High weatherability composite modified asphalt for high-speed railway asphalt concrete waterproof sealing layer

A technology of composite modified asphalt and asphalt concrete, which is applied in building components, building insulation materials, buildings, etc. It can solve the problem that the effectiveness of the waterproof sealing layer has not yet been studied, narrow the gap between modifier and asphalt density, and increase the modified asphalt system. Viscosity and other issues can be improved to improve thermal storage stability, reduce tire pollution, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

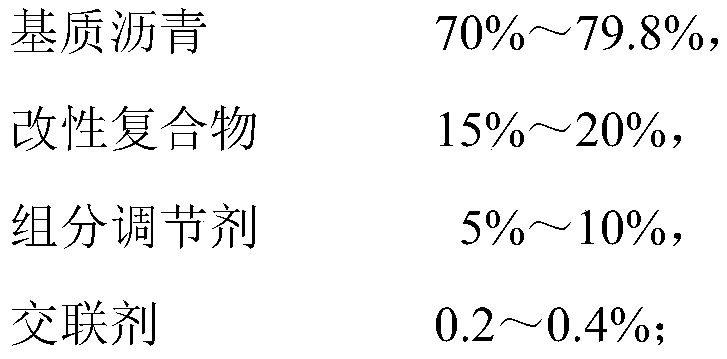

[0038] A composite modified asphalt (1#) for high-weather resistance high-speed railway asphalt concrete waterproof sealing layer, the composite modified asphalt is used for high-speed railway asphalt concrete waterproof sealing layer, and contains the following components in parts by weight:

[0039]

[0040] The modified compound is a mixture of styrene-butadiene-styrene copolymer, namely SBS copolymer, regenerated colloidal particles, anti-aging agent and interface enhancer.

[0041] in:

[0042] The base pitch is one or more of natural pitch, petroleum pitch or coal tar pitch.

[0043] The modified compound comprises the following components in parts by mass:

[0044]

[0045] The SBS copolymer is a linear SBS copolymer or a star SBS copolymer or a mixed copolymer of two, with an average molecular weight of 80,000-120,000 g / mol.

[0046]The reclaimed rubber is regenerated rubber particles obtained from rubber powder processed from waste tires through chemical reage...

Embodiment 2

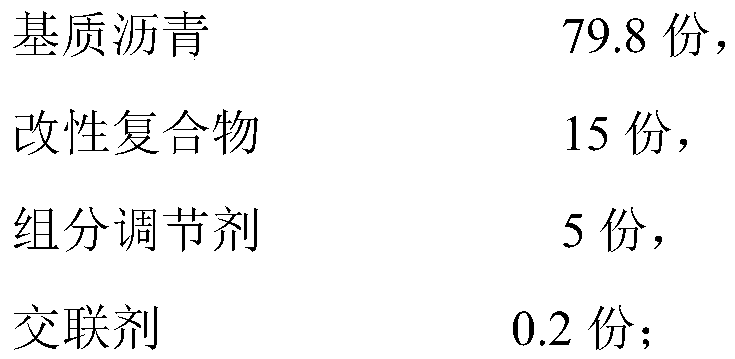

[0055] A composite modified asphalt (2#) for high-weather resistance high-speed railway asphalt concrete waterproof sealing layer, the composite modified asphalt is used for high-speed railway asphalt concrete waterproof sealing layer, and contains the following components in parts by weight:

[0056]

[0057] The modified compound is a mixture of styrene-butadiene-styrene copolymer, namely SBS copolymer, regenerated colloidal particles, anti-aging agent and interface enhancer.

[0058] in:

[0059] The base pitch is one or more of natural pitch, petroleum pitch or coal tar pitch.

[0060] The modified compound comprises the following components in parts by mass:

[0061]

[0062] The SBS copolymer is a linear SBS copolymer or a star SBS copolymer or a mixed copolymer of two, with an average molecular weight of 80,000-120,000 g / mol.

[0063] The reclaimed rubber is regenerated rubber particles obtained from rubber powder processed from waste tires through chemical reag...

Embodiment 3

[0072] A composite modified asphalt (3#) for high-weather resistance high-speed railway asphalt concrete waterproof sealing layer, the composite modified asphalt is used for high-speed railway asphalt concrete waterproof sealing layer, and contains the following components in parts by weight:

[0073]

[0074] The modified compound is a mixture of styrene-butadiene-styrene copolymer, namely SBS copolymer, regenerated colloidal particles, anti-aging agent and interface enhancer.

[0075] in:

[0076] The base pitch is one or more of natural pitch, petroleum pitch or coal tar pitch.

[0077] The modified compound comprises the following components in parts by mass:

[0078]

[0079]

[0080] The SBS copolymer is a linear SBS copolymer or a star SBS copolymer or a mixed copolymer of two, with an average molecular weight of 80,000-120,000 g / mol.

[0081] The reclaimed rubber is regenerated rubber particles obtained from rubber powder processed from waste tires through c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com