Patents

Literature

690results about How to "Easy fine-tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

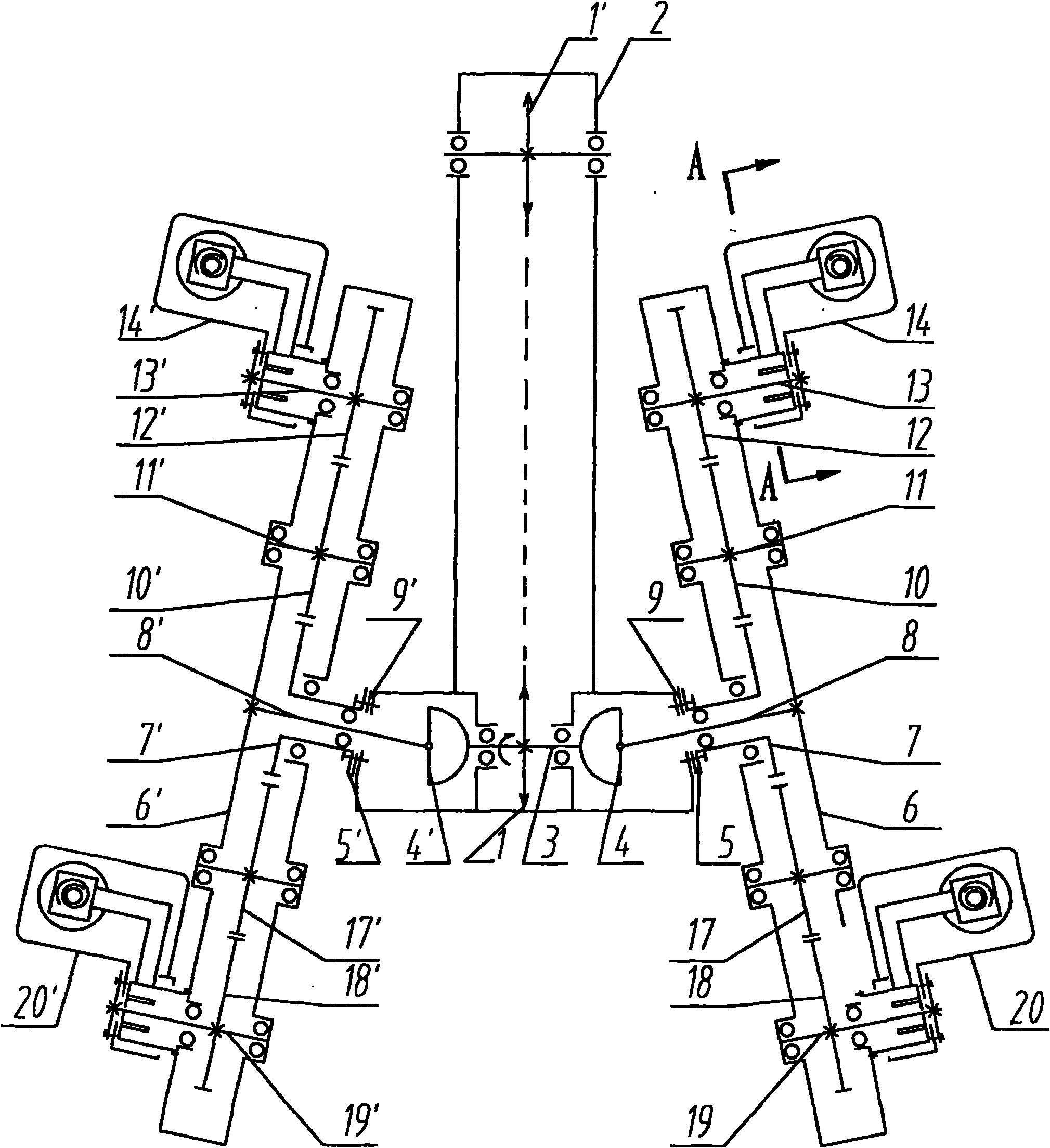

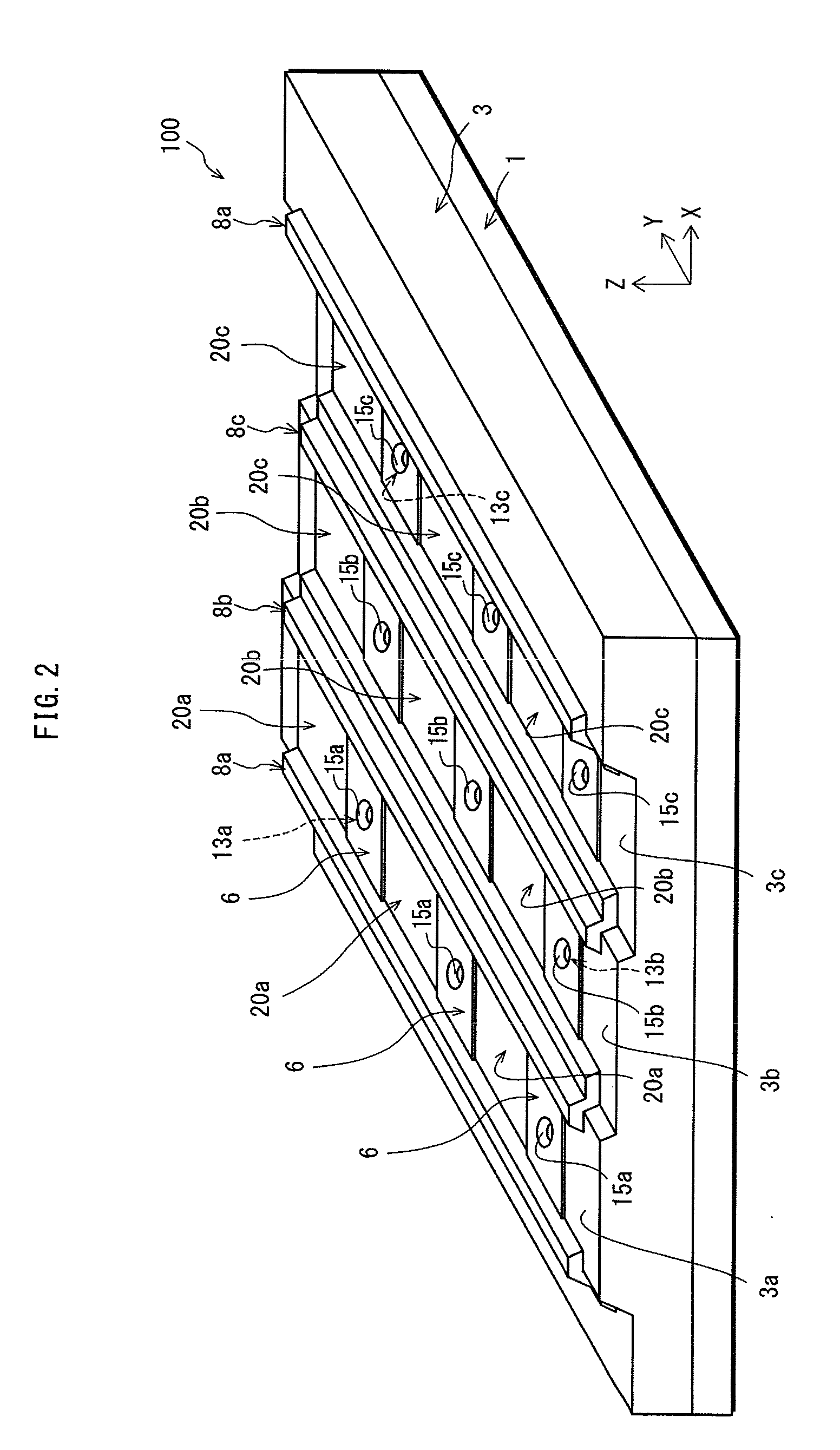

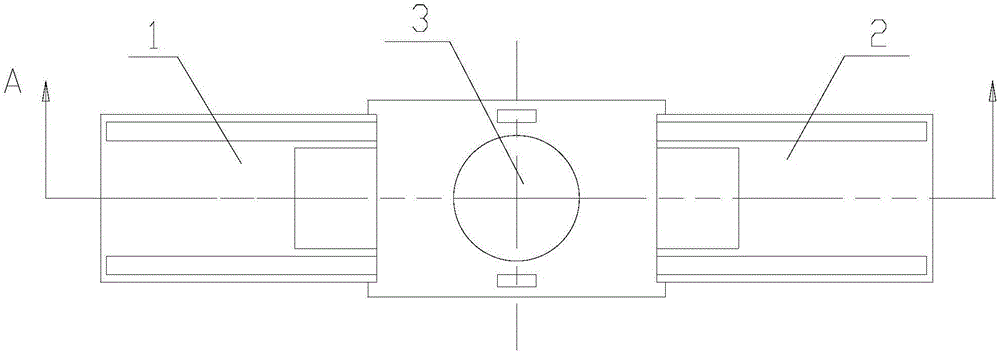

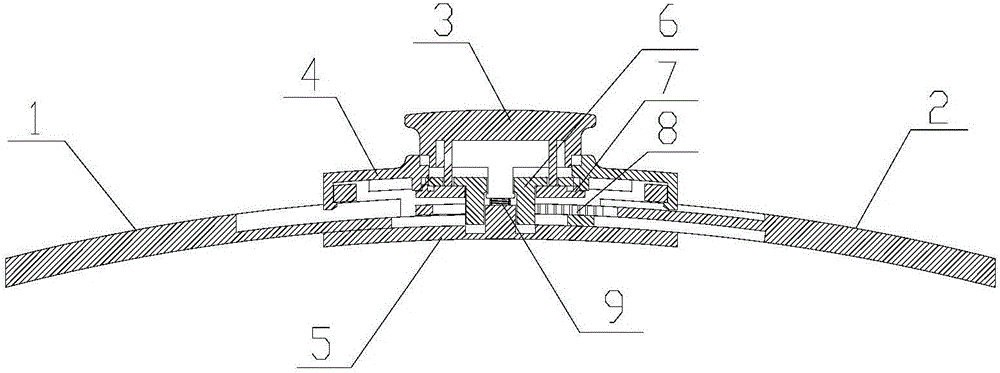

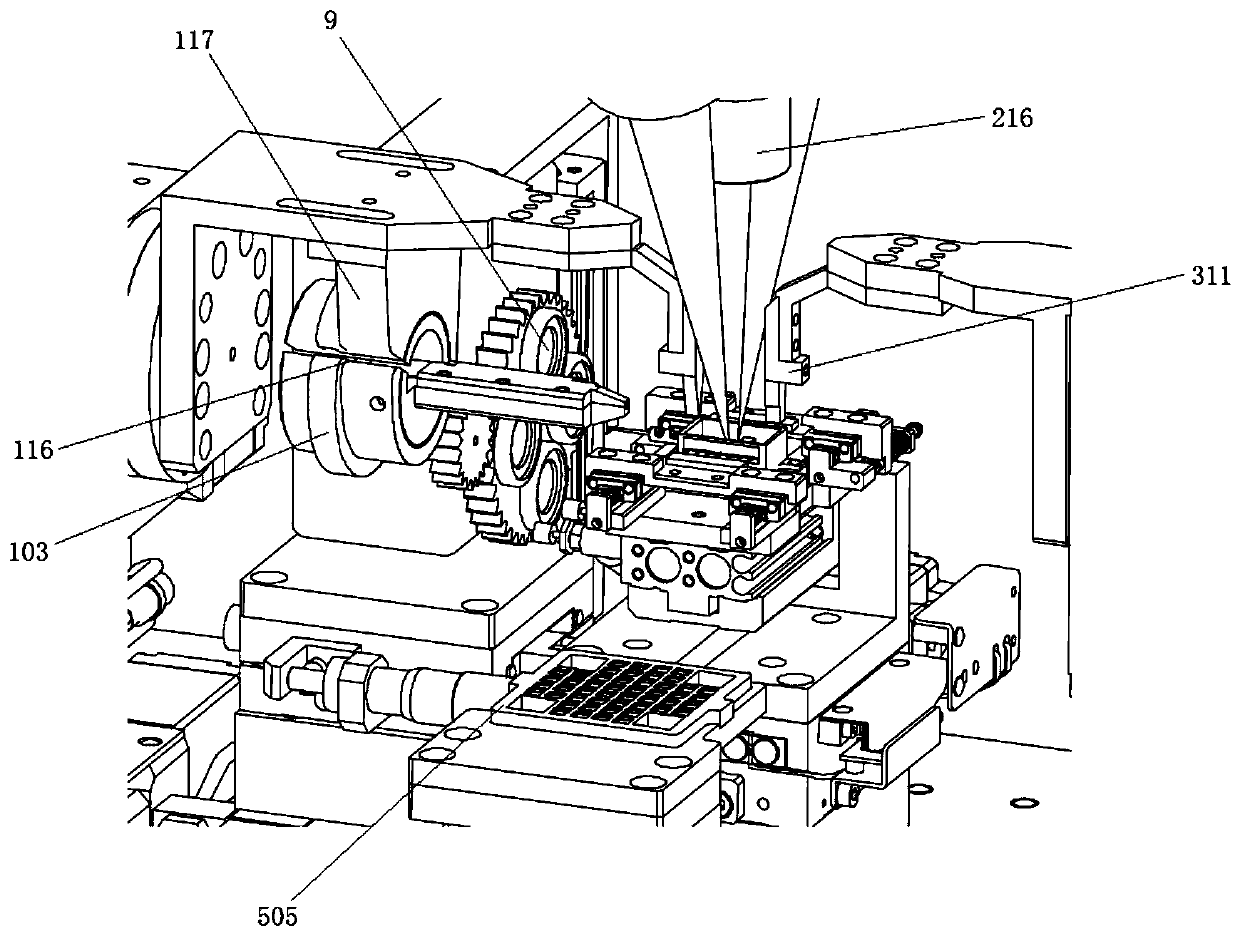

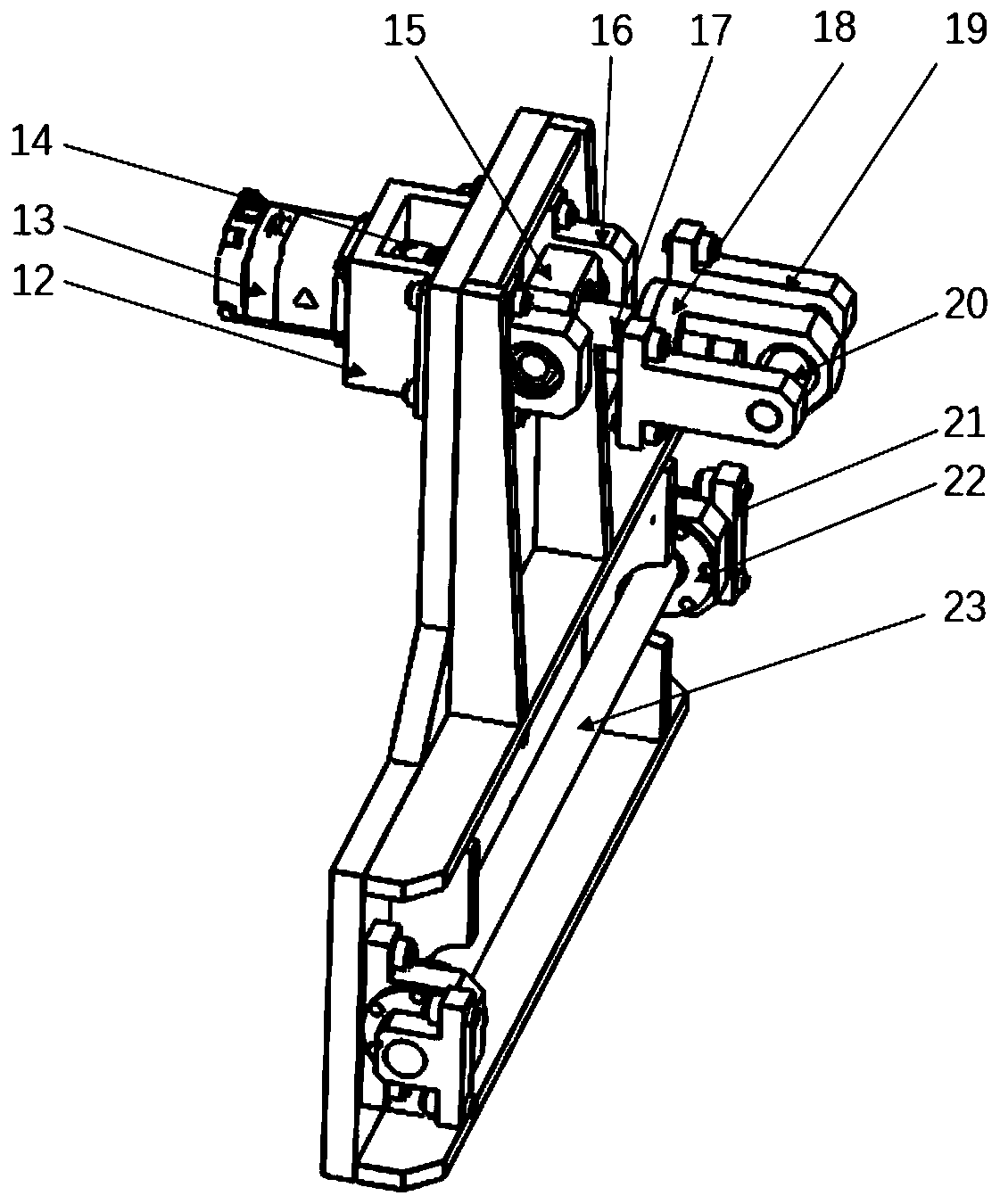

Universal joint-driven inclined wide-and-narrow separating-planting mechanism of rice transplanter

The invention discloses a universal joint-driven inclined wide-and-narrow separating-planting mechanism of a rice transplanter. Transmission cases of the same structure and planting arms of the same structure are arranged on the two sides of a chain wheel shaft respectively; the chain wheel shaft forms an inclination angle with an output shaft of a universal joint through the universal joint; the output shaft end of the universal joint is fixedly connected with a planet carrier; in the planet carrier, central gears are supported on the output shaft of the universal joint through bearings, are fixedly connected through flanges, adjustment gaskets and the flange on a transmission case body at the universal joint end and are connected with planet gears per se through idler wheels respectively; and planet gear shafts fixedly connected with the planet gears are connected with the planting arms per se respectively. In the universal joint-driven inclined wide-and-narrow separating-planting mechanism, seedling needles on the planting arms driven by the planet gears move in a plane inclined relative to the chain wheel shaft, the inclination of the planet carrier produces lateral movement relative to an advancing direction to move seedling inserting points leftwards or rightwards relative to seedling taking positions after the seedling needles take seedlings, and then rice transplantation positions are distributed in narrow and wide rows at unequal row spaces meeting agronomic requirements on the premise that seedling taking openings are distributed at equal intervals.

Owner:ZHEJIANG SCI-TECH UNIV +1

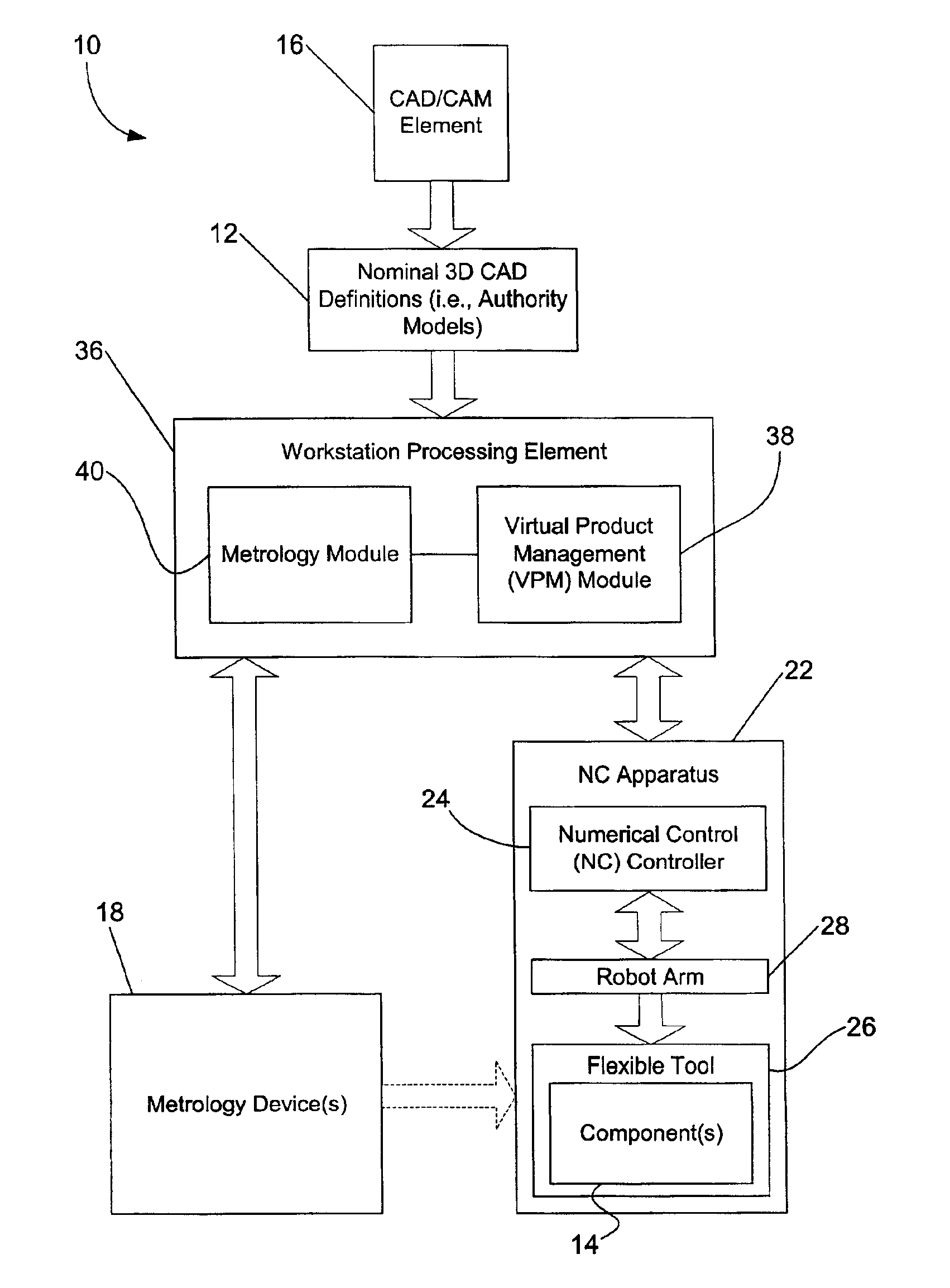

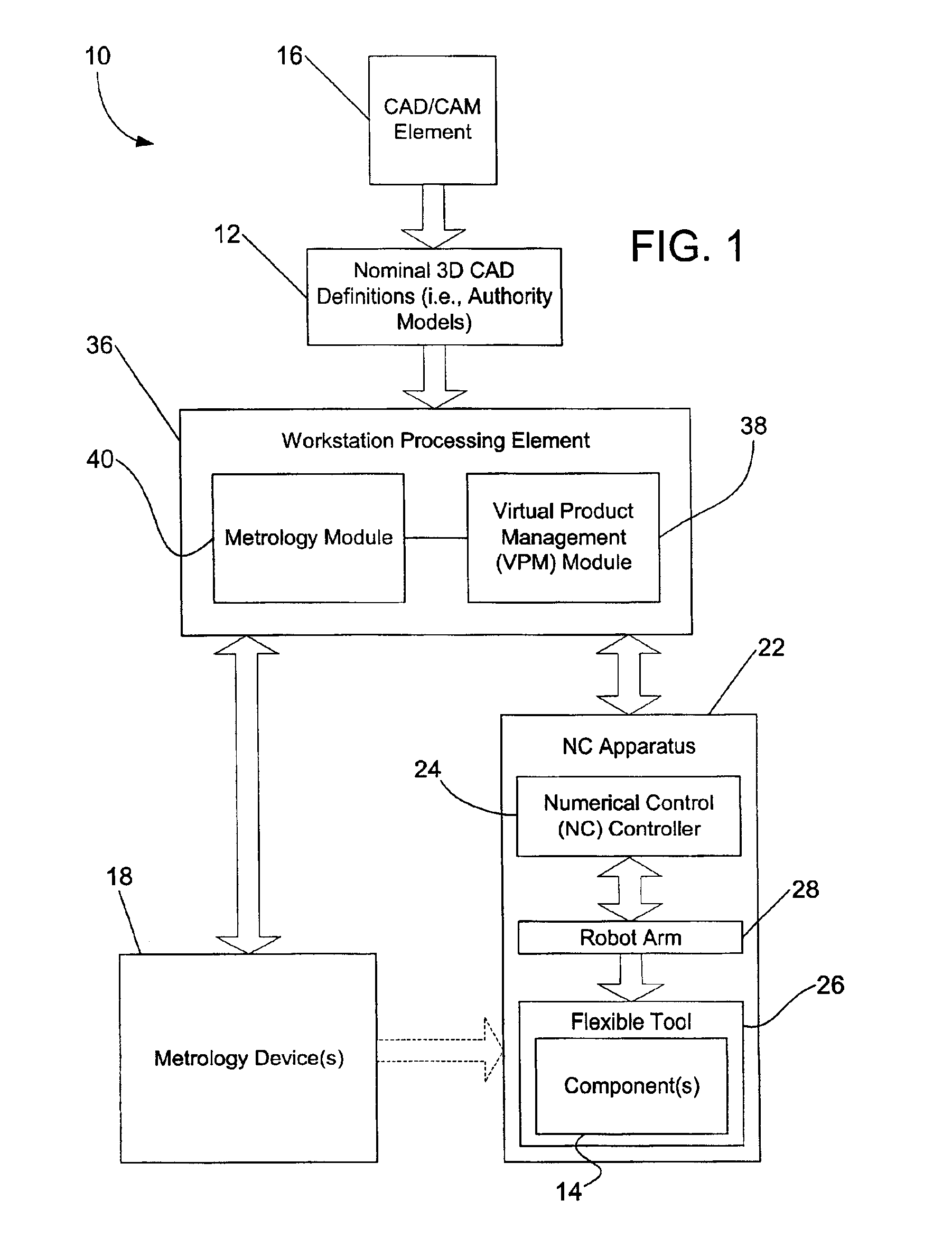

System and method for producing an assembly by directly implementing three-dimensional computer-aided design component definitions

InactiveUS6922599B2Lower the volumeImprove component reliabilityComputer controlSimulator controlComputer Aided DesignEngineering

A system for producing an assembly comprising at least one component includes at least one 3D metrology system, a workstation processing element, numerical control apparatus and a flexible work cell. The metrology system maps the components for use by the workstation processing element, which electronically displays three-dimensional authority models representative of the components. The workstation processing element compares the as-built models to an electronic display of three-dimensional authority models of the components, and alters a position of at least one of the at least one actual model and the at least one authority model. The workstation processing element then commands the numerical control apparatus to perform a machine operation on the components based upon the comparison. As the numerical control apparatus performs the machine operation on the components, the workstation processing element dynamically displays the actual models such that the electronic display of the actual models is automatically and repeatedly updated.

Owner:THE BOEING CO

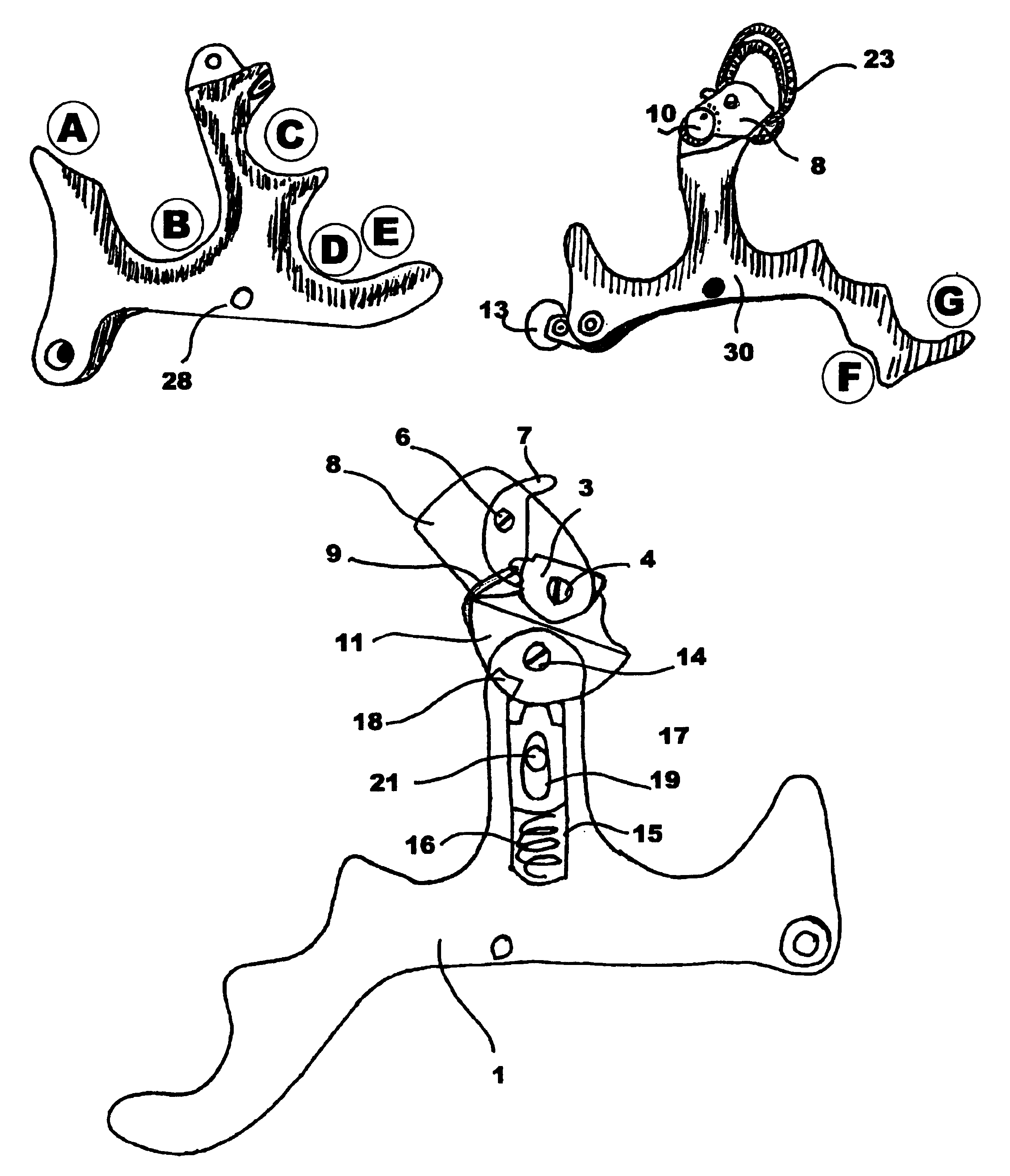

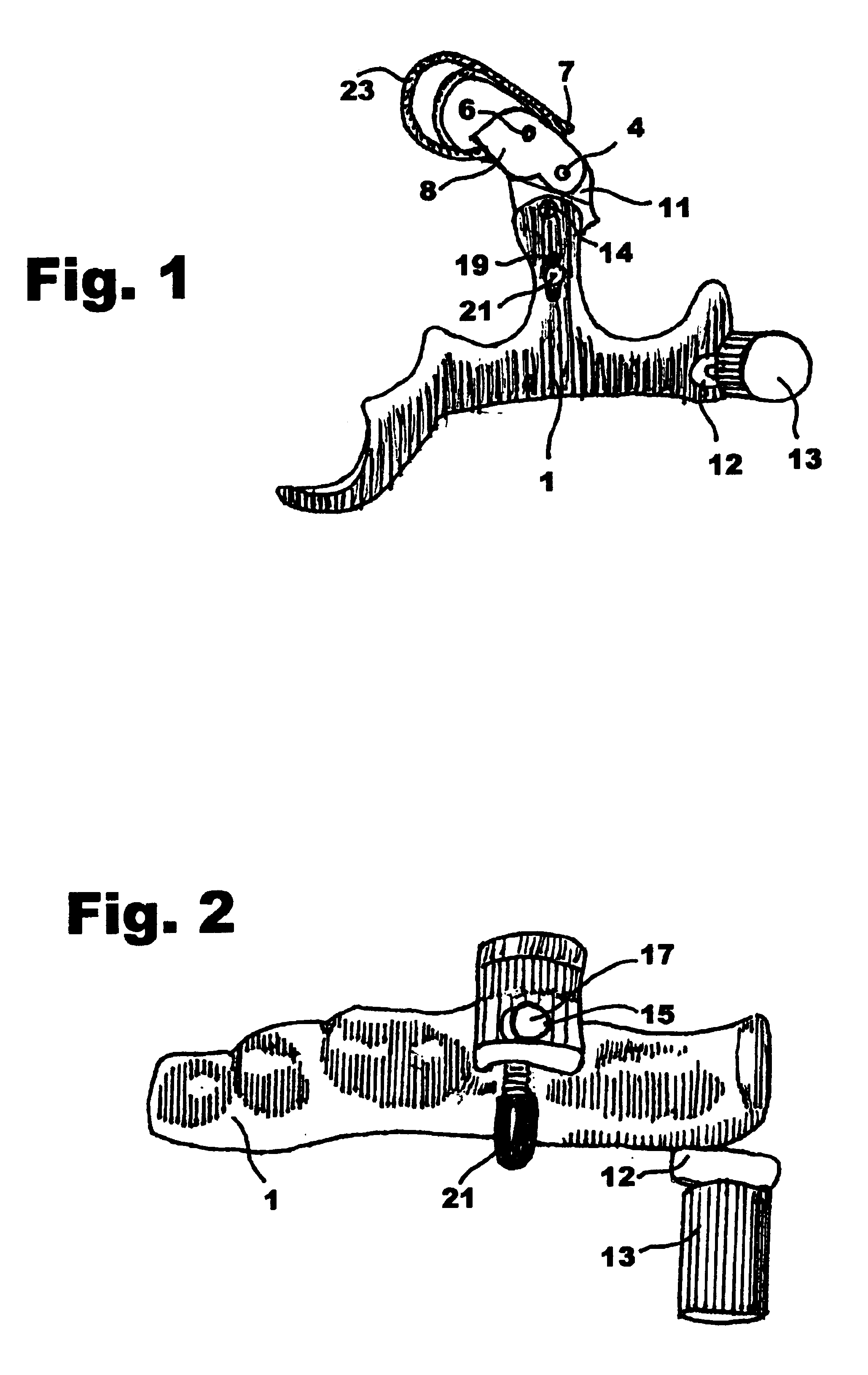

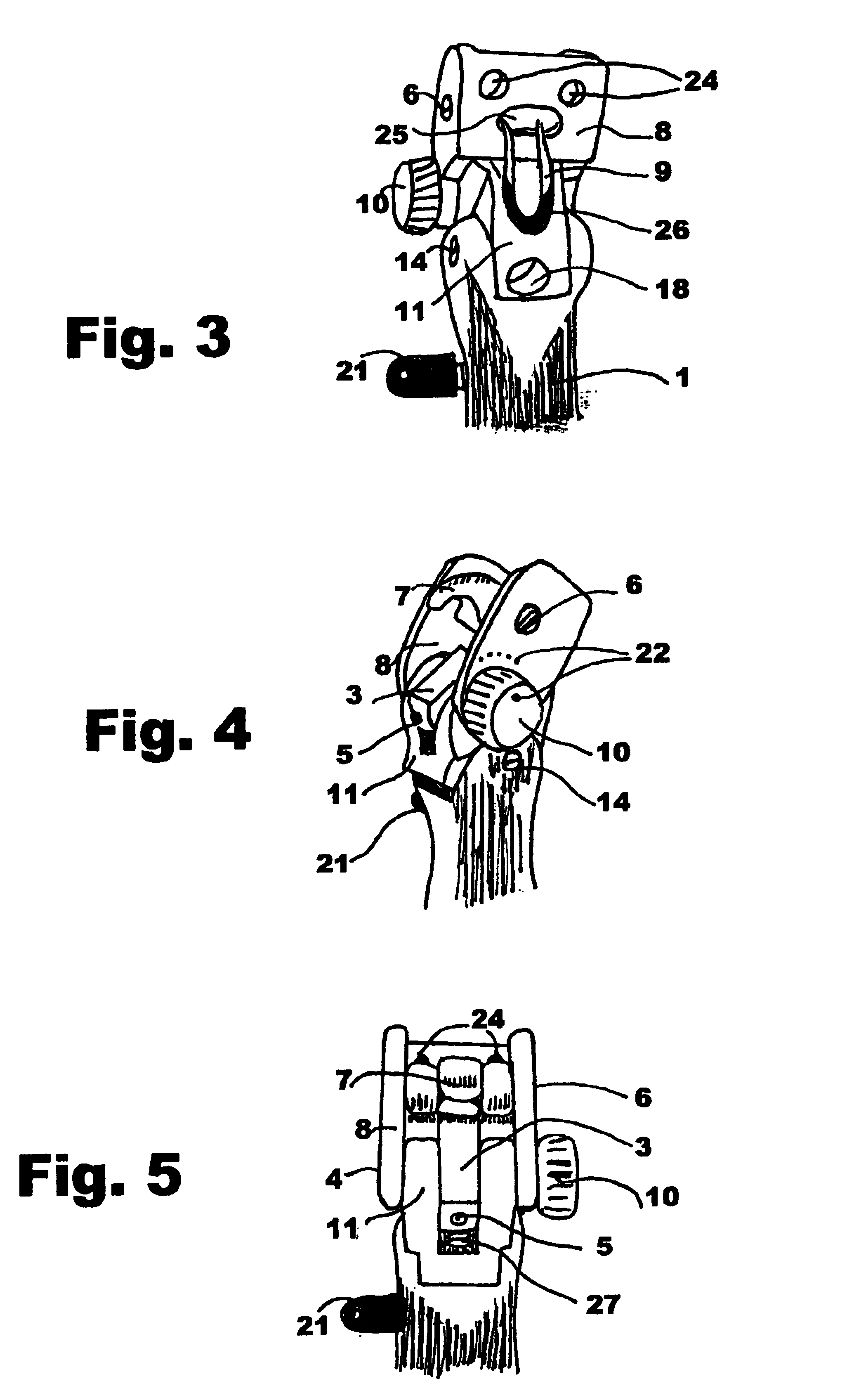

Triggerless release aids and laser-equipped pneumatic training aid for safe drawing of the bowstring

InactiveUS6945241B2Safely draw backReduce feedbackFiring/trigger mechanismsBows/crossbowsEngineeringCam

A bowstring release includes a handle, a bowstring catch, and a link between the handle and catch. The catch includes a hook for retaining the bowstring, and a cam for holding and releasing the hook. The handle is initially rotatably mounted with respect to the link, so as the bowstring is drawn, the cam will retain the hook to hold the bowstring regardless of handle position. The handle has a spring-biased piston, and the link has one hole that can receive the piston. At full draw, the archer may rotate the handle so the piston will enter the hole in the link, locking the handle and link together. Further rotation of the handle will cause the link and attached cam to rotate out of engagement with the hook, to release the bowstring.

Owner:TOG IP LLC

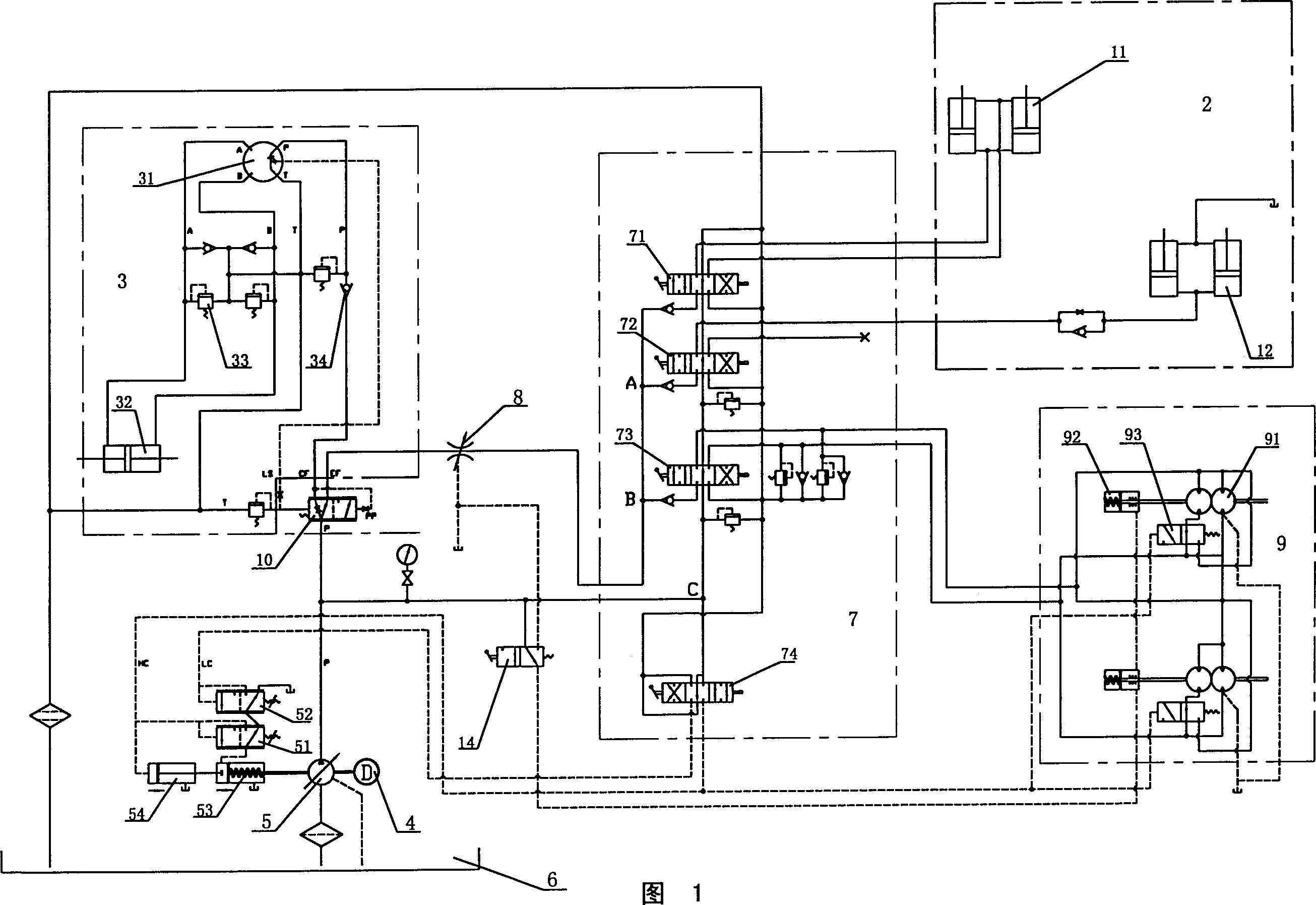

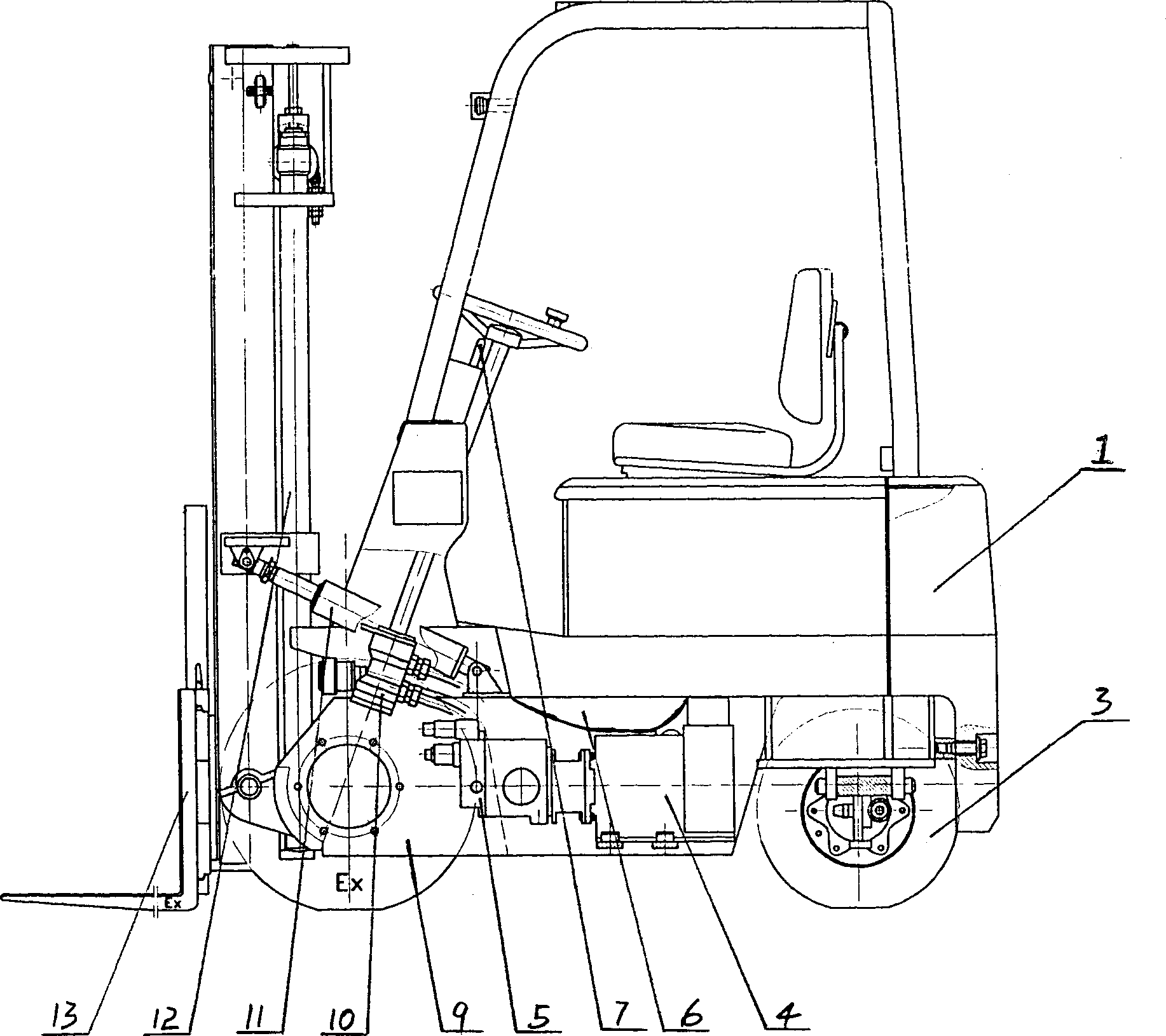

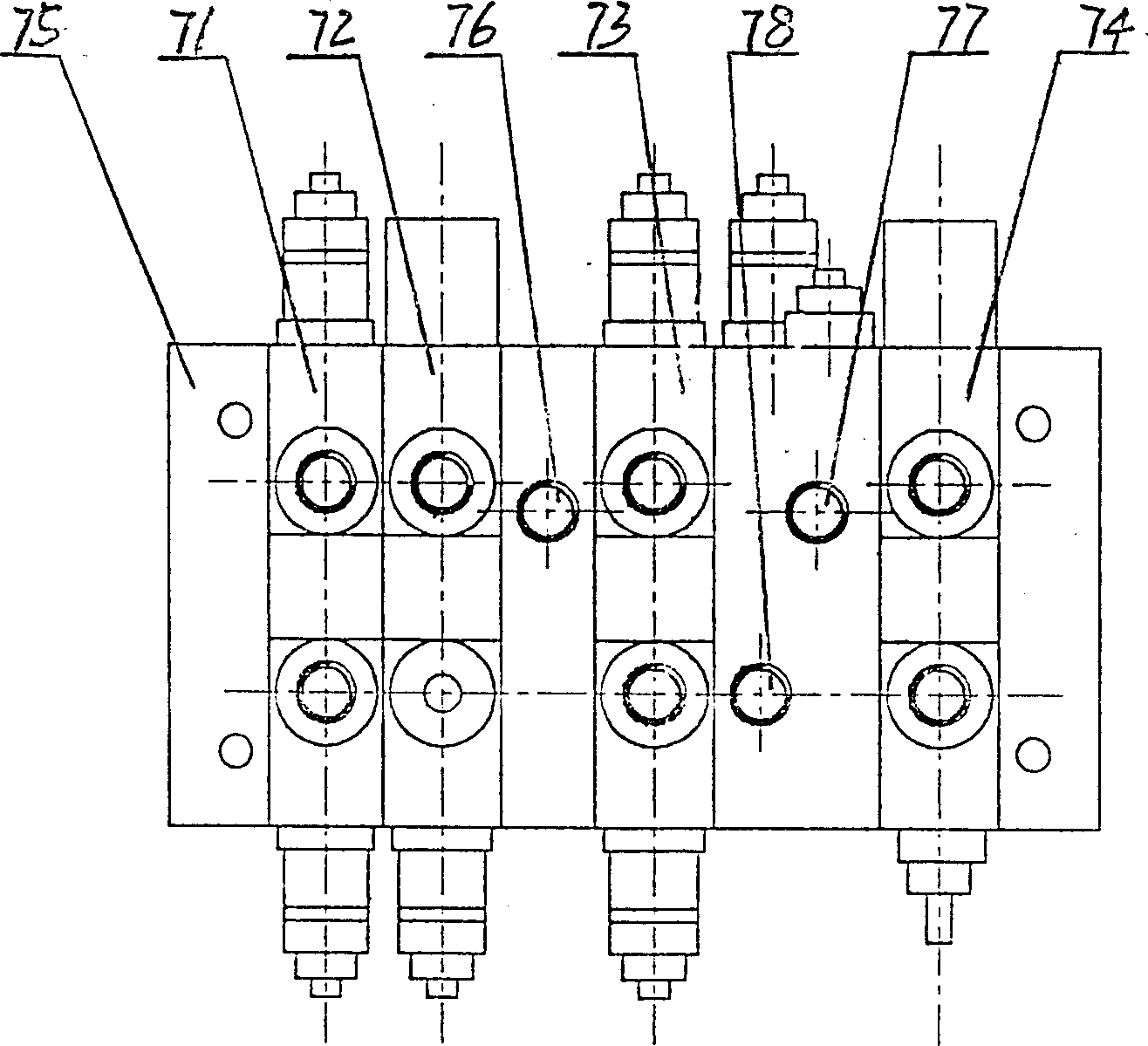

Fully-hydraulic electric fork truck

InactiveCN1405079ASimple structureEasy to maintainLifting devicesVariable displacement pumpElectric machinery

The invention relates to a full-hydraulic electric fork lifter, which comprises lifter body, double oil tank, motor variable displacement pump connected with motor, multiway valve, steering device, inclined lifting device and walking-driving device. It is characterized by that the said motor is single one, and said multiway valve comprise incline valve, lifting valve, walking valve and control valve, said four valves are connected into one body by a connecting component, said multiway valve is equipped with a main oil hole communicated with the said four valves and two brach oil holes, and between said two branch oil holes and variable displacement pump a precedence valve is set to implement single motor driving, hydraulic speed regulation.

Owner:ZHEJIANG JIALI TECH +1

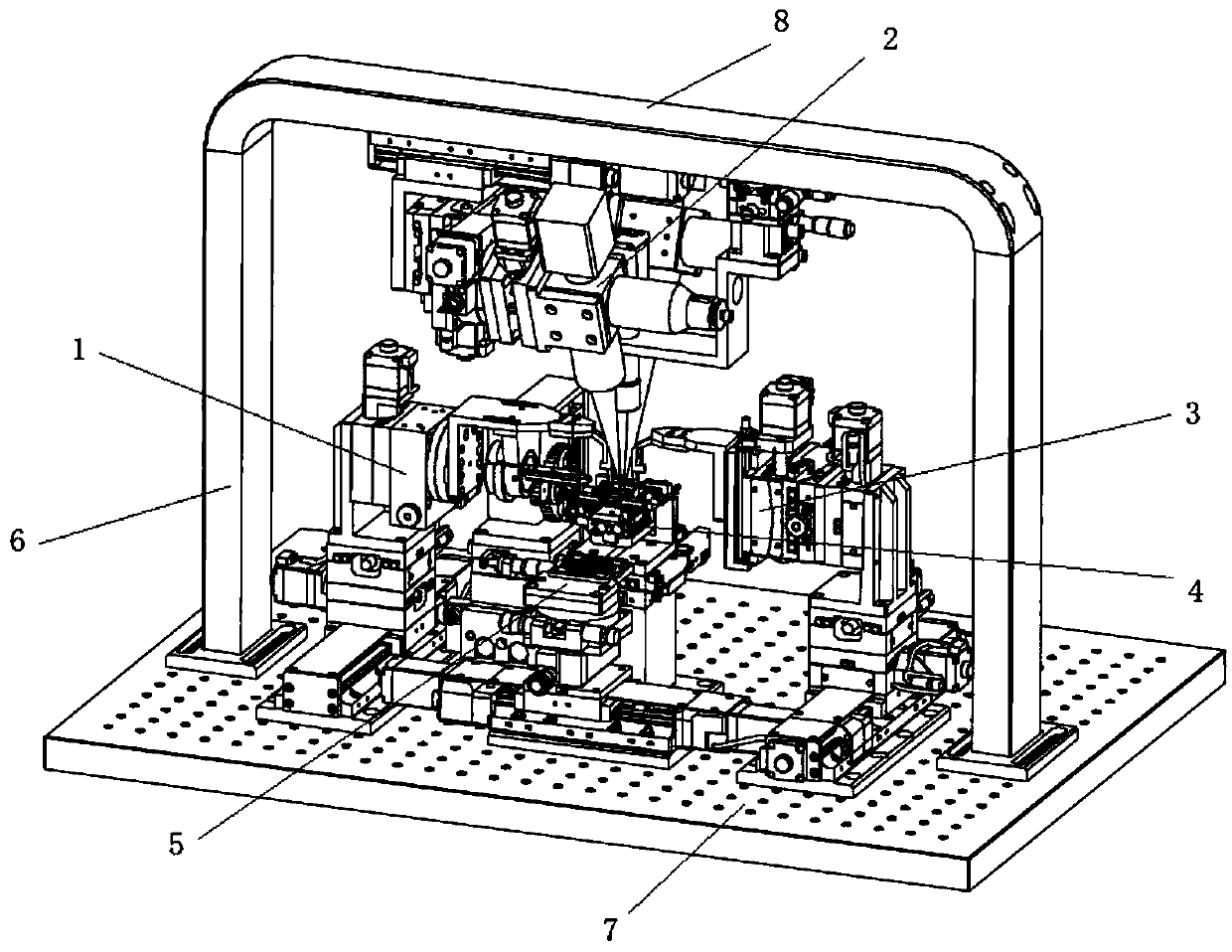

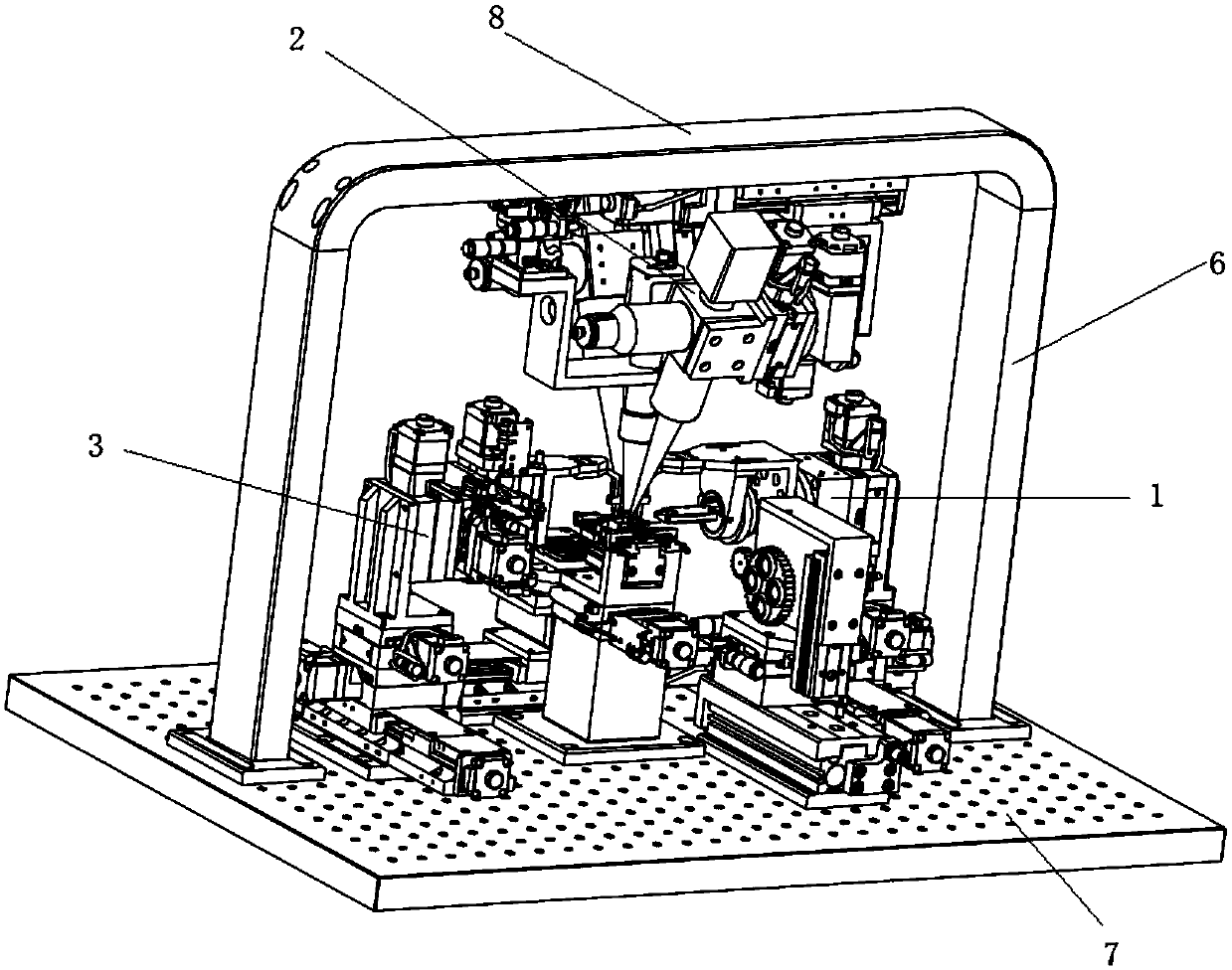

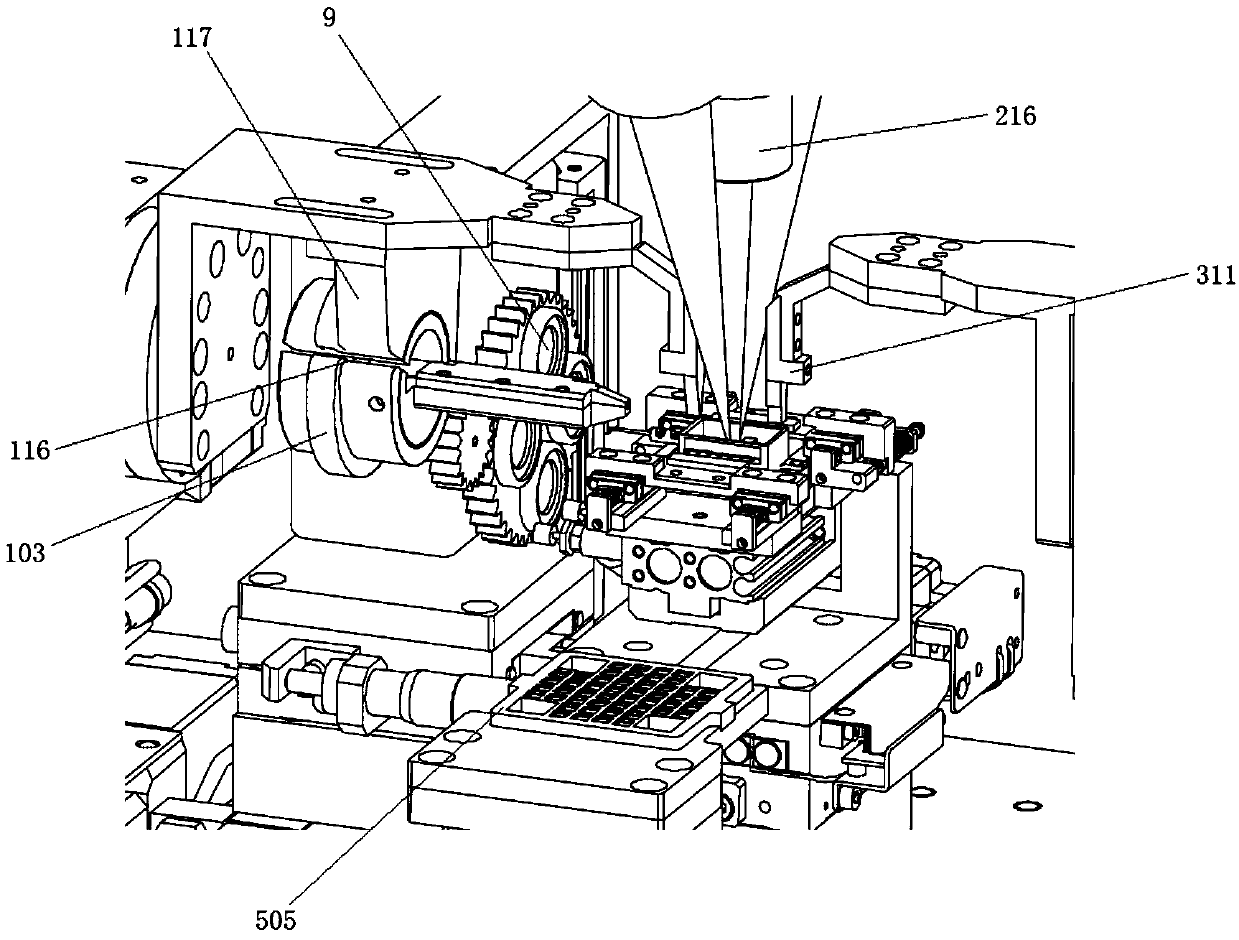

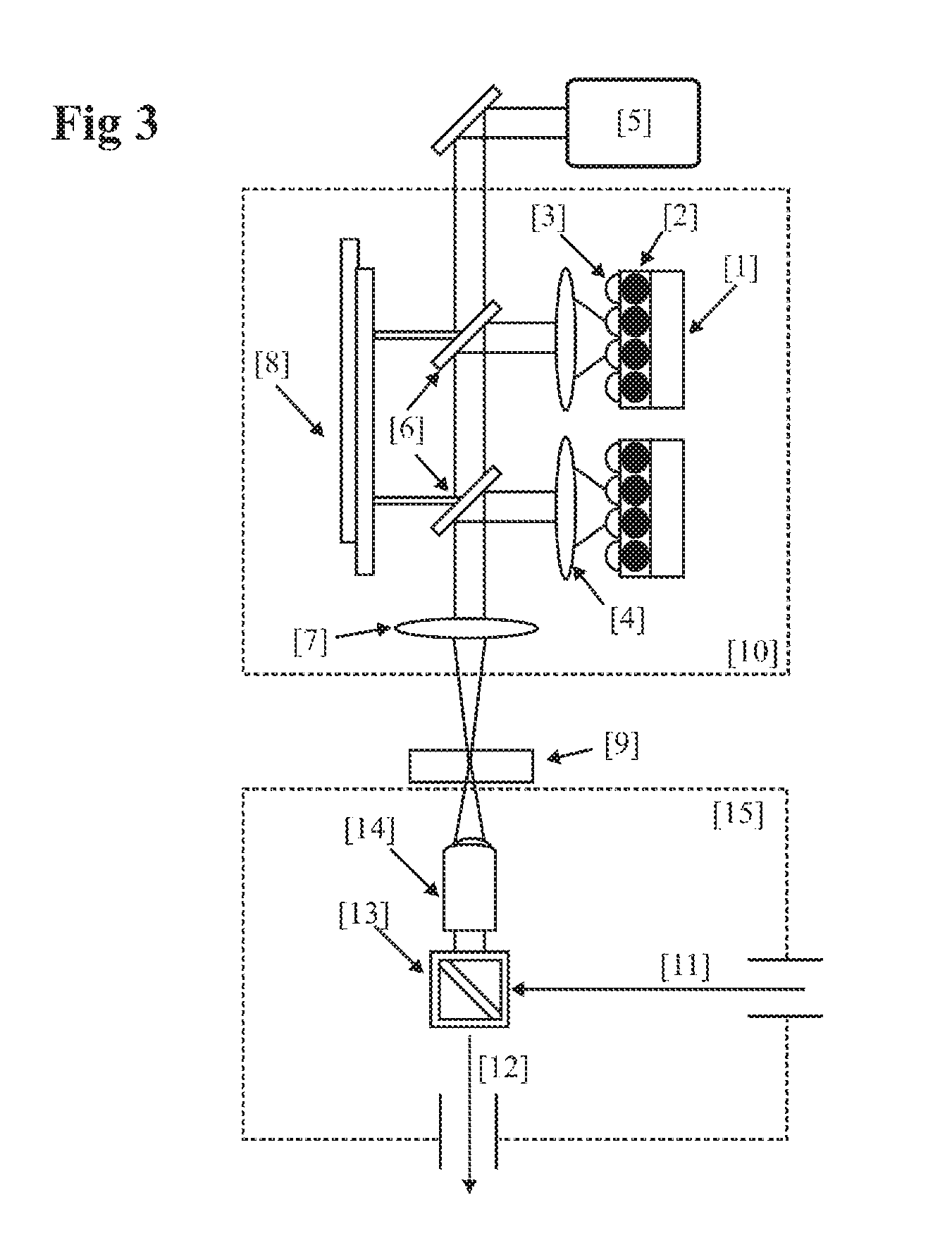

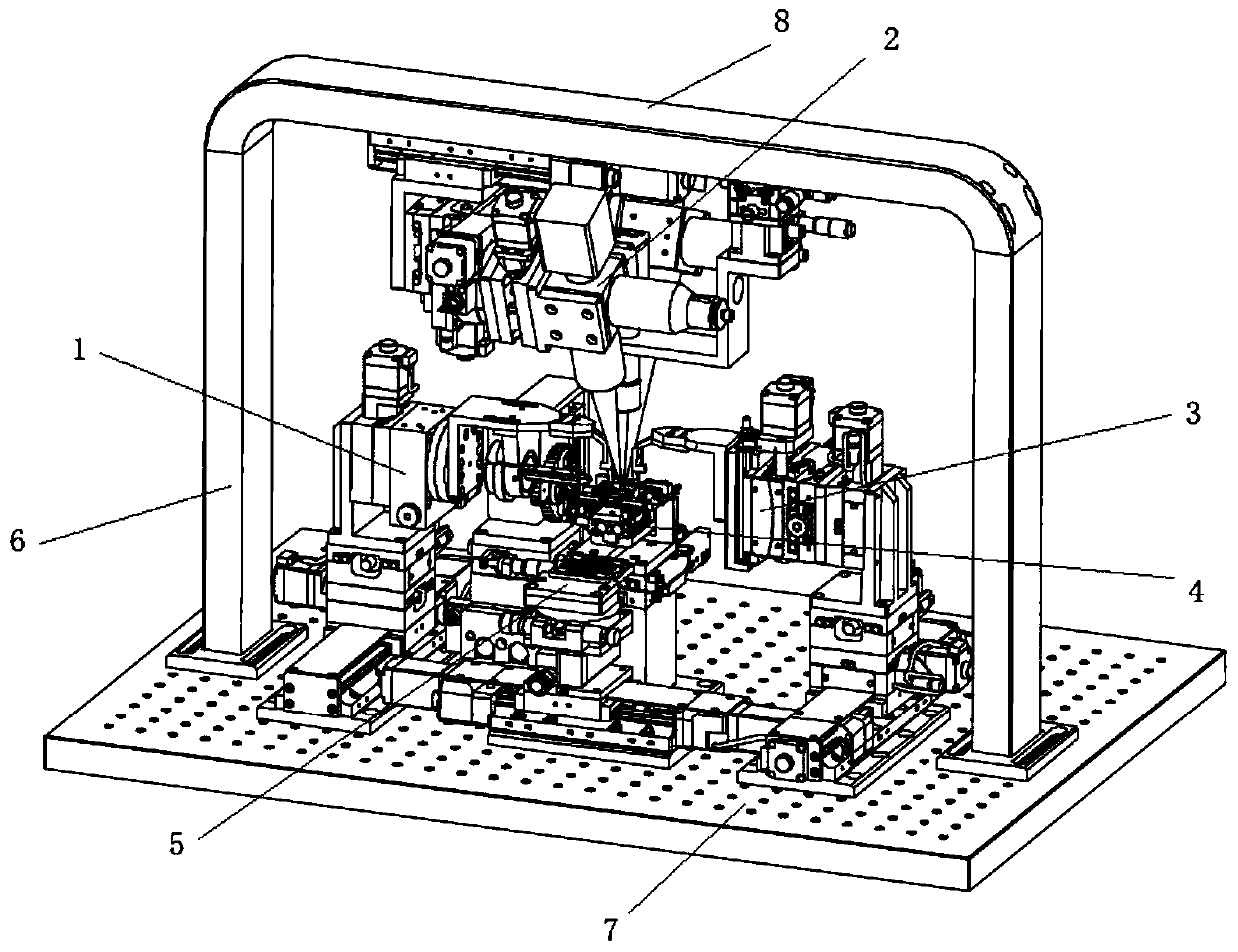

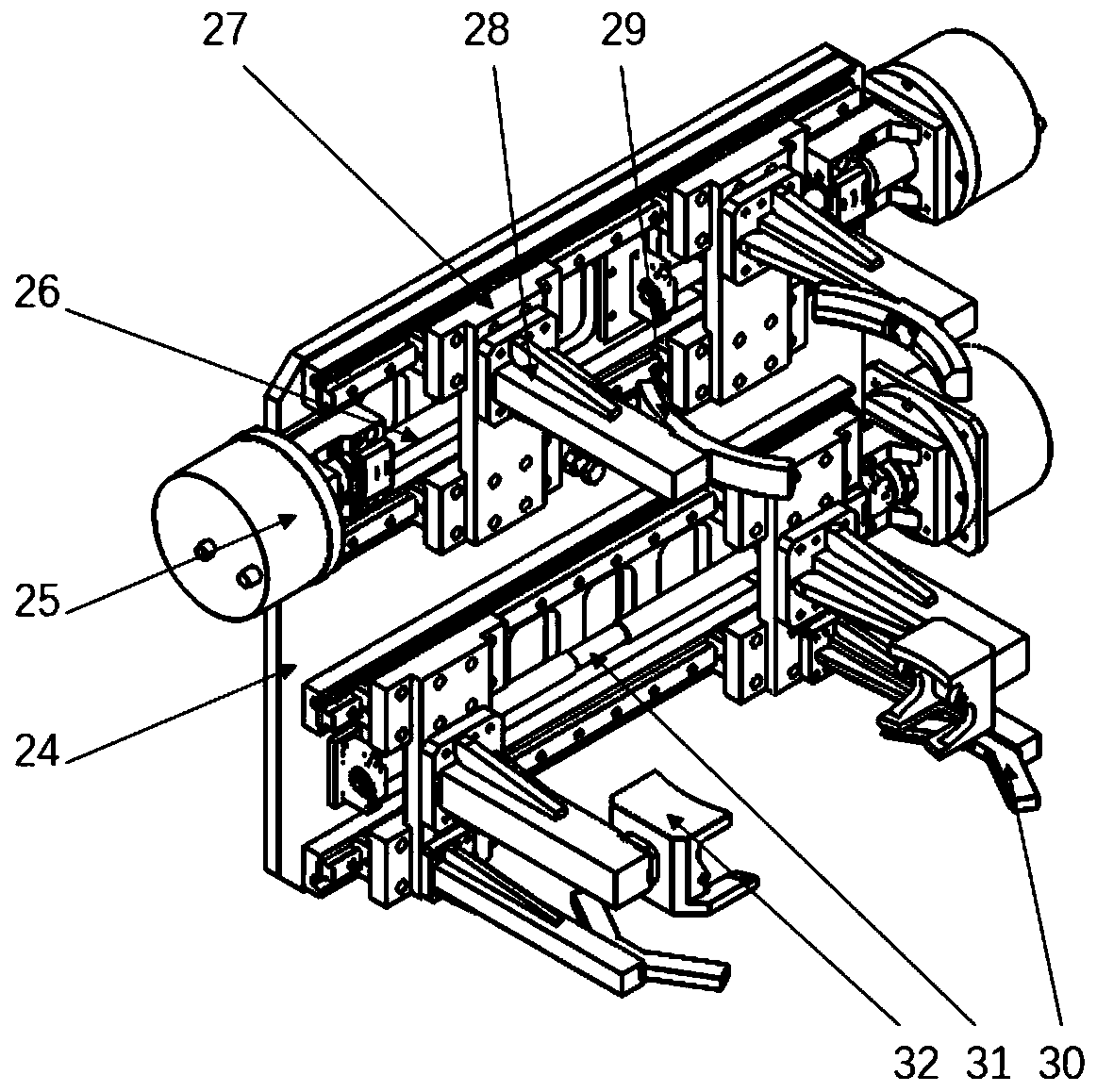

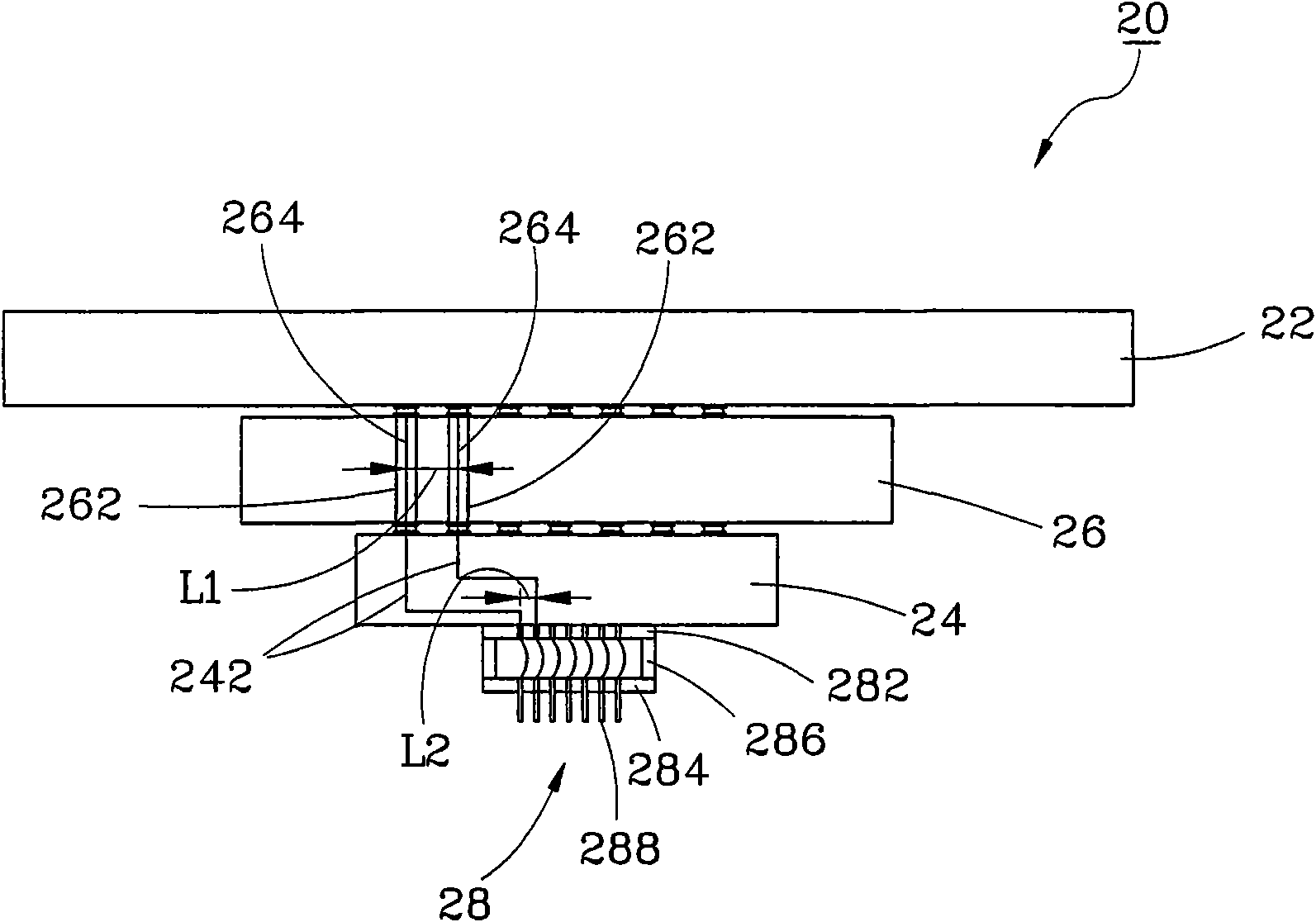

Butterfly-shaped semiconductor laser automatic coupling packaging device

ActiveCN109521536AHigh degree of automationIncrease productivityCoupling light guidesProduction lineCoupling

The invention discloses a butterfly-shaped semiconductor laser automatic coupling packaging device and relates to the automatic coupling packing field of an electronic device. The automatic coupling packaging device includes a column, a cross beam, and a fiber clamp, a lens clamp mechanism, a lower clamp device and a material disc mechanism arranged on a base, and a laser power meter, wherein thefiber clamp, the lens clamp mechanism and a fiber automatic angle adjusting welding device can be adjusted in position to realize accurate coupling and packaging of a butterfly-shaped semiconductor laser. The device is advantaged in that the structure design is reasonable, the whole subsequent operation from coupling, alignment and packaging can be automatically completed, compared with a traditional hand-operated production line, advantages of high automatic degree, simple and convenient operation, high production efficiency, low production cost and stable product quality are achieved.

Owner:CENT SOUTH UNIV

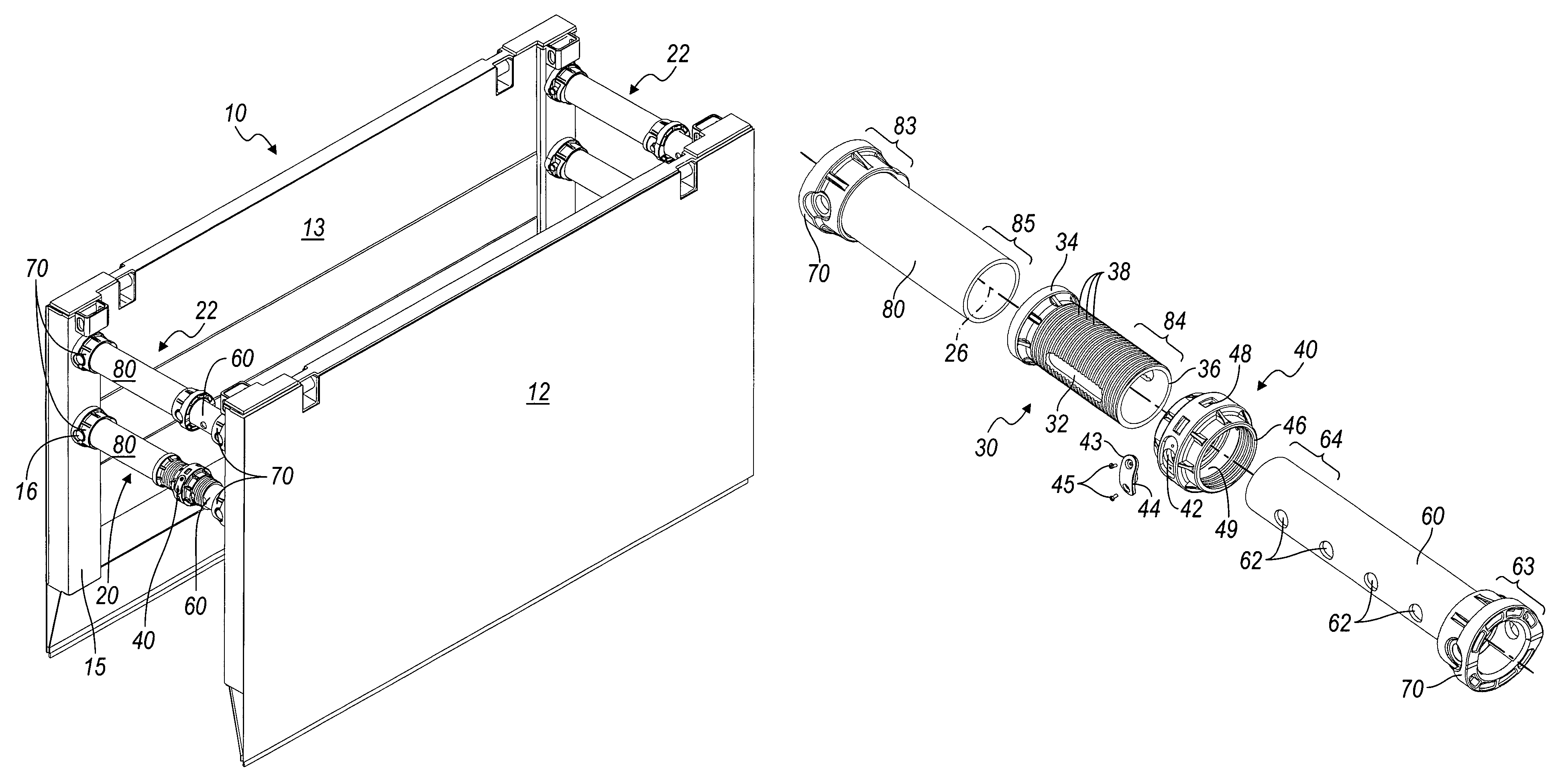

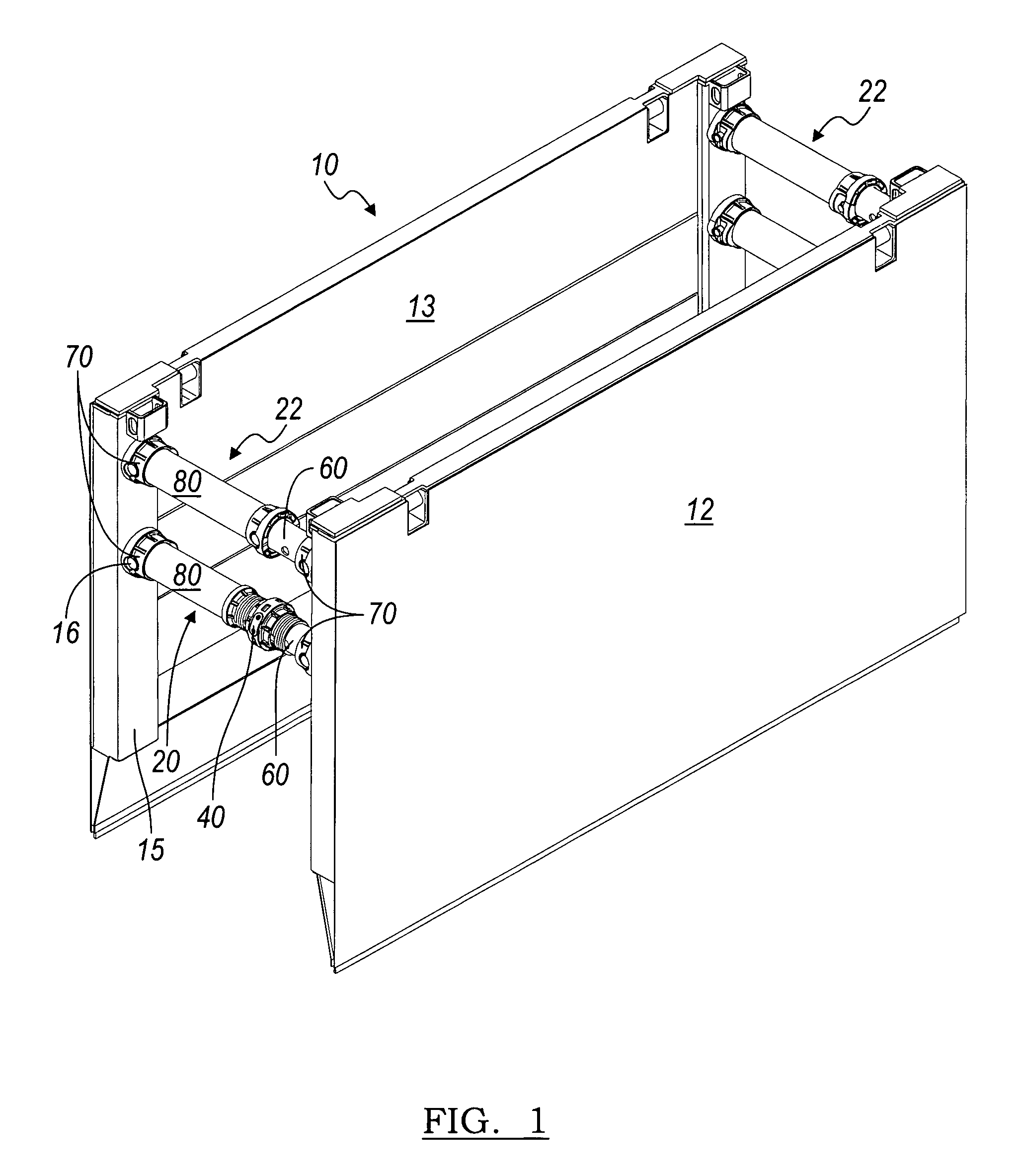

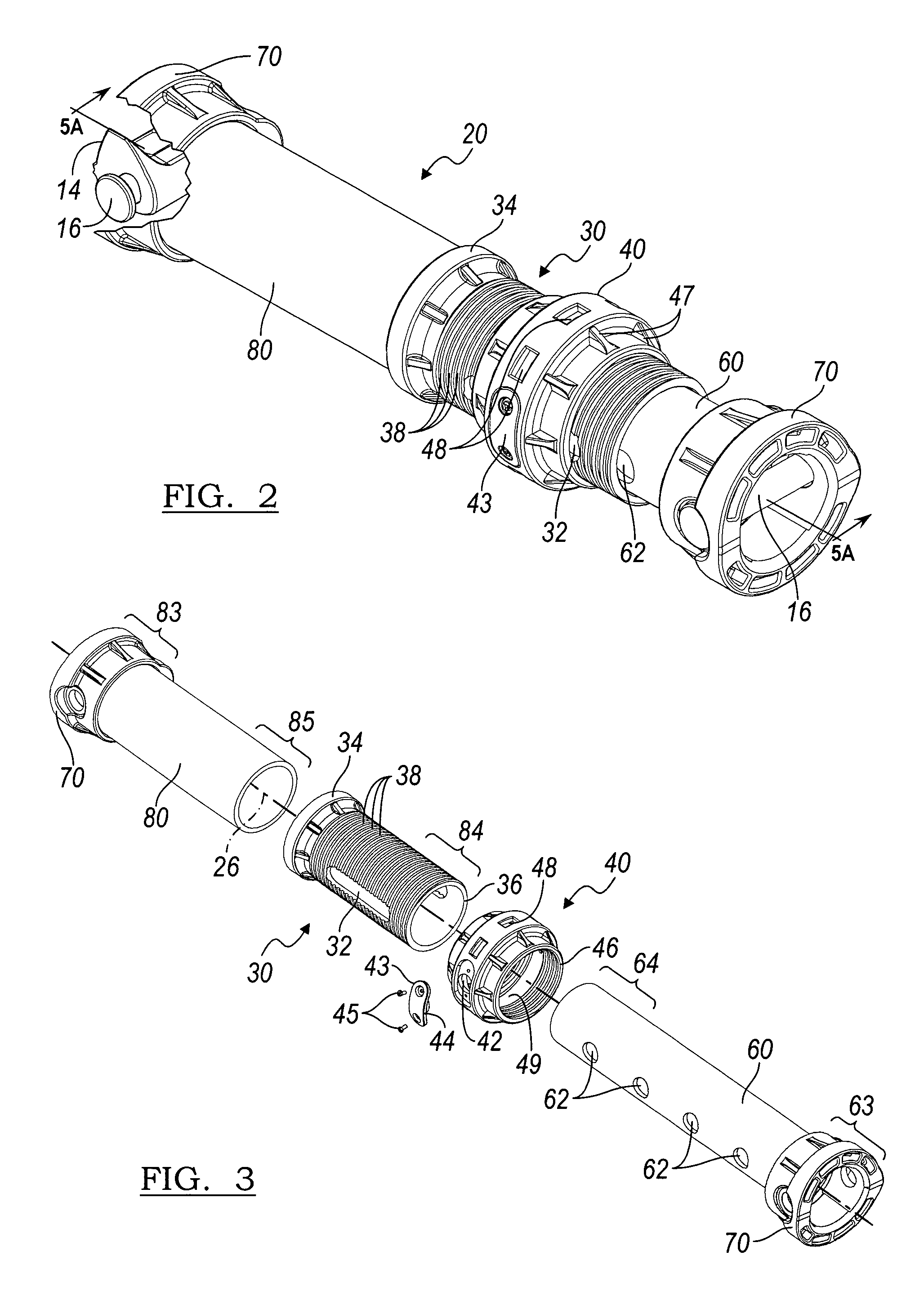

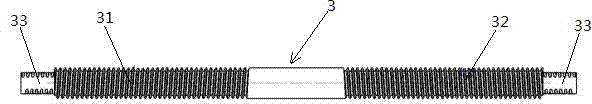

Adjustable trench box and spreader bar

ActiveUS7837413B1Easy to disassembleEasy to movePortable framesStands/trestlesEngineeringScrew thread

An adjustable spreader bar of a trench box has male and female telescoping pipes. The male telescoping pipe has a plurality of indexed openings, and the female telescoping pipe has an outer threaded portion with a groove to receive a locking pin. A sleeve is threadably attached to the outer threaded portion of the female telescoping pipe, and the sleeve has a sleeve opening and an inside channel for receiving the locking pin therethrough, so that fine adjustments, in the relationship between opposing panels of the trench box, can be made by rotating the sleeve about the threaded portion of the female pipe for extension or retraction of the male pipe, by forcing the locking pin along the groove.

Owner:KUNDEL INDS

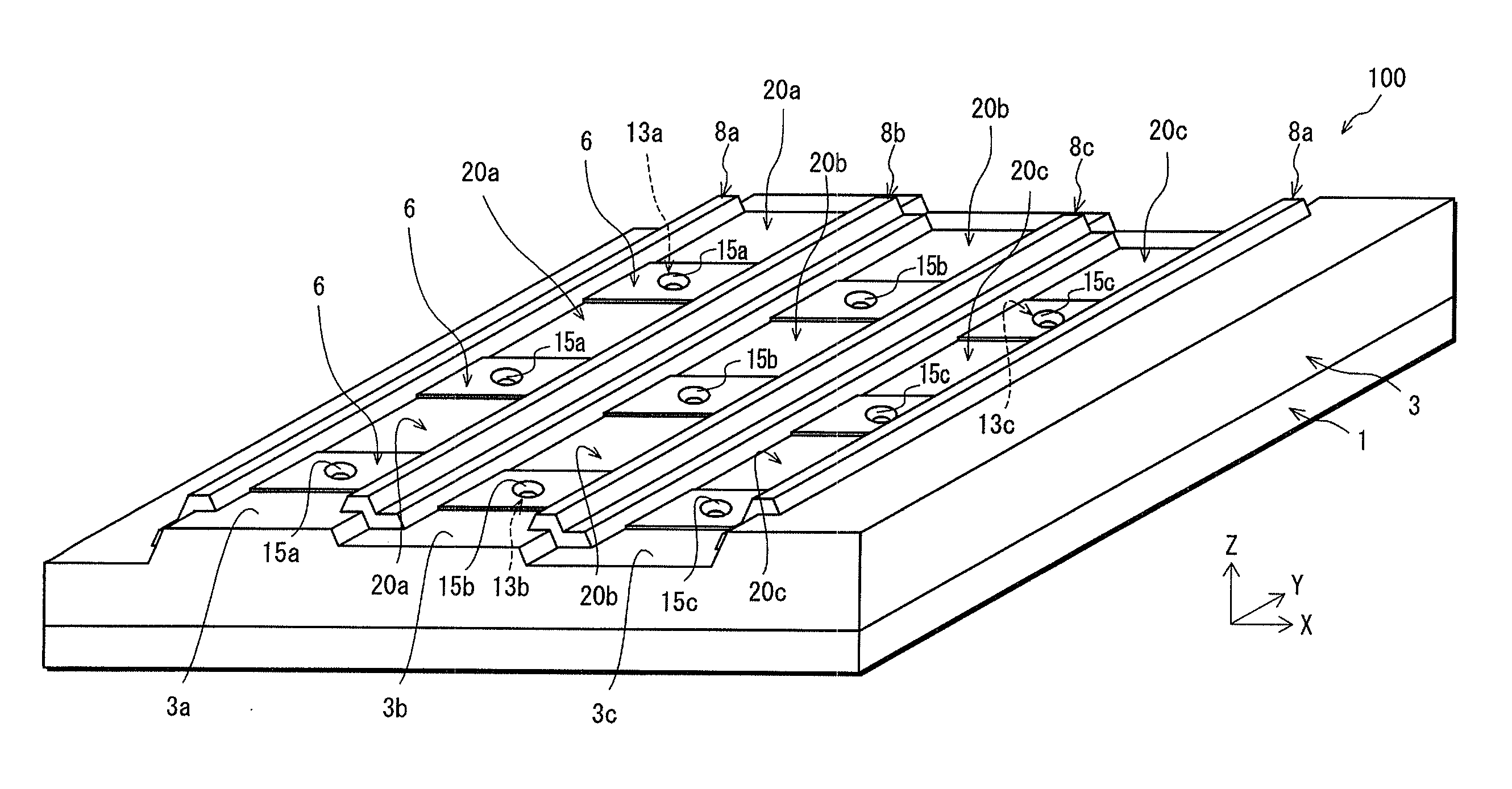

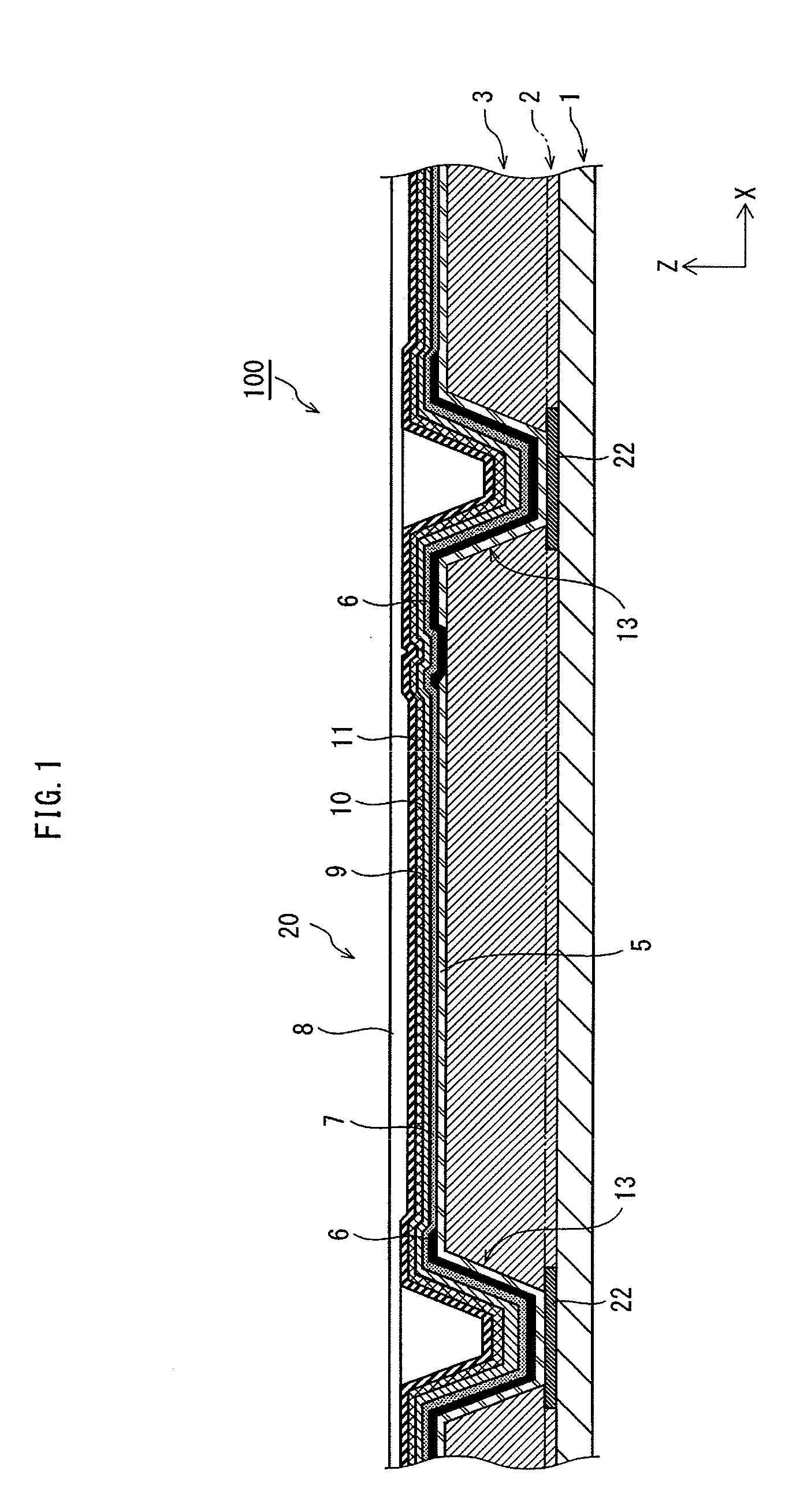

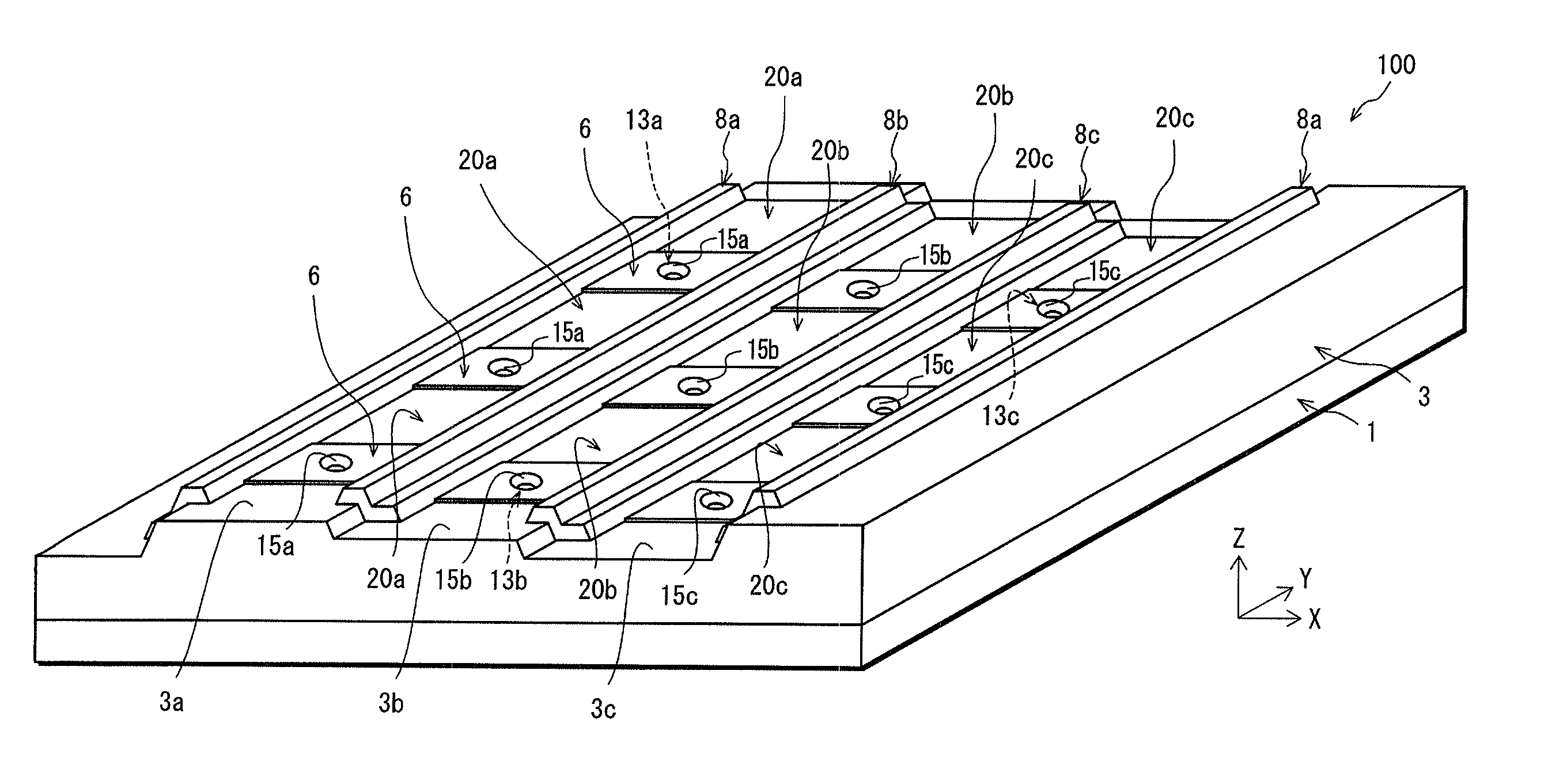

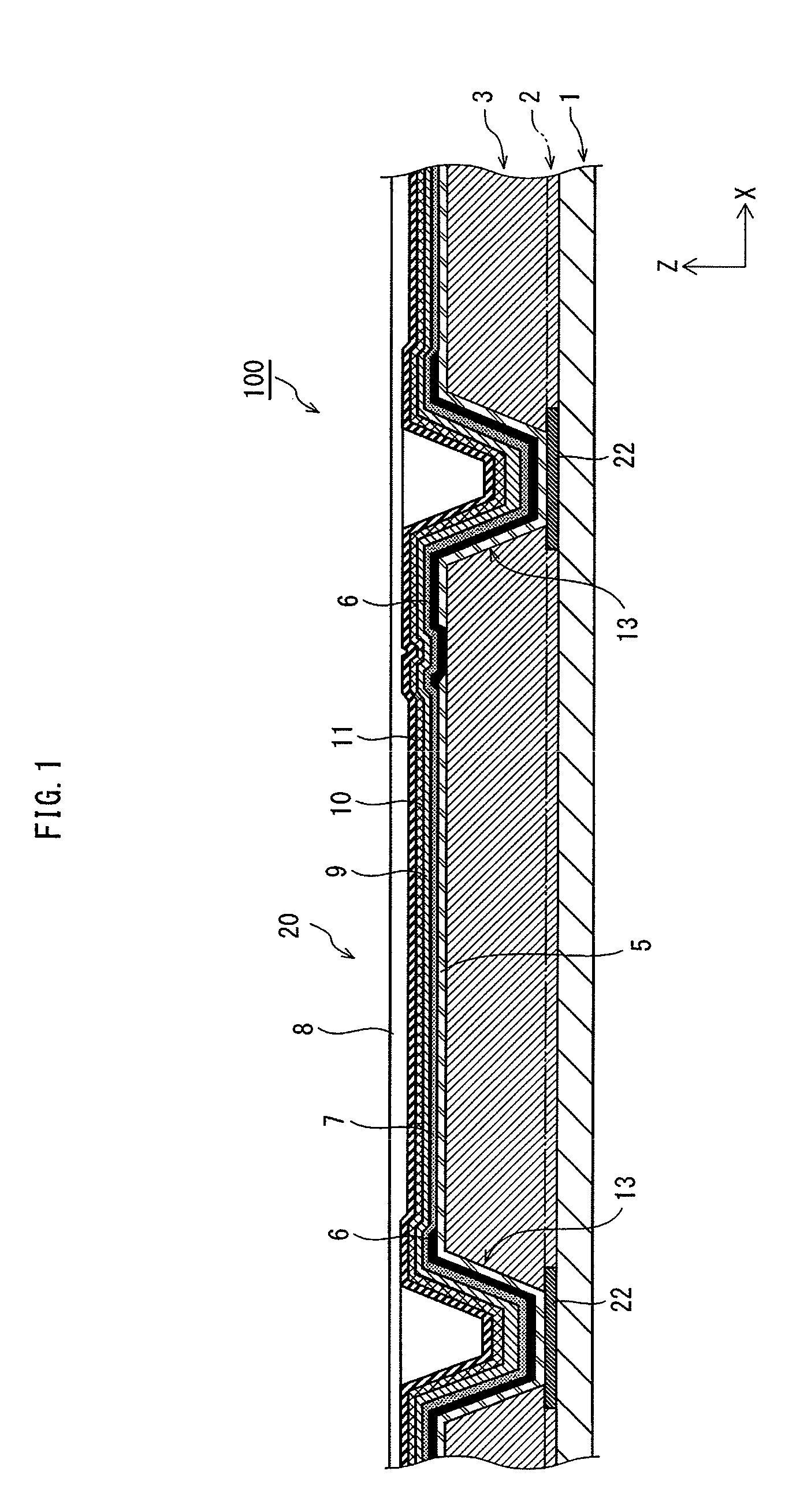

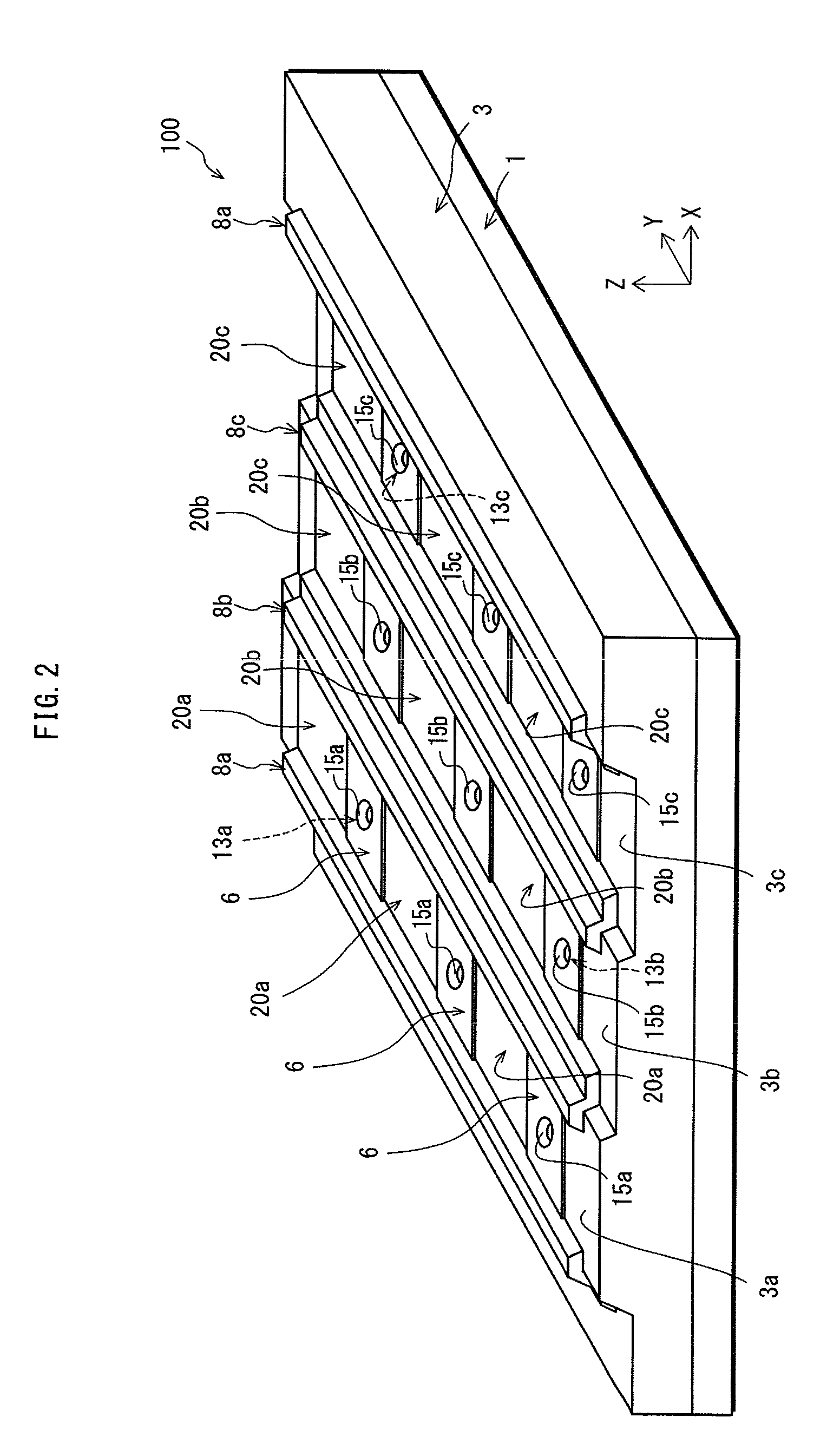

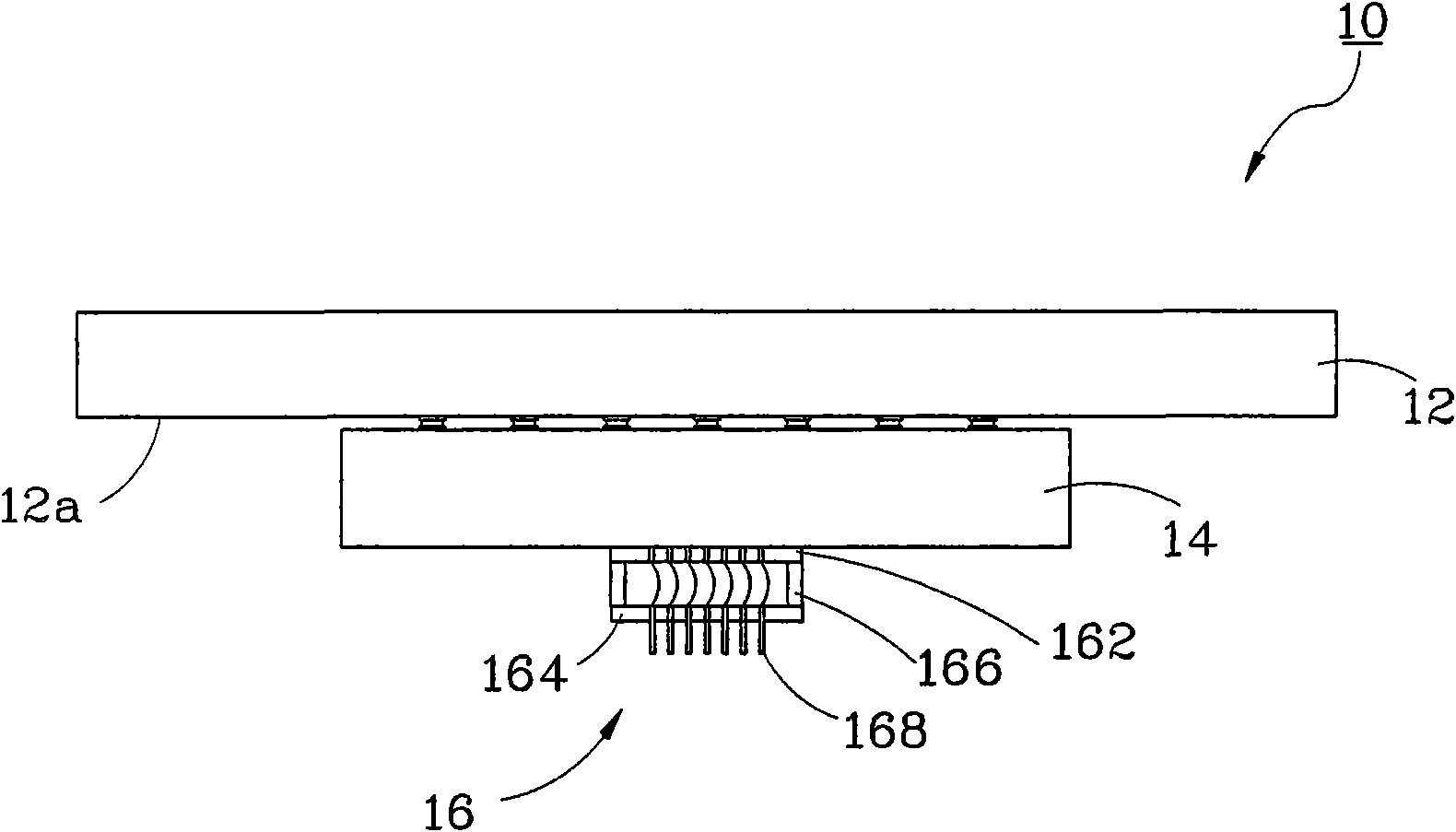

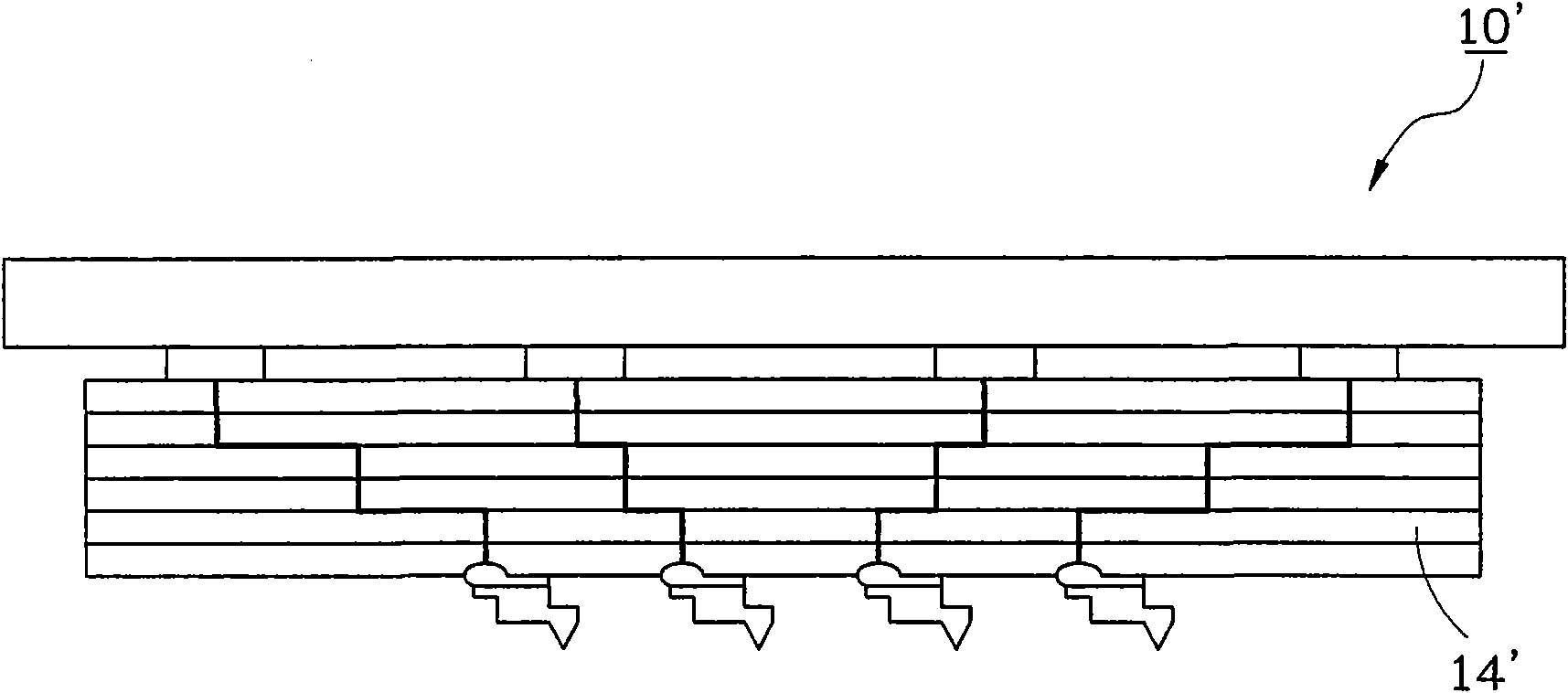

Organic light-emitting display panel, display device, and method of manufacturing organic light-emitting display panel

ActiveUS20120032207A1Improve luminous efficiencyEasy to adjustSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSurface plate

An organic light-emitting display panel is provided that improves luminous efficiency and luminescent color by adjusting the difference in film thickness between layers of different luminescent colors, such as intermediate layers, when the intermediate layer and light-emitting layers are formed by a wet method. By varying the film thickness of an interlayer insulation film, which is a lower layer of an organic light-emitting element, the volume of a contact hole is varied by color, thereby adjusting the volume of a concavity in each anode plate. When ink that includes material for the intermediate layer, or like, is sprayed by an inkjet method, the film thickness of the intermediate layer, or like, changes in accordance with the amount of ink filing the concavity. Therefore, by adjusting the difference in volume between concavities of different colors, the difference in film thickness between the intermediate layers, or like, is finely adjusted.

Owner:JOLED INC

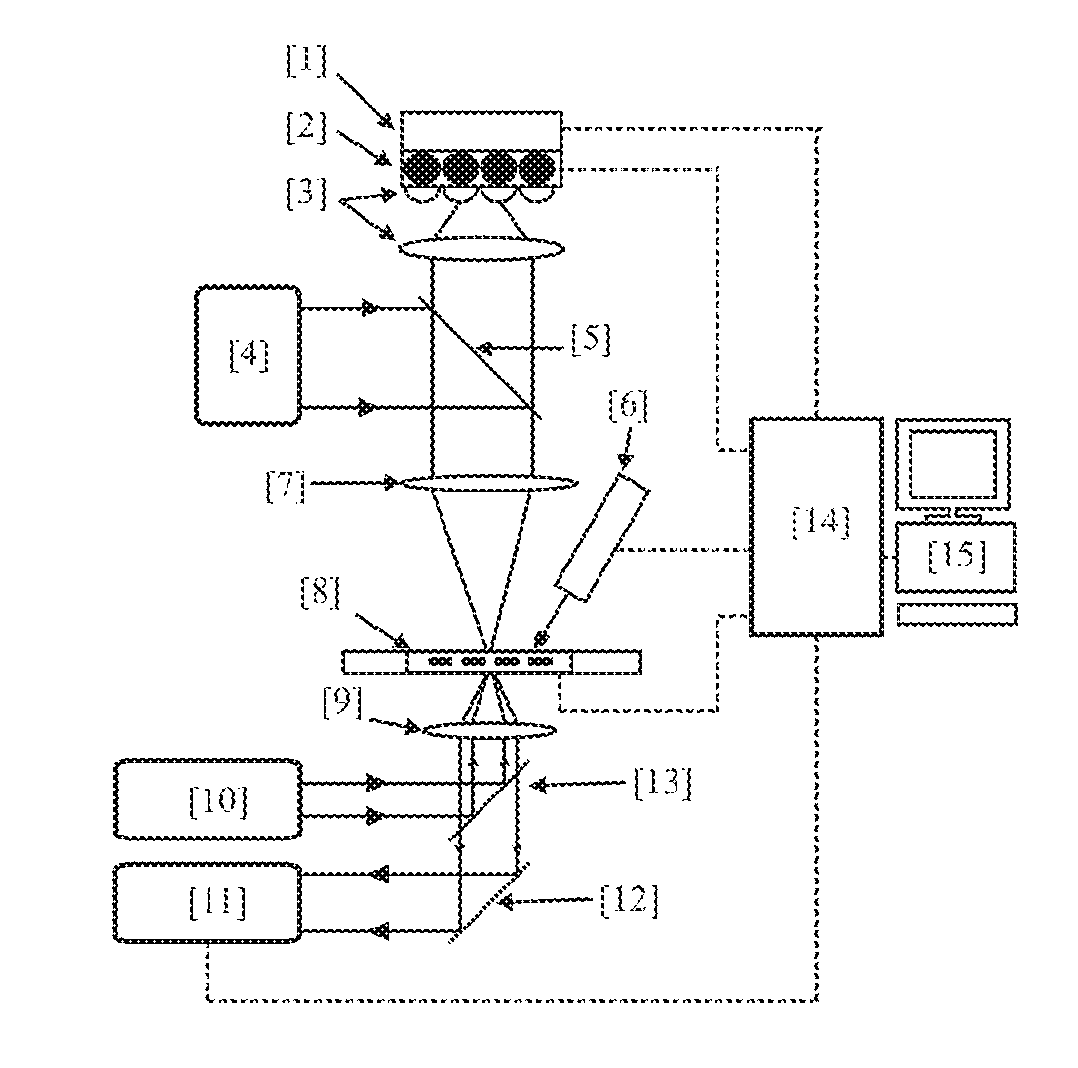

Optical stimulation of photosensitized cells

InactiveUS20110127405A1Improved kineticsImprove the kinetics of the photosensitized cellsPhotometry using reference valueMaterial analysis by optical meansOptical stimulationNeuron

This invention describes a device for optical stimulation of cells and other biological structures. It has an ability to target multiple cells and / or multiple sub-cellular targets. The stimulation optical pattern on each cell can be independently controlled with individual frequencies. The light sensitivity of the cells can be imparted as a result of genetic expression of surface and / or subsurface proteins, chemical modification of existing proteins, or via the release of caged entities which in turn act to stimulate the cell through chemical means. The embodiment is capable of functioning on neurons but can also be used for other cells. It can perform optimal stimulation with sub-cellular resolutions, record the activity of the targeted cells and perform processing to ensure calibration.

Owner:IMPERIAL INNOVATIONS LTD

Electrode with domes for plasma focusing

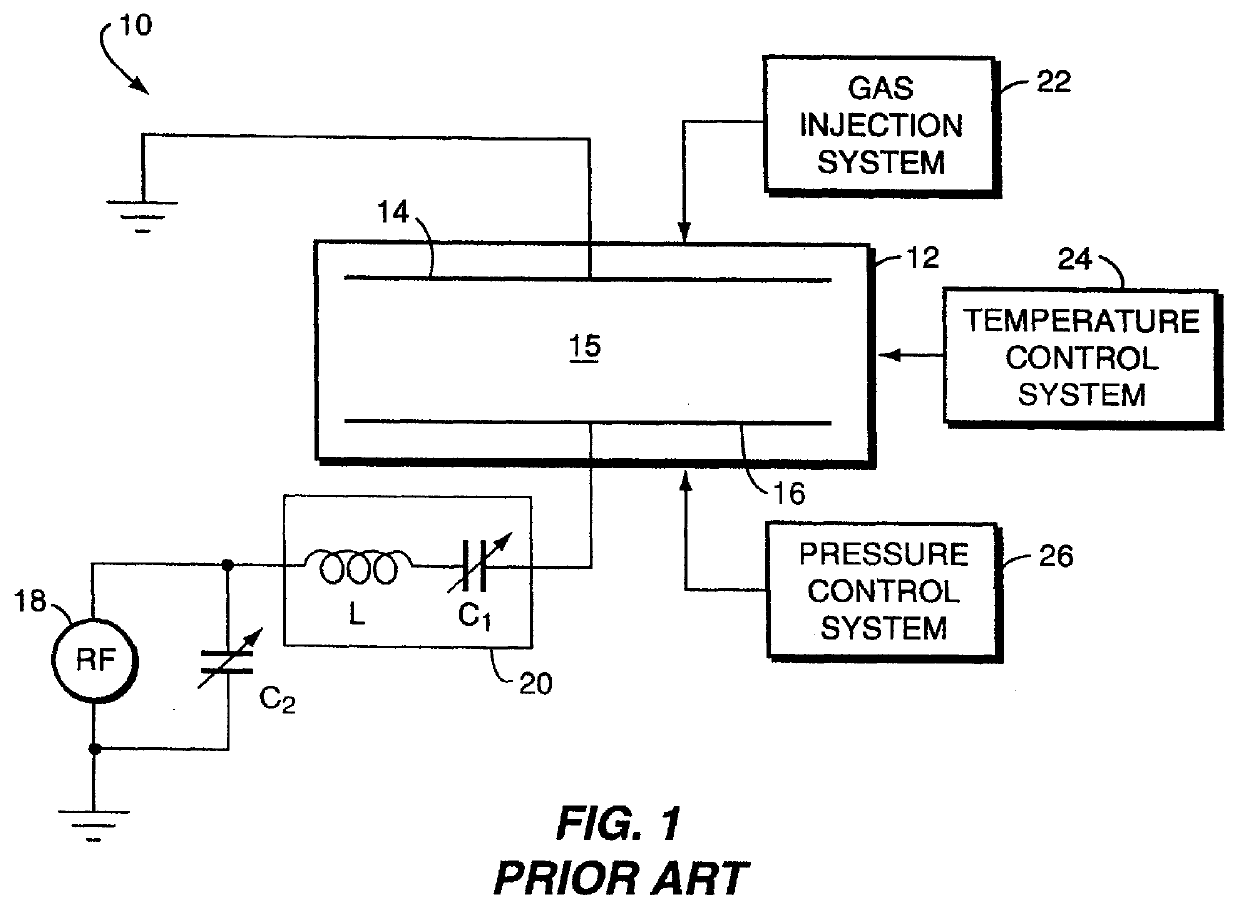

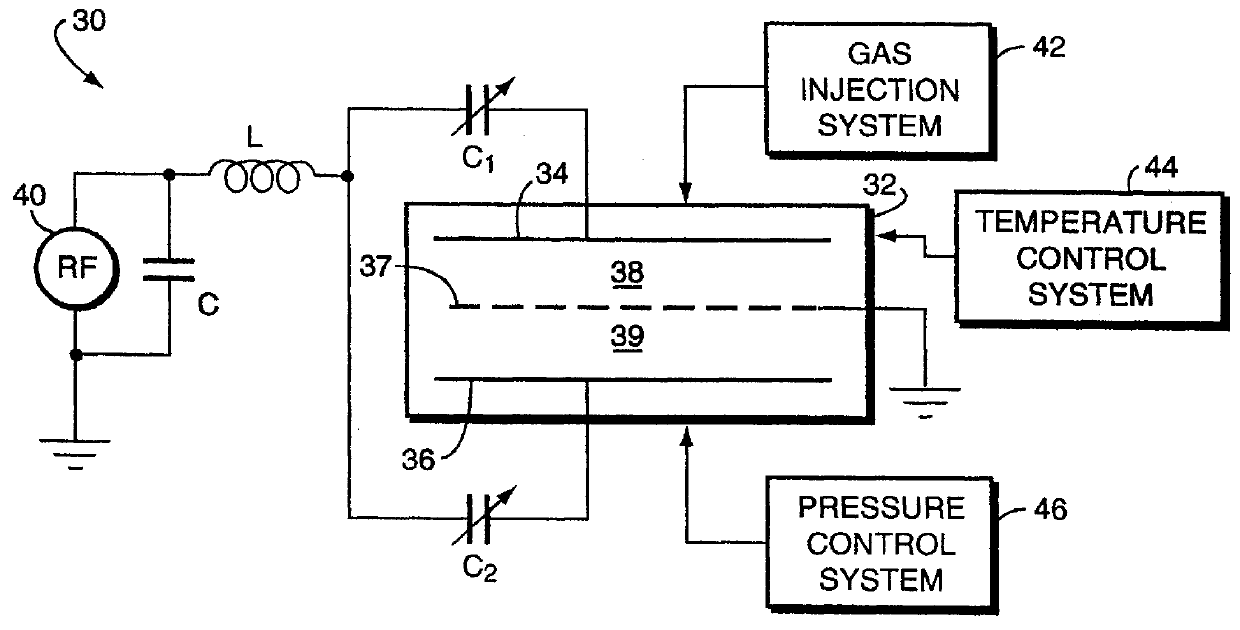

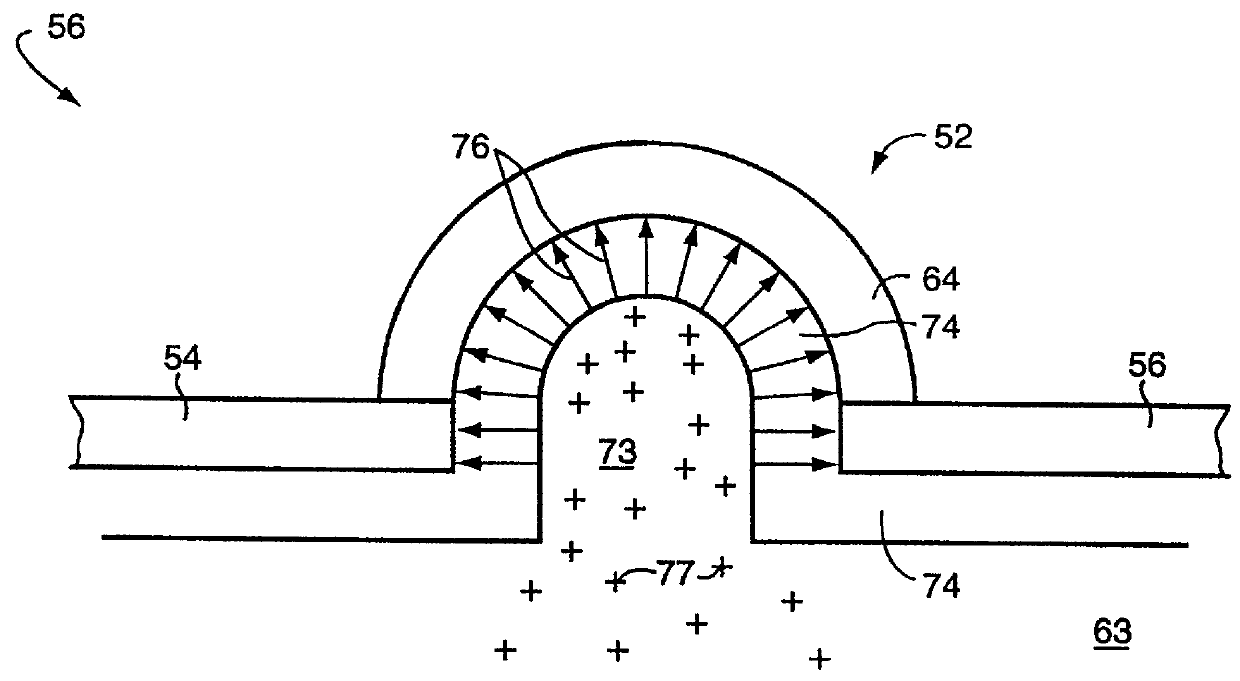

InactiveUS6010636AMinimize escapeInexpensively integrated into existing plasma-driven reactorElectric discharge tubesDecorative surface effectsPlasma densityReaction rate

An improved anode design, incorporating domes, for plasma reactors enhances plasma density at the anode. The domes give rise to a high-divergence, three-dimensional electric field distribution that accelerates electrons to a focused central region in the dome, thereby increasing ionization and dissociation. The enhanced plasma density increases the reaction rate at a substrate opposite the anode.

Owner:LAM RES CORP

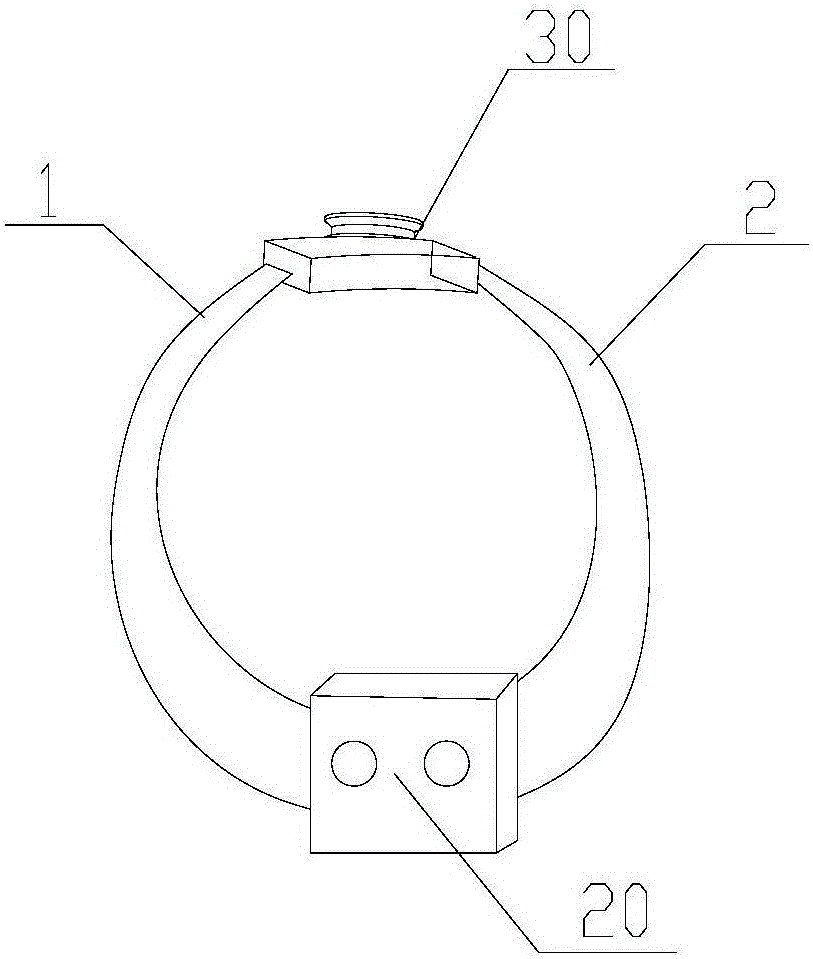

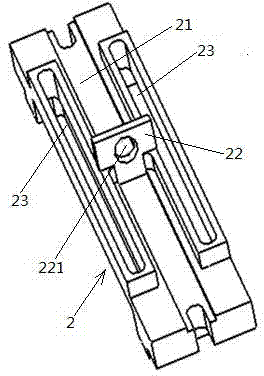

Bandage locking mechanism

The invention relates to a locking device and particularly relates to a bandage locking mechanism which comprises a button, a bandage, a housing, a drive structure and a locking structure, wherein the drive structure is held in the housing, the housing comprises a first housing, a through hole is formed in the first housing, the button passes through the through hole and can move along the axial direction or rotate along the circumference in the through hole, the button and the drive structure are stacked up and fixedly arranged, the drive structure moves along with the button and drives the bandage to stretch so as to adjust the length of the bandage, the locking structure is held in the housing and is fixedly connected with the drive structure, and the locking structure is matched with the first housing and used for locking the positions of the button and the drive structure so as to limit the driving of the button and the drive structure. The locking device has the advantages of saving space, realizing semi-automatic control, and being steady in structure transmission and excellent in locking and fine adjustment effects.

Owner:GEER TECH CO LTD

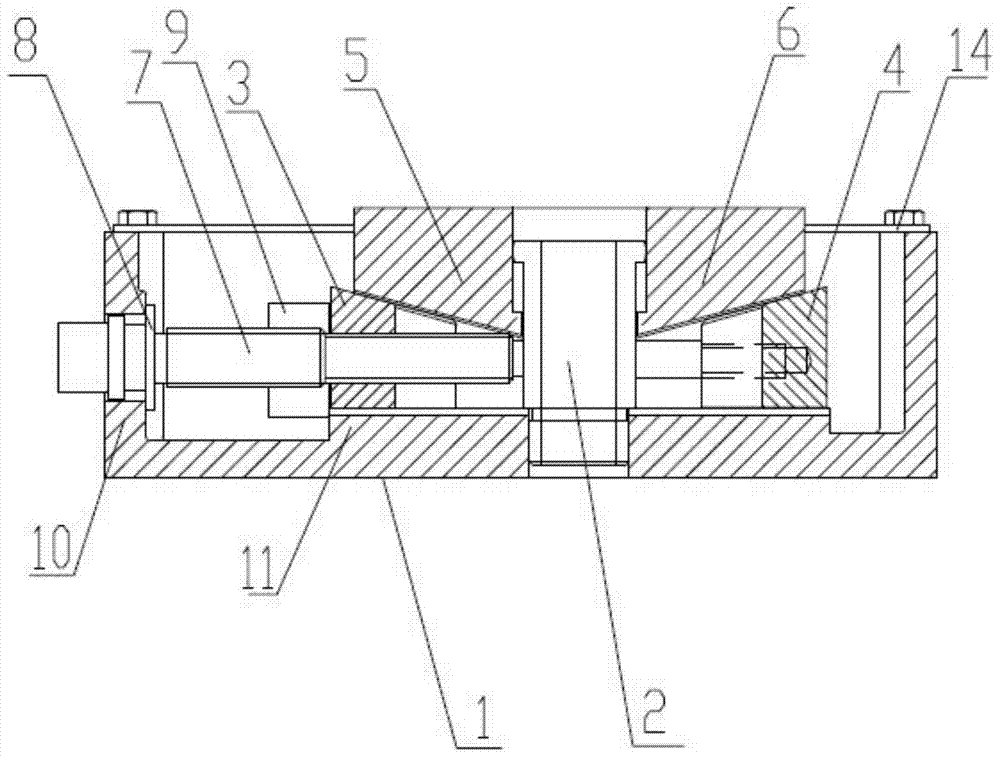

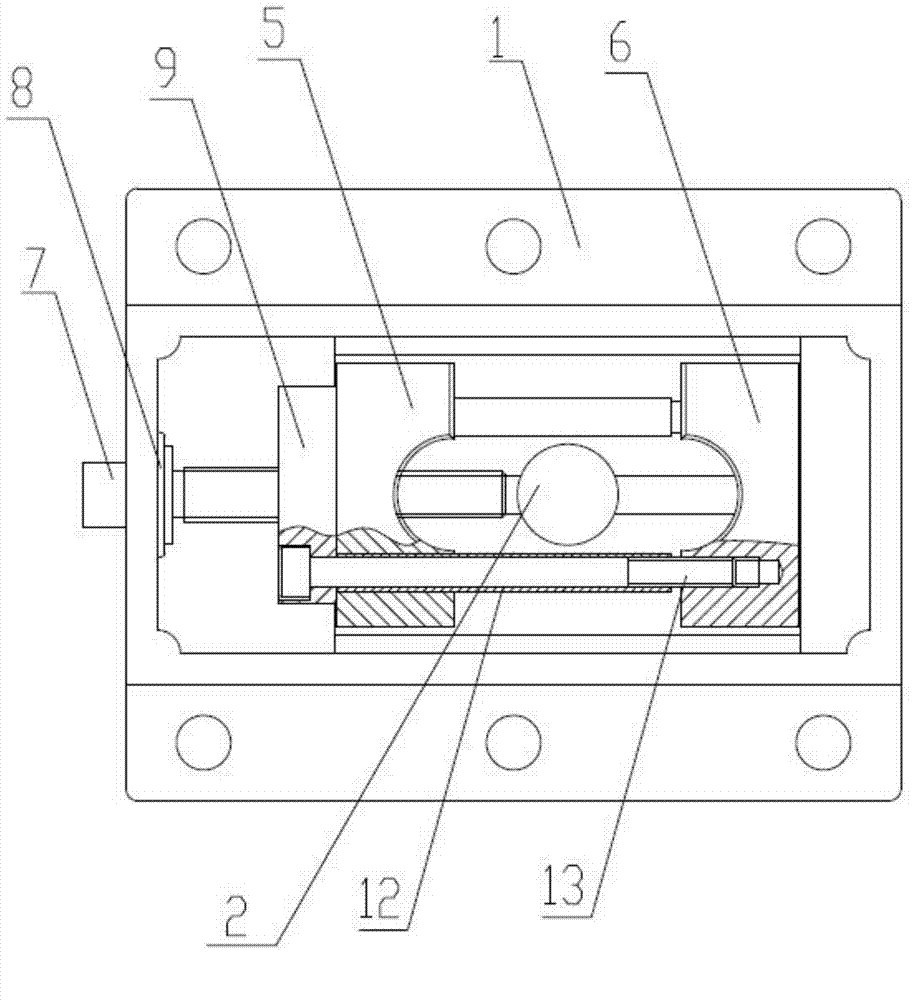

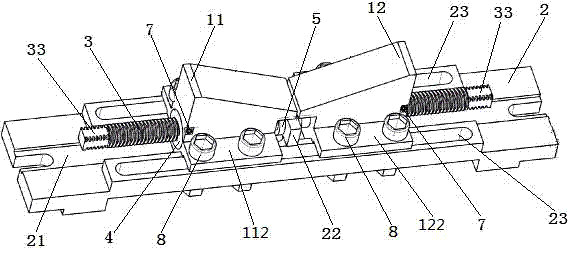

Machine tool fine adjustment sizing block

InactiveCN104329543AHigh precisionRealize the function of fine-tuning up and downMachine framesEngineeringScrew thread

The invention discloses a machine tool fine adjustment sizing block, and relates to the technical field of a device for installing a machine tool or regulating the machine tool height. The machine tool fine adjustment sizing block comprises a concave base, a positioning post, a first tapered wedge block, a second tapered wedge block, a first support block, a second support block and a fine adjustment screw bolt. The fine adjustment screw bolt clockwise or anticlockwise rotates, and the first tapered wedge block and the second tapered wedge block are positioned on the fine adjustment screw bolt in different threaded directions, so the moving directions of the first tapered wedge block and the second tapered wedge block are opposite, meanwhile, the first tapered wedge block and the second tapered wedge block move towards two sides or the middle, meanwhile, the first support block and the second support block are driven to descend or ascend, the vertical fine adjustment function is realized, the horizontal translation is avoided, the position precision of an adjusted element in the horizontal direction is ensured, and the fine adjustment effect is good.

Owner:BAODING BIAOZHENG MACHINE TOOL

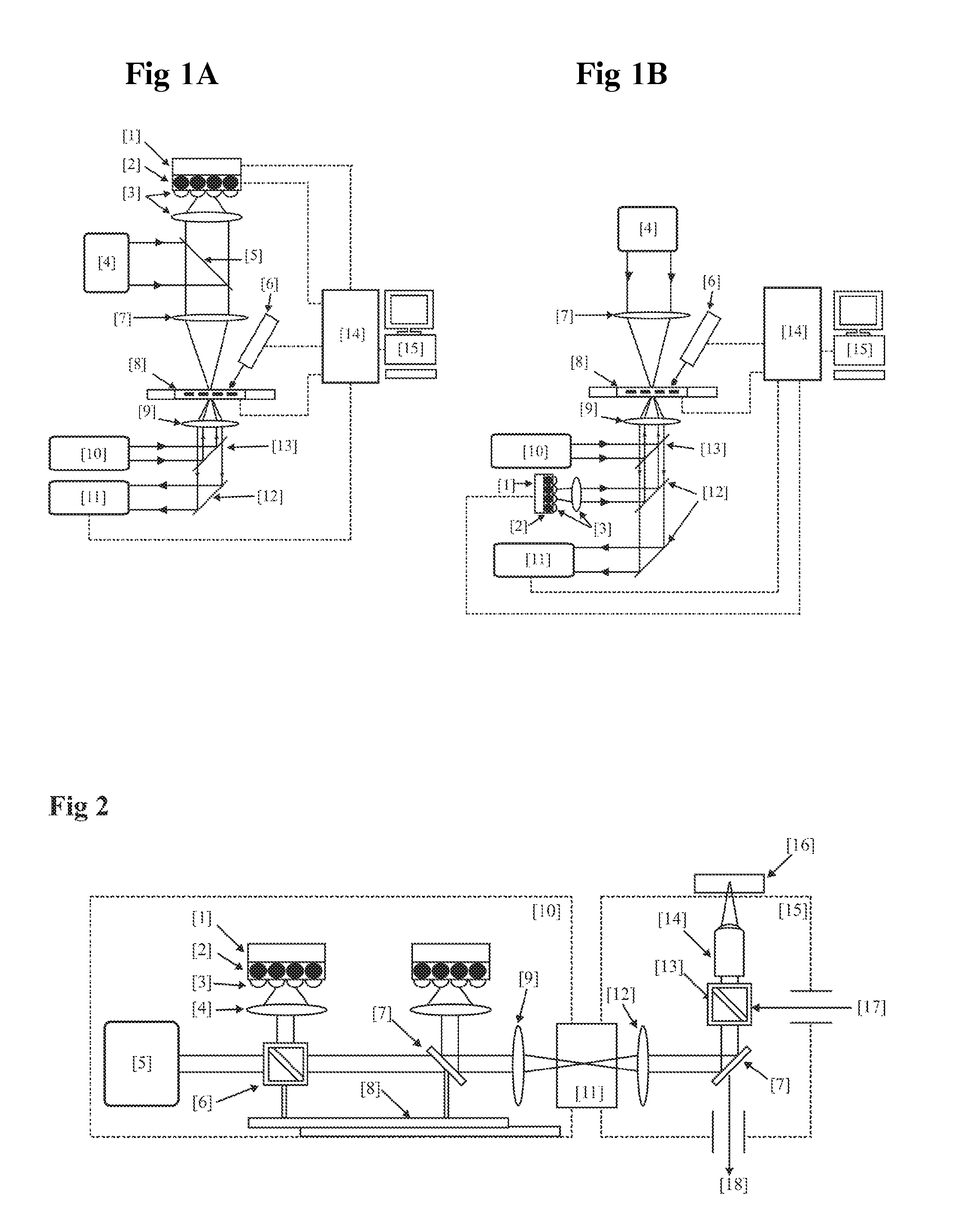

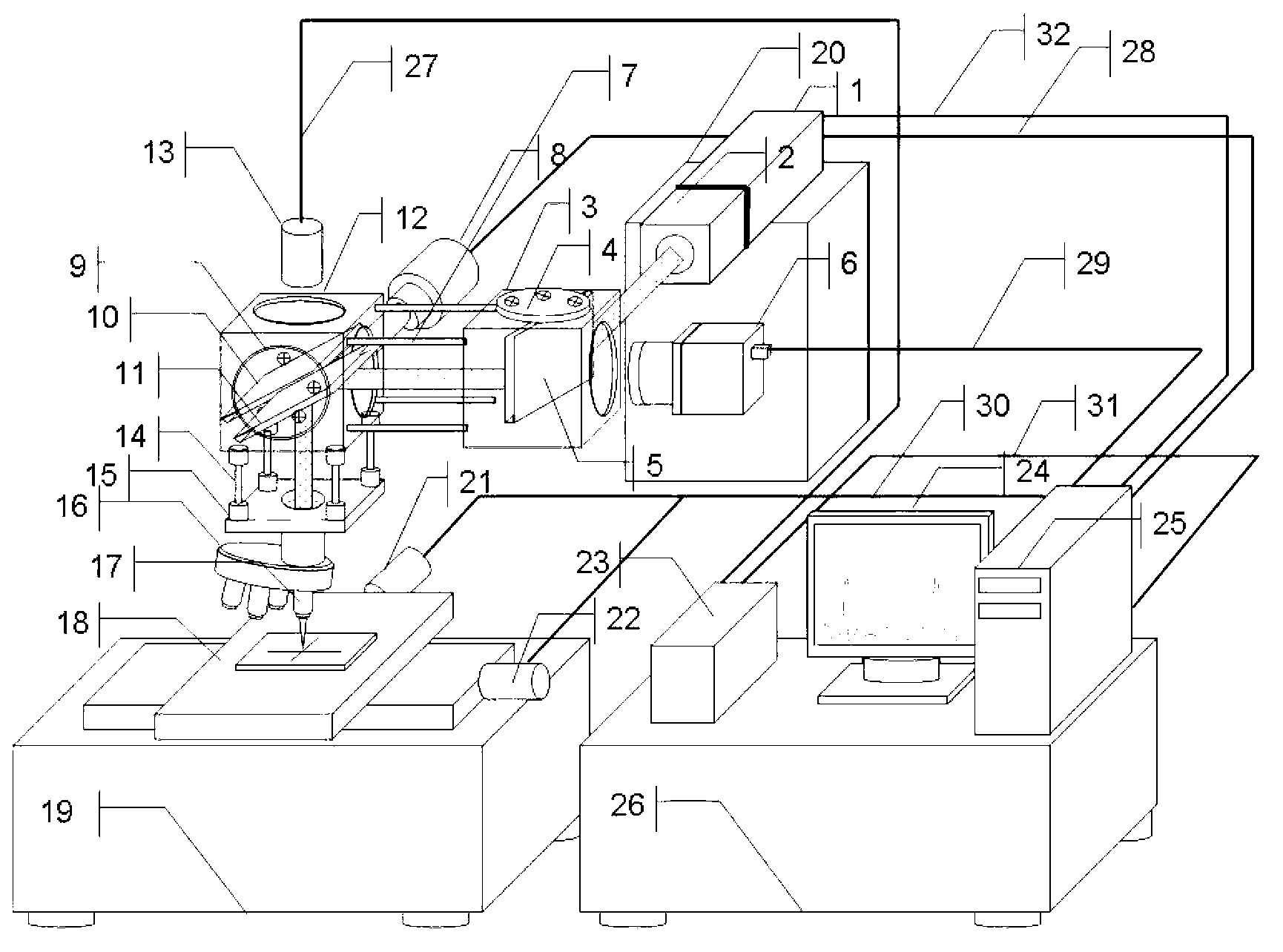

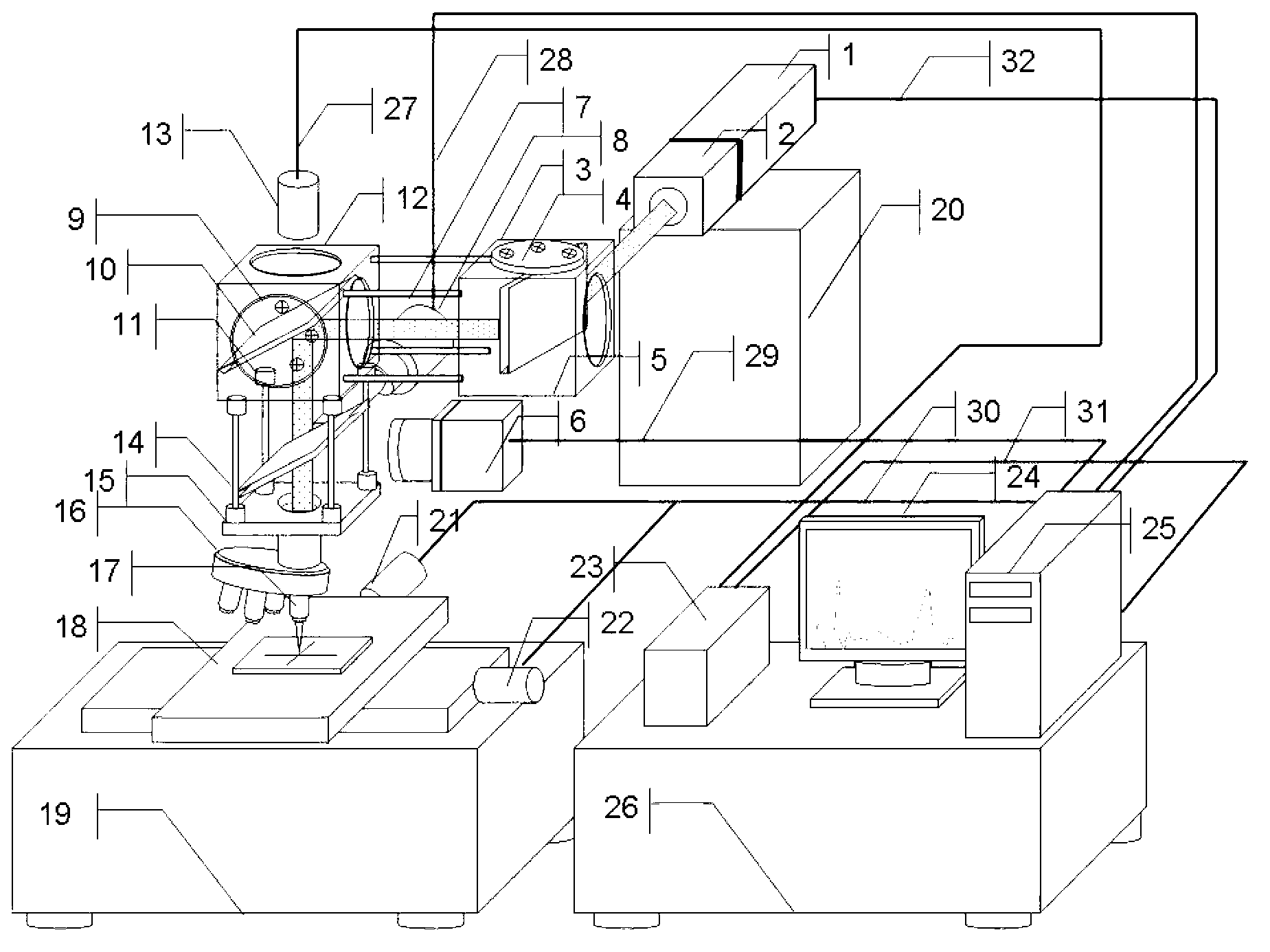

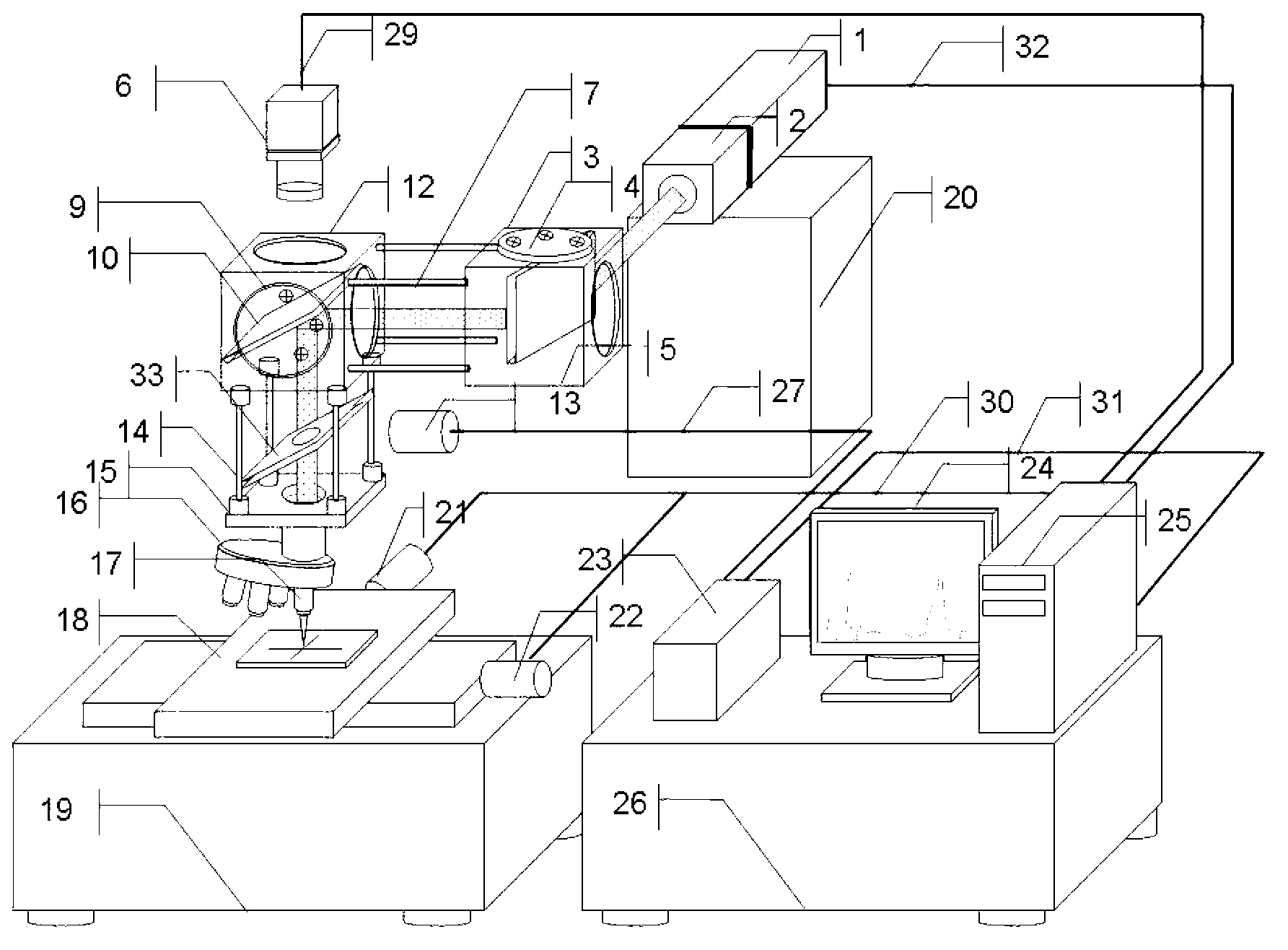

Integrated laser probe component analyzer for macroscopic and micro-area component analysis

ActiveCN103267746ARealize accurate qualitative analysisFast switching speedAnalysis by material excitationIndependent functionPrincipal component analysis

The invention belongs to the technical field of laser precision detection and discloses an integrated laser probe component analyzer for macroscopic and micro-area component analysis. The integrated laser probe component analyzer comprises a laser, a frequency multiplication module, two cage-type cubes, two laser wavelength reflectors, an industrial camera, a spectrum collector, an object lens converter, a focusing object lens, a spectrometer and a computer. A front end of a light outlet of the laser is provided with the frequency multiplication module. The laser is in an electric signal communication relationship with the computer. The integrated laser probe component analyzer can realize accurate qualitative analysis and high-precision quantitative analysis of macroscopic and micro-area components, can realize fast seamless switching of macroscopic and micro-area component analysis, has a modularization design and a compact structure, and improves an equipment integrated level. All the modules have independent functions and can be operated and maintained easily. Through the optical path modularization design, users can conveniently carry out optical path calibration before use so that operation time is saved and an analysis precision is improved.

Owner:WUHAN XINRUIDA LASER ENG +1

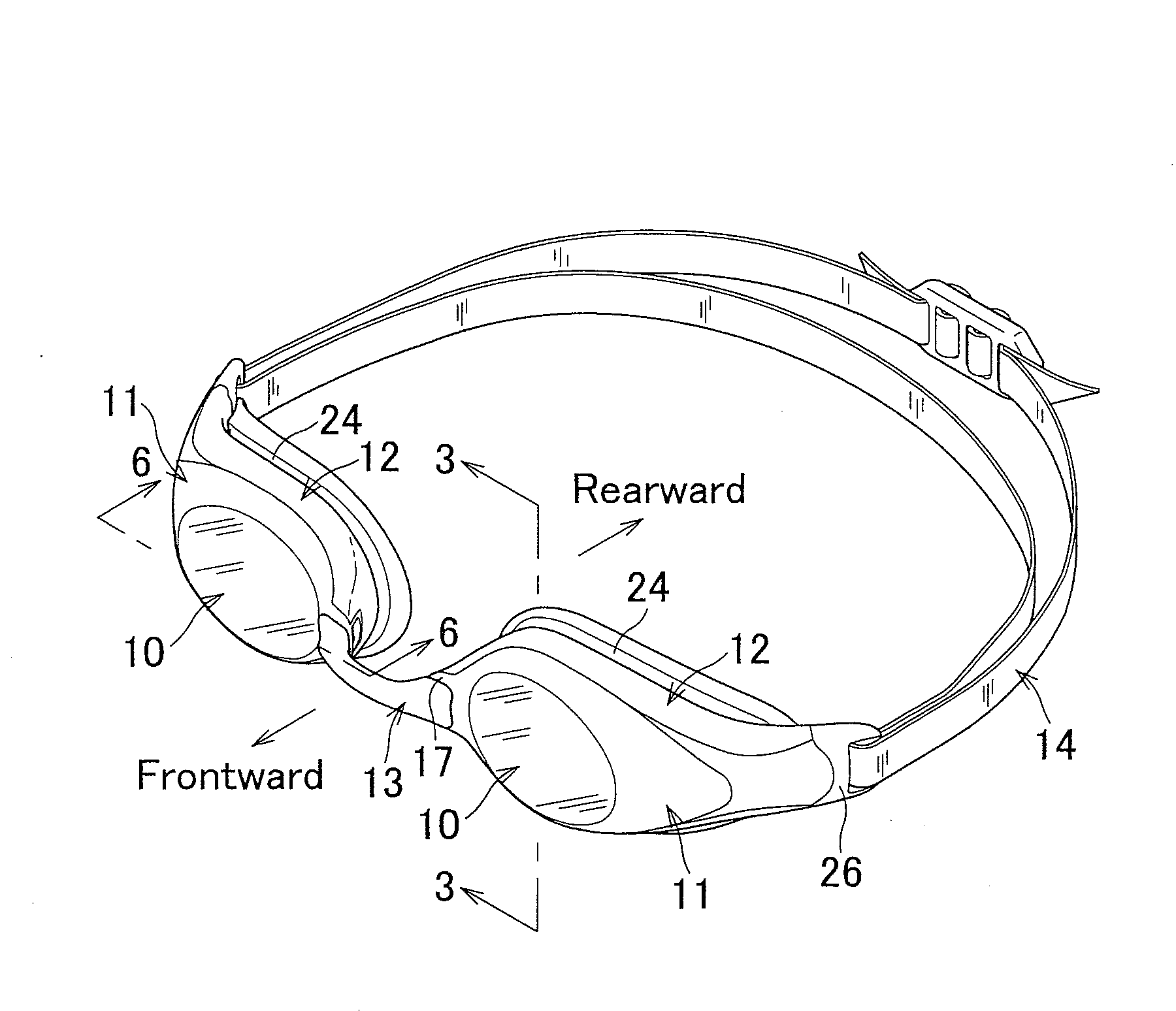

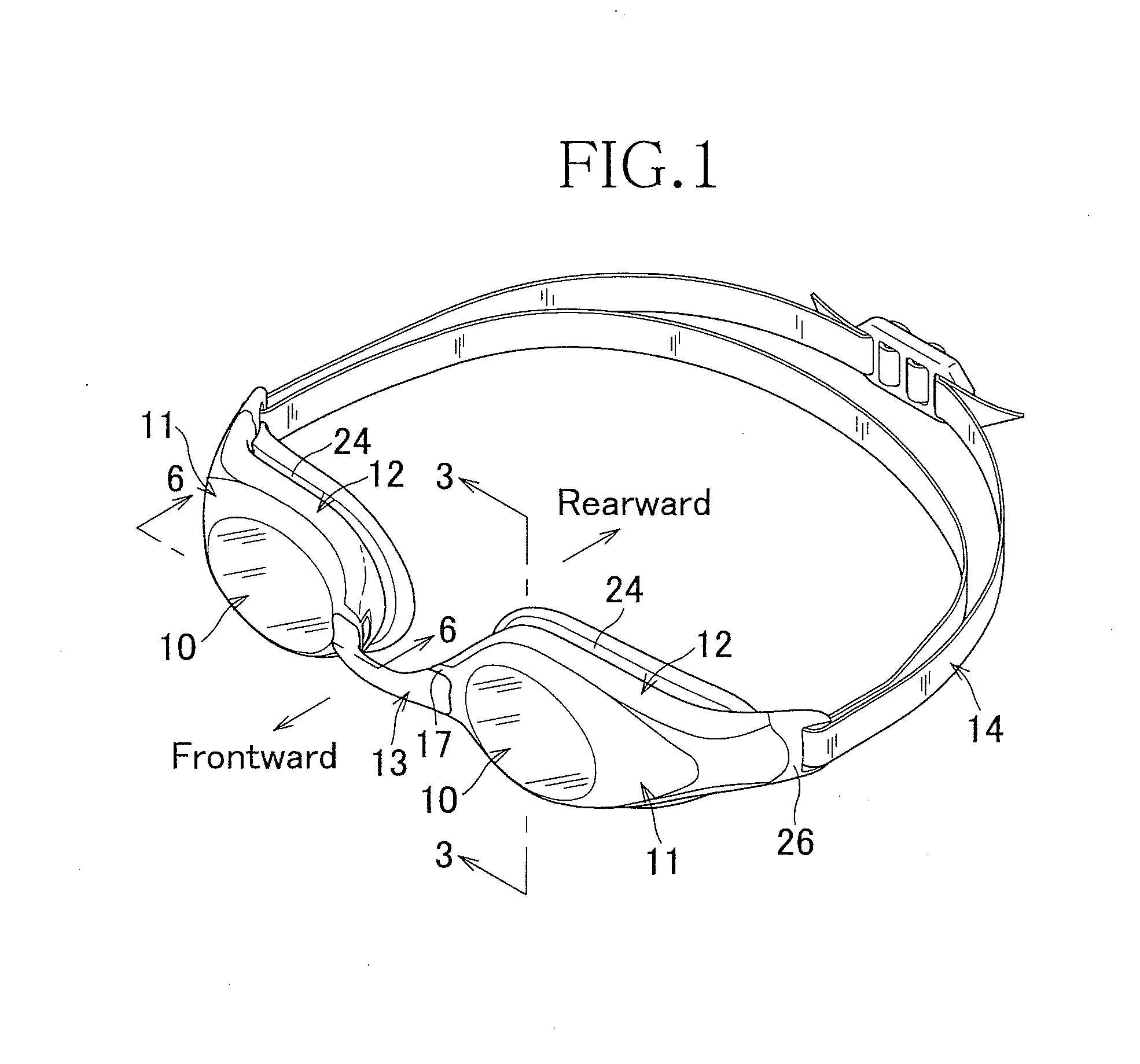

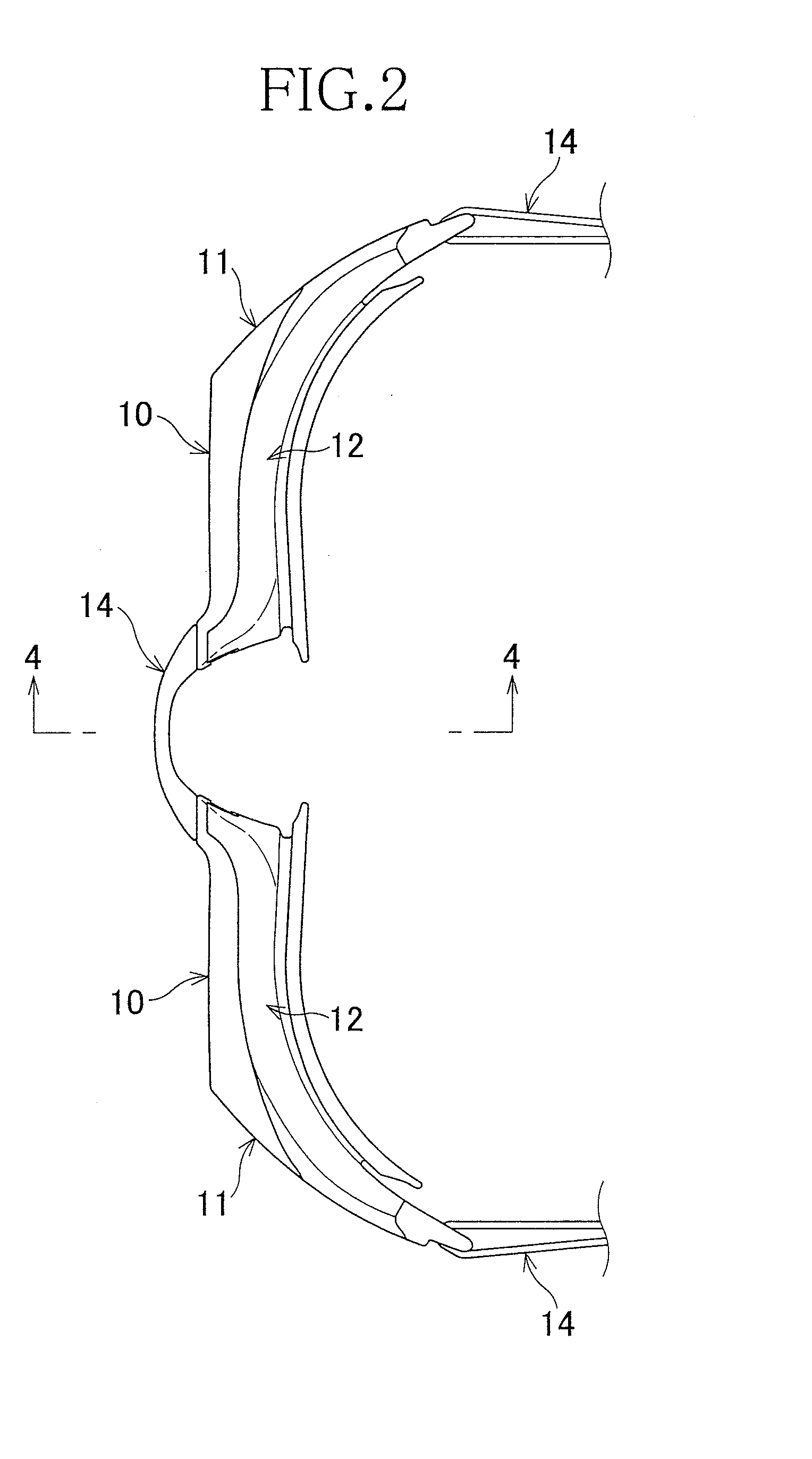

Swimming goggles

ActiveUS20080072366A1Eliminate the resistance against water flowReliably prevent from being unintentionally deformedGogglesSwim gogglesEngineeringElectrical and Electronics engineering

Swimming goggles includes lens units each made of transparent hard material, lens frame units each made of hard material and gasket units each made of soft and elastic material. Each of the gasket units is formed along an outer peripheral surface thereof with a convex rib.

Owner:TABATA

V-block tool allowing height adjustment for workpieces

InactiveCN104493605AReduce setup timeReduce labor intensityPositioning apparatusMetal-working holdersArchitectural engineeringEngineering

The invention discloses a V-block tool allowing height adjustment for workpieces. The V-block tool comprises a left support block, a right support block, a guide seat plate and a threaded rod. Two threaded sleeves are fixed in a mounting hole arranged in the left support block and a mounting hole arranged in the right support block, respectively; the left of the threaded rod is provided with a left thread; the right of the threaded rod is provided with a right thread; the left thread and the right thread spiral in different directions; the threaded rod penetrates the threaded sleeve arranged in the left support block and the threaded sleeve arranged in the right support block; the threaded rod is axially fixed on the guide seat plate; the left support block is provided with a left slope; the right support block is provided with a right slope; the left slope of the left support block and the right slope of the right support block jointly compose a V-shaped support face; the guide seat plate is provided with guide slides; the left support block and the right support block are slidably disposed on the guide seat plate. The V-block tool is convenient to operate, labor intensity is reduced for workers, production cost is reduced, labor productivity is improved, safety of use is improved, and machining quality is improved.

Owner:SUZHOU DOUSON VALVE CO LTD

Organic light-emitting display panel, display device, and method of manufacturing organic light-emitting display panel

ActiveUS8492754B2Improve luminous efficiencyEasy to adjustSolid-state devicesSemiconductor/solid-state device manufacturingInter layerDisplay device

An organic light-emitting display panel is provided that improves luminous efficiency and luminescent color by adjusting the difference in film thickness between layers of different luminescent colors, such as intermediate layers, when the intermediate layer and light-emitting layers are formed by a wet method. By varying the film thickness of an interlayer insulation film, which is a lower layer of an organic light-emitting element, the volume of a contact hole is varied by color, thereby adjusting the volume of a concavity in each anode plate. When ink that includes material for the intermediate layer, or like, is sprayed by an inkjet method, the film thickness of the intermediate layer, or like, changes in accordance with the amount of ink filing the concavity. Therefore, by adjusting the difference in volume between concavities of different colors, the difference in film thickness between the intermediate layers, or like, is finely adjusted.

Owner:JOLED INC

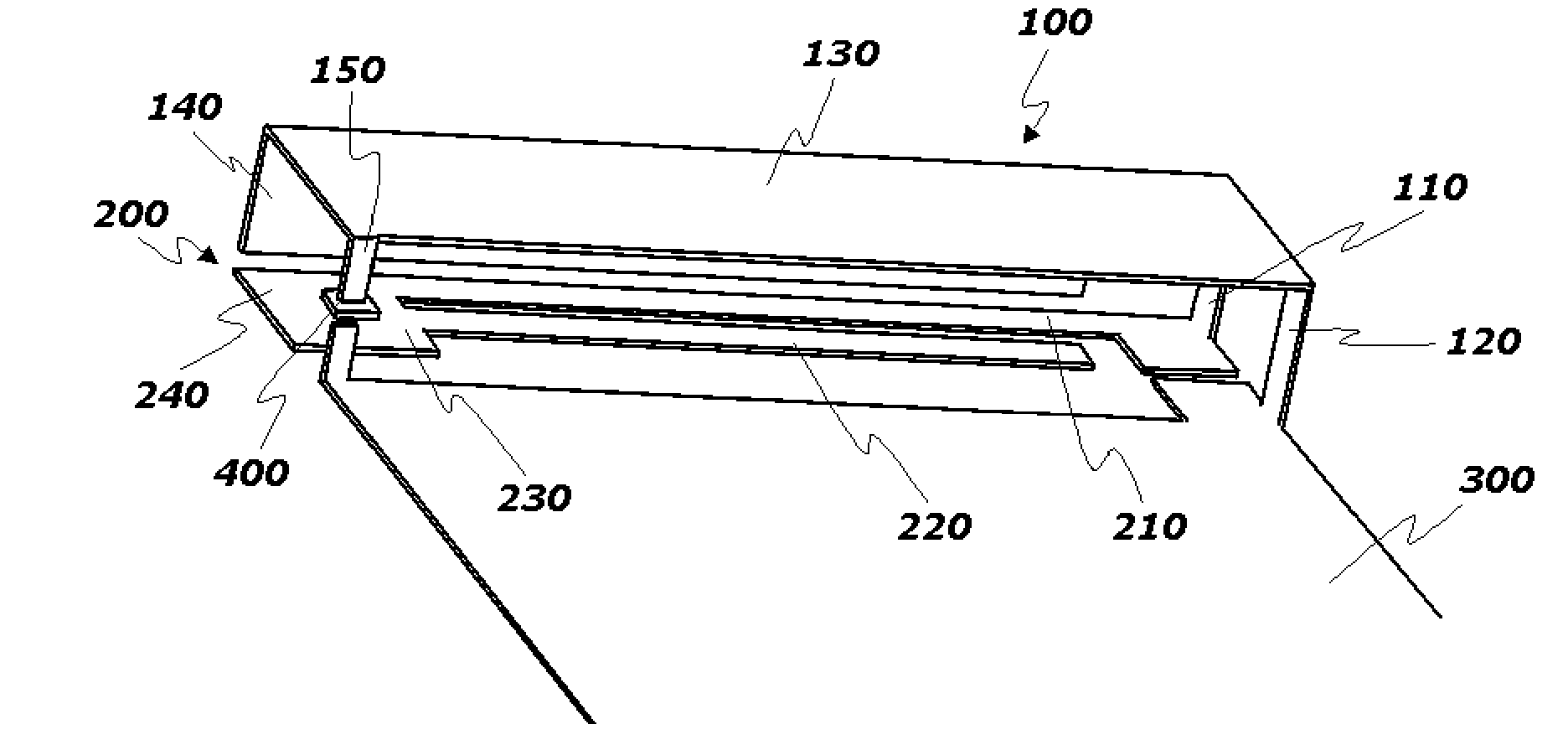

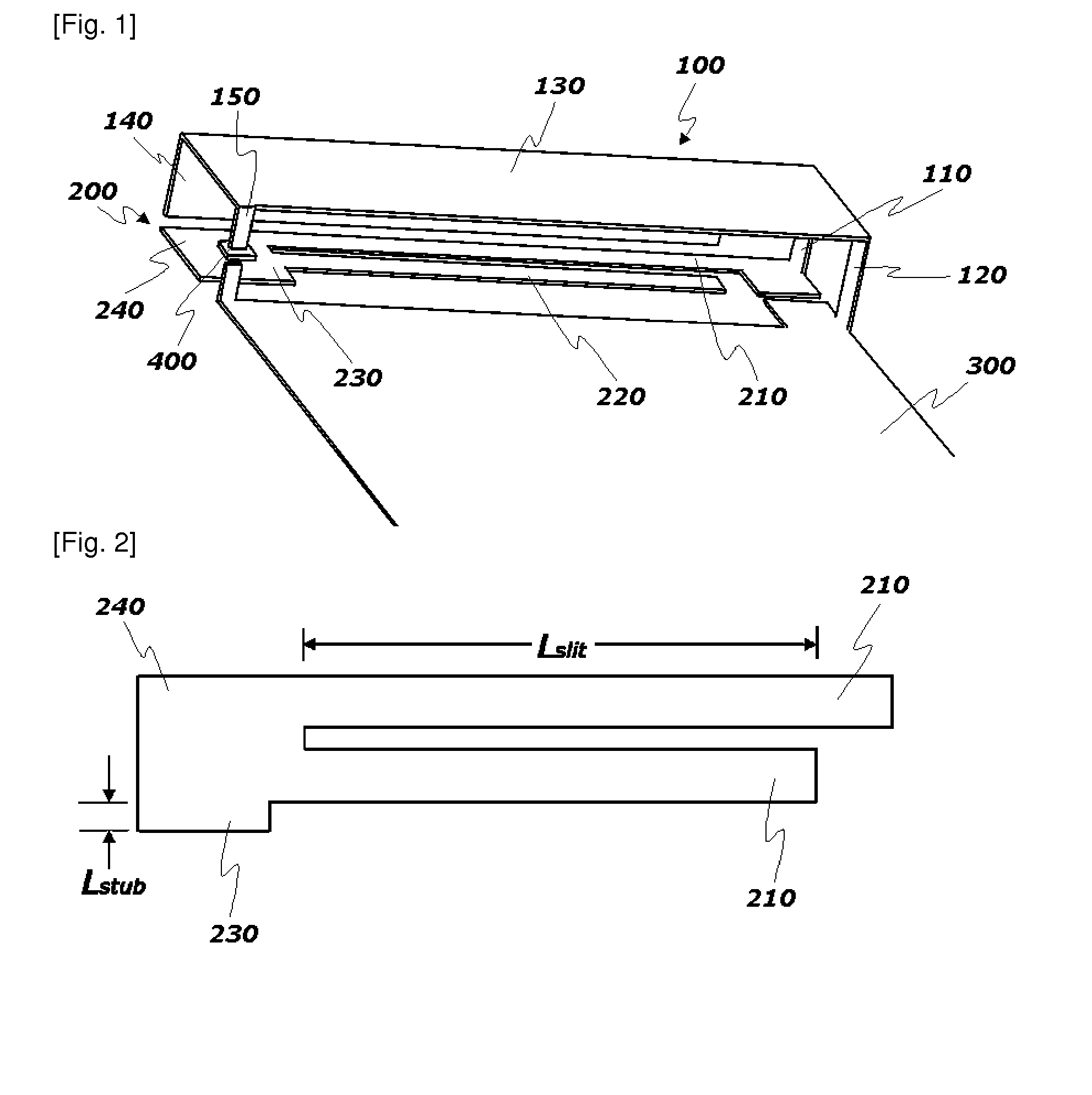

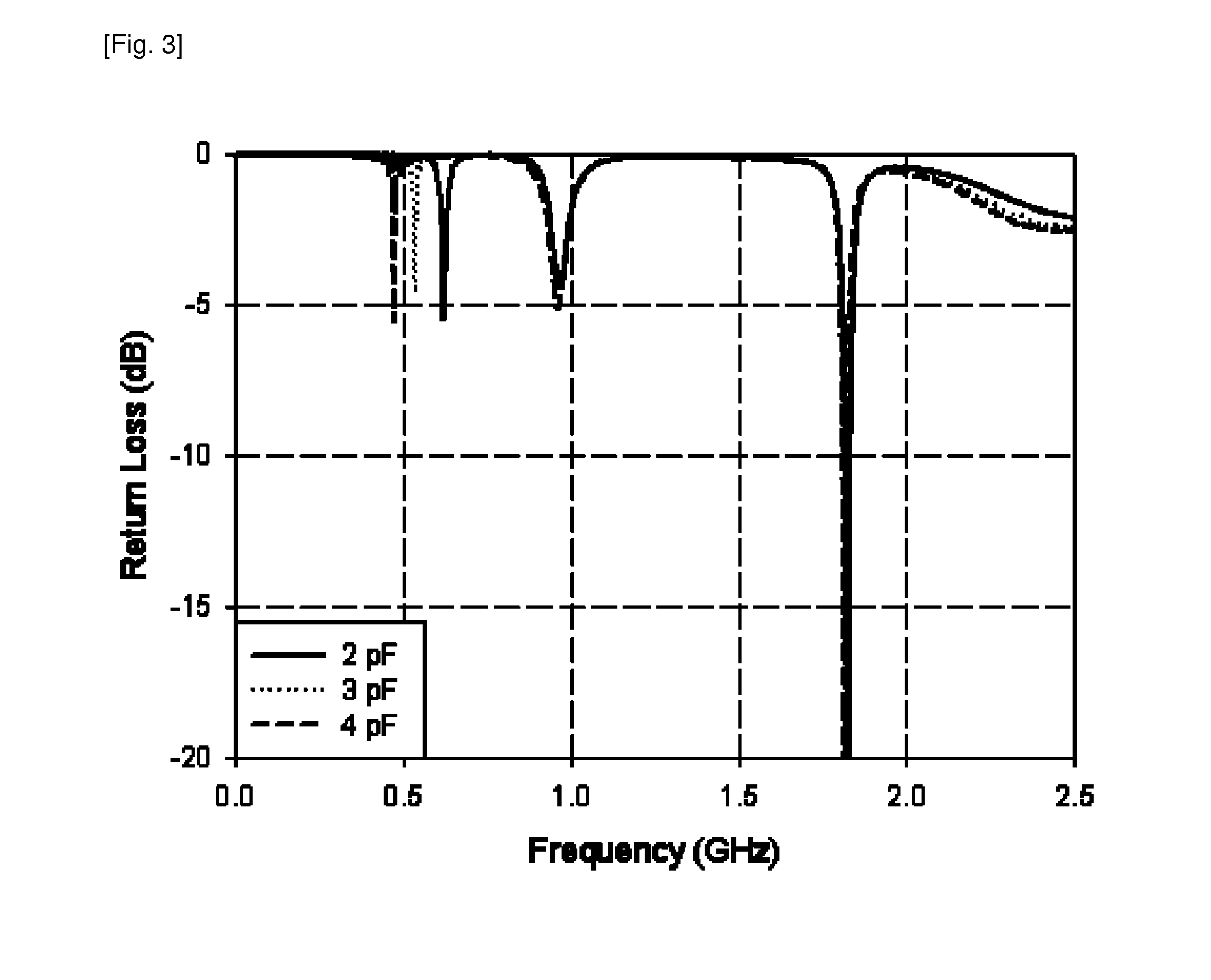

Multi-band antenna and wireless communication device including the same

InactiveUS20100214181A1Easy fine-tuningEasy to installSimultaneous aerial operationsAntenna supports/mountingsCapacitanceMulti band

There is herein disclosed a multi-band antenna which can adjust respective frequency bands independently. The multi-band antenna comprises a first radiation element having a PIFA structure and a second radiation element having a monopole structure. Also, a second ground terminal is disposed at one end of the first radiation element so as to be connected to a ground plane through a capacitor. The adjustment of the capacitance enables an independent adjustment of a first frequency band. The second radiation element includes a stub so as to allow the second frequency band to be independently adjusted, and a first sub-element and a second sub-element which defines a slit therebetween so as to allow the third frequency band to be independently adjusted. According to the present invention, it is possible to provide a multi-band antenna which can easily adjust respective frequency bands using multi-bands.

Owner:E M W ANTENNA CO LTD

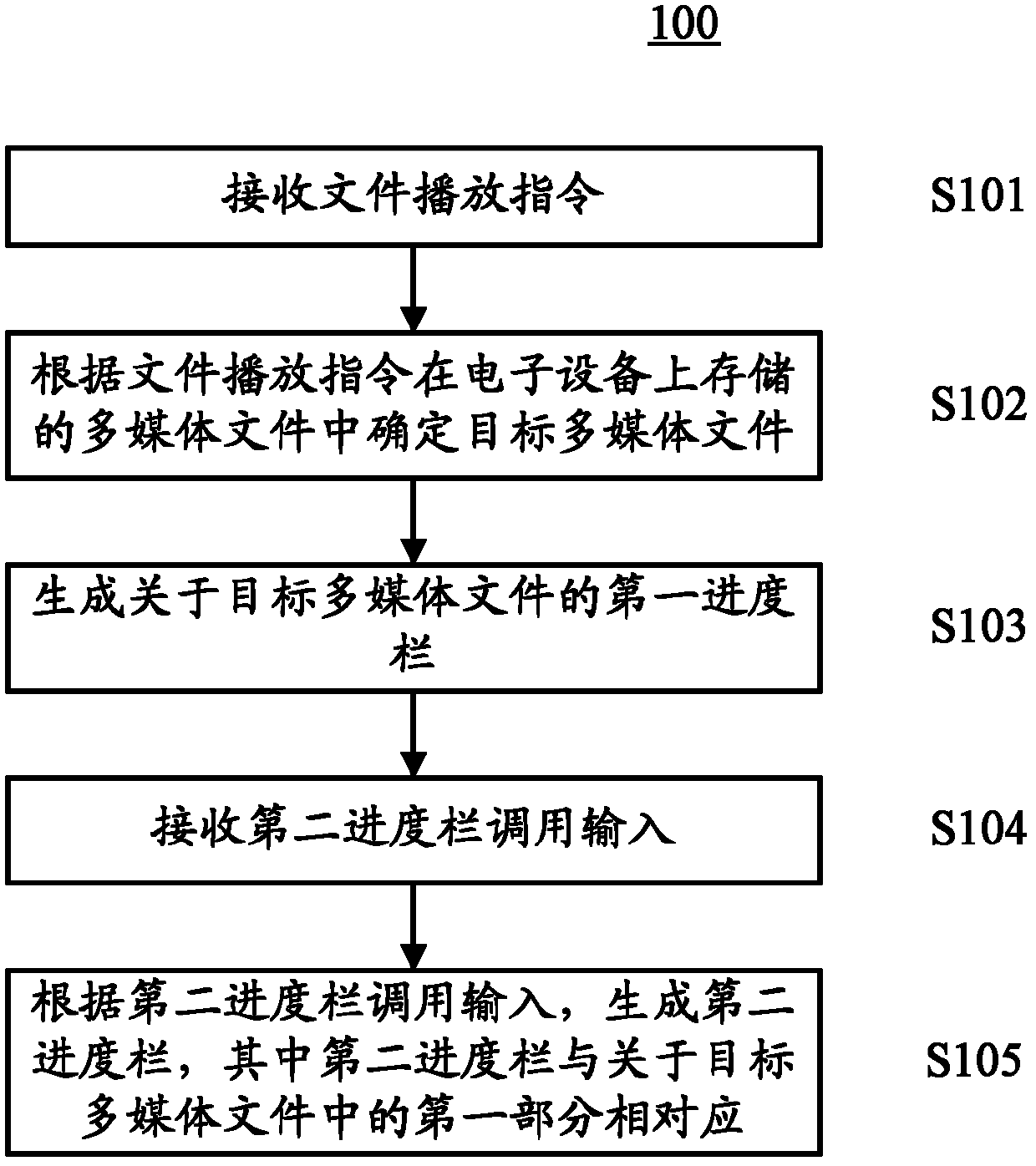

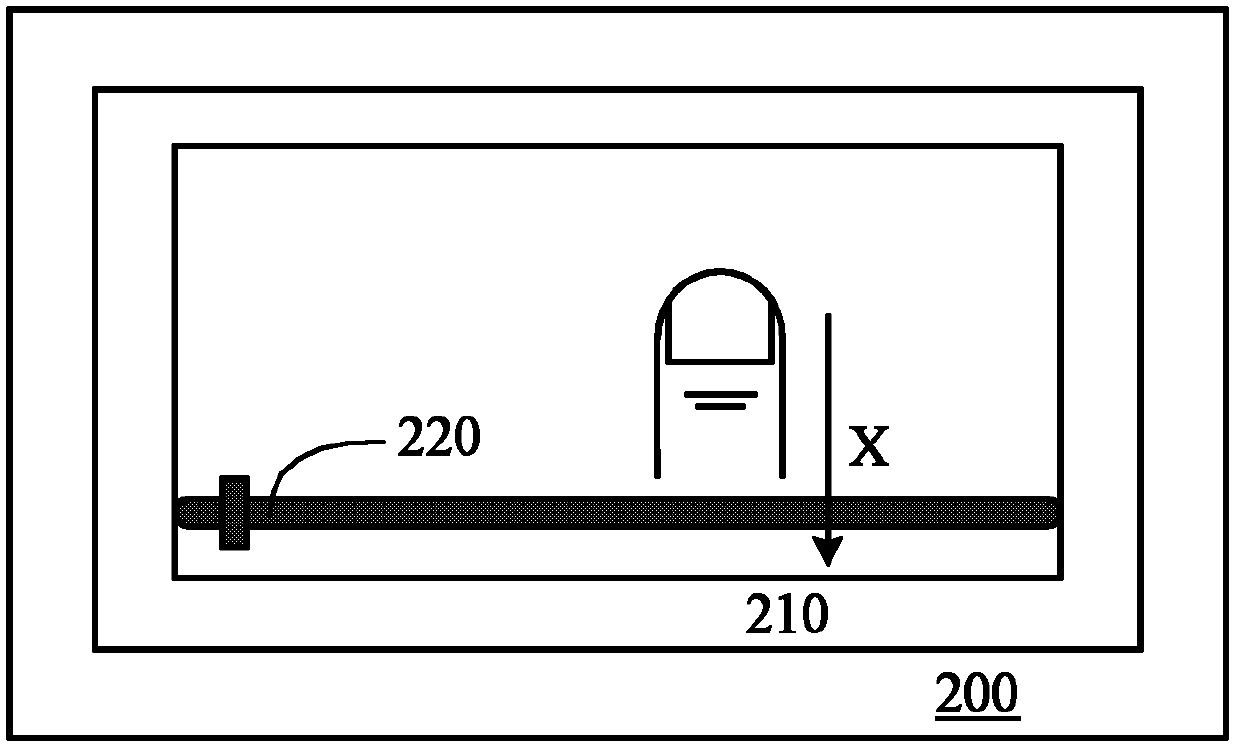

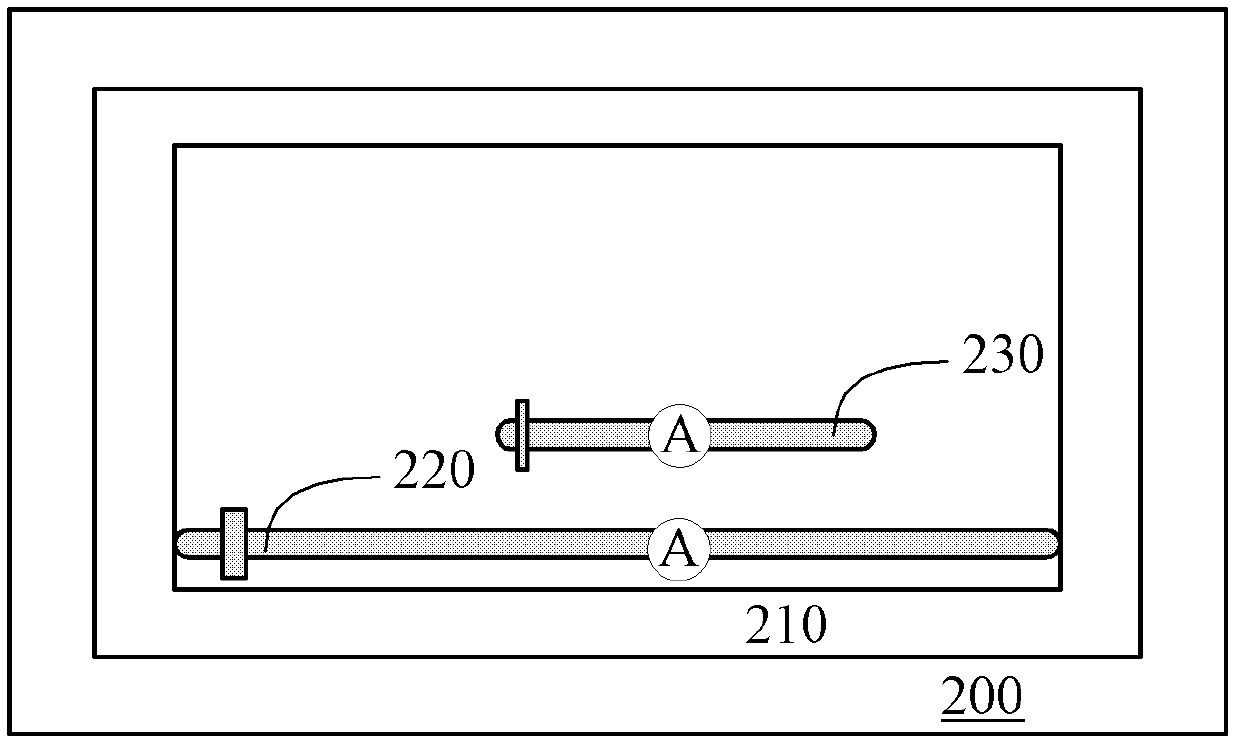

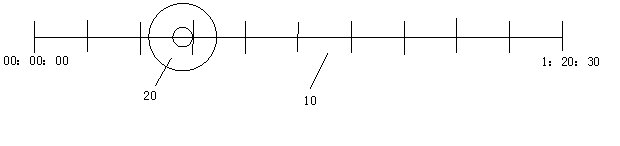

Method and electric device for controlling multimedia file playing

InactiveCN103294333AEasy fine-tuningAccurate and fast positioningInput/output processes for data processingProgress barStart time

The embodiment of the invention provides a method and an electric device for controlling multimedia file playing, wherein the method provided by the embodiment of the invention can be applied to the electric device, and comprises the following steps: receiving the file playing indication; determining a target multimedia file according to the file playing indication; generating a first progress bar with respect to the target multimedia file, wherein the start point of the first progress bar is corresponding to the playing start time of the target multimedia file, and the end point of the first progress bar is corresponding to the playing end time of the target multimedia file; receiving the calling input of a second progress bar; and generating the second progress bar according to the input of the second progress bar, wherein the second progress bar is corresponding to the first part of the target multimedia file.

Owner:LENOVO (BEIJING) CO LTD

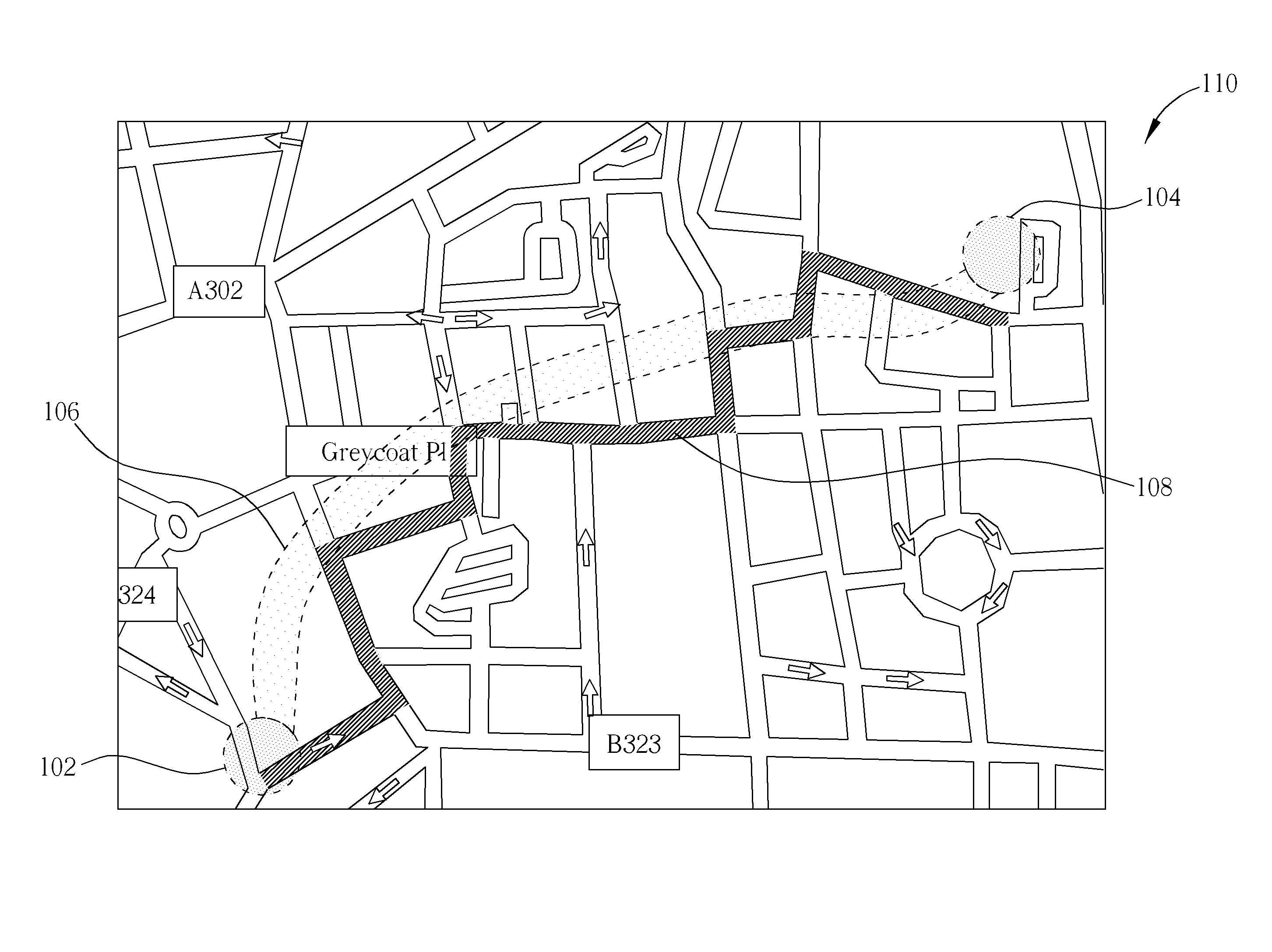

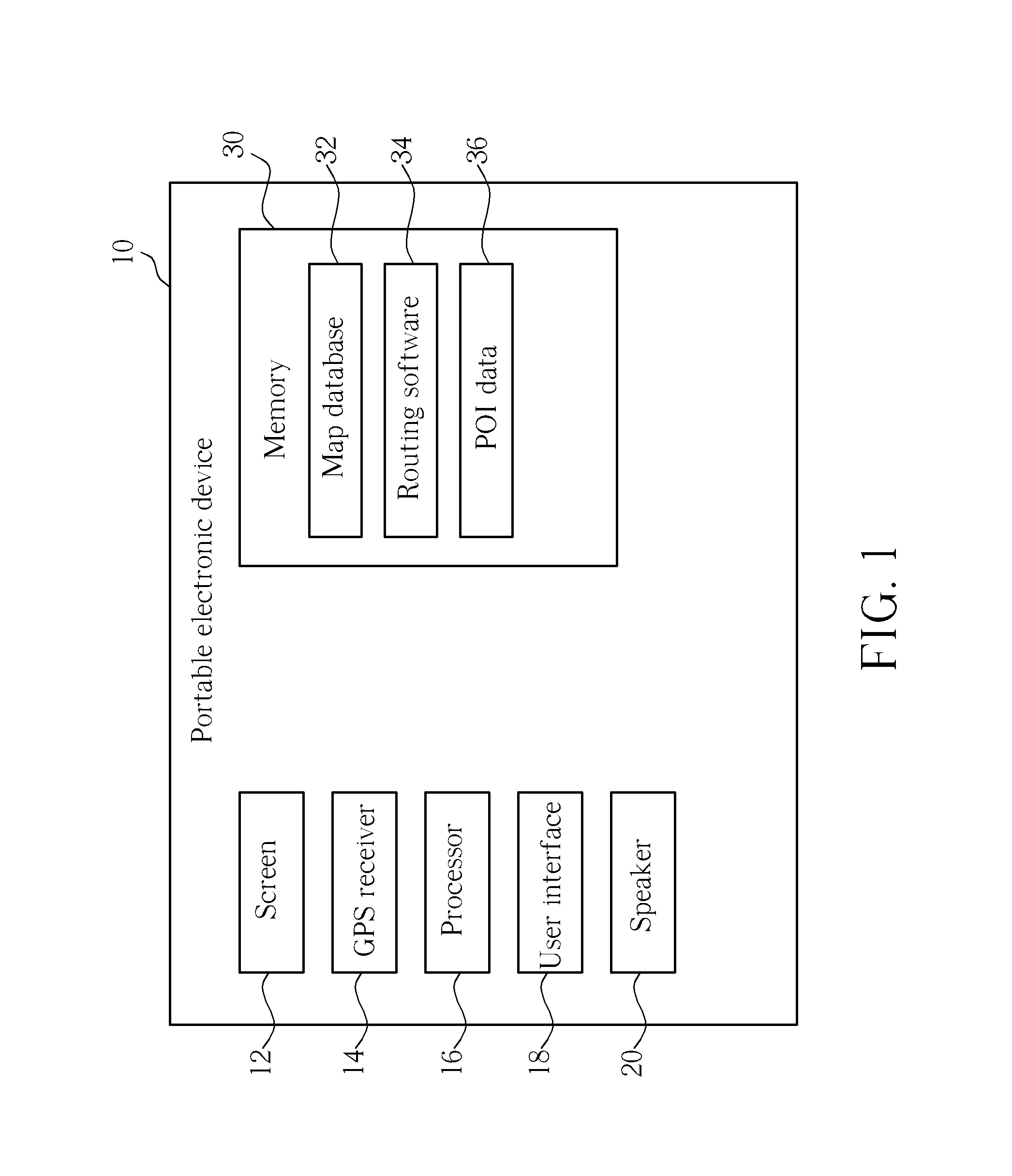

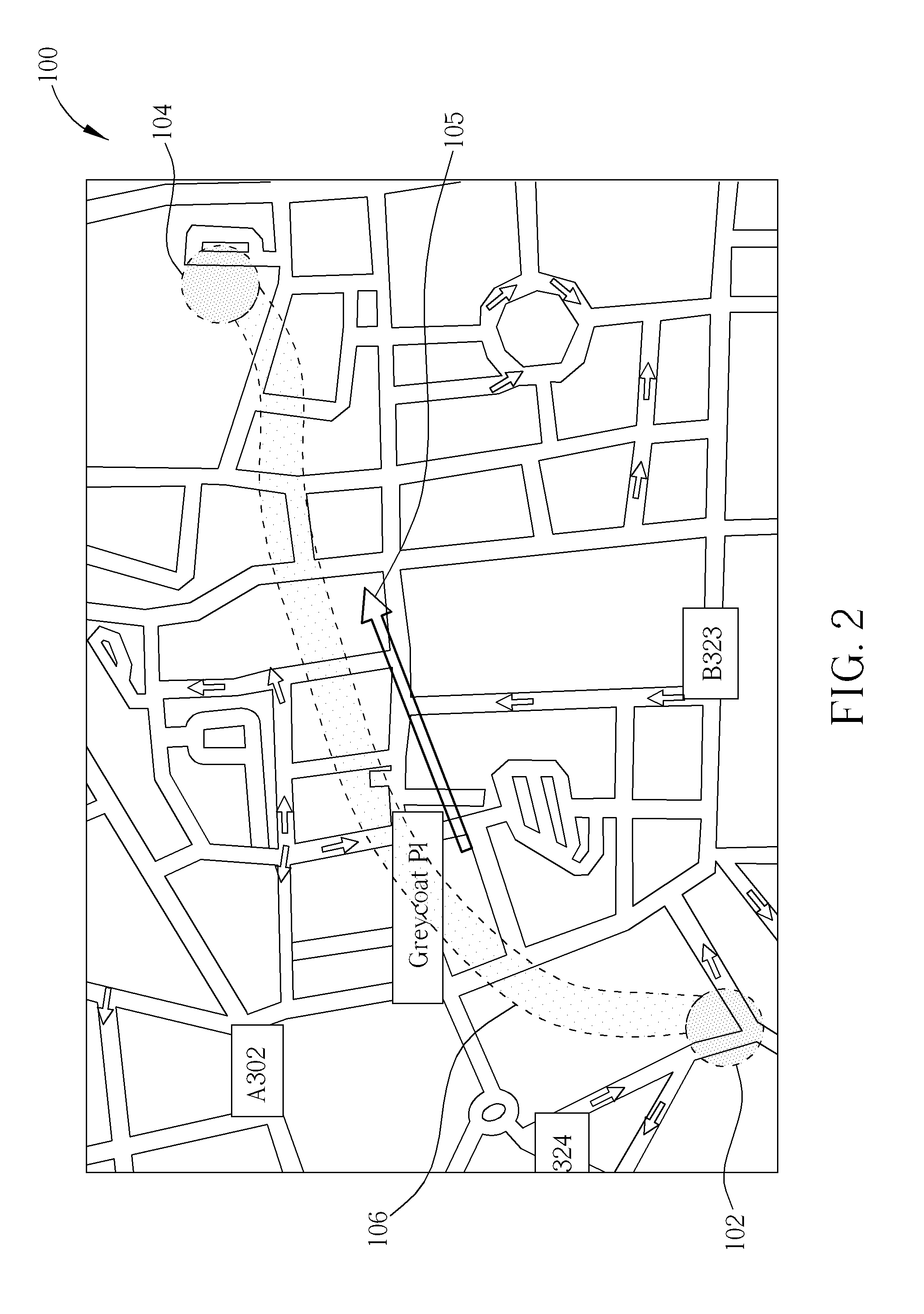

Method of generating a suggested navigation route based on touch input received from a user and related portable electronic device

ActiveUS8892360B2Easy fine-tuningSimple and fast and convenient inputInstruments for road network navigationRoad vehicles traffic controlNavigation assistanceTouchscreen

A method of generating a suggested navigation route with a portable electronic device includes presenting a map to a user on a touch-sensitive screen of the portable electronic device, and receiving touch input from a user stroking the touch-sensitive screen from a touch-down location corresponding to a starting point on the map to a release location corresponding to an ending point on the map for indicating a location of a preferred route, the preferred route beginning with the starting point and finishing with the ending point. The method further includes generating the suggested navigation route by selecting streets for the suggested navigation route according to the preferred route in order to closely approximate the preferred route, presenting the suggested navigation route to the user on the touch-sensitive screen, and providing navigation assistance to the user for guiding the user along the suggested navigation route.

Owner:MITAC INT CORP

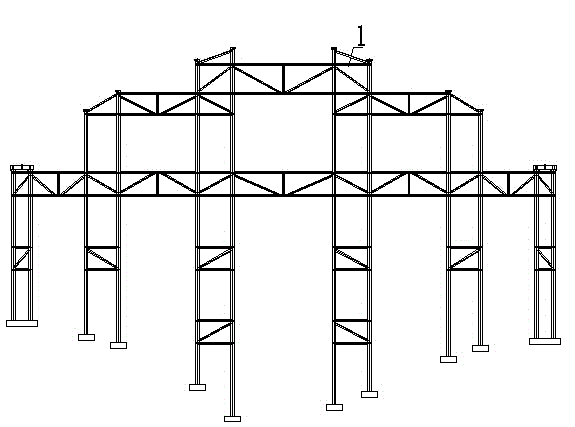

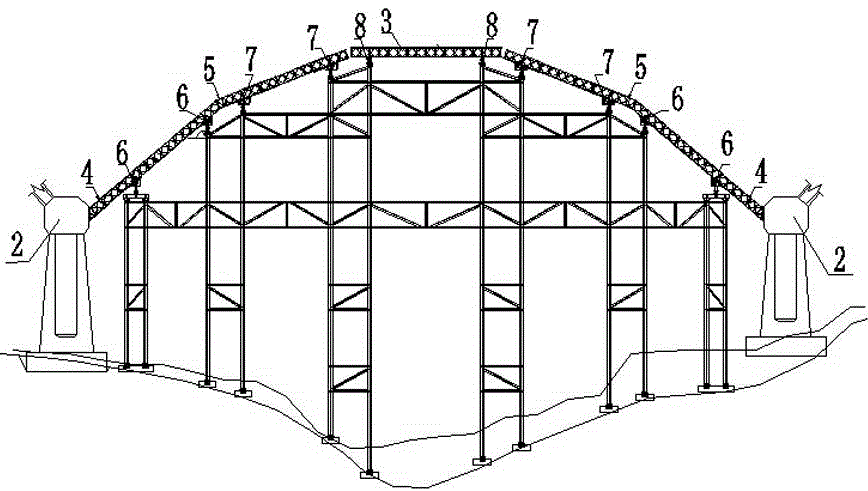

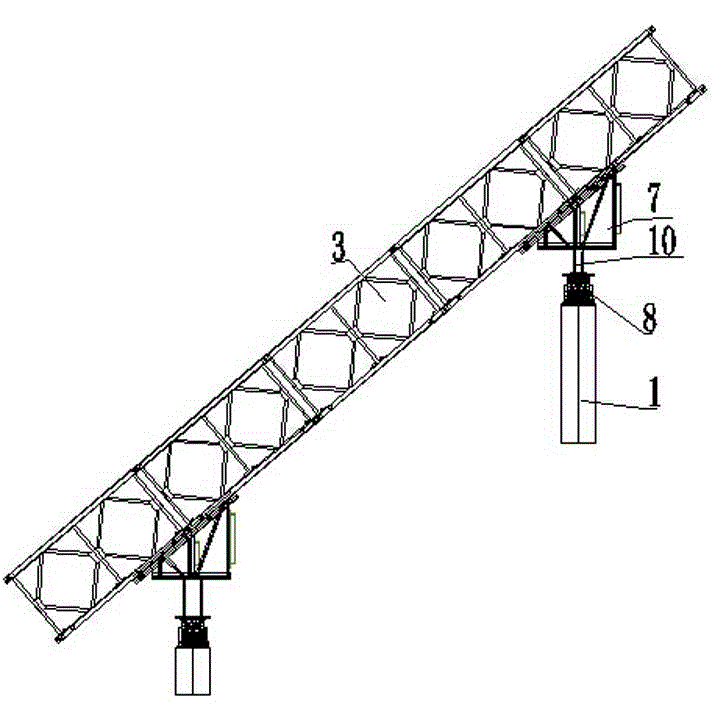

Arching structure of high large-span bridge bailey beams and construction method thereof

InactiveCN104099871AIncrease stiffnessReduce construction difficultyBridge erection/assemblyHeight differenceSpandrel

The invention provides an arching structure of high large-span bridge bailey beams and a construction method thereof. A fixed bracket is erected between piers on two sides through a plurality of supporting vertical columns and beams; an inclined plane is formed at top ends of every two supporting vertical columns; a plurality of inclined planes form a basic cambered surface; a standard bailey beam is erected on each inclined plane; the standard bailey beams are further connected with one another; an arc bracket is further erected on each inclined plane; casting templates are further erected on the arc brackets, so that the arching structure is formed; the preset height difference is formed through the supporting vertical columns; after the erecting of the supporting vertical columns, the arc requirement is initially achieved; the bailey beams are assembled into a plurality of inclined planes which are connected with one another; the bailey beams are erected on the inclined planes; one arc bracket is further arranged on each inclined plane. The method has the advantages of low construction difficulty, simple construction technology, convenience in operation, high safety factor and the like, and can be widely applied to construction of large span bridges, such as arch bridges and arch rings, with radian at bottoms.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP

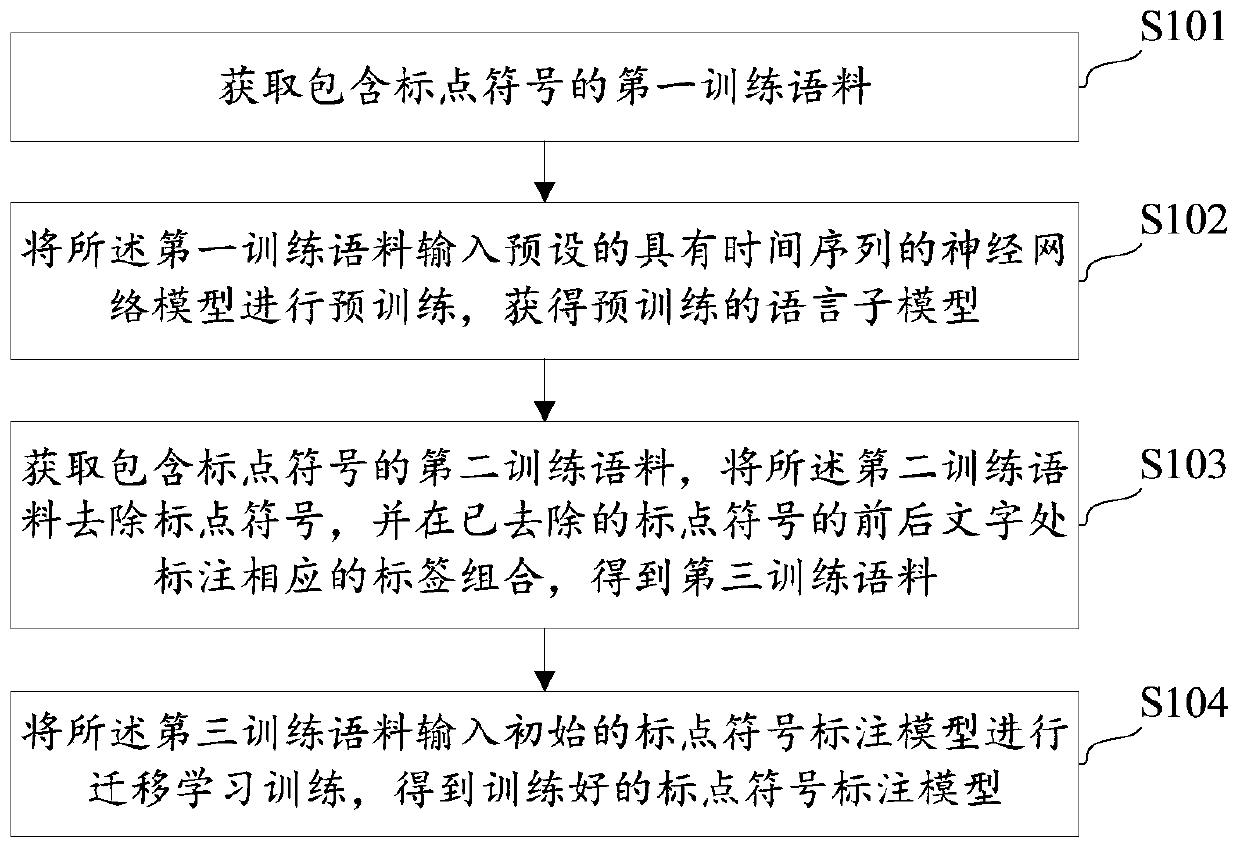

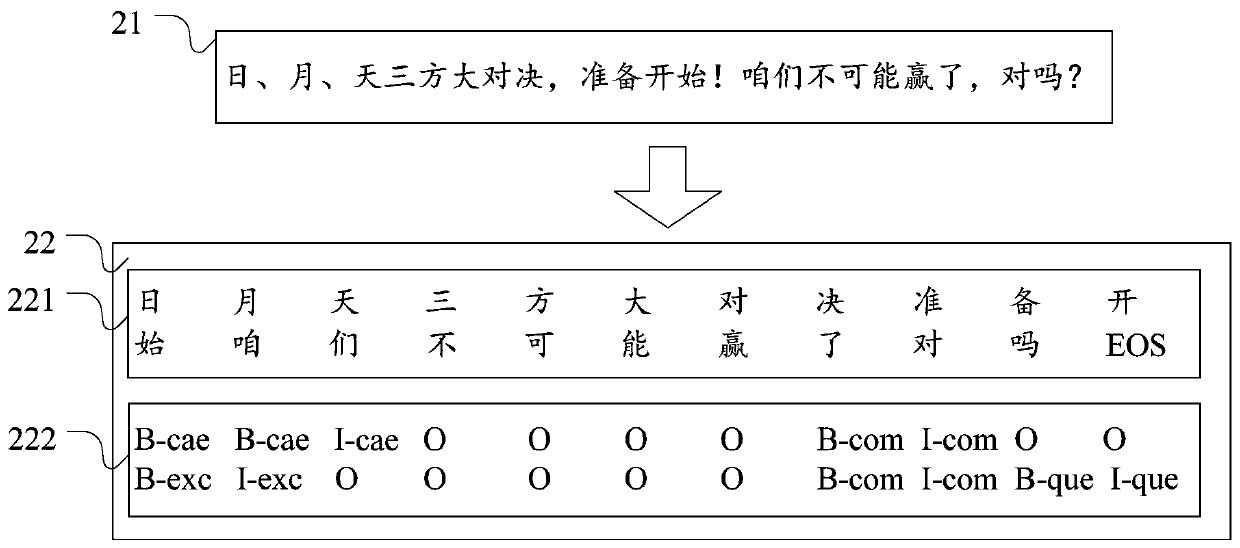

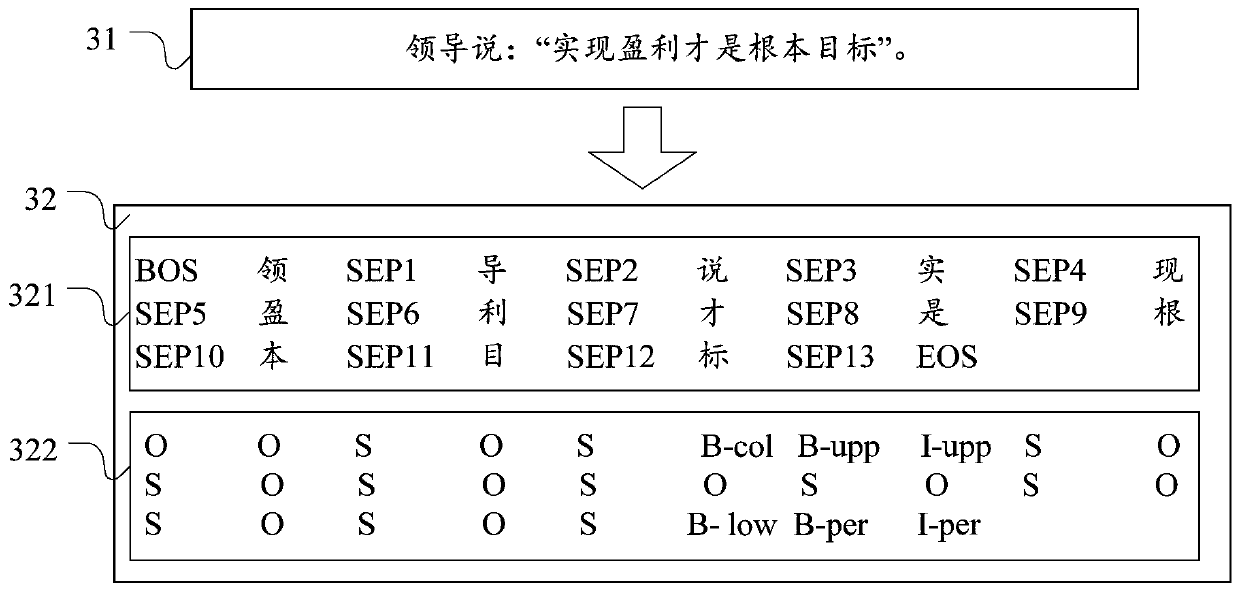

Punctuation mark labeling model and training method and device thereof, and storage medium

PendingCN110674629AImprove accuracyFast convergenceNatural language analysisNeural learning methodsNatural language processingMedicine

The invention discloses a punctuation mark labeling model and a training method and device thereof, and a storage medium. The method comprises the steps of obtaining a first training corpus containingpunctuation marks; inputting the first training corpus into a preset neural network model with a time sequence for pre-training to obtain a pre-trained language sub-model; obtaining a second trainingcorpus containing punctuation marks, removing the punctuation marks from the second training corpus, and labeling corresponding label combinations at front and rear word segmentation units of the removed punctuation marks to obtain a third training corpus; inputting the third training corpus into an initial punctuation mark labeling model for transfer learning training, obtaining a trained punctuation mark labeling model, the punctuation mark labeling model comprising a pre-trained language sub-model, and the third training corpus comprising a punctuation-free text set and a label sequence set. According to the scheme, a large amount of training data does not need to be manually labeled, the recall rate is increased, and the obtained punctuation mark labeling model has good generalizationability and universality.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

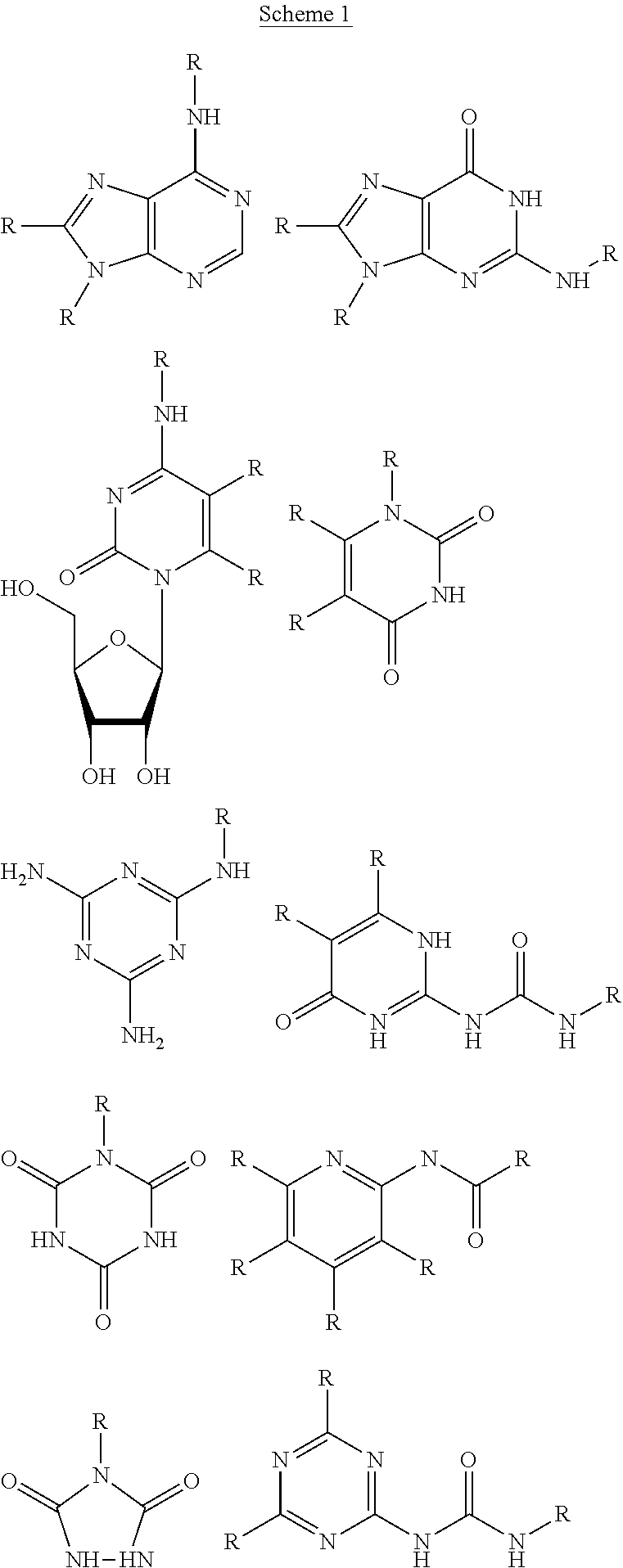

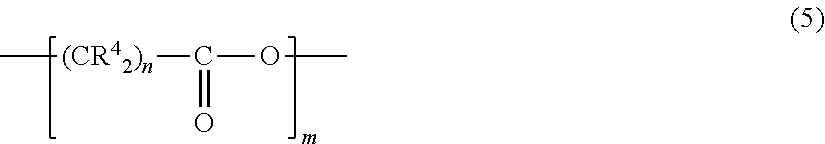

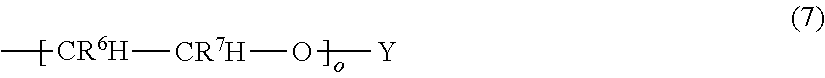

Fluorinated supramolecular polymers

ActiveUS20120136120A1Good processing characteristicsEasy fine-tuningPolyurea/polyurethane coatingsHydrogenPolymer science

Fluorinated supramolecular polymers containing at least 5% by weight of covalently bonded fluorine atoms, based on total weight of the polymers are disclosed. The polymers comprise a fluorinated polymer chain and a (self-)complementary unit capable of forming at least three hydrogen bonds being covalently bonded to the fluorinated polymer chain. Also disclosed are materials comprising (a) a fluorinated supramolecular polymer and (b) a non-fluorinated polymer and / or (c) a fluorinated compound, the non-fluorinated polymer being a polymer containing less than 5% by weight of covalently bonded fluorine atoms, based on the total weight of the non-fluorinated polymer, and the fluorinated compound being either a low molecular weight fluorinated compound comprising at least one fluorine atom and having a molecular weight of 34 to 600 amu, or a fluoropolymer containing at least 5% by weight of covalently bonded fluorine atoms and a Mn from about 600 to about 5000.

Owner:SUPRAPOLIX

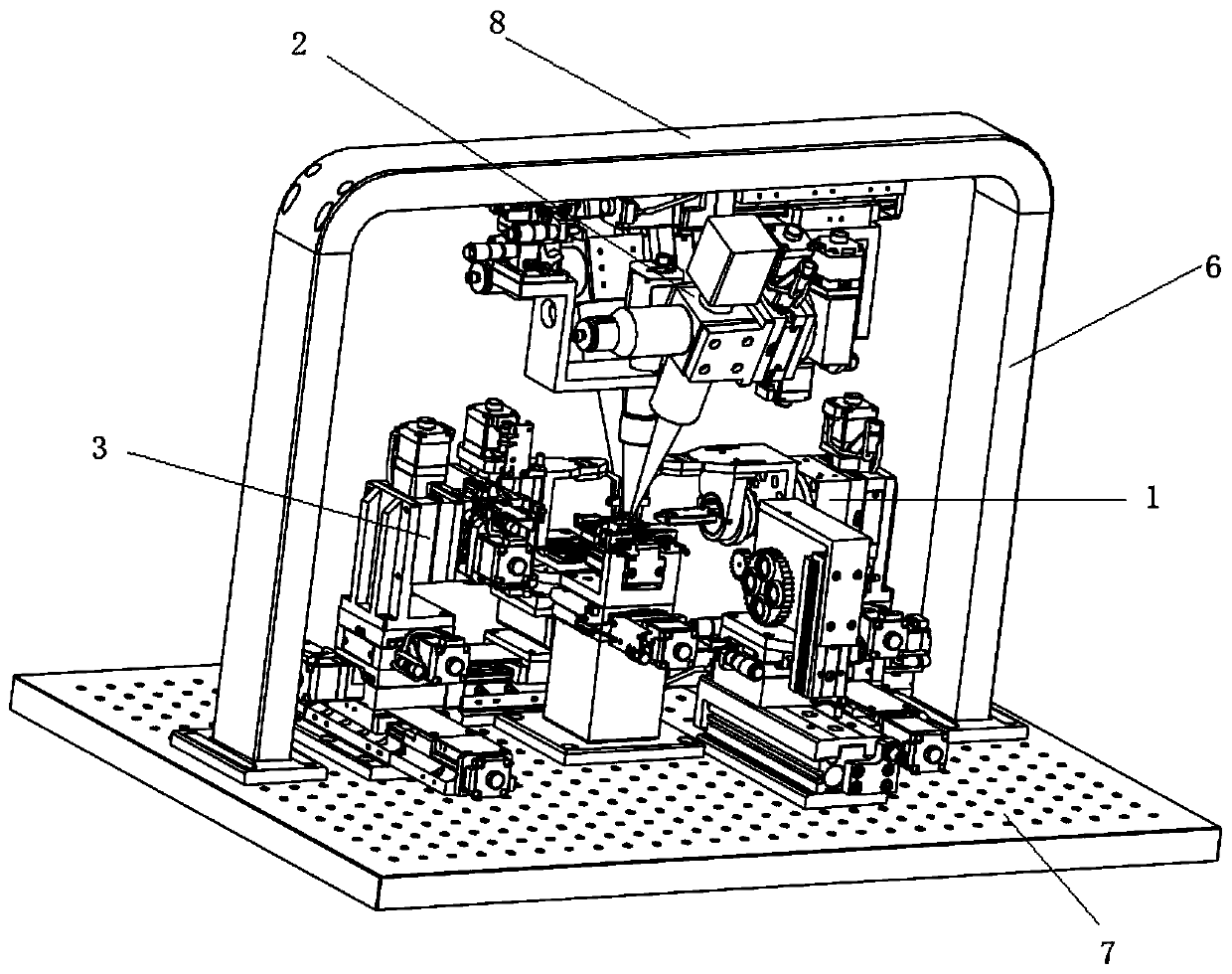

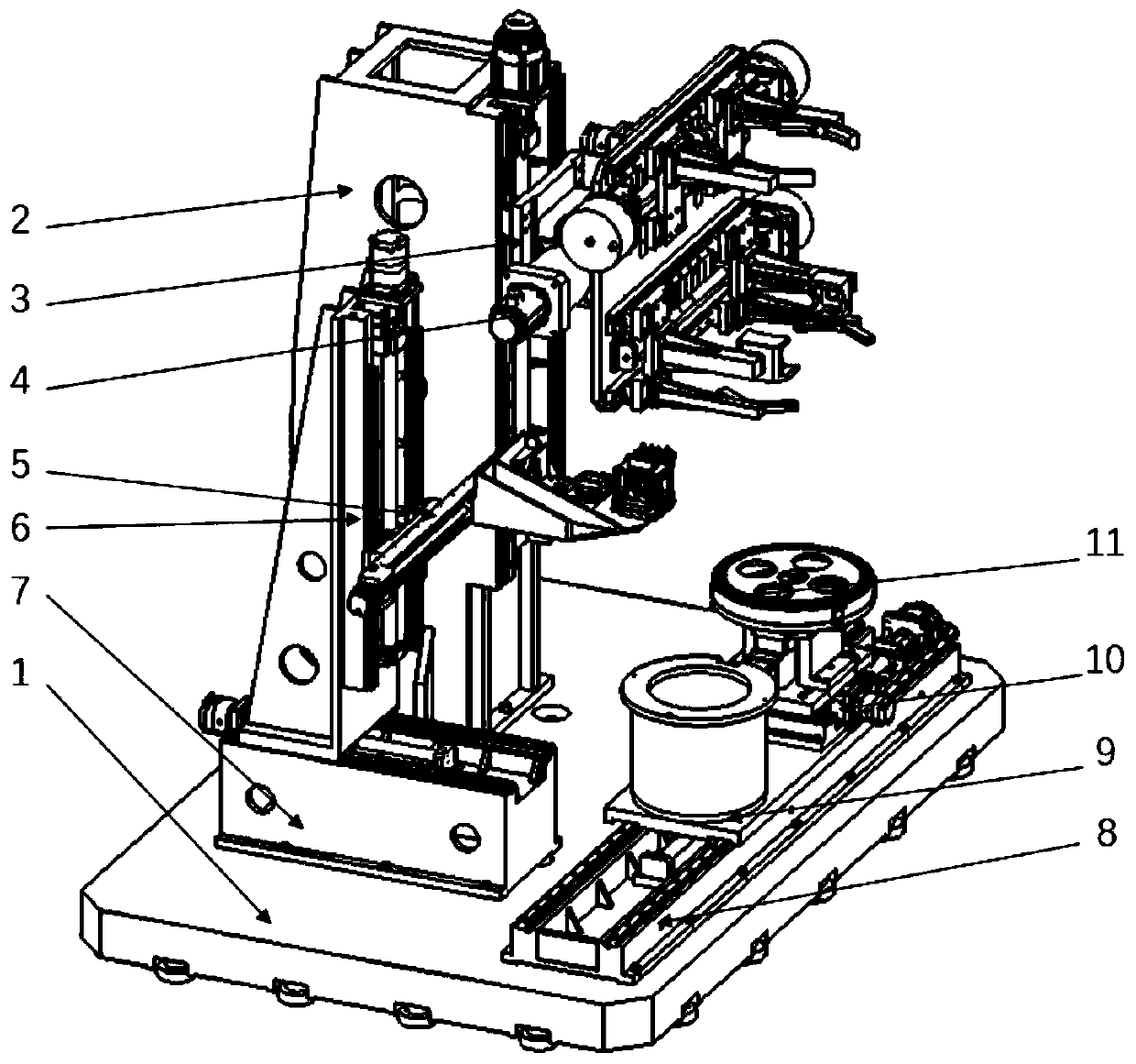

Automatic coupling package method of butterfly-shaped semiconductor laser

ActiveCN109752805AHigh degree of automationIncrease productivityCoupling light guidesProduction lineCoupling

The invention discloses an automatic coupling package method of a butterfly-shaped semiconductor laser, and relates to the field of automatic coupling package of electronic devices. The automatic coupling package method comprises the steps of feeding-onto-machine of accessories, coupling alignment, welding and the like. An automatic coupling package device realizing the automatic coupling packagemethod comprises vertical columns, a transverse beam, an optical fiber clamp, a lens clamp mechanism, a lower clamp device, a material disc mechanism, a laser power meter and the like, wherein the optical fiber clamp, the lens clamp mechanism, the lower clamp device, the material disc mechanism and the laser power meter are arranged on a base; and the positions of the optical fiber clamp, the lensclamp mechanism and an optical fiber automatic angle-adjusting welding device can be adjusted so as to realize accurate coupling package of the butterfly-shaped semiconductor laser. The automatic coupling package method is high in automation degree and high in package efficiency; the coupling package device adopted by the automatic coupling package method is reasonable in structural design, the complete subsequent procedures from coupling alignment to package can be automatically completed, and compared with a traditional manual production line, the automatic coupling package device has the advantages of being easy and convenient to operate, low in production cost, stable in product quality and the like.

Owner:CENT SOUTH UNIV

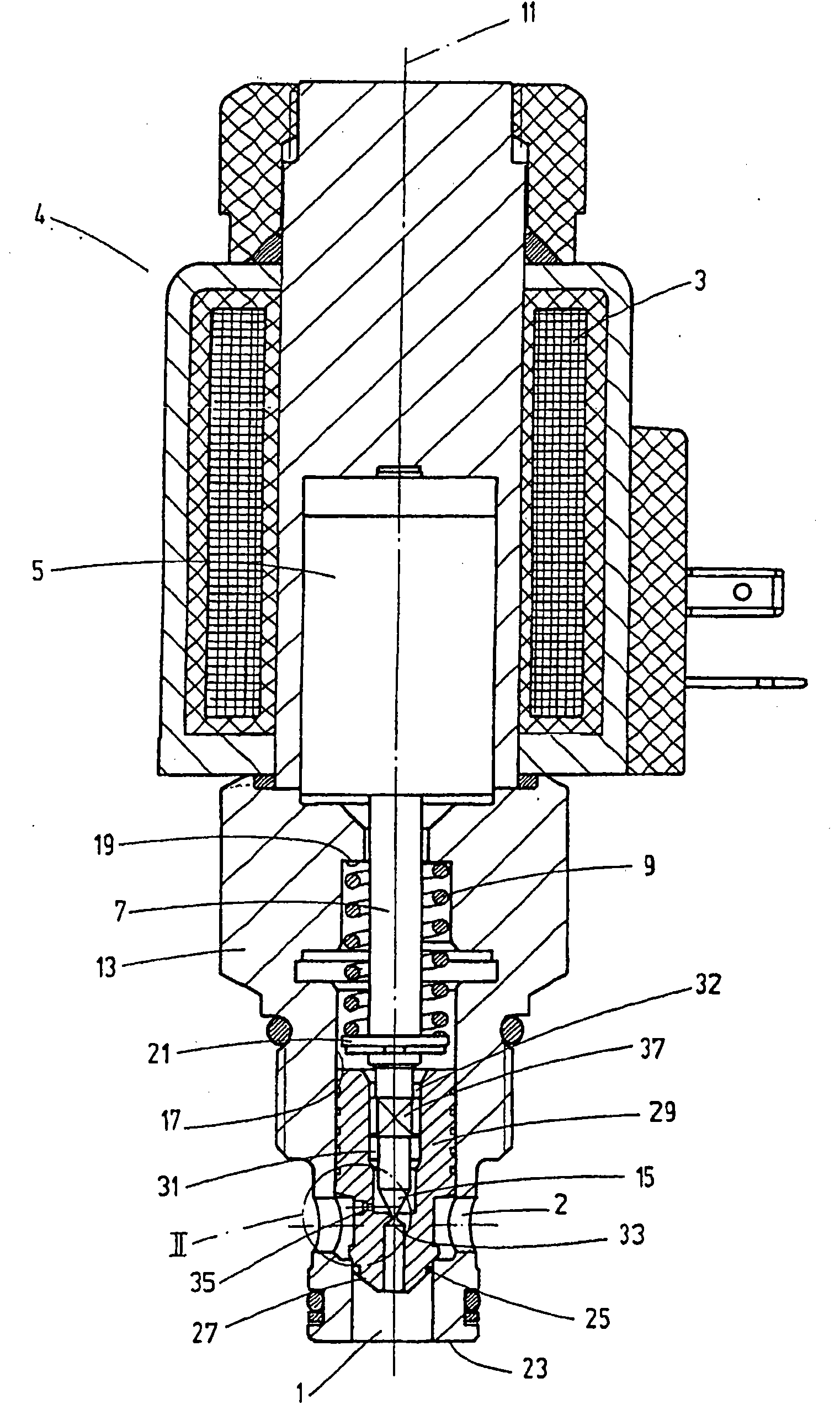

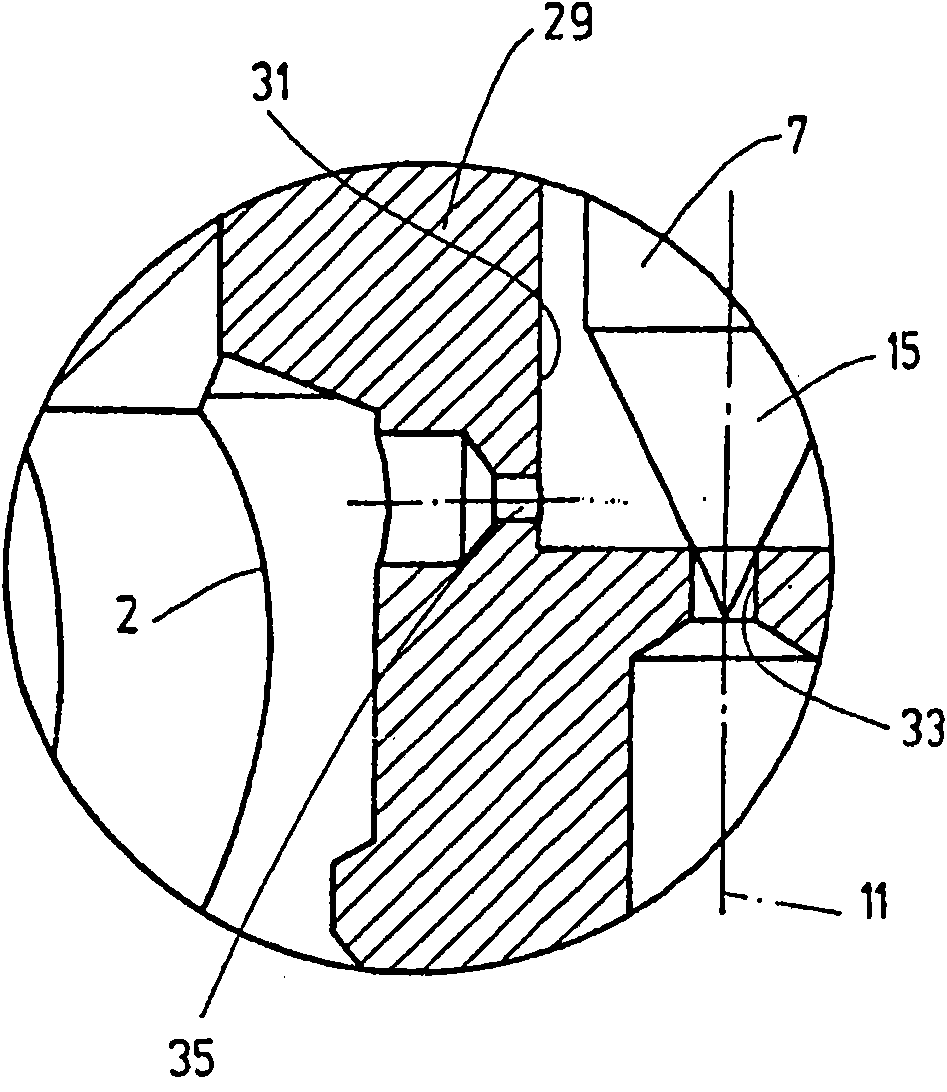

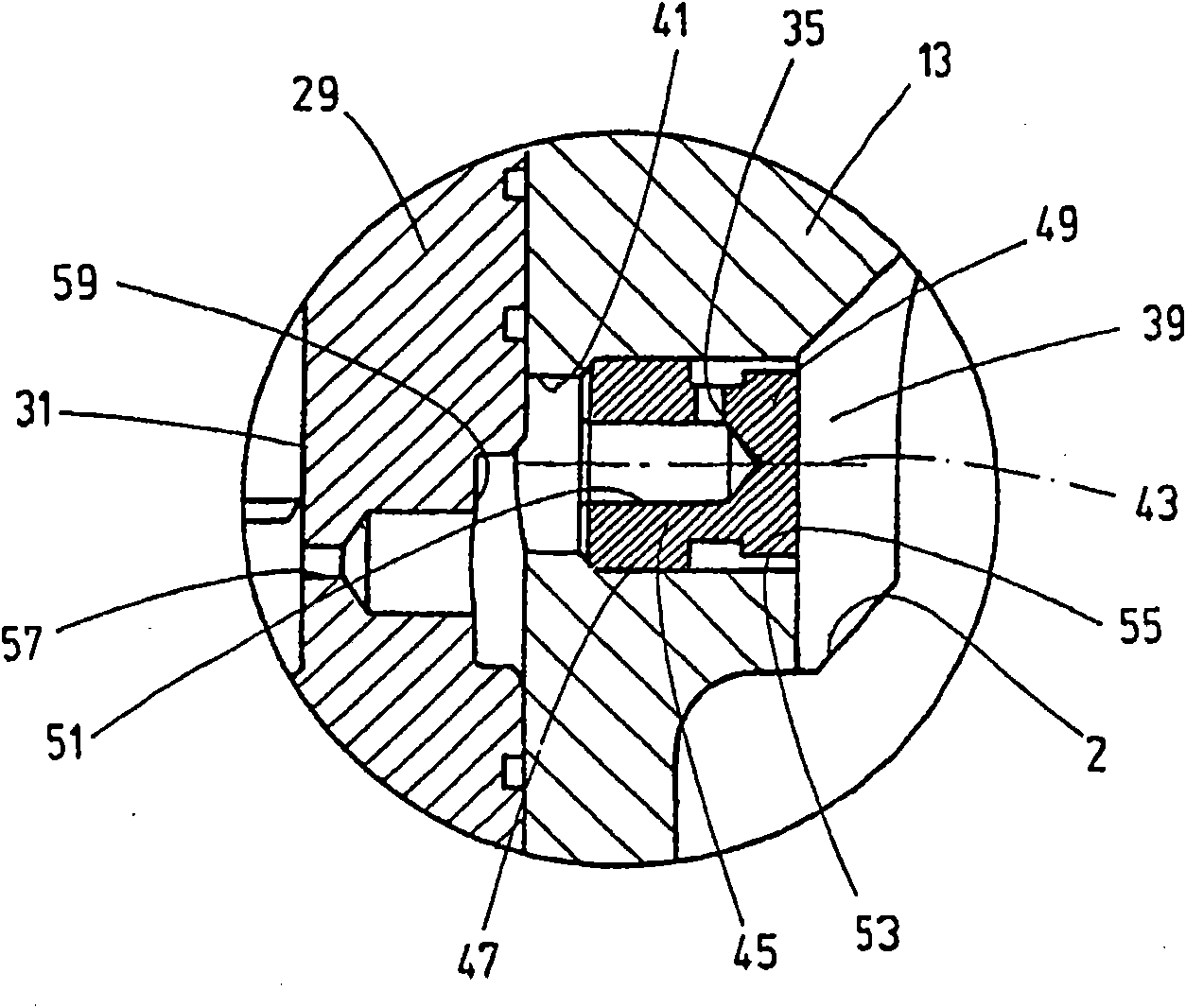

Piloted valve, particularly proportional throttle valve

InactiveCN101925768AAvoid contamination riskPilot control volume flow reductionOperating means/releasing devices for valvesThin material handlingMarine engineeringControl valves

Owner:HYDAC FLUITECHNIK GMBH

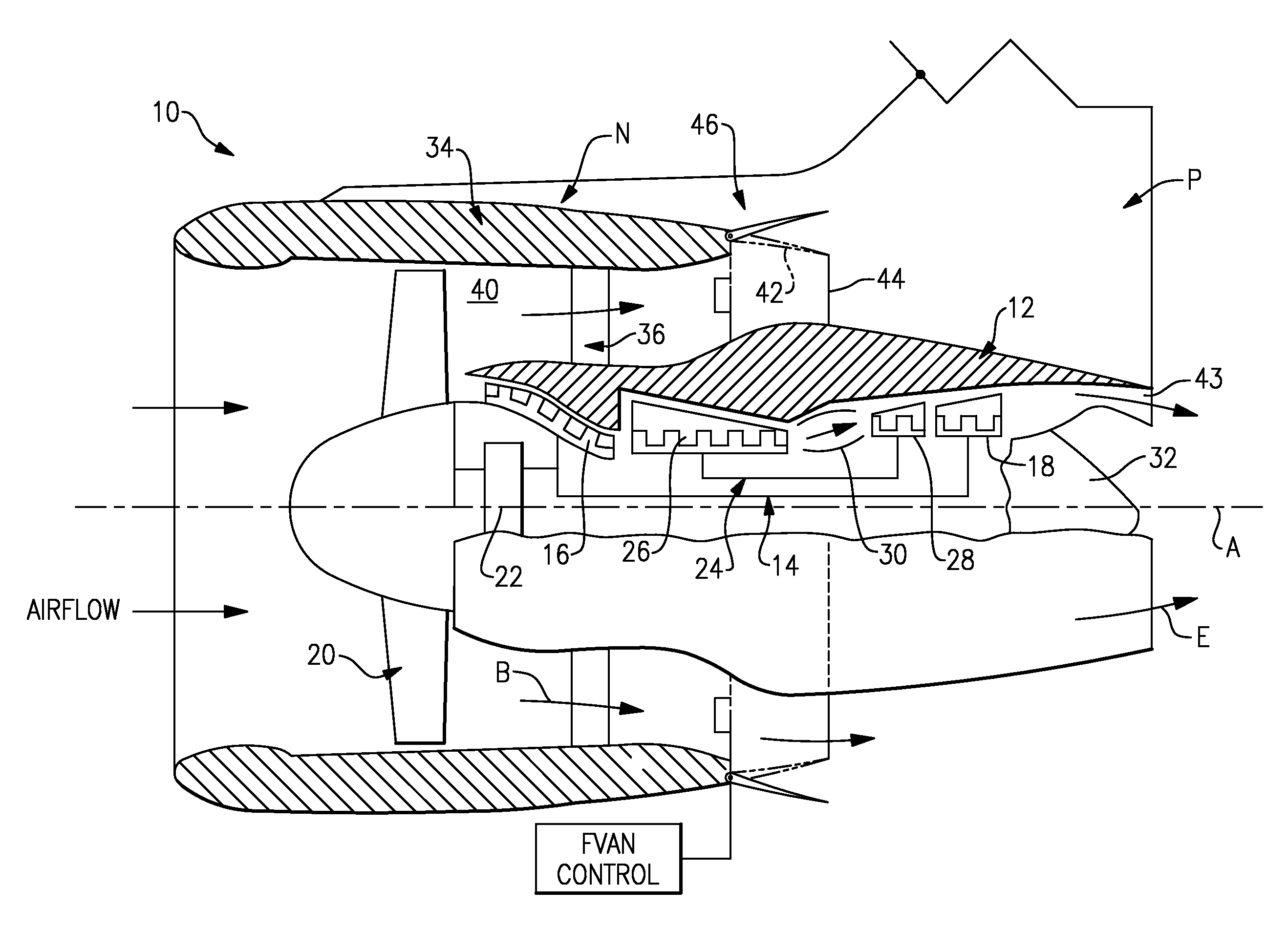

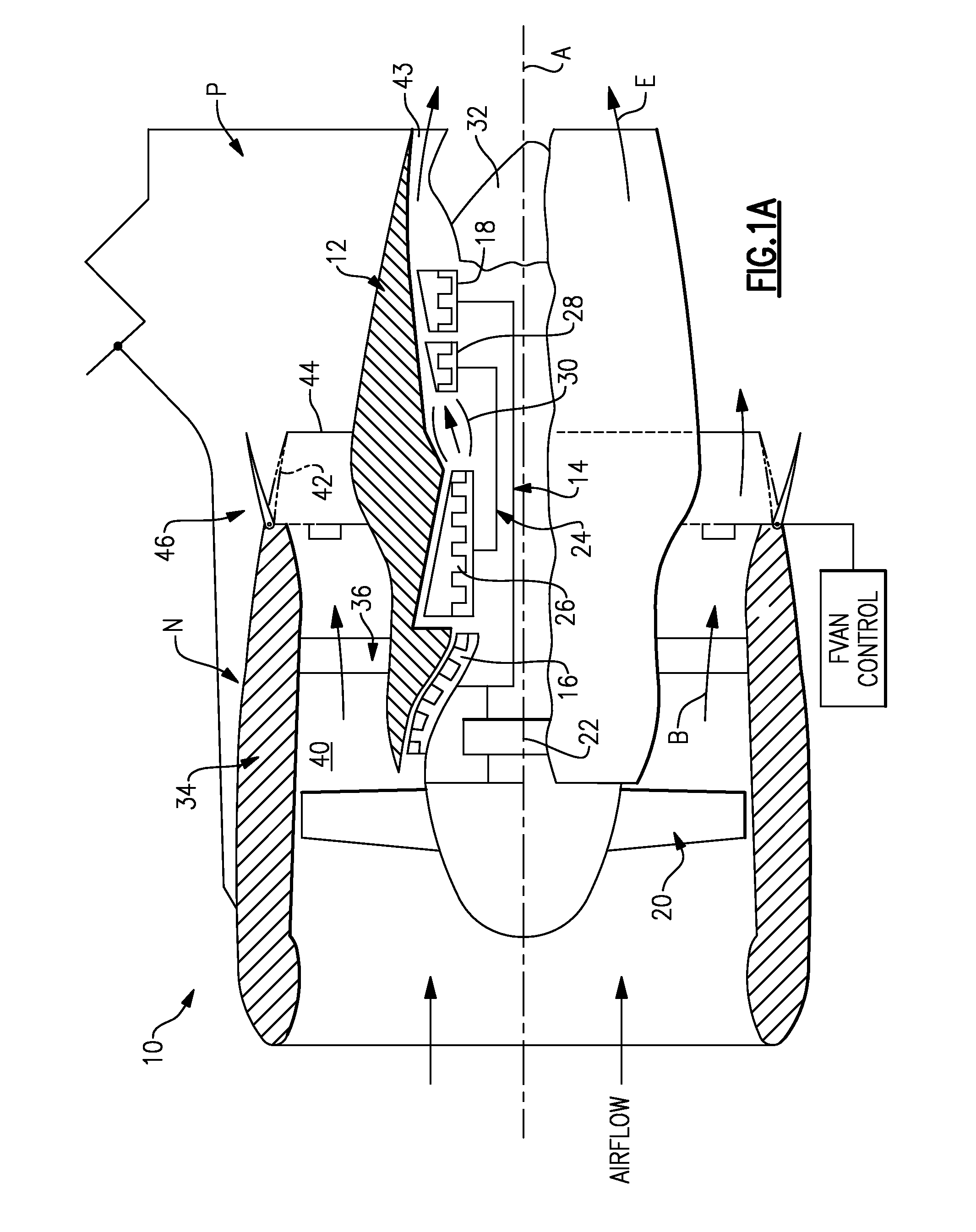

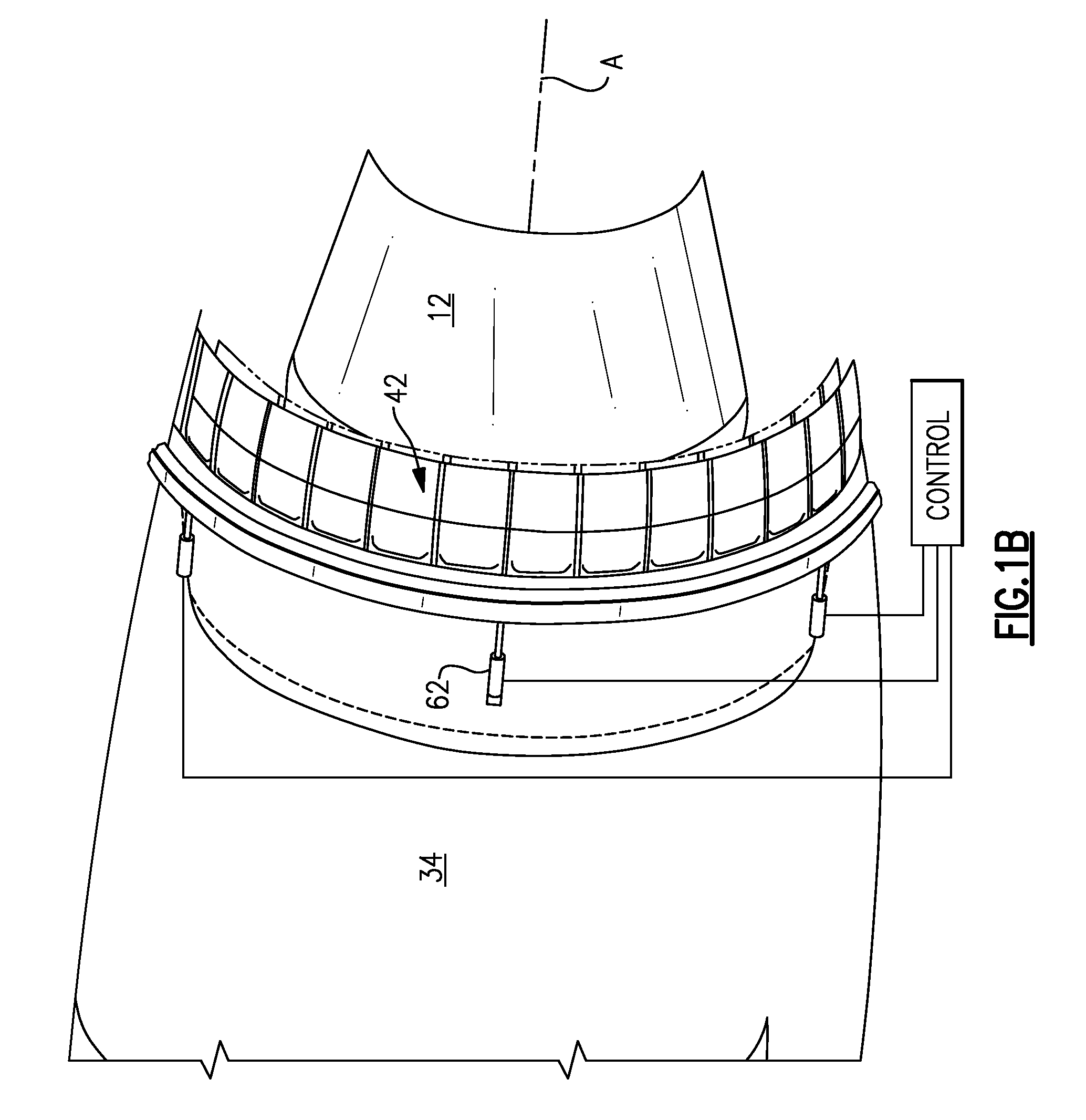

Fan variable area nozzle for a gas turbine engine fan nacelle with drive ring actuation system

ActiveUS20100058769A1Improve mobilityMaximize fuel economyEngine manufactureJet propulsion plantsNacelleEngineering

A fan variable area nozzle (FVAN) includes a flap assembly which varies a fan nozzle exit area. The flap assembly generally includes a multiple of flaps, flap linkages and an actuator system. The actuator system radially and axially translates a drive ring relative an engine centerline axis. A slot within the drive ring receives the flap linkages to asymmetrically and symmetrically vary the fan nozzle exit area in response to movement of the drive ring.

Owner:RTX CORP

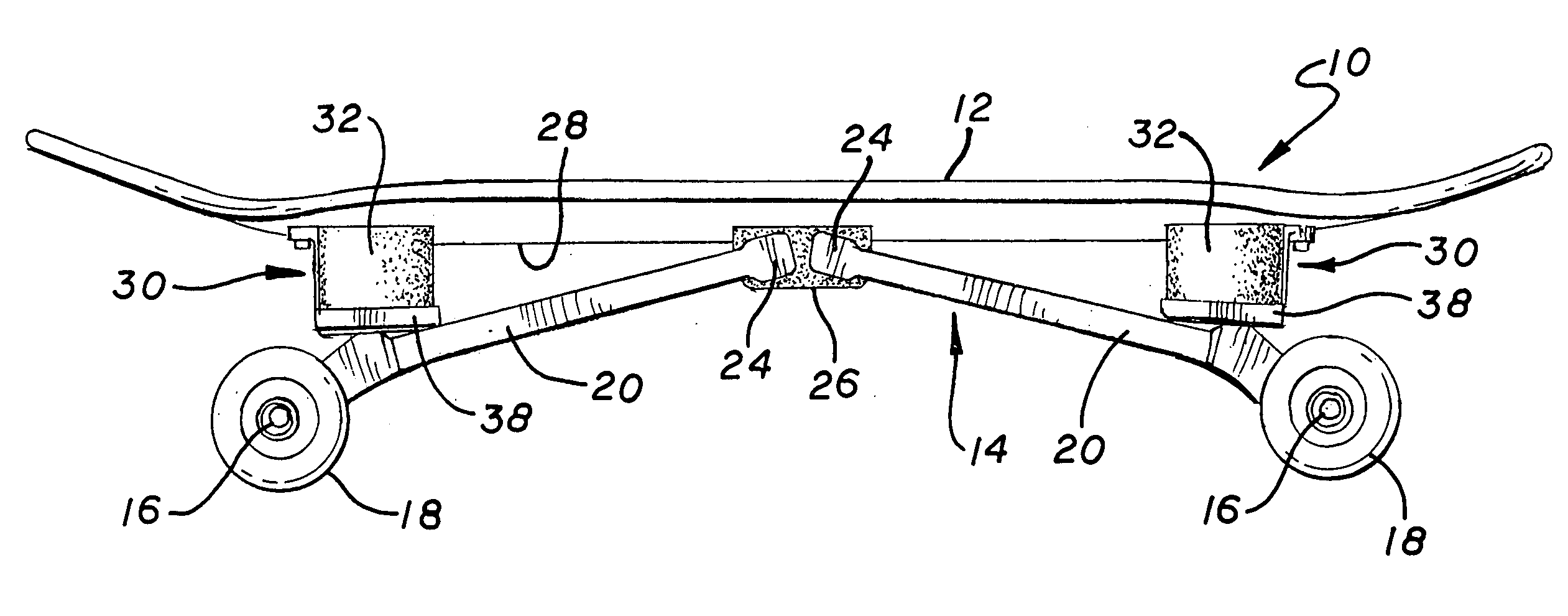

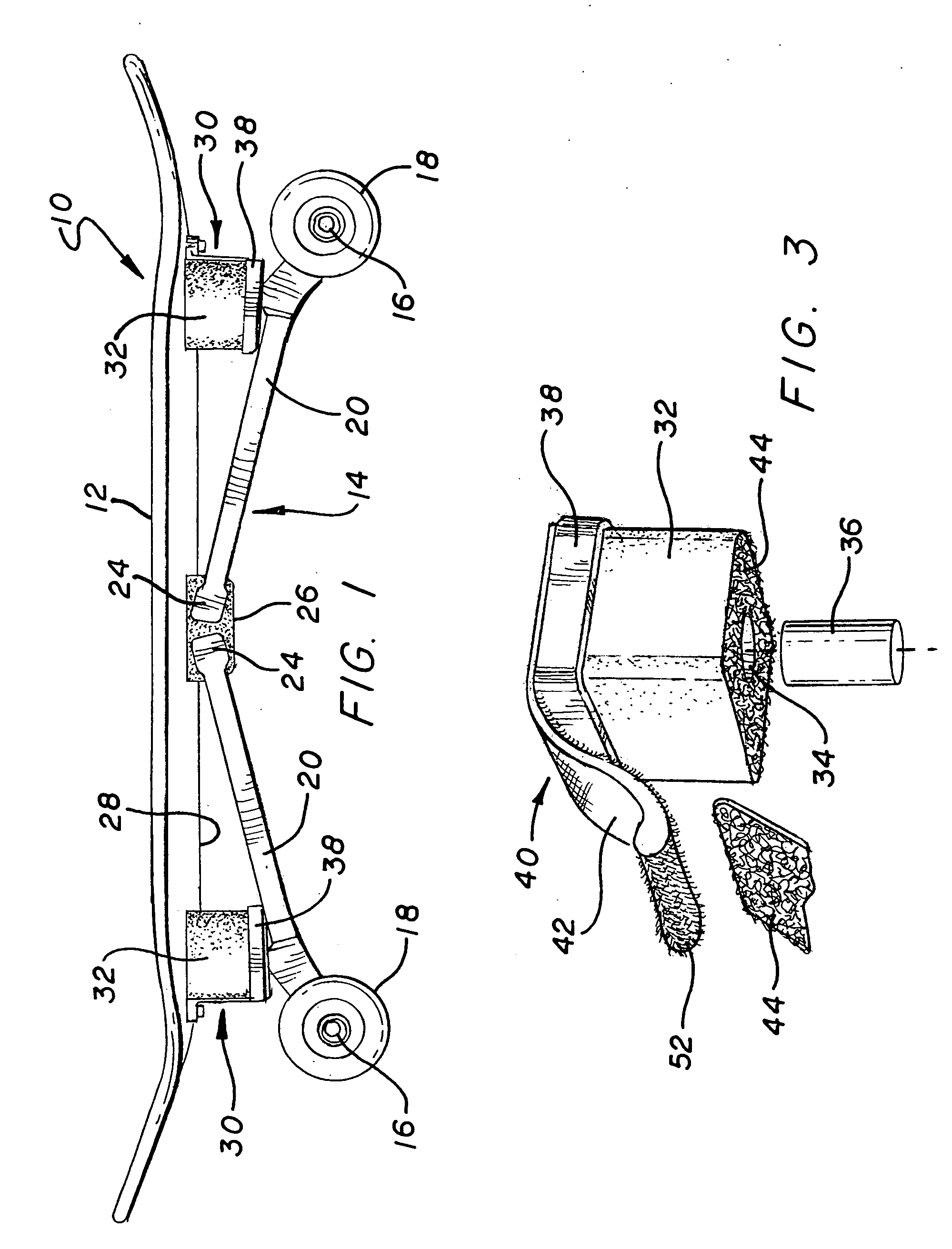

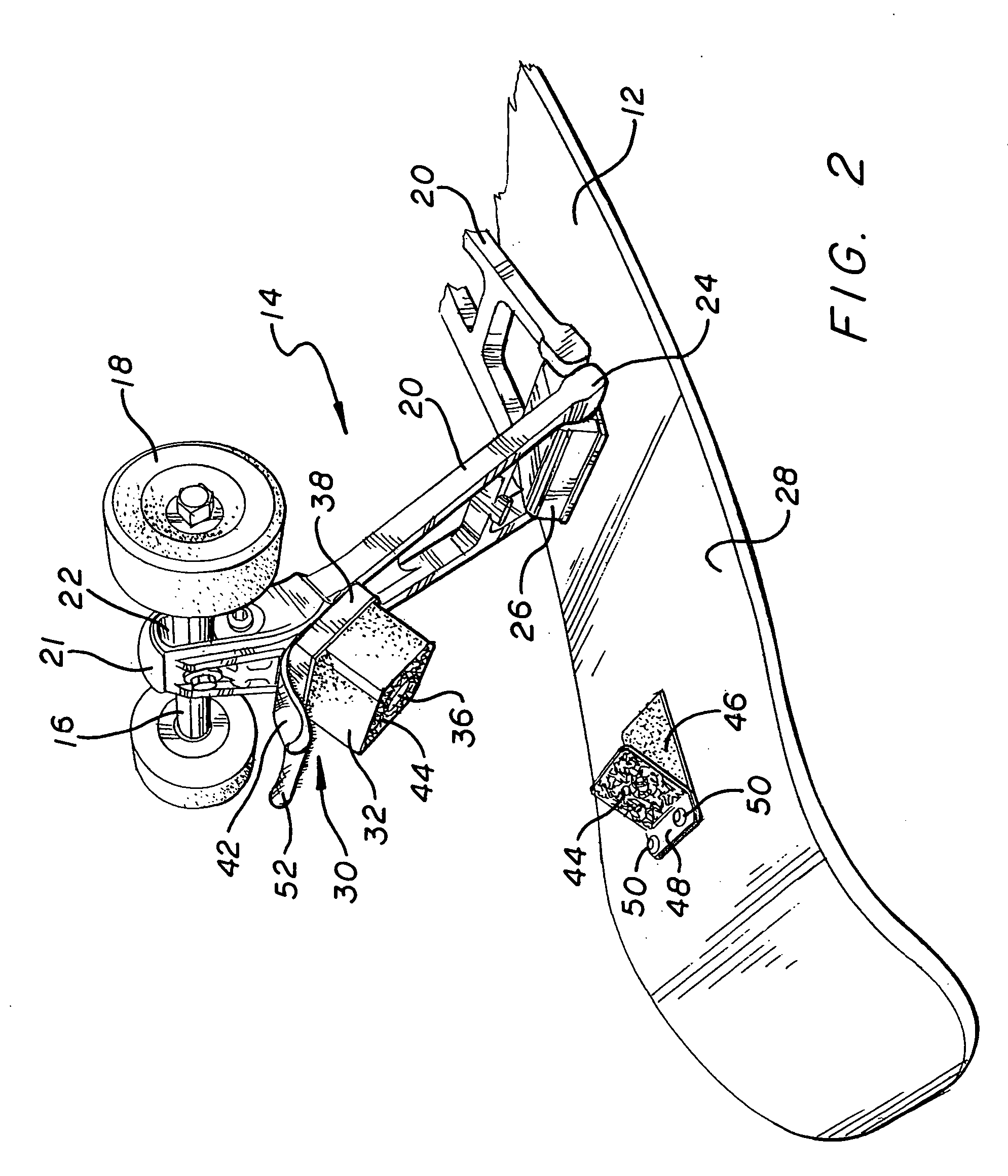

Skateboard assembly with shock absorbing suspension system

InactiveUS20060061054A1Improved and easily changeableEasy to handleRider propulsionSkate-boardsBogieControl system

A skateboard assembly includes a platform or board, a plurality of spaced wheel axles and pivotally secured set of arms connected to the frame at opposite ends of the skateboard. The truck suspension system provides shock-absorbing capabilities and includes an improved shock-absorbing system that can be easily interchanged to create a desired amount of shock-absorbing capability for the skateboard. The shock-absorbing system includes an outer shock member which encases at least one shock-absorbing insert. These shock-absorbing components are placed between each arm of the truck assembly and the board to absorb shock. The shock-absorbing insert is interchangeable so that the amount of shock absorption can be changed depending upon the rider's weight or to attain a particular ride feel. A quick release strap-down system utilizes hook and loop fasteners to create a system for easily and quickly interchanging the shock-absorbing components. A steering control system includes a resilient dampener which is adjustable to restrict the steering rotation of the wheel axles to provide shock absorption for the truck suspension system.

Owner:THIRD GENERATION SKATEBOARDS

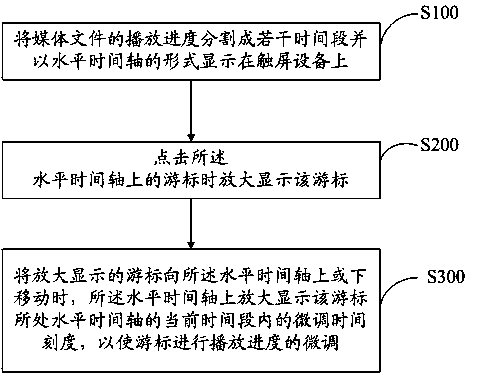

Touch screen equipment and control method of media playing progress thereof

InactiveCN103513913AEasy fine-tuningCarrier indexing/addressing/timing/synchronisingInput/output processes for data processingCurrent timeReal-time computing

The invention provides touch screen equipment and a control method of a media playing progress thereof. The touch screen equipment divides the playing progress of a media file into a plurality of time periods and enables the time periods to be displayed on the touch screen equipment in the mode of a horizontal time shaft; a cursor is displayed in an amplified mode when the cursor on the horizontal time shaft is clicked; when the cursor amplified during displaying is moved upwards or downwards on the horizontal time shaft, a fine adjustment time scale is amplified on the horizontal time shaft so that micro adjustment of the play progress can be carried out through the cursor. According to the touch screen equipment and the control method of the media playing progress thereof, the cursor for representing the playing progress can be amplified during displaying, when the progress of the media file is adjusted on the horizontal time shaft, the cursor displayed in an amplified mode is dragged upwards or downwards on the horizontal time shaft, and meanwhile, the micro adjustment time scale at a current time point of the cursor is displayed on the horizontal time shaft in a superposed mode, so that when the user adjusts the playing progress of the media file, the time scale of the current time period of the cursor can be displayed in an amplified mode, and the user can conveniently fine adjust the playing progress.

Owner:TCL CORPORATION

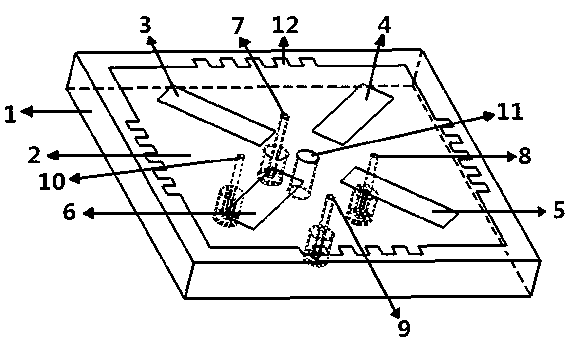

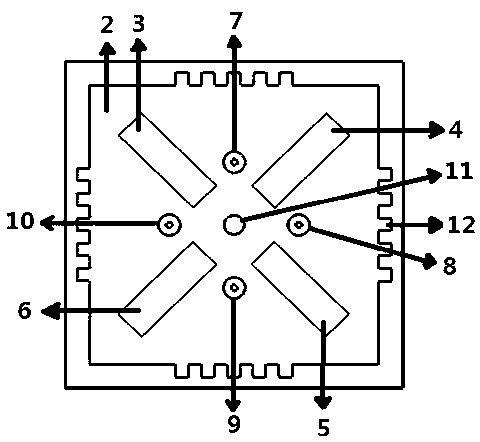

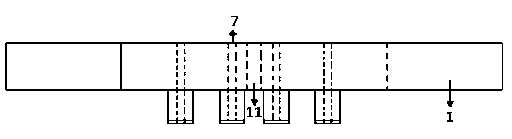

Patch antenna

InactiveCN103280624AImprove working bandwidthRealize widebandAntennas with plural divergent straight elementsRadiating elements structural formsDielectric substrateAxial ratio bandwidth

The invention relates to a patch antenna, which comprises a dielectric substrate (1) and a microstrip patch (2), wherein four radiating grooves (3, 4, 5 and 6) are respectively arranged on a surface of the microstrip patch (2) along diagonal positions of the dielectric substrate (1), and are distributed in a cross shape; four feeding points (7, 8, 9 and 10) are arranged on the microstrip patch (2); two feeding points are respectively arranged on a horizontal geometric center line and a longitudinal geometric center line; and the four feeding points (7, 8, 9 and 10) are symmetrical to a geometric center of the microstrip patch (2), and are provided with feeder lines for feeding. The patch antenna has wider impedance bandwidth and axial ratio bandwidth, and higher gain; the miniaturization of a structural dimension can be realized; and the stability performance of a phase center is better. According to the patch antenna, not only are the impedance bandwidth and the axial ratio bandwidth of the patch antenna greatly improved, but also favorable circular polarization performance and miniaturization effect are achieved, and the patch antenna is particularly suitable for an accurate measurement type navigation terminal.

Owner:GUANGDONG UNIV OF TECH

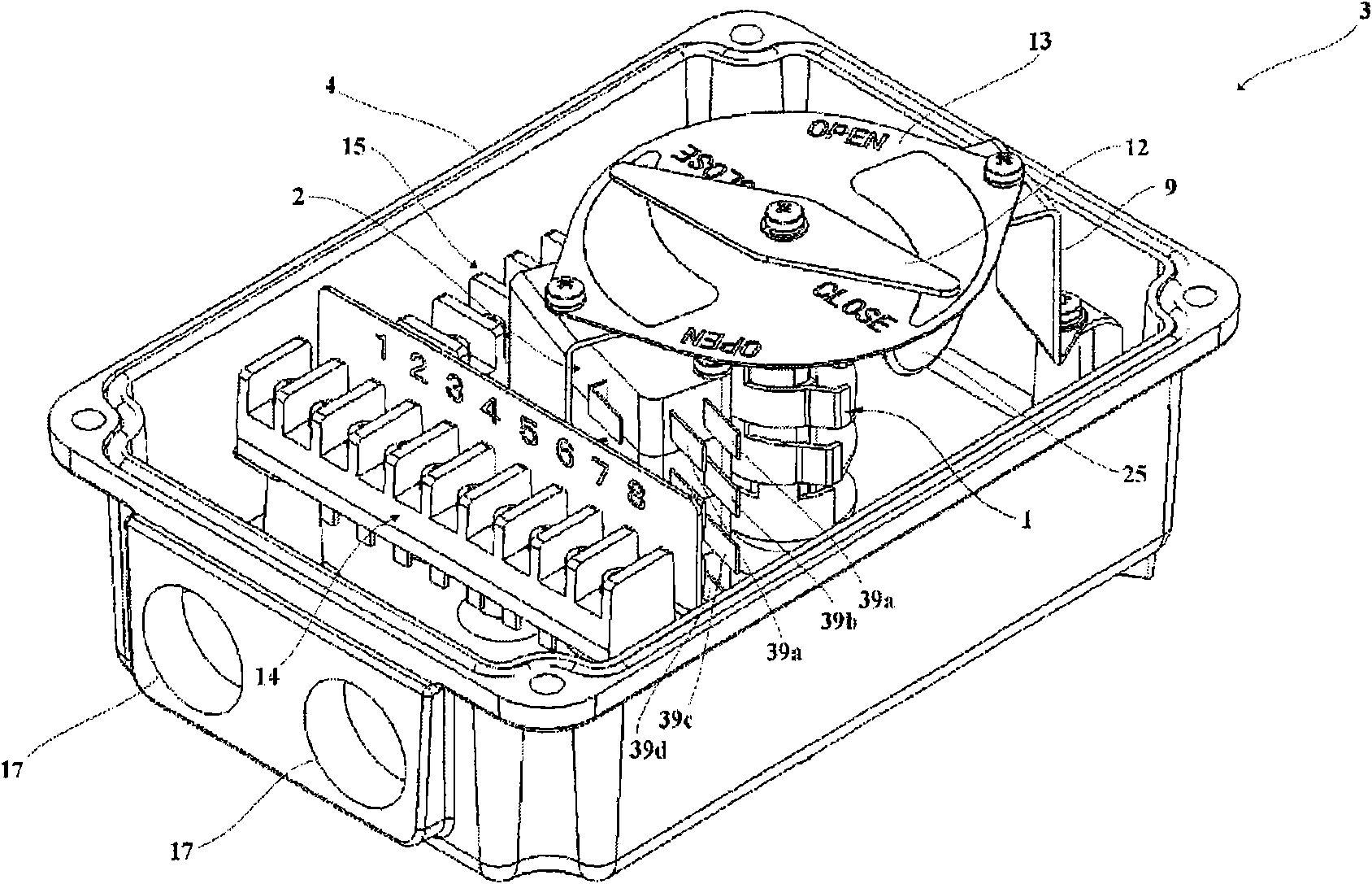

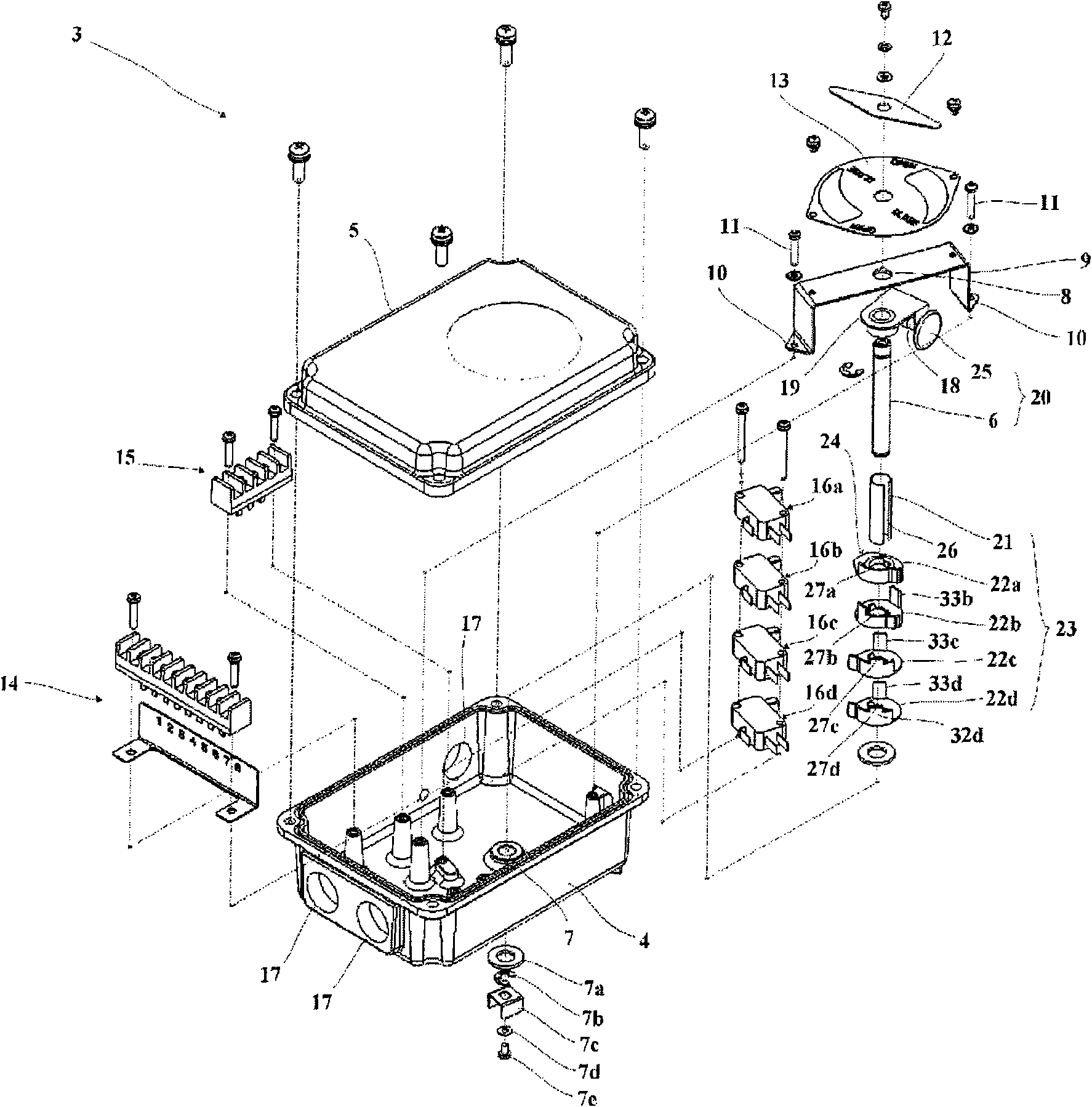

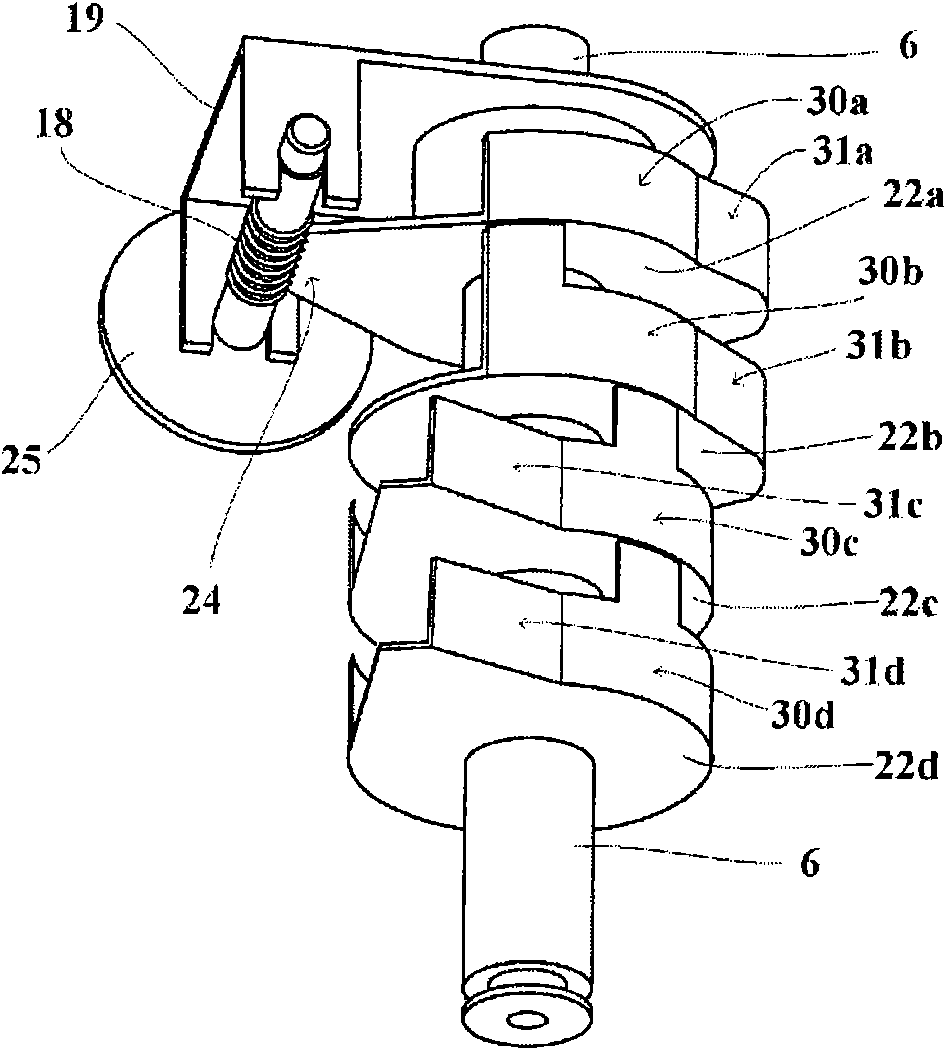

Valve opening degree detection device

InactiveCN101627243AEasy fine-tuningReduce the number of partsOperating means/releasing devices for valvesElectric switchesSynchronismValve opening

A valve opening degree detection device using a reduced number of parts, occupying less space, allowing multiple switches to be adjusted by a single adjustment, performing ON / OFF control of a switch at a desired angle, and enhancing work efficiency. ¢MEANS FOR SOLVING PROBLEMS! The valve opening degree detection device has a detection shaft rotating in synchronism with a valve rod corotating with a valve body of a valve device. A worm gear is connected to the detection shaft so as to corotate with it, a tubular member is rotatably fitted over the detection shaft, and a cam having a worm wheel meshing with the worm gear is corotatably connected to the tubular member. The limit switches are operated by the above construction.

Owner:TOMOE TECH RES CO LTD

Reconfigurable man-machine coordination assembling system for aero-engine

ActiveCN110238649AReduce the difficulty of operationOperation Difficulty GuaranteedAssembly machinesWork holdersAviationProduction rate

The invention discloses a reconfigurable man-machine coordination assembling system for an aero-engine. The system comprises a base, a lifting mechanism, a turnover mechanism, an angular fine-adjustment mechanism, a clamping mechanism, a feeding and assembling mechanism and a detecting mechanism, wherein the lifting mechanism drives the turnover mechanism to move up and down vertically; a feeding station and an assembling station are disposed on the feeding and assembling mechanism; the feeding station and the assembling station move horizontally in an X direction together; the assembling station can move horizontally in a Y direction and rotate around a C axis; to-be-assembled parts are put on the feeding station and the assembling station separately; the turnover mechanism drives the clamping mechanism to rotate around a B axis; the angular fine-adjustment mechanism is mounted between the clamping mechanism and the turnover mechanism so as to achieve fine-adjustment of the rotating amount of the clamping mechanism around an A axis; and the detecting mechanism finishes measurement of the plane gaps among the parts and the angle deflection amount, and deviation amount adjustment is finished through the feeding and assembling mechanism, the turnover mechanism and the angular fine-adjustment mechanism. By means of the reconfigurable man-machine coordination assembling system for the aero-engine, the on-site operation difficulty can be effectively lowered for workers, and the production rate is improved while the safety is ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Probe testing device

ActiveCN101644724AOvercome height restrictionsReduce difficultyElectrical measurement instrument detailsElectrical testingEngineeringTest fixture

Owner:MICROELECTRONICS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com