Patents

Literature

97results about How to "Help to combine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cation high molecular base petroleum resin neutral sizing agent

InactiveCN101649579AImprove stabilityImprove sizing effectWater-repelling agents additionPaper/cardboardFiberHigh pressure

The invention discloses a method for preparing a cation high molecular base petroleum resin neutral sizing agent. The method comprises the following steps: under the function of an organic solvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, a cation monomer and the like, as a copolymerization monomer and preparing cation saponin-free benzene emulsion by saponin-free emulsion polymerization; taking the cation saponin-free benzene emulsion as a cation high molecular emulsifying agent, emulsifying and dispersing petroleum resin modified by maleic anhydride and preparing cation high molecular base petroleum resin neutral sizing agent emulsion with favorable stability and sizing performance by homogenizing at high pressure. The product has favorable stability and sizing performance; the cation high molecular base petroleum resin neutral sizing agent prepared by the invention has stronger cation performance, particles have positive charges and are beneficial to retenting and combining with paper fibre, and the cation high molecular emulsifying agent also has a certain sizing synergistic action, thereby enhancing the stabilityand the sizing performance of the emulsion greatly.

Owner:SHAANXI UNIV OF SCI & TECH

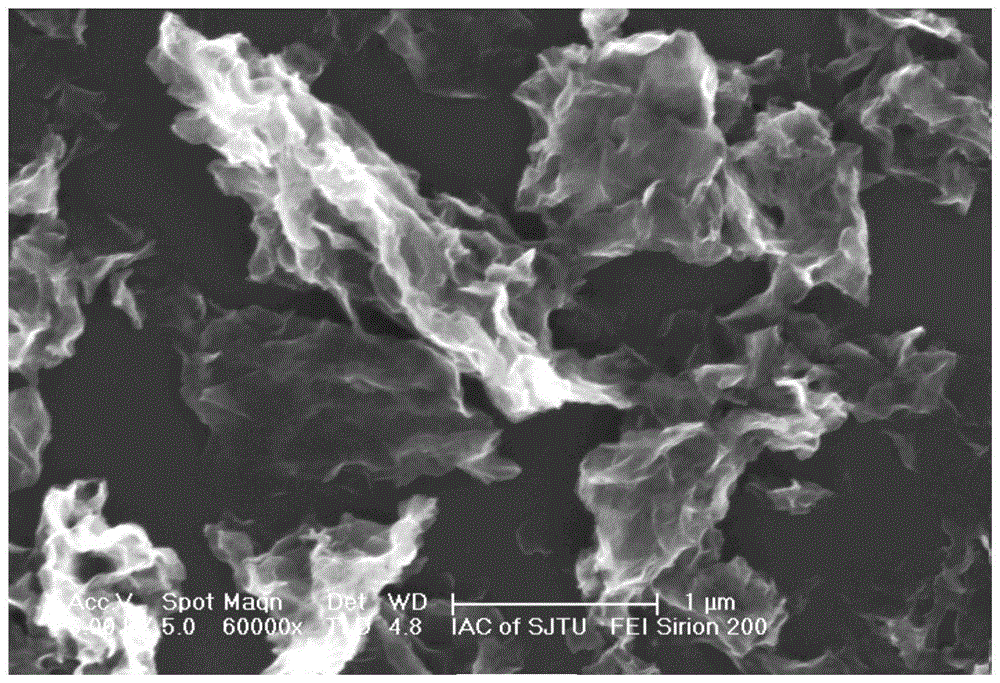

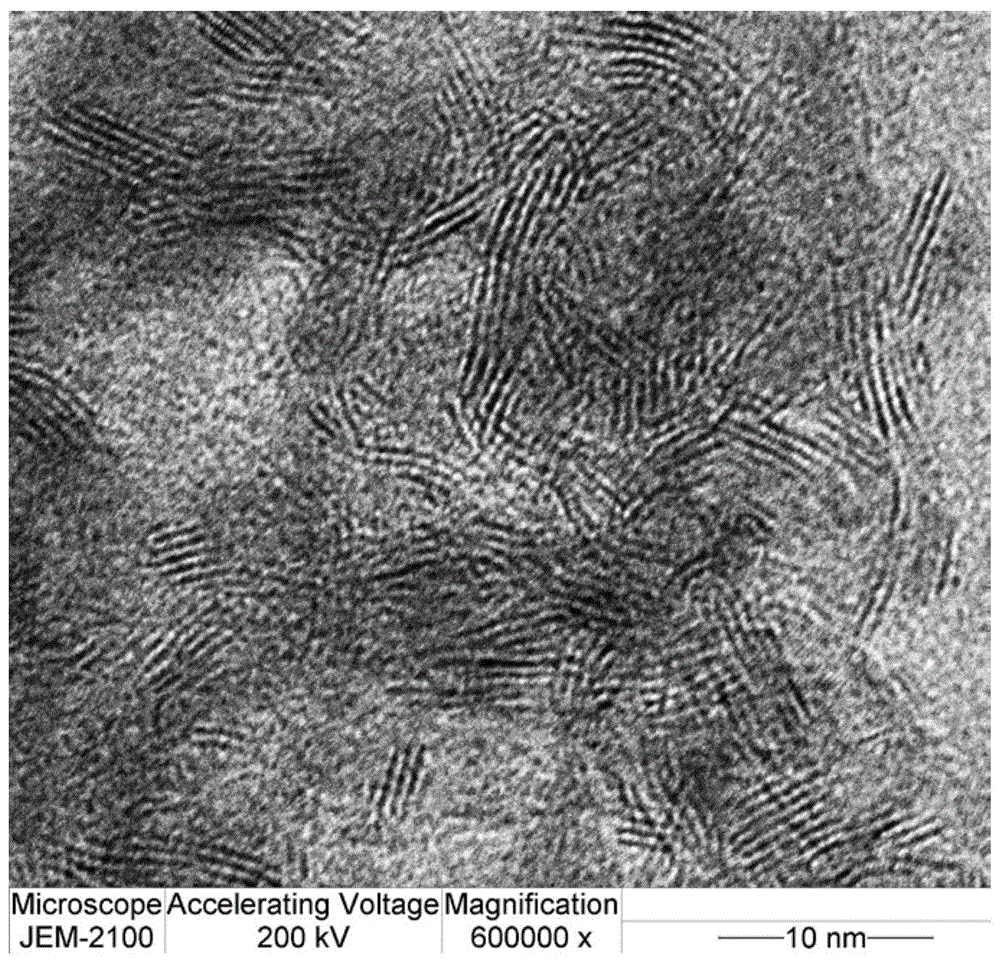

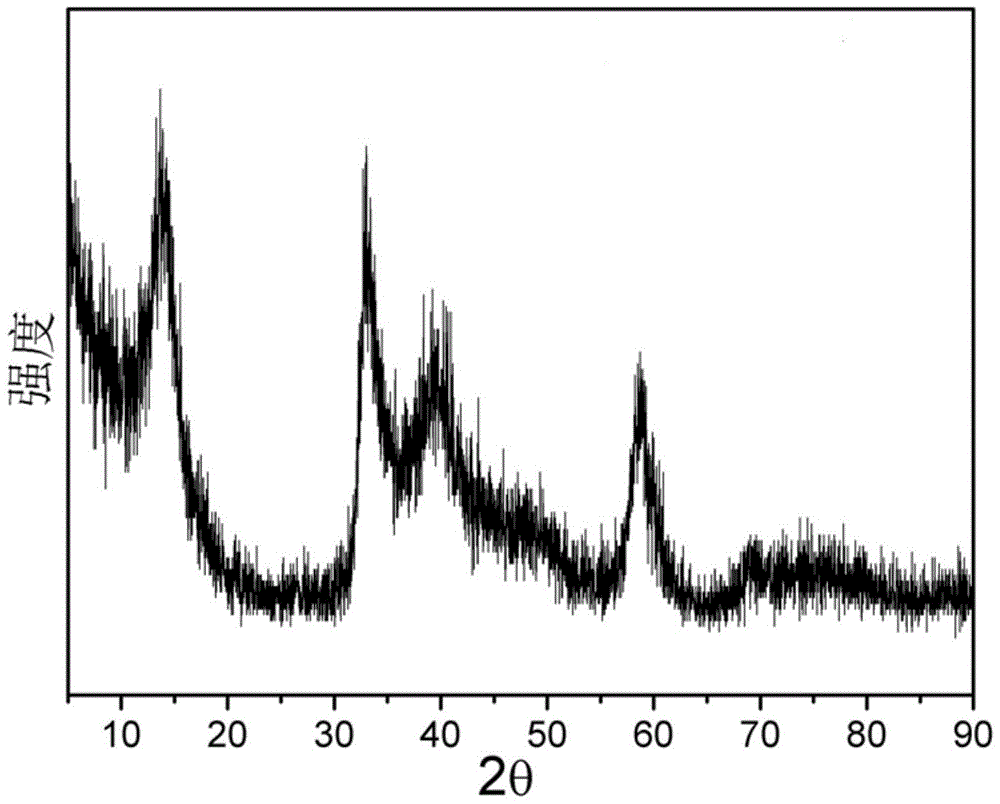

Nitrogen-doped graphene/molybdenum disulfide composite material and its preparation method and application

InactiveCN104393254BHigh activityImprove conductivityCell electrodesSecondary cellsSolventNitrogen doped graphene

The invention discloses a nitrogen-doped graphene / molybdenum disulfide composite material, and a preparation method and application thereof. The nitrogen-doped graphene / molybdenum disulfide composite material is obtained by mixing a graphite oxide solution, a nitrogen-containing precursor, a sulfur-containing precursor and a molybdenum-containing precursor in a solution, removing the solvent or hetero-ion to obtain a precursor material, performing heat treatment on the precursor material under the protection of an inert gas, and performing nitrogen doping and crystallization. The nitrogen-doped graphene / molybdenum disulfide composite material is applicable to lithium ion batteries, sodium cells, magnesium cells, hydrogen generation under electrocatalysis, hydrogen generation under photocatalysis and super capacitors, and is capable of improving the capacity of an anode material and also enhancing the cycling performance and the rate performance of the anode material when being used as a lithium ion battery anode material.

Owner:SHANGHAI JIAO TONG UNIV

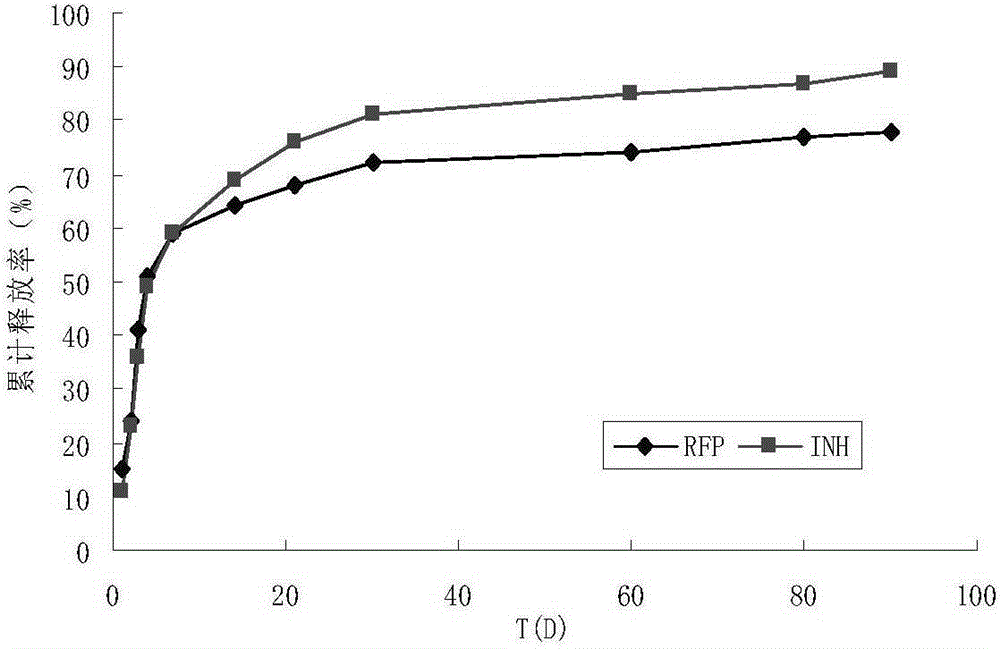

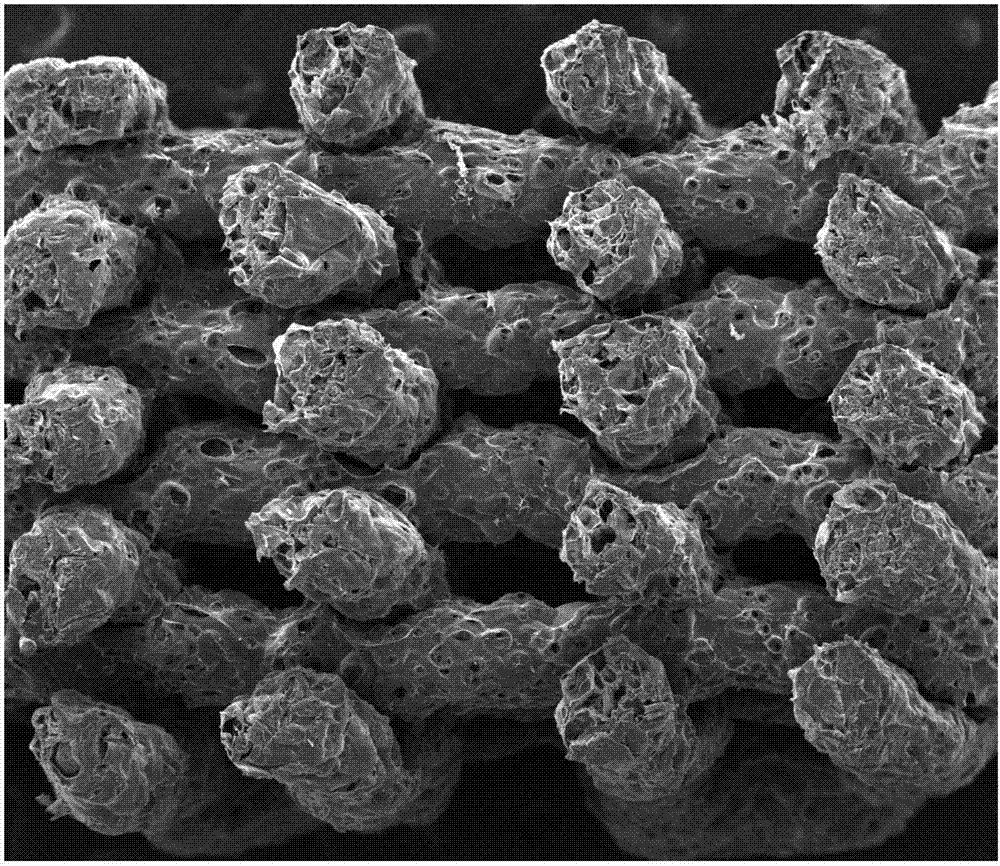

Bone tissue engineering stent and preparation method thereof

InactiveCN105268027AGood biocompatibilityEnhanced osteogenic propertiesAdditive manufacturing apparatusProsthesisAntituberculosis drugBone formation

The invention relates to a bone tissue engineering stent and a preparation method thereof. The bone tissue engineering stent is prepared from PLGA, isoniazide, rifampicin, allogeneic bone power and bone morphogenetic protein at the weight ratio of (87-51) to (1-6) to (1-6) to (10-30) to (1-7); according to the bone tissue engineering stent, polylactic acid-hydroxyacetic acid material, allogeneic bone power, antituberculosis drugs and bone morphogenetic protein are combined by adopting a 3D printing technology, a bioactive stent is manufactured by adopting the 3D printing technology, the physical, chemical and biological properties of the stent are detected, and the bone tissue engineering stent has the good biocompatibility and the good bone-formation promotion capacity and is biodegradable.

Owner:TIANJIN HAIHE HOSPITAL

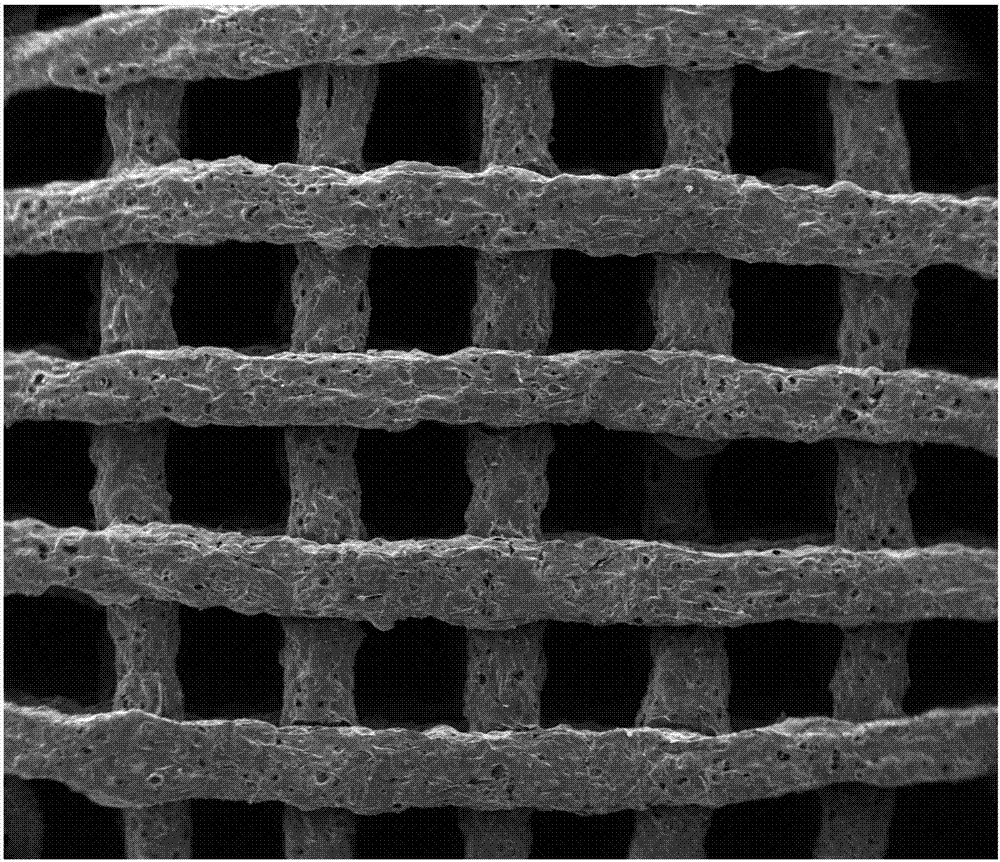

Sodium alginate-chitosan polyionic compound hydrogel and its 3D-printing preparation method

ActiveCN107537064AControllable external dimensionsHelp to combineAdditive manufacturing apparatusProsthesisBiocompatibility TestingOxygen

The invention discloses a sodium alginate-chitosan polyionic compound hydrogel and its 3D-printing preparation method. The compound hydrogel is the sodium alginate-chitosan polyionic compound hydrogelof which carboxylate radicals are crosslinked with ammonium ions, the biocompatibility is good, cell loss caused by material degradation in the cell culture process using hydrogel blocks can be effectively improved, and cells cultured on the materials easily obtain required oxygen and nutrient substances. The 3D-printing preparation method includes the following steps of preparation of a sodium alginate-chitosan polyionic compound solution and preparation of the sodium alginate-chitosan polyionic compound hydrogel. The sodium alginate-chitosan polyionic compound hydrogel is prepared by usingthe 3D-printing technology, the outside dimensions are controllable, pore structures which are visible in the macroscopic aspect and interconnected are obtained, combination between hydrogel materialsand tissue is easily achieved, and after material implantation, wear of materials at a tissue loss site is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Copper-based powder metallurgical pantograph sliding plate material taking spherical chromium powder as strengthening phase and preparation method thereof

ActiveCN109182833AImprove wear resistanceImproved resistance to arc ablationPowder metallurgyChromium

The invention discloses a copper-based powder metallurgical pantograph sliding plate material taking spherical chromium powder as a strengthening phase and a preparation method thereof. The copper-based powder metallurgical pantograph sliding plate material taking the spherical chromium powder as the strengthening phase is prepared from the following components in percentage by mass: 75 to 85 weight percent of Cu, 1 to 10 weight percent of the spherical chromium powder, 1 to 5 weight percent of Pb, 5 to 10 weight percent of Sn, 1 to 5 weight percent of Ni, 0.5 to 2 weight percent of flake graphite and 0.5 to 2 weight percent of molybdenum disulfide. The copper-based powder metallurgical pantograph sliding plate material prepared by the invention has excellent mechanical properties, good wear resistance and self-lubricating performance, low resistivity, high strength and good arc extinguishing performance. The copper-based powder metallurgical pantograph sliding plate material providedby the invention is mainly used for power-taking elements of urban rail transit and low-speed heavy-duty locomotives.

Owner:HEFEI UNIV OF TECH

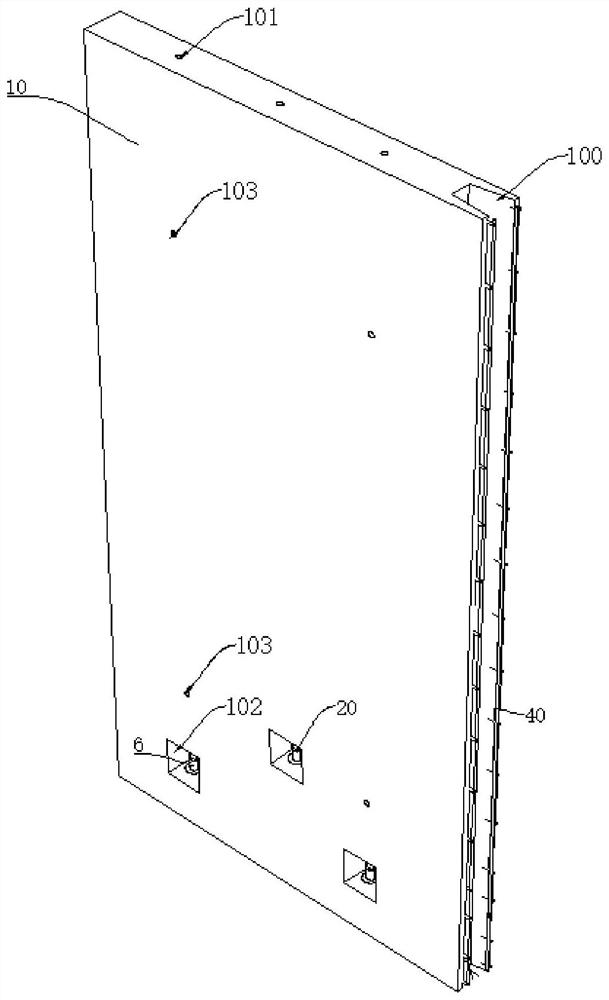

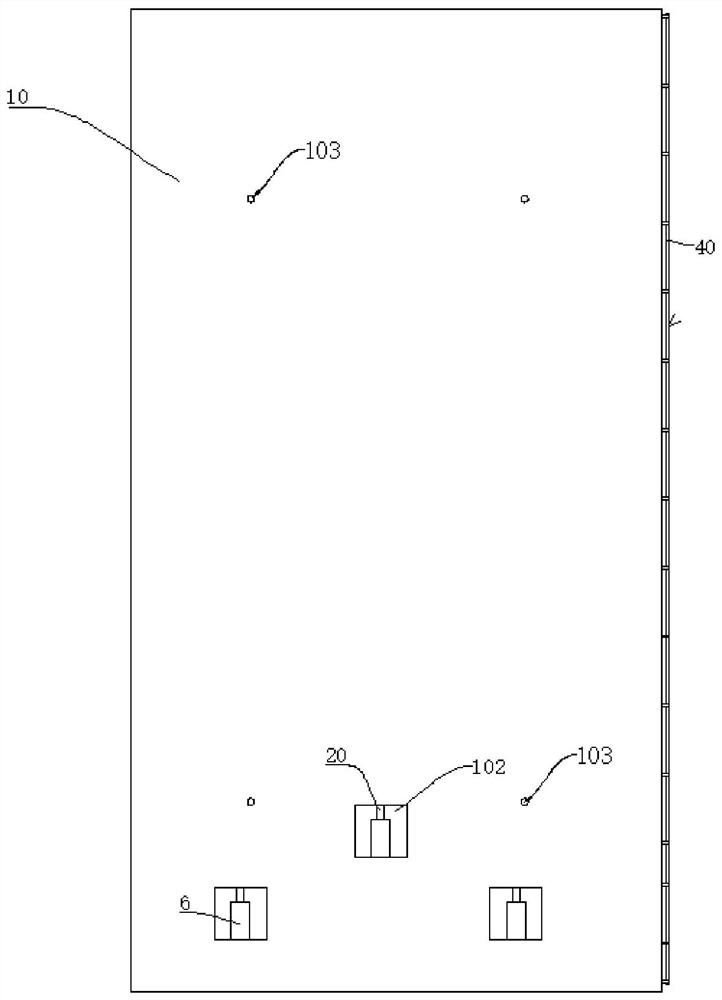

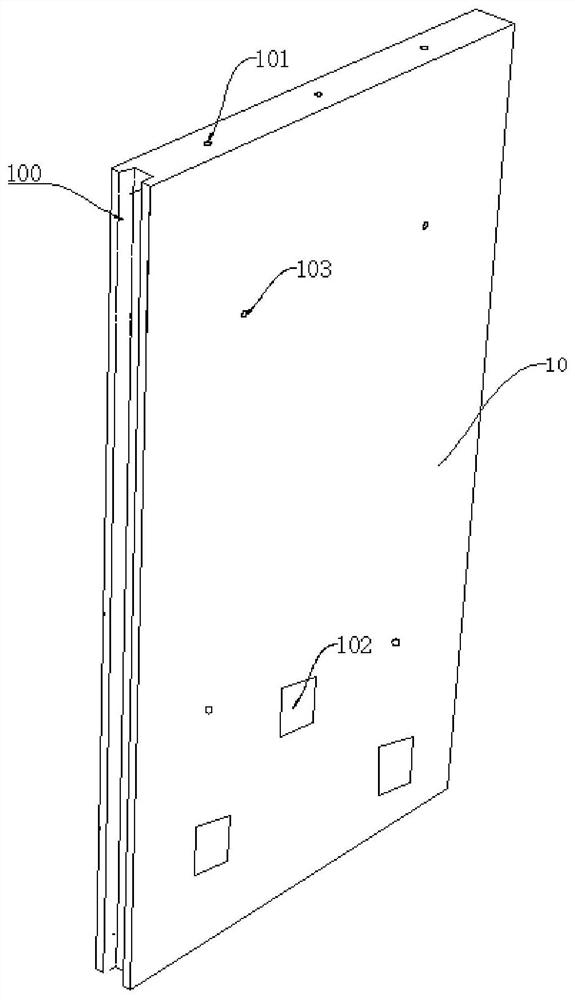

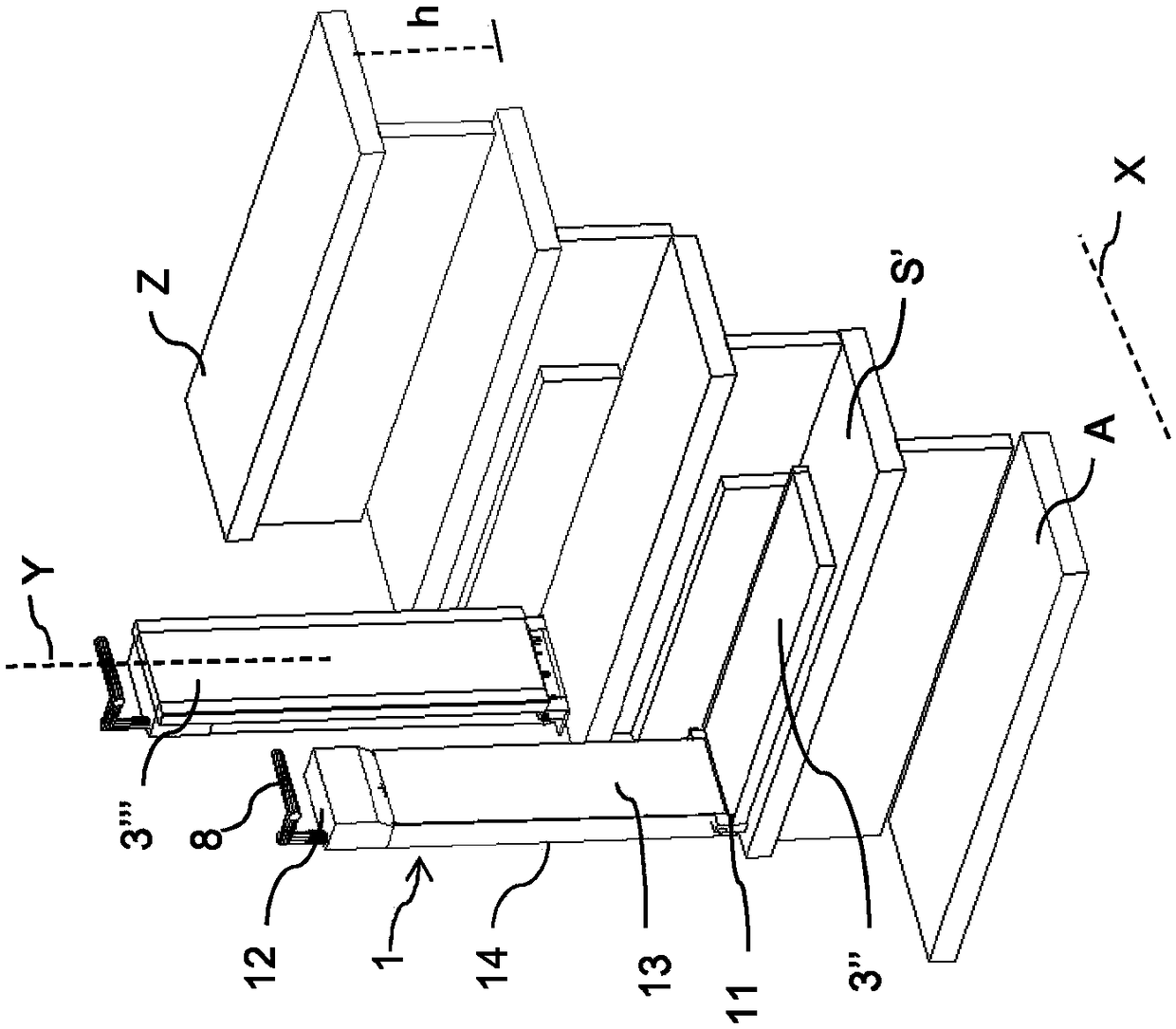

Prefabricated assembly type concrete wallboard and connecting structure and construction method thereof

PendingCN112282115APlay the role of resisting horizontal forceImprove waterproof performanceWallsArchitectural engineeringLap joint

The invention provides a prefabricated assembly type concrete wallboard and a connecting structure and a construction method thereof. The prefabricated assembly type concrete wallboard comprises a wallboard body, a plurality of vertically formed reinforcing steel bar through holes are formed in the wallboard body, and the reinforcing steel bar through holes are formed by metal corrugated pipes pre-buried before concrete is poured in a component factory. Pouring grooves are formed in the side edge of the wallboard body. Ribs are not exposed out of the four sides of the wallboard of a connectingstructure, field connection is divided into vertical connection and horizontal connection, the vertical connection is that steel bars are inserted into the pre-buried metal corrugated pipes, concreteis poured into the pre-buried metal corrugated pipes, and the vertical steel bars are in lap joint or welding or mechanical connection. The horizontal connection of the wallboard is that truss ribs are placed in the pouring grooves in the side edge of the wallboard, and the necessary vertical steel bars and horizontal steel bars are used as auxiliary materials. The ribs are not exposed on the four sides of the wallboard, and factory production is facilitated. The grouting-sleeve-free process for field connection is low in cost, reliable in connection and high in construction efficiency. The pouring grooves in the four sides of the wallboard and the post-poured concrete form a strong mechanical joint surface, and a good waterproof effect is achieved.

Owner:贺州通号装配式建筑有限公司 +2

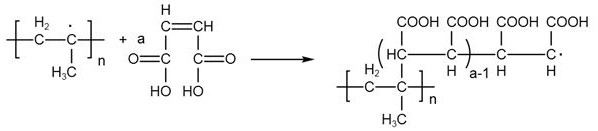

Ceramic insulating material for transformer and firing method of ceramic insulating material

ActiveCN106699219AHelp to combineDoes not affect strengthTransformers/inductances coils/windings/connectionsCeramicsTransformerKyanite

The invention discloses a ceramic insulating material for a transformer and a firing method of the ceramic insulating material. The ceramic insulating material is formed by firing a base material, a filling material and a pore forming agent; the base material consists of sintered kaolin, magnesite powder, quartz sand and sericite; the filling material consists of monatomic silicon powder, active alumina micro powder, modified nano-silicon dioxide and modified sepiolite fabric powder; the pore forming agent consists of fine silicon carbide powder, fine kyanite powder and vermiculite powder. The materials of the ceramic insulating material for the transformer contain certain open type air holes (or opening air holes), but the strength of the ceramic insulating material for the transformer cannot be affected; the open type air holes shrink obviously by adding the kyanite powder of which the volume is expanded at a high temperature, so that fine air holes are formed in the interior of the surface of ceramics; therefore, the bonding of the fired insulating material and other insulting materials, such as plastics and rubber, is facilitated.

Owner:ZHENGZHOU ELECTRIC POWER COLLEGE

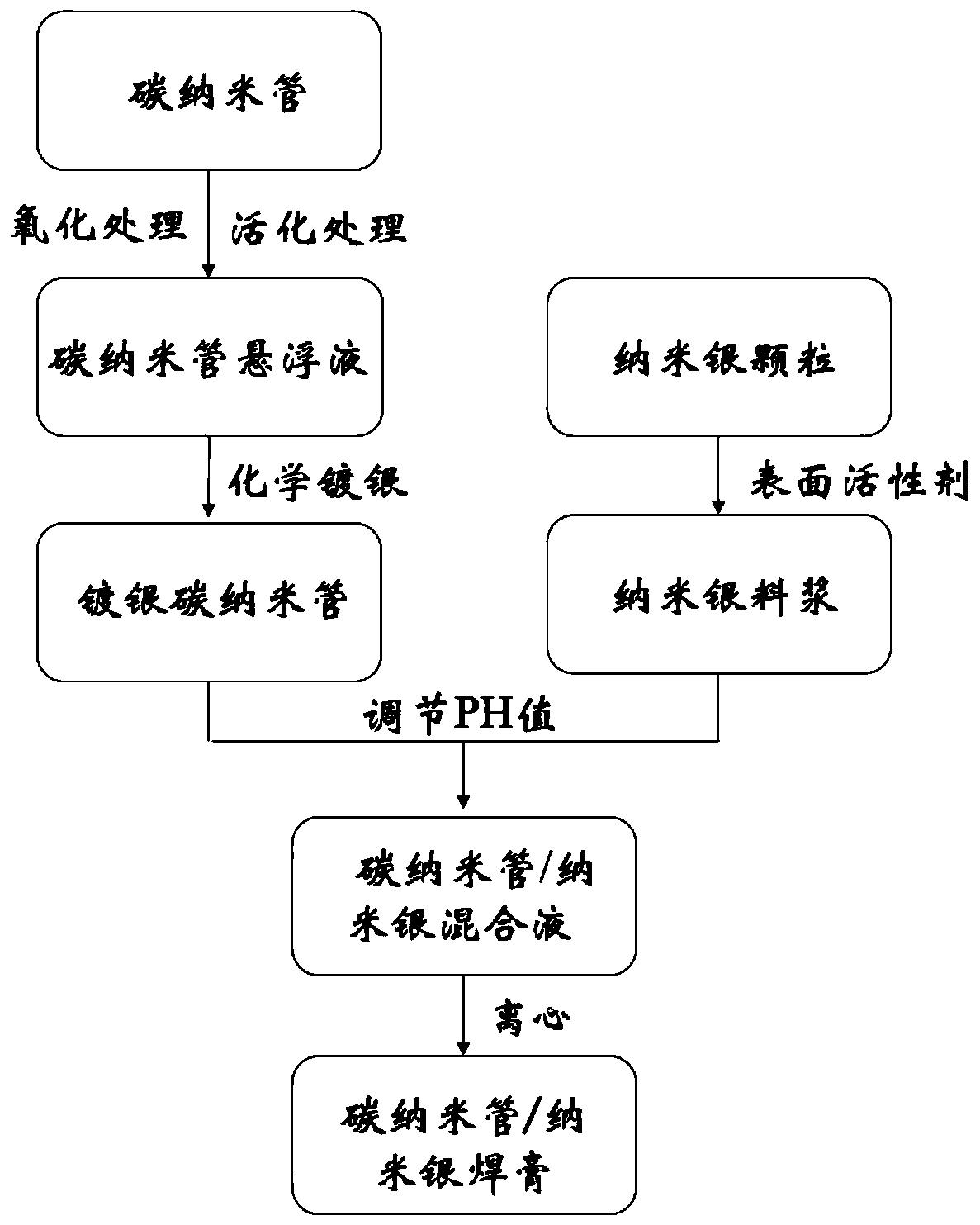

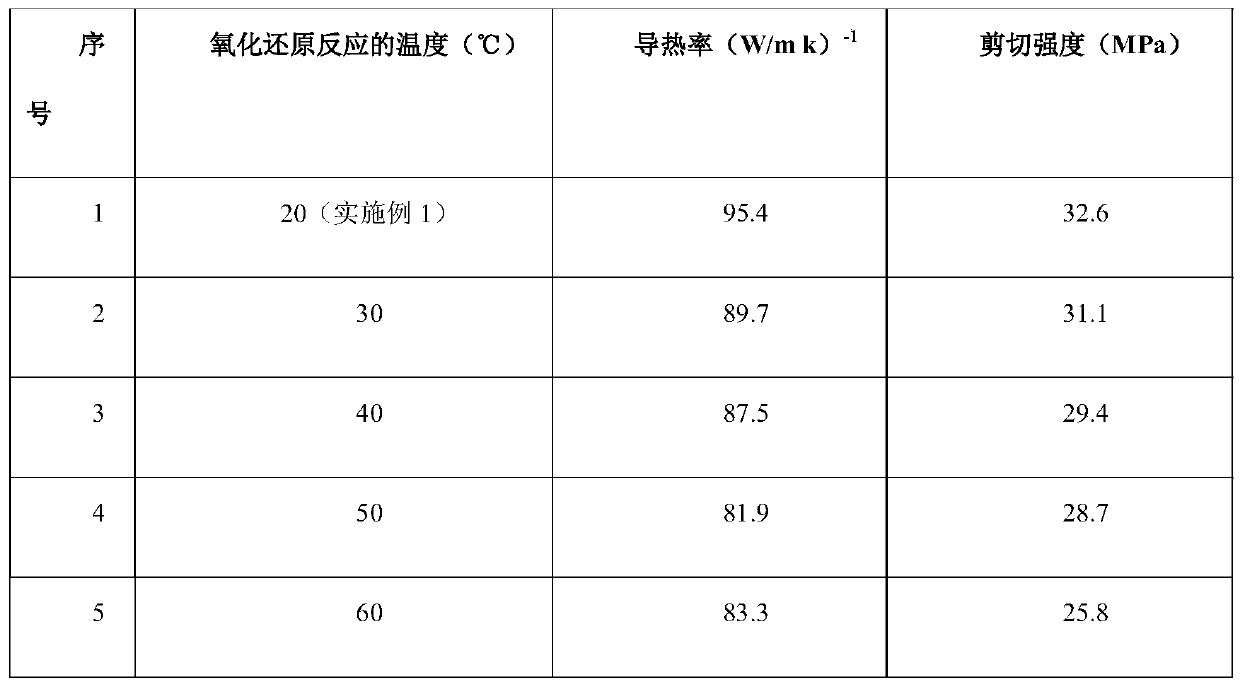

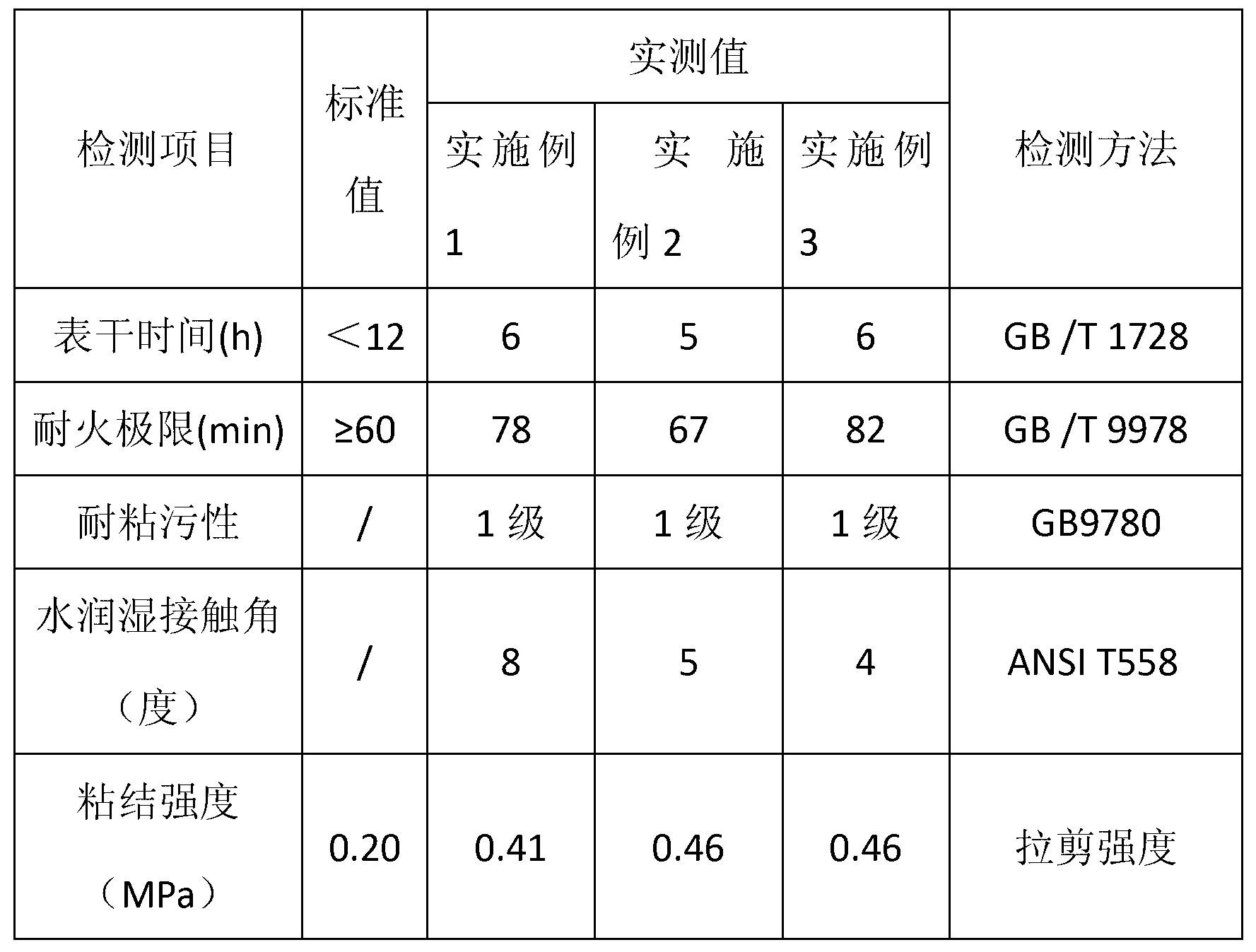

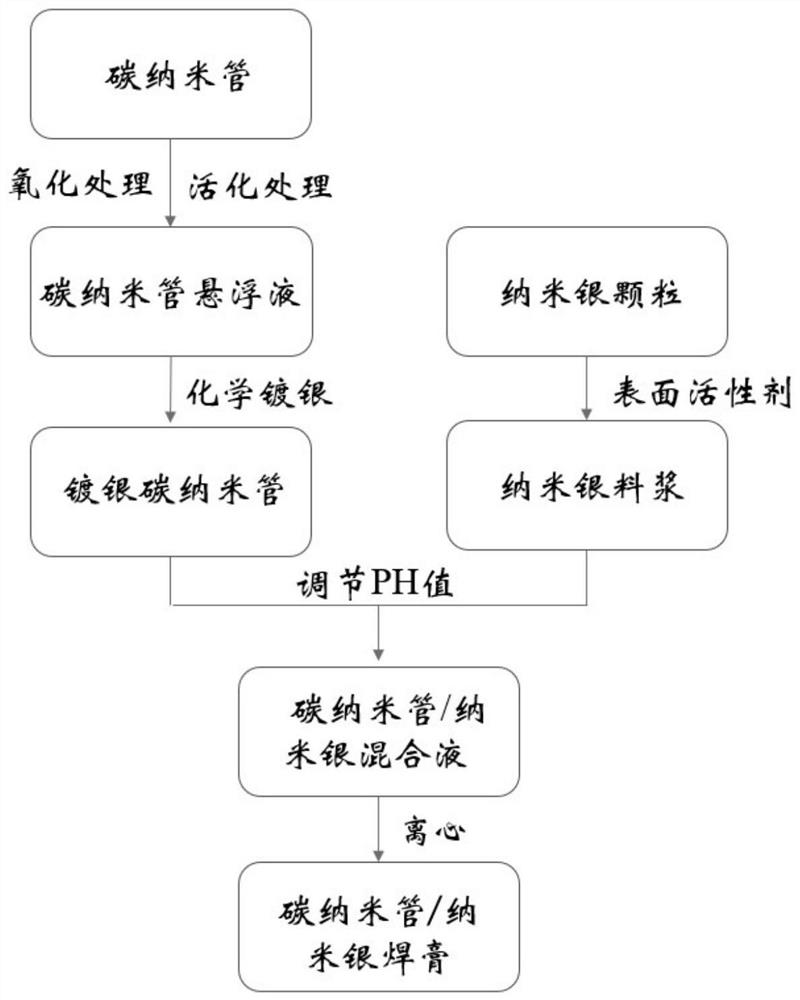

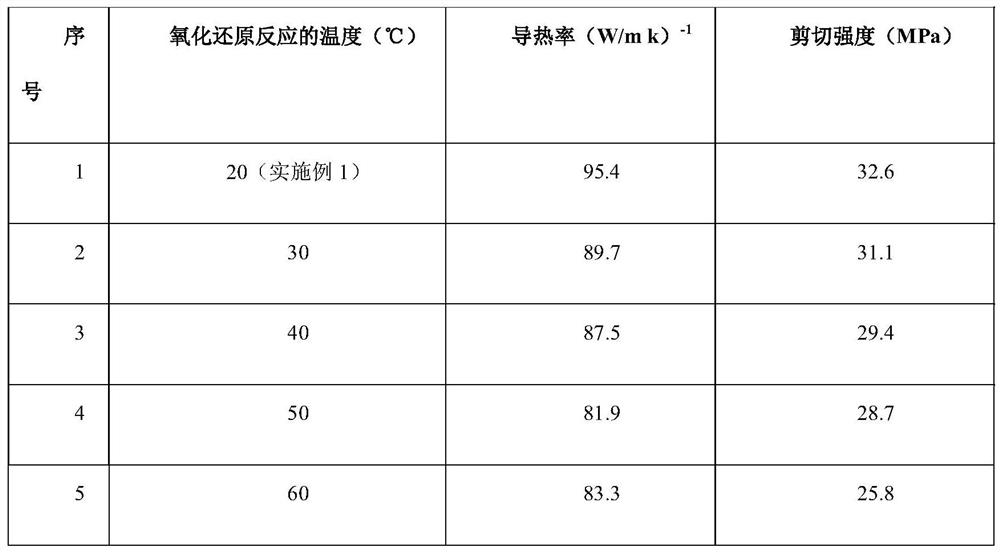

Carbon nano-tube/nano-silver soldering paste heat-conduction material and preparing method thereof

ActiveCN110549039AImprove wettabilityImprove the interface binding forceWelding/cutting media/materialsSoldering mediaCarbon nanotubeSilver particles

The invention discloses a carbon nano-tube / nano-silver soldering paste heat-conduction material and a preparing method thereof. A carbon nano-tube with the surface coated with silver is regarded as areinforced phase and doped in nano-silver soldering paste, so that nano-silver particles are effectively and uniformly adsorbed on the carbon nano-tube with the surface coated with silver. The heat-conduction material has the advantages of a high heat-conduction rate, high bonding strength, high shearing strength and the like; besides, by means of the carbon nano-tube / nano-silver soldering paste heat-conduction material and the preparing method thereof, the defect that the interface bonding capability between the carbon nano-tube and the nano-silver particles is weak is overcome, and the preparing technology is simple.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Nano composite carbon/chromium trioxide powder and its prepn

The present invention relates to nano composite carbon / chromium trioxide powder and its preparation. Polyaniline is oxide with hexad chromium compound to form the mixture precipitate of polyaniline and chromium hydroxide; the mixture precipitate is washed and dried to obtain nano composite polyaniline / chromium hydroxide powder; and under air isolating condition, the nano composite polyaniline / chromium hydroxide powder is heated to high temperature to obtain the nano composite carbon / chromium trioxide powder with carbon coating the nano chromium trioxide particle. The nano composite carbon / chromium trioxide powder of the present invention has small particle size and raised use effect as antiwear additive and is suitable for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

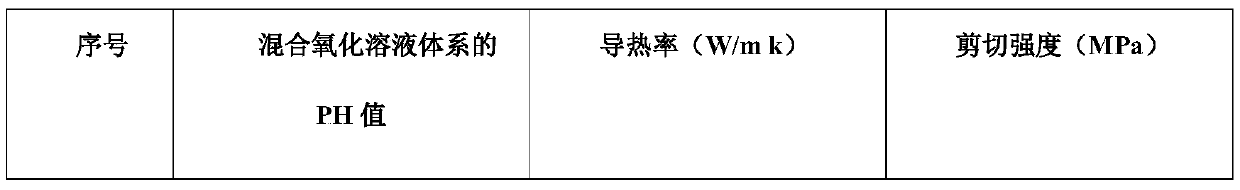

Anti-staining epoxy fire-retardant coating and preparation method thereof

ActiveCN103224746AImprove stain resistanceEasy to stickFireproof paintsEpoxy resin coatingsEnvironmental resistanceEpoxy

The invention provides an anti-staining epoxy fire-retardant coating and a preparation method thereof. The fire-retardant coating is prepared by mixing a component A and a component B, wherein the component A is prepared by the following ingredients of, by weight, 40-45% of a water-borne epoxy resin, 15% of modified ammonium polyphosphate, 6-8% of trimeric cyanamide, 6-8% of pentaerythritol, 3-7% of nano TiO2, 3-5% of nano silica, 3-7% of an organic silane coupling agent, 10-15% of brucite fibers and a proper amount of water, a total weight percentage of all the ingredients of the A component is 100%; and the component B is a curing agent accounting for 10% of the weight of the water-borne epoxy resin. The anti-staining epoxy fire-retardant coating prepared by the method has the functions of water-based environment protection, good anti-staining performance, capacity for resisting water immersion for a long time and long fire endurance. The anti-staining epoxy fire-retardant coating can not only resist stains and prevent fire, and has the function of sound absorption.

Owner:CHANGAN UNIV

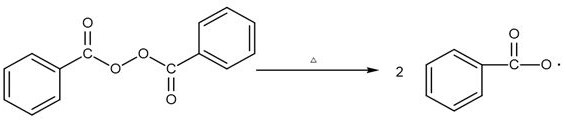

Lightweight high-strength foam concrete

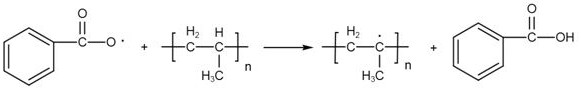

ActiveCN113582611AImprove hydrophilicity and adhesionHelp to combineSolid waste managementCeramicwareCement slurrySilicate Cement

The invention relates to the technical field of concrete, and particularly discloses lightweight high-strength foam concrete and a preparation method thereof. The lightweight high-strength foam concrete is prepared from the following raw materials in parts by weight: Portland cement and modified polypropylene fibers, and the modified polypropylene fiber is prepared from the following raw materials in parts by weight: a dibenzoyl peroxide solution, polypropylene fiber and a maleic acid solution. The preparation method of the lightweight high-strength foam concrete comprises the following steps: adding dibenzoyl peroxide into a xylene solution to prepare a mixed solution; adding polypropylene fibers into the mixed solution, performing swelling firstly, and then performing a reaction; then adding a maleic acid aqueous solution, and performing reacting to obtain a reaction crude product; drying the crude product to obtain modified polypropylene fiber; and mixing cement and water, then adding the modified polypropylene fiber and the additive, and performing stirring to obtain the cement slurry. The method can be used for improving the interface bonding performance of the polypropylene fiber and the cement matrix, and has the effect of improving the concrete strength.

Owner:南通吉泰新型建材有限公司

Toughening column type porcelain insulator and preparation method thereof

ActiveCN113354437AConducive to sequential generationPromote formationCeramicsCeramicwareStress concentrationSlurry

The invention relates to the technical field of porcelain insulators, and provides a toughening column type porcelain insulator and a preparation method thereof. The insulator is provided with an insulator body and an insulating layer, and a base material, a filler and a pore forming agent are adopted, so that it is ensured that sintered ceramic contains some fine open pores, the combination of the insulator body and other insulating materials is facilitated, and the strength of the insulator body is not affected; the insulator body is soaked in insulating slurry to obtain the insulating layer, so that the air holes are closed, the strength is ensured, and the insulating property is also improved. By using the raw material with relatively high Al2O3 content, the structure of the obtained insulator is more compact, the stress concentration of the insulator is effectively reduced, and the strength of the insulator is improved; zirconium oxide composite nanoparticles are added to serve as a dispersion phase to reinforce and toughen a matrix, so that the fracture toughness and bending strength of the insulator are improved; and by adding a water reducing agent, the fluidity of the slurry is enhanced, and the surface quality of the sintered insulator is ensured.

Owner:江西东维电气有限公司

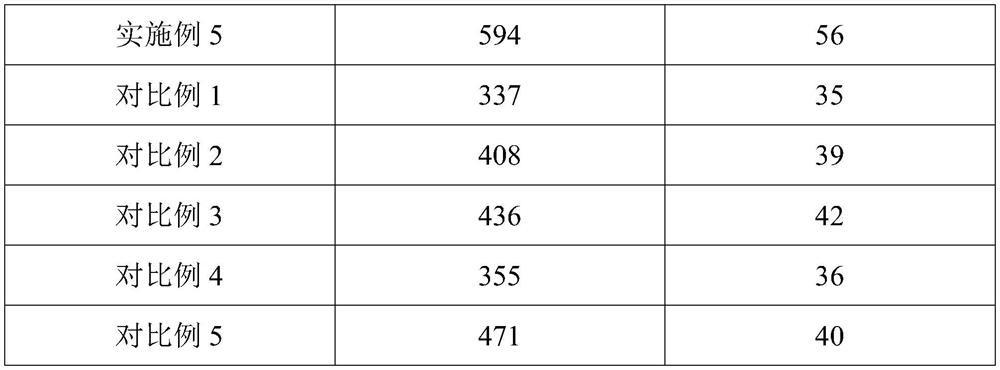

Manufacturing and firing method of jun porcelain ancient egg-shaped and holed wind instrument

The invention discloses a manufacturing and firing method of jun porcelain ancient egg-shaped and holed wind instrument. The method comprises the following steps: preparing clay, preparing a blank, biscuit firing, glazing, sintering, and detecting sound. Raw materials for preparing the clay consist of the following components in parts by weight: 40 to 50 parts of kaolin, 5 to 10 parts of alkaline stone, 10 to 15 parts of knot clay, 5 to 10 parts of quartz sand, 0.5 to 1 part of vermiculite, 1 to 2 parts of plant ash, 1 to 2 parts of sodium alginate, and 0.5 to 1 part of phenolic resin powder. A gradually heating multi-sectional heating way is adopted both in the biscuit firing process and the sintering process, so that the blank is slowly heated, the heating non-uniformity and stress change caused by the sudden change of the temperature can be avoided, so that cracks and crease on the surface of the jun porcelain ancient egg-shaped and holed wind instrument can be avoided, and the artistic ornamental value of the jun porcelain ancient egg-shaped and holed wind instrument can be improved; and moreover, the jun porcelain ancient egg-shaped and holed wind instrument fired by the invention is rigid in structure and unlikely to crack, the sound produced by the instrument is strong and ebb and flow, steady and dense and has penetration powder, and the playing requirement of the porcelain jun ancient egg-shaped and holed wind instrument can be met.

Owner:PINGDINGSHAN UNIVERSITY

Method for preparing mineral fiber printing paper with excellent printing applicability

InactiveCN108086042ALarge specific surface areaImprove adsorption capacityMagnesium silicatesInorganic fibres/flakesFiberDiameter ratio

The invention discloses a method for preparing mineral fiber printing paper with excellent printing applicability. According to the method, activated sepiolite and wollastonite are subjected to superfine crushing, so that superfine powder of a large length-diameter ratio can be prepared, crystal form protection can be facilitated, a mineral fiber has a relatively large specific surface area, excellent adsorption properties for printing ink are achieved, and then the paper has excellent printing applicability; in addition, the mineral fiber is coated by modified starch, so that packing can be well combined with a plant fiber, the packing retention is improved, and the strength of paper is improved; the modified starch used in the method belongs to organic humidity control materials, is capable of regulating the relative humidity of a system in the paper making process and eliminating static electricity of paper, and has the advantages that paper shrinkage is reduced, and printing applicability is improved.

Owner:ANHUI HONGSHI OPTOELECTRONICS HIGH TECH CO LTD

Composite absorbable interface screw and preparation method thereof

InactiveCN104984414AImprove mechanical propertiesGood dispersionSurgeryPosterior cruciate ligamentBone Cortex

The invention discloses a composite absorbable interface screw and a preparation method thereof. The composite absorbable interface screw comprises 70-95 mass% of a polylactic acid polymer and 5-30 mass% of a surface modified xenogeneic antigen-extracted cortical bone meal. A xenogeneic antigen-extracted cortical bone meal surface modification method comprises the steps: making a stearic acid ethanol solution with the concentration of 5-30 w / v% into a xenogeneic antigen-extracted cortical bone meal stearic acid ethanol solution with the concentration of 2-20 w / v%, then drying at the temperature of 30-80 DEG C and carrying out ball milling. The surface modified xenogeneic antigen-extracted cortical bone meal greatly improves interface compatibility with the polylactic acid polymer. The composite absorbable interface screw has relatively good biological activity and mechanical properties, and can be applicable for reconstruction and fixation of anterior and posterior cruciate ligaments.

Owner:SHAANXI BOYU REGENERATIVE MEDICINE CO LTD

White-smoke-free promotion flux for steel fastener hot dip galvanizing and application process of white-smoke-free promotion flux

PendingCN108193154AReduce pollutionImprove working environmentHot-dipping/immersion processesHexamethylenetetramineChloride

The invention relates to the technical field of steel fastener hot dip galvanizing, in particular to white-smoke-free promotion flux for steel fastener hot dip galvanizing and an application process of the white-smoke-free promotion flux. The white-smoke-free promotion flux for steel fastener hot dip galvanizing comprises the following components: 100-200g / L of zinc chloride, 10-40g / L of magnesiumchloride, 8.0-13g / L of nickel chloride, 6.0-12g / L of hydrochloric acid, 2.0-3.5g / L of hexamethylenetetramine, 2.0-10g / L of a flux additive, and the balance of water. The application process of the white-smoke-free promotion flux comprises steps of degreasing, water cleaning, rust-removing, secondary water cleaning, promotion flux adhering, drying, galvanizing and the like. The white-smoke-free promotion flux for steel fastener hot dip galvanizing disclosed by the invention does not contain ammonium chloride which generates white smoke while encountering molten metal zinc, and can greatly reduce generation of soot during hot-dip galvanizing of the steel fastener; and a hot-dip galvanizing process which uses the promotion flux is more optimized, and has the advantages of being low in production cost, stable in plating assistance quality, capable of producing steel fasteners for hot dip galvanizing on a large scale, and the like.

Owner:WENZHOU XINDE ELECTRIC FITTINGS +2

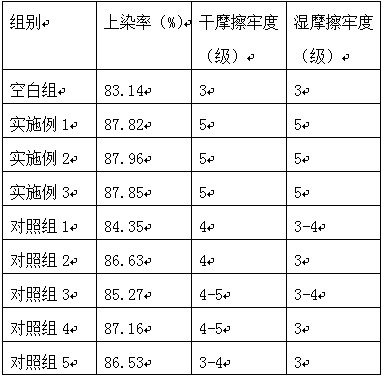

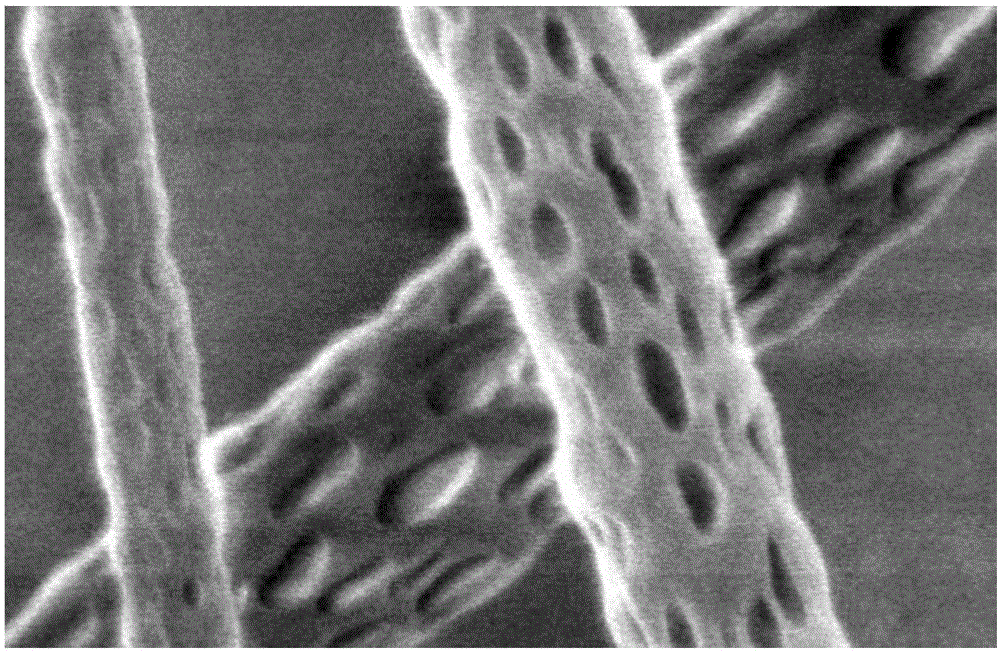

Pretreatment method for improving dyeing performance of bamboo materials

ActiveCN108972769AReduce hemicellulose contentChange structureRadiation/waves wood treatmentWood treatment detailsFiberPretreatment method

The invention belongs to the technical field of bamboo processing, and particularly relates to a pretreatment method for improving the dyeing performance of bamboo materials. The pretreatment method includes the steps of hydrochloric acid aqueous solution treatment, freezing treatment, treating agent treatment and drying-kiln drying treatment. Compared with the prior art, the pretreatment method has the advantages that through sequential hydrochloric acid dipping, microwave treatment, freezing treatment, treating agent treatment and drying-kiln drying treatment of the bamboo materials, the hemicellulose content in the bamboo materials is reduced, the cellulose structure is changed, and pores in fibers are enlarged; a siloxane coupling agent acts with a hydroxycarboxylic acid system to formcovalent bonds on the surfaces of the fibers, so that combination with dyestuff is benefited, the dye uptake is improved, the dyeing stability is improved, and the commercial property of products isenhanced.

Owner:阜南佳利工艺品股份有限公司

Biodiesel pour point depressant formula

InactiveCN104449891AImprove low temperature fluiditySmall molecular weightLiquid carbonaceous fuelsSolubilityBiodiesel

The invention discloses a biodiesel pour point depressant, belonging to the field of oil additives. The biodiesel pour point depressant is prepared from the following raw materials in percentage by mass: 50-70% of higher polymaleate-styrene-acrylamide, 10-15% of a surfactant and 15-40% of dimeric acid amide. A preparation method of the biodiesel pour point depressant comprises the following steps: firstly, adding higher polymaleate-styrene-acrylamide; then, adding the surfactant span and tween in sequence; and finally, adding dimeric acid amide to formulated amount, and sufficiently stirring and mixing to obtain a compound product, namely the biodiesel pour point depressant. The biodiesel pour point depressant disclosed by the invention can be used for promoting the solubility of the pour point depressant in oils and improving the low-temperature flowing property of the biodiesel.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

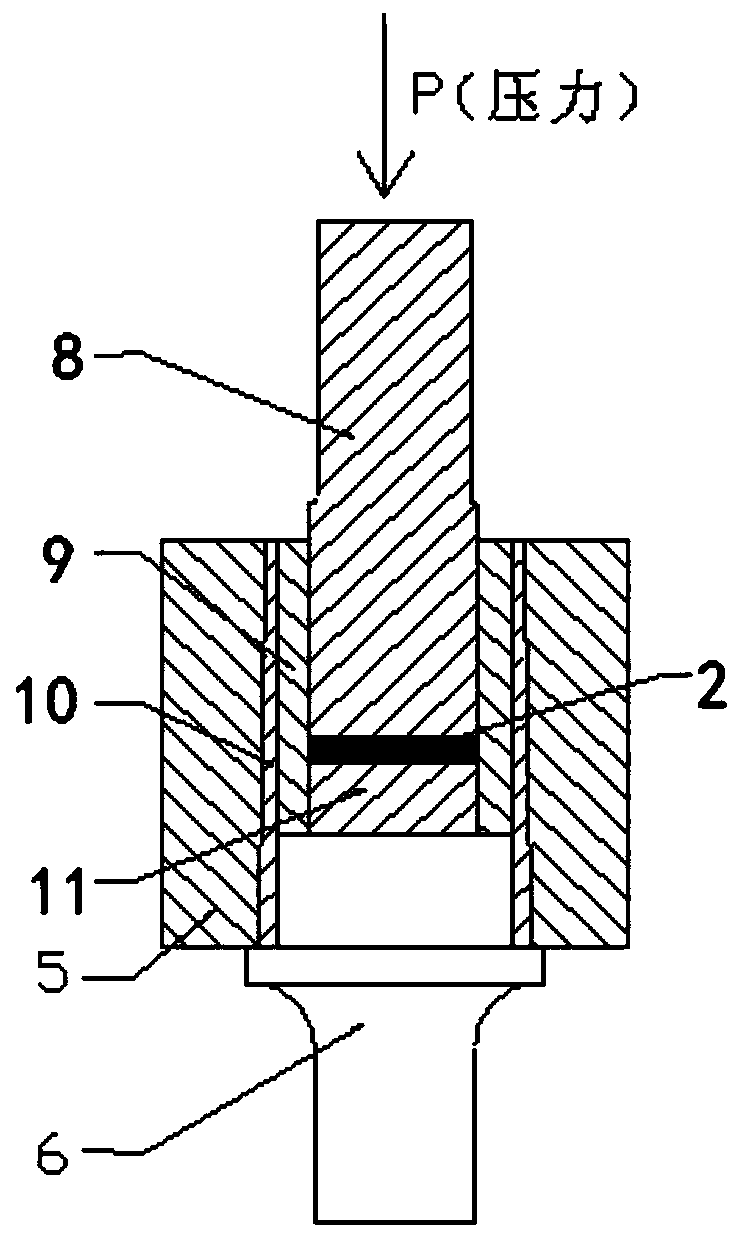

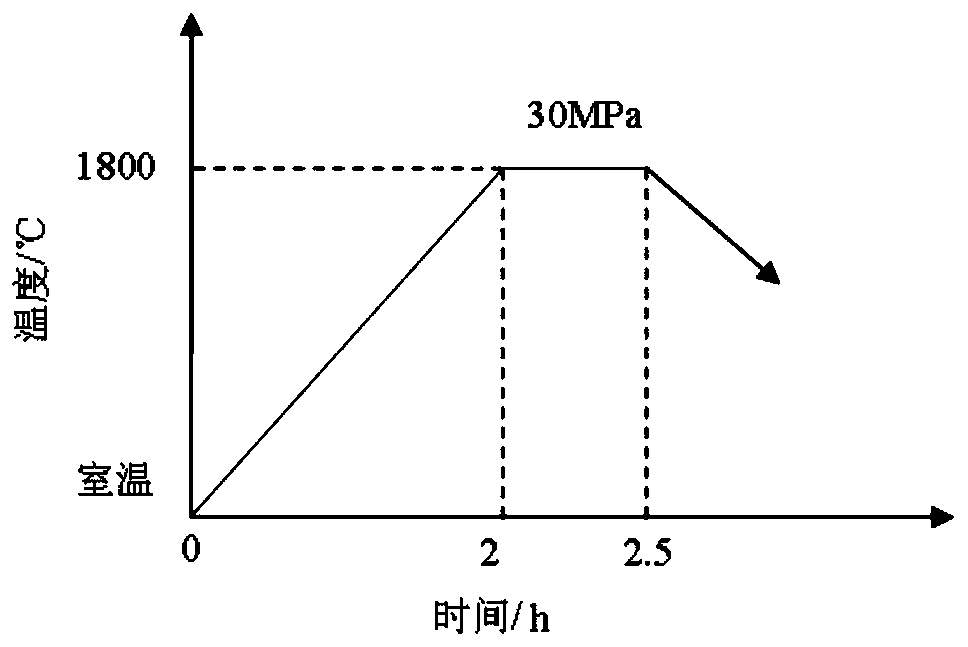

Layered ceramic composite material based on silicon nitride, and preparation method thereof

InactiveCN110698207AAchieve toughnessGreat improvement in brittlenessCeramic compositeHexagonal boron nitride

The invention discloses a layered ceramic composite material based on silicon nitride, and a preparation method thereof, and belongs to the field of ceramic materials. The preparation method comprises: using silicon nitride, hexagonal boron nitride and molybdenum as raw materials, and using a mixture of Al2O3 and Y2O3 as a sintering aid; mixing various ceramic powders, grinding, screening, weighing the mixed powder and molybdenum powder, putting into a metal mold, and carrying out cold pressing to form a biscuit; and sintering at a temperature of 1750-1850 DEG C under a pressure of 25-35 MPa in a nitrogen atmosphere to obtain the silicon nitride-based layered ceramic composite material. According to the invention, the obtained silicon nitride-based layered ceramic composite material retains high hardness and has good toughness.

Owner:SHAANXI UNIV OF SCI & TECH

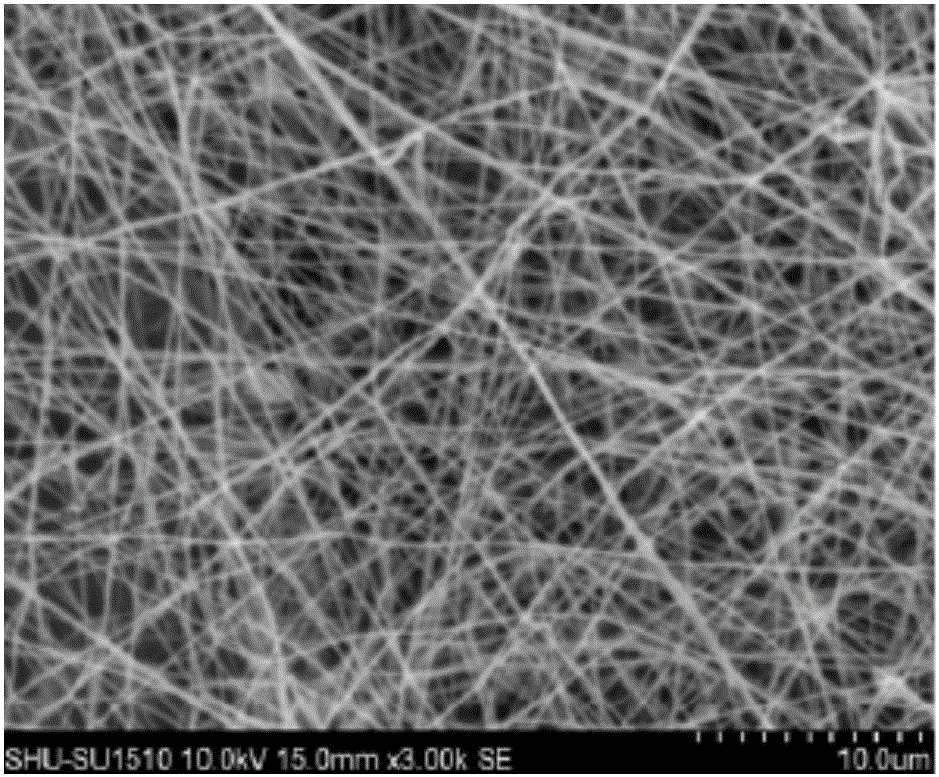

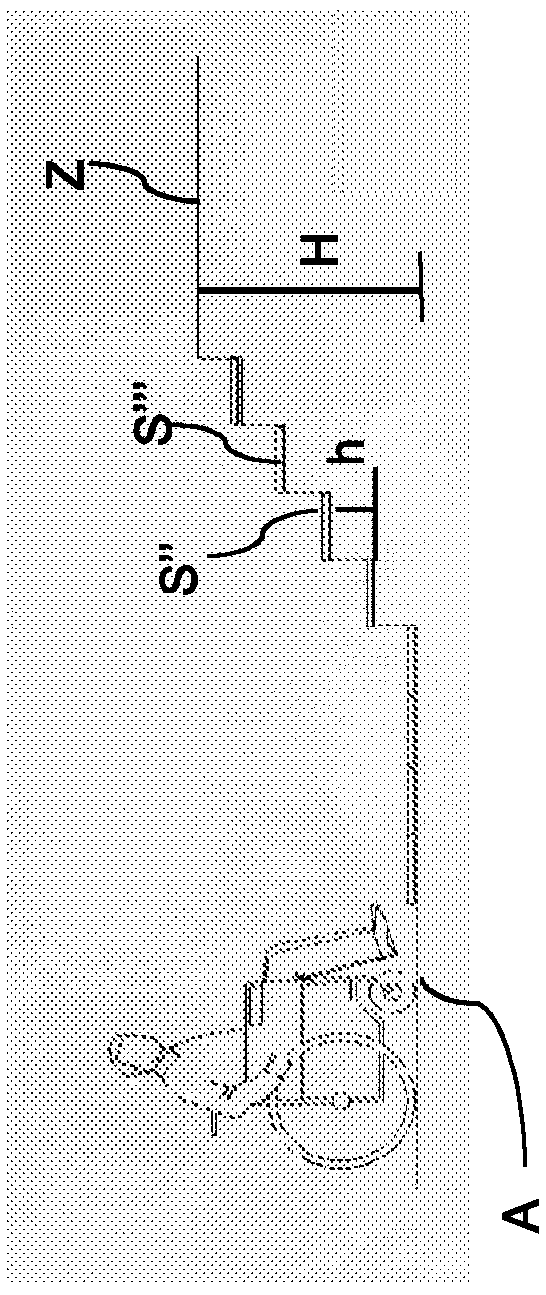

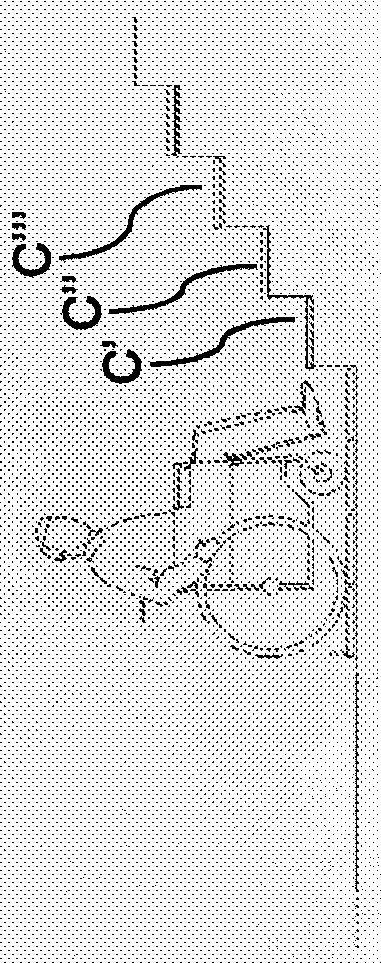

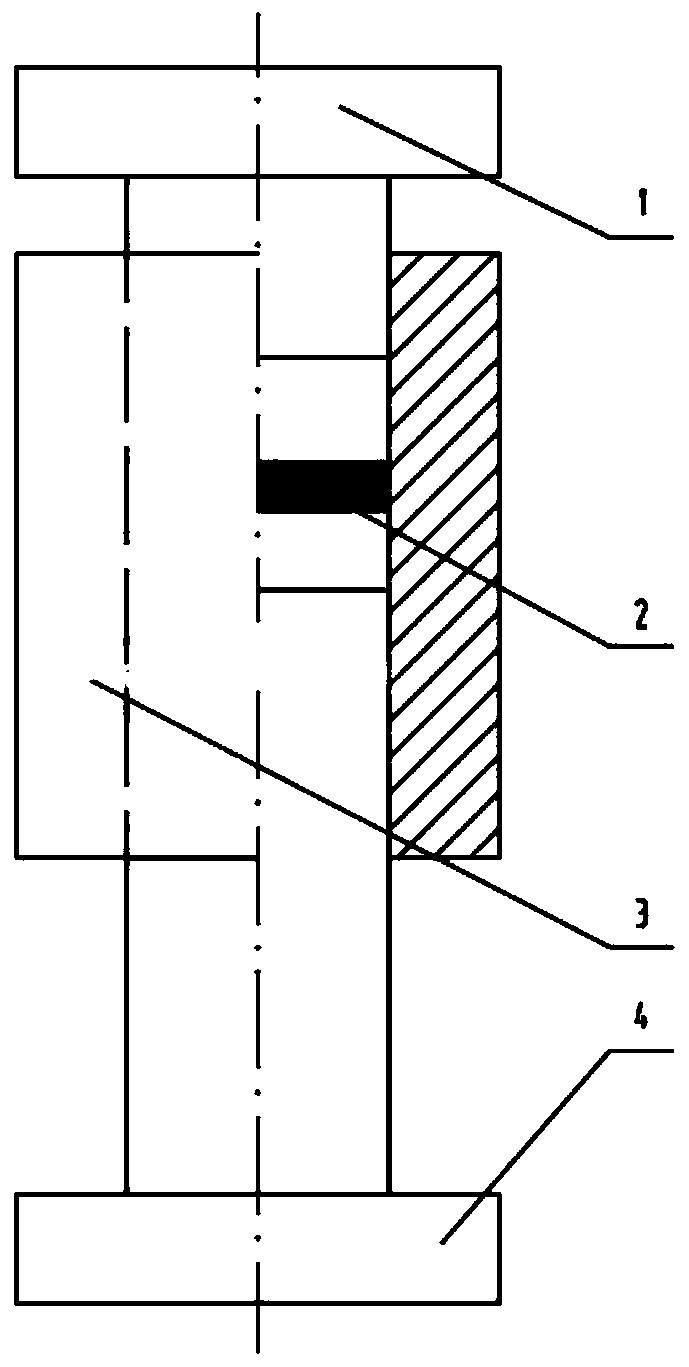

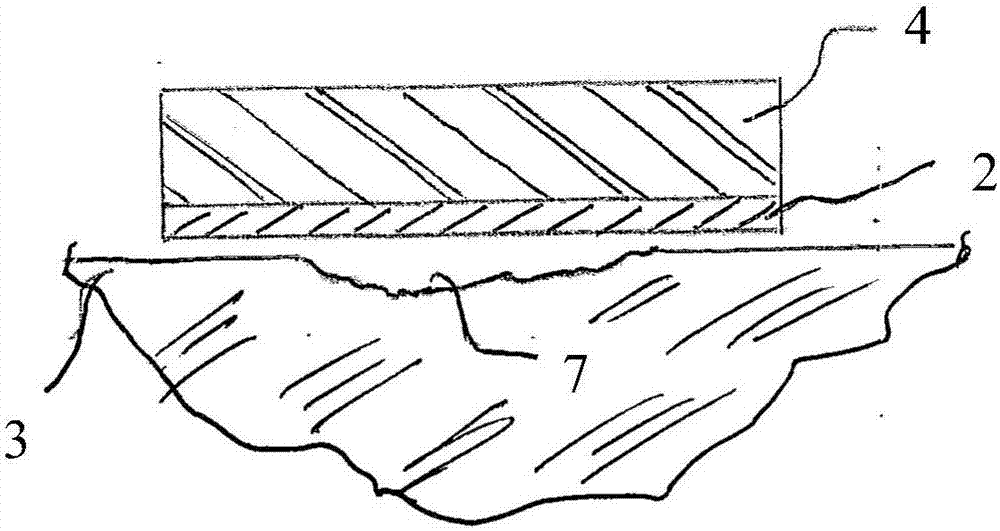

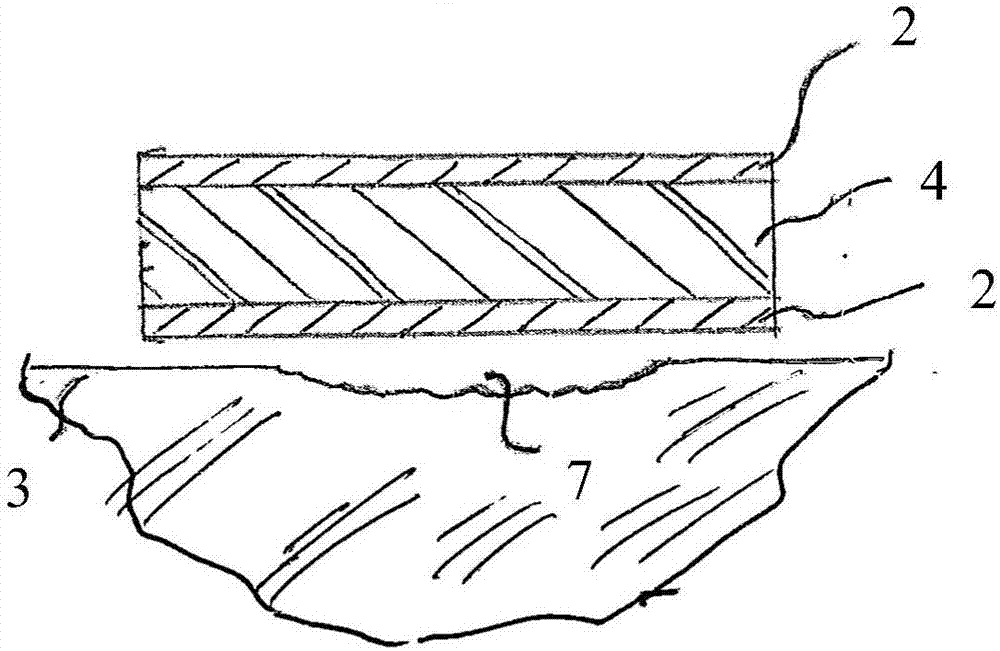

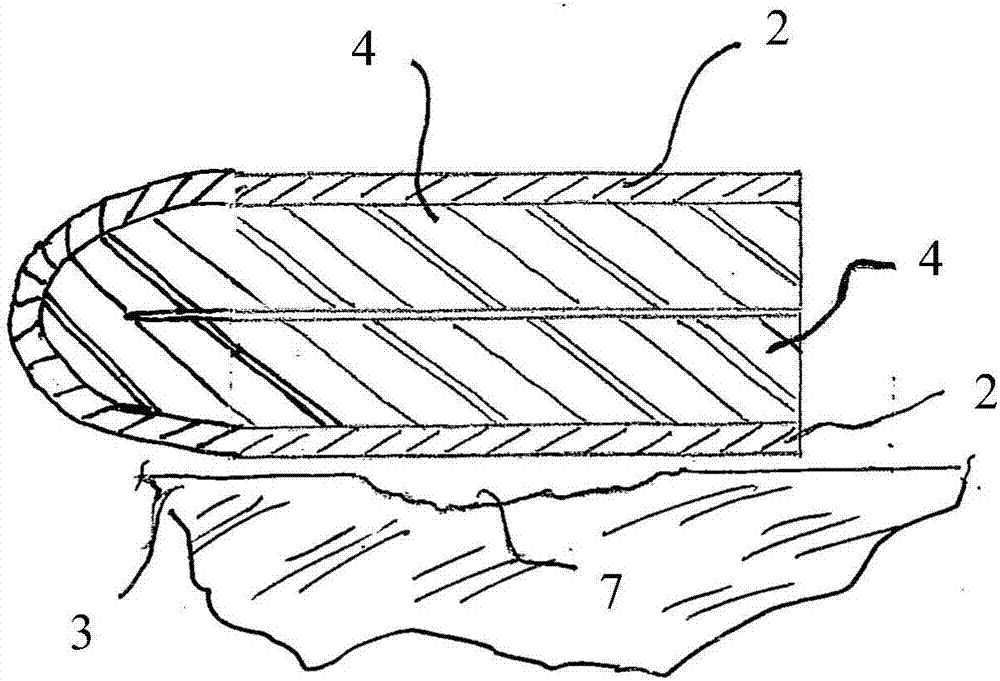

Device for wound dressing"

InactiveCN107106722AImprove static problemsGood adhesionNon-adhesive dressingsPharmaceutical delivery mechanismWound dressingMedicine

A wound dressing device comprising at least one layer (2) of silk fibroin nanofibers and an absorbent component (4); the layer of fibroin nanofibers contacts the wound of the user and helps in the healing process.

Owner:里奥纳迪诺有限公司

Thermal insulation coating sprayed on surface of Q235B steel under high-temperature condition and using method of thermal insulation coating

PendingCN112029322ALow priceEasy accessFireproof paintsAlkali metal silicate coatingsThermal insulationCement kiln

The invention belongs to the technical field of thermal insulation coatings, and particularly relates to a thermal insulation coating sprayed on the surface of Q235B steel under a high-temperature condition and a using method of the thermal insulation coating. The invention aims to solve the problems that the strength of the existing thermal insulation coating used for Q235B steel cannot meet theactual requirements, and the existing thermal insulation coating cracks and falls off along with the cooling and heating processes of the Q235B steel after being sprayed. According to the invention, light calcium carbonate and glass fibers are added into a common thermal insulation coating formula taking potassium silicate and glass beads as raw materials, so that the coating has a thermal expansion coefficient tending to be consistent with that of Q235B, and meanwhile, the strength of the coating is improved, so that the coating does not crack or fall off along with cooling and heating of theQ235B after being sprayed. The coating can be sprayed on the surface of scorching Q235B under the high-temperature operation condition when thermal equipment such as a cement kiln operates to be rapidly cured, and is tightly combined with the surface of steel.

Owner:吴征

Insulator for high-voltage power transmission line and manufacturing method of insulator

ActiveCN106653242AStrong combinationGuaranteed mechanical strengthInsulatorsElectric breakdownSodium bicarbonate

The invention provides an insulator for a high-voltage power transmission line and a manufacturing method of the insulator. The insulator comprises an insulator body and two fixed parts, wherein the two fixed parts are arranged at two ends of the insulator body; multiple large umbrellas and small umbrellas are distributed around the surface of the insulator body along the length direction of the insulator body, and the large umbrellas and the small umbrellas are arranged at intervals; the insulator body is formed by firing a base material, a filling material and a pore-forming agent; the base material comprises kaoline, knar clay and quartz; the filling material comprises kyanite powder, activated aluminum oxide micro-powder and modified nanosilicon dioxide; and the pore-forming agent comprises silicon carbide powder, sodium bicarbonate and soda lime. The fired insulator body can be soaked in an inorganic or organic insulating material, so that air holes in the insulator body are filled with the insulating material and the electric breakdown resistance of the insulator body is further strengthened.

Owner:ZHENGZHOU ELECTRIC POWER COLLEGE

Fiber costume material with antibacterial health function and preparation technology of fiber costume material

ActiveCN105155035ADoes not affect natural releaseNot easy to fall offFilament/thread formingConjugated synthetic polymer artificial filamentsFiberNanotechnology

The invention relates to a fiber costume material with an antibacterial health function and a preparation technology of the fiber costume material. By preparation of hole functional fibers with high distribution density, most of nano silver metal particles can be distributed in holes in the surfaces of the fiber in an embedded manner, and only a small part of nano silver metal particles are attached to the surfaces of the fibers; therefore, in the long-time use process of the costume material, the nano silver metal particles are unlikely to fall off even if the costume material is repeatedly washed in water; furthermore, the oxidization action of silver is suppressed, and efficient and full use of noble metal raw materials is realized.

Owner:ZHEJIANG CHAOFAN GARMENT CO LTD

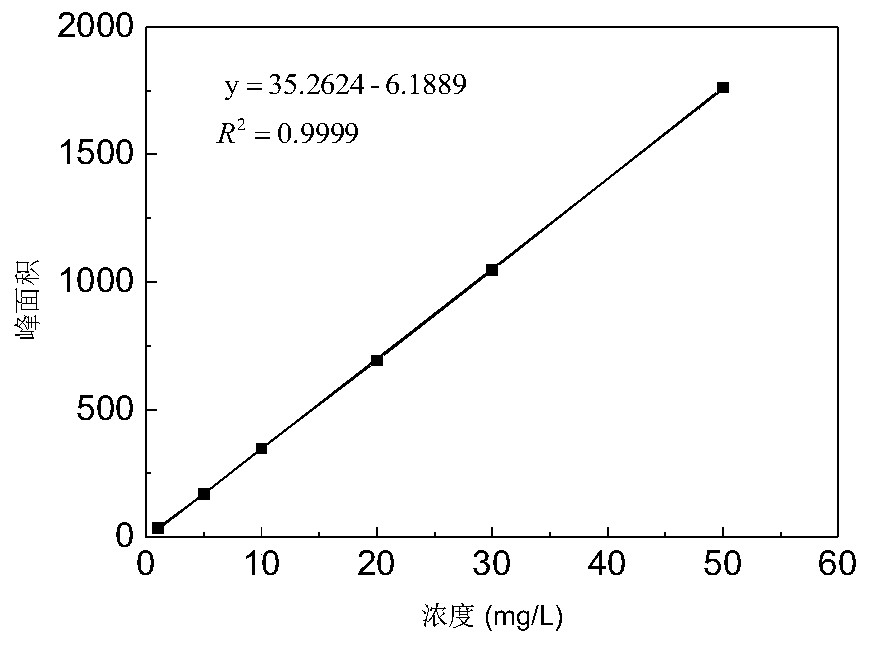

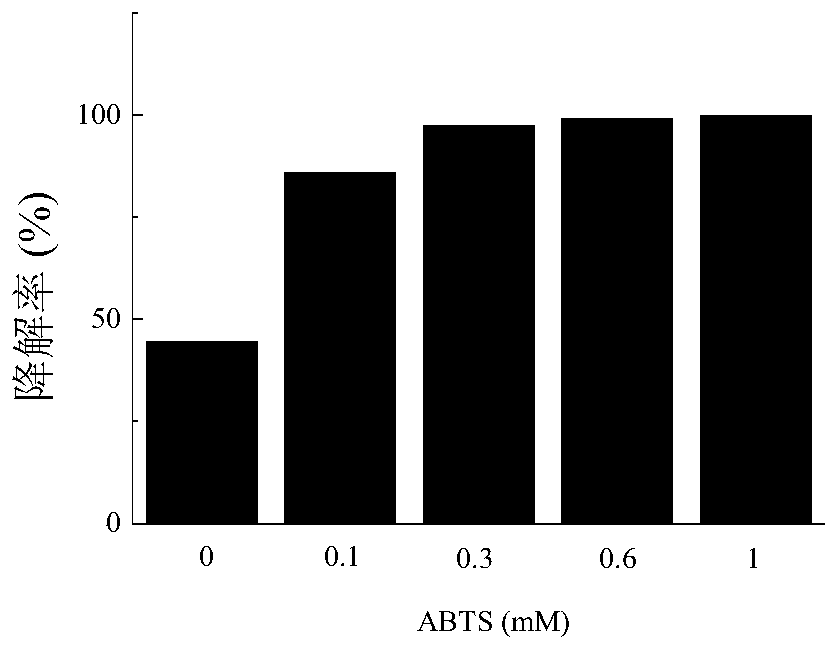

Method for increasing diethylstilbestrol degradation rate of laccase

ActiveCN110845018AHelp to combineReduced activityWater contaminantsEnzyme stabilisationEthyl acetateEnvironmental chemistry

The invention relates to a method for increasing the diethylstilbestrol degradation rate of laccase. The method specifically comprises: combining ABTS and a laccase solution to form a laccase-ABTS medium solution, mixing the laccase-ABTS medium solution and a diethylstilbestrol solution in a reaction system, placing the mixture into a shaking incubator, carrying out a reaction for a certain time,and extracting diethylstilbestrol by utilizing ethyl acetate to terminate the reaction, so that the degradation of diethylstilbestrol is realized. According to the invention, the laccase-ABTS medium solution is prepared and used for degrading diethylstilbestrol, so that the diethylstilbestrol degradation rate of laccase is increased to 99.9% from original 44.5% so as to easily achieve the treatment of diethylstilbestrol sewage, and the method has practical application value in the field of sewage treatment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

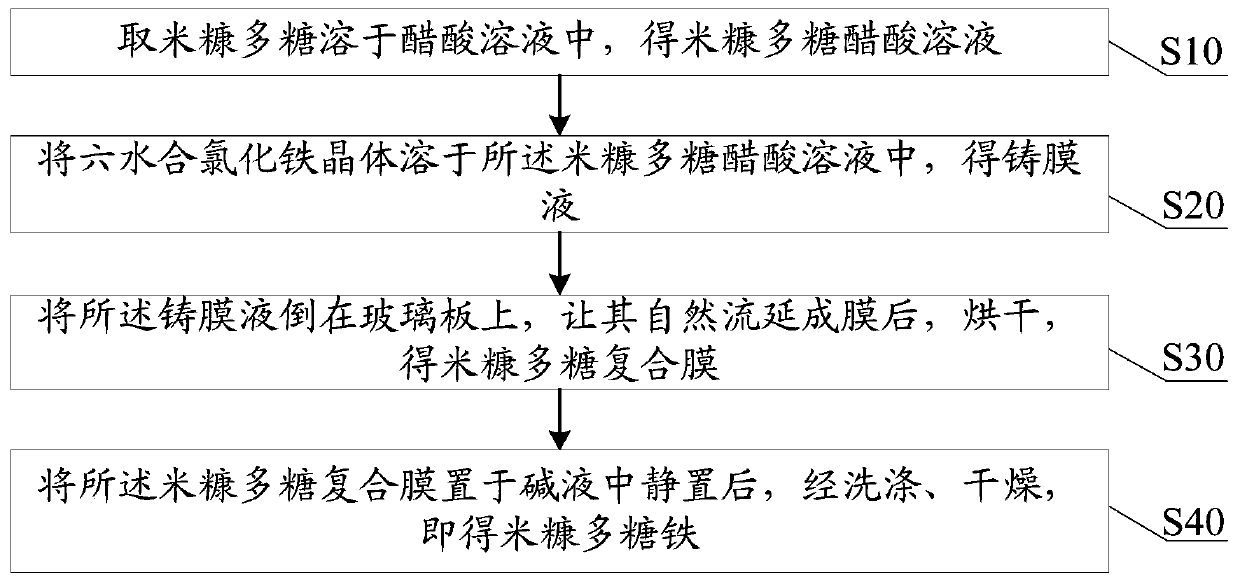

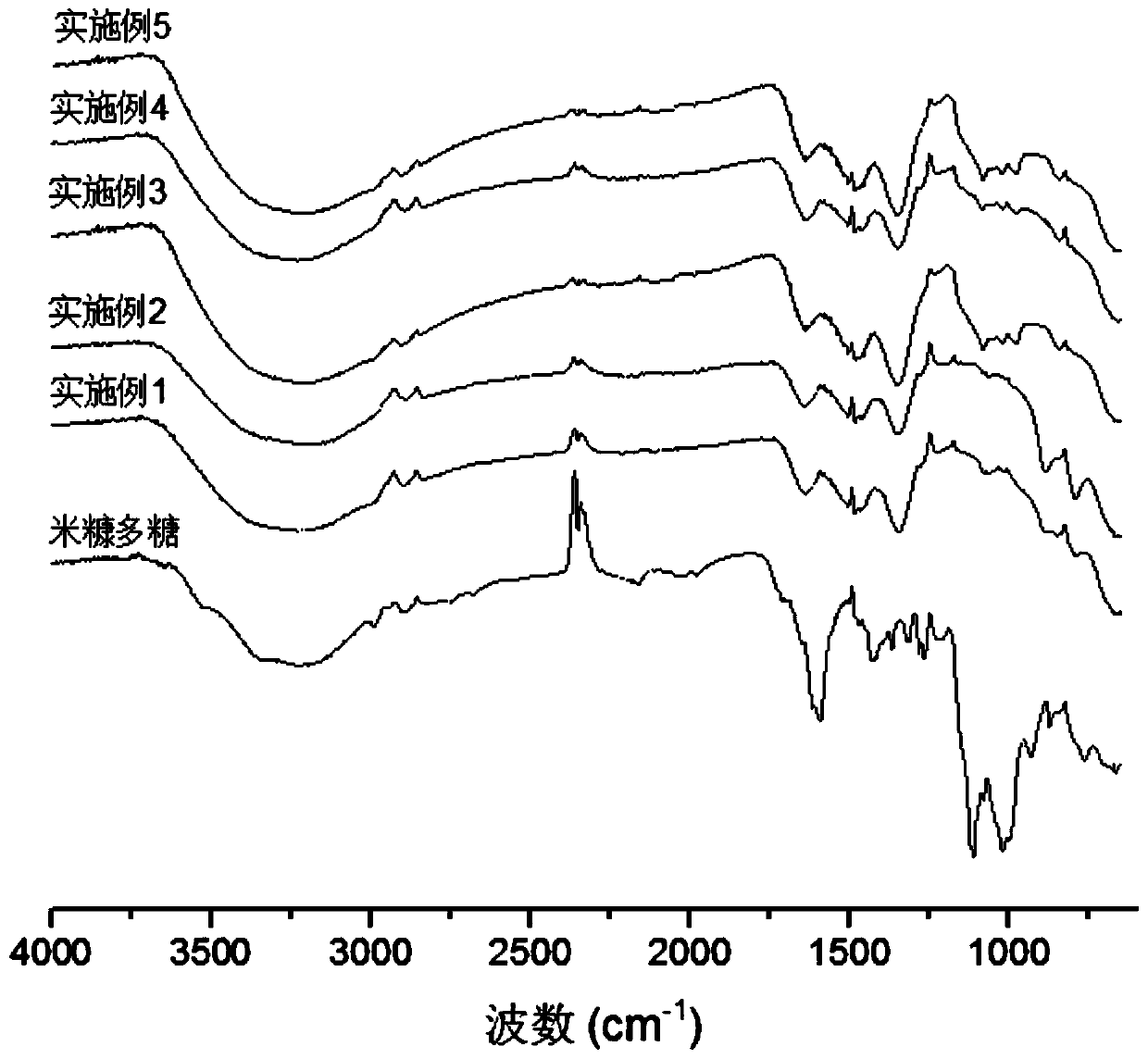

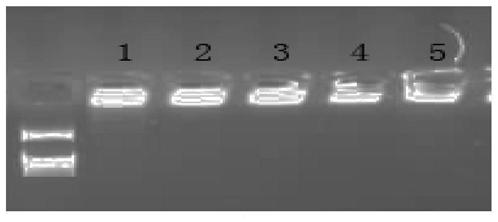

Preparation method and applications of rice bran polysaccharide iron

InactiveCN109824793ALow cytotoxicityPromote absorptionOther foreign material introduction processesFood scienceComposite filmCytotoxicity

The invention discloses a preparation method and applications of rice bran polysaccharide iron, and belongs to the technical field of polysaccharide. The preparation method comprises following steps:rice bran polysaccharide is dissolved in an acetic acid solution so as to obtain a rice bran polysaccharide acetic acid solution; ferric trichloride hexahydrate crystals are dissolved in the rice branpolysaccharide acetic acid solution so as to obtain a film casting solution; the film casting solution is poured onto a glass plate for natural curtain coating film forming and drying so as to obtaina rice bran polysaccharide composite film; the rice bran polysaccharide composite film is immersed in an alkaline solution for standing, and washing and drying are carried out so as to obtain rice bran polysaccharide iron. The rice bran polysaccharide iron can be taken as an iron supplementation agent, or a gene carrier. The rice bran polysaccharide iron is prepared using the preparation method,and is used in preparation of iron supplementation agents and gene carriers effectively, so that defects of conventional iron supplementation agents such as low bioavailability, low absorption efficiency, and large side effect are avoided, and the defects of conventional non-virus gene carriers such as high cytotoxicity are avoided.

Owner:WUHAN POLYTECHNIC UNIVERSITY

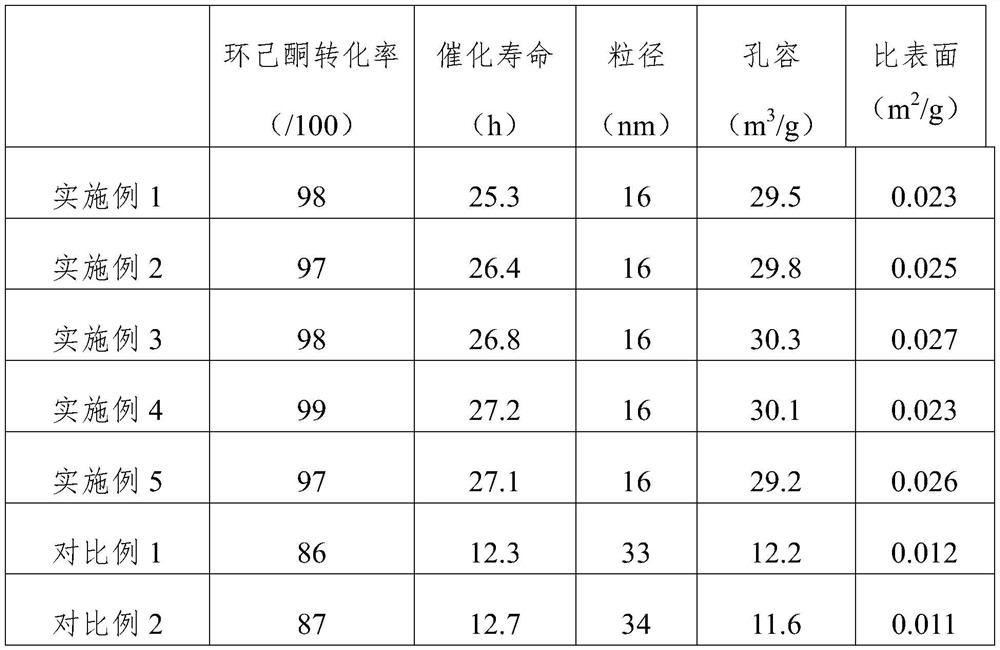

Ultrasonic-assisted titanium silicalite molecular sieve modification method

PendingCN112591762ARealize a modificationSmall grain sizeMolecular sieve catalystsTantalum compoundsMolecular sieveUltrasound wave

The invention discloses an ultrasonic-assisted titanium silicalite molecular sieve modification method, and relates to the technical field of molecular sieve modification, and the modification methodcomprises the following steps: S1, mixing a silicalite molecular sieve raw powder mother liquor, a template agent and mesoporous silica in proportion, and then carrying out primary heating for alcoholremoval; then adding tetra-n-butyl titanate, the template, mesoporous silica and tetra-n-butyl titanate in a molar ratio of (33-42): (5.5-14.8): 1; and S2, after heating and alcohol removal, carryingout secondary heating and alcohol removal on the mixed solution to prepare a titanium-silicon gelling reaction solution, heating and crystallizing the titanium-silicon gelling reaction solution at the temperature of 170-195 DEG C for 55-65 hours, carrying out solid-liquid separation on the obtained solid-liquid mixture to obtain a raw powder mother solution and a solid, and washing, drying and roasting the solid, carrying out superfine grinding treatment after roasting, and filtering with a 80-mesh sieve to obtain titanium silicalite molecular sieve raw powder. The method is beneficial to combination of the metal salt and the titanium silicalite molecular sieve, and the catalytic oxidation activity is further improved.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

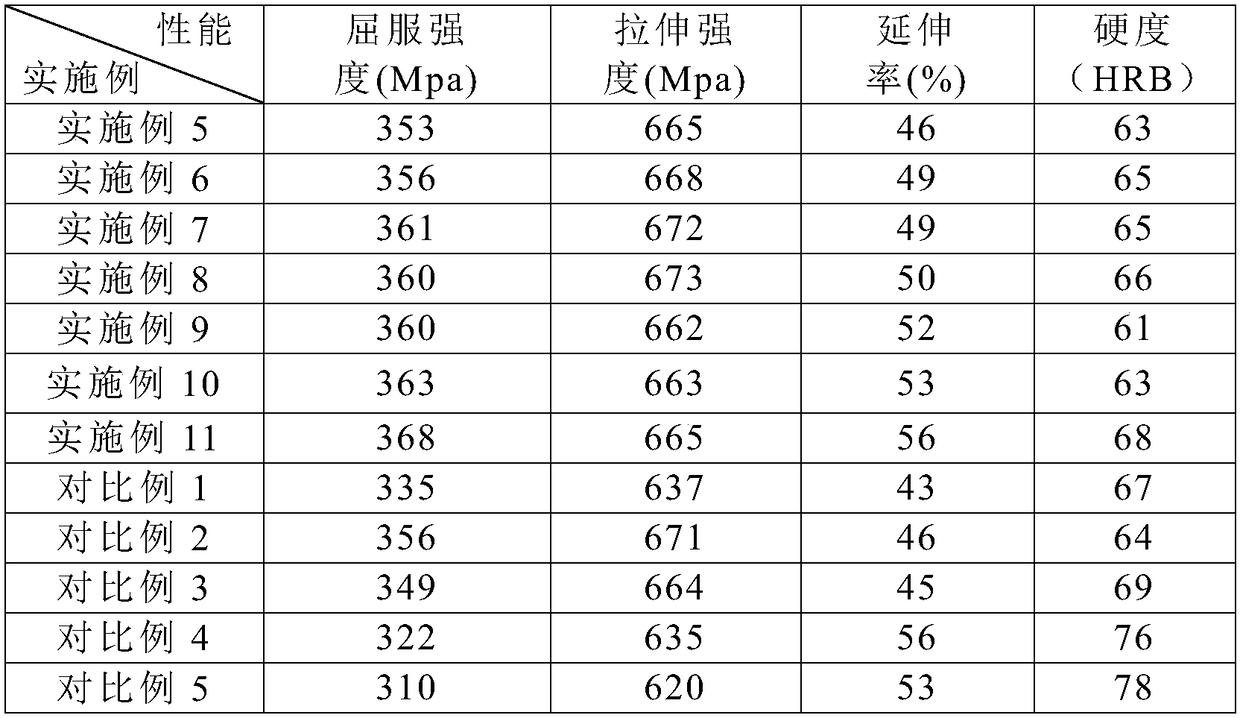

Metal wire for horseshoe nail and preparation method thereof

The invention relates to a metal wire for a horseshoe nail and a preparation method thereof, and belongs to the technical field of metal materials. The metal wire comprises, by mass percentage, 0.25-0.3% of C, 8.5-9.5% of Cr, 2.0-3.0% of Mo, 7.6-9.7% of Mn, 0.33-0.46% of Ni, 1.6-2.7% of nano CBN, 2.0-2.6% of nano WC, 0.2-0.3% of Gd, 2.3-3.8% of Co, 0.33-0.65% of N, Si=< 1.0%, P=< 0.045%, S=< 0.045%, and the balance is Fe. The metal wire for the horseshoe nail has the advantages of being biologically friendly, excellent in mechanical performance and long in service life.

Owner:宁波骑士马具用品制造有限公司

Black master batch for near-infrared classification as well as preparation method and application of black master batch

The invention relates to the technical field of master batch processing, and particularly discloses a black master batch for near-infrared classification as well as a preparation method and application of the black master batch. The black master batch is prepared from the following components in parts by weight: 160-220 parts of a resin matrix, 40-60 parts of reinforcing filler, 80-120 parts of iron black, 3-9 parts of a surfactant and 5-9 parts of an antioxidant; the preparation method comprises the following steps: (1) mixing the iron black, the antioxidant and the surfactant to obtain a mixture 1; (2) mixing the mixture 1 and a resin matrix to obtain a mixture 2; and (3) granulating by taking the reinforcing filler and the mixture 2 as raw materials to obtain the black master batch for near-infrared classification. The black master batch for near-infrared classification provided by the invention has relatively good reflection capability on near-infrared light and is easily identified by garbage recycling equipment, and after the black master batch for near-infrared classification is added into a plastic product for shading, the efficiency of recycling the plastic product can be improved.

Owner:绍兴市上虞鸿越塑业有限公司

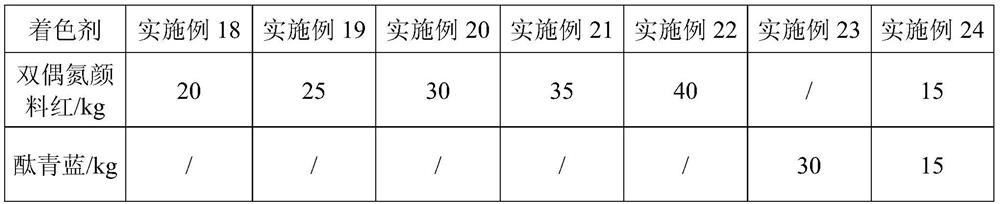

A kind of carbon nanotube/nanometer silver solder paste heat conduction material and preparation method thereof

ActiveCN110549039BImprove wettabilityImprove the interface binding forceWelding/cutting media/materialsSoldering mediaConductive materialsSilver particles

The invention discloses a carbon nanotube / nano-silver solder paste heat-conducting composite material and a preparation method thereof. Carbon nanotubes coated with silver on the surface are used as a reinforcing phase, and are doped into the nano-silver solder paste to make the nano-silver particles effective. Evenly adsorbed on the surface of silver-plated carbon nanotubes, the heat-conducting material has the advantages of high thermal conductivity, high bonding strength and shear strength, and the present invention overcomes the gap between carbon nanotubes and nano-silver particles. Weak interface binding ability, simple preparation process.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com