Patents

Literature

2316 results about "Carbon nanofiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

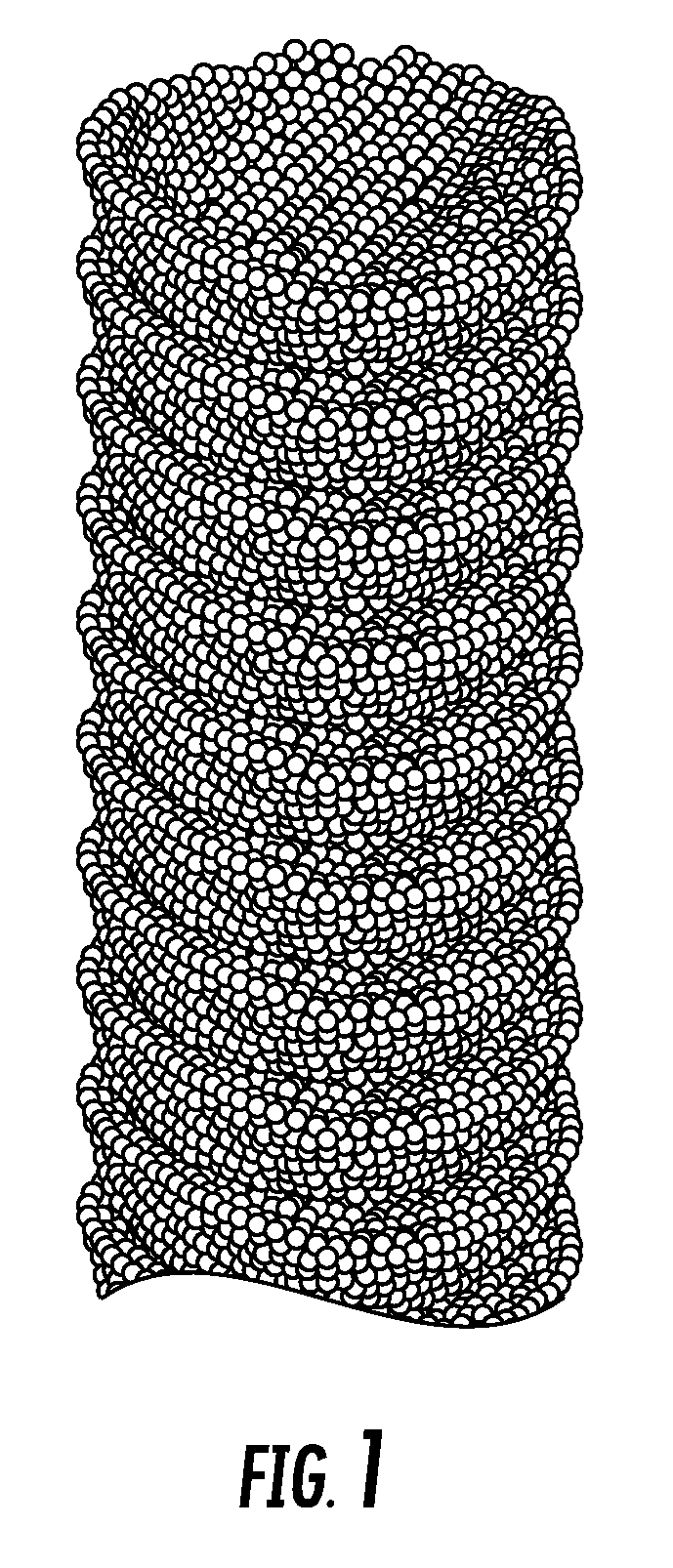

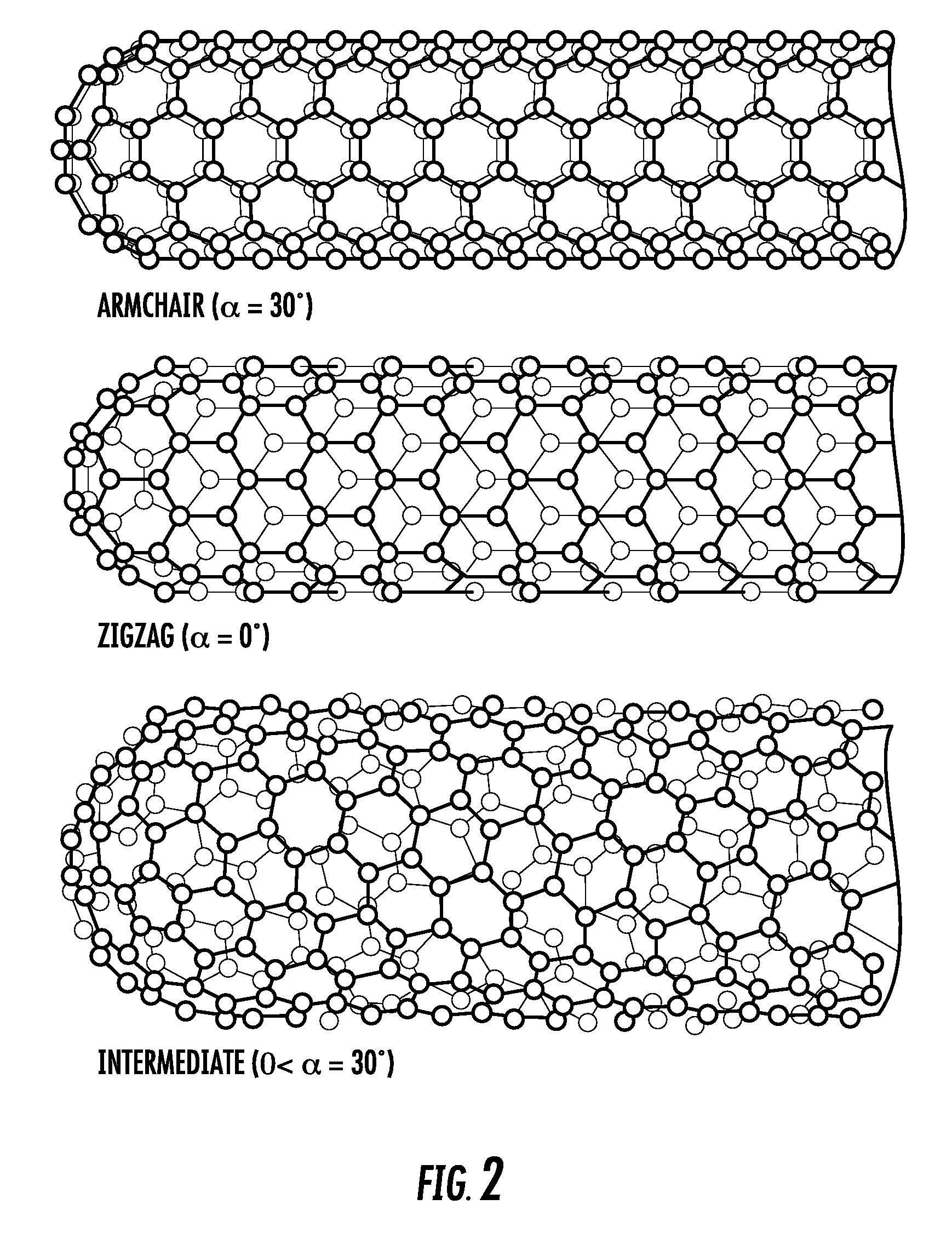

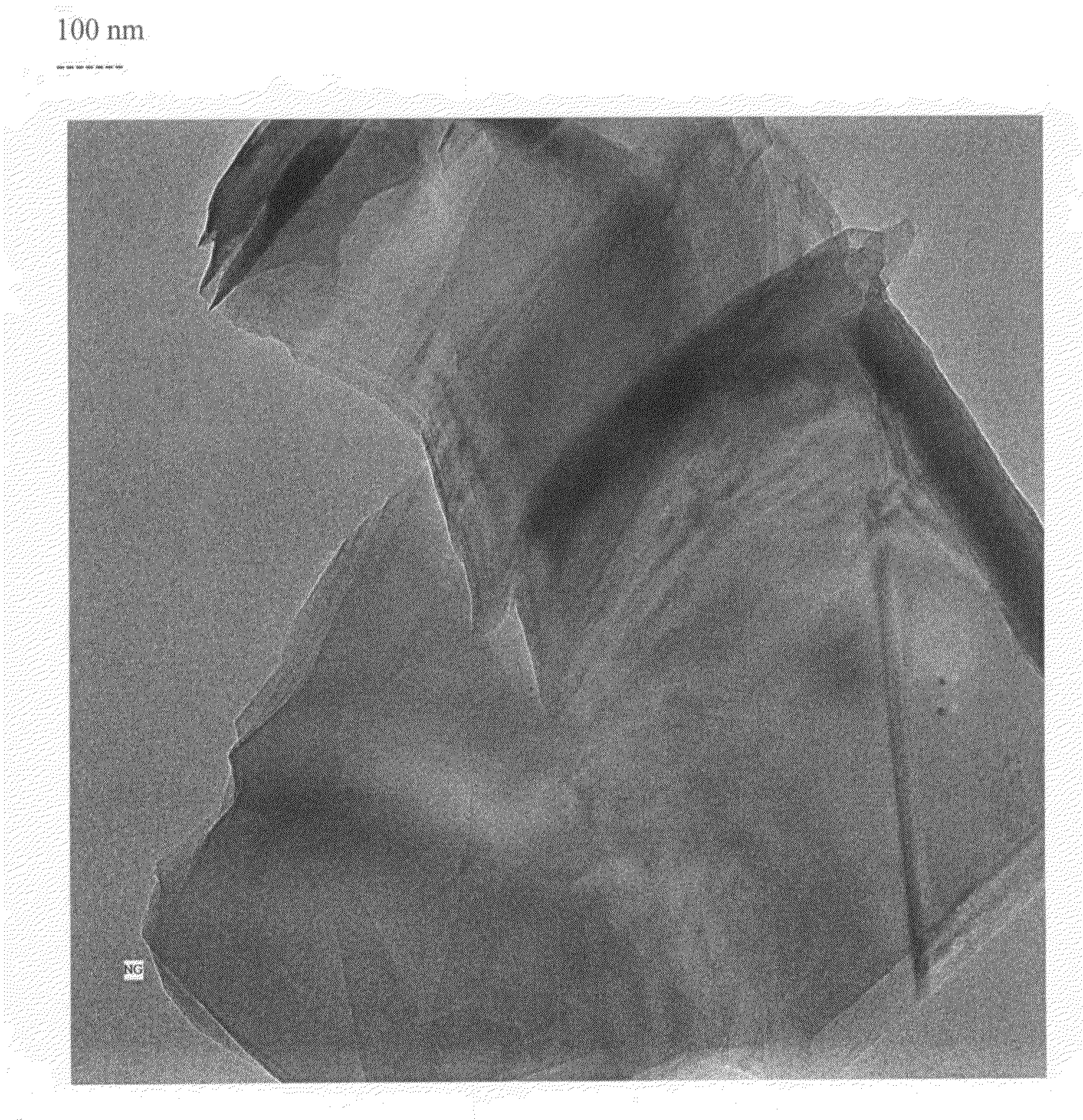

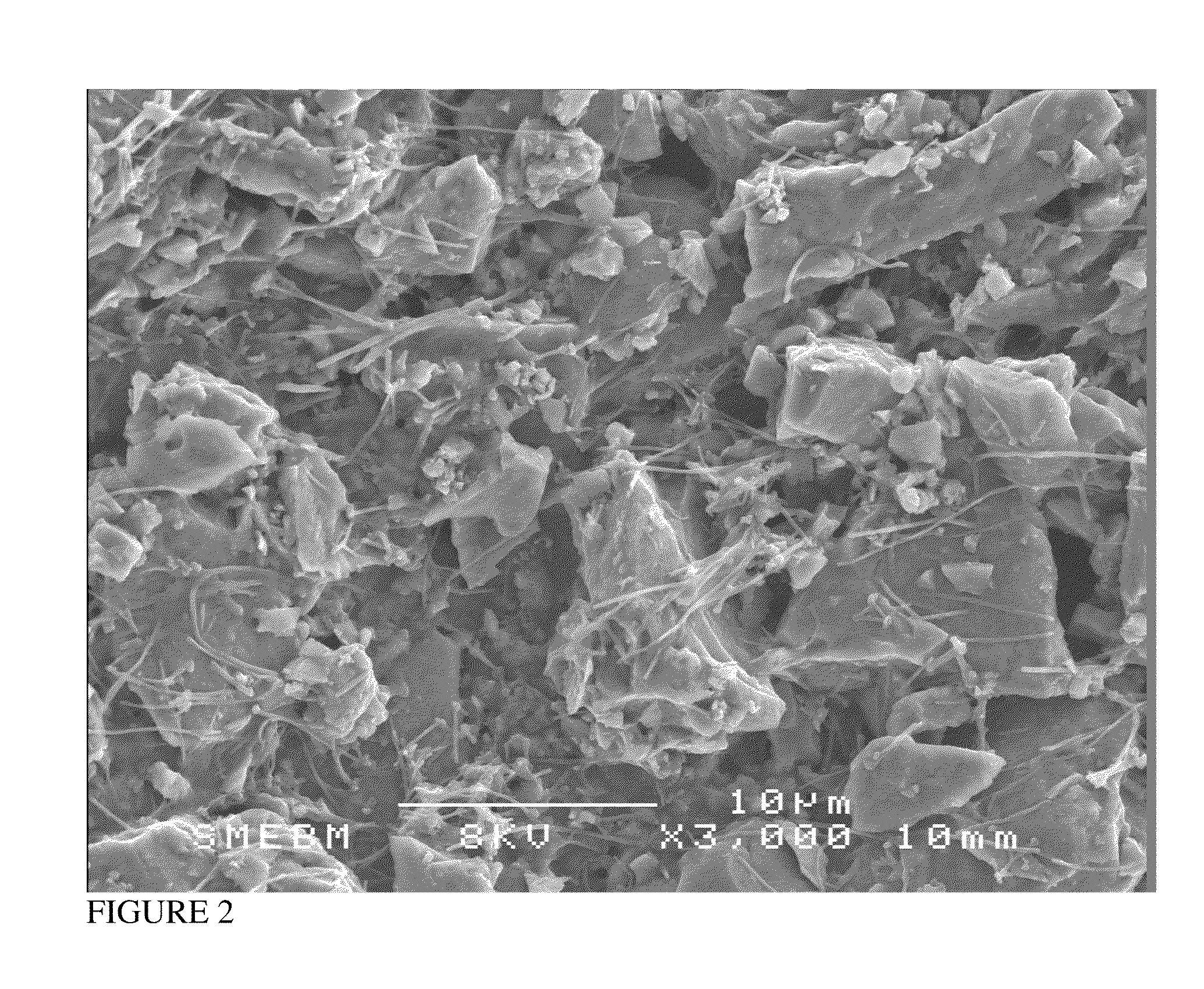

Carbon nanofibers (CNFs), vapor grown carbon fibers (VGCFs), or vapor grown carbon nanofibers (VGCNFs) are cylindrical nanostructures with graphene layers arranged as stacked cones, cups or plates. Carbon nanofibers with graphene layers wrapped into perfect cylinders are called carbon nanotubes.

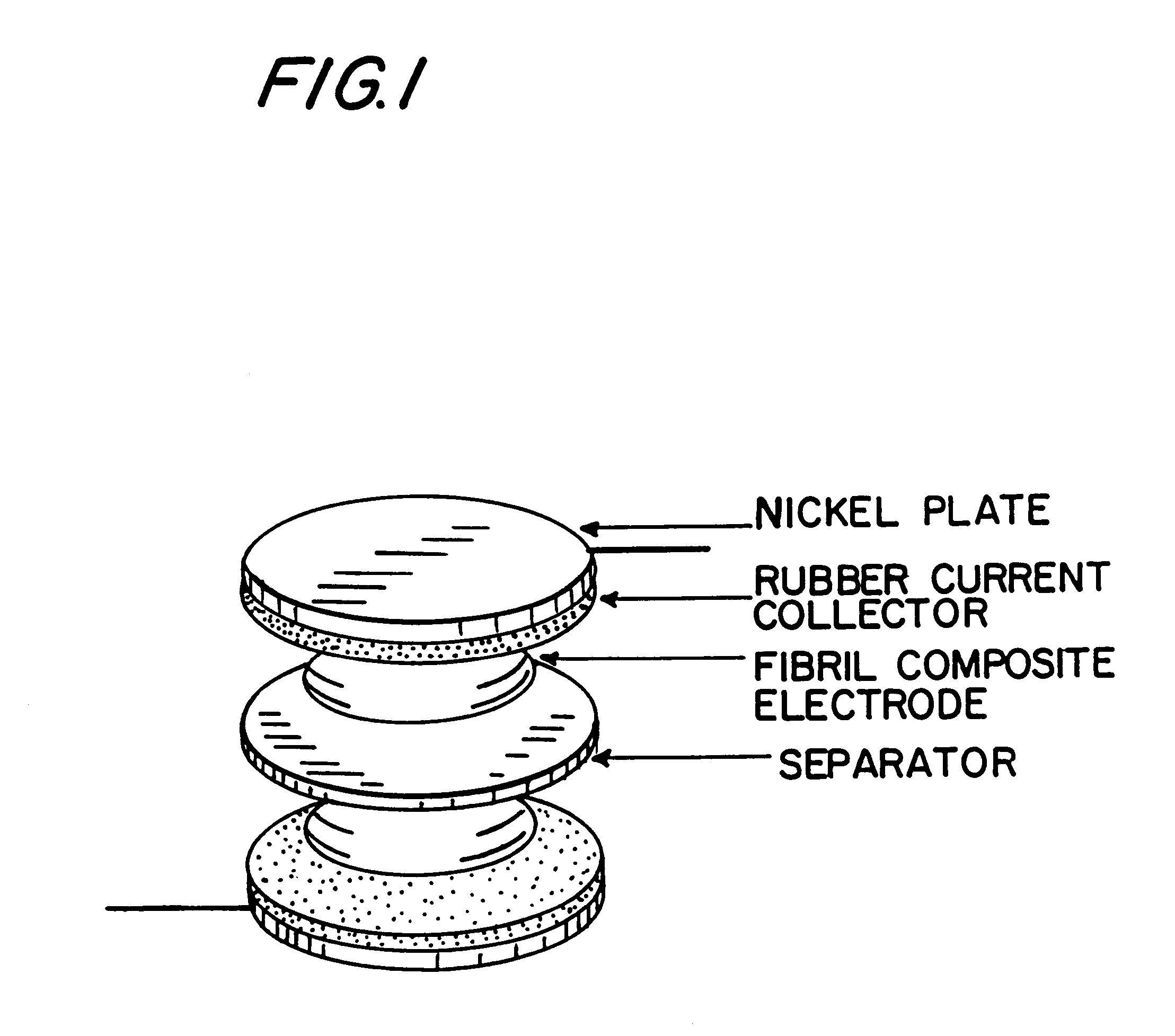

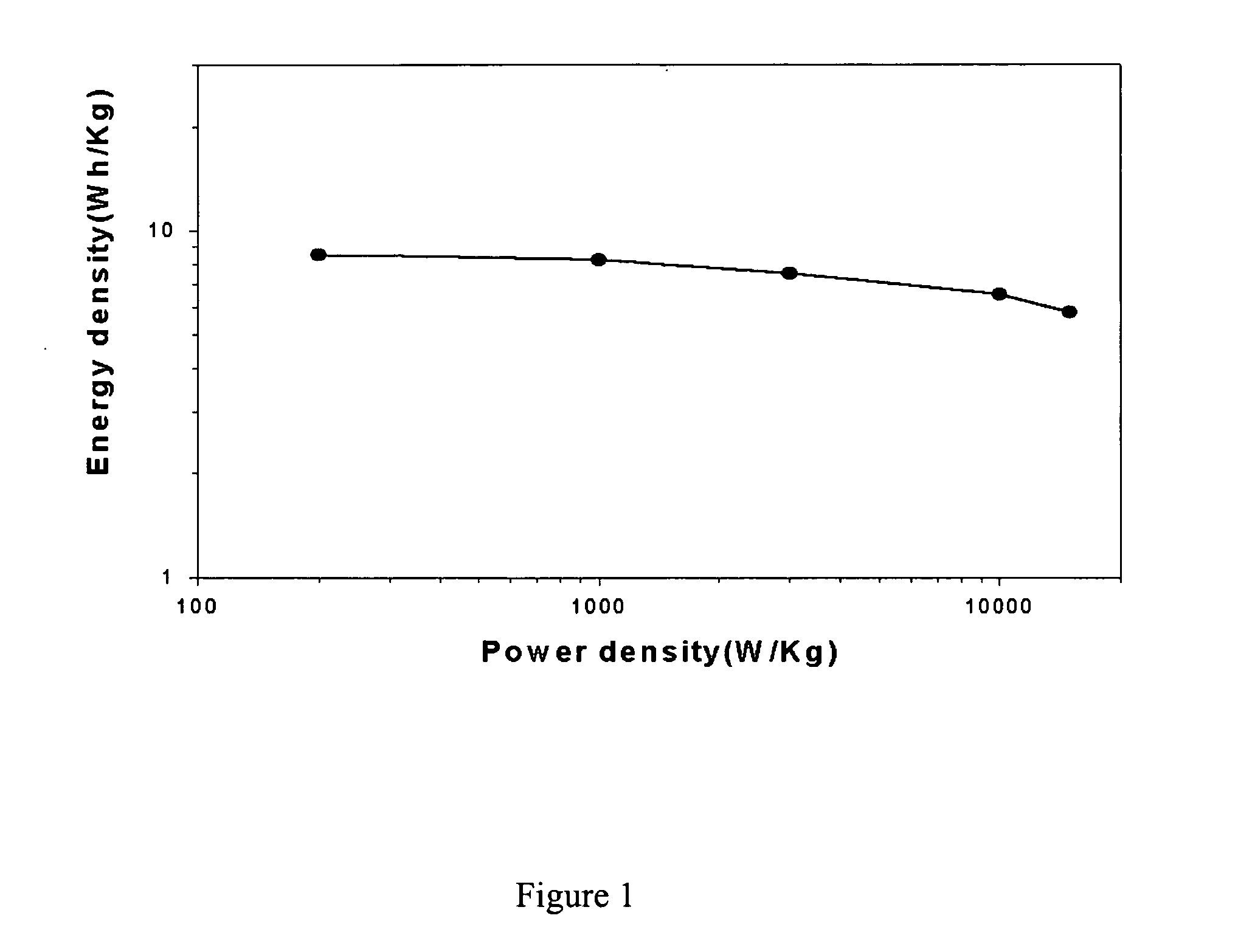

Fibril composite electrode for electrochemical capacitors

Owner:HYPERION CATALYSIS INT

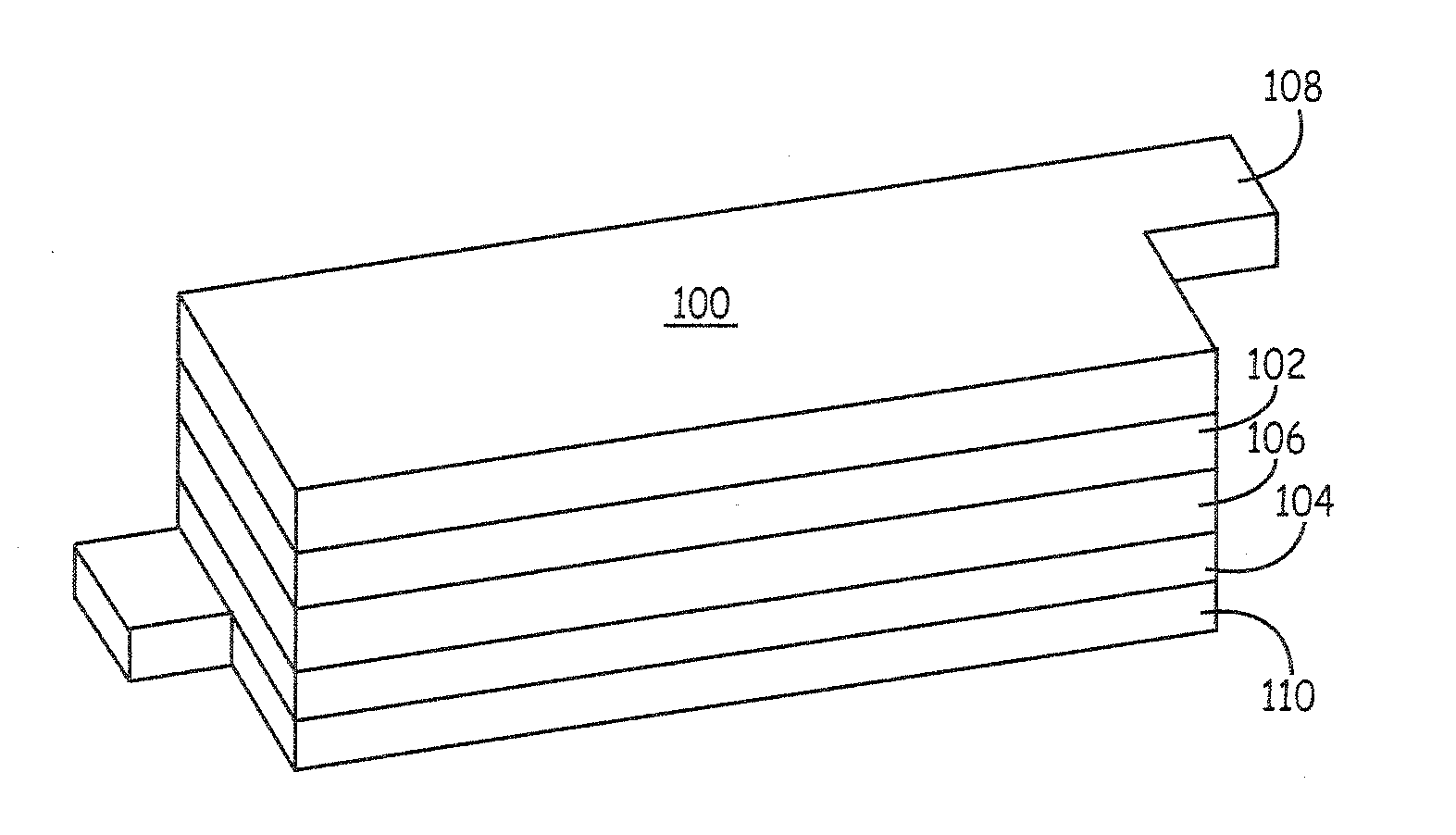

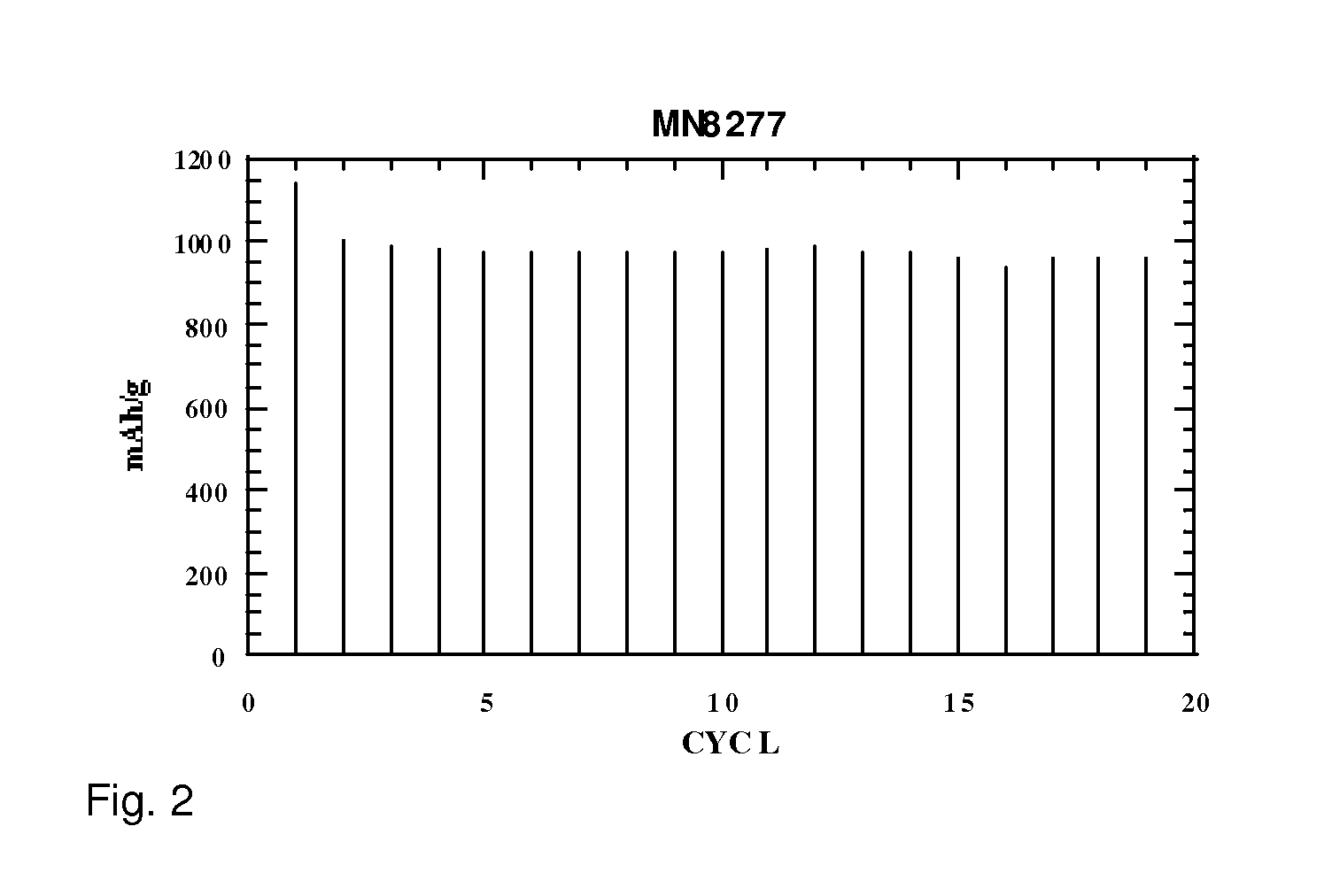

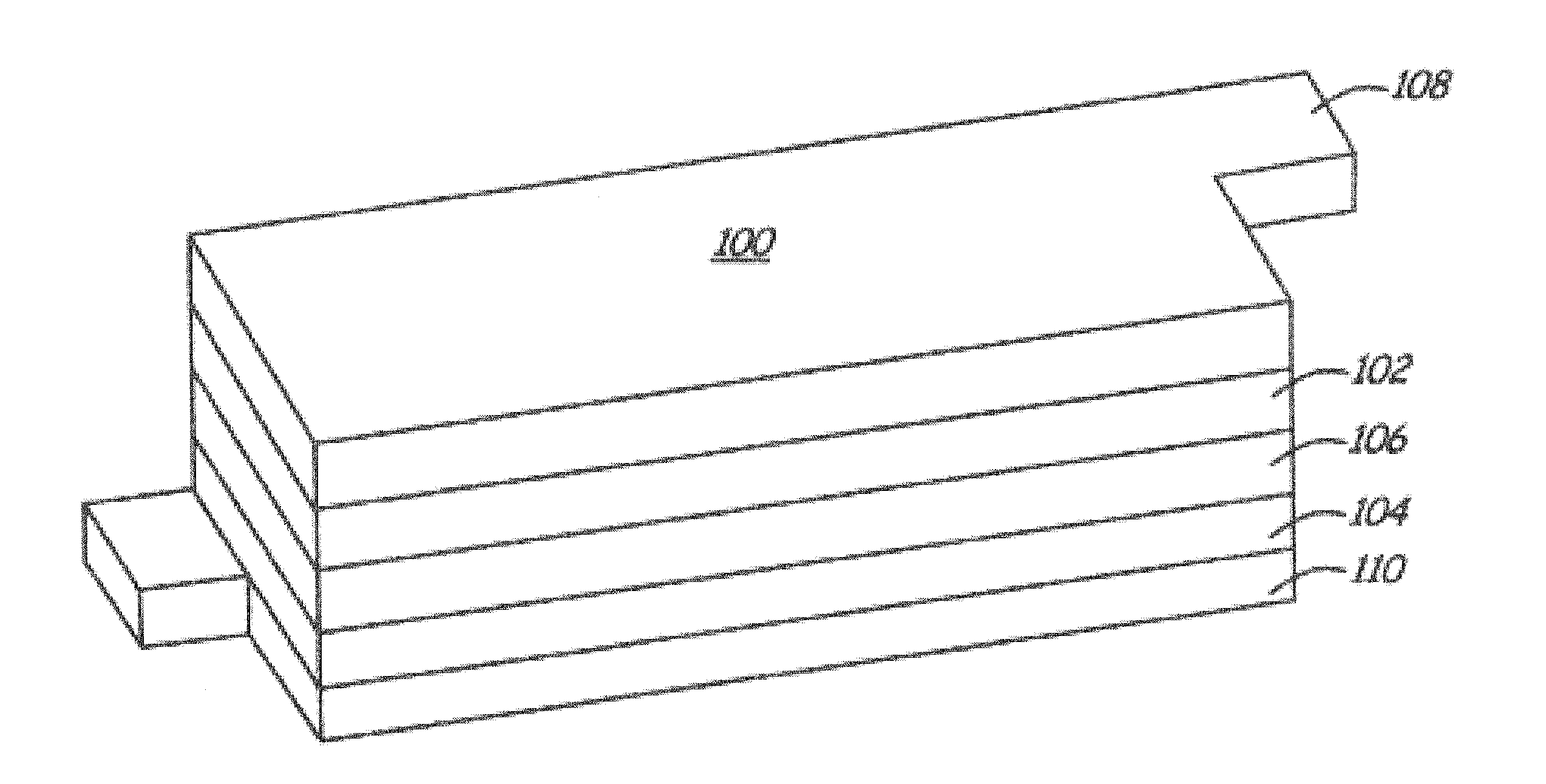

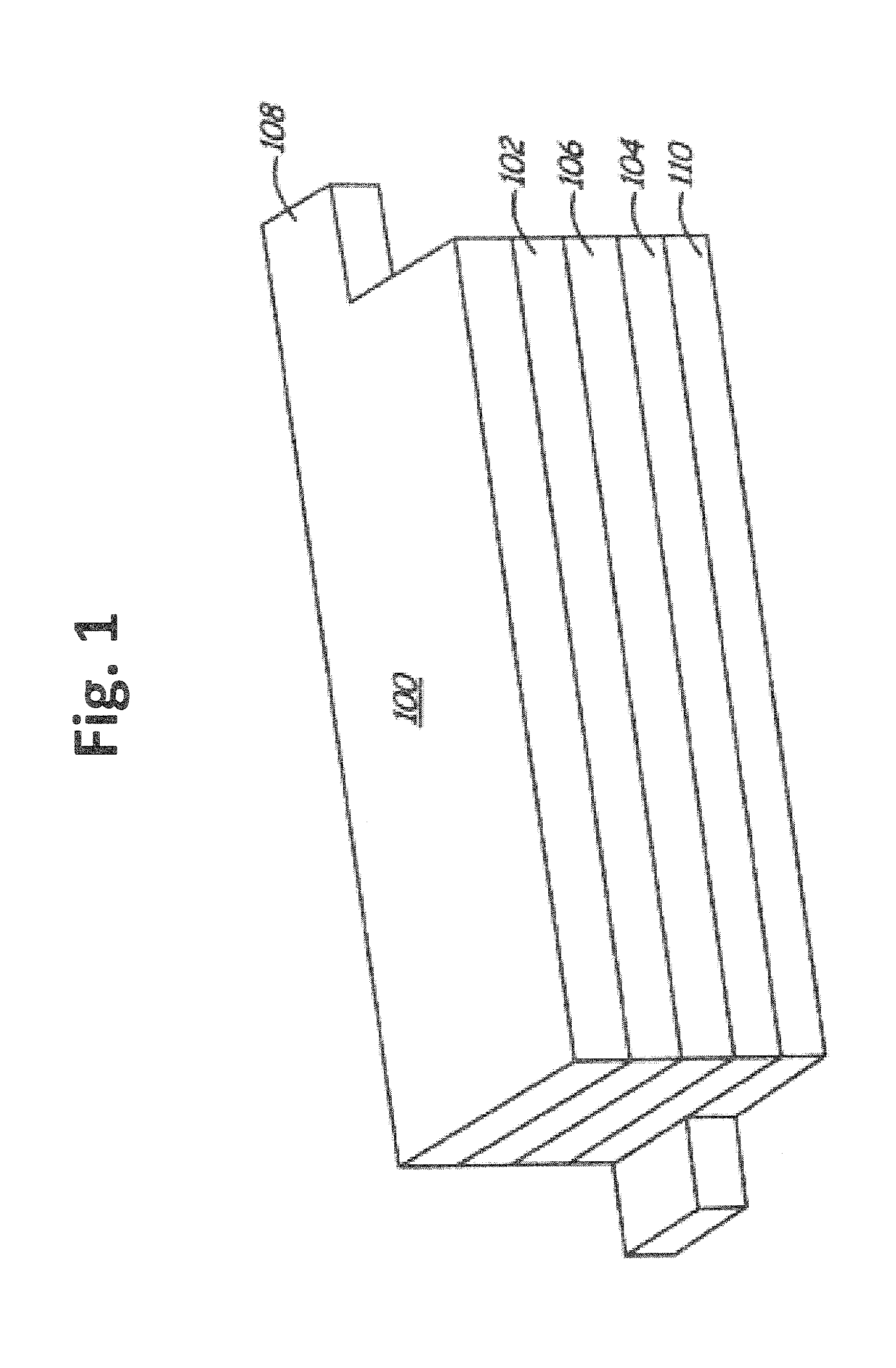

High Capacity Anode Materials for Lithium Ion Batteries

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

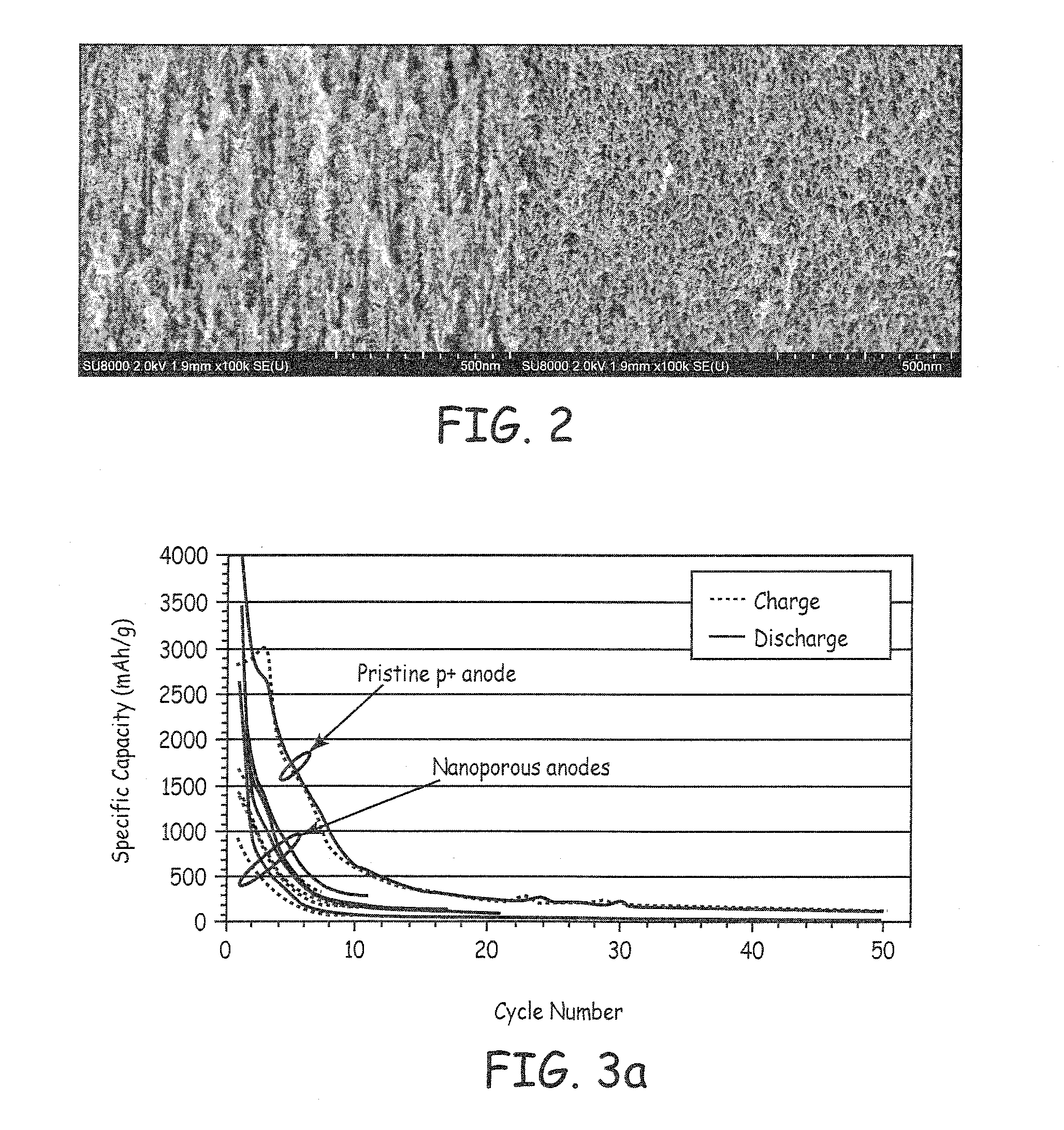

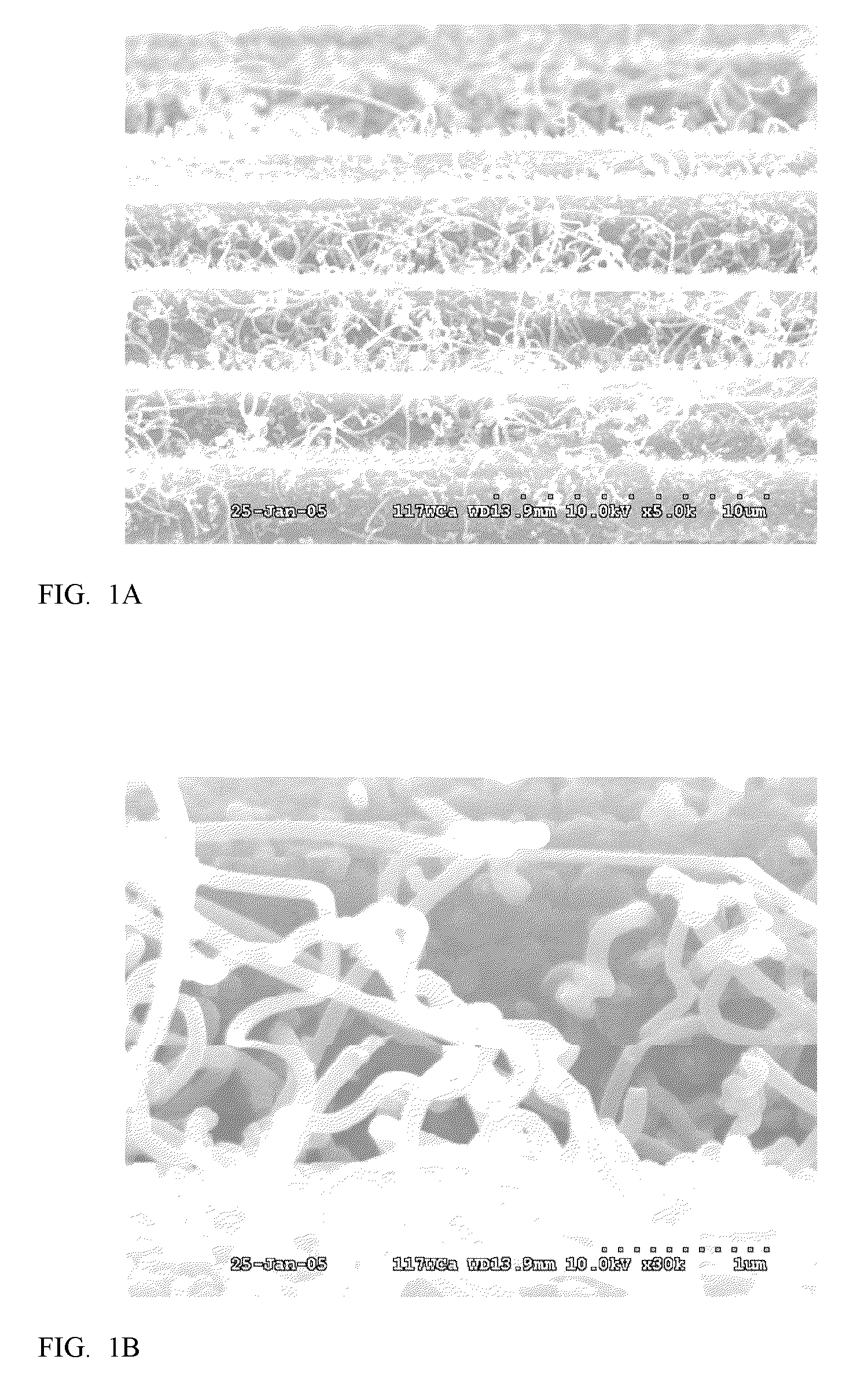

Method of depositing silicon on carbon materials and forming an anode for use in lithium ion batteries

ActiveUS20080261116A1Increase rangeMaterial nanotechnologyNanoinformaticsPhysical chemistryCarbon nanofiber

A method of modifying the surface of carbon materials such as vapor grown carbon nanofibers is provided in which silicon is deposited on vapor grown carbon nanofibers using a chemical vapor deposition process. The resulting silicon-carbon alloy may be used as an anode in a rechargeable lithium ion battery.

Owner:APPLIED SCI

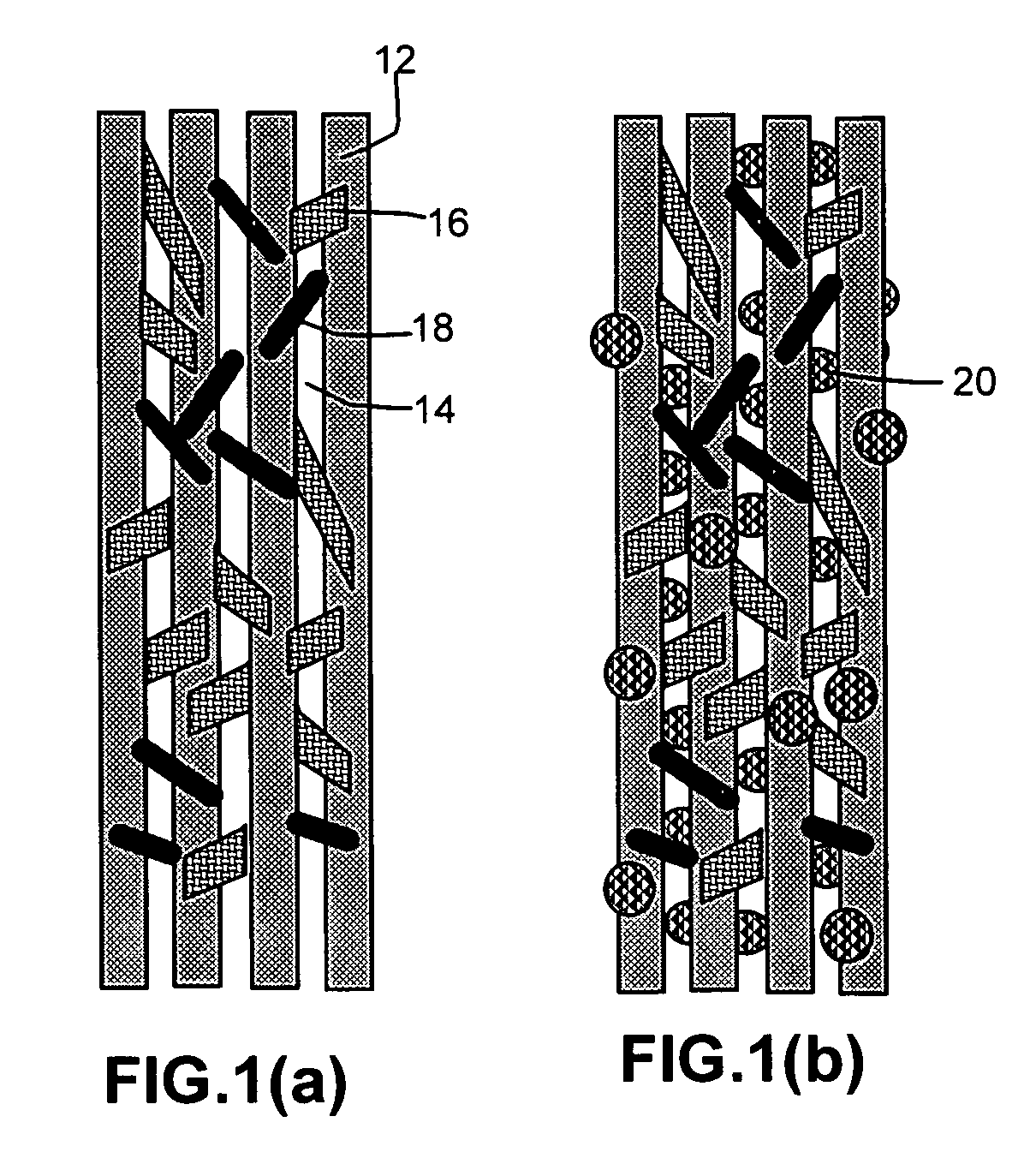

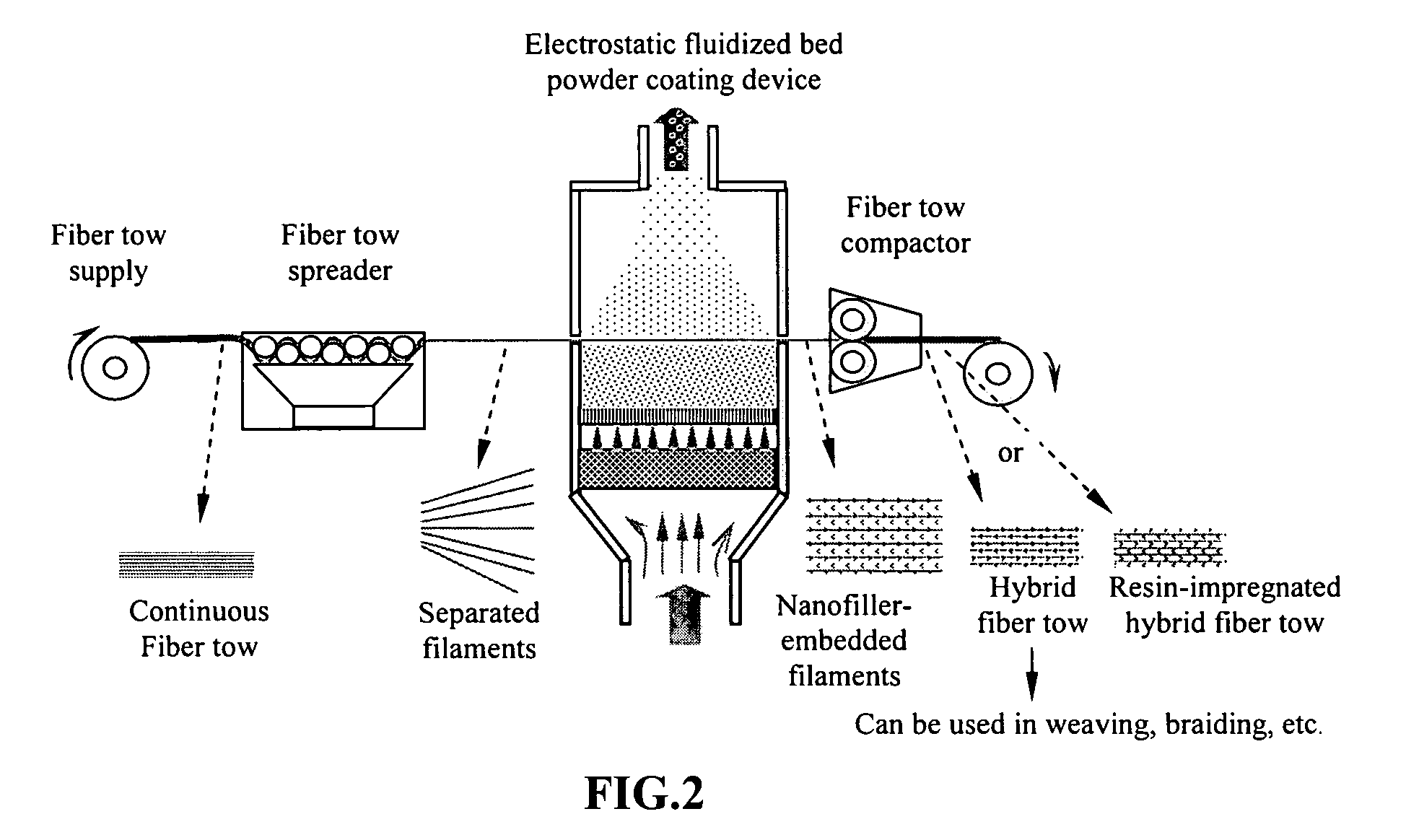

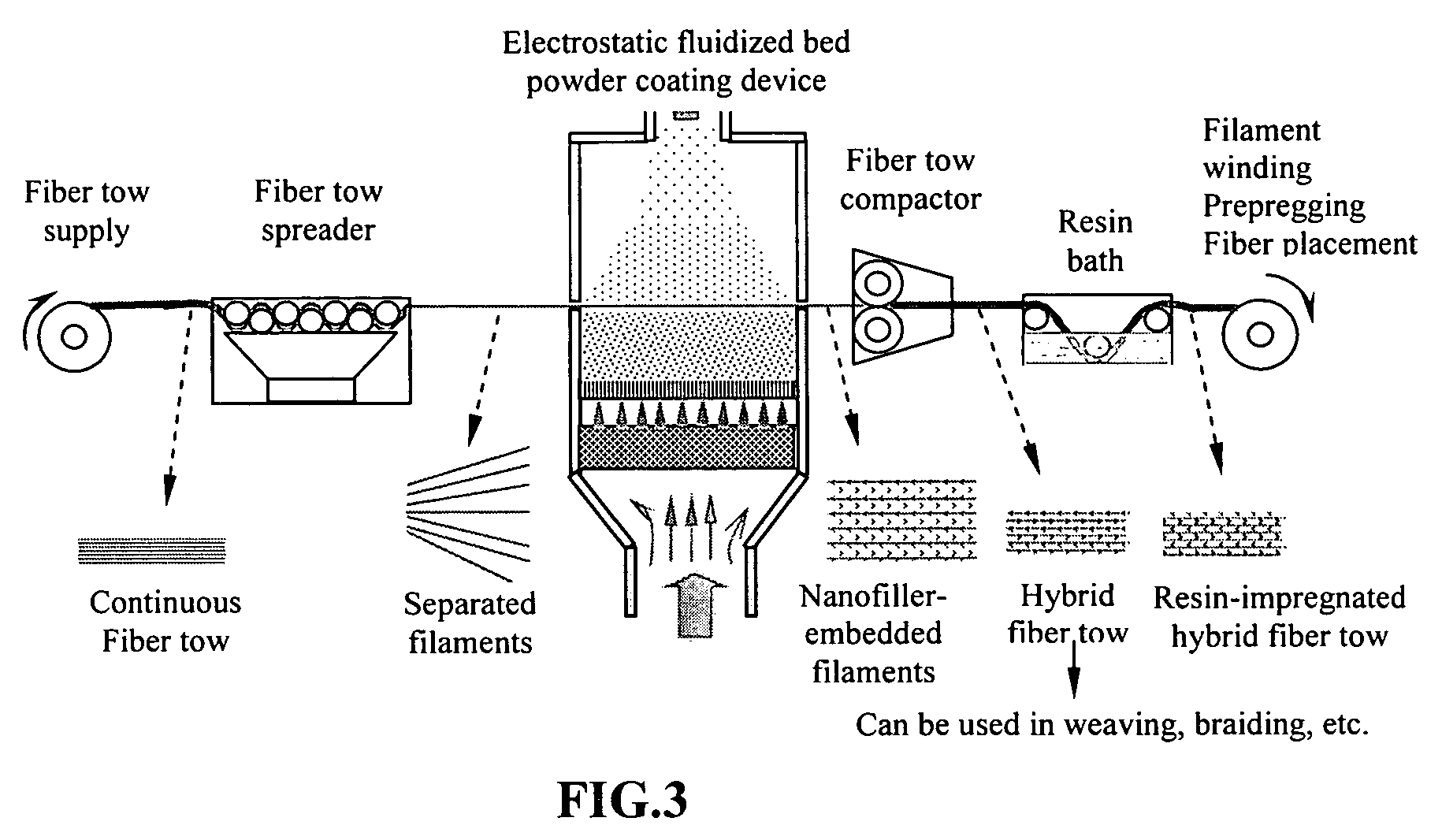

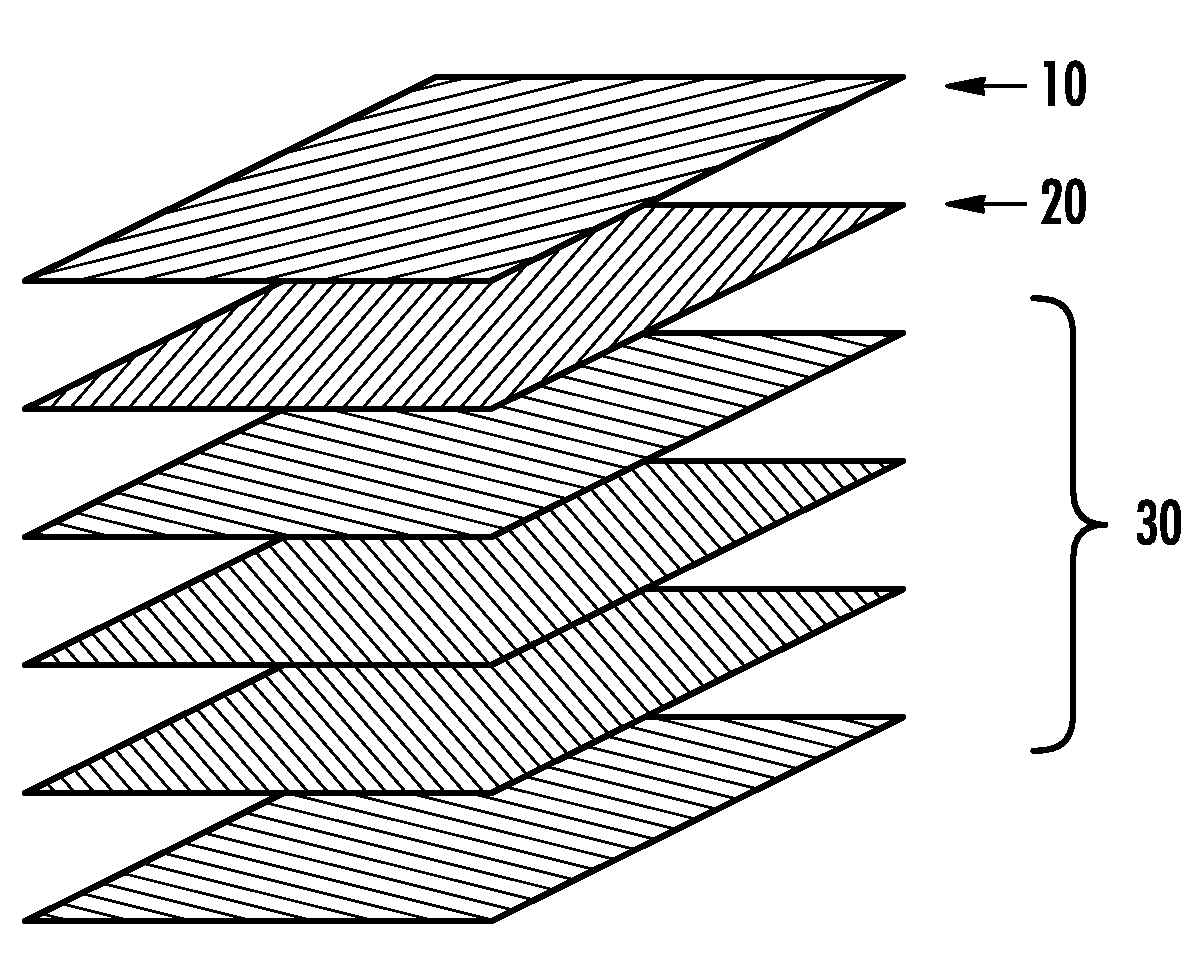

Hybrid fiber tows containning both nano-fillers and continuous fibers, hybrid composites, and their production processes

Disclosed is a hybrid fiber tow that comprises multiple continuous filaments and nanoscale fillers embedded in the interstitial spaces between continuous filaments. Nanoscale fillers may be selected from a nanoscale graphene plate, non-graphite platelet, carbon nano-tube, nano-rod, carbon nano-fiber, non-carbon nano-fiber, or a combination thereof. Also disclosed are a hybrid fiber tow impregnated with a matrix material and a composite structure fabricated from a hybrid fiber tow. The composite exhibits improved physical properties (e.g., thermal conductivity) in a direction transverse to the continuous fiber axis. A roll-to-roll process for producing a continuous fiber tow or matrix-impregnated fiber tow and an automated process for producing composite structures containing both continuous filaments and nanoscale fillers are also provided.

Owner:NANOTEK INSTR

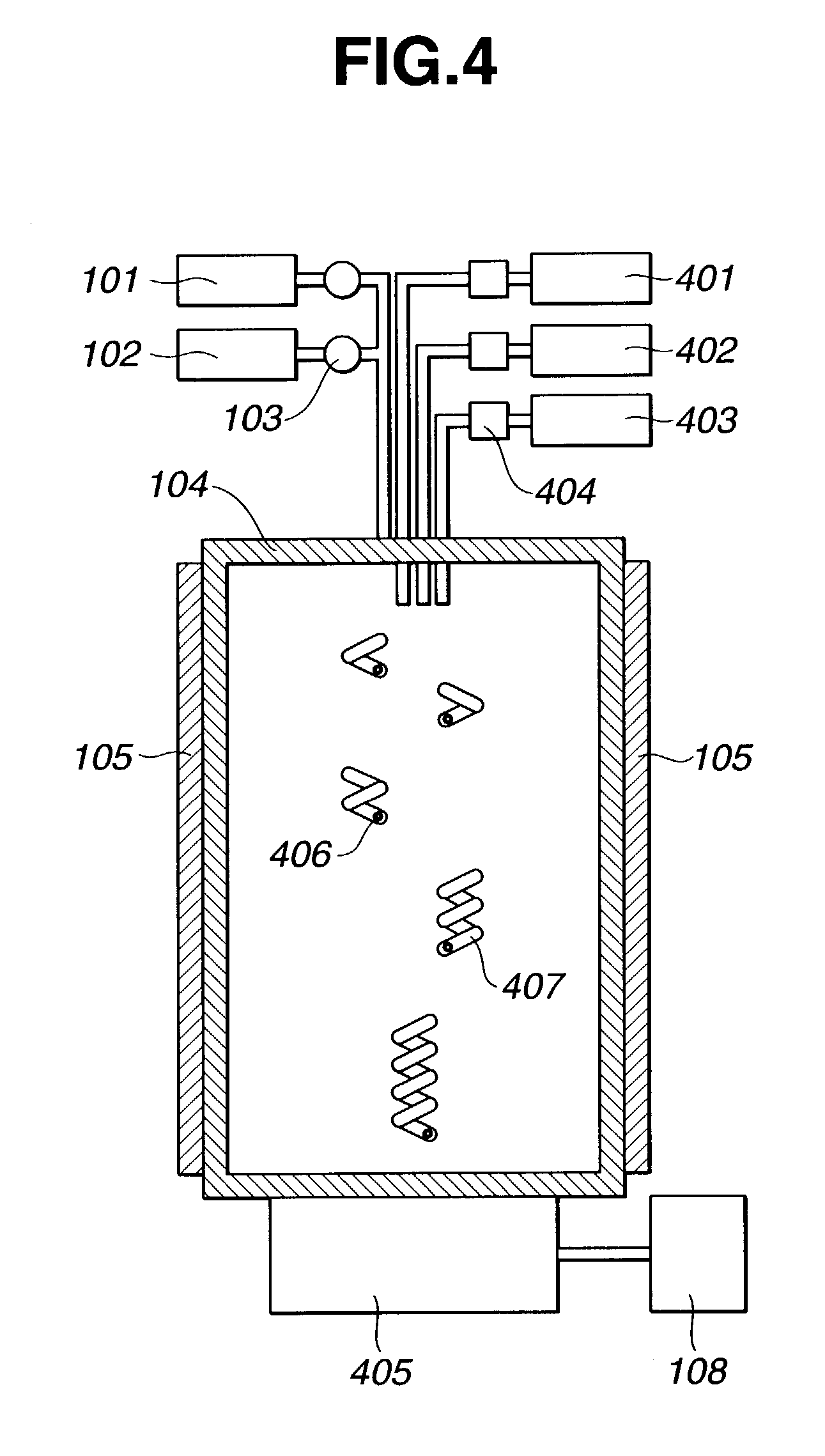

Method for preparing nano-carbon fiber and nano-carbon fiber

A carbon nano-fiber, particularly twisted carbon nano-fiber such as a carbon nano-coil, carbon nano-twist, carbon nano-rope is produced by means of a catalyst CVD method using carbon-containing gas as a raw material and a catalyst comprising one or plural components selected from the group consisting of Cr, Mn, Fe, Co, Ni and oxide thereof and one or plural components selected from the group consisting of Cu, Al, Si, Ti, V, Nb, Mo, Hf, Ta, W and oxide thereof is used.

Owner:FUTABA CORPORATION

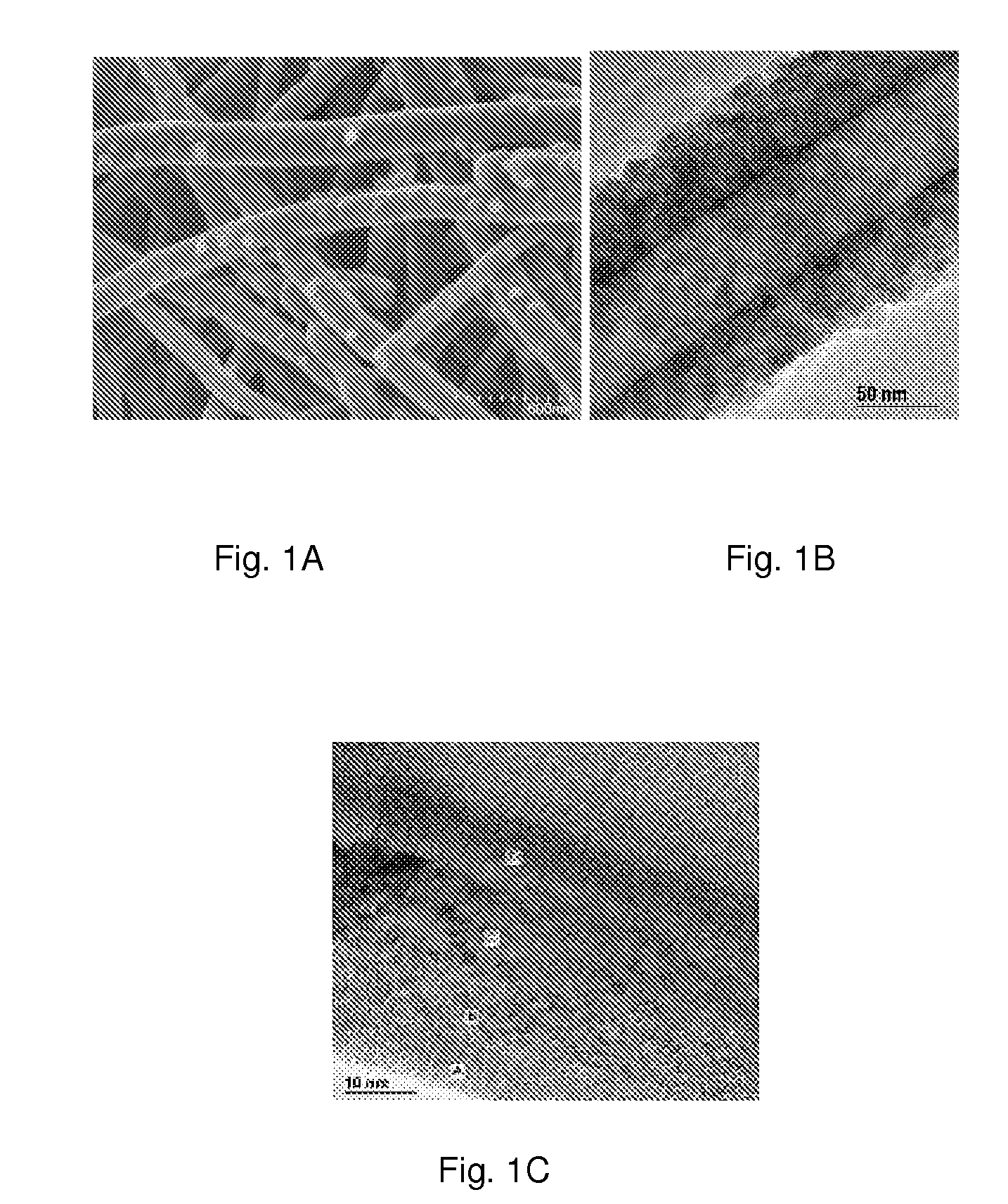

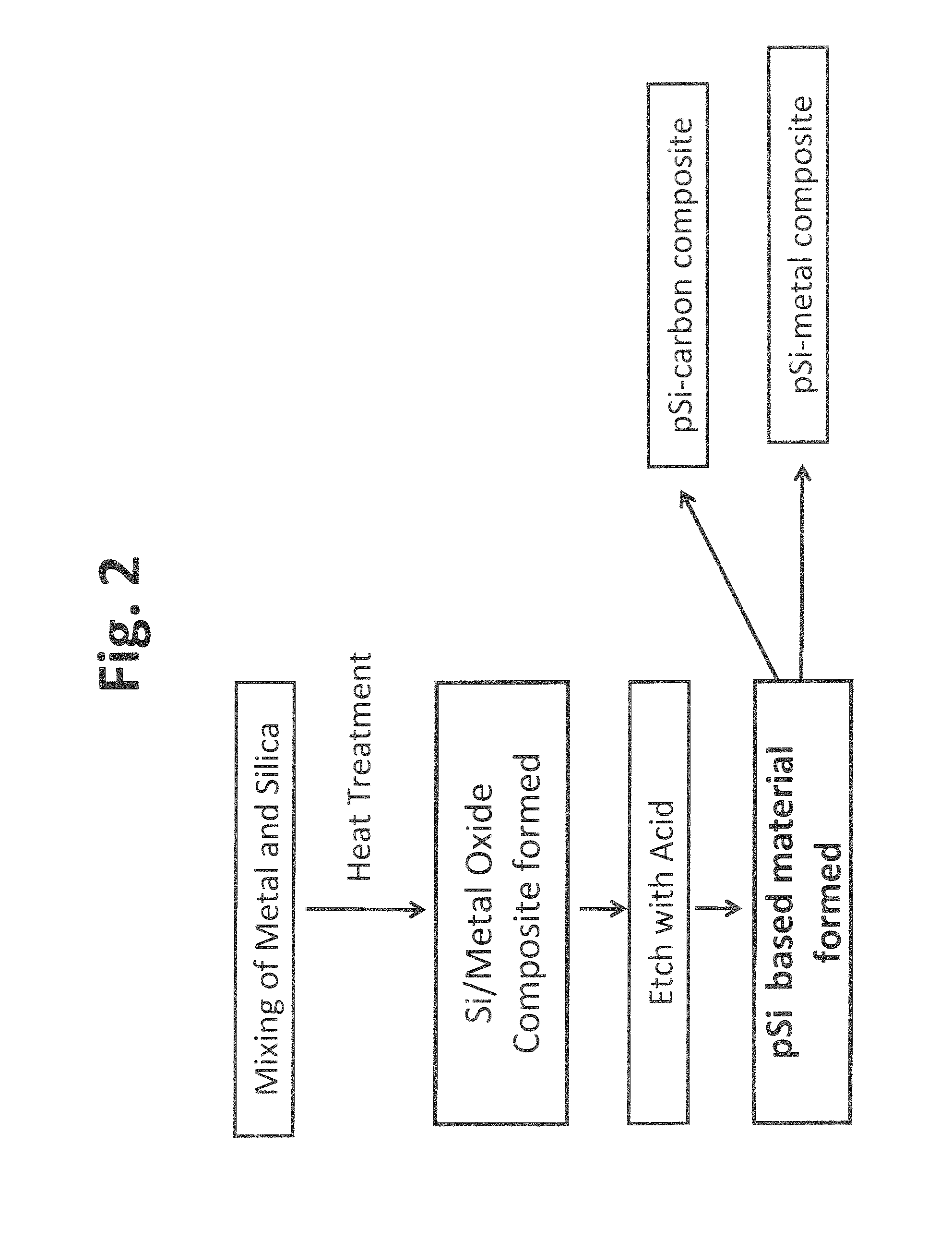

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

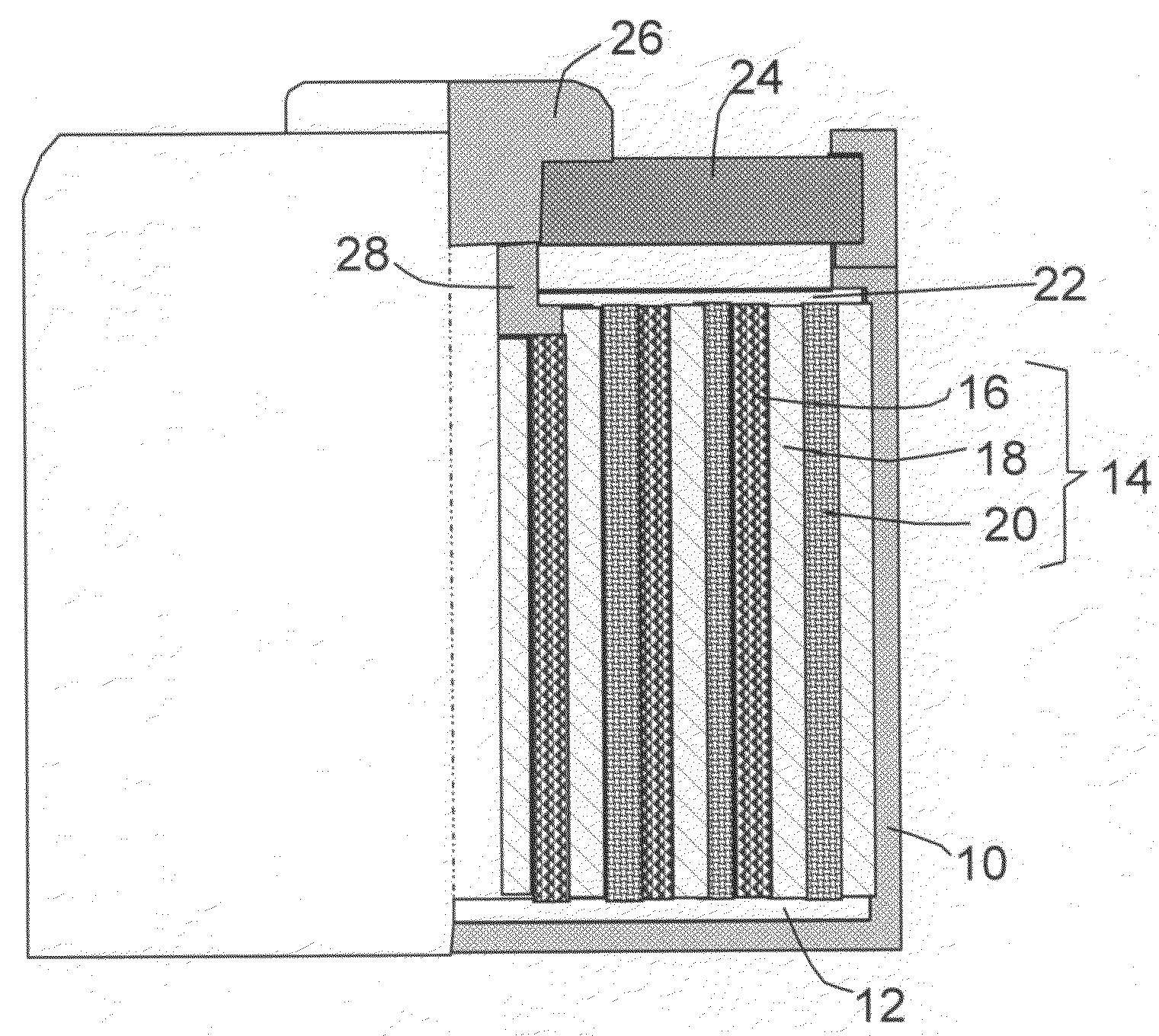

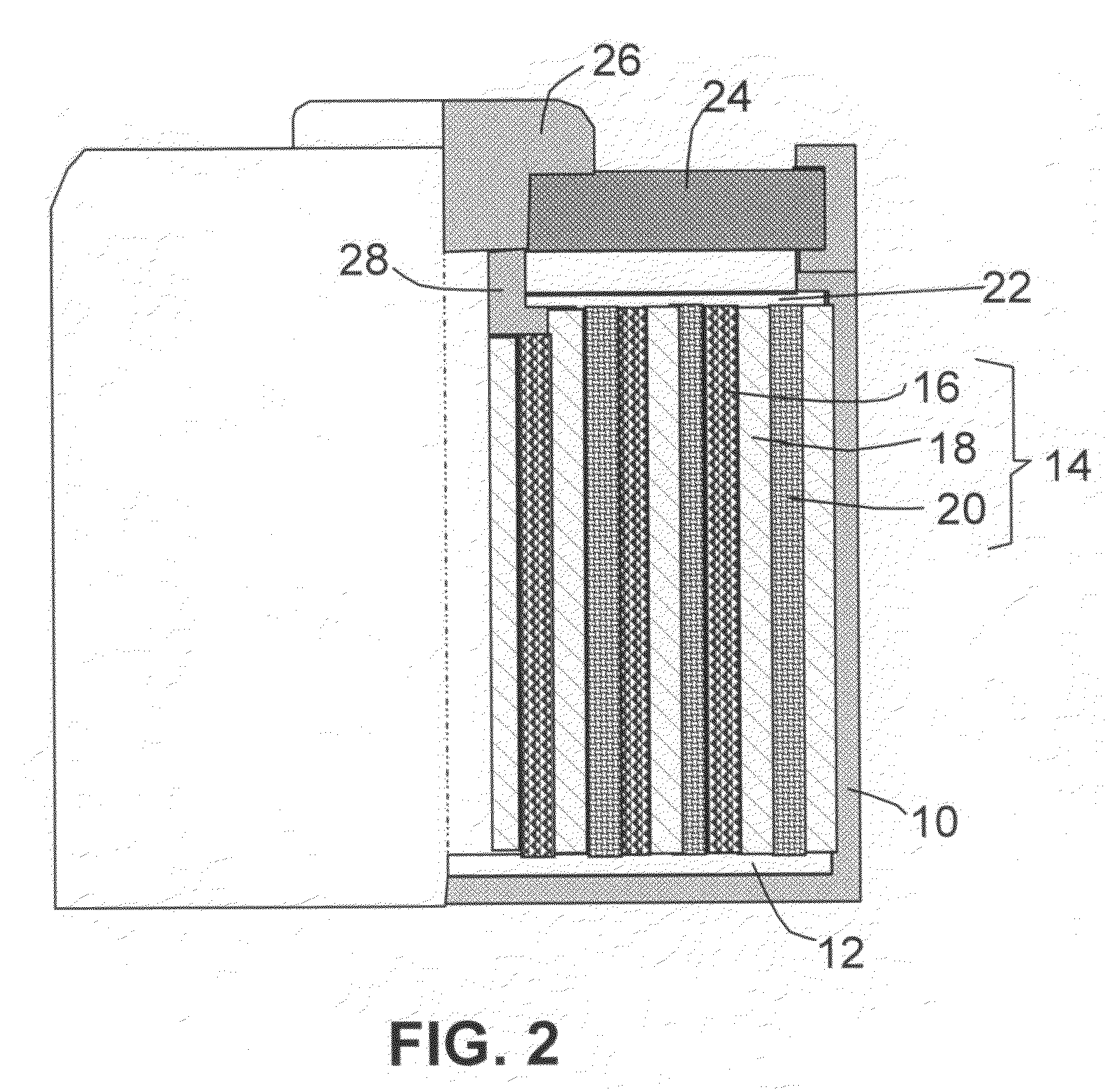

Mixed nano-filament electrode materials for lithium ion batteries

ActiveUS20090176159A1Improve conductivityEasy to collectActive material electrodesSecondary cellsFiberNanowire

This invention provides a mixed nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter / thickness less than 500 nm (preferably <100 nm) and a length-to-diameter or length-to-thickness aspect ratio greater than 10; and (b) Multiple nanometer-scaled, electro-active filaments comprising an electro-active material capable of absorbing and desorbing lithium ions wherein the electro-active filaments have a diameter or thickness less than 500 nm (preferably <100 nm). The electro-active filaments (e.g., nanowires) and the electrically conductive filaments (e.g., carbon nano fibers) are mixed to form a mat-, web-, or porous paper-like structure in which at least an electro-active filament is in electrical contact with at least an electrically conductive filament. Also provided is a lithium ion battery comprising such an electrode as an anode or cathode, or both. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

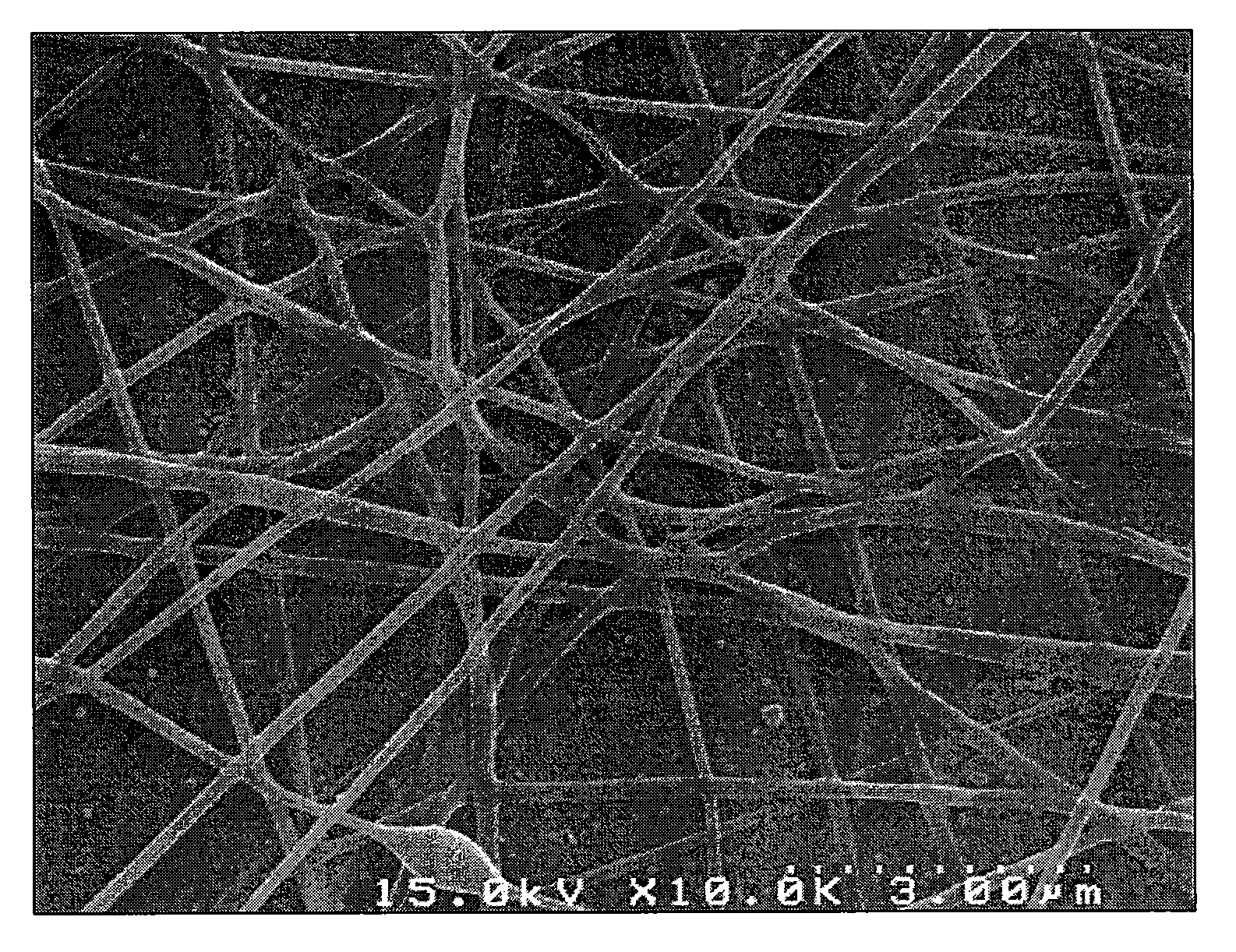

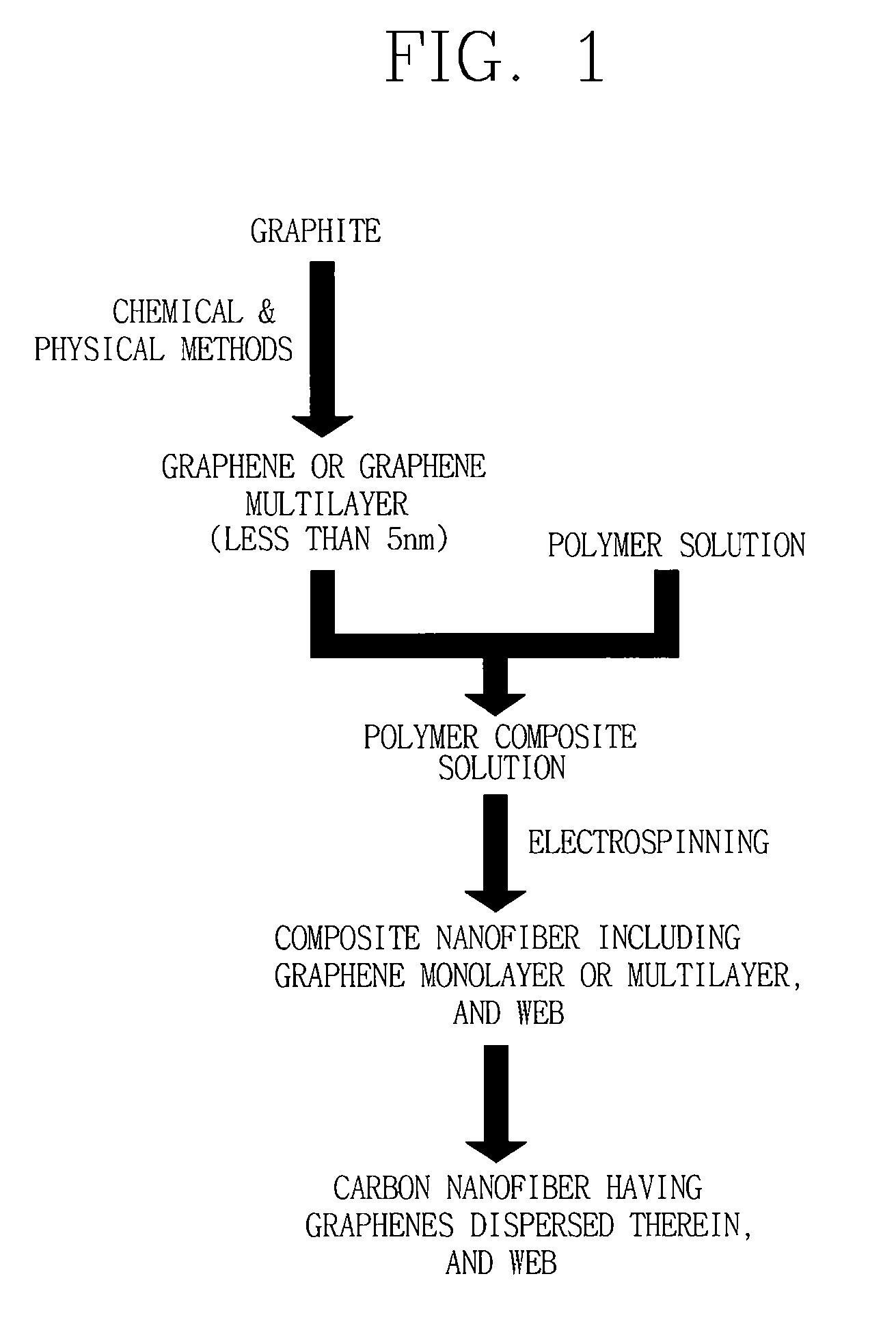

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

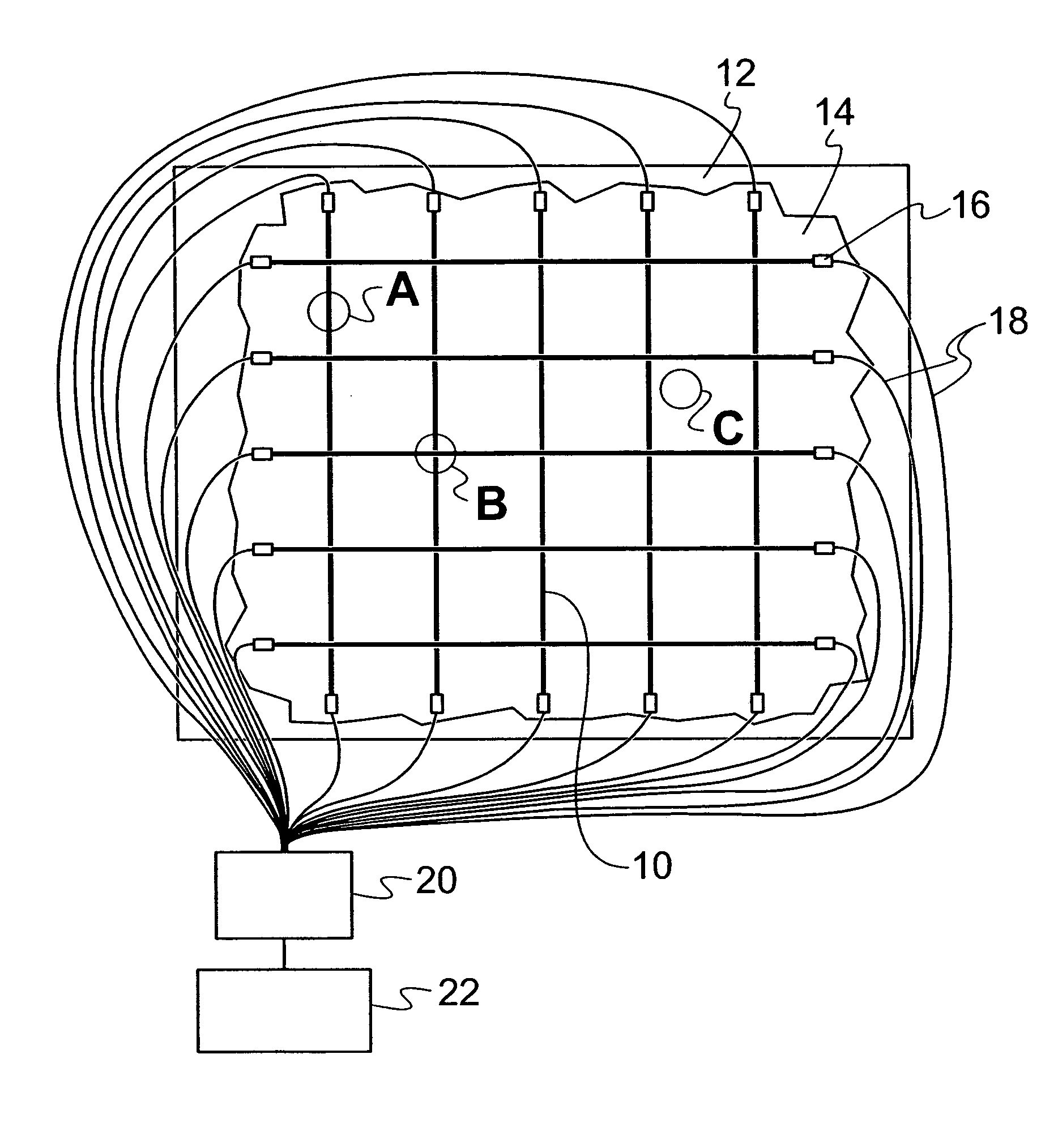

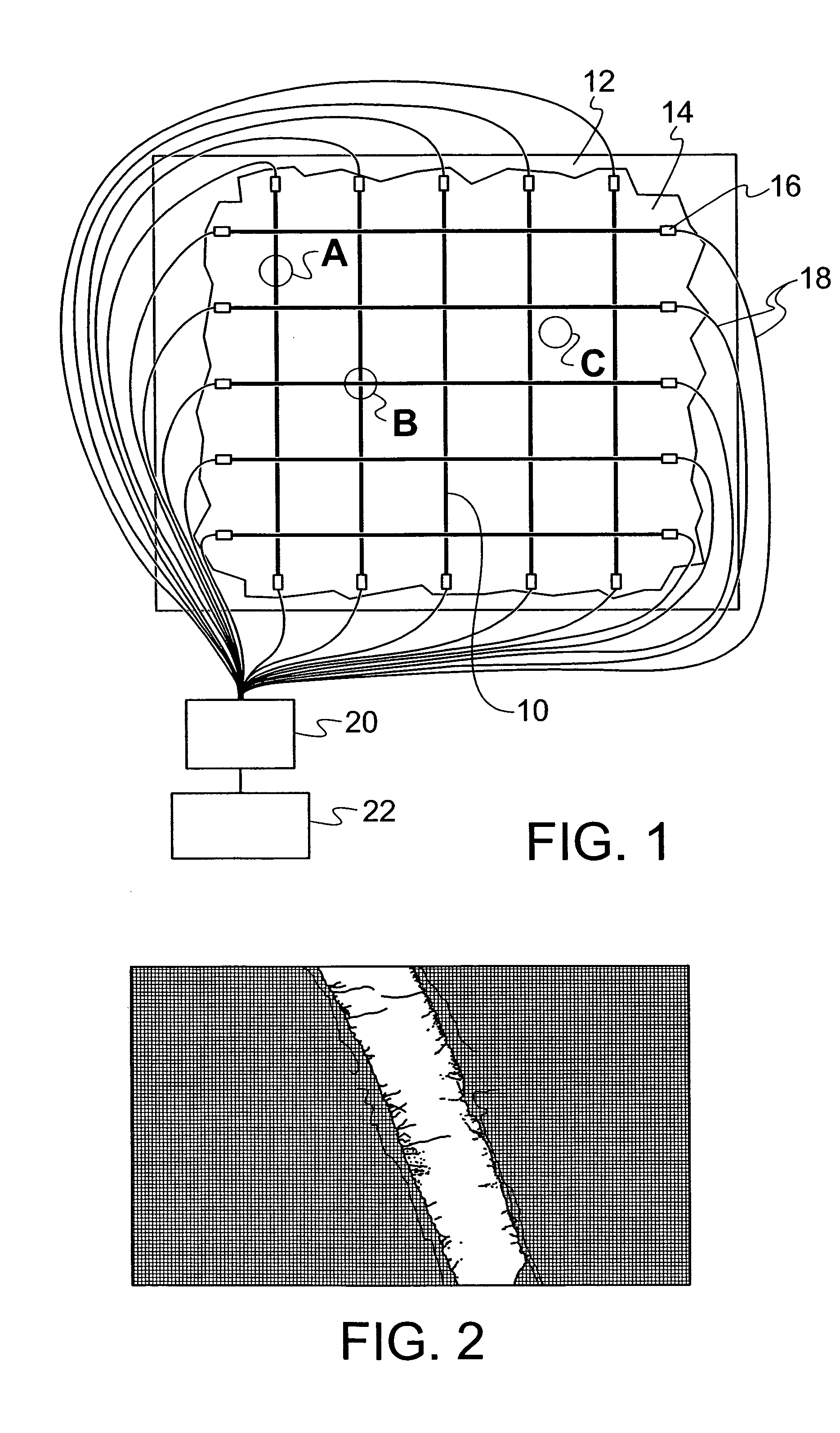

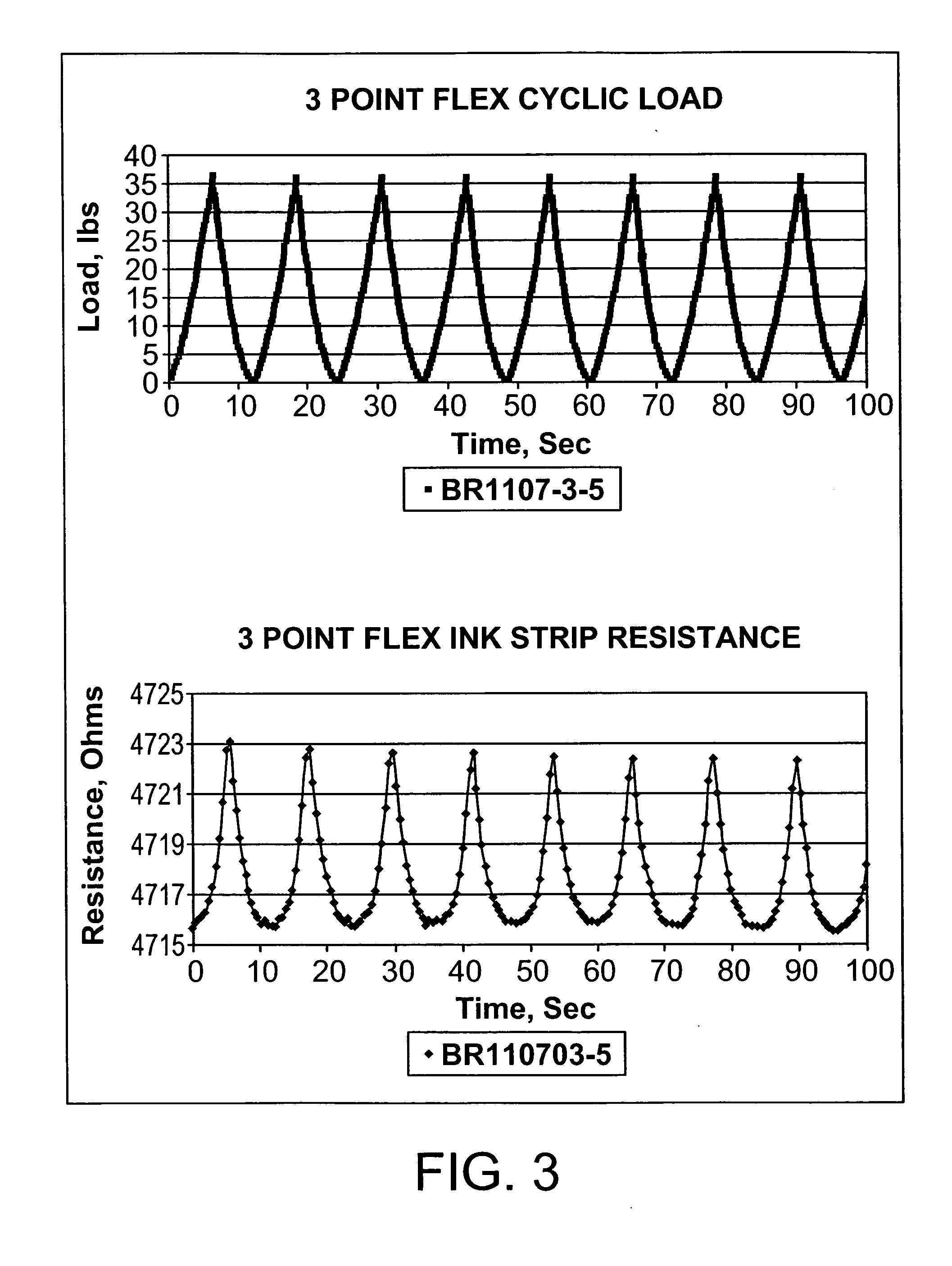

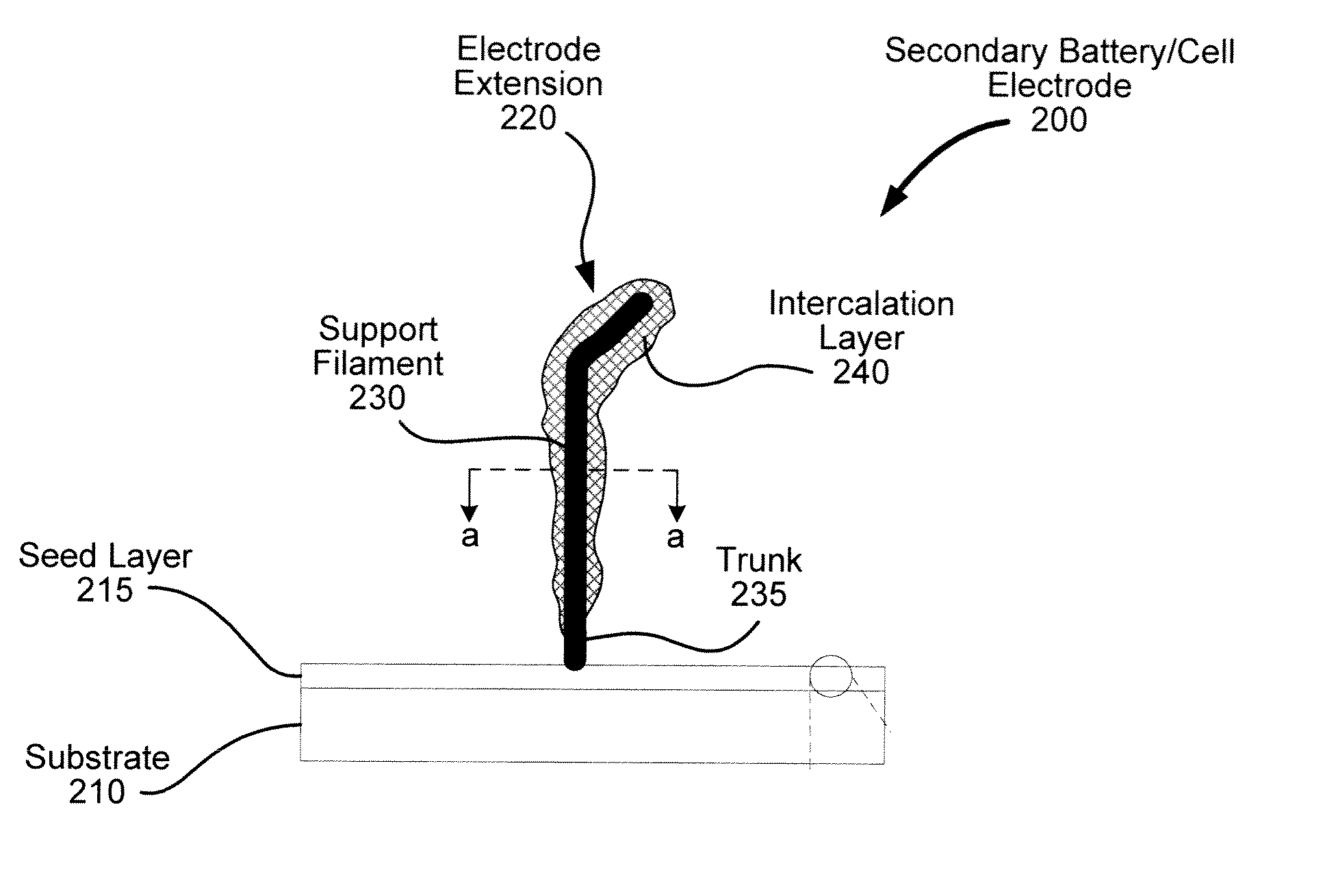

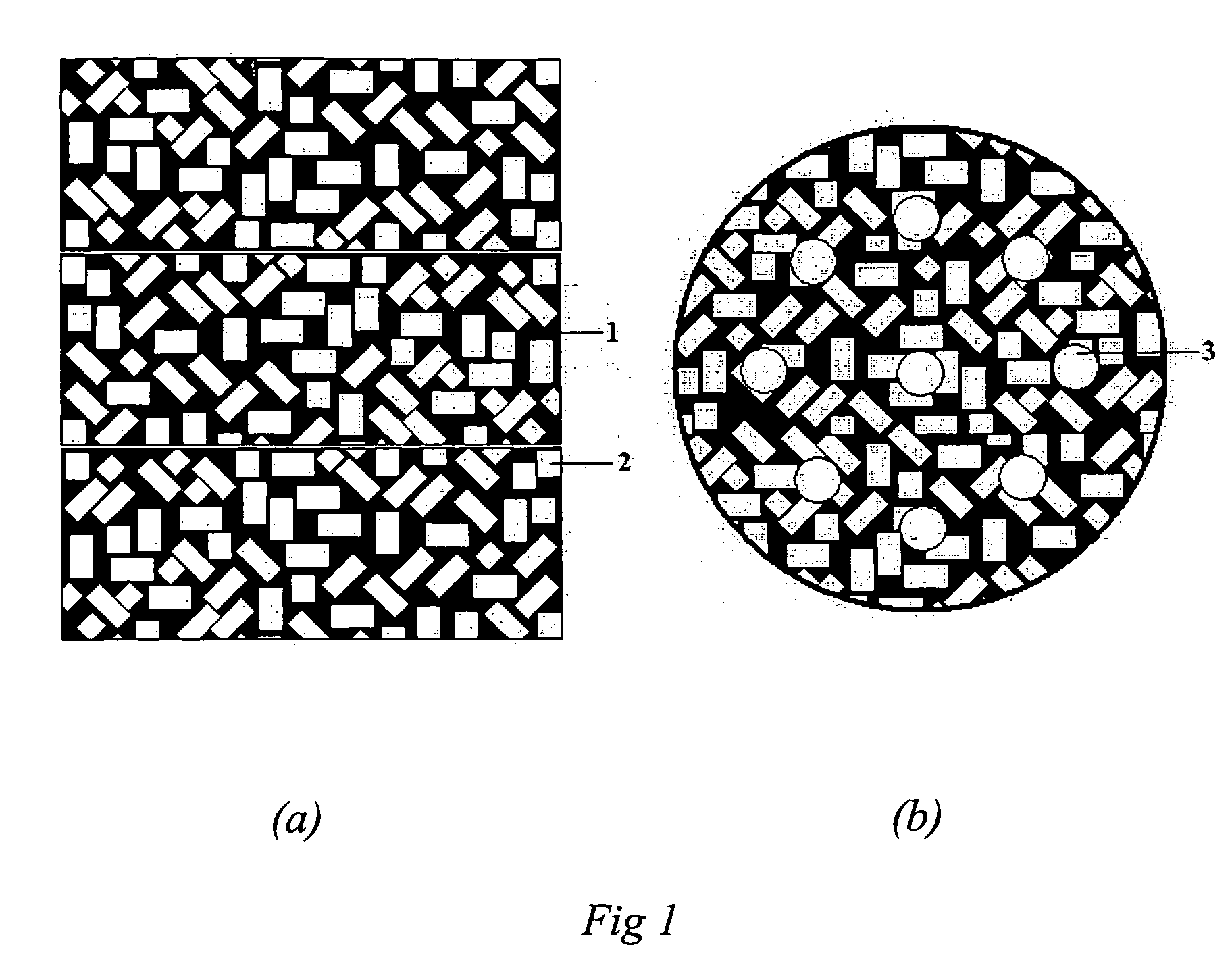

Sensing system for monitoring the structural health of composite structures

ActiveUS20050284232A1Easy to stickImprove signal-to-noise ratioUsing optical meansElectrical/magnetic solid deformation measurementGrid patternState of health

A sensing system for use in monitoring the structural health of a structure such as a polymeric matrix composite structure is provided. The system includes a sensor formed from a conductive ink containing carbon nanofibers and a polymeric resin, and a data acquisition system for acquiring and evaluating data from the sensor. The conductive ink may be applied directly to the structure to be monitored in the form of a grid pattern. Damage to the structure may be detected by measuring changes in resistance values detected from the sensor.

Owner:UNIV OF DAYTON

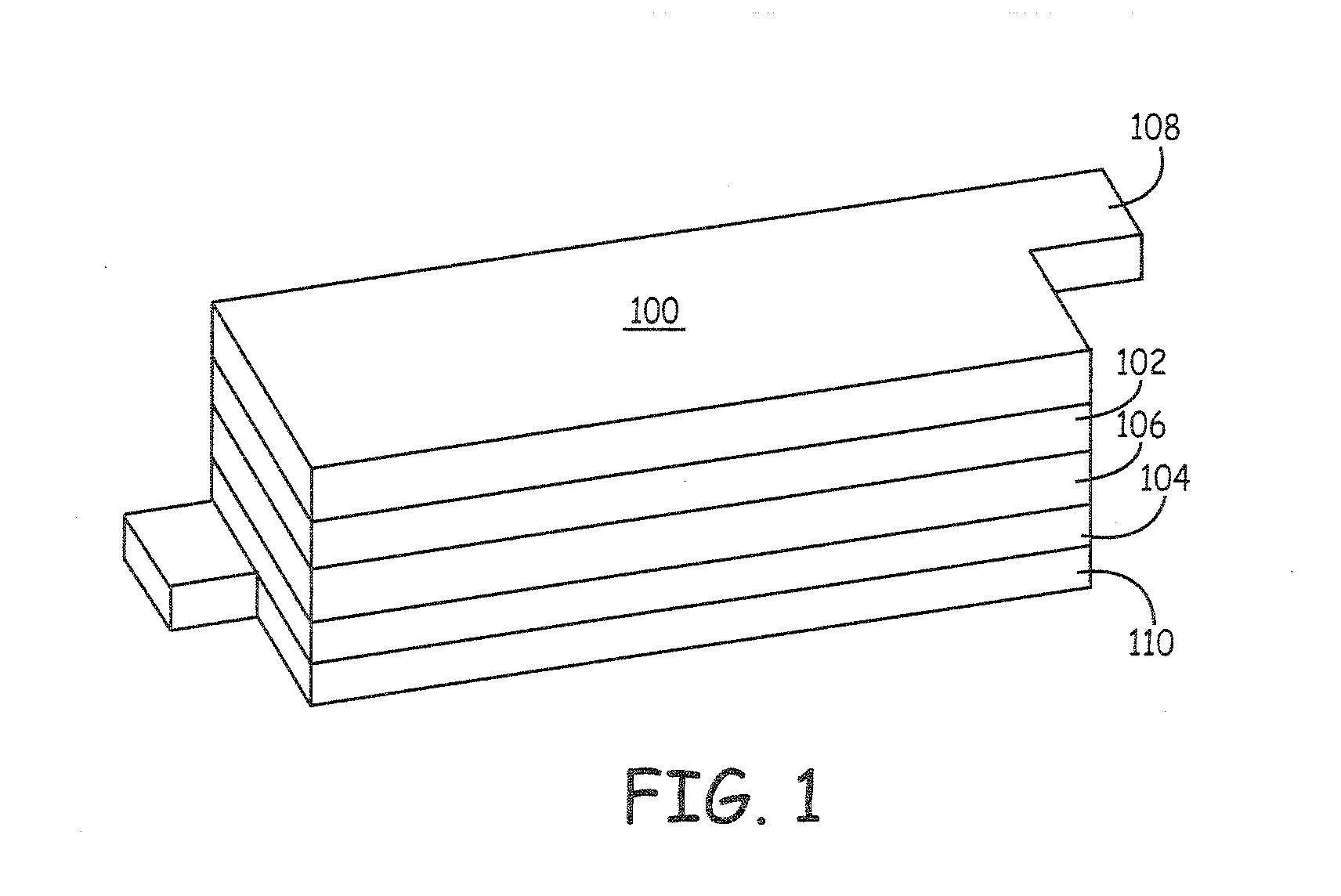

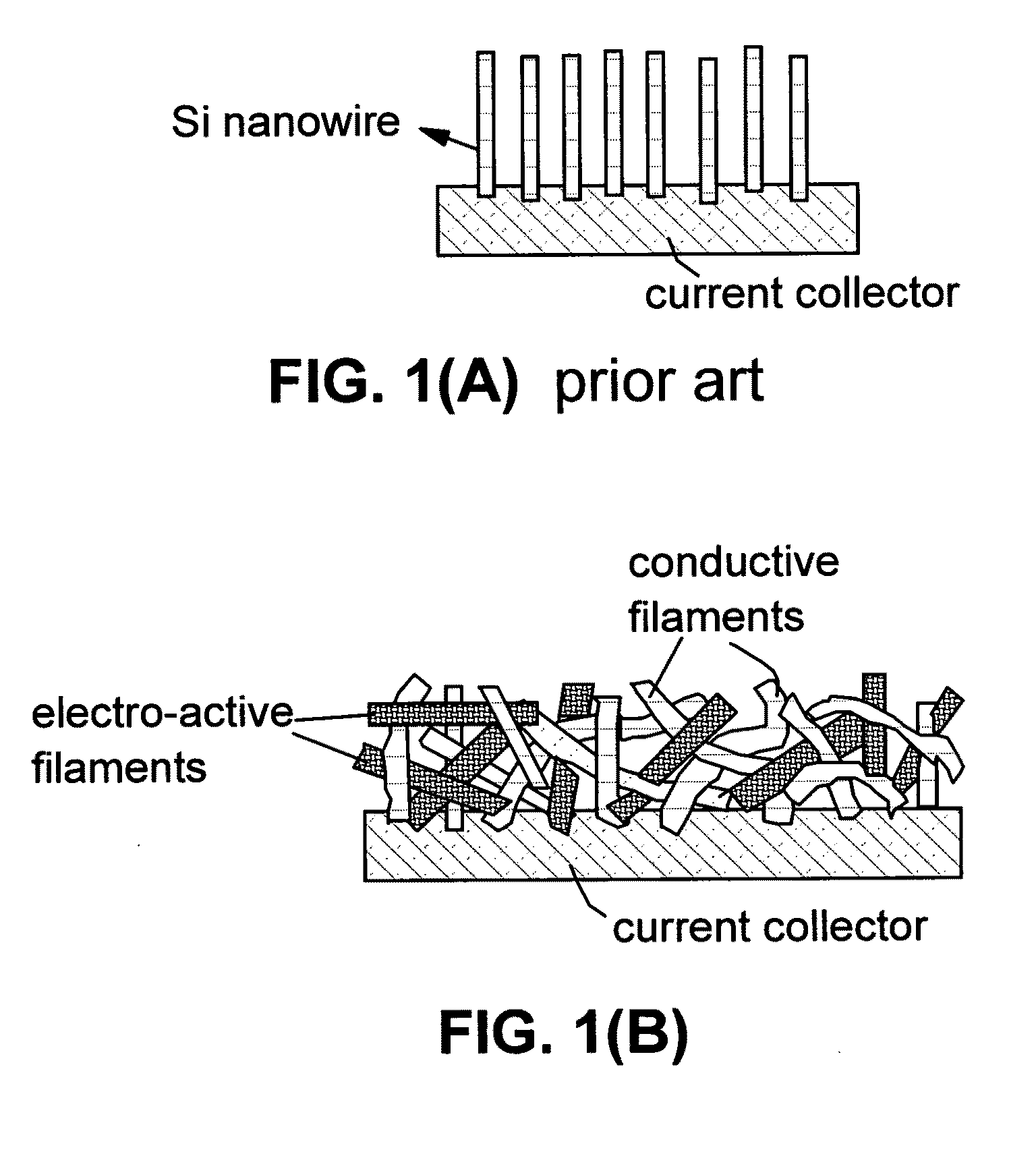

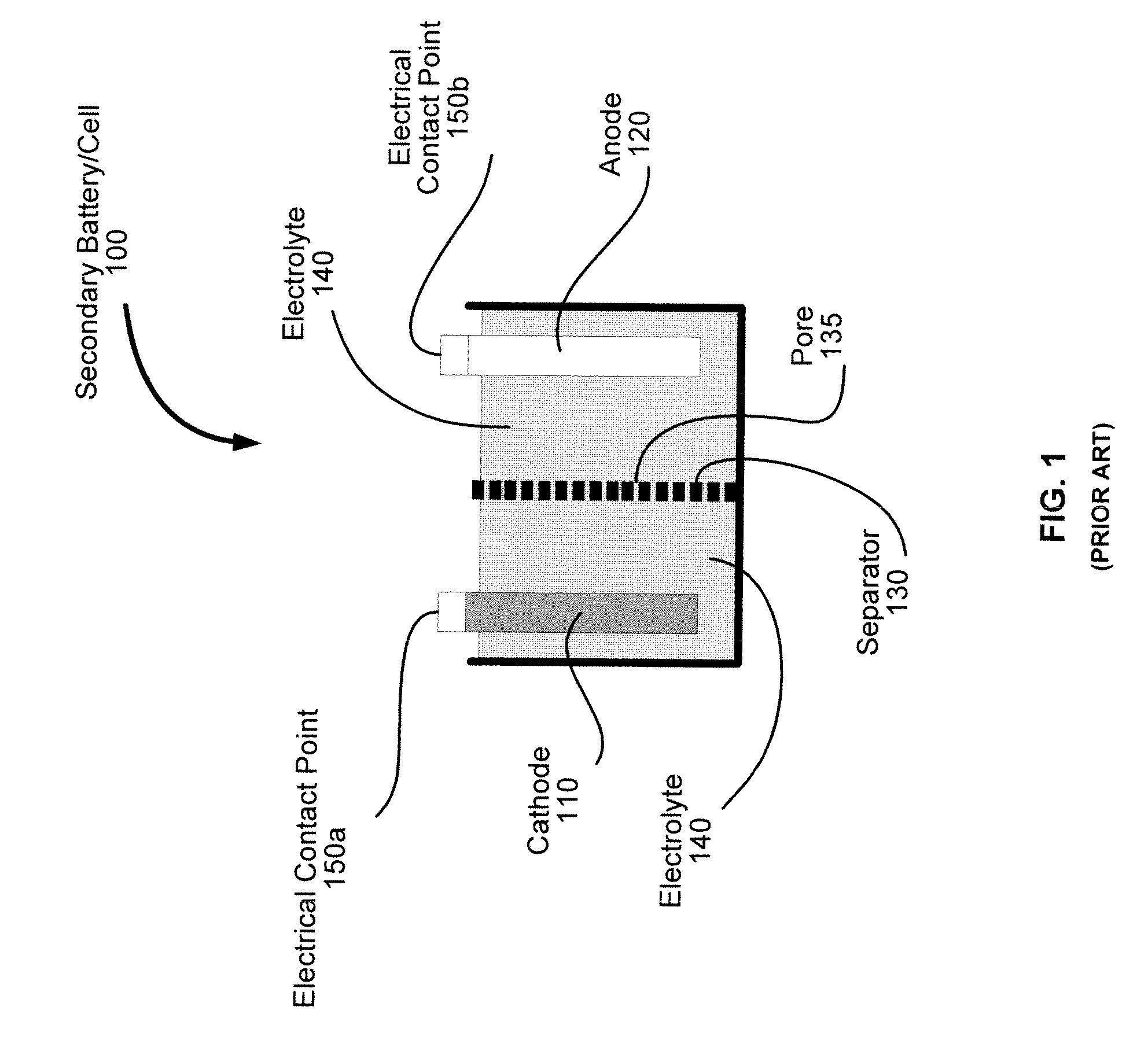

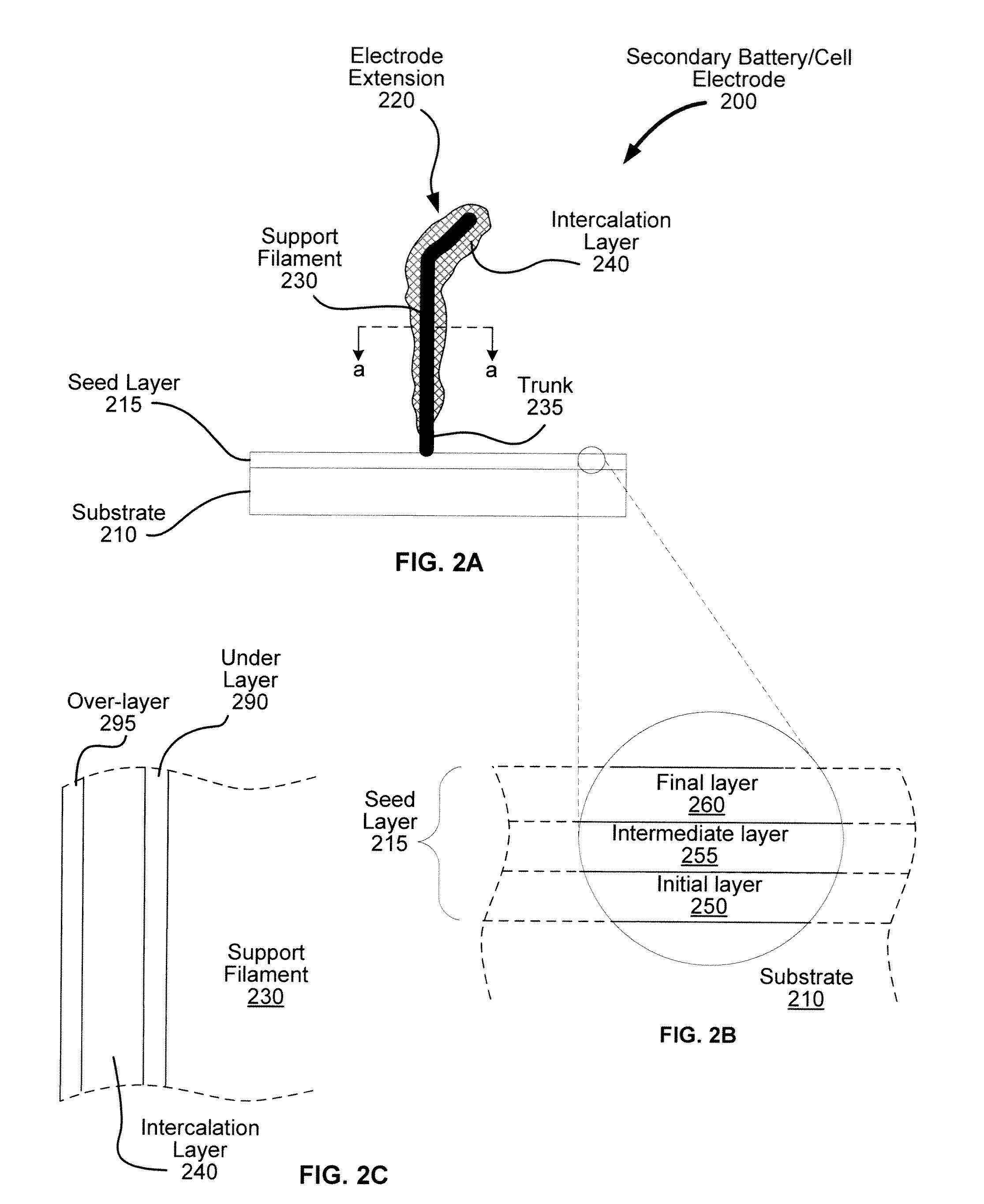

High Capacity Electrodes

A high capacity electrode includes a conducting substrate on which a plurality of support filaments are disposed. Each of the support filaments have a length substantially greater than their width and may include, for example, a carbon nano-tube (CNT), a carbon nano-fiber (CNF), and / or a nano-wire (NW). The support filaments are coated with a material, such as silicon, having a greater ion absorbing capacity greater than the neat support filaments. A trunk region of the support filaments proximate to the substrate is optionally kept free of ion absorbing material. This trunk region allows for the expansion of the ion absorbing material without detaching the support filaments form the substrate.

Owner:CF TRAVERSE LLC

Low density lightning strike protection for use in airplanes

ActiveUS20090227162A1Minimize micro-crackingWeight optimizationConductive materialWarp knittingFiberEpoxy

Surface films, paints, or primers can be used in preparing aircraft structural composites that may be exposed to lightning strikes. Methods for making and using these films, paints or primers are also disclosed. The surface film can include a thermoset resin or polymer, e.g., an epoxy resin and / or a thermoplastic polymer, which can be cured, bonded, or painted on the composite structure. Low-density electrically conductive materials are disclosed, such as carbon nanofiber, copper powder, metal coated microspheres, metal-coated carbon nanotubes, single wall carbon nanotubes, graphite nanoplatelets and the like, that can be uniformly dispersed throughout or on the film. Low density conductive materials can include metal screens, optionally in combination with carbon nanofibers.

Owner:ROHR INC +1

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

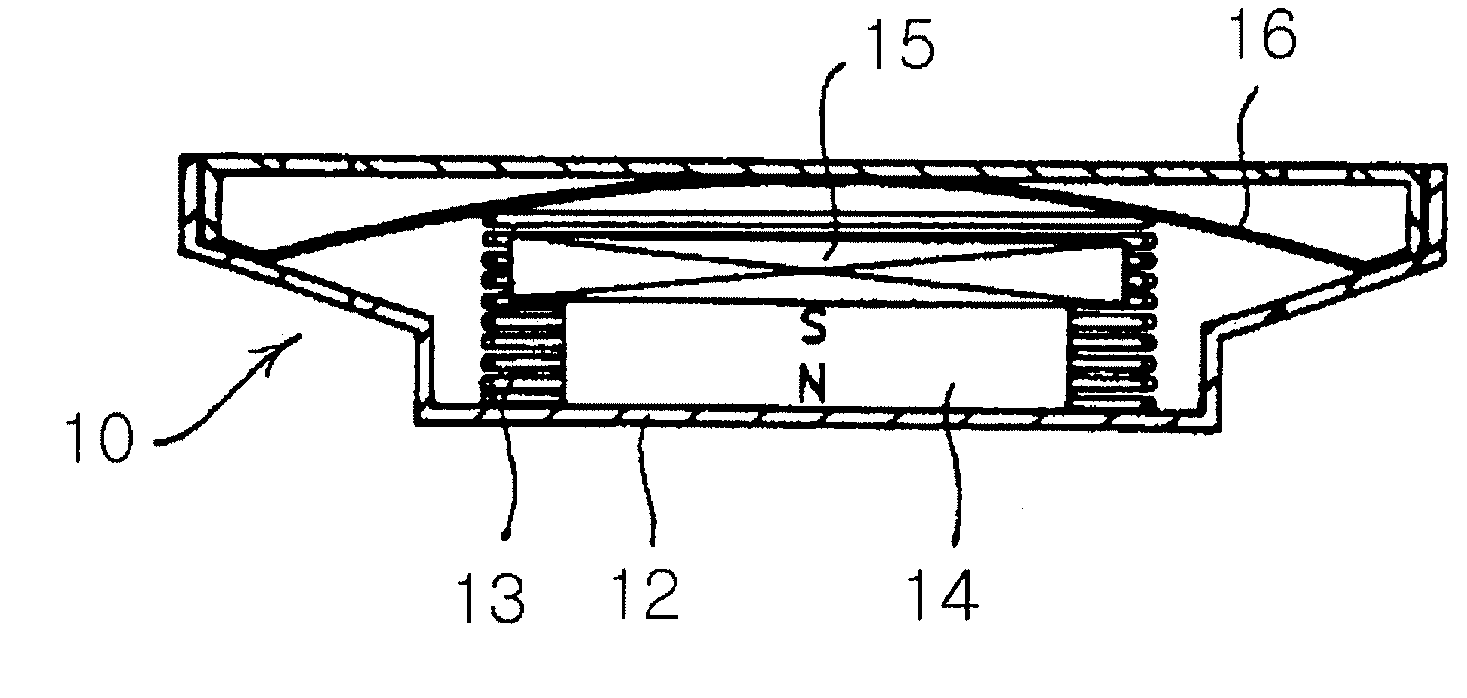

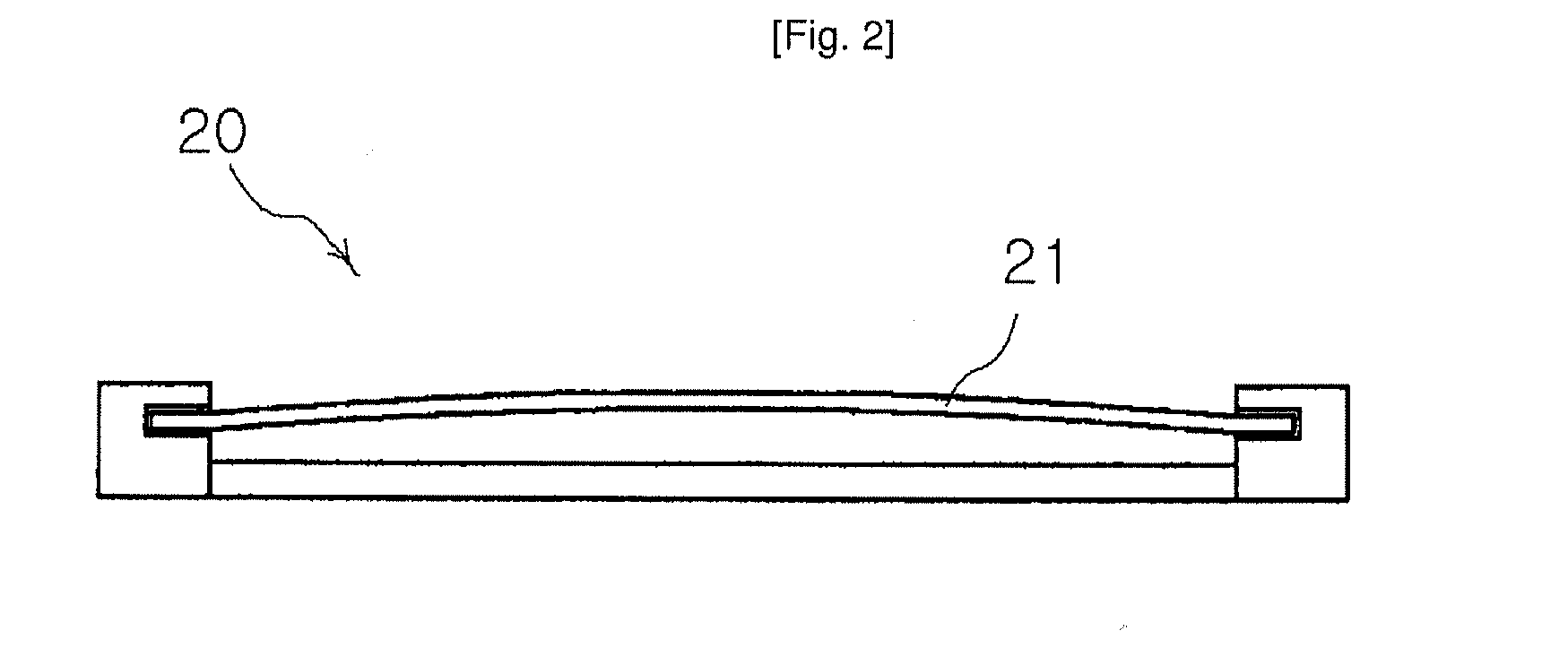

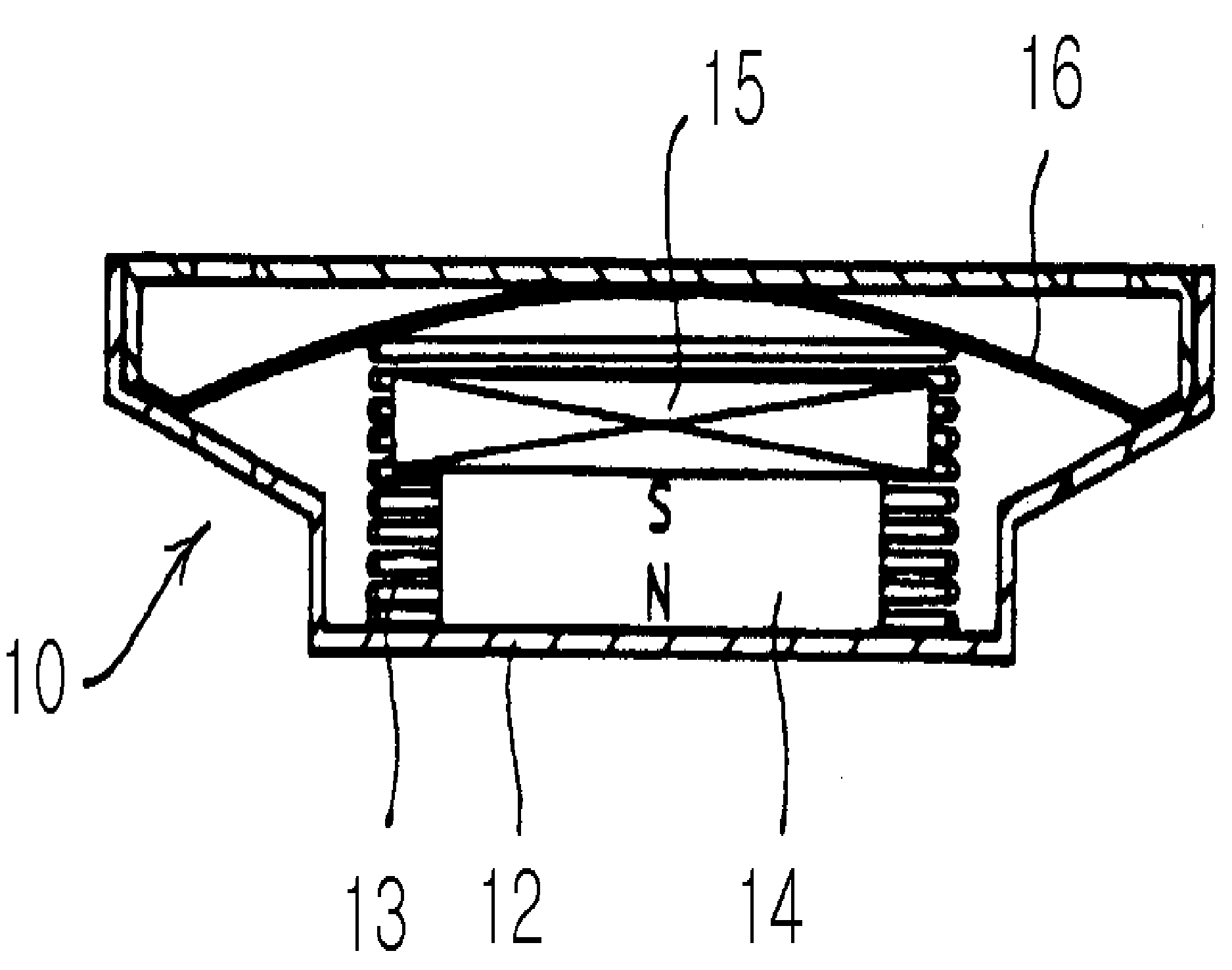

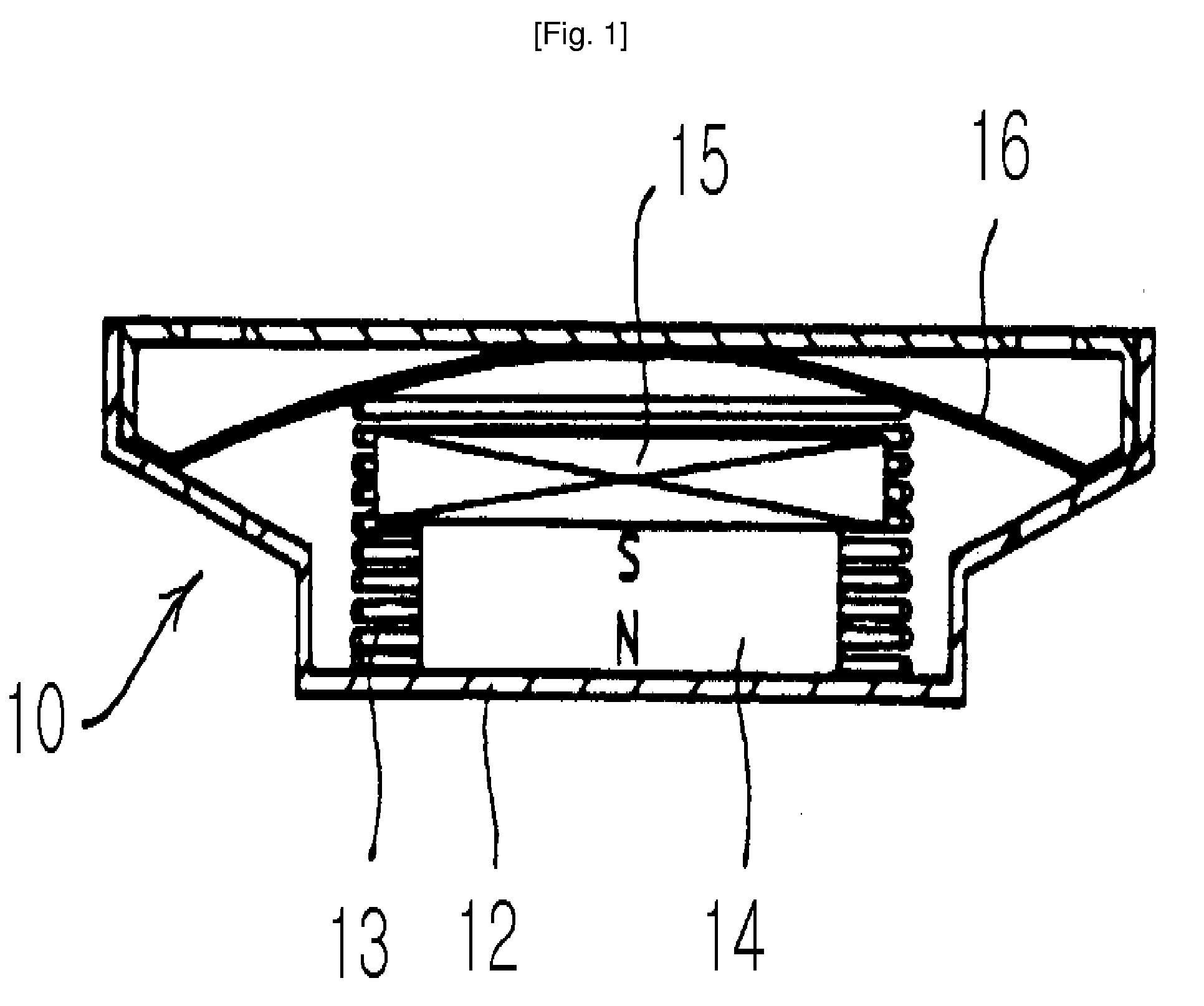

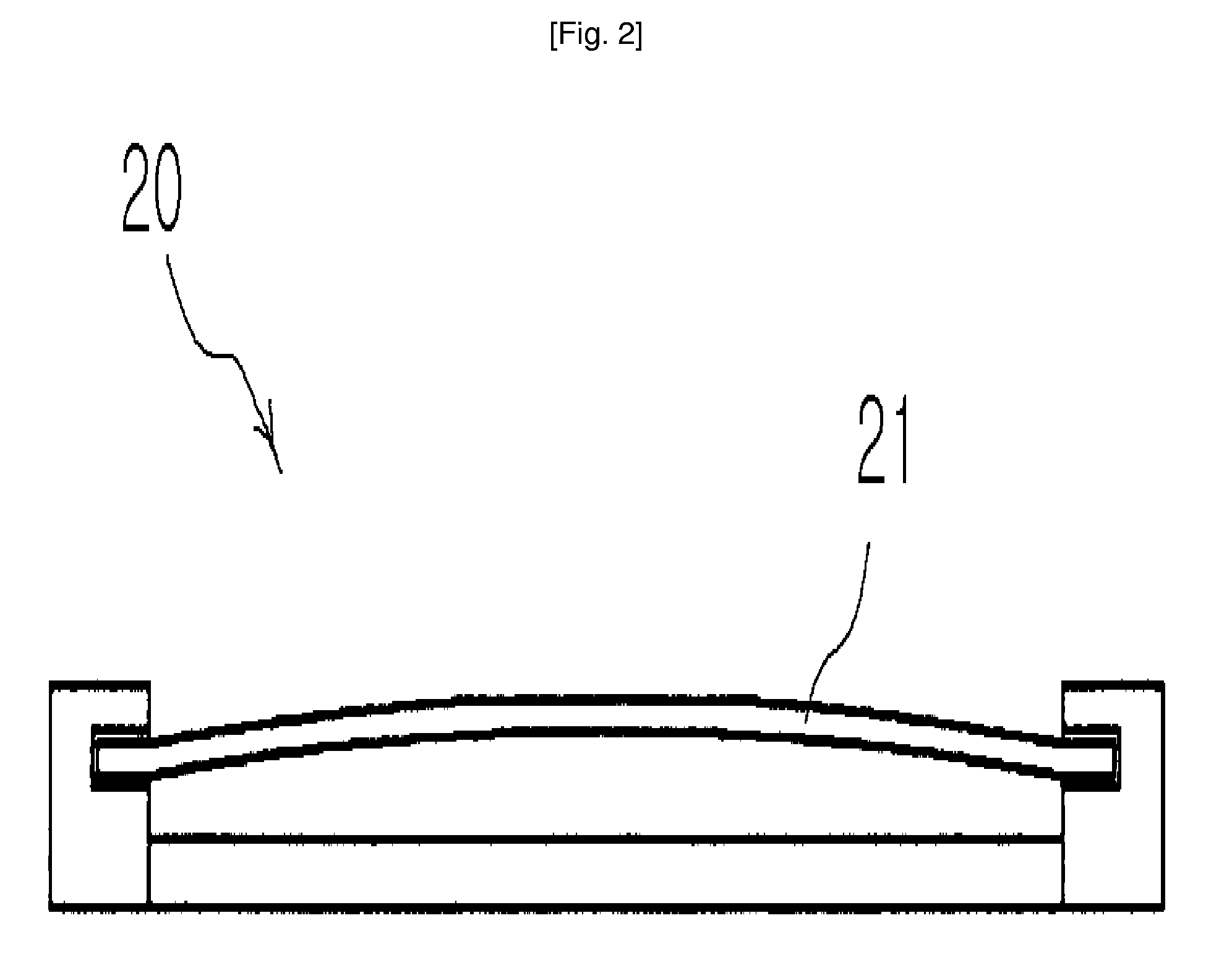

Acoustic Diaphragm and Speaker Having the Same

InactiveUS20080260188A1Good physical propertiesImprove sound qualityFibre diaphragmsPolymeric diaphragmsFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as major materials. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss and strength, it can effectively achieve superior sound quality and high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

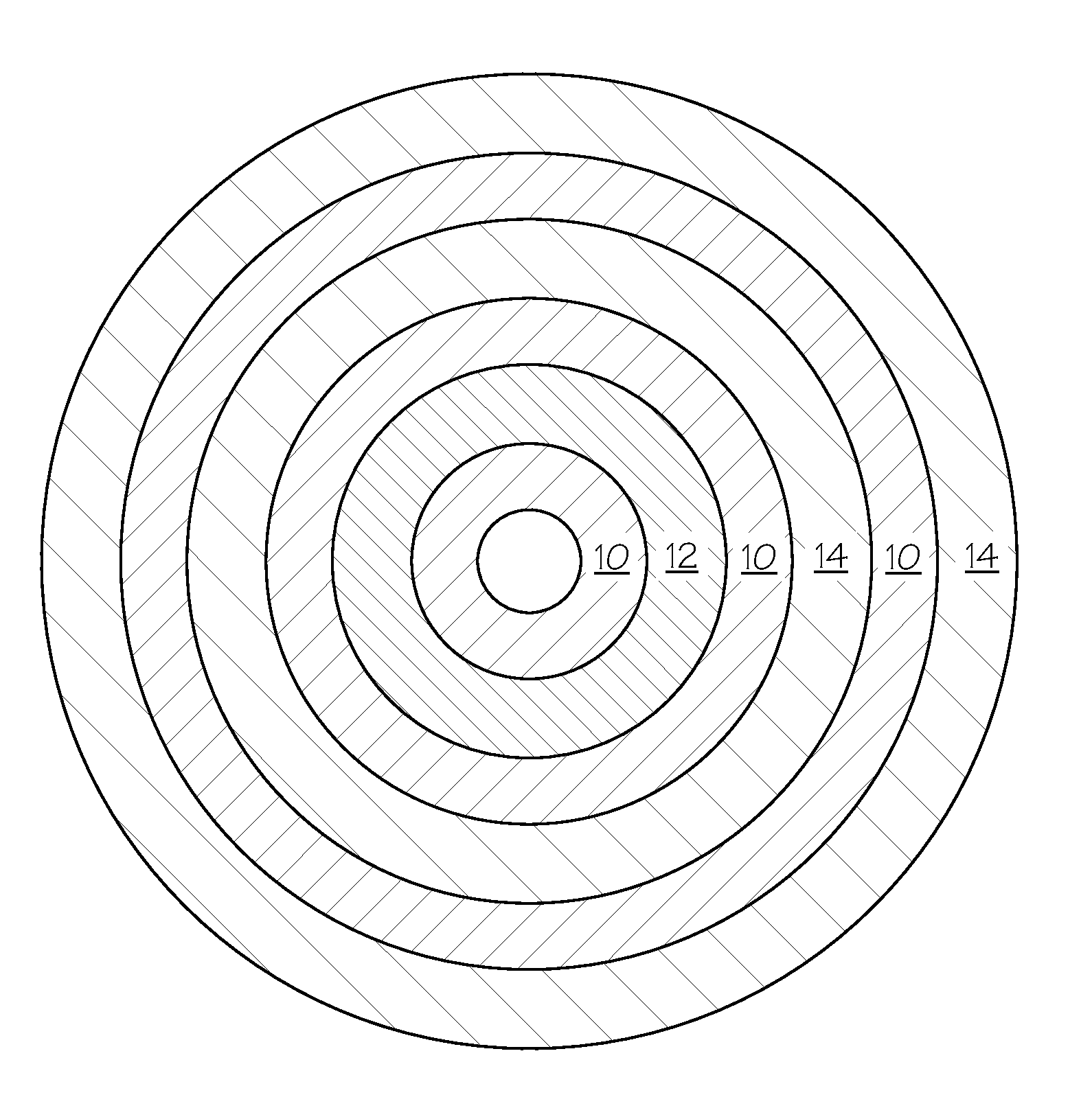

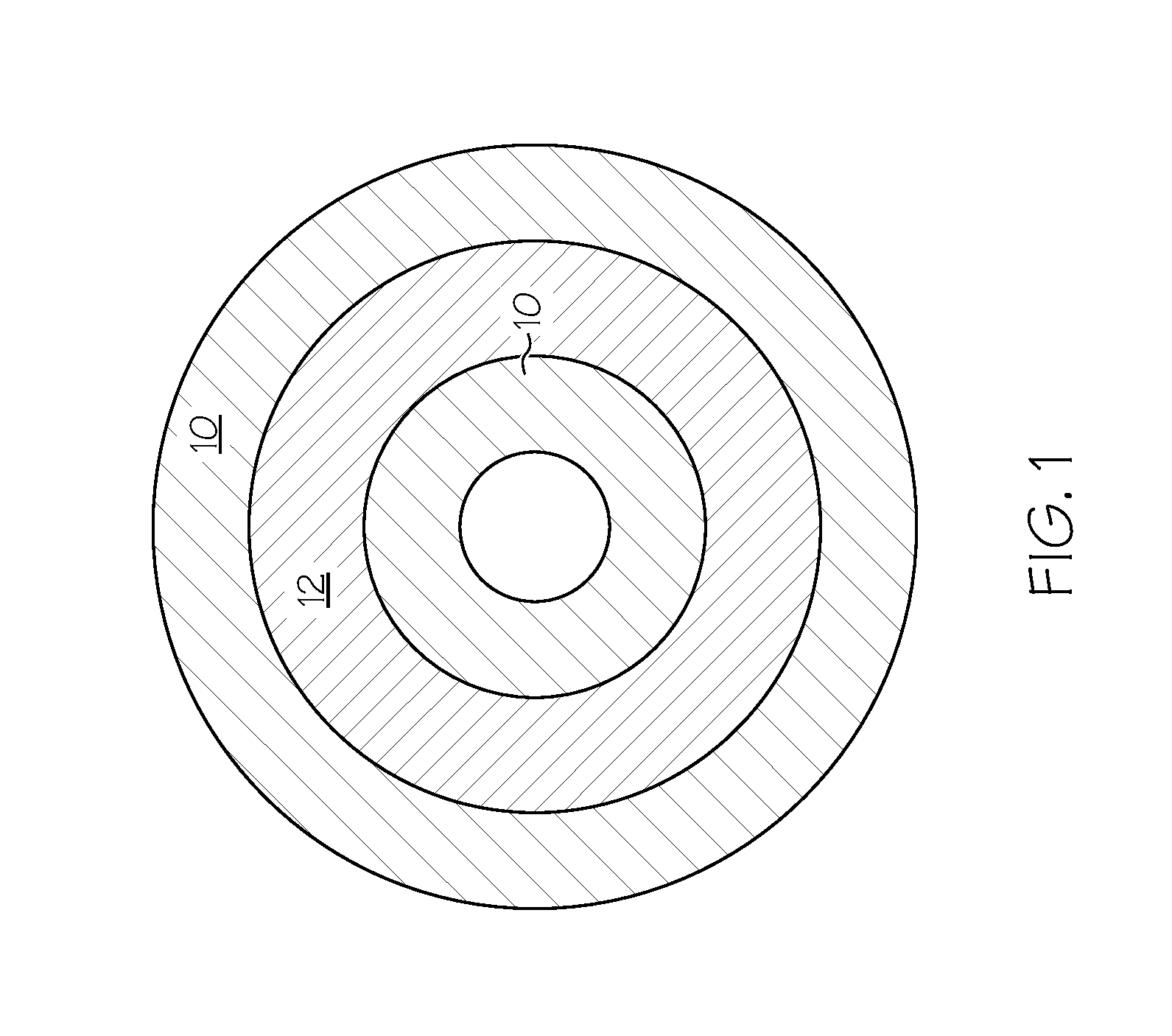

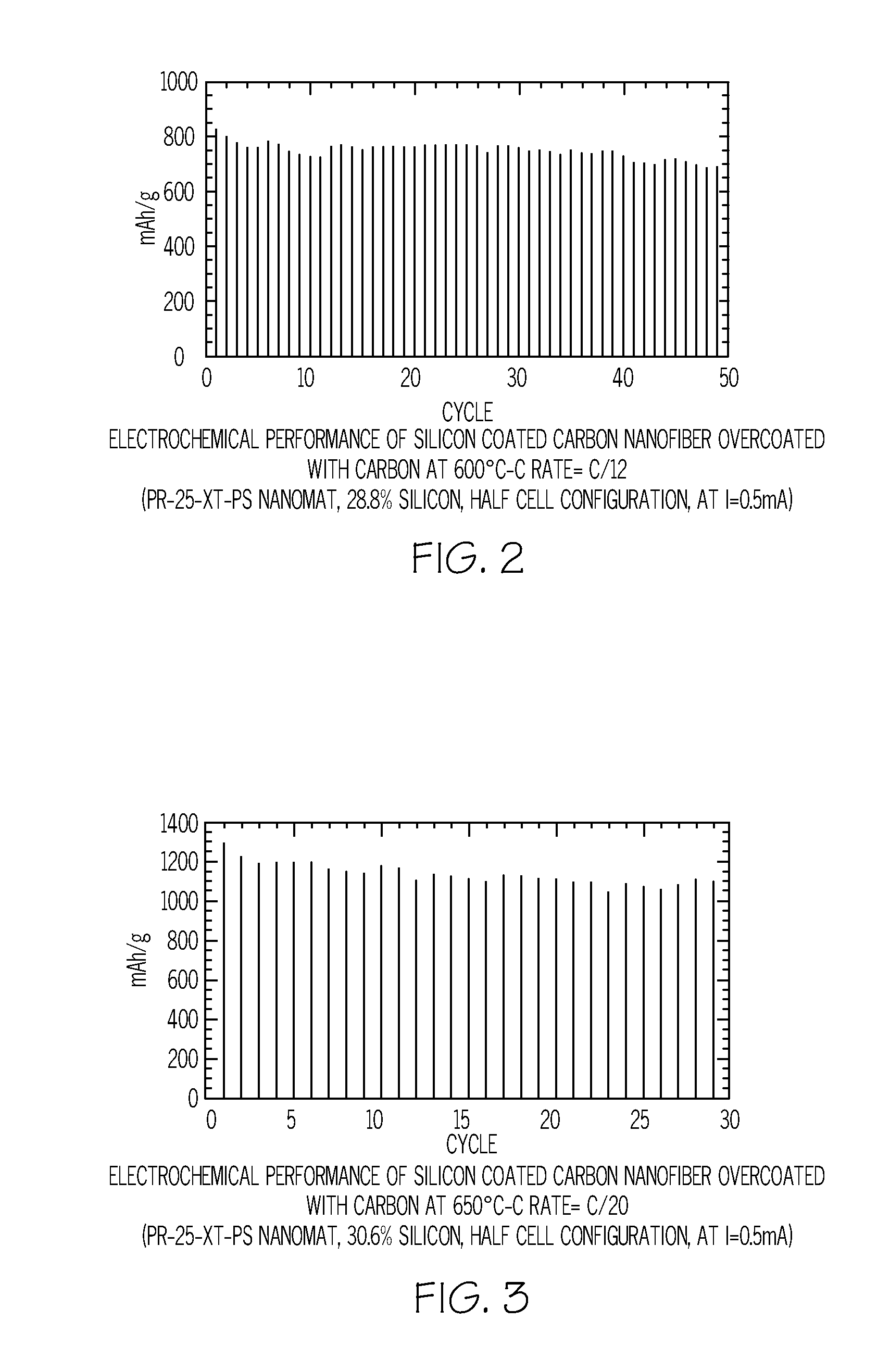

Method of depositing silicon on carbon nanomaterials

InactiveUS20120264020A1Increase surface areaHigh pore volumeMaterial nanotechnologyLiquid surface applicatorsCarbon coatingGas phase

A method of depositing silicon on carbon nanomaterials such as vapor grown carbon nanofibers, nanomats, or nanofiber powder is provided. The method includes flowing a silicon-containing precursor gas in contact with the carbon nanomaterial such that silicon is deposited on the exterior surface and within the hollow core of the carbon nanomaterials. A protective carbon coating may be deposited on the silicon-coated nanomaterials. The resulting nanocomposite materials may be used as anodes in lithium ion batteries.

Owner:APPLIED SCI

Acoustic Diaphragm and Speakers Having the Same

InactiveUS20090045005A1Good physical propertiesImprove sound qualityPiezoelectric/electrostrictive transducersNanotechnologyFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as reinforcing agents. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm or coated on the surface of the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss, strength and density, it can effectively achieve superior sound quality and a high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

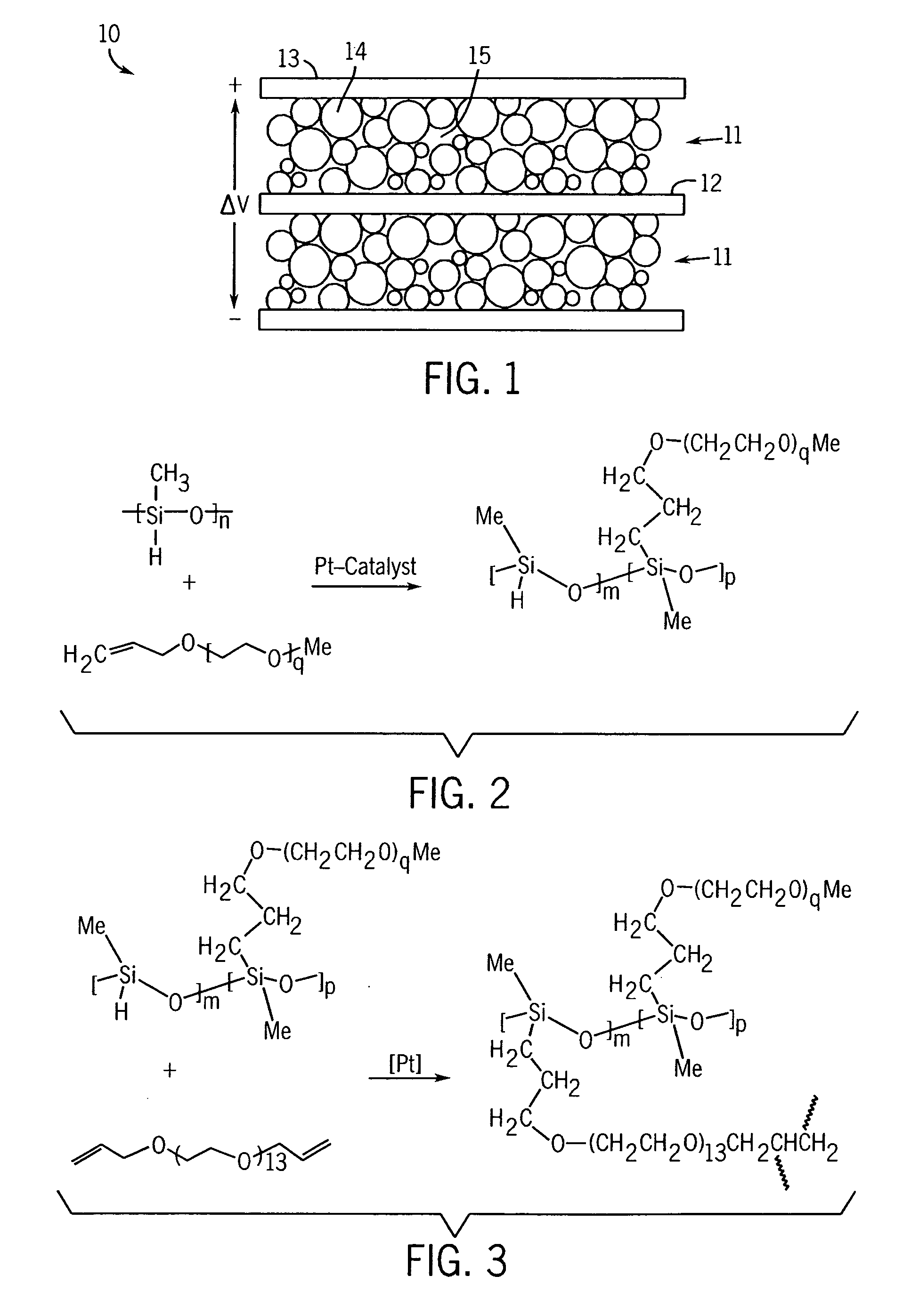

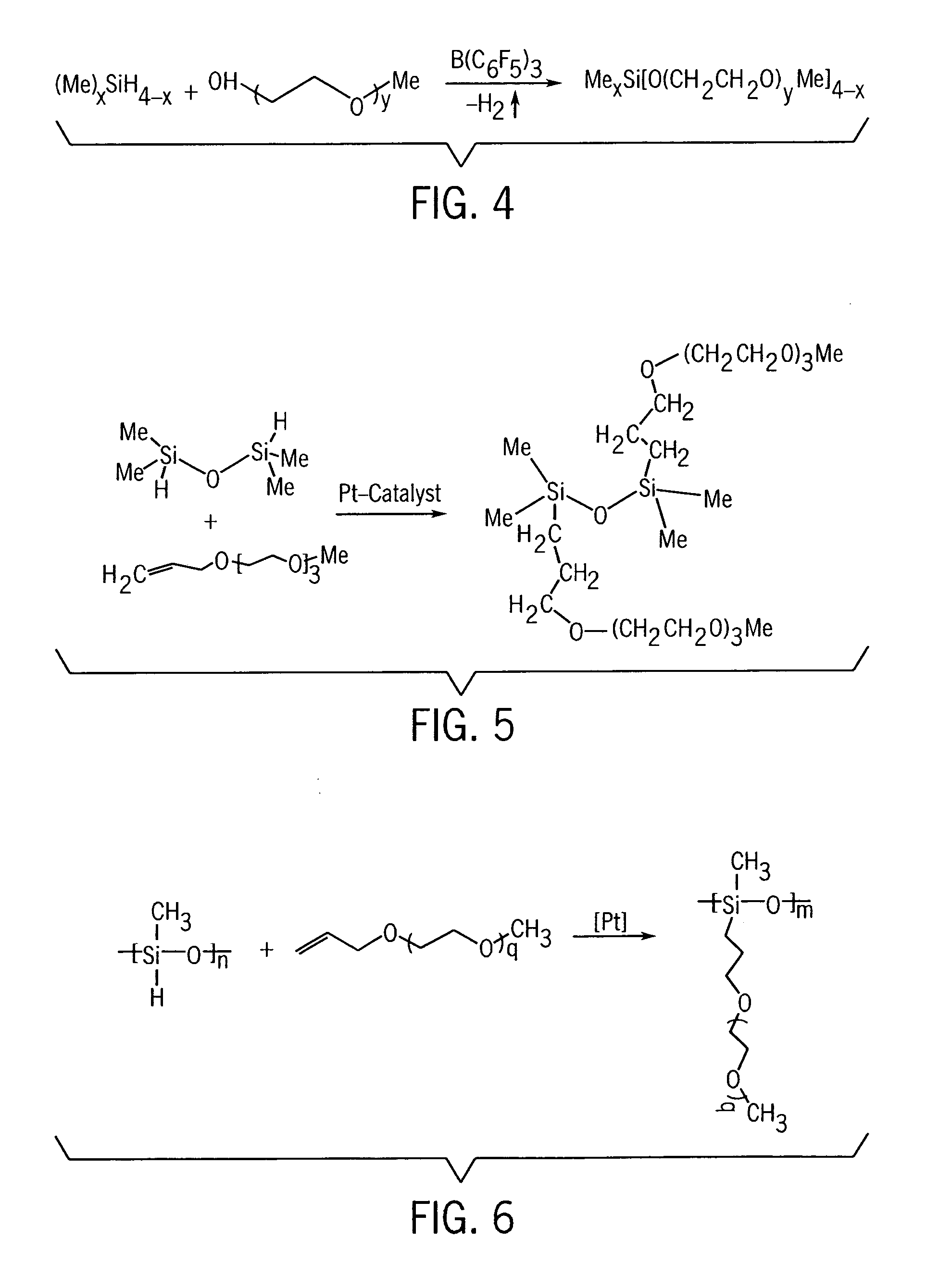

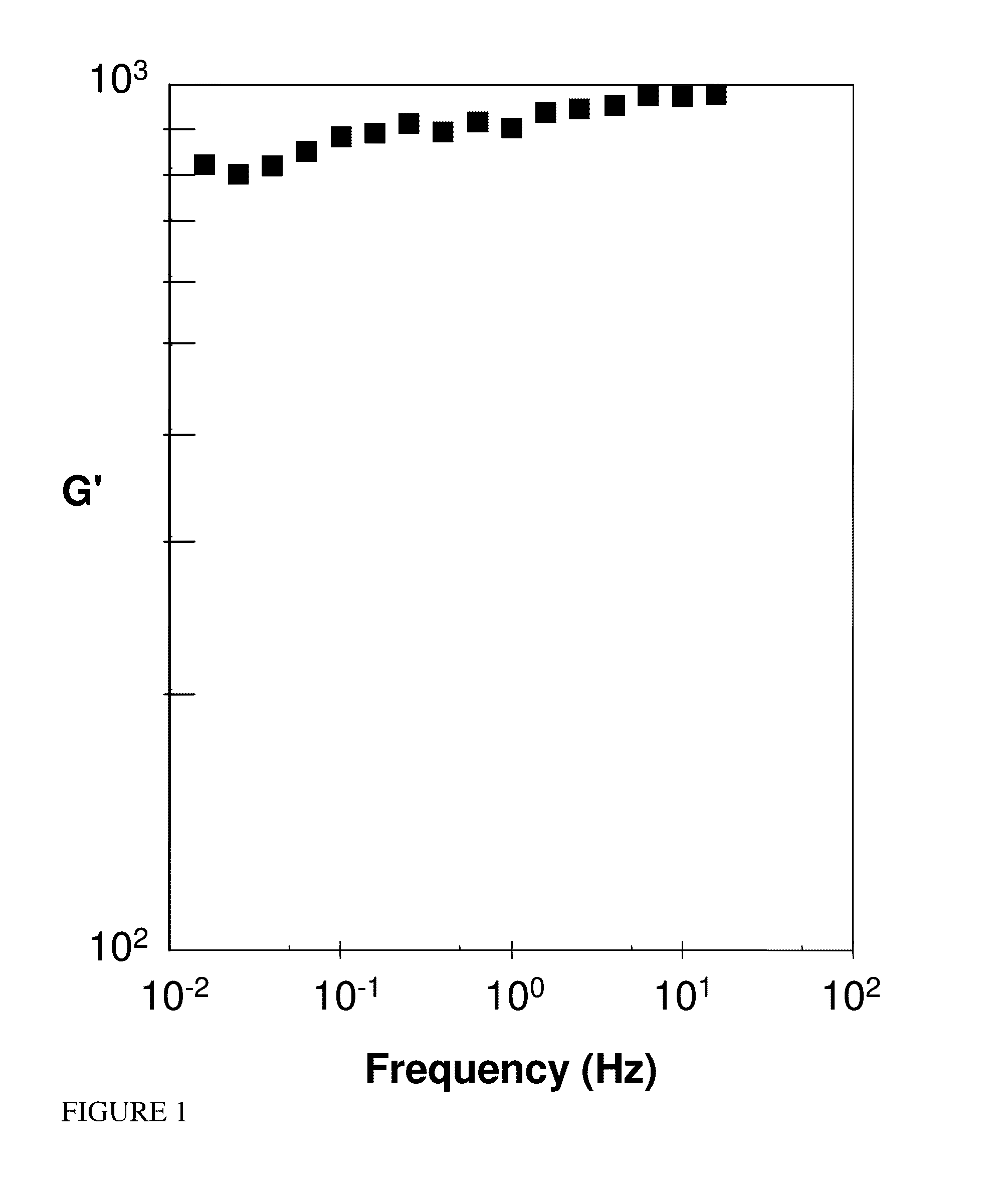

Electrochemical double-layer capacitor using organosilicon electrolytes

ActiveUS20070076349A1Simple processStable storageHybrid capacitor electrolytesLiquid electrolytic capacitorsPorous carbonElectrochemical double layer capacitor

Owner:WISCONSIN ALUMNI RES FOUND

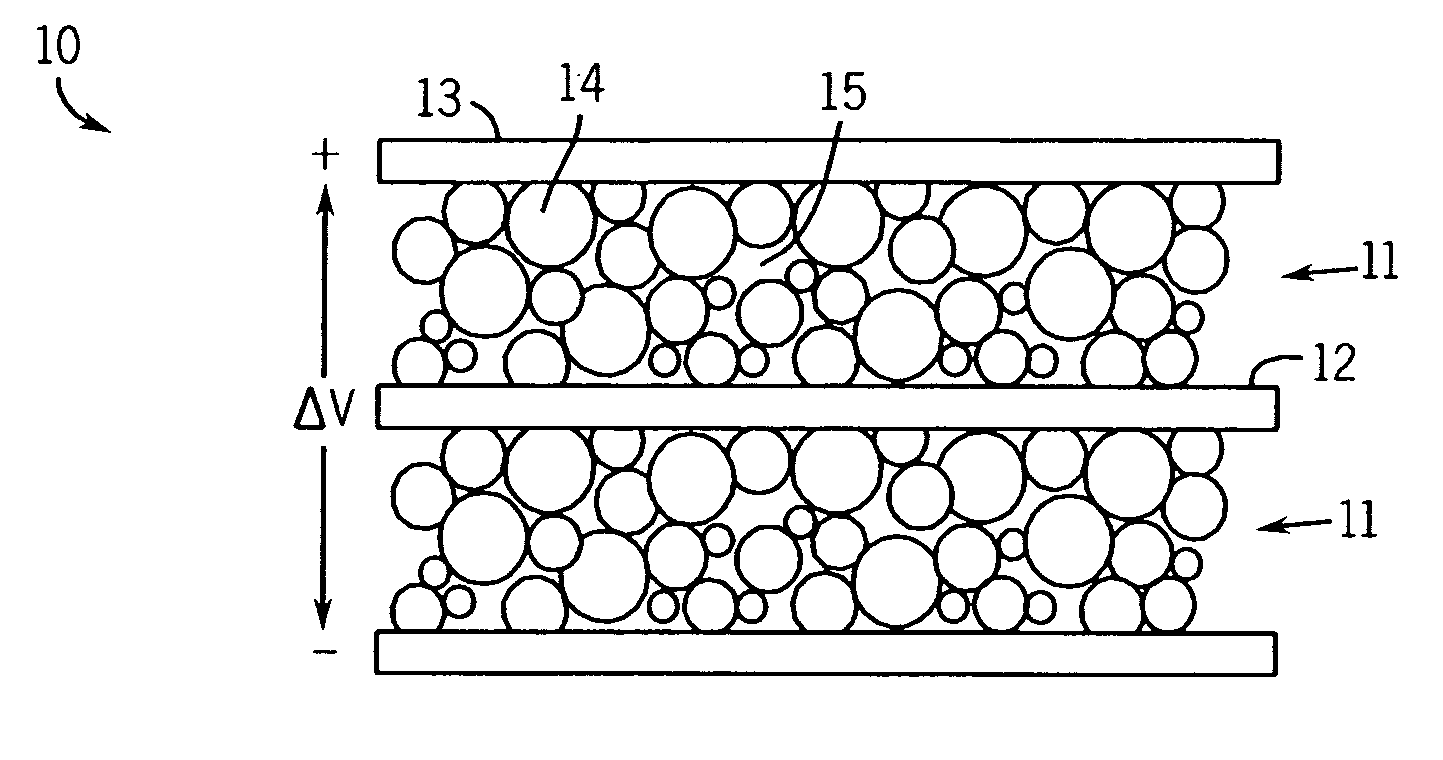

Electrode composite, battery electrode formed from said composite, and lithium battery comprising such an electrode

InactiveUS20110163274A1Improve cycle stabilityGood dispersionMaterial nanotechnologyNon-metal conductorsElectrical batteryCarbon nanofiber

An electrode composite and to its manufacturing process. The composite includes an active element, i.e. one exhibiting electrochemical activity, a conductive additive and a binder. The conductive additive is a mixture of conductive additives containing at least carbon nanofibres (CNFs) and at least carbon nanotubes (CNTs). Also, the negative electrodes for electrochemical devices of the lithium battery type including said composite and to the secondary (Li-ion) batteries provided with such a negative electrode.

Owner:ARKEMA FRANCE SA +1

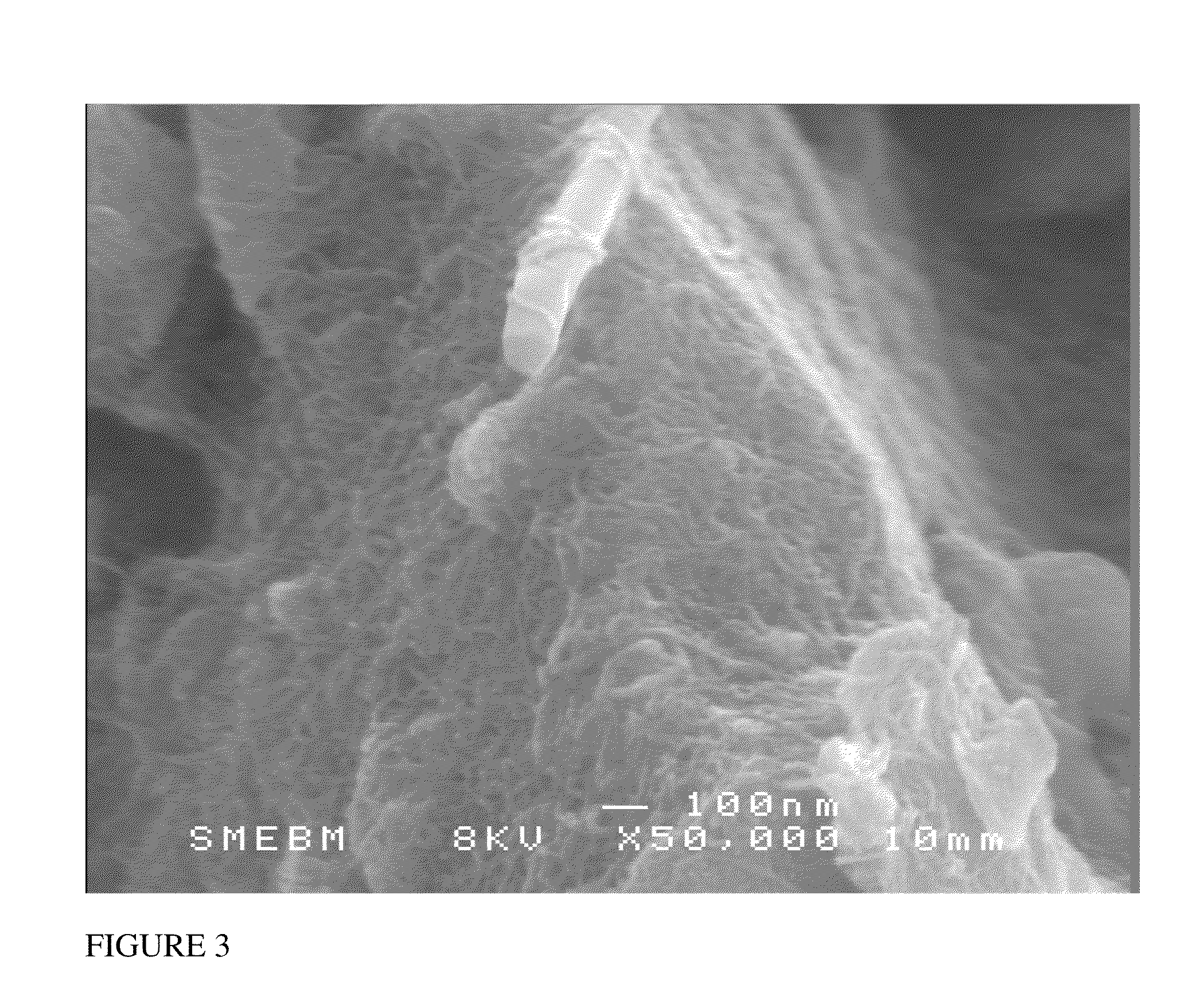

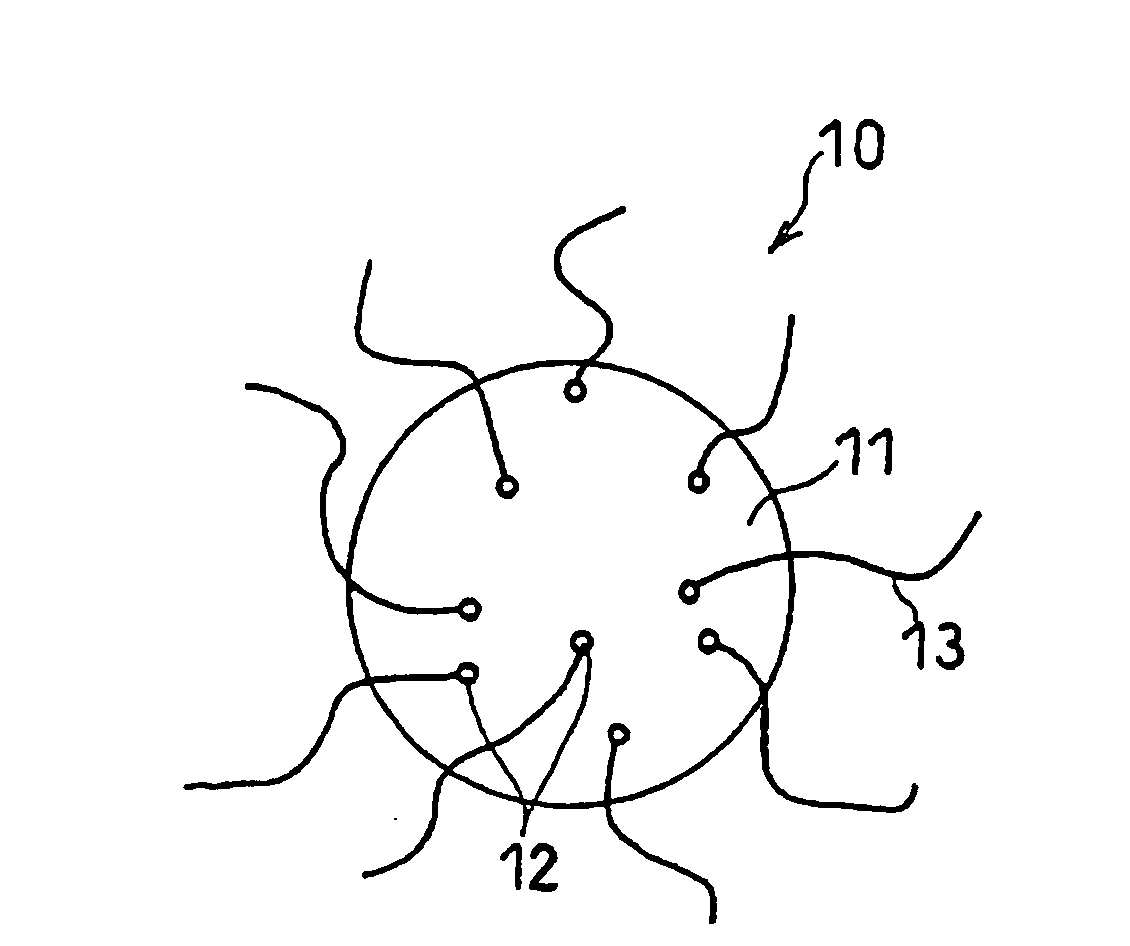

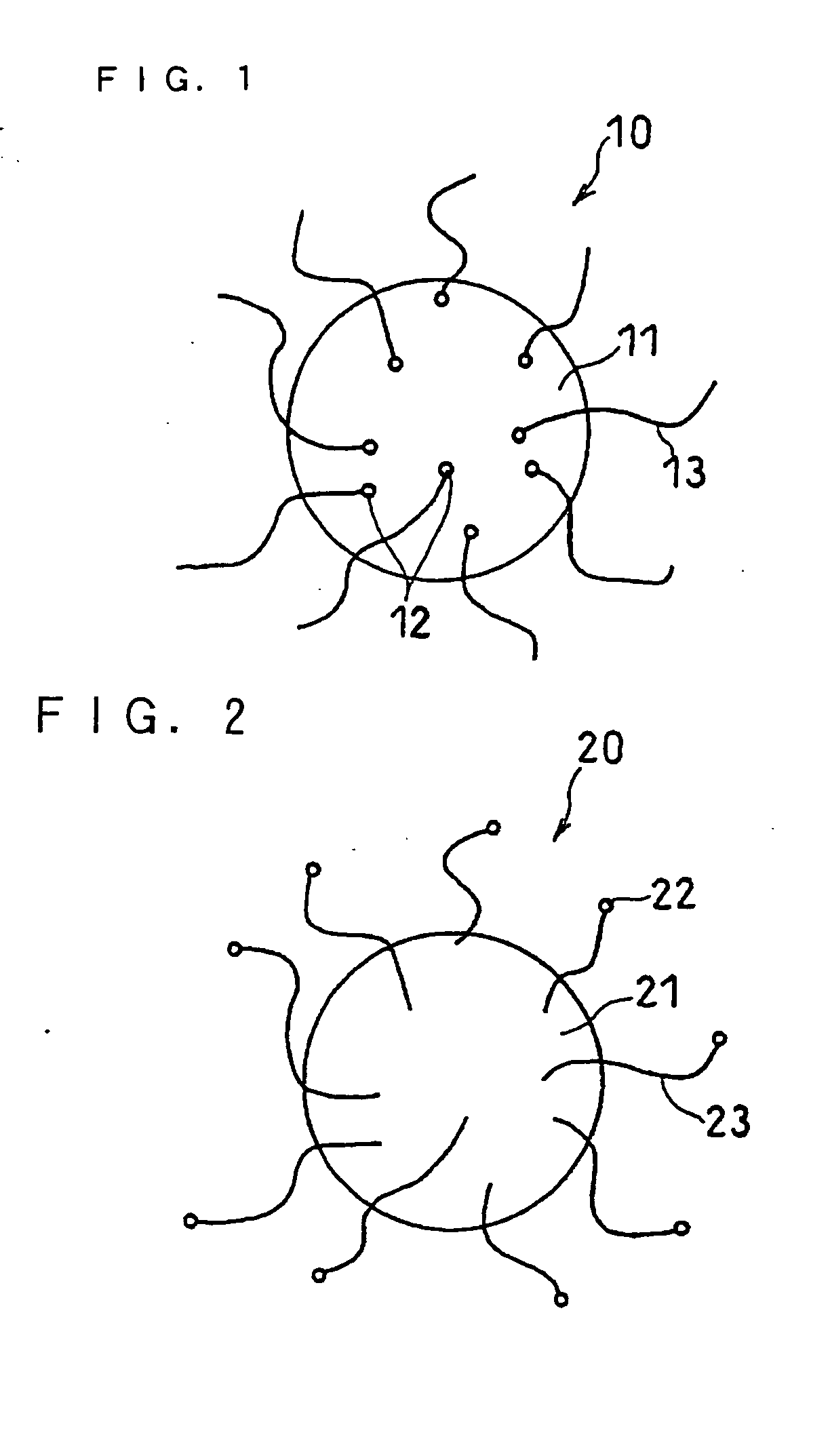

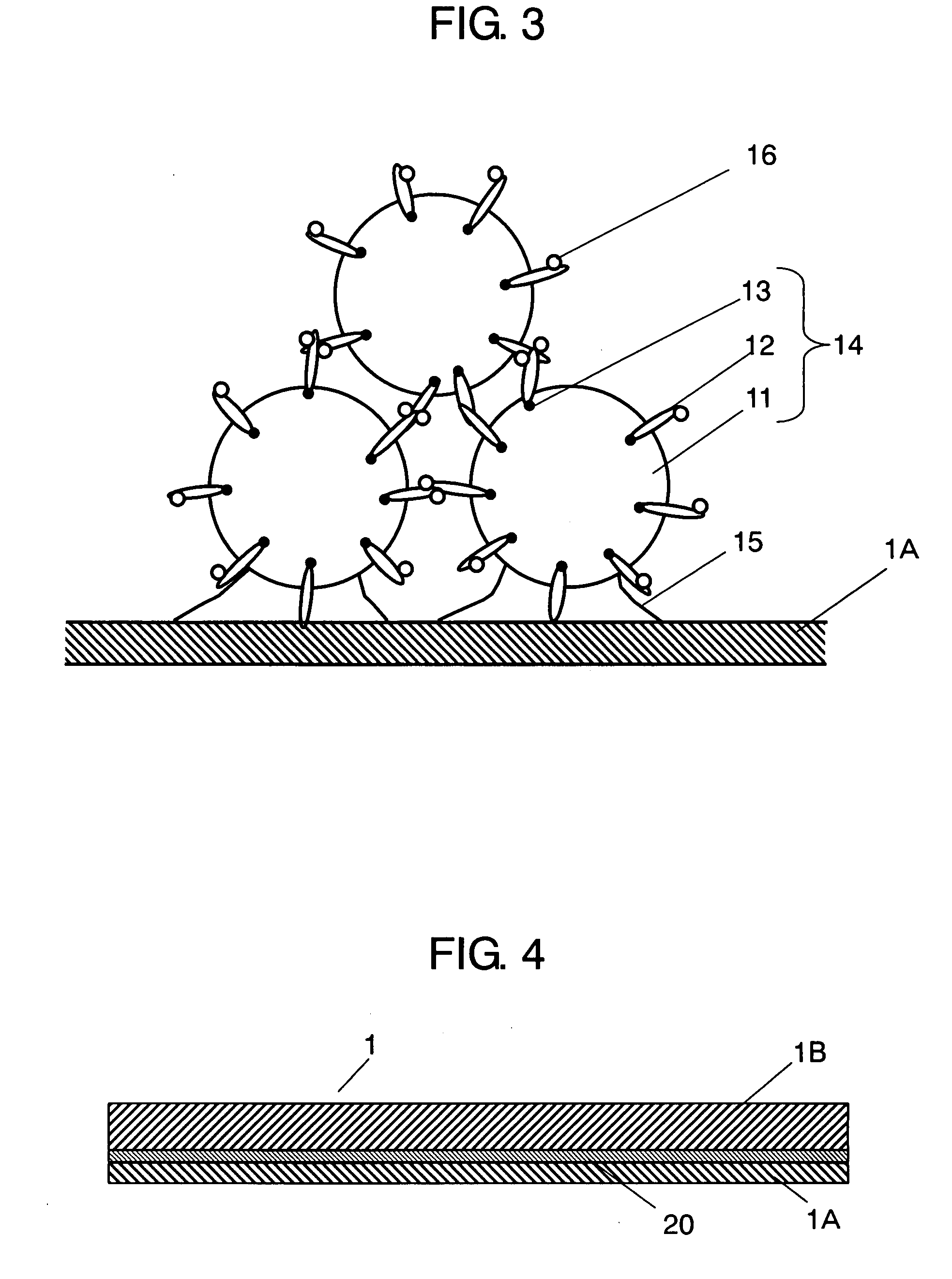

Composite Particle for Electrode, Method for Producing the Same and Secondary Battery

InactiveUS20080160409A1Improve electronic conductivityExcellent initial charge/discharge characteristicMaterial nanotechnologyElectrode manufacturing processesFiberSurface layer

A composite particle for an electrode including an active material particle, carbon nanofibers bonded to the surface of the active material particle, and a catalyst element for promoting the growth of the carbon nanofibers, wherein the active material particle includes an electrochemically active phase. As the catalyst element, for example, Au, Ag, Pt, Ru, Ir, Cu, Fe, Co, Ni, Mo, Mn and the like are used. The composite particle for an electrode may be produced, for example, by means of a method which includes: a step of preparing an active material particle including a catalyst element for promoting the growth of carbon nanofibers at least in the surface layer of the active material particle; and a step of growing carbon nanofibers on the surface of the active material particle in an atmosphere including a raw material gas.

Owner:PANASONIC CORP

Negative Electrode for Non-Aqueous Electrolyte Secondary Batteries, and Non-Aqueous Electrolyte Secondary Battery Having the Same

InactiveUS20090004566A1Excellent cycle characteristicsImproving impedanceFinal product manufactureElectrode carriers/collectorsCarbon nanofiberSilicon

A negative electrode for non-aqueous electrolyte secondary batteries has a mixture layer disposed on a current collector. The mixture layer includes a composite negative electrode active material, a first binder containing an acryl-group-containing polymer, and a second binder containing adhesive rubber particles. The composite negative electrode active material contains carbon nanofibers, a catalyst element, and silicon-containing particles capable of charging and discharging at least lithium ions. The first binder binds the silicon-containing particles to the current collector, and the second binder binds the carbon nanofibers together.

Owner:GK BRIDGE 1

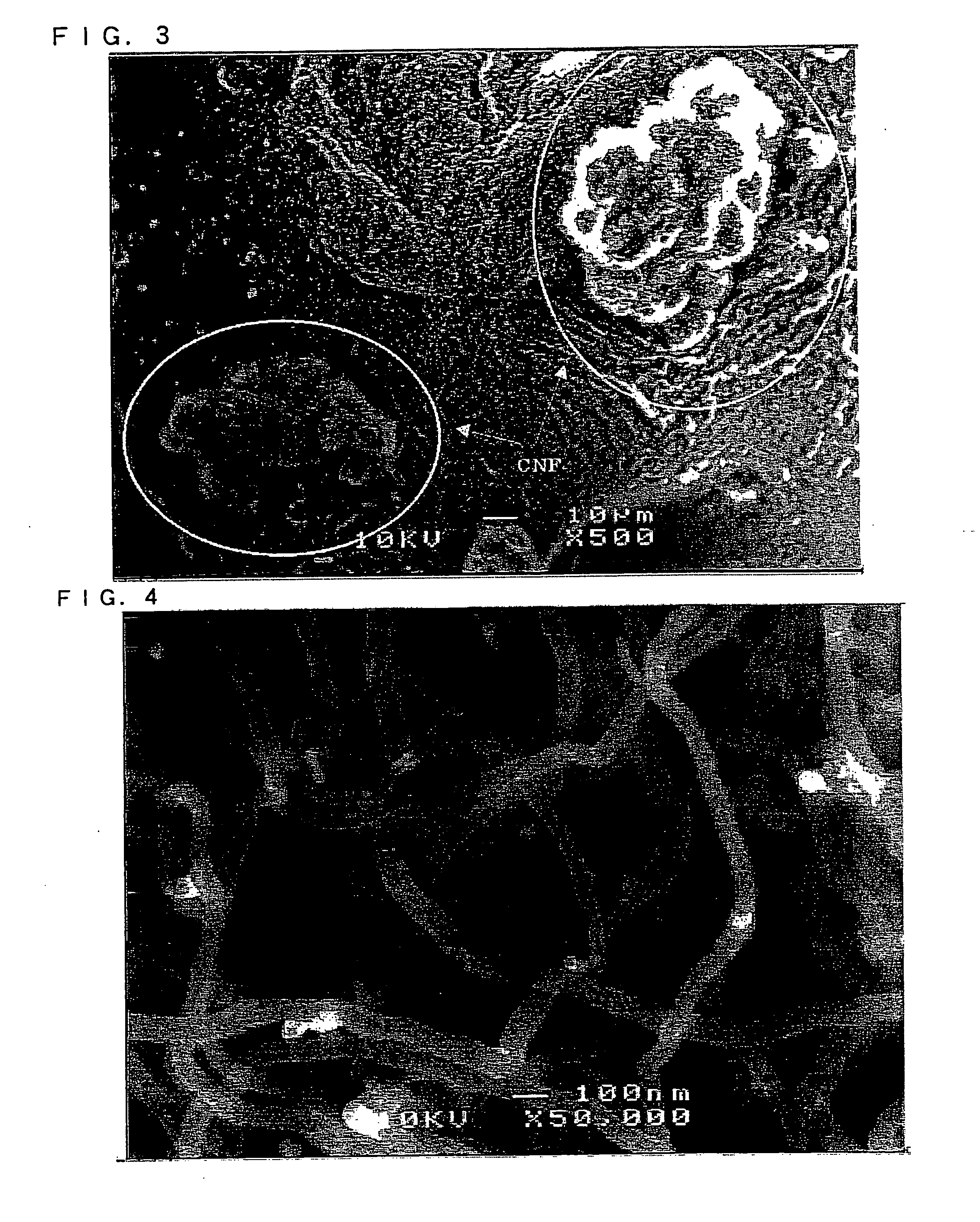

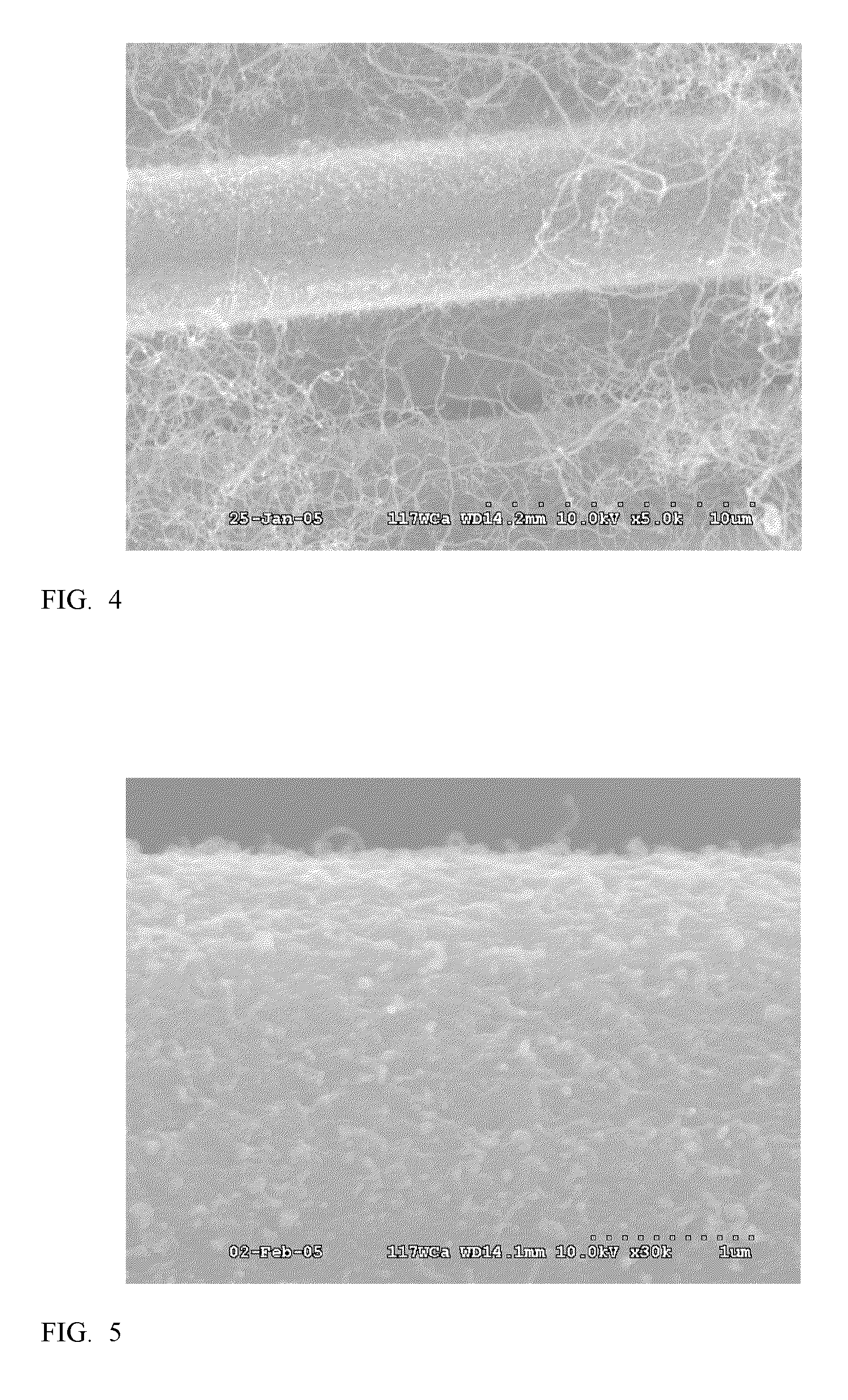

Continuous process for the production of carbon nanofiber reinforced continuous fiber preforms and composites made therefrom

ActiveUS20090220409A1Limited utilityLow yieldMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

This invention provides a continuous process for the growth of vapor grown carbon fiber (VGCNT) reinforced continuous fiber preforms for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCNT produced in situ resulting in a highly entangled mass of VGCNT infused with the continuous fiber preform. The continuous process disclosed herein provides denser and more uniform carbon nanotubes and provides the opportunity to fine-tune the variables both within an individual preform and between different preforms depending on the characteristics of the carbon nanotubes desired. The resulting continuous fiber preforms are essentially endless and are high in volume fraction of VGCNT and exhibit high surface area useful for many applications. The invention also provides for composites made from the preforms.

Owner:PERFORMANCE POLYMER SOLUTIONS

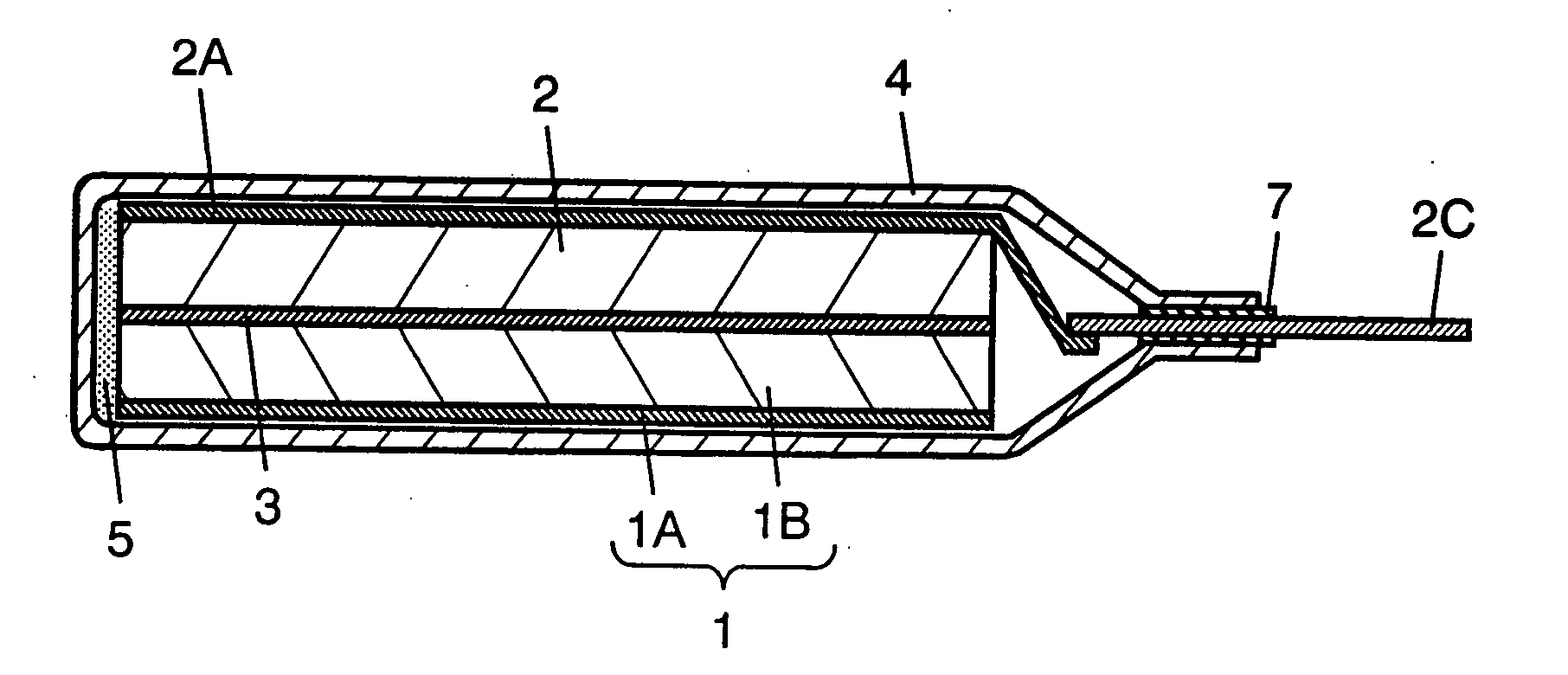

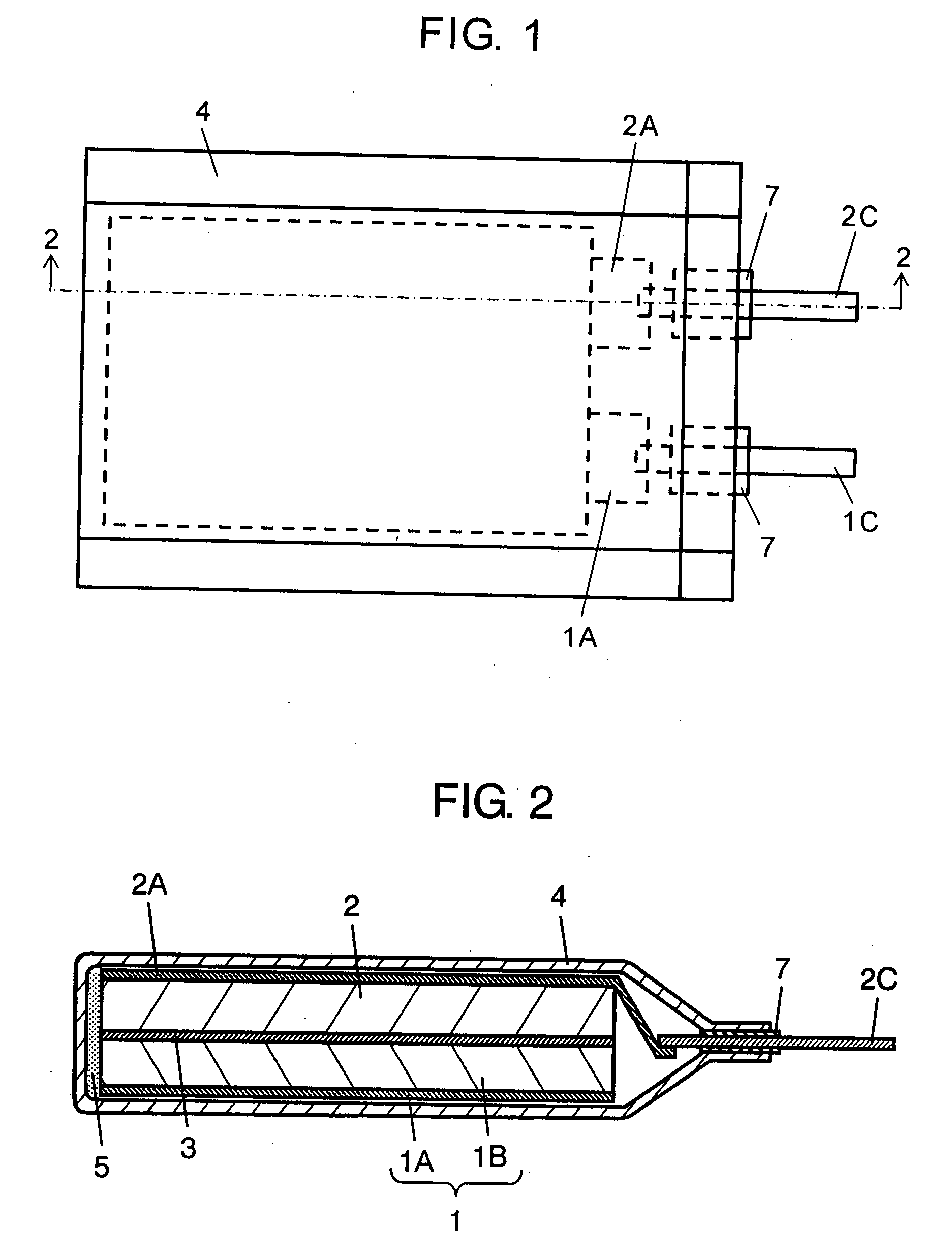

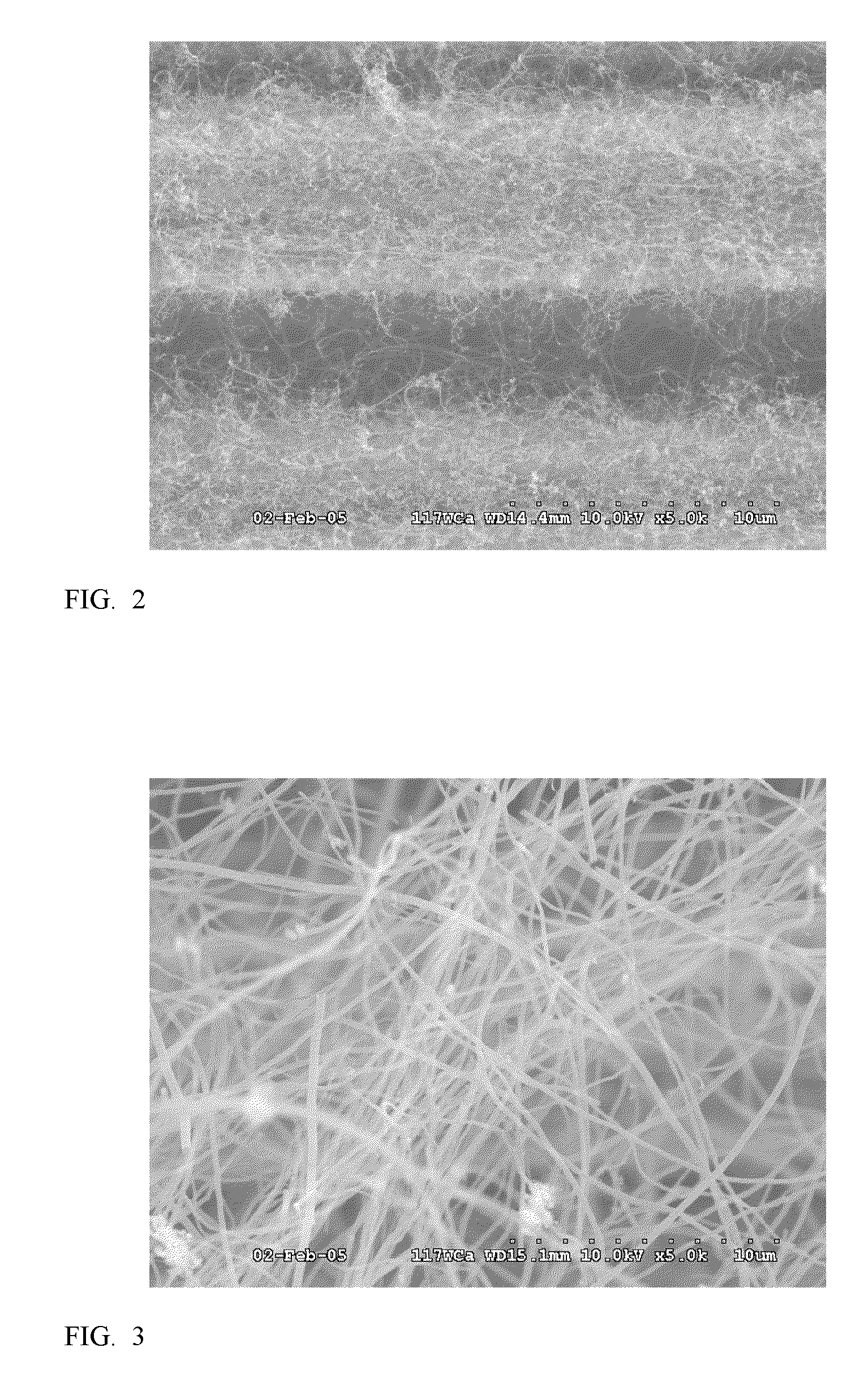

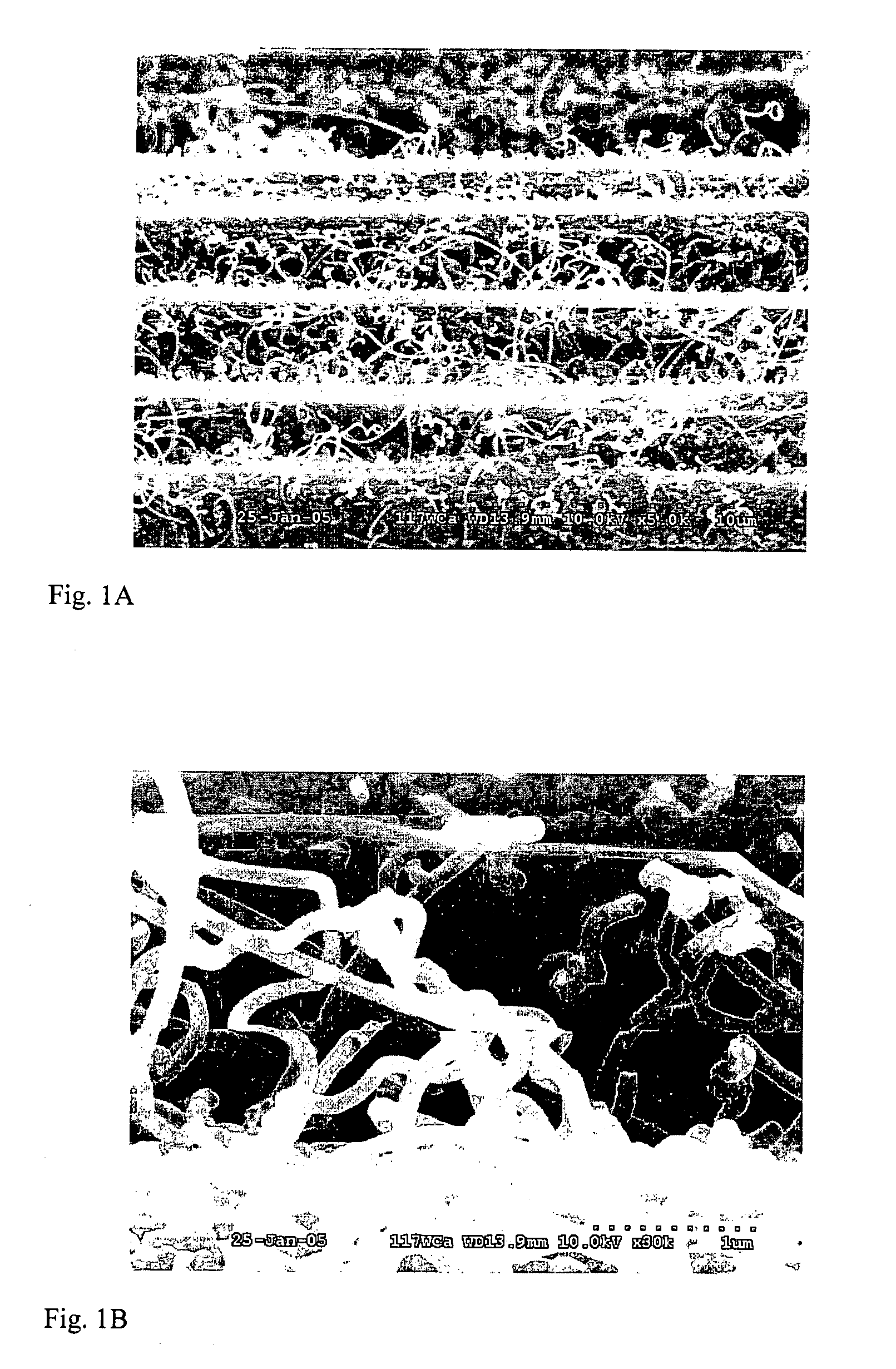

Vapor grown carbon fiber reinforced composite materials and methods of making and using same

ActiveUS7338684B1Low yieldReduce quality problemsMaterial nanotechnologyLiquid surface applicatorsFiberCarbon nanofiber

A process for producing-vapor grown carbon fiber (VGCF) reinforced continuous fiber performs for the manufacture of articles with useful mechanical, electrical, and thermal characteristics is disclosed. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCF produced in situ resulting in a highly entangled mass of VGCF infused with the continuous fiber preform. The resulting continuous fiber preforms are high in volume fraction of VGCF and exhibit high surface area useful for many applications. Furthermore, this invention provides for a continuous fiber preform infused with VGCF so that the carbon nanofibers are always contained within the fiber preform. This eliminates the processing steps for isolated carbon nanofibers reported in other carbon nanofiber composite approaches and therefore greatly reduces risk of environmental release and exposure to carbon nanofibers.

Owner:PERFORMANCE POLYMER SOLUTIONS

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

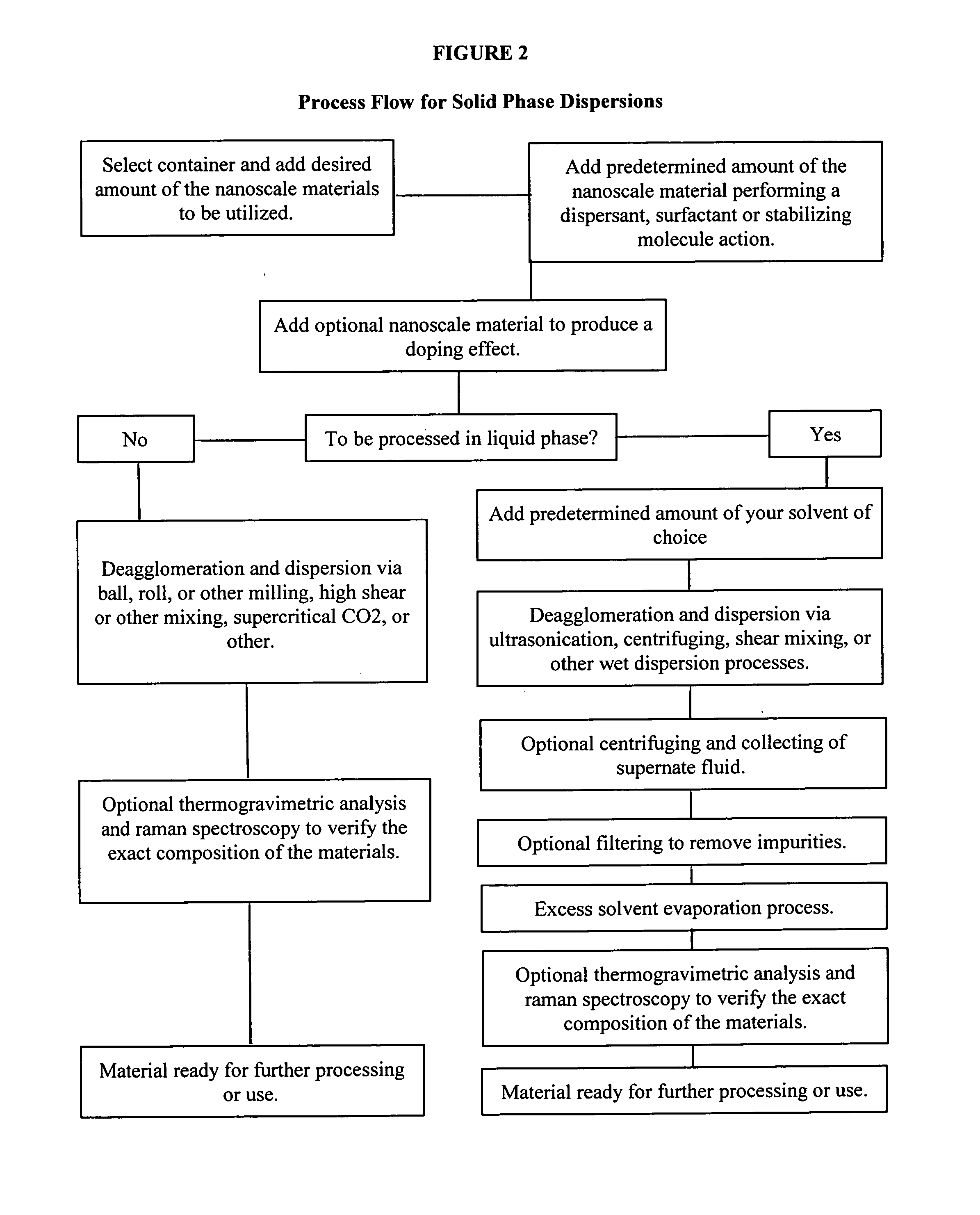

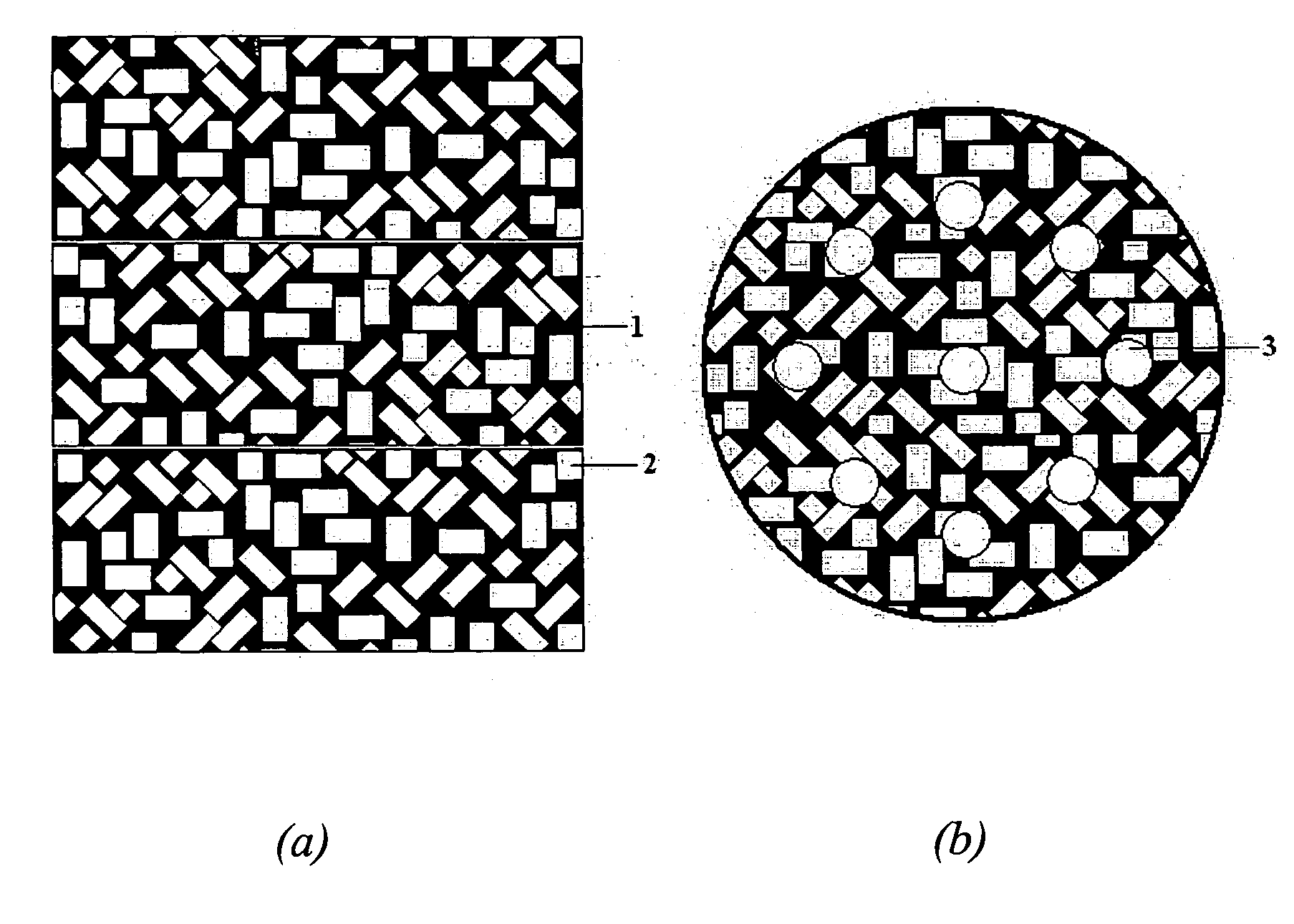

Utilizing nanoscale materials as dispersants, surfactants or stabilizing molecules, methods of making the same, and products produced therefrom

ActiveUS20110210282A1Good effectEasy to processMaterial nanotechnologyNanomagnetismDielectricCapacitance

Novel dispersions of nanoparticles such as carbon nanotubes, carbon nanofibers, boron nanotubes, clay nanotubes, other nanotube species, buckminster fullerenes, graphene, graphene nanoplatelets, elements, oxides, nanoparticles, nanoclusters, nanopowders, nanocrystals, nanoscale molecules, other nanoscale materials, as well as products produced therefrom are described. These dispersions can then be further processed into a wide variety of products including but not limited to composite materials, polymers, resins, epoxies, emulsions, cements, coatings, clays, films, membranes, paper, fibers, inks, paints, pastes, electronics, spintronics, optics, biotechnology materials, electrodes, field emission or other displays, plating, capacitance, ceramics, catalysts, clays, ballistic materials, drug delivery, doping, magnetics, dielectrics, barrier layers, selective ion flow membranes, batteries, fuel cells, solar and other applications. The invention can also be used to protect electronics from electromagnetic interference, radio frequency interference or radio frequency identification. Most applications that utilize nanoparticles can benefit from this invention.

Owner:CTI NANOTECH

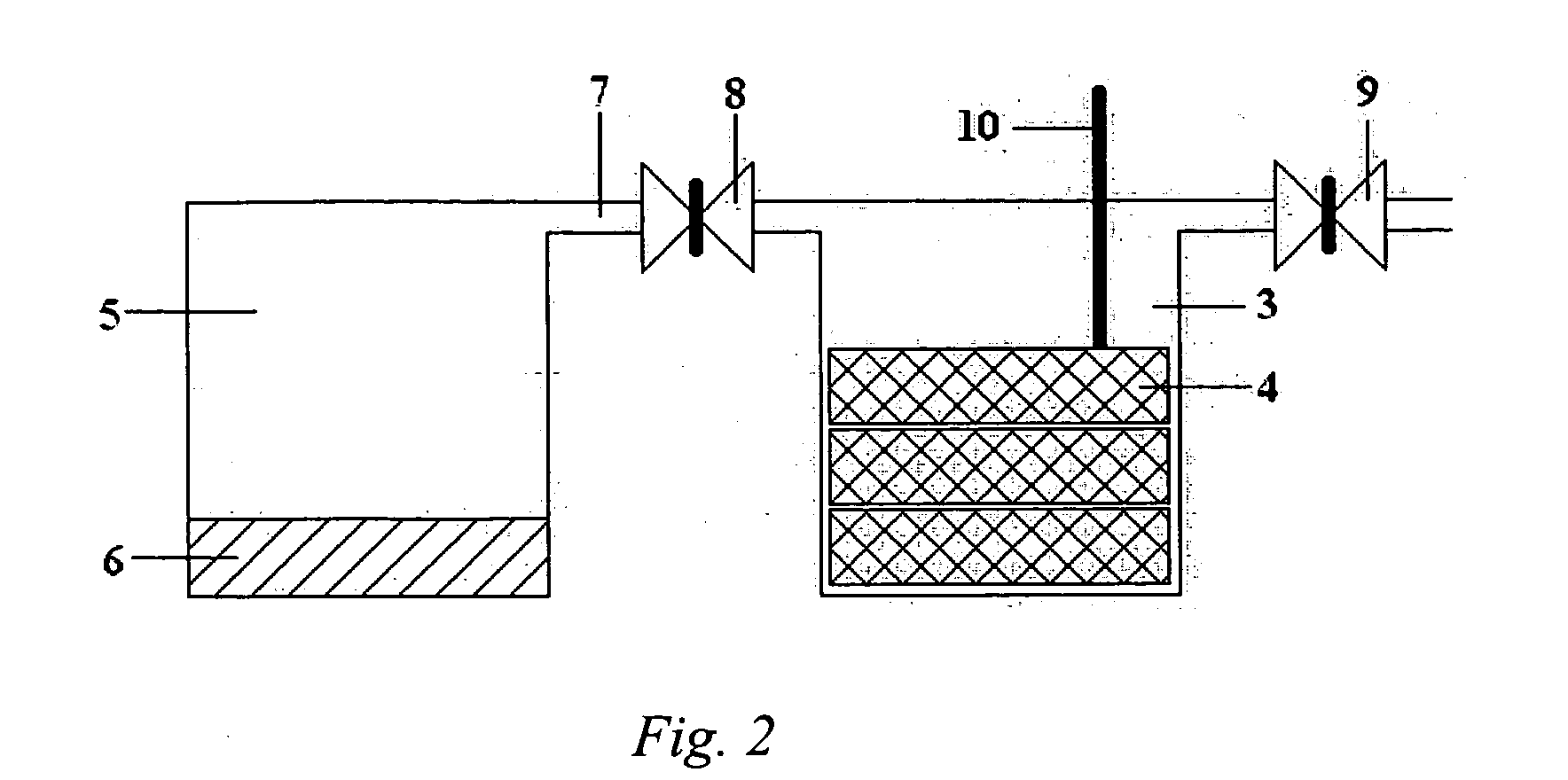

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

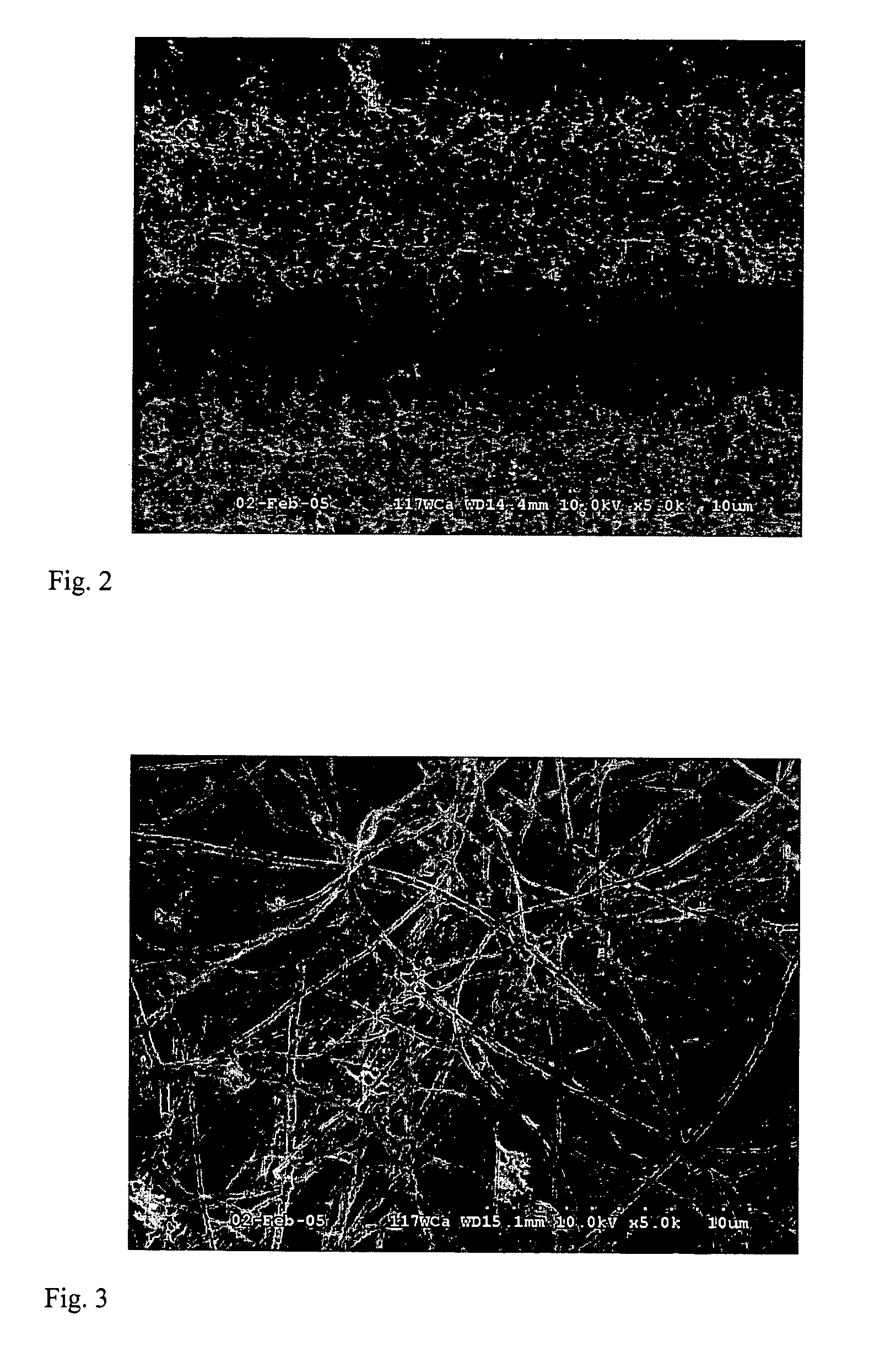

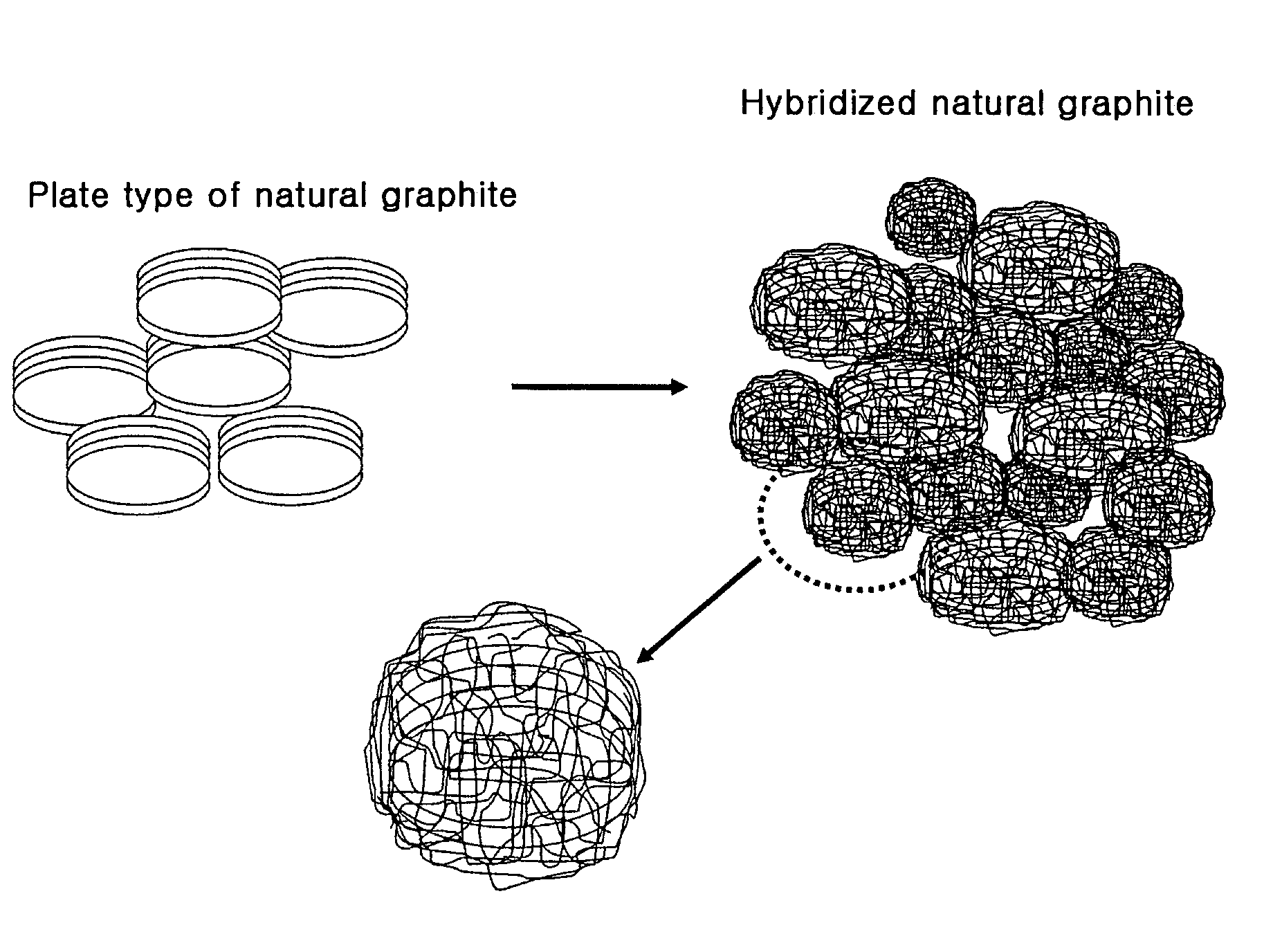

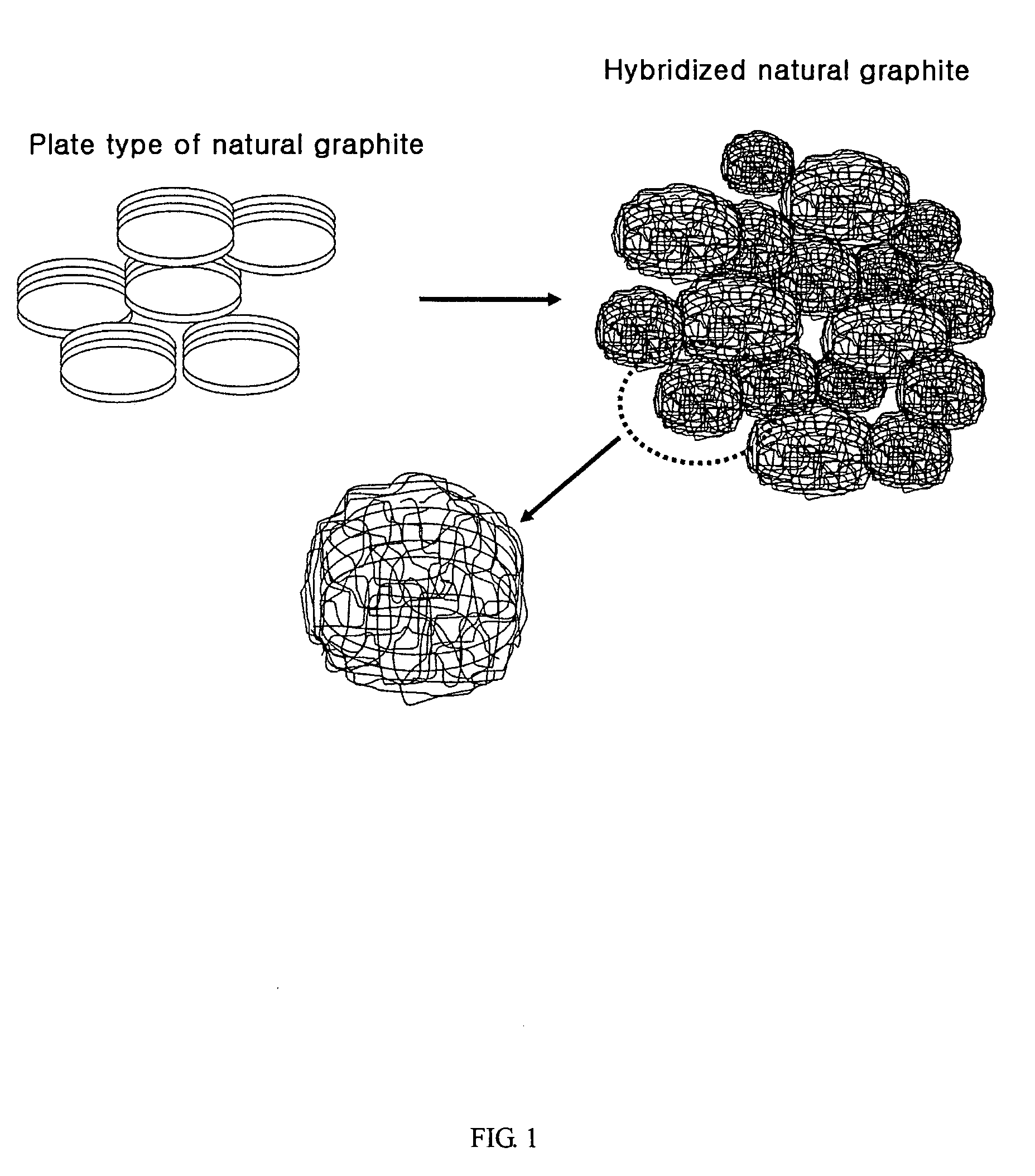

Anode active material hybridizing carbon nano fibers for lithium secondary battery

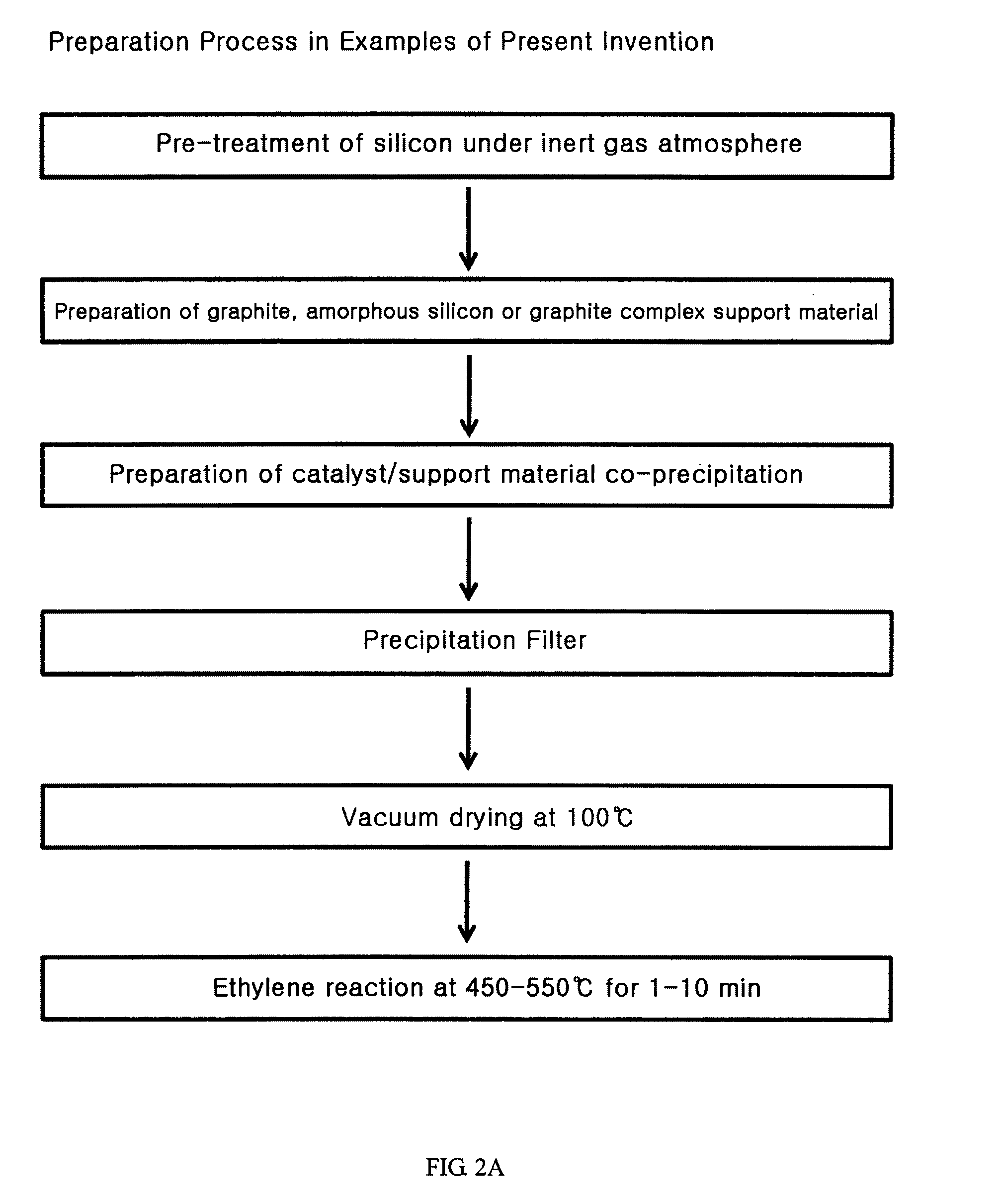

The present invention is to provide anode active material hybridized with carbon nano fibers for lithium secondary battery prepared by following steps comprising, i) dispersing the nano size metal catalyst to the surface of anode material selected from graphite, amorphous silicon or the complex of graphite and amorphous silicon; and ii) growing the carbon nano fiber by chemical vapor deposition method, wherein carbon nano fibers are grown in a vine form and surround the surface of anode active material.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

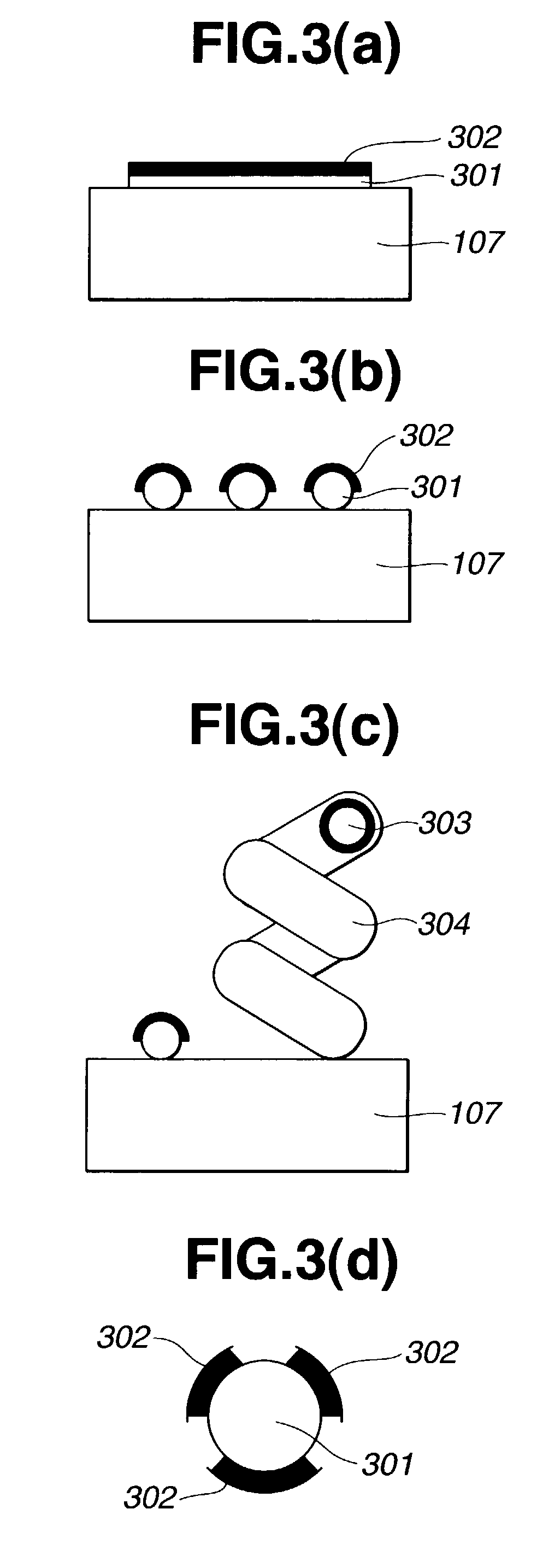

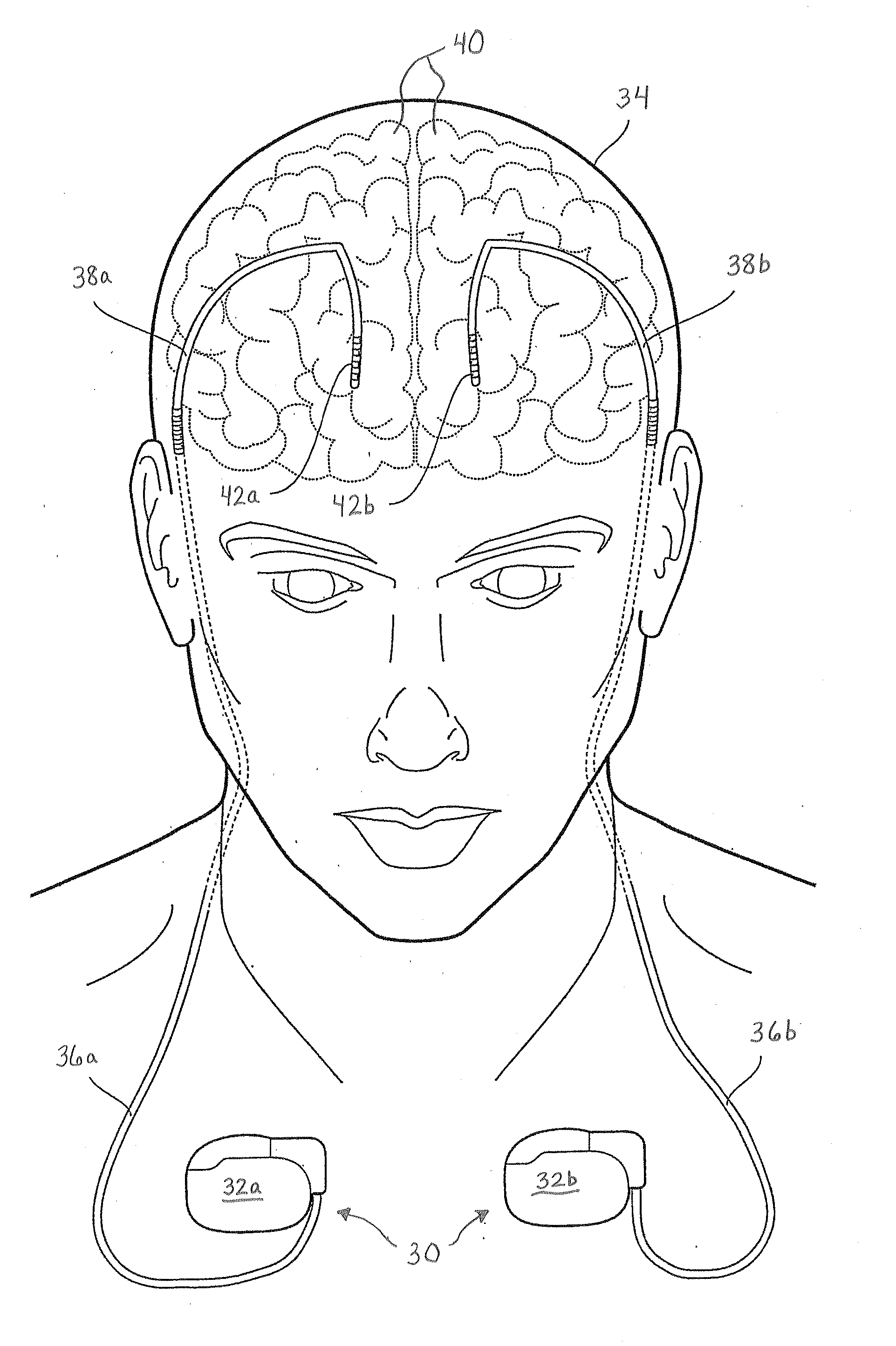

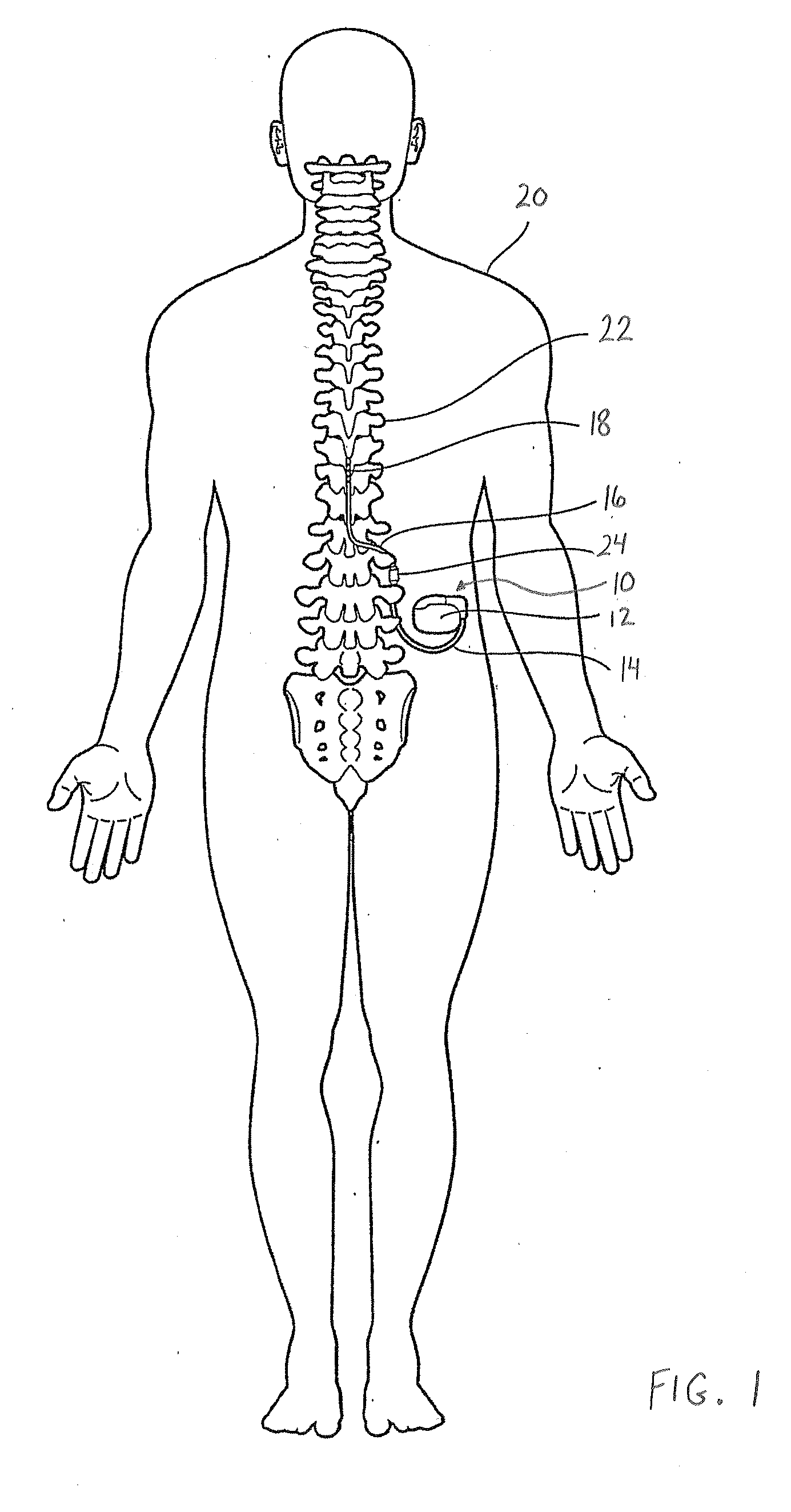

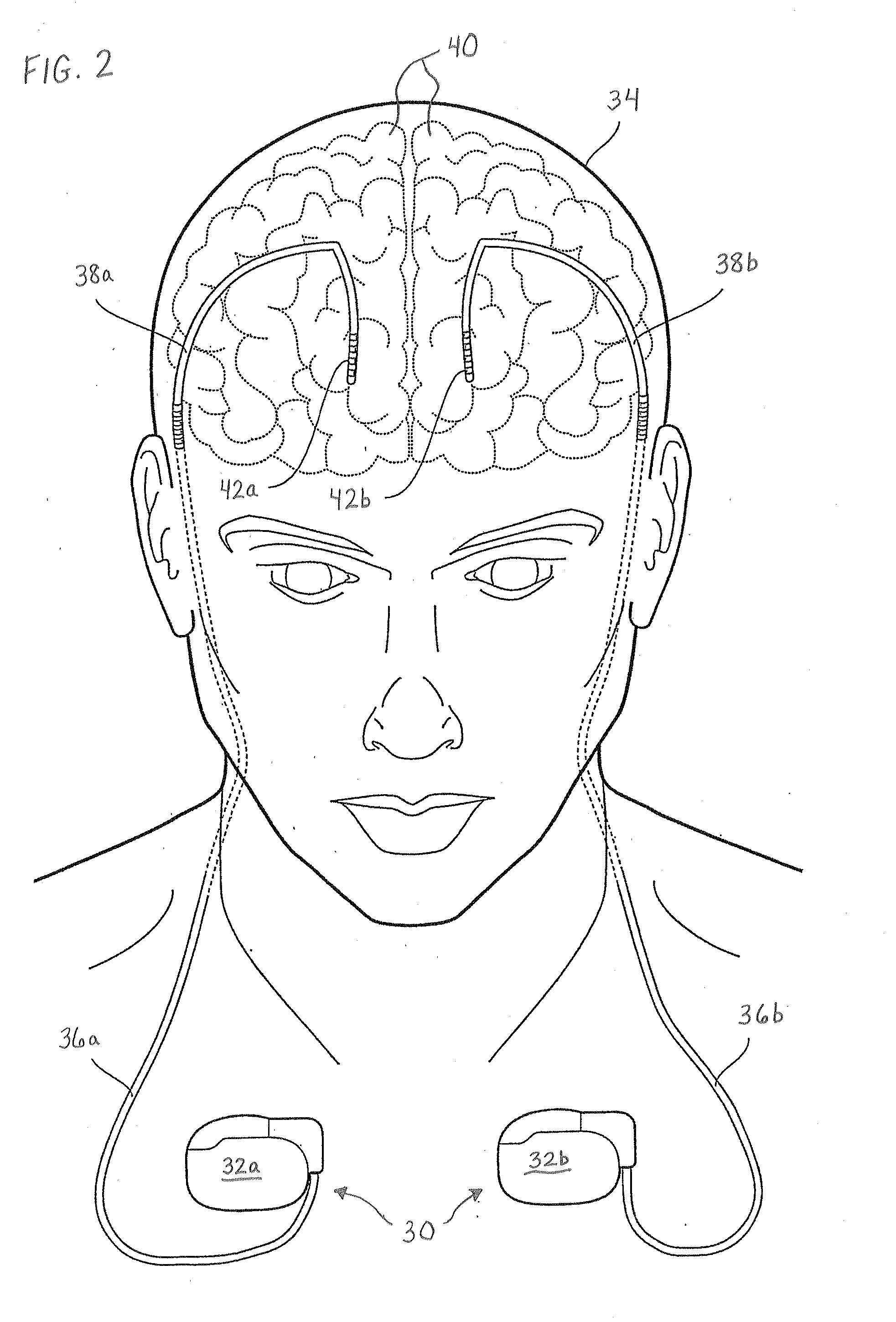

Continuous conductive materials for electromagnetic shielding

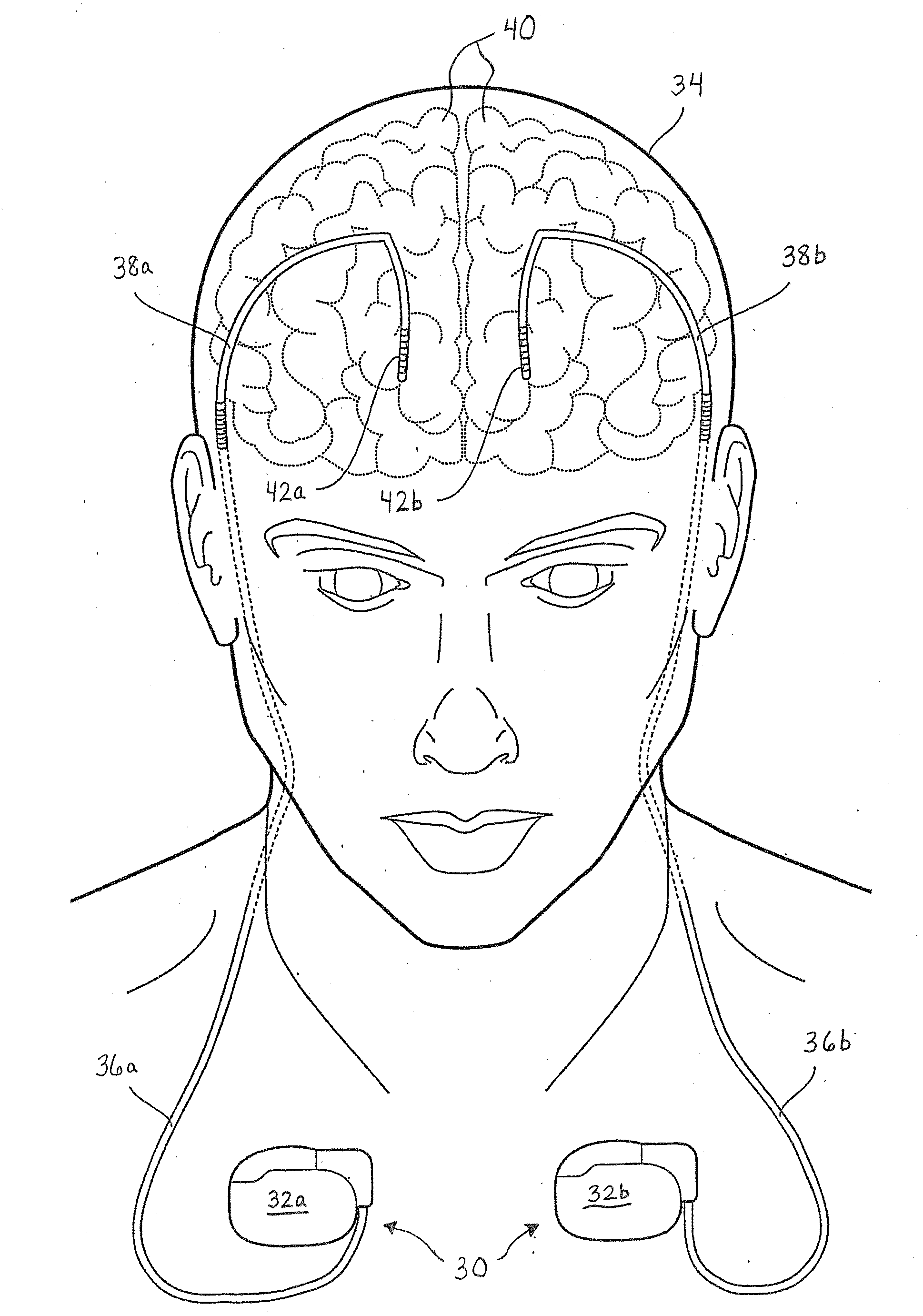

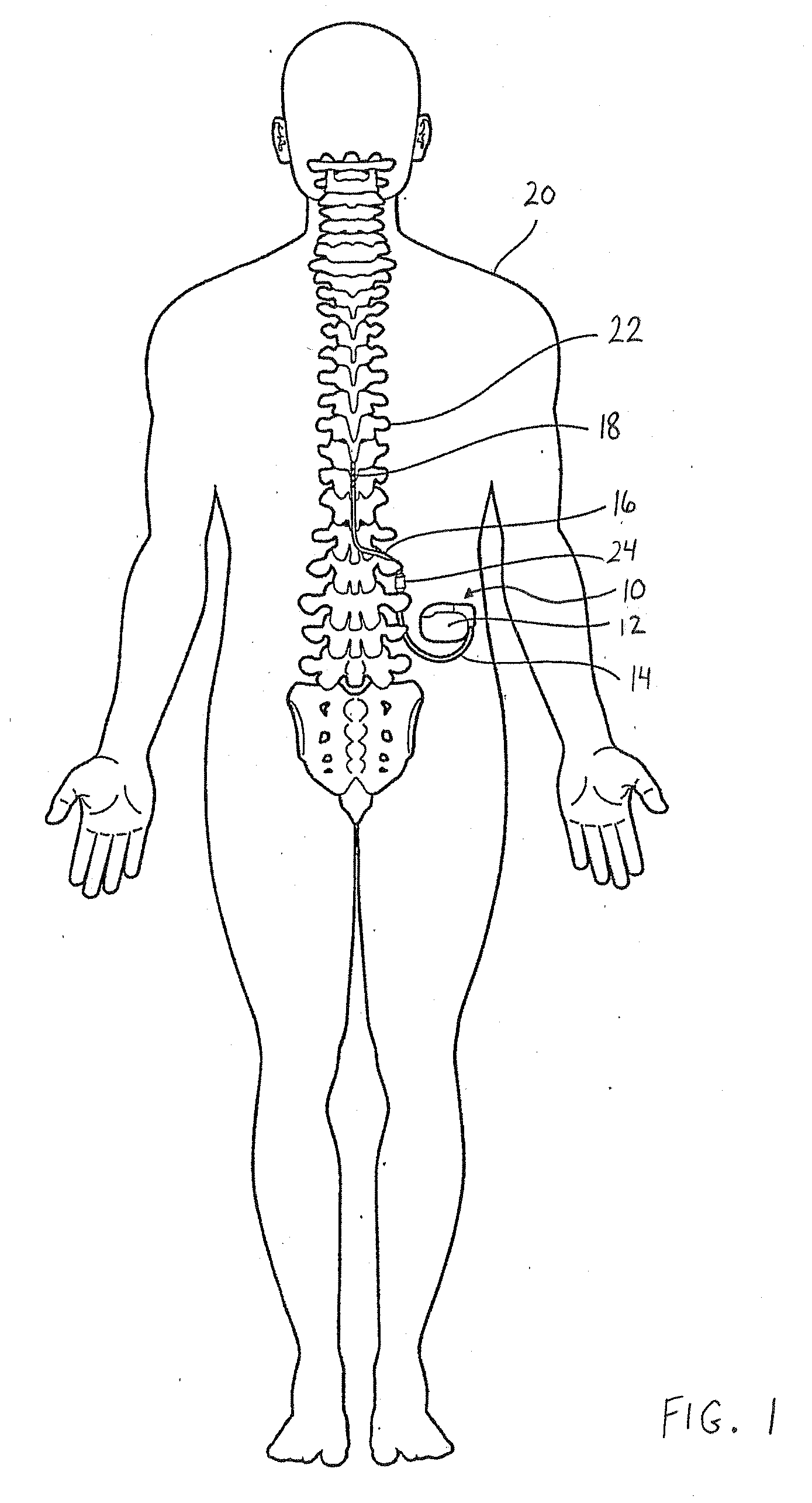

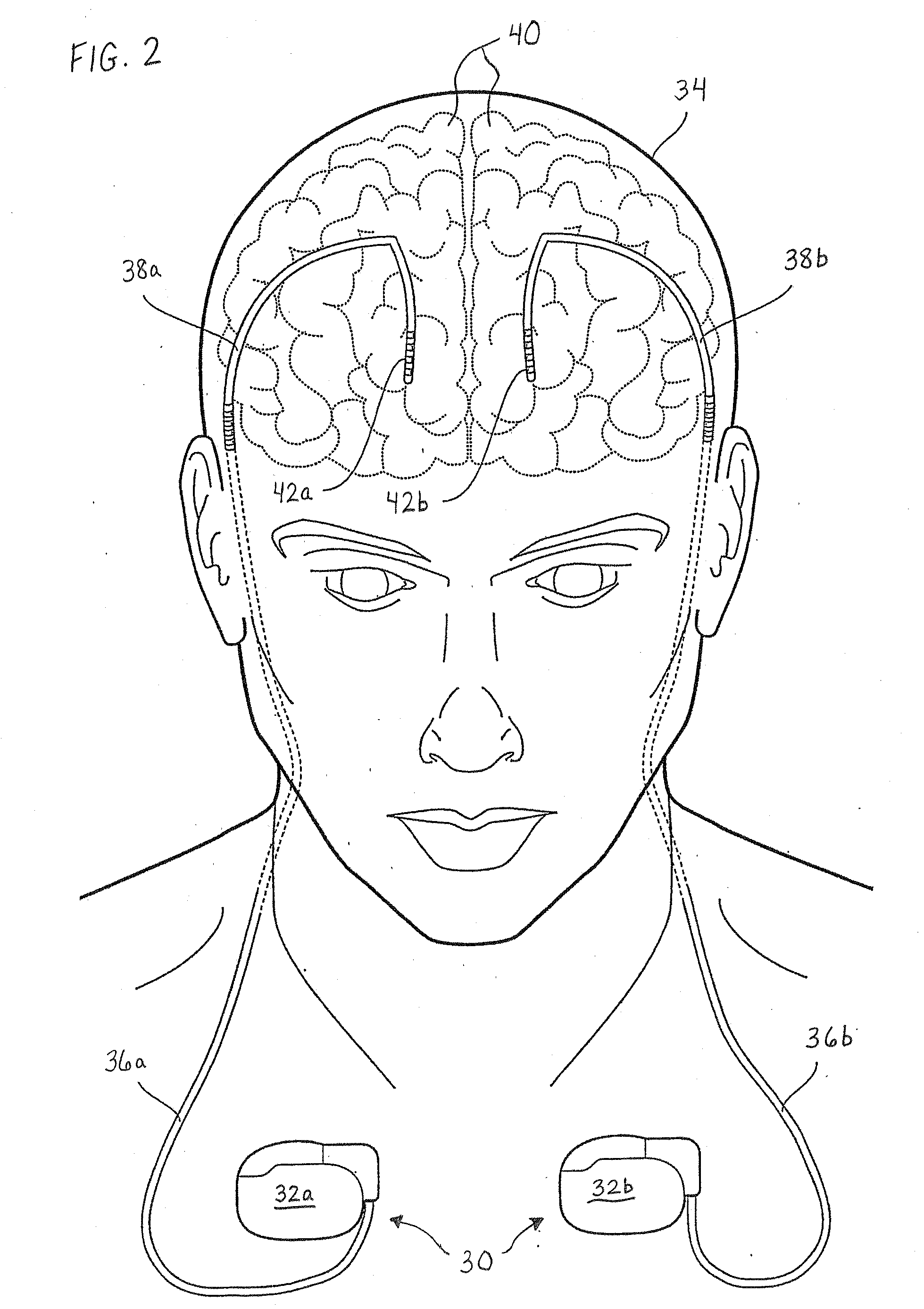

ActiveUS20080195186A1Efficient combinationSmall sizeSpinal electrodesExternal electrodesFiberCarbon fibers

A medical electrical lead having a conductor assembly covered by an insulating layer, and a shield covering positioned adjacent or proximate to at least a portion of the insulating layer in order to shield the conductor assembly from one or more electromagnetic fields. The shield covering is formed of a material that is electrically conductive, where the material is in a wrapped or woven form. The material is selected so as to have an effective combination of small size and high conductive surface area, e.g., as opposed to metal wire or coatings thinner than metal wire. As such, the shield covering exhibits sufficient conductivity in the presence of one or more high frequency electromagnetic fields so that interference to the operation of the conductor assembly is minimized. The material can have a coating formed of one or more metals. The material can include carbon. In turn, the carbon can be formed of one or more of carbon fiber, carbon nanofiber, and single or multi-walled carbon nanotube.

Owner:MEDTRONIC INC

Carbon nanotube or carbon nanofiber electrode comprising sulfur or metal nanoparticles as a binder and process for preparing the same

InactiveUS20040241532A1Material nanotechnologyHybrid capacitor electrodesFuel cellsInternal resistance

The present invention provides an electrode made of carbon nanotubes or carbon nanofibers and a process for preparing the same. The electrode comprising a current collector, sulfur or metal nanoparicles as a binder, and carbon nanotubes or carbon nanofibers is characterized in that the sulfur or metal nanoparticles are bonded, deposited, or fused on the surfaces of the carbon nanotubes or carbon nanofibers so that the carbon nanotubes or carbon nanofibers are bonded to each other and also bonded to the current collector. The electrode prepared according to the present invention exhibits low internal resistance, strong durability and low equivalent series resistance, and therefore the electrode can be effectively used for secondary batteries, supercapacitors or fuel cells.

Owner:KH CHEM CO LTD

Discontinuous conductive filler polymer-matrix composites for electromagnetic shielding

A medical electrical lead having a conductor assembly covered by an insulating layer, and a shield covering positioned adjacent or proximate to at least a portion of the insulating layer in order to shield the conductor assembly from one or more electromagnetic fields. The shield covering is formed of a polymer-matrix composite. The polymer-matrix composite includes a polymeric resin having discontinuous conductive fillers provided therein. The discontinuous conductive fillers include one or more of nano-sized metal structures and nano-sized non-metallic conductive structures. The nano-sized non-metallic conductive structures can have a coating formed of one or more metals. The nano-sized non-metallic conductive structures can be formed of carbon. In turn, the nano-sized non-metallic conductive structures can include one or more of carbon nanofibers, carbon filaments, carbon nanotubes, and carbon nanoflakes.

Owner:MEDTRONIC INC

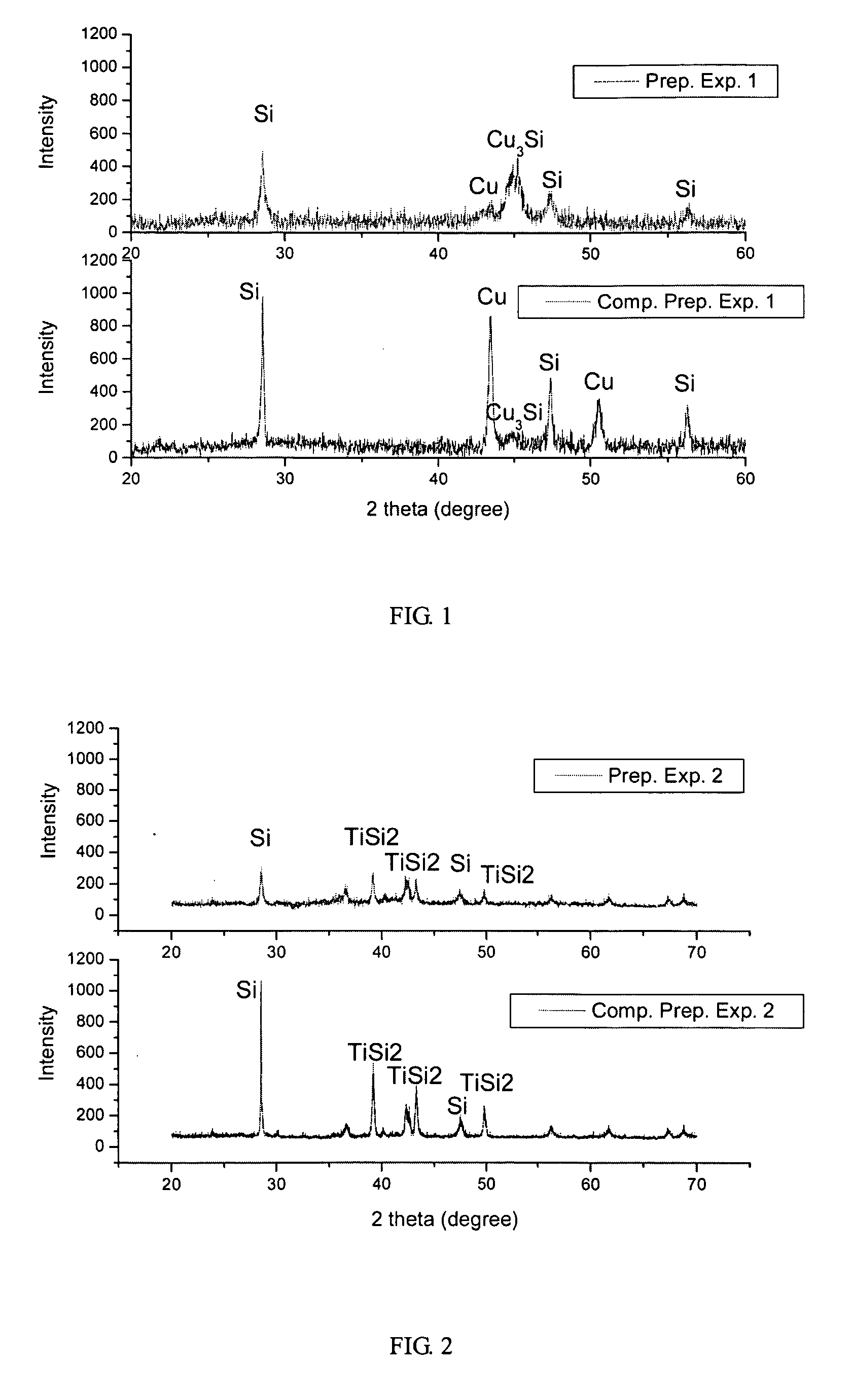

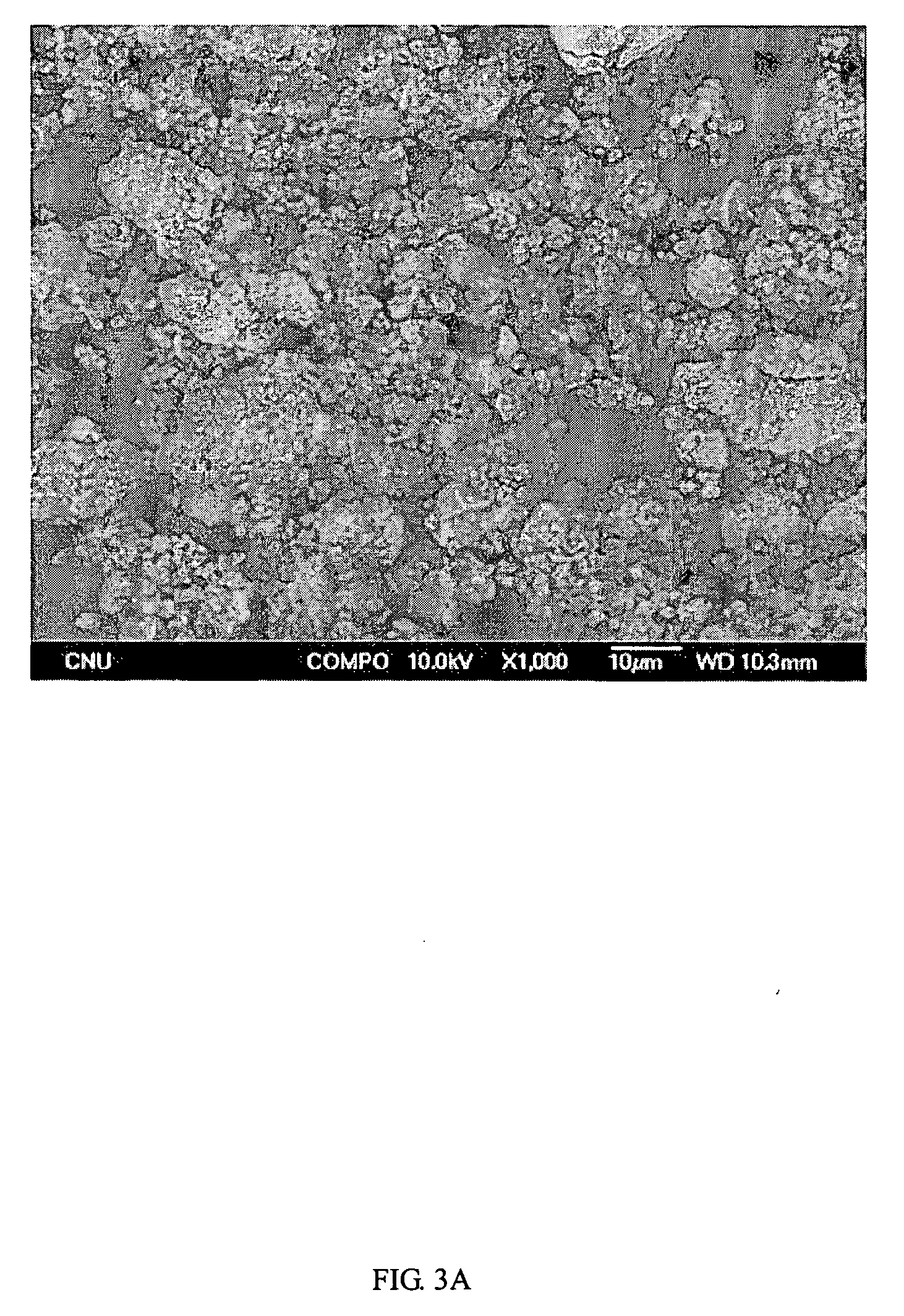

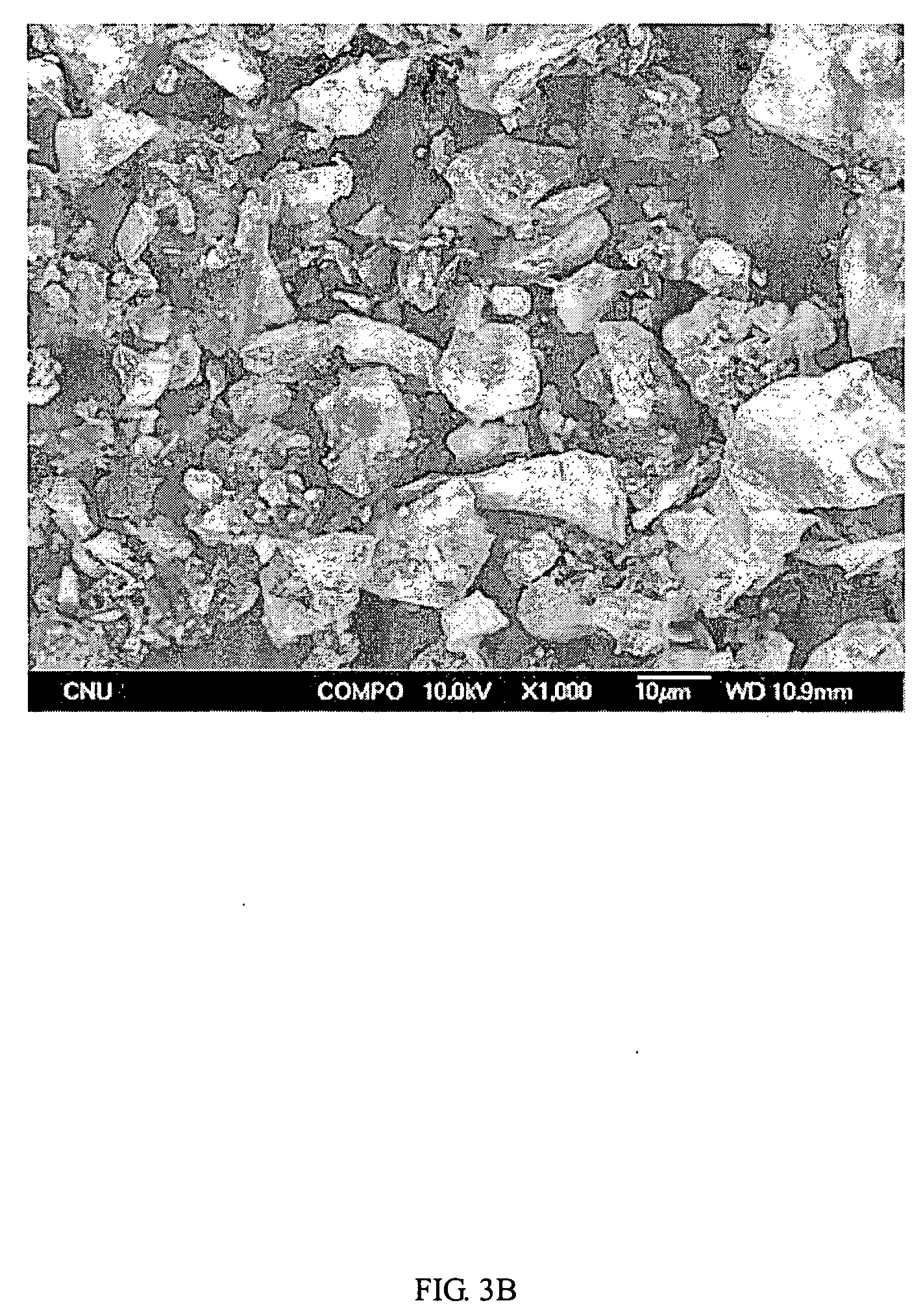

Anode active material hybridizing carbon nanofiber for lithium secondary battery

InactiveUS20090053608A1Material nanotechnologyNon-aqueous electrolyte accumulator electrodesFiberCarbon nanofiber

The present invention provides a composite silicon anode material hybridizing carbon nanofiber for lithium secondary battery prepared by the steps comprising: i) preparing a support made by amorphous silicon alloy after processing amorphous silicon and metal; ii) dispersing the catalyst selected from Fe, Co, Ni, Cu, Mg, Mn, Ti, Sn, Si, Zr, Zn, Ge, Pb or In on the surface of said support made by amorphous silicon alloy; and iii) growing the carbon nanofiber using a carbon source selected from carbon monoxide, methane, acetylene or ethylene on said support by a chemical vapor deposition method, wherein the amount of grown carbon nanofiber is 1˜110 wt % of the amount of said support.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

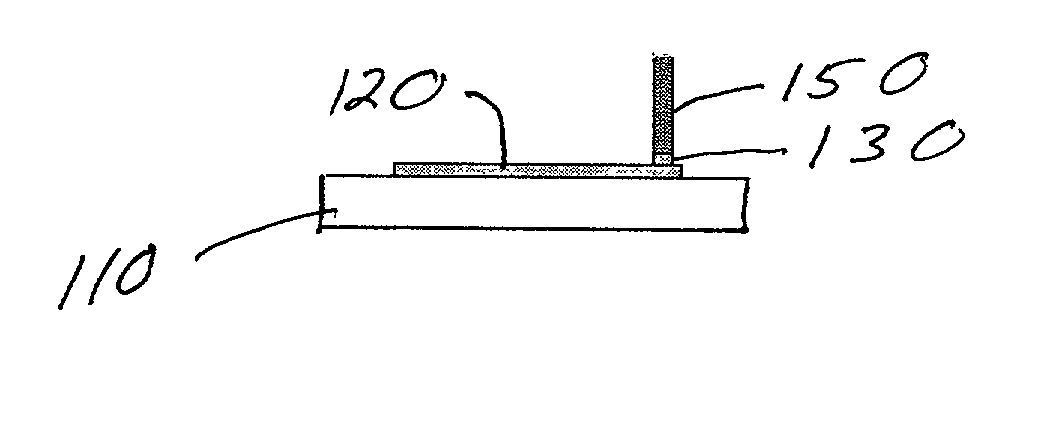

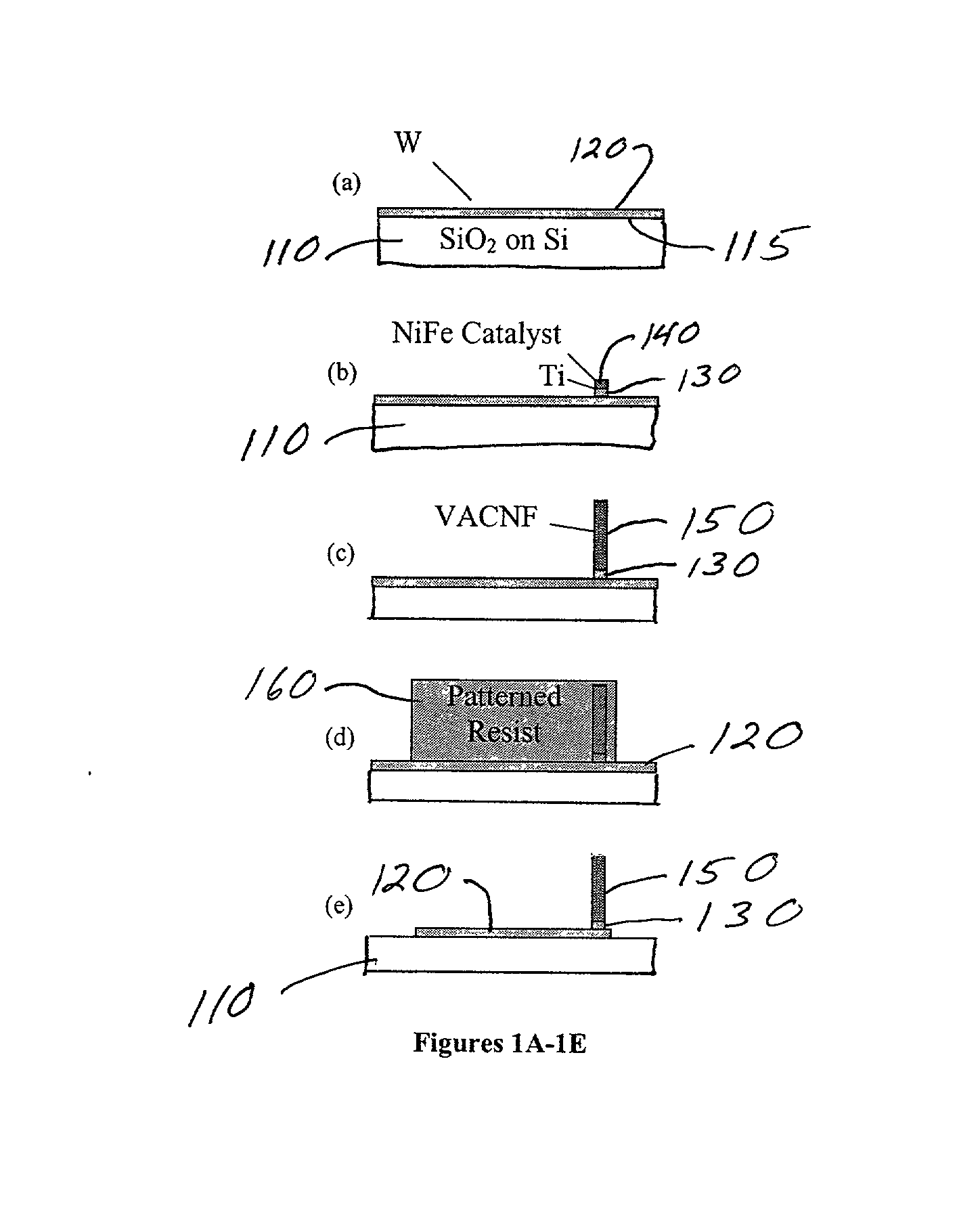

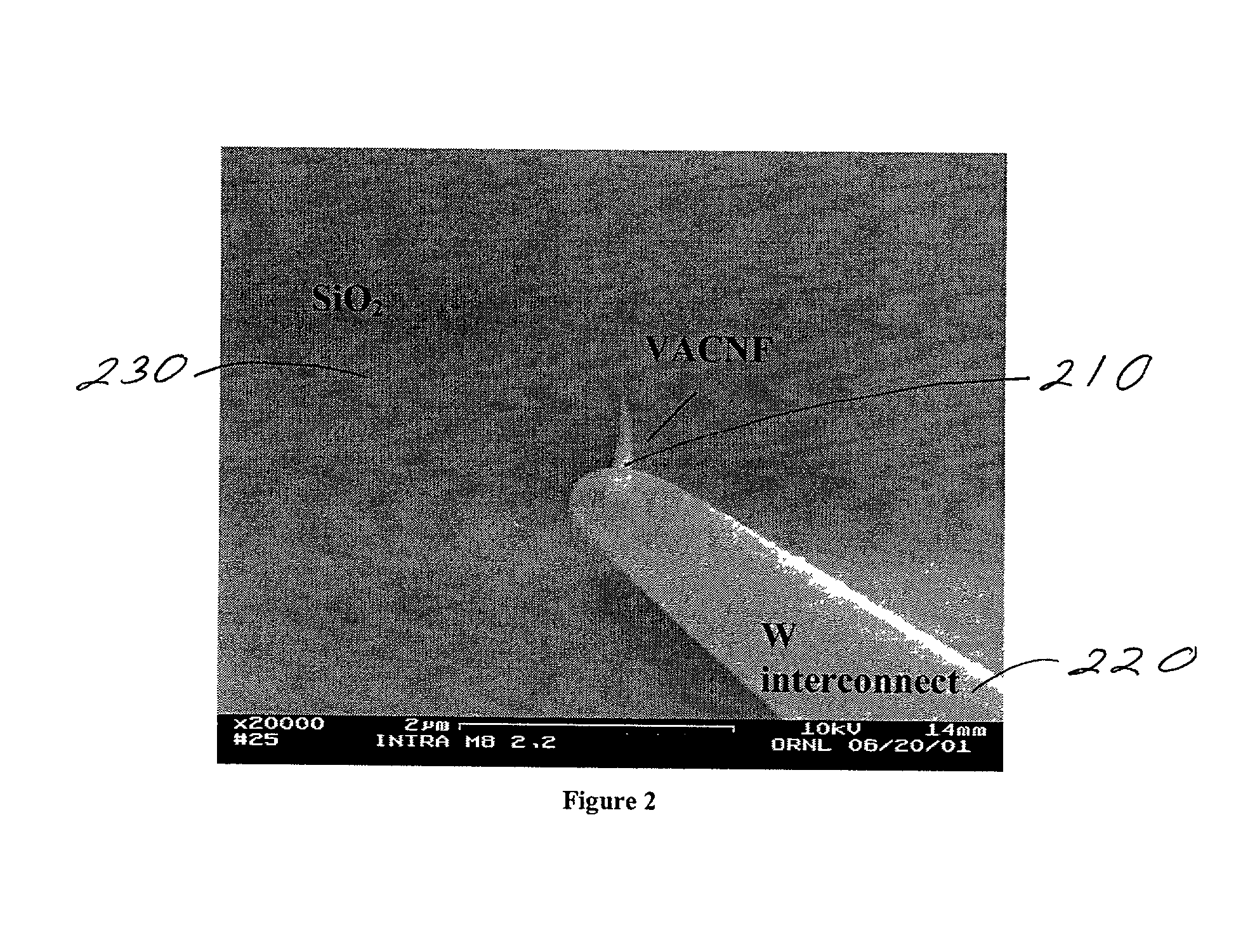

Individually electrically addressable carbon nanofibers on insulating substrates

Systems and methods are described for individually electrically addressable carbon nanofibers on insulating substrates. A method includes forming an electrically conductive interconnect on at least a part of an insulating surface on a substrate; and growing at least one fiber that is coupled to the electrically conductive interconnect. An apparatus includes an electrically conductive interconnect formed on at least a part of an insulating surface on a substrate; and at least one fiber coupled to the electrically conductive interconnect. A kit includes a substrate having an insulating surface; an electrically conductive interconnect formed on at least a part of the insulating surface; and at least one fiber coupled to the electrically conductive

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com