A method for improving the degradation rate of diethylstilbestrol by laccase

A technology of diethylstilbestrol and degradation rate, applied in chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve problems such as decreased laccase processing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

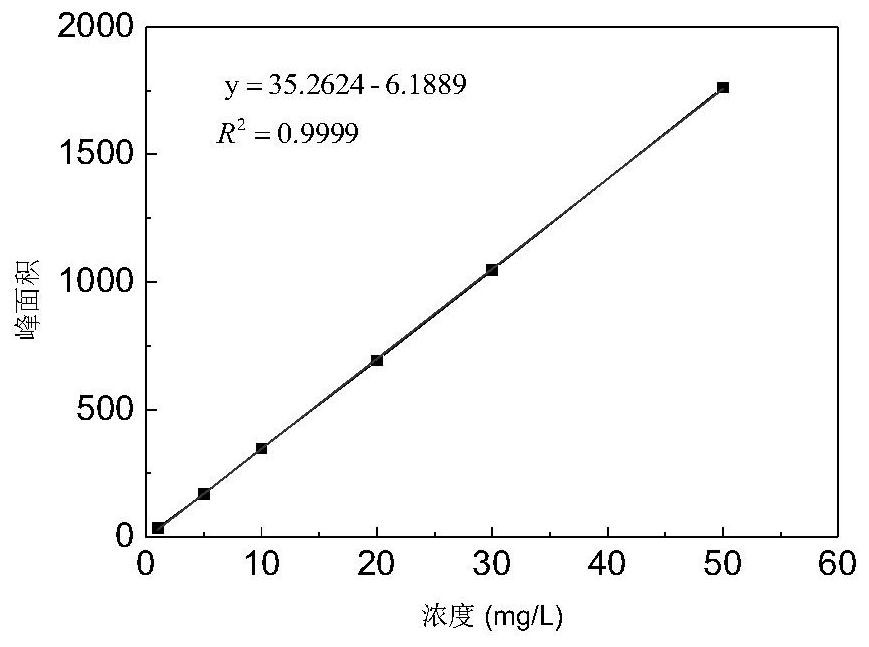

[0031] (1) Standard Preparation: diethylstilbestrol dissolved in methanol to form a 2.5g / L diethylstilbestrol mother liquor, the mother liquor was diluted diethylstilbestrol are released to a concentration 1,5,10,20,30,50mg / L, 100mg / L standard solution, diethylstilbestrol standard curve prepared using HPLC peak area detected.

[0032] The HPLC detection conditions are as follows:

[0033] Column: ZORBAX SB-C18 (150mm × 4.6mm × 5μm); detection conditions: injection volume 10μL, an equal volume of acetonitrile and water at the flow gradient 10min, the pump flow rate was 1.0mL / min, column temperature : 30 ℃, an ultraviolet detector at a wavelength of 240nm where the peak, the peak area value recording.

Embodiment 2

[0035] pH (1) using sodium acetate and acetic acid is formulated as a 0.01mol / L acetic acid 5.5 - sodium acetate buffer solution;

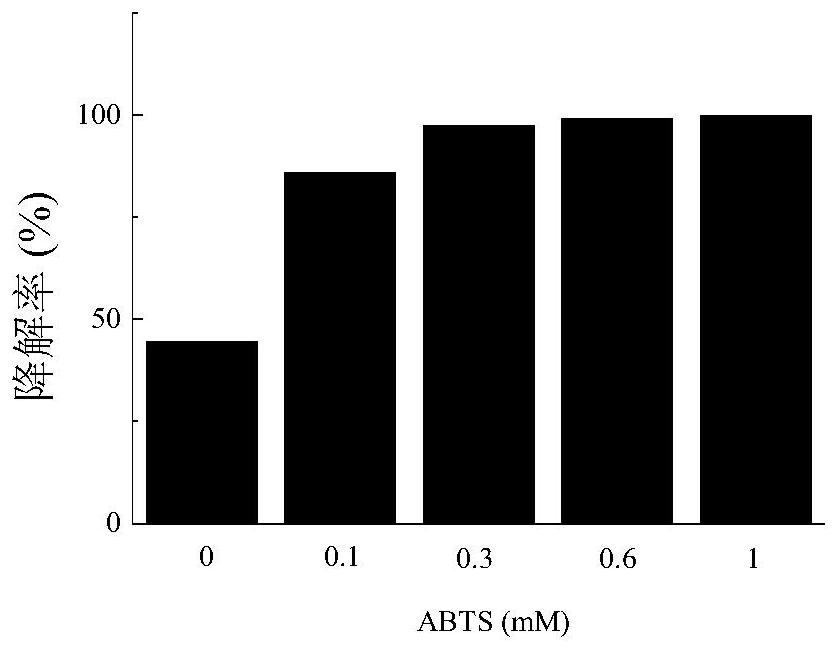

[0036] (2) Step (1) Preparation of acetic acid - sodium acetate buffer solution prepared at a concentration of 1mg / mL laccase mother liquor and the concentration of 0.01mol / L of ABTS solution, wherein the laccase is Coriolus versicolor produced, activity of 0.94U / mg;

[0037] (3) take 0.5mL laccase liquor, 0mL ABTS solution was added 0.4mL and 10mL DES mother liquor of the reaction system, the remaining solution is filled by the buffer, placed in a reaction 55 ℃ shaking incubator, set the speed 120r / min, the reaction using ethyl acetate solution was extracted twice after 0.5h, the organic phase was extracted rotary evaporated to dryness to do, using constant volume of methanol by vacuum filtration membrane sample, measure the concentration of the sample after the reaction by HPLC.

Embodiment 3

[0039] In Example 2, except that the step (3) Laccase 0.5mL mother liquor and the mother liquor and DES 0.4mL 0.1mL ABTS was added 10mL reaction system, filled by the remaining buffer solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com