Patents

Literature

85results about How to "Improve thermal storage stability" patented technology

Efficacy Topic

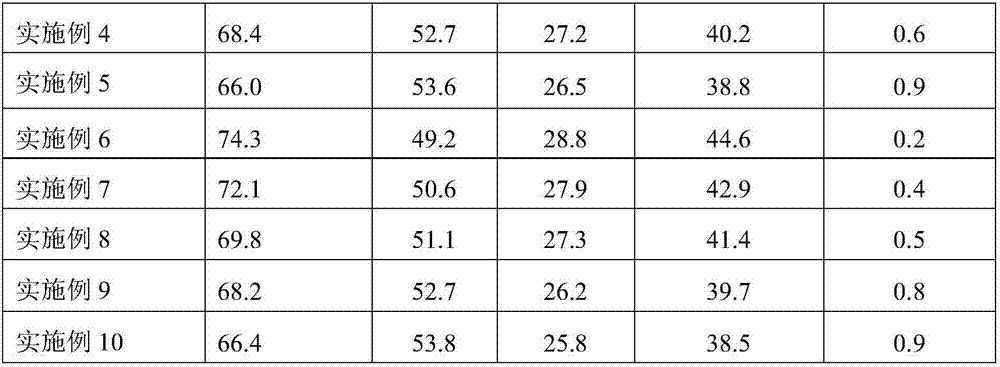

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

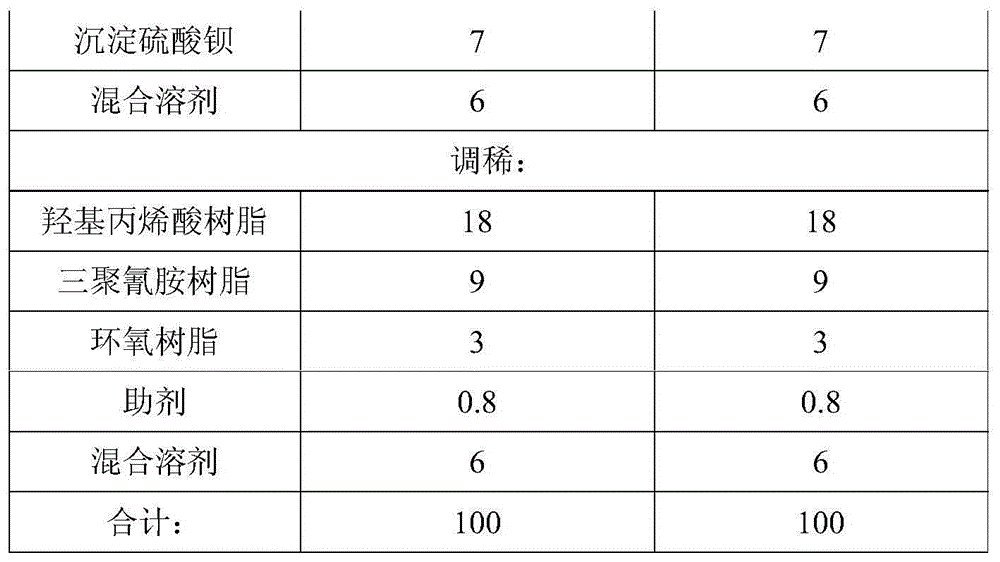

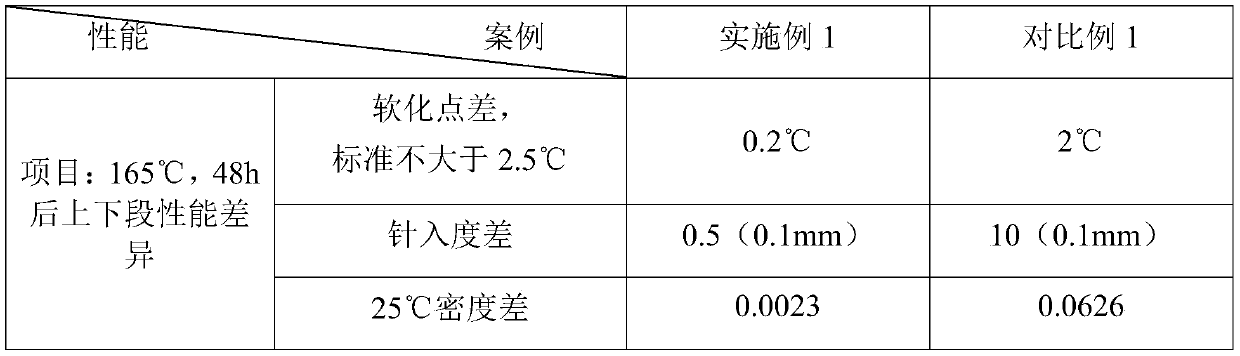

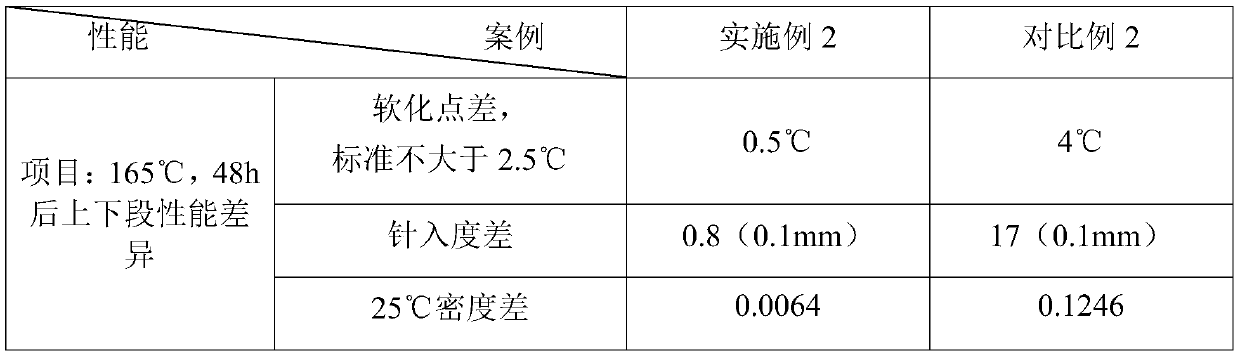

SBS (styrene-butadiene-styrene) modified asphalt with stable thermal storage and preparation process thereof

InactiveCN102585525AImprove thermal storage stabilityGood high and low temperature road performanceBuilding insulationsSolventButadiene-styrene rubber

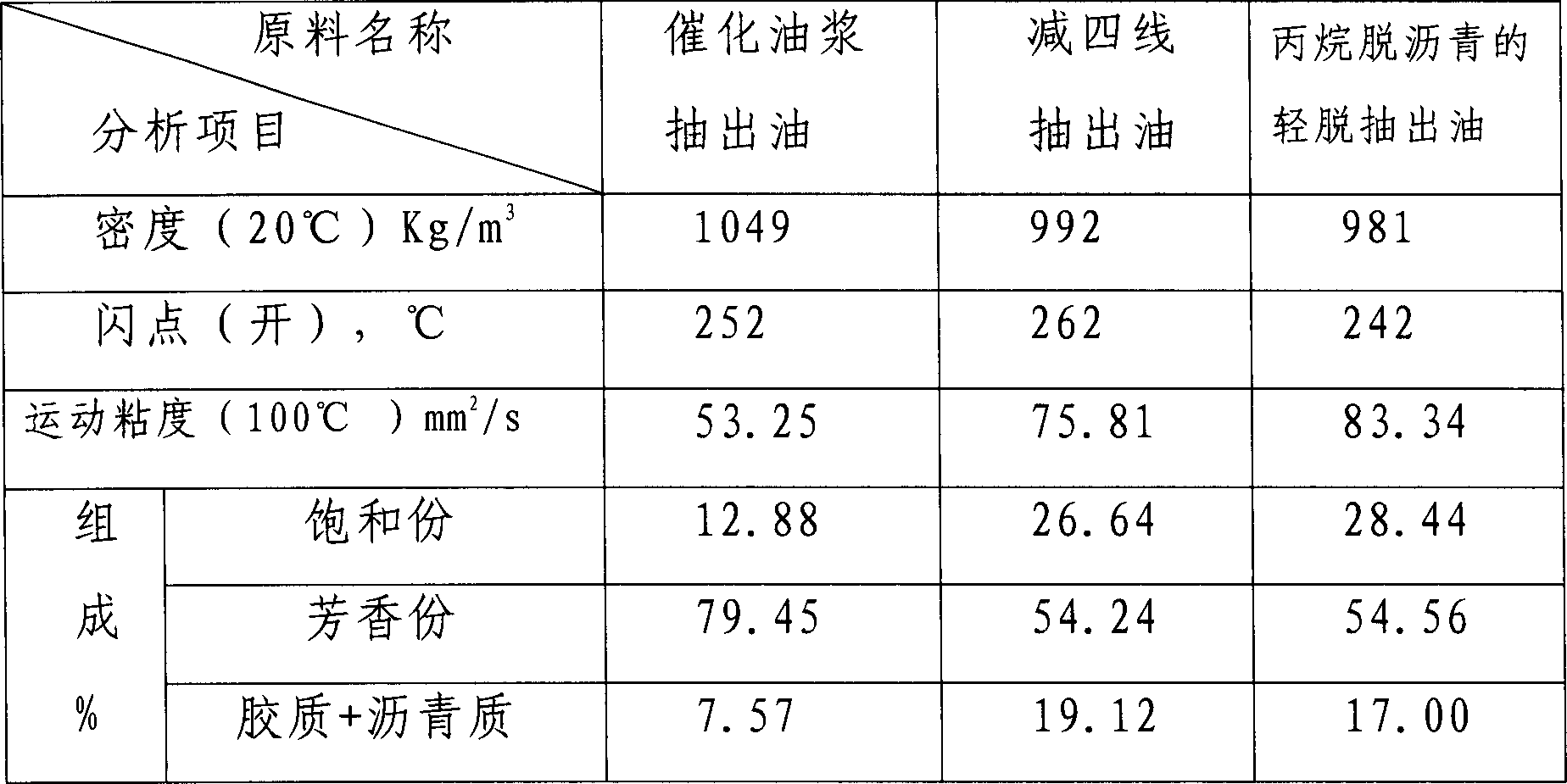

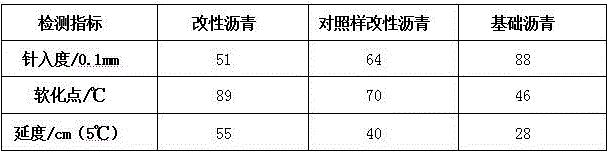

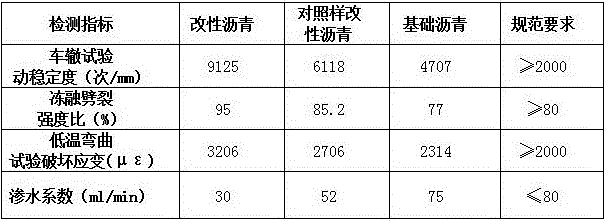

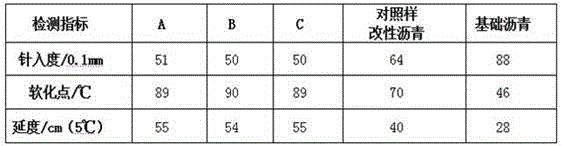

The invention discloses an SBS (styrene-butadiene-styrene) modified asphalt with stable thermal storage, which has significantly improved thermal storage stability and has good high-temperature and low-temperature road performance. The SBS modified asphalt is prepared by the step of adding a styrene-butadiene-styrene block copolymer, a stabilizer, a solubilizer and polyphosphate into base asphalt, wherein the weight of the styrene-butadiene-styrene block copolymer is 2-6% of the weight of the base asphalt, the weight of the stabilizer is 0.1-0.2% of the weight of the base asphalt, the weight of the solubilizer is 1-5% of the weight of the base asphalt, and the weight of polyphosphate is 0.1-1% of the weight of the base asphalt. The preparation process of the SBS modified asphalt comprises the following steps: (1) collecting base asphalt, and heating to 175-185 DEG C; (2) adding aromatic oil, and stirring for 40-80 seconds; (3) adding styrene-butadiene-styrene block copolymer, and shearing for 8-12 minutes; (4) adding sulfur powder, and shearing for 8-12 minutes; and (5) adding polyphosphate, and developing under stirring for 100-140 minutes to obtain the SBS modified asphalt with stable thermal storage.

Owner:SHANDONG HERITAGE HIGHWAY MATERIALS TECH

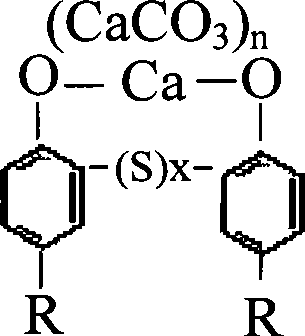

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

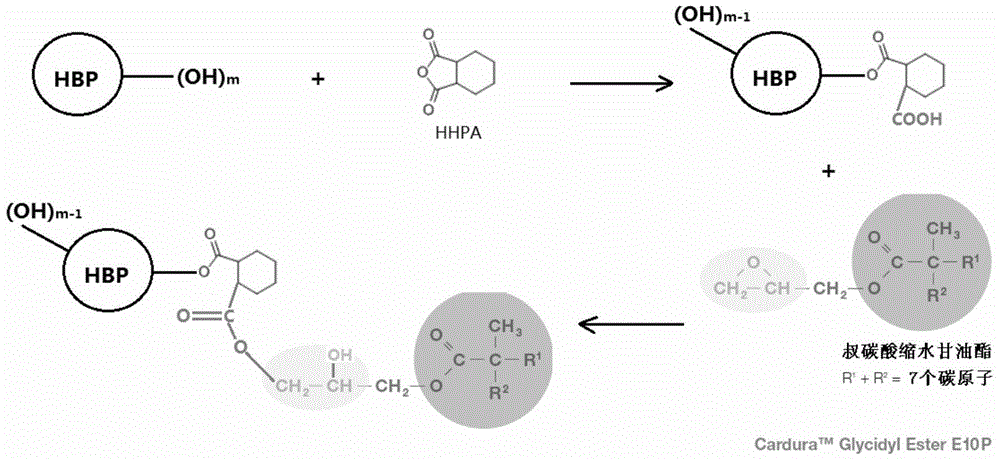

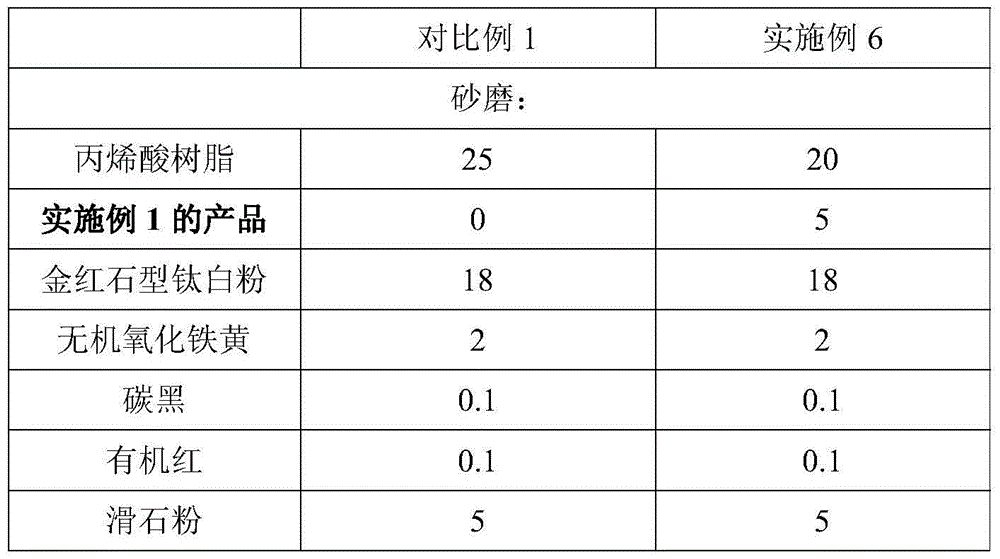

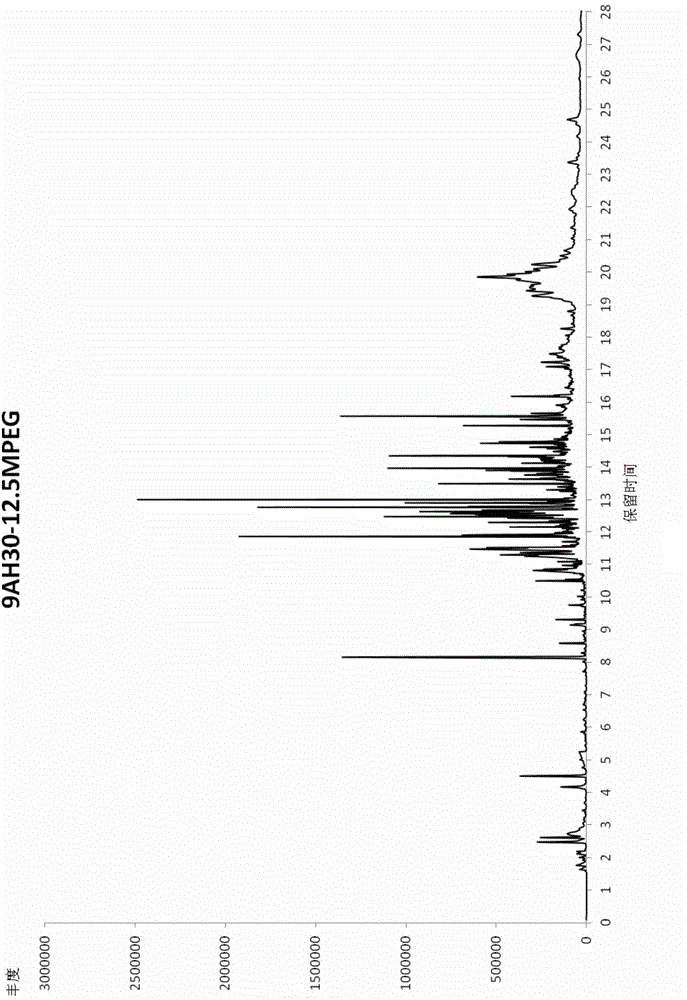

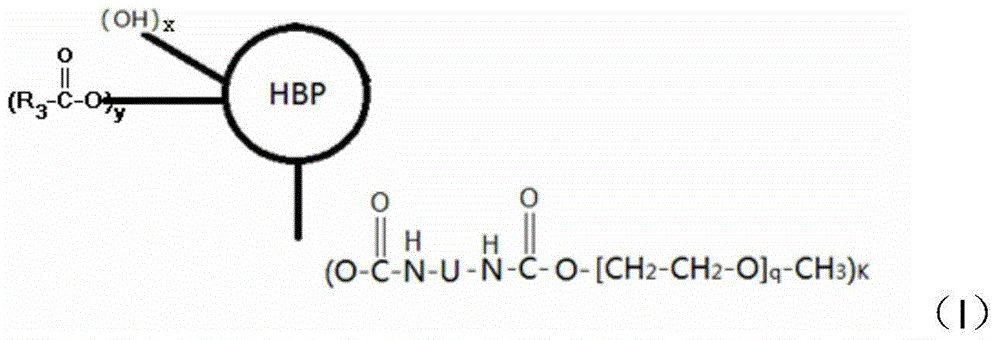

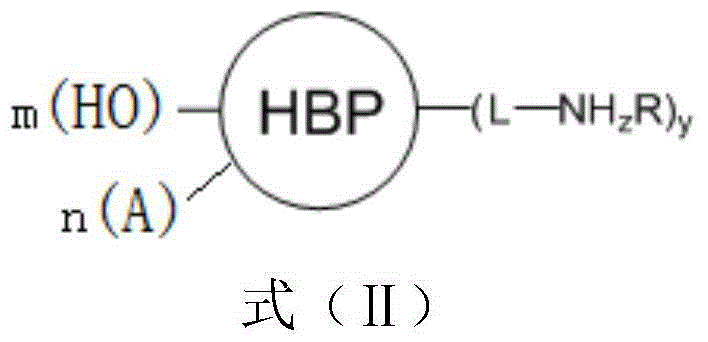

Hyperbranched polyester resin pigment dispersant as well as preparation method thereof, color paste and application of color paste

ActiveCN104086762AHigh hardnessImprove thermal storage stabilityTransportation and packagingMixingCarbon chainAryl radical

The invention discloses a hyperbranched polyester resin pigment dispersant as well as a preparation method thereof, color paste and application of color paste. The hyperbranched polyester resin pigment dispersant is a dendritic hyperbranched polyester with a hydroxyl functional group and a 3D structure, wherein number-average molecular weight of the polyester is 1500-20000, and solid content of the polyester is 20%-90%; the hyperbranched polyester resin pigment dispersant is prepared by reacting acid anhydride with hyperbranched polyester, and then reacting with a compound with a monoepoxy functional group at one end and a hydrophobic long-carbon chain at the other end. The long-chain alkyl / acryl introduced by the dispersant is just as a structure of a fish hook, has good compatibility with a paint main body resin molecular chain, and can lower re-flocculation or aggregation possibility of a dispersion system. Paint or color paste adopting the dispersant disclosed by the invention can reach fineness requirements by grinding within short time; the paint or the color paste is applied to finished product paint, so that the finished product paint has high hardness, and good thermal storage and room-temperature storage stability, and finished product paint precipitation and flooding can be effectively relieved.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

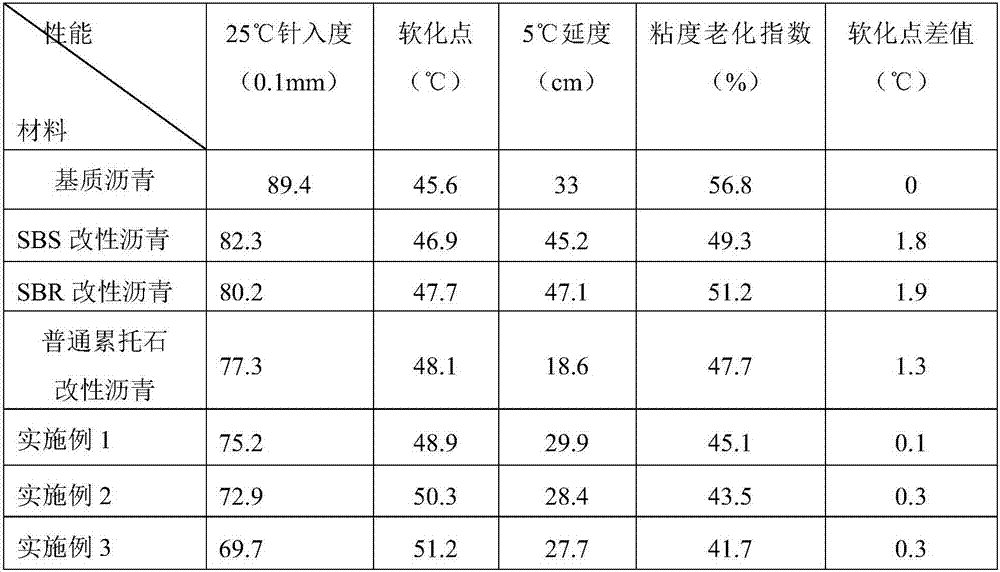

Composite high-viscosity modified asphalt and preparation method thereof

InactiveCN103819918AGood high and low temperature performanceImprove thermal storage stabilityBuilding insulationsEnvironmental effectEconomic benefits

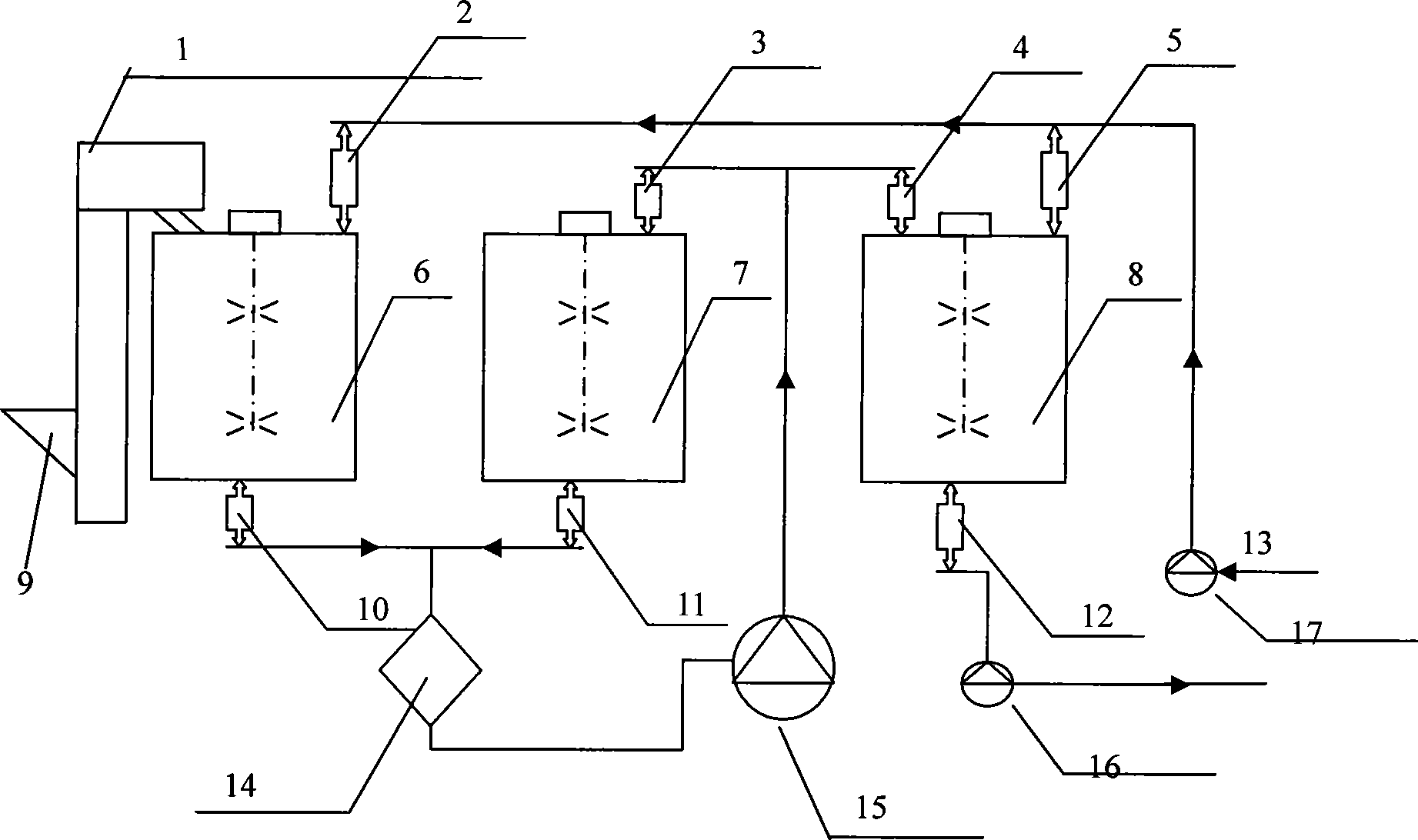

The invention relates to composite high-viscosity modified asphalt and a preparation method thereof. The raw material comprises the following components by weight percent: 84-88% of heavy duty bitumen and 12-16% of modified compounds. The method comprises the following steps: mixing SBS, desulfurized colloidal particles and a compatilizer containing an epoxy group to prepare a modified compound; preparing modified particles after mechanically pelletizing; adding the modified particles to asphalt at 170-190 DEG C; melting and refining compound particles after shearing at a high speed for 30-60 minutes on a high-speed mixing emulsifier; transferring the sheared asphalt to a high-speed disperser, and agitating to obtain the composite high-viscosity modified asphalt. The composite high-viscosity modified asphalt prepared by using the method has the characteristics of stable heat storage, and excellent high and low temperature properties, has good economic benefits and environmental effects because of use of waste rubber, and is free of sulphur as a stabilizer, the construction viscosity can be reduced, the construction environment can be improved, and the problem that incompatible asphalt is difficult to stabilize is solved.

Owner:SHANGHAI JIAO TONG UNIV

Process for preparing SBS modified asphalt

ActiveCN1775910ASimple processImprove thermal storage stabilityWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsChemical reactionThermoplastic elastomer

The invention belongs to manufacture process for SBS modificatioin asphalt. The feature is that: making SBS mucilage mother liquor and the raw materials are 10-20% sol solvent, 4-6% styrene-butadiene-styrene thermoplastic elastomer; adding the SBS mucilage mother liquor into ground substance asphalt that the temperature is 200-300 degree centigrade, fully whisking and making the SBS mucilage mother liquor to react with ground substance asphalt to finish the manufacture for storage modification asphalt. The effect is that: the compatibility of SBS and the asphalt would be improved; the harm to human health and environment would be conquered; and it could be directly used as the effective constituent of modification asphalt.

Owner:PETROCHINA CO LTD +1

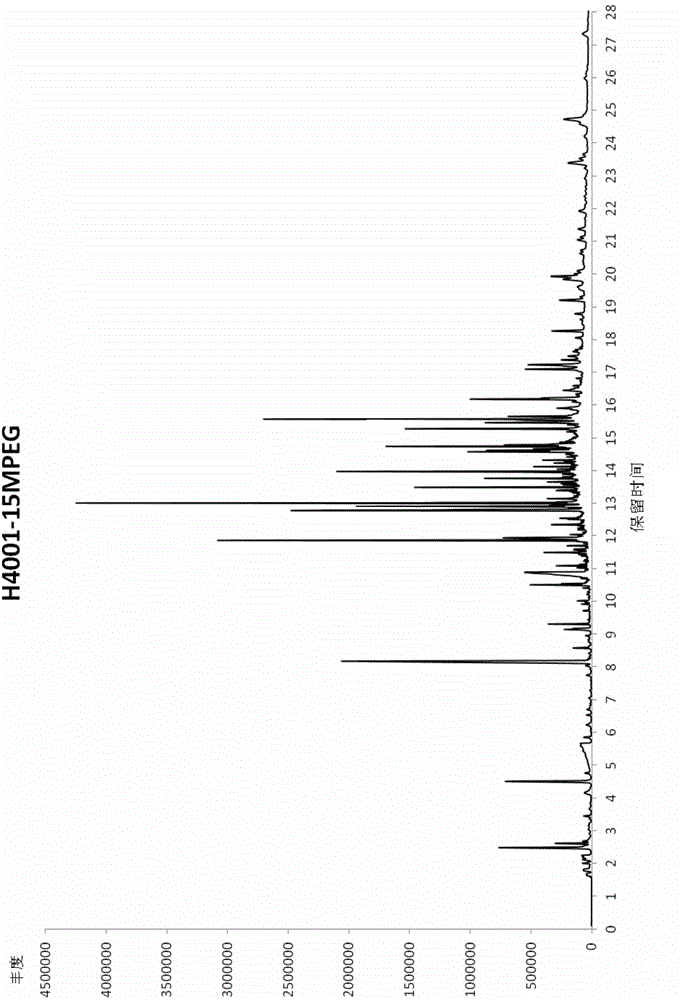

Hyperbranched resin pigment dispersant, preparation method and color paste thereof, and applications of color paste

InactiveCN105713174AImprove densification performanceReduce precipitationAnti-corrosive paintsEpoxy resin coatingsCarbon chainPigment

The invention discloses a hyperbranched resin pigment dispersant. The hyperbranched resin pigment dispersant possesses a hyperbranched structure, and following functional groups: a, hydroxyl; b, oxethyl (-OC2H4-), and c, hydrophobic carbon chains containing 5 to 18 carbon atoms. The hyperbranched resin pigment dispersant is capable of separating and dispersing pigments, strong anchoring effect with pigment can be achieved, compatibility of pigment with main resin is improved, color paste paint forming stability is improved, chromatic aberration is reduced, and the hyperbranched resin pigment dispersant can be applied to aqueous systems.

Owner:立邦投资有限公司 +1

SBR modified asphalt and preparation method thereof

ActiveCN110003672AWith low temperature performanceWith scalabilityBuilding insulationsAntioxidantPotassium

The invention discloses an SBR (styrene-butadiene rubber) modified asphalt and a preparation method thereof, and belong to the technical field of asphalt modification. Raw materials of the SBR modified asphalt comprise, by mass, 80-84.5% of matrix asphalt, 12-15% of aromatic oil and 3.5-5% of an SBR asphalt modifier, wherein raw materials of the SBR asphalt modifier comprise, by weight, 100 partsof a modified SBR emulsion (by dry rubber), 0.1-1 part of an antioxidant, 5-10 parts of an isolating agent, 3-6 parts of a dicyandiamide-formaldehyde condensate and 2-6 parts of potassium aluminum sulfate. The preparation method comprises the following steps: heating the matrix asphalt until melting, adding the aromatic oil and the SBR asphalt modifier, and shearing and swelling the obtained mixture to obtain the SBR modified asphalt. The SBR modified asphalt has good low temperature performances, ductility and bonding property, and has greatly improved viscosity, high temperature performancesand anti-aging property.

Owner:山东海方橡胶科技有限公司

Odor-free high-viscosity asphalt composition for water permeable pavement and preparation method of asphalt composition

InactiveCN108395718AStrong capture abilityImprove suppression effectClimate change adaptationBuilding insulationsAsphaltNOx

The invention provides an odor-free high-viscosity asphalt composition for a water permeable pavement. The asphalt composition is prepared from the following components in parts by weight: 80-88 partsof asphalt, 12-15 parts of a high-viscosity modifier, 0.2-2 parts of an odor inhibitor, 0.2-1 part of an interface activating agent and 0.2-0.5 part of a stabilizing agent. According to the odor-freehigh-viscosity asphalt composition provided by the invention, the generation and volatilization of the asphalt gas such as H2S, SO2, NOx and the like in asphalt production and construction processescan be reduced through the action of the odor inhibitor and the interface activating agent, so that a remarkable odor removal effect is achieved, the asphalt performance does not change obviously, andthe environmental protection and health of personnel are facilitated. The invention also provides a preparation method of the odor-free high-viscosity asphalt composition.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Chemically-modified asphalt cement and preparation method thereof

InactiveCN105111755AImprove thermal storage stabilityResolution timeBuilding insulationsPhosphoric acidMaterials science

The invention discloses chemically-modified asphalt cement which is prepared from the following raw materials in parts by weight: 100 parts of matrix asphalt, 0.8-1.8 parts of an RET asphalt modifier and 0.2-0.4 part of polyphosphoric acid. In addition, the invention further discloses a preparation method of the chemically-modified asphalt cement. The method comprises the following steps: heating the matrix asphalt to 175-185 DEG C, then adding the RET asphalt modifier into the matrix asphalt, uniformly stirring, finally adding the polyphosphoric acid, and continuously stirring uniformly so as to obtain the chemically-modified asphalt cement. The chemically-modified asphalt cement disclosed by the invention is simple in production process, relatively low in production cost and good in thermal storage stability.

Owner:CHANGAN UNIV

Modified asphalt for pouring asphalt concrete and preparation method thereof

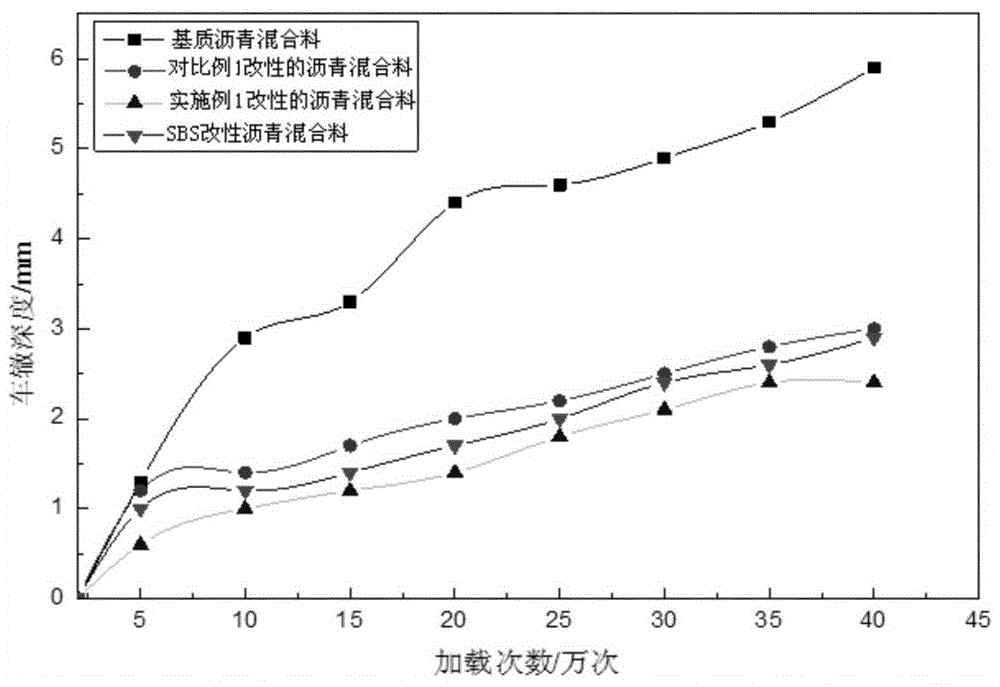

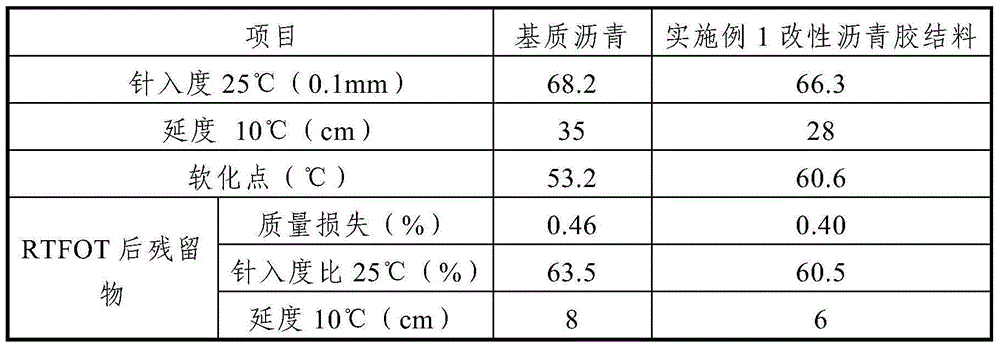

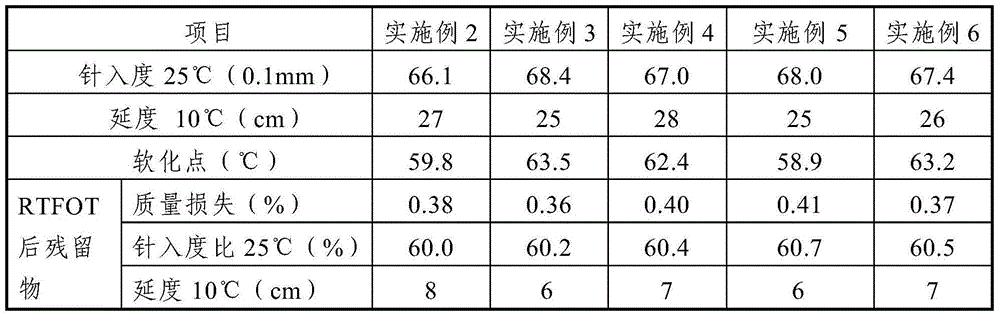

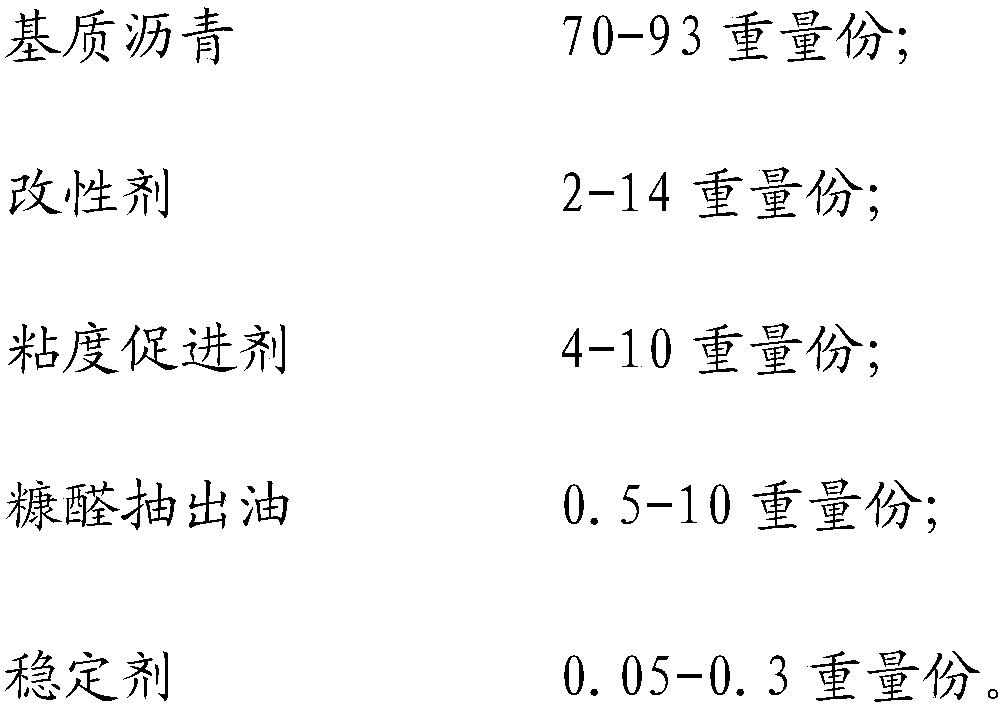

InactiveCN107739518AHigh softening pointHigh hardnessBuilding insulationsStiffness modulusRoad surface

The invention discloses modified asphalt for pouring asphalt concrete and a preparation method thereof. The modified asphalt is prepared from substrate asphalt, a modifier viscosity promoter, furfuralextraction oil and a stabilizer. The pouring asphalt concrete provided by the application has the advantages of higher softening point, higher hardness, high elastic recovery and thermal aging performance and very high thermal storage stability. By adopting the high-performance high-viscosity asphalt provided by the invention, the high-temperature performance of the pouring modified asphalt concrete can be enhanced, the pouring modified asphalt concrete has high strength and stiffness moduli in a high-temperature state, the rut resistance is enhanced, the stress state of the whole pavement structure is improved, and the service life of a pouring asphalt concrete pavement is prolonged.

Owner:中石油燃料油有限责任公司研究院

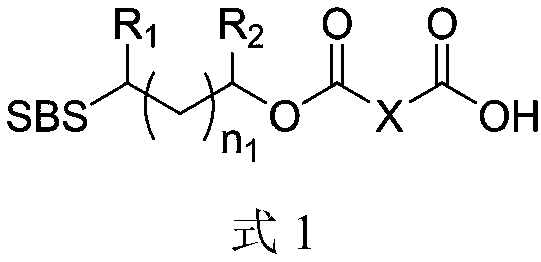

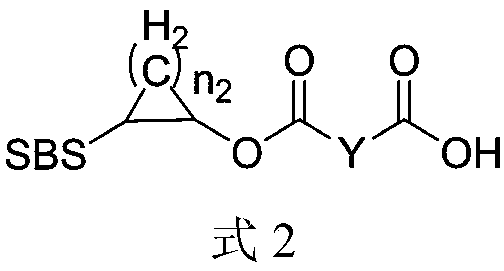

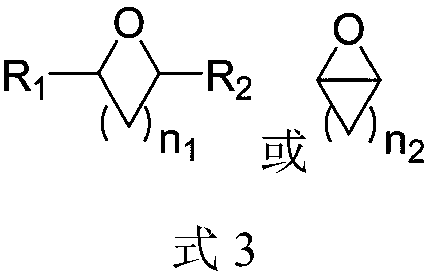

Terminal carboxyl group SBS, preparation and application thereof in asphalt modification

The invention discloses a terminal carboxyl group SBS, which has an epoxy ring opening flexible bond, an ester bond and a terminal carboxyl group and other structures. The preparation method of the terminal carboxyl group SBS is also disclosed, and active anionic SBS block polymer is prepared by using an anionic polymerization method; ring opening reaction is carried out on the anionic SBS block polymer and an epoxy hydrocarbon compound to obtain active oxygen anion SBS block polymer; terminal capping reaction is carried out on the active oxygen anion SBS block polymer and an acid anhydride compound; after the terminal capping reaction is finished, the terminal carboxyl group SBS is obtained after termination and post-treatment. Besides, the invention also discloses the application of theterminal carboxyl group SBS to asphalt modification. The terminal carboxyl group SBS can obviously improve the comprehensive performance of the asphalt and reduce a segregation value, thereby improving the transportation storage stability of modified asphalt. Besides, the preparation method of the terminal carboxyl group SBS is simple and is easy in industrialized implementation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature ductility and high-temperature-resistant storage stability auxiliaries for modified asphalt as well as preparation method for low-temperature ductility and high-temperature-resistant storage stability auxiliaries and modified asphalt

ActiveCN104693822AImprove low temperature ductilityImprove high temperature stabilityBuilding insulationsBulk chemical productionHigh temperature storagePolymer modified

The invention discloses low-temperature ductility and high-temperature-resistant storage stability auxiliaries for modified asphalt as well as a preparation method for the low-temperature ductility and high-temperature-resistant storage stability auxiliaries and modified asphalt. The preparation method comprises the following steps: performing complete desulfurization on regenerated waste rubber to prepare fluid regenerated rubber with main components of linear macromolecular polymer and aryl small molecules under the high-temperature strong-shearing effects of a twin-screw extruder; then, dissolving the fluid regenerated rubber with a diluent in certain proportion to prepare auxiliaries capable of remarkably improving low-temperature ductility and high-temperature-resistant storage stability of the modified asphalt. The low-temperature performances of the modified asphalt prepared by the auxiliaries can reach index requirements of JTG F40-2004 polymer modified asphalt I-B, the high temperature storage stability is obviously improved and no segregation is almost realized. The auxiliaries prepared by the preparation method can be stored for a long time, transported at a long distance, solve the application problem of sticky regenerated rubber, and can be widely applied to various-grade highway engineering.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

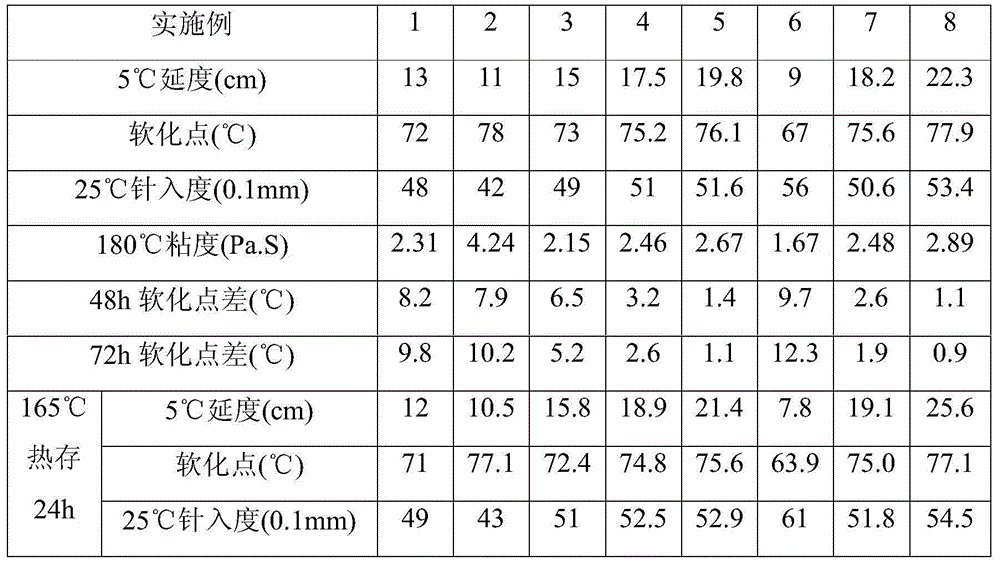

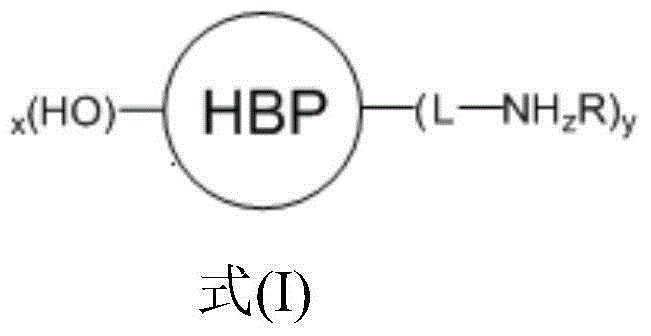

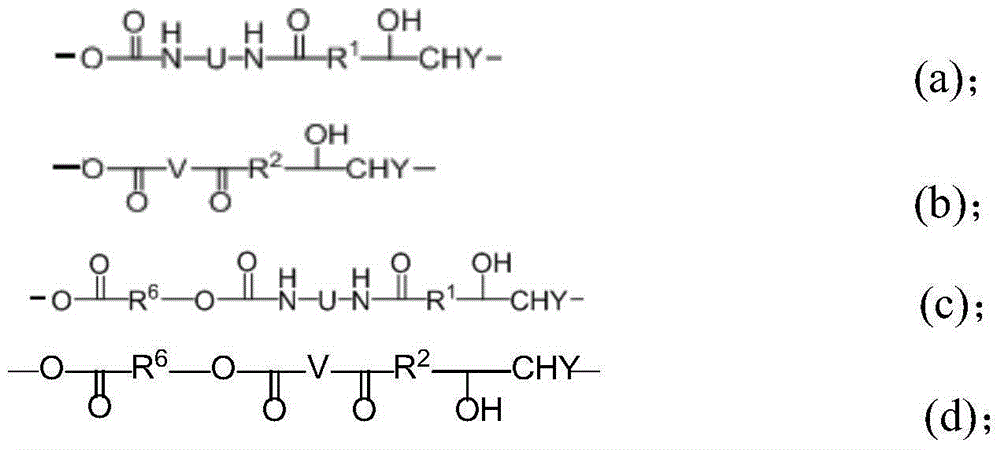

Amine modified hyper-branched hydroxyl polymer and applications of amine modified hyper-branched hydroxyl polymer in rapid dry and pigment dispersion system

ActiveCN105001427AHigh functionalityReduce viscosityEpoxy resin coatingsPolyester coatingsCross-linkPolymer resin

The present invention discloses an amine modified hyper-branched hydroxyl polymer, and applications of the amine modified hyper-branched hydroxyl polymer in a coating material rapid drying and pigment dispersion system. According to the present invention, the amine modified hyper-branched hydroxyl polymer resin is introduced into the coating material composition, such that the paint film drying time can be shortened, the cross-linking density of the coating can be improved, and the hardness, the scrub resistance and the chemical corrosion resistance of the paint film can be increased; with the application of the amine modified hyper-branched resin in the pigment paste system, the pigment can be effectively infiltrated and dispersed, and the fineness requirement can be met after grinding for a short time; and with the application of the pigment paste system containing the amine modified hyper-branched resin in the finished product paint, the hardness is high, the thermal storage stability and the room temperature storage stability are good, and the precipitation and the flooding of the finished product paint can be effectively slowed.

Owner:NIPPON PAINT IND COATINGS SHANGHAI +1

SBS-modified asphalt stabilizing agent

InactiveCN105733283AReduce the use of additivesGuaranteed qualityBuilding insulationsVulcanizationStearic acid

The invention discloses an SBS-modified asphalt stabilizing agent.The SBS-modified asphalt stabilizing agent is prepared from, by weight, 20-30 parts of a vulcanization accelerator TMTD, 10-15 parts of stearic acid 1801, 10-20 parts of an antioxidant 2246, 20-30 parts of sulphur, 10-15 parts of a heat stabilizer and 10-15 parts of a light stabilizer.After SBS and asphalt are mixed and milled under the action of a shear colloid mill, the SBS-modified asphalt stabilizing agent is added, and stirring is performed for 1.5-2 hours at the temperature of 175 DEG C-185 DEG C.The SBS-modified asphalt stabilizing agent can promote compatibility of the SBS and the asphalt substrate and decrease the adding dosage of the SBS, can improve the heat storage stability of the SBS-modified asphalt to prevent separation from occurring and can increase the content of aromatic ingredients and increase the compatibility rate of the asphalt substrate and the SBS.

Owner:WUXI HUATONG ASPHALT NEW TECH DEV

Road asphalt modifier containing double-ended hydroxyl styrene-butadiene rubber and preparation and usage method

The invention relates to a road asphalt modifier containing double-ended hydroxyl styrene-butadiene rubber and a preparation and usage method and belonging to the technical field of asphalt modifiers. The main modifier containing active-terminated hydroxyl butylbenzene liquid rubber serving as road asphalt is synthesized, can effectively form a crosslinked network structure with base asphalt to form a novel rubber structure system, so that the properties of the asphalt are improved compressively. Under the synergistic effect of other components, the road asphalt modifier containing the double-ended hydroxyl styrene-butadiene rubber is excellent in property, can remarkably improve the properties of the base road asphalt and has very good stability. The road asphalt modifier is low in adding amount, economic and environmentally friendly, and the adding amount of 3-5% by weight can meet the improvement requirements. The preparation method is simple, convenient, easy to operate and suitable for large-scale production and application, and the yield is above 95%.

Owner:浙江维克森沥青有限公司

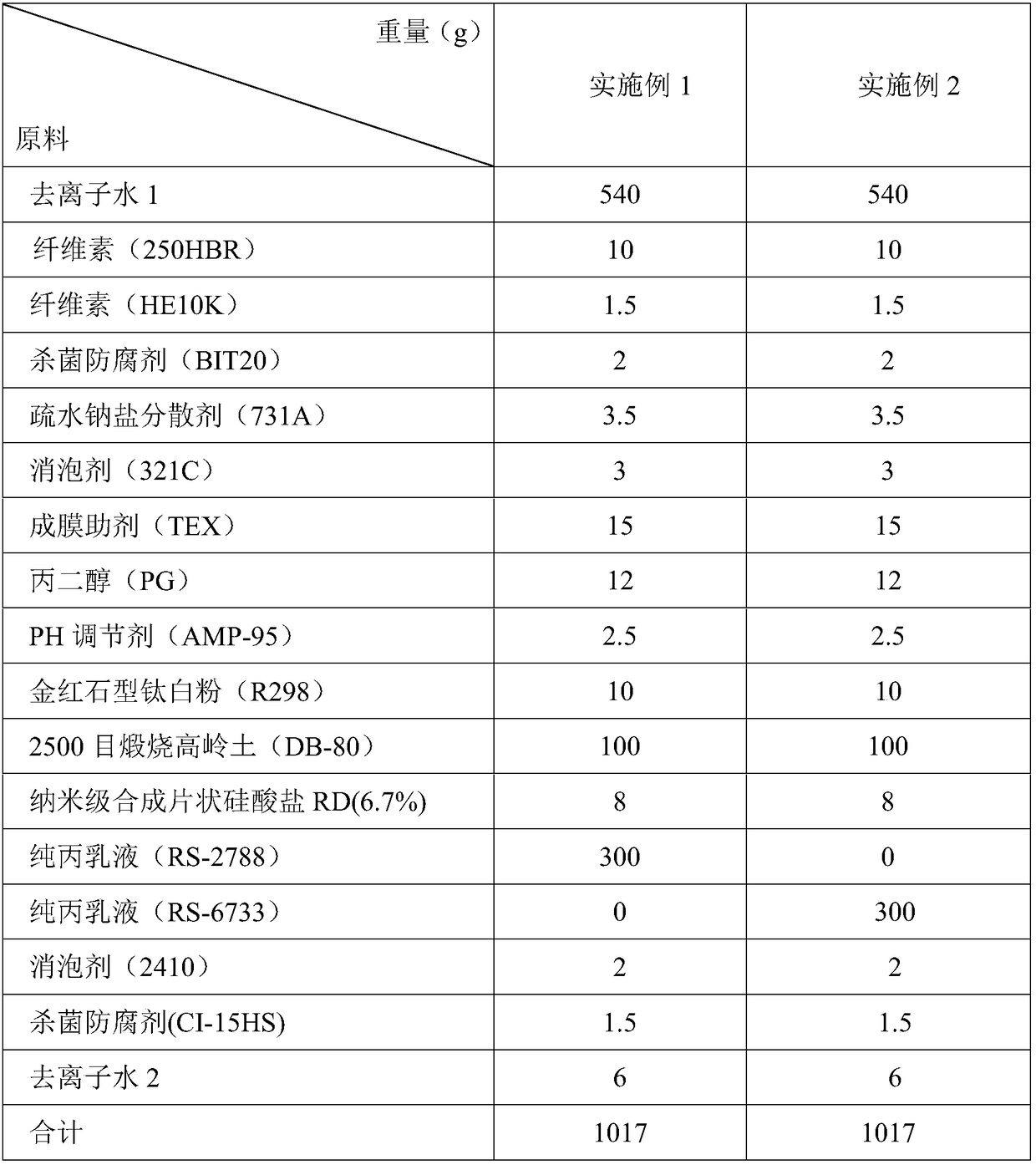

Waterborne multicolor coating with freeze-thaw resistance, basic paint for waterborne multicolor coating and method for preparing basic paint

InactiveCN109354953AGuaranteed freeze-thaw stabilityImprove thermal storage stabilityMulticolor effect coatingsHydrogenEmulsion

The invention provides waterborne multicolor coating with freeze-thaw resistance, basic paint for the waterborne multicolor coating and a method for preparing the basic paint. The basic paint for thewaterborne multicolor coating with the freeze-thaw resistance comprises, by weight, 10-12 parts of hydroxyethyl cellulose aqueous solution, 4-8 parts of dispersing agents, 2-6 parts of defoaming agents, 5-6 parts of coalescing agents, 10-12 parts of antifreezing agents, 0.1-3 parts of pH (potential of hydrogen) regulators, 8-12 parts of titanium dioxide, 80-90 parts of kaolin, 300-350 parts of pure acrylic emulsion, 1-5 parts of sterilizing preservatives, 2-5 parts of thickeners, 0-2 parts of leveling agents and 530-550 parts of deionized water. The waterborne multicolor coating, the basic paint and the method have the advantages that appropriate auxiliaries and emulsion are screened to prepare the basic paint, accordingly, the freeze-thaw stability of products can be guaranteed, and undesirable phenomena such as increase of broken points of multicolor particles, soft color points, frozen color points, post-thickening and the like can be prevented.

Owner:合肥科天环保节能科技有限公司 +1

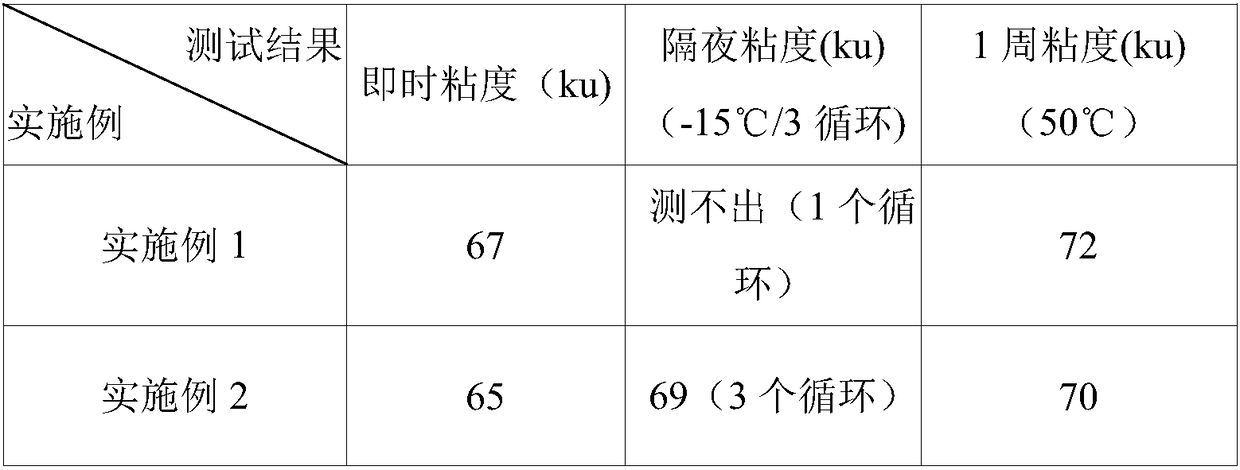

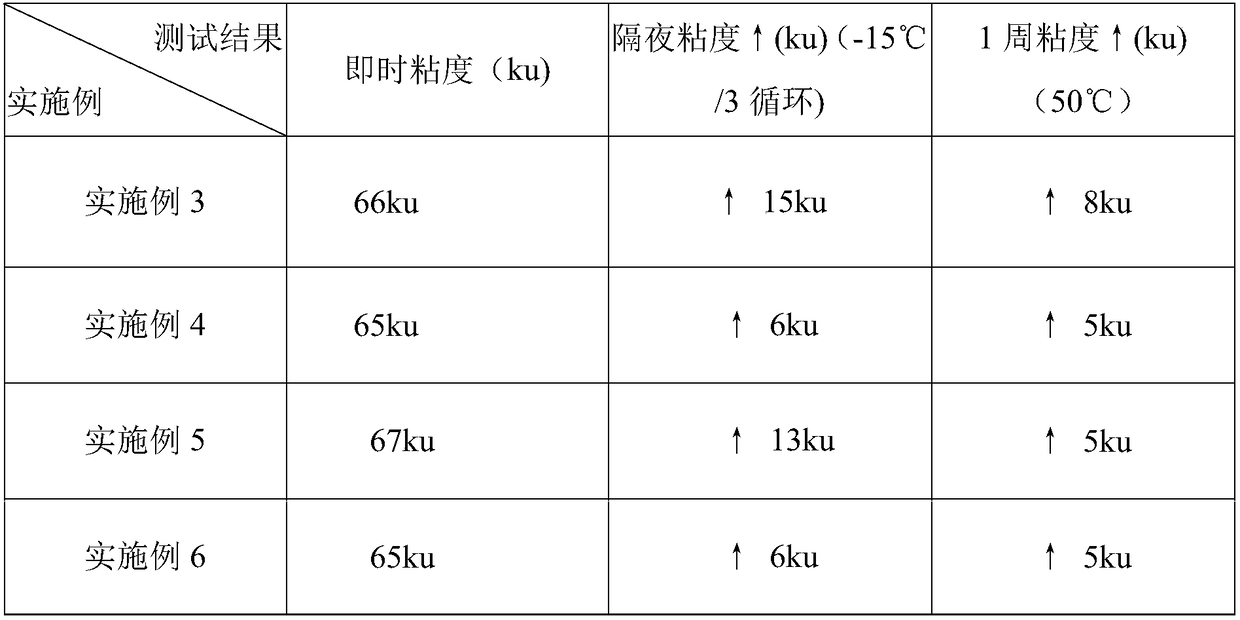

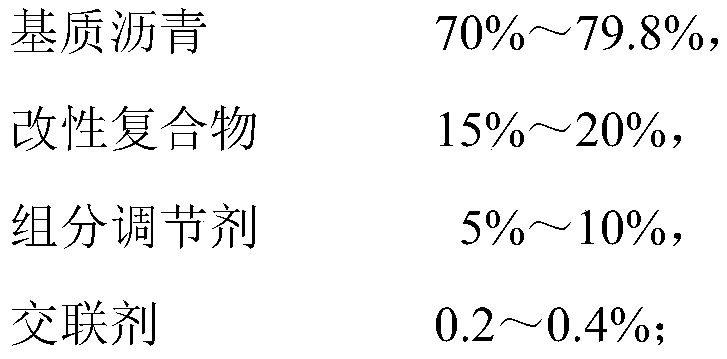

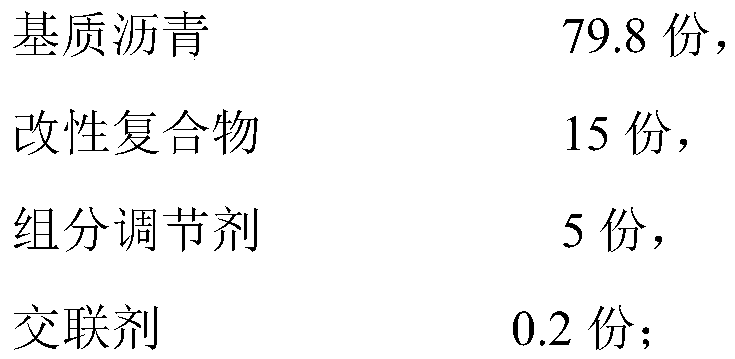

High weatherability composite modified asphalt for high-speed railway asphalt concrete waterproof sealing layer

The invention discloses high weatherability composite modified asphalt for a high-speed railway asphalt concrete waterproof sealing layer. The high weatherability composite modified asphalt is prepared from the following components in percentage by weight: 70% to 79.8% of matrix asphalt, 15% to 20% of a modified composite, 5% to 10% of a component modifier, and 0.2 to 0.4% of a crosslinking agent,wherein the modified composite comprises a styrene-butadiene-styrol copolymer, that is, SBS copolymer, regenerated colloidal particles, and a mixture of an anti-aging agent and an interface enhancingagent. According to the high weatherability composite modified asphalt for the high-speed railway asphalt concrete waterproof sealing layer, (1) the composite modifier prepared by using the SBS copolymer, the regenerated colloidal particles, the anti-aging agent, and the interface enhancing agent can comprehensively improve stability, aging, and weatherability of the matrix asphalt, waste tires are fully utilized, and the cost is lowered, so that a modified asphalt cementing agent is more suitable for the high-speed railway waterproof sealing layer; and (2) according to the method, the composite modifiers are firstly prepared and then granulated, the interface enhancing agent is beneficial to the association between a modifier and the matrix asphalt, micro-nano dispersion of modifier molecules can be realized, the use amount of rubber is increased, and tire pollution is reduced.

Owner:江苏宝利路面材料技术有限公司

Odorless high-viscosity asphalt modifier and asphalt mixture thereof

InactiveCN111662033AImprove thermal storage stabilityReduce interfacial energyElastomerPolymer science

The invention provides an odorless high-viscosity asphalt modifier. The odorless high-viscosity asphalt modifier is prepared from the following components in parts by weight: 4-7 parts of thermoplastic elastomer, 4-8 parts of rubber polymer, 5-8 parts of thermoplastic resin, 0.05-0.2 part of odor inhibitor and 0.1-0.5 part of surfactant. The invention also provides an asphalt mixture of the odorless high-viscosity asphalt modifier. According to the odorless high-viscosity asphalt modifier disclosed by the invention, the odorless high-viscosity asphalt modifier is prepared under the action of the odor inhibitor and the interfacial agent; the high-viscosity asphalt mixture is directly prepared, so that the odor in the production process of the high-viscosity asphalt mixture can be eliminated, the generation and volatilization of asphalt flue gas such as H2S, SO2 and NOX in the production and construction processes of asphalt are remarkably reduced, a remarkable odor eliminating effect isachieved, the performance of the asphalt mixture is not obviously changed, and the environmental protection and the body health of personnel are facilitated.

Owner:河源市海川新材料科技有限公司 +3

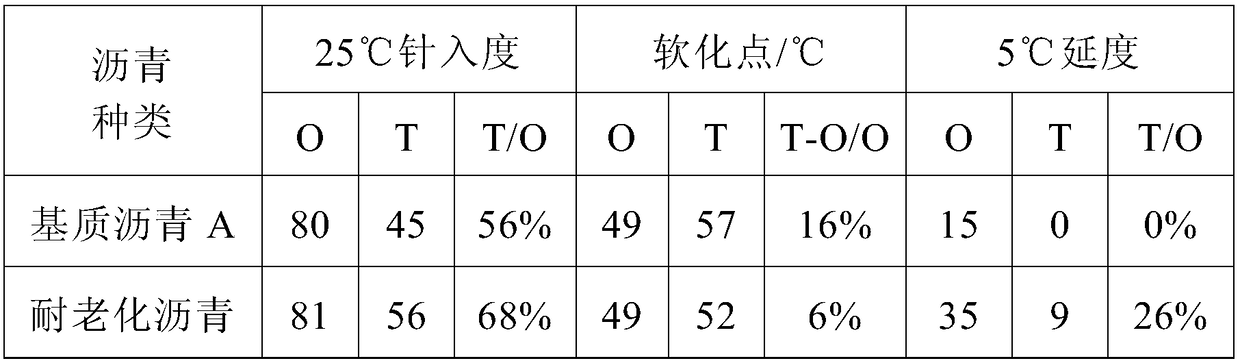

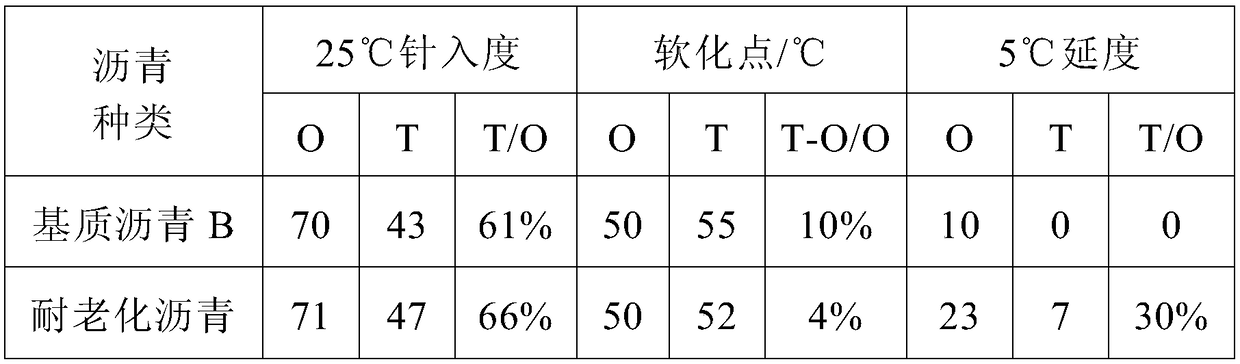

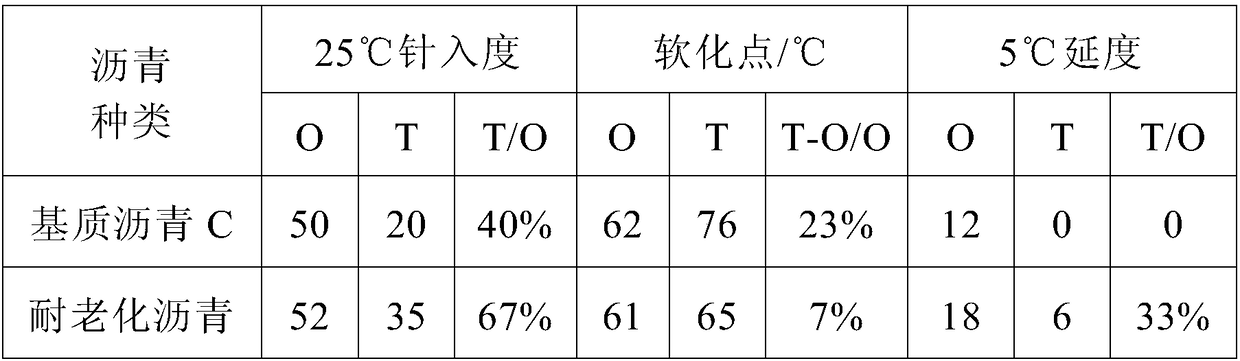

Anti-aging agent and anti-aging asphalt

InactiveCN108148419AReduce the effects of agingReduces the generation of free radicalsBuilding insulationsP-PhenylenediamineAsphalt

The invention provides an anti-aging agent and anti-aging asphalt. The anti-aging agent comprises the following components in parts by weight: 10-20 parts of nano carbon black, 40-60 parts of p-phenylenediamine, 5-15 parts of p-cresol, 0-10 parts of a petroleum resin and 30-40 parts of high-aromatic hydrocarbon oil. The anti-aging asphalt provided by the invention comprises asphalt and the anti-aging agent, and the content of the anti-aging agent is 0.5-1.0 wt%. By adopting the anti-aging agent provided by the invention, thermal oxidation aging of asphalt can be effectively inhibited, so thatthe thermal aging resistance of the asphalt is improved, and the storage stability of the asphalt can be improved.

Owner:PETROCHINA CO LTD

RS2000 anti-rutting modified asphalt processing technic

ActiveCN101531819AImprove high temperature stabilityImprove low temperature crack resistanceBuilding insulationsBridge engineeringMixed materials

The invention provides a RS2000 anti-rutting modified asphalt processing technic which belongs to the road and bridge engineering technique field, relates to a road asphalt processing technique. The technique uses a technical scheme as follows: the RS2000 anti-rutting modified asphalt is prepared by adding RS2000 modifying agent to basic asphalt which has characteristics that: adding 8% modifying agent into the basic asphalt evenly, heating to 160-170 DEG. C, and stirring 30 minutes with a stirring speed 350 revolutions per minute. The technique also can use a technical scheme as follows: adding RS2000 modifying agent into the basic asphalt which has characteristics of: adding 8% RS2000 modifying agent into the basic asphalt with 150-160 DEG. C, stirring 10 minutes, then rubbing the mixed material twice by a colloid mill. Compared with the prior modified asphalt, the modified asphalt provided by the invention has excellent performance and low cost.

Owner:JIANGXI GANYUE EXPRESSWAY

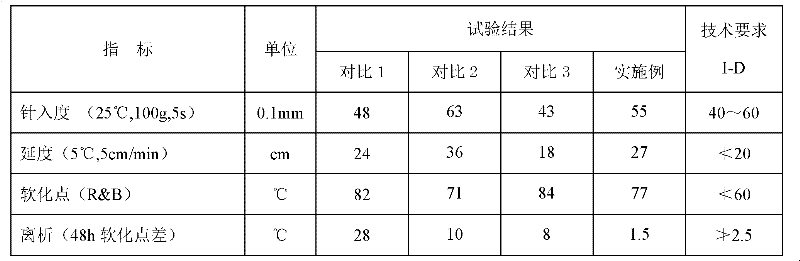

Preparation method and product of modified asphalt

InactiveCN105860109AImprove mechanical propertiesGood compatibilityBuilding insulationsPolymer modifiedDose rate

The invention discloses a preparation method and product of modified asphalt. The preparation method includes: by the total weight of matrix asphalt being 100 parts, evenly mixing 2-8 parts of styrene-butadiene-styrene segmented copolymer and 0-9 parts of compatibilizer with the matrix asphalt, and stirring for development for 0-8 hours to obtain primary modified asphalt material; spreading the primary modified asphalt material; irradiating the primary modified asphalt material with an electron beam with the dose rate being 30-800kGy to obtain the modified asphalt. The preparation method has the advantages that the asphalt is modified through electron beam irradiation instead of adding stabilizer, adverse effects on the other properties of the product are avoided, the problem that the stabilizer in the prior art easily pollutes environments is solved, and the prepared asphalt satisfy the requirements of I-D types polymer modified asphalt in JTG F40-2004 road asphalt pavement construction technical specifications.

Owner:HUAZHONG UNIV OF SCI & TECH

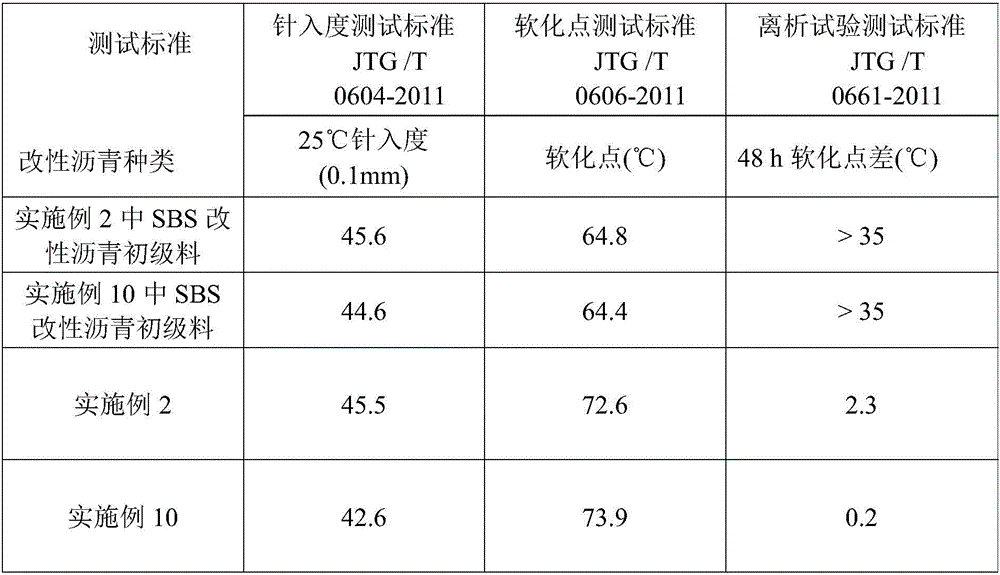

Modified asphalt with heat storage stability and preparation method thereof

ActiveCN107189458ALarge specific surface areaImprove lipophilicityBuilding insulationsActive pointAsphalt

The invention discloses modified asphalt with heat storage stability and a preparation method thereof. An organic reagent containing long-chain alkyls and a proper process are used for performing organizing on rectorite; then, the prepared organic rectorite is used for modifying the asphalt; in order to realize the more uniform and stable dispersion of the organic rectorite in the asphalt, composite additives are added; benzene ring groups of the organic agent have higher rigidity, the active points combined with the asphalt molecular chains are provided, the long-chain alkyls enable the rectorite to form a peeling type structure, so that the rectorite has larger specific area in an asphalt base body; the inhibition effect on the asphalt molecular chain motion is more obvious; meanwhile, through the benzyls and the long-chain alkyls, the rectorite has higher lipophilicity; the dispersion in the asphalt is easier, so that the obtained modified asphalt system has better excellent heat temperature stability, anti-aging performance and heat storage stability than the SBS modified asphalt; the heat storage stability is greatly improved.

Owner:CHANGAN UNIV

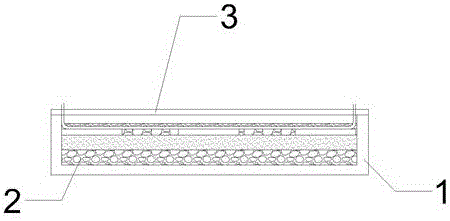

Asphalt road

InactiveCN106223150AImprove flatnessTightness of compactionIn situ pavingsTemporary pavingsLow voltageSlag

The invention discloses an asphalt road, and belongs to the field of roads. The asphalt road comprises a roadbed, a subgrade and a road surface. The subgrade is arranged in the roadbed and is provided with a horizontal layered structure. The subgrade is provided with a first mixed slag layer, a rubble layer, a second mixed slag layer and a concrete layer from bottom to top, and a geogrid and low-voltage shielded wires are arranged in the second mixed slag layer. A plurality of solar photovoltaic modules are arranged in the middle of the road surface in the road extension direction, and the solar photovoltaic modules are connected with a photovoltaic inverter through the low-voltage shielded wires. The asphalt road has the characteristics of being high in flatness, capable of avoiding the circumstances of insufficient partial compaction degrees, serious temperature segregation and the like, good in road surface temperature sensing property, good in elasticity and ageing-resistant performance, not prone to melting or flowing at high temperatures, good in toughness and not likely to be cracked at low temperatures, capable of meeting the using requirements of high-grade roads, and capable of fully utilizing high temperatures of the road surface to conduct solar power generation.

Owner:江西省地质工程集团有限公司

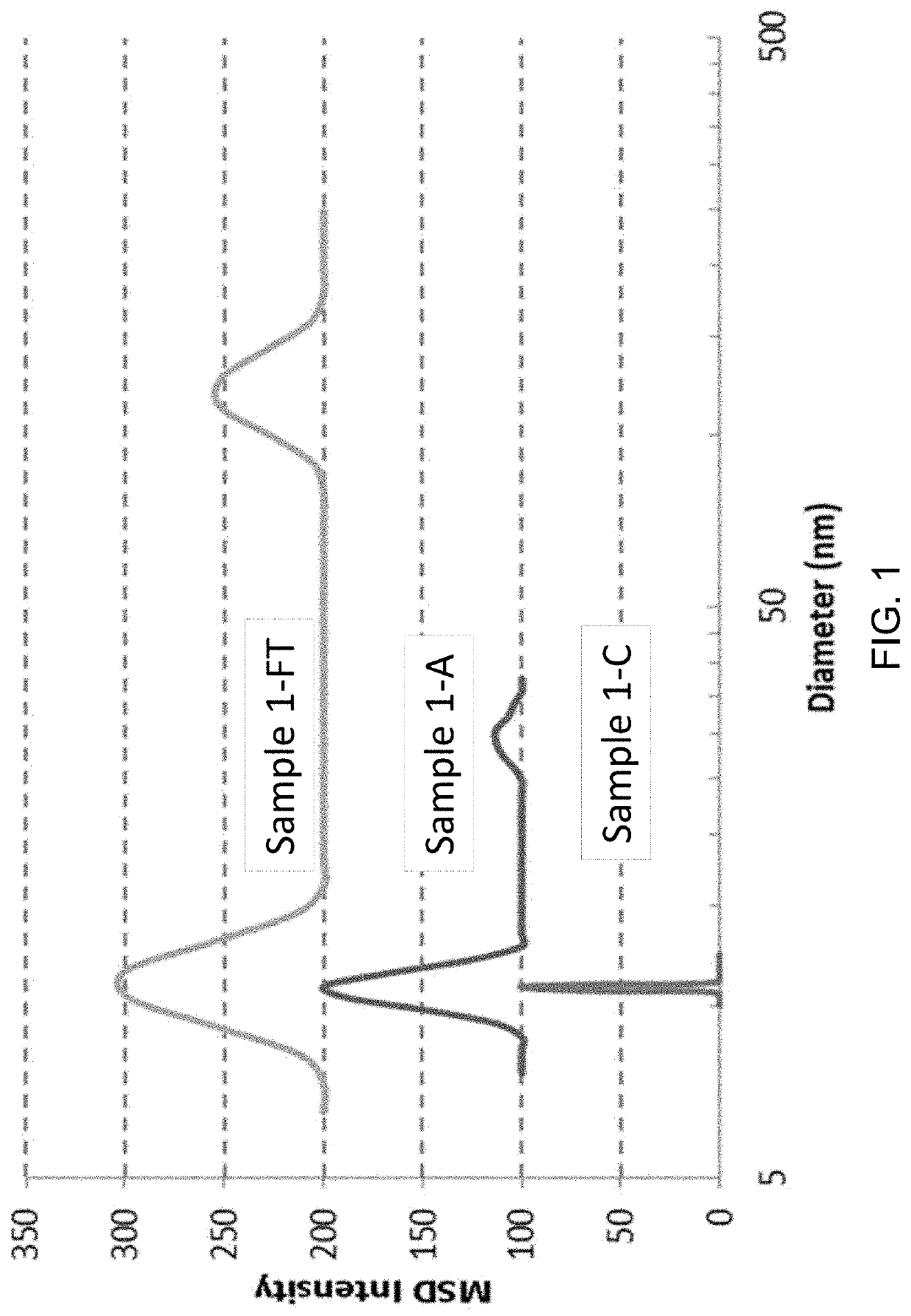

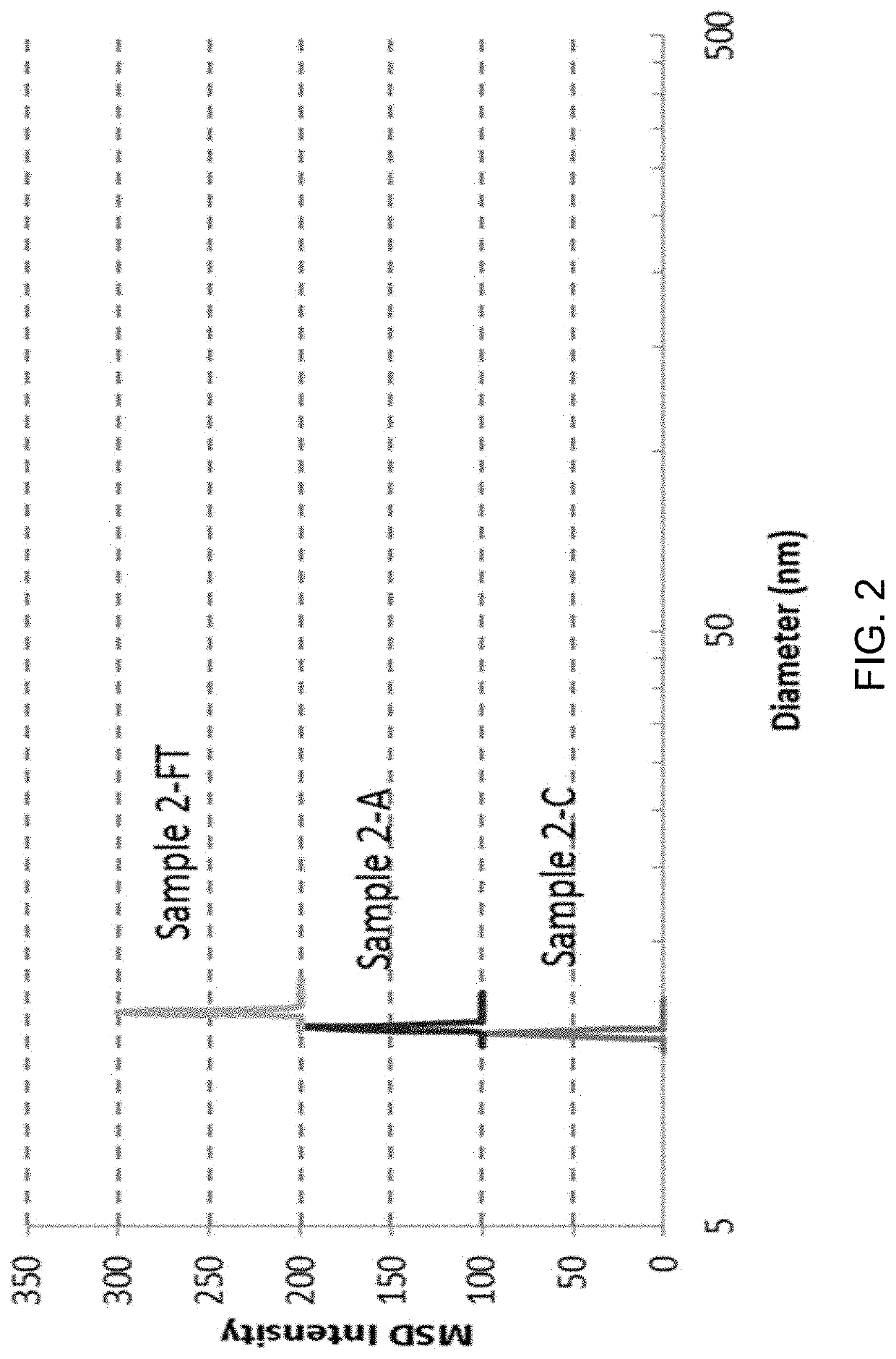

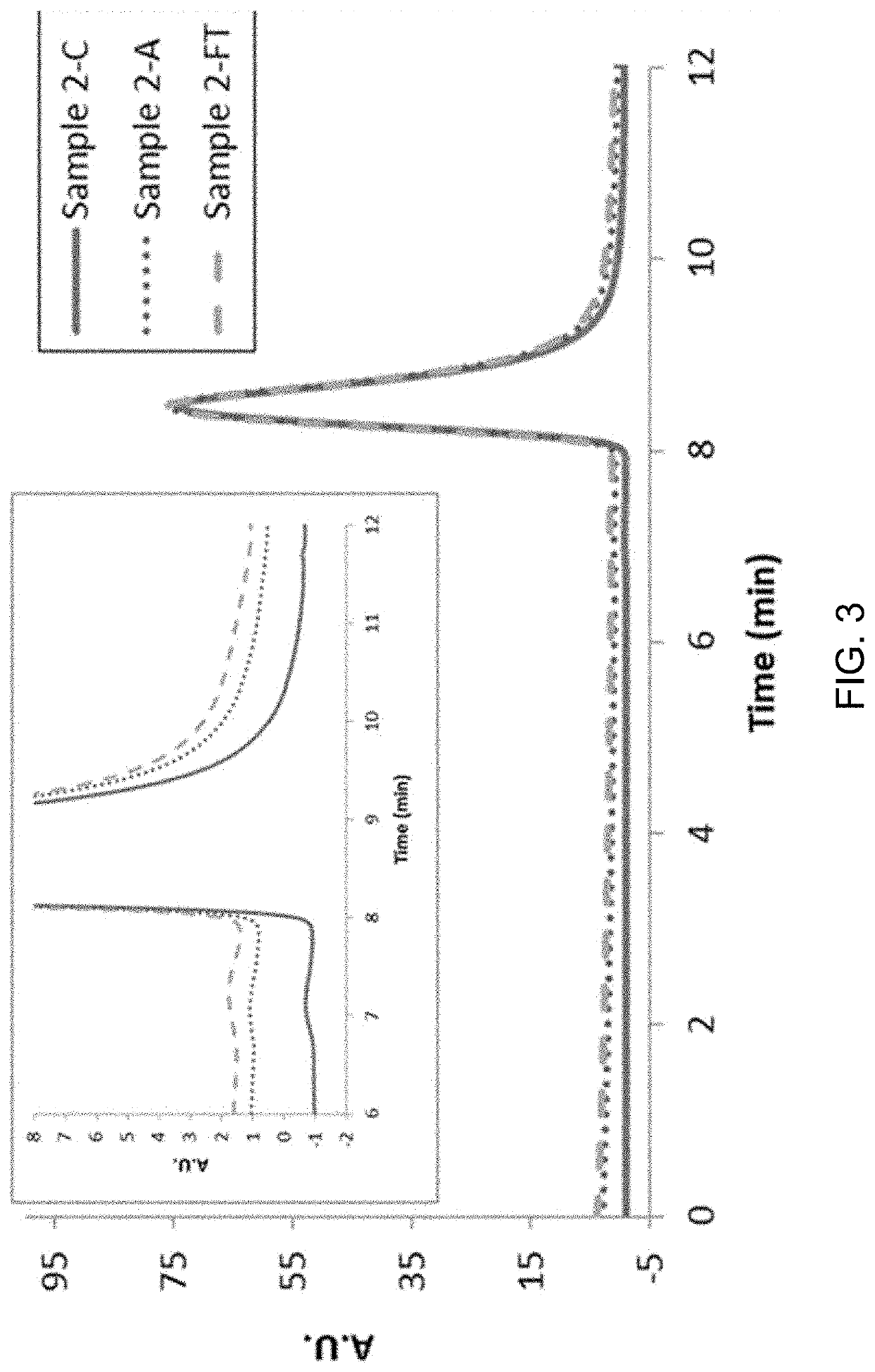

Excipient compounds for protein formulations

PendingUS20210113697A1Improve stabilityOptimization parametersPeptide/protein ingredientsSerum immunoglobulinsStability parameterTherapeutic protein

Disclosed herein are stability-enhanced formulations that comprise a therapeutic protein and a stability-improving amount of a stabilizing excipient, wherein the stabilized-enhanced formulation is characterized by an improved stability parameter in comparison to a control formulation otherwise identical to the stability-enhanced formulation but lacking the stabilizing excipient. Further disclosed herein are methods of improving stability of therapeutic formulations or improving parameters of protein-related processes.

Owner:COMERA LIFE SCI INC

Protection anti-sloughing agent for well drilling

InactiveCN104927813AGood sealing of cracksHigh softening pointDrilling compositionAluminum trichlorideChemistry

The invention relates to the technical field of petroleum chemical engineering products, and concretely relates to a protection anti-sloughing agent for well drilling. The protection anti-sloughing agent for well drilling comprises, by weight, 40-60 parts of petroleum asphalt, 2-3 parts of anhydrous aluminum trichloride, 4-8 parts of sodium hydroxide, 4-6 parts of potassium carbonate, 4-8 parts of ammonia water and 4-6 parts of dimethyl diallyl ammonium chloride. The purpose of the invention is to provide the protection anti-sloughing agent for well drilling, with ideal performances.

Owner:荆春芳

Stabilizer, application thereof, SBS modified asphalt and preparation method of SBS modified asphalt

InactiveCN111057167AImprove stabilityAvoid gatheringBuilding insulationsPolymer scienceAcid catalysis

The invention discloses a stabilizer and an application thereof, and SBS modified asphalt and a preparation method thereof. The stabilizer is prepared by a method comprising the following steps: carrying out an esterification reaction on a styrene-maleic anhydride copolymer and long-chain alcohol under the action of acid catalysis to obtain the stabilizer. The stabilizer disclosed by the inventioncan stably adsorb and act on polystyrene chains and asphaltene macromolecules of SBS; by utilizing the long-chain alkyl, the agglomeration of SBS and the aggregation and sedimentation of asphaltene in the heat storage process can be prevented, and the dispersion effect of light components in the asphalt on the SBS and the asphaltene can be enhanced, so that the SBS modified asphalt has long-termheat storage stability.

Owner:河南东方雨虹建筑材料有限公司

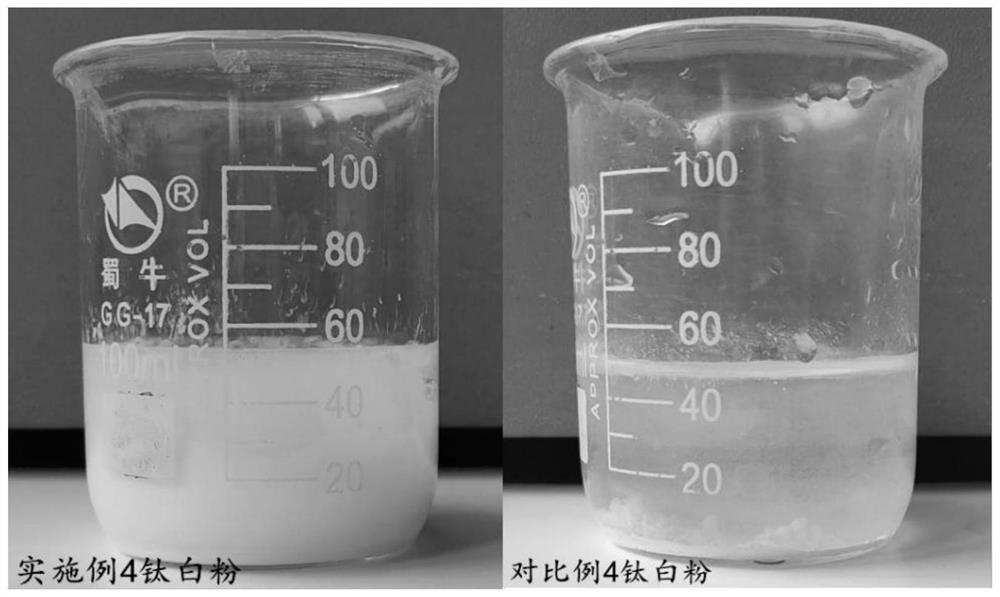

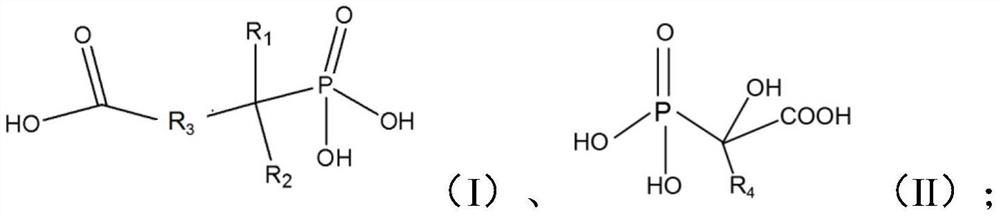

Titanium dioxide composite material and preparation method thereof

ActiveCN113583481AGood dispersion performanceGood thermal storage stabilityPigment treatment with non-polymer organic compoundsTitanium dioxideCompositermes

The invention relates to the field of titanium dioxide slurry and titanium dioxide preparation, in particular to a titanium dioxide composite material and a preparation method thereof. The titanium dioxide composite material is mainly prepared from a phosphine carboxylic acid compound and a titanium dioxide material with a coating layer, the phosphine carboxylic acid compound has a structure as shown in a general formula (I) or (II). The titanium dioxide composite material has excellent dispersing performance and can be quickly dispersed in water without the aid of external force; in addition, the titanium dioxide composite material also has relatively excellent heat storage stability and application performances such as hue, covering power and glossiness.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD +1

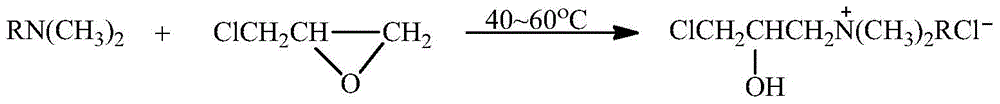

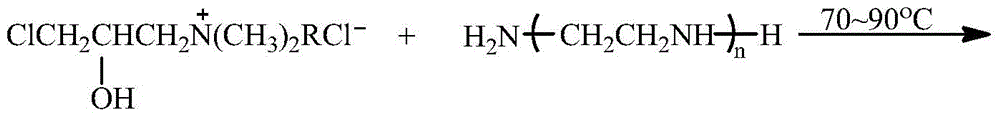

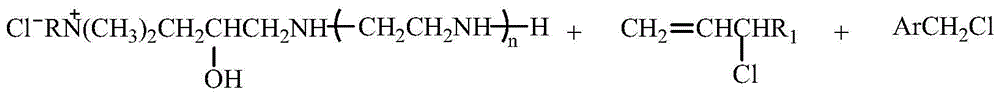

Chemical reaction type sbs modified asphalt heat storage stabilizer and preparation method thereof

InactiveCN104479169BAdaptableInhibition of segregationOrganic compound preparationBuilding insulationsChemical reactionRoad surface

The invention relates to a chemical reaction type SBS modified asphalt thermal storage stabilizer and a preparation method thereof. The preparation method comprises the following steps: adding dimethyl tertiary amine containing one long-chain alkyl, a catalyst and epoxy chloropropane into a reaction container; adding an alcohol solvent; stirring and reacting to obtain a quaternary ammonium salt midbody solution; adding polyethylene polyamine into the quaternary ammonium salt midbody solution, stirring and reacting to obtain a polyethylene polyamine midbody; and adding chloroalkene, aryl chloride and fatty alcohol chloride into the polyethylene polyamine midbody solution, stirring and reacting to obtain the chemical reaction type SBS modified asphalt thermal storage stabilizer. The chemical reaction type SBS modified asphalt thermal storage stabilizer disclosed by the invention is good in adaptability to matrix asphalts different in producing area and model number, is lasting in thermal storage stability and capable of remarkably improving the ageing resistance and high and low-temperature road surface usability of SBS modified asphalt and improving the usability of an SBS modified asphalt road surface.

Owner:WUHAN UNIV OF TECH

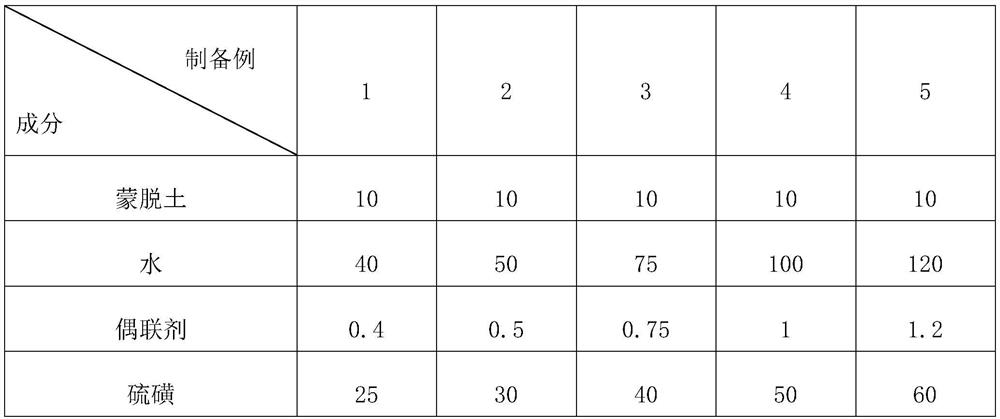

Modified asphalt binder and preparation method and application thereof

InactiveCN113185846APlay a sustained release roleImprove thermal storage stabilityBuilding insulationsPolymer scienceWaste rubber

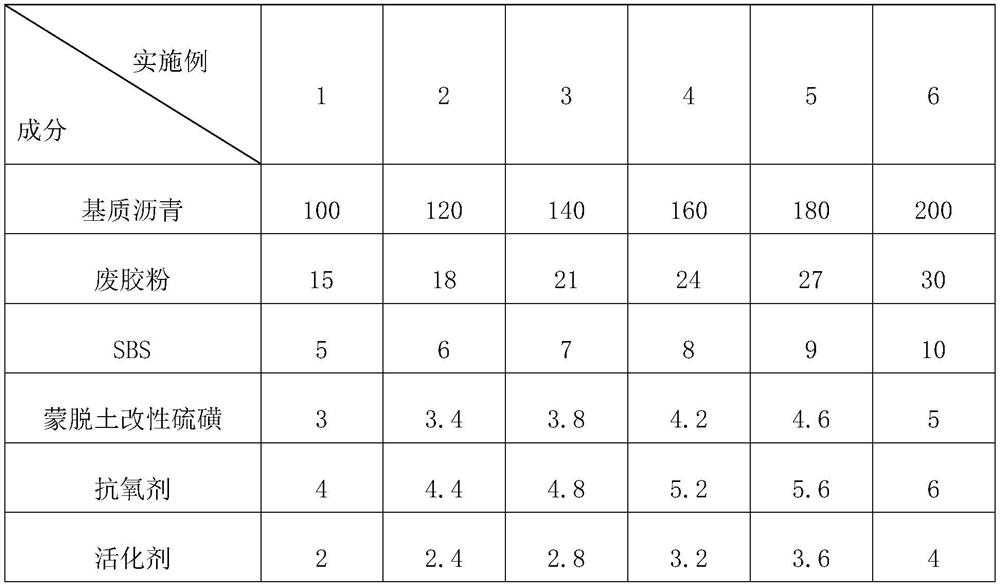

The invention relates to the field of asphalt binders, and particularly discloses a modified asphalt binder and a preparation method and application thereof. The modified asphalt binder is composed of the following components in parts by weight: 100-200 parts of matrix asphalt; 15-30 parts of waste rubber powder; 5-10 parts of SBS; 3-5 parts of montmorillonite modified sulfur; 4-6 parts of an antioxidant; 2-4 parts of an activator. The preparation method of the montmorillonite modified sulfur comprises the following steps: stirring and mixing montmorillonite and water to obtain a suspension A; adding a coupling agent into the suspension A, and grinding to obtain a suspension B; and adding sulfur into the suspension B, uniformly stirring, drying, crushing and sieving to obtain the montmorillonite modified sulfur. The modified asphalt binder disclosed by the invention has relatively good heat storage stability.

Owner:上海繁荣道路建设工程有限公司

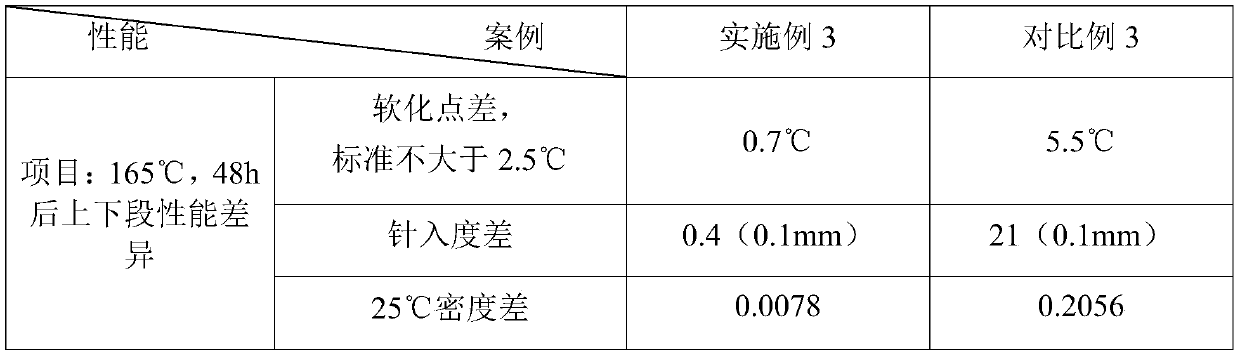

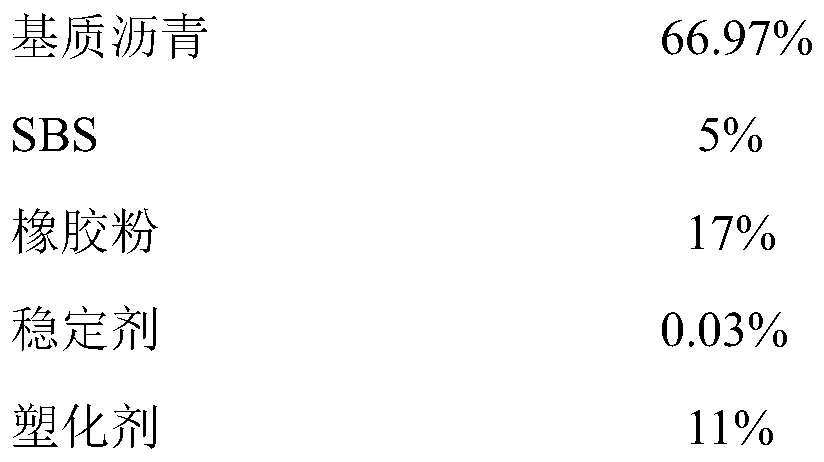

Pavement hot-pouring crack pouring glue with storage stability and preparation method thereof

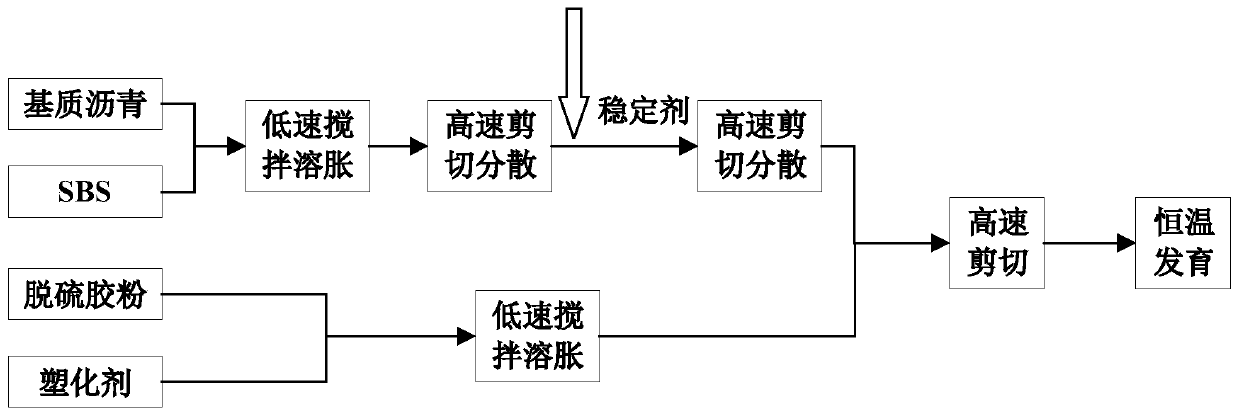

ActiveCN110628382AImprove thermal storage stabilityFluffy microstructureBituminous material adhesivesMacromolecular adhesive additivesPolymer scienceLow speed

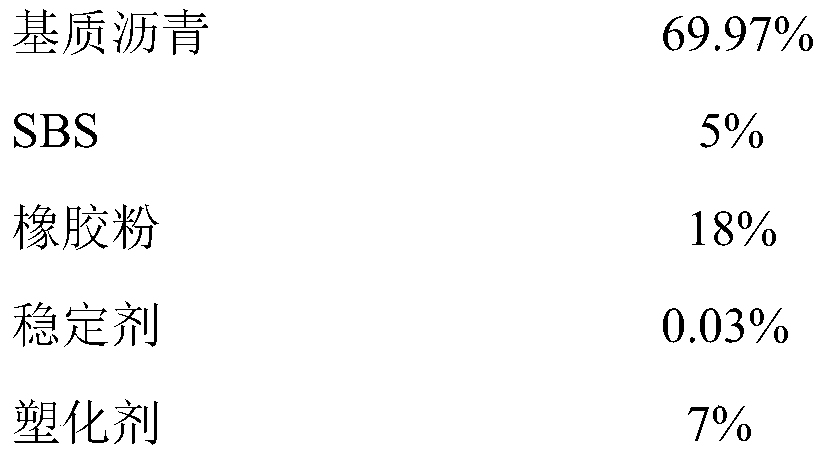

Belonging to the technical field of preparation of pavement hot-pouring crack pouring glues, the invention discloses a pavement hot-pouring crack pouring glue with storage stability and a preparationmethod thereof, and solves the problems that segregation can occur among the components of existing crack pouring glues in the storage process, and the segregation among the components can seriously affect the pavement service performance of crack pouring glues. The crack pouring glue comprises: 60%-70% of matrix asphalt, 3%-6% of SBS, 12%-20% of rubber powder, 0.02%-0.04% of a stabilizer and 6%-20% of a plasticizer. The preparation method of the crack pouring glue includes the steps of: firstly, conducting low speed stirring and swelling on the matrix asphalt and SBS, then performing high speed shearing, then adding the stabilizer, and further conducting shearing; mixing the rubber powder with the plasticizer, conducting low speed stirring and swelling, then adding the swelled mixture ofthe rubber powder and the plasticizer into the mixed system of the asphalt and SBS, and performing high-speed shearing; and finally conducting constant-temperature development so as to obtain the hot-pouring crack pouring glue with storage stability. The method provided by the invention can be applied to preparation of the pavement hot-pouring crack pouring glue with storage stability.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com