Balance assembly for rotary turbine component and method for installing and/or adjusting balance weight

a technology of rotary turbines and components, which is applied in the direction of marine propulsion, vessel construction, instruments, etc., can solve the problems of inaccessible balance weights, unable to synchronize the weight distribution of the balance assembly, and the inability to fully disassemble the balance assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

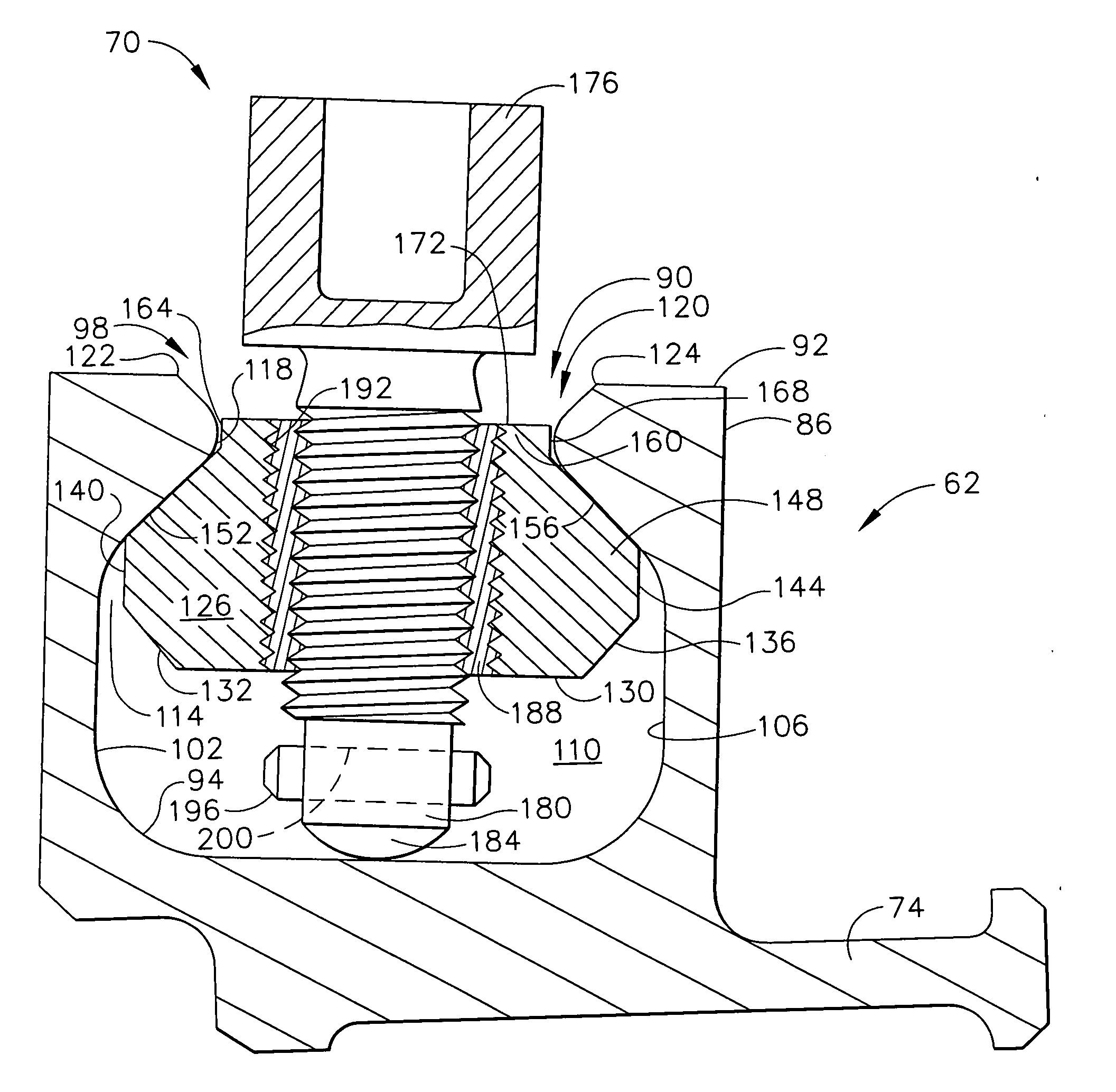

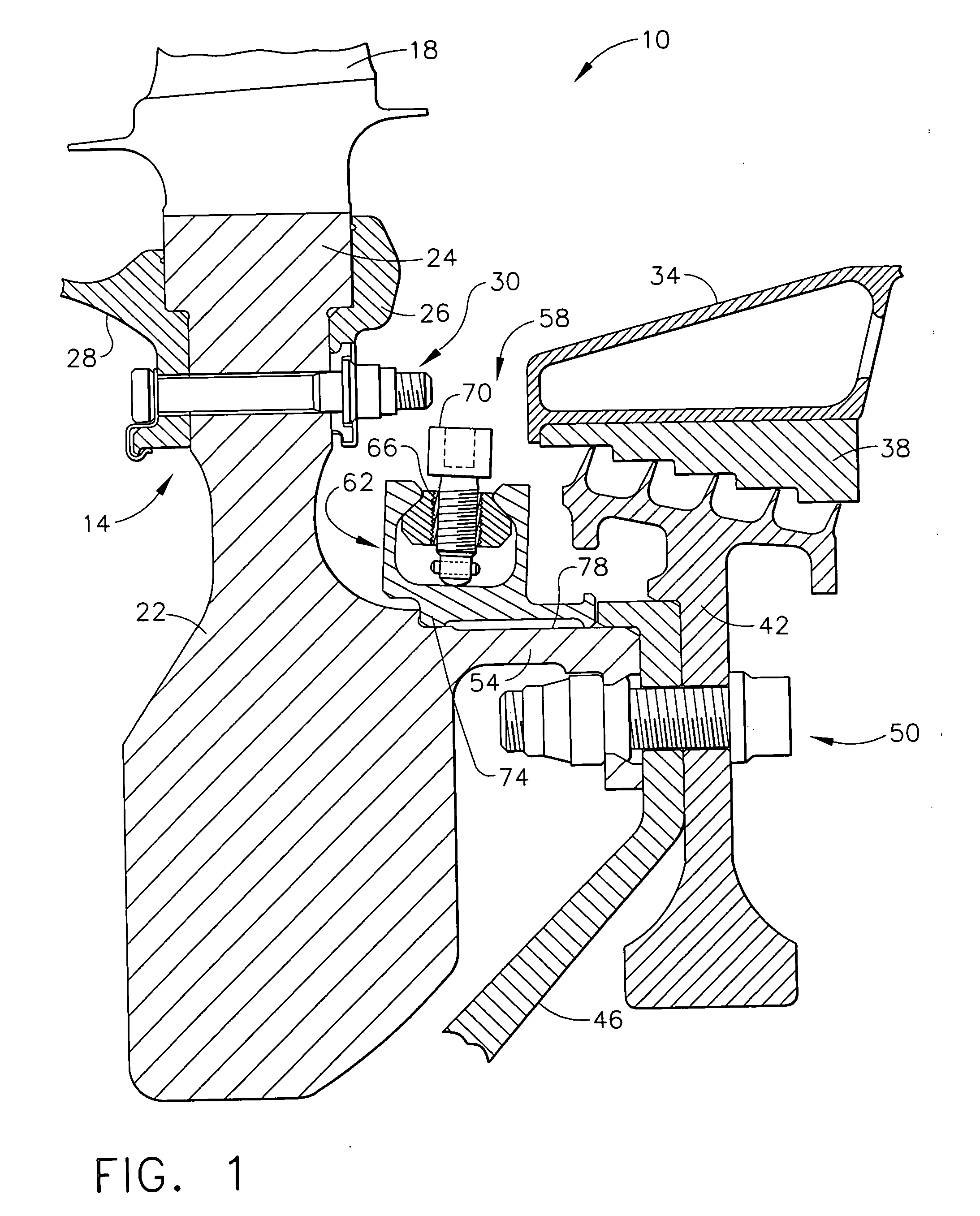

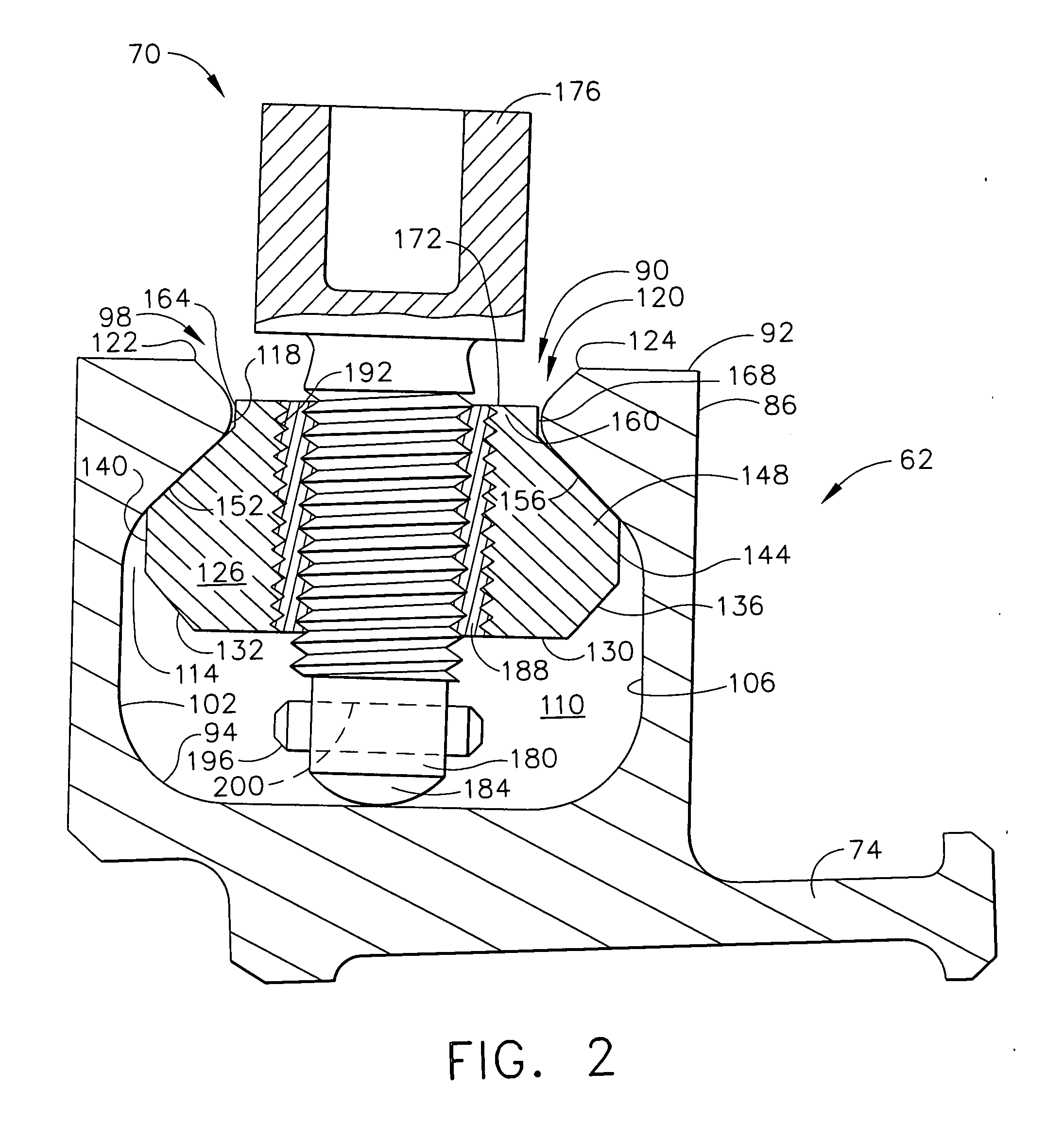

[0026] Referring to the drawings, FIG. 1 illustrates a fragmentary cross-section of a representative section of a turbine engine that is indicated generally as 10 in which the balance assembly of this invention can be used. Turbine engine section 10 is shown as having a turbine rotor indicated generally as 14. Turbine engine section 10 can be any section having such a rotor 14, including but not limited to a high pressure (HP) compressor section, a low pressure (LP) compressor section, an HP turbine section, a LP turbine section, an intermediate power (IP) turbine section, or a power (PW) turbine section. In other words, the turbine engine section 10 shown in FIG. 1, and as described hereafter, should be considered only representative of the use of the embodiment of the balance assembly of this invention.

[0027] As shown in FIG. 1, rotor 14 comprises a plurality of circumferentially spaced turbine blades, one of which is indicated as 18, that extend radially from a central hub or di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com