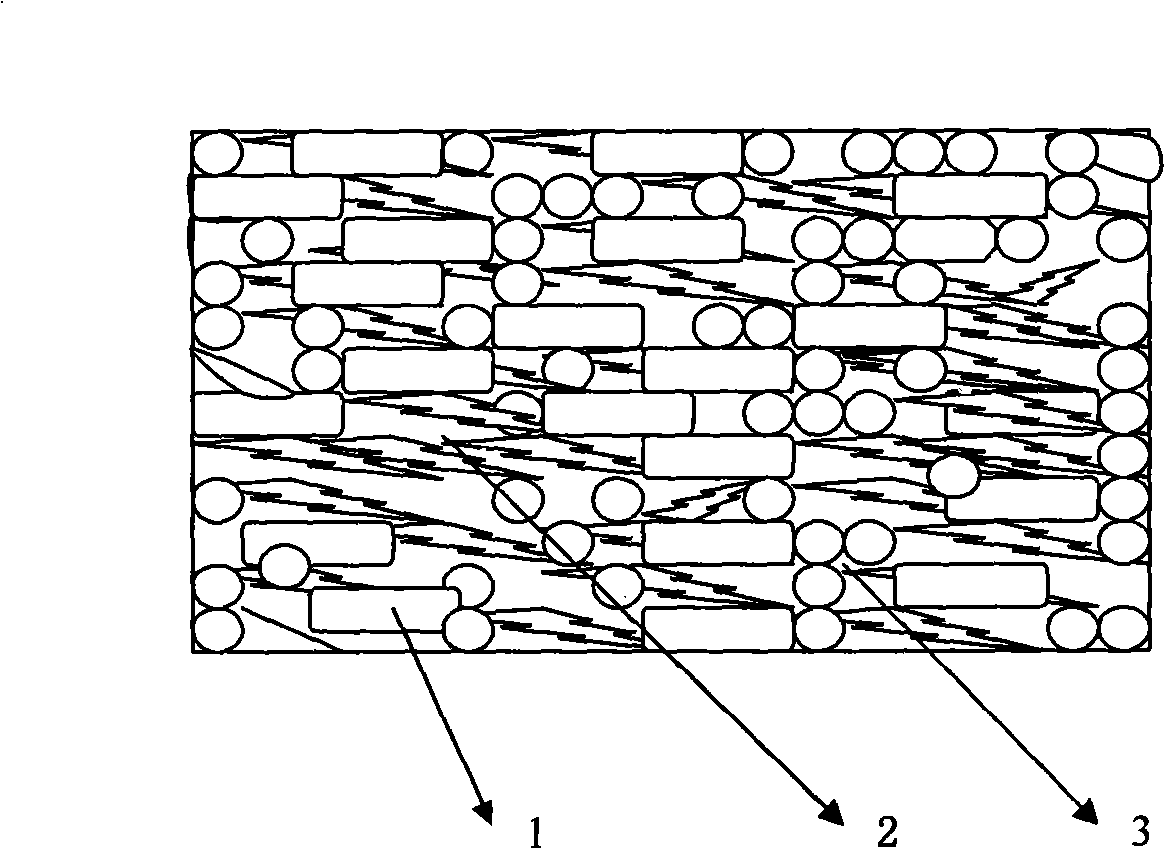

Rubber-wood-cement composite material

A technology for composite materials and wood materials, applied in the field of cement-based composite materials, can solve problems such as large differences in material properties, difficult research and application of composite materials, etc., to improve compatibility, facilitate heat preservation and energy saving, and improve continuity. degree and effect on labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw materials: 10 kg of rubber particles, 17 kg of wood shavings, 45 kg of cement, 0.3 kg of polyisocyanate (PMDI), 1.5 kg of sodium silicate, 14 liters of water, and 2% sodium hydroxide aqueous solution.

[0046] Raw material pretreatment: use waste tire rubber as raw material, process it into granule, the geometric size of rubber granule is 1mm. 0.15 kg of acetone (40% of the amount of PMDI) is fully mixed with PMDI and then poured into a hand-pressed watering can. The PMDI mixture is atomized by a pressure pump and evenly applied to the surface of the rubber particles.

[0047] The wood material is wood shavings, which are mixed with ordinary industrial wood shavings with geometric dimensions of 2mm-15mm in length, 0.2-20mm in width, and 0.2-2.0mm in thickness, which may contain sawdust. Prepare an aqueous solution with a mass concentration of 2% with sodium hydroxide, soak 17 kg of wood shavings for 5 hours, take them out and dry them until the water content is abou...

Embodiment 2

[0054] Raw material ratio: 12 kg of rubber particles, 18 kg of wood shavings, 42 kg of cement, 0.36 kg of polyisocyanate, 0.5 kg of organic reinforcing material PC, 1.5 kg of sodium silicate, 14 kg of water, and 2% sodium hydroxide aqueous solution.

[0055] Raw material pretreatment: use waste rubber tires as raw materials, use the same method as in Example 1 to make rubber granules with a geometric size of 2 mm, and apply the mixture of MDI and acetone evenly on the surface of the rubber granules.

[0056] The wooden material is selected from wood processing residues, and wood shavings with a length of 2 mm to 15 mm, a width of 0.2 to 20 mm, and a thickness of 0.2 to 2.0 mm are selected for mixing; the wood shavings are soaked in 2% sodium hydroxide aqueous solution for 5 hours, taken out and dried until The moisture content is about 7%.

[0057] The cement is made of ordinary Portland cement with a model number of 52.5.

[0058] The organic reinforcing material PC is a com...

Embodiment 3

[0062] Raw material ratio: 5 kg of rubber particles, 40 kg of short-needled rod-shaped wood shavings, 40 kg of cement, 0.4 kg of polyisocyanate, 0.2 kg of glass fiber, 0.8 kg of potassium sulfate, and 10 kg of water. The preparation process is similar to that of Example 1, except that the rubber particles are made of waste rubber product rubber soles, and the geometric size is 0.5mm; the wood material is selected from wood processing residues, and processed into about 25mm in length and 10mm in diameter The short-needled rod-shaped wood shavings are soaked in 2% sodium hydroxide aqueous solution for 5 hours and then dried to a moisture content of about 12%; the thickness of the slab is 12mm, and it is pressed at room temperature with a pressure of 3MPa and a time of 25min. .

[0063] Sheet properties: density is 1198kg / m 3 , static bending strength ≥ 14.3MPa, elastic modulus ≥ 2786MPa, tensile strength ≥ 4.7MPa, water absorption thickness expansion rate ≤ 5.1%, average bendin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com