Patents

Literature

734 results about "Lead alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead alloys Lead forms alloys with many metals.. ... Shot Lead is an Alloy of Lead, Antimony, and Arsenic. Lead Foil is made with Lead alloys.

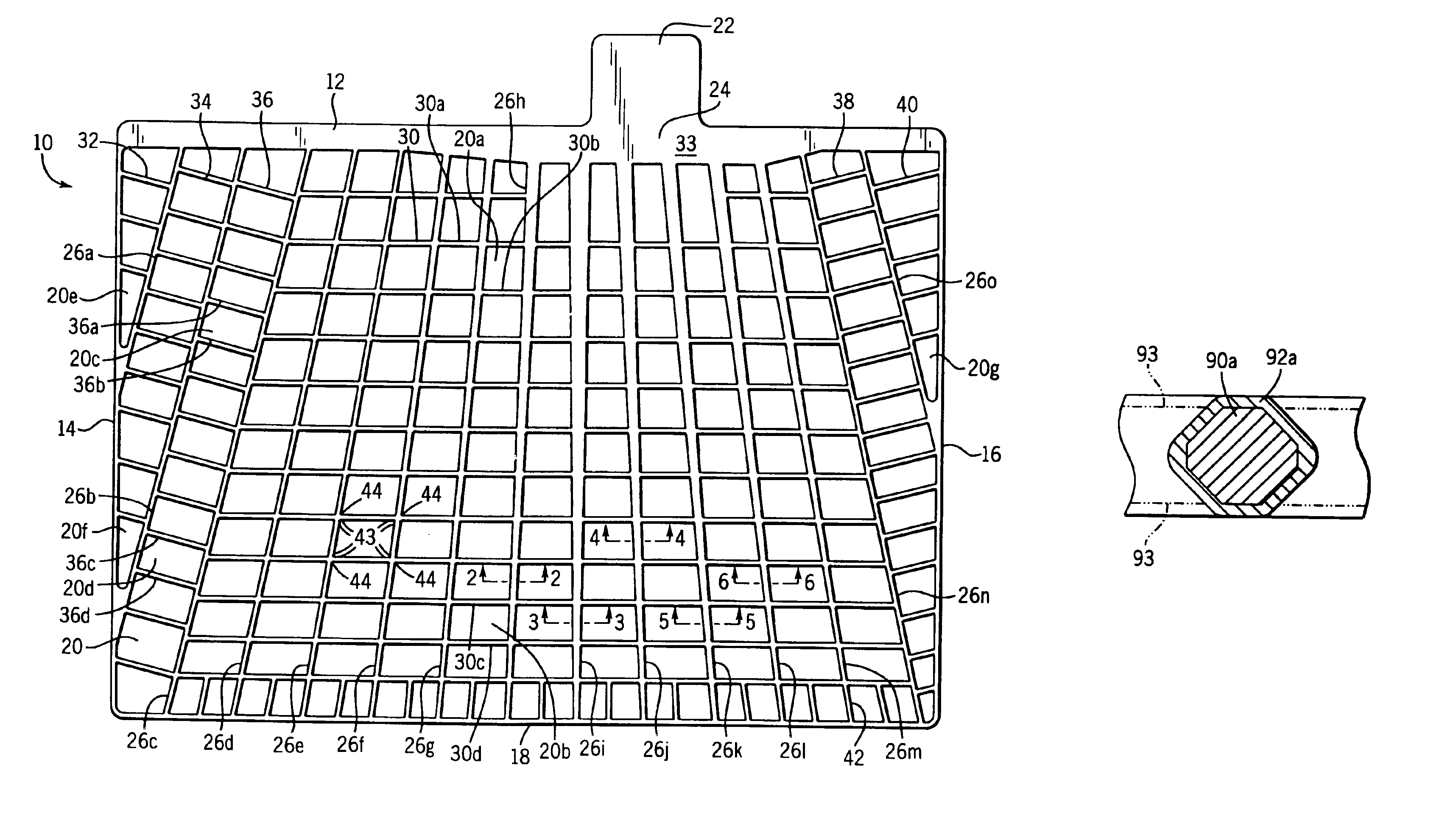

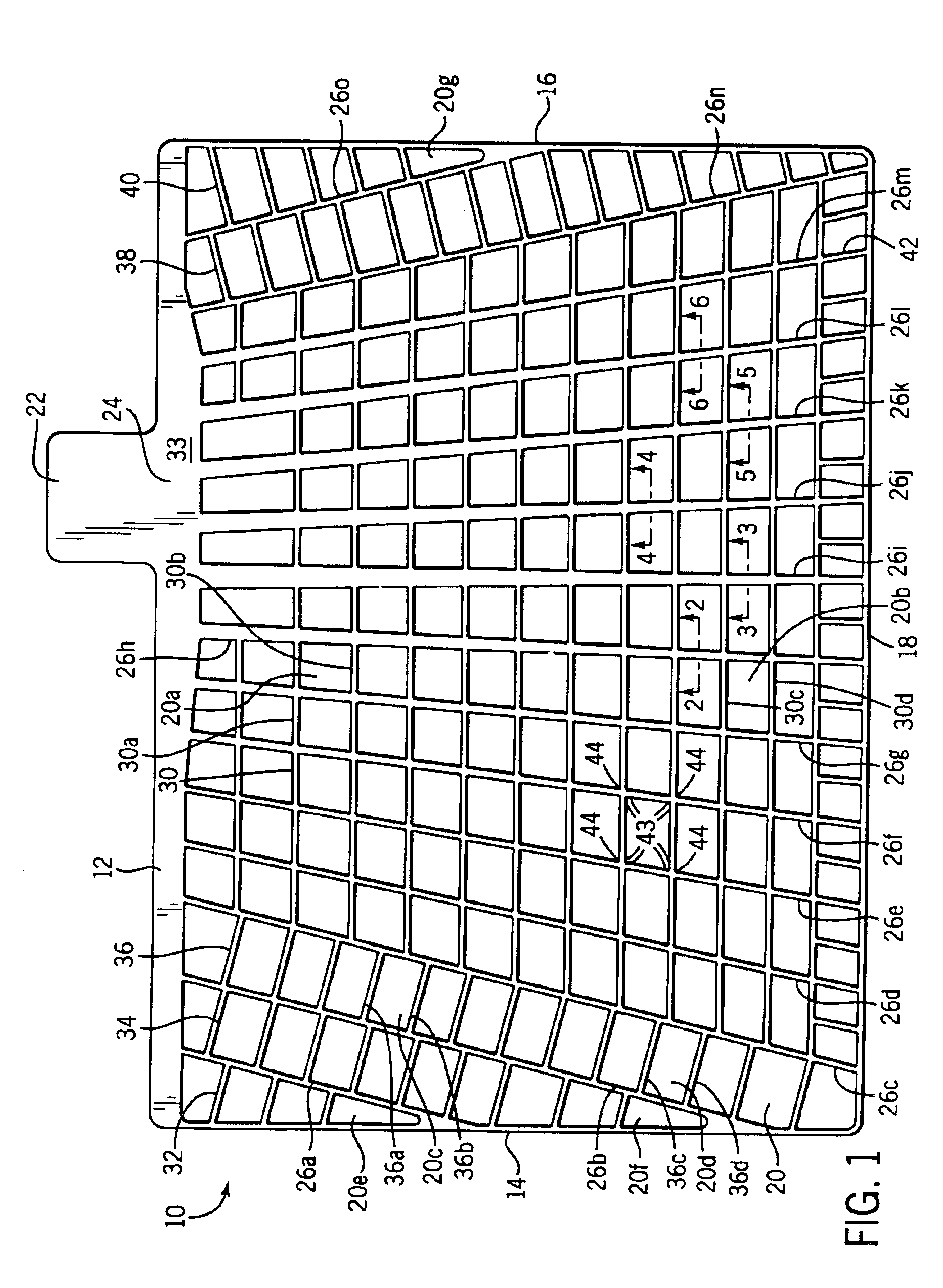

Battery grid

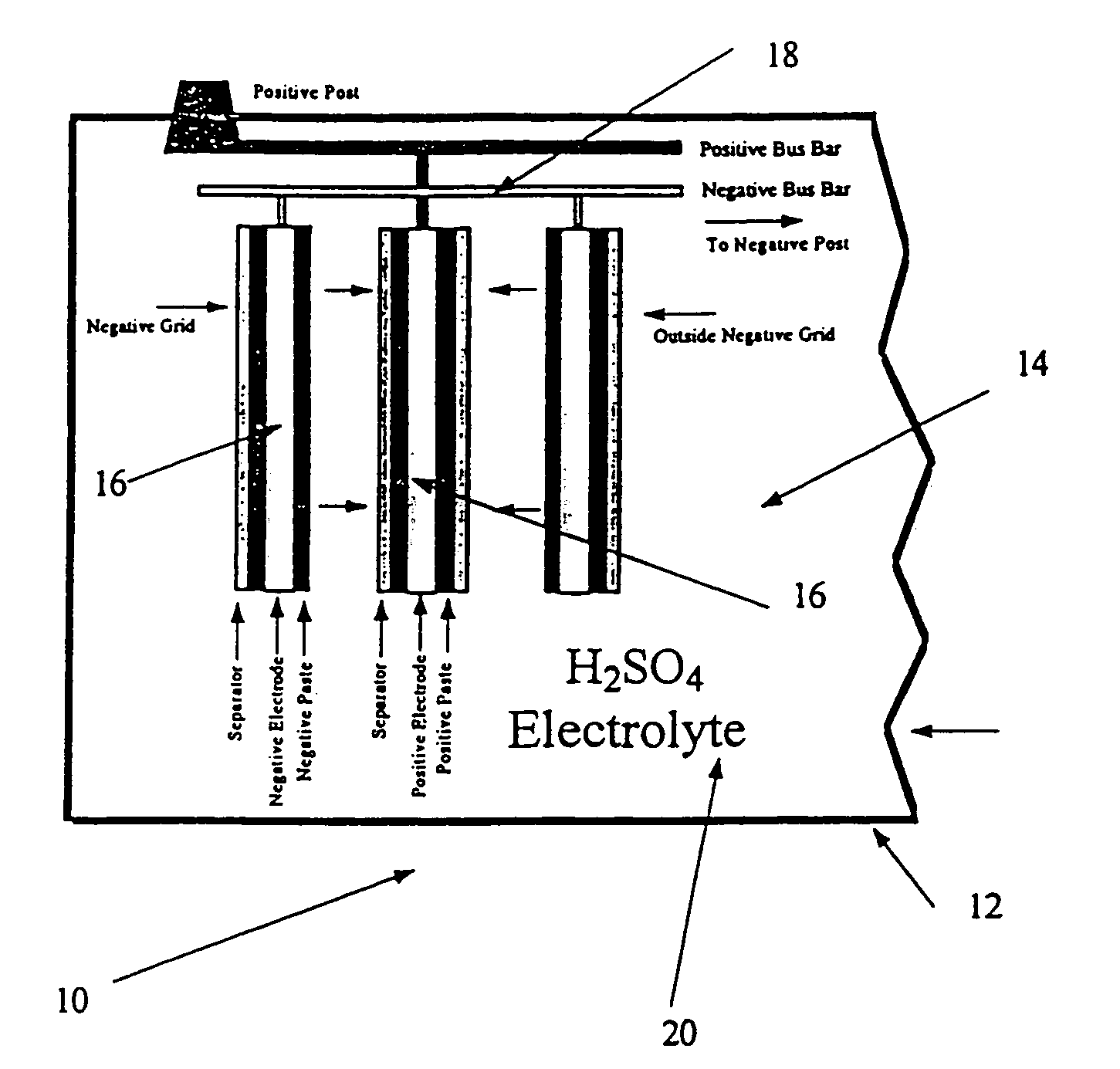

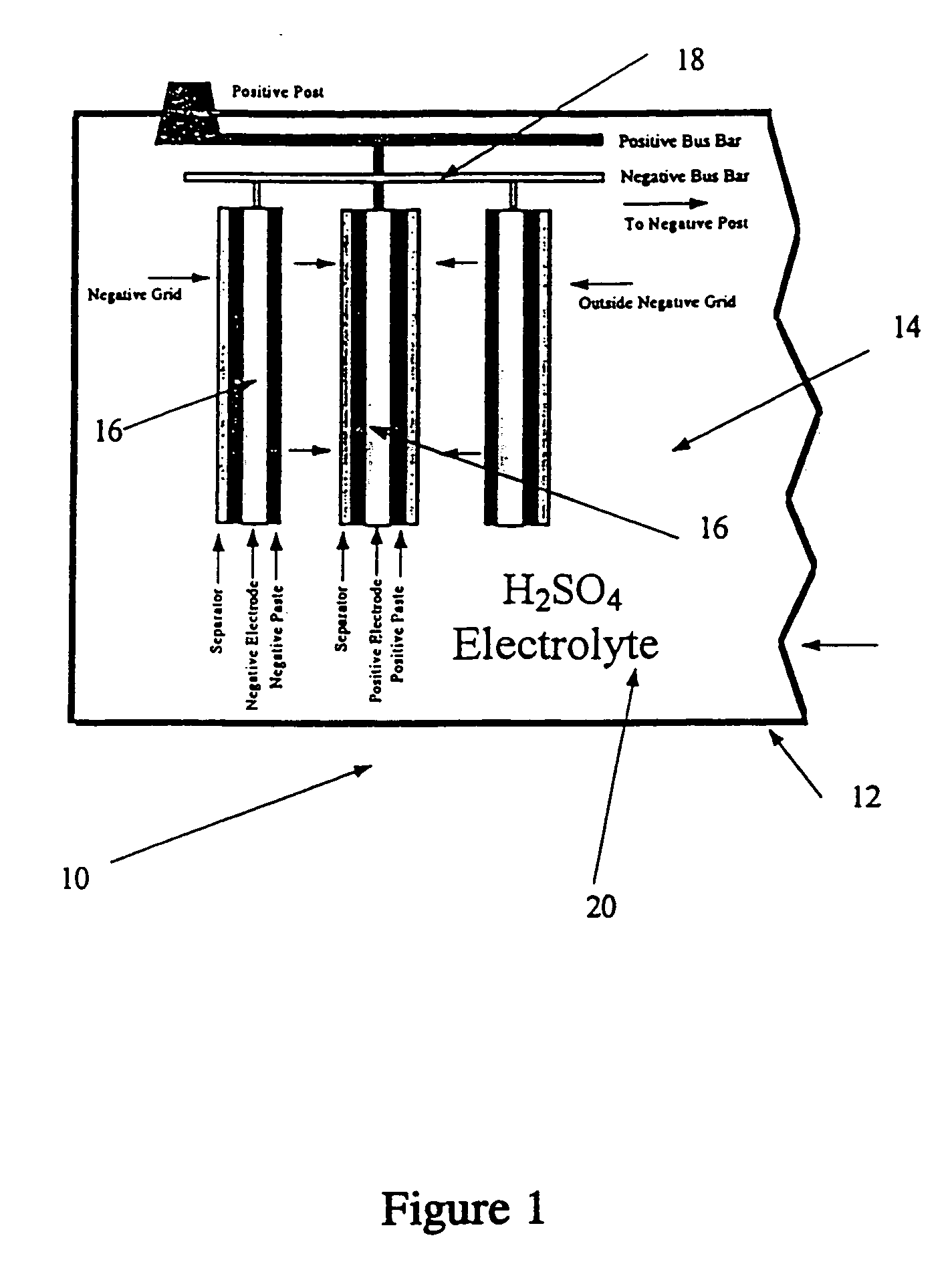

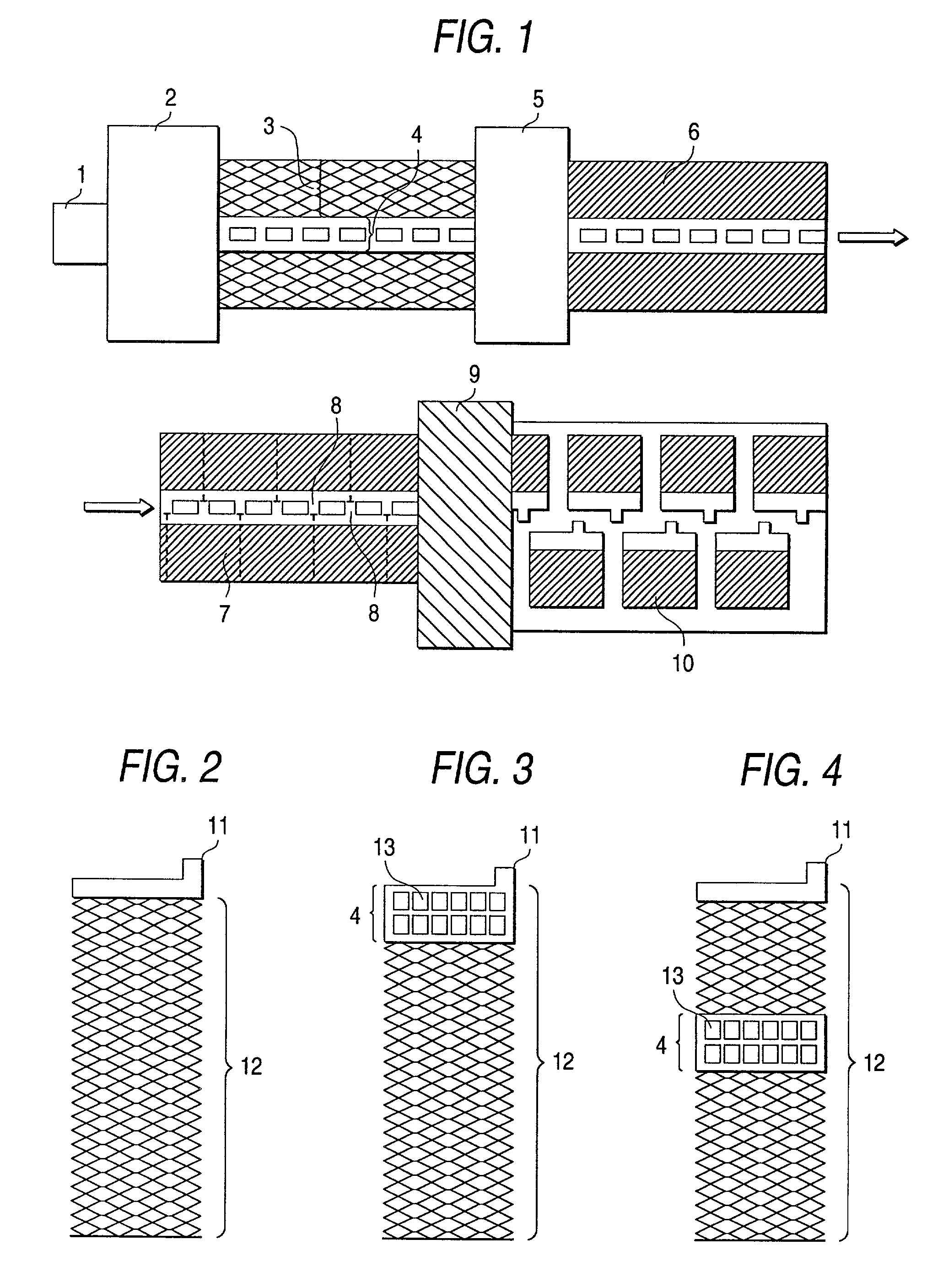

InactiveUS6953641B2Extend battery lifeImprove adhesionElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

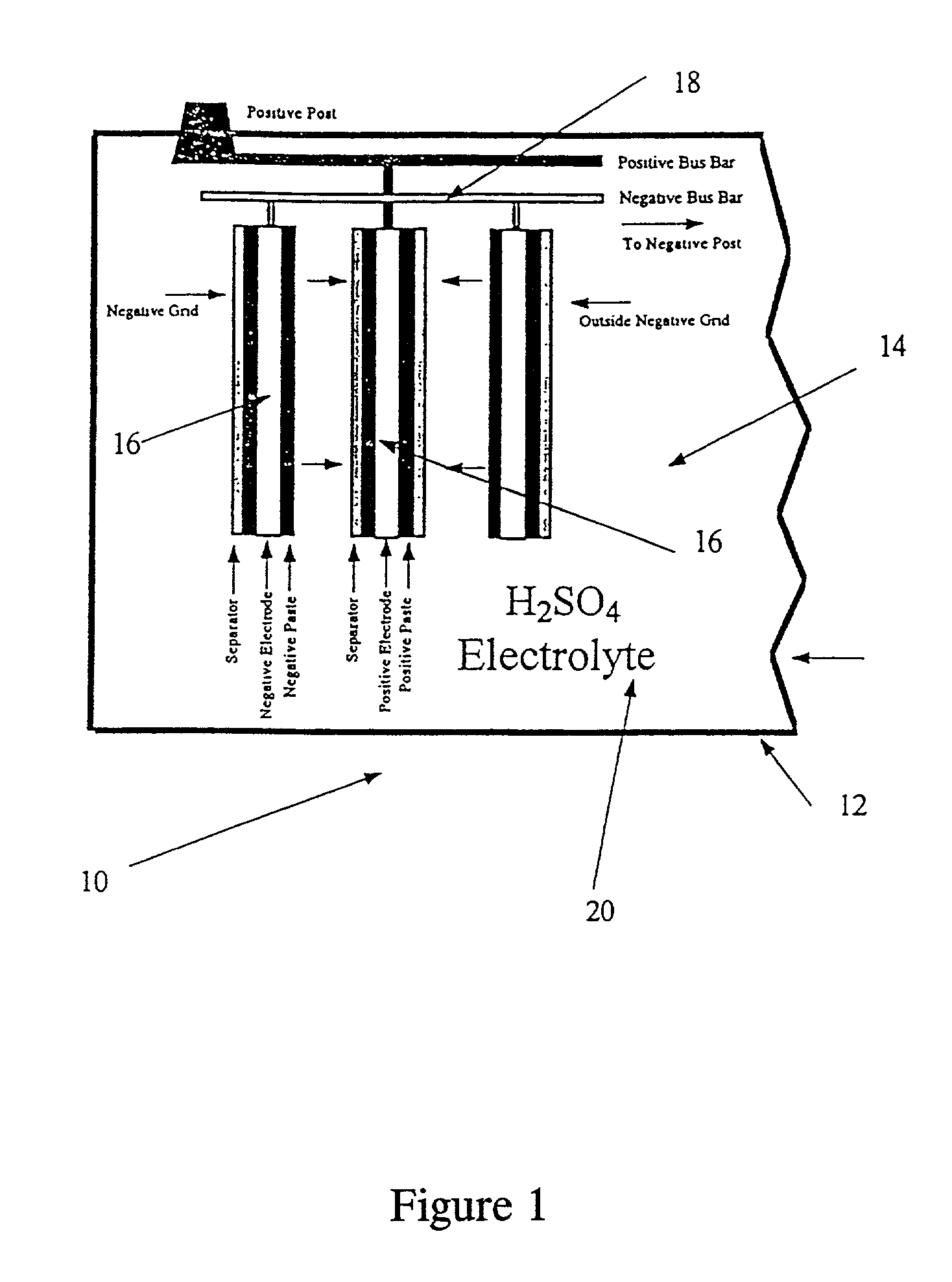

A method of forming battery grids or plates that includes the step of applying a lead alloy coating to a continuous strip of interconnected battery grids formed from a lead alloy grid material is disclosed. The battery grids may be formed by a continuous battery grid making process such as strip expansion, strip punching, or continuous grid casting. In one version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are immersed in a melt of the lead alloy coating. In another version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are deformed such that the grid wires have a cross-section other than the rectangular cross-section produced by the punching process and the strip of interconnected grids is immersed in a melt of the lead alloy coating. The method increases the cycle life of a battery.

Owner:CPS TECH HLDG LLC

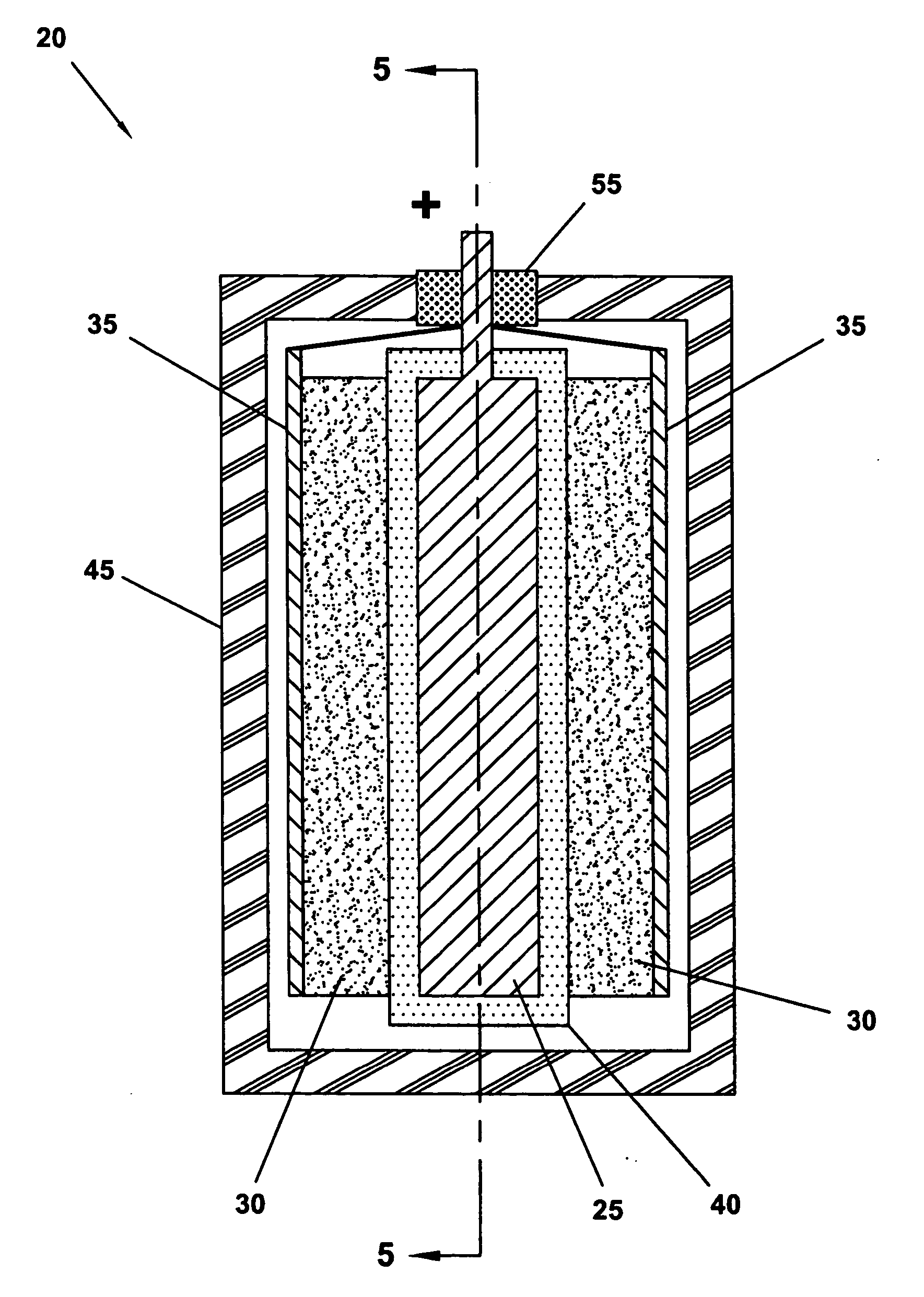

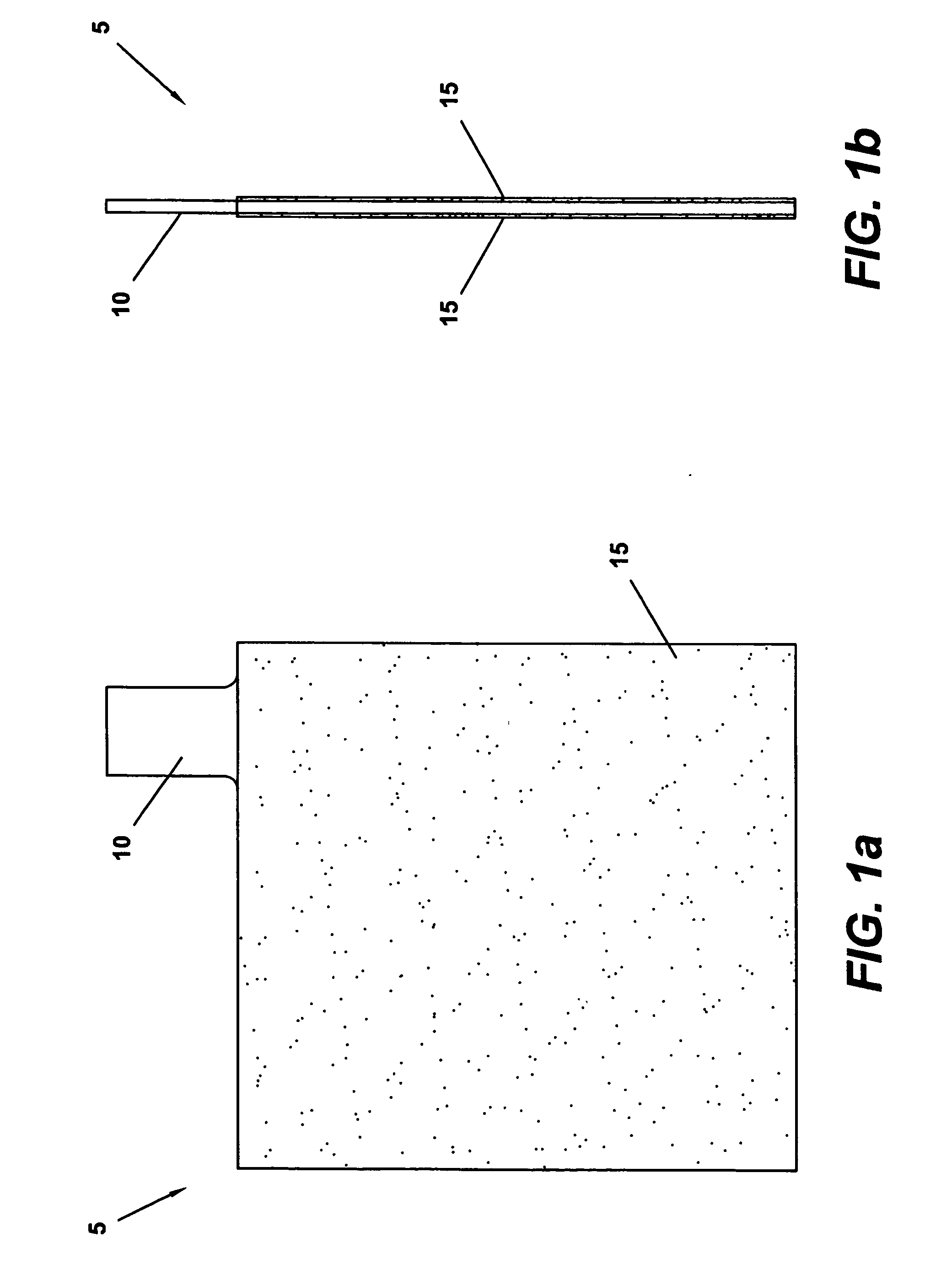

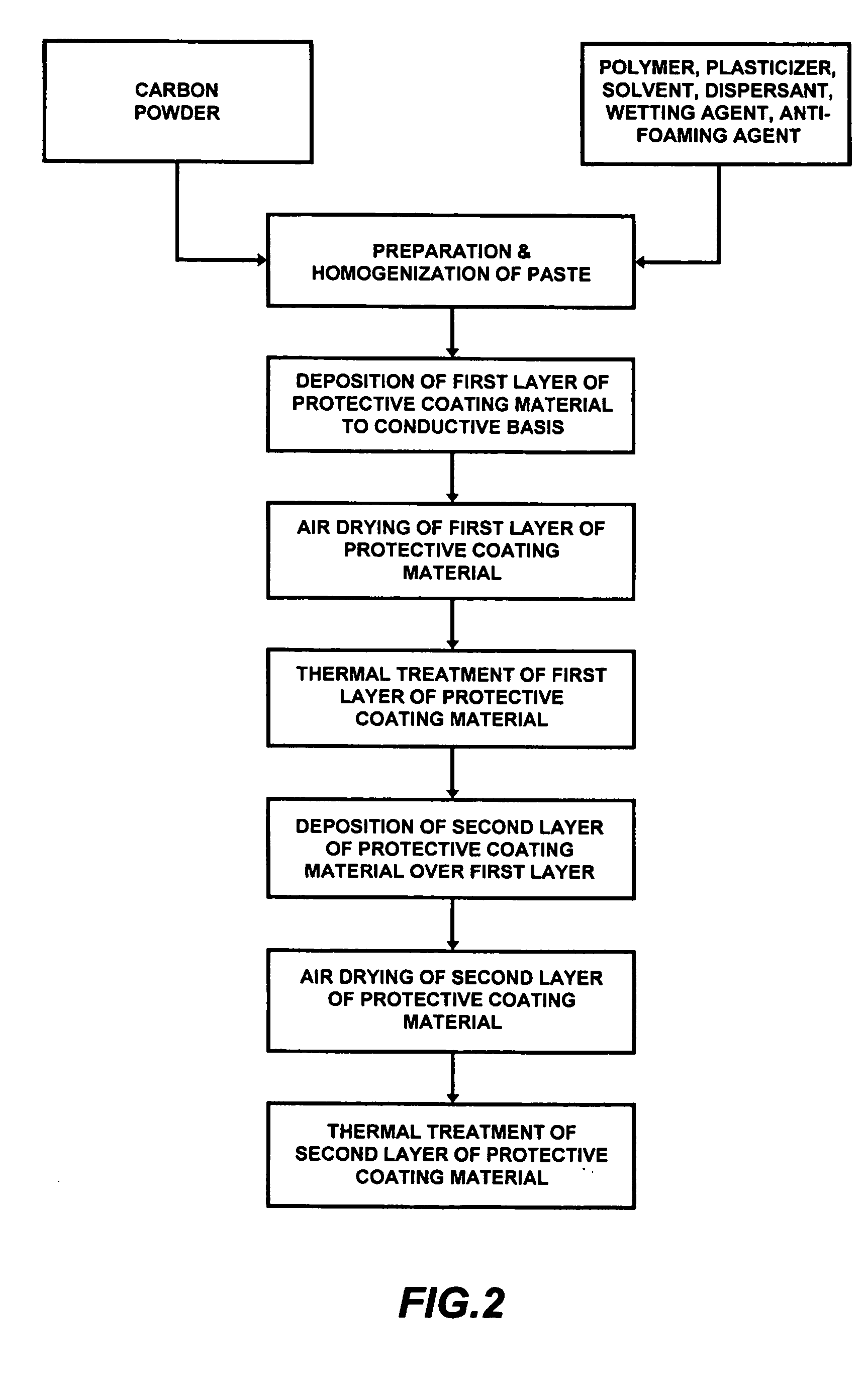

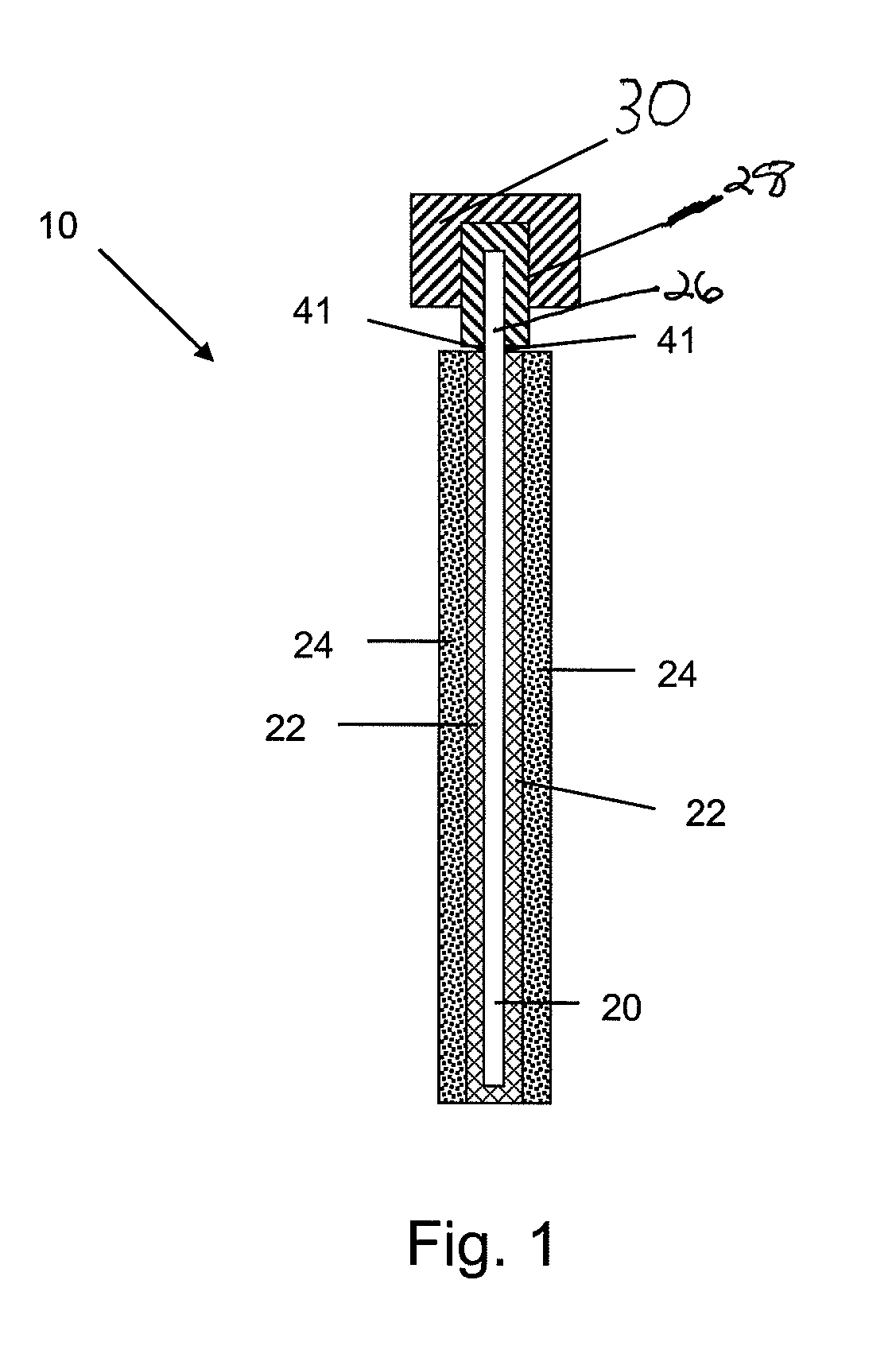

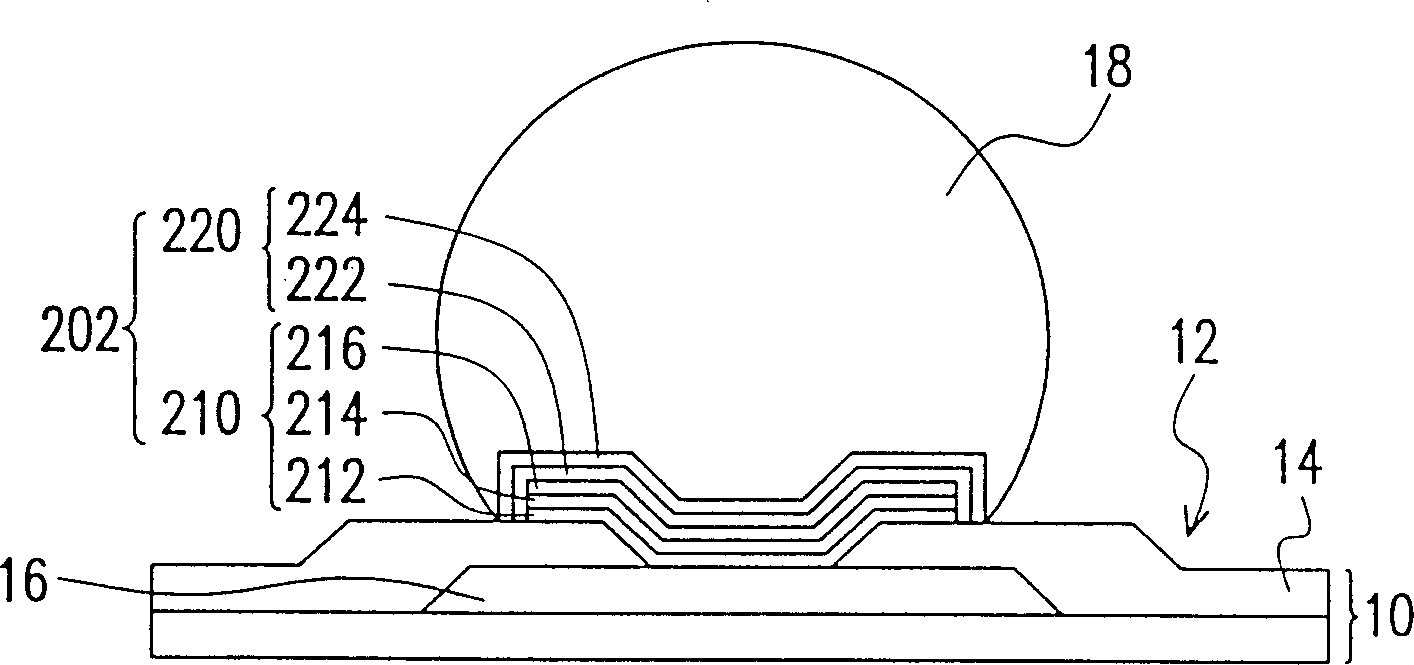

Current collector for double electric layer electrochemical capacitors and method of manufacture thereof

InactiveUS20060292384A1High of oxygen gassingReadily availableHybrid capacitor electrolytesHybrid capacitor electrodesAlloySolvent

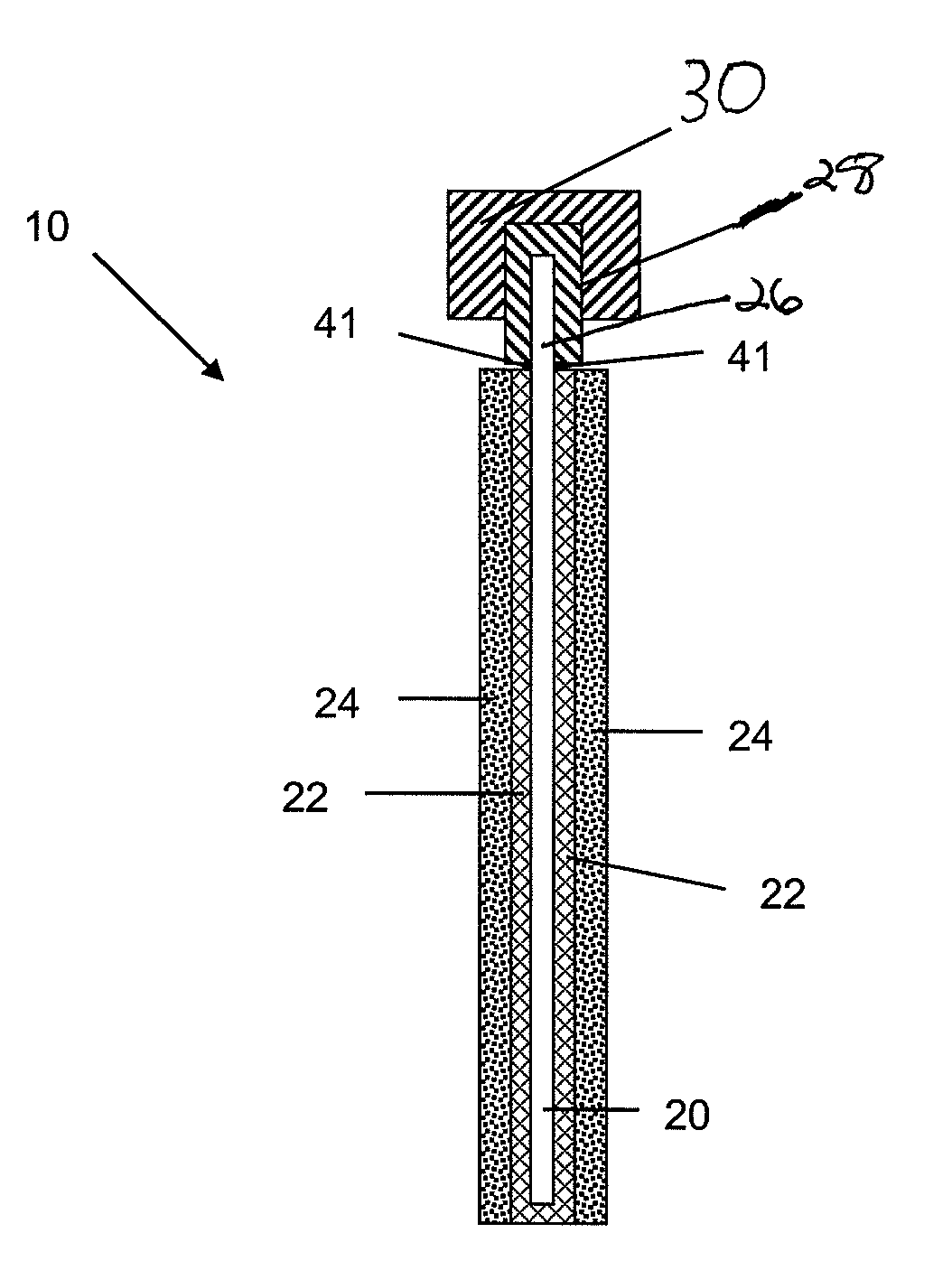

A current collector for use in a capacitor having an aqueous or non-aqueous electrolyte, such as an aqueous sulfuric acid electrolyte. The conductive basis of the current collector may be manufactured from a number of conductive metals but, preferably, is comprised of lead or a lead alloy. The portion of the conductive basis that will be in contact with the electrolyte is provided with a protective layer that is created by deposition of one or more layers of one or more protective coating materials thereto. Each protective coating material is comprised of at least a conductive carbon powder and a polymer binder that is resistant to the electrolyte. Preferably, but not essentially, the protective coating material(s) are applied to the conductive basis in the form of a paste, which is subsequently subjected to a solvent evaporation step and a thermal treatment step. The resulting protective layer is also substantially devoid of pores through which the electrolyte can permeate.

Owner:UNIVERSAL SUPERCAPACITORS LLC

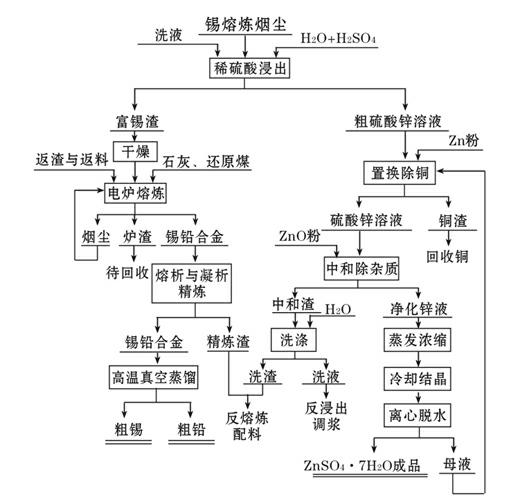

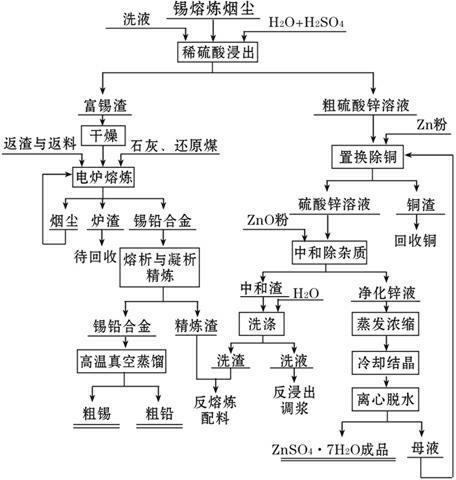

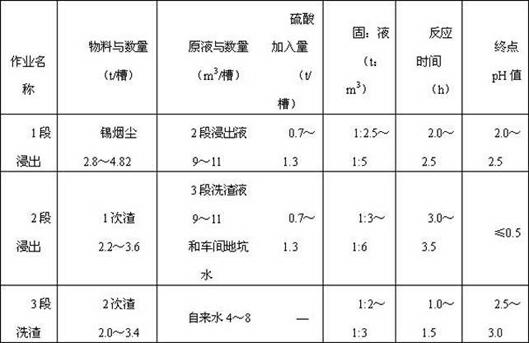

Method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust

InactiveCN102352443AHigh recovery rateReasonable process structureZinc sulatesProcess efficiency improvementSulfateCopper

The invention discloses a method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust. The method comprises the following steps of: (1) pretreating the raw material; (2) leaching with a dilute sulphuric acid to separate out zinc; (3) purifying the crude zinc sulfate solution, preparing zinc sulfate heptahydrate; (4) performing electric furnace smelting on the tin-rich residue to prepare a tin-lead alloy; (5) adopting the conventional liquation process (the temperature is 500-600 DEG C) and the agglutination method (the temperature is 230-240 DEG C) to refine the tin-lead alloy and increase the Sn-Pb grade of the alloy to 94%-96%, and sending the refining residue back to the electric furnace to perform smelting and dosing treatment; and (6) performing high temperature vacuum distillation to produce crude tin and crude lead. By adopting the method, the tin smelting dust can be effectively utilized, the resource can be saved and metals such as tin,lead, zinc and copper can be recovered together.

Owner:太仓市南仓金属材料有限公司

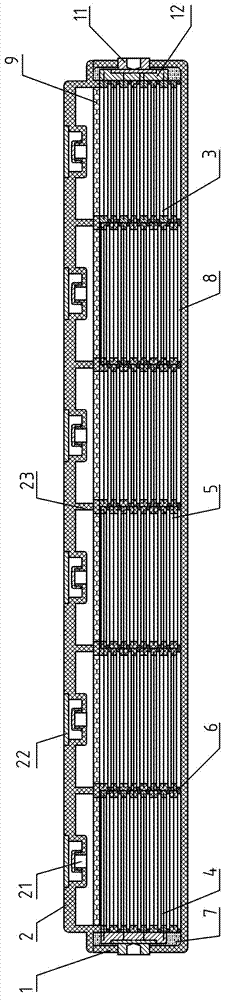

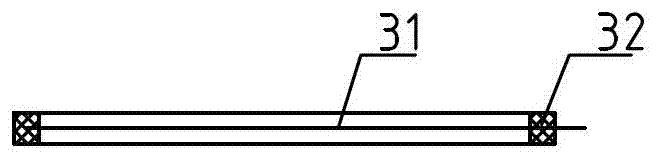

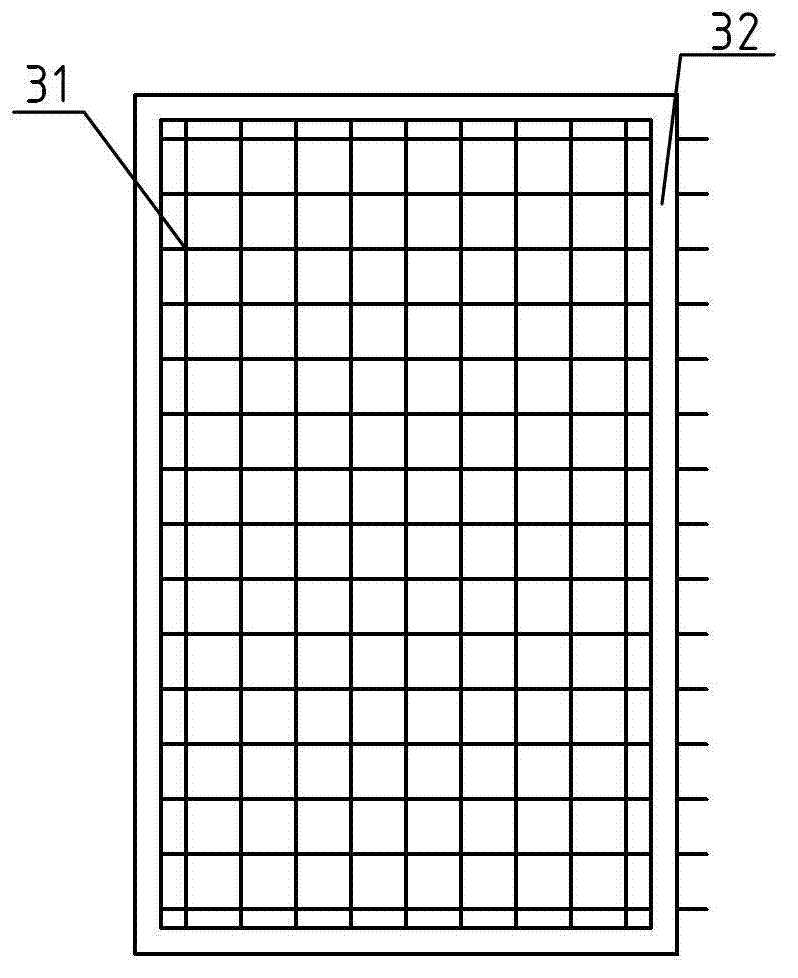

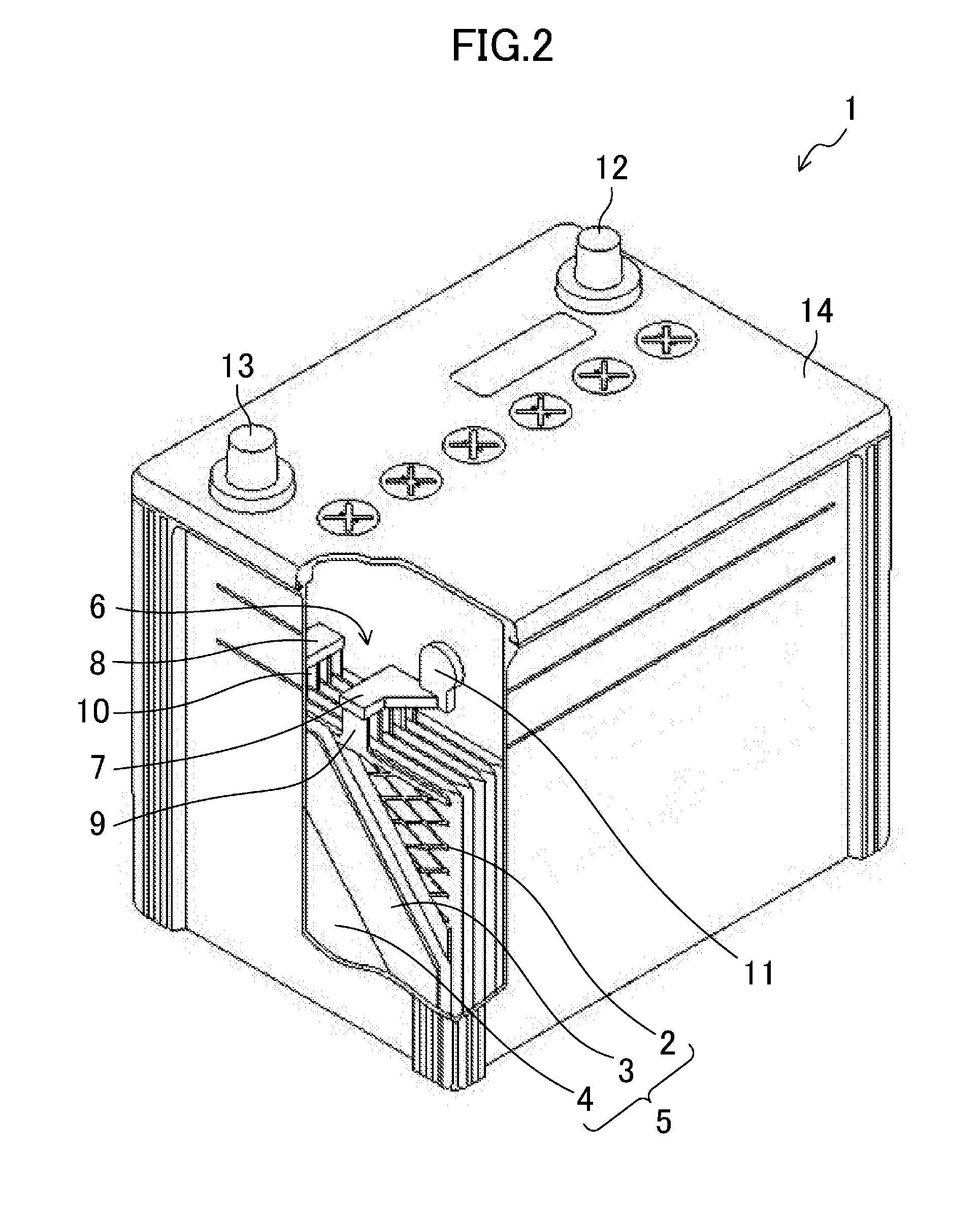

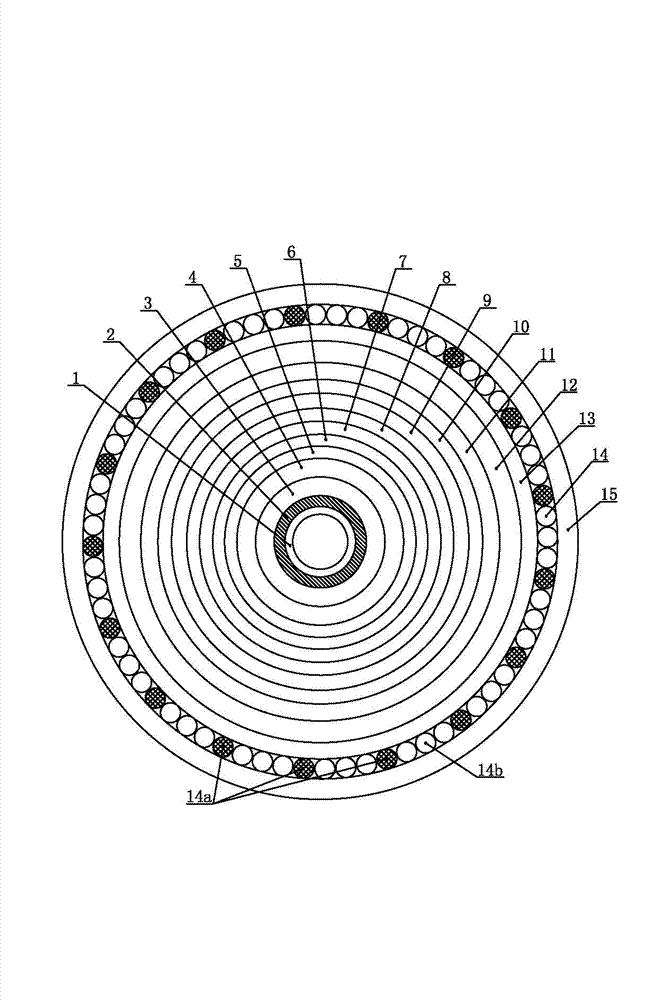

Horizon battery and manufacturing method thereof

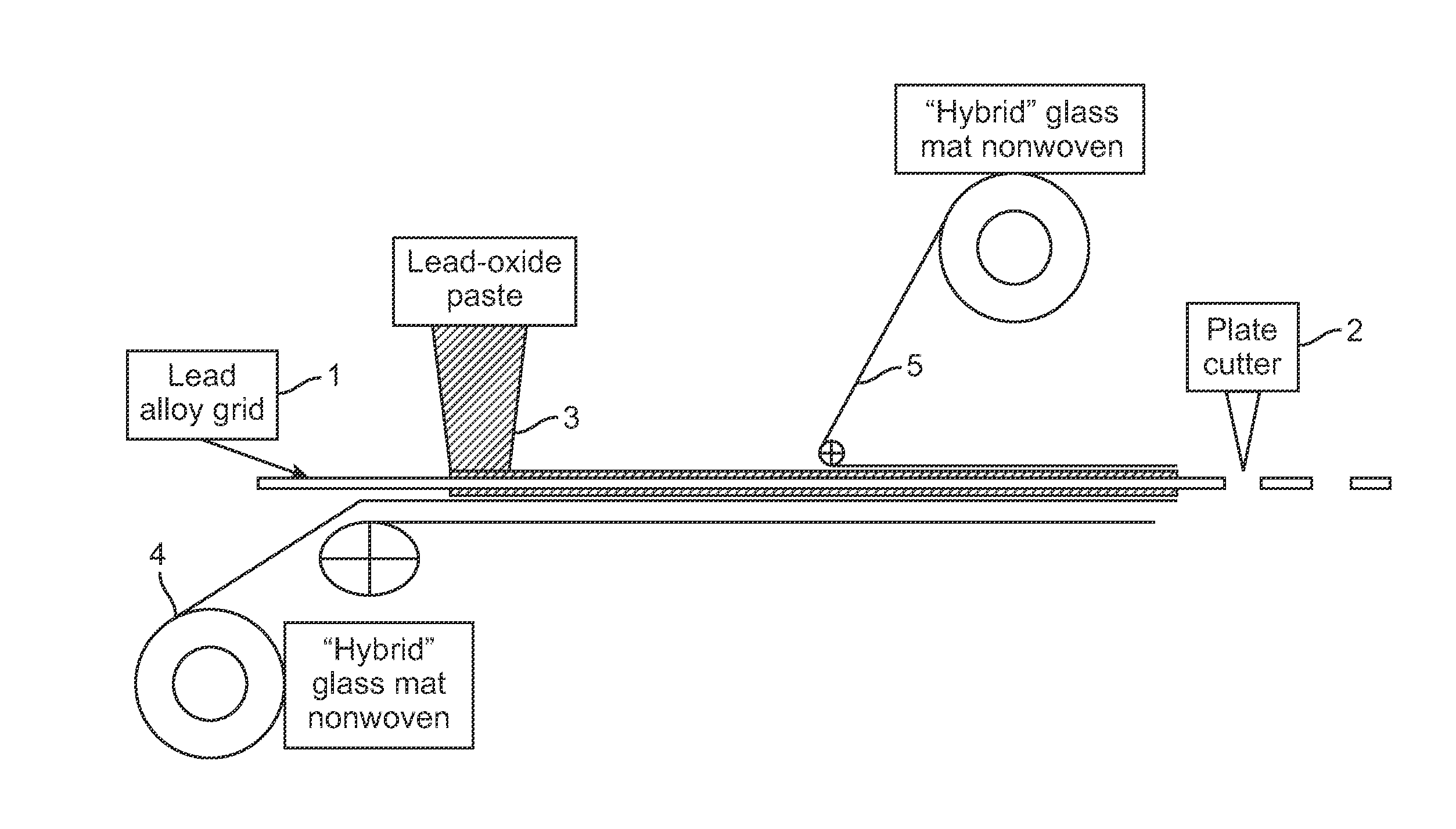

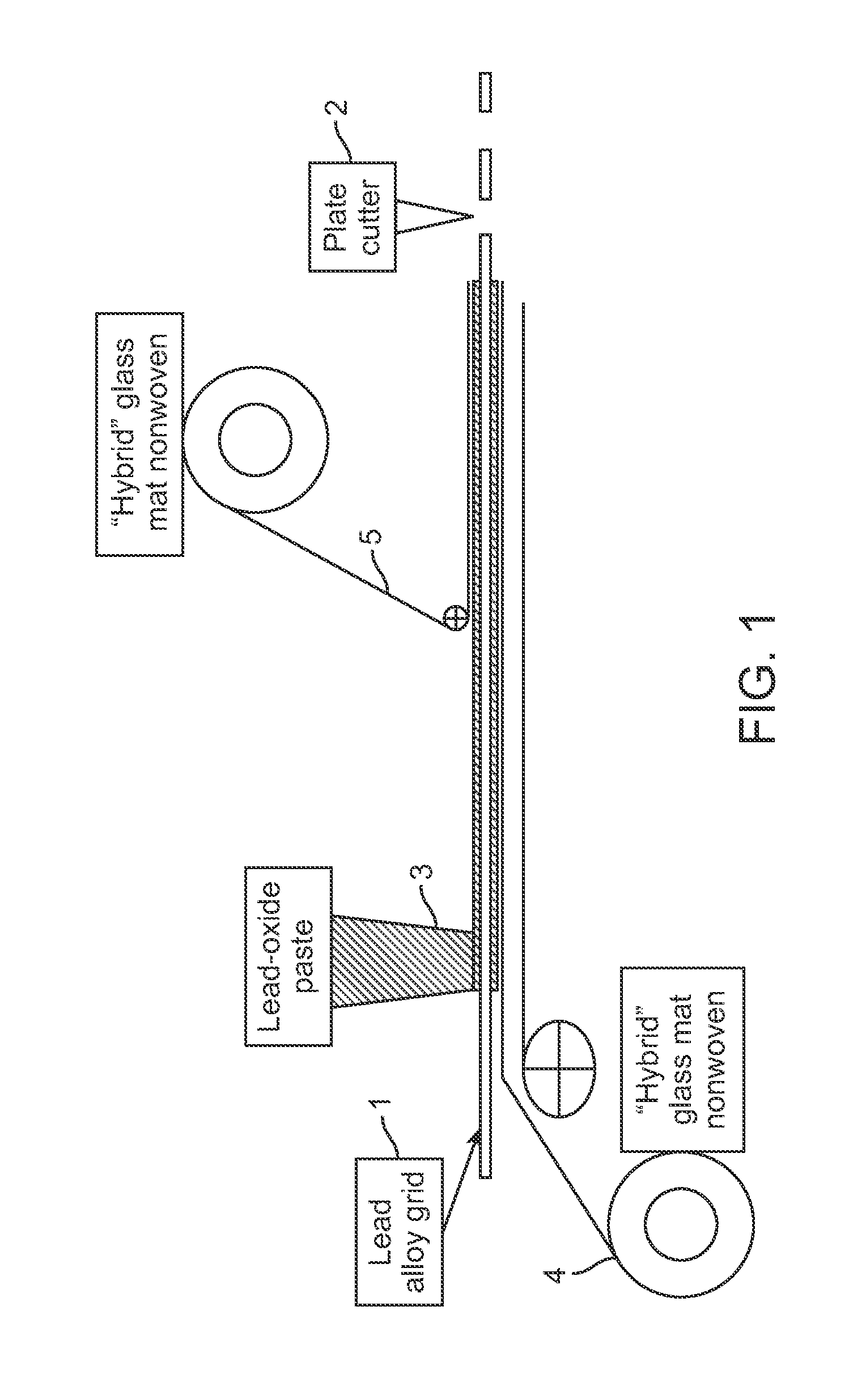

ActiveCN103208633ALight in massReduce dosageFinal product manufactureElectrode carriers/collectorsGlass fiberHorizon

Owner:CHAOWEI POWER CO LTD

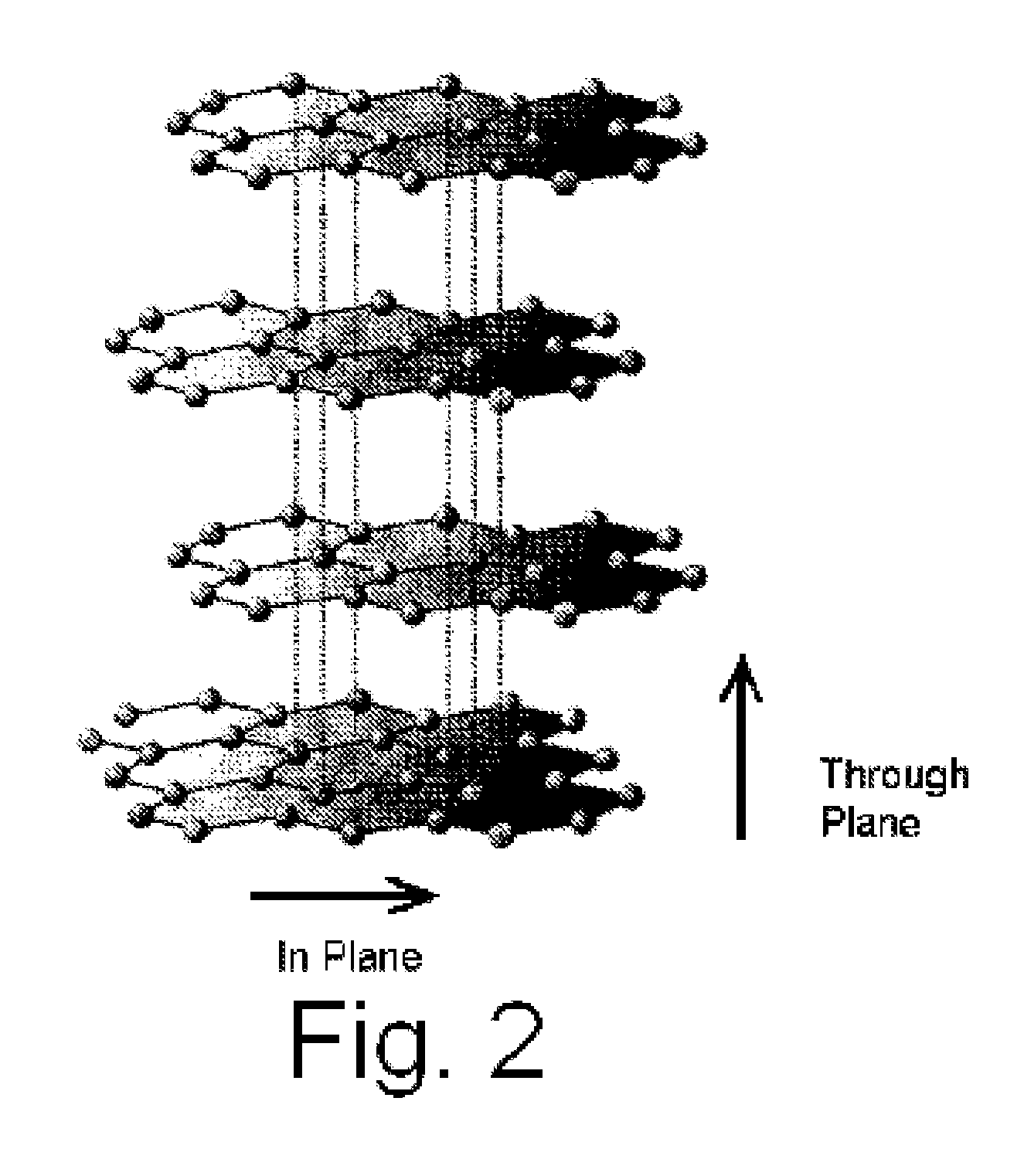

Thermo-mechanical treated lead and lead alloys especially for current collectors and connectors in lead-acid batteries

InactiveUS20040112486A1Improvement in lead-acid battery performanceSmall sizeElectrode carriers/collectorsElectrolysisMetallurgy

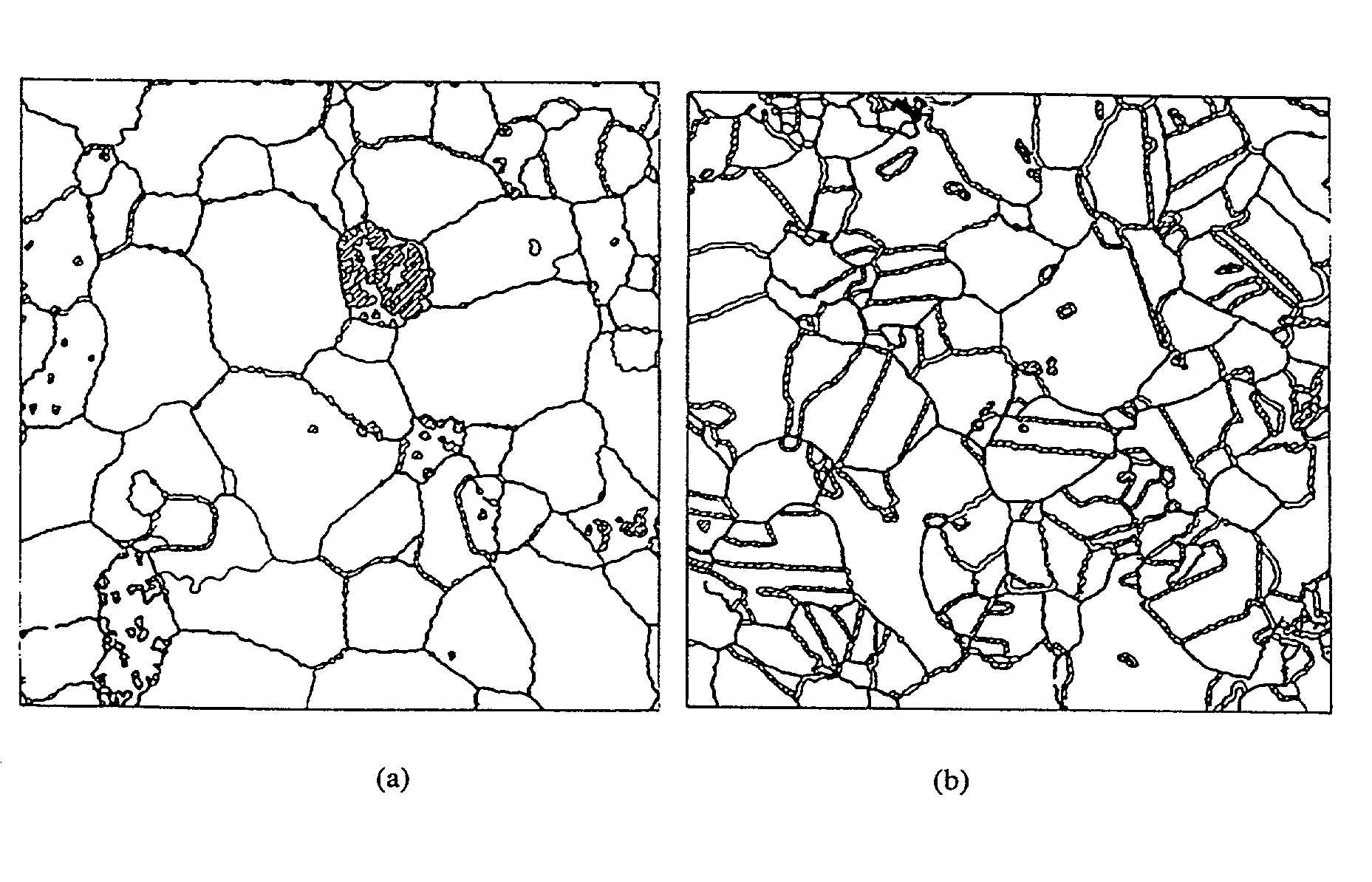

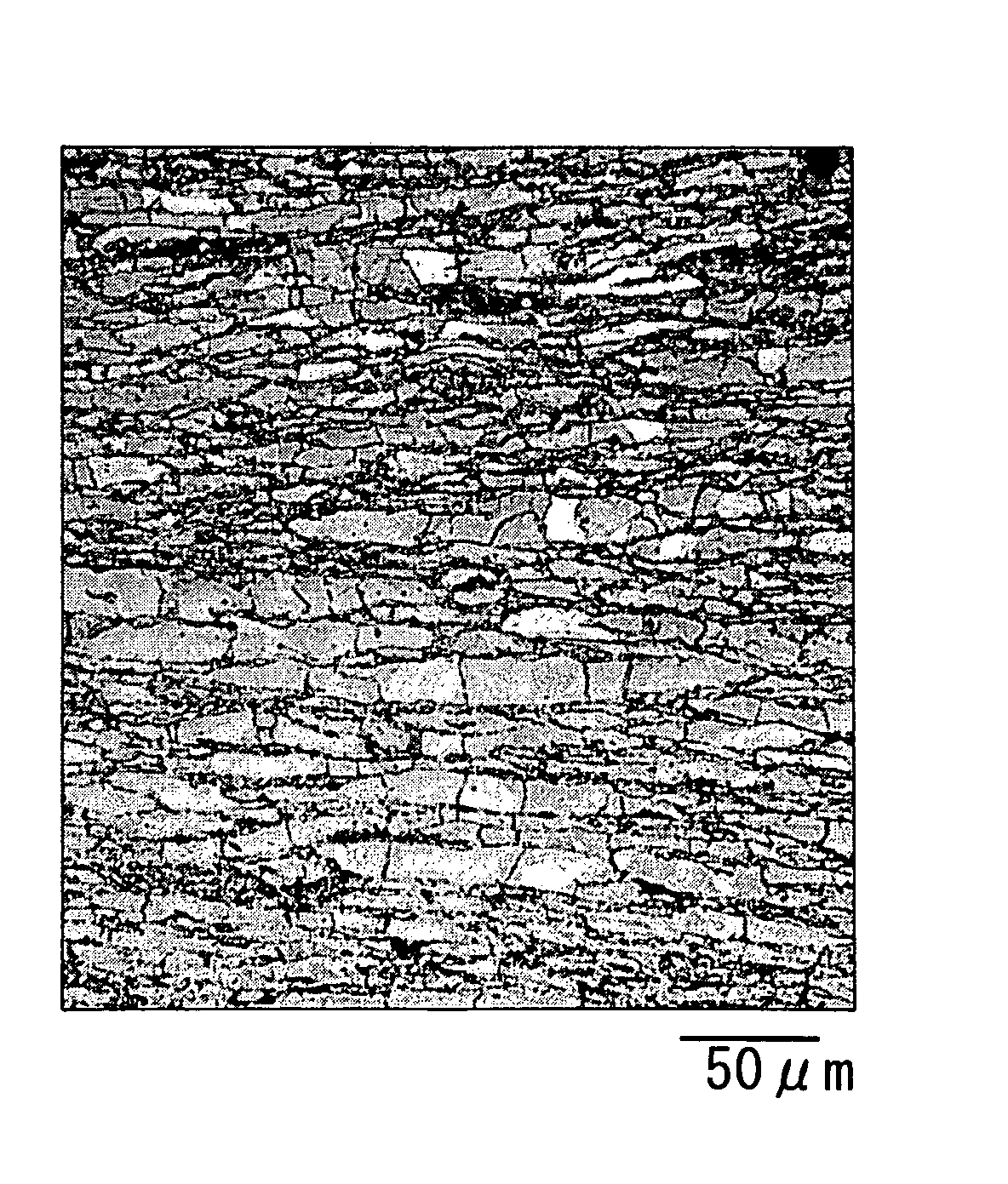

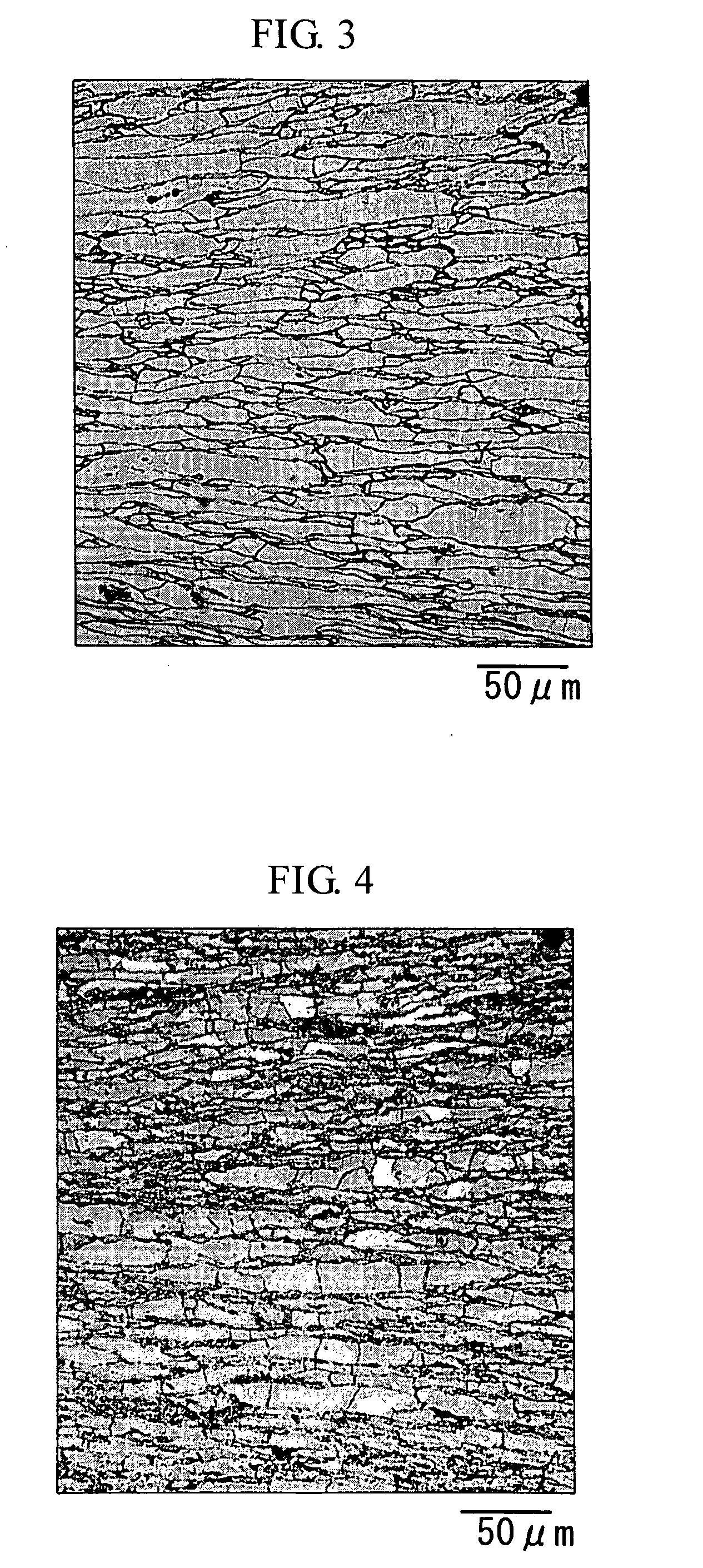

Recrystallized lead and lead alloy positive current collectors and connectors such as straps and lugs for use e.g. in lead acid batteries and electrowinning anodes, having an increased percentage of special grain boundaries in at least part of the microstructure, which have been provided by a process comprising of (i) cold or hot rolling or cold or hot extrusion or (ii) steps of deforming the lead or lead alloy, and subsequently annealing the lead or lead alloy. Either a single cycle of working and annealing can be provided, or a plurality of such cycles can be provided. The amount of deformation, the recrystallization time and temperature, and the number of repetitions of such steps are selected to ensure that a substantial increase in the population of special grain boundaries is provided in the microstructure, to improve resistance to creep, intergranular corrosion and intergranular cracking of the current collectors and connectors during battery service, and result in extended battery life and the opportunity to reduce the size and weight of the battery.

Owner:AUST KARL T +5

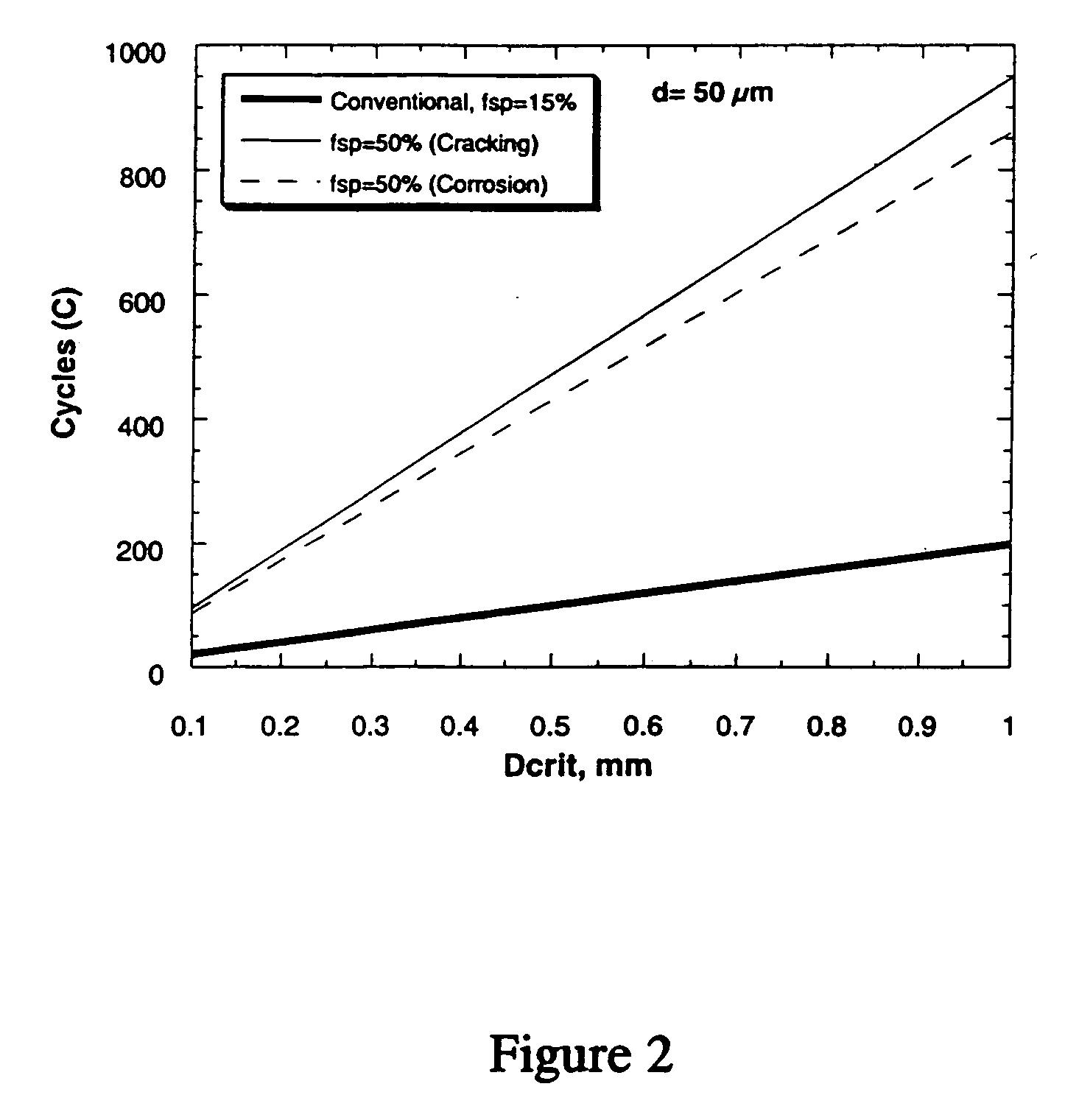

Method for waste lead-acid cell resourcization and lead-acid cell cyclic production

InactiveCN101488597AEliminate pollutionReserve availabilityWaste accumulators reclaimingBattery recyclingLead dioxideAlloy

The invention discloses a method for circularly producing lead acid batteries, aiming at thoroughly eliminating possible hazard of the lead acid battery on environment and leading the lead acid battery to be continuously useful in social life without causing negative effect. The method includes: the positive and negative plates of old and useless batteries are separated by a mechanical method, and then the positive and negative plates are subjected to electrochemical treatment, thus obtaining raw material for producing new lead acid battery and achieving the circular production of the lead acid battery including disassembly of the old and useless lead acid battery, purification of sulphuric acid electrolyte, the production of lead metal and lead dioxide by electrolyzing lead sulfate, the separation and regeneration of lead alloy as well as the production of new lead acid battery by the produced lead alloy, lead and lead dioxide. In theory, by the proposal, the raw material can be totally reused, thus achieving the aim of circularly producing the lead acid battery.

Owner:SOUTHEAST UNIV

Thermo-mechanical treated lead and lead alloys especially for current collectors and connectors in lead-acid batteries

InactiveUS20020088515A1Substantial deformationImprove corrosion resistanceElectrode carriers/collectorsElectrolysisMetallurgy

Recrystallized lead and lead alloy positive current collectors and connectors such as straps and lugs for use e.g. in lead acid batteries and electrowinning anodes, having an increased percentage of special grain boundaries in at least part of the microstructure, which have been provided by a process comprising of (i) cold or hot rolling or cold or hot extrusion or (ii) steps of deforming the lead or lead alloy, and subsequently annealing the lead or lead alloy. Either a single cycle of working and annealing can be provided, or a plurality of such cycles can be provided. The amount of deformation, the recrystallization time and temperature, and the number of repetitions of such steps are selected to ensure that a substantial increase in the population of special grain boundaries is provided in the microstructure, to improve resistance to creep, intergranular corrosion and intergranular cracking of the current collectors and connectors during battery service, and result in extended battery life and the opportunity to reduce the size and weight of the battery.

Owner:INTEGRAN TECH

Negative Electrode for Hybrid Energy Storage Device

InactiveUS20100040950A1Eliminate needGood contact resistance propertyHybrid capacitor electrodesElectrode carriers/collectorsActivated carbonConductive coating

A negative electrode for a hybrid energy storage device includes a current collector; a corrosion-resistant conductive coating secured to at least one face of the current collector; a sheet comprising activated carbon adhered to the corrosion-resistant conductive coating; a tab portion extending from a side of the negative electrode; and a lug comprising a lead or lead alloy that encapsulates at least part of the tab portion.

Owner:WAINWRIGHT D WALKER

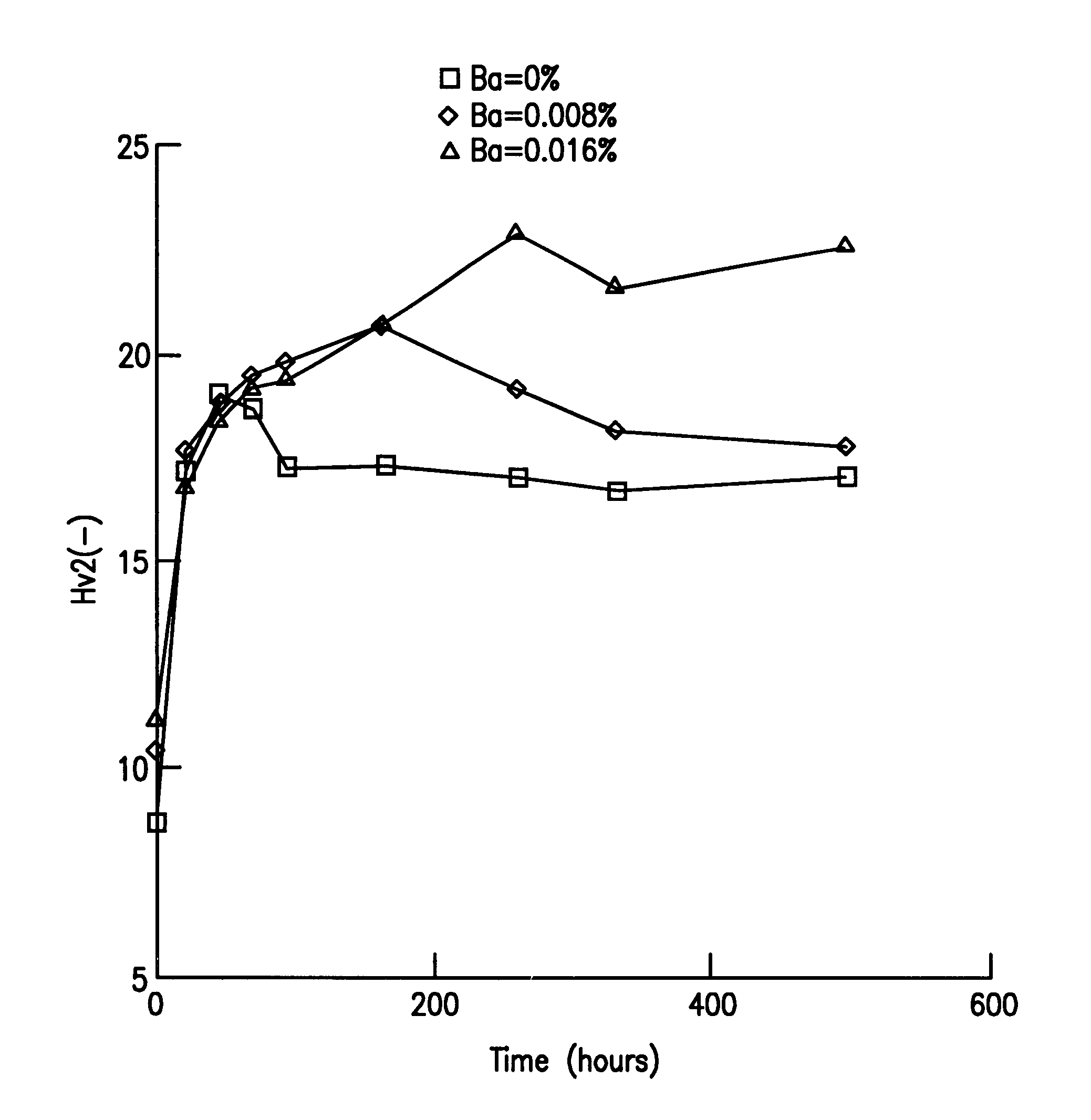

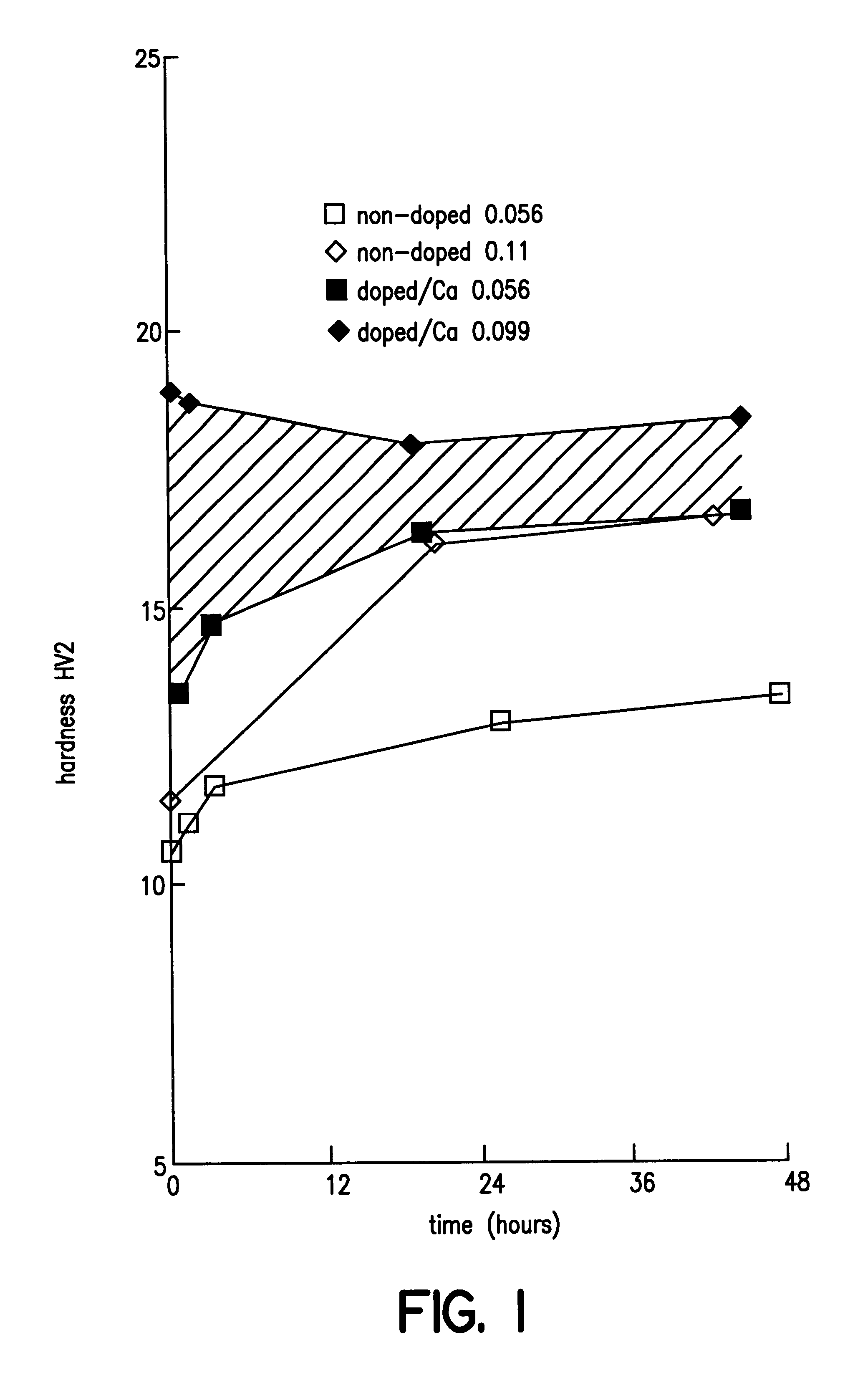

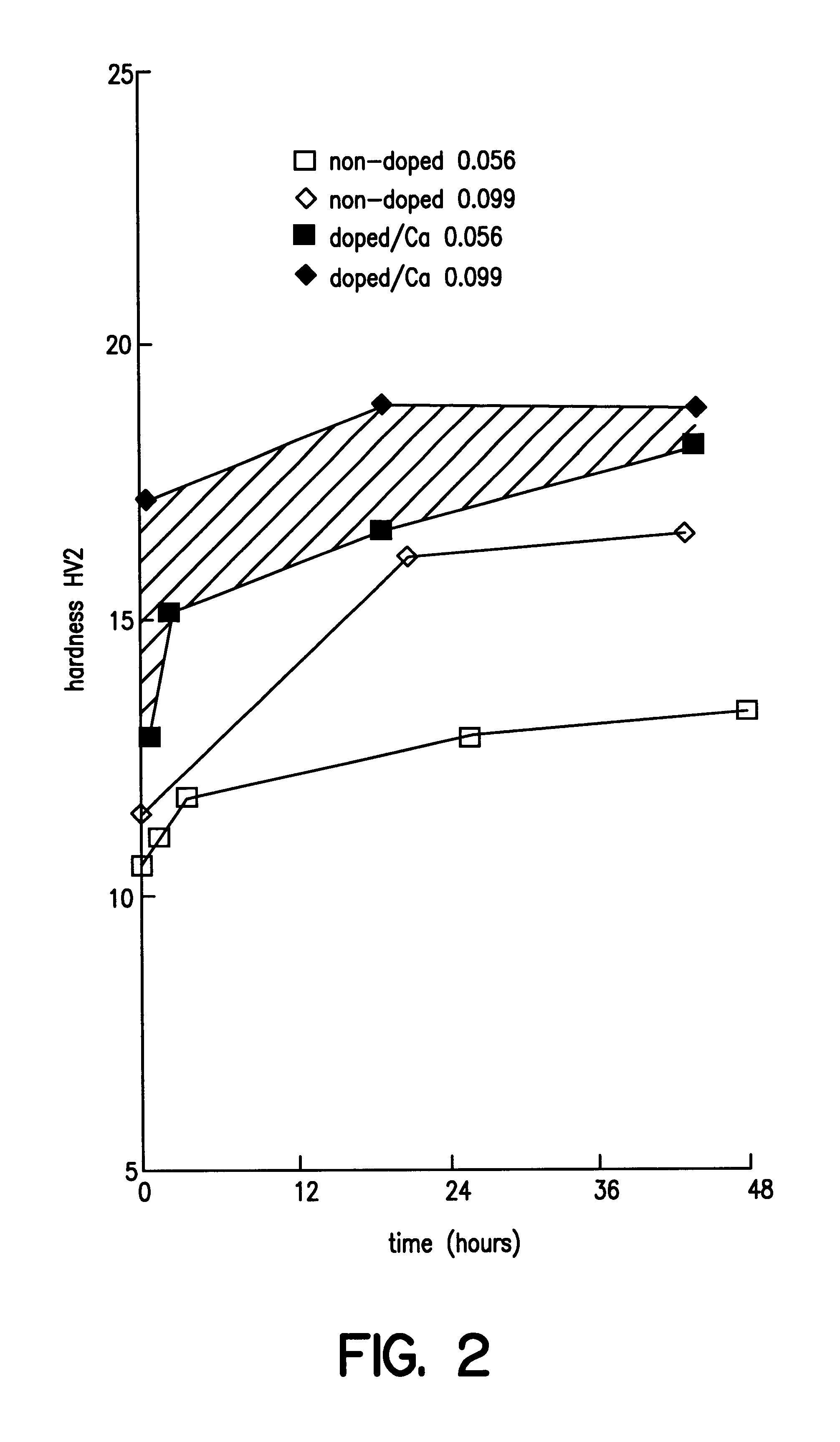

Lead-calcium alloys, particularly for battery grids

A lead alloy for battery grids is disclosed. The lead alloy contains calcium with a relative concentration by weight of between 0.05% and 0.12%; tin with a relative concentration by weight of less than 3%; aluminum with a relative concentration by weight of between 0.002% and 0.04%; and barium comprising a relative concentration by weight of less than 0.02%.

Owner:METALEUROP

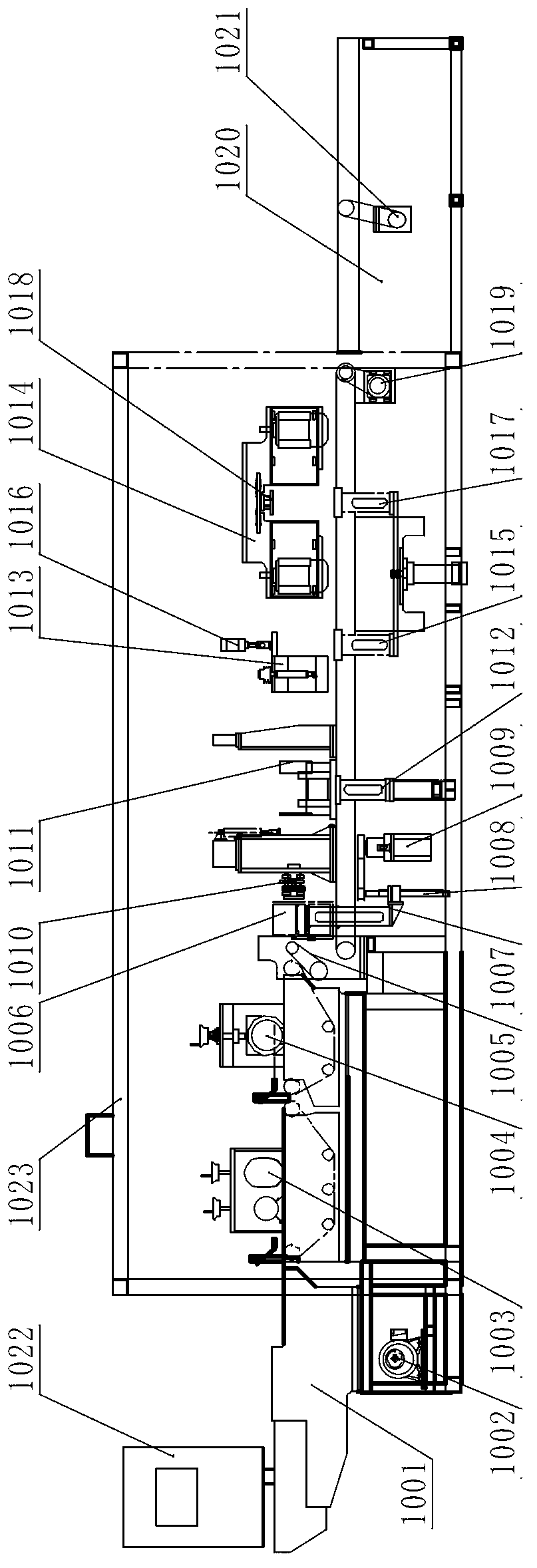

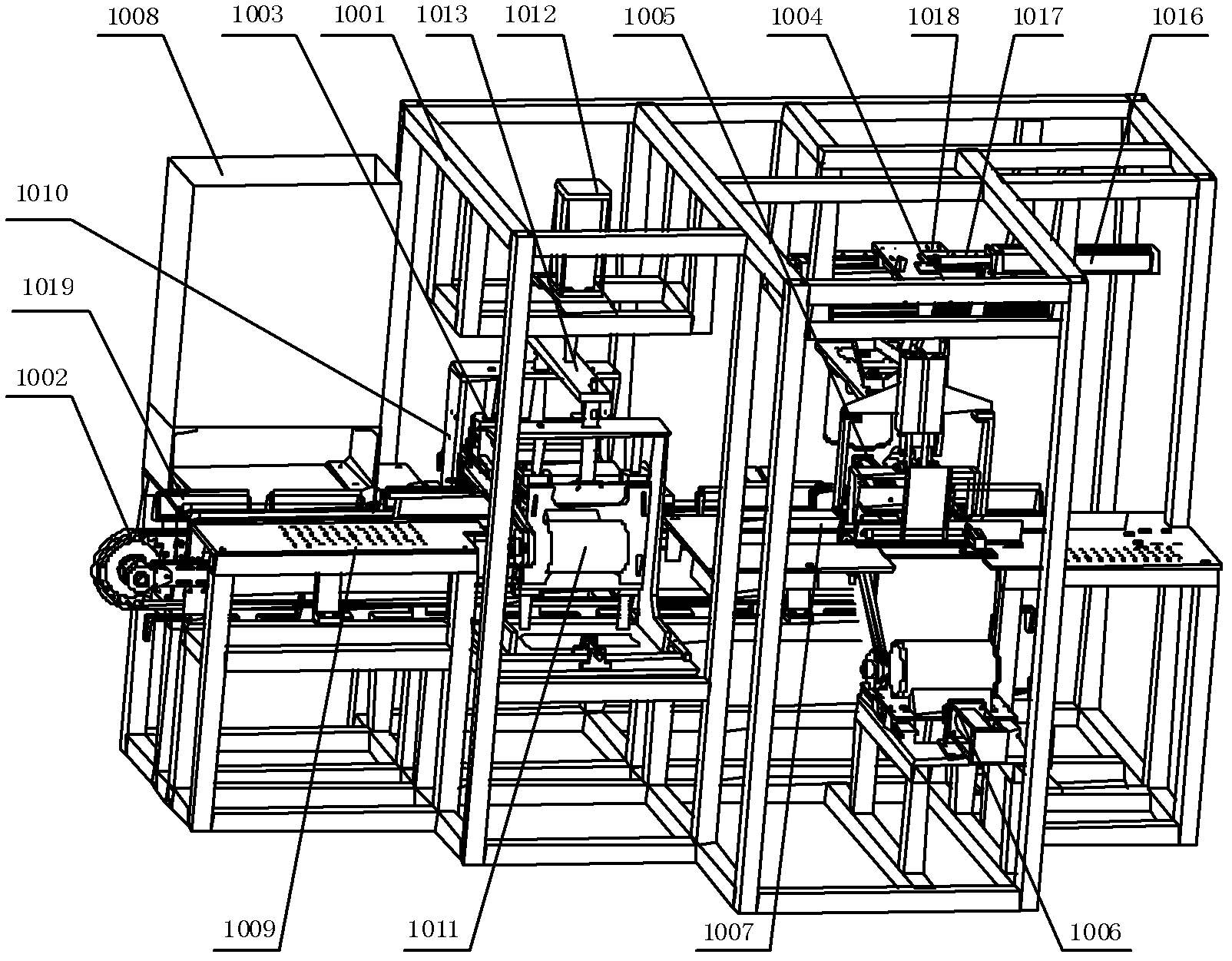

Automatic lug brushing-cutting and frame-brushing machine for storage battery plate

ActiveCN103066245AReduce deformation, loose lugs and other defectsReduce pollutionLead-acid accumulator electrodesOperational costsEngineering

The invention relates to a lug brushing-cutting and frame brushing machine for a high-dense storage-battery plate, and particularly relates to equipment for automatically brushing and cutting lugs and brushing four sides of a high-dense pole plate in the lead-acid battery production process. The lug brushing-cutting and frame brushing machine is a streamline device which formed by successive connection of a plate delivering device, a pole plate conveying device, a lug brushing device, a lug cutting device, a transition device, a laminating device, a reshaping device, a frame brushing device and a plate folding device, and the streamline device automatically cooperates under electric control. The lug brushing-cutting and frame brushing machine provided by the invention achieves the automatic lug brushing-cutting and frame brushing of a high-dense lead alloy pole plate, and finishes the transition of a production flow from a semi-automation operation to a full automatic serialization operation, so that labour operation intensity and operational cost are greatly reduced, the labour productivity is improved, and the damage to human bodies caused by the environmental pollution and lead dust can be alleviated.

Owner:武汉深蓝自动化设备股份有限公司

Electrolytic Generation of Manganese (III) Ions in Strong Sulfuric Acid

An electrolytic cell and a method of electrochemical oxidation of manganese(II) ions to manganese(III) ions in the electrolytic cell are described. The electrolytic cell comprises (1) an electrolyte solution of manganese(II) ions in a solution of at least one acid; (2) a cathode immersed in the electrolyte solution; and (3) an anode immersed in the electrolyte solution and spaced apart from the cathode. Various anode materials are described including vitreous carbon, reticulated vitreous carbon, woven carbon fibers, lead and lead alloy. Once the electrolyte is oxidized to form a metastable complex of manganese(III) ions, a platable plastic may be contacted with the metastable complex to etch the platable plastic. In addition, a pretreatment step may also be performed on the platable plastic prior to contacting the platable plastic with the metastable complex to condition the plastic surface.

Owner:MACDERMID ACUMEN INC

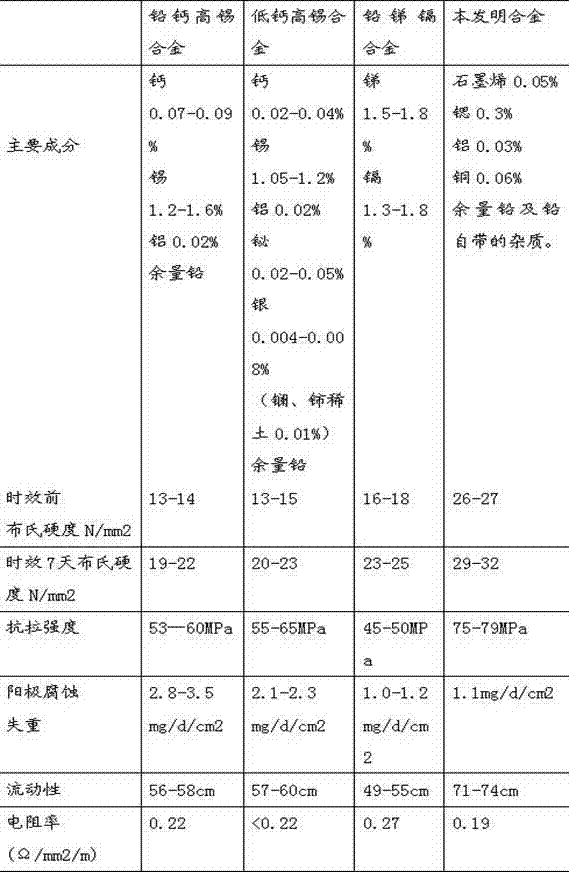

Graphene-lead alloy as well as preparation method and application thereof

The invention discloses a graphene-lead alloy as well as a preparation method and application thereof. The graphene-lead alloy is prepared from the following components in percentage by weight: 0.0015-0.1 percent of graphene, 96.96 percent of lead and any one, two, three or four of 0.1-1.6 percent of tin, 0.015-0.05 percent of aluminum, 0.05-1.2 percent of strontium and 0.05-0.09 percent of copper. The invention also discloses the preparation method and the application to a grid alloy. The graphene-lead alloy used by a grid is high in rigidity, good in toughness, mobility and creep resistance, strong in corrosion resistance and firm in combination of the grid and an active substance without a barrier layer. According to the invention, a battery manufactured by the graphene-lead alloy is little in water loss and long in cycle life.

Owner:XIAMEN MATE HI TECH NEW ENERGY CO LTD

Tin-lead welding strip for solar photovoltaic assembly and manufacturing method thereof

InactiveCN102254978AImprove adhesionImprove conductivityFinal product manufacturePhotovoltaic energy generationMicrometerDross

The invention discloses a tin-lead welding strip for a solar photovoltaic assembly, which comprises a copper strip base material, wherein a compact tin-lead alloy layer with a thickness of 3-20 micrometers covers the surface of the copper strip base material. A manufacturing method of the tin-lead welding strip for the solar photovoltaic assembly comprises the step of: covering the compact tin-lead alloy layer on the copper strip base material by adopting an electroplating method, wherein the thickness of the tin-lead alloy layer is 3-20 micrometers. Because the electroplating method is adopted, a cladding material has a crystal lattice characteristic and capacities of enhancing adhesive force of the welding strip and improving the conductivity of the photovoltaic welding strip. The welding strip has a volume resistivity of 0.0185-0.021omega mm<2> / m which is lower than that of the welding strip manufactured through thermal tin immersion and a melting point of 183-190 DEG C lower than that of a lead-free welding strip, and has no abnormal phenomena such as tin knobs, tin dross, copper cuttings, discoloration and the like. A process capability index (CPK) value is effectively increased.

Owner:SHANGHAI WELNEW MICRO ELECTRONICS

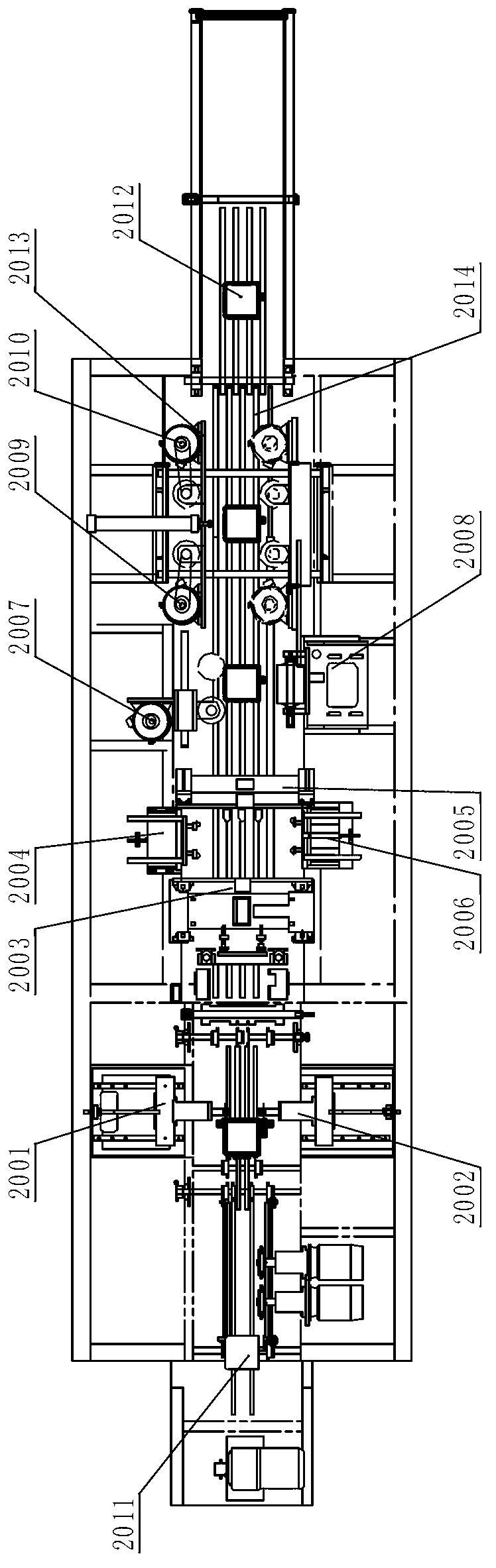

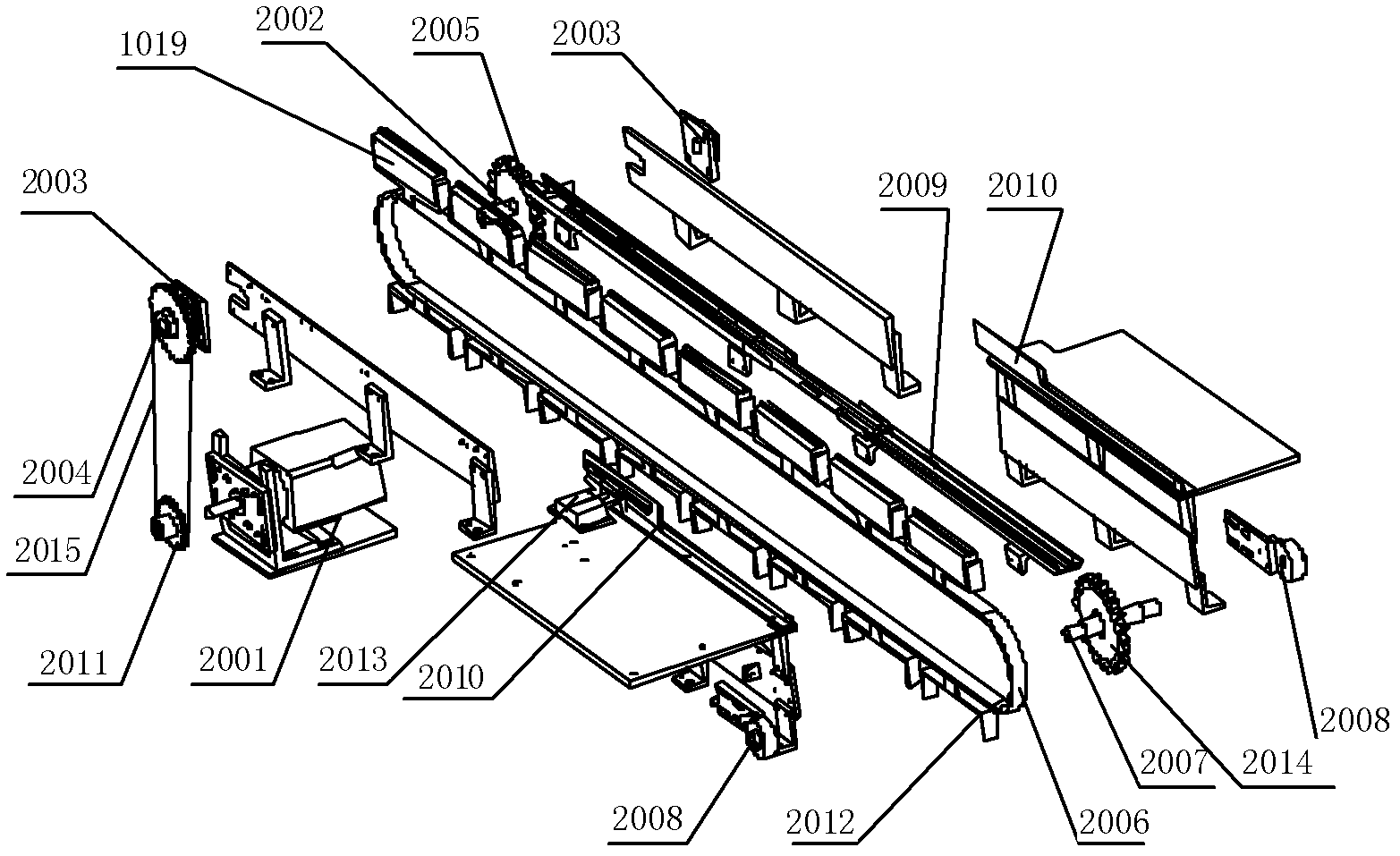

Automatic edge brushing machine for pipelined battery plate

InactiveCN102626891AEdge grinding machinesElectrode manufacturing processesDevice formMedium density

The invention relates to an automatic edge brushing machine for a pipelined battery plate, and particularly to equipment for brushing the four edges of a plate automatically in production process of a lead-acid battery. The invention discloses a frame brushing machine which is a pipelined device formed by connecting a rack, a plate running device, a side edge brushing device, an upside edge brushing device, a plate pushing device, a downside edge brushing device and a plate receiving device in sequence. The pipelined device coordinates automatically under electrical control. With the frame brushing machine provided by the invention, automatic edge brushing of low- and medium-density lead alloy plates is realized, the transformation of the production process from a semi-manual labor to an automatic operation is fulfilled, production intensity and operation cost of a manual operation are greatly reduced, labor productivity is improved, and pollution to environment and harm to human bodies caused by lead dust are reduced.

Owner:武汉深蓝自动化设备股份有限公司

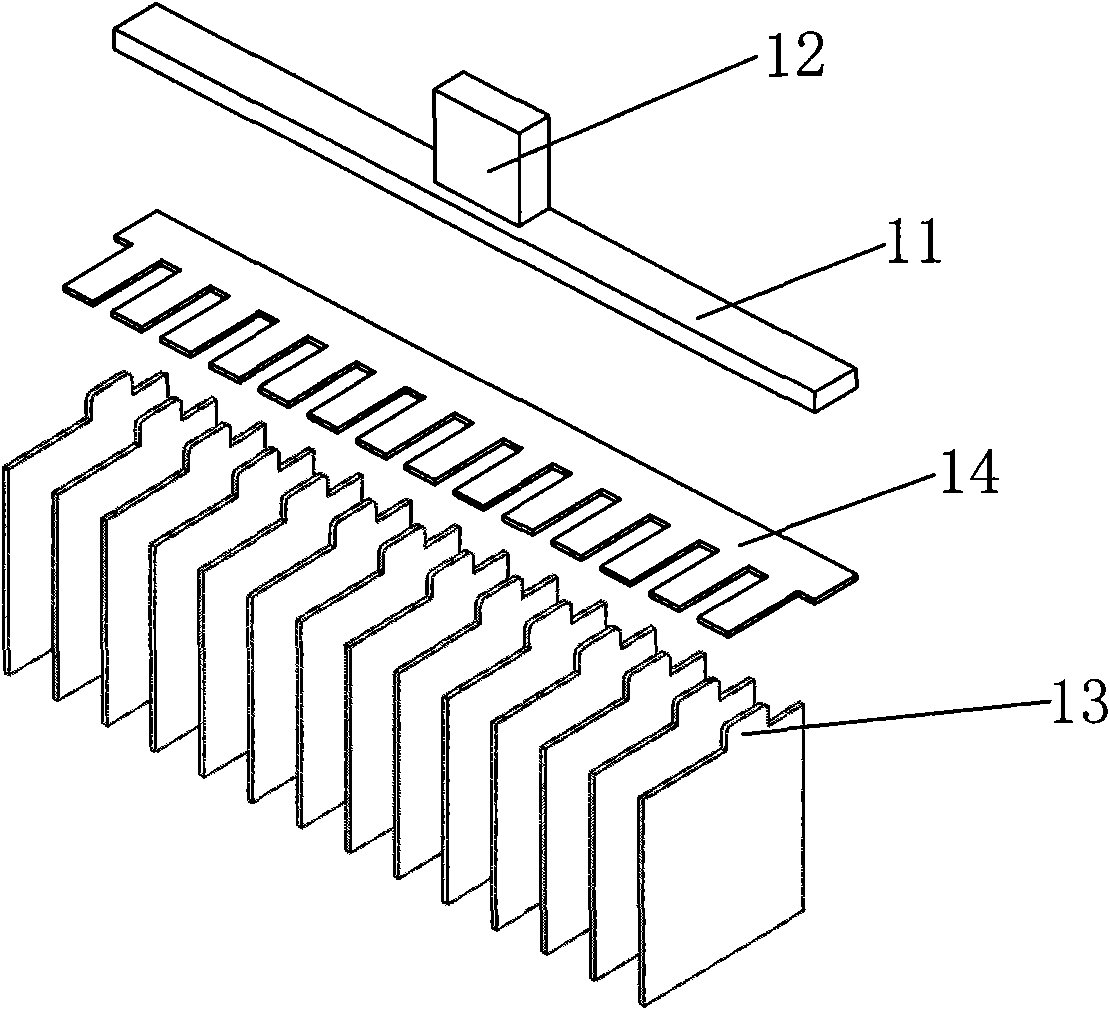

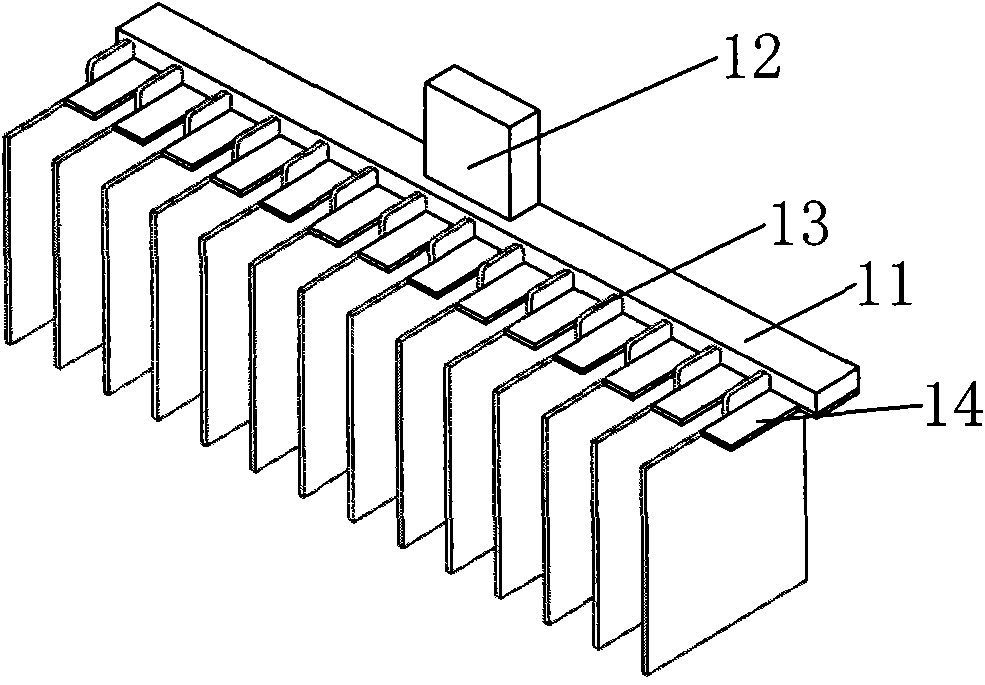

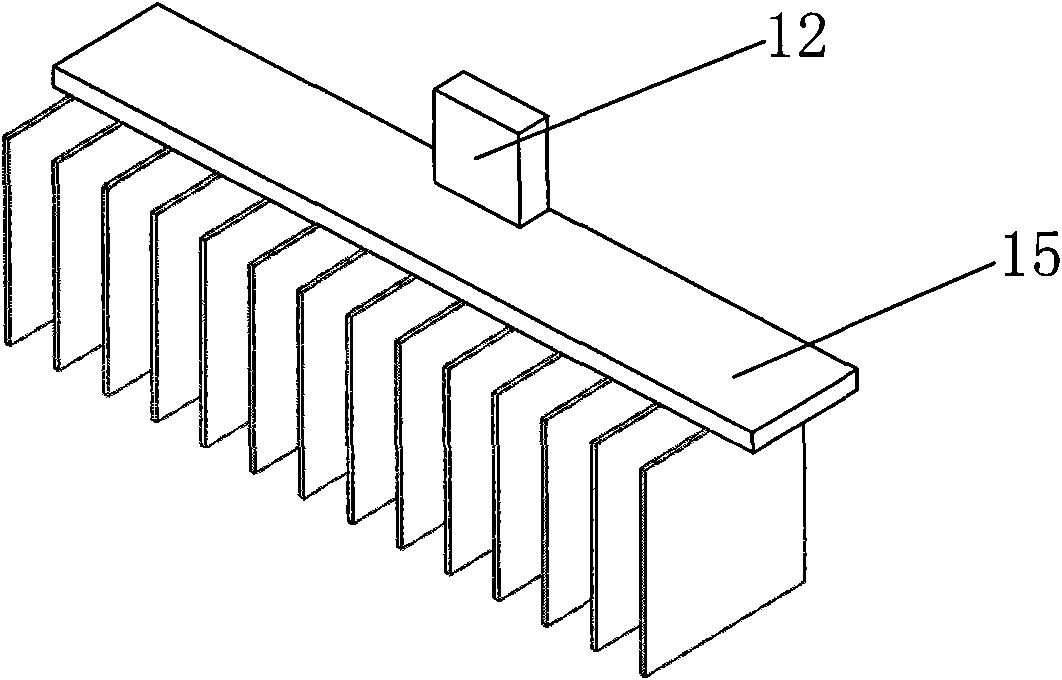

Precast piece for busbar of storage battery and method for welding same with polar plates of storage battery

ActiveCN101593822ACompact structureIncrease contact areaArc welding apparatusCell component detailsBusbarElectrical polarity

The invention provides a precast piece for a busbar used in a high-capacity lead-acid storage battery, parallelly connecting polar plates with the same polarity in the storage battery and leading the polar plates to electrode terminals. The precast piece comprises a connecting main board which is respectively welded with lugs of the polar plates of the storage battery; the connecting main board is strip-shaped; the middle of the connecting main board is provided with a post vertical to the connecting main board; and a pectinate material preparing threaded rod is extended along the lateral surface of a longer side of the connecting main board. Due to the existence of the pectinate material preparing threaded rod, the precast piece for the busbar can greatly reduce the melting time of workpieces and the feed amount of alloy solder in the welding, can complete solder sides for one time in short time, can reduce the air contacting opportunity of a lead alloy to the utmost, ensure the quality of weldments, and ensures that the busbar has compact structure to prolong the service life of the storage battery. The invention also provides a method for connecting the precast piece for the busbar and the lugs of the polar plates of the storage battery, which has simple operation and can obtain good welding quality by means of the prior welding conditions.

Owner:GUANGDONG DYNAVOLT NEW ENERGY TECH CO LTD

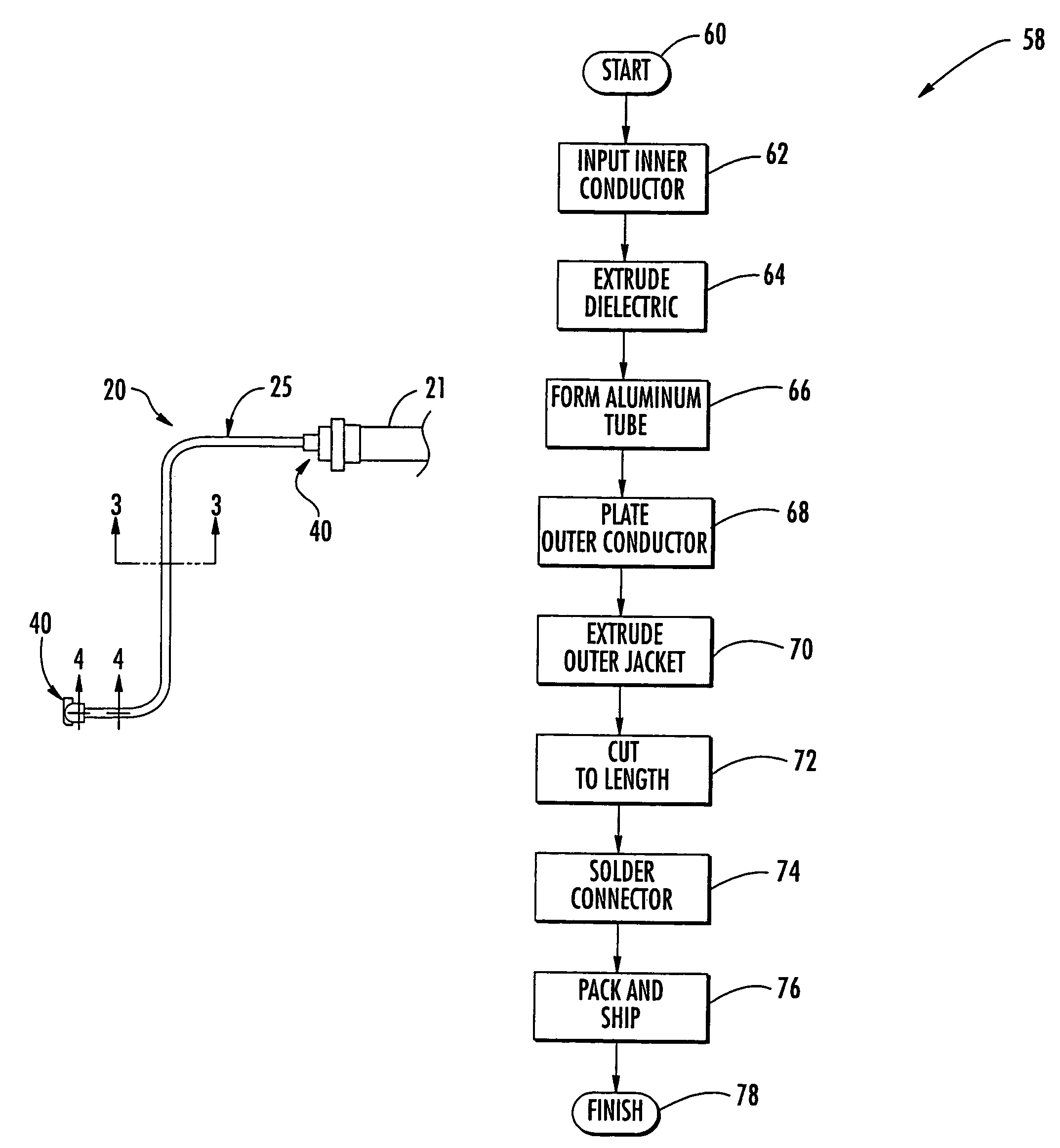

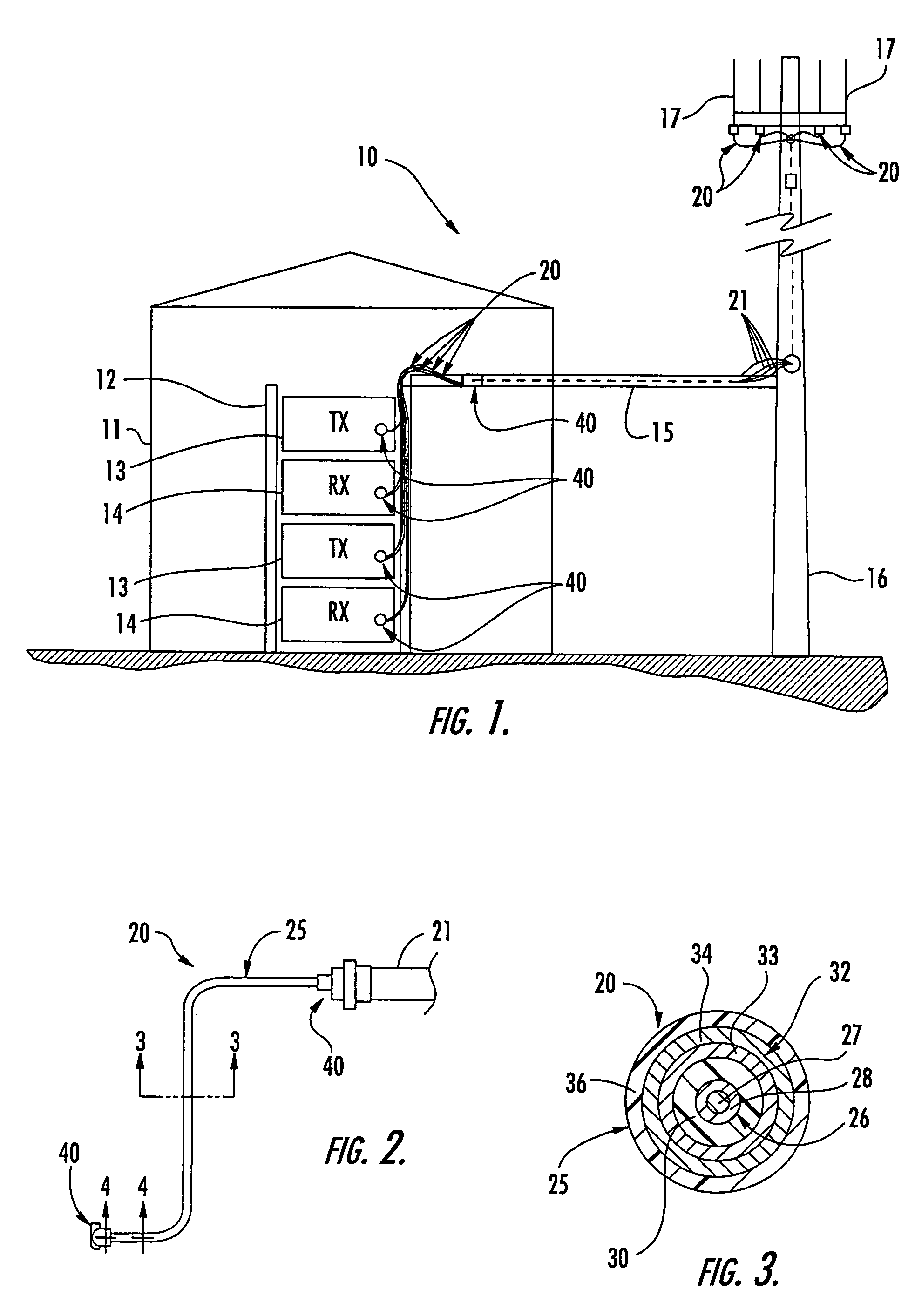

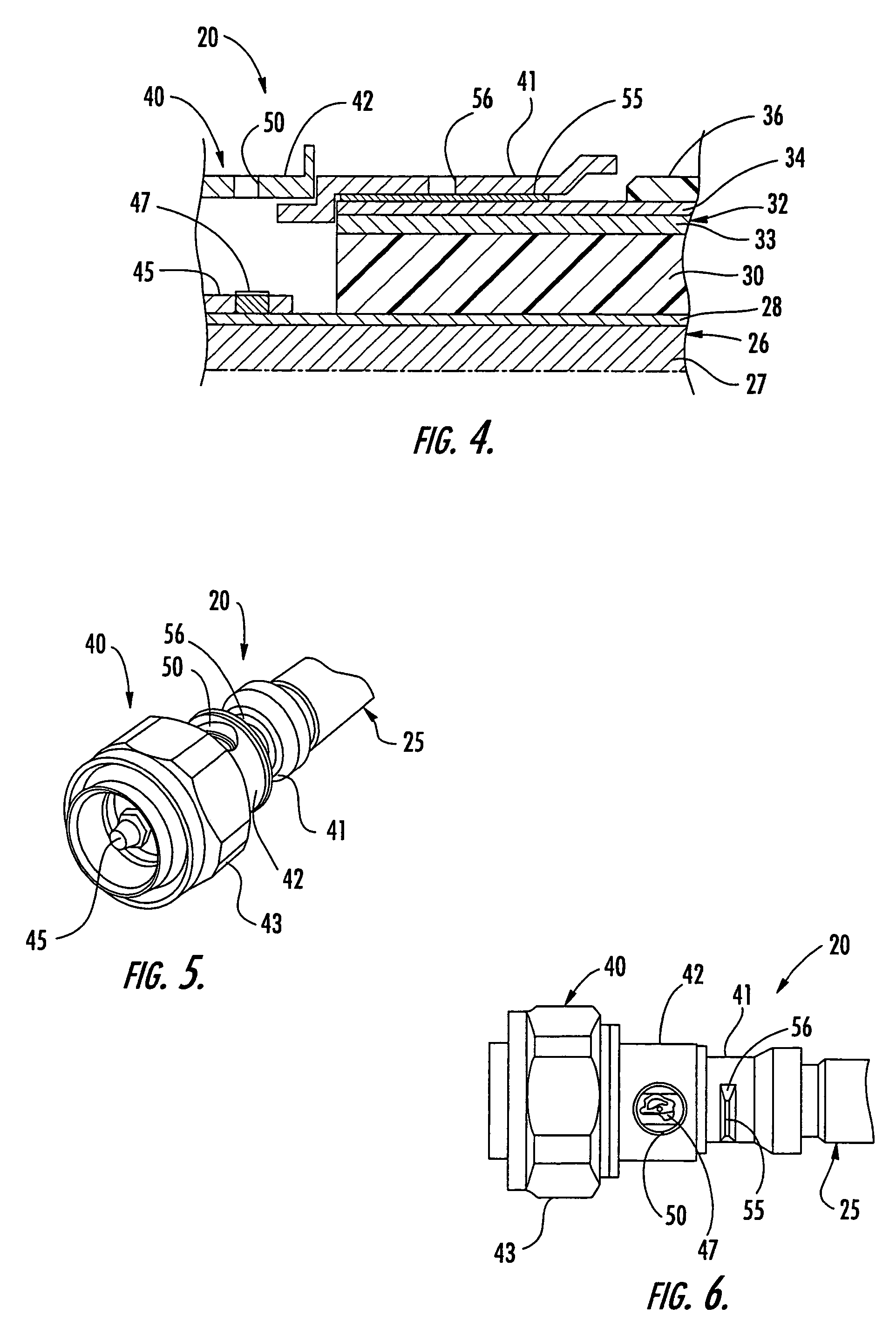

Method for marking coaxial cable jumper assembly including plated outer assembly

InactiveUS7127806B2Easy to manufactureShape-retaining qualityEngagement/disengagement of coupling partsPrinted circuit assemblingCoaxial cableElectrical conductor

A jumper coaxial cable assembly includes a jumper coaxial cable and at least one solder-type connector secured thereto. The cable may include an outer conductor, which, in turn, includes aluminum with a tin layer thereon. The tin layer permits an aluminum outer conductor to be used, yet facilitates soldering of the solder-type connector onto the outer conductor. The tin layer may be a tin alloy, such as a tin / lead alloy, for example. The outer conductor may have a continuous, non-braided, tubular shape, and the tin layer may extend continuously along an entire length of the outer conductor. The tin layer may be readily formed by tin plating during manufacturing of the jumper coaxial cable. The jumper coaxial cable assembly may be joined to a main coaxial cable and / or to electronic equipment.

Owner:COMMSCOPE INC

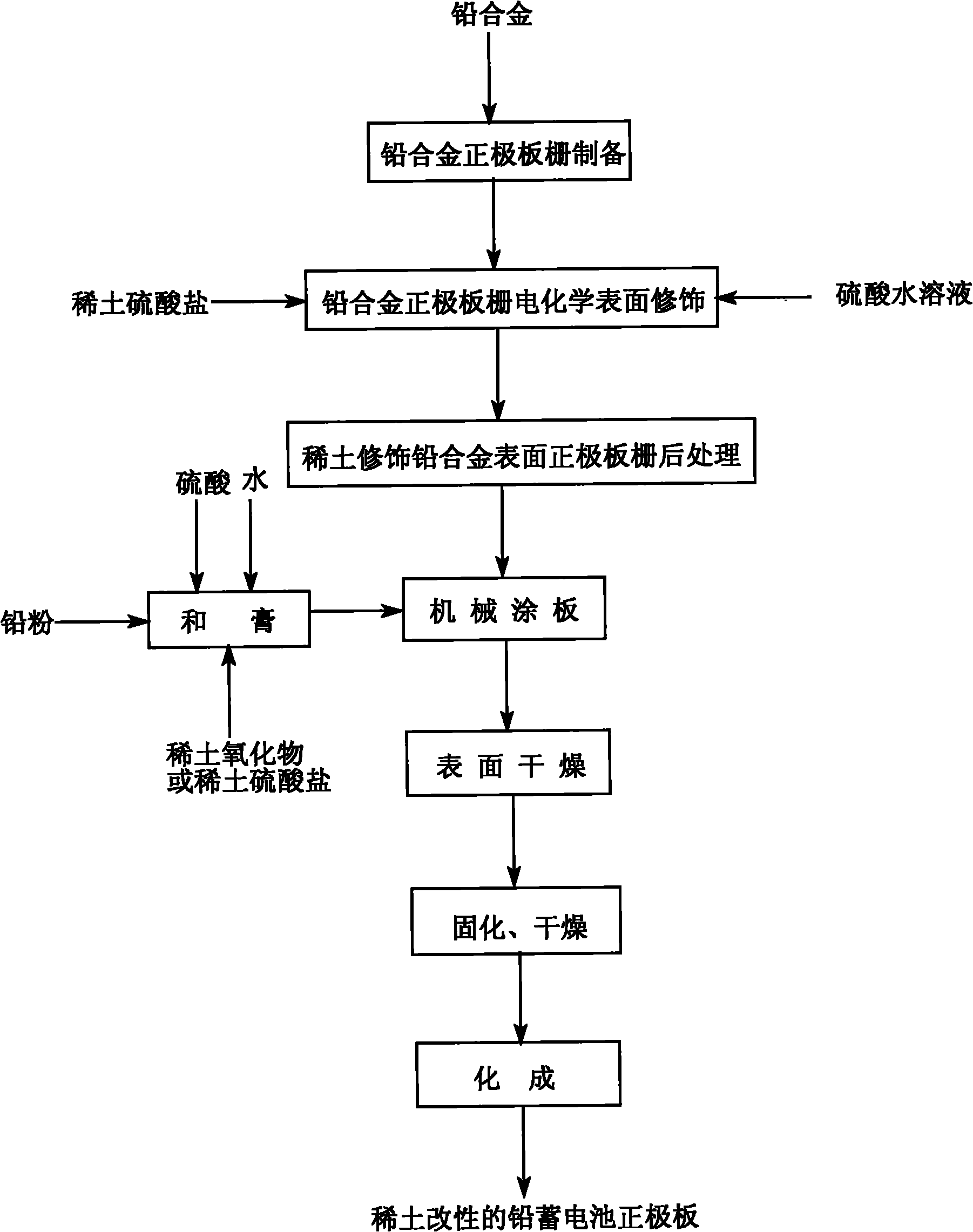

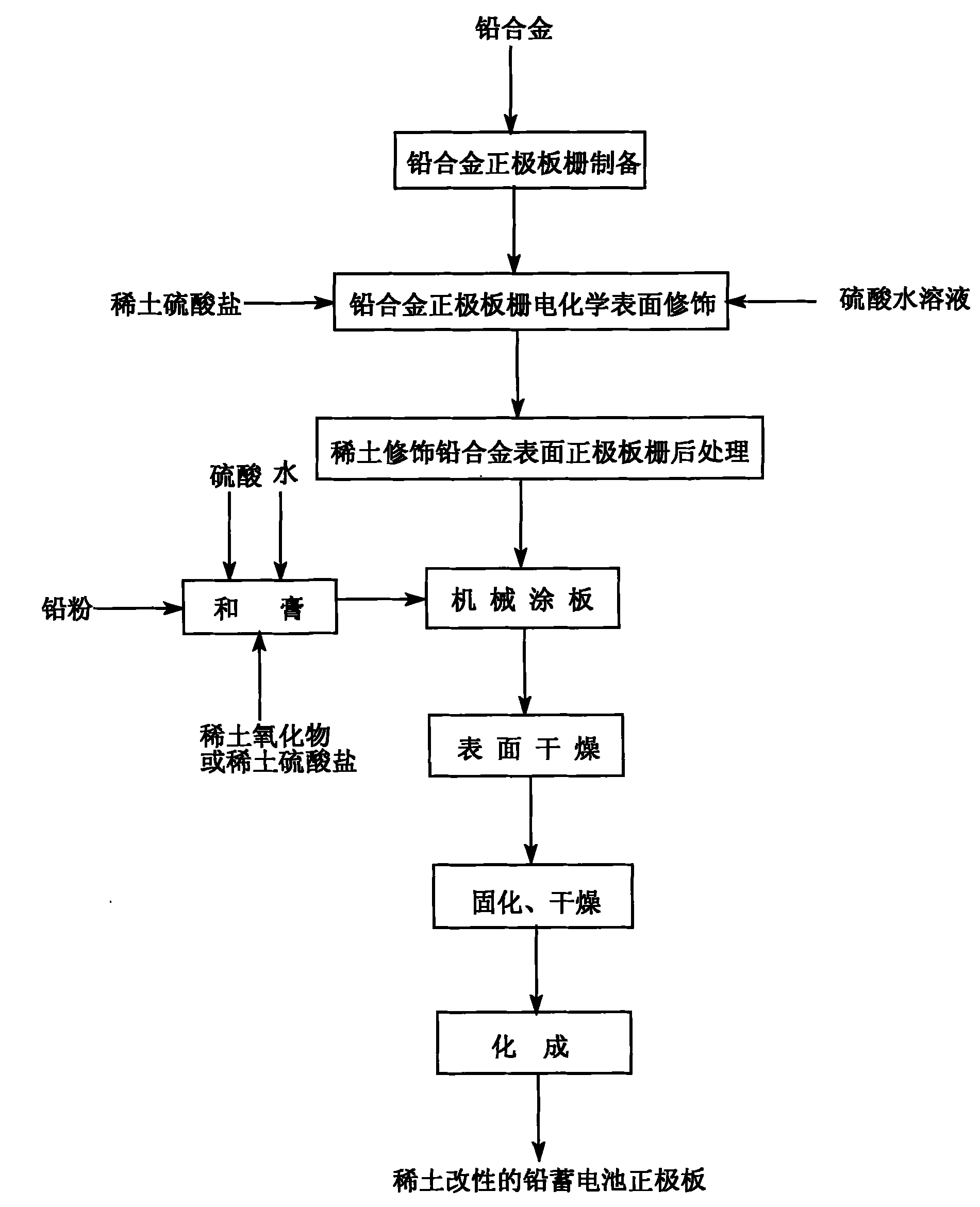

Method for preparing positive plate of lead storage battery

ActiveCN101841030AImprove performanceImprove power characteristicsElectrode carriers/collectorsLead-acid accumulator electrodesRare-earth elementAlloy

The invention discloses a method for preparing a positive plate of a lead storage battery, and belongs to the technical field of preparation of electrode materials, in particular to a process for a preparation method for the lead storage battery. In the method, a lead alloy is used as a raw material, a lead-alloy positive electrode grid formed by fusion and casting is used as the positive electrode and is subjected to surface modification in rare earth sulfate and sulphuric acid solution by an anodic electrochemical oxidation process to prepare a positive plate of the lead storage battery that the surface of the lead alloy is modified by the rare earth; and lead powder, water, sulfuric acid and rare earth oxides or rare earth sulfate and additives are mixed into a lead plaster, and the lead plaster is subjected to plate coating, solidification, drying and formation to prepare the rear-earth modified positive electrode grid of the lead storage battery. The method is simple, reduces the using amount of the rear earth and improves the utilization ratio of the rear earth, avoids the difficulty in preparing the positive electrode grid from the lead-rare earth alloy, is easy to uniformly and quantitatively dope trace rare-earth elements on the surface of the electrode, and realizes the control of the surface performance of the electrode.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV +1

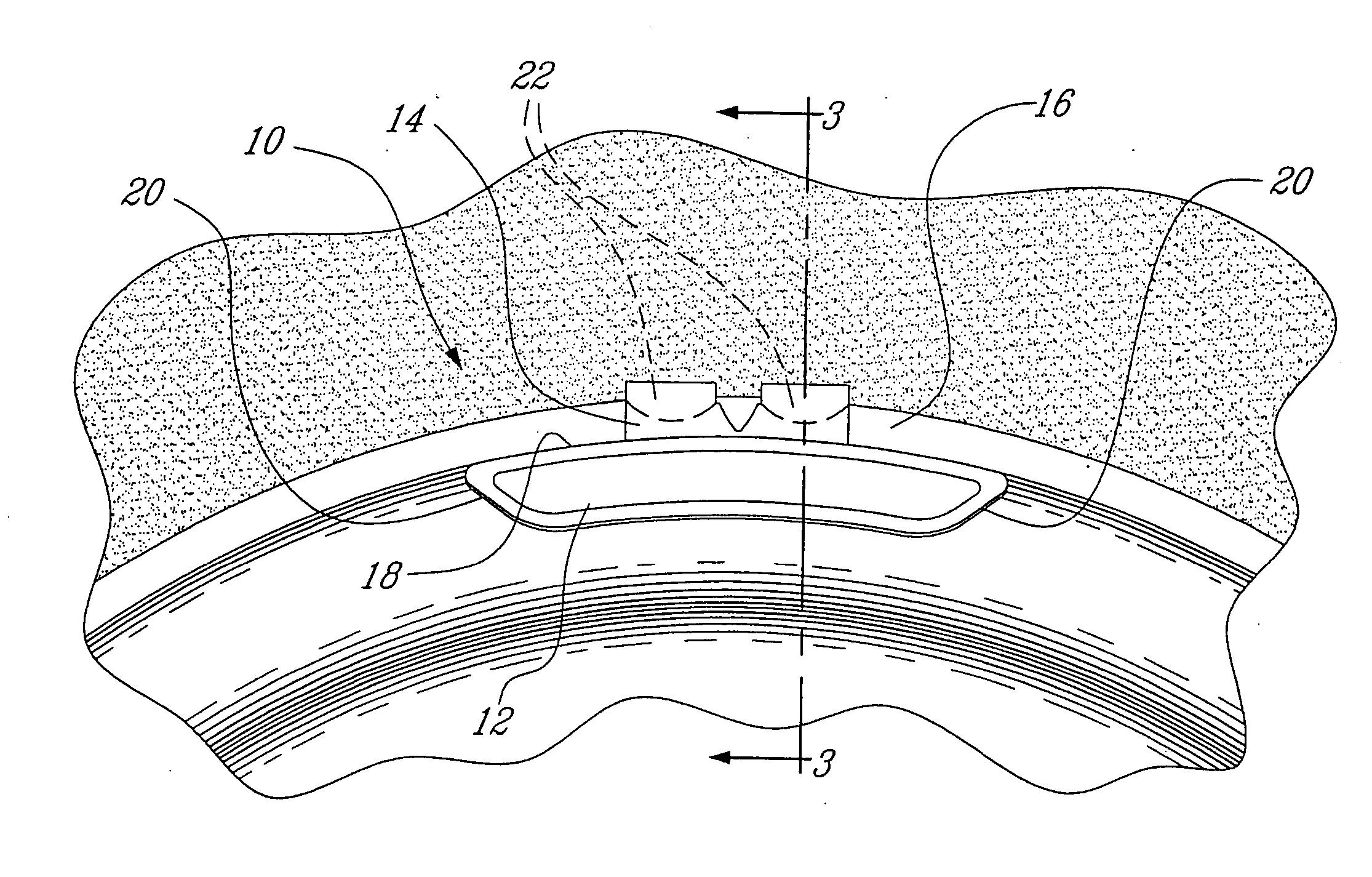

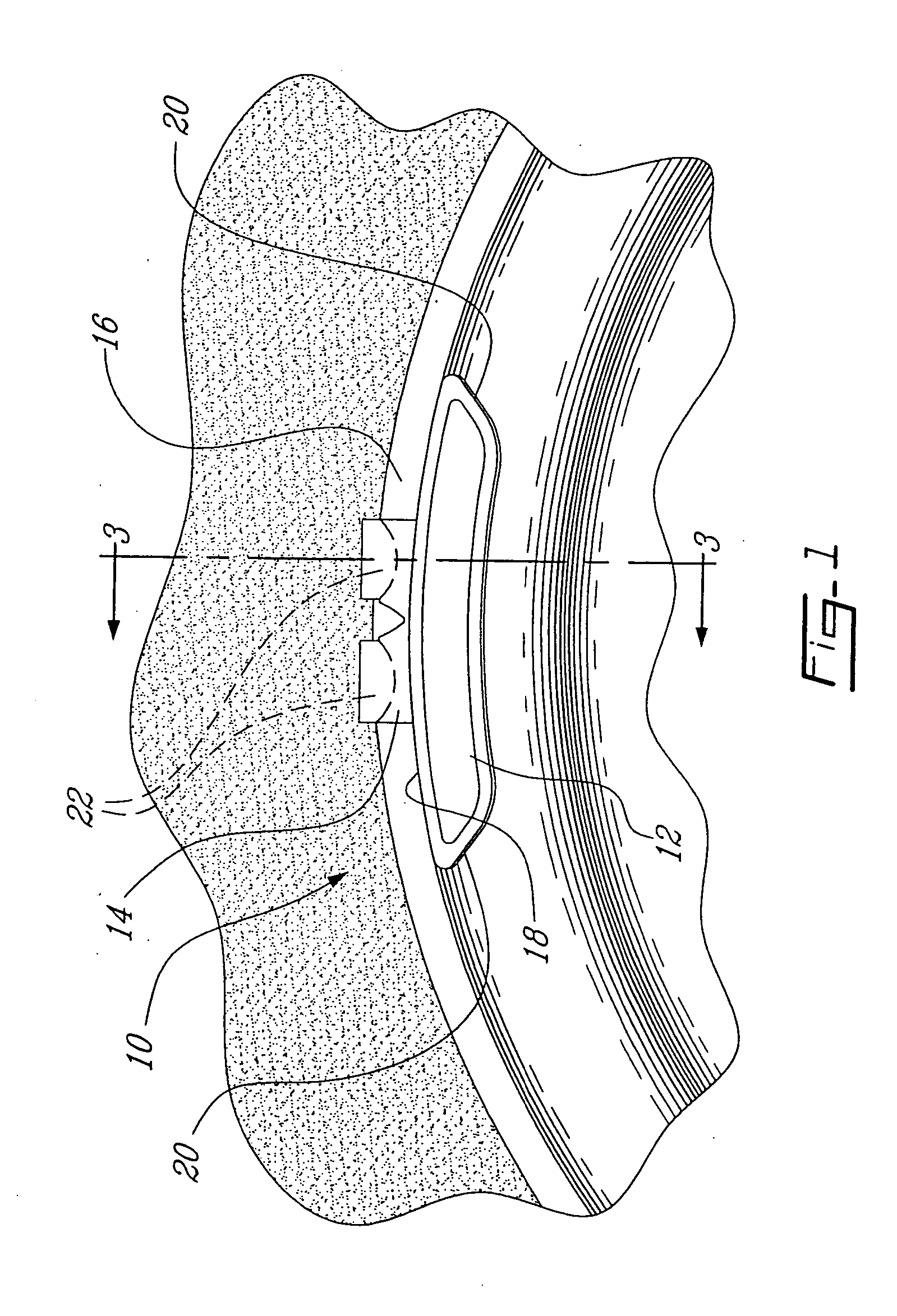

Lead-oxide battery plate with nonwoven glass mat

ActiveUS20110293988A1Limited penetrationFinal product manufactureElectrode carriers/collectorsGlass fiberLead oxide

Provided is a lead-oxide pasted battery plate comprising a lead alloy grid, lead oxide paste and a nonwoven glass fiber mat. The nonwoven glass mat is comprised of glass fibers having a diameter greater than 10 microns, a binder for the glass fibers, and a third component. The third component can comprise cellulosic fibers, glass micro-fibers, polymeric fibers, fillers or mixtures thereof. The presence of the third component restricts the penetration of the lead oxide paste through the thickness of the mat during the plate pasting operation, thereby keeping the process equipment free from the accumulation of lead oxide paste. The component can then dissolve in the battery acid solution, or work synergistically with the battery separator to deliver electrolyte to the lead oxide plate during the operation of the battery.

Owner:JOHNS MANVILLE CORP

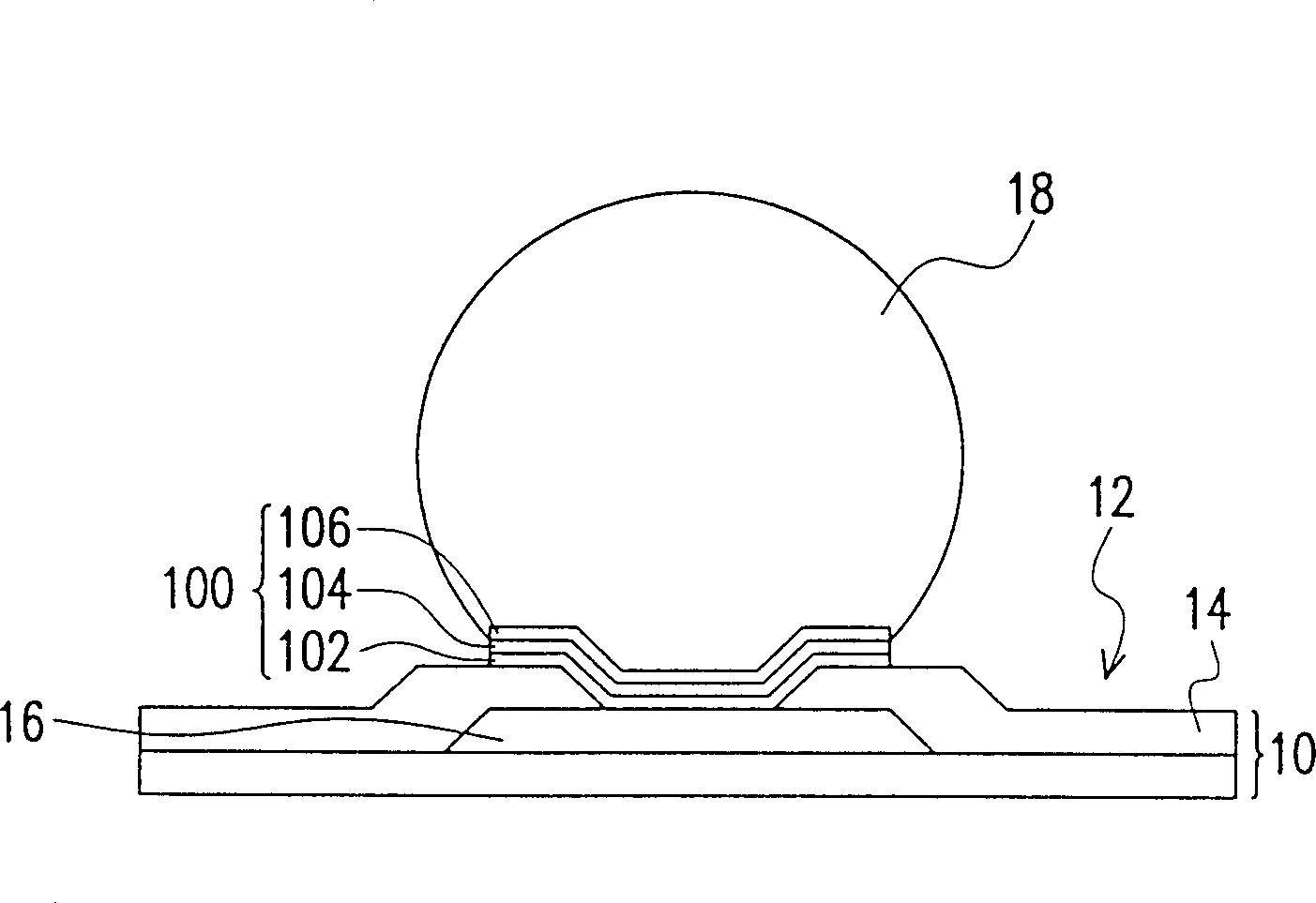

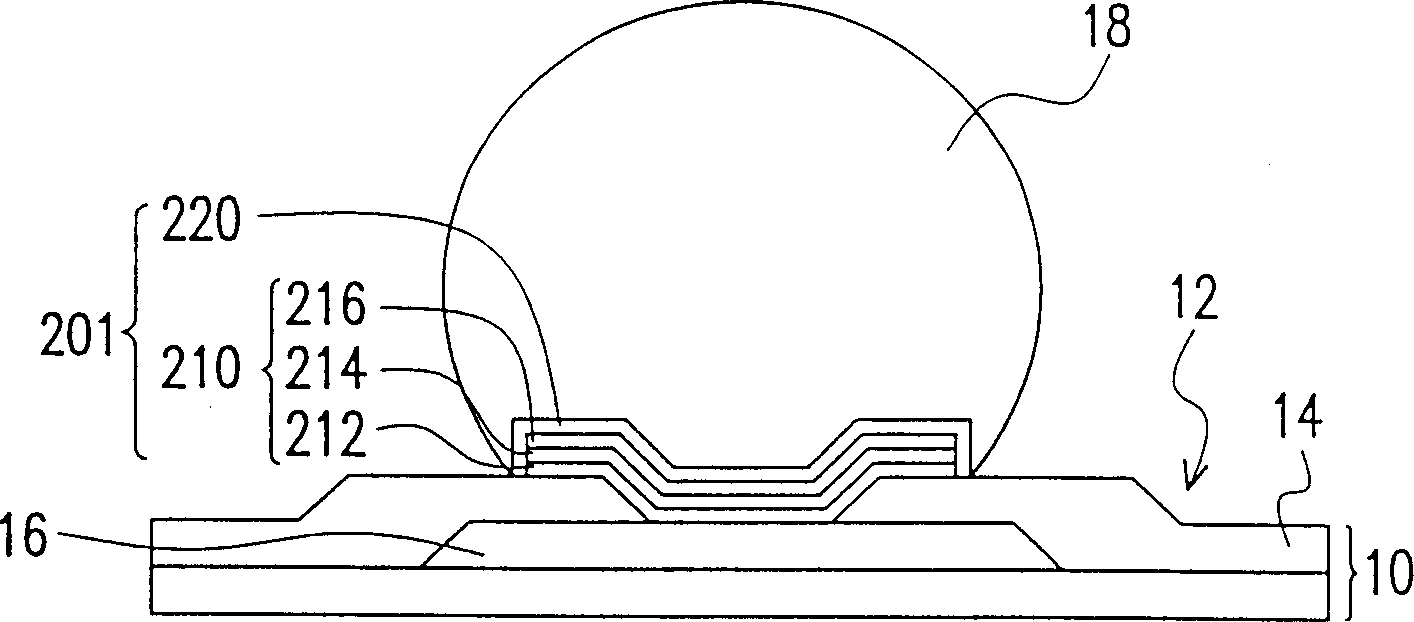

Bottom buffering metal lug structure

InactiveCN1392607AImprove mechanical propertiesImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesCompound (substance)Alloy

A bulge-bottom buffering metal structure is suitable for being disposed between a chip or a soldering pad for baseplate and a solder lug whose main component is tin-lead alloy. The said bulge-bottom buffering metal structure has at least one metal layer and one tuffing metal construction. This buffering metal construction can reduce or slow down the negative effect of electric and mechanical properties due to the generation of mesic metal compound when the metal layer combines with the solder lug. The metal layer disposed on the soldering pad of chip is composed of such components as Cu, Al, Ni, Ag or Au, etc. which may react on tin chemically, while the buffering construction disposed between the metal layer and the solder lug is used for reducing the possibility of generating the mesic metal compound between them.

Owner:VIA TECH INC

Method for manufacturing lead-carbon ultracapacitor battery cathode

ActiveCN101667637AIncrease specific energyImprove discharge capacityElectrochemical generatorsElectrode manufacturing processesCapacitanceActivated carbon

The invention discloses a method for manufacturing a lead-carbon ultracapacitor battery cathode, comprising the following steps: active substances taking lead powder as a main component and active substances taking active carbon as a main component are respectively coated on different areas of an electrode matrix, and then are dried to obtain the lead-carbon ultracapacitor battery cathode. The invention provides a manufacturing technology of lead-carbon ultracapacitor battery cathode, which takes a pure lead sheet or lead alloy sheet as a matrix, and adopts the active carbon and the lead powder as active substances. Compared with the cathode taking the pure active carbon as cathode active substance, the cathode piece manufactured by the method can greatly improve discharge capacity of thelead-carbon ultracapacitor batteries, the specific energy can reach more than 16wh / kg, the cycle life can reach more than 1500 times, working potential window can reach 2.0V, and the cost is only onethird to one fifth of that of the current inorganic system carbon-carbon symmetric form and nickel electrode-carbon mixed alkaline system.

Owner:SHUANGDENG GRP

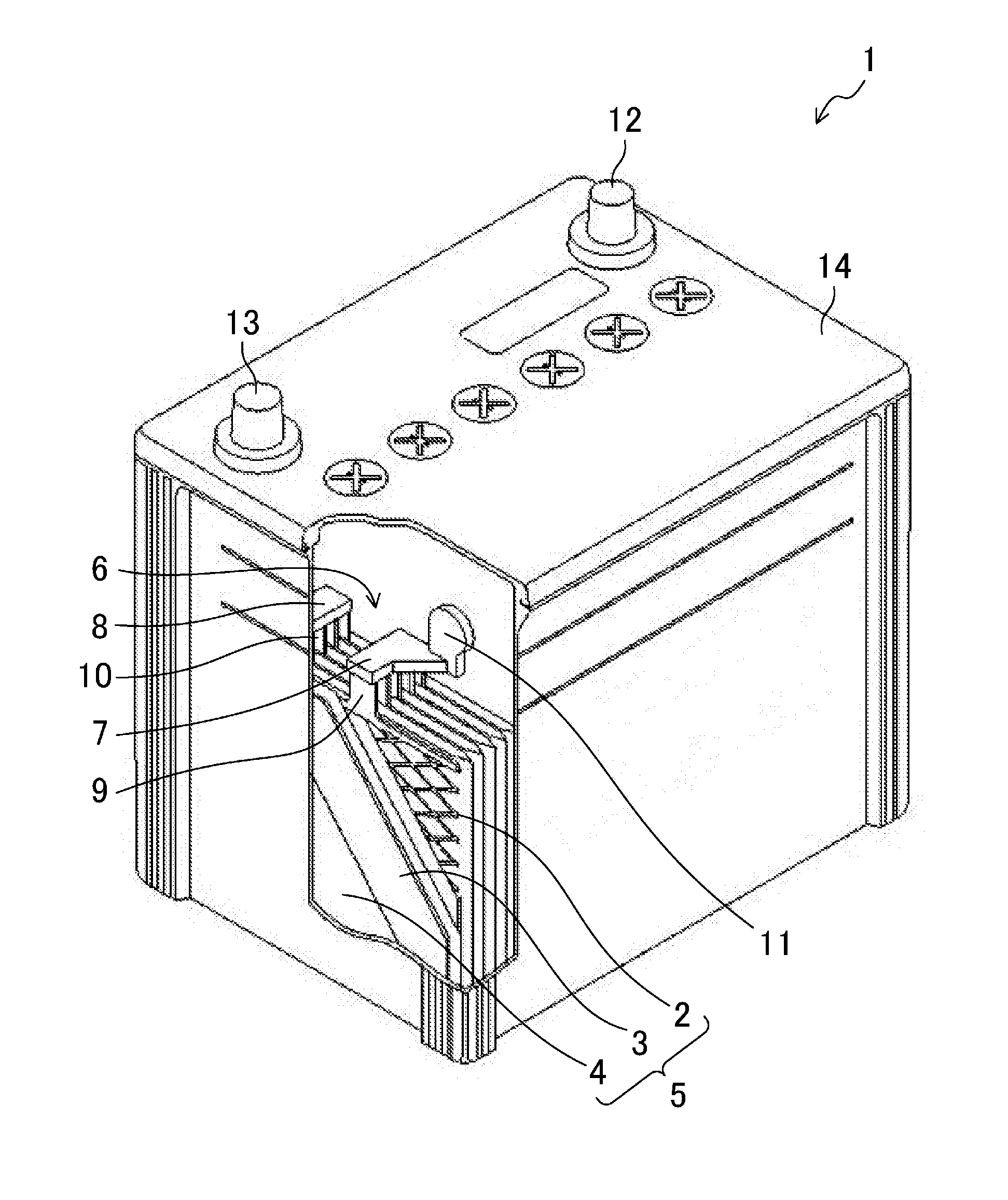

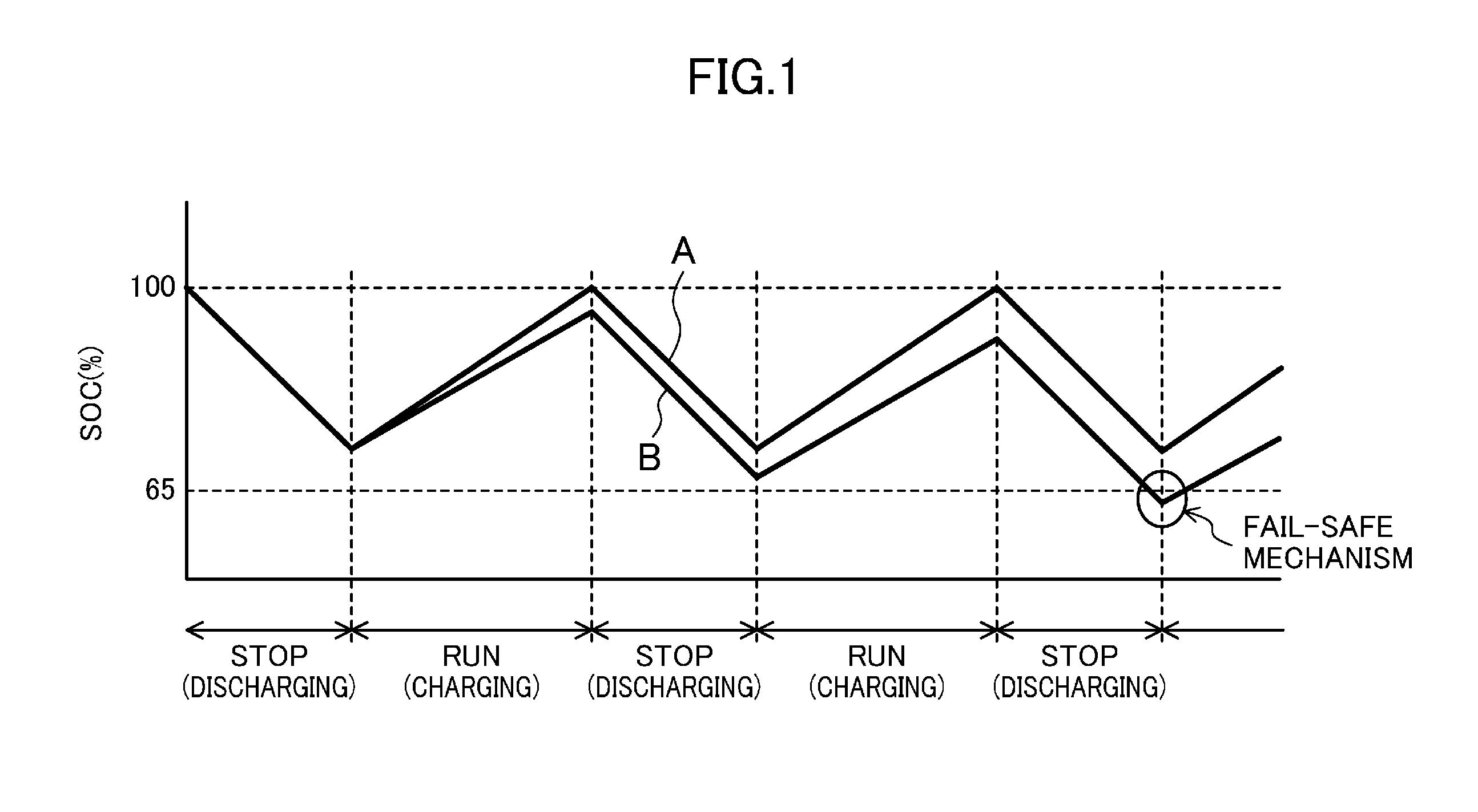

Lead-acid battery

ActiveUS20150200424A1Sufficient charge acceptanceSolve the lack of durabilityFinal product manufactureElectrode carriers/collectorsSurface layerAlloy

In a lead-acid batter including an electrode plate group housed in a cell chamber with an electrolyte, each positive electrode plate includes a positive electrode grid made of lead or a lead alloy containing no antimony, and a positive electrode active material with which the positive electrode grid is filled. Each negative electrode plate includes a negative electrode grid made of lead or a lead alloy containing no antimony, a surface layer formed on a surface of the negative electrode grid and made of a lead alloy containing antimony, and a negative electrode active material with which the negative electrode grid is filled. A mass ratio MN / MP falls within a range of 0.70 to 1.10, where MP represents the mass of the positive electrode active material per cell chamber, and MN represents the mass of the negative electrode active material per cell chamber.

Owner:GS YUASA INT LTD

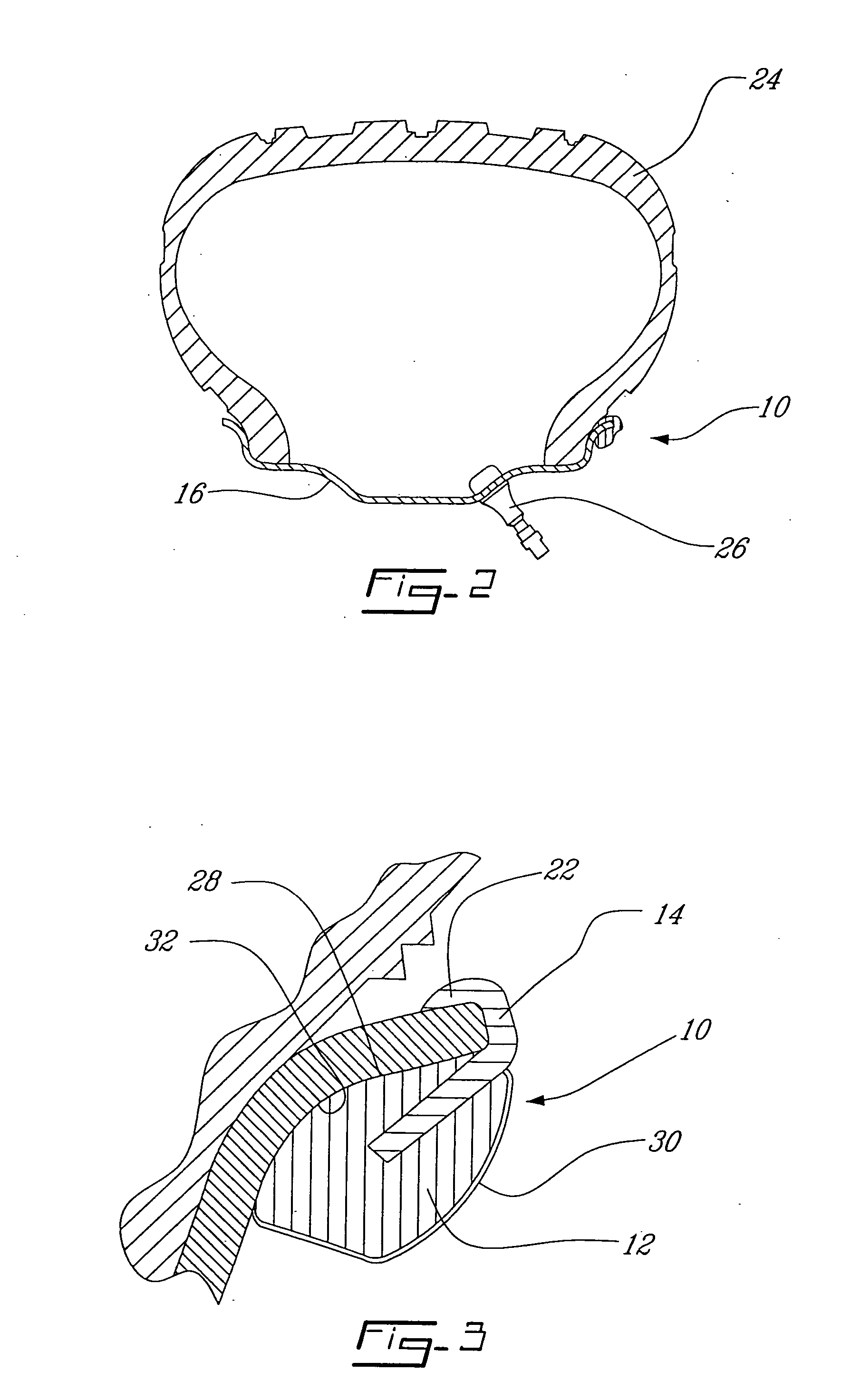

Zinc based material wheel balancing weight

InactiveUS20050062332A1Mitigate such drawbackReduce contentHubsRotating bodies balancingZincCorrosion

A wheel balancing weight attached to the rim of a wheel for balancing the wheel is disclosed. The wheel balancing weight comprises a weight mass manufactured from zinc composite or a zinc based material and a means for attaching said weight mass to the rim. The zinc composite or zinc based material wheel balancing weight exhibits physical characteristics in terms of corrosion resistance and ductility comparable to those of traditional lead alloy wheel balancing weights while at the same time providing an environmentally friendly alternative to lead.

Owner:NORANDA MINES

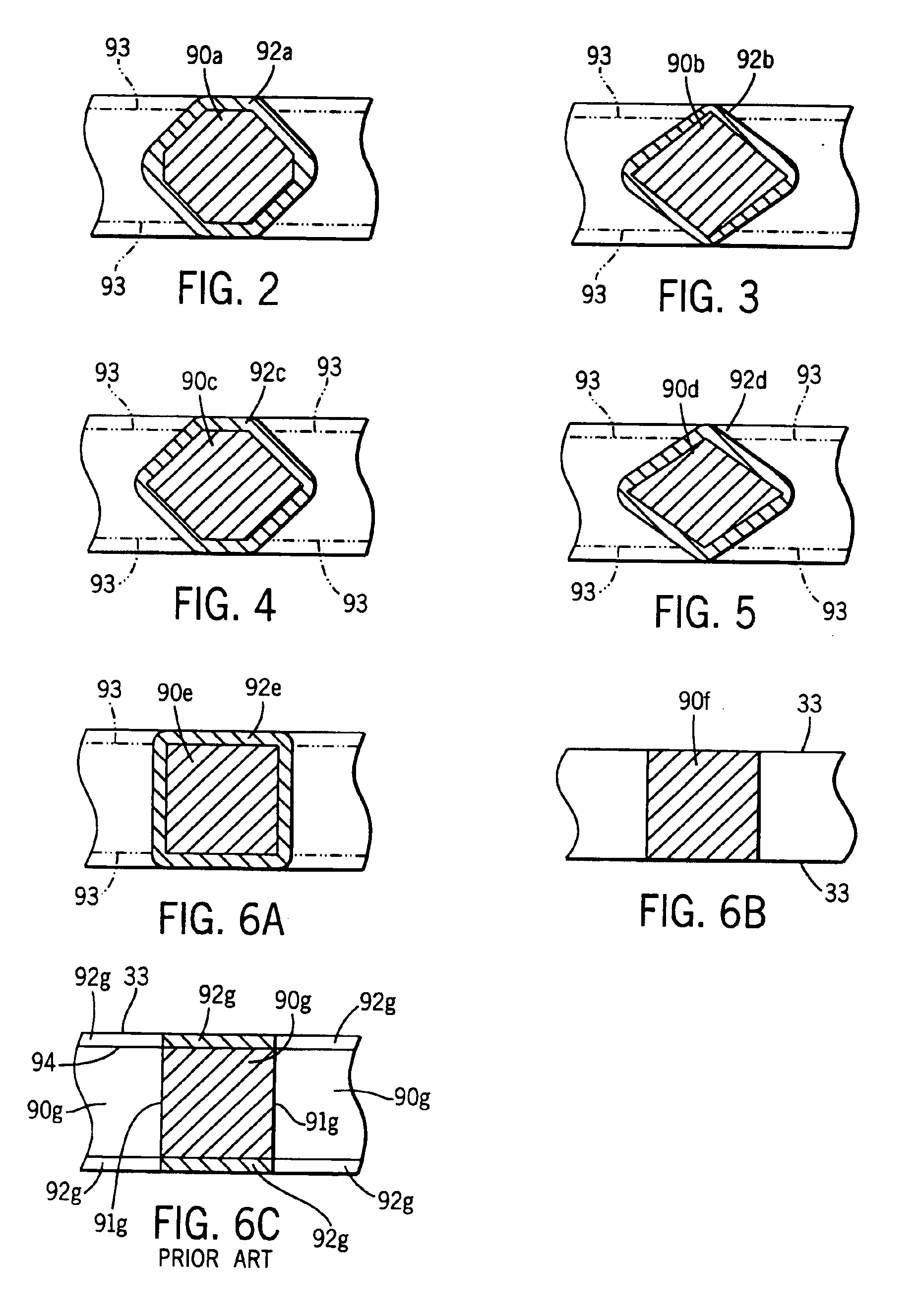

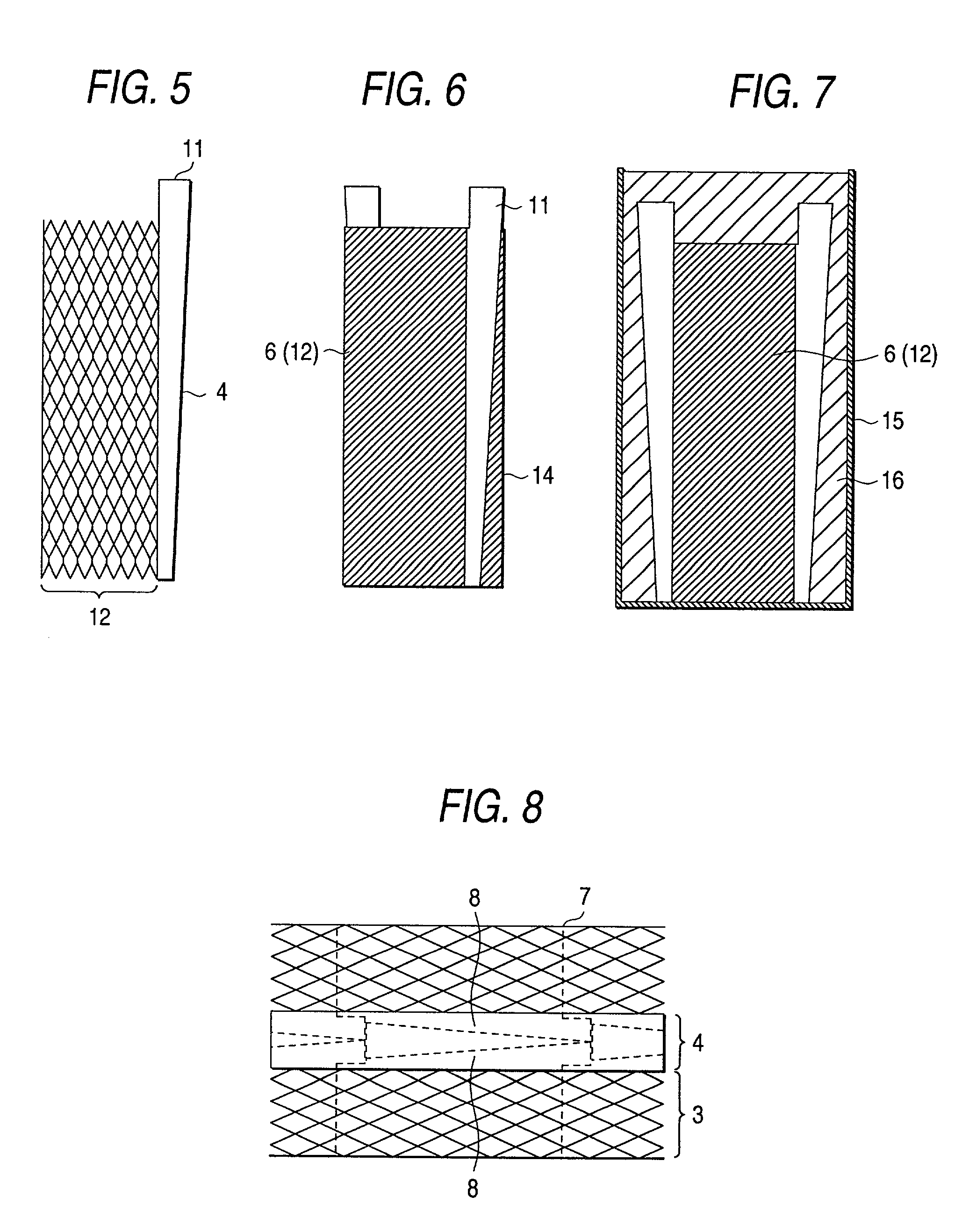

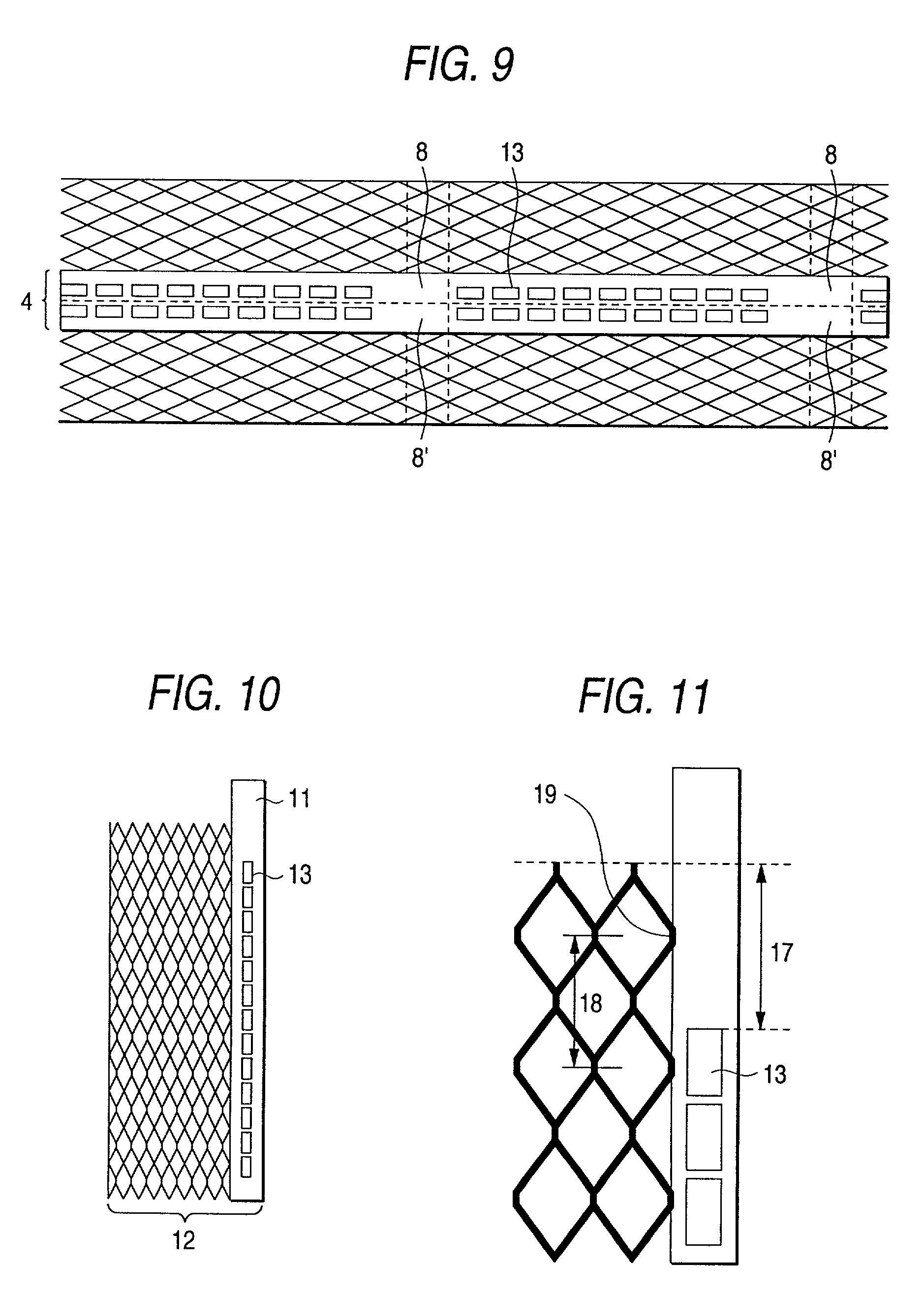

Perforated current collectors for storage batteries and electrochemical cells, having improved resistance to corrosion

InactiveUS6802917B1Increased longevityMaintain good propertiesElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesElectrical batteryChemical stability

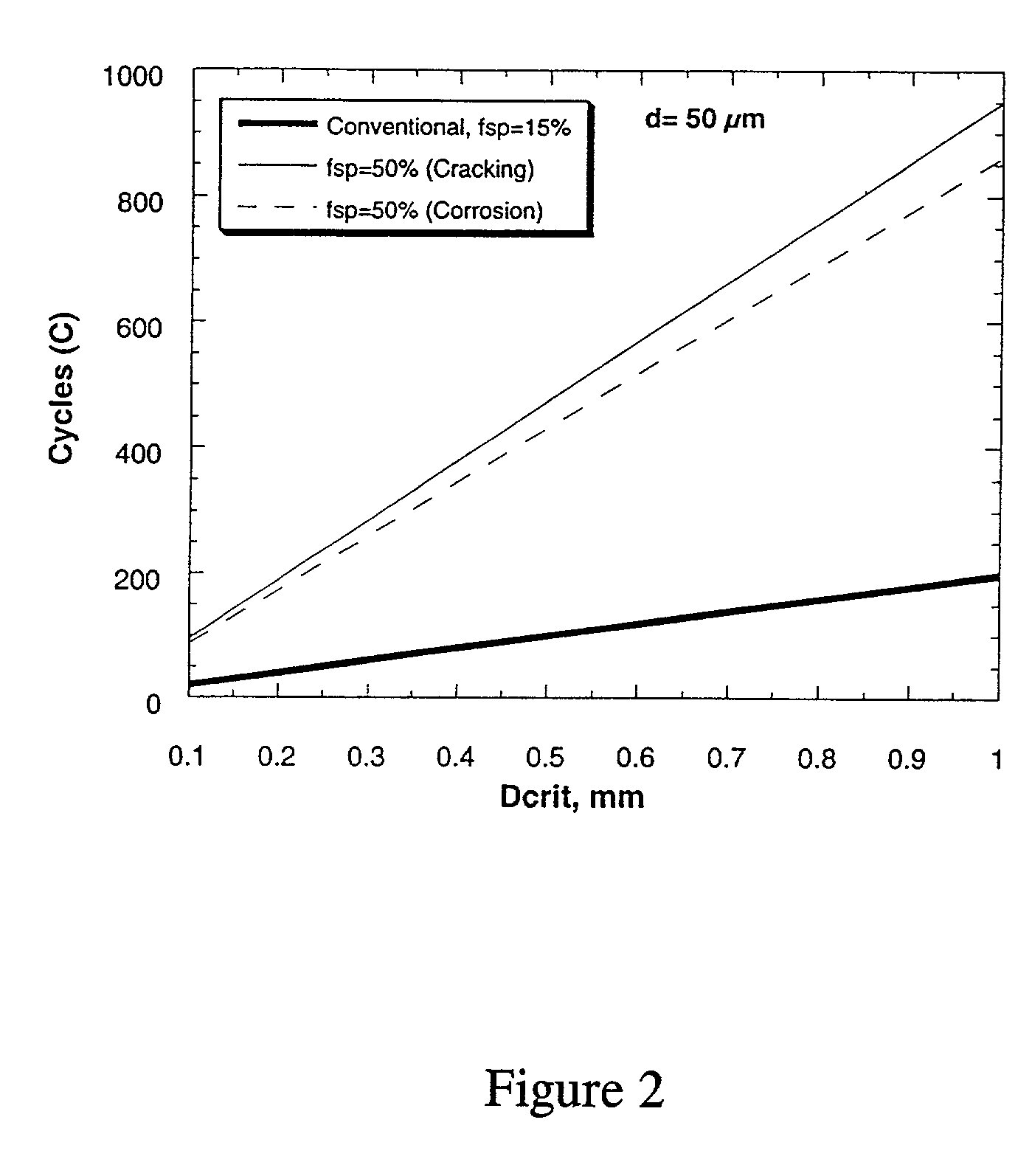

A process for enhancing chemical stability and corrosion resistance is described for perforated current collectors made by continuous production processes for use in electrochemical cells, including storage batteries such as lead-acid batteries. The process relies on utilizing a strip processing method, selected from the group of reciprocating expansion, rotary expansion and punching, to perforate the solid metal strip to form a grid or mesh, as a deformation treatment. The perforation-deformation treatment is followed in rapid succession by a heat-treatment to obtain a recrystallized microstructure in the current collector and optionally by quenching to rapidly reduce the temperature to below approximately 80° C. The process yields an improved microstructure consisting of a high frequency of special low Sigma CSL grain boundaries (>50%), exhibiting significantly improved resistance to intergranular corrosion and cracking. Perforated current collectors produced with this process from a solid lead-alloy strip exhibit superior growth and corrosion properties when employed as positive grids in a lead-acid battery.

Owner:INTEGRAN TECH

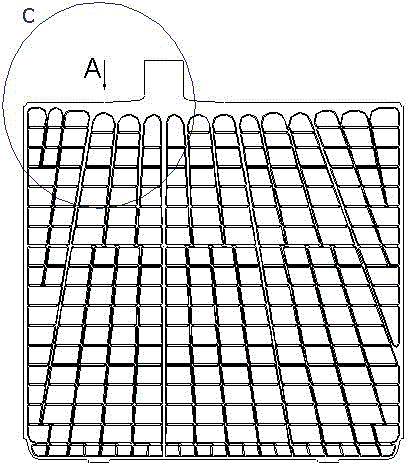

Electrode plate for lead-acid battery and manufacturing method thereof

InactiveUS20010042288A1Improve performanceIncrease productivityCurrent conducting connectionsElectrode carriers/collectorsMechanical engineeringBattery cell

A lead-acid battery electrode plate is manufactured by consecutively supplying a lead or lead alloy sheet; leaving a part in the vicinity of the center of the sheet as a non-expansion portion and expanding both sides like mesh to form a grid body; filling active material paste into the grid body; and cutting the grid body to predetermined dimensions. In the lead-acid battery electrode plate, the non-expansion portion forms a current collector part of the electrode plate along an expansion portion in an up and down direction of the electrode plate. One or more openings are made in a part of the non-expansion portion. A part of the non-expansion portion is projected above the position of an upper margin of the cut expansion portion as a current collector lug part. When the current collector lug part is placed upside, the expansion direction is the width direction of the electrode plate.

Owner:GS YUASA CORP

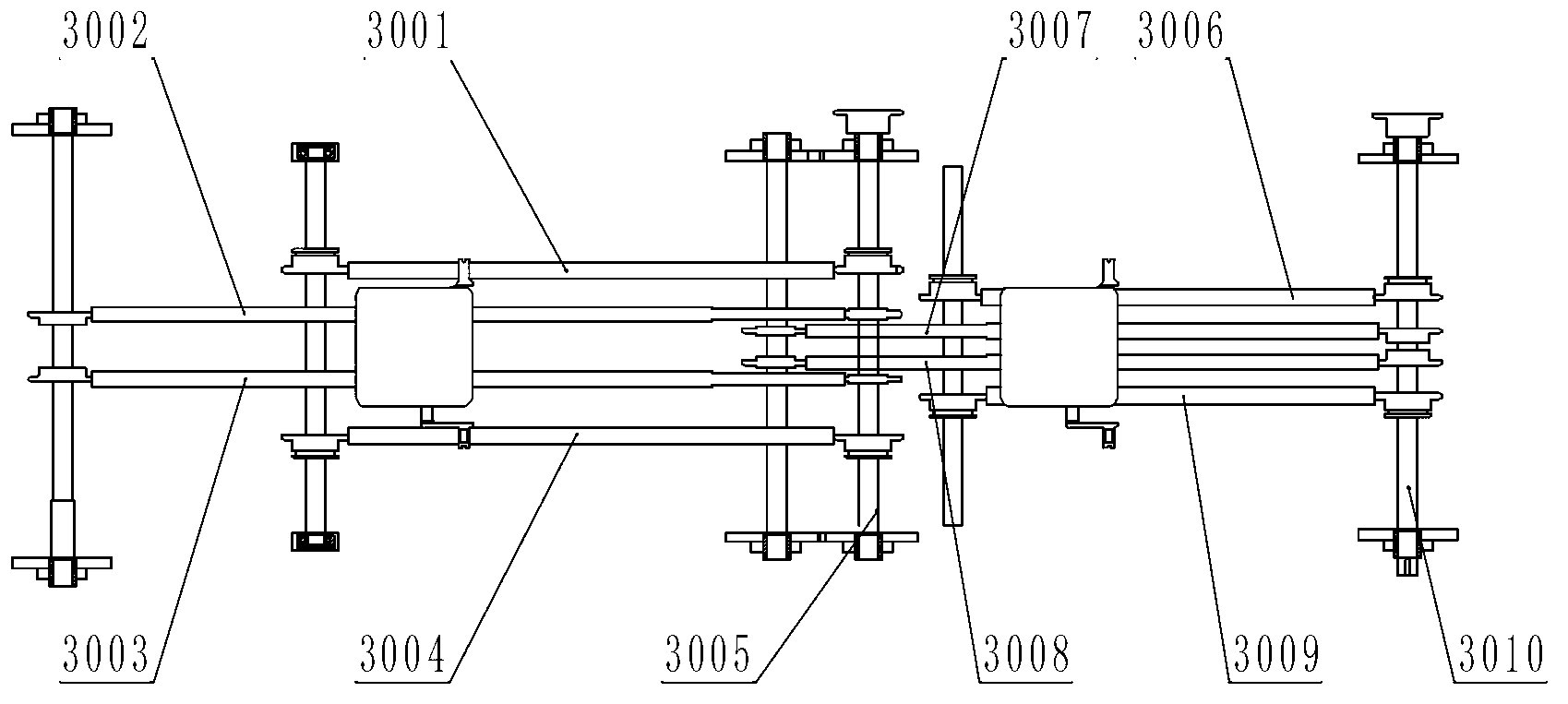

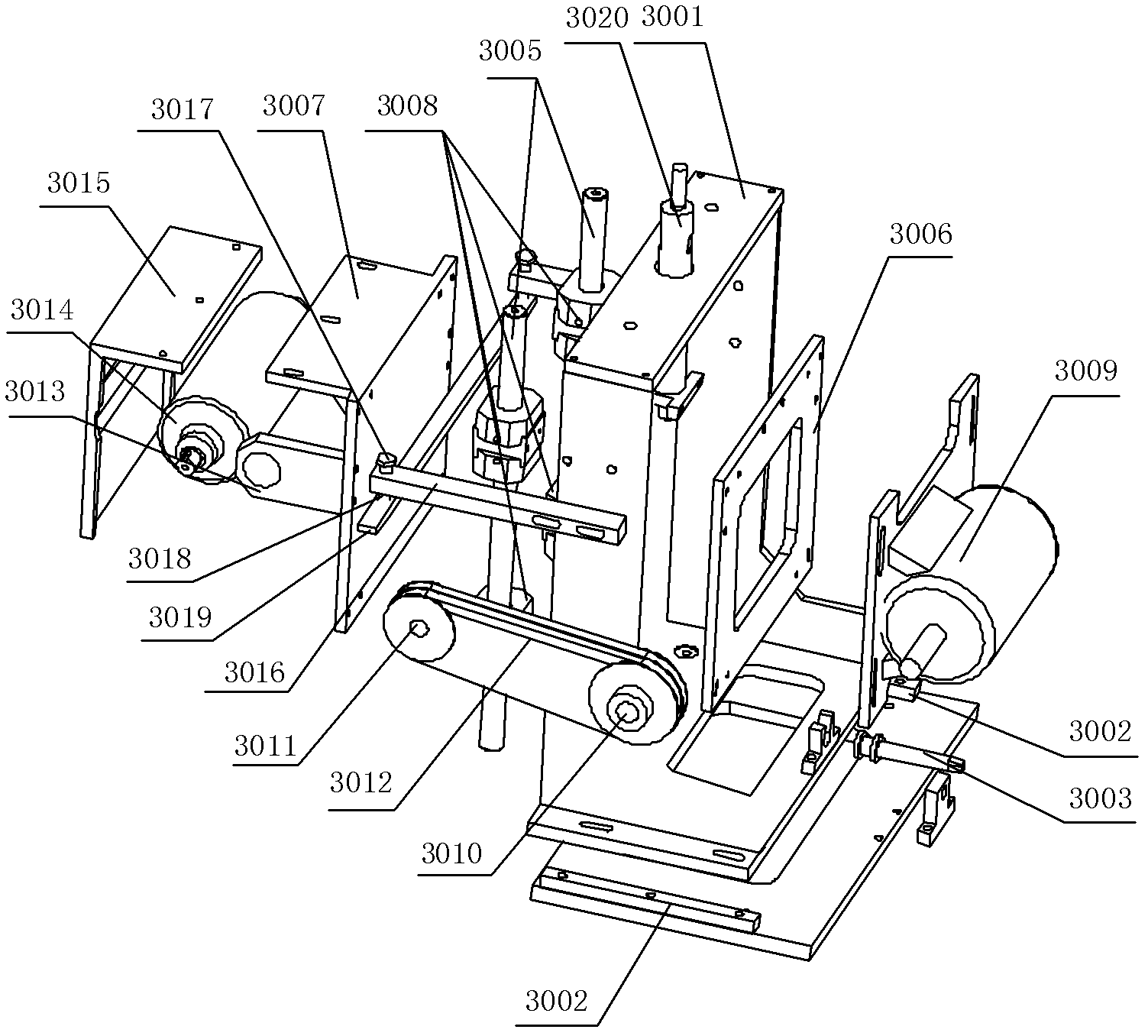

Lead-acid storage battery plate grid and forming surface treatment method

ActiveCN104821402AAdded roughening stepLower internal resistanceElectrode carriers/collectorsPunchingEngineering

The invention relates to a lead-acid storage battery plate grid and a forming surface treatment method, and belongs to the technical field of storage batteries. In the prior art, the existing punching plate grid has disadvantages of poor adhesion of lead paste, easy paste shedding during the production process, and influence on the battery performance. With the present invention, the problem in the prior art is mainly solved. The method is mainly characterized by comprising: 1, preparing a lead alloy; 2, melting the lead alloy; 3, casting a lead plate; 4, pressing a lead strip; 5, punching, wherein continuous punching is performed on the pressed lead strip to form a continuous plate grid framework structure; 6, carrying out a plate grid surface roughening treatment, wherein a roughening treatment is performed on the surface of the continuous plate grid framework structure, the roughness is 3.2-12.6, and the plate grid production is completed; and 7, coating and filling the pole plate, wherein lead paste coating and filling is performed on the plate grid framework so as to complete the pole plate production. According to the present invention, the bonding force of the punching plate grid and the lead paste can be improved, the plate grid thickness can be thinner than or equal to 1 mm, and the method is especially suitable for production of the high-power storage battery punching plate grid.

Owner:CAMEL GRP XIANGYANG BATTERY

Metal surface processing agent and steel plates with aluminum plated sub-lead alloys processed thereby

InactiveCN1530462AImprove corrosion resistanceGood alkali resistanceMetallic material coating processesSilanesSilicic acid

A surface treating agent for metallic material contains the water resin (urane resin or acrylic resin) with carboxy and acid-amine, the compound of metals chosen from Al, Mg, Ca, Zn, Ni, Co, Fe, Zr, Ti, V, W, Mn and Ce, and the surface treating agent (silicic acid, silicate, colloidal SiO2, or organic silane) containing silicon compound, but not Cr. A steel plate which is treated by said surface treating agent and plated by aluminium-plumbo alloy is also disclosed.

Owner:NIHON PARKERIZING

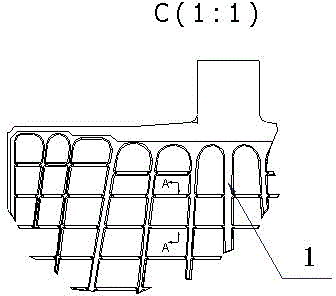

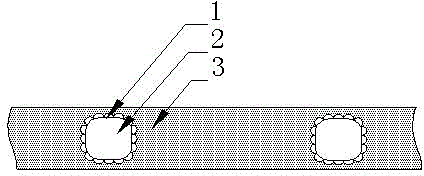

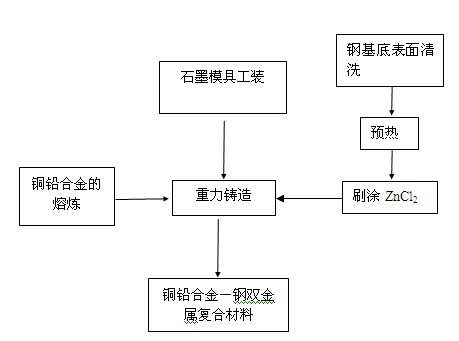

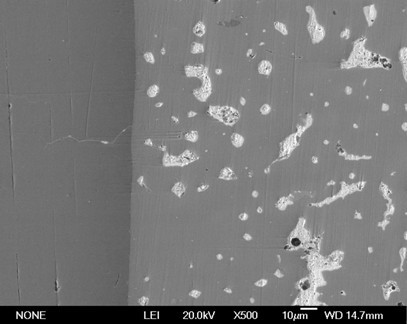

Method for preparing copper-lead alloy/steel bimetal laminated composite material

The invention discloses a method for preparing a copper-lead alloy / steel bimetal laminated composite material, which comprises the following steps of: treating a steel plate and preheating to the temperature of between 150 and 200 DEG C in a resistance furnace; coating saturated ZnCl2 solution on the surface of the steel plate and preheating to the temperature of between 200 and 600 DEG C; smelting copper-lead alloy liquid in a medium-frequency induction furnace, namely putting charcoal and electrolytic copper into the medium-frequency induction furnace in turn, adding tin and lead after the electrolytic copper is melted, uniformly mixing and deoxidizing to obtain the copper-lead alloy liquid; and preheating a graphite mold to the temperature of 600 DEG C in a box-type resistance furnace, putting a steel substrate into the graphite mold, casting the copper-lead alloy liquid at the temperature of between 950 and 1,100 DEG C, opening the mold to take the composite material out after the temperature of the alloy is reduced to 300 DEG C, and performing air cooling. The method has the advantages of simple process and low cost; and the composite material has the advantages of high interface bonding strength, good alloy structure, and capability of meeting the operational performance of the copper-lead alloy.

Owner:XIAN UNIV OF TECH

Current collector of lead-acid storage battery, and lead-acid storage battery

InactiveUS20060046148A1Reduce internal stressImprove reliabilityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesLead oxideCompound (substance)

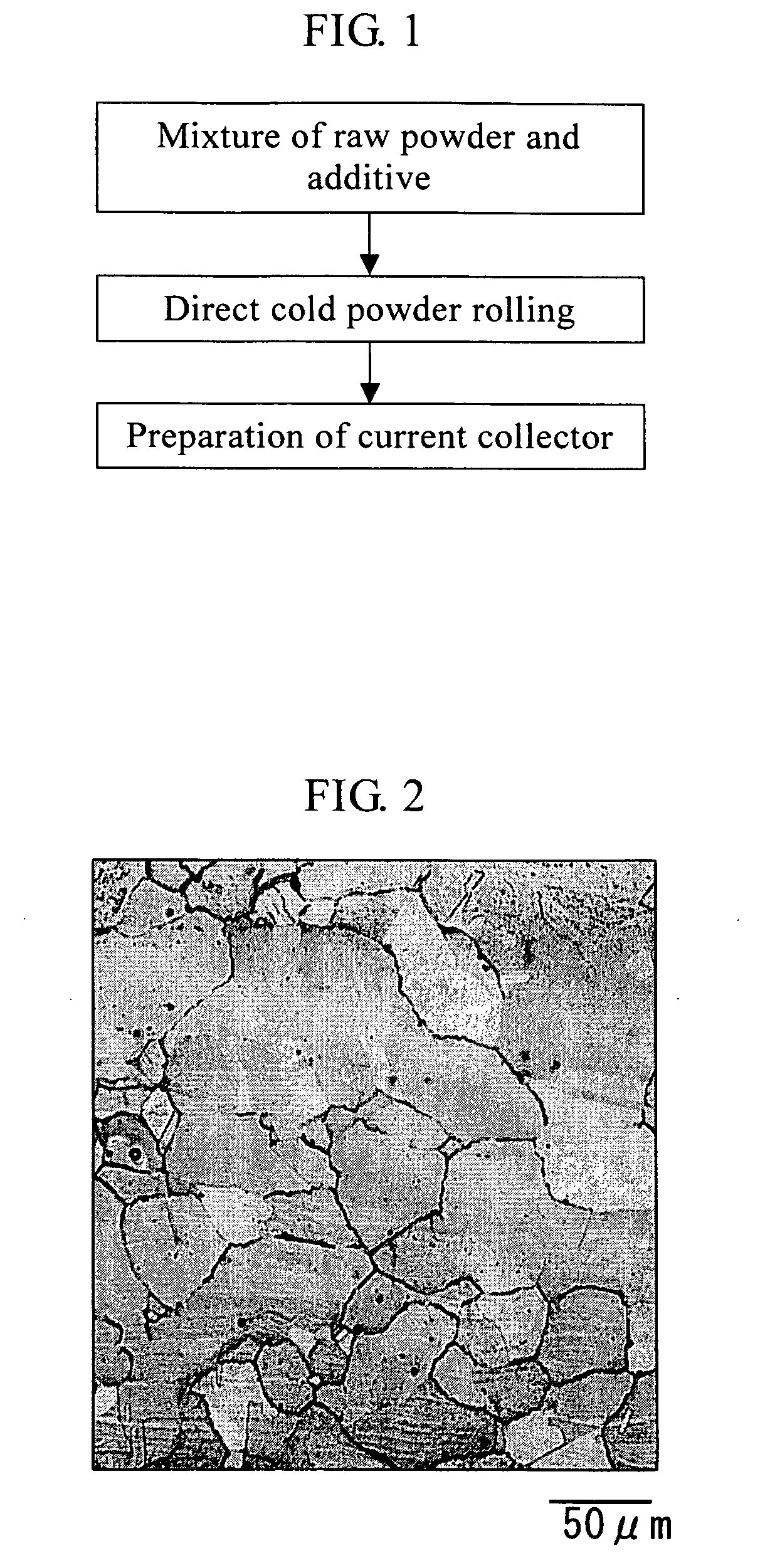

An object of the present invention is to take fundamental measures against the phenomenon that the positive current collector of a lead-acid battery elongates due to corrosion, in consideration of a mechanism, and to inhibit corrosion elongation. A current collector is prepared by the steps of: mixing a lead oxide of pinning compounds for inhibiting recrystallization with the atomized powder of lead or a lead alloy; and then powder-rolling the mixture. A lead-acid battery is composed with the use of the current collector.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

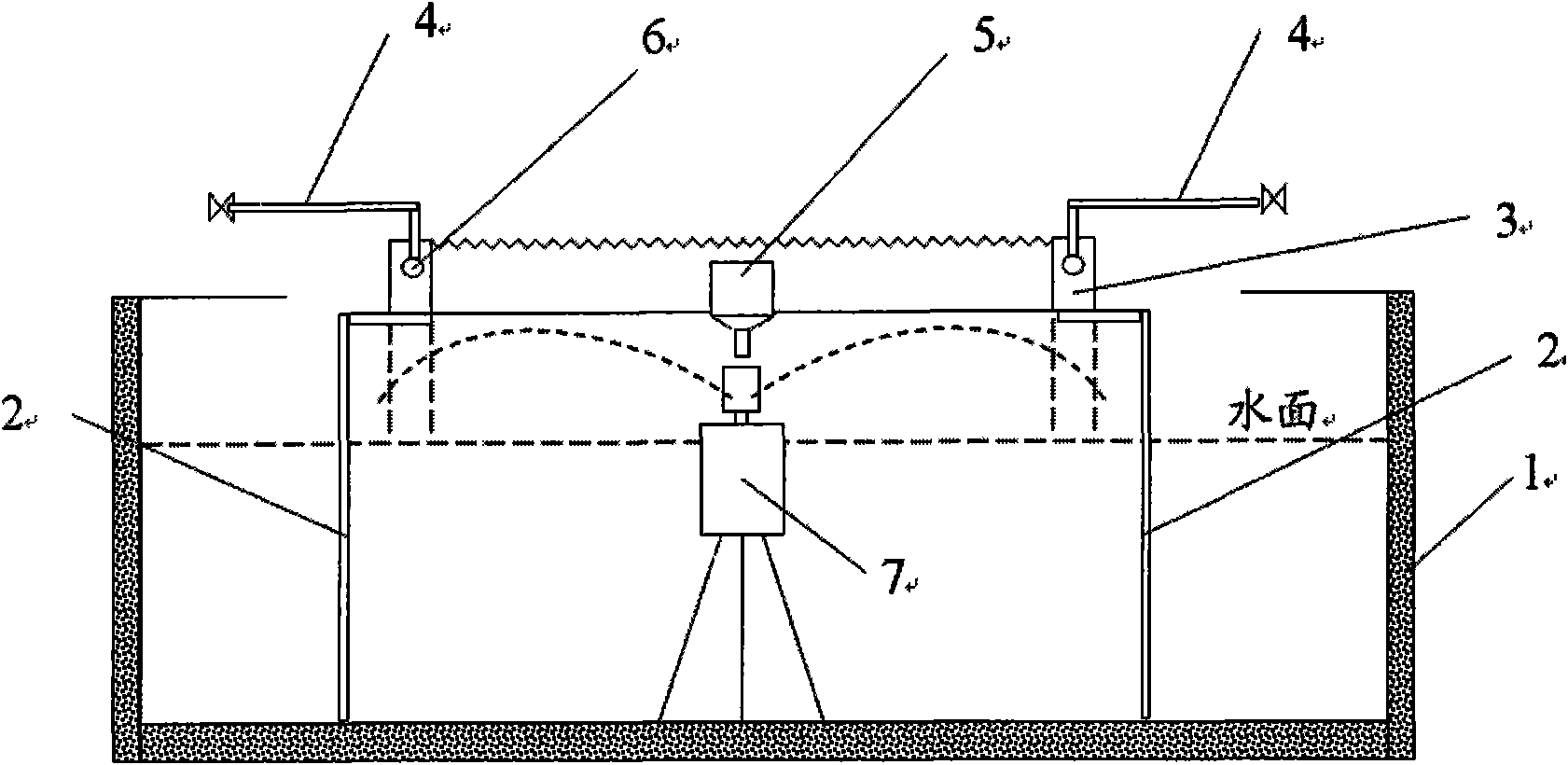

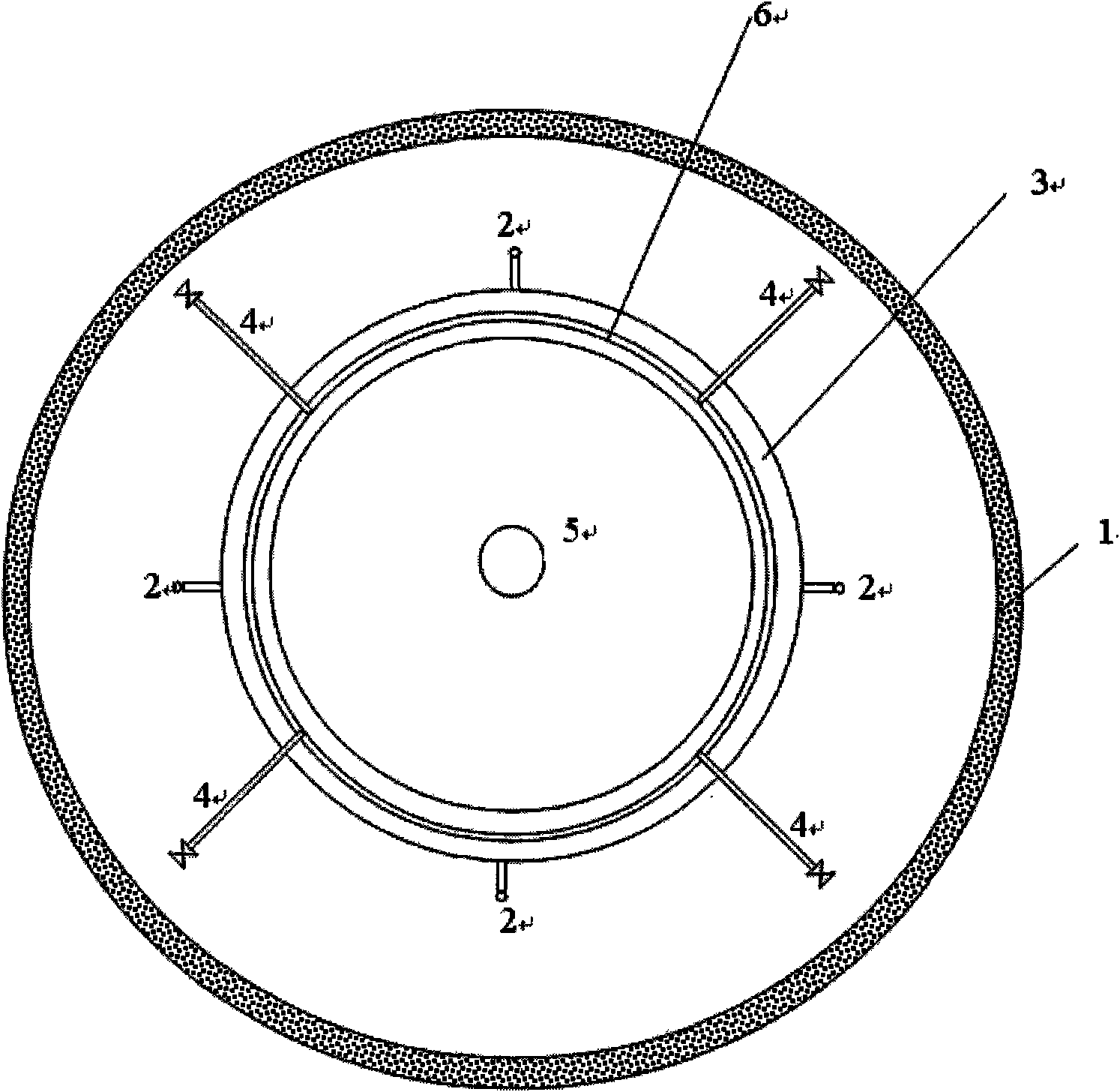

Submarine cable with increased current-carrying capacity

InactiveCN102969071AAvoid lossLarge carrying capacityPower cables with screens/conductive layersSubmarine cablesCopper wireHigh pressure

The invention relates to a submarine cable with an increased current-carrying capacity. Conductor layers comprising a plurality of annealed copper wires with high conductivity are tightly distributed at the periphery of a tin-plated copper spiral pipe; a carbon black paper conductor shielding layer, an oil-filled high-voltage cable paper insulating layer, a carbon black paper insulation shielding layer, a copper strip insulation shielding layer and a seamless lead-alloy sheath are wrapped at the periphery of the conductor layers sequentially; asphalt is evenly coated at the periphery of the seamless lead-alloy sheath; and a self-adhesive polyethylene strip inner cushion layer, double stainless steel strip strengthening layers, a self-adhesive polyethylene strip outer cushion layer, a non-woven fabric liner layer, a high-density polyethylene corrosion resisting layer, an armoured inner cushion layer formed by evenly soaking hemp ropes at intervals through polypropylene ropes in a concentric stranding manner, an armoured layer formed by uniform spacing of aluminum-magnesium-plated alloy steel wires and a copper wire in the concentric stranding manner and an outer protecting layer are wrapped at the periphery of the seamless lead-alloy sheath sequentially. The submarine cable has a larger current-carrying capacity and is excellent in water seepage resistance, seawater corrosion resistance, external water pressure resistance, voltage thermal shock resistance and tension bending resistance. In addition, the submarine cable also has the advantages of long service life and high reliability.

Owner:JIANGSU YUANYANG DONGZE CABLE

Alloy steel shot preparation method and device therefor

The invention discloses an alloy steel shot preparation method and a device therefor; the method is characterized in that a ring-shaped spraying device is additionally arranged outside a centrifugal shot making machine to lead alloy steel melt liquid to obtain small liquid drops by being ejected from a centrifugal machine, and then the small liquid drops are quenched by shock chilling via water, so that a microstructure of the alloy steel shot is improved, the strength of the alloy steel shot is enhanced, the alloy steel shot oxidation is reduced and finished product ratio is increased through shortening the retention time of the high-temperature alloy steel shot in the air. The invention has the characteristic of obviously improved strength of the alloy steel shot, and can cancel subsequent quenching process, thus simplifying production processes.

Owner:连云港倍特超微粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com