Patents

Literature

1992results about "Dental prosthetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Personal fit medical implants and orthopedic surgical instruments and methods for making

InactiveUS20070118243A1Minimizing Ni toxicityImprove visualizationElectrotherapyMechanical/radiation/invasive therapiesPersonalizationManufacturing technology

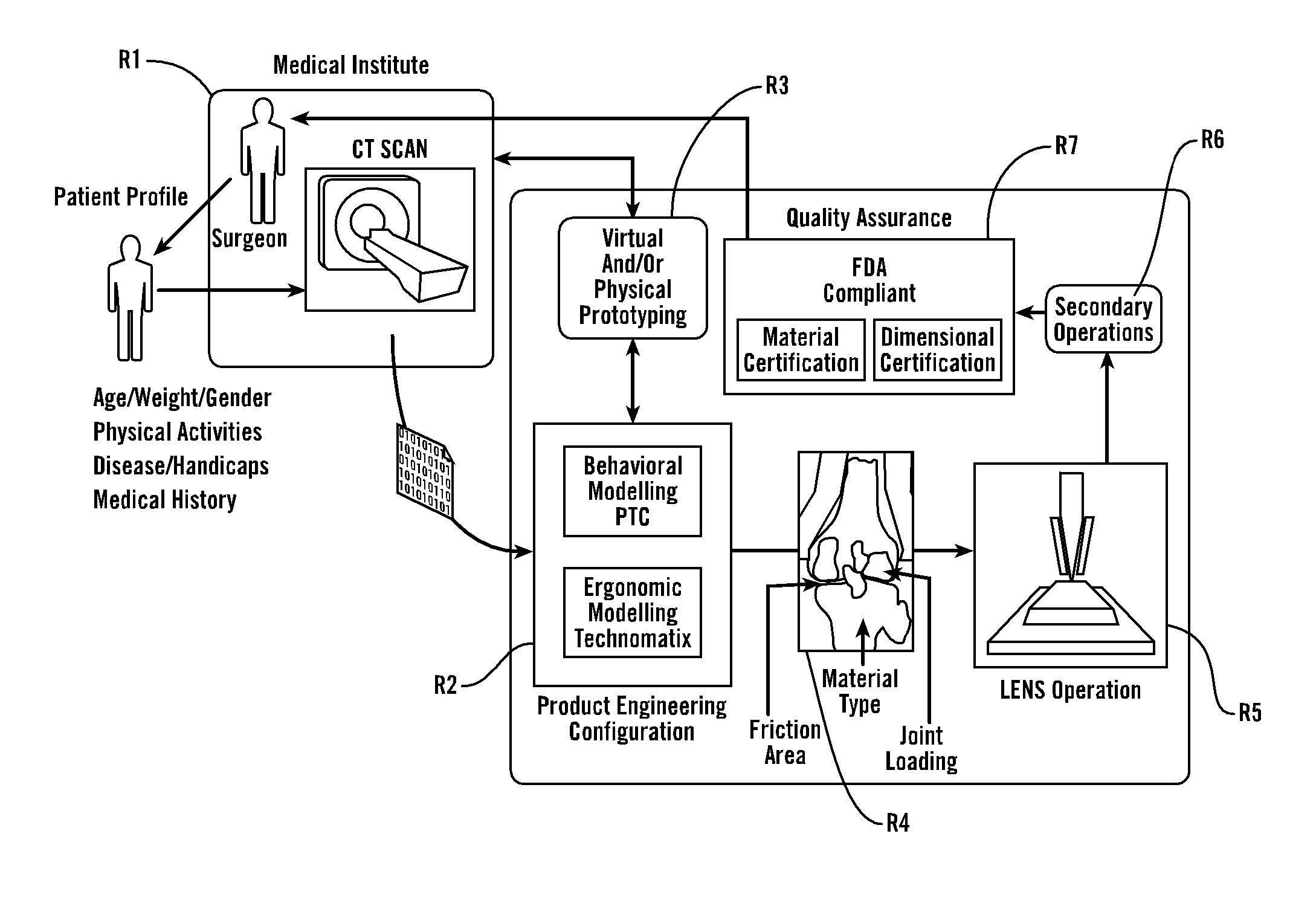

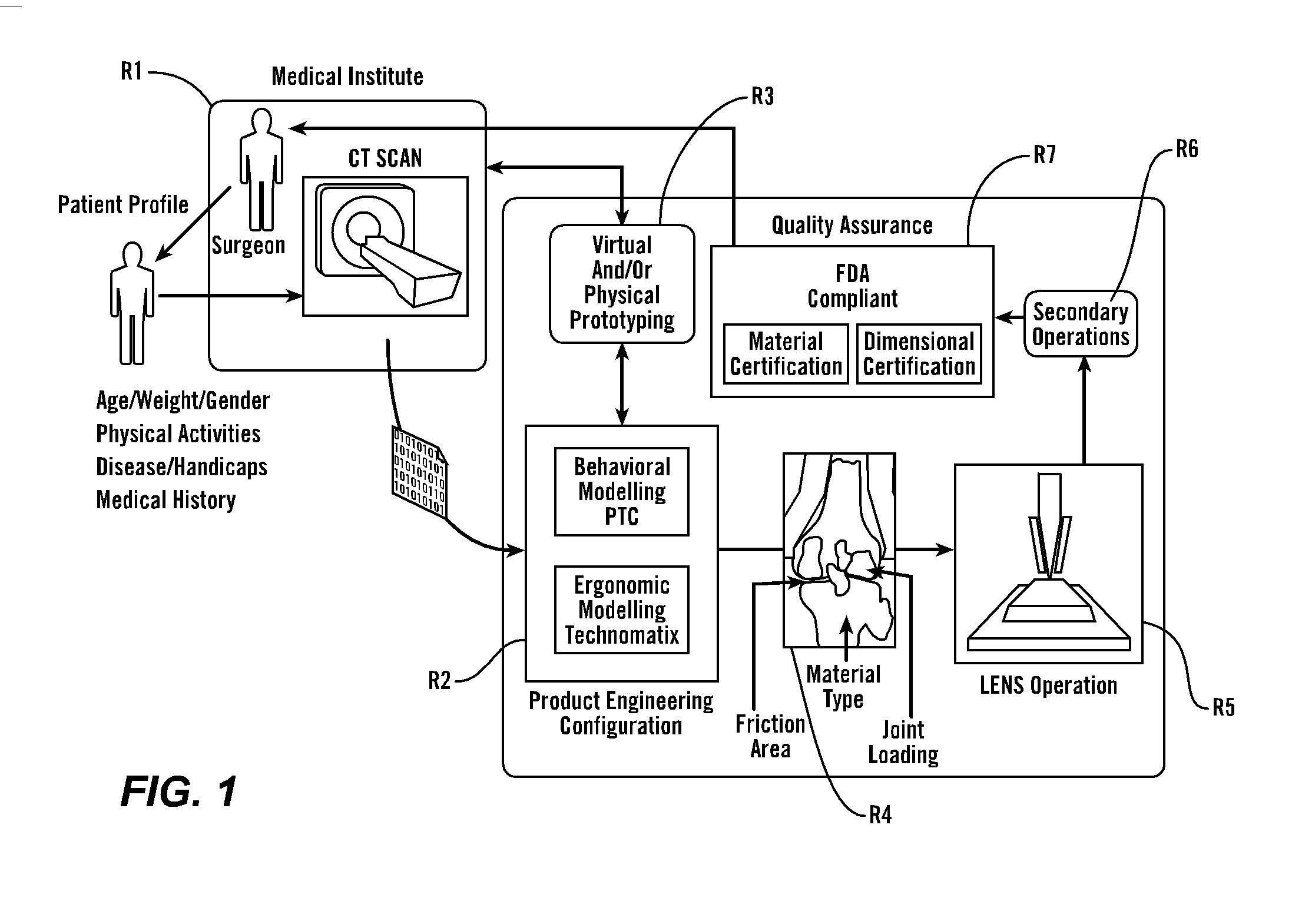

The present invention provides methods, techniques, materials and devices and uses thereof for custom-fitting biocompatible implants, prosthetics and interventional tools for use on medical and veterinary applications. The devices produced according to the invention are created using additive manufacturing techniques based on a computer generated model such that every prosthesis or interventional device is personalized for the user having the appropriate metallic alloy composition and virtual validation of functional design for each use.

Owner:VANTUS TECH CORP

Light emitting diode light source for curing dental composites

InactiveUS20010046652A1Sufficient powerSufficient structurePrinted circuit aspectsSolid-state devicesDental compositeHeat sink

Light Emitting Diode Light Sources for Dental Curing are disclosed. Some embodiments of the invention include structures such as Light Emitting Diode Array(s), heat sink, heat dissipation, heat pipe, and control circuitry are disclosed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

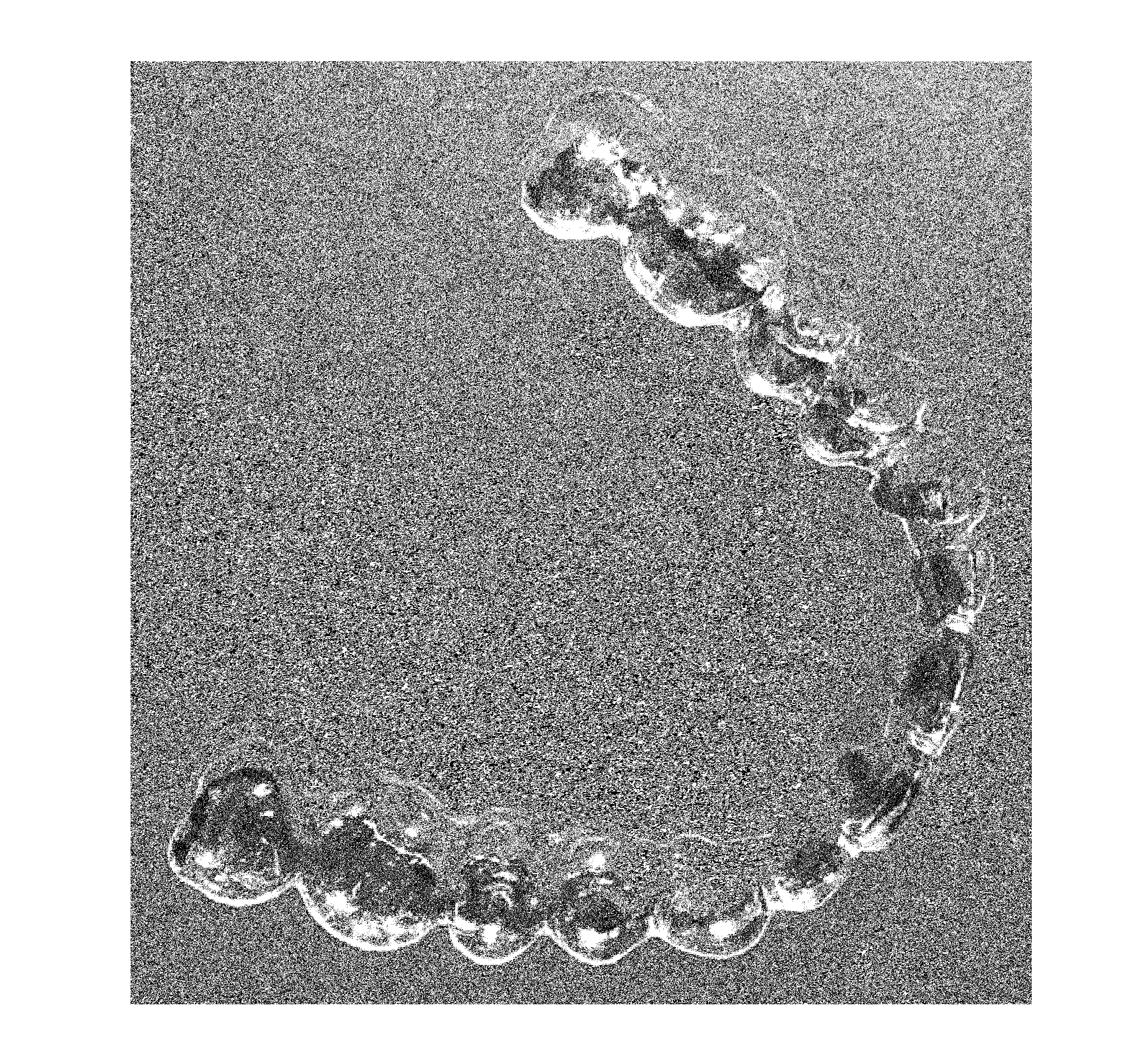

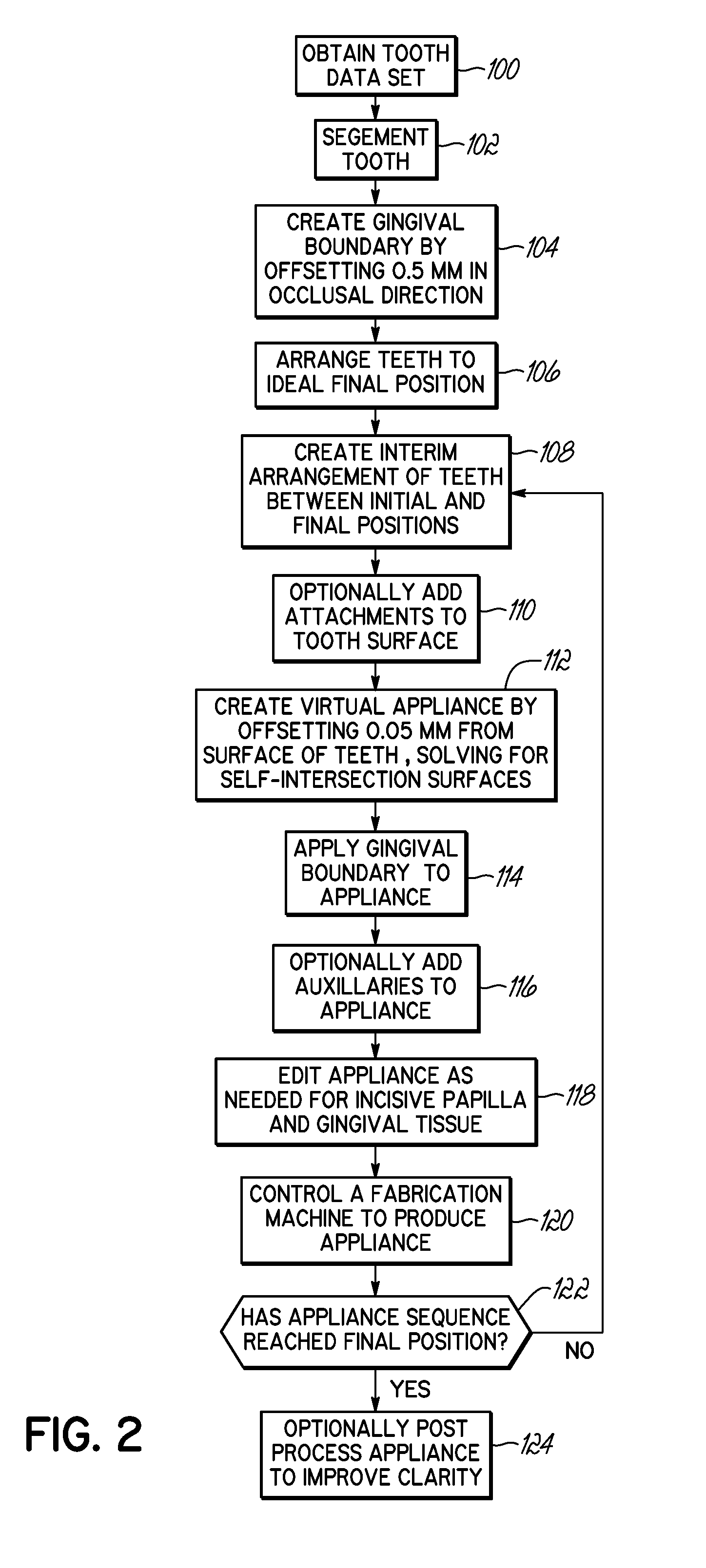

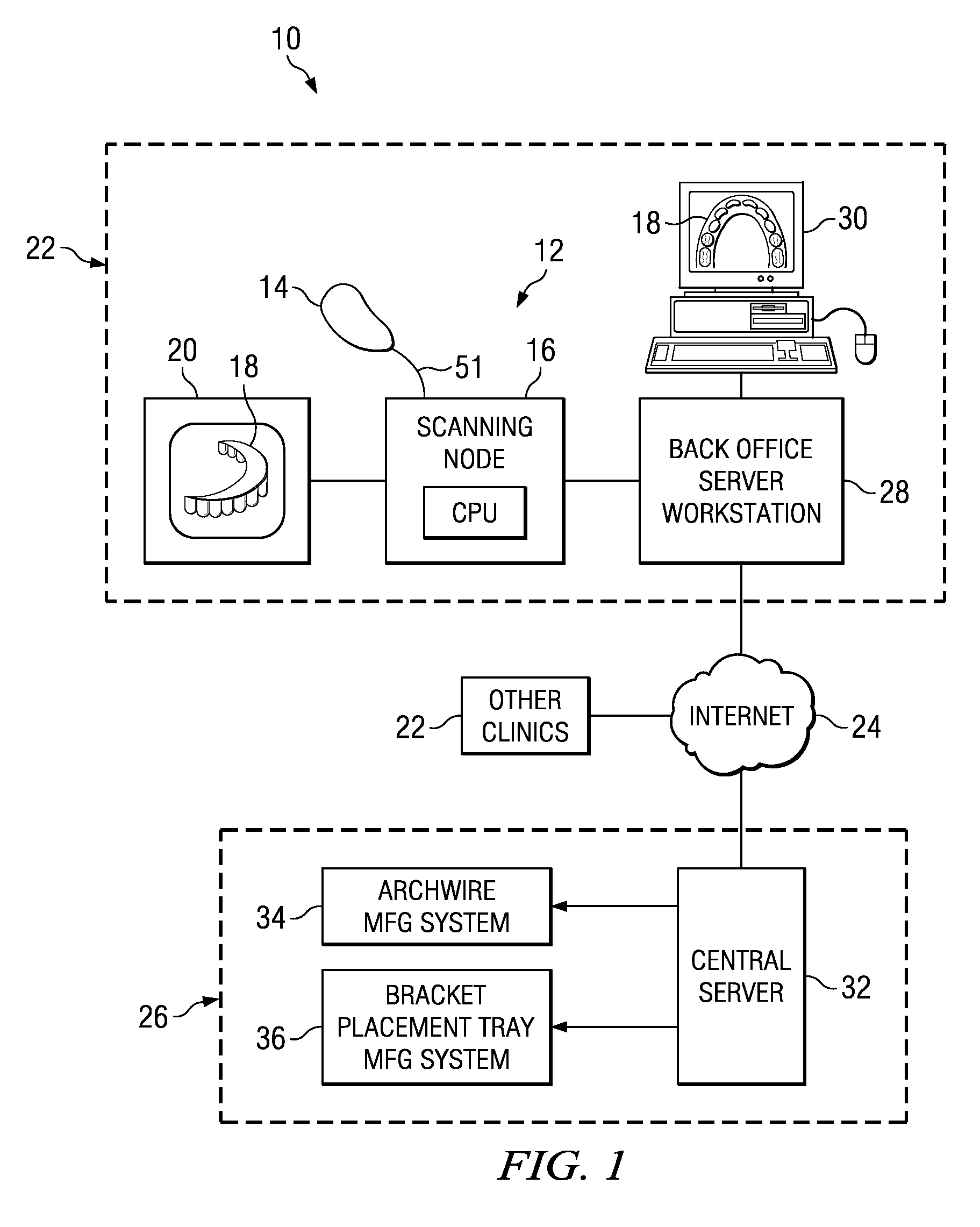

Direct Manufacture of Orthodontic Aligner Appliance

InactiveUS20130095446A1Fast deliveryAdditive manufacturing apparatusOthrodonticsMultiple layerPolymer

A method for direct fabrication of an orthodontic device having tooth-fitting cavities, such as an aligner, using layer-by-layer printing of a single or multiple polymeric materials. The cavities of the appliance are defined by the boundaries of the multiple layers, encapsulating up to fourteen teeth of a patient, and shaped to apply a load to at least one tooth that is sufficient to cause movement of the tooth, and remodeling of the adjacent bone. A series of such appliances may be used to treat malocclusion of teeth, each directly manufactured appliance used in series to incrementally move one or more teeth from initial positions toward a desired final position. The appliance may be fabricated with a variety of disclosed materials, and may include auxiliary features for interaction with other orthodontic elements.

Owner:ORMCO CORP

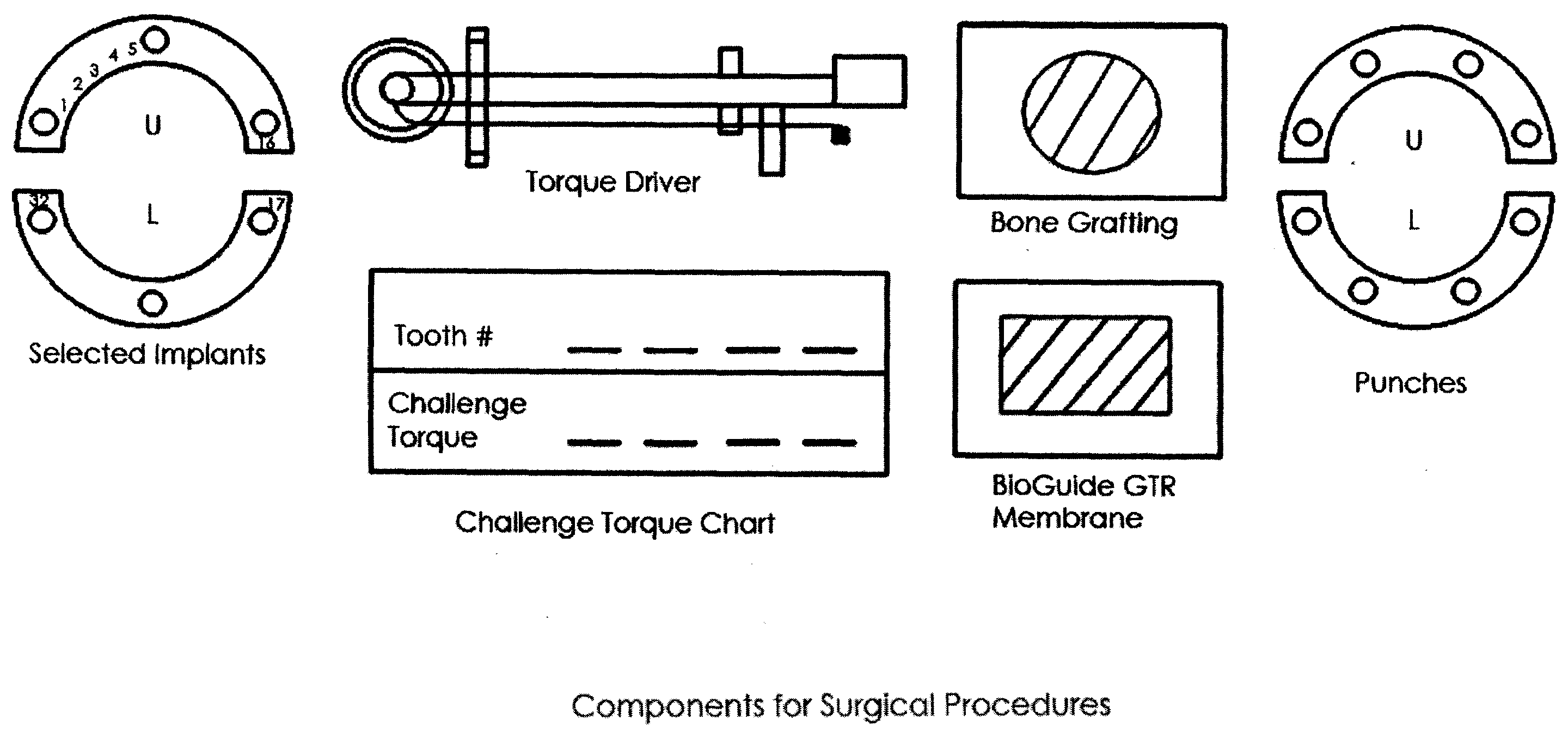

System, Method And Apparatus For Tooth Implant Planning And Tooth Implant Kits

InactiveUS20100105011A1Improve the level ofFacilitate proper fixture placementDental implantsDispensing apparatusPatient dataDental implant

Systems and methods support dental implant patient scheduling and treatment process relating to packaging one or more dental appliances as a kit which is readily used by dental professional during surgery, by communicating manufacturing progress information with a doctor over a network and performing patient scheduling and treatment when the dental appliances reach a certain manufacturing progress. A network-based service may also provide a doctor with a treatment solution including a surgical kit derived from patient data.

Owner:INPRONTO

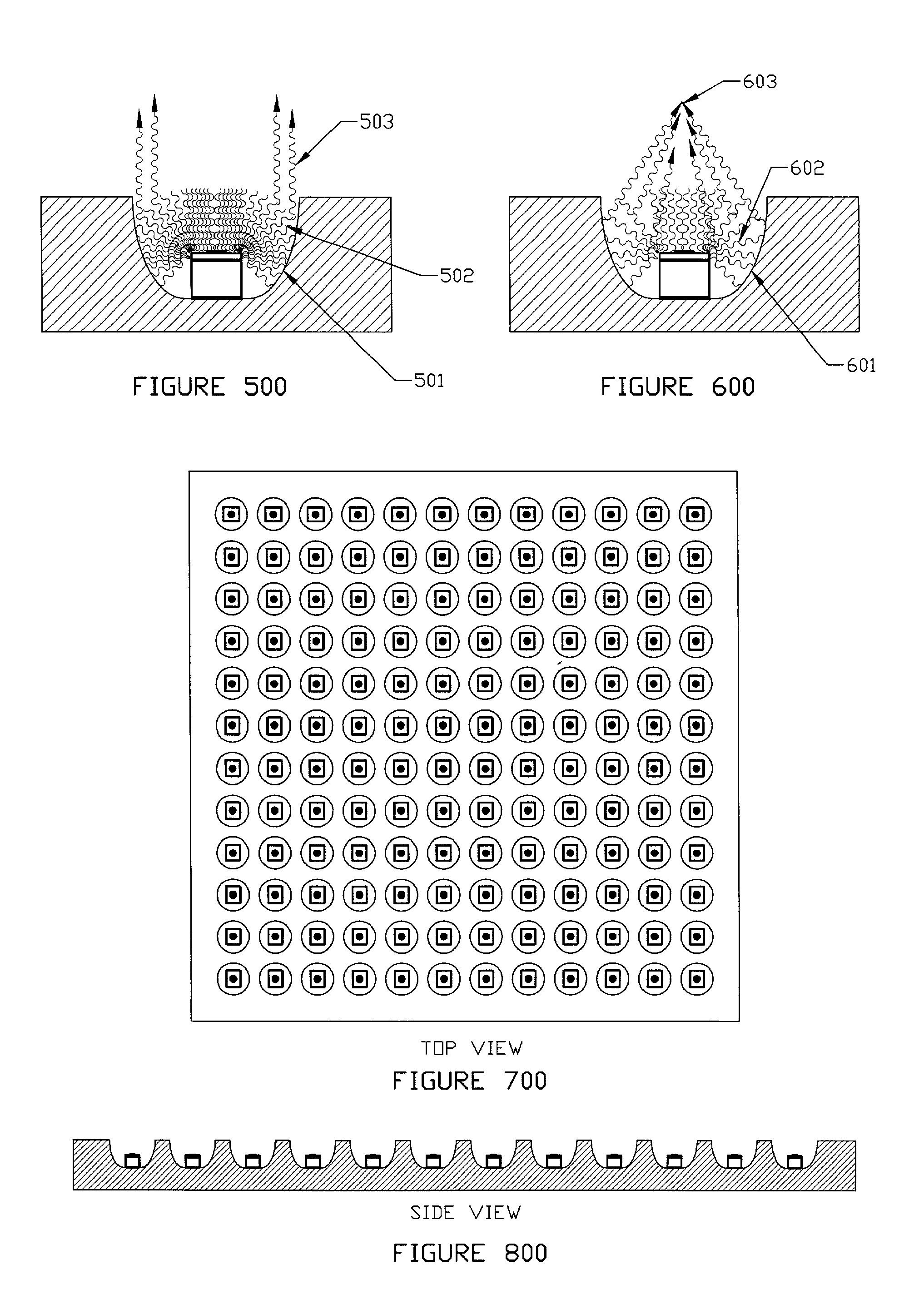

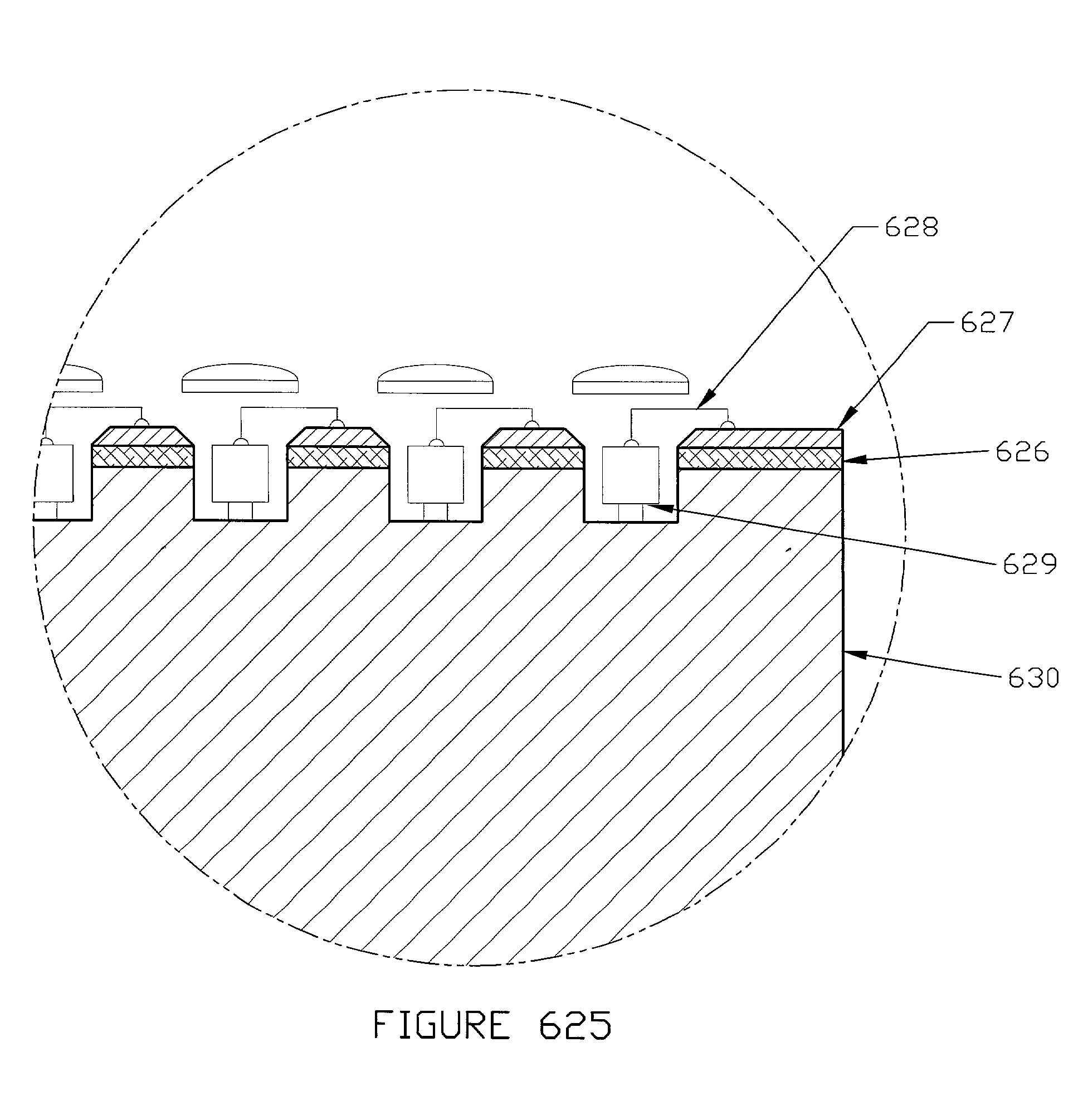

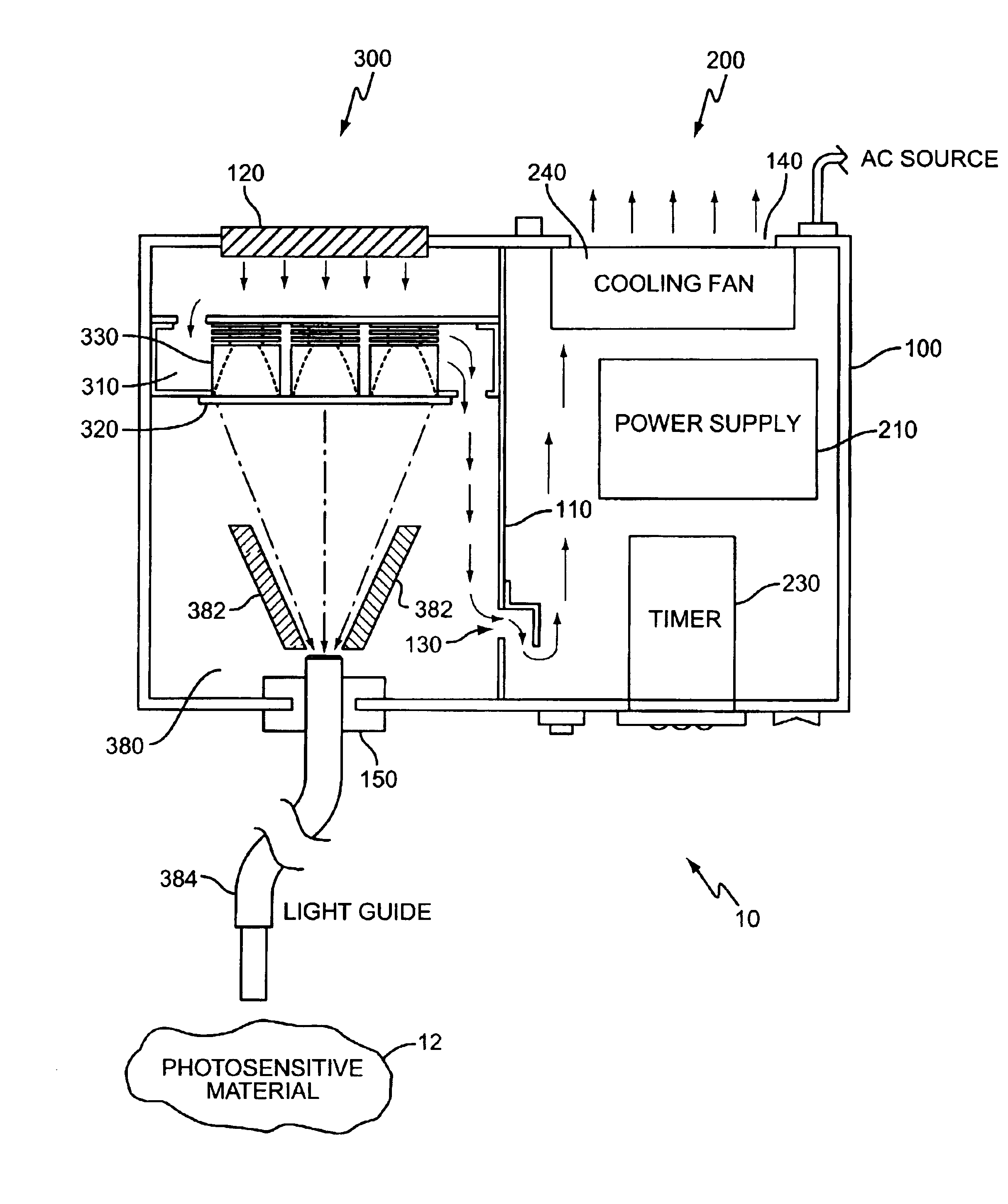

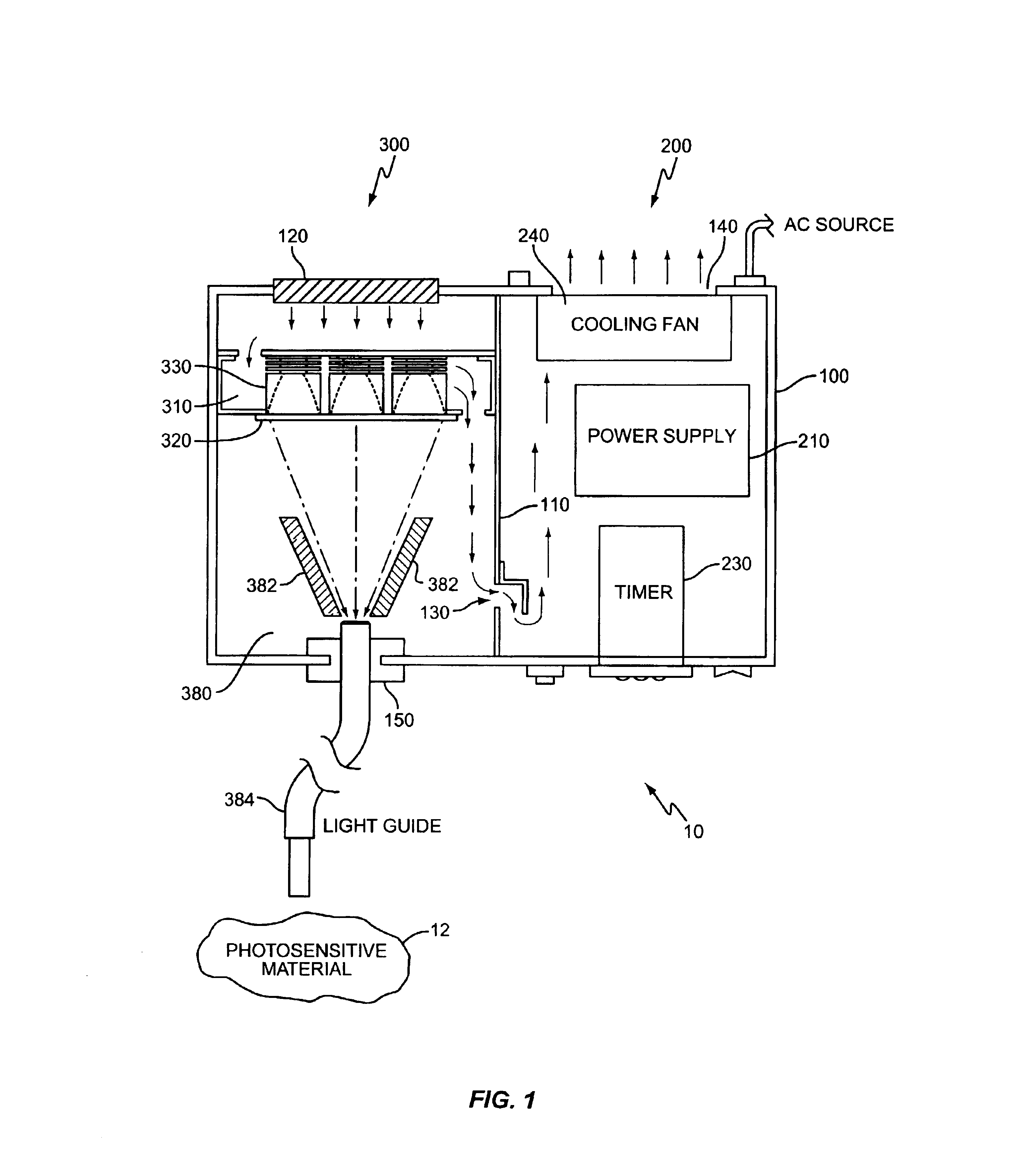

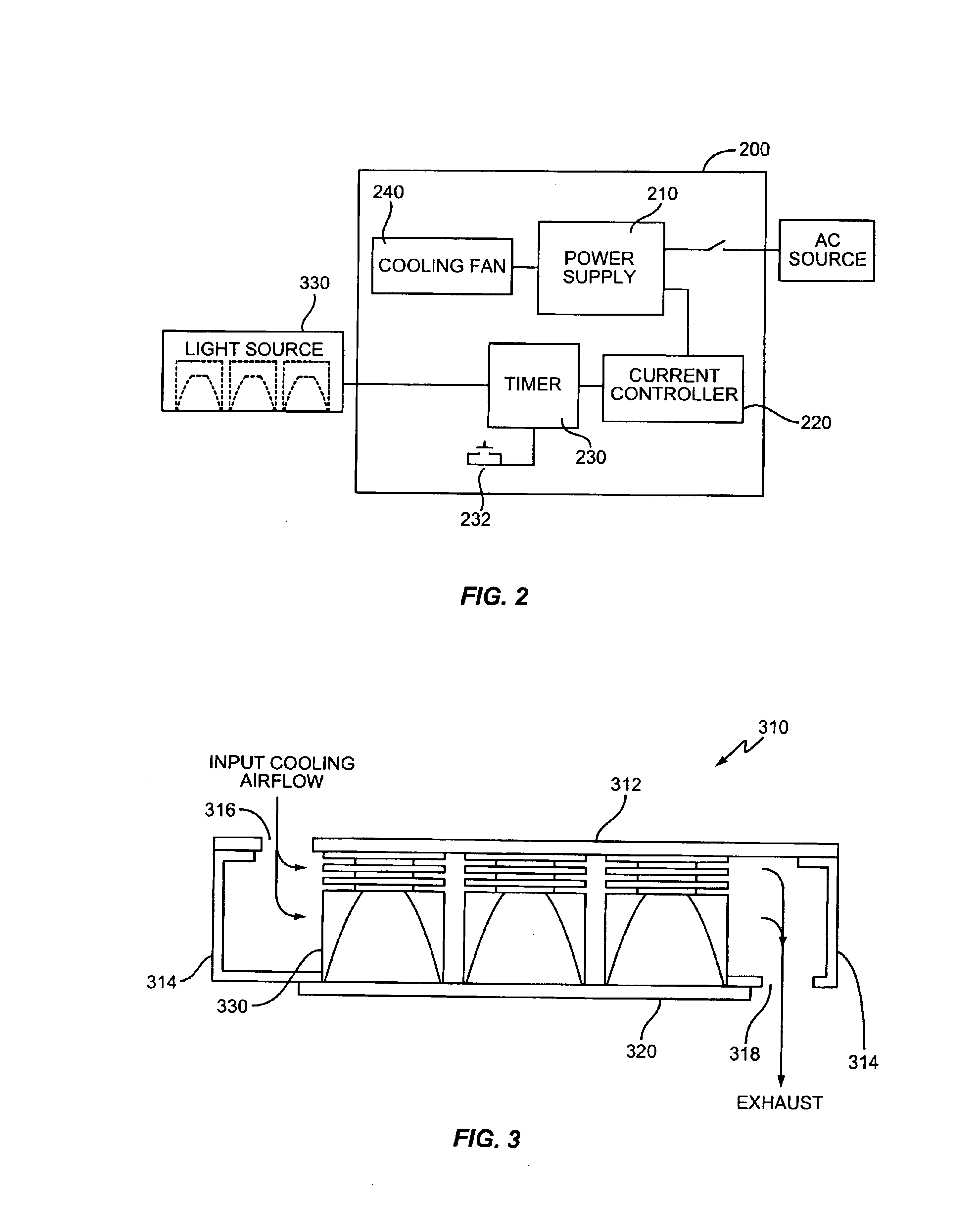

High intensity photocuring system

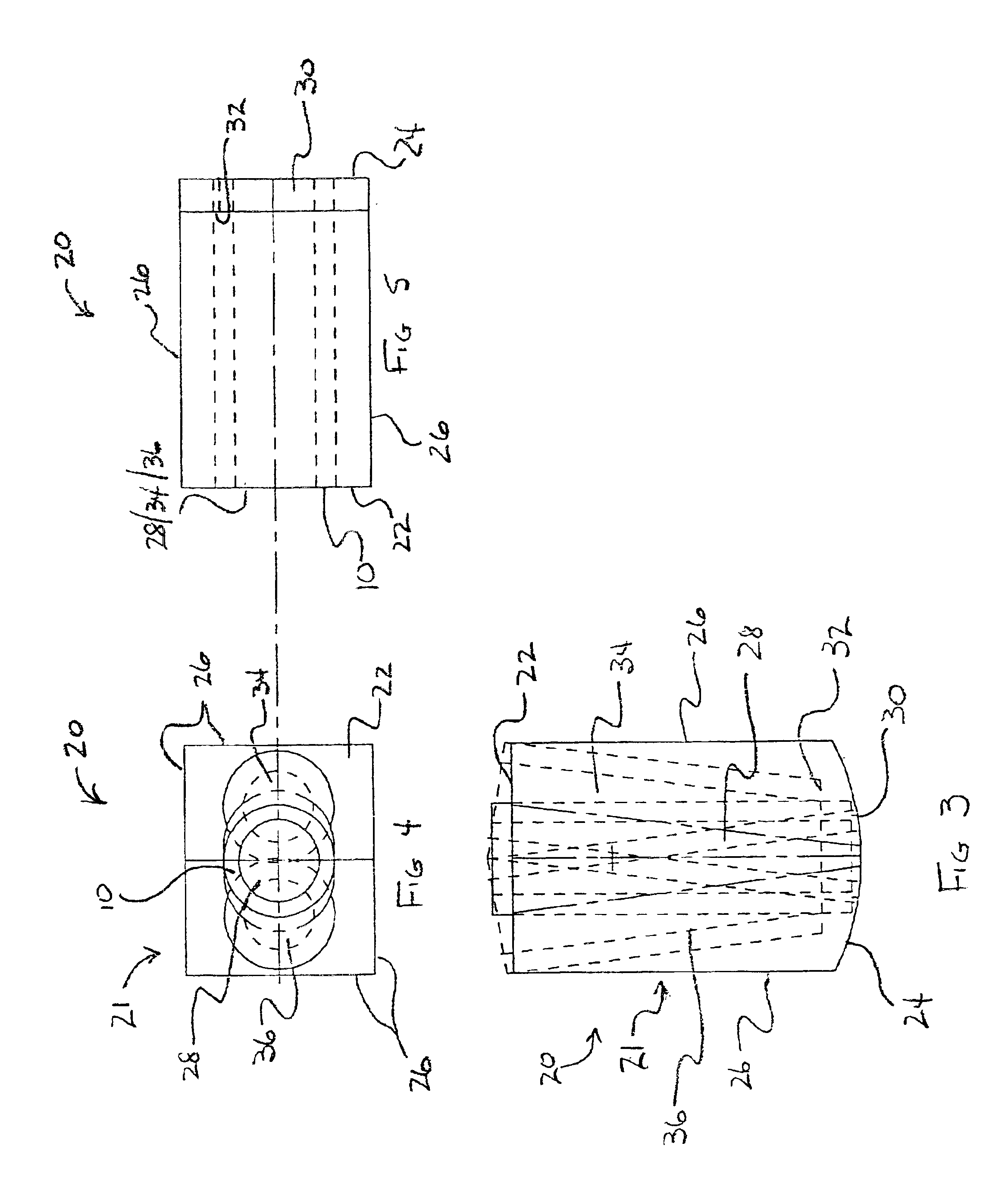

A method and apparatus for curing photosensitive materials uses LEDs and an optical concentrator to generate high optical power intensities. An LED array, comprising a plurality of LED assemblies, generates collimated light. A collection lens functions as an optical concentrator and focuses the collimated light to a desired spot size at a desired location. The LED assemblies may be at least partially disposed in a cooling plenum, where the cooling plenum is at least partially defined by the collection lens. Each LED assembly within the LED array may be detachably coupled to a mounting surface, enabling easy replacement of individual LED assemblies within the LED array. The photocuring assembly may also include a redirecting assembly disposed between the collection lens and the desired location that may further concentrate the light at the desired location. The photocuring assembly may include more than one of the above features.

Owner:SMD SOFTWARE

Method and apparatus for using light emitting diodes

InactiveUS20050231983A1Milk preservationLighting heating/cooling arrangementsThermal energyEngineering

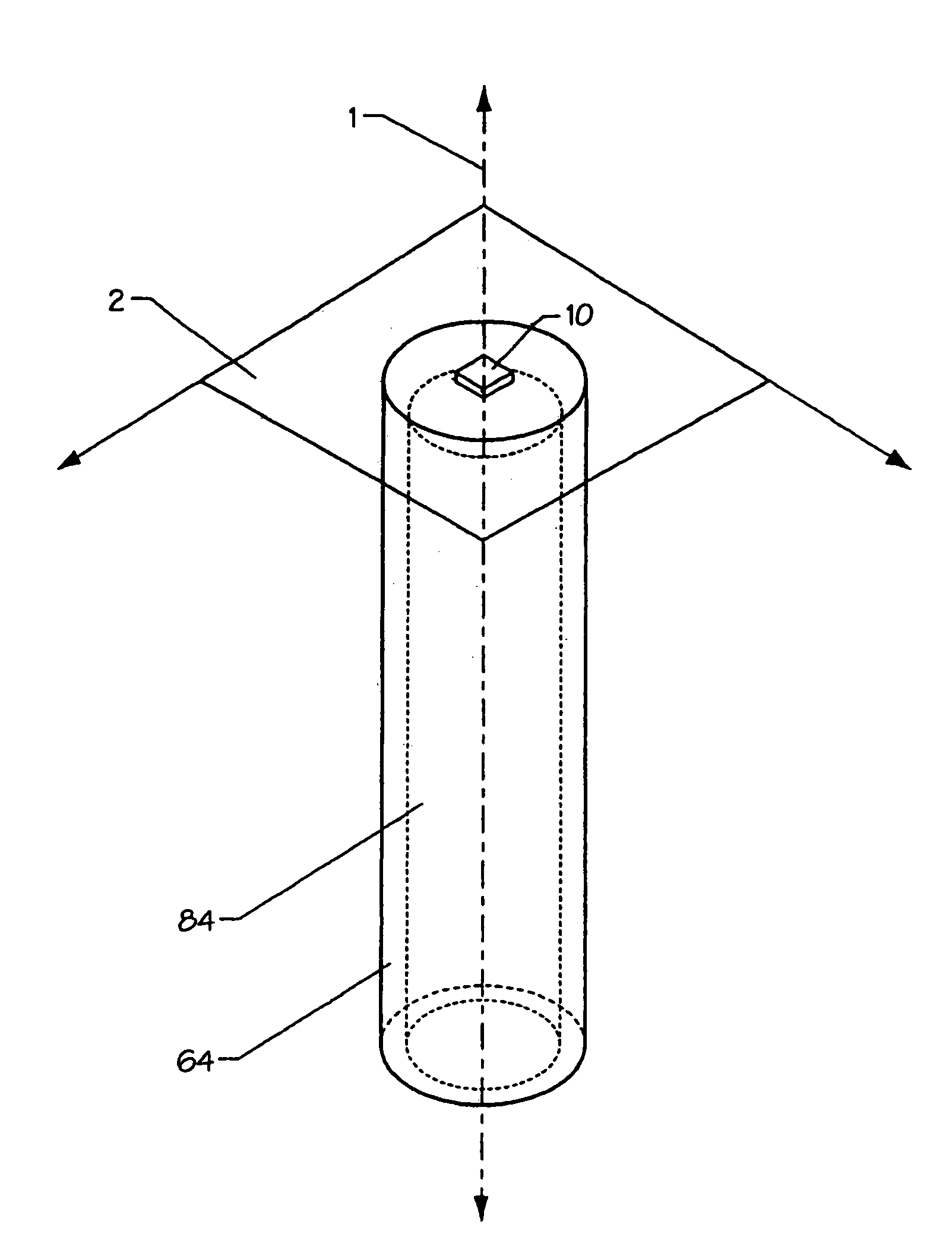

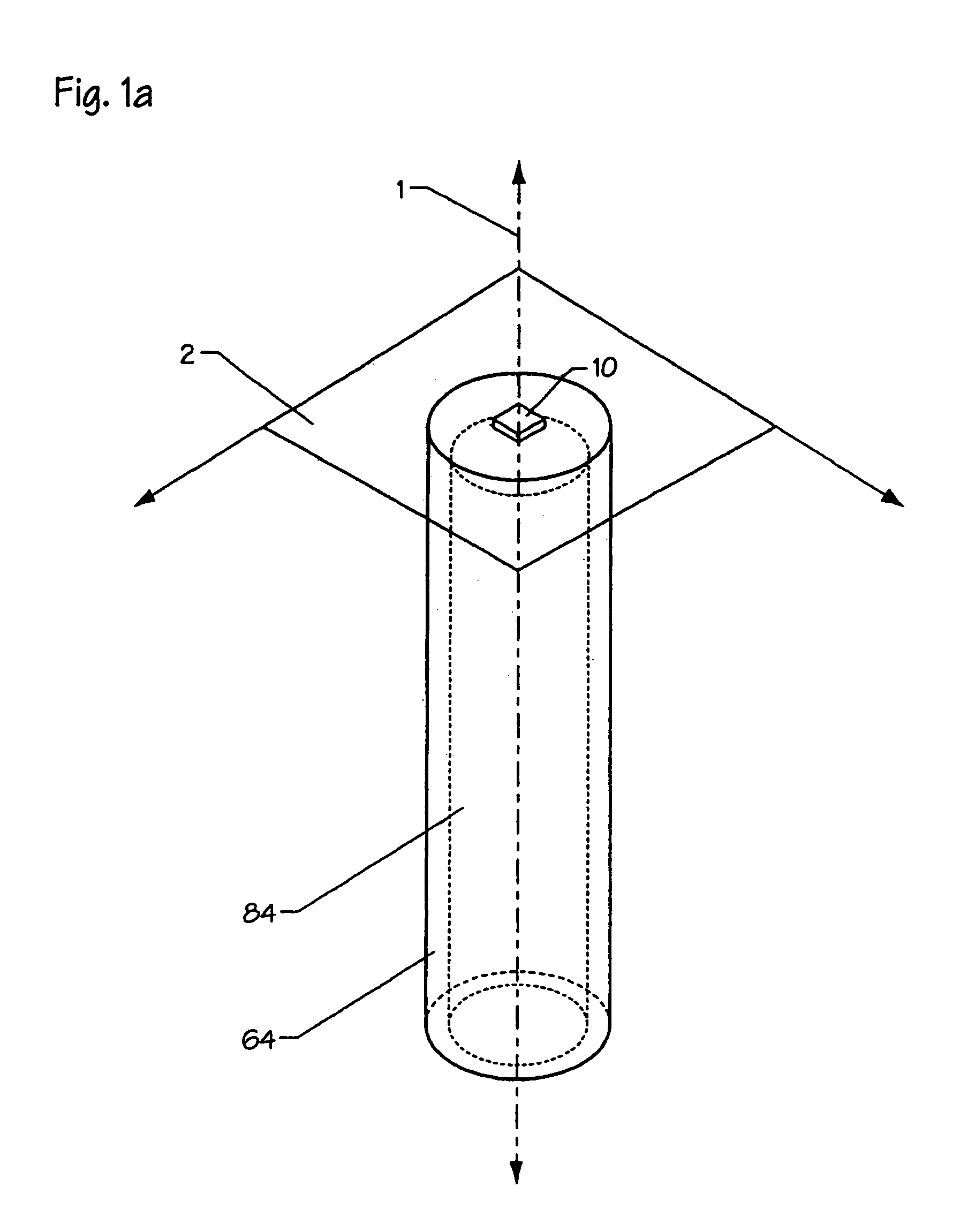

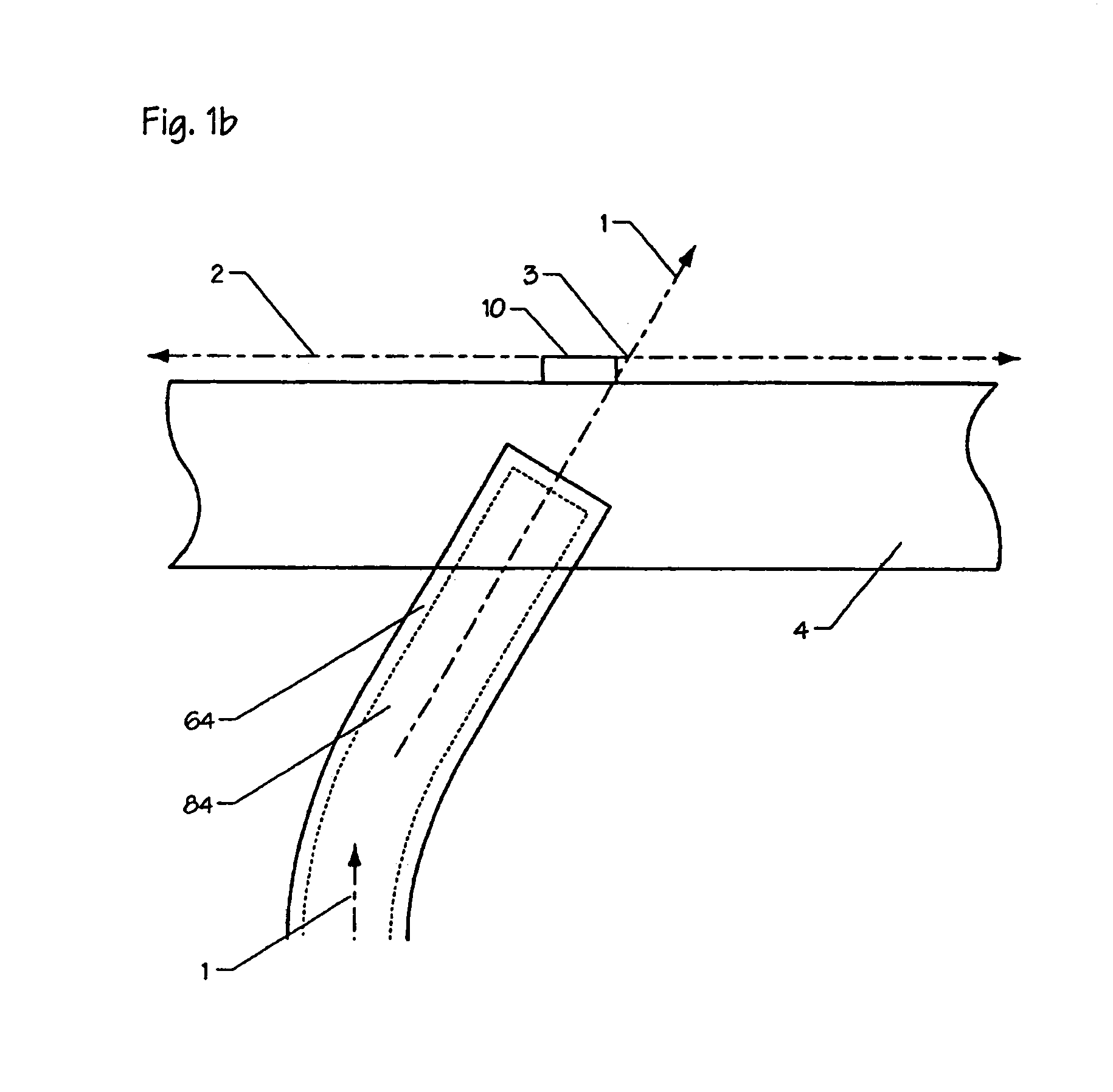

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

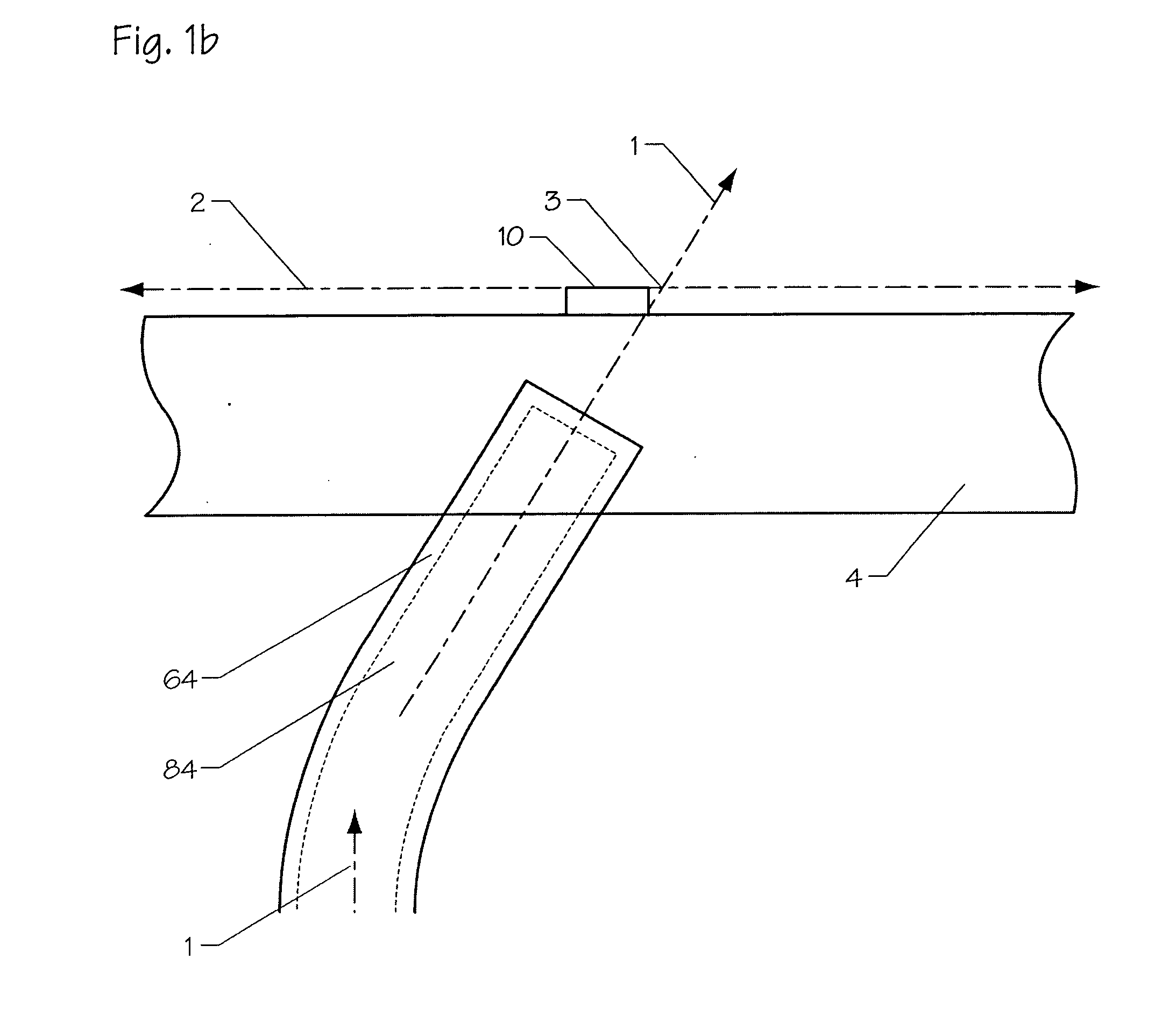

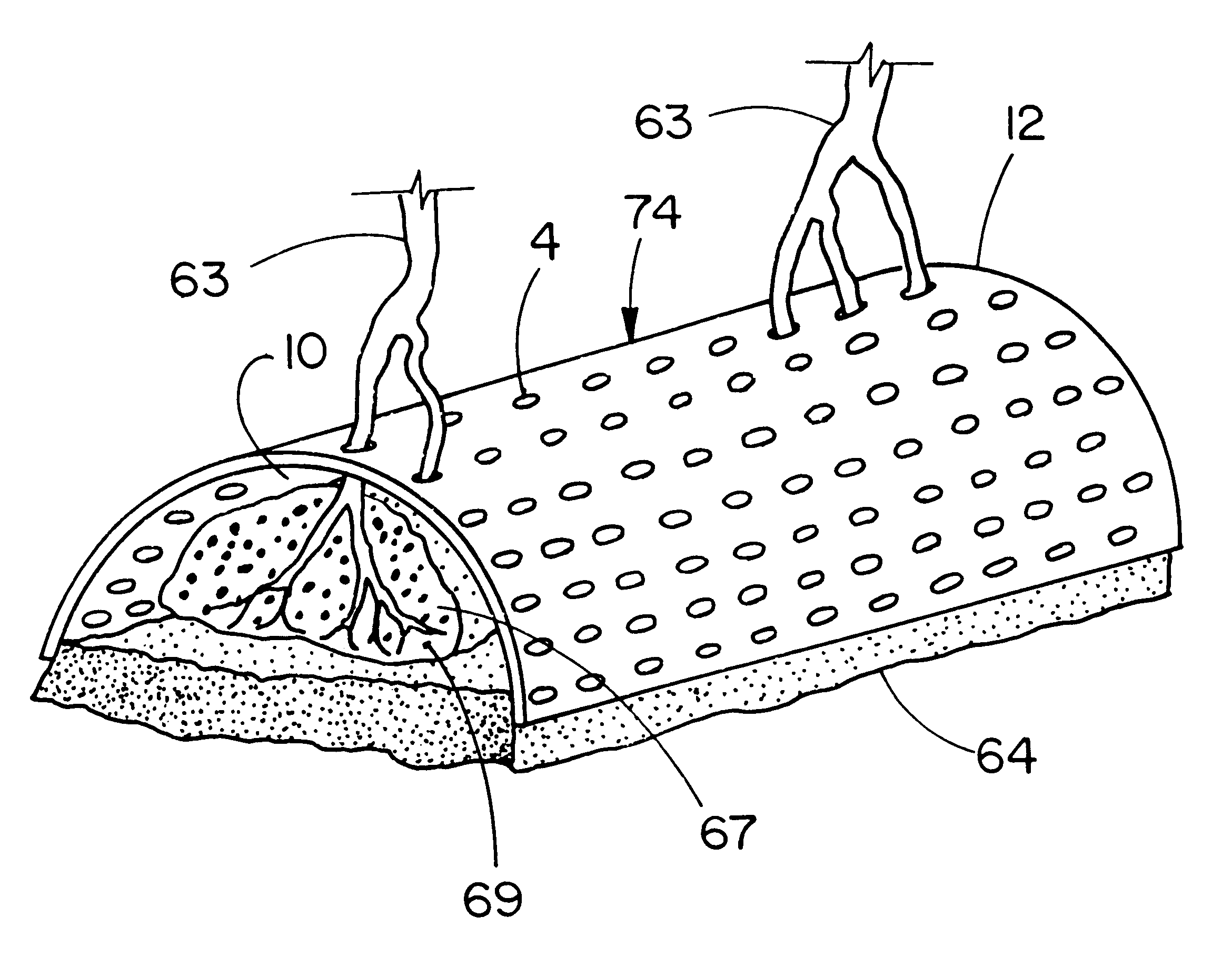

Methods and articles for regenerating bone or peridontal tissue

InactiveUS6409764B1Promote growth and developmentPromote cell differentiationDental implantsTeeth fillingPeriodontal tissueTransforming growth factor beta superfamily

There are numerous medical situations involving deficiencies of living bone or periodontal tissue and where increase of living bone or periodontal tissue mass is desired. Methods are described wherein a configured, shell-like device that is capable of being penetrated by living cells and tissues, is implanted into the body of a mammal in such a way as to establish a space, the space being at least partly, bounded by the device. The configuration of the device is such that the configuration of the established space is essentially the same as the configuration of living bone or periodontal tissue that is desired for treatment of the tissue deficiency. At least one protein from the Transforming Growth Factor-Beta Superfamily of proteins is placed within the established space for the purpose of stimulating the growth of living bone or periodontal tissue within the established space. A kit for the generation of living bone or periodontal tissue, comprised of the components mentioned above, is also disclosed.

Owner:WL GORE & ASSOC INC

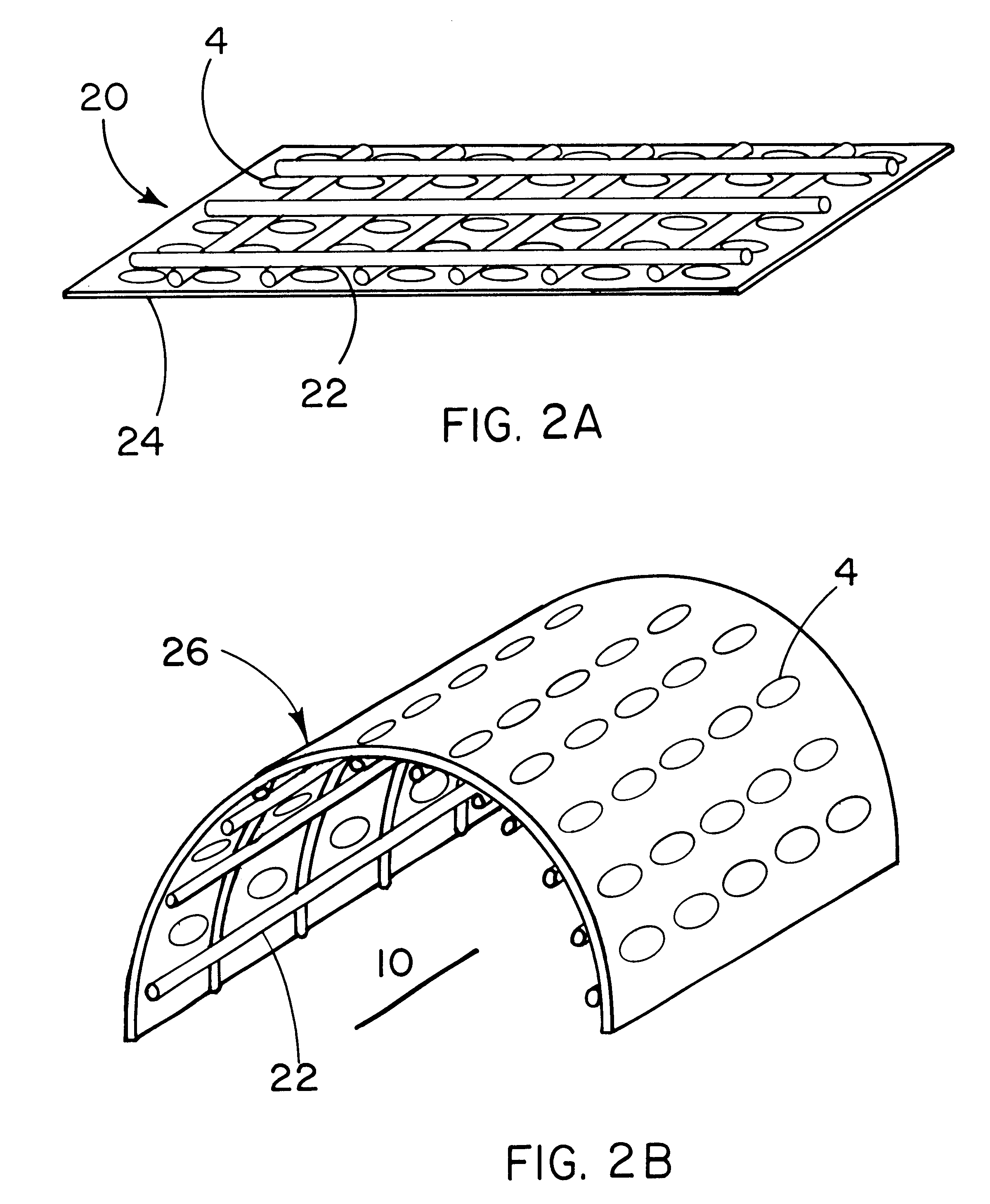

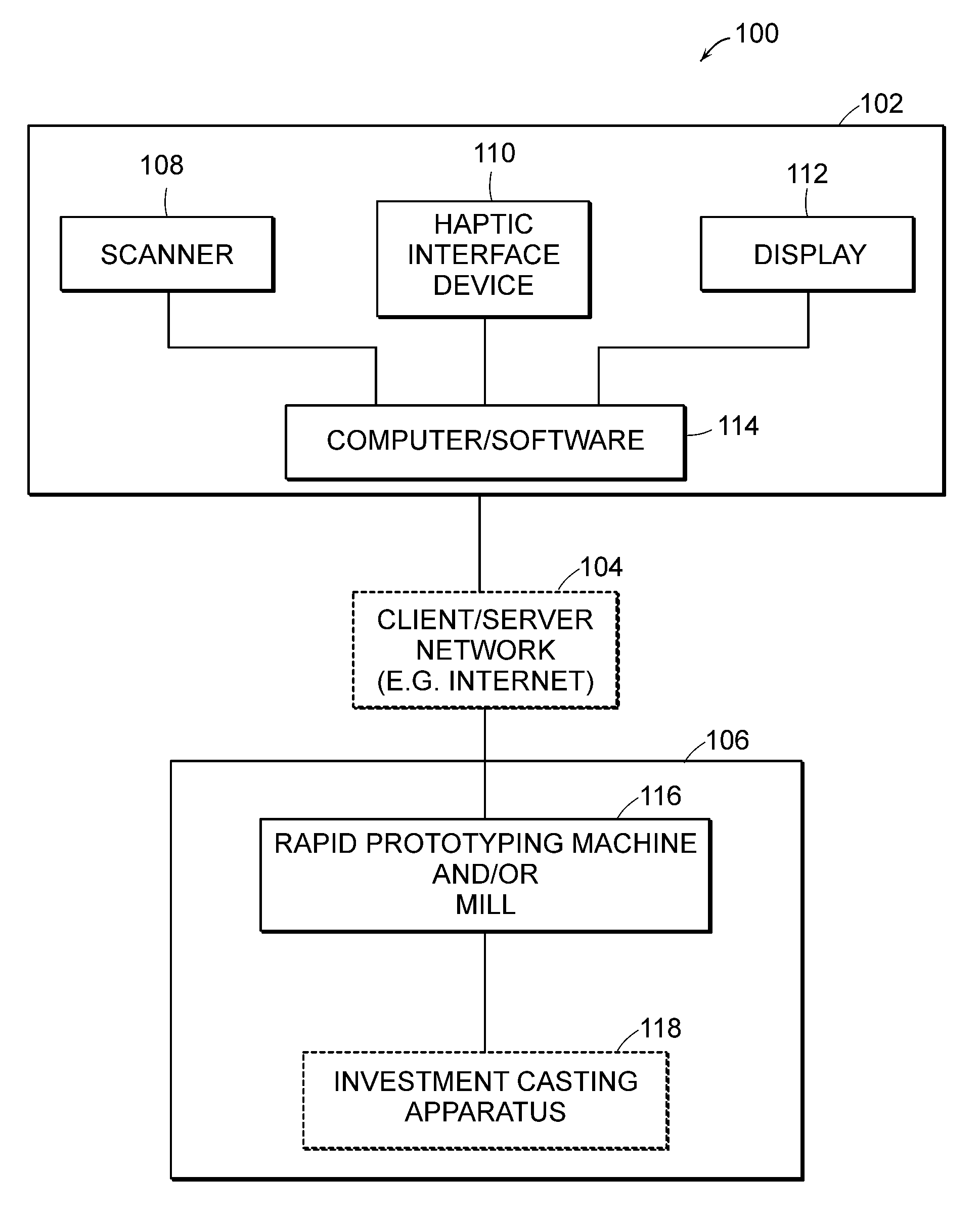

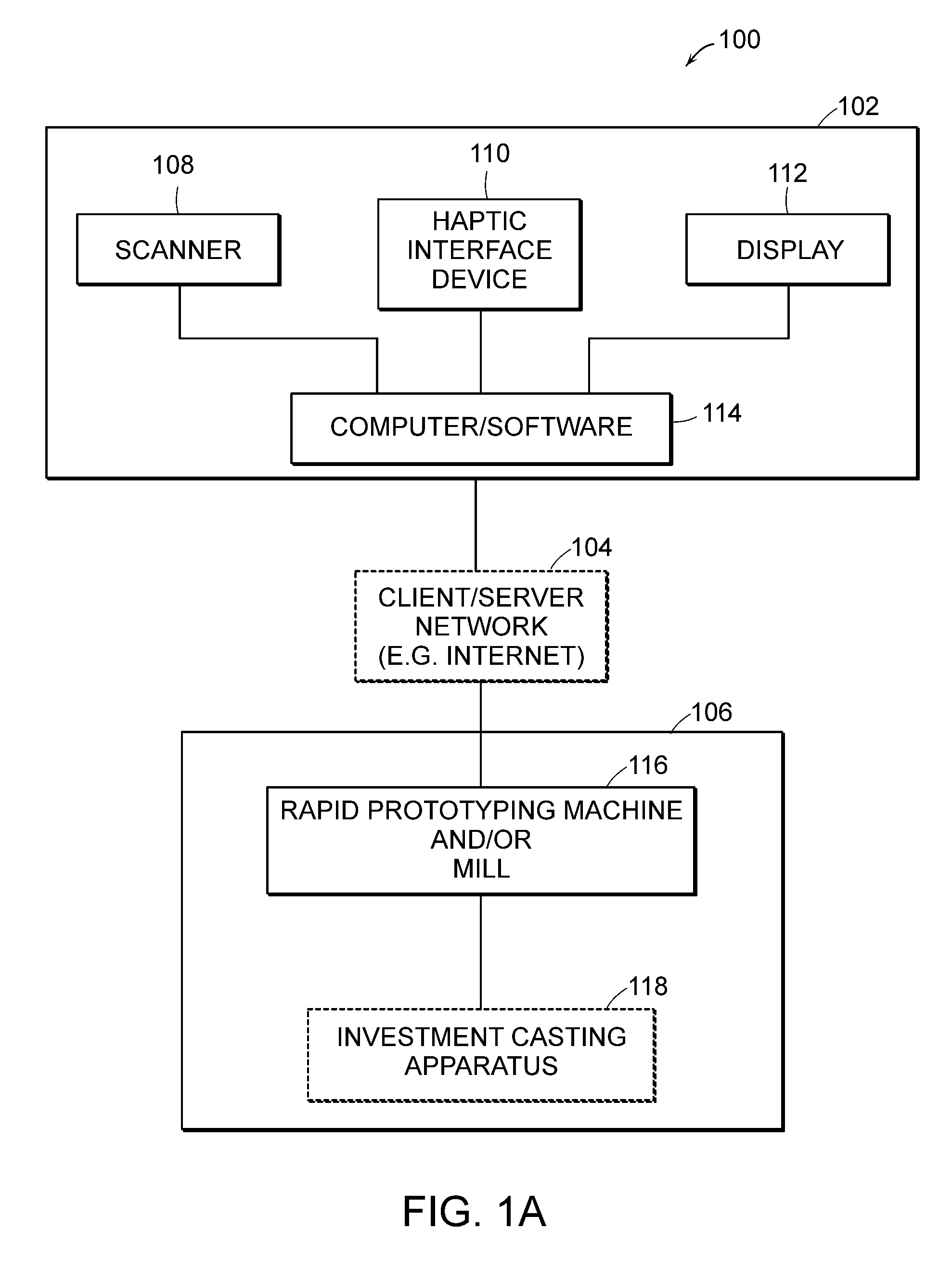

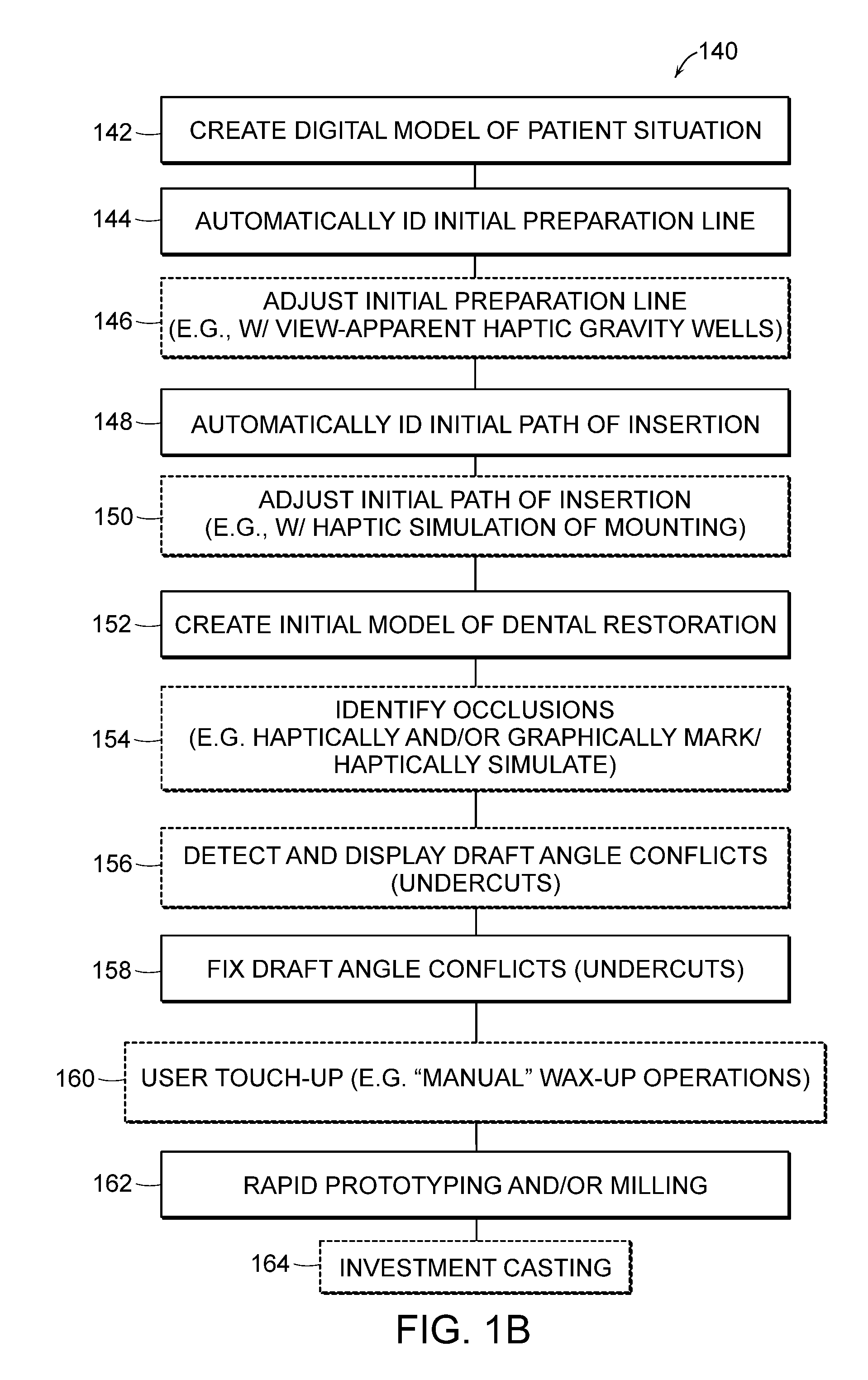

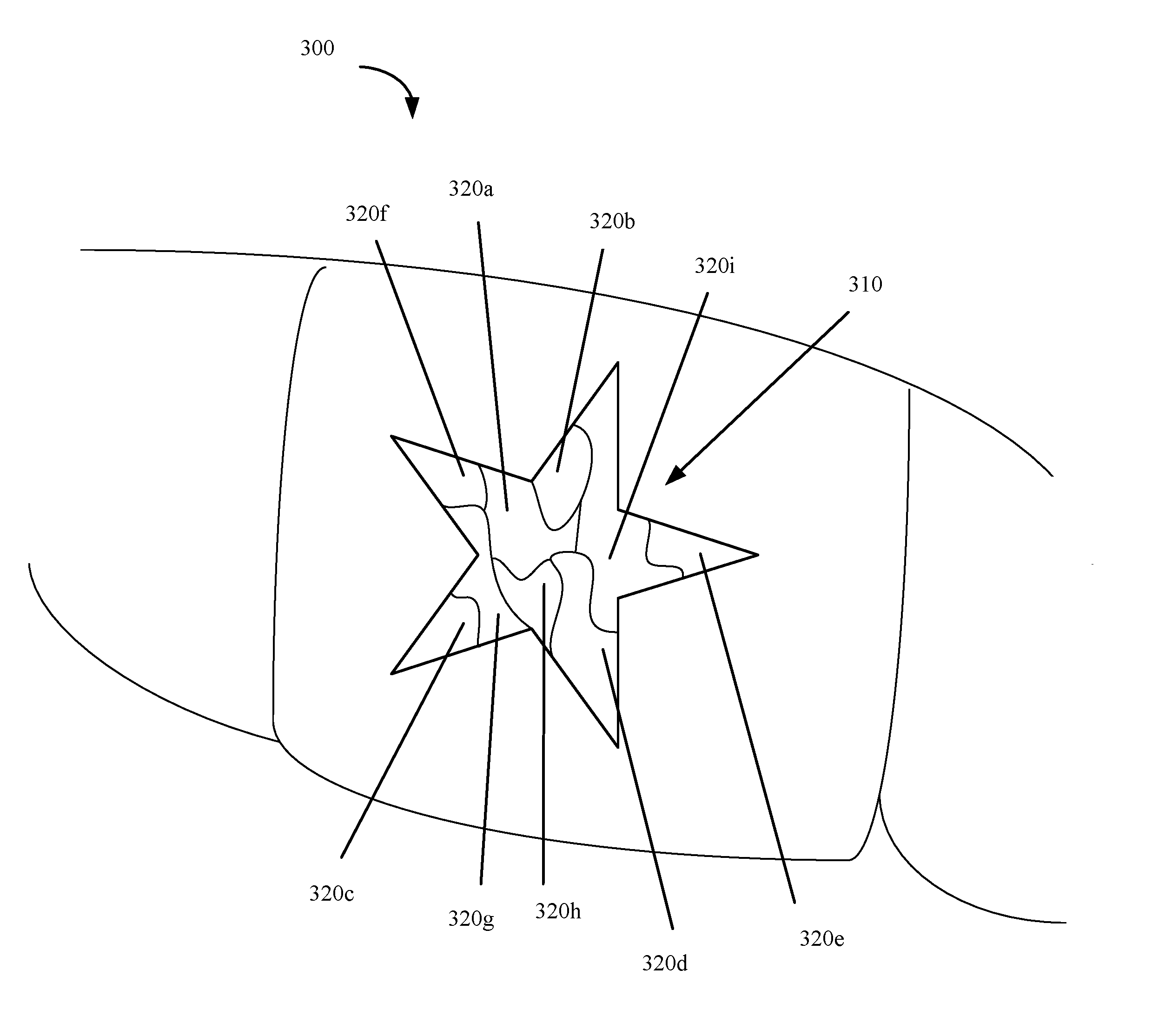

Systems for haptic design of dental restorations

InactiveUS20080261165A1Big advantageEasy to useAdditive manufacturing apparatusOthrodonticsVoxelInvestment casting

The invention provides systems for integrated haptic design and fabrication of dental restorations that provide significant advantages over traditional practice and existing computer-based systems. The systems feature technical advances that result in significantly more streamlined, versatile, and efficient design and fabrication of dental restorations. Among these technical advances are the introduction of voxel-based models; the use of a combination of geometric representations such as voxels and NURBS representations; the automatic identification of an initial preparation (prep) line and an initial path of insertion; the ability of a user to intuitively, haptically adjust the initial prep line and / or the initial path of insertion; the automatic identification of occlusions and draft angle conflicts (e.g., undercuts); the haptic simulation and / or marking of occlusions and draft angle conflicts; and coordination between design output and rapid prototyping / milling and / or investment casting.

Owner:SENSABLE TECH

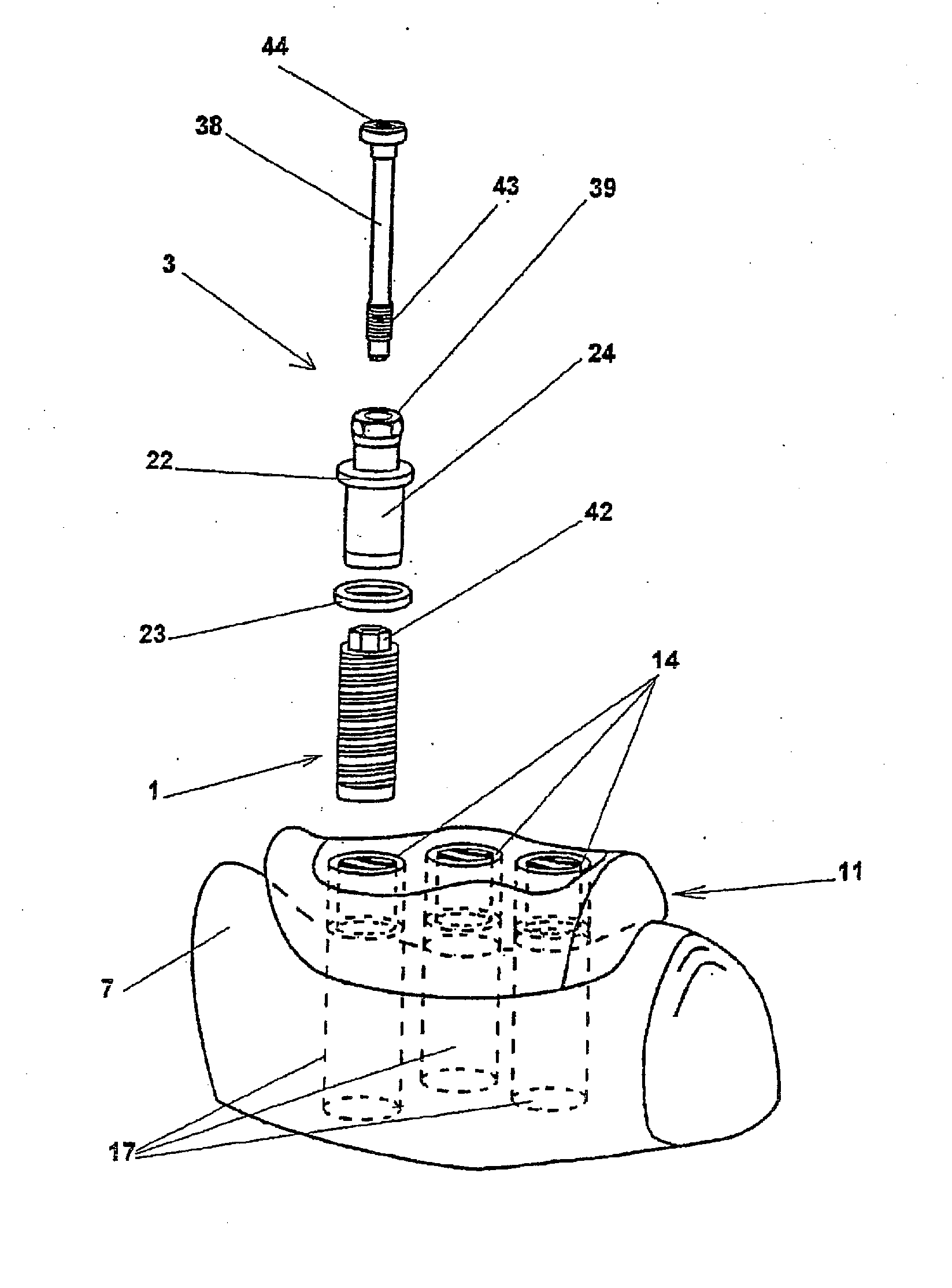

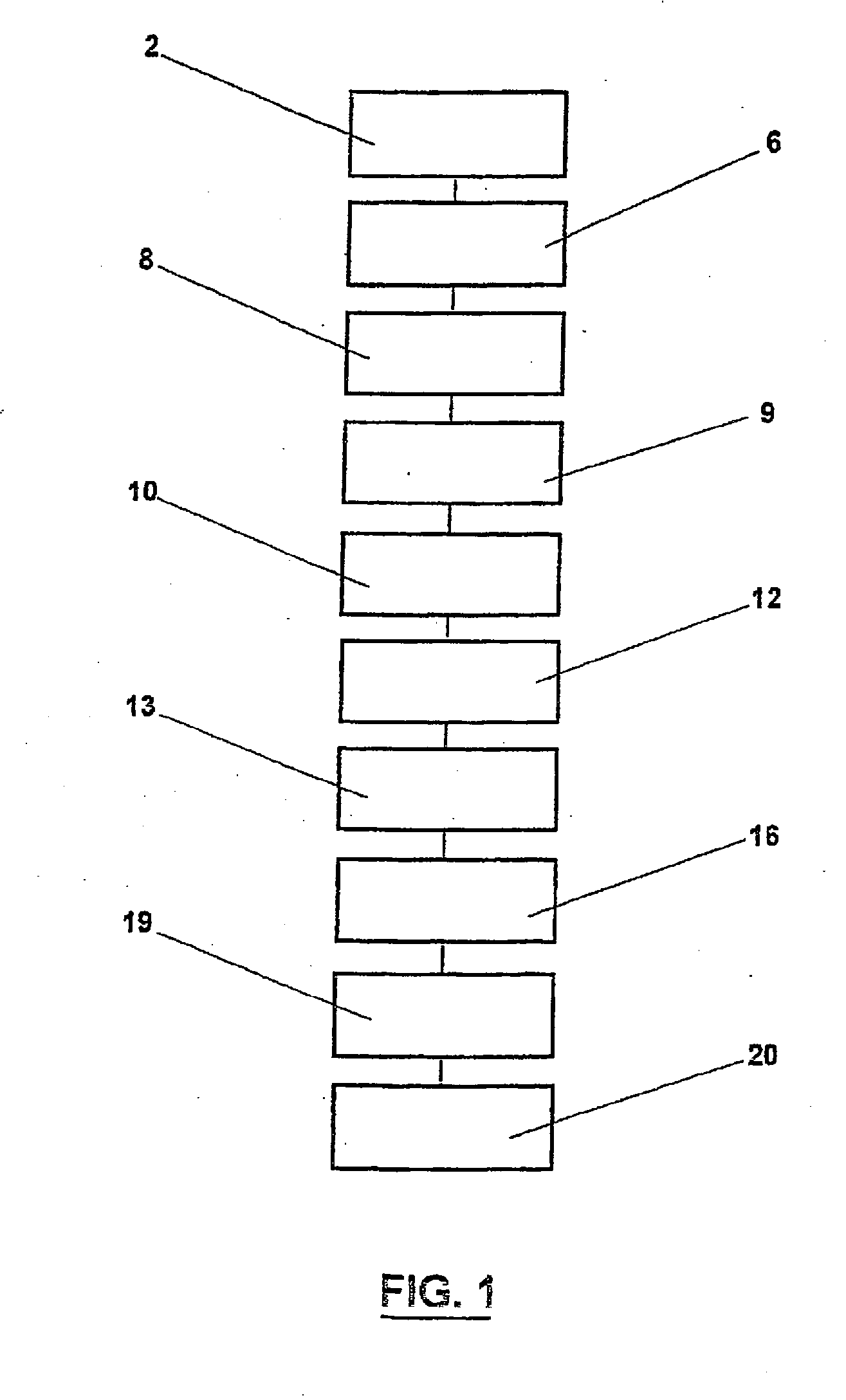

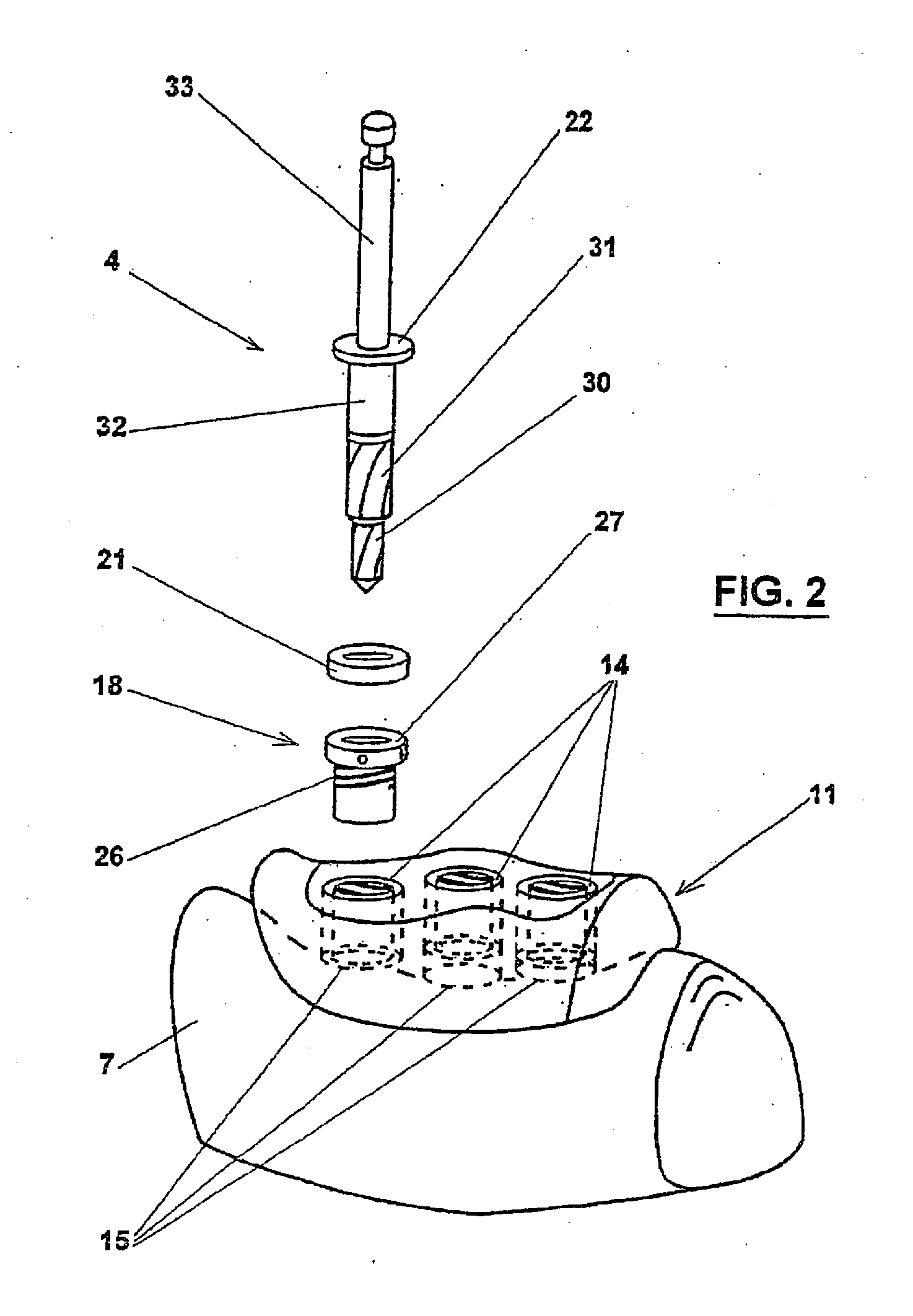

Method and device for placing dental implants

The invention relates to a method and device for placing implants using a surgical template which is made from tomographic cuts in the patient's jawbone. Step drills and calibrating drills, having a single standard diameter for each type of implant, are guided through drill bushings which are inserted into bores in the template in order to produce any drilling sequence corresponding to an implant plan. The penetration depth of the drills is controlled by the height of the bores or by the drill rings. The method limits the required number of drills and implant supports to the longest models only. The inventive method and device are particularly suitable for computer-assisted implantology systems.

Owner:DENTSPLY IMPLANTS NV

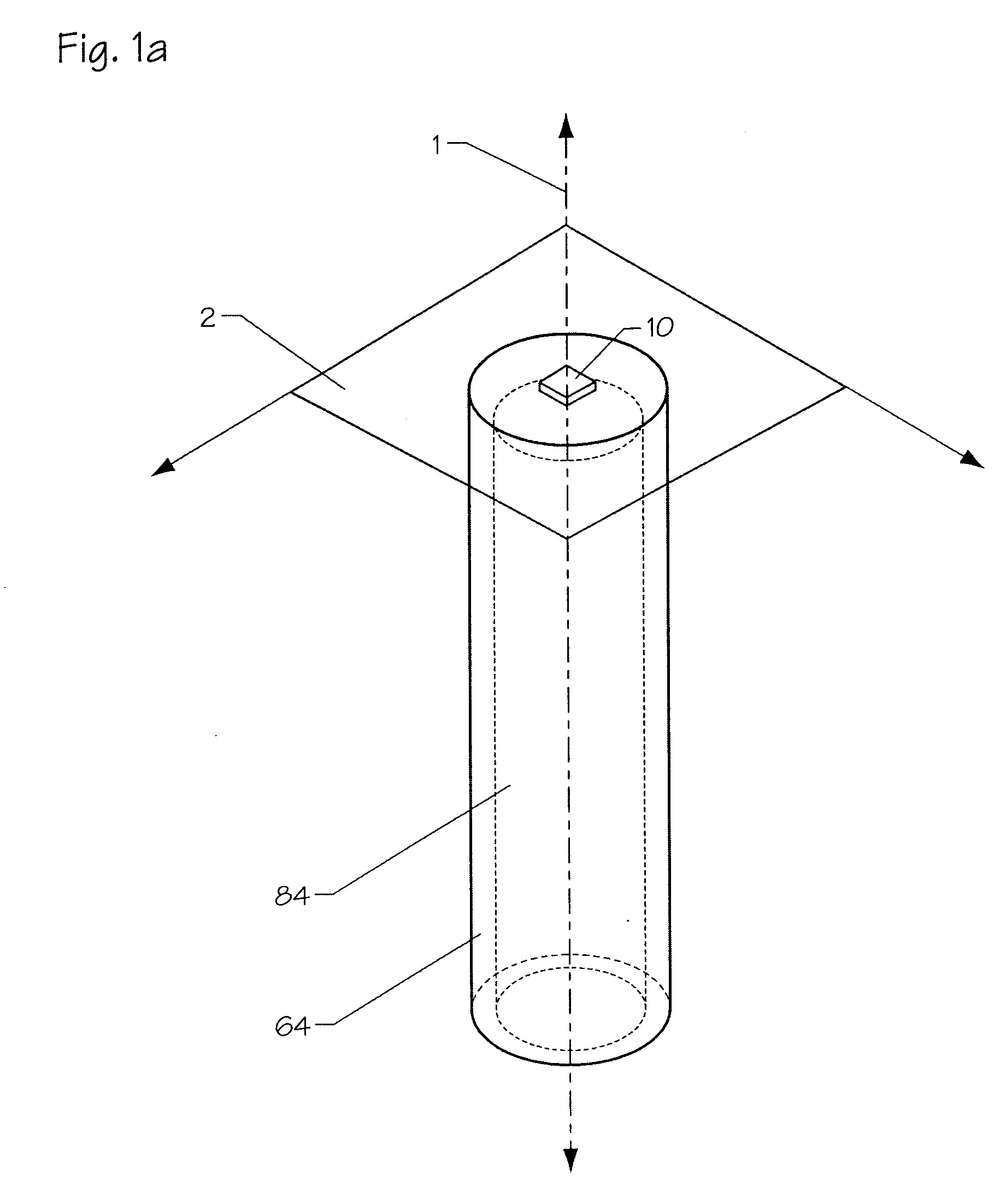

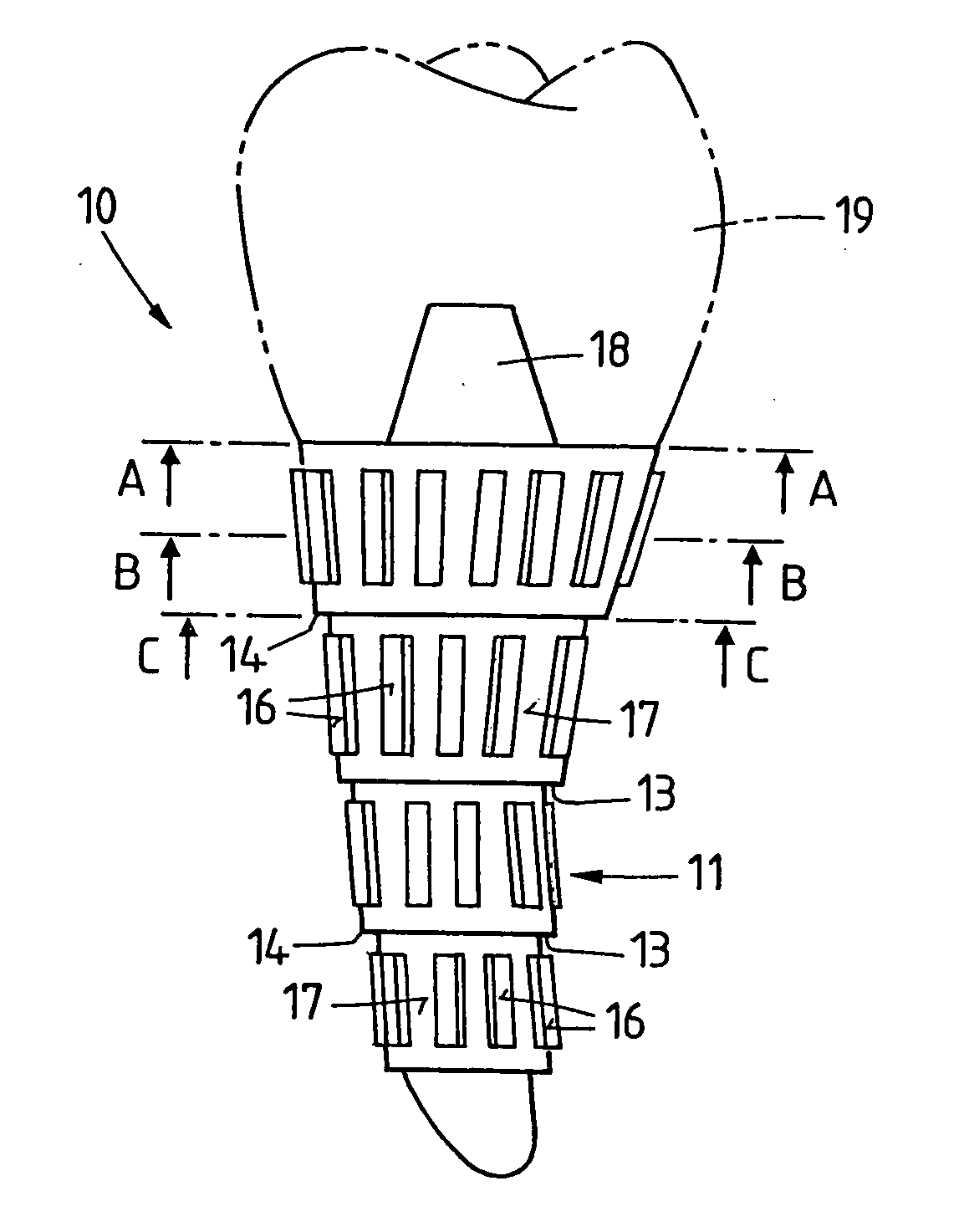

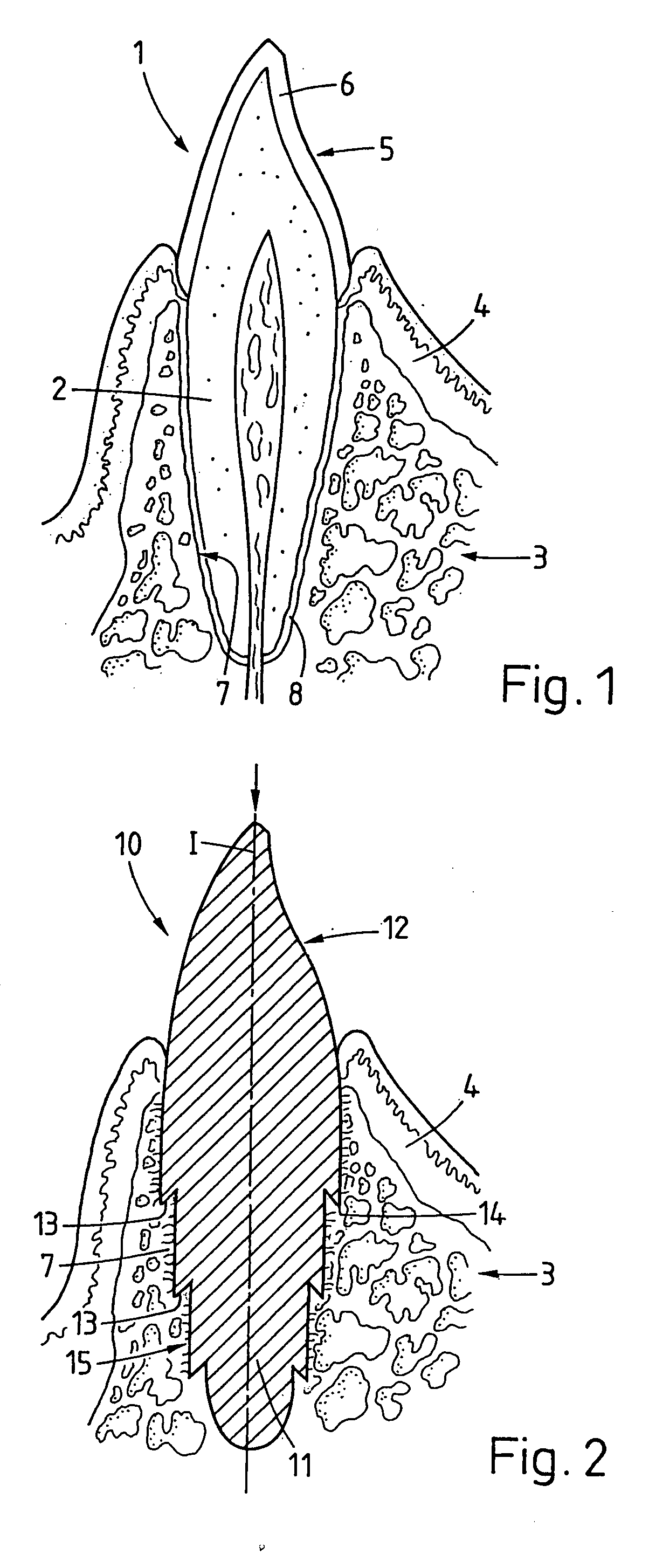

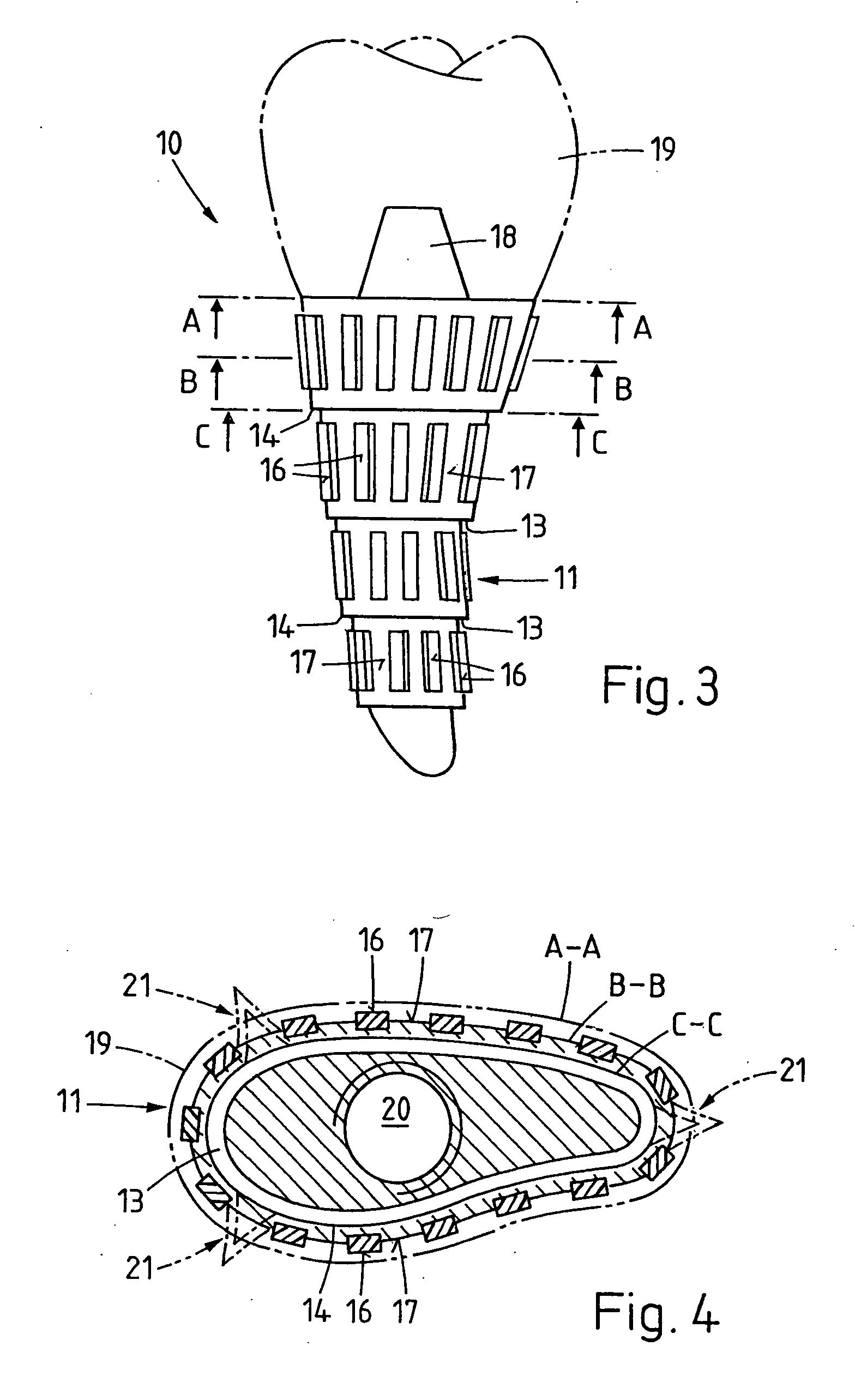

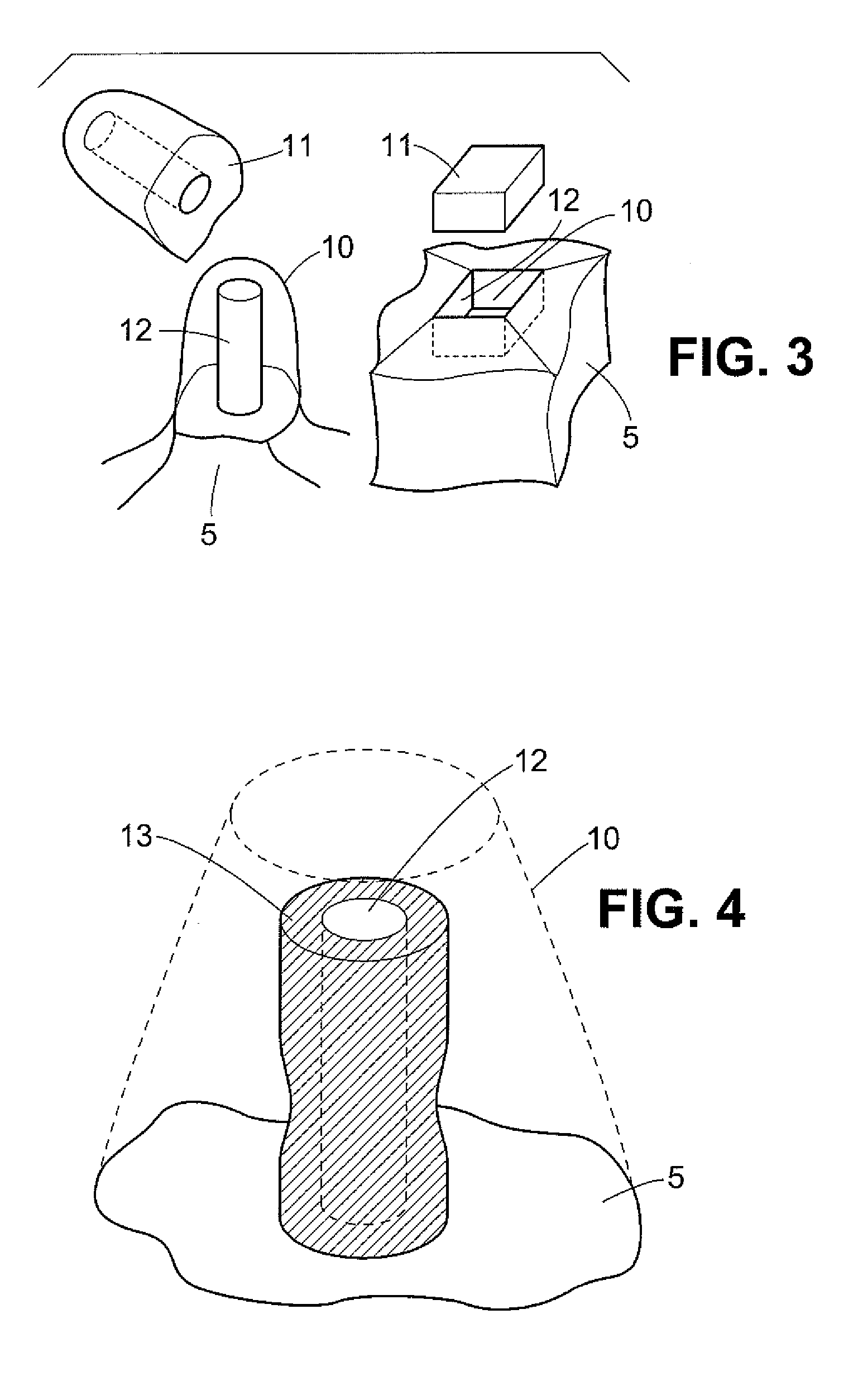

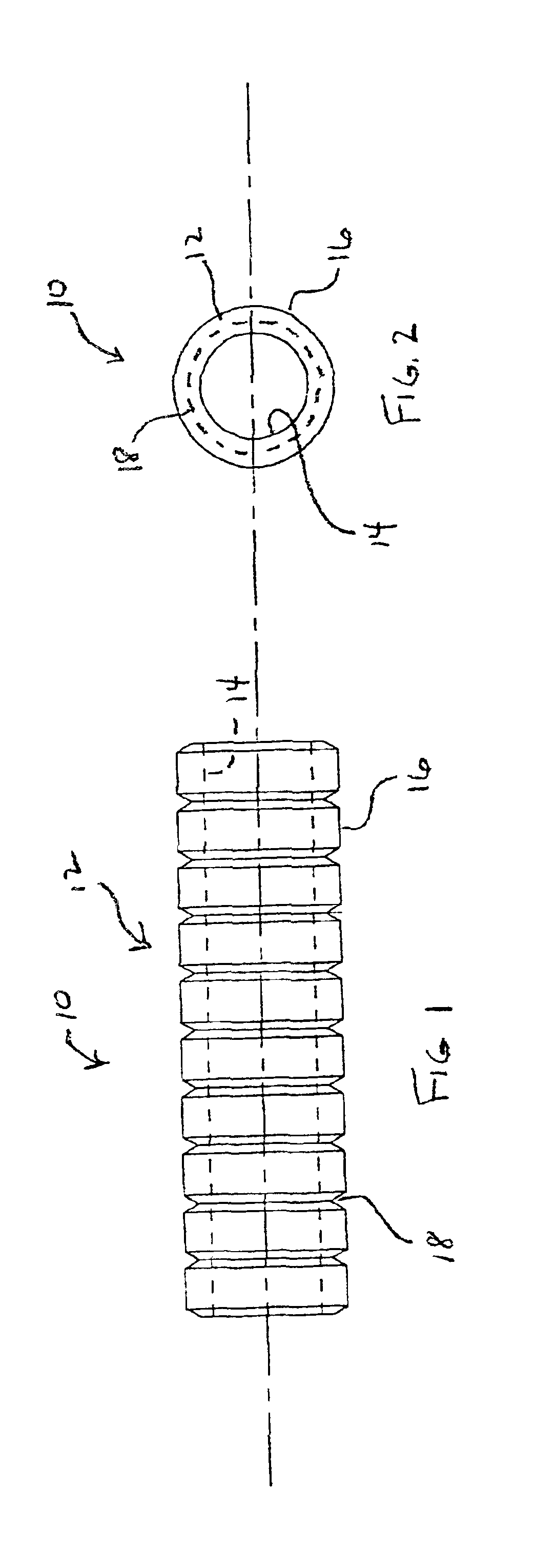

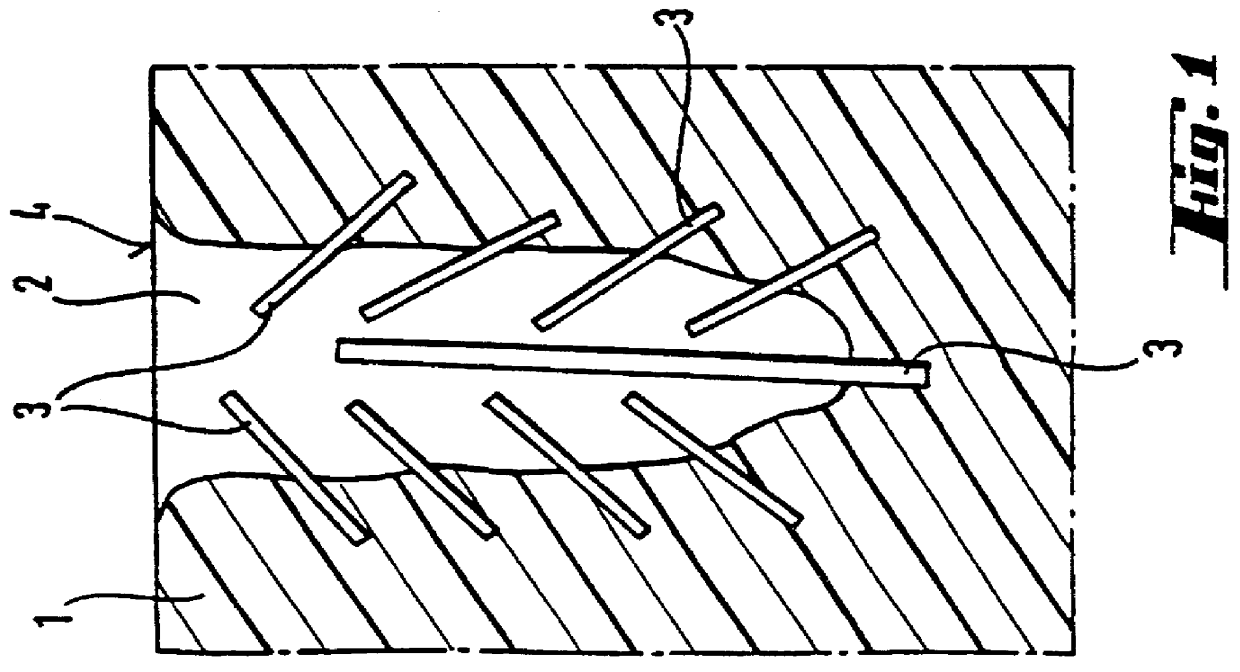

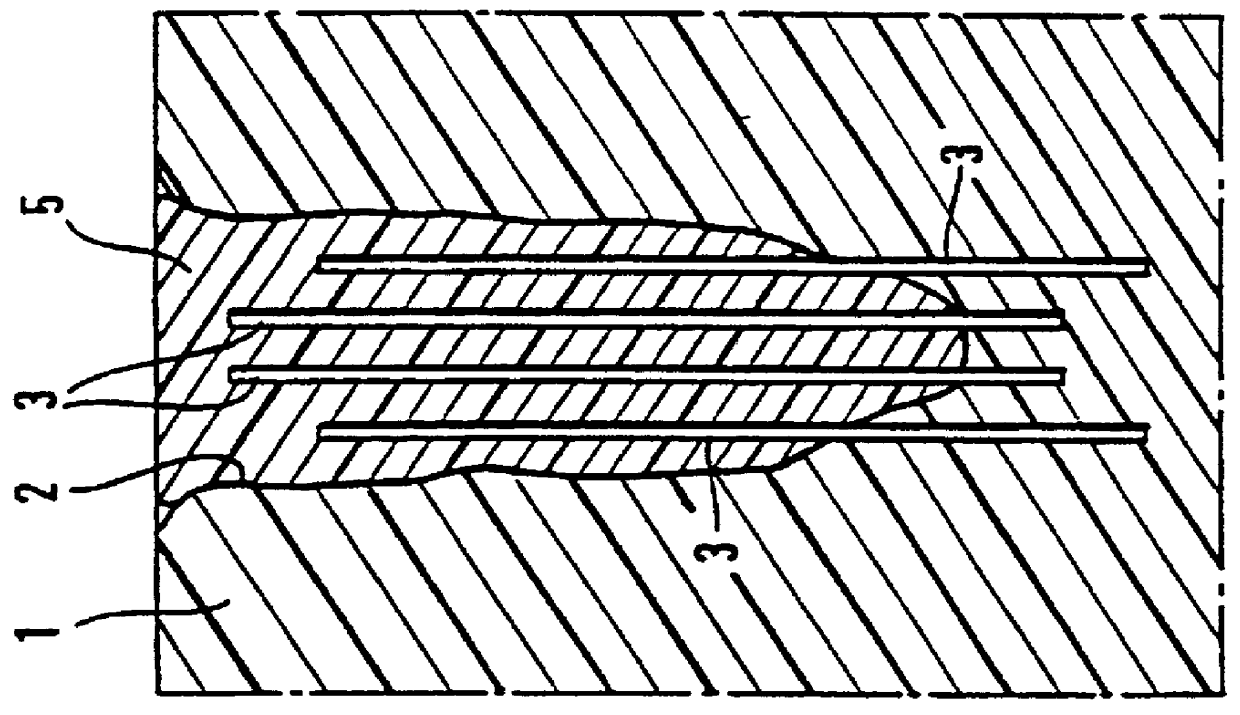

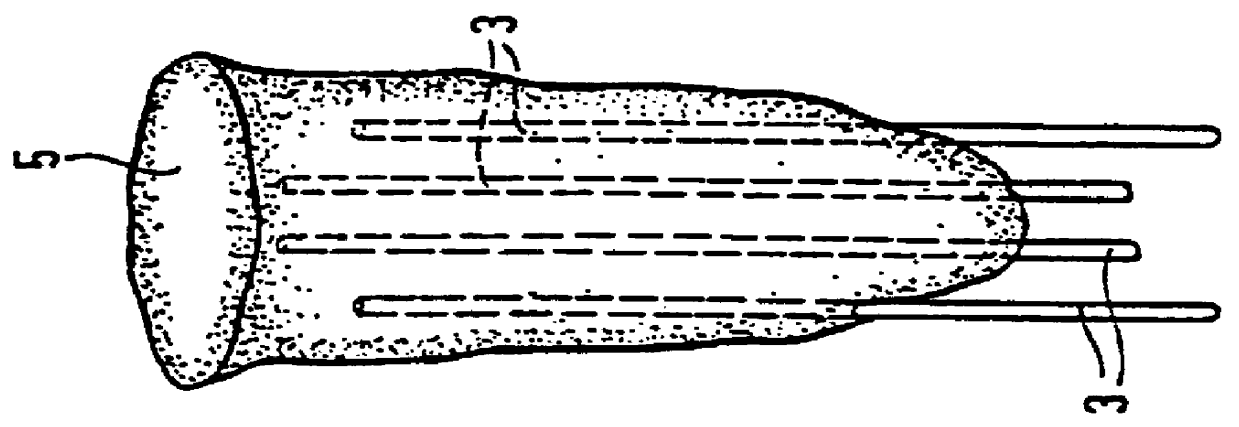

Implant that can be implanted in osseous tissue and method for producing said implant corresponding implant

ActiveUS20060105295A1Strong long-term anchoringProcess stabilityDental implantsInternal osteosythesisBone implantCavity wall

A bone implant (10) is implanted in a cavity parallel to an implant axis (I) and without substantial rotation. The implant includes, on an implant portion to be implanted, cutting edges (14), which do not extend in a common plane with the implant axis and are facing toward the distal end of the implant. The implant also includes surface ranges (16) of a material that is liquefiable by mechanical oscillations. The cutting edges (14) are dimensioned such that they are lodged in the cavity wall after implantation. For implantation, the implant is impinged with mechanical oscillations, resulting in the thermoplastic material being at least partially liquefied and pressed into unevennesses and pores of the cavity wall to form a form-fit and / or material-fit connection between implant (10) and cavity wall, when re-solidified. The cutting edges (14) anchor the implant in the cavity wall.

Owner:WOODWELDING

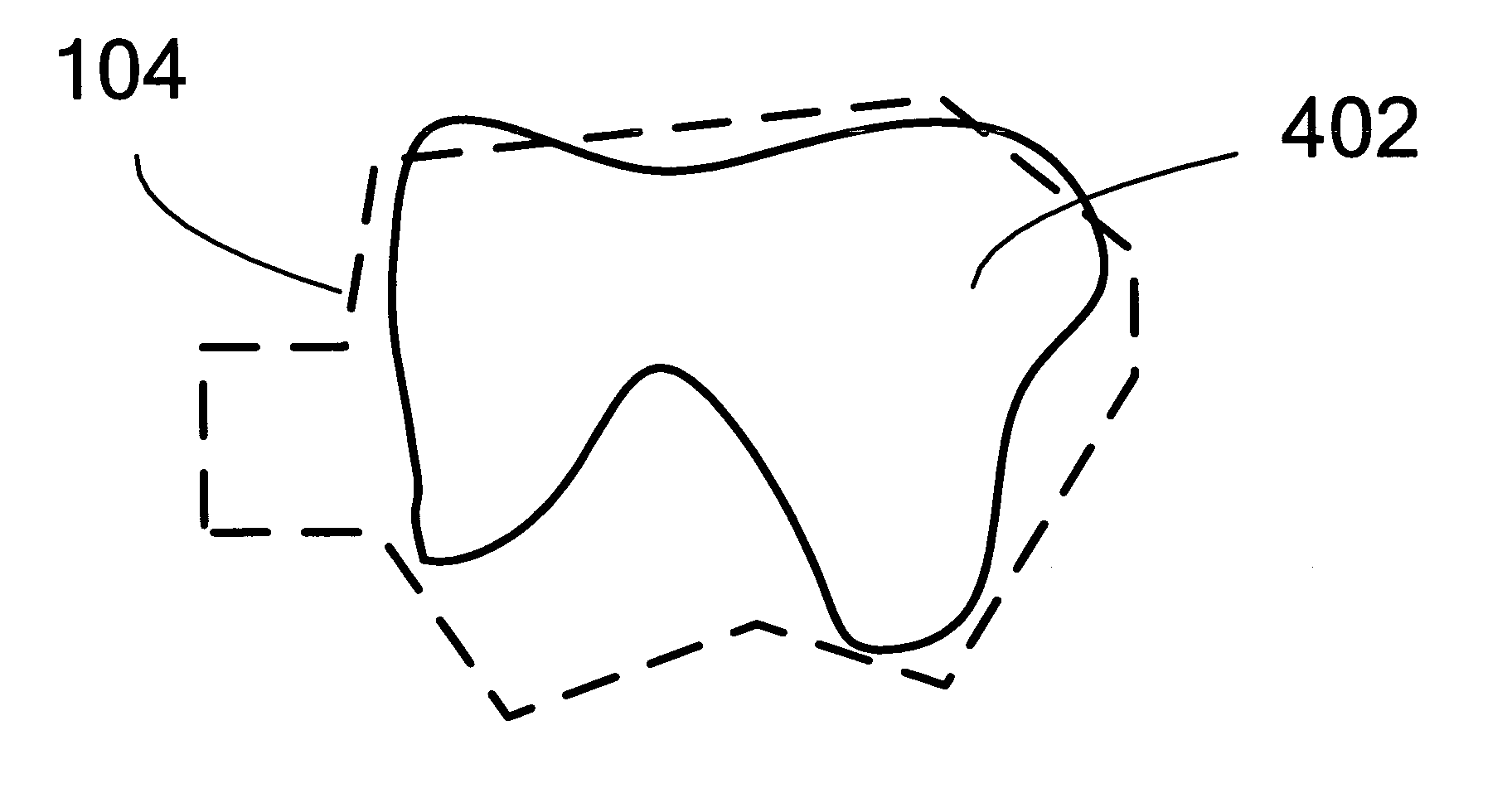

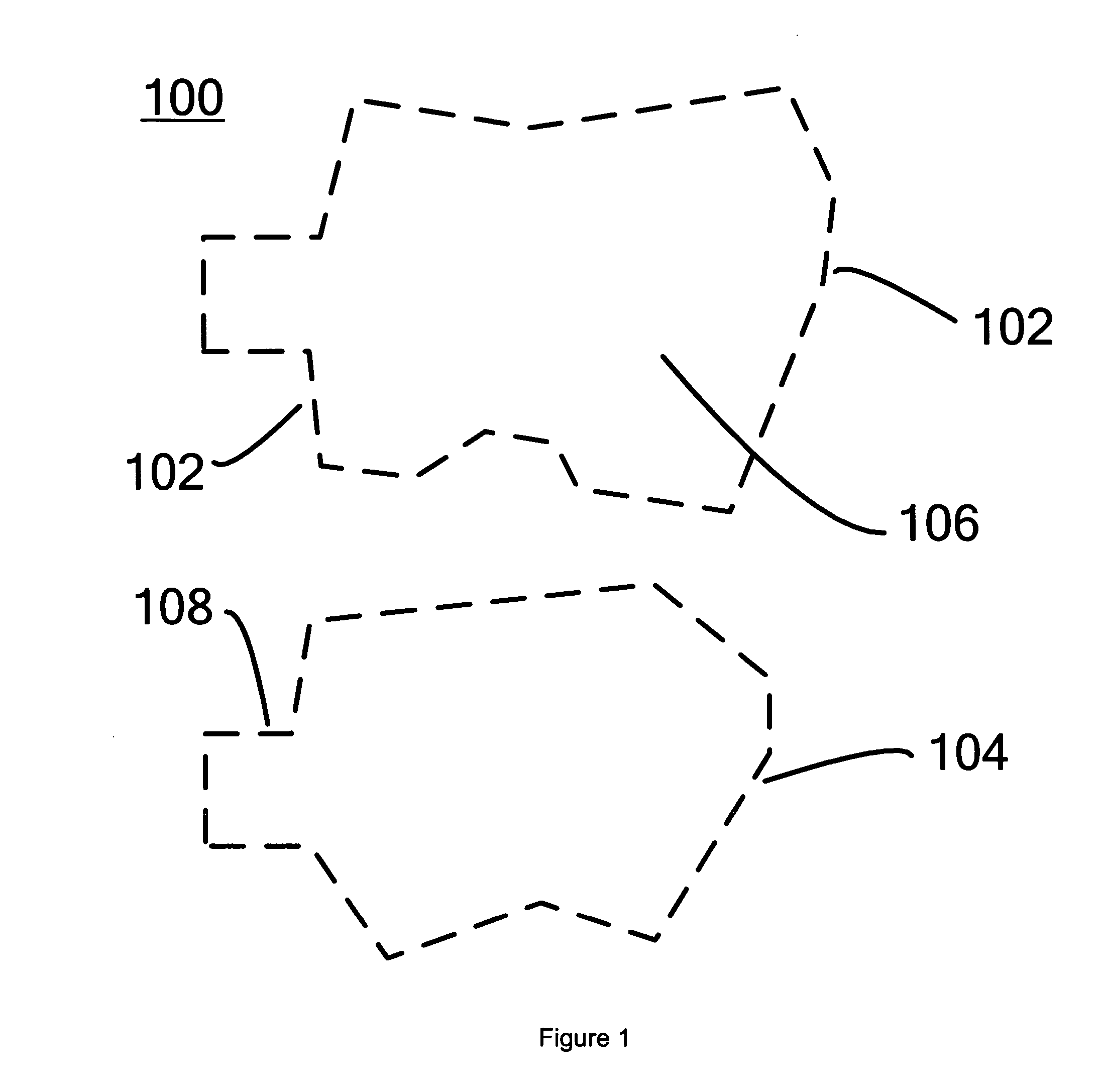

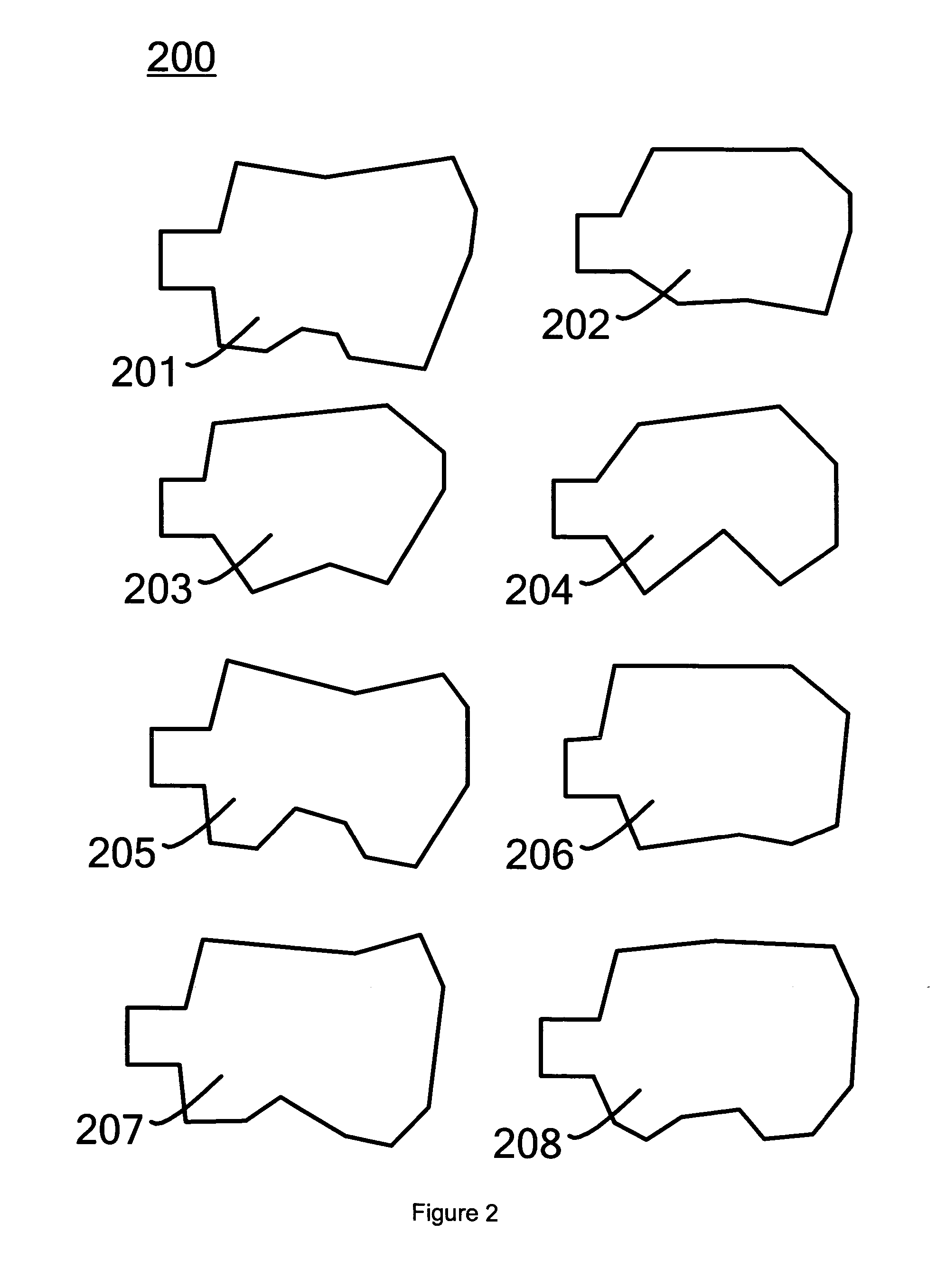

Mill blank library and computer-implemented method for efficient selection of blanks to satisfy given criteria

ActiveUS20050008887A1Easy to manufactureReduce material wasteDental implantsPerson identificationEngineeringInventory management

The present invention relates generally to mill blank constructions to facilitate the manufacture of dental restorations. A given mill blank is formed in a shape (i.e. with a given geometry) that has been predetermined to reduce material waste when the mill blank is machined into the final part. A set of two or more blanks each having such characteristics comprise a smart blank “library.” In one embodiment, a smart blank library includes a sufficient number of unique blanks such that, when the geometry of the designed restoration is known, the smart blank with a highest yield can be selected for use in milling the restoration. The “yield” of a given smart blank represents the amount of material of the smart blank that is actually used in the final restoration. Automated processes for smart blank inventory management and smart blank selection are also described.

Owner:D4D TECH LP

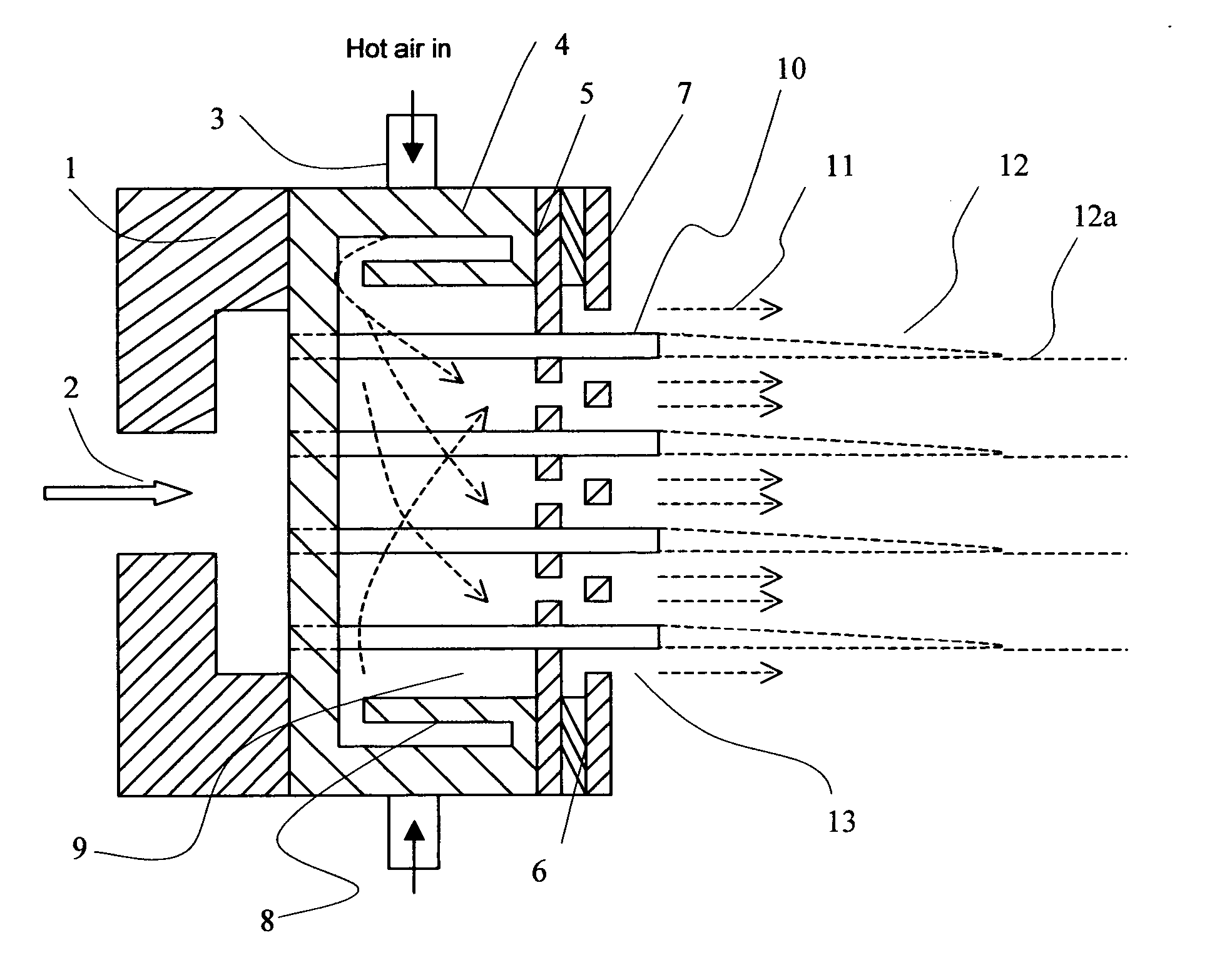

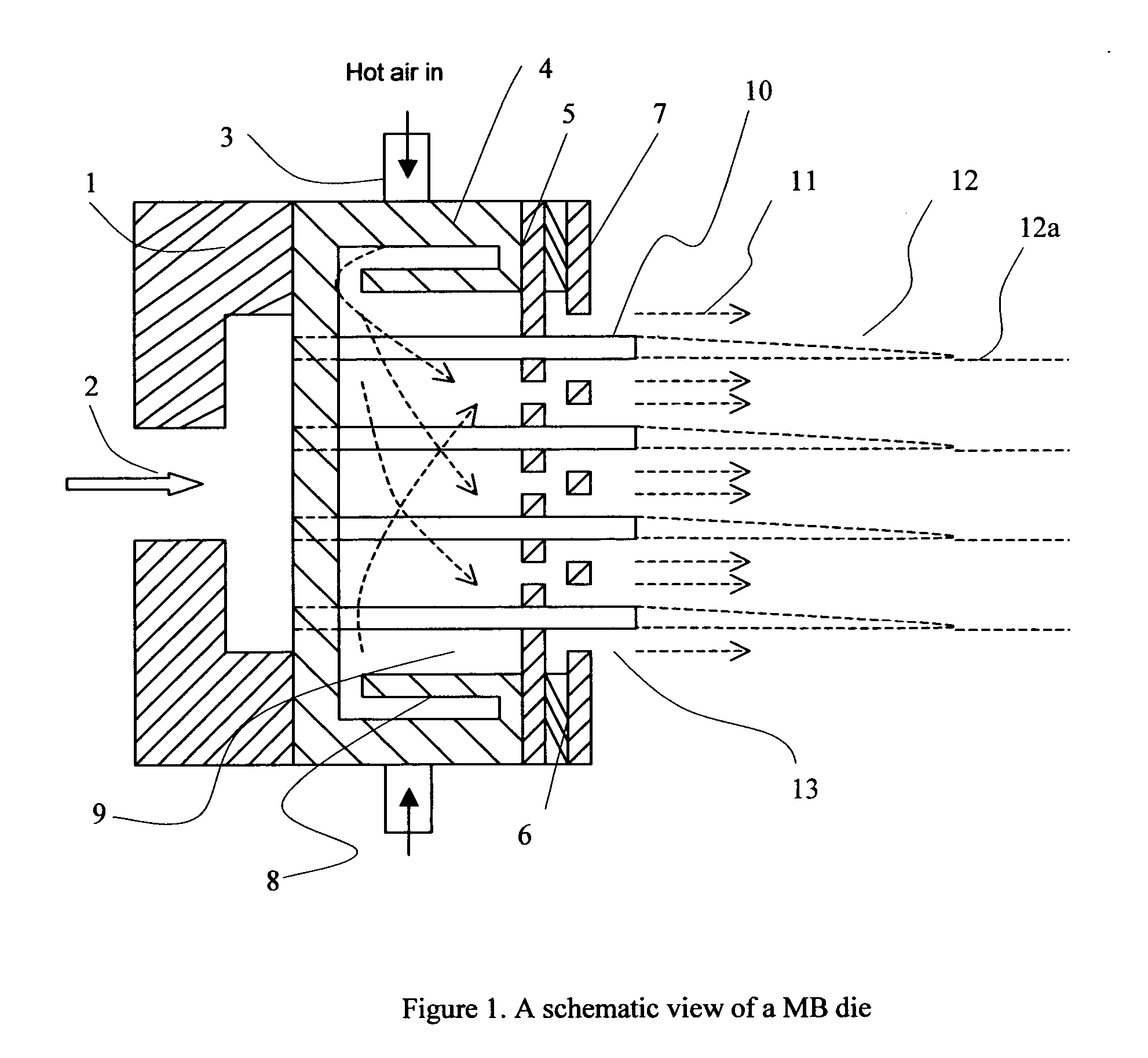

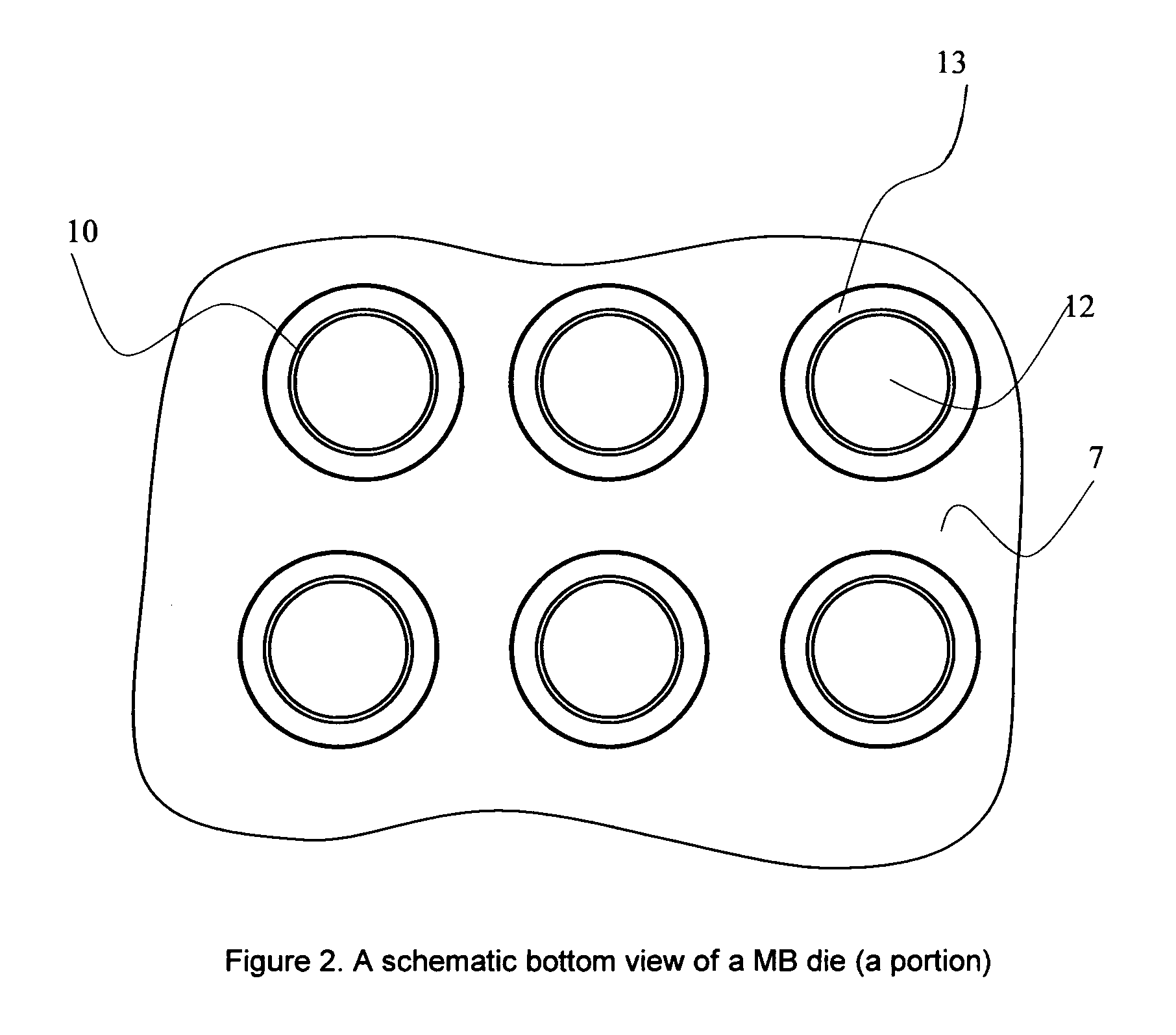

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

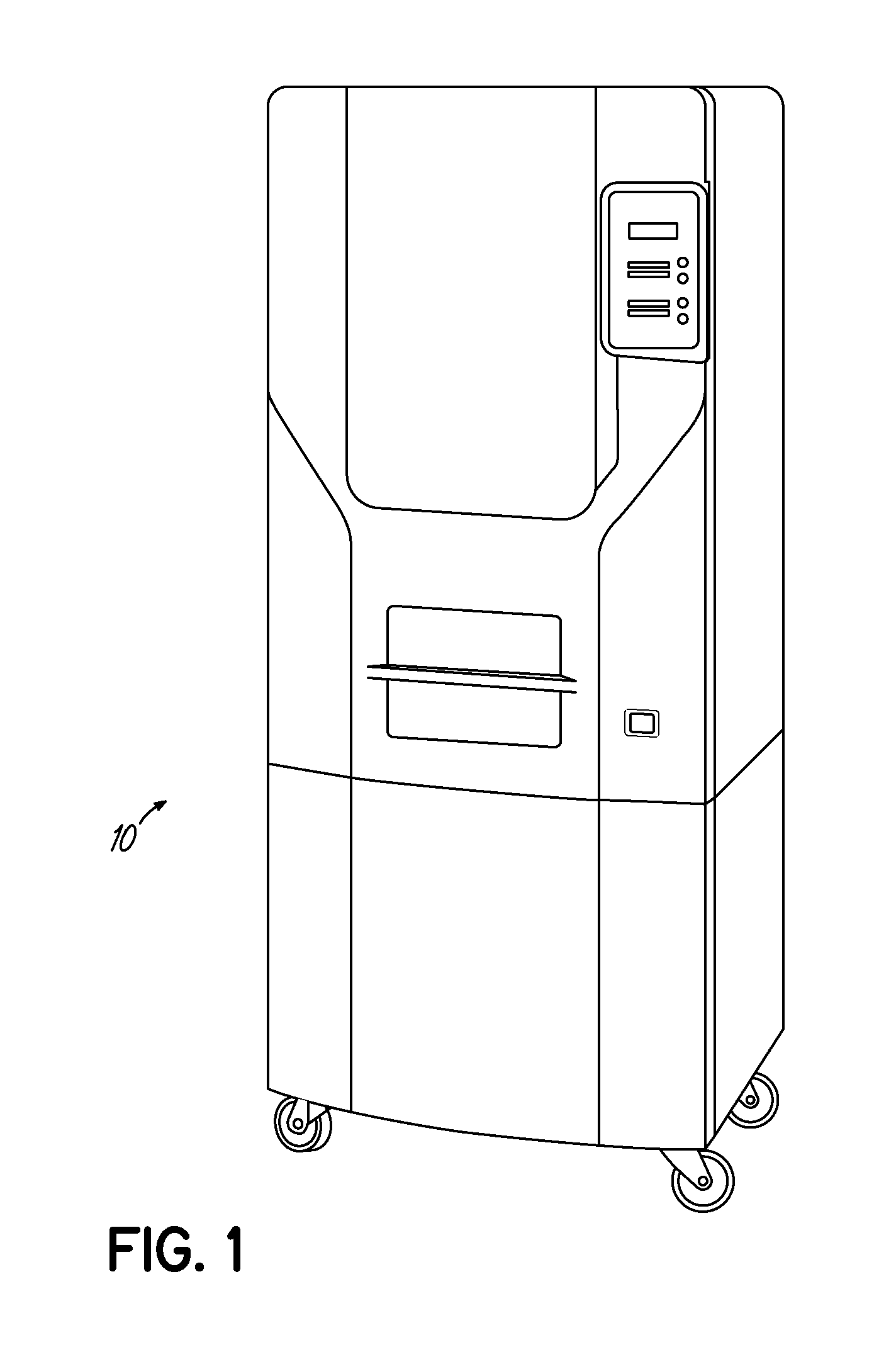

Three-dimensional fabricating systems for rapidly producing objects

InactiveUS20160288376A1High strengthAdditive manufacturing apparatus3D object support structuresFree Radical SuppressionPolypropylene

This invention relates to rapid prototyping systems, specifically, a composition for a release film comprising one or more base materials selected from the group consisting of silicone, polycarbonate, polyethylene, and polypropylene; and one or more free-radical inhibitors.

Owner:DENTSPLY SIRONA INC

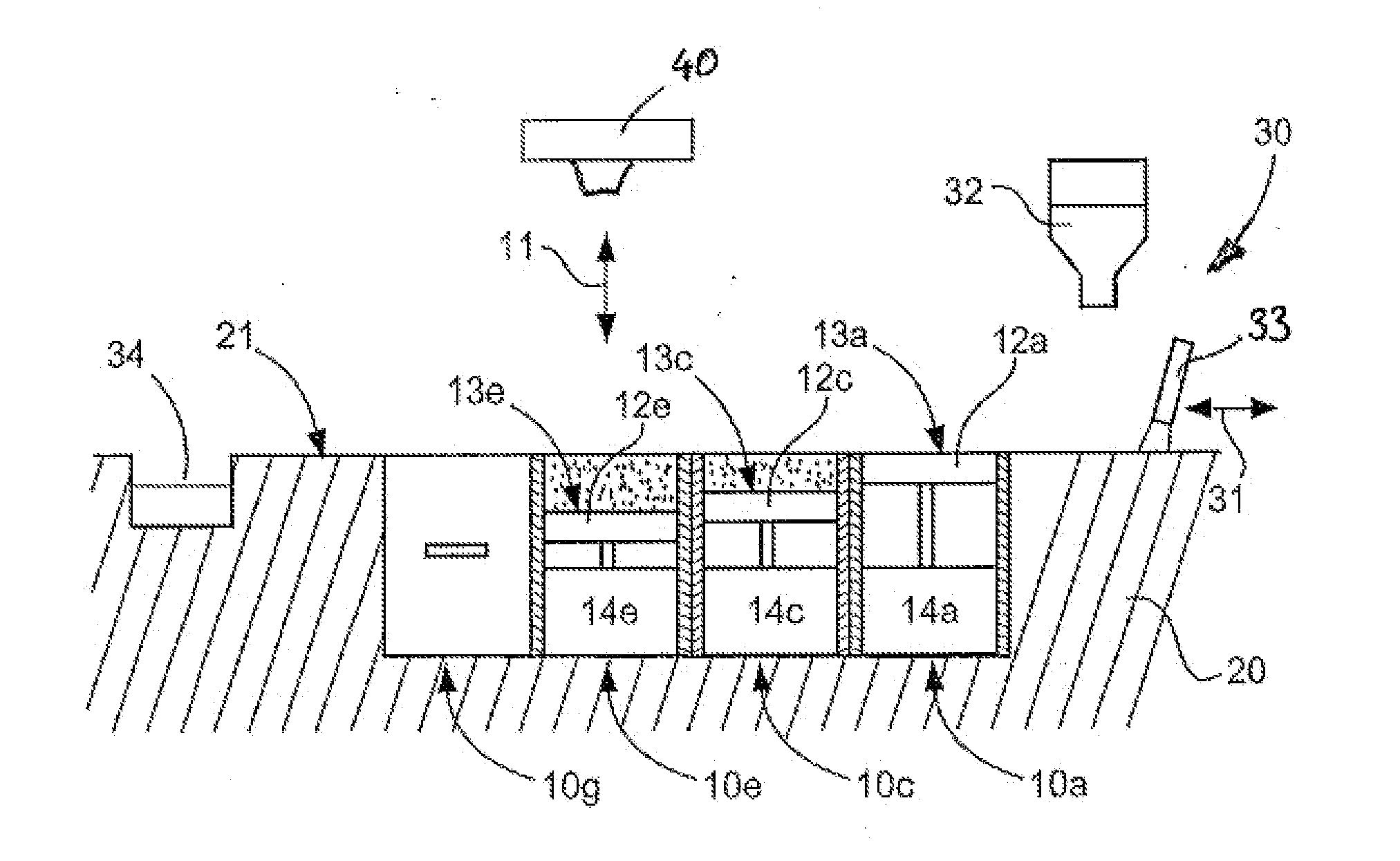

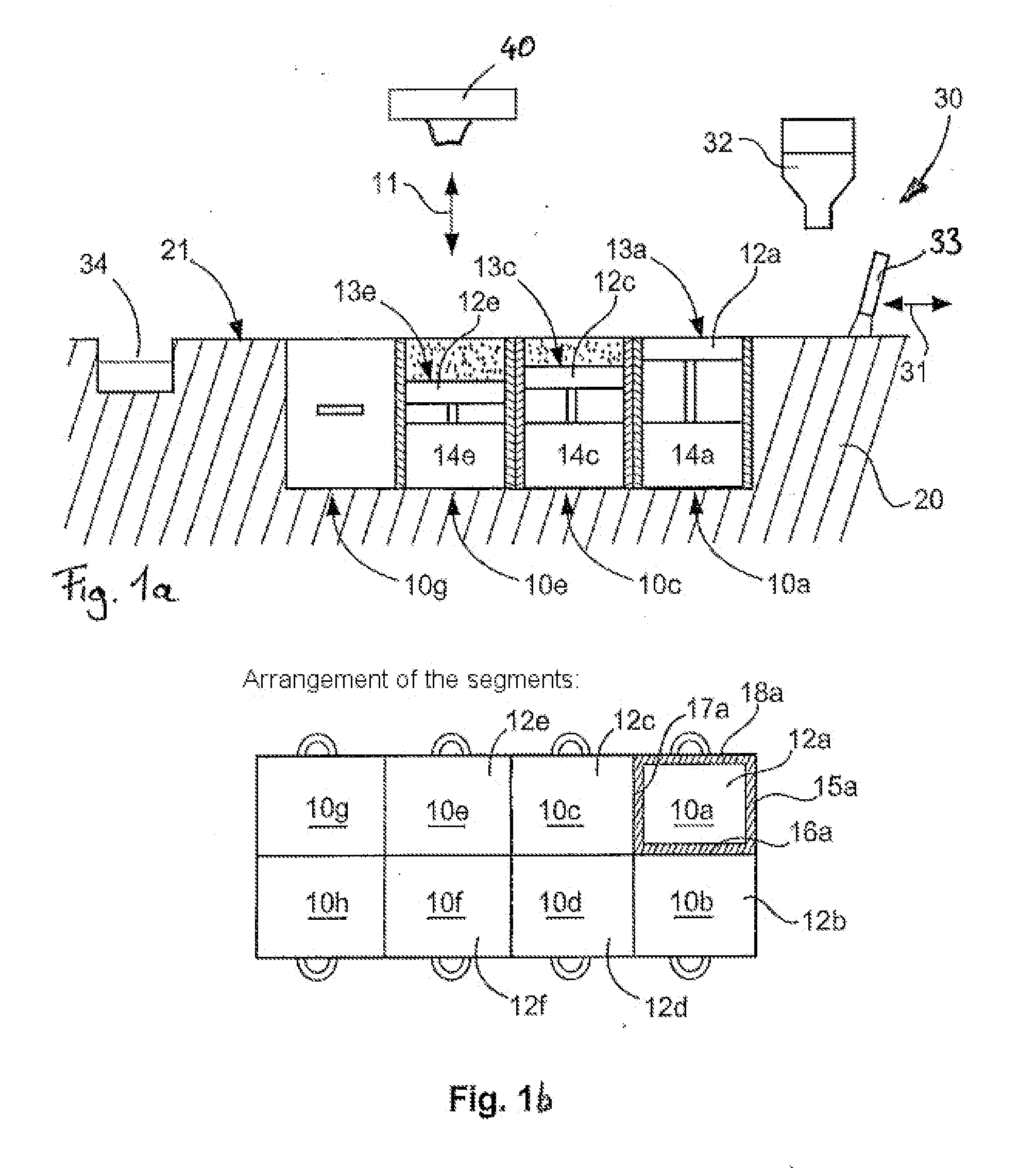

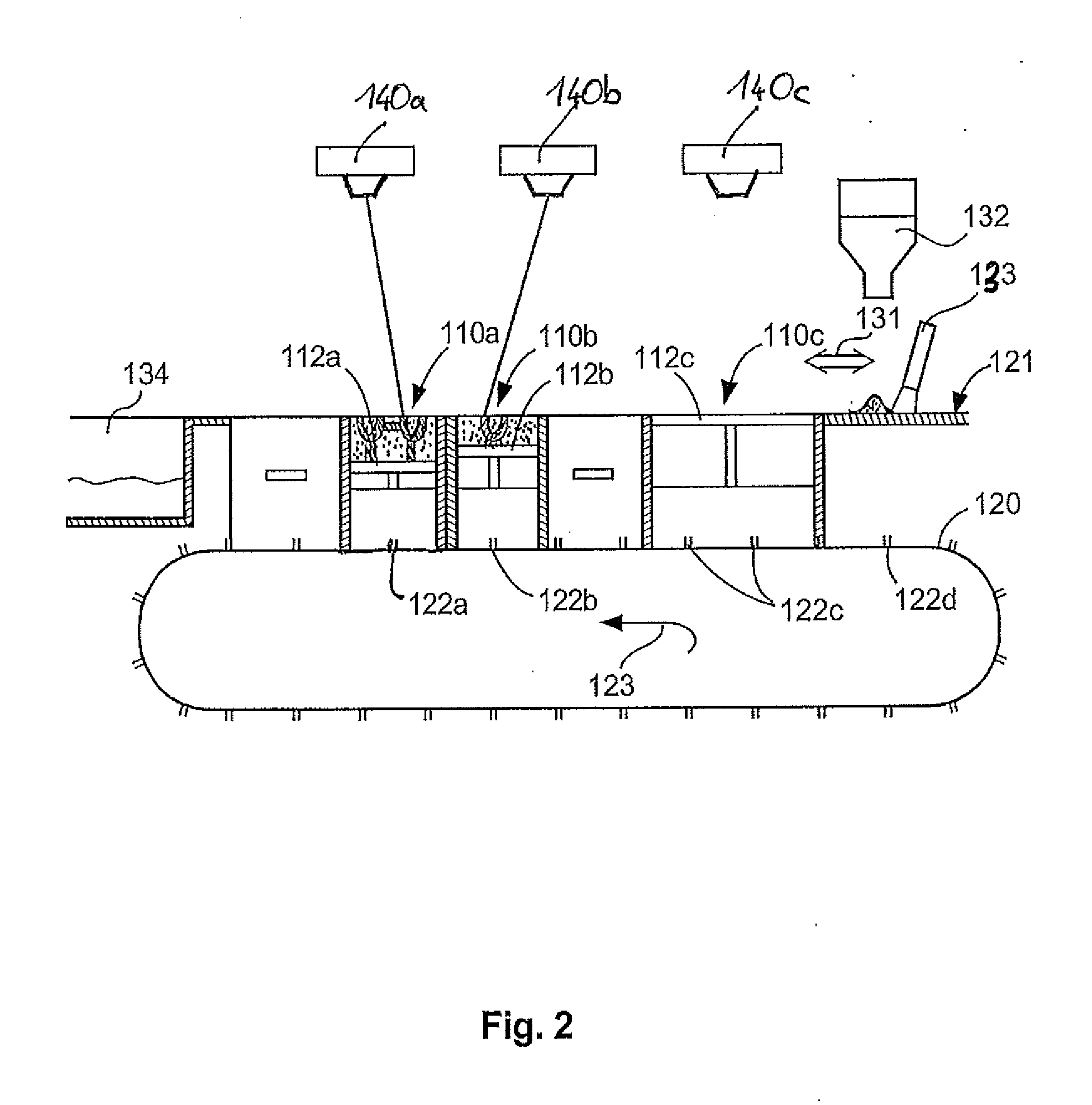

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

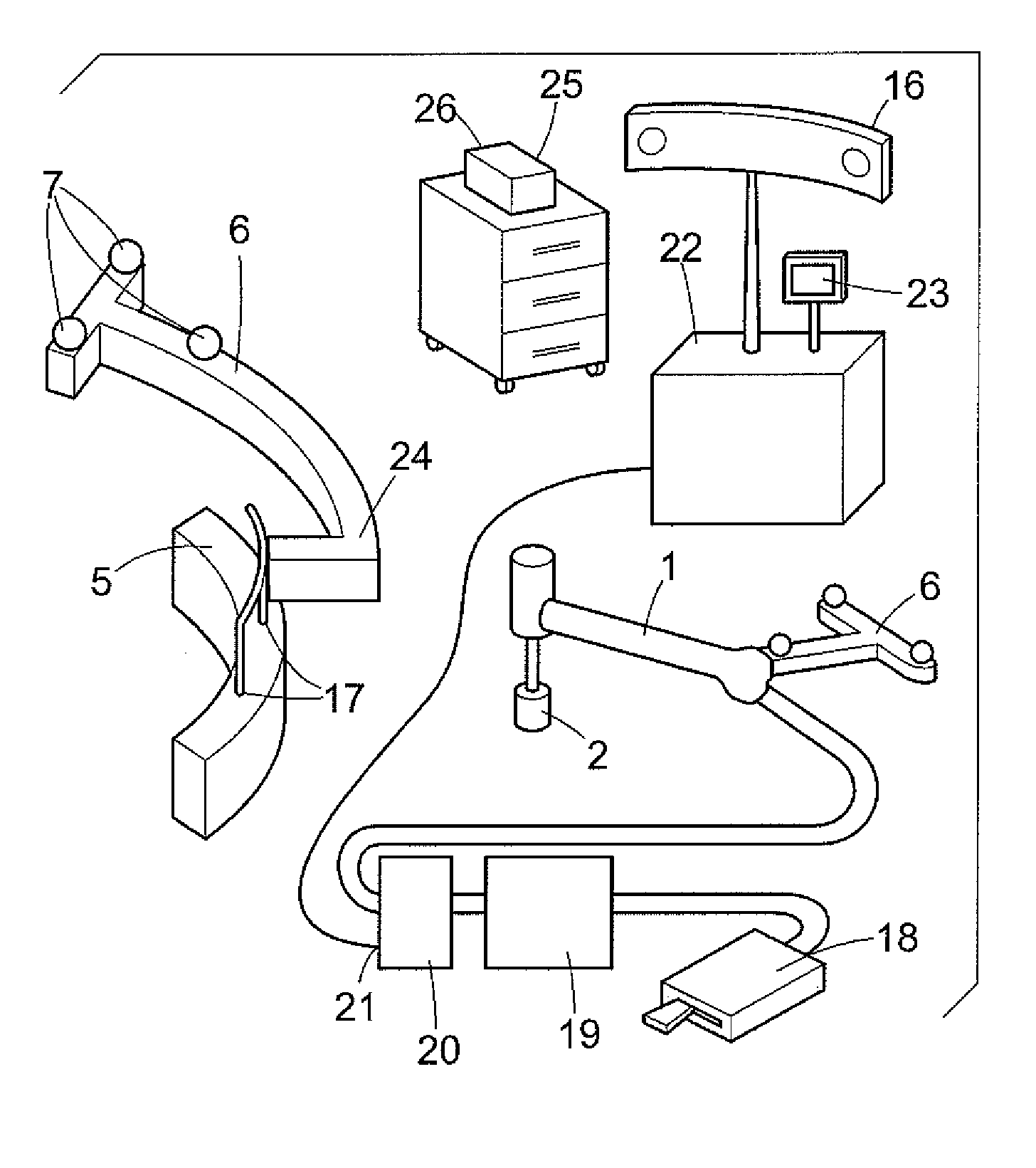

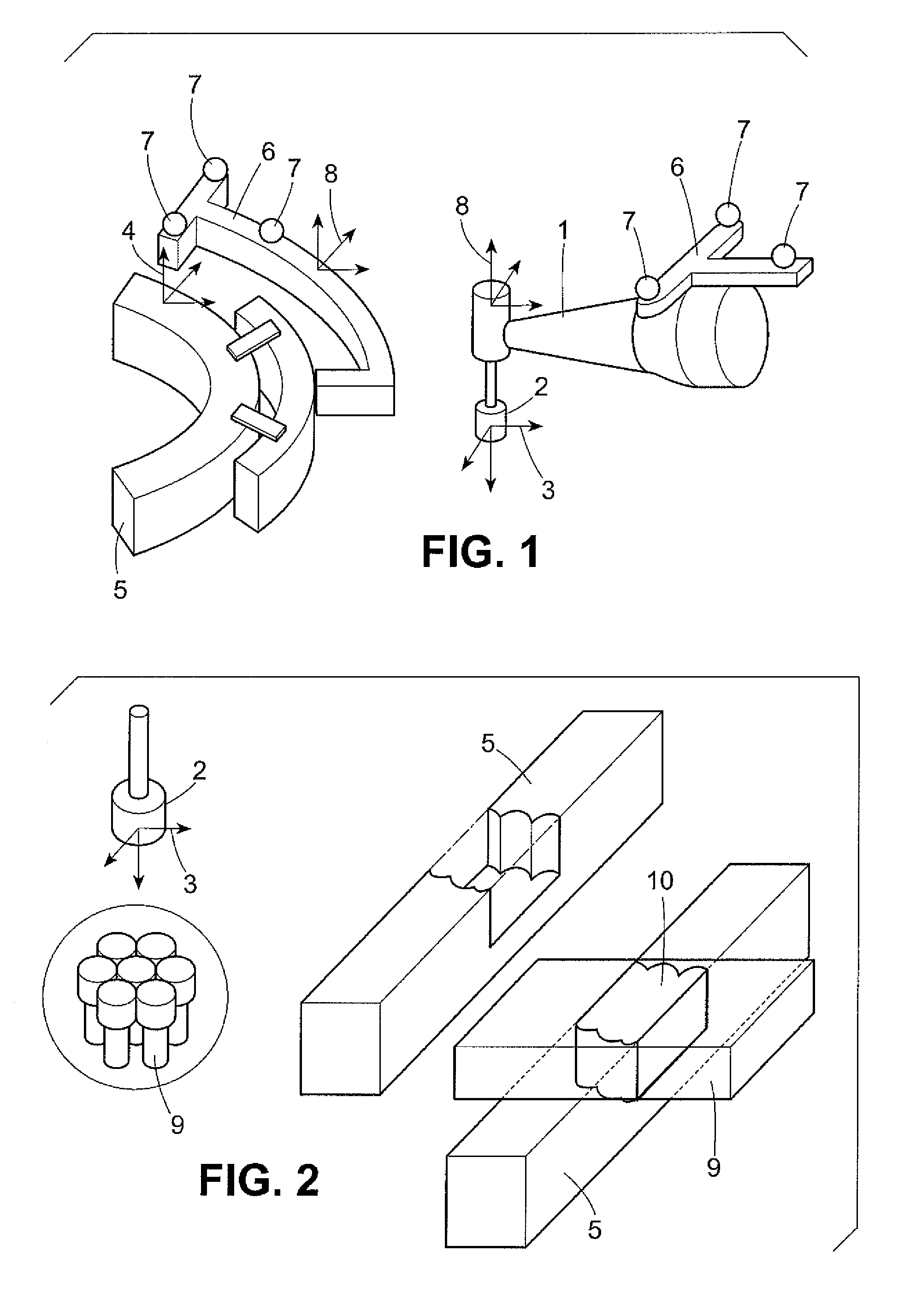

Method and device system for removing material or for working material

Method and system, for which can be used in the fields of medicine and dentistry as well as for the most varied types of material working in different areas of application and model working, provides that an exact removal of material or a highly precise, reproducible material working can be realized by acquiring, storing and processing data pertaining to position and / or orientation of an effector and their changes relative to the position of at least one reference body. The effector is controlled and / or regulated with regard to its power and / or parameterization based on a predetermined working volume, material volume removed and remaining material volume. A first marking support with markings is arranged on a handpiece with the effector, where the handpiece is connected to a control unit, and a second marking support with markings is attached to the material object or tissue object.

Owner:ALL OF INNOVATION MBH

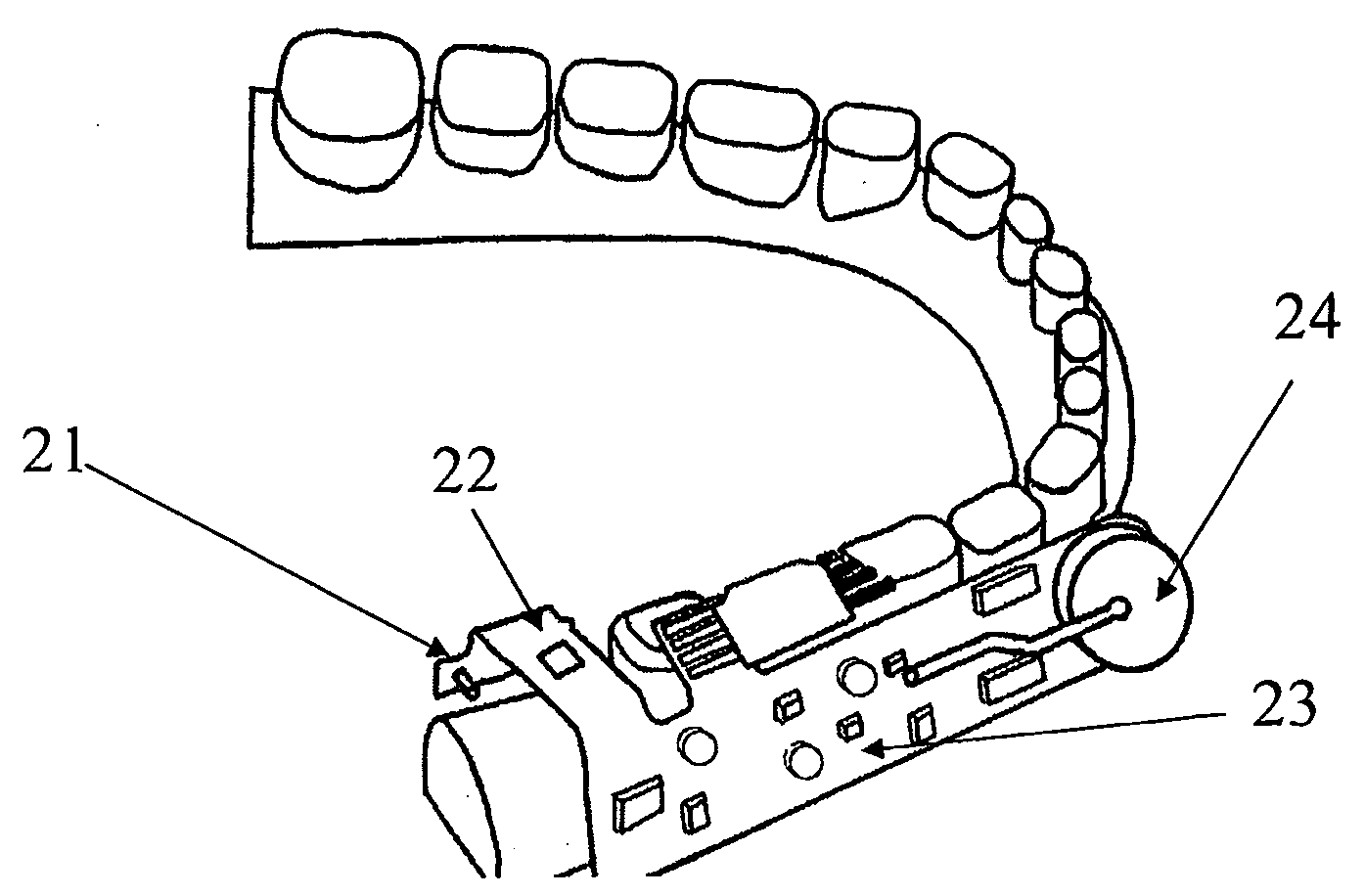

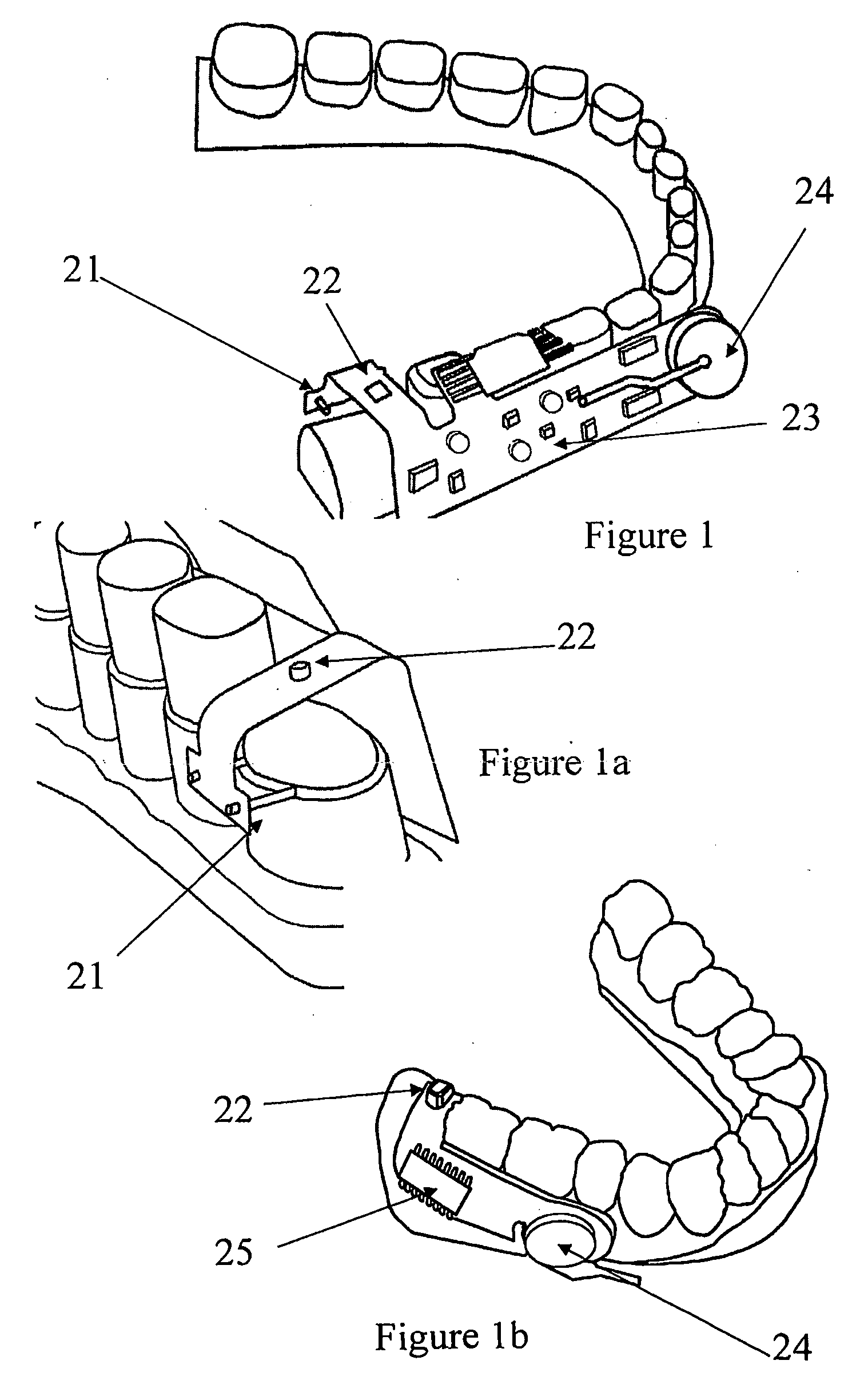

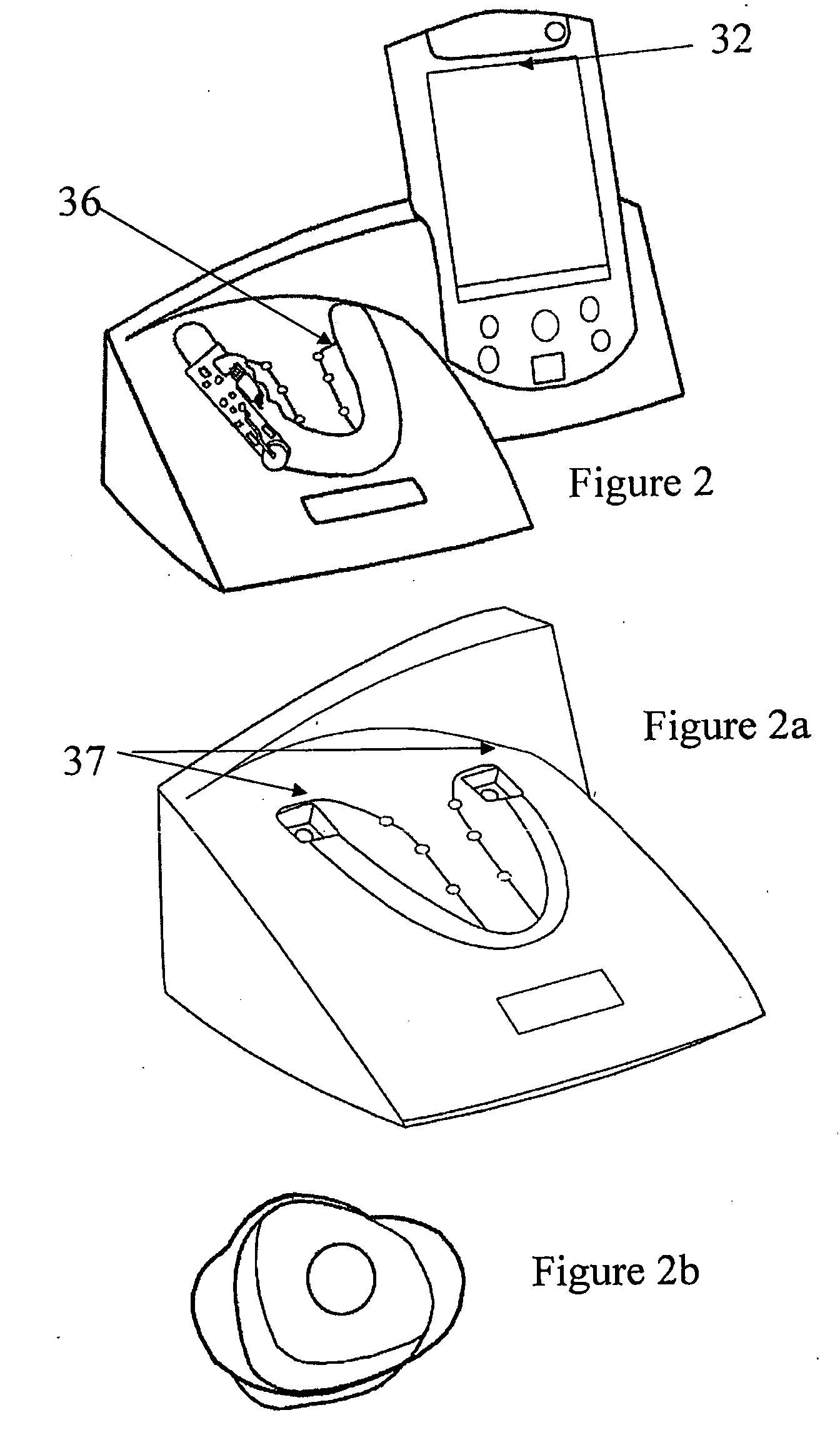

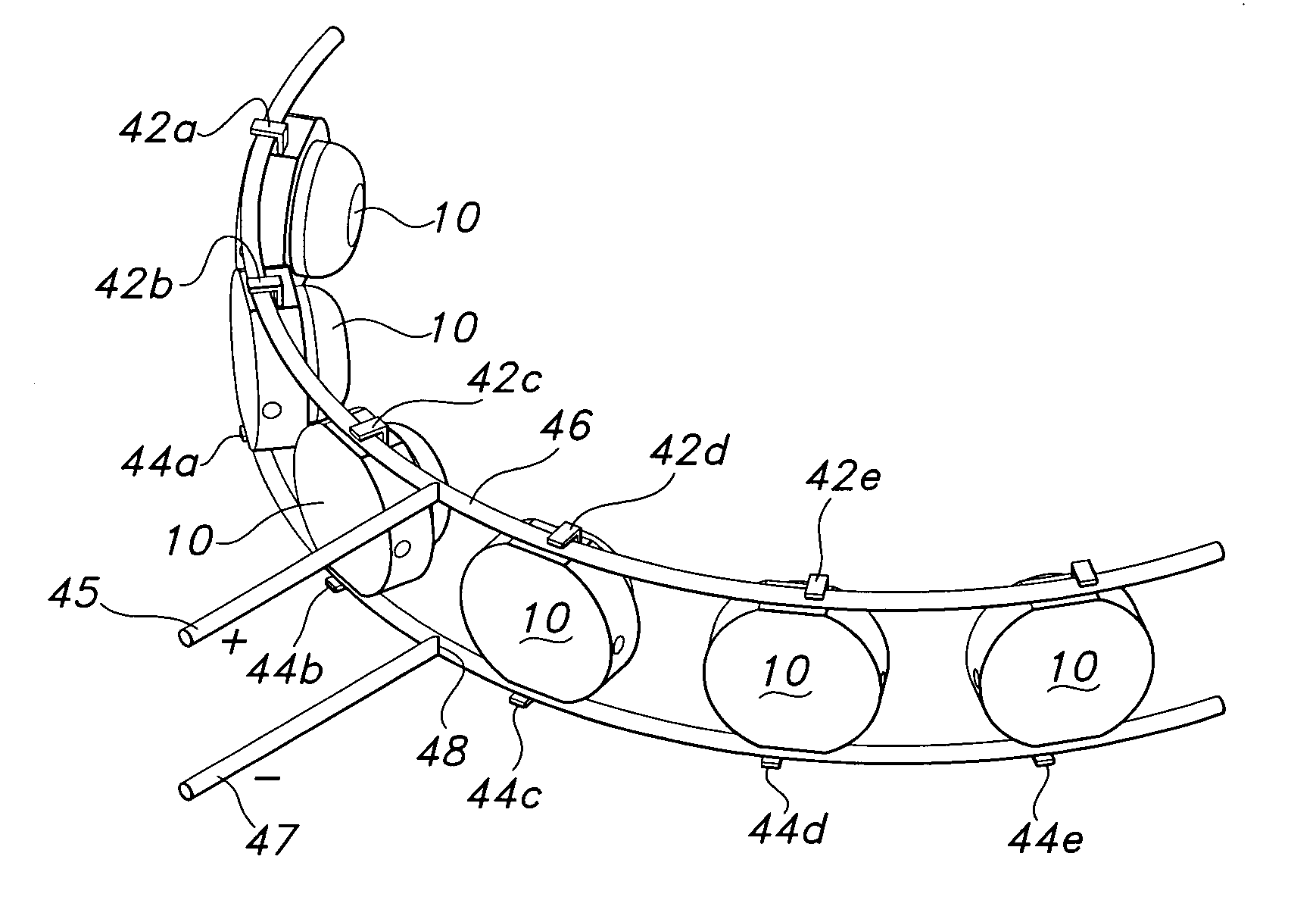

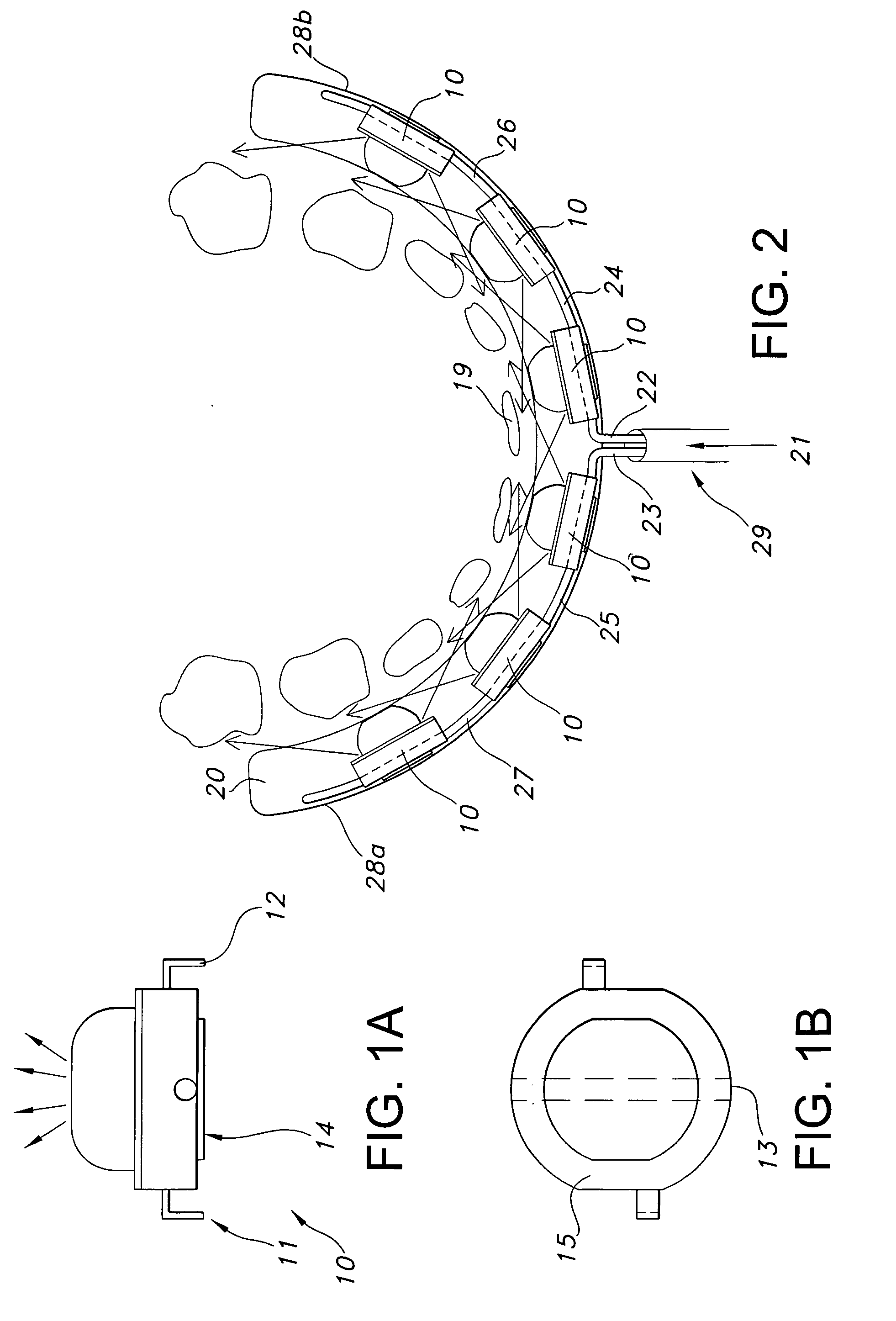

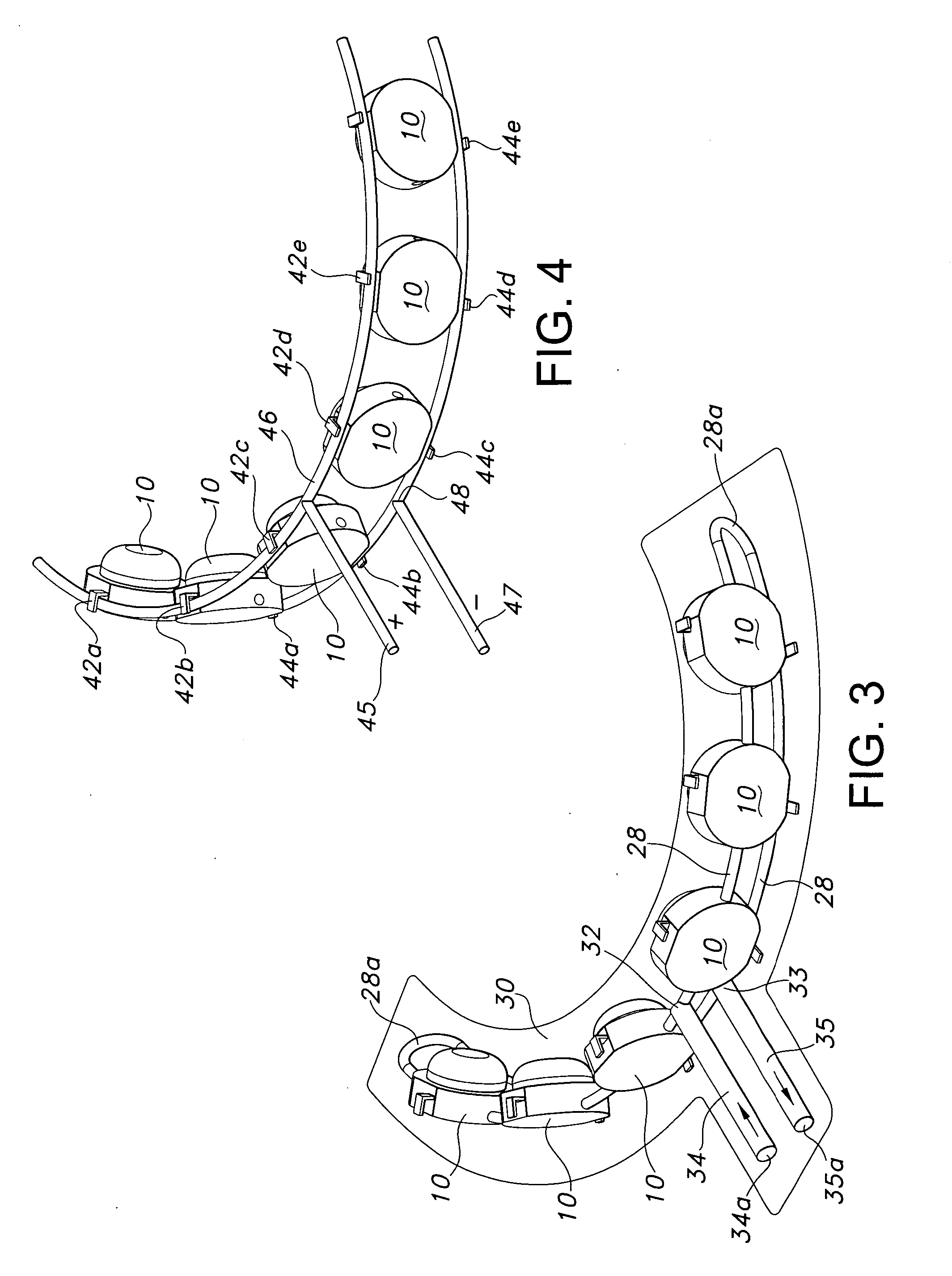

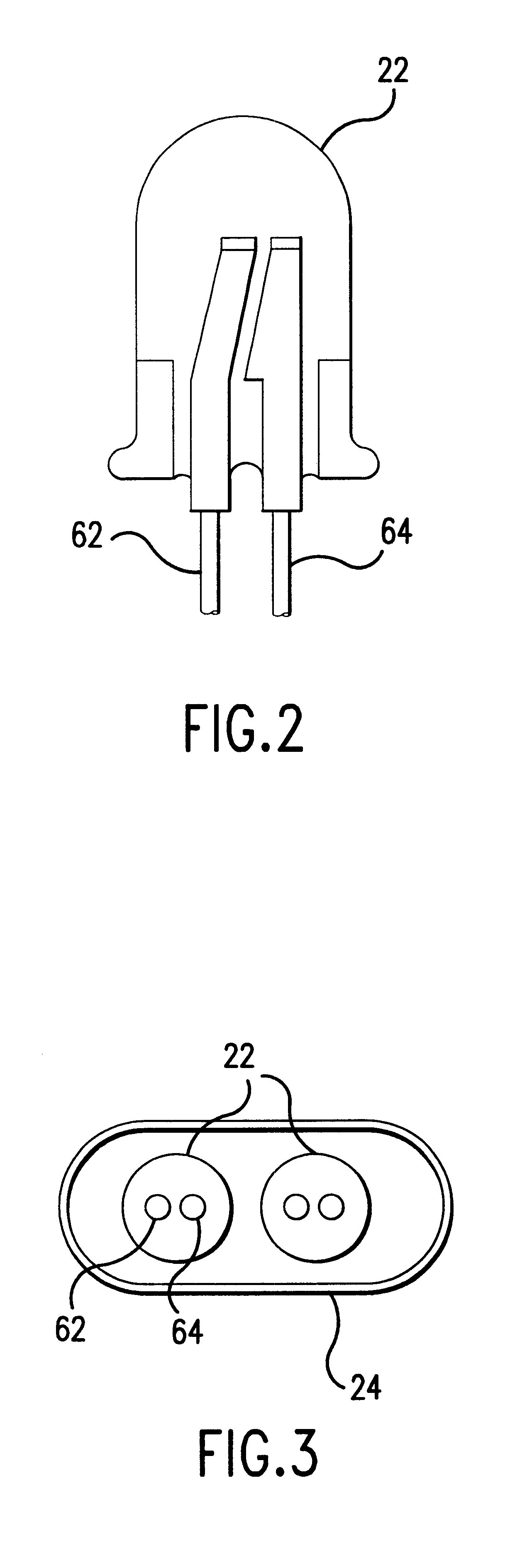

Manufacturing methods, testing methods, and testers for intra-oral electronically embedded devices

InactiveUS20090210032A1Minimize power consumptionLow power saving modeHead electrodesSnoring preventionDrying mouthWhole body

The invention is directed to manufacturing and testing methods of electronic intraoral devices for diagnose, monitor and treat local and systemic diseases and conditions for humans and animals. More specifically, the current invention deals with manufacturing techniques, testing methods and a testing apparatus of mainly three types of intra-oral devices: (a) electro-stimulators for various applications such as treatment of dry mouth by stimulating saliva secretion, apnea, sleeping disorders, eating disorders (obesity, anorexia, etc.) dysphagia and others, (b) drug delivery devices; and (c) bio-sensing and monitoring devices. The common parts or the devices are: (1) art electronic module embedded in the device: (2) or a power source being embedded in the device; (3) the devices (or part of them) being placed in the oral cavity.

Owner:BEISKI BEN ZION +1

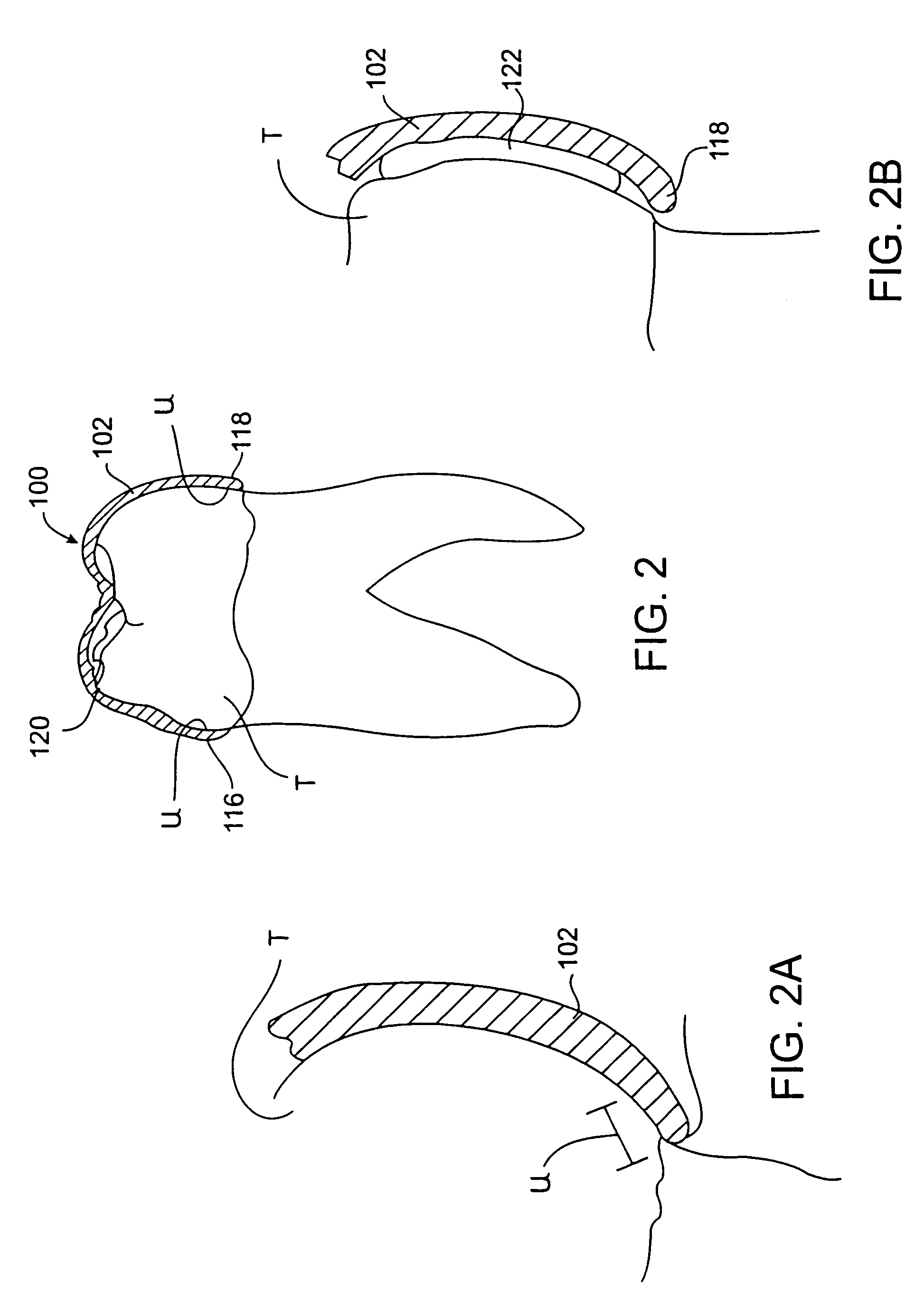

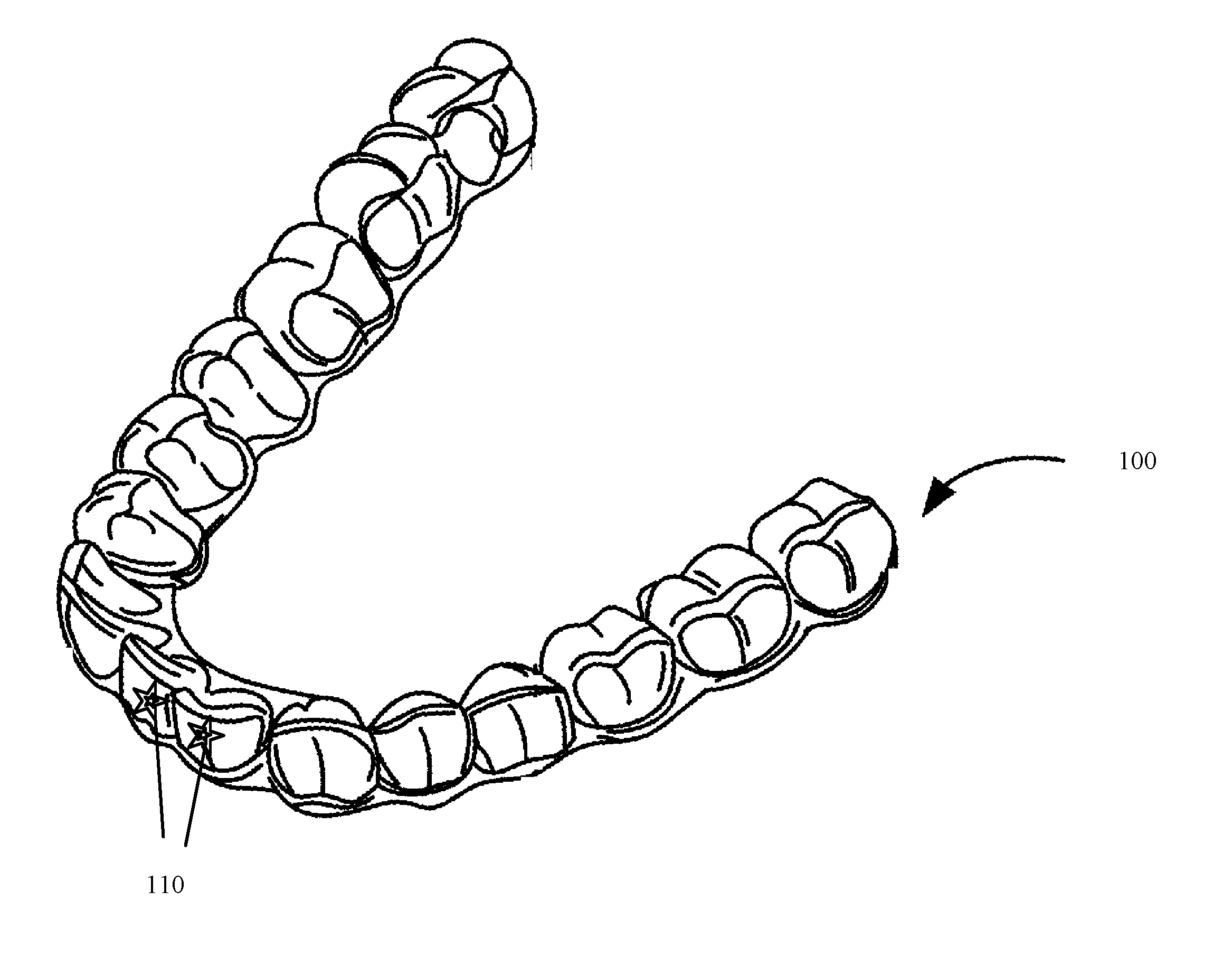

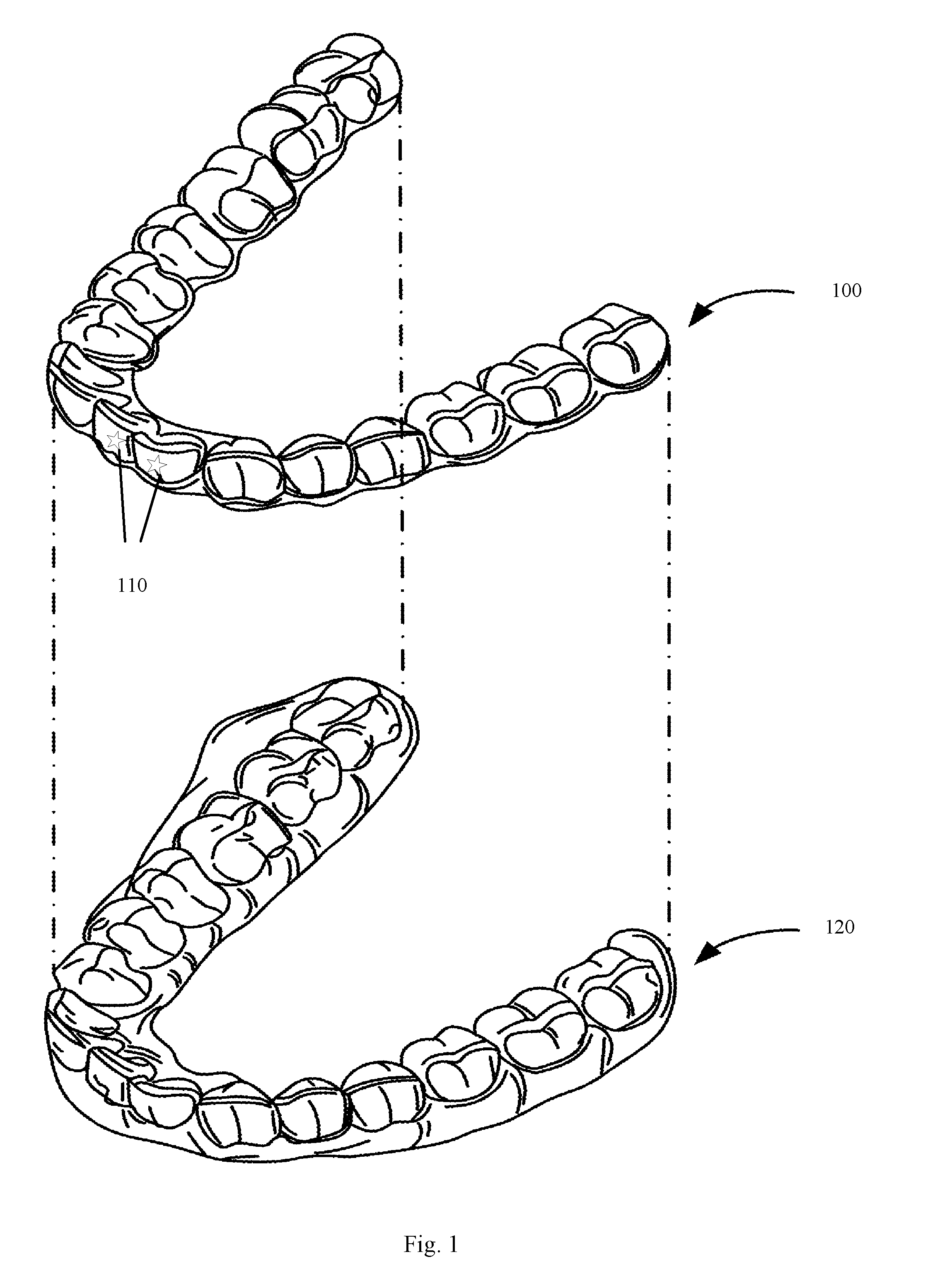

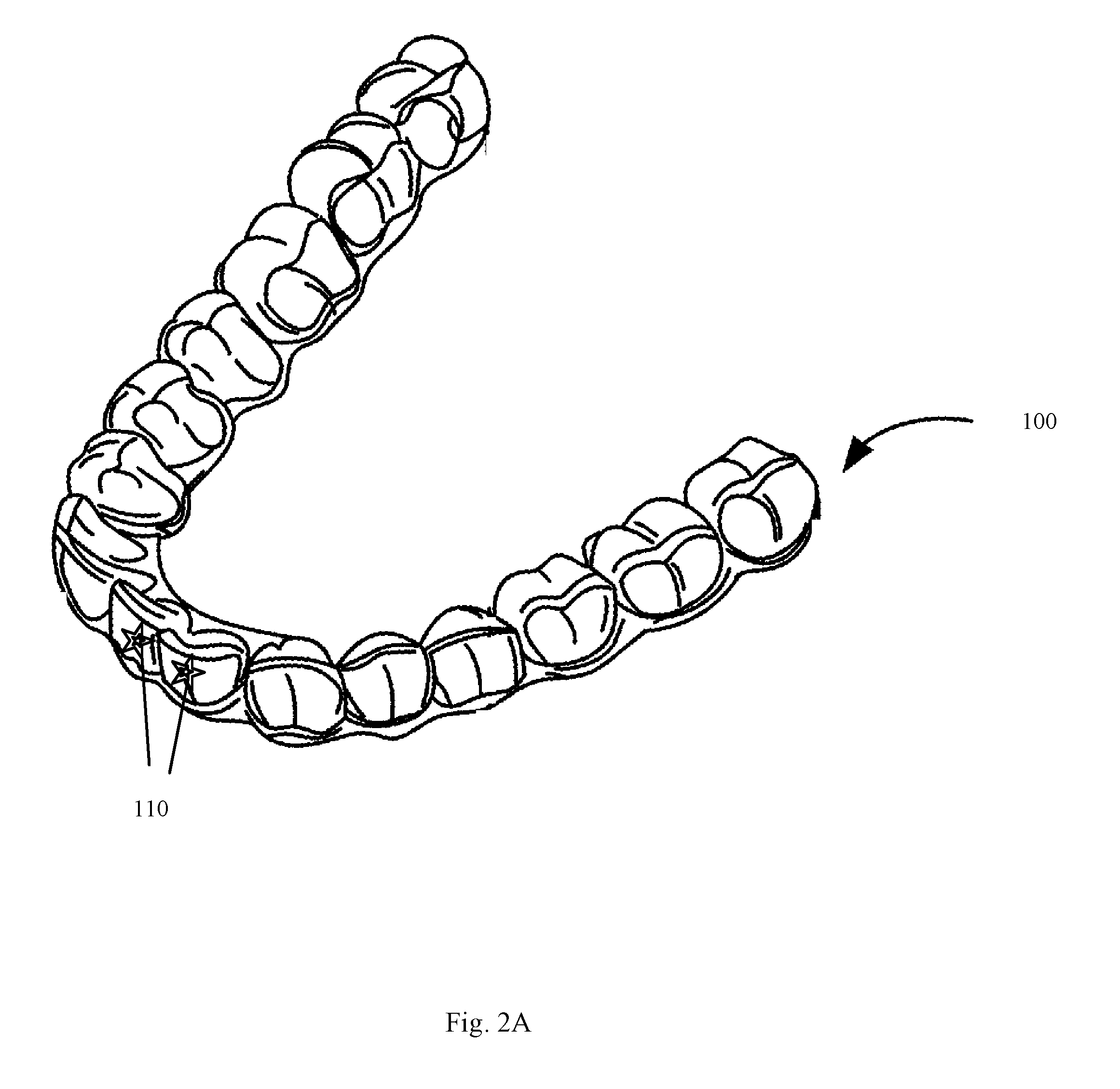

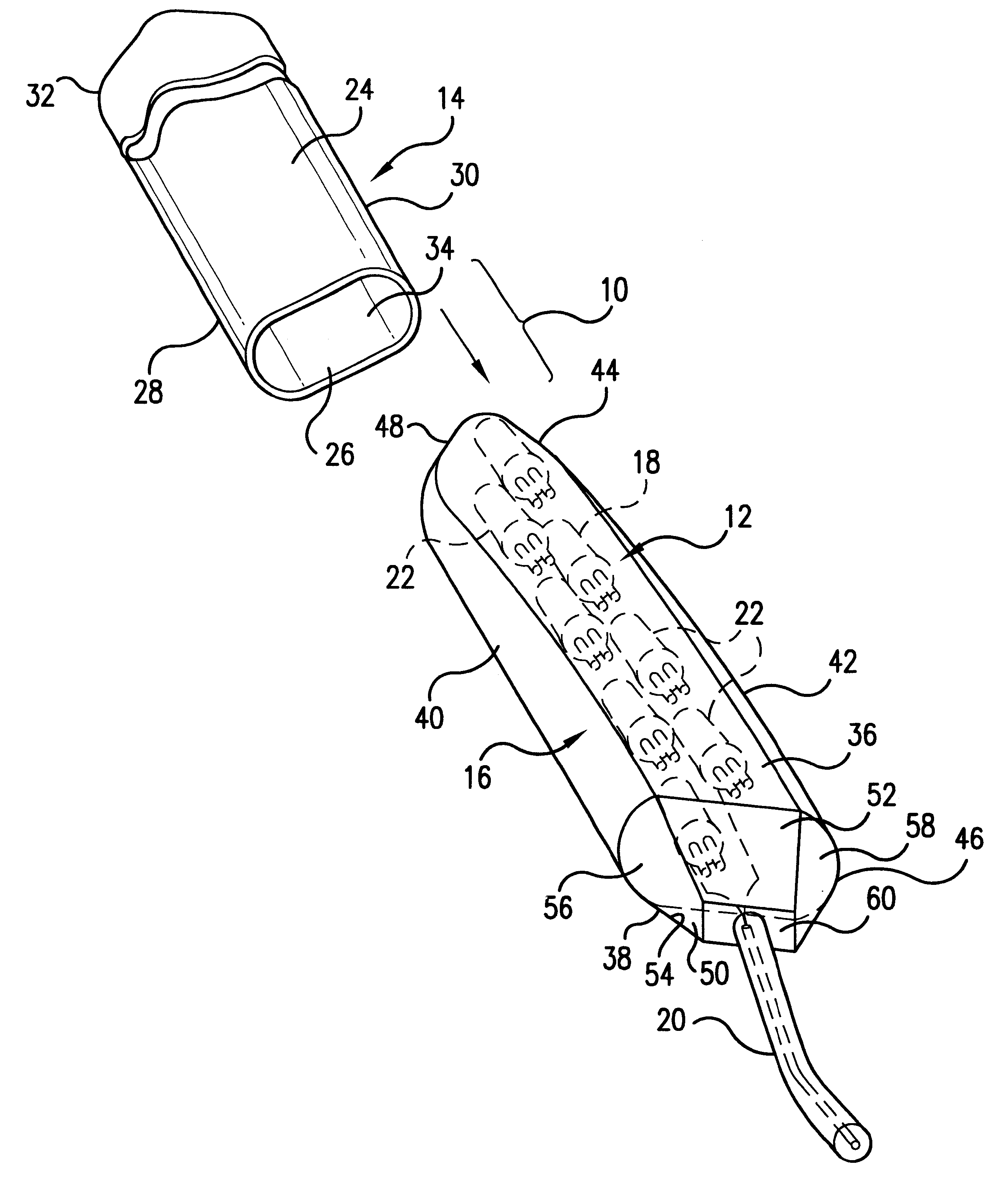

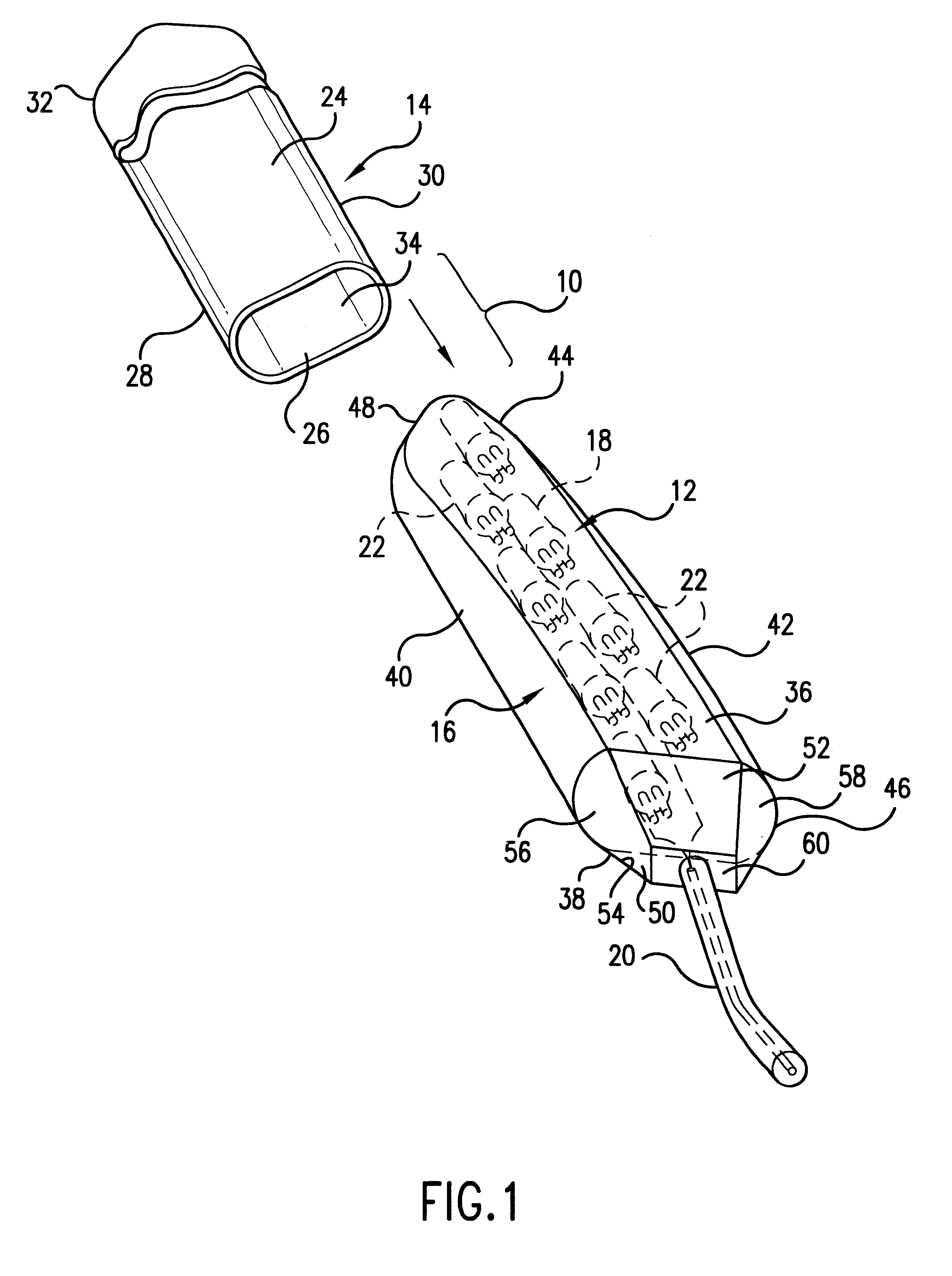

Systems, apparatuses and methods for substance delivery from dental appliance

ActiveUS20170007386A1Additive manufacturing apparatusOthrodonticsManufacturing technologyEngineering

Owner:ALIGN TECH

System and method for manufacturing full and partial dentures

There is provided a system for fabricating at least a portion of a denture. The system includes a three-dimensional scanning device for scanning a surface of a denture template, and a computer-readable medium including a computer program for receiving data from the scanning device, creating a 3-dimensional model of the surface, and optionally modifying the 3-dimensional model and / or adding features to the 3-dimensional model. The system also includes a fabricator for creating the at least the portion of the denture, from a selected material, based on the 3-dimensional model. The fabricator may be a device including a lathe, or a rapid prototyping machine. There is also provided a method for fabricating at least a portion of a denture.

Owner:SMITHKLINE BECKMAN CORP

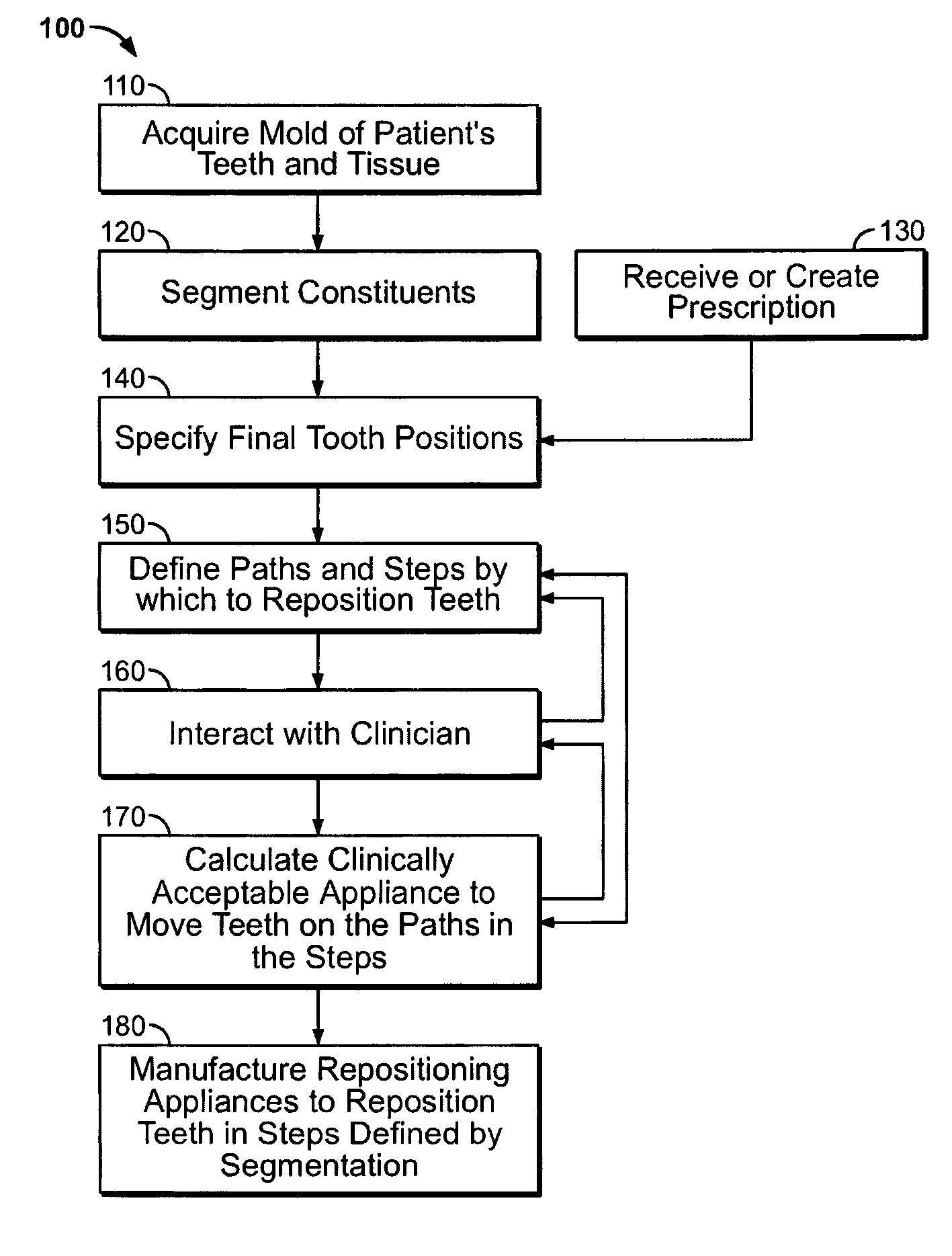

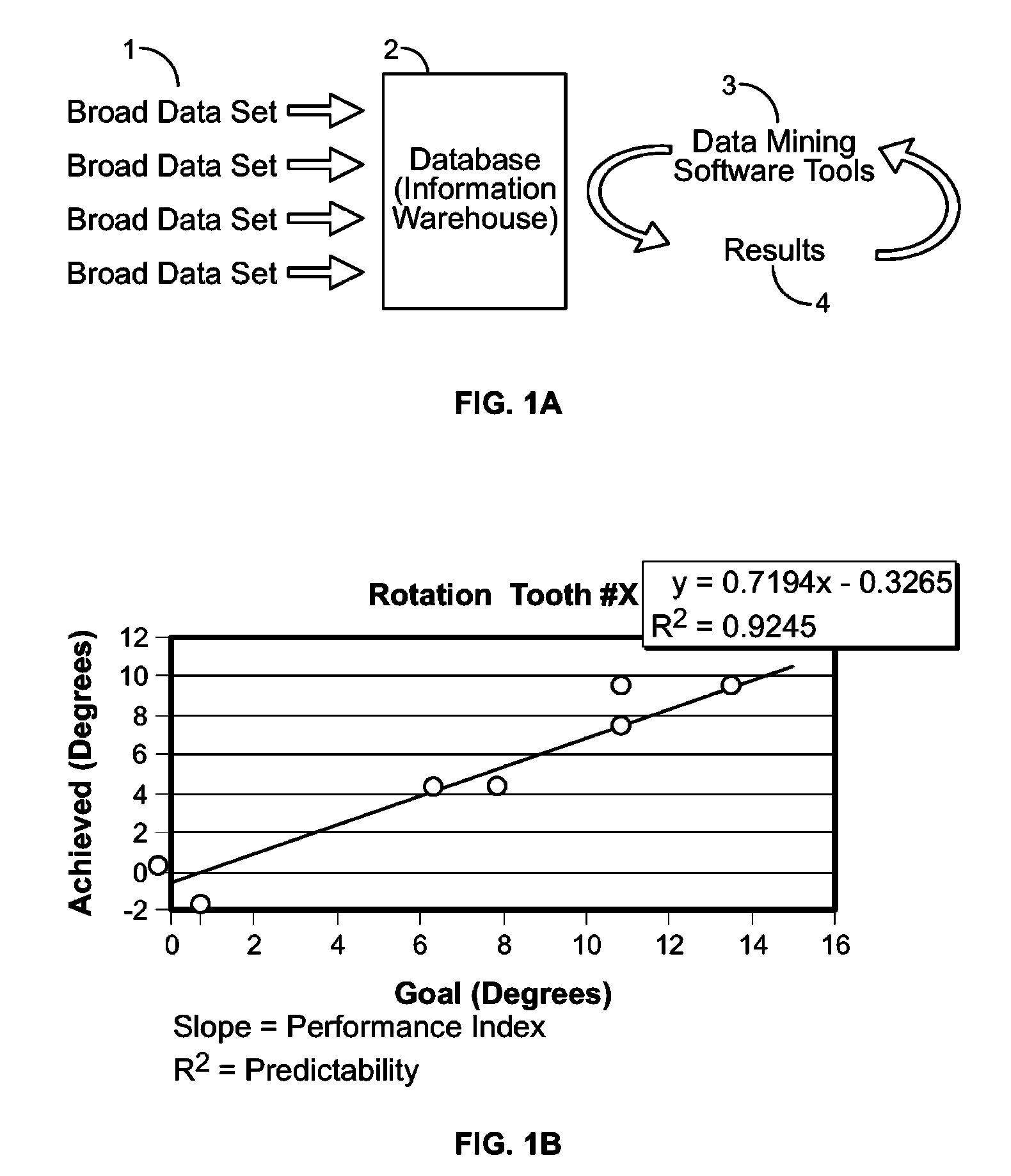

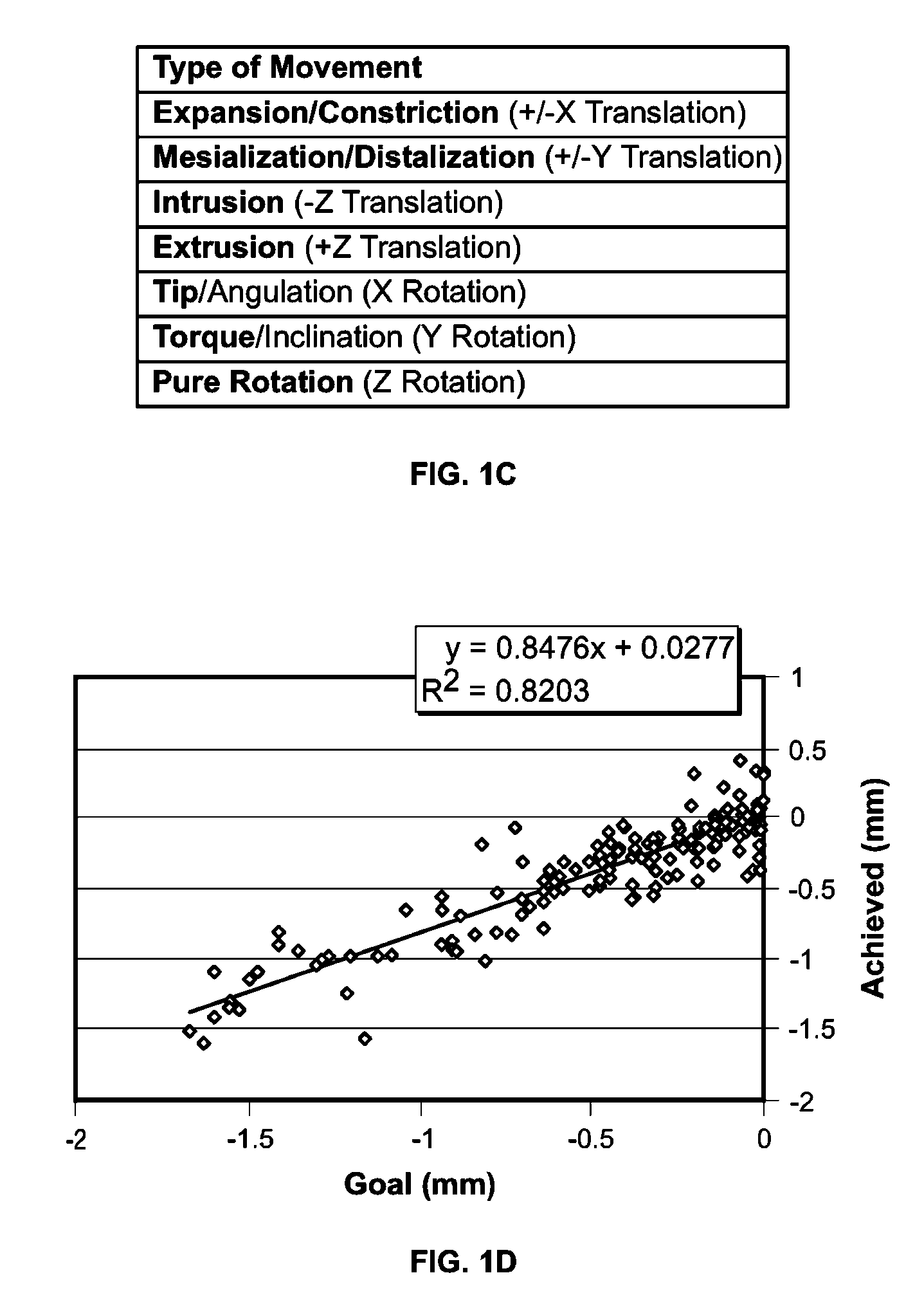

Method and System for Providing Dynamic Orthodontic Assessment and Treatment Profiles

Method and system for displaying an orthodontic related image including one or more image segments, selecting one or more movement indicators associated with a corresponding one or more of the image segments, and dynamically displaying a modified orthodontic related image based on the selected one or more movement indicators are provided.

Owner:ALIGN TECH

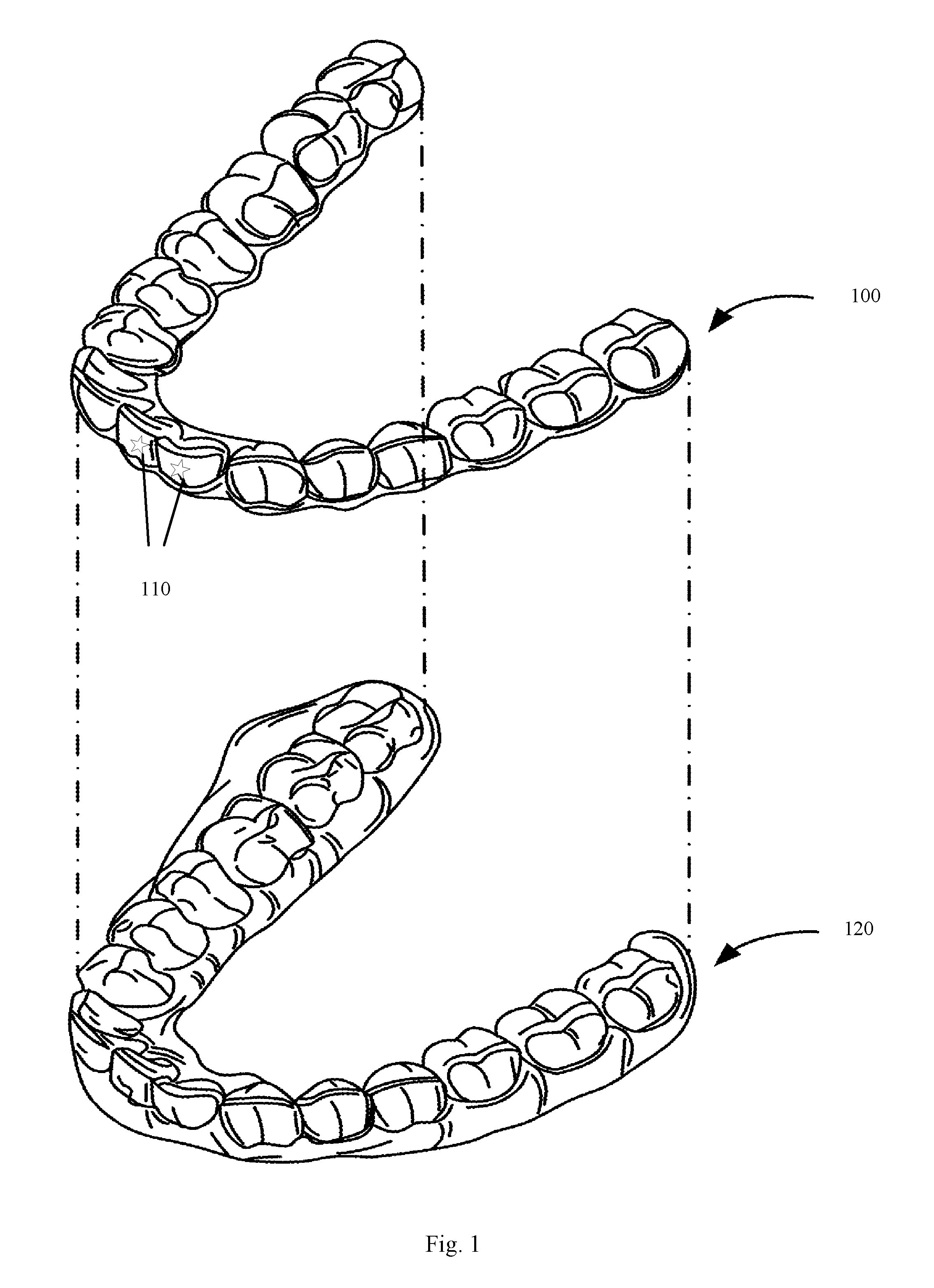

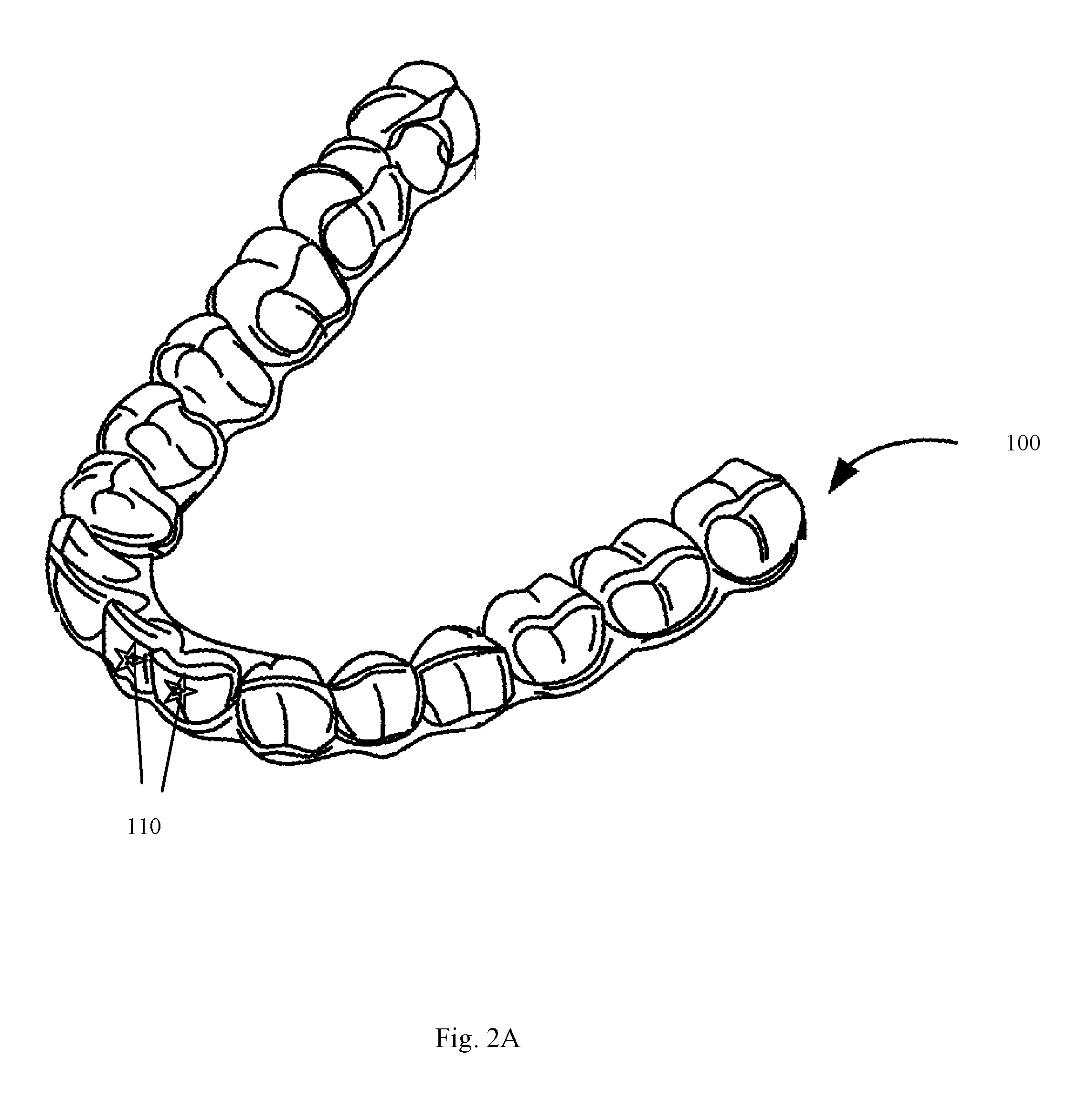

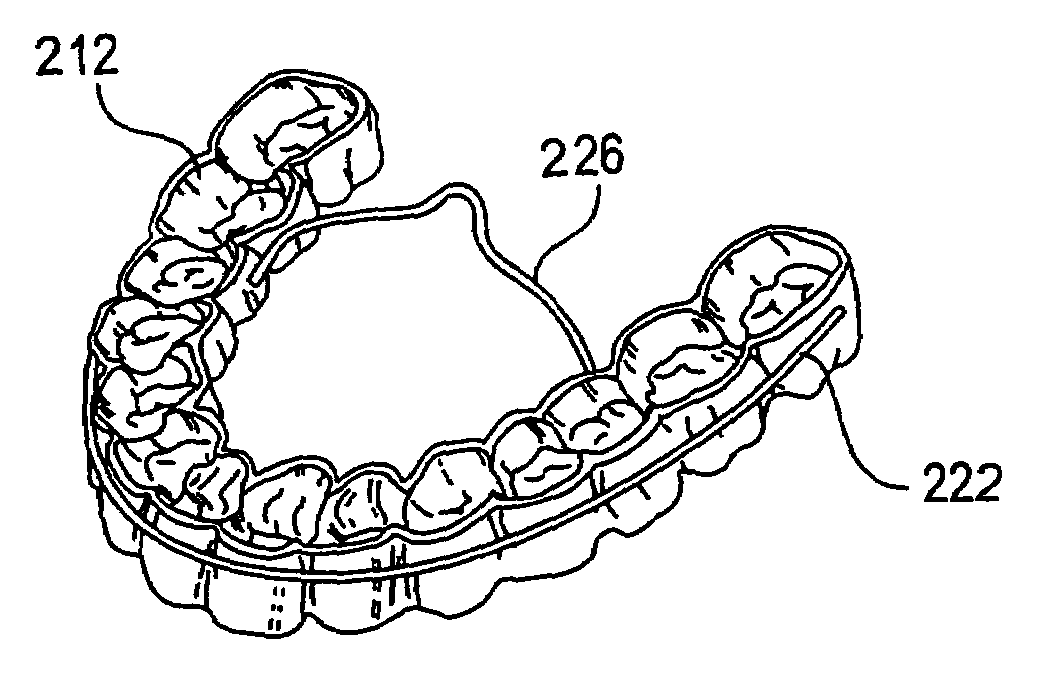

Tooth positioning appliances and systems

InactiveUS7121825B2Easy to implantSuitable for useOthrodonticsDental toolsState variationUltimate tensile strength

An improved dental appliance system, and methods for using and fabricating the improved appliance, including a polymeric overlay or shell having a teeth-receiving cavity formed therein and a wire mounted on or embedded in the polymeric shell. The dental appliance having the necessary stiffness or strength to firmly secure the appliance on the teeth and provide controlled forces required for repositioning the teeth, until such time as removal of the appliance is desired. The appliance may be configured for use with a removal mechanisim. The removal mechanism undergoes a state change stimulated by an environmental stimulus or environmental switch.

Owner:ALIGN TECH

Dental appliance having ornamental design

ActiveUS20170008333A1Additive manufacturing apparatusOthrodonticsManufacturing technologyEngineering

Owner:ALIGN TECH

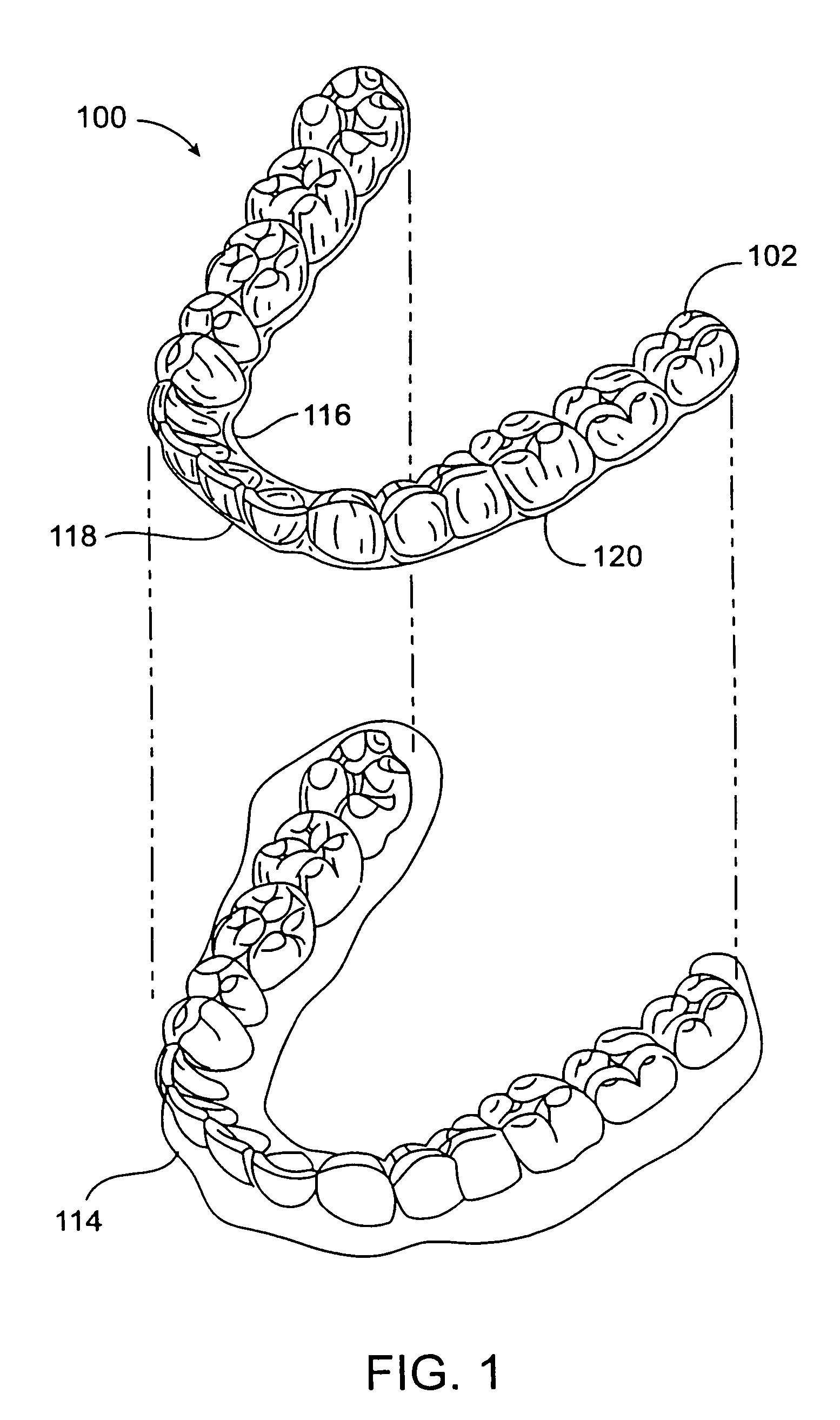

Orthodontic treatment planning using biological constraints

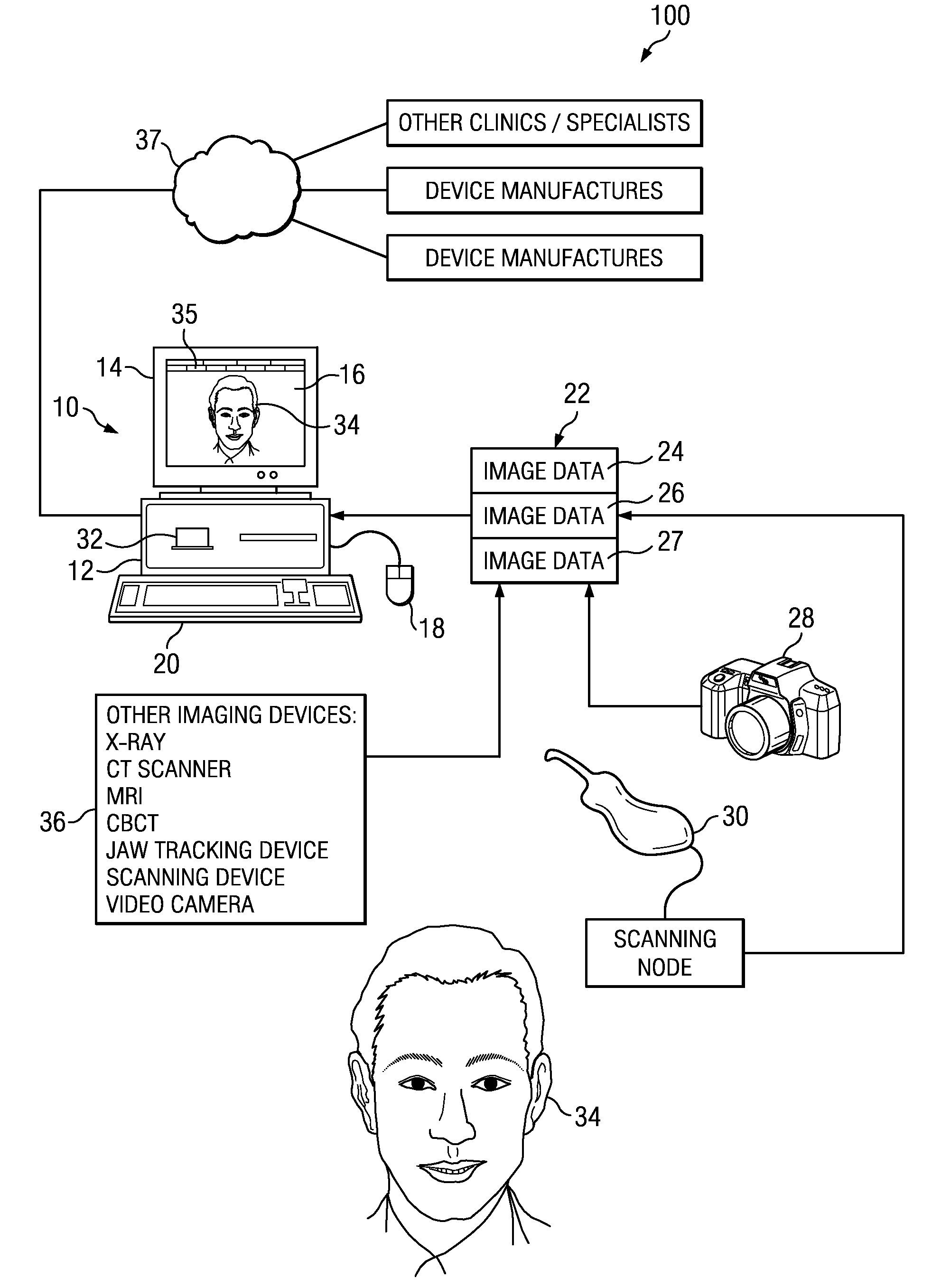

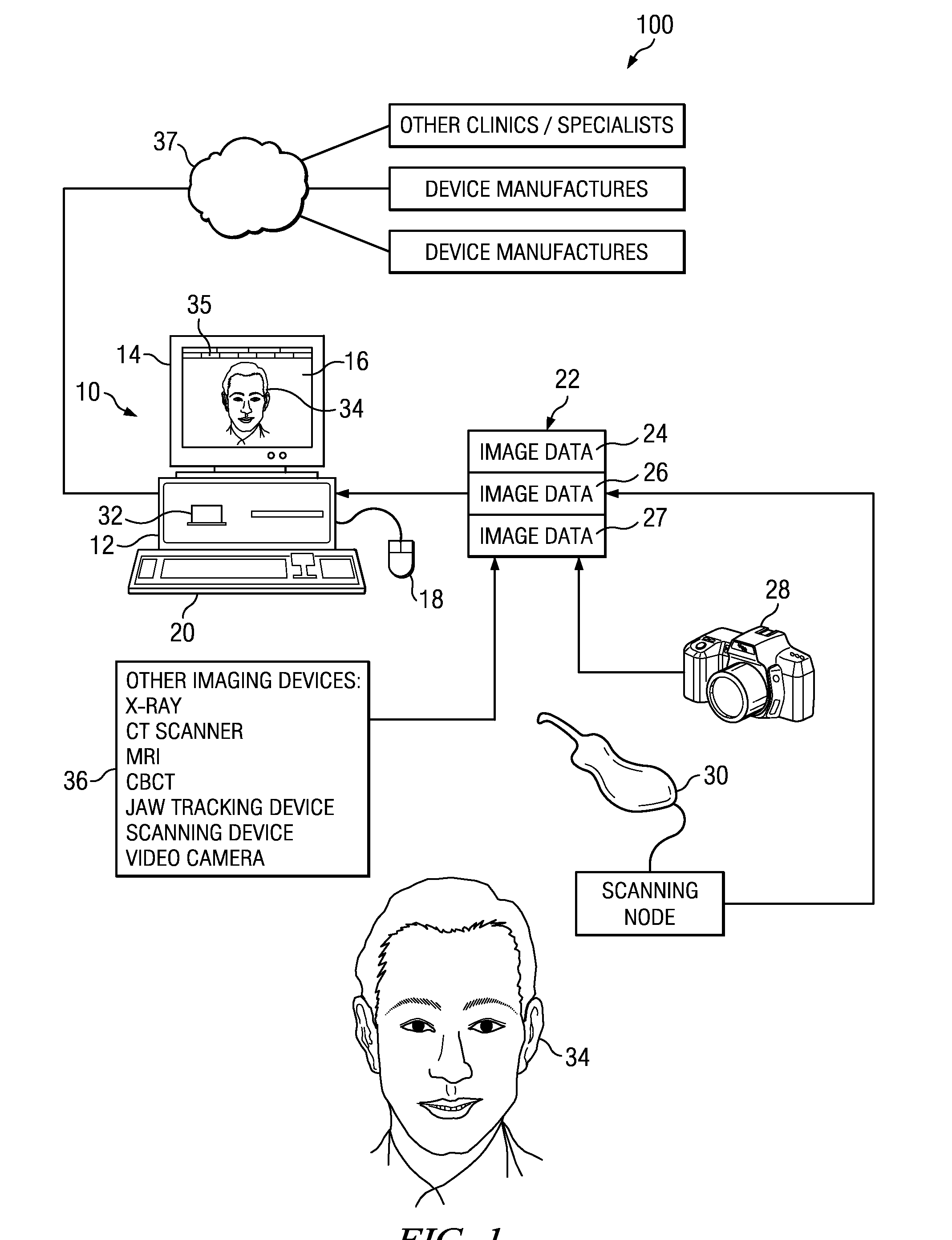

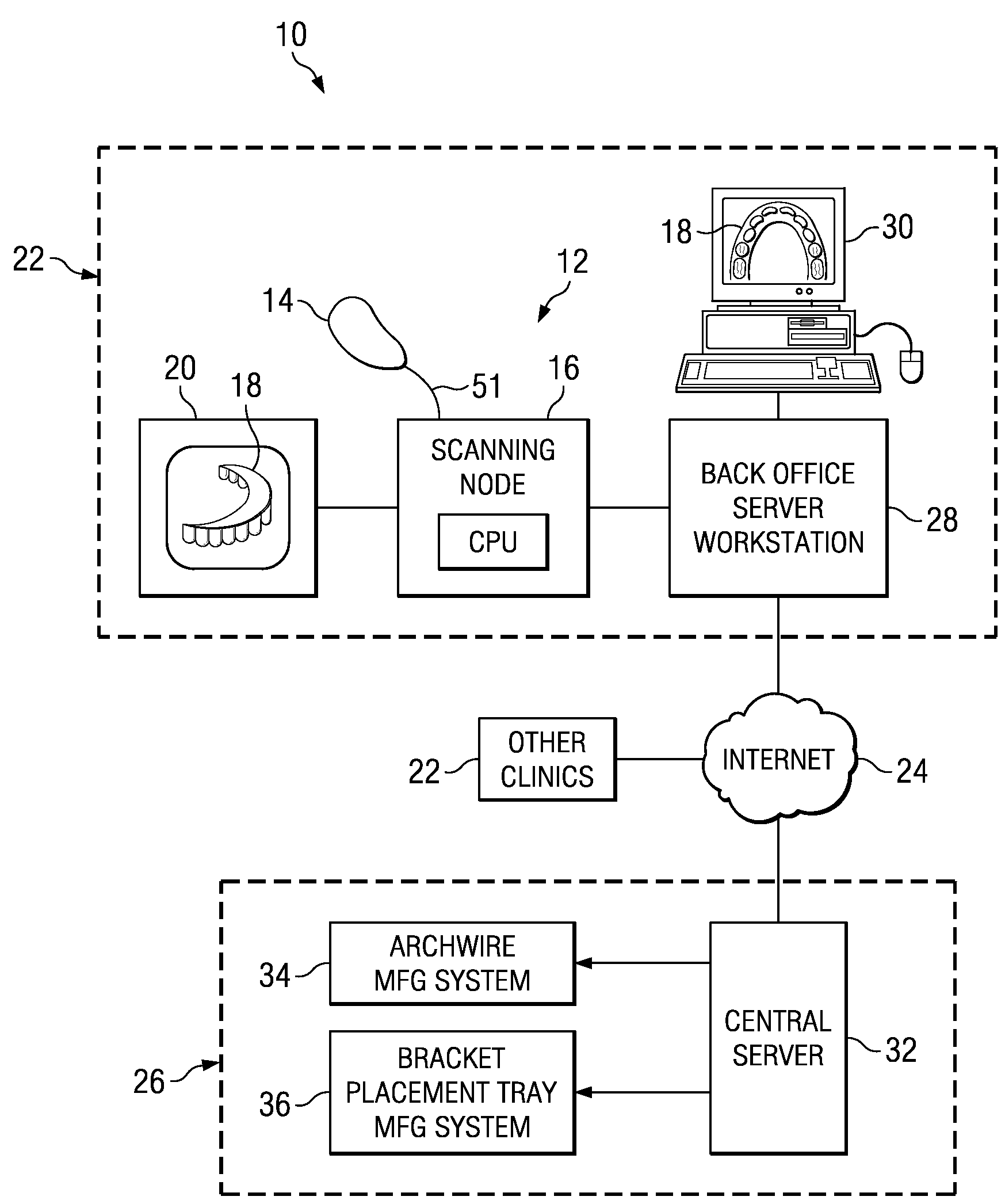

The invention relates to planning orthodontic treatment for a patient, including surgery, using biological constrains such as those arising from bone, soft tissue, and roots of patient's teeth. The invention disclosed herein provides capability to vary the movement ratio between the teeth and bone and soft tissue through treatment simulation to assess the risk factor associated with a particular treatment plan. The invention further provides capability to monitor results of the treatment to determine the actual movement ratio between the teeth and bone and soft tissue and update the database. Additionally, a method and apparatus are disclosed enabling an orthodontist or a user to create an unified three dimensional virtual craniofacial and dentition model of actual, as-is static and functional anatomy of a patient, from data representing facial bone structure; upper jaw and lower jaw; facial soft tissue; teeth including crowns and roots; information of the position of the roots relative to each other; and relative to the facial bone structure of the patient; obtained by scanning as-is anatomy of craniofacial and dentition structures of the patient with a volume scanning device; and data representing three dimensional virtual models of the patient's upper and lower gingiva, obtained from scanning the patient's upper and lower gingiva either (a) with a volume scanning device, or (a) with a surface scanning device. Such craniofacial and dentition models of the patient can be used in optimally planning treatment of a patient.

Owner:ORAMETRIX COM

Drilling guide for dental implantation

InactiveUS6913463B2Easy alignmentAccurate angleThread cutting machinesDental toolsOrthodonticsOral cavity

An adjustable drilling guide, removably mountable to a patient's teeth, having a guide block with at least one stent for guiding a dental drill is disclosed. In a first embodiment, the guide block has a plurality of guide holes disposed at differing angles which may receive a stent for precise drilling at the selected angle. If minor variations need be made, the stent may be moved to a second or third of the guide holes to adjust the angle. In a second embodiment, three distinct stents are formed directly in the guide block allowing for drilling at up to three different angles. A third embodiment has a stent which is pivotable about a pivot point within the guide block, allowing drilling at any angle within the arc of the pivot. The guide block may be fitted to a model of the patient's teeth prior to installation into the mouth to ensure proper fit.

Owner:BLACKLOCK GORDON D

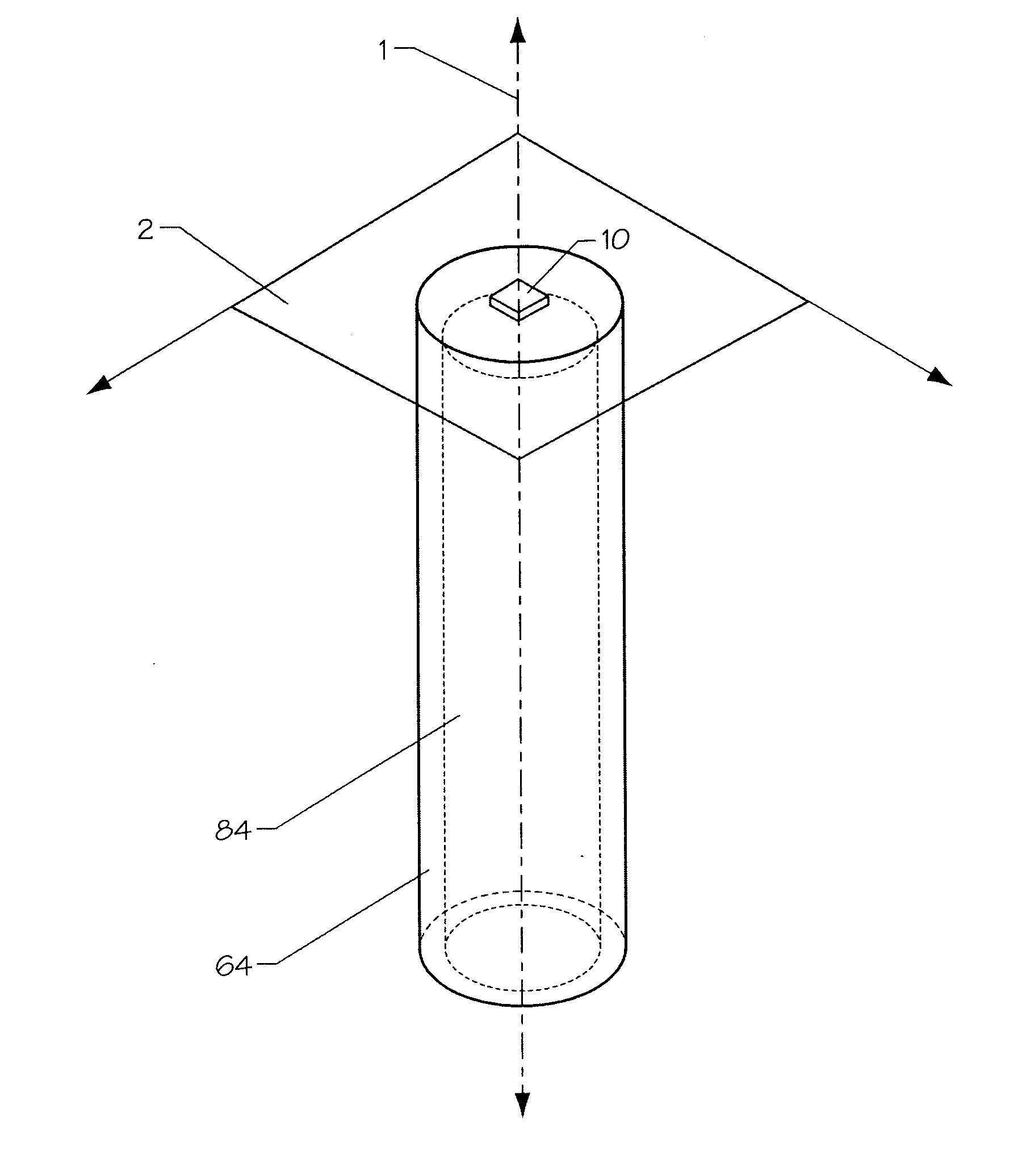

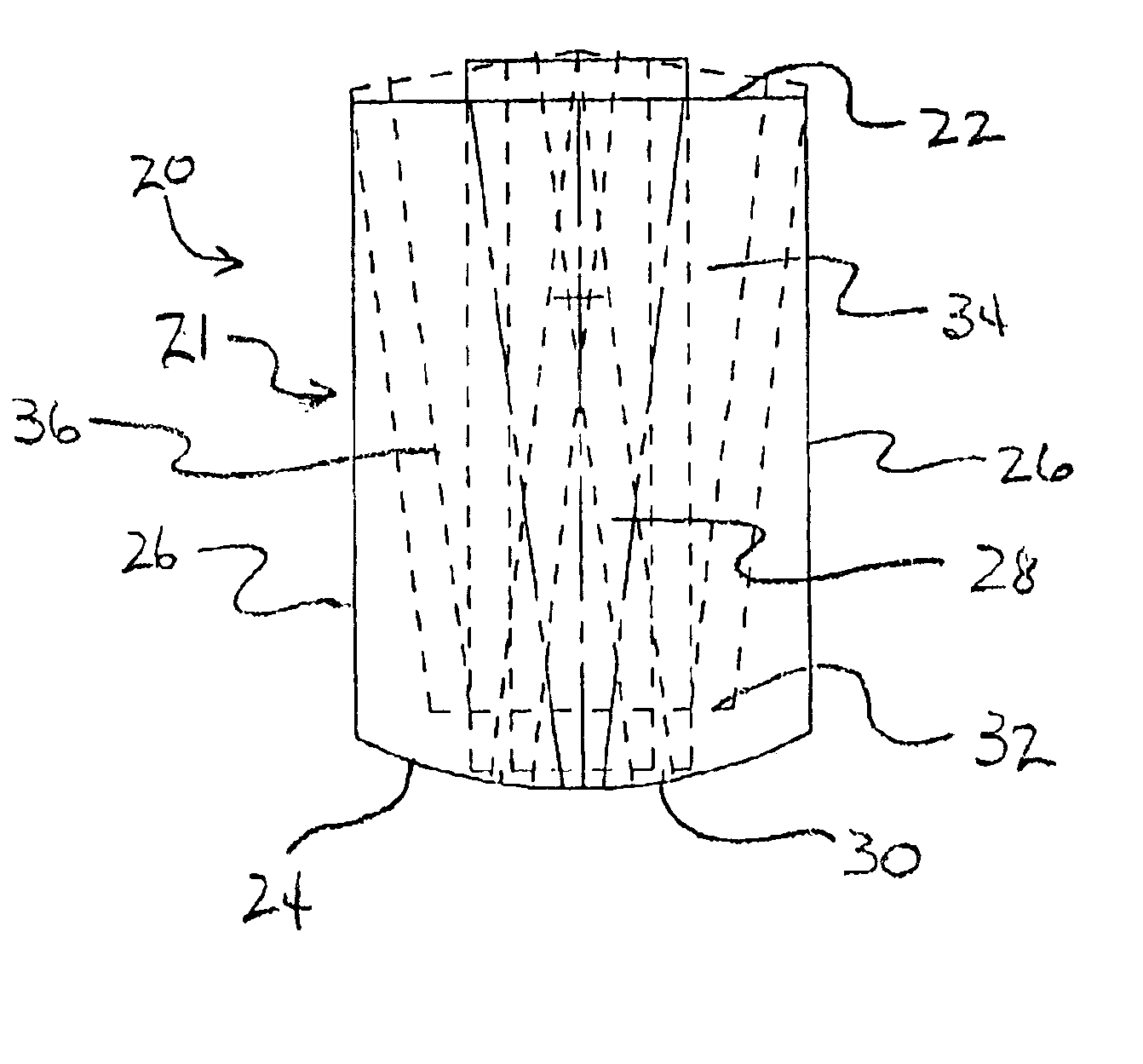

Light emitting apparatus

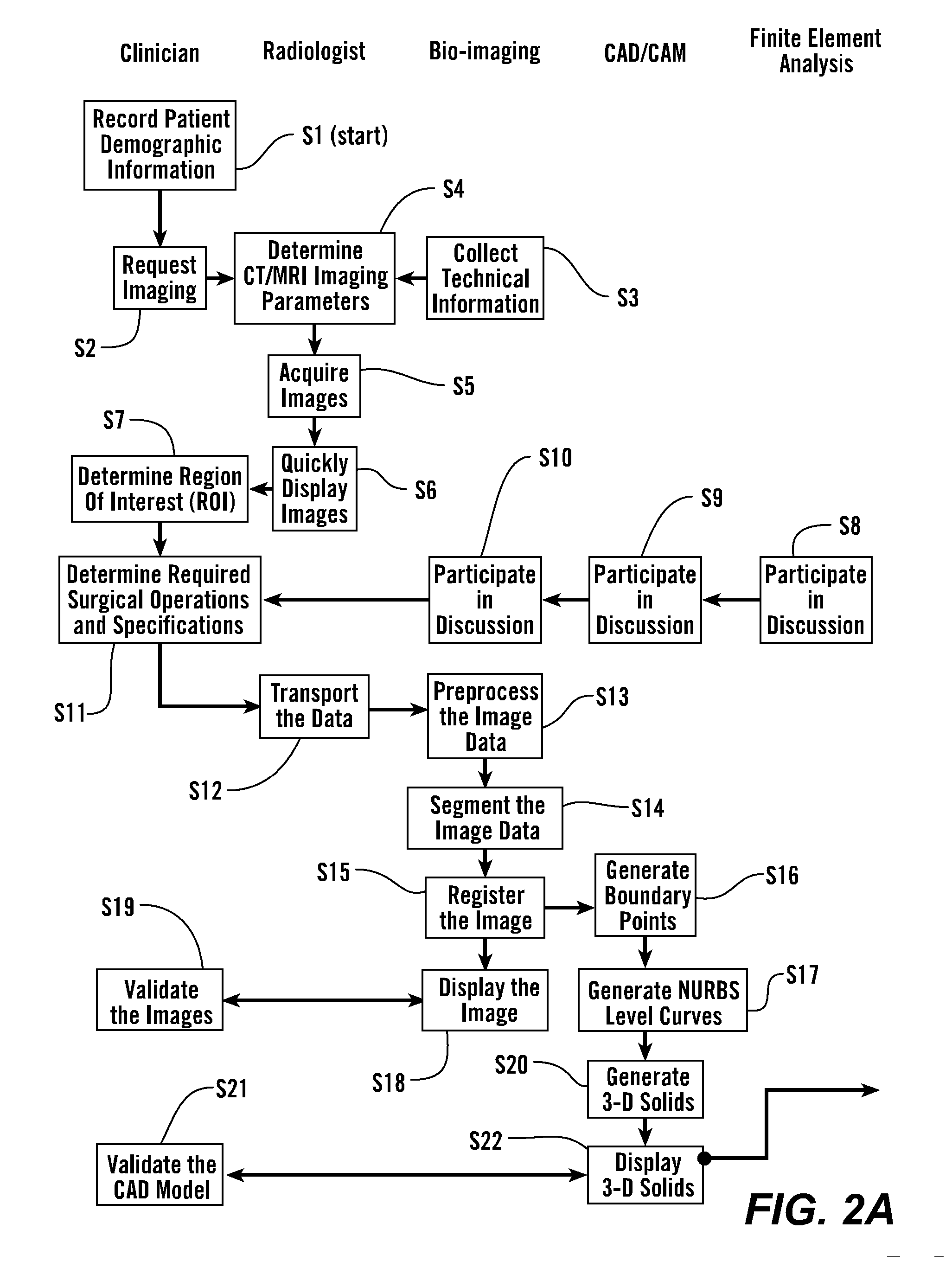

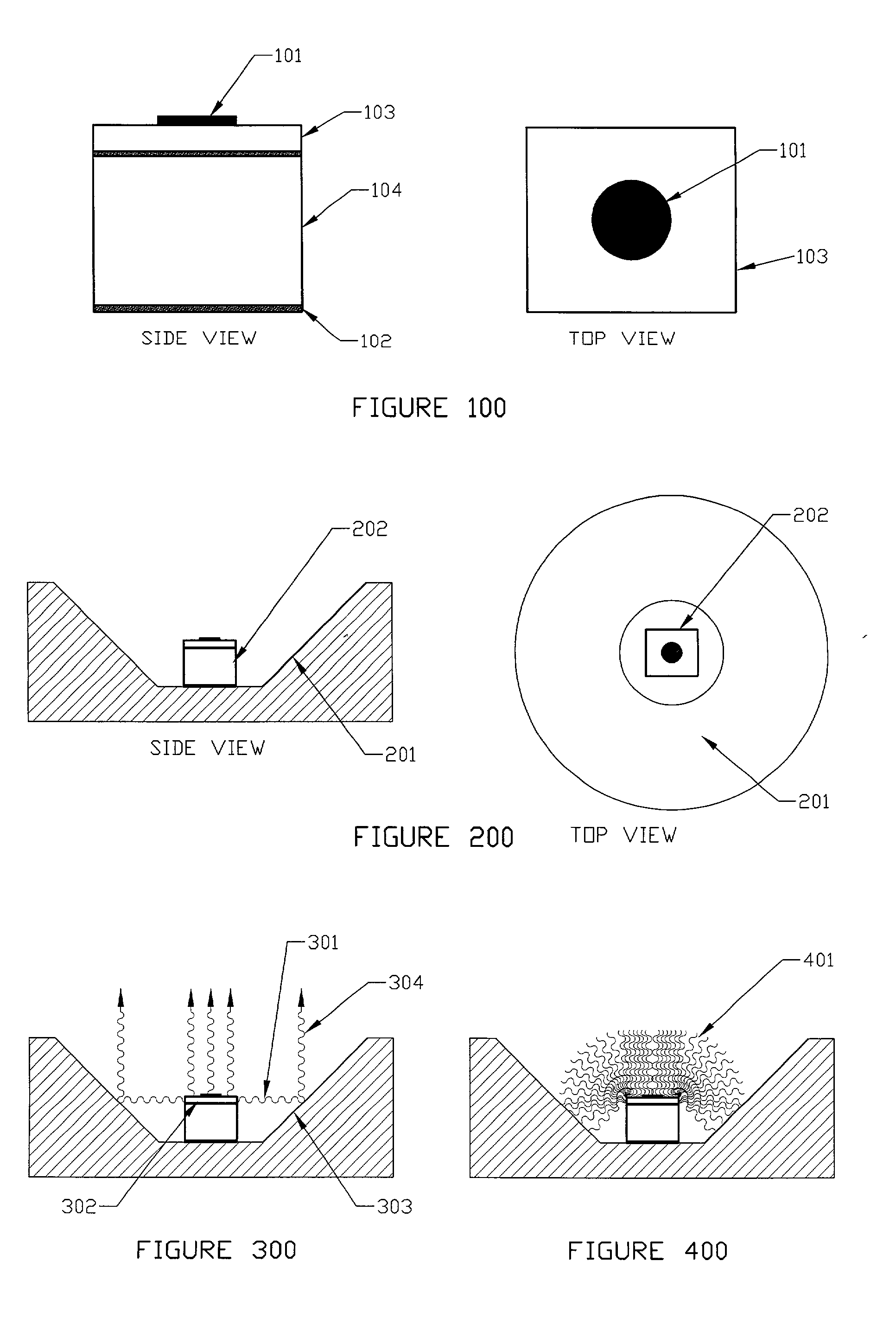

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINK PHILIPS ELECTRONICS NV

Method and apparatus for using light emitting diodes for curing

The present invention provides a method and apparatus for using light emitting diodes for curing in various applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention that utilizes heat pipes performs far more efficiently in much more compact space. This allows much more closely spaced LEDs operating at higher power and brightness.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

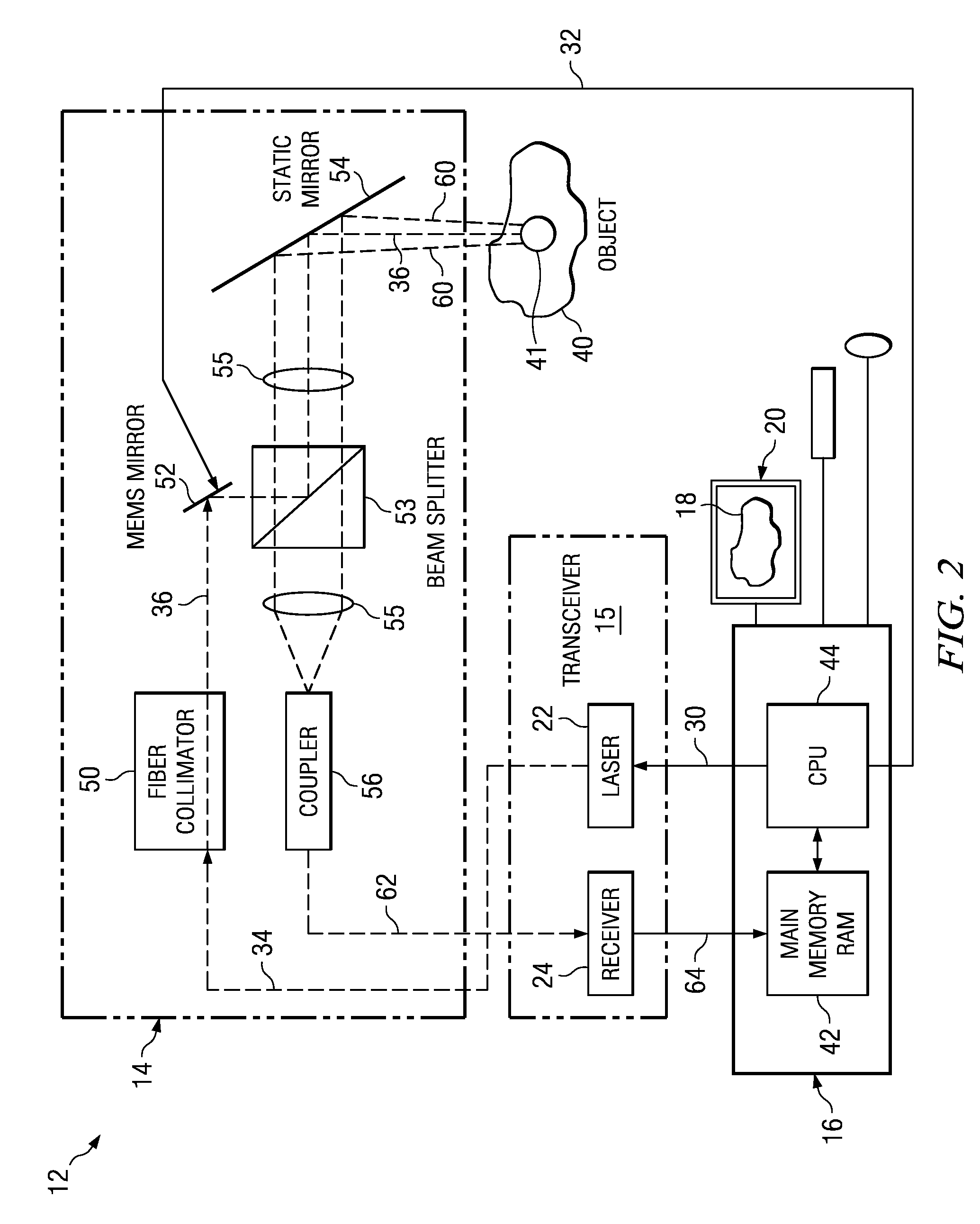

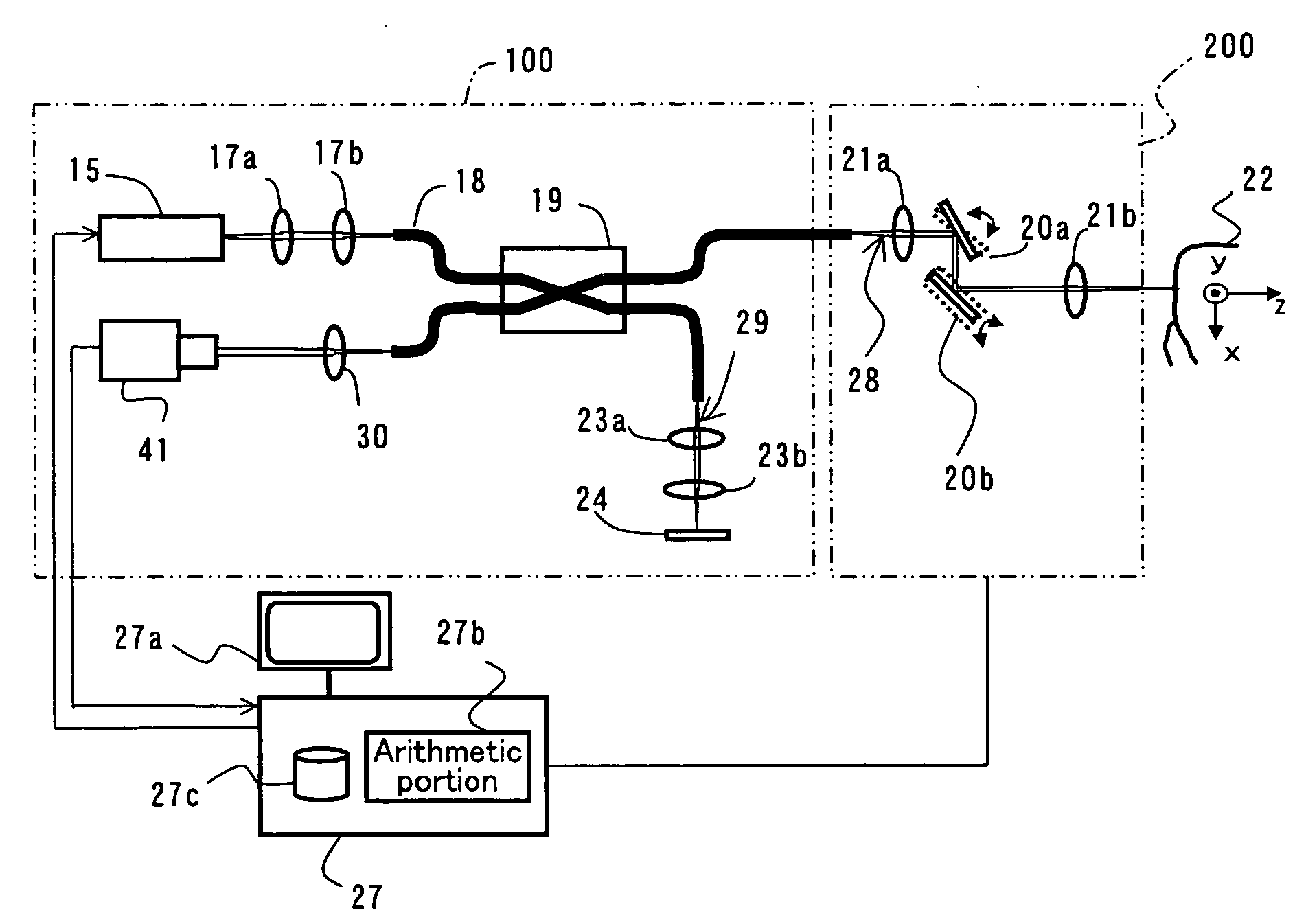

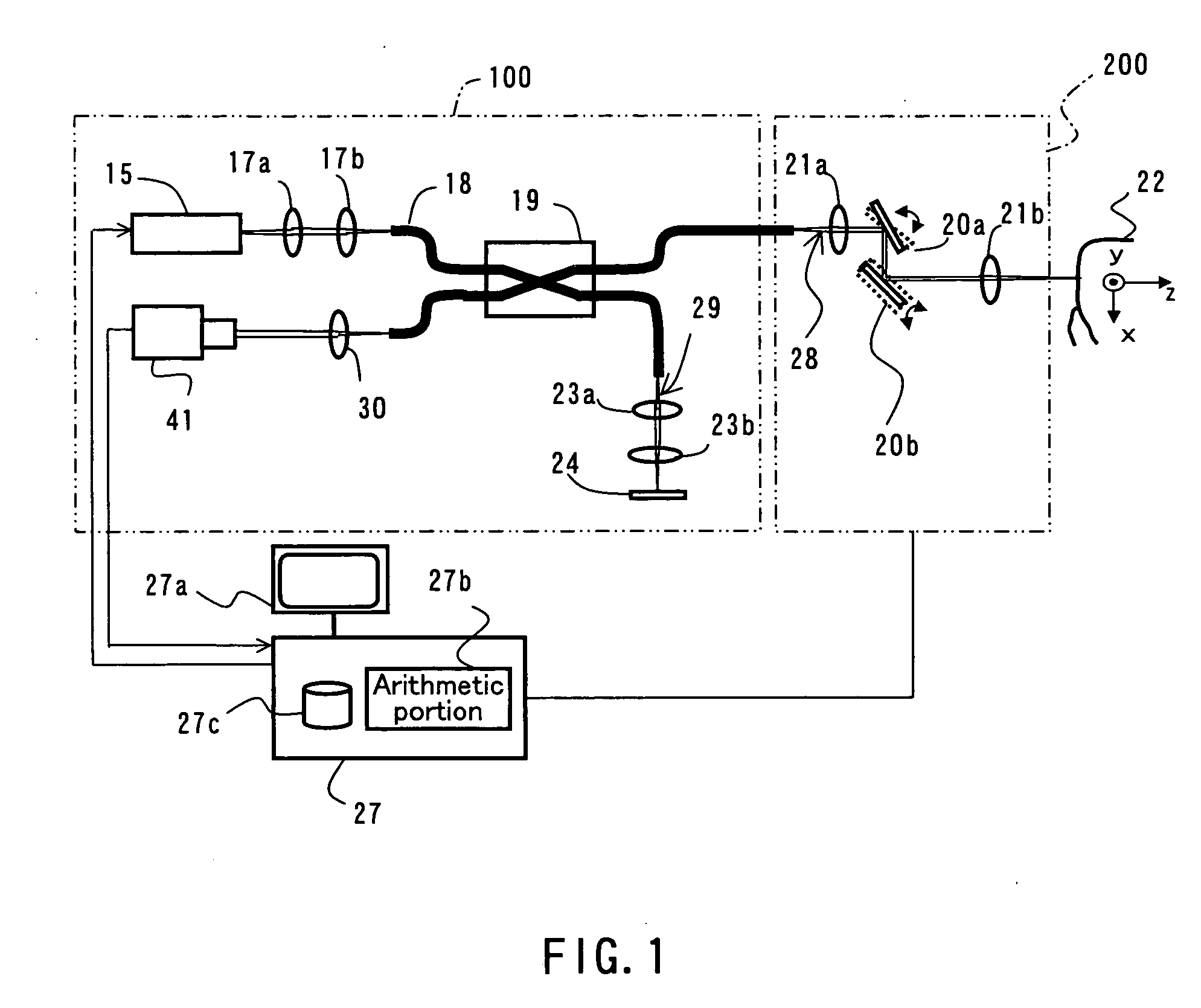

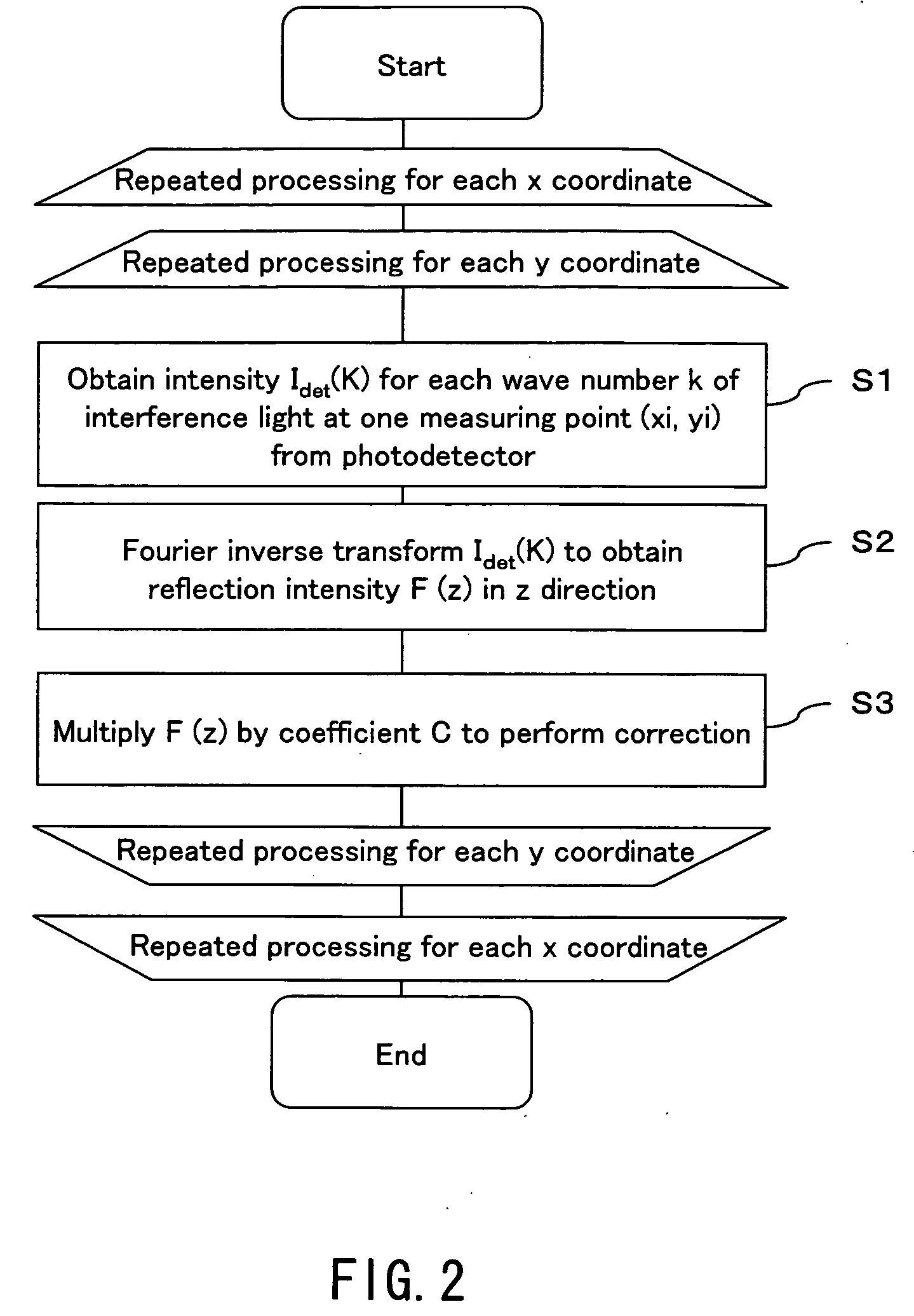

Dental Optical Coherence Tomograph

InactiveUS20090079993A1Simple structureHigh imagingInterferometersMaterial analysis by optical meansBiological bodyFourier transform on finite groups

A dental optical coherence tomography apparatus for measuring tissue in a stomatognathic region of a living body or an artificial composition in the stomatognathic region as a measured object includes: a variable wavelength light source (15); a light splitting portion (19) that splits light-source light emitted from the variable wavelength light source (15) into reference light (29) and measuring light (28); an interference portion (19) that causes the measuring light (28) and the reference light (29) to interfere with each other, thereby generating interference light; a photodetection portion (41) that measures the interference light; and an arithmetic portion (27b) that generates an image of a measured object (22) by Fourier transforming or inverse Fourier transforming the intensity of the interference light, whose wavelength changes with time, that has been detected by the photodetection portion for each of the wavelengths. Accordingly, an optical coherence tomography apparatus applicable to dental measurement can be provided.

Owner:SHOFU INC

Dental curing apparatus for light-sensitive materials

InactiveUS6514075B1Compact designGuaranteed multiple useDental toolsLight therapyAdhesiveEngineering

A dental curing apparatus for light-sensitive materials is disclosed. A light source for curing an adhesive is housed within a clear, transparent and / or translucent housing constructed of either a solid, such as a poured resin, or a hollow structure. The housing shape is selected to conform to an approximate shape of dentition. The housing is mountable within a disposable oversertion sheath. During use, the light source for curing an adhesive transmits light which cures the adhesives, sealants and / or whitening or coloring agents.

Owner:JACOB GREGORY S

Medical implant

PCT No. PCT / EP96 / 05506 Sec. 371 Date Aug. 12, 1998 Sec. 102(e) Date Aug. 12, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO97 / 22308 PCT Pub. Date Jun. 26, 1997The invention relates to a medical implant, in particular a dental implant, intended for implantation in available cavities. Dental implants are implanted in extraction sockets. The implant is provided with reservoirs for a biologically active substance. An advantage of the implant is that, for dental procedures, it can be manufactured and implanted as part of a single therapeutic treatment. However, the implant can also be used as a release system for biologically active substances.

Owner:DR JOUKO SUHONEN +1

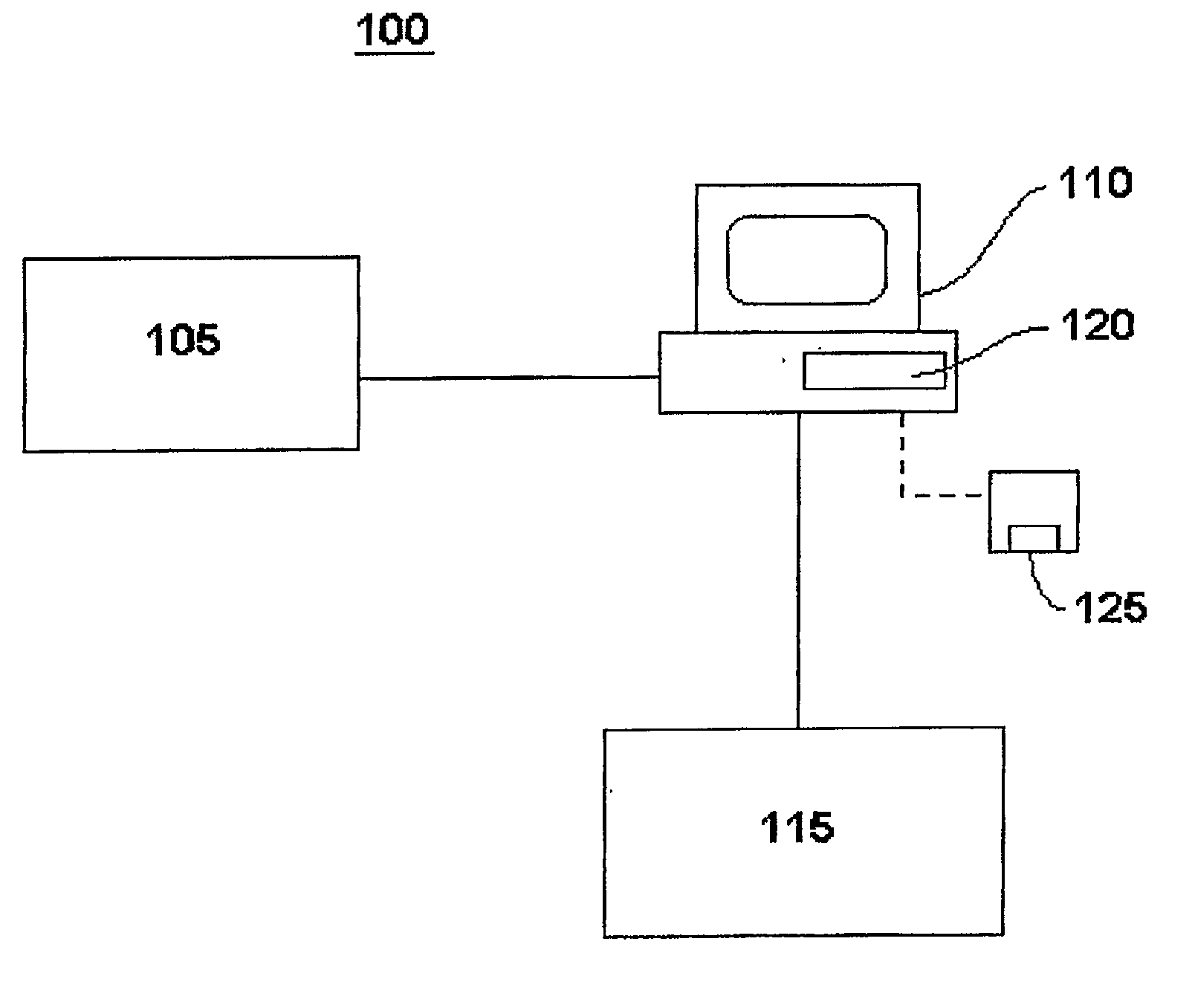

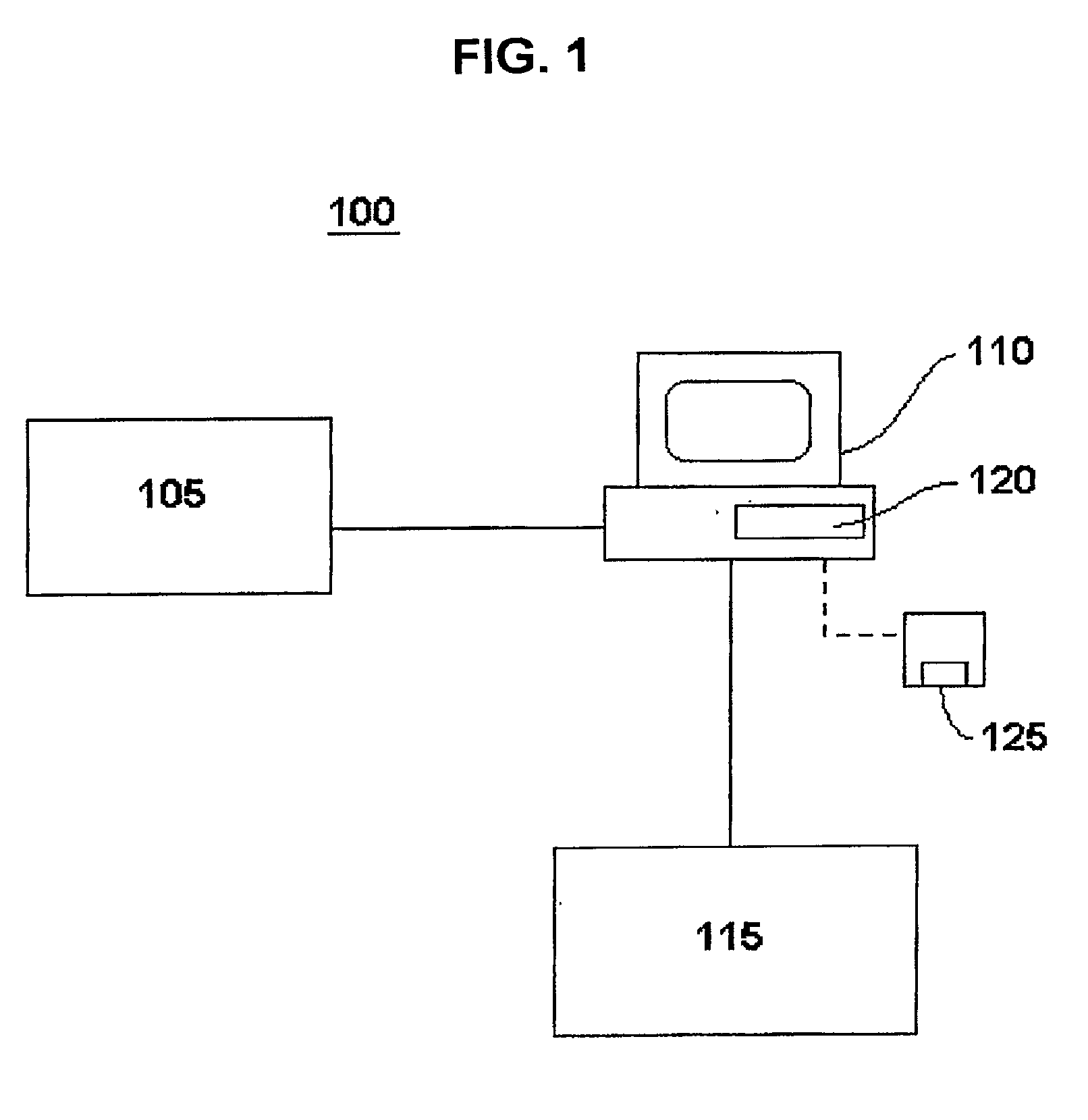

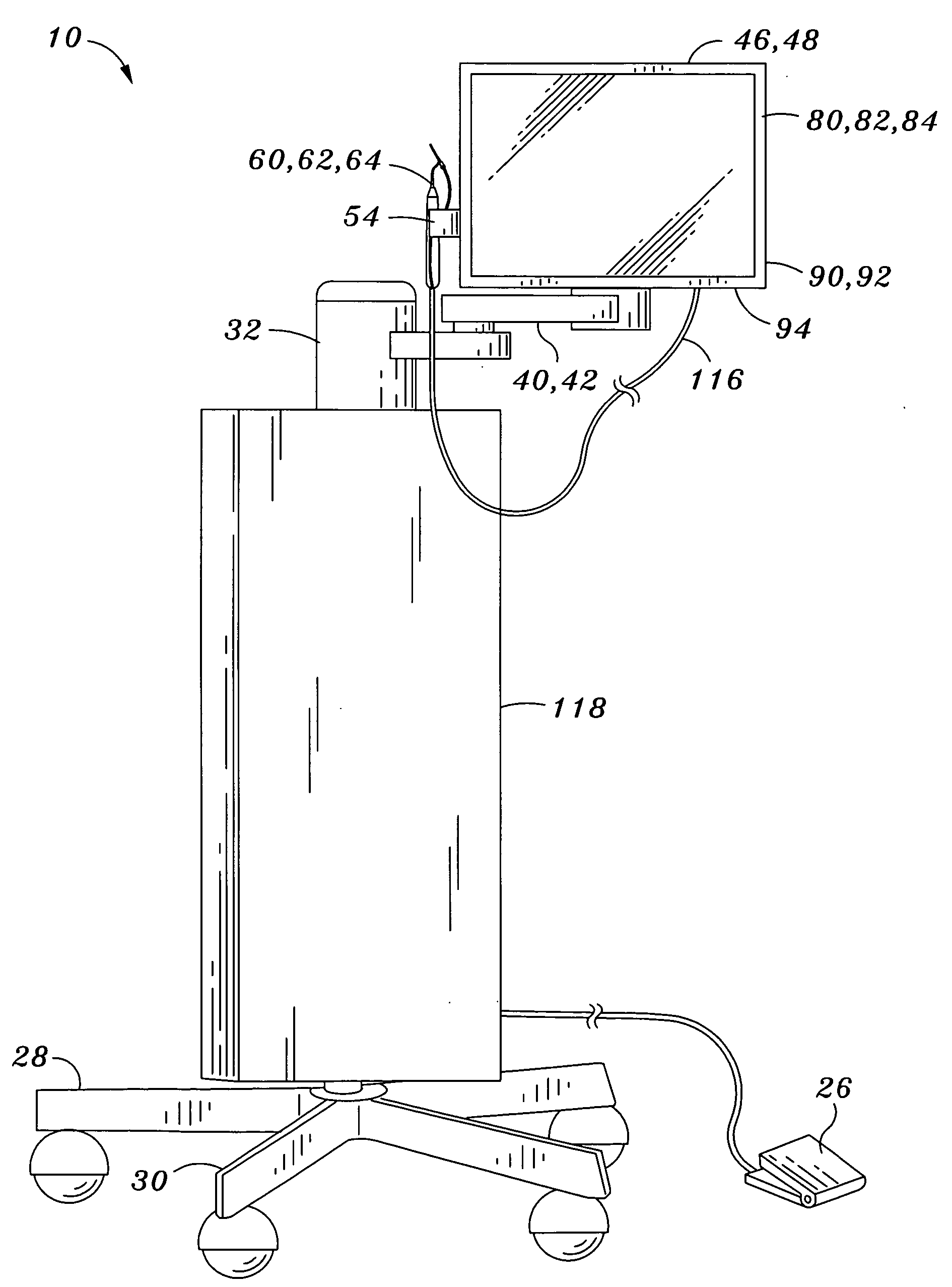

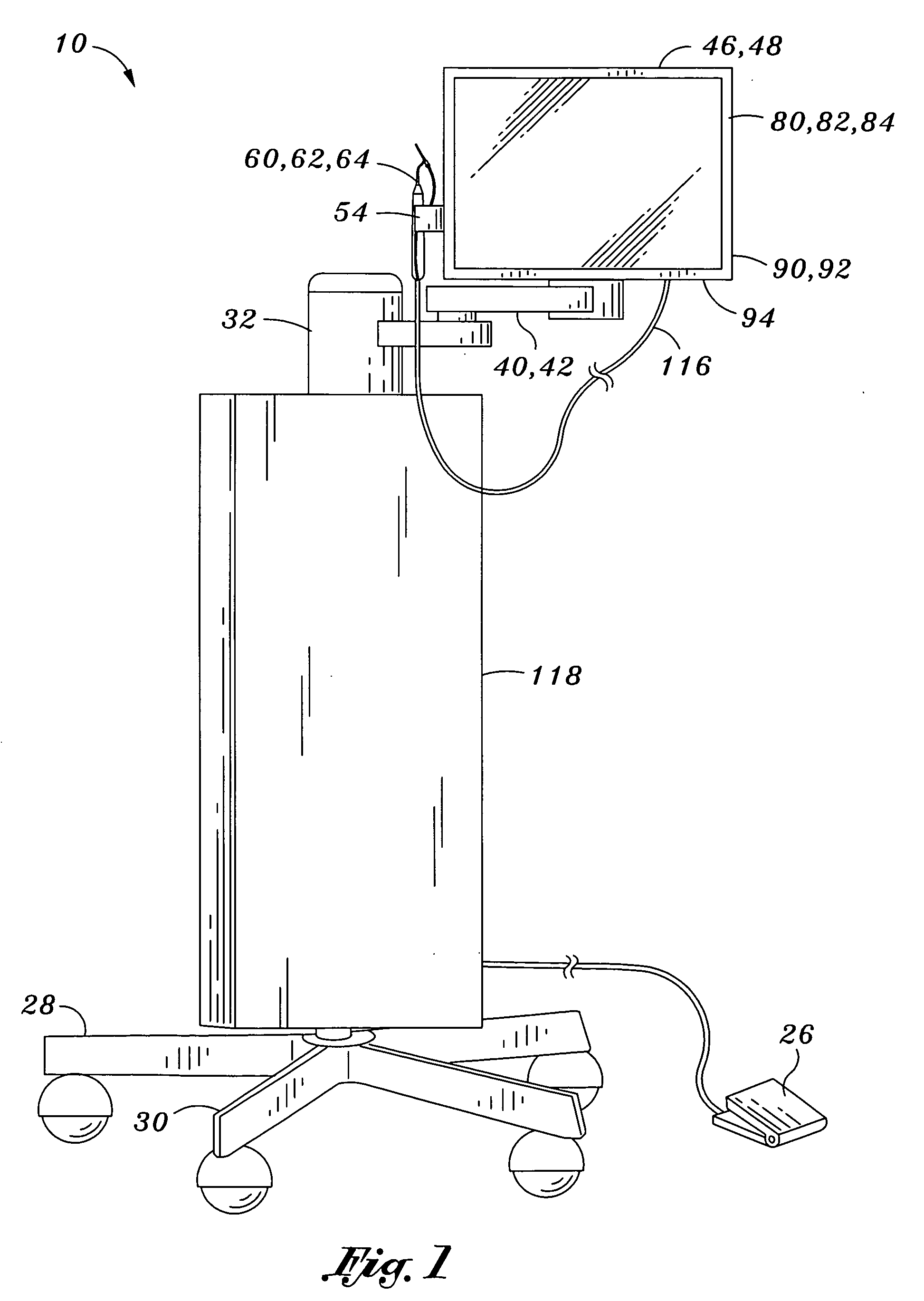

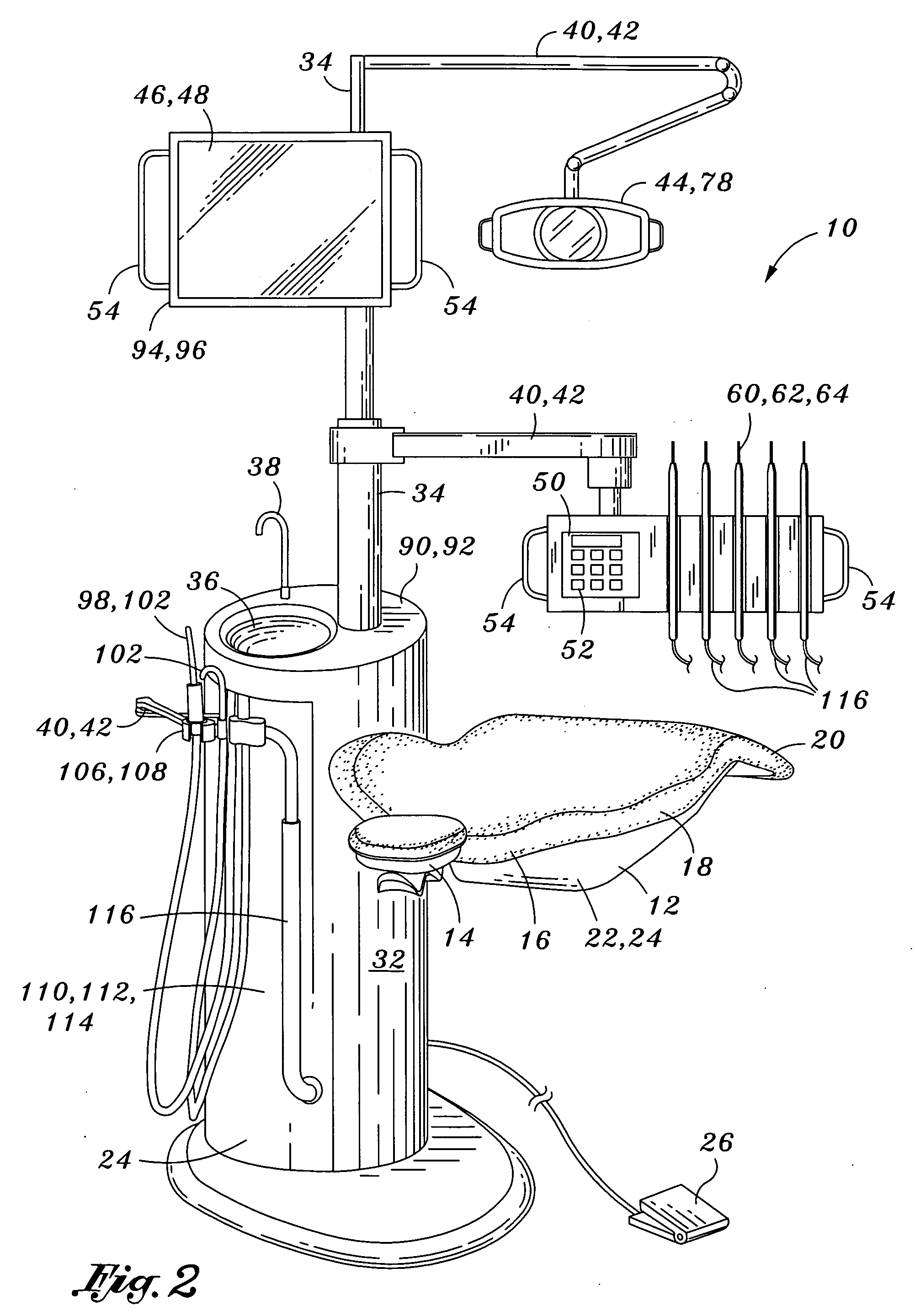

Dental imaging system and method of use

InactiveUS20060046226A1Easy to controlHigh resolutionOperating chairsDental chairsDisplay deviceEngineering

Provided is a dental imaging system comprising a support frame, an imaging device and a display device. The support frame may include an upright portion mounted upon a base portion which may be portably or stationarily mounted. The imaging device is integrally mounted to the support frame as is the display device. The display device is conductively connected to the imaging device and is preferably configured to display images produced by the imaging device. The dental imaging system is adapted for endoscopic viewing of subgingival anatomy in a unitary structure to minimize space limitations of dental facilities.

Owner:DENTALVIEW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com