Method for preparing false tooth support through 3D printing laser stereo-lithography technology

A 3D printing and three-dimensional molding technology, applied in the field of medical devices, can solve the problems of unmeasurable service life, single shape, and difficulty in meeting the individual needs of patients in size design. Satisfaction, excellent osseointegration properties and effects of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

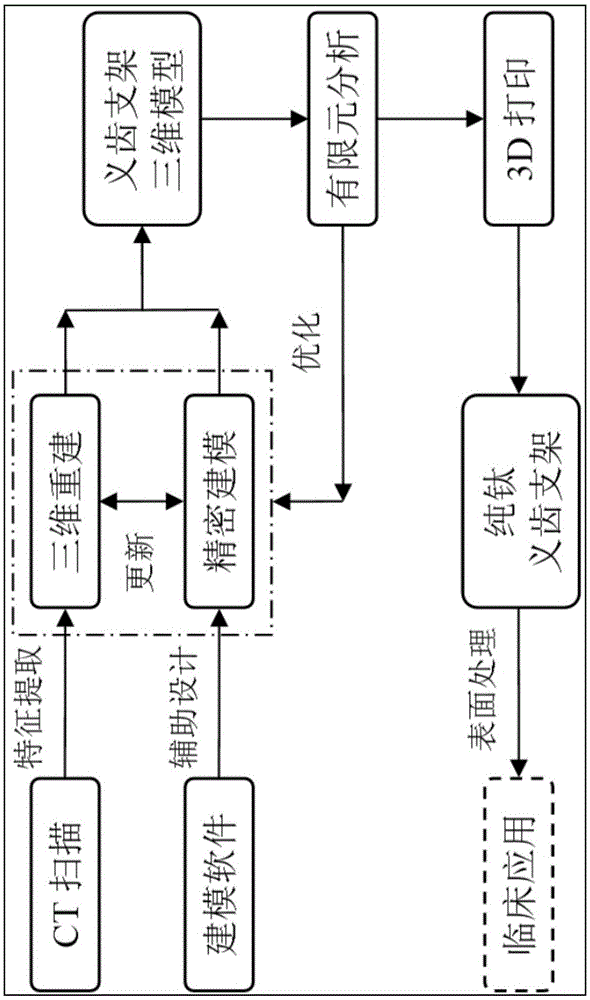

[0031] refer to Figure 1 to Figure 8 , the present invention is a method for manufacturing a denture bracket based on 3D printing laser stereoforming technology, comprising the following steps:

[0032] a) Construct the three-dimensional model of the denture bracket through forward modeling or reverse modeling;

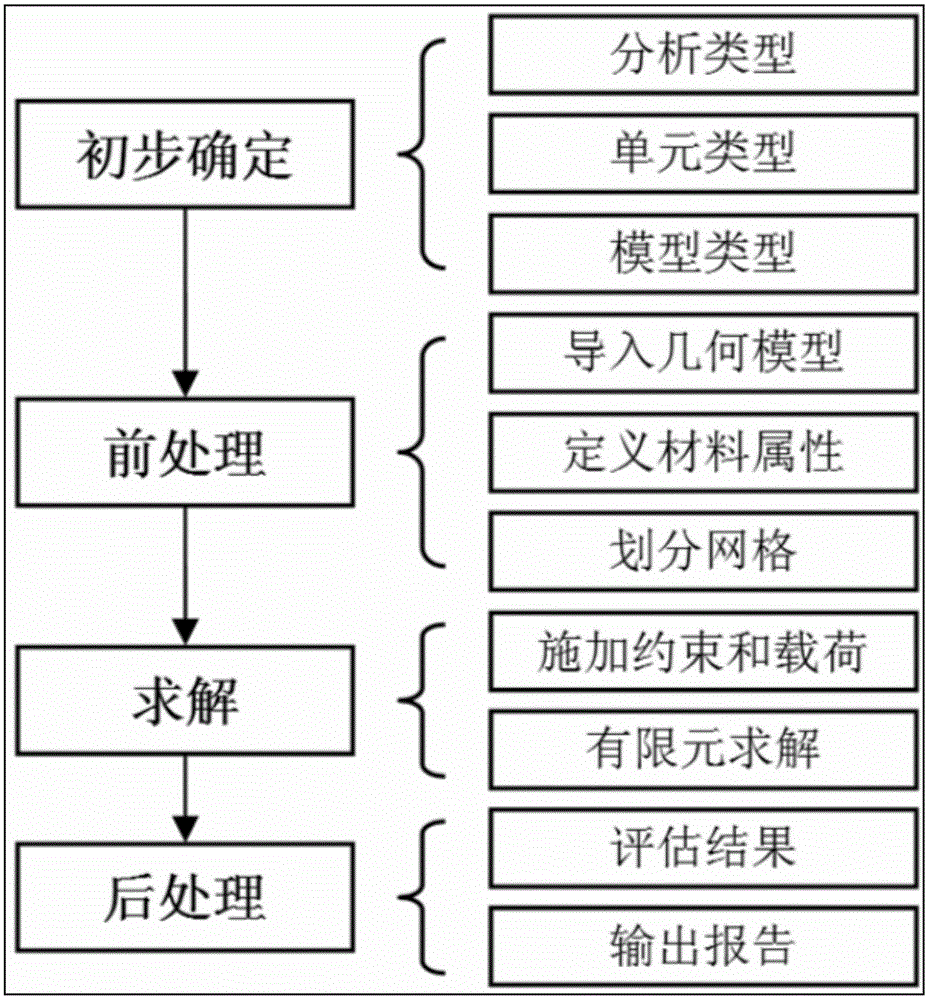

[0033] b) Stress analysis and fatigue analysis of the three-dimensional model of the denture bracket using finite element technology;

[0034] c) Print the denture bracket through 3D printing laser stereoforming technology;

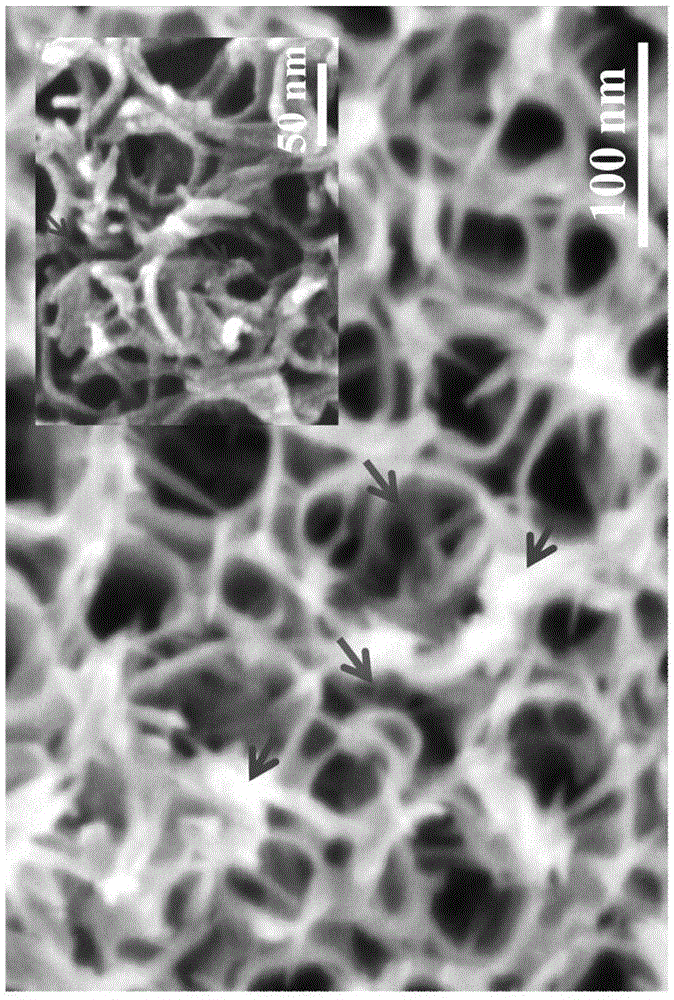

[0035] d) Using anodic oxidation and / or electrochemical deposition methods to carry out surface treatment on the denture bracket;

[0036] e) Use scanning electron microscope and / or electron probe and / or X-ray photoelectron spectroscopy and / or laser confocal microscope and / or goniometer to carry out biological evaluation on the denture frame;

[0037] f) Comparative analysis of the electrochemical behavior of localized corrosion on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com