Patents

Literature

747results about "Rotating bodies balancing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

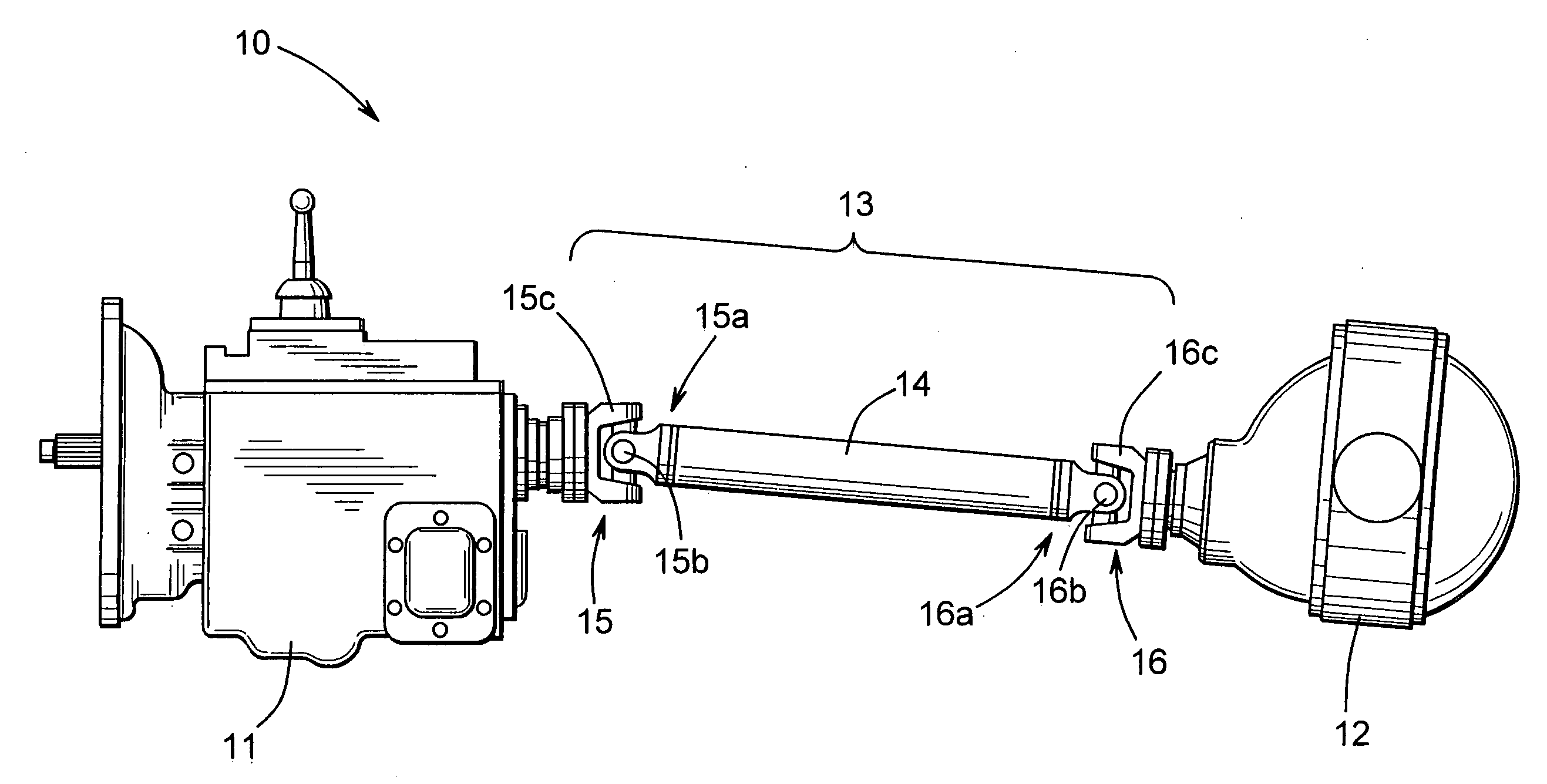

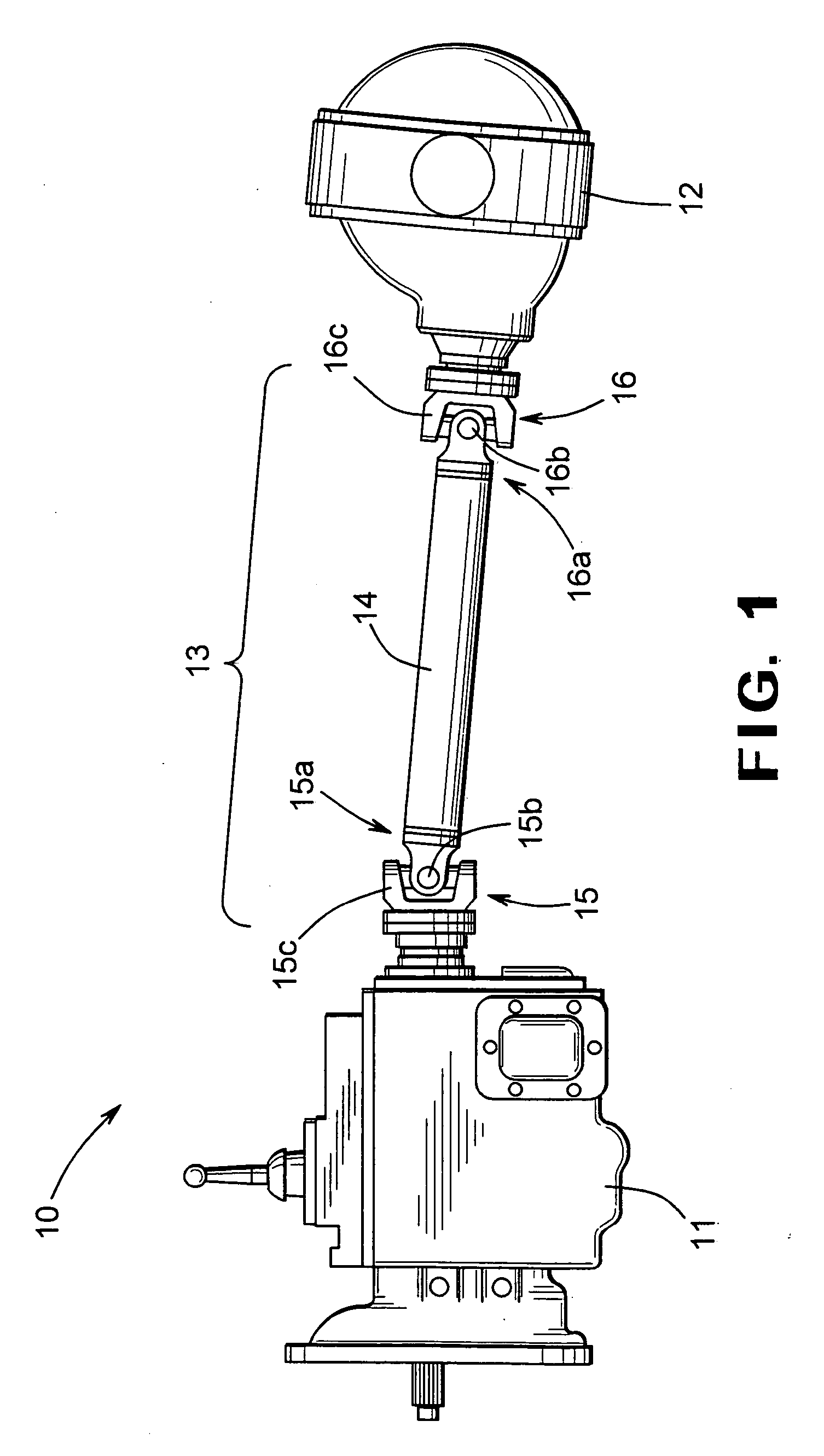

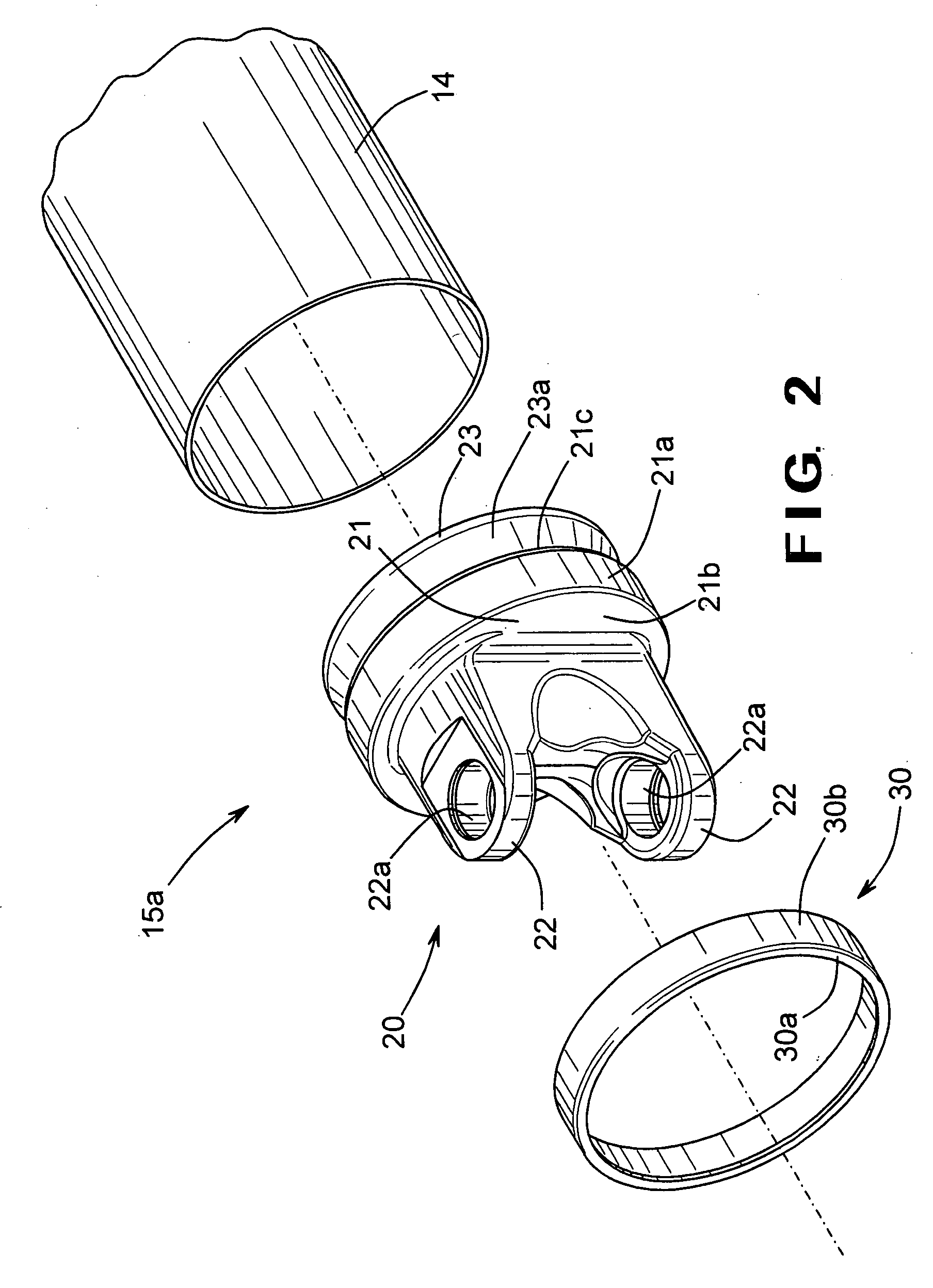

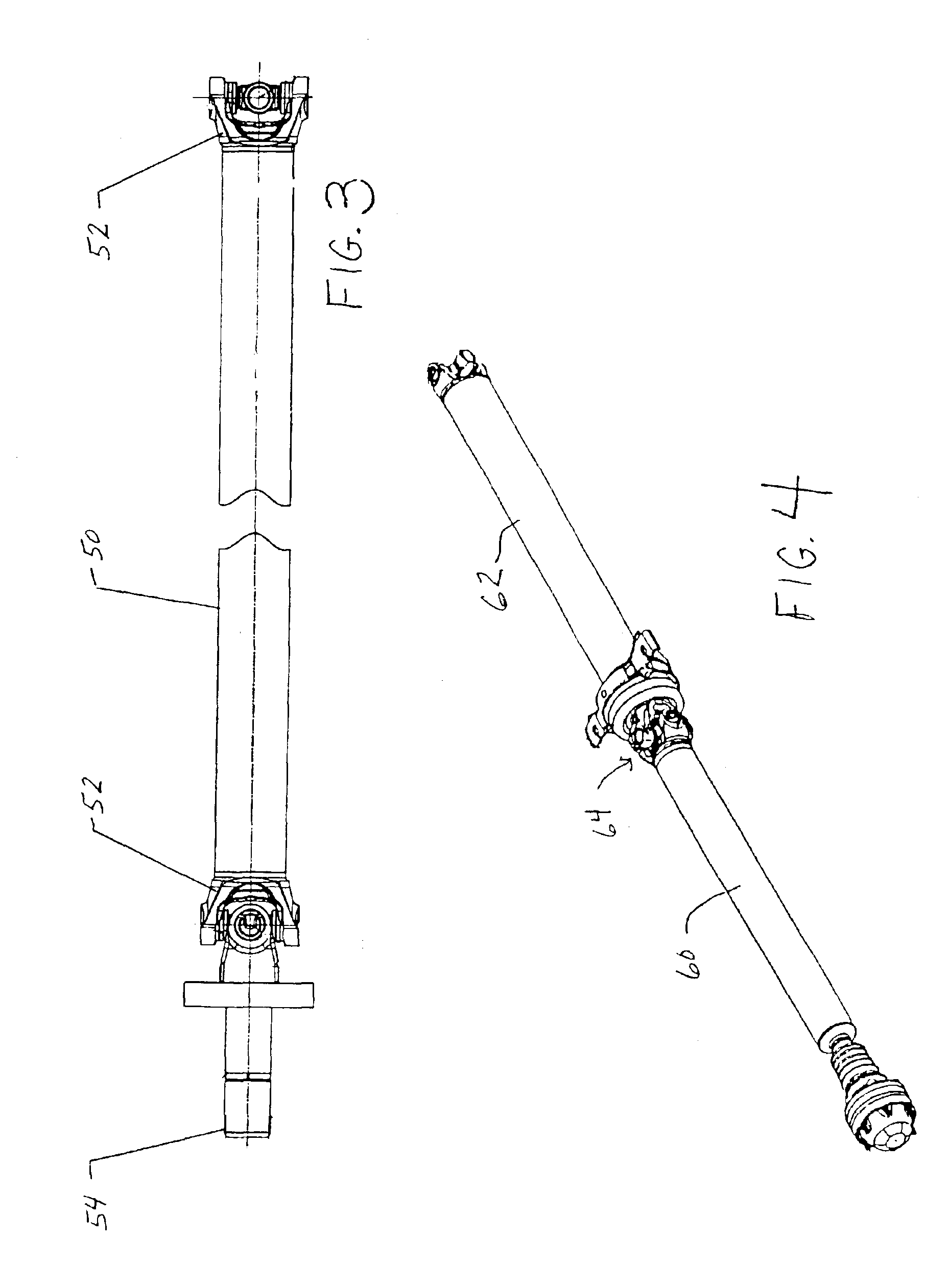

Driveshaft assembly and method of manufacturing same

InactiveUS20070066406A1Protection from damageSimple structureClutchesYielding couplingEngineeringMagnetic pulse welding

A driveshaft assembly includes a yoke including a body portion, a pair of opposed yoke arms that extends generally in a first axial direction from the body portion, and a neck portion that extends generally in a second axial direction from the body portion. A driveshaft tube is secured to the neck portion of the yoke, such as by magnetic pulse welding. A ring is secured to the body portion of the yoke, such as by press fitting, and a balance weight is secured to the ring, such as by welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

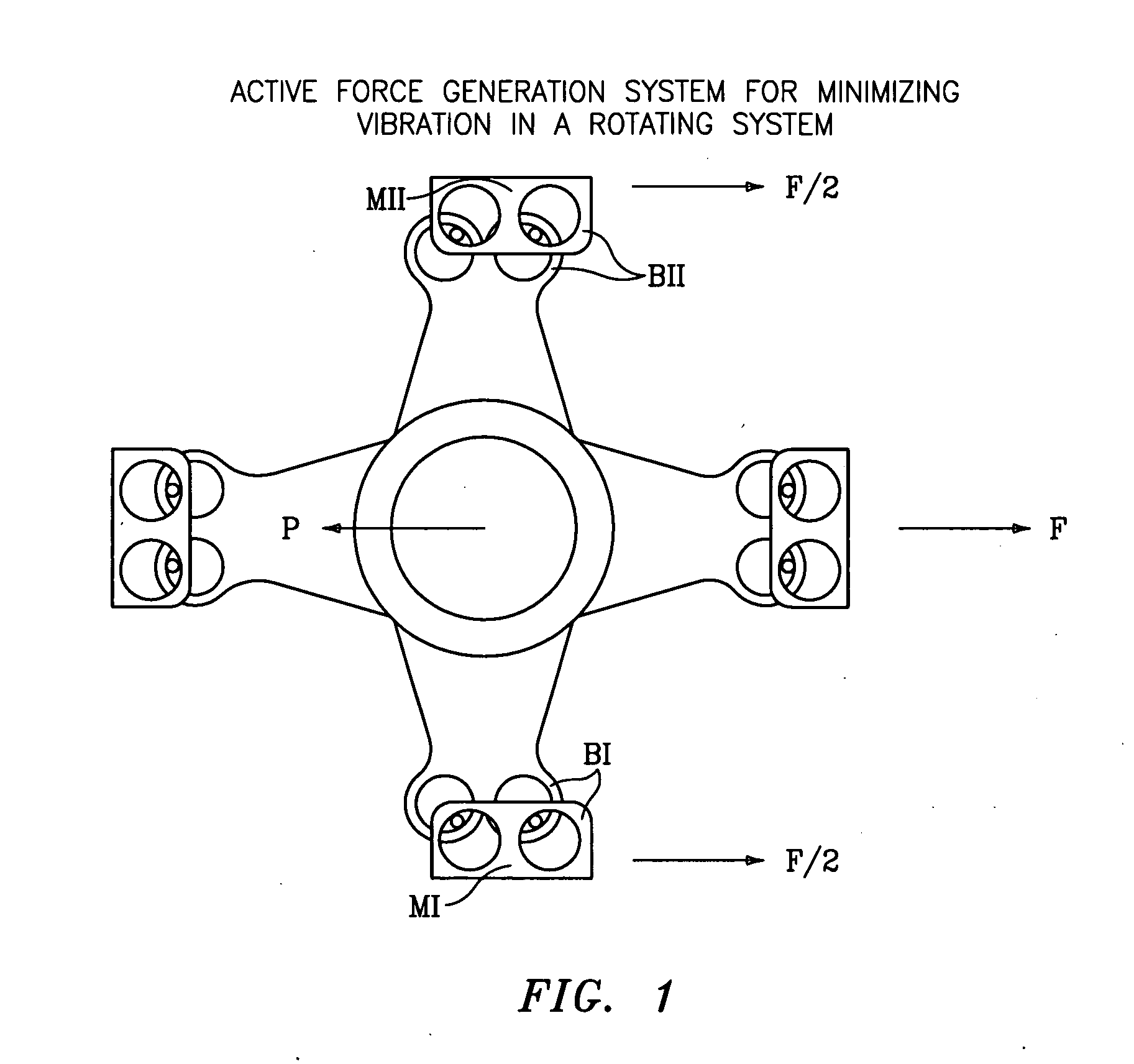

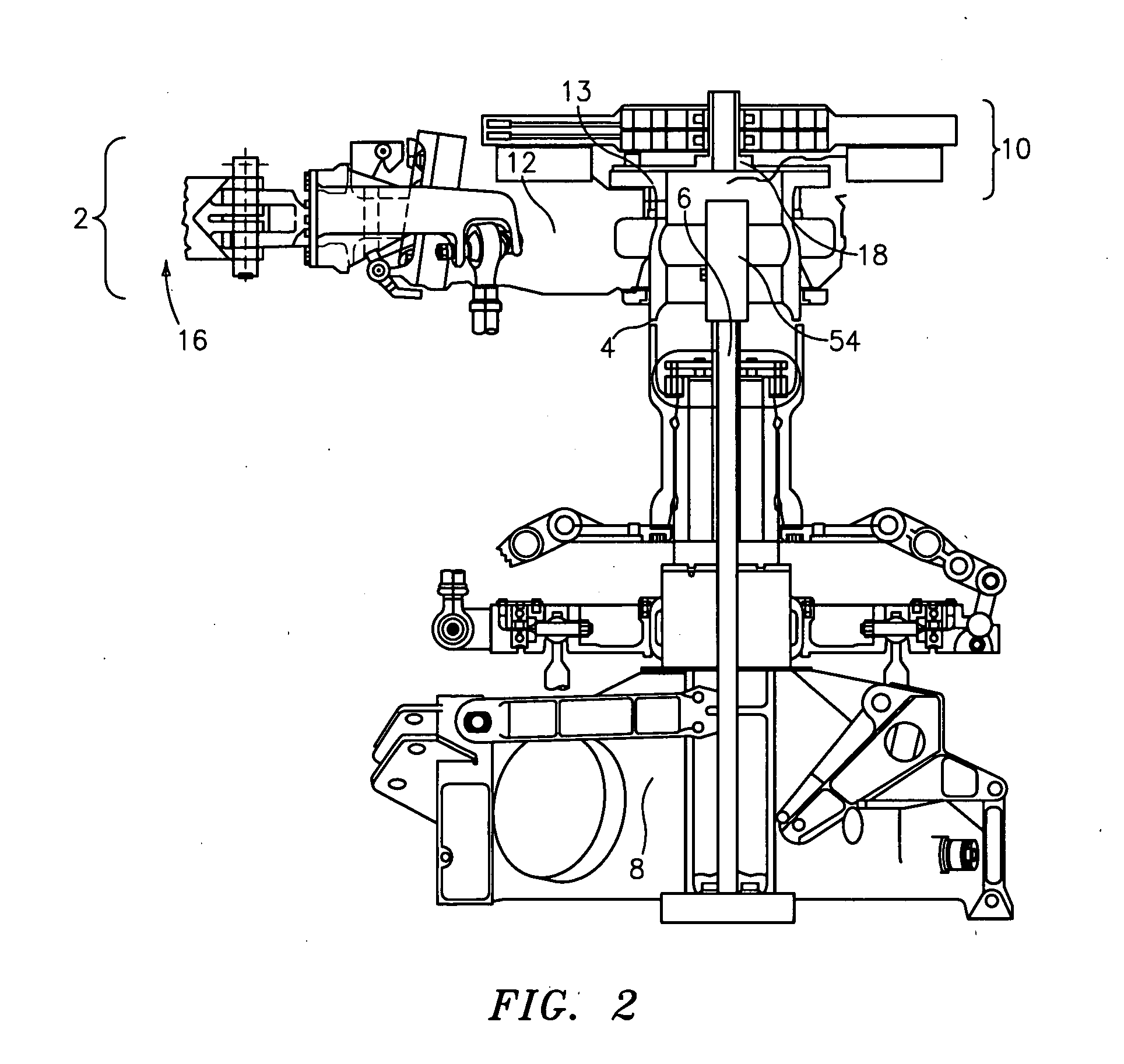

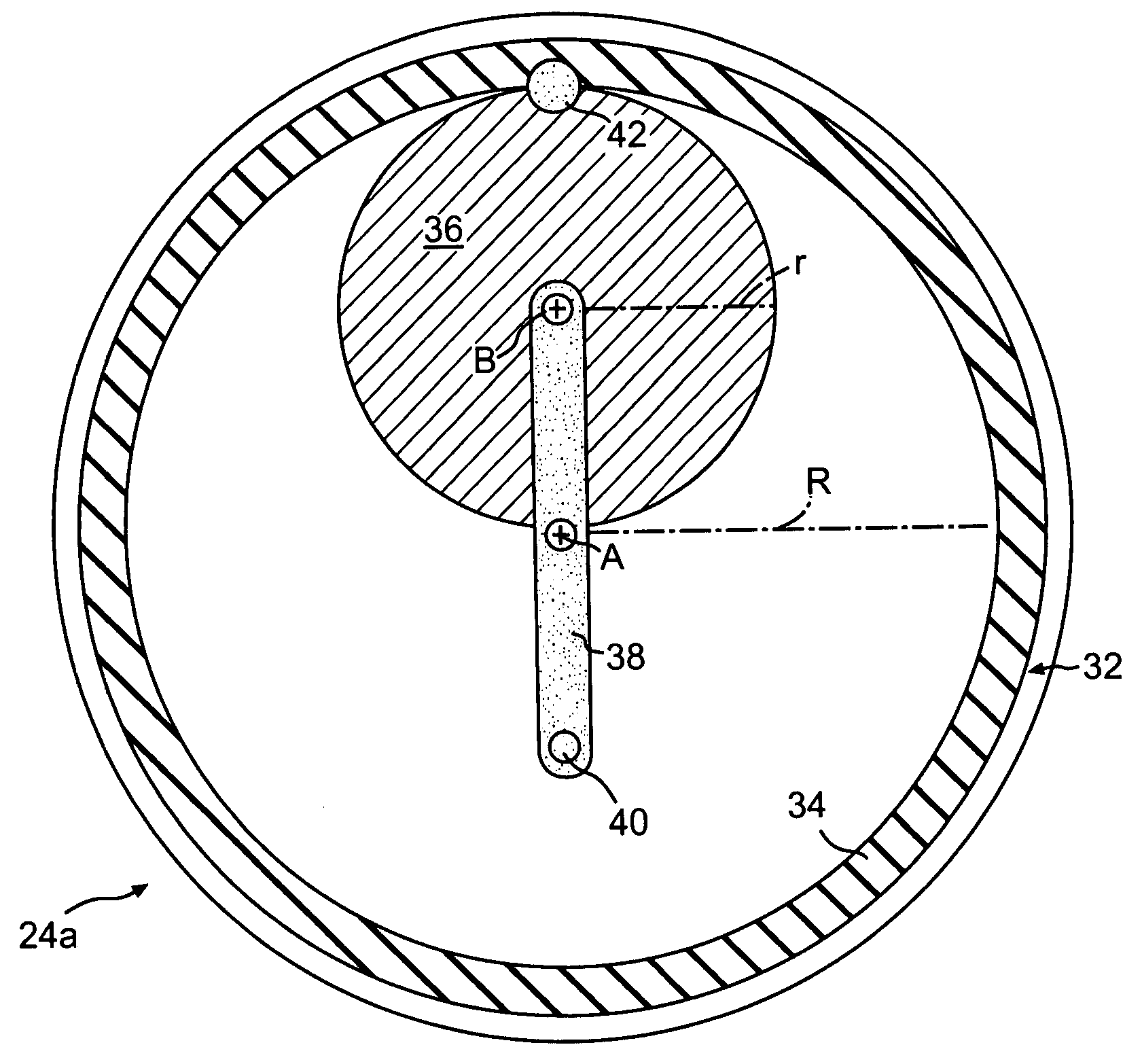

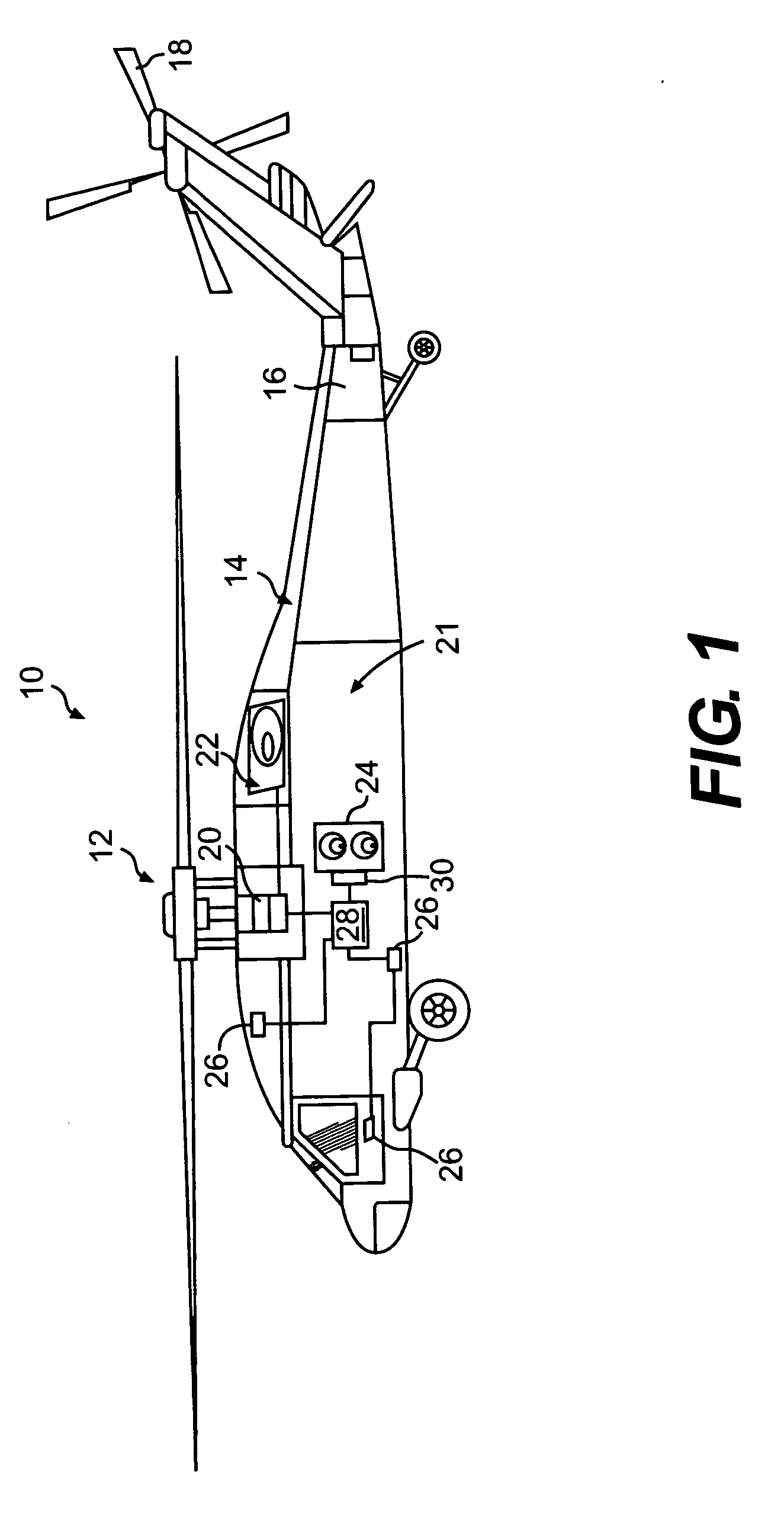

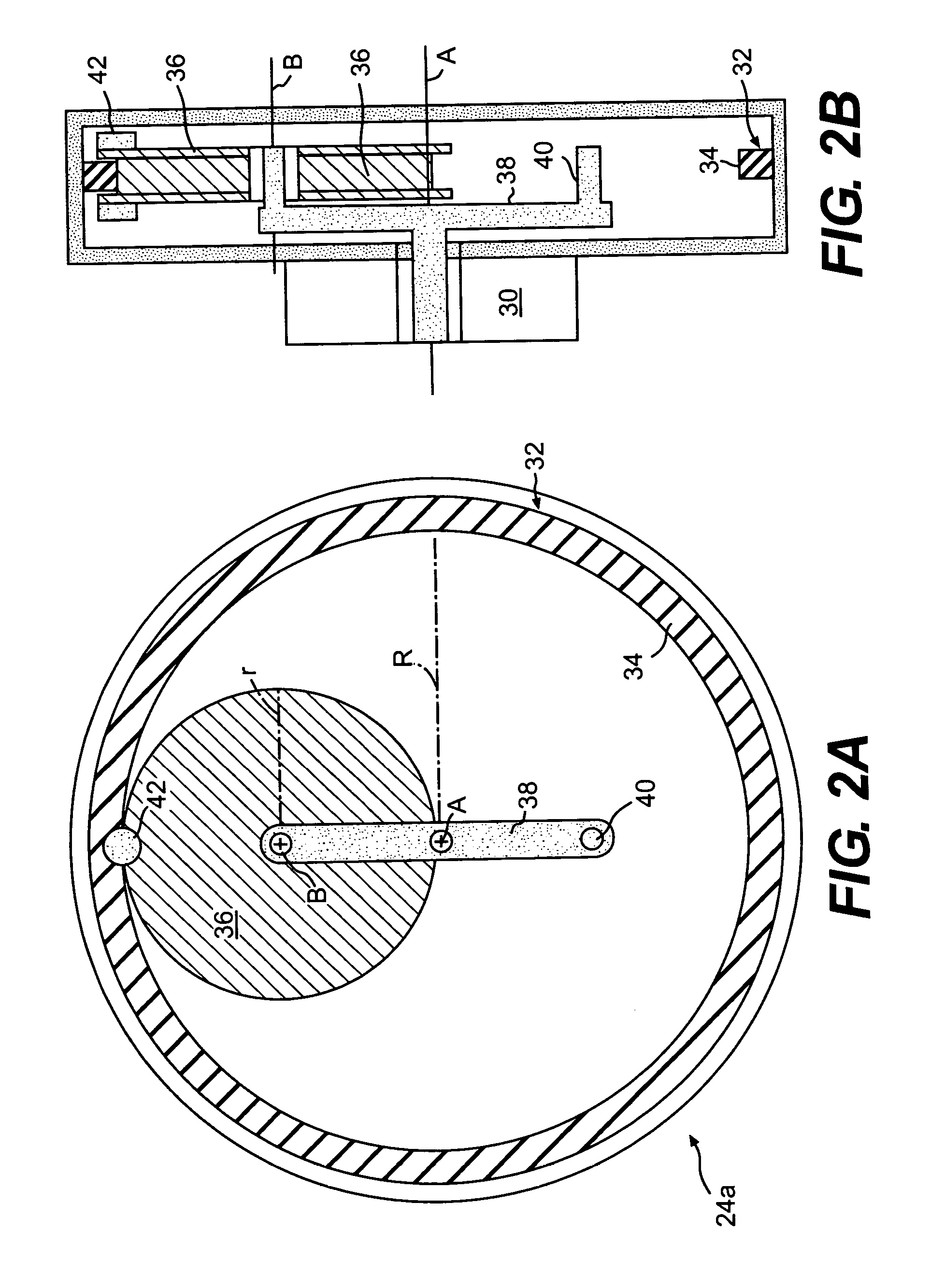

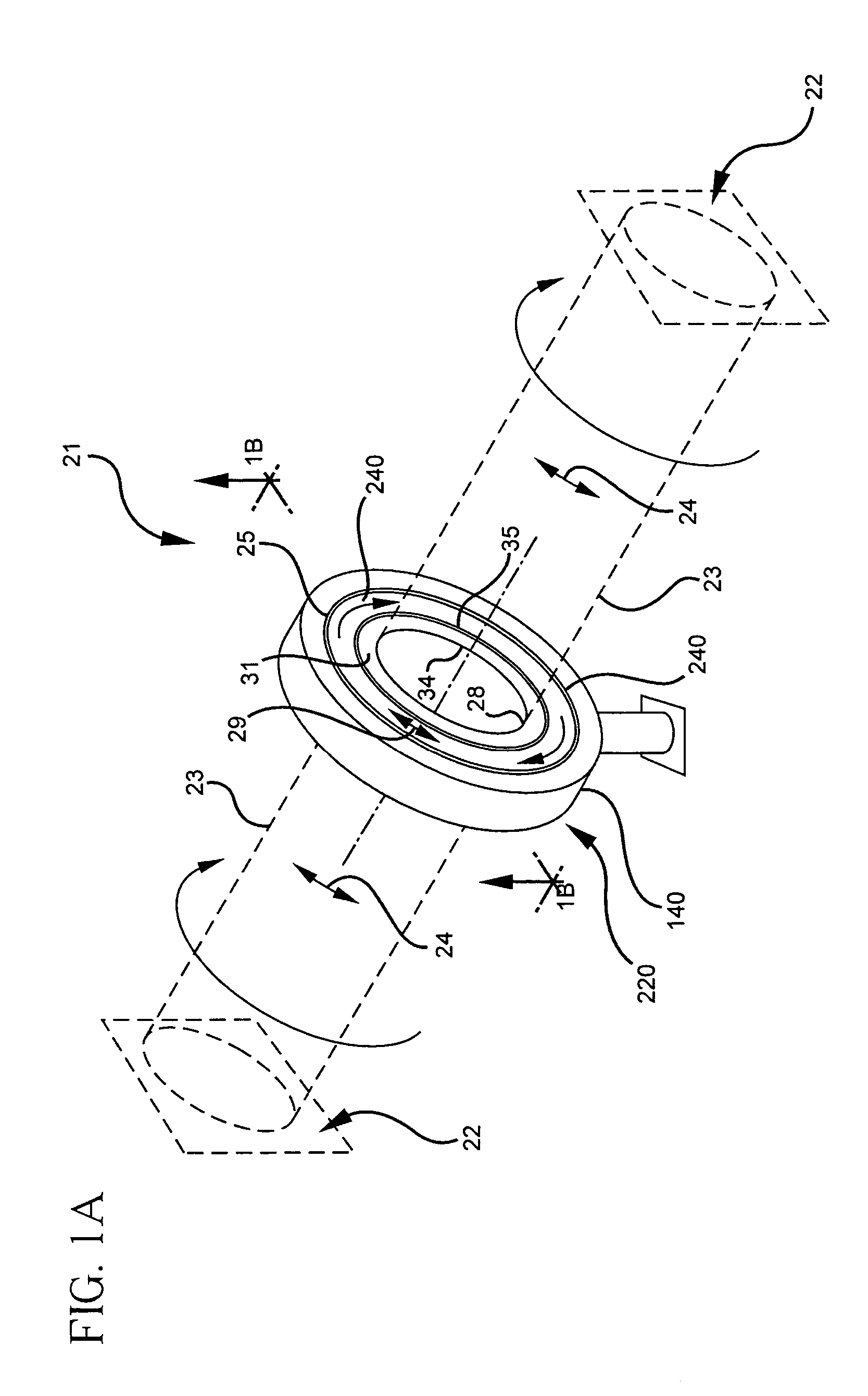

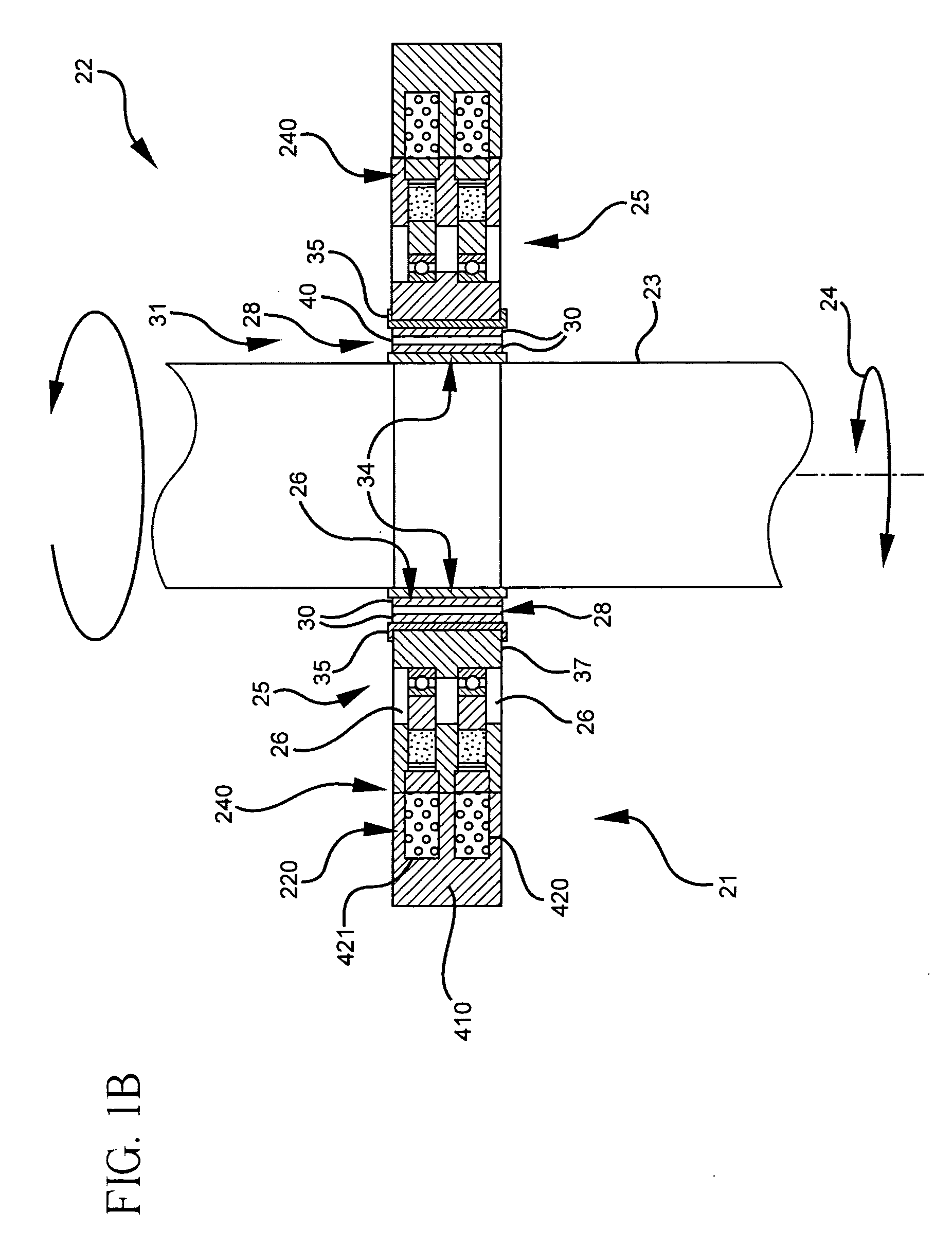

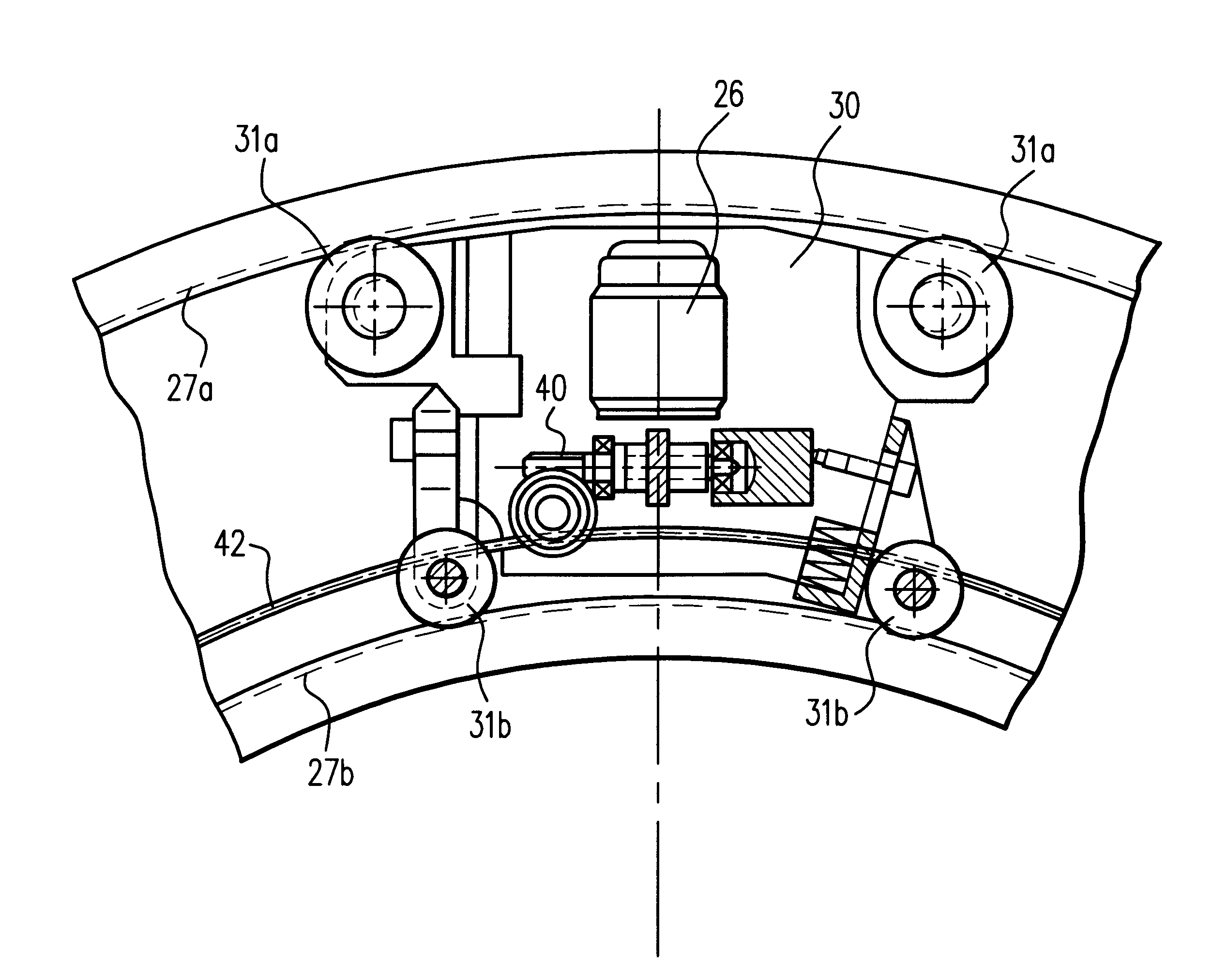

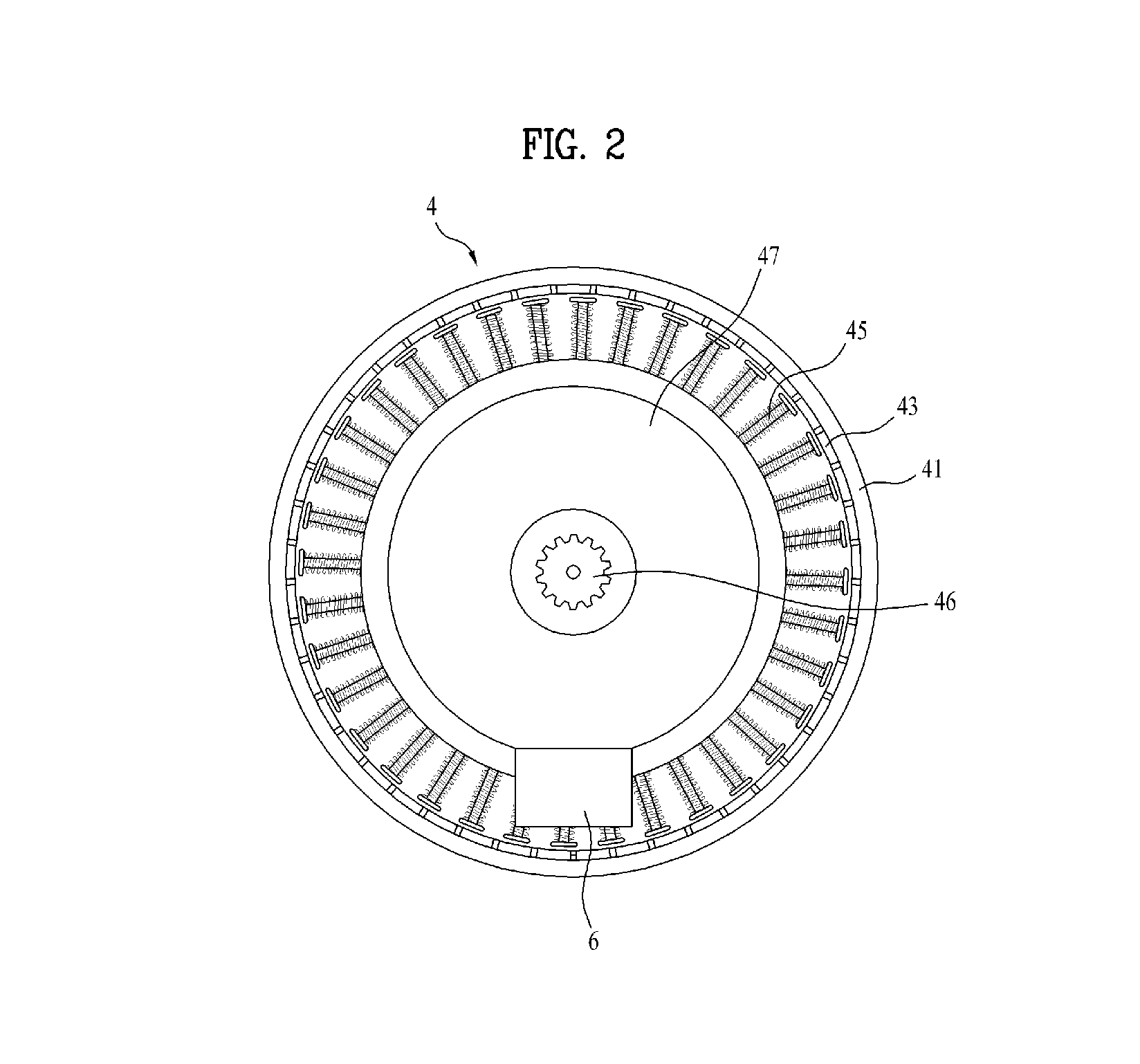

Active force generation system for minimizing vibration in a rotating system

ActiveUS20050079056A1Minimizing system weightReduce manufacturing costRotating vibration suppressionPropellersControl signalAngular velocity

A method and device for reducing vibratory noise in a system with an integral rotating member includes independently operable drive means for controlling the angular velocity of at least two masses. Control signals manipulate the drive means to allow each mass to rotate at optimal speed, direction and phase for reducing the noise induced in the system by the rotating member.

Owner:SIKORSKY AIRCRAFT CORP

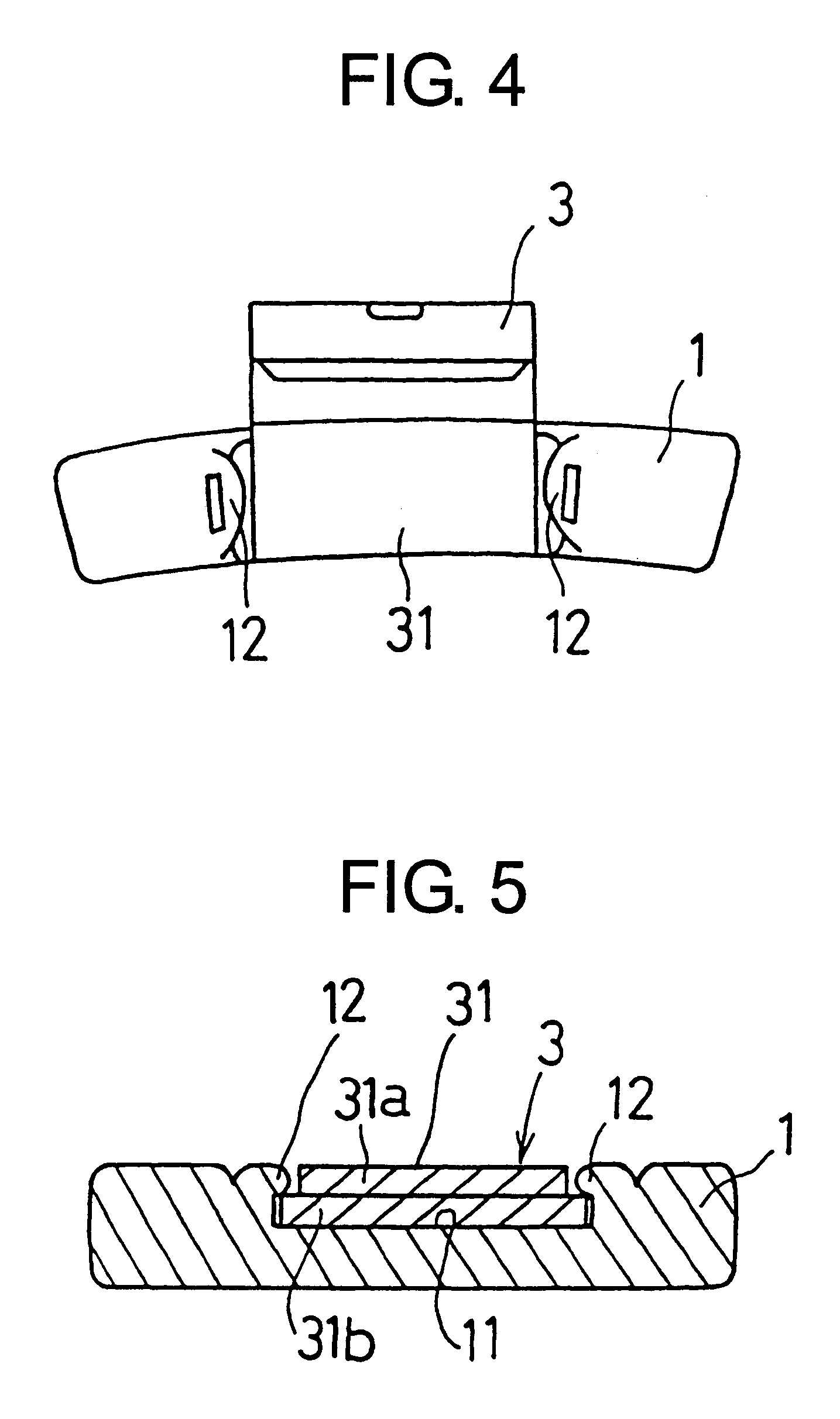

Wheel balance weight

Owner:TAIHO INDUSTRIES CO LTD +1

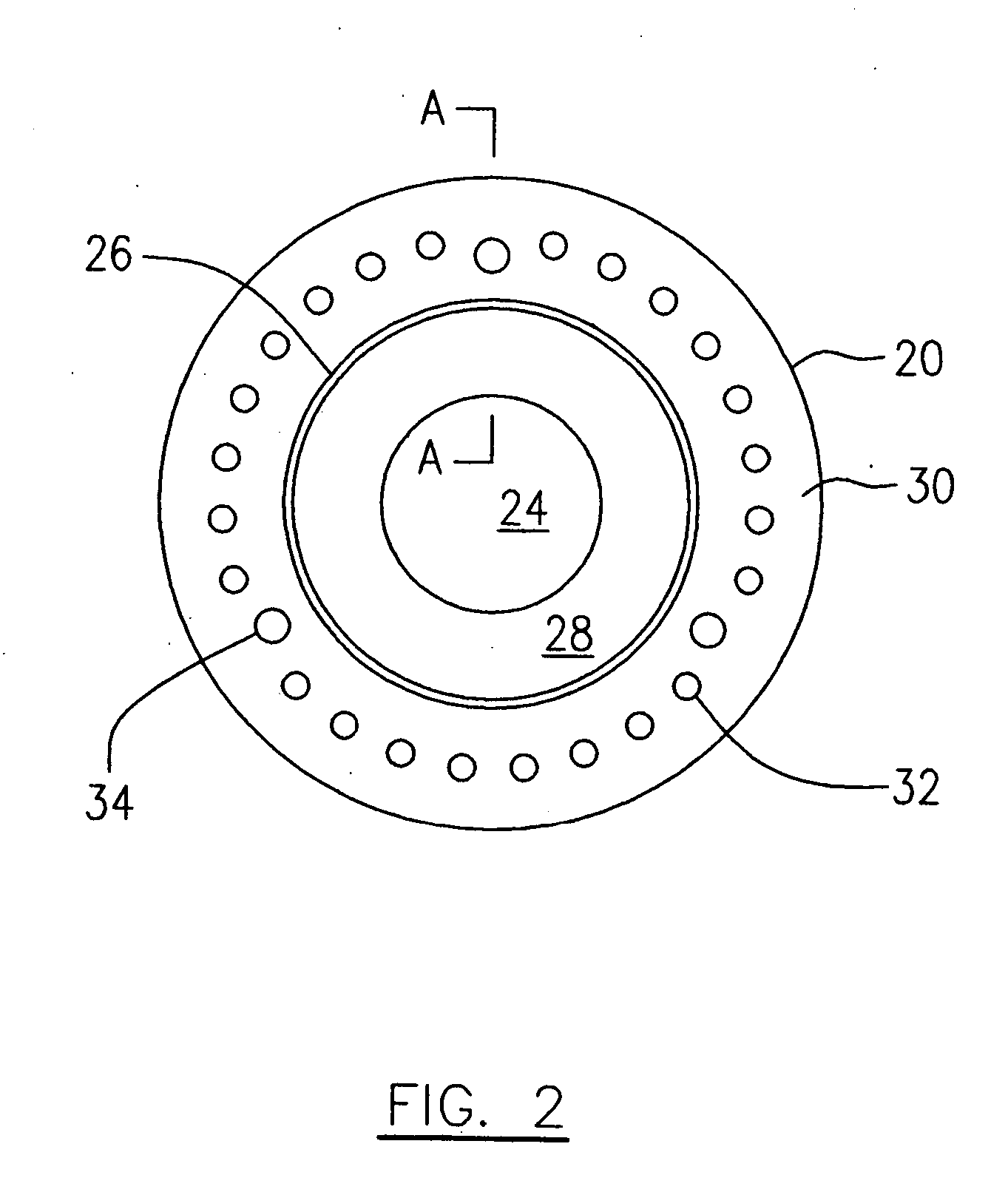

Harmonic force generator for an active vibration control system

A force generator for an active vibration control (AVC) system provides a mass located upon an inner circular member which is movable within an outer circular member to simultaneously complete one revolution about its axis as it orbits within the outer circular member to compensate for sensed vibrations. A crank mounts the inner circular member and a counterweight. The crank is rotated by a prime mover such as an electric motor. The mass will therefore generate a sinusoidal inertial force in a straight line. Multiple systems are suitably arranged to be used in conjunction with one another to provide a wide range of inertial force outputs.

Owner:SIKORSKY AIRCRAFT CORP

Automatic balance adjusting centrifuge

ActiveUS20100009831A1Simple structureImprove space efficiencyRotating bodies balancingStatic/dynamic balance measurementWeight transferEngineering

The present invention relates to the automatic balance adjusting centrifuge that enhances the efficiency of space utilization by simplifying the structure as well as supports a precise movement by improving the structure of the balance weight transport apparatus in the automatic balance adjusting centrifuge that compensates the unbalance of the centrifugal force by transferring the balance weight equipped in the rotor rotational arm.According to the automatic balance adjusting centrifuge of the present invention, the structure is simplified as well as the precise and exact transfer of the balance weight is possible by connecting the balance weight with the axis of the motor directly and adopting the length sensor. Furthermore, the efficiency of space utilization is enhanced because the axis of rotation of the balance weight transfer motor is in radial direction of the rotational arm.

Owner:HANLAB CORP

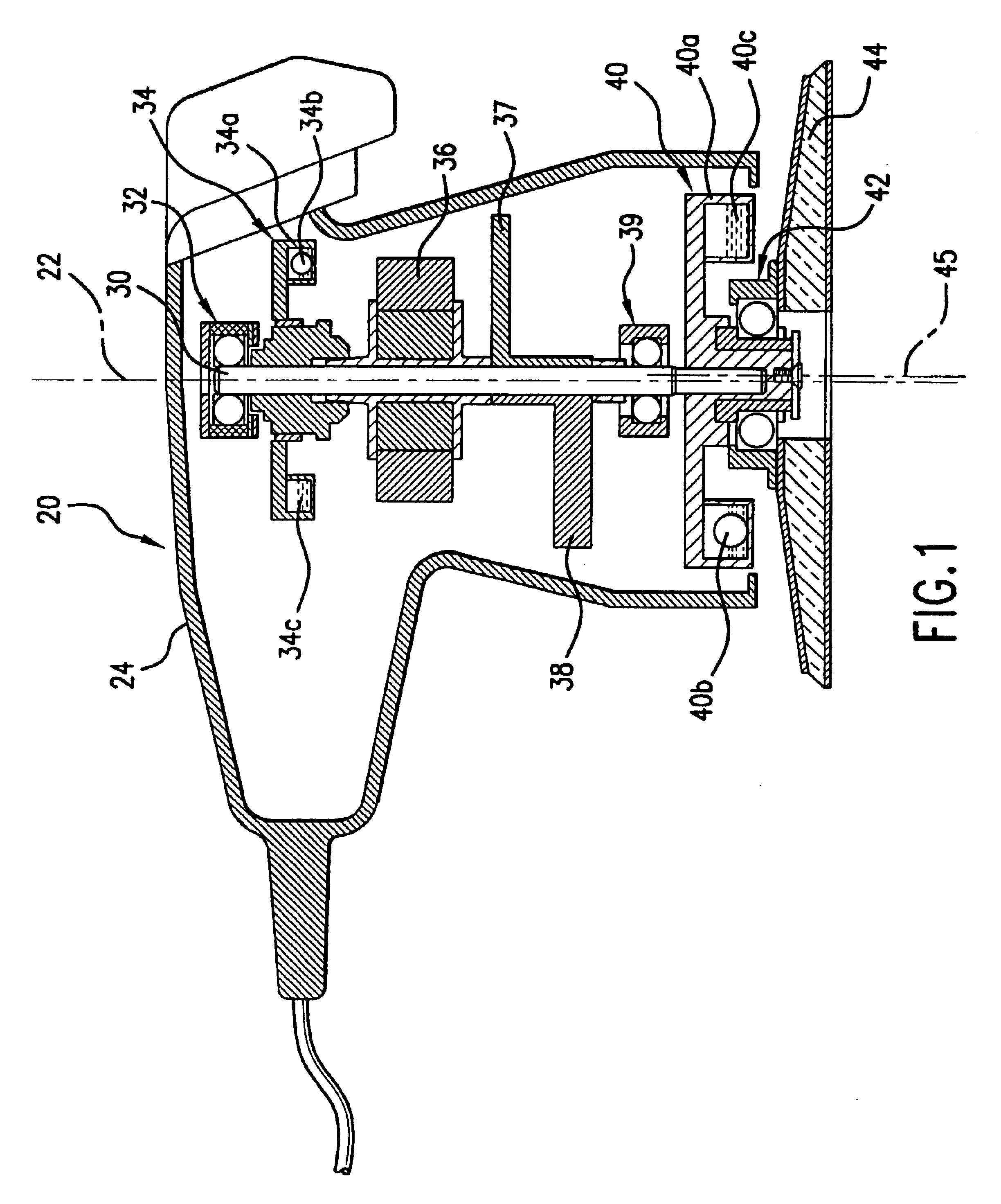

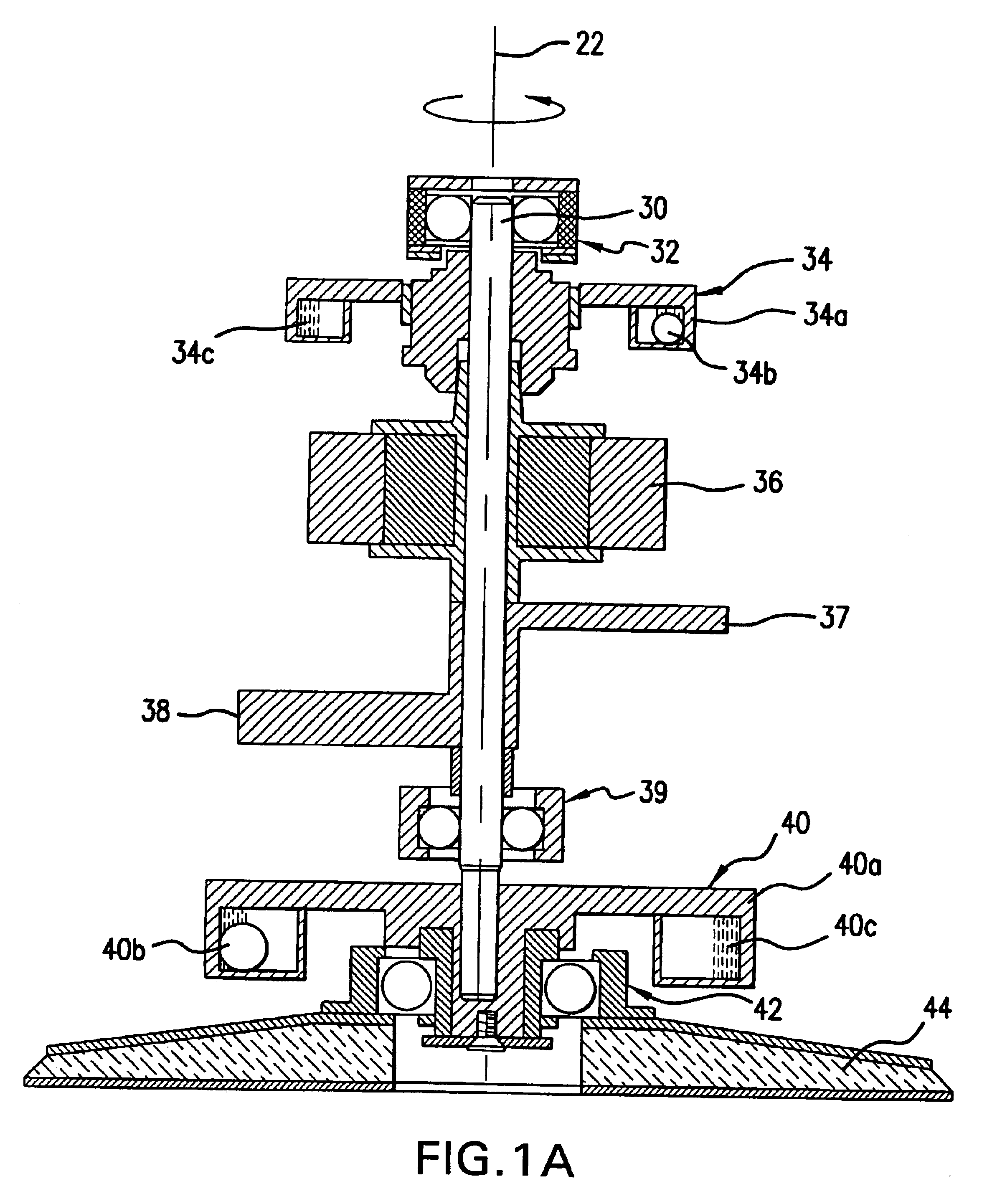

Rotating machine active balancer and method of dynamically balancing a rotating machine shaft with torsional vibrations

InactiveUS20060005623A1Rotating vibration suppressionRotating bodies balancingEngineeringTorsional vibration

An active balancer for dynamically balancing a rotating machine is provided. The active balancer has a balancer body which rotates with the rotating machine and at least one controllable position counter weight having a real-time adjustable position relative to the balancer body and the rotating machine inorder to produce an actively adjustable controllable counter weight balance force for dynamically balancing the rotating machine. The active balancer includes a spring with the balancer body mounted to the rotating machine through the spring wherein the balancer body mass resonates on the spring with a torsional vibration canceling frequency which cancels a torsional vibration of the rotating machine.

Owner:LORD CORP

Moving-weight, dynamic balancing apparatus for a rotary machine, in particular for industrial fans

InactiveUS6210099B1Easy to implementLow costPropellersWind motor controlDynamic balanceSystem monitor

A moving-weight, dynamic balancing apparatus for a rotary machine, in particular an industrial fan, having a rotary shaft, and at least one rotor carried by the rotary shaft and provided with main rotor bearings to allow rotary movement thereof. The balancing apparatus includes at least one moving-weight balancing unit is carried by the rotary shaft, and at least one monitoring and correcting system having a drive assembly. The at least one monitoring and correcting system monitors and corrects the unbalanced state of the rotor, and acts continuously on the at least one moving-weight balancing unit when the rotor is rotating to monitor and correct for rotor unbalance. The at least one moving-weight balancing unit has at least two balancing masses mounted to be movable under drive from the drive assembly controlled by the monitoring and correction system. The at least one moving-weight balancing unit is situated axially at a distance from the rotor to be balanced beyond the main rotor bearings, and includes a ring and at least one guide assembly. The at least two balancing masses include respective carriages that are moveable in the ring, guided by the at least one guide assembly, independently of each other along trajectories that form closed circuits around the rotary shaft under drive from the drive assembly associated with each of said at least two balancing masses.

Owner:FLAKT SOLYVENT VENTEC

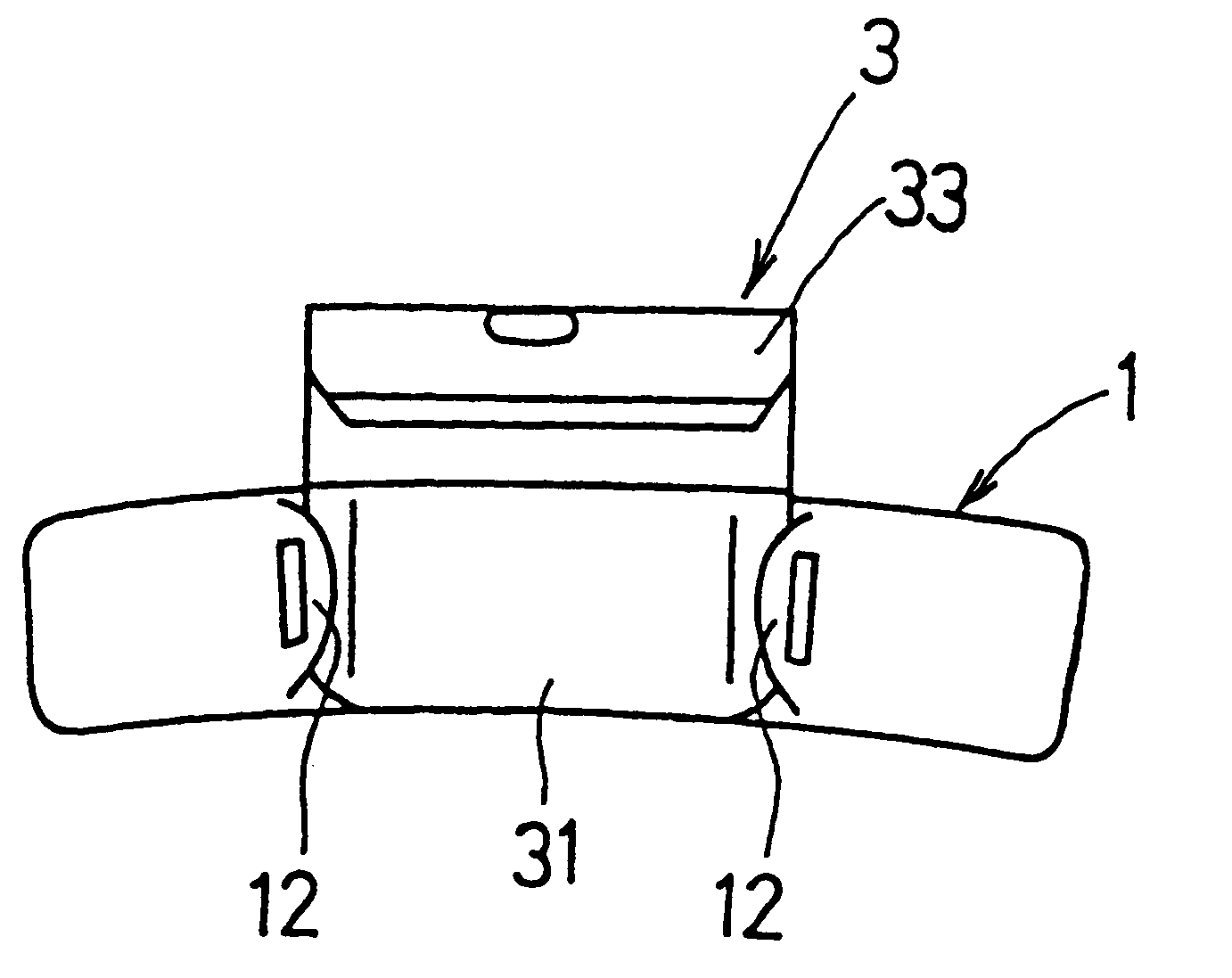

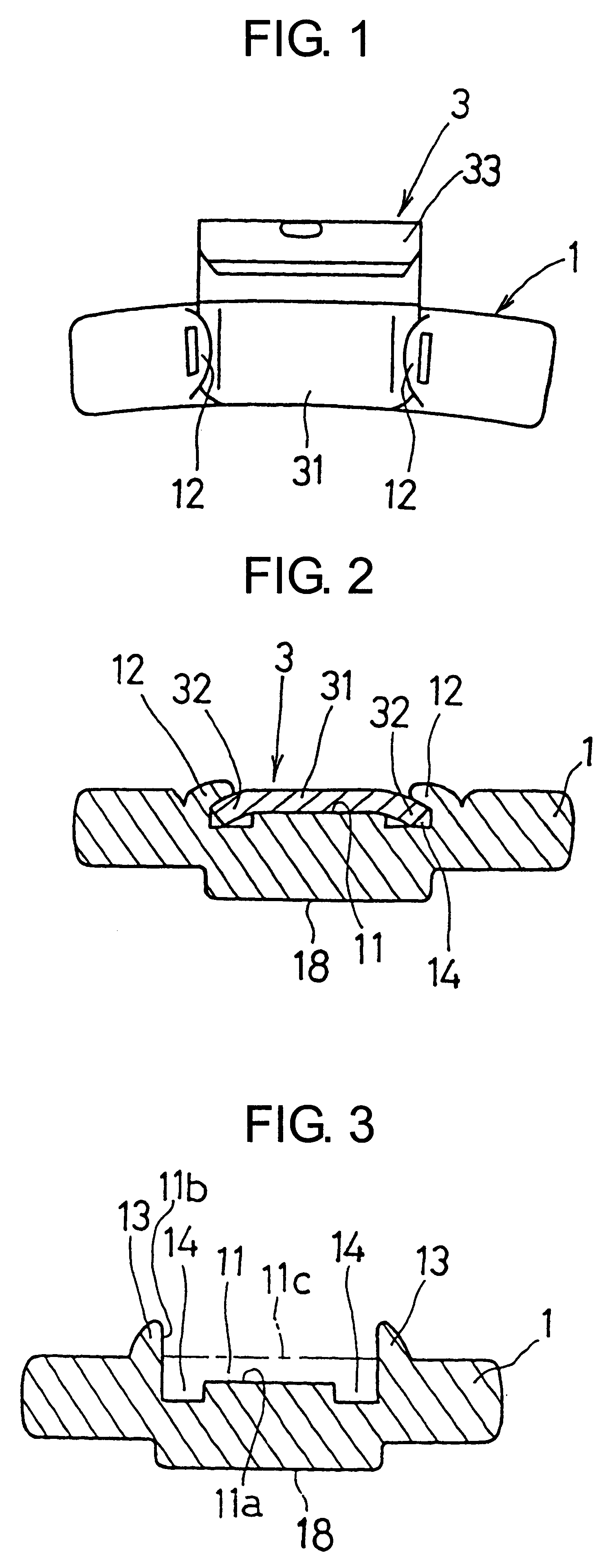

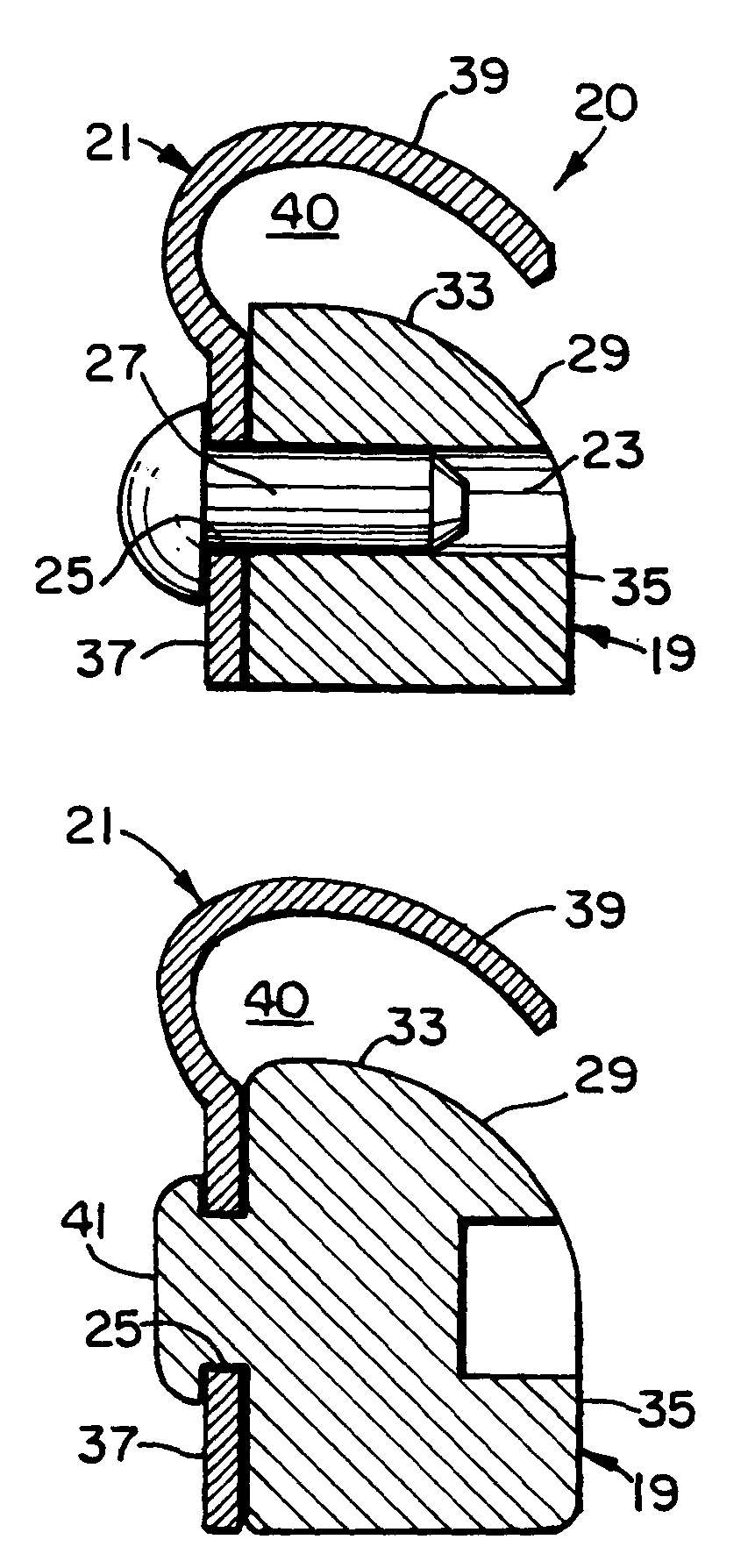

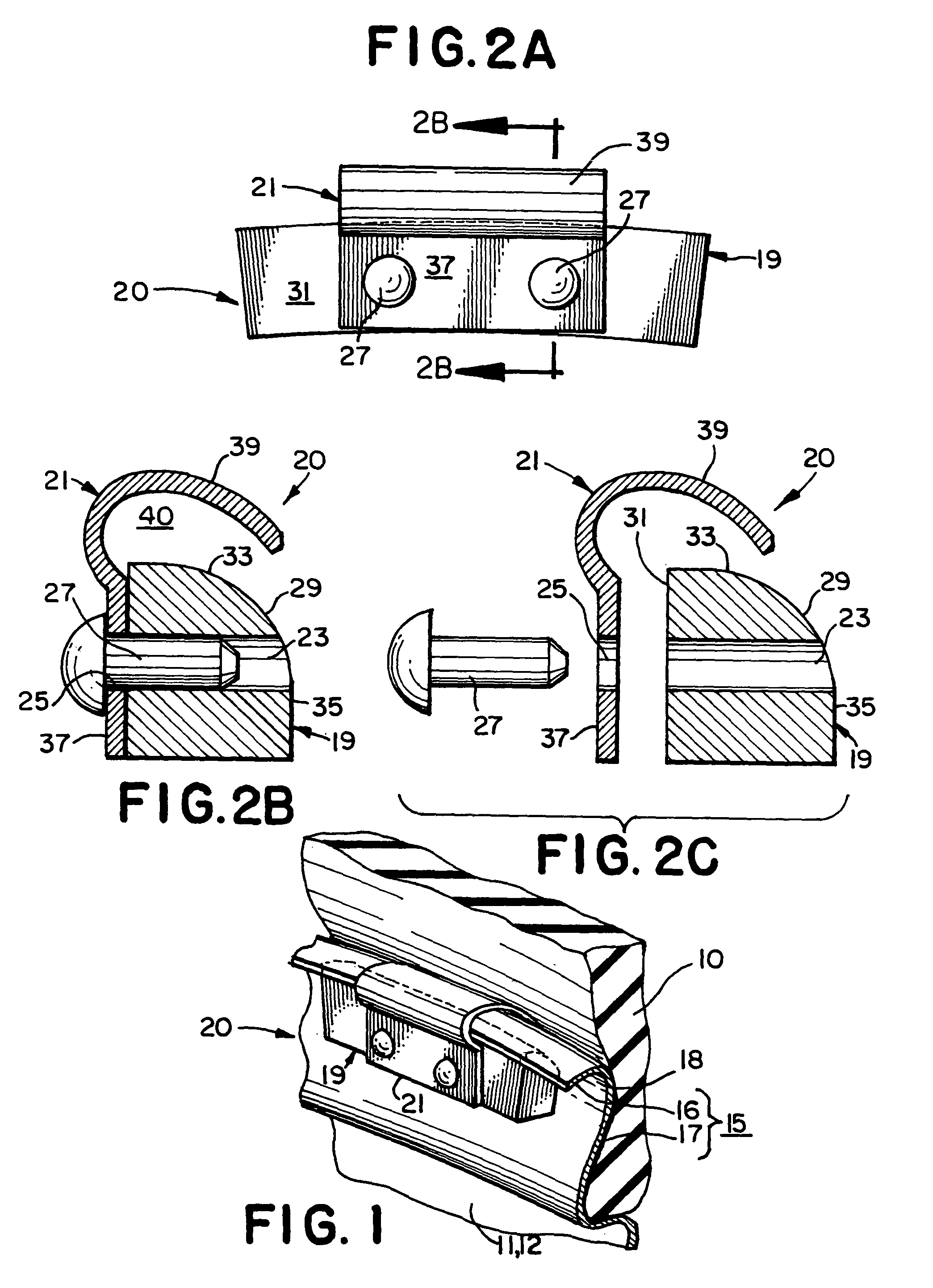

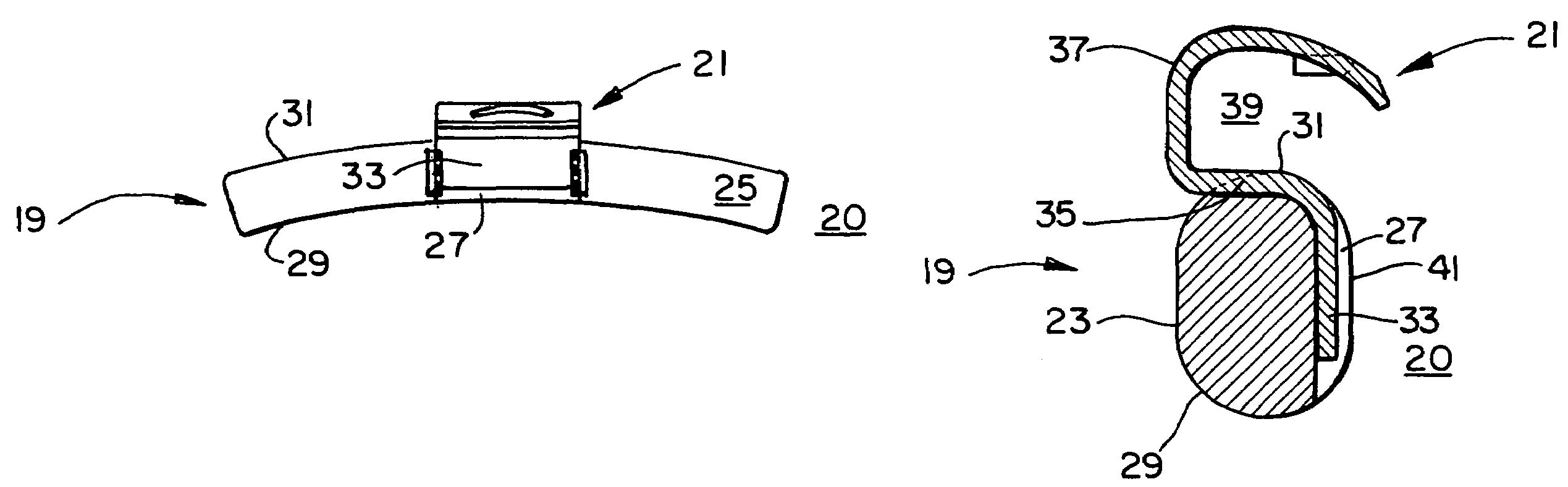

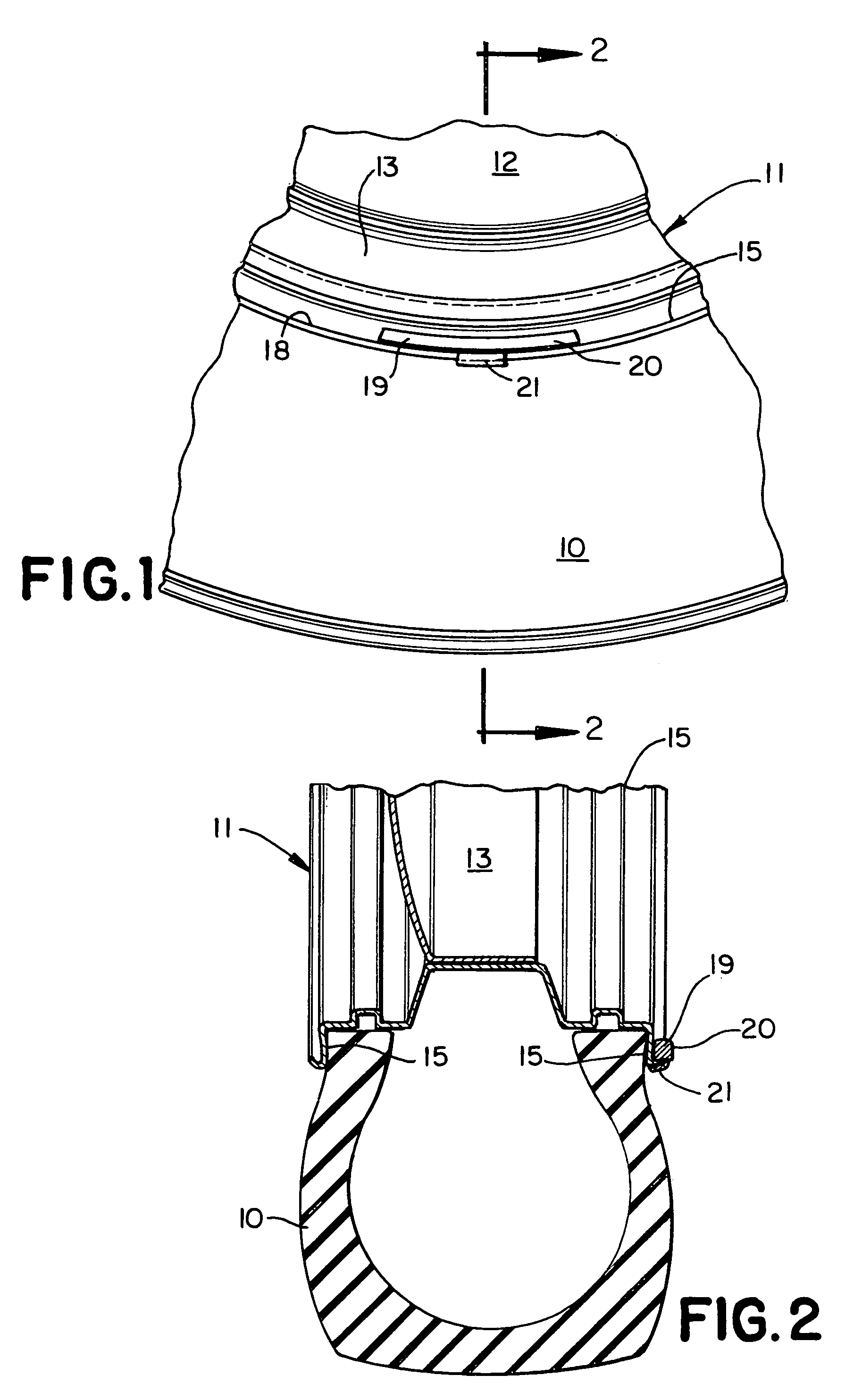

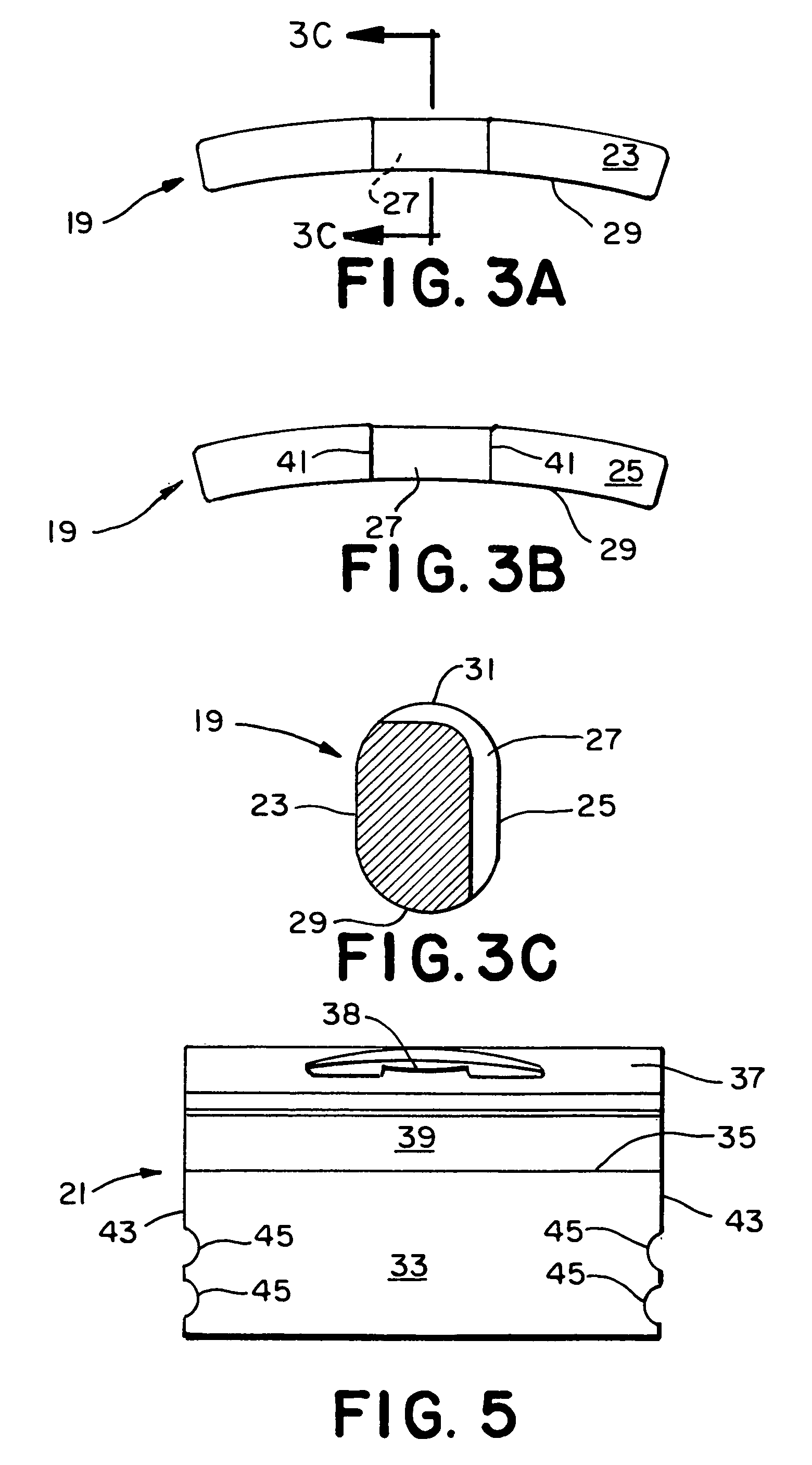

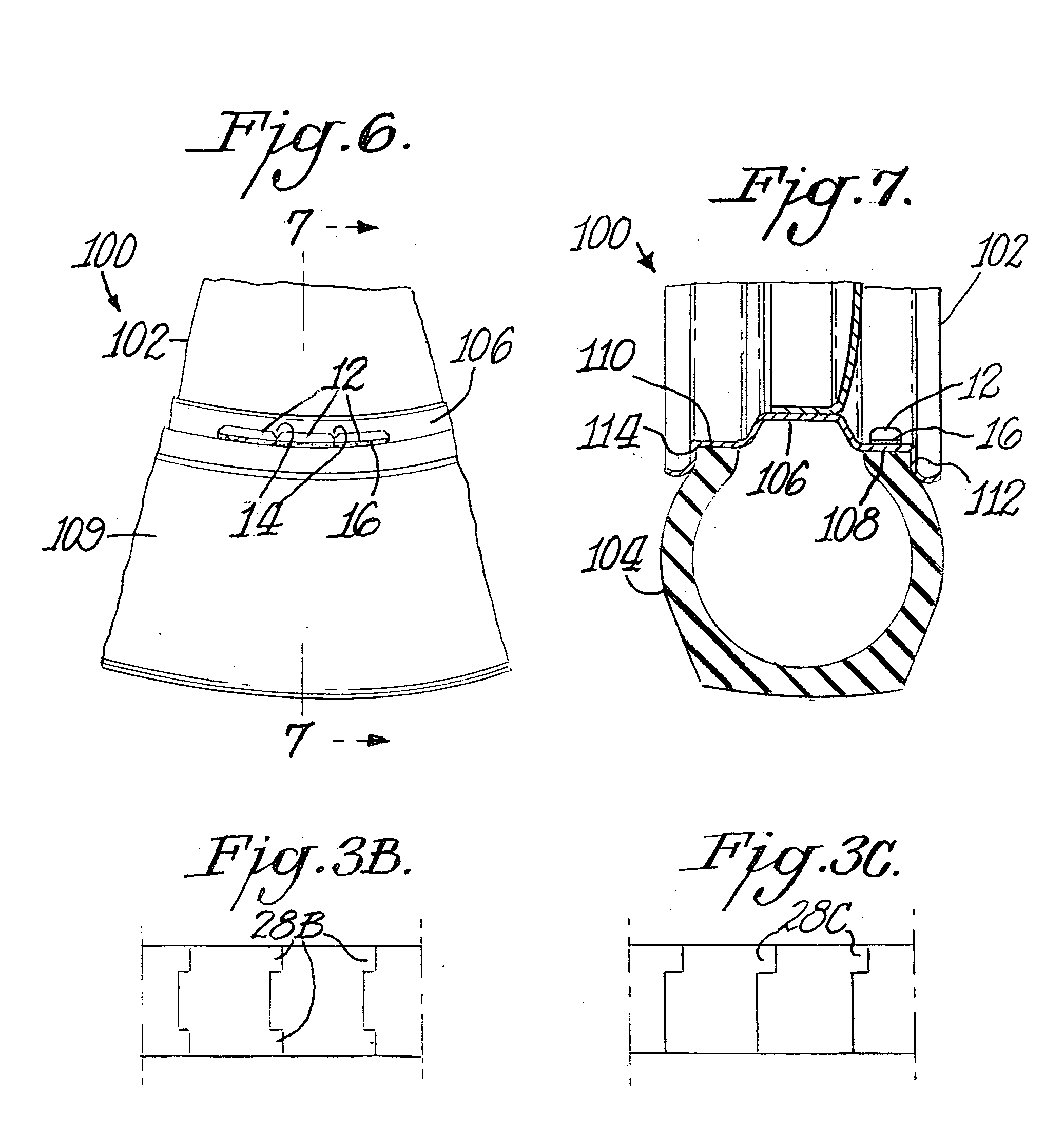

Wheel balancing weight with half-clip

A wheel-balancing weight mounts to a wheel with a flange. The weight has a weighted body and a clip securely attached thereto. The clip has a gripping section and the body has a gripping portion generally opposite the gripping section of the clip. The gripping section of the clip and the gripping portion of the body in combination define a compartment therebetween, where the compartment receives the flange therein when the weight is mounted thereto such that the gripping section of the clip and the gripping portion of the body are on opposite sides of the flange and grip the flange therebetween.

Owner:WEGMANN AUTOMOTIVE USA

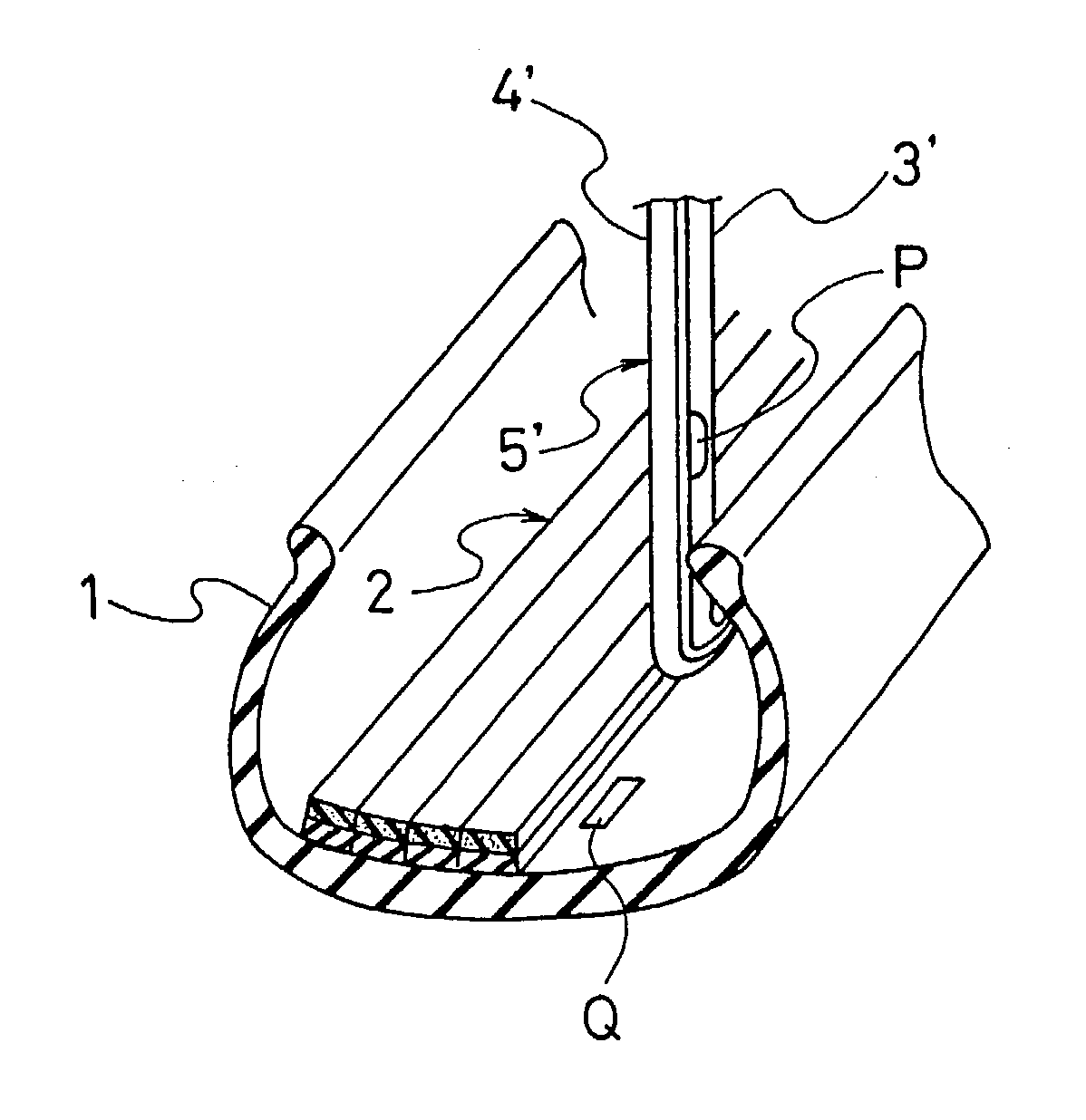

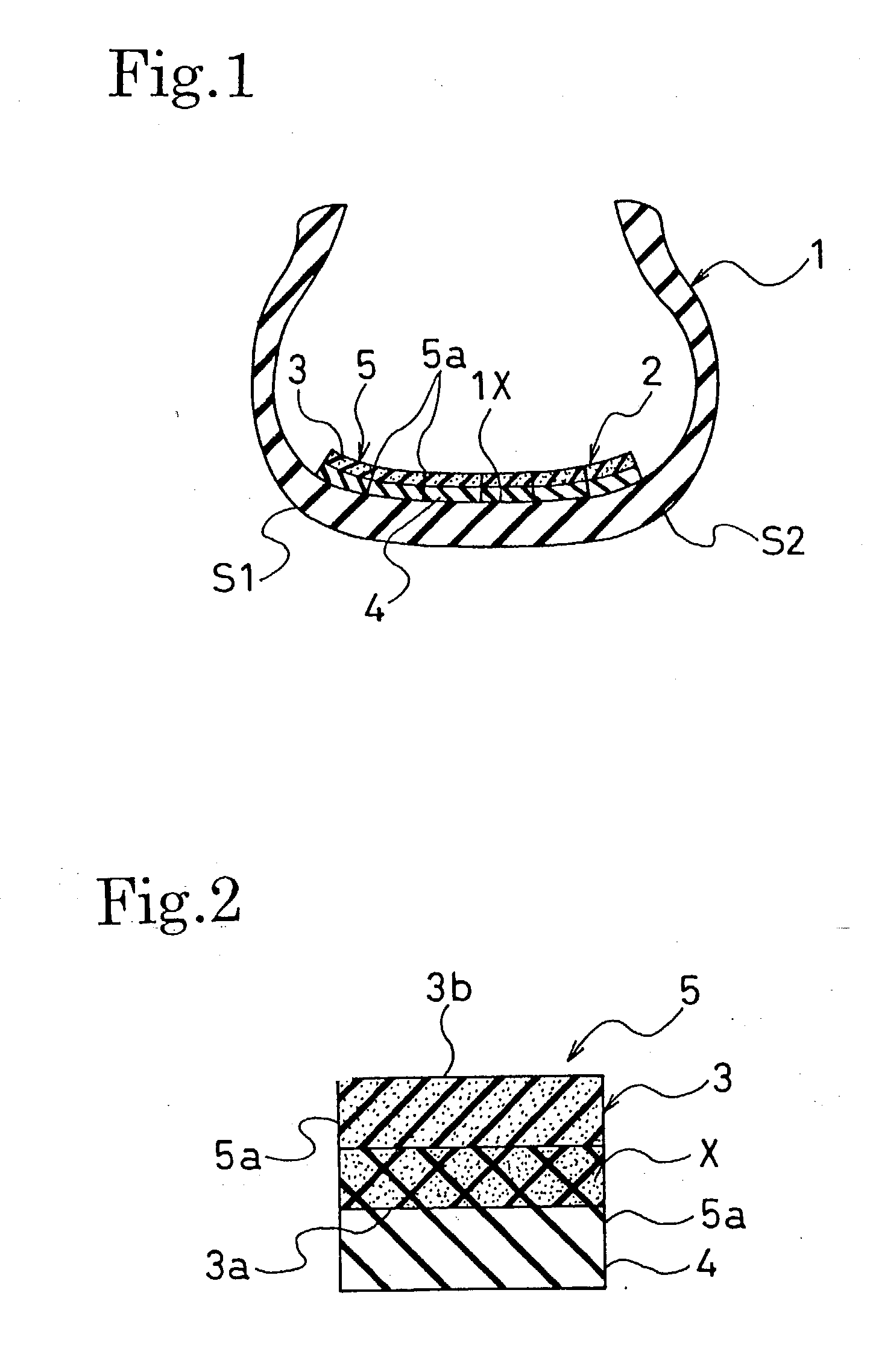

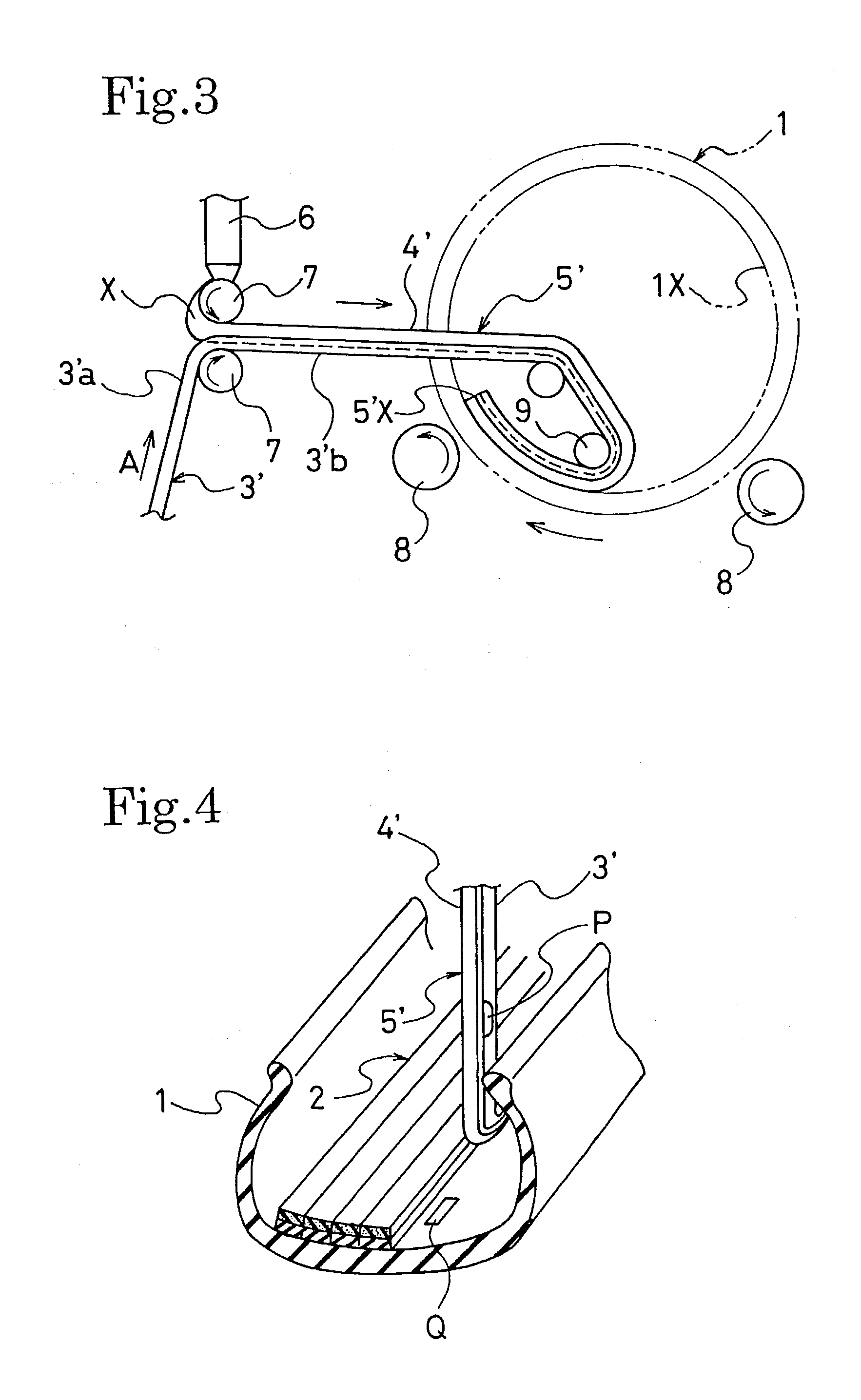

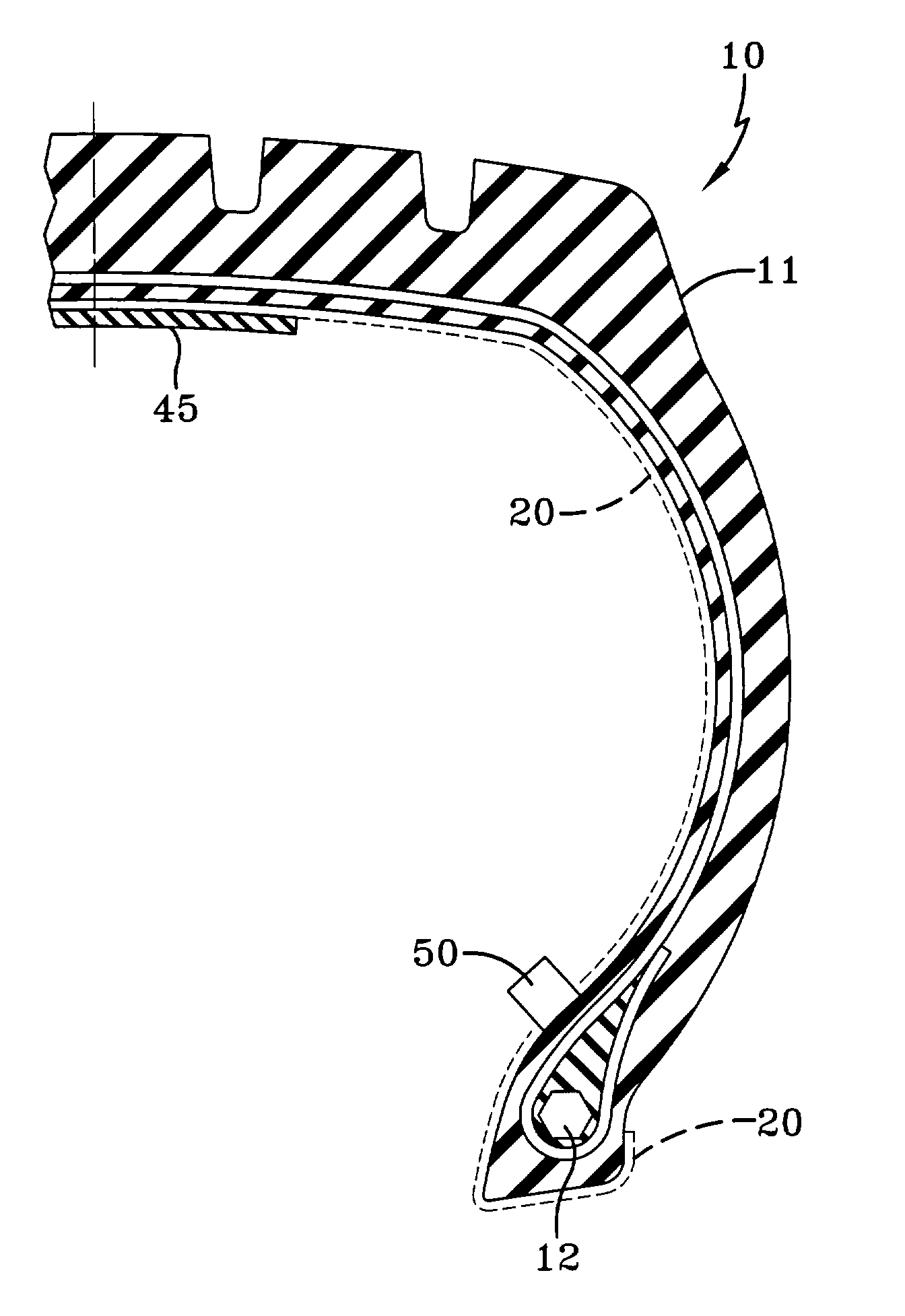

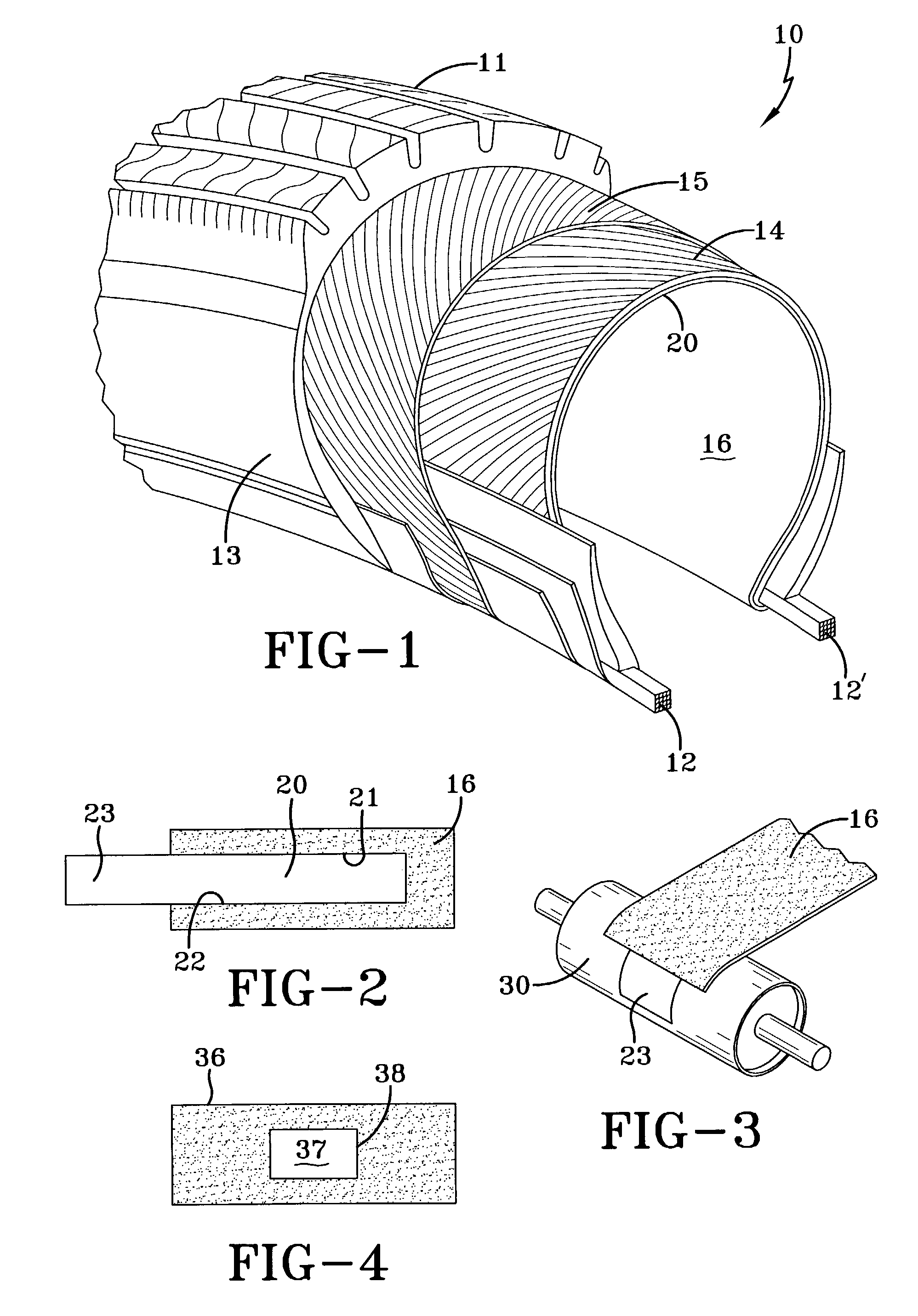

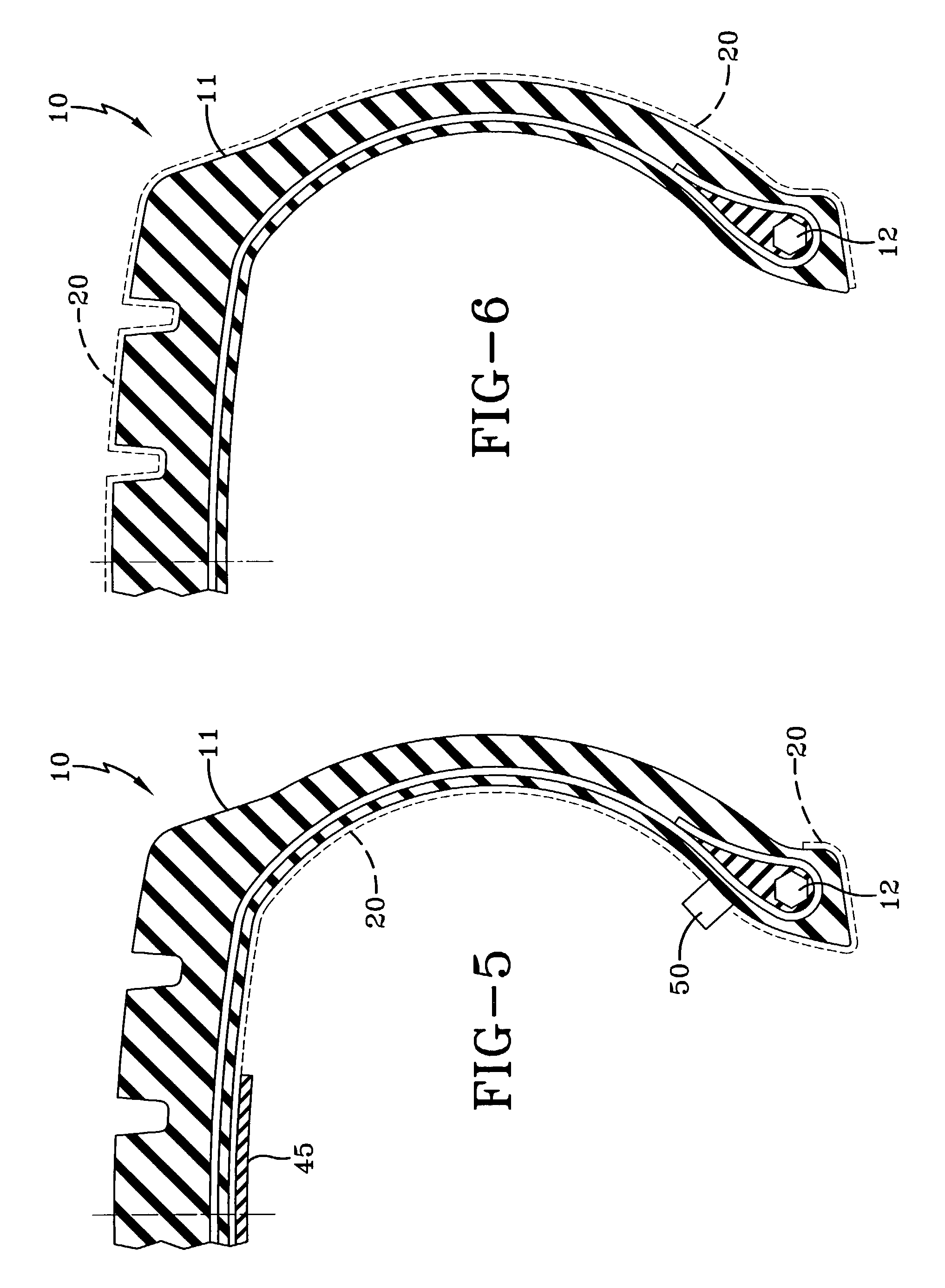

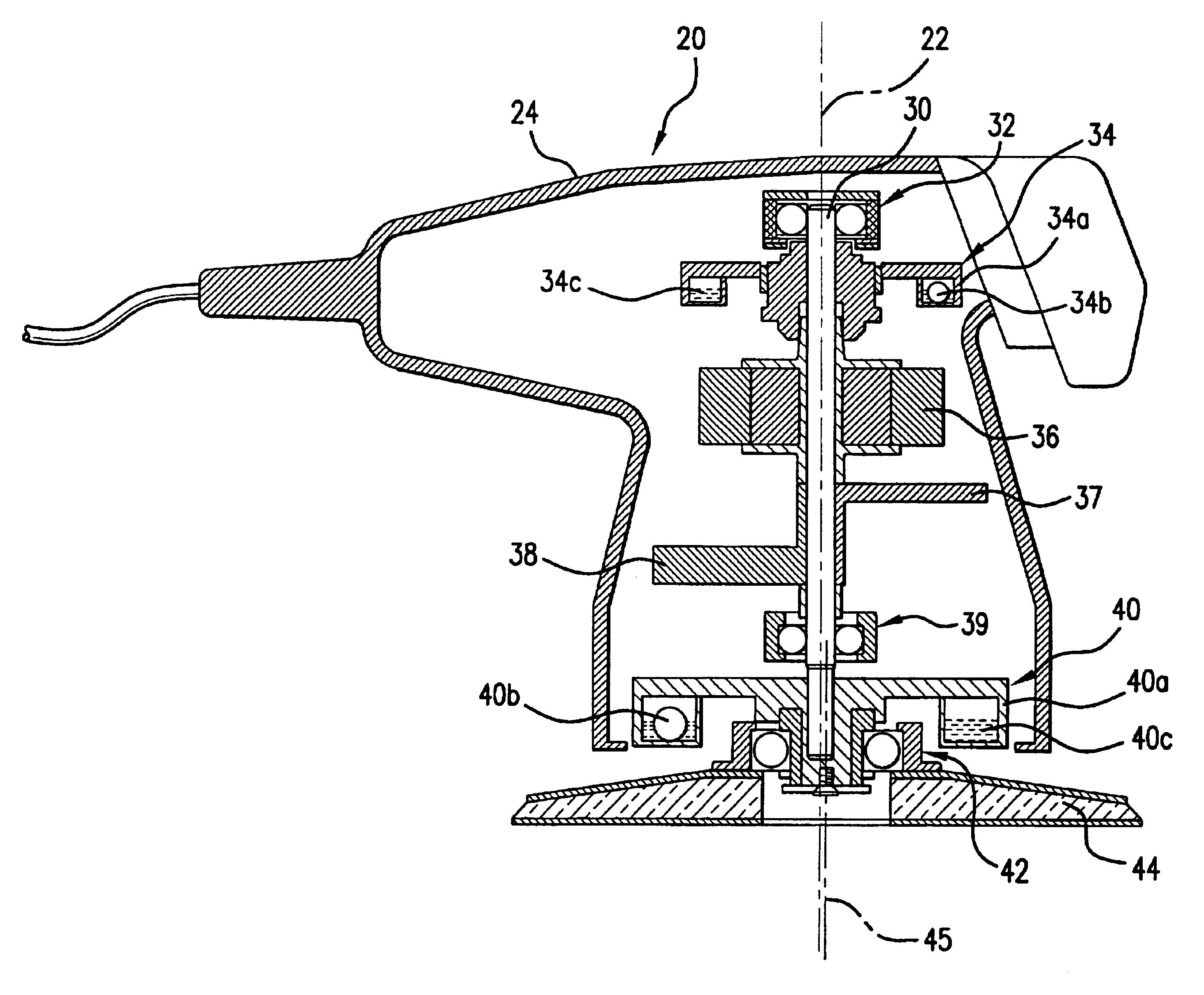

Self-seal tire and method of producing the same

A self-seal tire according to the present invention has a puncture sealing layer located all over a tire inner wall surface from one shoulder portion to the other shoulder portion of a pneumatic tire. The puncture sealing layer comprises at least one band-shape seal layer, which includes a band-shape sponge layer and a bonding layer, the band-shape sponge layer being impregnated with an adhesive so that it is exposed on a tier wall surface side face of the band-shape sponge layer and spaced apart from a tire counter wall surface side face thereof, and the bonding layer being made of adhesive and provided on the tire wall surface side face. The band-shape seal layer is bonded through the bonding layer on the tire inner wall surface with the band-shape seal layer being wound in a circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

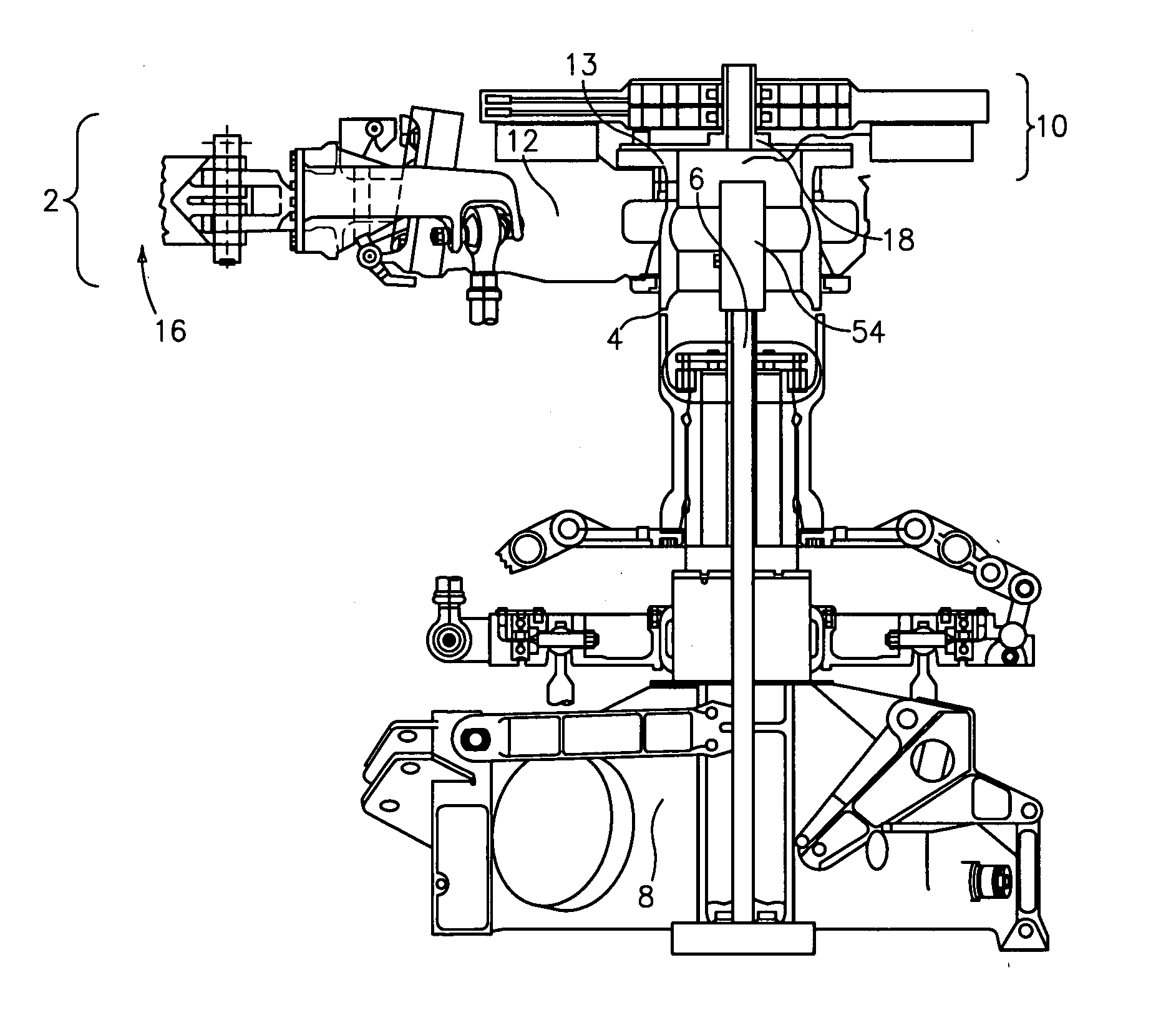

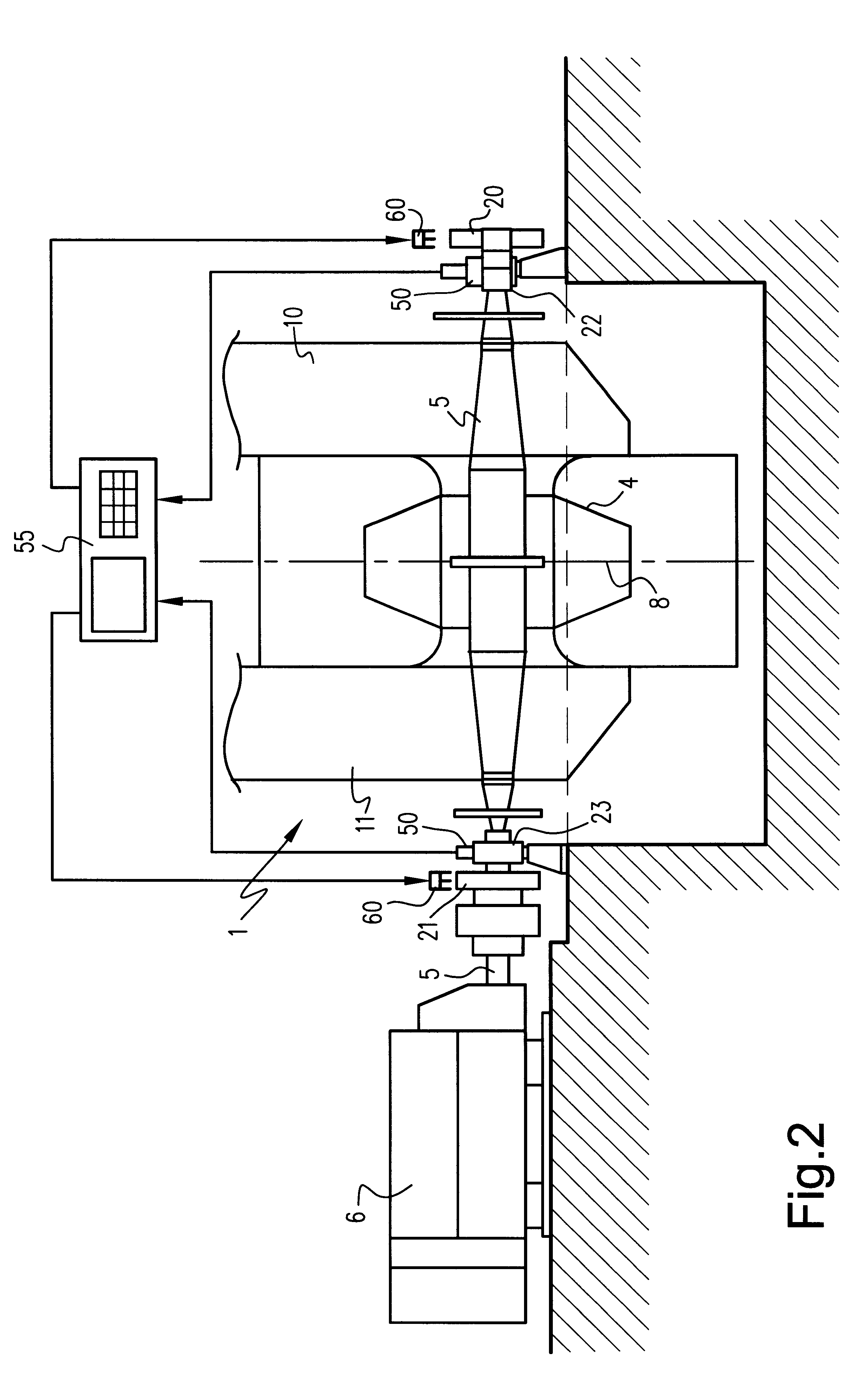

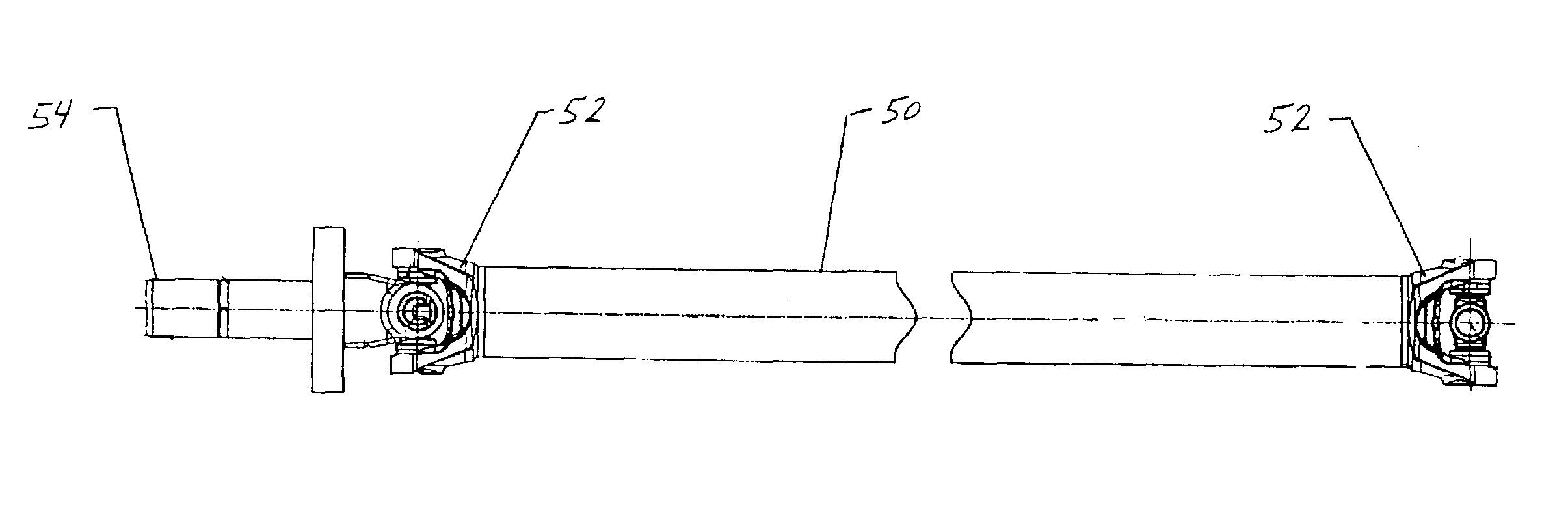

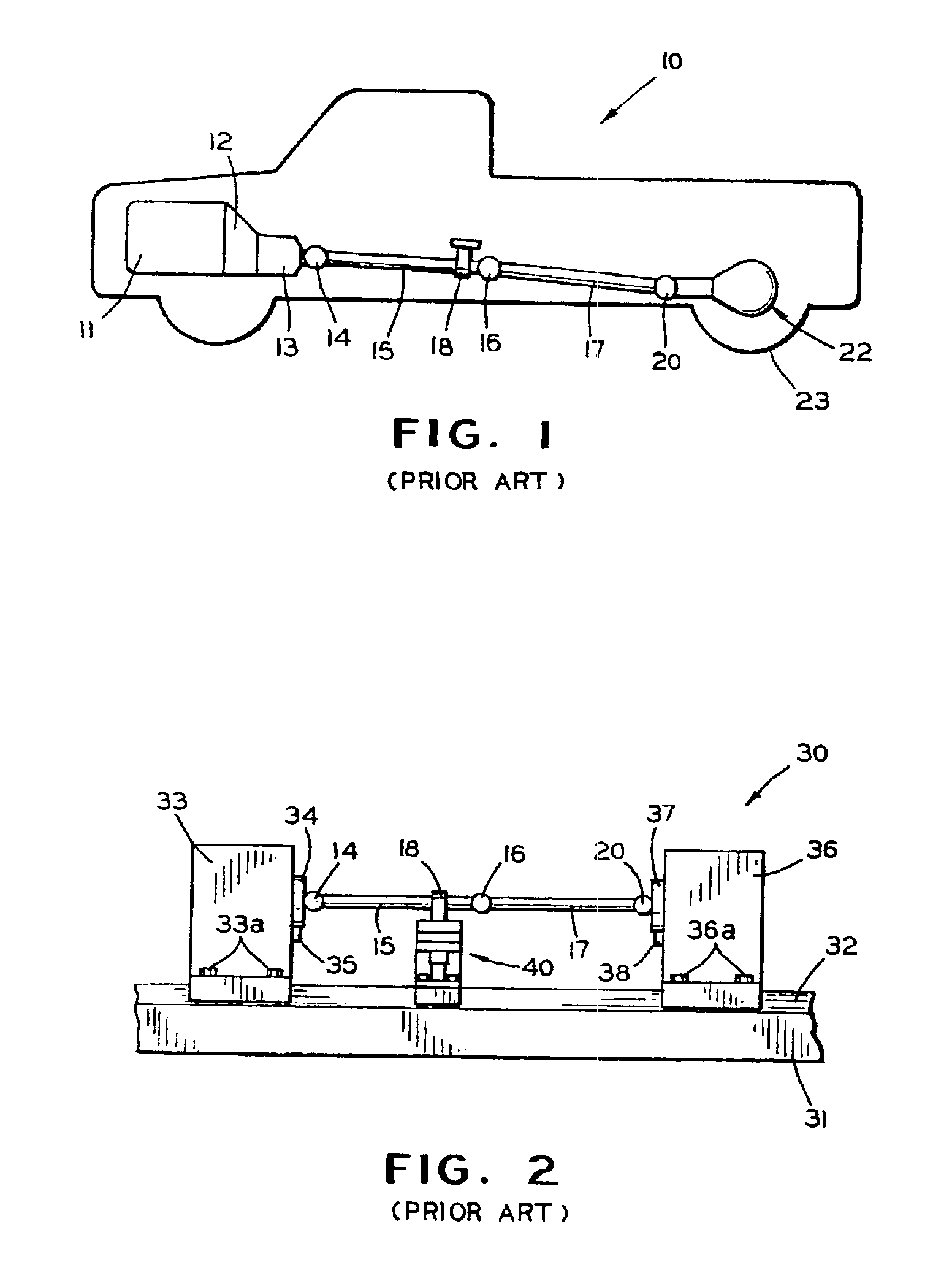

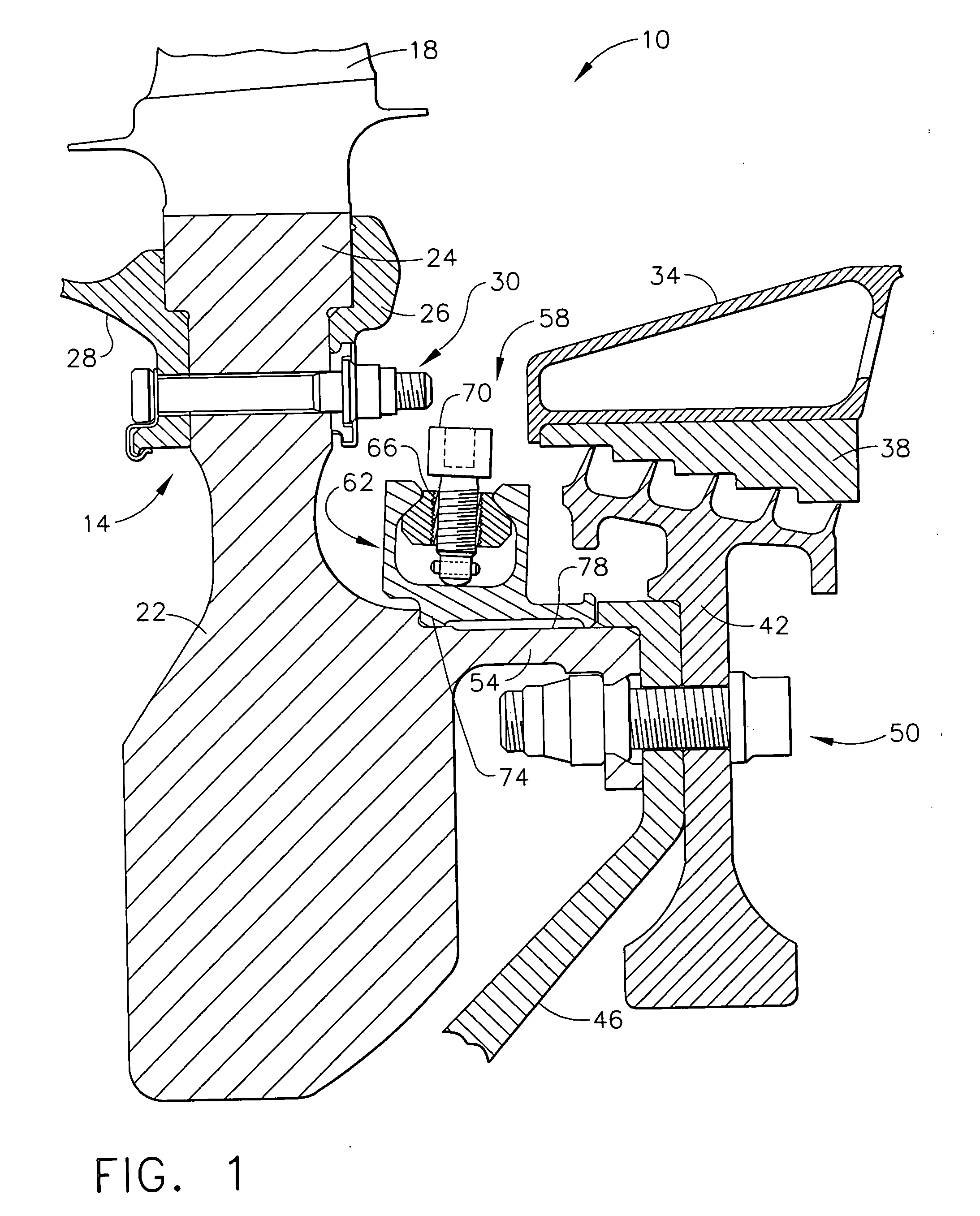

System and method for balancing a driveline system

InactiveUS6923058B2Reduce errorsReduce vibrationRotating vibration suppressionRotating bodies balancingDrive shaftUniversal joint

A process for balancing a vehicular driveline including a propeller shaft and an input shaft of a vehicle axle interconnected by a universal joint. First, the vehicle propeller shaft is balanced to a predetermined residual imbalance having an imbalance vector angle of 0° or 180° which lies inline with open set of cardan joint trunnions. The corrected residual imbalance is then visually marked. Next, the input shaft is balanced to a predetermined residual imbalance having an imbalance vector angle of 0° or 180° which lies inline with cross-holes in yoke ears. Again, the corrected residual imbalance on the input shaft is then visually marked. During the assembly of the vehicle, the assembly line operator couples the propeller shaft to the input shaft through a cardan joint cross by aligning the marks on the propeller shaft and the input shaft so that the marks are located opposite to each other.

Owner:TORQUE TRACTION TECH INC

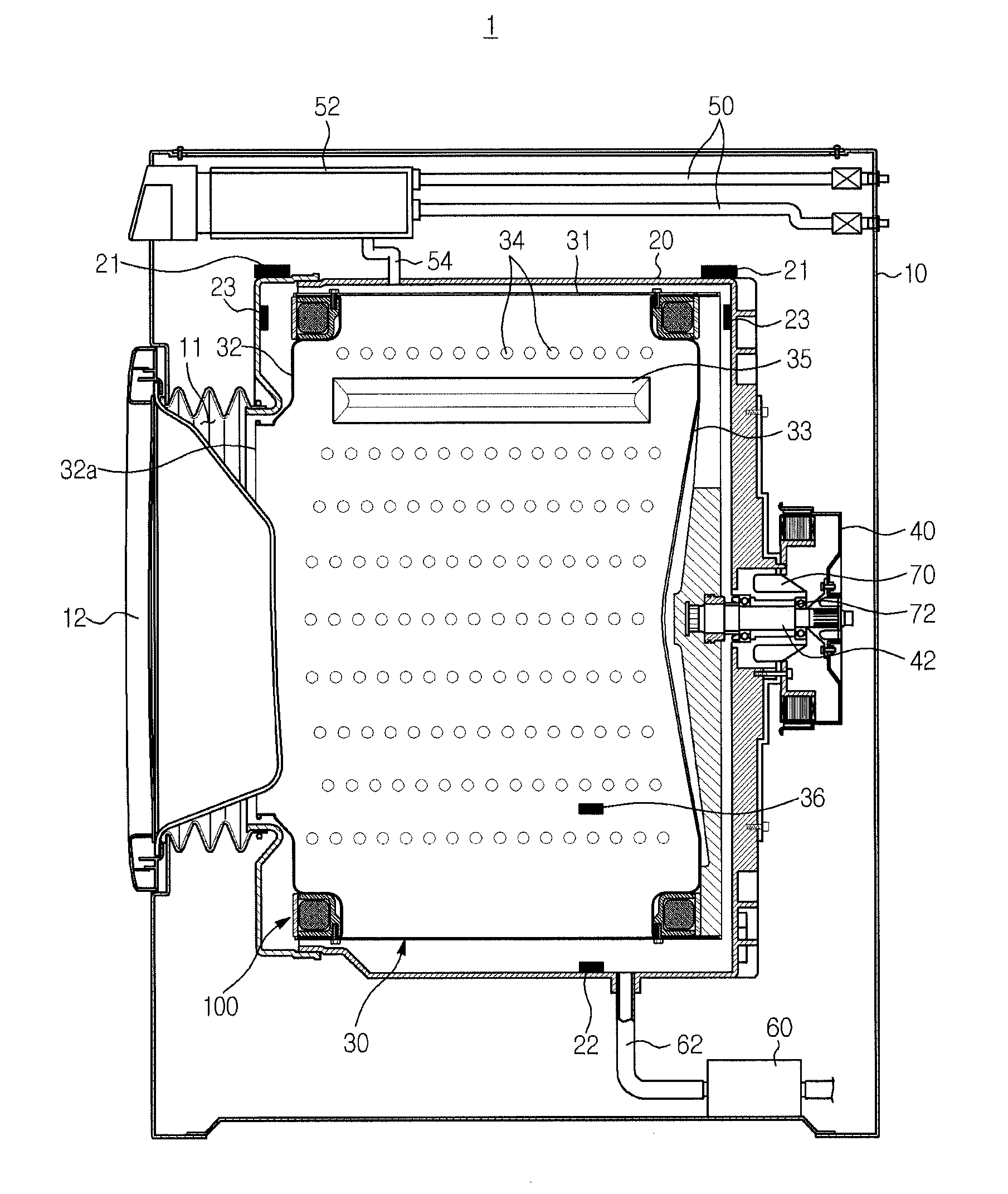

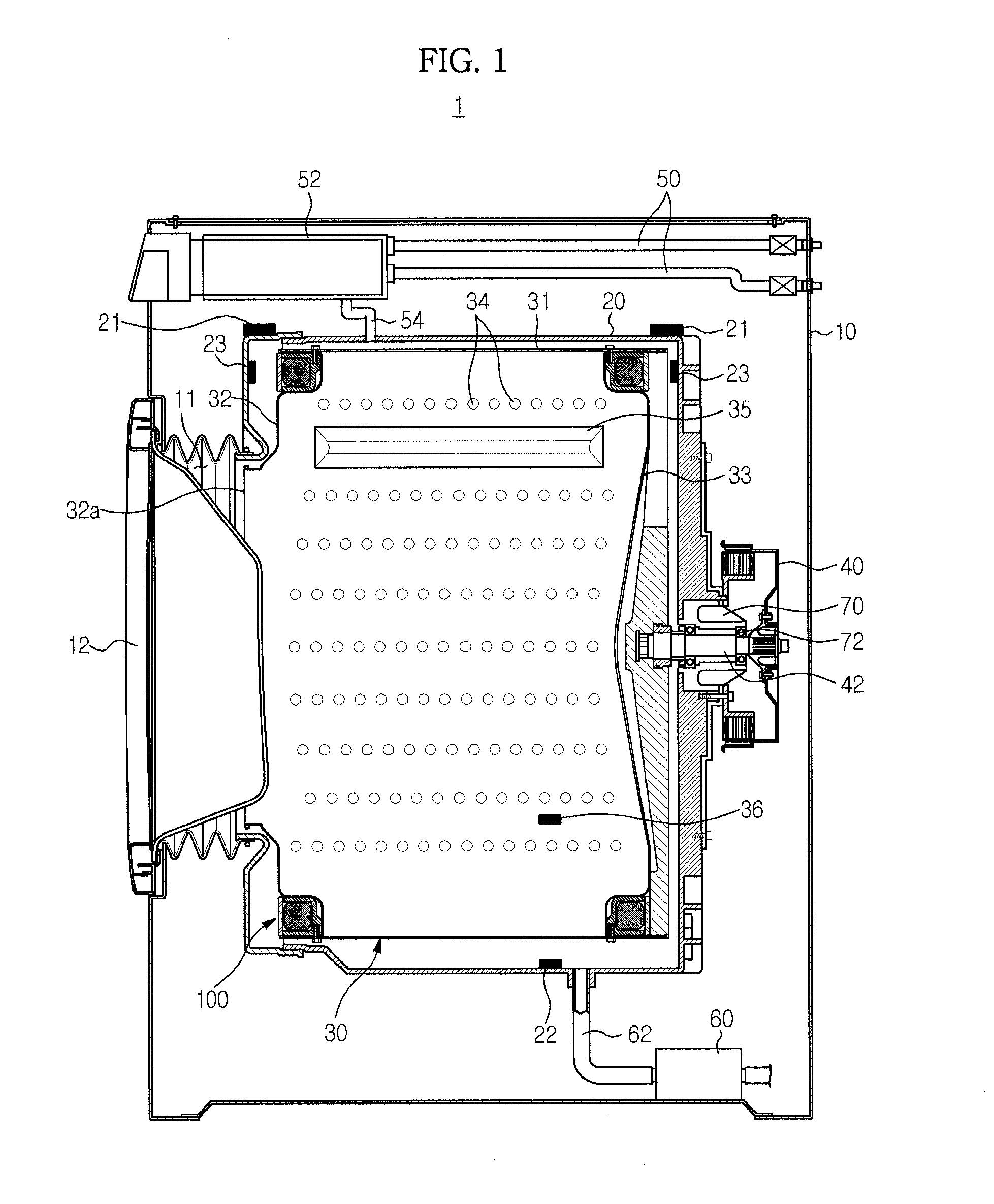

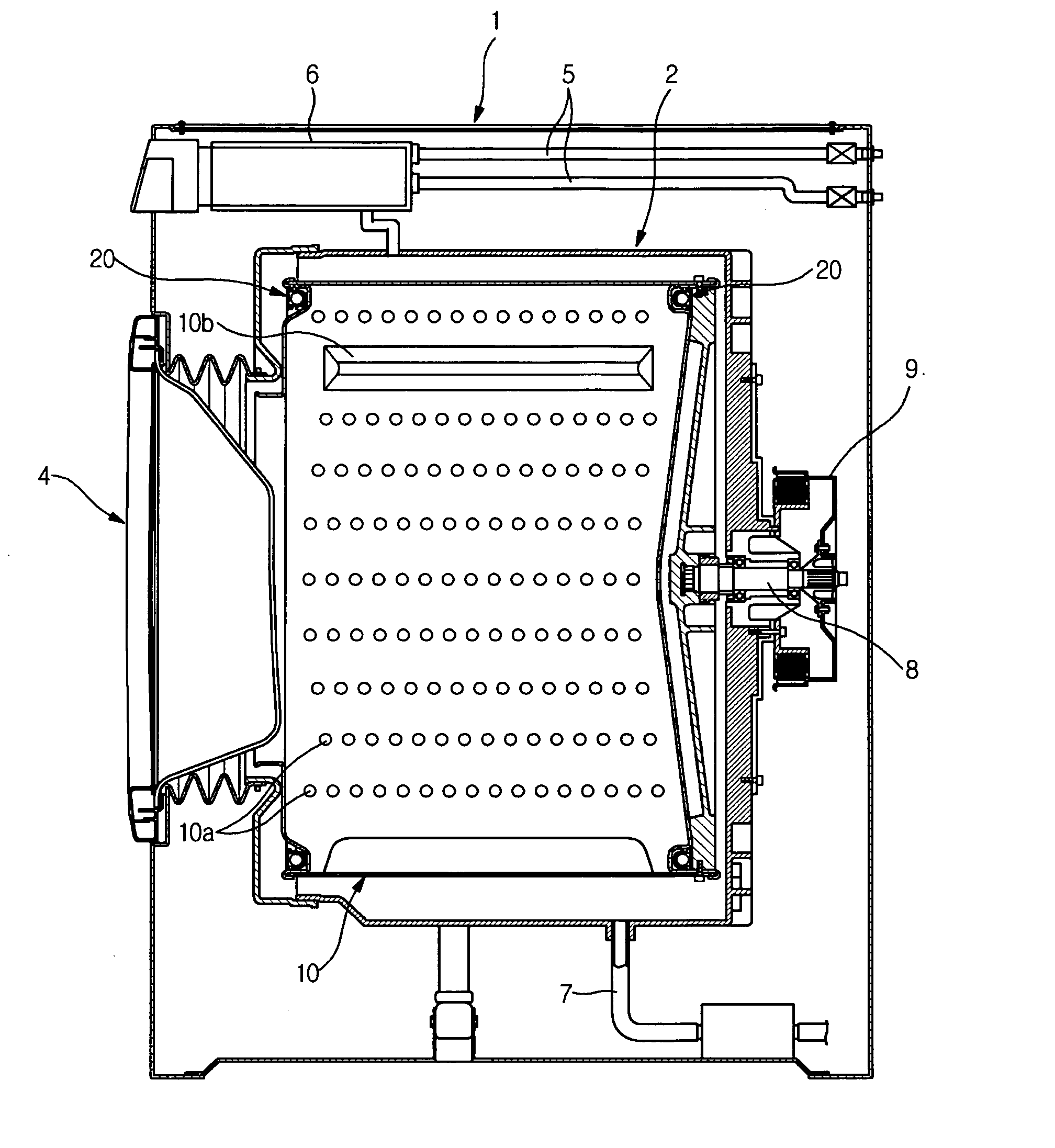

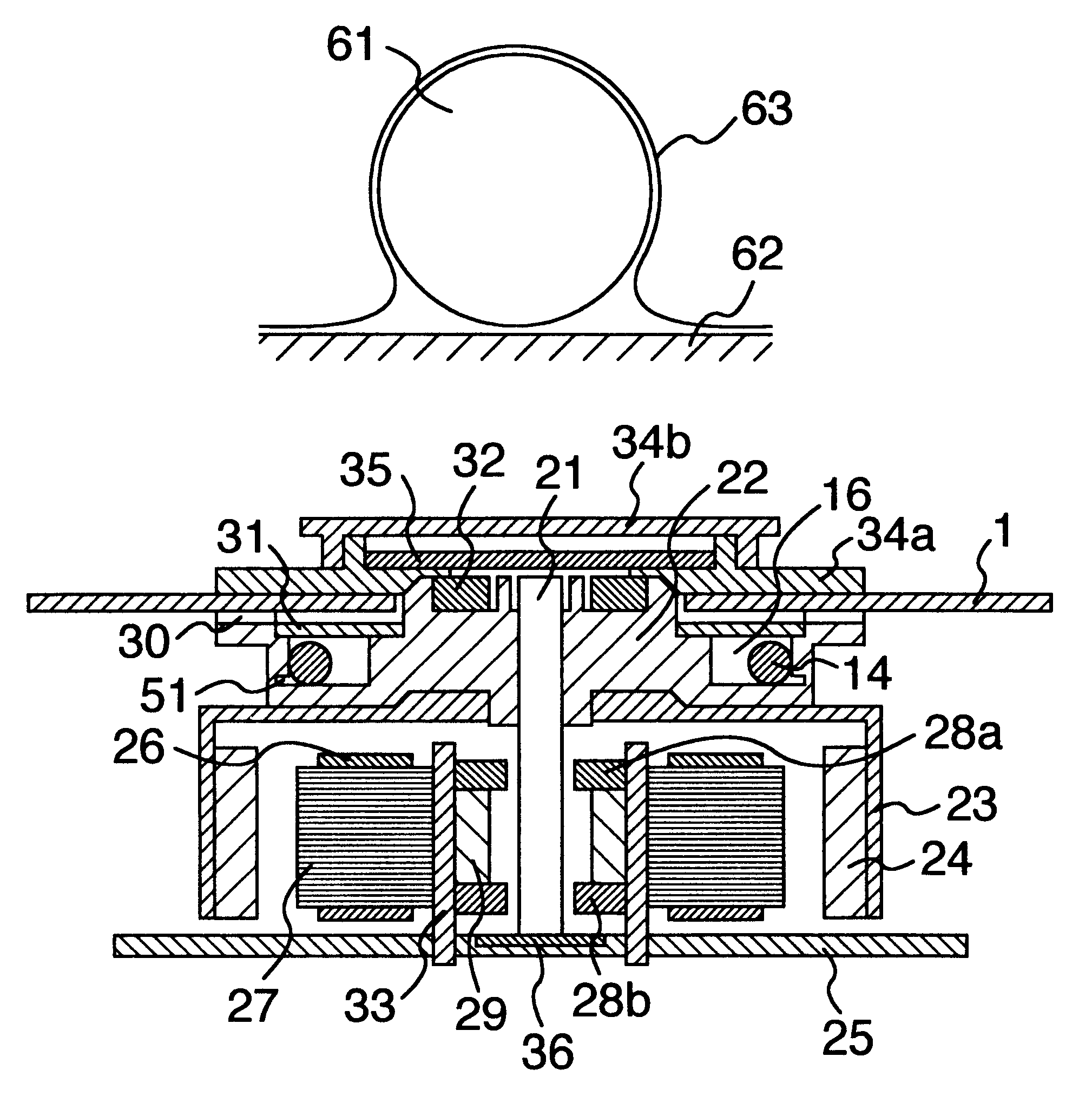

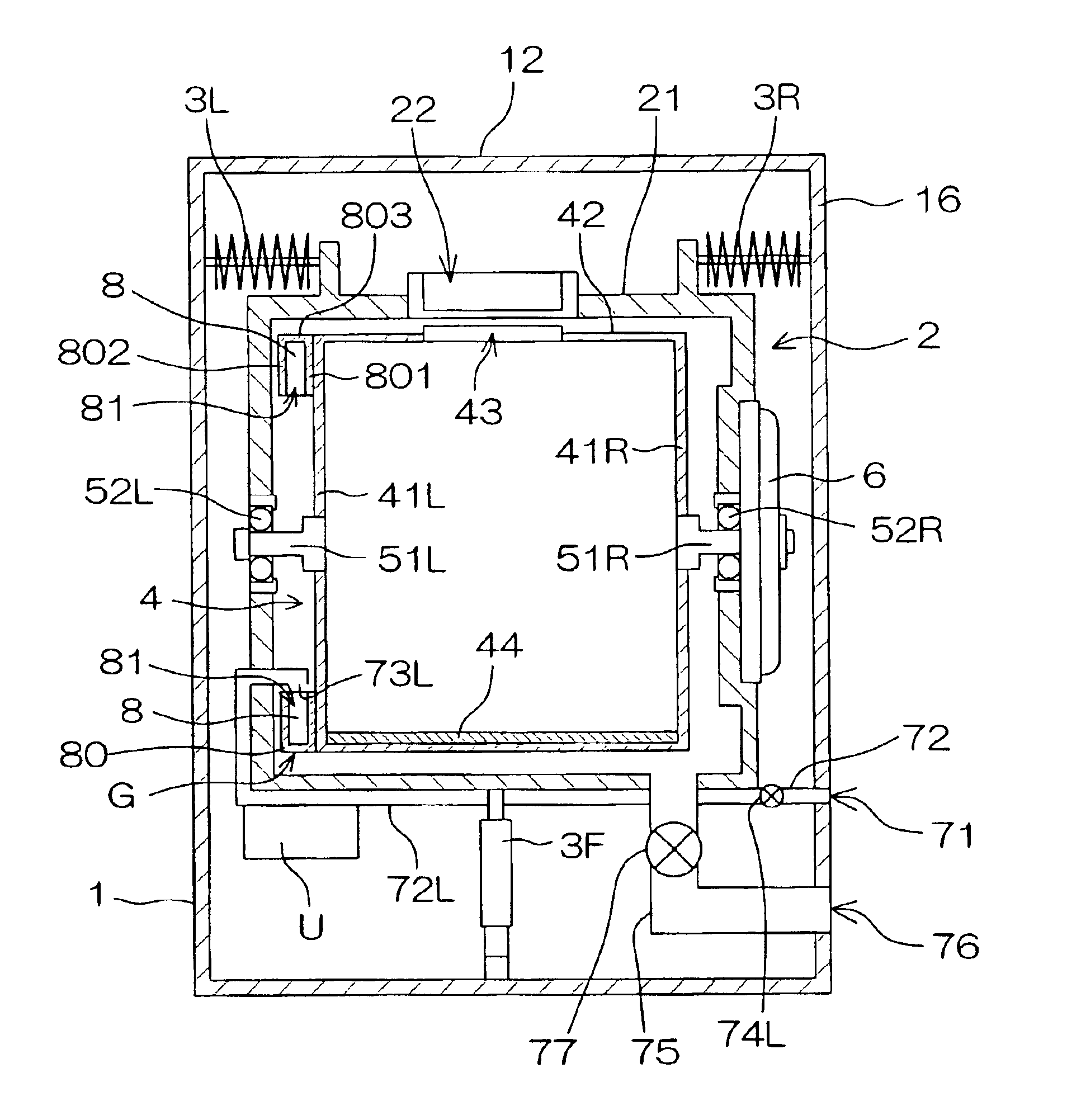

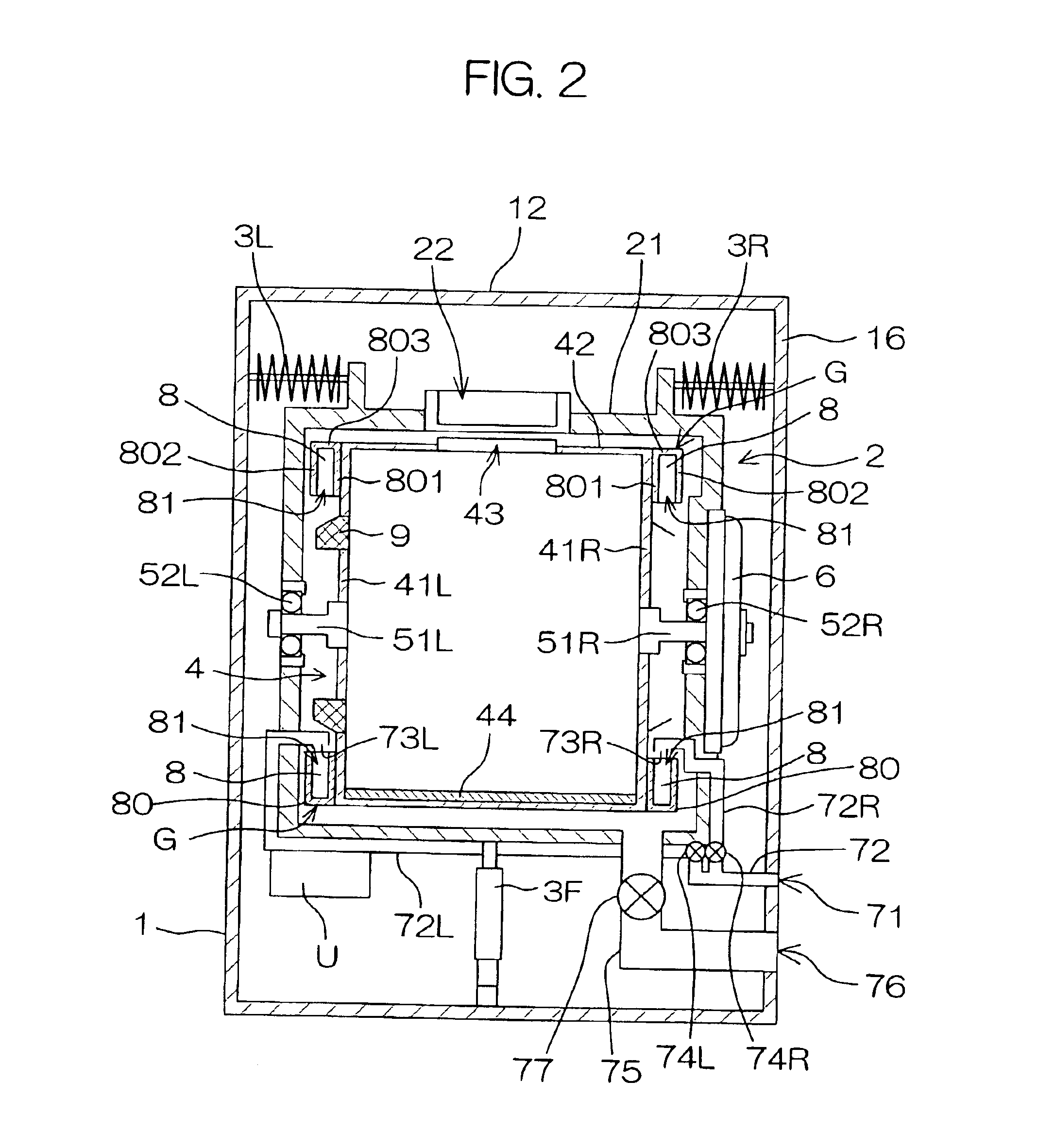

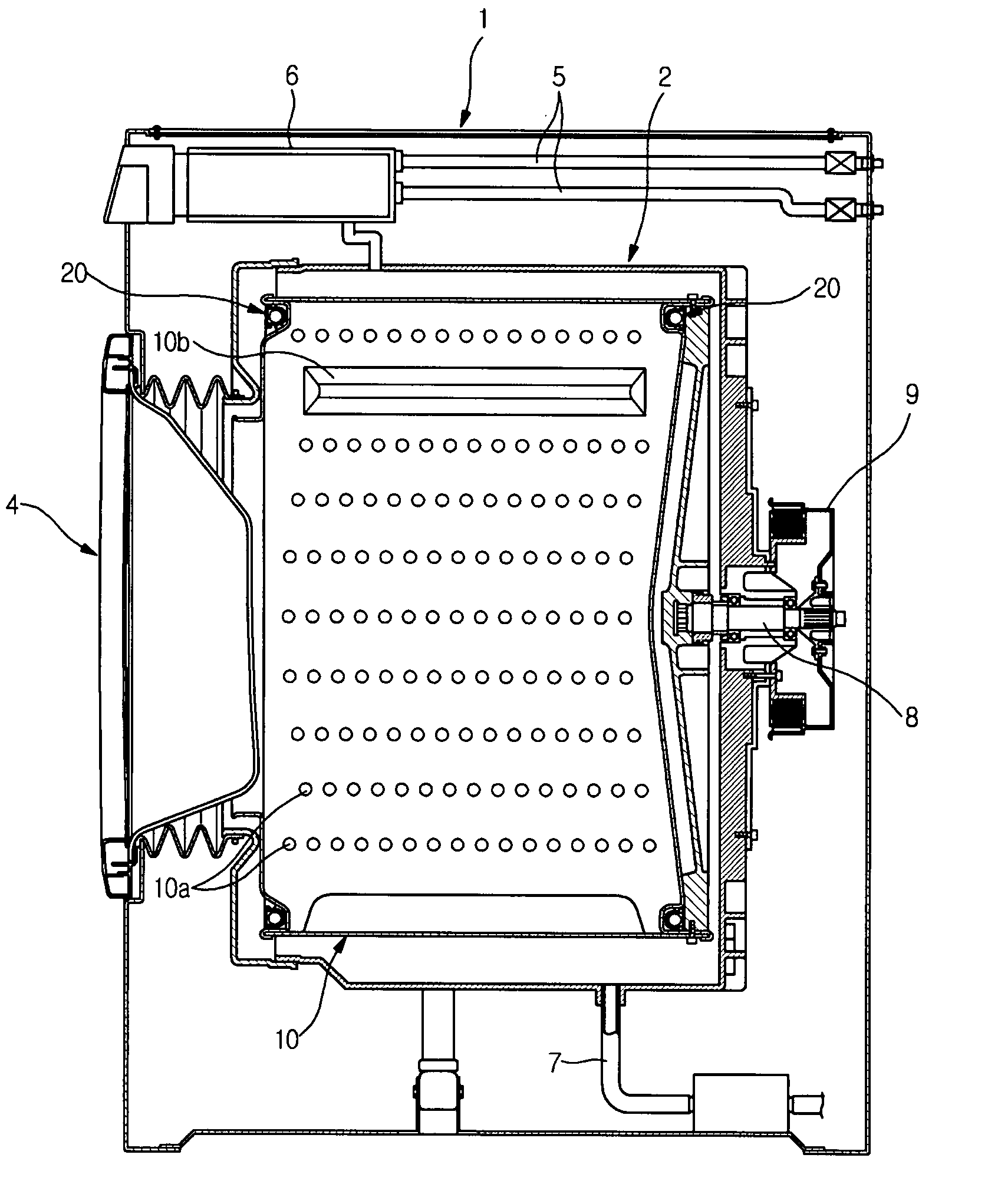

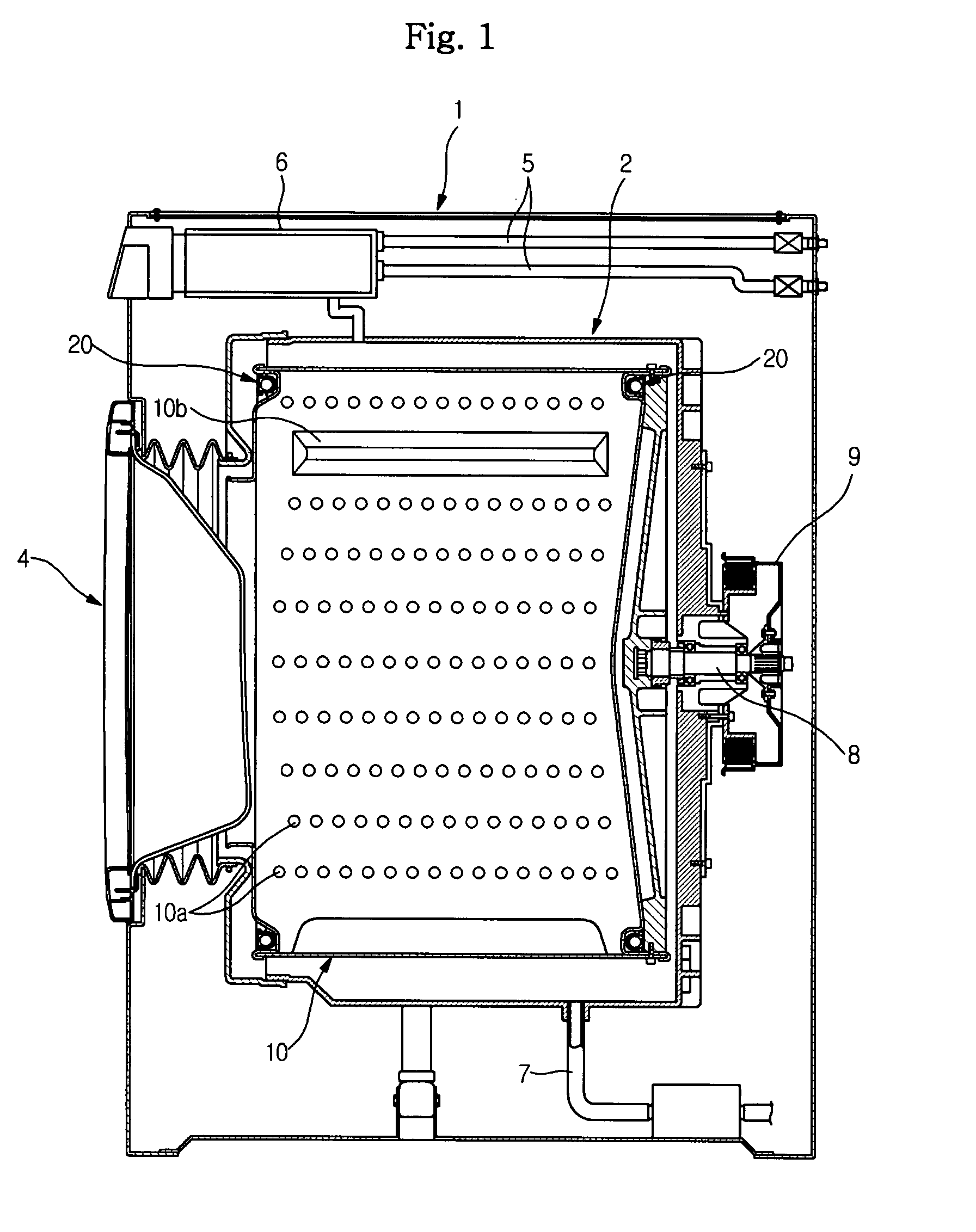

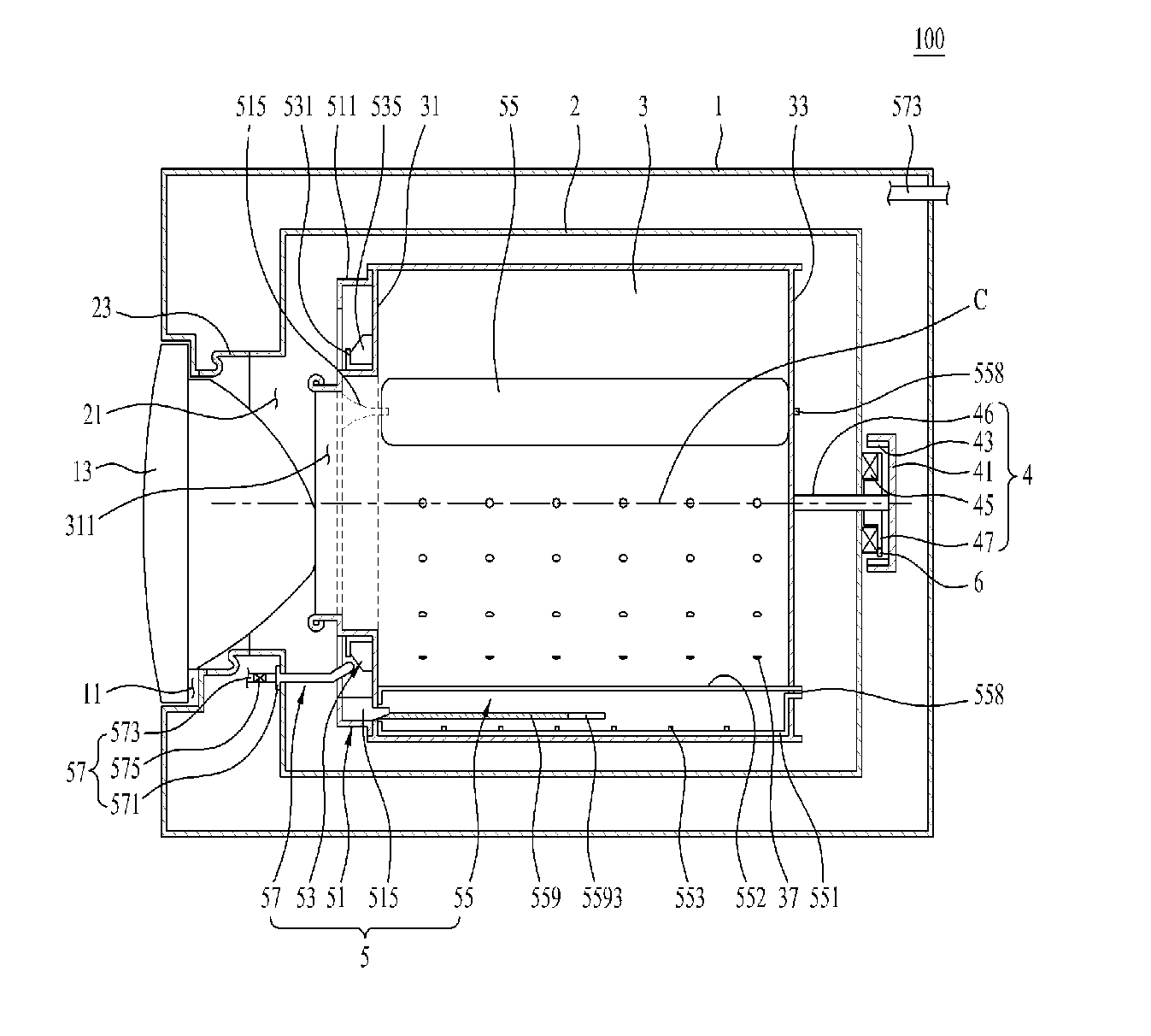

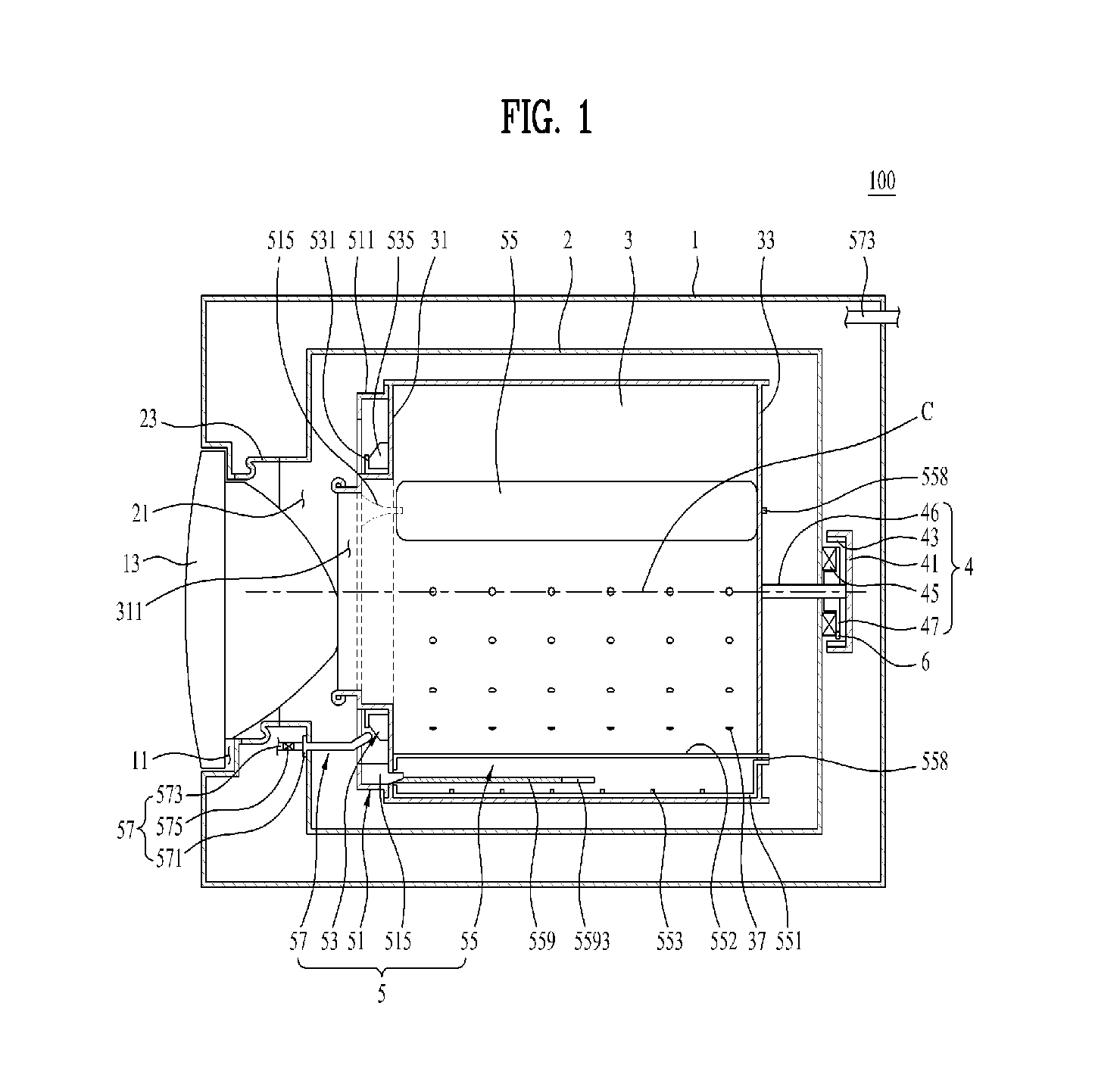

Washing machine and control method thereof

ActiveUS20120278996A1Improve performanceRotating vibration suppressionRotating bodies balancingEngineeringLaundry

A washing machine which improves performance of balancers, and a control method thereof. The washing machine includes a drum accommodating laundry and rotated by rotary force transmitted from a drive source, balancer housings mounted on the drum, each of the balancer housings including a disc-shaped channel formed therein, balancing modules movably disposed in the channels of the balancer housings, vibration sensors to sense unbalance applied to the drum during rotation of the drum, position sensors to sense the positions of the balancing modules, and a controller controlling movement of the balancing modules to positions to compensate for the unbalance sensed by the vibration sensors.

Owner:SAMSUNG ELECTRONICS CO LTD

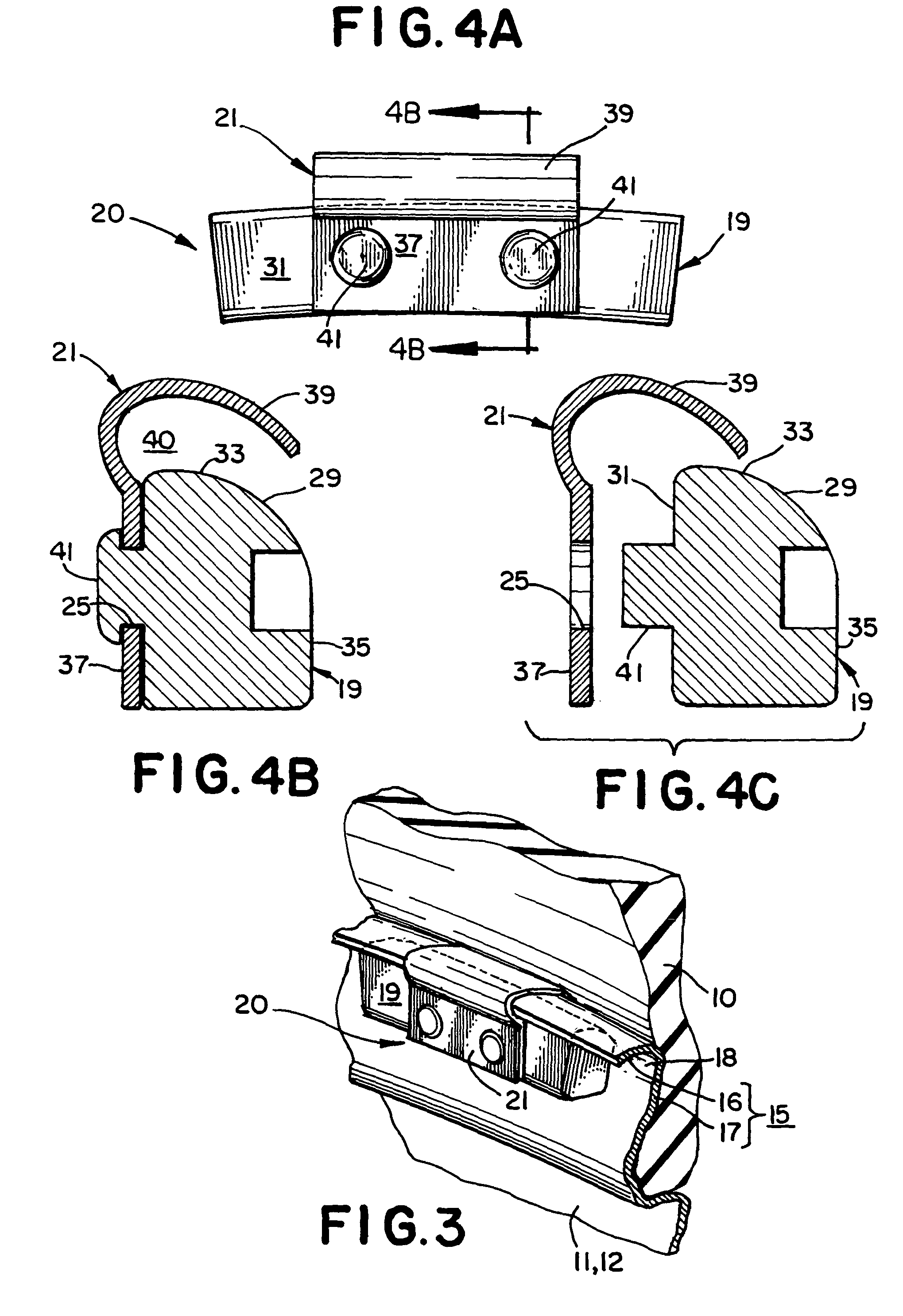

Wheel weight with body having recess and clip secured therein

A wheel-balancing weight mounts to a wheel with a flange. The weight has a weighted body and a clip securely attached thereto. The body defines a recess therein, and the clip has a securing portion formed to be securely positioned within the recess defined in the body and a grasping portion for securely grasping the flange. The recess of the body allows the clip to be axially positioned with respect to such body so that the body is axially shifted toward the mounted-to wheel to achieve a proper fit to the wheel. The securing portion of the clip is secured within the recess by flowing a portion of the body adjacent such clip into contact therewith.

Owner:WEGMANN AUTOMOTIVE USA

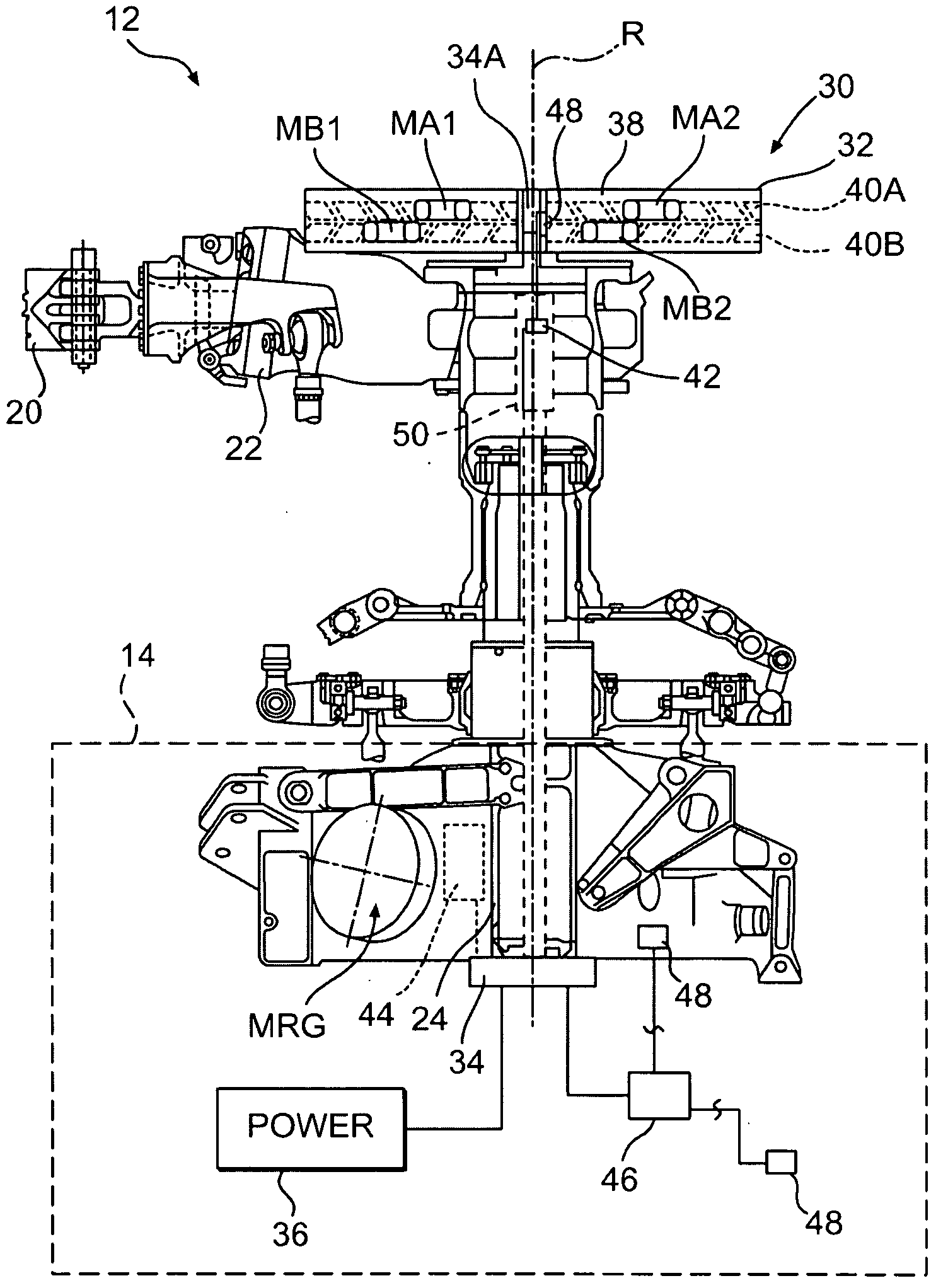

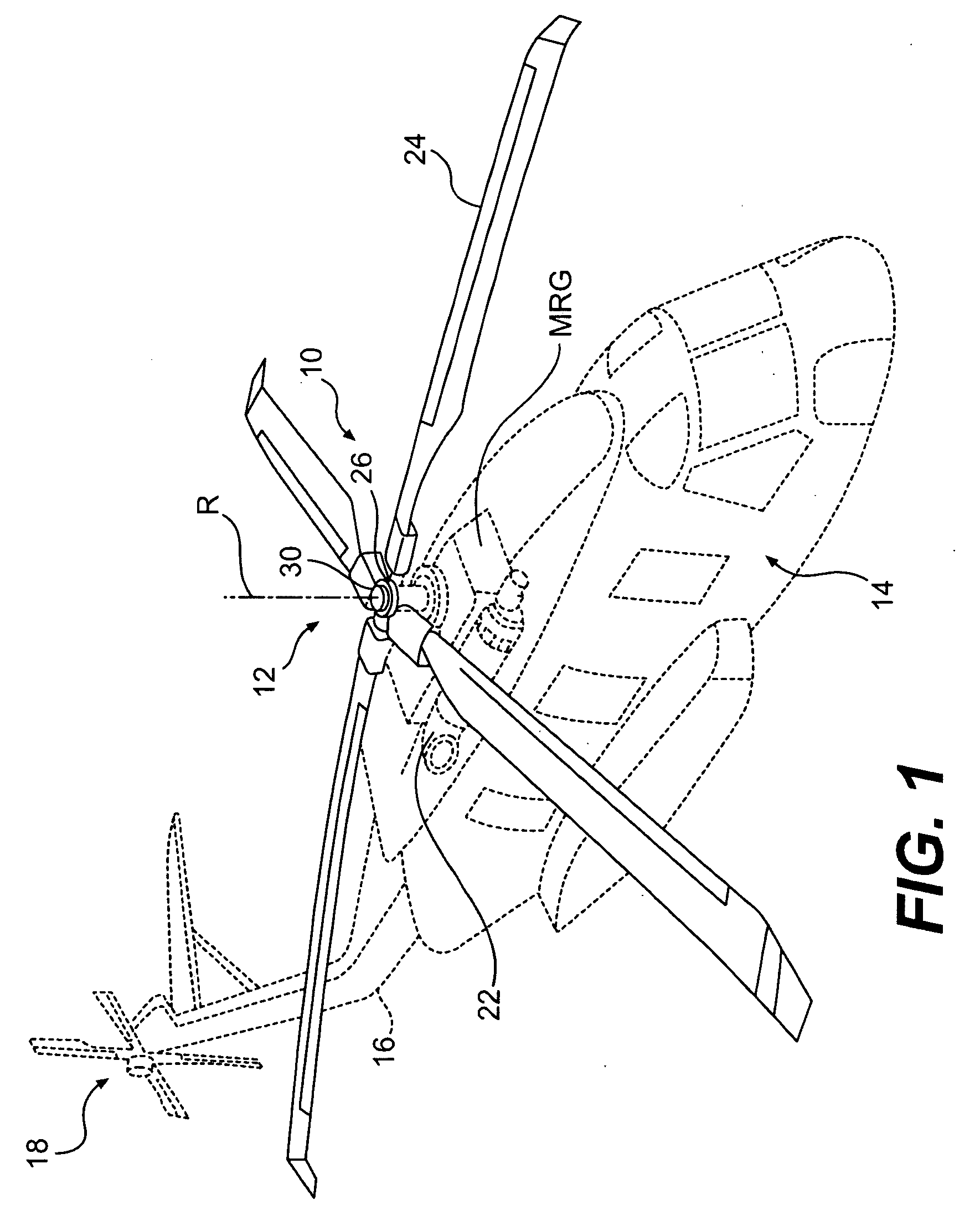

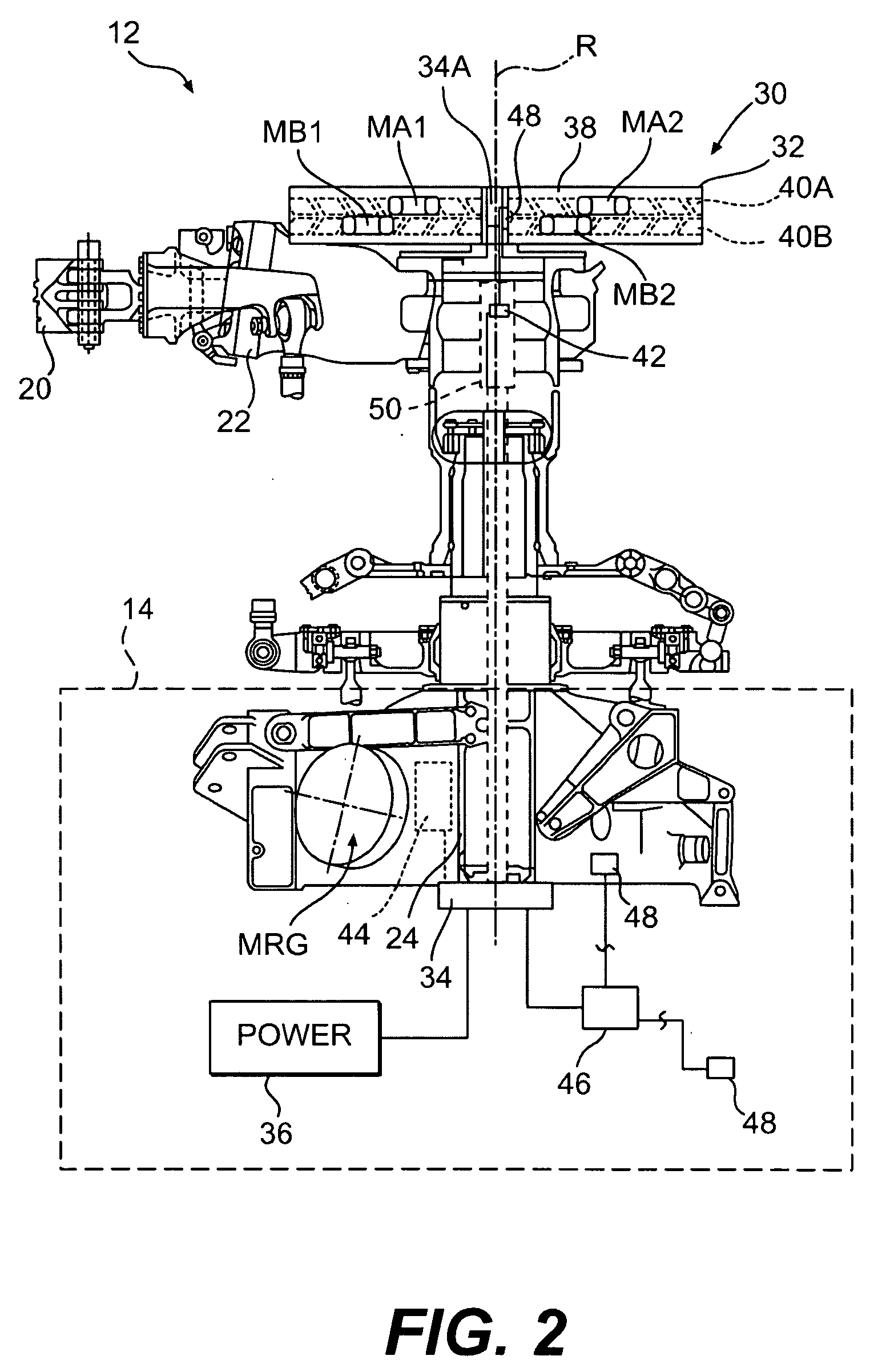

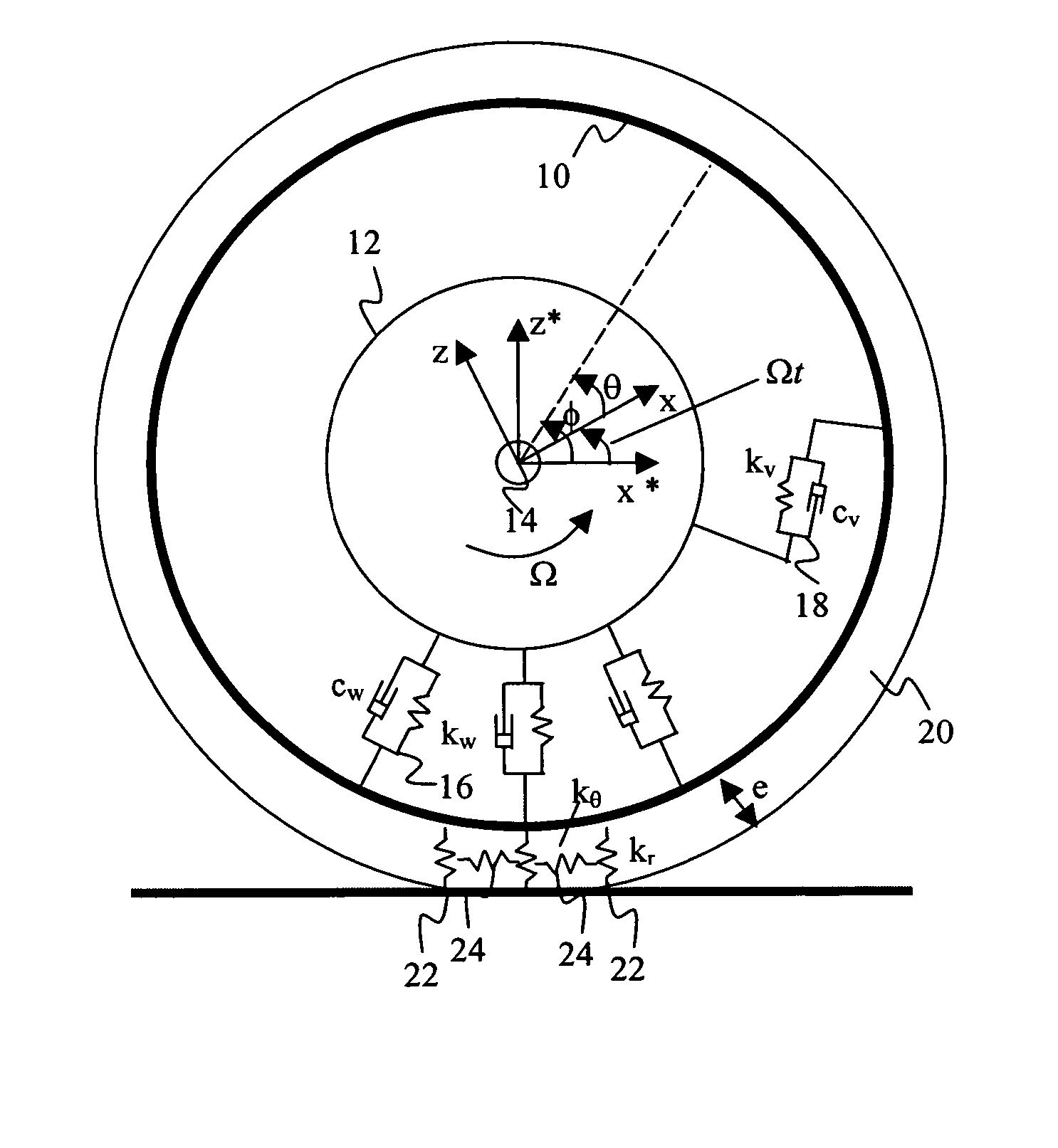

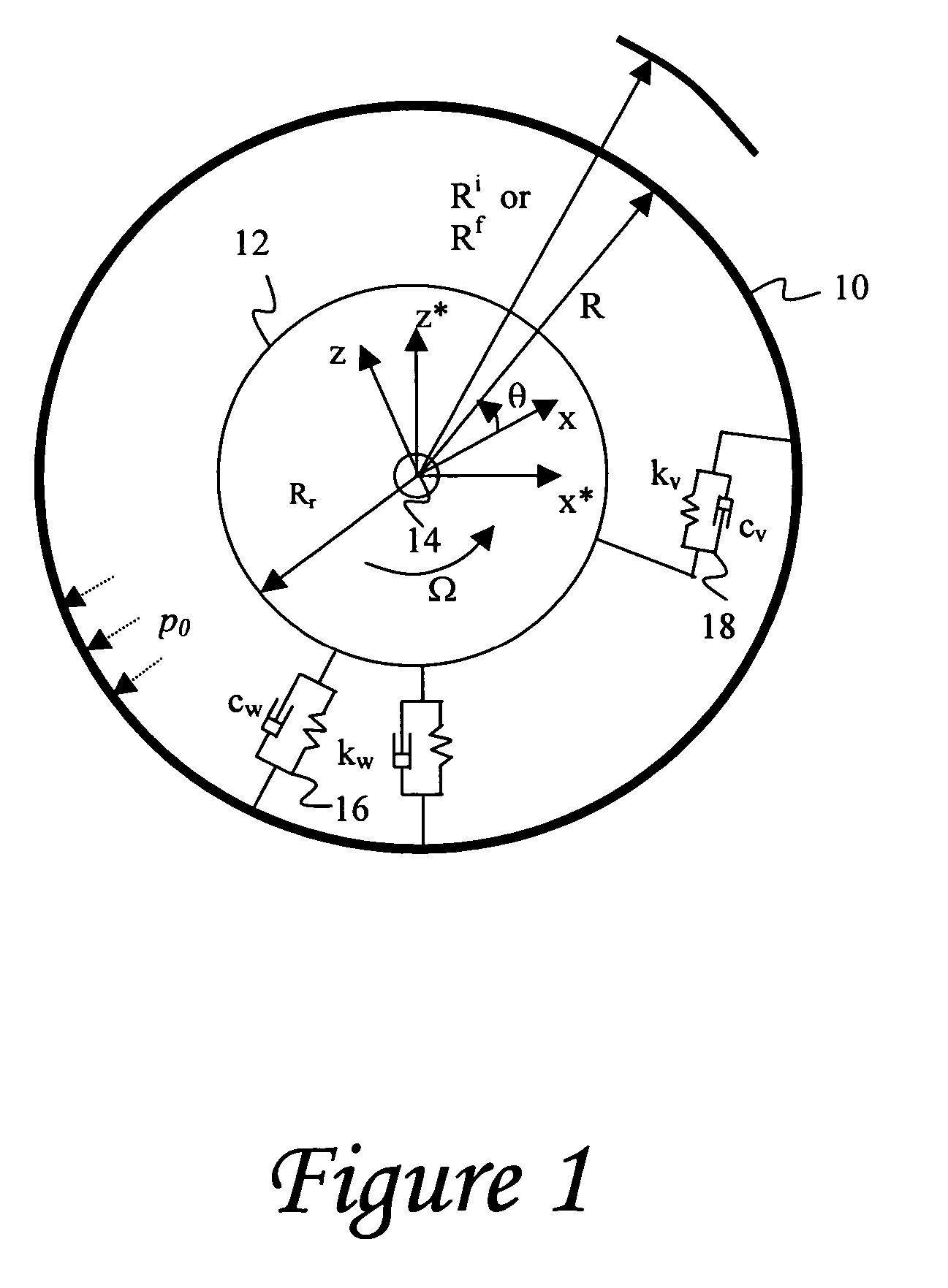

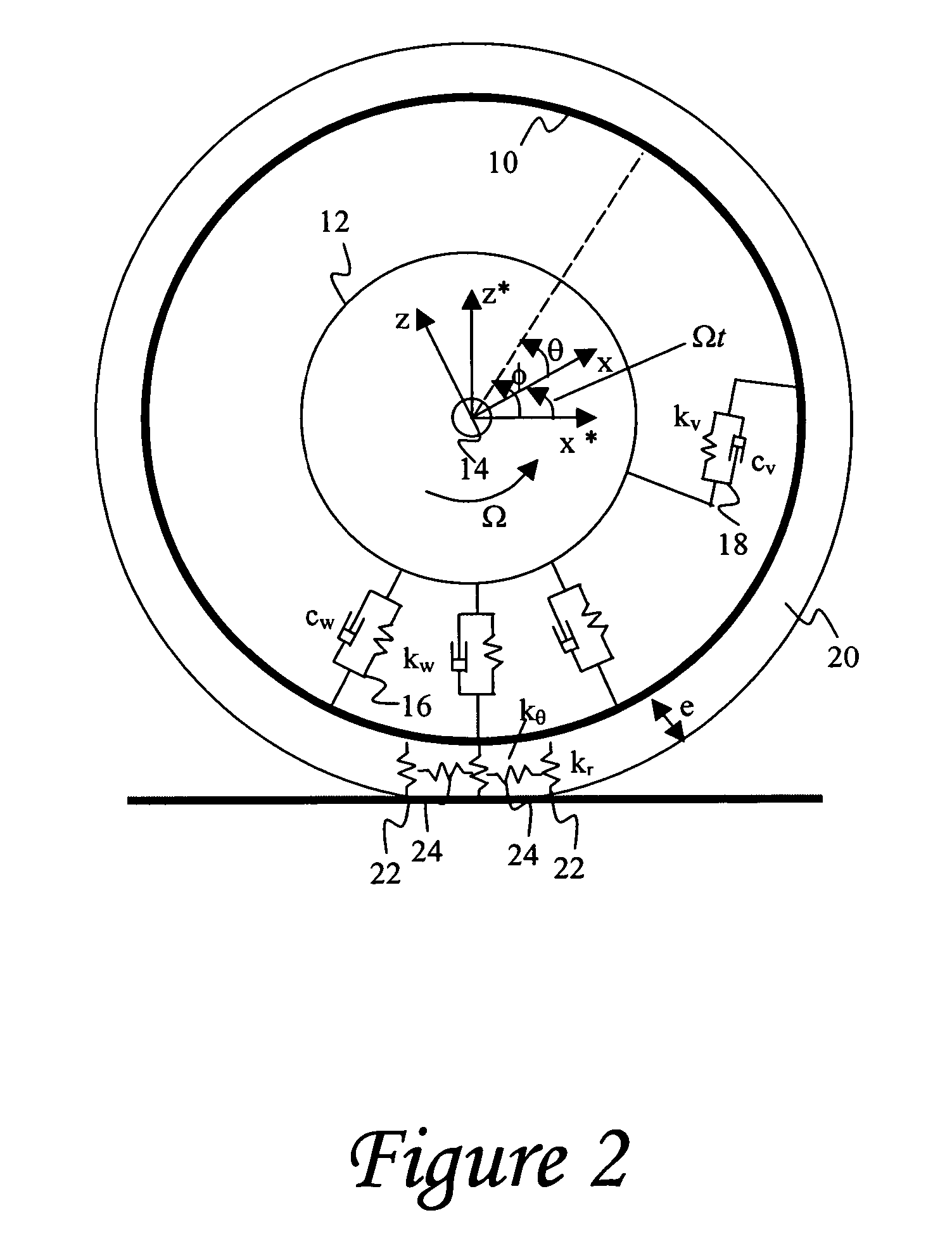

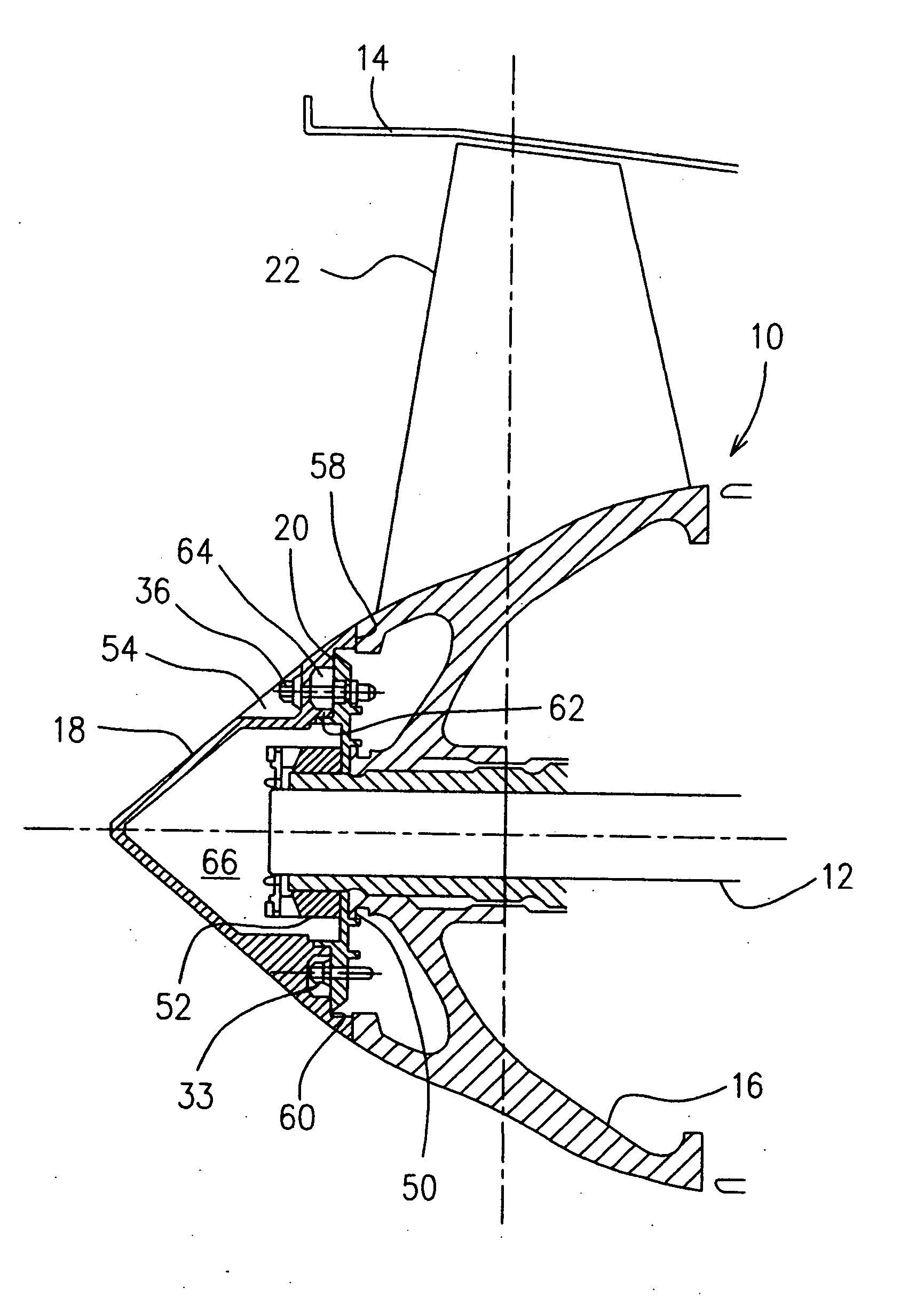

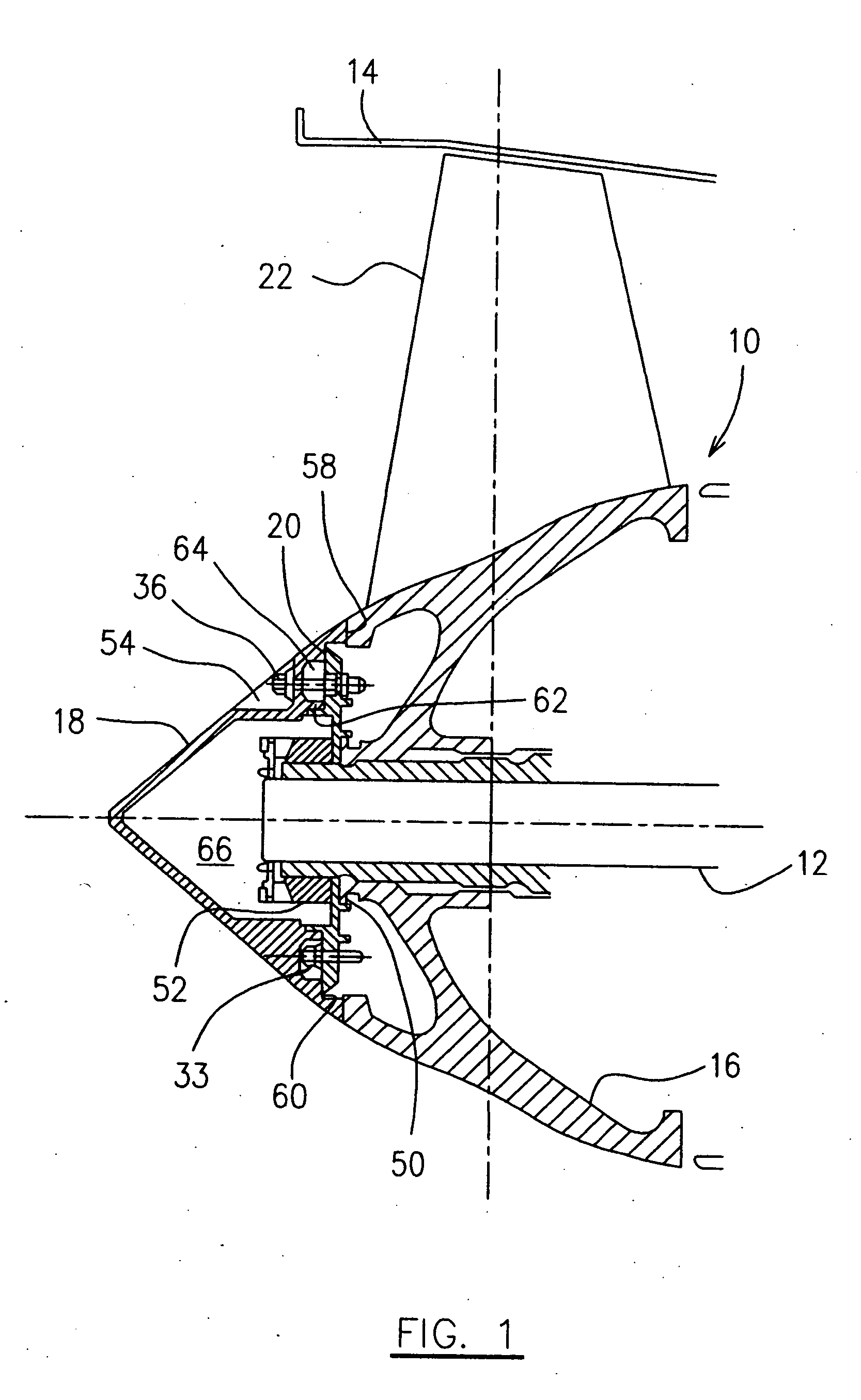

Dual frequency hub mounted vibration suppressor system

ActiveUS20090236468A1Reduce in-plane vibrationReduce NP vibrationRotating vibration suppressionTemperatue controlIn planeDual frequency

A vibration suppressor system includes an annular electric motor system which independently controls rotation of at least two masses about the axis of rotation to reduce in-plane vibration of the rotating system. A method of reducing vibrations in a rotary-wing aircraft includes independently controlling a relative angular position of a multiple of independently rotatable masses to reduce vibrations of a main rotor system.

Owner:SIKORSKY AIRCRAFT CORP

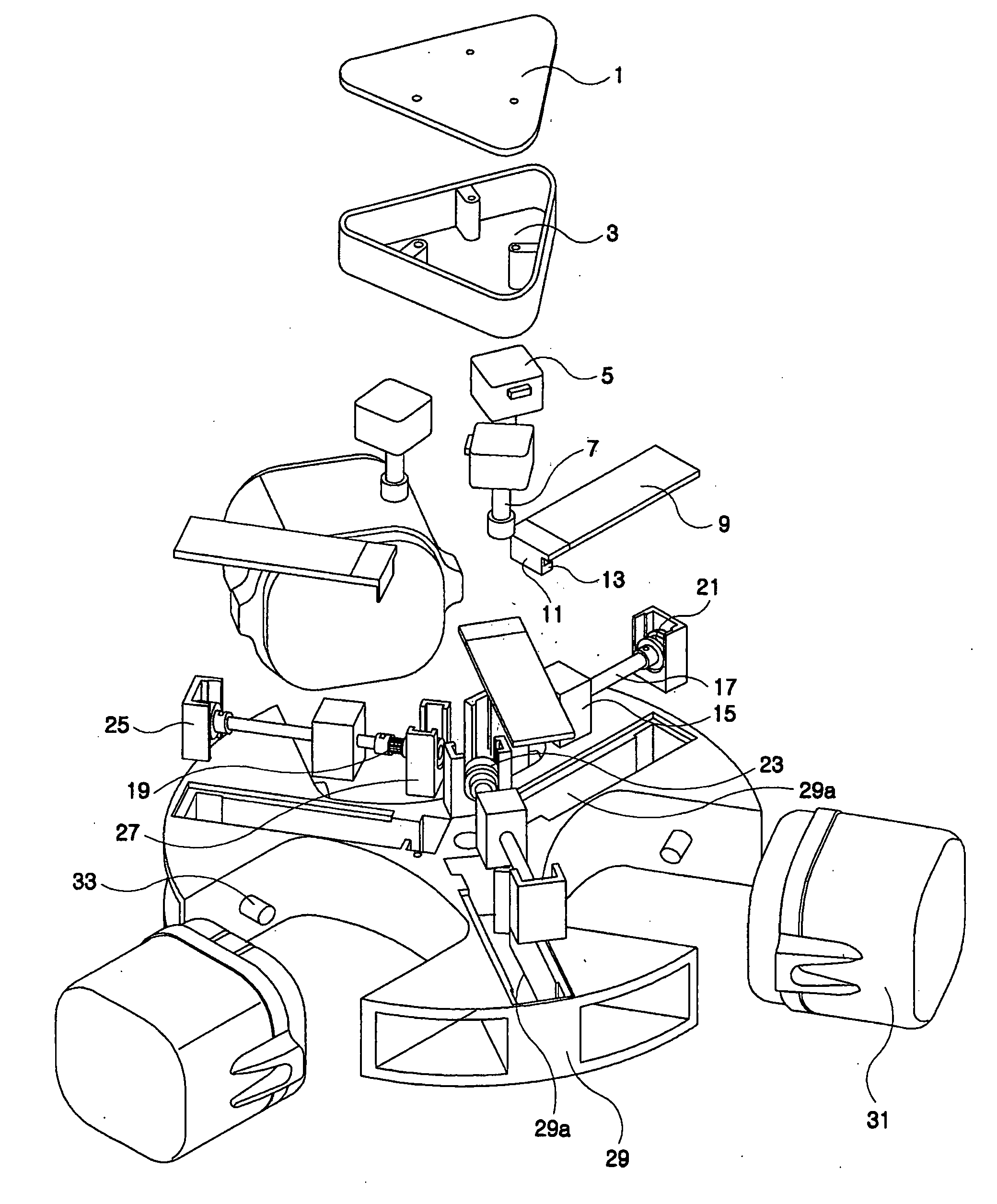

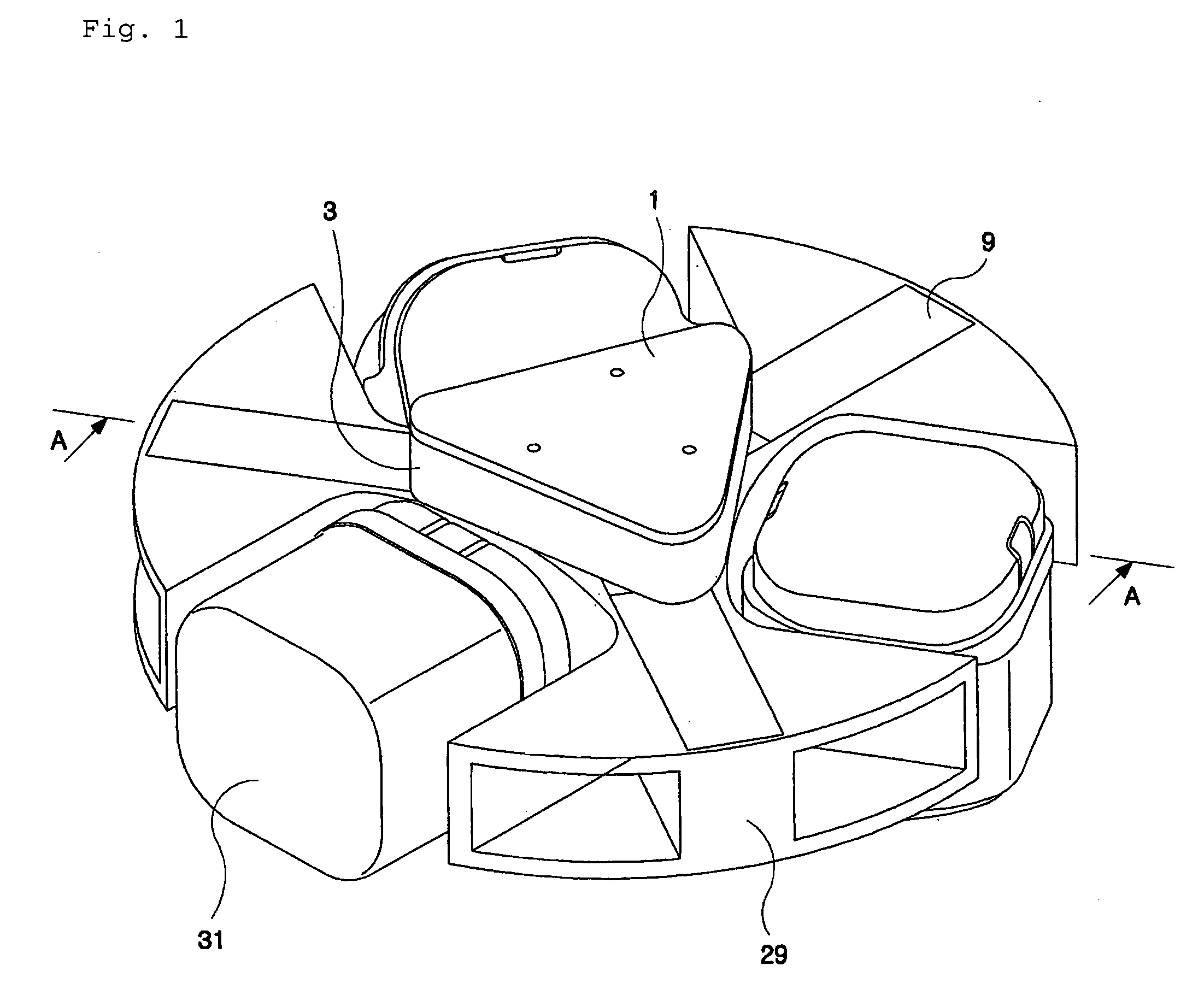

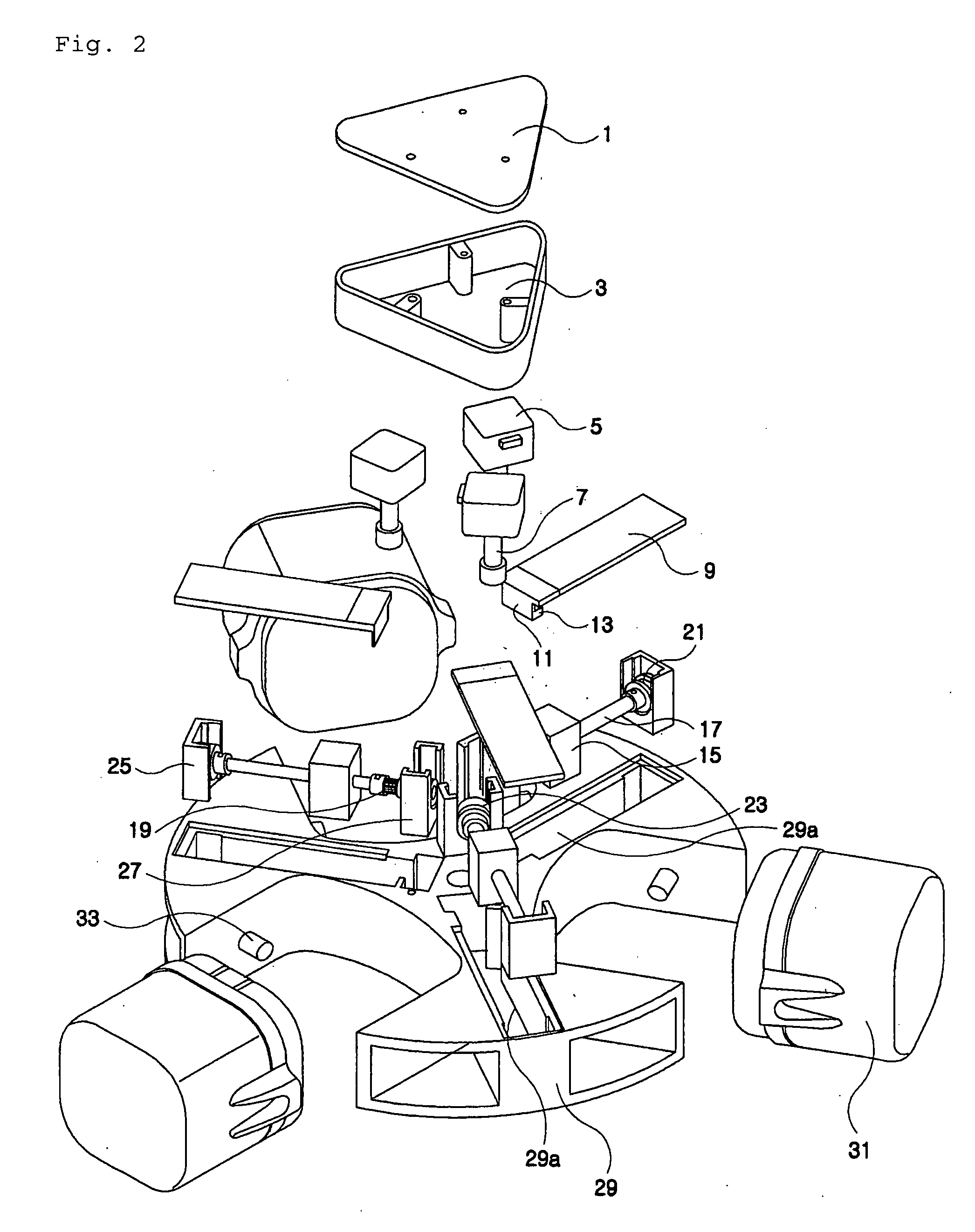

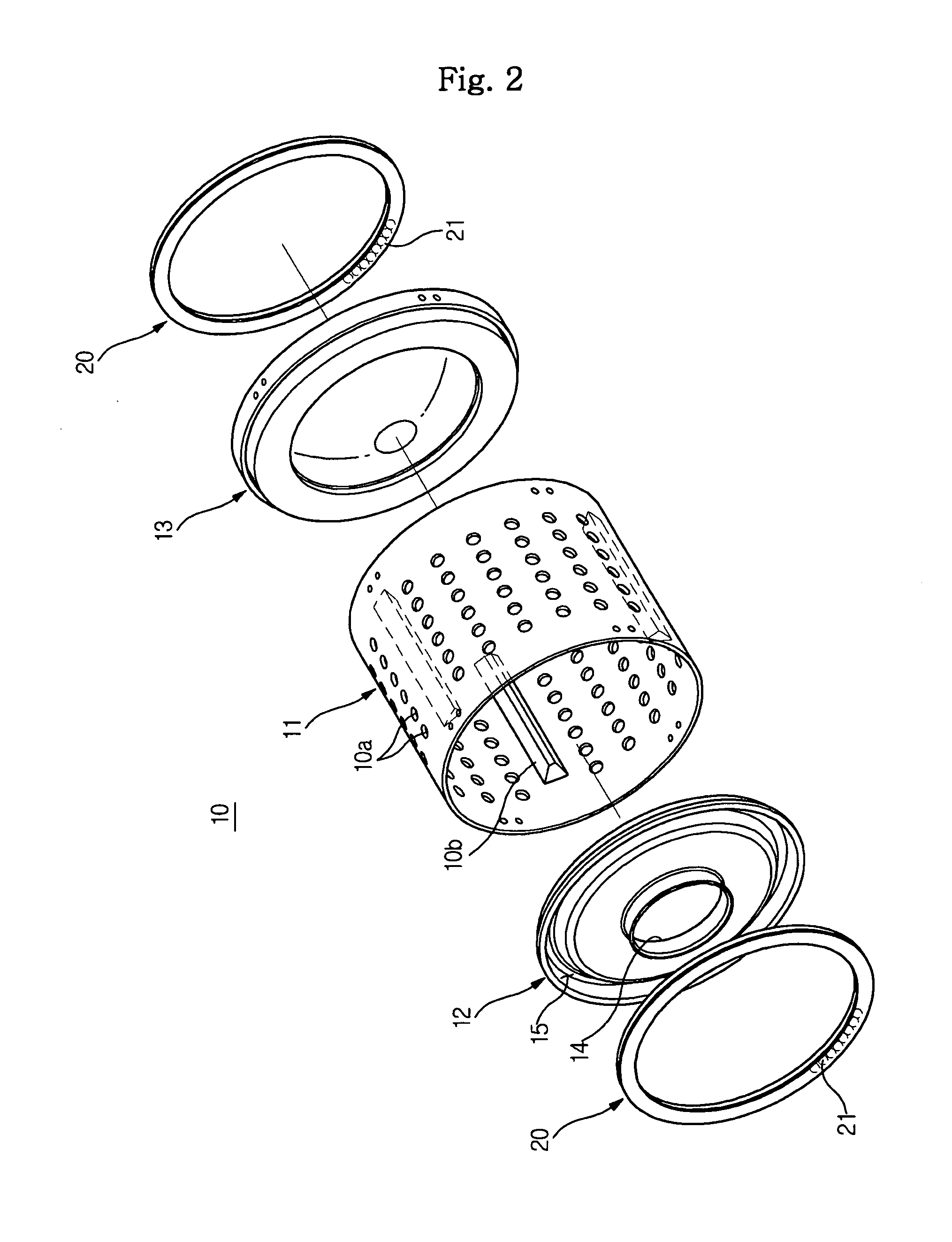

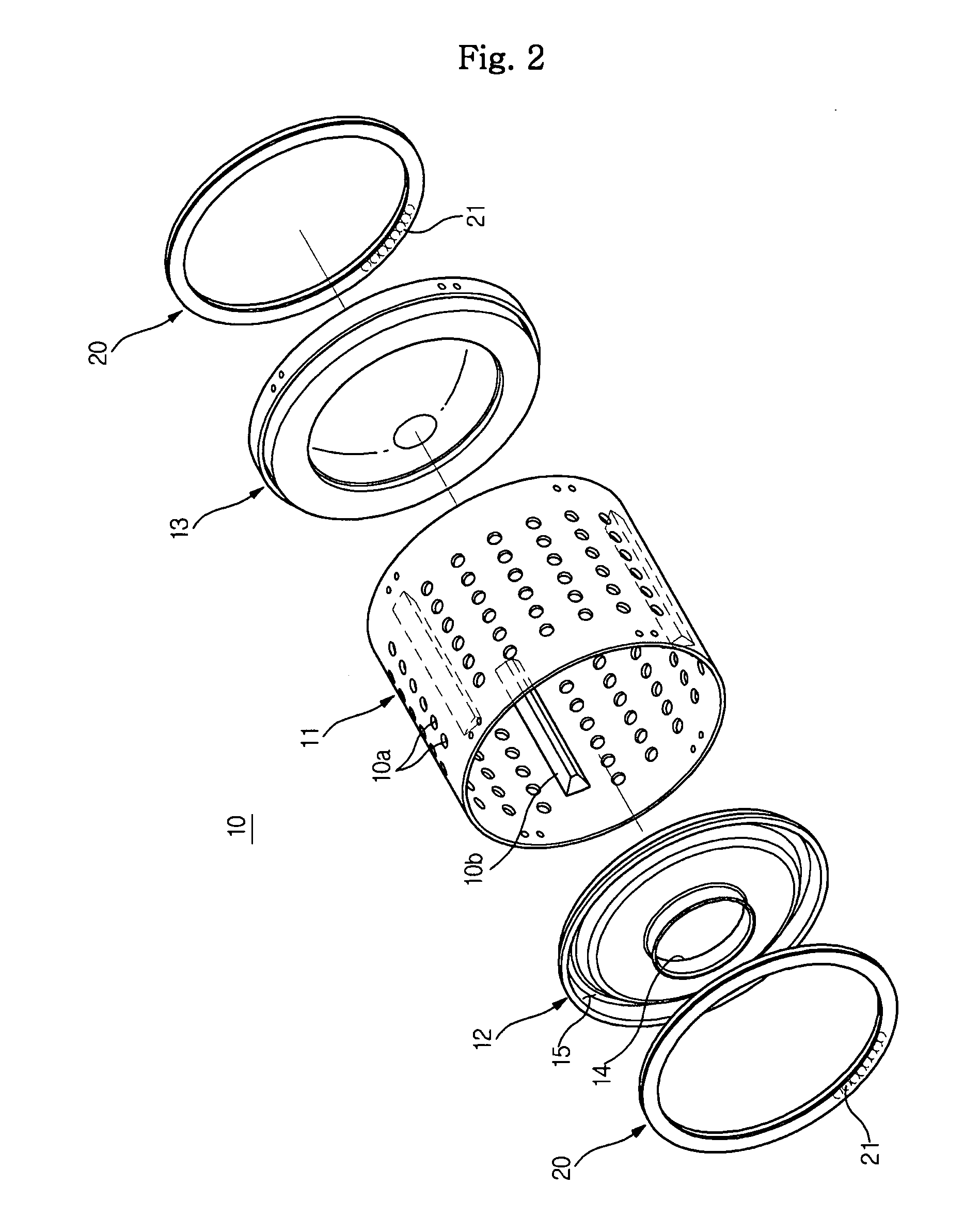

Washing machine having ball balancers

ActiveUS20110203325A1Reducing of vibration and noiseMaintain dynamic balanceRotating vibration suppressionControlling membersMechanical engineeringViscous oil

A washing machine having a ball balancer coupled to the drum to compensate for a dynamic imbalance during rotation of the drum, the ball balancer including a ring-shaped racer having a closed internal space in which a plurality of balls and viscous oil are accommodated, the ring-shaped racer including a first injection molded member and a second injection molded member joined to each other to form the closed internal space, the first injection molded member including a first side wall, a second side wall and a connecting wall between the first side wall and the second side wall, the first injection molded member having an open side opposite to the connecting wall, and the second injection molded member is adapted to cover the open side of the first injection molded member.

Owner:SAMSUNG ELECTRONICS CO LTD

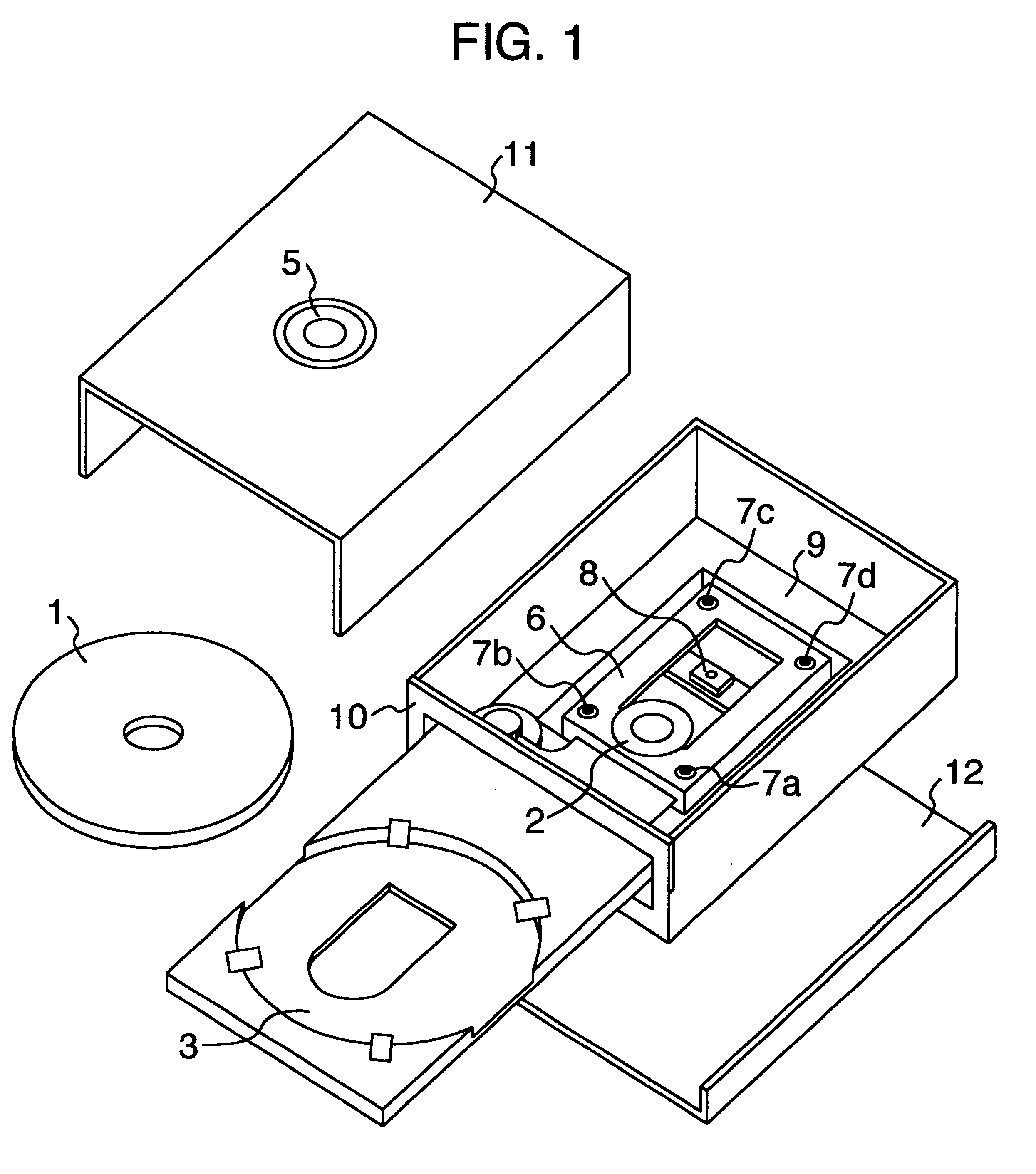

Disk drive with unbalance correcting mechanism

InactiveUS6477133B1Shorten the timeLow costUndesired vibrations/sounds insulation/absorptionRotating bodies balancingEngineeringBoron

A disk drive is realized, which omits running-in for stabilizing a change in a correcting function produced by sliding between balls and a rolling groove in an unbalance correcting mechanism, and prevents immobility and straying of balls, and which comprises a unit mechanism assembled by using 12 balls subjected to surface treatment with heptadecafluorodecyltrimethoxysilane and a turntable plated with a chemical nickel plating containing phosphorus and boron to have a thickness of 5 mum and by injecting 1 microliter of ester oil into the rolling groove, and further comprises a recess formed in a sidewall of the rolling groove of the unbalance correcting mechanism to prolong the service life of the correcting function.

Owner:HITACHI LTD

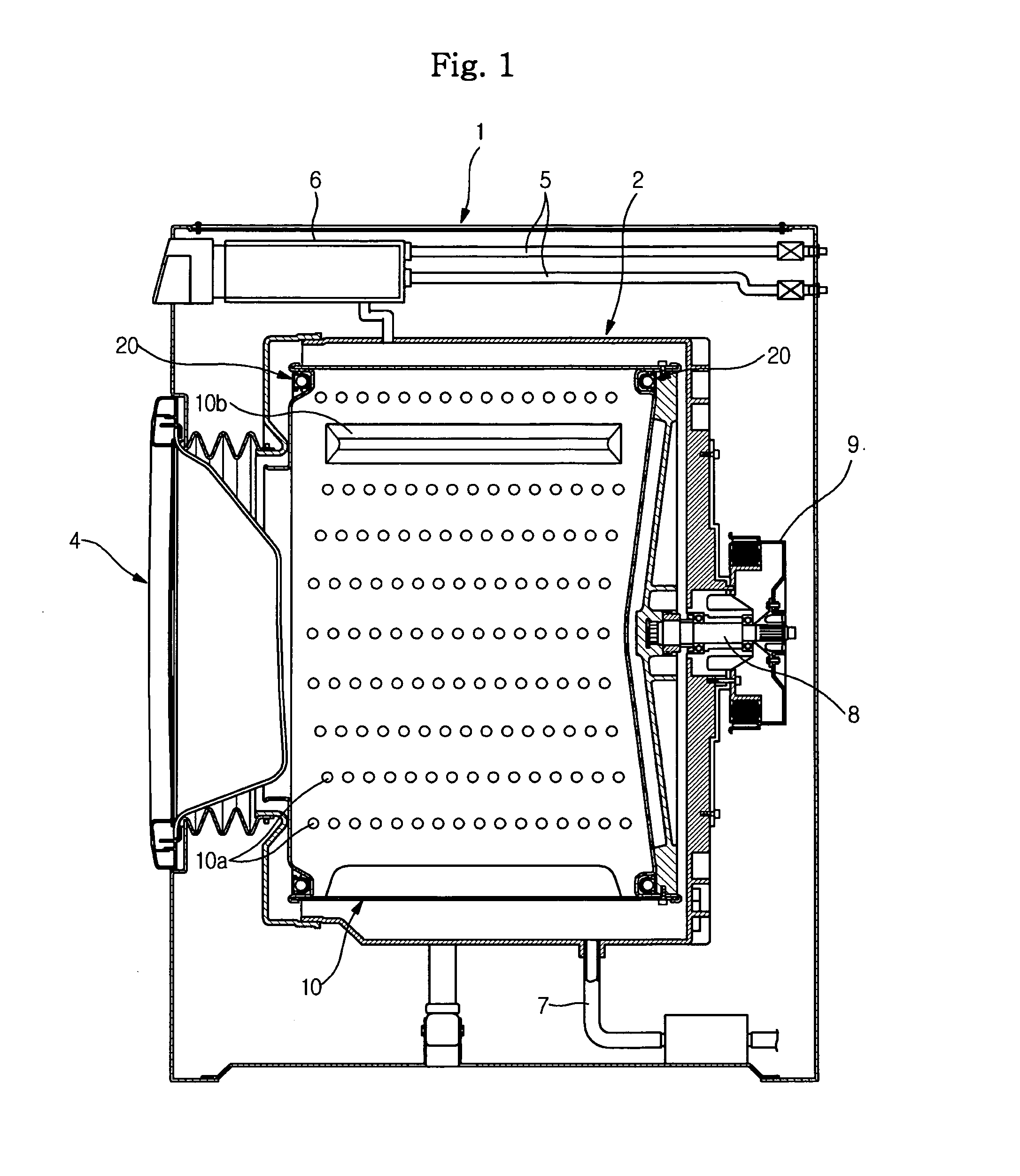

Drum washing machine

InactiveUS6782722B2Easy to useQuiet operating soundRotating bodies balancingOther washing machinesWater storageMechanical engineering

Owner:SANYO ELECTRIC CO LTD

Tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

Device for balancing a rotating part, in particular a turbojet rotor

A device for balancing a rotating part, in particular a turbine rotor in a turbomachine such as a turbojet or the like, the device comprising at least one balance weight comprising engagement means for engaging it on an annular flange of the part, and locking means associated with the balance weight and with the annular flange to prevent the balance weight from moving relative to the annular flange and to block itself against moving both in rotation and in axial translation relative to the balance weight.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

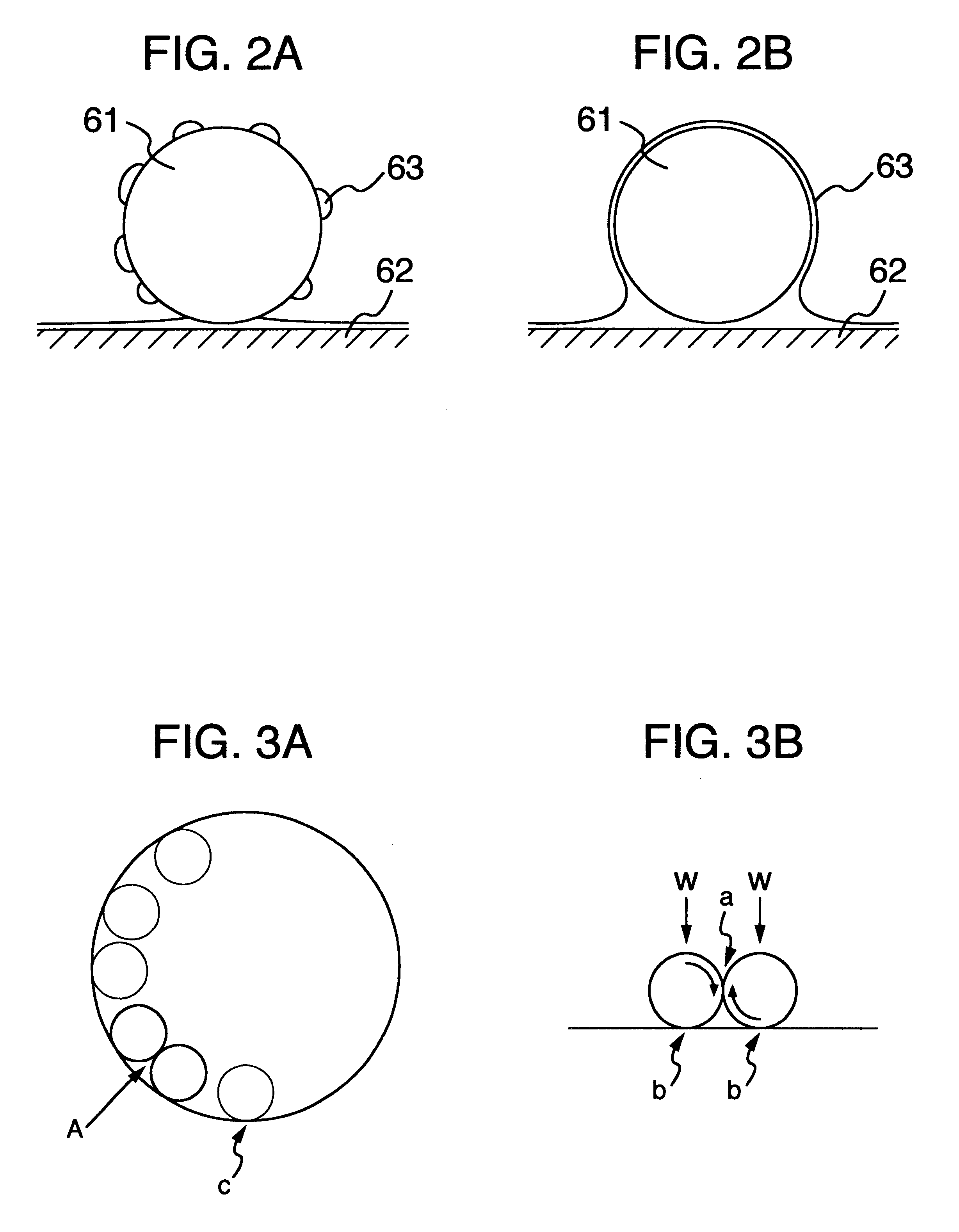

Washing machine having ball balancers

ActiveUS20080110212A1Reduce vibrationReduce noiseControlling membersRotating vibration suppressionProcess engineeringViscous oil

Disclosed is a washing machine having ball balancers, which adjust a relation between a gap, between the inner wall of a racer of each of the ball balancers and balls, and viscous oil, so as to reduce the vibration and noise of the washing machine. Each of the ball balancers of the washing machine includes balls and viscous oil accommodated in a racer, and the viscosity of the viscous oil is varied in proportion to a gap between the racer and the balls. When the viscosity of the viscous oil is 1˜100 cSt, the gap is set to 0.5˜1.0 mm, when the viscosity of the viscous oil is 100˜380 cSt, the gap is set to 1.0˜2.0 mm, and when the viscosity of the viscous oil is 380˜1,000 cSt, the gap is set to 2.0˜3.0 mm. Thereby, the relation between the gap and the viscous oil is optimized, and the ball balancers effectively exhibit a balancing function and thus minimize the vibration and noise of the washing machine.

Owner:SAMSUNG ELECTRONICS CO LTD

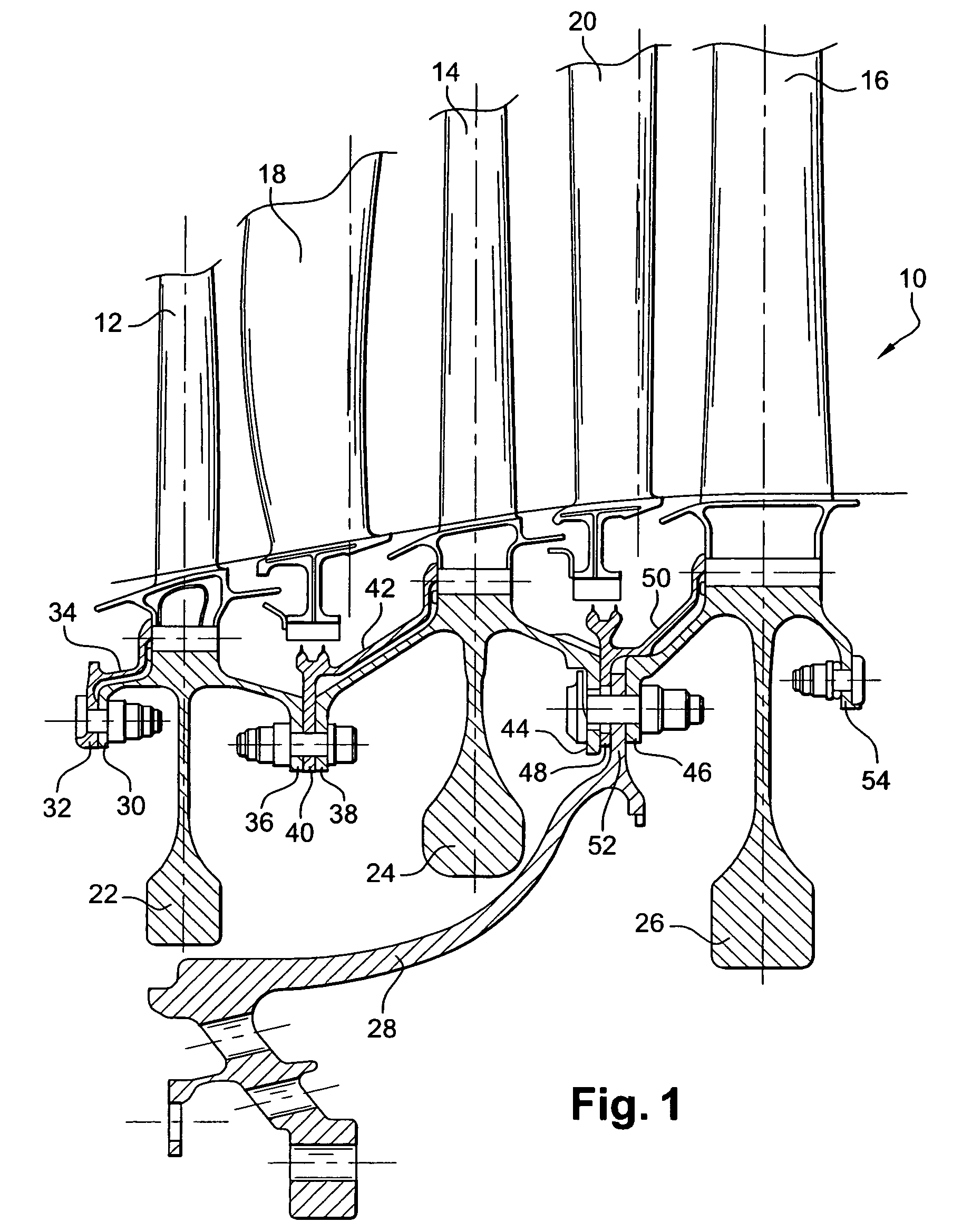

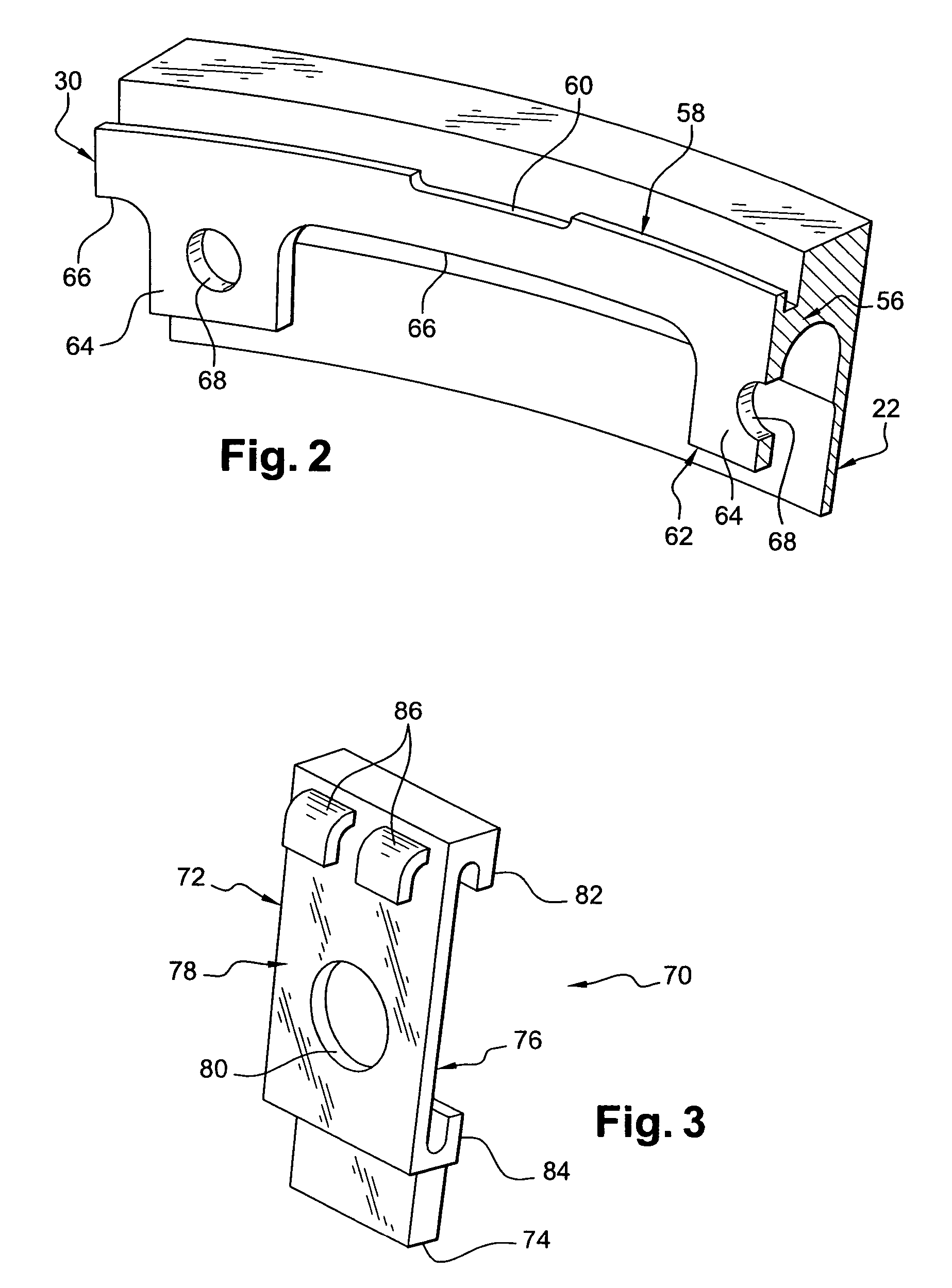

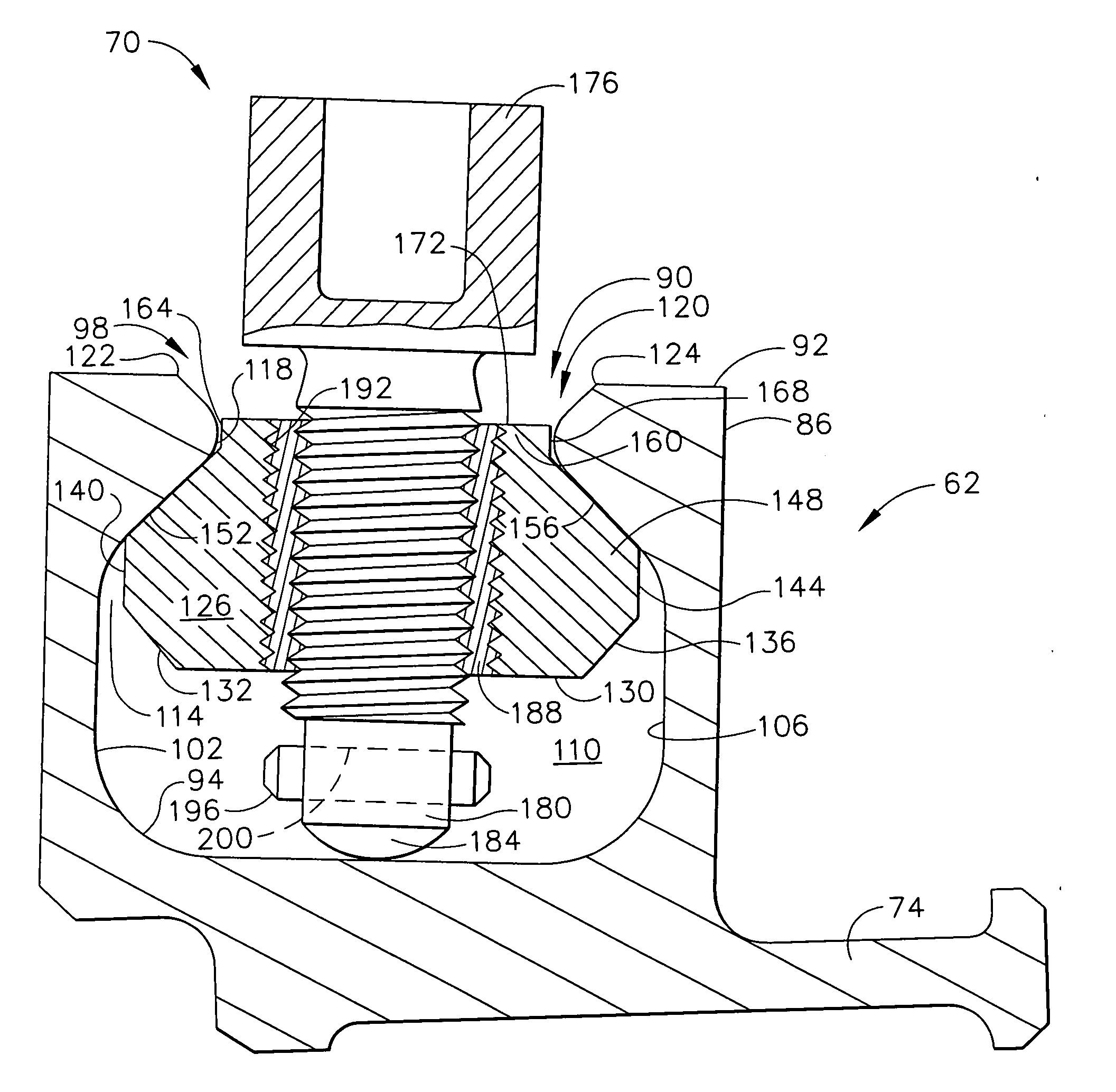

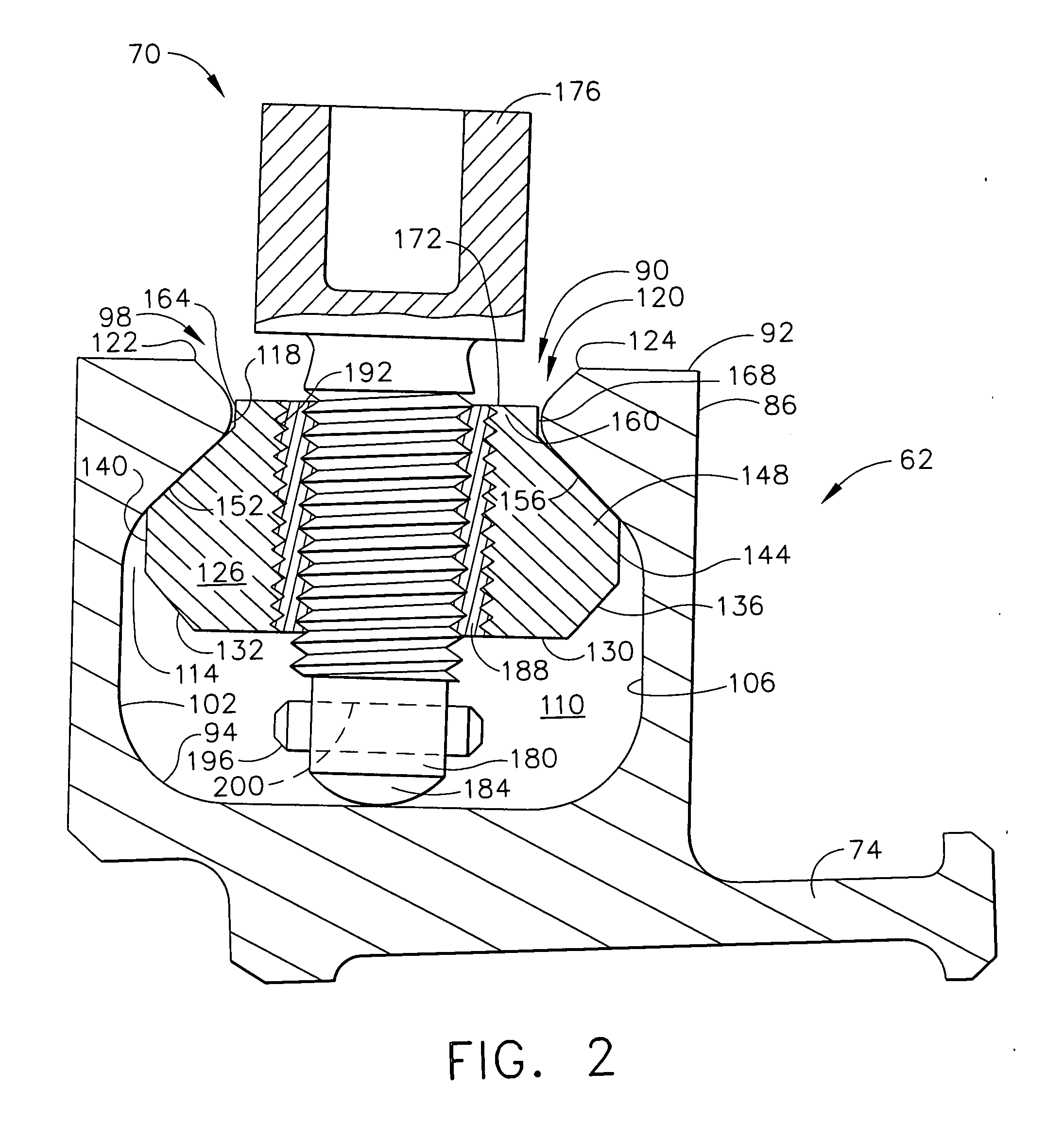

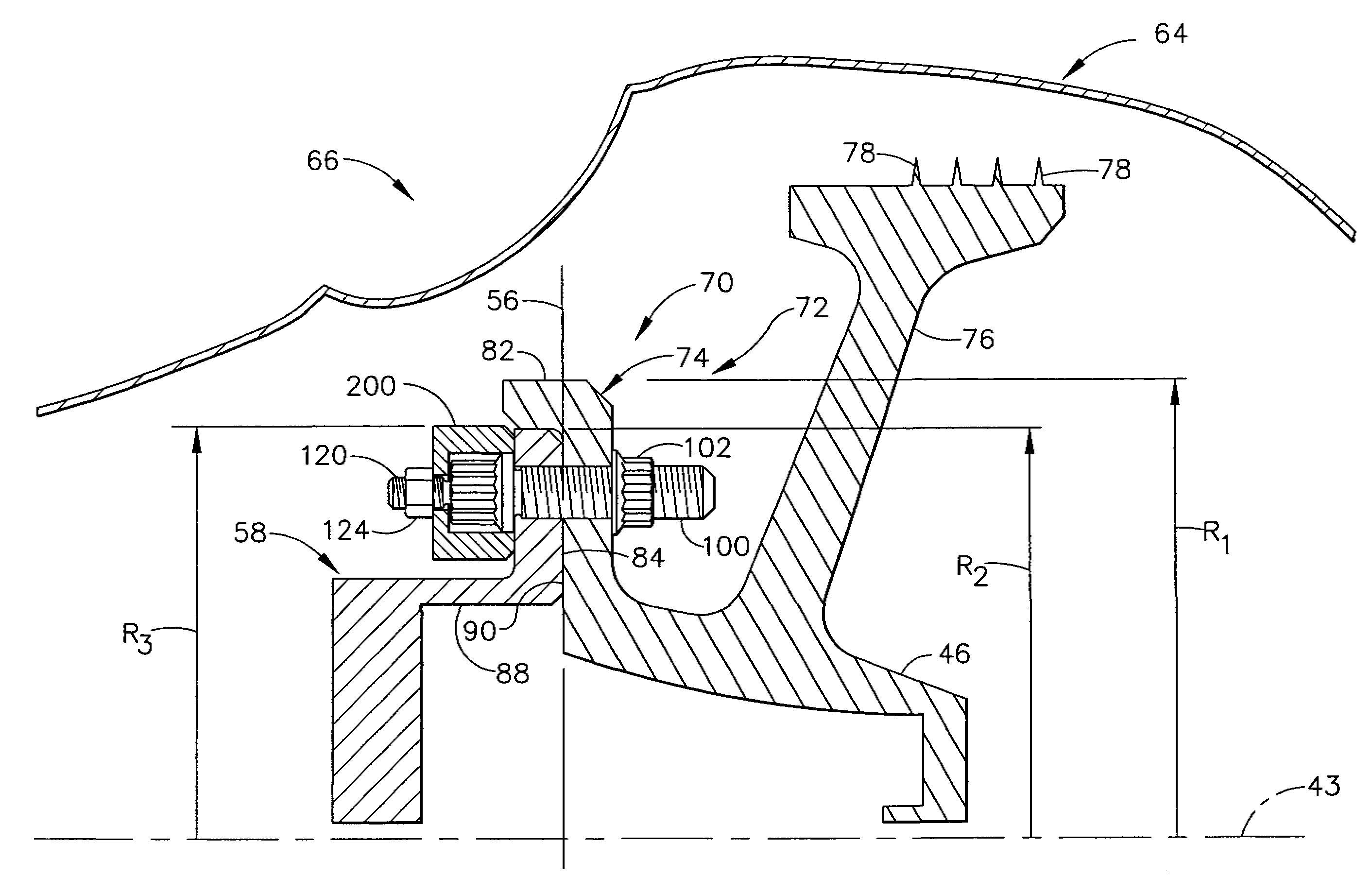

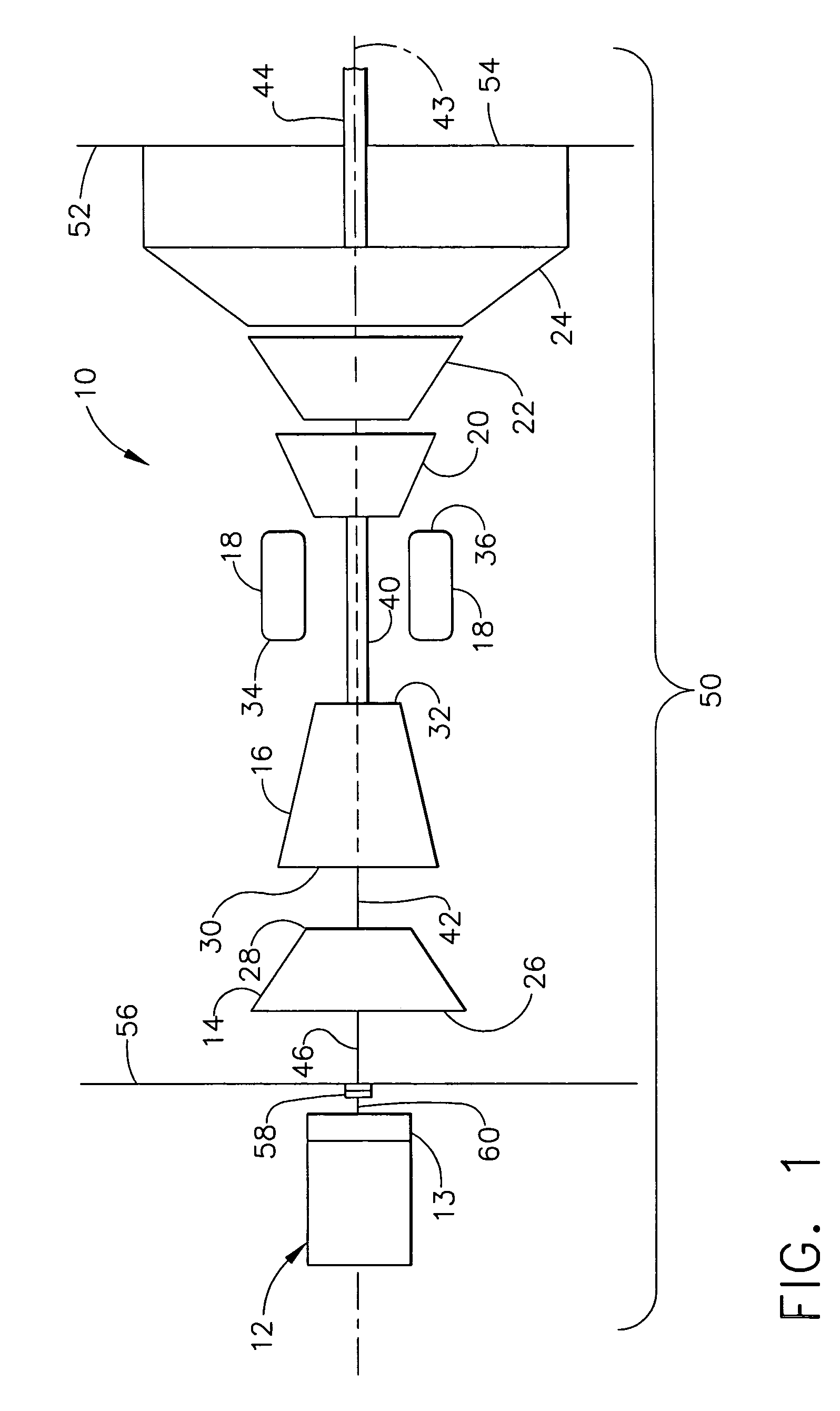

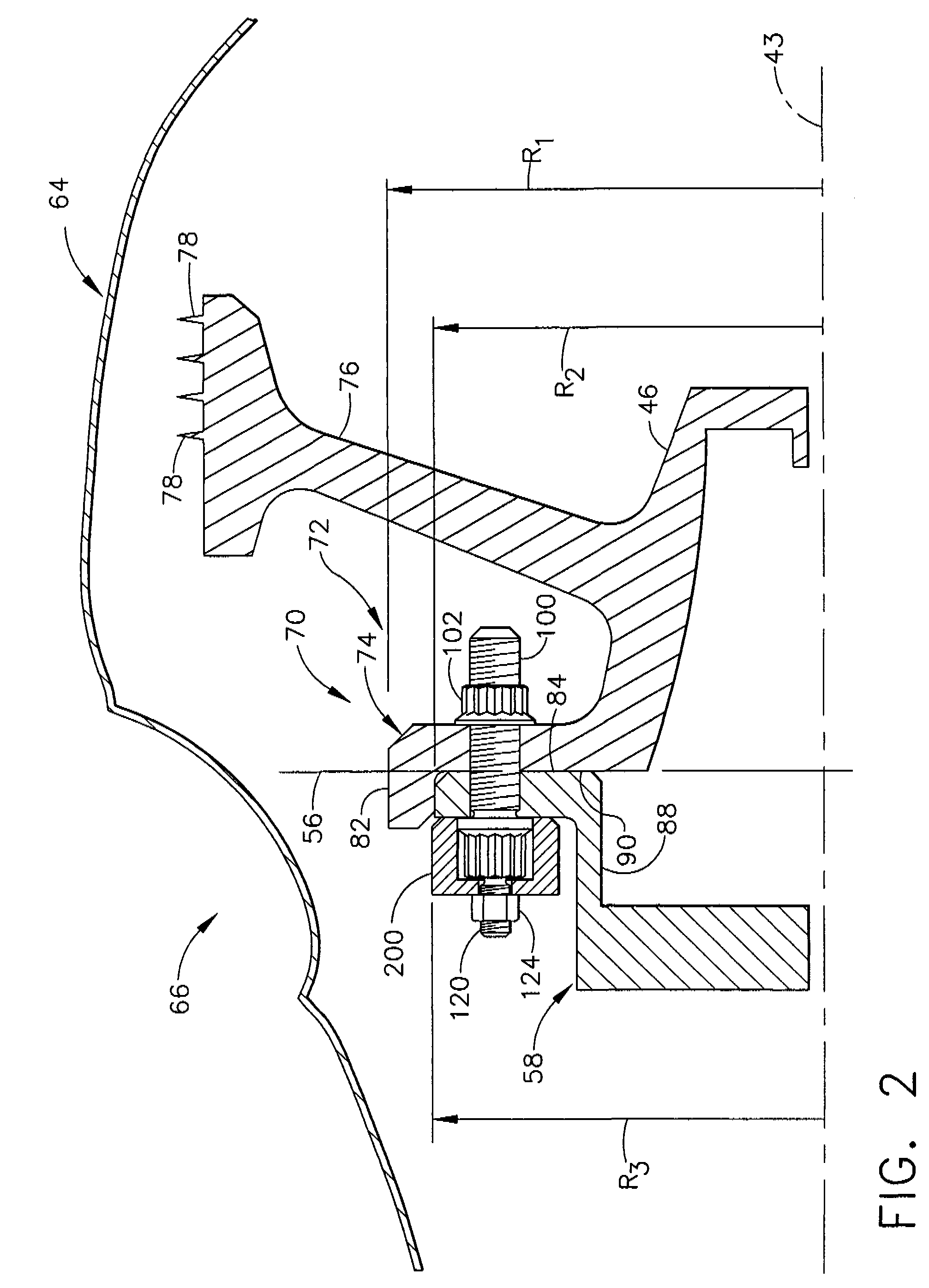

Balance assembly for rotary turbine component and method for installing and/or adjusting balance weight

A balance assembly for turbine rotating components, such as turbine rotors, as well as method for installing and / or adjusting at least one balance weight in the balance assembly and turbine section having this balance assembly and a radially extending access pathway for accessing this balance assembly. The balance assembly comprises; (a) a balance weight retention member having a circumferential periphery and a slot formed therein along at least a portion thereof, the slot having: (1) a bottom surface; (2) an opening; and (3) a pair of spaced apart and opposed side walls connecting the bottom surface and the opening, the side walls sloping inwardly between the bottom surface and the opening to define a balance weight engaging section; (b) at least one balance weight configured and sized to be insertable through the opening of the slot and to be positionable for movement within the slot and having a pair of spaced apart generally inwardly sloping shoulder surfaces capable of engaging the side walls of the slot at the balance weight engaging section; and (c) a balance weight securing member associated with the at least one balance weight that can be actuated to: (1) move the at least one balance weight away from the bottom surface so that the shoulder surfaces engage the side walls at the balance weight engaging section such that the at least one balance weight is in a secured position within the slot; or (2) move the at least one balance weight towards the bottom surface so that the shoulder surfaces do not engage the side walls at the balance weight engaging section such that the at least one balance weight is in a unsecured position within the slot.

Owner:GENERAL ELECTRIC CO

Adherent, removable barrier film for tire carcass

InactiveUS7332047B2Prevent scalingLamination ancillary operationsWithout separate inflatable insertsSulfurEngineering

A bond of a rubbery component to a virgin surface of a tire's cured innerliner which virgin surface has never been contaminated by the remnants of a release agent left after buffing with a wire brush and solvent-cleaning the cured innerliner, is unexpectedly stronger than a bond of the component to the contaminated but “cleaned surface”, cleaned as indicated. As an alternative, buffing with a wire brush results in a textured surface that impairs adhesion of a balance pad. Therefore, a pneumatic tire is provided with a virgin surface protected against contamination by a release agent at the curing temperature of the tire; protection is provided by a self-supporting barrier film of sulfur non-vulcanizable, expandable, thermoformable synthetic resinous material; and, a method is provided for maintaining a virgin cured surface within all or part of either the exterior or interior of a pneumatic tire's rubber carcass which is conventionally cured. The barrier film which is substantially inextensible at ambient temperature, is removable without tearing into pieces from the protected surface of the cured tire. When the interior surface is provided by an innerliner, any component to be included within the interior of the carcass may be adhesively secured to the virgin surface of the innerliner more securely than has been heretofore possible.

Owner:THE GOODYEAR TIRE & RUBBER CO

System and method for automatically compensating for unbalanced resistance forces

InactiveUS6974362B2Residual vibrationSevere damageGrinding drivesRotating bodies balancingAuto regulationEngineering

Owner:AB SKF

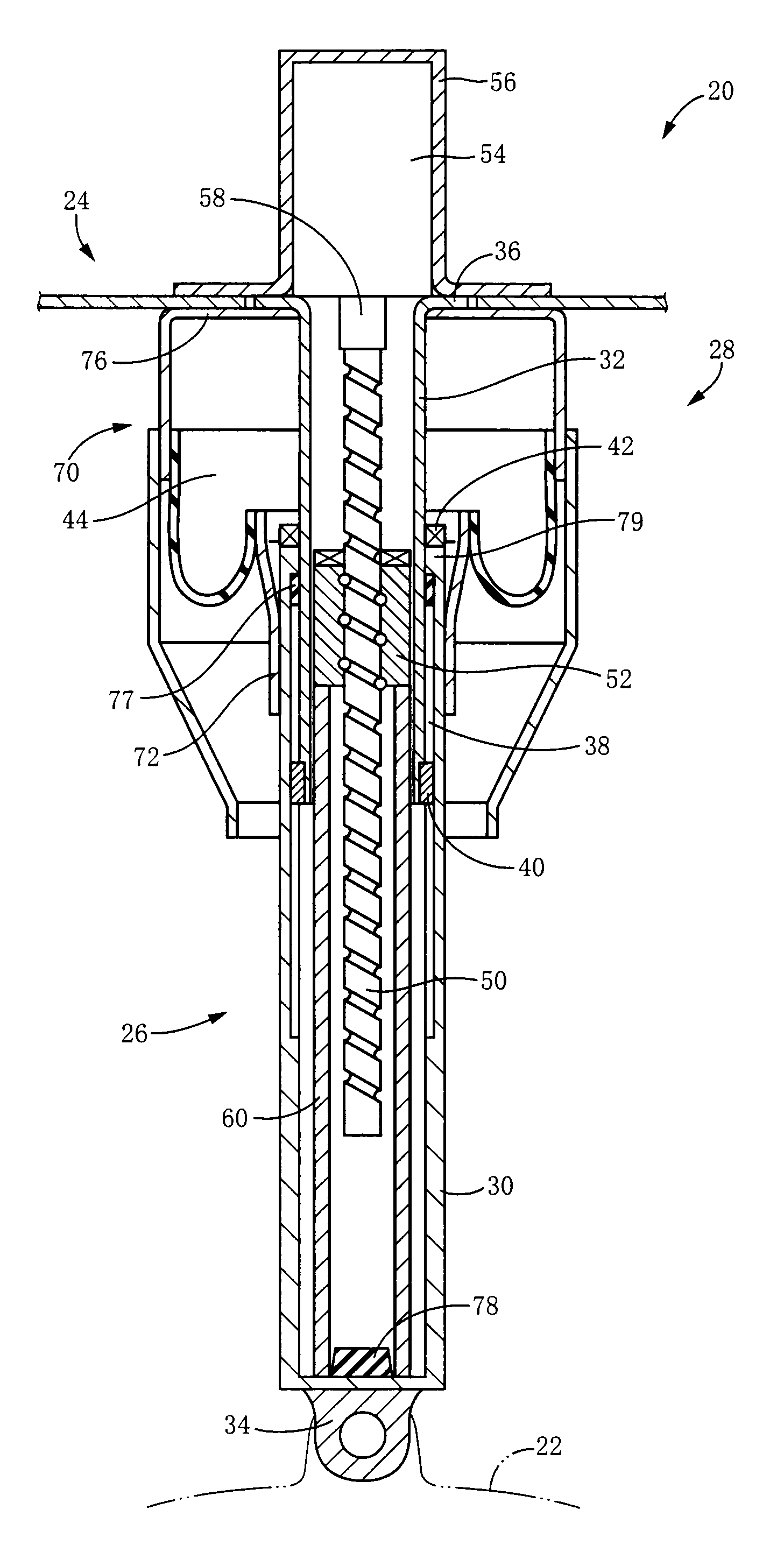

Apparatus and method of balancing a shaft

ActiveUS20050231052A1Reduce manufacturing costsInertia force compensationPropellersEngineeringBalance shaft

An apparatus for balancing a shaft of an aircraft engine preferably includes a plate and the use of standard fasteners. The plate provides mounting for nose cone, and the balancing apparatus may be accessed from the front of the assembled engine.

Owner:PRATT & WHITNEY CANADA CORP

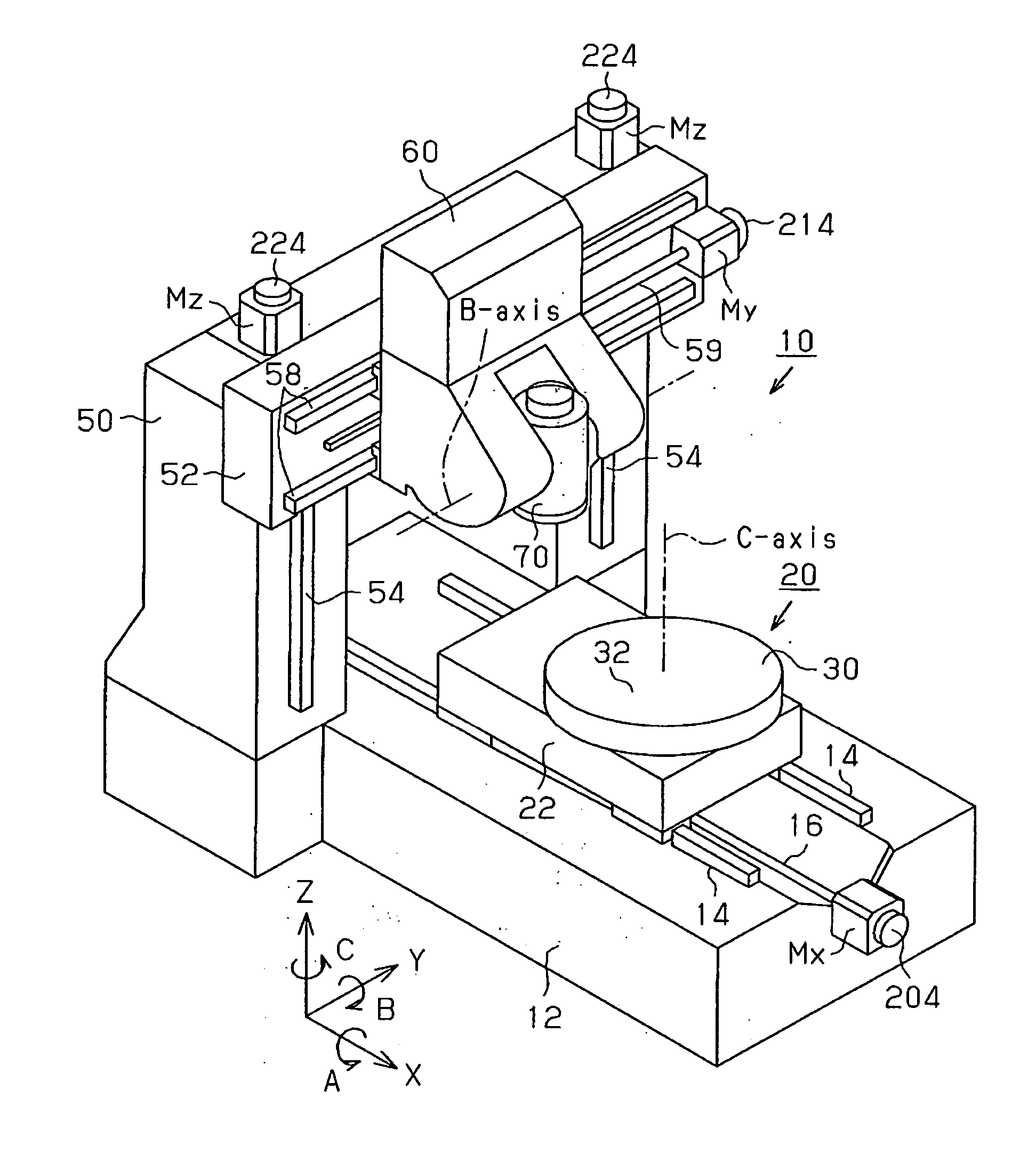

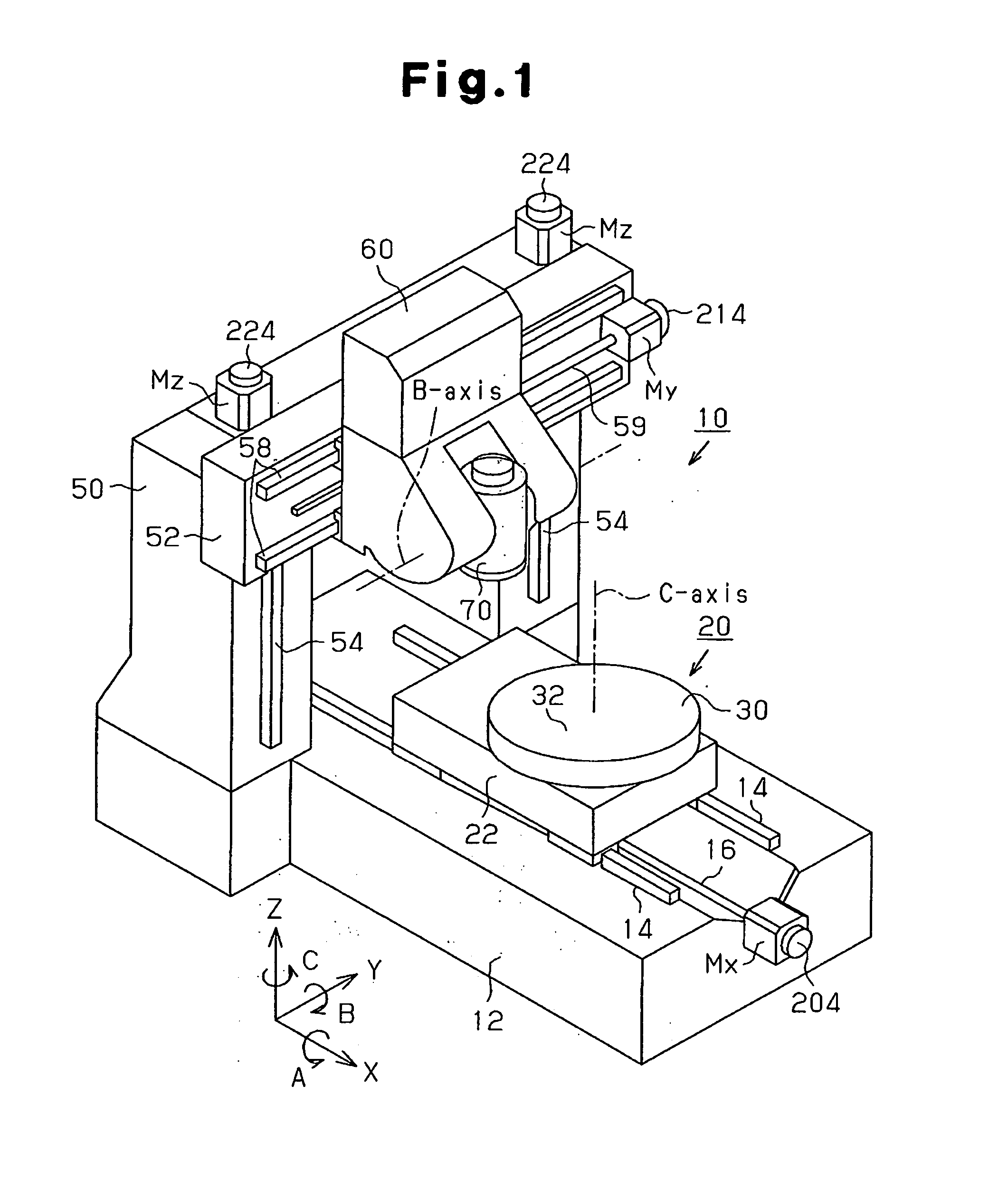

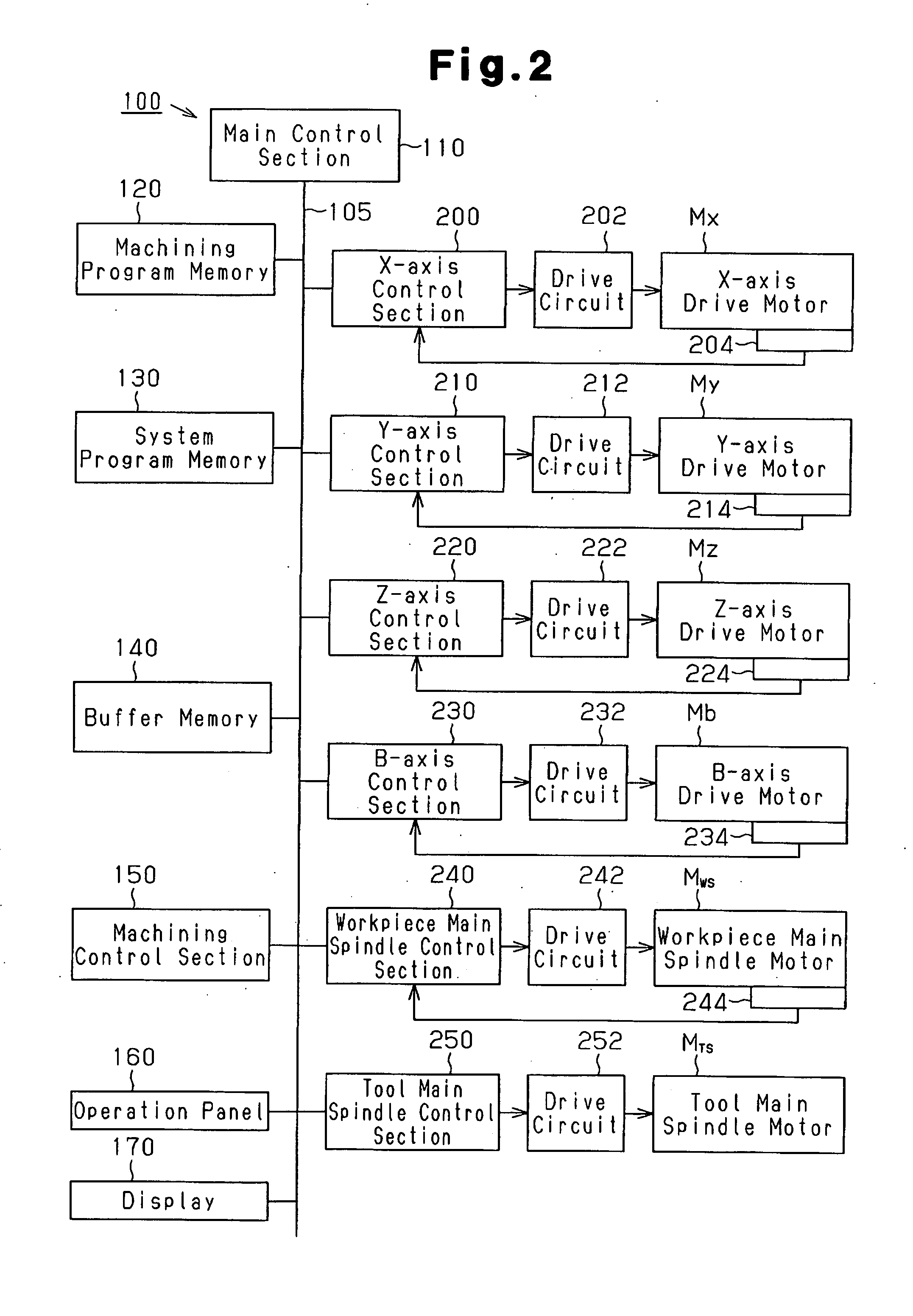

Machine tool and method for computing attachment position of balancer in machine tool

ActiveUS20060018725A1Easily achieve a suitable attachment positionInertia force compensationMachine tool componentsRotary stageControl theory

When a rotary table rotates, a main control section of a multi-tasking machine detects vibration of the rotary table on which a workpiece is mounted based on fluctuation of a position droop computed by a servo system. The main control section computes the arrangement position (the eccentricity amount and the eccentricity angle) of the workpiece with respect to the rotary table based on, for example, the detected vibration, the weight of the workpiece, and the rotation speed of the rotary table. The main control section computes the attachment position of a balancer with respect to the rotary table based on the computed arrangement position of the workpiece. Therefore, a suitable attachment position of a vibration suppressing balancer with respect to the rotary table is easily obtained.

Owner:YAMAZAKI MAZAK KK

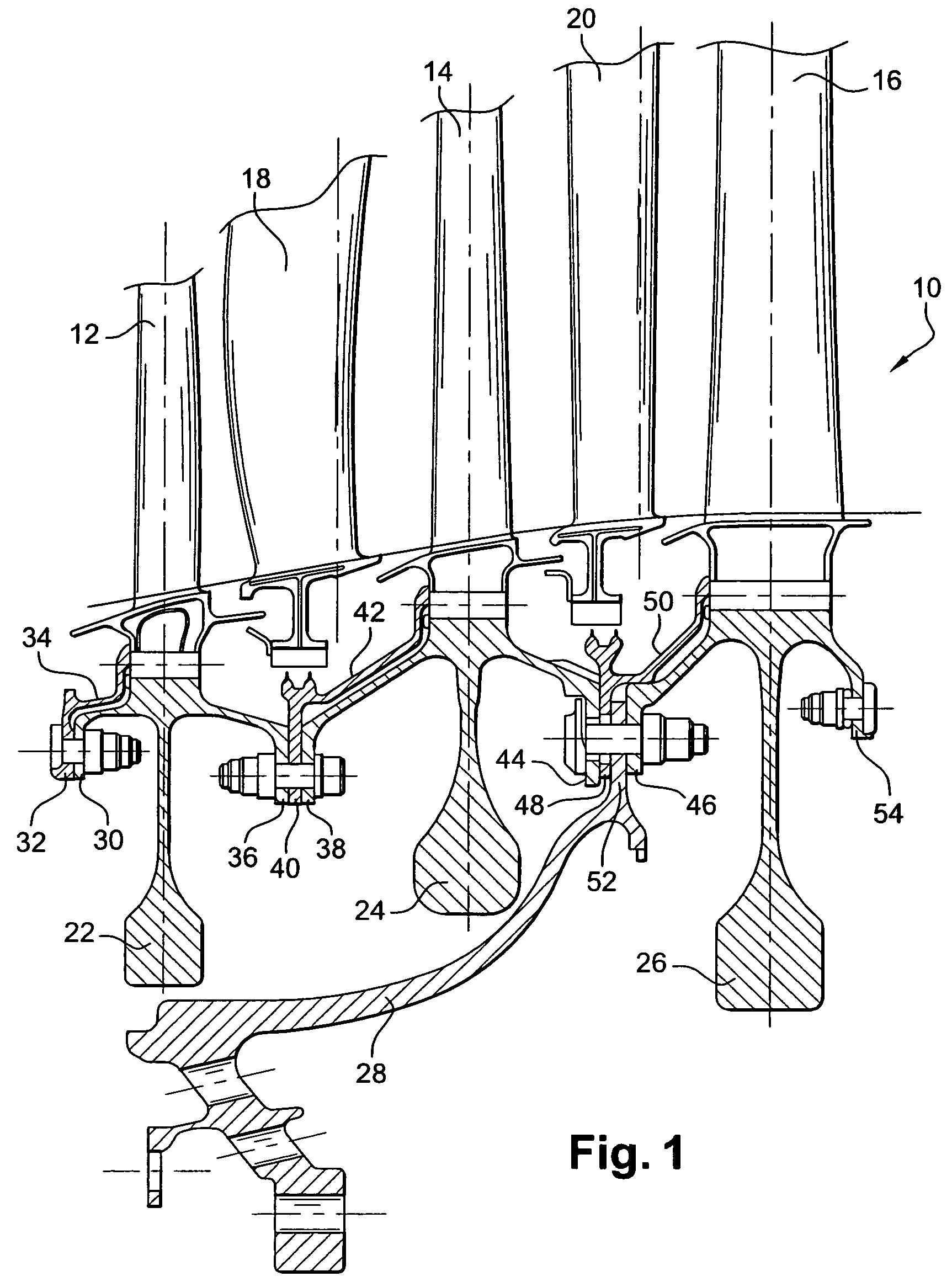

Method and apparatus for balancing gas turbine engines

A method, system, and balanced rotating assembly are provided for field balancing an assembly including a power turbine. The method, system and assembly includes coupling the power turbine to a load, identifying a first balancing plane that is aft of the power turbine, and identifying a second balancing plane that is forward of the power turbine. A balancing correction is determined at each of the first and second balancing planes. A balance weight is mounted at the first balancing plane based on the balancing correction determined for the first balancing plane, and a balance weight is mounted at the second balancing plane based on the balancing correction determined for the second balancing plane, wherein each balance weight is coupled to at least two respective bolt head without removing the bolts.

Owner:GENERAL ELECTRIC CO

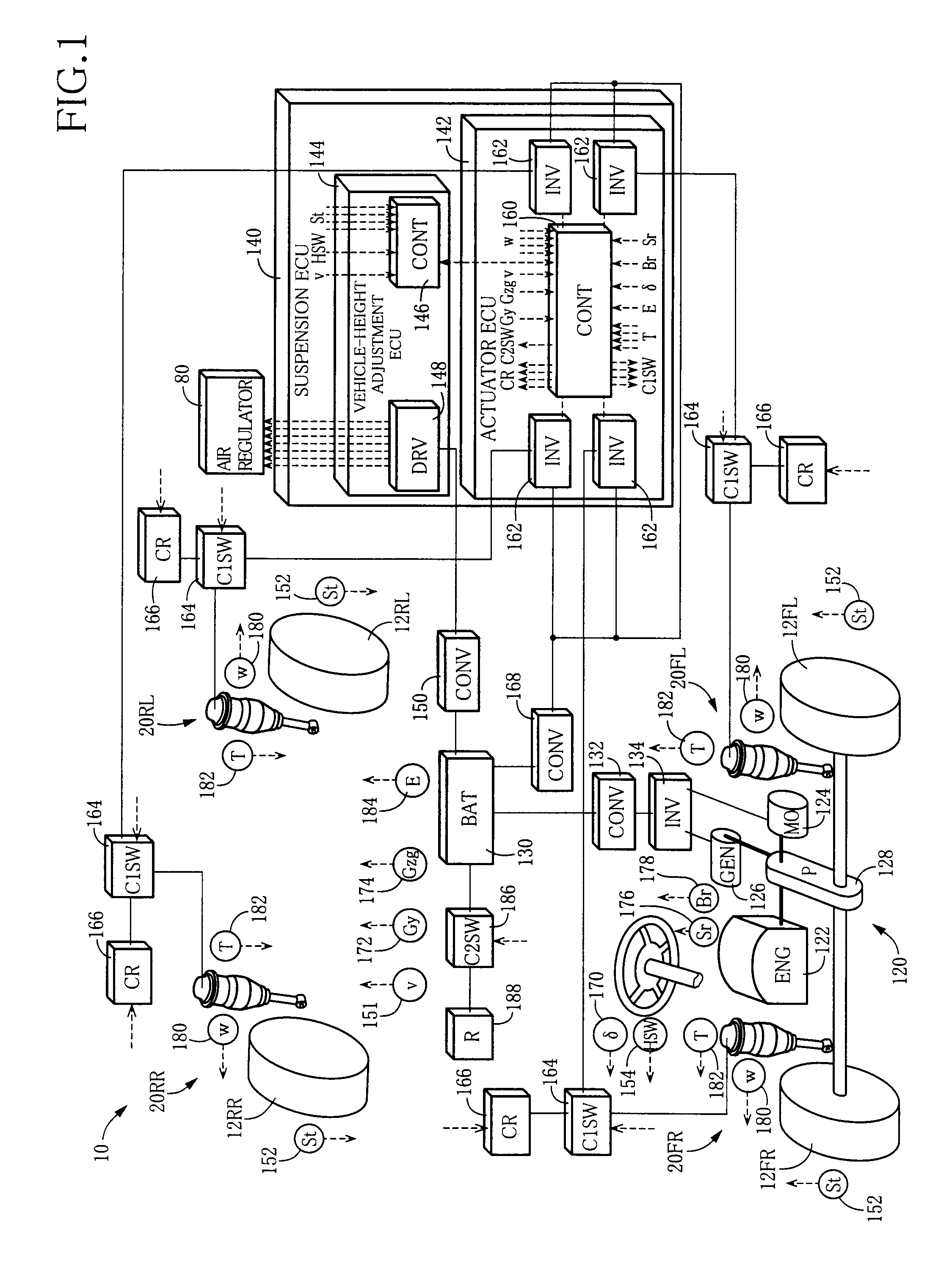

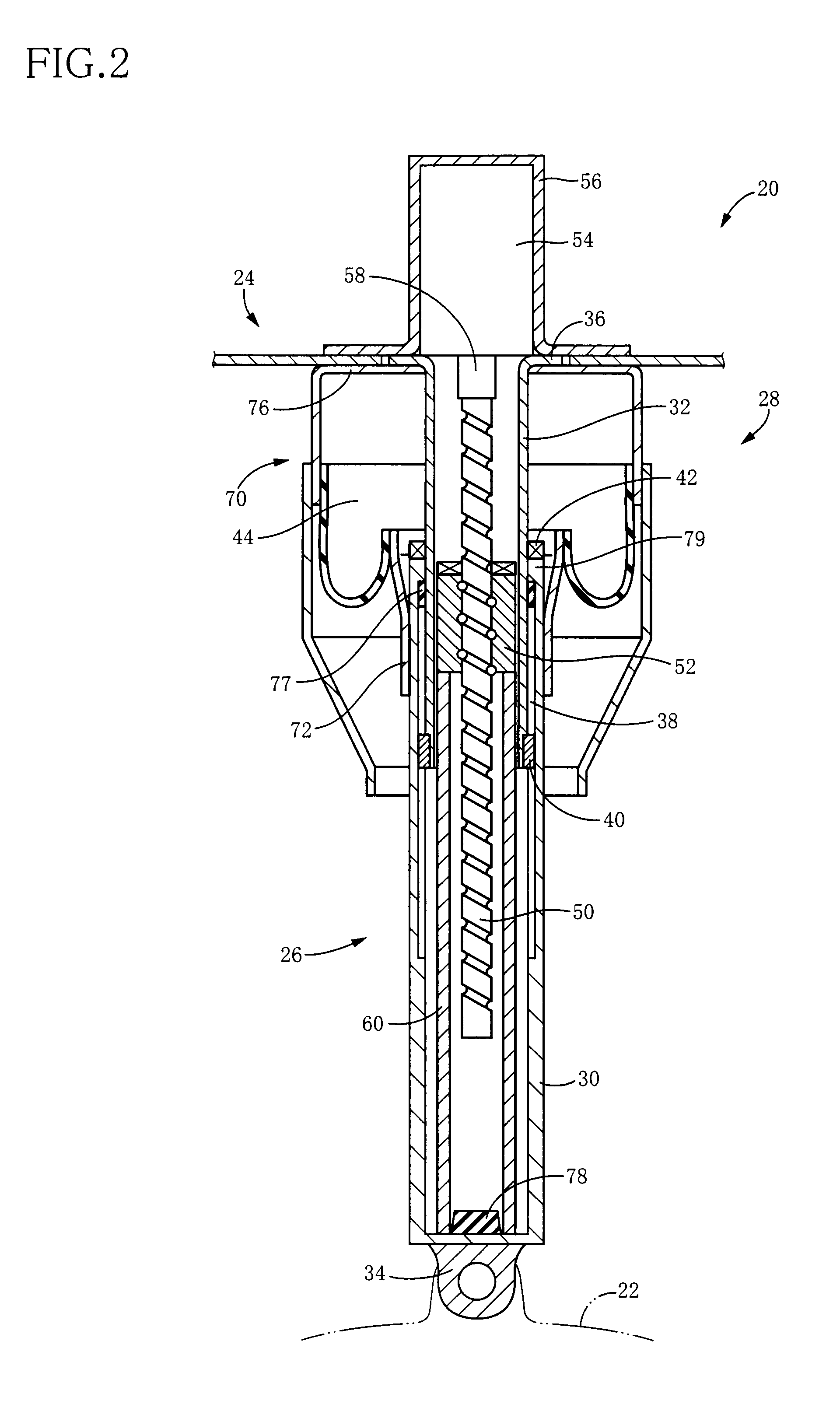

Vehicle suspension system

ActiveUS8191874B2Effective controlImprove applicabilityNon-rotating vibration suppressionRotating bodies balancingElectric power systemElectrical battery

A vehicle suspension system including: (a) a suspension spring interconnecting a vehicle body and a wheel; (b) an actuator having an electric motor, such that the actuator is capable of generating, based on a force of the electric motor, an actuator force forcing the body and the wheel toward and away from each other, and causing the generated actuator force to act as a damping force against displacement of the body and the wheel; and (c) a control device for controlling the actuator force generated by the actuator, by controlling operation of the electric motor. The control device is capable of establishing a constant-force generating state in which the actuator force is constantly generated as a constant actuator force by the actuator with supply of an electric power thereto from a battery as an electric power source of the electric motor such that the generated constant actuator force acts in a rebound direction or a bound direction. The control device controls the constant-force generating state, based on a charge state of the battery.

Owner:TOYOTA JIDOSHA KK

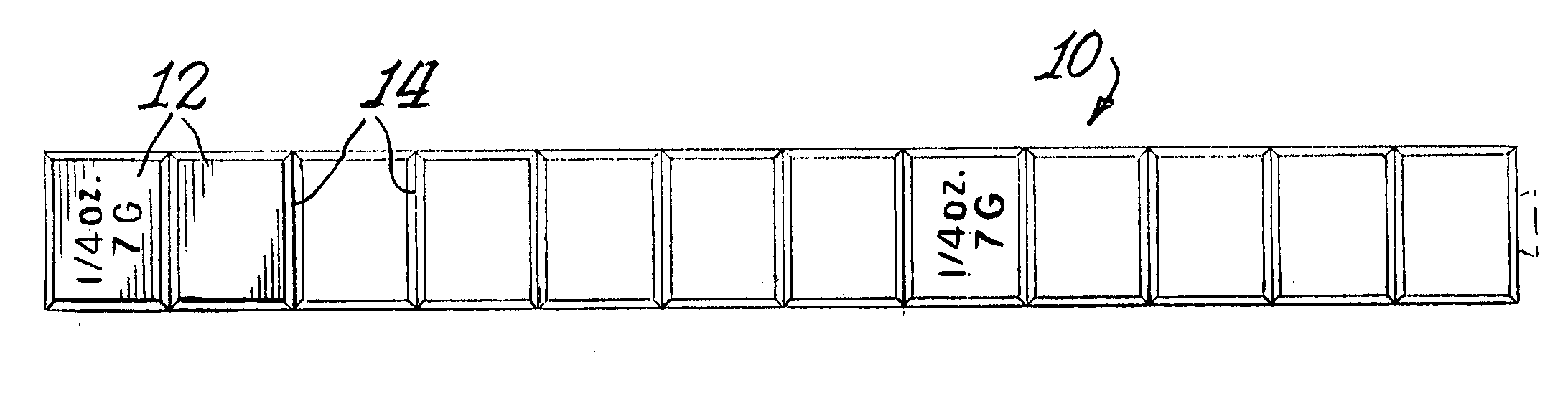

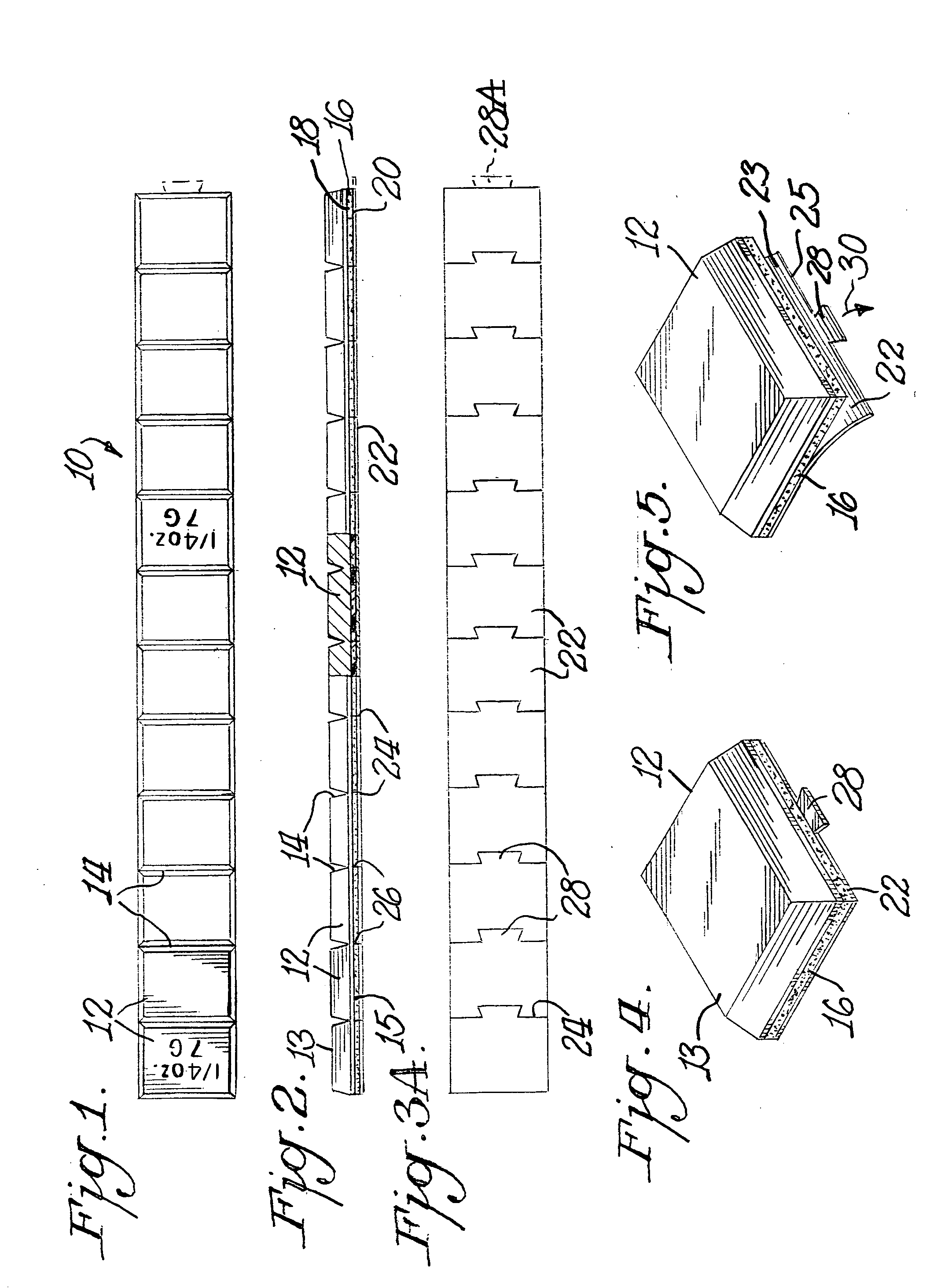

Adhesive wheel balancing weights having a serrated backing strip

InactiveUS20050104438A1Easy to separateEasy to disassembleHubsLayered productsBack-strippingMechanical engineering

Disclosed herein is a wheel balancing device having a plurality of wheel balancing weights attached to a top surface of an elongate tape, and a backing strip removably attached to and protecting an adhesive layer on the bottom surface of the tape. The backing strip is serrated below the grooves separating the individual wheel balancing weights to facilitate separation of the individual weights quickly and easily. Each backing strip serration may be in the shape of a lift tab or finger grip to further ease removal of the backing strip from the adhesive layer on the bottom surface of the tape.

Owner:HALKO MFG

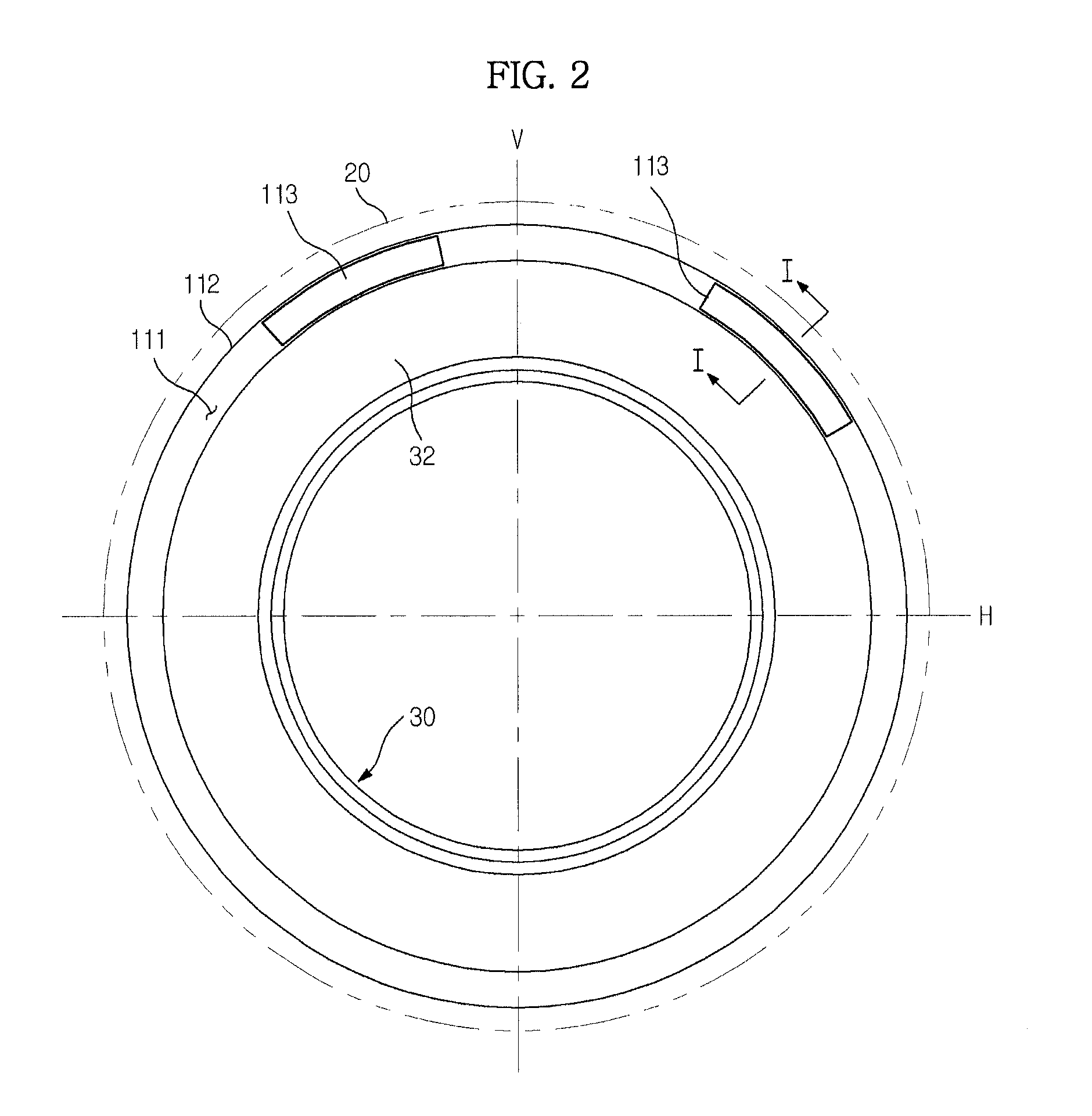

Laundry treatment apparatus

ActiveUS20140223969A1Prevent movementEliminate relative rotationRotating bodies balancingOther washing machinesEngineeringLaundry

A laundry treatment apparatus including a rotatable drum in which laundry is stored, at least three balancers mounted to the drum so as to be spaced apart from one another by the same angle around a rotation center of the drum. Liquid is introduced into and discharged from the balancers via a feeder supplying the liquid and a flow path structure mounted to the drum to guide liquid supplied from the feeder to the balancer located in a direction for removal of unbalance of the drum.

Owner:LG ELECTRONICS INC

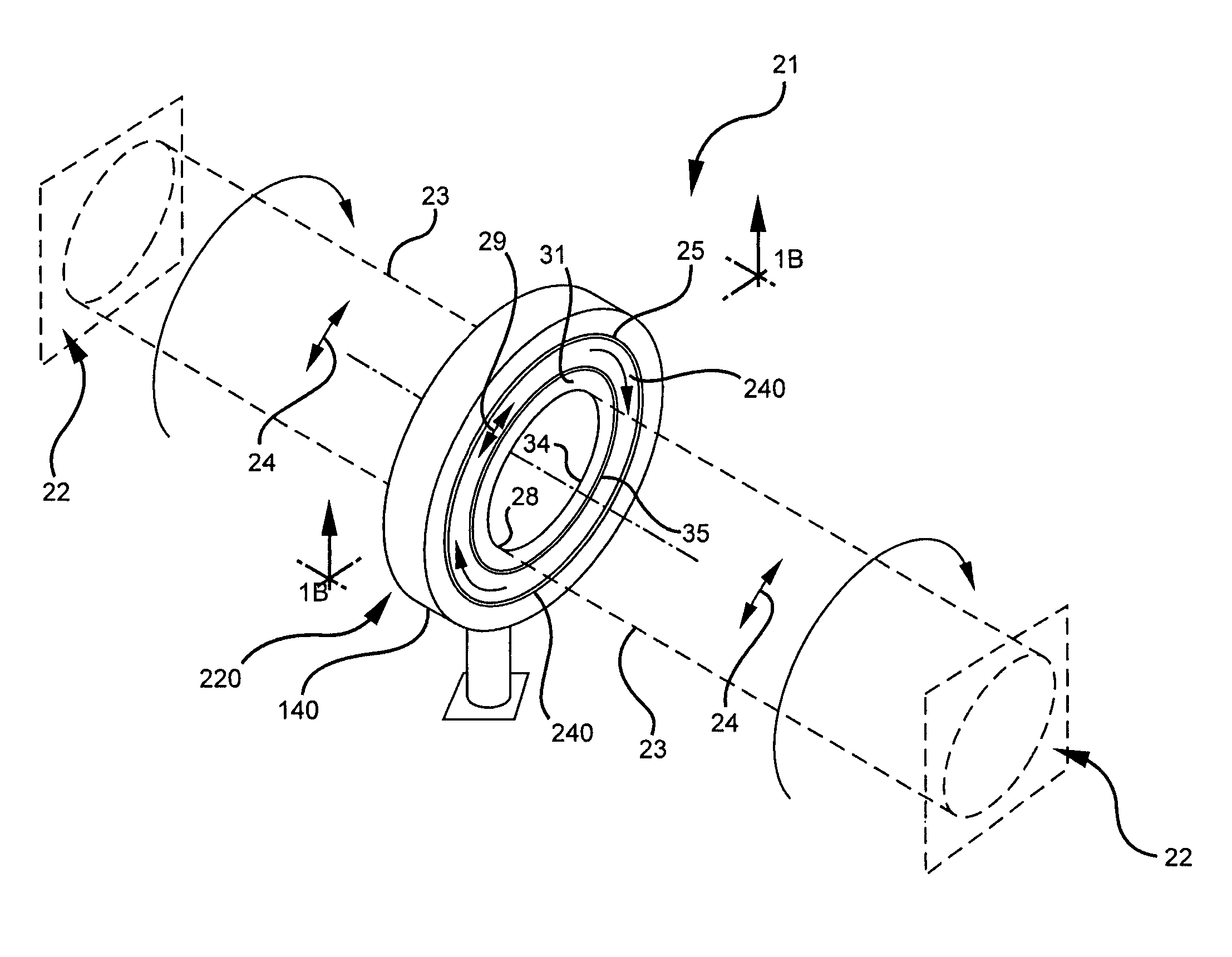

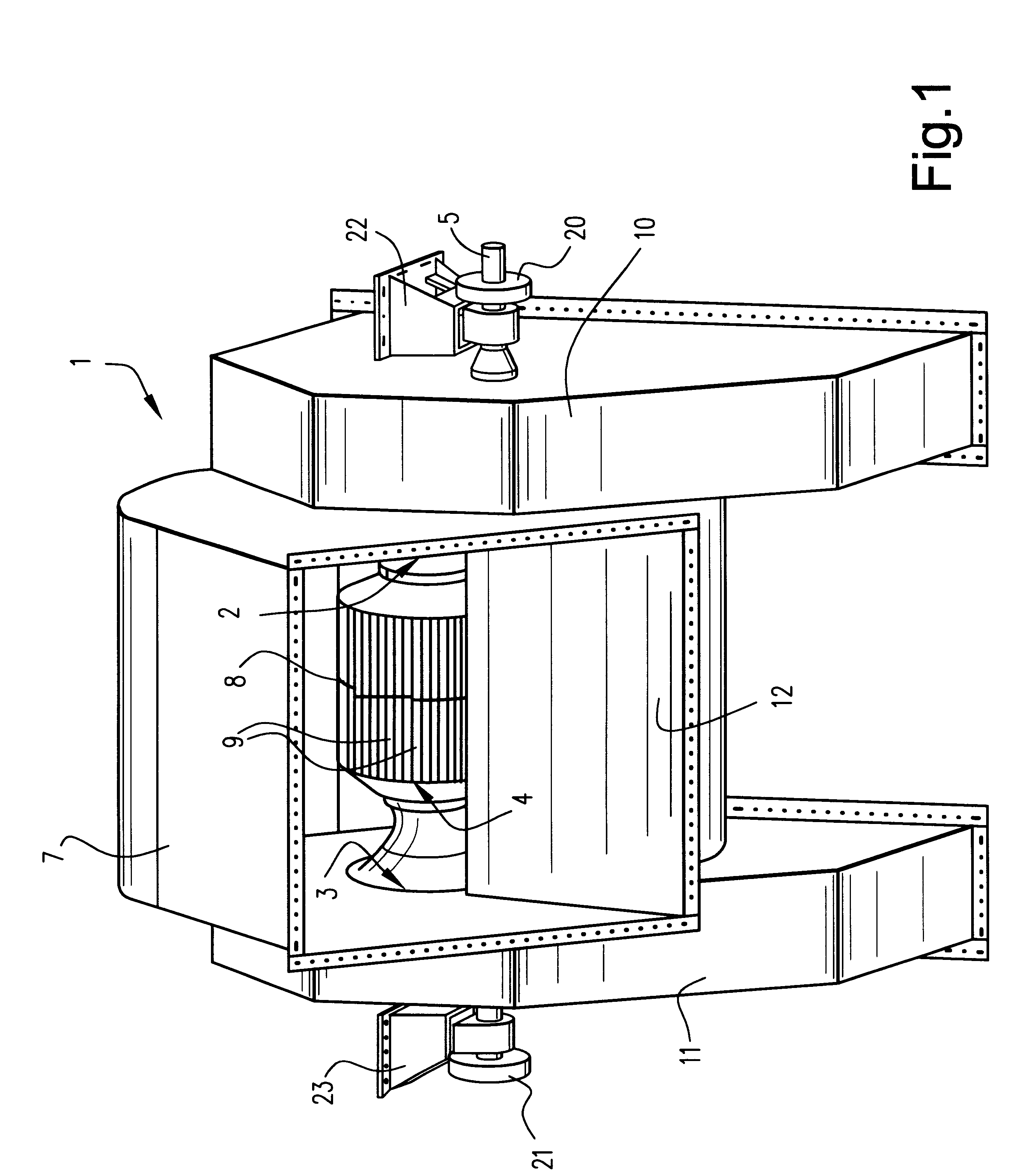

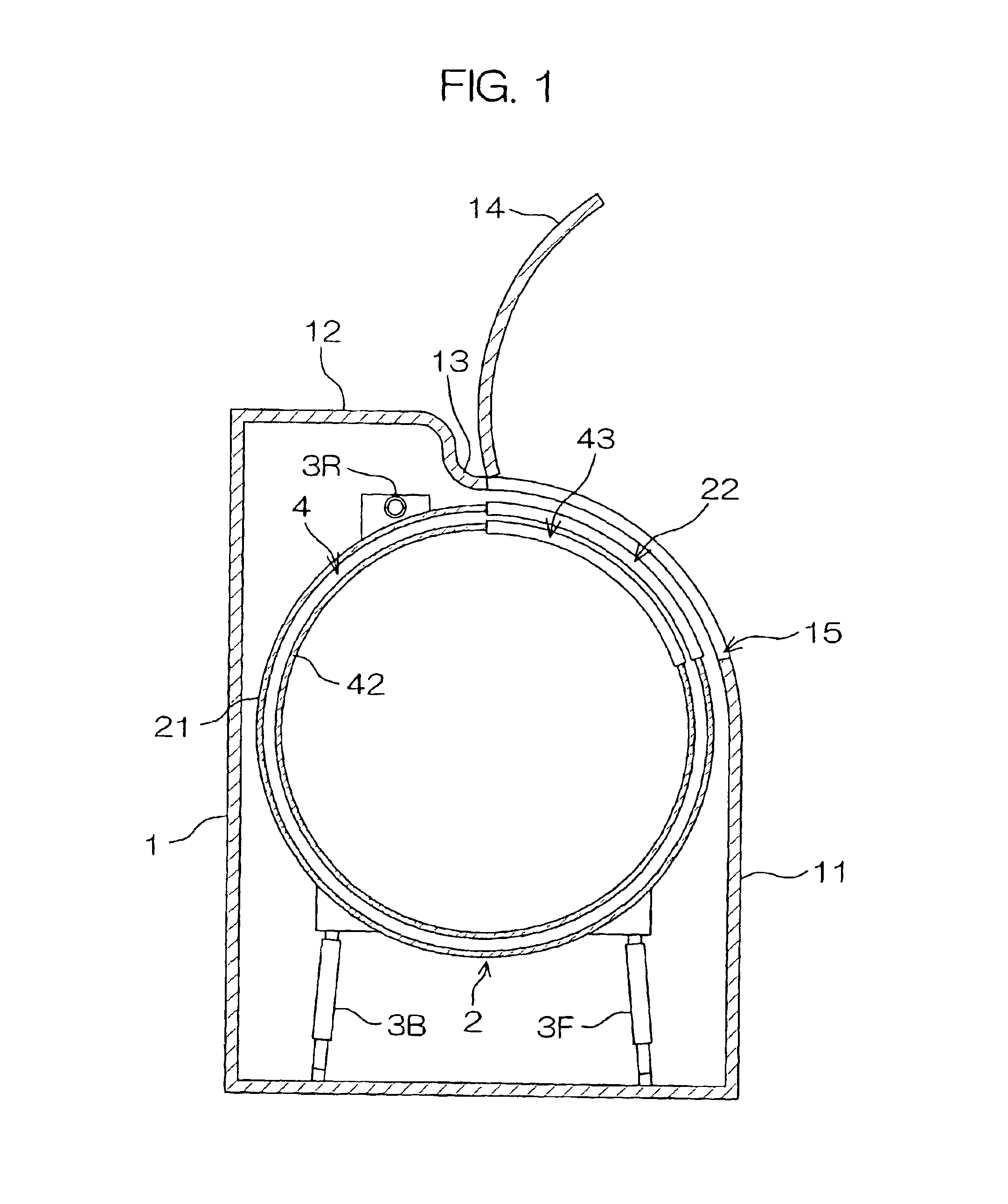

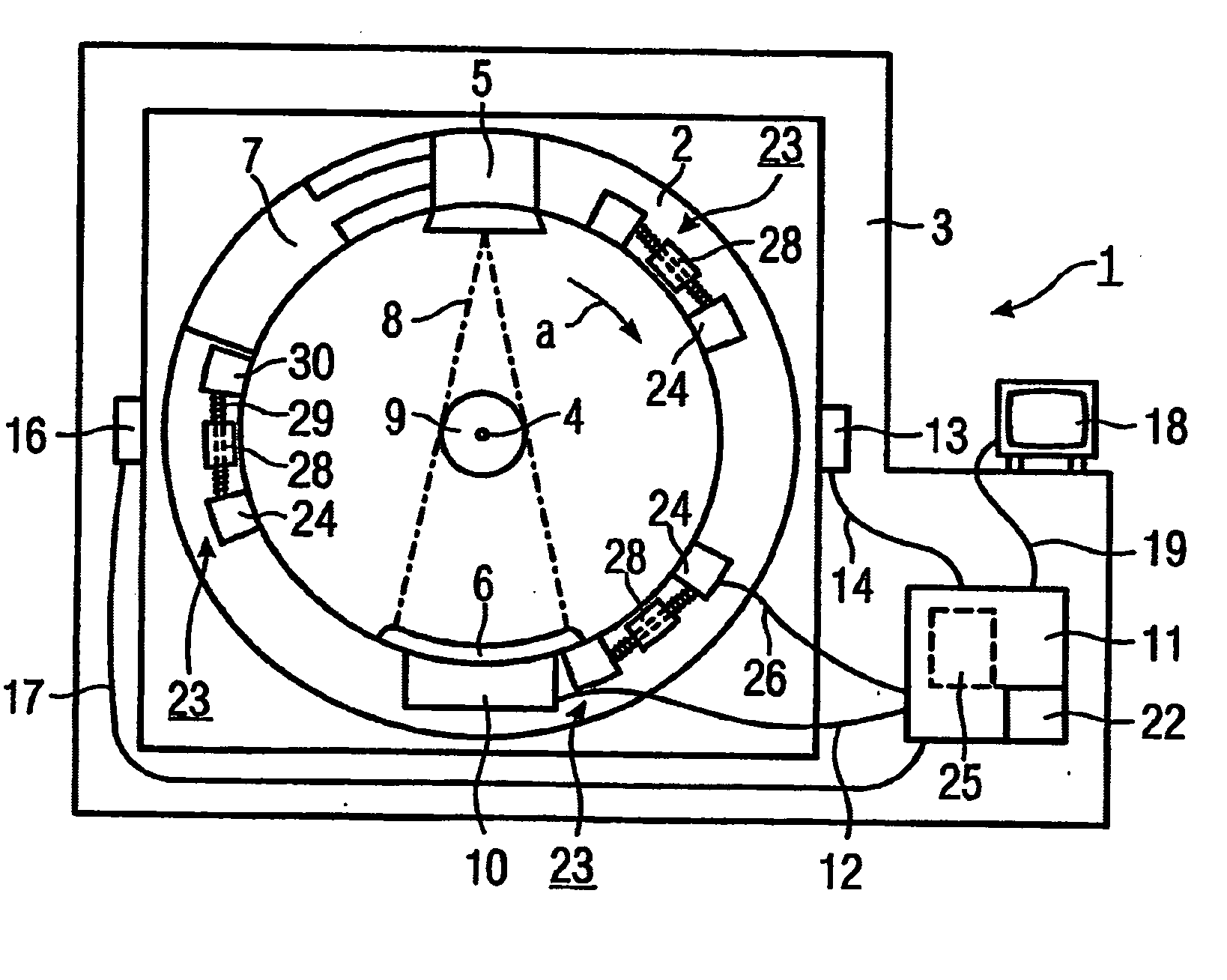

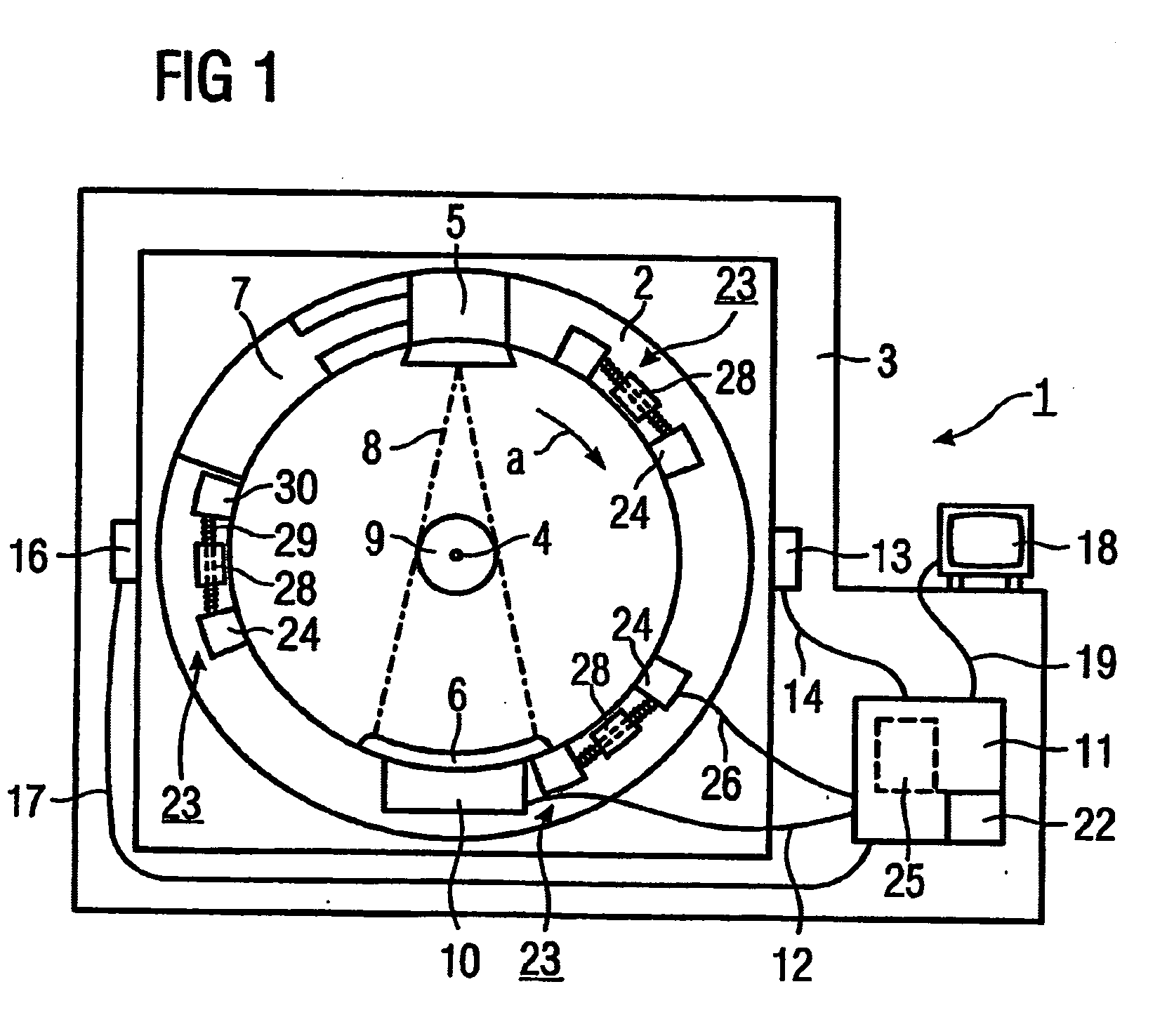

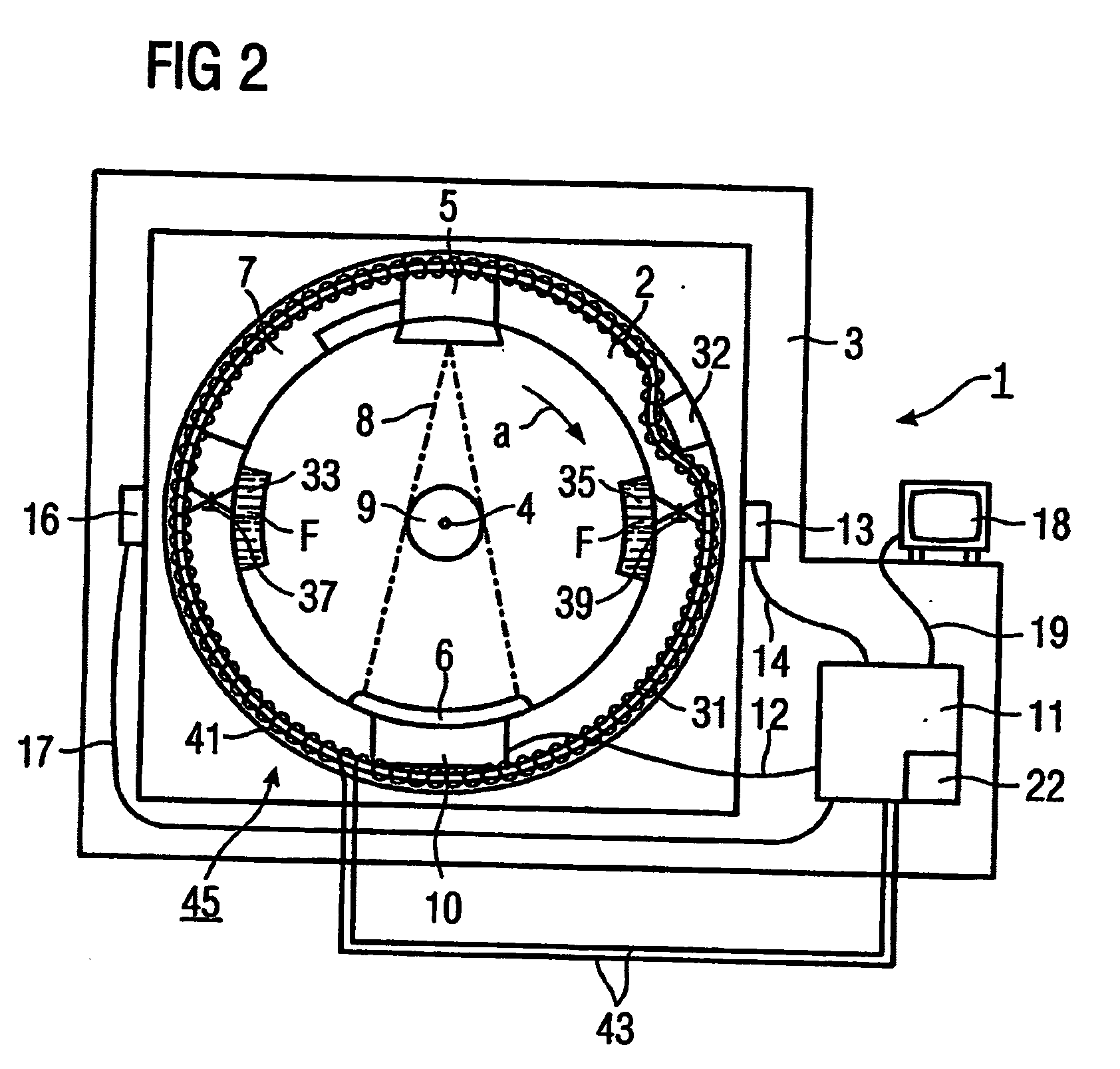

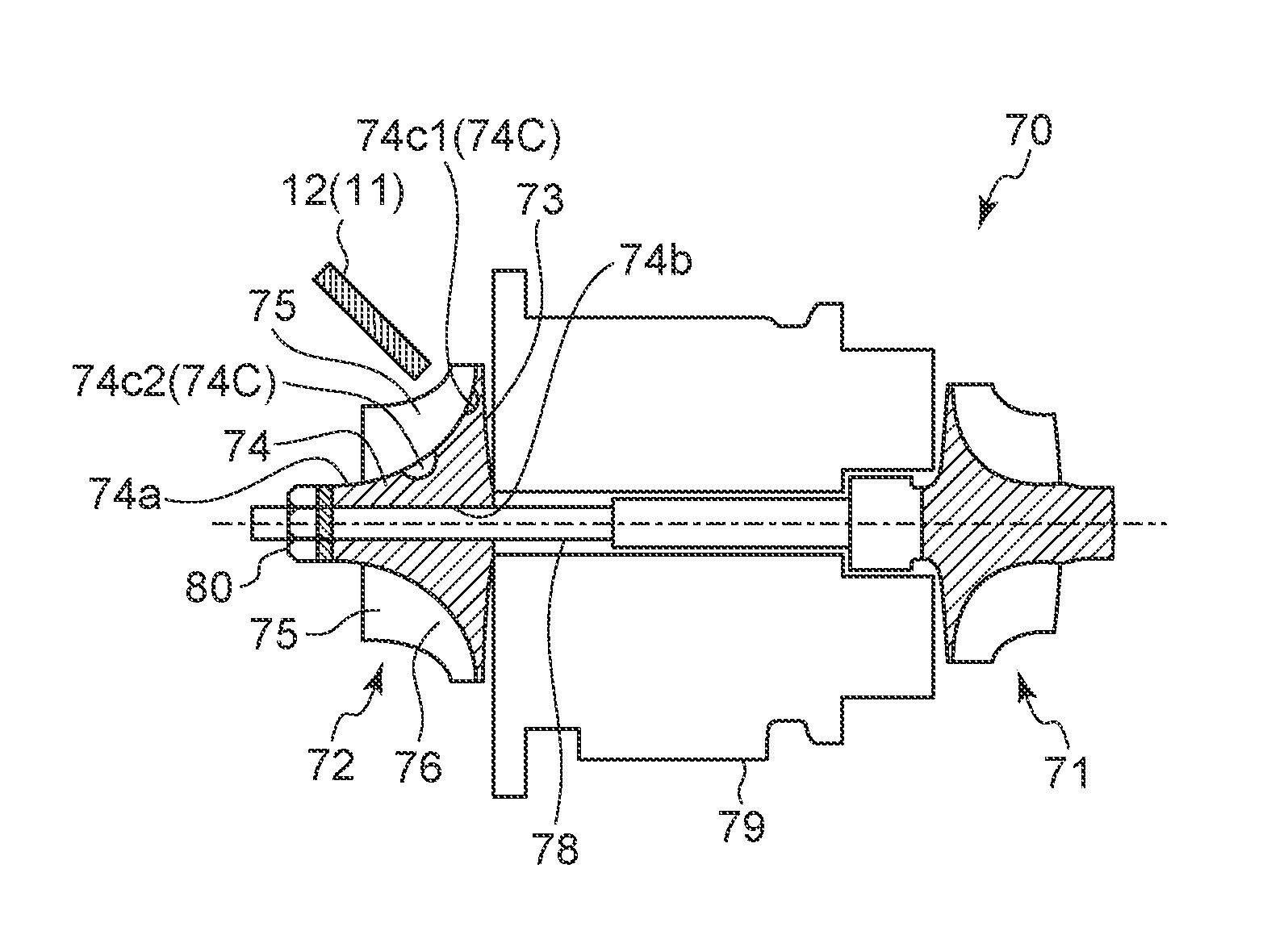

Automatic balancing system and method for a tomography device

InactiveUS20070041488A1Improve image qualityQuality improvementMaterial analysis using wave/particle radiationSpringsX-rayEngineering

The invention relates to a tomography device (1), especially an X-ray computer tomography device or ultrasound tomography device, comprising a balancing device (23; 45) for reducing an imbalance (61) that was determined by means of the measuring system (2) rotating about an axis of rotation (4). The balancing device (23; 45) comprising means mounted on the measuring system (2) for variably positioning a balancing mass and a control device (25) acting upon said means and designed in such a manner that the balancing mass, controlled by the control device (25), can be positioned in a location appropriate to reduce the imbalance (61). The balancing mass can be configured as a liquid (F) that is positioned in a liquid-tight channel. The invention also relates to a balancing method according to which a mass (m) of a liquid quantity balancing the imbalance (61) is determined and a magneto- and / or electro-rheological liquid (F) is introduced into an annular channel (31; 71; 81, 83, 85) in such a quantity that for the subsequent operation a quantity of liquid (F) dependent on the determined mass (m) is present in the annular channel (31; 71 81, 83, 85).

Owner:SIEMENS AG

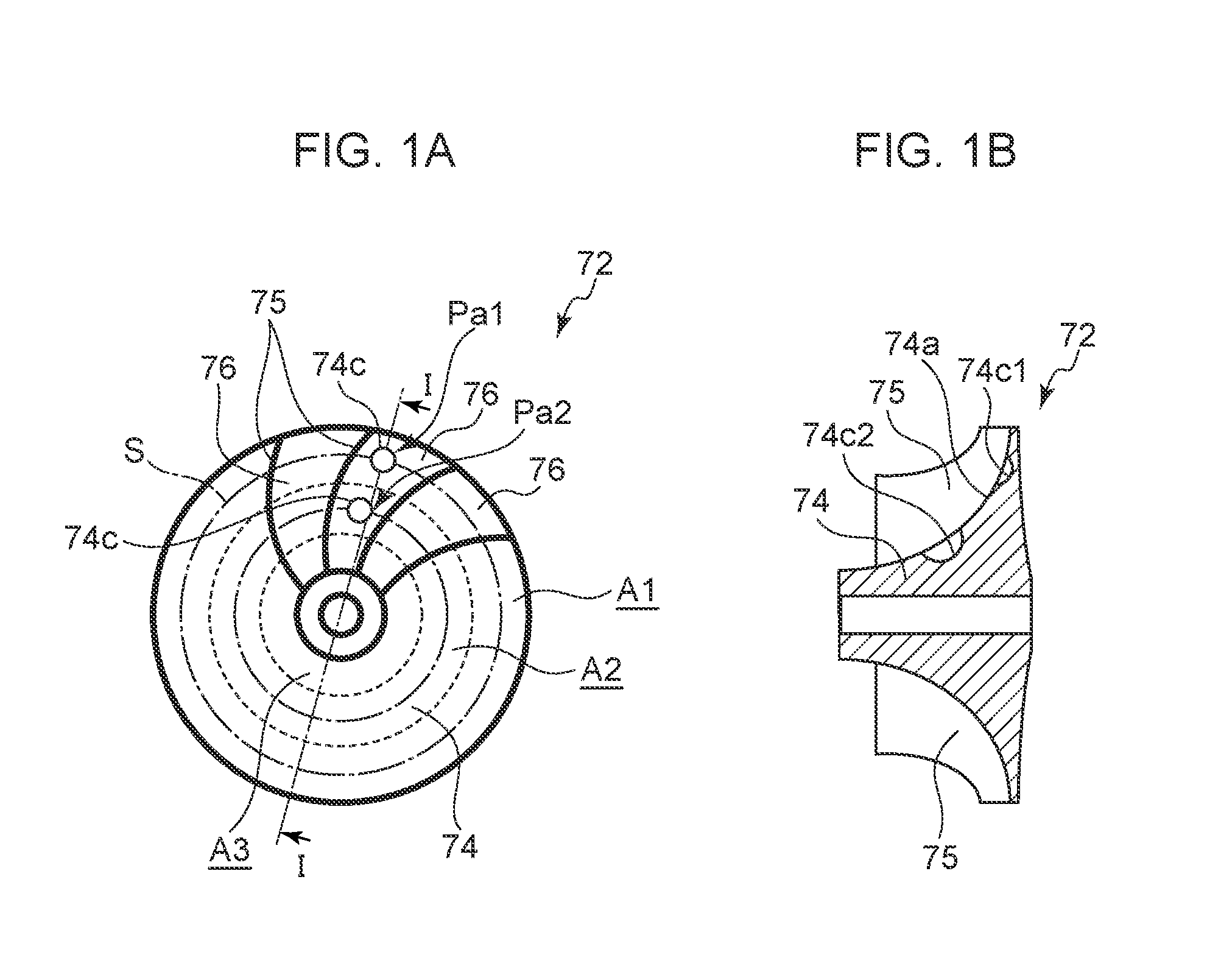

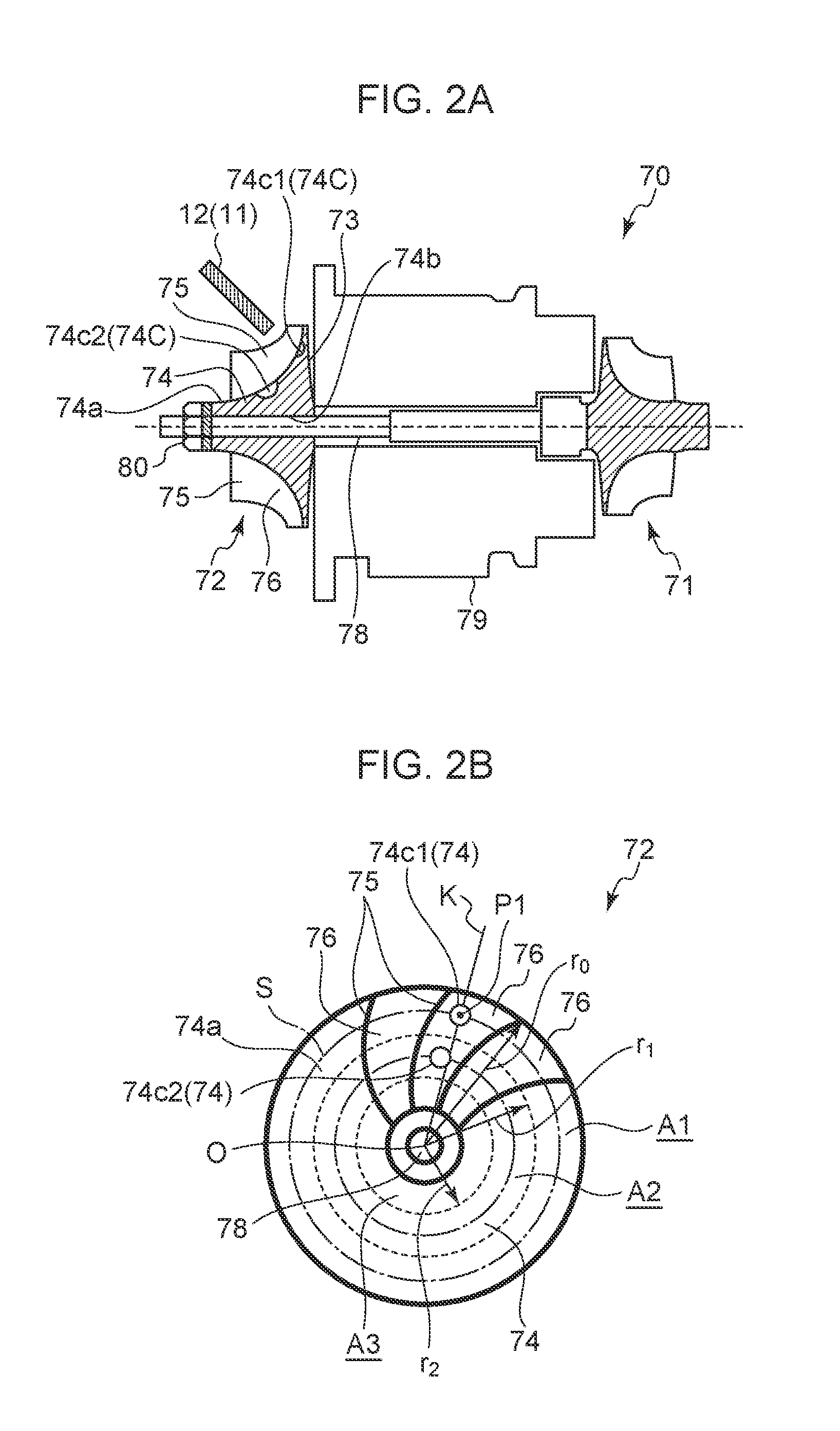

Rotary fluid element and method of correcting unbalance of rotary fluid element

ActiveUS20160363134A1Reduced strengthPump componentsRotating bodies balancingEngineeringUltimate tensile strength

An object is to provide a rotary fluid element and a method of correcting unbalance of a rotary fluid element, whereby unbalance of the rotary fluid element can be corrected multiple times in a necessary and sufficient amount without sacrificing strength of blades. A rotary fluid element includes: a plurality of blades extending in a centrifugal direction on an outer peripheral surface of a boss portion and disposed at intervals in a circumferential direction; and a cut-remove portion for reducing unbalance disposed in a blade gap between the blades adjacent in the circumferential direction. The cut-remove portion includes a first cut-remove portion which is cut and removed on a radially-outer rim portion between the blades, and an additional cut-remove portion which is cut and removed on a radially-inner portion disposed inside the first cut-remove portion with respect to a radial direction.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com