Universal joint-driven inclined wide-and-narrow separating-planting mechanism of rice transplanter

A technology that drives tilting and universal joints. It is applied in the direction of transplanting machinery, application, agriculture, etc., and can solve the problem that the transplanting position cannot form a wide and narrow row of rice seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

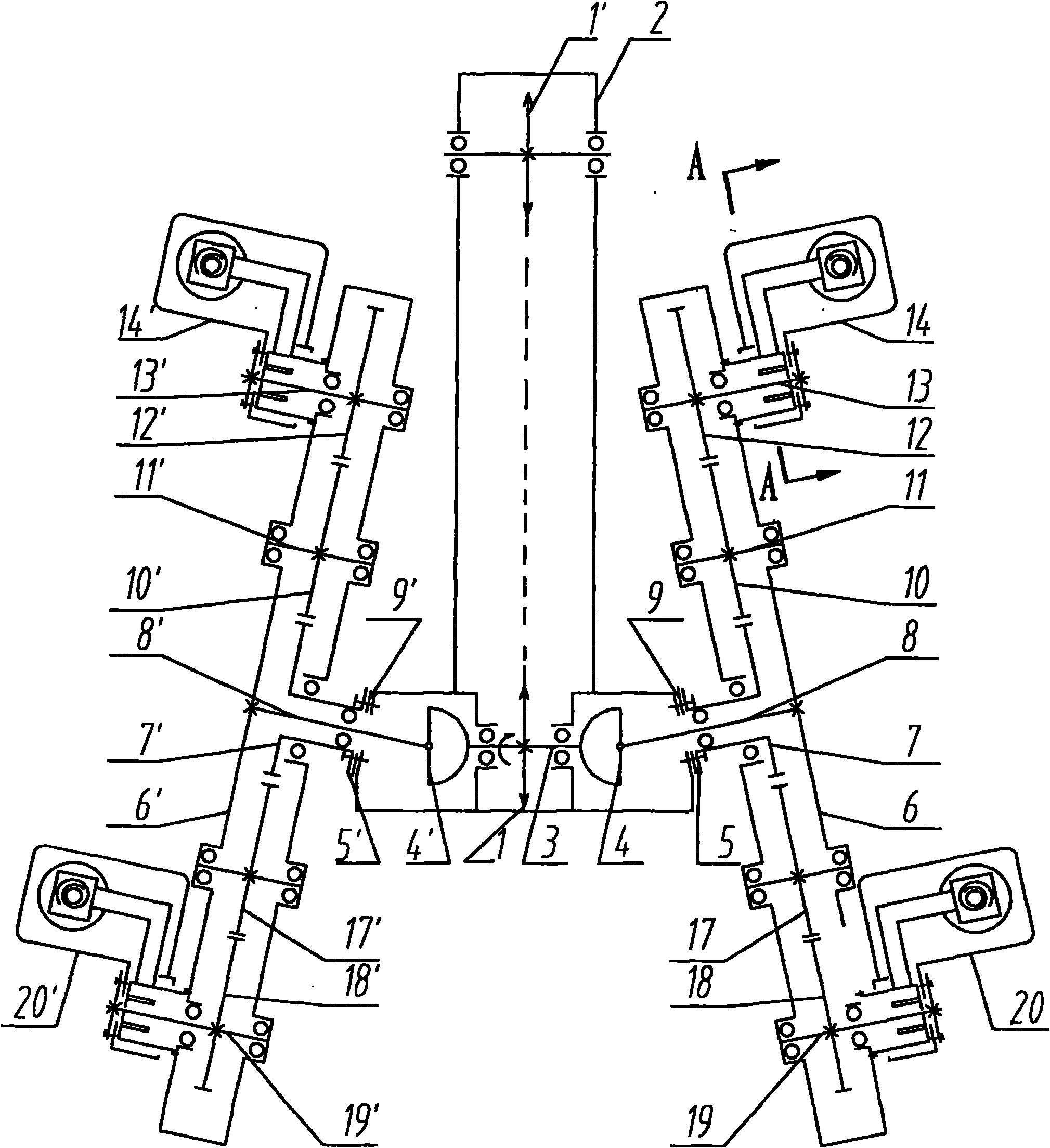

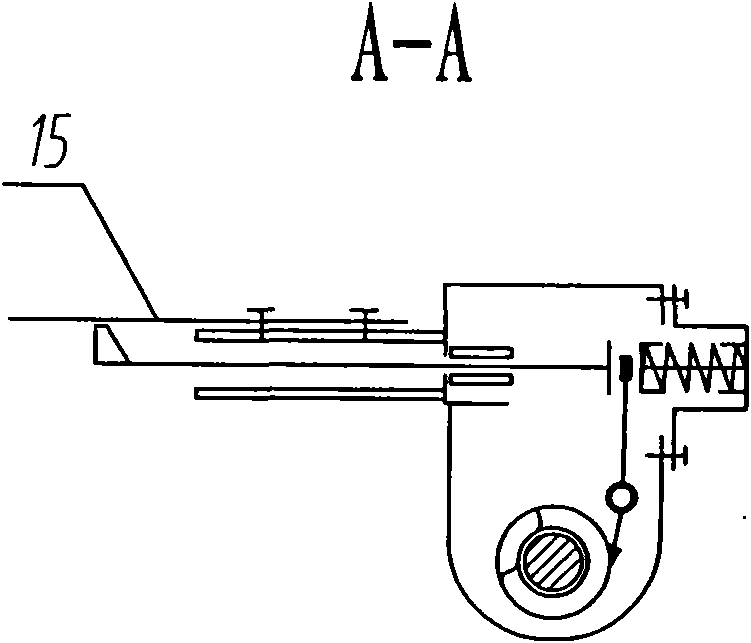

[0021] Such as figure 1 As shown, the power of the universal joint-driven inclined wide-narrow planetary gear train insertion mechanism of the present invention is transmitted from the first sprocket 1' to the second sprocket 1 through the chain, and the second sprocket 1 is fixed on the sprocket shaft 3 , the left and right transmission boxes with the same structure are respectively installed on both sides of the sprocket shaft 3, and the planting arms on the upper and lower sides of the left and right transmission boxes are installed; The output shaft 8 of the universal joint and the sprocket shaft 3 form an inclination angle, and the right end of the output shaft 8 of the right universal joint is fixedly connected with the right planetary carrier 6. In the right planetary carrier 6, the right sun gear 7 is supported on the output of the right universal joint through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com