Reconfigurable man-machine coordination assembling system for aero-engine

An aero-engine and assembly system technology, applied to assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problems of large volume and weight of the turbine case and combustion chamber, difficulty in handling and turning over during assembly, and long assembly cycle , to achieve the effect of compact structure, strong load capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

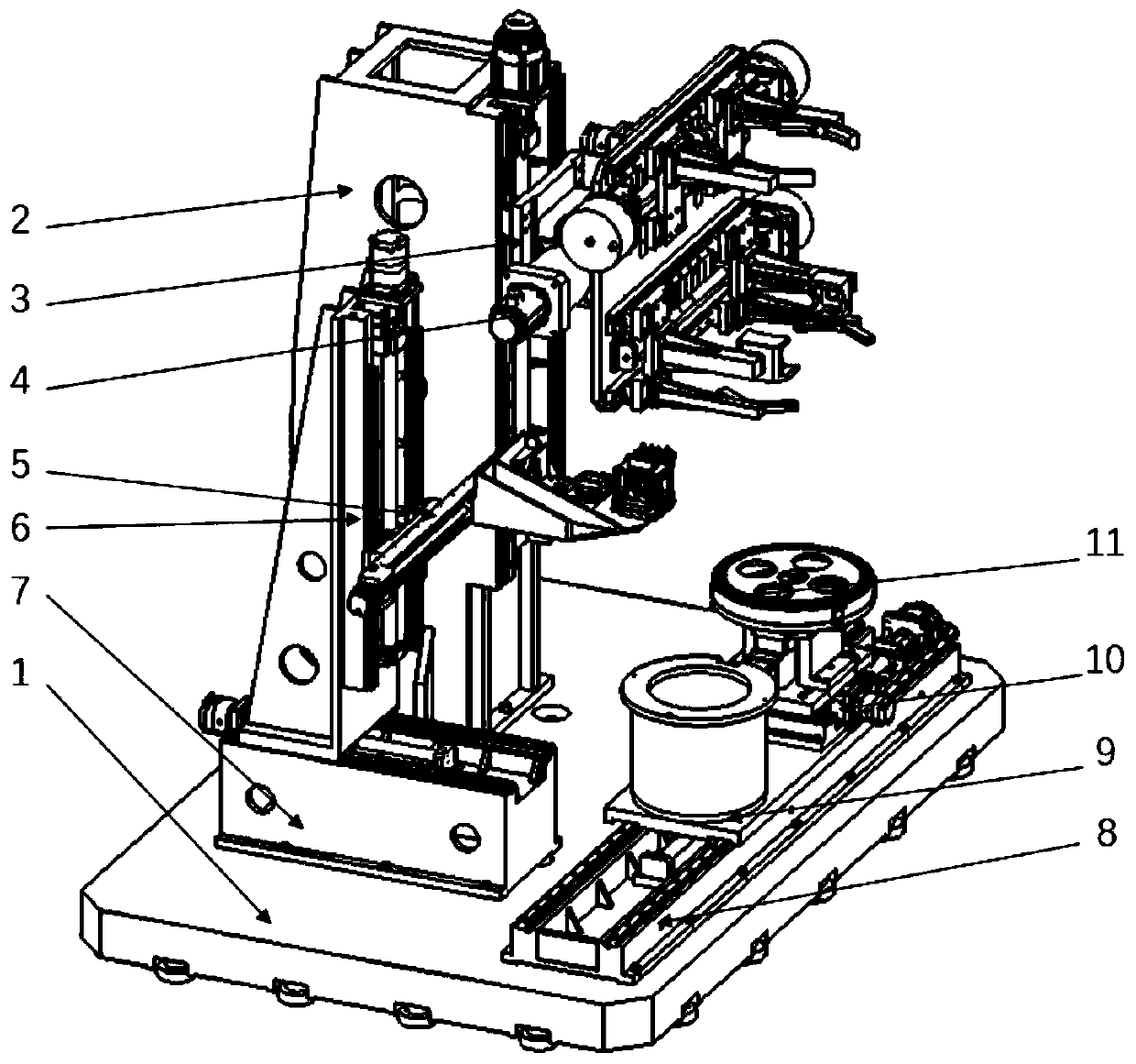

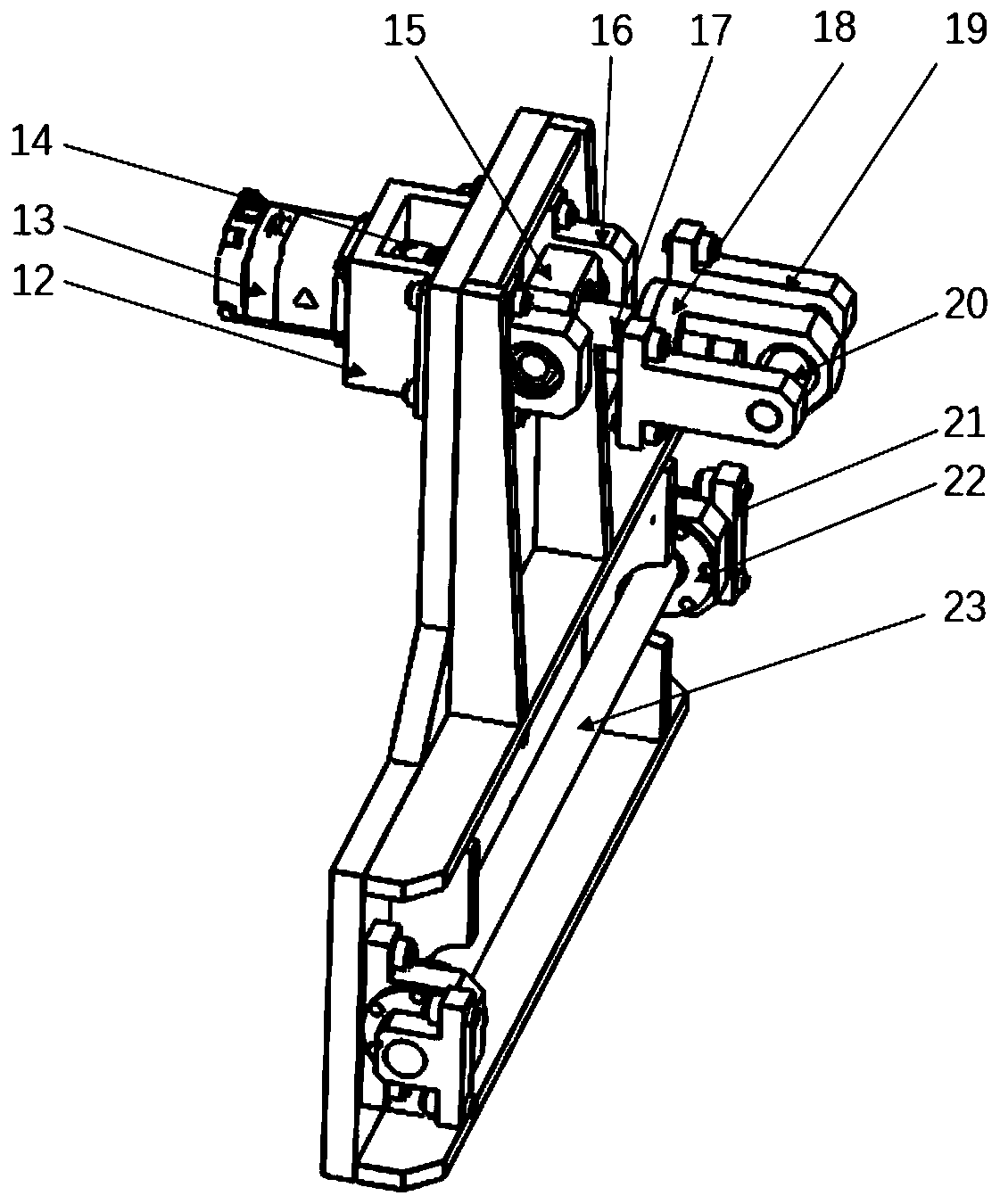

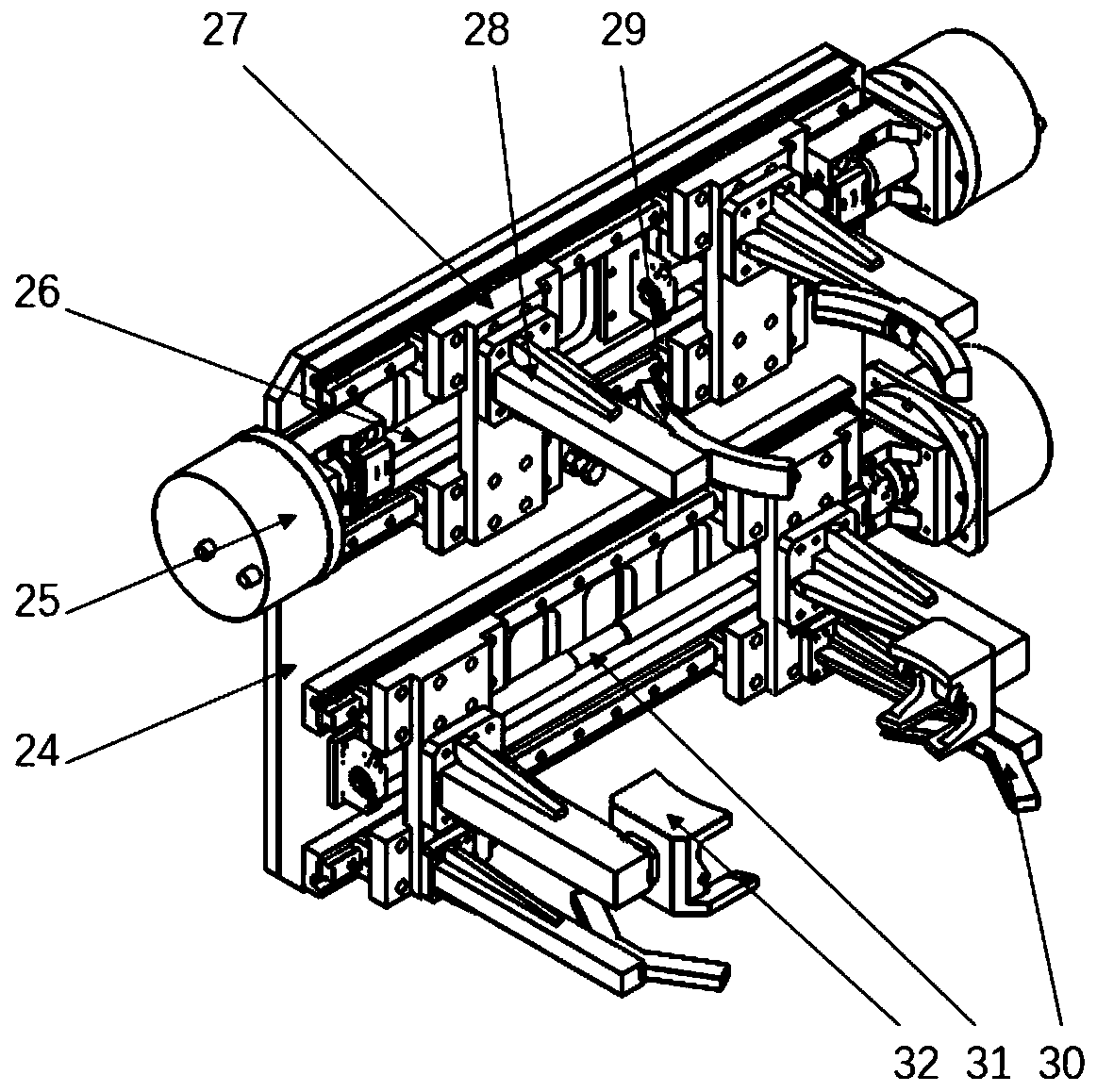

[0028] Attached below Figure 8 The two cylindrical parts to be assembled (the longer axial length is the turbine casing, and the shorter axial length is the combustion chamber) describe the present invention in detail:

[0029] Such as figure 1As shown, the present invention provides a reconfigurable human-machine collaborative assembly system for aero-engines. The whole system is supported by a cast iron base 1, carrying a column 2, a detection mechanism Y-direction translation platform 7, and an X-direction translation platform. 8. Each mechanism is fixed on the base of the cast iron material by screws. The turning mechanism 4 and other mechanisms are connected by screws in turn and finally attached to the front surface of the column 2. The Y-direction displacement platform 7 of the detection mechanism is used as a support for the detection mechanism, and it is connected with the X-direction of the detection mechanism. The translation platform 5 and the detection mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com