Method for producing ageing steel of martensite without cobalt in high tensile and high toughness

A maraging steel, high-strength and high-toughness technology, applied in the field of cobalt-free high-strength and high-toughness maraging steel processing, can solve the problem of high heat treatment cost, cumbersome production process of cobalt-free maraging steel, long production cycle, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

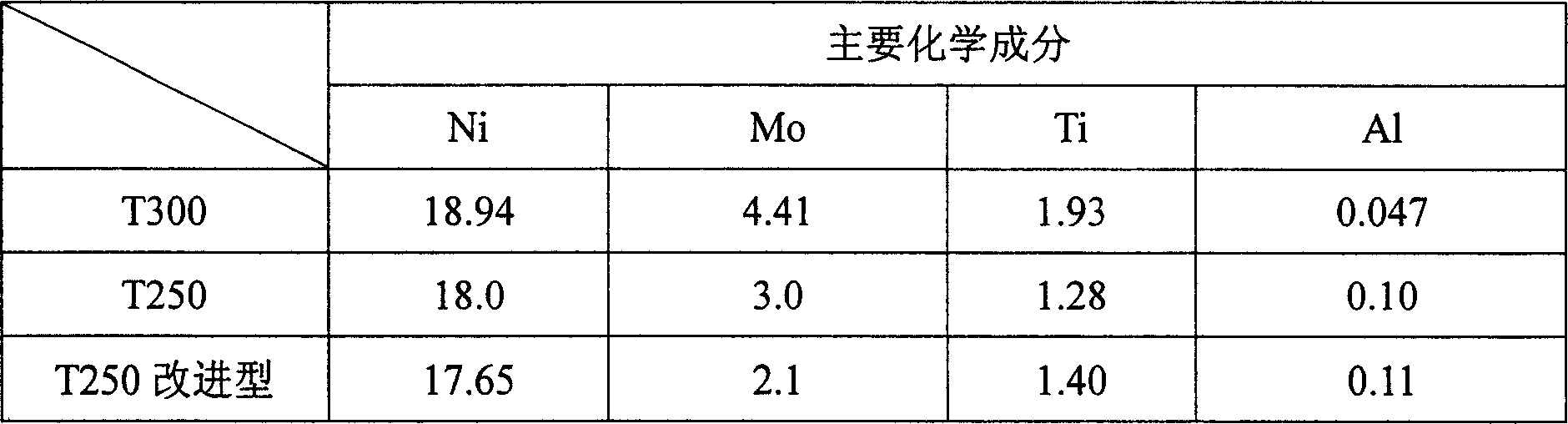

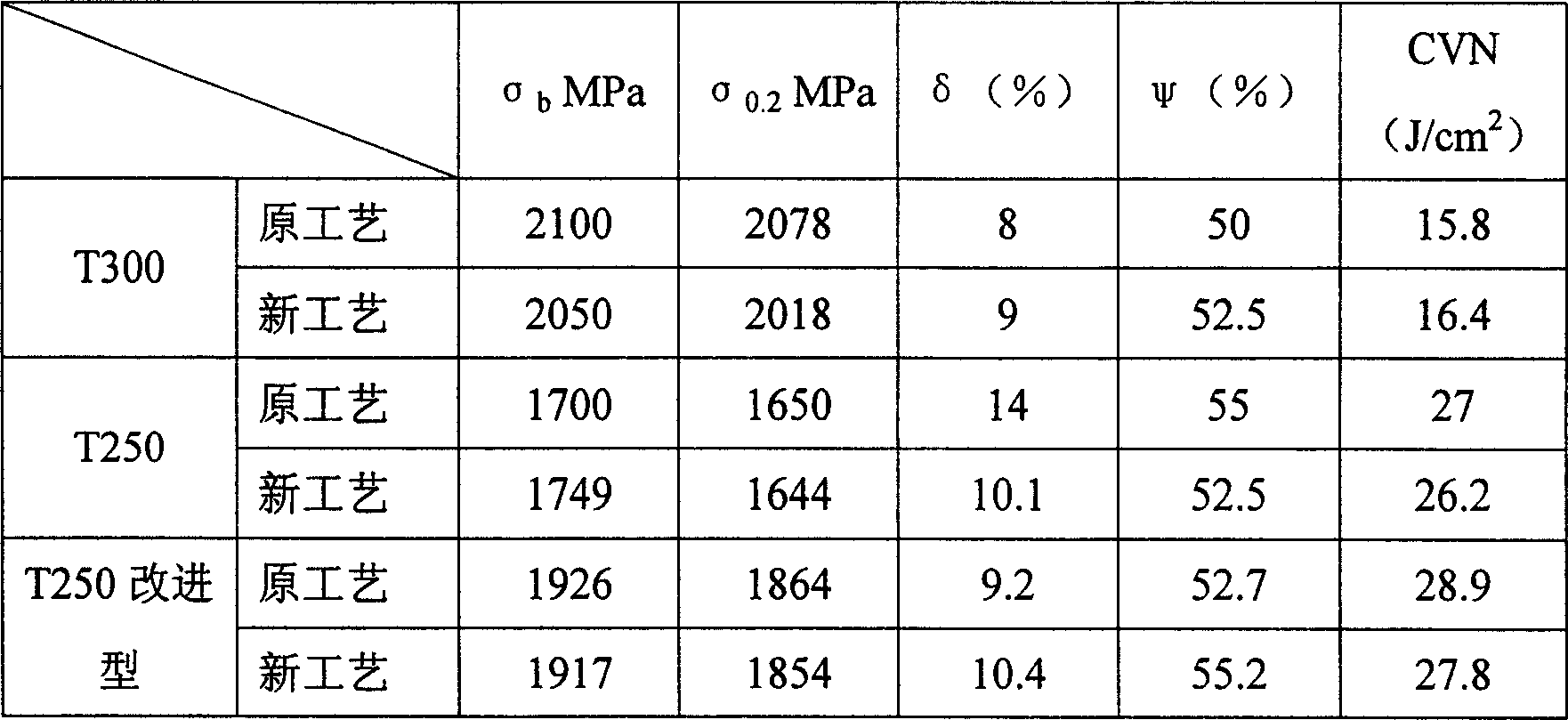

[0018] Three kinds of 18 (Ni) series cobalt-free maraging steel, each 10kg charge, the chemical composition after double vacuum smelting is shown in Table 2. After being forged at 1150°C and finally forged at 850°C to form a Φ18mm bar, it was air-cooled to room temperature and machined into a mechanical performance sample, then aged at 510°C for 2.5 hours, and then air-cooled to room temperature. Its mechanical properties are compared with those under the original processing technology as shown in Table 3.

[0019] Table 2:

[0020]

[0021] table 3:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com