Patents

Literature

473 results about "Dental appliances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

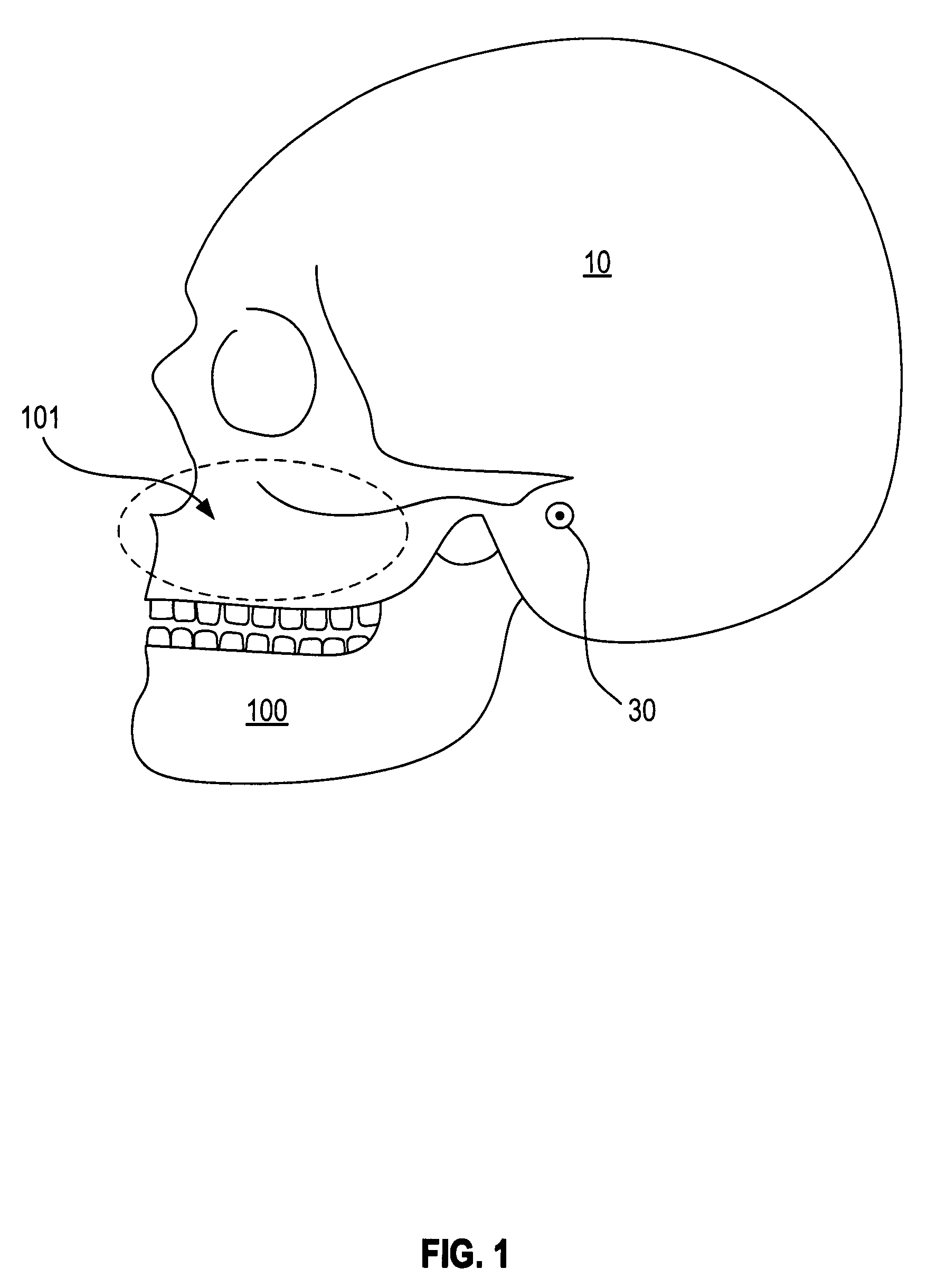

Types of Braces and Other Appliances. There are a number of dental appliances used today. But braces are still the primary means for straightening teeth and correcting misaligned bites in children ...

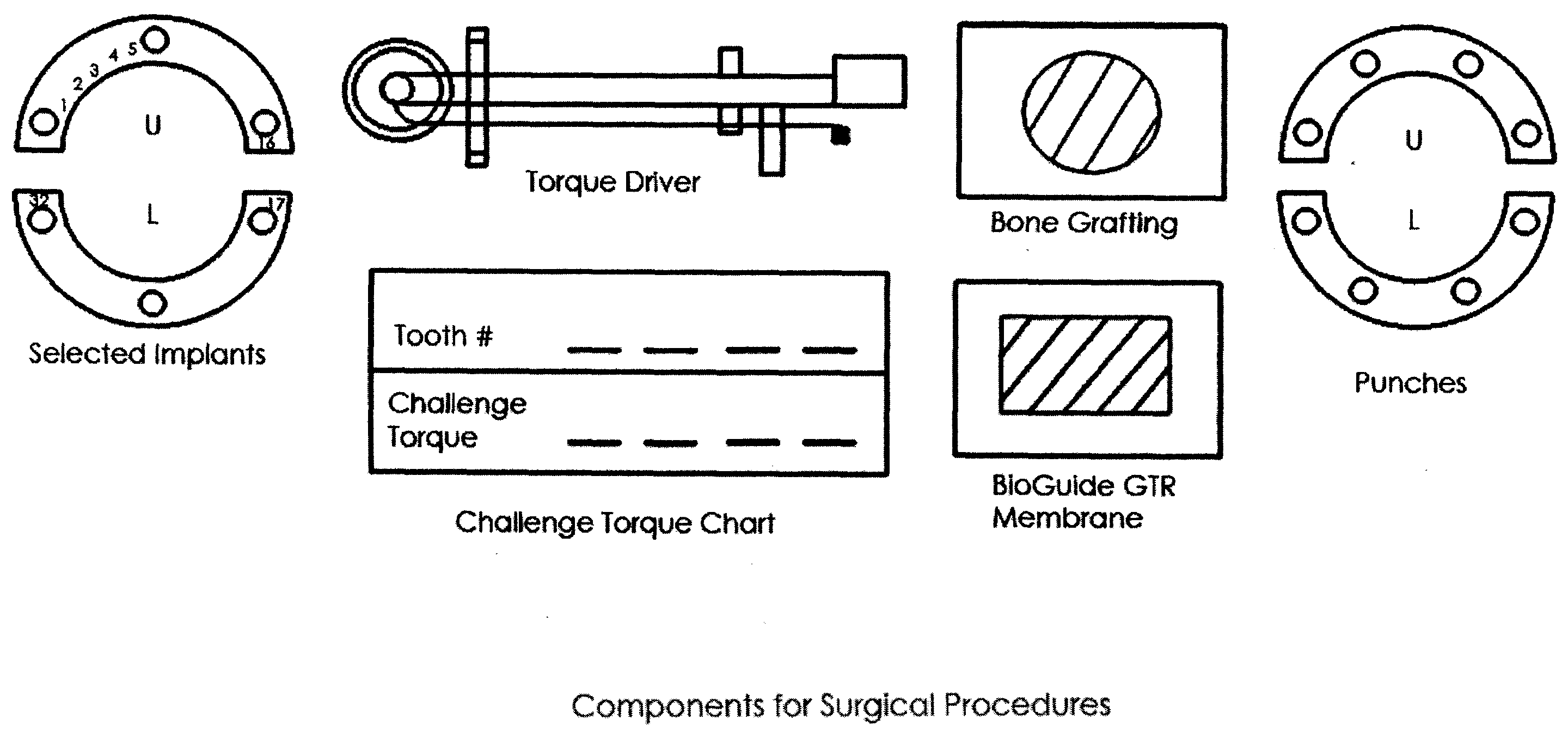

System, Method And Apparatus For Tooth Implant Planning And Tooth Implant Kits

InactiveUS20100105011A1Improve the level ofFacilitate proper fixture placementDental implantsDispensing apparatusPatient dataDental implant

Systems and methods support dental implant patient scheduling and treatment process relating to packaging one or more dental appliances as a kit which is readily used by dental professional during surgery, by communicating manufacturing progress information with a doctor over a network and performing patient scheduling and treatment when the dental appliances reach a certain manufacturing progress. A network-based service may also provide a doctor with a treatment solution including a surgical kit derived from patient data.

Owner:INPRONTO

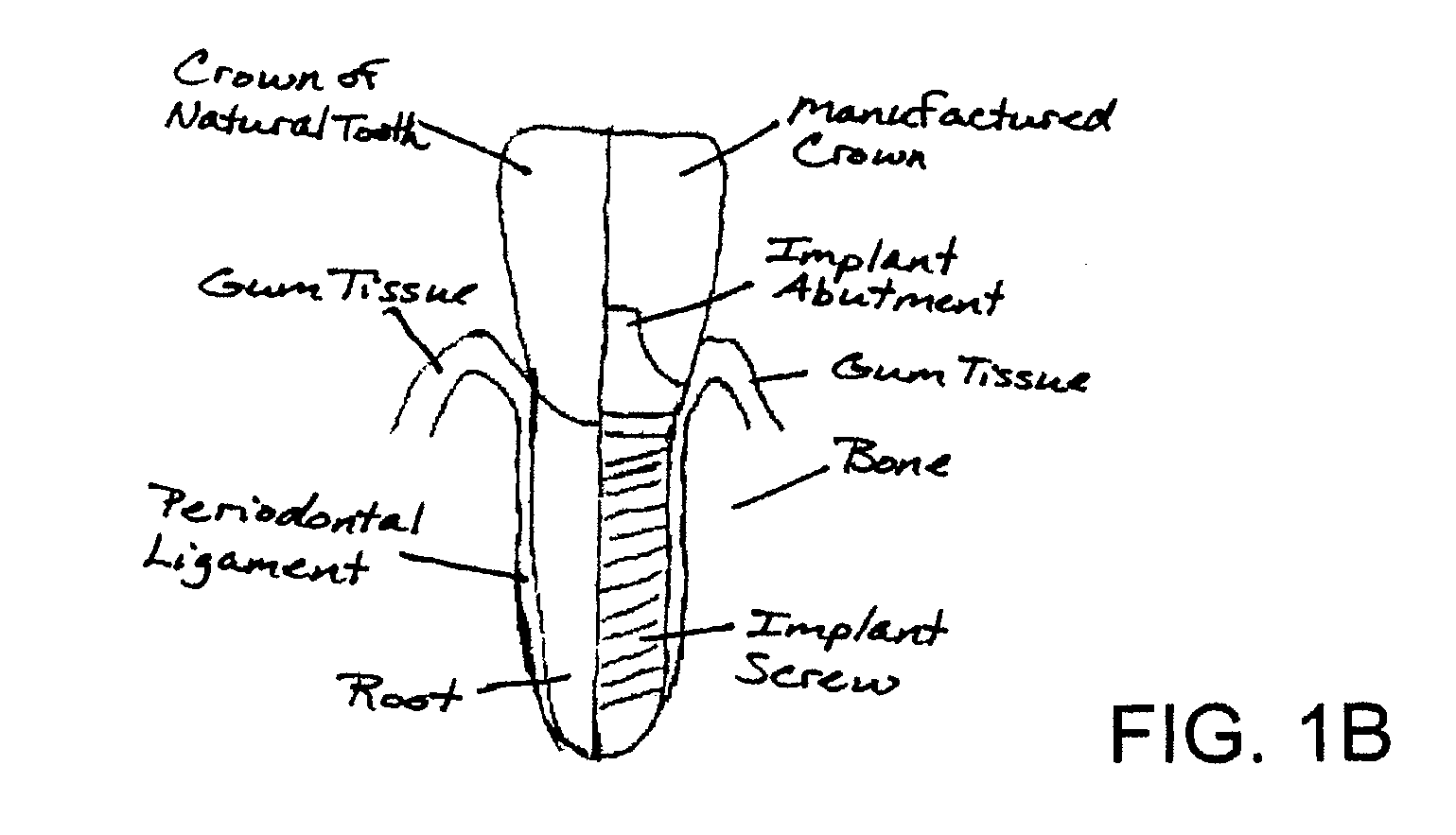

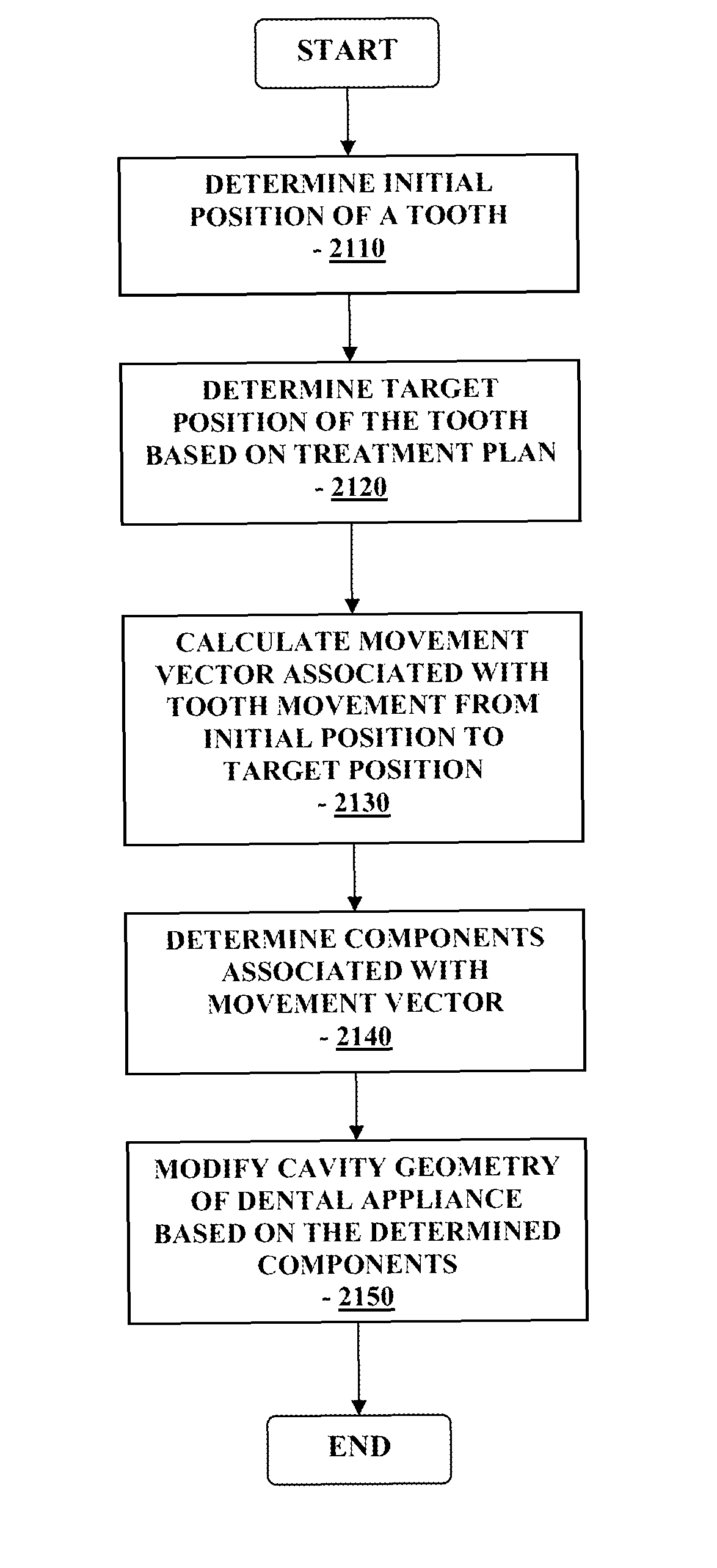

Method and system for optimizing dental aligner geometry

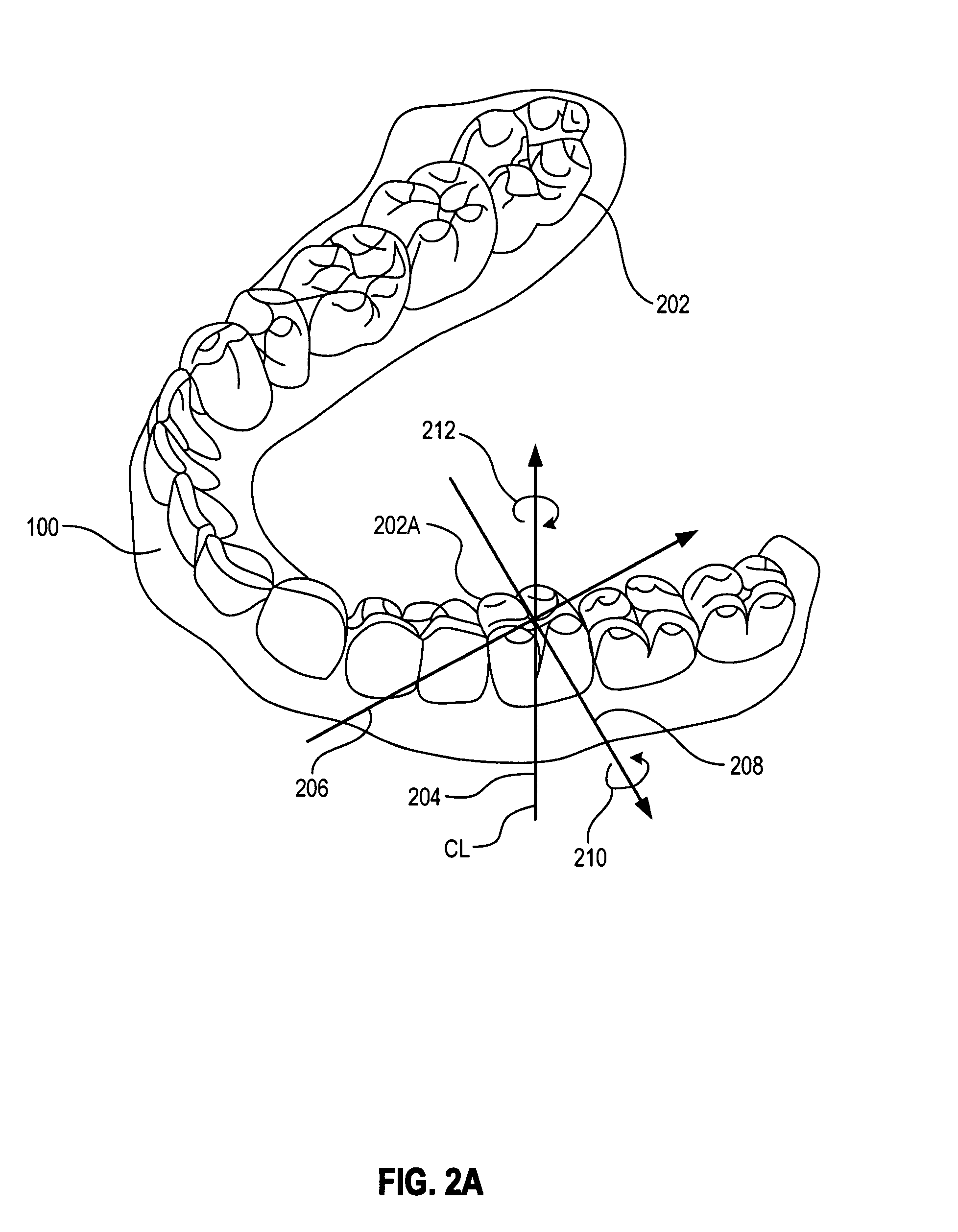

Method and system for establishing an initial position of a tooth, determining a target position of the tooth in a treatment plan, calculating a movement vector associated with the tooth movement from the initial position to the target position, determining a plurality of components corresponding to the movement vector, and determining a corresponding one or more positions of a respective one or more attachment devices relative to a surface plane of the tooth such that the one or more attachment devices engages with a dental appliance are provided.

Owner:ALIGN TECH

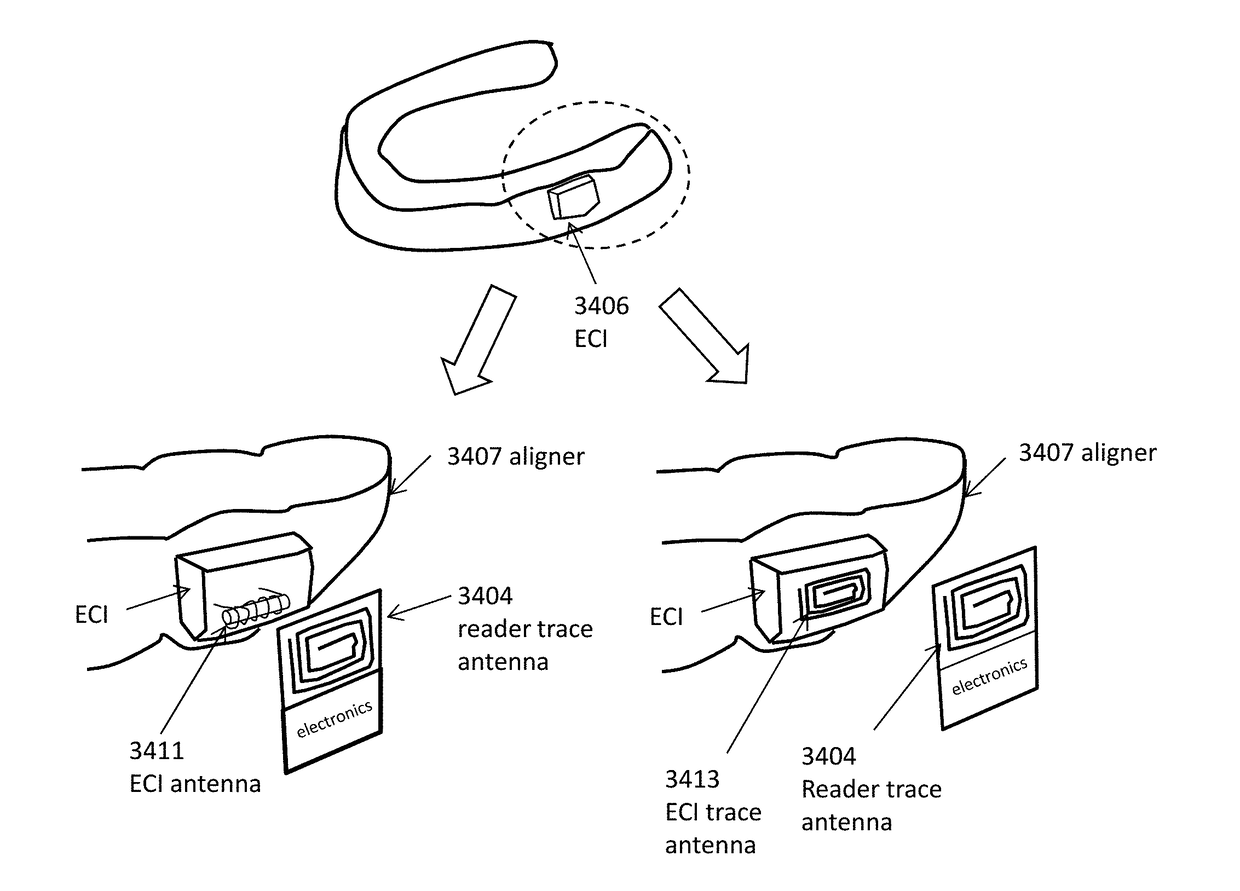

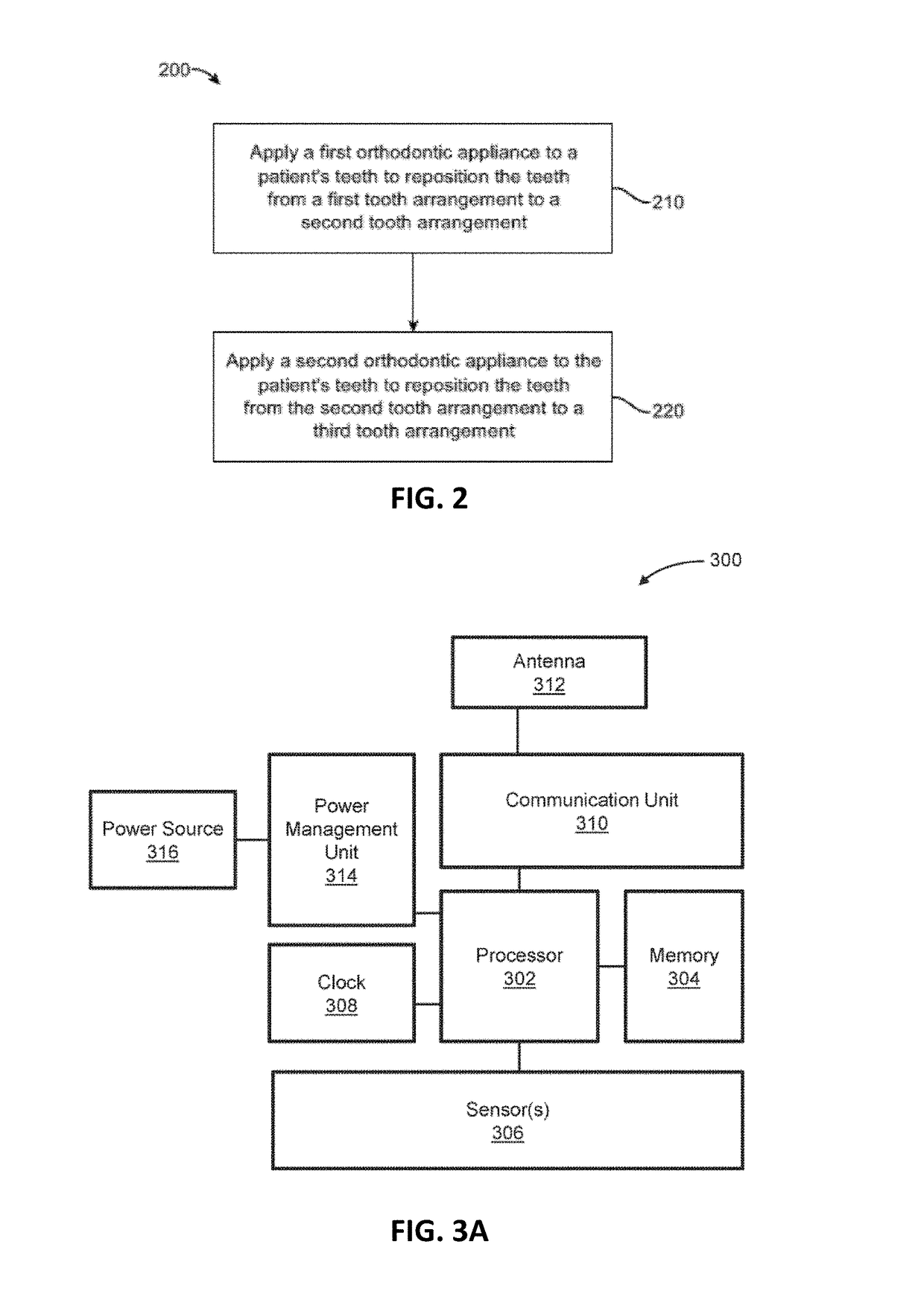

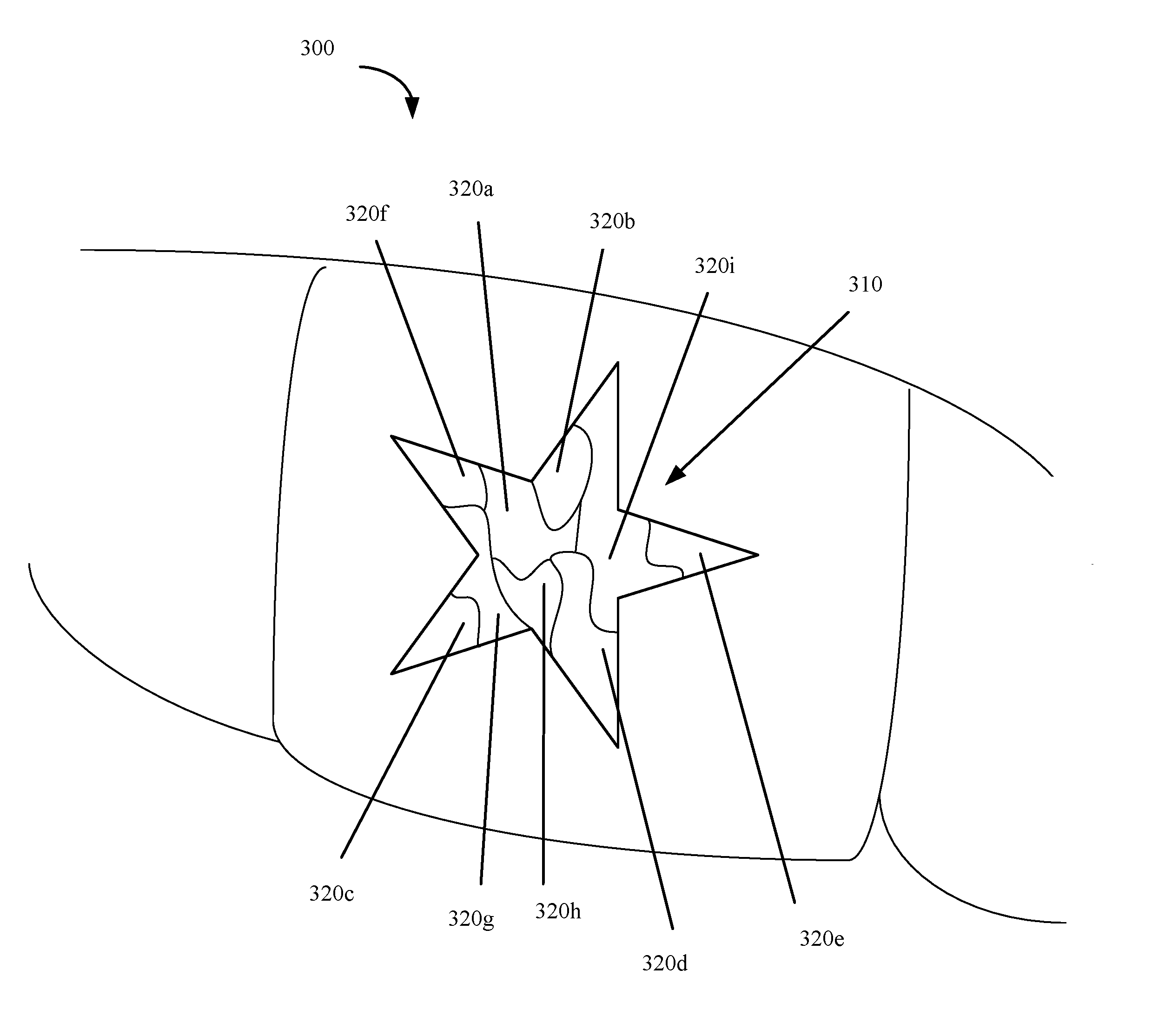

Intraoral appliances with sensing

ActiveUS20180000563A1Patient compliance is goodGood curative effectMobile data collection deviceOthrodonticsBiomedical engineeringIntraoral appliance

Detection of placement of dental aligners in patient mouth on teeth for indication of wearing compliance. Described herein are apparatuses and methods for detecting wearing, including compliance, and for reliably transferring data, by wired or wireless direct or indirect communication of electronic compliance information to a smartphone. Also described herein are dental appliances that can detect physiological parameters related to respiration and sleep. Also described herein are aligner cases that enable NFC communication with electronic compliance indicator (ECI) devices and Bluetooth communication with smartphones.

Owner:ALIGN TECH

Systems, apparatuses and methods for substance delivery from dental appliance

ActiveUS20170007386A1Additive manufacturing apparatusOthrodonticsManufacturing technologyEngineering

Owner:ALIGN TECH

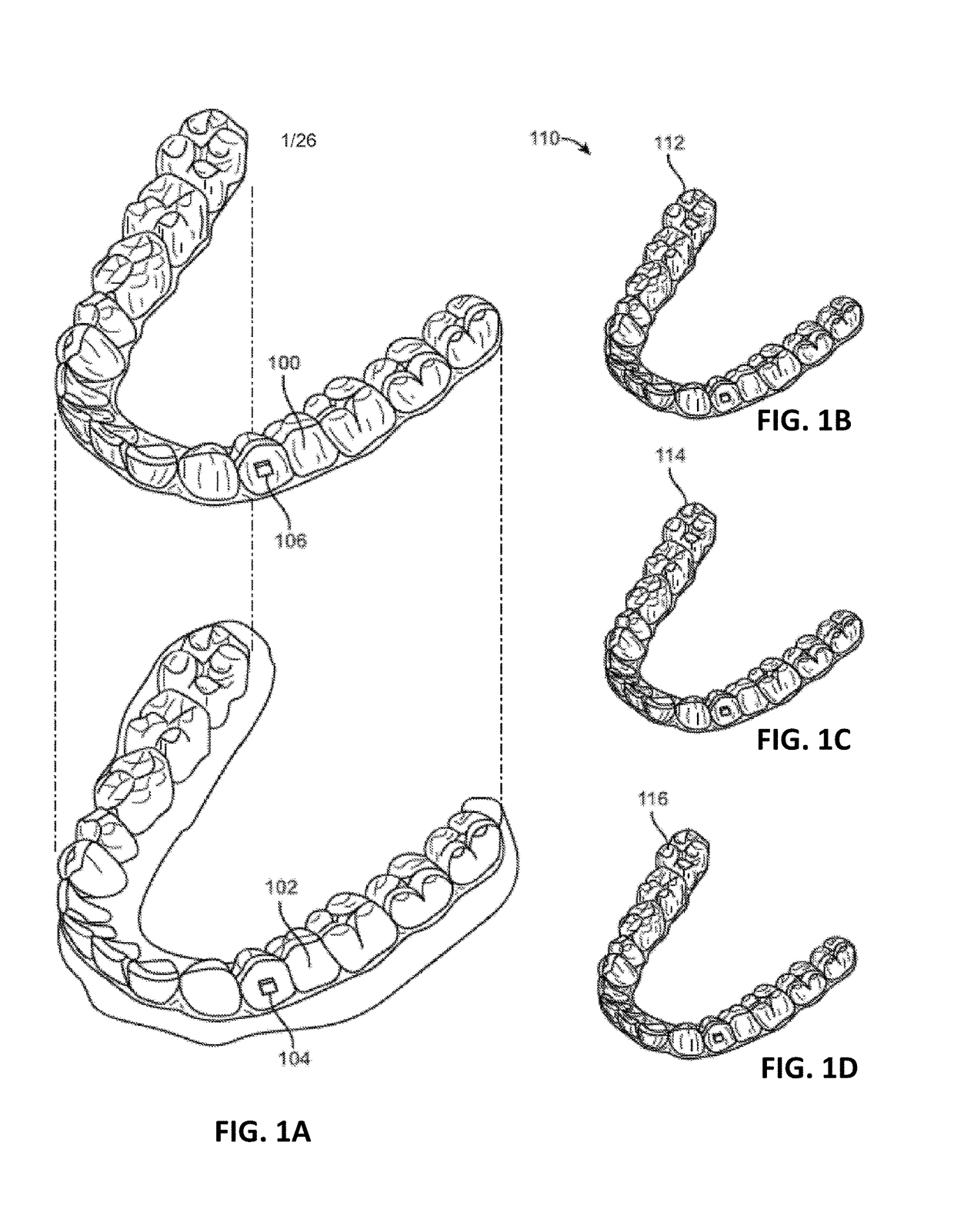

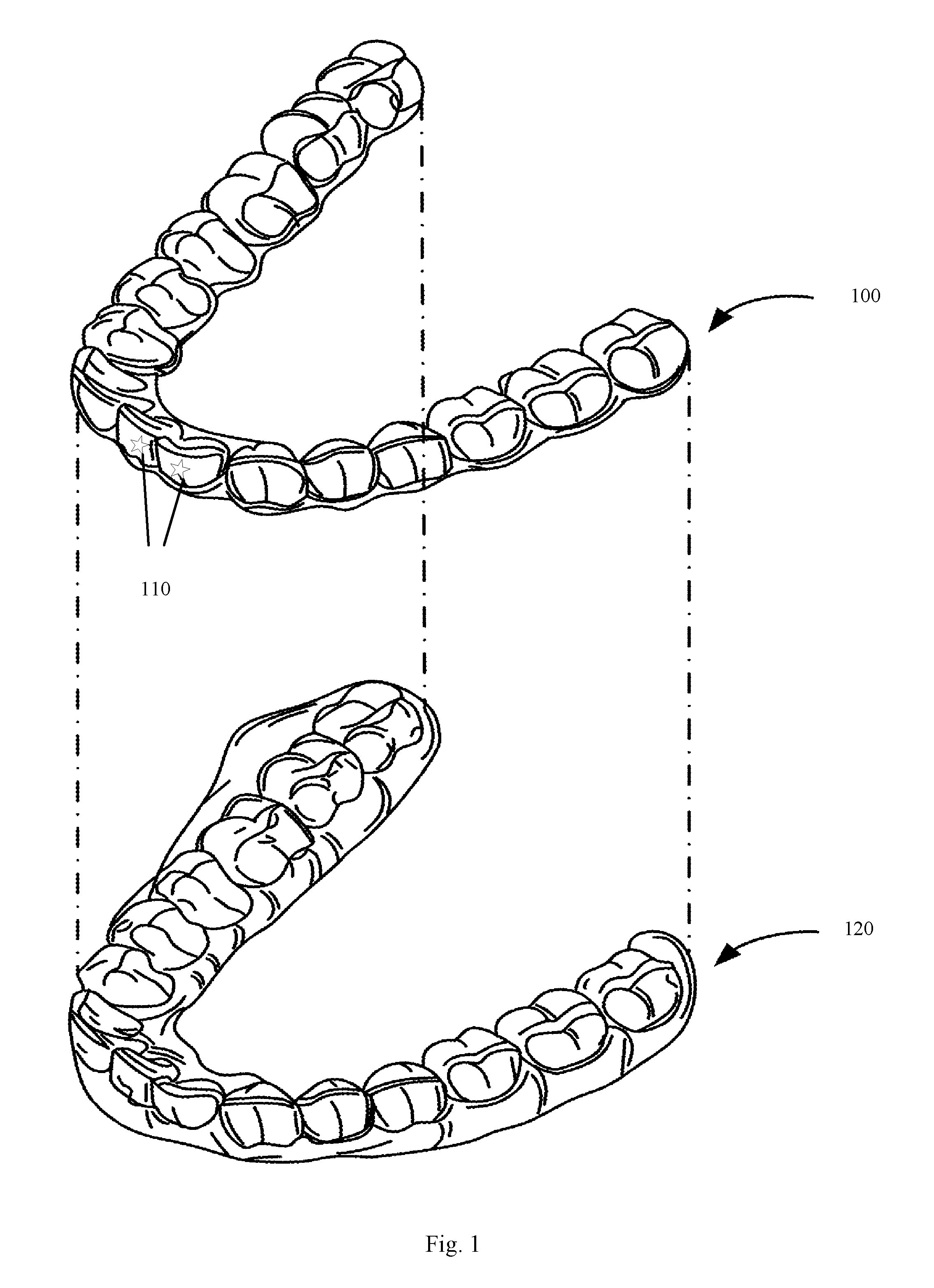

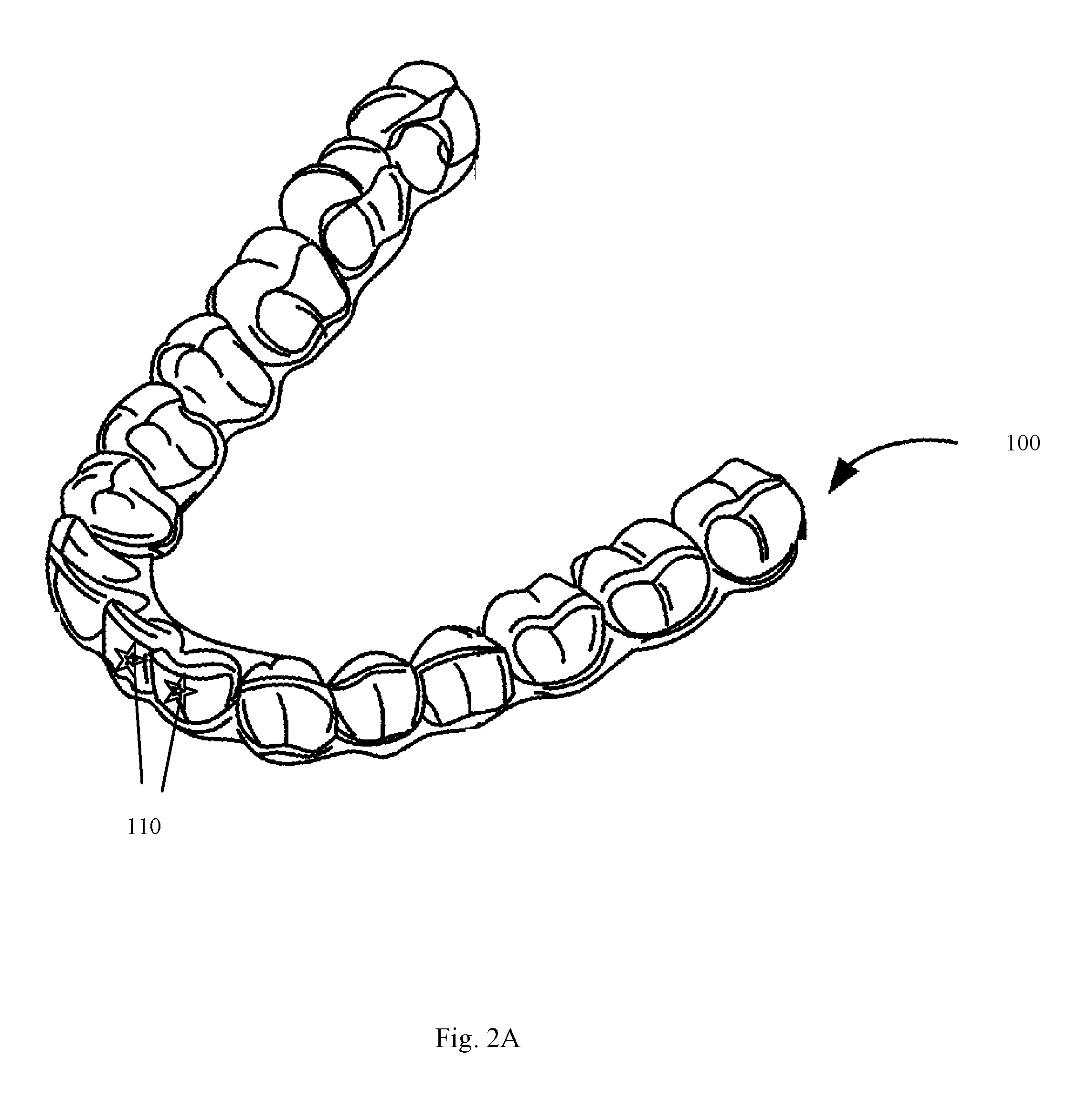

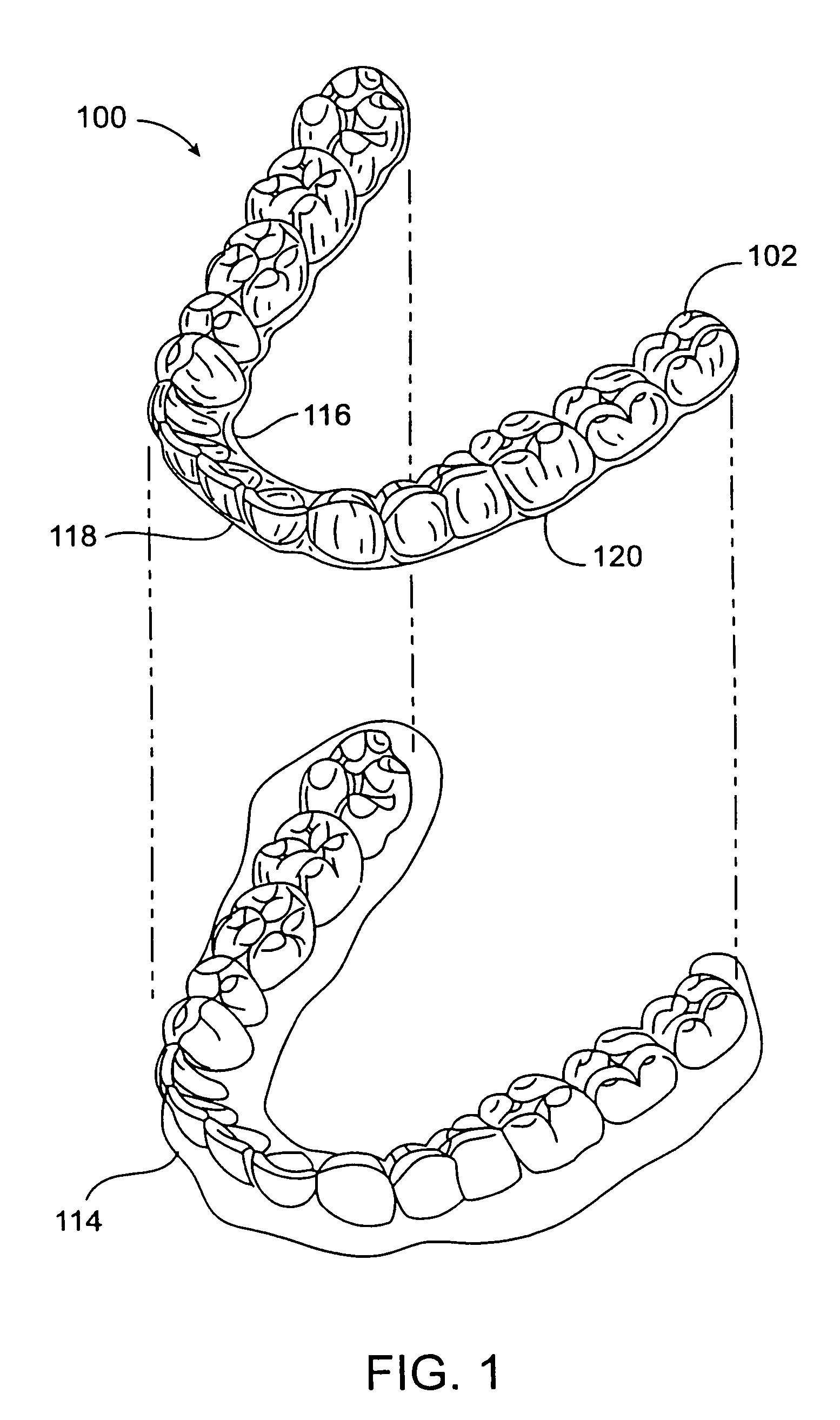

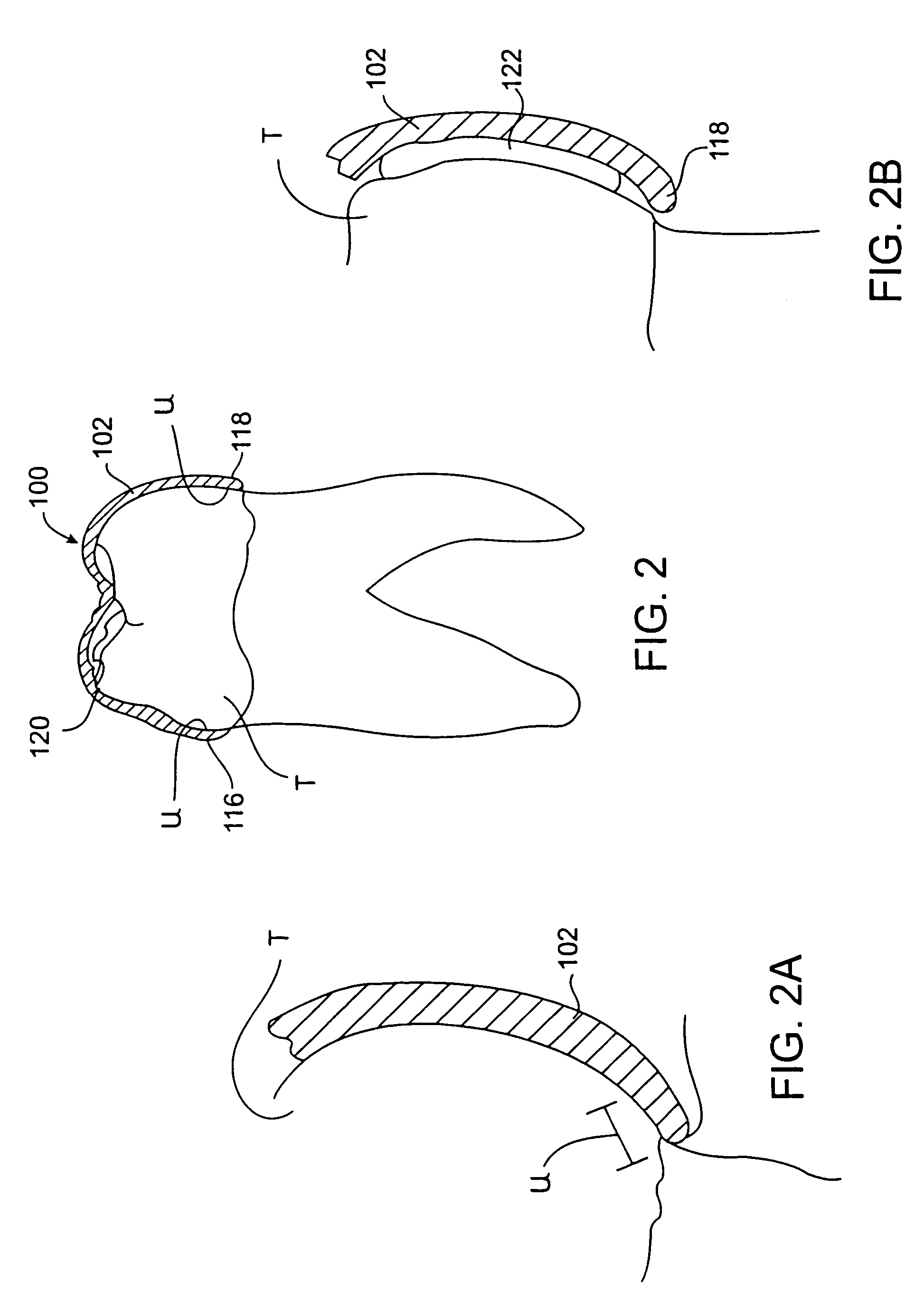

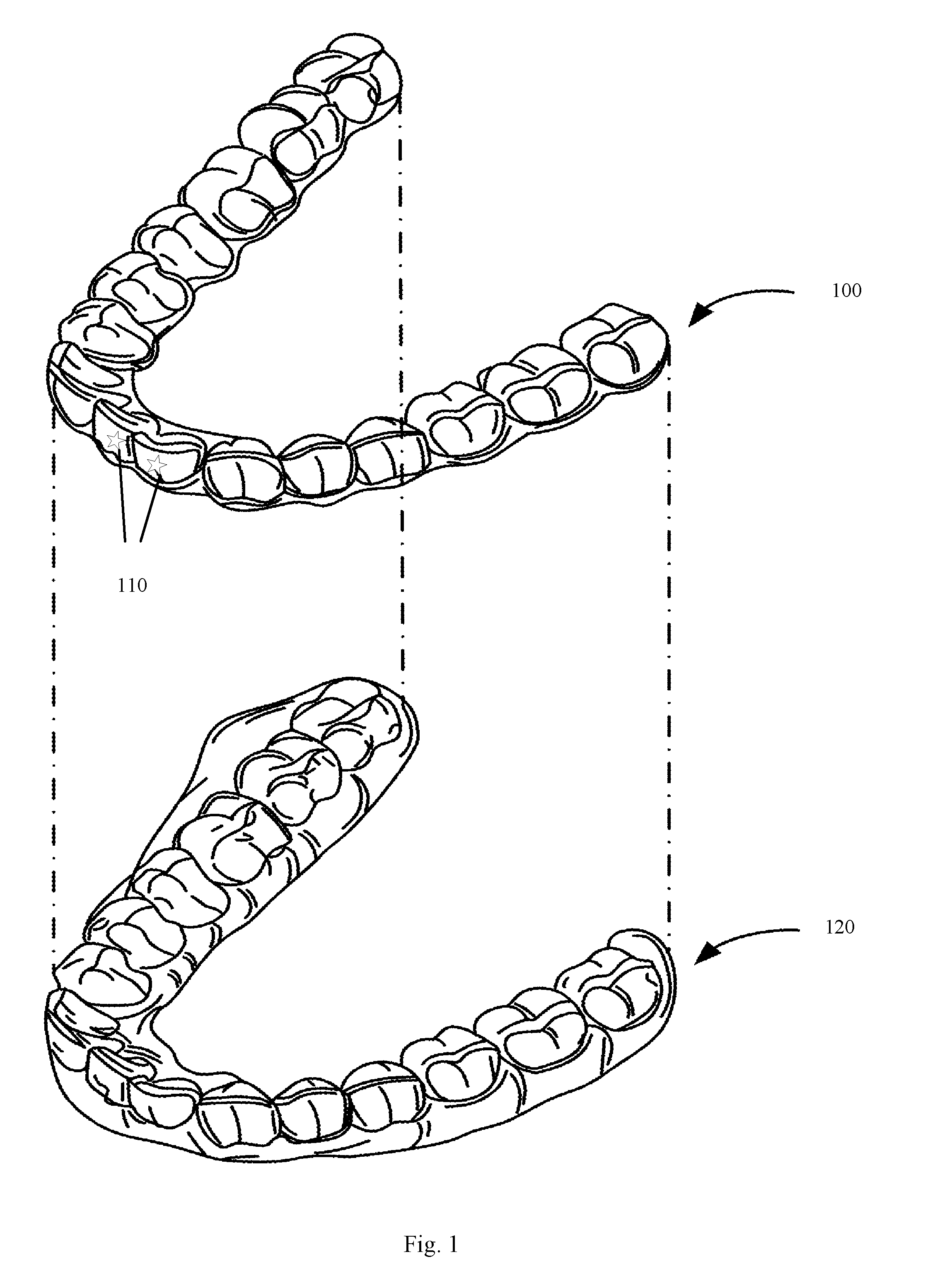

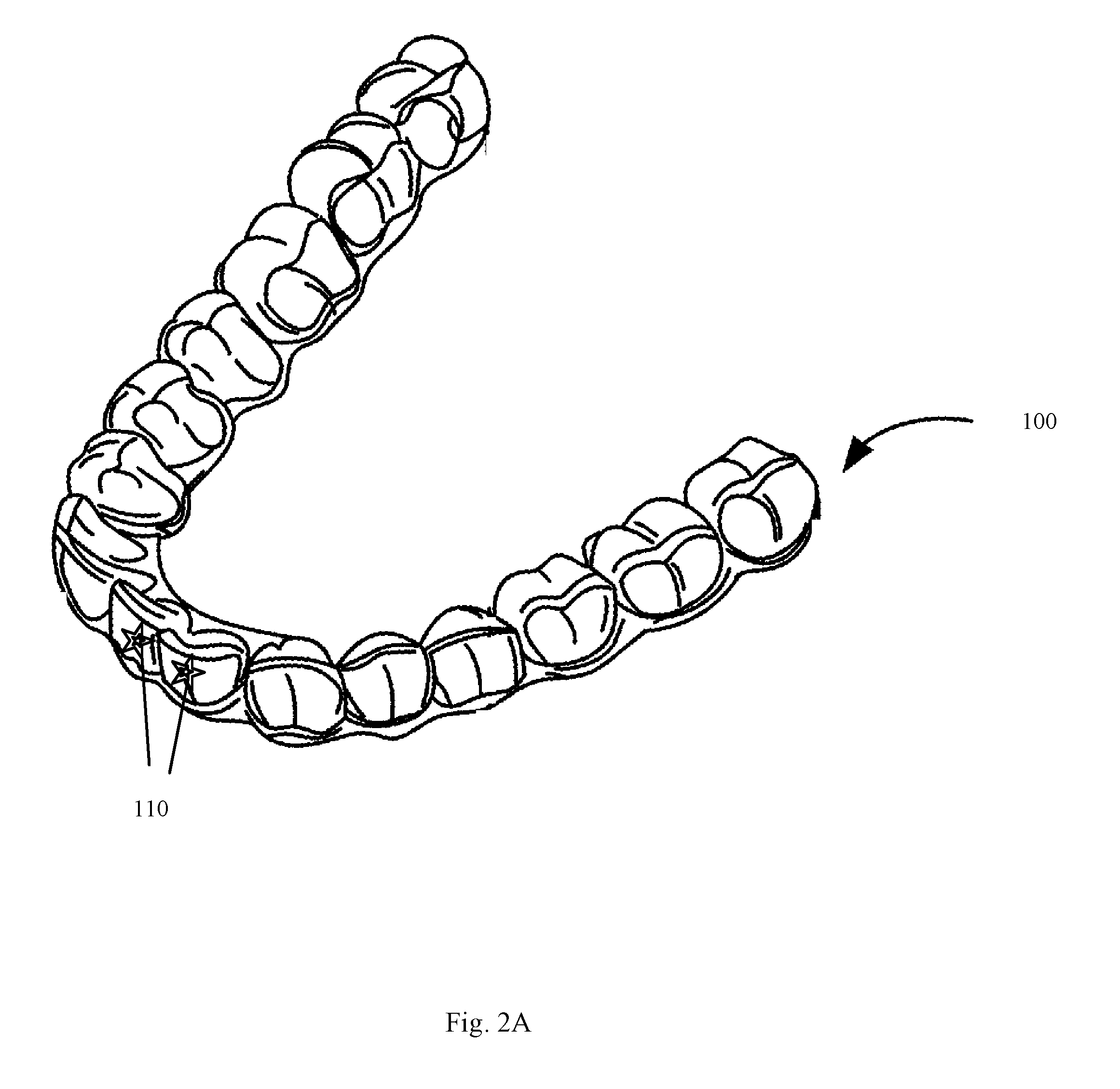

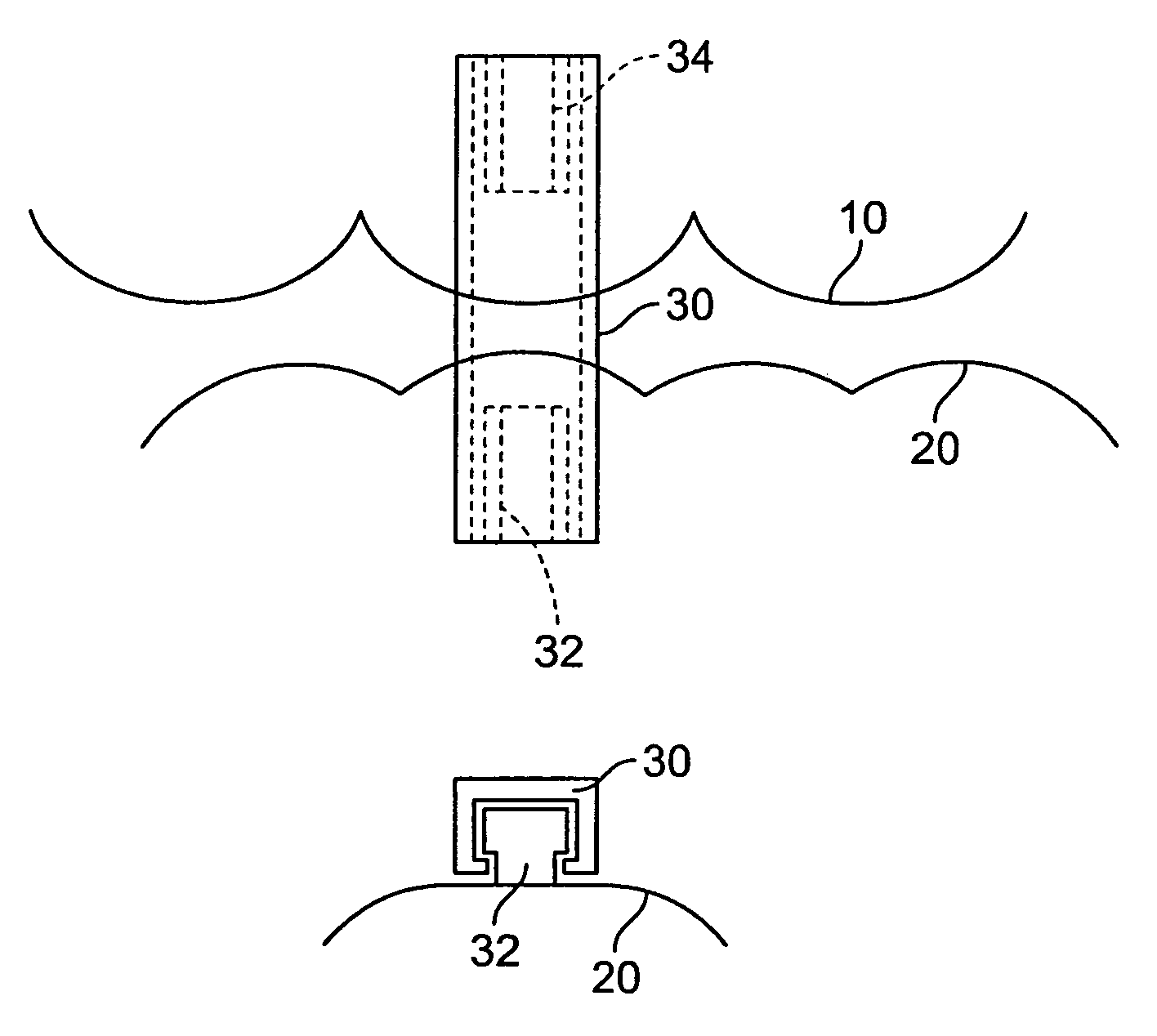

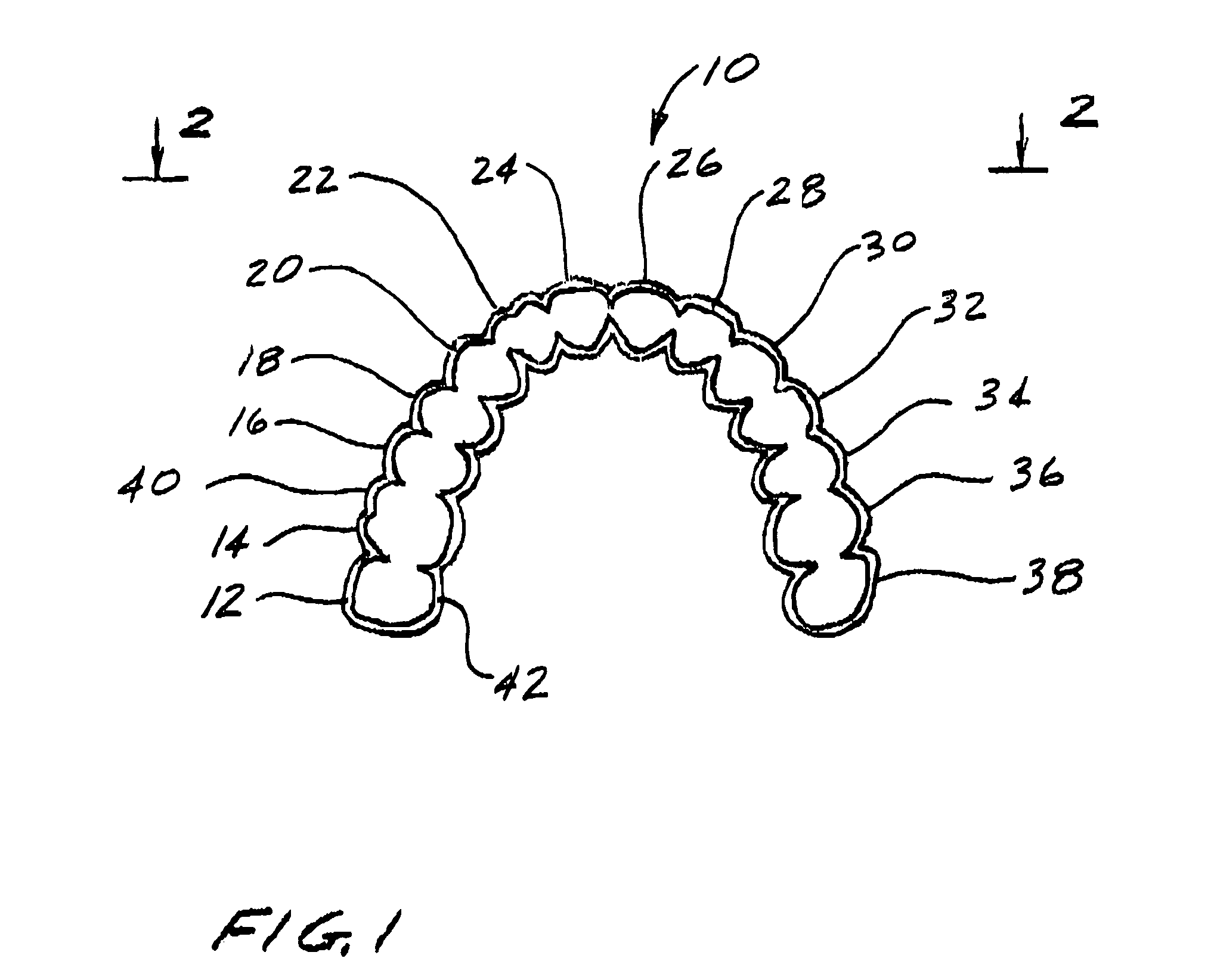

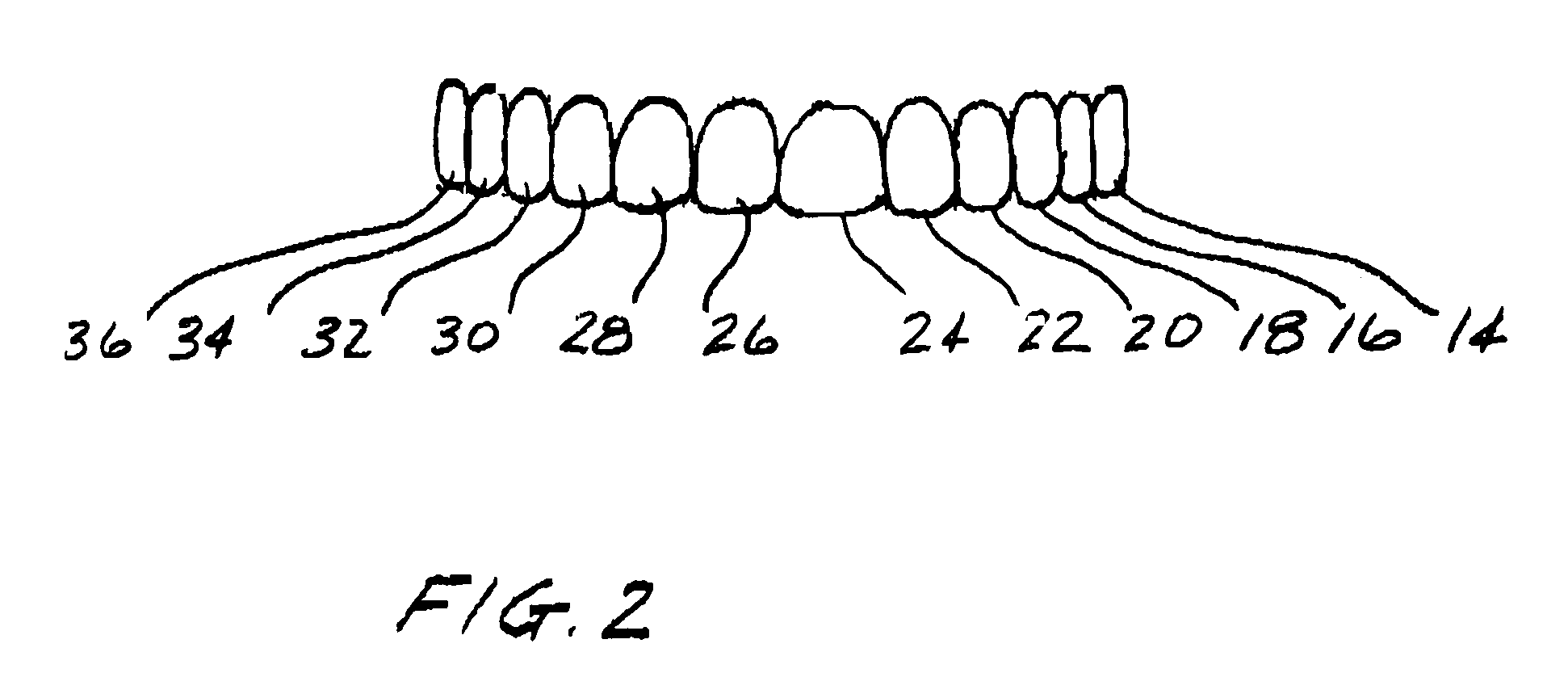

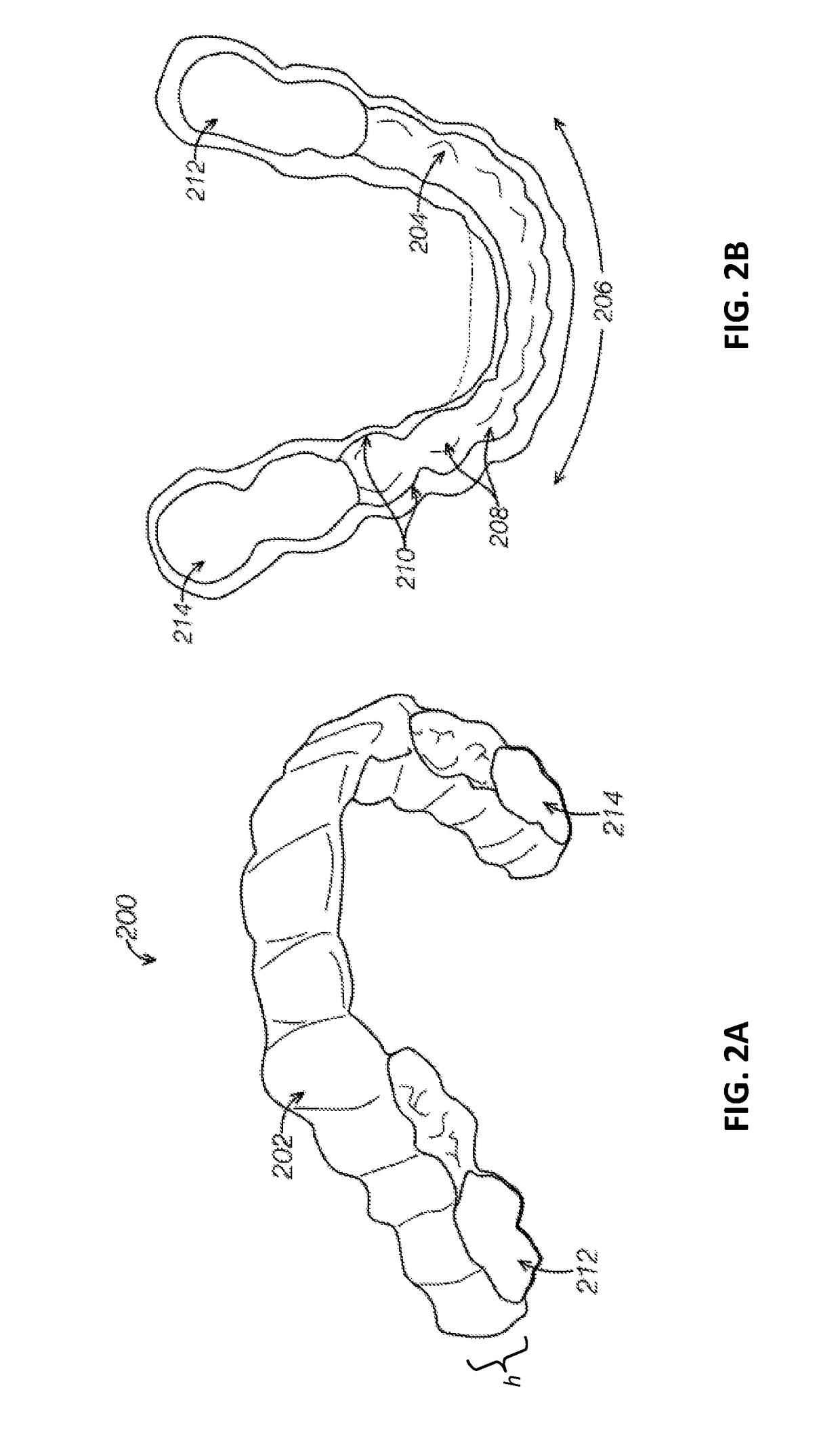

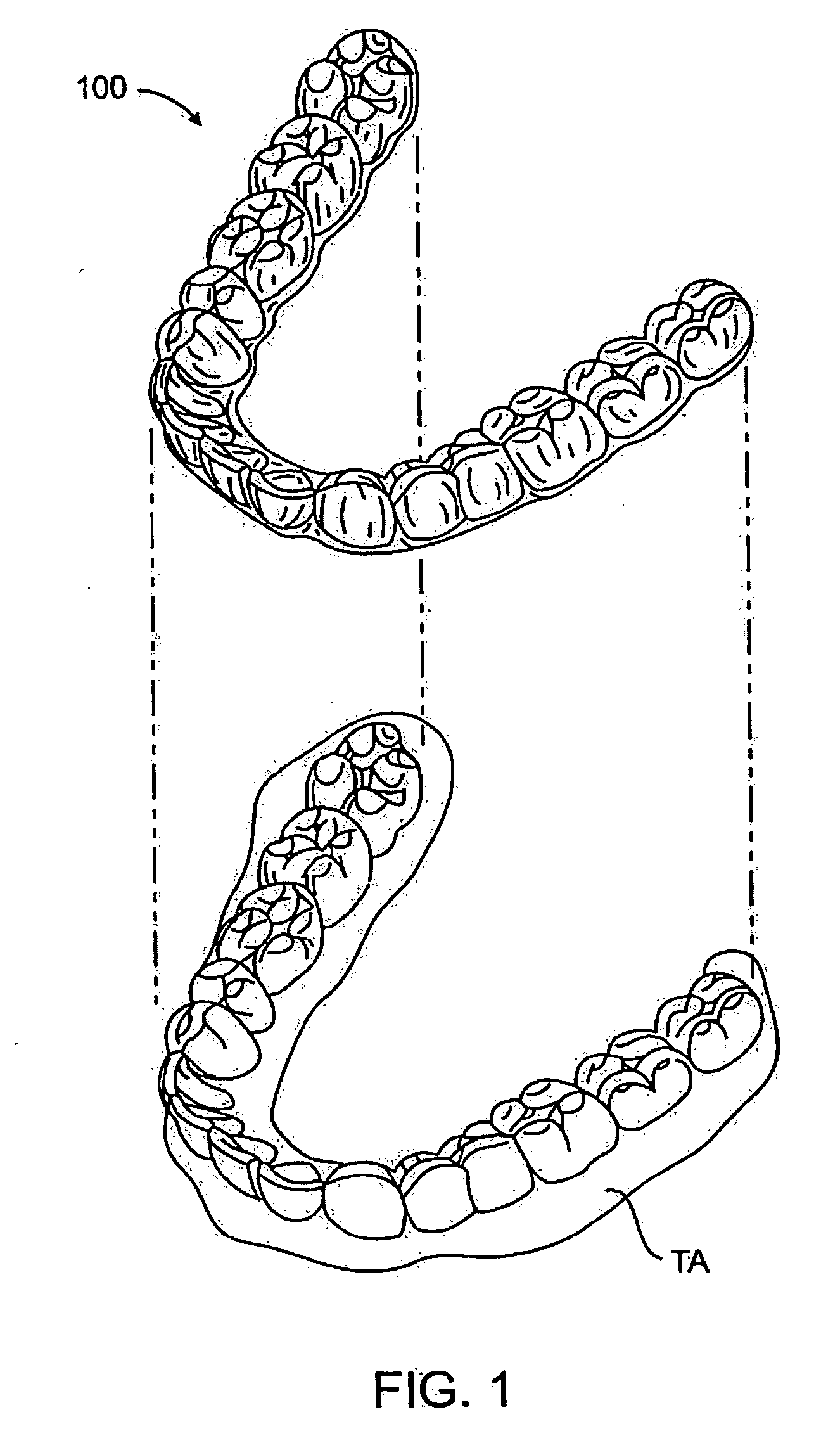

Tooth positioning appliances and systems

InactiveUS7121825B2Easy to implantSuitable for useOthrodonticsDental toolsState variationUltimate tensile strength

An improved dental appliance system, and methods for using and fabricating the improved appliance, including a polymeric overlay or shell having a teeth-receiving cavity formed therein and a wire mounted on or embedded in the polymeric shell. The dental appliance having the necessary stiffness or strength to firmly secure the appliance on the teeth and provide controlled forces required for repositioning the teeth, until such time as removal of the appliance is desired. The appliance may be configured for use with a removal mechanisim. The removal mechanism undergoes a state change stimulated by an environmental stimulus or environmental switch.

Owner:ALIGN TECH

Dental appliance having ornamental design

ActiveUS20170008333A1Additive manufacturing apparatusOthrodonticsManufacturing technologyEngineering

Owner:ALIGN TECH

Embedded features and methods of a dental appliance

Owner:ALIGN TECH

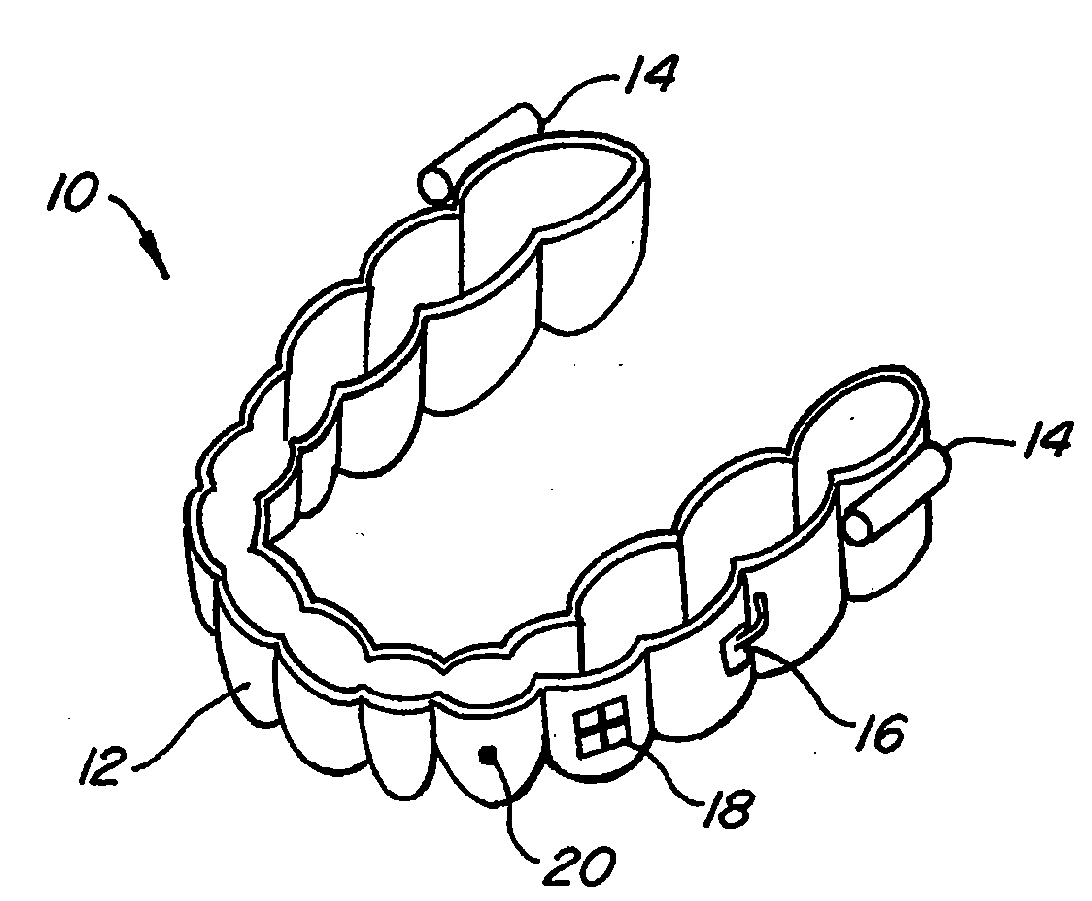

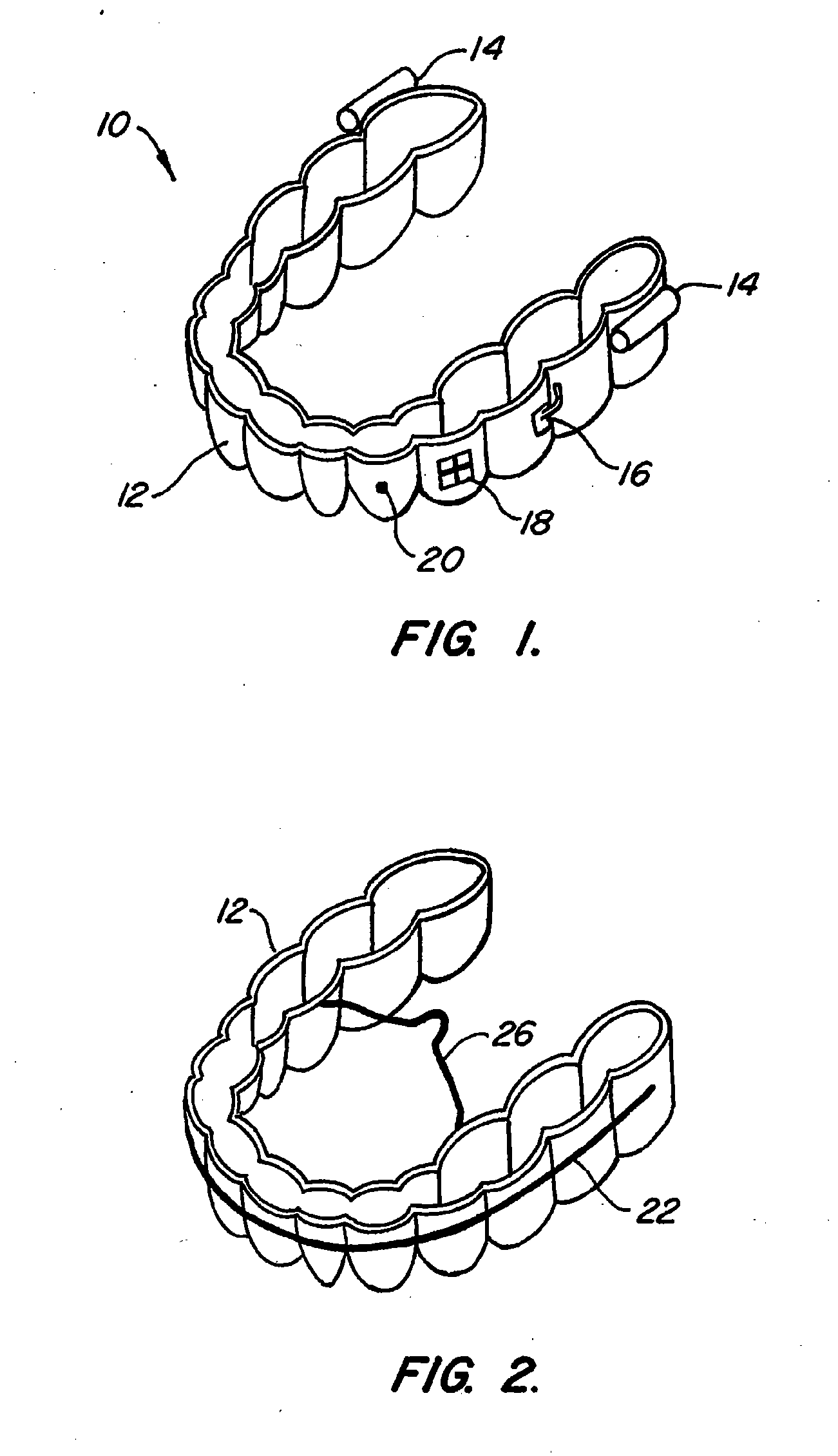

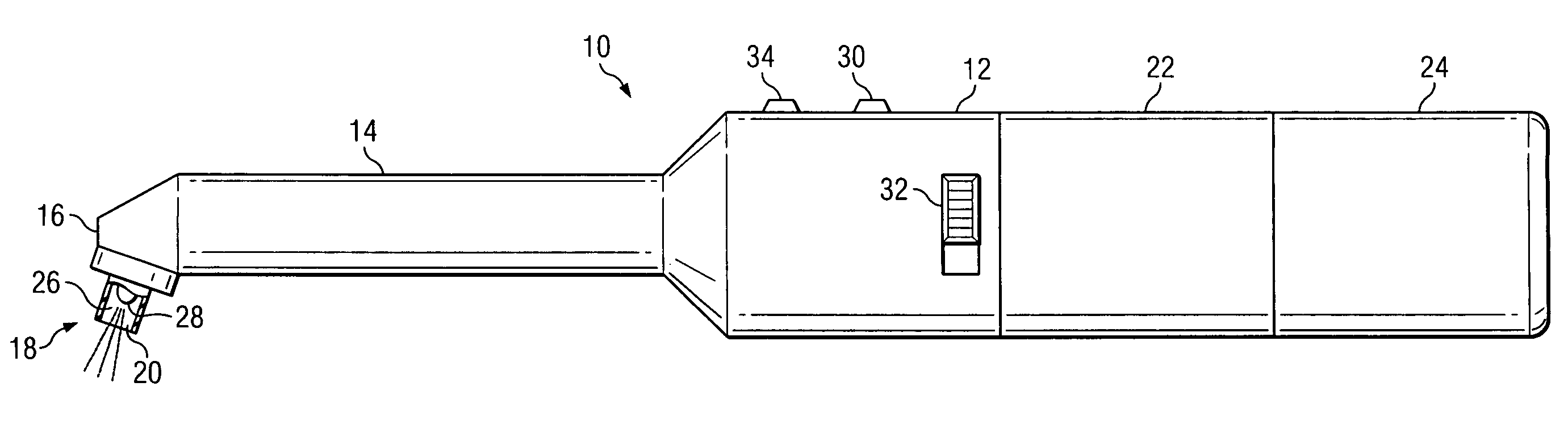

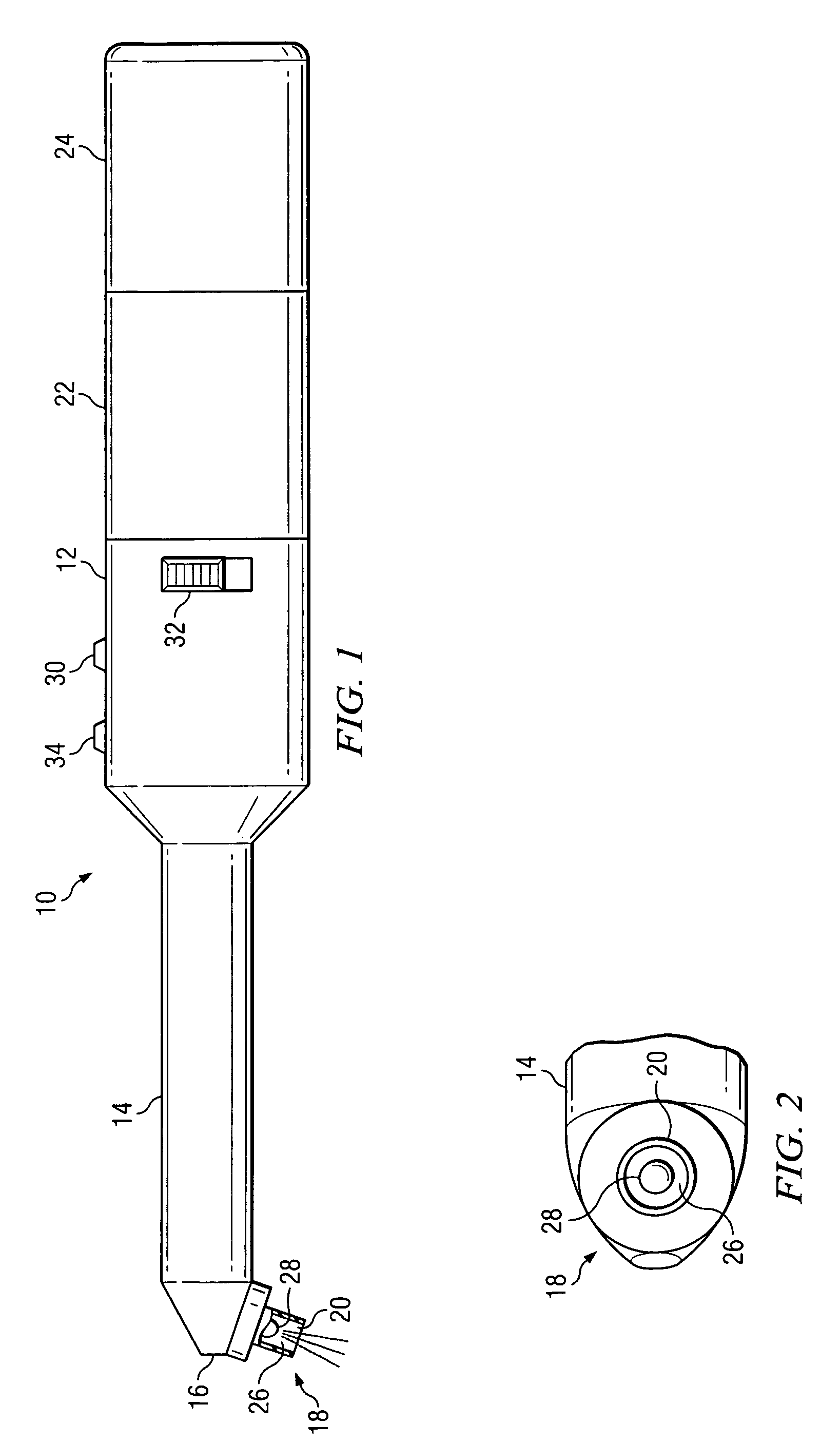

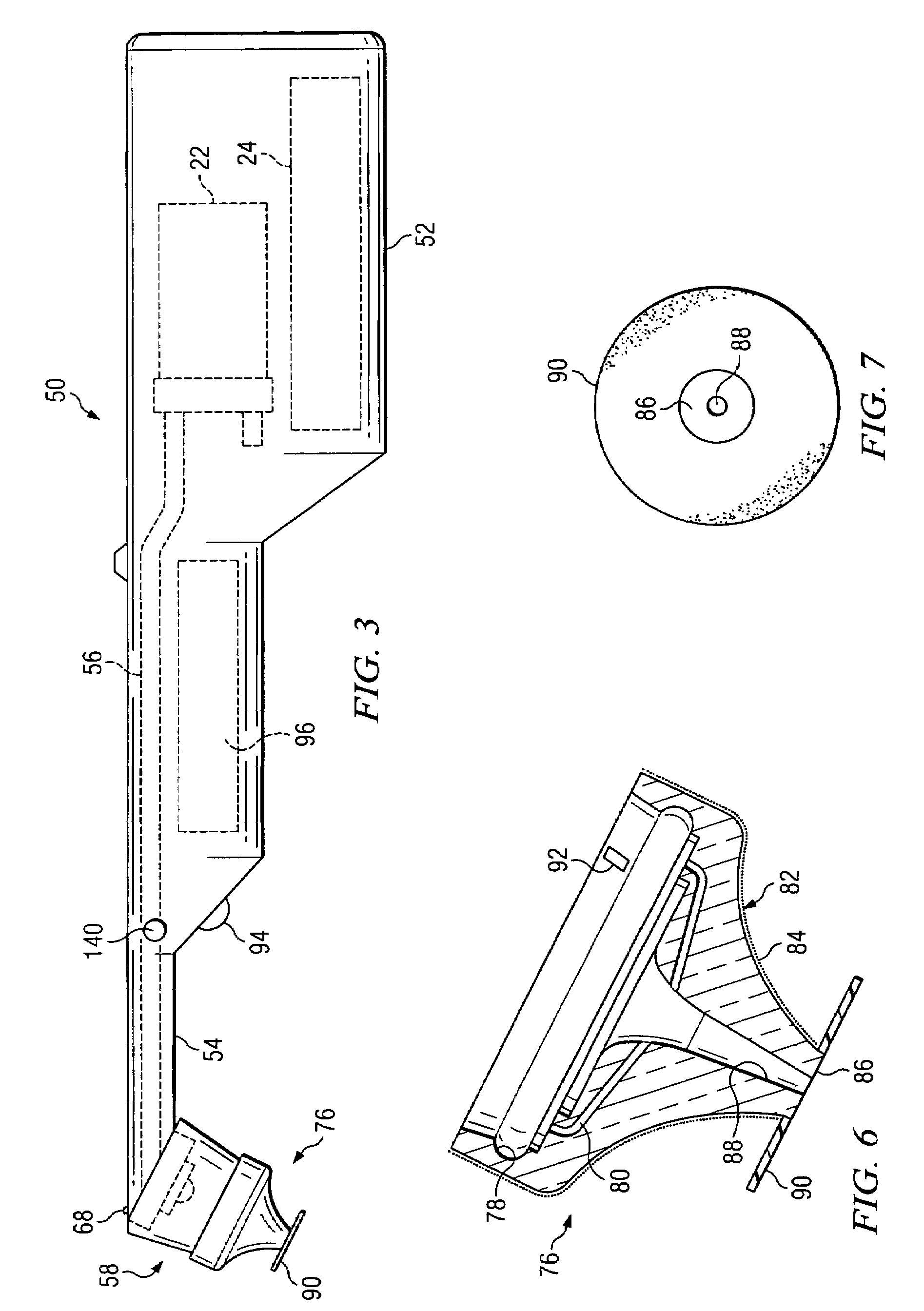

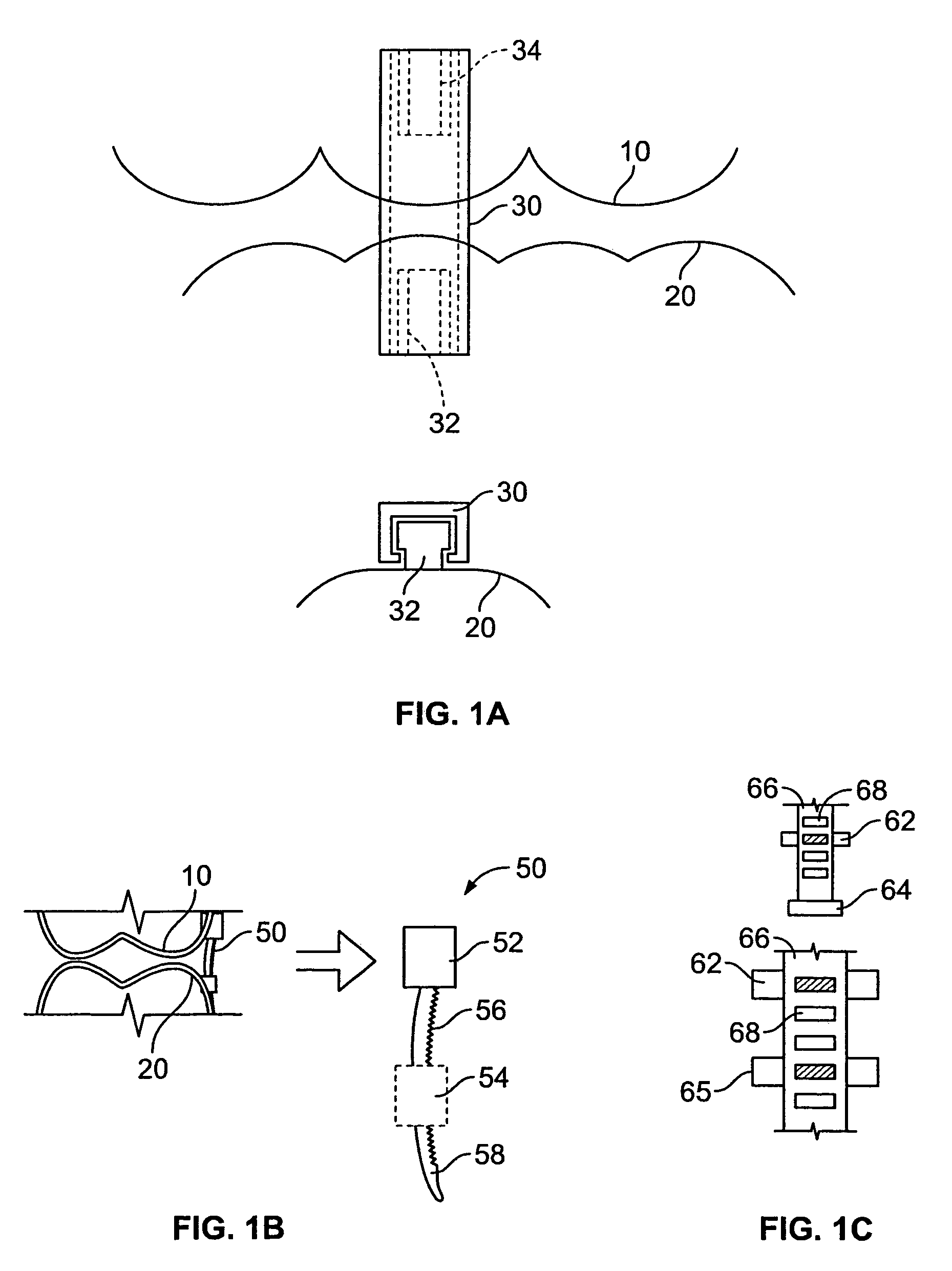

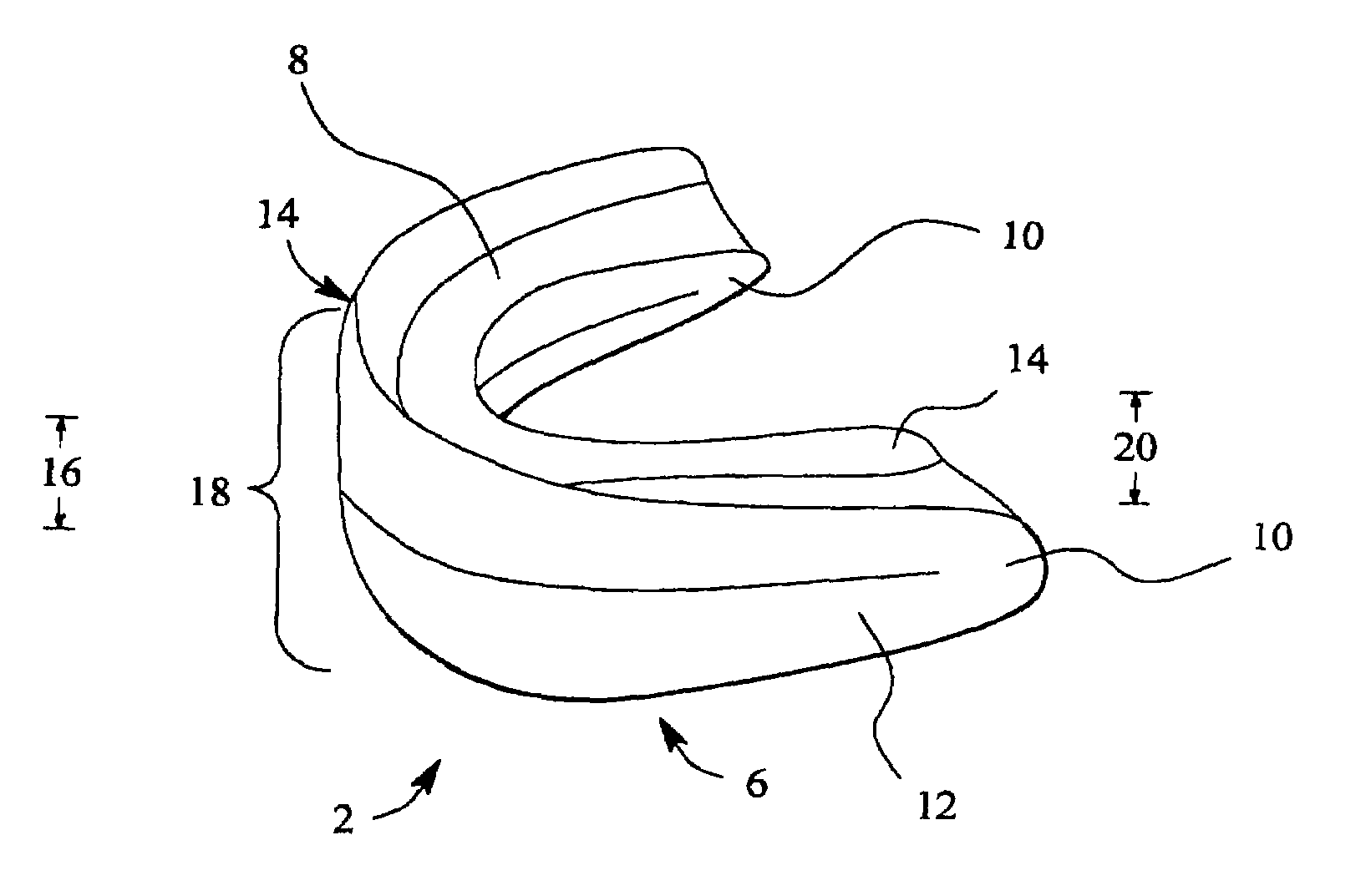

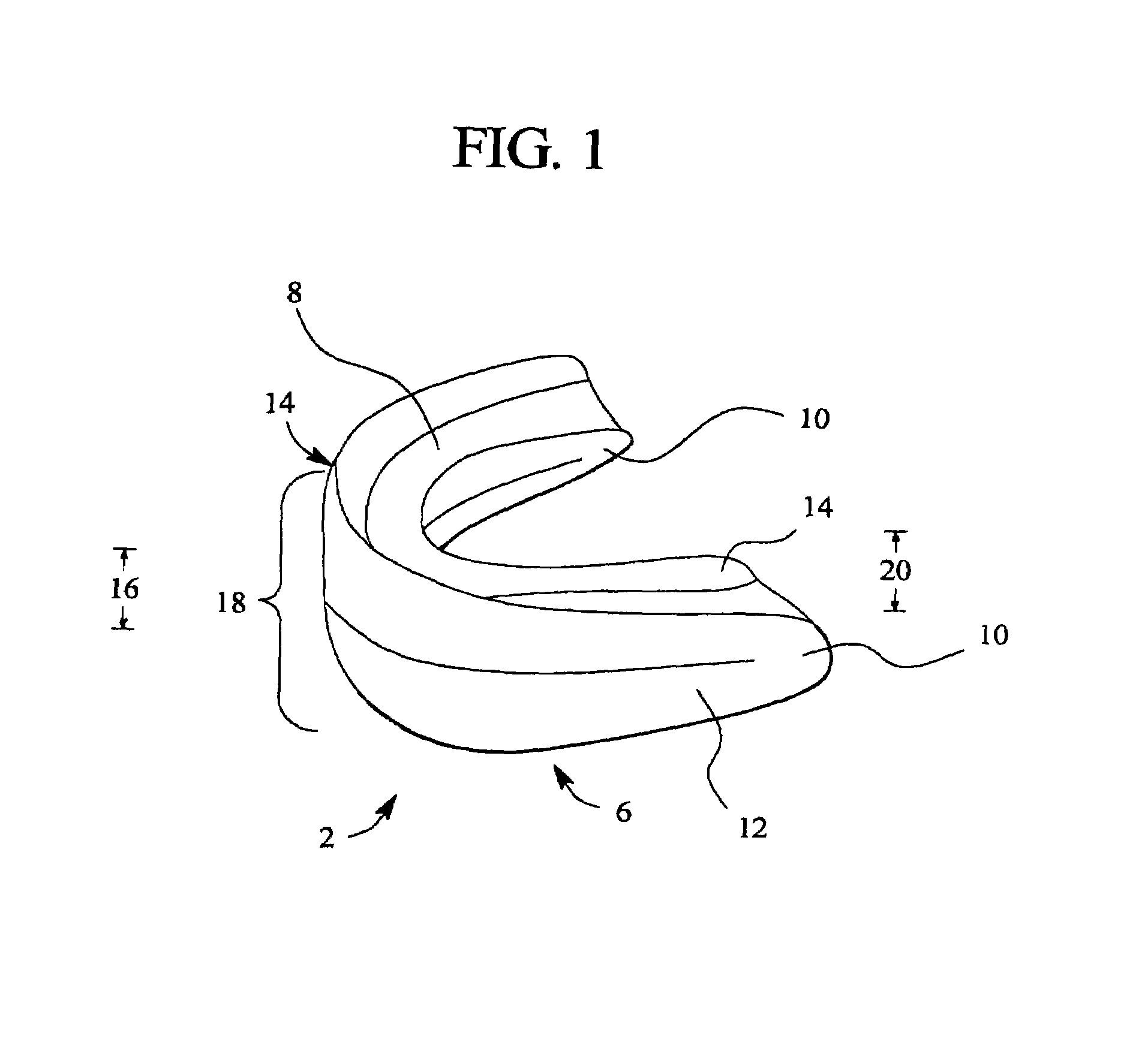

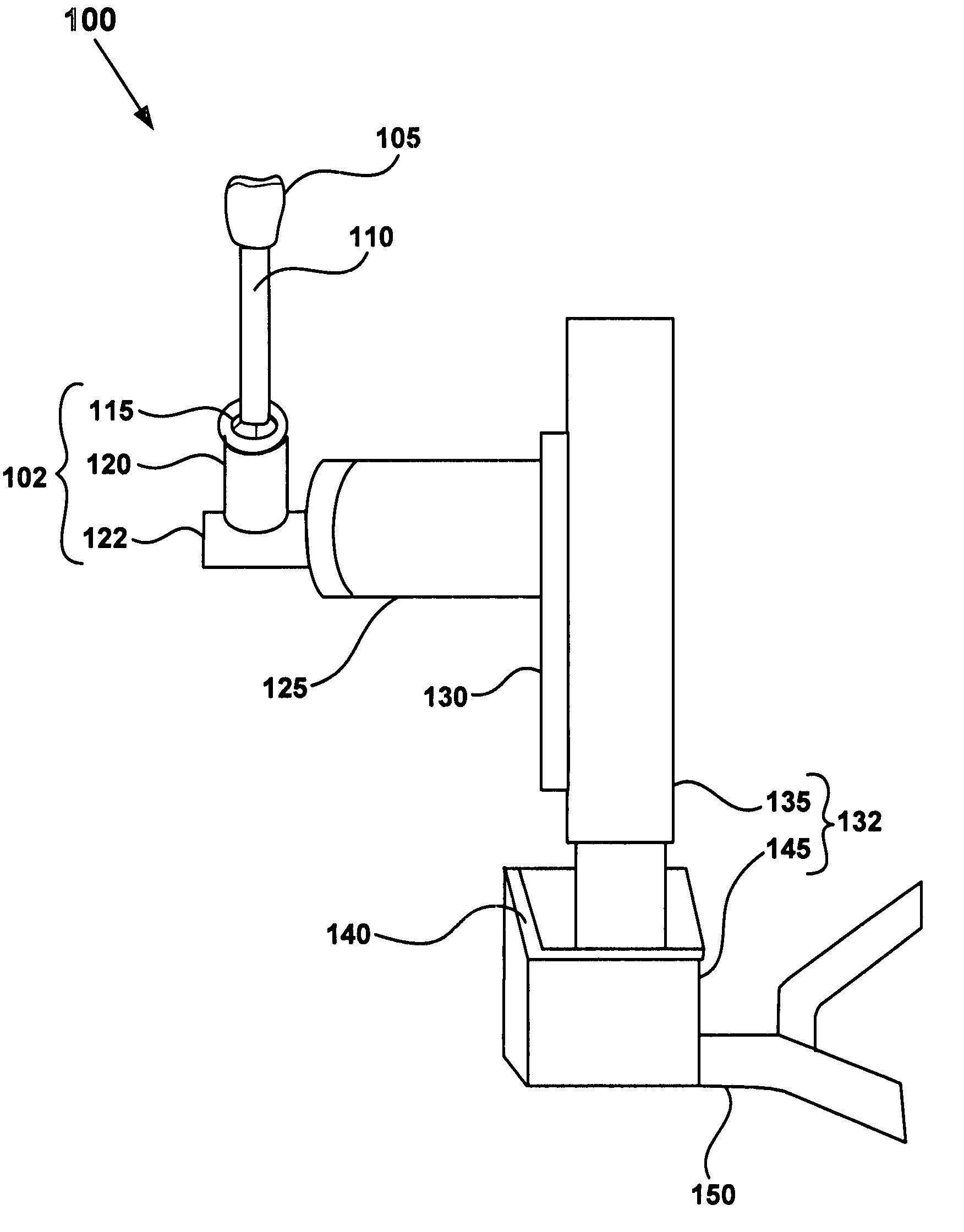

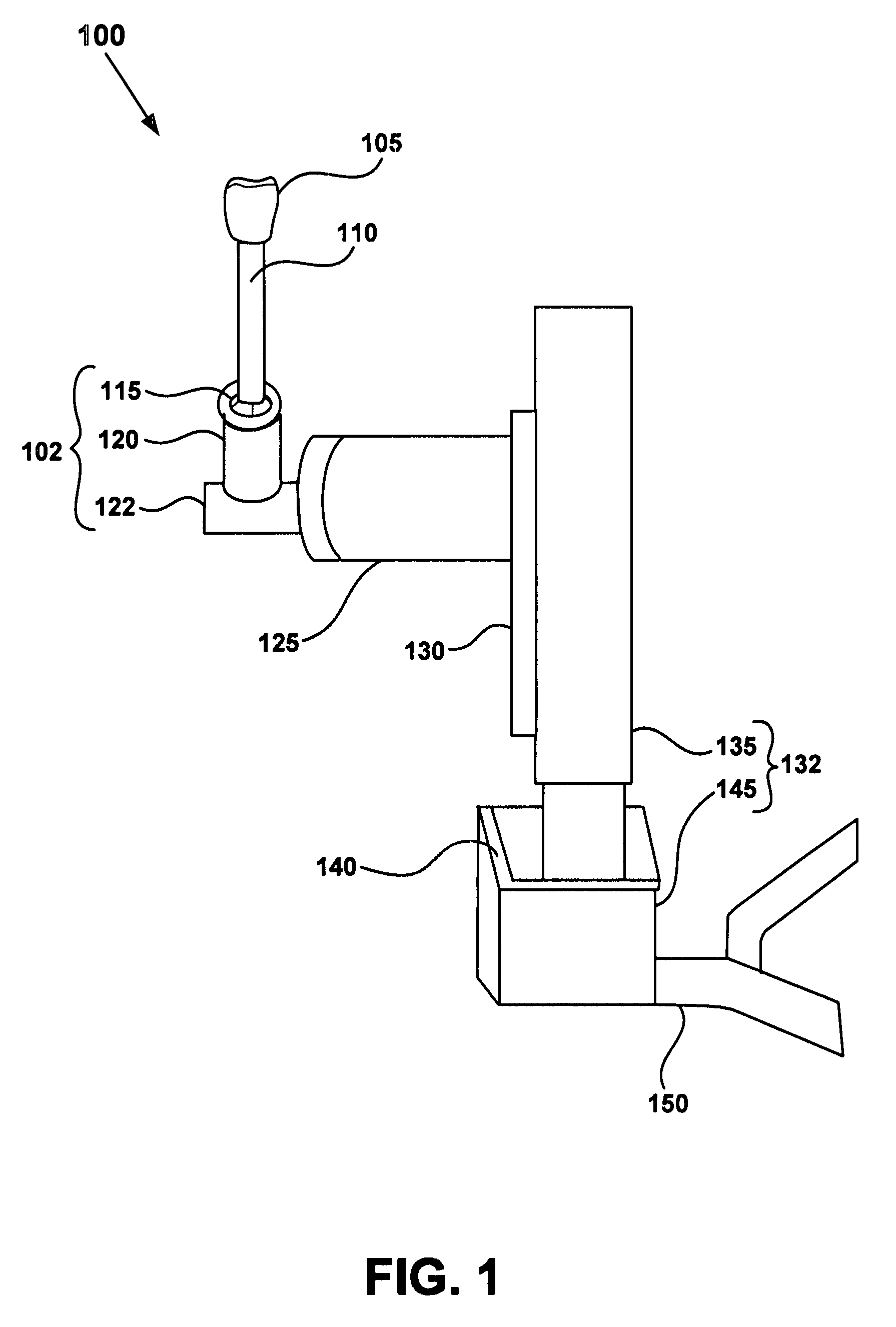

Combination placement tool and light

A combination placement tool and light device (10, 50) is disclosed which allows the dentist or surgeon to hold a dental appliance with a vacuum supplied to a flexible skirt (18, 90), position the dental appliance, and then tack the dental appliance in place with a light source (28, 60, 62) using light activated adhesive. The device (10, 50) can also be used to provide a full cure. The device (10, 50) can also have a source of drying air to aid the procedure. The device (50) can be used with a disposable molded acrylic collimator (76).

Owner:HALM GARY V

Surgical dental appliance

ActiveUS7354270B2Easily re-establish bite relationshipMitigate and eliminate in positionAdditive manufacturing apparatusOthrodonticsSurgical dentistrySurgical department

Owner:ALIGN TECH

Dental appliance

ActiveUS7357637B2Efficient use ofBeautiful smileOthrodonticsTooth crownsInterior spaceCosmetic appearance

An appliance fabricated to improve the appearance of a patient's smile includes a plurality of simulated teeth. The interior surfaces of each of the teeth closely fits and conforms to the surface of a patient's real teeth while the outer surfaces of each of the simulated teeth has an ideal surface configuration. The dental appliance provides the patient with the appearance of a perfect set of teeth and an ideal smile without a need to alter the dental structure of the patient's teeth.

Owner:DEN MAT HLDG

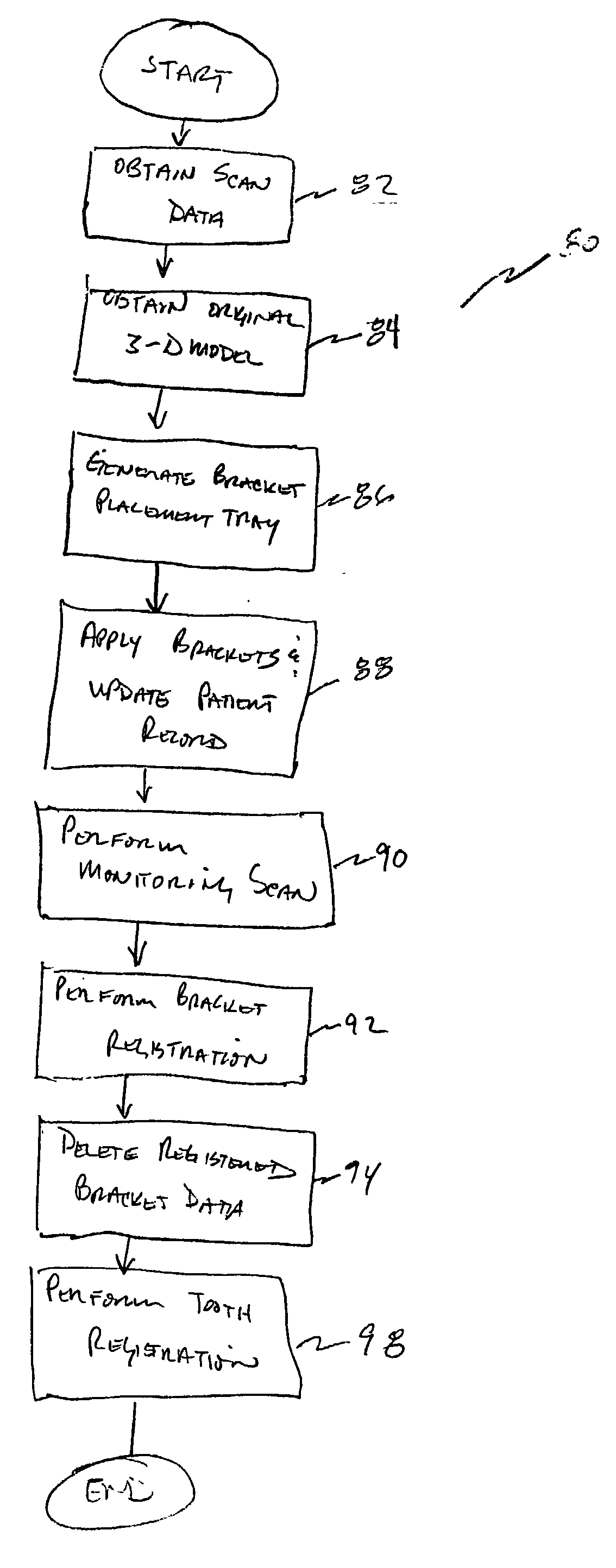

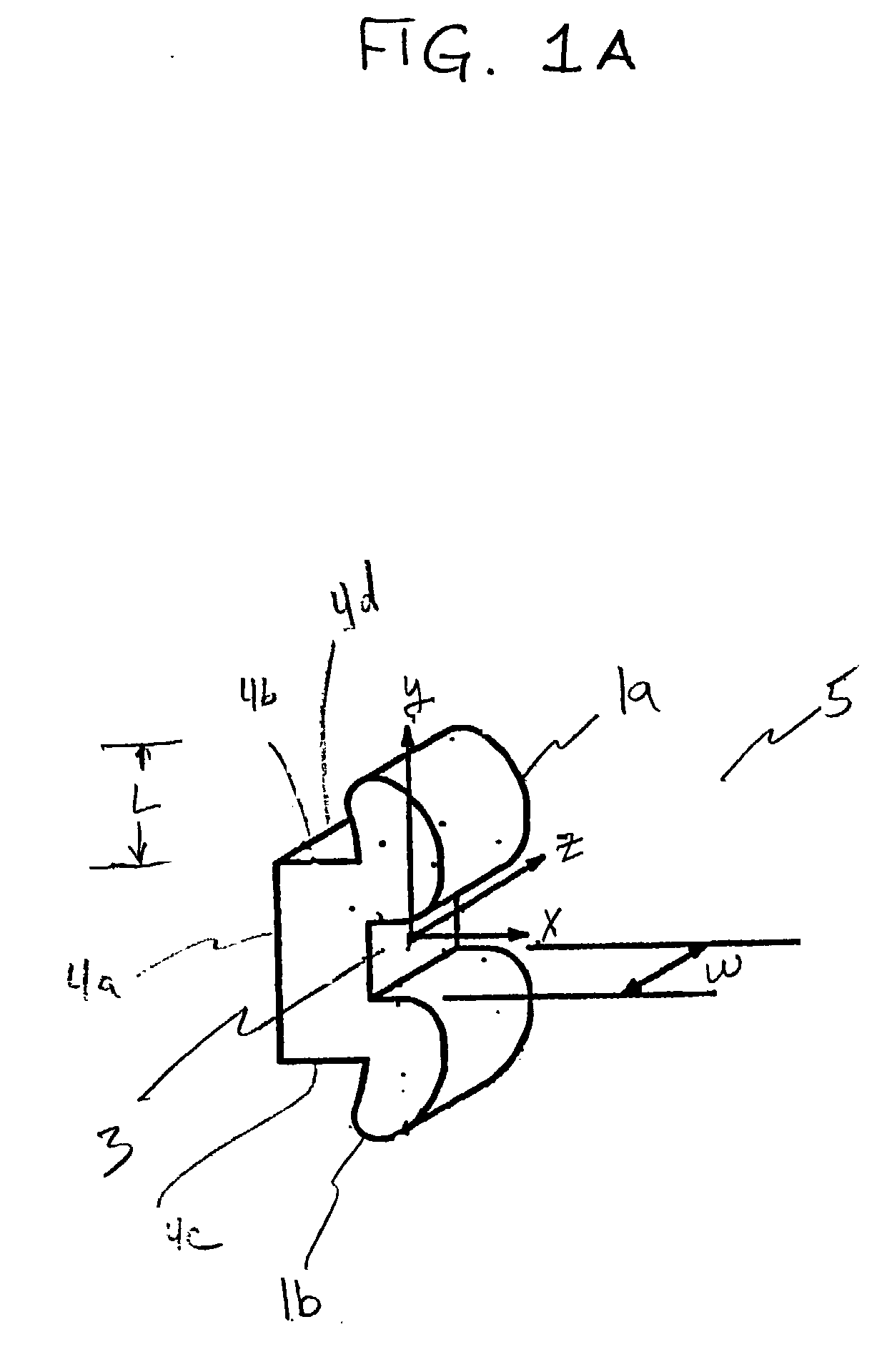

Method and apparatus for registering a known digital object to scanned 3-D model

Method and apparatus for registering an object of known predetermined geometry to scanned three dimensional data such that the object's location may be verified. Such a known object may comprise a less than ideal three-dimensional (3-D) digital object such as a tooth, a dental appliance (e.g., as a tooth bracket model) or other like object, including portions thereof. Knowledge of such an object's location is generally helpful in planning orthodontic treatment, particularly where the location of the object needs to be determined or confirmed or where incomplete or poor scan data is obtained. Aspects of the present invention provide methods of effectively verifying dental appliance location and displaying appliance locations using a computer and three-dimensional models of teeth.

Owner:ORAMETRIX

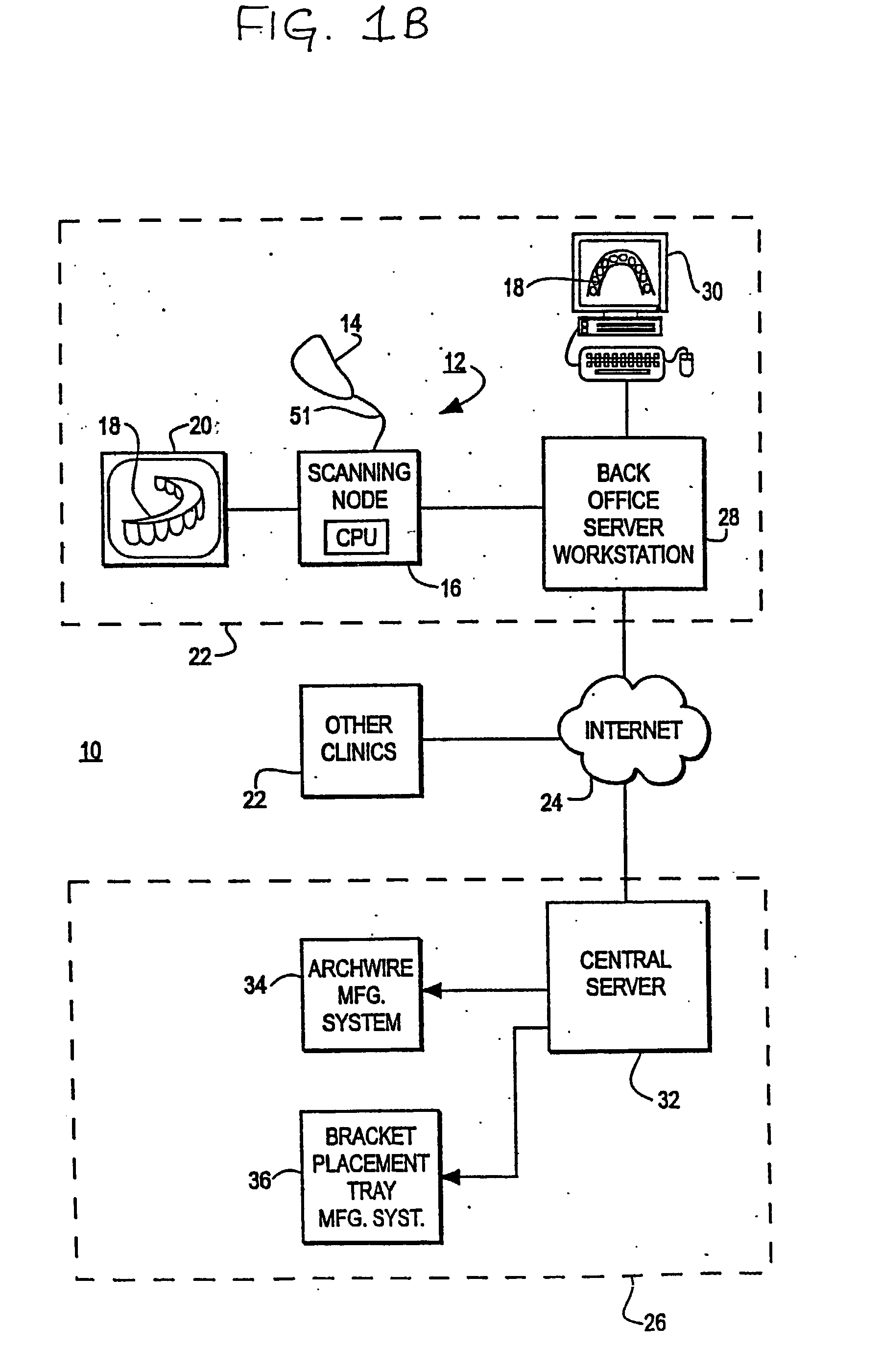

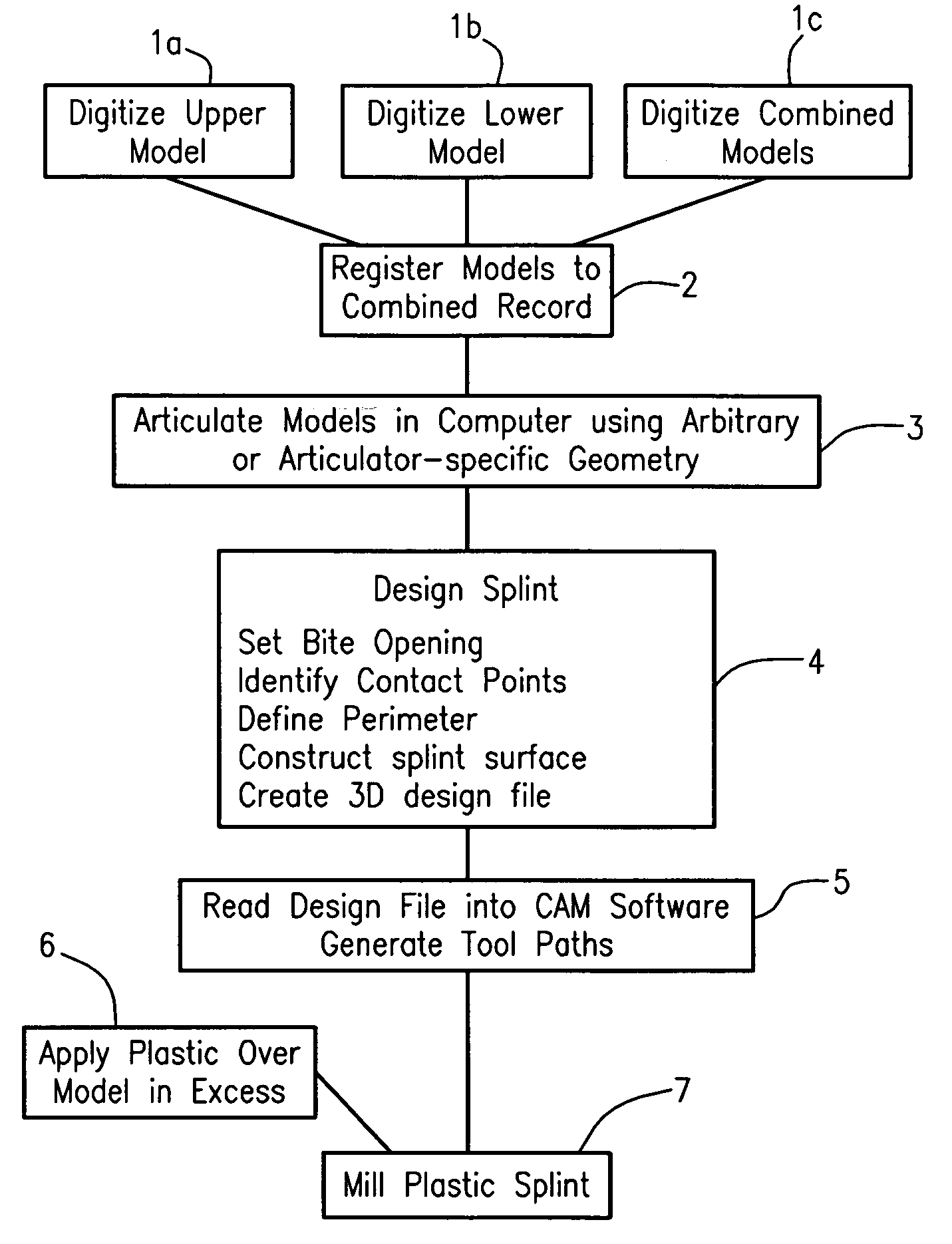

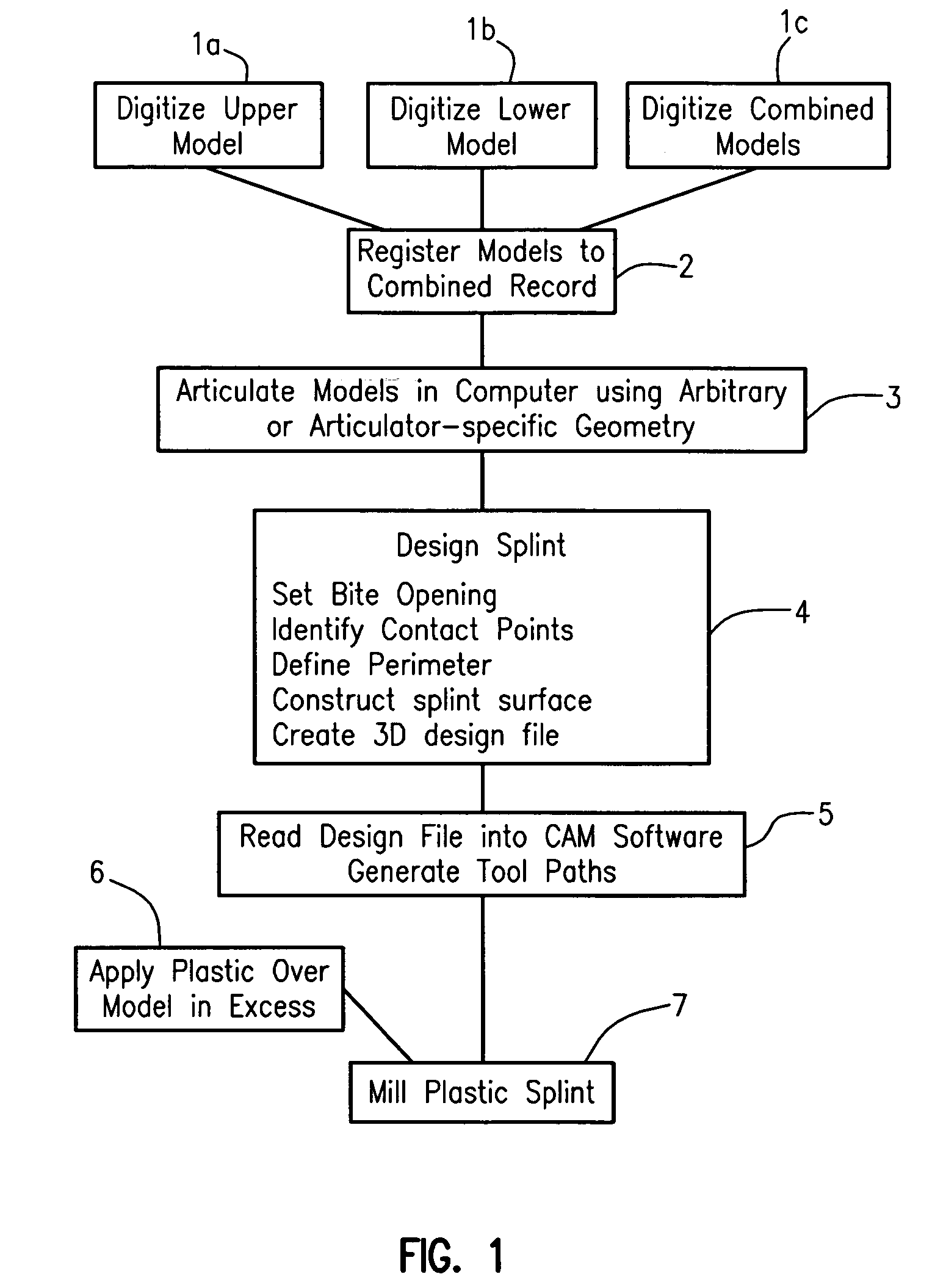

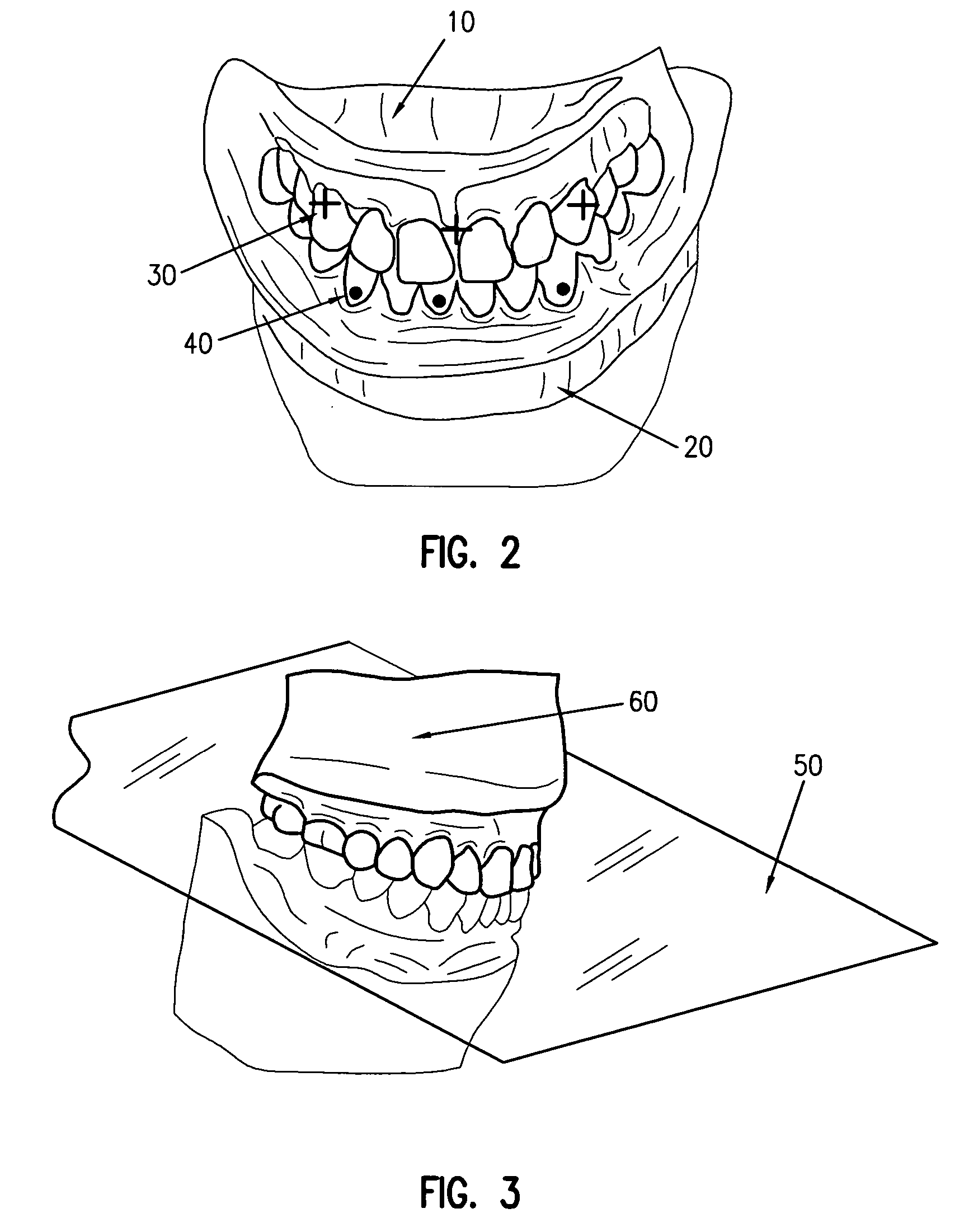

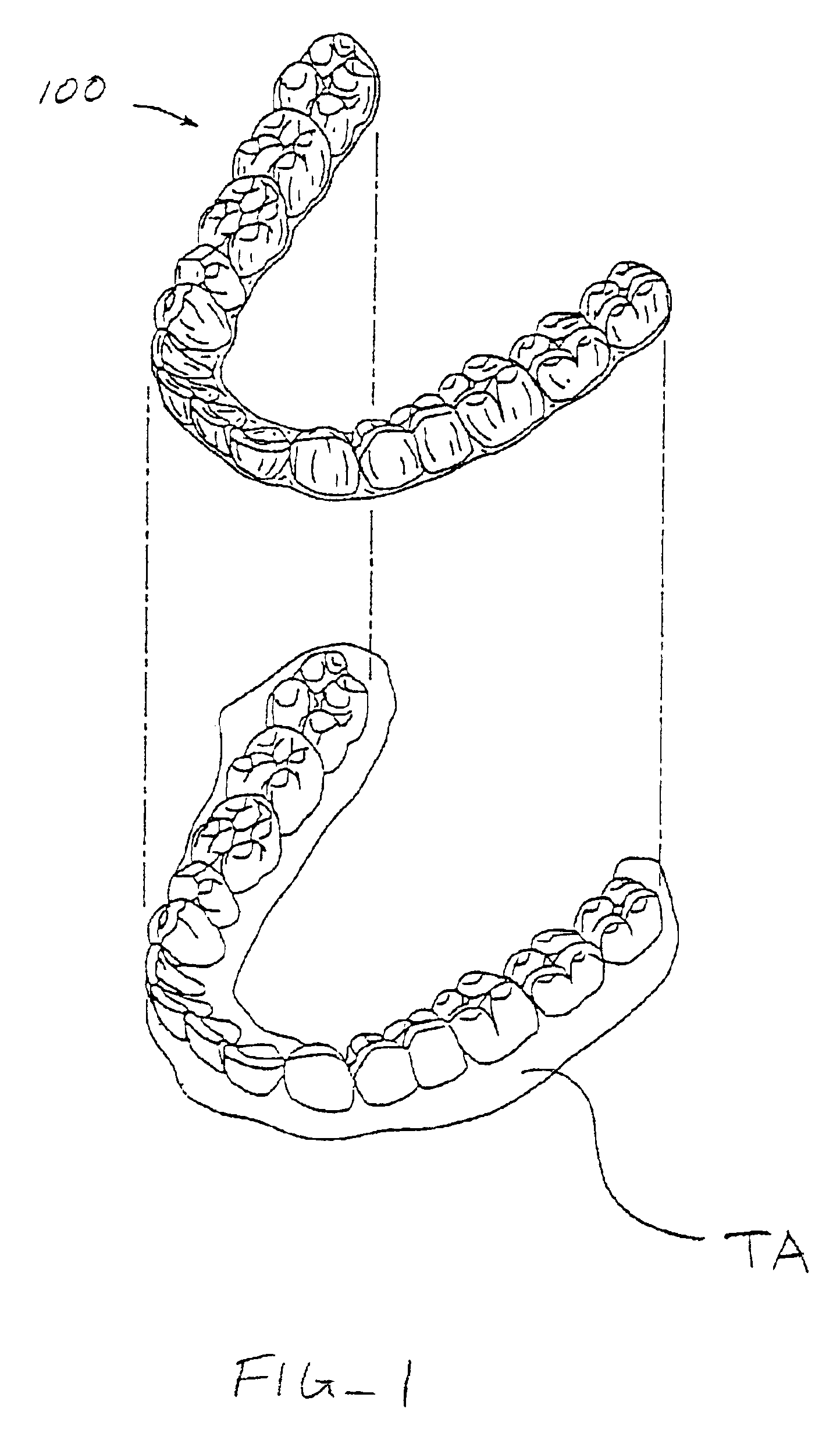

Digital manufacturing of removable oral appliances

InactiveUS20060003292A1Improved of final shapeReduce trimming timeMechanical/radiation/invasive therapiesOthrodonticsDental ArticulatorsCentric occlusion

A digitally-based method is described for the design and production of customized removable dental appliances. The plastic component of custom appliances is designed using software, and milled directly over a plaster model of the dentition. A patient's upper, lower, and bite-registered arches are digitized, registered to a bite or centric occlusion position, and articulated in software using either an average geometry or the geometry of a specific articulator. Appliance design is performed by defining the desired plastic surfaces and margins as dictated by the relative movement and positions of the arches as functionally required for a specific appliance. Standard CAM software is used to read the design file and command a multiaxis machine center to mill the plastic while directly on a plaster model.

Owner:GREAT LAKES ORTHODONTICS

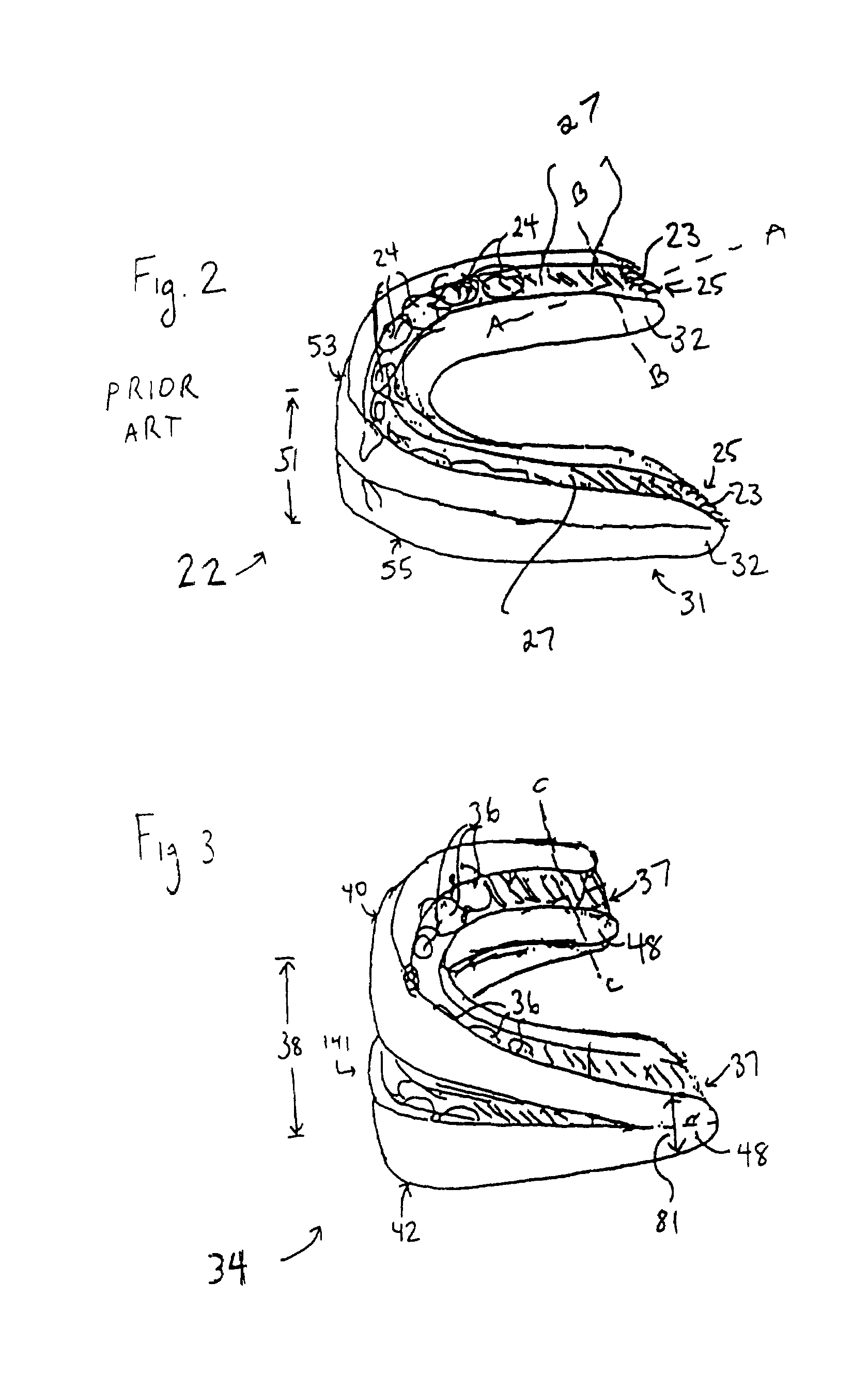

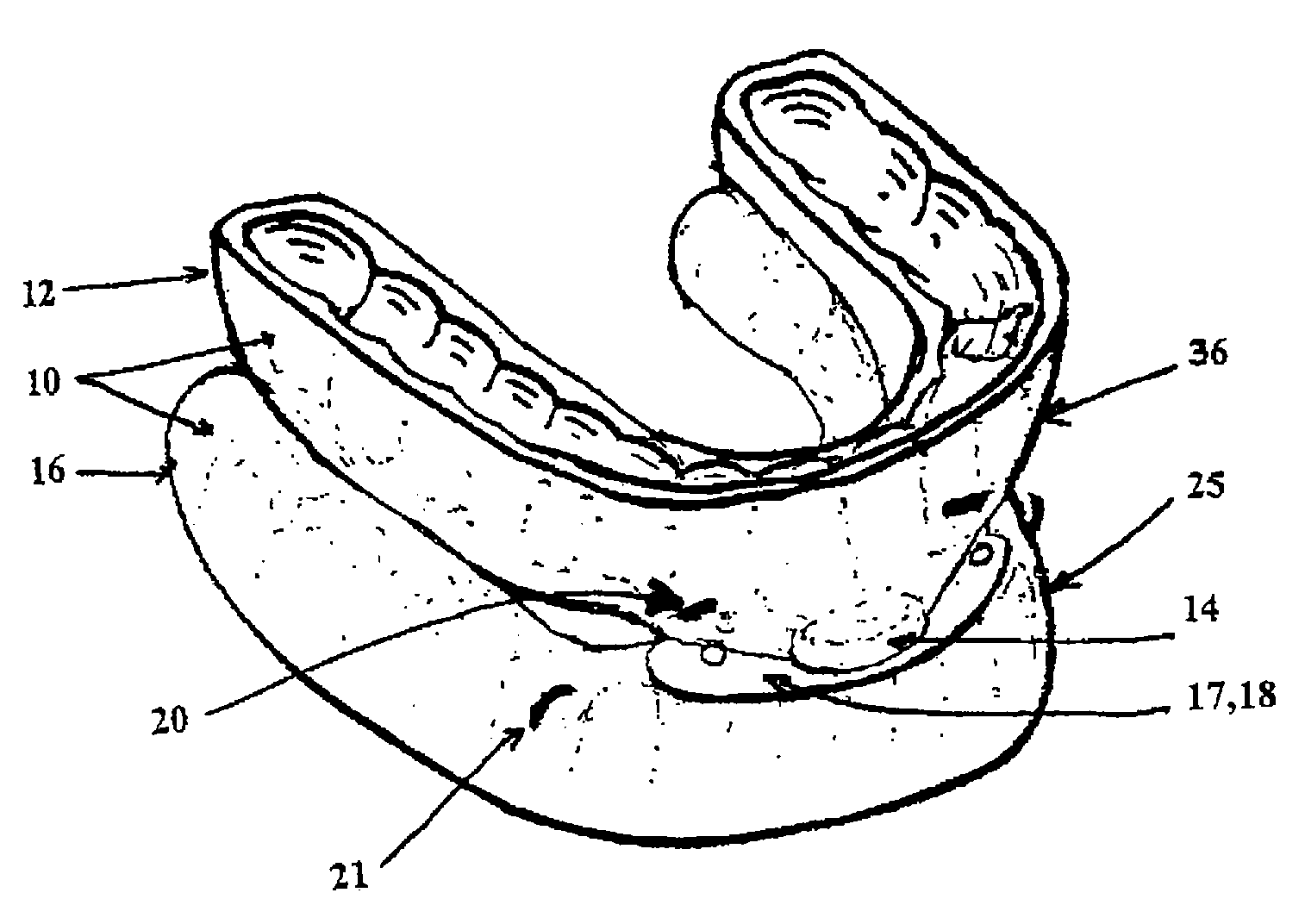

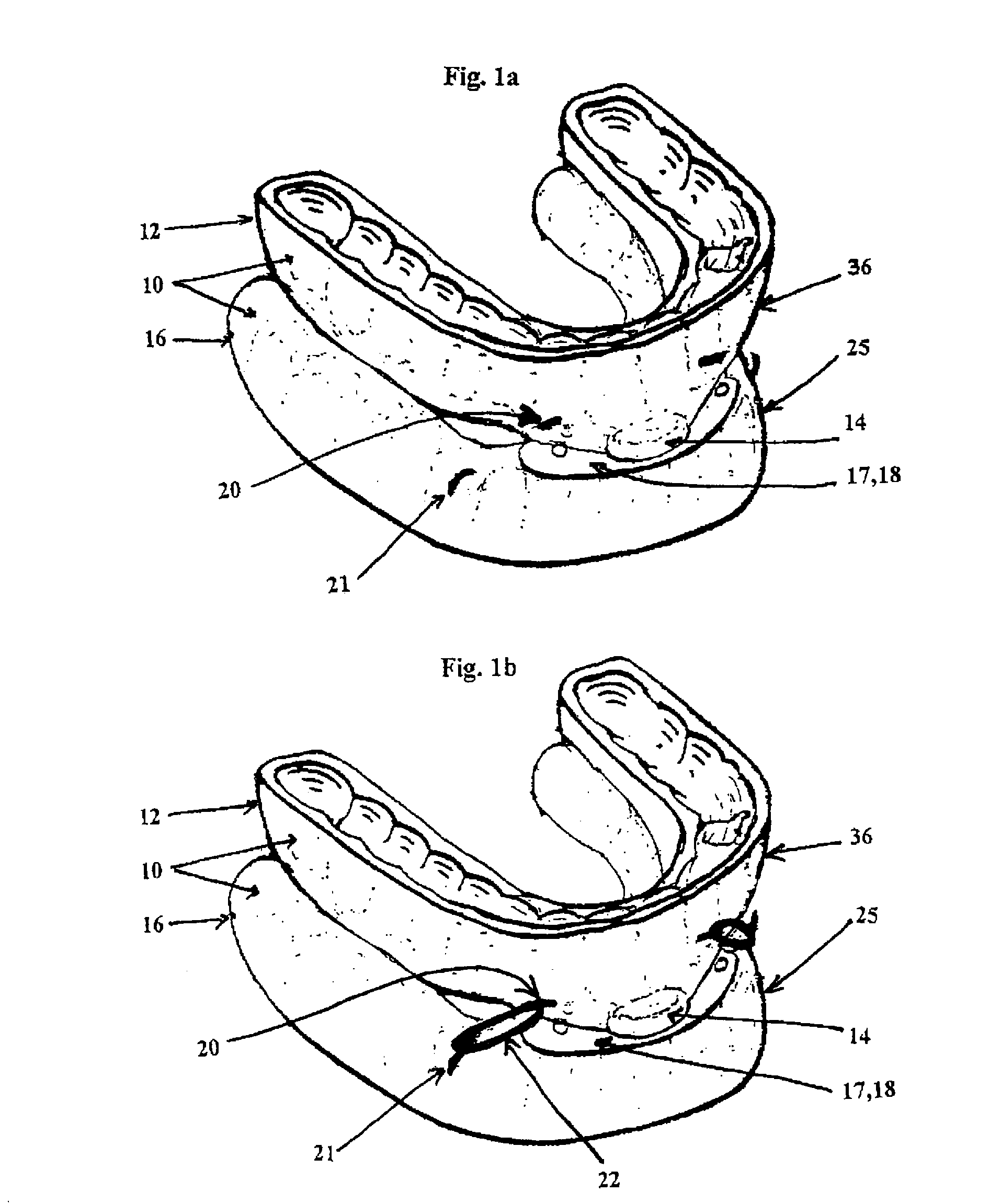

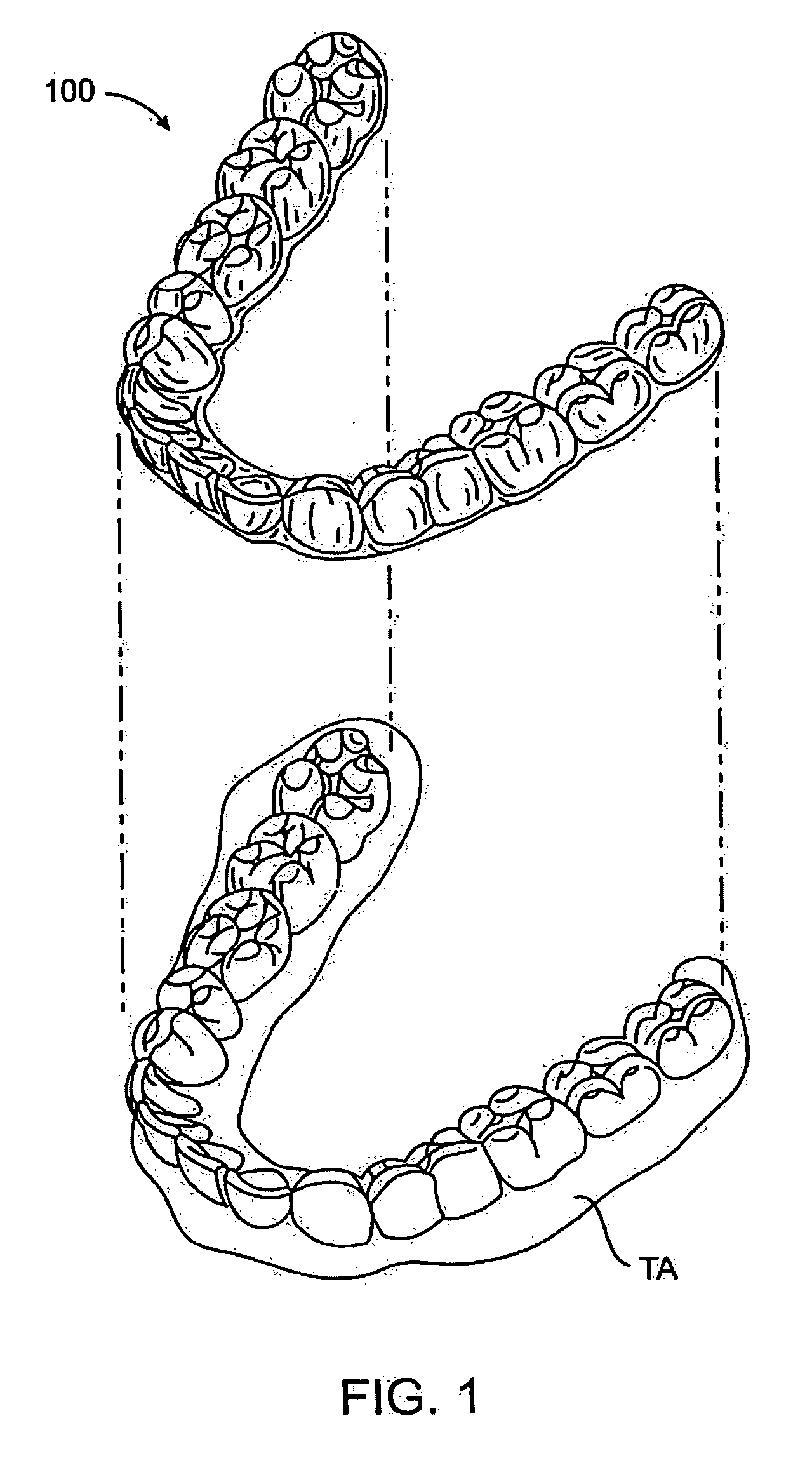

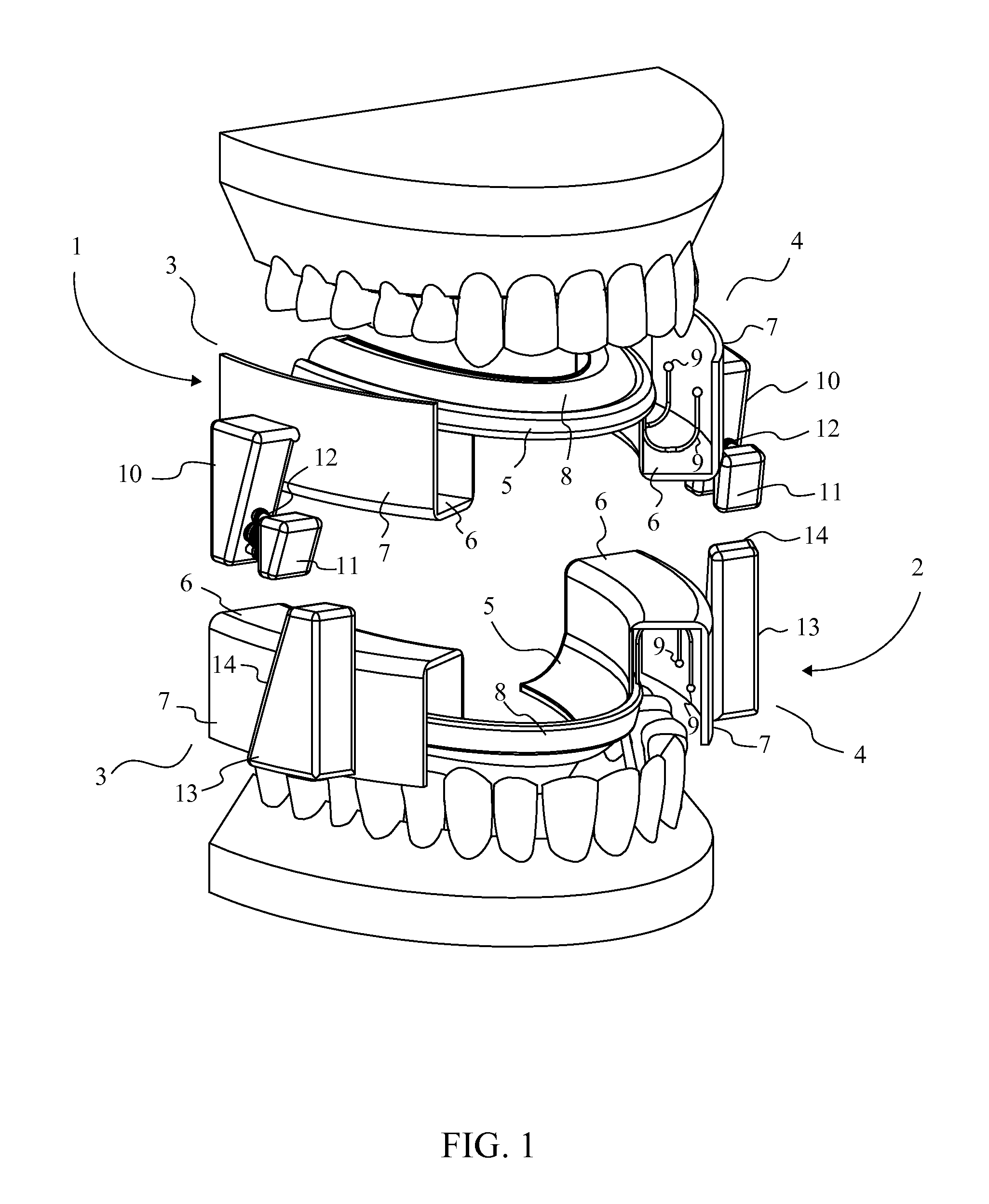

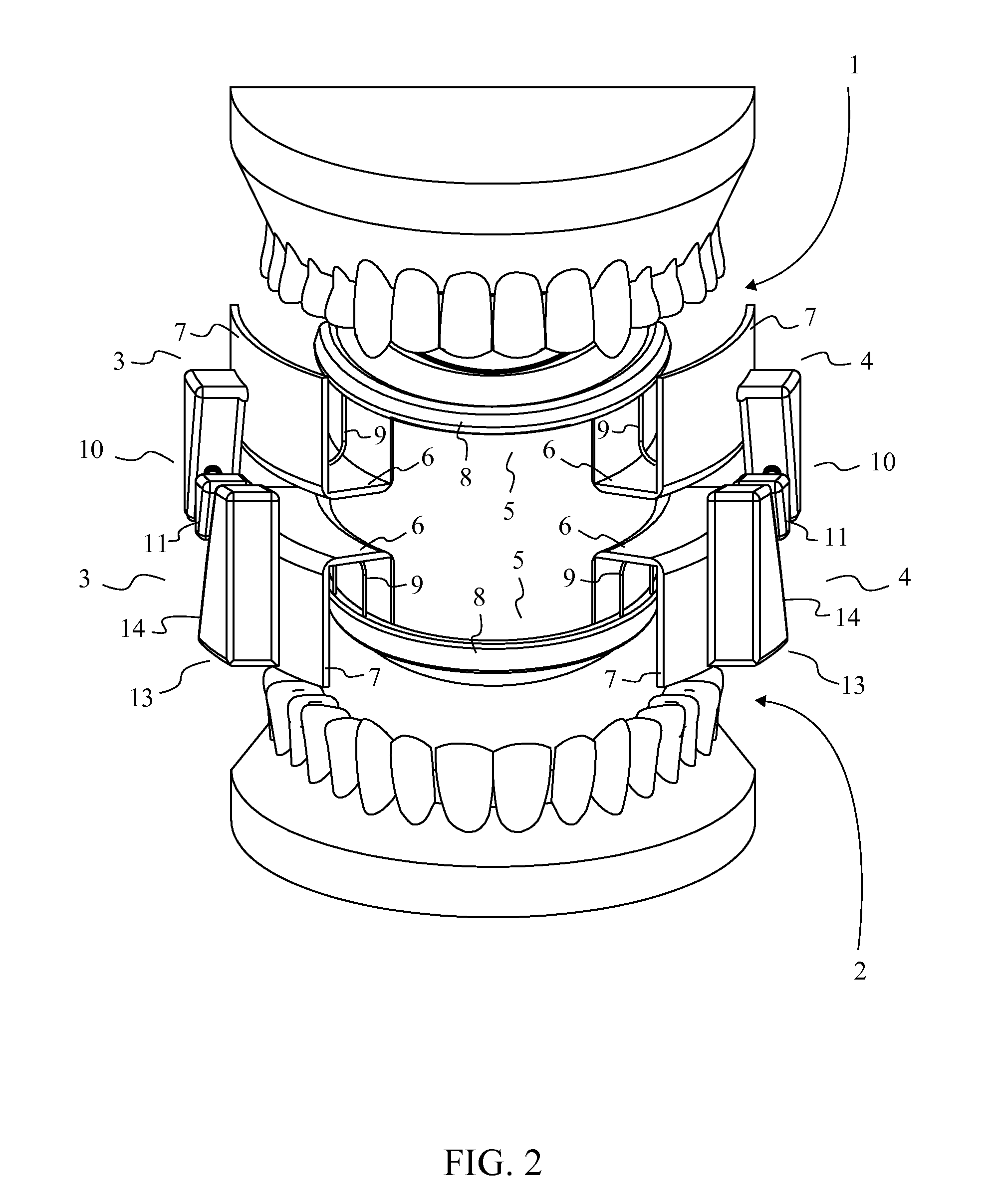

Dental appliance for the treatment of sleep disorders

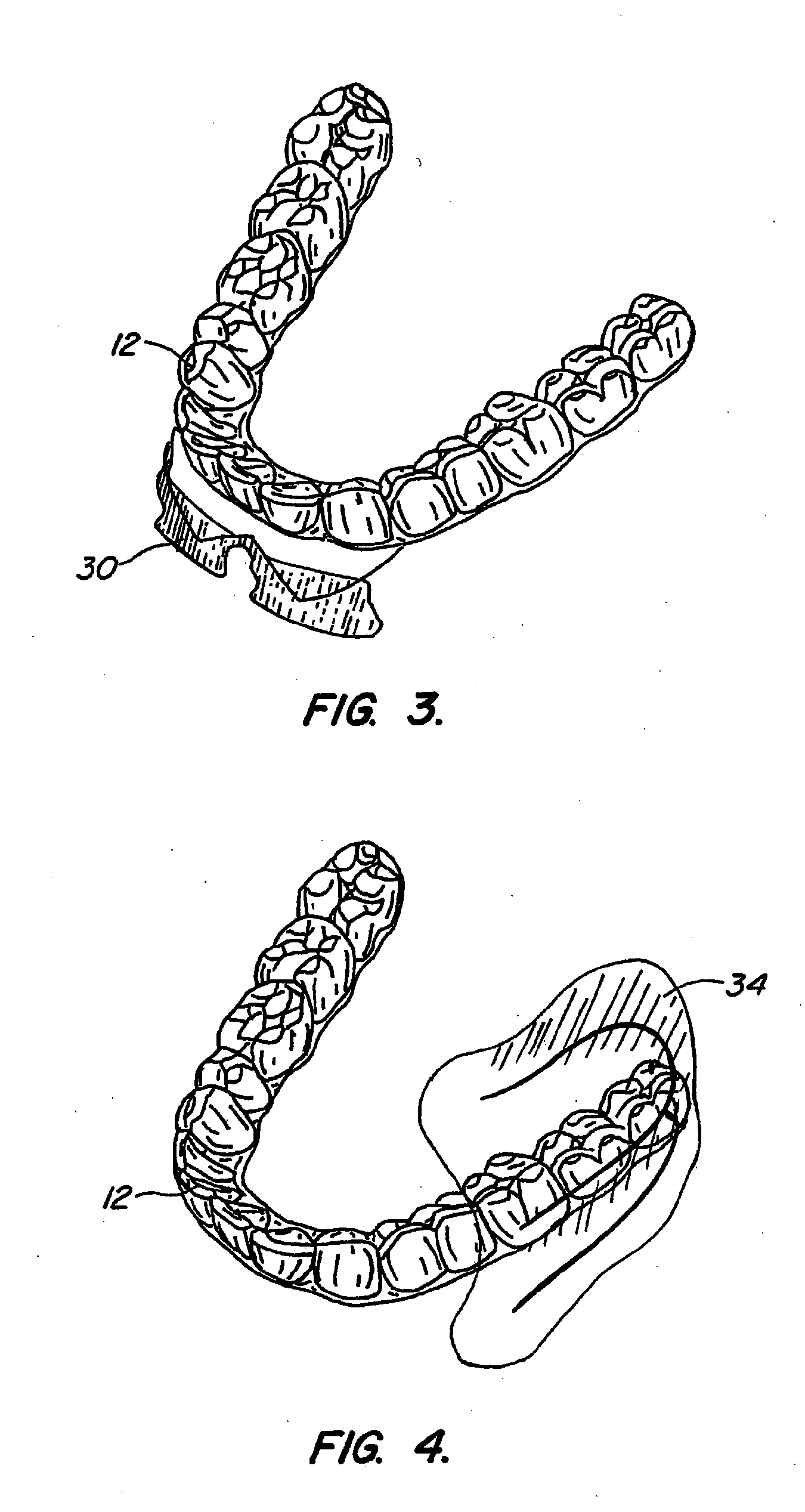

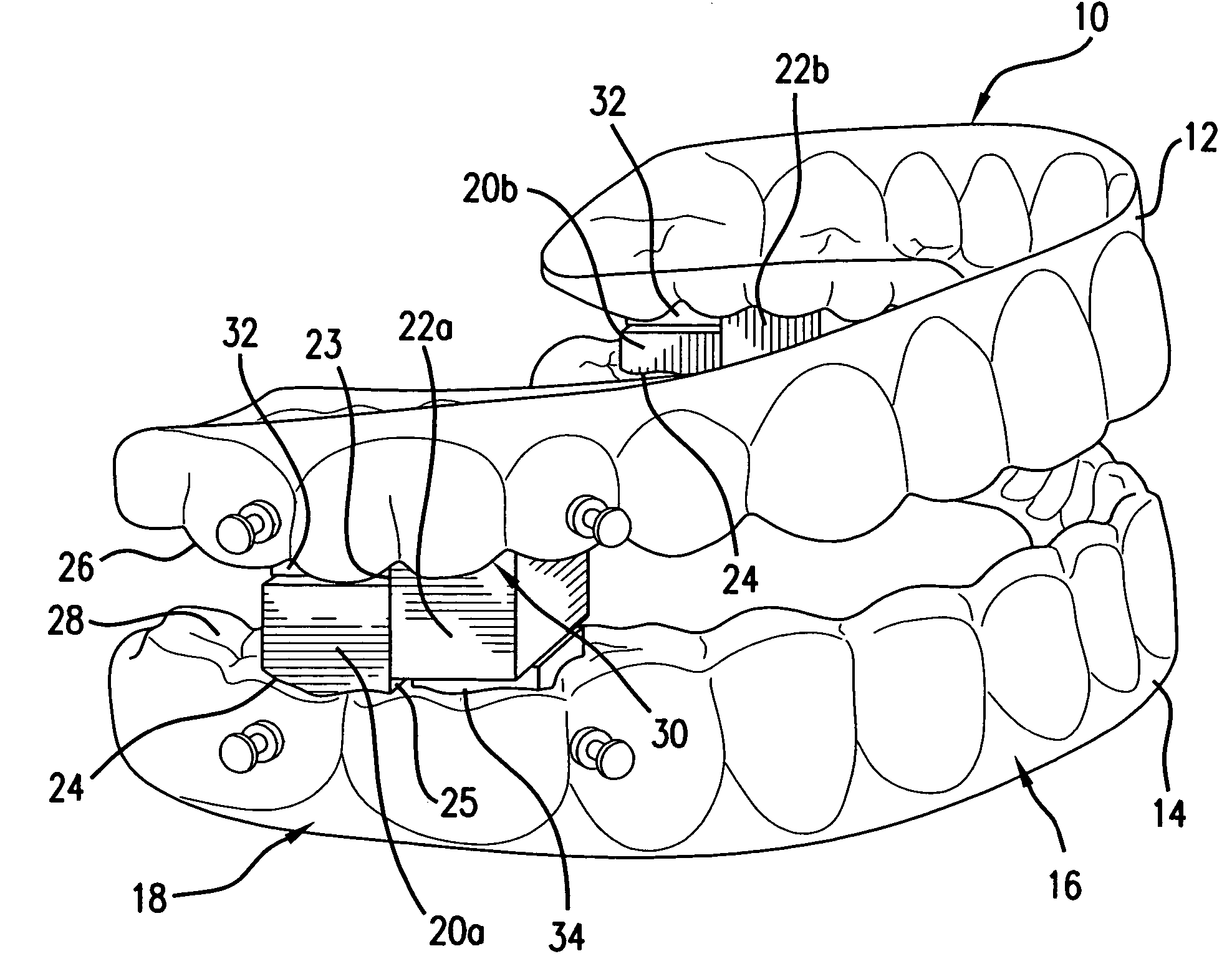

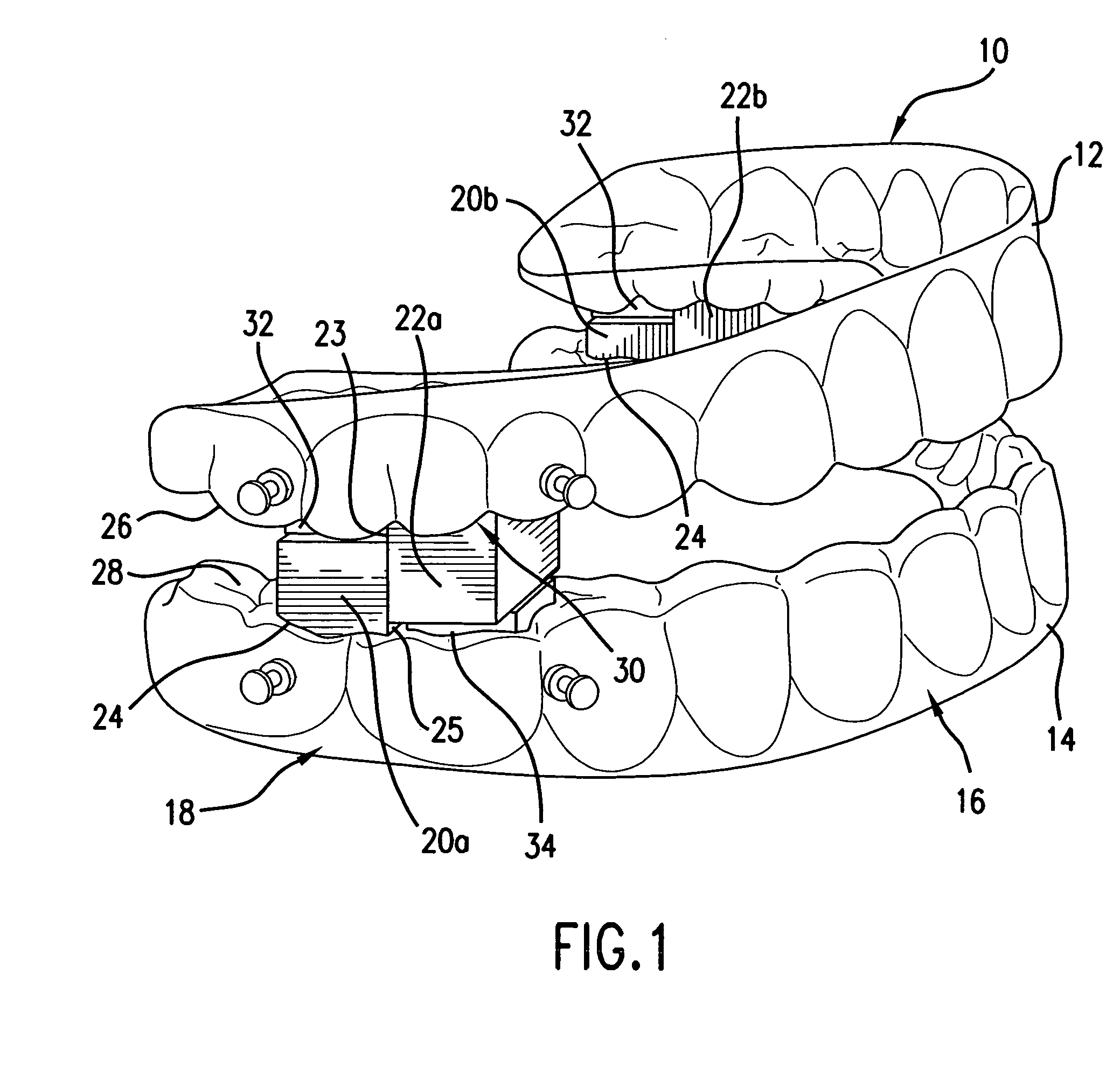

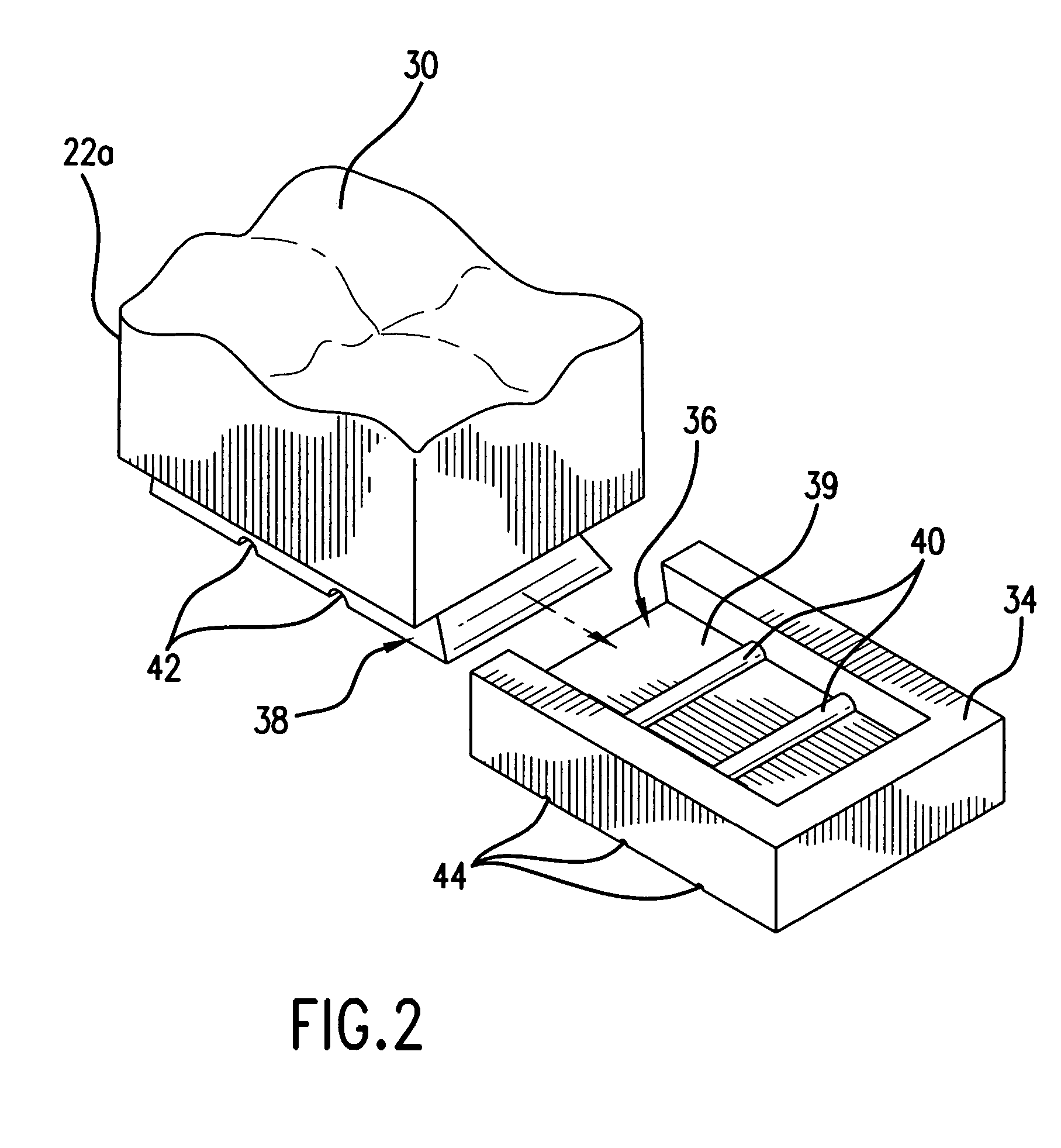

InactiveUS6983752B2Prevent backward movementMandible lateral and vertical flexibilityTeeth fillingSurgeryMandibular toothDental appliances

An upper tray for receiving the maxillary teeth and a lower tray for receiving the mandibular teeth. Upper bite pads carried by the upper tray and lower bite pads carried by the lower tray. The lower bite pads located anterior to the upper bite pads so that the lower bite pads are free to engage the maxillary occlusal surface of the upper tray, and the upper bite pads are free to engage the mandibular occlusal surface of the lower tray to maintain the occlusal surfaces of the trays in a predetermined spaced relationship. The upper and lower bite pads are arranged to abut each other for advancing the mandible and preventing posterior movement of the mandible while allowing limited vertical and lateral movement. The bite pads are releasably carried by the trays for interchanging different sizes of pads to customize the appliance to the needs of the user's mouth.

Owner:SLEEP SOUND SERVICES ZZZ

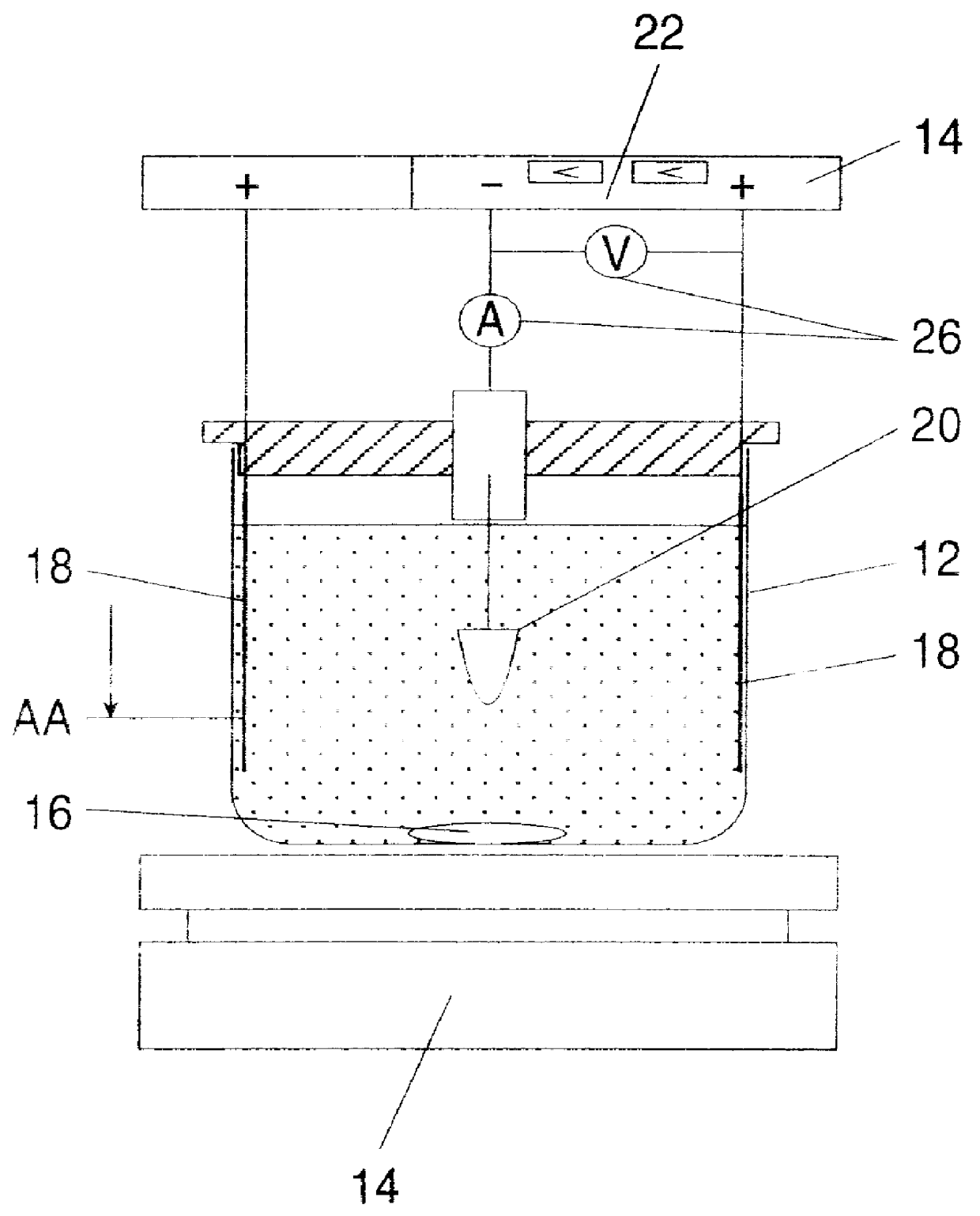

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

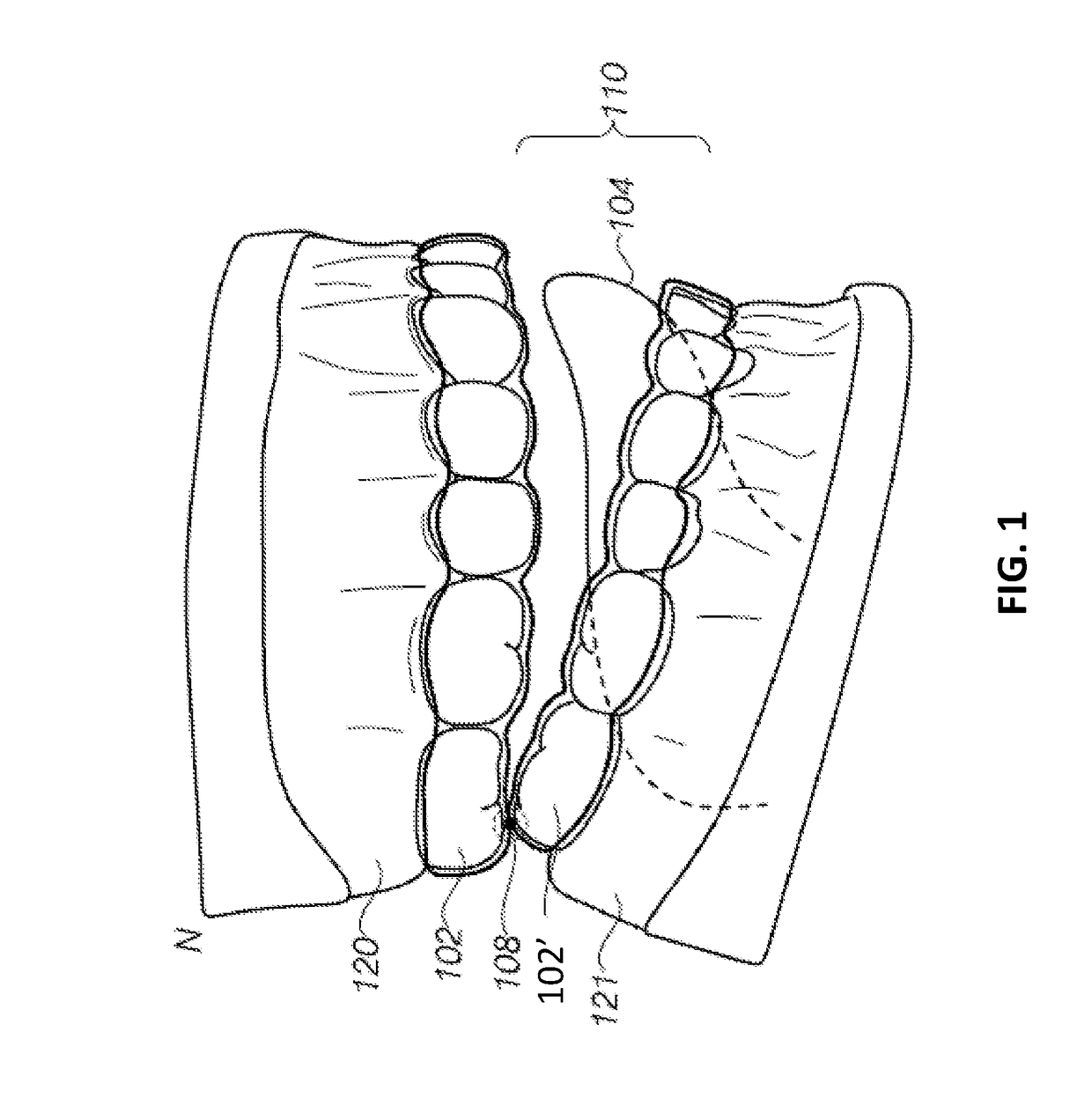

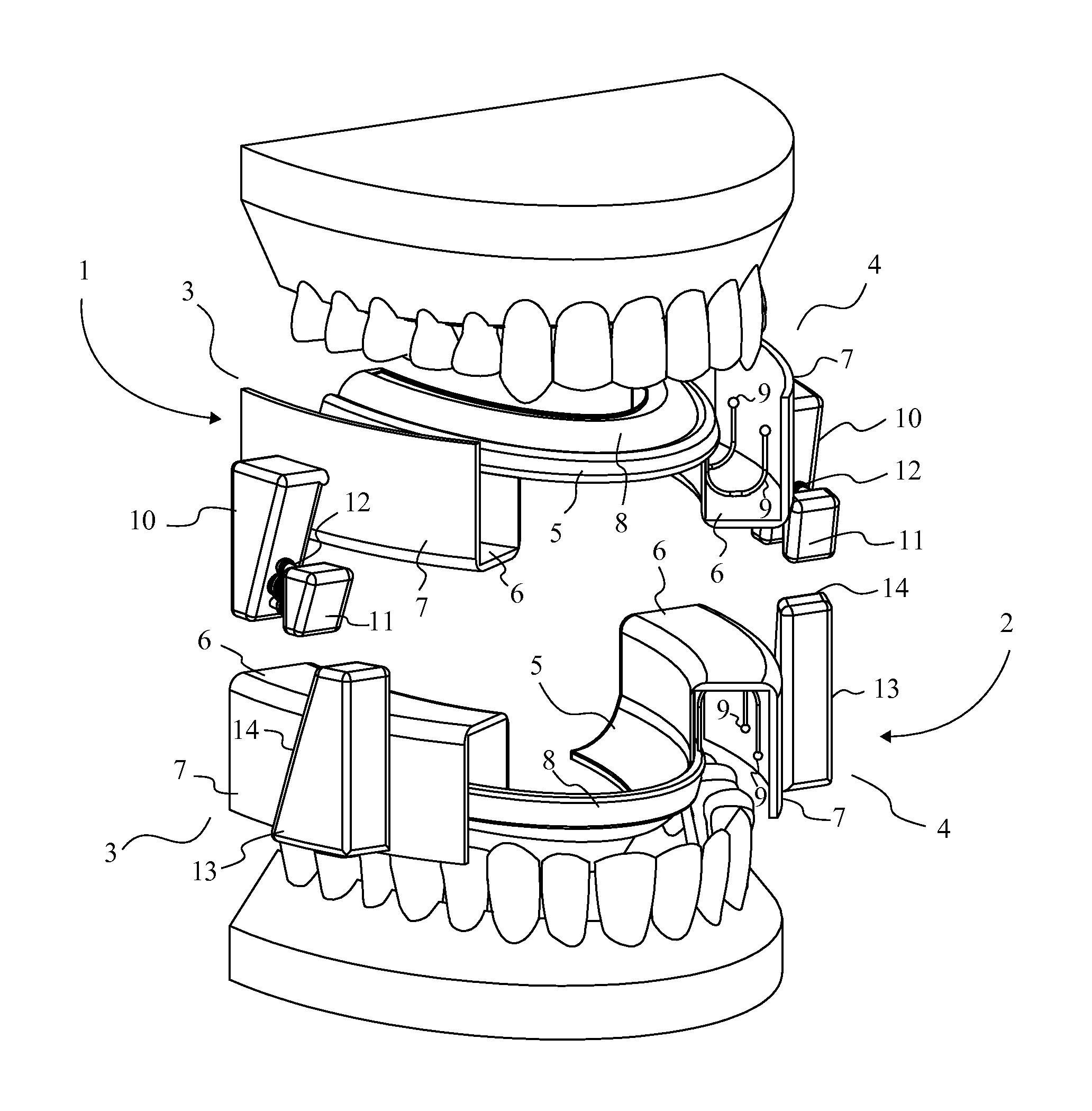

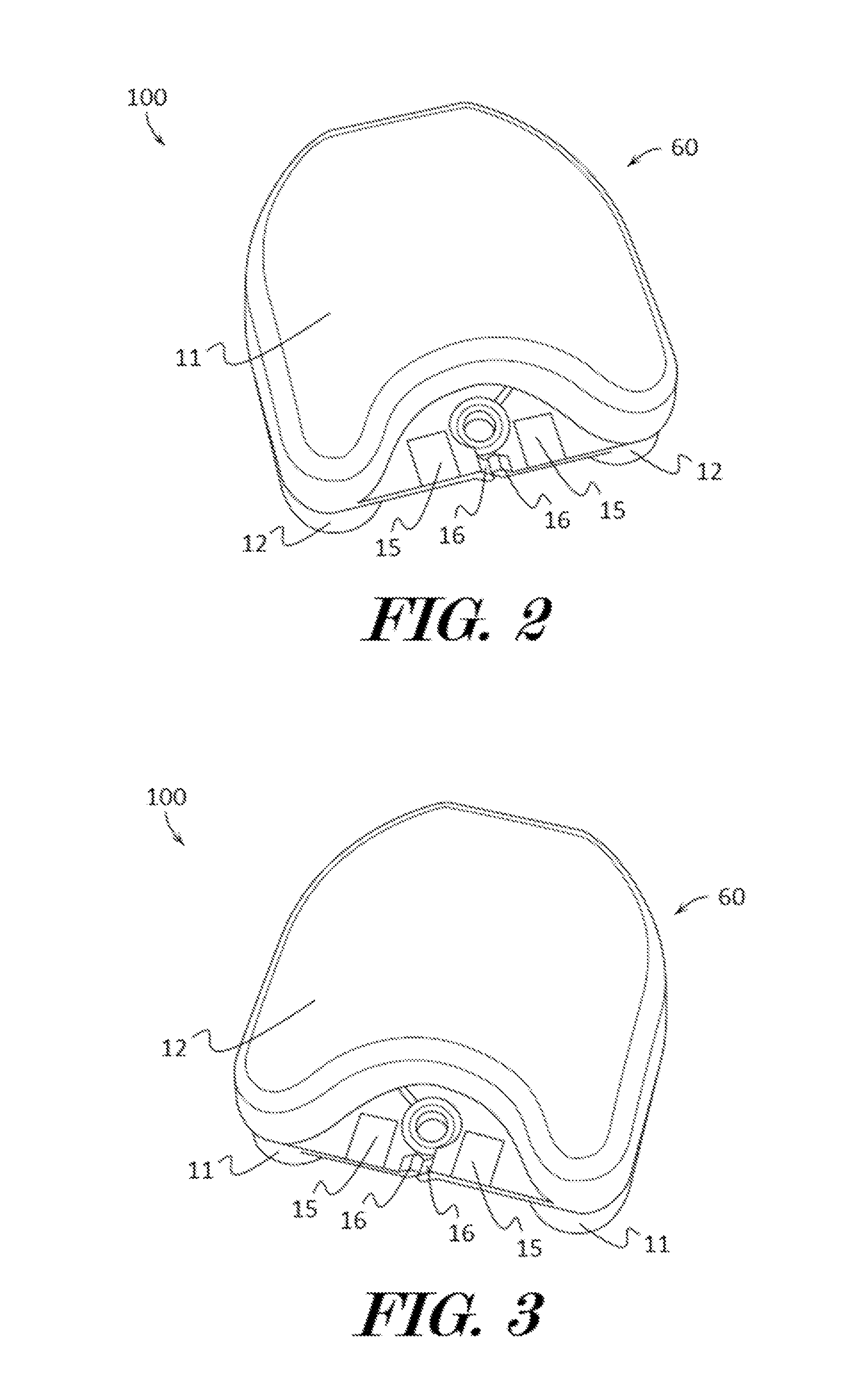

Dental appliance having an altered vertical thickness between an upper shell and a lower shell with an integrated hinging mechanism to attach an upper shell and a lower shell and a system and a method for treating malocclusions

ActiveUS7458810B2Increasing the thicknessMaintain positionAdditive manufacturing apparatusOthrodonticsOpen biteDecreased thickness

A dental appliance having increased or decreased thickness between an upper shell and a lower shell in combination with a hinging mechanism and a system and a method for treating malocclusions are provided. The dental appliance may have an upper shell and a lower shell which receive upper teeth and lower teeth, respectively, of a user. The upper shell and the lower shell may be attached at a hinge. The dental appliance may have an increased thickness between the upper shell and the lower shell as well as an increased thickness of the hinge. In an embodiment, the dental appliance may have a decreased vertical thickness and an insertable hinging mechanism. The dental appliance may then extend treatment of malocclusions to the rear teeth of the user and may correct a dental condition, such as, for example, overbite, overjet, open bite, crowding, rotations, spacing, cross-bites, gummy smiles and temporomandibular joint problems.

Owner:ORTHO TAIN INC

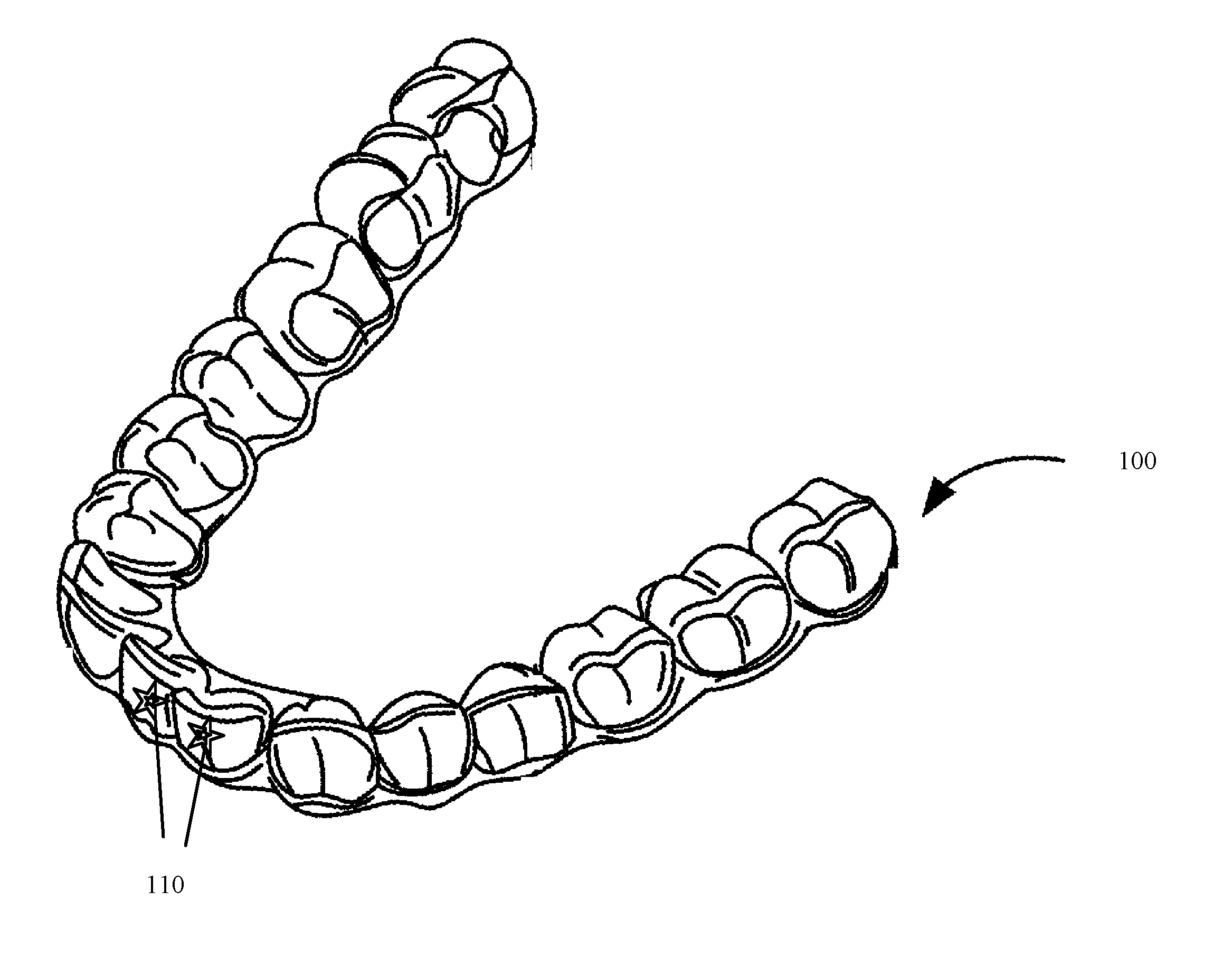

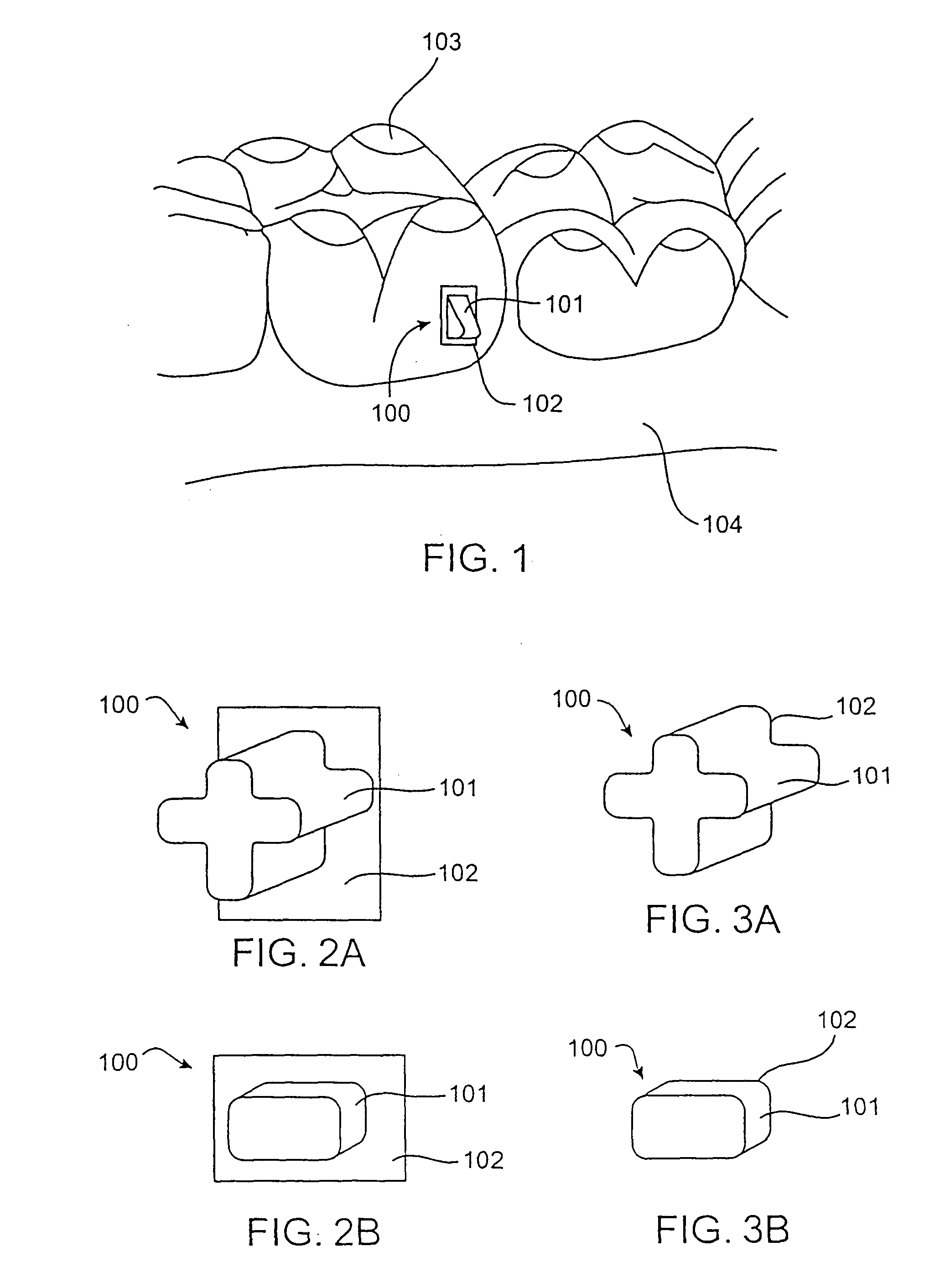

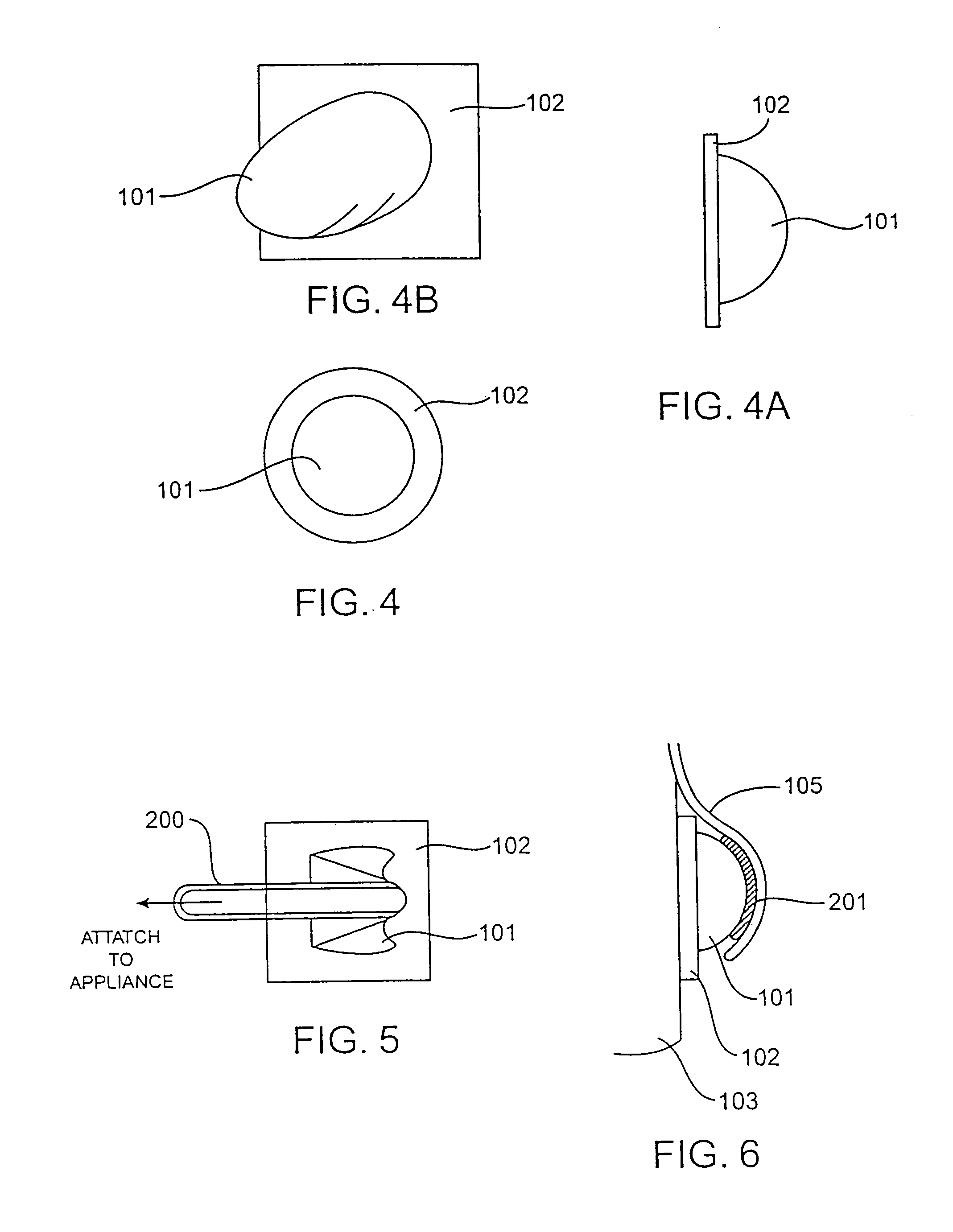

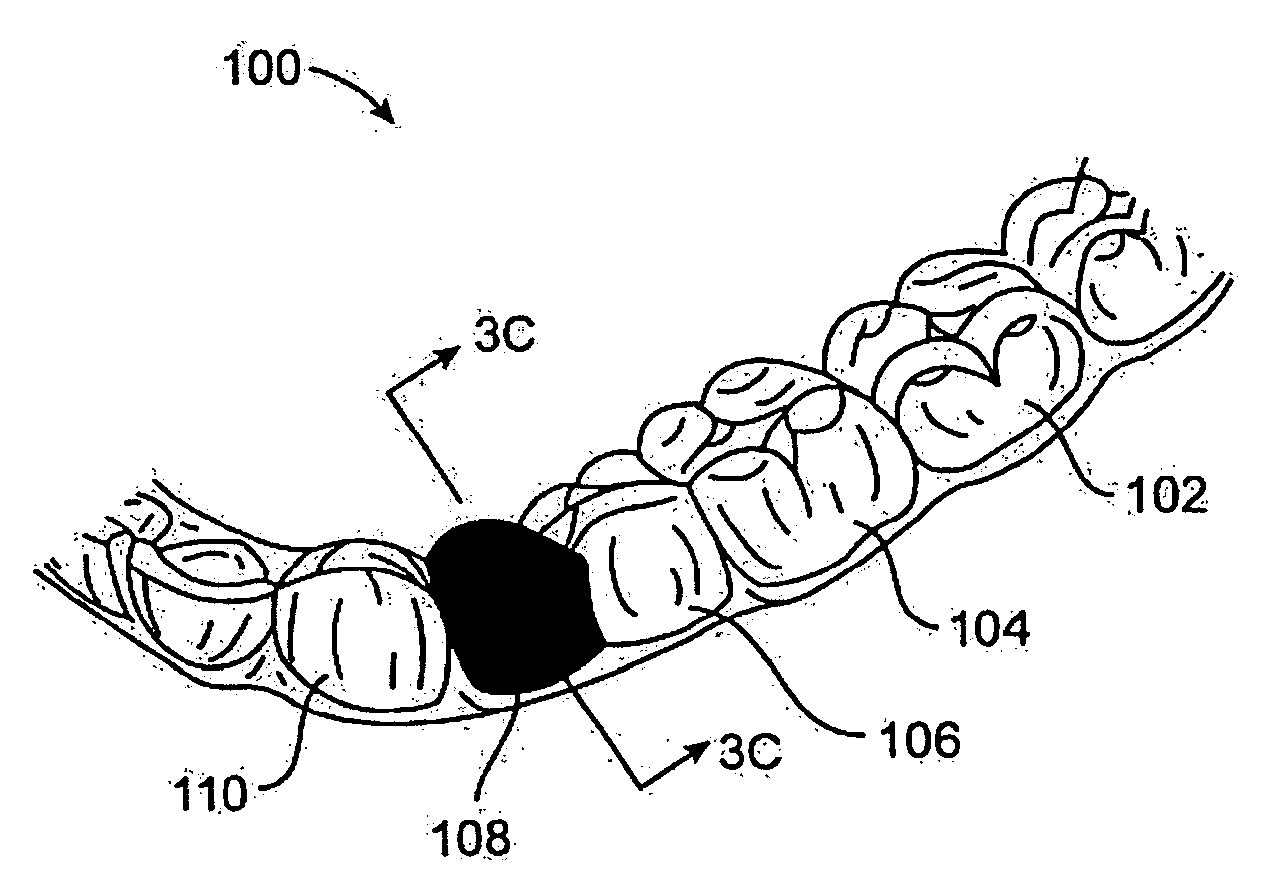

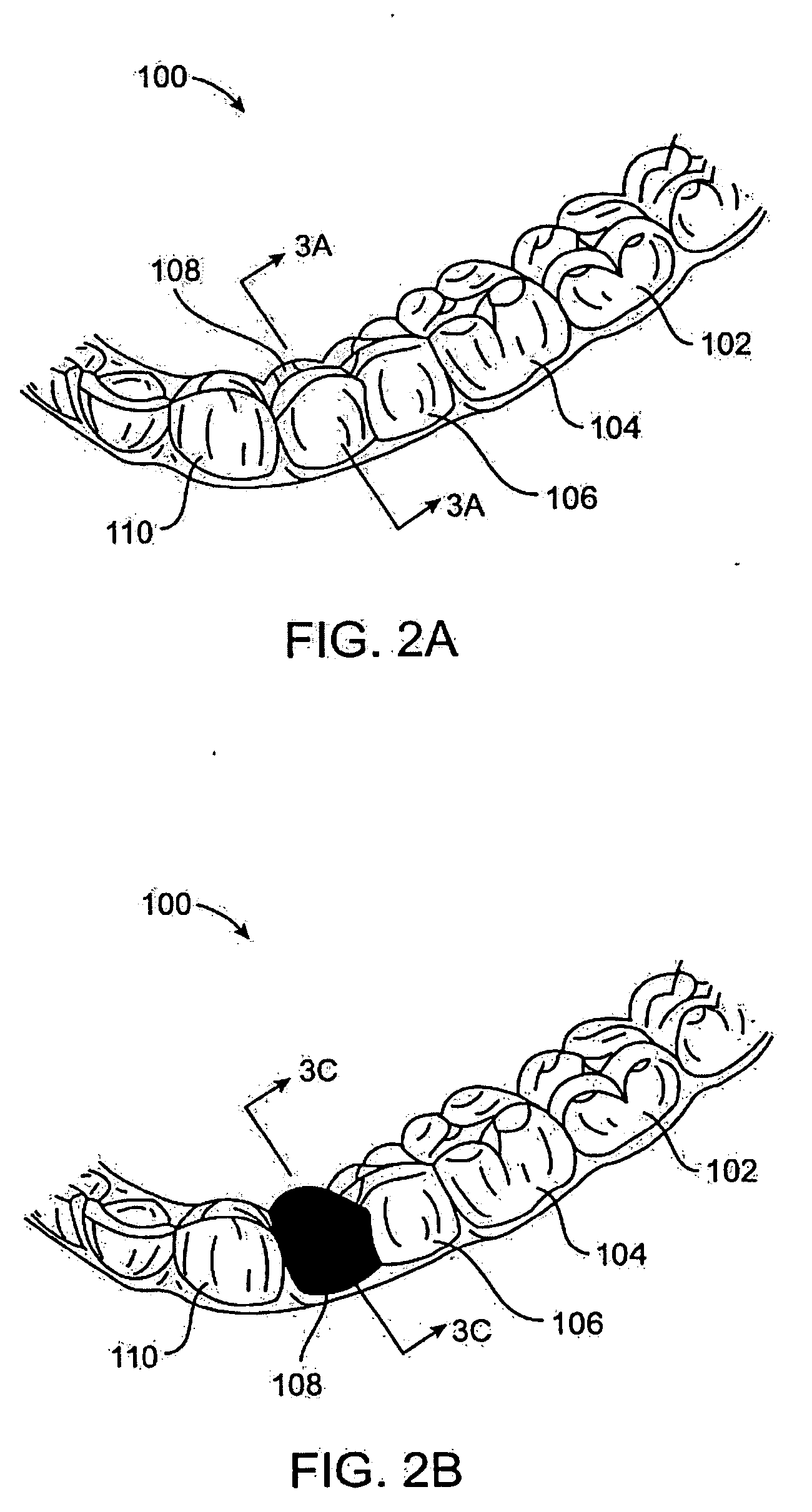

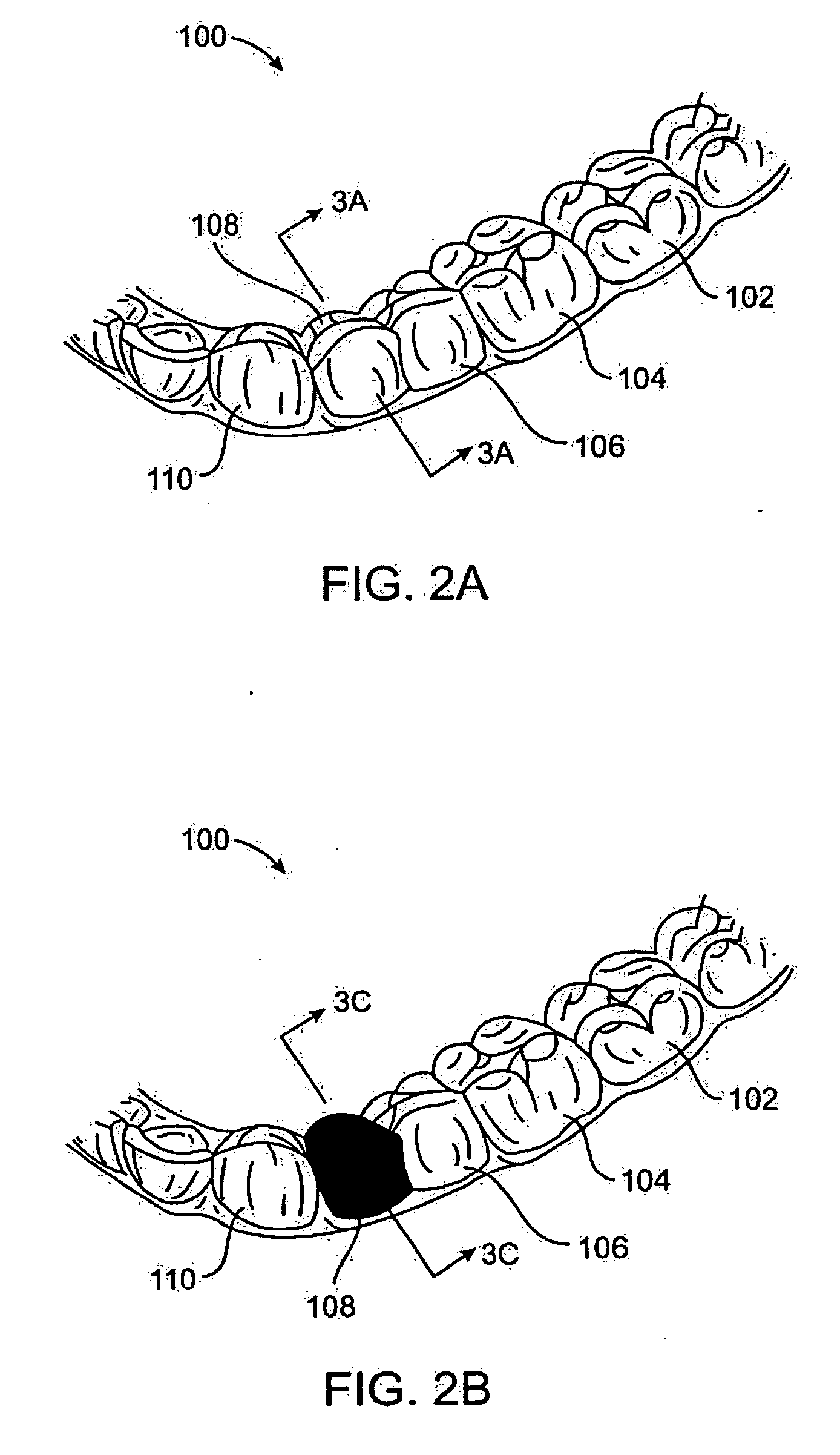

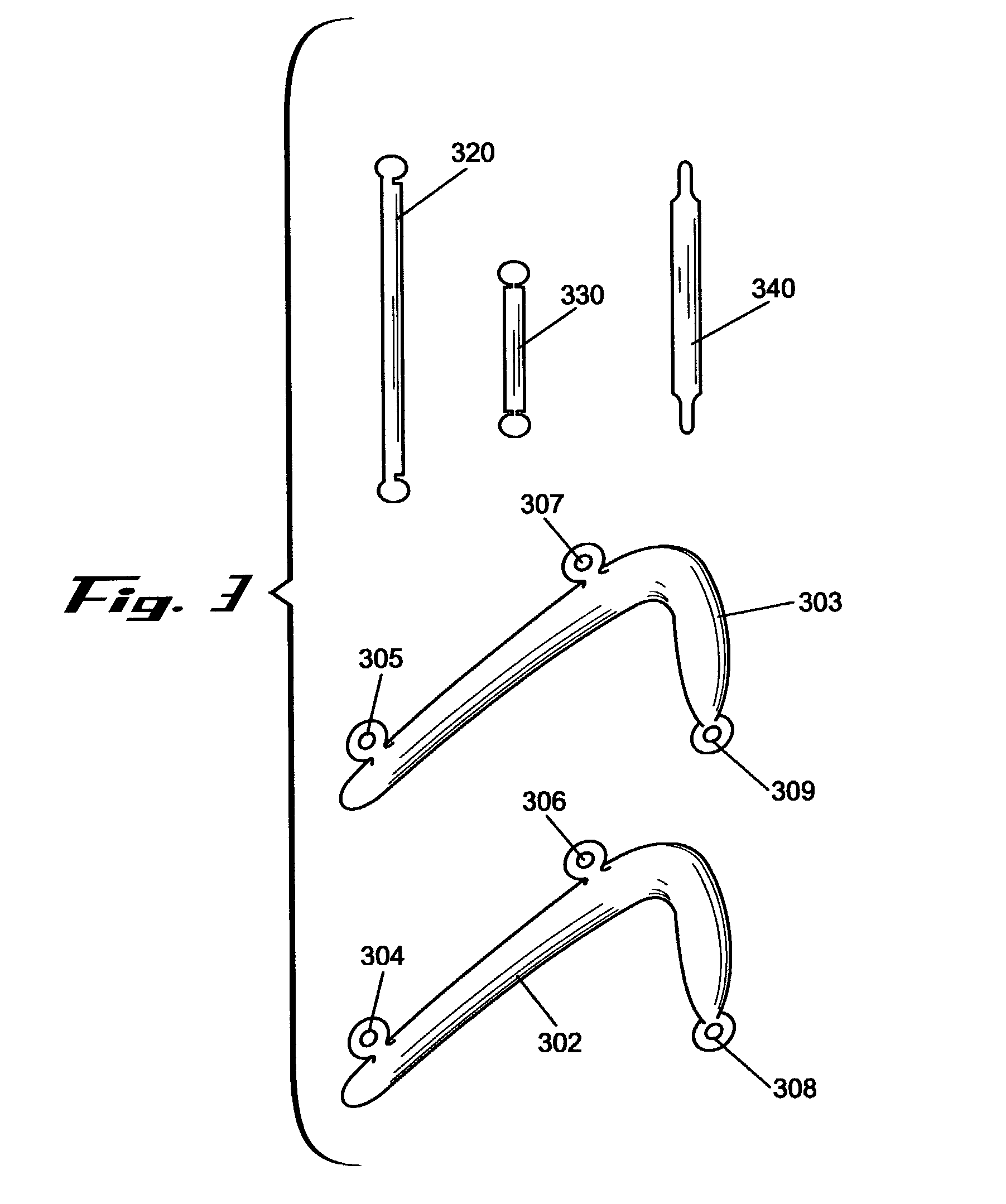

Attachment devices and methods for a dental appliance

InactiveUS7125248B2Sufficient forceAppropriate physical leverageImpression capsAdditive manufacturing apparatusOrthodonticsDental appliances

Owner:ALIGN TECH

Method and apparatus for constructing crowns, bridges and implants for dental use

A method, apparatus, and article of manufacture is disclosed for providing a dental crowns using electronic models, and more particularly to a method, apparatus, and article of manufacture for creating dental crowns using a lost-wax manufacturing process from electronic model files corresponding to patient teeth impressions and corresponding electronic models for tooth crowns. The system and method permit the electronic generation and specification of crown, bridge, and implant dental appliances that may be specified in an industry standard file specification. This specification is utilized in a rapid prototyping process to generate a wax impression for the appliance that may then be fabricated using standard lost-wax fabrication techniques.

Owner:NAT DENTEX LLC

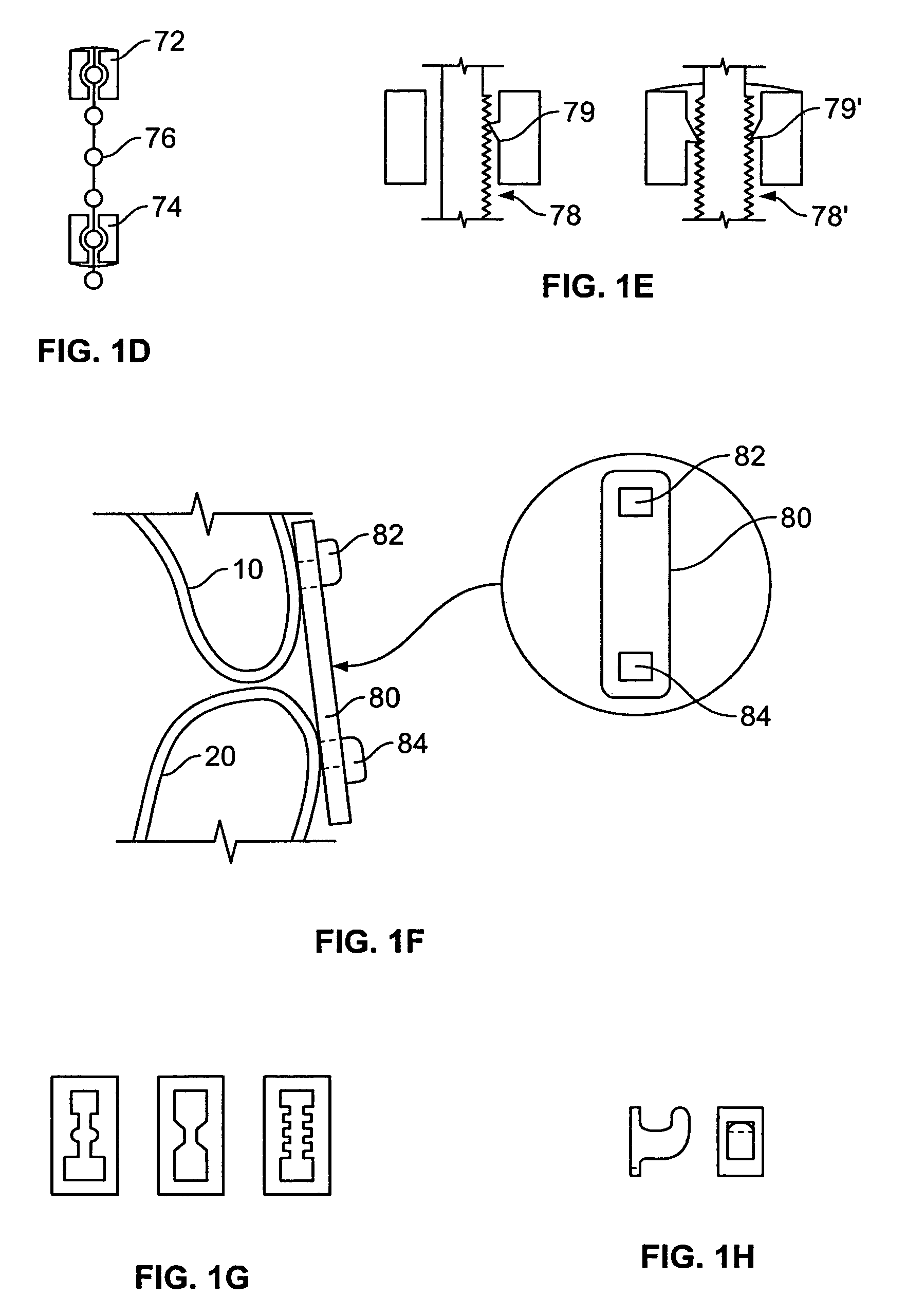

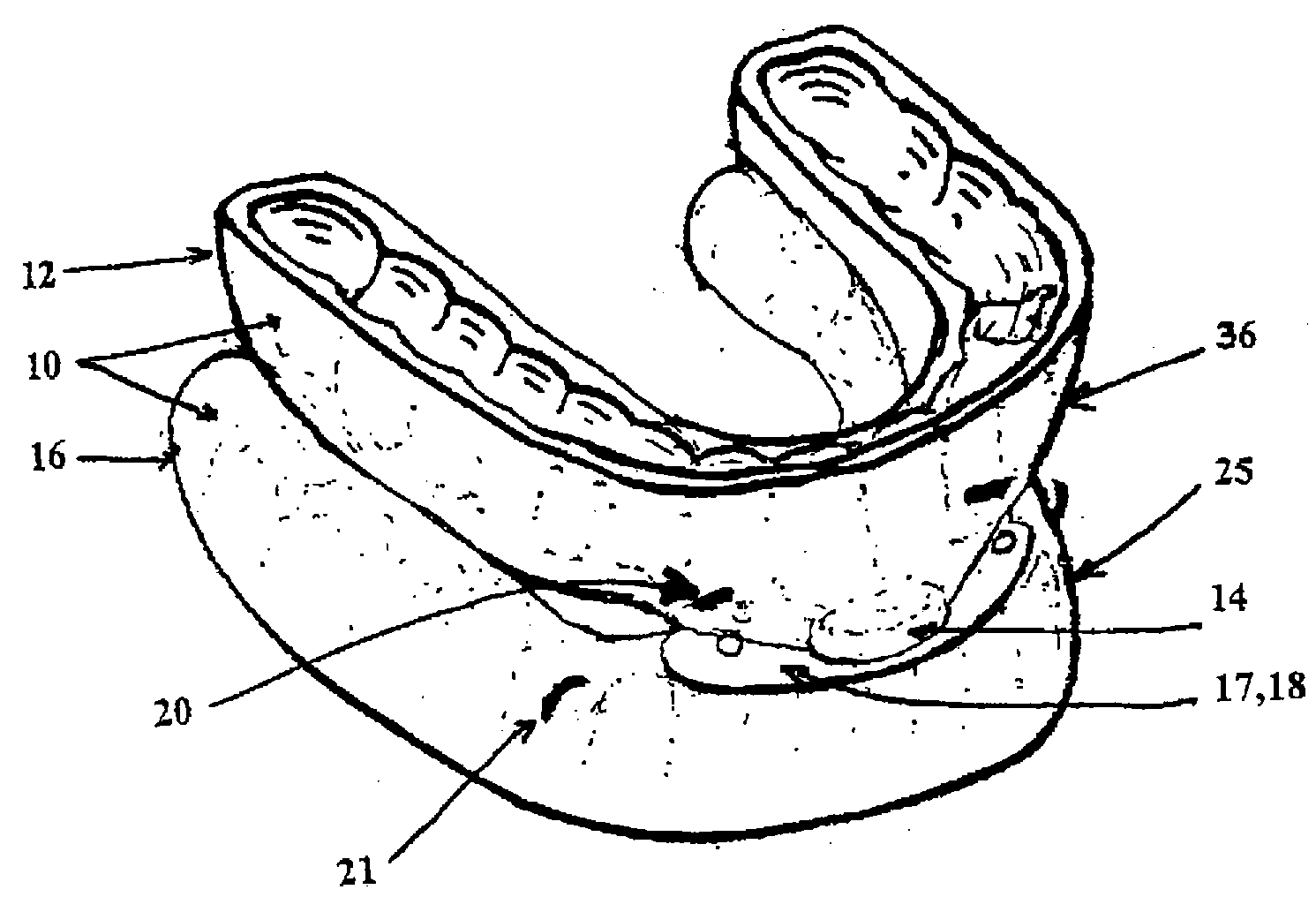

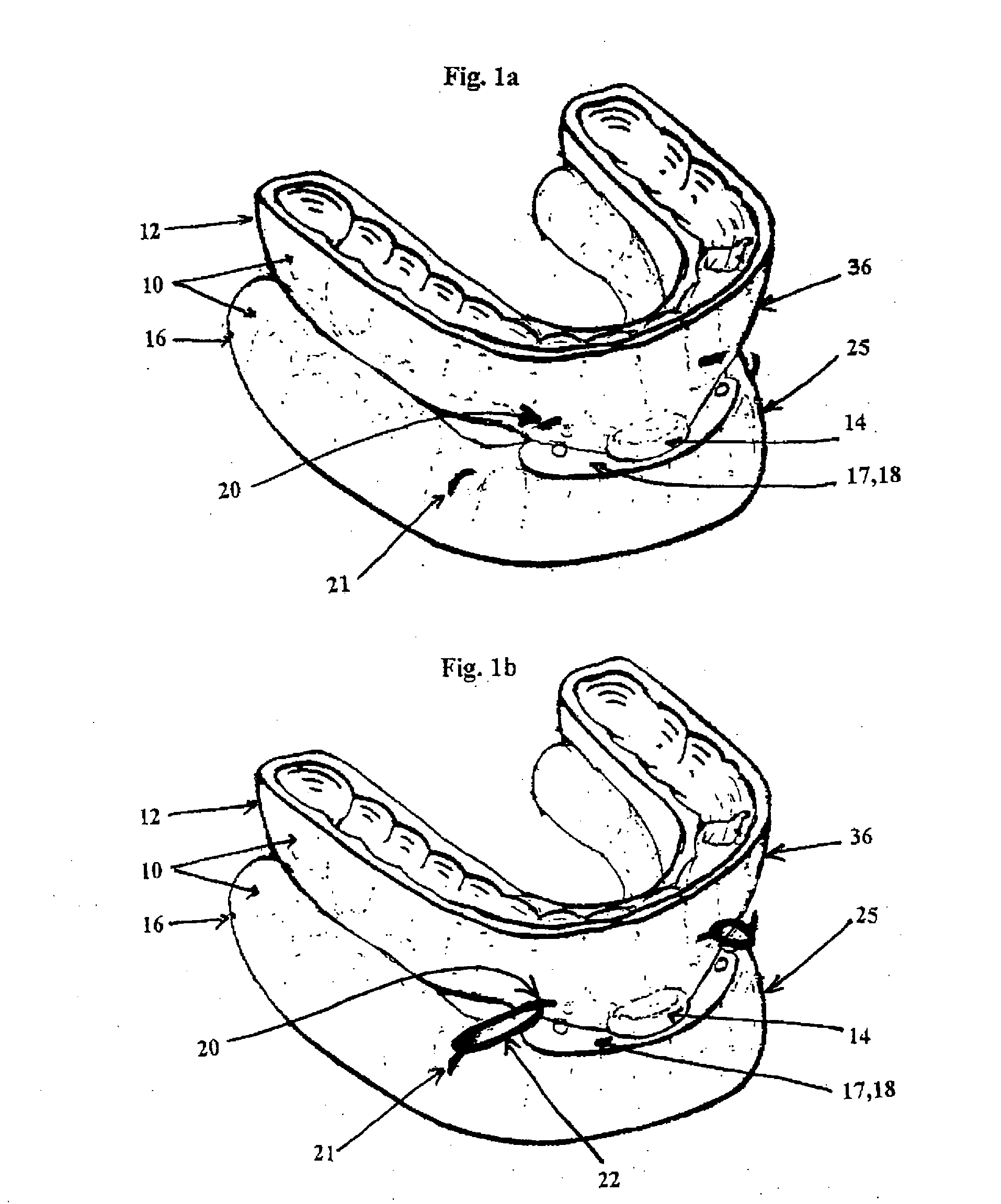

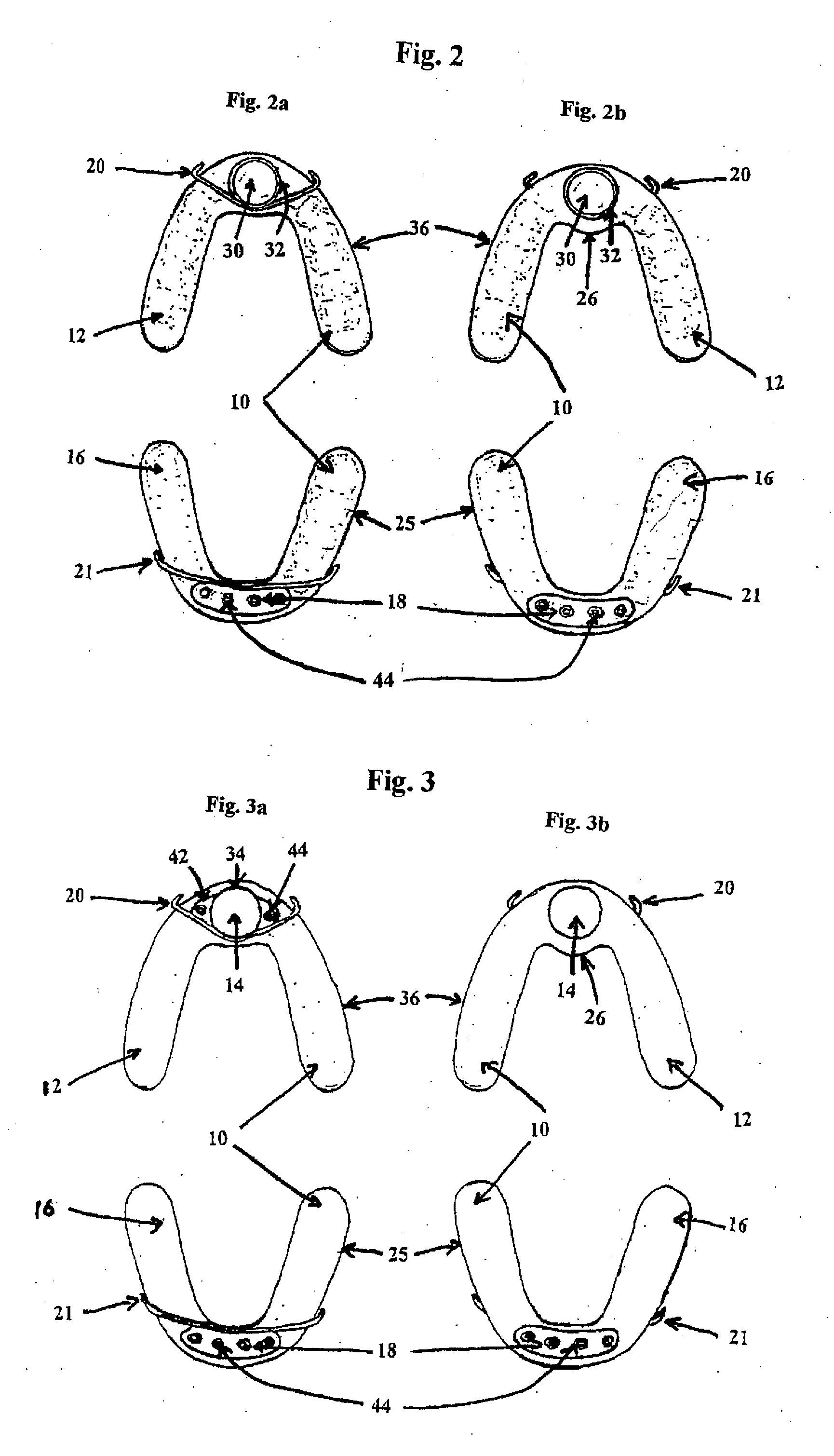

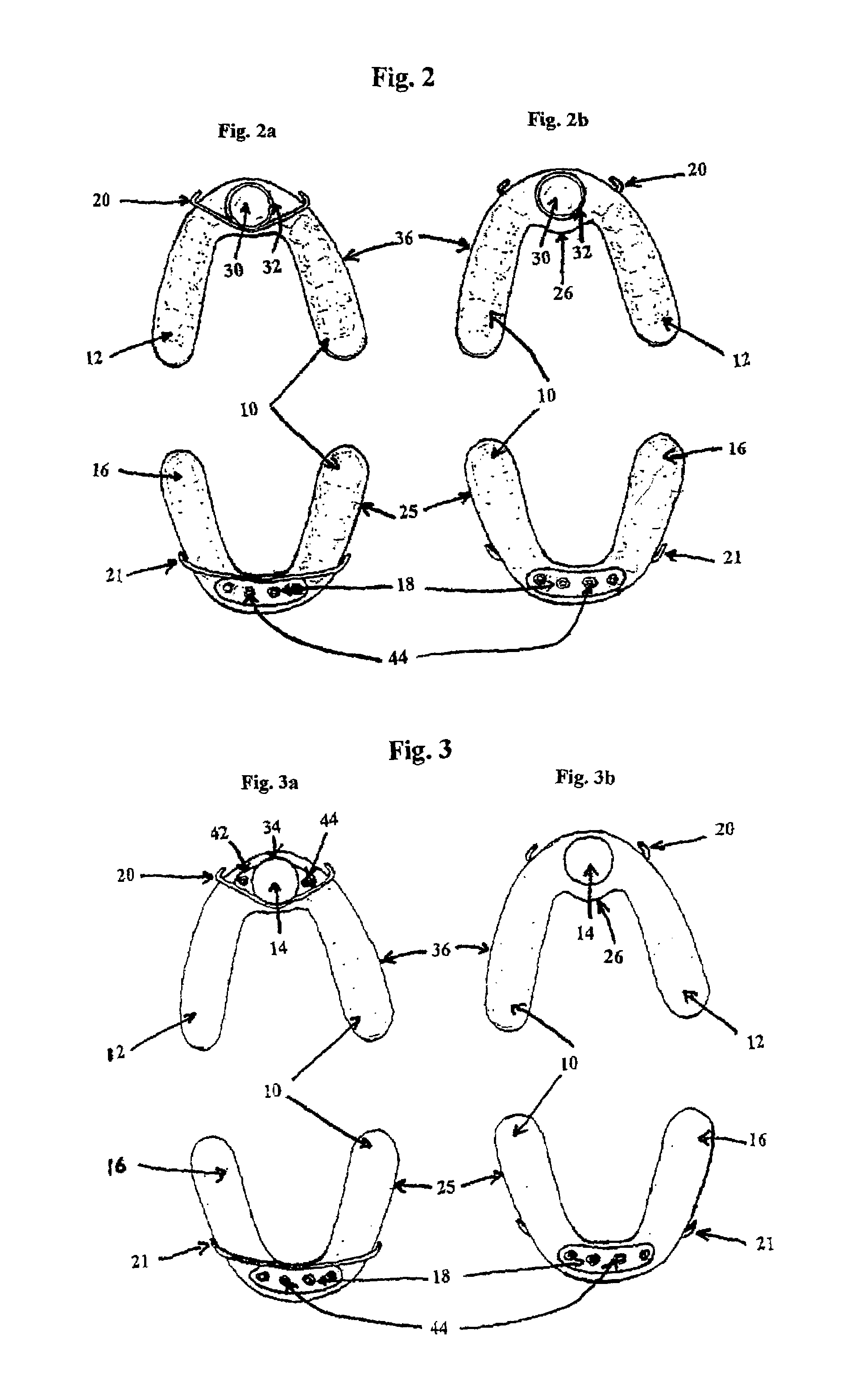

Magnetic dental appliance

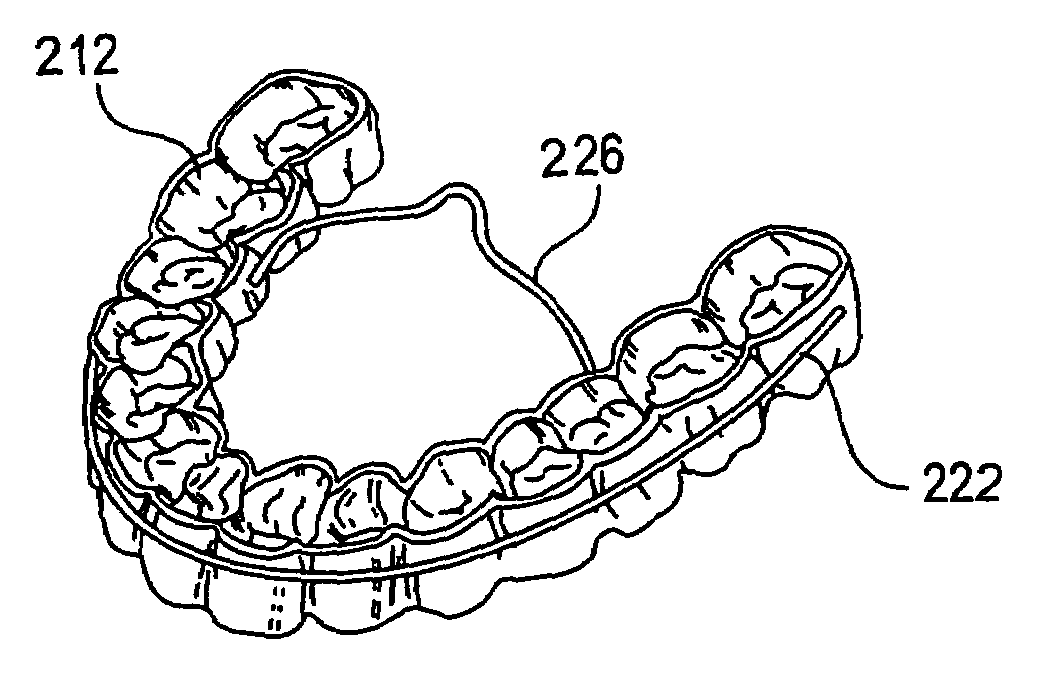

InactiveUS20080199824A1Improve comfortPatient compliance is goodSnoring preventionDental toolsBody of mandibleMyofascial pain

A removable magnetic dental appliance is provided. The magnetic dental appliance can be used in the treatment of various conditions, including but not limited to, snoring, sleep apnea, some forms of temporomandibular joint pain or inflammation, myofascial pain or bruxism. The appliance comprises an upper arch attachment member and a lower arch attachment member, each for removably engaging at least a portion of the dentition. A magnetic component is positioned anteriorly on one of the upper arch attachment member or the lower arch attachment member and a magnet-attracted element is provided on the other arch attachment member for magnetic engagement with the magnetic component when the upper and lower arch attachment members are substantially vertically aligned. The appliance uses magnetic force to selectively position the mandible while still permitting movement of the mandible relative to the maxilla for improved comfort. A use of the magnetic dental appliance and a kit comprising the magnetic dental appliance are also provided

Owner:3D SCANNERS LTD

Dental appliance features for speech enhancement

ActiveUS20180153733A1Avoid problemsReduce and prevent air leakageStammering correctionOthrodonticsSpeech soundSpeech enhancement

Provided herein are orthodontic devices and methods for patients whose orthodontic devices are causing a lisp. The device can comprise an aligner configured to fit over a patient's dental arch and comprising an occlusal surface section positioned over an occlusal surface of the patient's teeth. The aligner can comprise a barrier portion extending laterally and adjacent to a region of the dental arch, the barrier portion allowing the patient's tongue to form a seal against the barrier portion when the patient is speaking while wearing the device.

Owner:ALIGN TECH

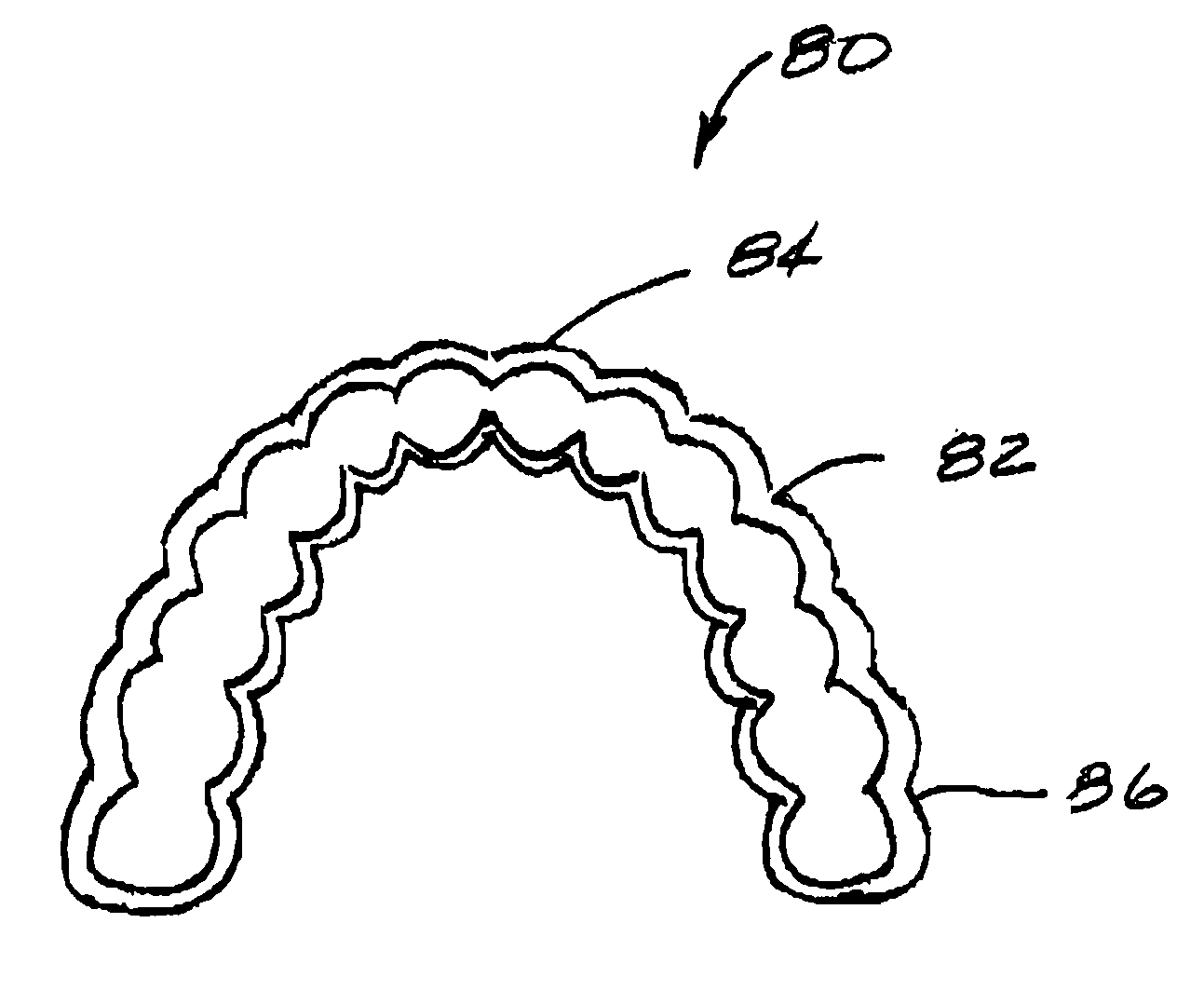

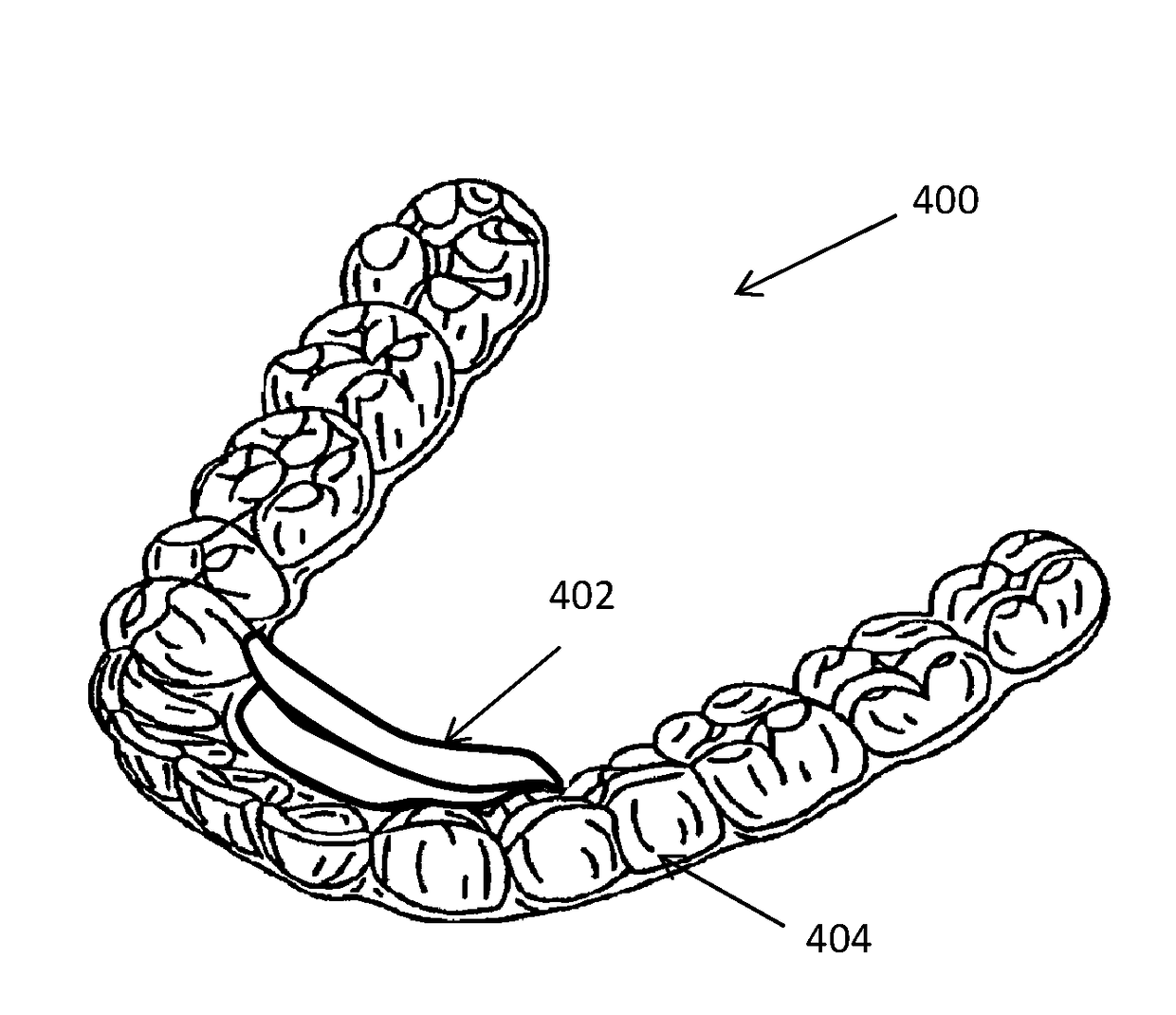

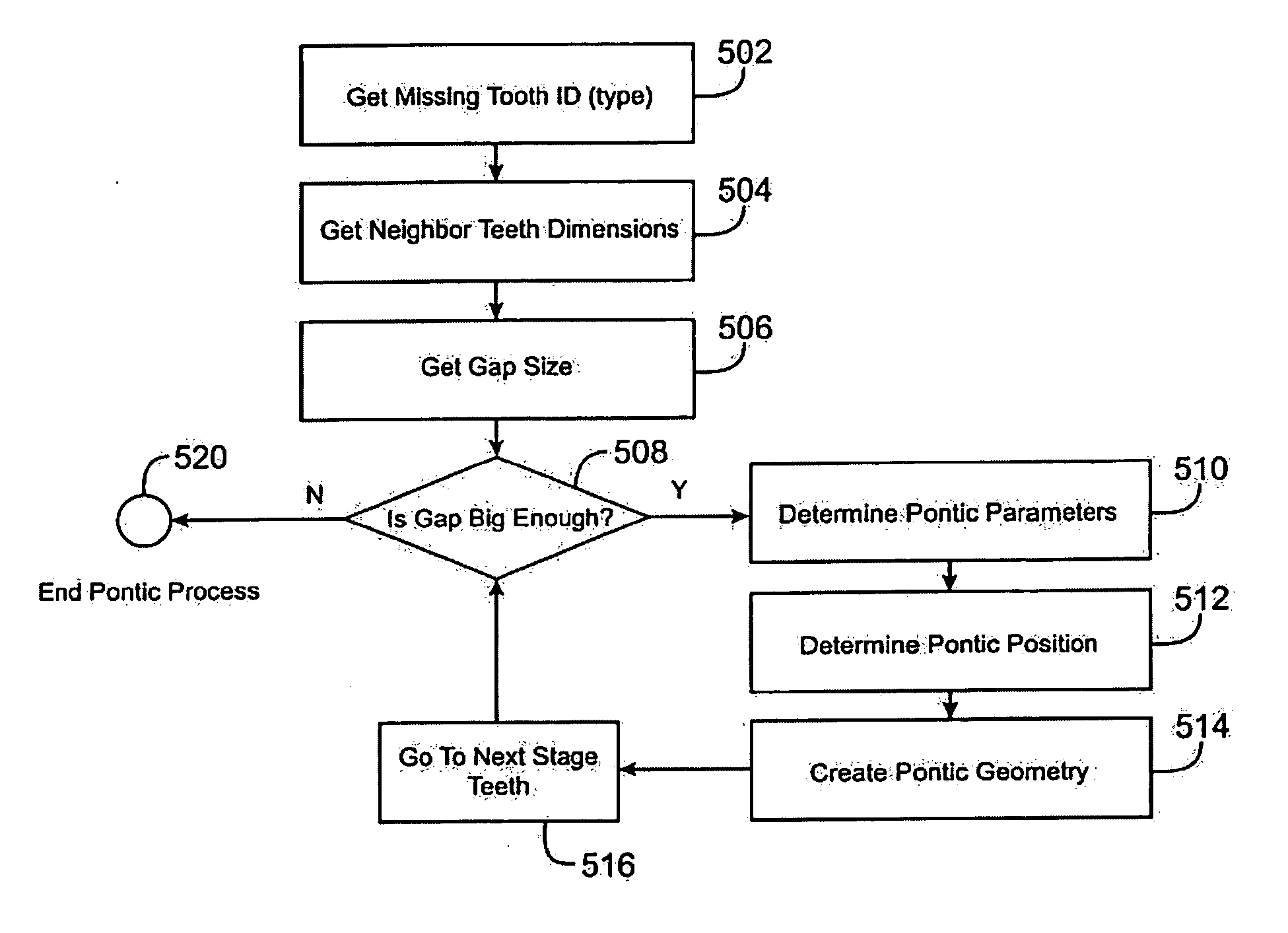

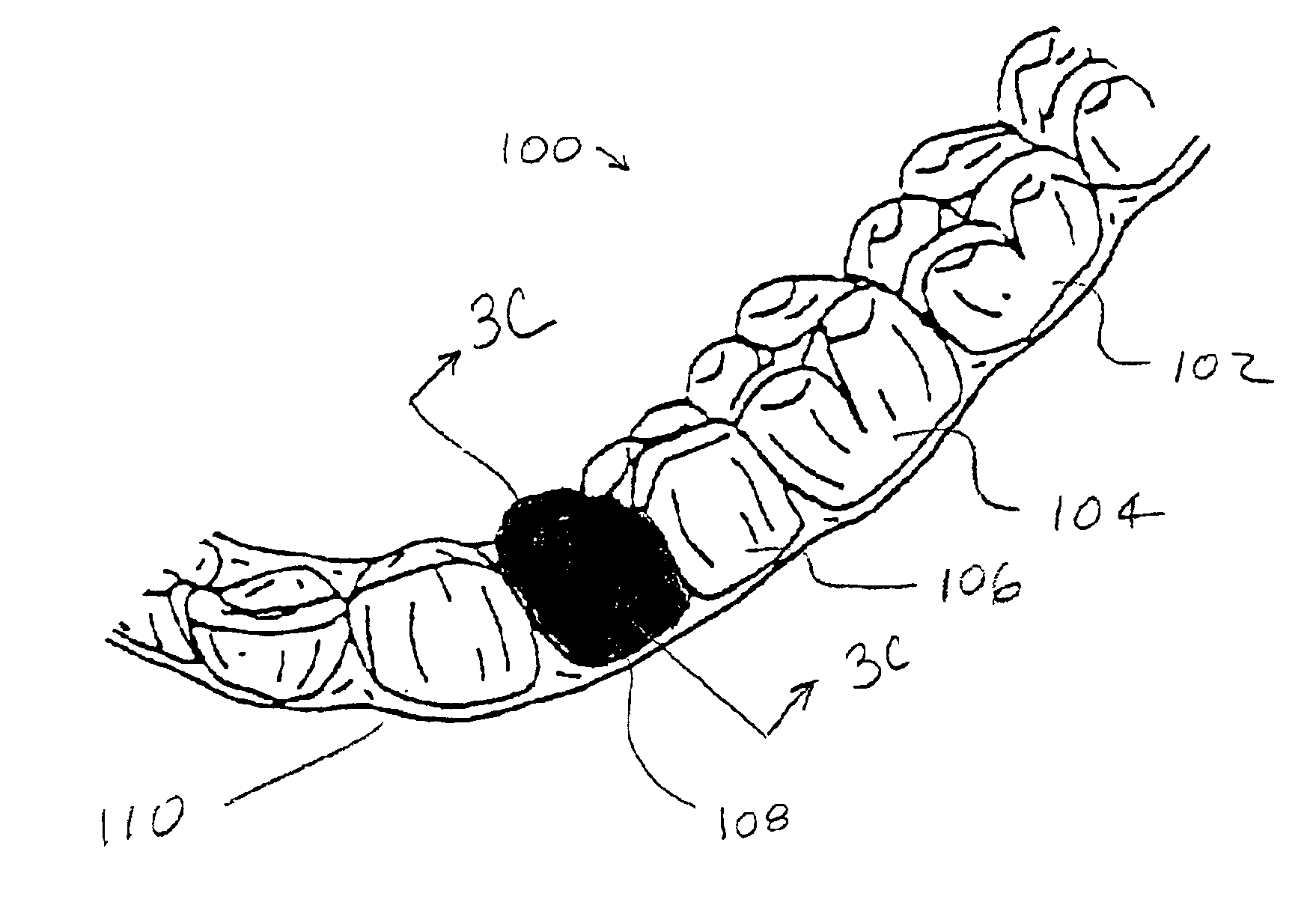

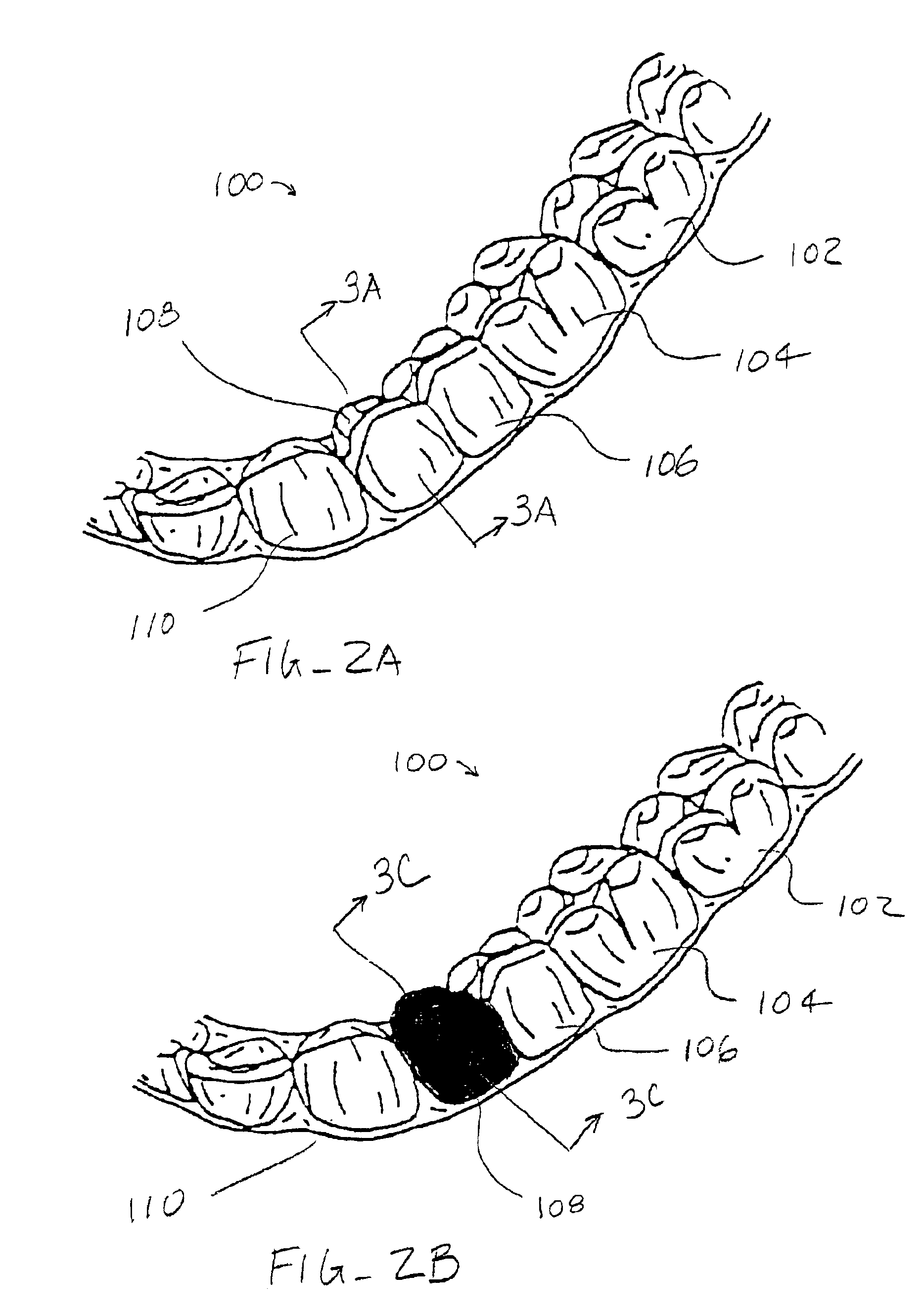

Method and kits for forming pontics in polymeric shell aligners

Systems and methods are disclosed for forming a pontic in a polymeric shell dental appliance, including providing a polymeric shell dental appliance of the type which is removably placeable over a patient's dentition, said shell having a concave trough which conforms to the teeth when the appliance is placed over the dentition and a location in the trough corresponding to a missing tooth; and depositing a flexible, durably affixed material in the location to form the pontic.

Owner:ALIGN TECH

Magnetic dental appliance

InactiveUS7712468B2Improve comfortPatient compliance is goodSnoring preventionDental toolsMyofascial painTemporomandibular joint pain

A removable magnetic dental appliance is provided. The magnetic dental appliance can be used in the treatment of various conditions, including but not limited to, snoring, sleep apnea, some forms of temporomandibular joint pain or inflammation, myofascial pain or bruxism. The appliance includes an upper arch attachment member and a lower arch attachment member, each for removably engaging at least a portion of the dentition. A magnetic component is positioned anteriorly on one of the upper arch attachment member or the lower arch attachment member and a non-magnet magnet-attracted element is provided on the other arch attachment member for magnetic engagement with the magnetic component when the upper and lower arch attachment members are substantially vertically aligned. The appliance uses magnetic force to selectively position the mandible while still permitting movement of the mandible relative to the maxilla for improved comfort.

Owner:3D SCANNERS LTD

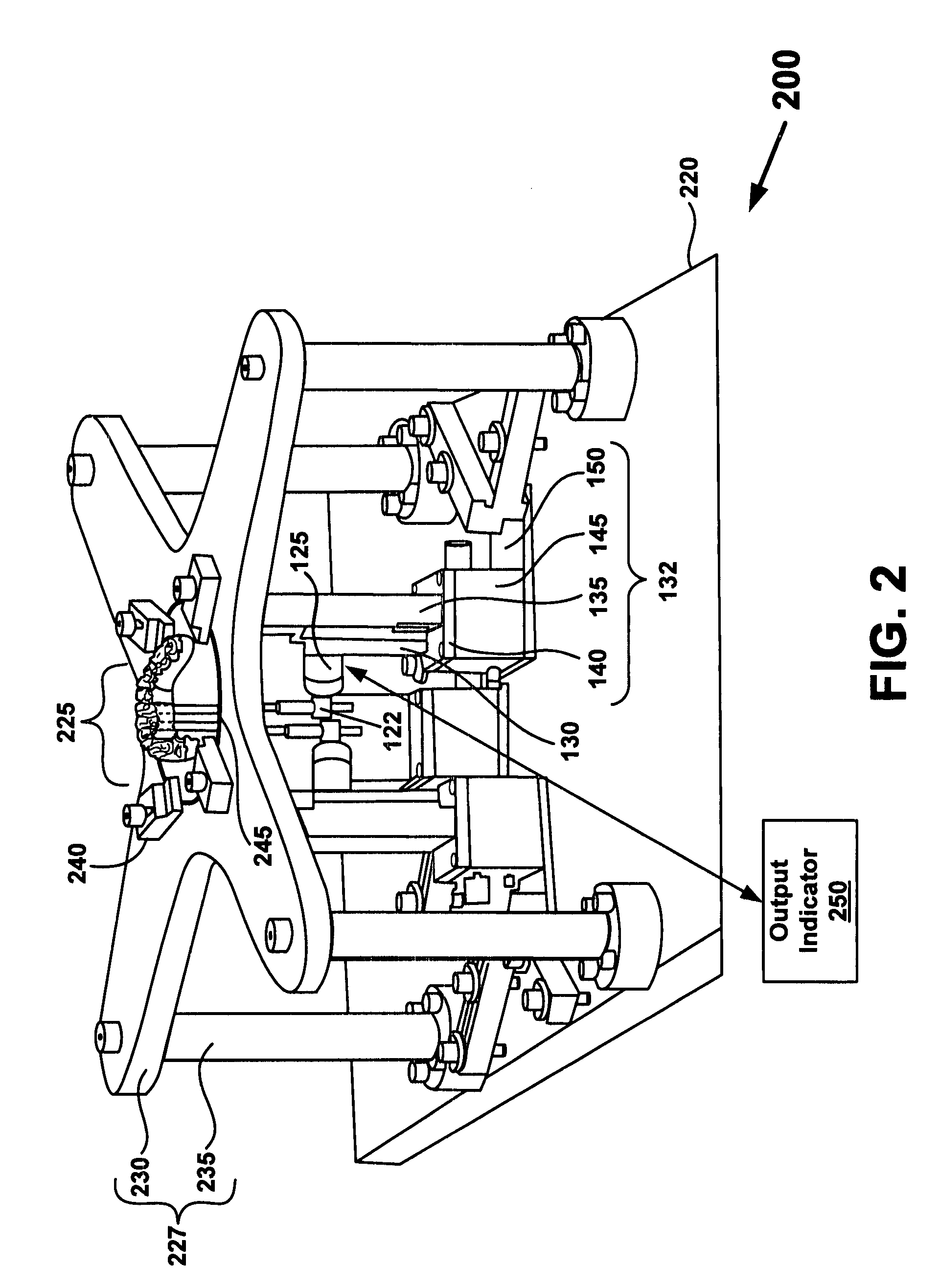

Concurrently measuring a force exerted upon each of a plurality of teeth

A system and method for concurrently measuring a force exerted upon a tooth is disclosed. In one aspect of the invention, the system includes a target tooth attached to a force gauge which is coupled to a motion module for adjusting the tooth to a reference position. The method includes utilizing a motion module of a force measurement device is utilized to adjust each target tooth of a plurality of target teeth to be located in a reference position. Next, each target tooth receives a dental appliance. Then an exerted force is measured by the dental appliance upon each target tooth utilizing a coordinate system of the force gauge.

Owner:ALIGN TECH

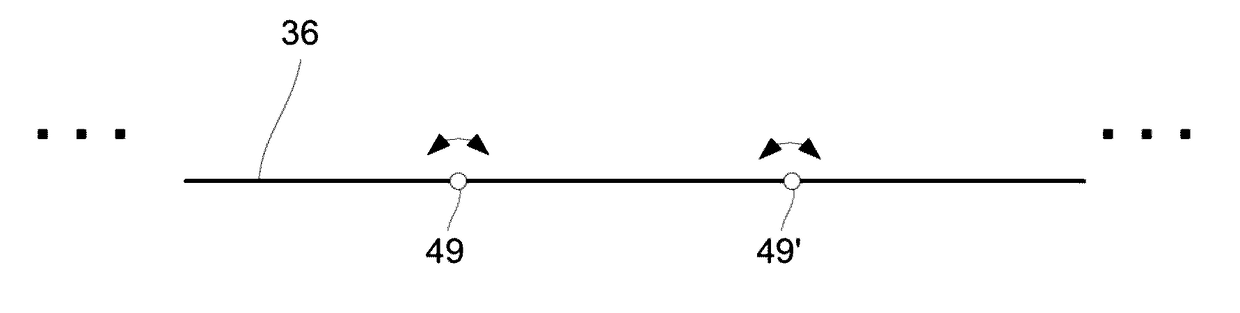

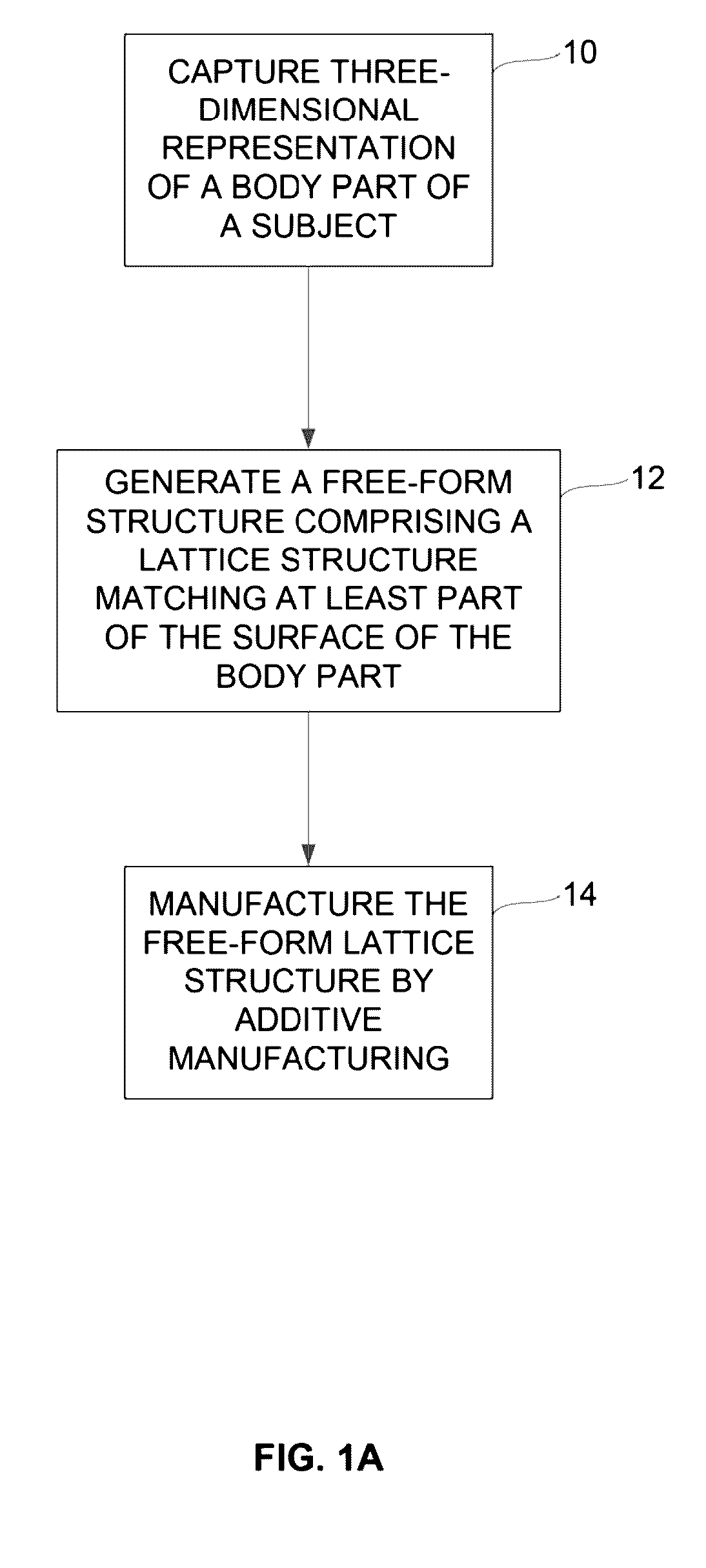

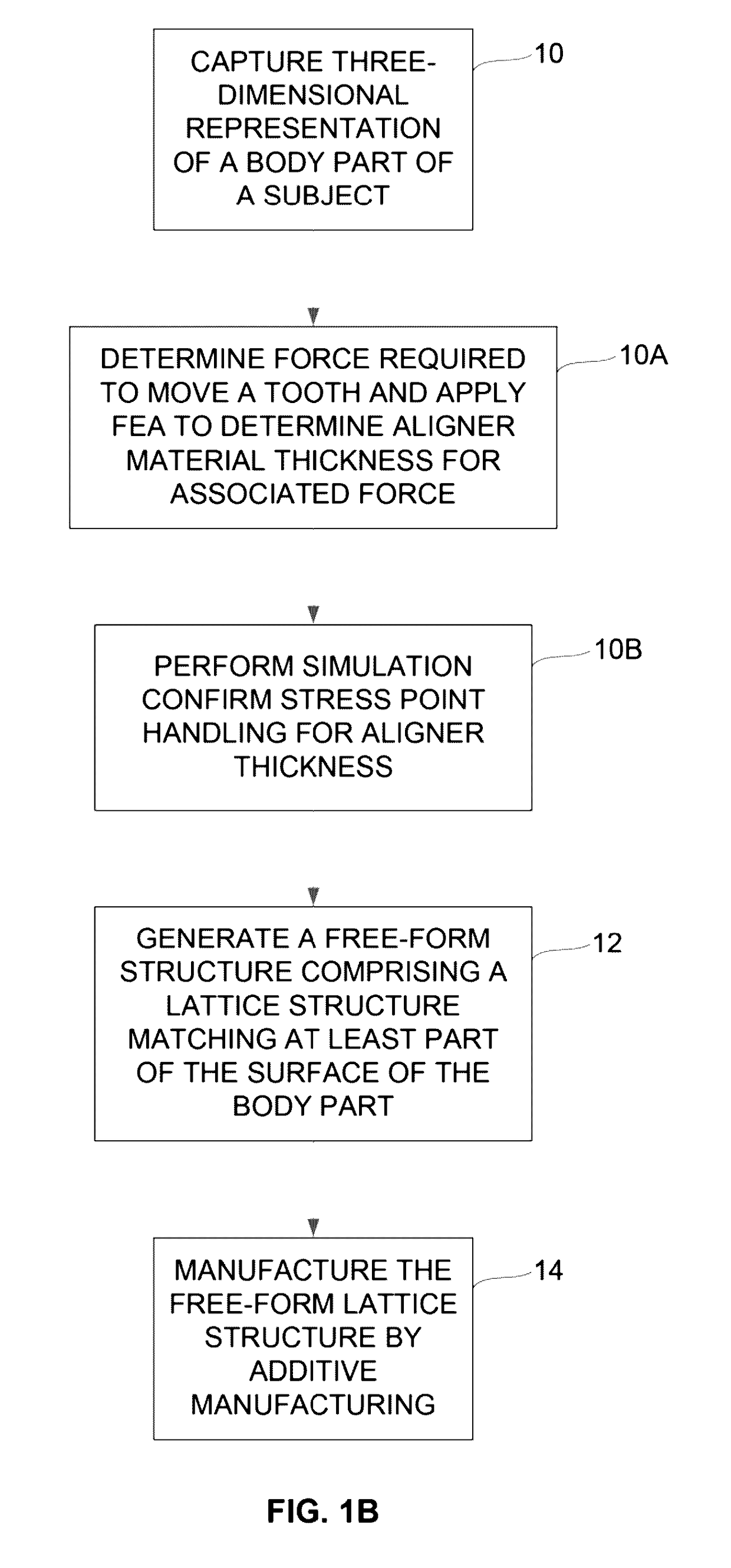

Three-dimensional printed dental appliances using lattices

Method and apparatus for fabricating an oral appliance are described for correcting malocclusions on a dentition of a subject. A three-dimensional representation of the dentition may be captured and a free-form structure having a lattice structure which matches at least part of a surface of the dentition is generated. The lattice structure defines a plurality of open spaces such that the free-form structure is at least partially transparent. The lattice structure may then be manufactured by impregnating or covering a coating into or upon the lattice structure such that the oral appliance is formed.

Owner:ULAB SYST INC

Method and kits for forming pontics in polymeric shell aligners

Owner:ALIGN TECH

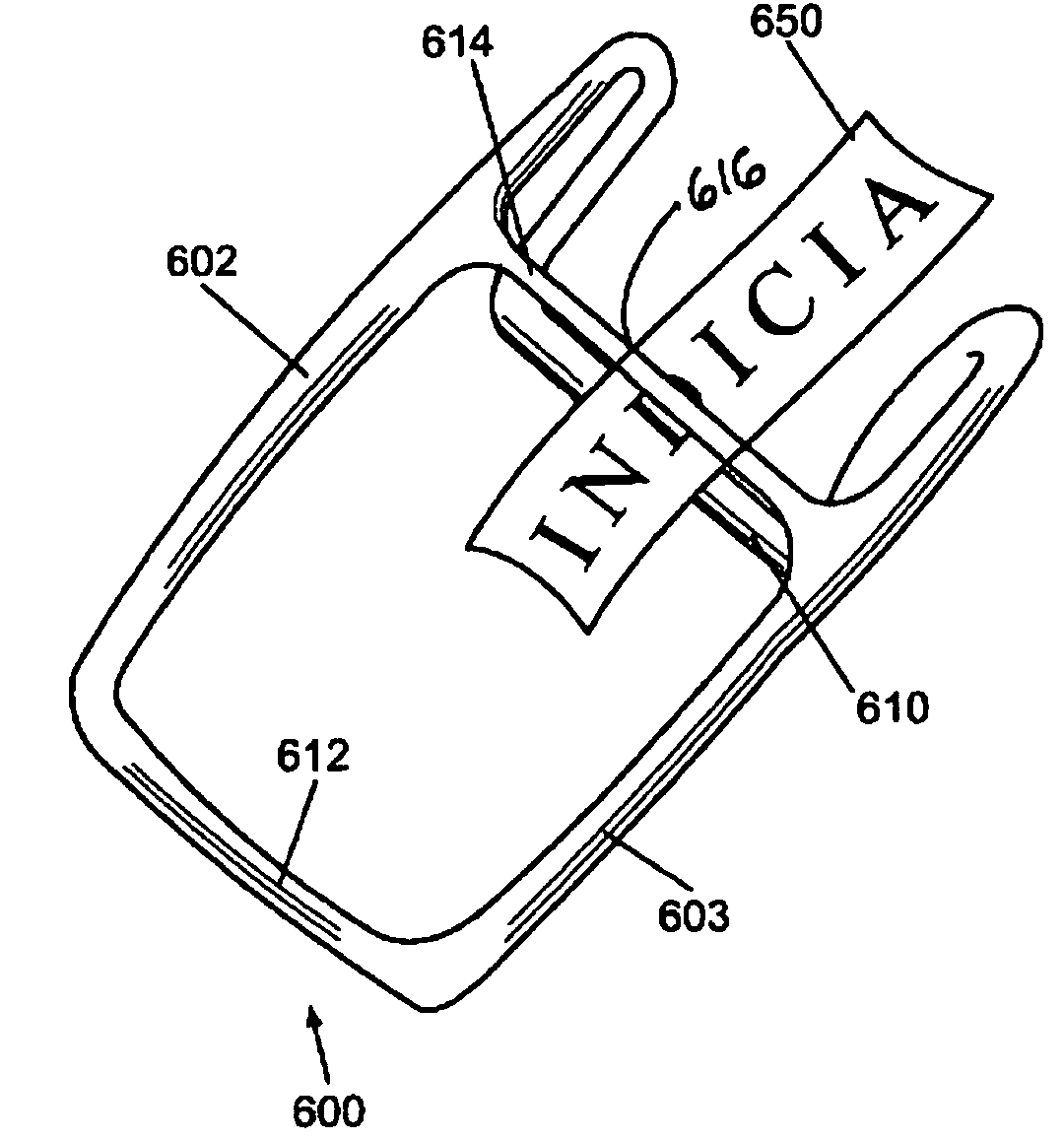

Disposable photographic cheek retraction apparatus and method of using the same

InactiveUS6988893B2Economically manufacturedReduce needSurgeryLip/mouth protectorsEngineeringHigh pressure

In an exemplary embodiment in accordance with the present invention, a disposable dental appliance and method of use is provided. In particular, a cheek retraction apparatus is provided, which is formed from a lightweight yet durable biocompatible polymer. The apparatus is sufficiently durable to withstand recurrent use, however, the it is economically manufactured so as to be disposable. Moreover, the apparatus is pre-sterilized to alleviate the need for autoclaving and / or dry heat sterilization. A cheek retraction apparatus in accordance with the present invention also provides an indicia display medium that allows the dental practitioner to display patient information, whitening treatment measurements, or other indicia that might be useful to them during oral photography.

Owner:MEDICAL COLLEGE OF GEORGIA RES INST

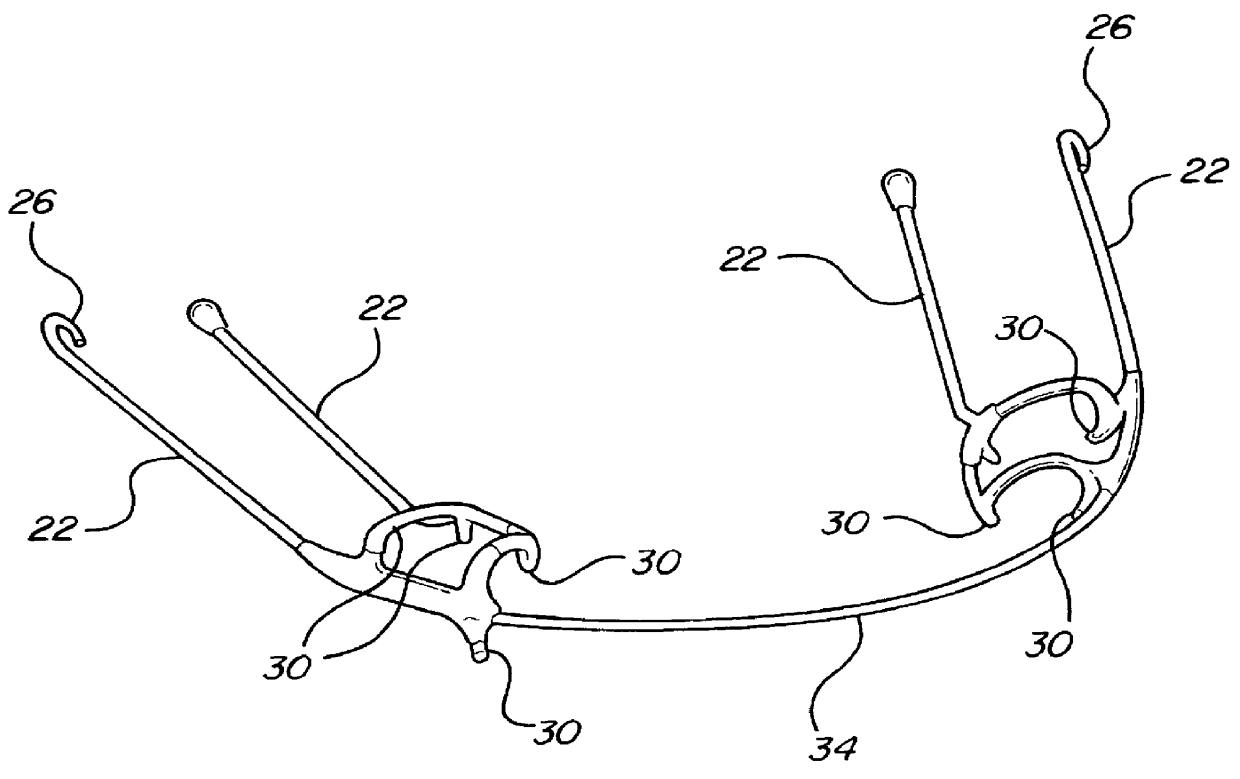

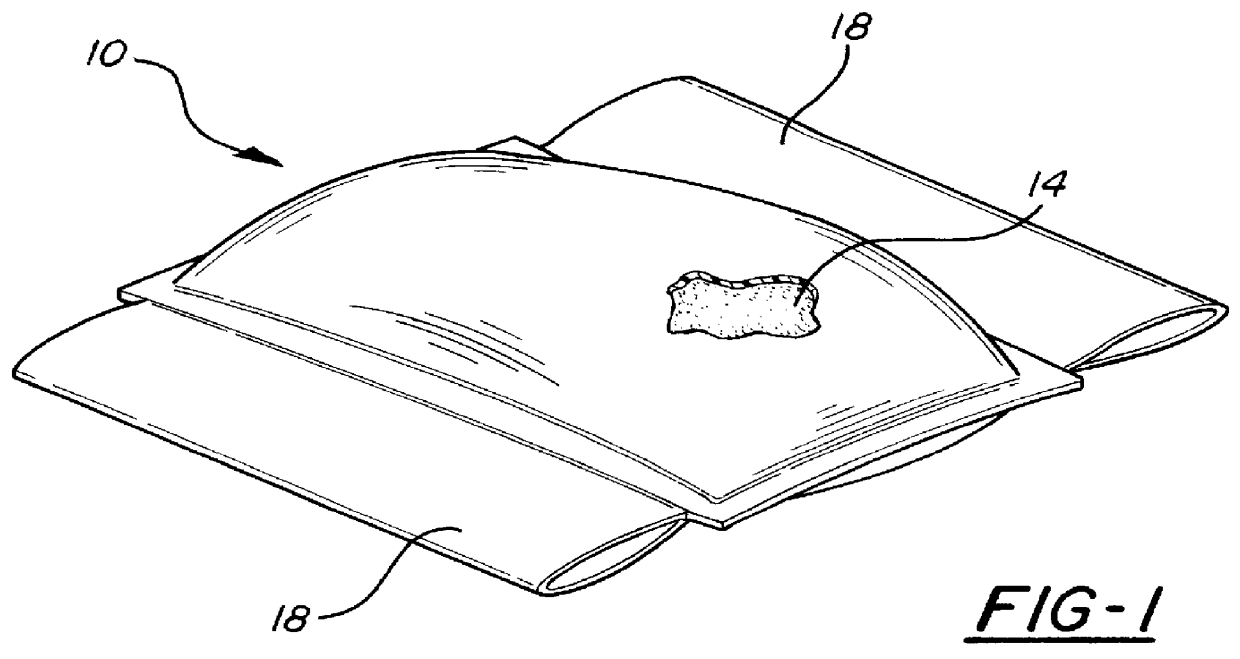

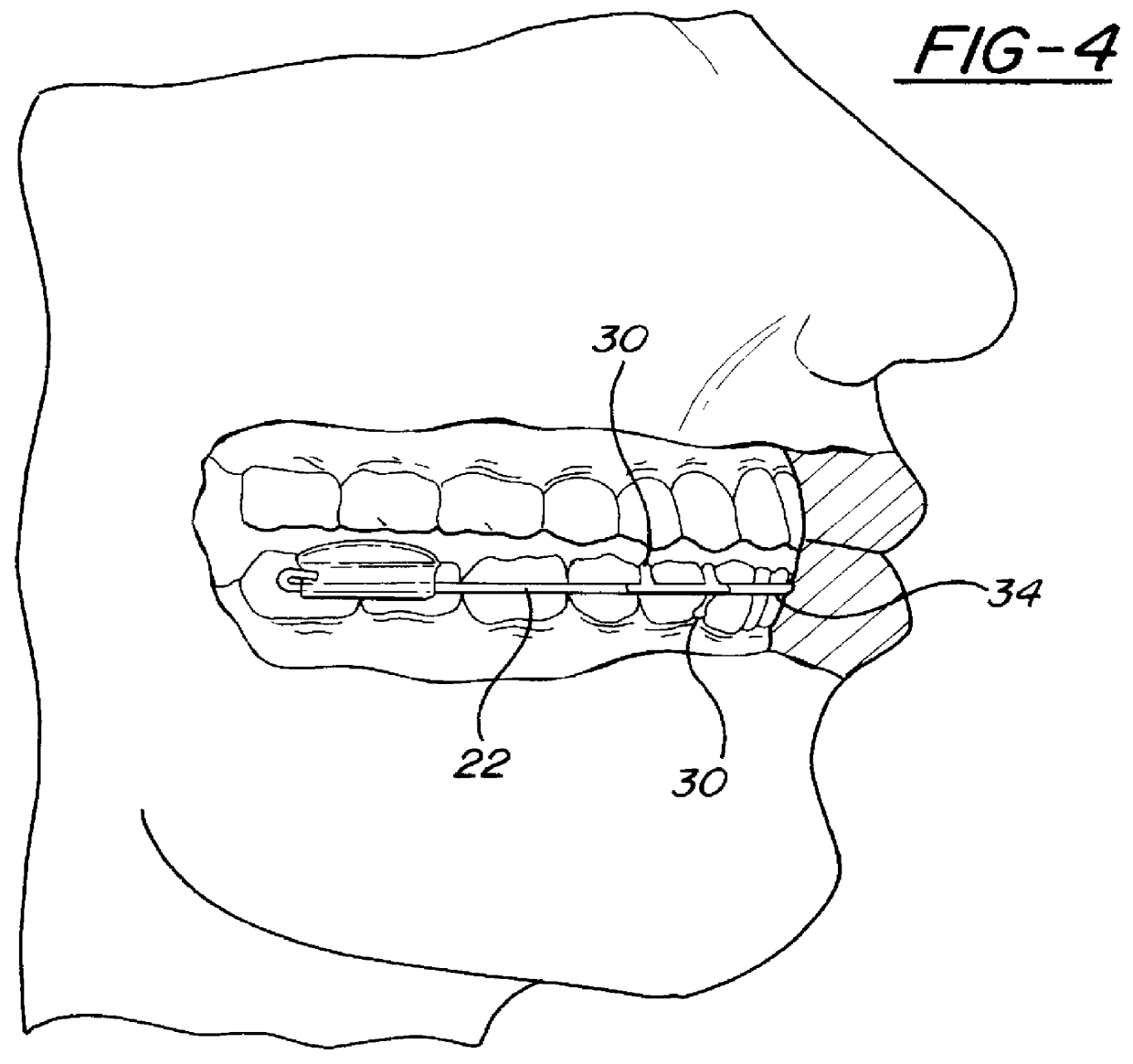

Taste-based approach to the prevention of teeth clenching and grinding

A new biofeedback modality for the treatment of bruxism. A mildly aversive, safe, liquid is inserted into, and sealed in, small, bilaterally-sleeved, polyethylene capsules. Two capsules are attached to a specially-constructed dental appliance which comfortably and securely places them between the lower and upper teeth. The appliance and capsules are worn at night or at other times when bruxism is suspected to occur. Whenever a sleeping or an awake patient attempts to brux, the capsules rupture and the liquid is released into the mouth. The liquid then draws the patient's conscious attention to, and forestalls, any attempt of teeth clenching or grinding. Variations of the method and device can be used to diagnose bruxism and to sustainably release medications and odor-masking substances into the mouth,.

Owner:NISSANI MOTI

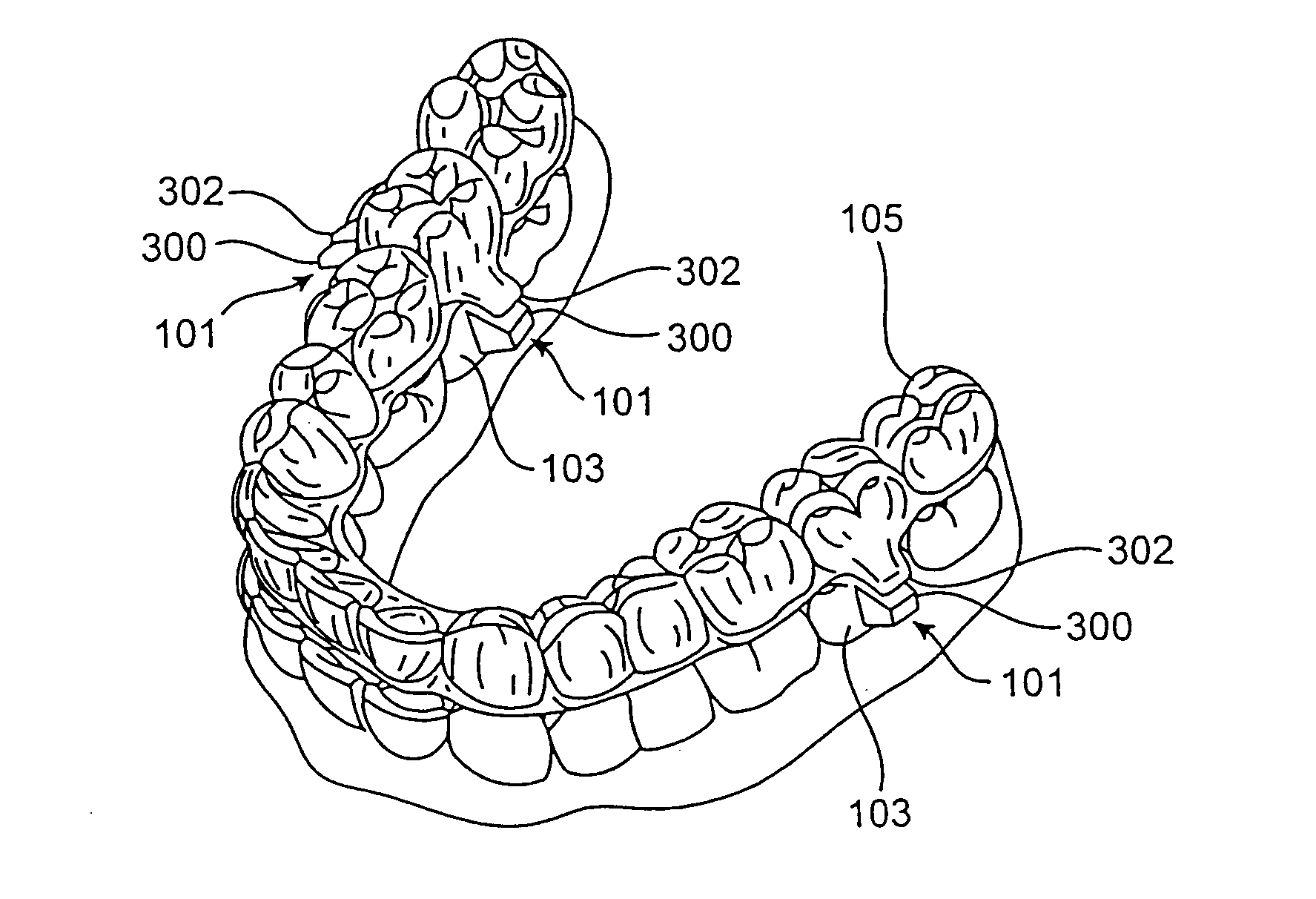

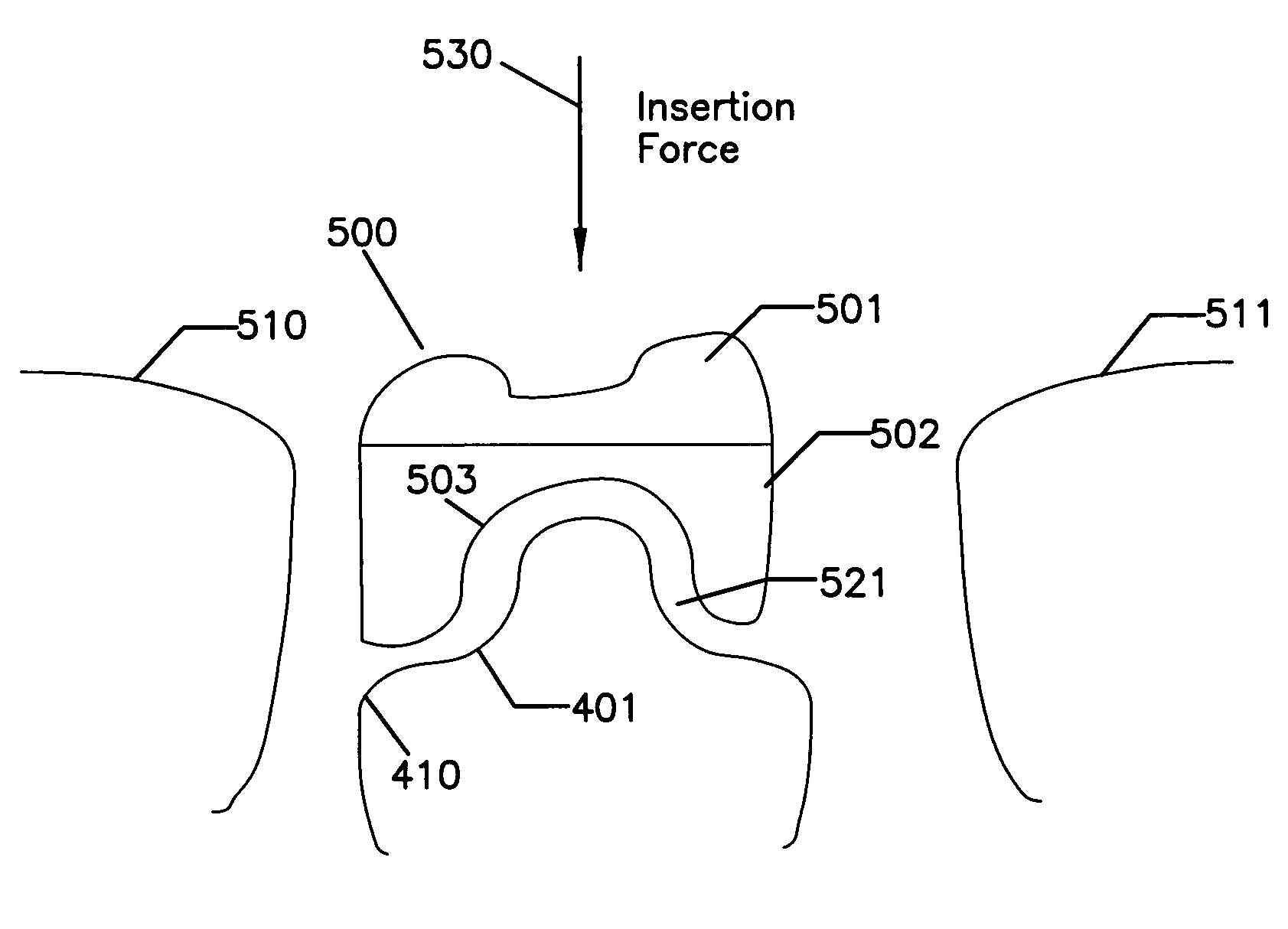

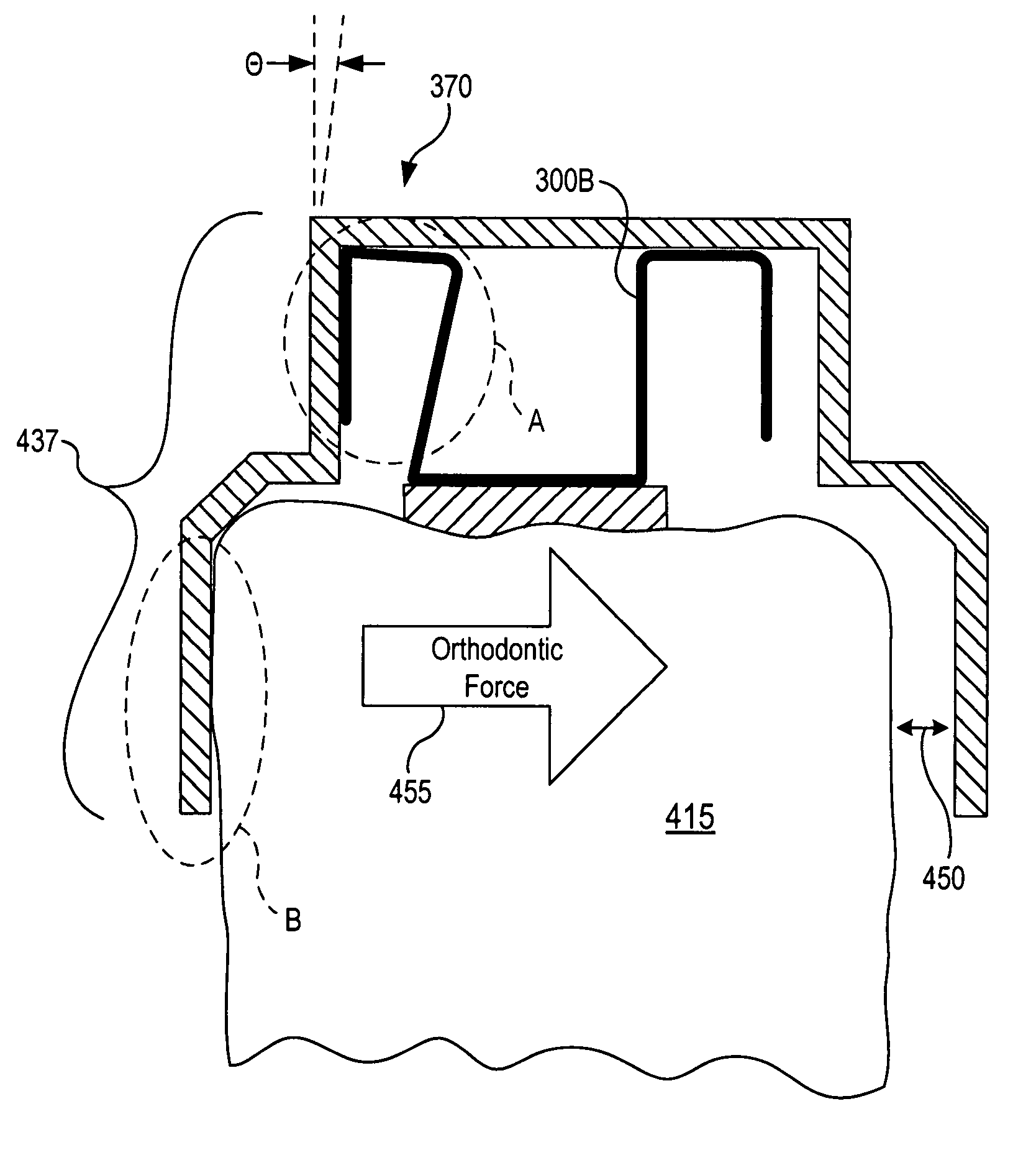

Active attachments for interacting with a polymeric shell dental appliance

An active dental attachment. Specifically, an attachment device for interacting with a polymeric shell dental appliance is described. The attachment device includes an anchoring attachment body. A bonding surface is coupled to the anchoring attachment body, wherein the bonding surface is configured for anchoring the anchoring attachment body to a dental feature of a patient's dentition. A force-applying active mechanism is coupled to the anchoring attachment body. A polymeric shell dental appliance contact region is coupled to the force-applying active mechanism. The polymeric shell dental appliance contact region is configured to contact the force-applying active mechanism and apply a force generated by the force-applying active mechanism between the dental feature and the polymeric shell dental appliance when the polymeric shell dental appliance engages the force-applying active mechanism.

Owner:ALIGN TECH

Oral Sleep Apnea Device

An oral sleep apnea device is a dental appliance designed to advance the lower jaw of a user suffering from sleep apnea while reducing lingual discomfort and the risk of harmful tooth movement and rotation during use. The present invention accomplishes this through the use of a maxillary and a mandibular dental plate coupled to the upper and lower jaw, respectively, without direct contact with the incisal or labial surfaces of the anterior teeth. Both appliances comprise a lingual surface mount. The maxillary dental plate comprises an advancement mechanism. The advancement mechanism being operatively engaged to the mandibular dental plate repositions the mandibular plate to a forward location relative to the maxillary dental plate. During the repositioning of the mandibular dental plate the mandibular lingual surface mount distributes pressure evenly to the lingual surfaces on the lower jaw, reducing localized pressure points which can cause tooth movement.

Owner:STEIN IVAN F

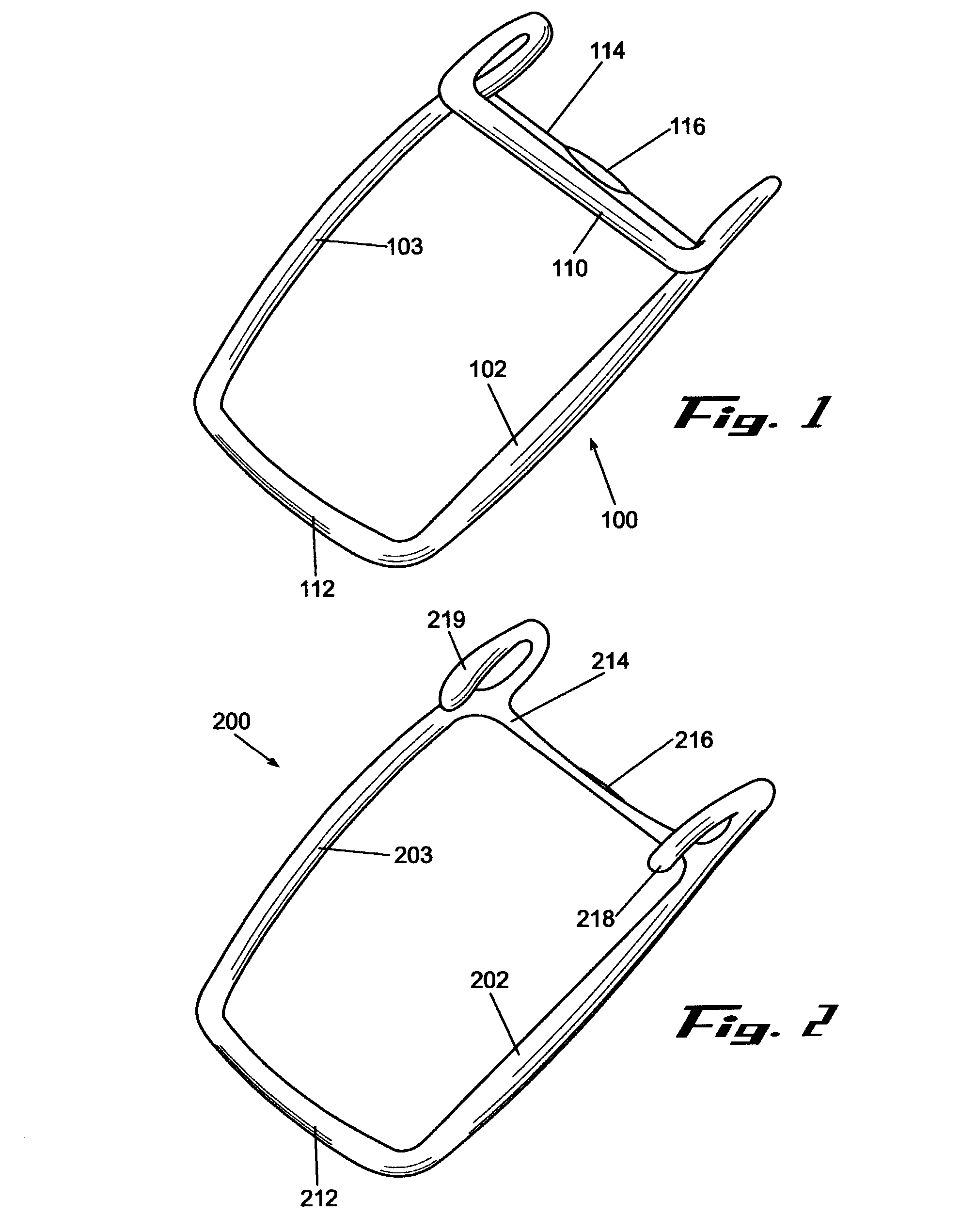

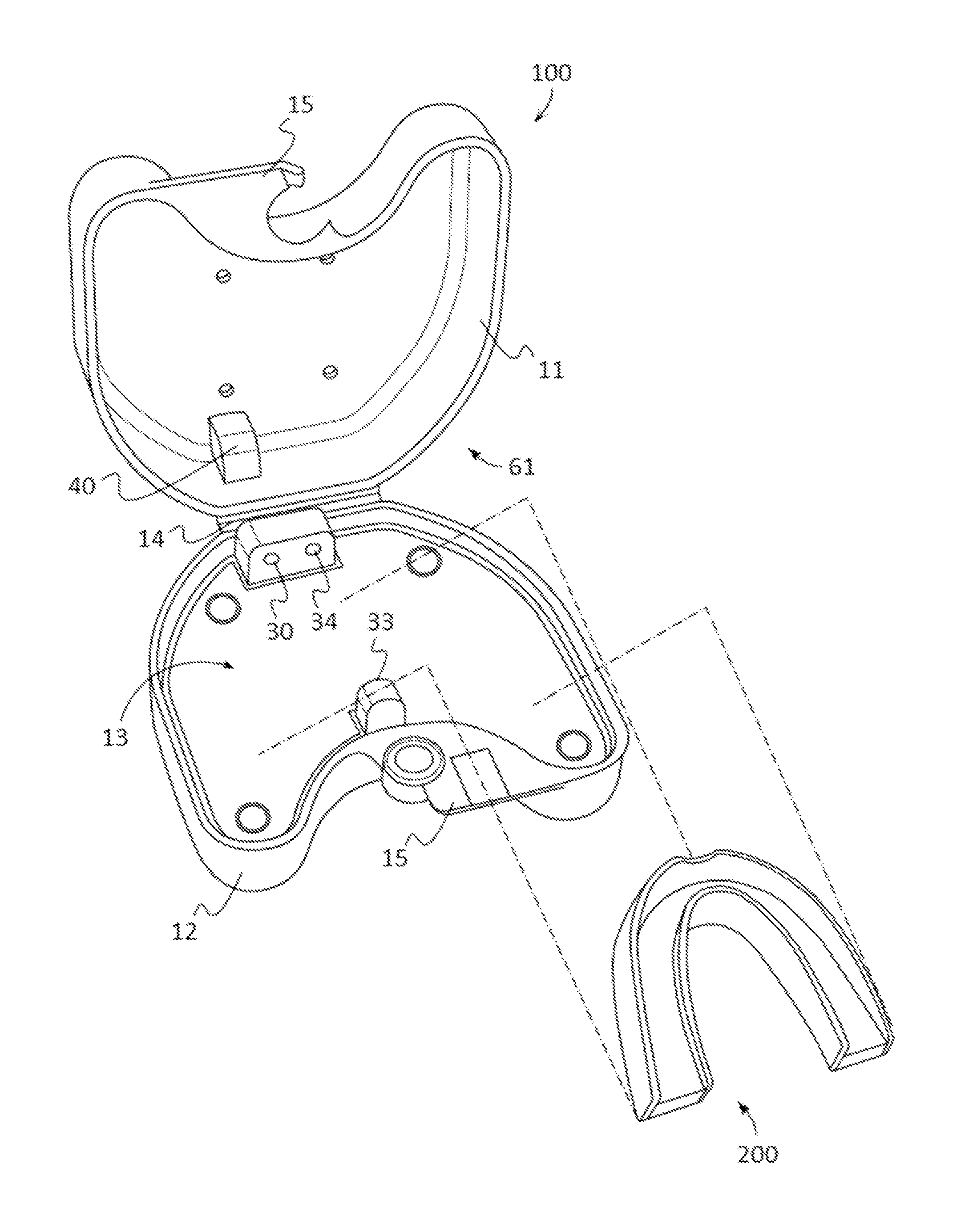

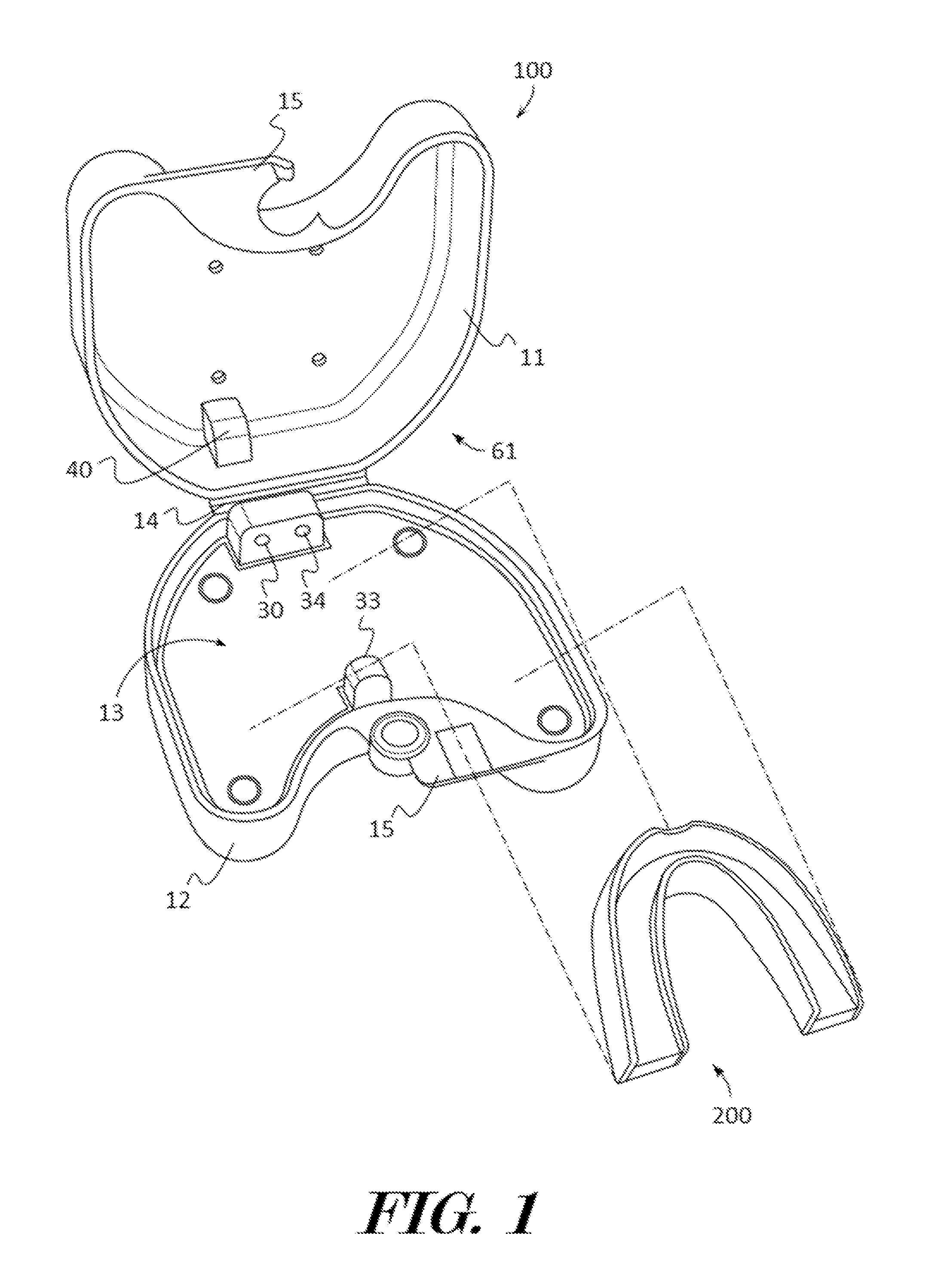

Dental appliance case

A dental appliance case for receiving a dental appliance is provided. In some embodiments, the case may include a power source, a sound device, an occupancy sensor, and a processing unit. The sound device may be configured to create an audible alert sound. The occupancy sensor may be operable to detect the presence of a dental appliance. The processing unit may be in electrical communication with the power source, occupancy sensor, and the sound device. The processing unit may be operable to operate the sound device to create an audible alert in response to an electronic communication from the occupancy sensor.

Owner:WILSON WESLEY +2

Method and kits for forming pontics in polymeric shell aligners

Systems and methods are disclosed for forming a pontic in a polymeric shell dental appliance, including providing a polymeric shell dental appliance of the type which is removably placeable over a patient's dentition, said shell having a concave trough which conforms to the teeth when the appliance is placed over the dentition and a location in the trough corresponding to a missing tooth; and depositing a flexible, durably affixed material in the location to form the pontic.

Owner:ALIGN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com