Tantalum target and manufacturing method thereof

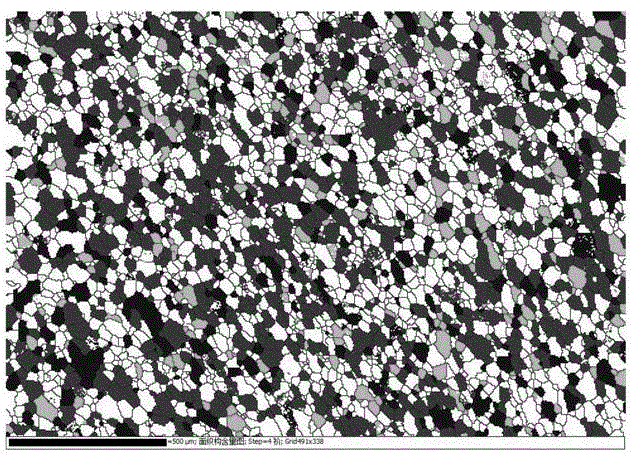

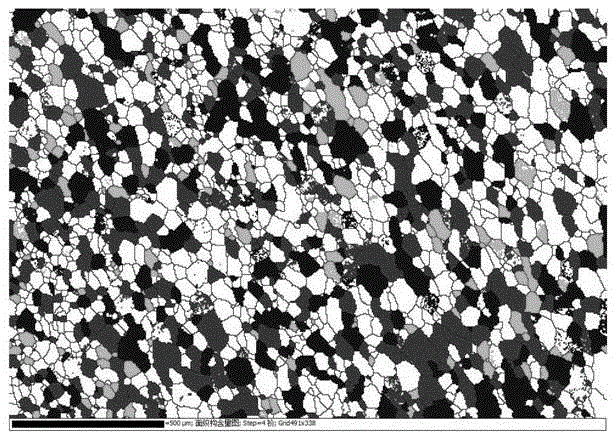

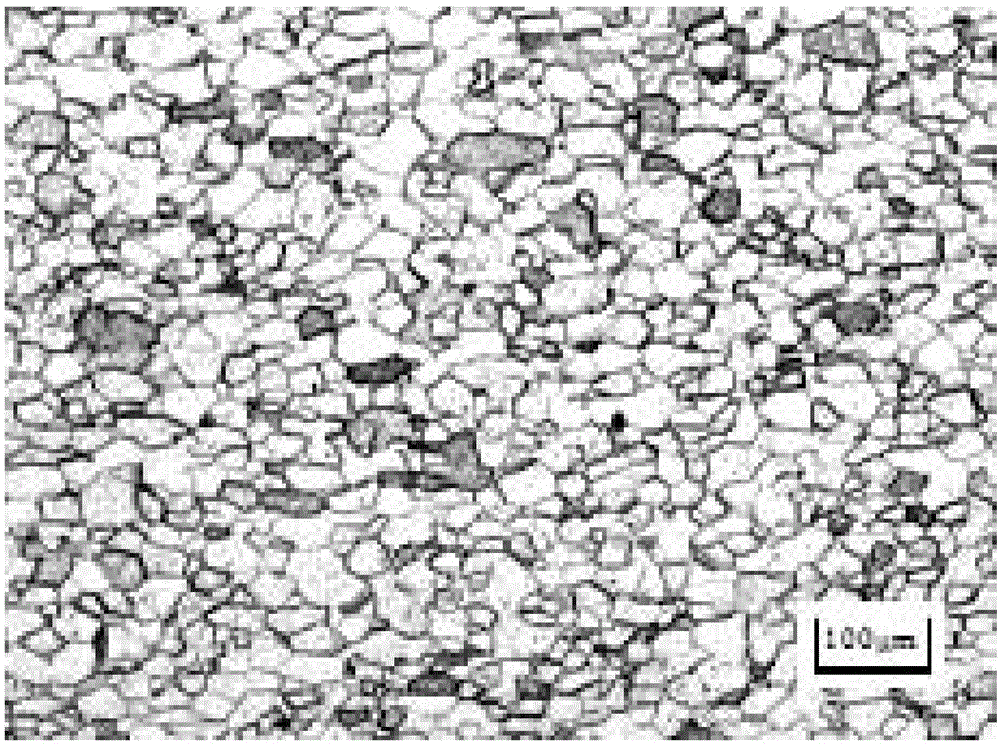

A technology for tantalum targets and tantalum ingots, applied in the field of tantalum targets and their preparation, can solve the problems of increased difficulty, increased size of sputtering targets, and inability to provide tantalum targets, and achieves large size, compactness and high quality. The effect of good texture distribution uniformity, uniform structural properties and microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention discloses a method for preparing a tantalum target, which comprises the following steps:

[0040] A) After the tantalum ingot is forged for the first time, a forging blank is obtained;

[0041] B) After the primary forging blank obtained in the above steps is subjected to the second forging and the first heat treatment, the secondary forging blank is obtained;

[0042] C) after the secondary forging blank obtained in the above steps is subjected to the third forging and the second heat treatment, the third forging blank is obtained;

[0043] D) after the third forging blank obtained in the above steps is subjected to the fourth forging and the third heat treatment, four forging blanks are obtained;

[0044] E) After the four forging blanks obtained in the above steps are rolled and subjected to the fourth heat treatment, a tantalum target is obtained;

[0045] The first forging is rotary forging; the temperature of the first forging is 800-1400°C.

[0046...

Embodiment 1

[0062] A tantalum ingot with a chemical composition of Ta≥99.99% and a diameter of Φ=300mm is selected.

[0063] First, after the first hot forging (rotary forging) of the tantalum ingot at 1100°C, the tantalum ingot is axially elongated and radially rounded to a diameter of Φ=145mm to obtain a primary forging billet.

[0064] Then saw the above-mentioned primary forging billet to L=340mm, carry out the second forging under the condition of 1100°C (axial pier rough drawing and long forging), axial upsetting and drawing 3 times, each time upsetting to H=200, After pulling out long and square to side length □=130mm; then use HCl:HF:H 2 SO 4 The mixed acid with a volume ratio of 5:3:2 pickled the first forging billet after the second forging, until the surface impurities were removed, and the tantalum metal was shiny and free of speckles when observed with the naked eye, and then the second forging was carried out at 1200°C. A heat treatment, after 90 minutes of treatment, a se...

Embodiment 2

[0071] A tantalum ingot with a chemical composition of Ta≥99.99% and Φ=300mm is selected.

[0072] First, after the first hot forging (rotary forging) of the tantalum ingot at 1100°C, the tantalum ingot is axially elongated and radially rounded to a diameter of Φ=145mm to obtain a primary forging billet.

[0073] Then saw the above-mentioned primary forging billet to L=340mm, carry out the second forging under the condition of 1100°C (axial pier rough drawing and long forging), axial upsetting and drawing 3 times, each time upsetting to H=200, After pulling out long and square to side length □=130mm; then use HCl:HF:H 2 SO 4 The mixed acid with a volume ratio of 5:3:2 pickled the first forging billet after the second forging, until the surface impurities were removed, and the tantalum metal was shiny and free of speckles when observed with the naked eye, and then the second forging was carried out at 1200°C. The first heat treatment, after 90 minutes of treatment, the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com