Patents

Literature

1994 results about "Waste tires" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste or Scrap tires, also known as End-of-Life Tires (ELT), are used rubber tires that because of their abrasion state ("tire wear") are not safe for public traffic. Waste tires can go into tire recycling or will be dumped, either in legal landfills or illegally; another portion may be pyrolysed to produce tire-derived fuel or heat energy.

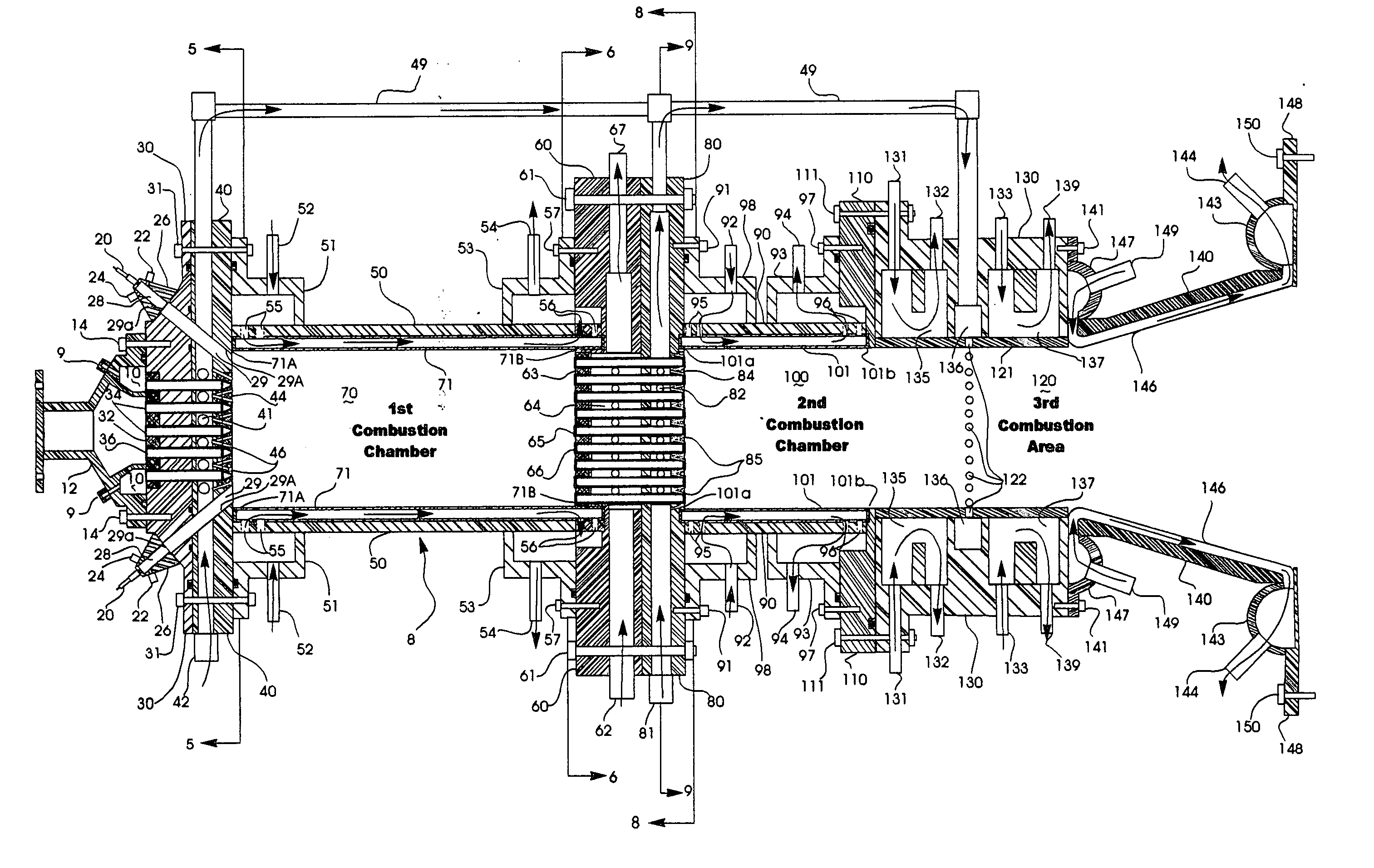

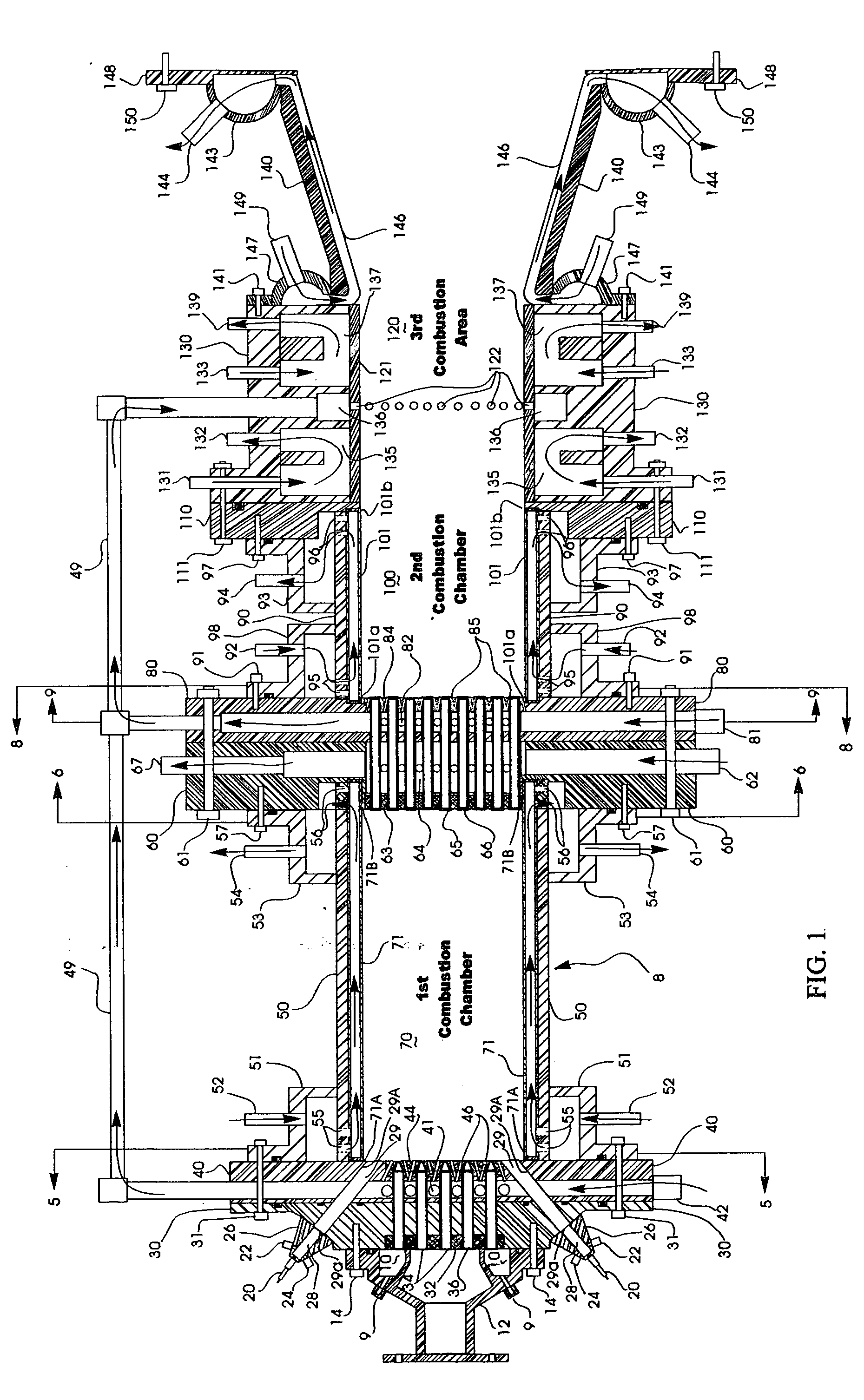

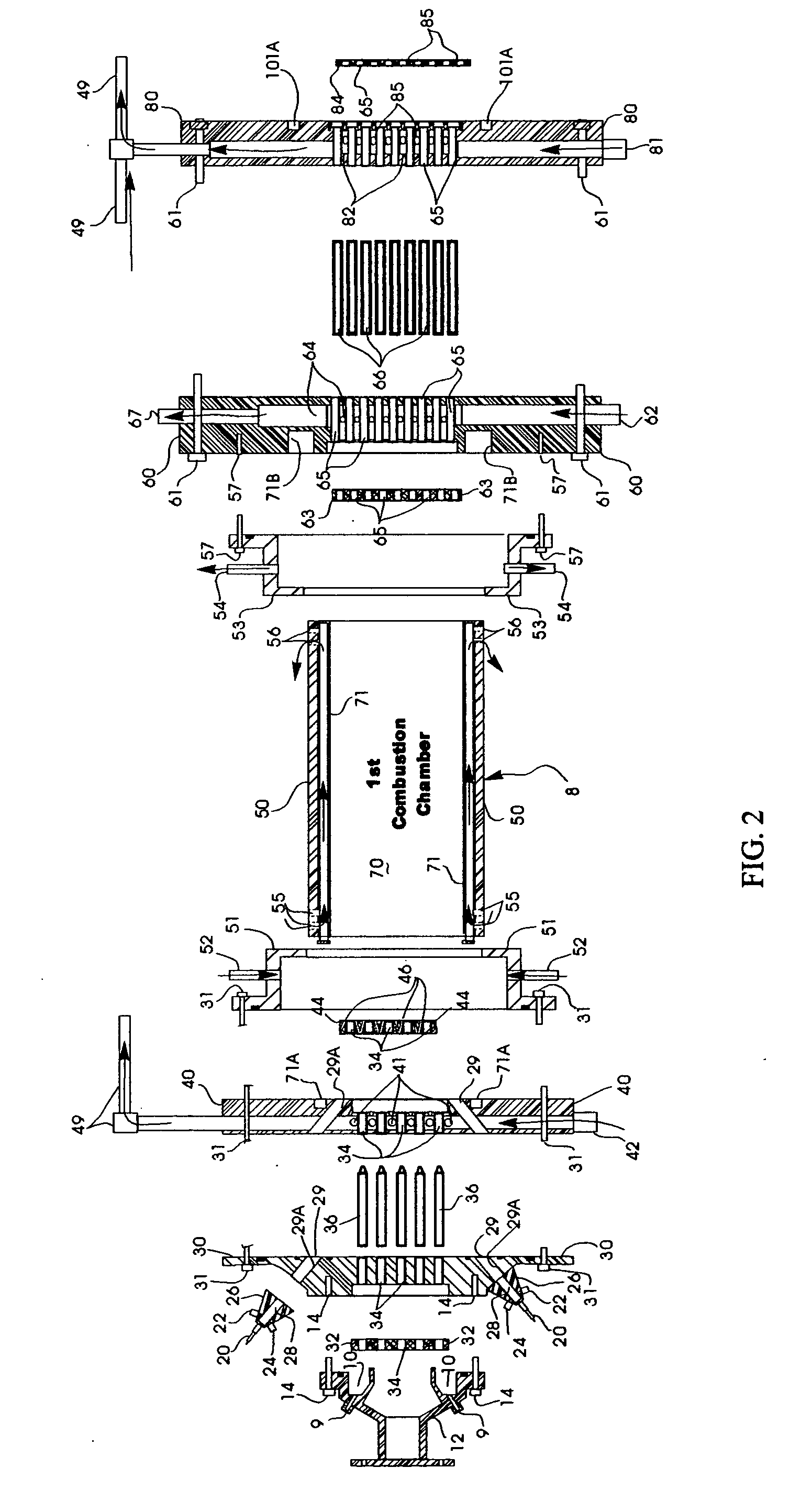

Method and apparatus for the production of energy

ActiveUS20060053791A1Zero atmospheric emissionSafely and rapidly and cost-effectively and efficiently producing and controlling high-energy and high purityIndirect carbon-dioxide mitigationCasings/liningsScrapElectric energy

The invention provides processes and apparatuses for safely, rapidly, cost-effectively and efficiently producing a superheated steam product or dry saturated steam product that can be employed to generate electrical power, or in other manufacturing and / or non-manufacturing processes, in an environmentally clean manner without causing corrosion to electrical power-generating devices. These processes and apparatuses involve the combustion of one or more fuels containing the elements hydrogen and / or carbon, which can be derived from waste materials, such as the rubber from scrap tires. Water that circulates around one or more combustion chambers and / or areas, but that does not enter into the combustion chambers or areas, becomes converted into a high purity steam product The present invention also provides processes and apparatuses for recycling or eliminating waste materials, and for transforming hazardous materials into non-hazardous materials, and fuels that can be employed in the foregoing processes and apparatuses.

Owner:ADVANCED COMBUSTION ENERGY SYST

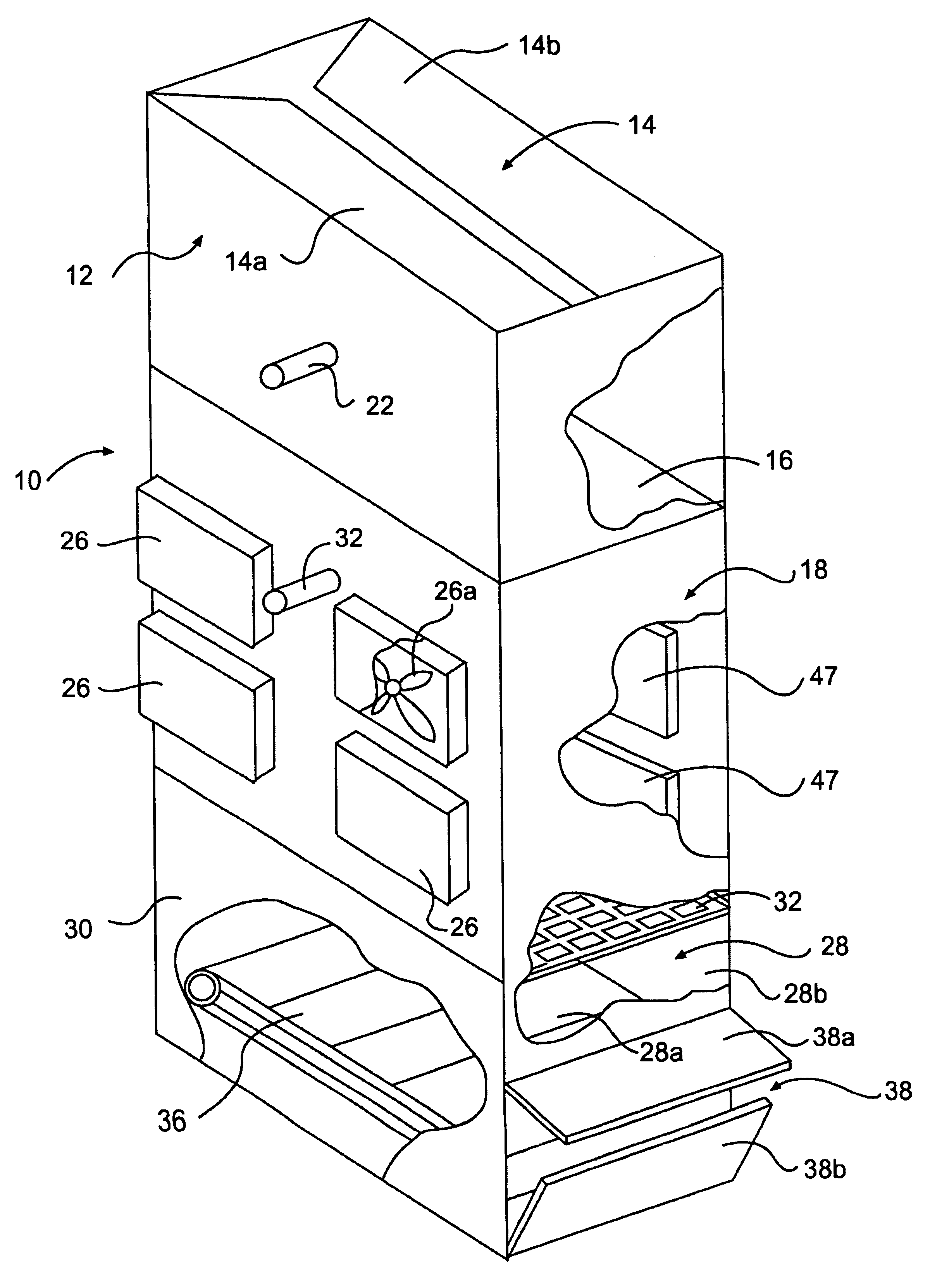

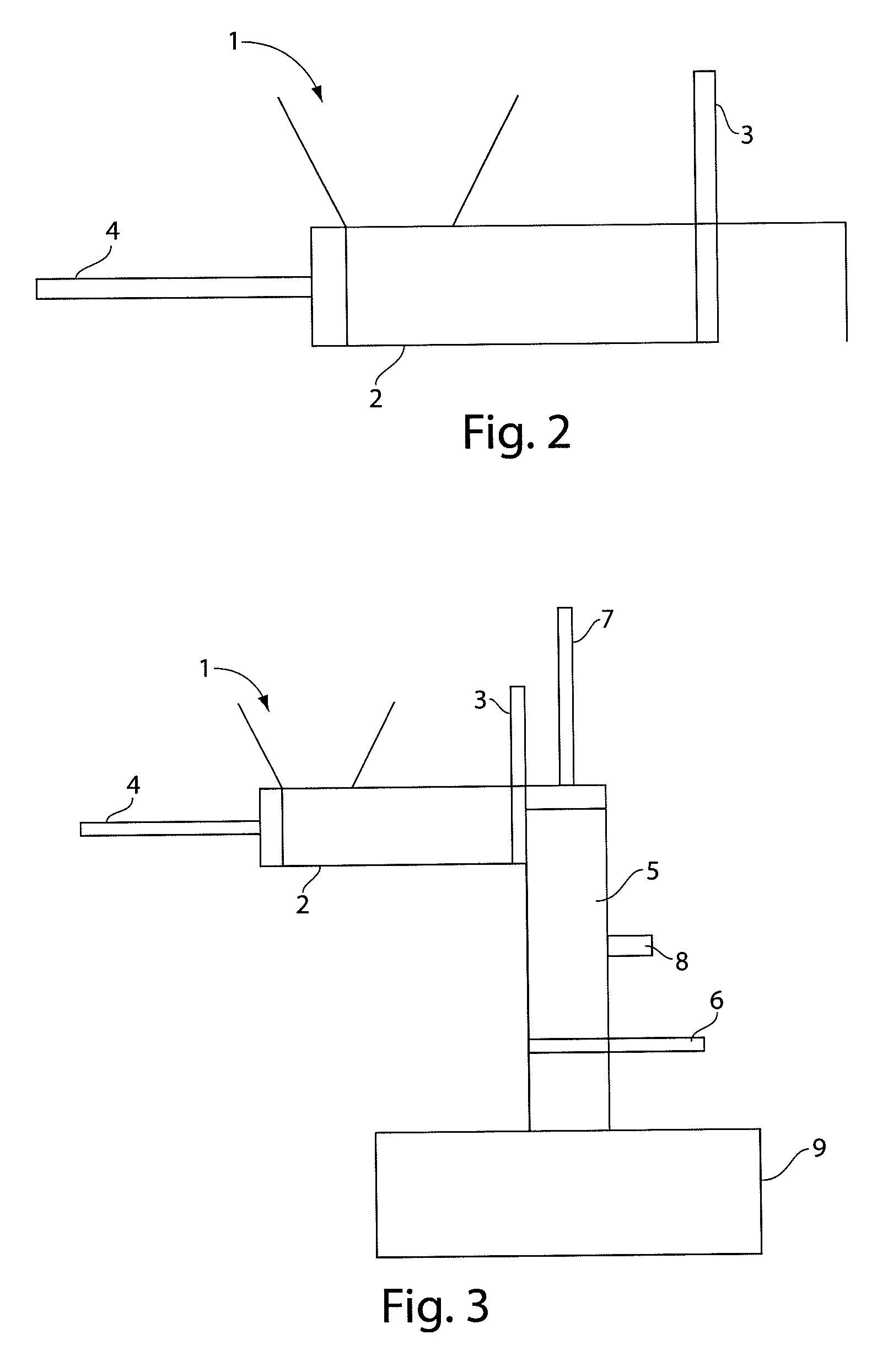

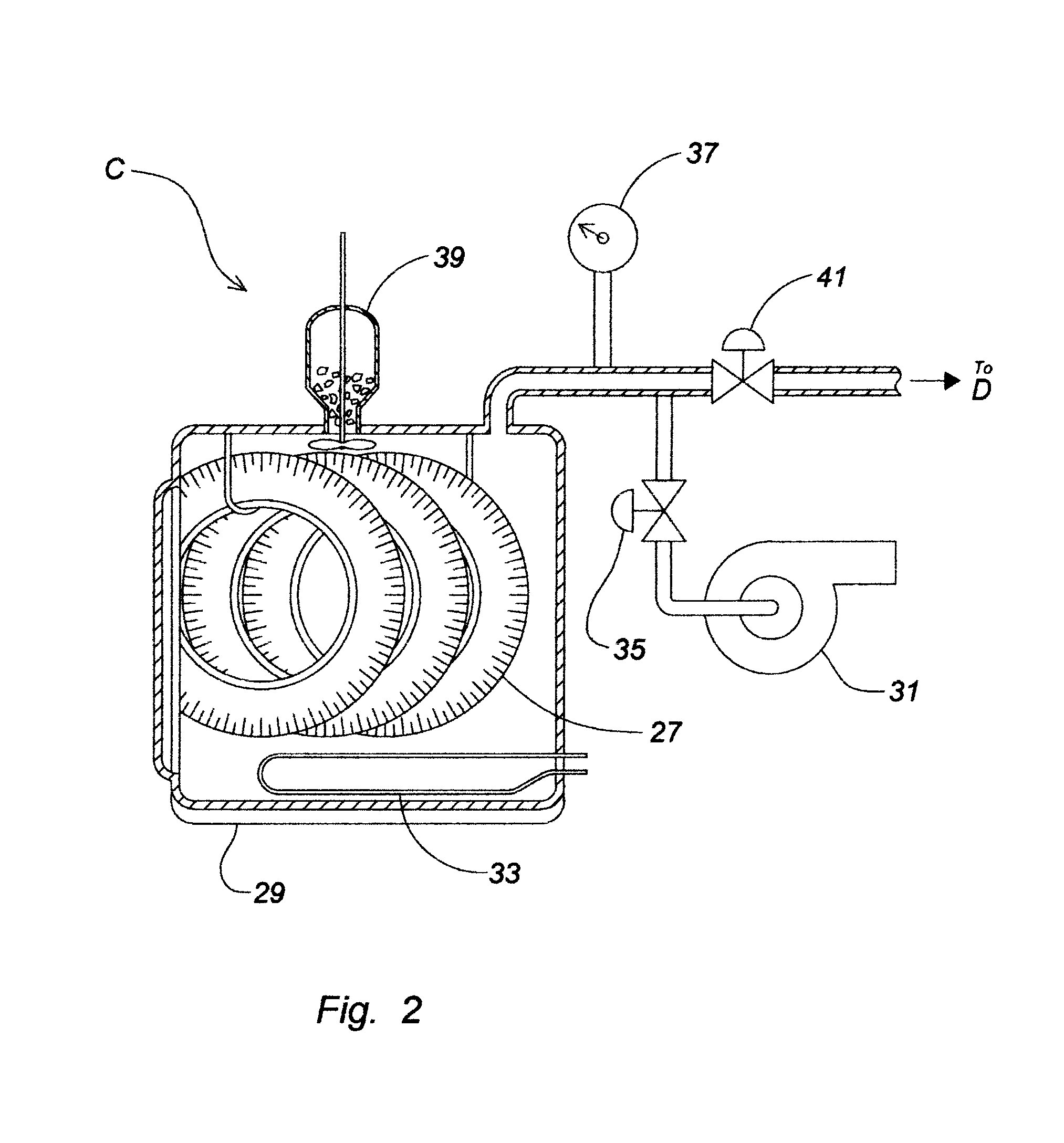

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

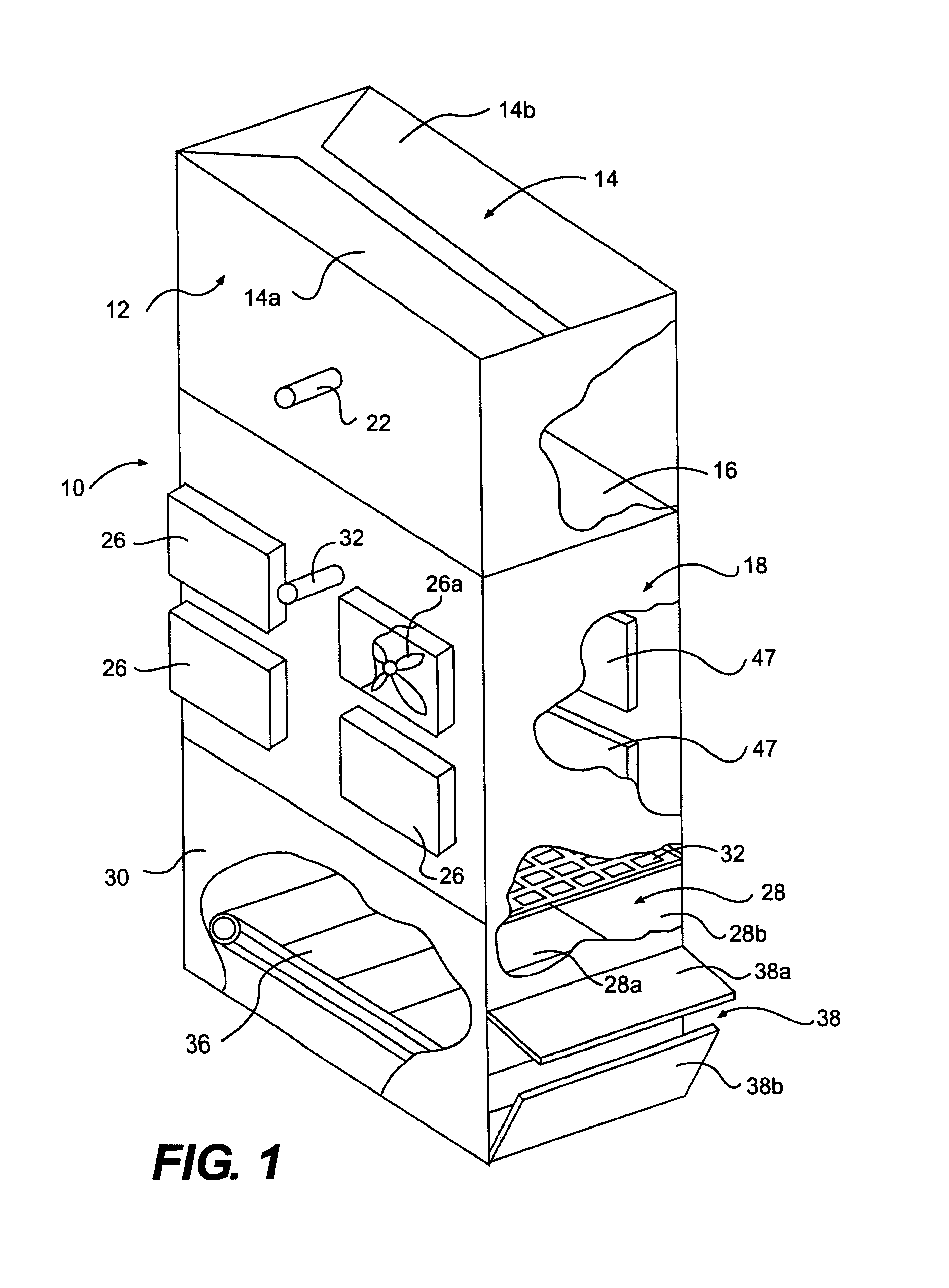

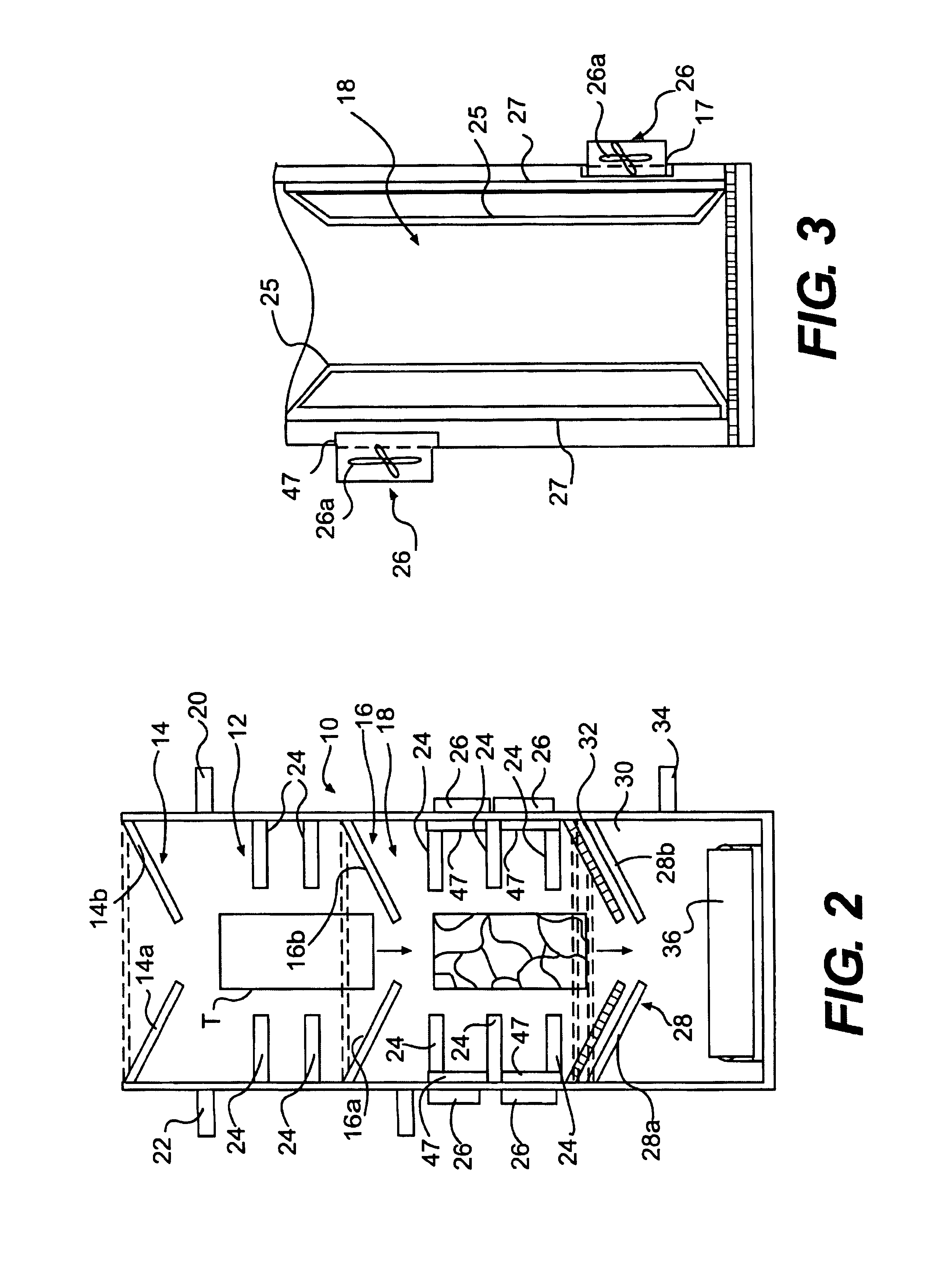

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

Ultra-thin wearing layer of pavement

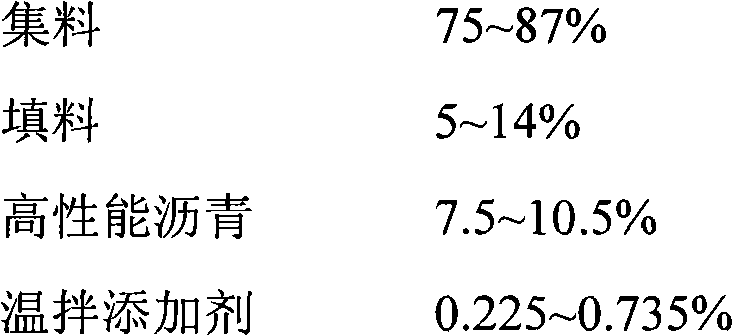

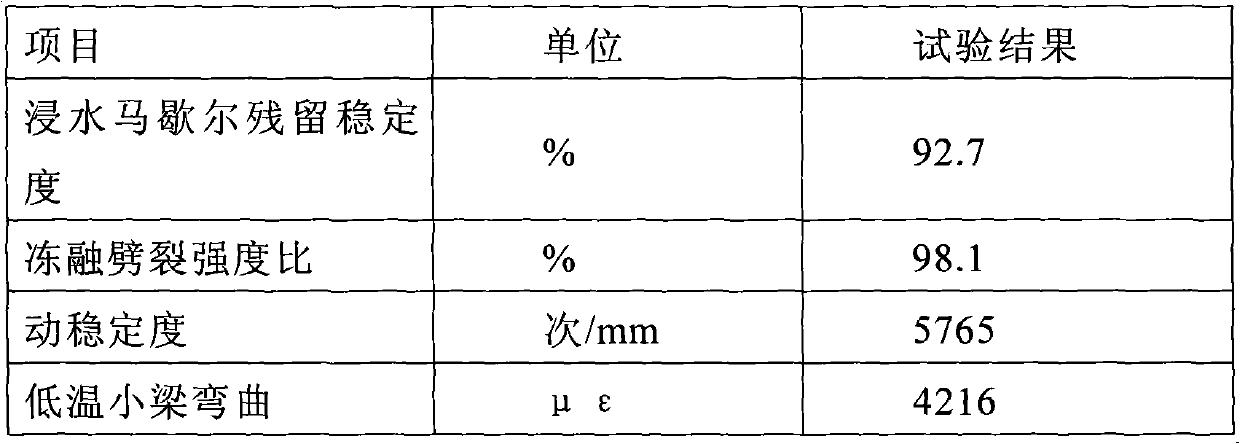

The invention belongs to the technical field of a building material used in road engineering, and specifically relates to drainage asphalt mixture for an ultra-thin wearing layer. The mixture comprises aggregated material, stuffing, high-performance asphalt and warm mixing additive; the maximal nominal size of the mixture is 6.7mm; the thickness of a pavement layer is 10-20mm; the aggregated material is basalt or dolerite; the used stuffing is mixture of limestone powder and common silicate cement, and the used high-performance asphalt is prepared from general modified asphalt by adding waste tire rubber powder which is 20-28% of weight of the asphalt and modifying. An ultra-thin finishing coat and low-temperature construction are realized by the asphalt mixture by adding the warm mixing additive; the ultra-thin wearing layer has the advantages of low construction cost, convenience in construction and the like, and is suitable for building of an asphalt concrete pavement and function-improving works of the pavement.

Owner:上海砼仁环保技术发展有限公司

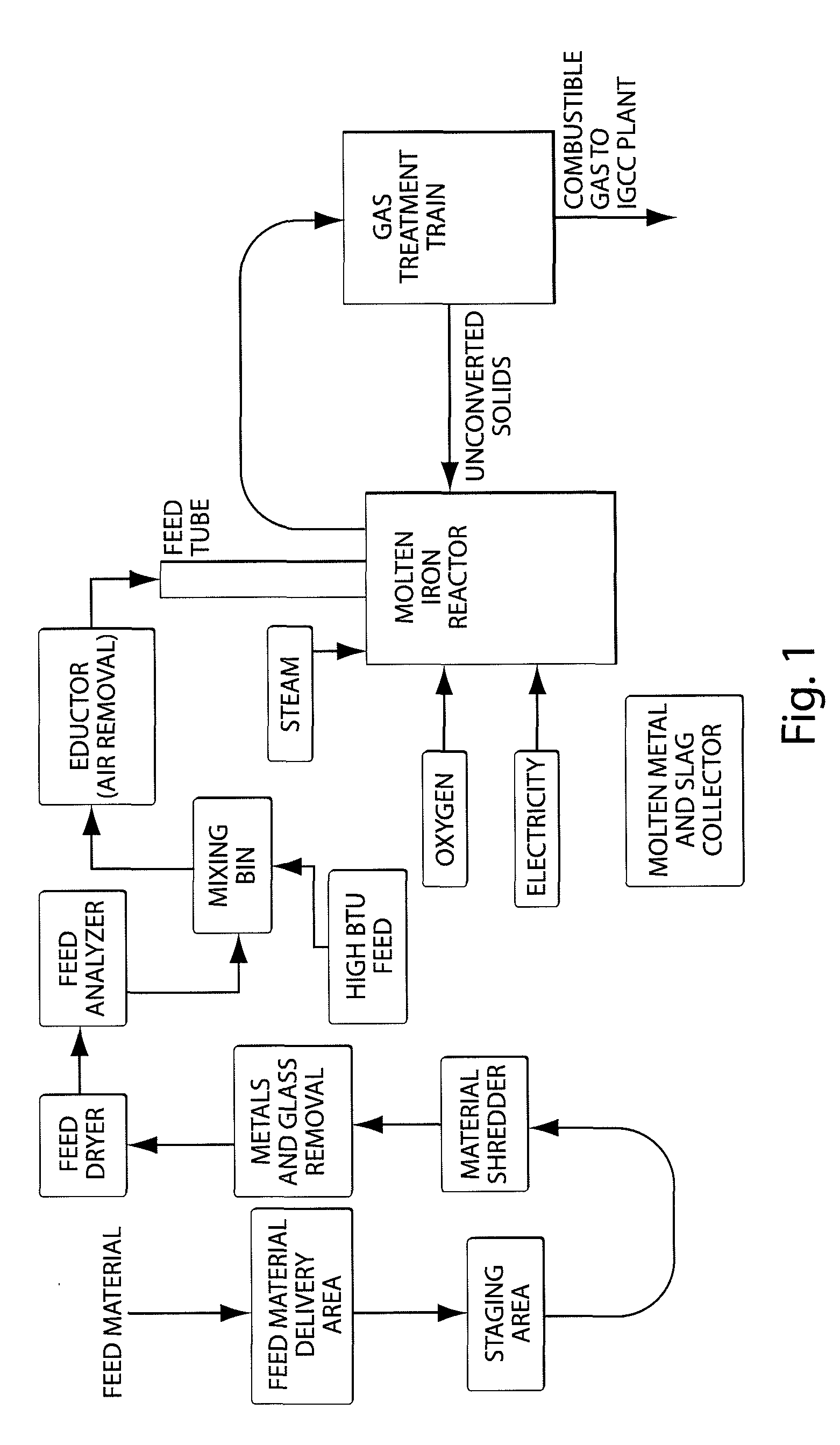

Method for controlling syngas production in a system with multiple feed materials using a molten metal bath

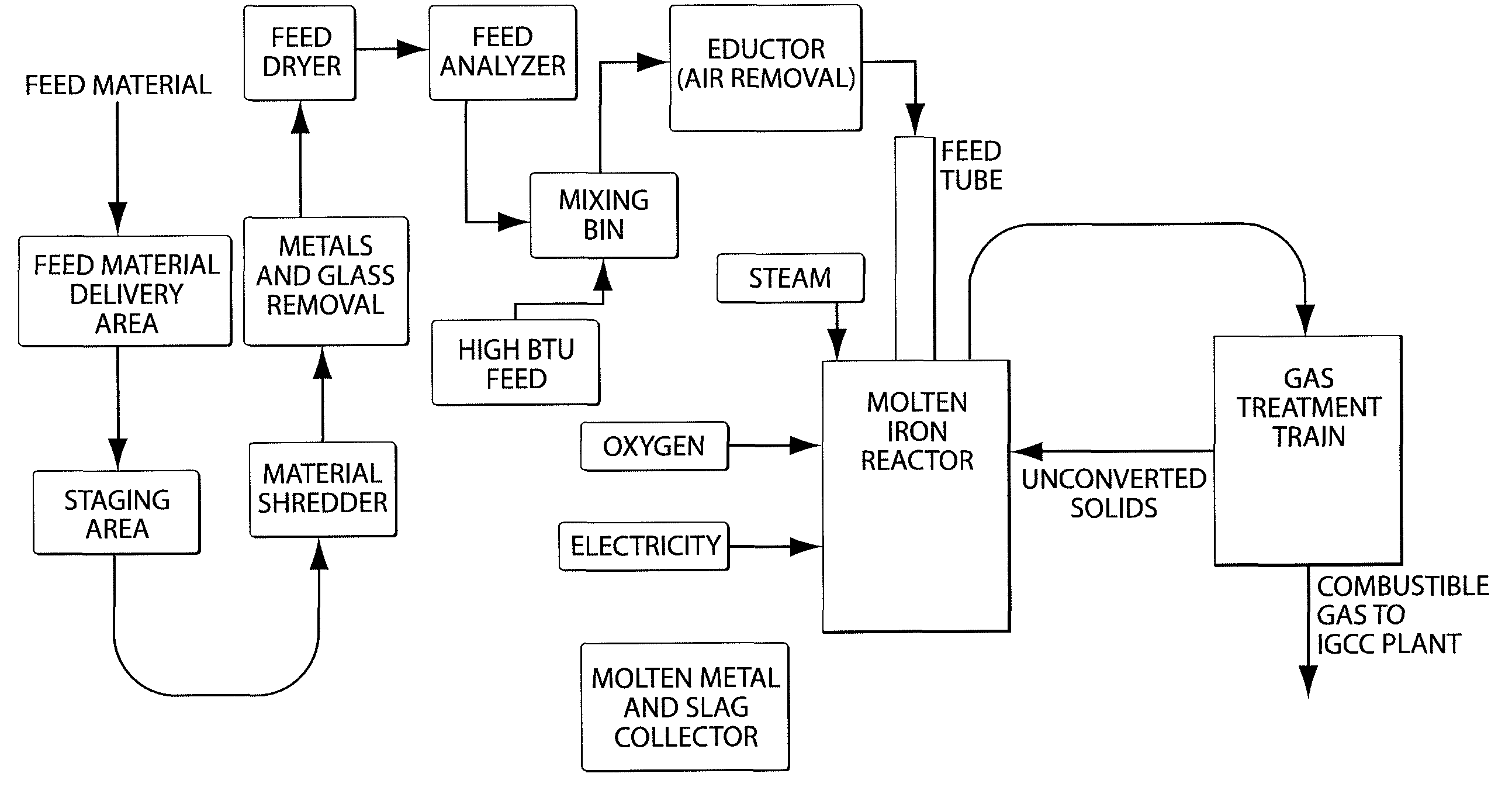

Processes and apparatus for treating organic and inorganic materials in a metal bath contained in a high temperature reactor to produce synthesis gas are provided. Two or more feed materials that possess differing syngas generation potentials are mixed in a mixer and fed as a composite feed stream into a gasifier to produce syngas. The feed materials are prepared and analyzed for heat value prior to injection and the composition of materials in and exiting the reactor are monitored. By controlling the feed rate of the mixture into the gasifier as well as the feed rates of one or more of the individual feed materials into the mixer, the syngas is produced at a target production rate, with target energy content (BTU). Based upon the results of the analysis and monitoring, oxygen, steam, and / or other feed materials are also injected into the reactor, to control processing and synthesis gas quality. Potential feed materials include, but are not limited to, construction and demolition (C&D) debris, municipal solid waste (MSW), other sewage-related solids, waste tires, and other substances that contain varying levels of organic compounds capable of producing a syngas.

Owner:ZE-GEN

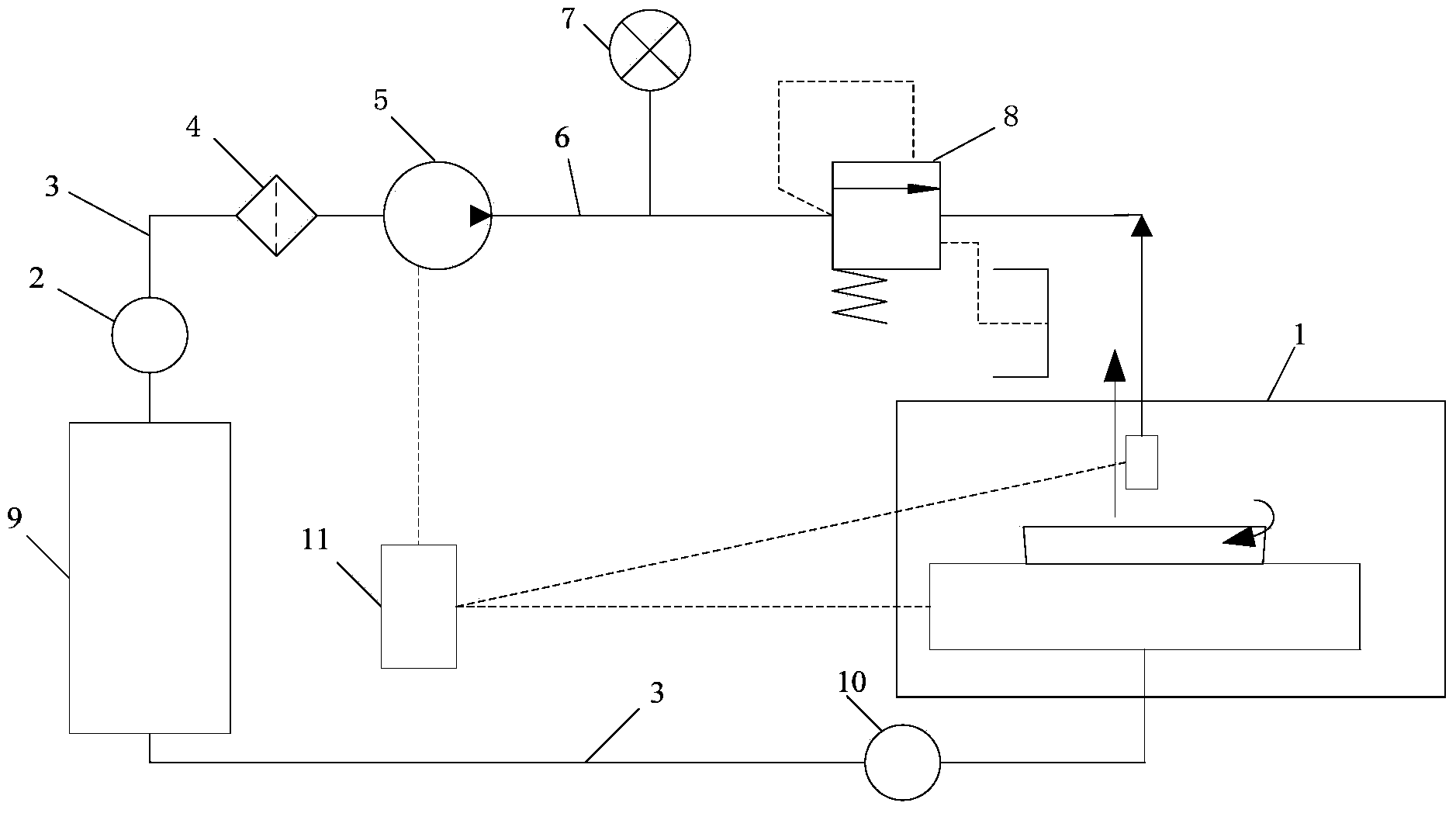

Waste tire recycling method and device

The invention provides a waste tire recycling method and device. The method comprises the following steps: placing a waste tire to be recycled on a workbench; driving the waste tire to rotate at a low speed with a driving device; arranging rotatable sprayers at the radial periphery of the waste tire, wherein at least two nozzles into which high-pressure water jets can be connected are arranged on each sprayer; starting a high-pressure water pump when all the nozzles are aligned with corresponding working positions of the waste tire, wherein water flows sprayed from the nozzles form high pressure water jet cutters to impact and cut the surface of the waste tire, and decompose the surface of the waste tire layer by layer, peeled rubber granules flow into recovery tanks with sprayed liquid, and wires and fiber are recycled in a centralized manner after being peeled off. As the high pressure water jet treatment technology is used for recycling the waste tire, the treatment process can be simplified, the production efficiency is improved, the energy consumption can be reduced effectively, the whole treatment environment is dust-free and smoke-free, and waste water of treatment can be recycled after filtering; meanwhile, as water jets serve as a non-contact tool, the problem of mechanical knife abrasion is solved, the halting time for maintenance can be shortened, and the treatment cost is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

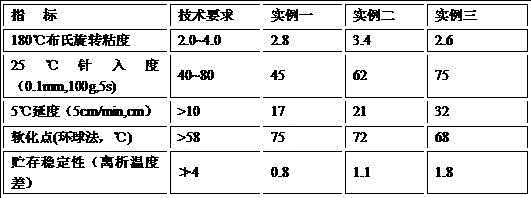

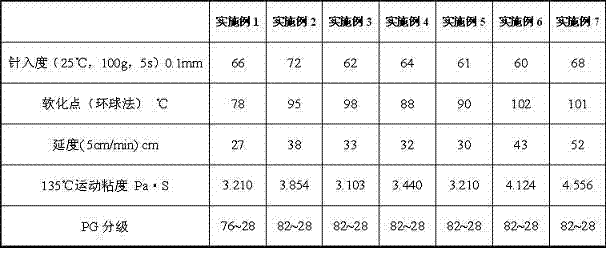

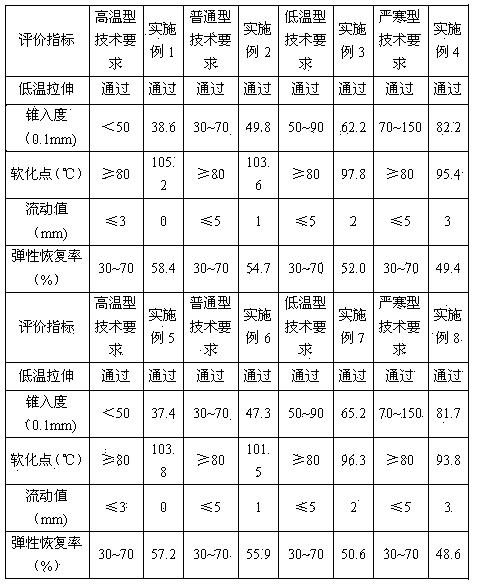

Pitch modified from waste tire rubber powder and preparation method thereof

InactiveCN101831184ATake advantage ofSolve the problem of swellingPlastic recyclingBuilding insulationsMicrowaveCost savings

The invention provides pitch modified from waste tire rubber powder and a preparation method thereof. The preparation method comprises the following steps of: heating 2-14 parts by weight of heavy fraction oil to 90-130 DEG C; adding 84-97.8 parts by weight of waste tire rubber powder and 0.2-2 parts by weight of additives to evenly mix; radiating the mixture by a microwave for 3-10 min; adding 60-85 parts by weight of pitch to 15-40 parts by weight of modified waste tire rubber powder at 160-200 DEG C to mix evenly; and shearing the mixture at a high speed to obtain a mixture, i.e. the modified pitch of the invention. By selecting waste tires as raw materials, the invention has simple and easily obtained raw material, cost saving, environmental protection and pitch performance improvement. The waste tire rubber powder is decarbolized under the microwave radiation to improve the storage stability of the modified pitch. Meanwhile, the waste tires are utilized. The invention has simple modified pitch preparation process and strong practicability.

Owner:JIANGHAN UNIVERSITY

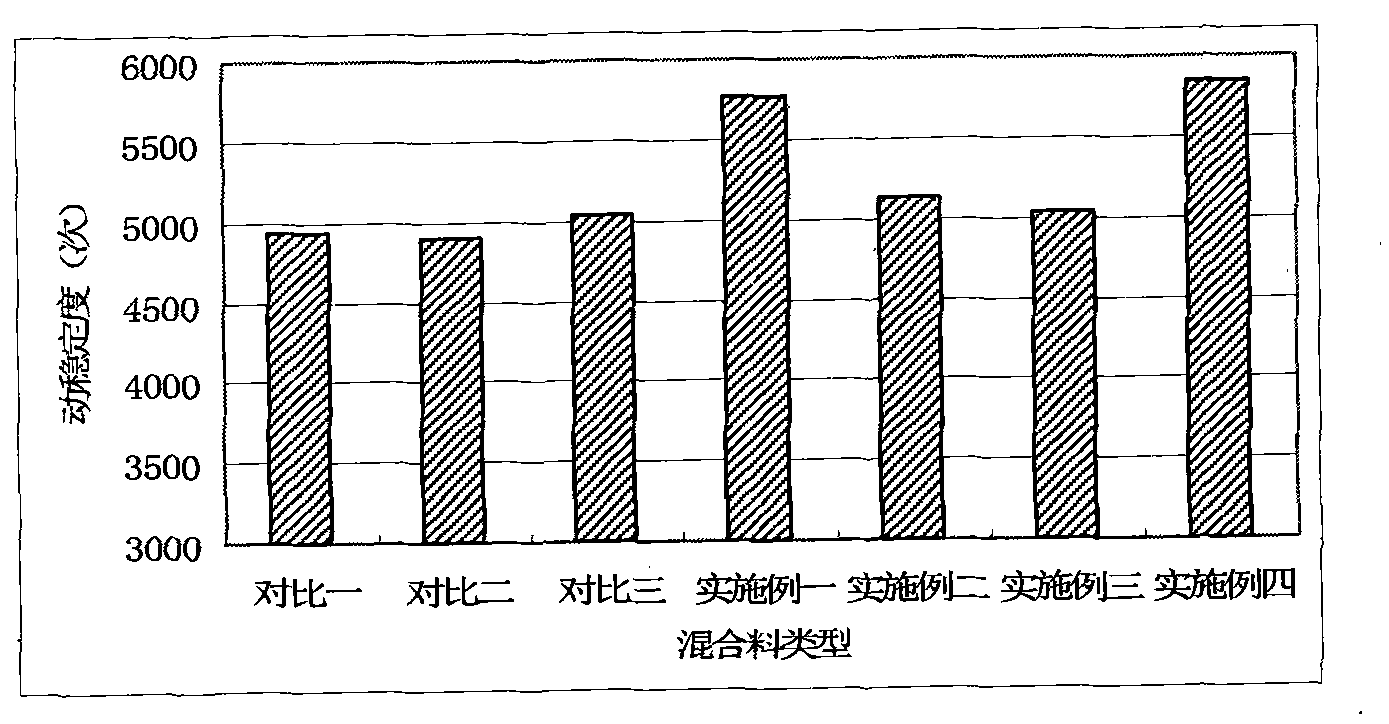

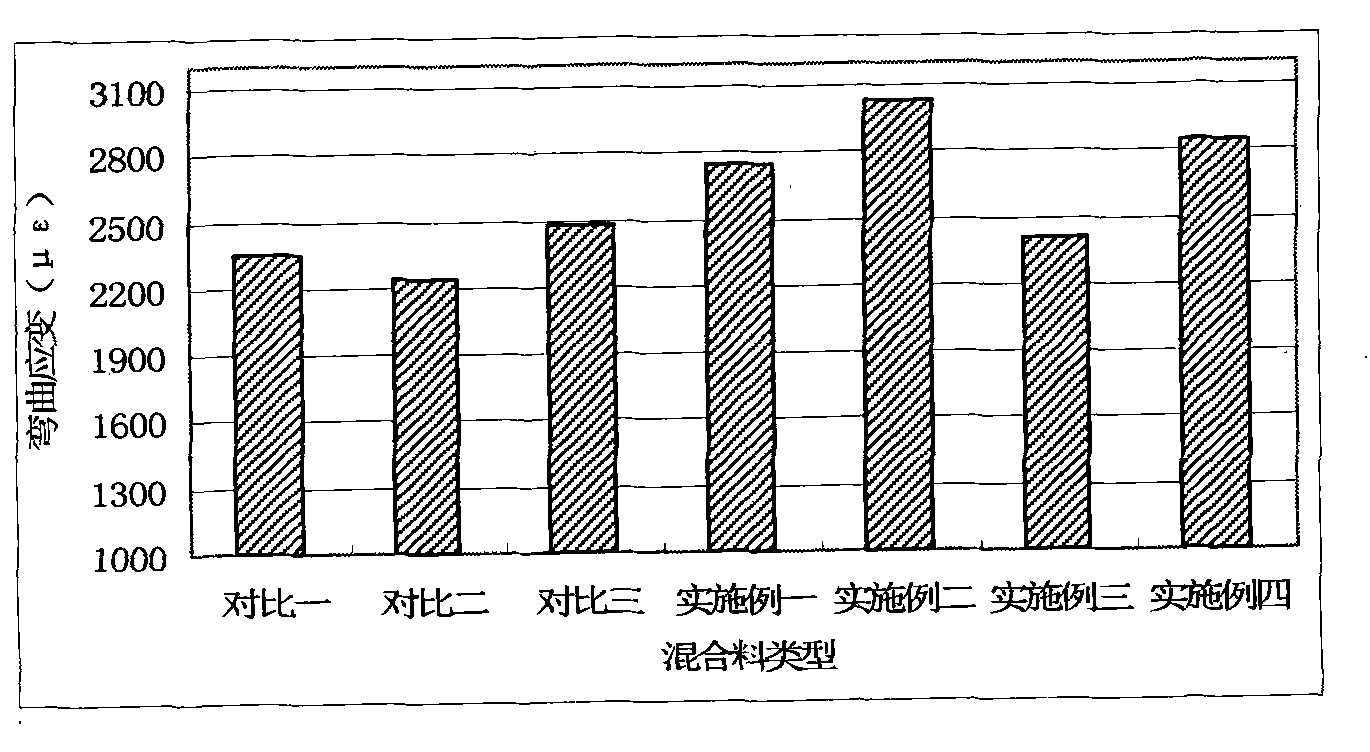

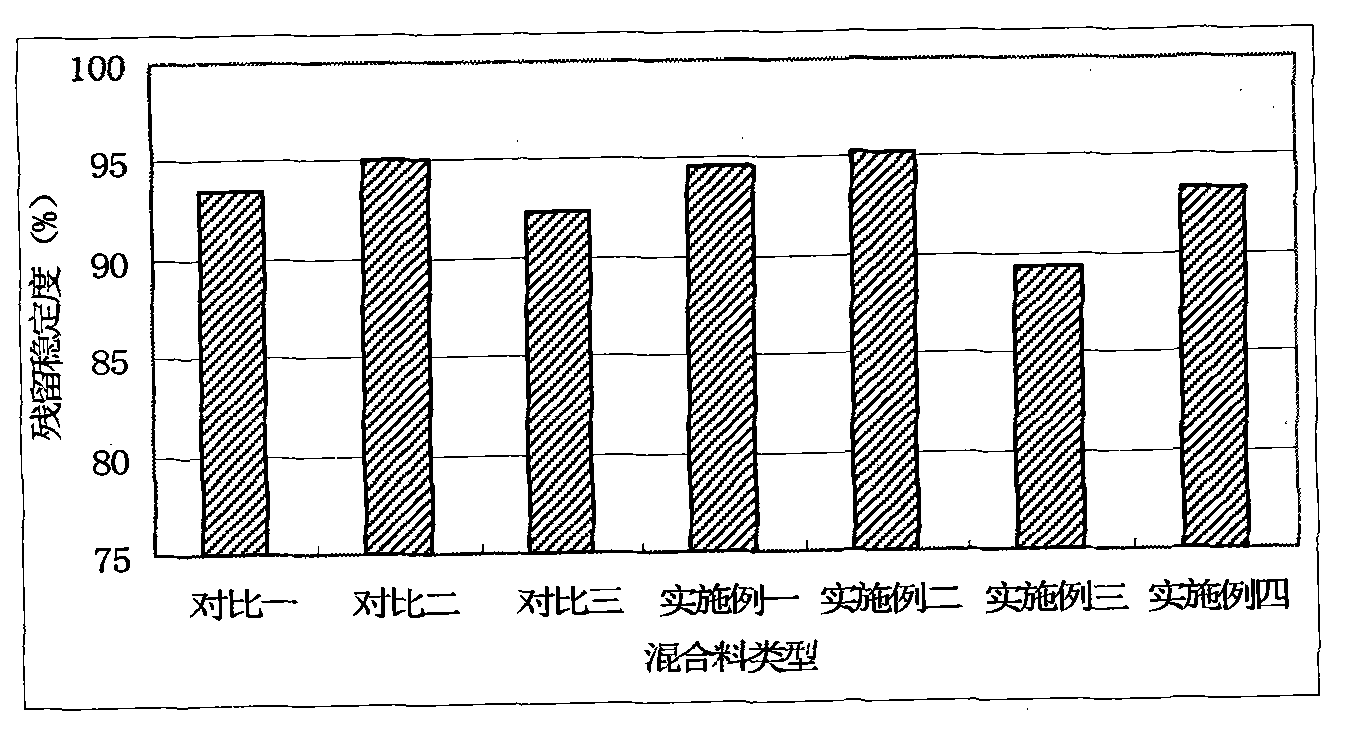

Rubber modified asphalt mixture and preparation and construction methods thereof

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methodshave the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by blackpollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

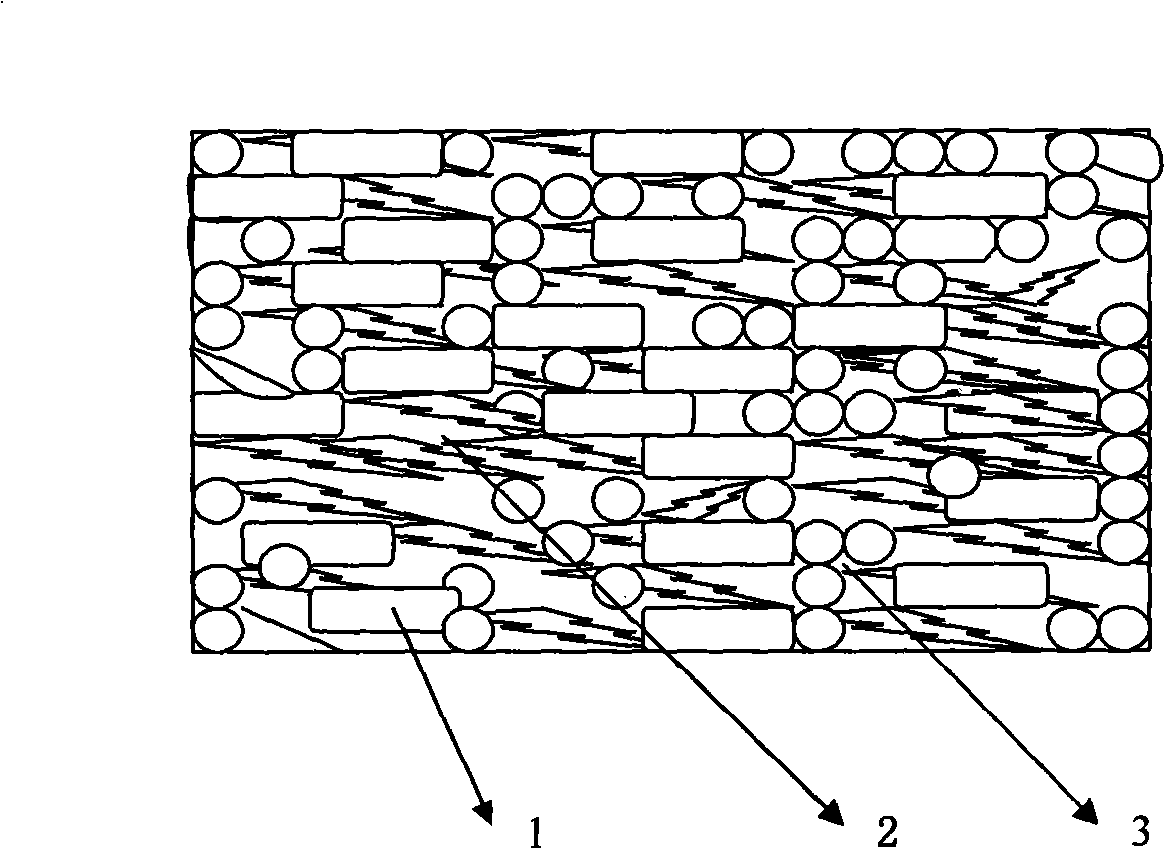

Preparation method for thermoset resin/waste rubber powder/waste tire fiber composite material

The invention discloses a thermoset resin / waste rubber powder / waste tire fiber environment-friendly composite material and a preparation method thereof. The thermoset resin is used as a base body and an adhesive, a waste tire fiber is used as a reinforcing and toughening material, and the waste rubber powder is used as a toughening and filling material. The surface of the waste rubber powder is processed by a monomer and the waste tire fiber is processed by a modifying agent, thereby effectively improving the interface combination of each component of the composite material. The environment-friendly composite material with the advantages of light weight, excellent mechanical property, wide temperature using range and low cost can be prepared by adopting the process of mould pressing or injection moulding and adjusting the proportion of each component.

Owner:SOUTH CHINA UNIV OF TECH

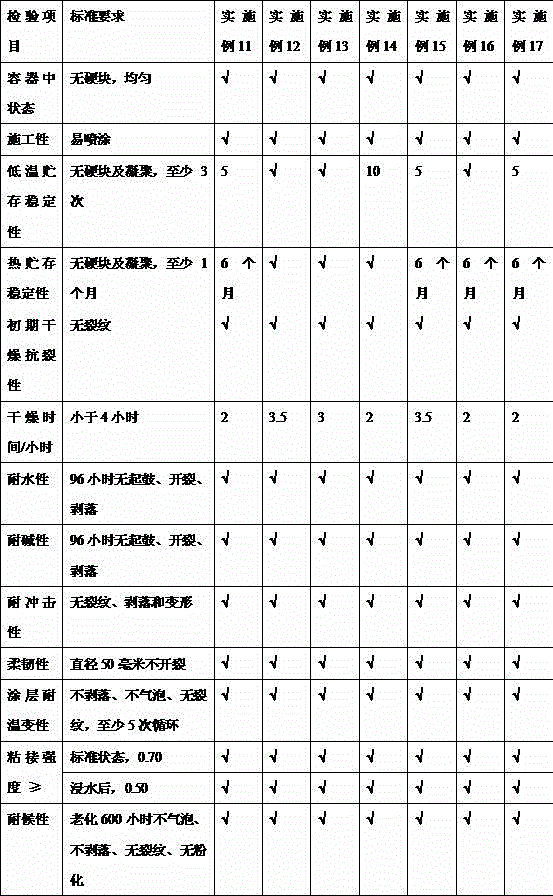

Light stone-imitating particulate matter and water-based stone-imitating coating prepared by adopting same

The invention provides a light stone-imitating particulate matter and a water-based stone-imitating coating prepared by adopting same, and belongs to the technical field of water-based architectural coatings. The preparation method comprises the following steps: smashing or cutting waste or a leftover material of rubber, resin and engineering plastics or reclaimed rubber into particles, coating a colored film on the surface to prepare the light stone-imitating particulate matter. The water-based stone-imitating coating prepared by adopting the stone-imitating particulate matter comprises the following ingredients in percentage by weight: 8-30% of emulsion, 30-80% of a light stone-imitating particulate matter, 1-40% of an inorganic pigment filler, 1-8% of a wetting dispersant, 0.5-8% of a thickening agent, 0.1-5% of an antifoaming agent, 0.5-5% of a film coalescing aid, 0.1-1% of a mildew inhibitor, 1-10% of an anti-freezing agent, and proper amount of water, wherein the pH value is regulated to be 8-9.5 with a pH regulator. The imitated stone is life-like, and presents strong artistic feeling. As the specific weight of the light stone-imitating particulate matter is low, the flexibility is good, and the abrasiveness to a mixing plant is low; a lot of thickening agents or anti-setting agents are not required to be added, and the prepared stone-imitating coating has high stability, long storage life, and convenience in construction. Moreover, the technology avoids black pollution such as waste tires, and is beneficial to environment protection.

Owner:HEBEI UNIV OF ENG

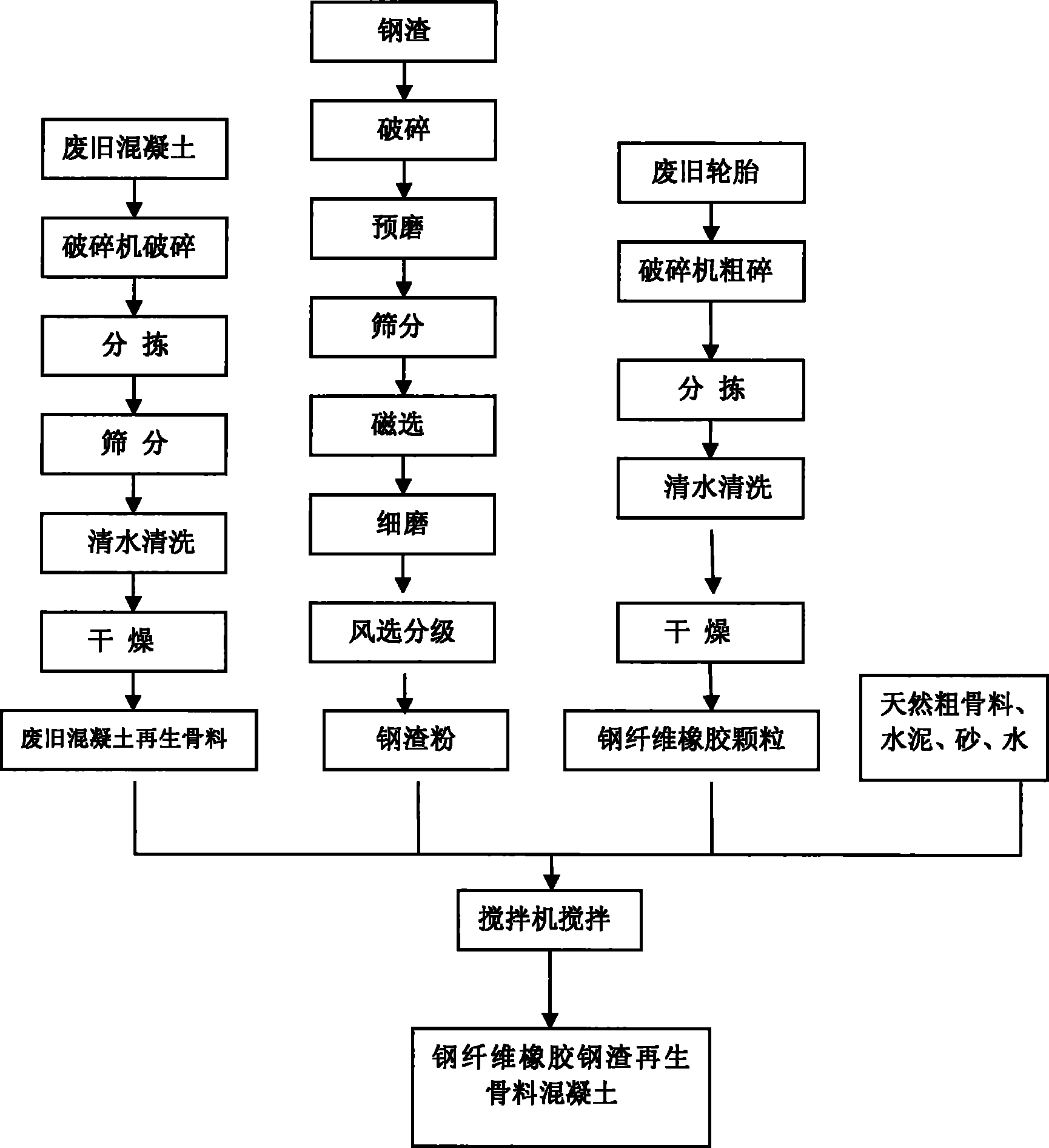

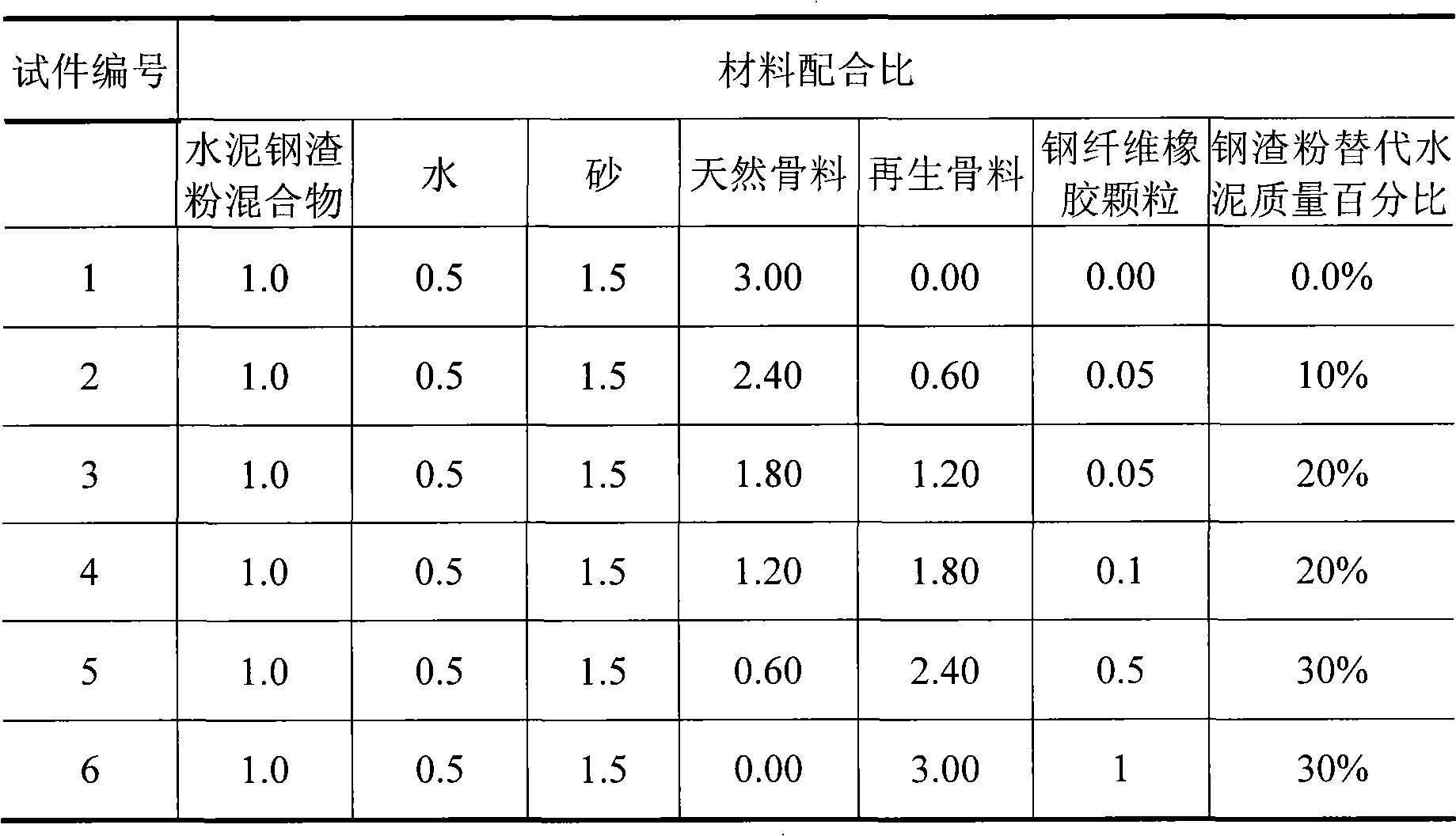

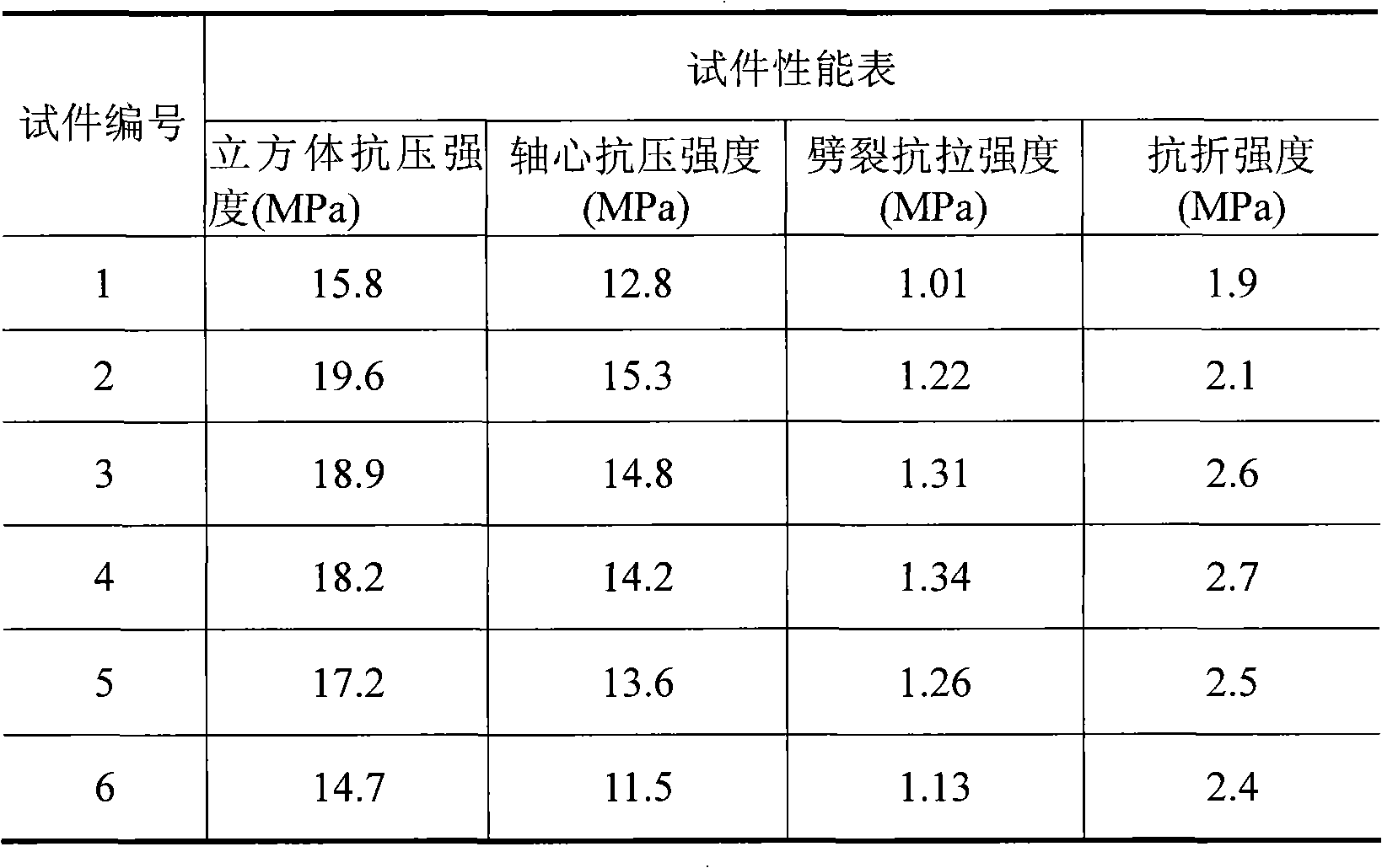

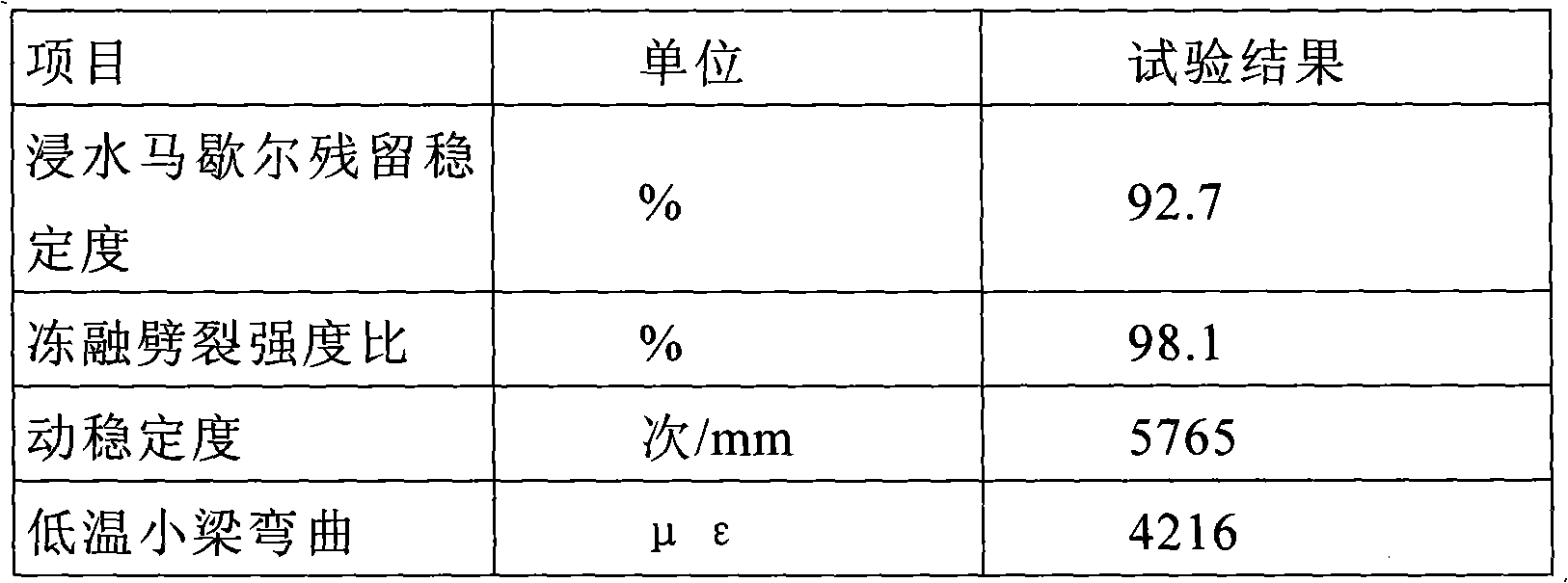

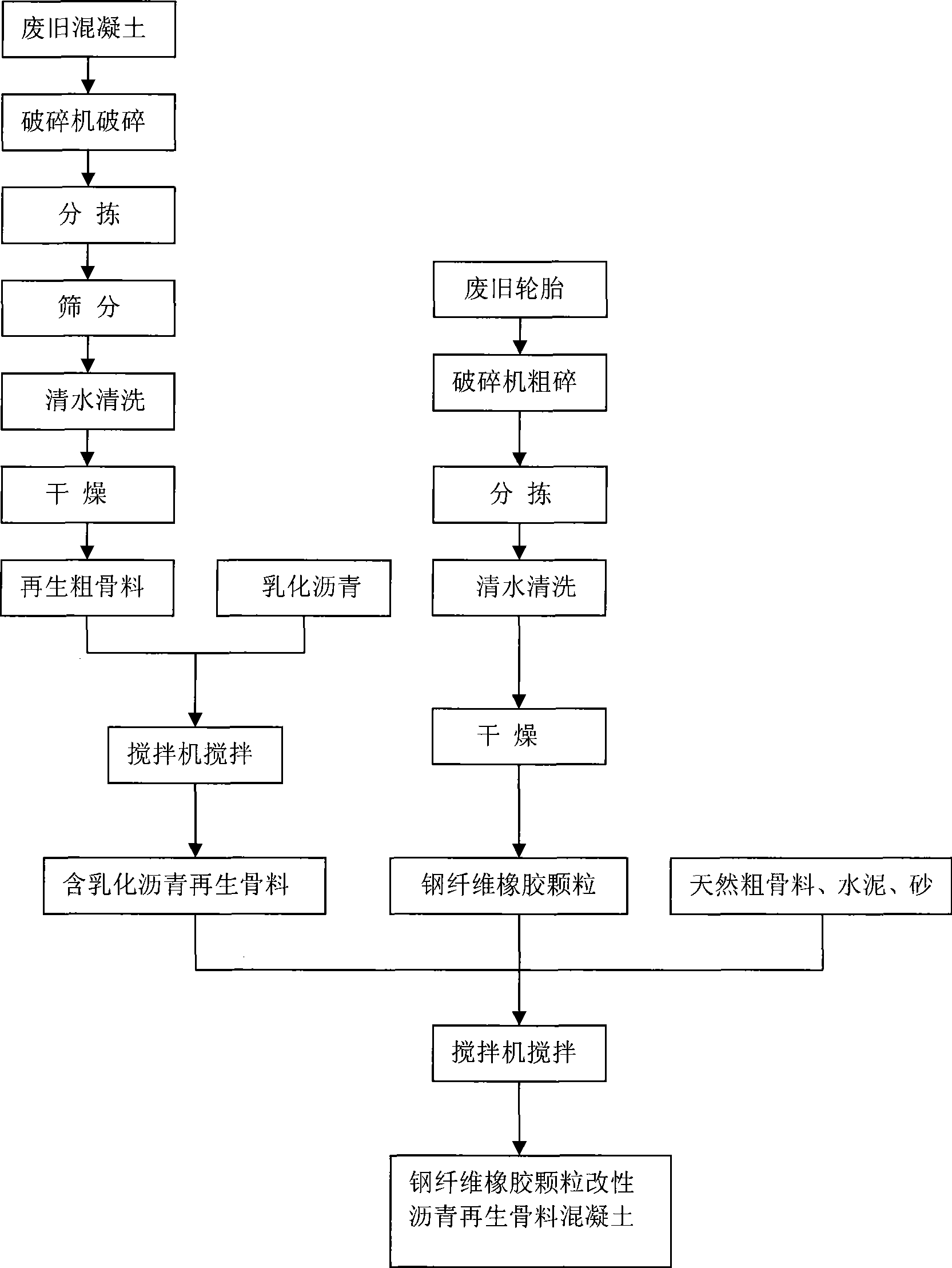

Method for preparing recycled aggregate concrete from steel fiber rubber and slag

ActiveCN101774223AImprove crack resistanceImprove insulation effectSolid waste managementClimate change adaptationCrack resistancePowder mixture

The invention discloses a method for preparing recycled aggregate concrete from steel fiber rubber and slag. The method comprises the following steps: waste concrete is crushed, separated, screened, washed and dried to obtain waste concrete recycled aggregate; waste tires are coarsely crushed, separated, washed and dried to obtain steel fiber rubber particles; the slag is crushed, screened, magnetically separated and classified by air to obtain slag powder; the waste concrete recycled aggregate, the steel fiber rubber particles, cement slag powder mixture, natural coarse aggregate, sands and water are stirred in proportion; the cracking resistance, thermal insulation performance and energy absorbing and noise reducing performance of the recycled aggregate concrete can be effectively improved by modifying the steel fiber rubber particles; the working performance of green concrete and contraction performance of the concrete in each curing time can be improved by modifying the slag powder; and the infiltration resistance and carbonization resistance can be effectively improved and chloride ion diffusion velocity of the concrete can be effectively reduced. The material is a cycled economical building material, and can improve the material performance on the basis of not increasing cost.

Owner:GUANGDONG DIANBAI CONSTR GRP

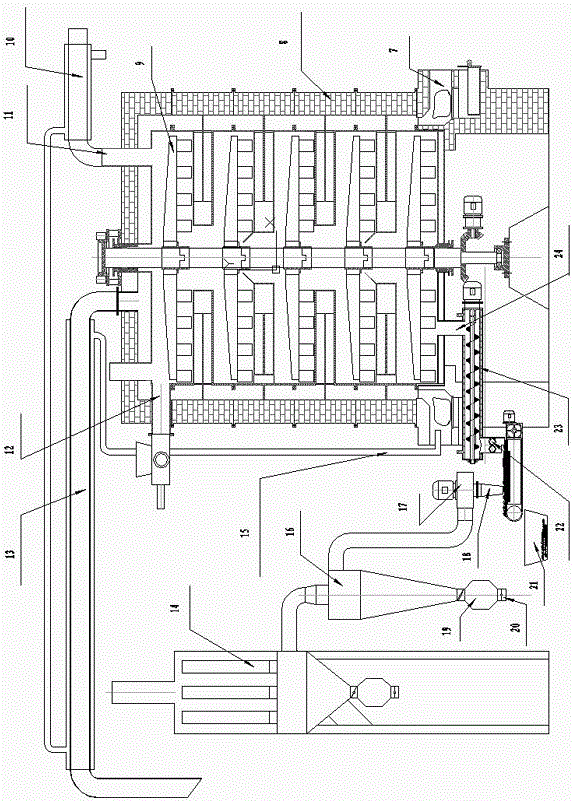

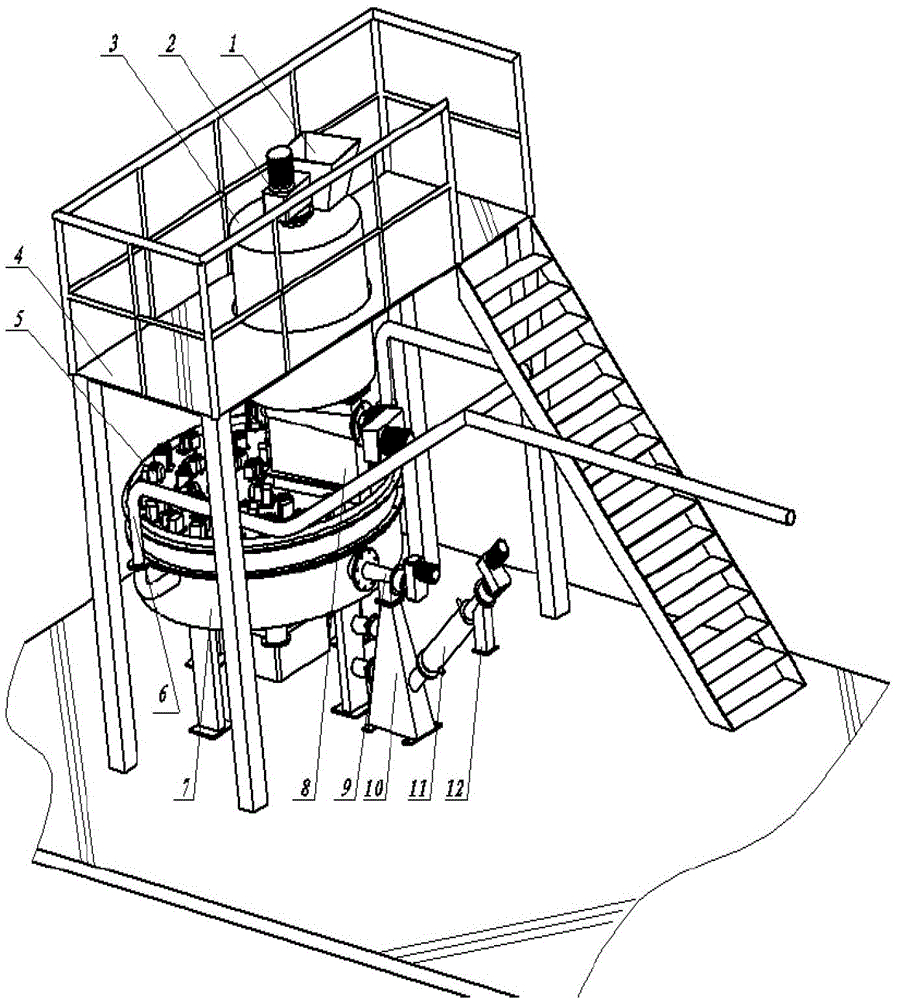

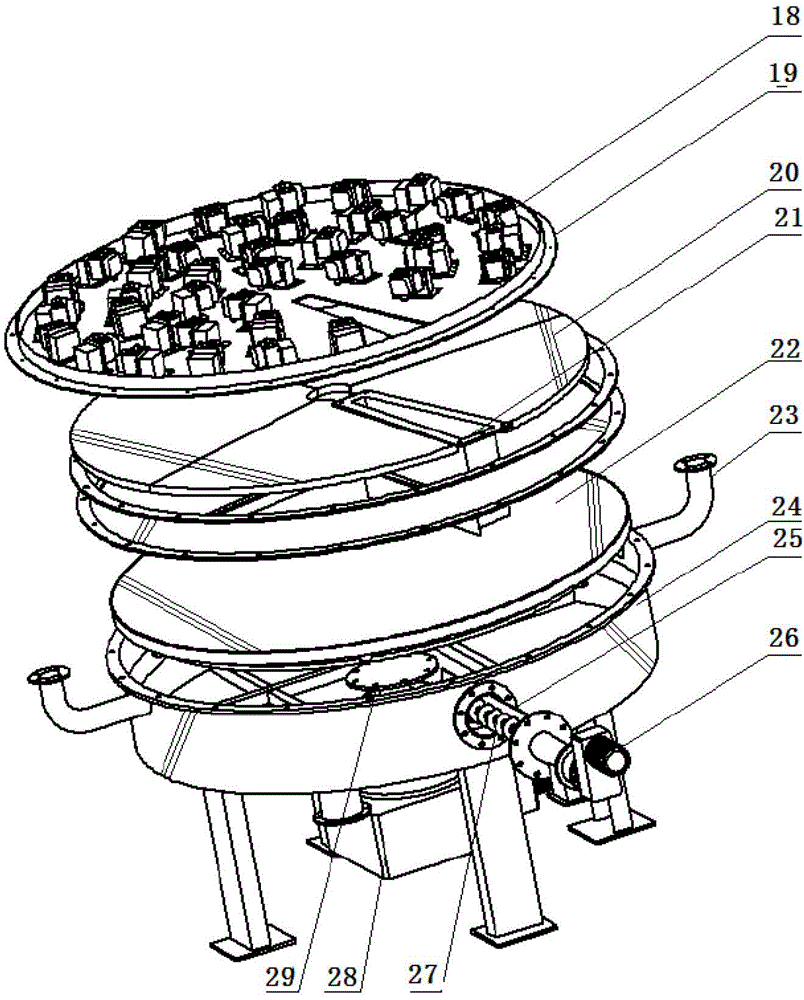

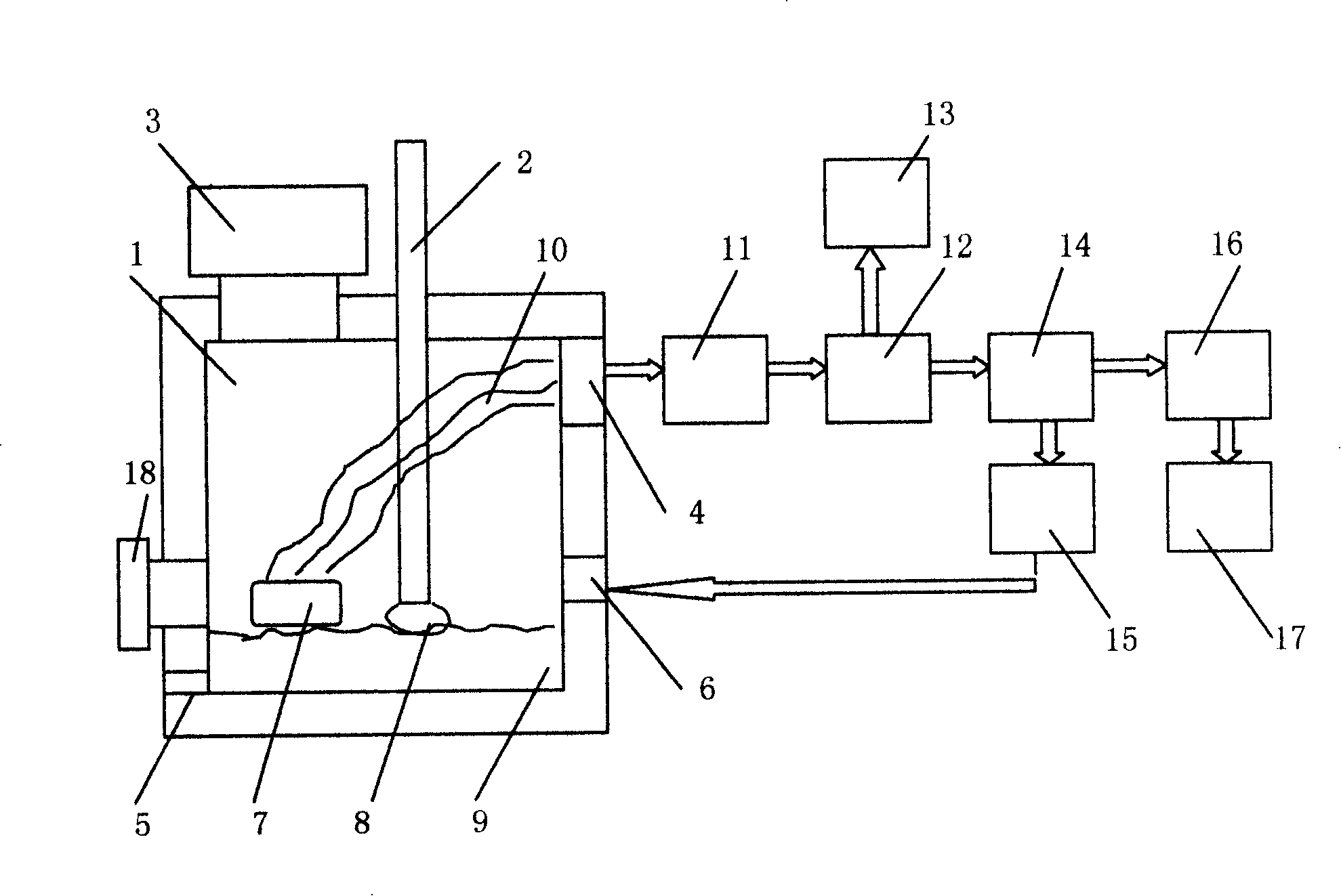

Waste tire thermal cracking device

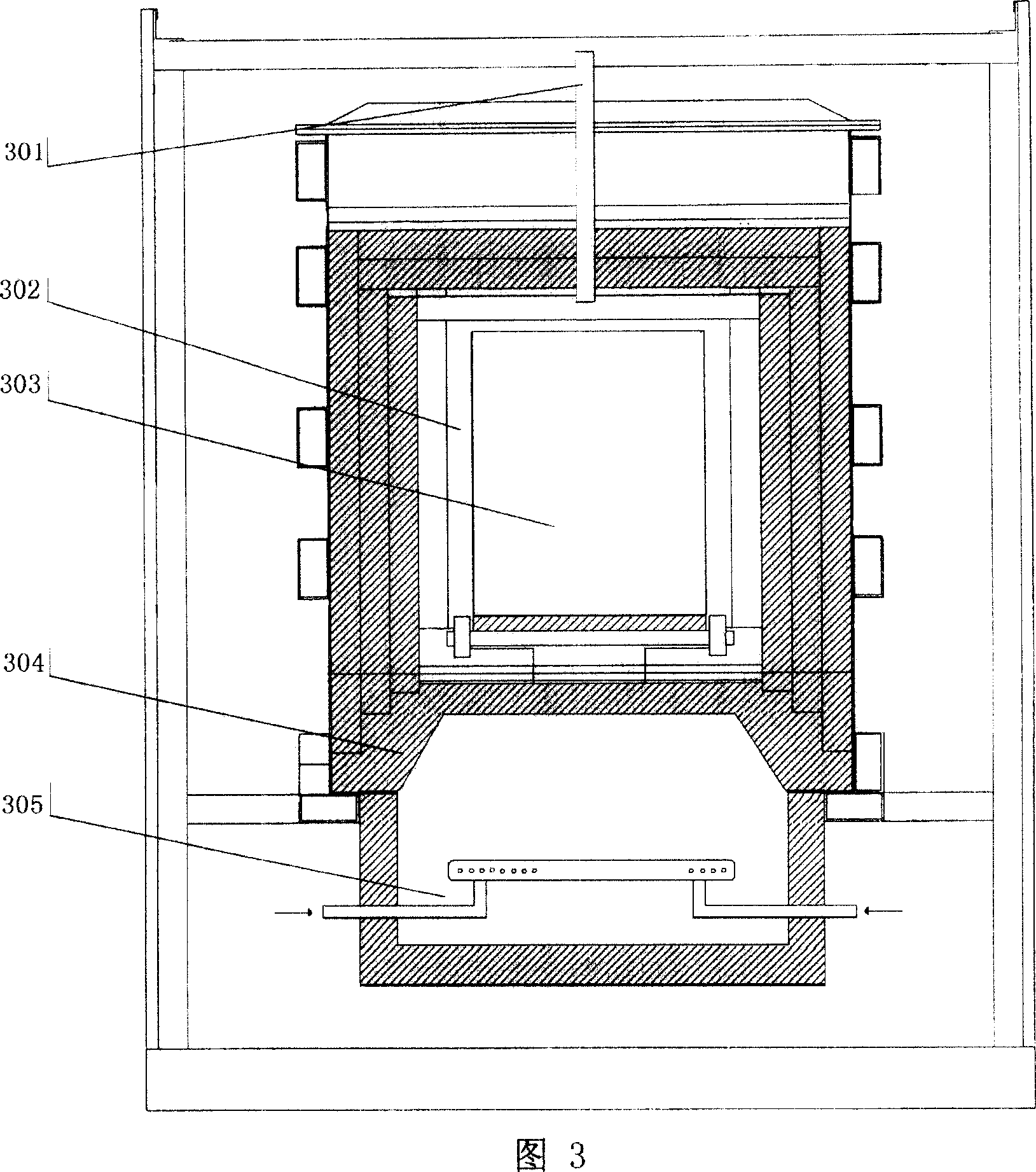

ActiveCN106147820ASolve pollutionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCombustion chamberCombustible gas

The invention discloses a waste tire thermal cracking device which comprises a waste tire breaking device, a thermal cracking furnace, an oil gas recycling system, a smoke discharge system and a solid material recycling system, wherein the thermal cracking furnace is provided with a closed furnace body; a smoke-through chamber is arranged between the inner wall of the thermal cracking furnace and the furnace bed body and communicated with a combustion chamber; a rotary central spindle is arranged at the central part of the furnace bed body; multiple layers of material chambers are arranged in the furnace bed body from top to bottom; the rotary central spindle is provided with a stirring device extending into each material chamber; a furnace section is arranged between adjacent material chambers and comprises an inner blanking furnace section and an outer blanking furnace section; the broken waste tire is heated layer by layer by the closed thermal cracking furnace for thermal cracking; the generated oil gas is condensed and recycled, and the uncondensable combustible gas heats the thermal cracking furnace through the combustion chamber; and moreover, effective recycling of residual value and environment-friendly discharge are realized through the smoke discharge system and the solid material recycling system. Continuous production can be realized, the energy is saved while the environment is protected, and the problem of pollution of waste tire is solved.

Owner:张新华

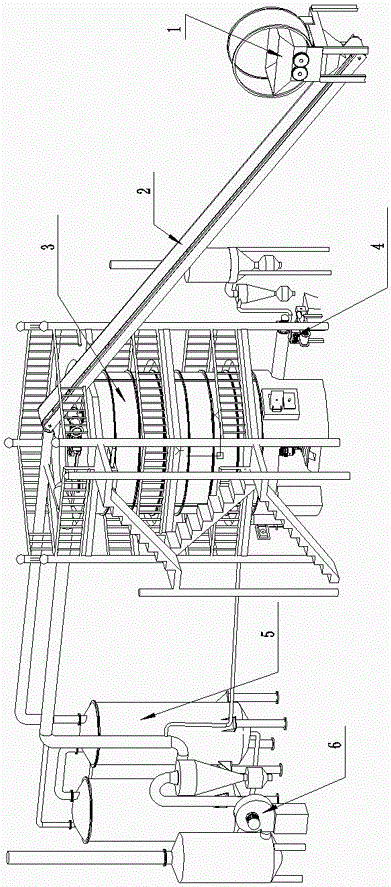

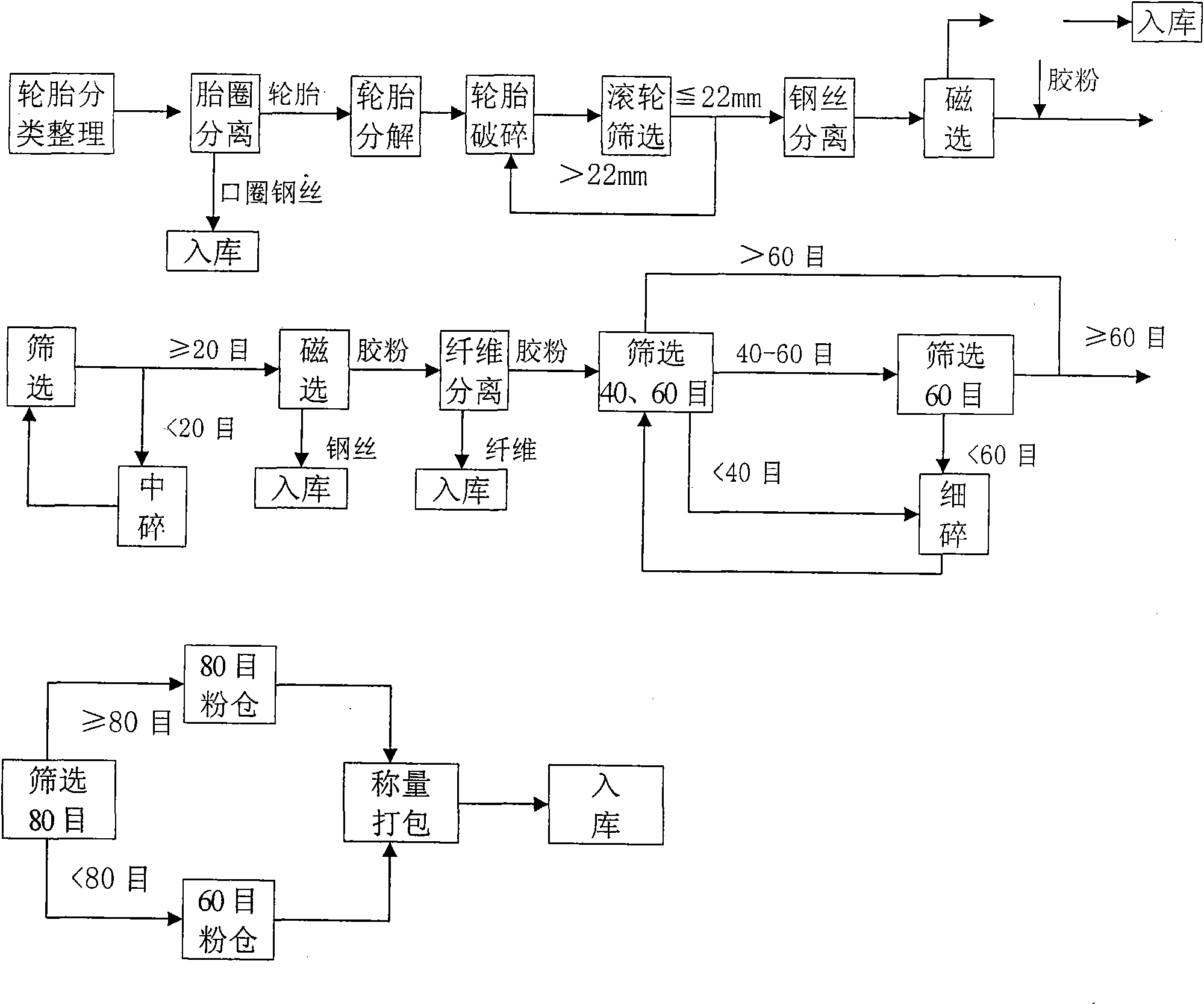

Method for producing gelatine powder under normal temperature by using waste tires

InactiveCN101670625ALow investment costLow production costSolid waste disposalPlastic recyclingTire beadRoom temperature

The invention discloses a method for producing gelatine powder under normal temperature by using waste tires, which relates to the technical field of producing gelatine powder under normal temperatureby using waste rubber products, and comprises the detailed steps of: a. separating a tire bead; b. crashing the tire; c. separating steel wires; d. magnetically separating for the first time; e. screening for the first time; f. magnetically separating for the second time; g. screening for the second time; and h. screening for the third time. The method has simple technique, is convenient for large-scale industrial production, and has lower investment and production cost; the grain diameter quality of the produced gelatine powder is stable; moreover, the method can produce the gelatine powderwith different grain diameter specifications, thus meeting the demands of different users.

Owner:SICHUAN LESHAN YALIAN MACHINE

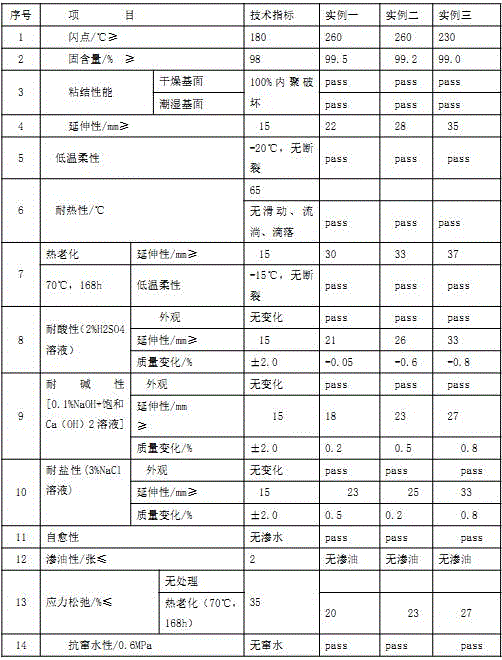

Non-curing rubber asphalt waterproof material and preparation method thereof

ActiveCN105542496AAdapt to deformation requirementsImprove performancePlastic recyclingBuilding insulationsCross-linkBituminous waterproofing

The invention discloses a non-curing rubber asphalt waterproof material and a preparation method thereof. The non-curing rubber asphalt waterproof material comprises raw materials in parts by weight as follows: 30-70 parts of base asphalt, 15-40 parts of waste tire rubber powder, 0.25-1.0 part of a desulfurizing agent, 0.8-4 parts of a composite modifier, 0.5-5 parts of a softening agent, 0.25-3 parts of a cross-linking agent and 5-15 parts of filler, wherein the grain size of the waste tire rubber powder is 20-80 meshes. The preparation method comprises steps as follows: raw material preparation, hot melting and mixture homogenization are performed; finally, the cross-linking agent and the filler in parts by weight are sequentially added to a storage tank and are stirred and mixed for 15-20 min, and the non-curing rubber asphalt waterproof material is formed. The waste tire rubber powder is directly subjected to circular shearing desulfurization by a high-shear homogenizer under the action of the desulfurizing agent in a high-temperature asphalt medium, rubber molecules are uniformly dispersed in an asphalt system in a linear structure manner and then form a stable stereoscopic meshed rubber structure with the filler under the action of the cross-linking agent, and the product performance is more stable.

Owner:河北交投特种材料科技有限公司 +1

Rubber-wood-cement composite material

ActiveCN101298379AShorten the production cycleHigh degree of continuitySolid waste managementWear resistantAdhesive

The invention provides a rubber-timber-cement functional environment-friendly compound material, which belongs to the field of cement-base compound material. The material adopts the waste tire rubber, waste rubber products, woody material and silicate cement as raw materials, an isocyanate-based adhesive is coated on the surface of the waste rubber particles, then the woody material is soaked and dried, and the treated rubber particles, the woody material and cement are mixed to form a blank material, which is finally laid, pressed and cured so as to obtain the compound material. The compound material provided by the invention can absorb and insulate sound, has high shock resistance and damping property, and is wear-resistant, antistatic, mothproof, waterproof and anticorrosive; also the material is heat-insulating and friendly to the environment, etc.; the production process has no chemical pollution source, no radioactivity, no light pollution and no noise. The invention blazes a new path for solving the 'black pollution' of increasing waste tires, which is a global problem; additionally, the compound material can be used for producing structural lumber.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

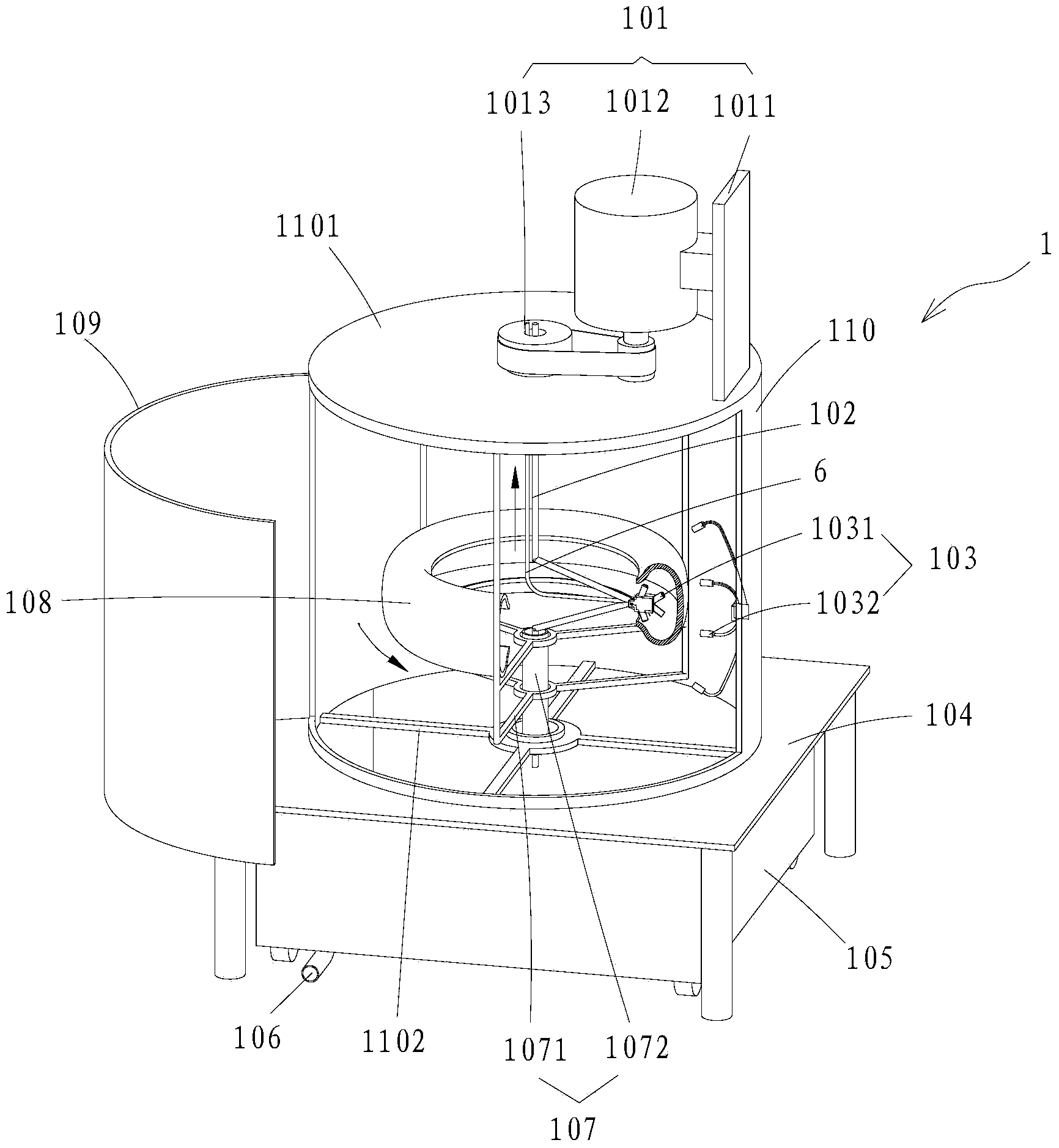

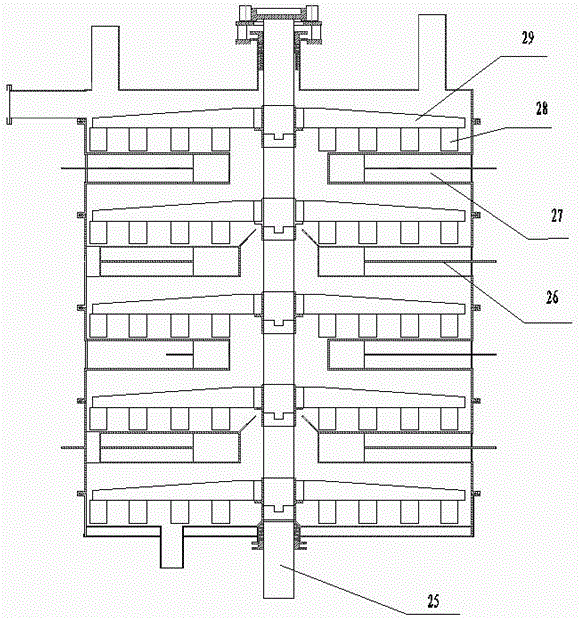

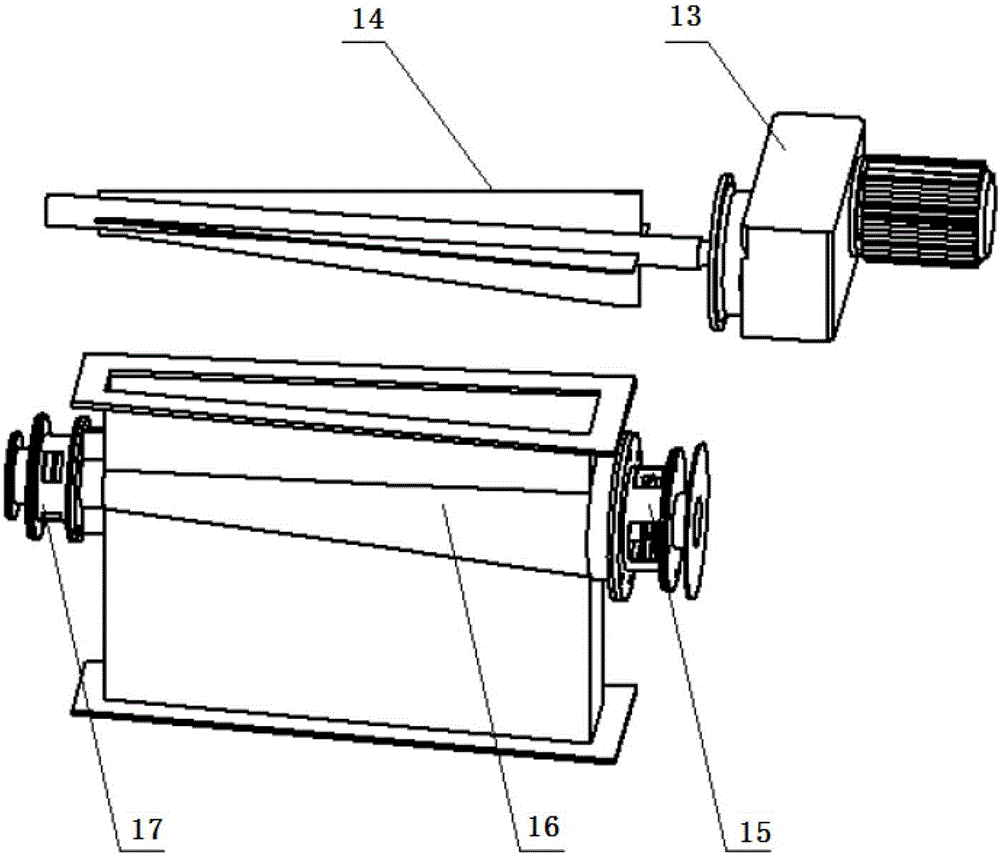

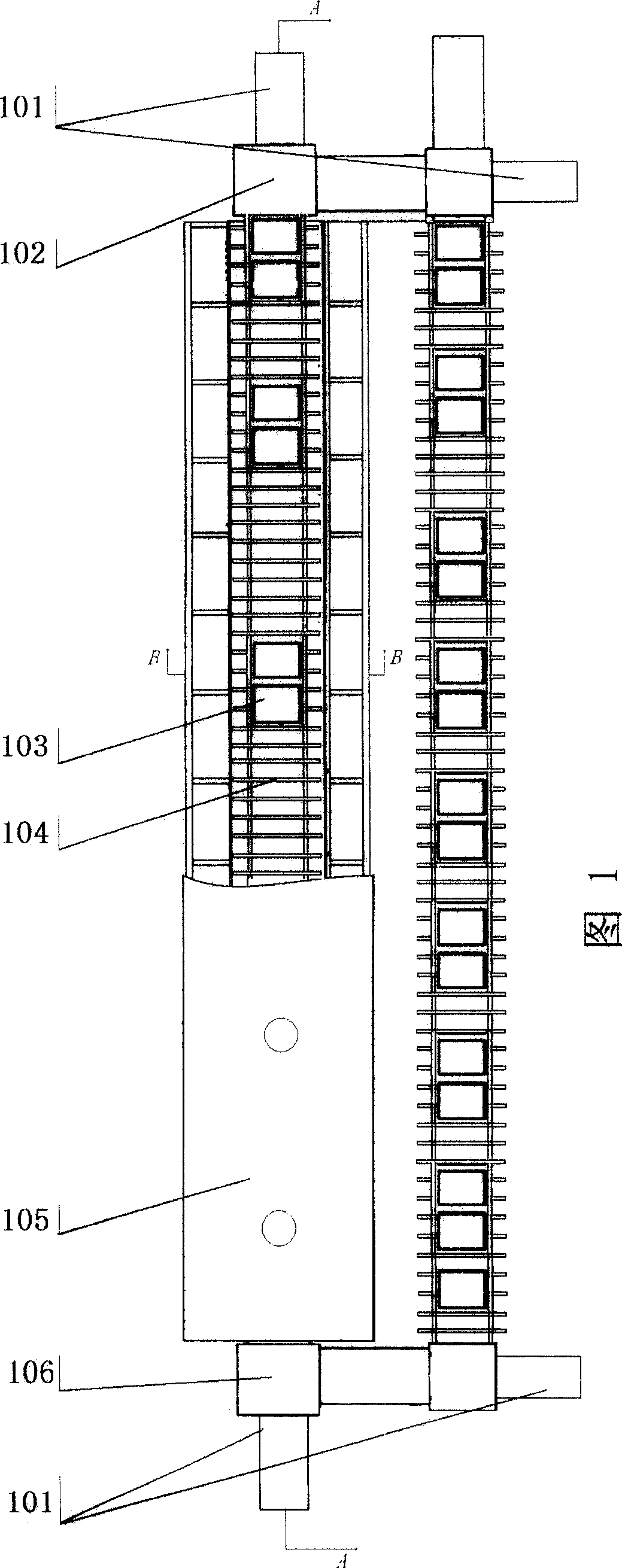

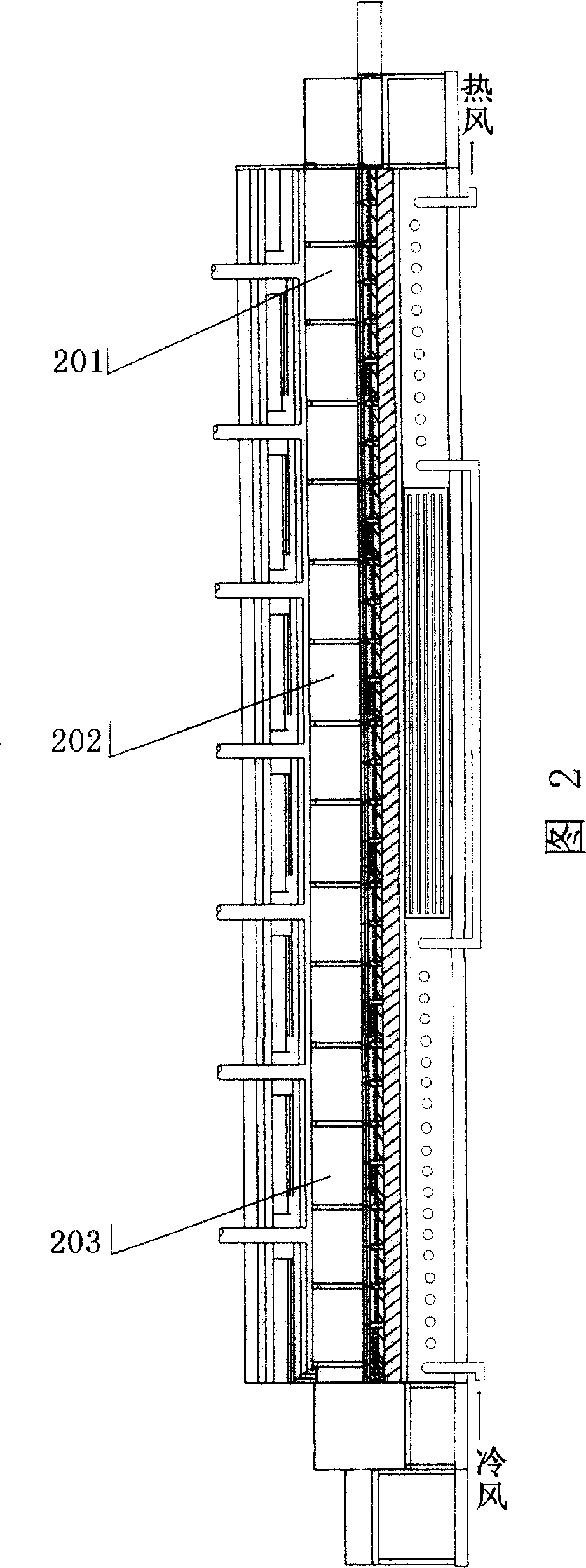

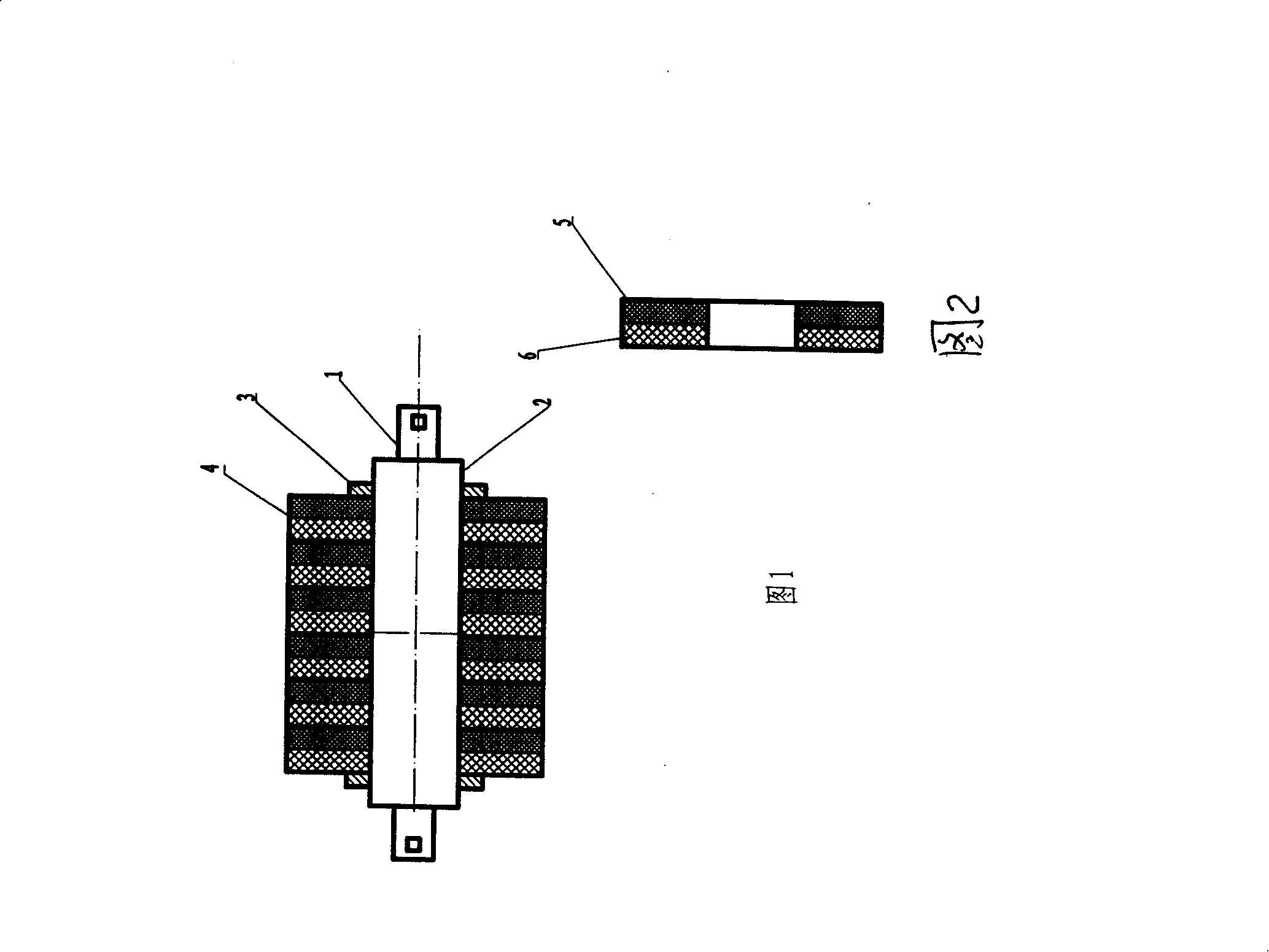

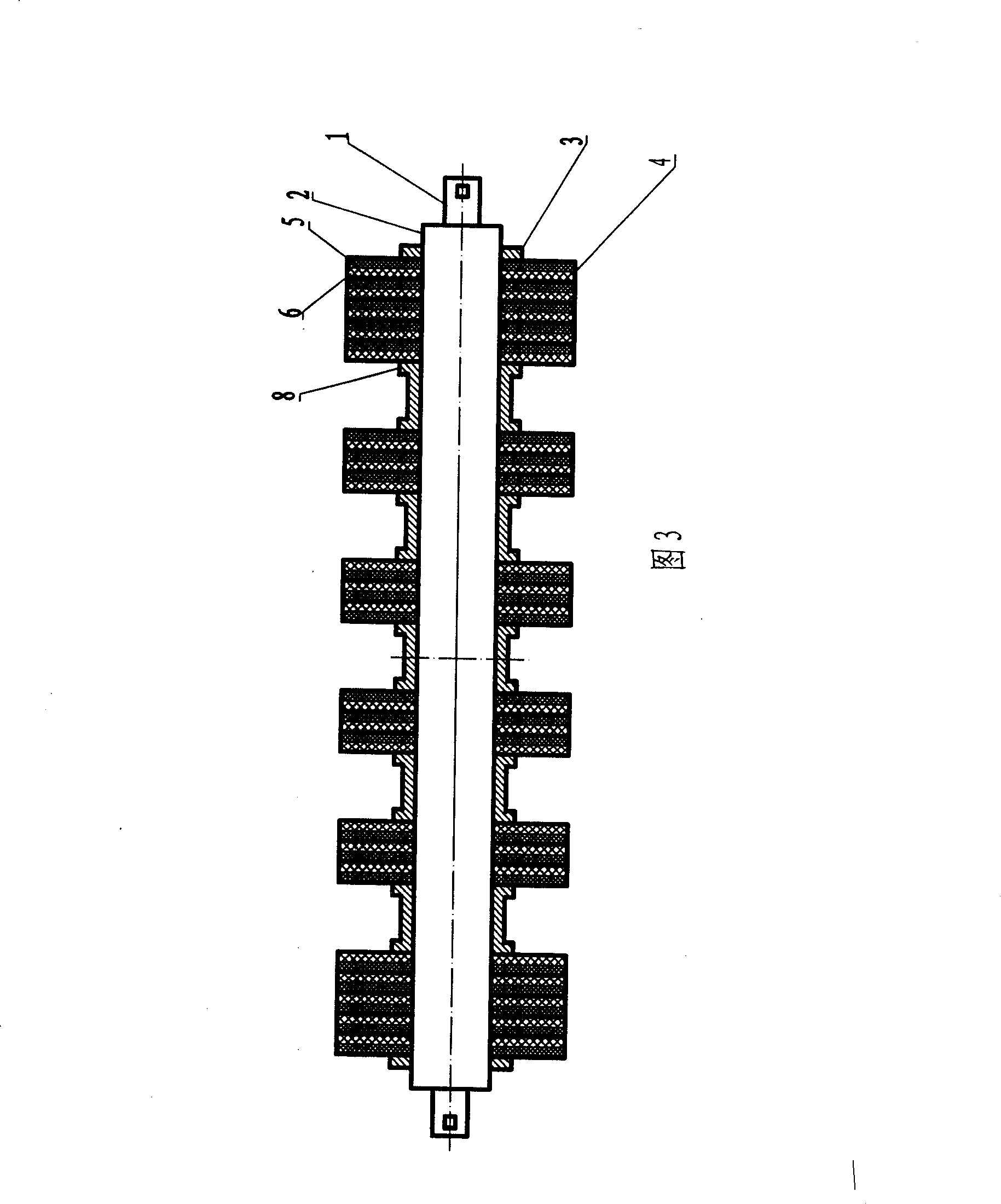

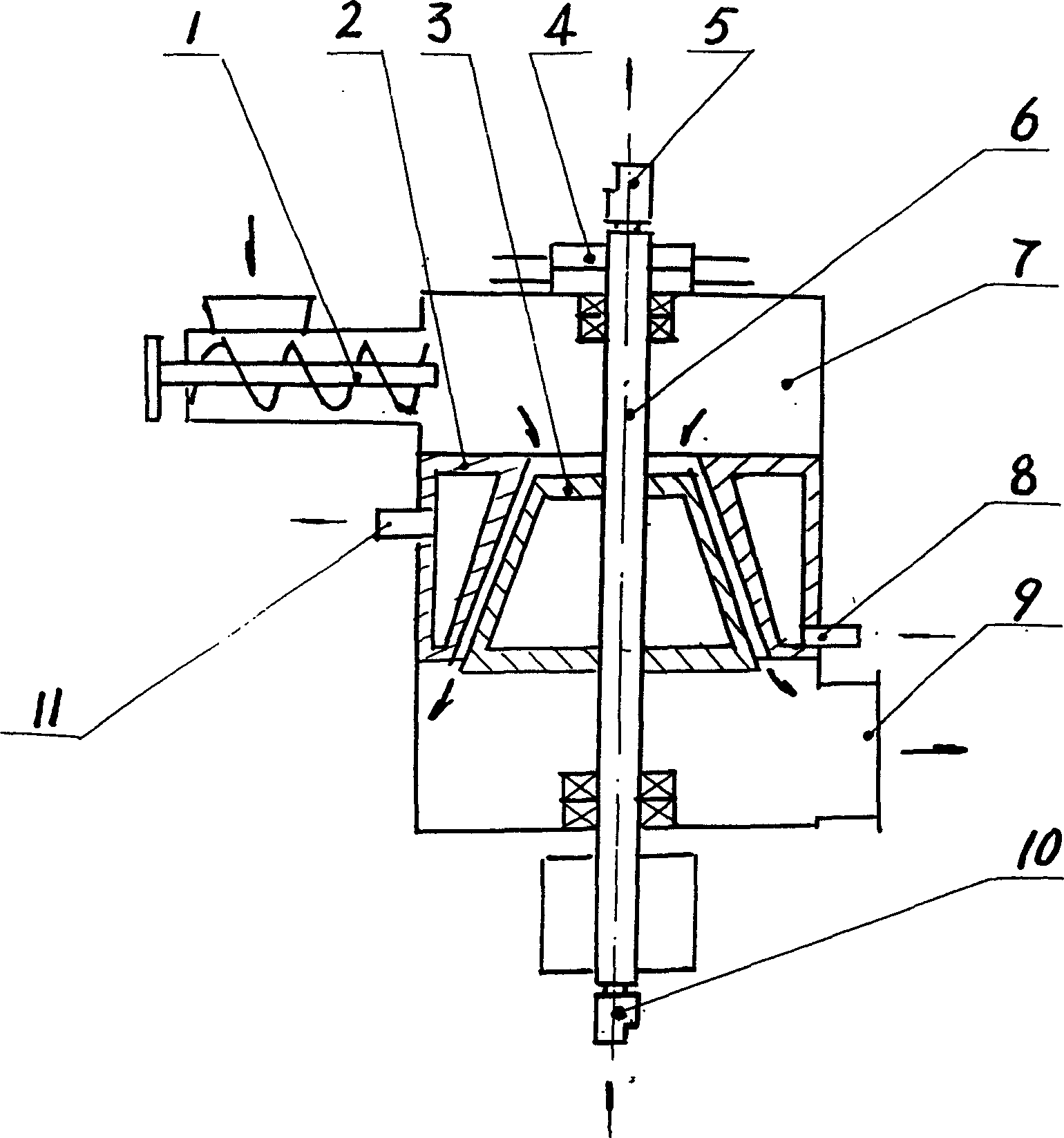

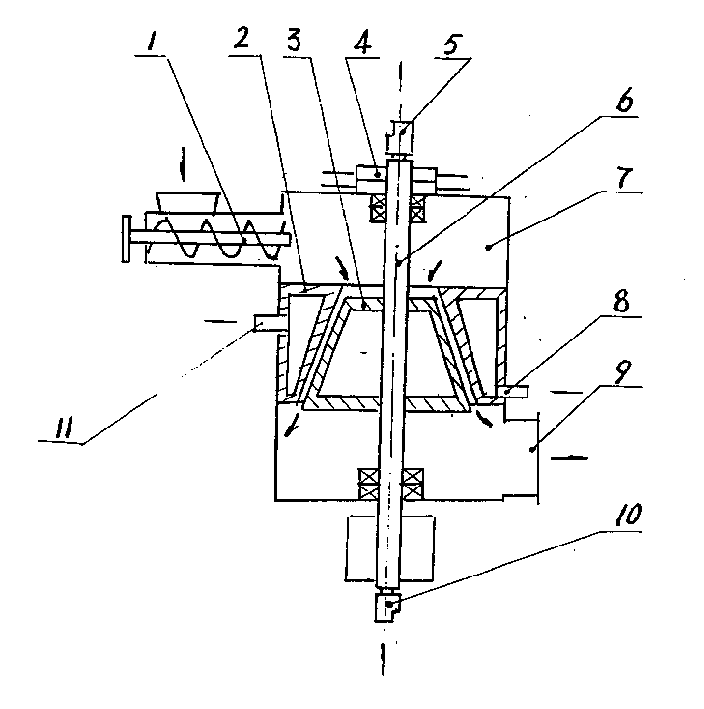

Disc-type microwave continuous splitting device and method for splitting waste rubber

ActiveCN103333709ASmooth runningImprove microwave cracking efficiencyPigmenting treatmentPlastic recyclingMicrowaveWaste rubber

The invention discloses a disc-type microwave continuous splitting device. The disc-type microwave continuous splitting device comprises a feeding assembly, a microwave splitting assembly, a discharging assembly and a control assembly which are sequentially communicated with one another, wherein the microwave splitting assembly comprises a microwave generator, a nonmetal sealing plate, a splitting cavity, a rotating disk and a disk driving motor, the nonmetal sealing plate is used for dividing the splitting cavity into an upper part and a lower part, the rotating disk is arranged at the lower part of the splitting cavity and is matched with the disk driving motor in a driving rotation manner, and the microwave generator is arranged on a circular flange on the splitting cavity. The invention aslo discloses a method for splitting waste rubber by using the splitting device; the disc-type splitting cavity is adopted in the method and is divided into an upper cavity and a lower cavity through the nonmetal sealing plate, so that the microwave splitting efficiency of waste tires is improved; and in order to ensure the stable operation of a disk and prevent the high-temperature deformation, one or a plurality of annular guide rails are arranged on the lower surface of the rotating disk and are used for supporting the rotating disk, so that the rotating disk rotates on a guide rail so as to optimize the splitting effect.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

Tire rubber powder modified recycled plastic and preparation method thereof

The invention relates to composite materials, in particular to a tire rubber powder modified recycled plastic and a preparation method thereof. The invention aims to solve the existing zero pollution reclamation difficulty and other problems of waste tire rubber, waste plastics, etc. The tire rubber powder modified recycled plastic provided in the invention is prepared from the following raw materials by mass: 20%-70% of waste plastics, 10%-40% of tire rubber powder, 5%-26% of a flame retardant, 1%-10% of a compatibilizer, 0.1%-3% of a lubricant, 0.5%-5% of a plasticizer, and 0.05%-4% of an antioxidant. In the invention, by modifying tire rubber powder to prepare the recycled plastic, the resource utilization rate of waste tire rubber powder is enhanced, a new application technology of rubber powder is developed, the application scope of rubber powder is expanded, and at the same time, the prepared recycled plastic still has good mechanical properties, and the production cost of the recycled plastic is greatly reduced, so that the application fields of recycled plastics can be expected to be further expanded.

Owner:荆门格林循环电子废弃物处置有限公司

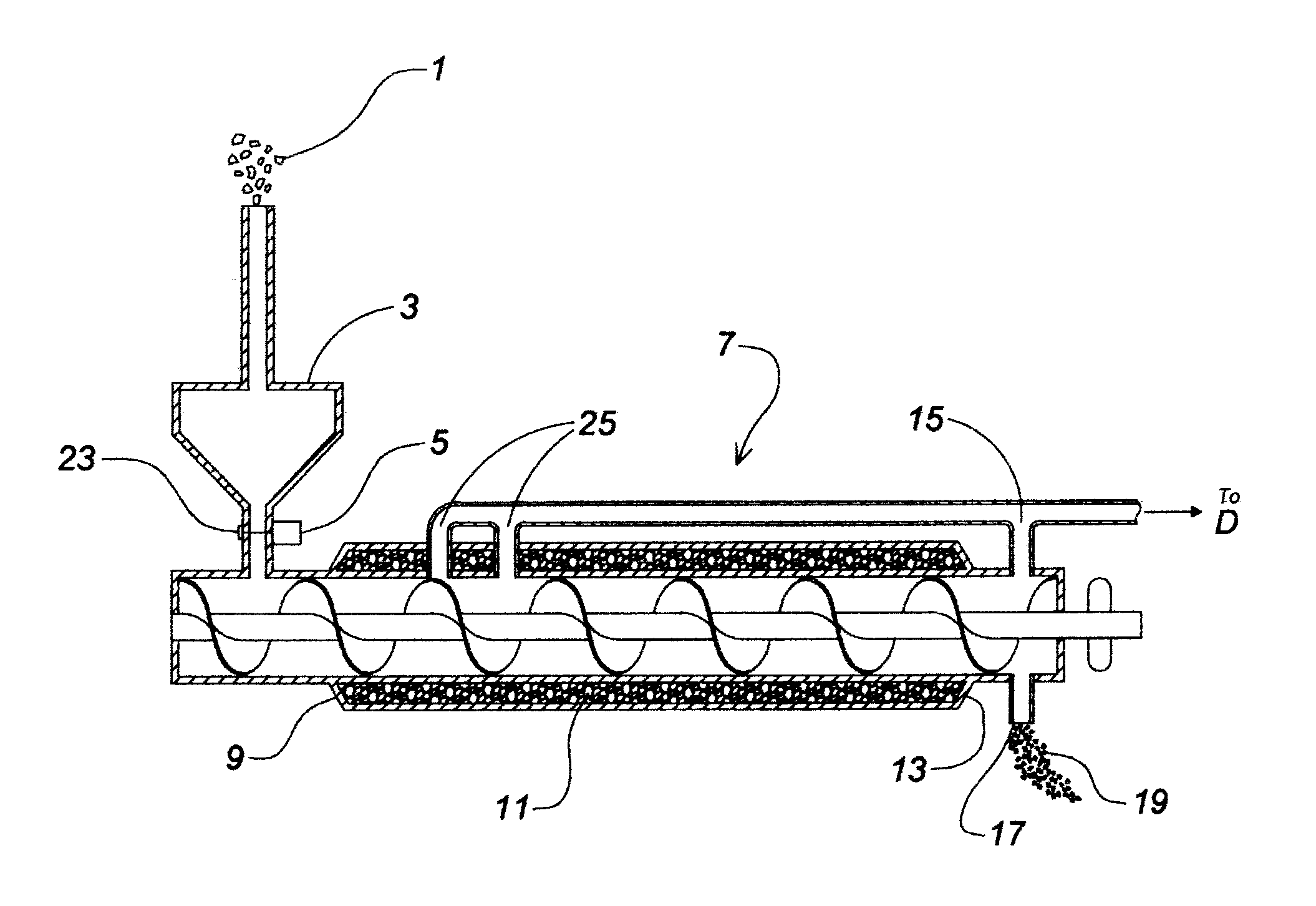

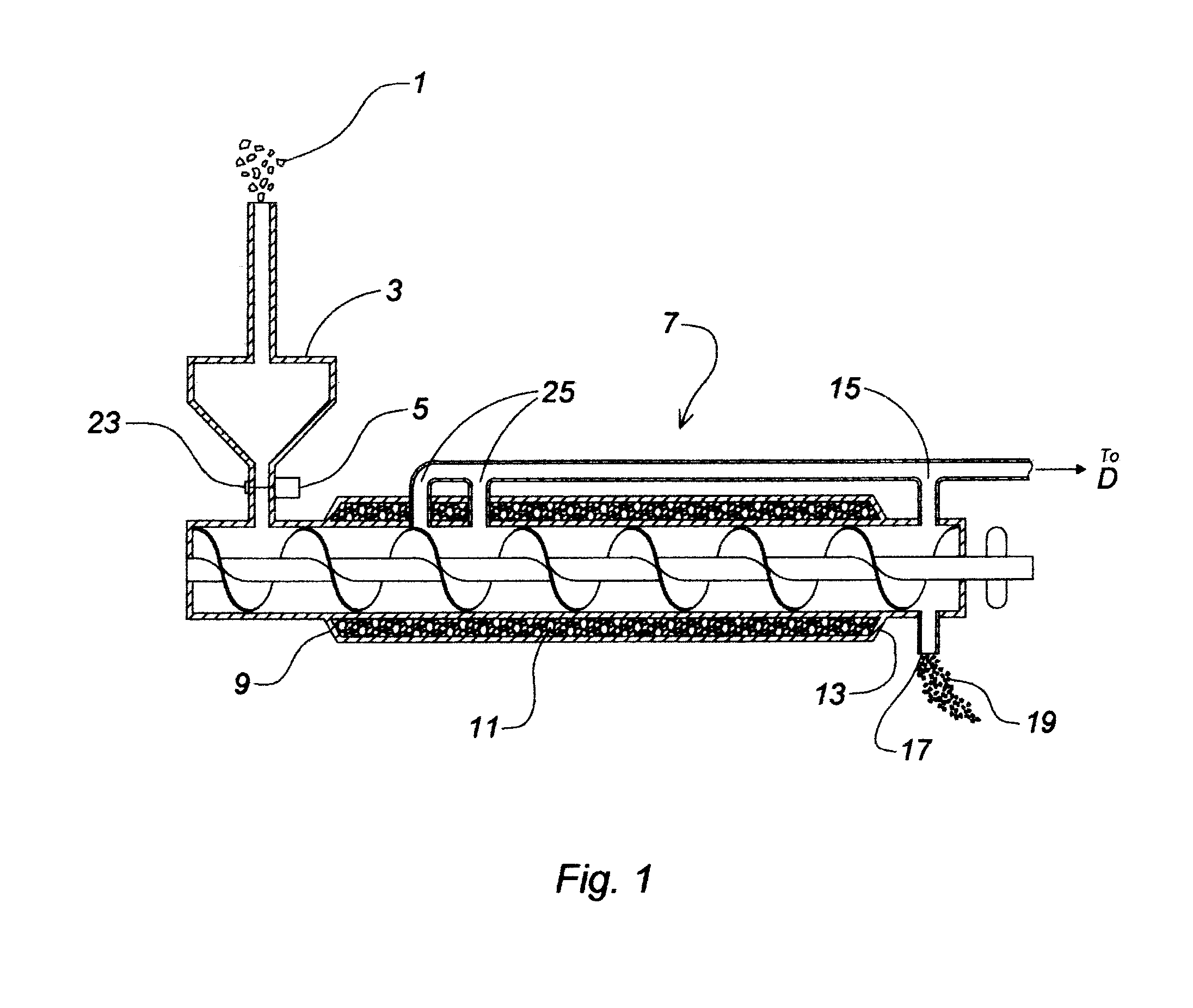

Device and process for the recovery of increased volumes of pure terpenes and terpenoids from scrap polymers and elastomers

Owner:BEAVER EARL R +1

Porous pavement partially taking steel slag as coarse aggregate

ActiveCN101973726ASolve traffic problemsSolve environmental problemsIn situ pavingsSolid waste managementSlagPorous pavement

The invention belongs to the technical field of porous pavements and particularly relates to a porous pavement partially taking steel slag as a coarse aggregate and taking rubber asphalt as an adhesive. In the porous pavement partially taking the steel slag as the coarse aggregate, the thickness of a structural layer of the porous pavement is between 2.0 and 4.0 centimeters; and the maximum nominal particle size of a construction mixture is 9.5 millimeters. The porous pavement consists of the coarse aggregate, a fine aggregate and a filler, wherein the coarse aggregate is the mixture of the steel slag coarse aggregate and a natural stone coarse aggregate; the fine aggregate is a limestone, diabase or basalt aggregate; and the filler is cement or the mixture of limestone mineral powder and slaked lime. The used rubber asphalt is produced from waste large tire rubber powder of which the particle size is more than or equal to 20 meshes and smaller than or equal to 40 meshes. Traffic and environmental problems caused by a nonporous pavement are solved to the greatest extent, the long-term pavement performance of an asphalt pavement is improved by using the steel slag and waste tires, the supply pressure of a high-quality aggregate is relieved and engineering cost is lowered.

Owner:上海砼仁环保技术发展有限公司

Method for regenerating aggregate concrete from steel fibre rubber granule modified asphalt

InactiveCN101381216AHigh dampingIncrease frictionSolid waste managementCrack resistanceEnergy absorption

The invention discloses a method for preparing steel fiber rubber particle modified asphalt recycled aggregate concrete. In the method, waste concrete is subjected to crushing, separating, screening, washing and drying to obtain the recycled aggregate, and the recycled aggregate is stirred with emulsified asphalt until the emulsified asphalt is covered on the surface of the recycled aggregate; waste tire is subjected to coarse crushing, separating, washing and drying to obtain the steel fiber rubber particle; and the recycled aggregate containing the emulsified asphalt, steel fiber rubber particles, natural aggregate, cement, sand and water are stirred according to certain ratio to obtain the steel fiber rubber particle modified asphalt recycled aggregate concrete. In the invention, the waste tire is subjected to crushing process to produce the steel fiber rubber, and the crack resistance, the heat preservation capability and the energy absorption and noise reduction capability of the asphalt recycled aggregate concrete are effectively improved by the modification of the steel fiber rubber; and the material is a circular economy building material, and by producing the material, the environmental pollution is reduced, and the performance of the material can be improved under the condition of not increasing cost.

Owner:GUANGDONG UNIV OF TECH

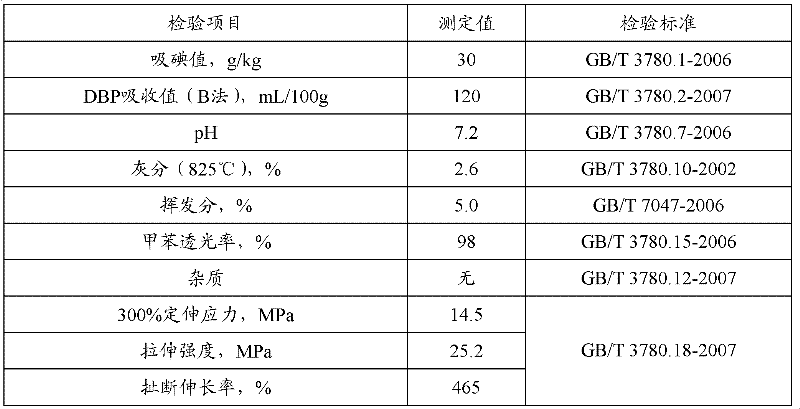

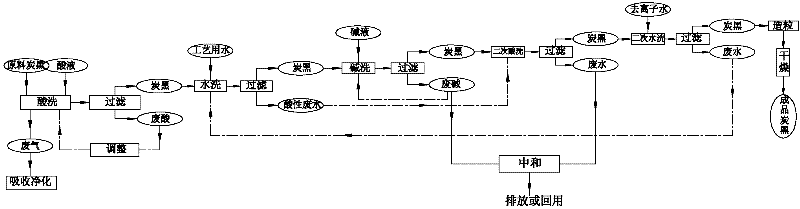

Purification process of pyrolysis carbon black of waste tire

The invention relates to a carbon black purification process, and in particular relates to a purification process of pyrolysis carbon black of a waste tire, which comprises the steps of washing with acid, washing with alkali, and performing acid washing once again to carbon black which is subjected to acid and alkali washing processes. According to the purification process, the ash content of carbon black is reduced to 2.6 percent from 18.7 percent, the volatile component content is reduced to 5.0 percent from 9.5 percent, and the reinforcing property to rubber is superior to that of a semi-reinforcing carbon black and basically reaches the reinforcing level of N330. The acid-wash filtrate generated in the production process can be reused in a purification system after being adjusted.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

Method for continuously thermal decomposing waste tire using gas burning kiln

InactiveCN1944581AContinuous operationGreat operating flexibilityLiquid hydrocarbon mixture productionTunnel kilnSlag

The process of continuously thermal decomposing waste tire in a gas burning kiln belongs to the field of solid waste treating technology. The process includes setting cleaned and air dried waste tire and catalyst in the thermal decomposing container on a push plate, pushing the container with a hydraulic device into the tunnel kiln via a sealing cabin, moving the push plate on rollers and pushing out the thermal decomposed product; condesing the gaseous product exhausted from the kiln top in a condensator to obtain mixed fuel oil or returning the gaseous product to the kiln for use as heat source; and collecting the carbon slag from the container for preparing carbon black filler and other material. The present invention can operate continuously, has great treating capacity, low power consumption and other advantages, and may be used in treating other solid wastes.

Owner:TSINGHUA UNIV

Belt conveyor rubber idler and production method thereof

The invention discloses a rubber idler of a belt conveyor, comprising an idle shaft and an idler steel pipe; a wear-resistant buffer layer with an arc outer surface consisting of more than one rubber rings of waste tires is sleeved on the idler shaft in the manner of interference. The invention also discloses a method for manufacturing the rubber idler of the belt conveyor. A wear-resistant idler, a buffer idler, a comb-shaped idler, a taper aligning idler, a friction aligning idler and a rubber aligning idler made of the rubber rings of waste tire are applied. Under the precondition of guaranteeing the sealing performance of the idler, the idler steel pipe or the shaft is sleeved by the wear-resistant idler, the buffer idler, the comb-shaped idler, the taper aligning idler, the friction aligning idler and the rubber aligning idler made of the rubber rings of waste tire. The idlers have comprehensive functions such as anti-corrosion, anti-tarnishing, abrasion resistance, compact resistance, aging resistance, tear resistance, light weight and large elastic force. In addition, the idlers can protect the belt and largely prolong the service life of the belt.

Owner:孙明昭

Modified asphalt and method for making same

The invention discloses a modified tar and making method, which is characterized by the following: allocating tar and activated rubber powder with weight rate at 70-85:30-15; doping activator tetramethyl alkynediols into waste tyre powder; blending; wetting to obtain activated rubber powder; adding tar and activated rubber powder into autoclave according to proportion; stirring completely; heating to 170-180 deg.c; insulating 0.5-1h; cooling to indoor temperature naturally to obtain modified tar. The invention avoids tar from separating, which doesn't desulfrize in the whole course.

Owner:四川盖瑞新材料科技有限公司

Rubber bituminous mixture partially using slag as coarse aggregate

InactiveCN101948272AImprove long-term road performanceLow costSolid waste managementCrack resistanceSlag

The invention belongs to the technical field of building materials used in road engineering, particularly relating to a high-strength wear-resisting rubber bituminous mixture partially using slag as coarse aggregate. The mixture comprises slag coarse aggregate, natural stone coarse aggregate, fine aggregate, filler and rubber asphalt, wherein part of coarse aggregate is the slag; part of coarse aggregate is basalt, diabase or limestone; the fine aggregate is limestone, diabase or basalt; the filler is cement or a mixture of limestone mineral powder and slaked lime; and the rubber asphalt is produced by selecting waste cart tire rubber powder with a granularity greater than or equal to 20 meshes and lower than or equal to 40 meshes. The invention fully utilizes the slag, waste tires and other waste materials and turns waste into wealth, thereby effectively relieving environmental pollution caused by the slag and the waste tires. The mixture is a dense grade bituminous mixture using the slag as the coarse aggregate and using the rubber asphalt as a matrix, which has good high-temperature stability, low-temperature crack resistance, normal-temperature fatigue resistance and other performances, and is applicable to various traffic road engineering.

Owner:上海佳砼新材料科技发展有限公司

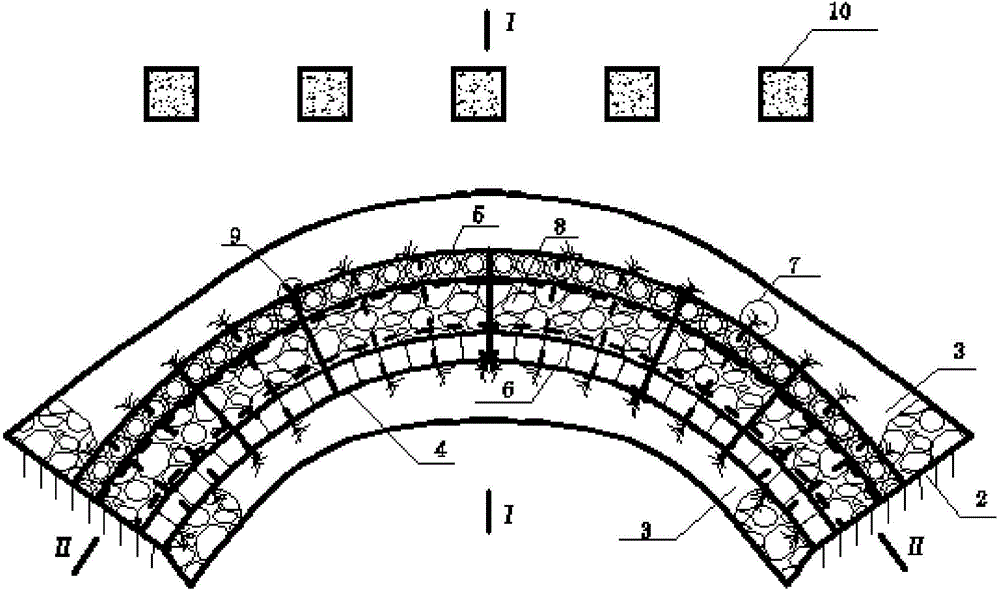

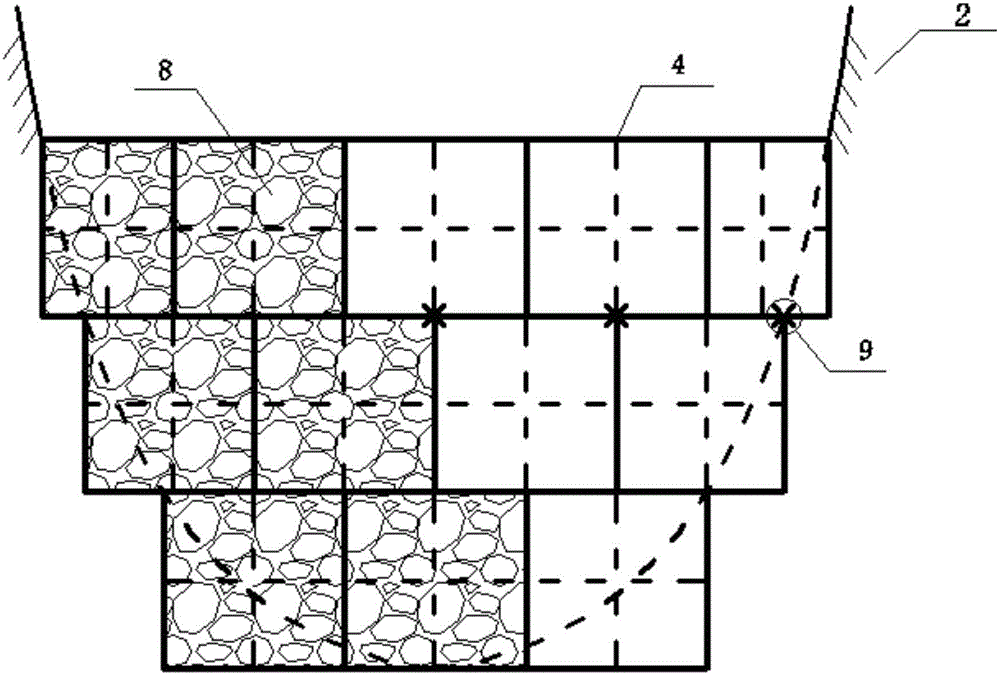

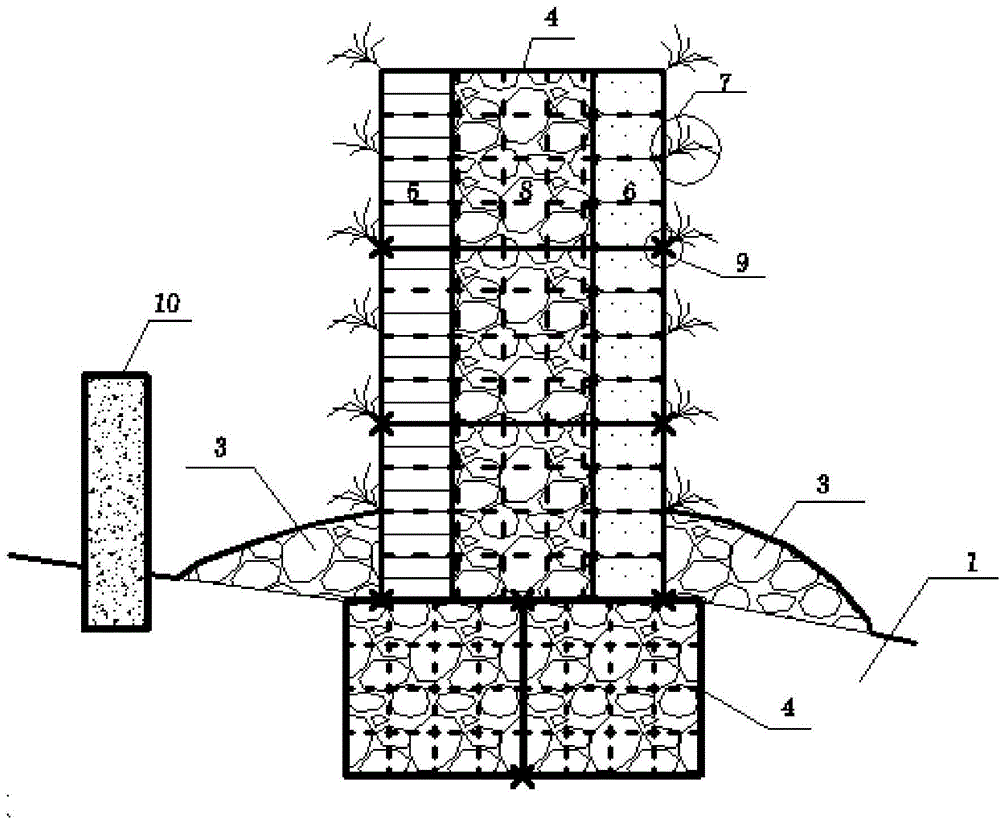

Gabion arch ecological flexible debris flow blocking dam and building method thereof

ActiveCN104164851AReasonable mechanical designSimple construction processDykesArch damsEnvironmental resource managementGabion

The invention provides a gabion arch ecological flexible debris flow blocking dam and a building method of the gabion arch ecological flexible debris flow blocking dam. The gabion arch ecological flexible debris flow blocking dam is an arch-shaped blocking dam. According to the structure of the gabion arch ecological flexible debris flow blocking dam, gabion box pieces filled with rock ballast are stacked and piled on a foundation, and the gabion box pieces are bound, so that the integrality of the whole blocking dam structure is improved; waste tires filled with clinosol layer by layer are horizontally laid on the upstream face of the inner side of the gabion box pieces; ecological bags filled with clinosol layer by layer are piled on the downstream face of the inner side of the gabion box pieces; the areas between the waste tires and the ecological bags are filled with rock ballast which is compacted through vibrating. According to an optimal scheme, vegetation is placed in soil between layers of the waste tires and the ecological bags on the upstream side and the downstream side of the gabion arch blocking dam through cuttage, the plant anchor rod function and the ecological surface protection function are achieved, and then the gabion arch ecological flexible debris flow blocking dam is formed. The gabion arch ecological flexible debris flow blocking dam has the advantages that the mechanical design is reasonable, the construction technology is simple, cost is low, popularization is easy, the gabion arch ecological flexible debris flow blocking dam can replace a masonry blocking dam and a concrete dam which are prone to damage, and a debris flow disaster can be effectively prevented and handled.

Owner:NANJING HYDRAULIC RES INST +1

Wide temperature range modified asphalt for roads and preparation method thereof

The invention relates to wide temperature range modified asphalt for roads. The asphalt is composed of, by weight, 80-90 parts of matrix asphalt, 1-6 parts of SBS (styrene-butadiene-styrene) modifier, 10-30 parts of activated waste tire rubber powder, 2-6 parts of light oil, 0.1-0.5 part of terpene resin and 0.1-0.5 part of elemental sulfur. The wide temperature range modified asphalt for the roads has good performances of being free of flowing at high temperature and being free of cracking at low temperature, usage temperature range can reach higher than 100 DEG C, the preparation method is simple, and production can be directly performed on original SBS modifier production devices, so that cost investment of production equipment is reduced.

Owner:甘肃交通规划勘察设计院有限责任公司

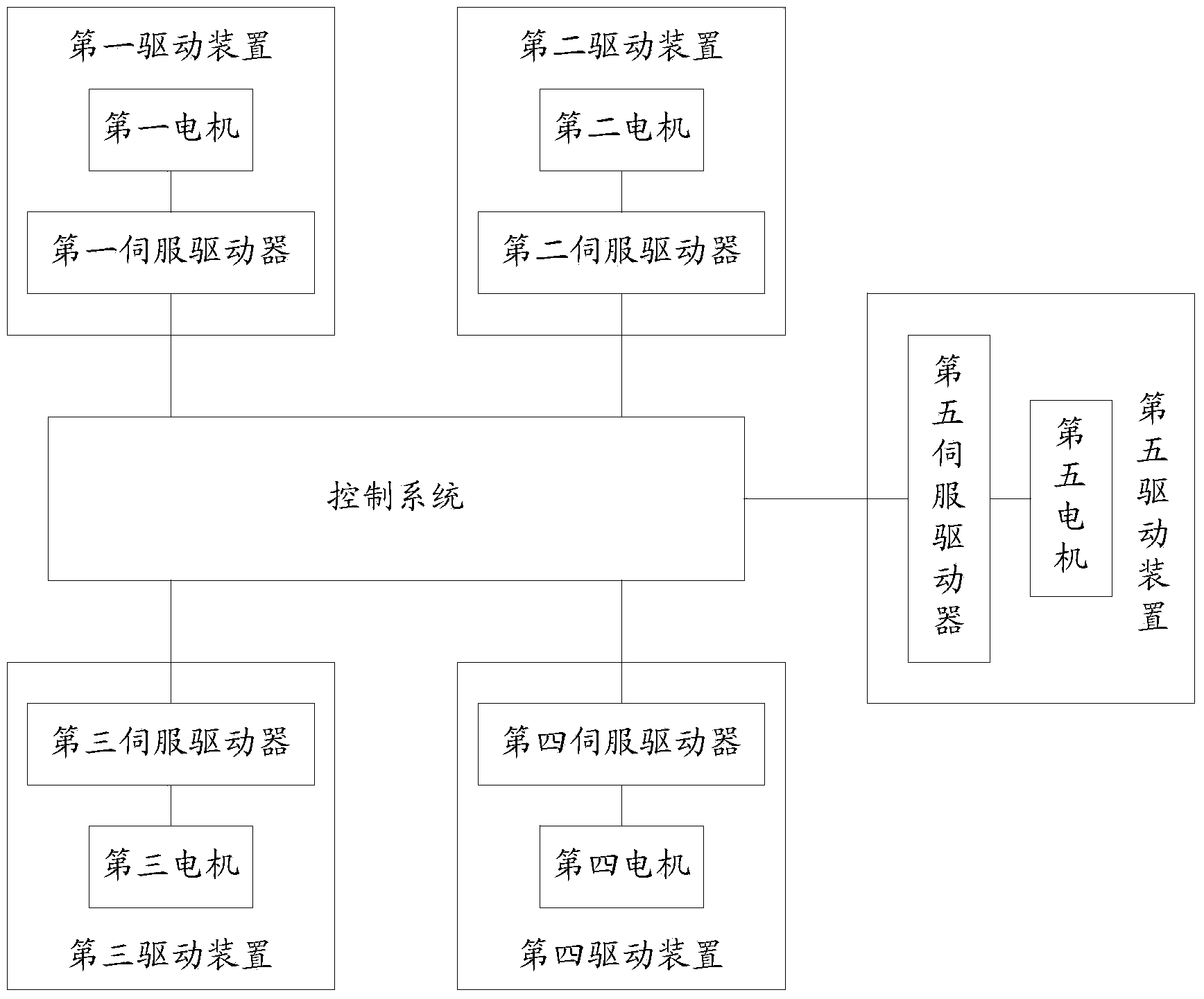

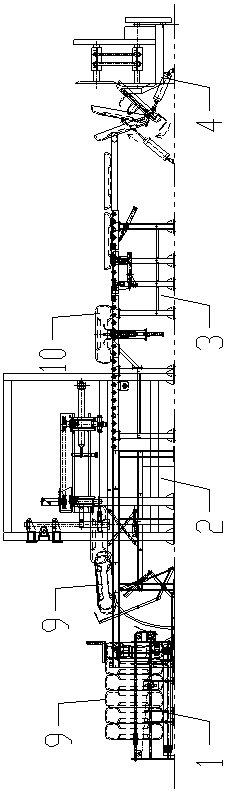

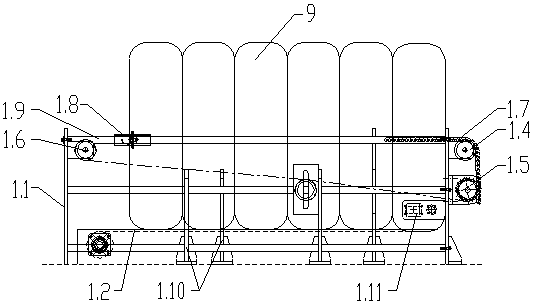

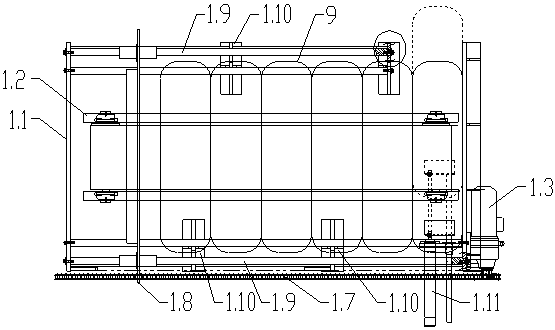

Automatic waste tire dicing production line

ActiveCN108274655AImprove work efficiencyHigh degree of automationPlastic recyclingTyresProduction lineMaterial supply

The invention relates to an automatic waste tire dicing production line comprising a tire material supply device, an automatic tire splitting cutting device, an automatic tire overturning device, a tire slitting machine, a tire dicing machine, an opening ring conveyer belt, a rubber block conveyer belt and an opening ring frame. According to the automatic waste tire dicing production line, the whole system achieves continuous operation, the automation degree is high, the cost is low, and cutter wear is slow.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

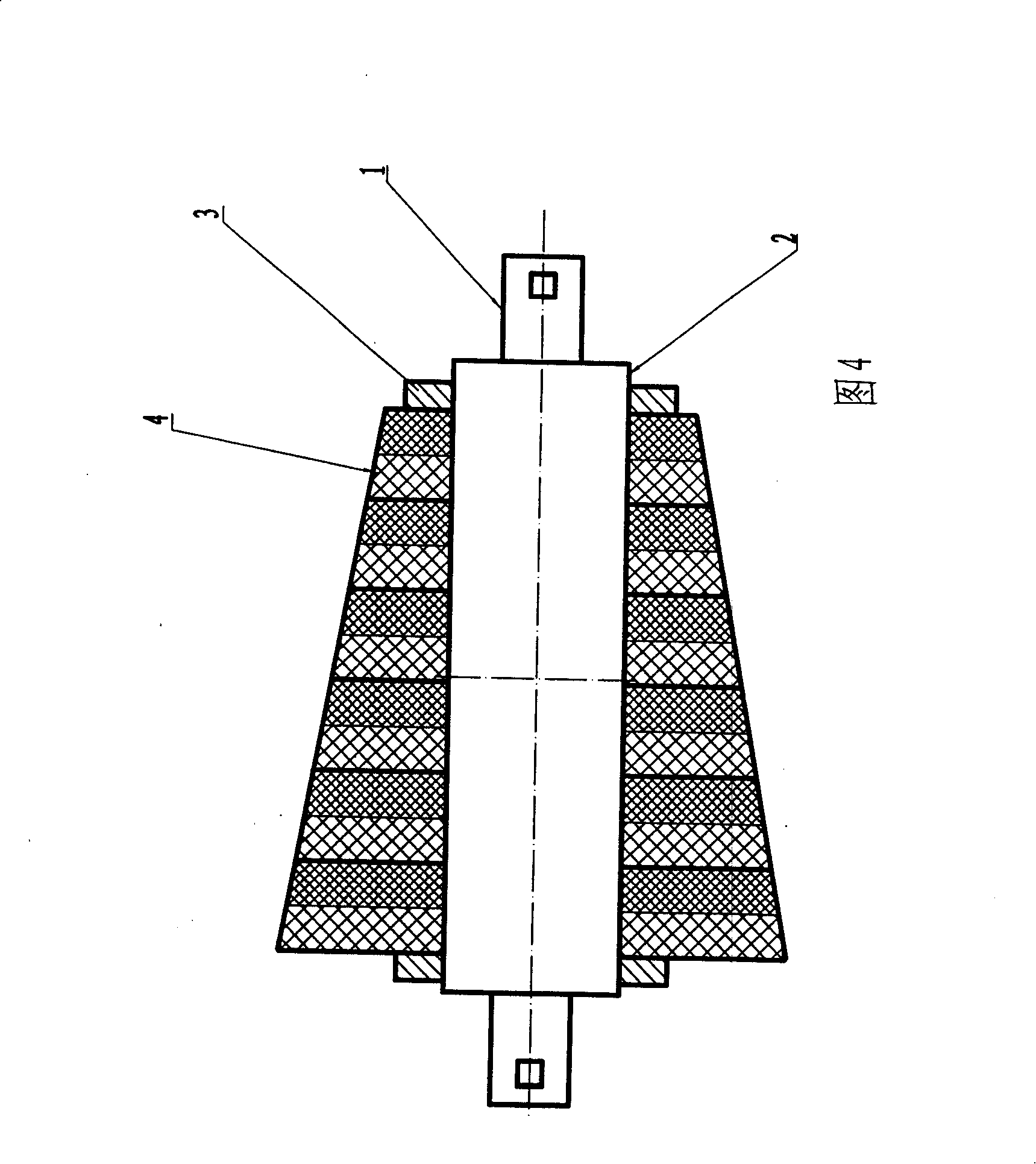

Waste type pulverizer and the rubber powder preparing process therewith

InactiveCN1548232AHigh glue rateEffective productionPlastic recyclingGrain treatmentsWear resistantAgricultural engineering

The waste tire pulverizer includes waste tire inner ring cutting and separating machine, tire crushing machine, steel wire separating machine and waste tire rubber pulverizing machine. The rubber powder preparing process with waste tire includes: cutting and separating waste tire inner ring, crushing tire, separating steel wire and eliminating iron and crushing rubber. The rubber pulverizing machine is provided with wear-resistant high-hardness WC alloy cutters embedded in the inner conic surface of the conic stator and the outer conic surface of the conic rotor, and cooling water cavity in the conic stator and the conic rotor to control temperature raise, so that it can crush rubber into rubber powder of over 60-mesh fineness at normal temperature. The present invention has long service life, fine size of rubber powder, low power consumption and low cost.

Owner:浙江绿环工程机械有限公司

Method for preparing carbon black by electrocracking waste and old tyre

InactiveCN101215387ANo emissionsNo pollution in the processPigmenting treatmentPlastic recyclingExhaust gas emissionsEngineering

The invention relates to a process for preparing carbon black by utilizing electric arc to crack waste and old tires, which utilizes a closed container and electric arc to regulate and control oxygen to constitute an electric-arc cracking furnace, and waste and old tires are cracked in the electric-arc cracking furnace. Steel lines in the waste tires are fused in the electric-arc temperature, steel ingots are directly prepared to recycle, the chemical bond of rubber in the waste and old tires are fractured under the electric-arc temperature and are cracked into carbon black, carbon monoxide, hydrogen gas and the like. The carbon black which is prepared by the upper method has the advantages of big specific surface area, high activity and high utilization valve, the surface characteristic of the carbon black which is originally added in the waste and old tires is restored and improved after the electric-arc temperature. Gases such as carbon monoxide, hydrogen gas and the like which are produced in the electric-arc temperature can be directly utilized by city gas after the process of de-oiling and desulfurizing, the process has no waste gas to be discharge and no pollution.

Owner:王胤

High-performance rubber asphalt pouring sealant and preparation method thereof

InactiveCN103421467AReduce pollutionImprove performanceMineral oil hydrocarbon copolymer adhesivesOther chemical processesCrack resistanceProcess engineering

The invention discloses high-performance rubber asphalt pouring sealant and a preparation method thereof. The high-performance rubber asphalt pouring sealant is made from rubber powder, modifier, petroleum asphalt, tackifier, cosolvent, and stabilizer. The preparation method includes: heating the asphalt to 150-160 DEG C, adding the modifier, stirring to obtain liquid, adding the cosolvent and mixing for 30 minutes, heating to 190-200 DEG C, slowly adding the rubber powder, mixing for 30 minutes, adding the tackifier and the stabilizer, and mixing for 15 minutes to produce high-performance rubber asphalt pouring sealant. The rubber powder of waste tires is utilized, and accordingly product performance is improved, product cost is reduced and environmental pollution is reduced; the modifier, the rubber powder and the asphalt are mixed into stable, even mixture through the cosolvent, so that resin groups, rubber powder groups and asphalt groups can form a stable interlinked structure; through the modifier, route performance of the sealant can be improved, for example, softening point is increased and low temperature cracking resistance is improved; new cracks can be prevented effectively.

Owner:XIYUEFA INT ENVIRONMENTAL PROTECTION NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com