Vertical combined crushing and grinding machine

A technology of crushing, grinding and crushing mechanism, which is applied in the direction of grain processing, etc., can solve the problems of large investment in the early stage, high energy consumption in the later stage, and high maintenance cost, and achieve the effects of improving efficiency, saving processes, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments.

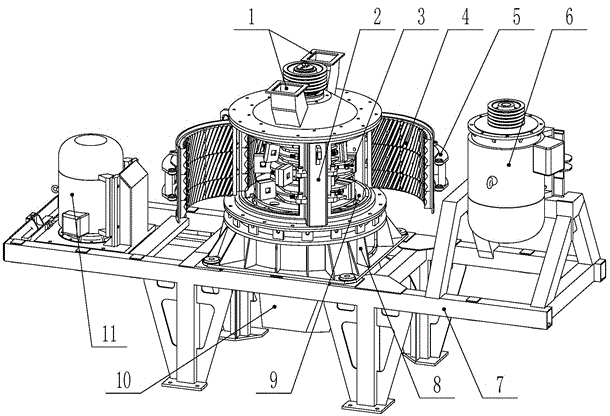

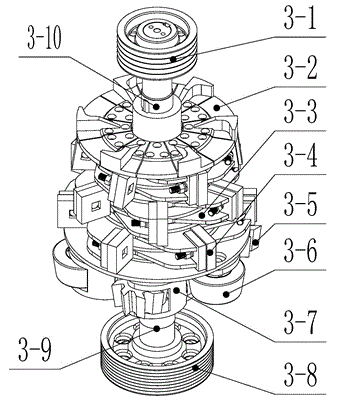

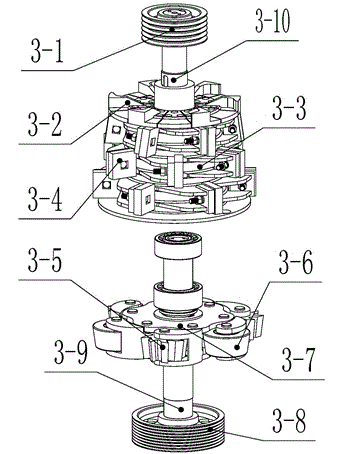

[0022] Such as Figure 1 to Figure 4 As shown, a vertical compound crushing and grinding machine includes an integral support 7, a grinding cavity seat 8, a cylinder body 2, a vertical rotor body 3, a spiral counterattack plate 4, a hopper 10, a hopper 1, a flip door 5, Grinding chamber wall liner 9, motor I 6, motor II 11, crushing mechanism and grinding mechanism. Wherein, the crushing mechanism includes a vertical shaft I 3-10, a belt pulley I 3-1, a material throwing tray 3-2, a tower type blow bar seat 3-3 and a hammer head 3-4. The grinding mechanism includes a vertical shaft II 3-9, a pulley II 3-8, a centrifugal rotary scraper 3-5, a centrifugal rotary rolling wheel 3-6 and a centrifugal rotor frame 3-7.

[0023] The discharge hopper 10 is arranged under the overall support 7, the upper part of the overall support 7 is fixedly connected to the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com