Patents

Literature

606 results about "Electrochemical capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

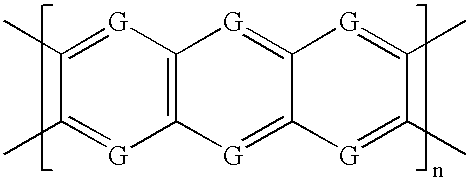

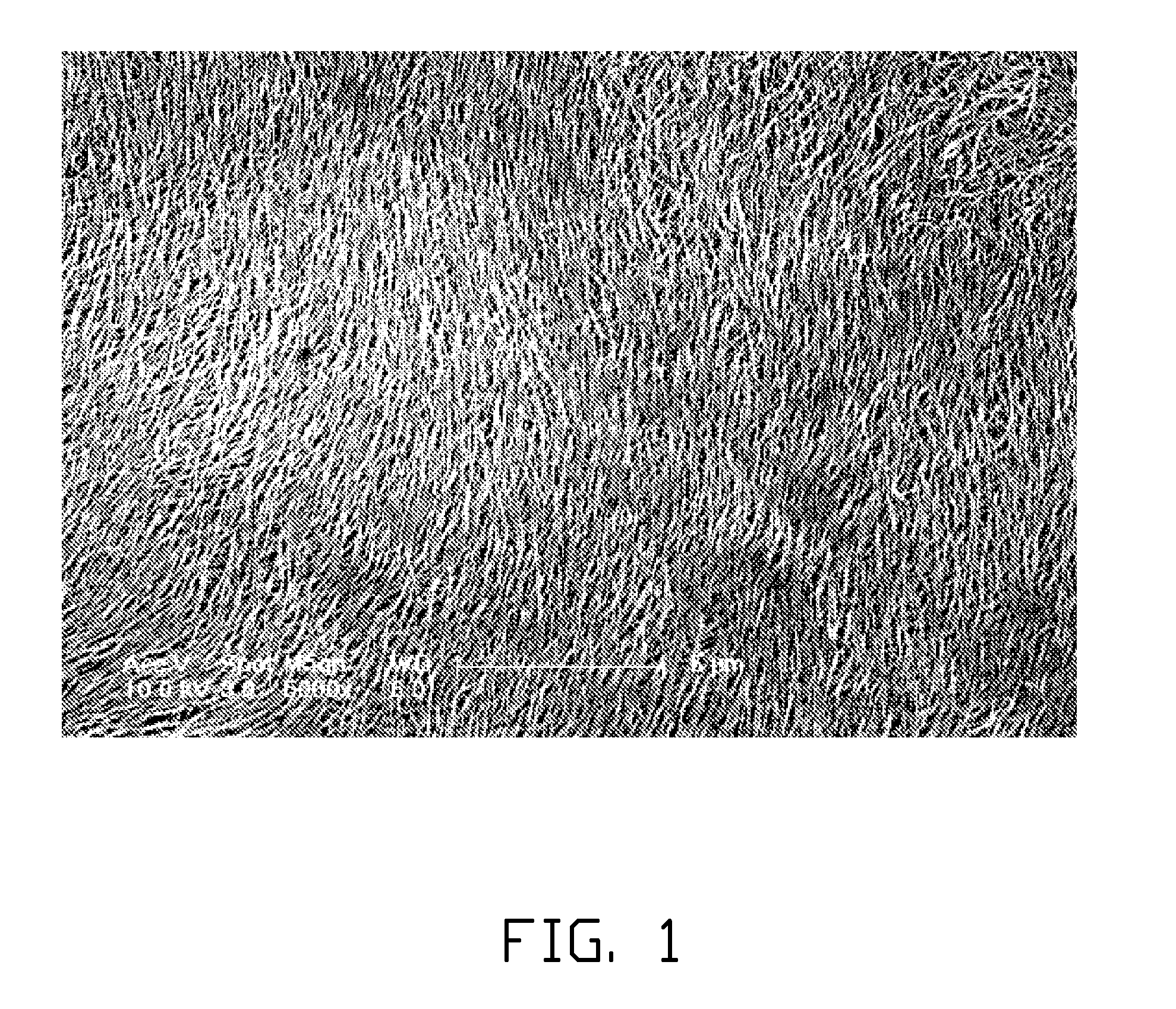

Graphitic nanofibers in electrochemical capacitors

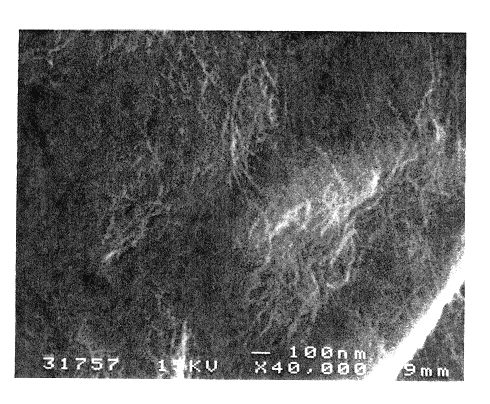

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors. Preferred nanofibers have a surface area greater than about 200 m2 / gm and are substantially free of micropores.

Owner:HYPERION CATALYSIS INT

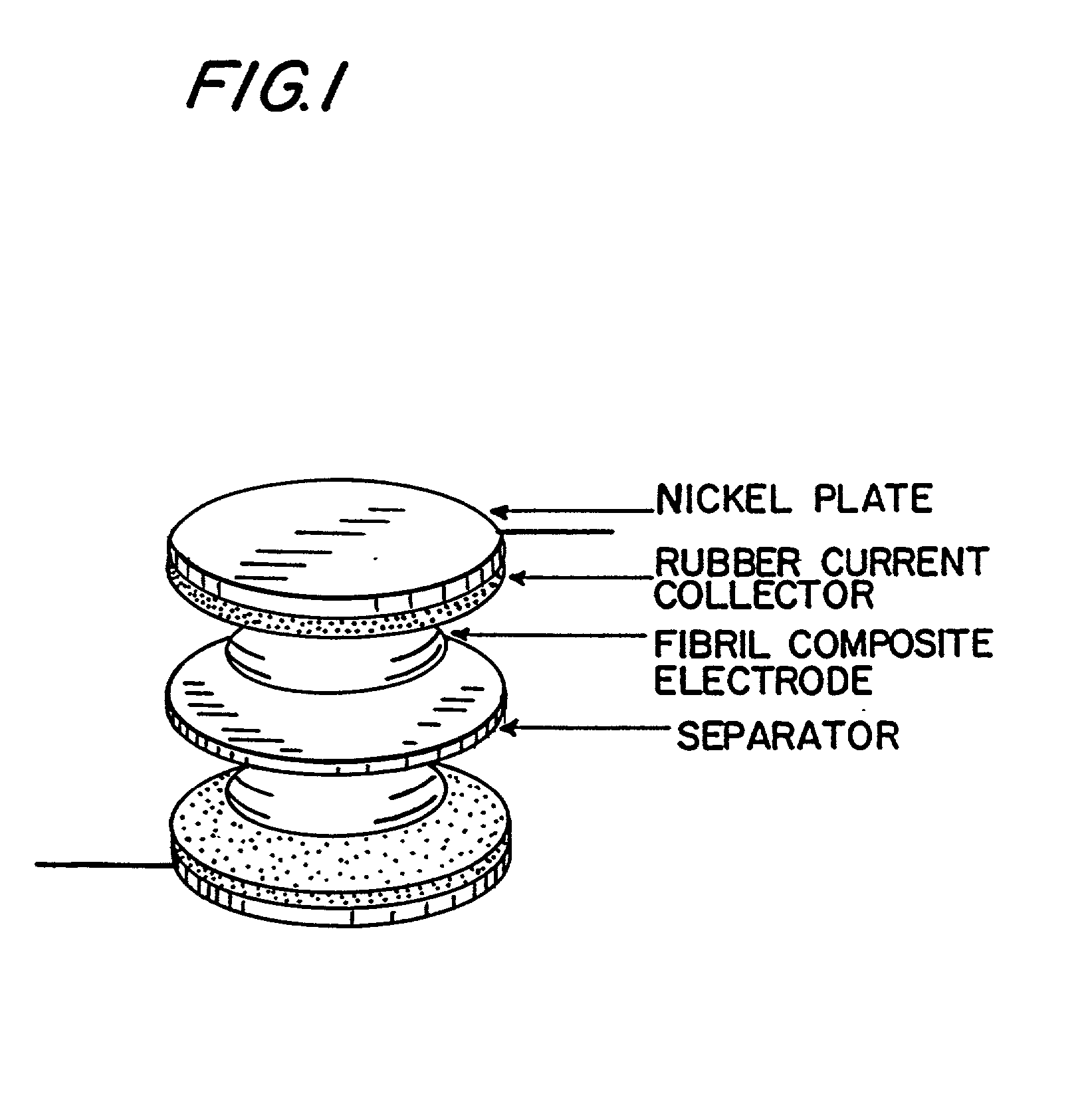

Fibril composite electrode for electrochemical capacitors

Owner:HYPERION CATALYSIS INT

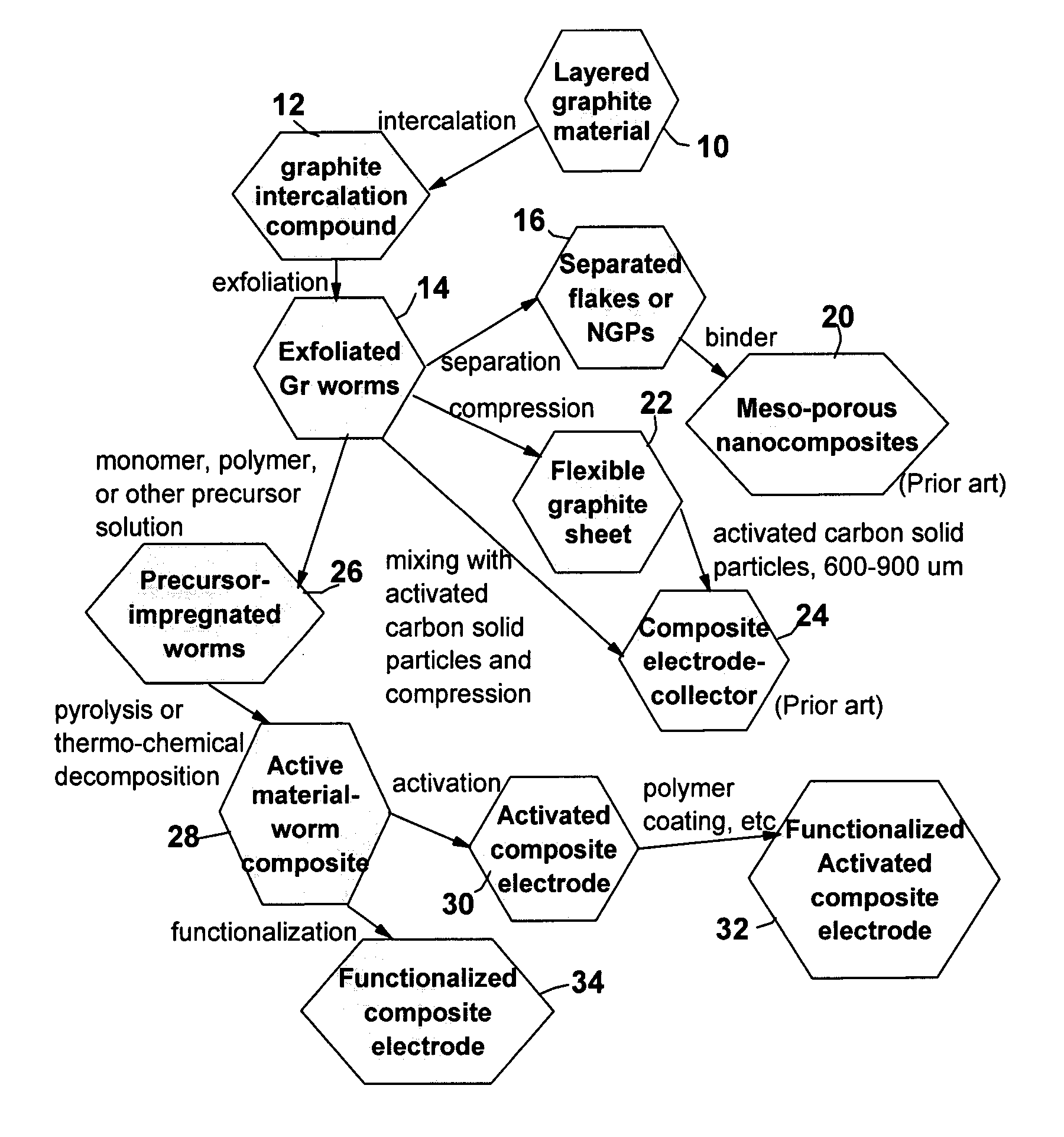

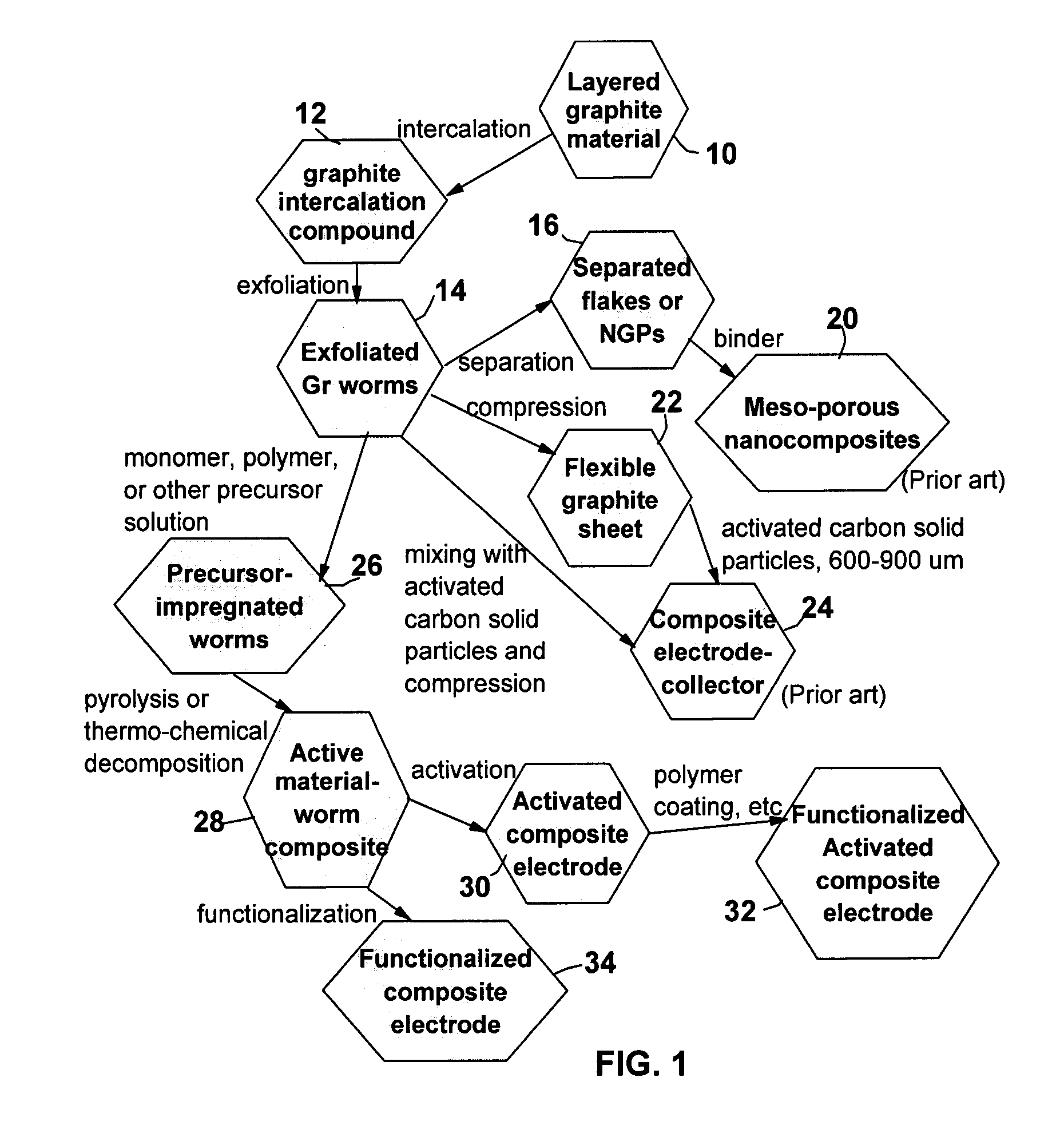

Method of producing graphite-carbon composite electrodes for supercapacitors

InactiveUS20090061312A1Reduce conductivityLower internal resistanceFixed capacitor electrodesHybrid capacitor electrodesCarbon nanotubeElectrochemical capacitance

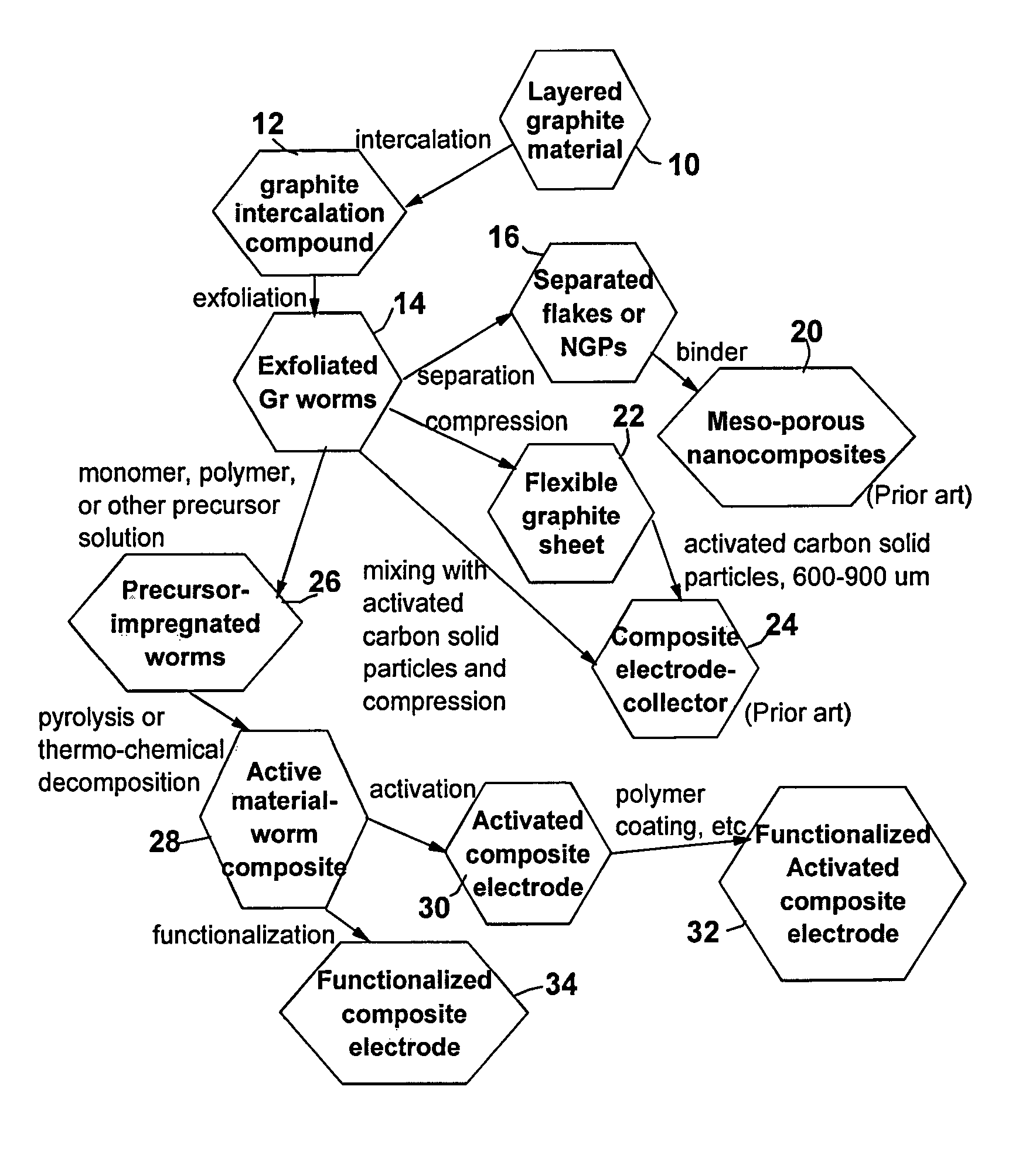

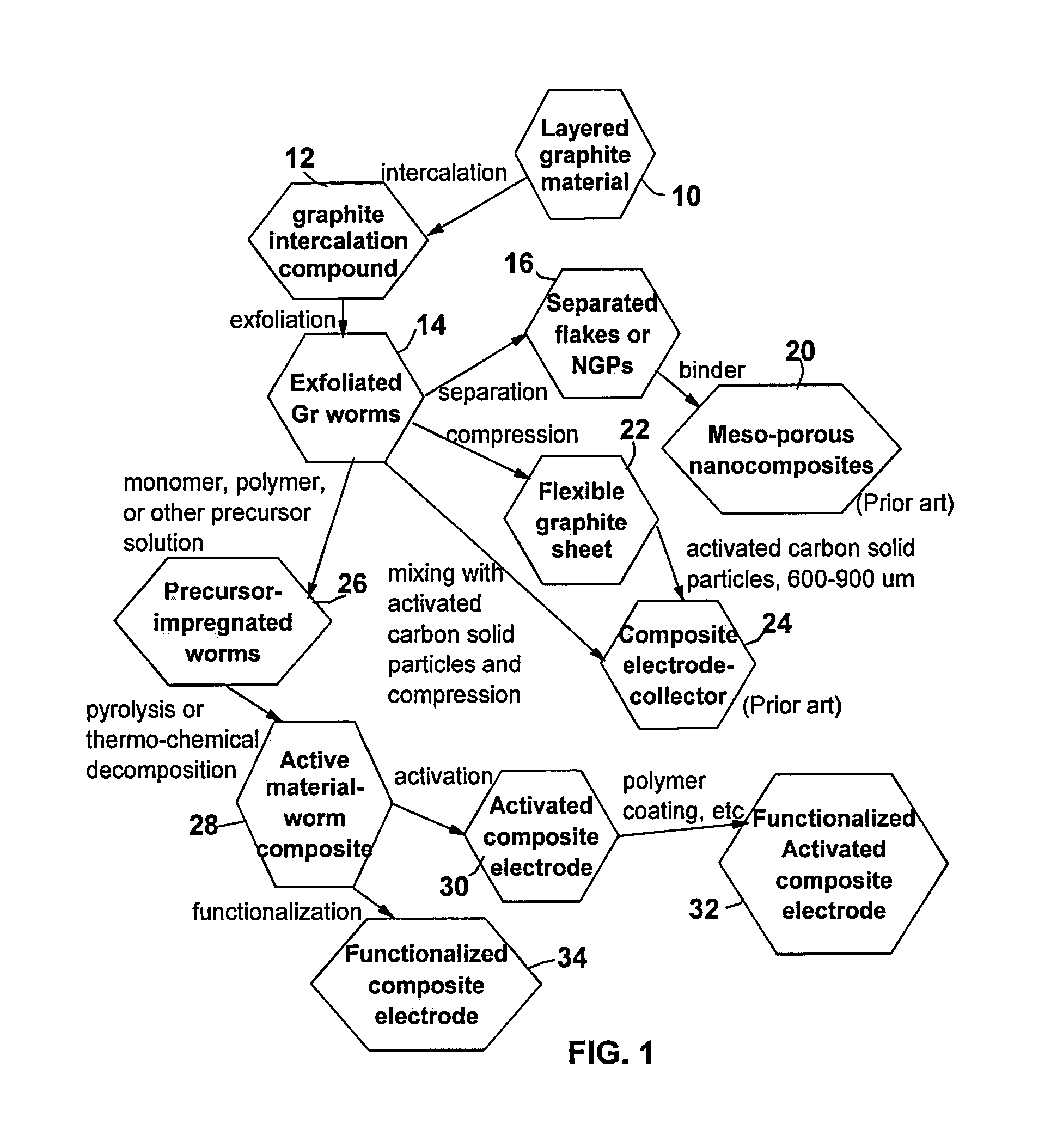

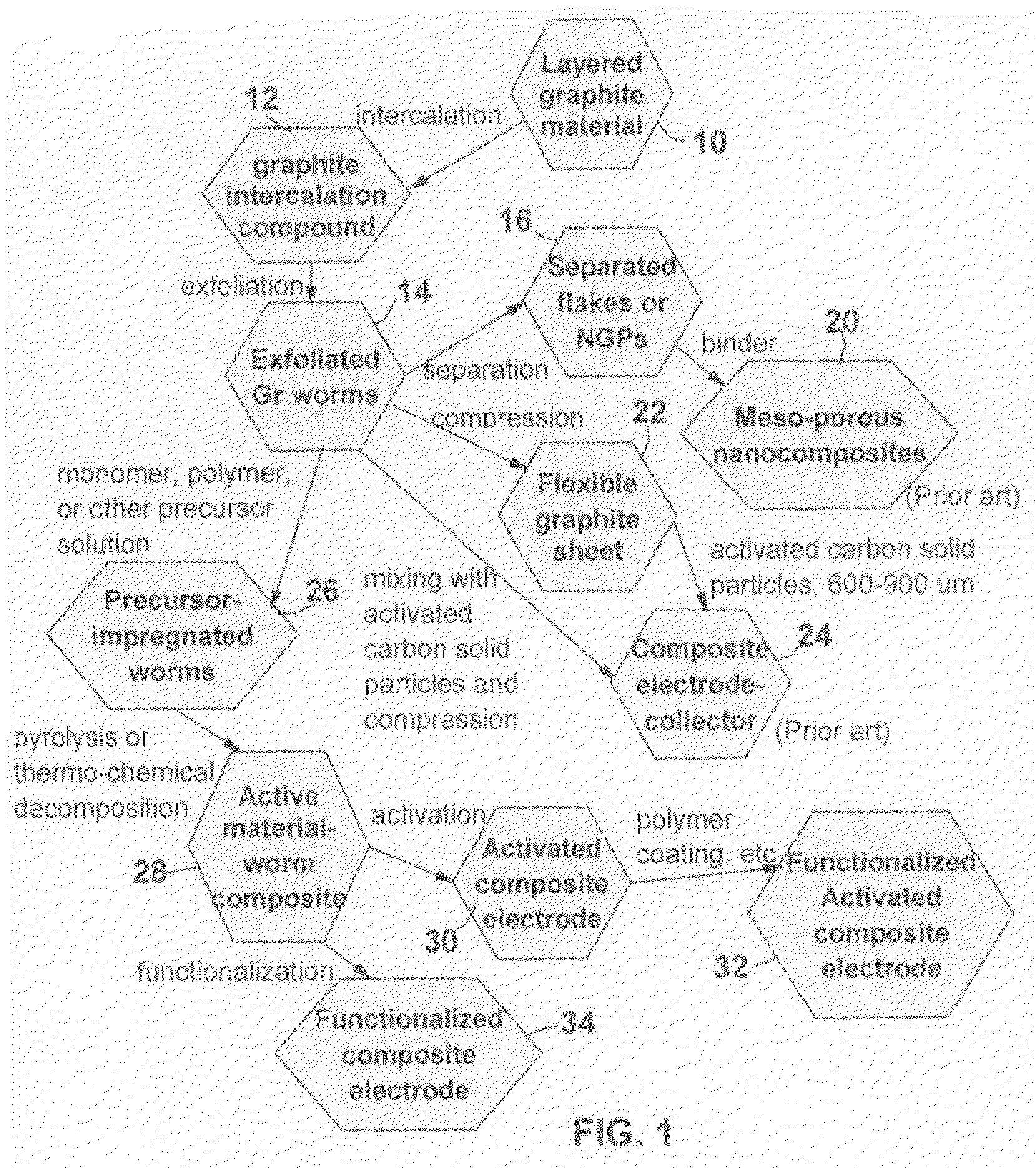

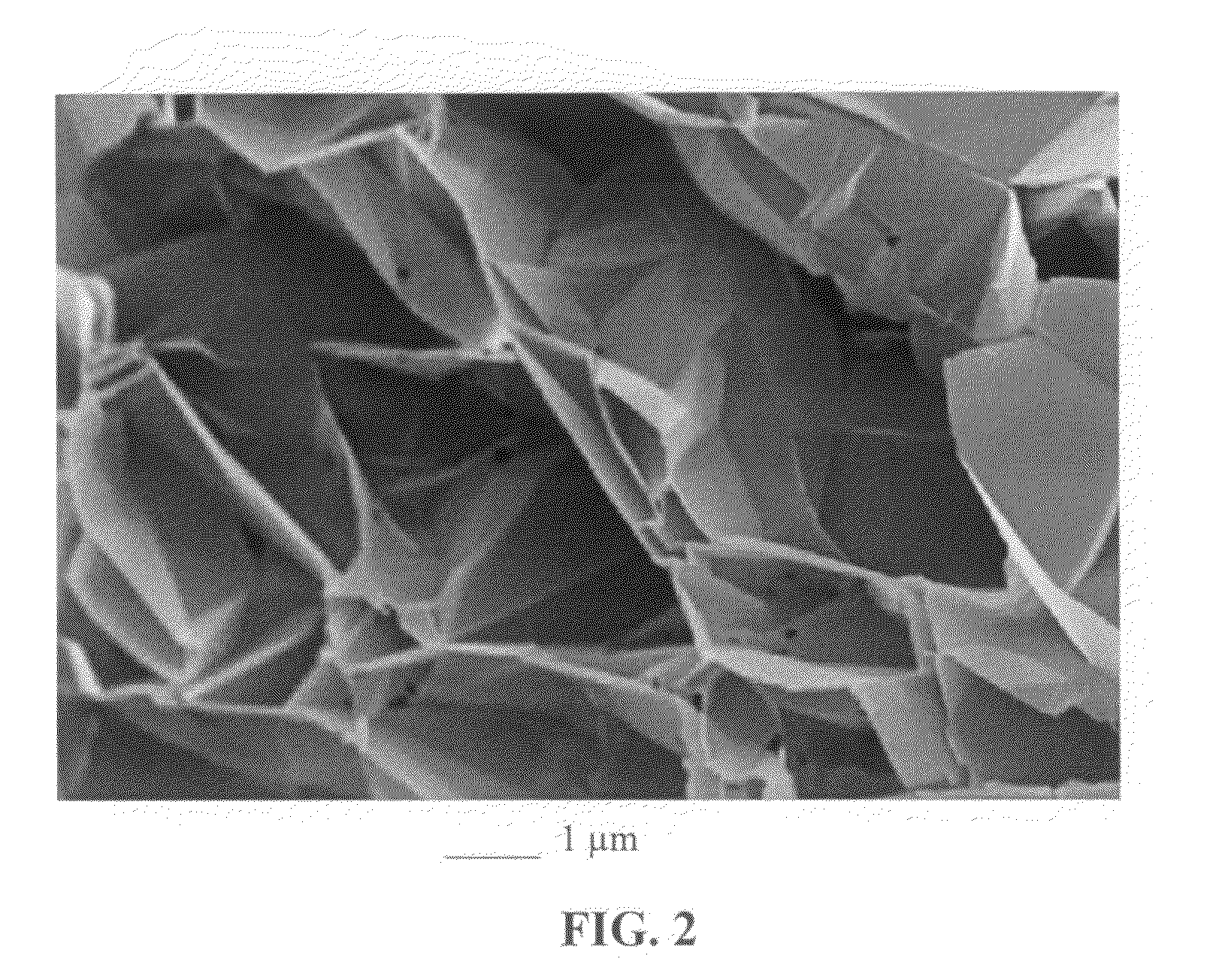

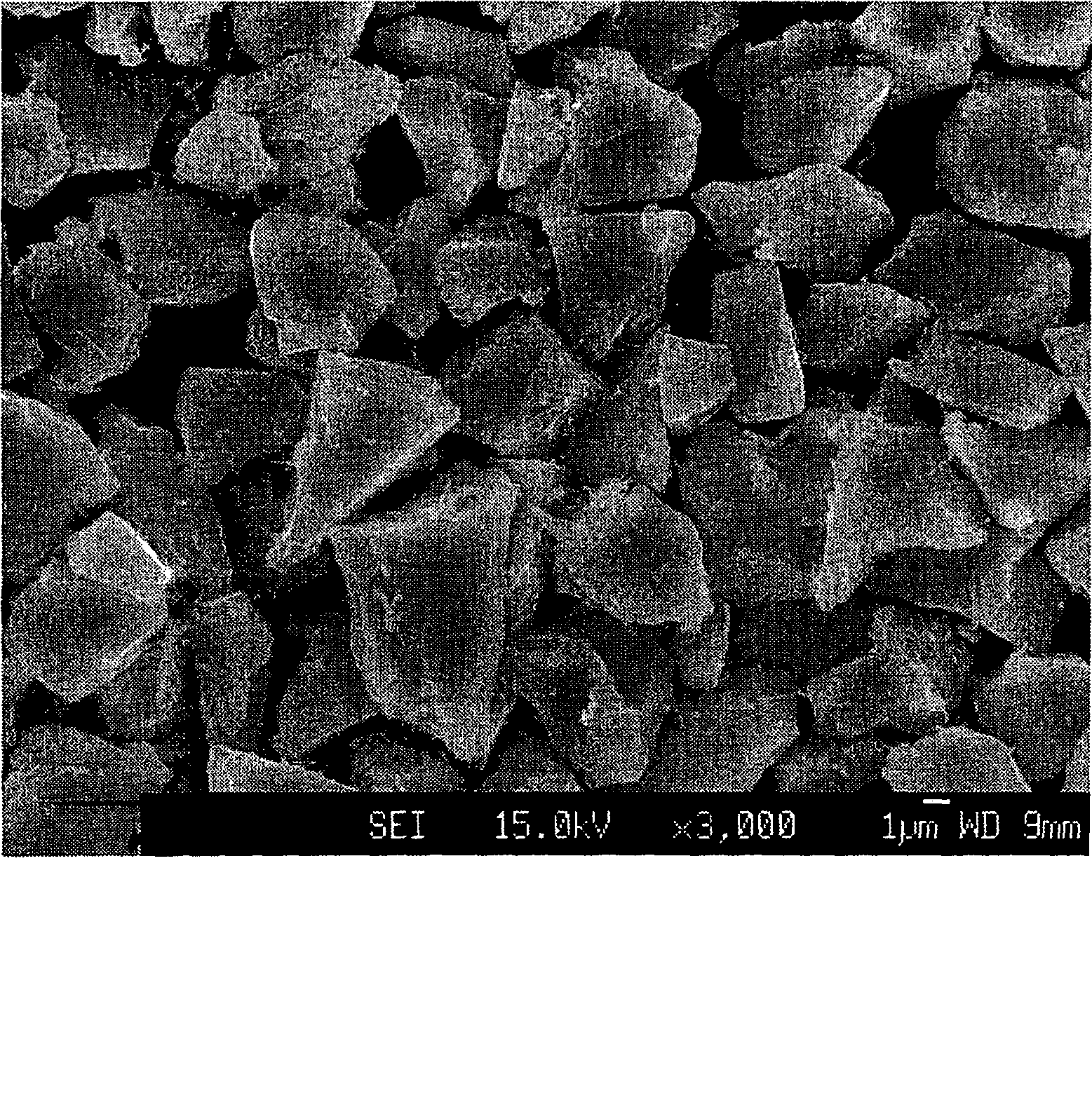

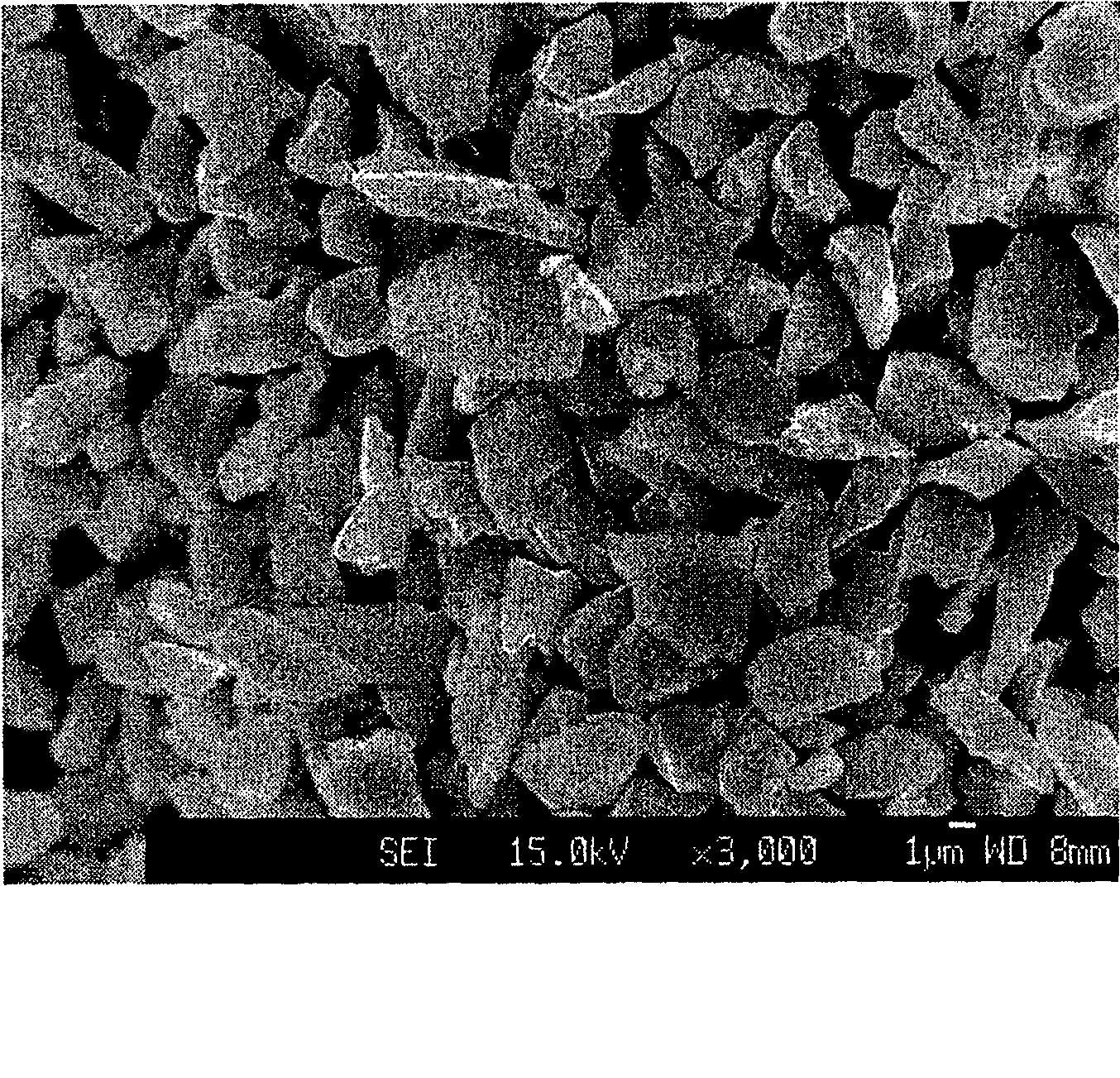

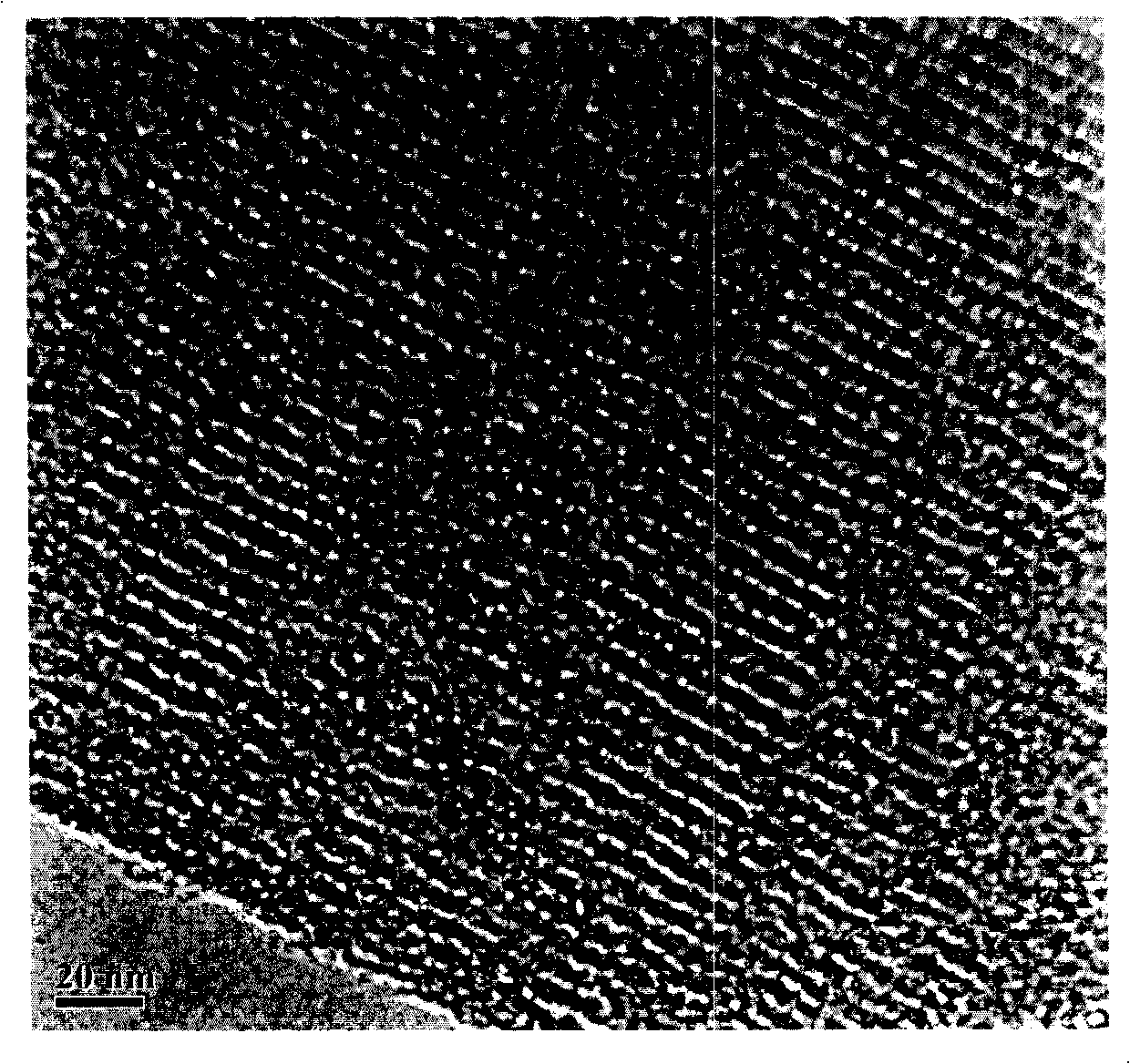

A method of producing a composite electrode having a specific surface area of at least 100 m2 / gm for use in an electrochemical capacitor. The method comprises (a) providing exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores; and (b) incorporating an electrochemically active material into at least a pore of the graphite network to form the composite electrode. The exfoliated graphite flakes are preferably obtained from the intercalation and exfoliation of a laminar graphite material selected from natural graphite, spheroidal graphite, synthetic graphite, highly oriented pyrolytic graphite, meso-carbon micro-bead, carbon / graphite fiber, carbon / graphite whisker, carbon / graphite nano-fiber, carbon nano-tube, or a combination thereof. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and low equivalent series resistance.

Owner:NANOTEK INSTR GRP LLC

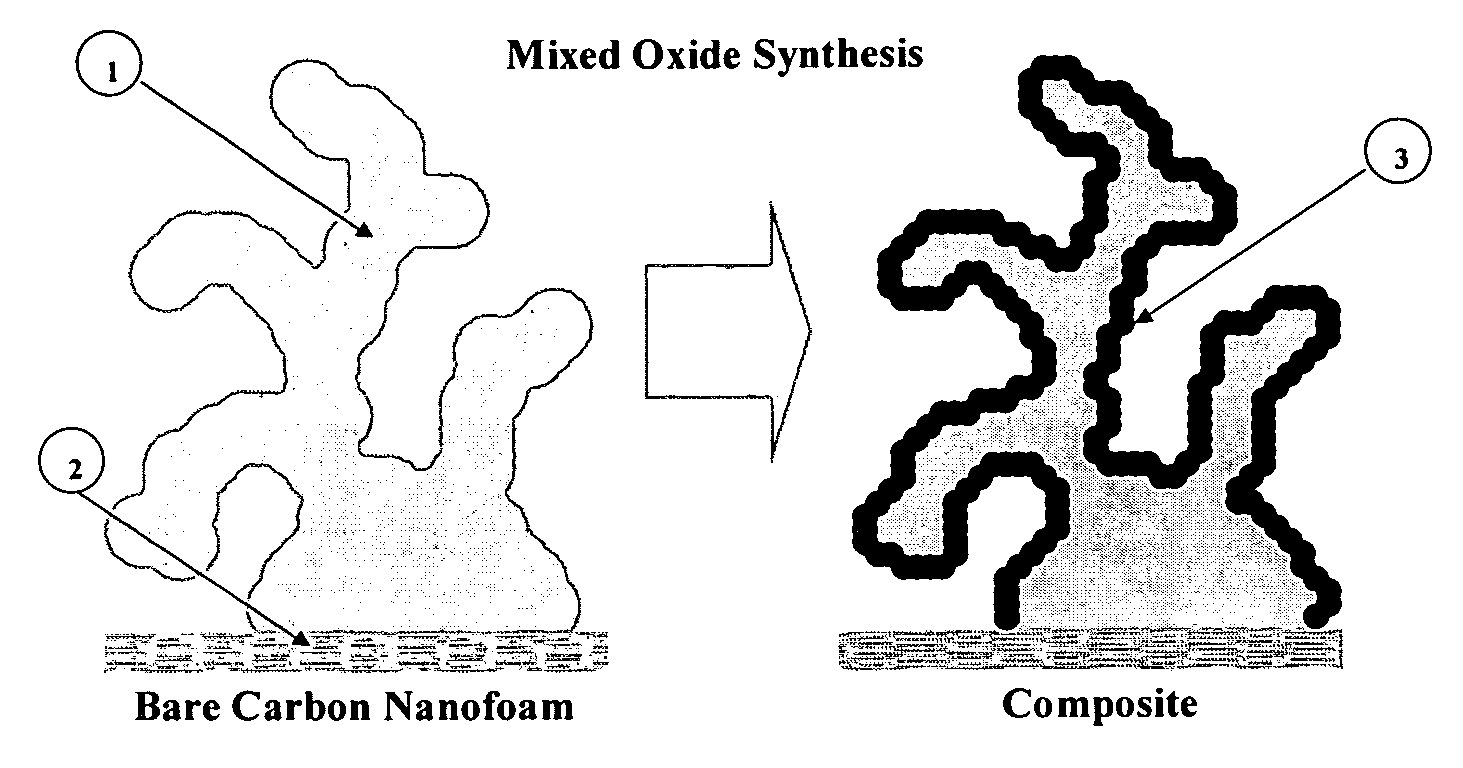

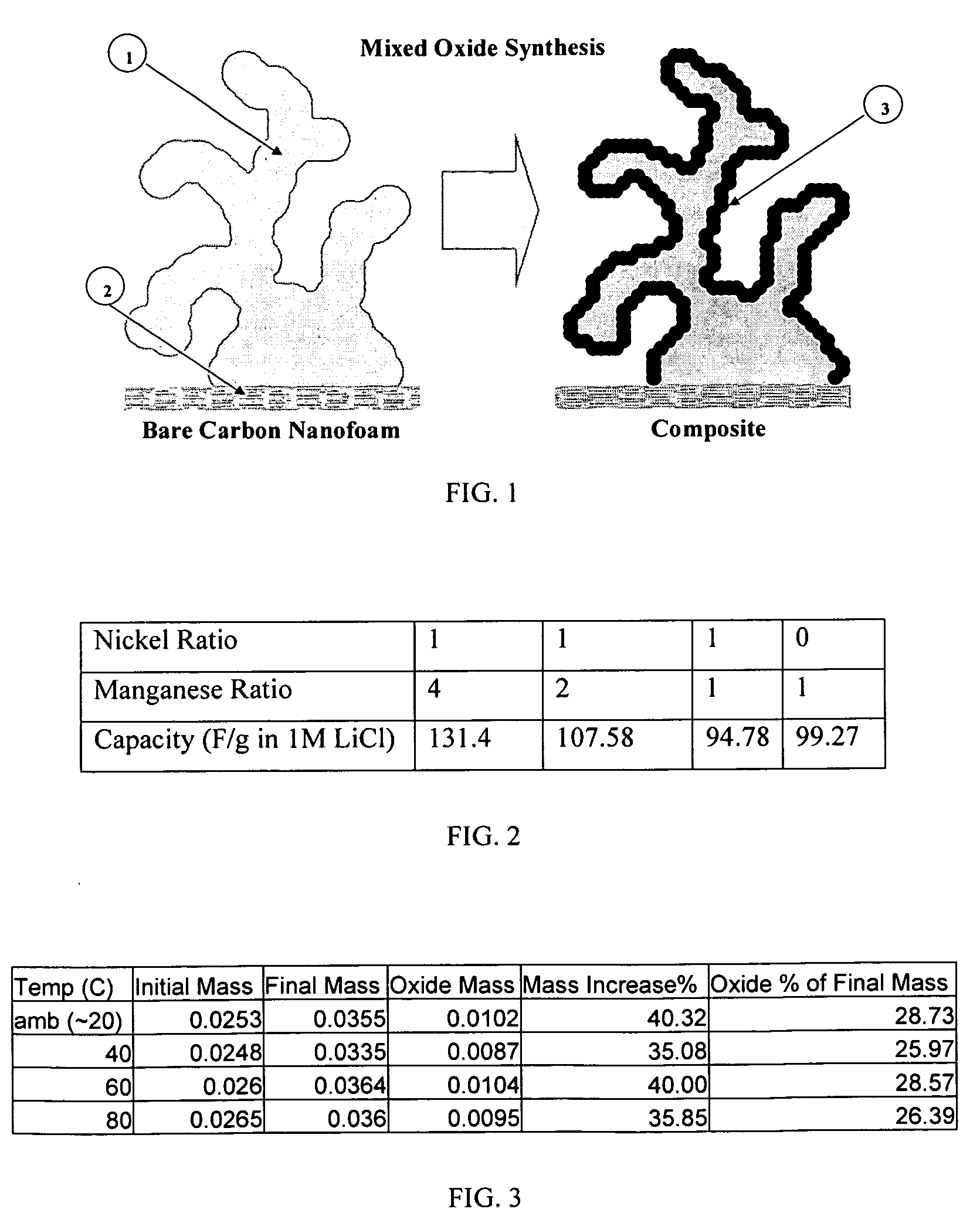

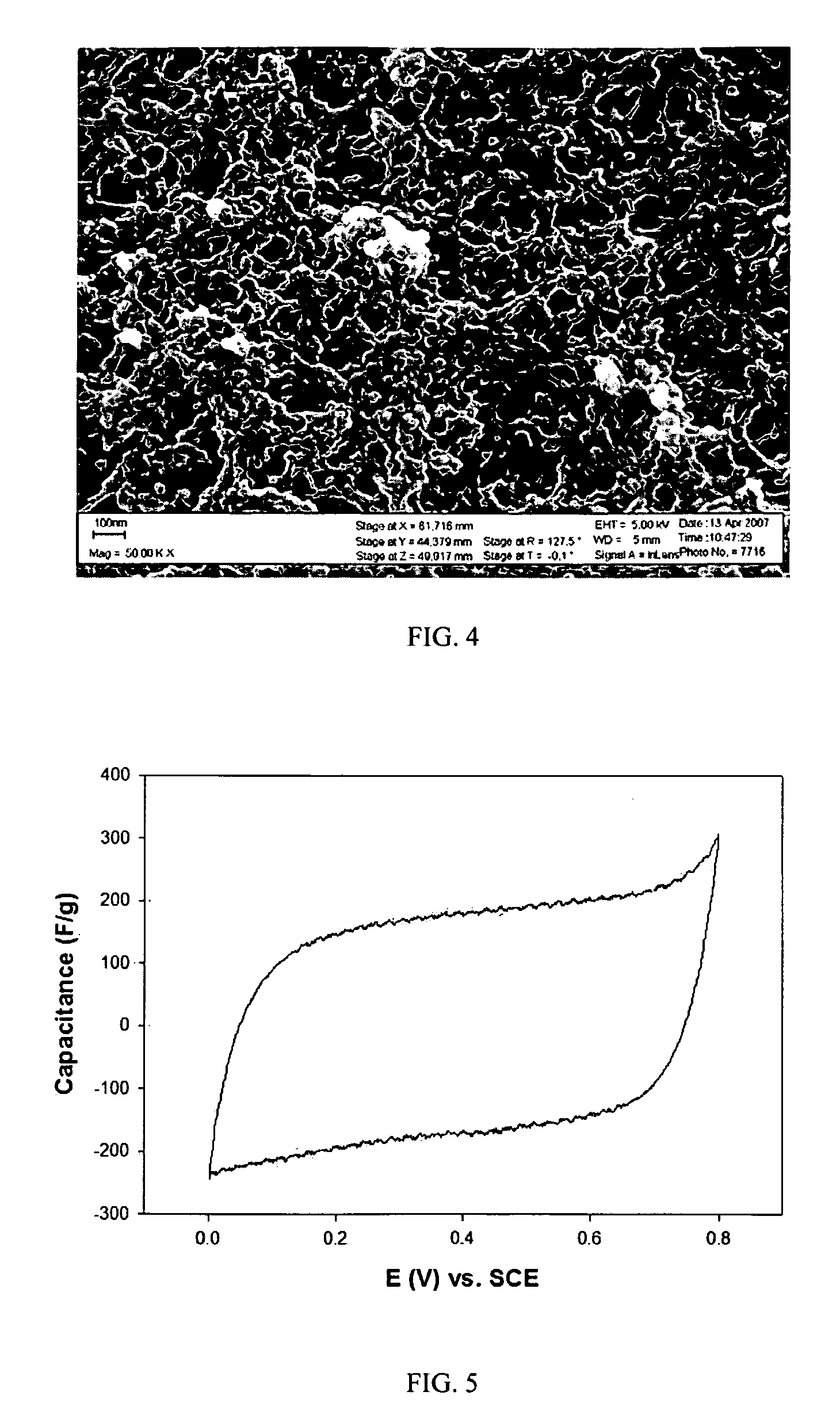

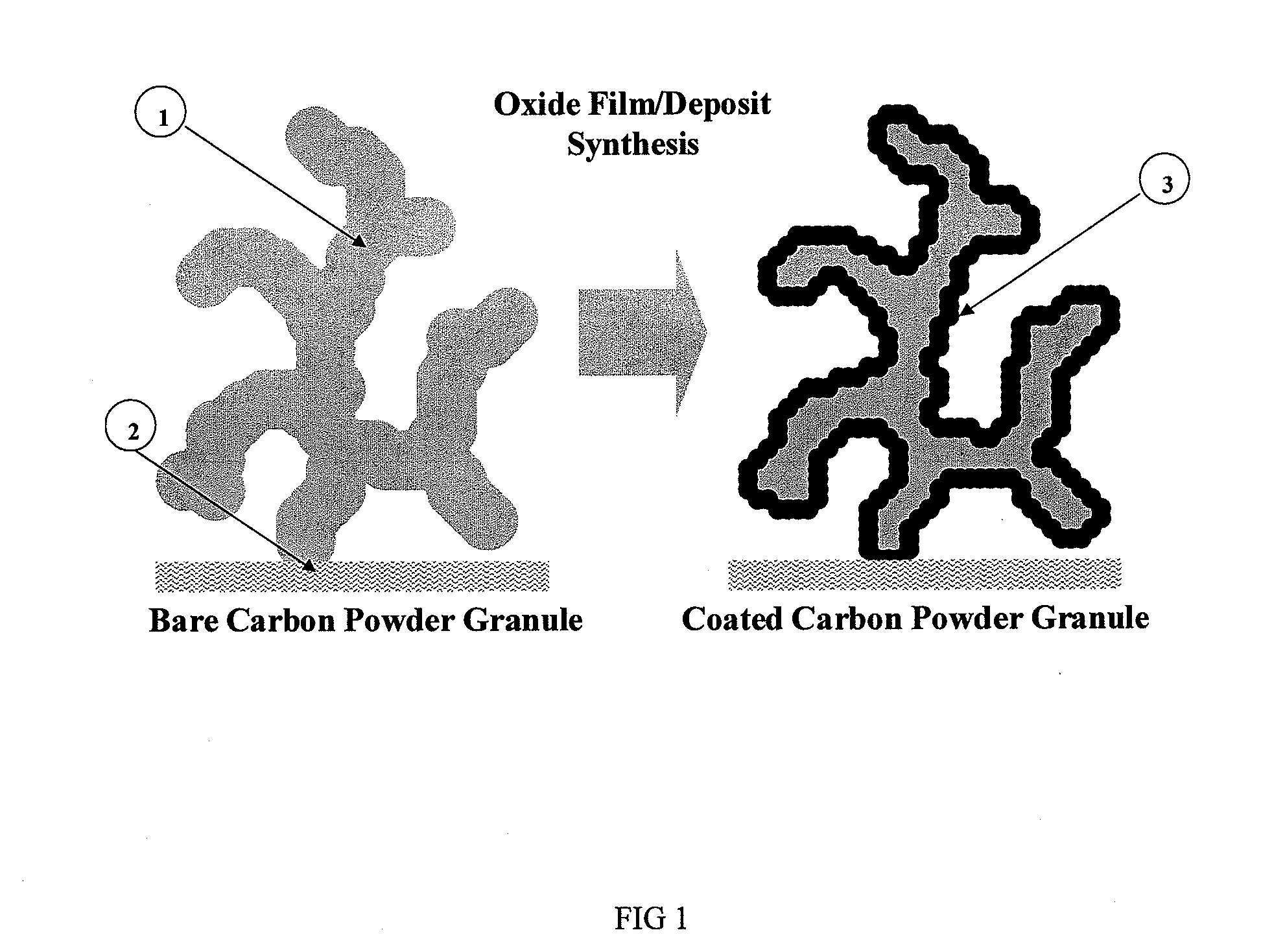

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

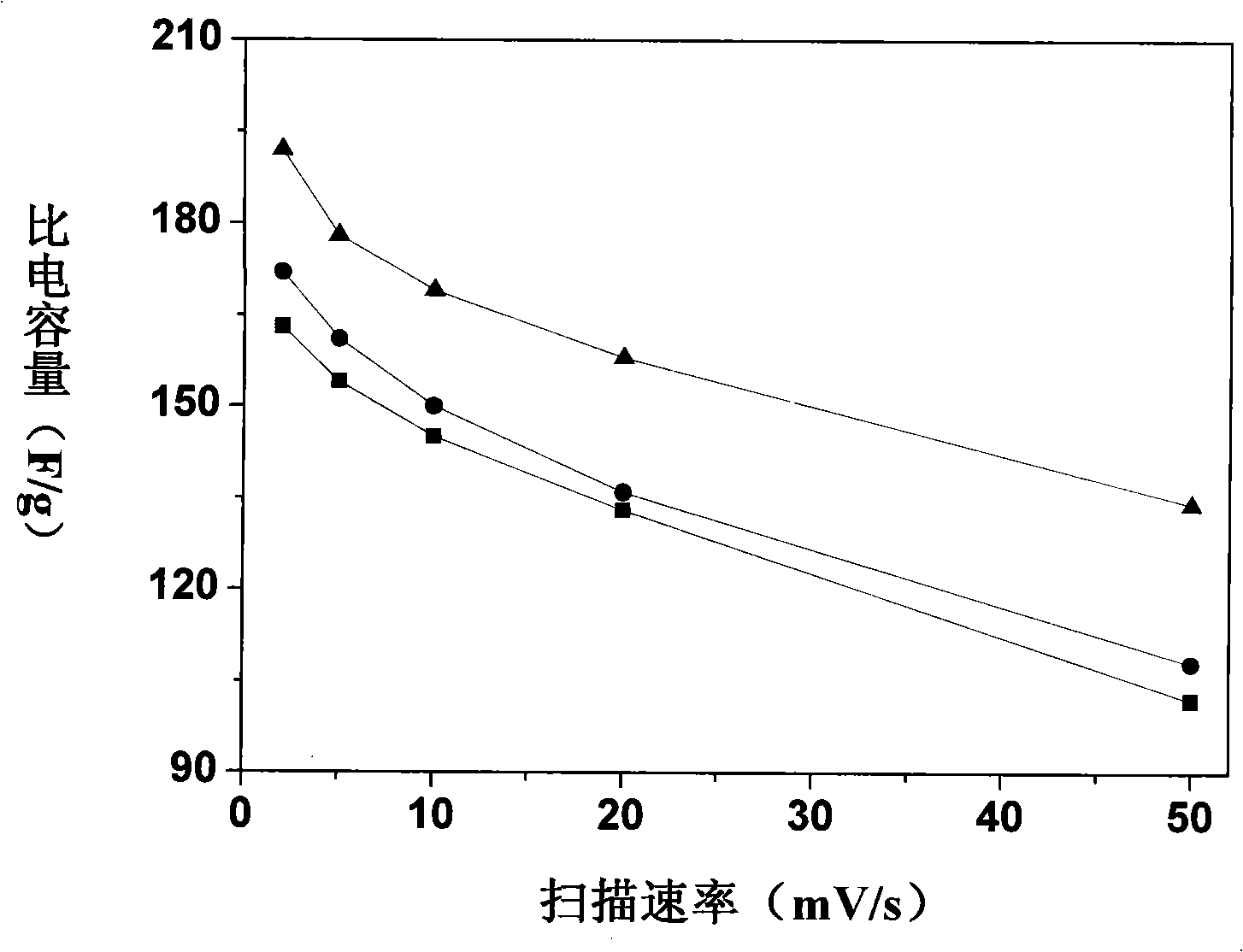

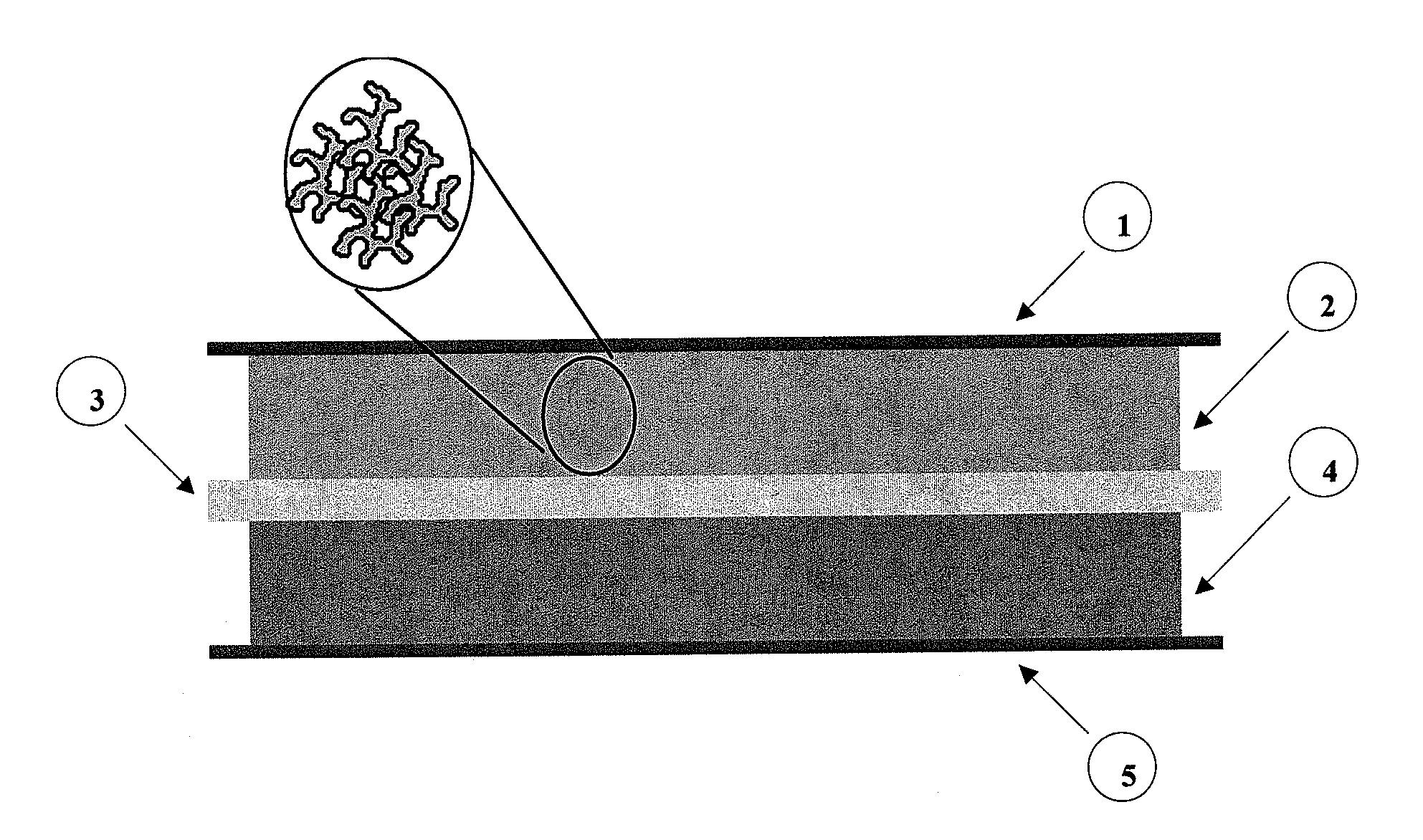

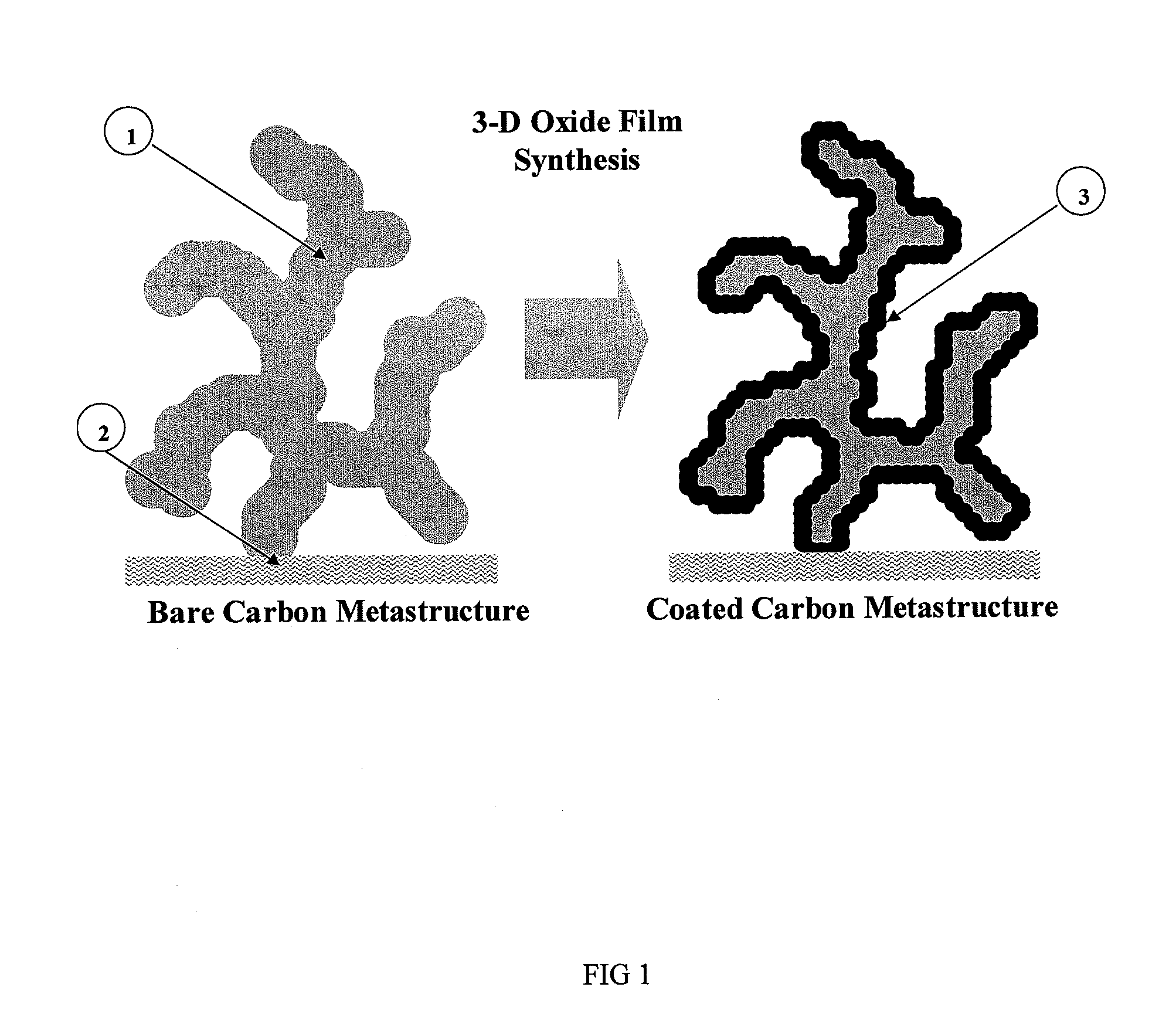

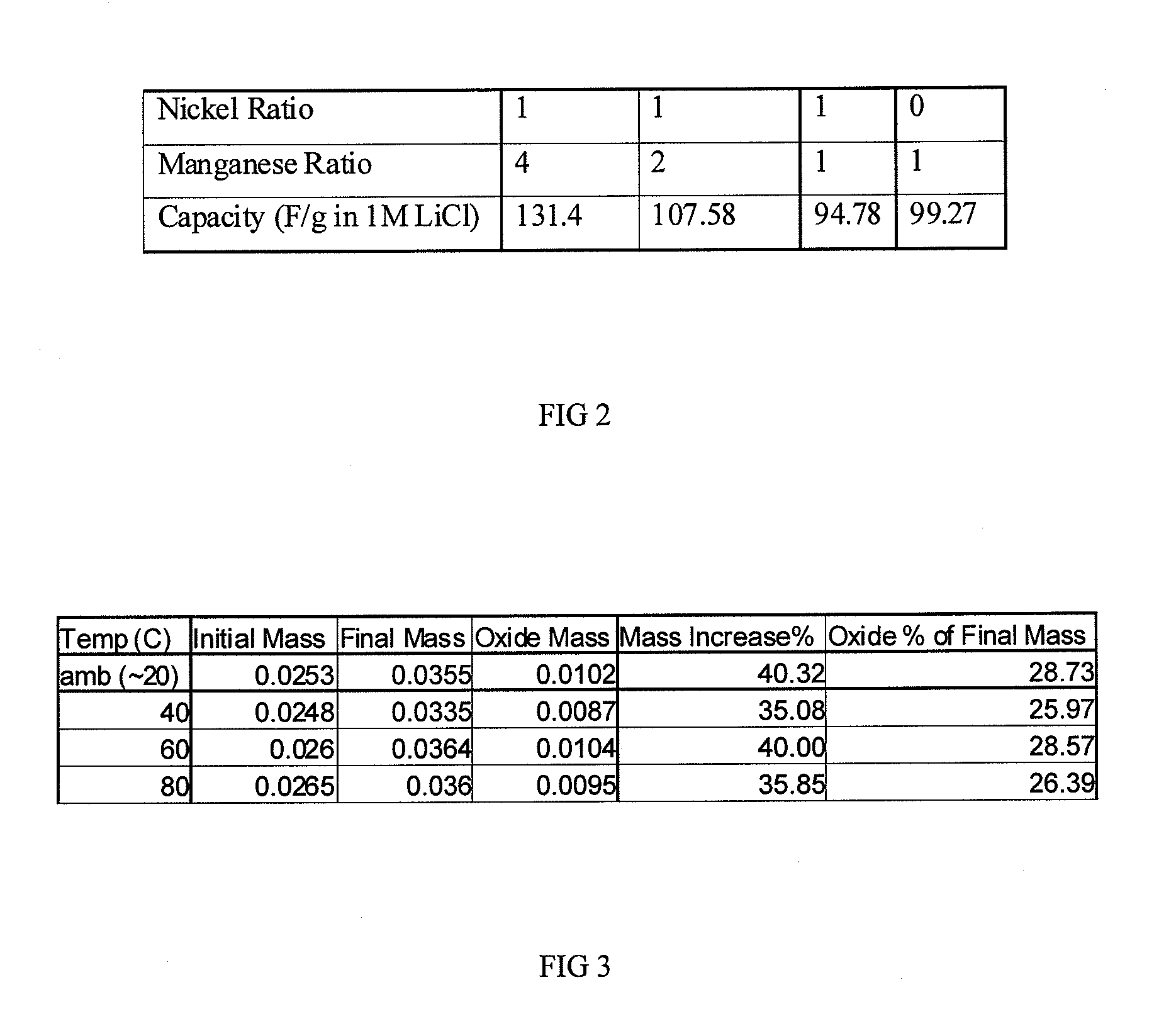

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

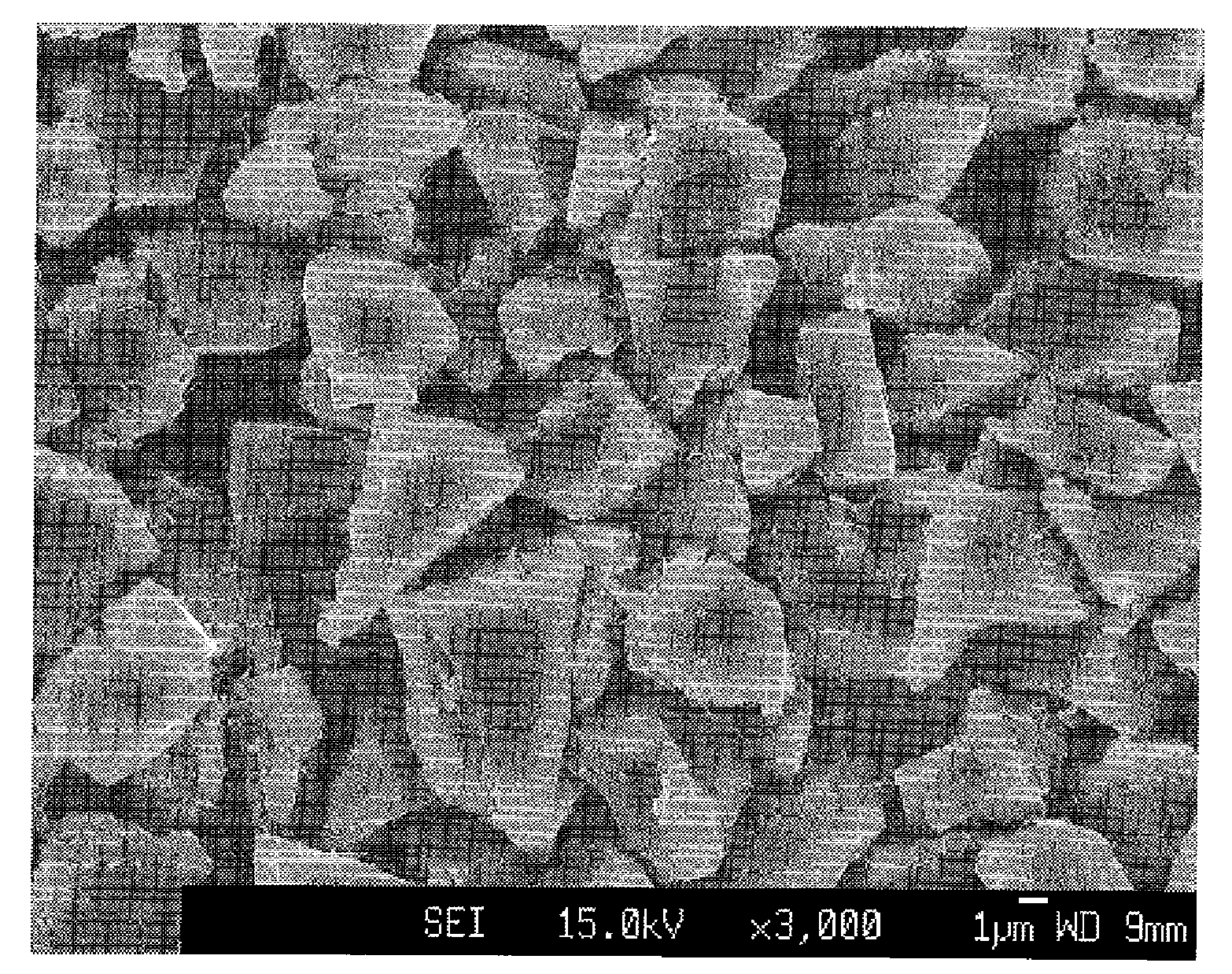

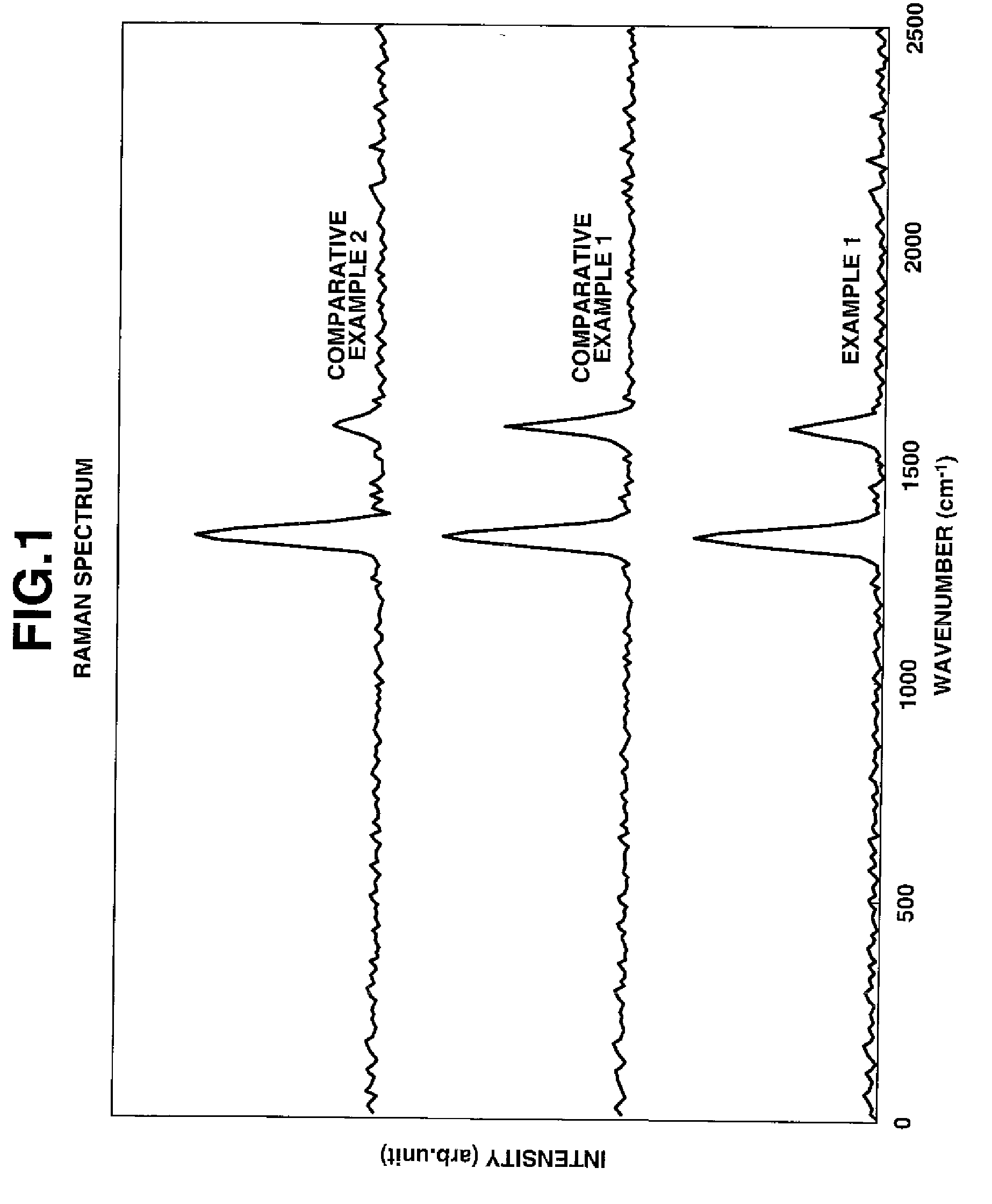

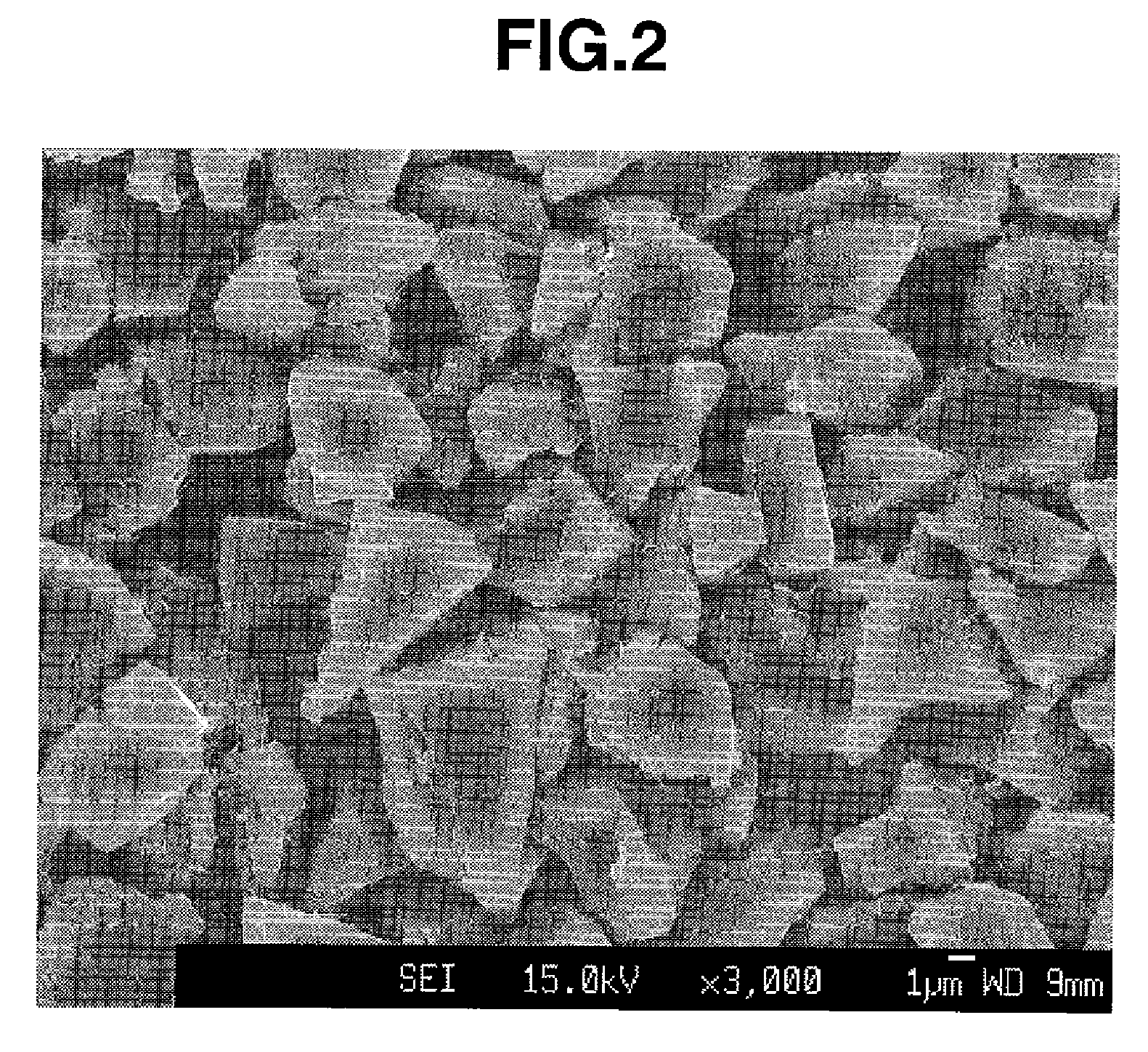

Non-aqueous electrolyte secondary battery negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20090202911A1Improve cycle performanceLarge capacityHybrid capacitor electrodesLiquid electrolytic capacitorsGraphiteCapacitor

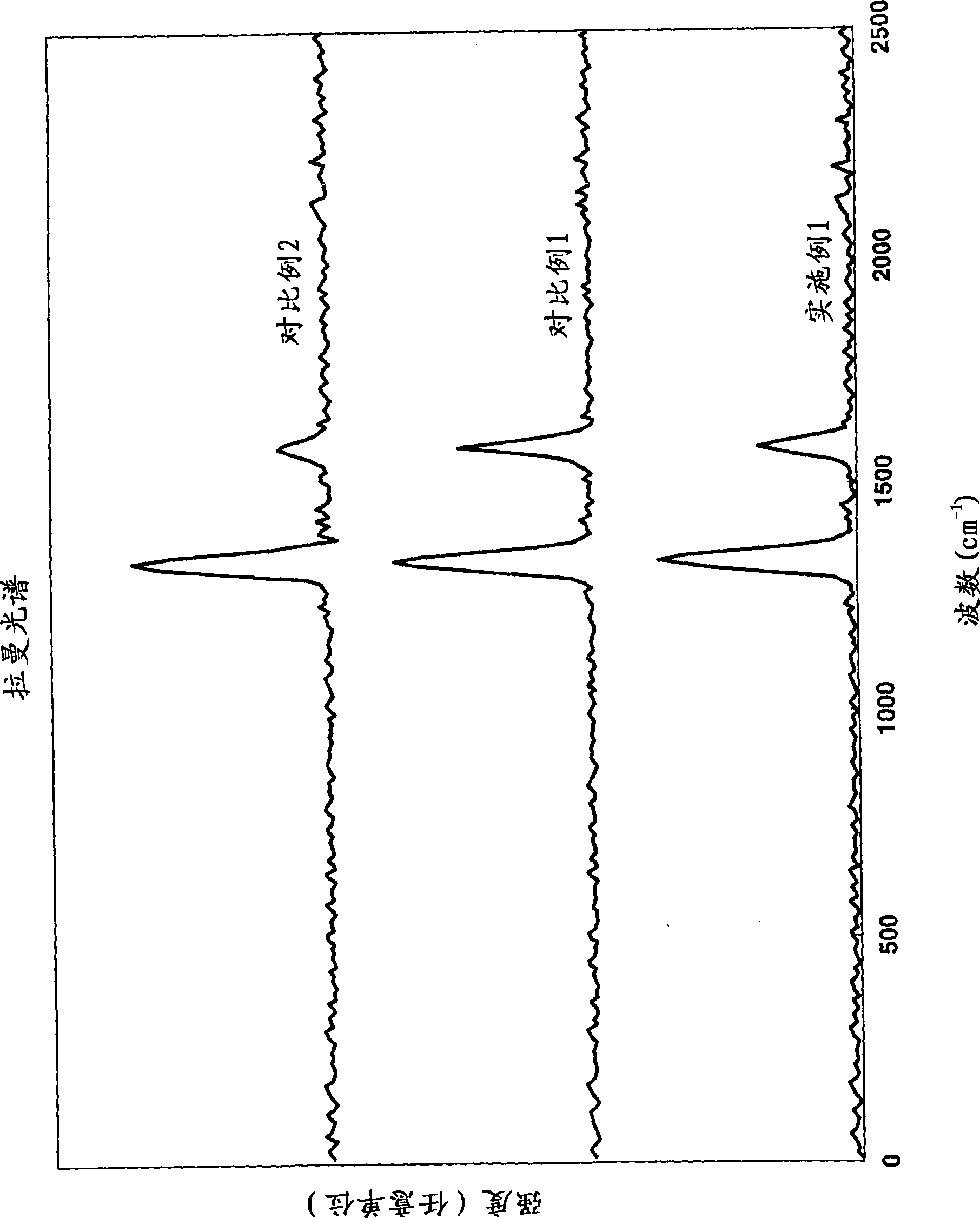

A negative electrode material comprises a conductive powder of particles of a lithium ion-occluding and releasing material coated on their surface with a graphite coating. The graphite coating, on Raman spectroscopy analysis, develops broad peaks having an intensity I1330 and I1580 at 1330 cm−1 and 1580 cm−1 Raman shift, an intensity ratio I1330 / I1580 being 1.5<I1330 / I1580<3.0. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance can be manufactured.

Owner:SHIN ETSU CHEM IND CO LTD

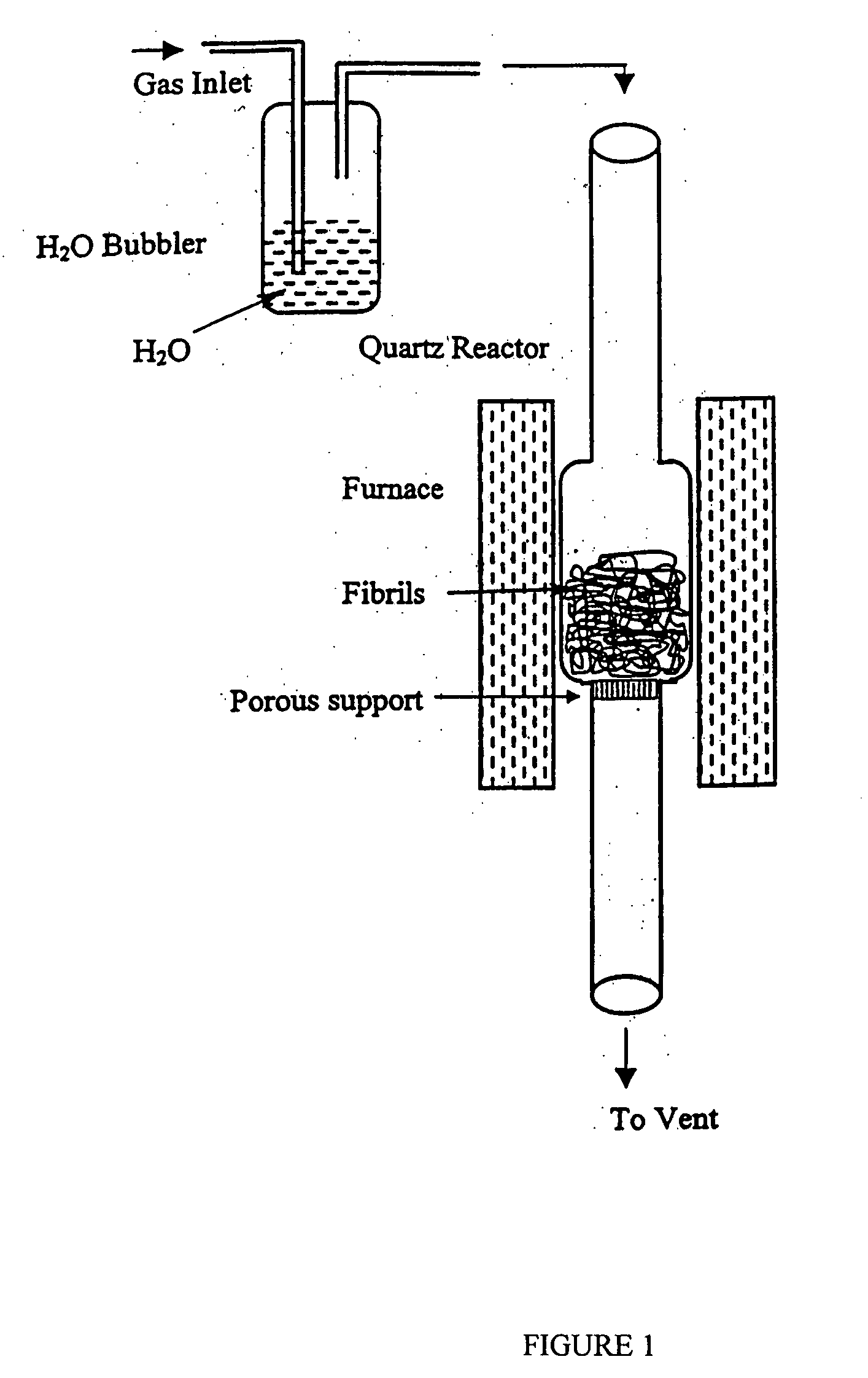

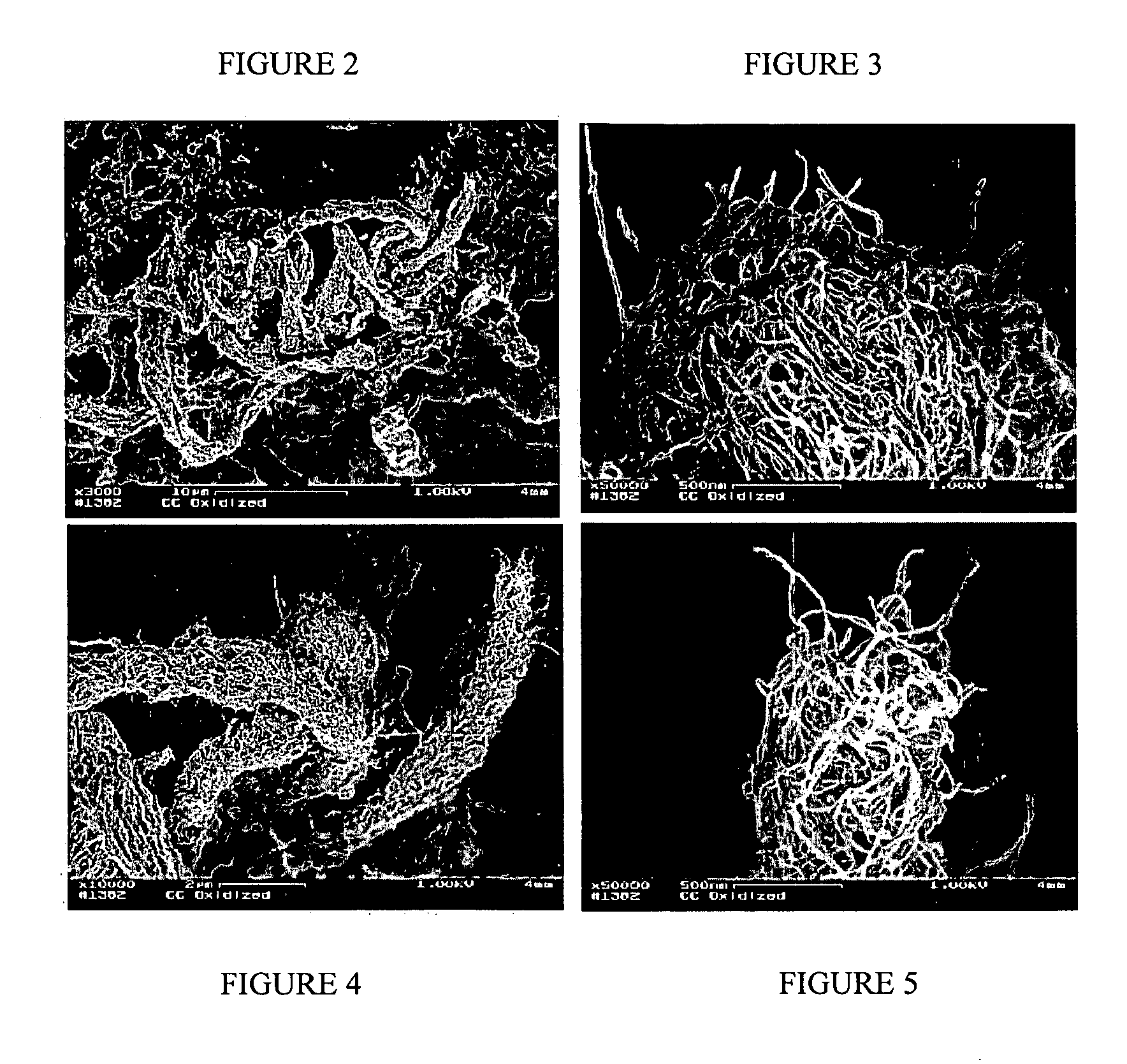

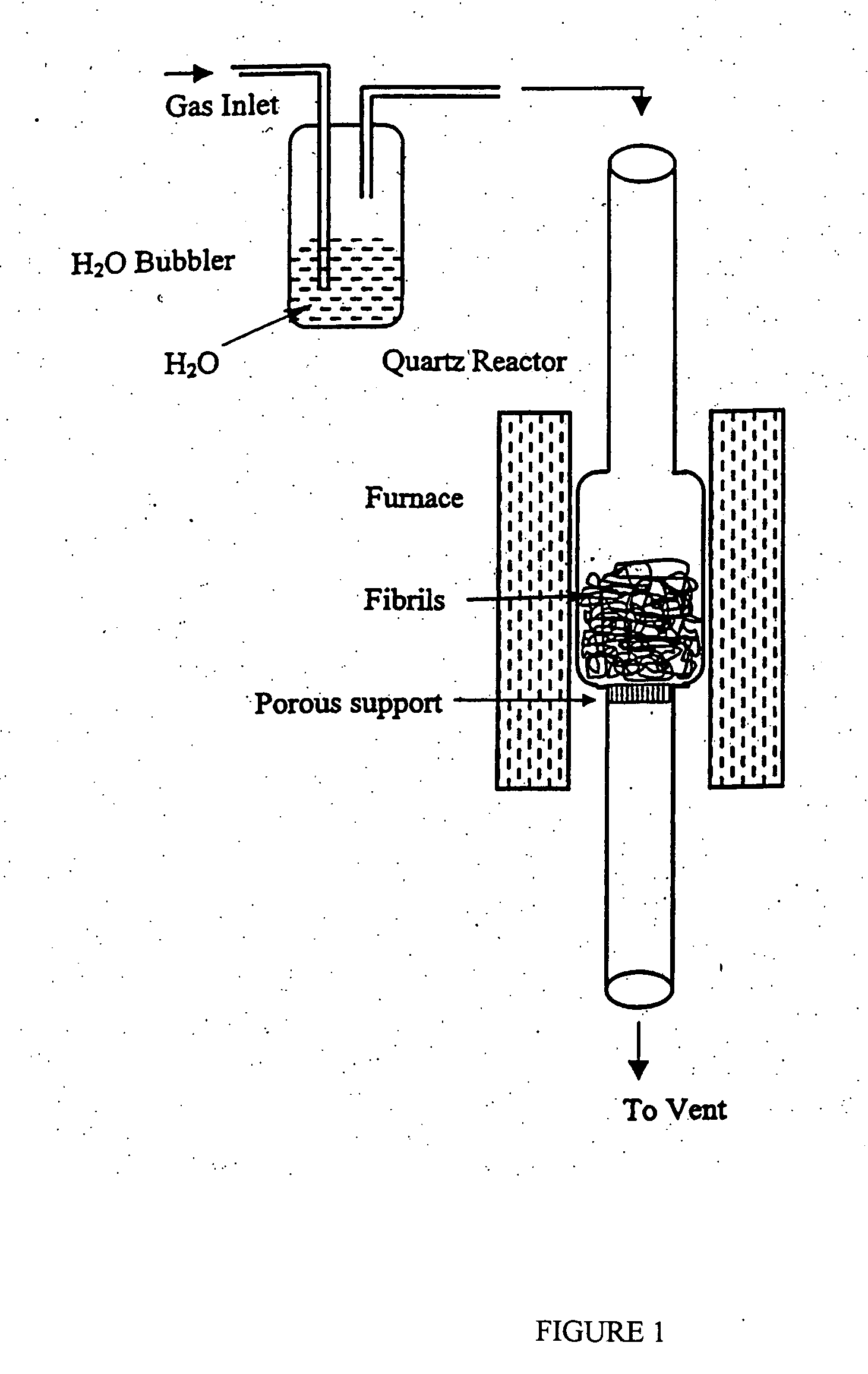

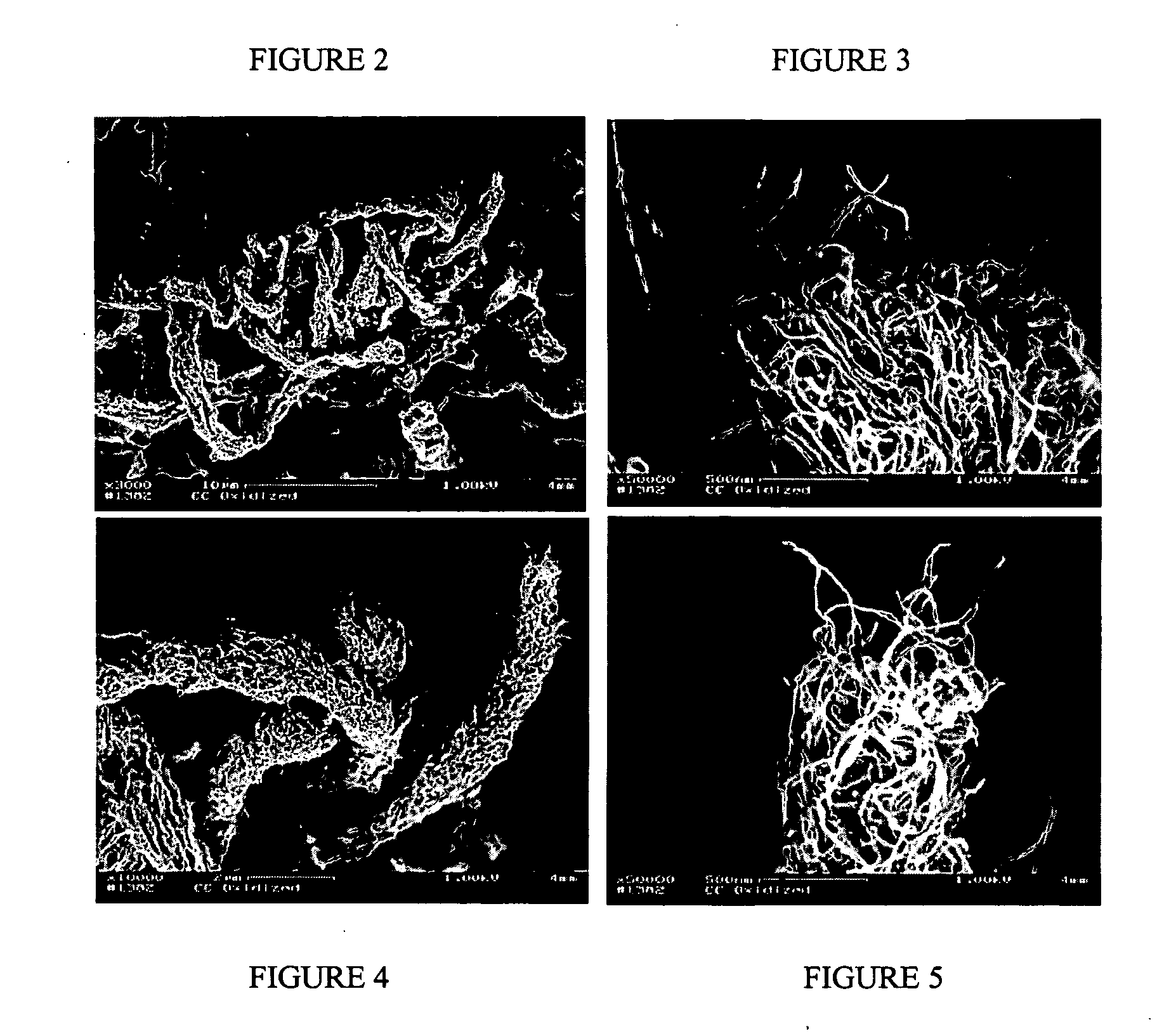

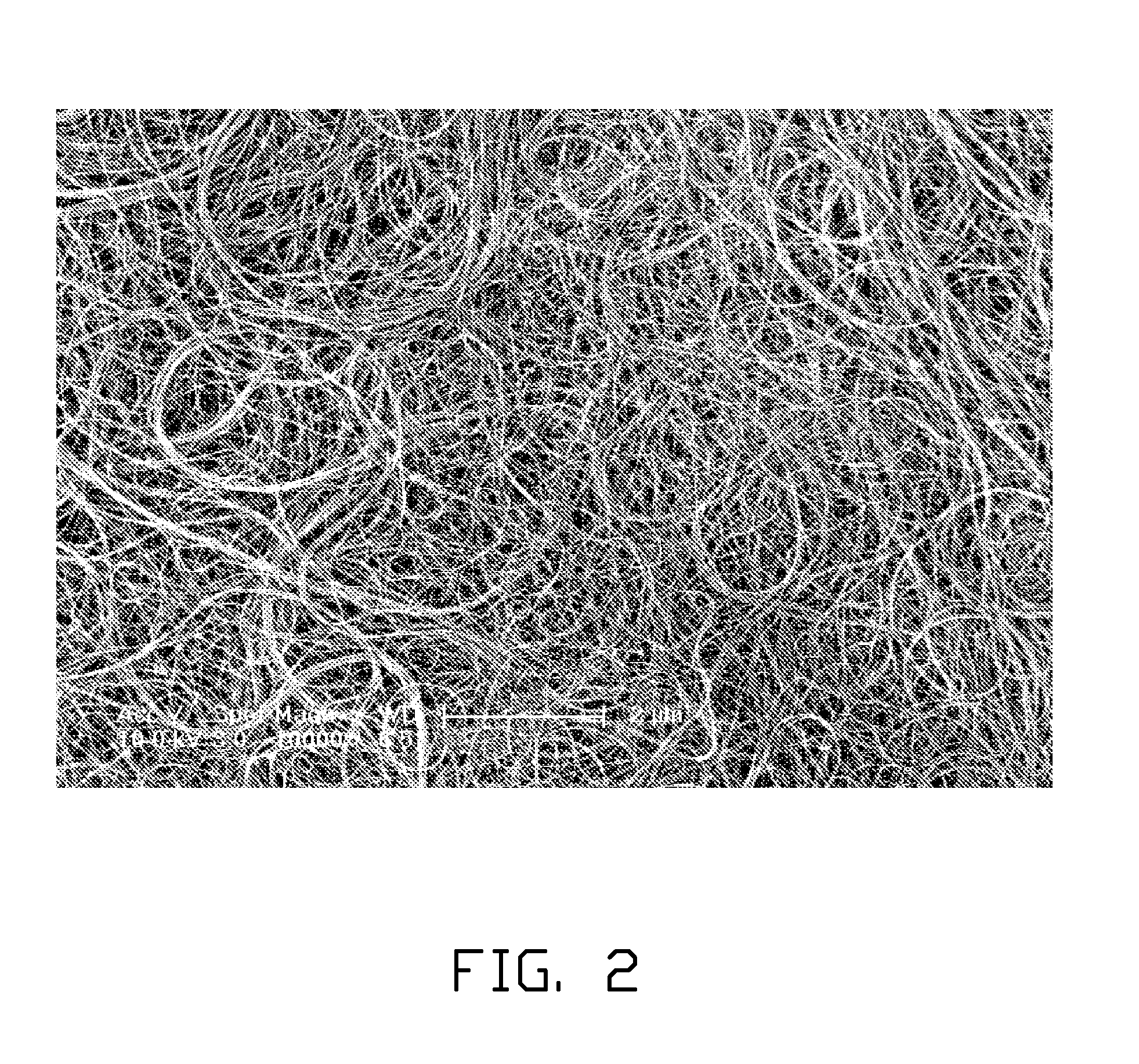

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20060239891A1Good electrochemical propertiesMaterial nanotechnologyHybrid capacitor electrodesMultiwalled carbonElectrochemistry

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

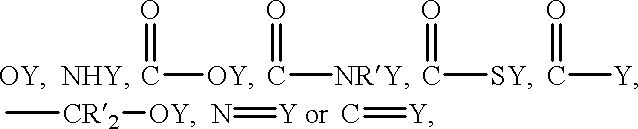

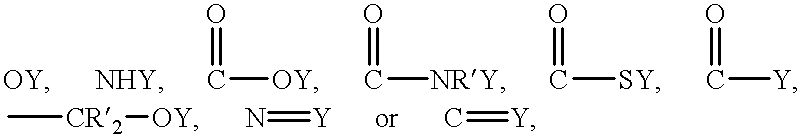

Functionalized Carbon Electrode, Related Material, Process for Production, and Use Thereof

InactiveUS20140113200A1Low costSimple processElectrolytic capacitorsHybrid capacitor electrodesFuel cellsPorous carbon

The present invention relates to a material for use as an electrode for electrochemical energy storage devices such as electrochemical capacitors (ECs) and secondary batteries, primary batteries, metal / air batteries, fuel cells, flow batteries and a method for producing the same. More specifically, this invention relates to an electrode material consisting of a functionalized porous carbon, a method for producing the same, and an energy storage device using said electrode materials.

Owner:SEYMOUR FRASER

Negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20100009261A1Improved in rate and cycle propertySimple preparation processElectrode thermal treatmentHybrid capacitor electrodesSilicon oxideSilicon dioxide

Particles of a silicon oxide of formula: SiOx wherein x is 0.5 to 1.6, a silicon composite comprising silicon dispersed in silicon dioxide and having a molar ratio Si / O from 1:0.5 to 1:1.6, or a mixture thereof are doped with 50-100,000 ppm of phosphorus. A negative electrode material comprising the phosphorus-doped particles is suited for use in non-aqueous electrolyte secondary batteries. A lithium ion secondary battery having satisfactory cycle and rate properties is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

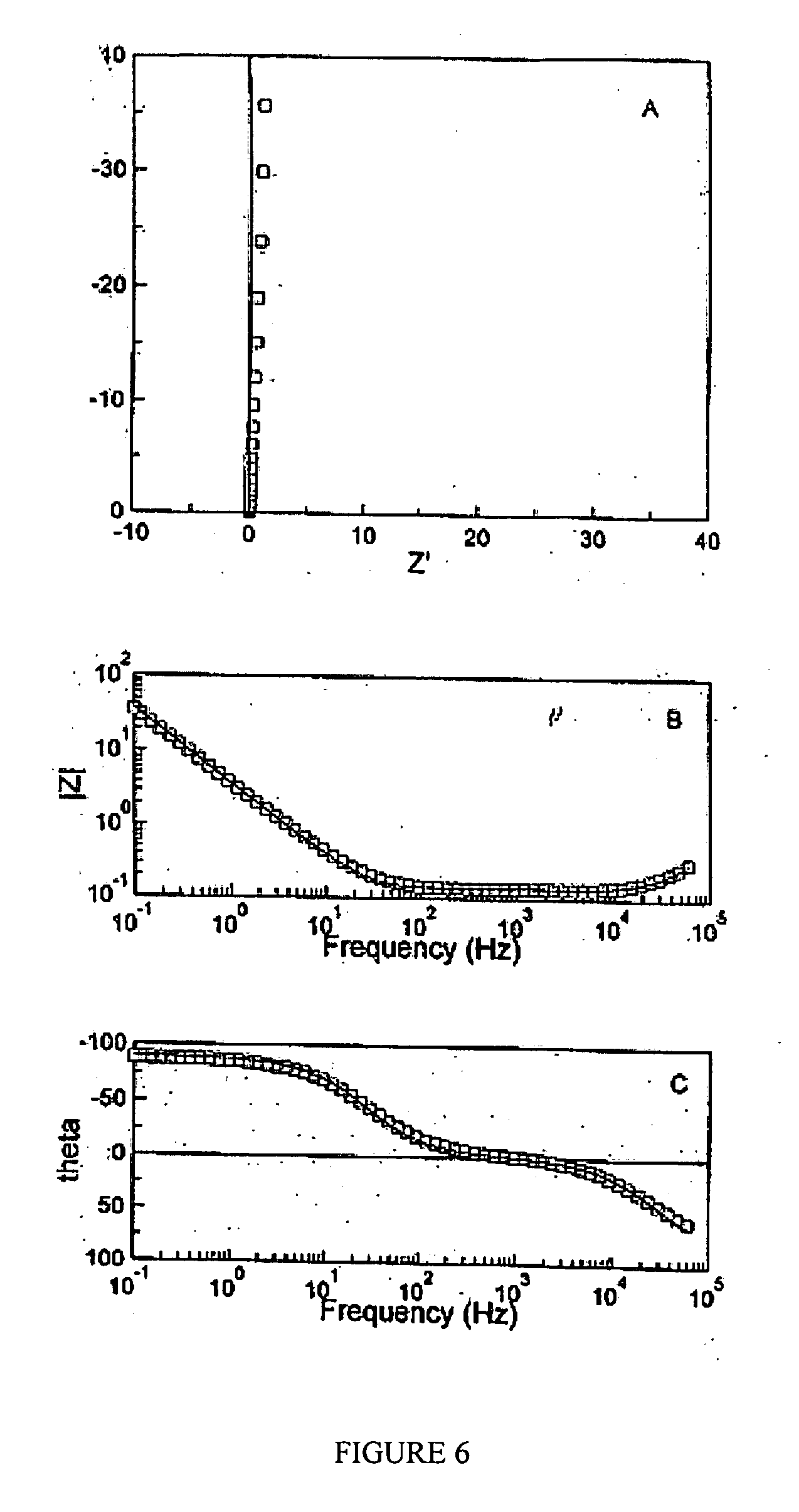

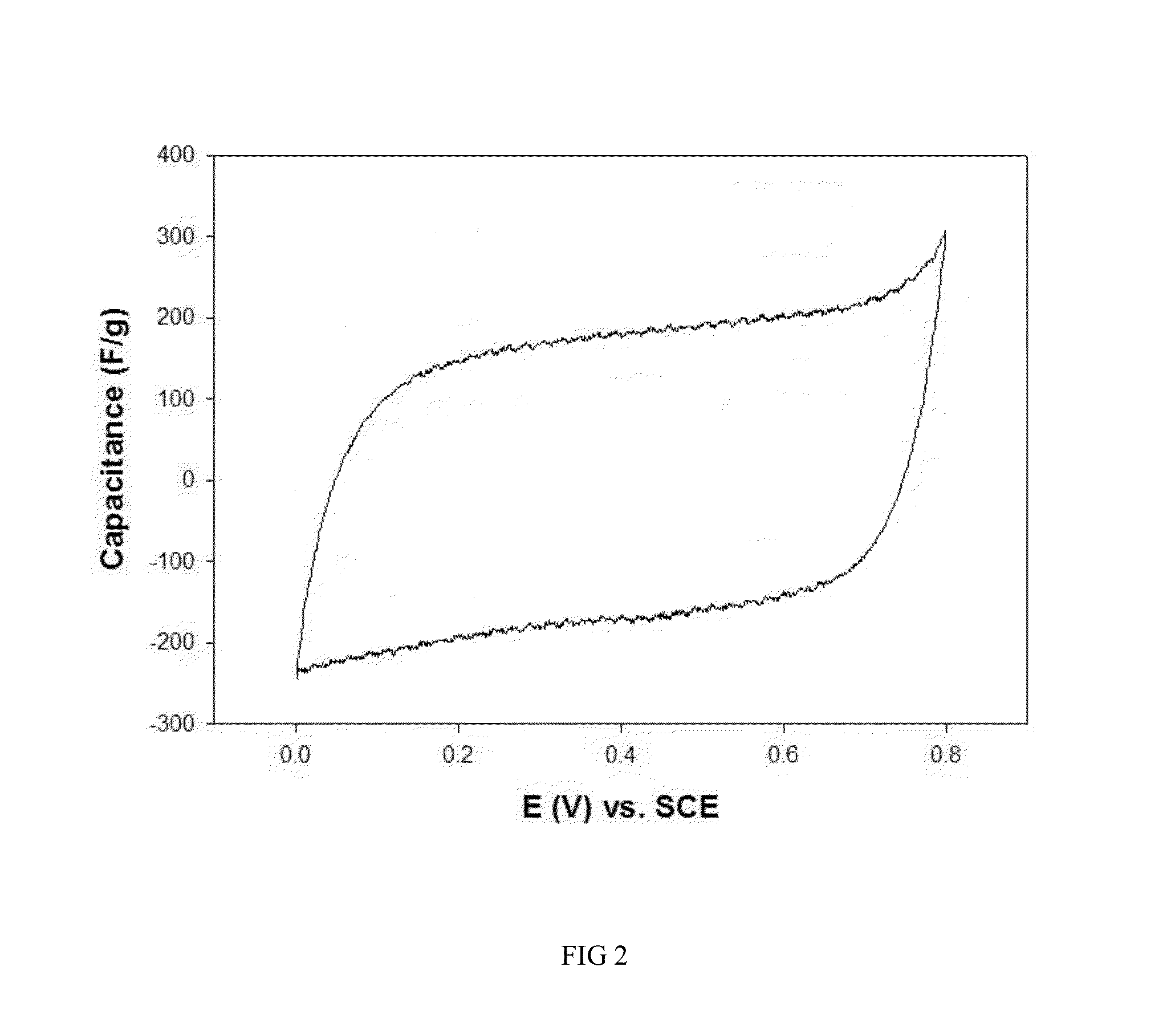

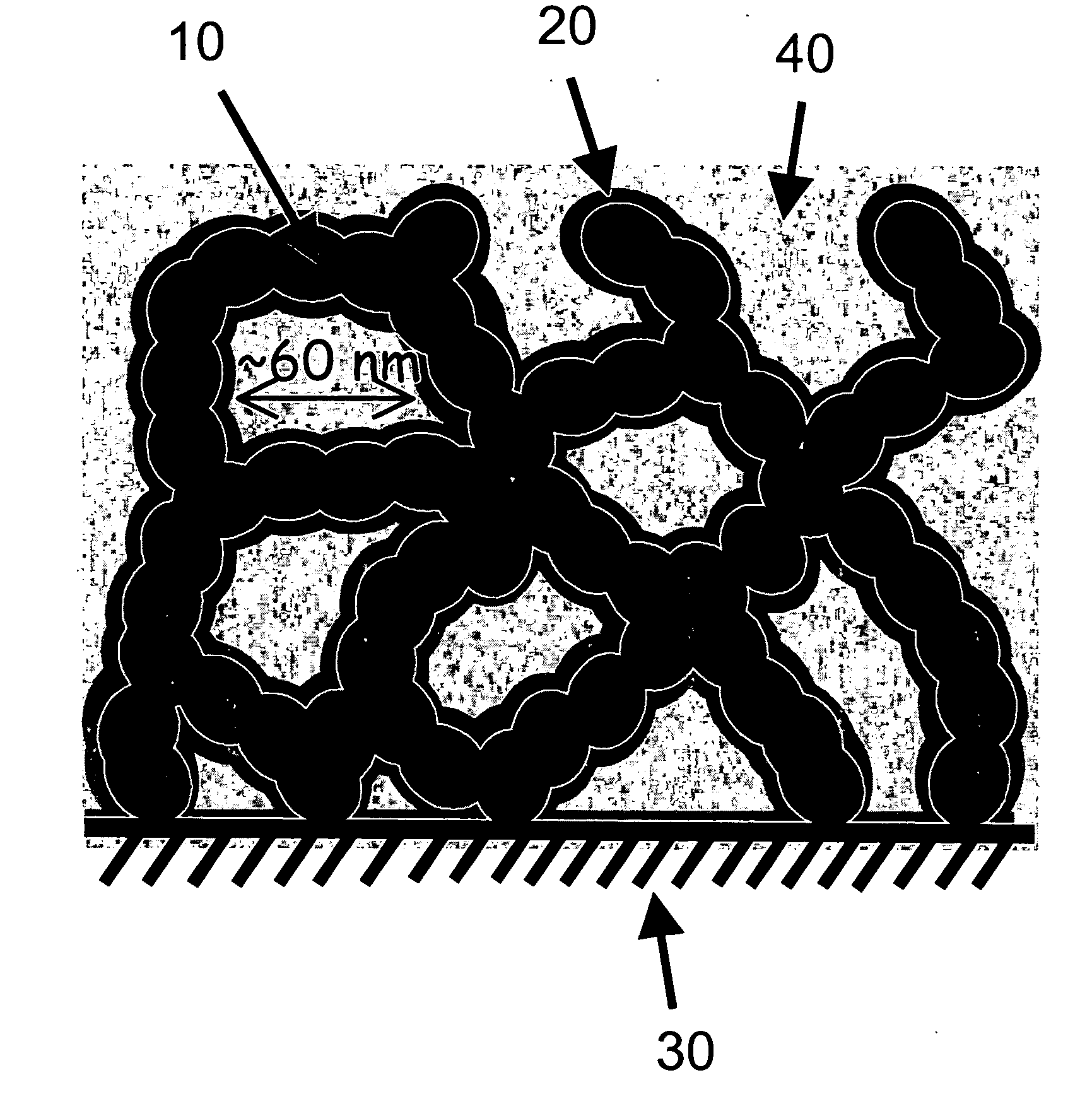

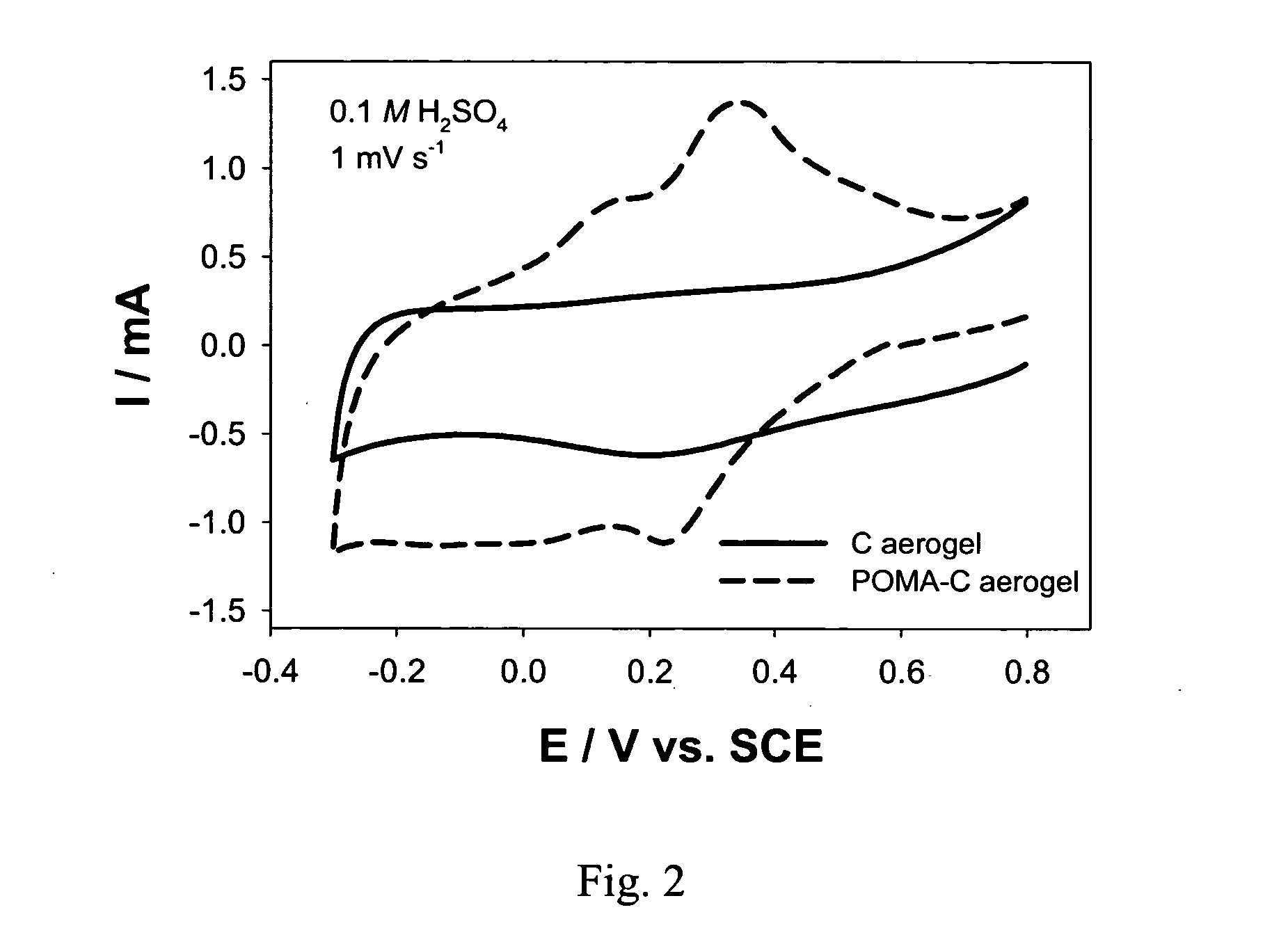

Carbon nanoarchitectures with ultrathin, conformal polymer coatings for electrochemical capacitors

ActiveUS20050153130A1Hybrid capacitor electrolytesElectrolysis componentsSelf limitingPolymer science

A composite having an electroactive polymer coating on a porous carbon structure is disclosed. The composite may be used in capacitor electrodes. The composite may be made by self-limiting electropolymerization of a monomer on the carbon structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

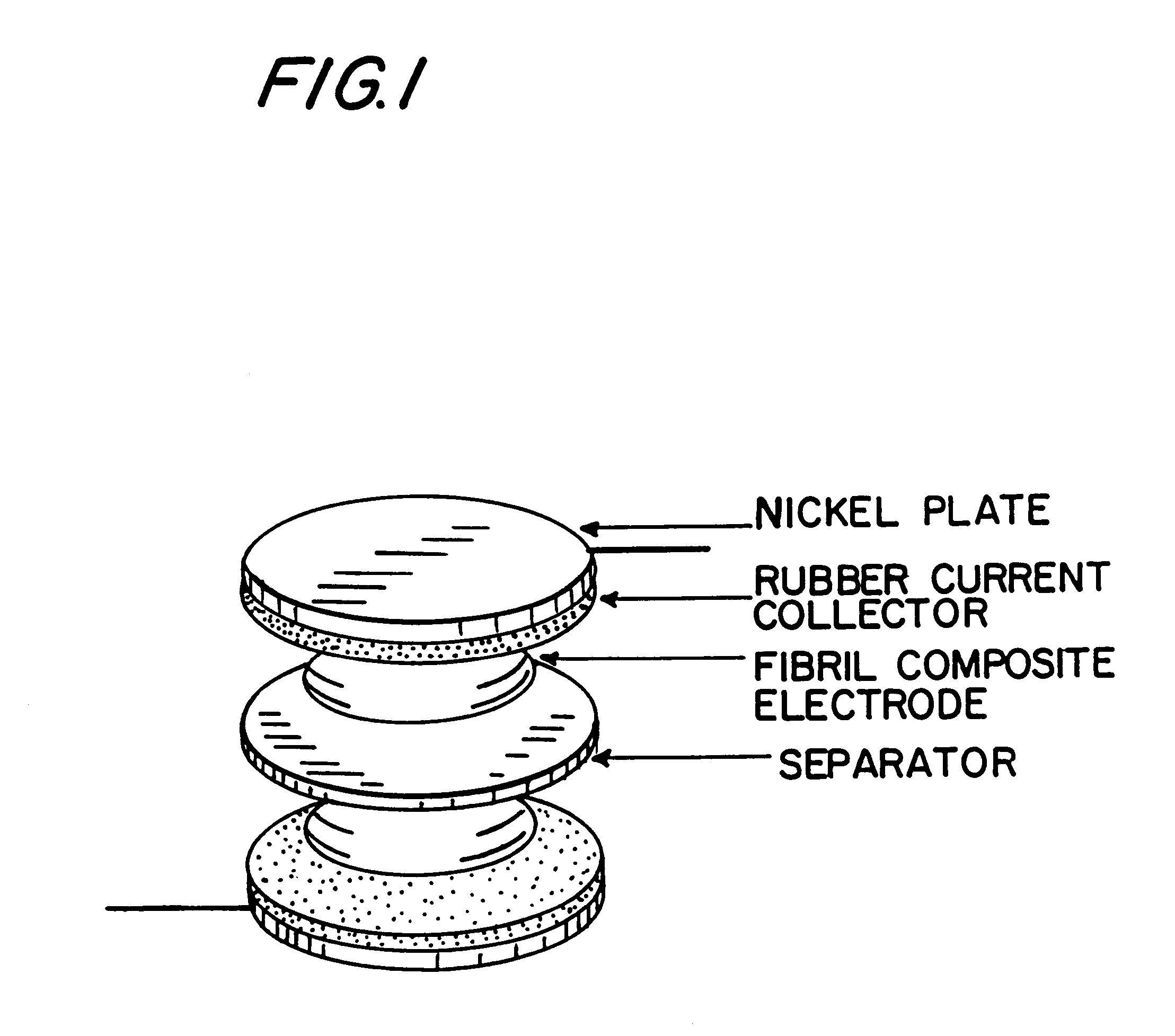

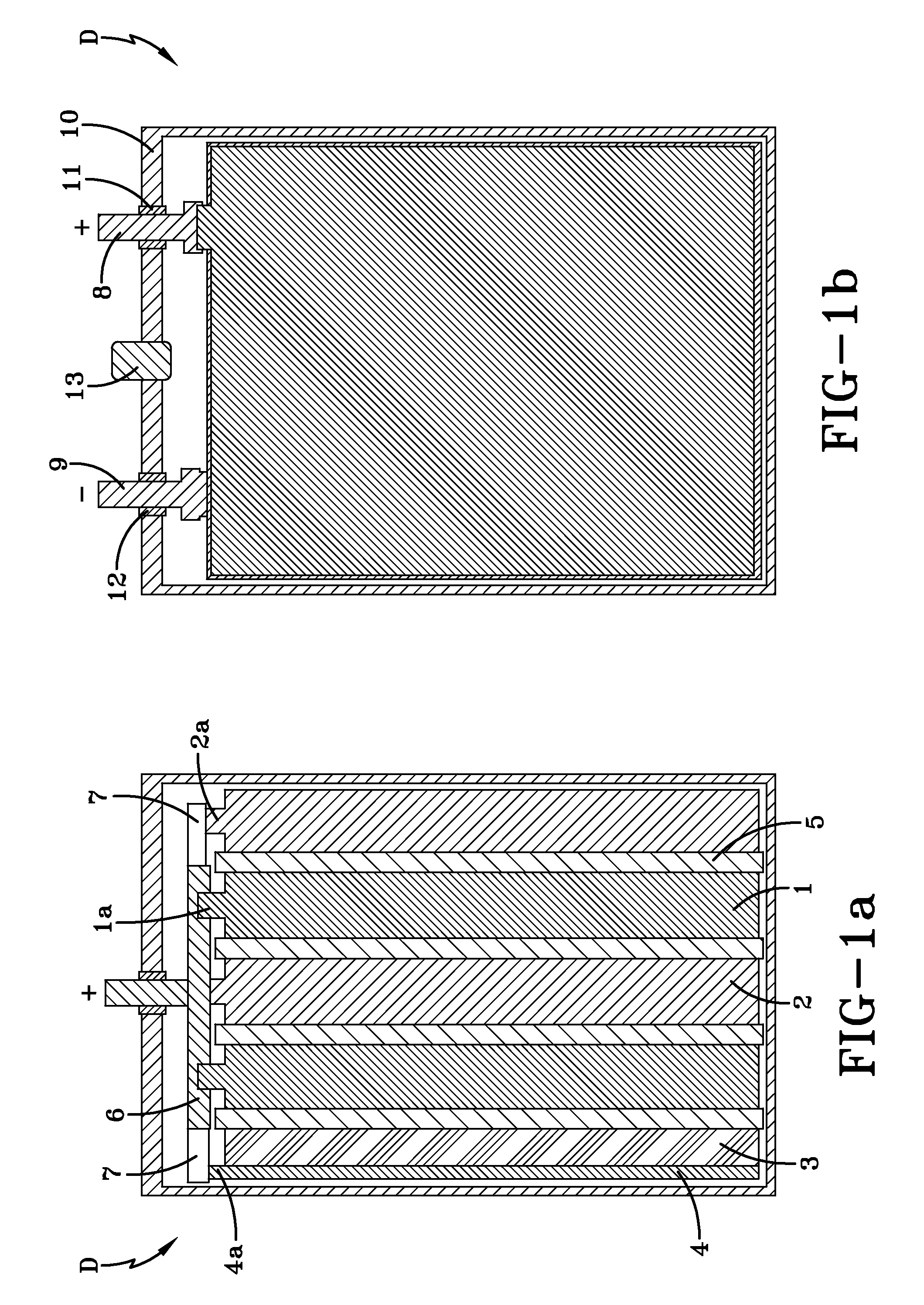

Fibril composite electrode for electrochemical capacitors

InactiveUS20020008956A1Improve electrochemical performanceReadily and highly dispersible in polar solventsNon-fibrous pulp additionNanotechComposite electrodeCarbon nanofiber

Composite electrodes comprising carbon nanofibers (fibrils) and an electrochemically active material are provided for use in electrochemical capacitors. The fibril composite electrodes exhibit high conductivity, improved efficiency of active materials, high stability, easy processing, and increase the performance of the capacitor. A method for producing the composite electrodes for use in electrochemical capacitors is also provided.

Owner:HYPERION CATALYSIS INT

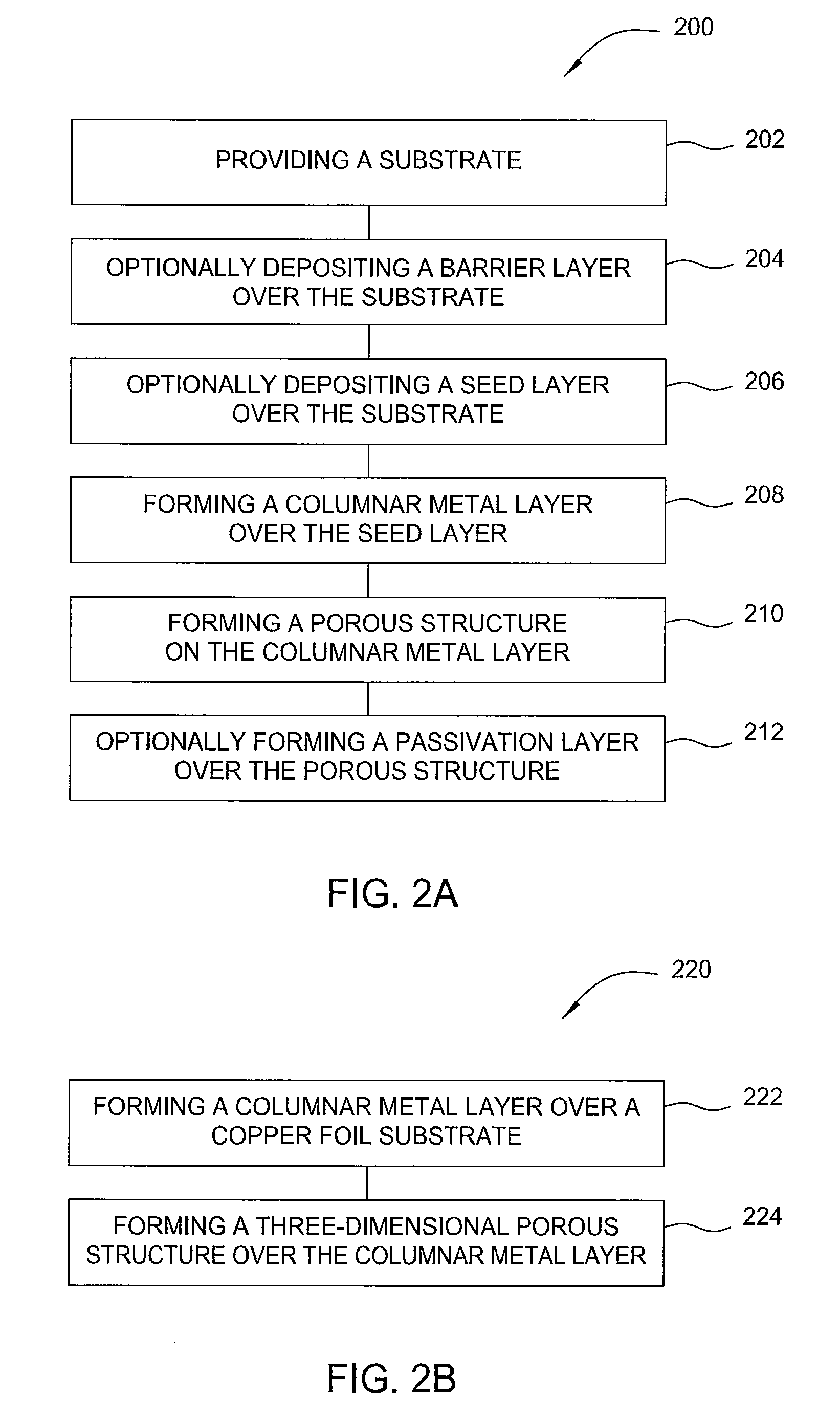

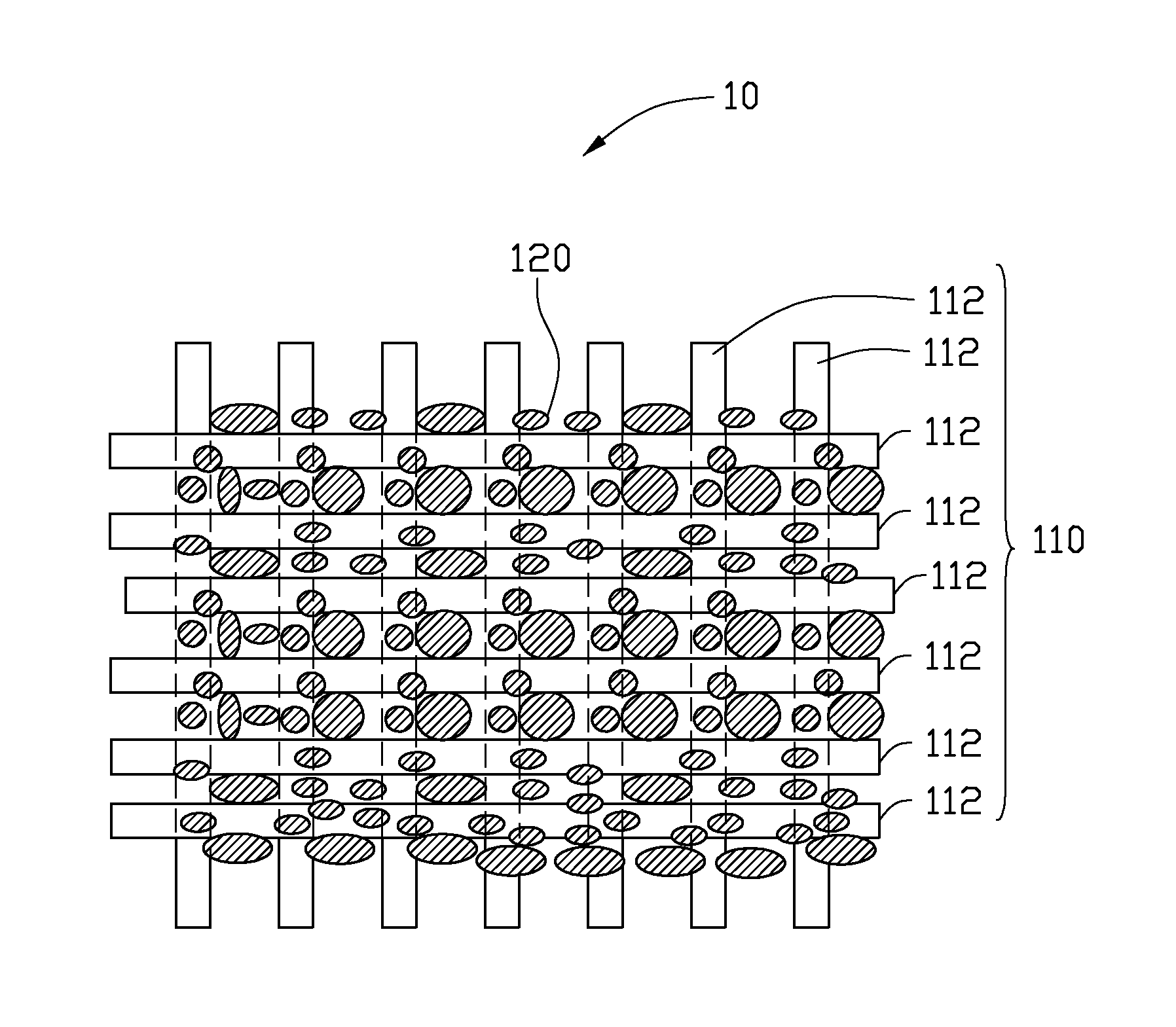

Porous three dimensional copper, tin, copper-tin, copper-tin-cobalt, and copper-tin-cobalt-titanium electrodes for batteries and ultra capacitors

InactiveUS20100193365A1Electrochemical processing of electrodesElectrolysis componentsTitanium electrodePorous electrode

A method and apparatus for forming a reliable and cost efficient battery or electrochemical capacitor electrode structure that has an improved lifetime, lower production costs, and improved process performance are provided. In one embodiment a method for forming a three dimensional porous electrode for a battery or an electrochemical cell is provided. The method comprises depositing a columnar metal layer over a substrate at a first current density by a diffusion limited deposition process and depositing three dimensional metal porous dendritic structures over the columnar metal layer at a second current density greater than the first current density.

Owner:APPLIED MATERIALS INC

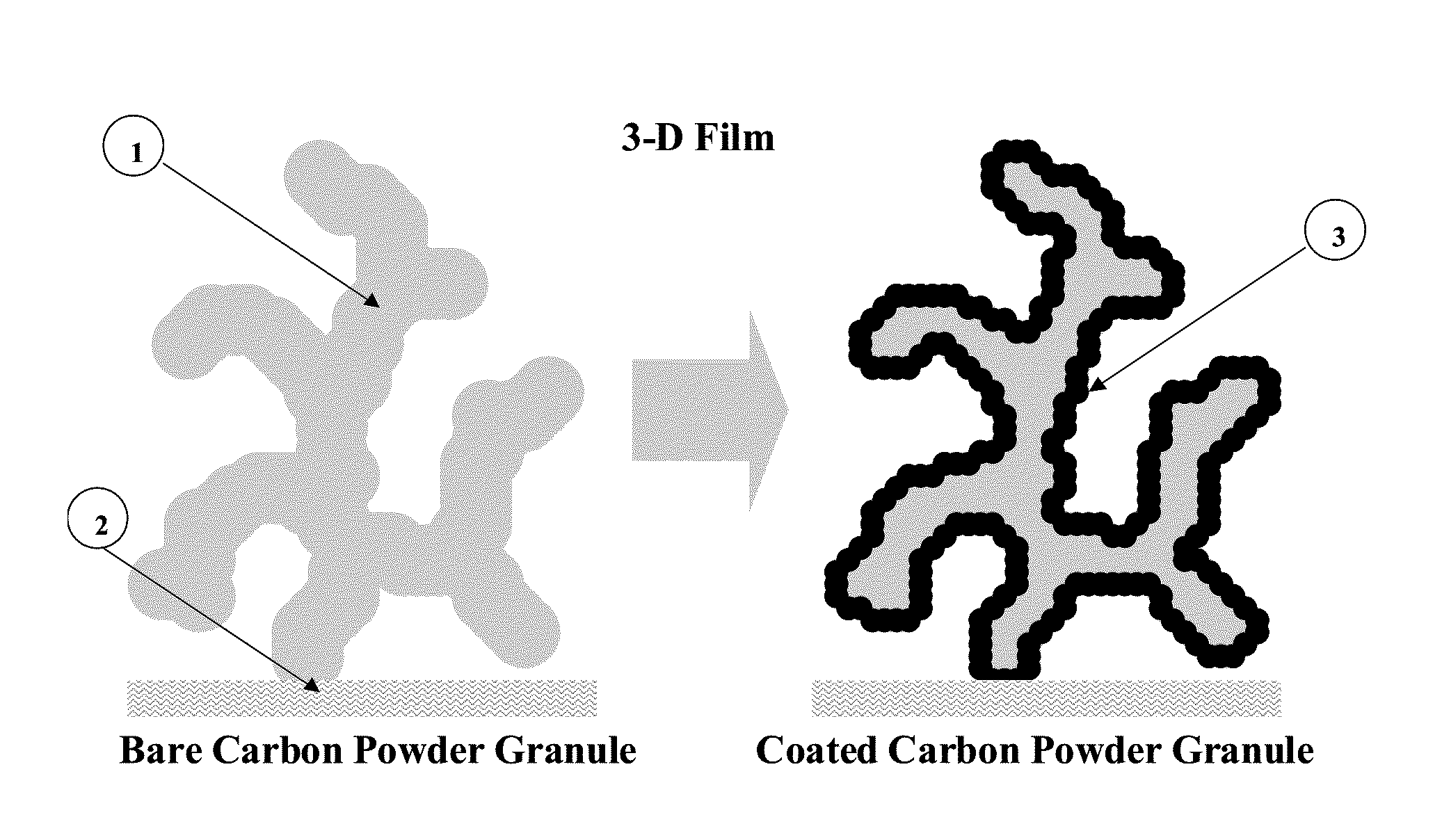

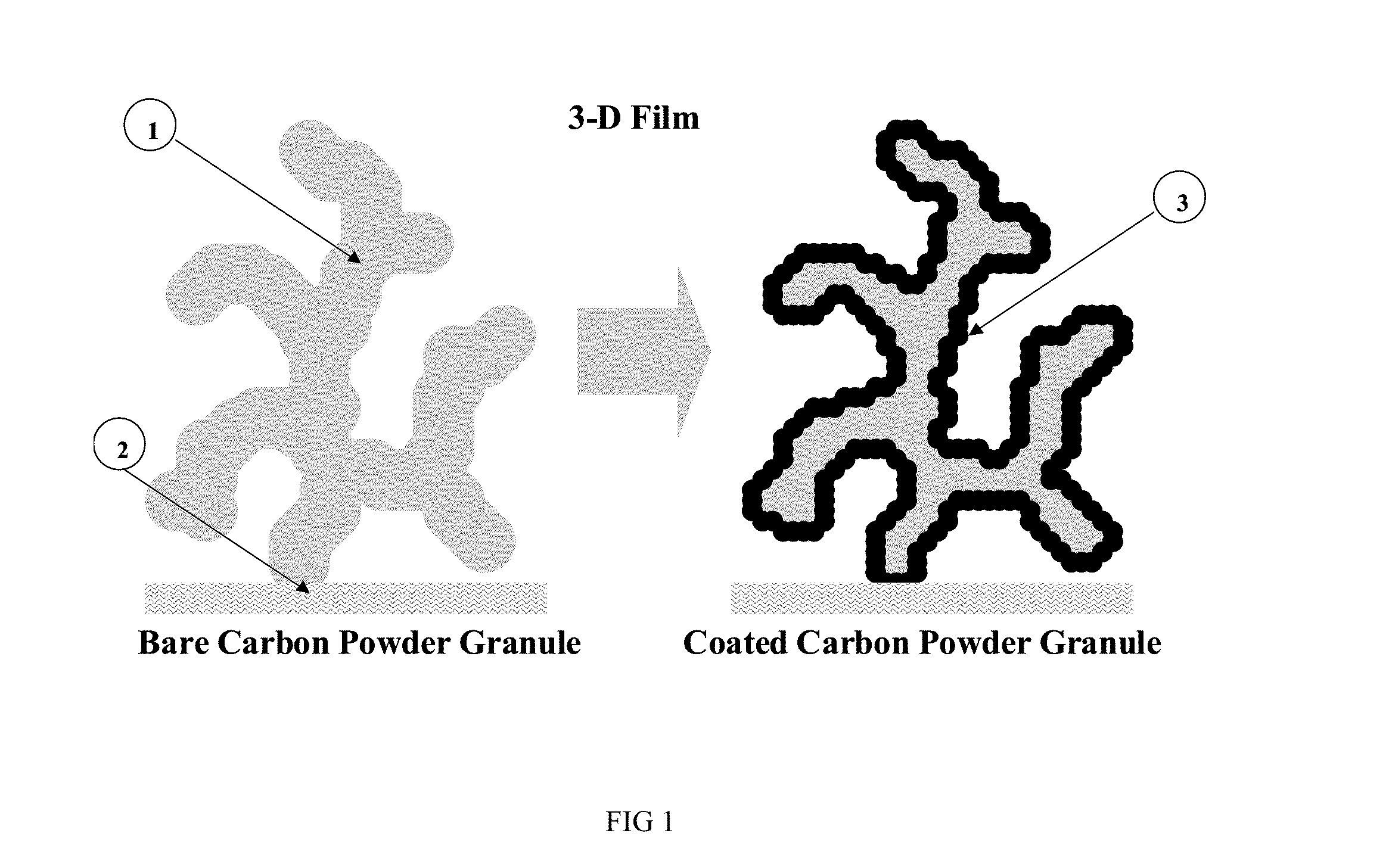

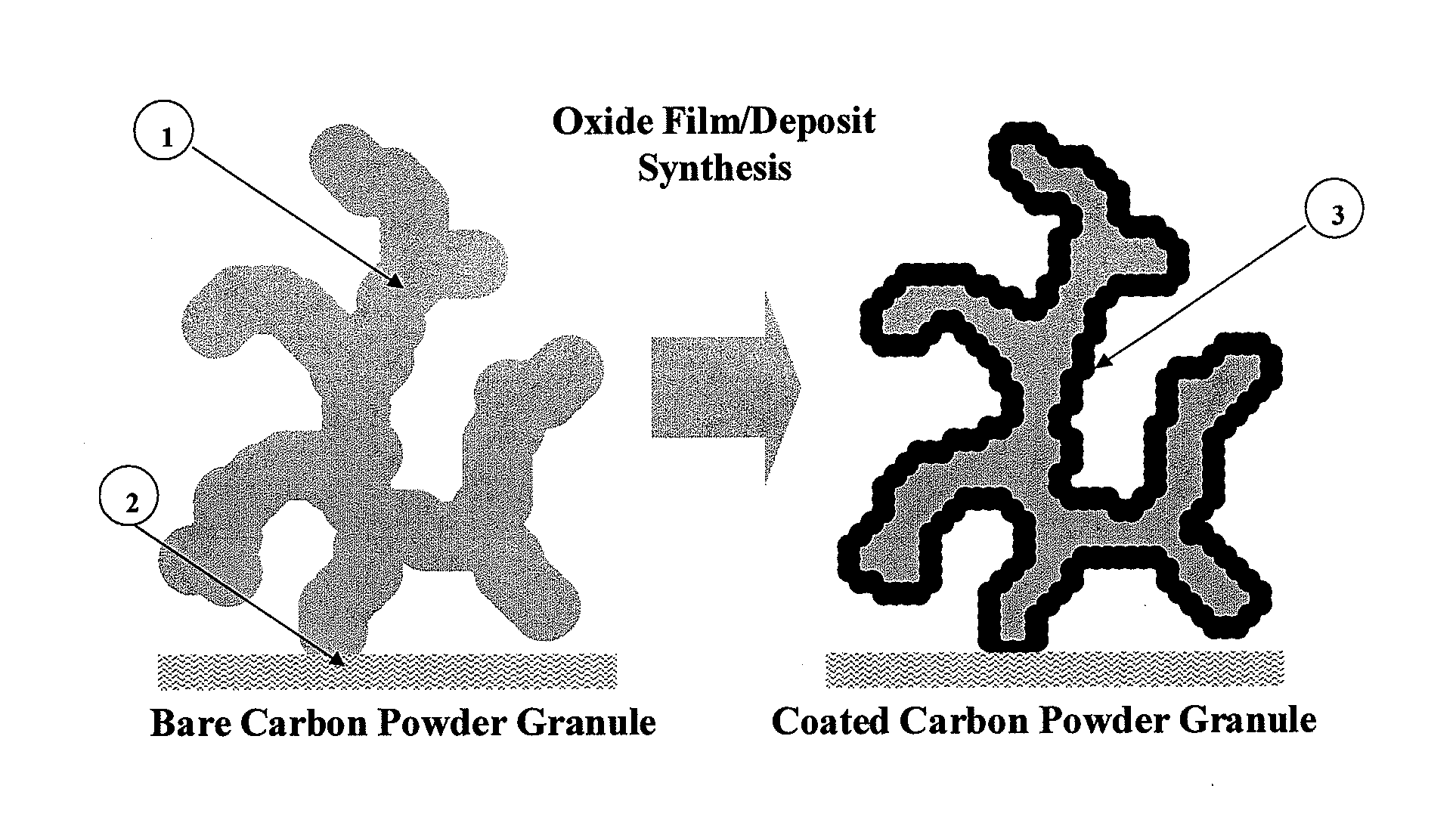

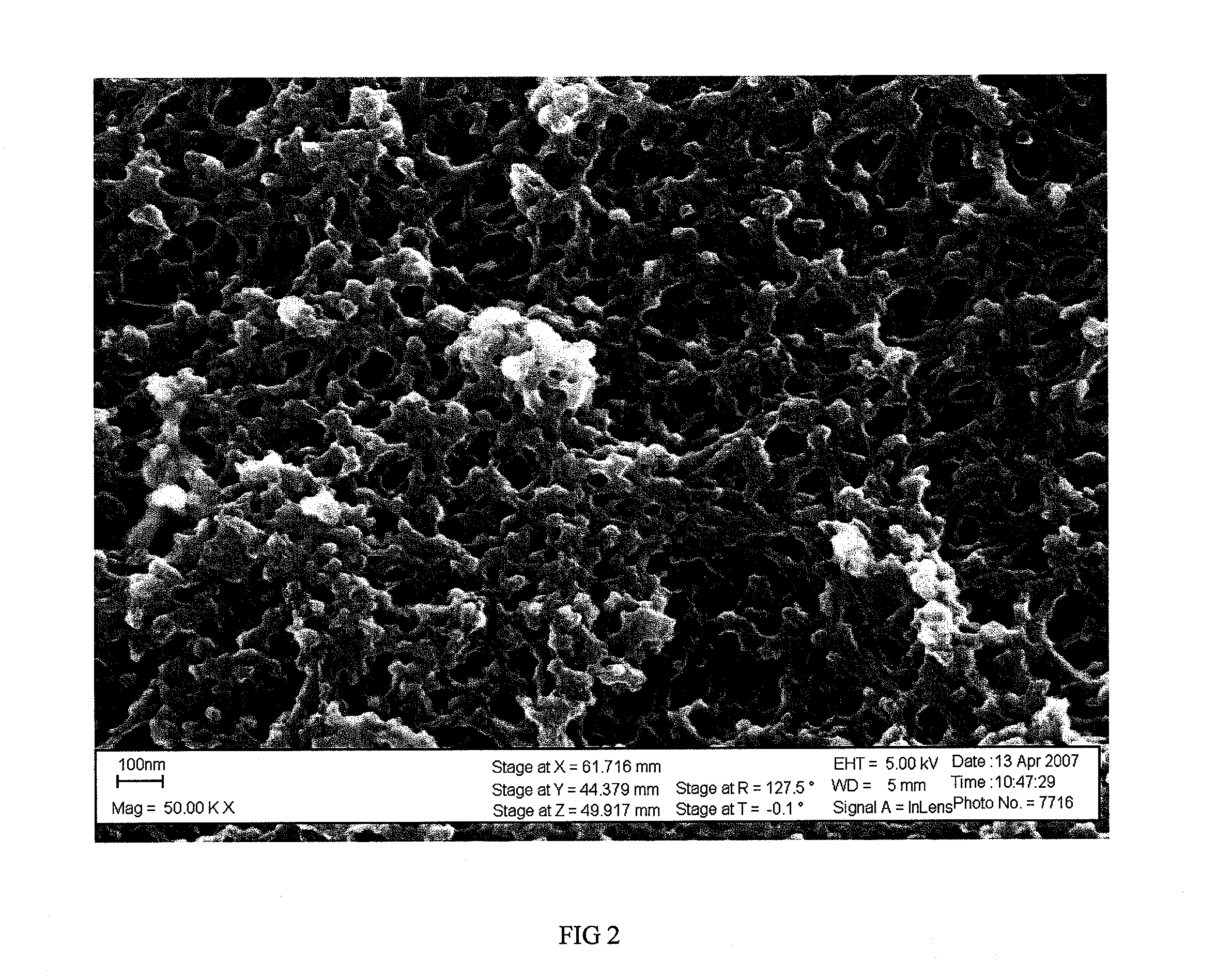

Nanoscale intercalation materials on carbon powder, process for production, and use thereof

InactiveUS20110281176A1Shorten charging timeIncreased usable storage capacityMaterial nanotechnologyElectric discharge heatingMethods of productionOxide coating

An electrode material is created by forming a thin coating or small deposits of metal oxide as an intercalation host on a carbon powder. The carbon powder performs a role in the synthesis of the oxide coating, in providing a three-dimensional, electronically conductive substrate supporting the metal oxide, and as an energy storage contribution material through ion adsorption or intercalation. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

Graphitic nanofibers in electrochemical capacitors

InactiveUS20030030963A1Improve performanceMaterial nanotechnologyFixed capacitor electrodesFiberFibril

Owner:HYPERION CATALYSIS INT

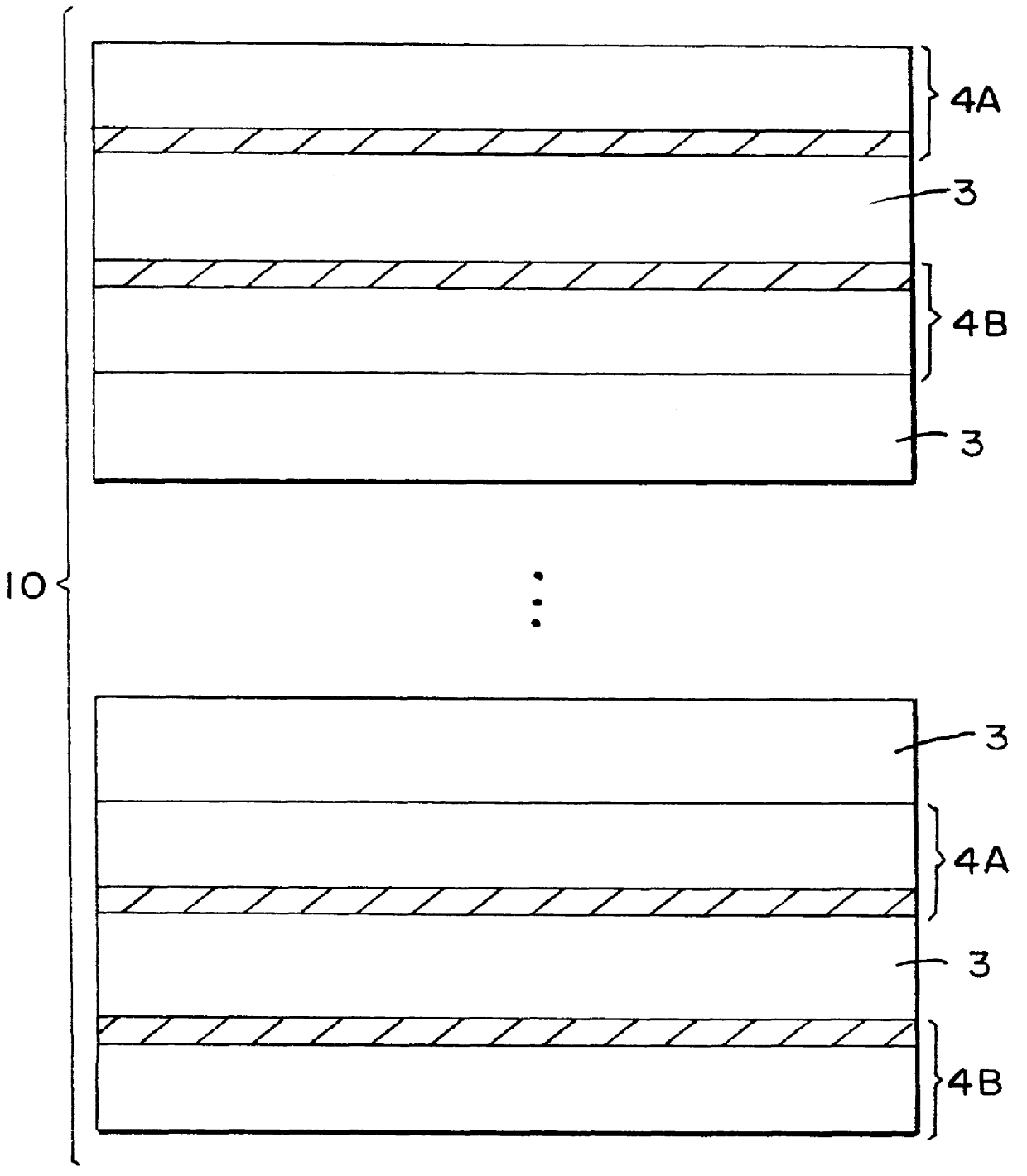

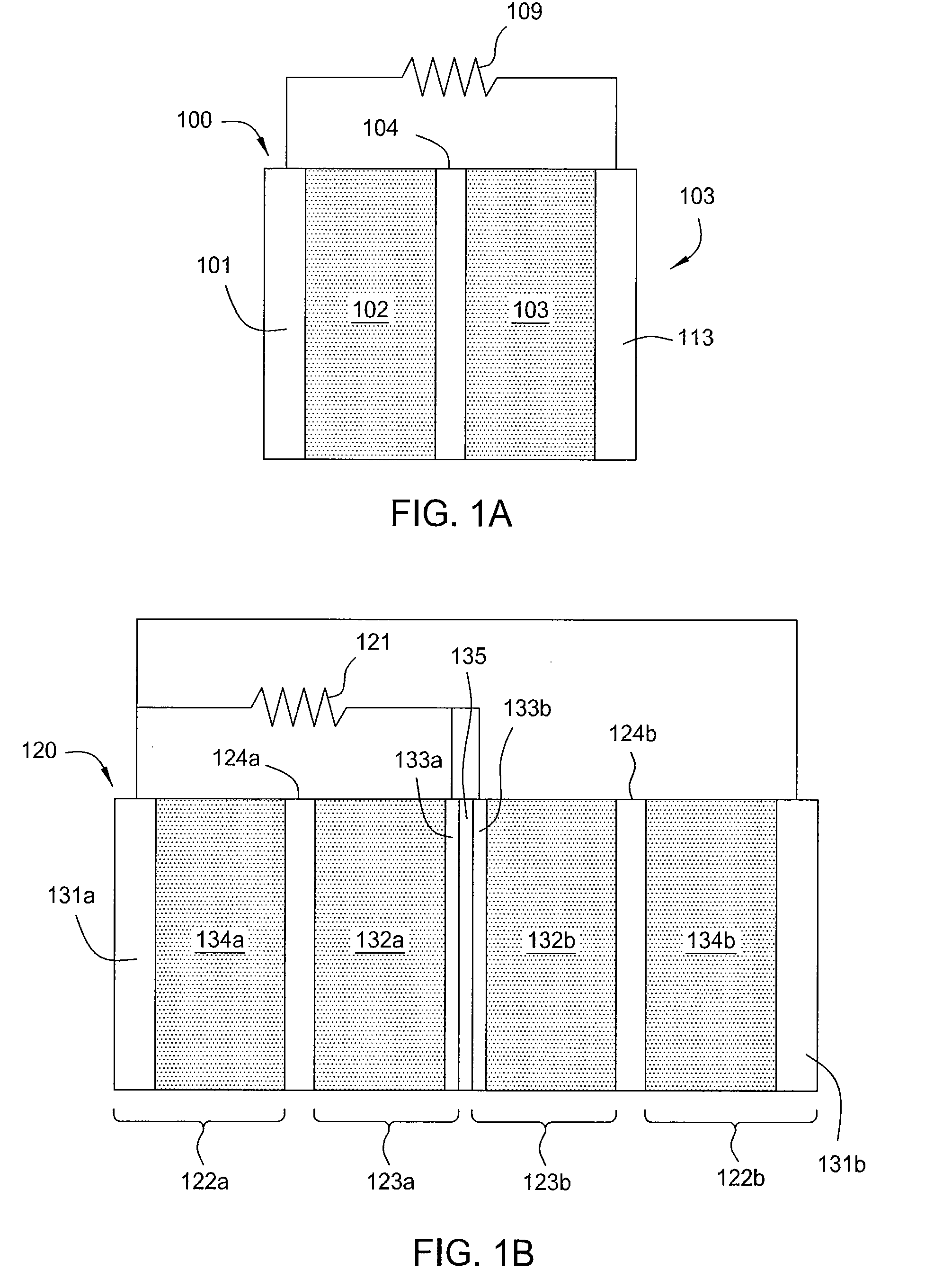

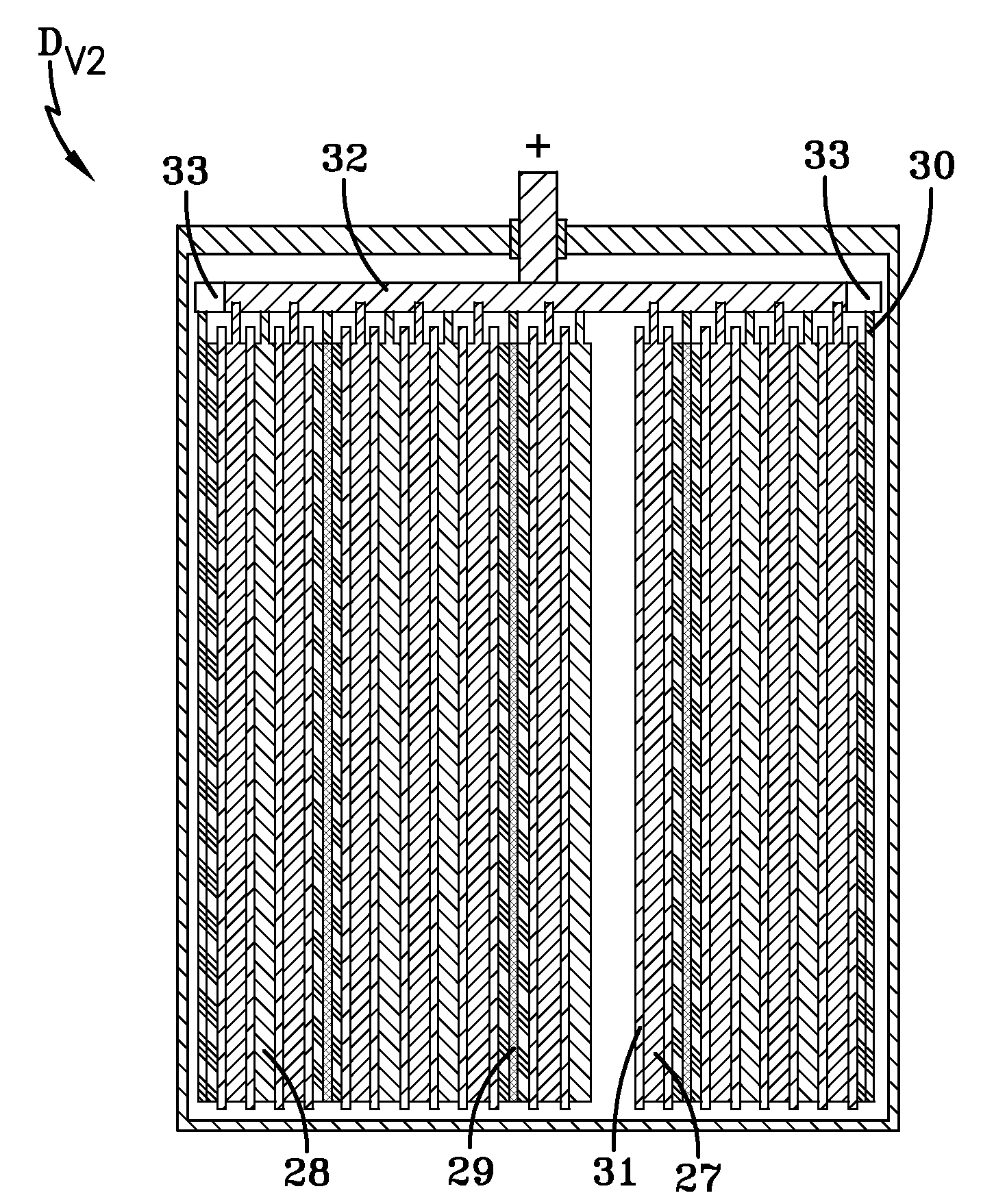

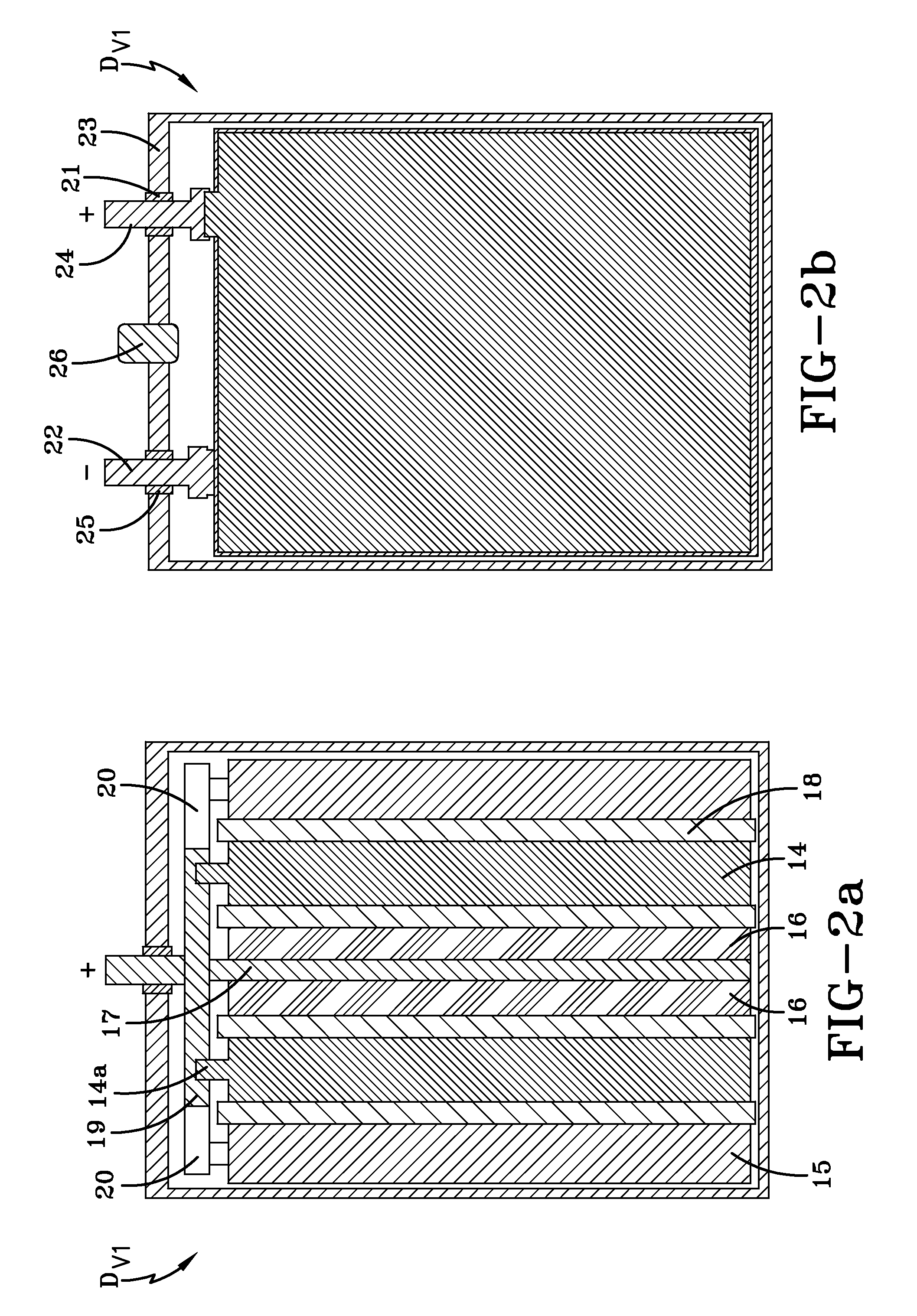

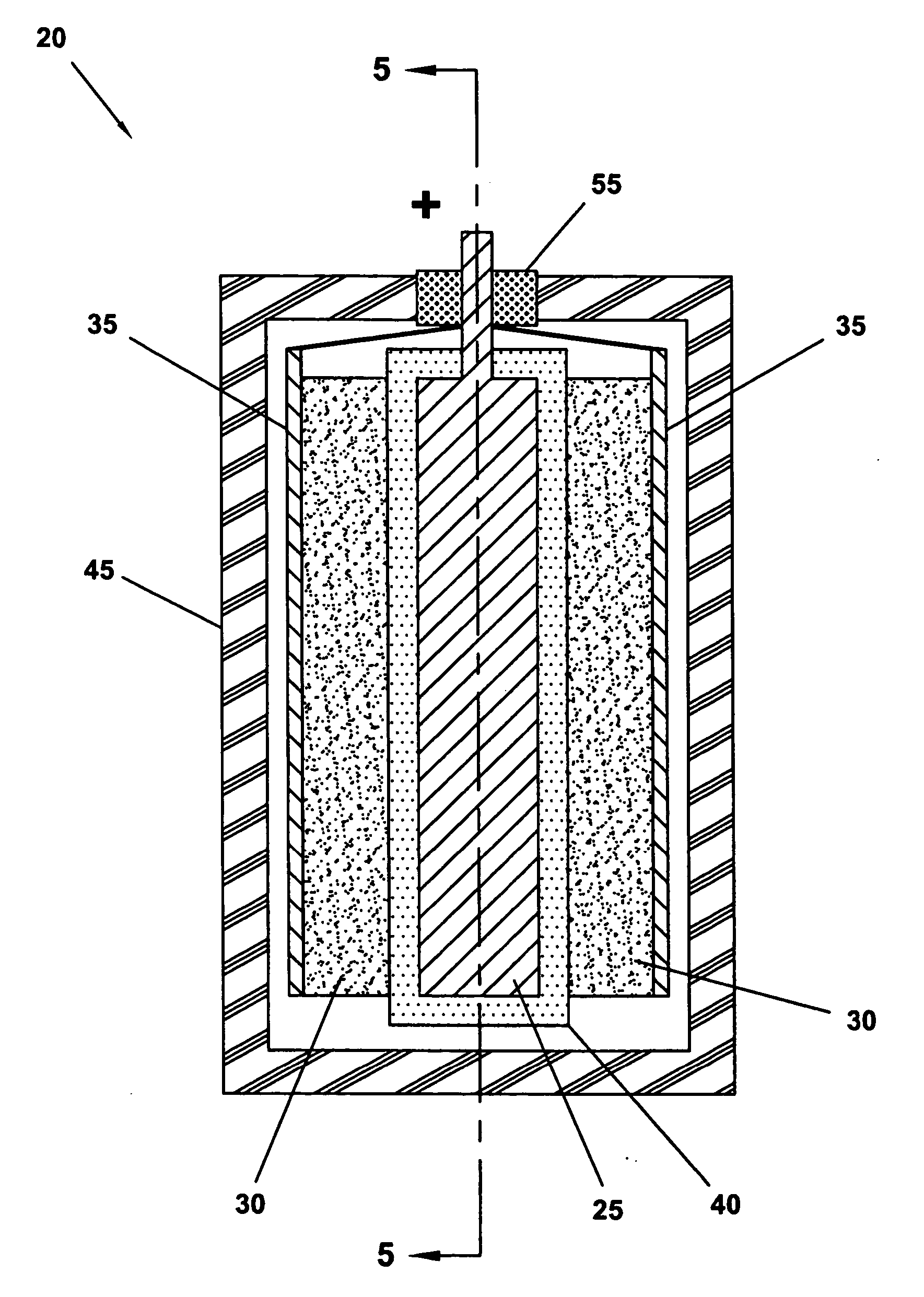

Electrochemical supercapacitor/lead-acid battery hybrid electrical energy storage device

InactiveUS20080199737A1Low costHybrid capacitor electrolytesCapacitor and primary/secondary cellsEngineeringElectrochemistry

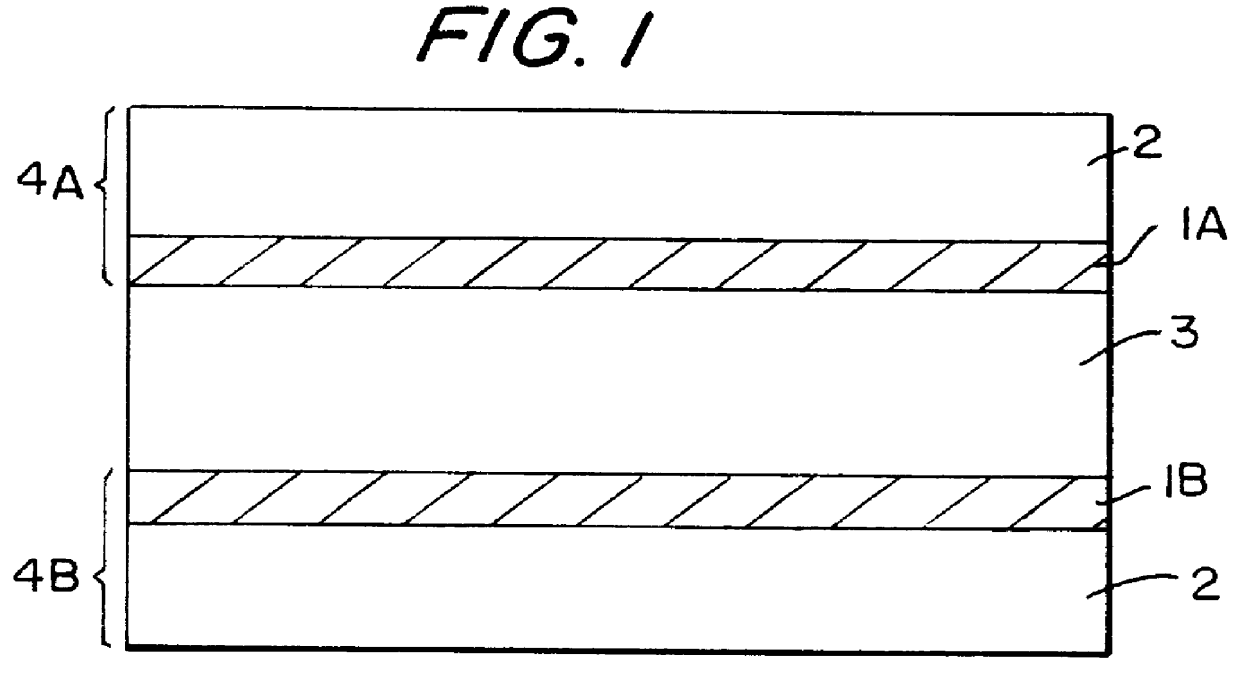

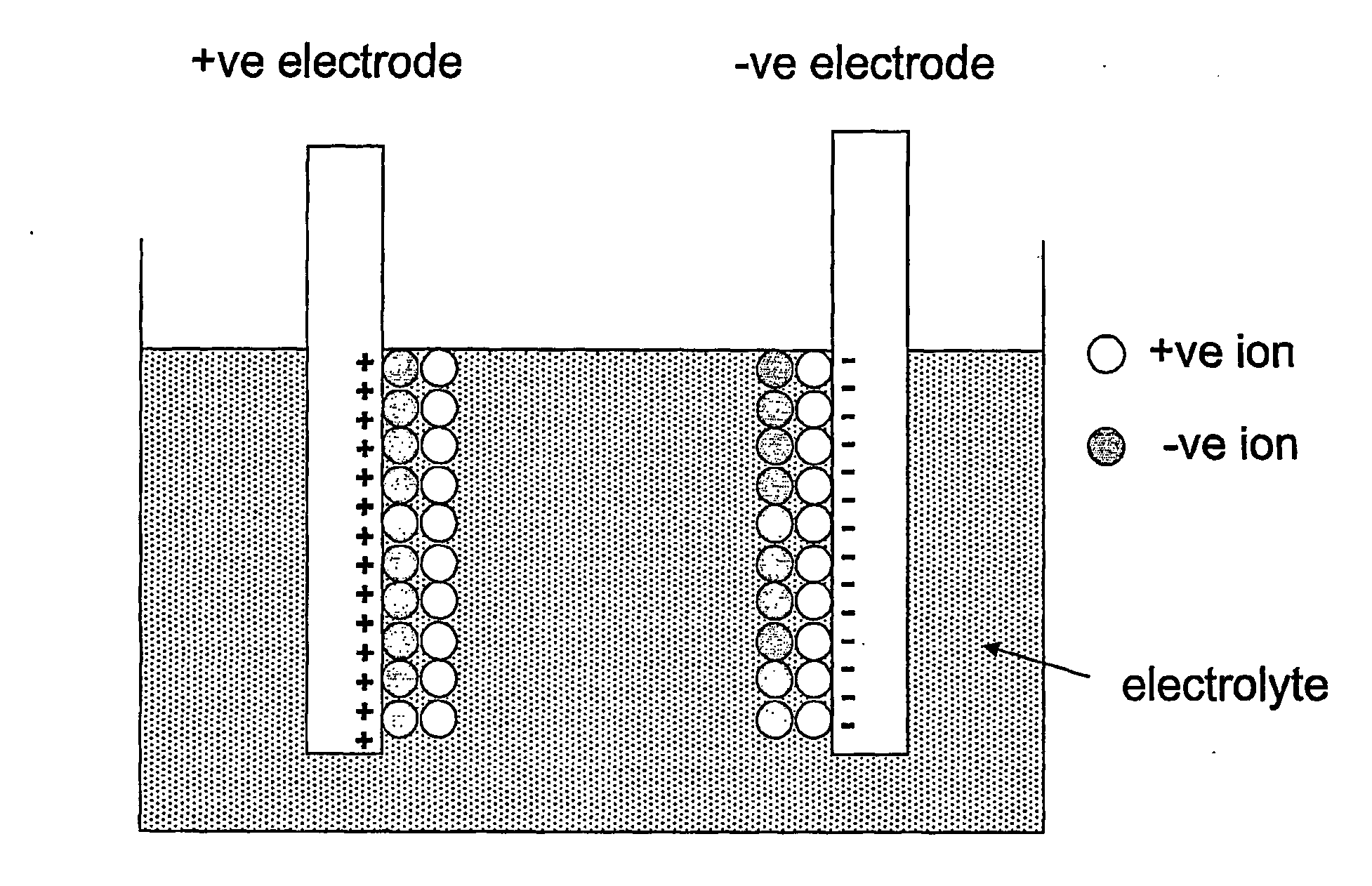

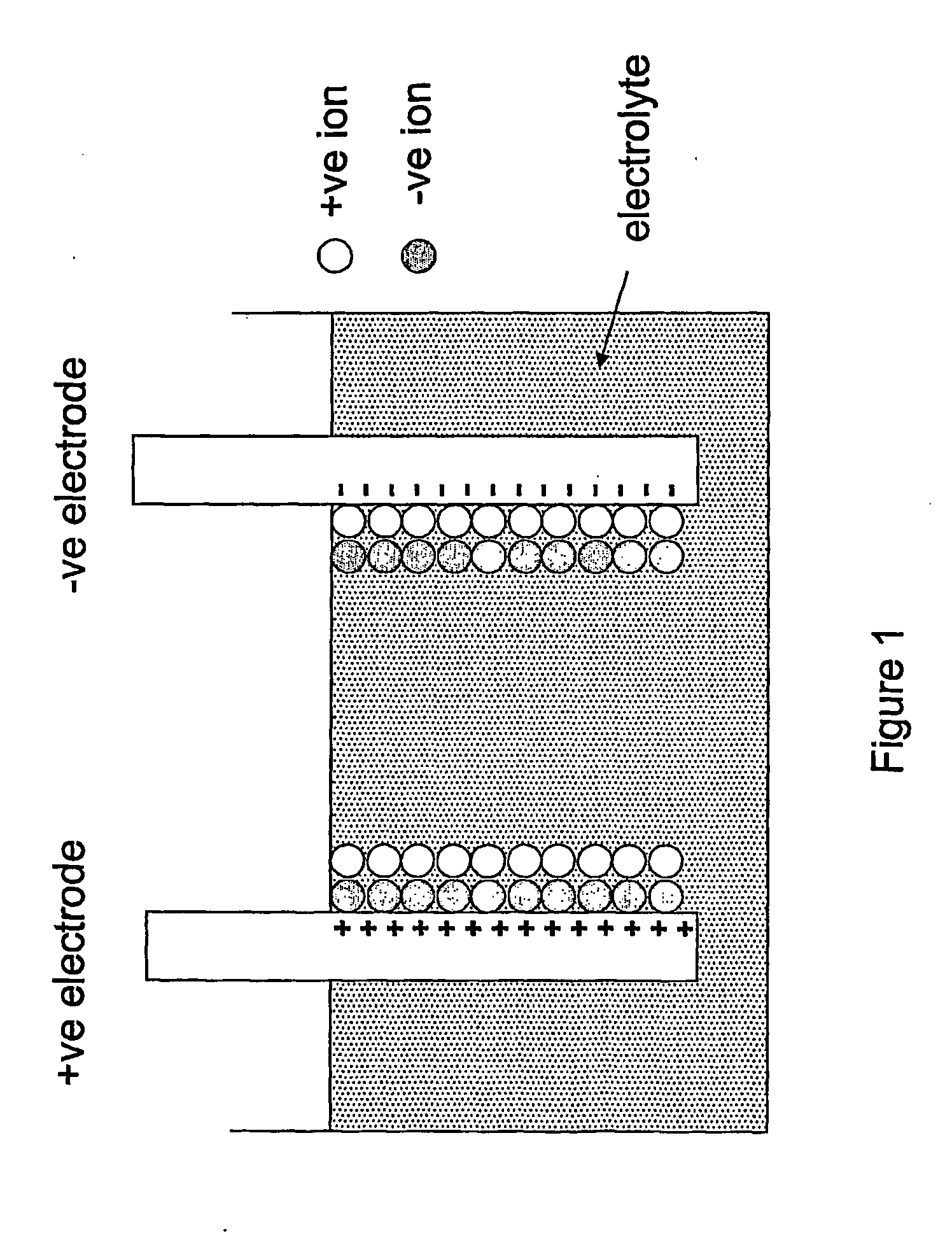

A hybrid lead-acid battery / electrochemical capacitor electrical energy storage device. The lead-acid battery and electrochemical capacitor reside in the same case and are electrically connected. Preferably, a hybrid device of the present invention includes at least one non-polarizable positive electrode, at least one non-polarizable negative electrode, and at least one polarizable electric double layer negative electrode. Separators reside between the electrodes and the separators and electrodes are impregnated with an aqueous sulfuric acid electrolyte. A hybrid device of the present invention exhibits high power characteristics.

Owner:UNIVERSAL SUPERCAPACITORS LLC

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20050002850A1Good electrochemical propertiesSpecificMaterial nanotechnologyElectrolytic capacitorsMultiwalled carbonChlorine dioxide

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

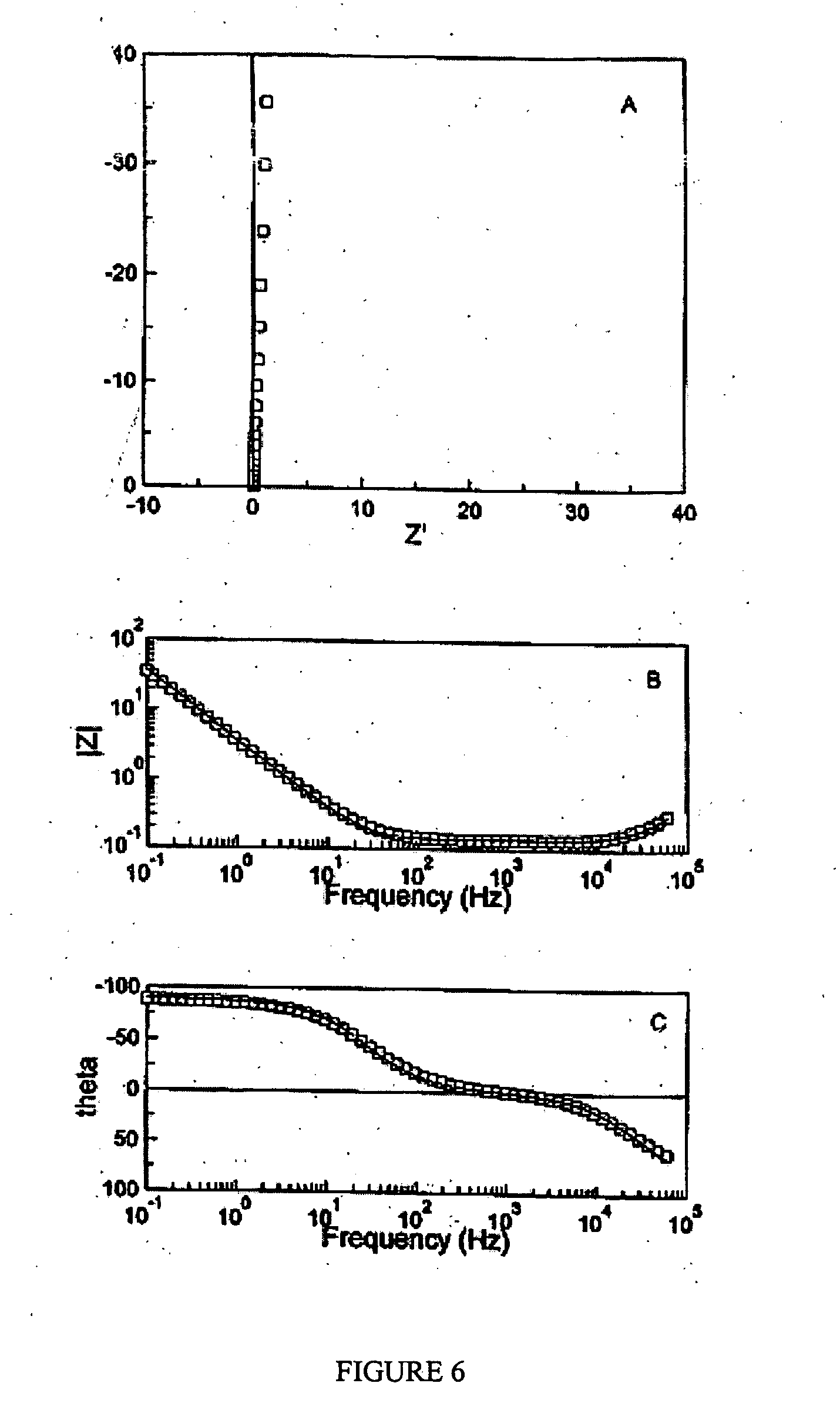

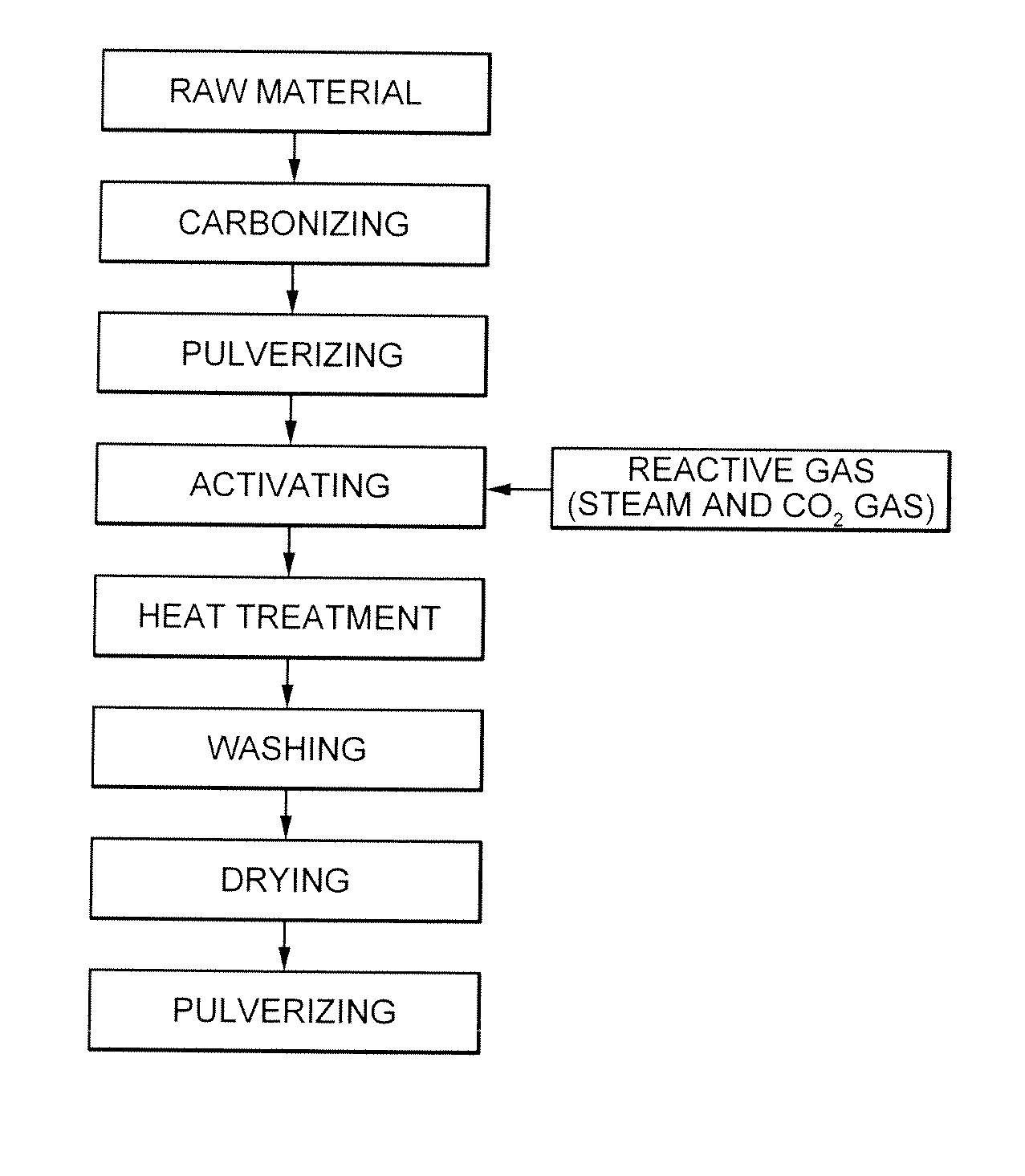

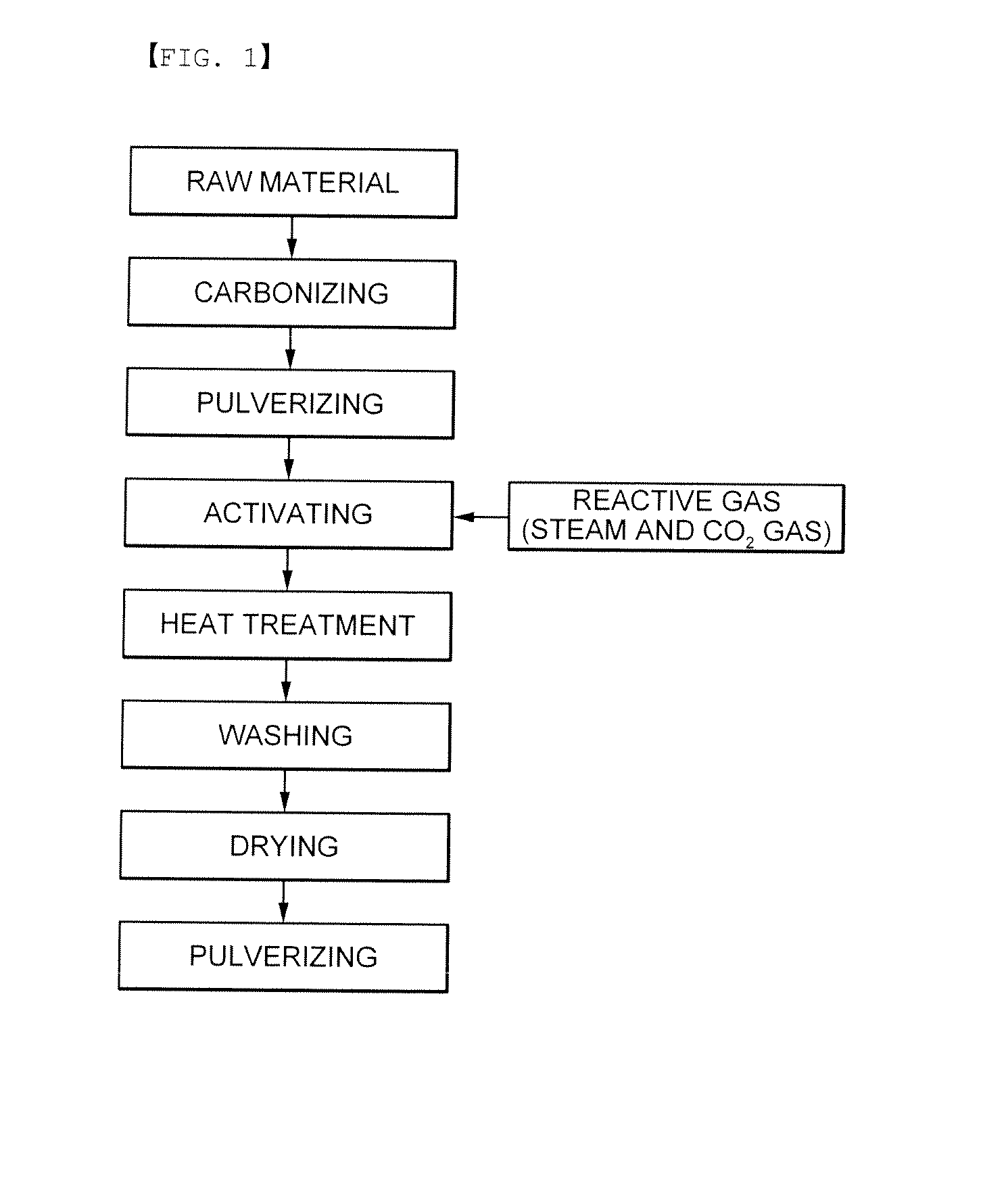

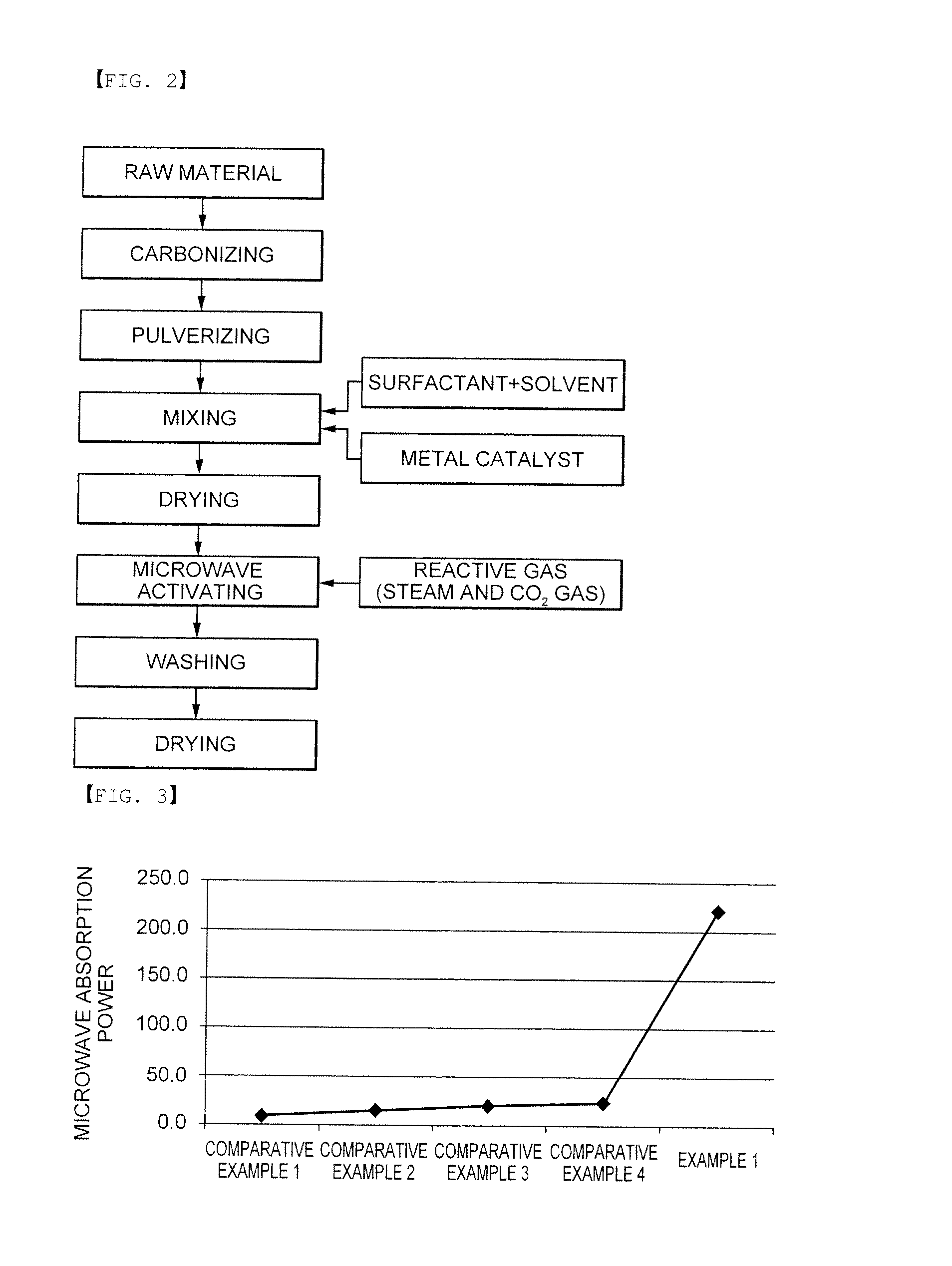

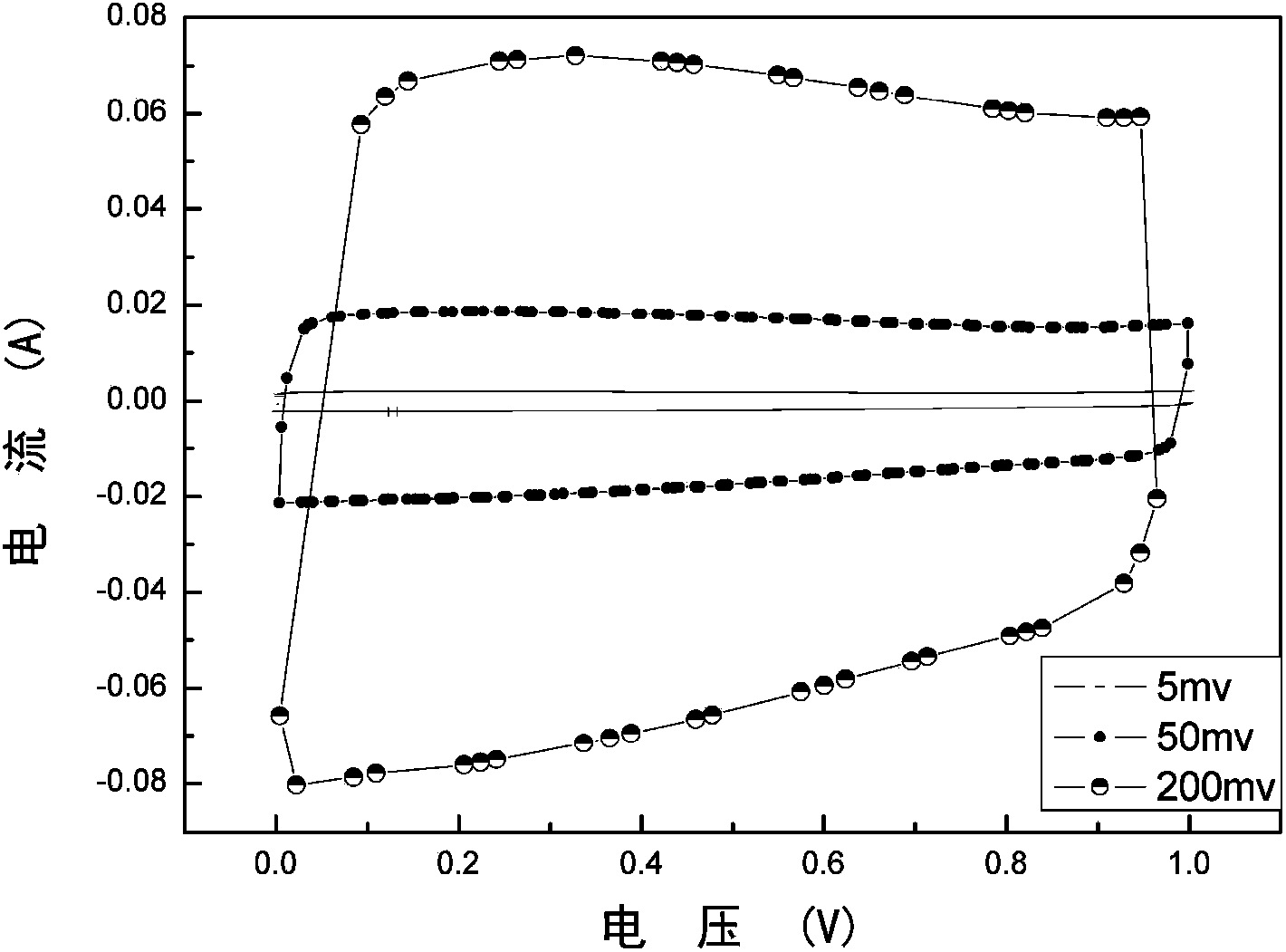

Activated carbon, method for preparing the same, and electrochemical capacitor including the same

InactiveUS20140177136A1Less surface functional groupUniform sizePigmenting treatmentCarbon compoundsActivated carbonHigh rate

Disclosed herein are an activated carbon in which pores with pore sizes of 0.3˜5 nm account for 80% or higher based on an overall pore volume, a method for preparing the activated carbon, and an electrochemical capacitor including the activated carbon, so that, since the activated carbon has uniform sized fine pores, high-rate discharge characteristics, high-rate charging and discharging characteristics, and low-temperature characteristics can be improved; since the content of functional groups on the surface of the activated carbon is low, there can be provided a supercapacitor and a lithium ion capacitor, having improved high voltage and lifespan characteristics; and the time for preparing an active material can be significantly shortened and thus the material cost and the process cost can be remarkably reduced.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

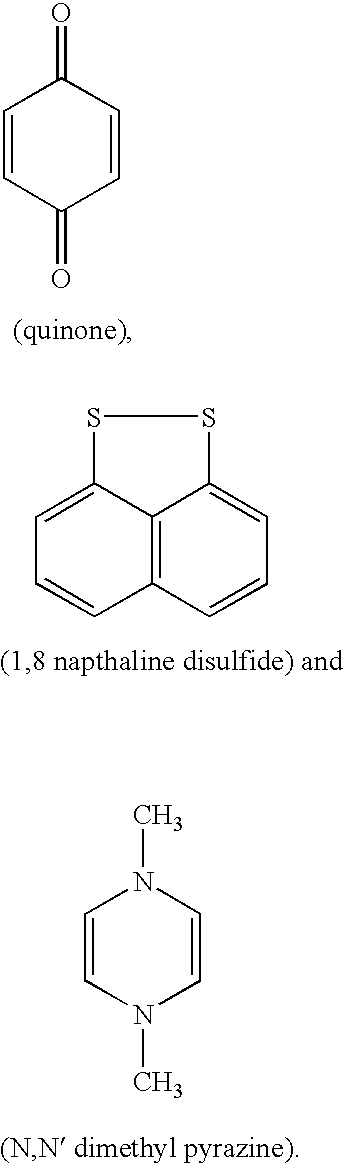

Electrochemical capacitors having electrodes with diverse redox potentials

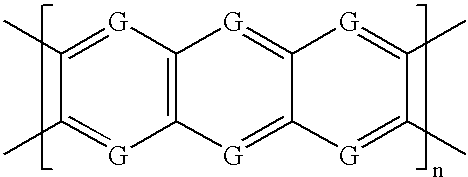

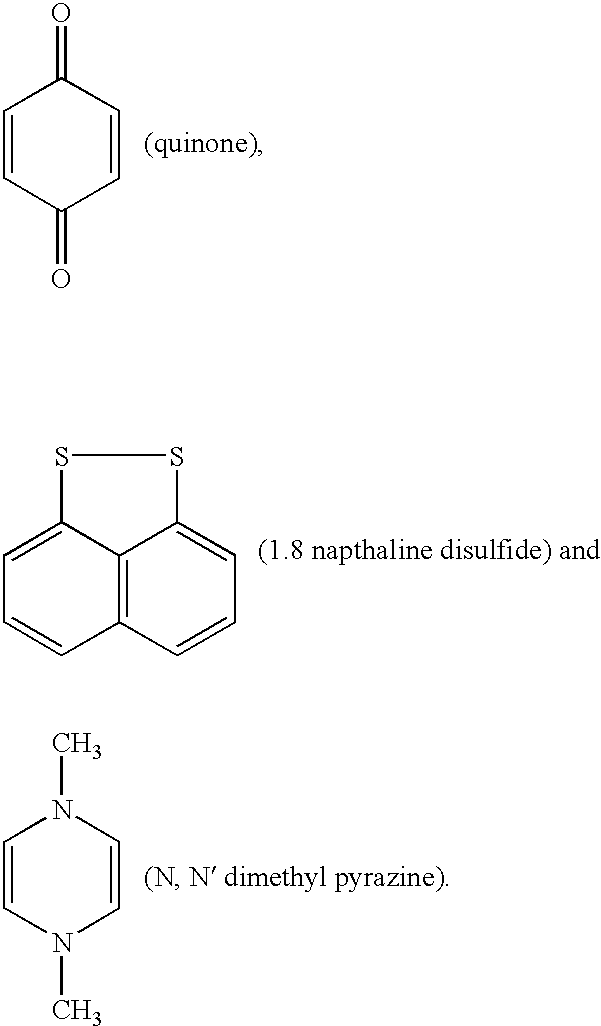

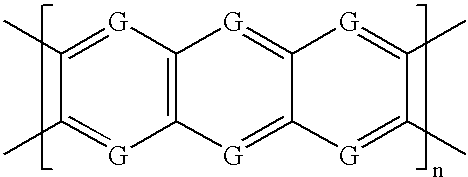

InactiveUS6414836B1Improve performanceMaterial nanotechnologyLiquid electrolytic capacitorsFiberFibril

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

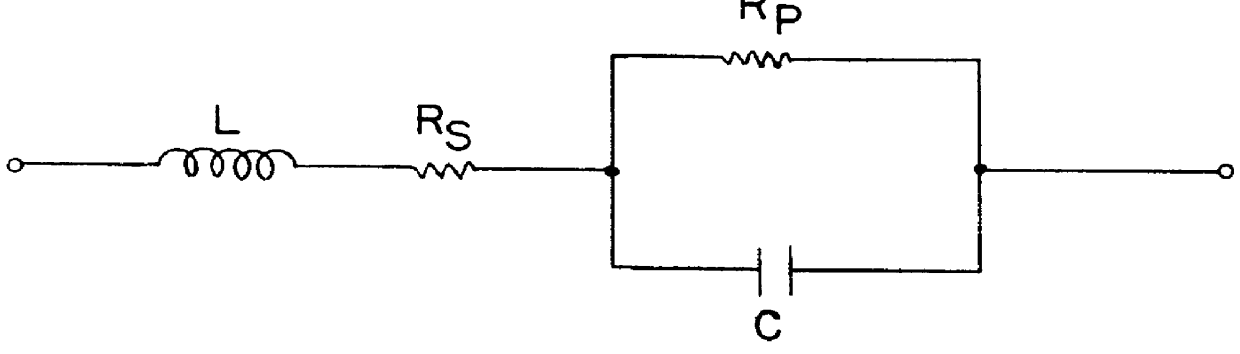

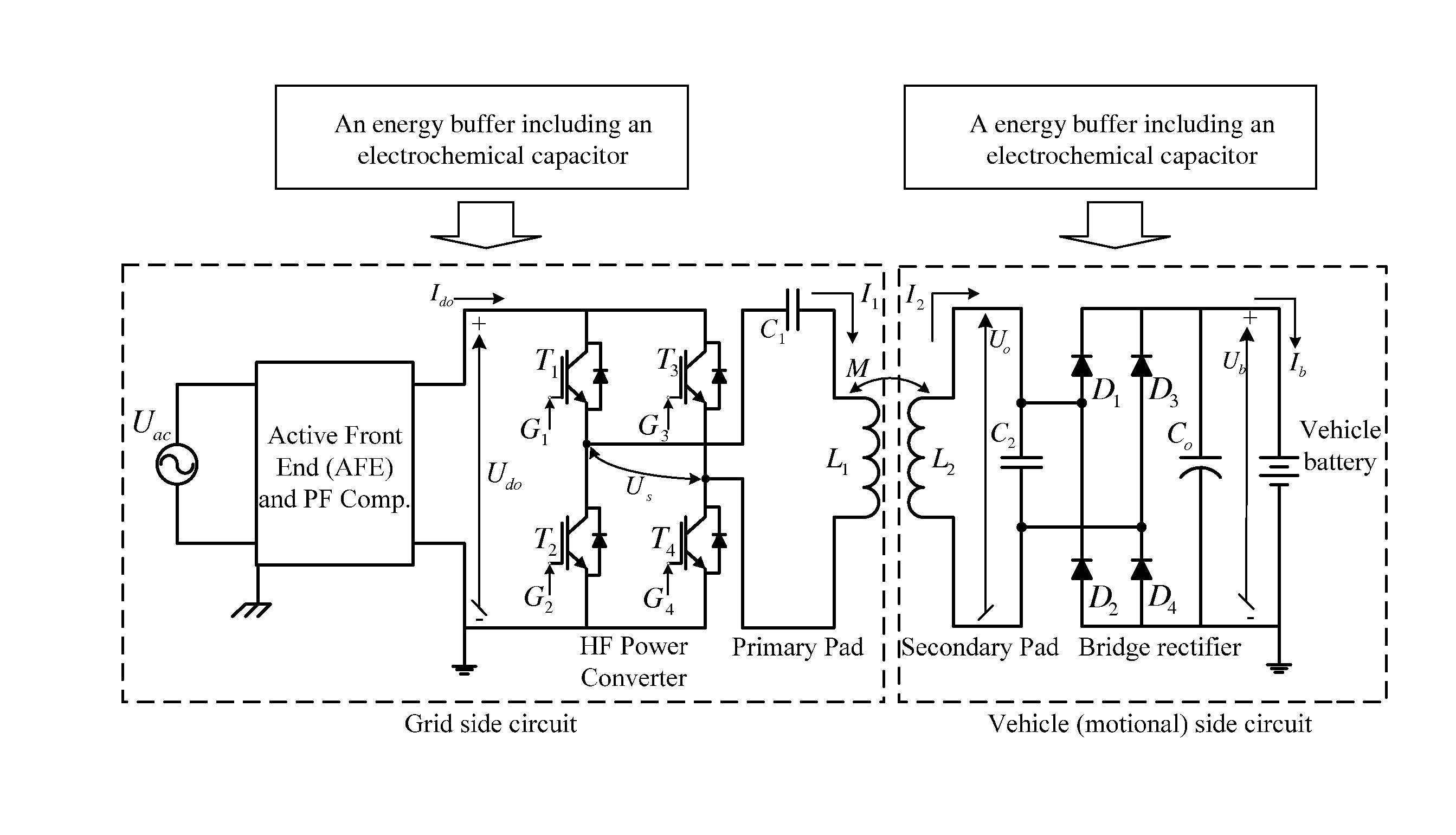

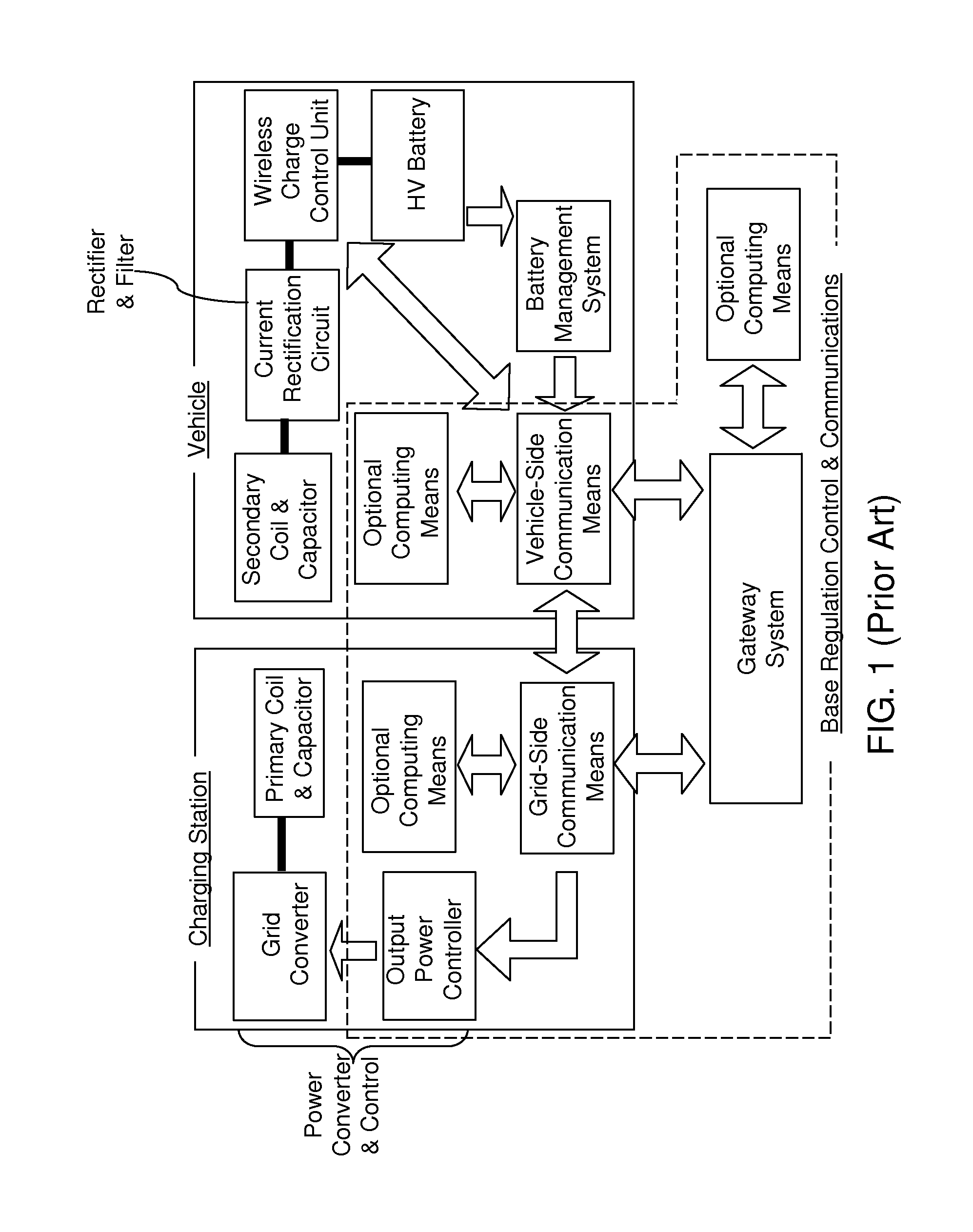

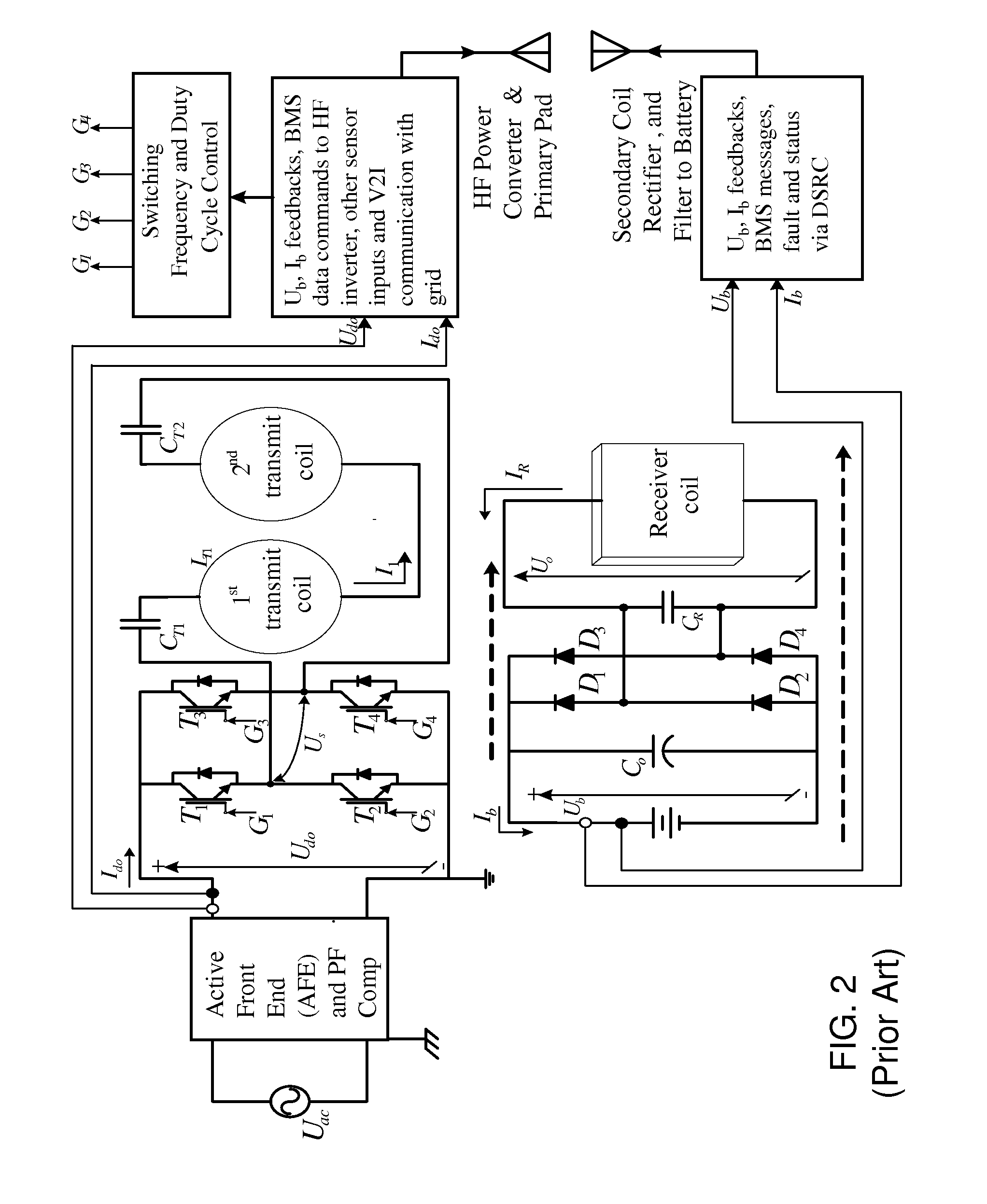

Buffering energy storage systems for reduced grid and vehicle battery stress for in-motion wireless power transfer systems

InactiveUS20160001662A1Reduce peak currentProlong lifeBatteries circuit arrangementsCharging stationsElectric power transmissionElectrical battery

An energy buffer including an electrochemical capacitor can be added to the primary circuit and / or to the secondary circuit of in-motion wireless power transfer system. The energy buffer(s) can smoothen the power delivered by the power grid and captured by a vehicle passing over an array of transmit coils through in-motion wireless power transfer. The reduction in the transient power transfer can reduce the peak current that flows through various components of the in-motion wireless power transfer system including a vehicle battery on the vehicle, and prolong the life of the in-motion wireless power transfer system.

Owner:UT BATTELLE LLC

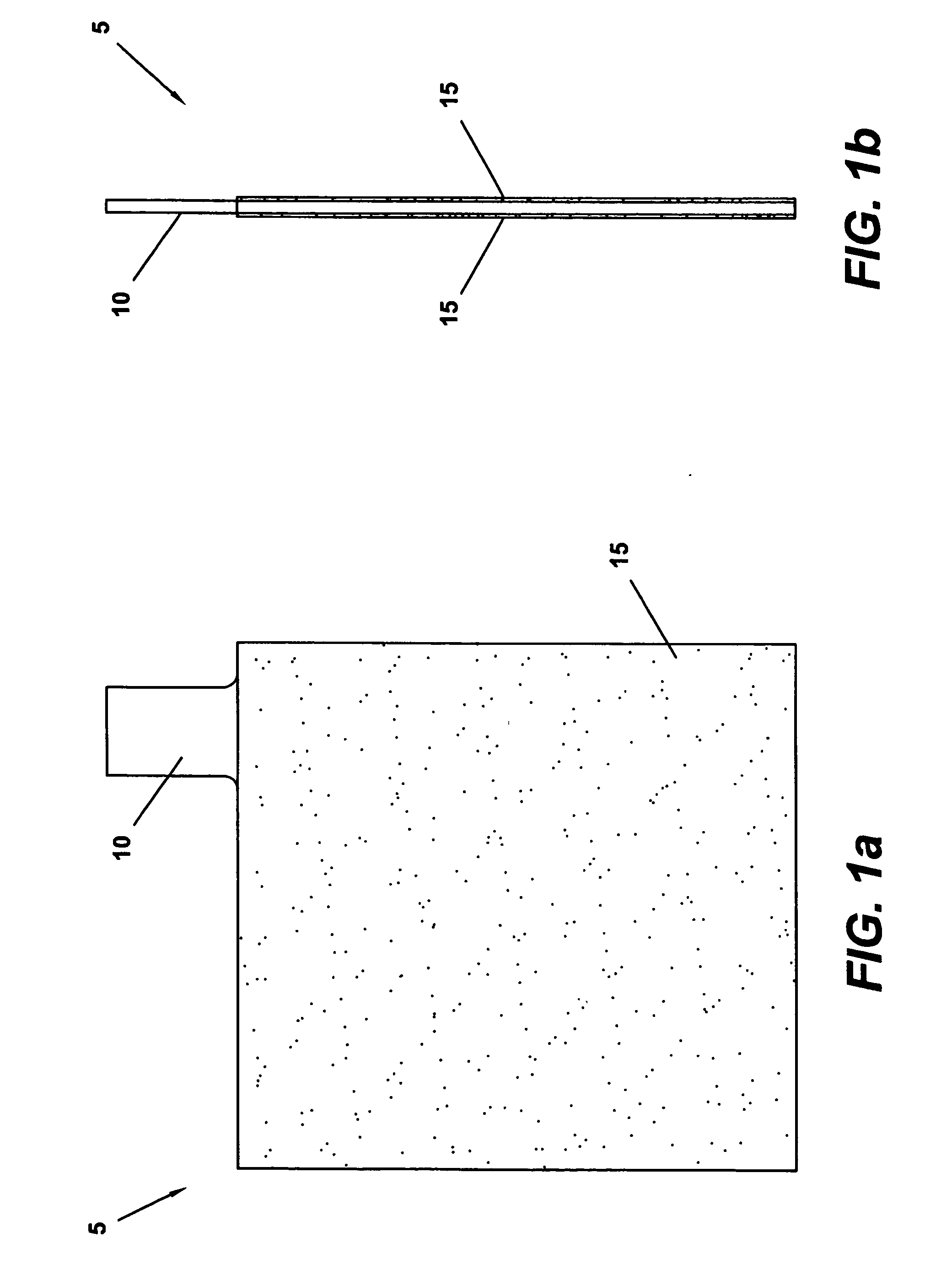

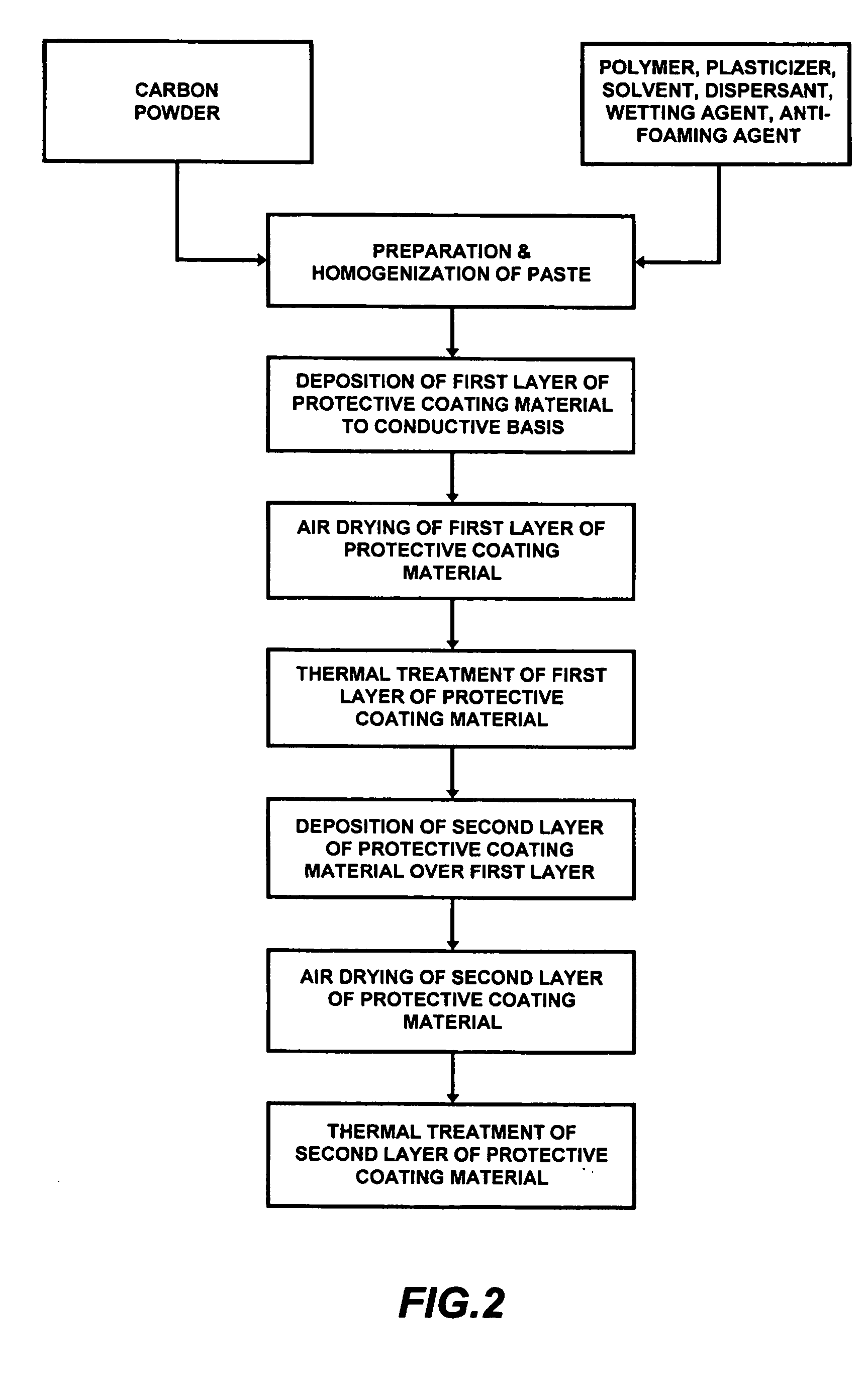

Current collector for double electric layer electrochemical capacitors and method of manufacture thereof

InactiveUS20060292384A1High of oxygen gassingReadily availableHybrid capacitor electrolytesHybrid capacitor electrodesAlloySolvent

A current collector for use in a capacitor having an aqueous or non-aqueous electrolyte, such as an aqueous sulfuric acid electrolyte. The conductive basis of the current collector may be manufactured from a number of conductive metals but, preferably, is comprised of lead or a lead alloy. The portion of the conductive basis that will be in contact with the electrolyte is provided with a protective layer that is created by deposition of one or more layers of one or more protective coating materials thereto. Each protective coating material is comprised of at least a conductive carbon powder and a polymer binder that is resistant to the electrolyte. Preferably, but not essentially, the protective coating material(s) are applied to the conductive basis in the form of a paste, which is subsequently subjected to a solvent evaporation step and a thermal treatment step. The resulting protective layer is also substantially devoid of pores through which the electrolyte can permeate.

Owner:UNIVERSAL SUPERCAPACITORS LLC

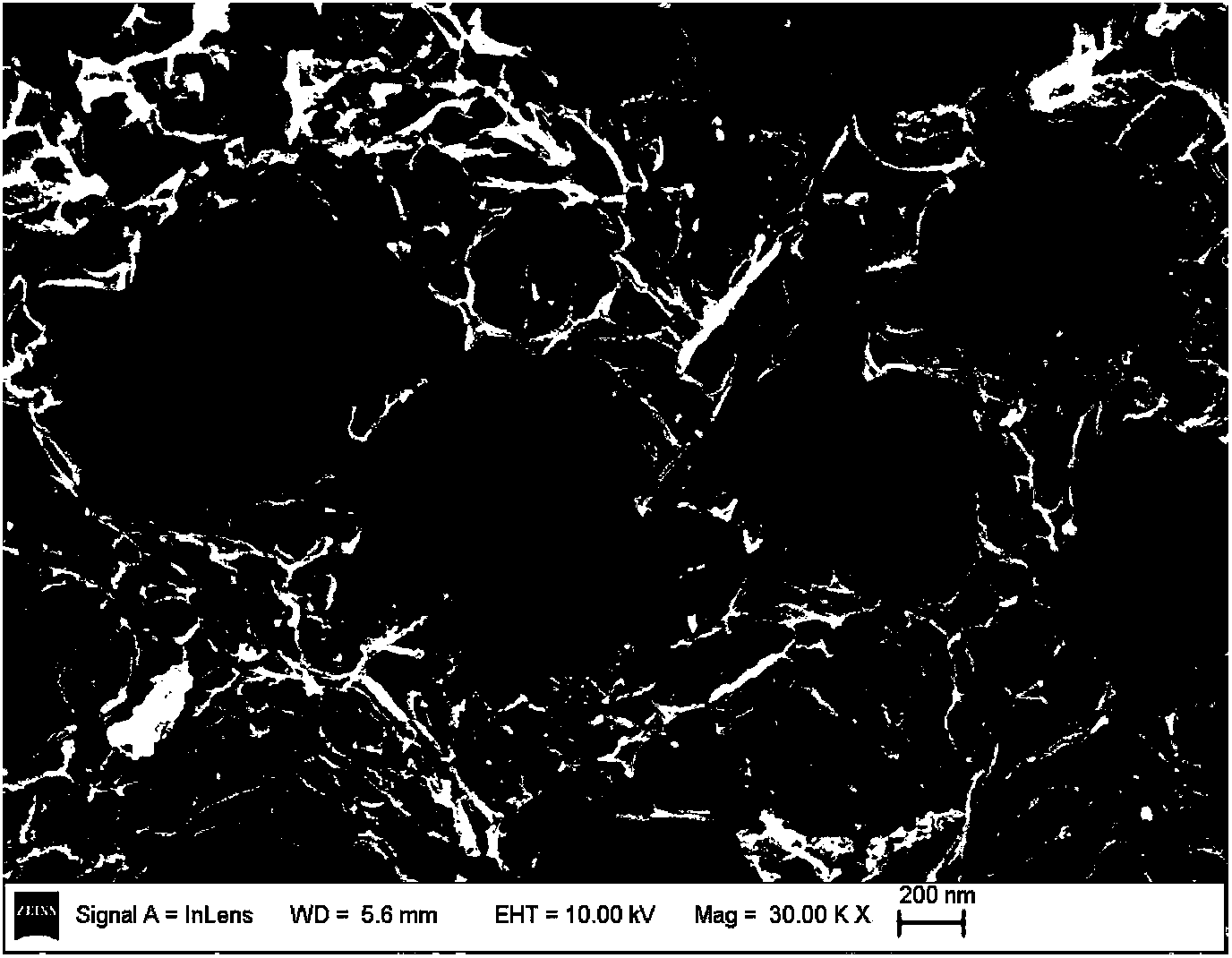

Porous carbon material and preparation method and application thereof

InactiveCN103420353AReduce manufacturing costReduce dosageElectrolytic capacitorsCell electrodesDecompositionPorous carbon

The invention relates to a porous carbon material and a preparation method and application thereof. Organic and inorganic materials in shrimp shell and crab shell are used as carbon sources and natural templates, meanwhile the pore formation effect of template structures during high temperature decomposition is utilized, and a proper activator is mixed to produce the porous carbon material. The difficulties of methods those in the prior art in a preparation process, preparation of templates is needed, carbon precursors need to be soak in the templates, and the like, are overcome; and the nitrogen-containing carbon material with multistage pore structures is prepared by using the characteristic that the carbon sources themselves contain nitrogen element. The preparation method of the porous carbon material is simple, is low in cost, is strong in process controllability, and is suitable for industrial production, the porous carbon material shows very good application effects in electrochemical capacitors and secondary cells, and the porous carbon material not only provides a new material for the new energy, but also opens up a new way for the effective use of waste, namely the shrimp shell and crab shell in aquatic products industry.

Owner:BEIJING UNIV OF CHEM TECH

Method of producing graphite-carbon composite electrodes for supercapacitors

A method of producing a composite electrode having a specific surface area of at least 100 m2 / gm for use in an electrochemical capacitor. The method comprises (a) providing exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores; and (b) incorporating an electrochemically active material into at least a pore of the graphite network to form the composite electrode. The exfoliated graphite flakes are preferably obtained from the intercalation and exfoliation of a laminar graphite material selected from natural graphite, spheroidal graphite, synthetic graphite, highly oriented pyrolytic graphite, meso-carbon micro-bead, carbon / graphite fiber, carbon / graphite whisker, carbon / graphite nano-fiber, carbon nano-tube, or a combination thereof. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and low equivalent series resistance.

Owner:NANOTEK INSTR GRP LLC

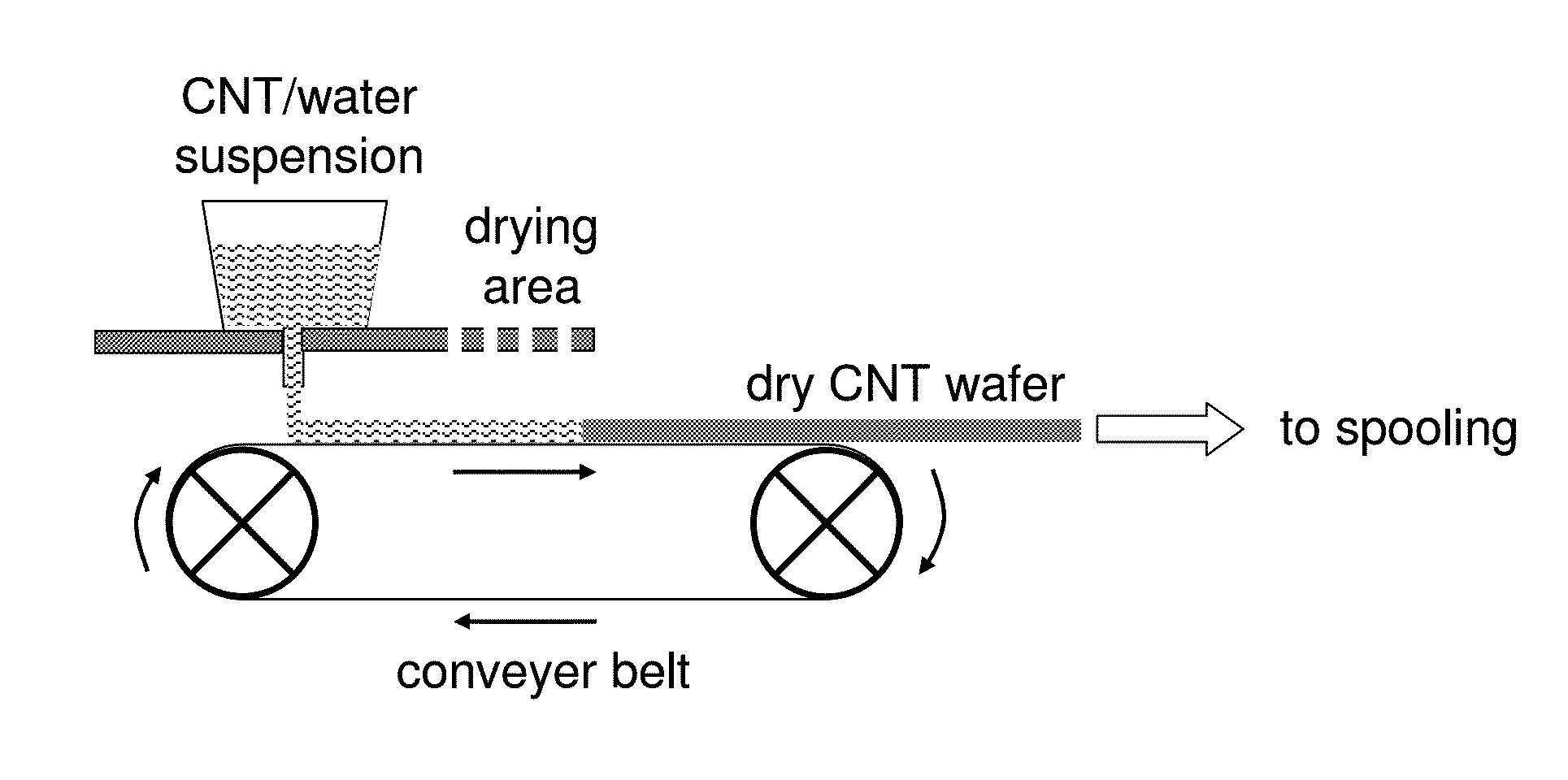

Method of making cohesive carbon assembly and its applications

Cohesive carbon assemblies are prepared by obtaining a functionalized carbon starting material in the form of powder, particles, flakes, loose agglomerates, aqueous wet cake, or aqueous slurry, dispersing the carbon in water by mechanical agitation and / or refluxing, and substantially removing the water, typically by evaporation, whereby the cohesive assembly of carbon is formed. The method is suitable for preparing free-standing, monolithic assemblies of carbon nanotubes in the form of films, wafers, discs, fiber, or wire, having high carbon packing density and low electrical resistivity. The method is also suitable for preparing substrates coated with an adherent cohesive carbon assembly. The assemblies have various potential applications, such as electrodes or current collectors in electrochemical capacitors, fuel cells, and batteries, or as transparent conductors, conductive inks, pastes, and coatings.

Owner:YAZAKI CORP

Graphite-carbon composite electrode for supercapacitors

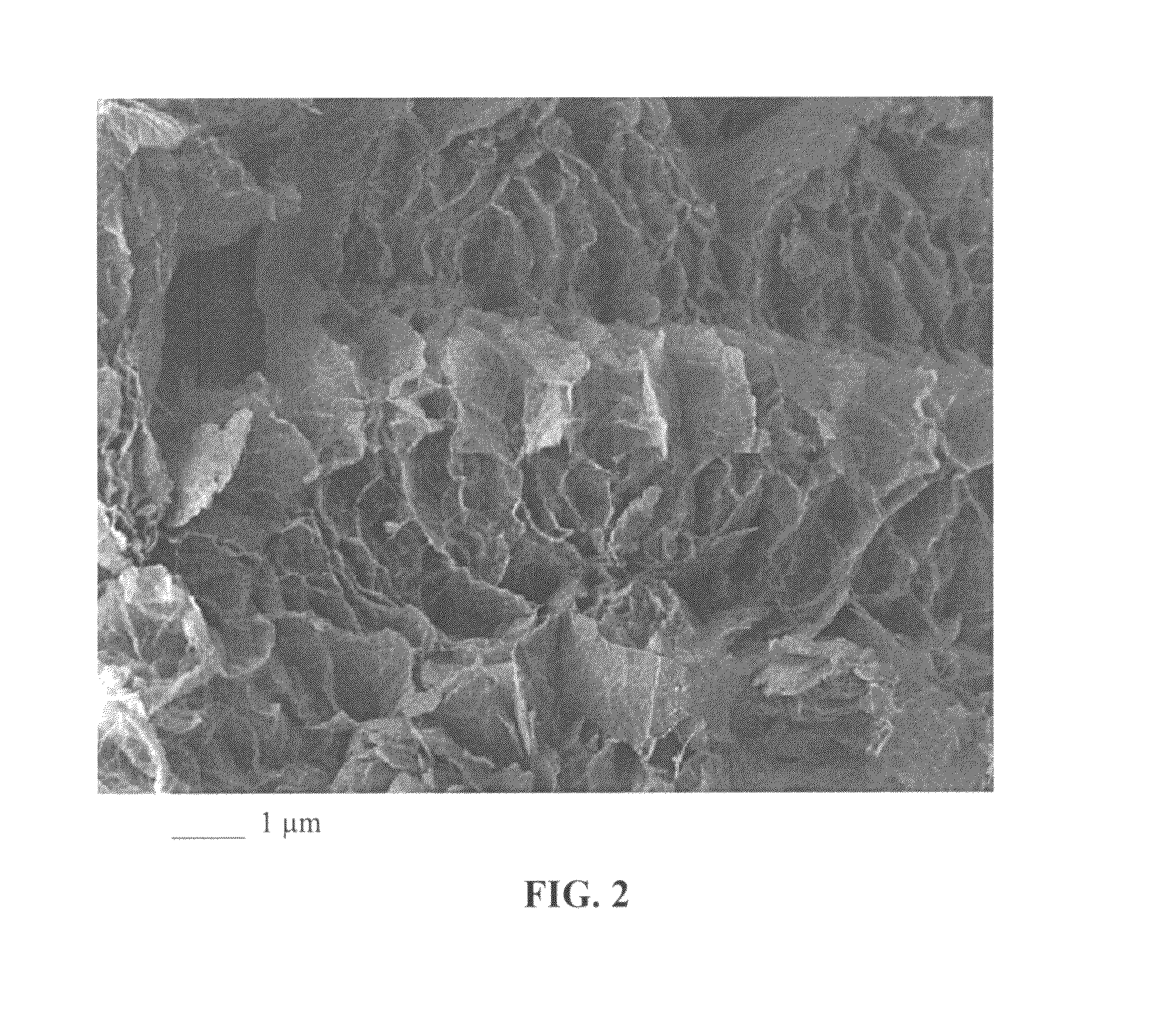

A composite composition for use in an electrode for electrochemical capacitors, comprising: (a) an electrochemically active material; and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least a portion of the active material resides in a pore of the network. The composite composition is characterized by having liquid accessible pores which provide a surface area greater than about 200 m2 / gm, preferably greater than 500 m2 / gm, more preferably greater than 1000 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a composite composition. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and high electrical conductivity.

Owner:SAMSUNG ELECTRONICS CO LTD +1

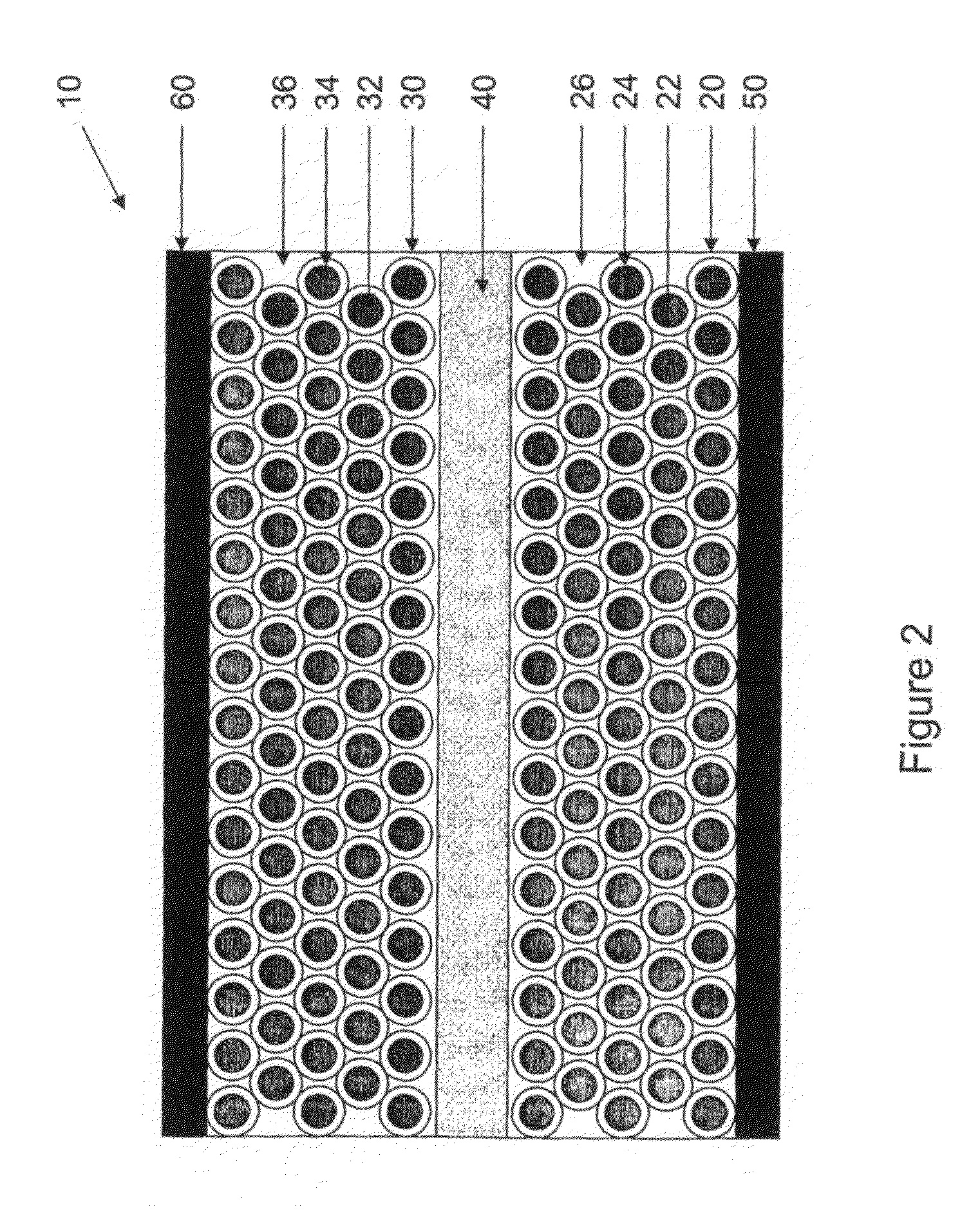

Core-shell nanoparticles in electronic battery applications

InactiveUS20130078510A1Shorten cycle lifeCompromise capacitanceMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesCore shell nanoparticlesCore shell

The present invention provides an improved supercapacitor-like electronic battery comprising a conventional electrochemical capacitor structure. A first nanocomposite electrode and a second electrode and an electrolyte are positioned within the conventional electrochemical capacitor structure. The electrolyte separates the nanocomposite electrode and the second electrode. The first nanocomposite electrode has first conductive core-shell nanoparticles in a first electrolyte matrix. A first current collector is in communication with the nanocomposite electrode and a second current collector is in communication with the second electrode. Also provided is an electrostatic capacitor-like electronic battery comprising a high dielectric-strength matrix separating a first electrode from a second electrode and, dispersed in said high-dielectric strength matrix, a plurality of core-shell nanoparticles, each of said core-shell nanoparticles having a conductive core and an insulating shell.

Owner:OERLIKON ADVANCED TECH +1

Non-aqueous electrolyte secondary battery negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

ActiveCN101504980AIncrease capacityImprove cycle performanceHybrid capacitor electrodesDouble layer capacitorsGraphiteUltimate tensile strength

A negative electrode material comprises a conductive powder of particles of a lithium ion-occluding and releasing material coated on their surface with a graphite coating. The graphite coating, on Raman spectroscopy analysis, develops broad peaks having an intensity I 1330 and I 1580 at 1330 cm -1 and 1580 cm -1 Raman shift, an intensity ratio I 1330 / I 1580 being 1.5 < I 1330 / I 1580 < 3.0. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance can be manufactured.

Owner:SHIN ETSU CHEM IND CO LTD

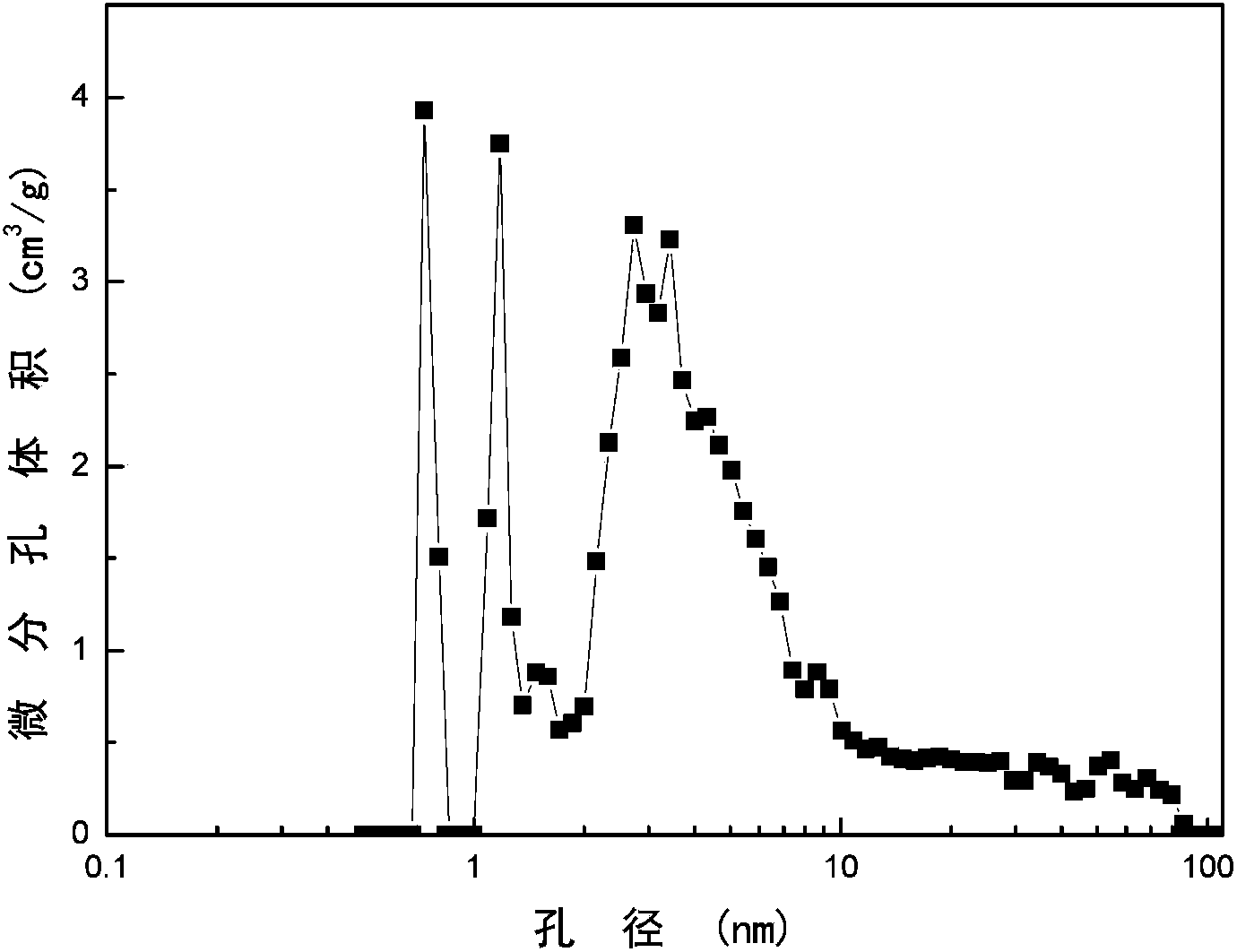

Stephanoporate carbon electrode material and preparation method thereof

InactiveCN101299397AFast deliveryExcellent electrochemical capacitance performanceHybrid capacitor electrodesElectrolytic capacitorsPorous carbonCarbonization

The invention relates to a porous carbon electrode materials and the preparation method, belonging to the electrochemistry and the novel energy source materials, wherein the porous carbon electrode materials adopt the template carbonization and the method combined with the CO2 post-processing using the meso-porous oxide silicon as the remplate, and the cane sugar, furfuryl alcohol, polyacrylonitrile and the like as the precursors, through the technology steps of the liquid phase impregnation, the high temperature carbonization and the template removal and the like, then combines high temperature process, obtaining the super capacitor porous carbon electrode materials. The porous carbon electrode materials prepared by the method has high surface area, large pore volume, adjustable pore structure and multilevel-microporous pore structure, wherein the pore channel is composed of a meso-porous of 2-5 nm and the microporous with the meso-porous wall of 0.1-2 nm, so the electrochemistry capacity of the prepared porous carbon electrode is marked increased, and the integral property of good.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Electrode, related material, process for production, and use thereof

InactiveUS20110281157A1Increase capacityProlong lifeMaterial nanotechnologyElectrode manufacturing processesMeta structureConformal coating

An electrode material is created by forming a thin conformal coating of metal oxide on a highly porous carbon meta-structure. The highly porous carbon meta-structure performs a role in the synthesis of the oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of metal oxide. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

Carbon nanotube composite, method for making the same, and electrochemical capacitor using the same

A carbon nanotube composite includes a free-standing carbon nanotube structure and an amount of reinforcements. The free-standing carbon nanotube structure includes an amount of carbon nanotubes. The reinforcements are located on the carbon nanotubes and combining the carbon nanotubes together.

Owner:TSINGHUA UNIV +1

Negative electrode material, non-aqueous electrolyte secondary battery, and electrochemical capacitor

InactiveUS20090317722A1Improve cycle performanceGood rate characteristicsHybrid capacitor electrodesLiquid electrolytic capacitorsMetallurgyNuclear reaction

Silicon particles are irradiated with neutrons so that 30Si of silicon isotopes is transformed to 31P through nuclear reaction. A negative electrode material comprising the P-doped silicon powder exhibits good cycle performance of silicon and is endowed with a high conductivity while maintaining the high initial efficiency and high battery capacity of silicon, and is thus useful as an active material in a negative electrode of a non-aqueous electrolyte secondary battery.

Owner:SHIN ETSU CHEM IND CO LTD

Negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20090311606A1High charge and discharge capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsLiquid electrolytic capacitorsElectrical resistance and conductanceX-ray

A conductive powder is provided in which particles having silicon crystallites dispersed in a silicon compound are coated on their surface with carbon. The conductive powder develops a diffraction peak assigned to Si(111) around 2θ=28.4° on x-ray diffractometry (Cu—Kα) using copper as the counter cathode, the peak having a half width of at least 1.0°, and has a specific resistance of up to 50 mΩ. The powder is used as a negative electrode material to construct a non-aqueous electrolyte secondary battery, which has a high charge / discharge capacity and improved cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com