Active quantum dot(at)porous carbon material as well as preparation thereof and application thereof in lithium-sulfur battery

A technology of porous carbon materials and lithium-sulfur batteries, applied in lithium batteries, active material electrodes, battery electrodes, etc., can solve problems such as weak chemical polarity and weak chemical adsorption capacity of lithium polysulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

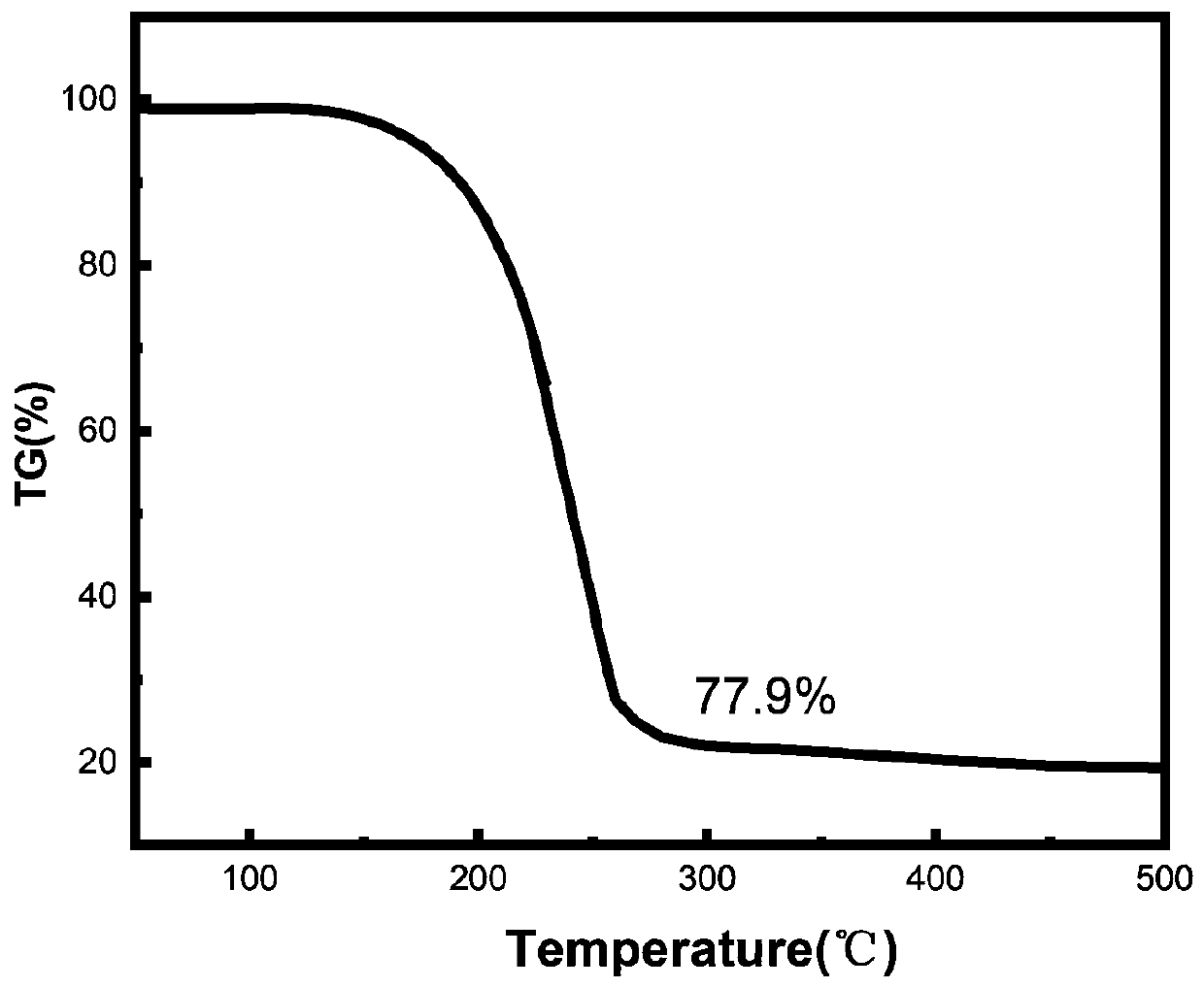

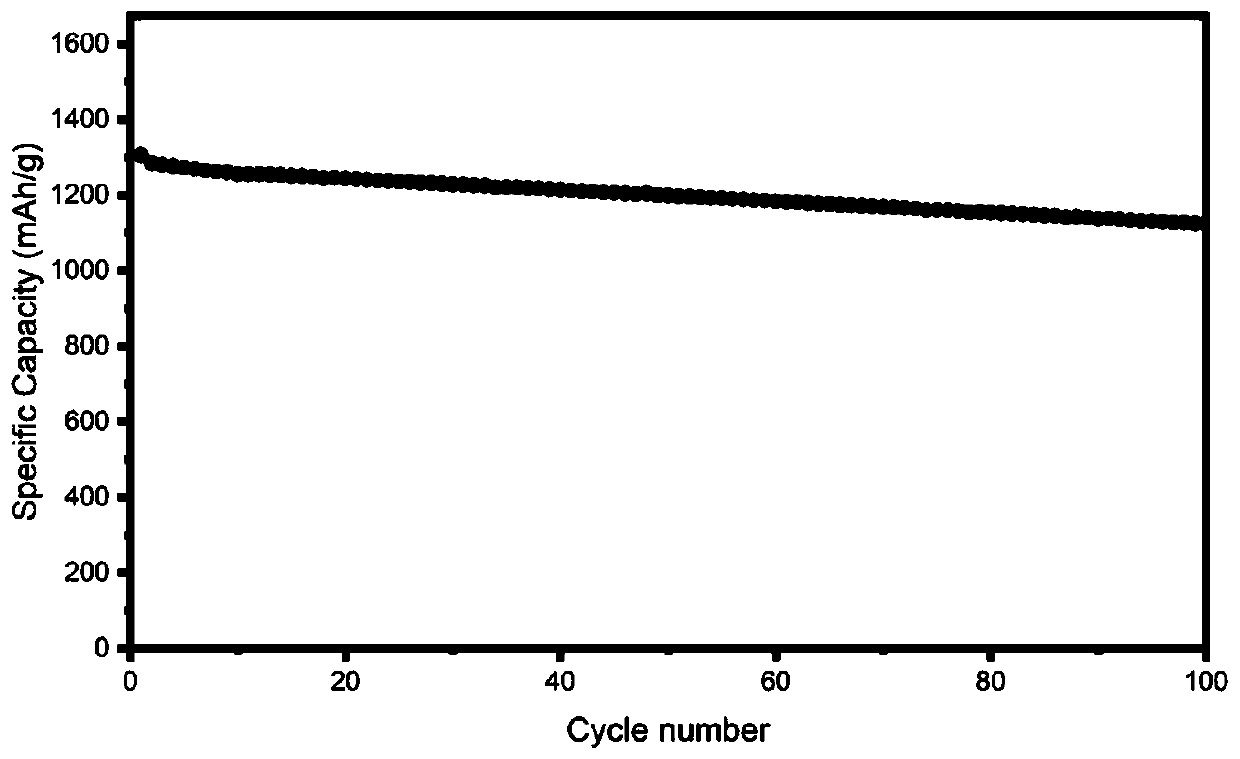

Embodiment 1

[0098] 5 kg of starch, 5 kg of 50nmSiO 2 Add the template dispersion and 50 g of sodium dodecylsulfonate into 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 1200°C for three hours in an atmosphere; the carbonized product is washed to remove SiO with 10M sodium hydroxide solution at a temperature of 100°C 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried and dispersed in alcohol, and ultrasonicated for 2 hours to form a uniform dispersion. Add 30ml tetrabutyl titanate solution and continue ultrasonication for one hour, then heat and stir at 80°C to remove alcohol, stop heating when there is still a small amount of alcohol in the mixture, put the material into the fluidized bed, and blow nitrogen (30L / min) Suspend the material and then increase the water vapor content in the nitrogen until it cha...

Embodiment 2

[0101] Compared with Example 1, the main difference is that the preparation process of the porous template carbon is adjusted, specifically:

[0102] 5 kg of starch, 5 kg of 500nmSiO 2 Add the template dispersion and 50 g of sodium dodecylsulfonate into 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 800°C for three hours in an atmosphere; the carbonized product is washed with 10M sodium hydroxide solution at a temperature of 100°C to remove SiO 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried and dispersed in alcohol, and ultrasonicated for 2 hours to form a uniform dispersion. Add 30ml tetrabutyl titanate solution and continue ultrasonication for one hour, then heat and stir at 80°C to remove alcohol, stop heating when there is still a small amount of alcohol in the mixture, put the material in...

Embodiment 3

[0105] Compared with Example 1, the main difference is that the preparation process of the porous template carbon and the ratio of the porous carbon to the titanium source are adjusted, specifically:

[0106] 5 kg of starch, 5 kg of 150nmSiO 2 Add the template dispersion and 50 g of sodium dodecylsulfonate into 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 1000°C for three hours in an atmosphere; the carbonized product is washed to remove SiO with 10M sodium hydroxide solution at a temperature of 100°C 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried and dispersed in alcohol, and ultrasonicated for 2 hours to form a uniform dispersion. Add 10ml tetrabutyl titanate solution and continue ultrasonication for one hour, then heat and stir at 80°C to remove alcohol, stop heating when there is still...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com