Longitudinal separation adjustable rod guider

A technology of front-to-back distance and guide device, which is applied in the field of guide device, can solve problems such as looseness, small contact area between screws and guide device, and cannot fasten the guide device, so as to increase the contact area, improve work efficiency and economic benefits , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

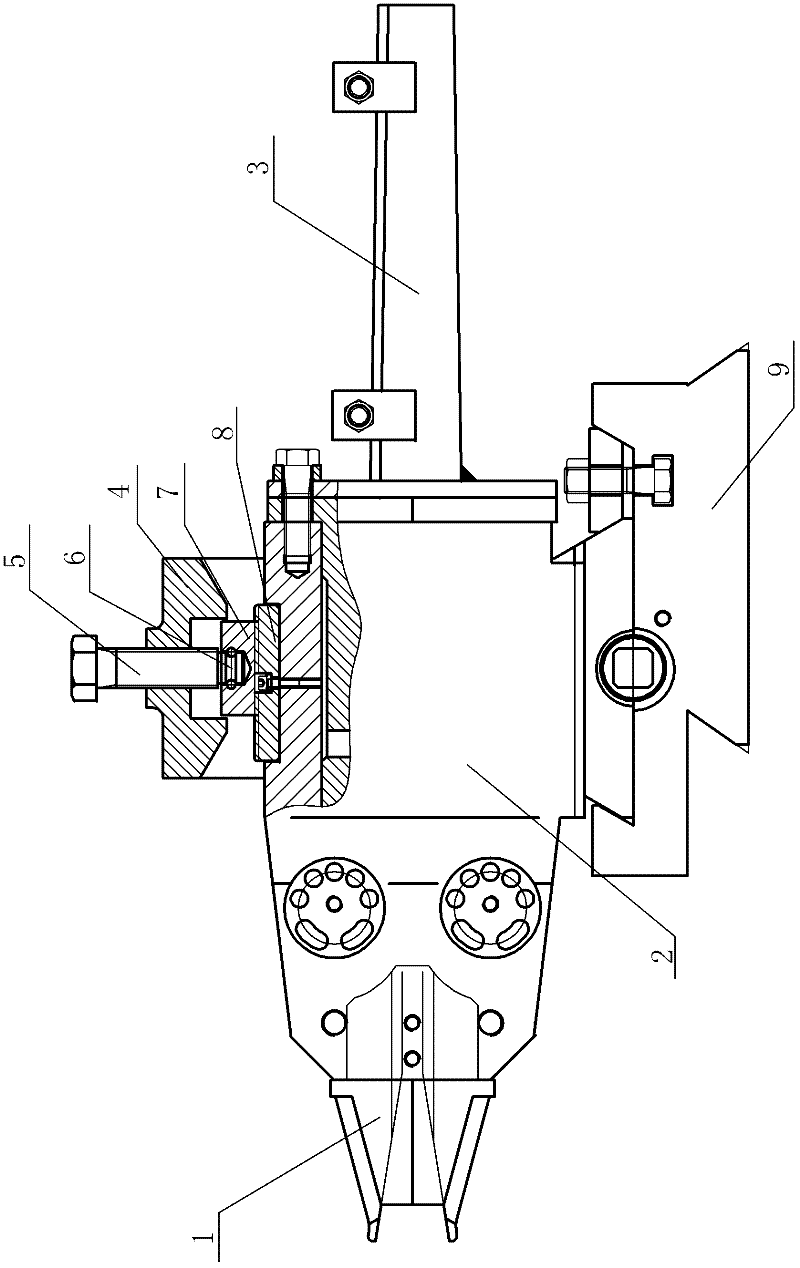

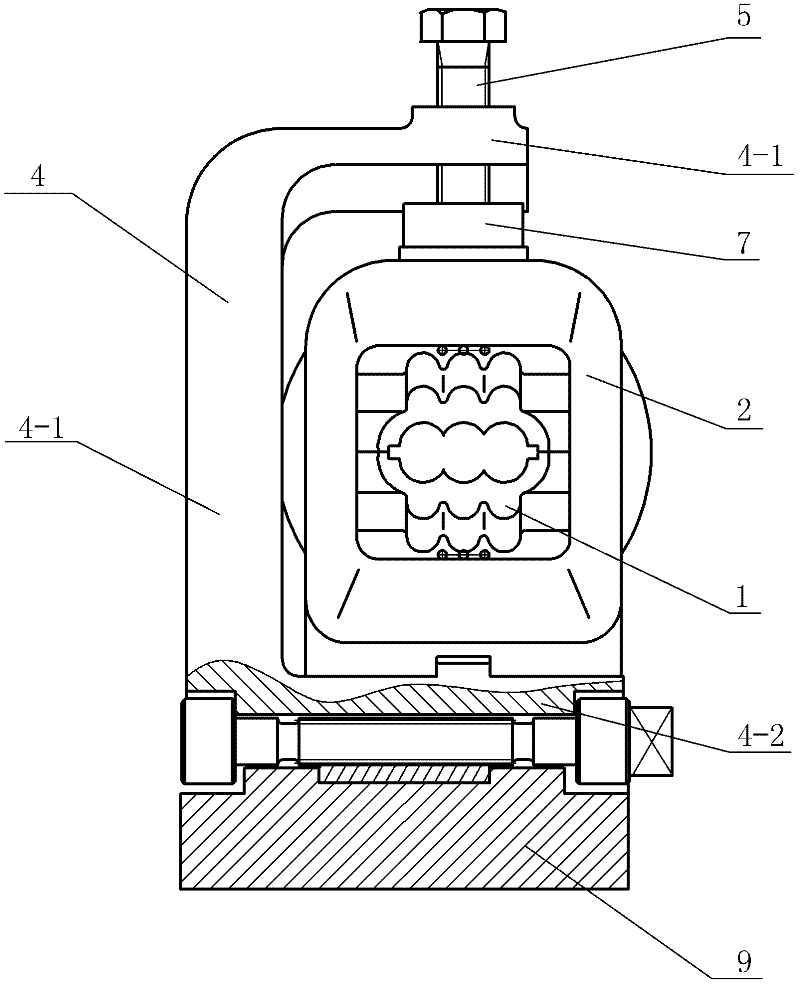

[0007] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, a front-rear distance-adjustable rod guide device described in this embodiment includes a nose cone 1, a guide assembly 2, a guide groove 3, a bracket assembly 4, a compression screw 5, an elastic cylindrical pin 6, an upper Tooth block 7 and lower tooth block 8, described bracket assembly 4 is made up of upper crossbeam 4-1, lower crossbeam 4-2 and vertical plate 4-3, described upper crossbeam 4-1, lower crossbeam 4-2 are respectively connected with vertical The upper end and the lower end of the plate 4-3 are fixed into one body, and the upper beam 4-1 and the lower beam 4-2 are arranged side by side in parallel on one side of the vertical plate 4-3, and the guide assembly 2 is installed on the lower beam 4-2 On the upper surface of the upper surface, the nose cone 1 is connected to one end of the guide assembly 2, the guide groove 3 is connected to the other end of...

specific Embodiment approach 2

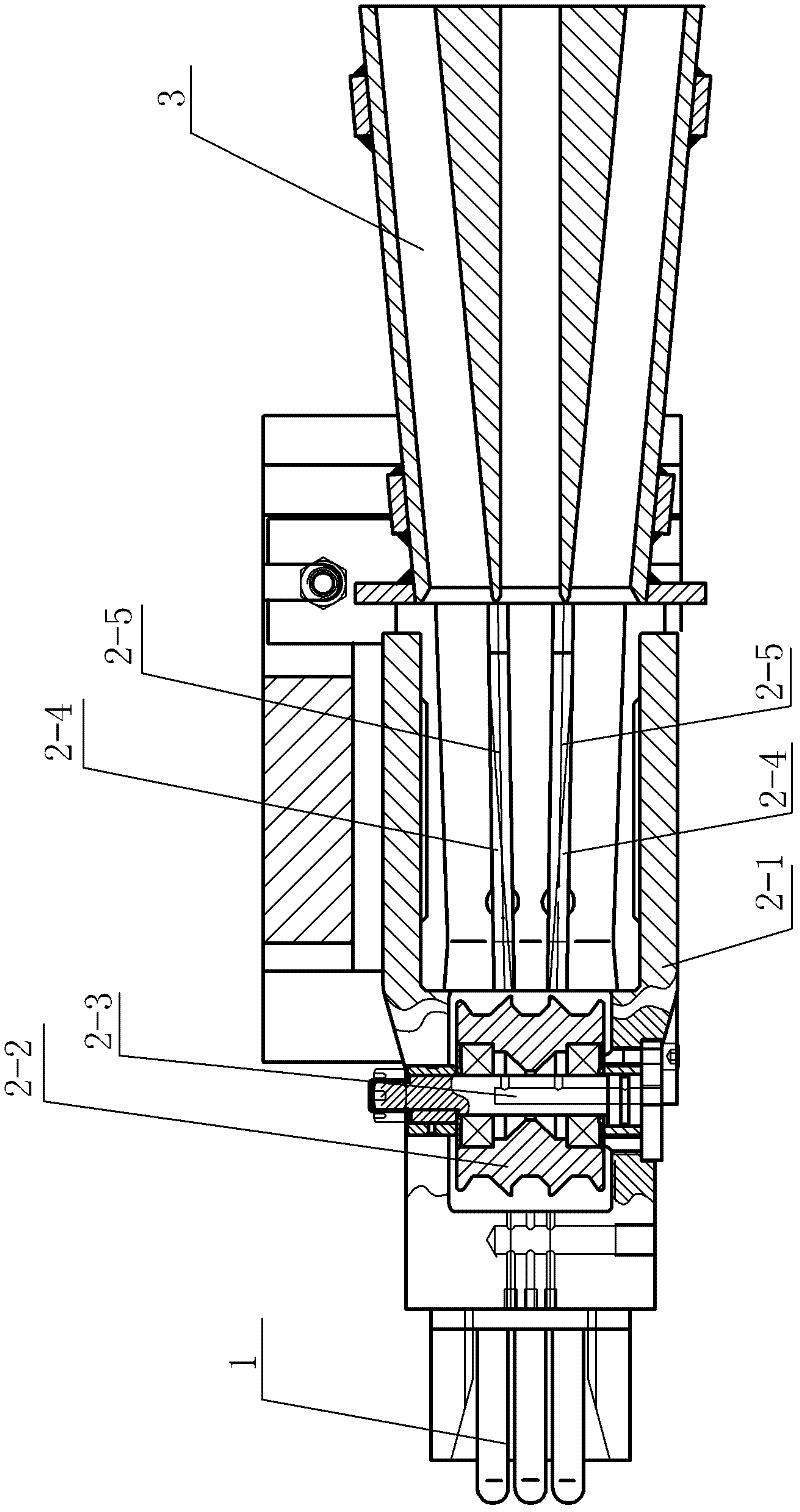

[0008] Specific implementation mode two: combination figure 1 This embodiment is described. The guide assembly 2 of a front-rear distance-adjustable bar guide device in this embodiment includes a box body 2-1, two dividing wheels 2-2, two eccentric shafts 2-3, Two tool holders 2-4 and two blades 2-5, two eccentric shafts 2-3 are inserted side by side and parallel in one end of the box body 2-1 from top to bottom, and each cutting wheel 2-2 is set separately On an eccentric shaft 2-3, two knife rests 2-4 are installed side by side in parallel in the other end of the box body 2-1 along the length direction of the box body 2-1, and the two knife rests 2-4 are on the same horizontal plane Inside, a blade 2-5 is respectively installed on each knife holder 2-4. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 , figure 2 and image 3 To illustrate this embodiment, the front-rear distance-adjustable bar guide device in this embodiment further includes a base 9 on which the bracket assembly 4 is installed. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0010] working principle

[0011] When the present invention is used, the box body 2-1 is installed on the lower crossbeam 4-2, after adjusting the position of the box body 2-1, the upper tooth block 7 is pushed down by the compression screw 5 until the upper tooth block 7 and the lower tooth block 7 The tooth blocks 8 are firmly meshed, and the workpiece is sent into the guide assembly 2 for cutting; after the work is completed, the upper tooth block 7 is pulled by the compression screw 5 to move upward until the upper tooth block 7 and the lower tooth block 8 are separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com