Patents

Literature

97results about How to "High degree of continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated high-strength floor deck and preparation method thereof

InactiveCN105110743AQuick releaseIncrease profitSolid waste managementSurface layerMaterials science

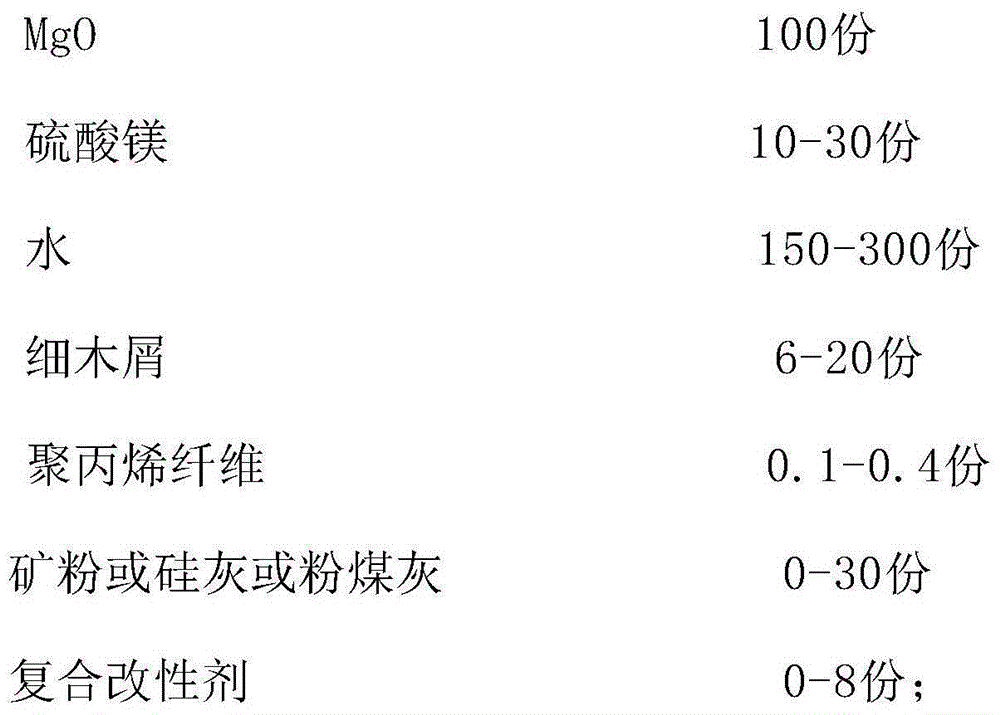

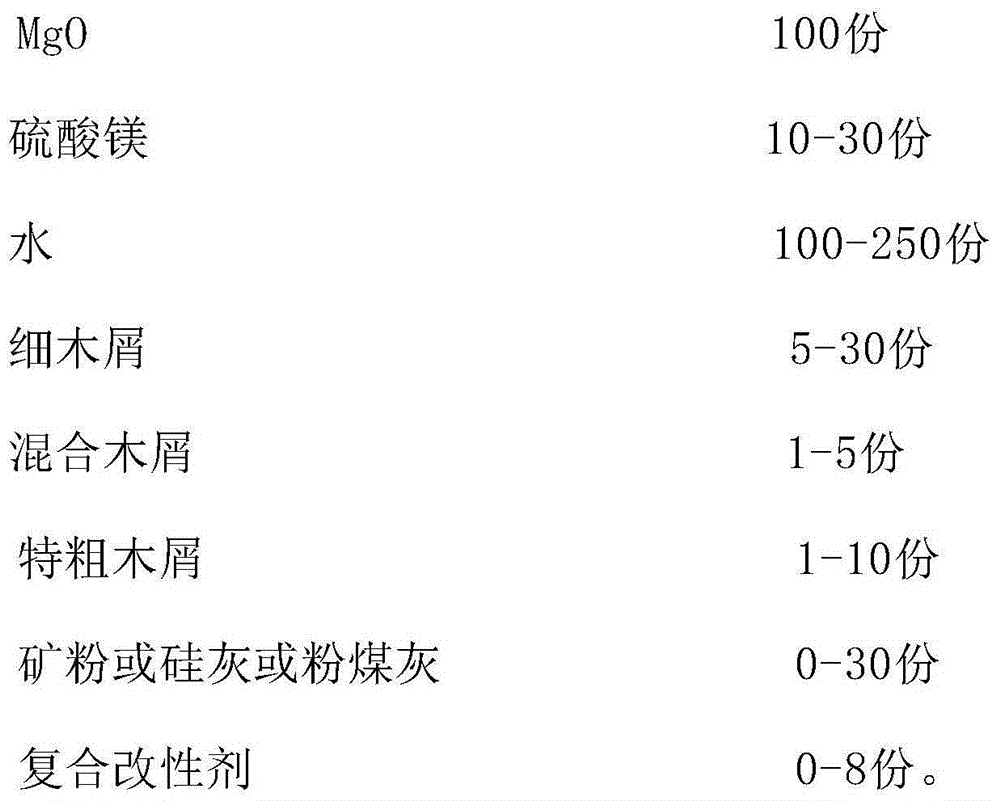

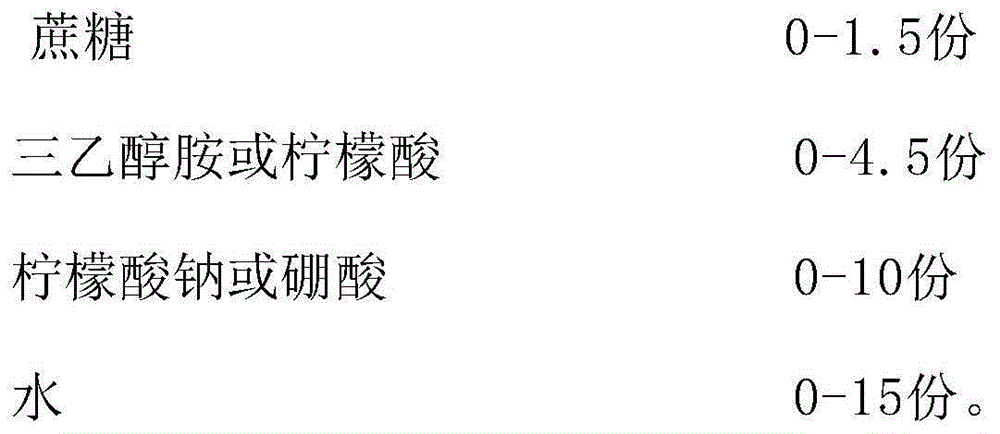

The invention discloses a prefabricated high-strength floor deck and a preparation method thereof. The floor deck comprises an upper surface layer, a middle material layer and a bottom surface layer, wherein the upper and bottom surface layers are both composed of MgO, magnesium sulfate, water, fine wood chip, and polypropylene fibre, and the middle material layer is composed of MgO, magnesium sulfate, water, fine wood chip, mixed wood chip, and extra thick wood chip. Compared with the prior art, the floor deck can realize industrialization of building the floor deck, and overcome the disadvantages of intensive labor force, need for various work types, long completion period, and heavy workload in a traditional floor deck installation process.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Novel method for recovering solvent for polymerization of poly(p-phenytene terephthalamide)

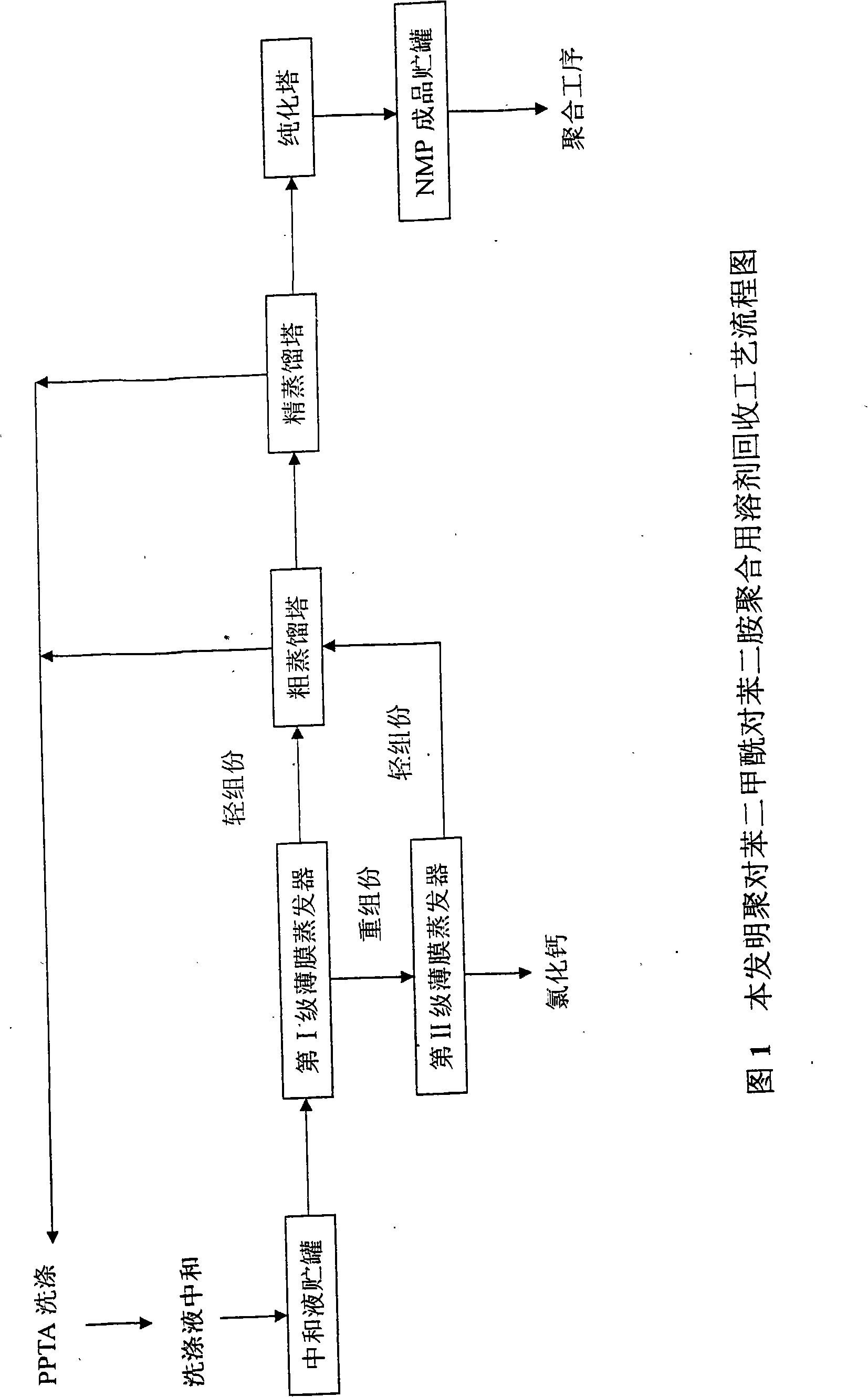

The invention relates to a novel method for recycling a solvent used for polymerizing the poly (p-phenylene terephthalamide) which has a shortened form of para-aramid or PPTA. The method comprises the following steps that: the PPTA polymer made by the low-temperature solution polycondensation contains a large amount of solution N-Methyl pyrrolidine which has a shortened form of NMP and certain amount of calcium chloride (CaCl2), the PPTA polymer is washed by deionized water for a plurality of times, the PPTA polymer is collected to enter a drying system, a scrub solution is neutralized and enters a neutralizing liquid storage tank of a solvent recycling system; the neutralizing fluid is processed by a two-stage film evaporator to remove the CaCl2 added to the polyreaction and generated by the neutralizing reaction, the hydration NMP enters the middle part of a topping still from the top of the film evaporator in a state of mixed gas to remove most of water by the distillation process, the purity quotient of NMP is improved further and the minim water inside the NMP is lowered by the rectification and purification processes, the obtained NMP has a purity quotient higher than 99.5 percent, a water content lower than 100ppm, thereby completely satisfying the requirement of PPTA polymerization. The technique is used for recycling the solvent for PPTA polymerization; the recycling rate of the NMP is higher than 96 percent, thereby lowering the cost further and providing reliable guarantee for the industrialization of the para-aramid.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

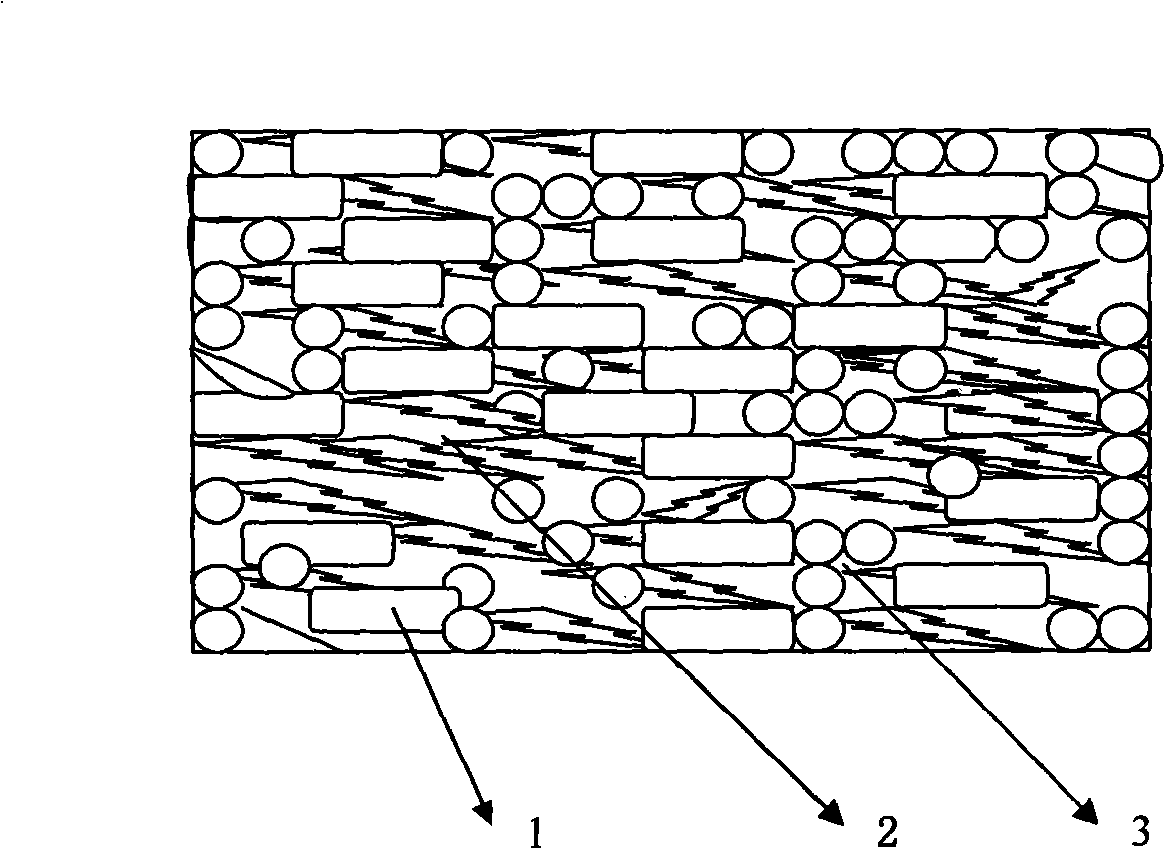

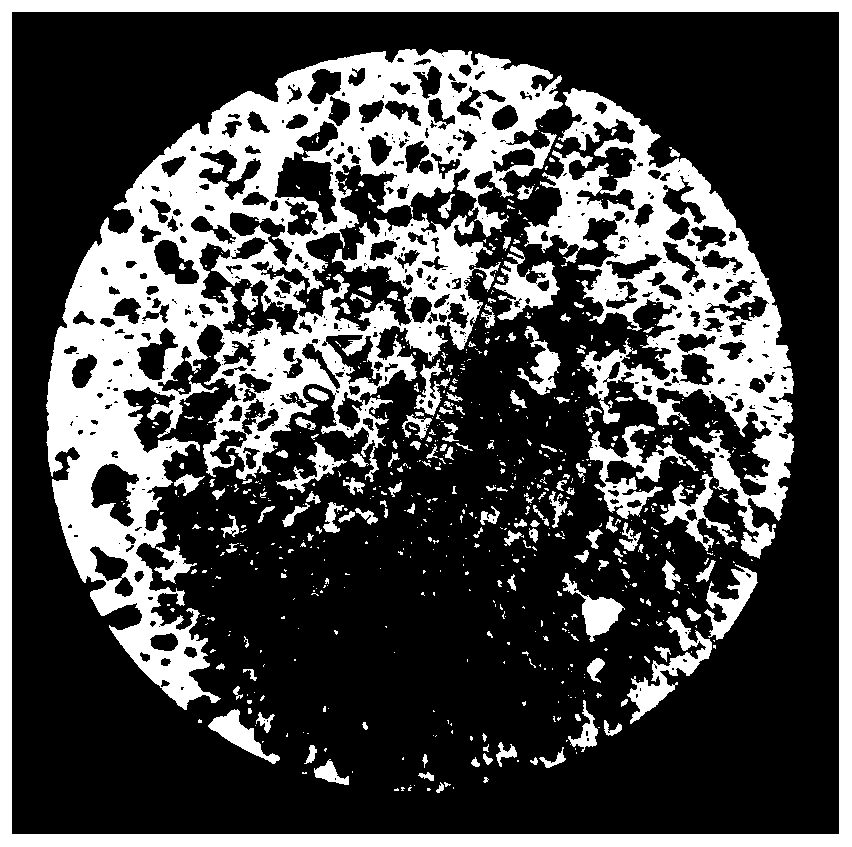

Rubber-wood-cement composite material

ActiveCN101298379AShorten the production cycleHigh degree of continuitySolid waste managementWear resistantAdhesive

The invention provides a rubber-timber-cement functional environment-friendly compound material, which belongs to the field of cement-base compound material. The material adopts the waste tire rubber, waste rubber products, woody material and silicate cement as raw materials, an isocyanate-based adhesive is coated on the surface of the waste rubber particles, then the woody material is soaked and dried, and the treated rubber particles, the woody material and cement are mixed to form a blank material, which is finally laid, pressed and cured so as to obtain the compound material. The compound material provided by the invention can absorb and insulate sound, has high shock resistance and damping property, and is wear-resistant, antistatic, mothproof, waterproof and anticorrosive; also the material is heat-insulating and friendly to the environment, etc.; the production process has no chemical pollution source, no radioactivity, no light pollution and no noise. The invention blazes a new path for solving the 'black pollution' of increasing waste tires, which is a global problem; additionally, the compound material can be used for producing structural lumber.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

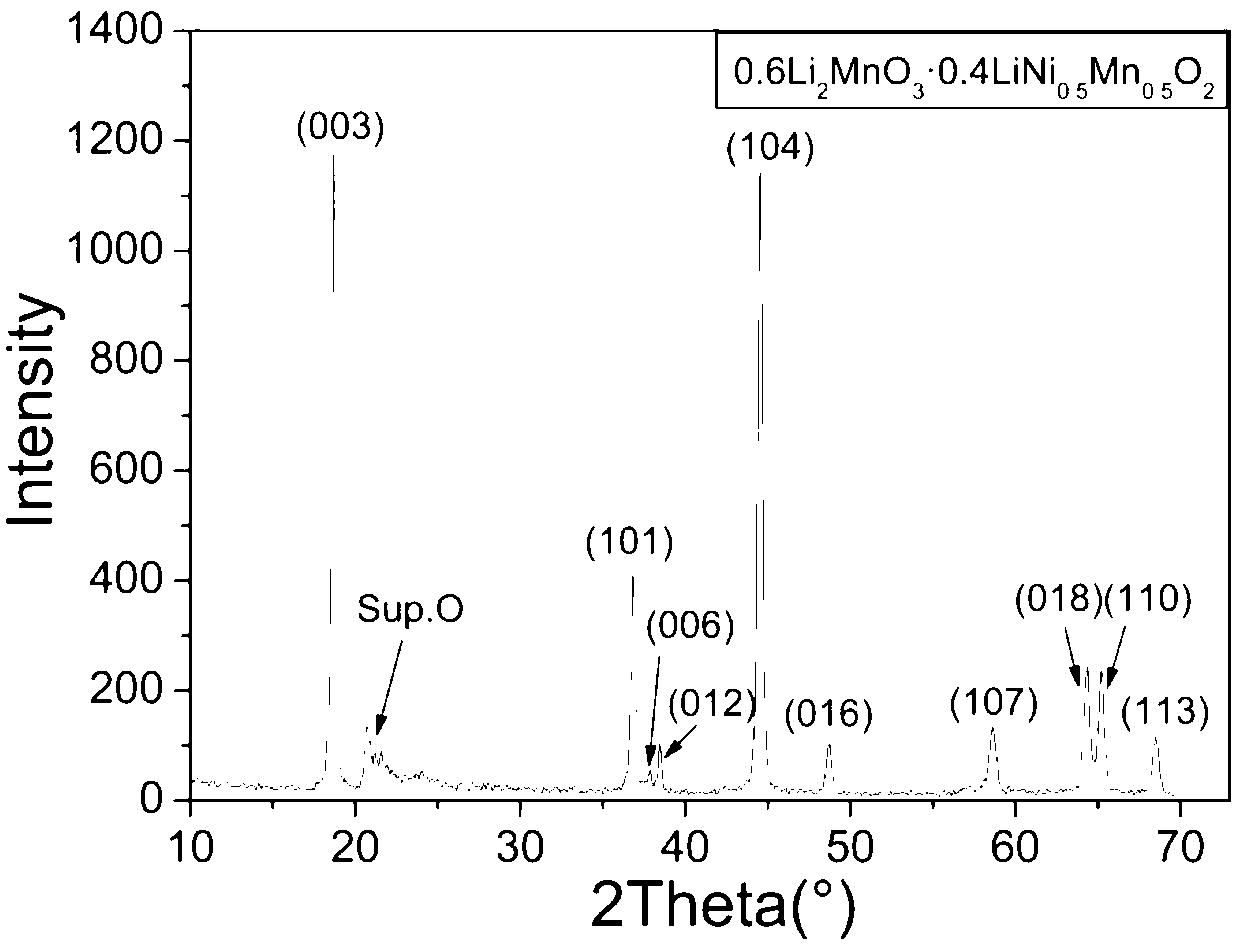

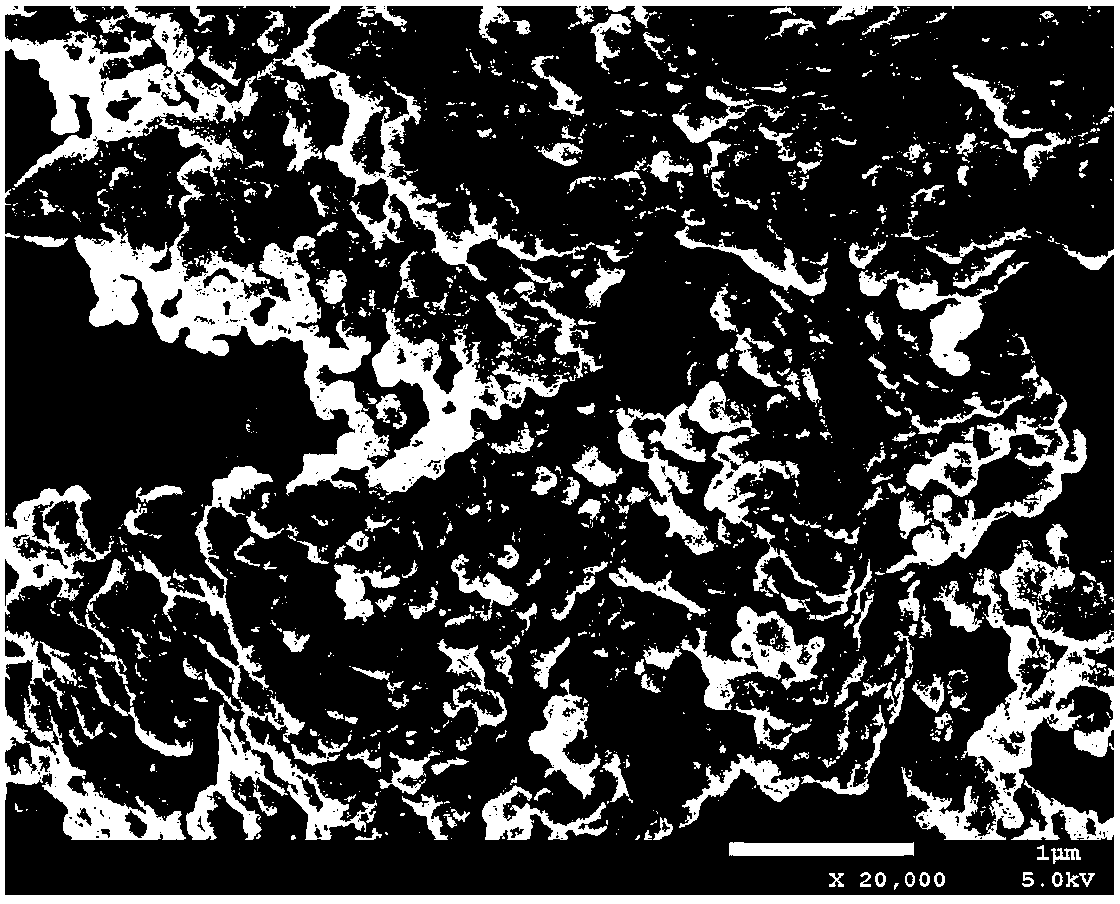

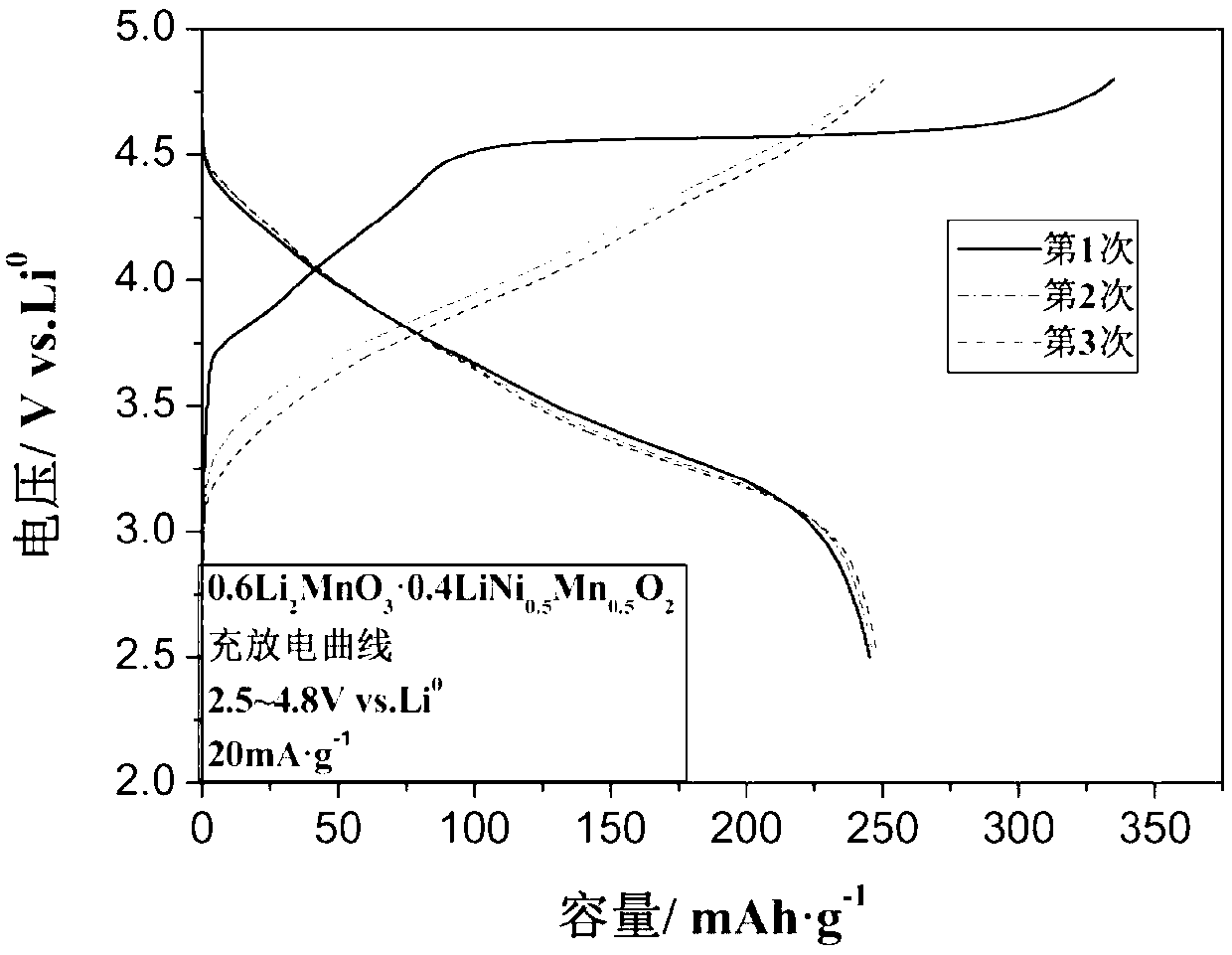

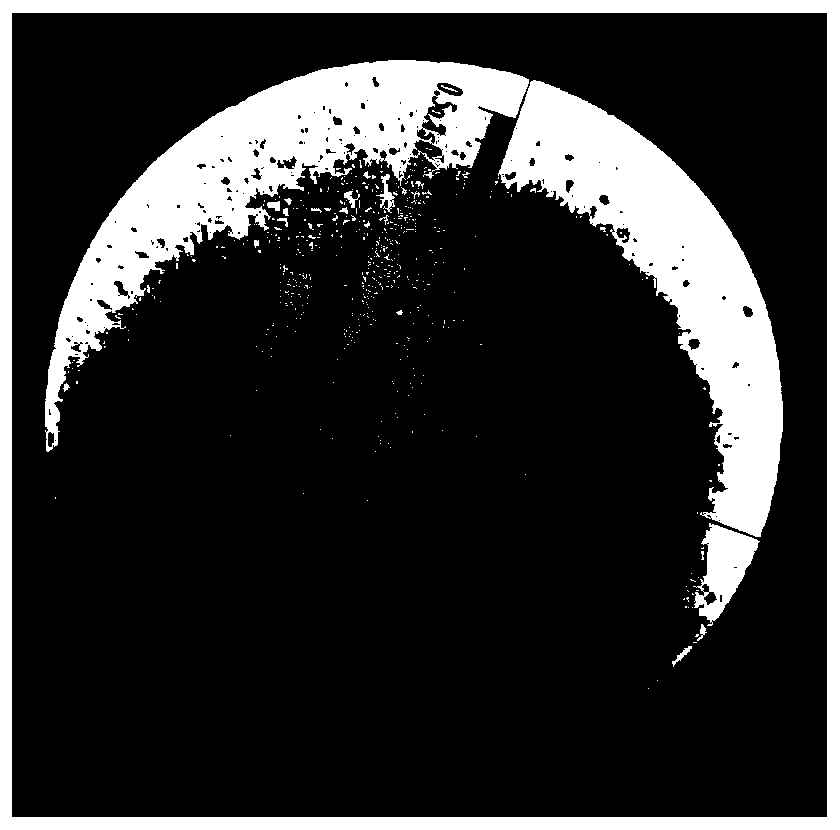

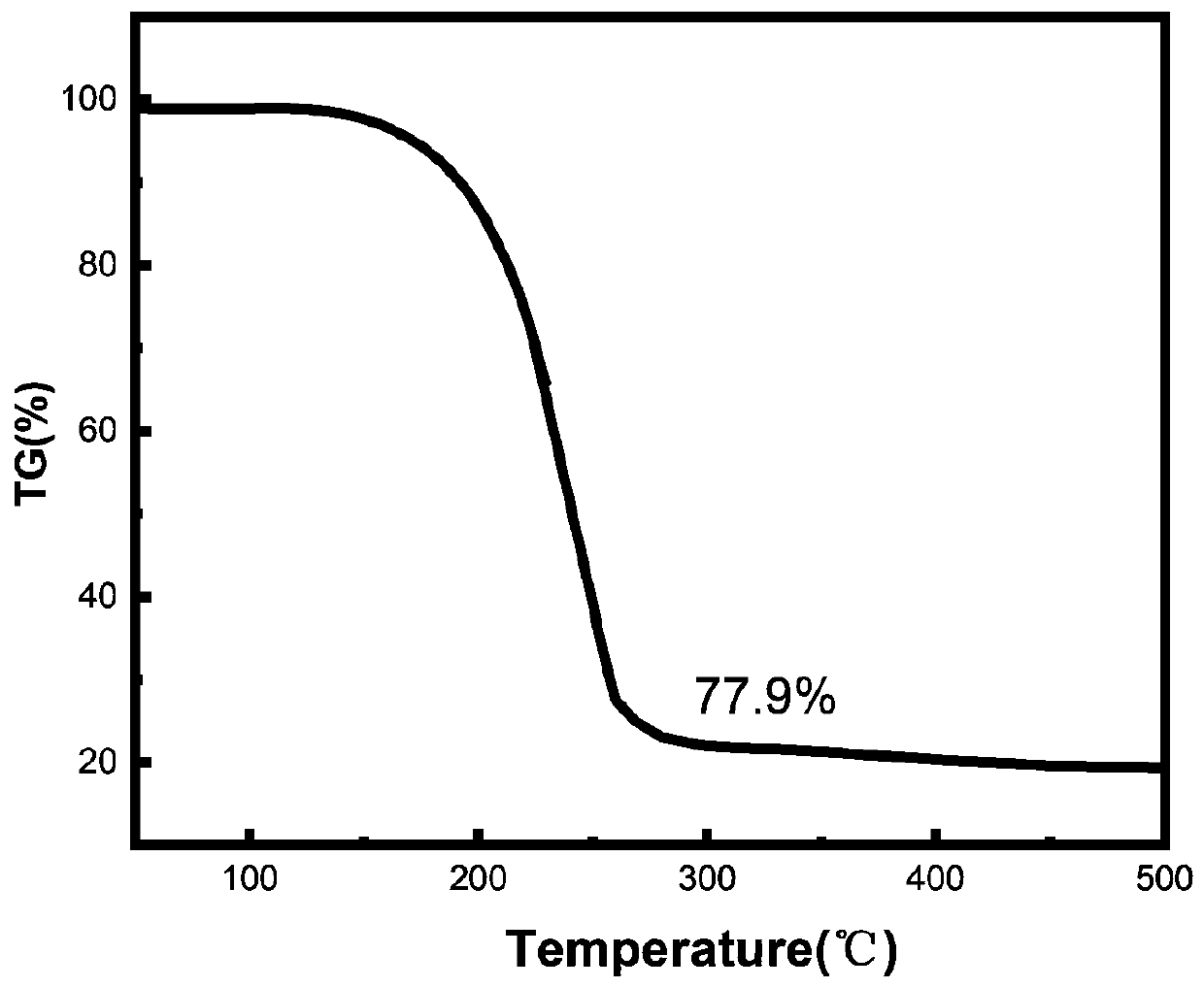

Lithium-rich manganese-based material and preparation method thereof

The invention relates to a lithium-rich manganese-based material and a preparation method thereof. The preparation method is a sol-spray pyrolysis method and comprises the steps of precursor sol preparation, spray drying, high-temperature calcining and the like. The preparation method disclosed by the invention has the advantages of simple process flow, less equipment input, high continuous degree and no exhaust of tail gas or discharge of waste liquid. The lithium-rich manganese-based anode material disclosed by the invention has excellent electrochemical performance, discharge capacity as high as 225-250A.h.g<-1> and favorable excellent performance; and under the multiplying power of 0.5C, the discharge capacity of the lithium-rich manganese-based material can be maintained over 150mA.h.g<-1>.

Owner:SICHUAN UNIV

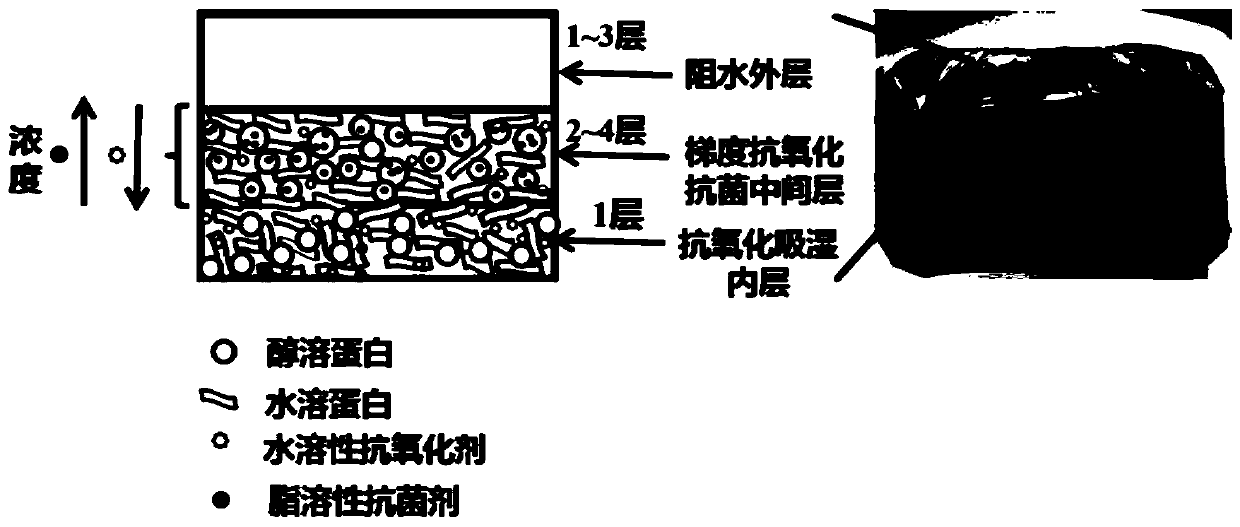

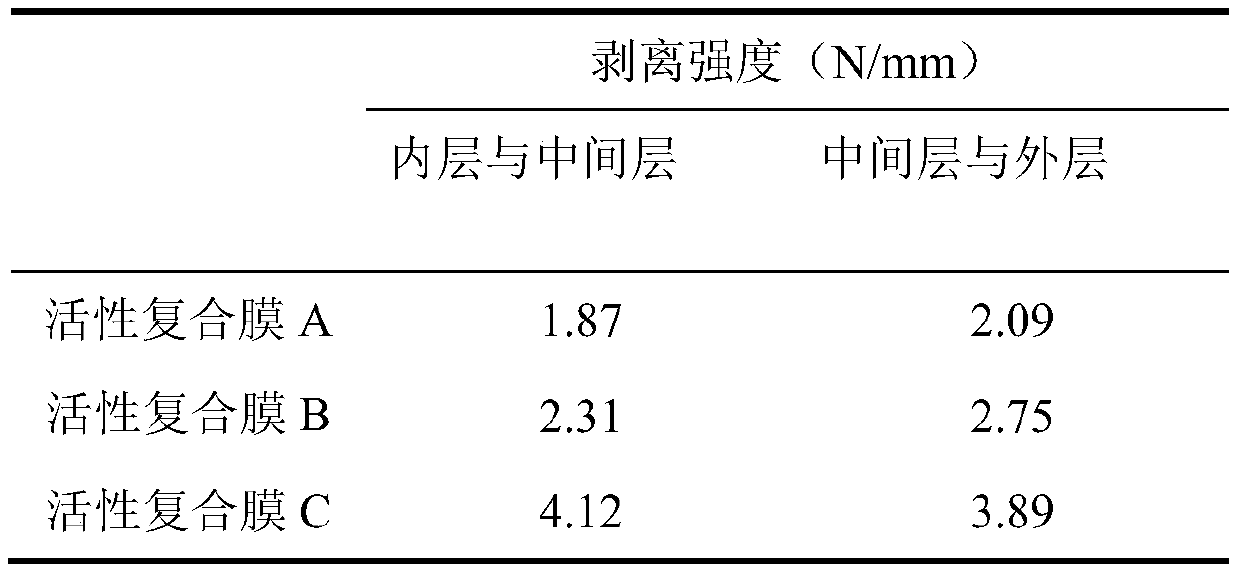

Gradient-slow-release type active composite film and preparing method thereof

ActiveCN110202860AHigh retention rateRealize double encapsulation structureFlexible coversWrappersComposite filmMass ratio

The invention discloses a gradient-slow-release type active composite film and a preparing method thereof. The active composite film is composed of an anti-oxidation moisture absorption inner layer, at least one layer of gradient antibacterial anti-oxidation middle layer and at least one layer of waterproof outer layer from inside to outside. The anti-oxidation moisture absorption inner layer is prepared from an alcohol-soluble protein and water-soluble protein substrate and a water-soluble antioxidant. Each gradient antibacterial anti-oxidation middle layer is prepared from an alcohol-solubleprotein and water-soluble protein substrate, fat-soluble plant essential oil and a water-soluble antioxidant. The mass ratio of alcohol-soluble protein to water-soluble protein is (1-2):(1-2). Each waterproof outer layer is composed of a hydrophobic alcohol-soluble protein layer. The active composite film has long-acting anti-oxidation performance, long-acting antibacterial performance, one-way moisture resistance and good mechanical performance, can effectively improve the retention rate and long-acting performance of active matter, can effectively prevent fruits, vegetables, meat and otherfoods from water loss, oxidization and corrosion, and is high in film forming process continuation degree and short in production cycle, and the large-scale industrial production can be realized.

Owner:SOUTH CHINA AGRI UNIV

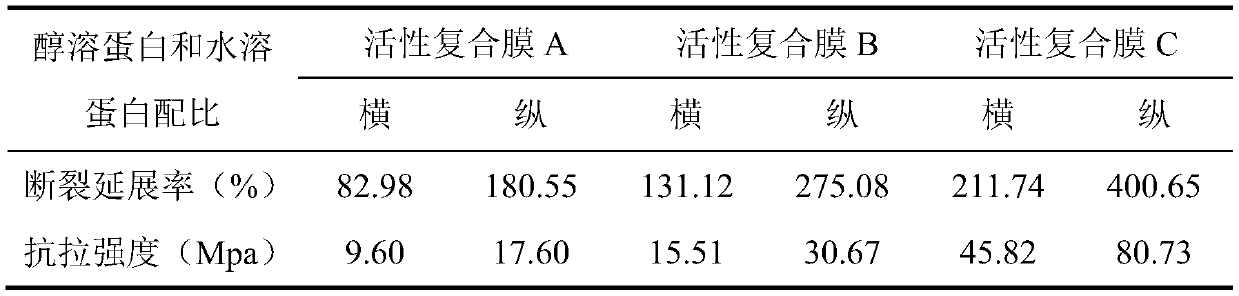

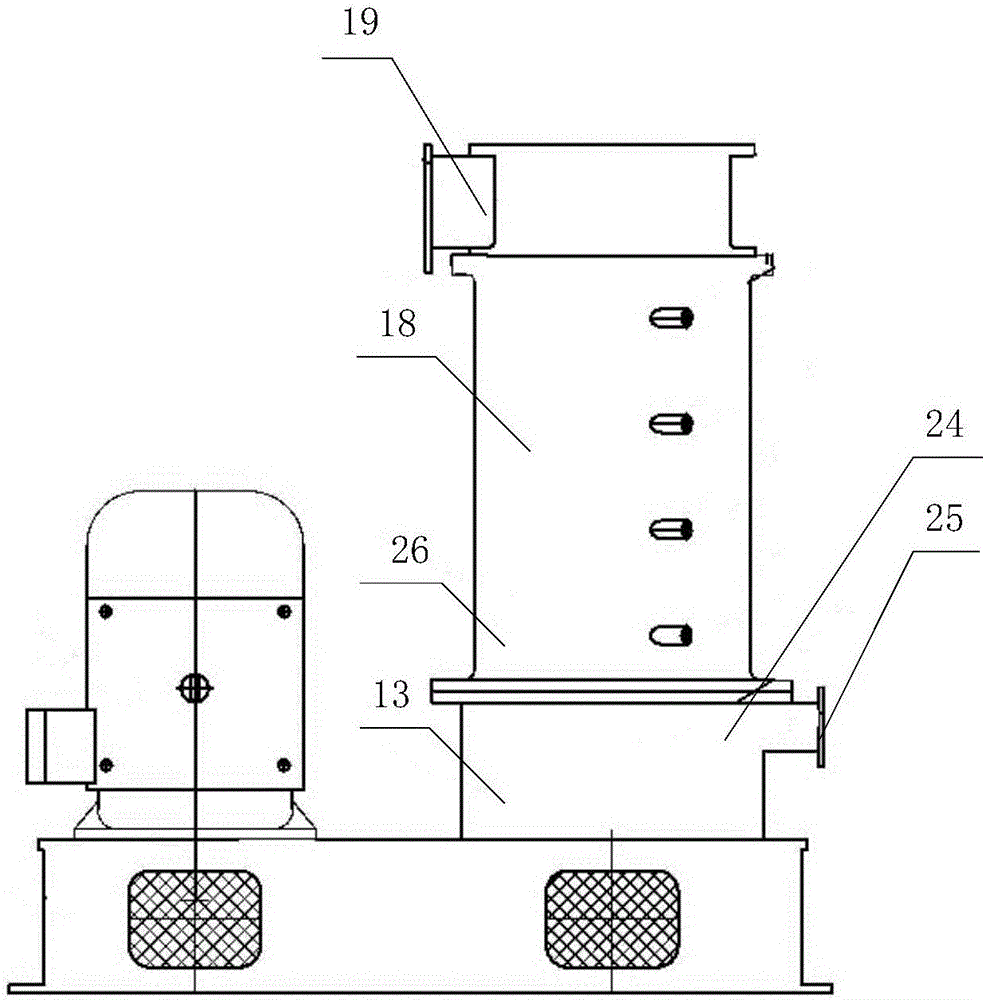

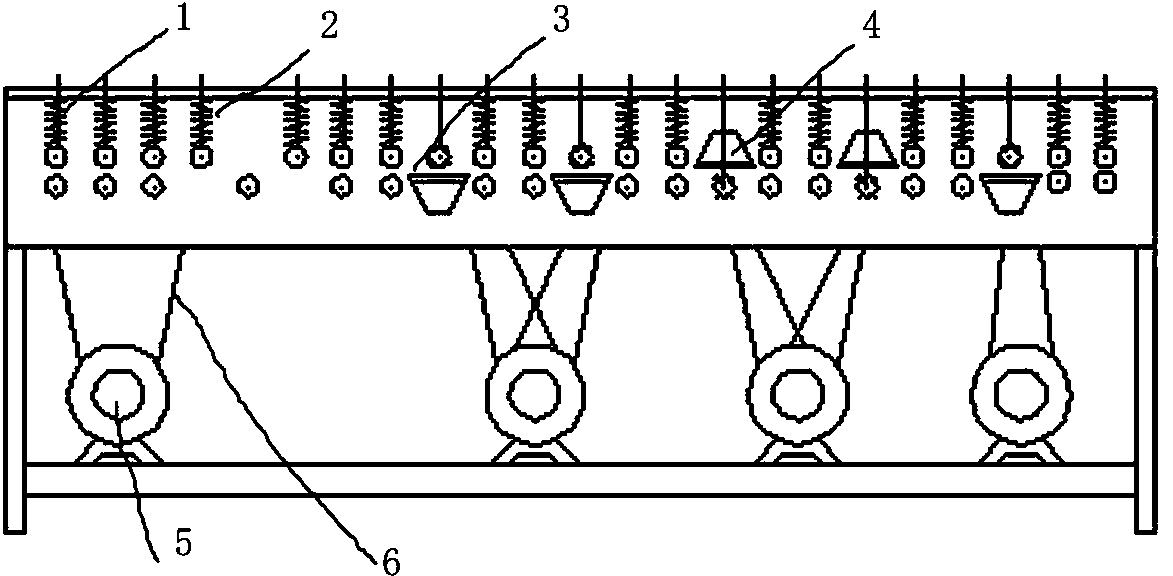

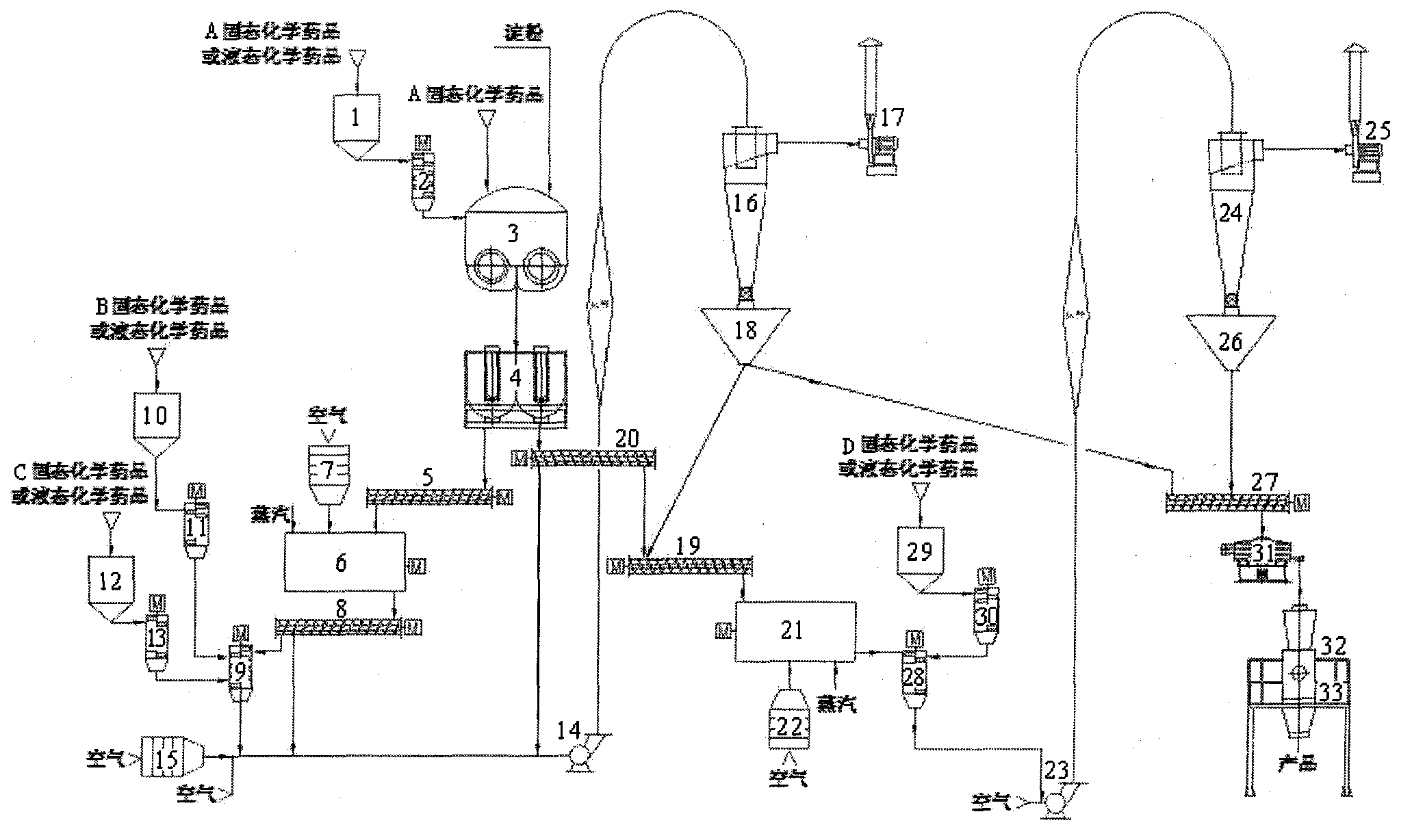

Production line of powder compound modification machine

InactiveCN105773873AHigh degree of continuityAdjustable temperatureFlow mixersTransportation and packagingProduction lineDepolymerization

The invention discloses a production line of a powder compound modification machine. The production line comprises the powder compound modification machine, a raw material bin, a hot air generator and a drug feeding device, wherein the raw material bin and the hot air generator are connected with a feed inlet of the powder compound modification machine; a metering and feeding device is connected between the feed inlet and the raw material bin; a discharge outlet of the powder compound modification machine is connected with an induced draft fan; a finished product and removed dust collecting device is connected between the induced draft fan and the discharge outlet; and the drug feeding device is connected with a modifying agent inlet and a scattering agent inlet of the powder compound modification machine. According to the production line of the powder compound modification machine, a system is made to be of negative pressure by means of the induced draft fan and the hot air generator, the metering and feeding device is used for weighing and metering powder, the powder compound modification machine is used for scattering and depolymerizing the powder, and the powder is scattered sufficiently and depolymerized completely within an extremely short period and forms a unimolecule wrapping film finally. The production line integrates the functions of powder drying, grinding depolymerization, compound modification and scattering treatment and can achieve scale production.

Owner:CHANGSHA WANRONG MILLING EQUIP

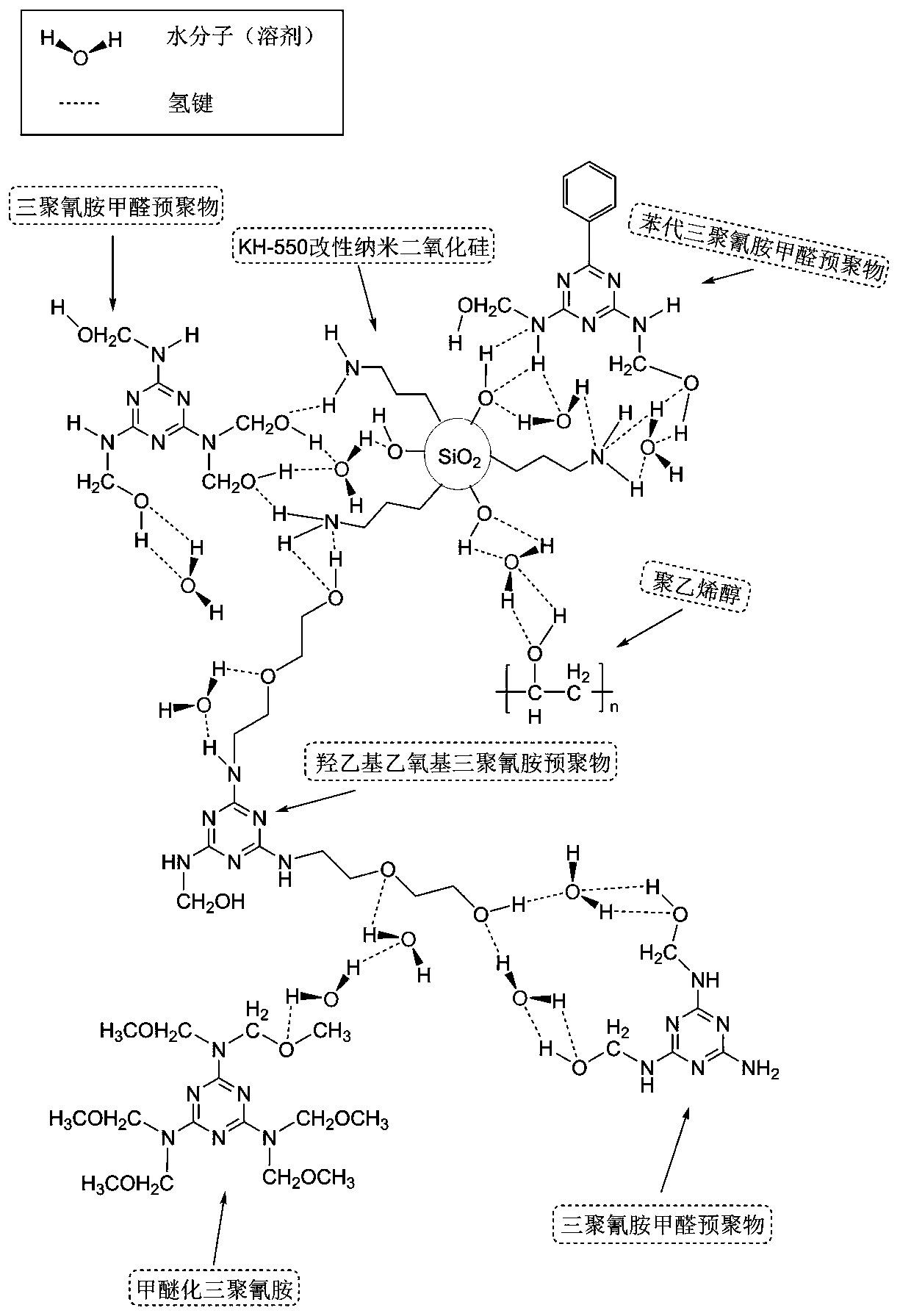

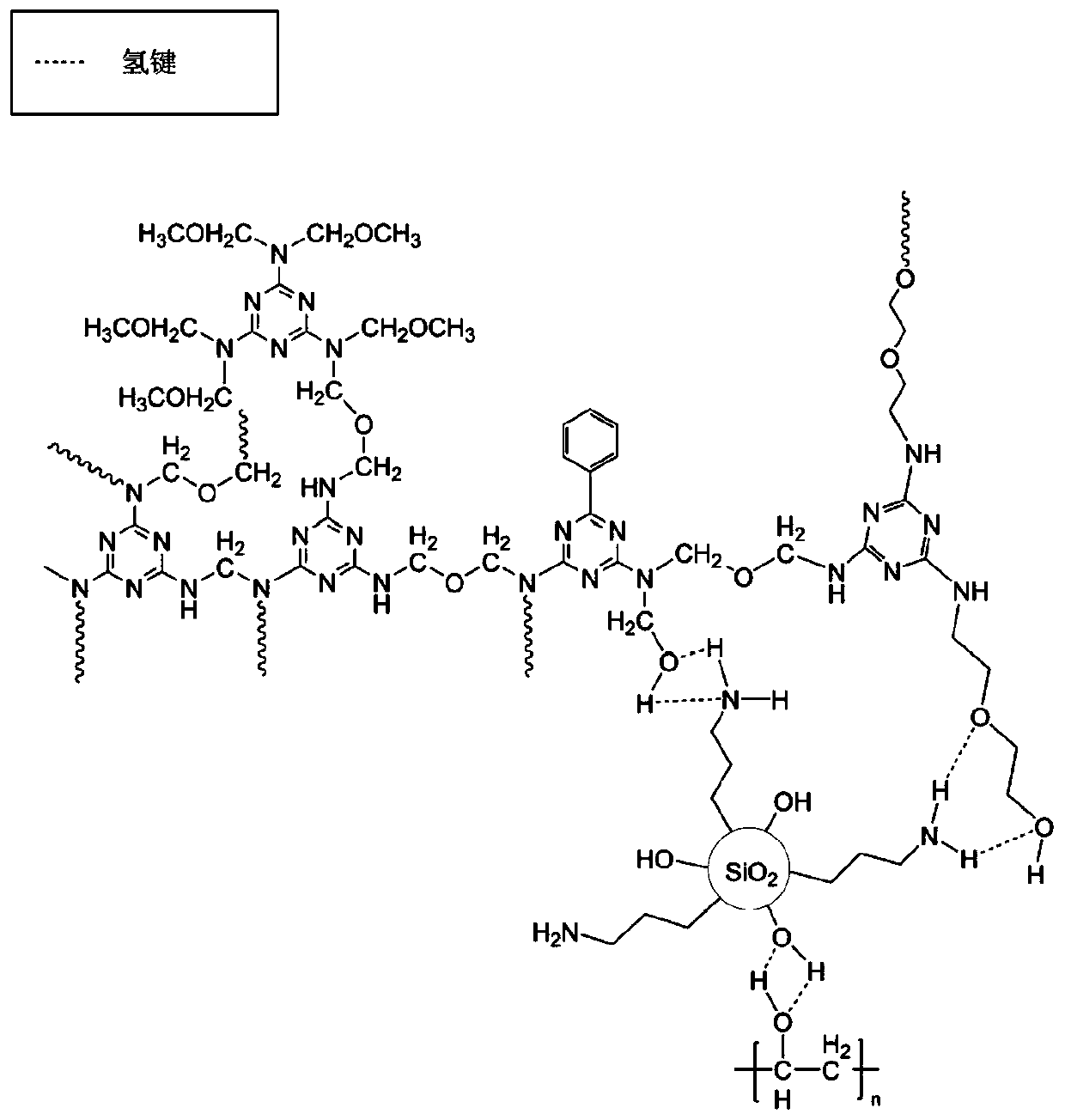

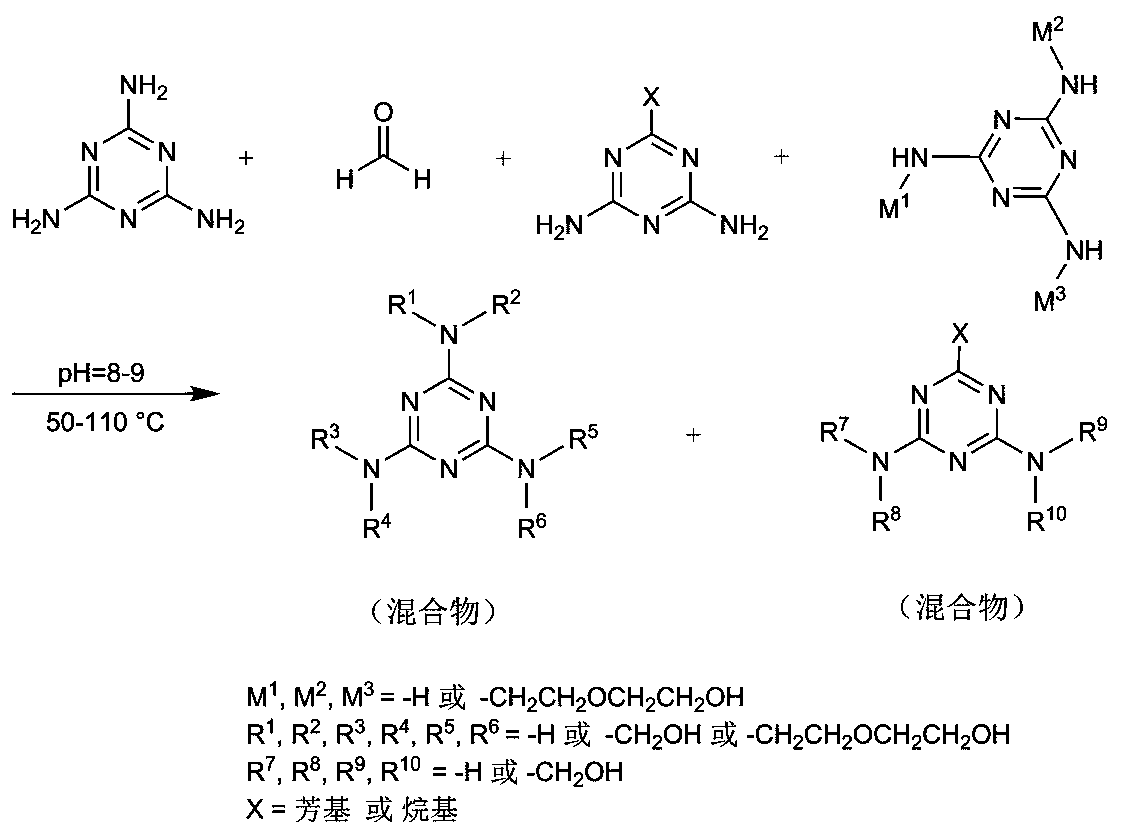

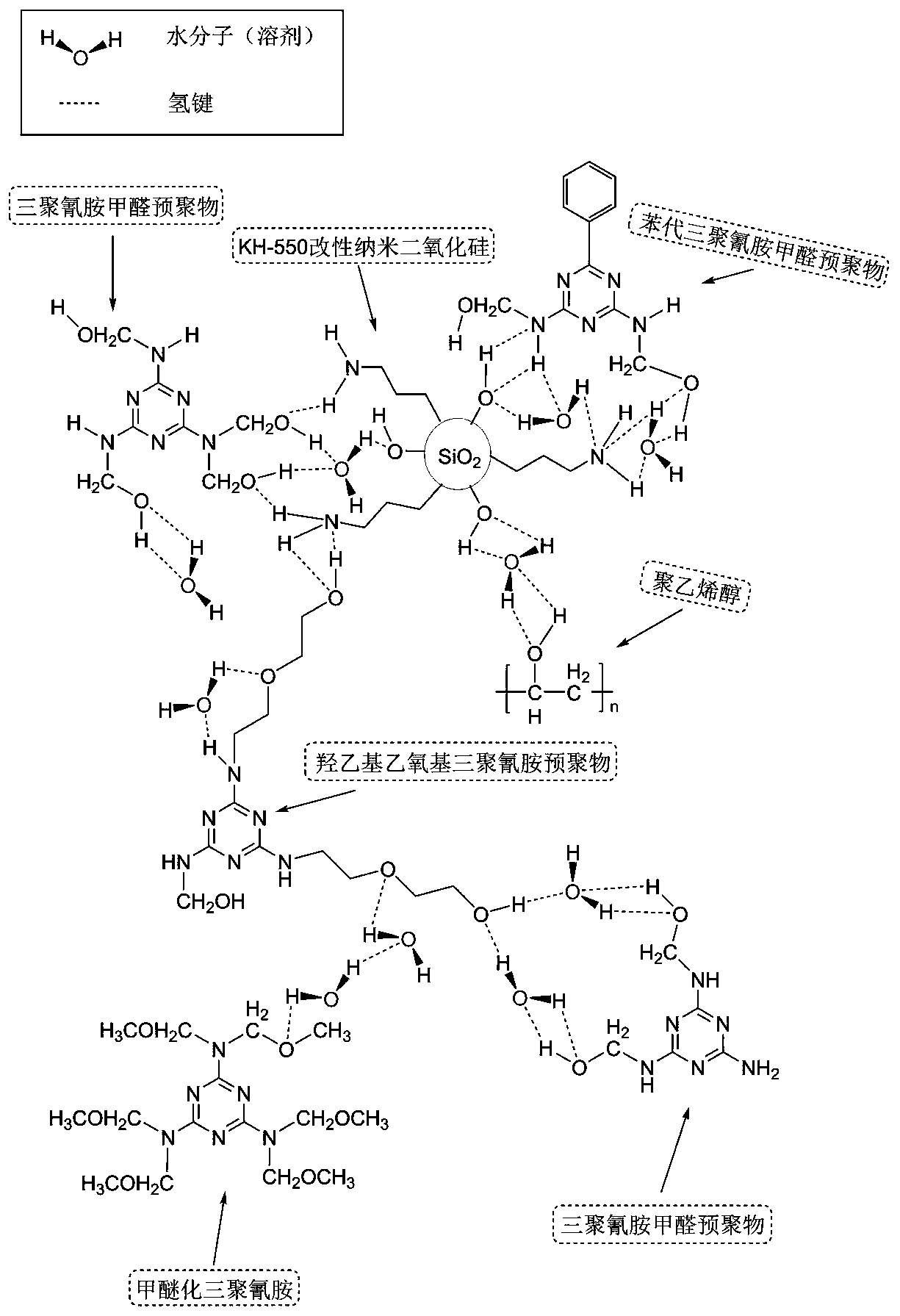

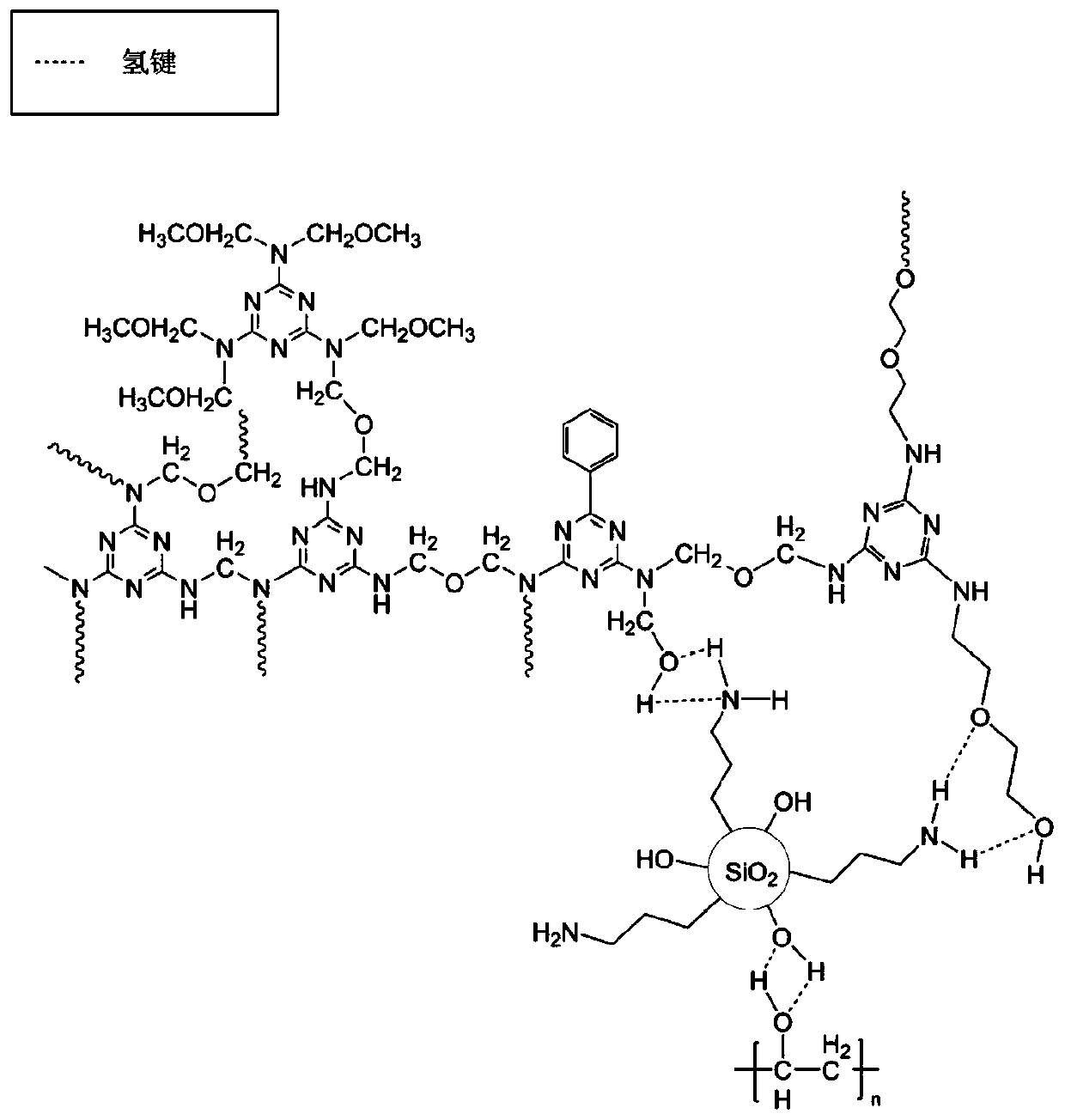

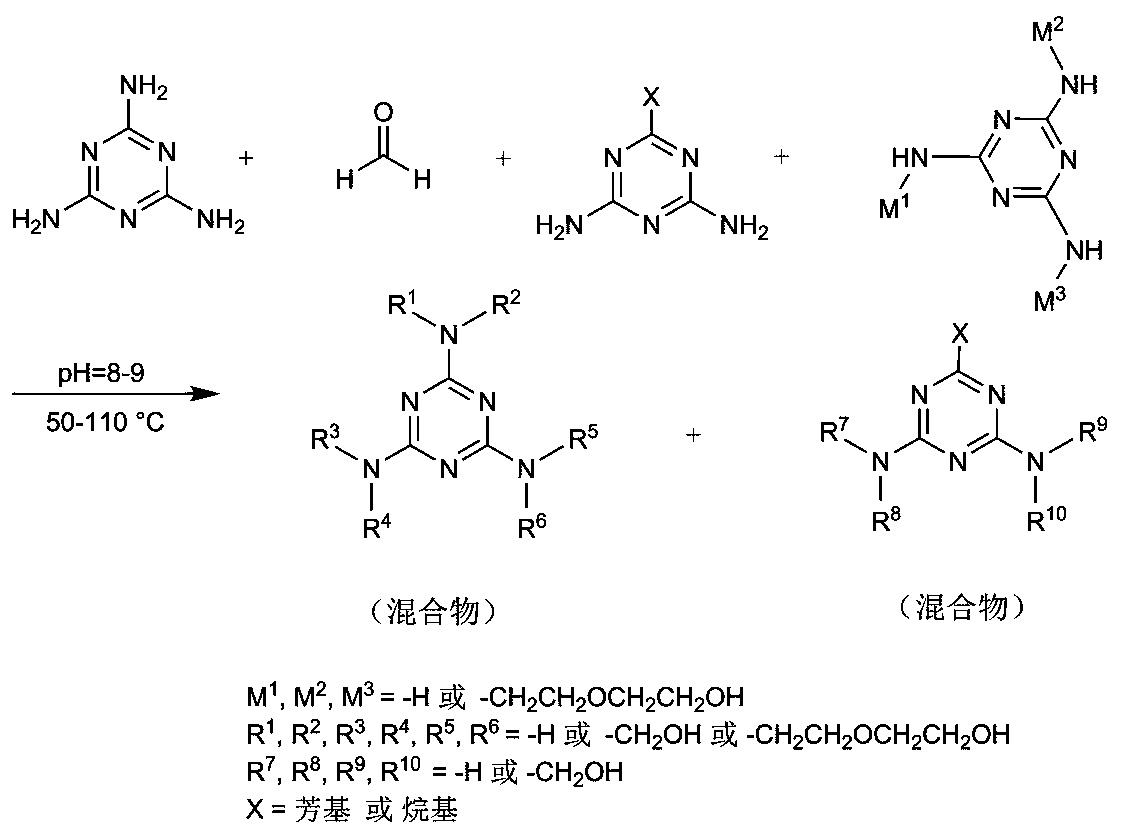

Melamine composite fiber and manufacturing method thereof

ActiveCN109881293AImprove rheologyEliminate Bubble ProblemsFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberHydrogen

The invention discloses a melamine composite fiber and a manufacturing method thereof. The melamine composite fiber is prepared from melamine formaldehyde modified resin, an inorganic nano material subjected to surface modification through a coupling agent and a water-soluble polymer, the composite fiber is less in internal defect and high in strength and toughness, the tensile strength of the composite fiber reaches 2-6 cN / dtex, and the elongation at break reaches 15%-40%; the flame resistance is excellent, the composite fiber is extinguished immediately after leaving a flame, no molten droplet exists, smoldering does not occur, and the limit oxygen index reaches 38%-45%. According to the melamine composite fiber manufacturing method, in the spinning solution manufacturing process, hydrogen bonds are formed among all components of a spinning solution, and the compatibility is good; by means of the inorganic nano material subjected to surface modification through the coupling agent, alarge number of bubbles in the spinning solution are eliminated, the fluidity of the spinning solution is improved, and meanwhile the stability and the fiber forming property of the spinning solutionare improved; by means of the method, the melamine composite fiber can be manufactured economically.

Owner:SICHUAN UNIV

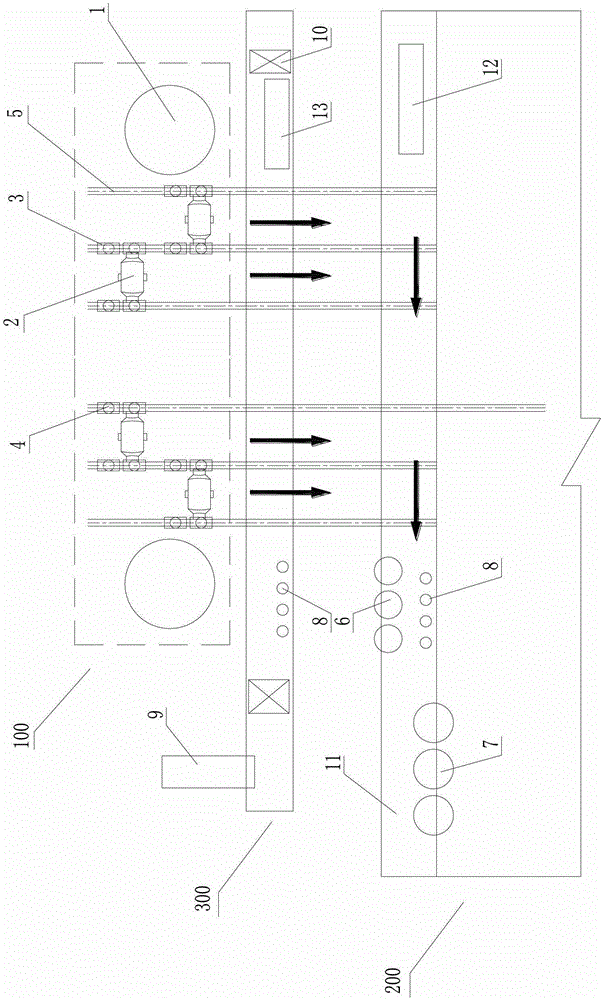

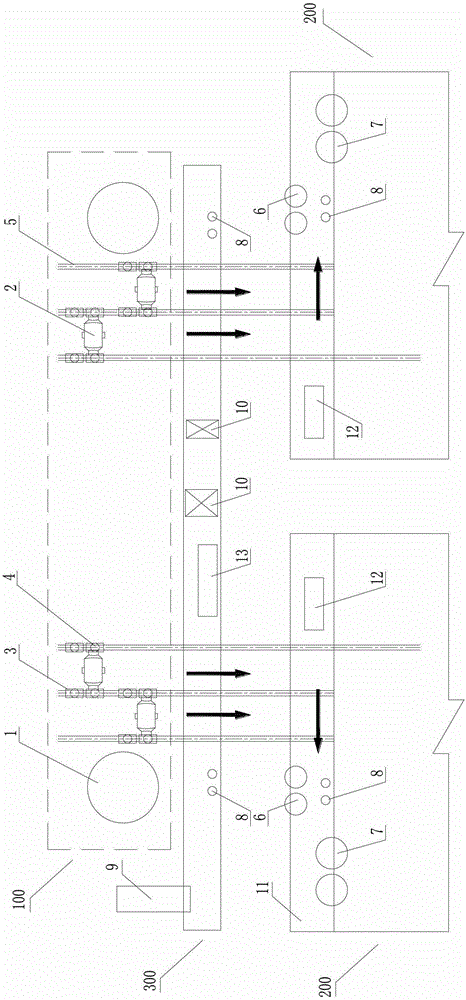

Batch production method of graphene film and graphene film prepared by method

PendingCN110980703AImprove coating efficiencyReduce baking timeSynthetic resin layered productsGrapheneBatch productionGraphene membrane

The invention provides a batch production method of a graphene film and the graphene film prepared by the method. The batch production method comprises the following steps: (I) dispersing and crushinggraphite oxide to obtain a graphene oxide solution; (II) coating a porous grid substrate with the graphene oxide solution, and drying to obtain a graphene oxide film; and (III) sequentially carryingout carbonization and graphitization treatment on the graphene oxide film to obtain the graphene film. The efficient and low-cost high-performance graphene membrane batch preparation method has the advantages that a graphene oxide filter cake is directly subjected to pre-dispersion by a double-planet stirrer and physical dissociation and crushing by a high-pressure homogenizer to obtain the graphene oxide solution, and the obtained solution is good in uniformity, high in solid content and high in operability. Compared with the prior art, the method is simple in process, good in stability, highin continuous degree and low in cost, and the obtained graphene film is good in performance and can meet the market requirements.

Owner:深瑞墨烯科技(福建)有限公司

Rare earth polishing powder and production method thereof

ActiveCN102031063AUniform grain changeUniform heat and mass transferPolishing compositions with abrasivesGranularityRare earth

The invention discloses rare earth polishing powder which is prepared by the following steps: mixing rare earth carbonate and ammonium salt in parts by weight into a compound, drying, pulverizing and screening, then adding into a suspended calciner for calcining to prepare clinker, and pulverizing by a pulverizer. The invention also discloses a production method of the rare earth polishing powder, which comprises the following steps: (1) compounding; (2) drying, pulverizing and screening; (3) calcining; and (4) pulverizing by gas flow. The invention has the advantages that raw materials are calcined in a suspension flowing state, so that heat and mass transfer is kept even, the polishing powder product has ideal and evenly distributed granularity, and the rare earth polishing powder has the advantages of high continuity degree, good product uniformity, high production efficiency, high yield, low cost, high gain and no pollution.

Owner:INNER MONGOLIA WINNER METALS & CHEM

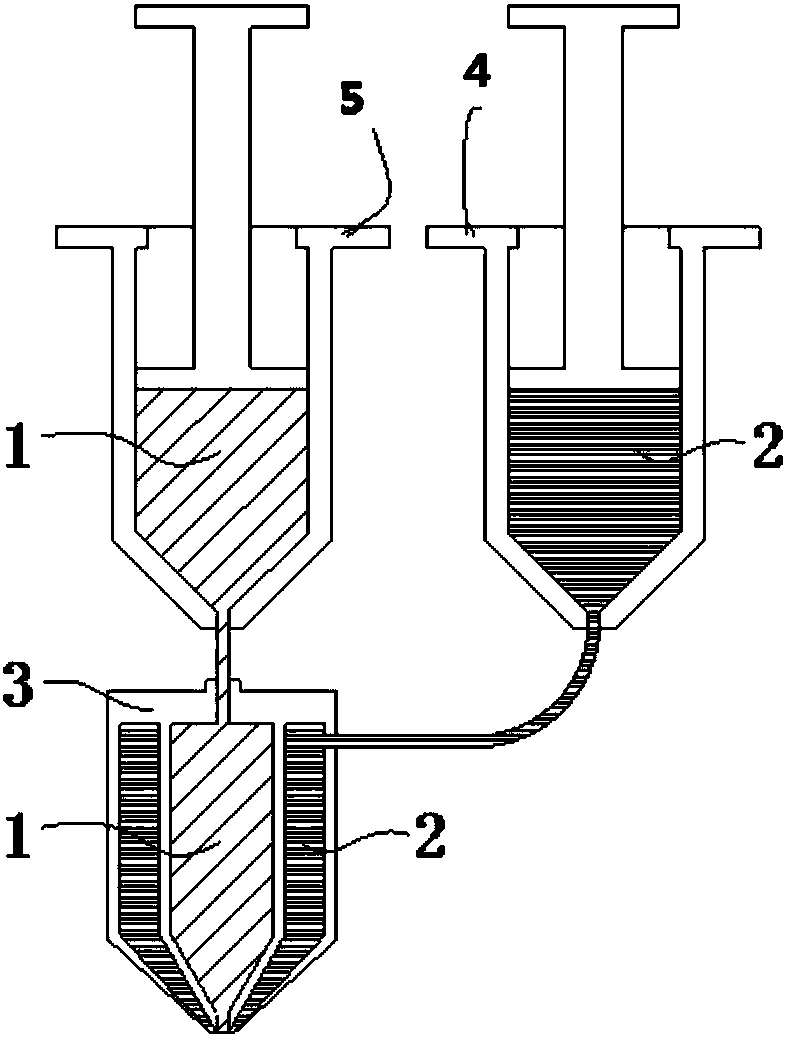

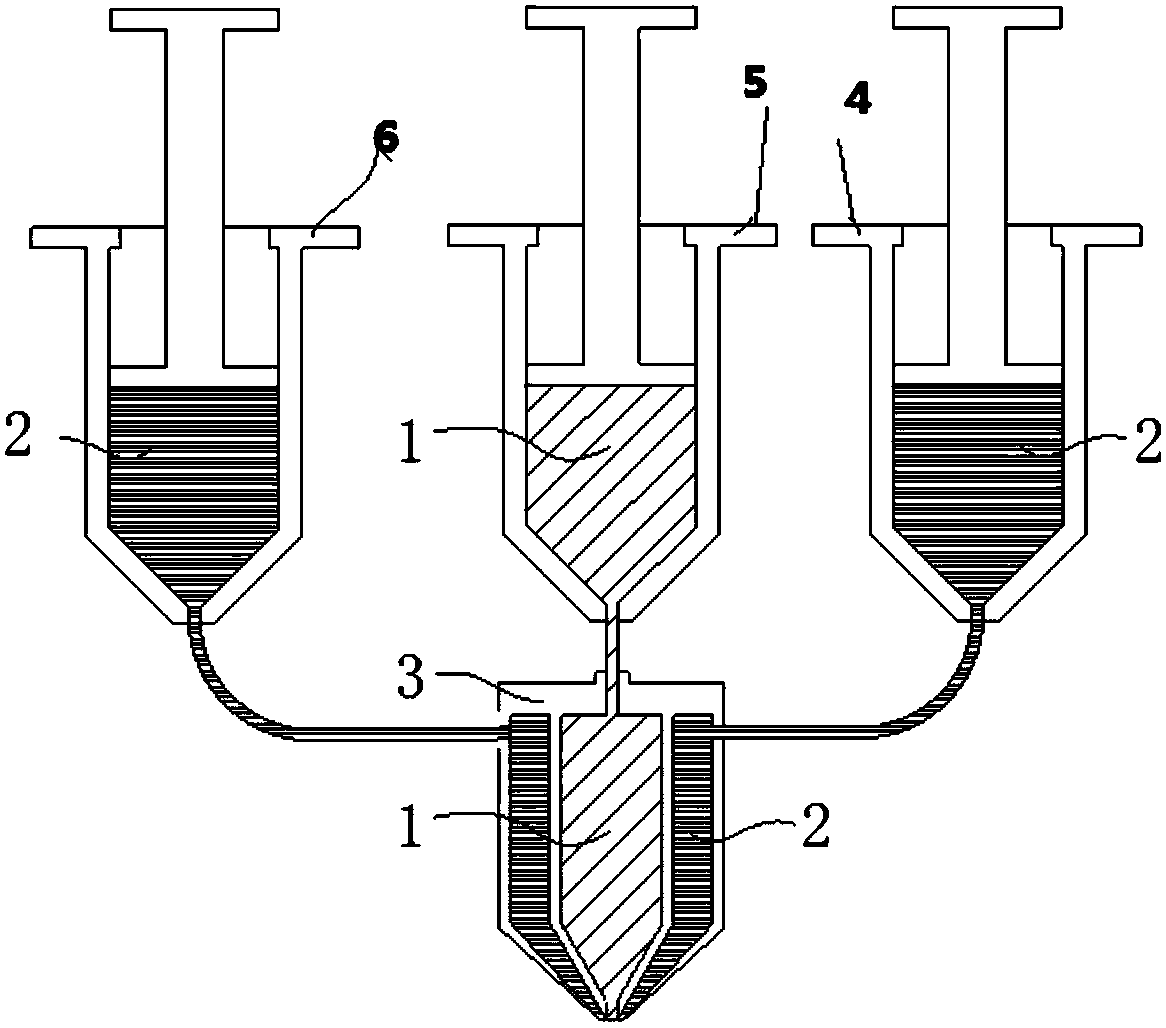

Crystallization method of cephalosporins

ActiveCN107602588AHigh degree of continuityEasy to operateOrganic chemistryAntibiotics beta lactamChemistry

Belonging to the field of industrial production technologies of beta-lactam antibiotics, the invention discloses a crystallization method of cephalosporins. The method is carried out in 2-4 crystallization kettles continuously. The method has the advantages of high continuation degree, simple operation and high production efficiency, and is suitable for large-scale industrialized production, improves equipment utilization rate and product yield, and the obtained cephalosporins finished product has an ideal short rod-like crystal form, and the crystals have the characteristics of good integrity, uniform granularity, high purity, good fluidity, and convenient separation, drying and packaging.

Owner:NORTH CHINA PHARMA COMPANY +1

Production process and equipment for round bamboo expansion flat plate

InactiveCN104070584ASimple production processSolve storage deterioration and drying outWood impregnation detailsAqueous solutionEngineering

The invention discloses a production process for a round bamboo expansion flat plate and an expanding, shaping and thickness-fixing all-in-one machine. The process comprises the following steps: sawing round bamboo off, removing outer and inner segments to form a bamboo barrel, digging grooves in tabasheer on the inner surface of the bamboo barrel, and putting the bamboo barrel into a 0.5-1.5 mass percent sodium pyrosulfite aqueous solution for storing; (2) slitting the bamboo barrel stored in the sodium pyrosulfite aqueous solution, softening at a high temperature, expanding, cooling for shaping, and planing and fixing thickness on double sides to obtain the round bamboo expansion flat plate. In the all-in-one machine, an expansion drum, a shaping barrel and a thickness-fixing planer tool are arranged in sequence on the same conveying belt, thereby realizing combination of three procedures and increasing the mechanical and automatic degrees. By adopting the production process and the all-in-one machine, the production of the round bamboo expansion flat plate is not influenced by weather or limited by raw materials any more, the technical problems of deterioration and drying of round bamboo stored under the natural condition are effectively solved, continuous large-scale production is realized, and the product quality is good. The production process and the all-in-one machine have high practicability and wide application prospects.

Owner:怀化市恒裕竹木开发有限公司

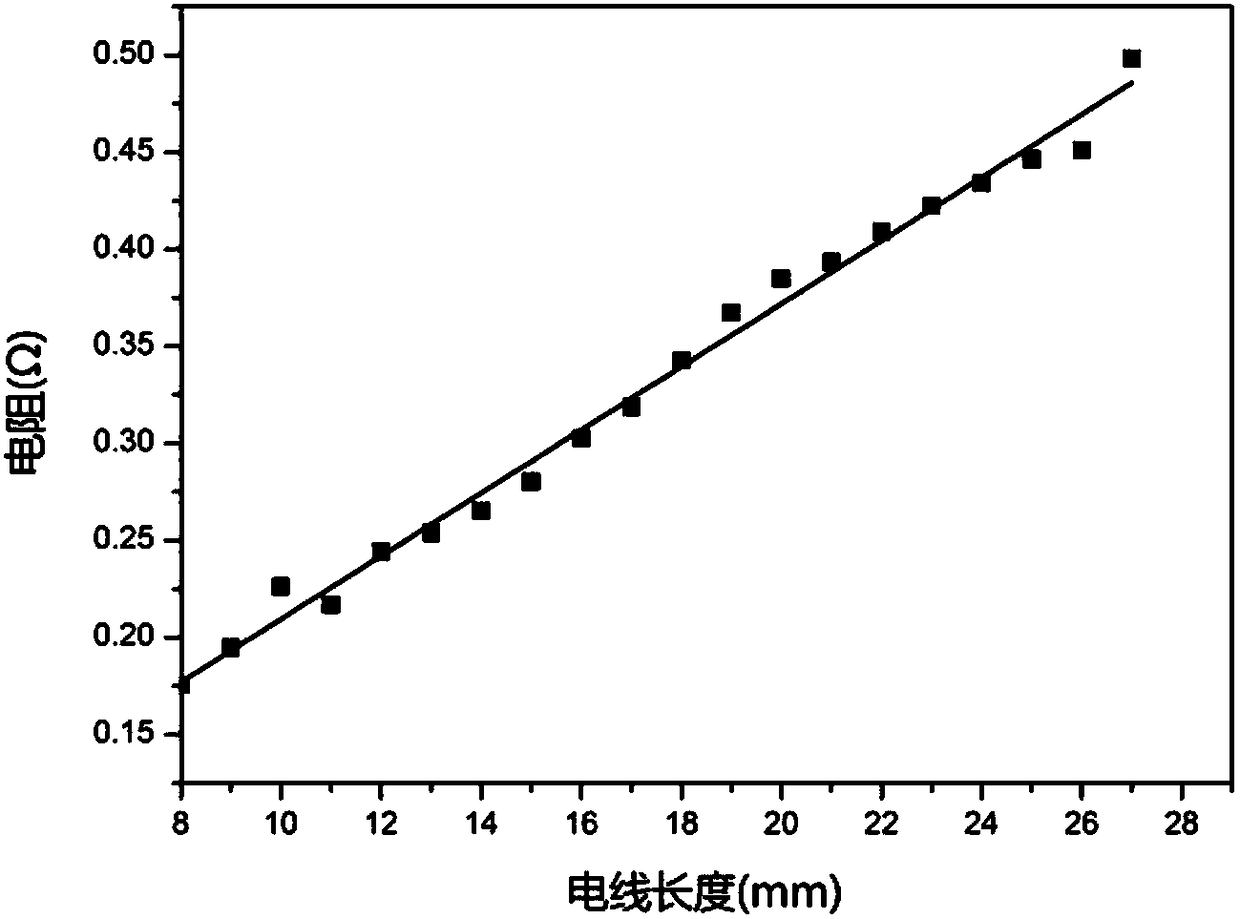

Elastic cable and preparation method thereof

ActiveCN108133770ASatisfy any 3D graphicsFulfil requirementsAdditive manufacturing apparatusInsulated cablesHigh volume manufacturingMetal

The invention discloses an elastic cable, which comprises three parts, namely an elastic conducting core layer, an elastic insulating layer and metal joints, wherein the elastic conducting core layerand the insulating layer are molded through extrusion systems at the same time; and the metal joints are packaged at two ends of the elastic cable. According to a method, the disadvantage of a lot ofwastes of manpower, time and cost in a traditional casting preparation method is overcome; the elastic cable has the advantages of good molding, high continuous degree and continuous process, massiveproduction can be implemented and the labor cost, the time cost and the production cost are reduced.

Owner:刘禹 +2

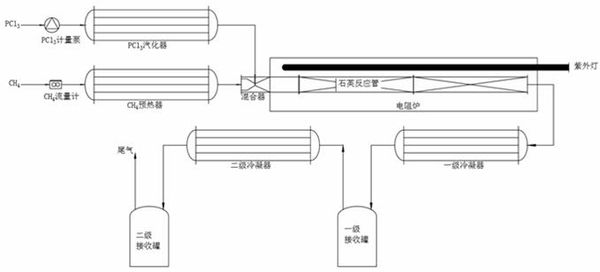

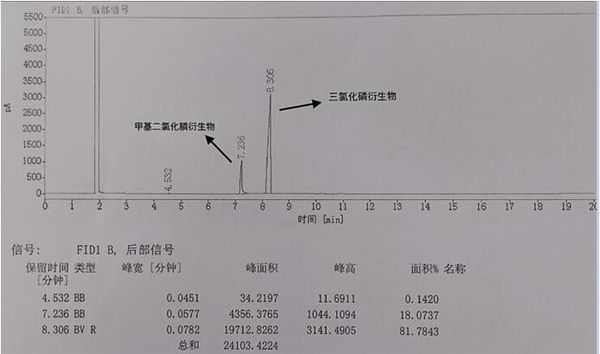

Method for synthesizing methyl phosphine dichloride

ActiveCN111909201ALow costOperational securityGroup 5/15 element organic compoundsPtru catalystPhysical chemistry

The invention mainly aims at the problems of high reaction temperature, certain reaction pressure, easy generation of solid impurities, low continuous production capacity, high cost, high environmental pressure and the like in the existing process of synthesizing methyl phosphine dichloride by a high-temperature method, and provides a method for synthesizing methyl phosphine dichloride by using methane and phosphorus trichloride as raw materials. According to the synthetic method, the reaction selectivity and yield are maintained. Meanwhile, no toxic initiator is added, the pressure, temperature and other conditions required by the reaction are reduced, the problem that the reaction conversion rate is reduced due to the fact that the surface of the solid catalyst is covered and inactivatedis solved, the continuous degree is higher, and the yield is higher. According to the method, a product with the content of methyl phosphine dichloride being greater than 17wt% can be synthesized, and after the product is rectified, a methyl phosphine dichloride product with the content being greater than 99wt% and phosphorus trichloride with the content being greater than 98.5 wt% can be obtained.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

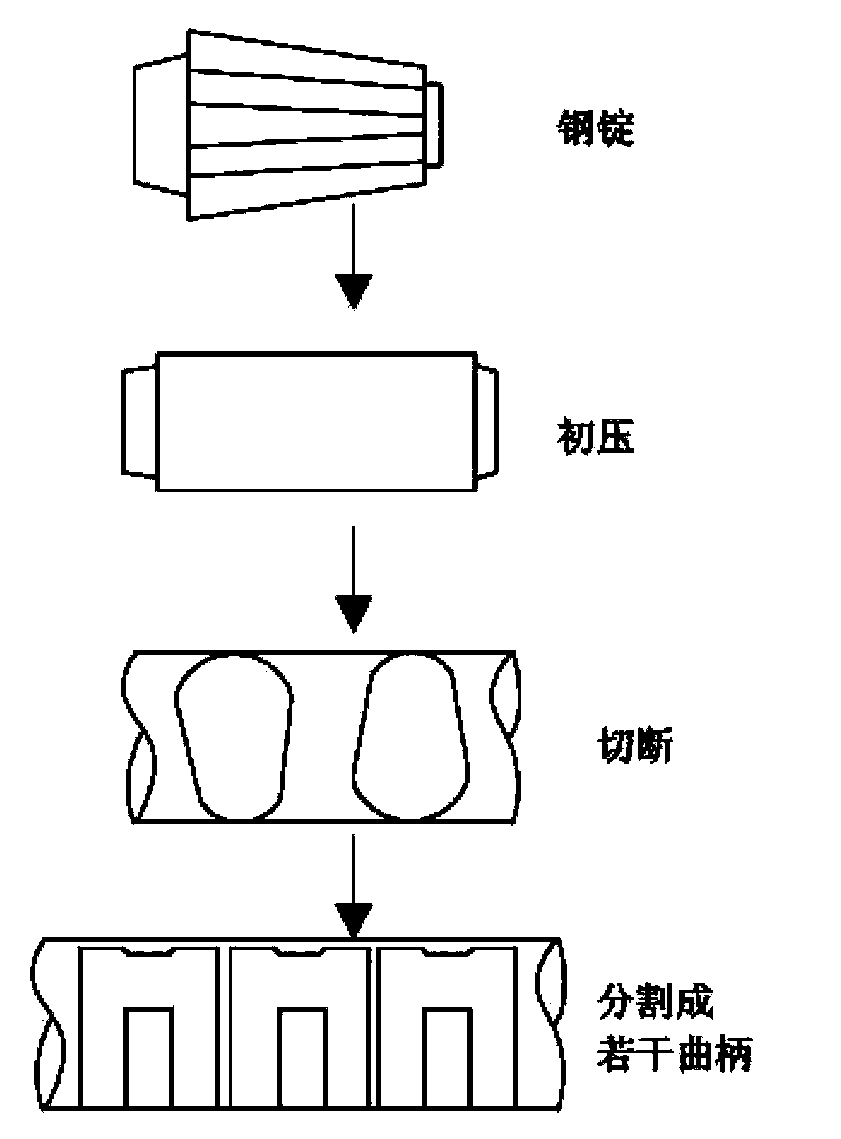

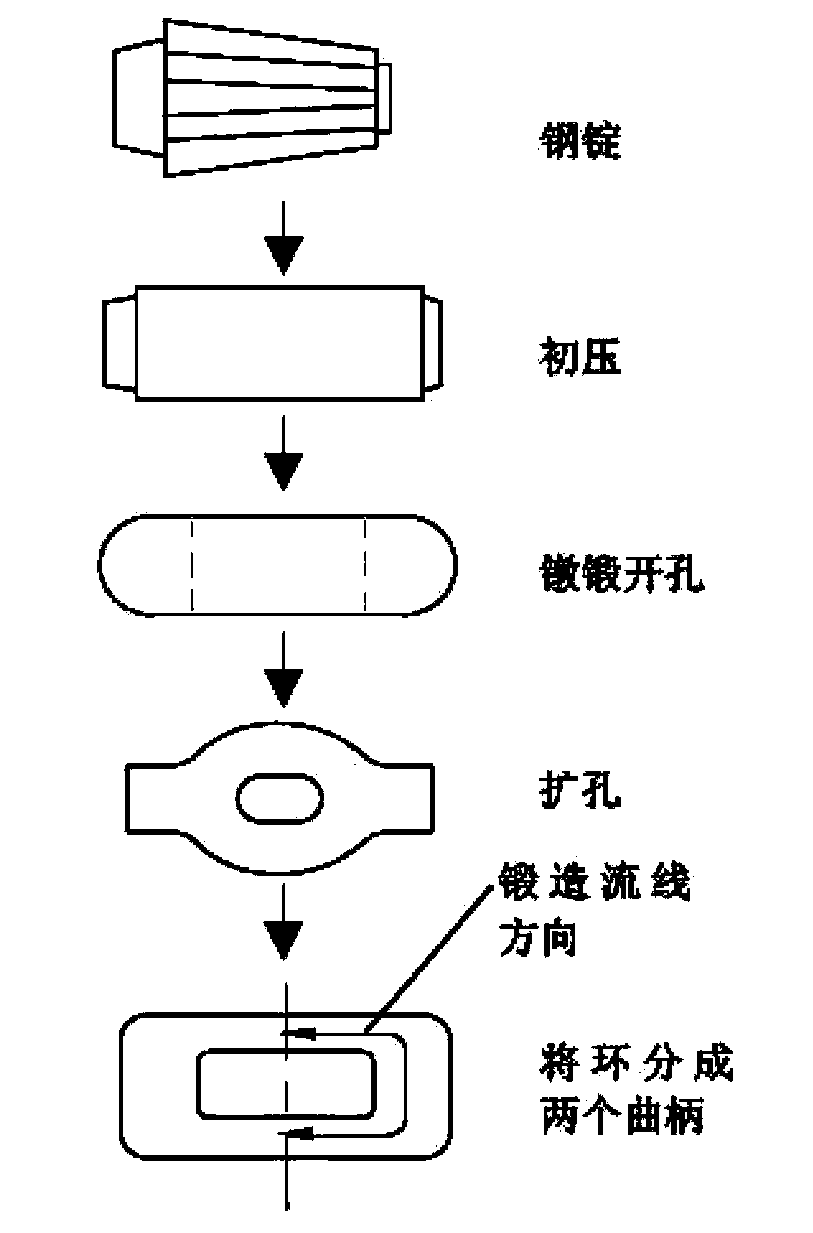

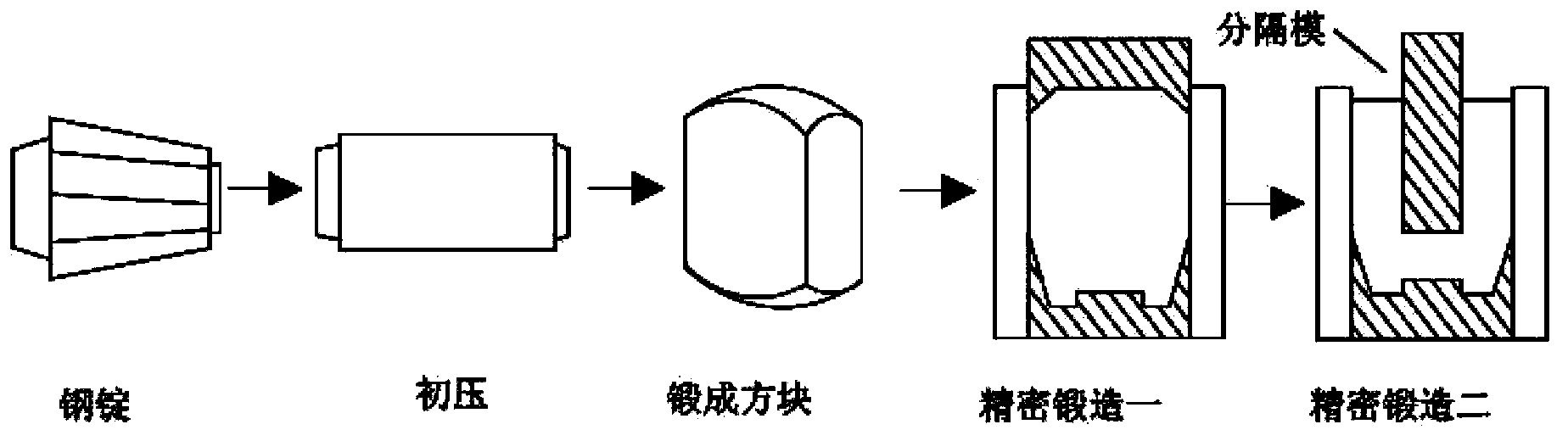

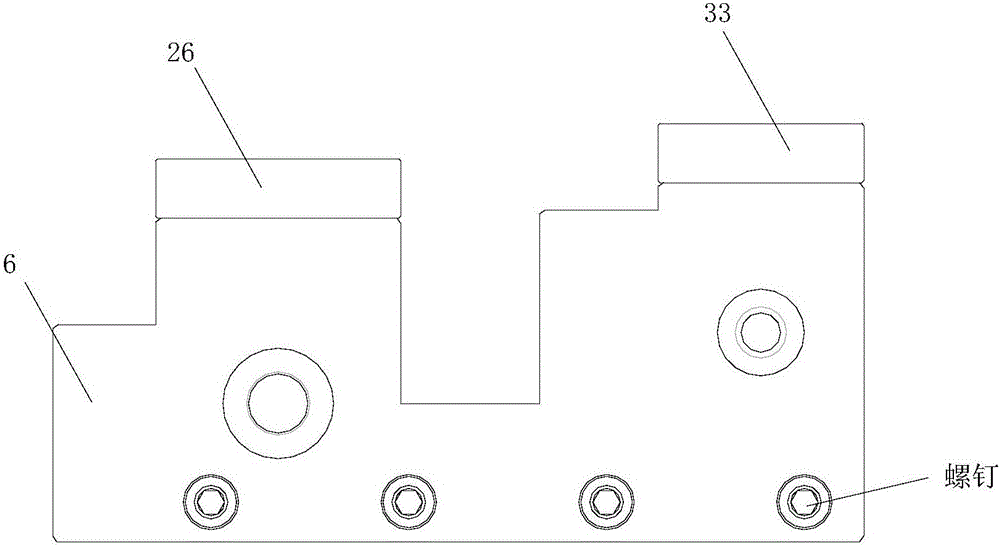

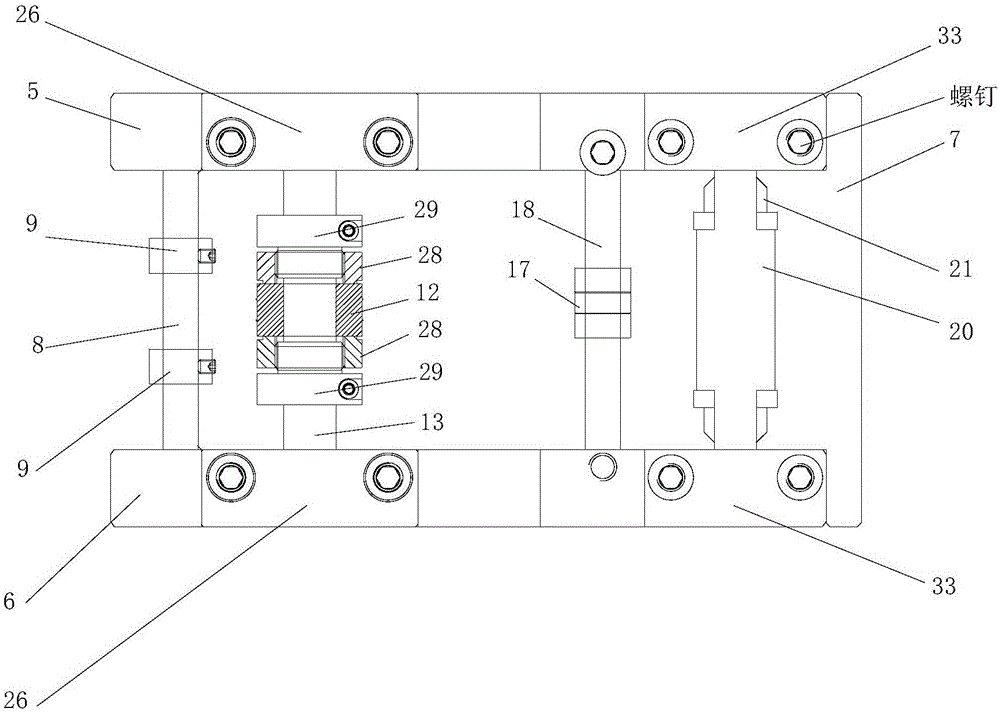

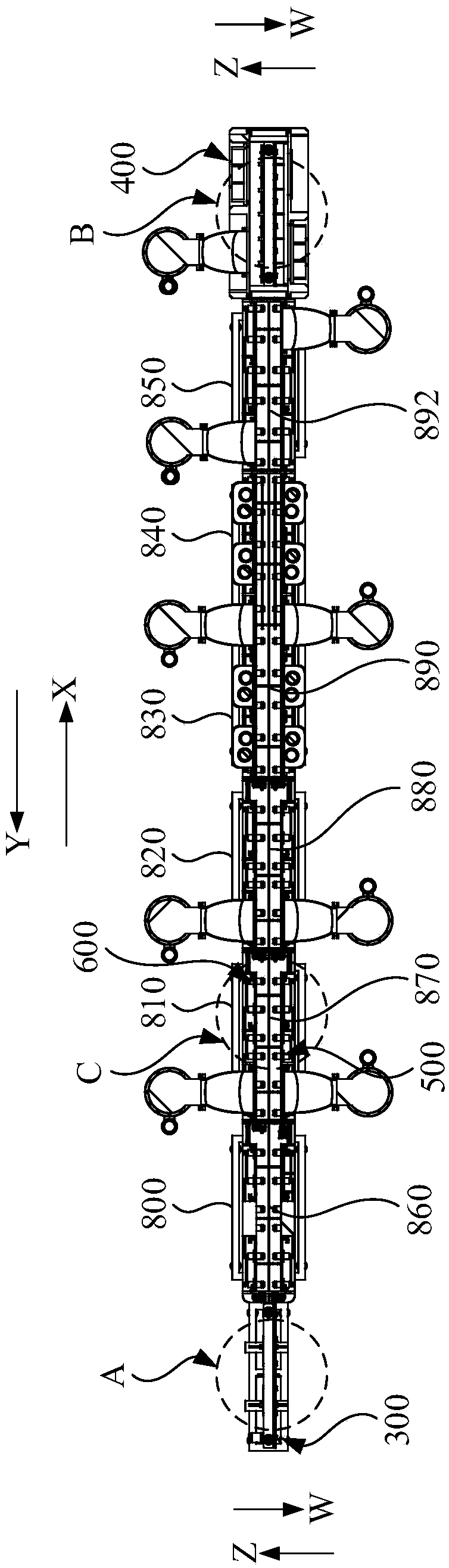

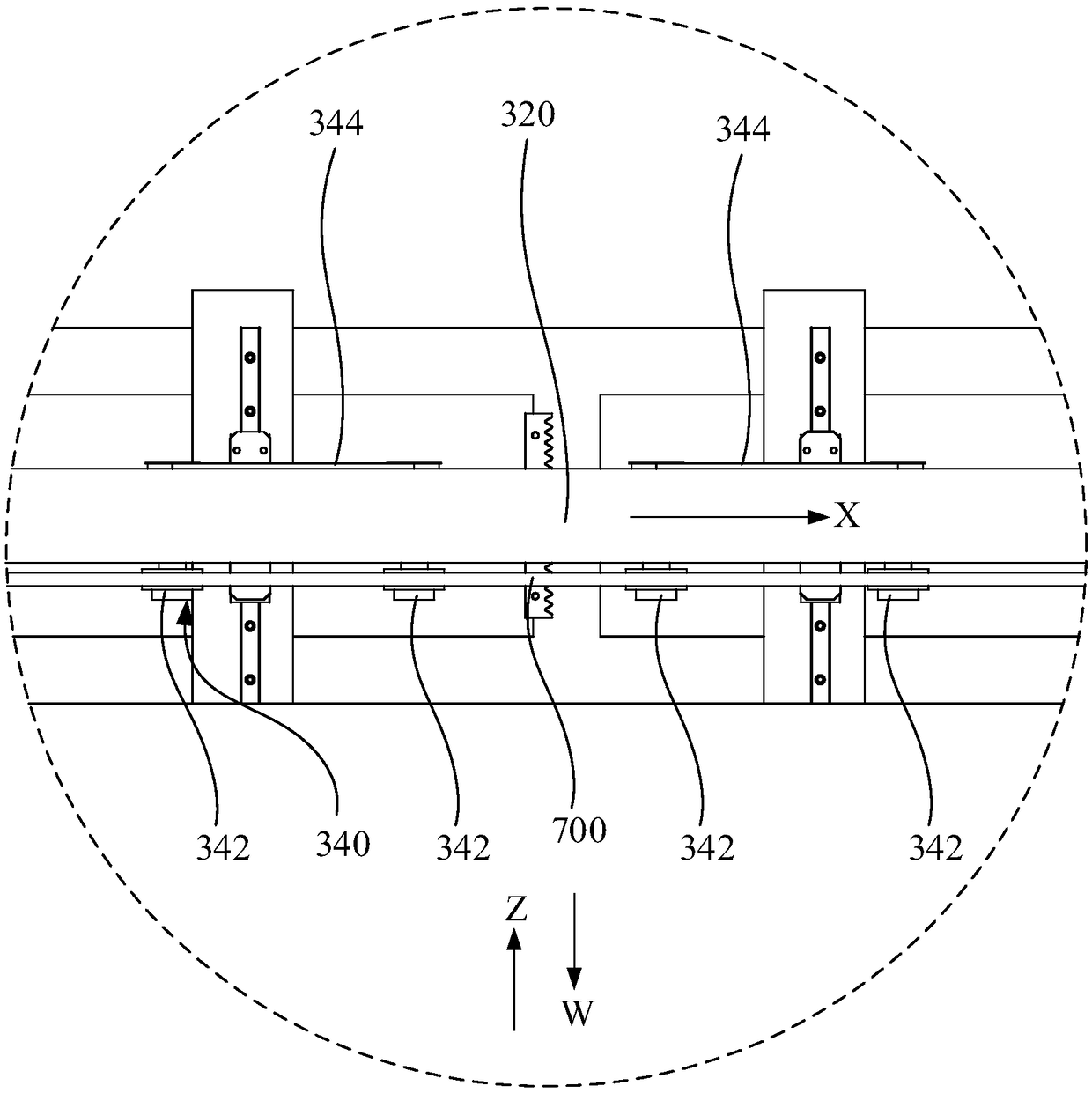

Extrusion forming device and method for crank shaft and crank throw for large-size ship

The invention discloses an extrusion forming device for a crank shaft and a crank throw for a large-size ship. The extrusion forming device comprises a lower molded cavity consisting of two lower sliding chutes and two lower side plates and an upper molded cavity consisting of two upper sliding chutes and two upper side plates, wherein the lower molded cavity is positioned above the upper molded cavity; a female die is arranged in the lower molded cavity; the inner side of each upper sliding chute is movably connected with a sliding block through an inclined rail; the sliding blocks can slide along the inclined rails relative to the upper sliding chutes; the contact surfaces of the lower surfaces, which are in contact with the lower sliding chutes, of the sliding blocks are slopes; the two upper side plates are fixedly connected with at least one cylinder; a plunger of each cylinder is fixedly connected with a male die; the male die is fixedly connected with the upper ends of pull rods; the lower ends of the pull rods are movably connected with the upper side plates. According to the extrusion forming device, the machining allowance can be greatly reduced, and the utilization rate of a material can be increased. The extrusion forming device can realize quick demolding and is high in continuous degree, so that the manufacturing period of a product is shortened, the working procedure is short, the efficiency is high, and the operation is simple. The invention also discloses a forming method for the crank shaft and the crank throw for the large-size ship.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

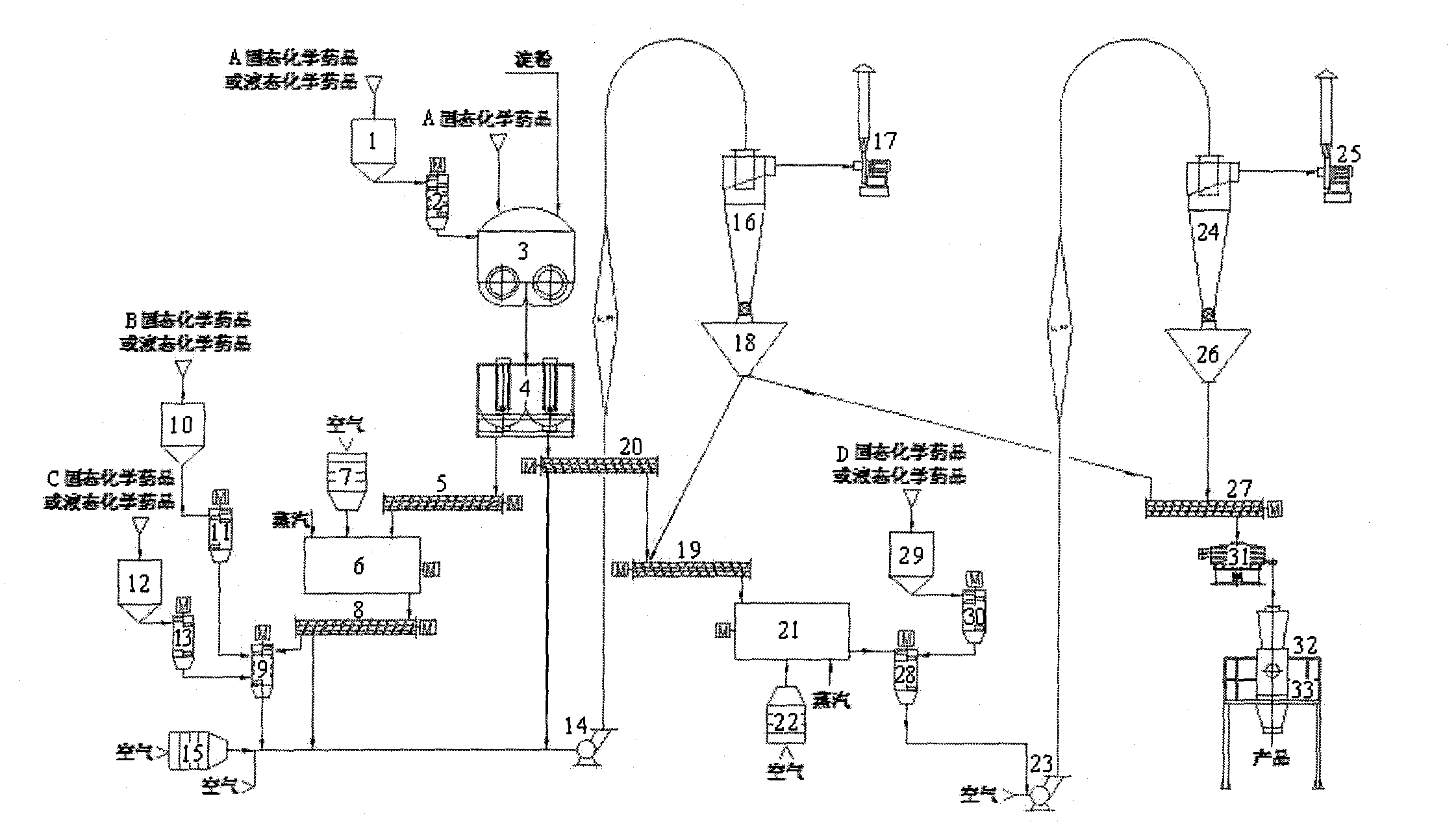

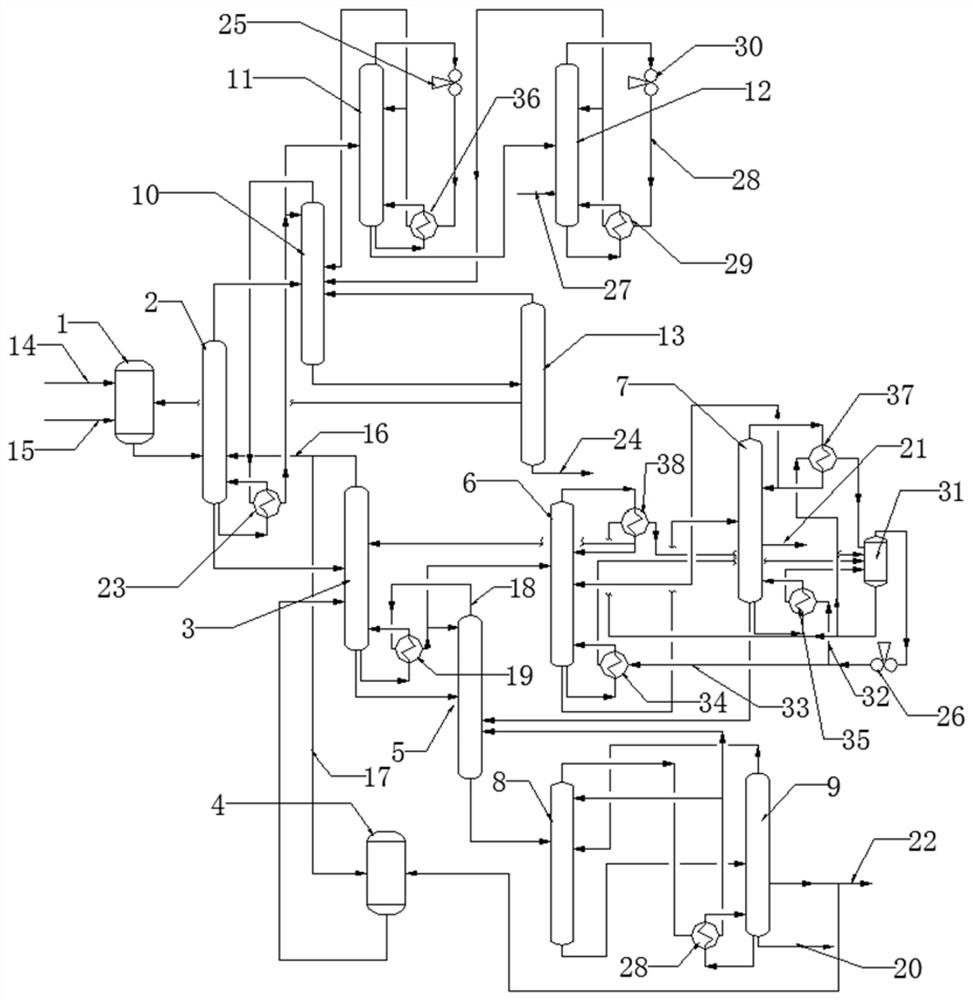

Dry-method double-modified starch continuous production device

InactiveCN102276740AEasy to replaceRealize large-scale continuous productionEcological environmentPhosphate

The invention discloses a dry-method double-modified starch continuous production device which is characterized by comprising a liquor tank, an atomization device, a mixer, a powder storage tank, a speed regulating and metering powder feeder, a reactor, a heater, a screw conveyer, a continuous mixer, a lifter, a classifier, an induced draught fan, a powder collection tank, a vibrating screen, a weighing scale and a packaging machine. Continuous feeding, discharging and reacting are realized; the reaction uniformity is high; starch reaction time is controlled by regulating powder feeding speedof the speed regulating and metering powder feeder; reaction temperature is controlled by regulating flow rates of hot air and steam; and the device meets the requirements of large-scale continuous production of dry-method double-modified or single-modified starch, such as cationized-phosphoric esterified starch, acidified-cationized starch, acidified-phosphoric esterified starch, dextrin, cationic starch, phosphate starch and the like. The production device has the advantages of less investment, high reaction conversion rate, high product yield, low production cost, high adjustability of production capacity, stable product quality and obvious ecological environment friendliness and economic benefits.

Owner:广西农垦明阳生化有限公司

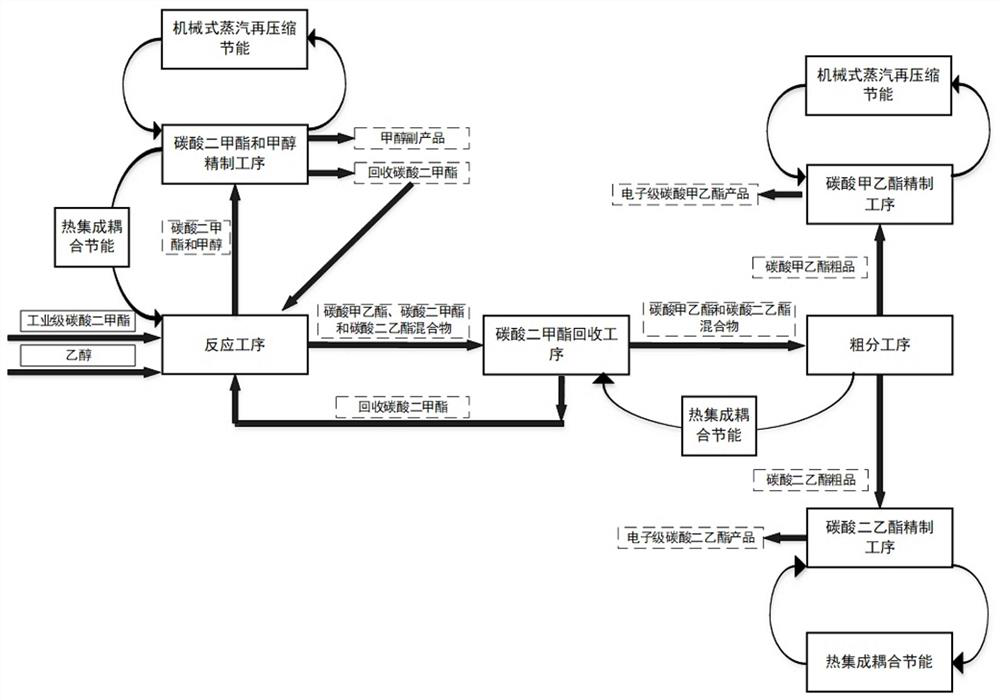

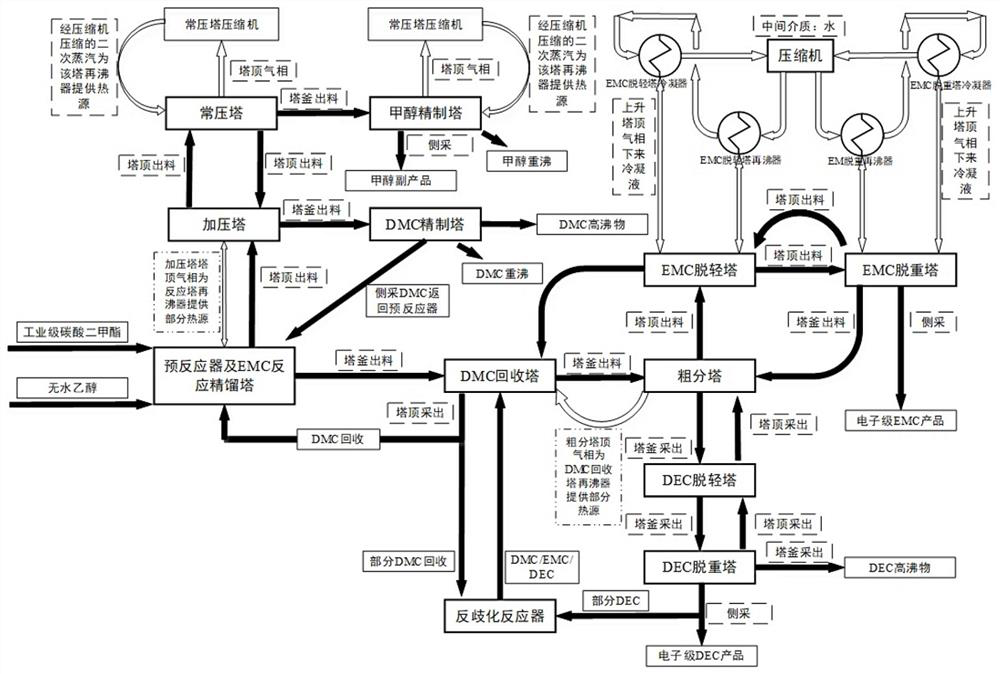

Preparation method of energy-saving electronic-grade carbonic ester

ActiveCN114380692AImprove qualityHigh yieldChemical industryPreparation from organic carbonatesCarbonate esterEthyl ester

The invention discloses an energy-saving preparation method of electronic-grade carbonate, which comprises the following steps: preheating industrial-grade dimethyl carbonate and absolute ethyl alcohol by a preheater, then entering a reaction process, and carrying out esterification reaction under the action of a catalyst to obtain a mixture containing dimethyl carbonate, ethyl methyl carbonate and diethyl carbonate; and an azeotrope of dimethyl carbonate and methanol; the mixture enters a dimethyl carbonate recovery process to recover unreacted dimethyl carbonate; the mixture of the ethyl methyl carbonate and the diethyl carbonate enters a coarse separation process to obtain an ethyl methyl carbonate crude product and a diethyl carbonate crude product; the ethyl methyl carbonate crude product is subjected to an ethyl methyl carbonate refining process to obtain electronic-grade ethyl methyl carbonate, and the diethyl carbonate crude product is subjected to a diethyl carbonate refining process to obtain electronic-grade diethyl carbonate. The product prepared by the method is high in quality and high in yield.

Owner:天津众望创业科技有限公司

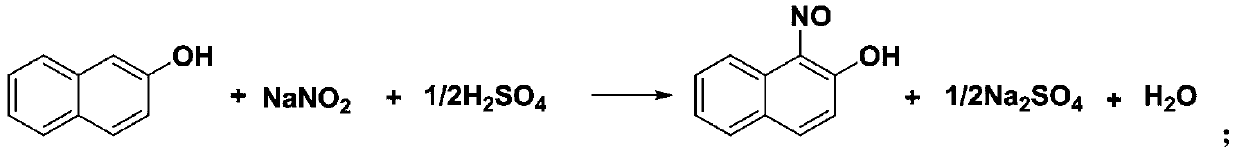

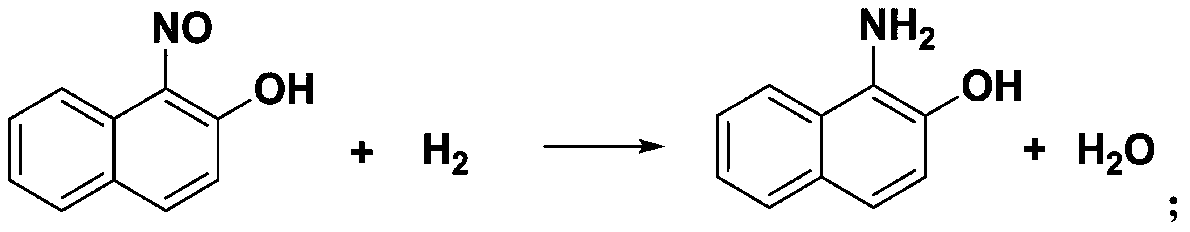

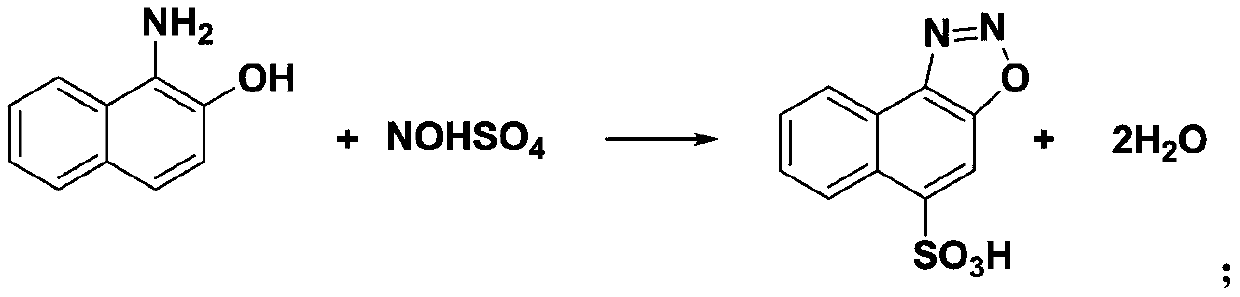

Method for preparing 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate

ActiveCN111217764ASolve the need to consume a lot of acidSolve with alcohol as solventOrganic chemistryNitrosoFixed bed

The invention discloses a method for preparing 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate. The method comprises the following steps: carrying out a nitrosation reaction on 2-naphthol serving as a raw material, sodium nitrite and dilute sulfuric acid in a tubular reactor to generate 1-nitroso-2-naphthol, carrying out catalytic hydrogenation on the 1-nitroso-2-naphthol and hydrogen in a Raney nickel immobilized fixed bed reactor to generate 1-amino-2-naphthol, carrying out sulfonation diazotization cyclization on 1-amino-2-naphthol and nitrosyl sulfuric acid in the tubular reactor, and nitrifying with nitric acid to obtain the final product 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate. According to the novel synthesis method of the 6-nitro-2-diazo-1-naphthol-4-sulfonic acid hydrate, hydrogen is used for reduction in the route, nitrosyl sulfuric acid is used for sulfonation diazotization cyclization, so the problem that a large amount of solid waste is generated in a traditional route is avoided, the atom utilization rate is high, the yield is increased, the safety coefficient is increased by using a tubular process, and the method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

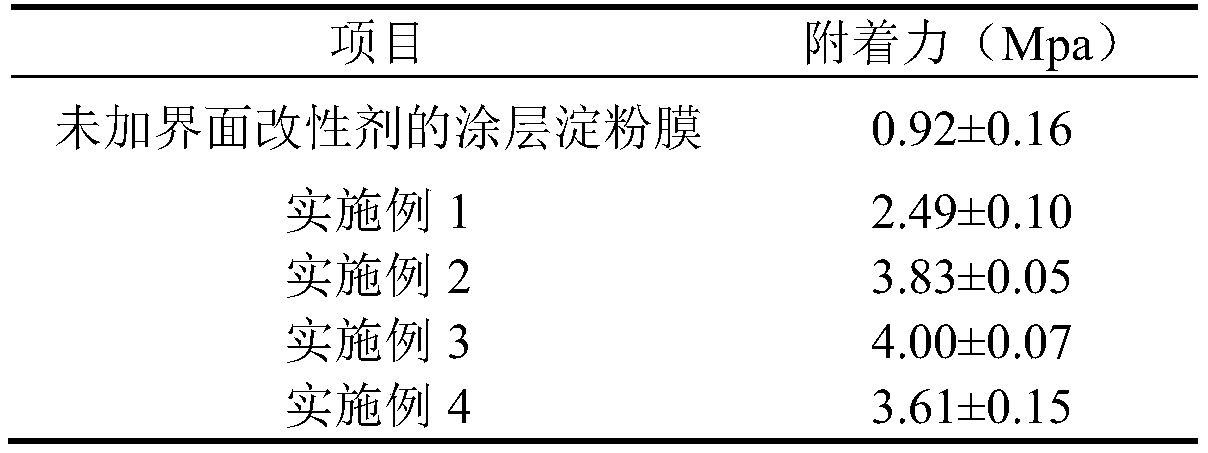

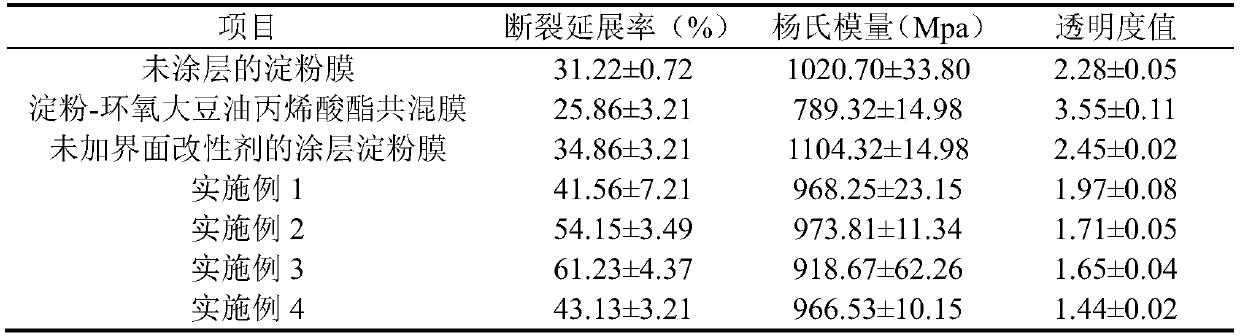

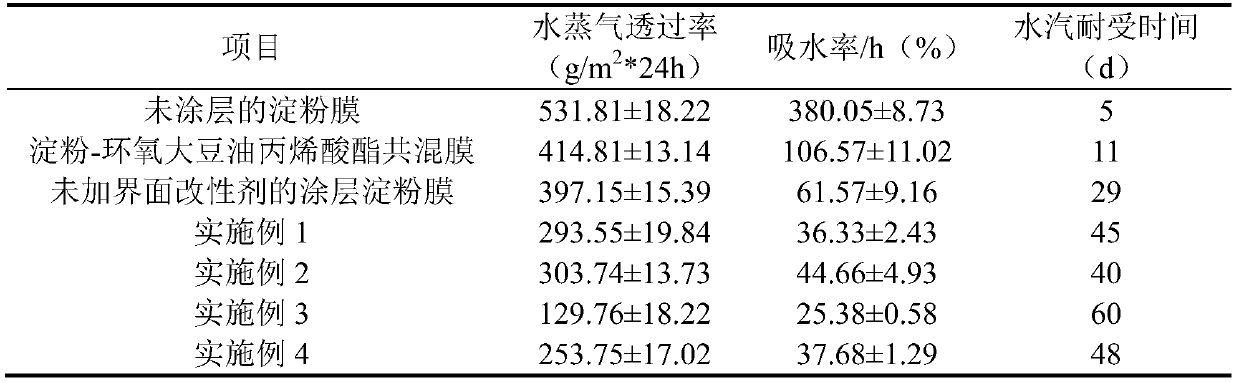

Waterproof starch film using epoxy soybean oil acrylate as coating and preparation method thereof

InactiveCN110511415ALow transparencyHigh transparencyFlexible coversWrappersEpoxyEnvironmental resistance

The invention discloses a waterproof starch film taking epoxy soybean oil acrylate as a coating and a preparation method thereof, belonging to the technical field of packaging materials. The waterproof starch film is prepared by taking a full starch-based film material as a core layer, and forming an epoxy soybean oil acrylate coating on both sides of the core layer by adopting a light curing coating combined with an interface modifier; the epoxy soybean oil acrylate coating is prepared by preparing epoxy soybean oil acrylate, a photoinitiator and the interface modifier into a photocuring solution in a solvent, and surface coating is performed by coating the starch film layer with the photocuring solution. The waterproof starch film prepared by the invention has good mechanical performance, transparency and waterproof performance, and has the advantages of good adhesion between the coating and the film, good controllability, environmental protection and safety, simple and convenient preparation process, low cost and the like.

Owner:SOUTH CHINA UNIV OF TECH

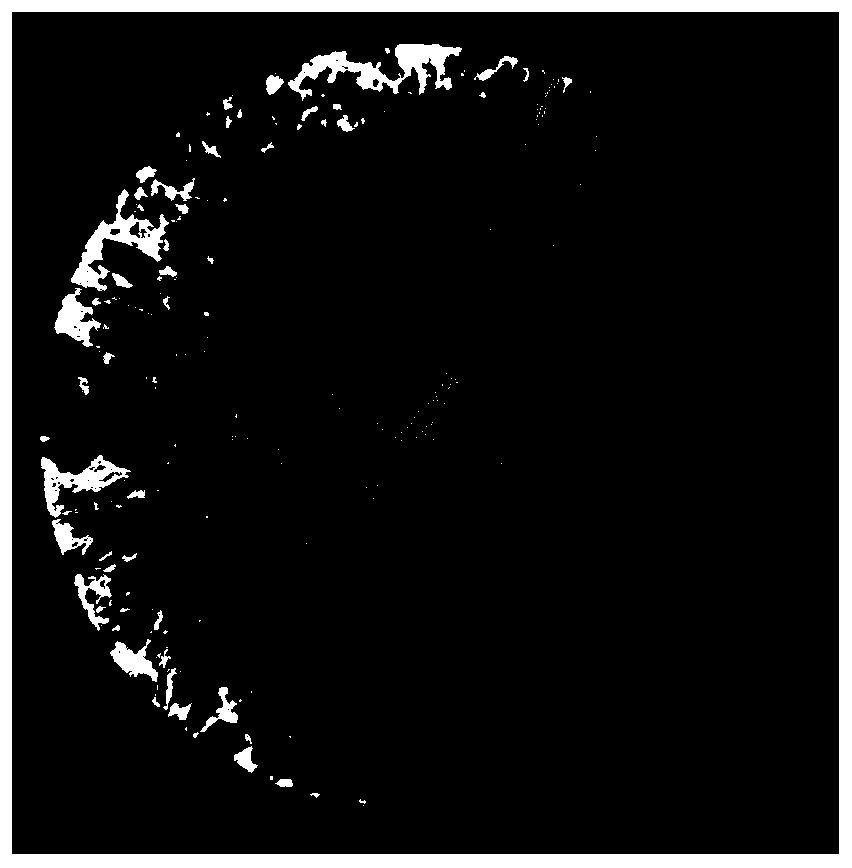

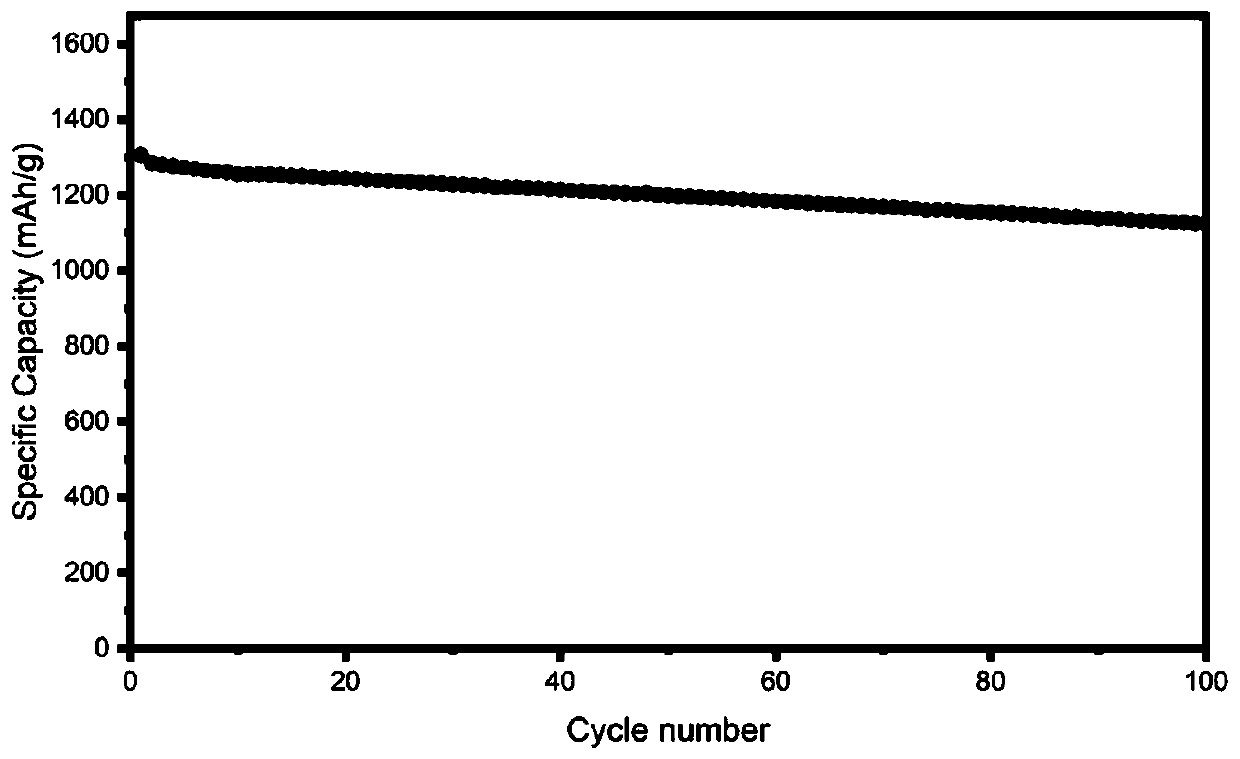

Active quantum dot(at)porous carbon material as well as preparation thereof and application thereof in lithium-sulfur battery

ActiveCN111244416AEffective catalytic conversionRaise the ratioPositive electrodesLi-accumulatorsLithium–sulfur batteryPorous carbon

The invention belongs to the field of lithium-sulfur batteries, and particularly relates to an active quantum dot(at)porous carbon material which comprises porous carbon and active quantum dots loadedon the porous carbon in situ, wherein the active quantum dots are titanium nitride and / or titanium dioxide-titanium nitride heterojunctions. The invention also relates to a fluidization preparation method of the material and an application of the material in a lithium-sulfur battery. According to the material disclosed by the invention, the titanium nitride quantum dots and / or the silicon dioxide-titanium nitride heterojunction quantum dots are loaded on the porous carbon in situ, so that the adsorption and catalytic performance of the material on polysulfide can be remarkably improved, and the rate capability, the capacity and the cycle performance of the sulfur-loaded material can be remarkably improved.

Owner:CENT SOUTH UNIV

Manufacture device and manufacture method for height limit type preformed soldering terminals

ActiveCN106736051AHigh degree of continuityStrong controllabilityWelding/cutting media/materialsSoldering mediaSolderingControllability

The invention particularly relates to a manufacture device and a manufacture method for height limit type preformed soldering terminals. The manufacture device comprises a support, a guide mechanism, a slotting mechanism, a metal wire guide mechanism and a wire implanting mechanism, and the guide mechanism, the slotting mechanism, the metal wire guide mechanism and the wire implanting mechanism are arranged on the support in sequence. The manufacture method includes: digging a slot on a weld blank strip through the slotting mechanism, the wire implanting mechanism pressing a metal wire into the slot dug out in the weld blank strip, and punching the weld blank strip into one preformed soldering terminal according to the length requirement of the soldering terminal. The manufacture device is high in continuation degree, strong in controllability and wide in applicability, can manufacture the height limit type preformed soldering terminals instead of manual production, assures dimensional accuracy and stability of products, and is high in production efficiency and low in use and manufacture cost.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS

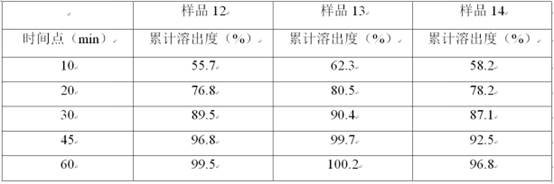

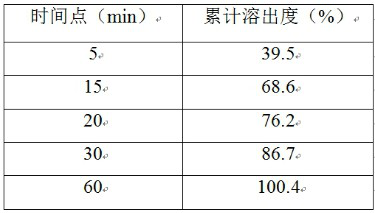

Hot-melt extrusion composition containing traditional Chinese medicine volatile oil and preparation method and pharmaceutical preparation thereof

ActiveCN112353845AReduce humidityHigh degree of continuityPharmaceutical non-active ingredientsPlant ingredientsBiotechnologyPolyethylene glycol

The invention relates to the field of traditional Chinese medicine preparations, and provides a hot-melt extrusion composition containing traditional Chinese medicine volatile oil, a preparation method thereof and a pharmaceutical preparation. The hot-melt extrusion composition disclosed by the invention contains traditional Chinese medicine volatile oil, a water-soluble carrier material and a plasticizer, wherein the plasticizer at least contains stearic acid and / or polyethylene glycol 15 hydroxystearate. The hot-melt extrusion composition containing the traditional Chinese medicine volatileoil is stable and free of oil leakage and has the traditional Chinese medicine volatile oil drug loading capacity as high as 25%-35%. The composition subjected to hot-melt extrusion can be crushed atnormal temperature, and can be subsequently and conveniently prepared into a solid preparation. The prepared solid preparation has the advantages of controllable dissolution, easiness in oral administration, good storage stability and the like.

Owner:上海智同医药科技有限公司

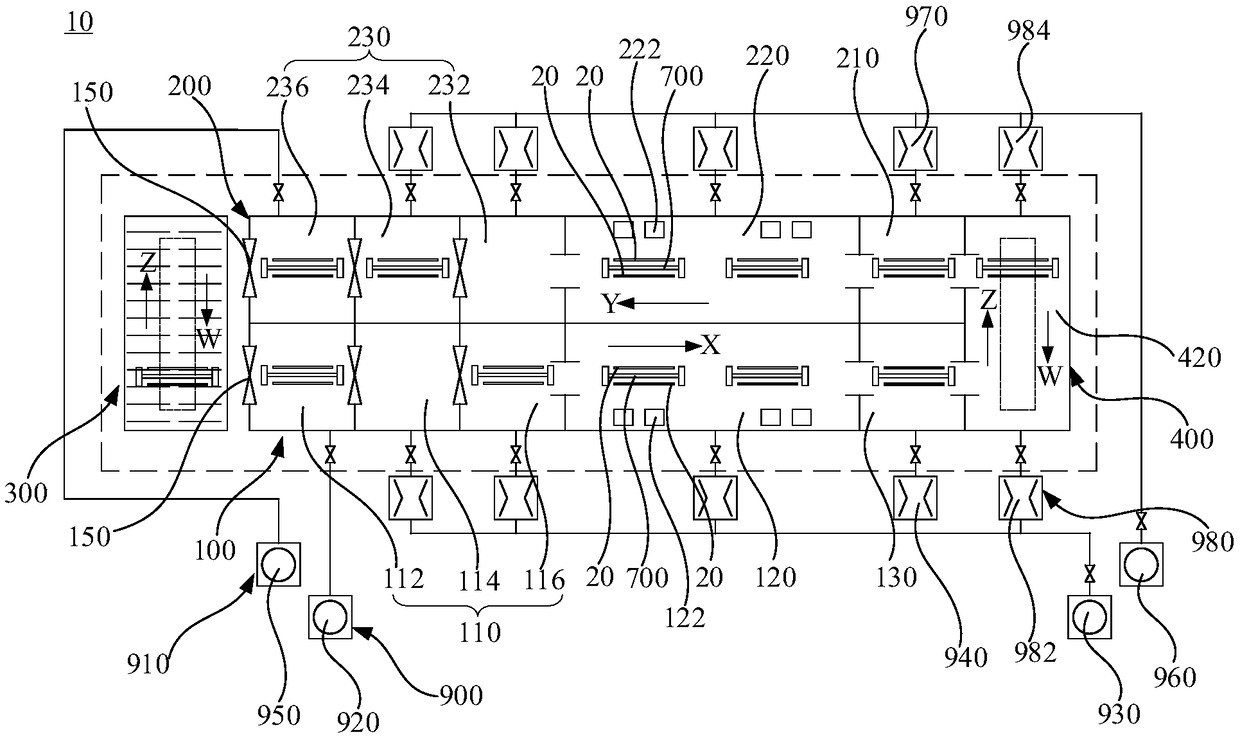

Vacuum film coating device

ActiveCN109468611AImprove the efficiency of vacuum degassing coatingReduce consumptionVacuum evaporation coatingSputtering coatingEngineeringTransfer mechanism

The invention relates to a vacuum film coating device. The vacuum film coating device comprises a first vacuum chamber row, a second vacuum chamber row, a first transfer mechanism, a second transfer mechanism, a first driving mechanism, a second driving mechanism and a substrate frame. The first vacuum chamber row, the second transfer mechanism and the second vacuum chamber row are arranged in sequence to form a cycle. The opposite sides of the substrate frame are used for loading substrates. The first driving mechanism is used to drive the substrate frame to penetrate through the first vacuumchamber row in the first direction so that the substrate loaded on the first side of the substrate frame can be subjected to the vacuum degassing film coating; the second transfer mechanism is used to transfer the substrate frame from the first vacuum chamber row to the second vacuum chamber row so that the substrate frame can be driven by the second driving mechanism to penetrate through the second vacuum chamber row in the second direction, so that the substrate loaded on the second side of the substrate frame is subjected to the vacuum degassing film coating; and the first transfer mechanism is used to transfer the substrate frame reloaded with the substrates on opposite sides from the second vacuum chamber row to the first vacuum chamber row.

Owner:东莞市一粒米薄膜科技有限公司

Terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and organic extraction agent

InactiveCN113355538AHigh degree of continuous extractionHigh degree of continuityLanthanide oxides/hydroxidesProcess efficiency improvementO-Phosphoric AcidPhysical chemistry

The invention relates to the technical field of rare earth extraction, in particular to a terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and an organic extraction agent, and solves the technical problems that in the prior art, a nitric acid method is adopted for decomposing the ion ore to produce phosphoric acid, and then rare earth is separated out through neutralization precipitation, extraction and other processes; and the problem of co-precipitation exists in neutralization precipitation, and certain difficulties exist in both the economic aspect and the technical aspect. The terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and an organic extraction agent comprises the following steps: producing phosphoric acid by decomposing the ion ore with hydrochloric acid when wet-process phosphoric acid is adopted, and feeding one part of rare earth into a phosphoric acid solution and the other part of rare earth into phosphogypsum in the treatment process. According to the mode provided by the invention, the continuous degree of extraction is relatively high, the recovery rate and the purity are obviously improved, meanwhile, the process for extracting the rare earth from the phosphoric acid is simple, and particularly, the continuous extraction method is high in continuous degree and easy to realize industrial production.

Owner:中稀(常州)稀土新材料有限公司

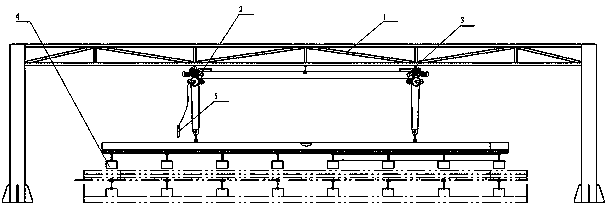

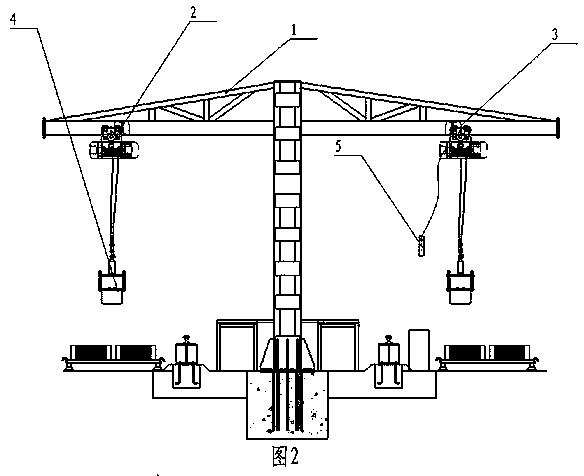

Automatic loading and unloading device of large plasma cutting machine

InactiveCN103639577AHigh degree of continuityImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesAutomatic programmingPlasma cutting

The invention discloses an automatic loading and unloading device of a large plasma cutting machine. The automatic loading and unloading device comprises a truss, a loading and delivering mechanism, an unloading and delivering mechanism, an electromagnetic lifter jack, an operating control device and the like. The horizontal and vertical motions of the electromagnetic lifter jack are controlled by adopting two electric walking blocks having a lifting function, and plates are positioned on a large plasma cutting platform by utilizing positioning pins. The automatic loading and unloading device is suitable for devices loading and unloading large plates inconveniently, automatic programming can be achieved without manual operation, the working efficiency is greatly improved, the labor intensity of workers is reduced, and potential safety hazard caused by the manual operation is avoided.

Owner:SHANDONG PENGXIANG AUTOMOBILE

Longitudinal high-thermal-conductivity gasket, preparation method and application

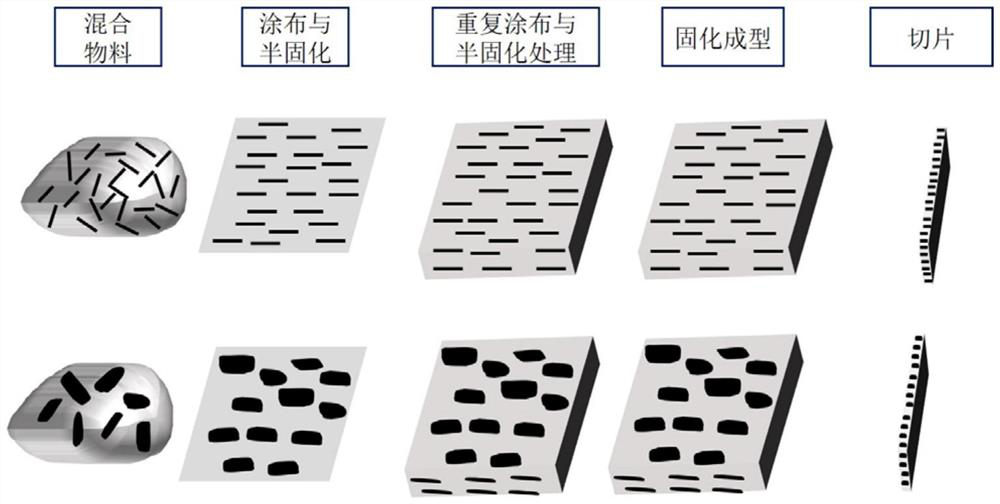

PendingCN113560146AHigh degree of continuityLow cost of preparationLiquid surface applicatorsCoatingsContinuous productionCoating

The invention provides a method for preparing a longitudinal high-thermal-conductivity gasket. The method comprises the steps that materials are evenly mixed to obtain a mixed material, and the materials comprise a binder, anisotropic thermal-conductivity filler and optional isotropic thermal-conductivity filler; the surface of a matrix material is coated with the mixed material, and a coating is obtained on the surface of the matrix material; the obtained coating is treated to be in a semi-vulcanized state, and a coating in the semi-vulcanized state is obtained; the obtained coating in the semi-vulcanized state is coated with the mixed material again; and the steps of semi-vulcanization and coating are repeated for multiple times, the coating is subjected to vulcanization forming, slicing is conducted in the direction perpendicular to coating, and the longitudinal high-thermal-conductivity gasket is obtained. The invention further provides the longitudinal high-thermal-conductivity gasket and application. Directional arrangement of the anisotropic thermal-conductivity filler in the matrix binder is realized, the preparation process is simple and easy to implement, large-scale continuous production is easy to realize, bubbles are effectively eliminated, and the thermal-conductivity property of the material is further improved.

Owner:CHANGZHOU FUXI TECH CO LTD

Hot-press forming coal gangue and building rubbish plate

InactiveCN106273831AWide variety of sourcesEasy to useSolid waste managementLaminationFiberCarbonization

The invention discloses a hot-press forming coal gangue and building rubbish plate, which belongs to the technical field of building material preparation. The hot-press forming coal gangue and building rubbish plate consists of a surface material layer and a middle material layer, wherein the surface material layer is prepared from the following substances: 100 parts of coal gangue, 5 to 20 parts of alkali excitants, 30 to 50 parts of water, 100 to 300 parts of building rubbish and 0.1 to 1.2 parts of alkali-resistant fiber; the middle material layer is prepared from the following substances: 100 parts of coal gangue, 5 to 20 parts of alkali excitants, 20 to 40 parts of water, 400 to 1000 parts of building rubbish and 0.5 to 2.0 parts of alkali-resistant fiber. The coal gangue and the building rubbish are used as raw materials for plate preparation; the characteristics of low cost and wide sources are realized; in addition, the usage amount of the coal gangue is great; the utilization rate is high; waste materials are changed into valuable materials; the prepared plate has the advantages of light weight, high impact resistance, high toughness, low shrinking percentage, good fatigue resistance performance, high anti-carbonization capability and good durability.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Compact hot metal transport system

ActiveCN103343632BSmall footprintReduce investmentBlast furnace detailsIndustrial buildingsSteelmakingIron transport

Owner:BERIS ENG & RES CORP

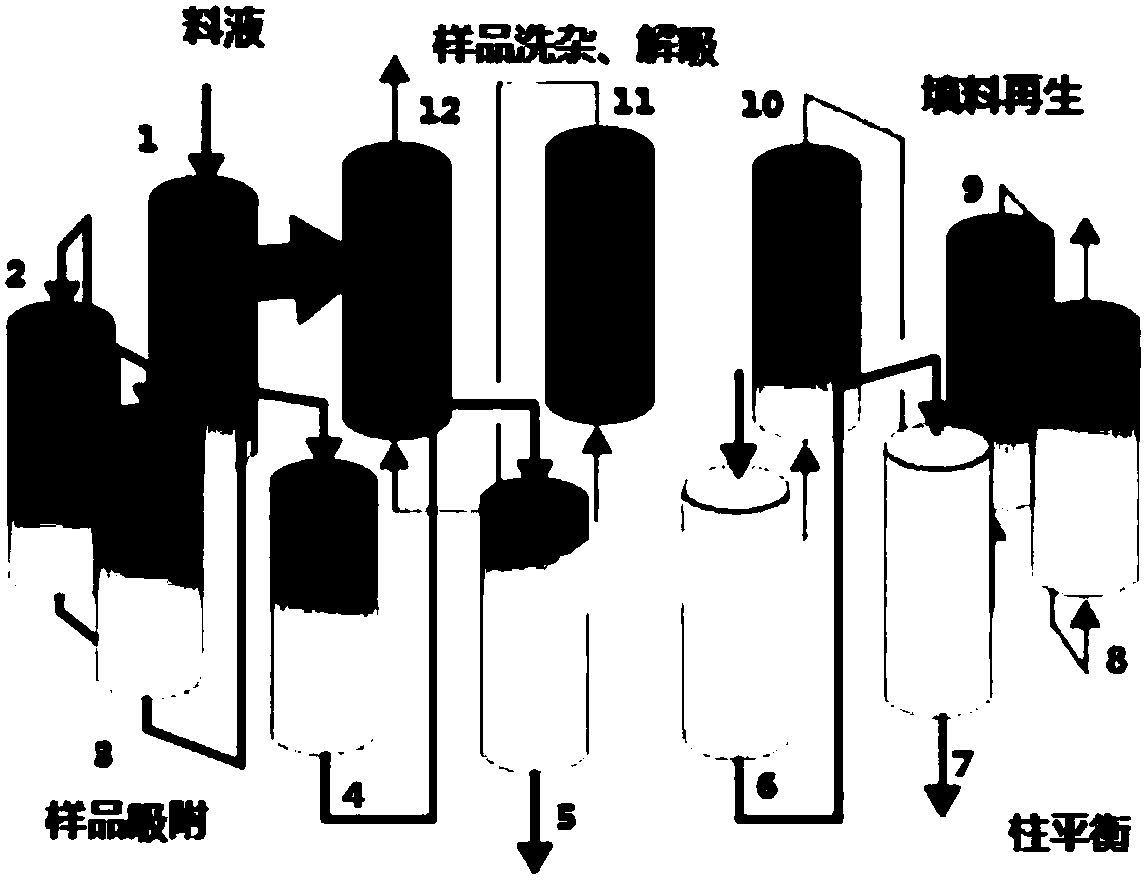

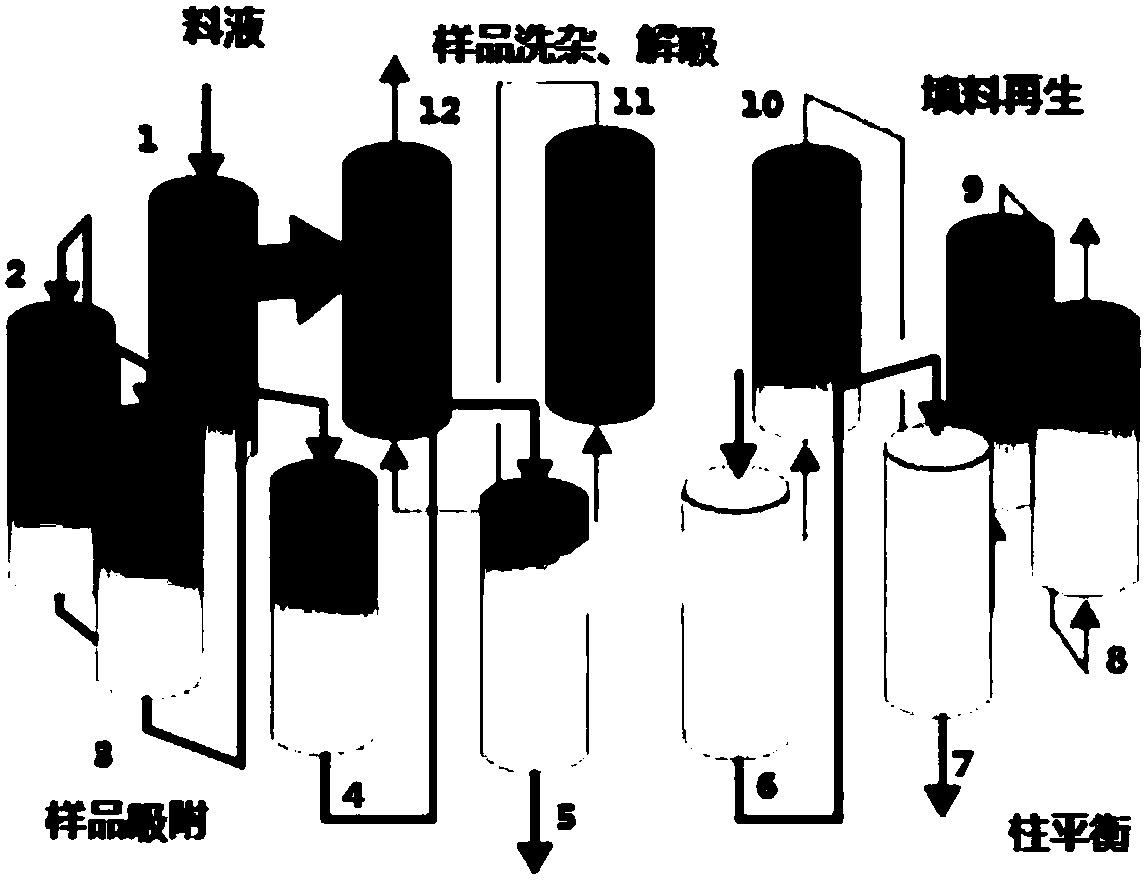

Method for separating and purifying FMD inactivated virus antigen by applying simulated flow bed

ActiveCN109836479AImprove continuityEasy to operateVirus peptidesPeptide preparation methodsDesorptionElution

The invention relates to a method for separating and purifying an FMD inactivated virus antigen by applying a simulated flow bed, wherein the method comprises the following steps: balancing a chromatographic column of the simulated flow bed with a balanced buffer solution; loading an FMD inactivated virus antigen sample into the chromatographic column of the simulated flow bed, during sample loading, simultaneously carrying out antigen sample impurity cleaning and sample desorption elution as well as chromatographic filler cleaning and regeneration and balanced liquid balancing on the chromatographic column, and continuously desorbing and eluting the collected and purified sample in the process. The simulated flow bed is applied to separation and purification of the FMD inactivated virus antigen for the first time, the continuous saturated sample loading separation operation can be realized and the sample loading amount is greatly improved; moreover, through the continuous separation and purification via multiple monomer columns, the degree of continuity is high, the separation and purification time is greatly shortened, the preparation efficiency is improved and the operation costis reduced. Moreover, the rigid filler is selected specifically, the loading capacity of the filler namely the pressure resistance is greatly improved, the use amount of the chromatographic filler isreduced, and the service life of the chromatographic column in the simulated flow bed is prolonged.

Owner:SHANGHAI SHEN LIAN BIOMEDICAL CORP

A kind of melamine composite fiber and its manufacturing method

ActiveCN109881293BGood storage stabilityImprove fiber performanceFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a melamine composite fiber and a manufacturing method thereof. The melamine composite fiber is prepared from melamine formaldehyde modified resin, an inorganic nano material subjected to surface modification through a coupling agent and a water-soluble polymer, the composite fiber is less in internal defect and high in strength and toughness, the tensile strength of the composite fiber reaches 2-6 cN / dtex, and the elongation at break reaches 15%-40%; the flame resistance is excellent, the composite fiber is extinguished immediately after leaving a flame, no molten droplet exists, smoldering does not occur, and the limit oxygen index reaches 38%-45%. According to the melamine composite fiber manufacturing method, in the spinning solution manufacturing process, hydrogen bonds are formed among all components of a spinning solution, and the compatibility is good; by means of the inorganic nano material subjected to surface modification through the coupling agent, alarge number of bubbles in the spinning solution are eliminated, the fluidity of the spinning solution is improved, and meanwhile the stability and the fiber forming property of the spinning solutionare improved; by means of the method, the melamine composite fiber can be manufactured economically.

Owner:SICHUAN UNIV

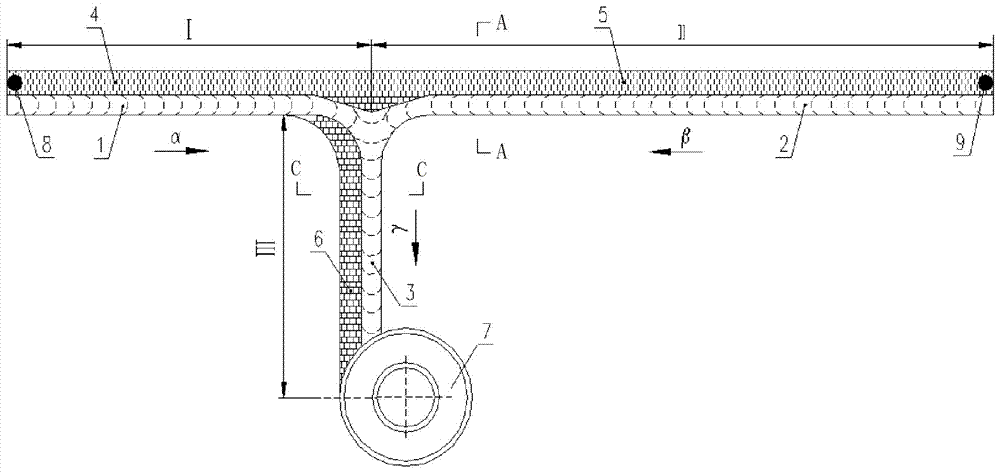

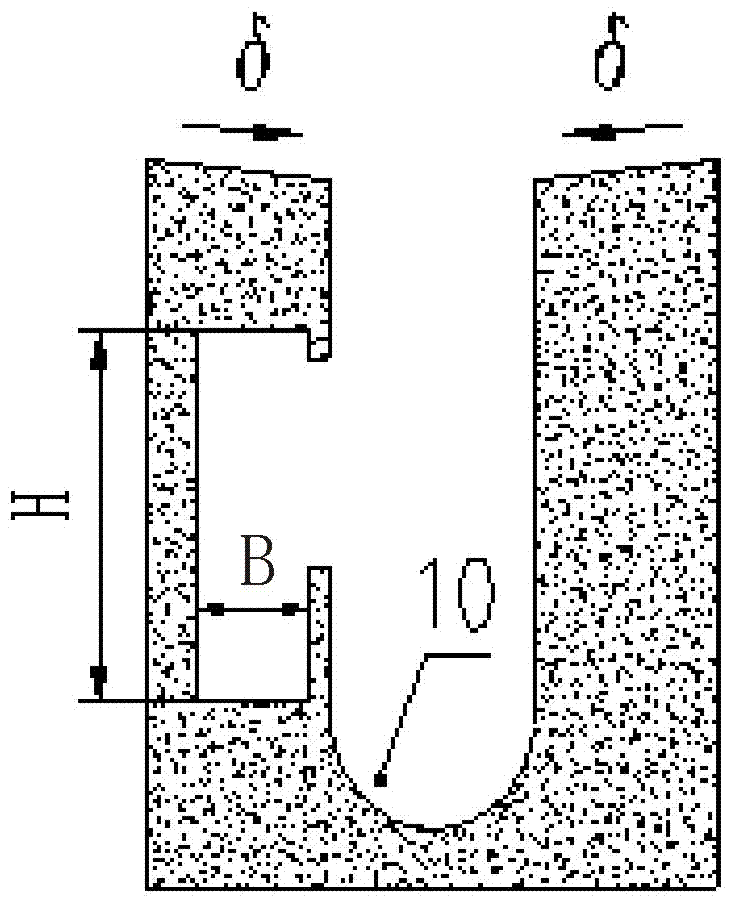

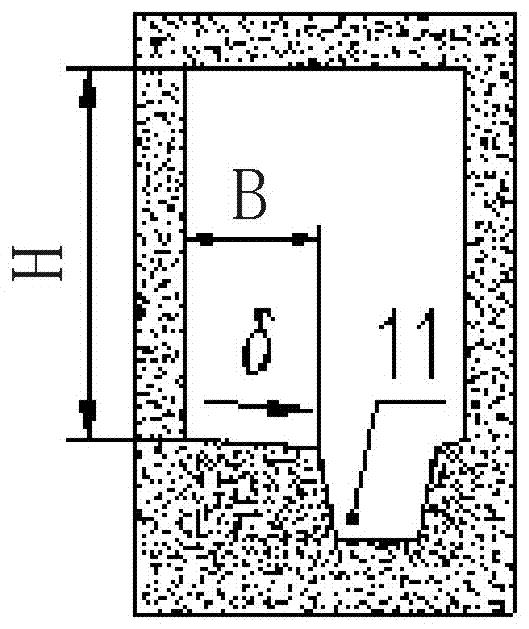

Non-ferrous metal line rolling slag flushing channel

ActiveCN107225156ACompact and reasonable structure designSmall footprintWork treatment devicesMetal rolling arrangementsTreatment effectSlag

The invention discloses a non-ferrous metal line rolling slag flushing channel which comprises a front rolling channel, a rear rolling channel and an external discharging area rolling channel. The front rolling channel is located in a heating furnace and high-pressure water scale removing area; the rear rolling channel is located in a hot rolling mill and mill-front mill-rear area; the external discharging area rolling channel is located in a confluence external discharging area; the front rolling channel, the rear rolling channel and the external discharging area rolling channel are each internally provided with a front passage, a rear passage and an external discharging area passage; the front passages, the rear passages and the external discharging area passages communicate in a Y shape; the front end of the heating furnace and high-pressure water scale removing area is provided with a front water spraying point; the rear end of the hot rolling mill and mill-front mill-rear area is provided with a rear water spraying point; and the rear end of the confluence external discharging area is provided with a rotational flow well and a sedimentation tank. The automation degree and the continuity degree are high, the treatment effect of wastewater containing scales is good, and energy saving and consumption reduction are achieved.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com