Patents

Literature

4203 results about "Butadiene Dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

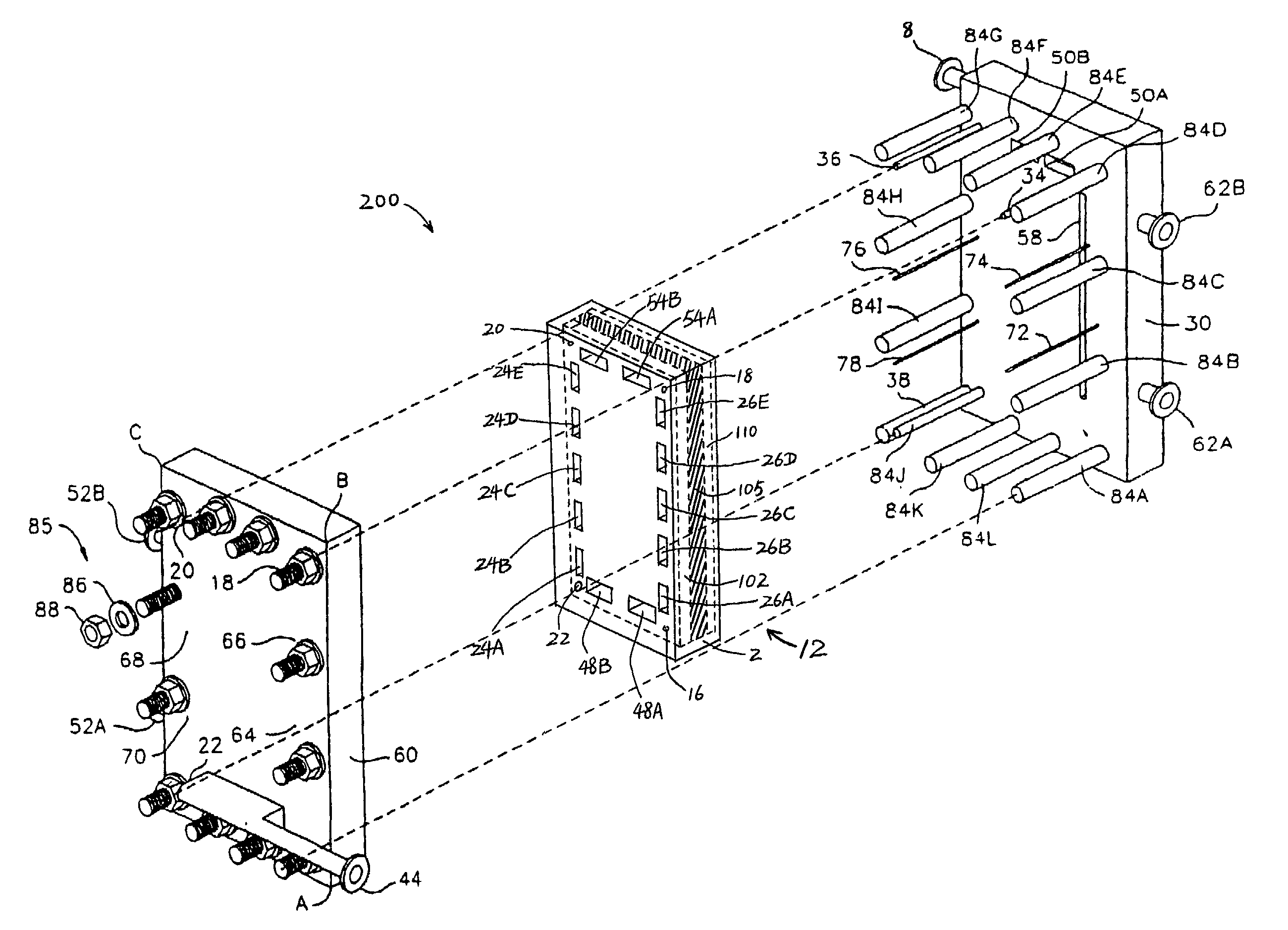

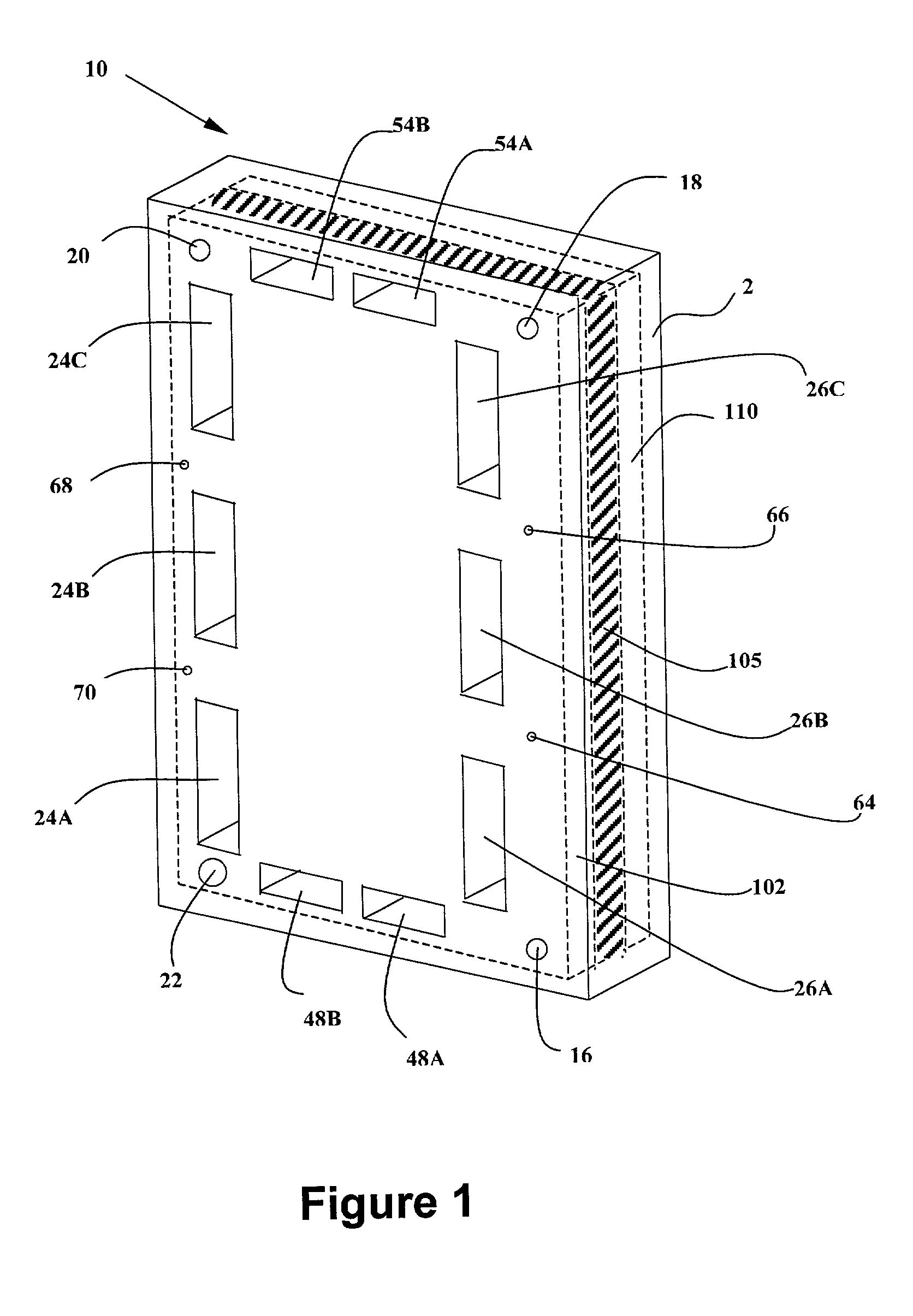

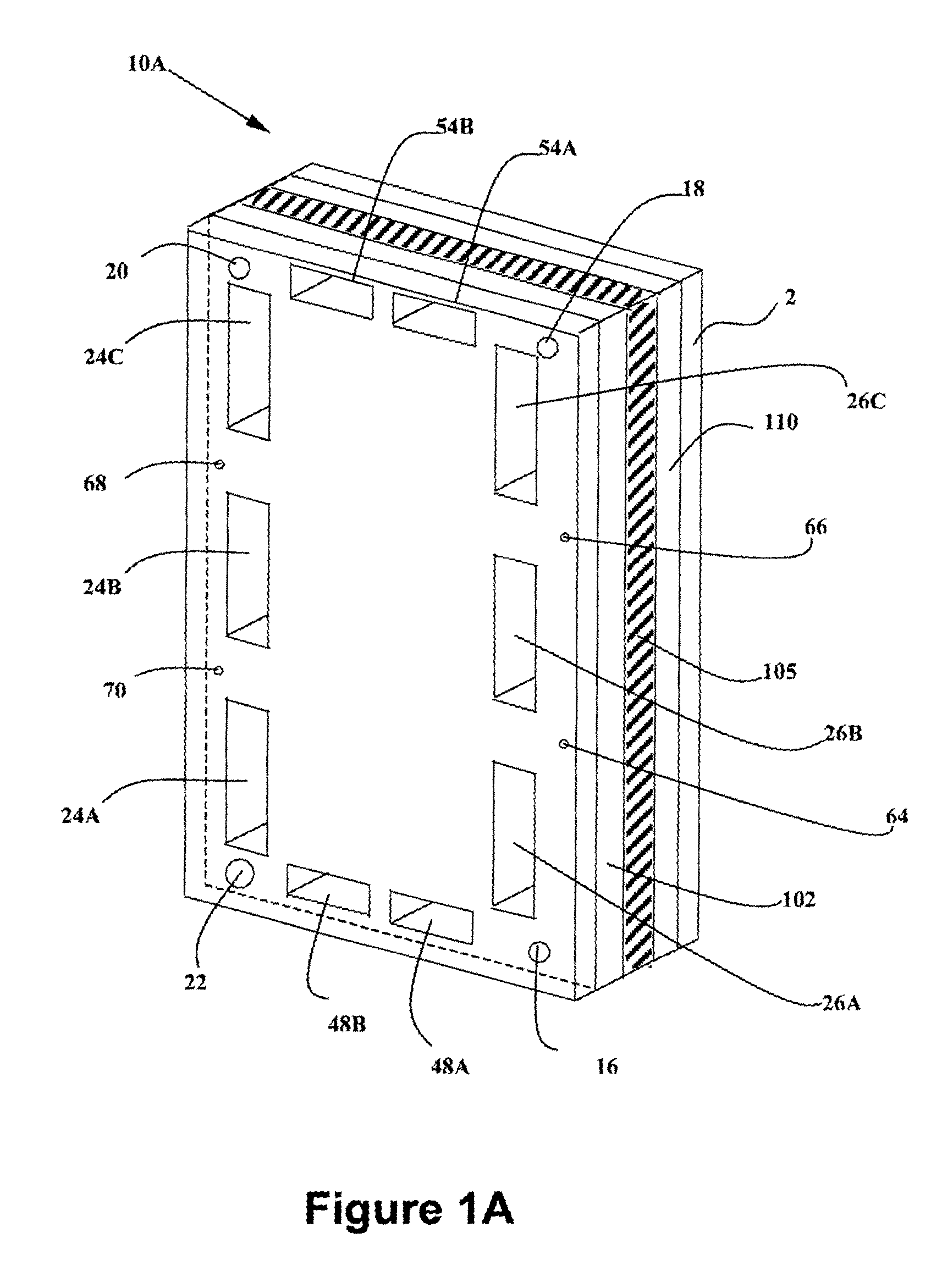

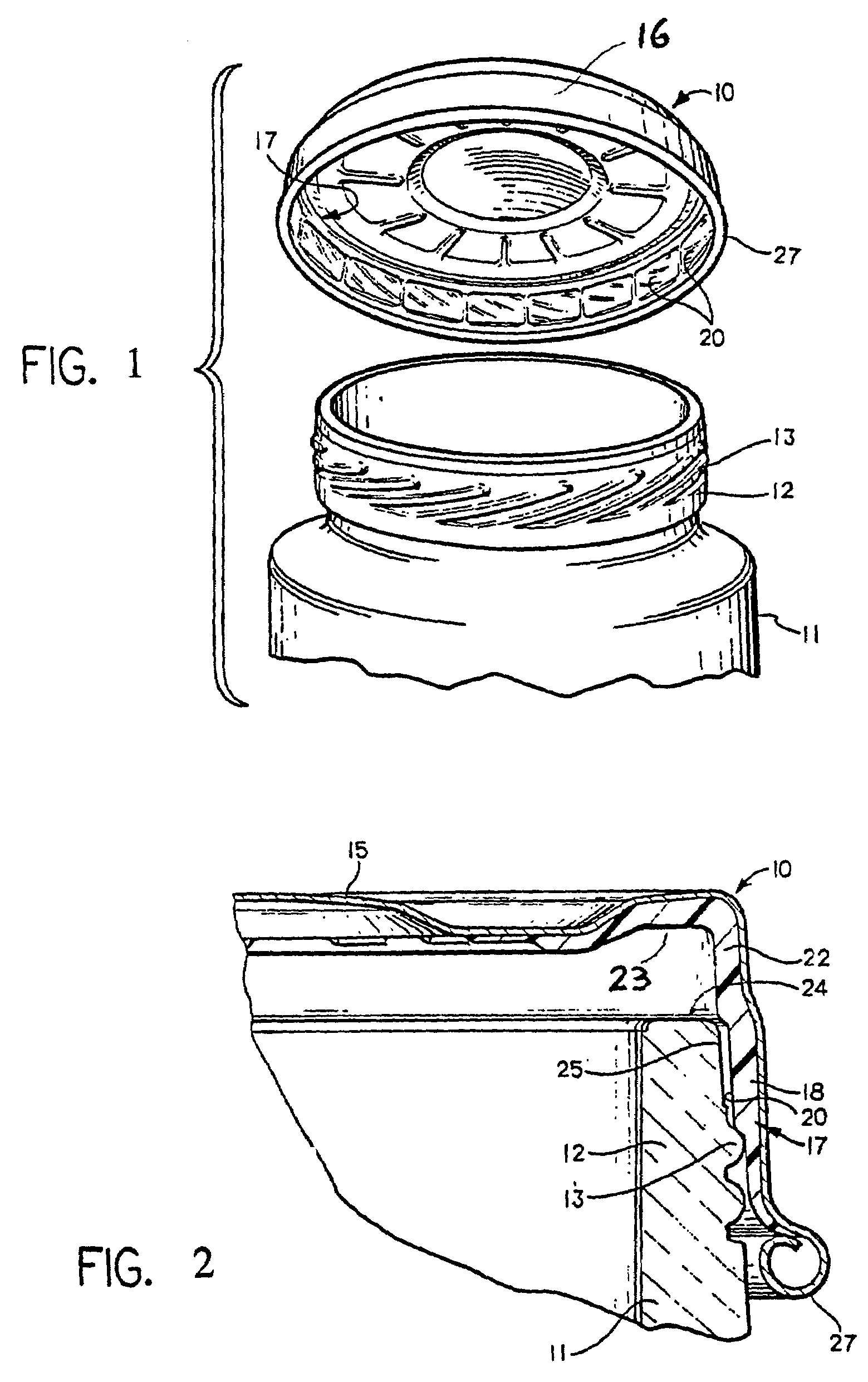

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

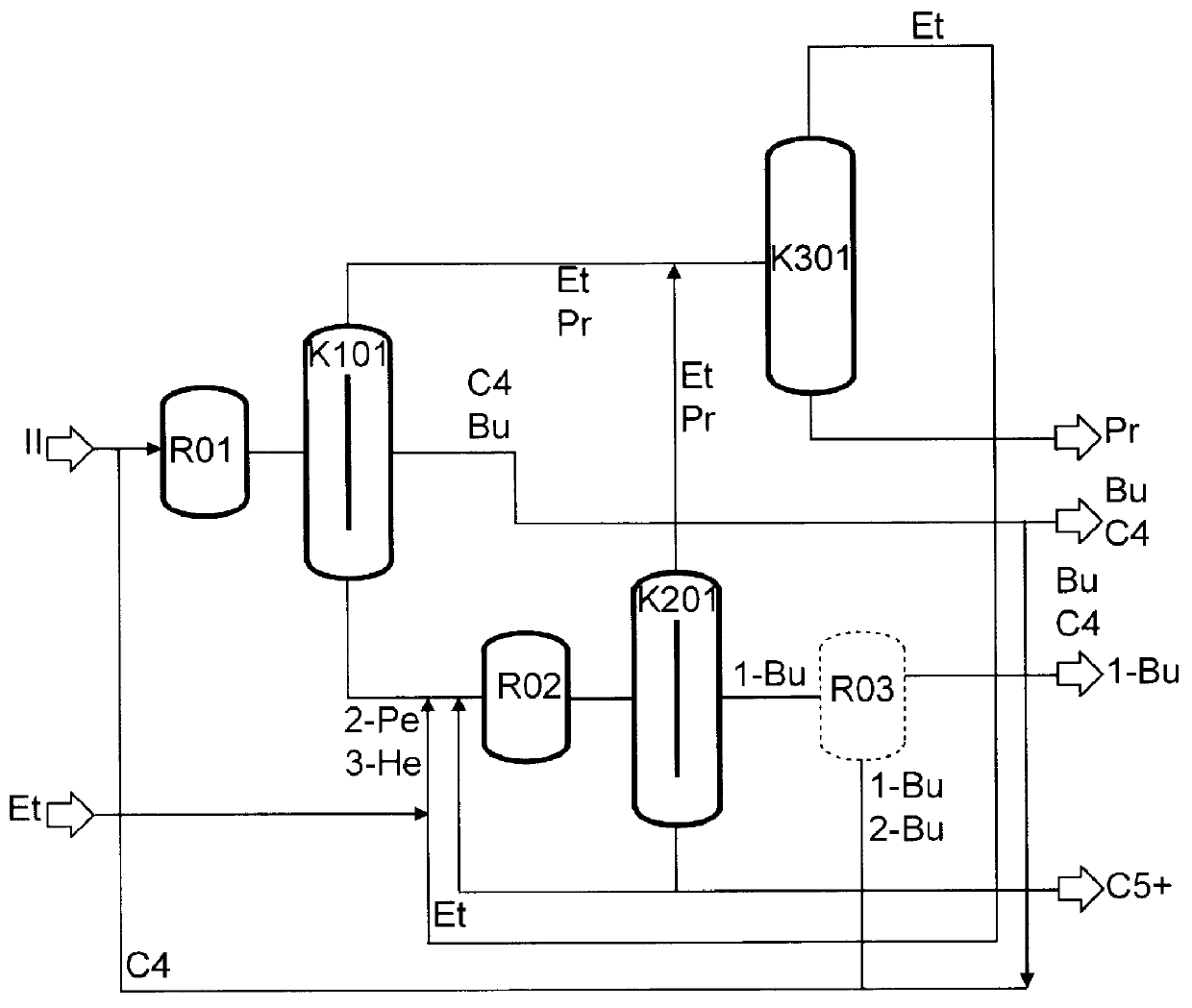

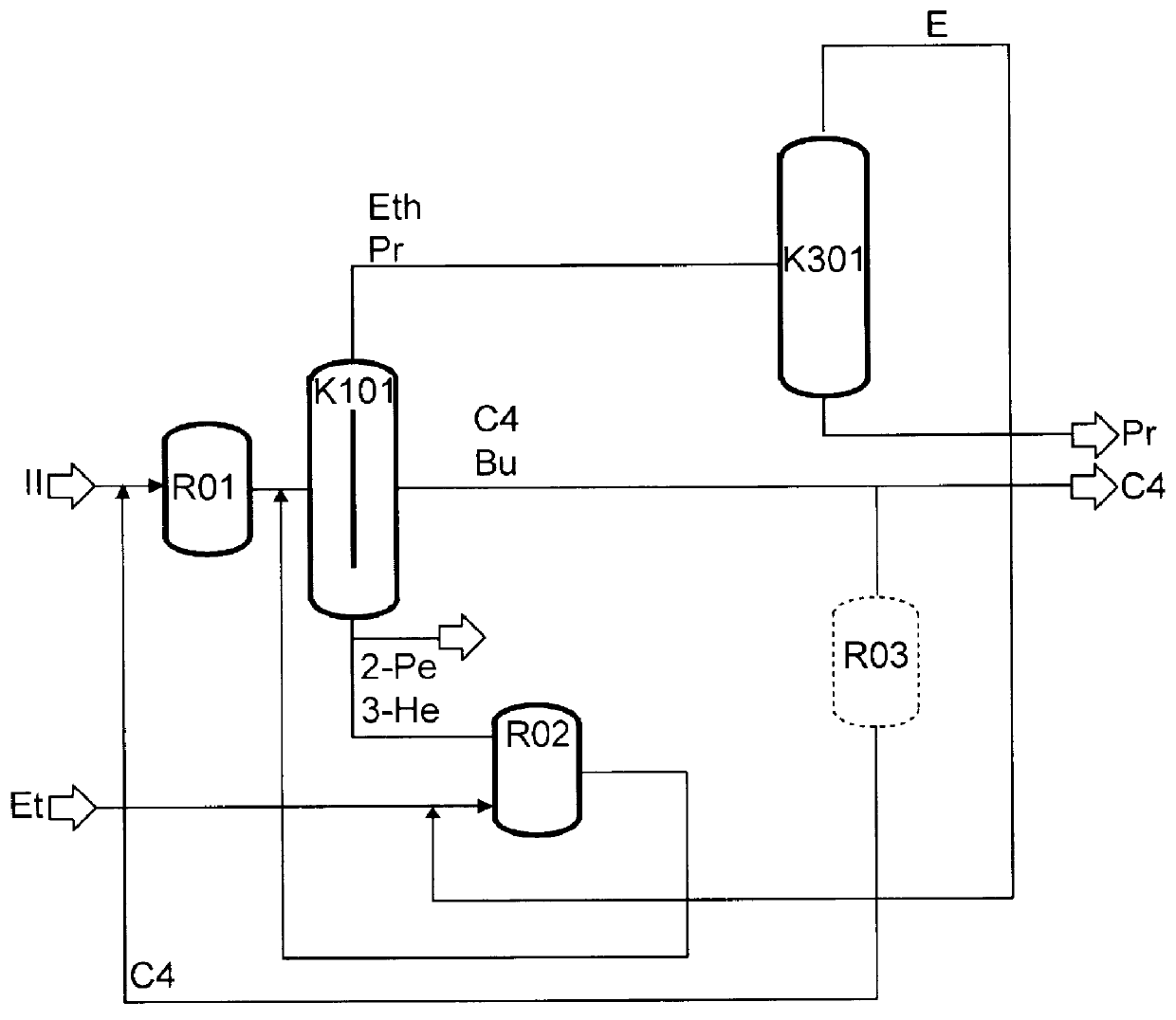

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

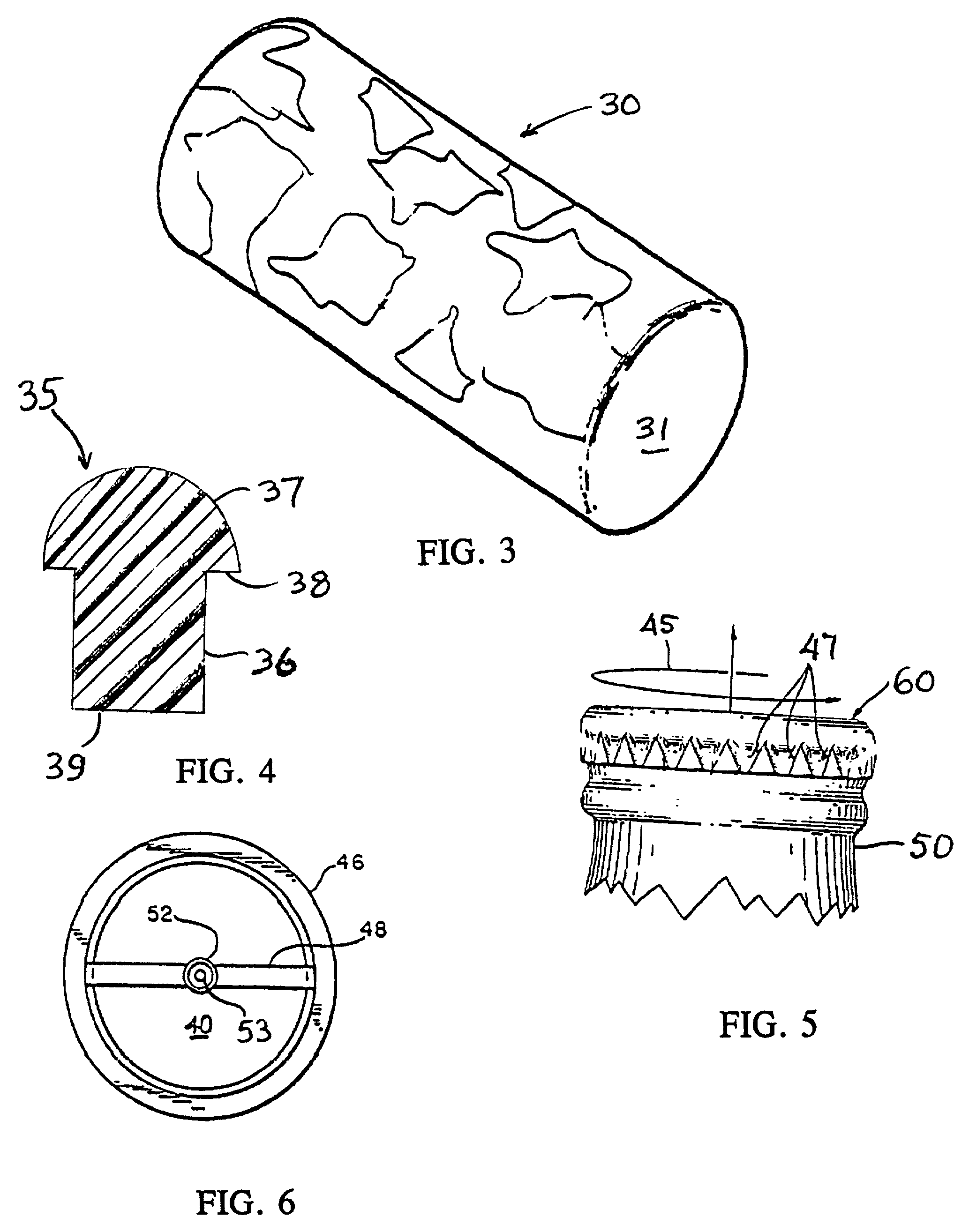

Multi-piece solid golf ball

InactiveUS7086969B2Improve spin performanceIncrease total distance traveledGolf ballsSolid ballsPtru catalystSulphur compound

Owner:BRIDGESTONE SPORTS

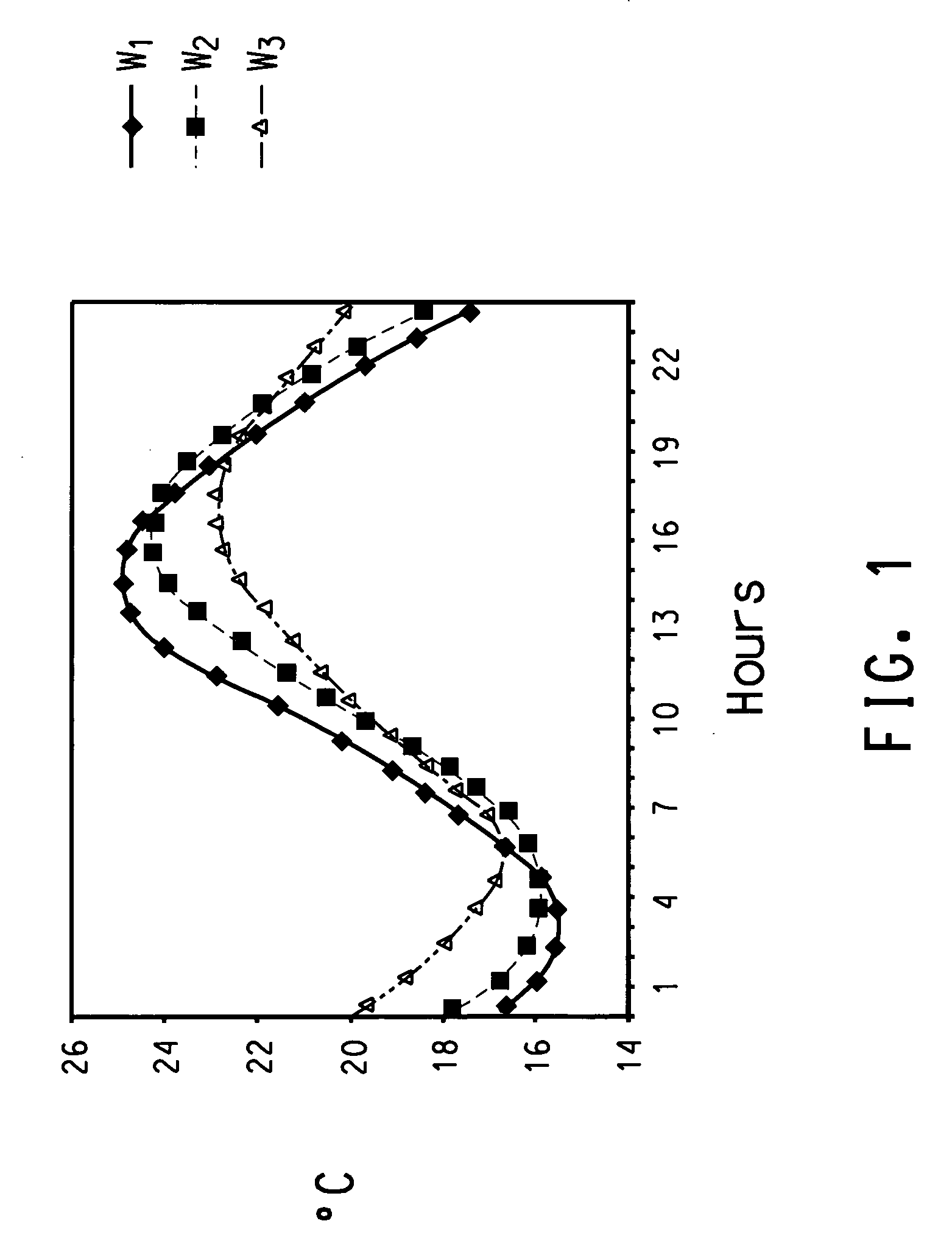

Phase change material (PCM) compositions for thermal management

The present invention relates to a Phase Change Material (PCM) composition comprising a) from 20 to 80 wt % of a PCM; and b) from 20 to 80 wt % of one or more polymers chosen from the group consisting of b1) Very Low Density Polyethylene (VLDPE) having a density equal or lower than 0.910 g / cm3 measured according to ASTM 792; b2) Ethylene Propylene Rubber (EPR) having a density equal or lower than 0.900 g / cm3 measured according to ASTM 792; b3) Styrene Ethylene Butadiene Styrene (SEBS) copolymers; and b4) Styrene Butadiene Styrene (SBS) copolymers. The PCM composition of the present invention can be used in applications where thermal management is needed, like for example in building, automotive, packaging, garments and footwear.

Owner:EI DU PONT DE NEMOURS & CO

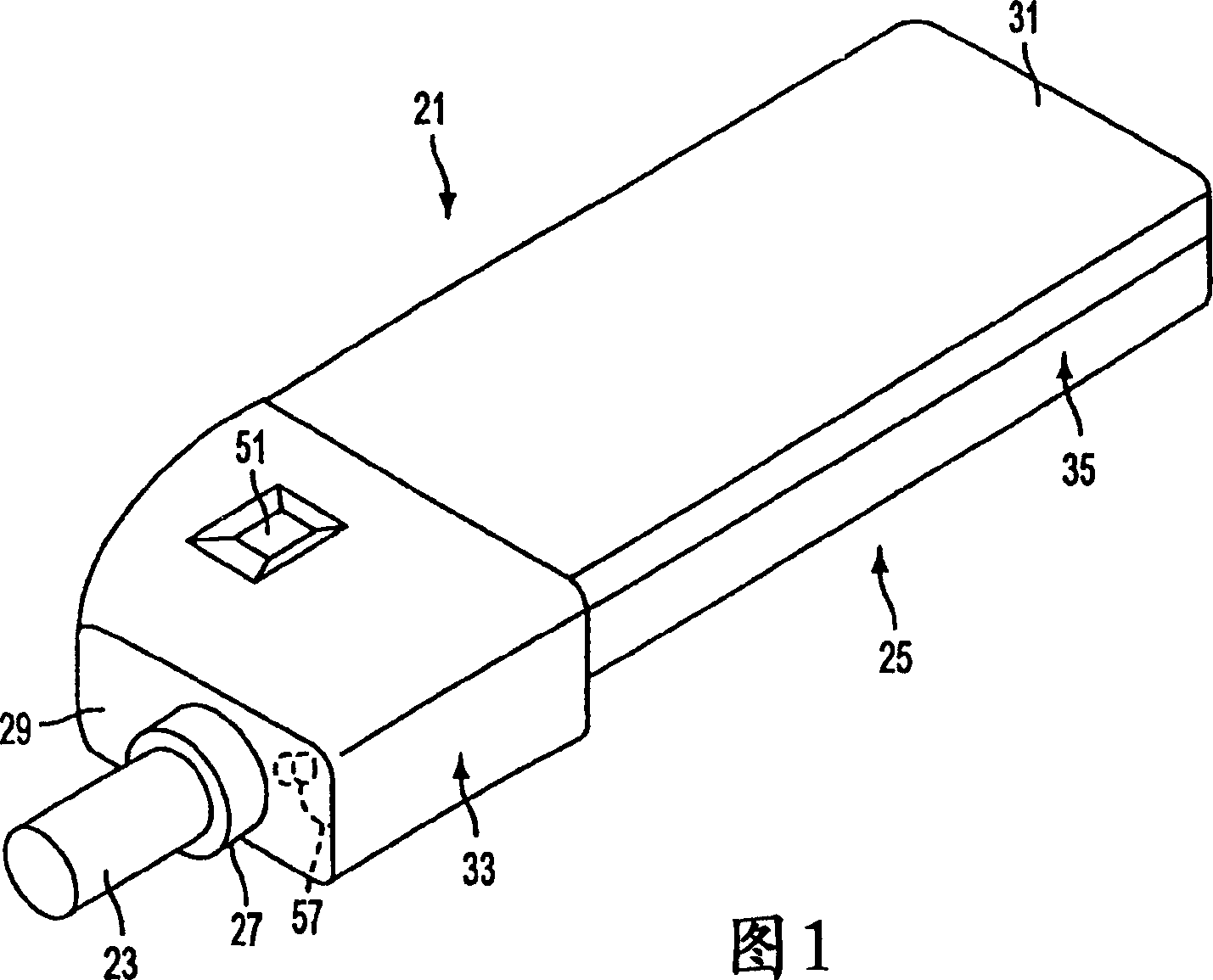

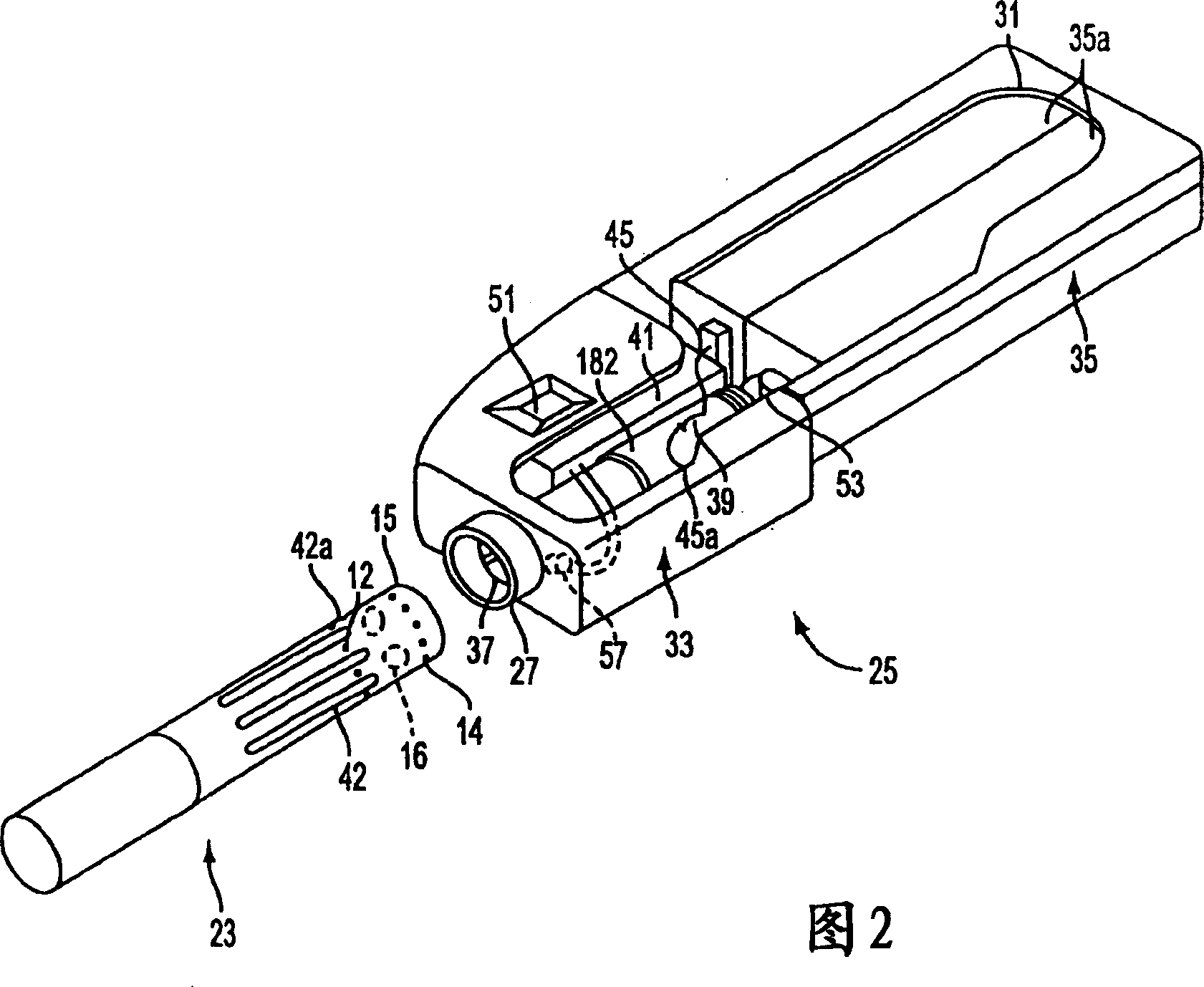

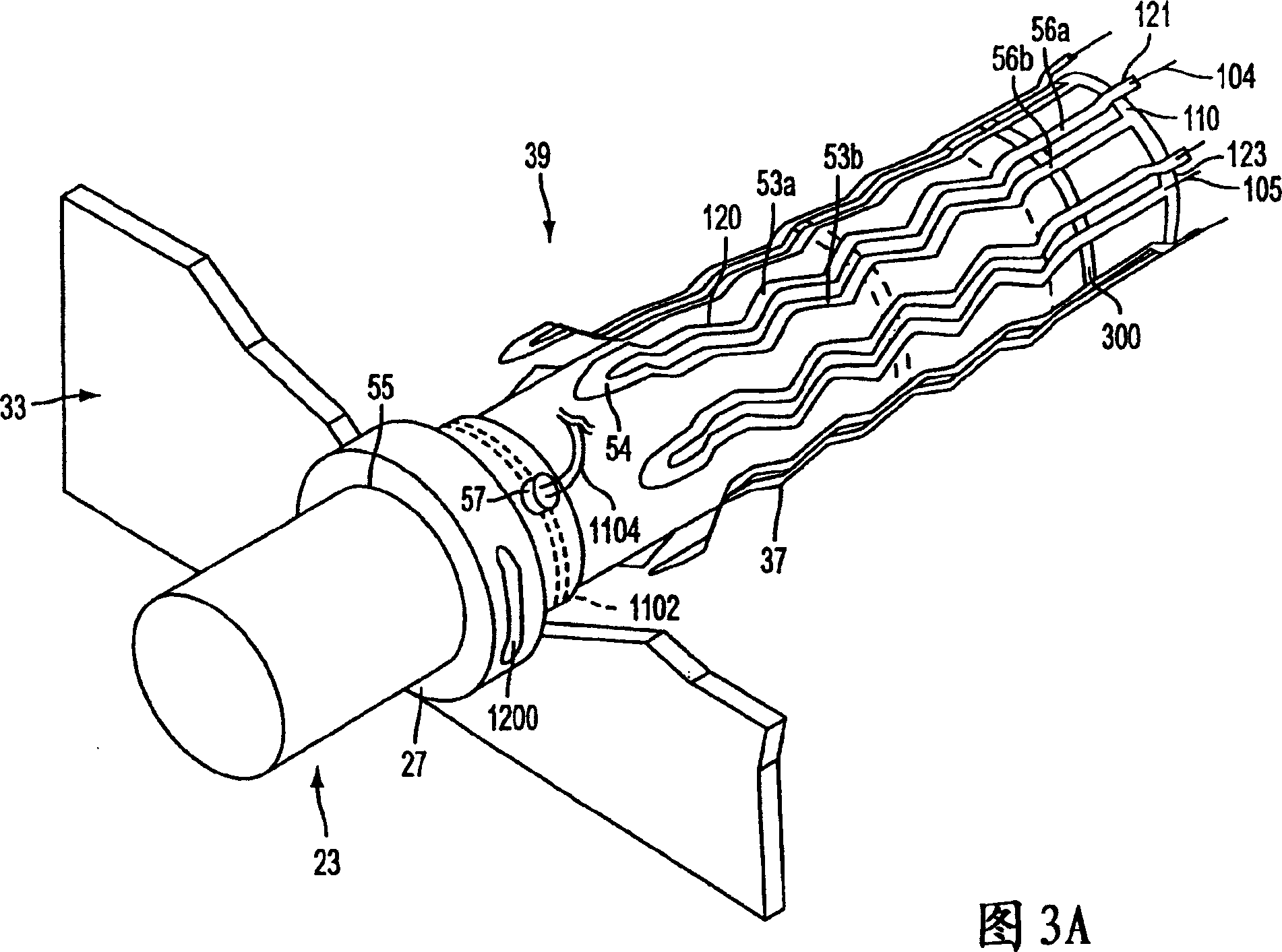

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

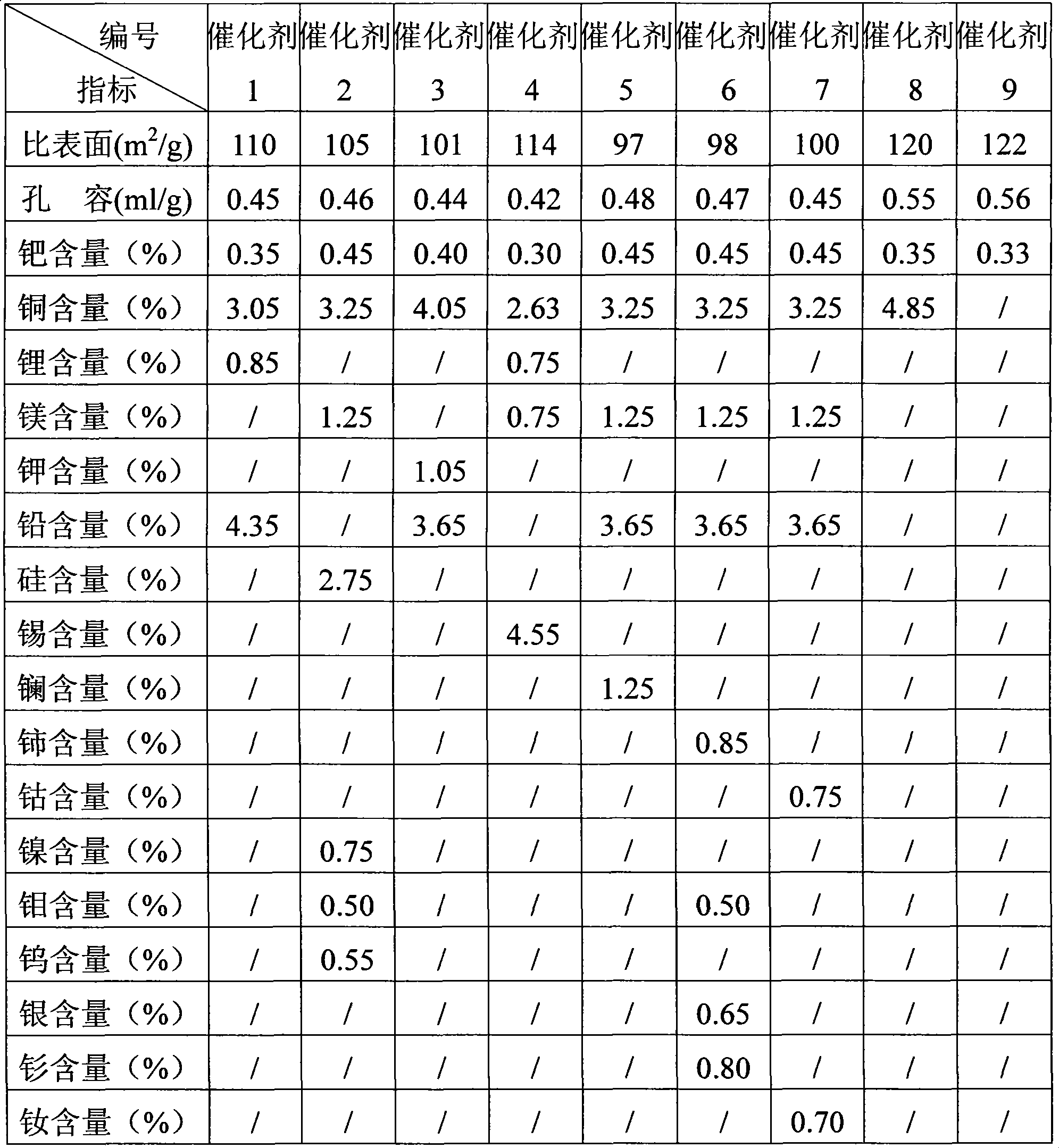

Acetylene hydrocarbon selective hydrogenation method

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

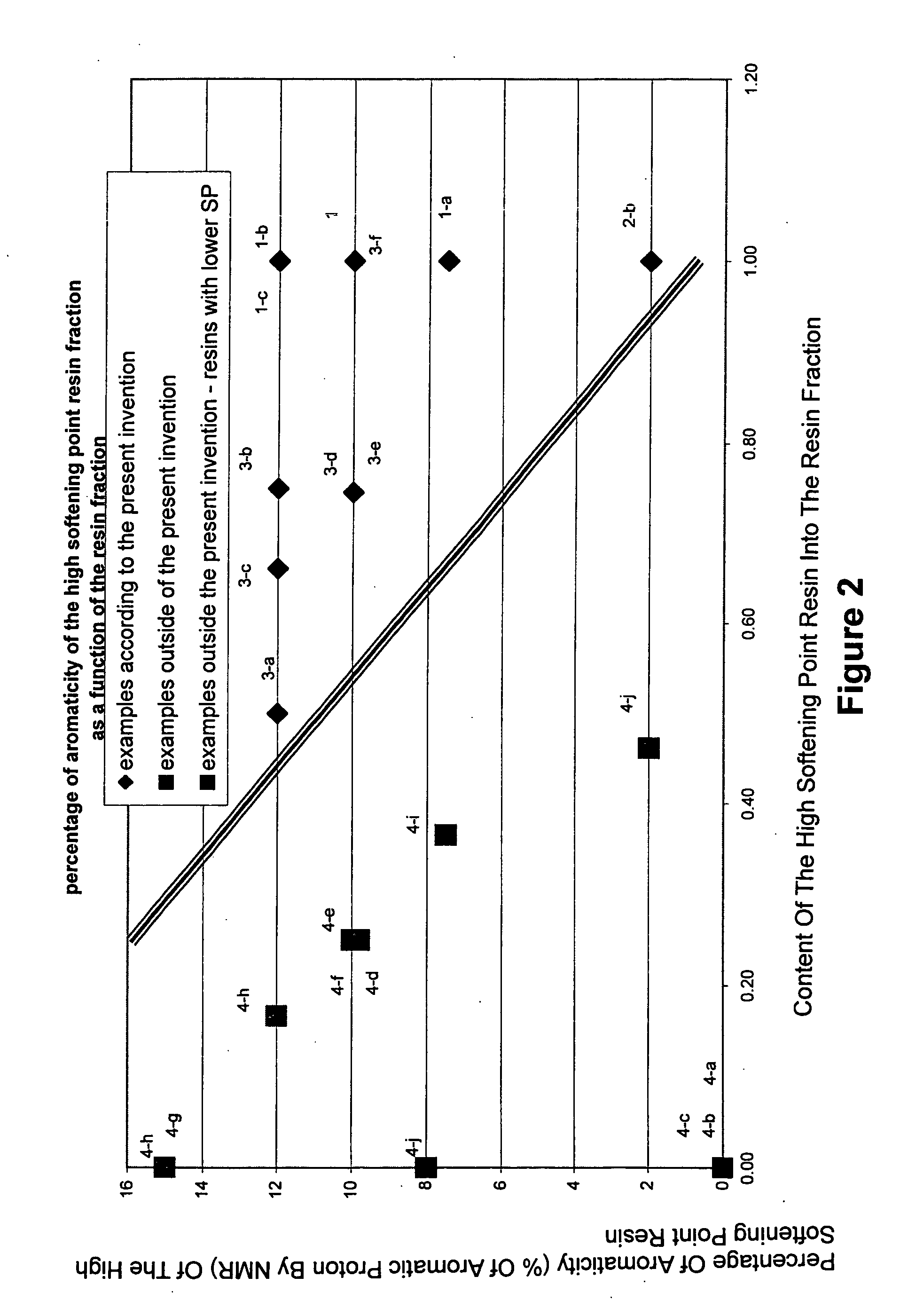

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Rubber composition for use in tires

ActiveUS20110144236A1Good dispersionImprove wet grip performanceSpecial tyresPolishing compositionsVitrificationPolymer science

A rubber composition for use in tires including from 60 to 120 parts by weight of a silica having a CTAB specific surface area of from 70 to 175 m2 / g and from 3 to 25 parts by weight of an aromatic modified terpene resin excluding terpene phenol resins per 100 parts by weight of a diene rubber including from 30 to 80 weight % of a terminal-modified styrene-butadiene rubber and from 10 to 50 weight % of a butadiene rubber. An average glass transition temperature of the diene rubber is −55° C. or lower and an average glass transition temperature of a component formed from the diene rubber, the aromatic modified terpene resin, and an optional plasticizer is −45° C. or lower.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire having a component containing low PCA oil

There is disclosed a pneumatic tire having a component comprising a vulcanizable rubber composition comprising, based on 100 parts by weight of elastomer (phr), from about 40 to about 90 phr of a solution polymerized styrene-butadiene having a styrene content of greater than 38 percent by weight; from about 10 to about 60 phr of at least one additional elastomer; and from about 10 to about 70 phr of a process oil having a glass transition temperature of from about −80° C. to about −40° C. and a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method.

Owner:THE GOODYEAR TIRE & RUBBER CO

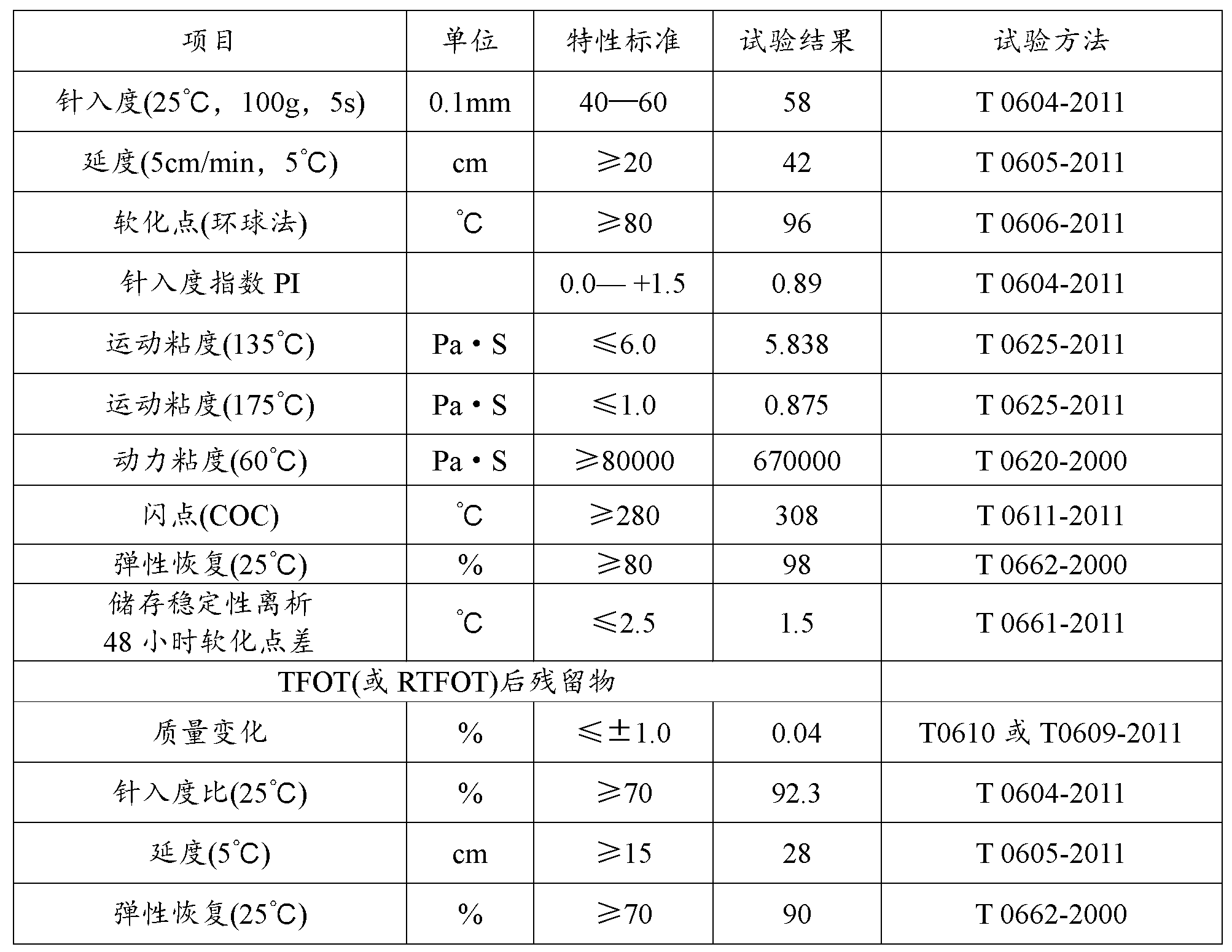

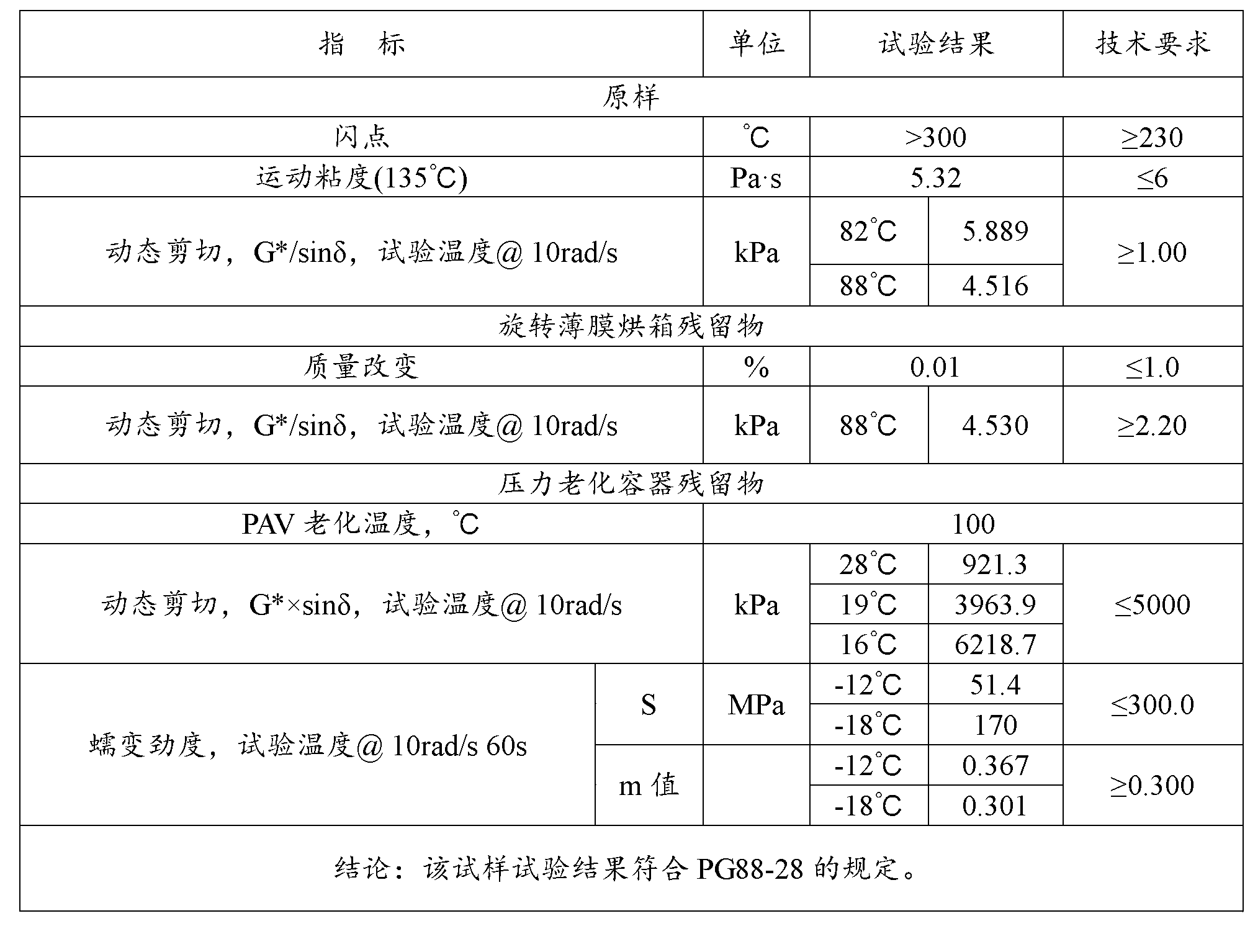

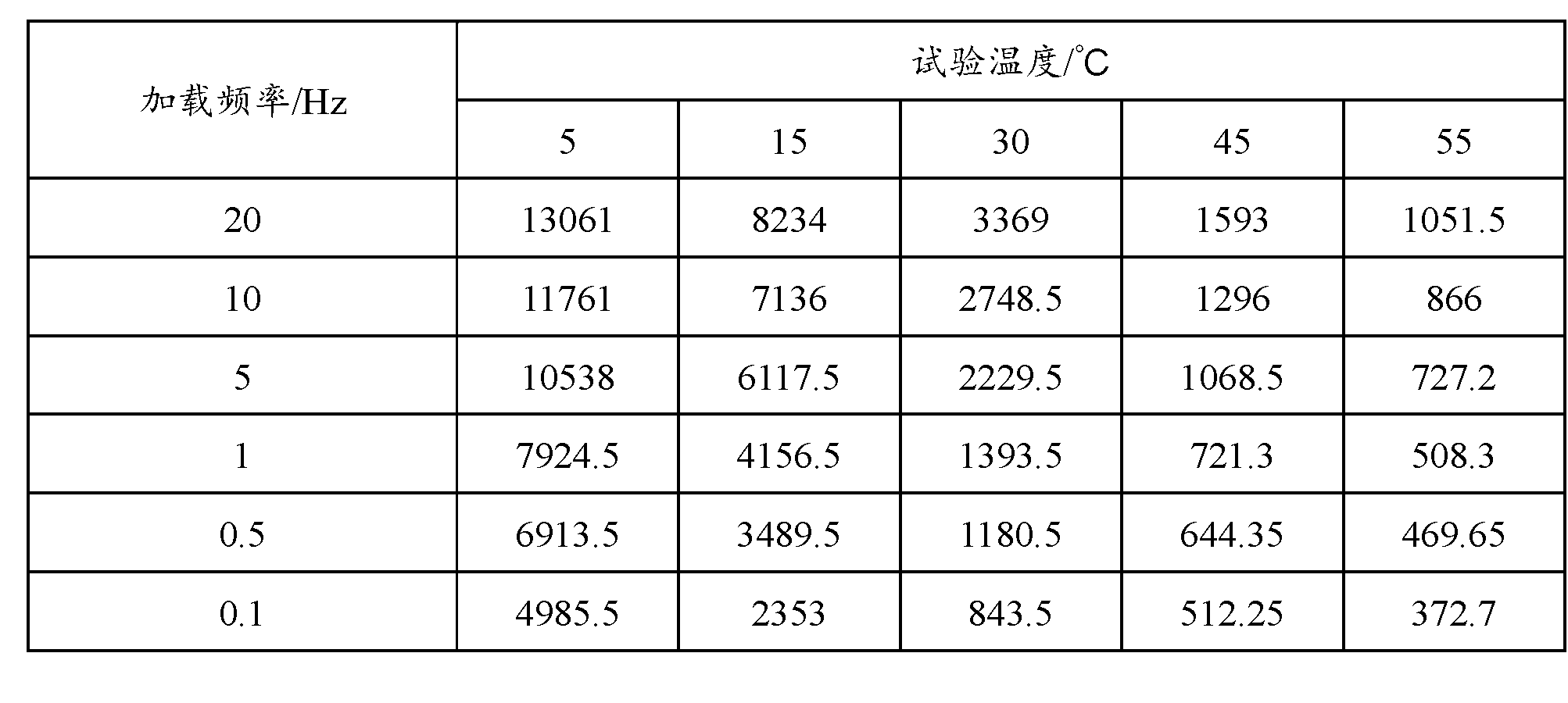

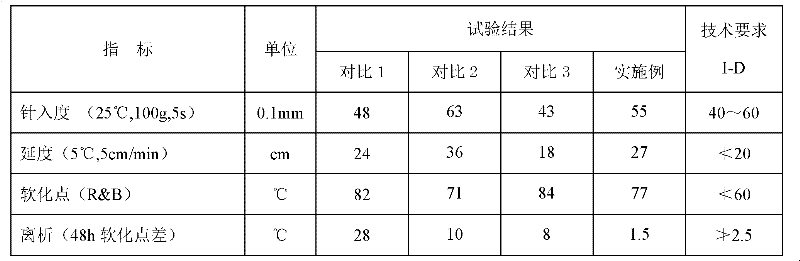

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Essentially gas-impermeable thermoplastic elastomer

A thermoplastic elastomer (“TPE”) which is oxygen-permeable is provided with excellent barrier properties against oxygen by melt-blending with a liquid polyisobutene oil plasticizer in an amount insufficient to render the plasticized elastomer tacky. If made tacky, enough detackifier is used to allow the product to be formed into a removable seal. The TPE may be a conventional thermoplastic vulcanizate or a block copolymer of a vinylaromatic compound, typically styrene, and a conjugated diene, typically butadiene or isoprene, or mixtures thereof; the block may be a diblock, triblock or higher block, but the preferred polyblock copolymer is a triblock with styrene end-blocks and a butadiene / isoprene mid-block. Preferably the diene mid-block is hydrogenated to provide a poly(lower)monoolefin mid-block. When the TPE is a TPV, some or all of the mineral oil used to make the TPV processable may also be substituted with the polyisobutene plasticizer. The elastomeric product is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:AVIENT CORP

Solvent based, elastomeric coatings with lower VOC

The present invention relates to solvent based coatings which have a low level of volatile organics compounds (VOC) meeting California VOC regulations and which can be spray applied as a coating on a variety of surfaces. The coating formulation comprises a hydrogenated styrene / butadiene triblock copolymer, a hydrogenated styrene / butadiene diblock copolymer, at least one hydrocarbon solvent, at least one VOC exempt solvent, a midblock tackifying resin, and a pigment or filler. The relative amounts of solvent, tackifying resin and pigment are adjusted to obtain a solvent based, elastomeric coating having a VOC content of no more than 250 grams per liter and a viscosity no higher than 2,000 centipoise @ 25° C. as measured according to ASTM D2196.

Owner:ST CLAIR DAVID JOHN

Mineral wax composite shape-setting phase-change material and process for preparation

The invention provides a mineral wax composite shape-setting phase-change material and process for preparation, wherein the material comprises 70-80 wt% paraffin wax substance with 44-50 deg. C melting point, 4-15% of cross bond high-density polyethylene, 4-15 wt% of styrene / ethane-butylene / styrene copolymer (SEBS), and 4-6 wt% of expanded graphite.

Owner:BEIJING UNIV OF TECH

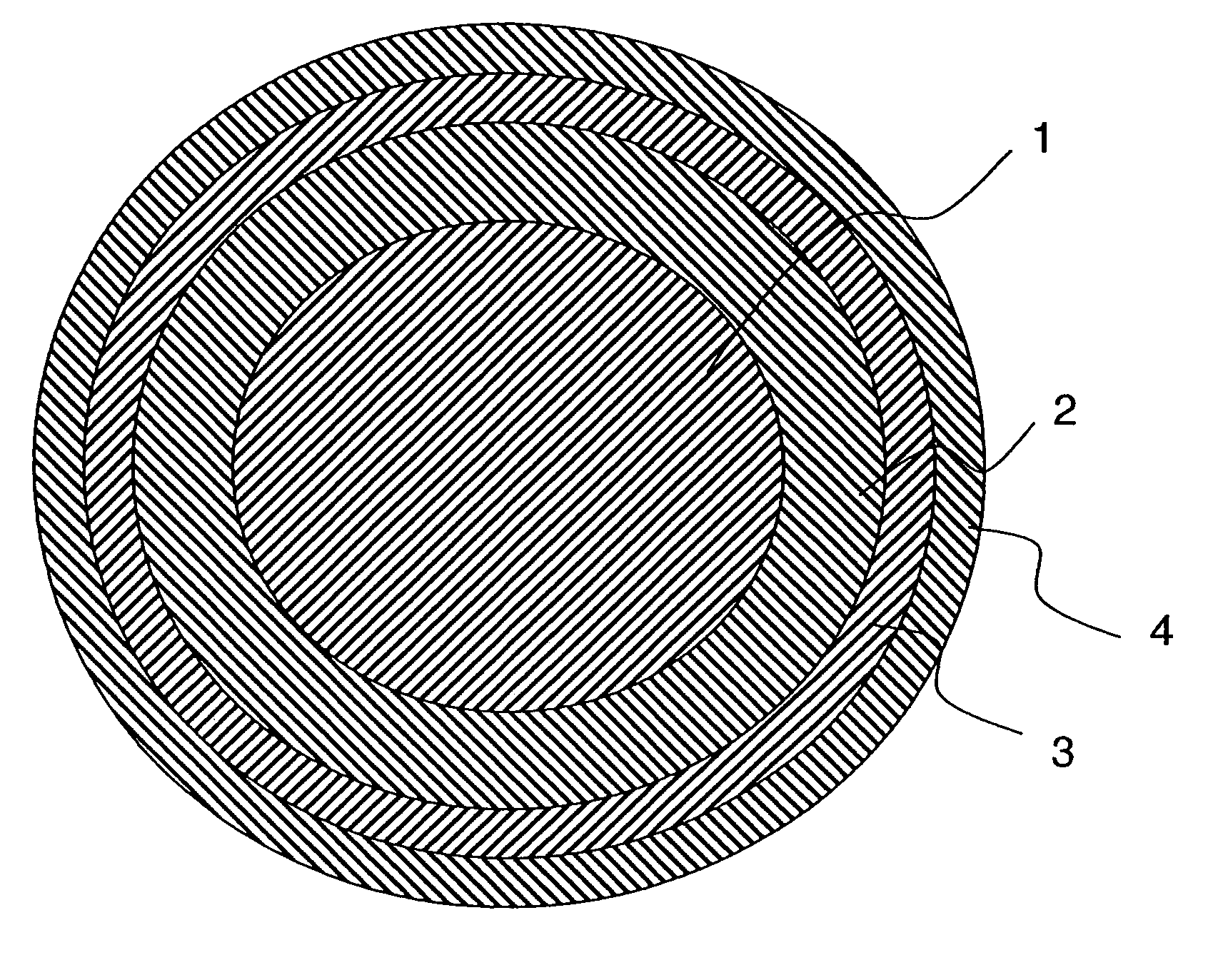

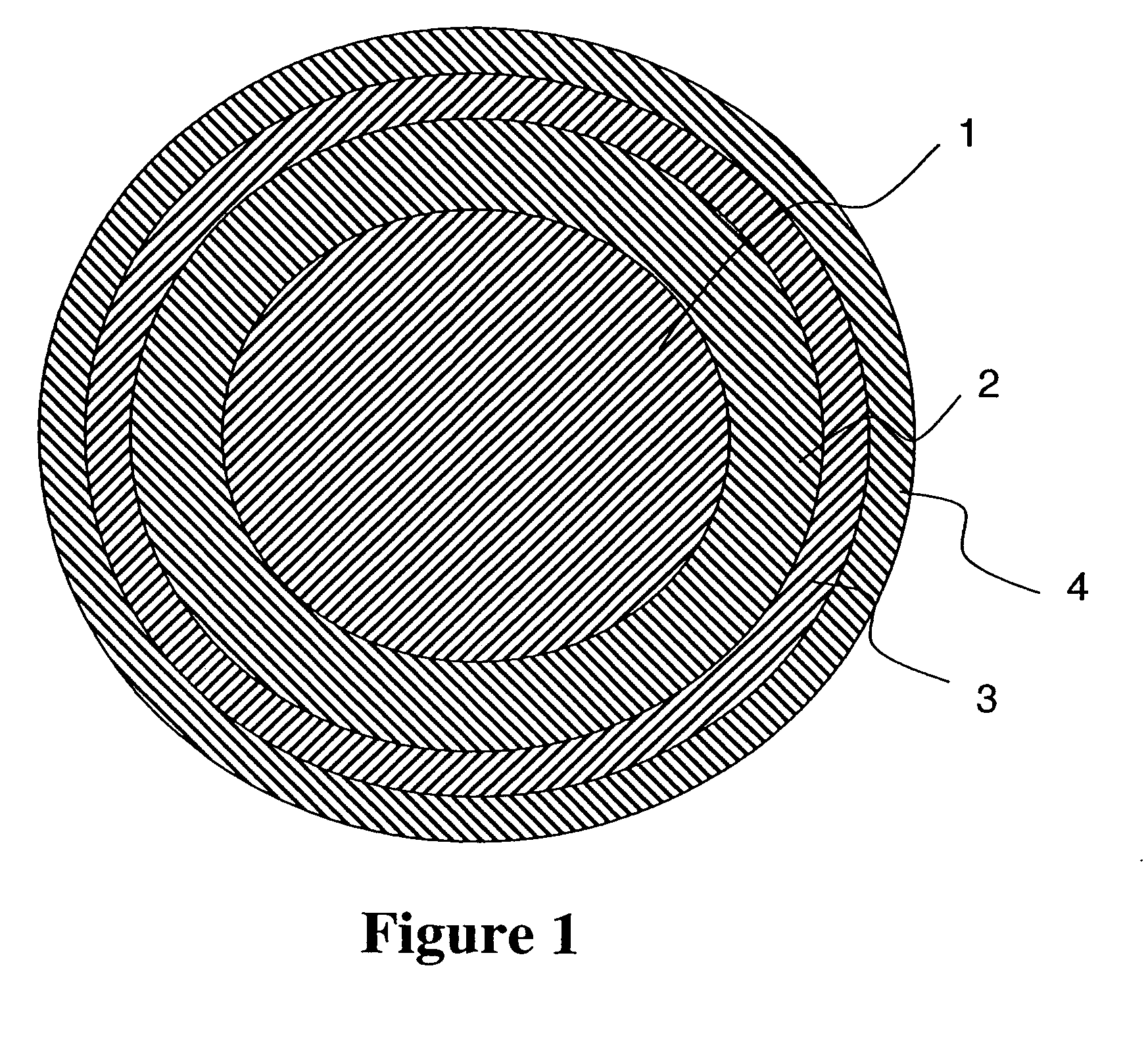

Surface-treated microporous membrane and electrochemical device prepared thereby

ActiveUS20090291360A1Improve adhesionAvoid breakingSecondary cellsCell component detailsPorous substrateElectrochemistry

Disclosed is a porous film comprising: (a) a porous substrate having pores; and (b) a coating layer formed on at least one region selected from the group consisting of a surface of the substrate and a part of the pores present in the substrate, wherein the coating layer comprises styrene-butadiene rubber. An electrochemical device using the porous film as a separator is also disclosed. The porous film is coated with a styrene-butadiene polymer, whose rubbery characteristics can be controlled, and thus provides improved scratch resistance and adhesion to other substrates. When the porous film is used as a separator for an electrochemical device, it is possible to improve the safety of the electrochemical device and to prevent degradation in the quality of the electrochemical device.

Owner:LG ENERGY SOLUTION LTD +1

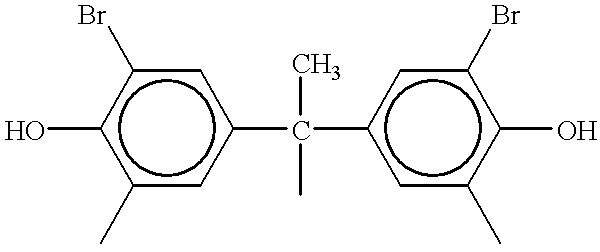

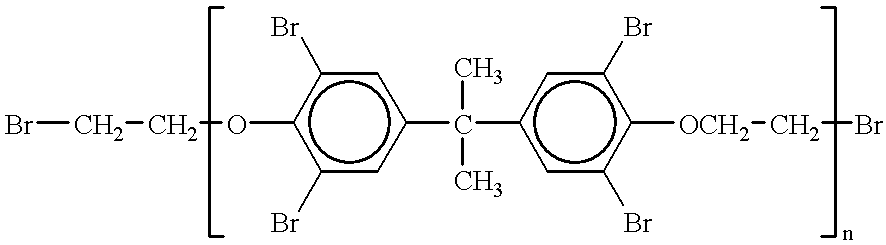

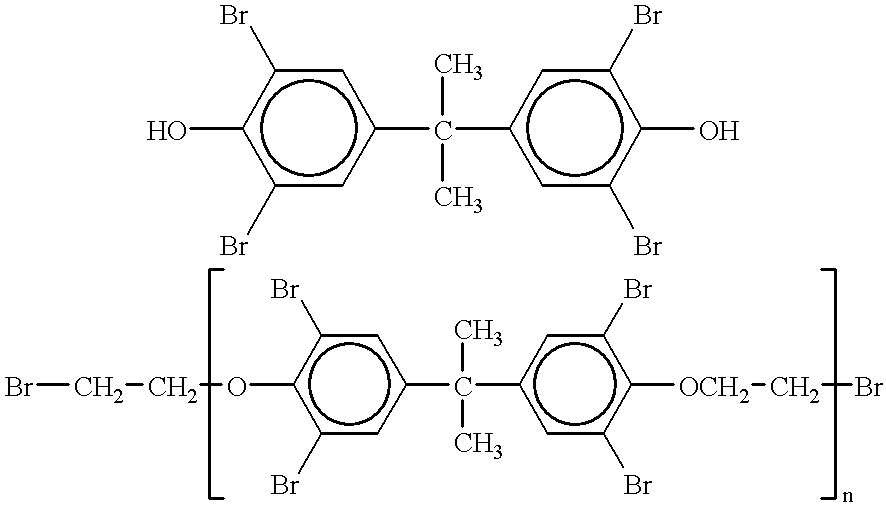

Electrically conductive adhesive composition, electrically conductive adhesive sheet and use thereof

InactiveUS6344155B1Improve rendering capabilitiesImprove conductivityCross-talk/noise/interference reductionSynthetic resin layered productsEpoxyFolding endurance

An electrically conductive adhesive composition which has flexibility and folding endurance and is feasible for use as a shield against electromagnetic waves from a flexible printed circuit, comprises 100 parts by weight of (a) an acrylonitrile-butadiene copolymer, 20 to 500 parts by weight of (b) a phenolic resin and / or an epoxy resin, 1 to 100 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (c) an electrically conductive filler and 1 to 50 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (d) a bromine-containing flame retardant.

Owner:TOMOEGAWA PAPER CO LTD

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

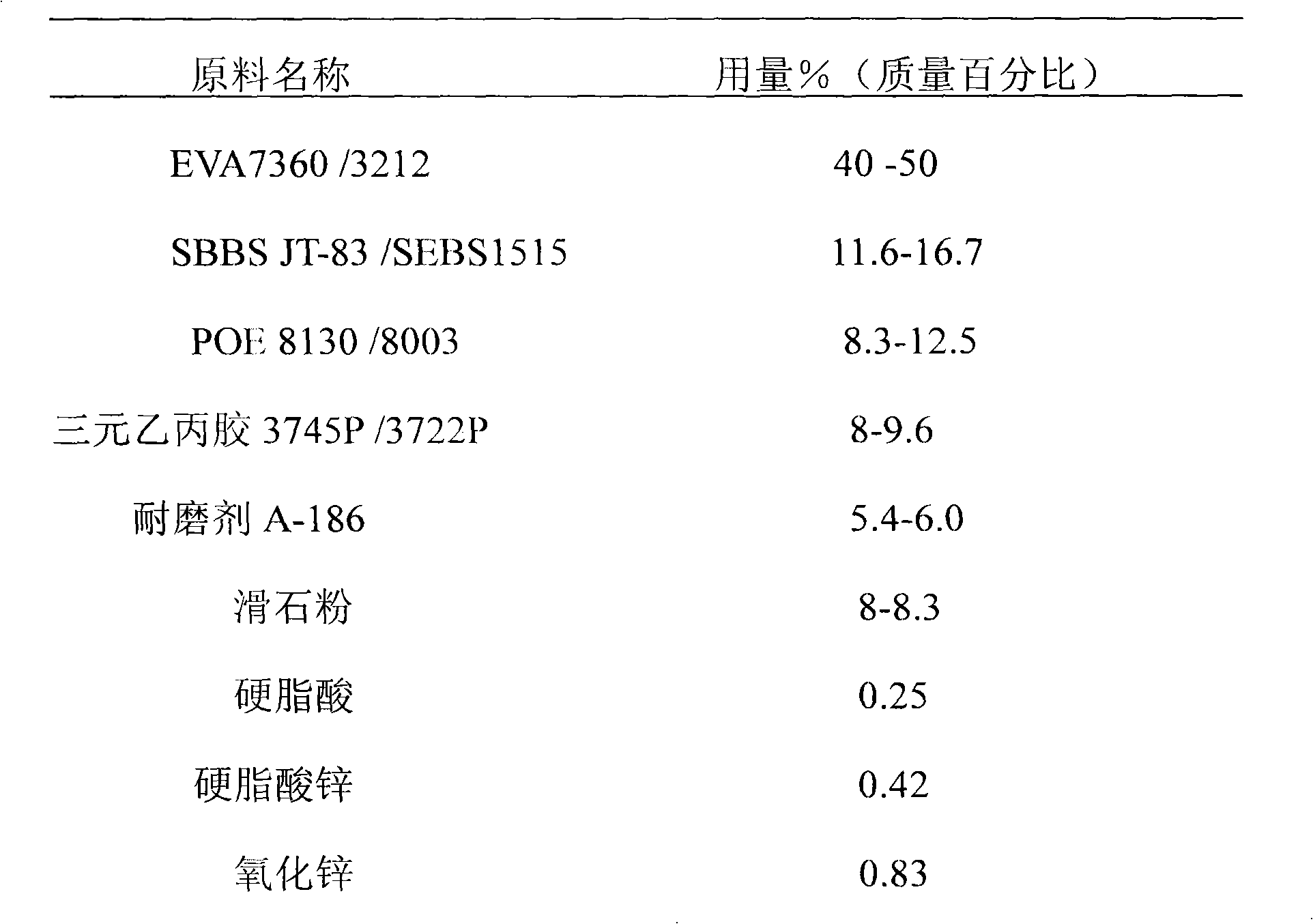

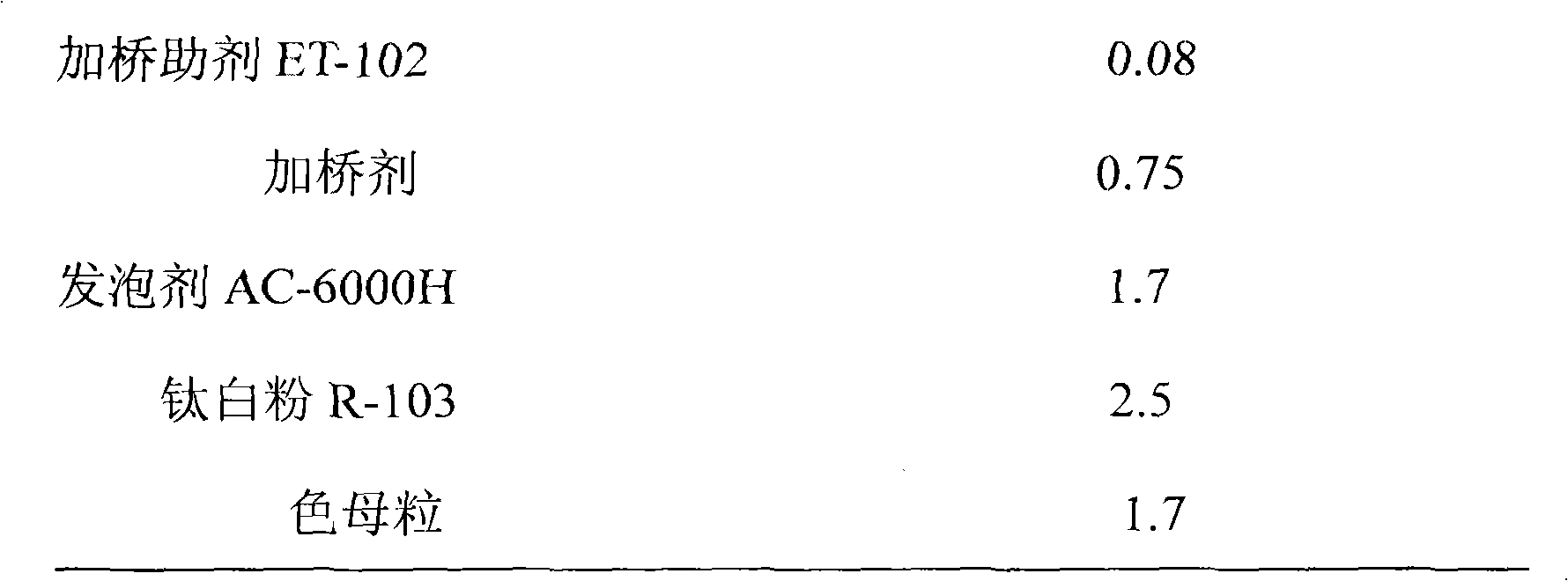

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

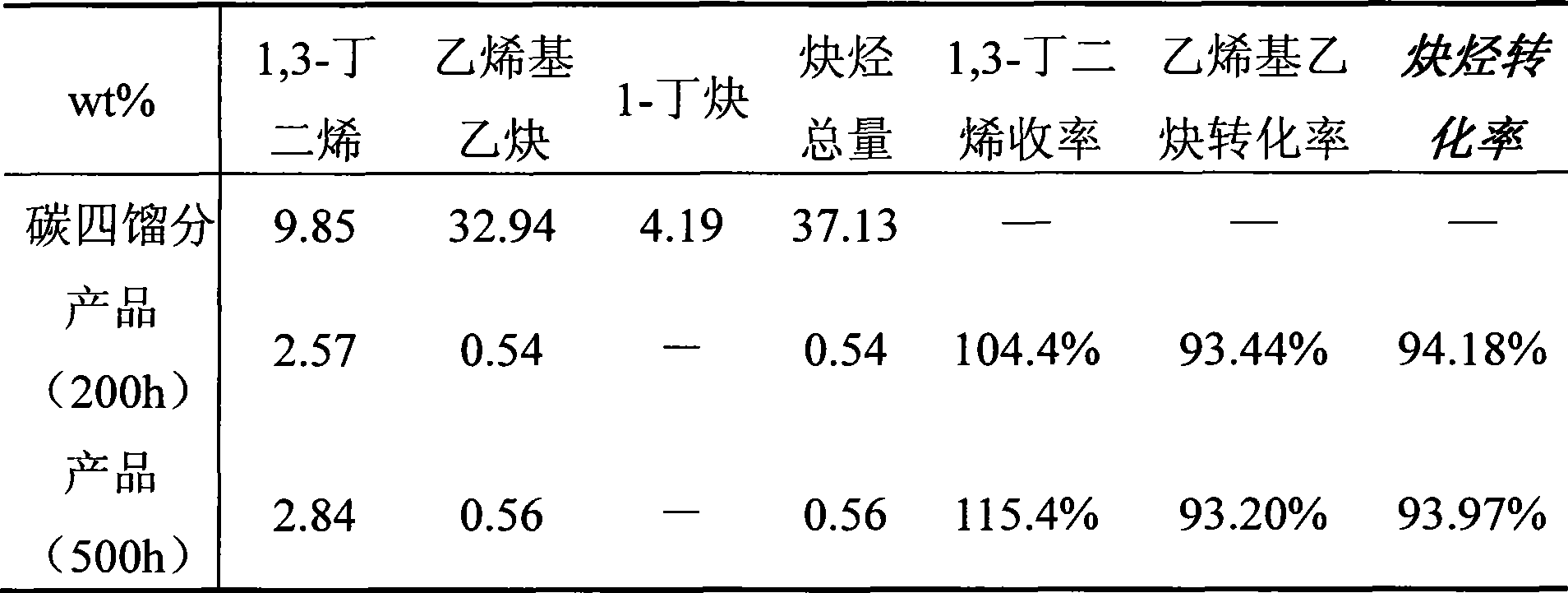

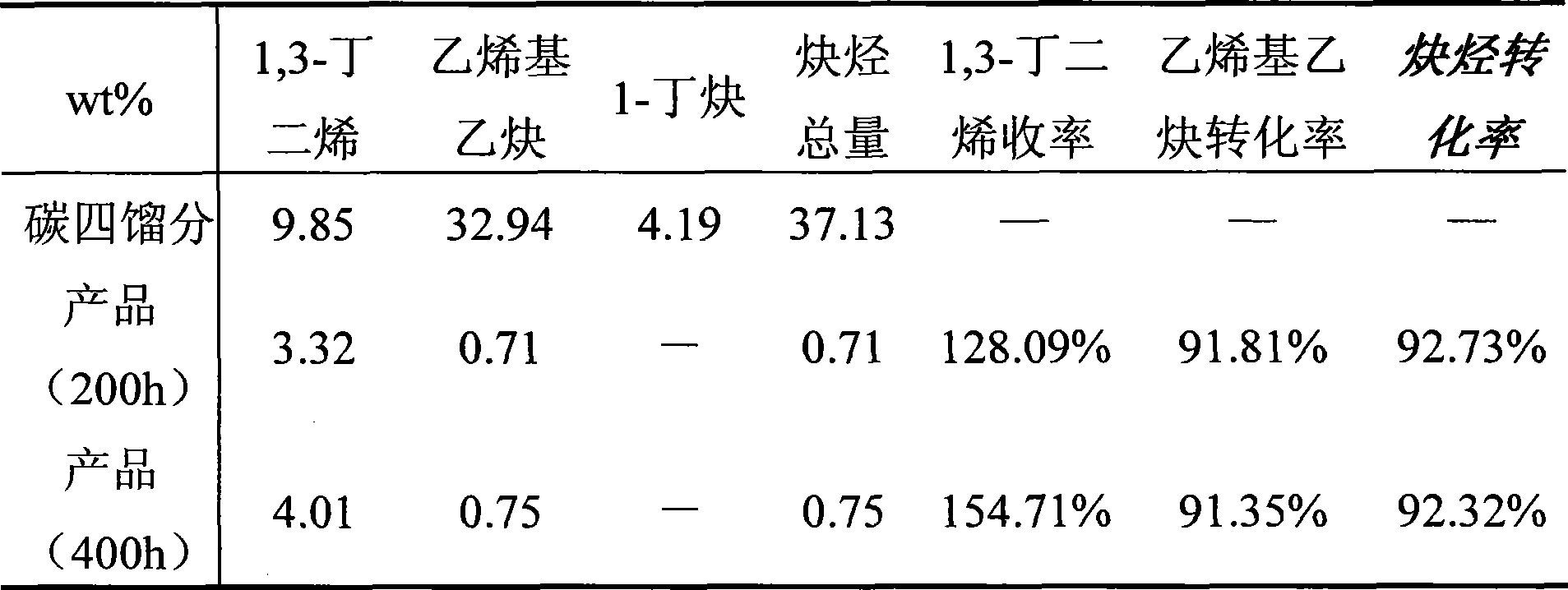

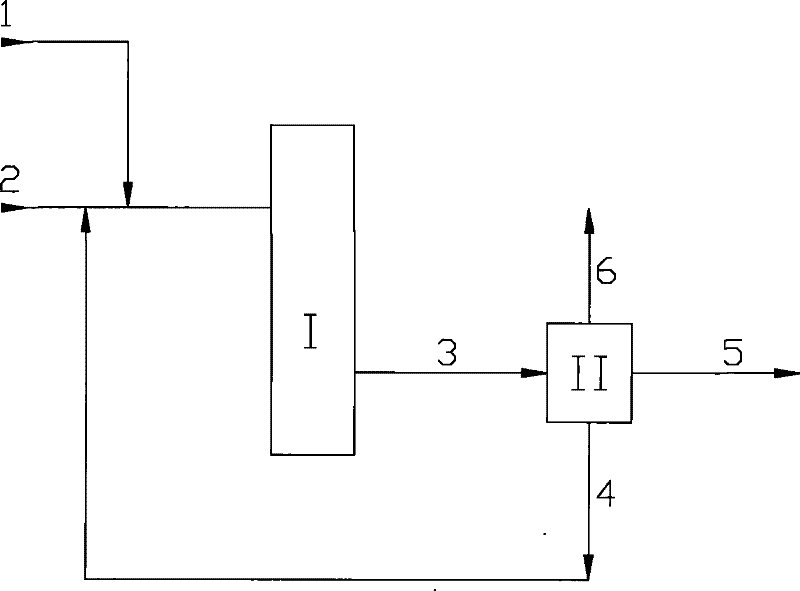

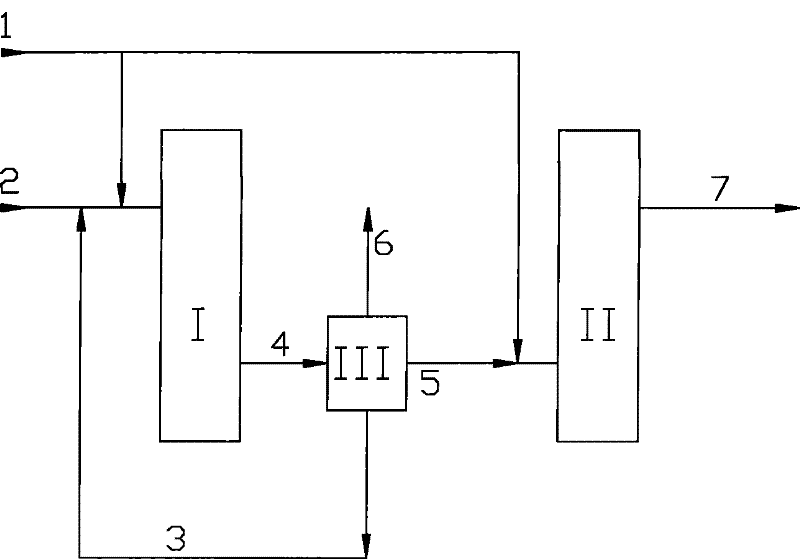

A selective hydrogenation process for C4 stream with high butadiene content

ActiveCN102285859AReasonable useHydrocarbon by hydrogenationHydrocarbon purification/separationHigh concentrationButene

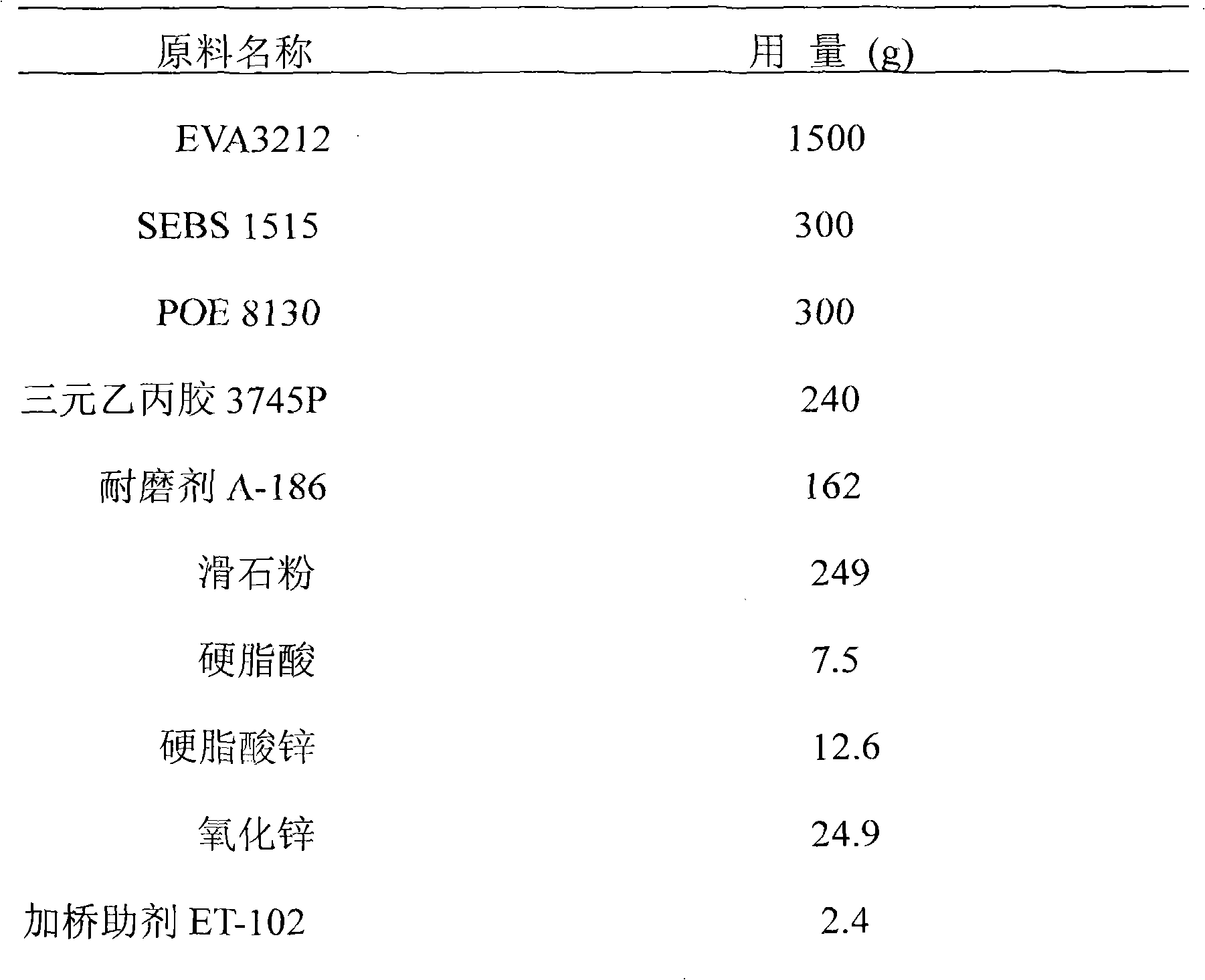

The invention relates to a selective hydrogenation process for a C4 material flow with high concentration of butadiene. The selective hydrogenation process comprises the following steps of: enabling the C4 material flow with the high concentration of butadiene to pass through one or more fixed bed hydrogenation reactors (I) with circulation pipelines, carrying out a selective hydrogenation reaction on the C4 mixture with high concentration of butadiene under the action of a catalyst to remove the butadiene and alkyne and generate butylene, enabling the reactor to pass through a terminal reactor (II) without the circulation pipeline, and further removing the residual butadiene and alkyne from the C4 material flow with the low concentration of butadiene. By utilizing the selective hydrogenation process and the catalyst provided by the invention, the controlled concentration range of the butadiene and the C4 alkyne of the C4 material flow is 5-80wt%, the concentrations of the butadiene and the alkyne of the hydrogenated C4 material flow can be respectively reduced to below 10ppm, the selectivity of the 1-butene generation by the butadiene can be more than 50%, and the butadiene can be taken as the raw material of preparing the 1-butene. According to the selective hydrogenation process disclosed by the invention, the C4 material flow is reasonably utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Binder for electrode for lithium ion secondary battery, and utilization thereof

InactiveUS6881517B1Improve featuresEasy to repeatElectrode carriers/collectorsElectrode collector coatingLithiumPhysical chemistry

A binder for a lithium ion secondary battery characterized by comprising a polymer containing structural units derived from 1,3-butadiene, said polymer having a 1,2-vinyl structure content in the range of 2% to 25% by mole. A lithium ion secondary battery provided with an electrode made using this binder exhibits improved characteristics at repetition of charge-discharge cycle and improved storage stability.

Owner:ZEON CORP

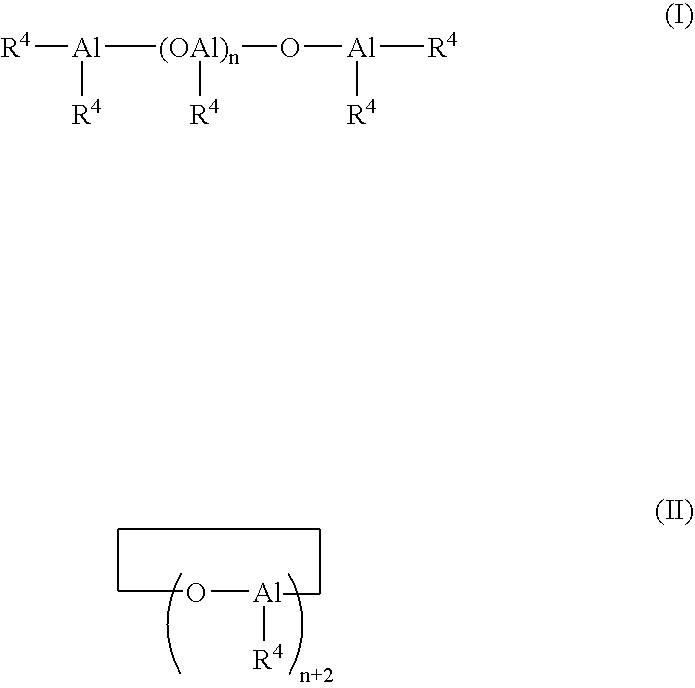

Polymer production at supercritical conditions

InactiveUS20060293474A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSolventCloud point

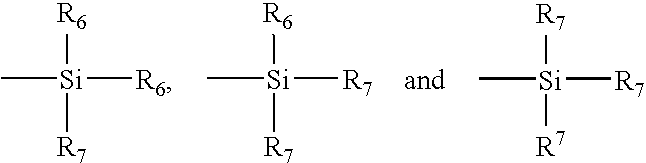

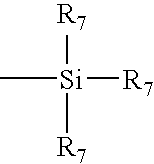

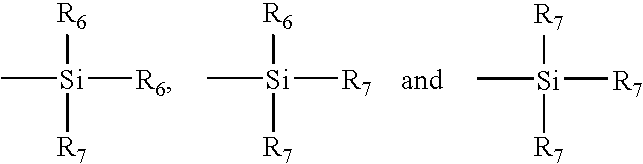

This invention relates to a process to polymerize olefins comprising contacting, in a polymerization system, olefins having three or more carbon atoms with a catalyst compound, activator, optionally comonomer, and optionally diluent or solvent, at a temperature above the cloud point temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system, where the polymerization system comprises any comonomer present, any diluent or solvent present, the polymer product, where the olefins having three or more carbon atoms are present at 40 weight % or more, wherein the metallocene catalyst compound is represented by the formula: where M is a transition metal selected from group 4 of the periodic table; each R1 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and functional group, and any two R1 groups may be linked, provided that if the two R1 groups are linked, then they do not form a butadiene group when M is Zr; each R2 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and two or more R2 groups may be linked together to form an aliphatic or aromatic ring; R3 is carbon or silicon; R4 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group; a is 0, 1, or 2; R5 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, R4 and R5 may be bound together to form a ring, and R5 and R3 may be bound together to form a ring; b is 0, 1, or 2; R6 is carbon or silicon; and R4 and R6 may be bound together to form a ring; each R7 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group; each R8 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and R7 and R8 may be linked together to form an aliphatic or aromatic ring; each R9 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and two R9 groups may be linked together to form a ring, R9 and R8 may be linked together to form a ring, R9 and R16 may be linked together to form a ring, R9 and R11 may be linked together to form a ring; c is 0, 1 or 2; R10 is -M2(R16)h- where M2 is B, Al, N, P, Si or Ge, h is an integer from 1 to 2, such that the valence of M2 is filled, and R16 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and two R16 groups may be linked together to form a ring; d is 0, 1, or 2; each R11 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and two R11 groups may be linked together to form a ring. R11 and R8 may be linked together to form a ring. R11 and R16 may be linked together to form a ring; e is 0, 1, or 2; where the sum of c, d, and e is 1, 2 or 3; R12 is carbon or silicon; R13 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and R13 and R14 may be bound together to form a ring, and R13 and R15 may be bound together to form a ring, when g is 0; f is 0, 1, or 2; R14 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and R14 and R12 may be bound together to form a ring, when f is 0; g is 0, 1, or 2; and R15 is carbon or silicon.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of star branched polyisobutylene or butyl rubber

The invention relates to a preparation method of star-shaped branched polyisobutylene or butyl rubber, which uses polystyrene / isoprene block copolymers containing silicon chloride groups at the end or polystyrene / isoprene block copolymers containing silicon chloride groups at the end. As the initiator-grafting agent of cationic polymerization, the diene block copolymer directly participates in cationic polymerisation; through the initiation of cationic polymerisation by silicon chloride group, the star-branched polymer is prepared by participating in the grafting reaction through unsaturated bonds. Isobutylene and butyl rubber products; the advantages of the present invention are: the synthesized branched polymer exhibits different processing properties from the original linear branched polymer molecule in terms of colloidal strength and stress relaxation balance, and has excellent performance, involving thermoplastic elasticity body more.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber compositions

InactiveUS20010053813A1Reduced wear resistance requirementsReduced processabilityRoof covering using tiles/slatesEmulsion paintsButadiene DioxideEngineering

The present invention provides a rubber composition which has satisfactory processability and dimension stability, exhibits excellent tensile strength and wearing resistance, and the like when vulcanized and is useful as a material for an industrial product such as a rubber roll, a grinding roll, a belt, a hose and a rubber-coated fabric, a shoe part for example of a transparent shoe, a tire of a large-sized or small sized car such as a tread and a side wall and a sanitary material such as a contraceptive rubber or the like. A rubber composition of the invention comprises (1) a crosslinked rubber particle containing as repeating units (a) 39.89 to 79.89% by weight of a conjugated diene unit such as 1,3-butadiene or the like, (b) 20 to 60% by weight of an aromatic vinyl unit such as styrene, (c) 0.01 to 10% by weight of a monomer unit having at least two polymerizable unsaturated group such as divinylbenzene, and the like, and (d) 0.1 to 30% by weight of a monomer unit having one polymerizable unsaturated group and an amino group such as vinylbenzylmethylamine, and the like and (2) a conjugated diene / aromatic vinyl copolymeric rubber such as styrene-butadiene copolymeric rubber and the like.

Owner:JSR CORPORATIOON

Laminates containing an active substance transdermal system

InactiveUS6902741B1Increase loadGood storage stabilityPowder deliveryOrganic active ingredientsPolystyreneCrosslinked polymers

The transdermal system includes a sex hormone-containing adhesive matrix, which contains inclusions of a sex hormone in a hydrophilic non-crosslinked polymer in dissolved or dispersed form. The inclusions have a concentration of 20 to 90 percent by weight of the sex hormone, which is more than 50 percent by weight amorphous. The hydrophilic non-crosslinked polymer can be polyvinylpyrrolidone, methylcellulose, ethylcellulose or hydroxyethylcellulose. The adhesive matrix can be a polyisobutylene, ethylene-vinyl-acetate copolymer or a polystyrene-butadiene block copolymer.

Owner:BAYER INTELLECTUAL PROPERTY GMBH +1

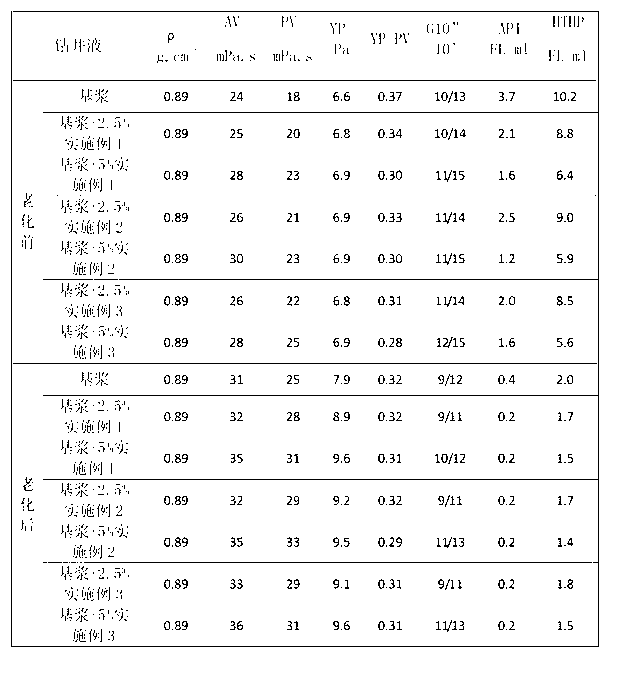

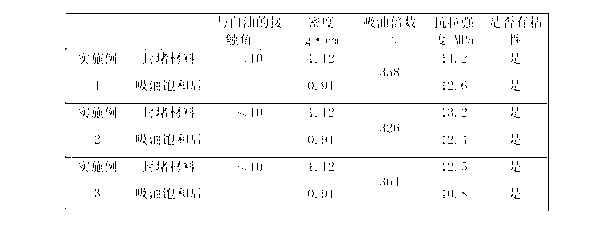

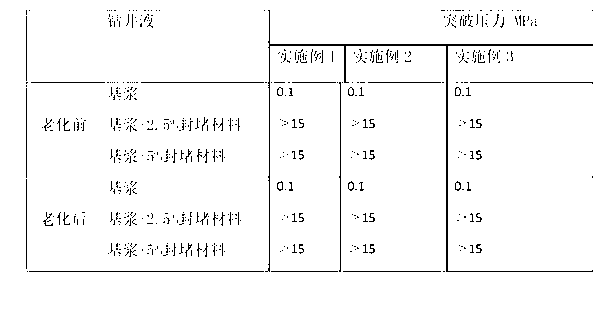

Plugging material used for oil base drilling fluid, and preparation method thereof

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

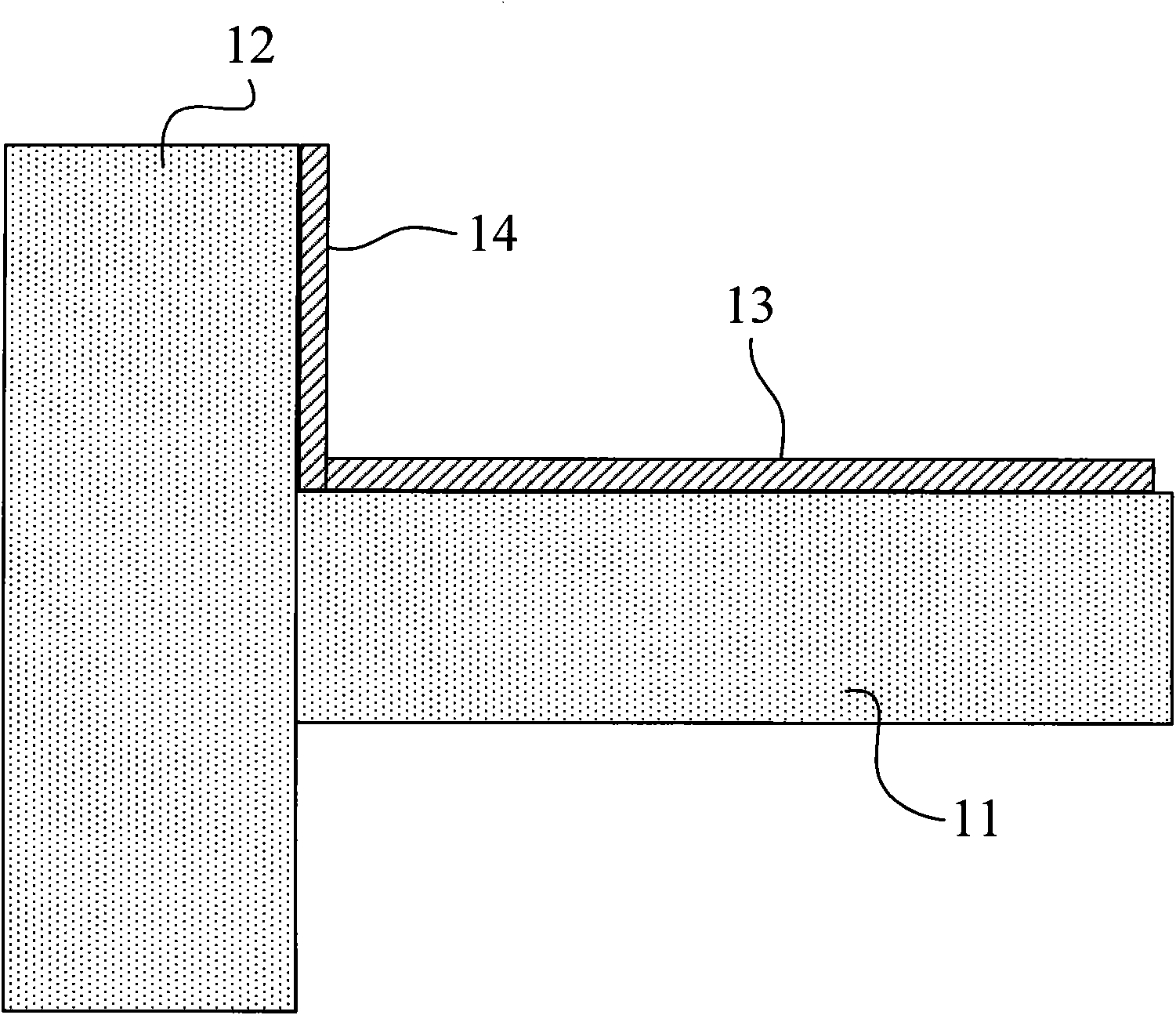

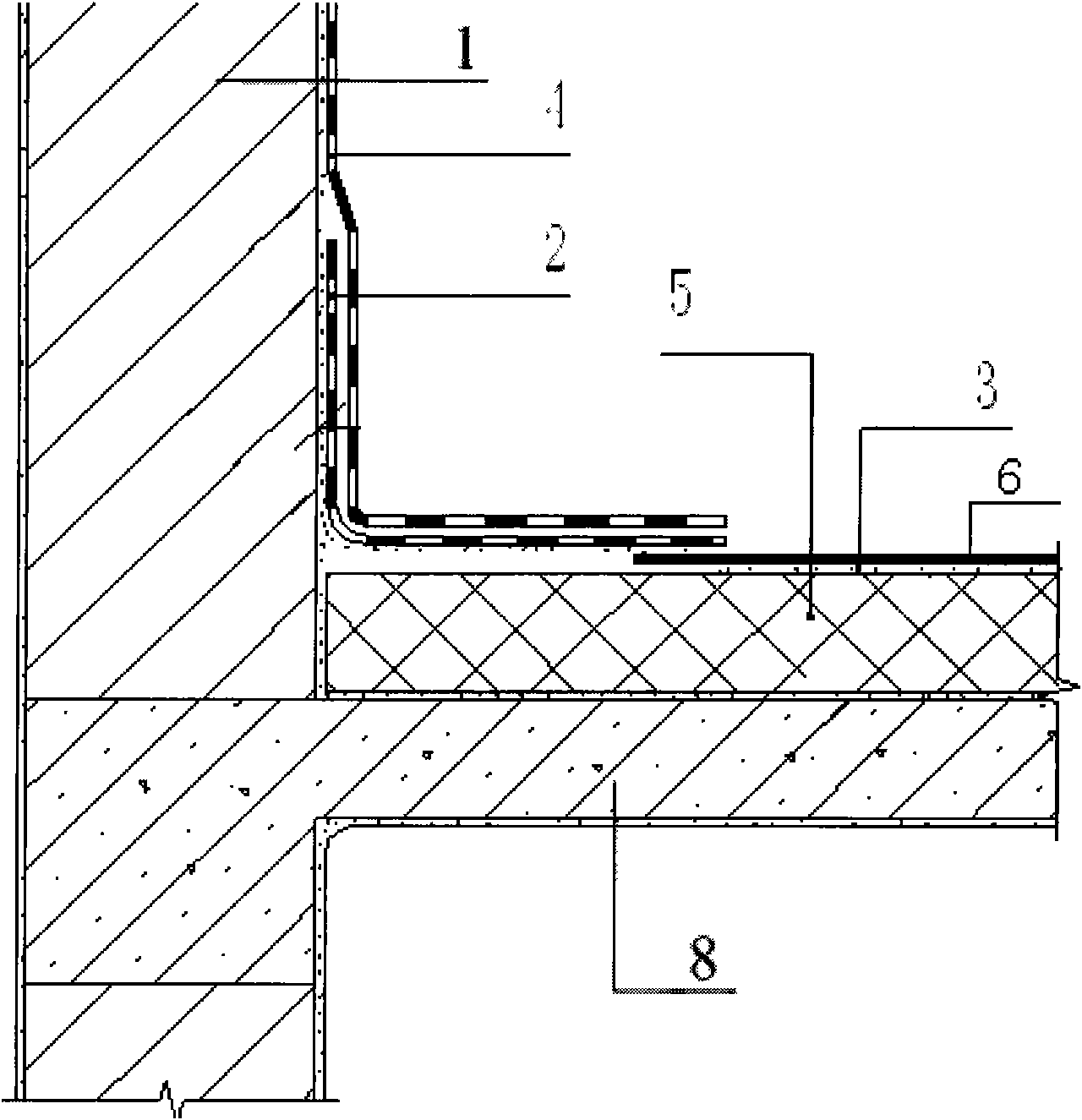

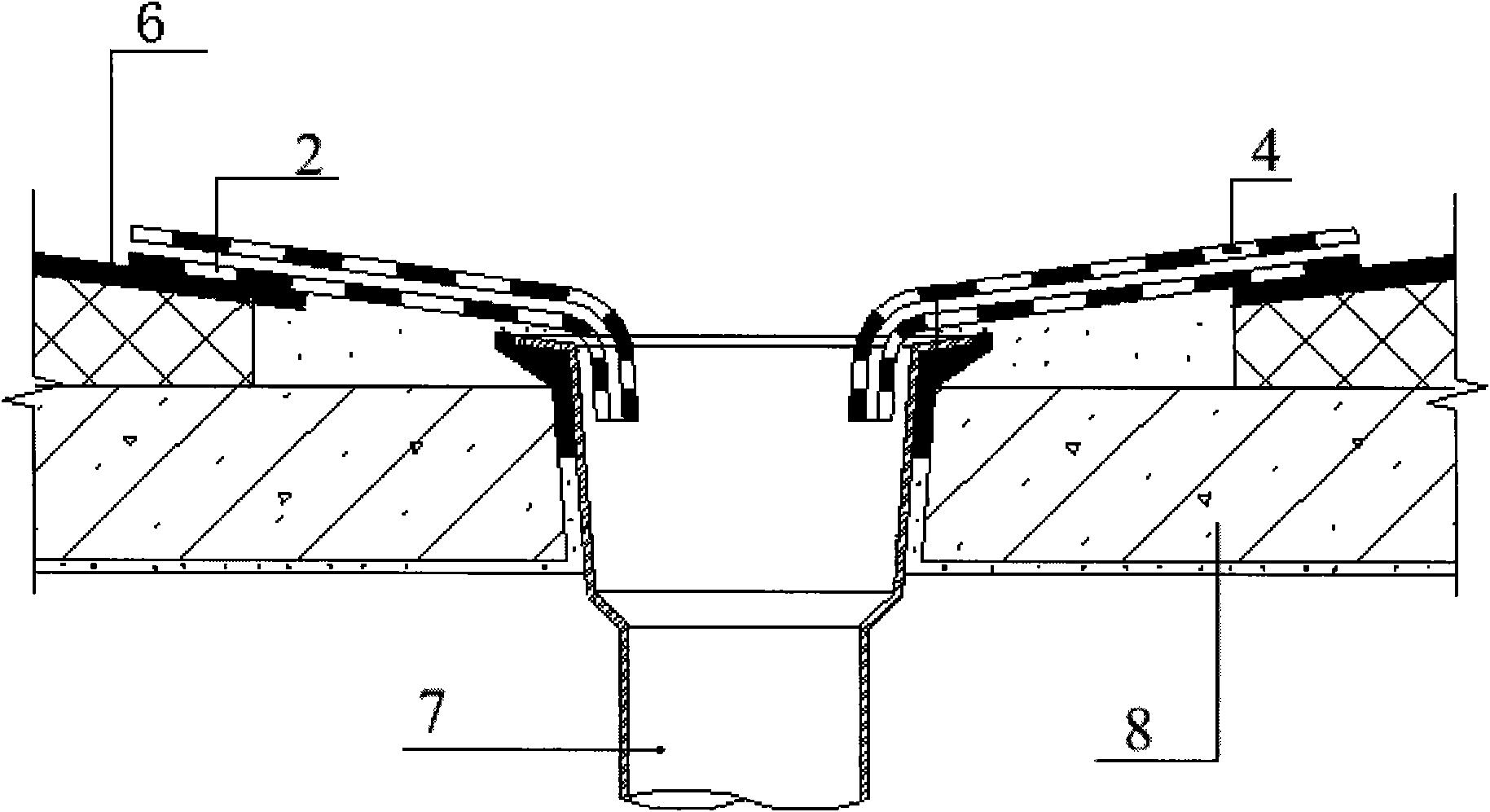

Waterproof structure and manufacturing method thereof

The invention relates to a waterproof structure and a manufacturing method thereof. The waterproof structure is used for waterproofing of detail joints on roofing and comprises a waterproof coiled material layer and a waterproof coating layer which is arranged on the position of the detail joints and is overlapped and struck with the waterproof coiled material layer, wherein the inside of the waterproof coating layer can comprise a reinforcing layer made of polyester or nylon non-woven fabrics or textile fabrics; and the material of the waterproof coating layer is exposed polyurea waterproof paint or modified waterproof paint thereof, exposed polyurethane waterproof paint or modified waterproof paint thereof, exposed polymethyl methacrylate waterproof paint or modified waterproof paint thereof or exposed polystyrene-ethylene-butadiene-styrene or modified waterproof paint thereof. Because the waterproof coating layer of the waterproof structure has large bonding force, strong capability to resist stretching and high elasticity, when the detail joints on the roofing are deformed because of gusty condition or other reasons, the waterproof coating layer is not destroyed and still has excellent waterproof effect.

Owner:北京森聚柯高分子材料有限公司 +1

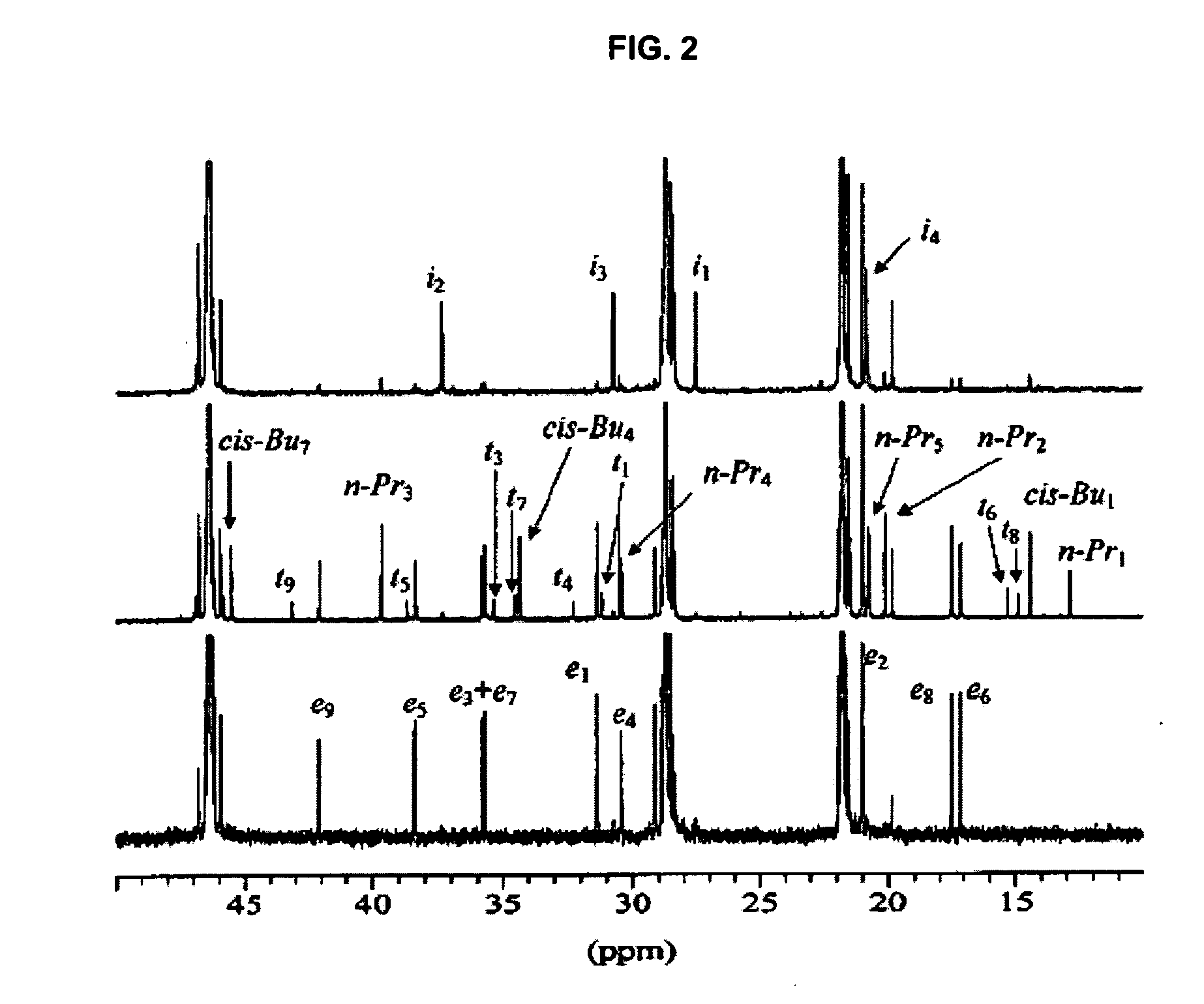

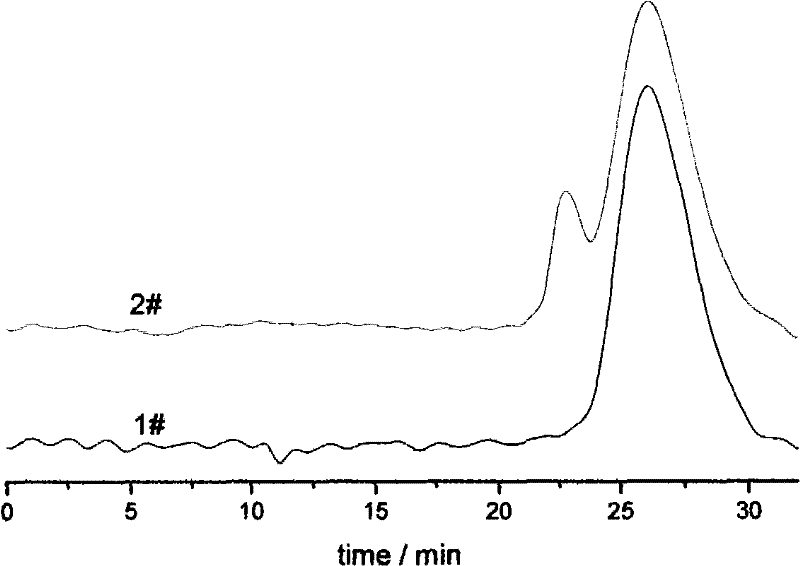

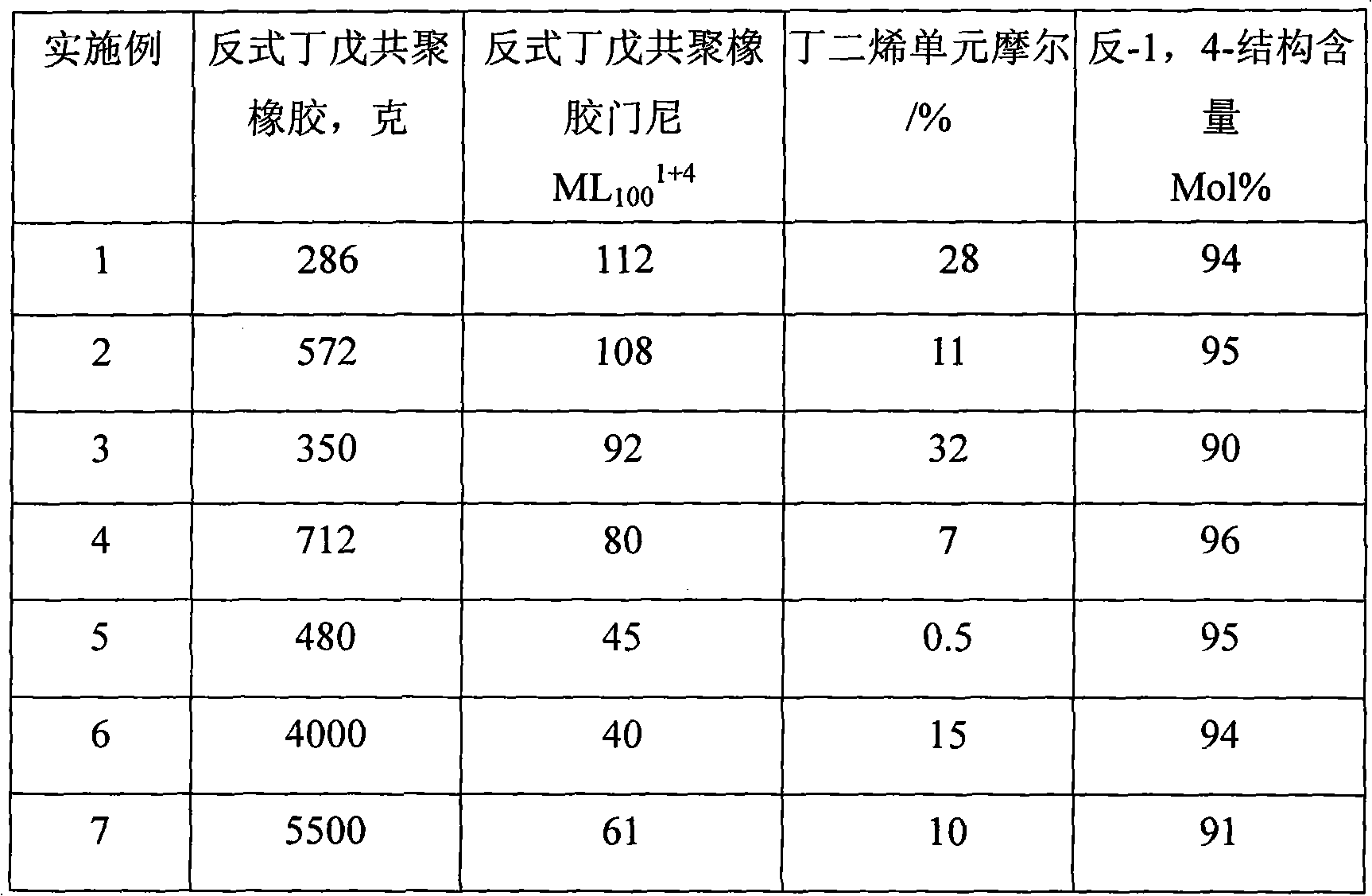

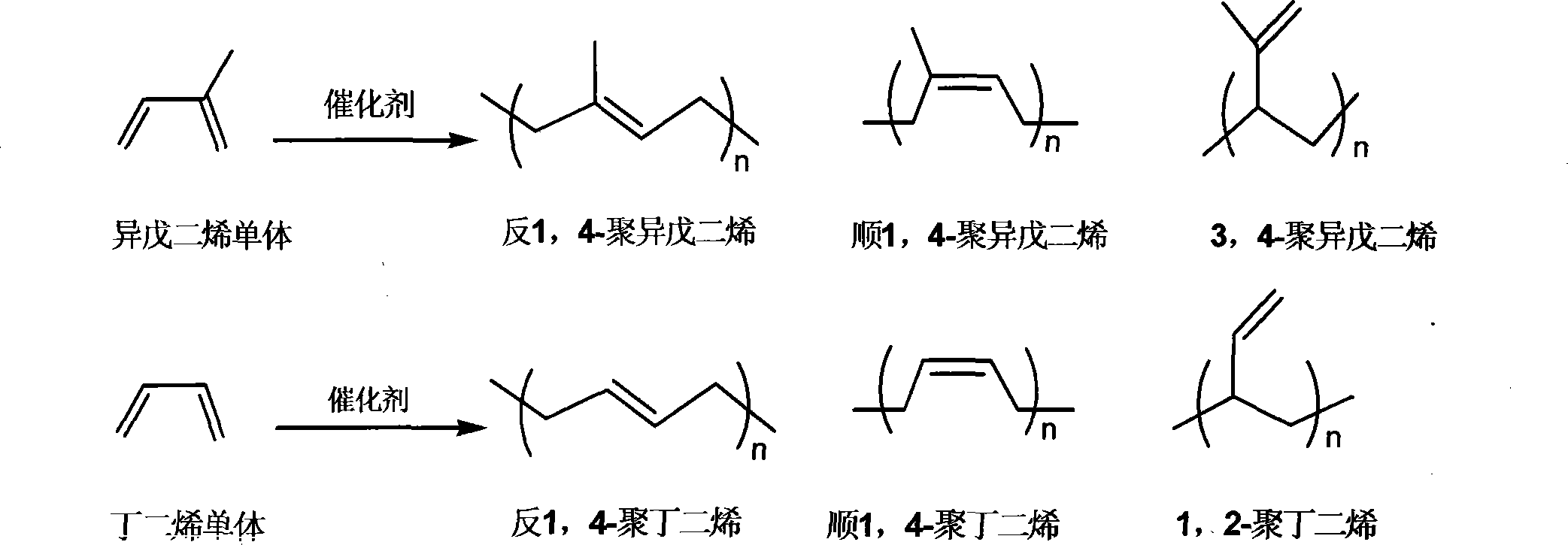

Trans-1, 4-structured butadiene-isoprene copolymer rubber and preparation method thereof

A trans-1, 4-structured butadiene-isoprene copolymer rubber and a preparation method thereof. A Ziegler-Natta catalytic system containing MgCl2 loaded titanium and an organic aluminium compound is used to catalyze butadiene and isoprene for copolymerization synthesis of the butadiene-isoprene copolymer with trans 1, 4-structure greater than 90%; and the copolymer rubber comprises, by molar fraction, 20-99.5% of an isoprene unit and 0.5-80% of a butadiene unit. One preparation method of the trans copolymer rubber is by maintaining a feeding ratio of butadiene to isoprene, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with gradient composition at 0-90 DEG C. A second preparation method of the trans copolymer rubber is by maintaining the concentration of butadiene in reaction materials, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with relatively uniform composition at 0-90 DEG C. The trans copolymer rubber has characteristics of low heat, good abrasion resistance and excellent flex and fatigue resistant performance, and is suitable rubber products for dynamic usage.

Owner:QINGDAO UNIV OF SCI & TECH +1

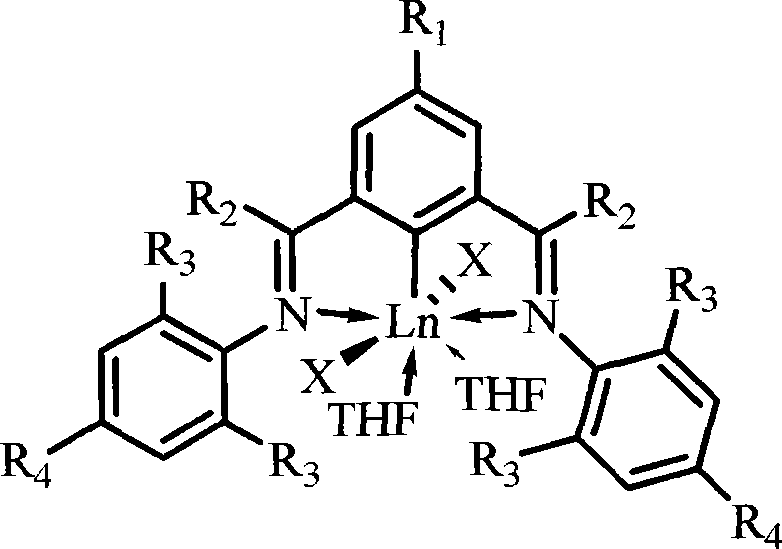

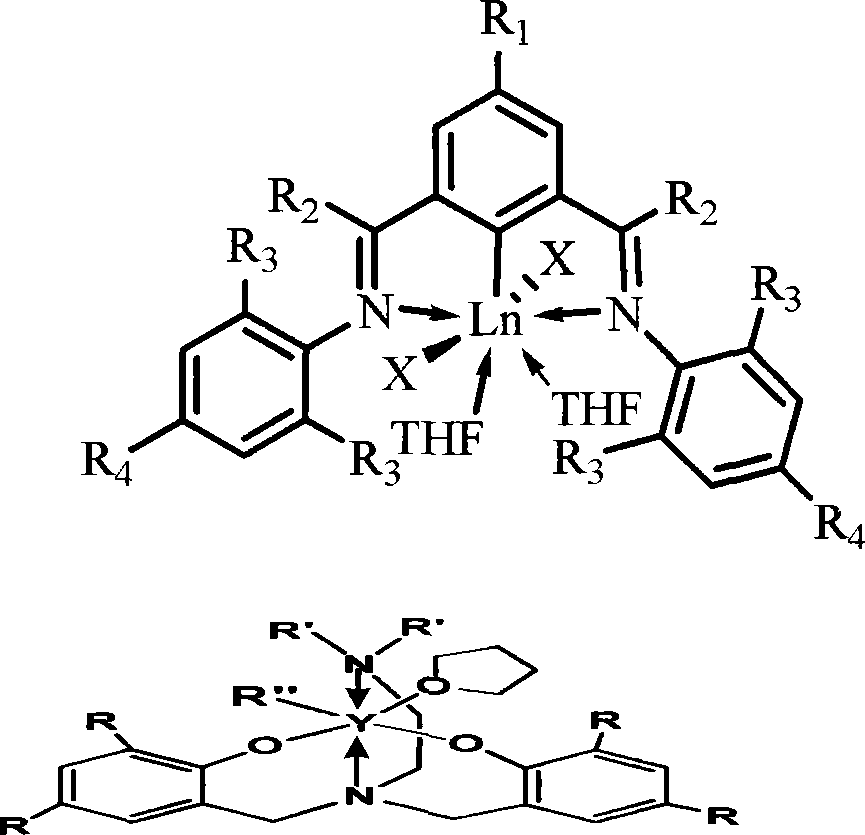

Rare earth catalyst for catalyzing syn form 1,4-selectivity polymerization of isoprene or butadiene

The invention relates to a rare-earth catalyst for catalyzing selective polymerization of isoprene or butadiene, while the catalyst system composed of the rare-earth catalyst can catalyze isoprene or butadiene to prepare polyisoprene or butadiene rubber with high cis-1, 4- structure. The rare-earth catalyst is composed of split-core type rare-earth complex, alkyl aluminium and organic boron salt. The solvent of polymerization is toluene or chlorobenzene. When catalyzes the polymerization of isoprene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 55.0-98.8%, and when catalyzes the polymerization of butadiene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 90.1-99.99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

SBS (styrene-butadiene-styrene) modified asphalt with stable thermal storage and preparation process thereof

InactiveCN102585525AImprove thermal storage stabilityGood high and low temperature road performanceBuilding insulationsSolventButadiene-styrene rubber

The invention discloses an SBS (styrene-butadiene-styrene) modified asphalt with stable thermal storage, which has significantly improved thermal storage stability and has good high-temperature and low-temperature road performance. The SBS modified asphalt is prepared by the step of adding a styrene-butadiene-styrene block copolymer, a stabilizer, a solubilizer and polyphosphate into base asphalt, wherein the weight of the styrene-butadiene-styrene block copolymer is 2-6% of the weight of the base asphalt, the weight of the stabilizer is 0.1-0.2% of the weight of the base asphalt, the weight of the solubilizer is 1-5% of the weight of the base asphalt, and the weight of polyphosphate is 0.1-1% of the weight of the base asphalt. The preparation process of the SBS modified asphalt comprises the following steps: (1) collecting base asphalt, and heating to 175-185 DEG C; (2) adding aromatic oil, and stirring for 40-80 seconds; (3) adding styrene-butadiene-styrene block copolymer, and shearing for 8-12 minutes; (4) adding sulfur powder, and shearing for 8-12 minutes; and (5) adding polyphosphate, and developing under stirring for 100-140 minutes to obtain the SBS modified asphalt with stable thermal storage.

Owner:SHANDONG HERITAGE HIGHWAY MATERIALS TECH

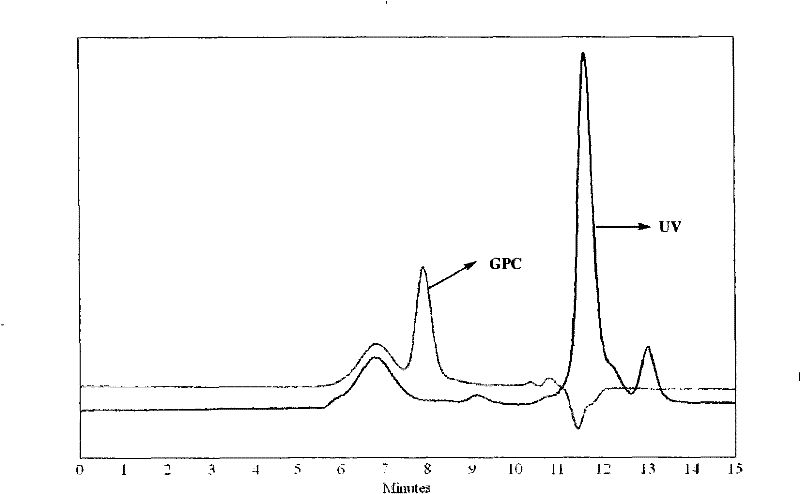

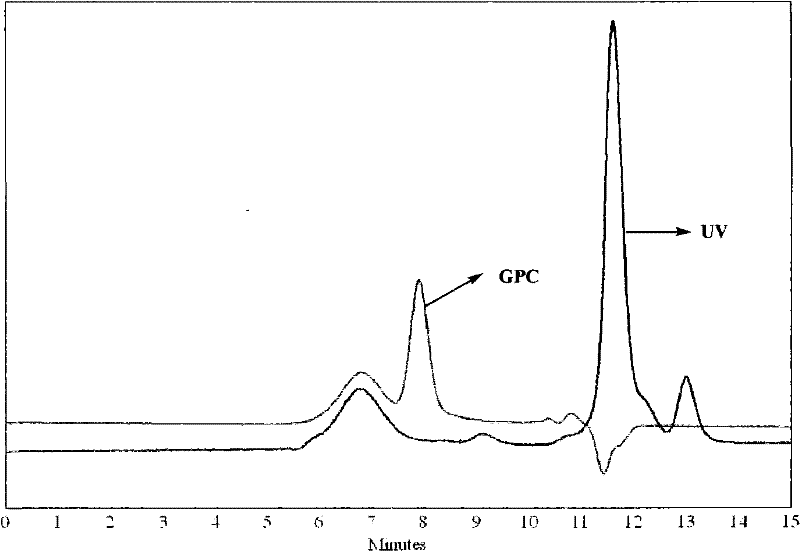

Star-shaped comb type butadiene/phenylethylene block copolymers and preparation method thereof

ActiveCN101456938AThe synthetic route is simpleAchieve high performanceMaterial synthesisMacromolecule

The invention belongs to the technical field of polymer material synthesis and preparation, relating to a star-shaped comb butadiene / styrene segmented copolymer, which is characterized in that the copolymer has the following structure: An-C, wherein A is the butadiene / styrene segmented copolymer, C is star-shaped seed tree coupler residue which is an epoxidation liquid star-shaped copolymer, n is branching degree which is larger or equal to 3, the number average molecular weight of the star-shaped comb segmented copolymer An-C is 5*10<4>-50*10<4>, the number average molecular weight of the segmented copolymer A is 1*10<4>-15*10<4>, the content of styrene is 55 percent to 85 percent (weight percent, same below), the content of butadiene is 15 percent to 45 percent, the content of 1, 2-structure is less than 30 percent (weight percent, which is counted by 100 percent of the total amount of monomer butadiene). The synthesis has the effect and benefit of simplifying the synthetic route of the star-shaped comb butadiene / styrene segmented copolymer, which can be widely applied to the preparation of the star-shaped comb butadiene / styrene segmented copolymer.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com