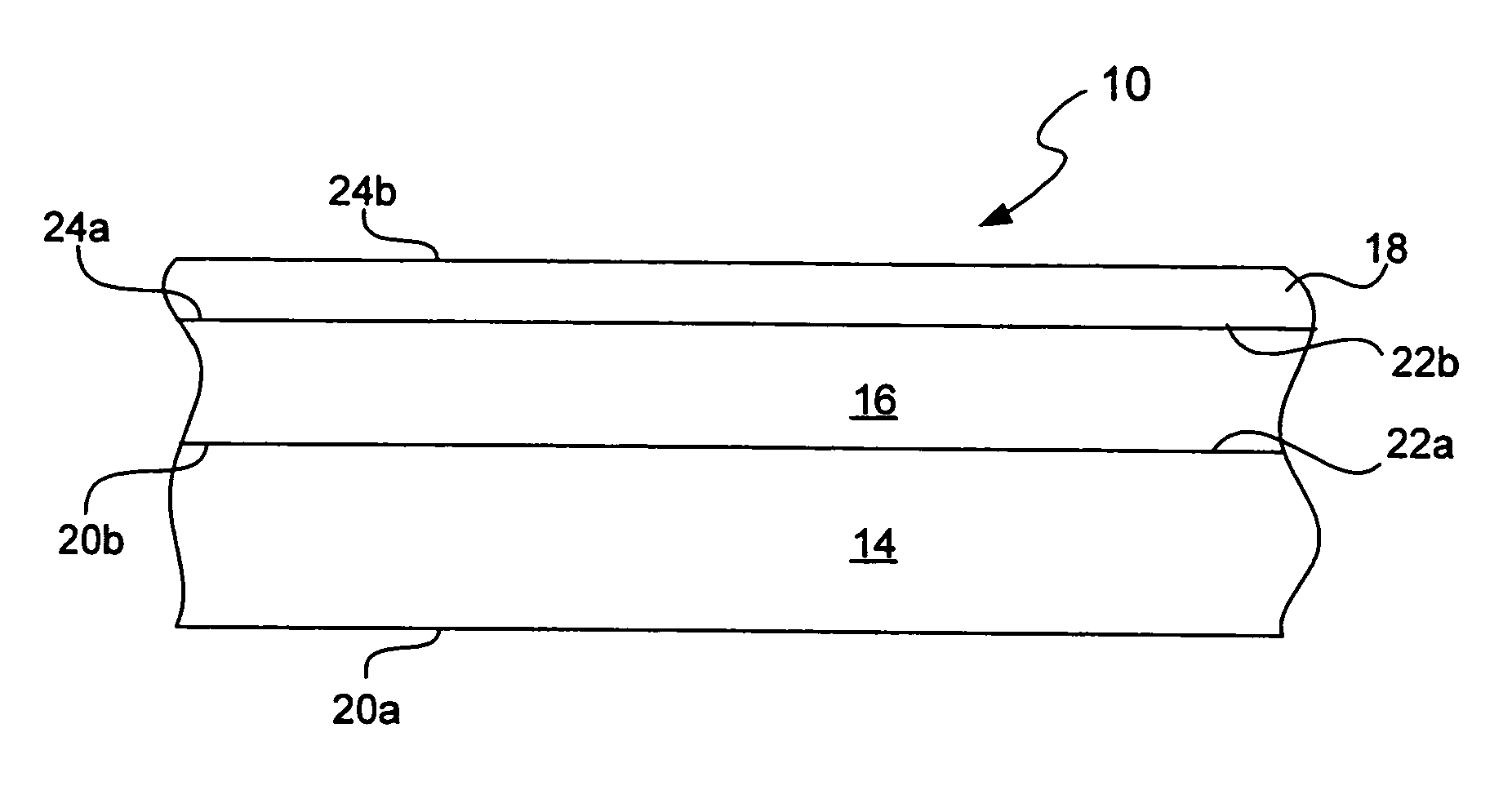

Separator for a high energy rechargeable lithium battery

InactiveUS6432586B1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesCeramic compositeMetallurgy

The instant invention is directed to a separator for a high energy rechargeable lithium battery and the corresponding battery. The separator includes a ceramic composite layer and a polymeric microporous layer. The ceramic layers includes a mixture of inorganic particles and a matrix material. The ceramic layer is adapted, at least, to block dendrite growth and to prevent electronic shorting. The polymeric layer is adapted, at least, to block ionic flow between the anode and the cathode in the event of thermal runaway.

Owner:CELGARD LLC

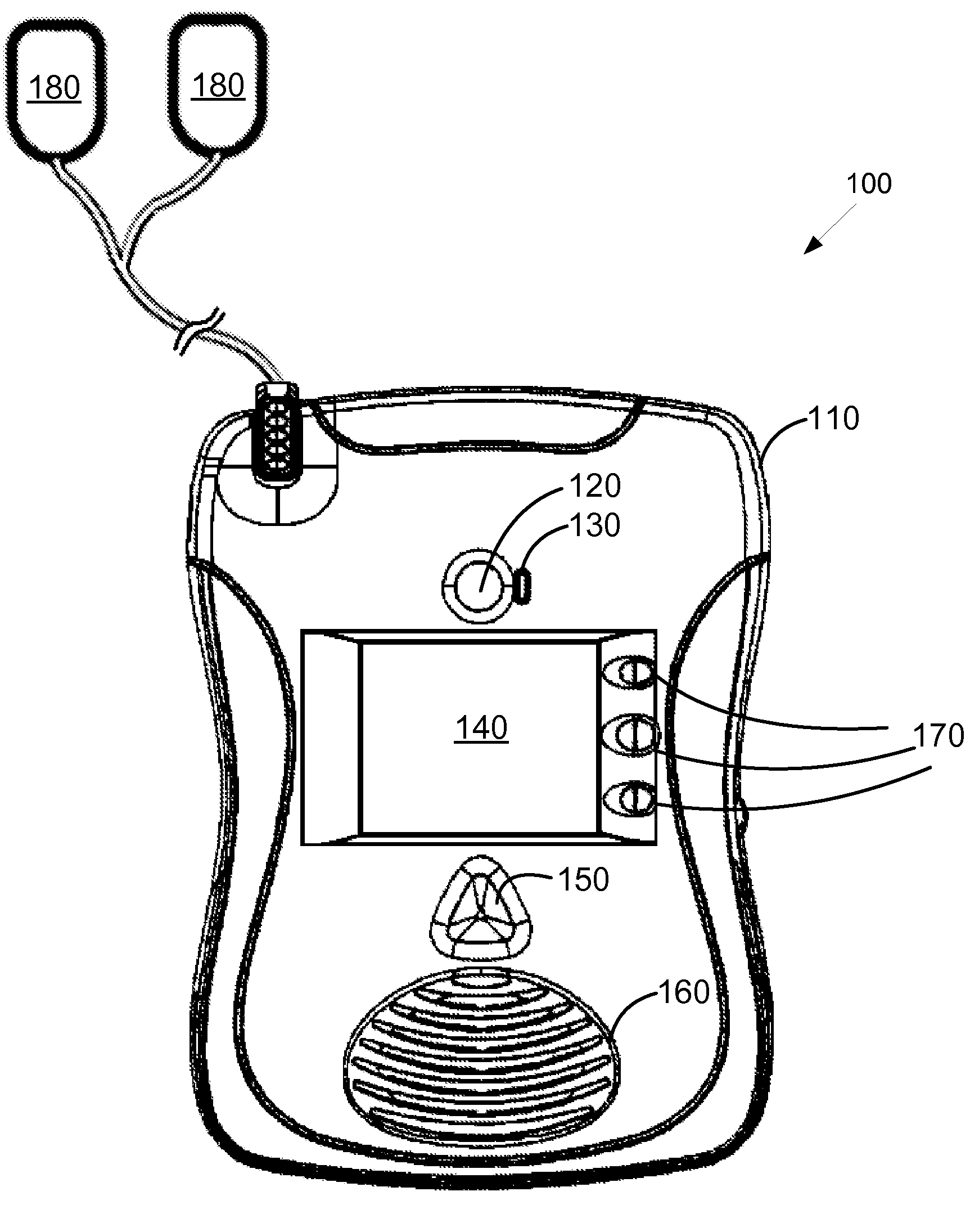

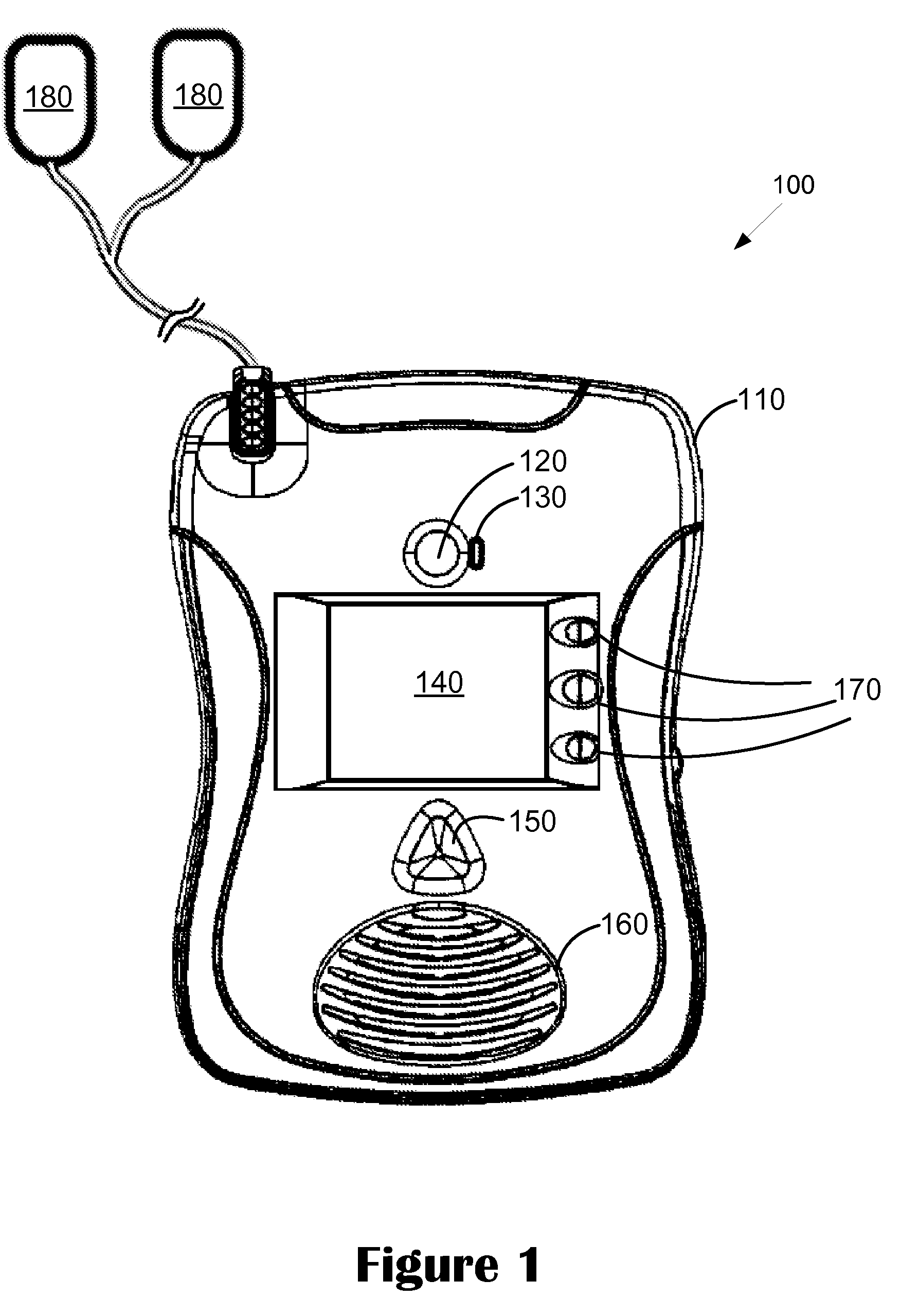

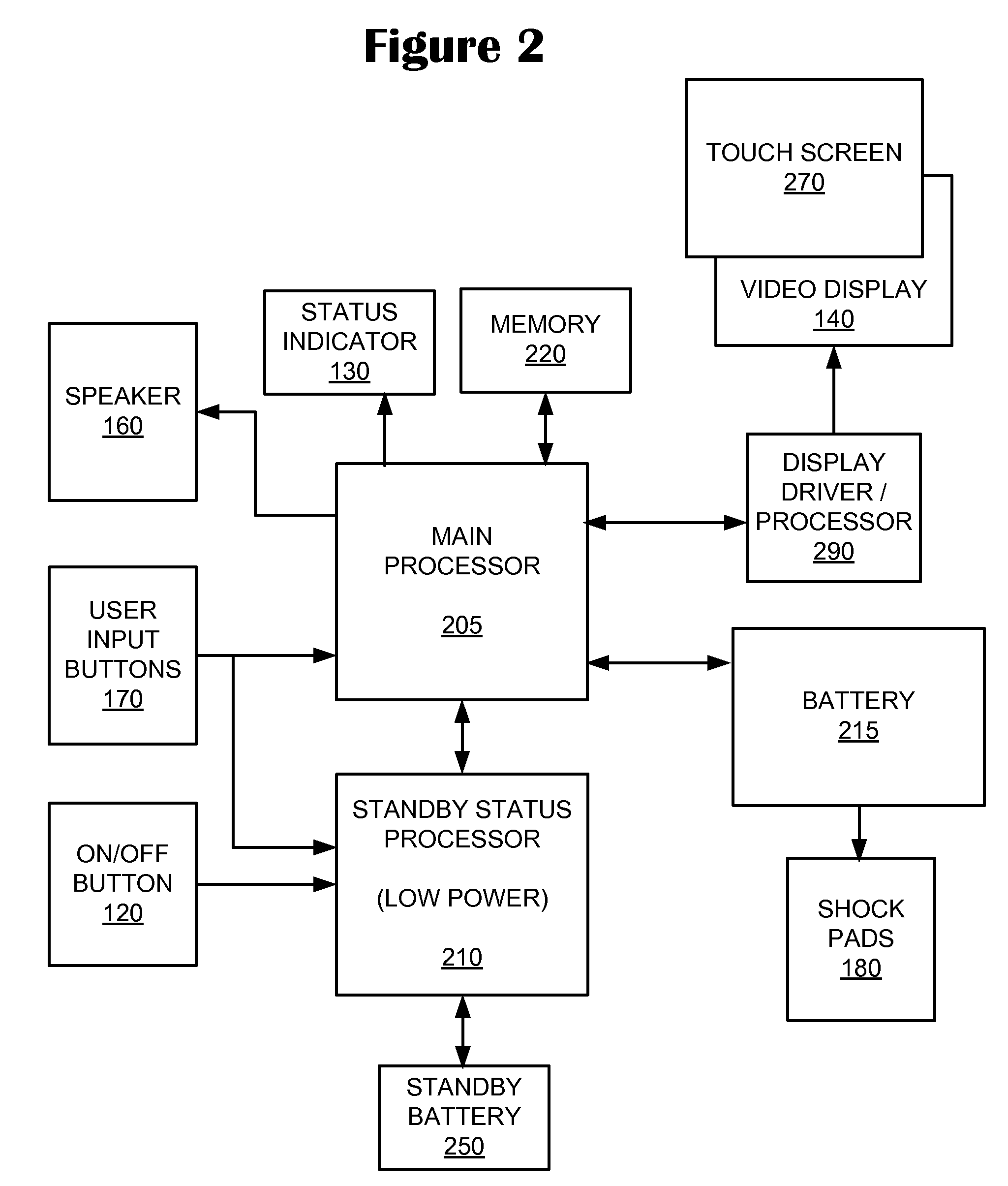

System and Method for Conditioning a Lithium Battery in an Automatic External Defibrillator

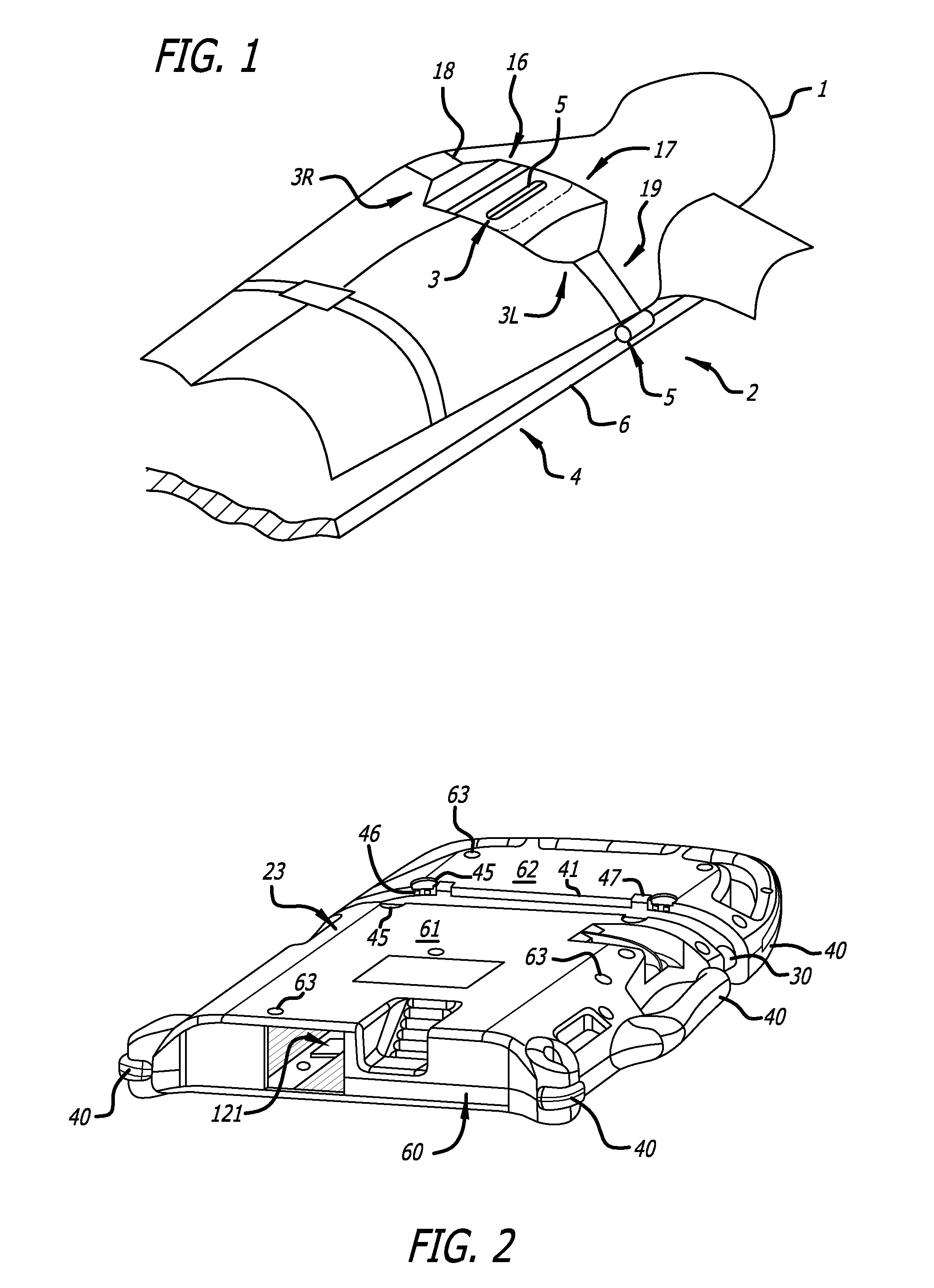

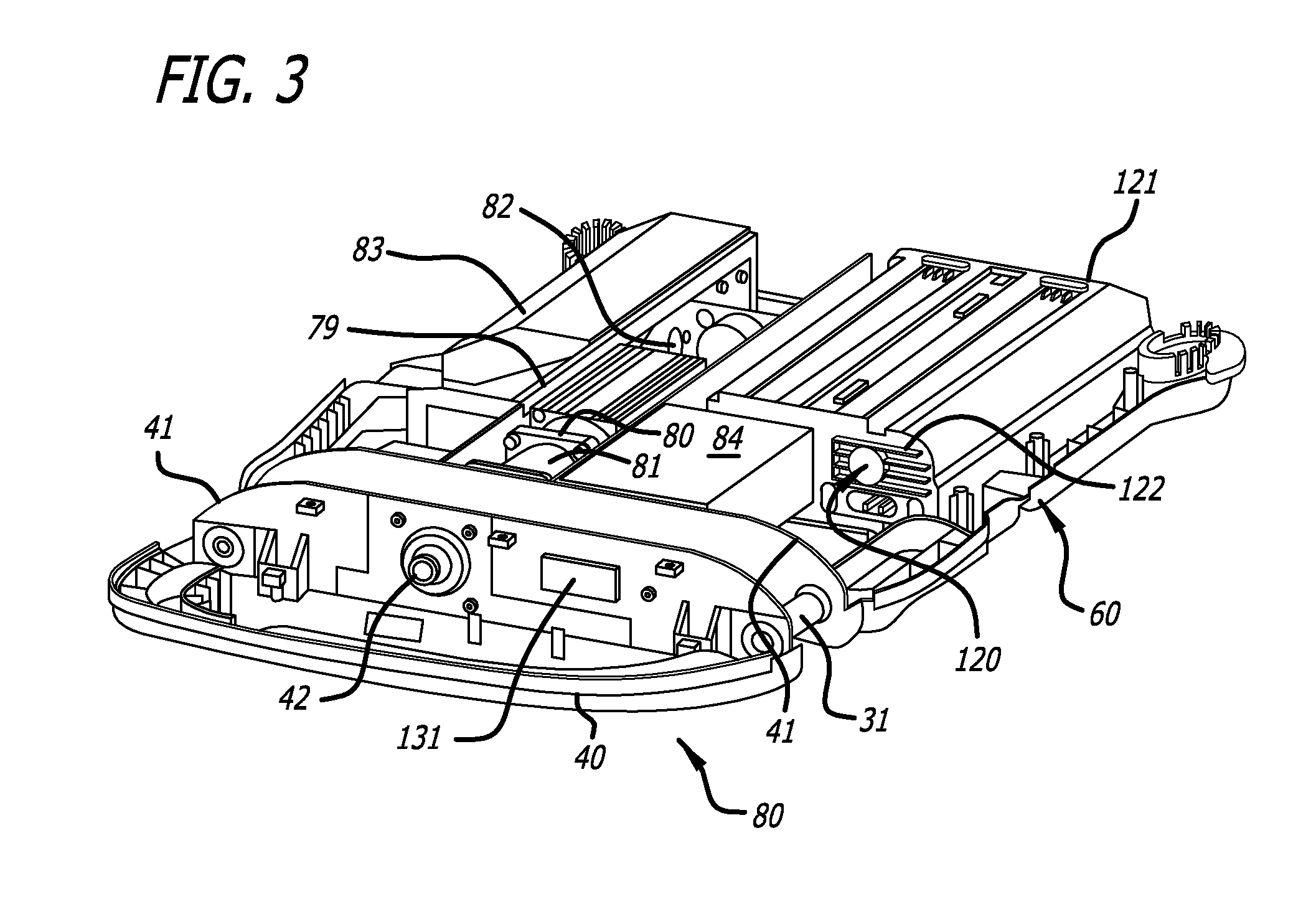

An inventive system and method de-passivates a direct current (DC) power source of an Automatic External Defibrillator (AED), such as an AED lithium battery. The system includes a main processor and standby processor. The standby processor monitors the age and usage of the battery. Based on the status of the monitored parameters, the system executes a conditioning discharge to remove a layer of salt crystals on the DC power source.

Owner:DEFIBTECH

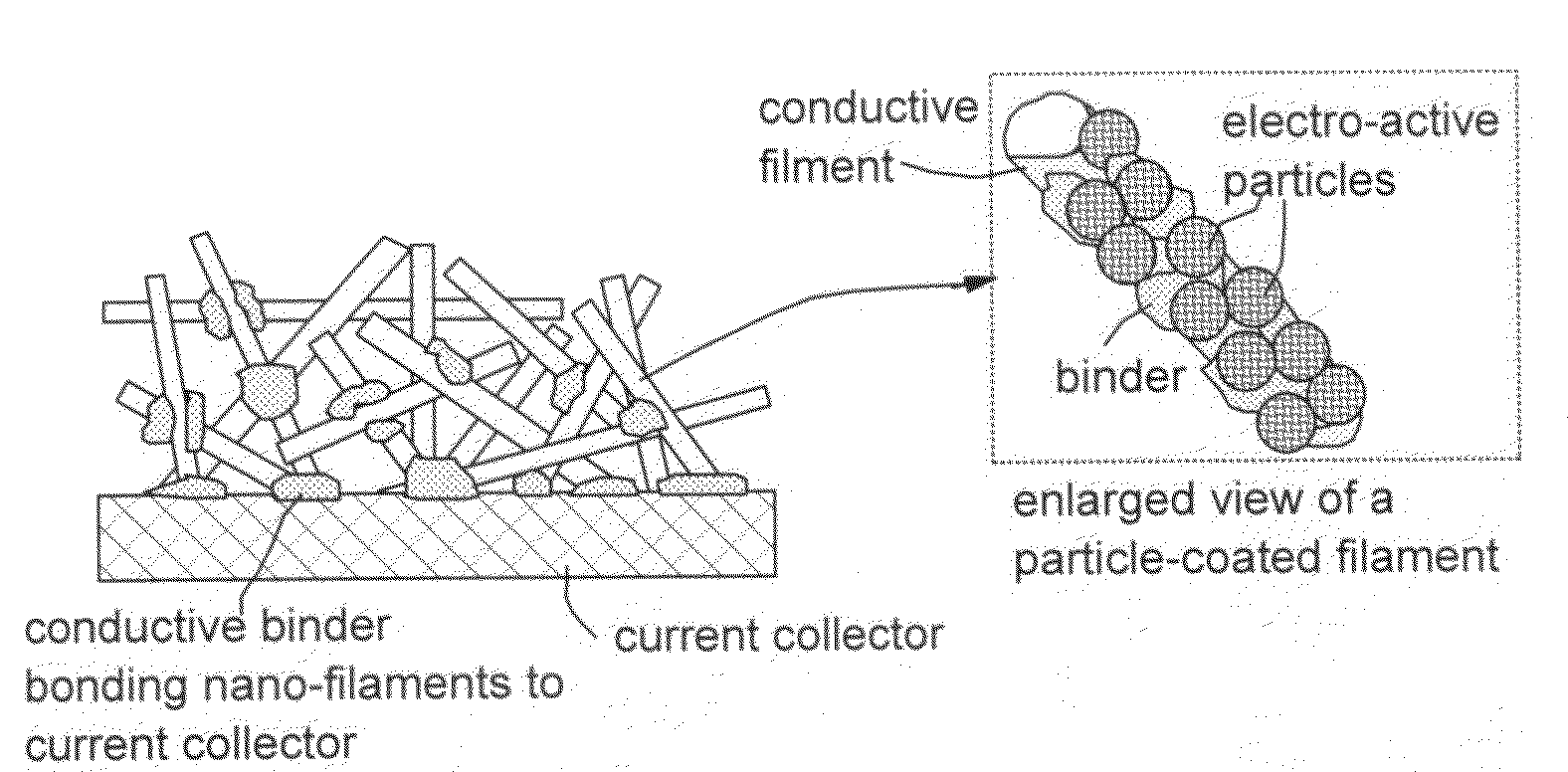

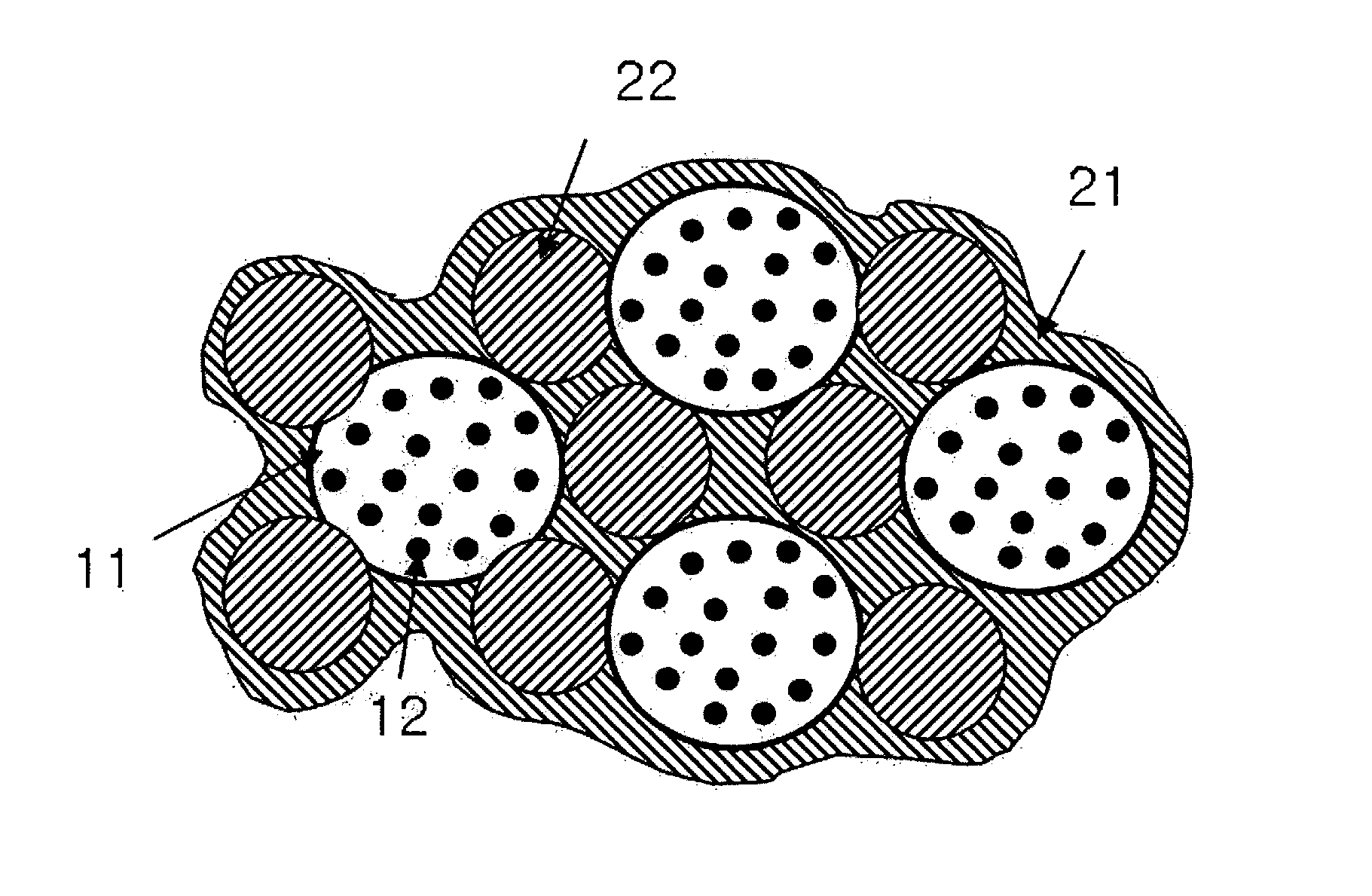

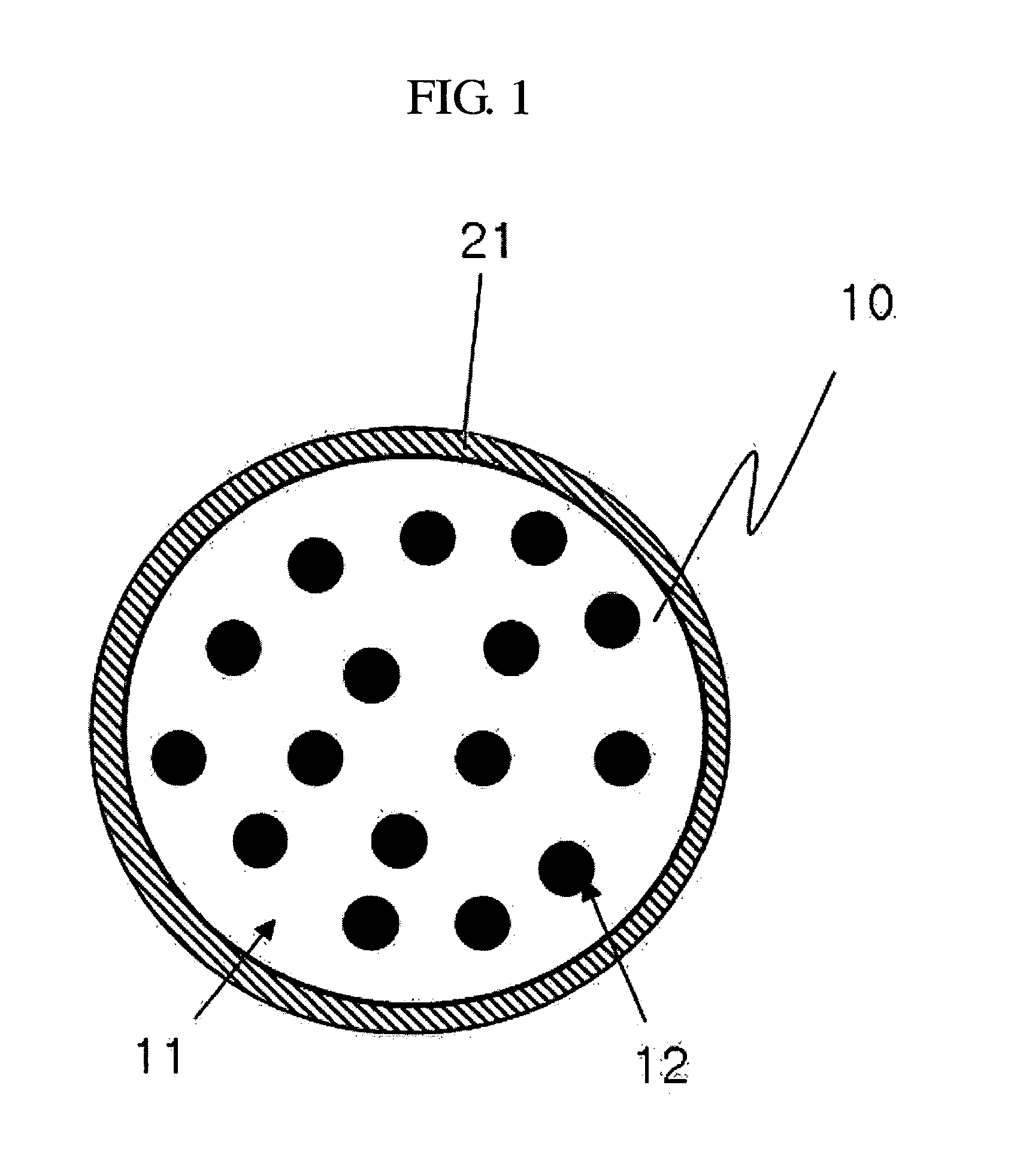

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

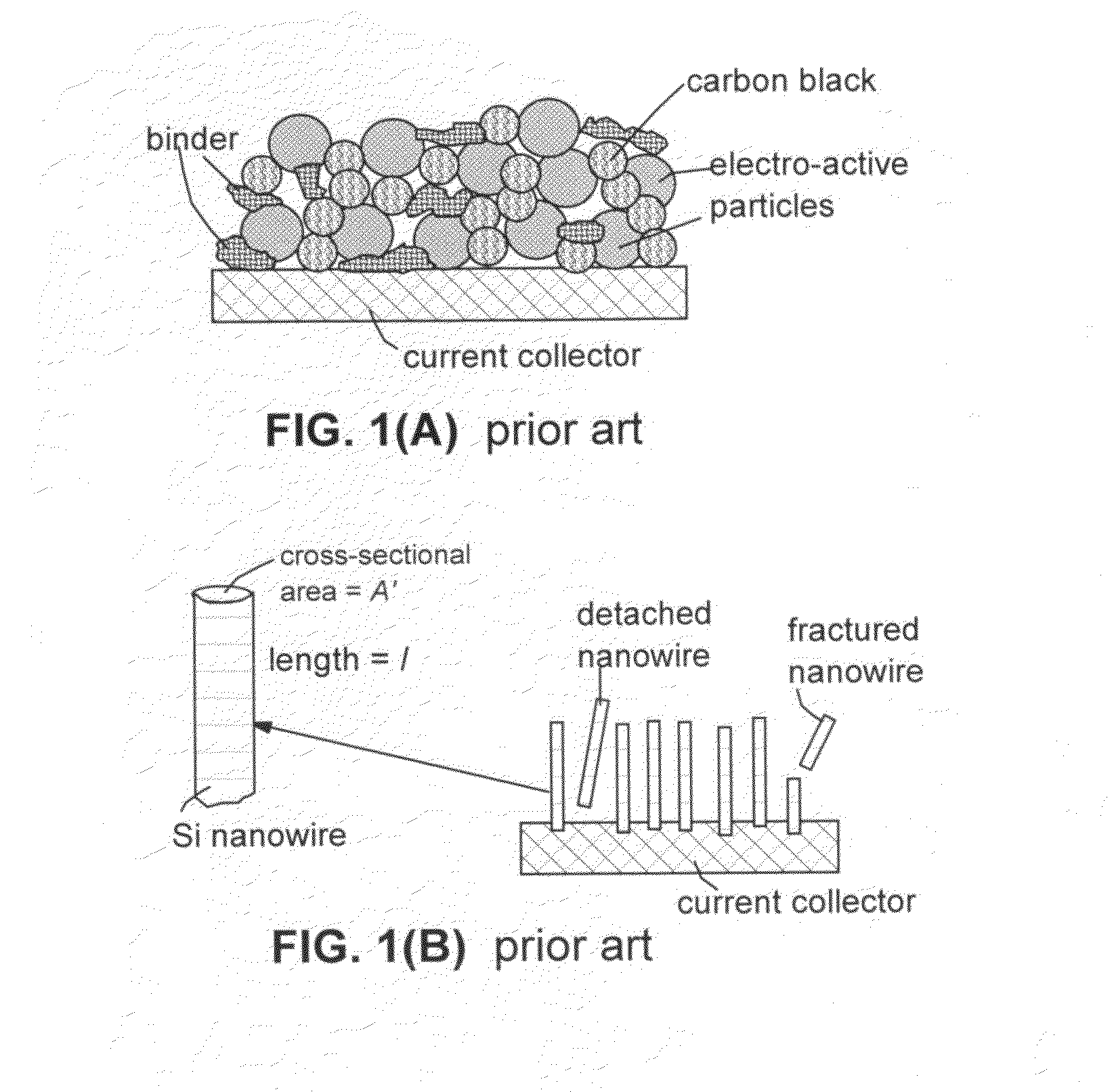

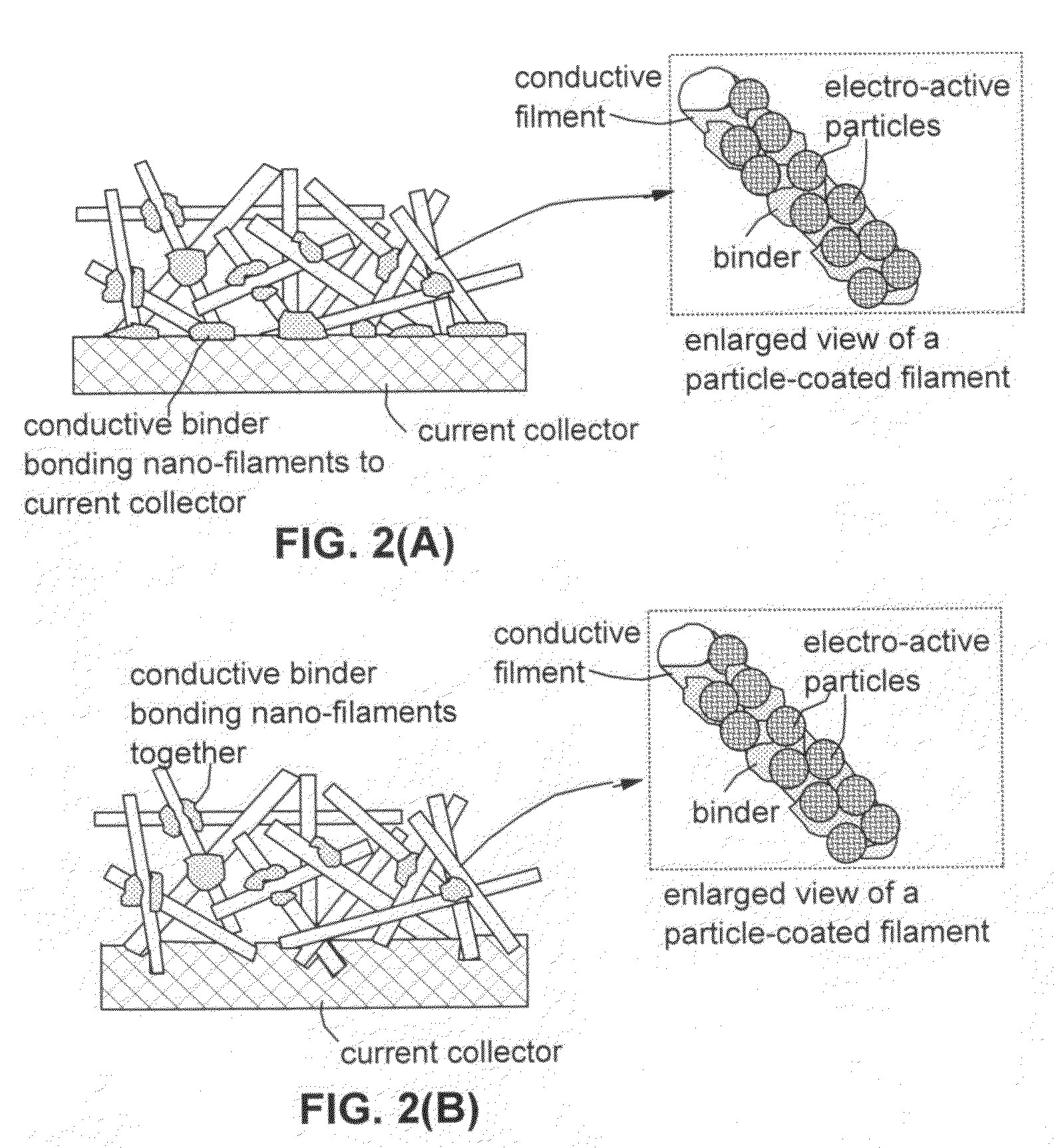

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Medical disposable electric motor saw

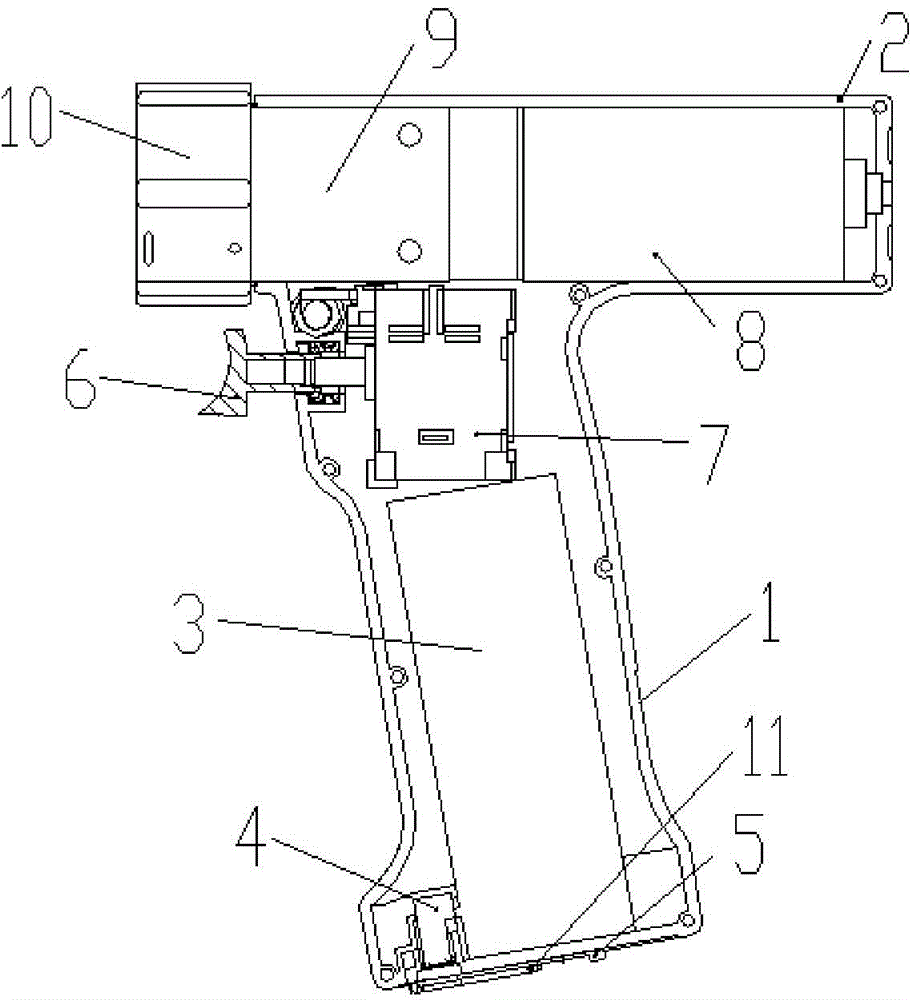

InactiveCN104586463ASmooth transmissionImprove braking effectSurgical sawsElectric machineDrive shaft

The invention discloses a medical disposable electric motor saw, which comprises a handle and an enclosure main body, wherein a non-removable battery and a circuit control panel which is connected with the battery are arranged in the handle; a press part of the handle is provided with a speed adjusting switch which is connected with the circuit control panel; a hollow motor which is provided with a driving shaft is arranged in the enclosure main body; the battery is a rechargeable lithium battery; a charging socket is formed in the bottom or the lateral part of the handle; a sterile sealing bag is arranged on the outer sides of the handle and the enclosure main body. After the structure is adopted, and the hollow motor is used, the medical disposable electric motor saw is stable in transmission and good in braking performance, the weight of the medical disposable electric motor saw is about a half of that of an electric motor saw with a common motor, the structure is simple, the fault rate is low, the medical disposable electric motor saw is easy to carry and use, the manufacturing cost is low, the battery cannot be detached, so the loosening or dropping phenomenon cannot occur, and the completion quality of a surgery is effectively ensured. The sterile sealing bag is used, the wait for high-temperature high-pressure sterilization is not needed, and the medical disposable electric motor saw can be used any time. The precious operation time is saved for an emergency operation patient.

Owner:SUZHOU WANRUN MEDICAL SCI & TECH CO LTD

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

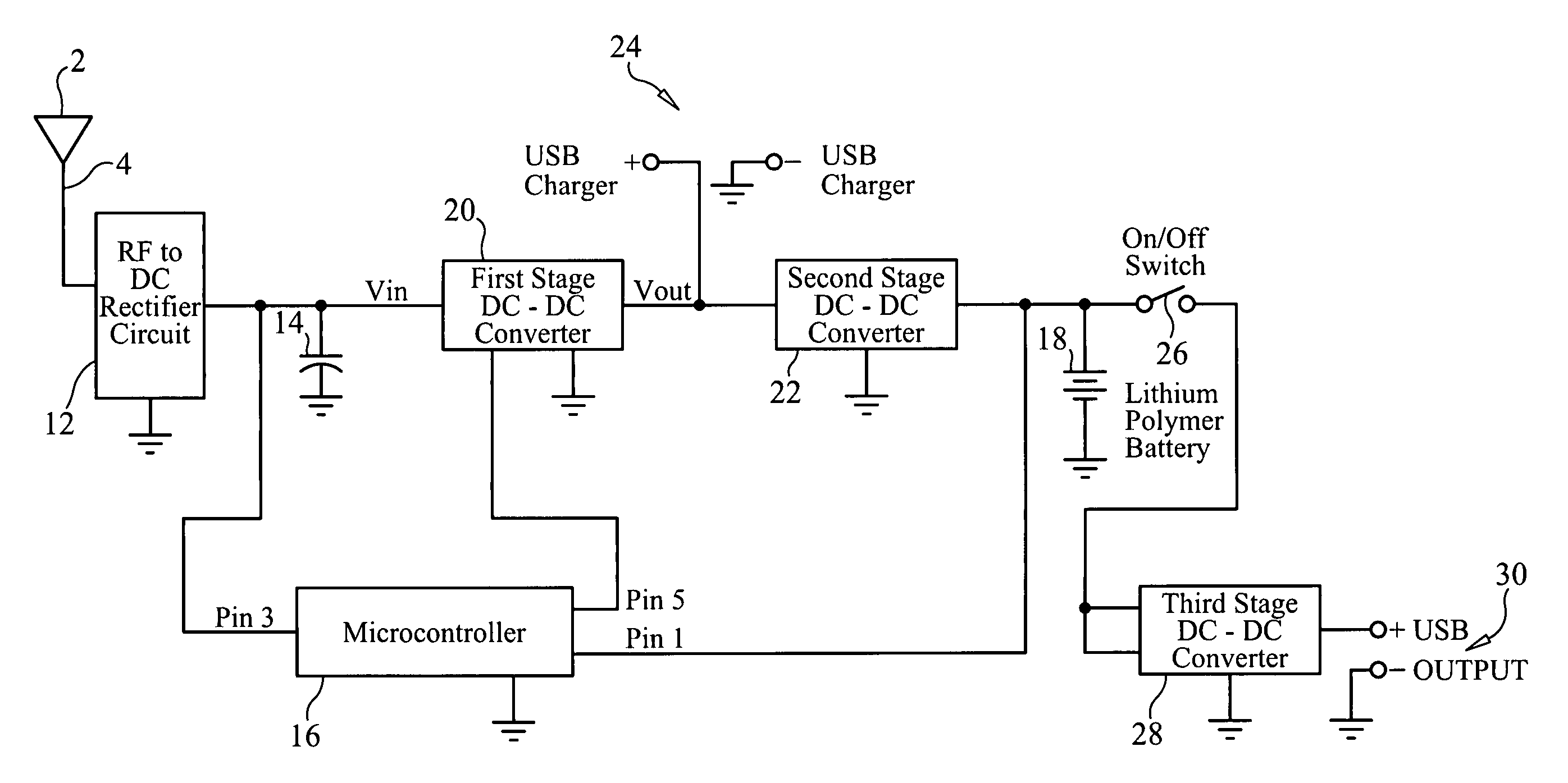

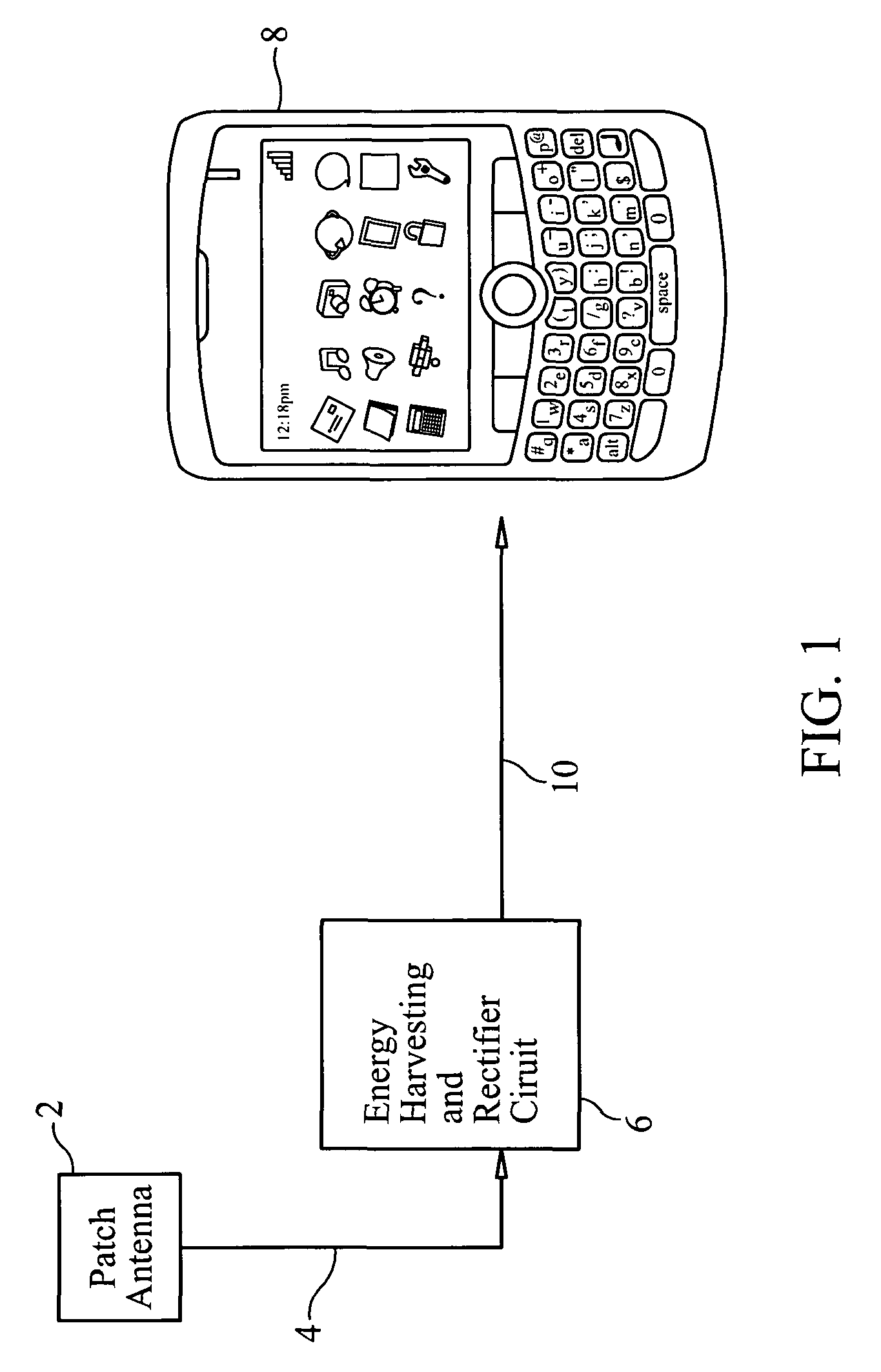

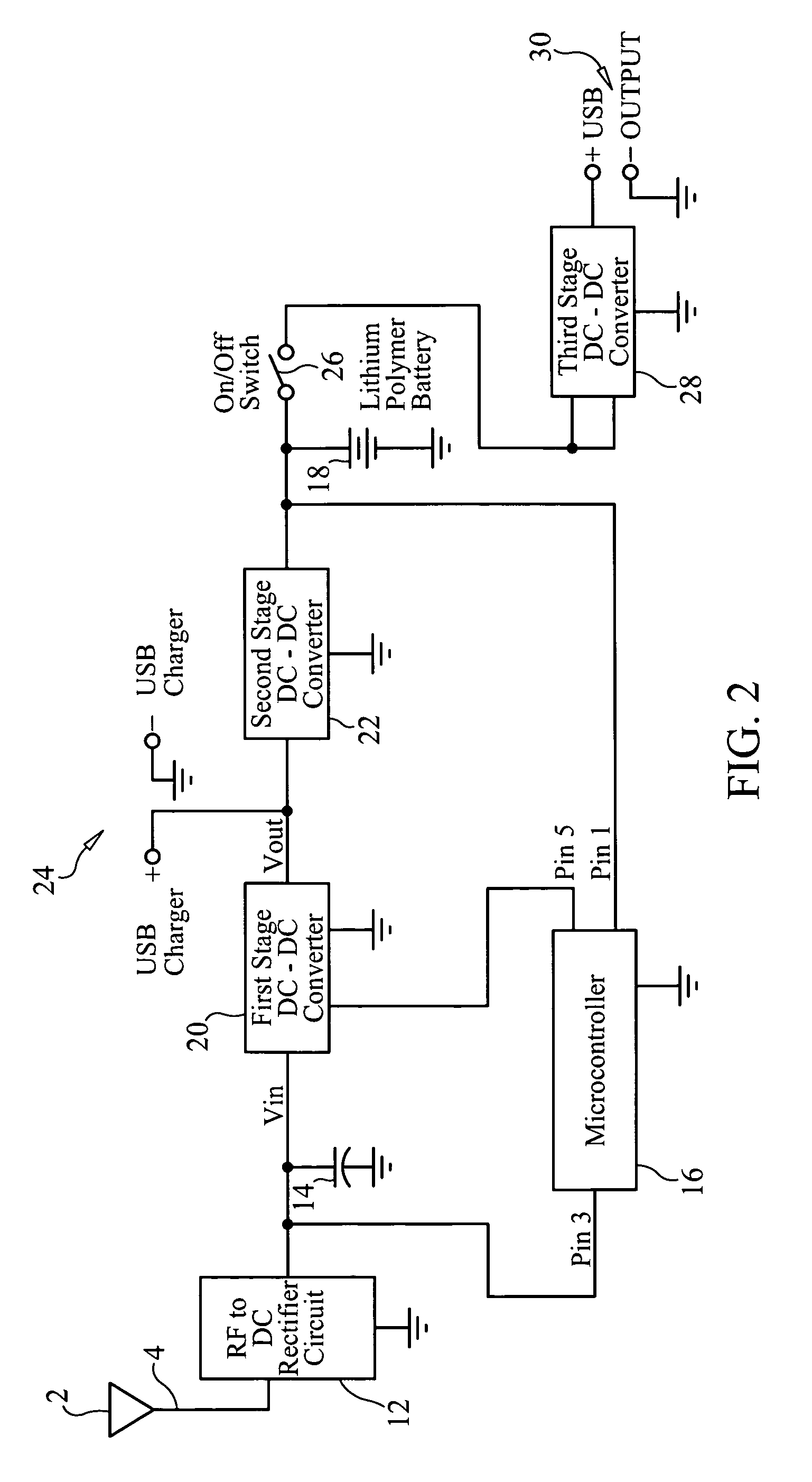

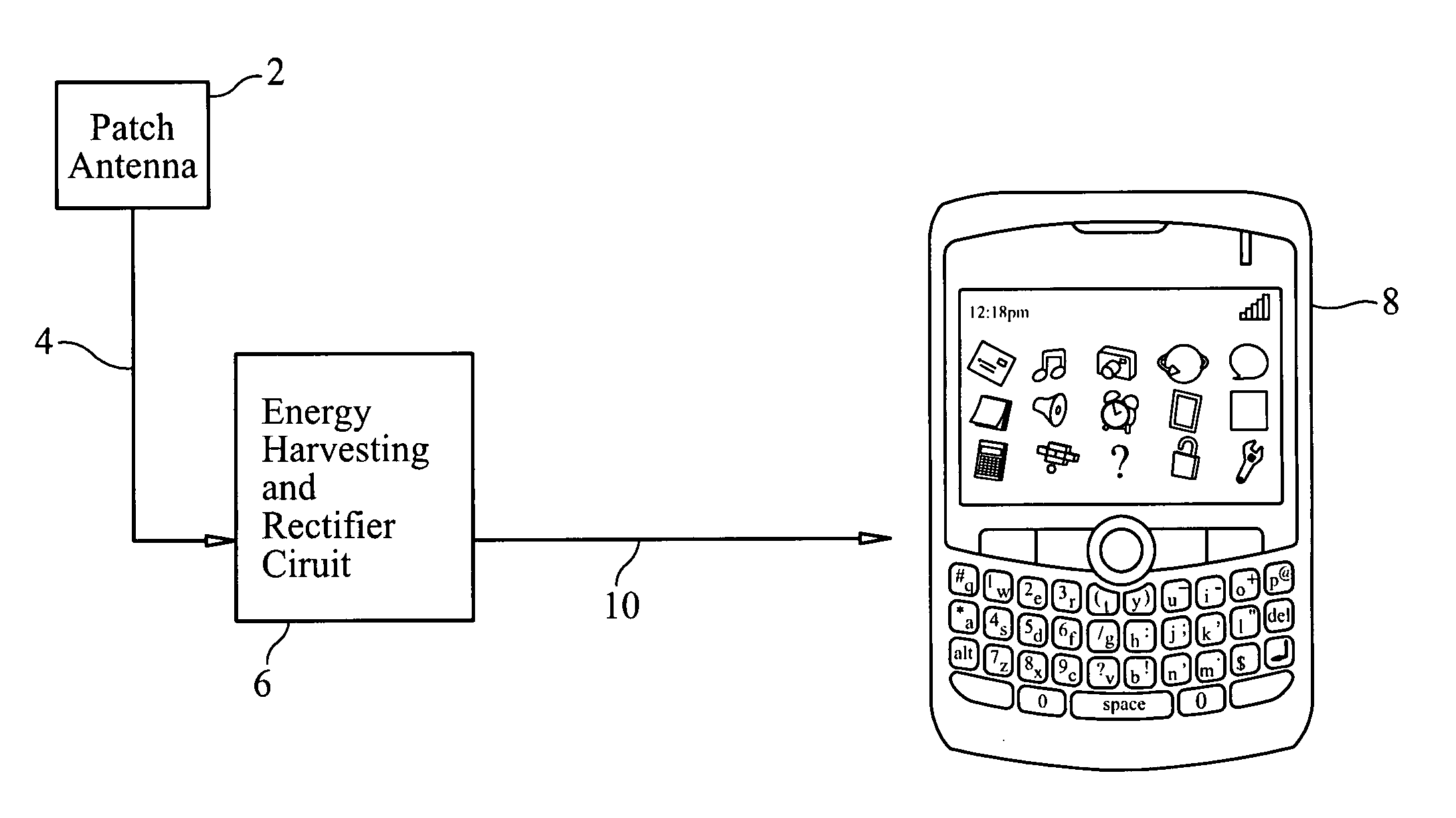

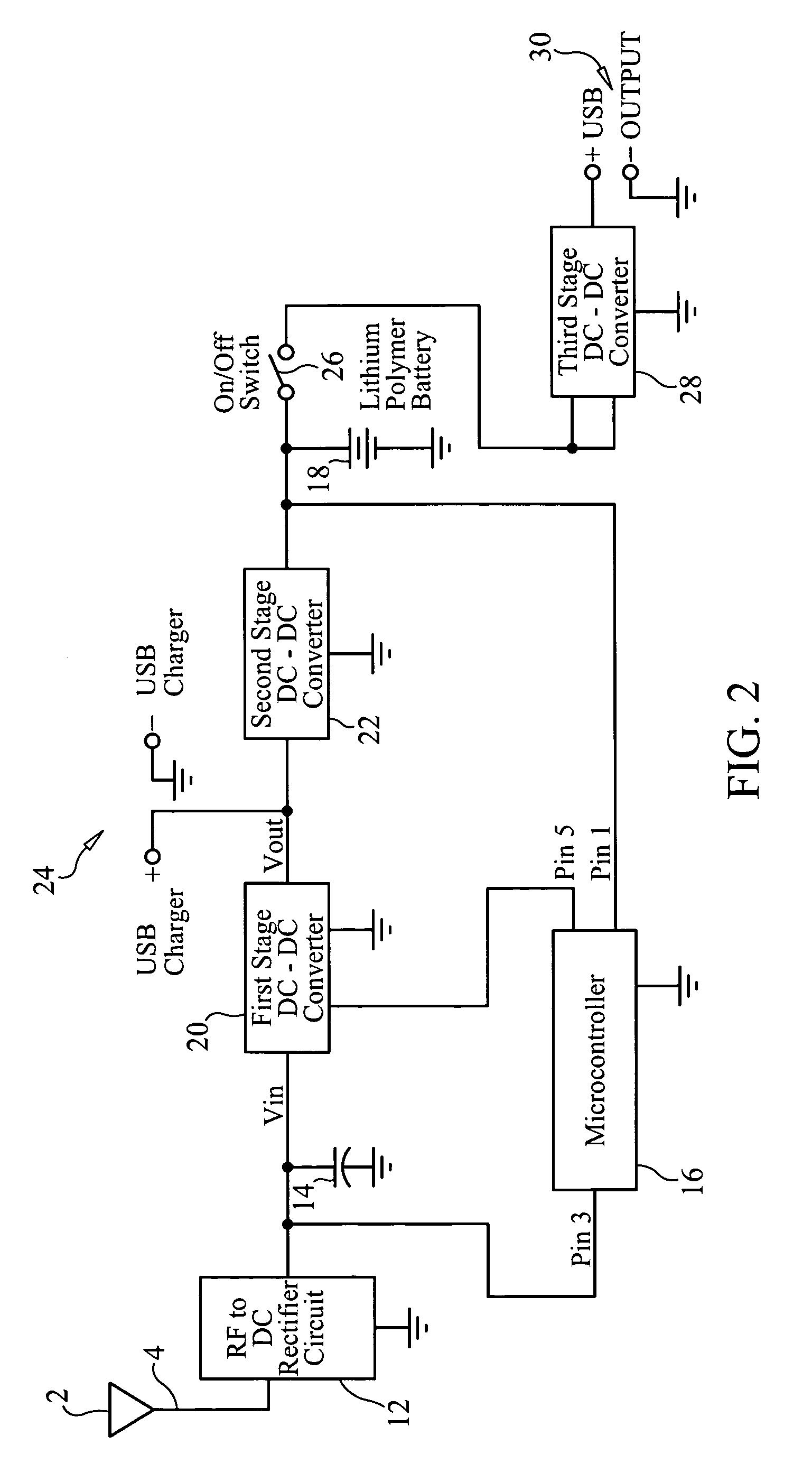

Method and apparatus for harvesting energy

ActiveUS8362745B2Batteries circuit arrangementsElectromagnetic wave systemElectrical batteryBroadband

An energy harvesting circuit includes one or more broadband or narrow band antennas to detect WIFI (wireless fidelity) or other RF (radio frequency) signals. The signals are rectified and voltage multiplied, and the resultant DC voltage is provided to a power management circuit. The output of the power management circuit charges a lithium battery or other storage device within the energy harvesting circuit. The energy stored in the battery or storage device is provided through a DC / DC converter circuit to a USB output connector to power or recharge the batteries of an external electronic device connected to the USB output connector of the energy harvesting circuit.

Owner:VOXX INTERNATIONAL

Method and apparatus for harvesting energy

ActiveUS20110175461A1Batteries circuit arrangementsElectromagnetic wave systemEngineeringRadio frequency

An energy harvesting circuit includes one or more broadband or narrow band antennas to detect WIFI (wireless fidelity) or other RF (radio frequency) signals. The signals are rectified and voltage multiplied, and the resultant DC voltage is provided to a power management circuit. The output of the power management circuit charges a lithium battery or other storage device within the energy harvesting circuit. The energy stored in the battery or storage device is provided through a DC / DC converter circuit to a USB output connector to power or recharge the batteries of an external electronic device connected to the USB output connector of the energy harvesting circuit.

Owner:VOXX INTERNATIONAL

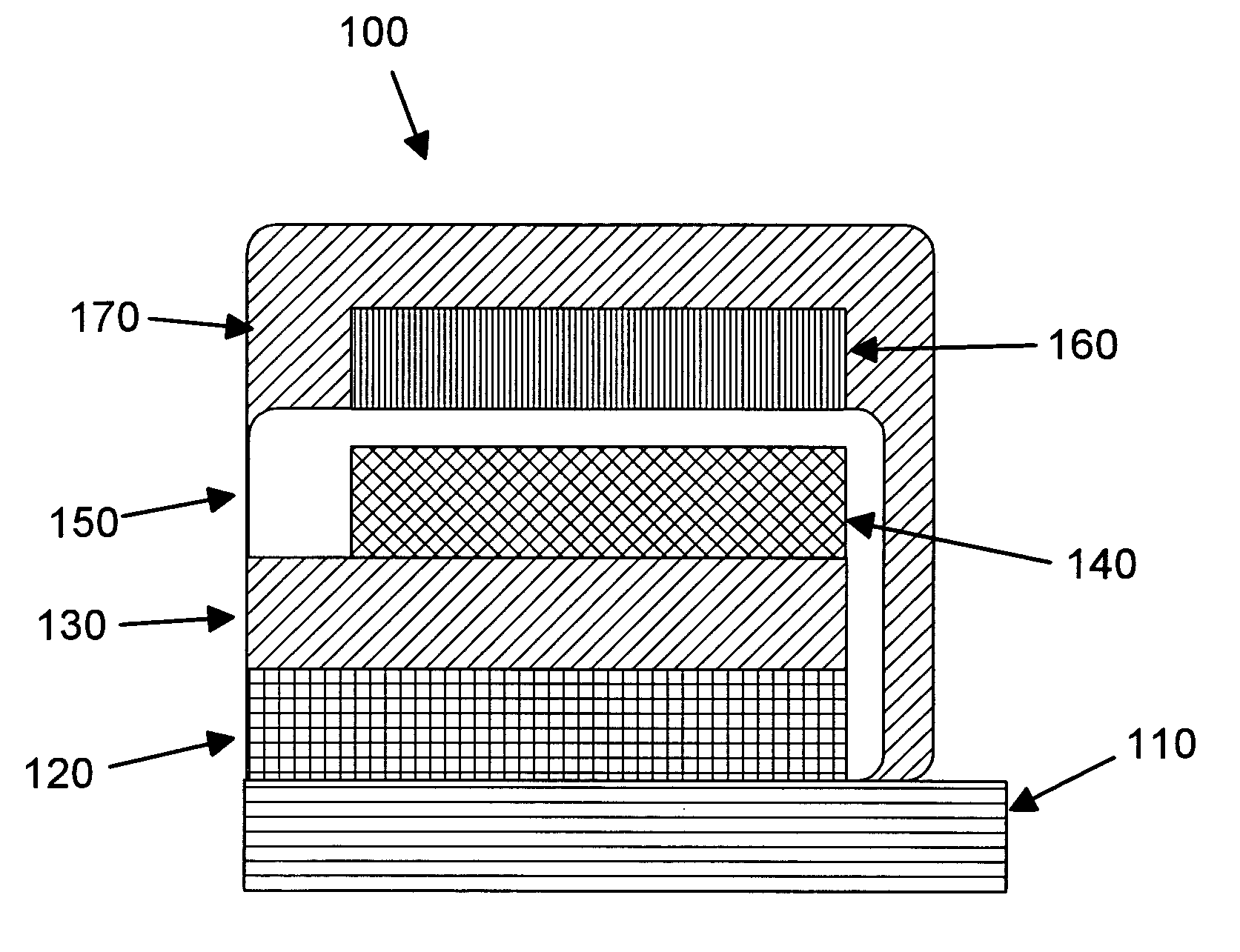

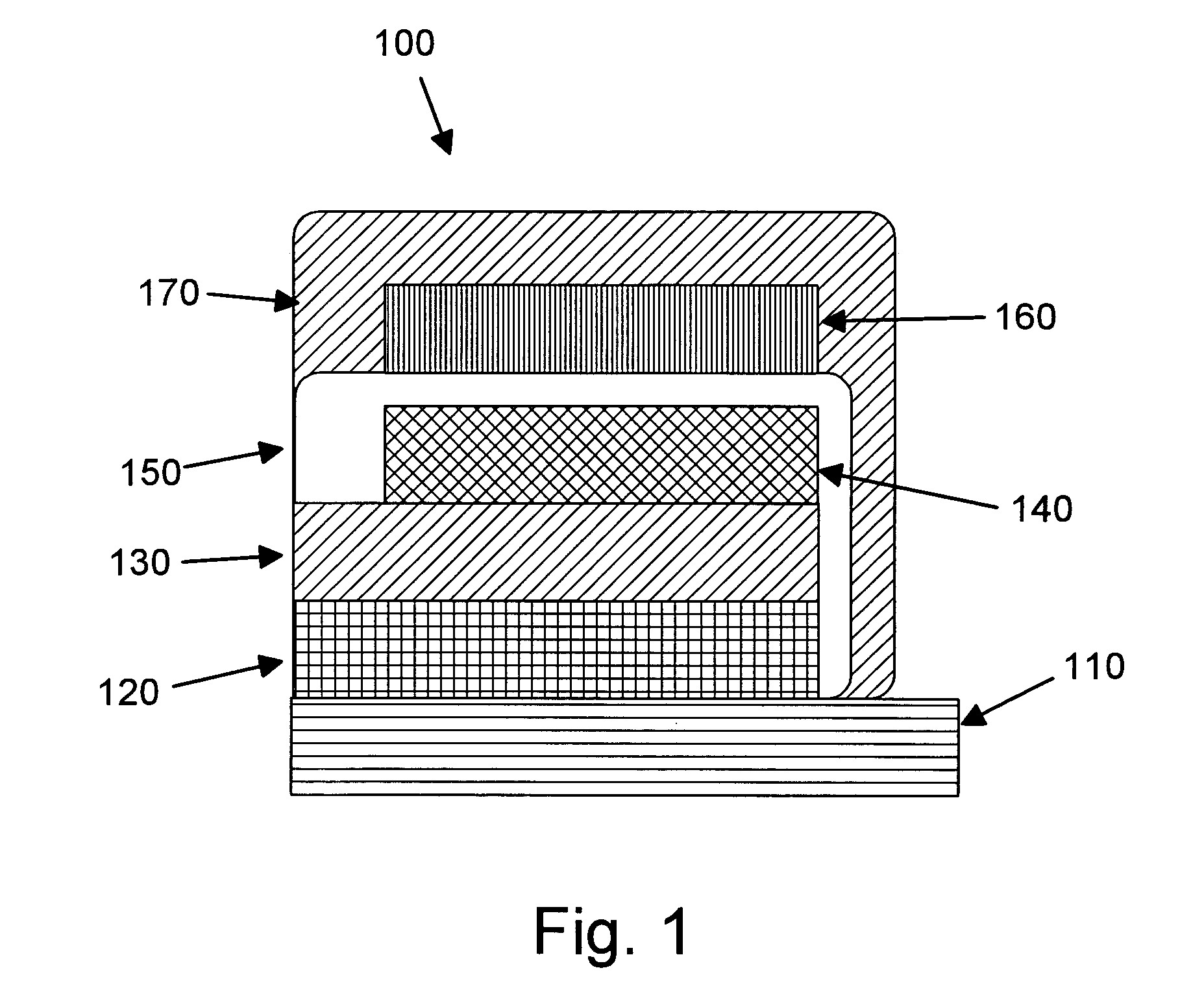

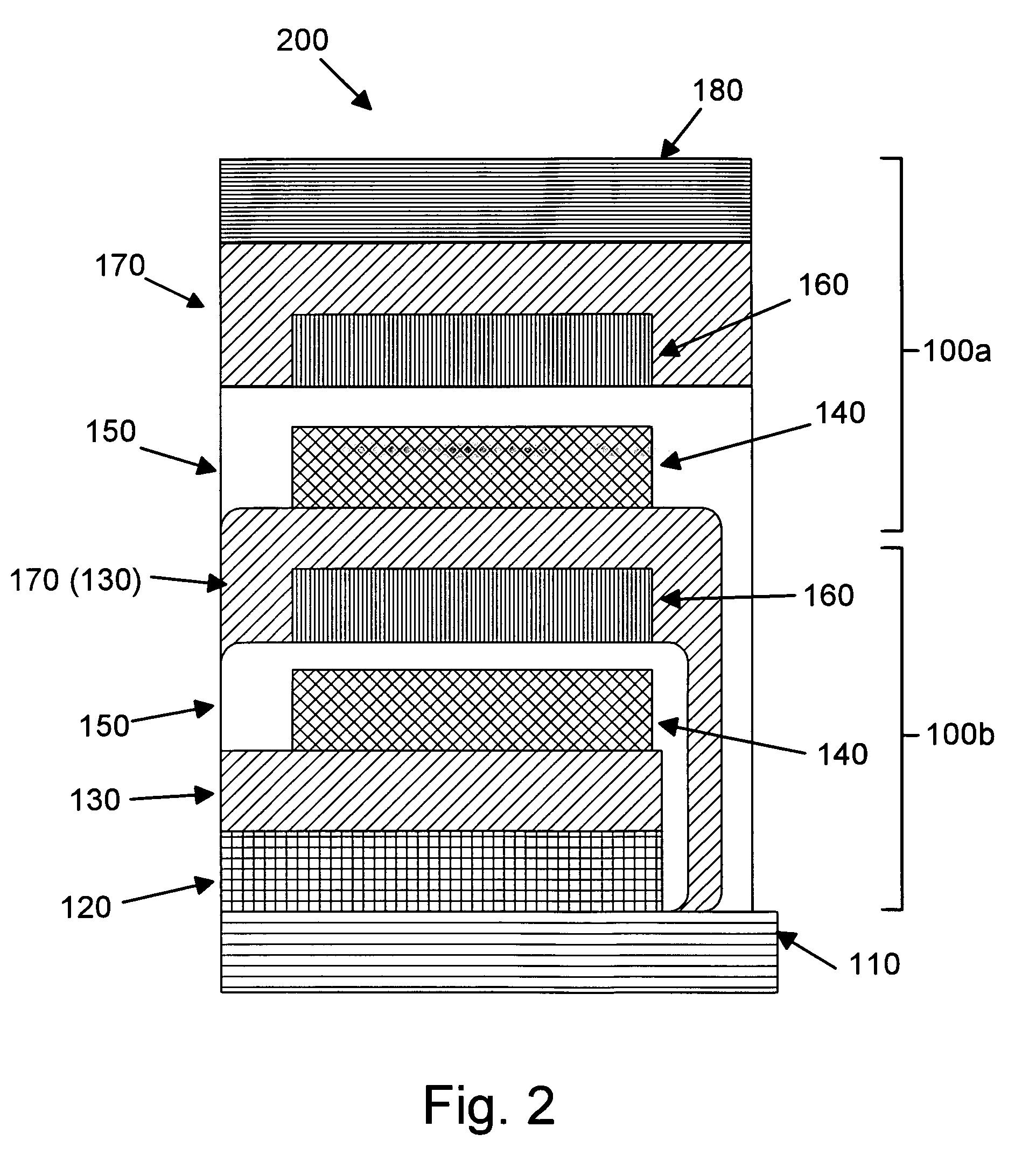

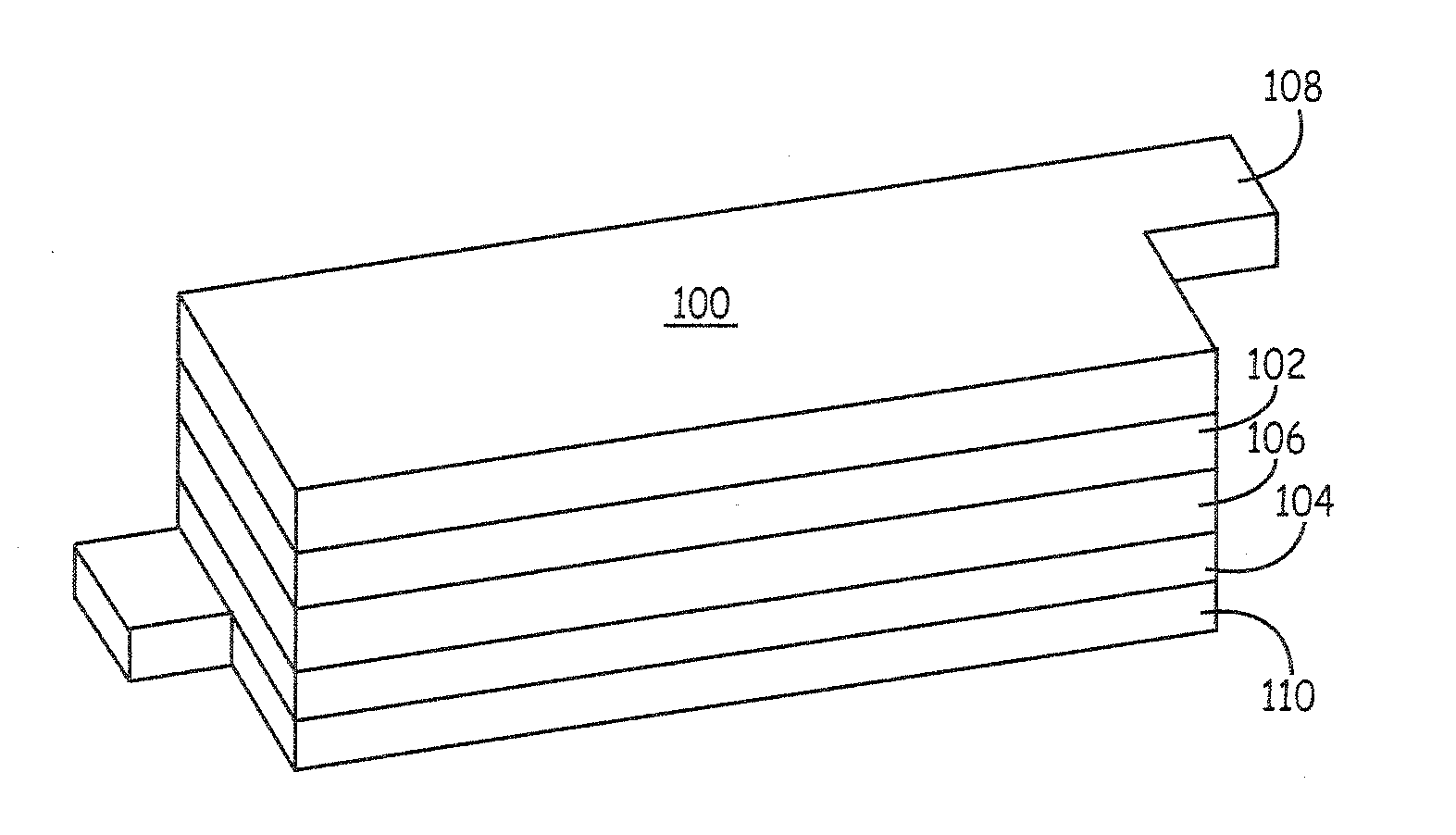

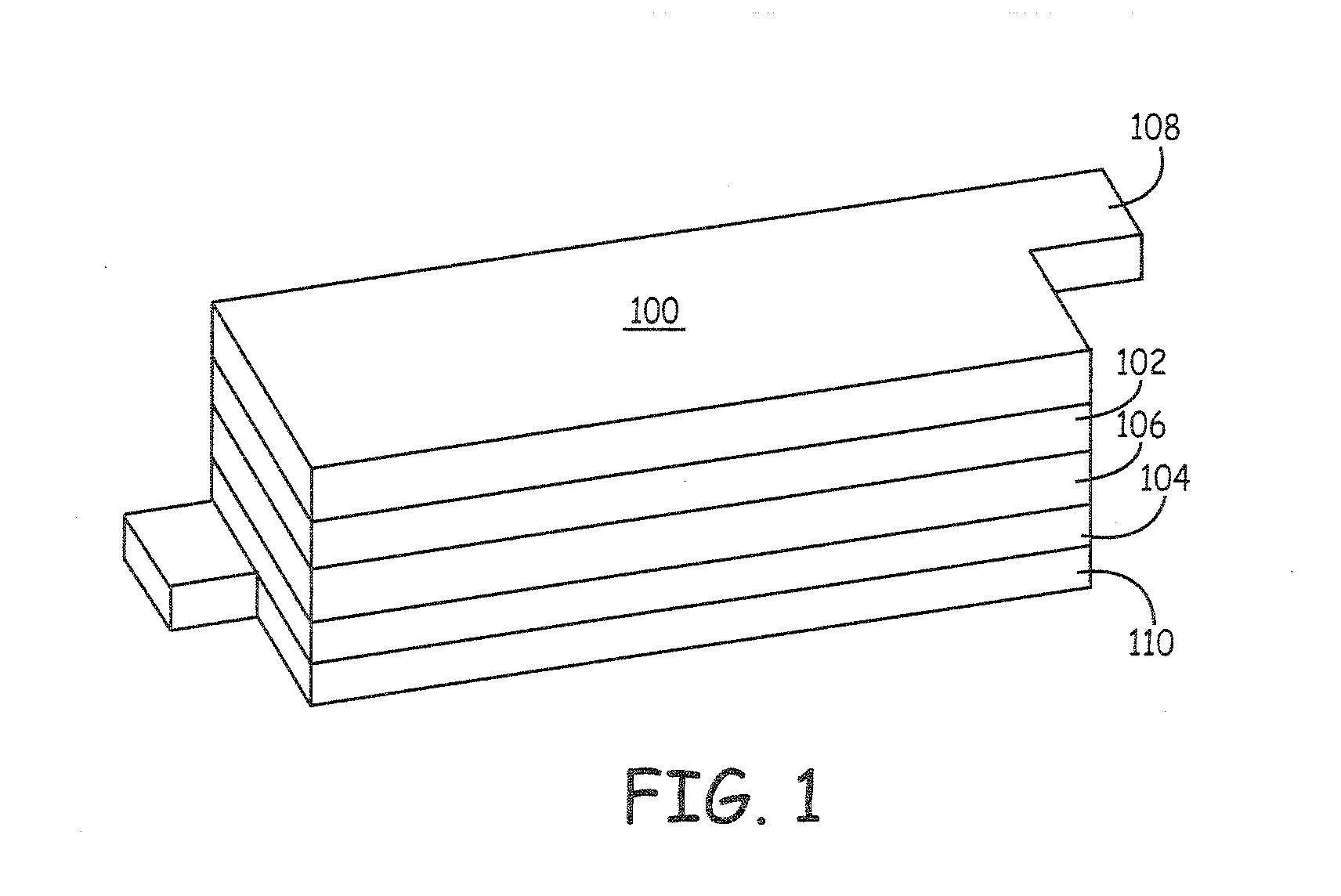

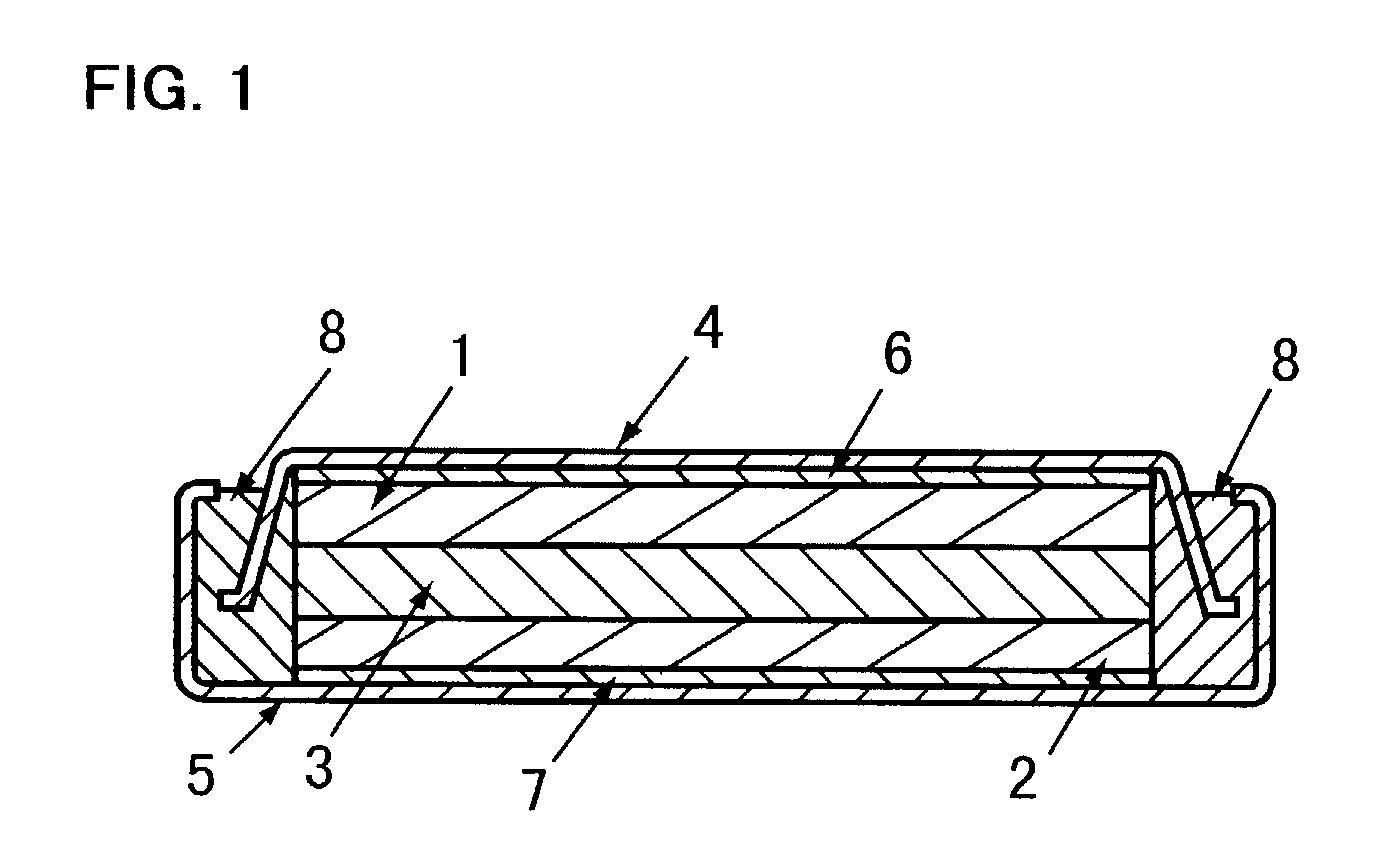

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

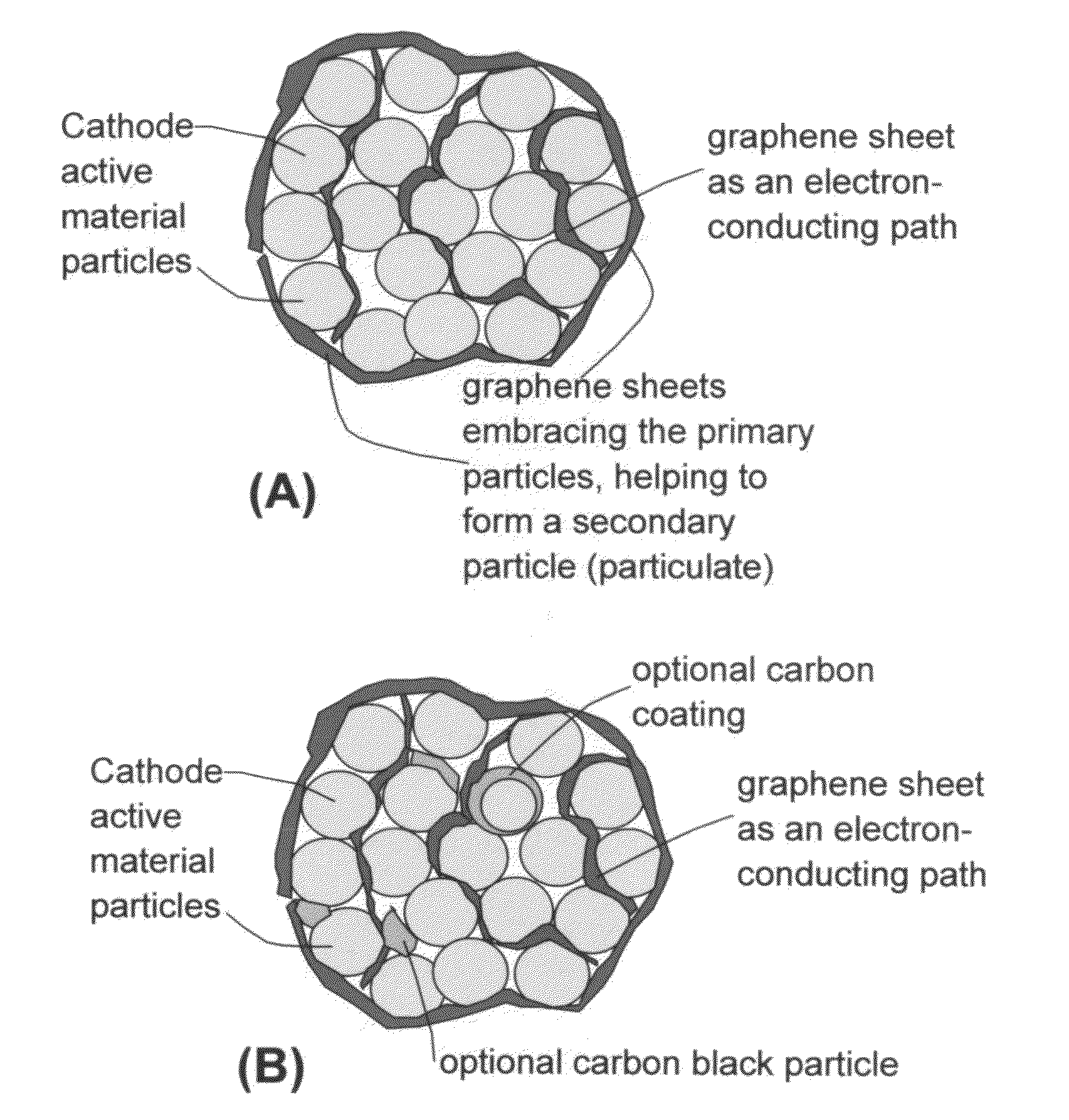

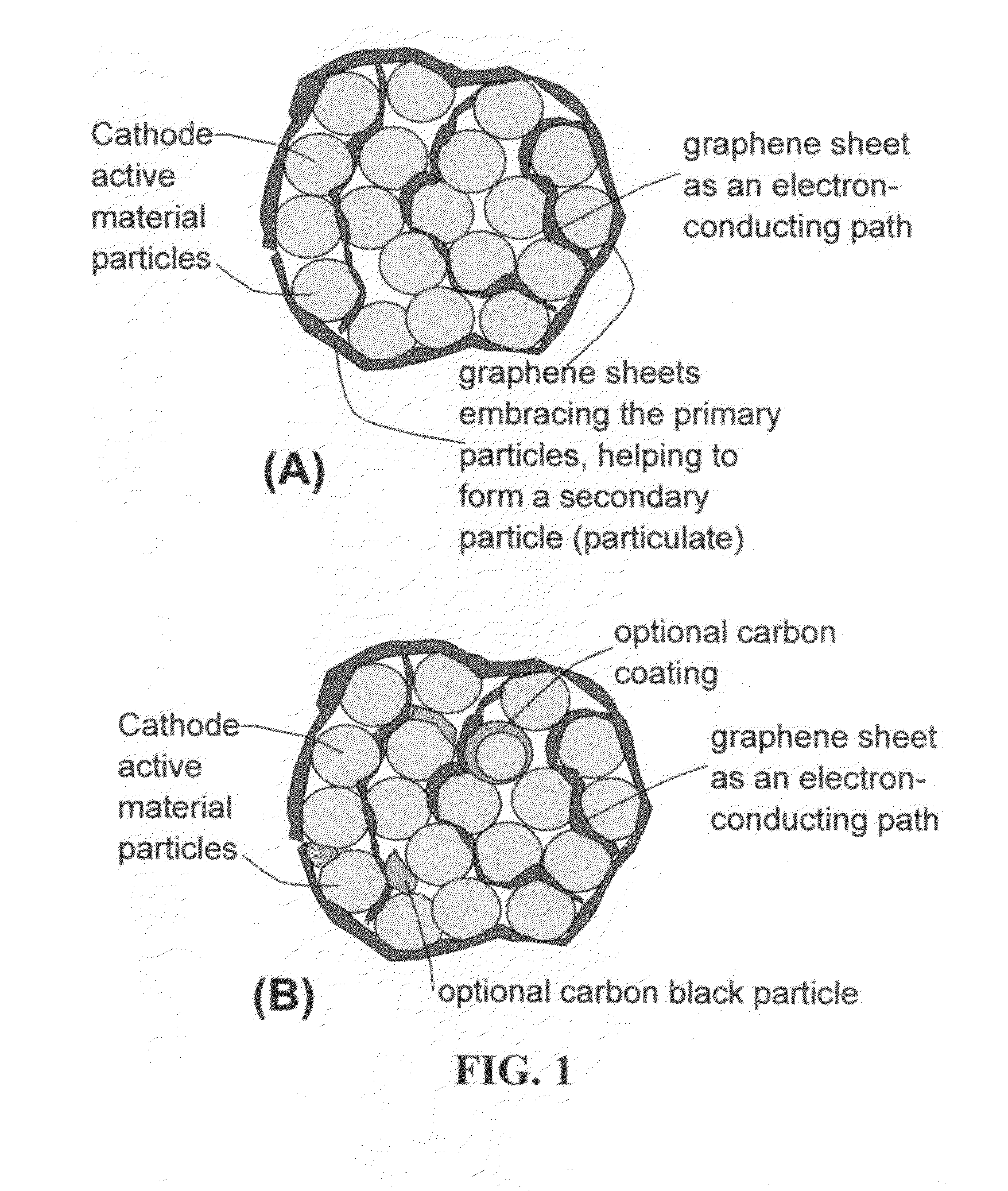

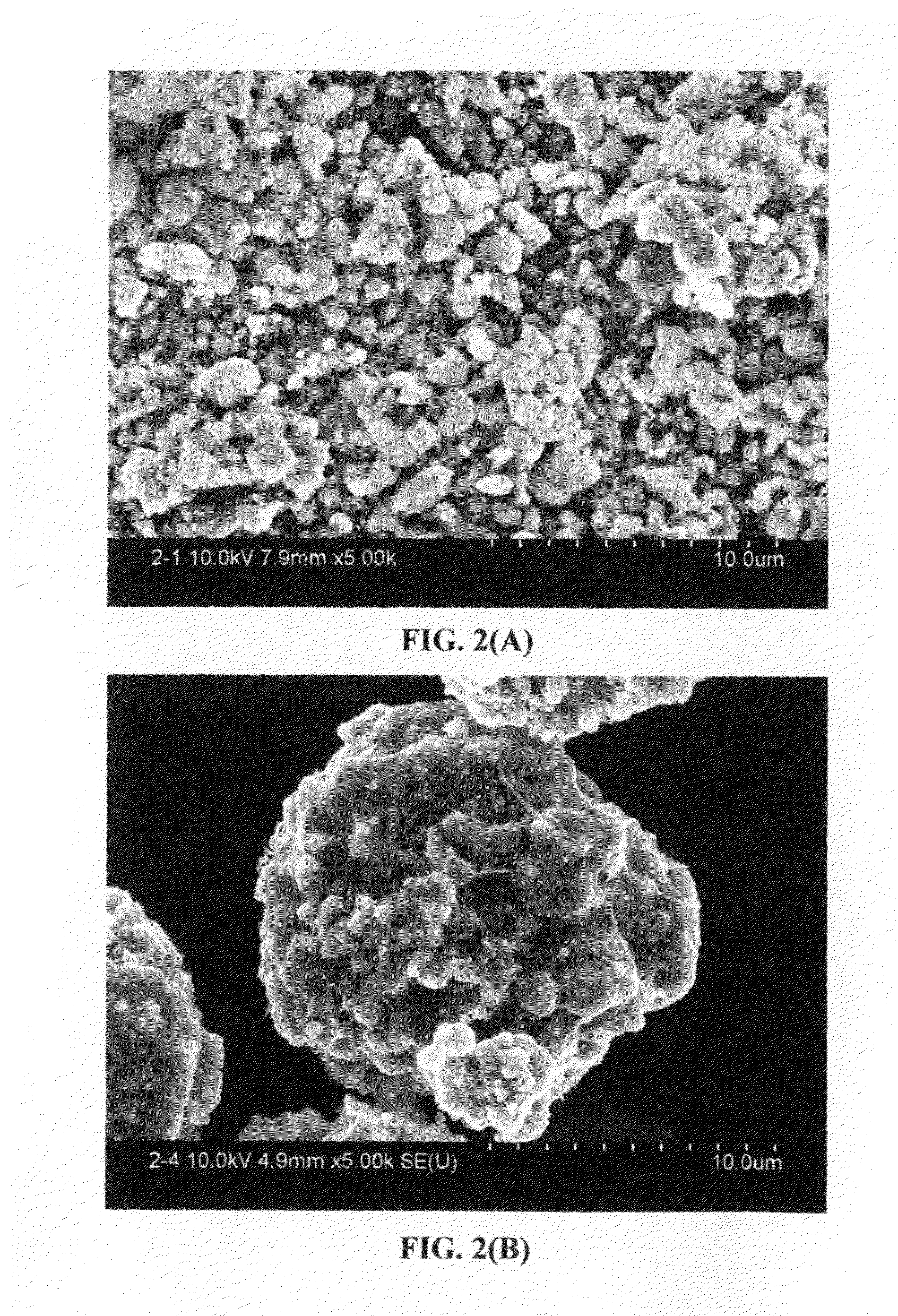

Graphene-Enhanced cathode materials for lithium batteries

ActiveUS20120058397A1Short timeEasy dischargeNon-metal conductorsMaterial nanotechnologyParticulatesCvd graphene

A nano graphene-enhanced particulate for use as a lithium battery cathode active material, wherein the particulate is formed of a single or a plurality of graphene sheets and a plurality of fine cathode active material particles with a size smaller than 10 μm (preferably sub-micron or nano-scaled), and the graphene sheets and the particles are mutually bonded or agglomerated into an individual discrete particulate with at least a graphene sheet embracing the cathode active material particles, and wherein the particulate has an electrical conductivity no less than 10−4 S / cm and the graphene is in an amount of from 0.01% to 30% by weight based on the total weight of graphene and the cathode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

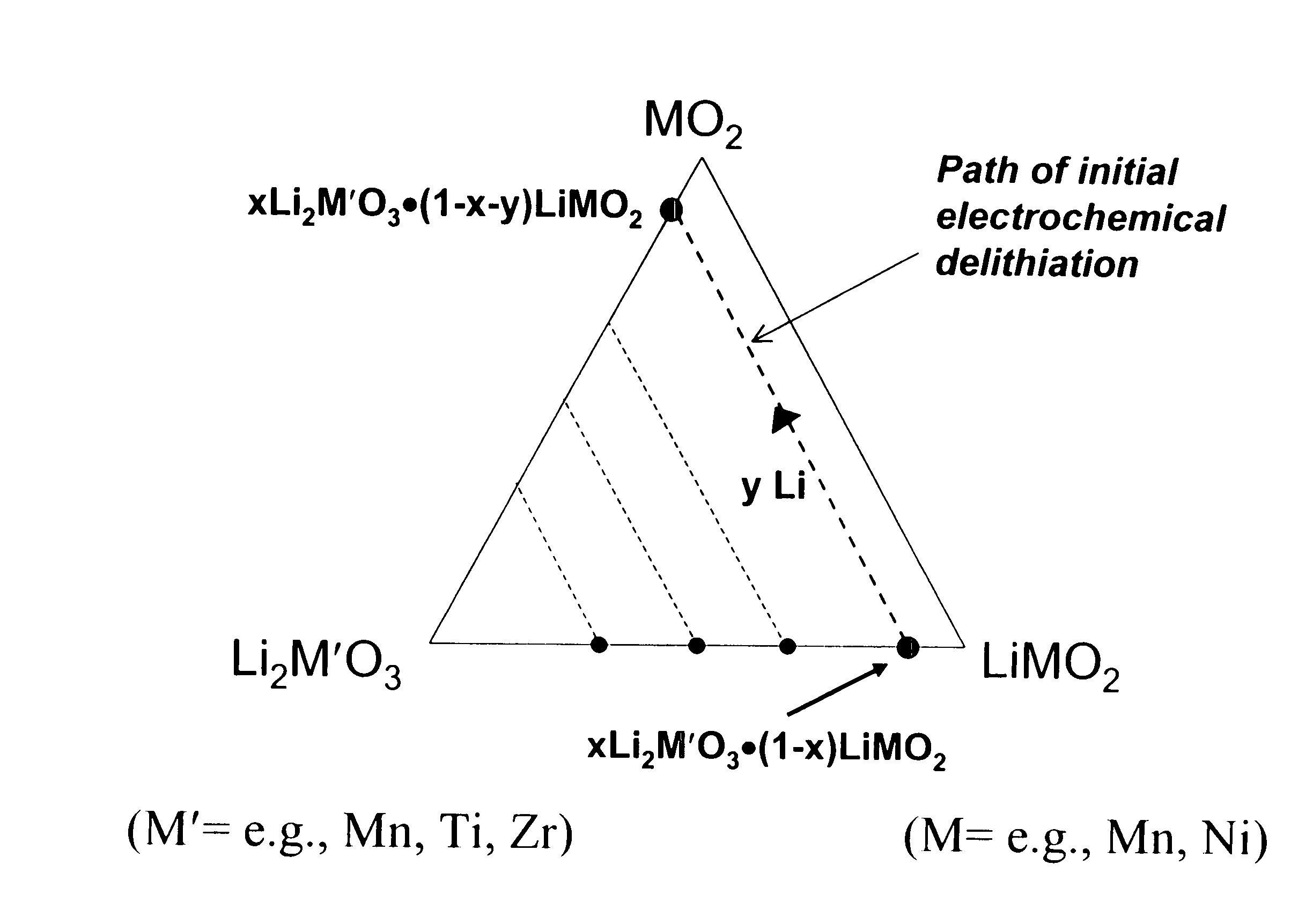

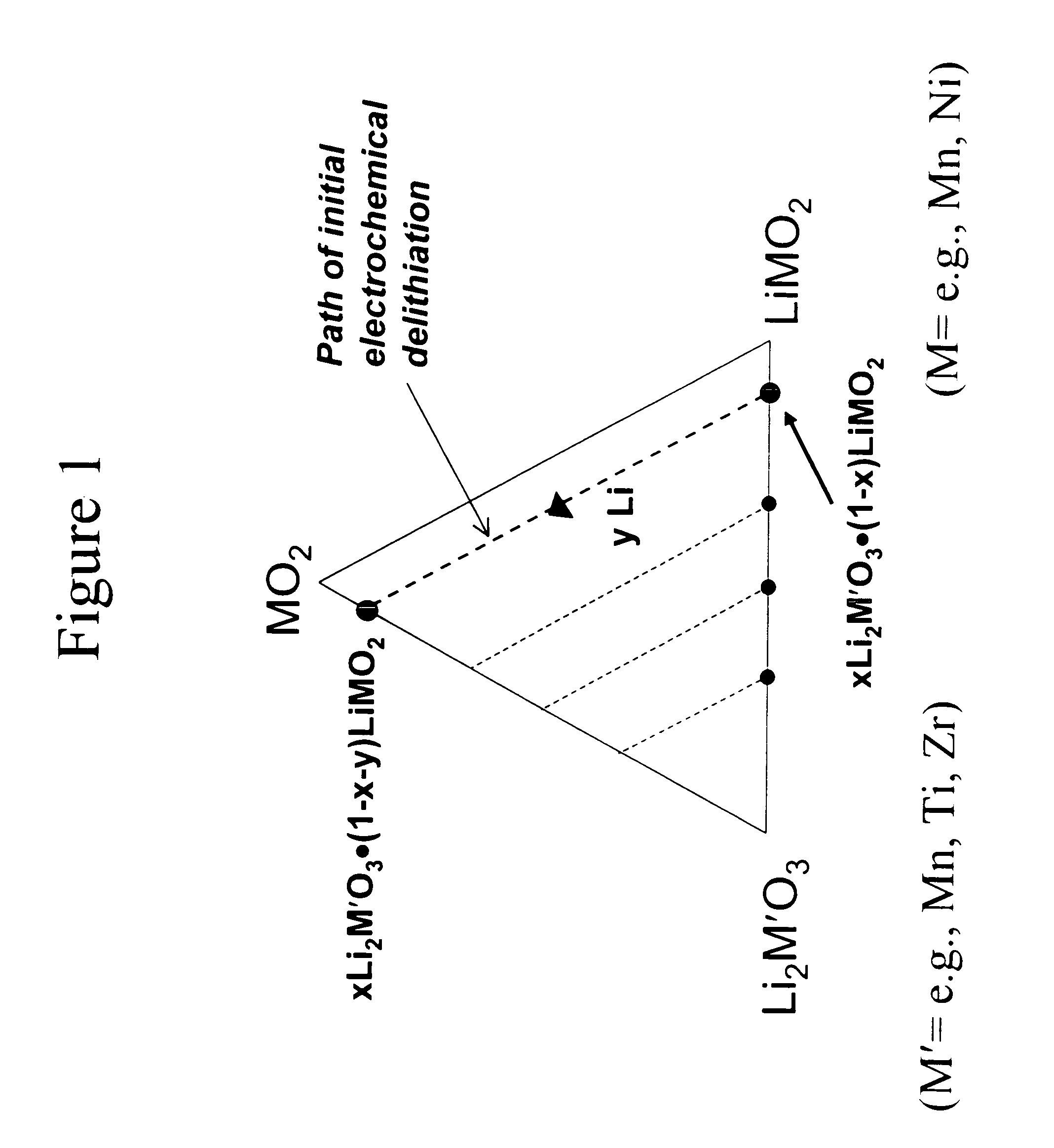

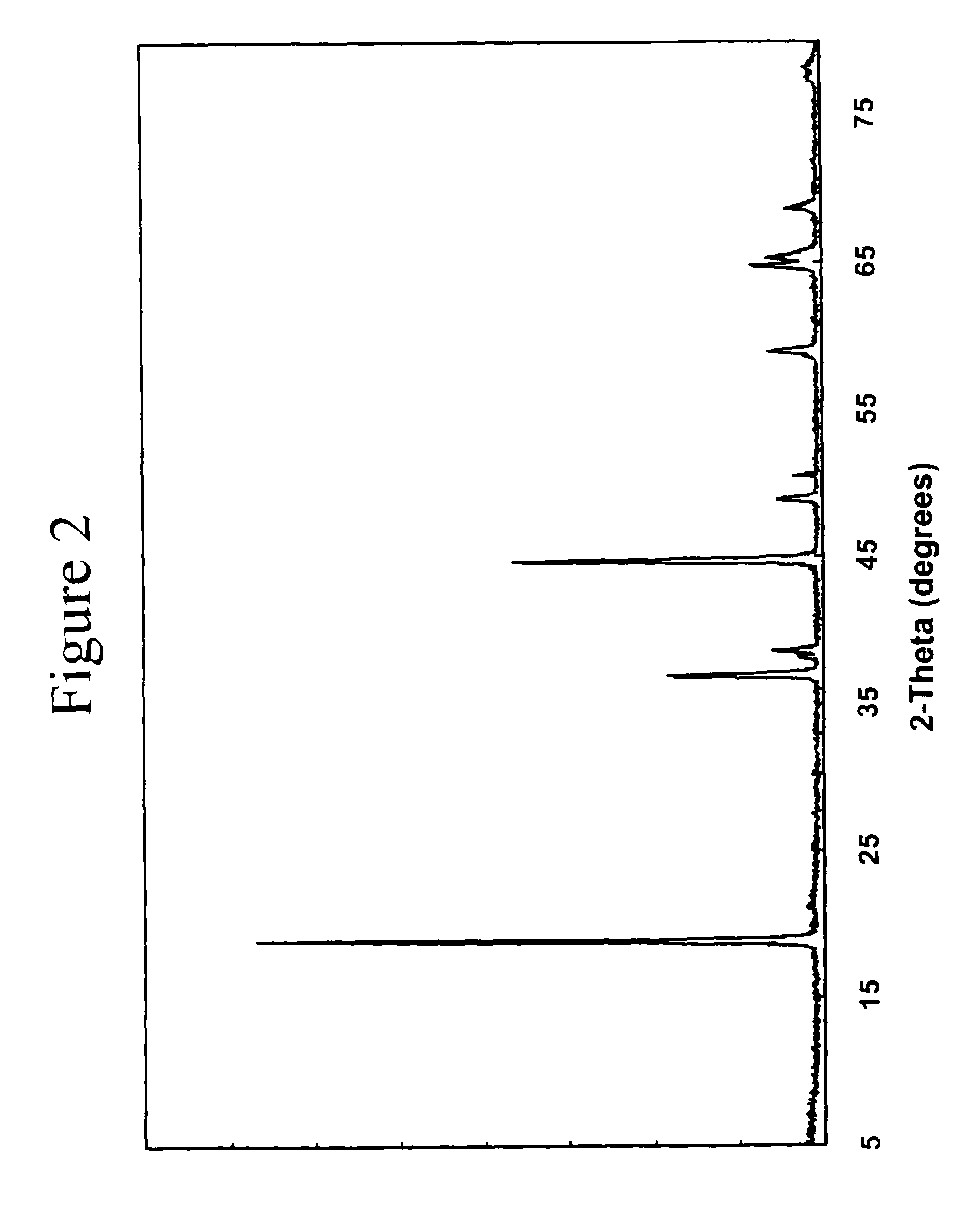

Lithium metal oxide electrodes for lithium cells and batteries

InactiveUS7135252B2Improve structural stabilityImprove stabilityZirconium compoundsSecondary cellsLithium metalOxidation state

A lithium metal oxide positive electrode for a non-aqueous lithium cell is disclosed. The cell is prepared in its initial discharged state and has a general formula xLiMO2.(1-x)Li2M′O3 in which 0<x<1, and where M is more than one ion with an average trivalent oxidation state and with at least one ion being Ni, and where M′ is one or more ions with an average tetravalent oxidation state. Complete cells or batteries are disclosed with anode, cathode and electrolyte as are batteries of several cells connected in parallel or series or both.

Owner:CHICAGO UNIV OF THE +1

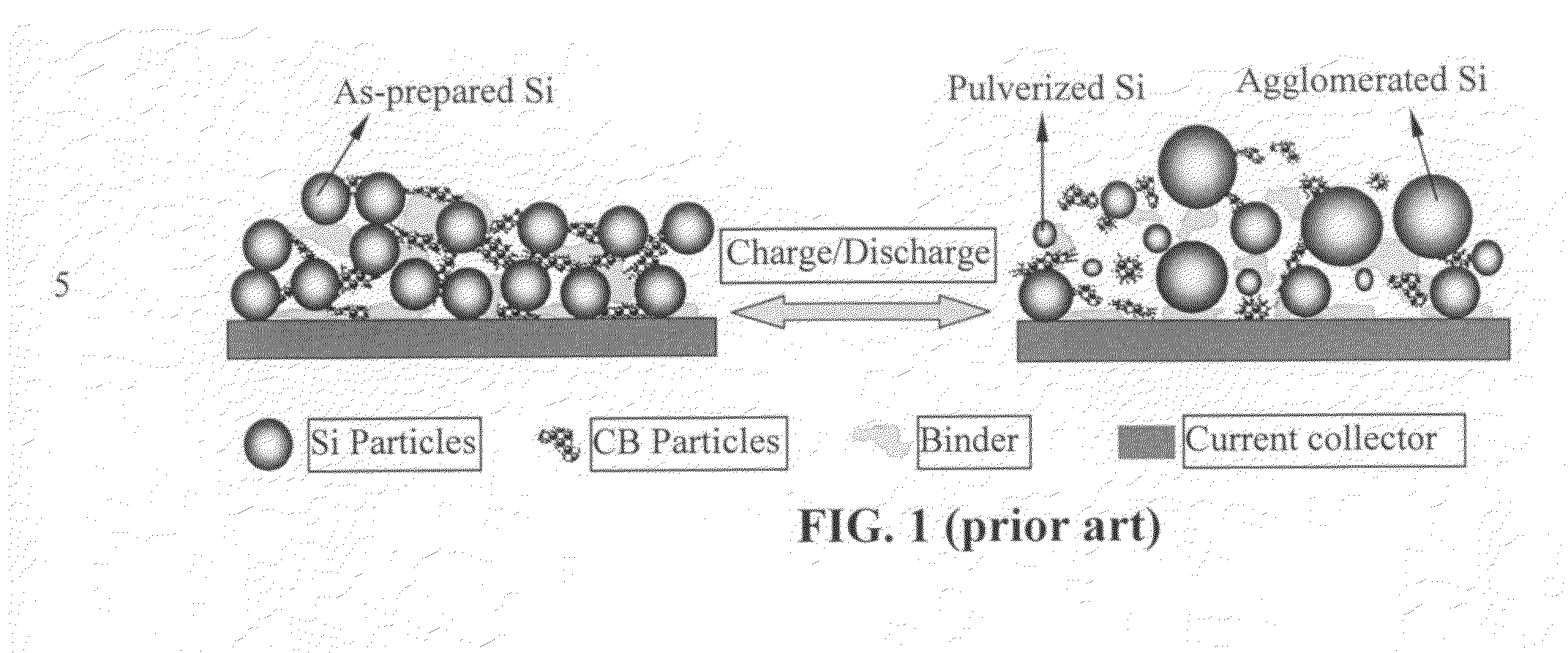

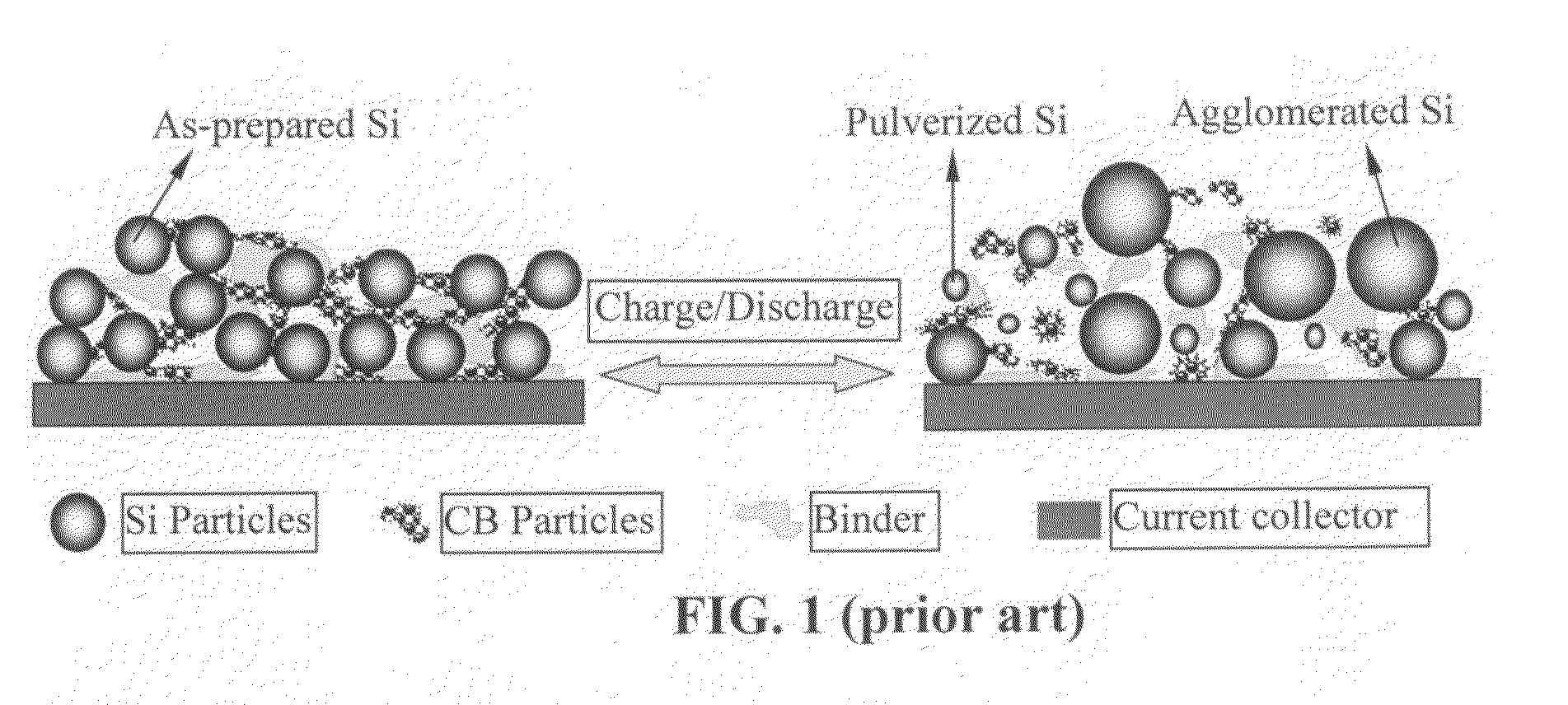

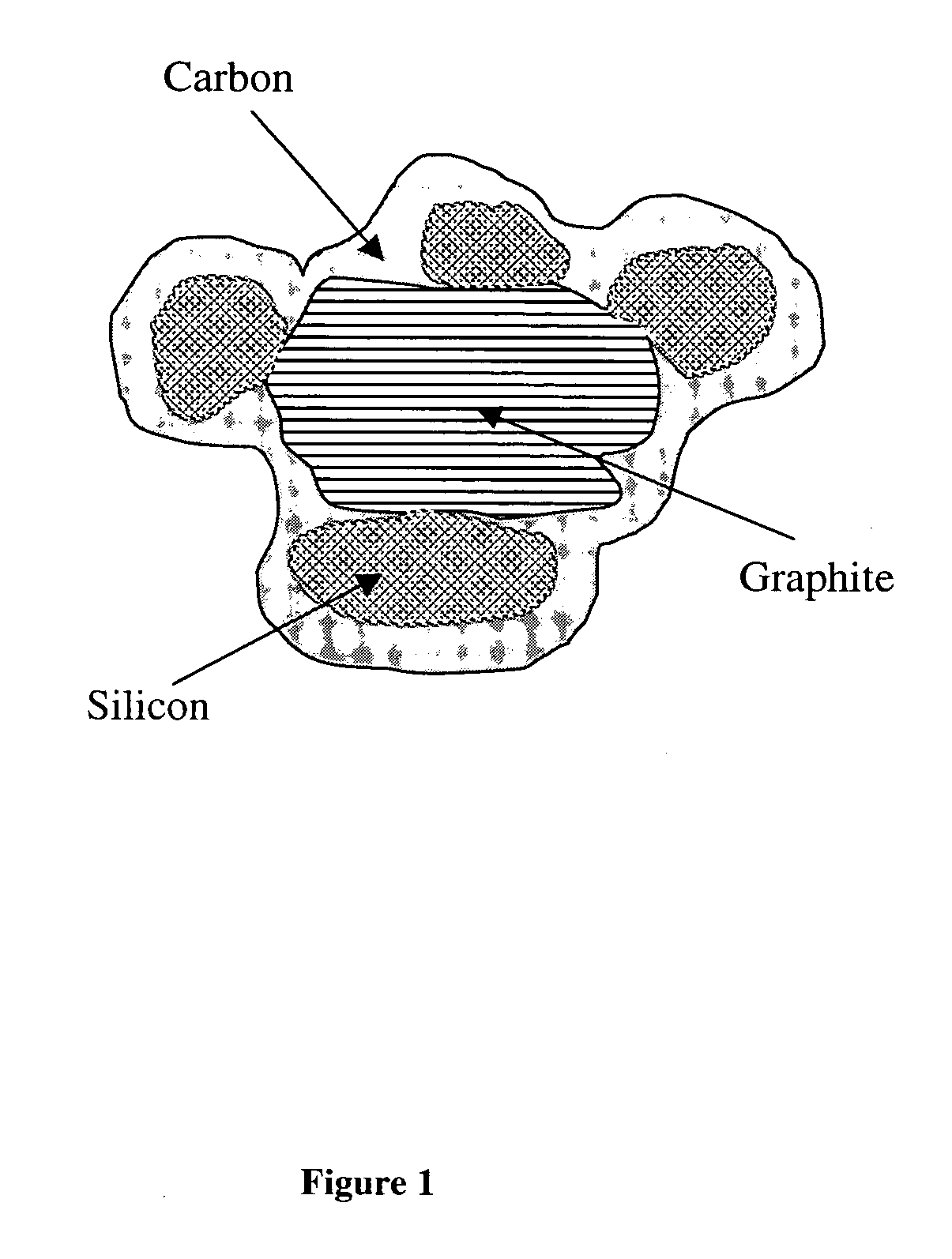

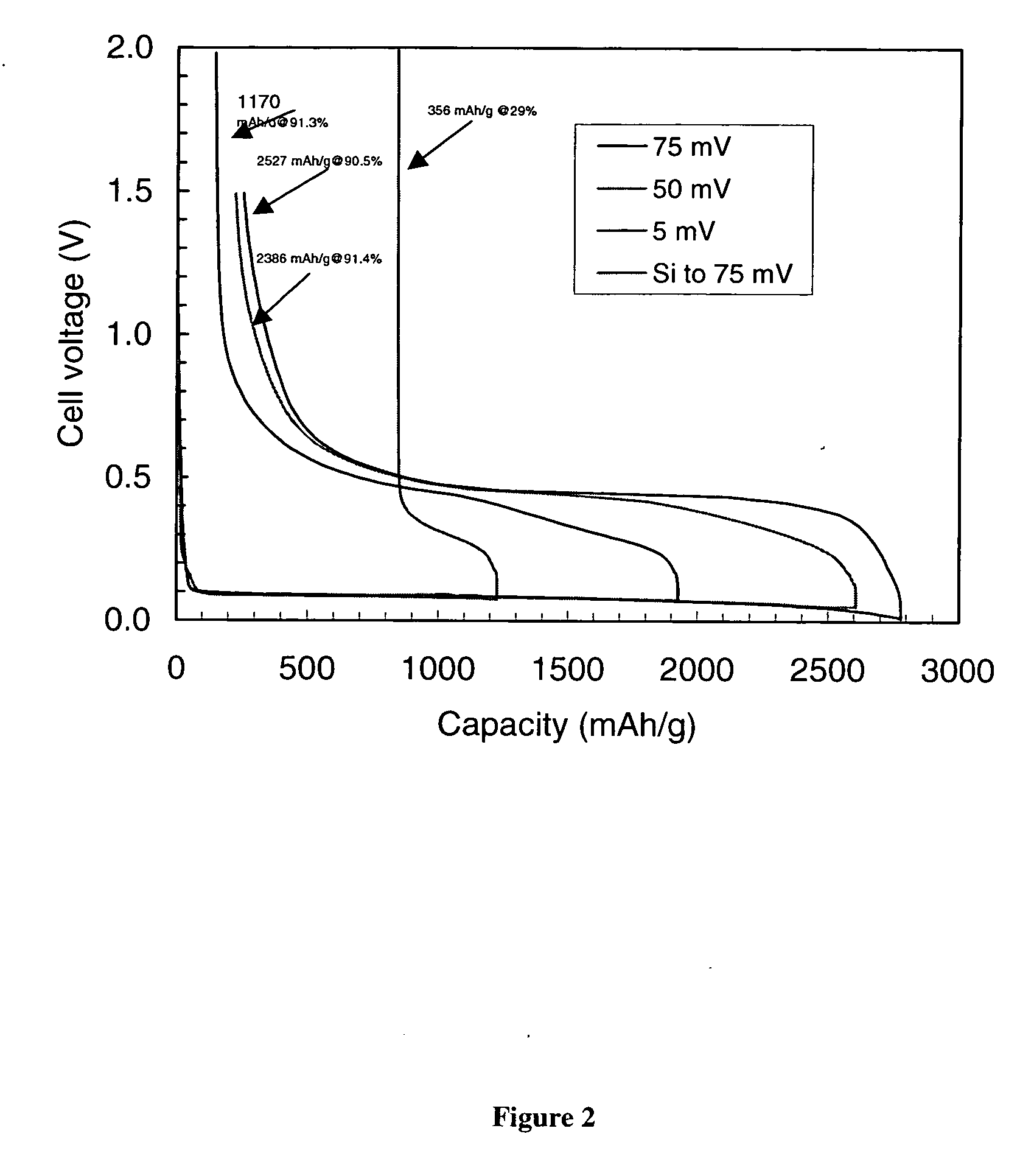

High Capacity Anode Materials for Lithium Ion Batteries

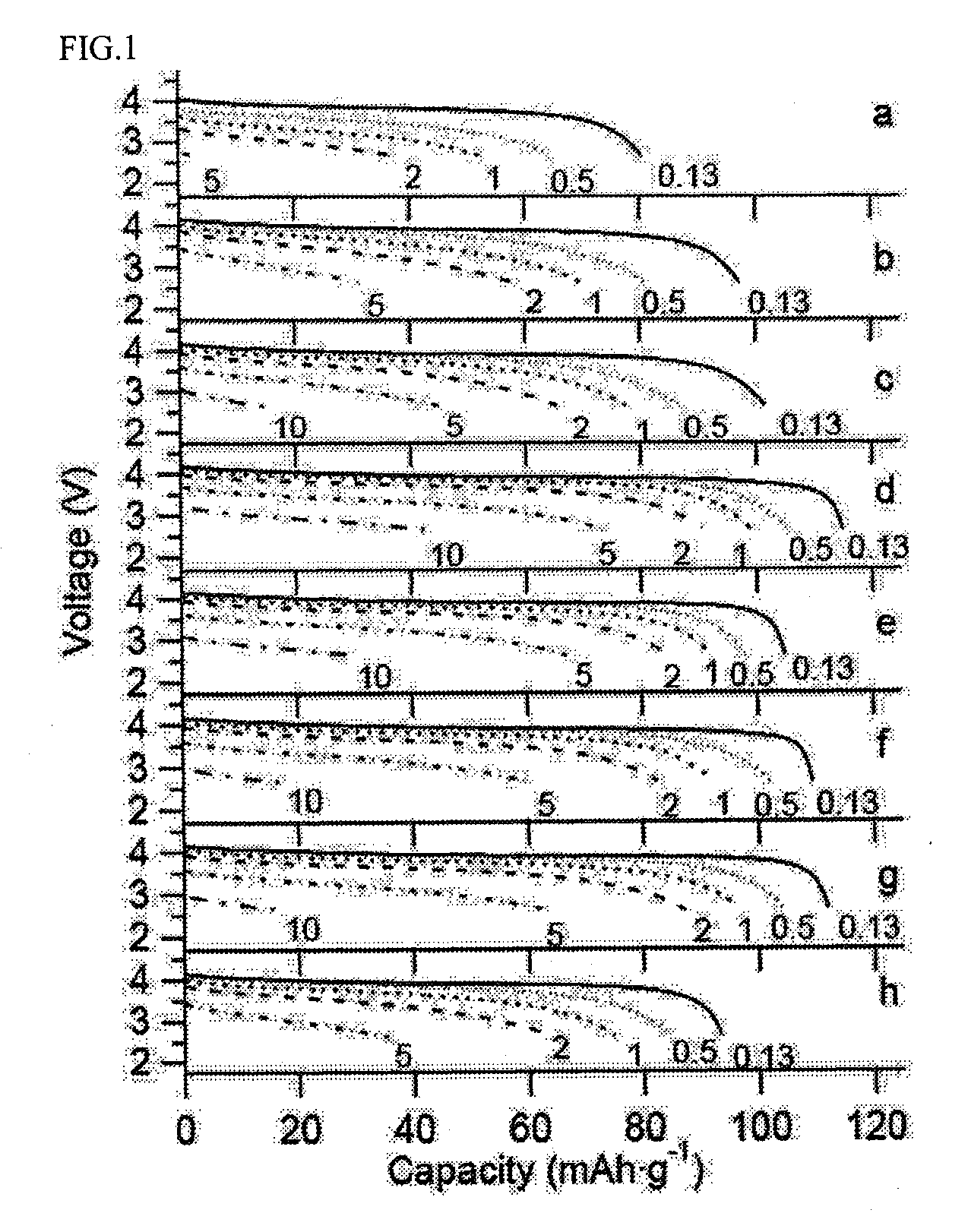

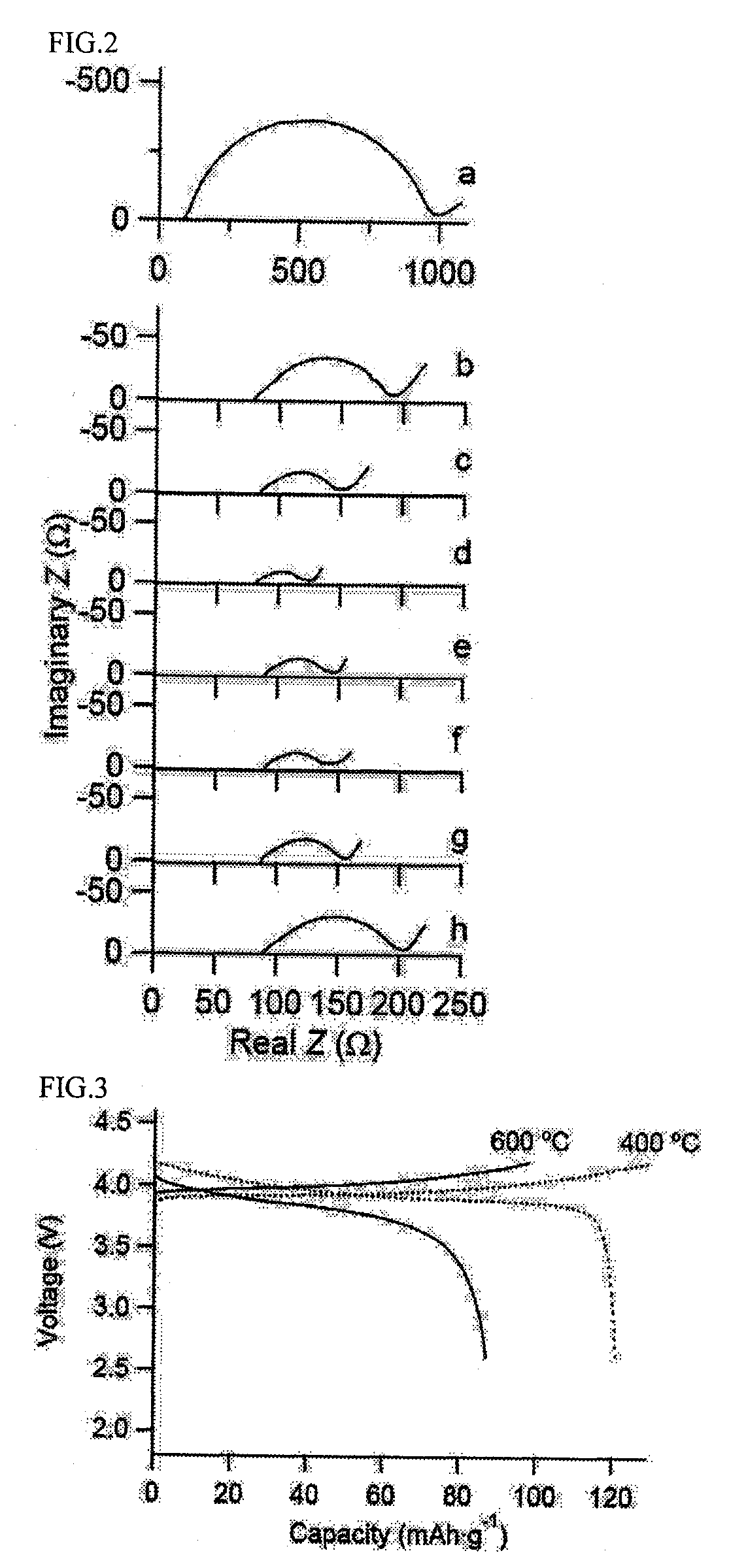

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

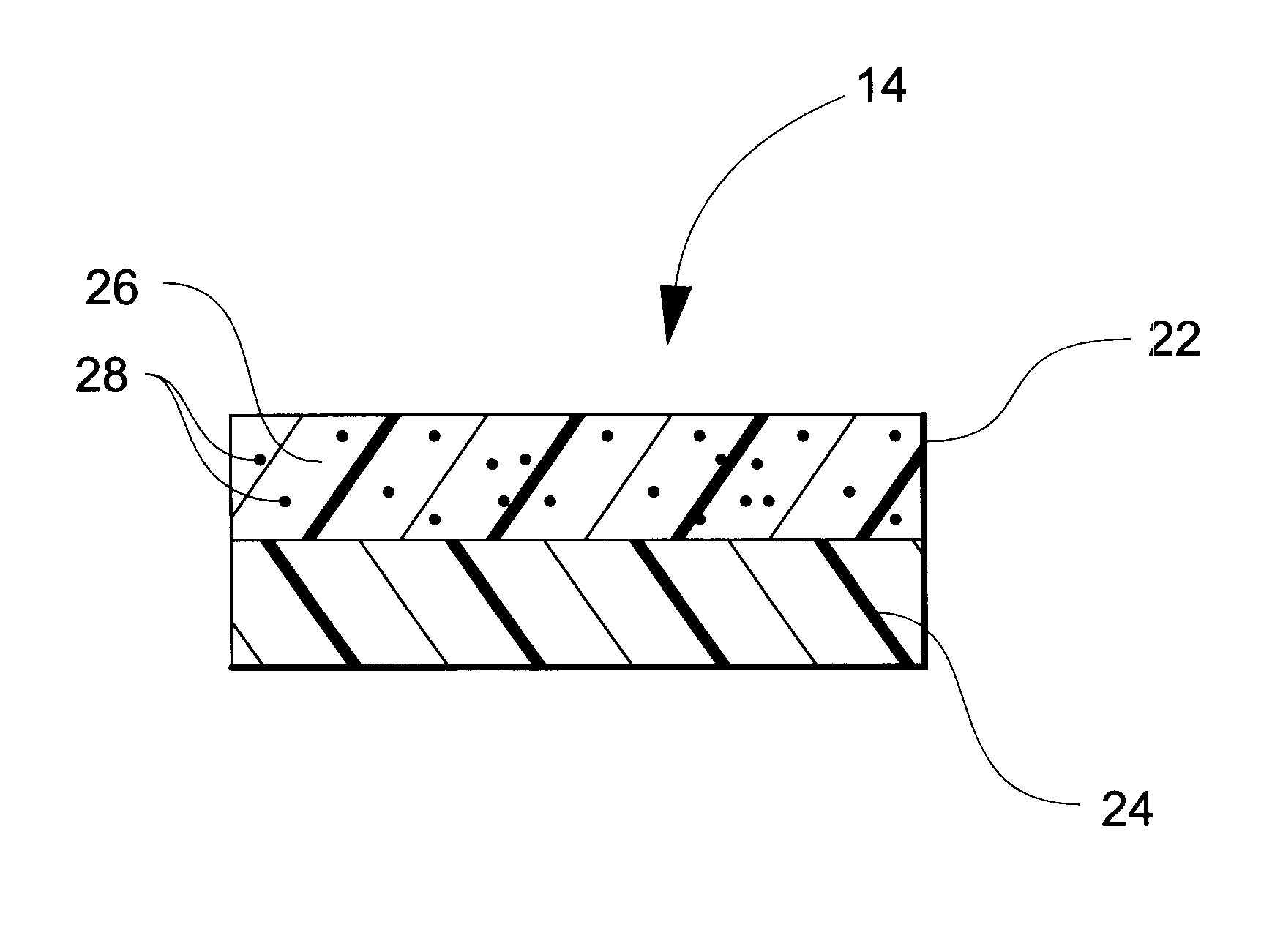

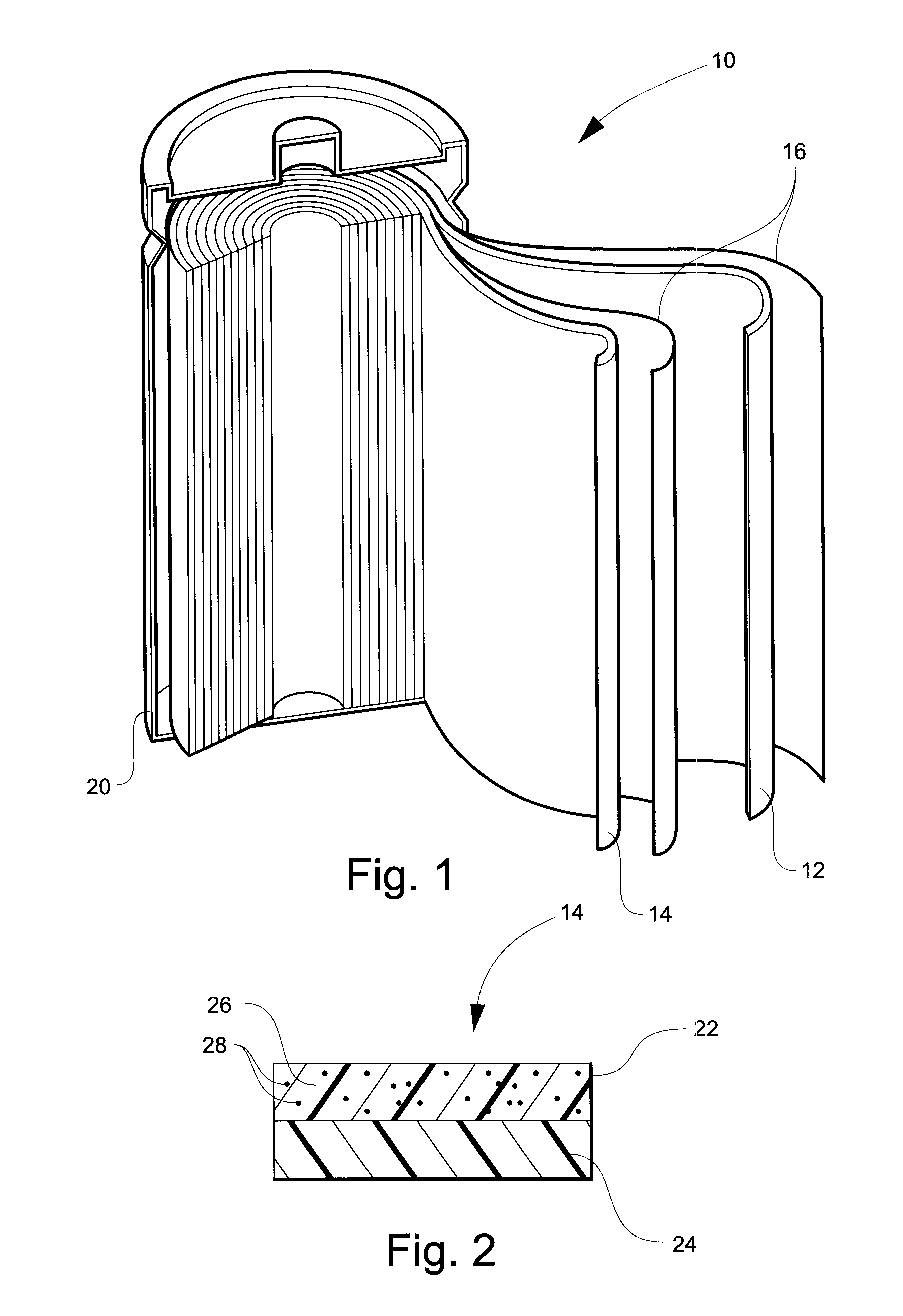

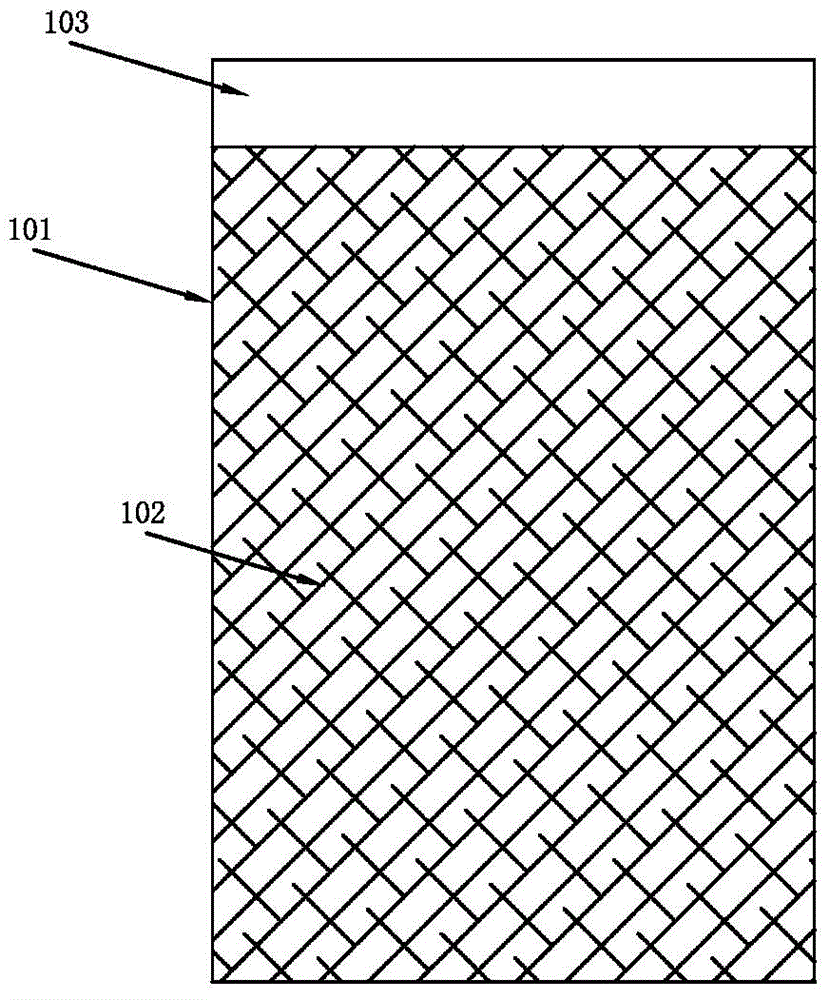

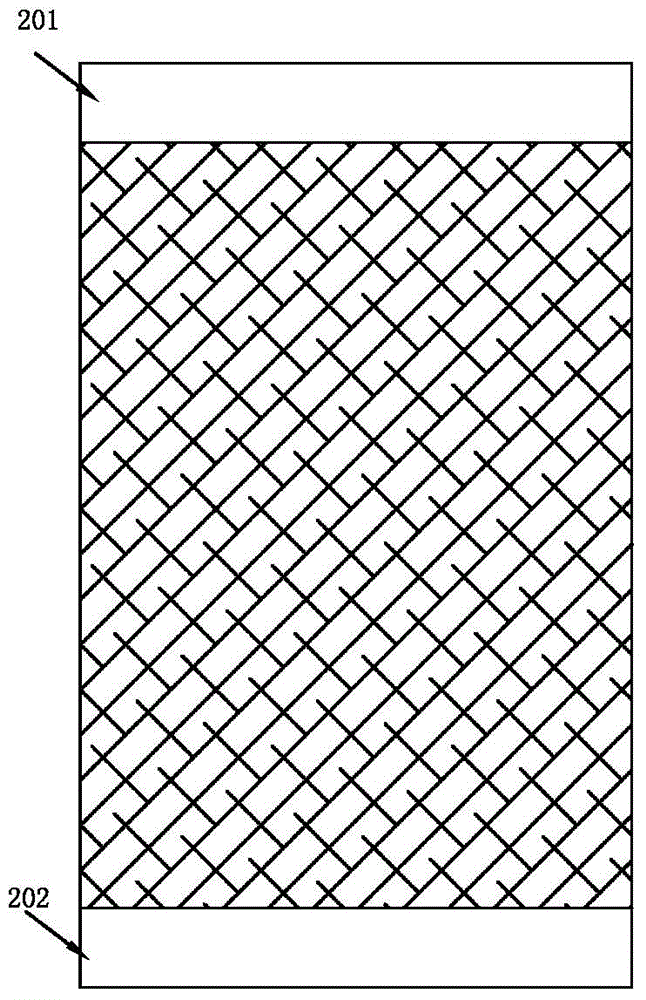

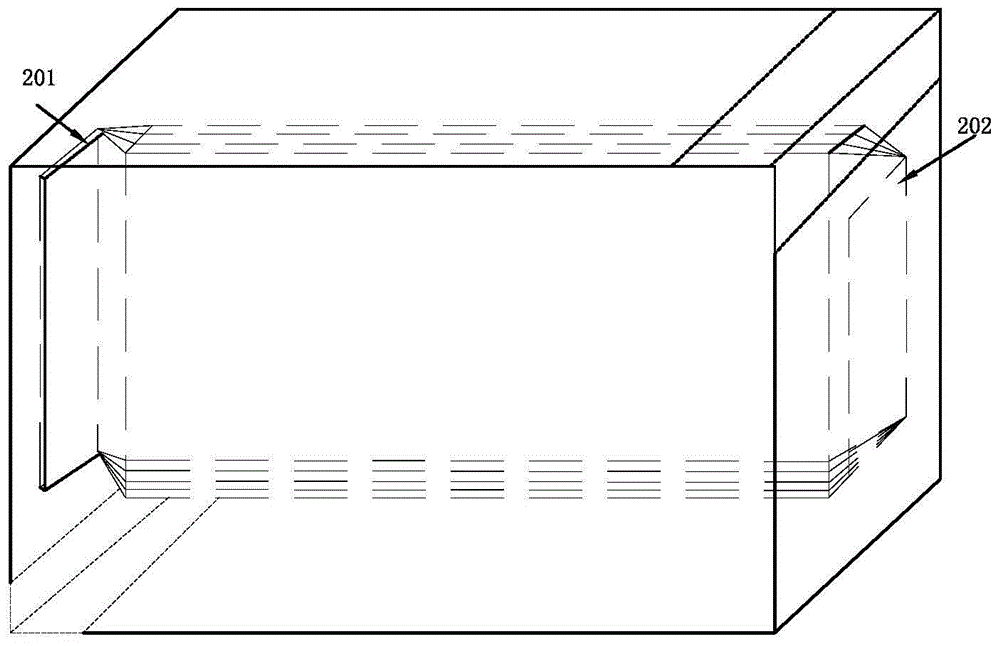

Laminated lithium ion battery, battery pack comprising same and pole piece of laminated lithium ion battery

InactiveCN104882635AImprove cooling effectReduce welding processFinal product manufactureElectrode carriers/collectorsInternal resistanceElectrical battery

Disclosed are a laminated lithium ion battery, a battery pack comprising the same and a pole piece of the laminated lithium ion battery. The pole piece comprises a current collector and an active material layer, wherein the current collector is coated with the active material layer. A section of continuous uncoated area is arranged at the tail end of a first width end portion of the pole piece, the top face and the bottom face of the uncoated area are not coated with the active material layer, the current collector is exposed in the uncoated area, and the exposed current collector serves as a pole lug of the pole piece. By the pole piece, internal resistance of the lithium ion battery is reduced and heat dissipation performance of the battery is improved.

Owner:SHENZHEN GREPOW BATTERY CO LTD

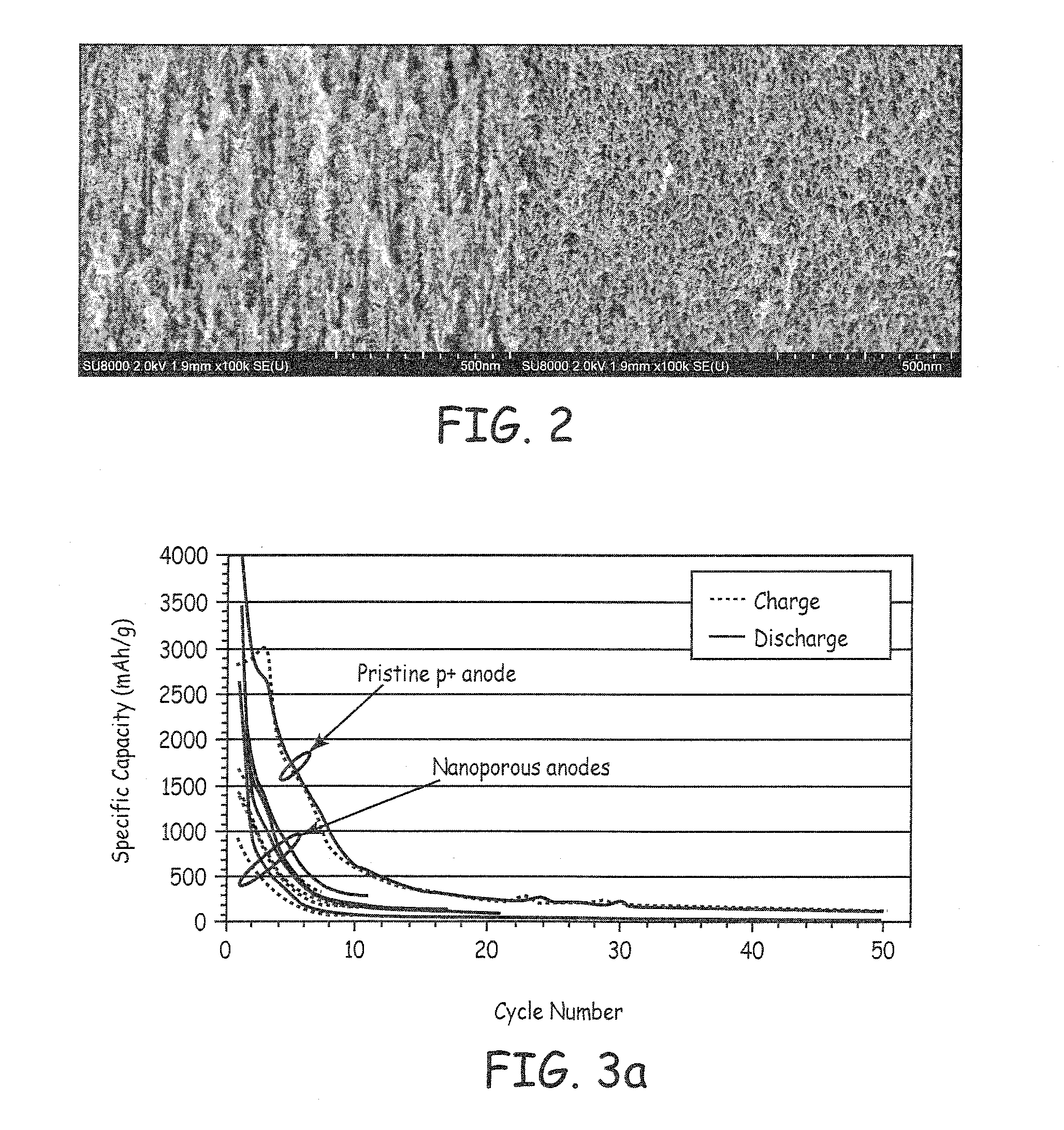

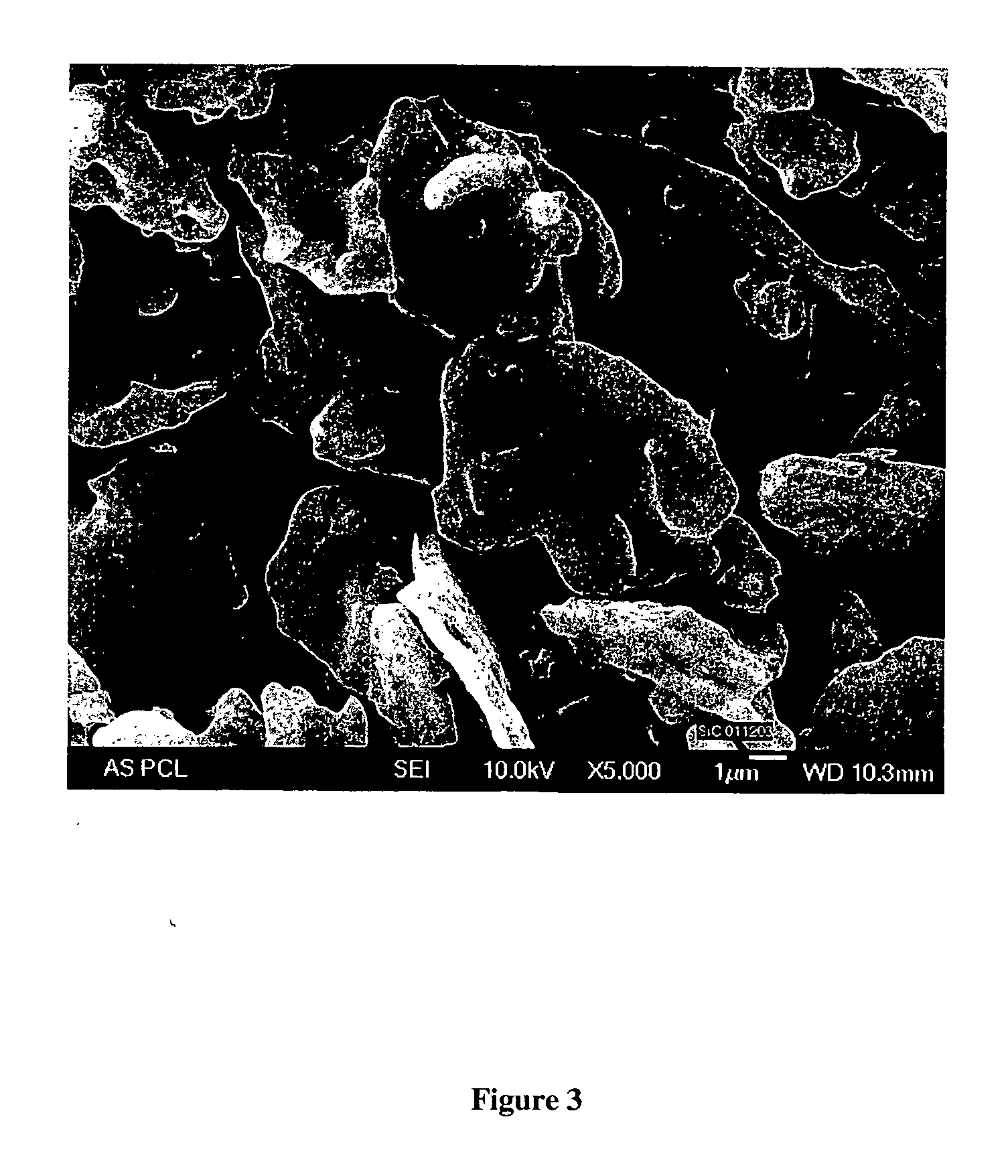

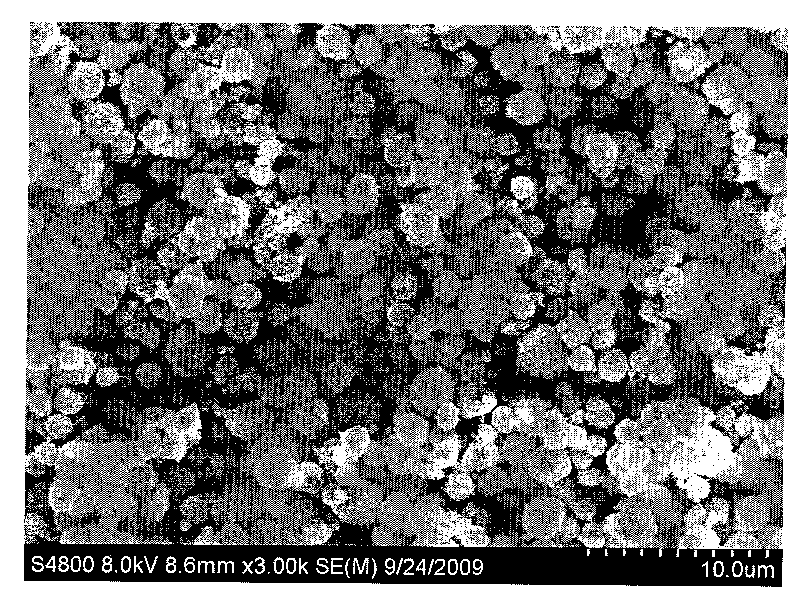

Porous silicon particulates for lithium batteries

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

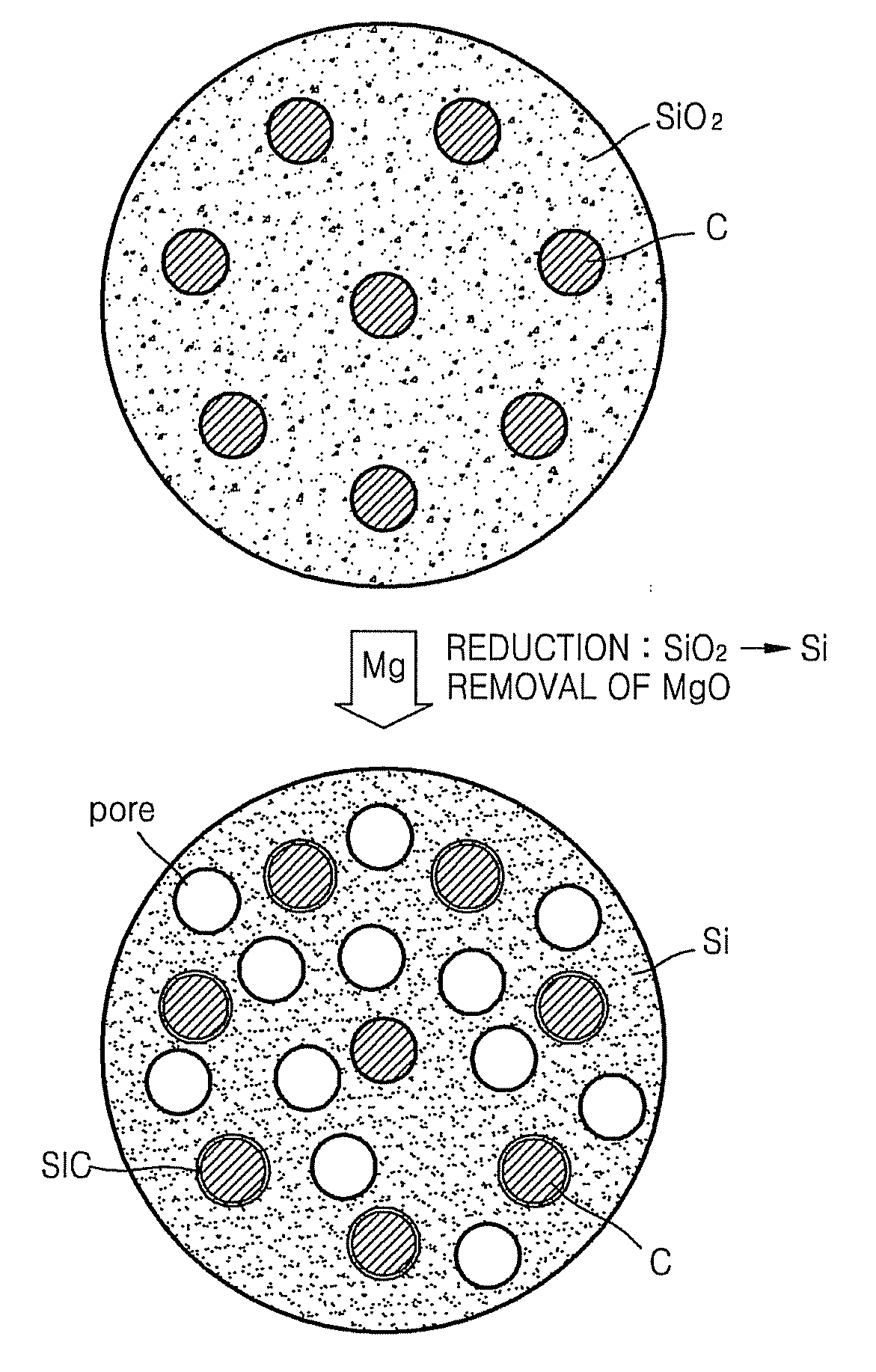

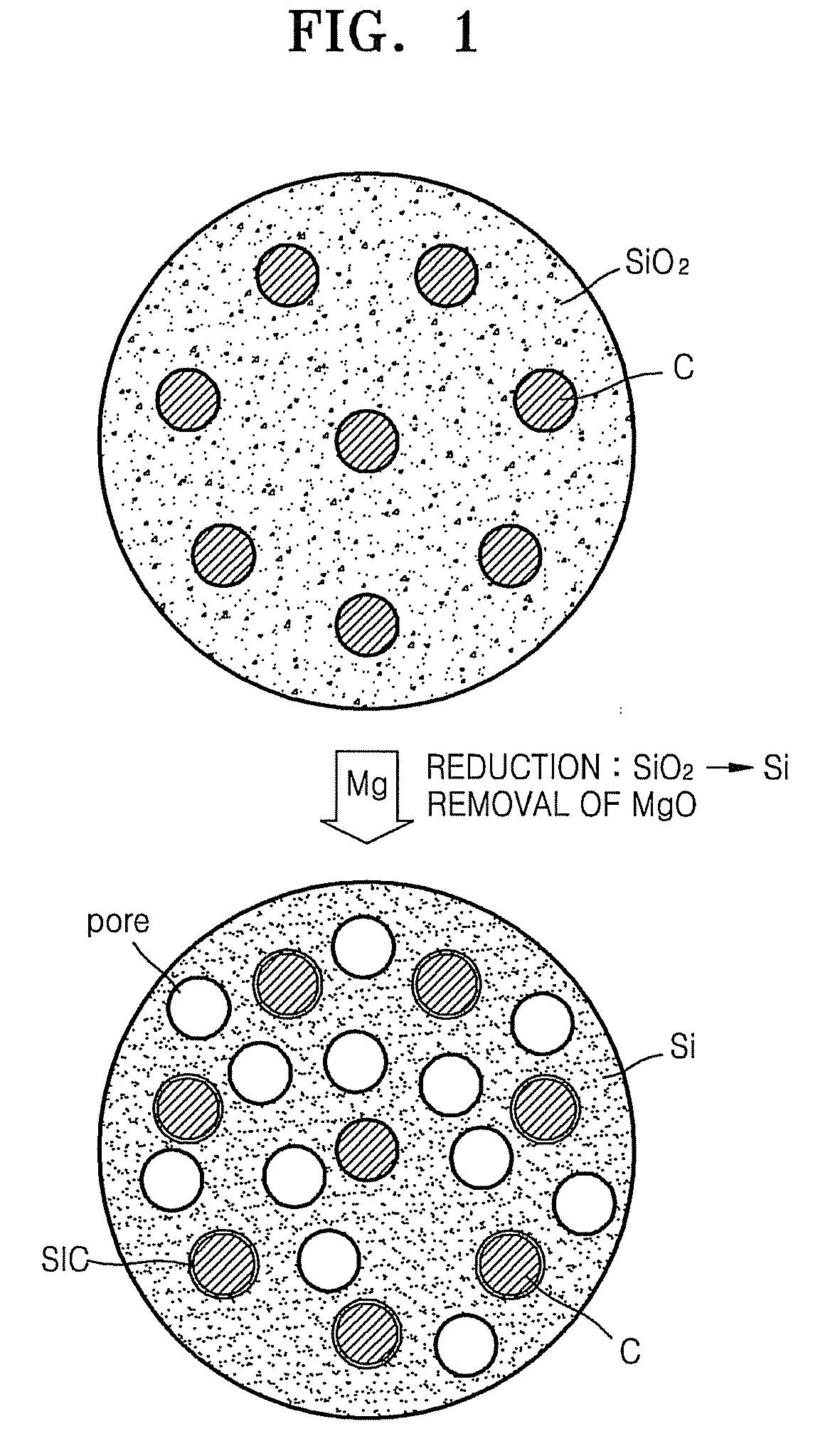

Si/c composite, anode active materials, and lithium battery including the same

ActiveUS20090029256A1Improve initial Coulombic efficiencyGood capacity retentionLiquid surface applicatorsElectrode manufacturing processesLithium-ion batteryPorous silicon

An Si / C composite includes carbon (C) dispersed in porous silicon (Si) particles. The Si / C composite may be used to form an anode active material to provide a lithium battery having a high capacity and excellent capacity retention.

Owner:SAMSUNG SDI CO LTD

Carbon-coated silicon particle power as the anode material for lithium batteries and the method of making the same

InactiveUS20050136330A1Large capacityImprove efficiencyElectrode thermal treatmentElectrode carriers/collectorsCarbon compositesSilicon particle

A process for the production of coated silicon / carbon particles comprising: providing a carbon residue forming material; providing silicon particles; coating said silicon particles with said carbon residue forming material to form coated silicon particles; providing particles of a carbonaceous material; coating said particles of carbonaceous material with said carbon residue forming material to form coated carbonaceous particles; embedding said coated silicon particles onto said coated carbonaceous particles to form silicon / carbon composite particles; coating said silicon / carbon composite particles with said carbon residue forming material to form coated silicon / carbon composite particles; and stabilizing the coated composite particles by subjecting said coated composite particles to an oxidation reaction. The coated composite particles will have a substantially smooth coating. The particles may be coated with multiple layers of carbon residue forming material /

Owner:PYROTECK INC

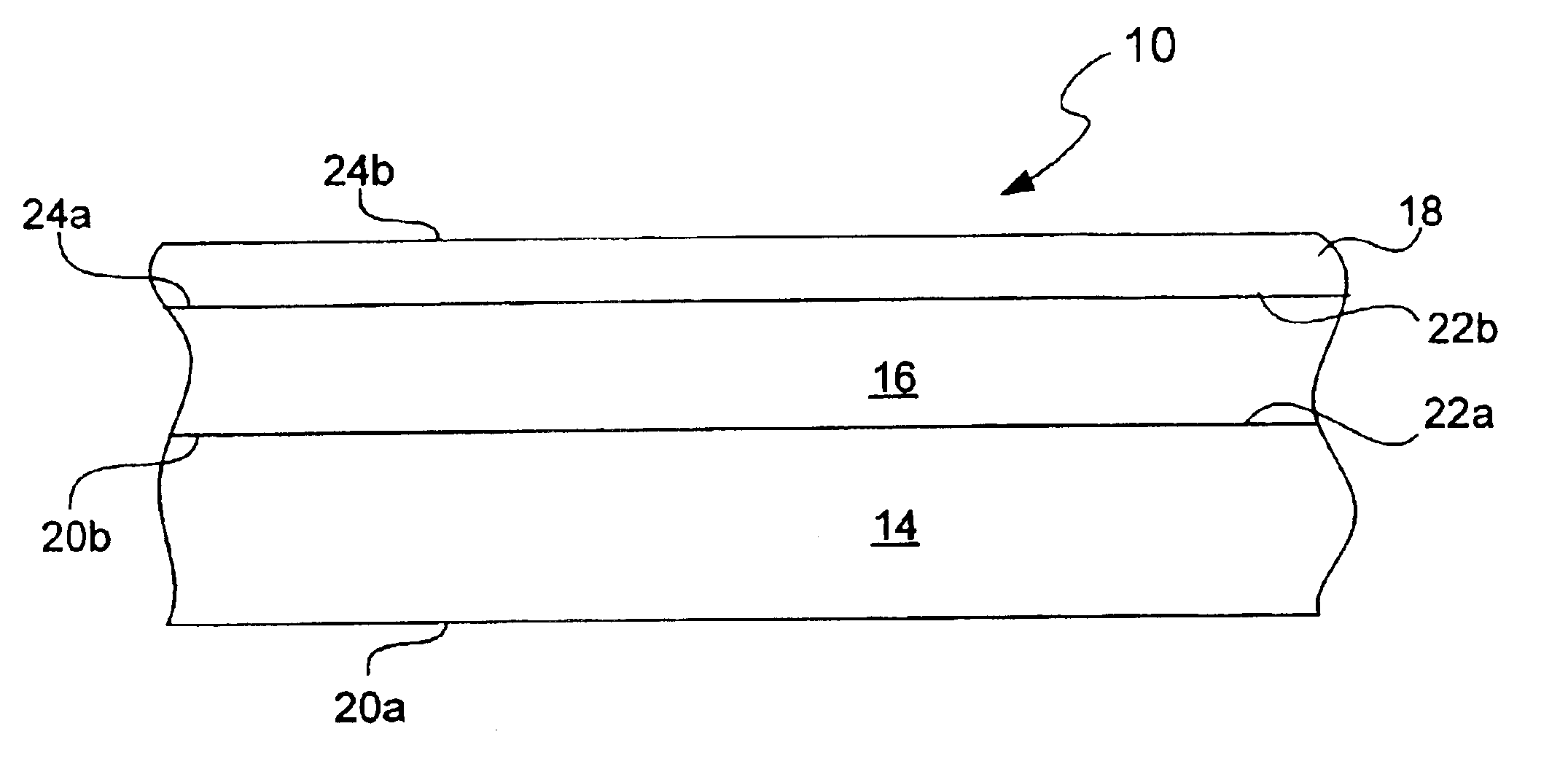

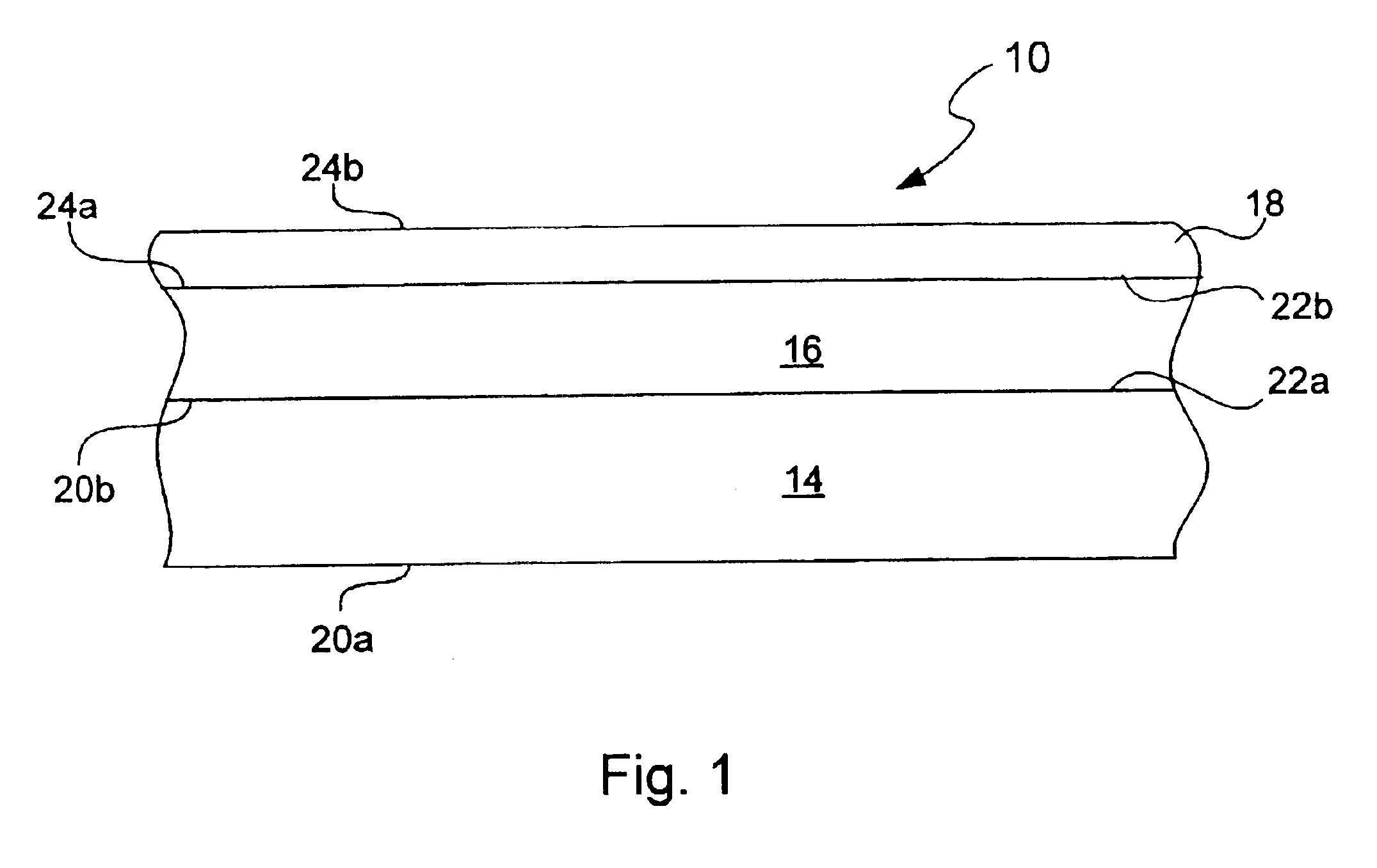

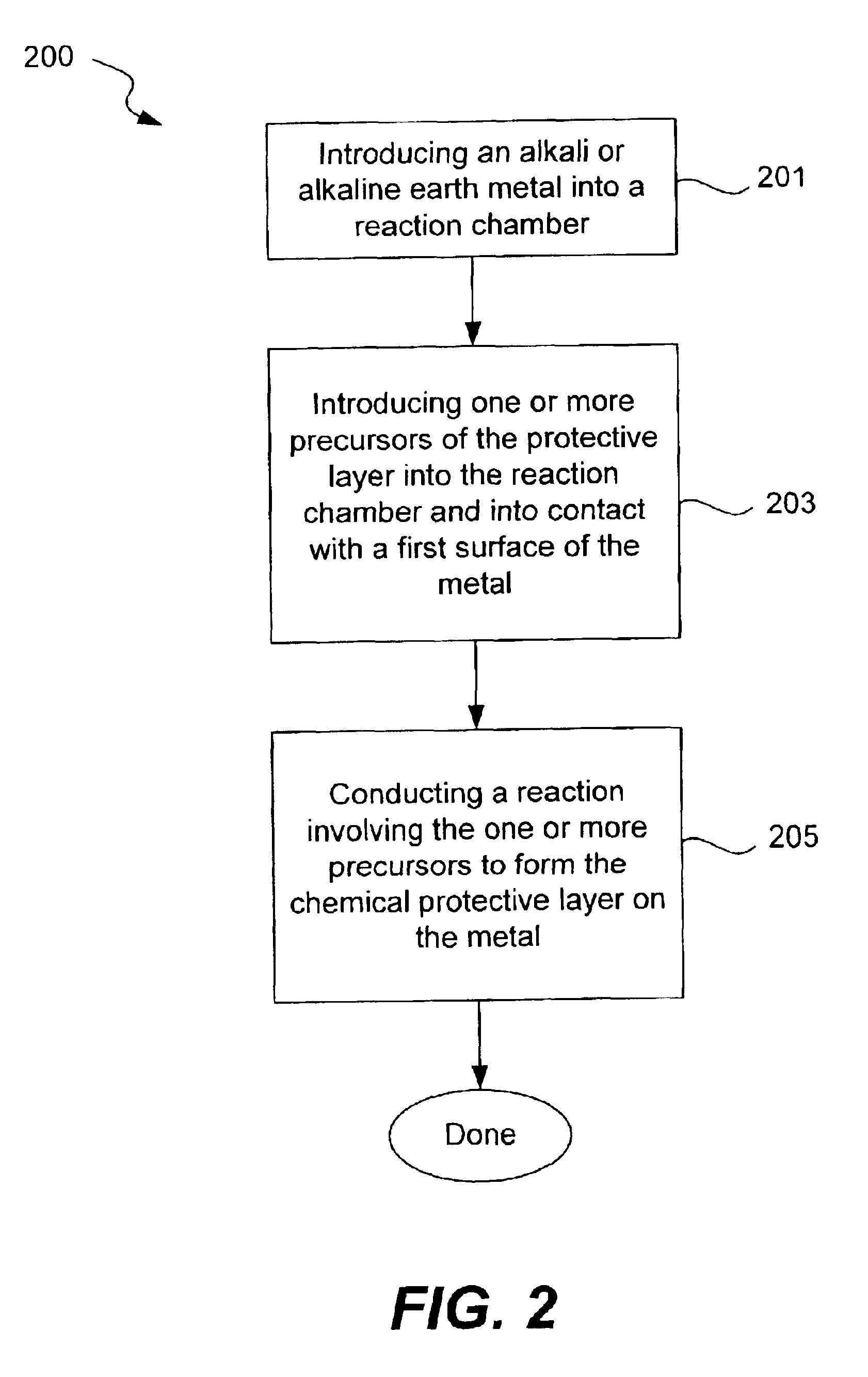

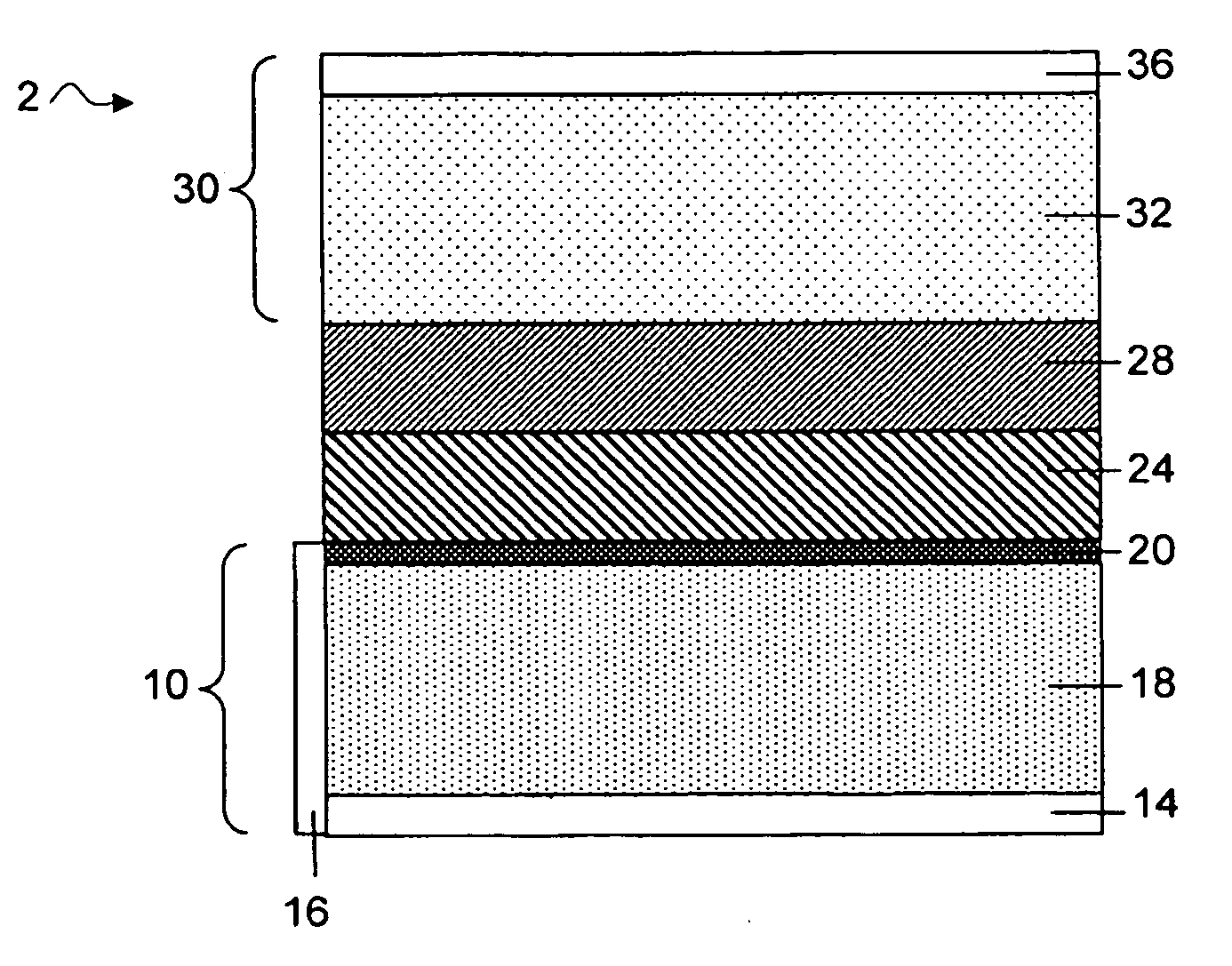

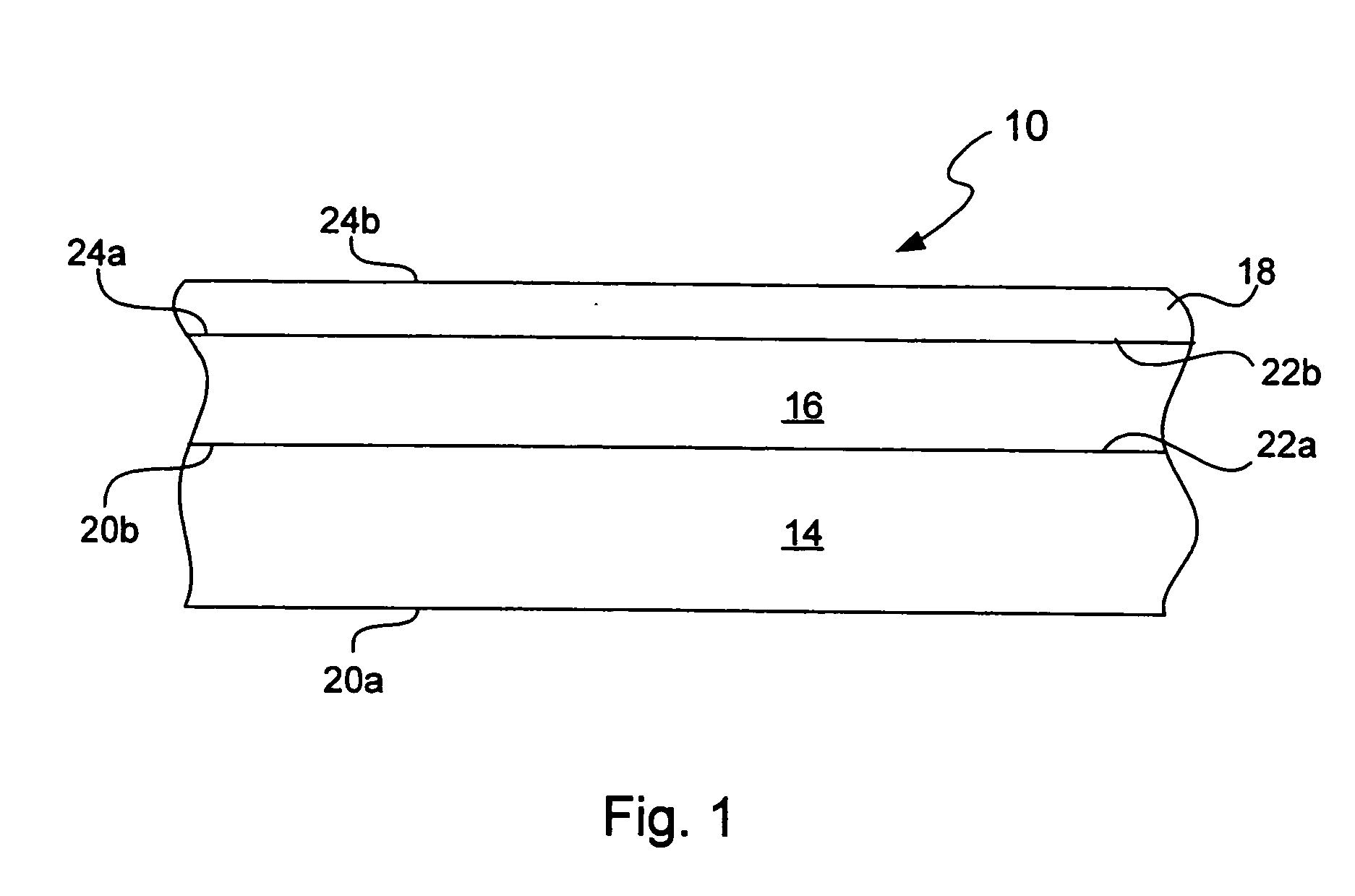

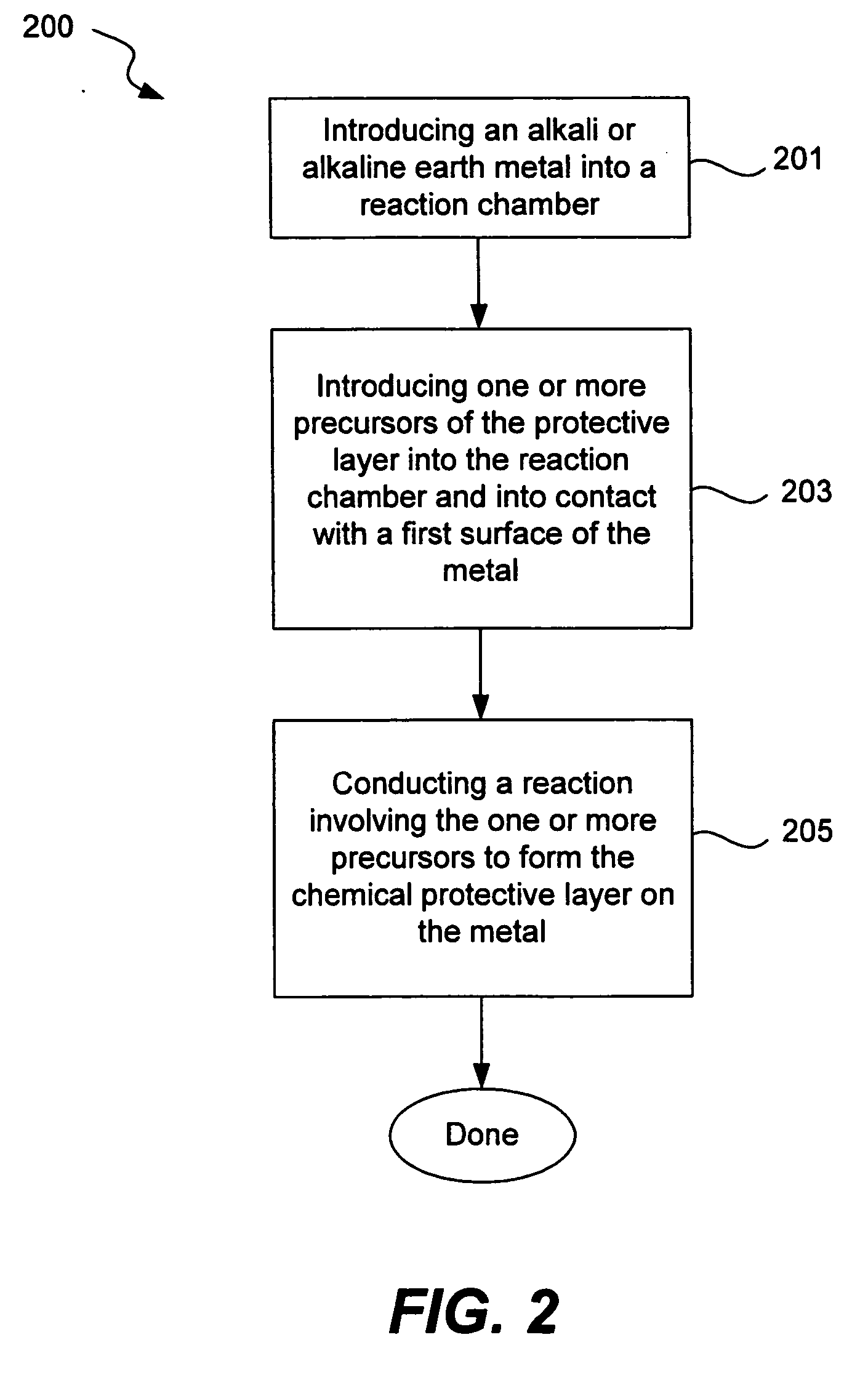

Chemical protection of a lithium surface

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Separation of electrolytes

Methods and articles relating to separation of electrolyte compositions within lithium batteries are provided. The lithium batteries described herein may include an anode having lithium as the active anode species and a cathode having sulfur as the active cathode species. Suitable electrolytes for the lithium batteries can comprise a heterogeneous electrolyte including a first electrolyte solvent (e.g., dioxolane (DOL)) that partitions towards the anode and is favorable towards the anode (referred to herein as an “anode-side electrolyte solvent”) and a second electrolyte solvent (e.g., 1,2-dimethoxyethane (DME)) that partitions towards the cathode and is favorable towards the cathode (and referred to herein as an “cathode-side electrolyte solvent”). By separating the electrolyte solvents during operation of the battery such that the anode-side electrolyte solvent is present disproportionately at the anode and the cathode-side electrolyte solvent is present disproportionately at the cathode, the battery can benefit from desirable characteristics of both electrolyte solvents (e.g., relatively low lithium reactivity of the anode-side electrolyte solvent and relatively high polysulfide solubility of the cathode-side electrolyte solvent).

Owner:SION POWER CORP

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

ActiveUS20050233213A1Improved cycle-life characteristic and charge and discharge characteristicIncrease chanceElectrode manufacturing processesNon-aqueous electrolyte accumulatorsHigh rateSilicon oxide

The present invention relates to a negative active material for a rechargeable lithium battery, which includes a silicon-based composite having a silicon oxide of the form SiOX where x≦1.5 and at least one element selected from the group consisting of B, P, Li, Ge, Al, and V, and a carbonaceous material. The negative active material of the present invention can improve the cycle-life and high-rate charge / discharge characteristics of a rechargeable lithium battery.

Owner:SAMSUNG SDI CO LTD

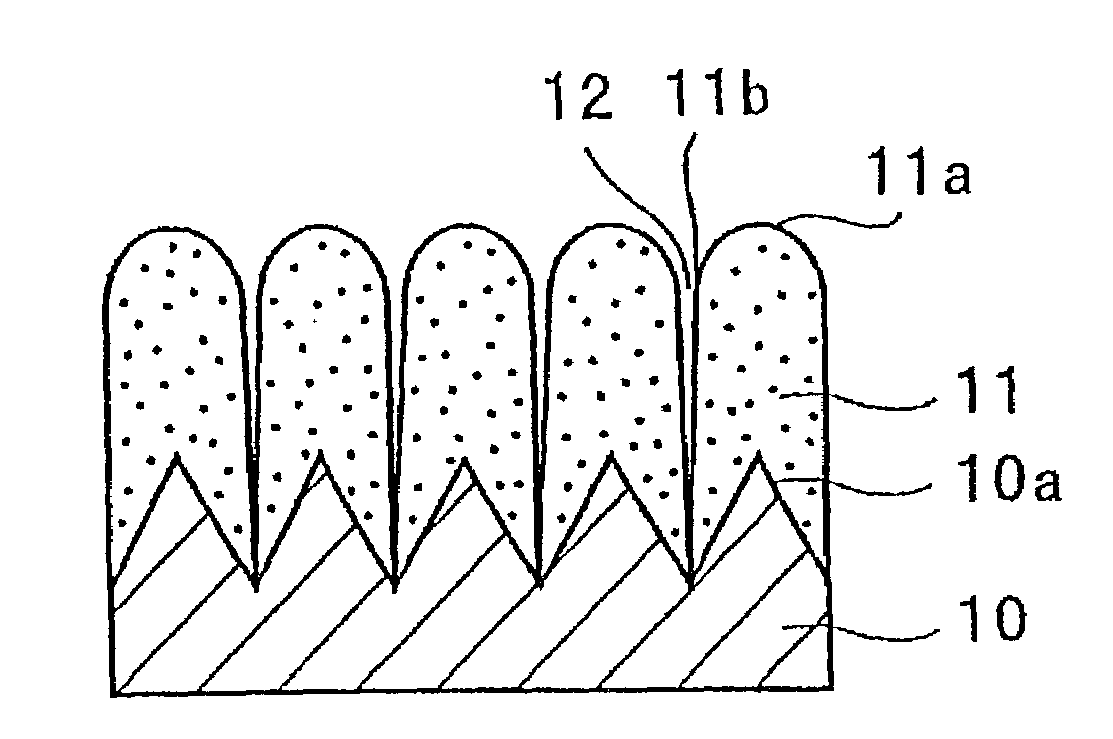

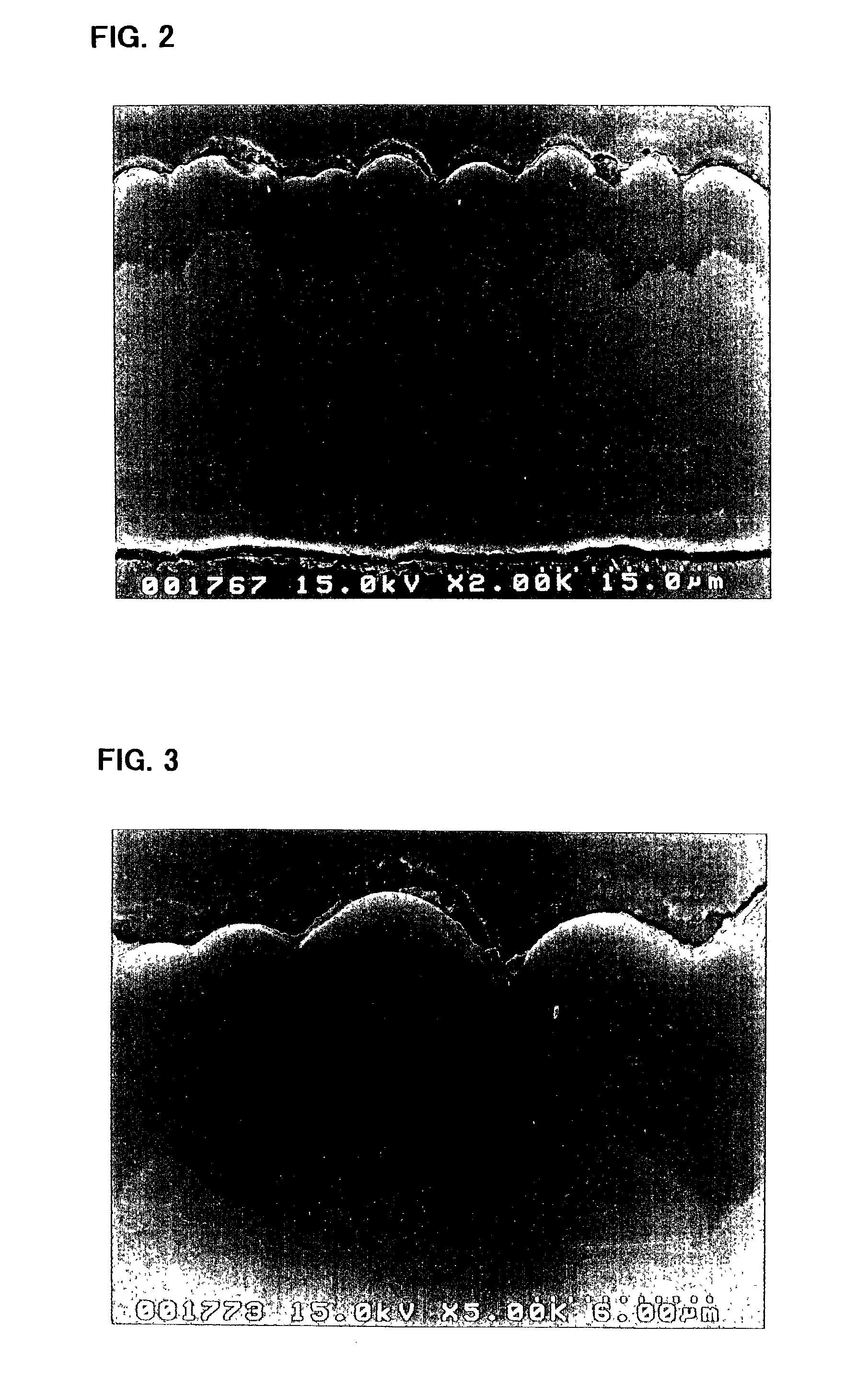

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7192673B1Improve charge and discharge cycle characteristicsInhibition formationElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconMaterials science

An electrode for a rechargeable lithium battery which includes a thin film composed of active material that expands and shrinks as it stores and releases lithium, e.g., a microcrystalline or amorphous silicon thin film, deposited on a current collector, characterized in that said current collector exhibits a tensile strength (=tensile strength (N / mm2) per sectional area of the current collector material×thickness (mm) of the current collector) of not less than 3.82 N / mm.

Owner:SANYO ELECTRIC CO LTD

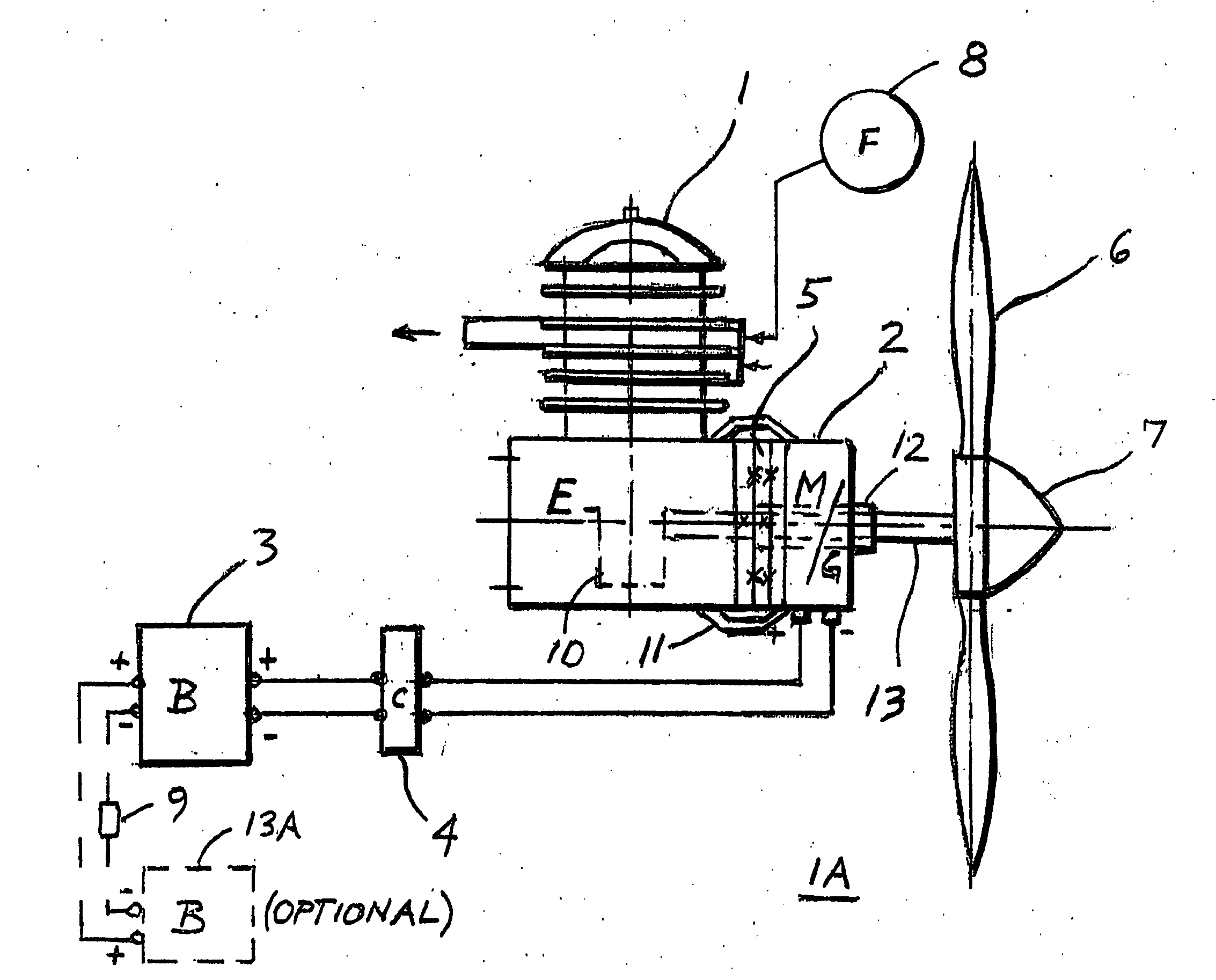

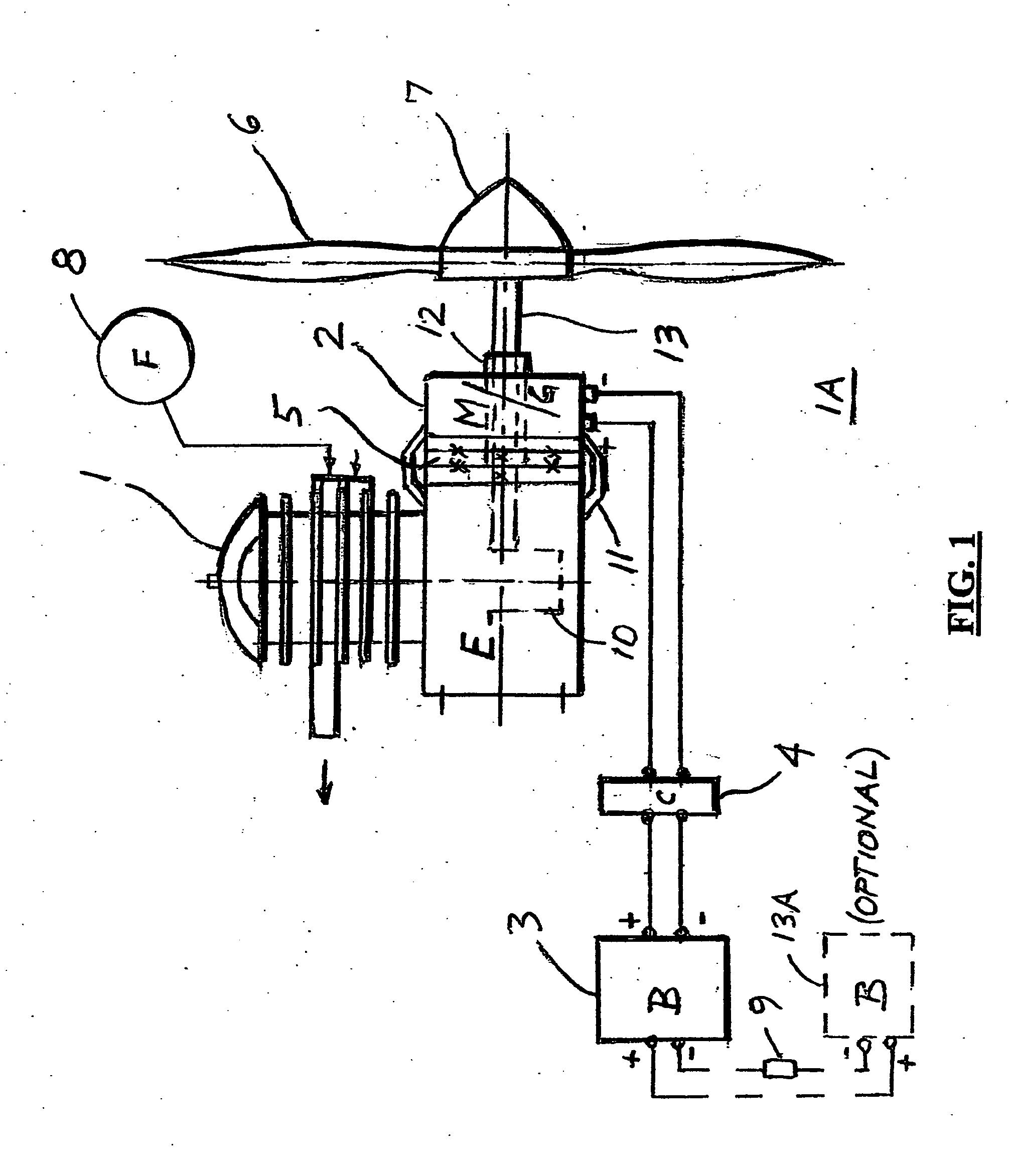

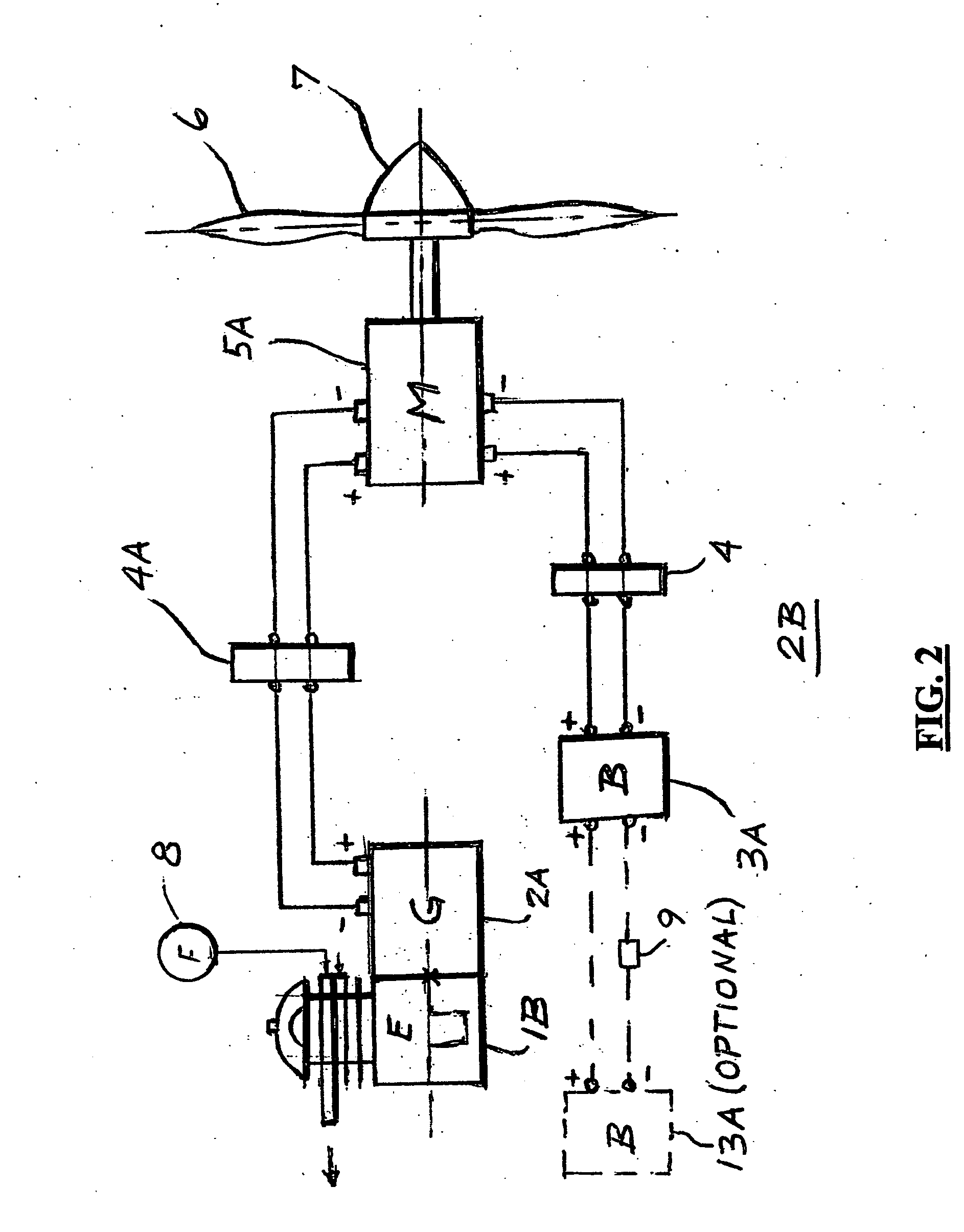

Long range hybrid electric airplane

InactiveUS20080184906A1Long range of flightLow system efficiencyPropellersAircraft stabilisationOperational costsCombustion

An advanced internal combustion-electric hybrid airplane, having at least double the flight range and flight duration than a conventional equivalent airplane, while using the same amount of any desirable fuel. This is achieved by using 2-3× smaller and ultra-lightweight engine for cruising, and ultra-lightweight electric motor powered by lithium batteries during take-off and climbing. The electric motor becomes a generator during cruising and descent, recharging said batteries. The airplane has also temporary silent electric stealth capability and added safety by the electric back-up power. Due to its high efficiency, the operational cost is substantially reduced. Additional features include highly advanced, minimum drag and weight airframe.

Owner:KEJHA JOSEPH B

Batteries including improved fine fiber separators

Alkaline and lithium batteries are disclosed that advantageously include separators comprising at least one porous layer of fine fibers having a diameter of between about 50 nm and about 3000 nm that provide improved combinations of reduced thickness, dendritic barrier against short-circuiting and low ionic resistance as compared with known battery separators.

Owner:DUPONT SAFETY & CONSTR INC

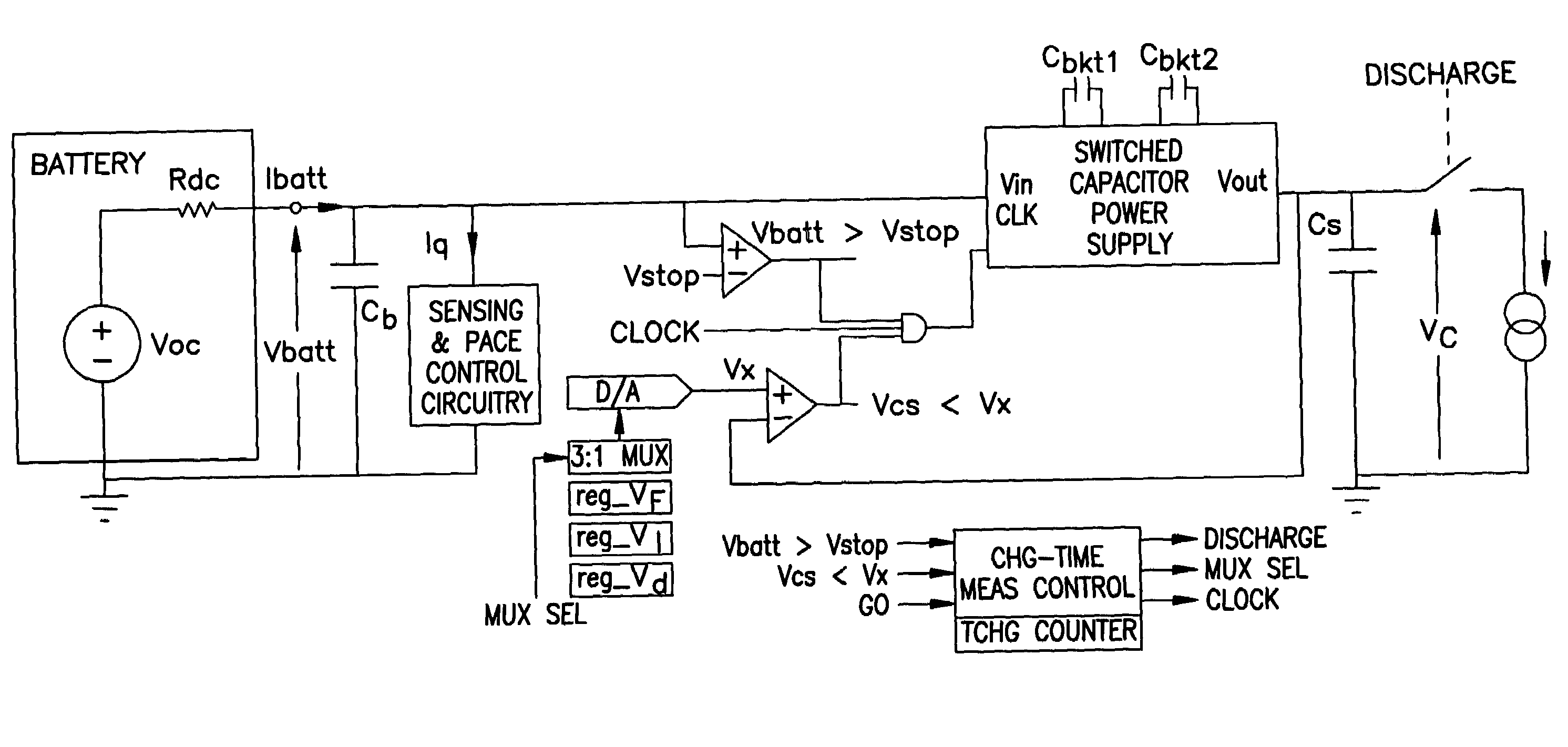

Method for monitoring end of life for battery

InactiveUS7251527B2Good estimateCircuit monitoring/indicationElectrical testingElectricityElectrical battery

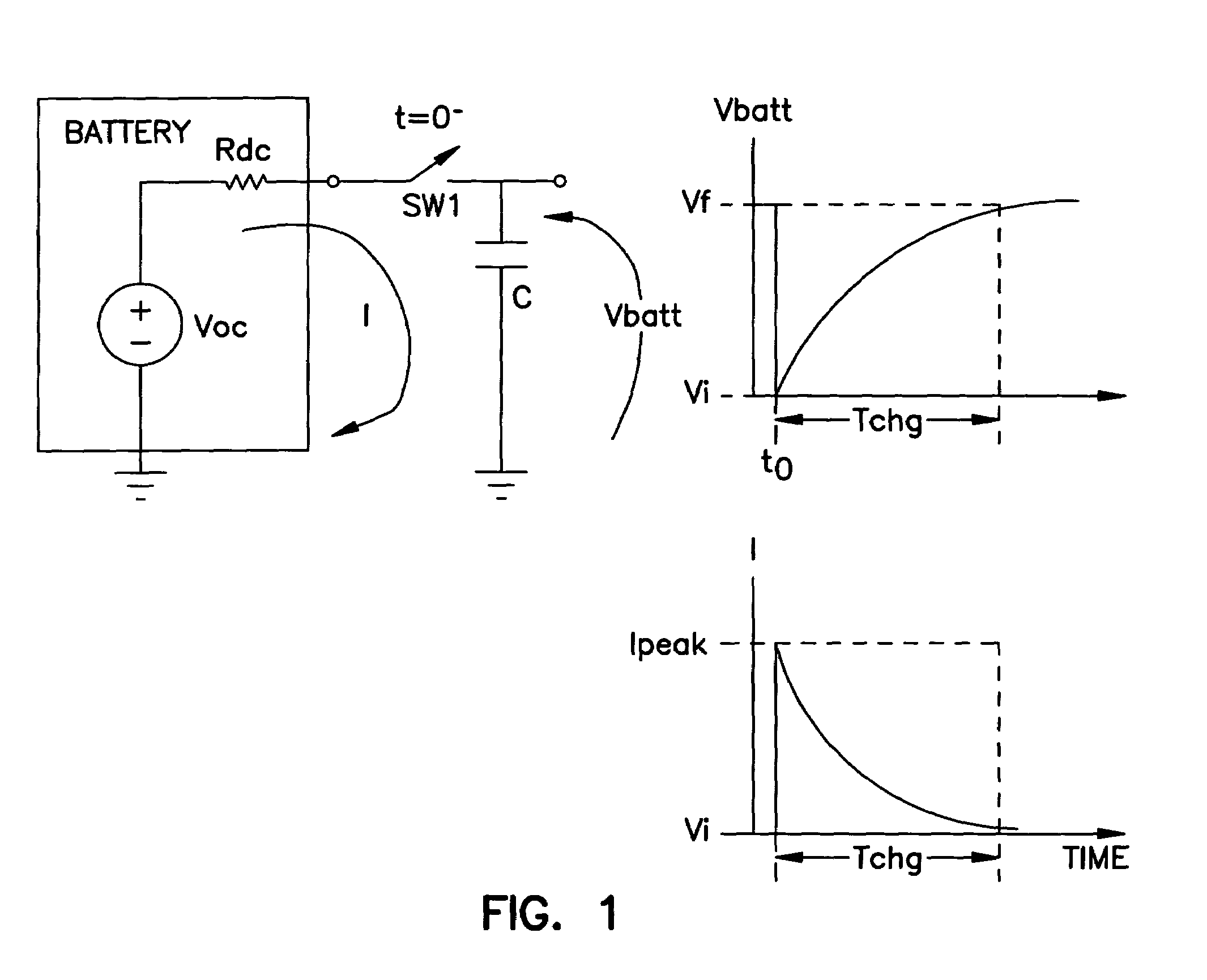

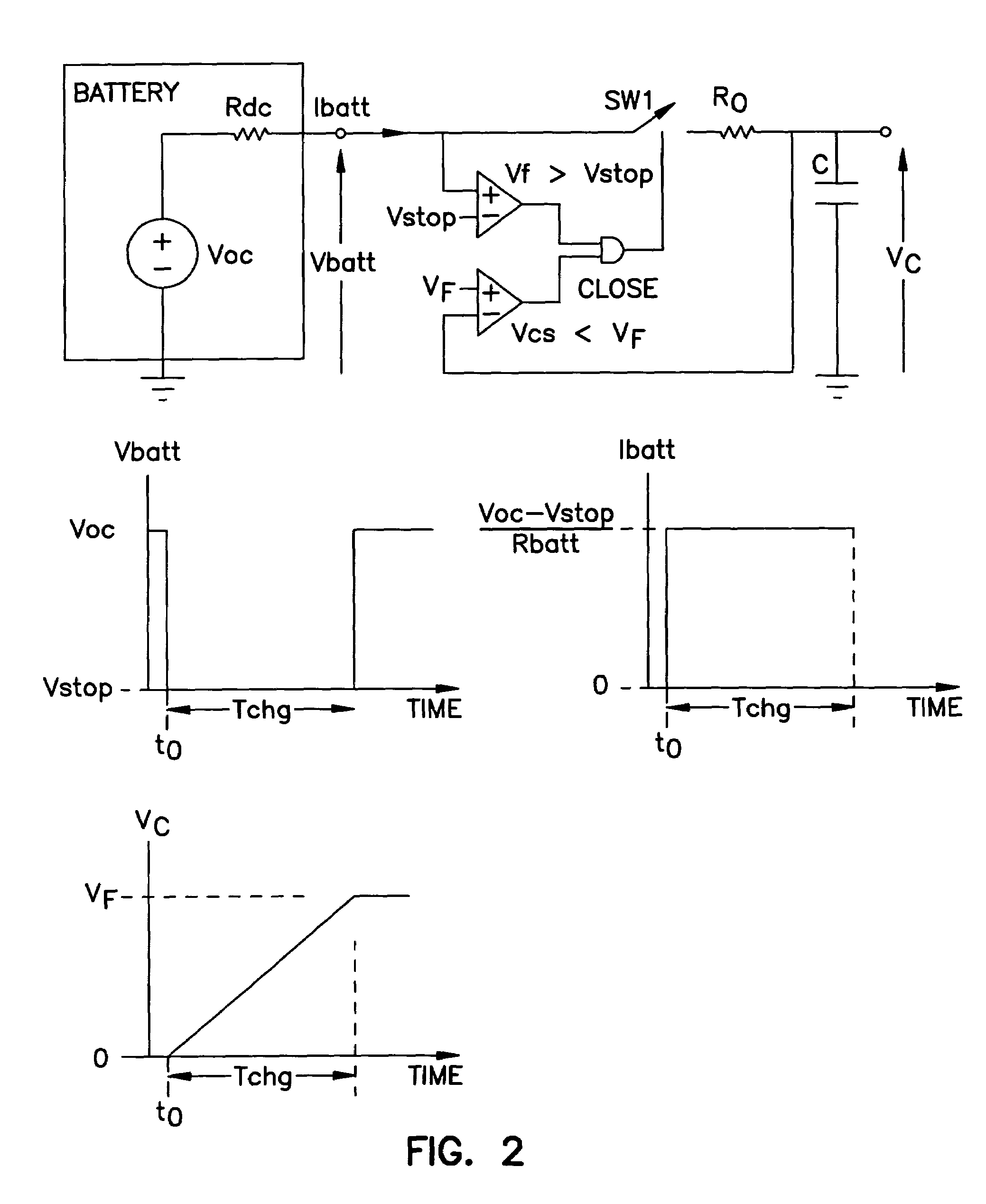

A system is described. The system includes a lithium battery, a charge storage capacitor electrically connected to the lithium battery, a first device, and at least one second device. The first device is electrically connected to the lithium battery and is powered by the lithium battery. The at least one second device is attached to the charge storage capacitor and adapted to read a rate of charge storage in the charge storage capacitor or to calculate the rate of charge storage by measuring both a time of charging and a charge stored or added to the charge storage capacitor during the time of charging.

Owner:CARDIAC PACEMAKERS INC

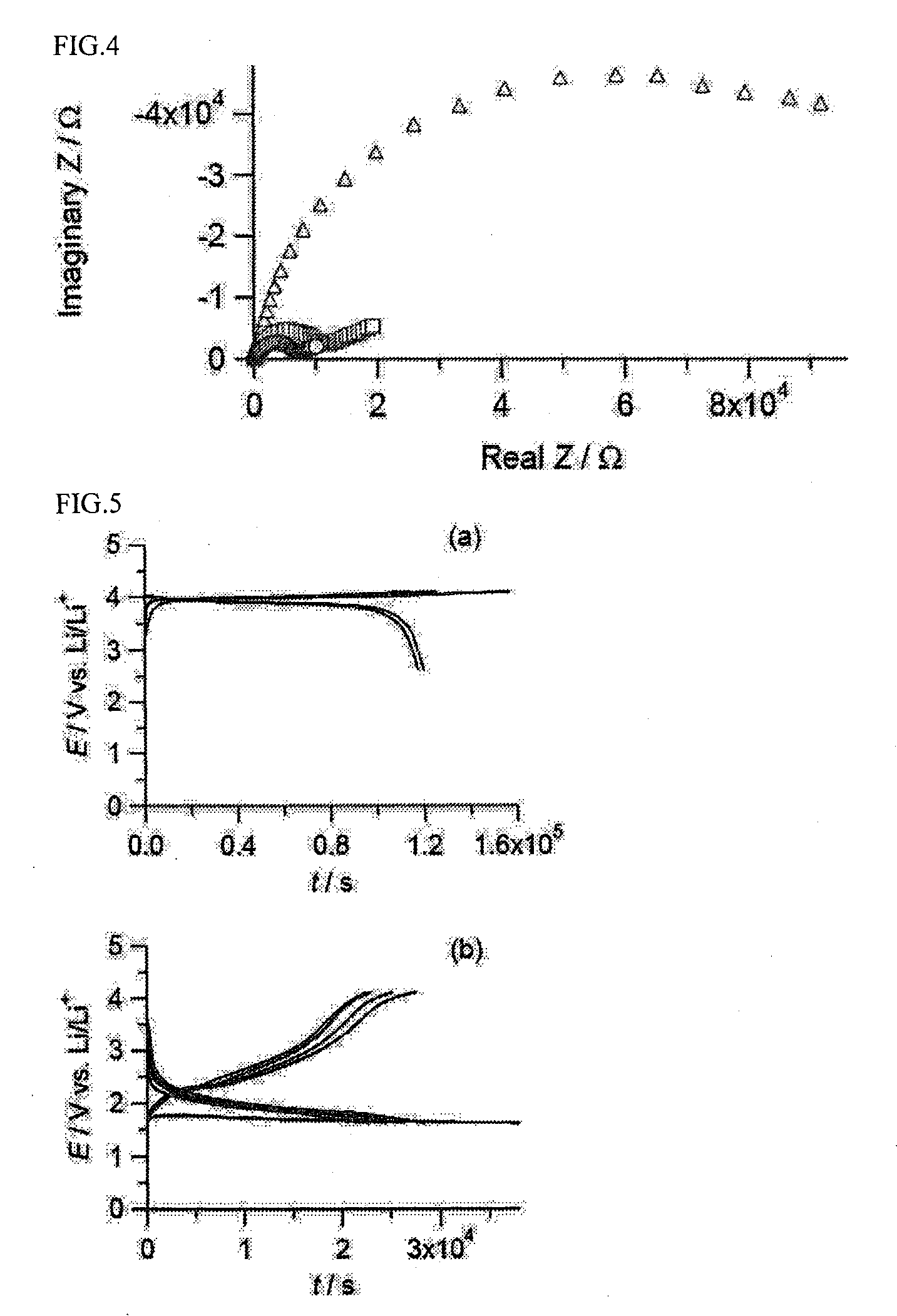

All-solid lithium battery

ActiveUS20090081554A1Improve output performanceLayer formationSolid electrolytesElectrode carriers/collectorsRedoxSulfide

Owner:NAT INST FOR MATERIALS SCI

Lithium ion conductive solid electrolyte and production process thereof

InactiveUS20070231704A1Increase battery capacitySimple and convenient manufactureSecondary cellsSolid electrolyte cellsPorosityLithium metal

A lithium ion conductive solid electrolyte formed by sintering a molding product containing an inorganic powder and having a porosity of 10 vol % or less, which is obtained by preparing a molding product comprising an inorganic powder as a main ingredient and sintering the molding product after pressing and / or sintering the same while pressing, the lithium ion conductive solid electrolyte providing a solid electrolyte having high battery capacity without using a liquid electrolyte, usable stably for a long time and simple and convenient in manufacture and handling also in industrial manufacture in the application use of secondary lithium ion battery or primary lithium battery, a solid electrolyte having good charge / discharge cyclic characteristic in the application use of the secondary lithium ion battery a solid electrolyte with less water permeation and being safe when used for lithium metal-air battery in the application use of primary lithium battery, a manufacturing method of the solid electrolyte, and a secondary lithium ion battery and a primary lithium battery using the solid electrolyte.

Owner:OHARA

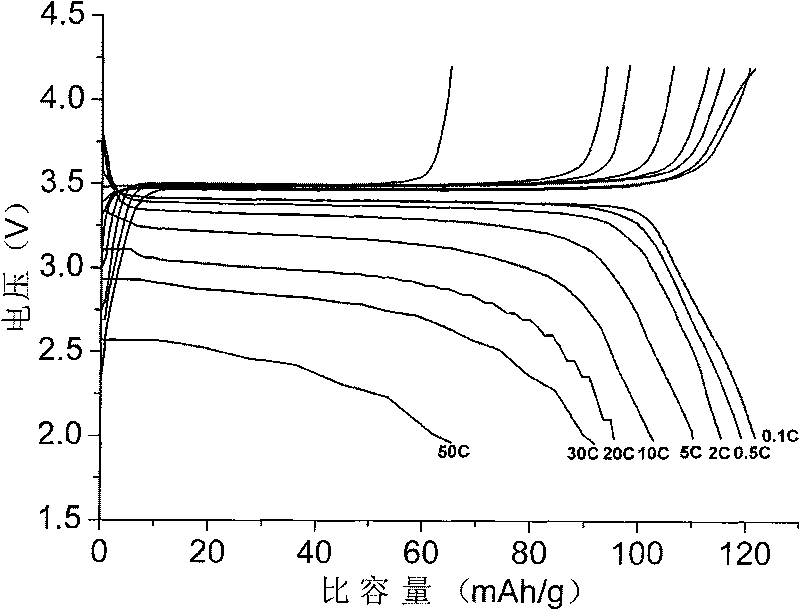

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

Chemical protection of a lithium surface

InactiveUS20050186469A1Easy to produceEasy to processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process is the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Anode active material, method of preparing the same, and anode and lithium battery containing the material

ActiveUS20060134516A1Improve capacity efficiencyImprove charge/discharge efficiencyElectrode thermal treatmentNon-aqueous electrolyte accumulatorsFiberGraphite

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com