Patents

Literature

145 results about "Upper tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

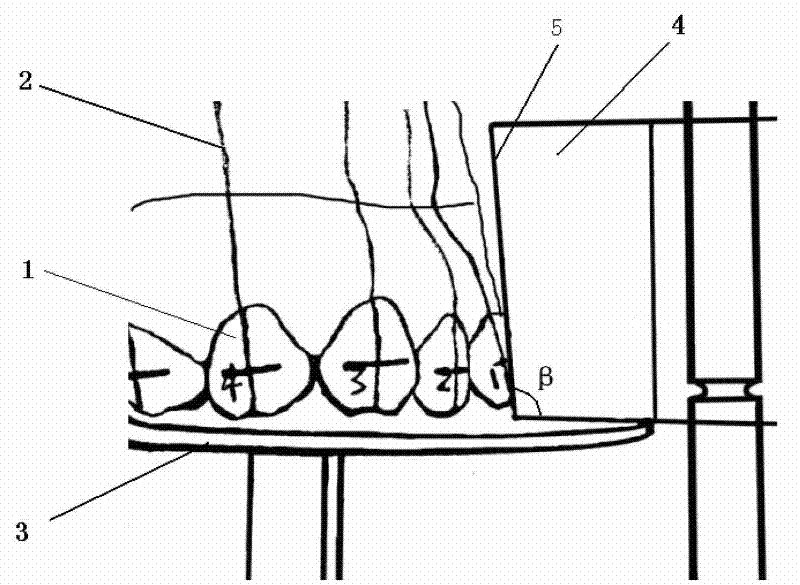

Taste-based approach to the prevention of teeth clenching and grinding

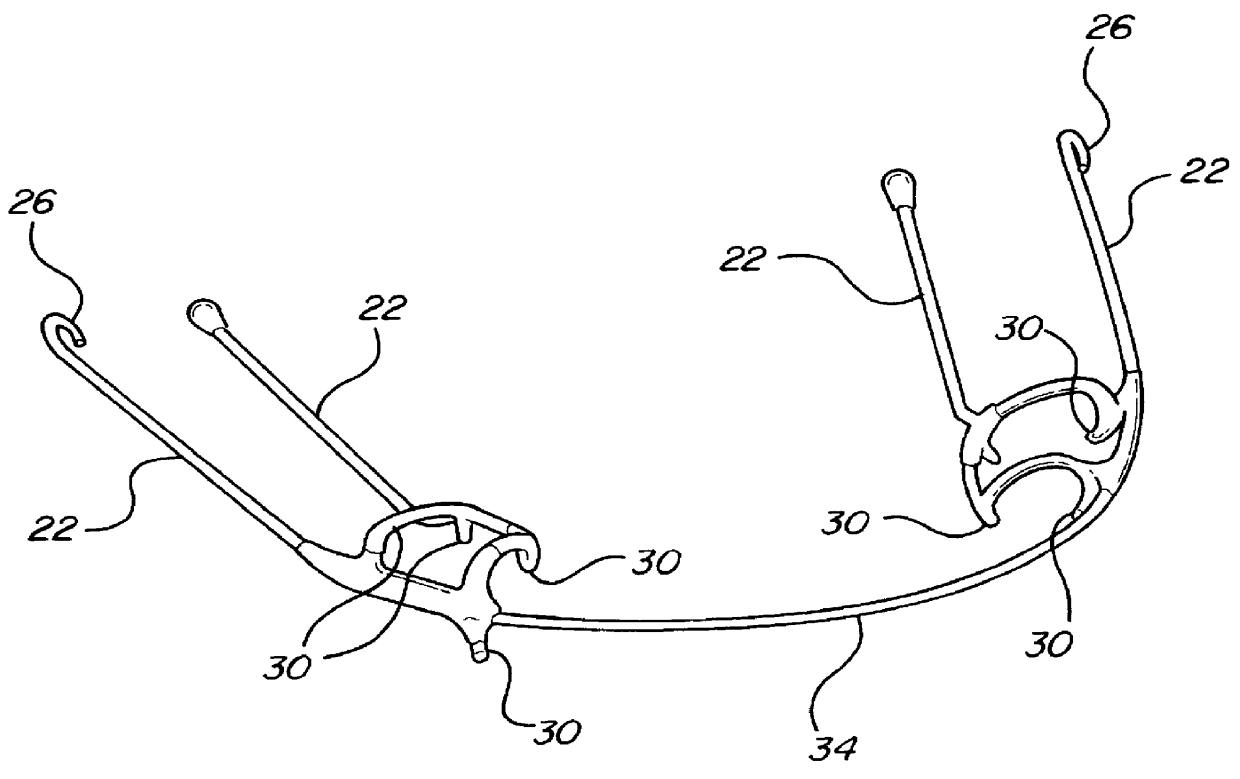

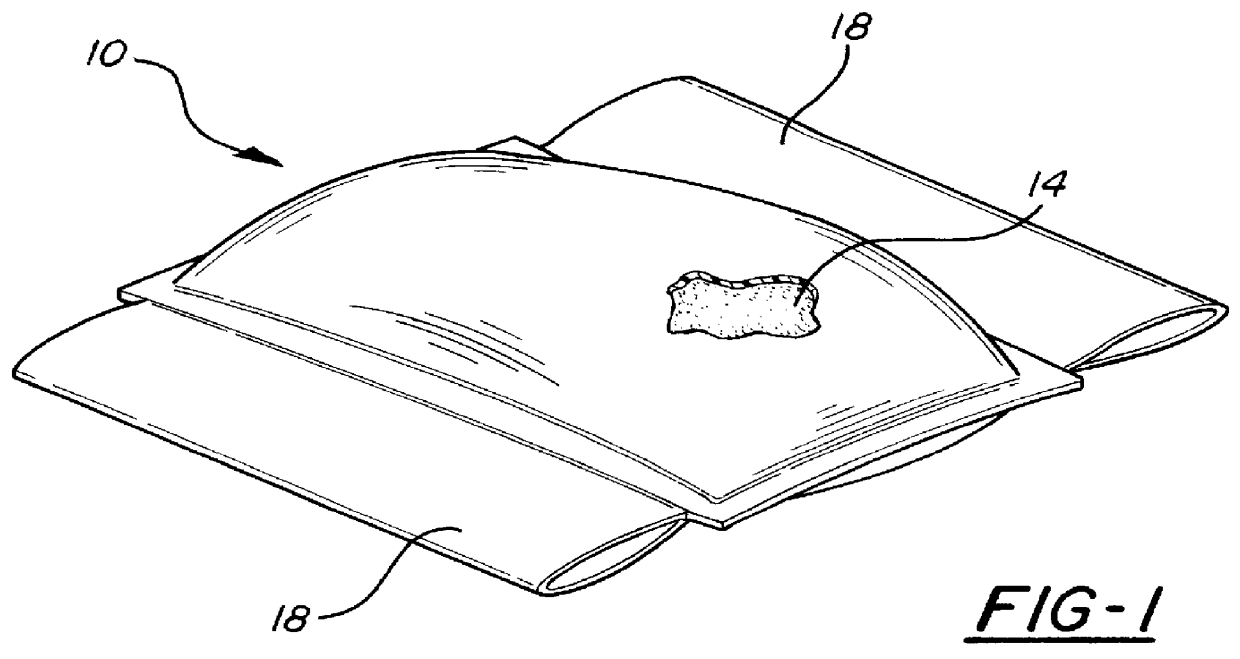

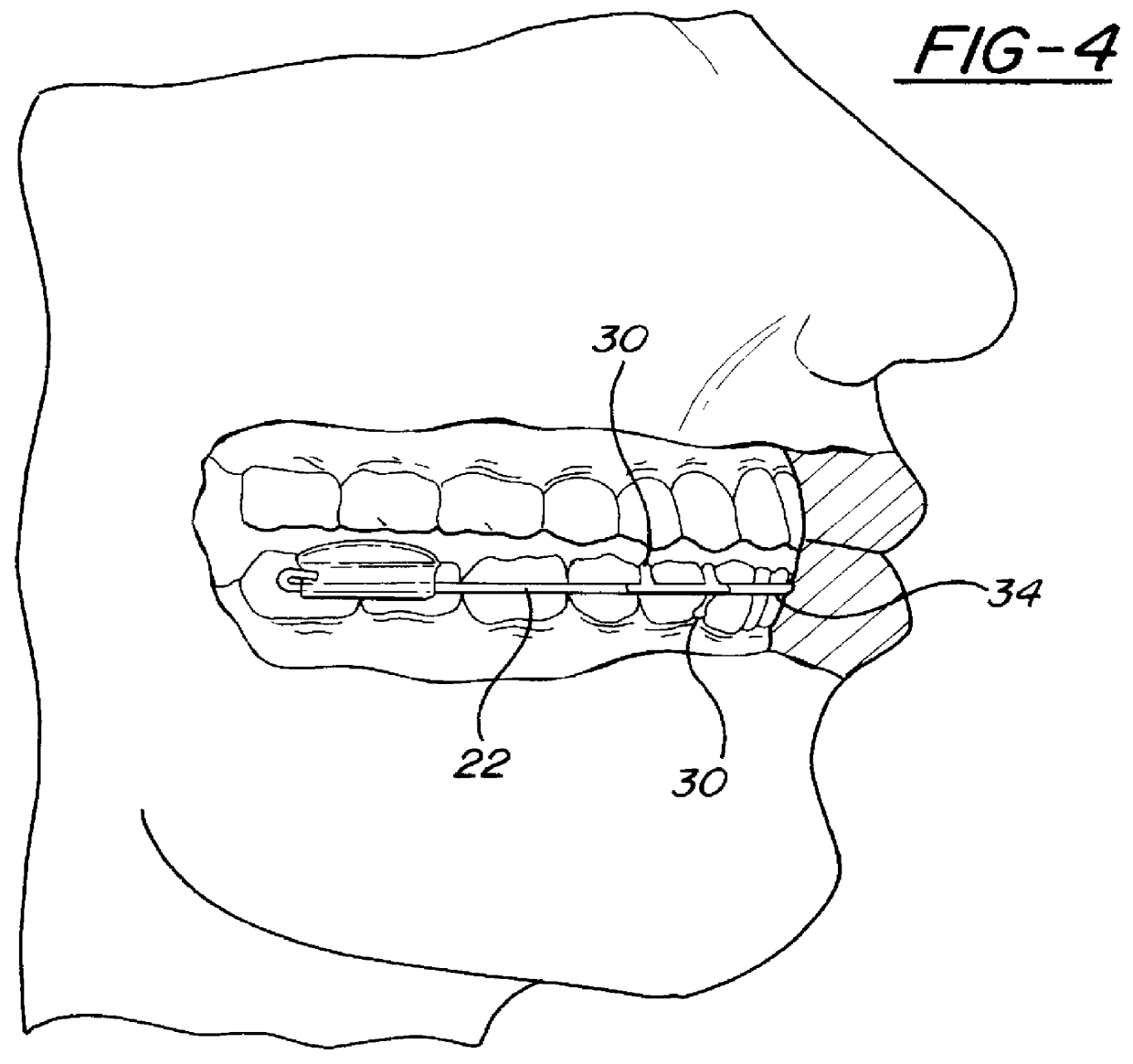

A new biofeedback modality for the treatment of bruxism. A mildly aversive, safe, liquid is inserted into, and sealed in, small, bilaterally-sleeved, polyethylene capsules. Two capsules are attached to a specially-constructed dental appliance which comfortably and securely places them between the lower and upper teeth. The appliance and capsules are worn at night or at other times when bruxism is suspected to occur. Whenever a sleeping or an awake patient attempts to brux, the capsules rupture and the liquid is released into the mouth. The liquid then draws the patient's conscious attention to, and forestalls, any attempt of teeth clenching or grinding. Variations of the method and device can be used to diagnose bruxism and to sustainably release medications and odor-masking substances into the mouth,.

Owner:NISSANI MOTI

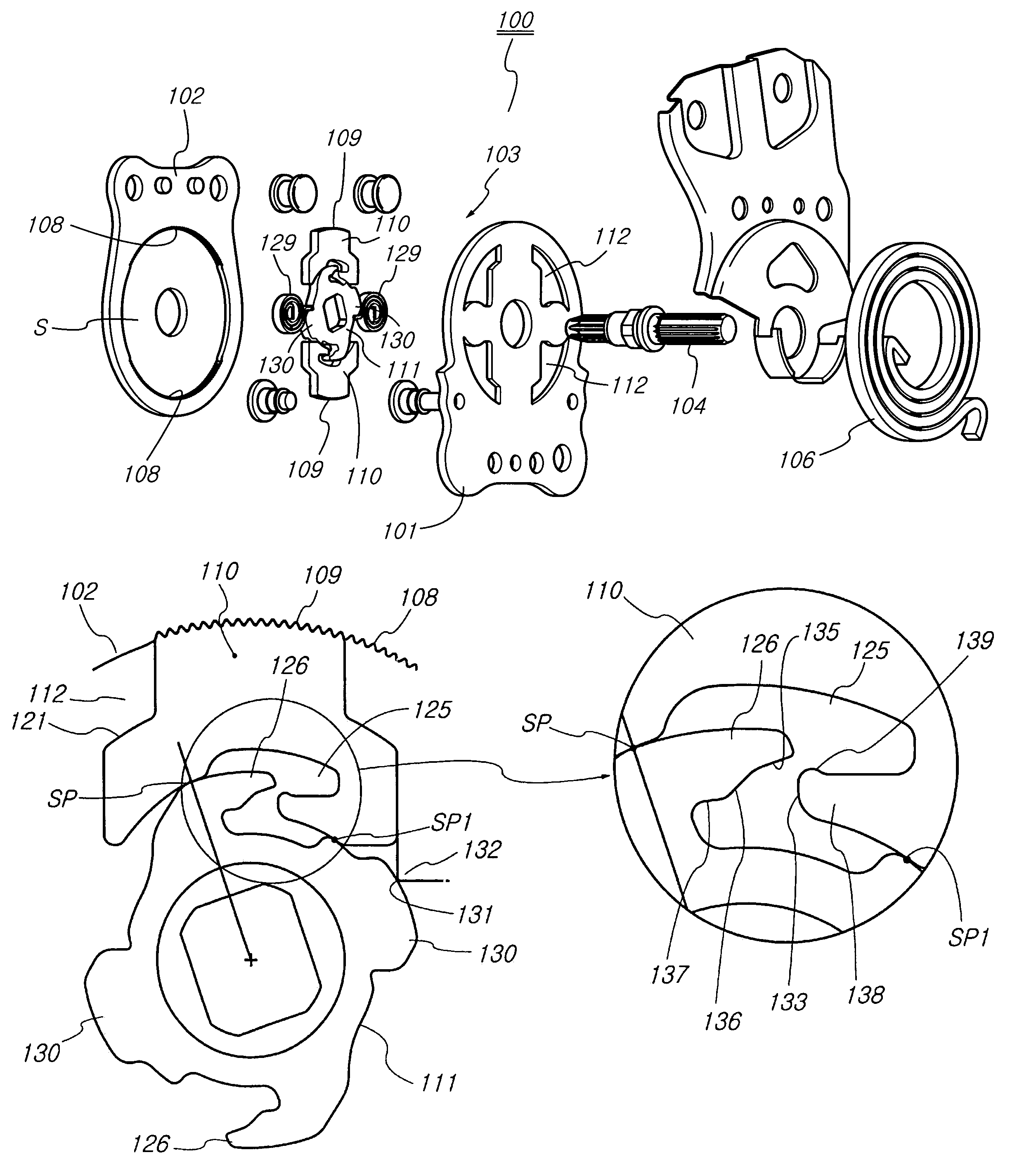

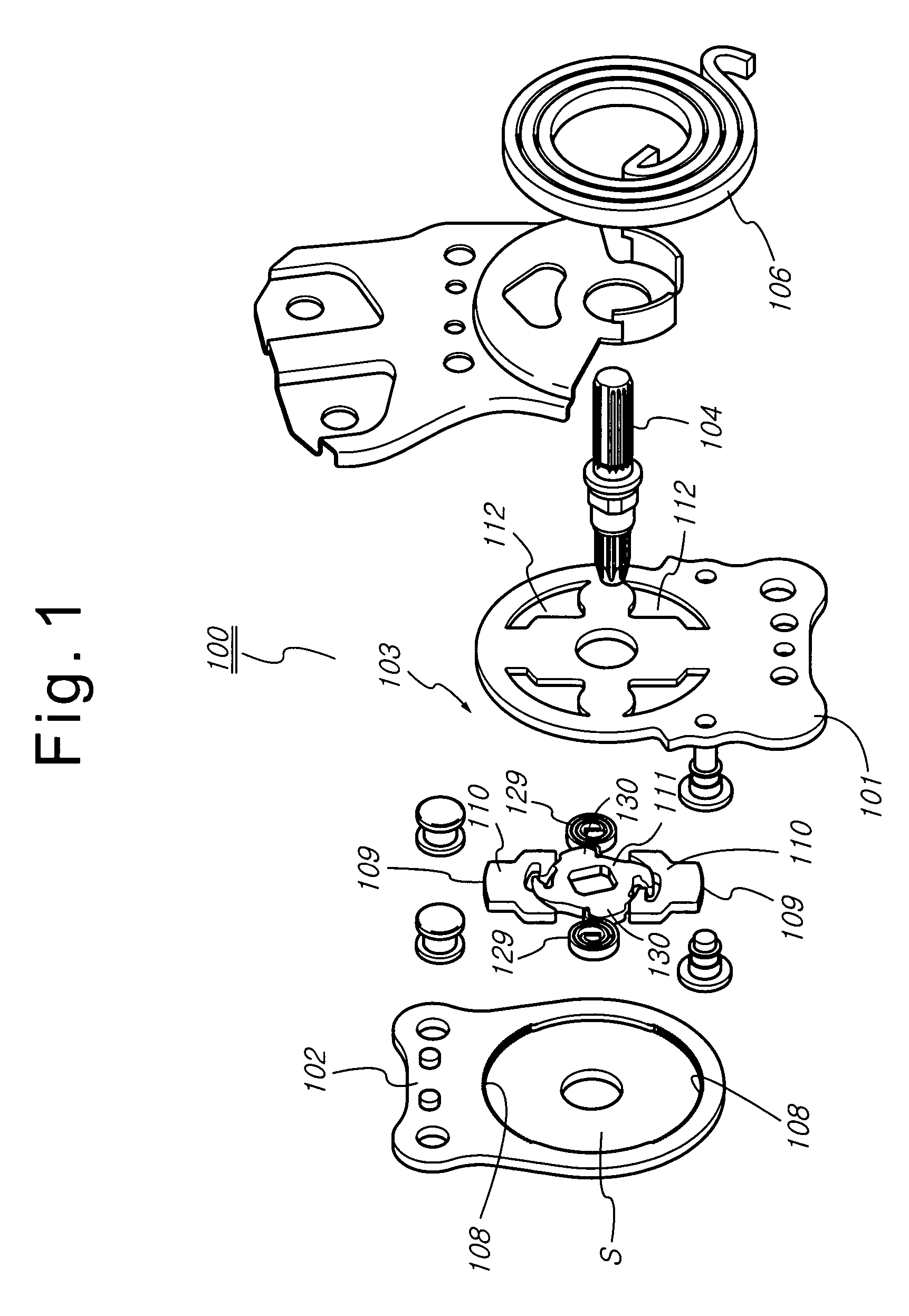

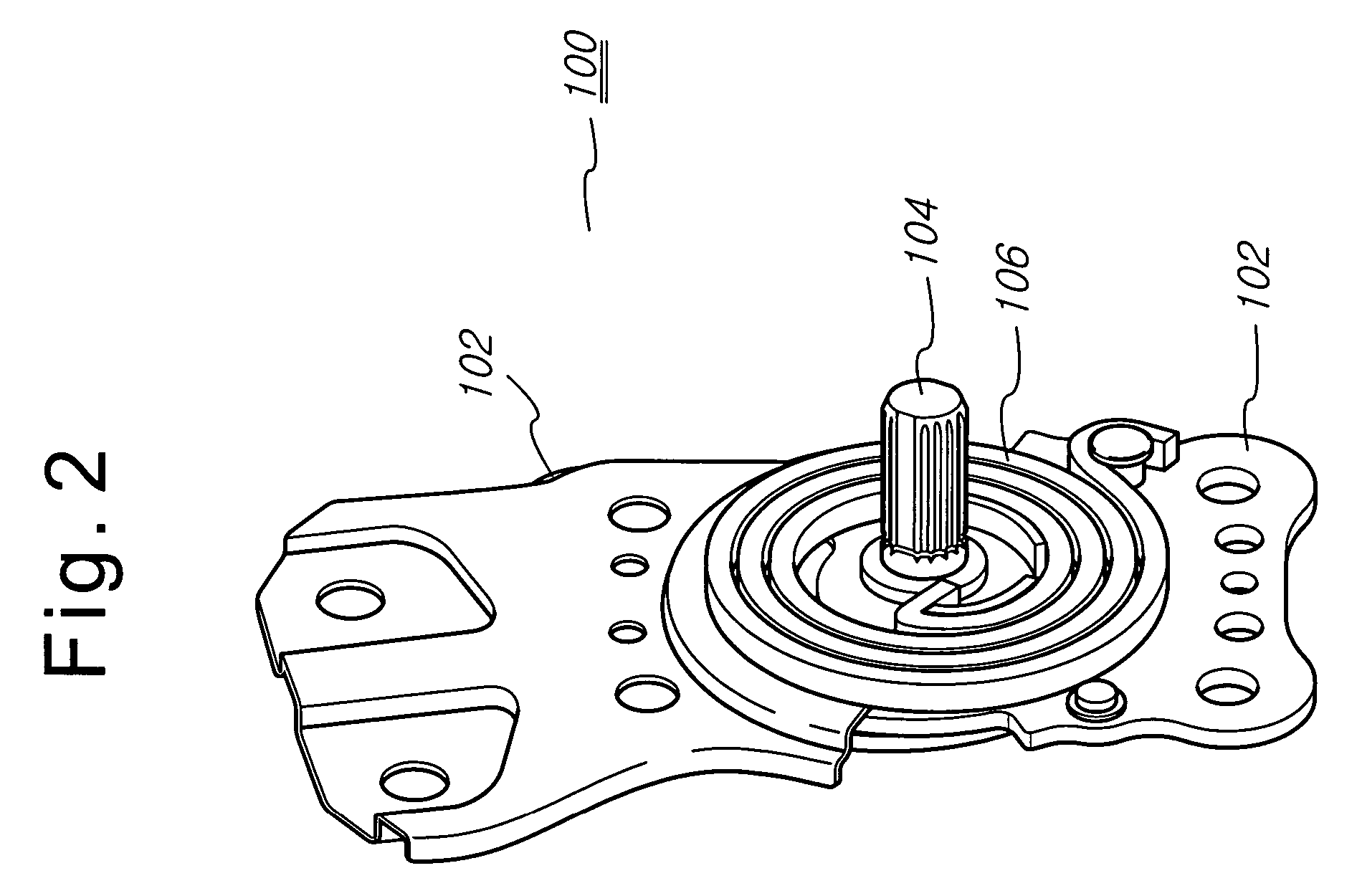

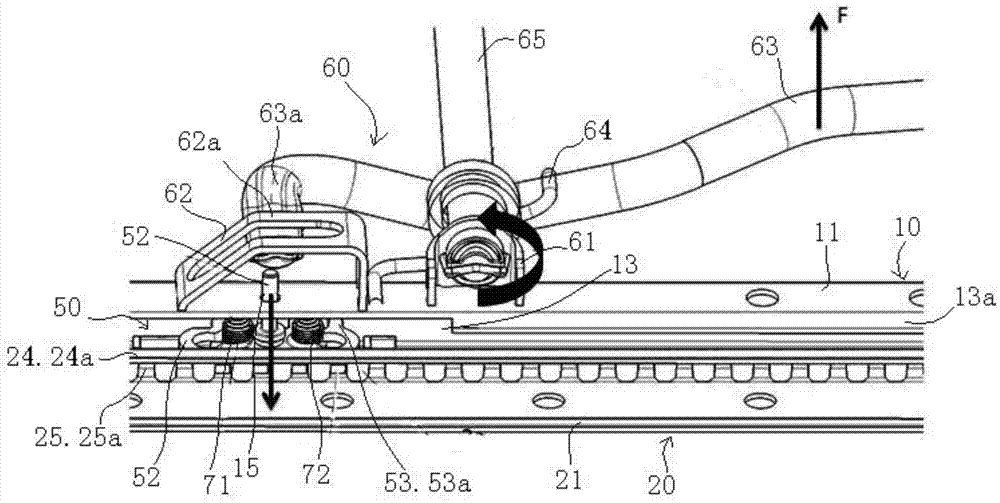

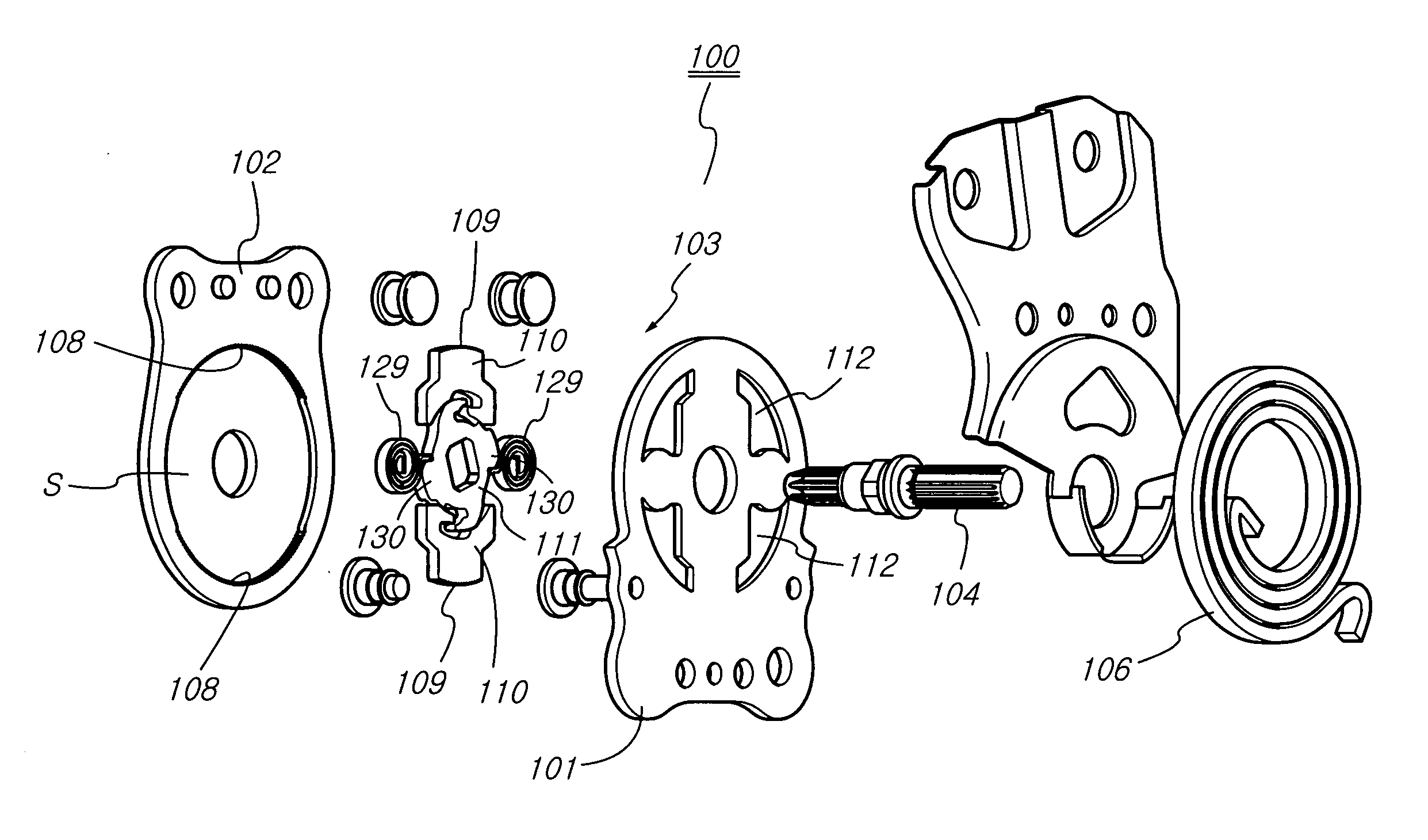

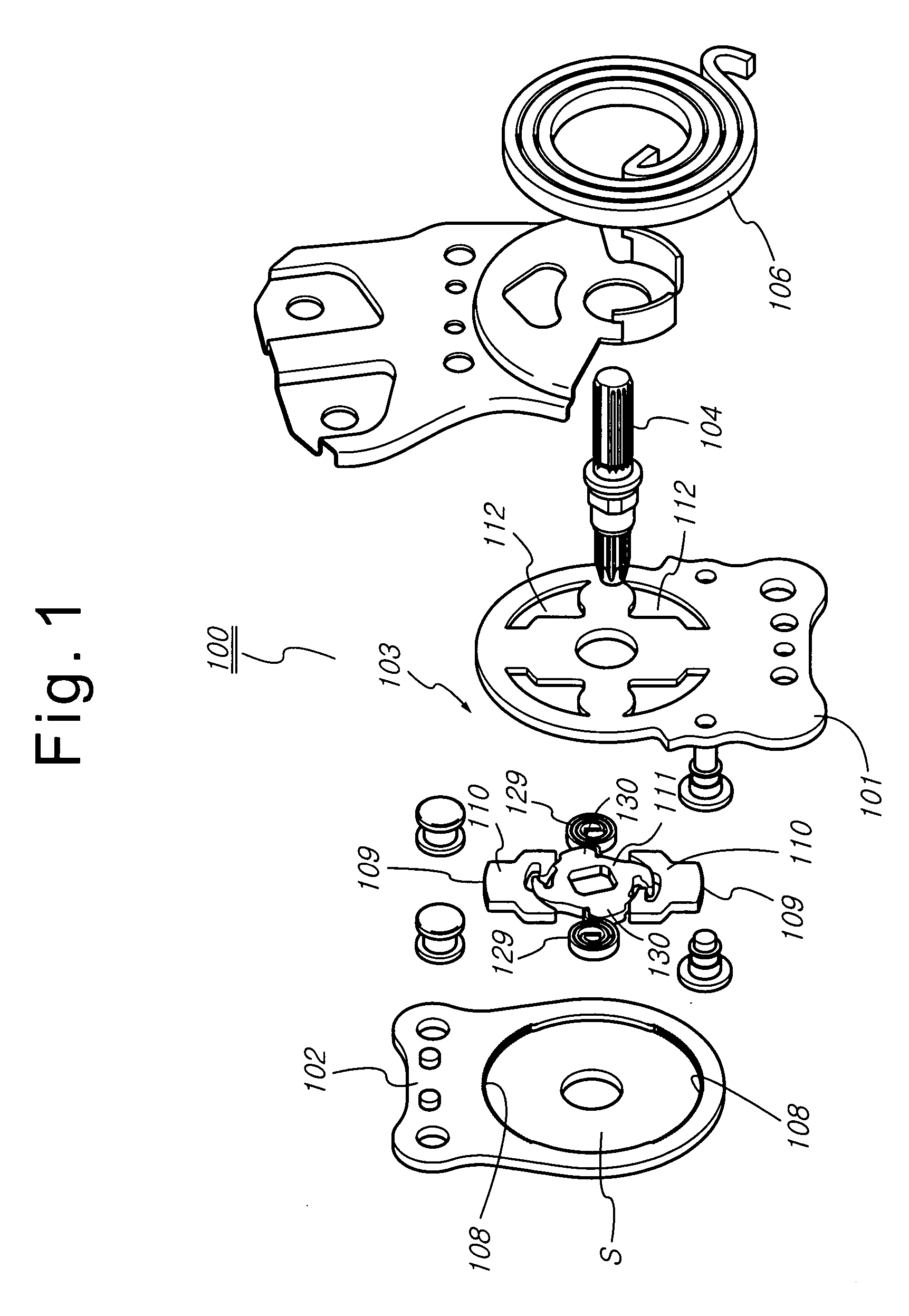

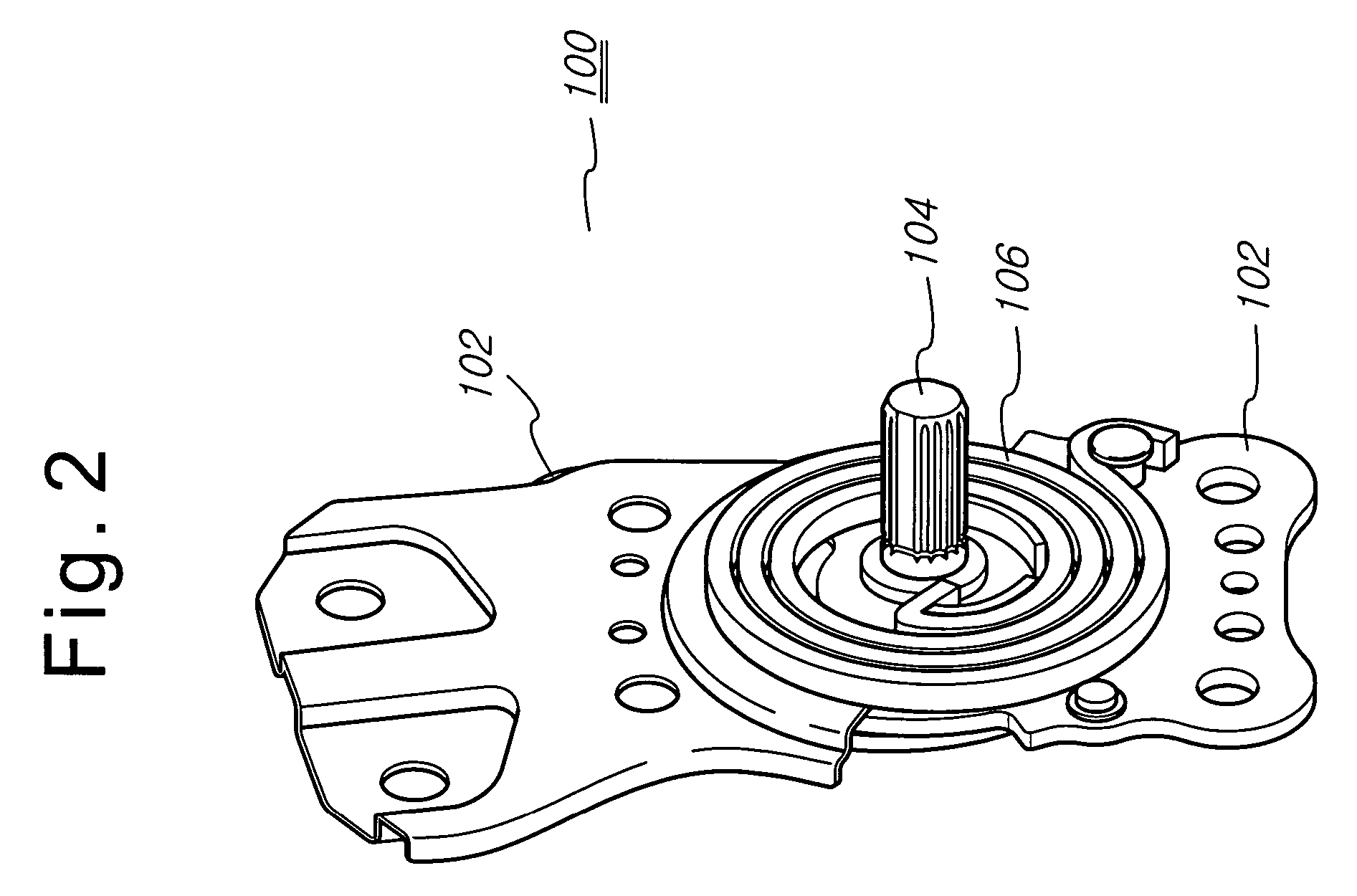

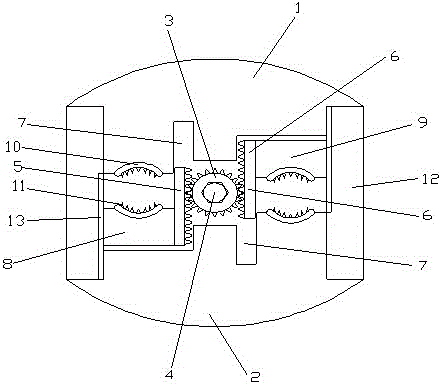

Reclining device of vehicle seat

A reclining device of a vehicle seat for easily locking and releasing the vehicle seat so as to increase performance of the vehicle seat and to improve quality thereof. The reclining device is easily assembled, by removing minor shortcomings that may occur during the assembly process, and enhances engagement of the locking teeth with the upper teeth when the reclining device is installed to a vehicle, so that the convenience as well as quality, strength, and durability of the reclining device are enhanced.

Owner:DAS CO LTD

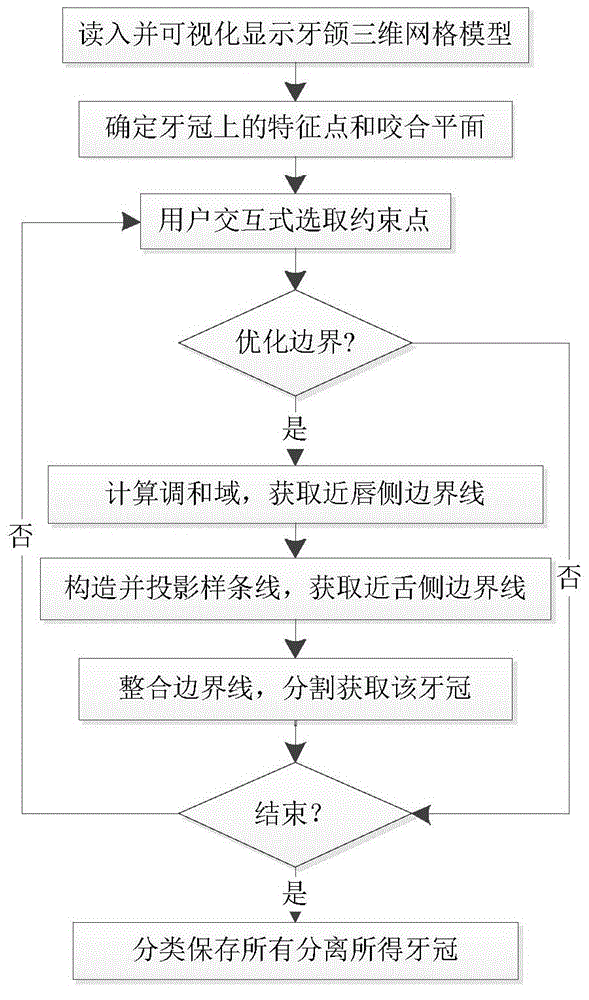

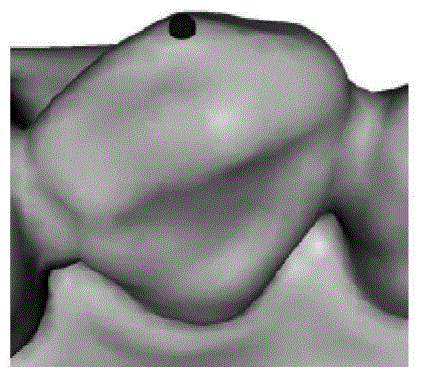

Computer interaction type method for segmenting single tooth crown from three-dimensional jaw model

InactiveCN104392492AImprove robustnessEasy to useImage data processingSpecial data processing applicationsUpper toothBorder line

The invention discloses a computer interaction type method for segmenting a single tooth crown from a three-dimensional jaw model. The method includes the steps: reading and visually displaying the three-dimensional jaw grid model; detecting anatomic characteristic points and an occlusion plane of upper teeth of a jaw in the three-dimensional jaw grid model; assigning constraint points of harmonic fields of the three-dimensional jaw grid model; calculating the harmonic fields according to constraint conditions to obtain a tooth crown segmenting border line; performing grid cutting according to the obtained tooth crown segmenting border line to obtain a tooth crown model. By the method, a tooth segmenting border can be accurately obtained, the method is simple to use, and a user interactively determines two border points on a visual view of the jaw model for a single tooth to be separated, so that the tooth crown grid model of the tooth can be accurately obtained. The method has important significance for dental orthodontics, virtual jaw surgery simulation and the like.

Owner:CENT SOUTH UNIV

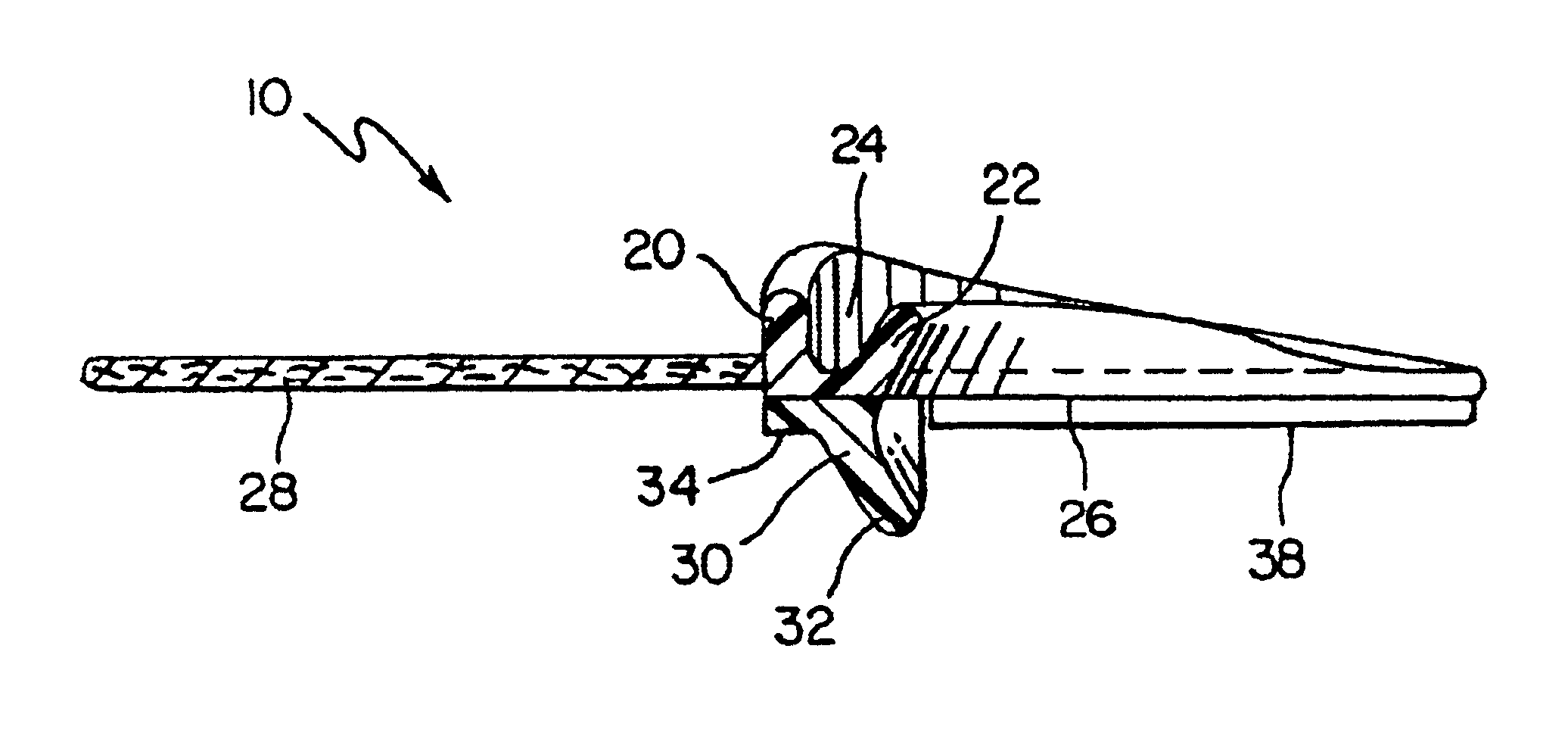

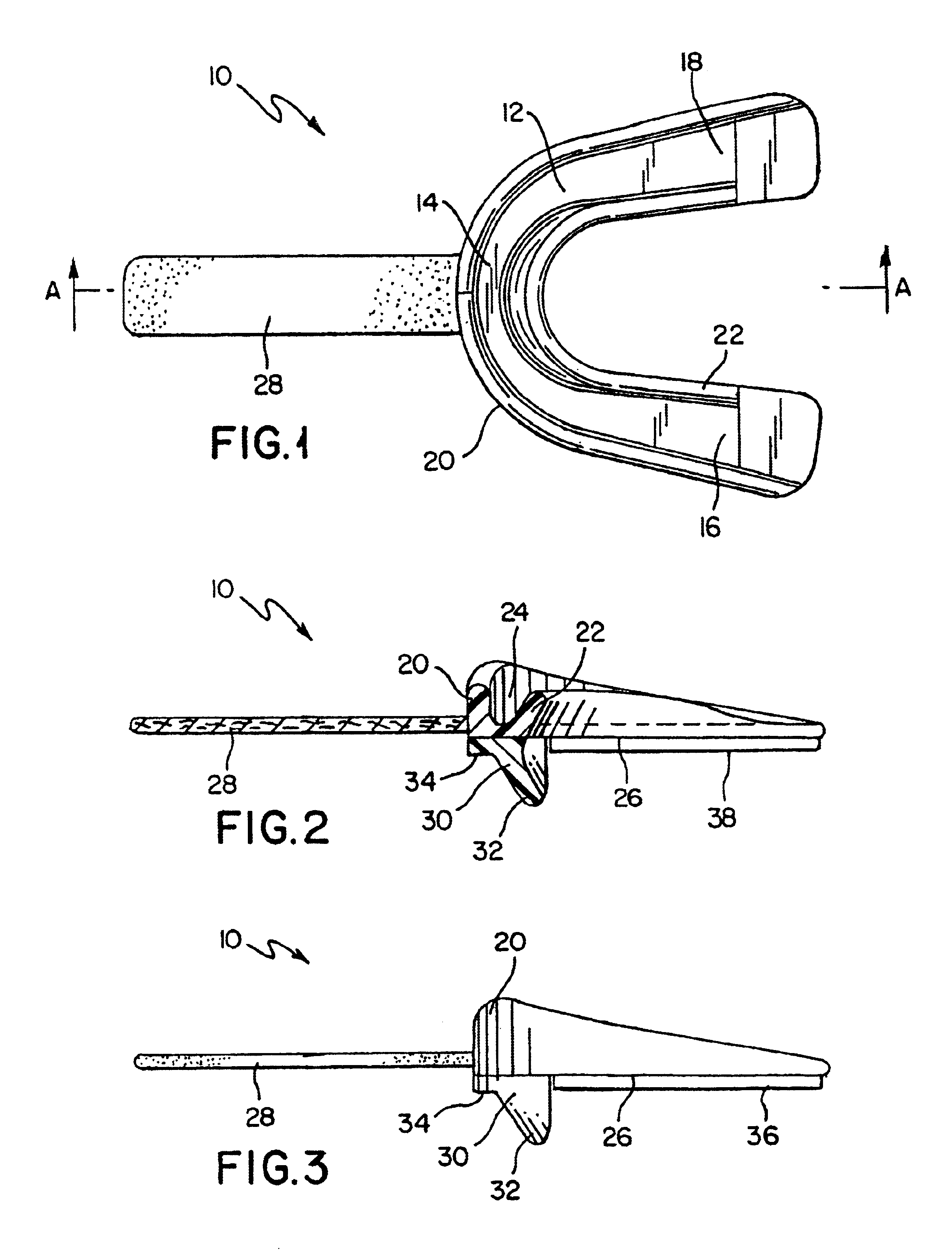

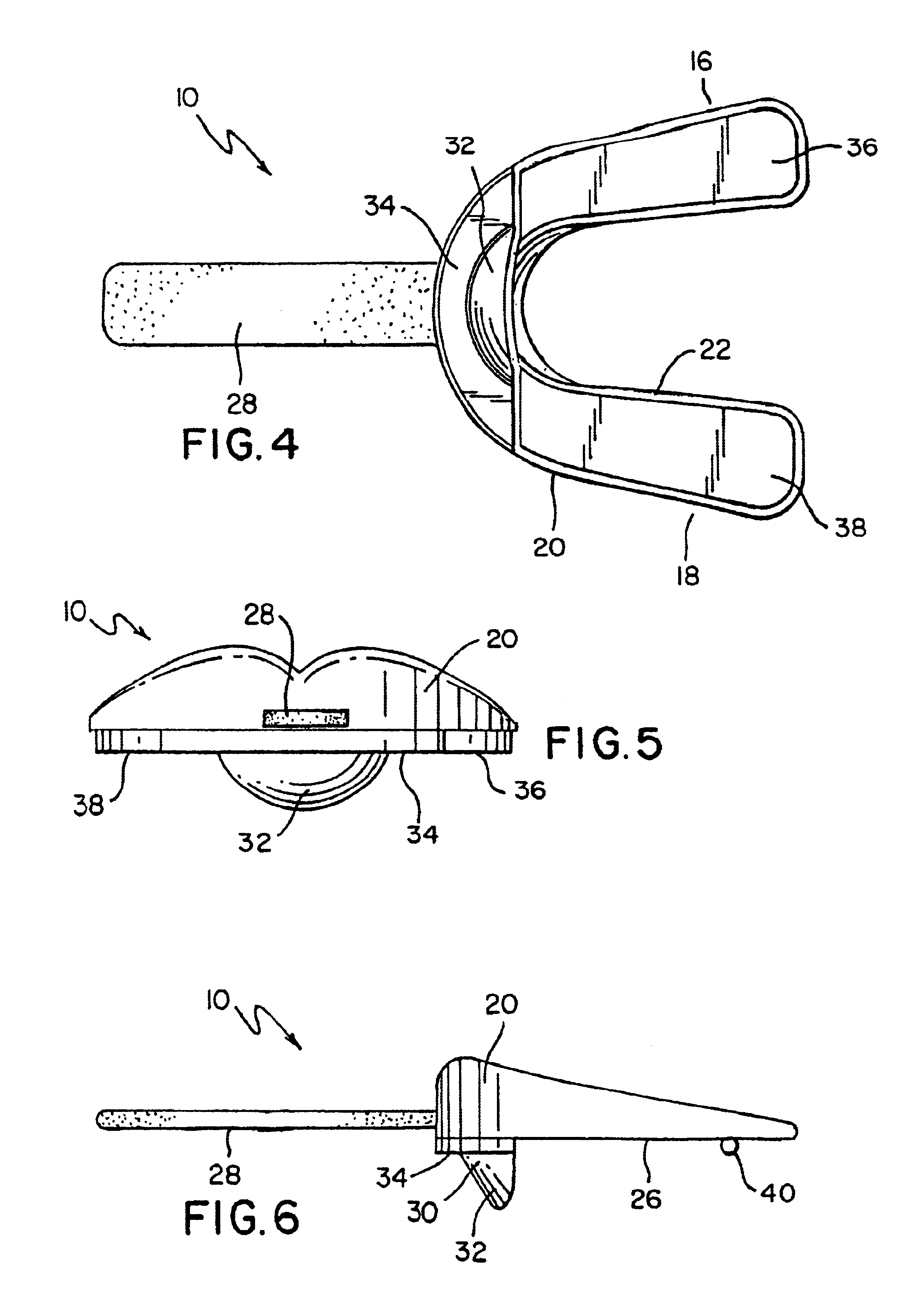

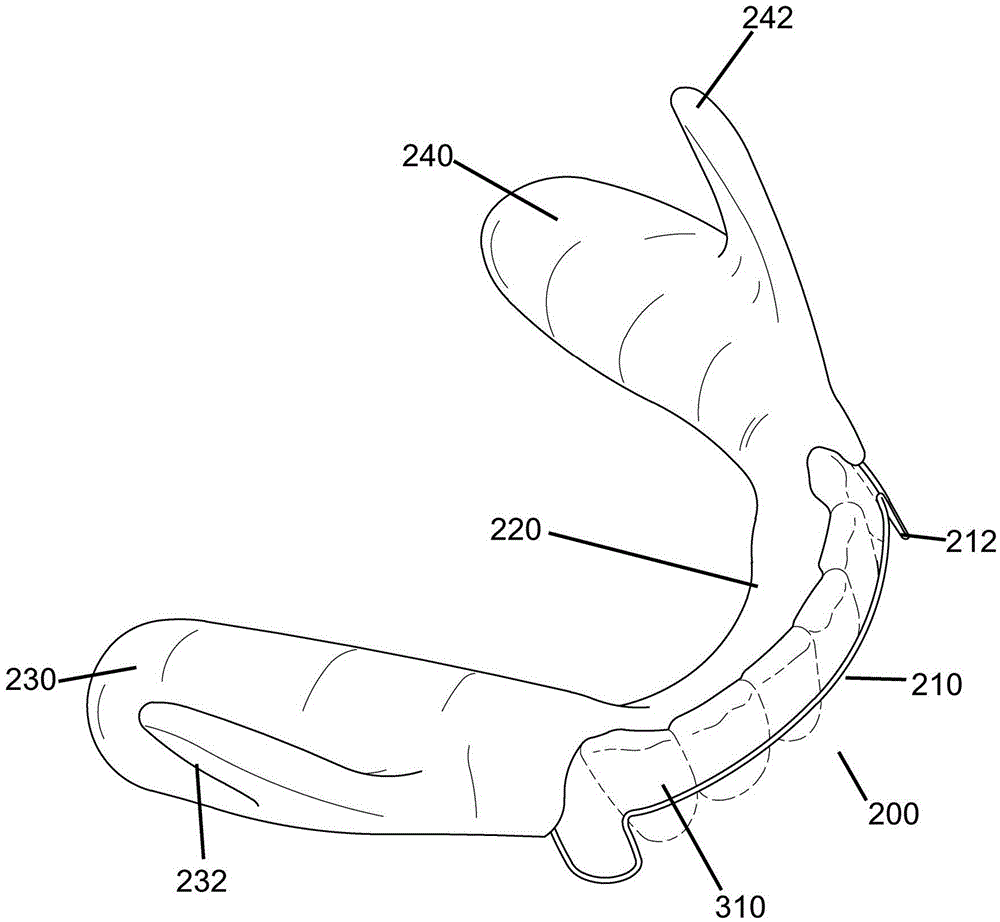

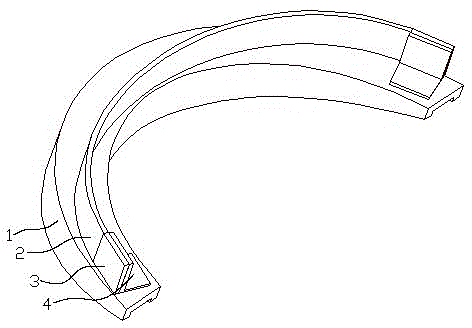

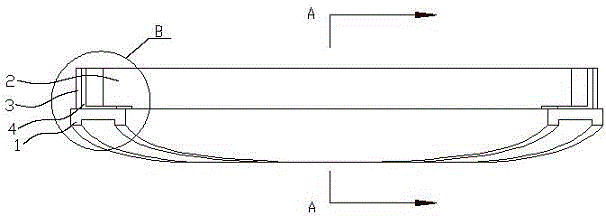

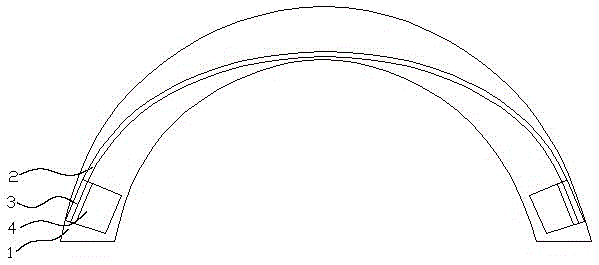

Custom tray for reducing dental clenching

InactiveUS6895970B1Reducing dental clenchingPreventing dental clenchingTeeth fillingSurgeryVertical alignmentUpper tooth

An orthotic device for reducing dental clenching is provided along with a method for custom fitting said device. The orthotic device includes a tray for receiving the user's upper teeth, a guide ramp for position the user's lower jaw, and a plurality of spacers for providing a gap between the tray and the user's lower posterior teeth during fitting of the orthotic device. When worn by the user, the orthotic device positions the user's upper and lower anterior teeth in substantial vertical alignment thereby preventing contact between a user's upper and lower posterior teeth.

Owner:LAWRENCE ERIC S +2

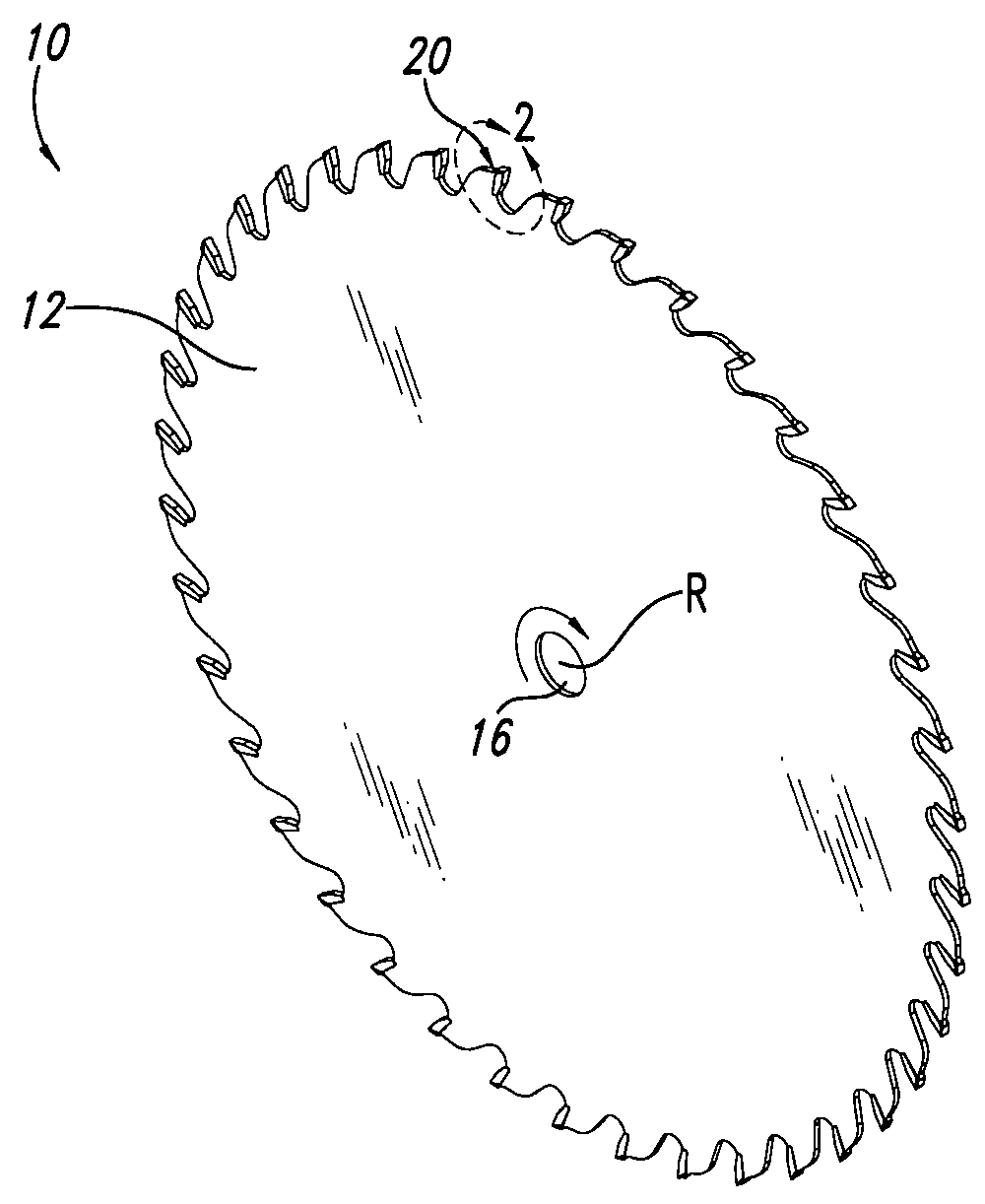

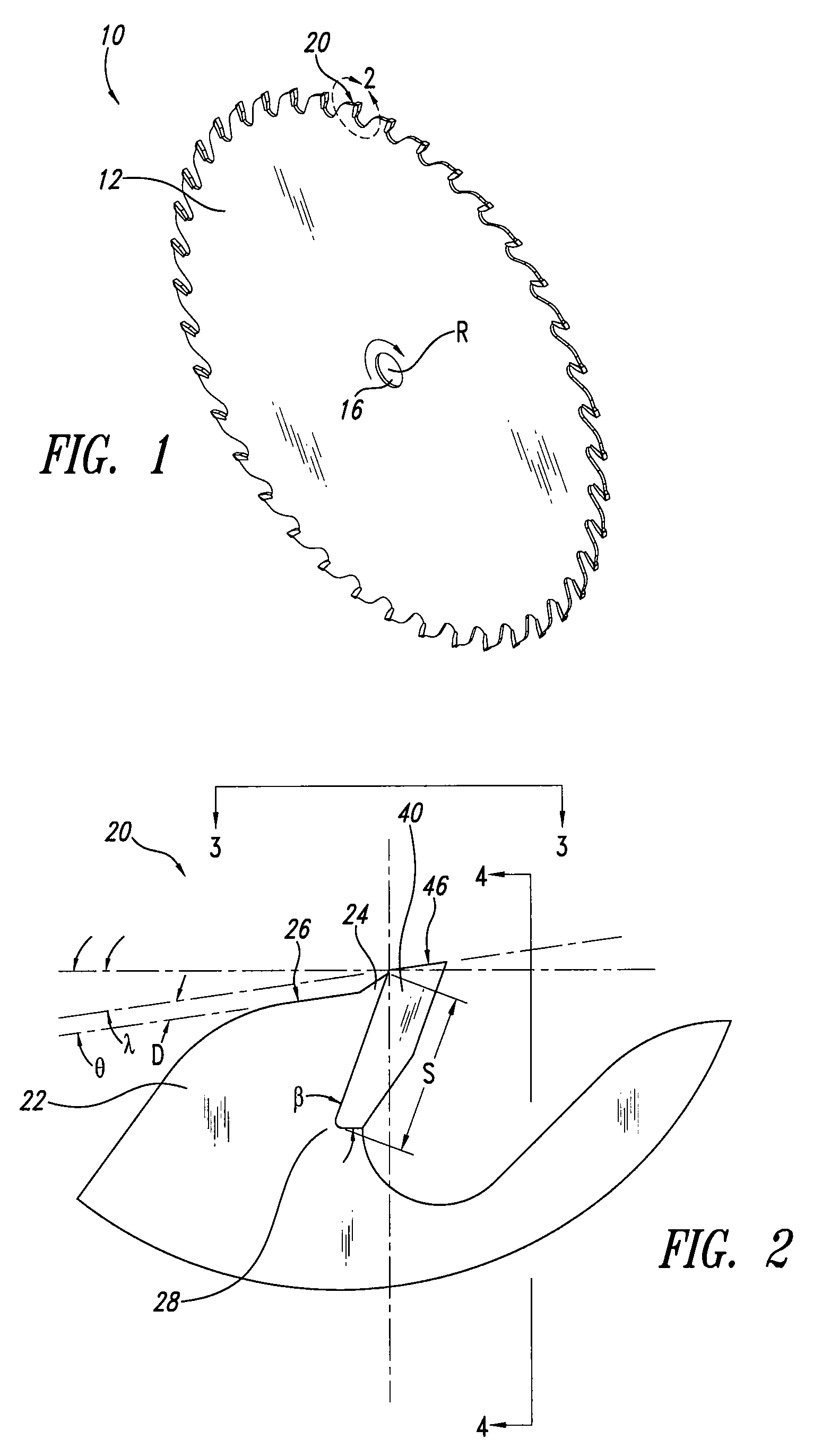

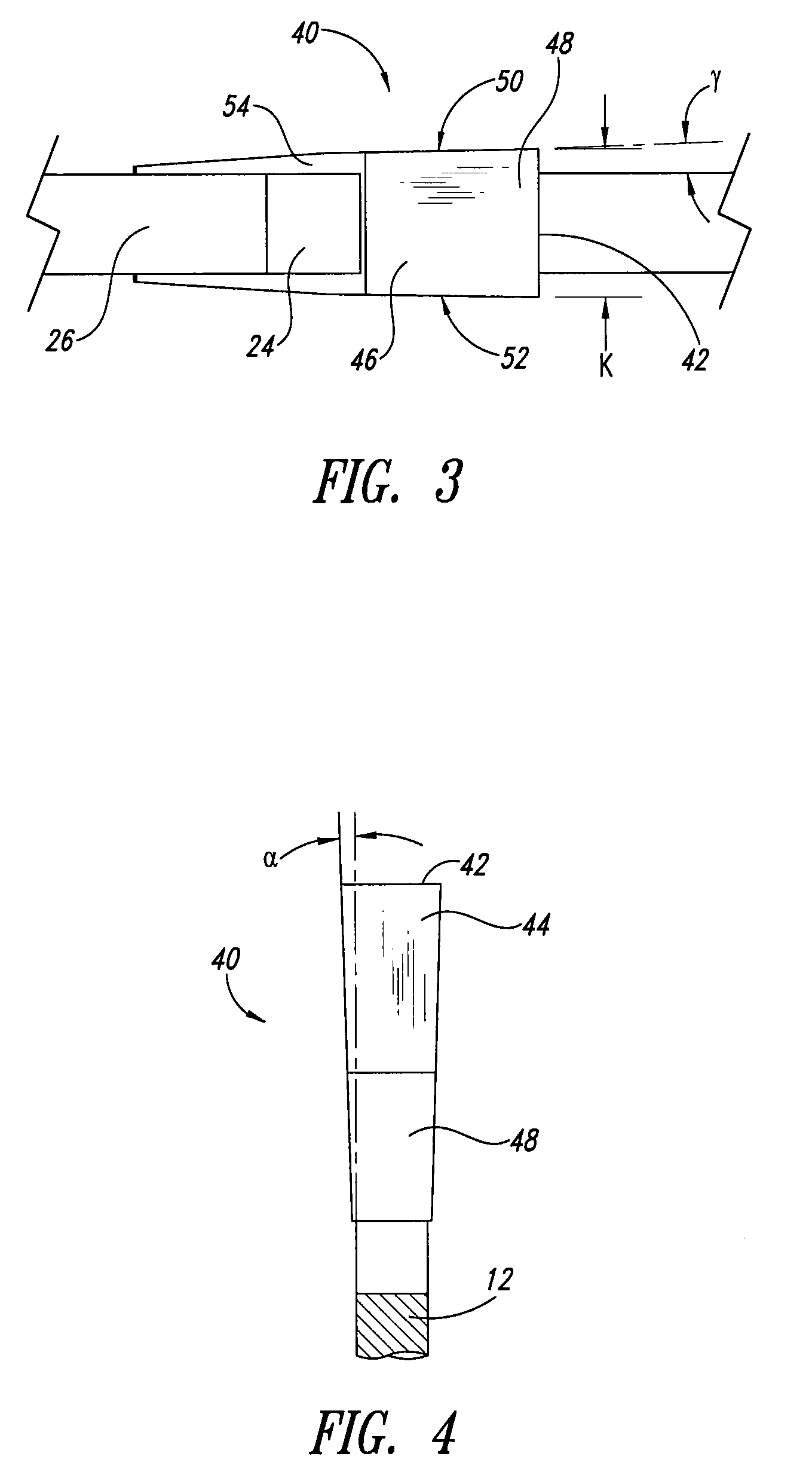

Saw blade and method of manufacturing the same

InactiveUS20100126326A1Constant widthGain is not constantMetal sawing devicesMetal sawing tool makingUpper toothCircular saw

A circular saw blade includes a substantially circular body having a plurality of protruding tip support regions spaced around the periphery thereof, each tip support region including at least a seat for supporting a cutting tip. The tip support region may further include a substantially planar upper tooth face, a grindable tip reinforcement portion and / or a lower tip angle less than 90 degrees. A cutting tip is secured to the seat of each tip support region preferably with a top face of each cutting tip substantially parallel to and offset from an upper tooth face of each tip support region. Each cutting tip of the circular saw blade is further configured to maintain a cutting edge at a substantially constant width when material is removed from the top face thereof. A method of manufacturing a saw blade is also provided.

Owner:CLOUTIER MICHAEL F

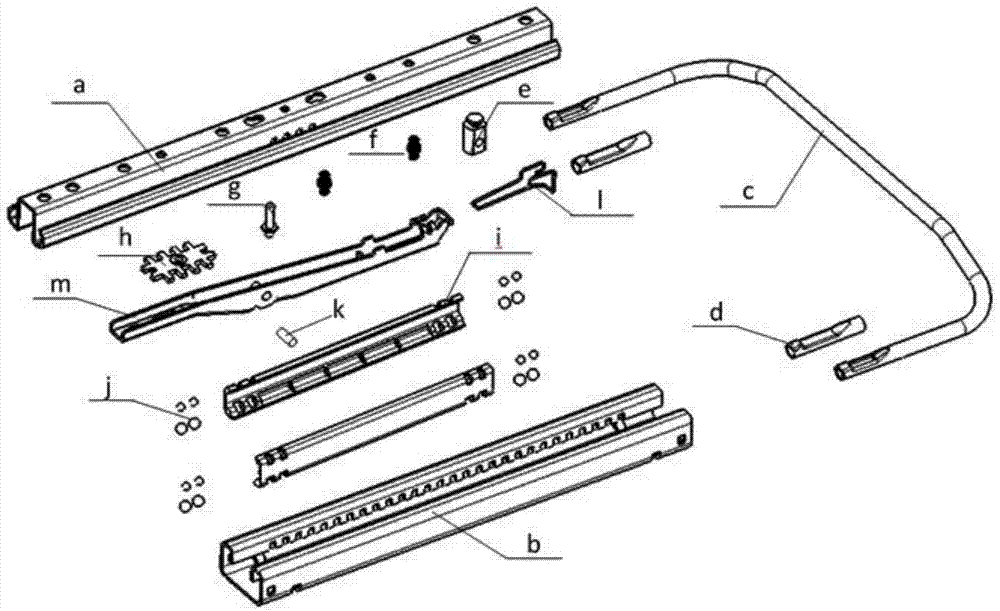

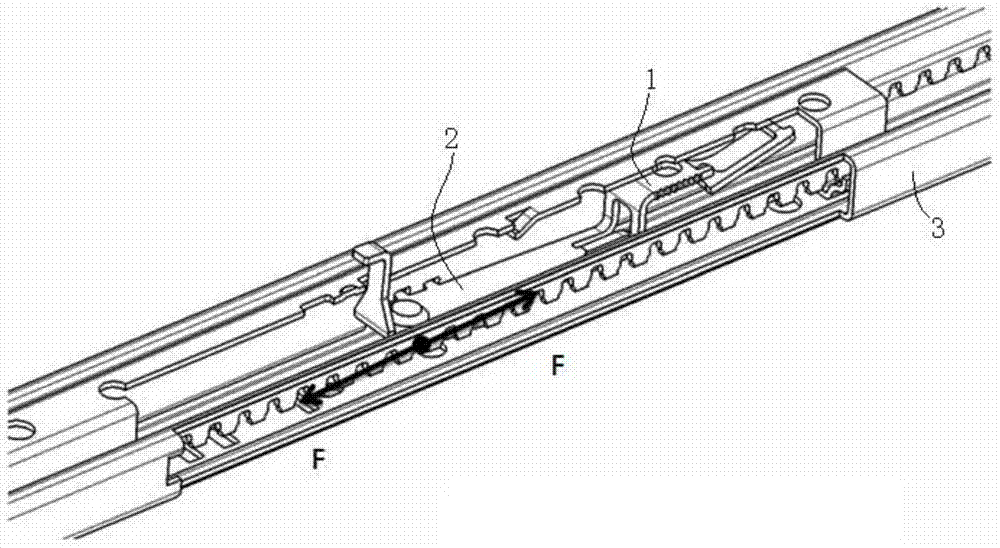

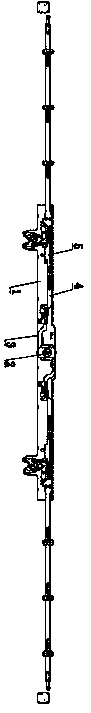

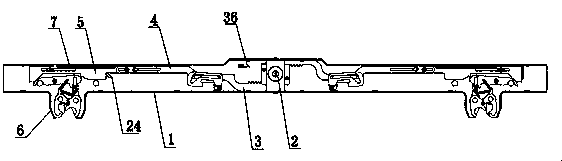

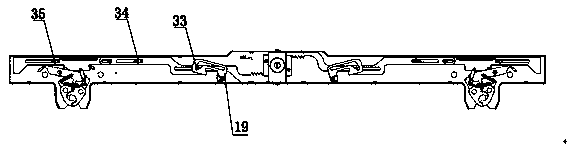

Automotive seat slide rail

The invention discloses an automotive seat slide rail. The automotive seat slide rail comprises an upper slide rail body, a lower slide rail body, a spring component, a locking component and an unlocking component, wherein the unlocking component drives the locking component to move up and down to achieve locking and unlocking of the upper slide rail body and the lower slide rail body, the locking component comprises a locking sheet and a guide pin, locking tooth parts are arranged on the two sides of the locking sheet, the lower end of the guide pin is connected with the locking sheet in an anchoring mode, and the upper portion of the guide pin penetrates through a guide pin hole in the upper wall of the upper slide rail body; the spring component acts on the space between the locking sheet and the upper wall of the upper slide rail body or the space between the locking sheet and the lower wall of the lower slide rail body; when the upper slide rail body and the lower slide rail body are in a locked state, the locking tooth parts penetrate through an upper tooth window on the upper slide rail body and a lower tooth window on the lower slide rail body; when the upper slide rail body and the lower slide rail body are in an unlocked state, the locking tooth parts disengage from the lower tooth window on the lower slide rail body. According to the automotive seat slide rail, structure becomes simpler, assembly becomes easily, quality control is facilitated, cost is reduced, the weight of the whole slide rail is reduced, and the stress on the spring component from the slide rail in long-time use is effectively eliminated.

Owner:KEIPER (CHANGSHU) SEATING MECHANISMS CO LTD

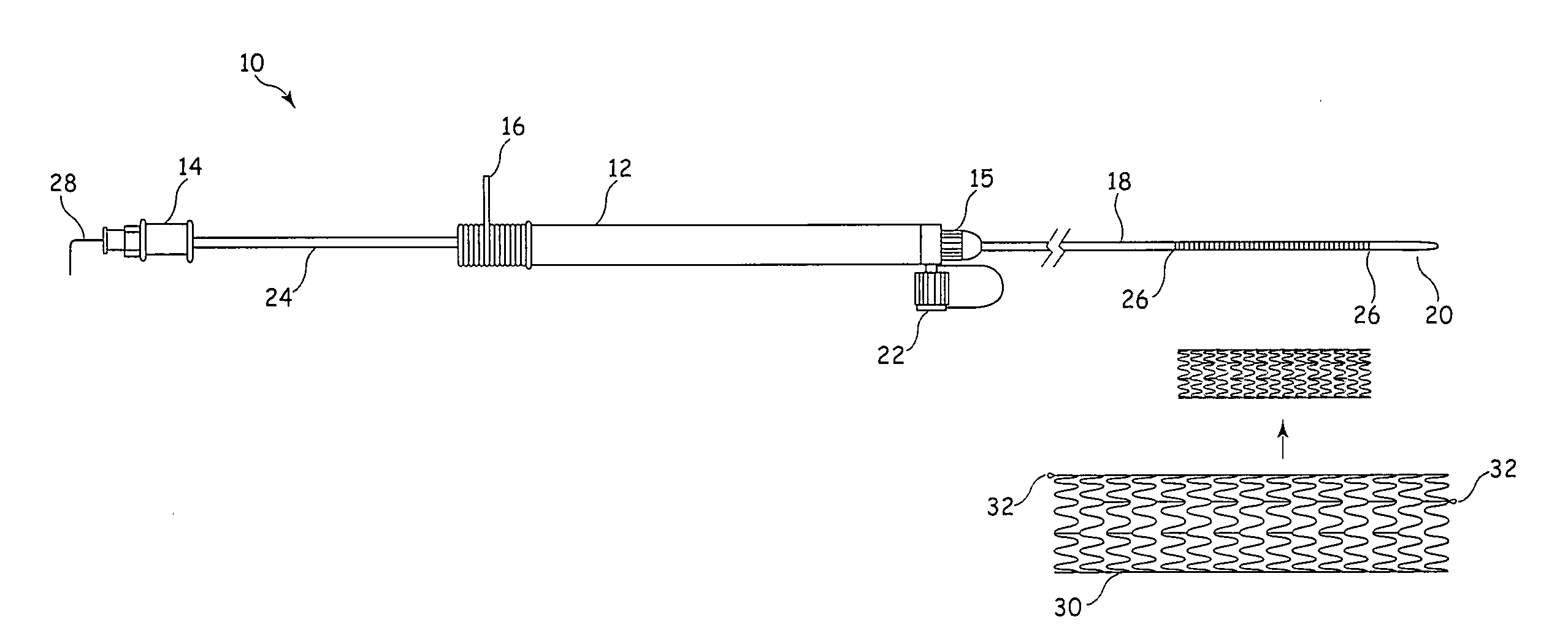

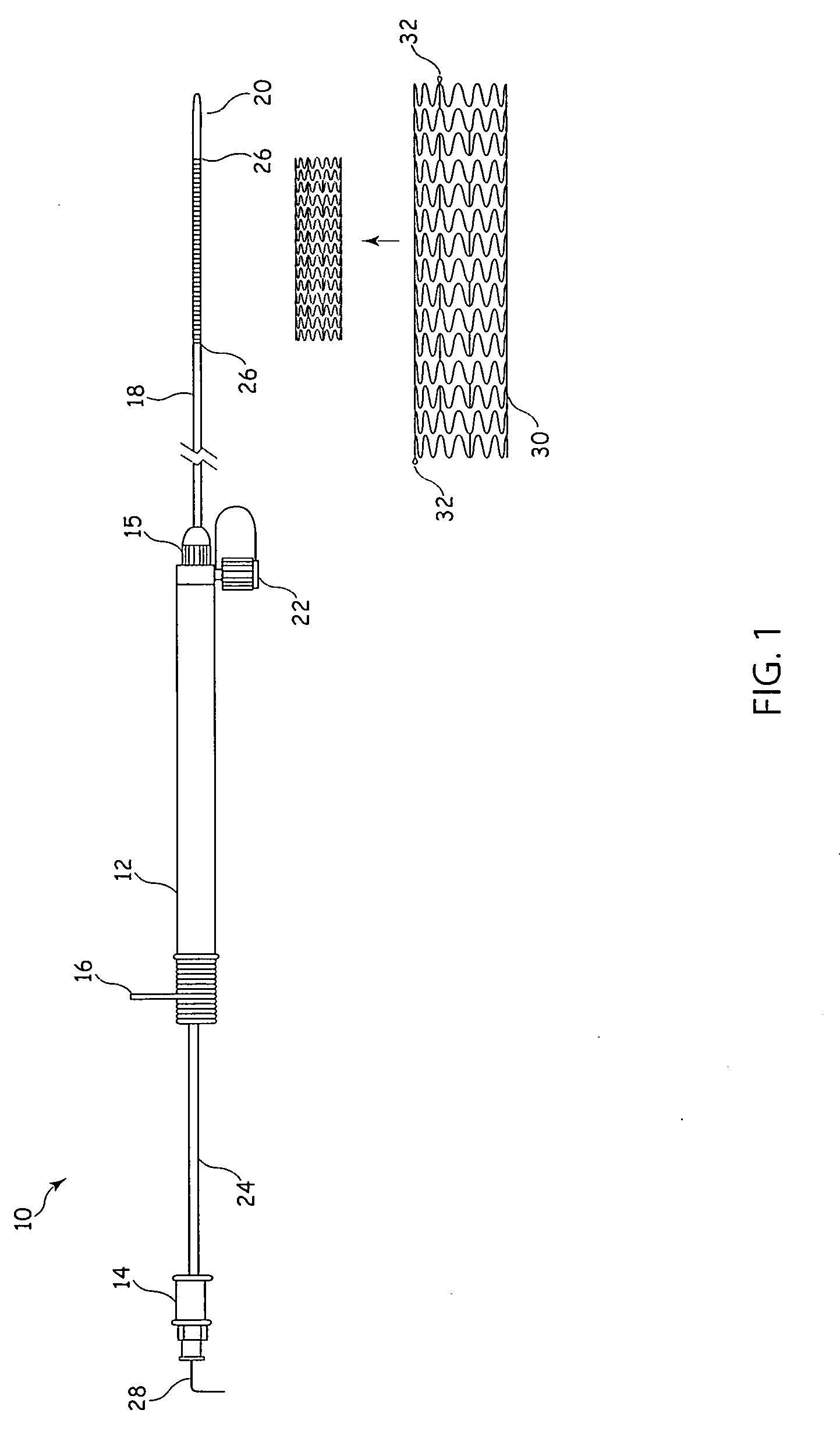

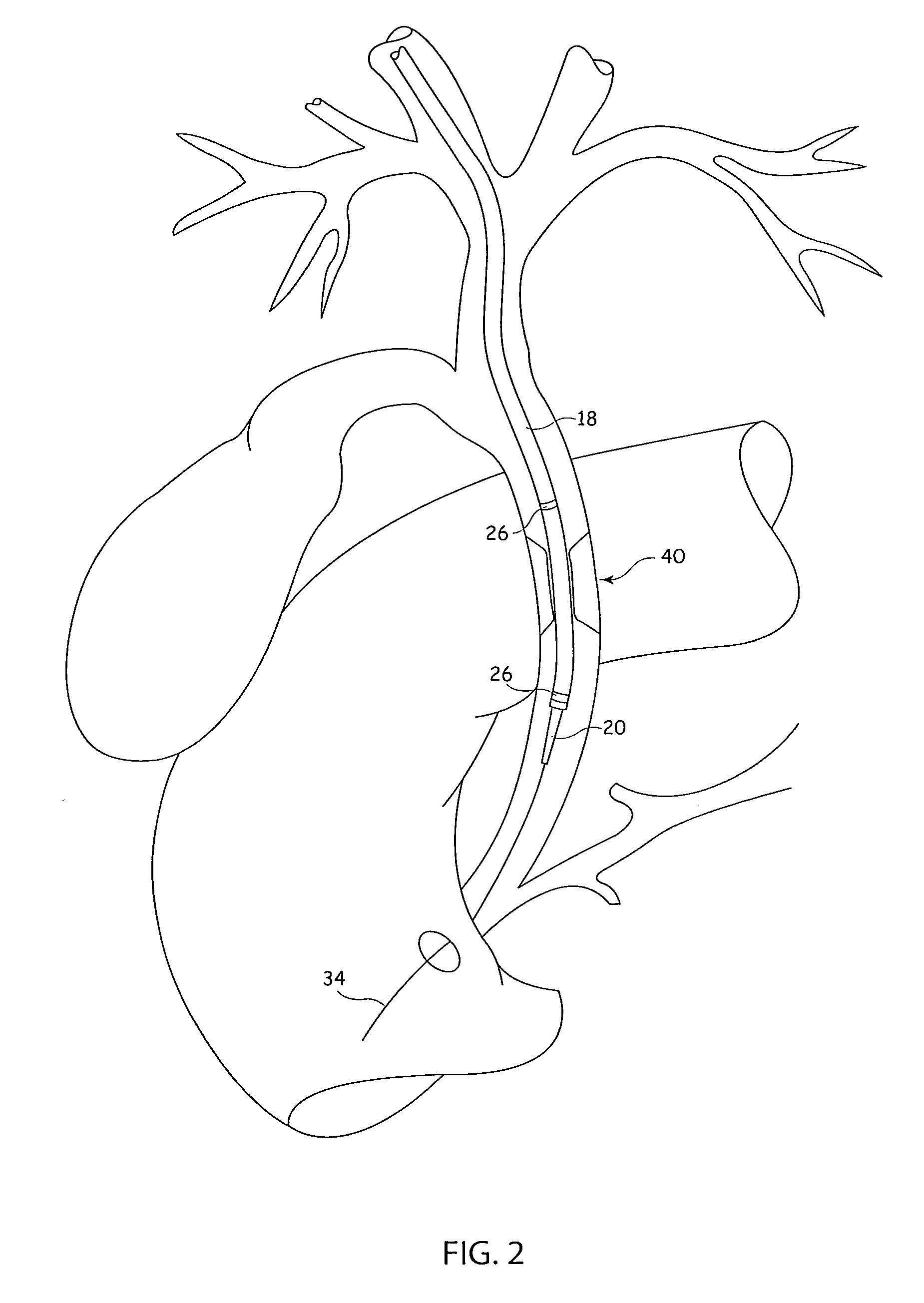

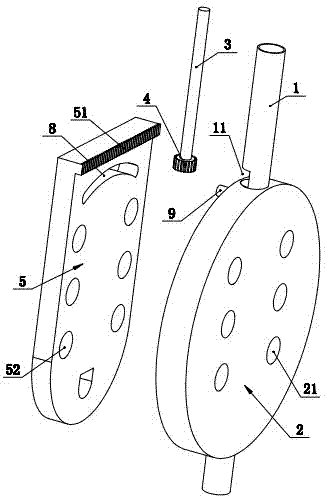

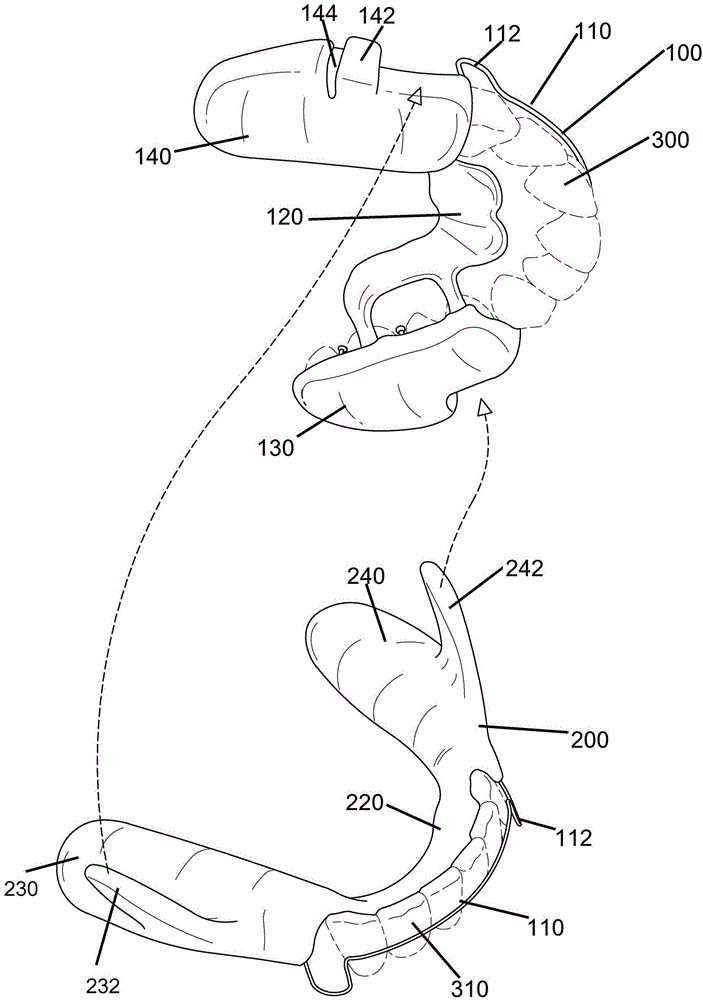

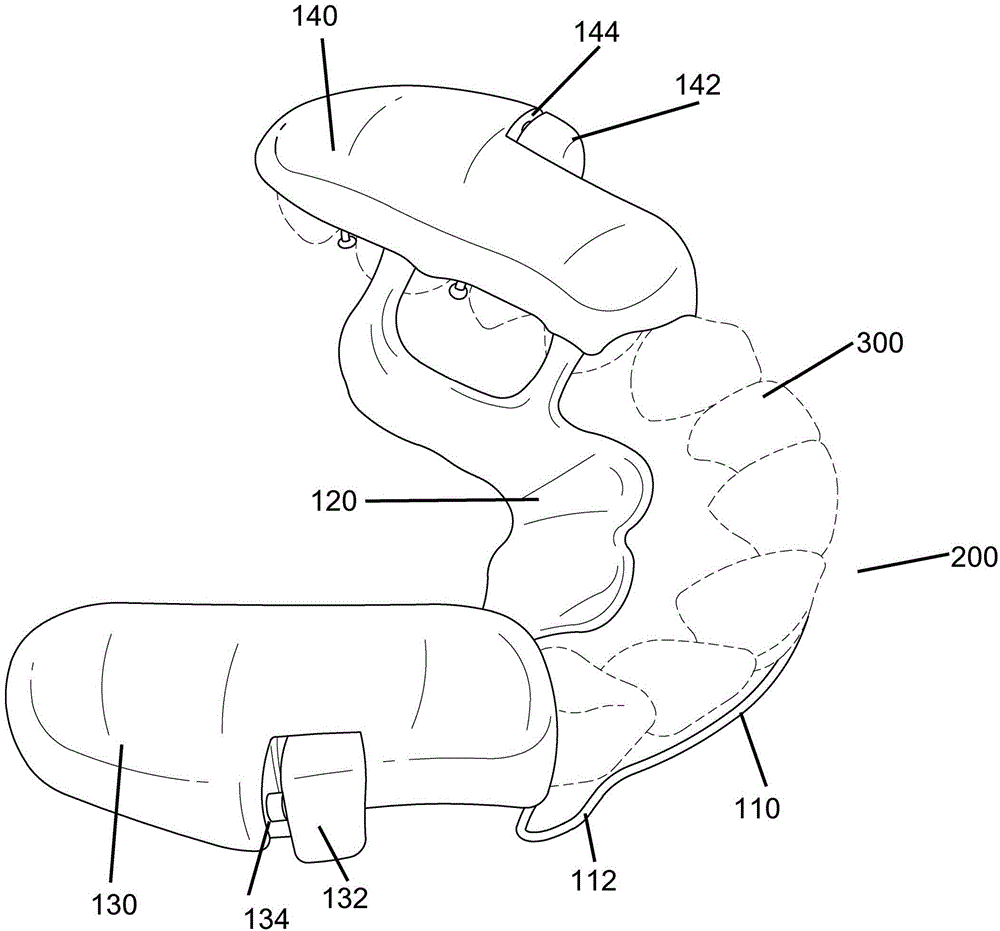

Deployment handle for an implant deployment device

ActiveUS20090171428A1Improved deployment handleEasy to assembleStentsEar treatmentUpper toothEngineering

A deployment handle (112) for an implant deployment device (10) facilitates withdrawal of a sheath (18). The deployment handle (112) includes two separate actuators: a trigger (130) and a sliding actuator (330). The trigger (130) can be used to effect small step-wise movement of a carriage (120) that is connected to a sheath (18) to be withdrawn. The sliding actuator (330) can be used to effect continuous movement of a carriage (120) to withdraw a sheath (18). In order to transmit movement of either the trigger (130) or the sliding actuator (330) to the carriage (120), a flexible rack (380) is used. The flexible rack (380) includes upper teeth (390) and lower teeth (395) for engagement with the trigger (130) and the sliding actuator (330) respectively. The ability of the flexible rack (380) to bend back on itself means that unnecessary elongation of the deployment handle (112) is avoided.

Owner:COOK MEDICAL TECH LLC

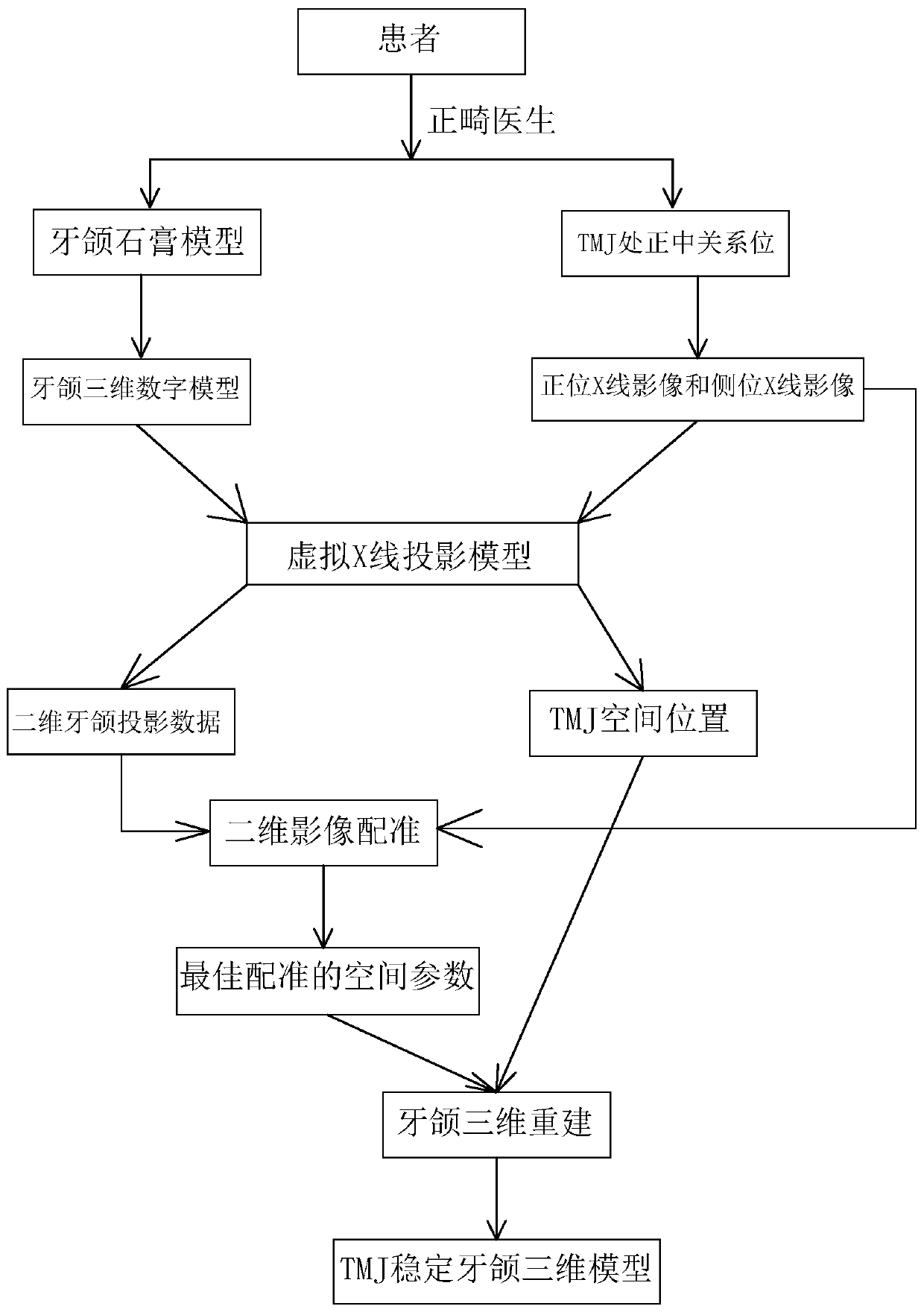

Tooth jaw three-dimensional digital modeling method based on temporal-mandibular joint stability

ActiveCN110147647APromote universal adoptionMaintain stabilityImage analysisSustainable transportationDecompositionProjection image

The invention discloses a tooth jaw three-dimensional digital modeling method based on temporal-mandibular joint stability. The tooth jaw three-dimensional digital modeling method comprises the following steps of using a three-dimensional scanner for scanning to obtain a tooth jaw three-dimensional digital model of a patient; taking a positive position X-ray image and a lateral position X-ray image of the head of the patient at the median relation position; constructing a virtual X-ray projection model and a reference coordinate system; respectively adjusting positions and angles of upper andlower tooth jaws of the tooth jaw three-dimensional digital model in the virtual X-ray projection model, and calculating a two-dimensional X-ray projection image; registering the two-dimensional X-rayprojection images of the upper tooth jaw and the lower tooth jaw with an actual skull positive position X-ray image and an actual lateral position X-ray image, and recording parameters of the upper tooth jaw and the lower tooth jaw in a reference coordinate system during optimal registration; inversely solving spatial position information of the temporal-mandibular joint; reconstructing a dentaljaw three-dimensional digital model by using the upper and lower dental jaw three-dimensional digital model information during optimal registration; and further constructing a jaw occlusion motion model and a mechanical decomposition model of the three-dimensional digital model, and providing a virtual operation function and an operation prediction function according to the model.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

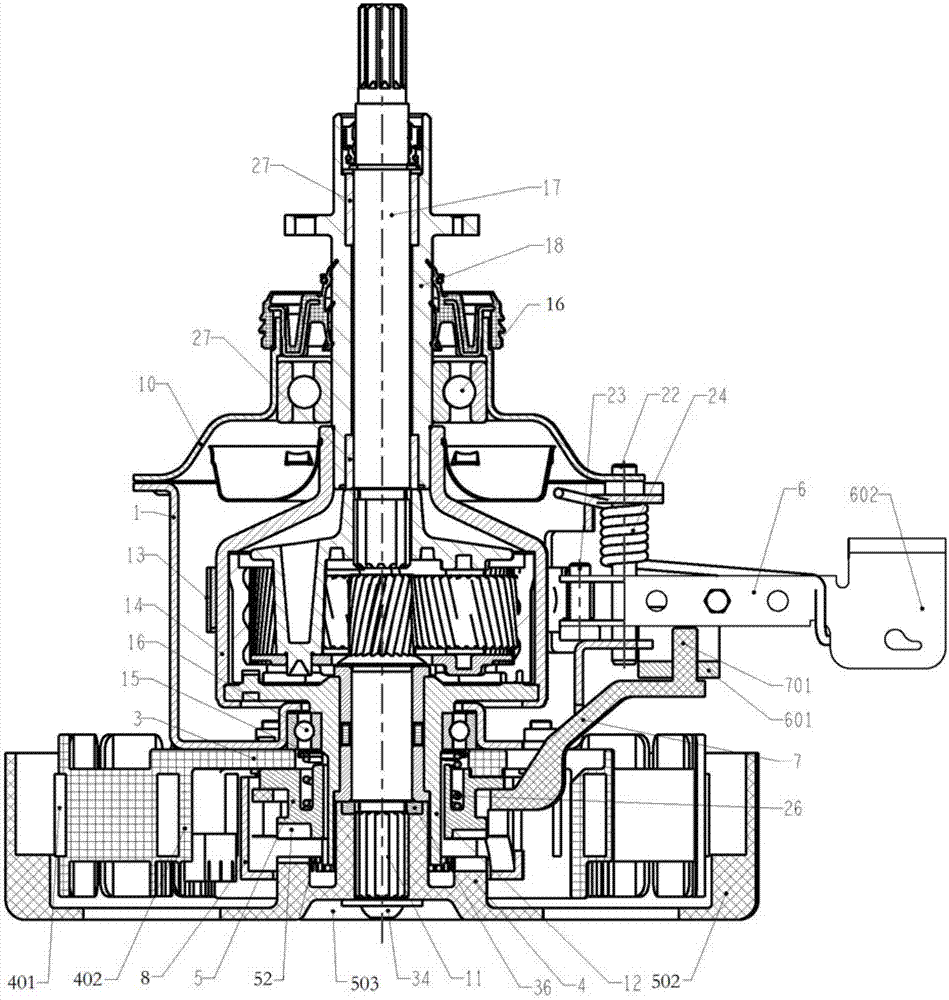

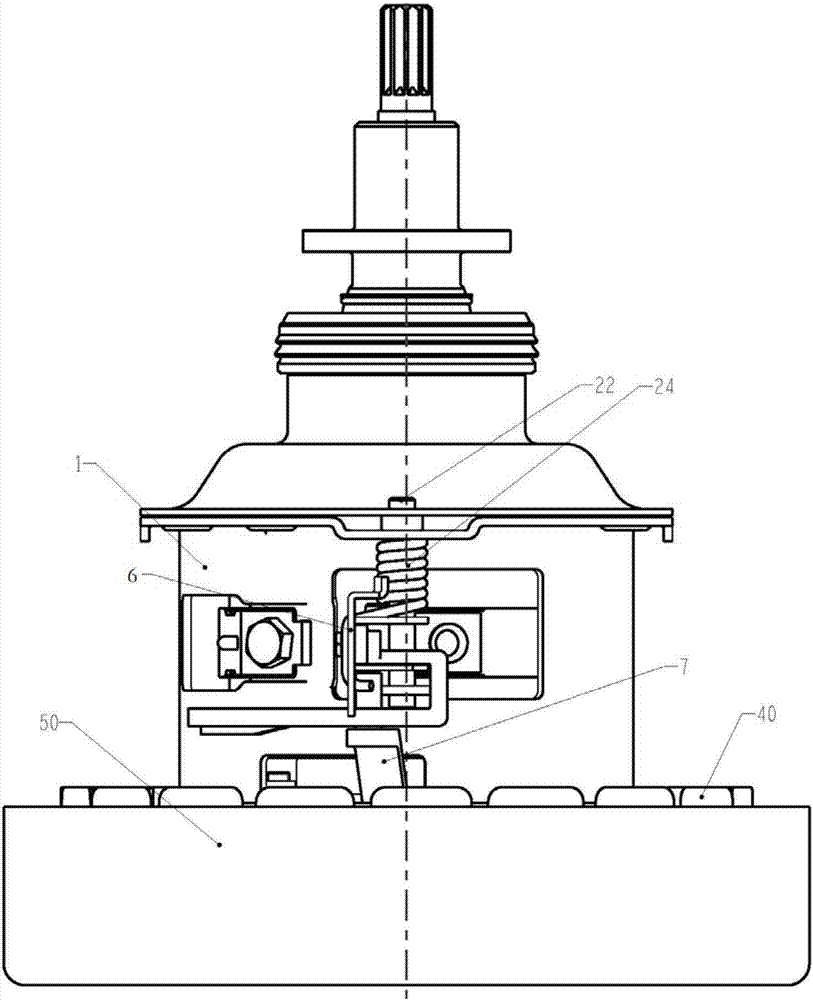

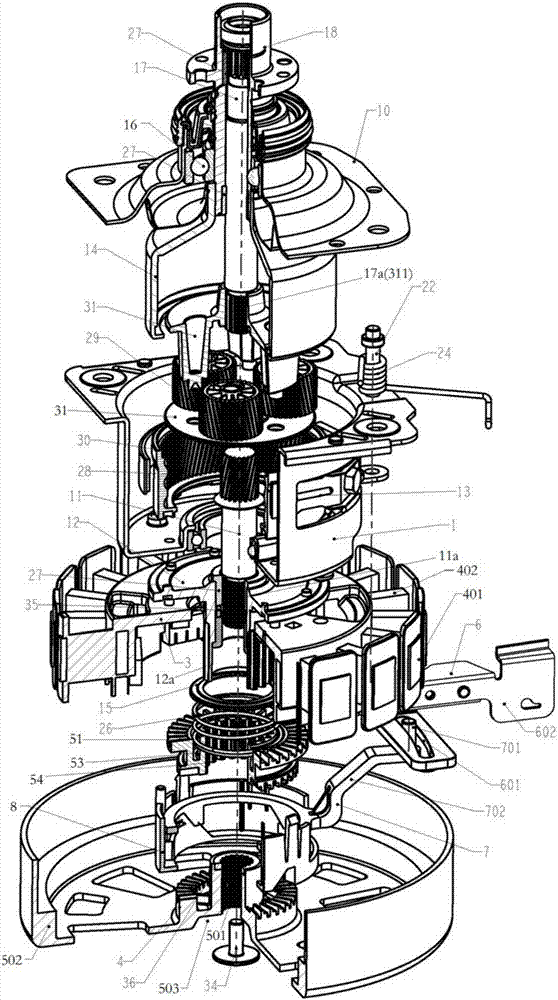

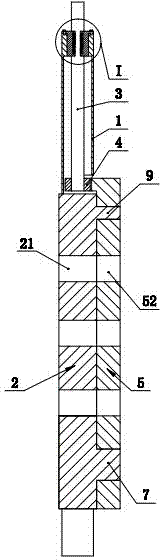

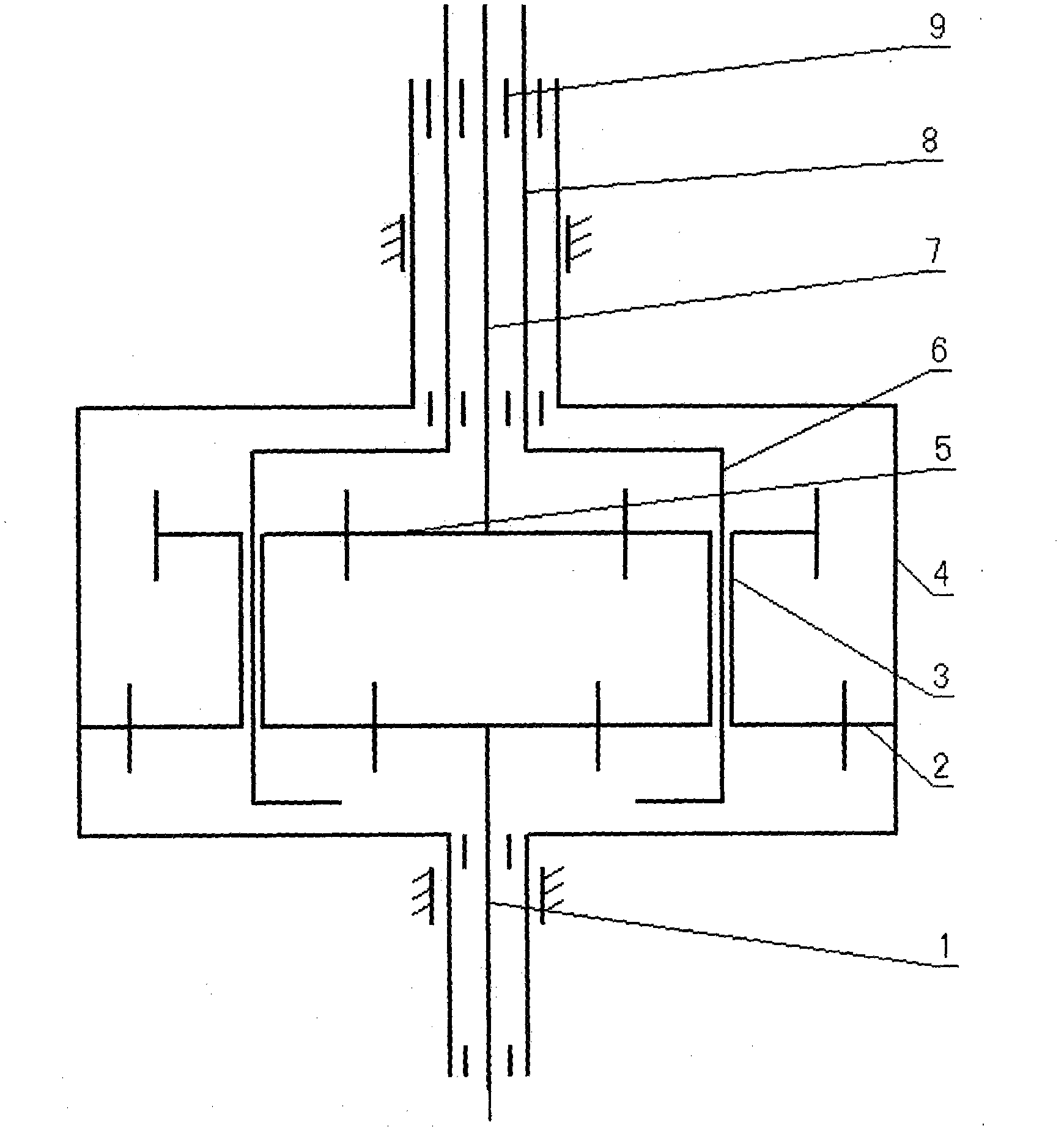

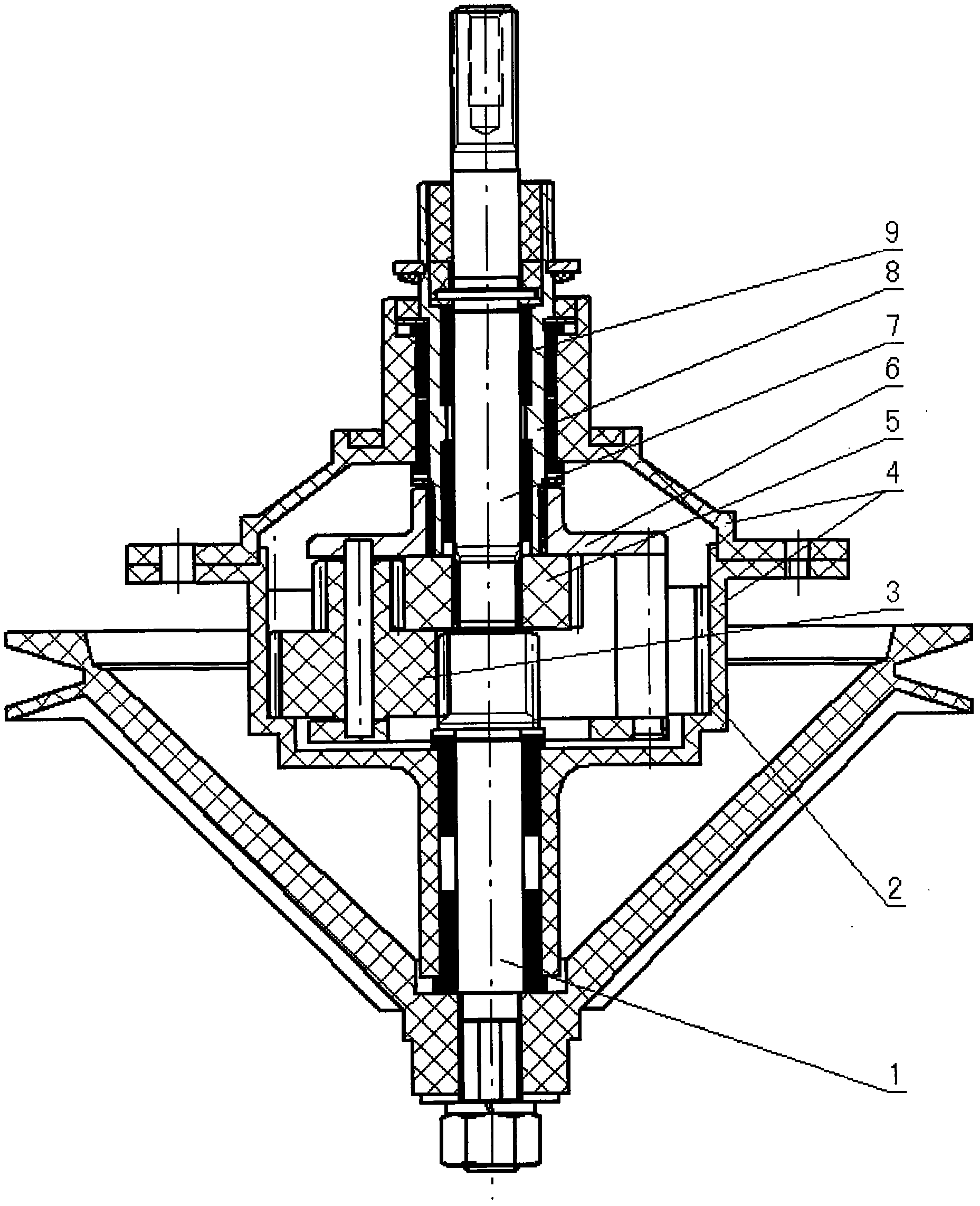

Washing machine and driving system thereof

ActiveCN107287829AImprove efficiencyHigh positioning accuracyOther washing machinesTextiles and paperLaundry washing machineClutch control

The invention relates to the field of washing machines and discloses a washing machine driving system and a washing machine with the same. A clutch mechanism of the driving system is axially positioned between a stator portion (40) and a rotor portion (50) of a motor component and can be driven by a clutch control mechanism to slide towards the stator portion (40) or the rotor portion (50) to make a first joint tooth portion (3) mesh with an upper tooth portion (51) or a second joint tooth portion (4) mesh with a lower tooth portion (52). Precision in positioning between the rotor portion (50) and the stator portion (40) is improved, an rotor-stator air gap can be reduced reasonably, efficiency of the motor component is improved, and simplification of a mounting structure and matching design is facilitated due to joint manufacturing of the clutch mechanism and the motor component.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

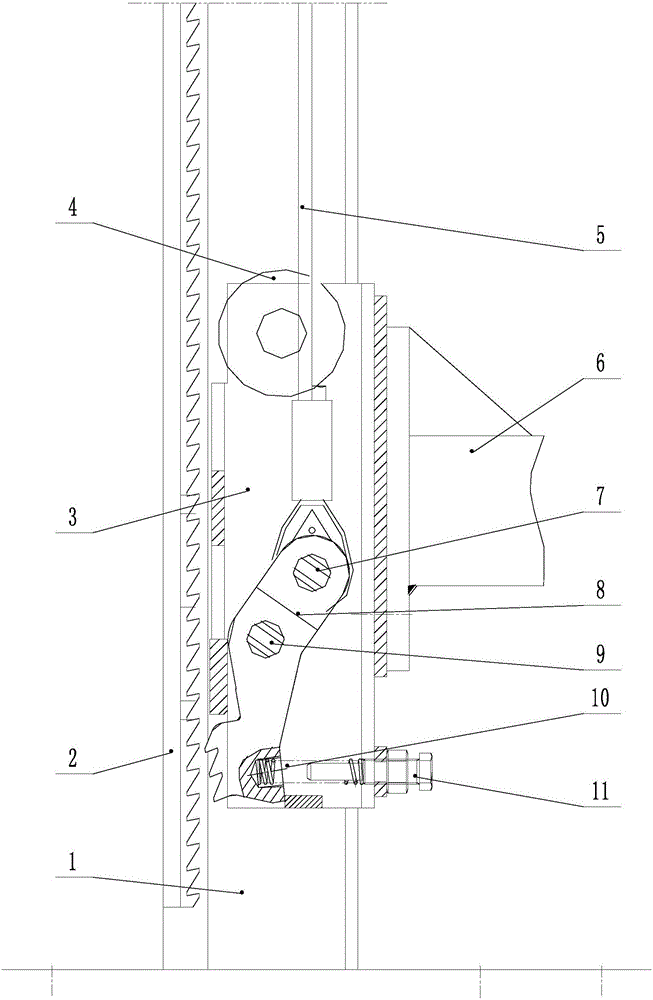

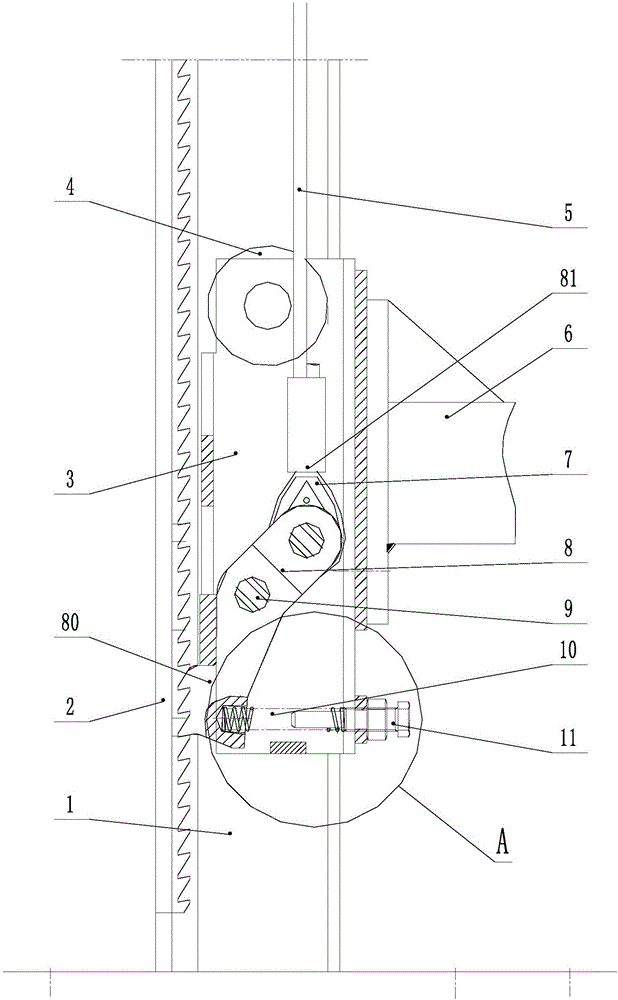

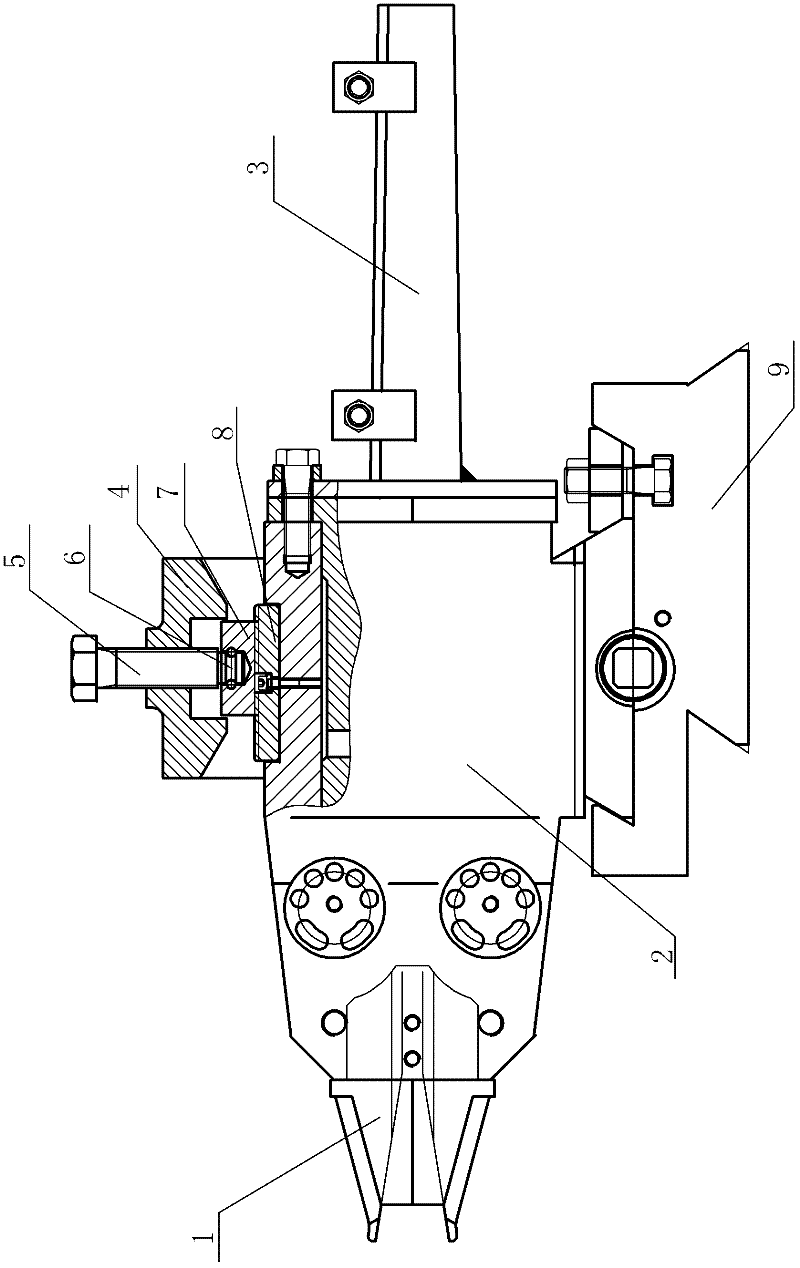

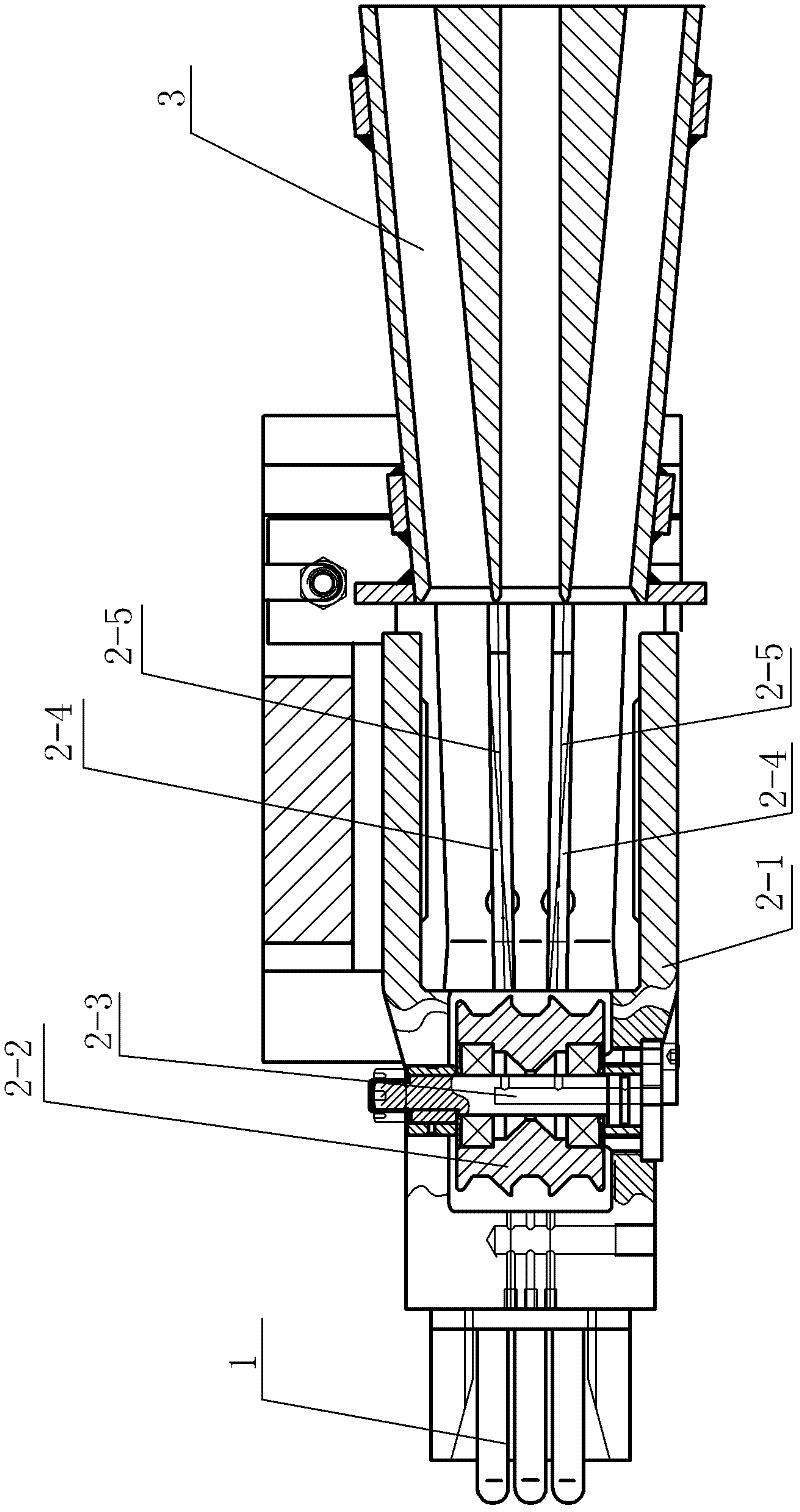

Dropping prevention mechanism of device for lifting four-corner drill tower from ground

The invention discloses a dropping prevention mechanism of a device for lifting a four-corner drill tower from the ground. The dropping prevention mechanism comprises a column, a lifting bracket, a dropping prevention rack, a trailer, a guiding wheel, a traction rope, a traction pin, a pawl, a fixing pin, a spring and a bolt, wherein an opening is formed in the side face of a column, teeth of the dropping prevention rack are zigzag, a working face is a right-angle side or an approximately right-angled bevel side, the other side is a bevel side greater than 90 degrees, the dropping prevention rack is installed on the side face of the column, the trailer is movably installed in the column, the guiding wheel is installed at the front end of the trailer in a rotary mode, the pawl is rotatably installed on the trailer by utilizing the fixing pin, and the fixing pin is located in the middle of the pawl. A ratchet is arranged at one end of the pawl and faces the dropping prevention rack, the other end of the pawl is rotatably provided with a connector by utilizing the traction pin, and the traction rope is connected with the connector. After the traction rope breaks, the springs rapidly presses the ratchet, the ratchet is matched with the dropping prevention rack due to the fact that the upper tooth-shaped side of the dropping prevention rack is the right-angle side, the right-angle side serves as a supporting surface for supporting the trailer, the trailer rapidly stops to prevent dropping.

Owner:ANHUI LIANGHUAI KELI MACHINERY MFG

Gear upper tooth groove polishing device

ActiveCN106735608AUniform sandingImprove grinding effectGear teethUpper toothAgricultural engineering

The invention belongs to treatment devices of gears, and particularly relates to a gear upper tooth groove polishing device. A cross shaft is fixedly mounted on a rack, a gear is mounted on the cross shaft, and a supporting frame is hinged to the rack. A lead screw is mounted on the supporting frame, a sliding sleeve is mounted on the lead screw, a push plate is mounted on the sliding sleeve, and the free end of the push plate deeply penetrates a gear tooth groove. The lower end of the supporting frame is connected with a first connecting rod, and a vertical supporting plate is hinged to the end, away from the supporting frame, of the first connecting rod. A first rotary wheel is mounted on the vertical supporting plate, a cam is arranged on the side, away from the vertical supporting plate, of the first rotary wheel, and a second rotary wheel is arranged above the cam. An inductor is mounted on a high-pressure gun at the position, above the second rotary wheel, of the rack, the high-pressure gun is connected with a first through pipe, and the first through pipe is connected with a sand spraying box. The left end of the first through pipe is connected with a hollow rotary shaft, a plurality of sand spraying holes are formed in the rotary shaft, a hollow sand spraying wheel is mounted on the rotary shaft, and small holes are formed in teeth of the sand spraying wheels. The problem that due to the fact that the polishing process of saw teeth on a gear is uneven, chatter marks are likely to exist on the polished gear is solved.

Owner:重庆博创知识产权运营有限公司

Throttling-governing butterfly valve

The invention discloses a throttling-governing butterfly valve. The throttling-governing butterfly valve comprises a valve rod, a butterfly plate, a gear shaft, a gear and a throttle plate, wherein the gear is fixedly mounted at the end part of the lower end of the gear shaft, a gap which is used for exposing a part of the gear is correspondingly formed in the valve rod, a tooth face which forms engaged linkage with the exposed part of the gear is correspondingly formed at the upper end of the throttle plate, the lower end of the throttle plate is hinged to the lower end of the butterfly plate, the hinged turning of the throttle plate on the butterfly plate can be formed through the matched turning between an upper tooth face of the throttle plate and the gear, a plurality of flow guiding holes are uniformly formed in the butterfly plate, a throttling hole, which has the same hole diameter as that of each flow guiding hole, is formed in the throttle plate corresponding to the location of each flow guiding hole, and the throttling holes and the flow guiding holes can form mutual misalignment or alignment due to the hinged turning of the throttle plate and the butterfly plate. Through the structural arrangement, the butterfly valve can more accurately adjust flow when the butterfly plate is in a fixed opening angle, and the butterfly valve can be slightly opened when the butterfly plate is in a closed state.

Owner:SHANGHAI HUGONG VALVE FACTORY (GRP) CO LTD

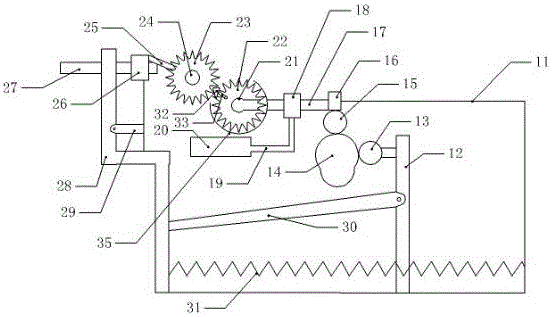

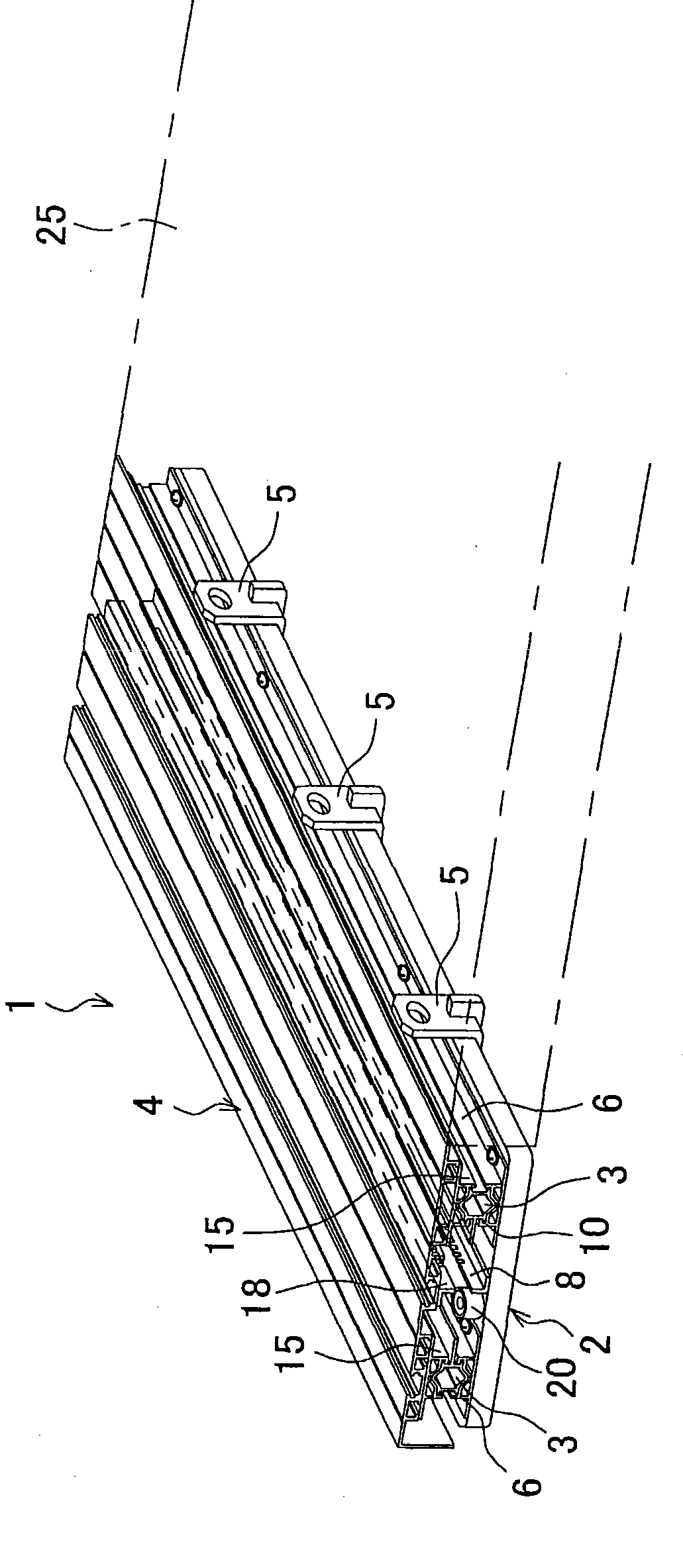

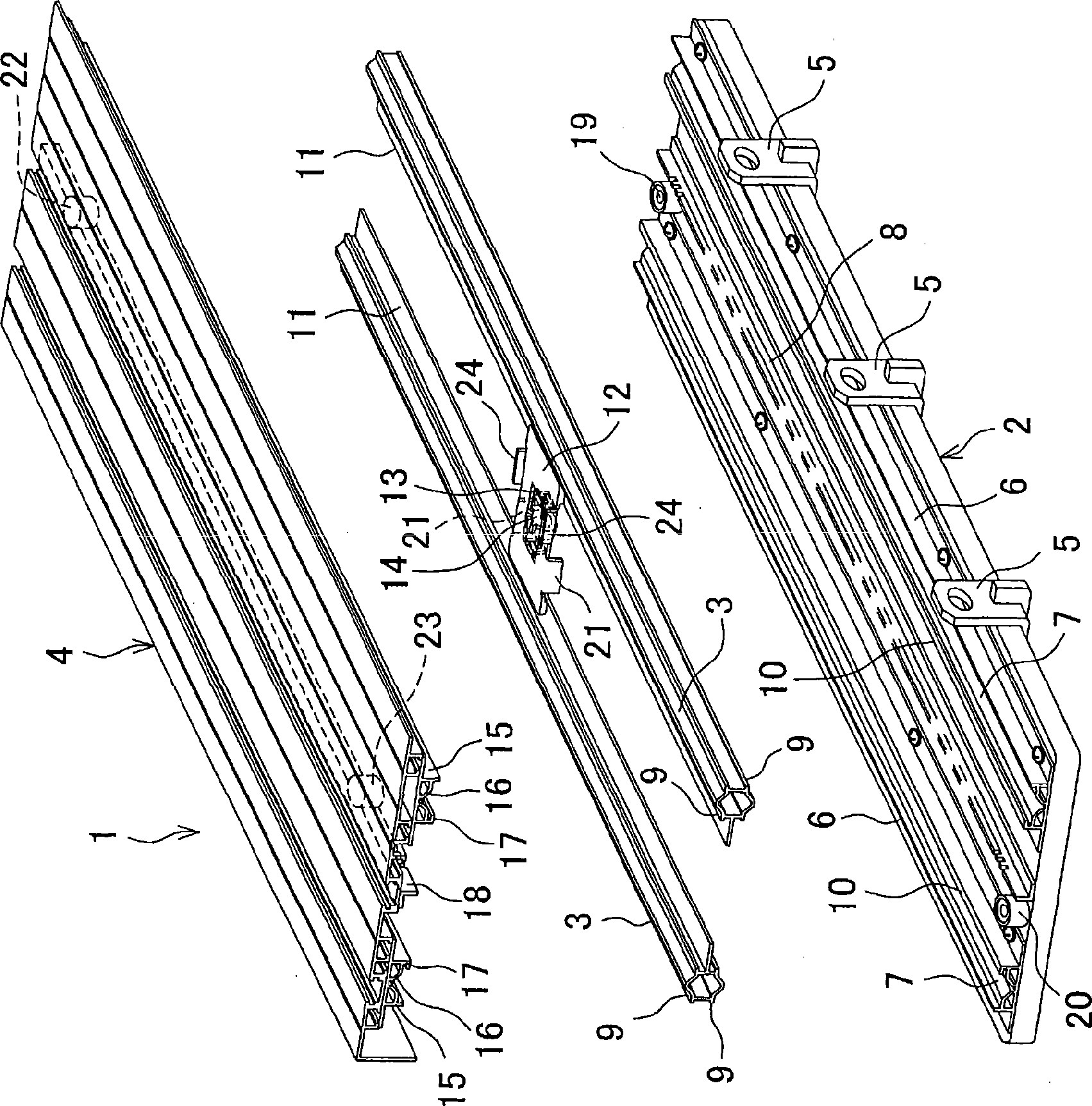

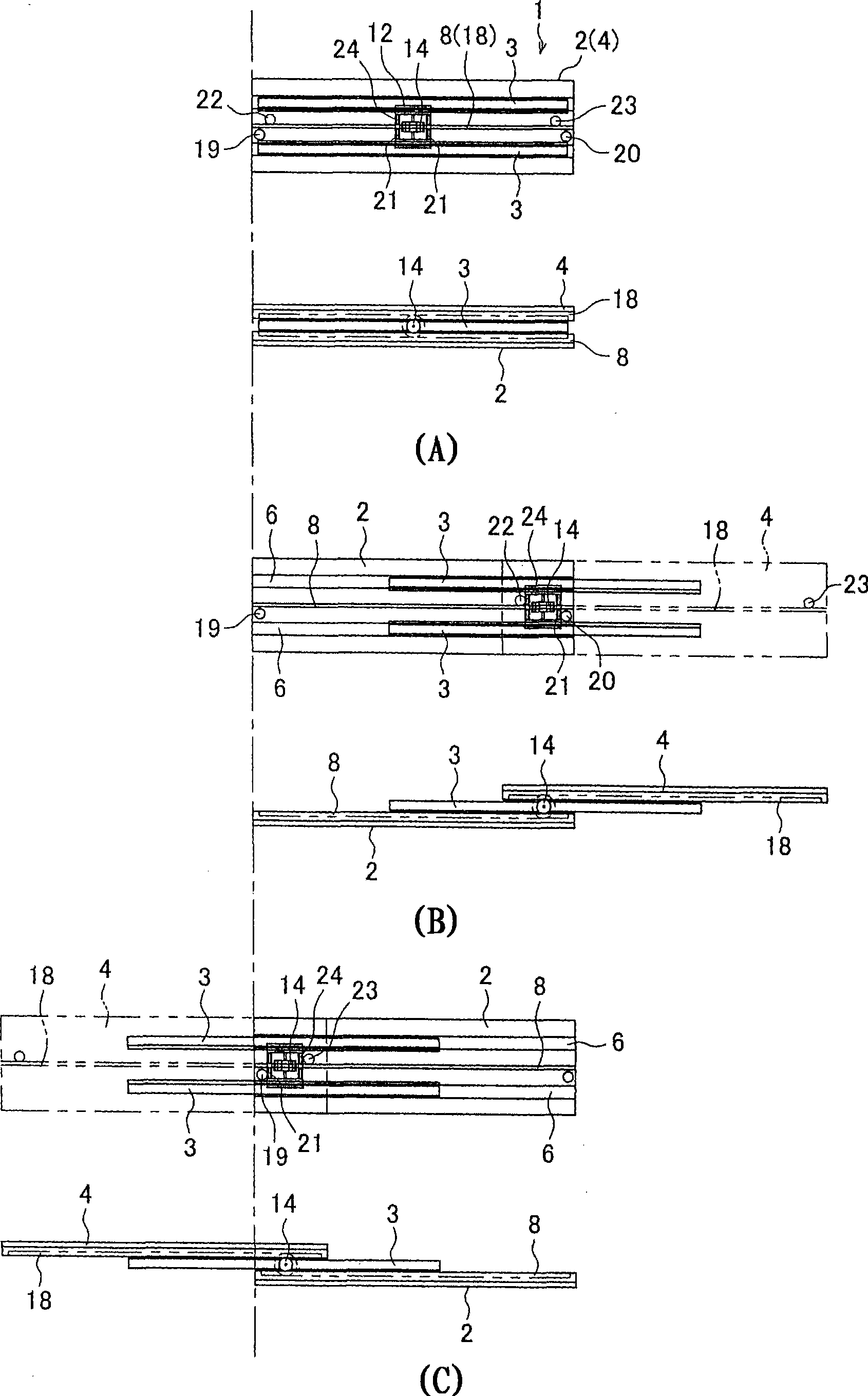

Sliding table for cutting machine

ActiveCN101468408AImprove workabilityGood cutting precisionMetal sawing devicesLarge fixed membersGear wheelUpper tooth

The present invention provides a slide table-board which is used for cutter. The side way of the slide table-board does not effect the operation. The operability and cutting precision can be well maintained. On a sliding panel (1), a connecting piece (12) is provided between the middle parts of rail (3, 3) and is installed with a pinion (14) of which the axis is in the left-right direction on one hand, and on the other hand the upper surface of baseboard (2) is installed with a lower teeth bar (8) engaged with the pinion (14). The lower surface of panel (4) is installed with an upper teeth bar (18) engaged with the pinion (14). When the panel (4) and the upper teeth bar (18) slide simultaneously, the pinion (14) rolls on the lower teeth bar (8) on the baseboard (2) so that the rail (3, 3) move along with the sliding of panel (4).

Owner:MAKITA CORP

Reclining device of vehicle seat

A reclining device of a vehicle seat for easily locking and releasing the vehicle seat so as to increase performance of the vehicle seat and to improve quality thereof. The reclining device is easily assembled, by removing minor shortcomings that may occur during the assembly process, and enhances engagement of the locking teeth with the upper teeth when the reclining device is installed to a vehicle, so that the convenience as well as quality, strength, and durability of the reclining device are enhanced.

Owner:DAS CO LTD

Oral appliance for treating obstructive sleep apnea (OSA) and sleep bruxism

The invention discloses a device used for treating sleep apnea and consisting of a top denture and a bottom denture and an application method of the device. Each of the dentures is suitable for keeping the corresponding upper teeth and lower teeth; and the bottom denture is provided with two flanges upwardly extending from the roughly flat side of the denture at the bottom, and the other side of the denture is propped against teeth. Therefore, during wearing of the device, the flanges extend to the top denture. A corresponding flat area is arranged on each side of the top denture, and the flat areas can be cut in the planes on the outer sides (relative to teeth) of the dentures. The flanges are accordingly propped against the flat parts on the outer sides of the dentures to push the bottom denture and push the lower teeth and the tongue forwards. When a wearer wears the dentures in sleep, respiratory obstruction caused by the tongue in sleep is avoided.

Owner:肯尼斯·卢科

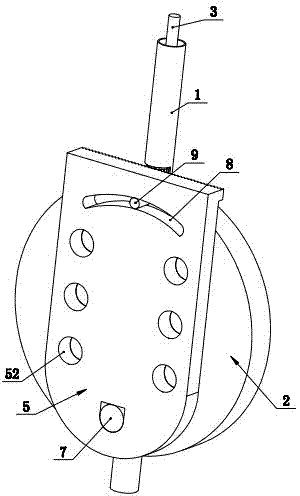

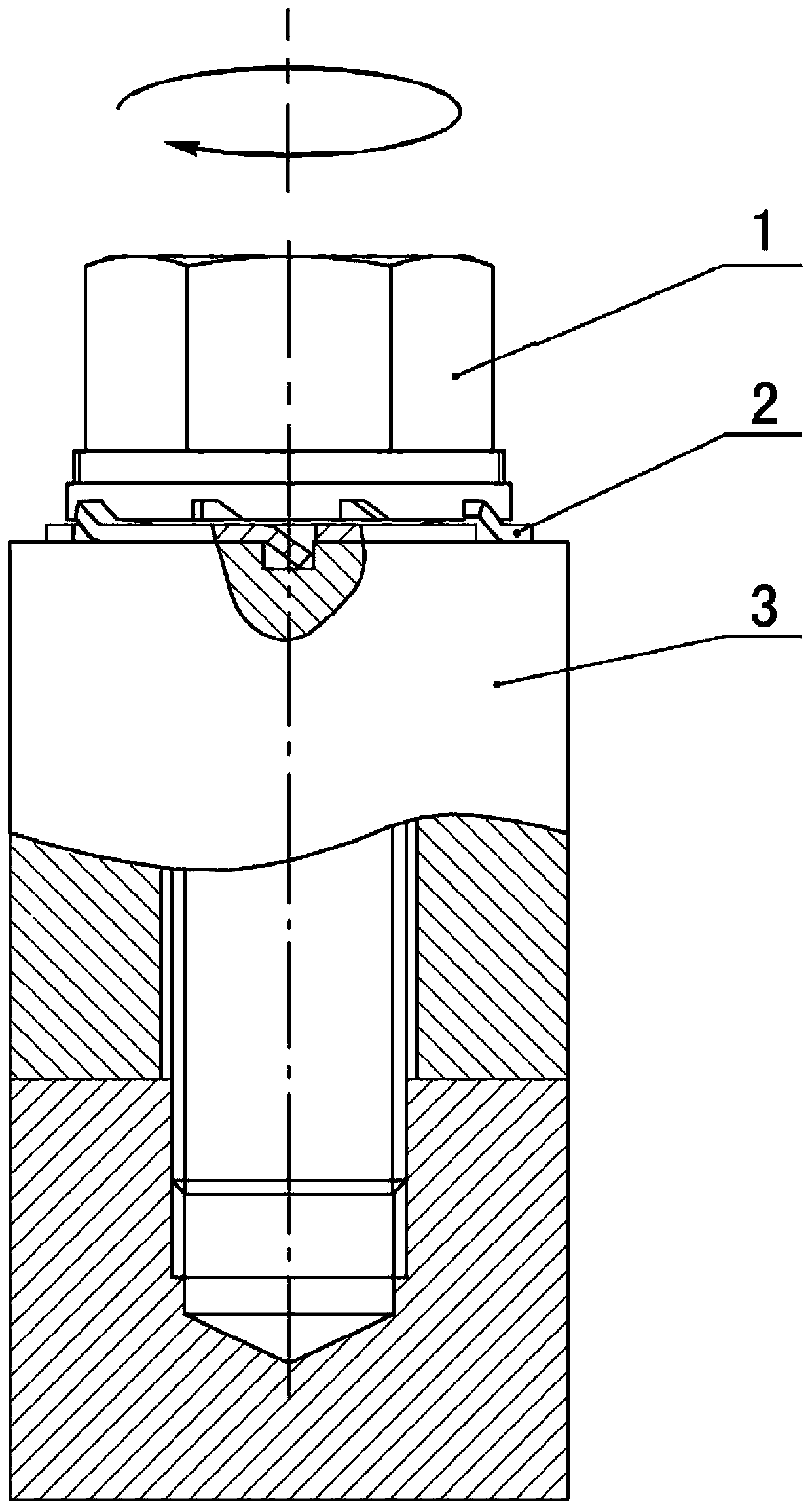

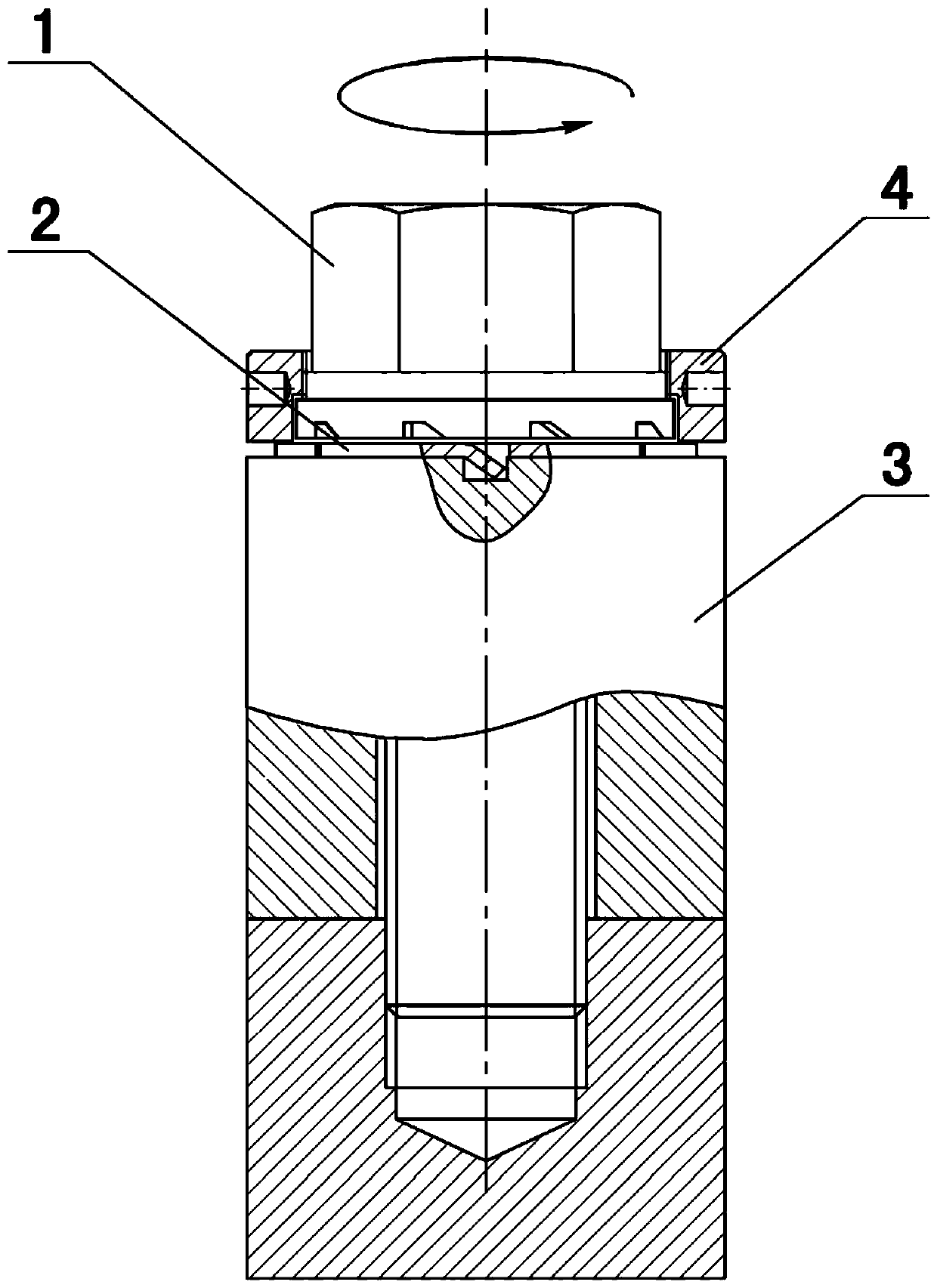

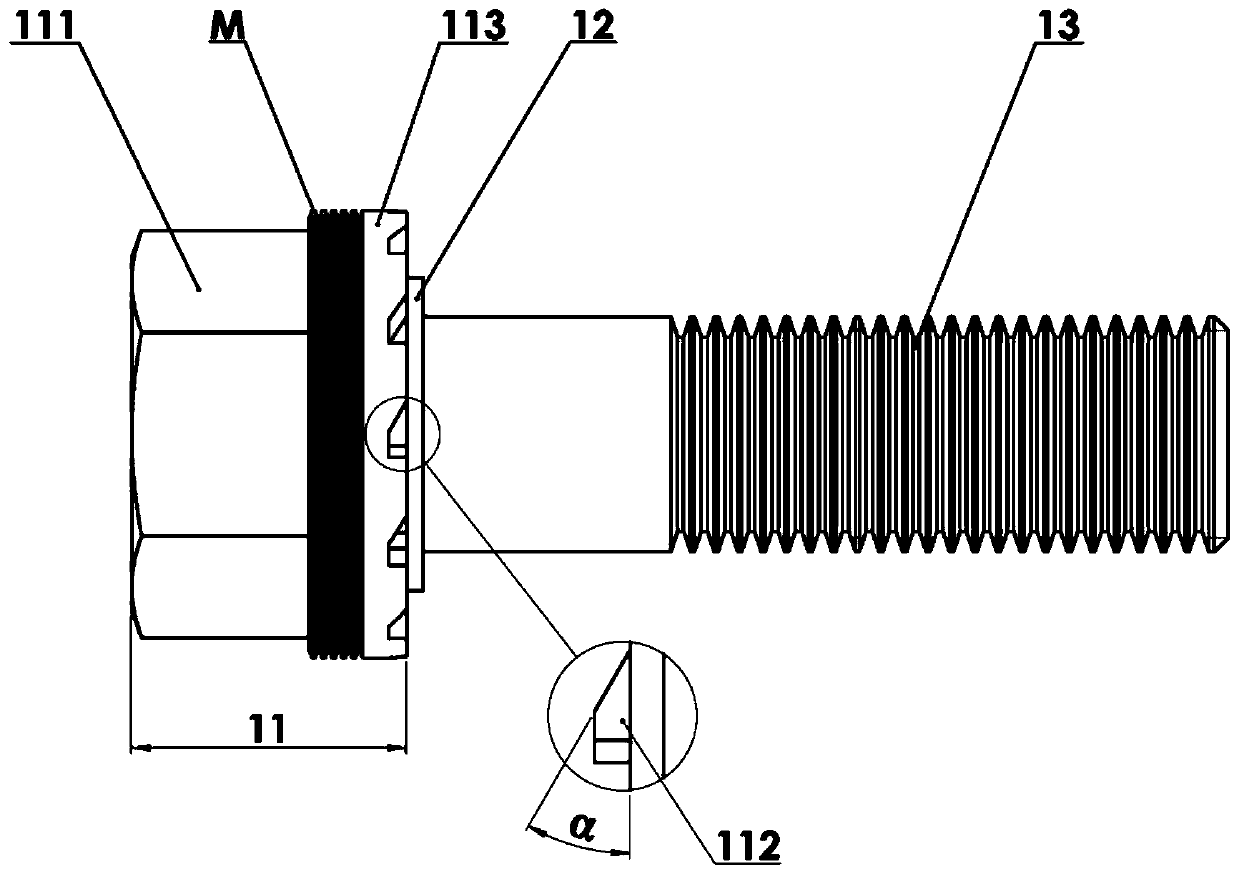

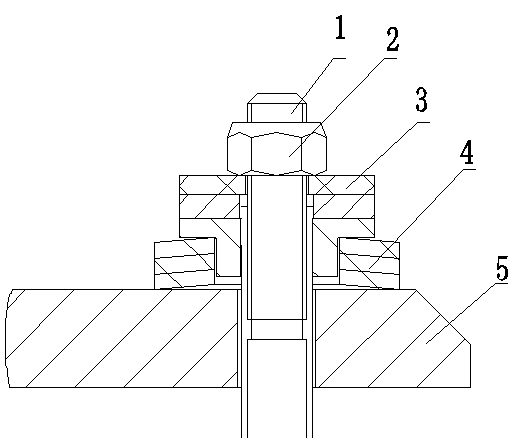

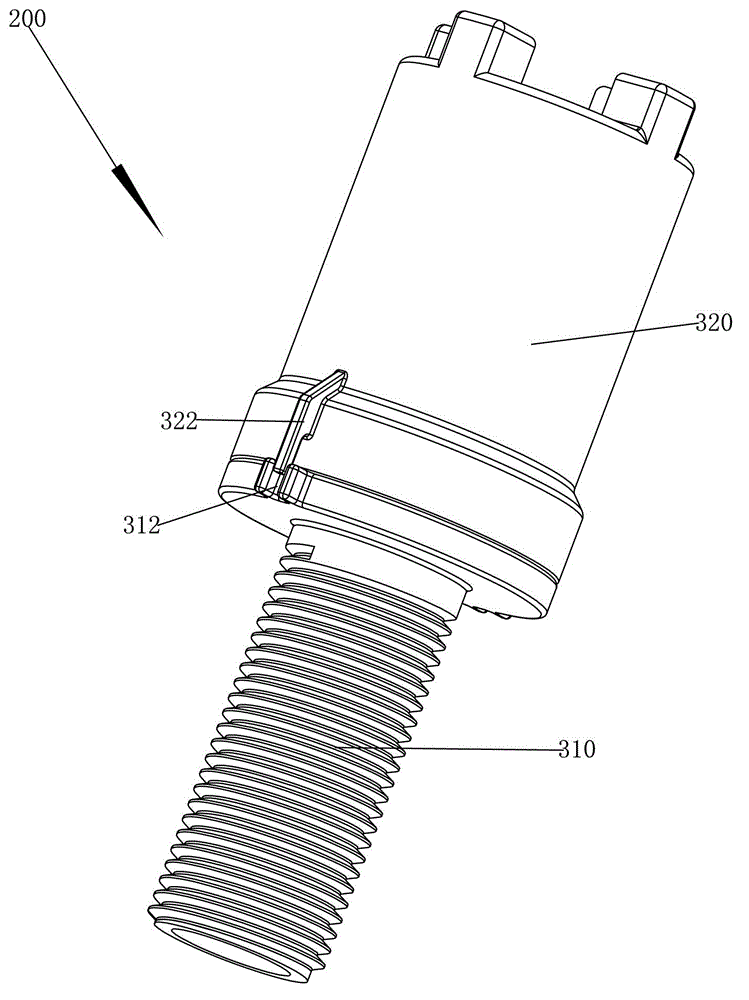

Anti-loose bolt device

The invention discloses an anti-loose bolt device and a use method thereof. The anti-loose bolt device comprises a non-return flange bolt (1), a non-return gasket (2), a through hole part (3), a disassembly compression ring (4) and a threaded hole part, wherein the non-return flange bolt (1) comprises a flange section (11) and a screw (13) connected with the lower end of the flange section (11); the screw (13) is sleeved with the non-return gasket (2), the upper end of the non-return gasket (2) is provided with upper teeth (21), the lower surface of the flange section (11) is provided with non-return grooves (112) matched with the upper teeth (21), and the lower end of the non-return gasket (2) is provided with lower teeth (22); the through hole part (3) is arranged on the screw (13) in asleeving manner and located at the lower end of the non-return gasket (2), and the upper surface of the through hole part (3) is provided with through hole part groove bodies (31) matched with the lower teeth (22); the lower end of the screw (13) is connected with the threaded hole part; and the flange section (11) is sleeved with the disassembly compression ring (4), and the disassembly compression ring (4) can move up and down relative to the flange section (11). The anti-loose bolt device has a good anti-loose effect at high temperature and high frequency, the strength of the bolt is high,and the anti-loose bolt device has the advantages of being convenient to disassemble, energy saving and environment friendly.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

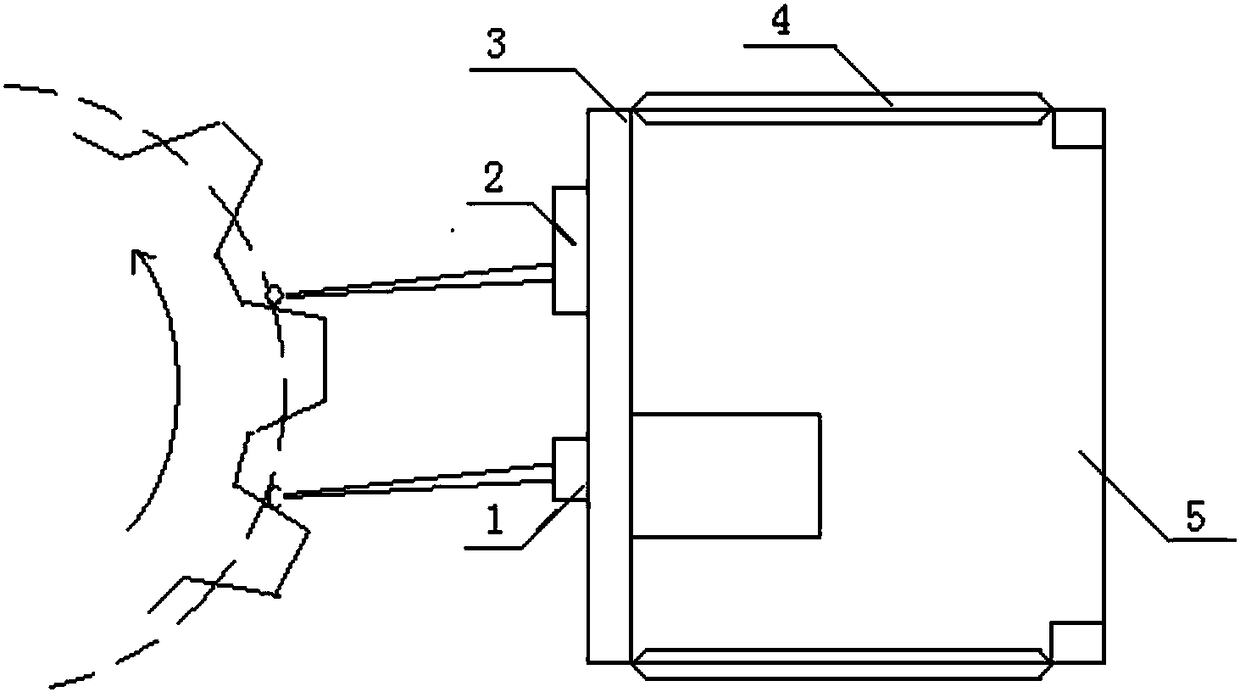

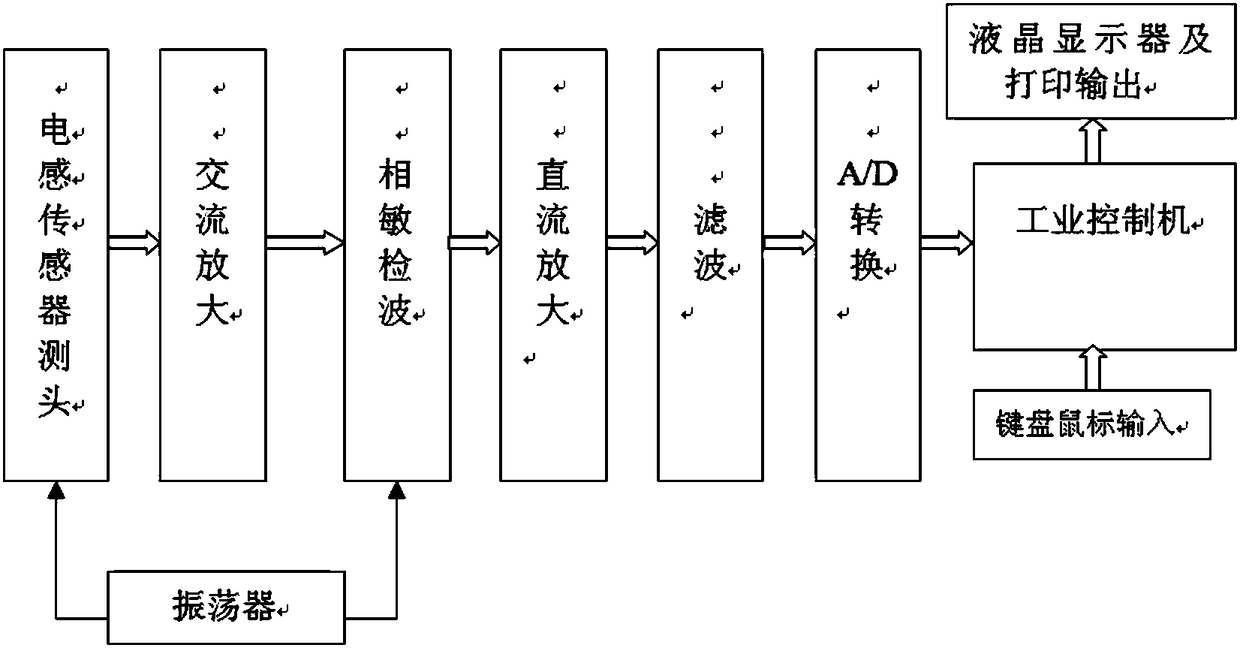

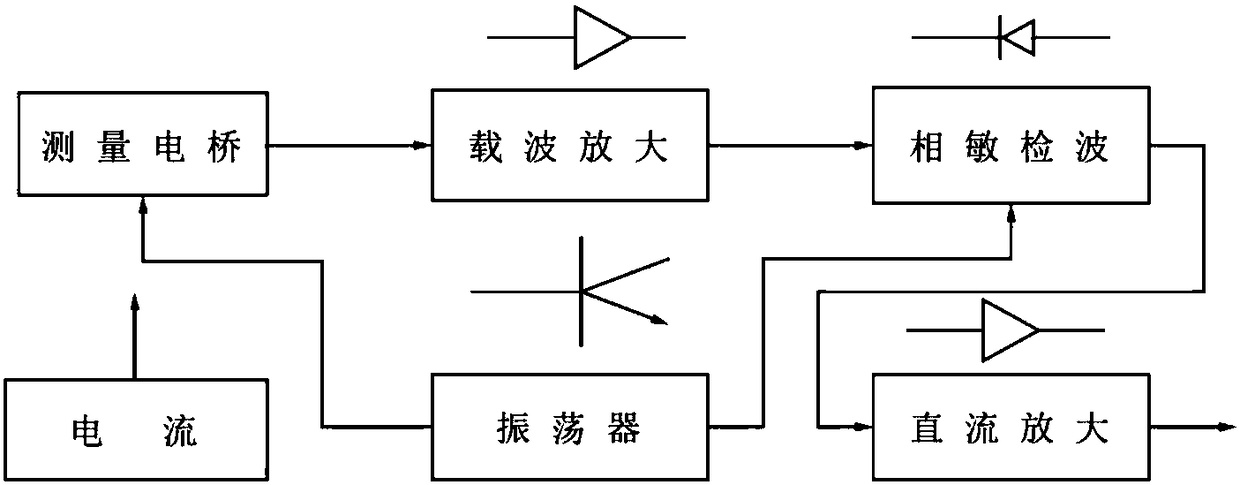

Upper tooth pitch measuring instrument for large gear hobbing machine

The invention belongs to the technical field of gear detection and relates to an upper tooth pitch measuring instrument for a large gear hobbing machine. By adoption of an upper relative measurement method, relative measurement of tooth pitch errors of straight gears, bevel gears and worm gears machined on a gear machine tool is carried out. The measurement method is free of any indexing standards, tooth pitches of tested gears are subjected to one-by-one own tooth pitch comparison according to the circumference closed principle, and an industrial controller is used as a data processing systemfor calculating single tooth pitch deviation, N tooth pitch cumulative deviations and total tooth pitch cumulative deviation. The upper tooth pitch measuring instrument has advantages that online detection of the single tooth pitch deviation, the tooth pitch cumulative deviation and the total tooth pitch cumulative deviation of the tested gears can be realized, machining conditions are adjusted according to deviation values, and time of workpiece moving, lifting and recalibration in testing can be saved.

Owner:CHONGQING MACHINE TOOL GROUP

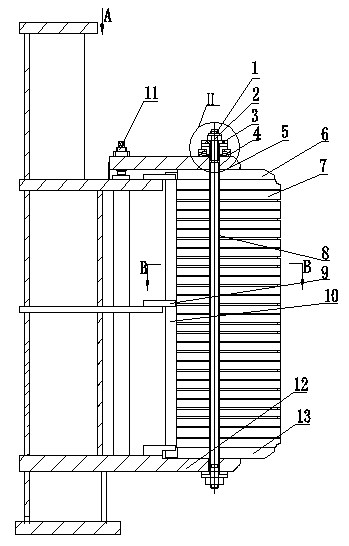

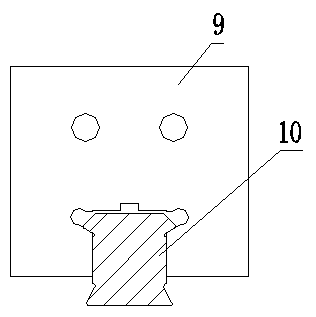

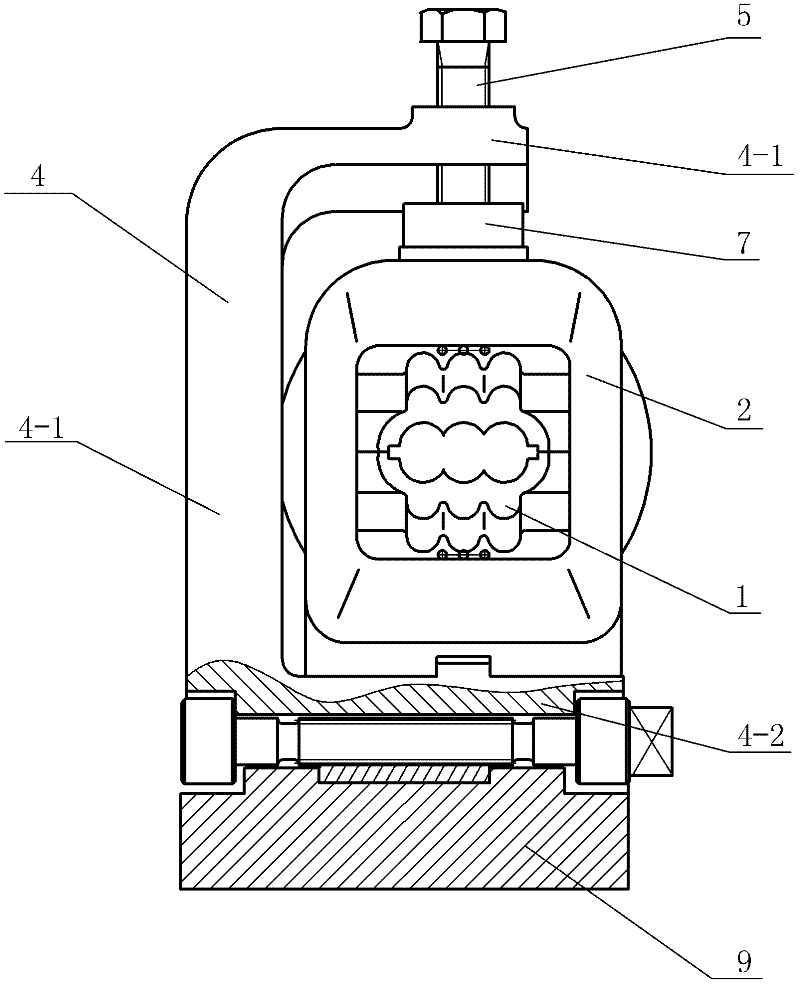

Stator floating iron core locating and tensioning device and stator floating iron core installing method

InactiveCN104779752AIncrease stiffnessStrong thermal deformation abilityManufacturing stator/rotor bodiesUpper toothEngineering

The invention provides a stator floating iron core locating and tensioning device and a stator floating iron core installing method. The stator floating iron core locating and tensioning device comprises an engine base ring plate (12), a lower tooth support (13), an upper tooth support (6), stator iron core chips (7), a stator pressing plate (5), through bolts (1), double dove-tail bar supporting plates (9) and double dove-tail bars (10). The through bolts (1) penetrate through the stator pressing plate (5), the upper tooth support (6), the stacked stator iron core chips (7), the lower tooth support (13) and the engine base ring plate (12). Each through bolt (1) is sleeved with an insulating sleeve (8). Locking nuts (2) are arranged at the two ends of each through bolt (1) respectively. The upper end of each through bolt (1) is sleeved with a belleville spring (4) and a bolt insulating spacer (3). The two ends of the double dove-tail bars (10) are connected with the double dove-tail bar supporting plates (9) and the stator iron core chips (7) respectively. The two ends of the stator iron core chips are bonded into one, and therefore in the iron core press-fitting process, iron cores are heated after being pressed under a cold state, and then pressed again under a hot state.

Owner:湖南云箭科技有限公司

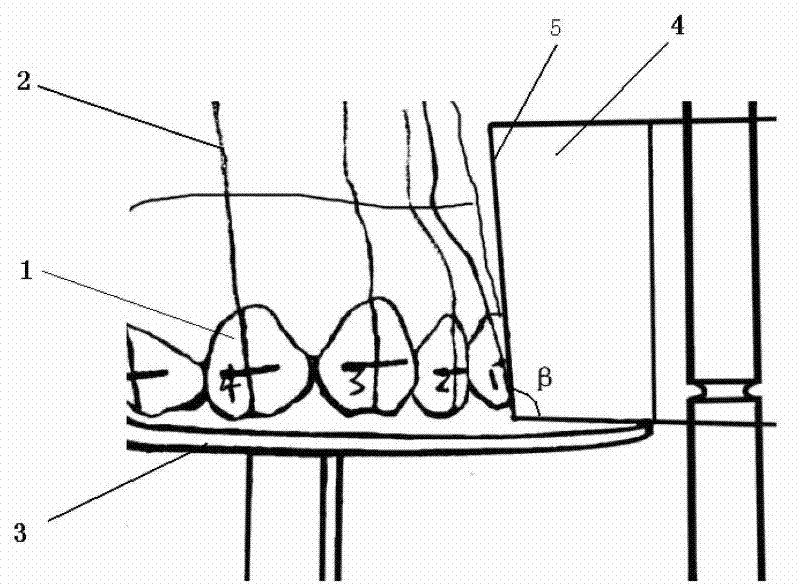

Anatomic model tooth arranging method for personalized tongue side correction

ActiveCN102648874AGuaranteed aestheticsIncrease torqueOthrodonticsPersonalizationDental Articulators

The invention relates to an anatomic model tooth arranging method for personalized tongue side correction. The anatomic model tooth arranging method for the personalized tongue side correction comprises the following steps of: 1) making a correcting plan; 2) manufacturing an impression and transferring to an occlusal frame: manufacturing a plaster model and recording and transferring an occlusal position to the anatomic occlusal frame through a face arch; 3) model marking and trimming; 4) drawing a standard arch; 5) according to the standard arch, arranging teeth by using an upper tooth arch; and 6) arranging teeth by using a lower tooth arch, wherein in the step 2), a relationship between an eye and ear plane and an occlusal plane is transferred to the anatomic occlusal frame through the anatomic face arch, so that the anatomical positions of the teeth in a mouth are really represented; and in the step 5) and the step 6), adducent amounts and torque change values of maxillary anterior teeth are transferred to an angular relationship between a tangent line of a dentilabial surface and the occlusal plane by using a self-made angle ruler, and the positions of mandicular anterior teeth are determined according to the positions of the maxillary anterior teeth and an occlusal relationship, so that the teeth on one side are in standard arrangement and the teeth on the other side are malocclusive.

Owner:张栋梁 +3

High voltage electric power piercing connector

ActiveCN106025589AExtended service lifeImprove anti-loosening performanceElectric connection structural associationsContact members penetrating/cutting insulation/cable strandsUpper toothHigh pressure

The invention discloses a high voltage electric power piercing connector. The high voltage electric power piercing connector comprises an upper line voltage cover and a lower line voltage cover, wherein a gear is arranged at a middle portion between the upper line voltage cover and the lower line voltage cover, the gear is transversely provided with a fixing bolt, a left side of the gear is engaged with a lower tooth bar, a right side of the gear is engaged with an upper tooth bar, the upper line voltage cover corresponding to the lower tooth bar is provided with a tooth bar limit groove, the lower line voltage cover corresponding to the upper tooth bar is further provided with a tooth bar limit groove, a left side of a lower portion of the lower tooth bar is fixedly provided with a lower engagement cover, a right side of an upper portion of the upper tooth bar is provided with an upper engagement cover, the upper engagement cover and the lower engagement cover are respectively provided with an arc-shaped insulation sheath, and the insulation sheaths are provided with piercing blades. Compared with a mode of utilizing a traditional bolt assembly to clamp an electric power cable, the high voltage electric power piercing connector realizes clamping of the electric power cable through mutual engagement of the gear and the tooth bars, the excellent anti-loosing effect is realized, and long-term stable reliable operation is effectively guaranteed.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

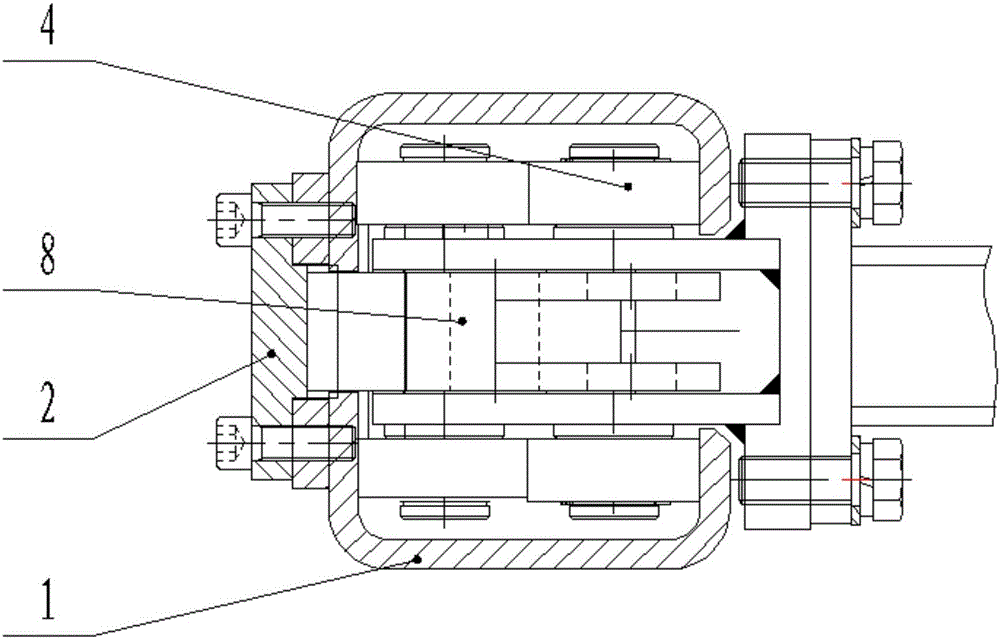

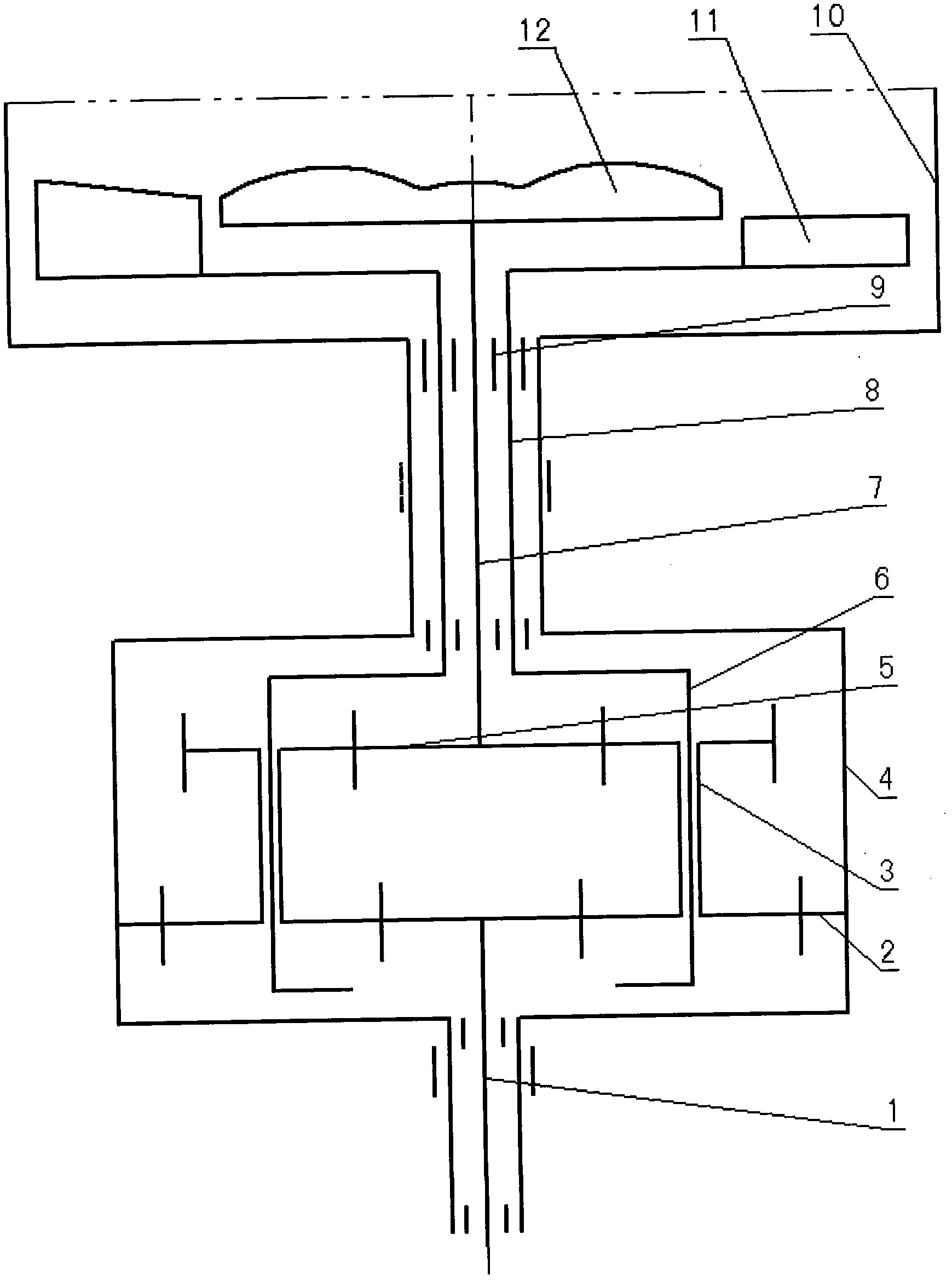

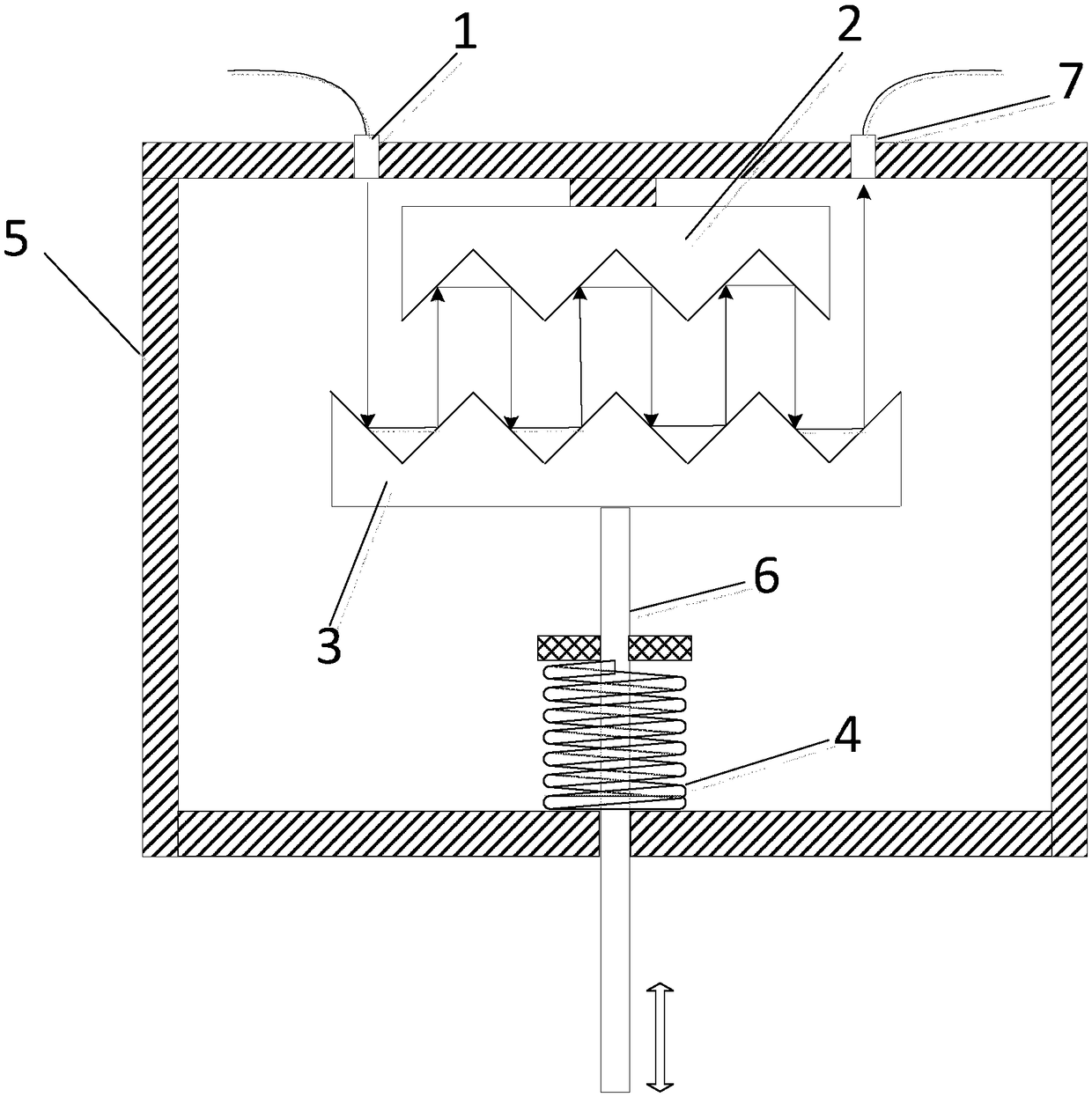

Reducer and washing machine and washing mode thereof

InactiveCN103132284AImprove washing effectReduce the probability of entanglementOther washing machinesWashing machine with receptaclesImpellerShake up

The invention provides a reducer, a washing machine and a washing mode thereof, and relates to the technical field of washing machines, in particular to an impeller type washing machine. An output shaft consists of an output inner shaft and an output outer shaft, a planet wheel is a dual gear, the output inner shaft is meshed with an upper tooth of the dual gear by an upper center gear, the output outer shaft is connected with the planet wheel, and an inner gear and a shell body are connected to be a whole. A barrel body of the washing machine is connected with a shell body of the reducer, an inner impeller is connected with the output inner shaft of the reducer, and an outer impeller is connected with the output outer shaft of the reducer. When washing is conducted, the inner impeller and the outer impeller conduct bidirectional and reciprocating rotation in the barrel body in the same direction and different speed, the outer impeller drives clothes to shake up and down in the barrel body, and the clothes are scattered. One power input and two power outputs can be provided, and a different washing mode can be provided, so that winding rate is reduced, and washing effect of the washing machine is improved.

Owner:ANHUI JULONG TRANSMISSION TECH

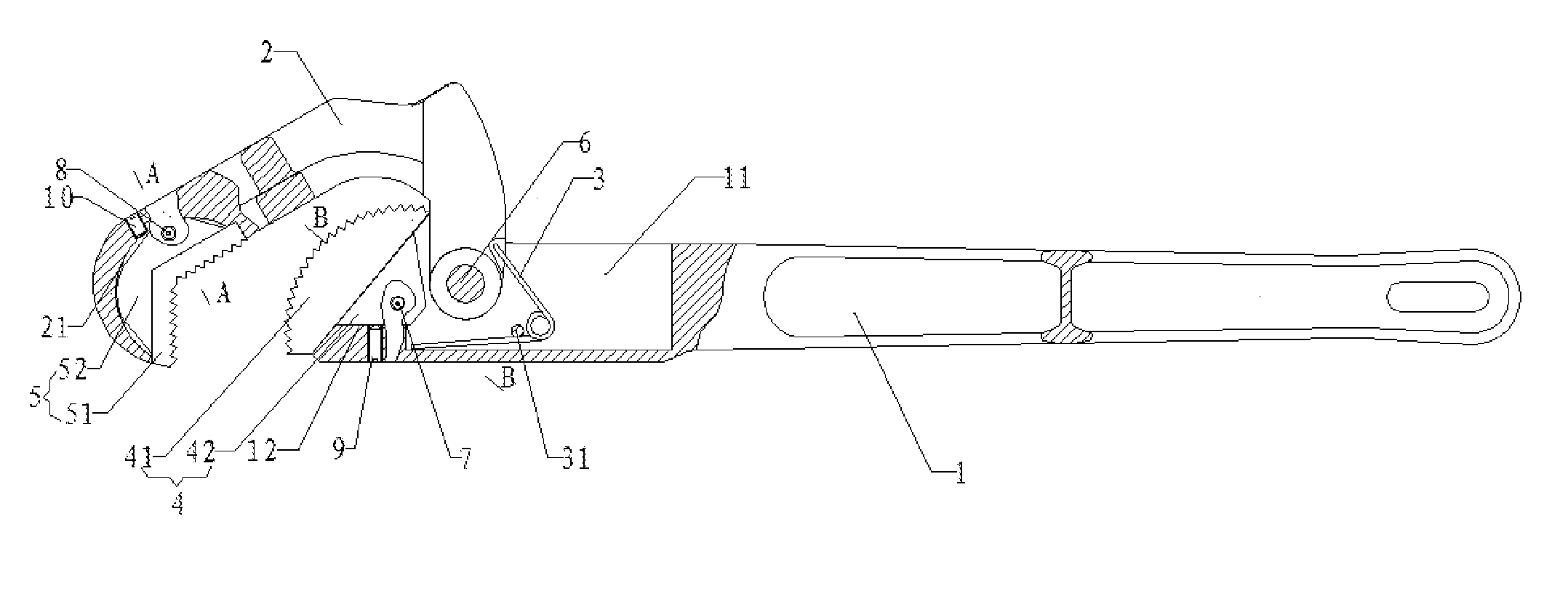

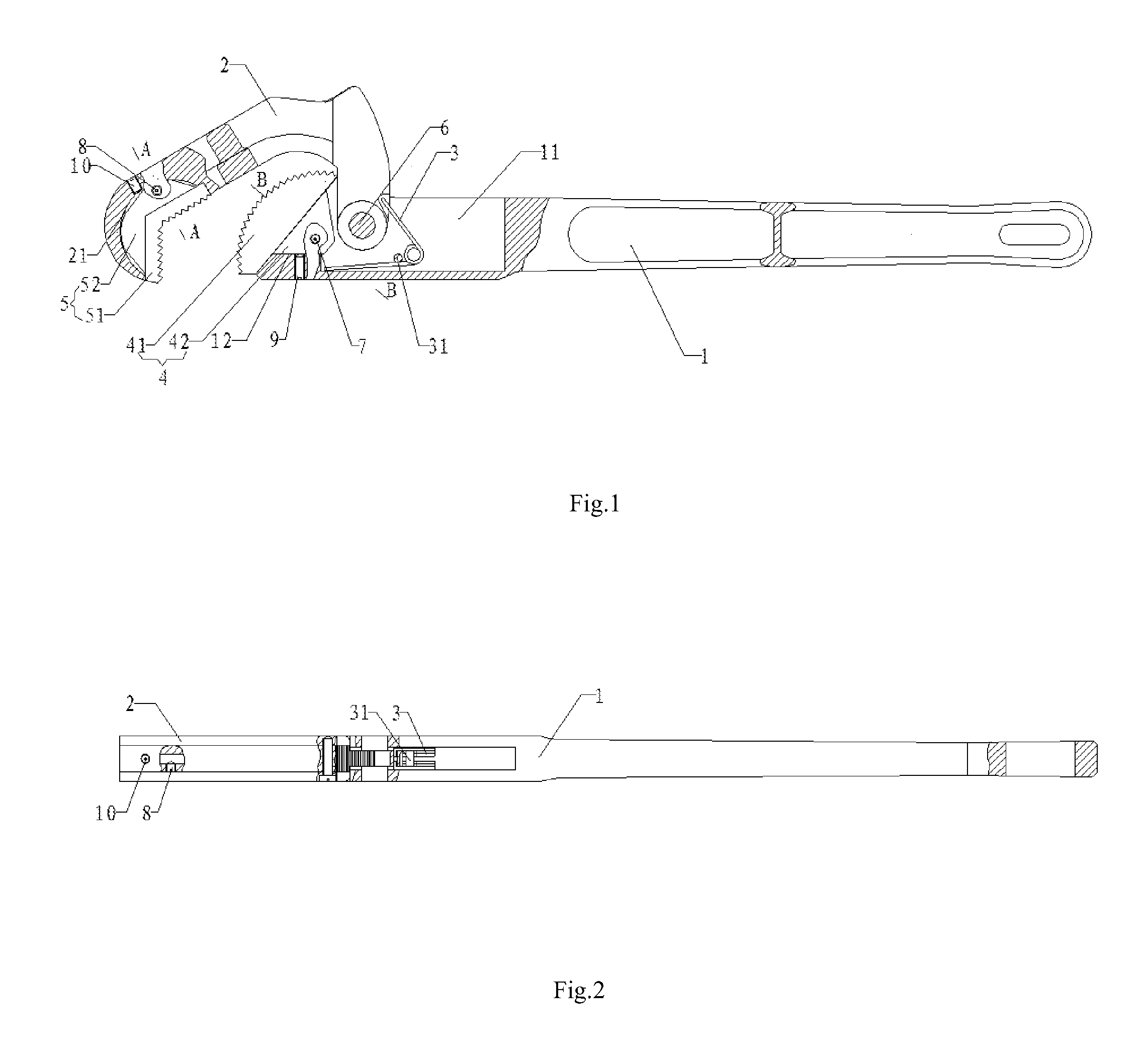

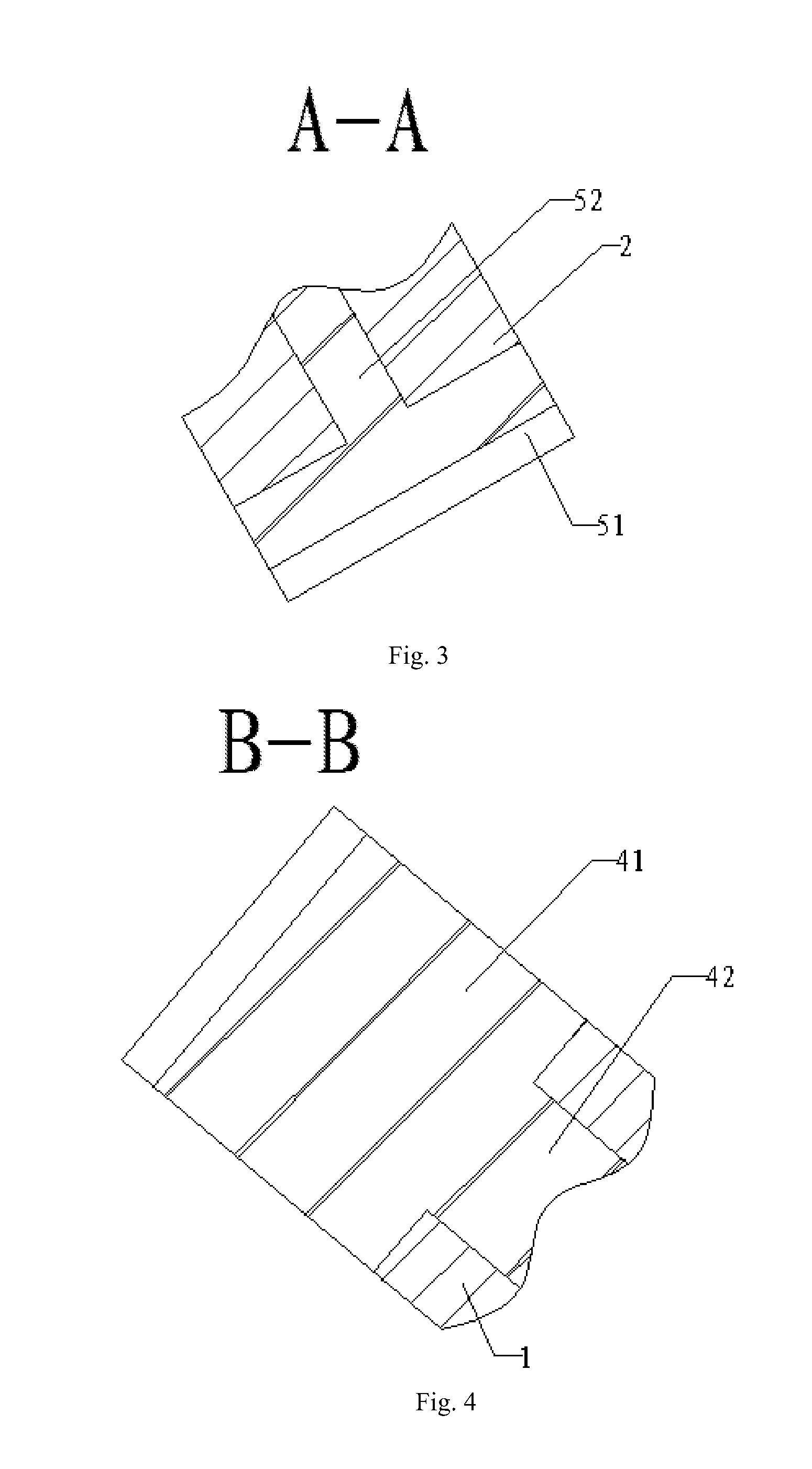

Multi-purpose ratchet piper pliers

InactiveUS20150360350A1Quality improvementReasonable structureSpannersWrenchesUpper toothEngineering

A piece of multi-purpose ratchet pipe plier comprise a handle, an upper jaw clamp, a pin shaft, a torsion spring, an arc-shaped tooth surface insert block and an upper tooth surface inert block, wherein the upper jaw clam is hinged on the handle through the pin shaft, the torsion spring is arranged in the assembly slot of the handle and connect with upper jaw clam and the bottom of assembly slot in the ends, the arc-shaped tooth surface insert block is fixed on the handle by tenon, and the upper tooth surface insert block is fixed on the upper jaw clamp by tenon. The anti-skip teeth on the handle and the upper jaw clamp are disassembled and replaced, the whole plier opening can clamp the pipe through the tooth surfaces at three different directions for realizing anti-skip function.

Owner:JIANG ZHANGMEI

Physical dislocation anti-snoring tooth sleeve

ActiveCN104546265ASimple structureSimple preparation processSnoring preventionTongue rootUpper tooth

The invention discloses a physical dislocation anti-snoring tooth sleeve which comprises a lower tooth sleeve and an upper tooth positioning belt which is staggered with the front end of the lower tooth sleeve. The lower tooth sleeve and the upper tooth positioning belt are connected through a connecting device. The physical dislocation anti-snoring tooth sleeve is simple in structure, low in manufacturing cost, comfortable to use and less prone to shedding, and a lower gum can be forwards stretched to enable an upper gum and the lower gum to be staggered to drive a tongue root to move forwards by 2-8mm, so that respiratory disorder caused by the fact that a respiratory track is blocked by the tongue root which falls rearwards is avoided.

Owner:HUNAN TECH NEW MEDICAL SYST

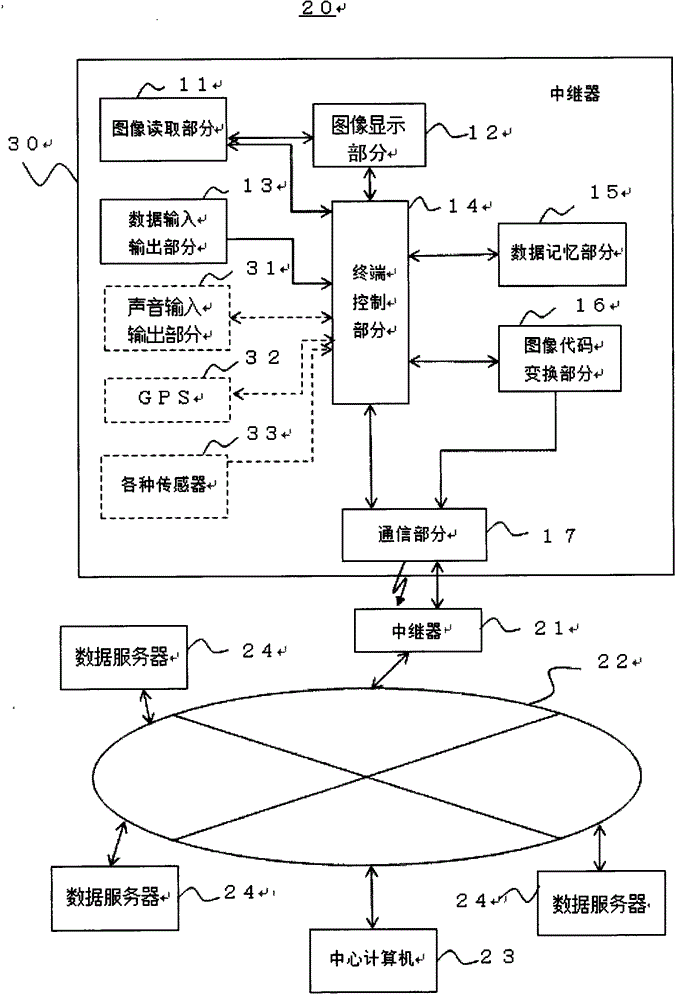

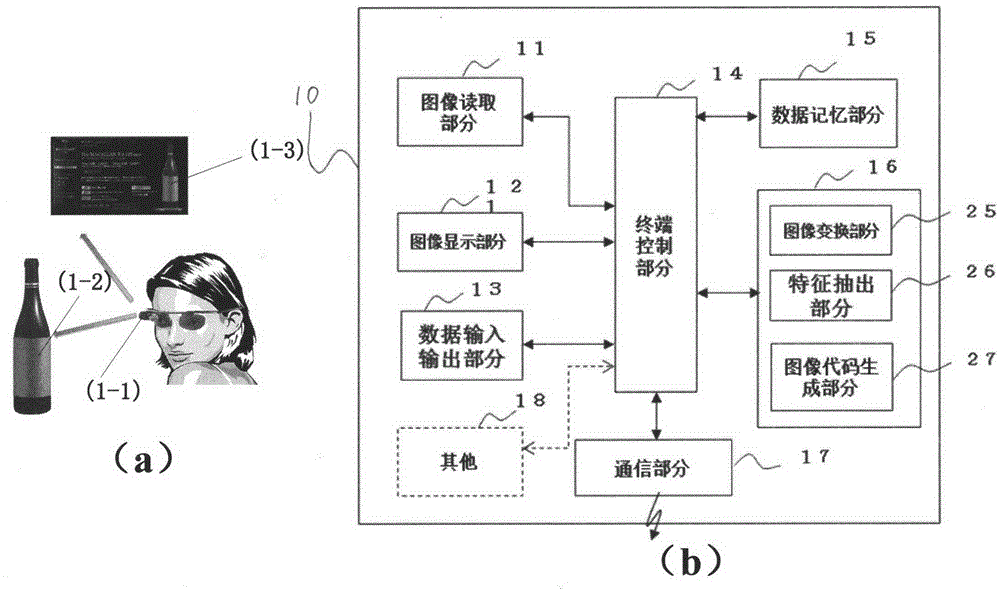

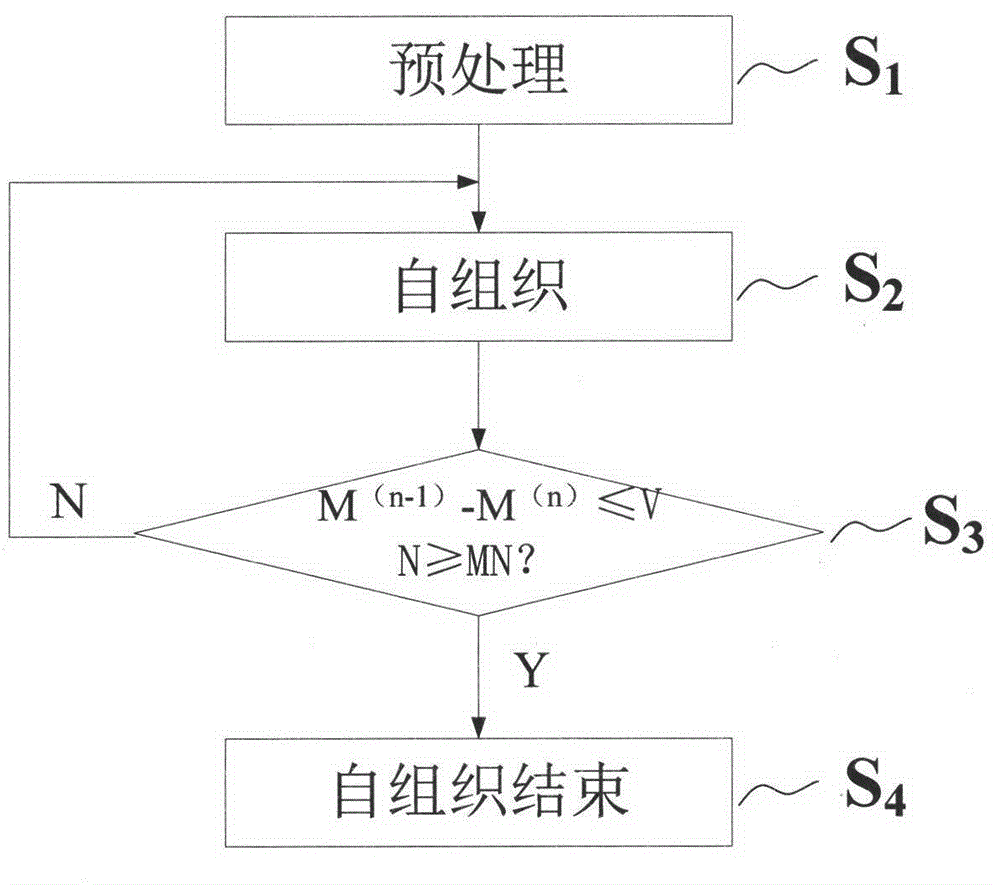

Method for constituting Internet of Things website system for Google project glass

ActiveCN104376314ASolve the problem that automatic function switching cannot be performedInput/output for user-computer interactionWeb data indexingNetwork connectionControl signal

The invention discloses a method for constituting an Internet of Things website system for the Google project glass and belongs to the field of image processing. The method for constituting the Internet of Things website system for the Google project glass comprises the steps that an original image obtained from an image reading device can be converted into a plurality of unfolded images in the geometrical or physical form, the characteristic information of each image is extracted based on the self-organizing probability scale, numeralization processing is conducted, and then an image code is generated; in order to achieve automatic function switching of the Google project glass, input information for function switching is obtained from a sensor containing at least one kind of information of the human eyeball moving information, the human eyelid turning information, the information of collision between upper teeth and lower teeth, the human head shaking information and the sound recognition information and is converted into a control signal for function switching, and then the switching function of the Google project glass is controlled; the image code generated by an image code generating part can be taken as a network entry codethrough which wireless terminals are connected with a website. The method for constituting the Internet of Things website system for the Google project glass is characterized in that webcasting media websites in new forms, social websites in new forms, online shopping websites in new forms, network retrieval websites in new forms and webpage inquiry websites in new forms can be obtained through network connection.

Owner:天津市阿波罗信息技术有限公司

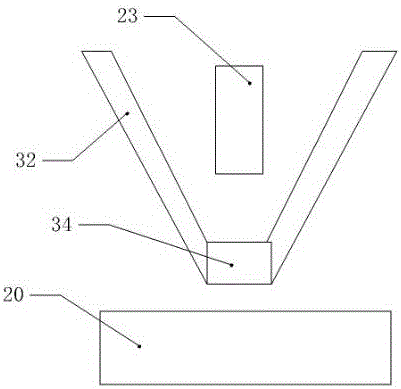

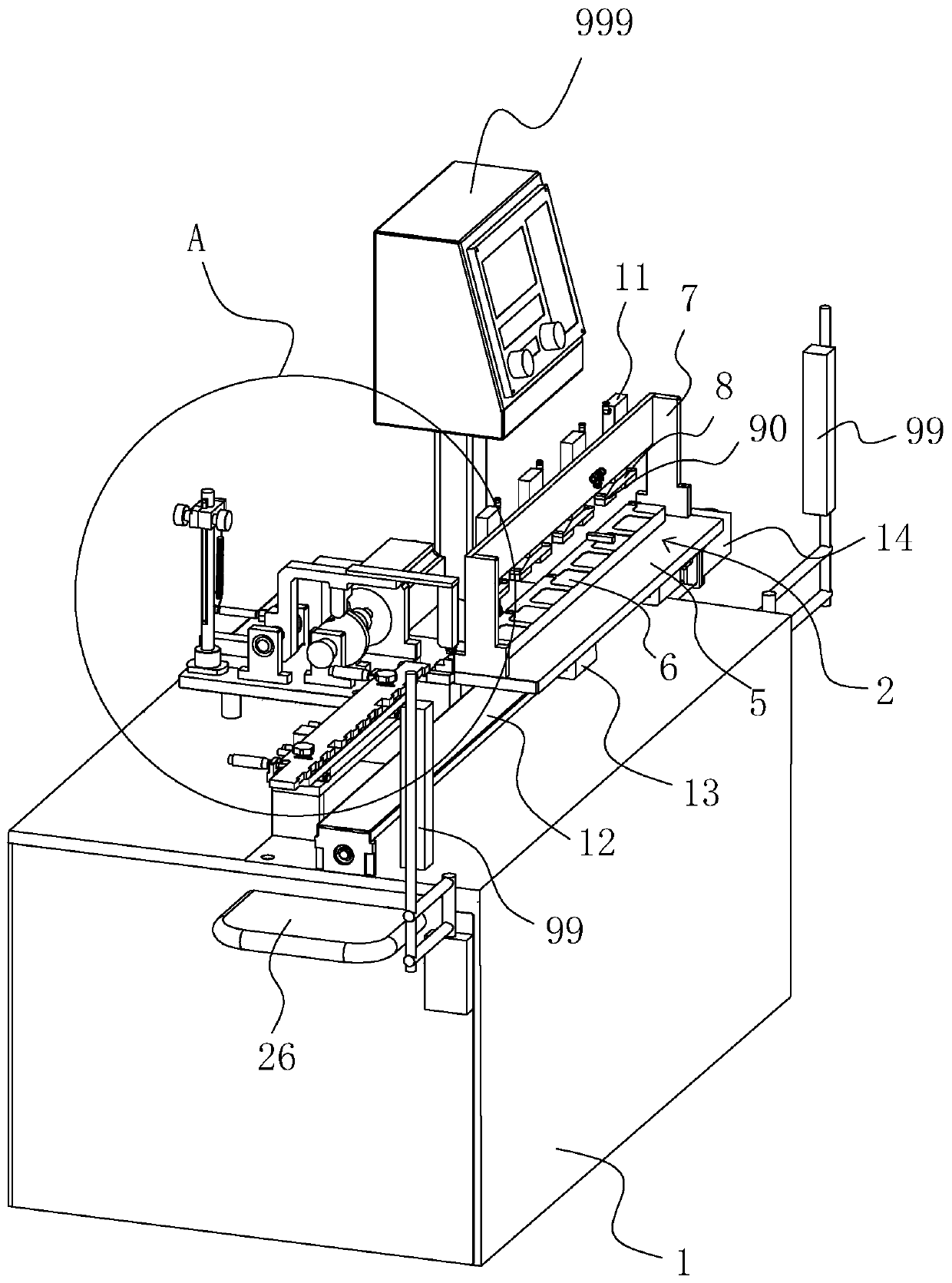

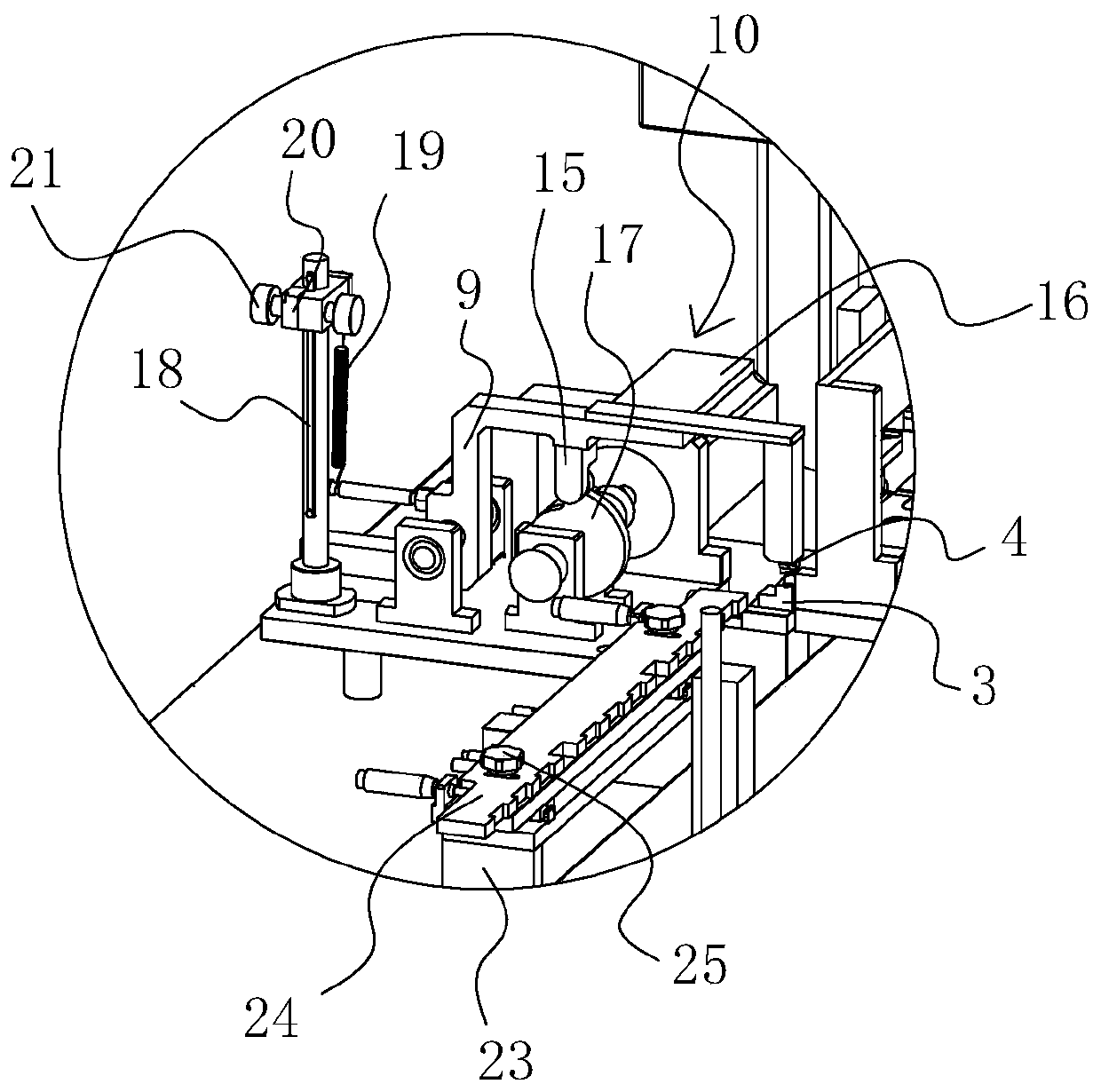

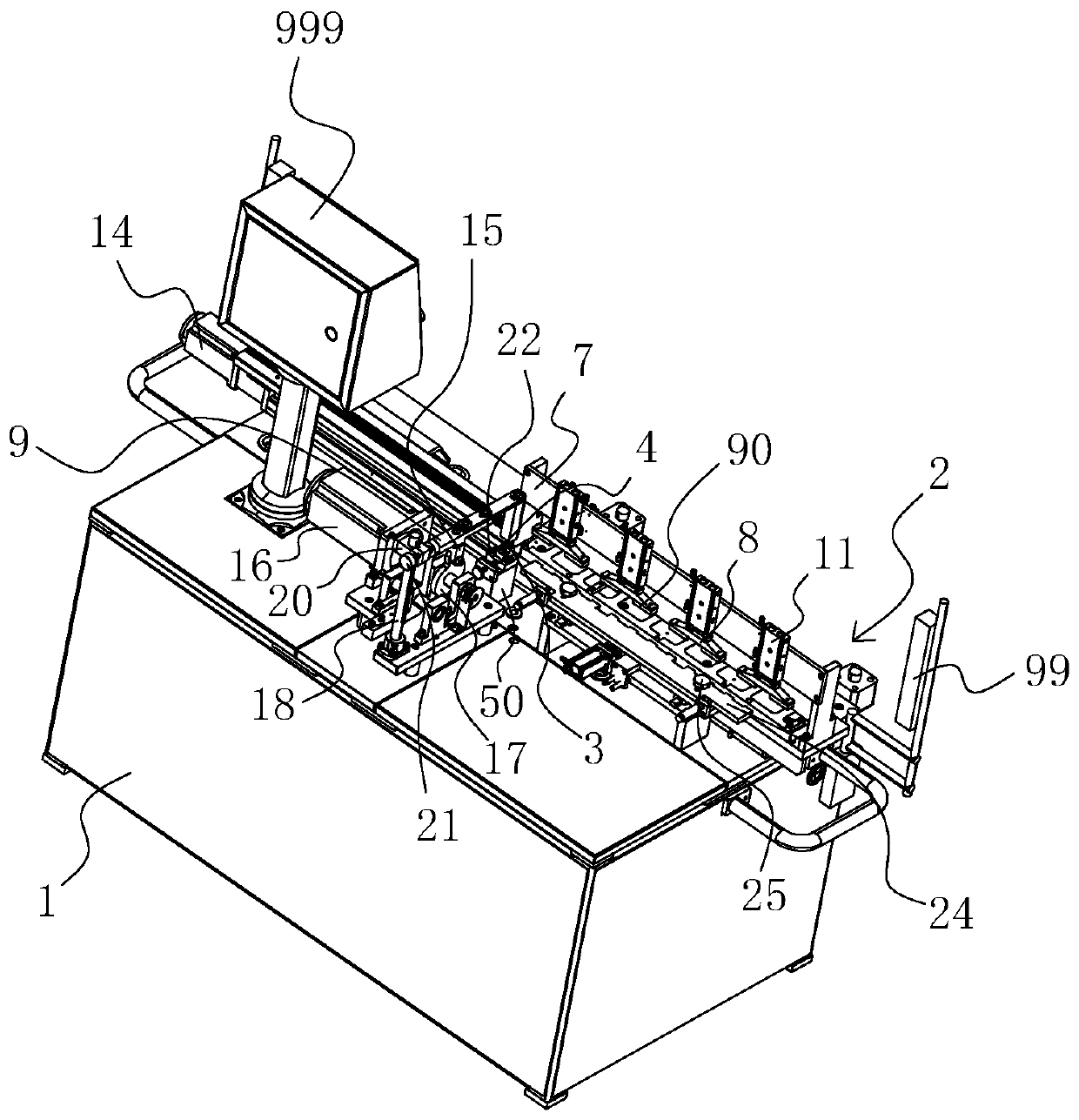

High-precision tooth separating machine

PendingCN110548926ARealize automatic tooth separationHigh tooth precisionMetal sawing tool makingLinear motionReciprocating motion

The invention belongs to the technical field of machining, and particularly relates to a high-precision tooth separating machine. The high-precision tooth separating machine comprises an operating table, wherein a saw blade fixing assembly which is used for fixing a saw blade and can achieve reciprocating linear motion is arranged on the operating table; a lower tooth separating mould is further arranged on the operating table; an upper tooth separating mould which can perform reciprocating linear motion in a direction perpendicular to a plane on which the saw blade is located is arranged above the lower tooth separating mould; and the saw blade fixing assembly separately corresponds to the position of the lower tooth separating mould and the position of the upper tooth separating mould. According to the high-precision tooth separating machine disclosed by the invention, the lower tooth separating mould and the upper tooth separating mould are arranged, and the upper tooth separating mould knocks saw teeth vertically to realize automatic tooth separating, so that tooth separating precision is high, once tooth-separating forming is achieved, tooth separating amount can be flexibly regulated and tooth separating amount is adjustable; and in a tooth separating process, the fixing effect is good, so that each tooth can be separated, automation degree and working efficiency are high, manual labor intensity is reduced, and product quality is good.

Owner:ZHEJIANG JUXING TOOL

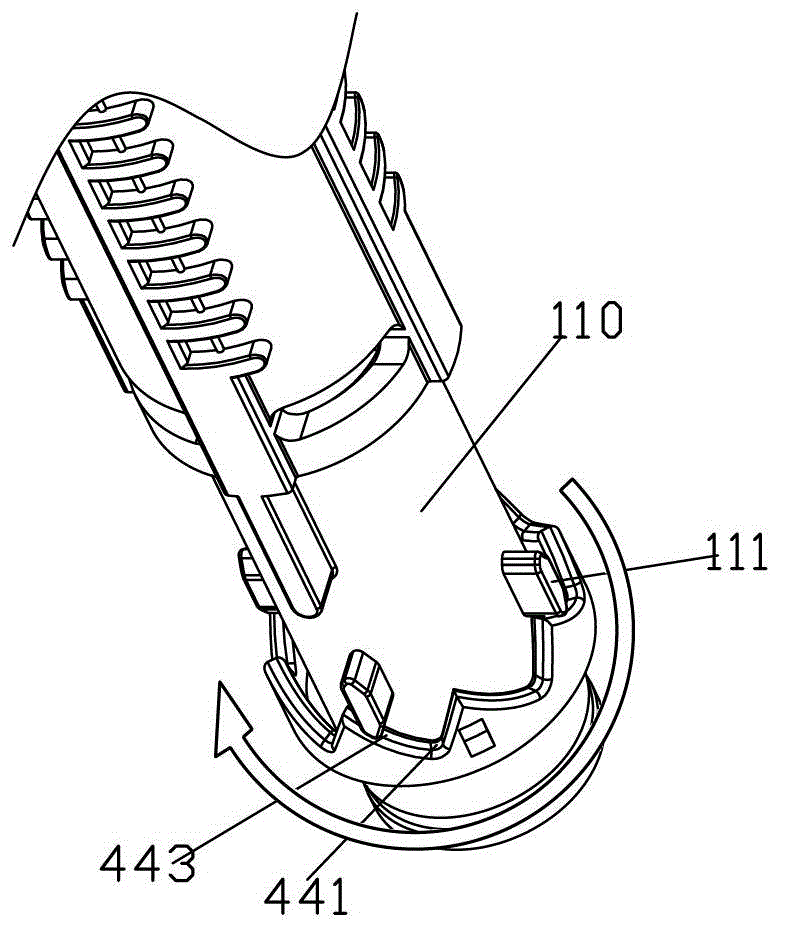

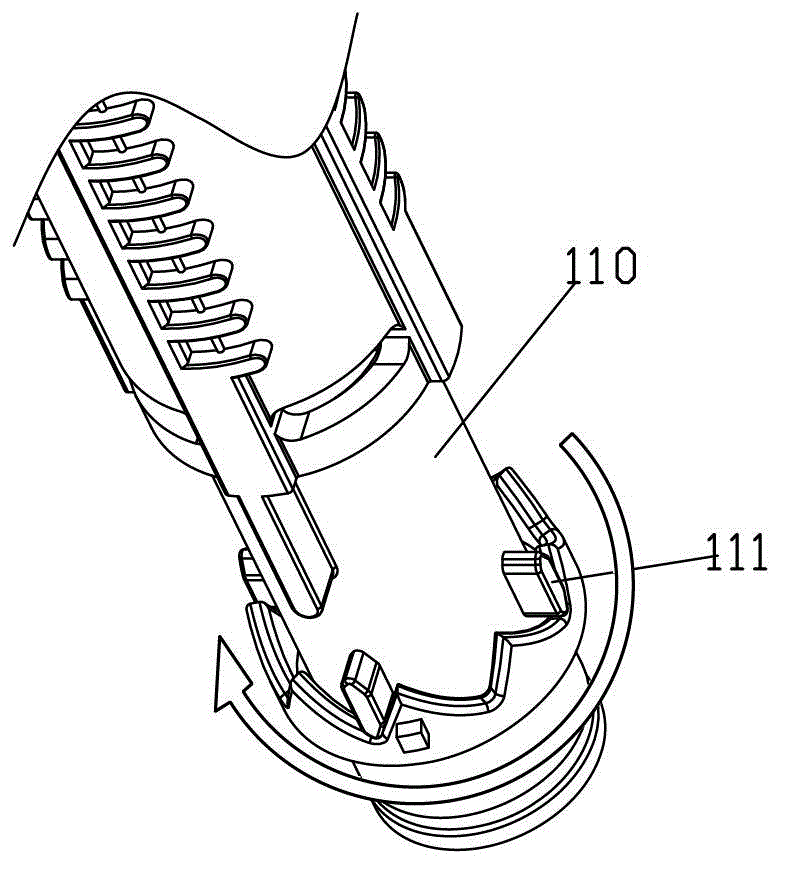

Quick disassembly mechanism for water inlet valve

ActiveCN102864828AEasy to separateEasy to assemble and disassembleFlushing devicesPush and pullInlet valve

The invention discloses a quick disassembly mechanism for a water inlet valve. The quick disassembly mechanism comprises the water inlet valve and a quick disassembly mechanism; the water inlet valve is provided with a water inlet pipe, and at least one limiting rib is arranged at the periphery of the water inlet pipe; the quick disassembly mechanism comprises an upper tooth part and a lower tooth part which are arranged in a spacing manner in the axial direction and face to each other, and the upper tooth part is provided with at least one opening groove which yields to the limiting rib; and the limiting rib is driven to be sequentially matched with the lower tooth part and the upper tooth part by axially pushing / pulling the water inlet valve, the connection between the water inlet valve and the quick disassembly mechanism is realized when the limiting rib and the opening groove are offset, and the separation of the water inlet valve from the quick disassembly mechanism is realized when the limiting rib and the opening groove are aligned. The quick disassembly mechanism for the water inlet valve has the following advantages that a water tank is provided with a certain push-and-pull space in the axial direction only and has no need of a yielding space in the horizontal direction, so that the disassembly is convenient, and the quick disassembly mechanism is applicable to any water tank, particularly small water tanks.

Owner:XIAMEN R&T PLUMBING TECH

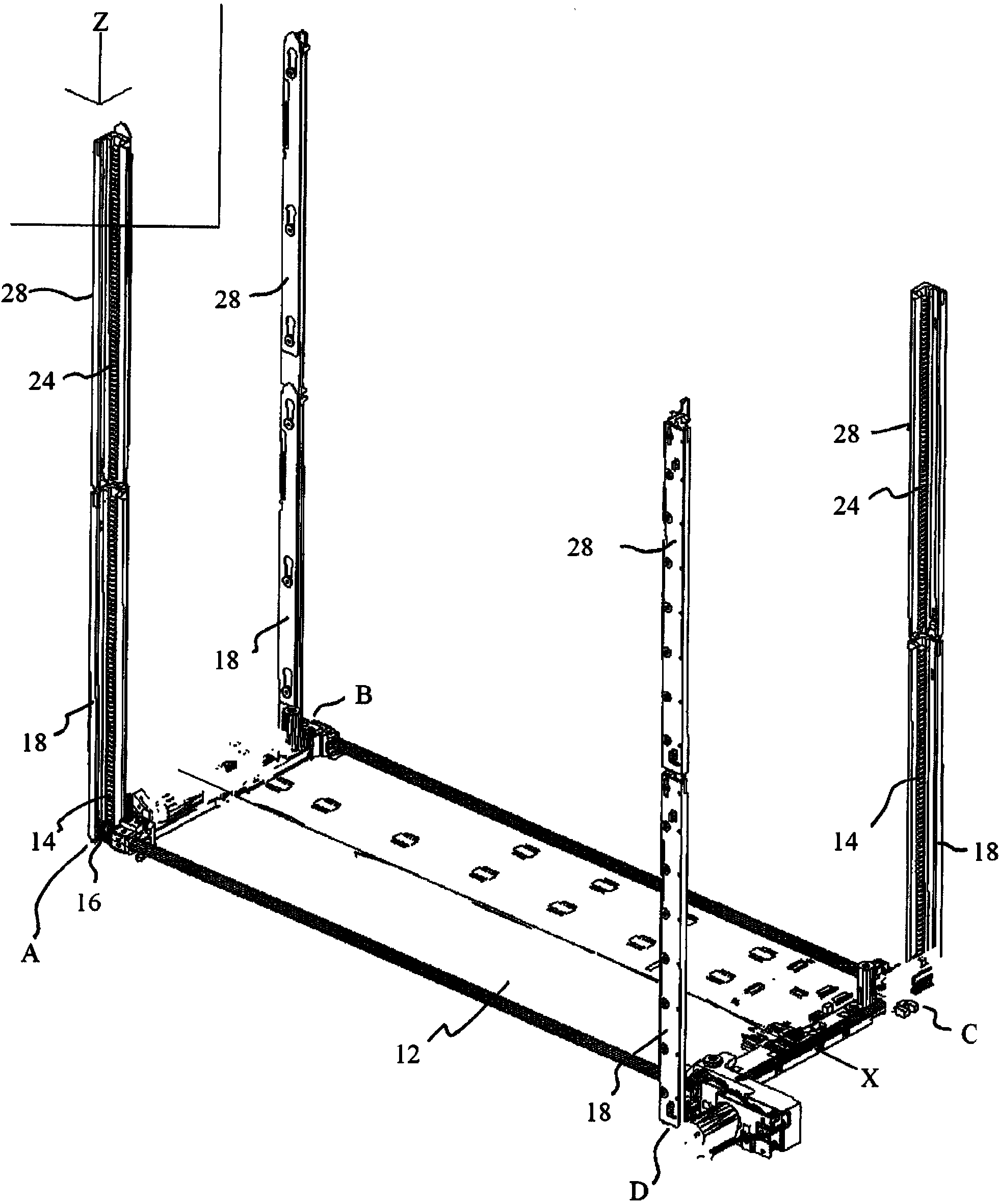

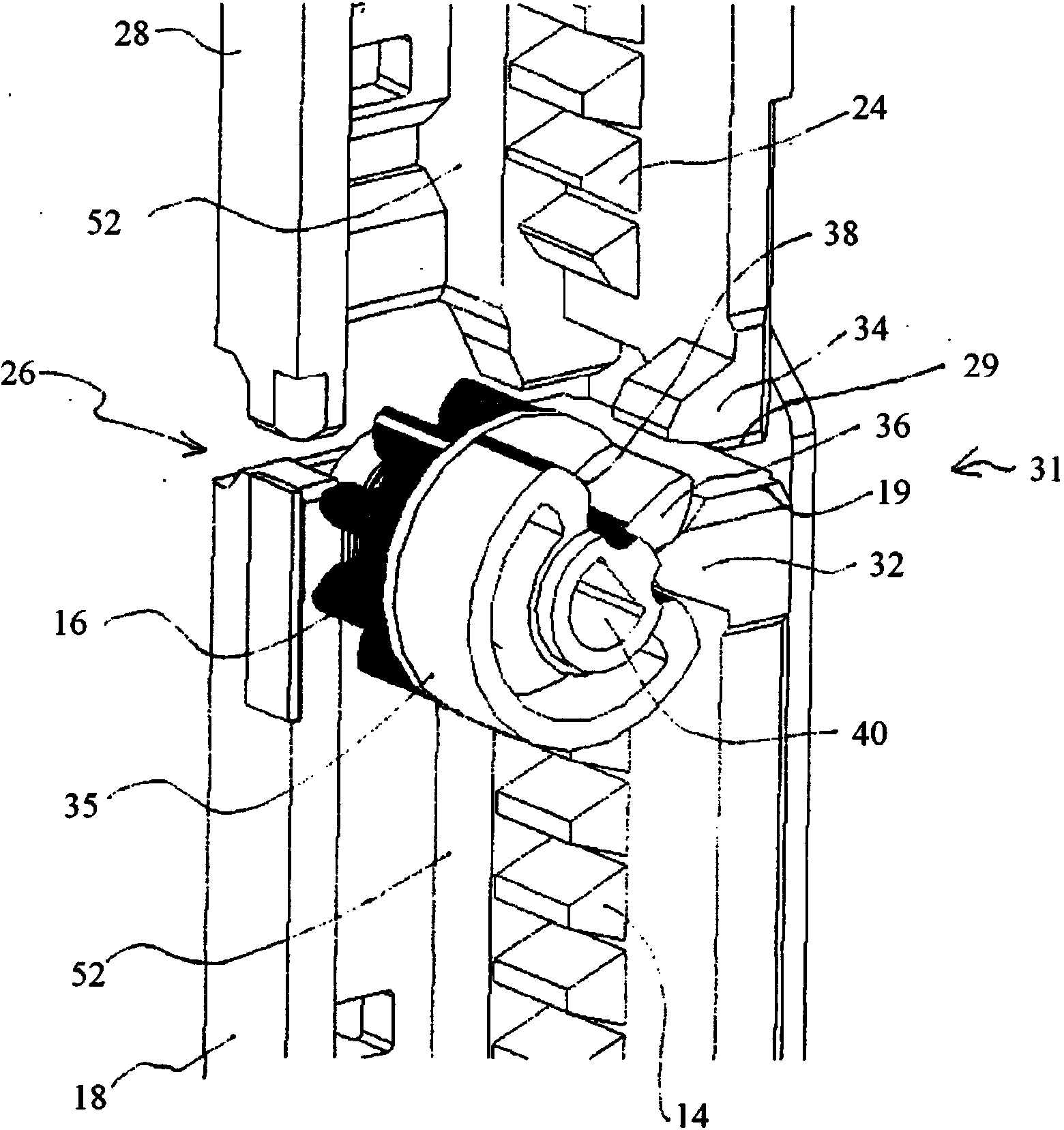

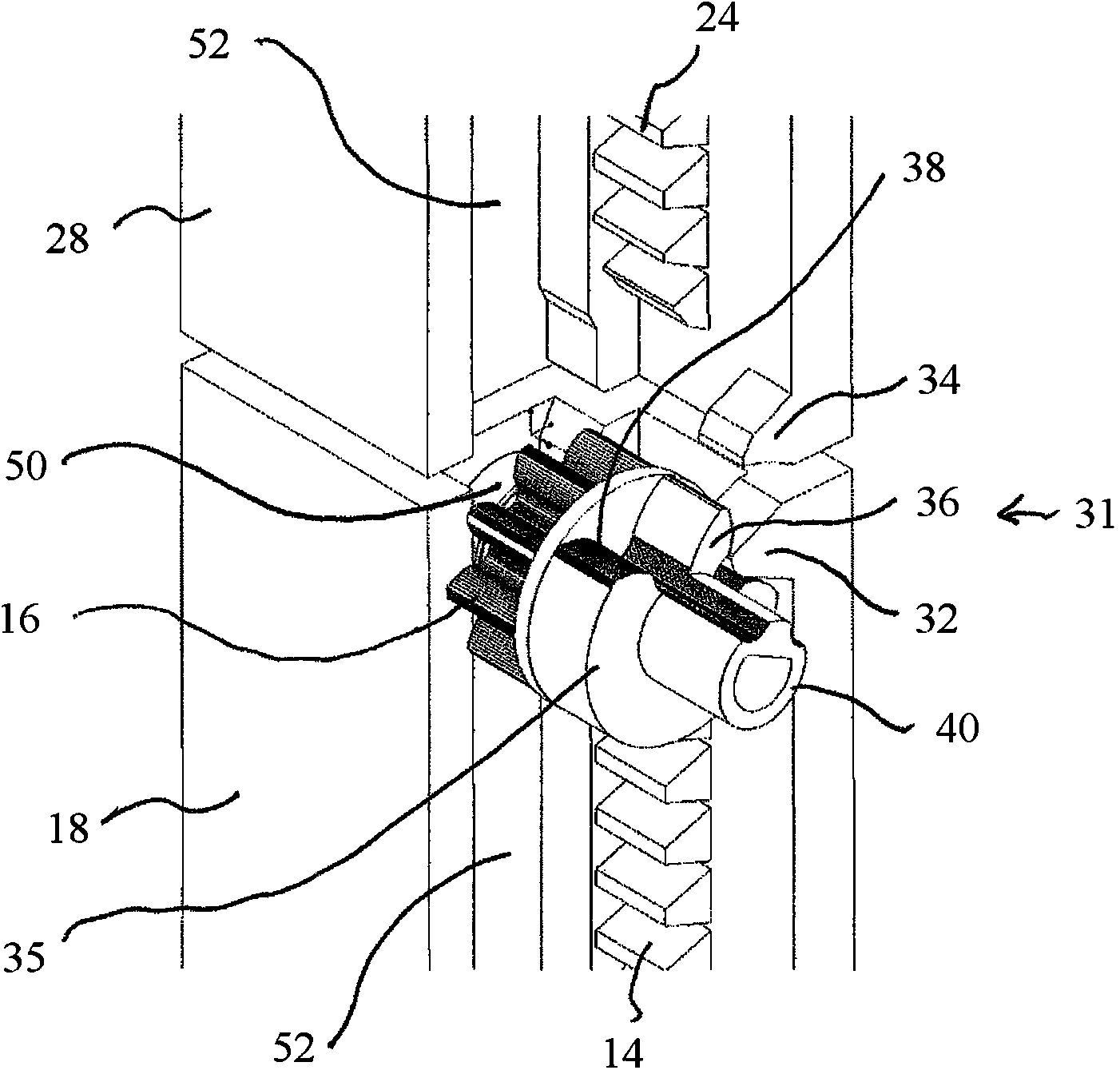

A transmission apparatus

InactiveCN103563002AApparatus modification to store record carriersFilamentary/web record carriersUpper toothEngineering

A transmission apparatus for use in a stack of data library units, the stack comprising a lower data library unit and an upper data library unit, each data library unit of the stack comprising a plurality of upright frames, the transmission apparatus comprising a tray for transporting a tape cartridge; a plurality of positioning pinions rotatably attached to the tray; a plurality of racks each disposed on each of the plurality of upright frames and configured to be engaged by the corresponding plurality of positioning pinions for vertical positioning of the tray within each data library unit; a plurality of partial racks each comprising an upper tooth and a lower tooth disposed adjacent the plurality of racks at each of the plurality of upright frames, the upper tooth being disposed adjacent a lower end of the frame of the upper data library unit and the lower tooth being disposed adjacent an upper end of the frame of the lower data library unit; a plurality of cross-over pinions each rotatably attached to the tray and disposed co-axially with each of the plurality of positioning pinions, each cross-over pinion having a tooth profile configured to engage each of the partial racks for effecting movement of the tray between the lower data library unit and the upper data library unit.

Owner:VENTURE CORP LTD

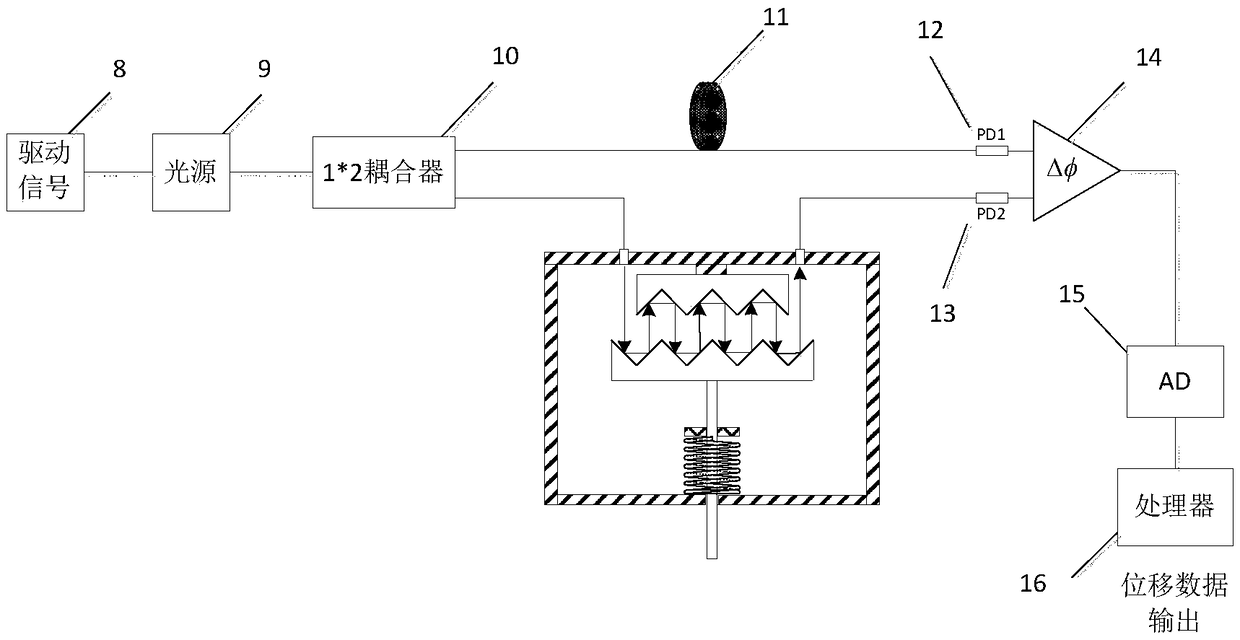

Pressure type optical fiber micro-change sensor

PendingCN109141491AEliminate distractionsHigh sensitivityForce measurement by measuring optical property variationThermometers using physical/chemical changesElectricityUpper tooth

The invention provides a pressure type optical fiber micro-change sensor, which can solve the problems of inaccurate measurement and easy failure of a displacement sensor at present in a high temperature and strong electromagnetic environment. The pressure type optical fiber micro-change sensor is realized according to the following technical scheme: light signals modulated by a signal modulationportion are divided into two beams through optical fiber coupling, one beam of light signals directly reaches a photoelectric detector through an optical fiber ring to serve as a reference light pathof an optical fiber light path, the other beam of light signals enters a lower tooth groove reflecting angle of a lower moving toothed plate reflecting mirror through a first collimating lens and is reflected to an upper tooth groove reflecting angle of an upper fixed toothed plate reflecting mirror through a completely reflecting mirror formed by tooth grooves, the incident light is reflected formultiple times by multiple tooth angles and enters a photoelectric detector pd2 connected through an optical fiber from a second collimating lens, and the light path serves as a measurement light path. The displacement change will cause the phase change of the light signals of the measurement light path relative to the reference light path, and the displacement change can be demodulated through detecting two phase variations by a phase comparator.

Owner:CHENGDU KAITIAN ELECTRONICS

Longitudinal separation adjustable rod guider

InactiveCN102430590AIncrease contact areaPrevent looseningGuiding/positioning/aligning arrangementsUpper toothEngineering

A longitudinal separation adjustable rod guider is disclosed, and relates to a guider, in particular to a longitudinal separation adjustable rod guider. The invention solves the problems that the contact area of the screw and guiding of an adjustor of the longitudinal separation before guiding the bar is small so as not able to fasten the guider and the guider is loosened always. The longitudinal separation adjustable rod guider comprises a nose cone, a guiding assembly, a guide slot, a bracket assembly, a compressing screw, an elastic cylindrical pin, an upper tooth piece and a lower tooth piece. The bracket assembly consists of an upper beam, a lower beam and a vertical plate. The upper and lower beams are respectively connected fixedly with the upper and lower ends of the vertical plate as a whole. The guiding assembly is installed on the upper surface of the lower beam. The nose cone is connected with one end of the guiding assembly while the other end of the guiding assembly is connected with the guide slot. The lower tooth piece is installed on the upper surface of the guiding assembly, the compressing screw penetrates through the upper beam up and down and the upper tooth piece is connected with the lower end of the compressing screw through the elastic cylindrical pin. The invention is used to ensure that the rolled pieces move along a correct in-and-out roller.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Anti-theft floor lock of roller shutter door

PendingCN111395942APrevent lock pickingPrevent copyingDoor/window protective devicesBuilding locksGear wheelUpper tooth

The invention discloses an anti-theft floor lock for a roller shutter door. The anti-theft floor lock is characterized by comprising a lock body, a lock cylinder, a tension spring, a stroke transmission mechanism, a locking mechanism and an anti-pull-back mechanism, wherein the lock cylinder is arranged in the middle of the lock body; the stroke transmission mechanism comprises a lock rod, a firsttransmission lock rod and a second transmission lock rod, wherein the lock rod comprises an upper tooth lock rod and a lower tooth lock rod, and the upper tooth lock rod and the lower tooth lock rodare arranged on the upper portion and the lower portion of the lock cylinder respectively and meshed with a lock cylinder gear; and the lock rod is connected with one end of the first transmission lock rod, the second transmission lock rod is connected with the other end of the first transmission lock rod, and the anti-pull-back mechanism is arranged on one side of the joint of the lock rod and the first transmission lock rod. The anti-theft floor lock for the roller shutter door is high in applicability, excellent in prying resistance, convenient to use, low in failure rate and convenient todisassemble, assemble and maintain.

Owner:南宁市天道锁具科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com