Quick disassembly mechanism for water inlet valve

A disassembly mechanism and water inlet valve technology, which is applied to water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of inconvenient disassembly and assembly, and achieve the effects of convenient disassembly, good effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

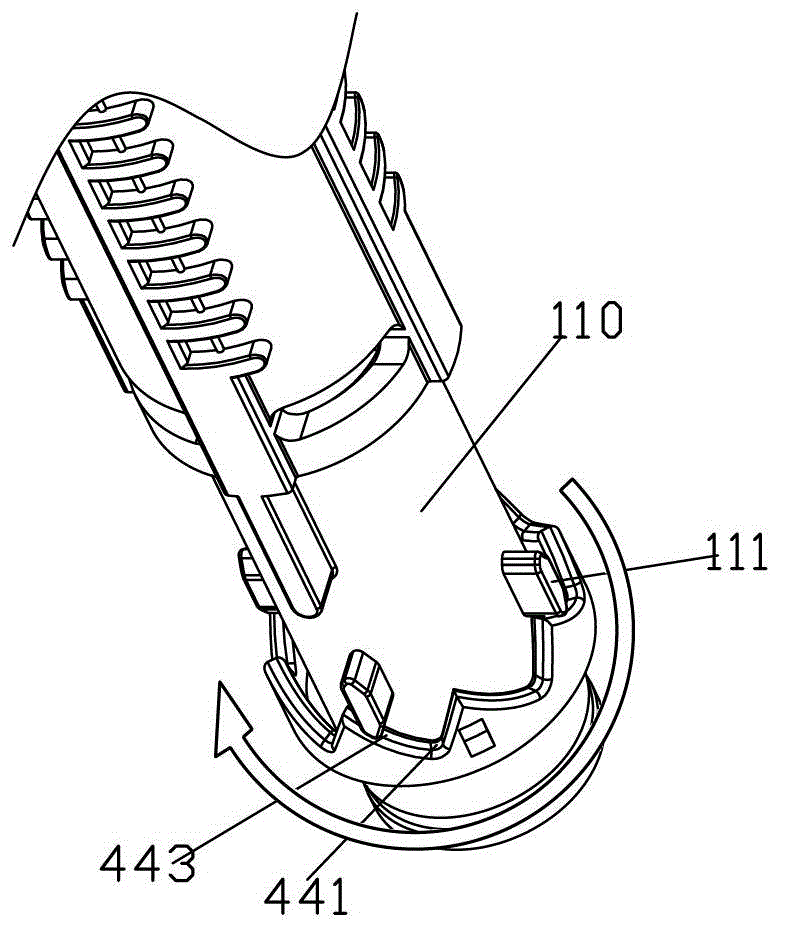

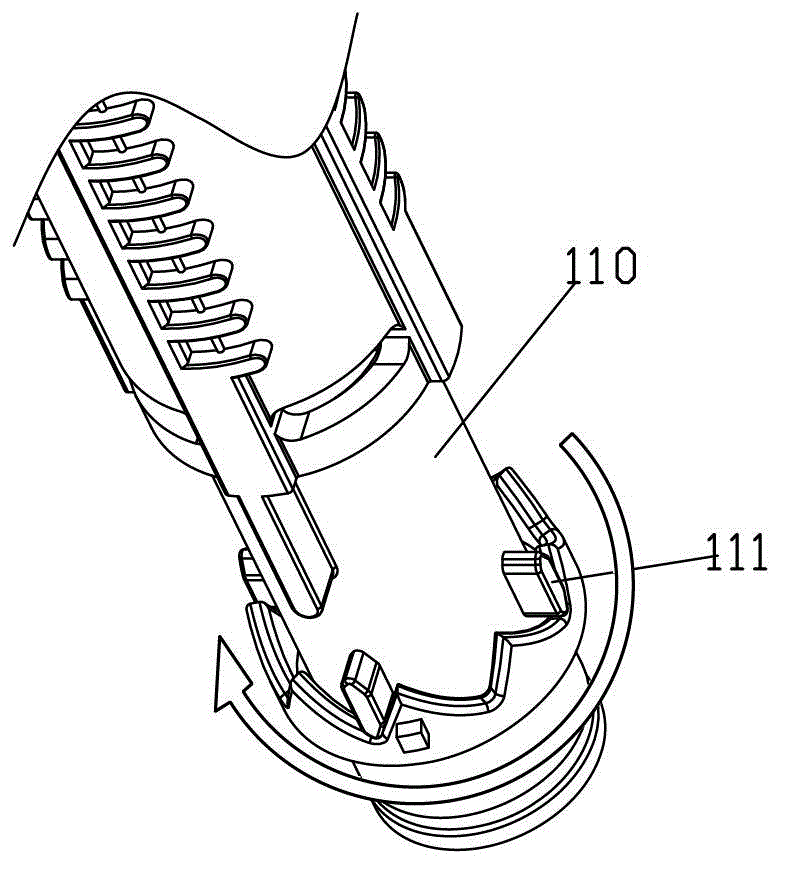

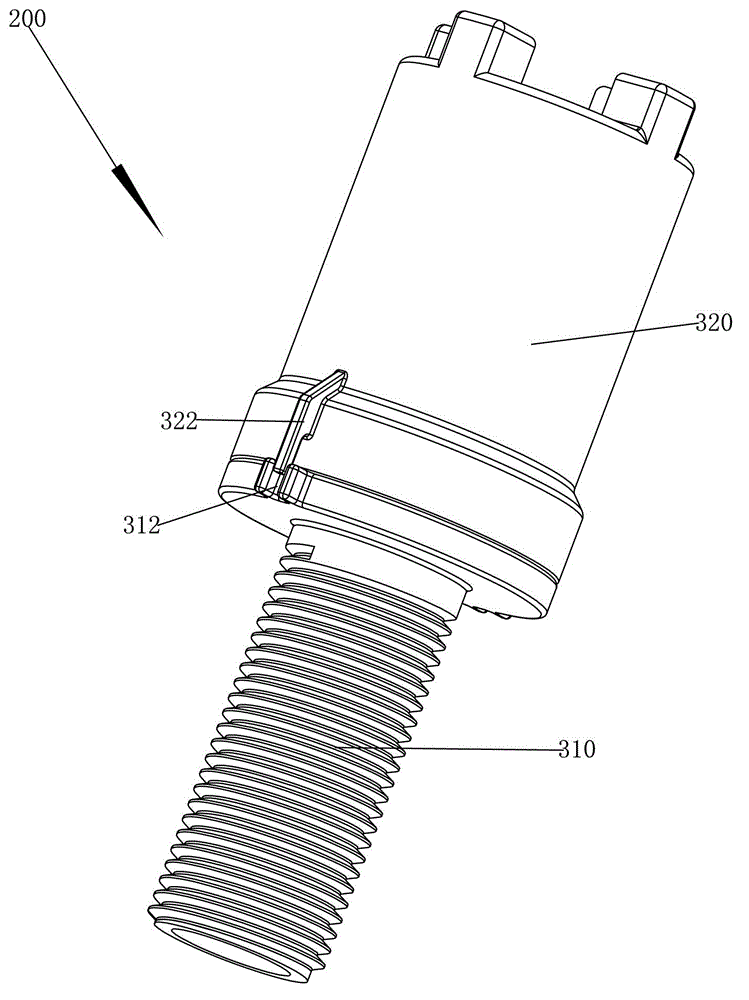

[0043] Please check Figure 1 to Figure 13 , a preferred embodiment of the quick disassembly mechanism for the water inlet valve, the quick disassembly mechanism for the water inlet valve includes a water inlet valve 100 and a quick disassembly mechanism 200 .

[0044] The water inlet valve 100 is provided with a water inlet pipe 110 , and the outer periphery of the water inlet pipe 110 is provided with at least one limiting rib 111 . In this embodiment, the number of the limiting ribs 111 is set to four and are evenly spaced on the same circumference. Preferably, the outer circumference of the water inlet pipe 110 is also provided with a seal 112 that can position the quick disassembly mechanism 200 when the limiting rib 111 and the slot 411 are misaligned, and the outer circumference of the water inlet pipe 110 is also provided with a limiter. Bitbar 113. In this embodiment, the sealing member 112 functions to seal the waterway and quickly position the water inlet valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com