Patents

Literature

57results about How to "Achieve toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

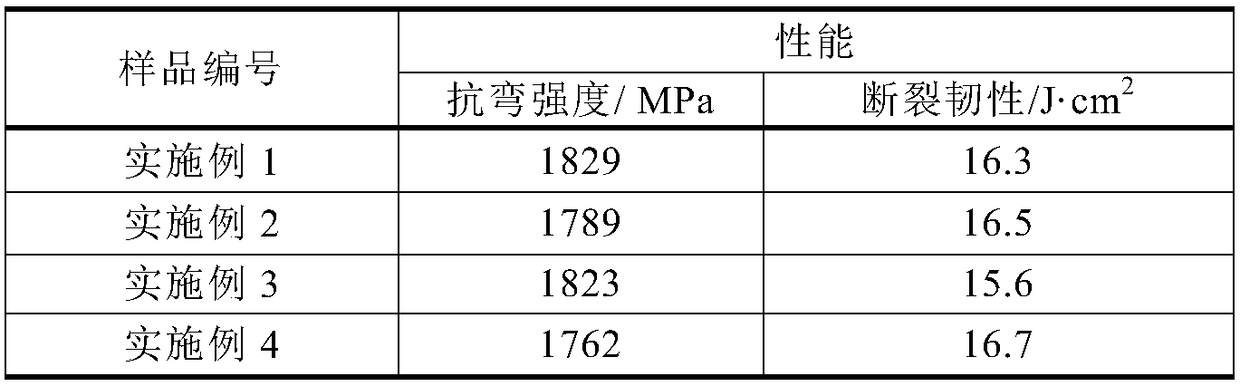

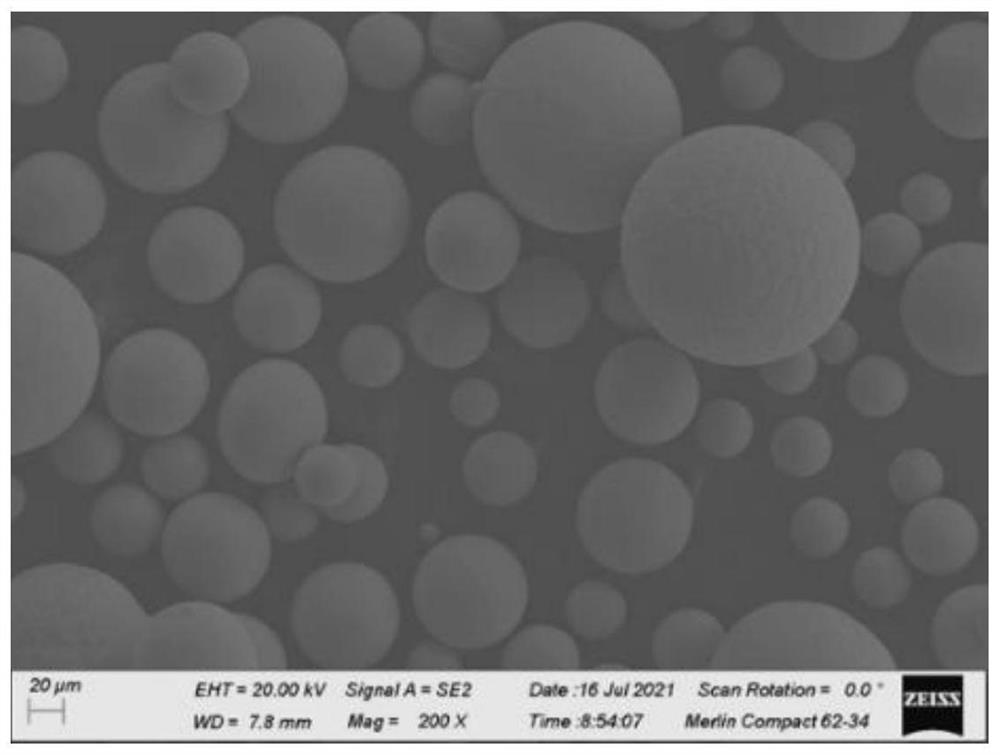

Powder metallurgy preparation method for high-strengthening-toughening metal-based composite material

ActiveCN108080644AImproved deformation coordinationAchieve toughnessMetal matrix compositeMetal powder

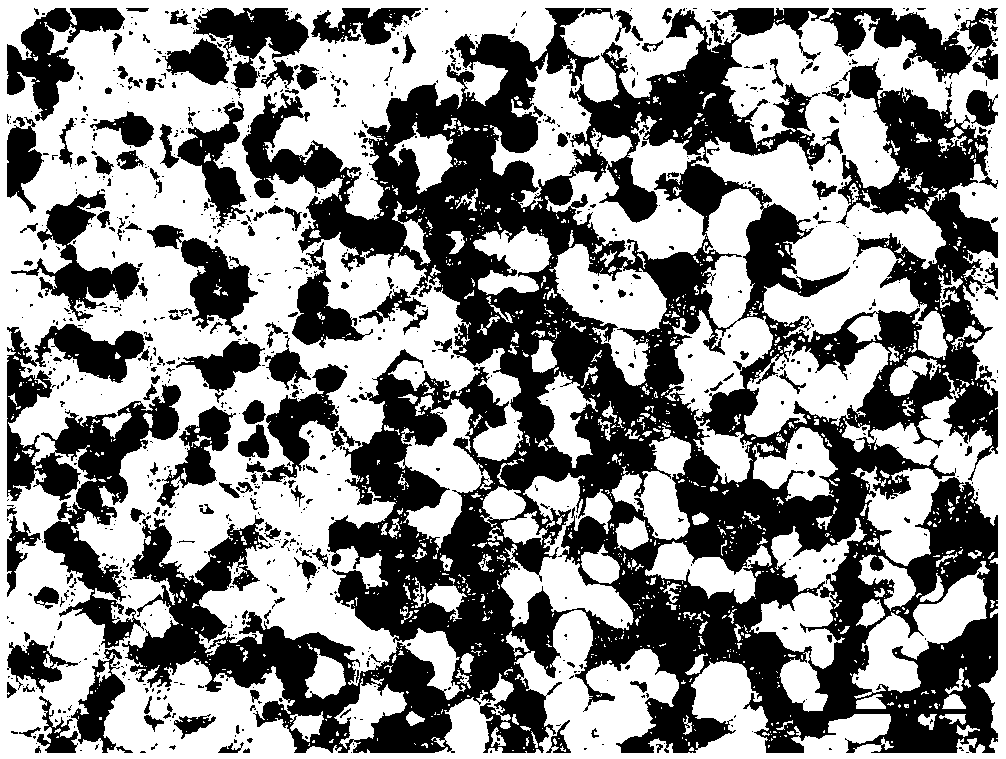

The invention discloses a powder metallurgy preparation method for a high-strengthening-toughening metal-based composite material and belongs to the field of metal-based composite materials. The method comprises the steps that (1), mixed powder of metal powder and part reinforcing phase is subjected to ball-milling treatment, and ball-milling is stopped before all crystal particles in the metal powder reach ultrafine crystal; (2), the rest reinforcing phase is added to the powder after ball-milling in the step (1), the ball-milling is continued, and the ball-milling is stopped until the reinforcing phase is completely dispersed; (3), after the powder after the ball-milling in the step (2) is treated by powder metallurgy sintering process, then the high-strengthening-toughening metal-basedcomposite material is obtained. According to the powder metallurgy preparation method for the high-strengthening-toughening metal-based composite material, the reinforcing phase is made to be orderlydistributed in a base body by adding the reinforcing phase step by step; crystal particle distribution is adjusted and controlled utilizing the crystal particle refining effect of the reinforcing phase on the base body, a coarse and fine crystal gradient grading structure is formed, thus the strengthening-toughening of materials is realized; and by means of the powder metallurgy preparation methodfor the high-strengthening-toughening metal-based composite material, the process procedure can be simplified, and the strong plasticity of the materials can be improved at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

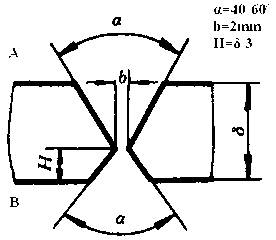

Easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process

InactiveCN103231155AImprove welding working conditionsImprove welding productivityArc welding apparatusHeat-affected zoneSemi automatic

The invention relates to an easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process which mainly comprises the following contents that: the large-thickness easy-welding 700MPa-level high-strength steel plate with the thickness of 40-80mm is matched with a high-strength high-toughness welding wire with high deoxidation element content, a 80 percent Ar+20 percent CO2 active mixed gas shielded semi-automatic or automatic welding method is adopted, due to the preheating-free treatment before welding and heating-free treatment after welding, the welding process parameters are strictly controlled, the welding sequence is reasonably arranged, the asbestos cloth coated weldment is used for heat insulation, the defect-free excellent-performance welding joint is obtained, the tensile strength of the joint is not lower than the base metal standard requirement due to mechanical performance detection, the welding line and heat affected zone are good in texture, low-temperature charpy impact absorption work (KV2) is high in surplus amount, and the application environments of the low-temperature environment can be completely met. According to the method, the production process is reduced, the labor conditions of workers are improved, the production cost is saved, and the production efficiency is improved.

Owner:JIGANG GRP

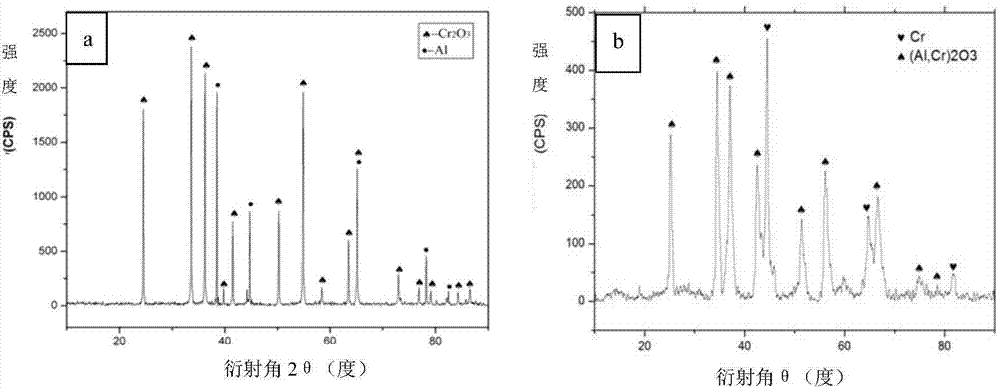

Method for reactive spraying preparation of ceramic solid solution-based ceramic-metal eutectic nanometer composite coating

ActiveCN104762584APerformance adjustableAchieve toughnessMolten spray coatingCeramic coatingComposite ceramic

The invention discloses a method for reactive spraying preparation of a ceramic solid solution-based ceramic-metal eutectic nanometer composite coating. The method comprises the following steps of 1, raw material powder preparation: selecting raw materials for reactive spraying preparation of the ceramic solid solution-based ceramic-metal eutectic nanometer composite coating and a ratio of the raw materials, 2, composite fed material preparation, and 3, eutectic nanometer composite coating preparation: preparing the [Cr+(Crx, Al1-x)2O3] eutectic nanometer composite coating by an atmospheric plasma spraying method. The eutectic nanometer composite ceramic coating is characterized in that a matrix is a component-controllable ceramic solid solution, and a metal phase in a form of nanometer particles (rods) is dispersively distributed on the ceramic matrix so that the ceramic solid solution-based ceramic-metal eutectic nanometer composite coating is obtained. The prepared [Cr+(Crx, Al1-x)2O3] eutectic nanometer composite coating has high toughness, good wear resistance, high temperature oxidation resistance and corrosion resistance.

Owner:HEBEI UNIV OF TECH

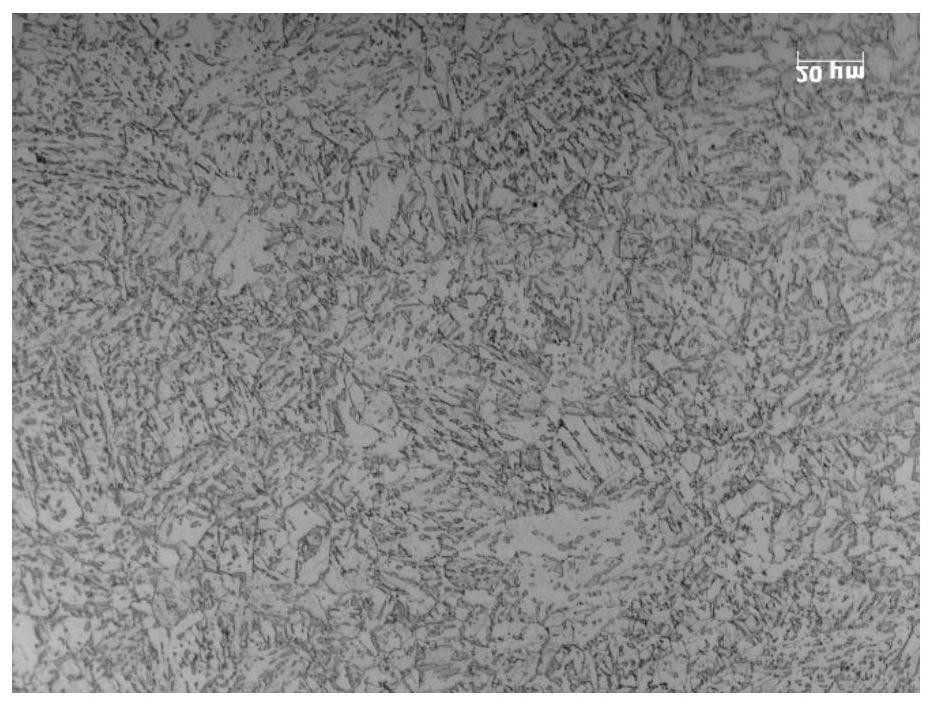

Si-containing high-strength low-modulus Beta-type titanium alloy and preparation method and application thereof

ActiveCN107034383AAvoid mechanical propertiesAchieve toughnessTissue regenerationProsthesisNiobiumTitanium alloy

The invention belongs to the field of titanium alloy materials, and discloses Si-containing high-strength low-modulus Beta-type titanium alloy and a preparation method and application thereof. The preparation method includes the steps that according to the atomic percent of 60%-70% of Ti, 10%-20% of Nb, 5%-15% of Zr, 1%-10% of Ta and 1%-5% of Si, sponge titanium, sponge zirconium, tantalum-niobium intermediate alloy and silicon are used as raw materials to prepare alloy compositions, then the alloy compositions are evenly smelted to obtain a solidified ingot casting, afterwards, the obtained ingot casting is subjected to high-temperature plastic deformation, the deformation temperature is 800-900 DEG C, the deformation amount is 60%-80%, and water quenching is performed to an indoor temperature; and finally an obtained sample is heated to a recrystallization temperature, heat preservation lasts for 1-4h, air cooling is conducted to an indoor temperature after annealing treatment is completed, and accordingly the Si-containing high-strength low-modulus Beta-type titanium alloy can be obtained. The titanium alloy obtained through the method has the higher strength, larger plasticity, lower elasticity modulus and finer grain sizes, thereby being more suitable for medical implant materials.

Owner:SOUTH CHINA UNIV OF TECH

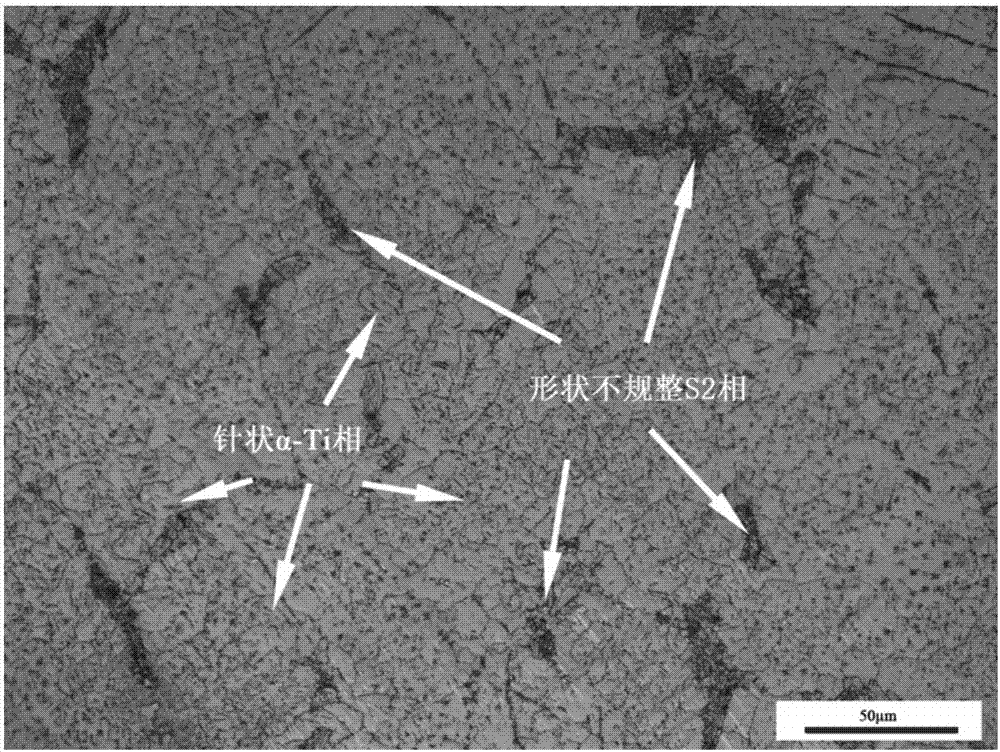

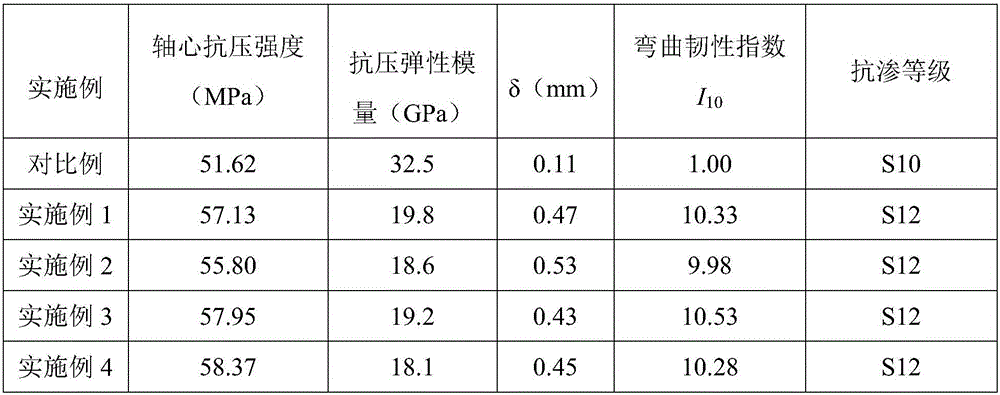

Cement concrete for wet connection seam of system sequentially comprising simply-supported bridge and continuous bridge, and preparation method thereof

The present invention discloses a cement concrete for the wet connection seam of a system sequentially comprising simply-supported bridge and continuous bridge, and a preparation method thereof, wherein the cement concrete comprises cement, river sand, water, a polycarboxylic acid-based efficient water reducer, rice hull ash, apatite, sericite, sepiolite, a sodium polyacrylate high water absorption resin, talc powder, nanometer calcium carbonate, polyethylene fibers and polyester fibers, and with the synergistic effect among the mineral components such as the apatite, the sericite and the sepiolite and the two fibers, the toughening can be achieved, the impact resistance and the extension ability of the concrete can be improved, and the problems that the wet connection seam concrete is damaged and the bridge surface cracks can be effectively solved. According to the present invention, the cement concrete has advantages of high compressive strength, good toughness, impact resistance, permeation resistance, self-leveling, and the like.

Owner:CHANGAN UNIV

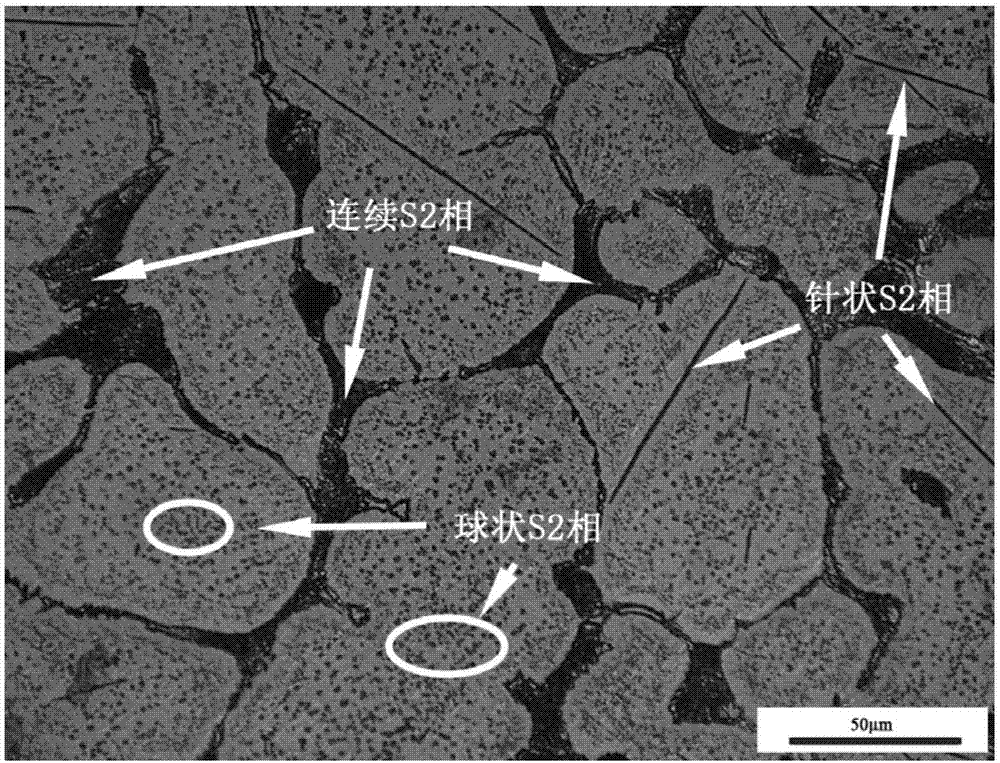

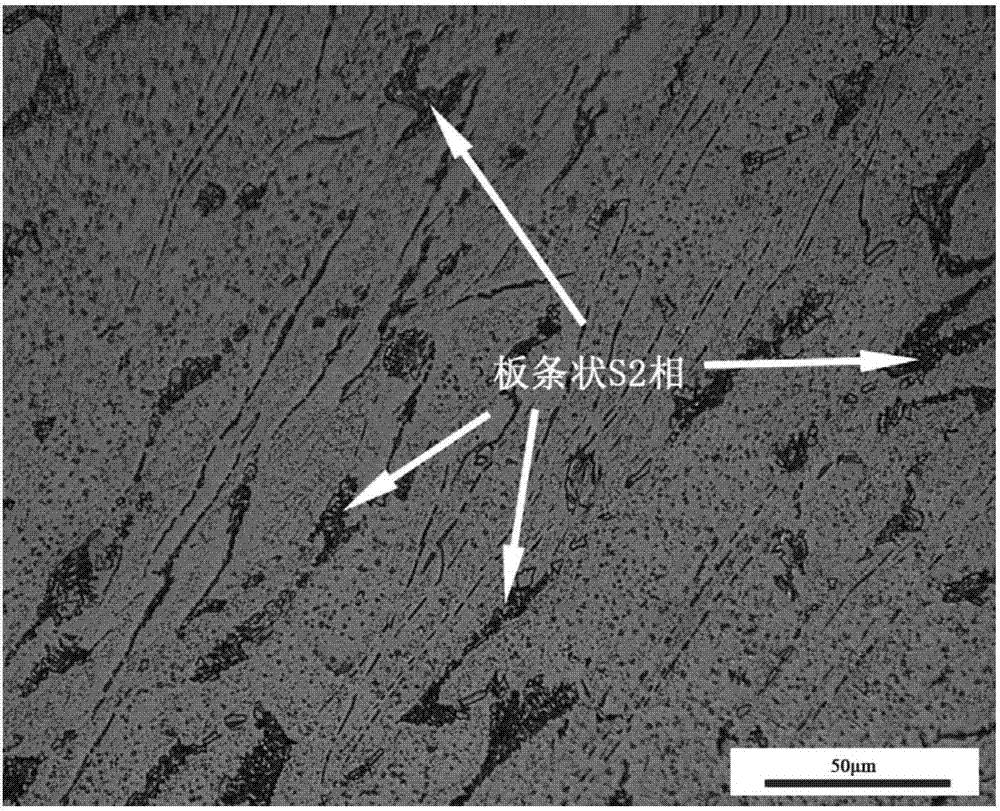

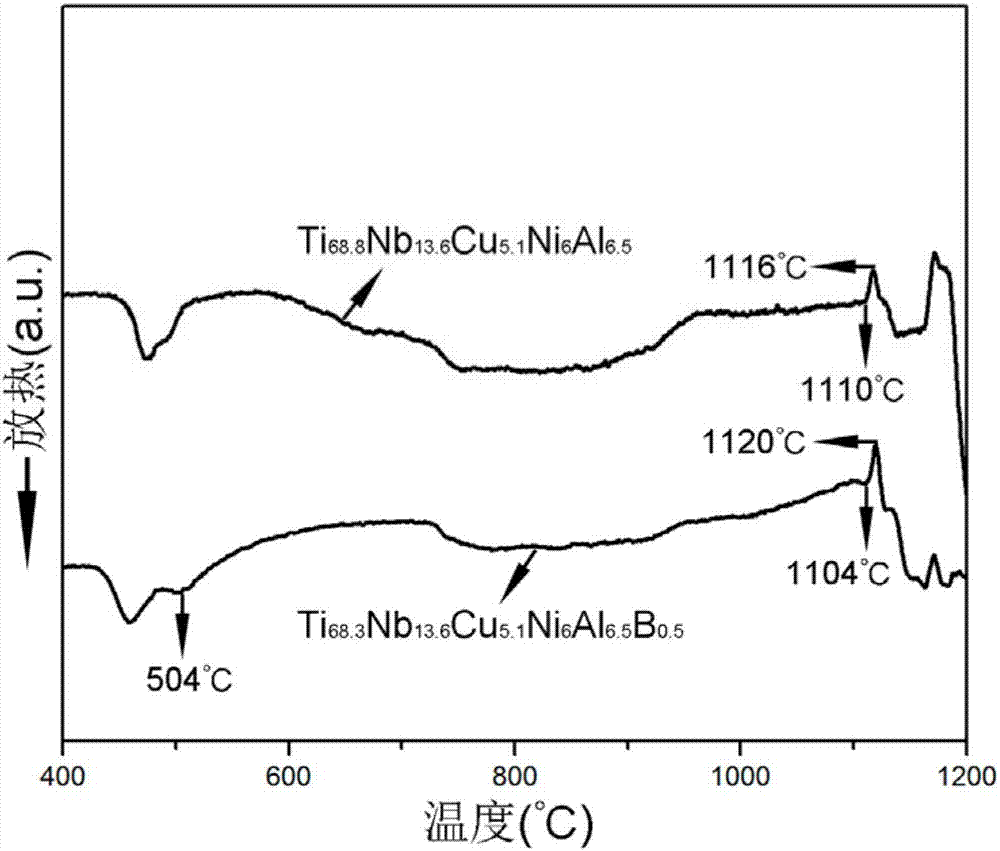

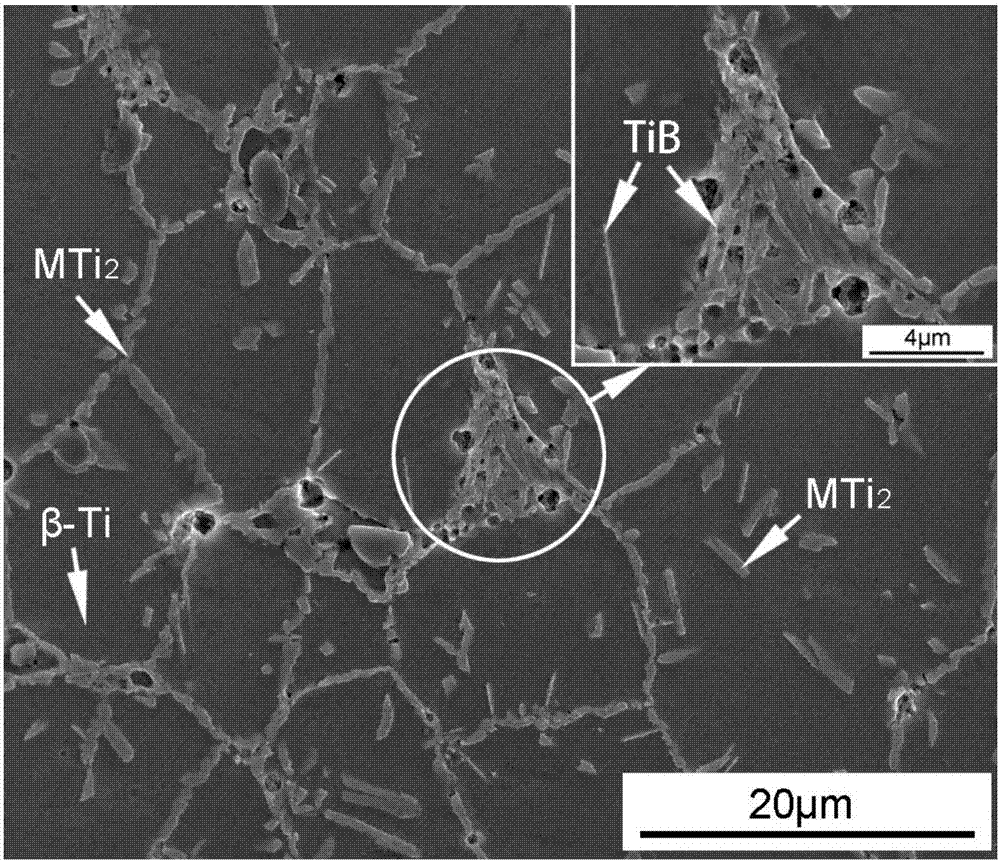

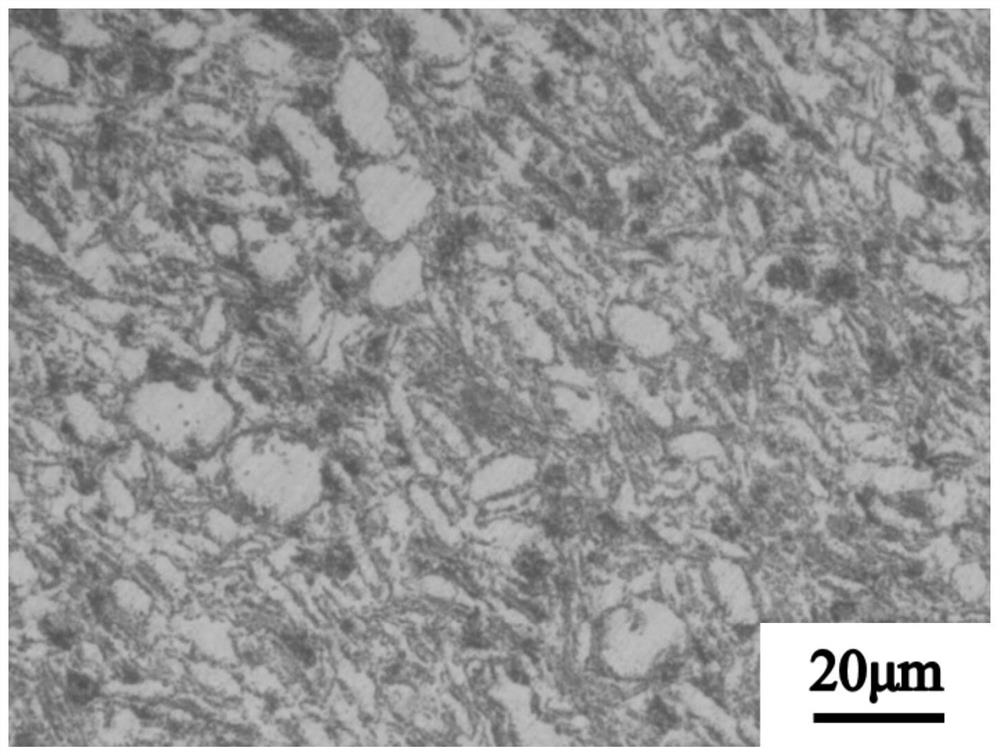

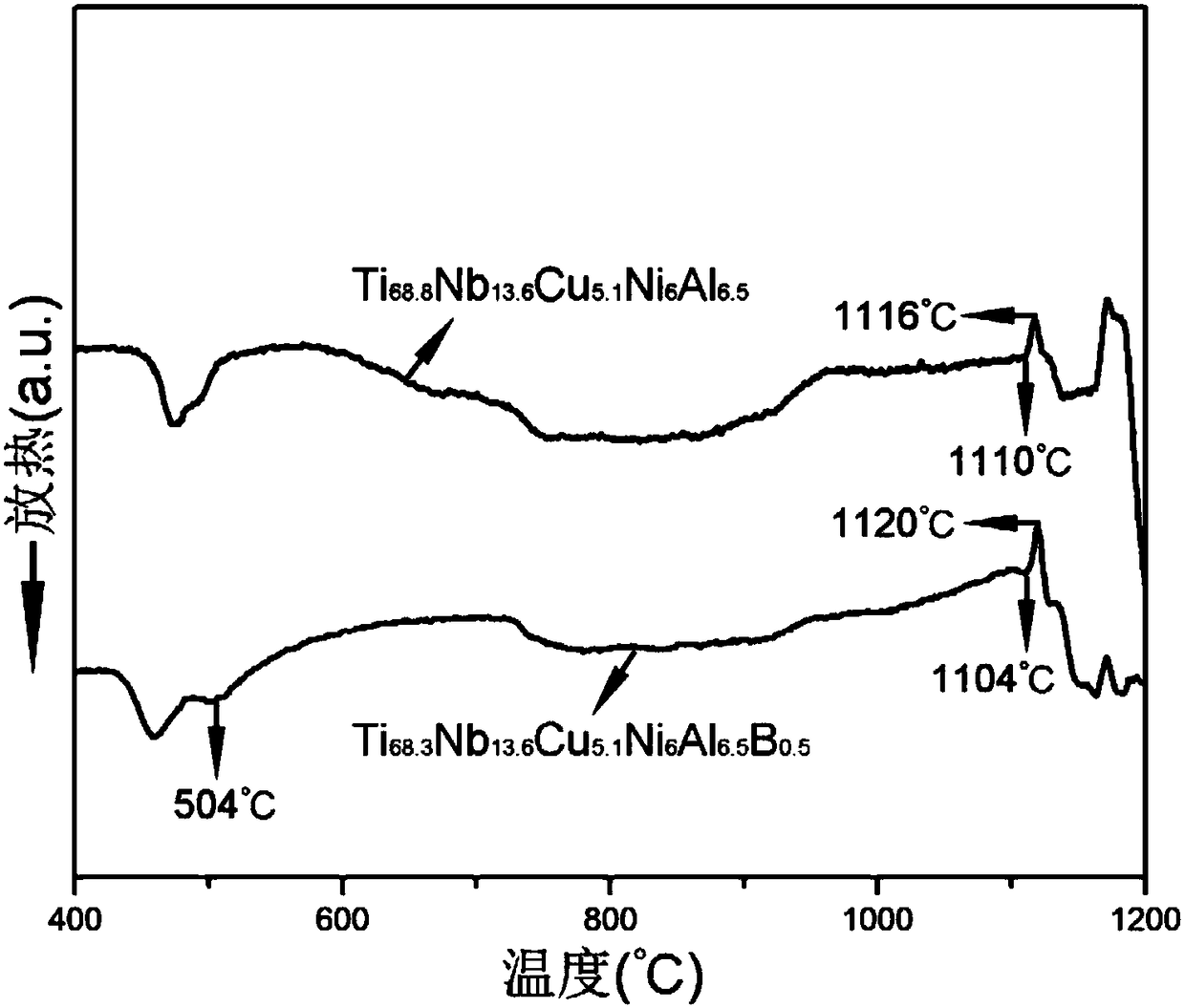

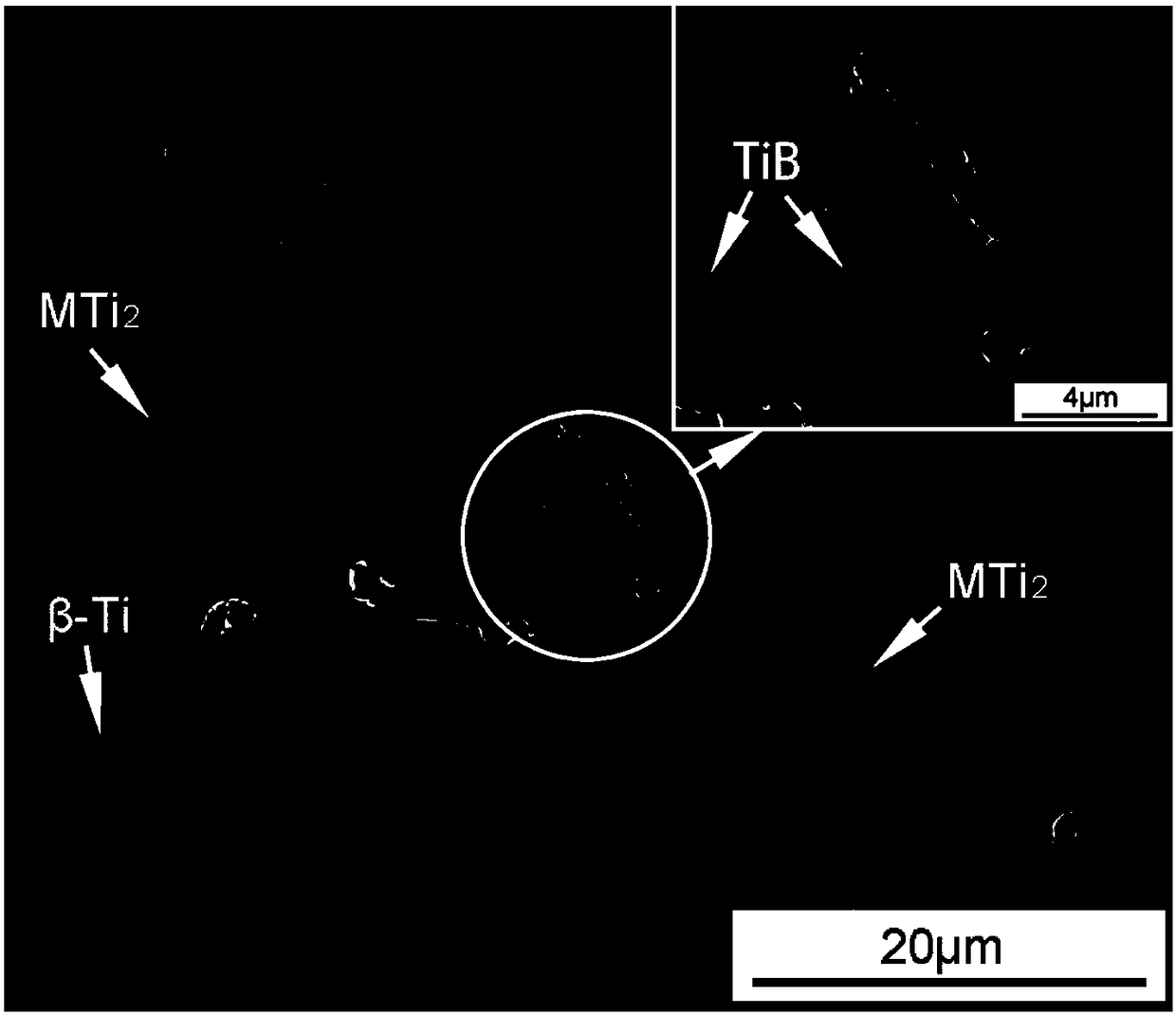

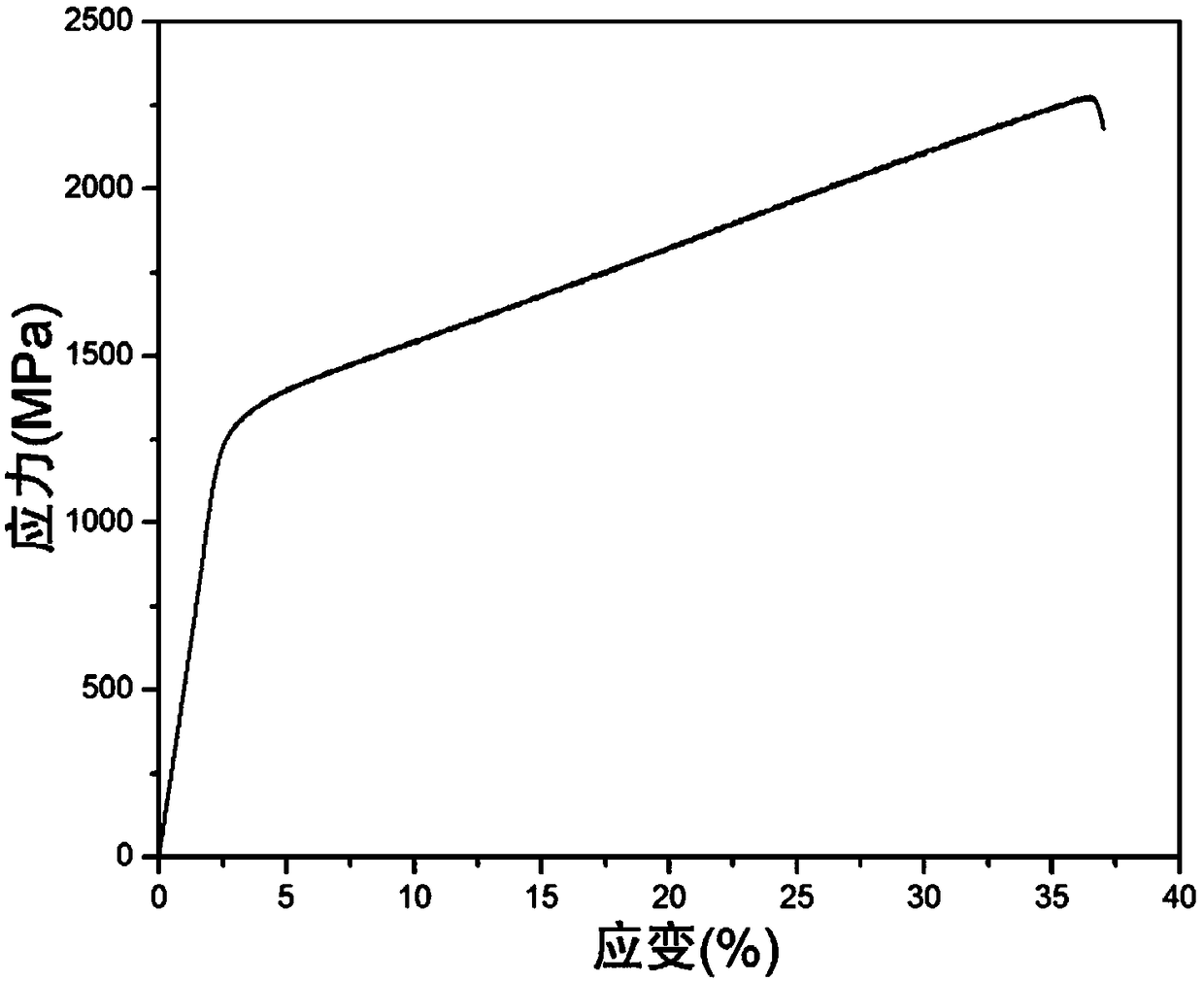

Double-scale structure titanium alloy based on in-situ whisker strengthening and toughening, preparation and application

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

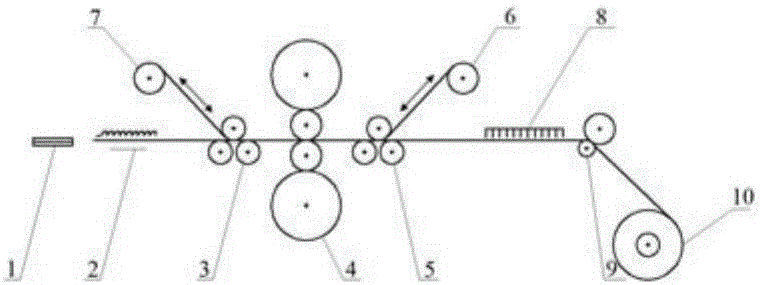

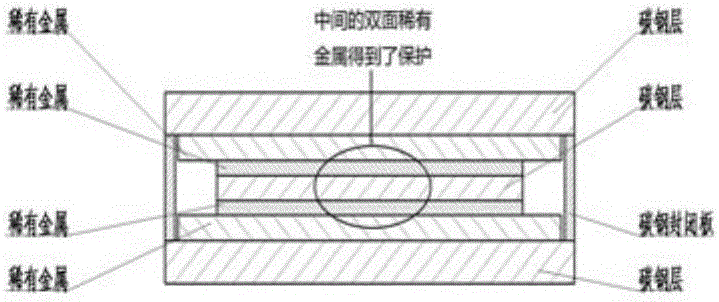

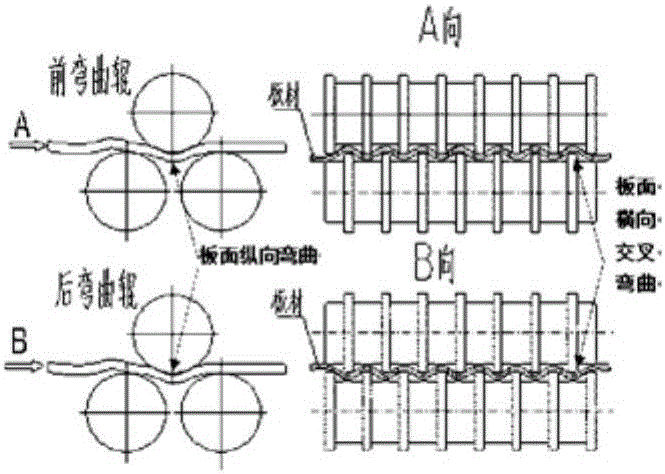

Multilayer metal coupling deformation rolling combined method and device

ActiveCN106001110AReduce the number of rolling millsLess investmentTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

The invention provides a multilayer metal coupling deformation rolling combined method and device. The device comprises a compound blank heating furnace, a high-pressure water descaling machine, a four-roller reversible rolling mill, a front reeling holding furnace, a rear reeling holding furnace, a front board criss cross bending deformation unit, a rear board criss cross bending deformation unit, a laminar cooling unit and a finished product reeling machine. According to the method, the reeling heating furnaces are equipped in front of and in rear of the single-frame four-roller reversible rolling mill, and the tension bending units are arranged between the front reeling furnace and the rear reeling furnace, the tension bending rollers are flower rollers of which the surfaces are of a convex and concave structure, three flower rollers form a reverse bending deformation unit, and a convex-concave structure of a front roller surface and a convex-concave structure of a rear roller surface are arranged in a staggered mode, so that a temperature controlling reeling coupling deformation rolling combined mechanism used for applying tension and achieving board criss cross bending deformation is formed, residual stress of a compound interface is remarkably reduced, and board shape quality is ensured; and meanwhile, the bonding strength and binding rate of the compound interfaces are greatly improved, the structure performance and comprehensive mechanical performance of composite boards are improved, and the production efficiency and yield are remarkably improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

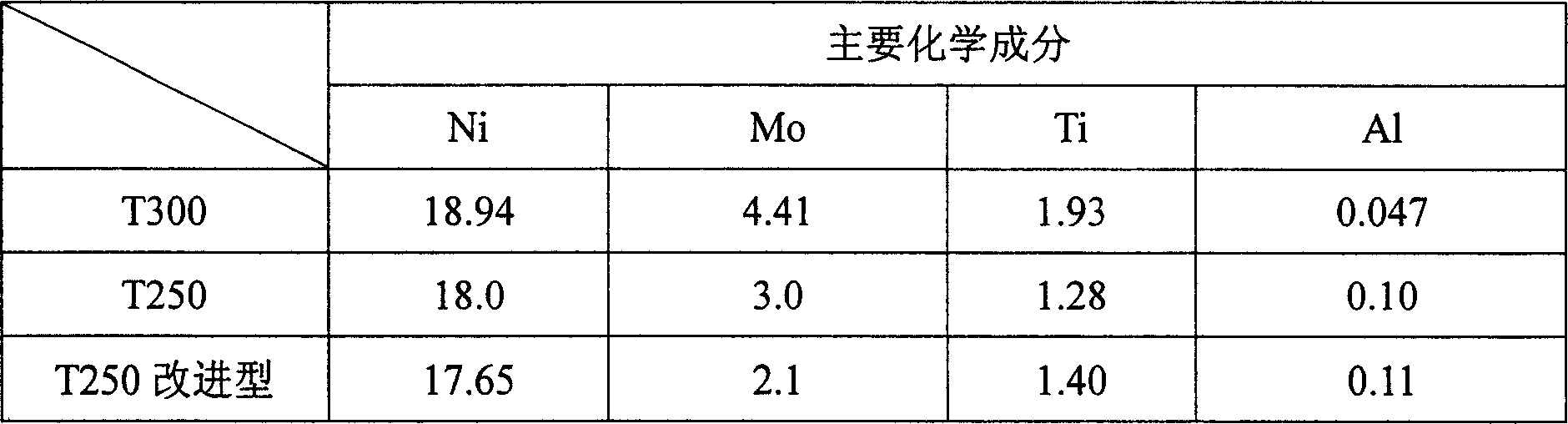

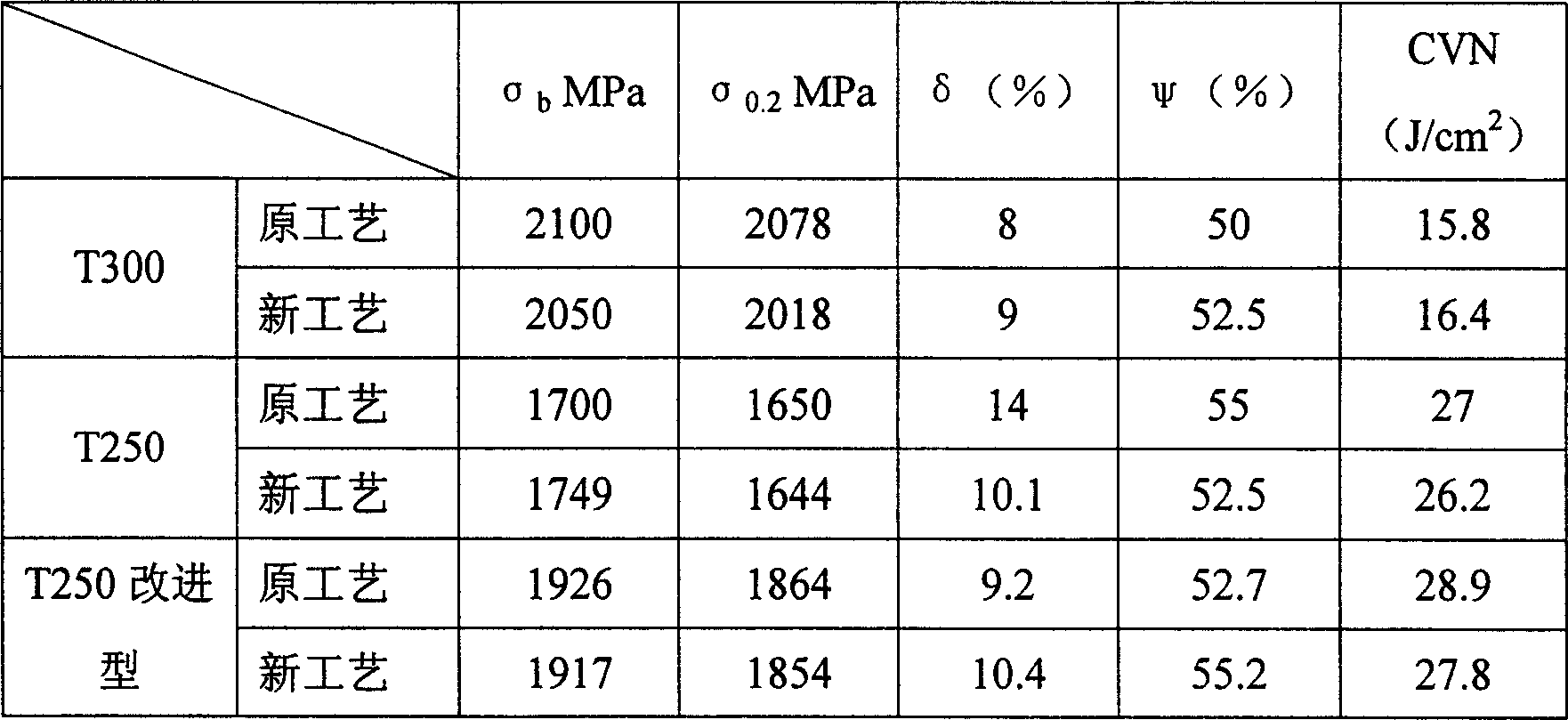

Method for producing ageing steel of martensite without cobalt in high tensile and high toughness

InactiveCN1626686AUniform deformationIncrease temperatureSolution treatmentHigh volume manufacturing

A machining technology for the aged 18(Ni)-series non-Co martensite steel with high strength and toughness includes hot working, cold working by direct cold rolling or machining without solution treatment, ageing at 400-600 deg.C for 0.5-3 hrs, and air or water cooling. Its advantages are short period and simplified heat treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

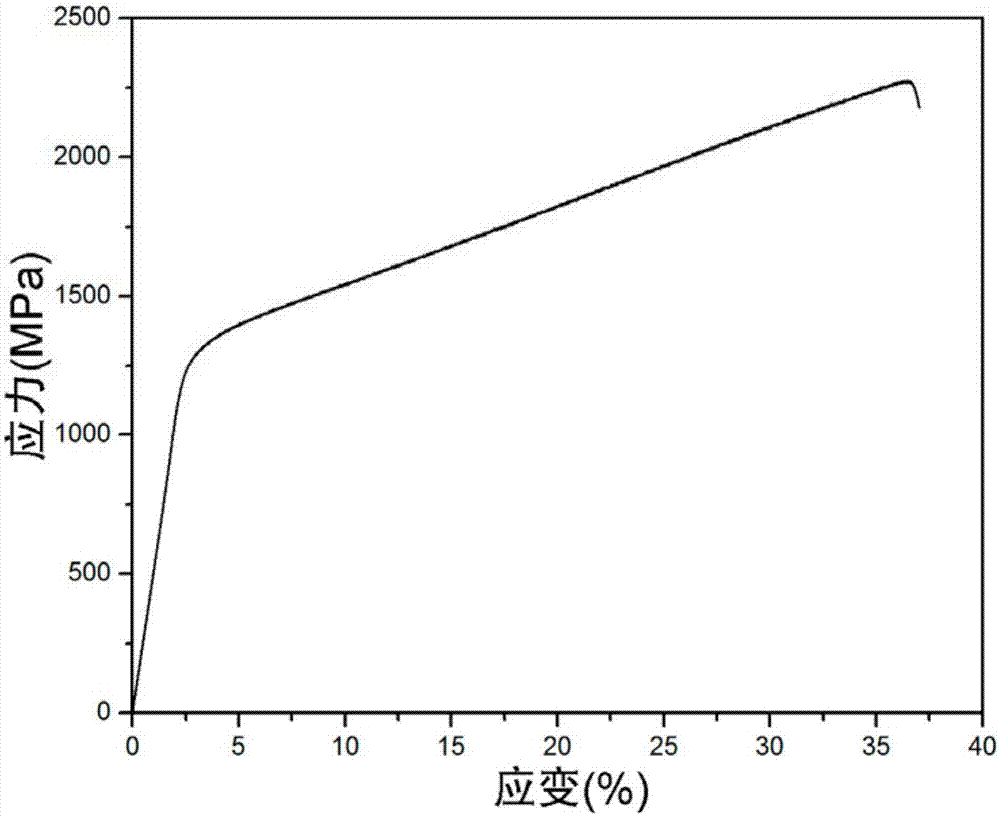

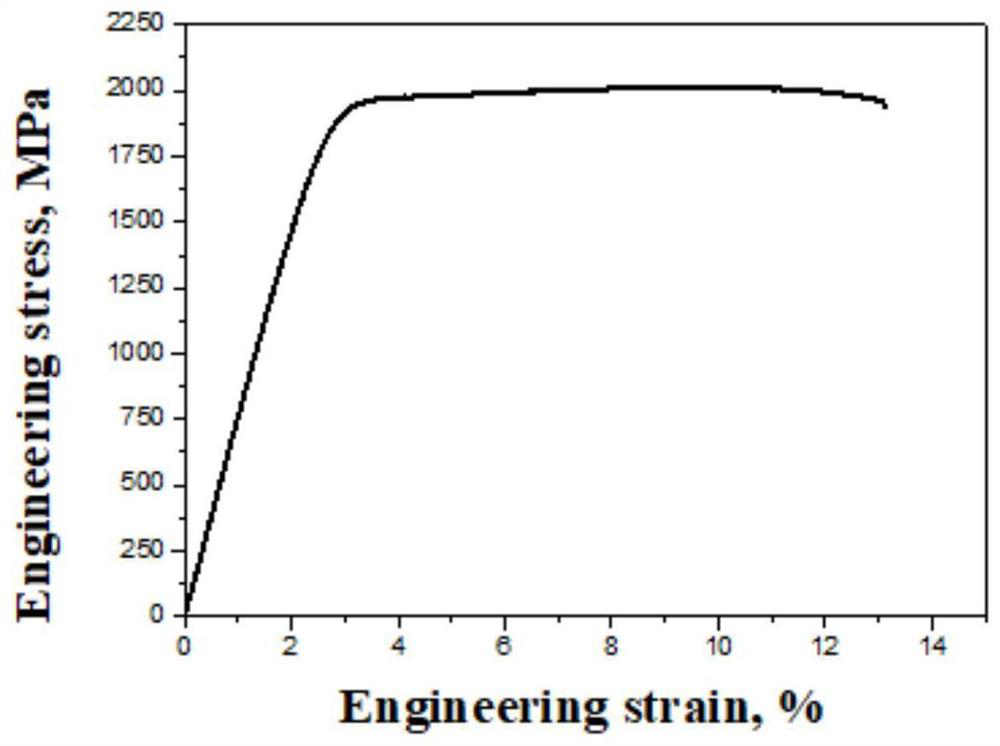

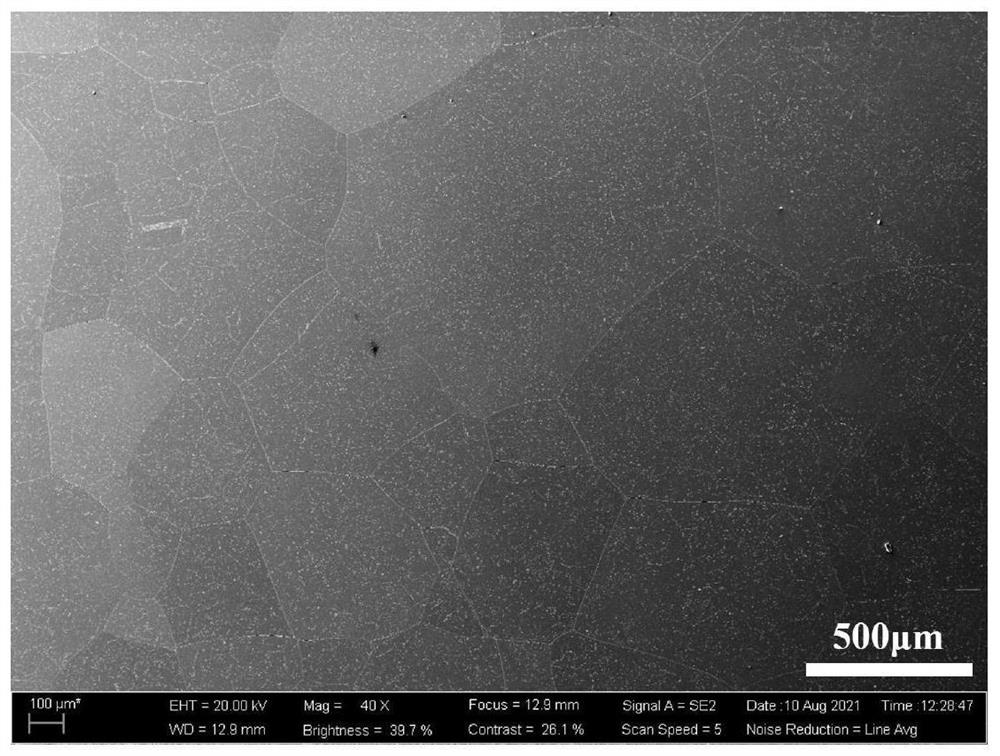

2.0 GPa-grade ultrahigh-yield-strength plastic CoCrNi-based medium-entropy alloy and preparation method thereof

ActiveCN114086049AHigh-strength plastic performance indexHigh yield strengthAlloyOil and natural gas

The invention belongs to the field of preparation of high-performance alloy materials, and particularly relates to a 2.0 GPa-grade ultrahigh-yield-strength plastic CoCrNi-based medium-entropy alloy and a preparation method thereof. The alloy is prepared through fusion casting, homogenization treatment, solid solution heat treatment, cold deformation and aging heat treatment. Through cold deformation and aging heat treatment, the prepared alloy has a dual heterogeneous micro-structure formed by discontinuous precipitation and incomplete recrystallization of a strengthening phase. The CoCrNi-based medium-entropy alloy disclosed by the invention has ultrahigh yield strength (2.0 GPa) and sufficient use safety (uniform elongation is greater than 8%), can be processed into various forms of products, and is widely applied to the production of fasteners used in the fields of aerospace, navigation, petroleum and natural gas, food processing, springs, non-magnetic components, instrument parts and the like.

Owner:SHENYANG AEROSPACE UNIVERSITY

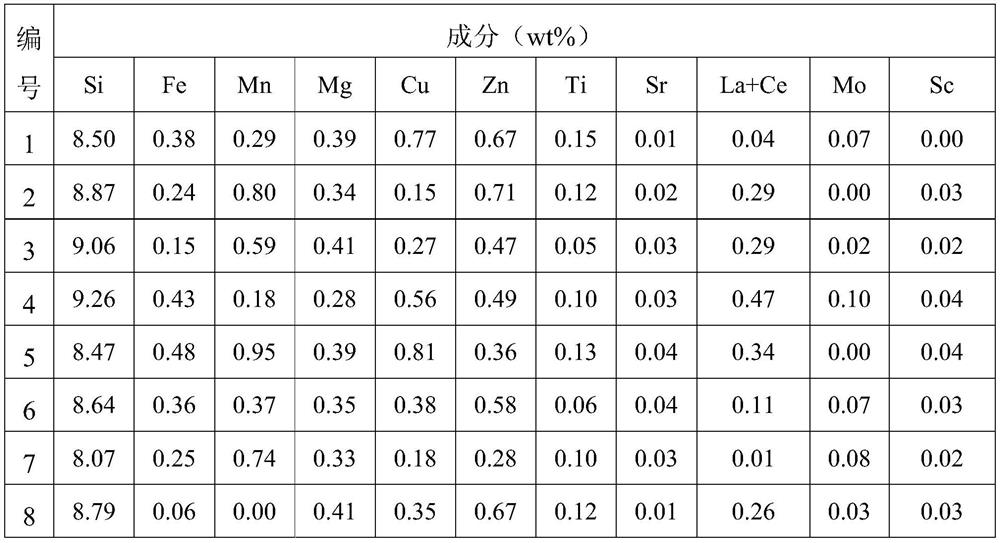

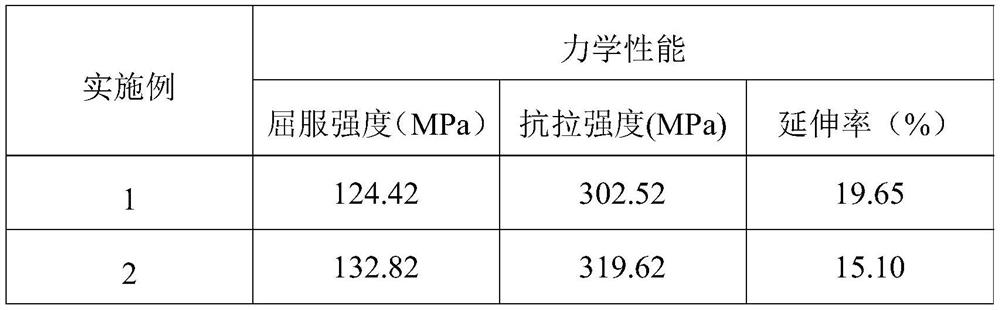

High-toughness die-casting aluminum alloy for new energy automobile and preparation method of high-toughness die-casting aluminum alloy

The invention relates to a high-strength and high-toughness die-casting aluminum alloy for a new energy automobile and a preparation method of the high-strength and high-toughness die-casting aluminum alloy. The alloy comprises the following elements in percentage by weight: 8wt%-10wt% of Si; fe: 0.05 to 0.5 wt%; mn < lt >; 1.0 wt%; mg: 0.1 to 0.5 wt%; cu: 0.1 to 1.0 wt%; zn < lt >; 1.0 wt%; ti: 0.05 to 0.2 wt%; sr: 0.005 wt% to 0.05 wt%; la + Cult; 0.5 wt%; molt; 0.1 wt%; sclt; Sclt; 0.05 wt% of an additive; the sum of the weight percentages of the other impurities is controlled to be 0.5 wt% or below. Compared with the prior art, the Al-Ti-C-B intermediate alloy amorphous powder, the Al-20La + Ce intermediate alloy amorphous powder, the Al-20Mo intermediate alloy amorphous powder and the Al-3Sc intermediate alloy amorphous powder are prepared by adopting a melt-spinning method in combination with high-energy ball milling, Al-Ti-C-B, Al-Mo and Al-Sc are added as refiners and modifiers, and the ductility of the material is remarkably improved; and through heat treatment at 200 DEG C for 4 hours, the tensile strength is larger than 300 MPa, the yield strength is larger than 120 MPa, and the ductility is 15-20%.

Owner:苏州慧金新材料科技有限公司

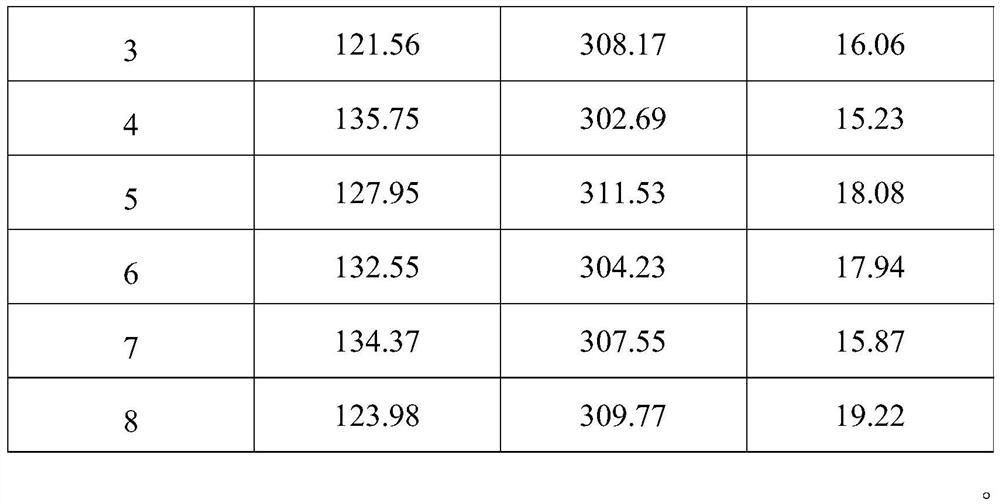

Method for improving room temperature plasticity of refractory high-entropy alloy

ActiveCN110777273AImproved room temperature compression plasticityNo reduction in yield strengthElectric arc furnaceHigh entropy alloys

The invention discloses a method for improving the room temperature plasticity of refractory high-entropy alloy, and relates to the field of metal materials and preparation thereof. According to the specific scheme, the method includes the steps that 1) all component materials required for smelting the alloy are obtained and purified; 2) the materials obtained in the step 1) are placed in a non-consumable vacuum arc furnace, and hydrogen and argon are introduced after vacuumizing; and 3) smelting is carried out to obtain a room temperature plastic alloy material. The room temperature compression plasticity of the alloy obtained after melt hydrogenation is remarkably improved, the yield strength of the alloy is not reduced, and the microstructure is refined. The method solves the problems of poor room temperature plasticity and poor cold deformation capability of the refractory high-entropy alloy, improves the cold state plastic deformation limit of the alloy, realizes strengthening andtoughening of the refractory high-entropy alloy, and plays an important role in promoting engineering application of the alloy.

Owner:HARBIN INST OF TECH

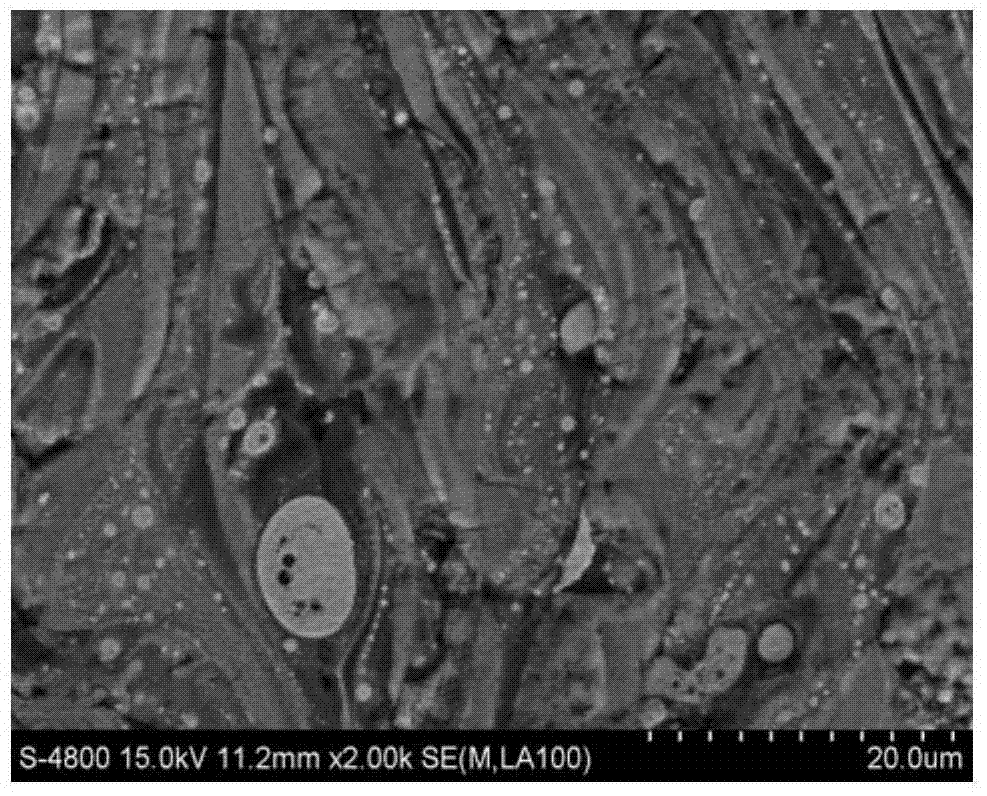

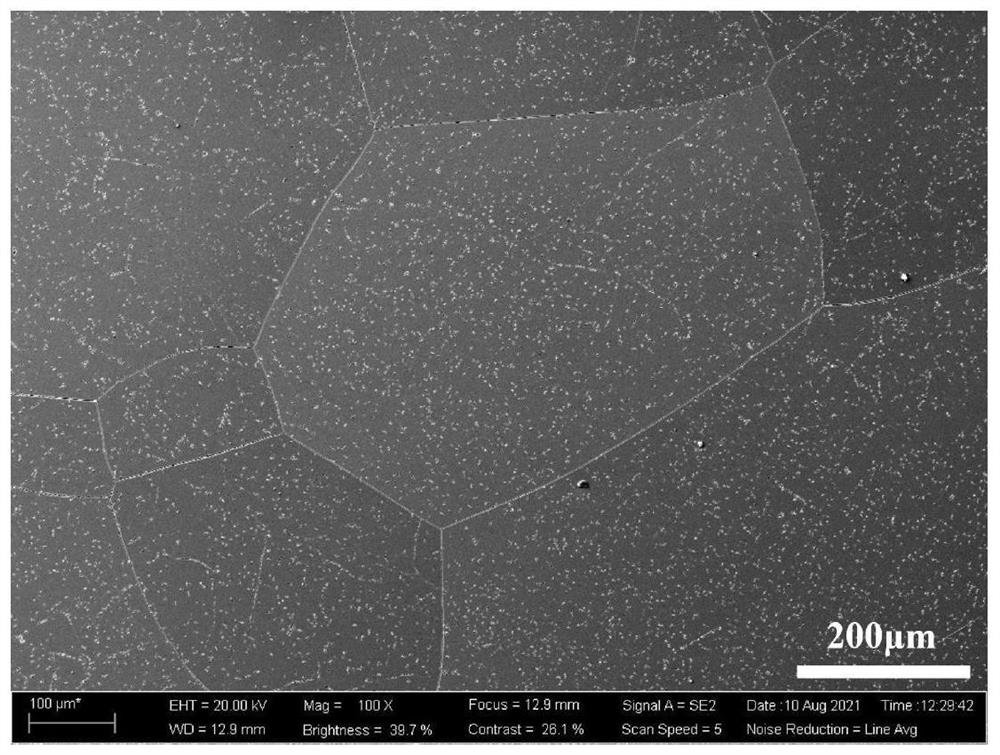

Laser additive manufacturing method for synergistically improving surface precision and strength of titanium alloy

InactiveCN110523984ASynergistically improve surface accuracySynergistically enhance surface strengthAdditive manufacturing apparatusIncreasing energy efficiencyScan lineLaser scanning

According to the laser additive manufacturing method for synergistically improving the surface precision and strength of the titanium alloy, the forming structure is adjustable, the surface is smoothand clean, the surface is self-strengthened, and extra surface treatment and other procedures are not needed. The method comprises the following steps: uniformly and continuously pre-paving Ti6Al4V alloy powder on a forming cabin substrate of laser additive manufacturing equipment, and printing and forming layer by layer to obtain a Ti6Al4V alloy test piece; when each layer is printed and formed,using laser beams to adjacently scan line by line to form an internal solid plane, after forming the internal solid plane, performing laser scanning of a contour along the edge of the internal solid plane to form an external contour, and finish forming of the printing layer; repeating the forming process of the printing layers until laser additive manufacturing forming of the Ti6Al4V alloy test piece is completed, wherein the laser power for printing internal solid plane is not less than the laser power for printing the external contour, and the scanning speed for printing the internal solid plane is not greater than the scanning speed of the printing external contour.

Owner:SHANGHAI AIRCRAFT DESIGN & RES INST COMML AIRCRAFT OF CHINA +1

Method for preparing titanium material through powder metallurgy with modifier

The invention discloses a method for preparing a titanium material through powder metallurgy with a modifier, relates to a method for preparing the titanium material through powder metallurgy and aimsto solve the problems that a titanium material prepared by using a conventional powder metallurgy material is large in texture and degraded in plasticity as textures cannot be controlled. The methodcomprises the following steps: I, performing mechanical powder stirring and mixing, namely mechanically mixing modifier powder, pure titanium and titanium alloy powder by using a stirring and mixing machine so as to obtain composite powder; II, performing sintering, namely sintering the composite powder in a vacuumed sealed container, and naturally cooling to a room temperature, thereby obtaininga modified powder metallurgy titanium material with controllable textures.

Owner:HARBIN INST OF TECH

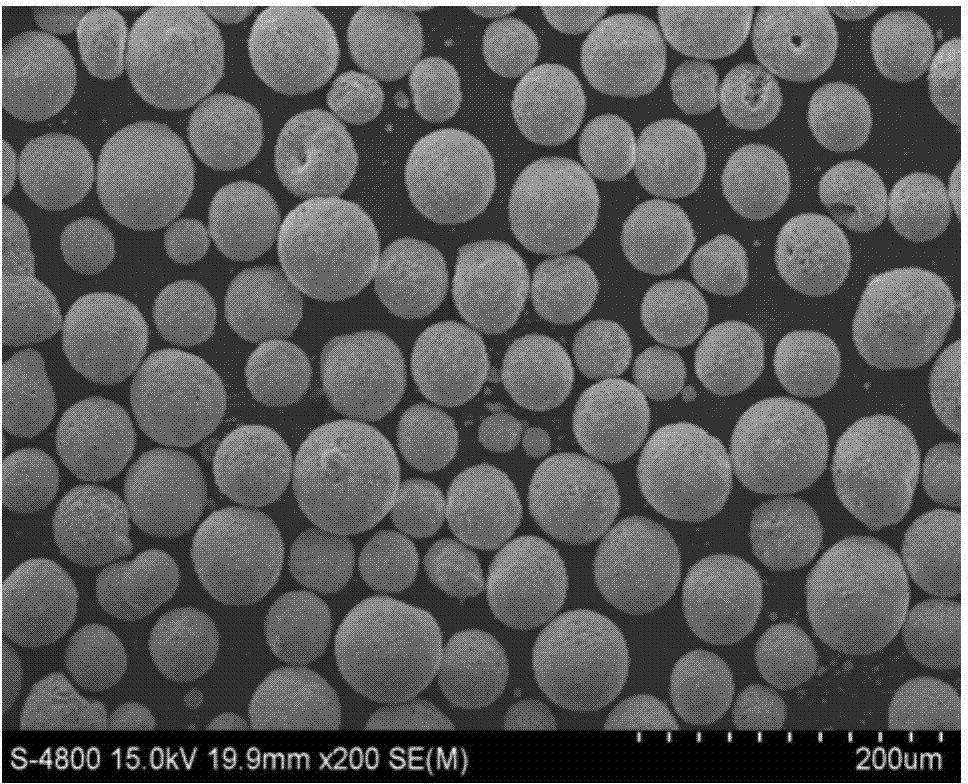

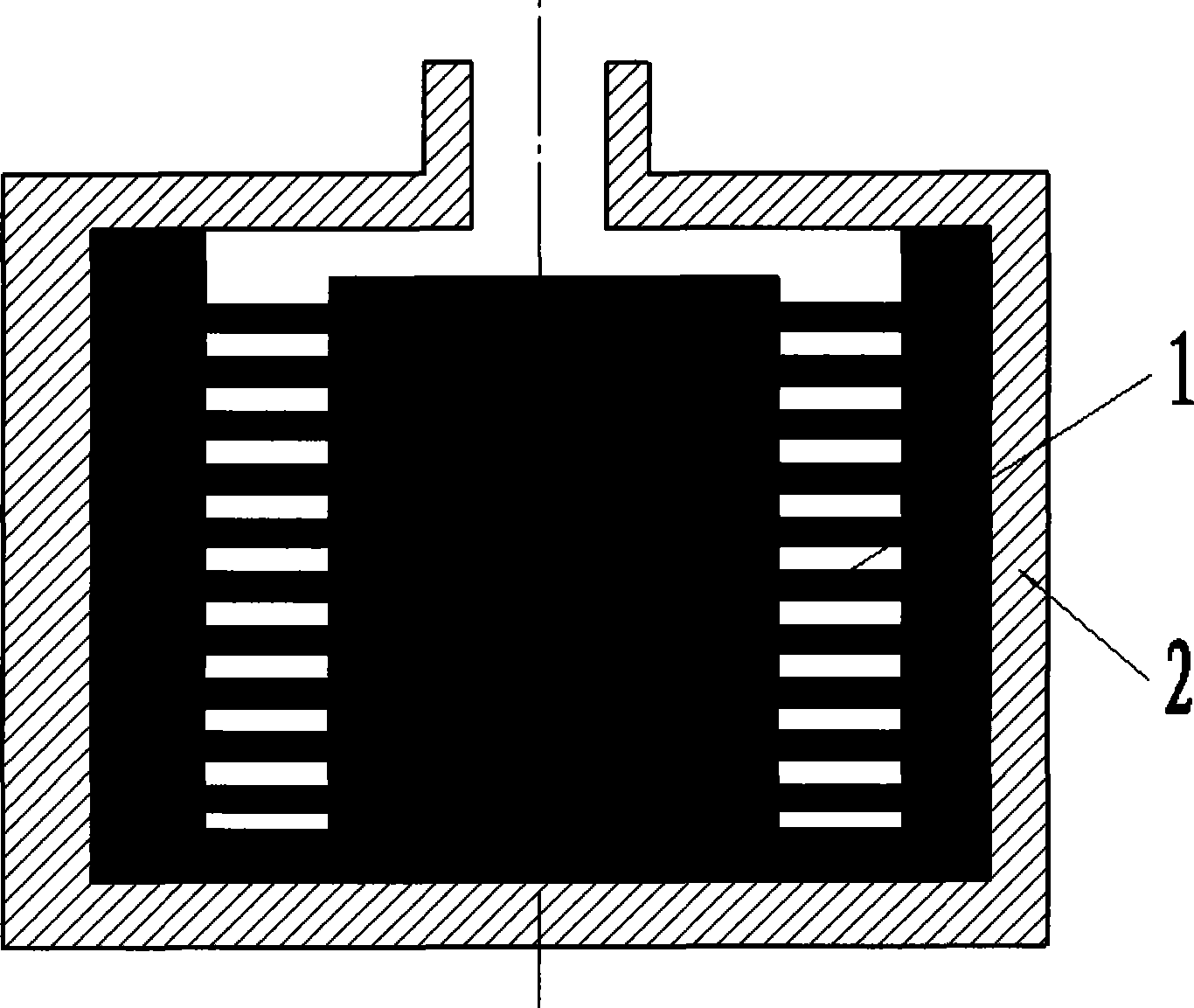

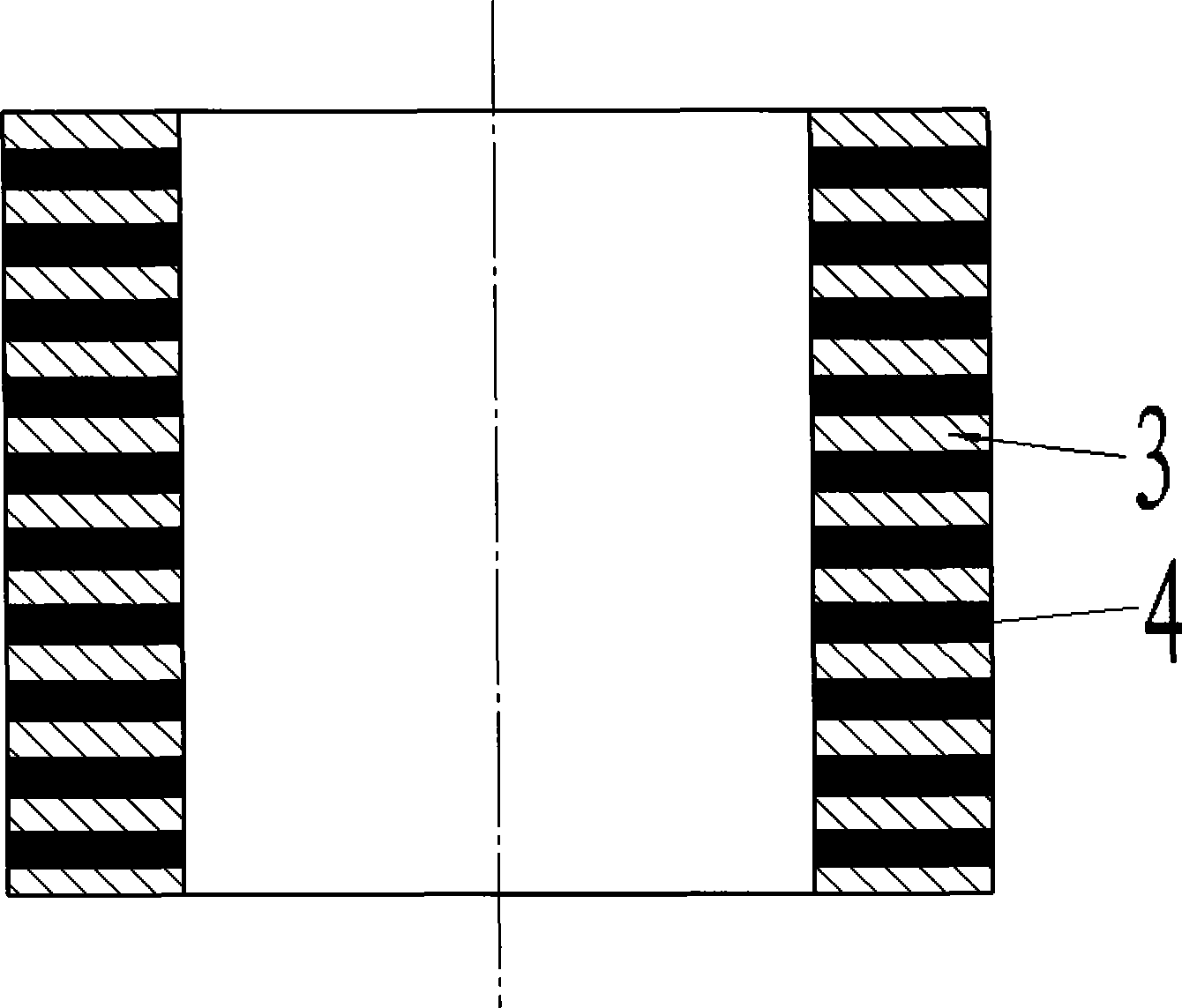

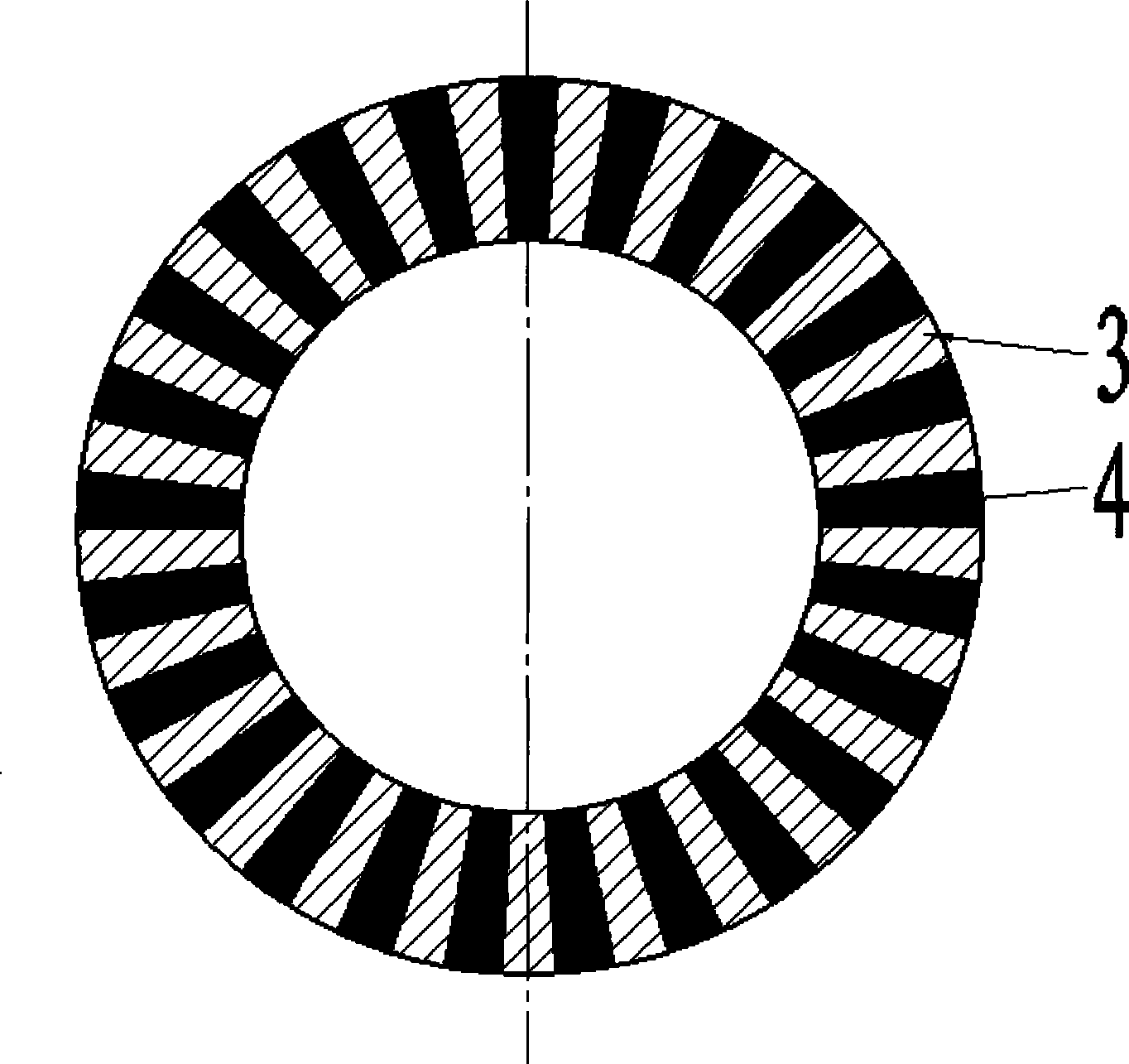

Preparation method of cell structure gradient tungsten alloy material

The invention discloses a preparation method of a cell structure gradient tungsten alloy material. The preparation method comprises the following steps that high-tungsten base prealloy powder and low-tungsten base prealloy powder are obtained through prealloying treatment in advance, after the high-tungsten base prealloy powder is atomized and pelletized and is uniformly mixed with the low-tungsten base prealloy powder, compression forming is carried out in a cold isostatic pressing machine, two-step sintering is carried out in a high-temperature vacuum tube type furnace, and finally the cellstructure gradient tungsten alloy material is obtained.

Owner:SHAANXI SCI TECH UNIV

Method for preparing composite wear-resistant roller

The invention discloses a method for preparing a composite antiwear roller, which is characterized by comprising the following steps: alloy dust core bars are bound into bundles and arranged in a roller casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the antiwear roller; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite antiwear roller which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite antiwear roller has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of light titanium-rich Ti-Zr-Nb-Al series refractory high-entropy alloy-based composite material

The invention relates to the field of preparation of novel metal materials, in particular to a preparation method of a light titanium-rich Ti-Zr-Nb-Al series refractory high-entropy alloy-based composite material. The invention aims to solve the problems of high density, poor plasticity and incapability of large-size preparation of an existing refractory high-entropy alloy. The method comprises the steps that firstly, raw materials are weighed according to the proportion, the raw materials are mixed and smelted into metal ingots, powder is prepared through a high-energy-density plasma rotating electrode atomization technology, and matrix powder is obtained; 2, additional reinforcement powder is weighed; 3, the matrix powder and the additional reinforcement powder are mixed, and low-energy ball milling is conducted in a high-purity argon atmosphere to obtain mixed powder; and 4, the mixed powder is subjected to vacuum hot press sintering, a compact block material, namely the light titanium-rich Ti-Zr-Nb-Al series refractory high-entropy alloy-based composite material, is obtained. The method is used for high-temperature structural members.

Owner:HARBIN INST OF TECH

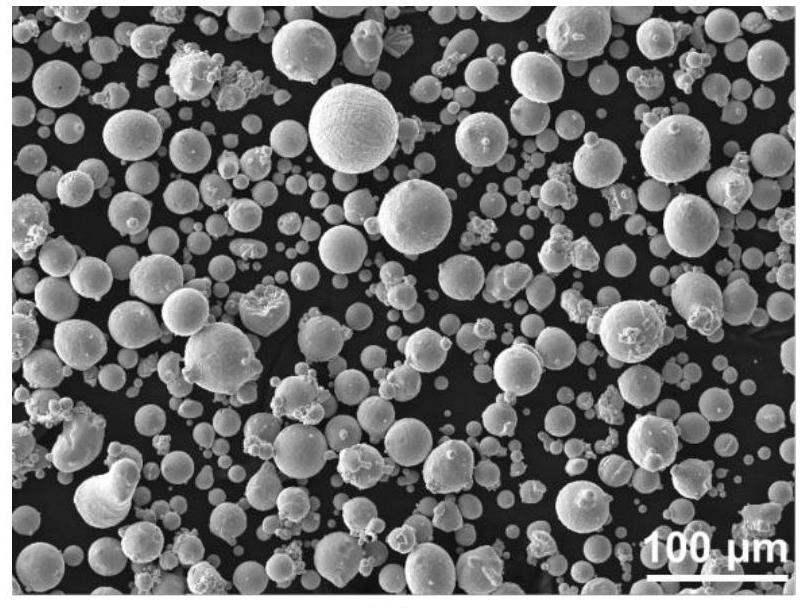

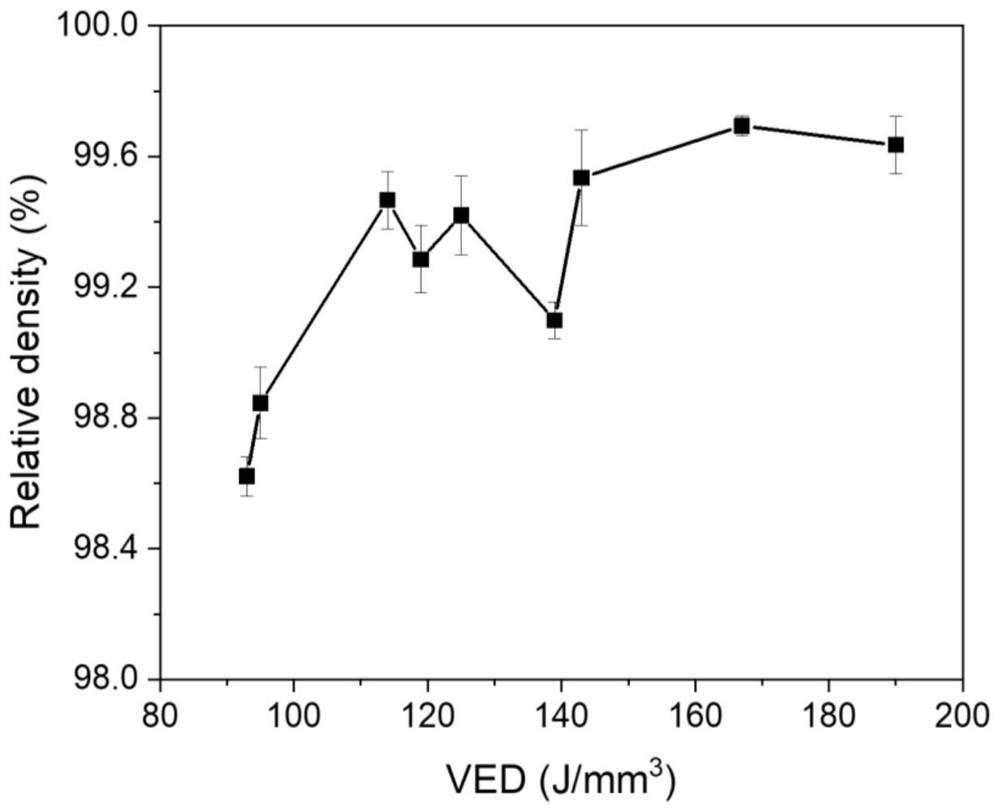

Precipitation strengthening type medium-entropy alloy suitable for laser additive manufacturing and preparation method of precipitation strengthening type medium-entropy alloy

ActiveCN114411035AReduce sensitivityPromote productionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingLaser additive manufacturing

The invention provides a precipitation strengthening type medium-entropy alloy suitable for laser additive manufacturing and a preparation method thereof, the precipitation strengthening type medium-entropy alloy is NiaCobCrcAldMe, M is one or more elements of Ti, Ta, Nb and Mo, a, b, c, d and e respectively represent the molar percentage corresponding to each element, b is 20%-40%, c is 20%-25%, and dgt is 1%-2%; 1%, egt; 0, d + ilt; a + b + c + d + e = 100%. The precipitation strengthening type medium-entropy alloy is prepared through the selective laser melting forming technology or the laser three-dimensional forming technology, and preparation of the novel precipitation strengthening type medium-entropy alloy which is high in compactness, free of cracks and excellent in comprehensive mechanical property is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of multi-layer large-gradient hard alloy material easy to weld

The invention discloses a preparation method of a multi-layer large-gradient hard alloy material easy to weld. The preparation method of the multi-layer large-gradient hard alloy material easy to weldcomprises the steps that pre-alloying is conducted to obtain WC-Co pre-alloyed powder, WC-Ni pre-alloyed powder and WC-Fe pre-alloyed powder; then a forming agent is added to the WC-Co pre-alloyed powder, the WC-Ni pre-alloyed powder and the WC-Fe pre-alloyed powder to conduct compression molding; an obtained green body material is arrayed according to additive components, and nickel powder is spread between different layers; and the green body material is conveyed into a rapid hot-pressing sintering furnace to be sintered, so that the multi-layer large-gradient hard alloy material easy to weld is finally obtained.

Owner:SHAANXI SCI TECH UNIV

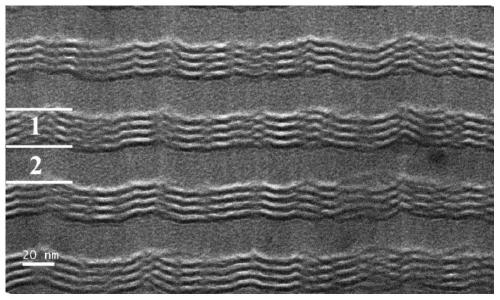

Carbon-based composite film and preparation method thereof

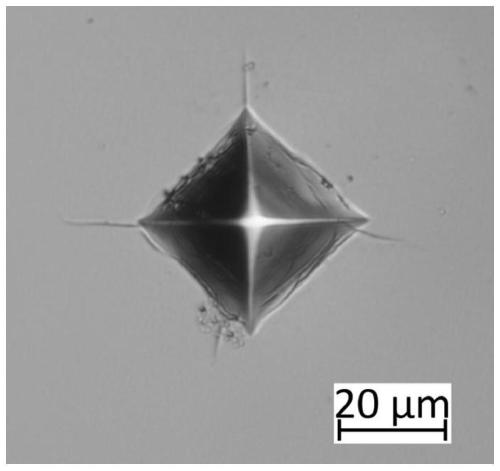

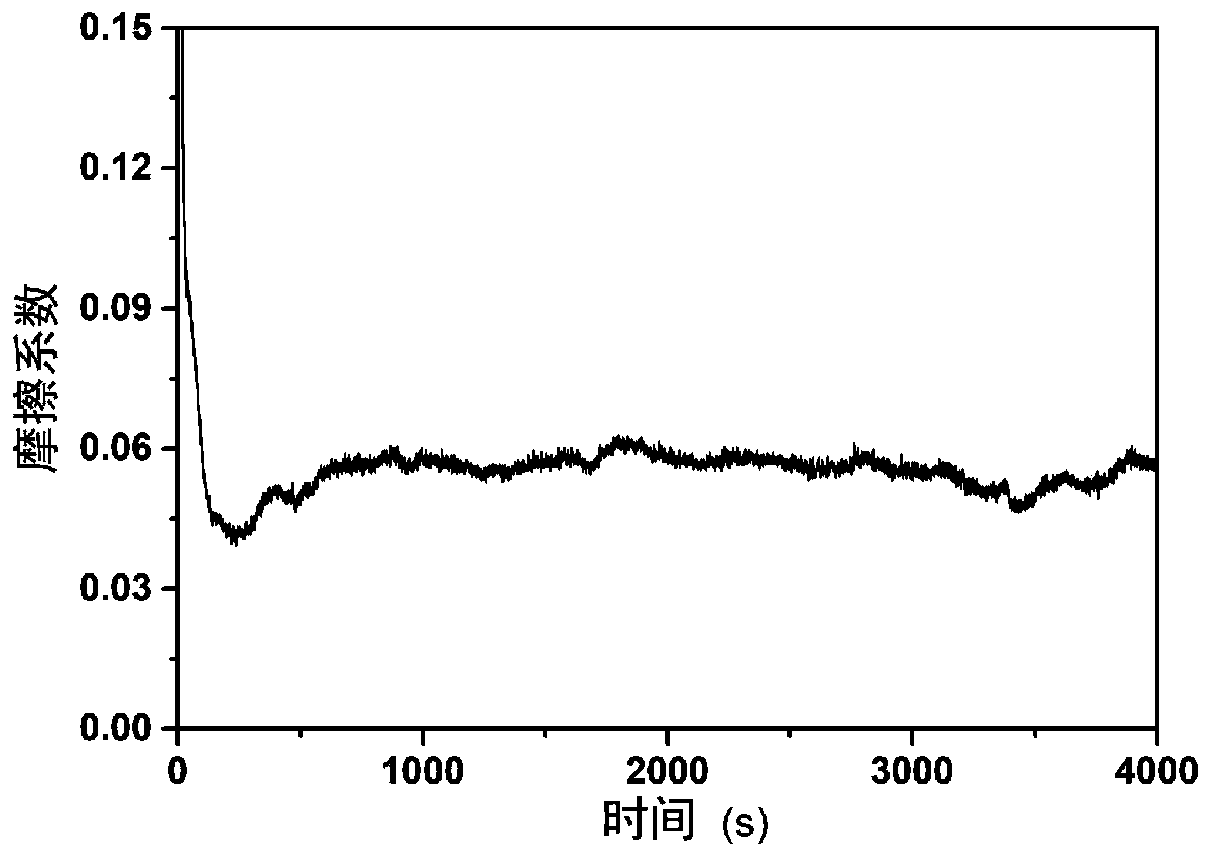

ActiveCN111074226AImprove toughnessImprove tribological performanceVacuum evaporation coatingSputtering coatingSputteringSurface engineering

The invention provides a carbon-based composite film and a preparation method thereof, and belongs to the field of surface engineering. According to the carbon-based composite film and the preparationmethod thereof, a carbon target and a metal carbide target serve as a sputtering target material, based on closed field unbalanced magnetron sputtering plasma space distribution characteristics and the rule of influence of the rotation speed of a sample rotating stand on a film structure, only through cyclic control over high-speed and low-speed rotation of the sample rotating stand, and the double-structure carbon-based composite film comprising both a nanolayer structure and a nano composite structure is spontaneously formed in the deposition process; the carbon target and the metal carbidetarget are oppositely arranged in a vacuum cavity, when the rotation speed of the rotating stand is high, a composite film with the nano composite structure is deposited out, and when the rotation speed of the rotating stand is low, a composite film with a nano multi-layer structure is deposited out; and the size of nanocrystalline in the nano composite structure and the modulation period of thenano multi-layer structure can be achieved through adjusting of the rotation speed of the rotating stand, and the thickness of a nano composite structure layer and the thickness of a nano multi-layerstructure layer can be achieved by controlling the time for cyclic adjustment of the rotation speed of the sample rotating stand.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

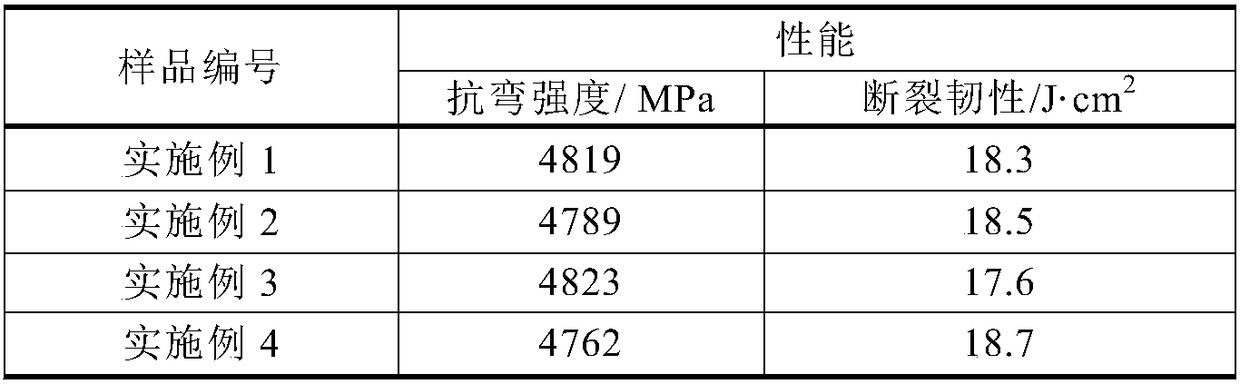

Preparation method of complex-phase co-strengthening hard alloy material

The invention discloses a preparation method of a complex-phase co-strengthening hard alloy material. According to the method, firstly, pre-alloying treatment is carried out to obtain tungsten carbidebase pre-alloying powder and titanium carbonitride base pre-allying powder, the two kinds of powder are mixed with cobalt powder uniformly, the powder is subjected to secondary atomizing, drying andpelletizing, then pressed and formed in a cold pressing machine, and finally sintered in a high-temperature vacuum pipe type furnace, and finally, the complex-phase co-strengthening hard alloy material is obtained.

Owner:SHAANXI SCI TECH UNIV +1

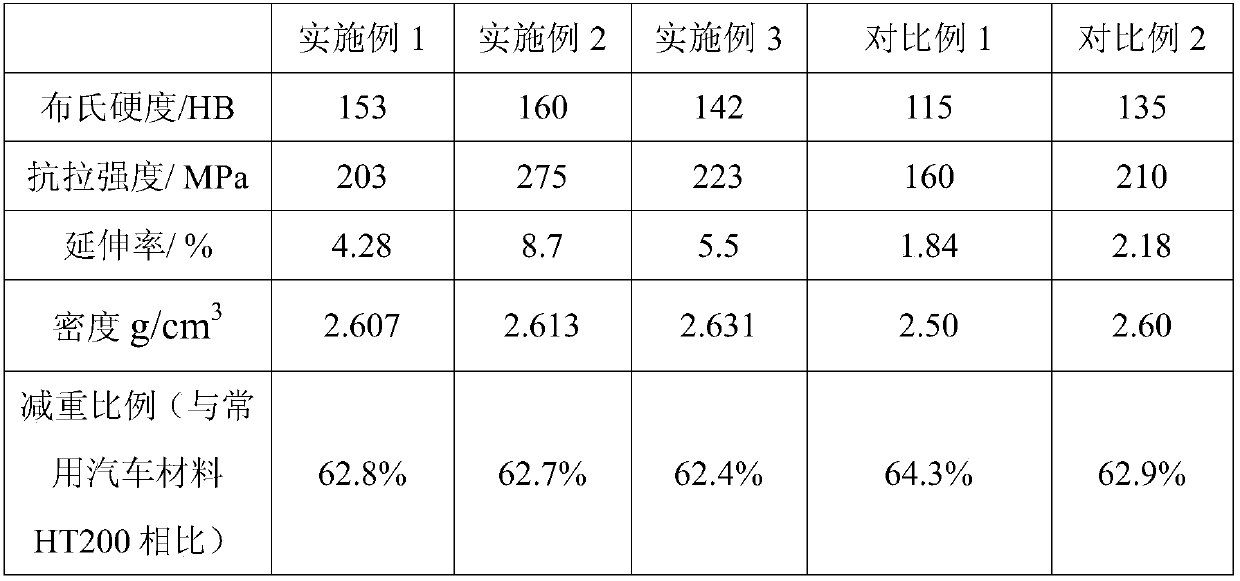

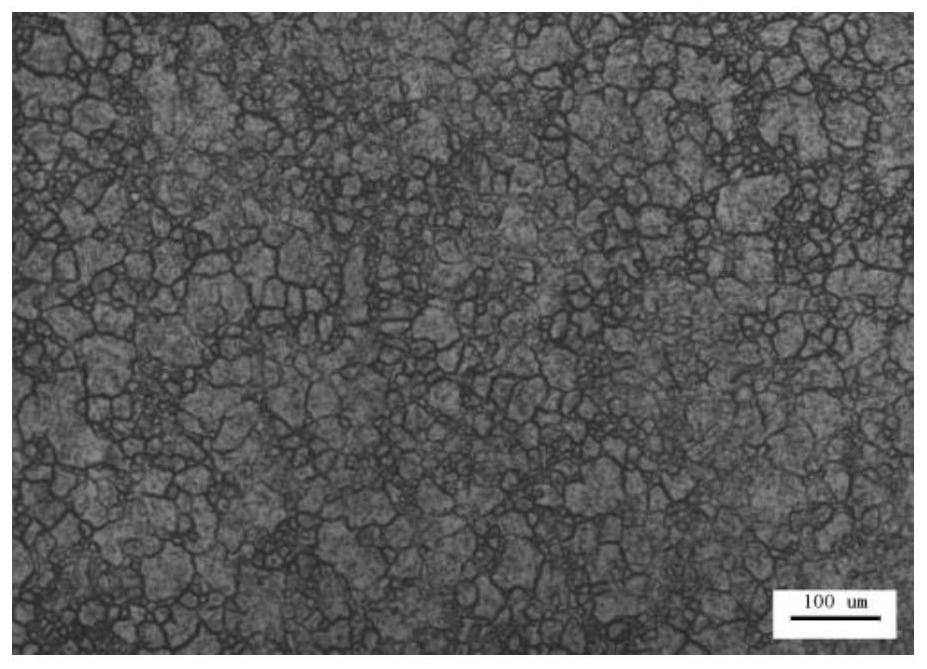

Automobile lightweight aluminum matrix composite and preparation method thereof

InactiveCN109628780AImprove organizational formImprove mechanical propertiesMetal matrix compositeMechanical property

The invention provides an automobile lightweight aluminum matrix composite and a preparation method thereof, and belongs to the technical field of metal matrix composites. The composite is made from the following raw materials: by weight part, 700-710 parts of Al-20Si intermediate alloy, 103-106 parts of industrial pure Mg, and 29-31 parts of Cu-14P intermediate alloy, wherein, the primary phase in the composite is Mg2Si accounting for the mass percentage of the composite by 20%. The invention further provides the preparation method for the automobile lightweight aluminum matrix composite. Thecomposite is high in tissue morphology and excellent in mechanical properties, the density of the composite is much lower than that of a traditional automobile engine cylinder and a cylinder sleeve material, the weight reduction effect is obvious, and the automobile lightweight aluminum matrix composite can serve as the lightweight composite to apply to the components such as an automobile enginecylinder and a cylinder sleeve.

Owner:BEIHUA UNIV

Welding wire steel for manual argon arc welding

ActiveCN110385545AAchieve toughnessEasy to useWelding/cutting media/materialsSoldering mediaWeld seamAlloy

The invention discloses welding wire steel for manual argon arc welding. The welding wire steel comprises, by mass, 0.0001%-0.08% of C, 0.80%-1.50% of Mn, 0.70%-0.95% of Si, 0.0001%-0.010% of S, 0.0001%-0.020% of P, 0.0001%-0.40% of Cr, 0.10-0.30% of Mo, 0.0001%-0.40% of Ni, and the balance Fe and inevitable impurity elements. The welding wire steel is low in cost, high in welding seam strength and toughness, stable in quality and good in welding performance, and can meet the use requirements of welding wire manufacturers. According to the welding wire steel, the welding performance of the low-alloy high-strength welding wire is improved in a limited mode while the high-strength of weld metal is ensured, the occurrence of cold cracks is controlled, the splashing rate is small, and the welding requirements of the low-alloy high-strength steel are met.

Owner:TANGSHAN NORMAL UNIV +1

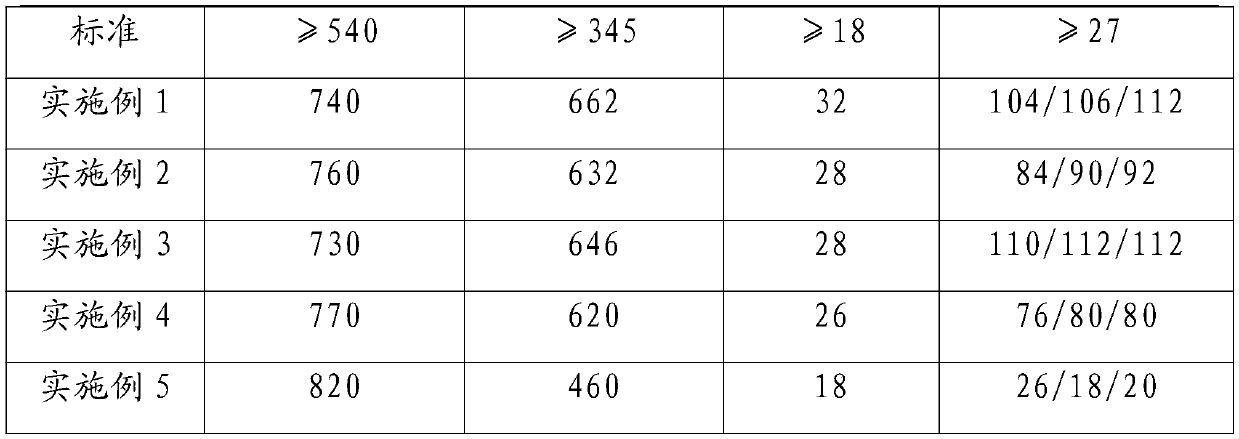

Preparation method of iron-based diamond tool material without graphitizing conversion

ActiveCN109234646AForm evenlyEliminate interface graphitizationDiamondIron powderAdditive ingredient

The invention discloses a preparation method of an iron-based diamond tool material without graphitizing conversion. The preparation method comprises the steps: firstly, homogenizing and surface ionizing iron powder, copper-tine alloy powder and silicon powder to prepare iron-based alloy powder; then obtaining polygonal diamond powder through diamond breaking treatment; evenly mixing the two kindsof powder and firing and shaping under the weak reduction atmosphere; finally, obtaining the iron-based diamond tool material without graphitizing conversion. The method has the advantages of high ingredient control accuracy, stronger technology stability and repeatability and ability in achieving toughness, stable interfaces without graphization and long service life of iron-based diamond cutters.

Owner:SHAANXI SCI TECH UNIV

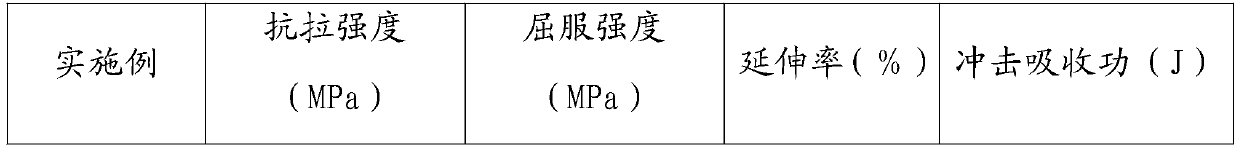

Large-thickness quenched and tempered FO460 ship steel plate and manufacturing method thereof

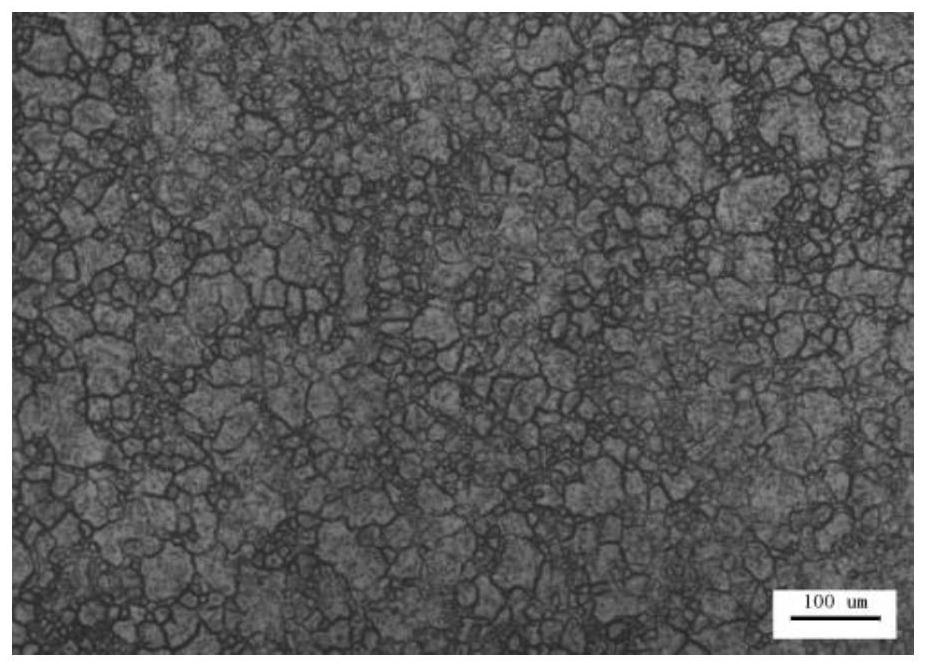

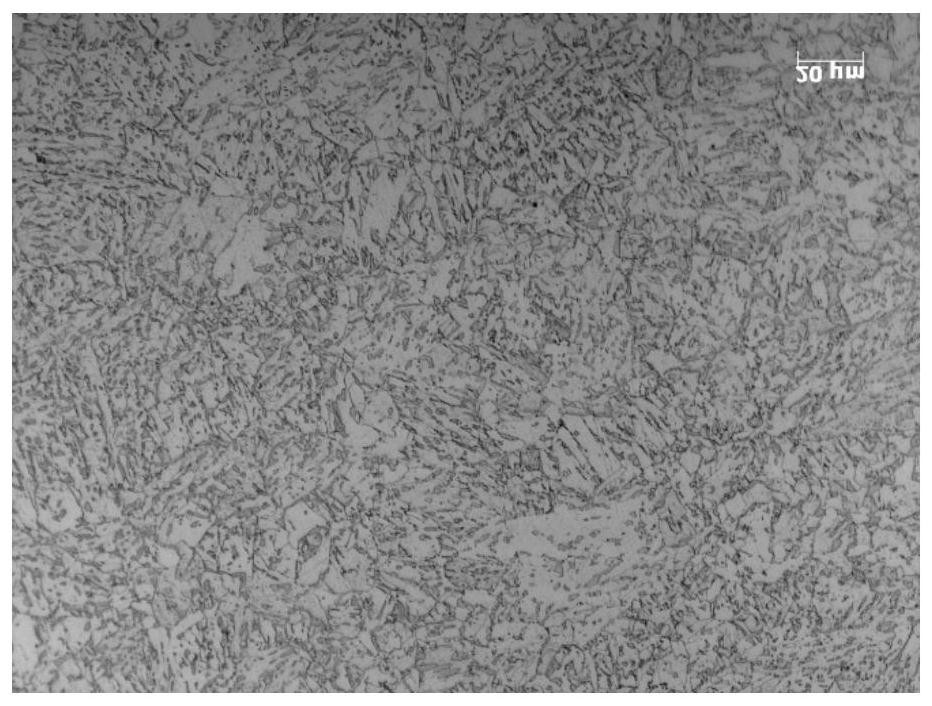

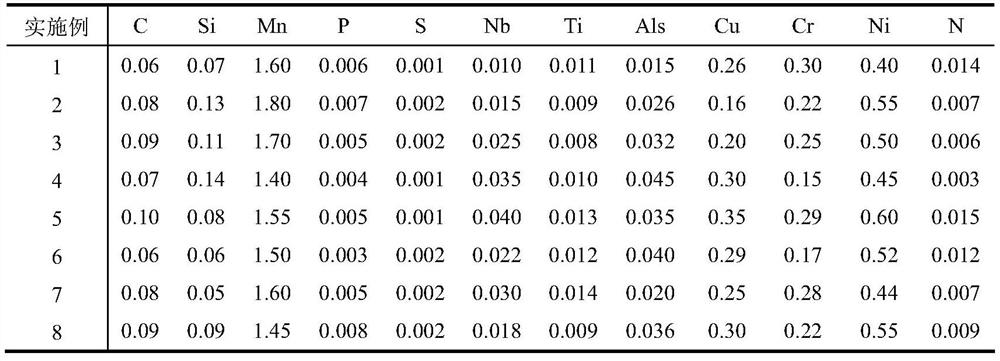

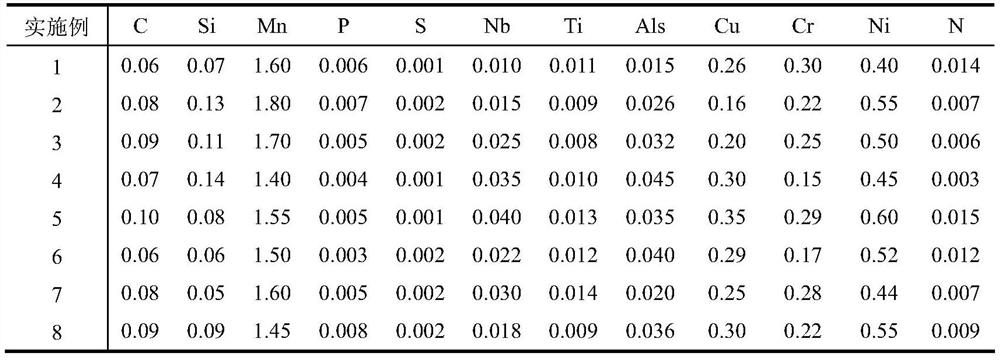

The invention discloses a large-thickness quenched and tempered FO460 ship steel plate and a manufacturing method of the large-thickness quenched and tempered FO460 ship steel plate. The steel plate comprises the following chemical elements in percentage by mass: C: 0.06%-0.10%; Si: 0.05%-0.14%; Mn: 1.40%-1.80%; S: less than or equal to 0.002%; P: less than or equal to 0.008%; Als: 0.015%-0.045%; N: 0.003%-0.015%; Nb: 0.01%-0.04%; Cu: 0.16%-0.35%; Ni: 0.30%-0.60%; Cr: 0.15%-0.30%; Ti: 0.008%-0.014%; and the balance of Fe and inevitable impurities. The technical requirements of the ship steel plate in severe and harsh ocean environments can be met.

Owner:ANGANG STEEL CO LTD

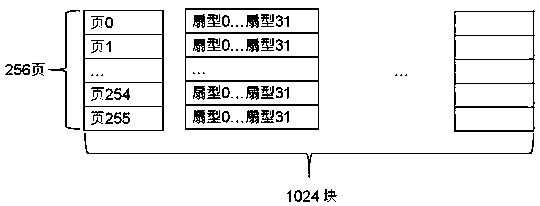

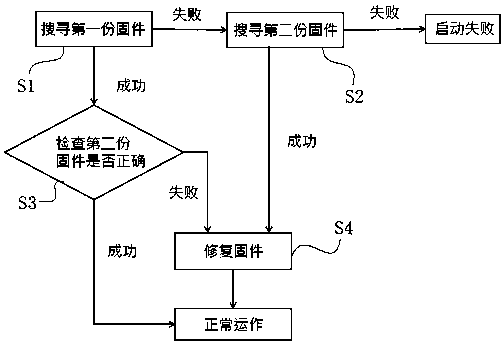

Self-repairing method of firmware in intelligent memory device

The invention discloses a self-repairing method of firmware in an intelligent memory device. The firmware is written into two different blocks in the intelligent memory device, and mutually remembersthe position information of opposite sides; when the data of one side is corrupted, the firmware with wrong data is repaired by utilizing the firmware with correct data. The wrong firmware can be corrected, and the normal data of the wrong firmware is recovered.

Owner:JIANGSU HUACUN ELECTRONICS TECH CO LTD

Preparation method for dual model-structure graphene-reinforced aluminum matrix composite

ActiveCN111996407AAvoid reunionHigh strengthTemperature control deviceGrapheneThermal deformationIngot

The invention provides a preparation method for a dual model-structure graphene-reinforced aluminum matrix composite and relates to a preparation method for an aluminum matrix composite. By means of the preparation method, the problems that graphene is easy to agglomerate when the graphene-reinforced aluminum matrix composite is prepared, and that strength-tenacity inversion exists in the preparedcomposite are solved. The preparation method comprises the steps that an ascorbic acid solution is added to an oxidized graphene dispersion liquid, and oxidized graphene colloid is acquired; vacuum freeze-drying is conducted, and a three-dimensional graphene framework is acquired; after the three-dimensional graphene framework and aluminum metal powder are mixed, ball milling is conducted, and mixed powder is acquired; and then pressure infiltration ingot preparation, heat deformation treatment and heat treatment are conducted sequentially. By means of the prepared three-dimensional grapheneframework structure, the phenomenon of agglomeration can be avoided; and through a dual-model structure of mixing of coarse grains and fine grains, the material strength is elevated, and in the meantime, the material tenacity can also be guaranteed. The preparation method for the dual model-structure graphene-reinforced aluminum matrix composite is applicable to preparation of graphene-reinforcedaluminum matrix composites.

Owner:HARBIN INST OF TECH

A large-thickness quenched and tempered FO460 marine steel plate and its manufacturing method

The invention discloses a large-thickness quenched and tempered FO460 steel sheet for ships and a manufacturing method thereof. C: 0.06% to 0.10%; Si: 0.05% to 0.14%; Mn: 1.40% to 1.80%; S: ≤ 0.002%; P : ≤0.008%; Als: 0.015%~0.045%; N: 0.003%~0.015%; Nb: 0.01%~0.04%; Cu: 0.16%~0.35%; Ni: 0.30%~0.60%; Cr: 0.15%~ 0.30%; Ti: 0.008% to 0.014%; the balance is Fe and inevitable impurities. It can meet the technical requirements of marine steel plates in harsh and harsh environments.

Owner:ANGANG STEEL CO LTD

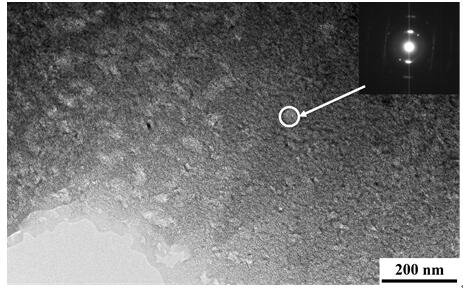

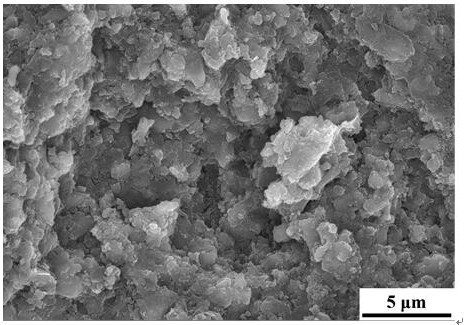

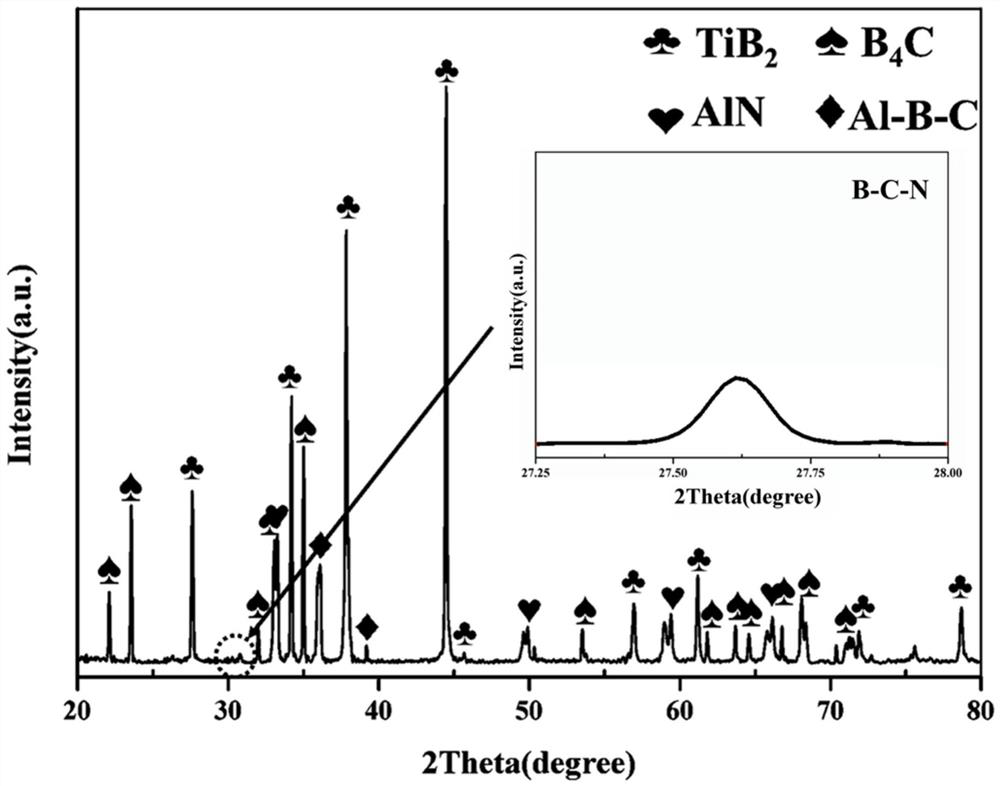

Preparation method of BCN nano amorphous phase toughened TiB2-B4C composite ceramic

The invention relates to a preparation method of BCN nano amorphous phase toughened TiB2-B4C composite ceramic, and belongs to the technical field of preparation of high-performance structural ceramic. According to the preparation method disclosed by the invention, the content proportion of each phase component in the raw material powder of the composite ceramic and the preparation process are limited, so that the BCN nano amorphous phase strengthened and toughened TiB2-B4C composite ceramic is prepared. The nano amorphous phase is an effective means for strengthening and toughening ceramic, and the main implementation ways comprise dispersion refinement, mixed crystal structure strengthening, pinning theory, residual stress field theory and the like. The invention aims to prepare a nano amorphous phase through an in-situ reaction, change the microstructure of TiB2-B4C composite ceramic and further improve the particle bonding mode and fracture mode of the TiB2-B4C composite ceramic, so that the strength and toughness of the ceramic material are improved, and a novel strengthening and toughening means of the structural ceramic material is provided.

Owner:NANJING INST OF TECH

Titanium alloy with double-scale structure based on in-situ whisker strengthening and toughening and its preparation and application

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

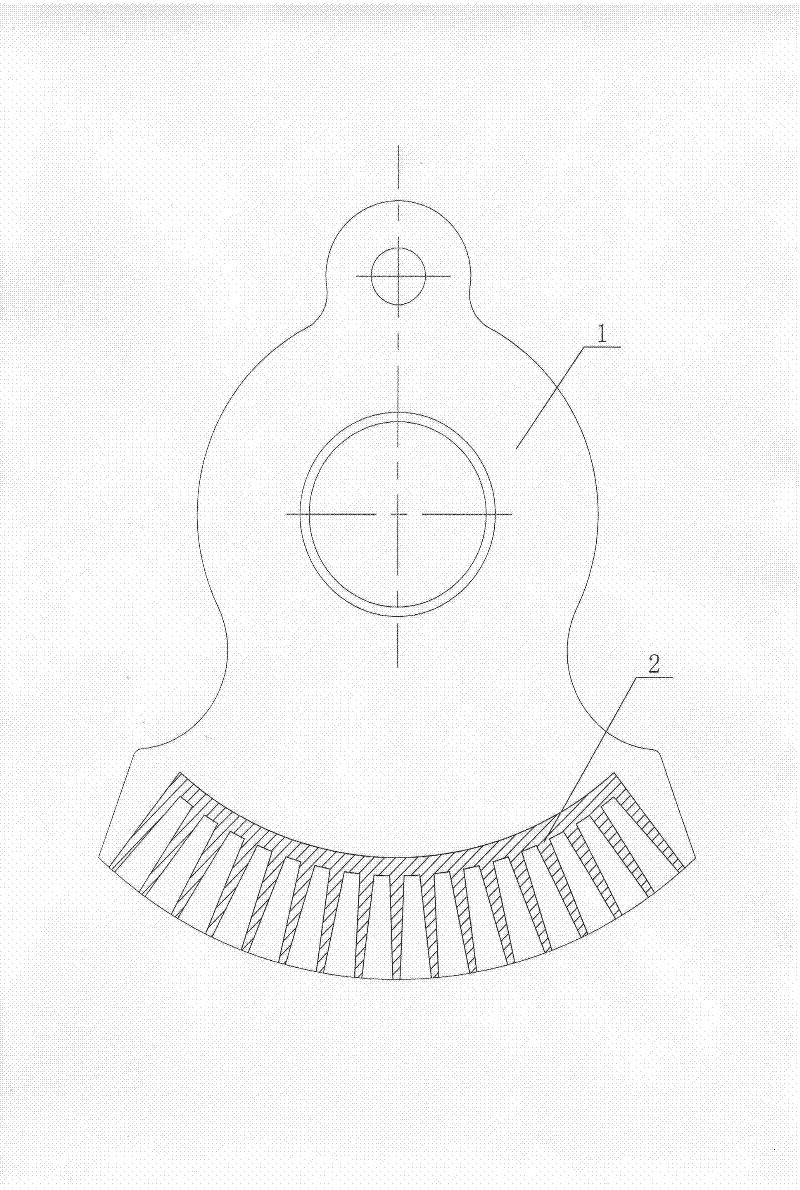

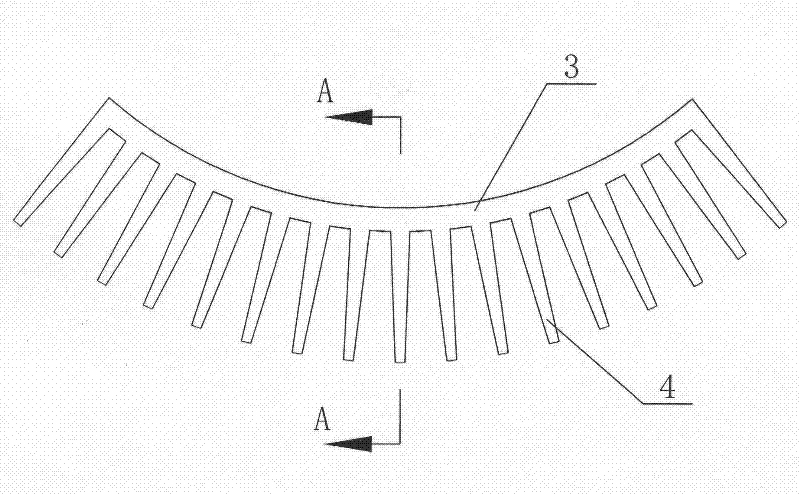

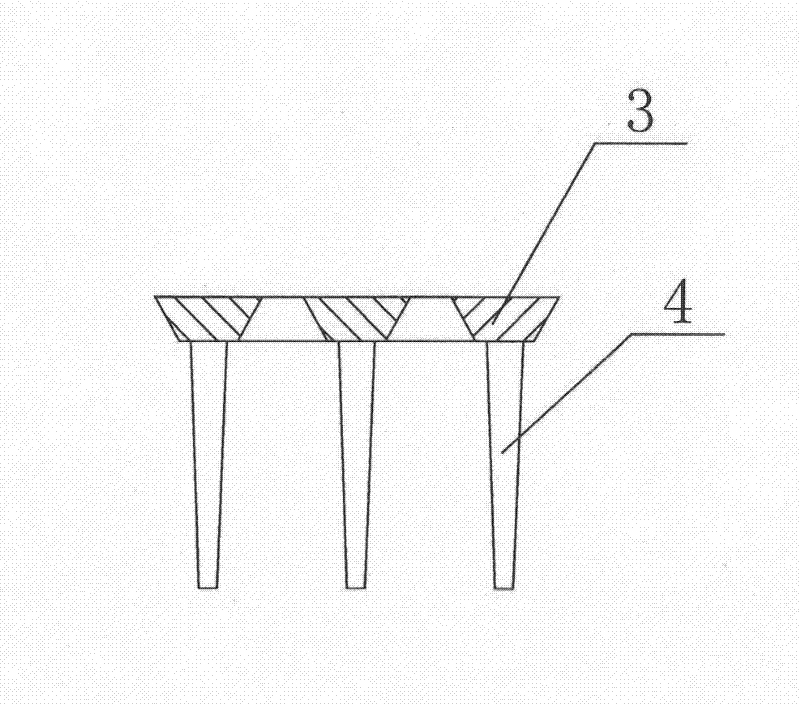

Combined hammer head and manufacturing process thereof

ActiveCN101934242BHigh strengthImprove impact toughnessGrain treatmentsManufacturing technologyEconomic benefits

The invention belongs to the technical field of preparation of hammer heads widely used in the fields of crushing, pulverizing and the like, in particular to a combined hammer head and a manufacturing process thereof. The combined hammer head comprises a framework and a hammer block, wherein the framework is arranged in the hammer block, and is adjacent to the front end of the hammer block; the framework is a high-chromium iron framework and comprises a frame; the frame is in a circular arc shape and is provided with conical rods; the conical rods are distributed on the circular-arc bottom surface of the frame at equal intervals; and the hammer block is a low-carbon multivariant low alloy steel hammer block. The invention is characterized in that the framework is arranged in the hammer block and is obtained by carrying out integral casting on hypereutectic high-chromium iron; the framework and the hammer block are subject to composite casting; the hammer block adopts low-carbon multivariant low alloy steel, and has higher strength and favorable impact toughness; the abrasion resistant framework has excellent abrasive resistance; and the invention gives full play to the advantages of the two materials, thereby obviously prolonging the service life of the hammer head of a crusher and reducing the equipment maintenance rate; and the process is simple, the production efficiency ishigh, and the economic benefits are considerable.

Owner:ZHENGZHOU HI TECH MECHANICAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com