Patents

Literature

3930 results about "Cavity wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cavity wall is a type of wall that has a hollow center. They can be described as consisting of two "skins" separated by a hollow space (cavity). The skins typically are masonry, such as brick or cinder block. Masonry is an absorbent material and therefore slowly draw rainwater or even humidity into the wall. One function of the cavity is to drain water through weep holes at the base of the wall system or above windows. The weep holes allow wind to create an air stream through the cavity that exports evaporated water from the cavity to the outside. Usually, weep holes are created by separating several vertical joints approximately two meters apart at the base of each story. Weep holes are also placed above windows to prevent dry rot of wooden window frames. A cavity wall with masonry as both inner and outer skins is more commonly referred to as a double wythe masonry wall.

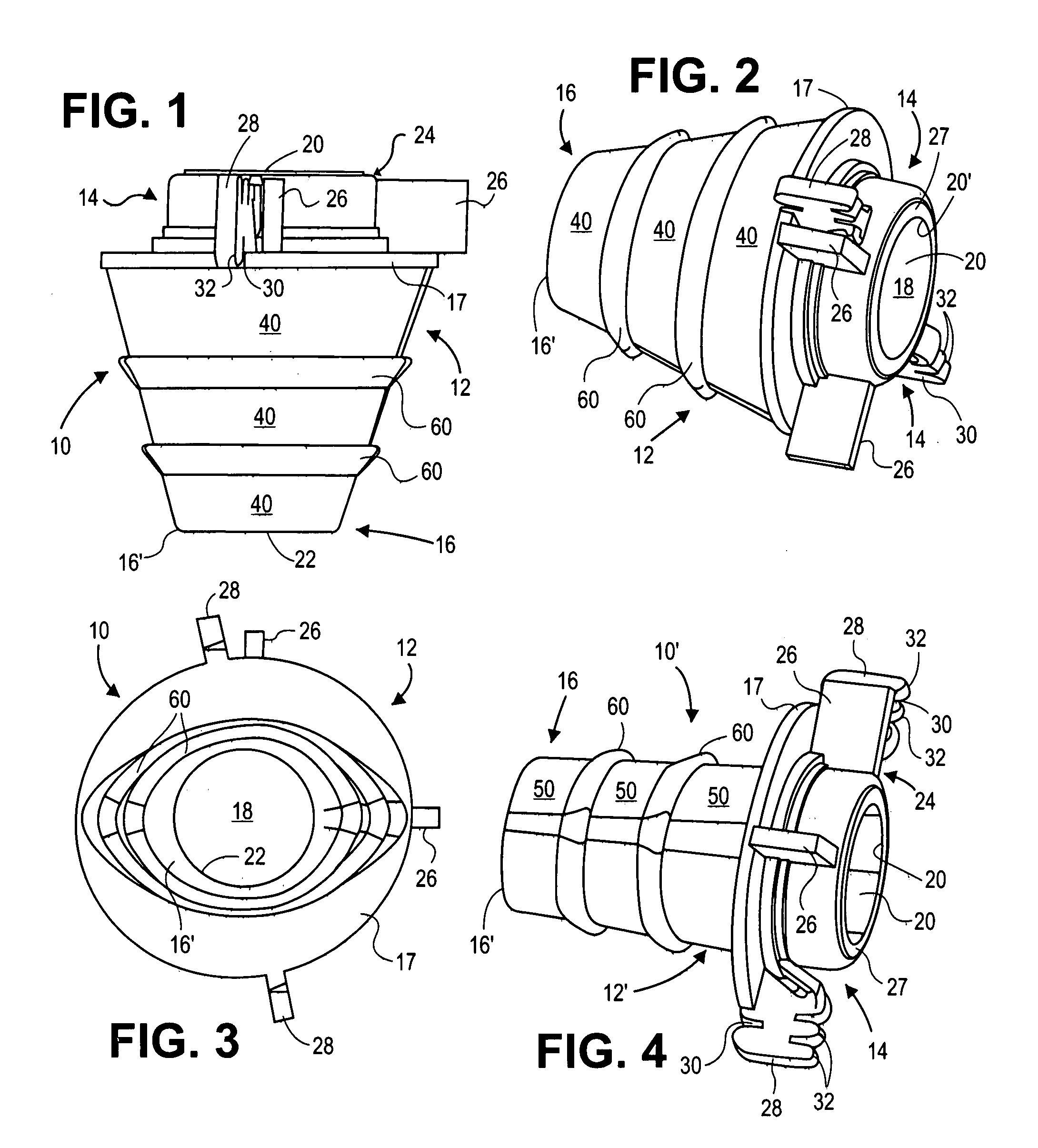

Deployment device, system and method for medical implantation

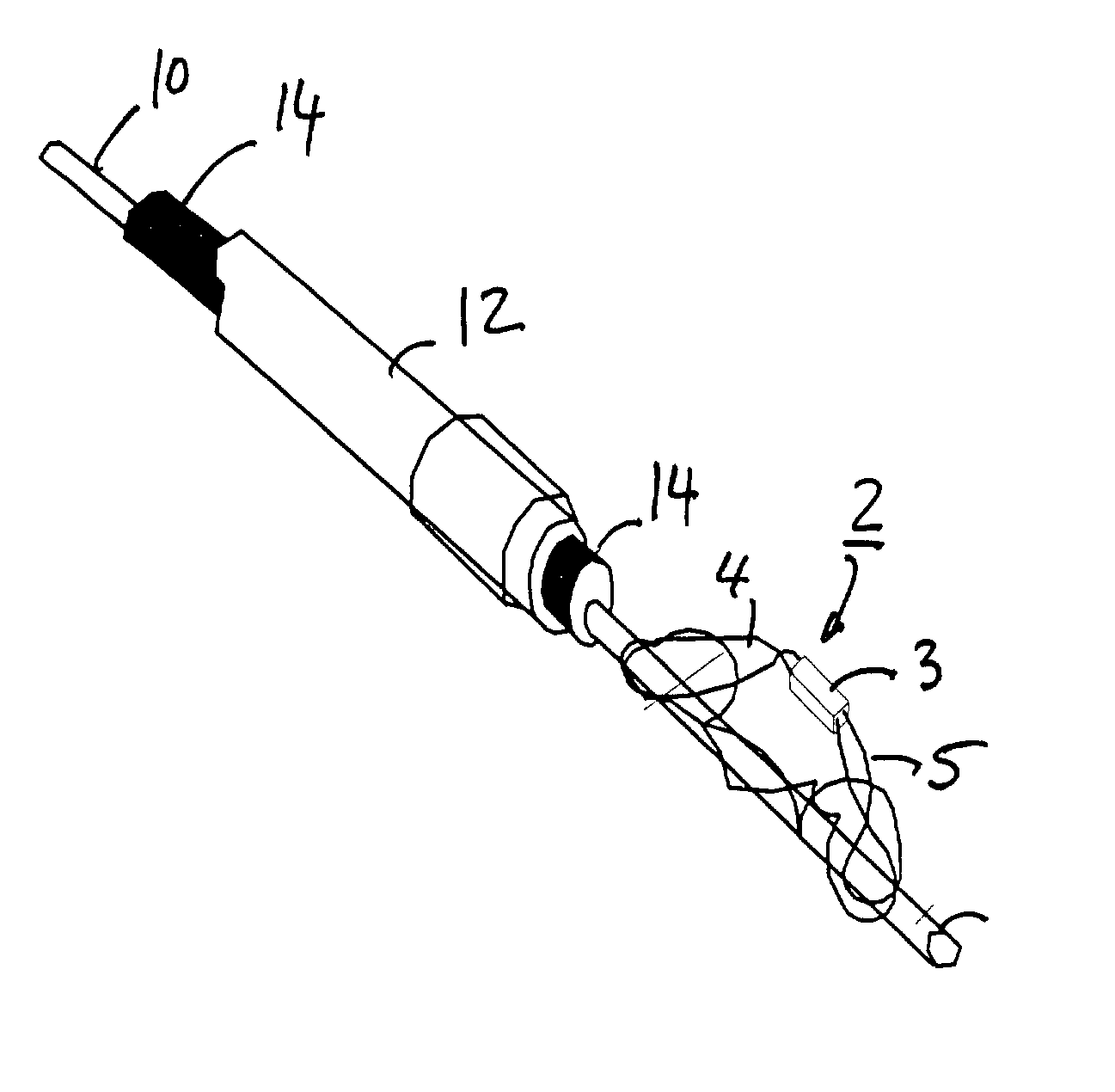

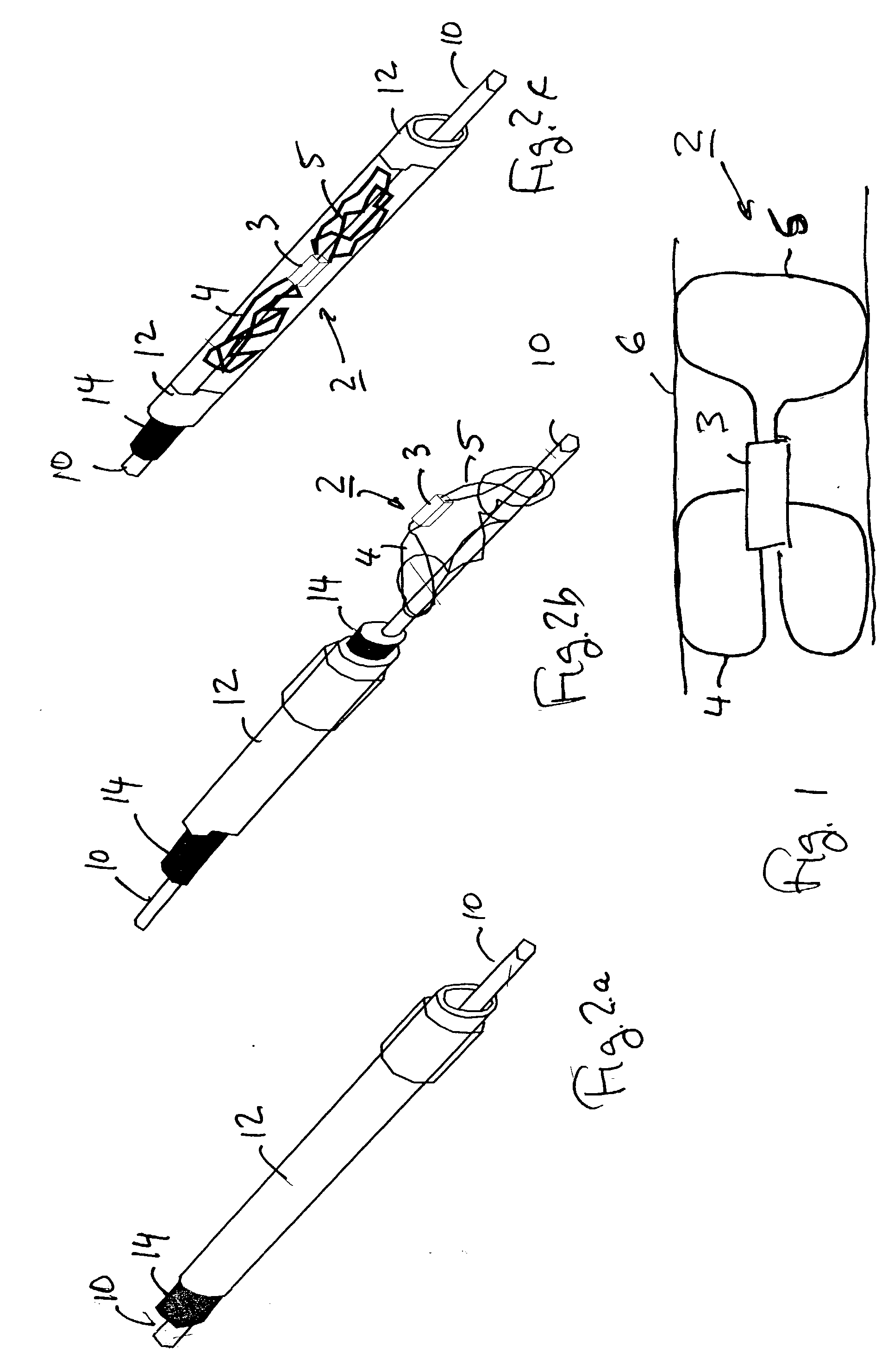

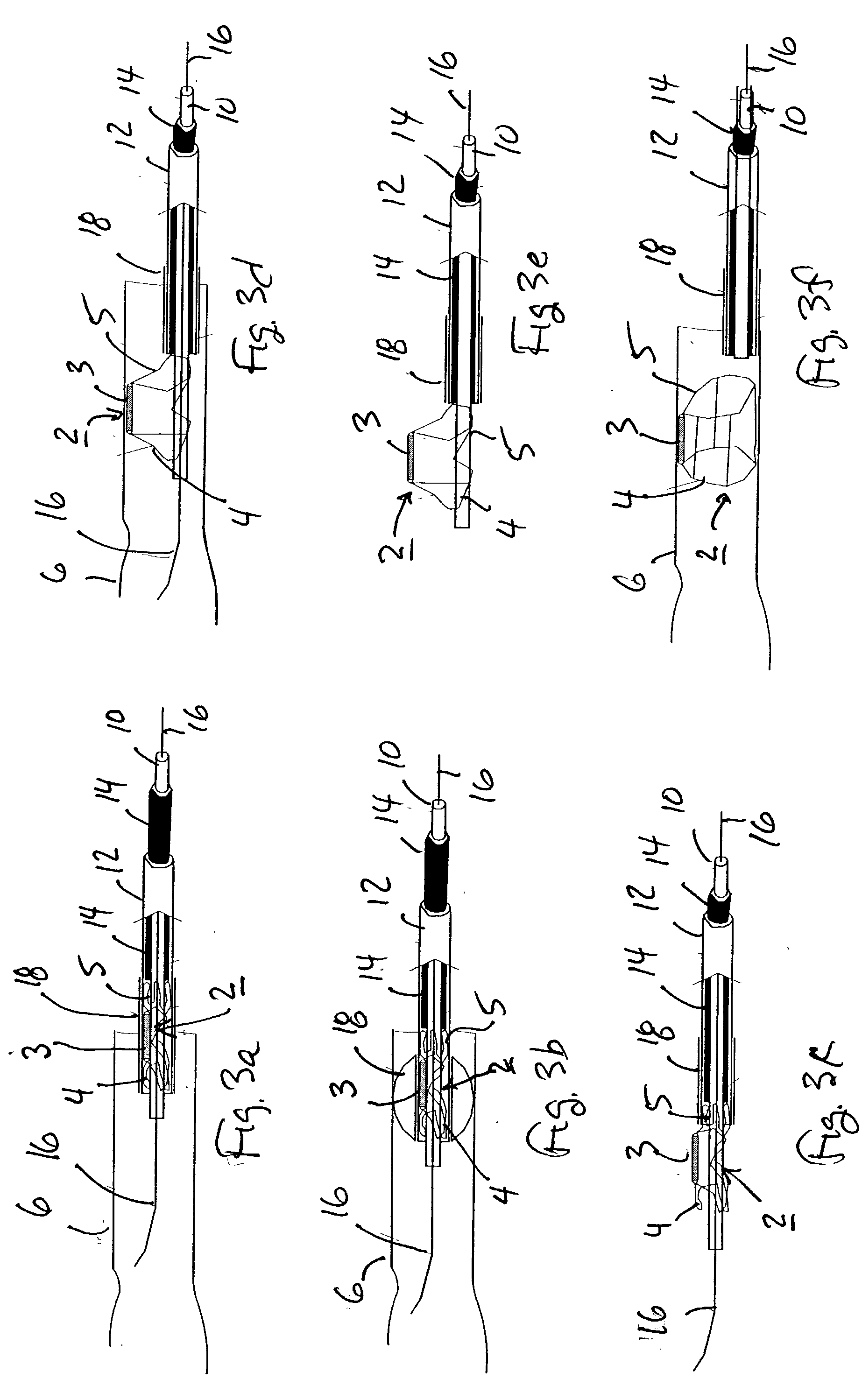

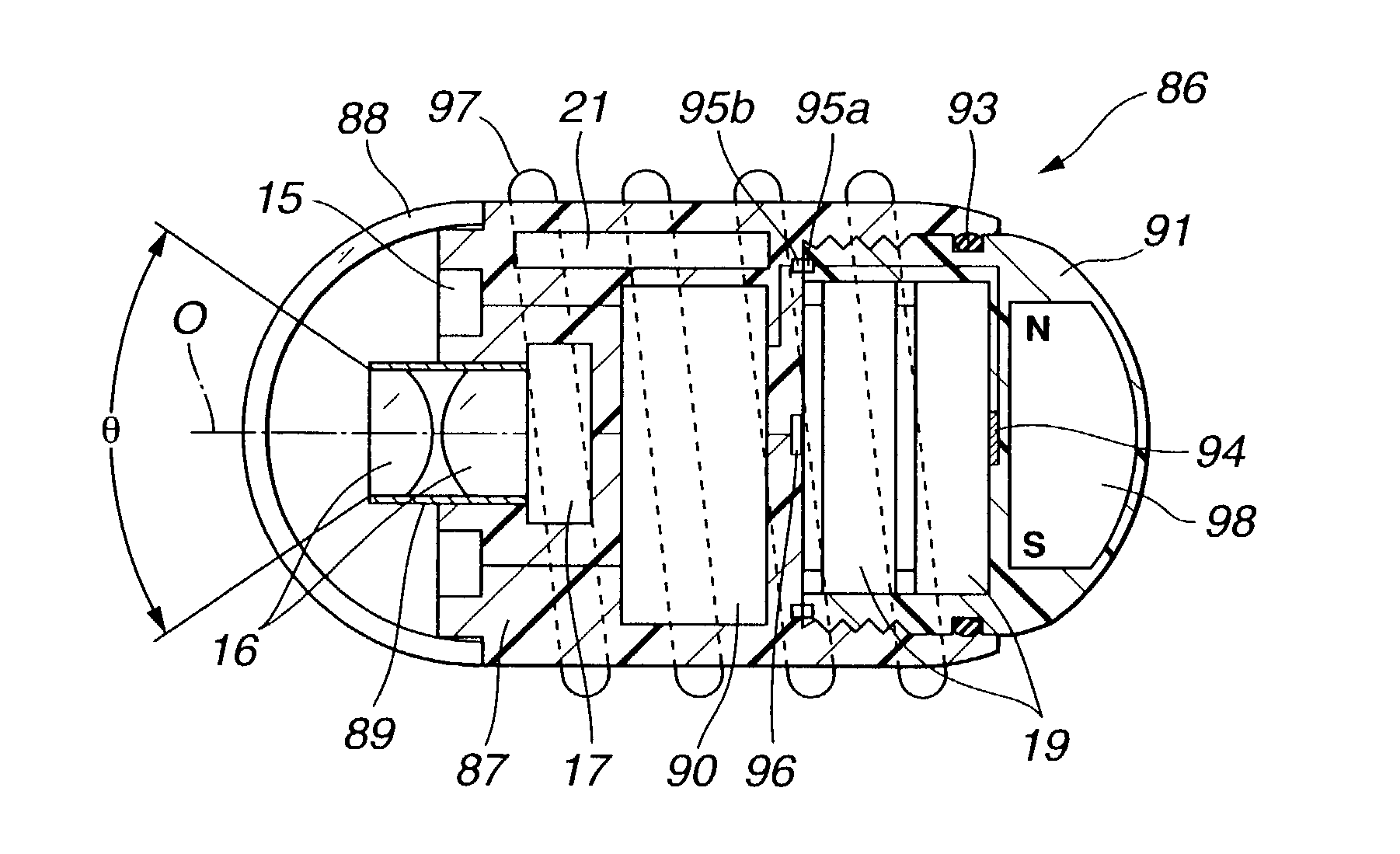

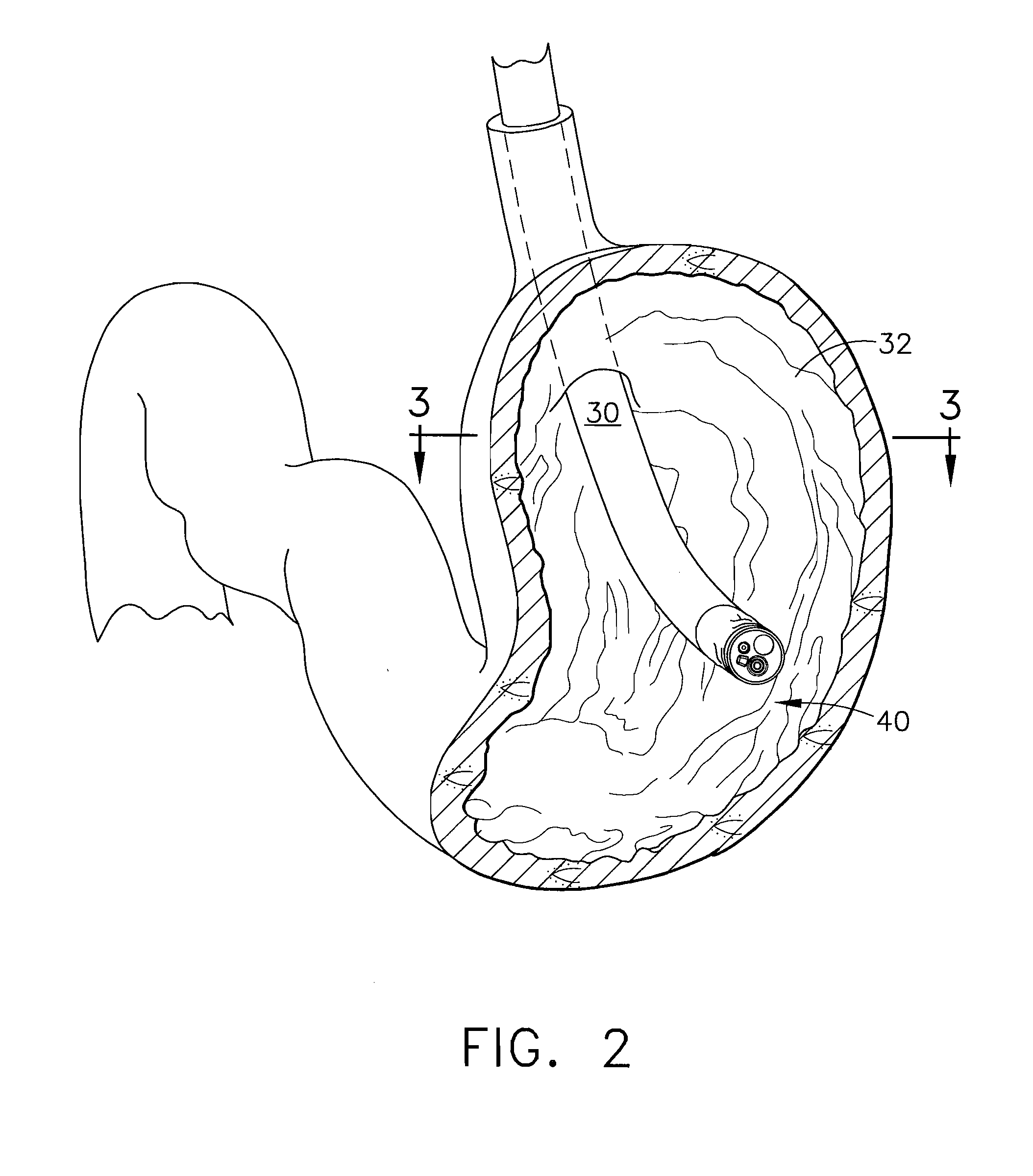

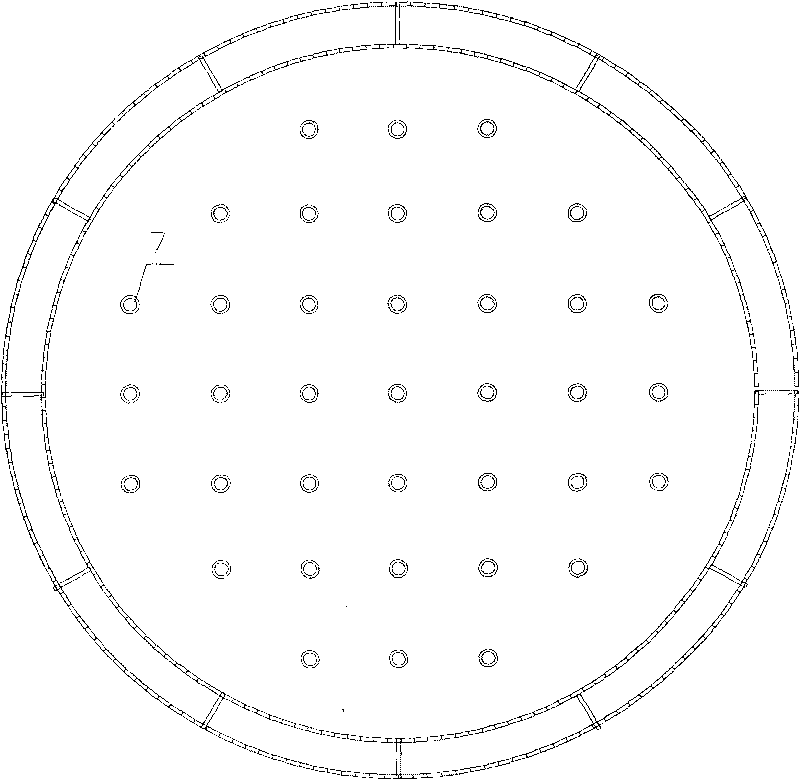

A deployment device for deploying a self-expansible medical implant at a target location in a body cavity, is provided. While generally, the expansion of self-expansible structures tends to be abrupt, and the impact of expansion may cause injury, a two-stage expansion process of the present invention minimizes the impact of exapnsion. Additionally, an ability to manuever the medical imlant into position, after the first stage of expansion, provides for accurate positioning. Thus the present invention is of a deployment device for precise and well-controlled manner of deployment, so as to minimize damage to the cavity wall and to position the implant accurately at the target location. The deployment device includes: an inner tube; an outer tube; and an implant received on the inner tube and enclosed by the outer tube. The implant has a self-expansible anchoring element which is in a contracted condition when enclosed by the outer tube, expands to a partially-expanded condition when the outer tube is retracted, and expands to a fully-expanded condition when the inner tube is removed.. The implant is deployed by introducing the deployment device to the target location in the body cavity; retracting the outer tube with respect to the implant such that the anchoring element self-expands from its contracted condition to its partially-expanded condition; and withdrawing the inner tube from the implant such that the anchoring element self-expands from its partially-expanded condition to its fully-expanded condition to firmly fix the implant at the target location within the body cavity.

Owner:REMON MEDICAL TECH

Virtual ports devices and method

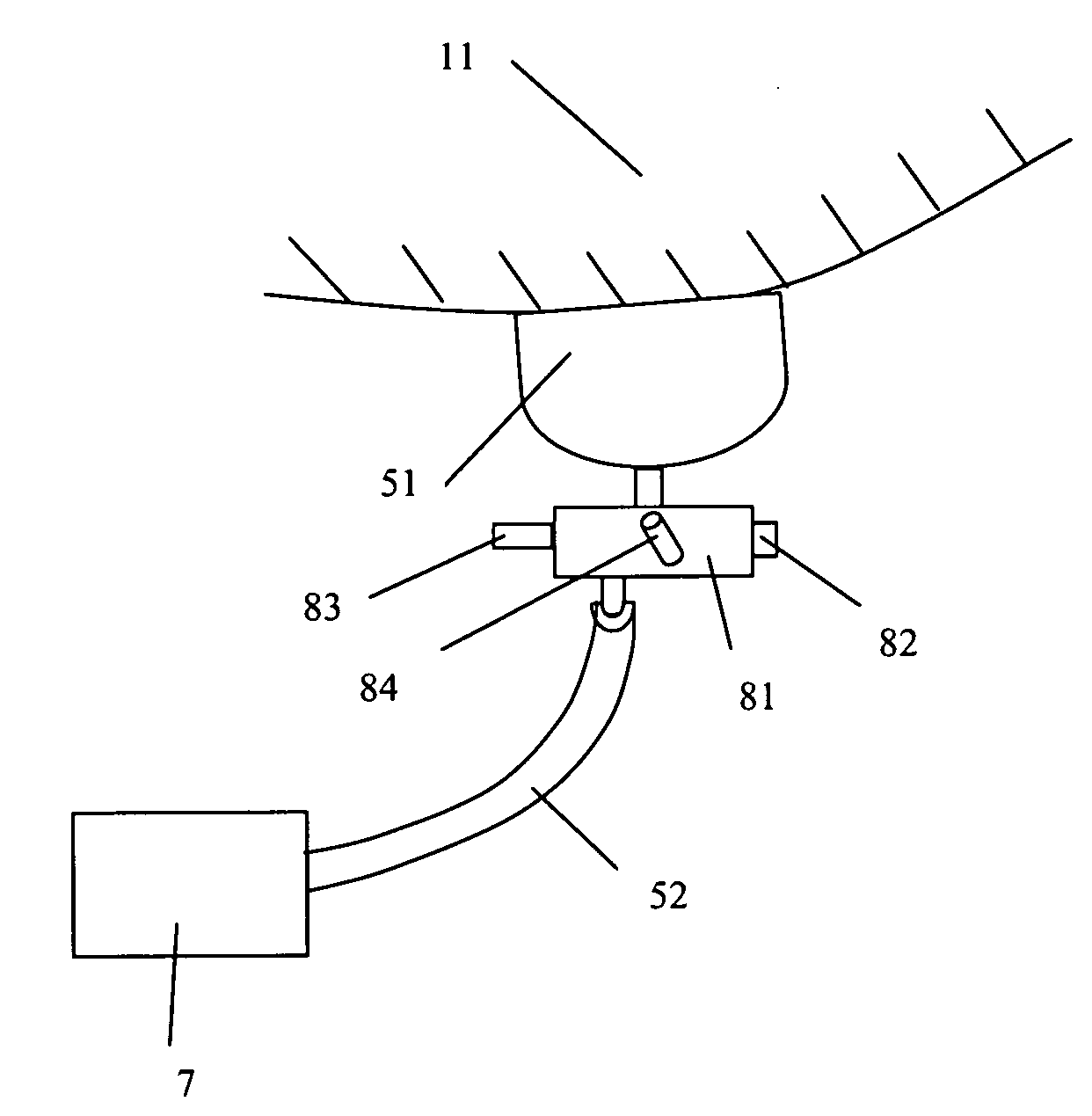

A device auxiliary to surgery, for anchoring and lifting cavity walls or internal organs of a patient. The device provides a virtual port, that is an instrument that can he non-invasively, or minimally invasively and removably attached to the undersurface of a patient's cavity, or to various tissues within a cavity, and to which various retracting means are attached. The device includes means allowing it to be moved from one position to another and reattached to the undersurface of the abdominal wall, or to various tissues within a cavity, without creating any additional openings in the cavity wall. The device includes means for attaching various retractors.

Owner:VIRTUAL PORTS

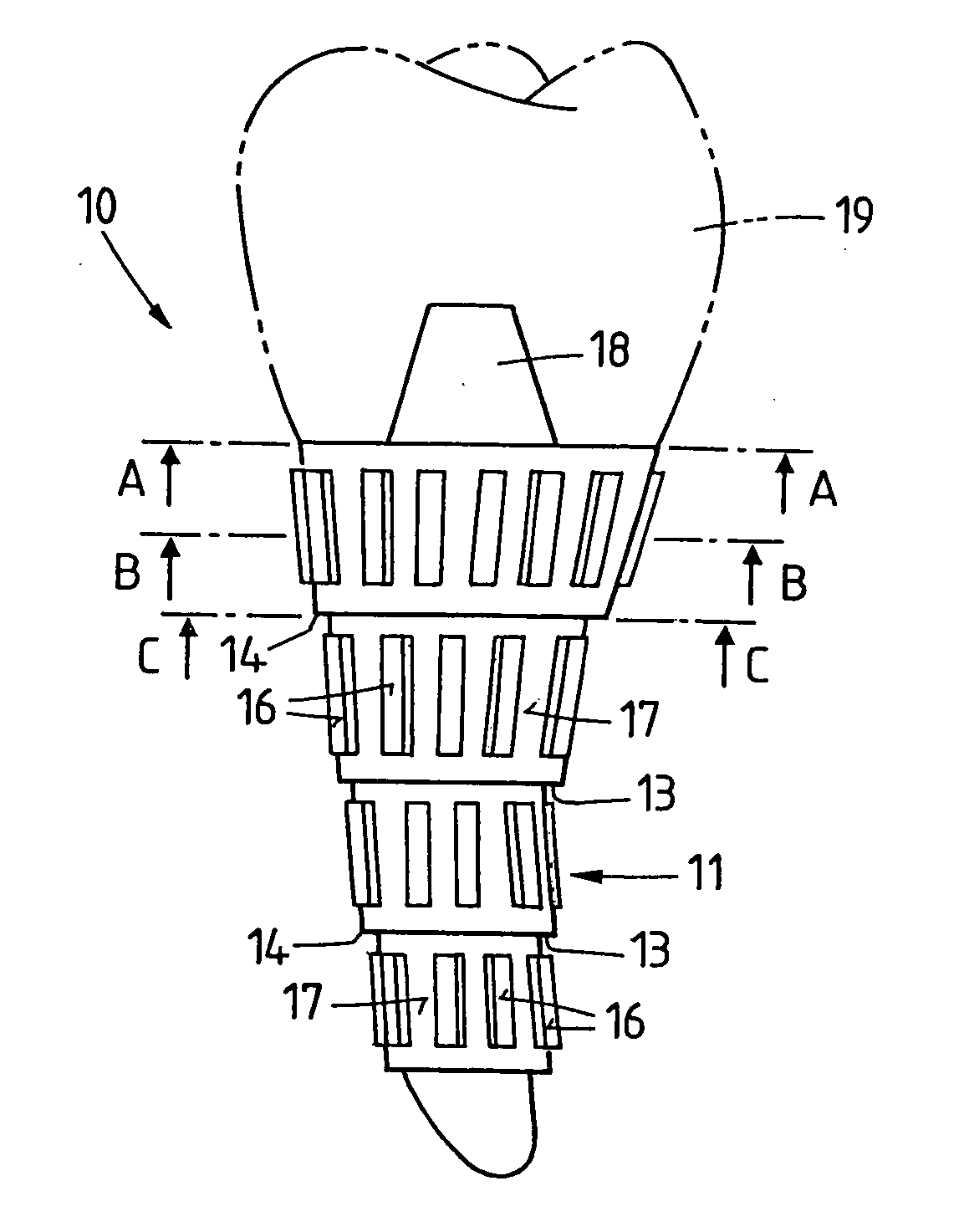

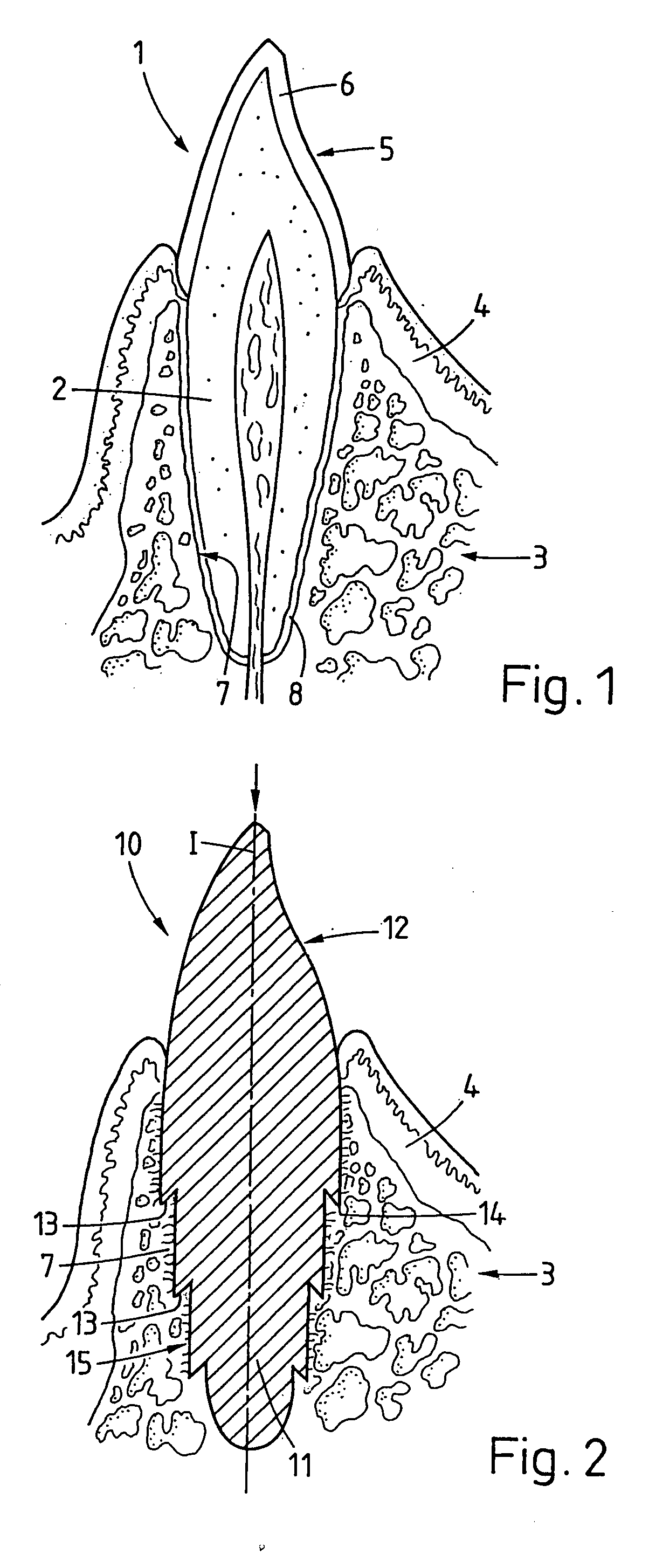

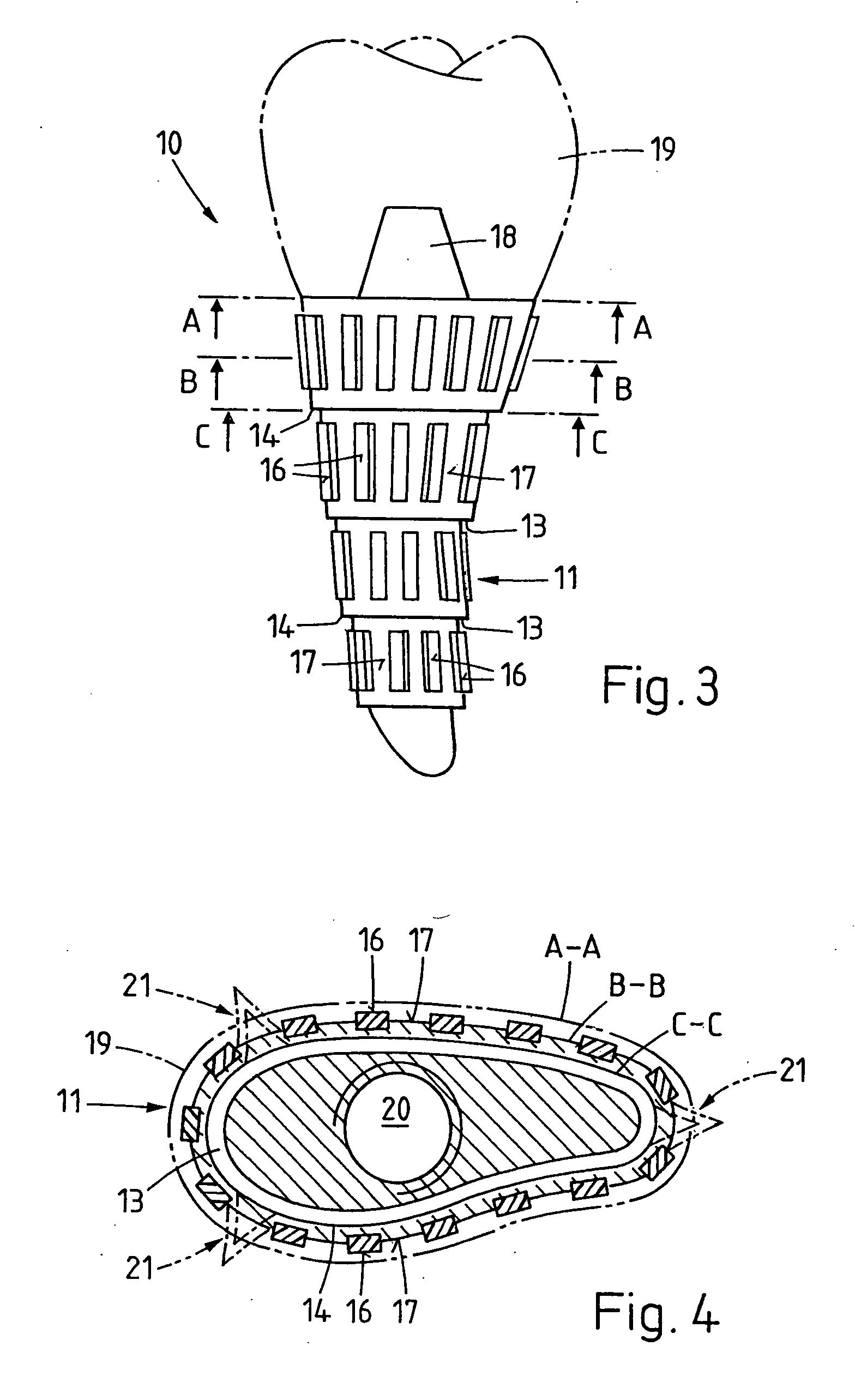

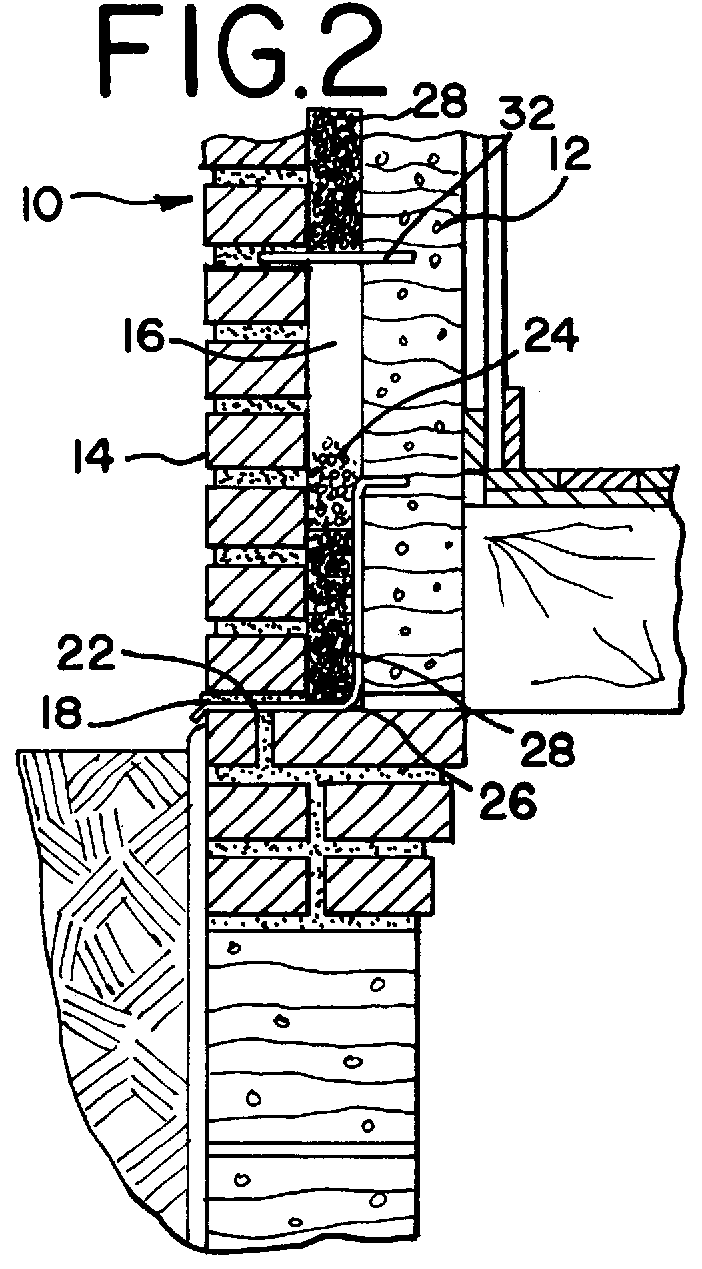

Implant that can be implanted in osseous tissue and method for producing said implant corresponding implant

ActiveUS20060105295A1Strong long-term anchoringProcess stabilityDental implantsInternal osteosythesisBone implantCavity wall

A bone implant (10) is implanted in a cavity parallel to an implant axis (I) and without substantial rotation. The implant includes, on an implant portion to be implanted, cutting edges (14), which do not extend in a common plane with the implant axis and are facing toward the distal end of the implant. The implant also includes surface ranges (16) of a material that is liquefiable by mechanical oscillations. The cutting edges (14) are dimensioned such that they are lodged in the cavity wall after implantation. For implantation, the implant is impinged with mechanical oscillations, resulting in the thermoplastic material being at least partially liquefied and pressed into unevennesses and pores of the cavity wall to form a form-fit and / or material-fit connection between implant (10) and cavity wall, when re-solidified. The cutting edges (14) anchor the implant in the cavity wall.

Owner:WOODWELDING

Introducer assembly for medical instruments

ActiveUS7316699B2Expand the working areaLimit escapeCannulasSurgical needlesDistal portionEngineering

An assembly structured to introduce a trocar or other medical instrumentation into a body cavity through an entry site formed in the cavity wall. The introducer assembly includes a base formed of a semi-rigid, flexible and / or a semi-flexible material having an instrument receiving passage extending there through, and further including an exterior sealing surface extending between proximal and distal portions of the base. The sealing surface has a predetermined configuration which is shaped to conform to the shape of the entry site as the base passes into the entry site. A fluid restricting seal is thereby established between the exterior of the base and the peripheral tissue surrounding the entry site, particularly when the entry site is formed by an incision commonly utilized an open laparoscopic procedure.

Owner:TELEFLEX MEDICAL INC

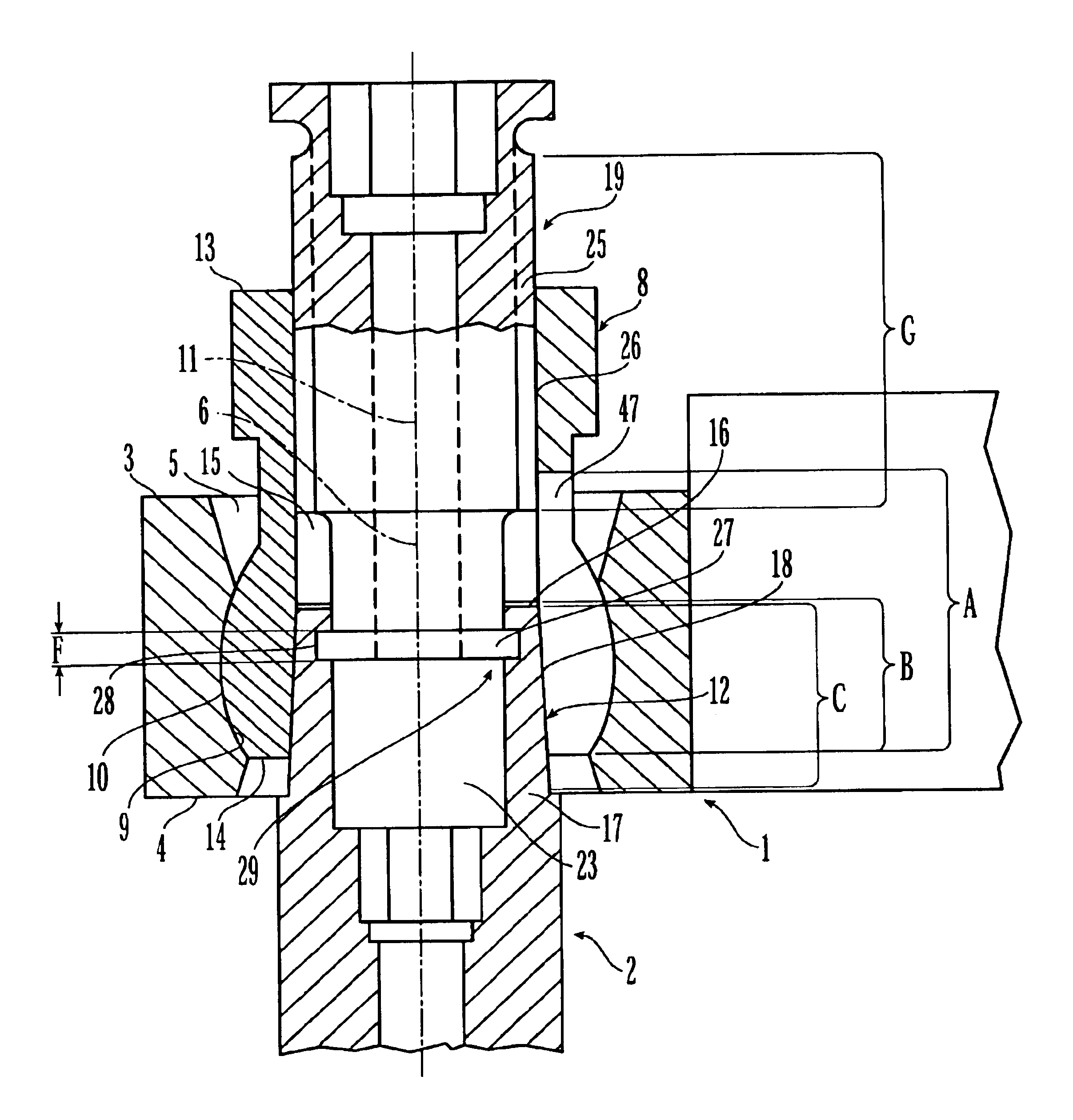

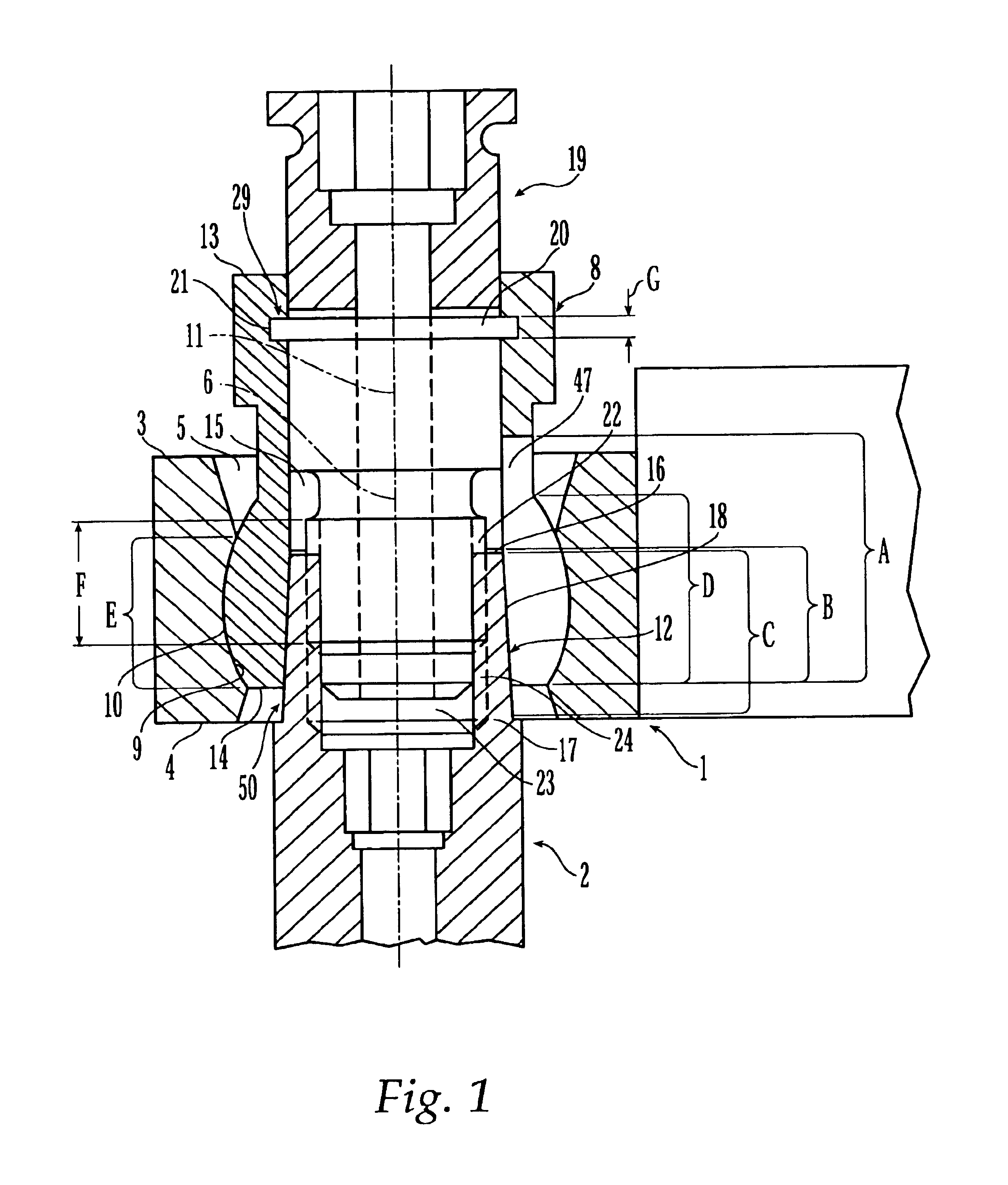

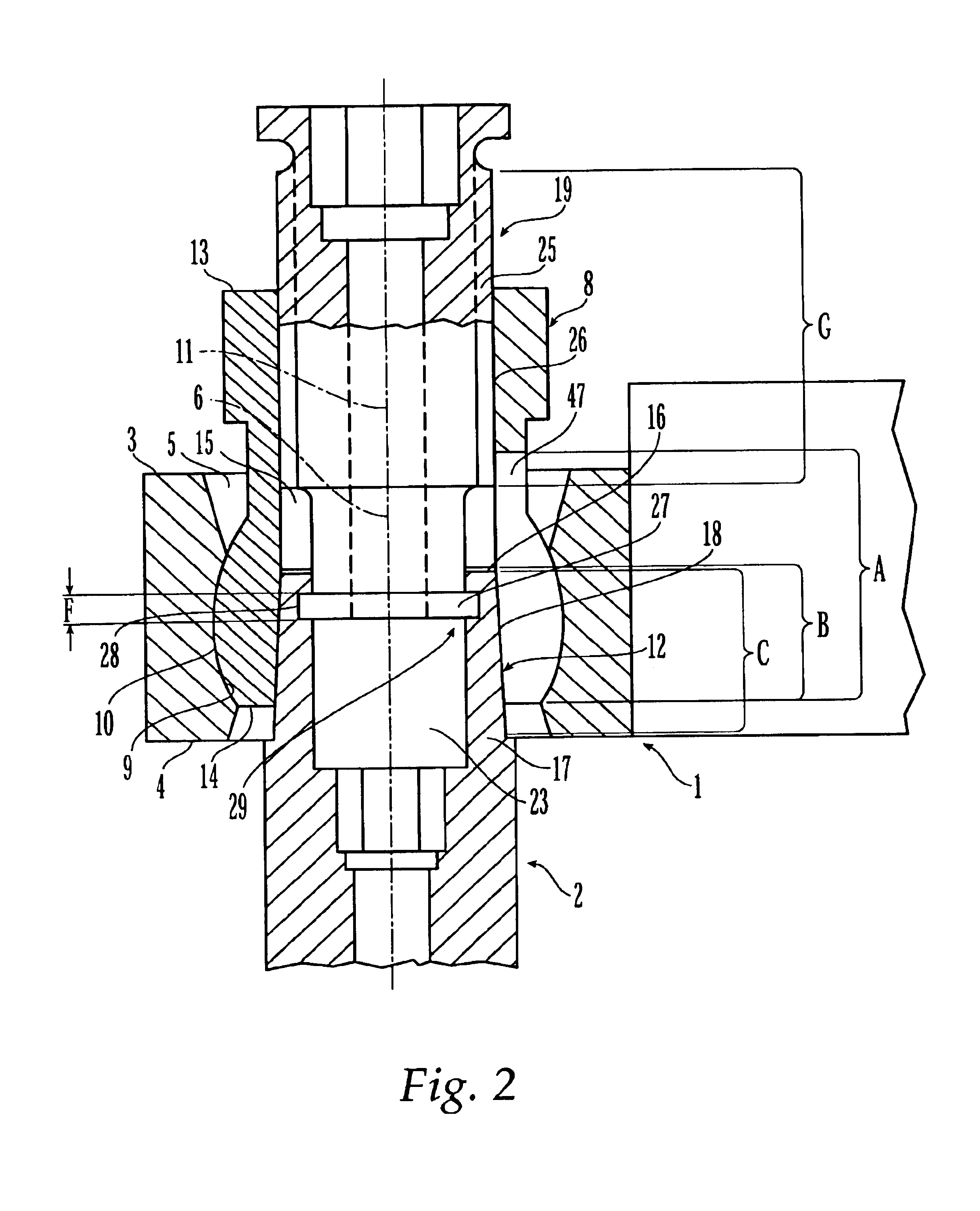

Device for the articulated connection of two bodies

InactiveUS6869432B2Easy to manufactureQuick releaseSuture equipmentsInternal osteosythesisAxial displacementEngineering

A device is provided for the articulated connection of two bodies comprising a first body, a clamping member, at least one tension member, and a second body. The first body comprises a cavity extending coaxially along a central axis. The clamping included a longitudinal axis and a coaxial bore with at least one aperture, the clamping member being complementary to the cavity and resiliently deformable in a direction orthogonal to the longitudinal axis. The at least one tension member is insertable coaxially with respect to the longitudinal axis into the bore. An axial displacement of the at least one tension member within the corresponding aperture may cause the clamping member to be expanded to contact the cavity wall and be releasably locked within the cavity. The second body is releasably connectable to the first body by means of the at least one tension member and the clamping member. A driving member is provided for displacing the at least one tension member axially relative to the corresponding aperture, wherein the driving member is connected to both the clamping member and the at least one tension member in positive axial engagement while rotatable about the longitudinal axis.

Owner:SYNTHES USA

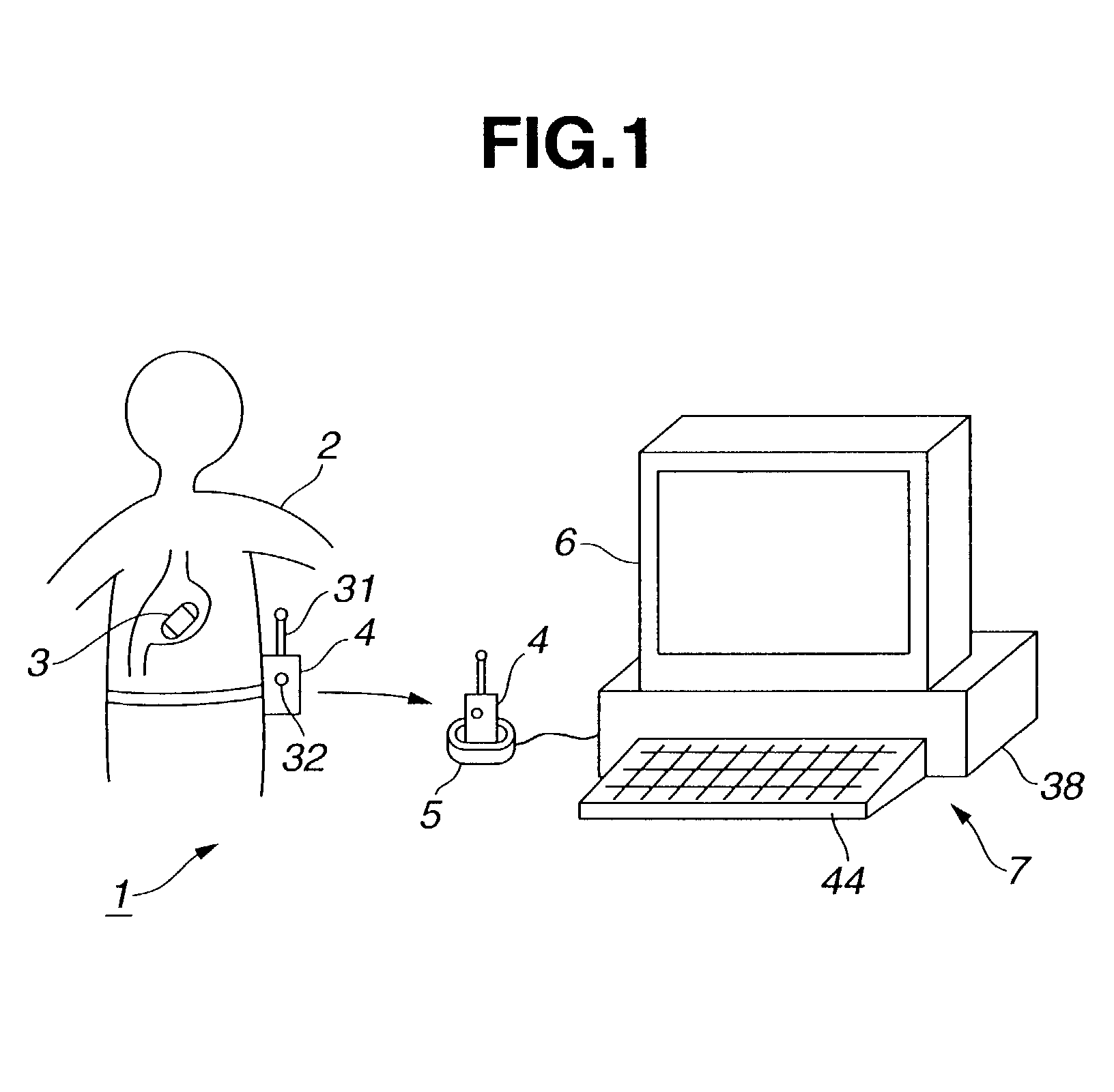

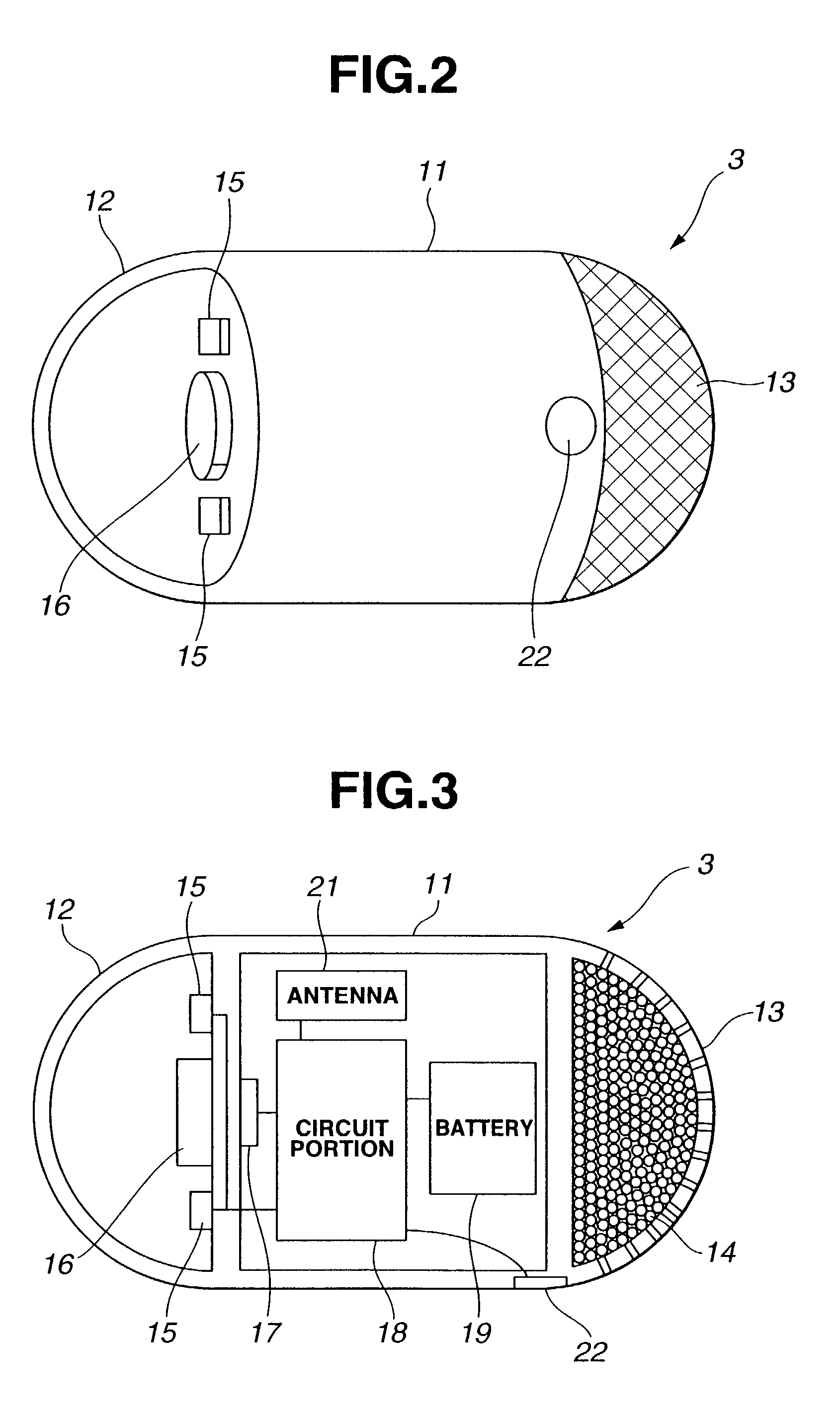

Capsule-type medical apparatus

InactiveUS7511733B2Easy to useEasy power-supply switchingEndoscopesEndoradiosondesVisual field lossElectrical battery

A battery self-containing body, which self-contains a battery or a battery accommodating body, which accommodates a battery removably is attached to a capsule body including a drive circuit for driving an imaging device and an illuminating device. Thus, the power supply can be turned ON easily. In addition, the inside portion is sealed water-tightly. Thus, the battery self-containing body or a battery can be exchanged easily, which allows the easy reuse. The direction of the visual field of the imaging device is diagonal with respect to the axis of the capsule body. Furthermore, spiral-shape projections are provided on the peripheral surface of the cylinder form. Thus, the rotation allows the surface of canal cavity wall to be examined easily.

Owner:OLYMPUS CORP

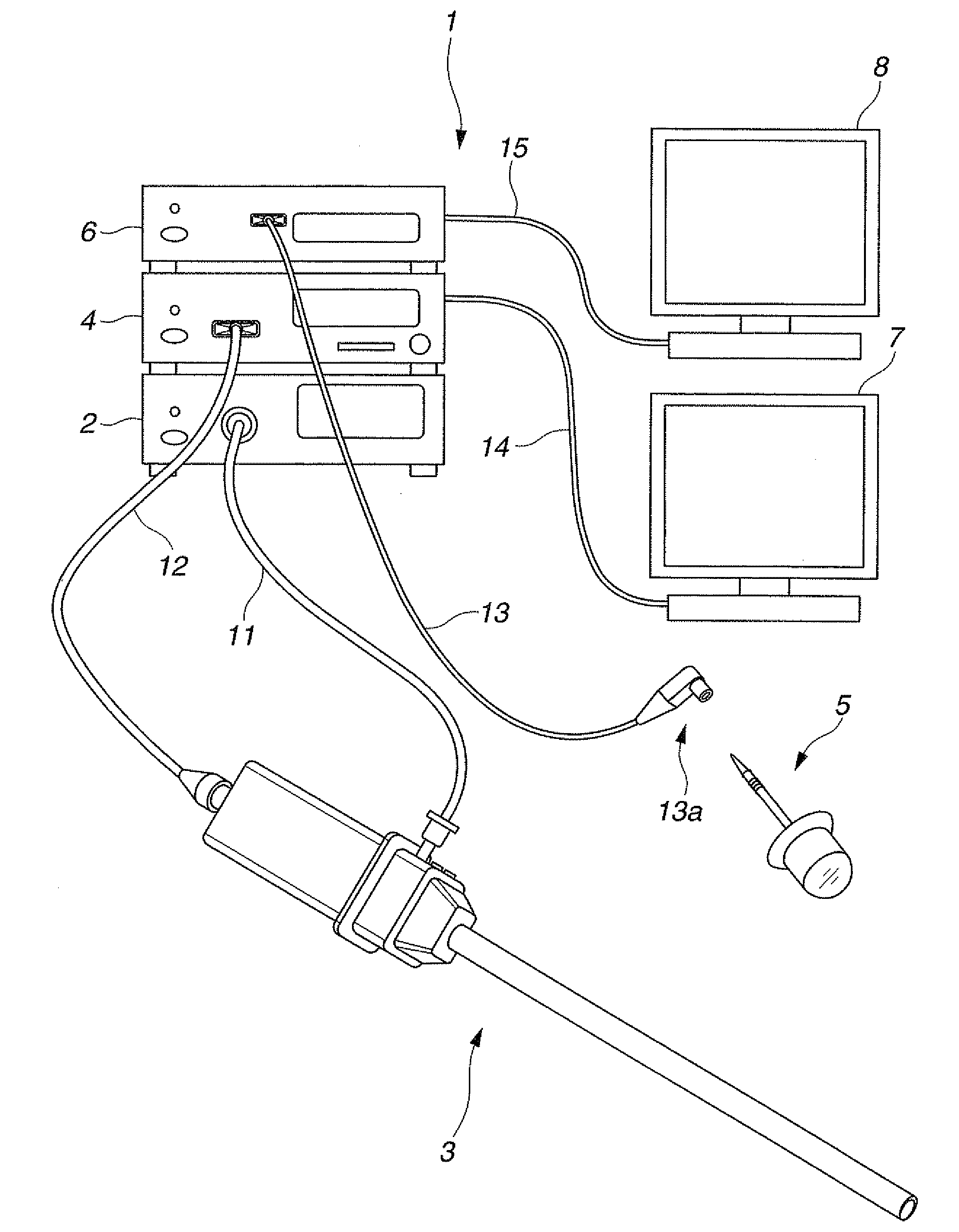

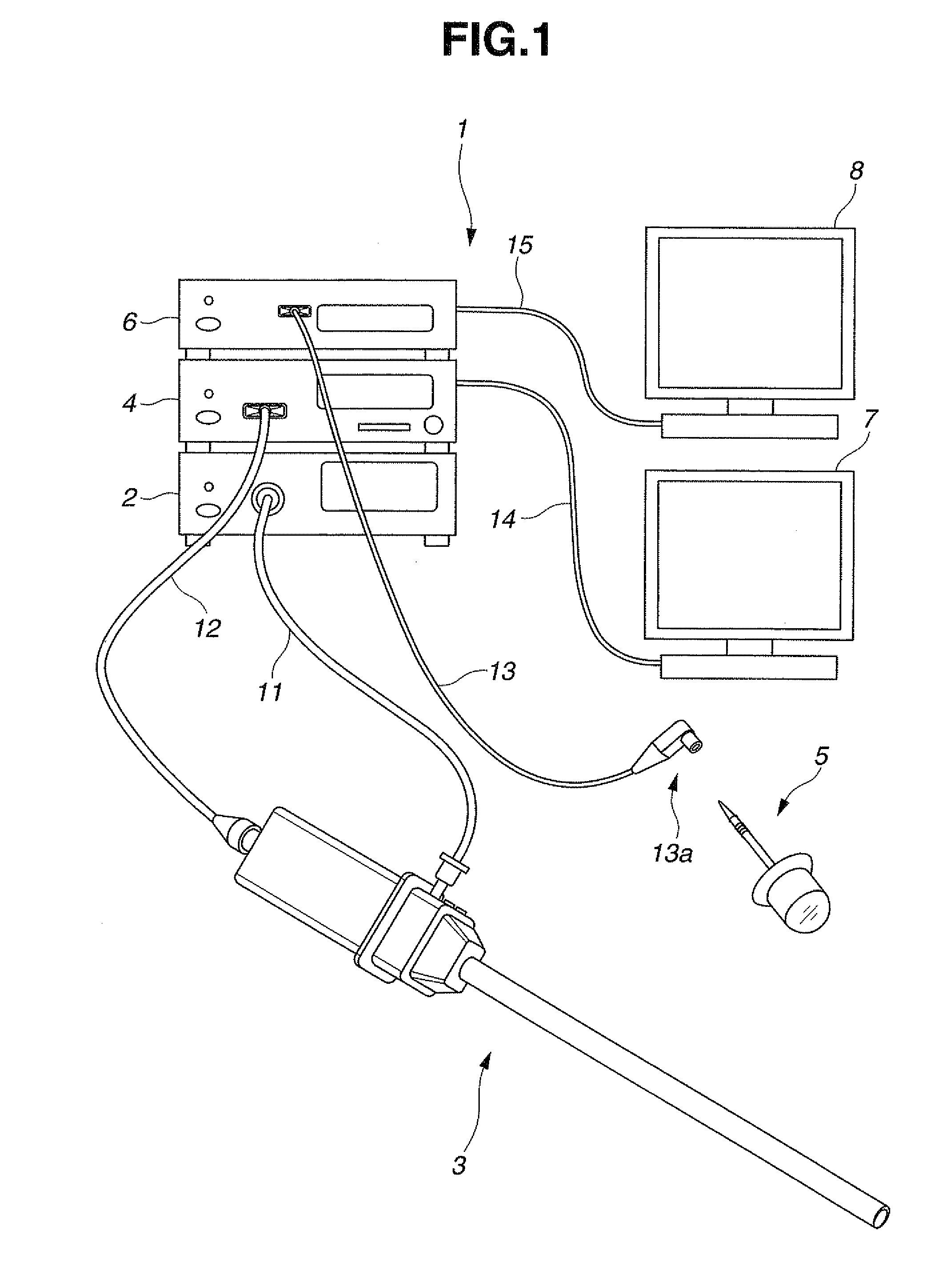

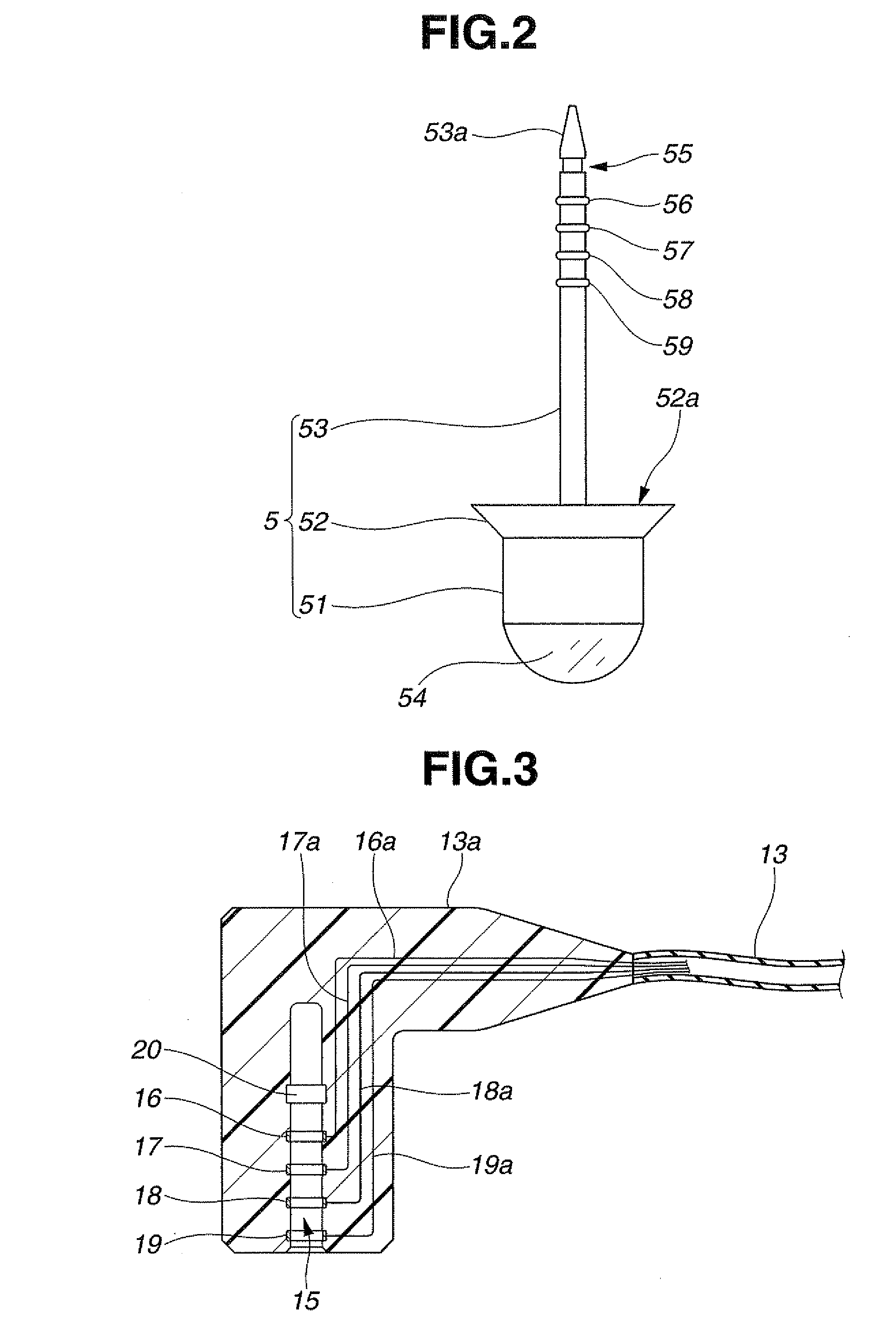

Endoscope system, camera set on body cavity inner wall and method of setting the camera set on body cavity inner wall on inner surface of body cavity wall

An endoscope system has a camera which picks up an image in a body cavity, and a needle portion which is an electrode for transmitting a signal picked up by the camera, and which is pierced through a body wall, to transmit the signal from the camera to the outside of the body cavity.

Owner:OLYMPUS MEDICAL SYST CORP

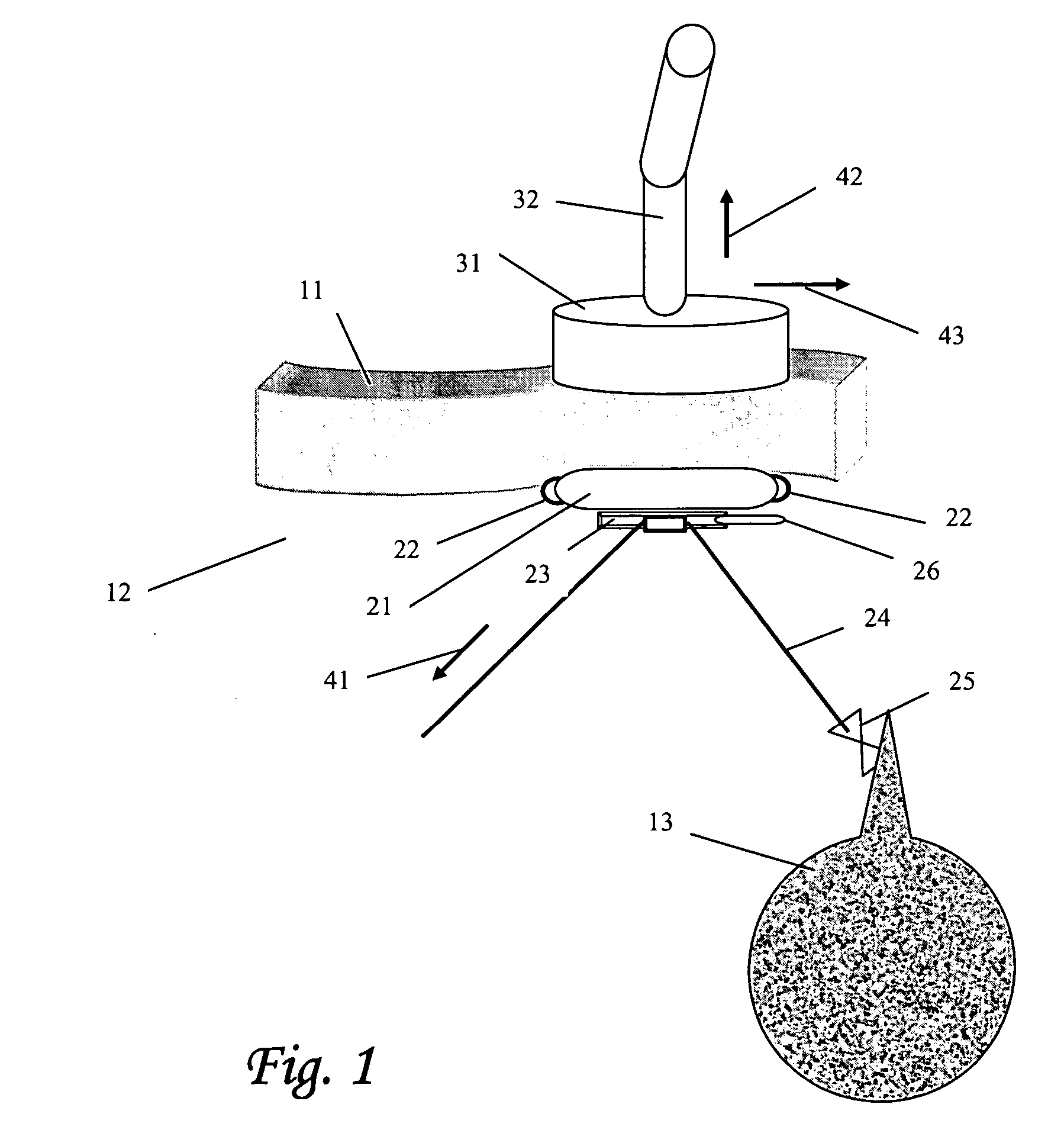

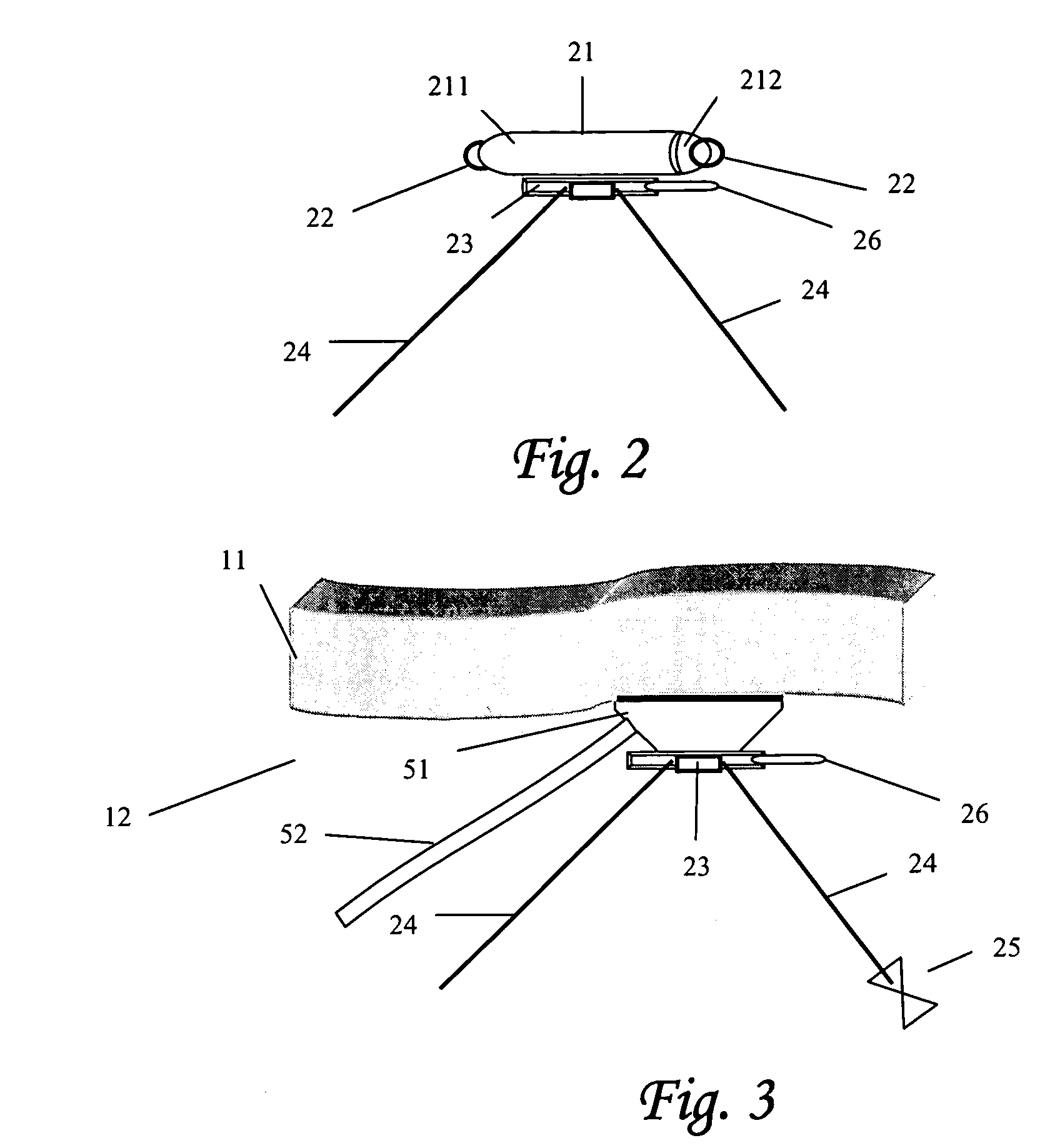

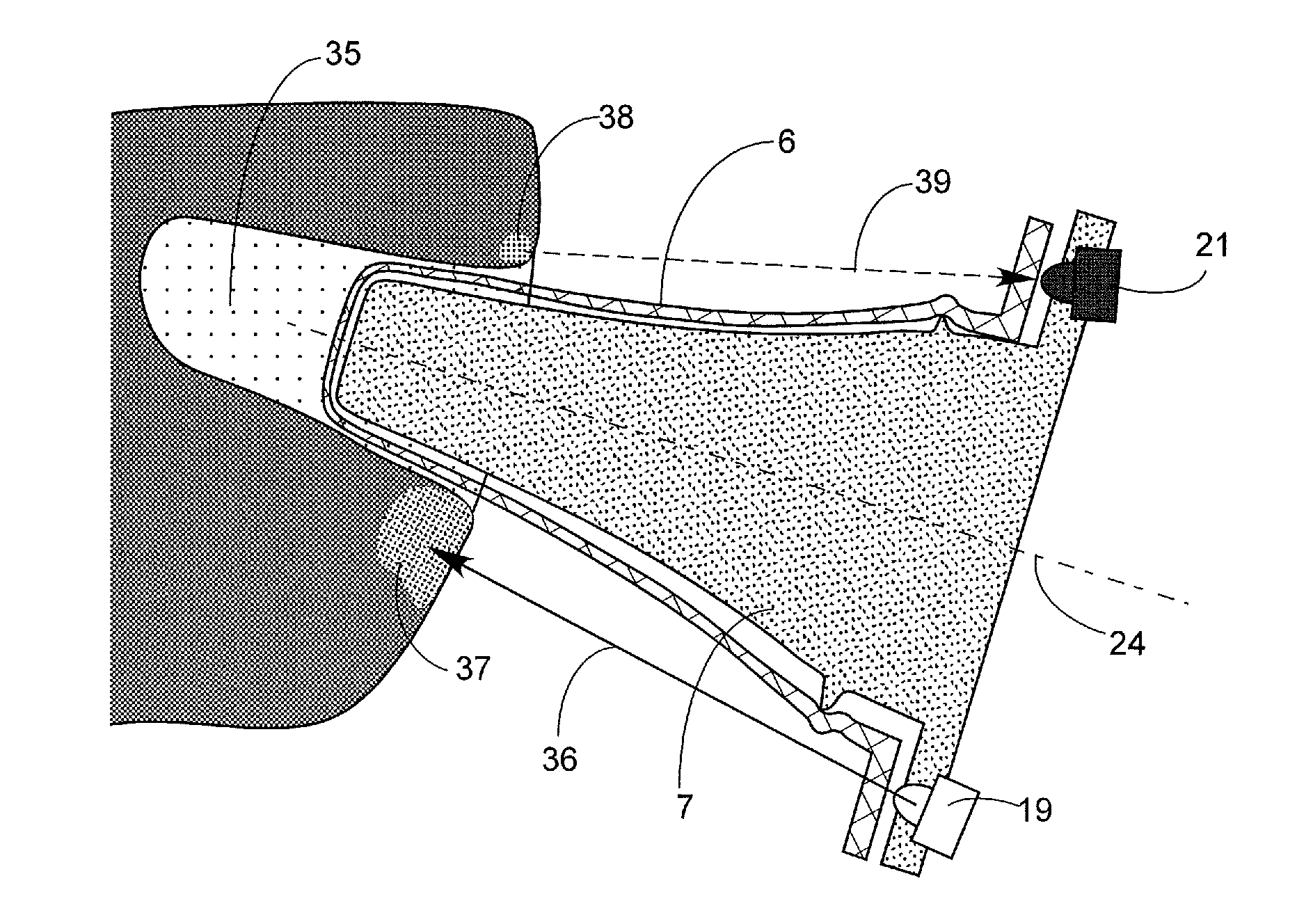

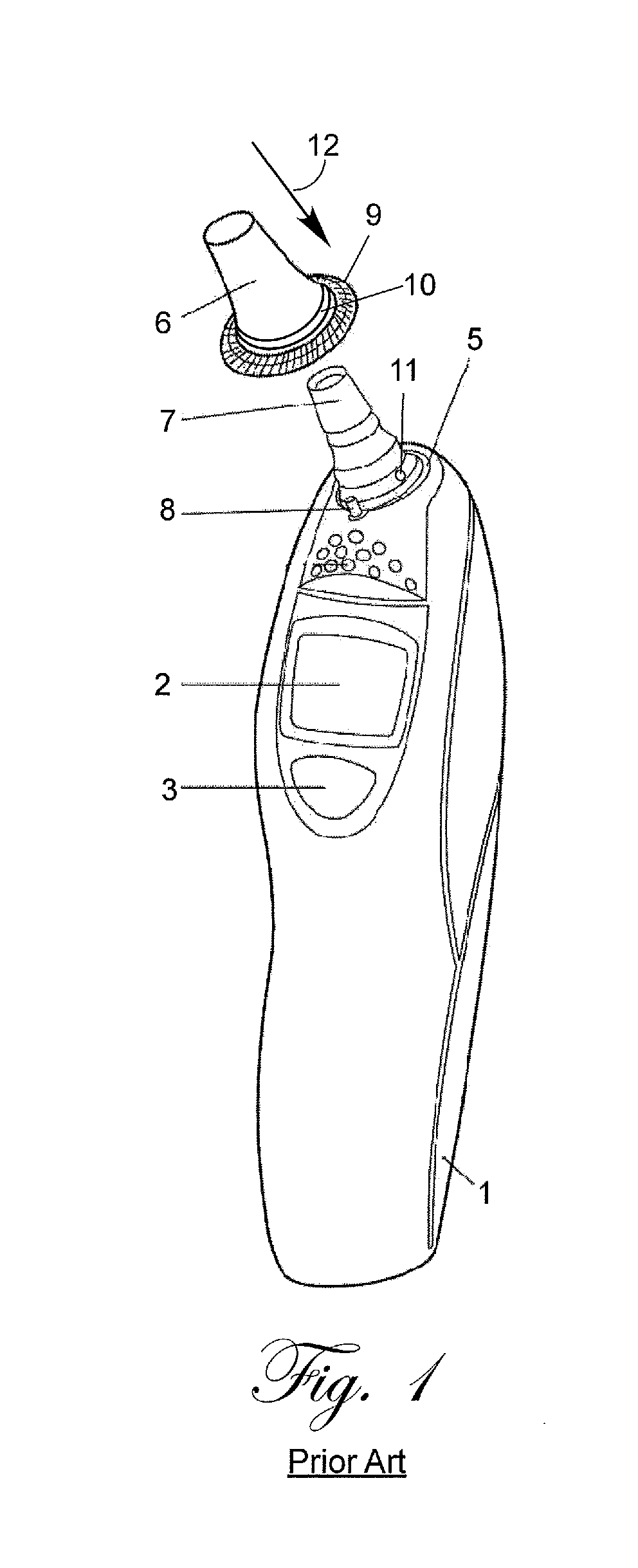

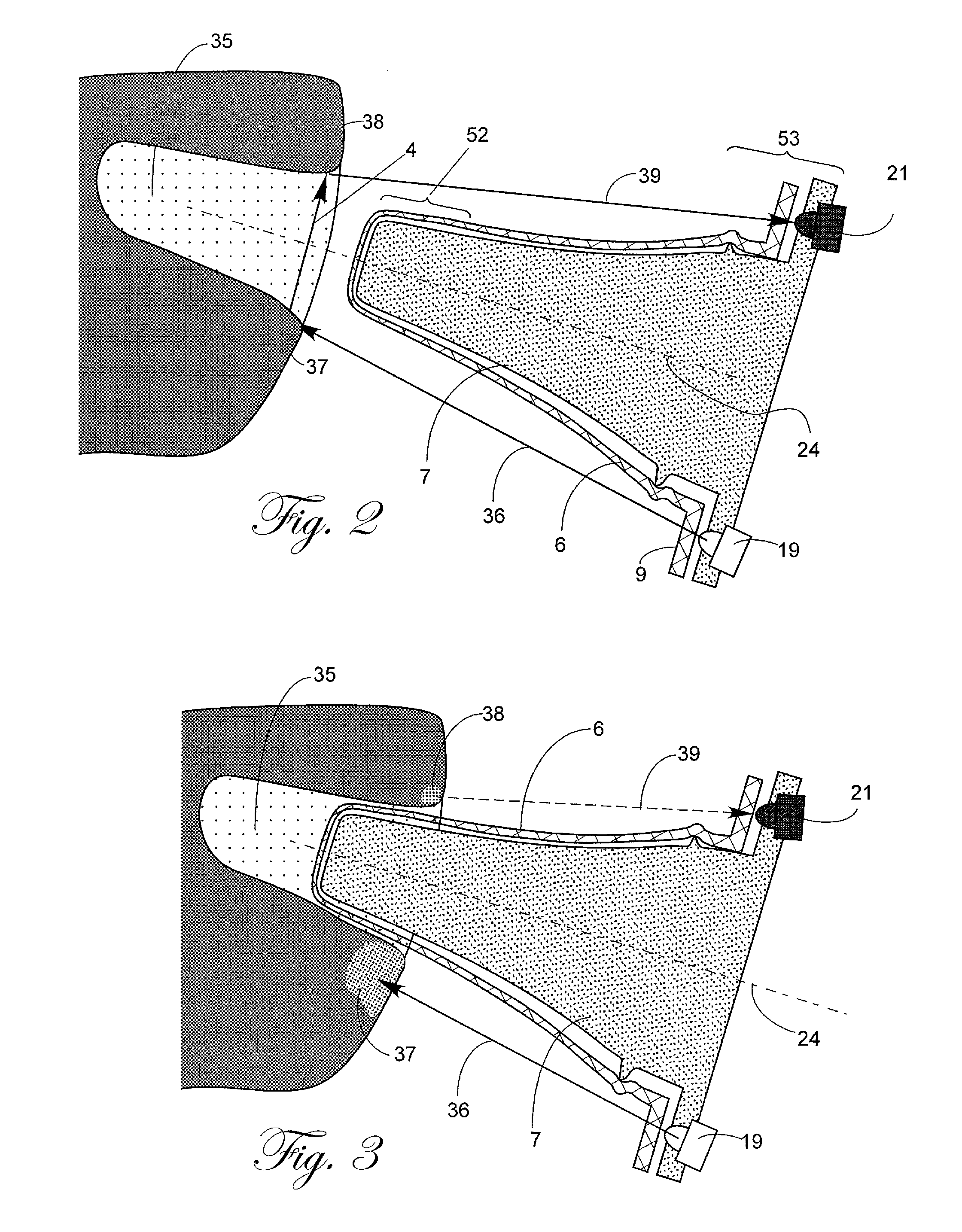

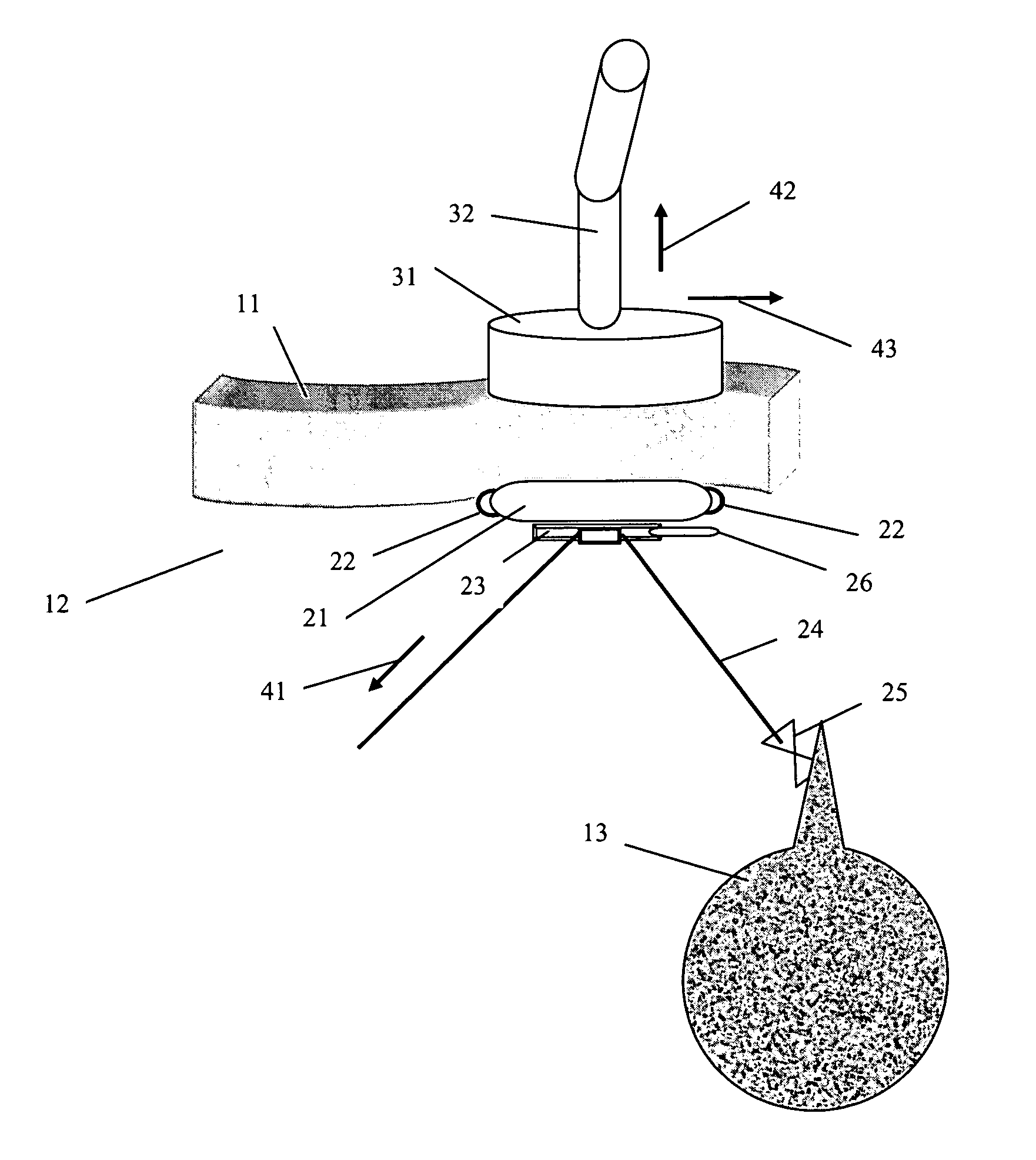

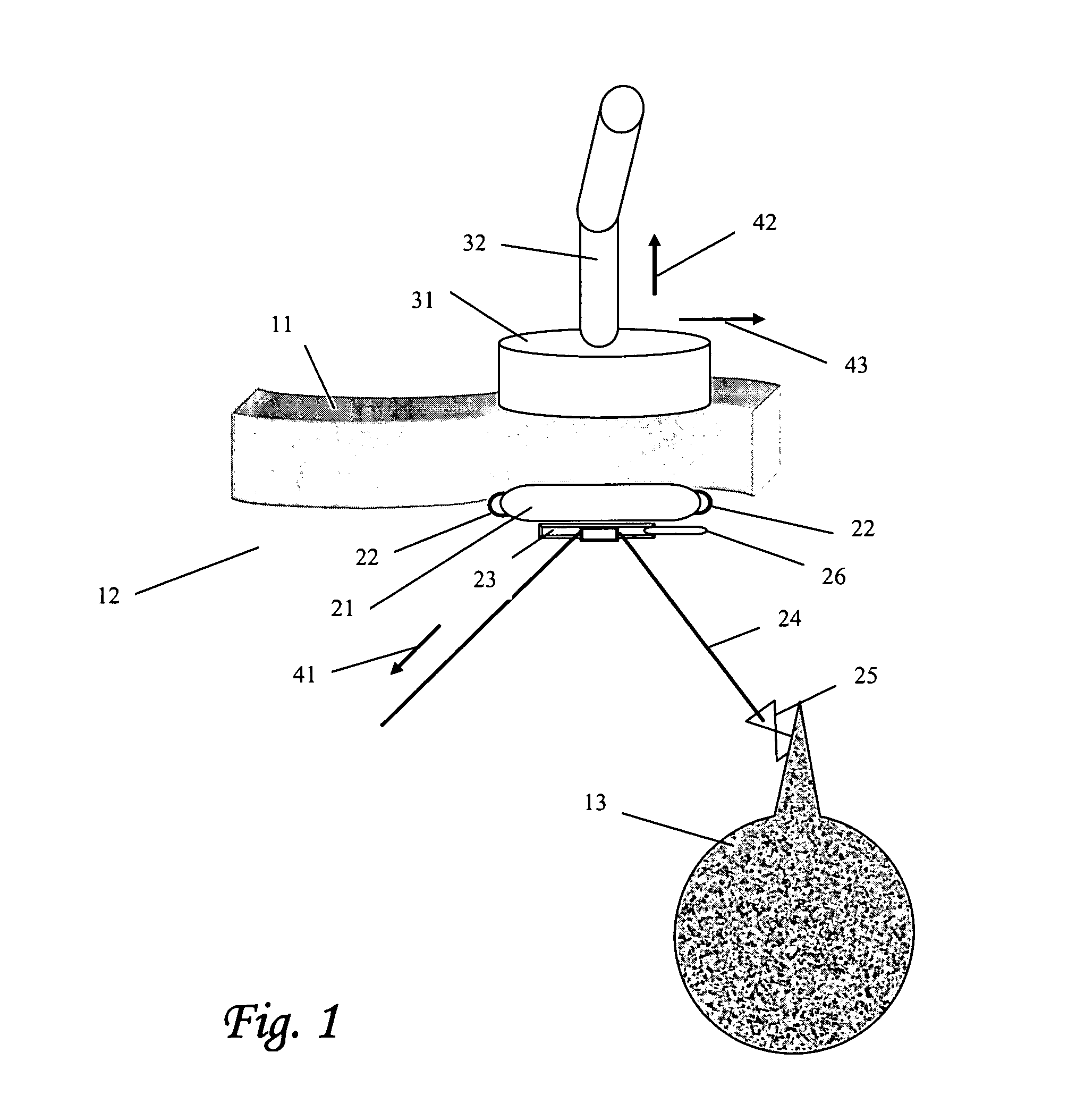

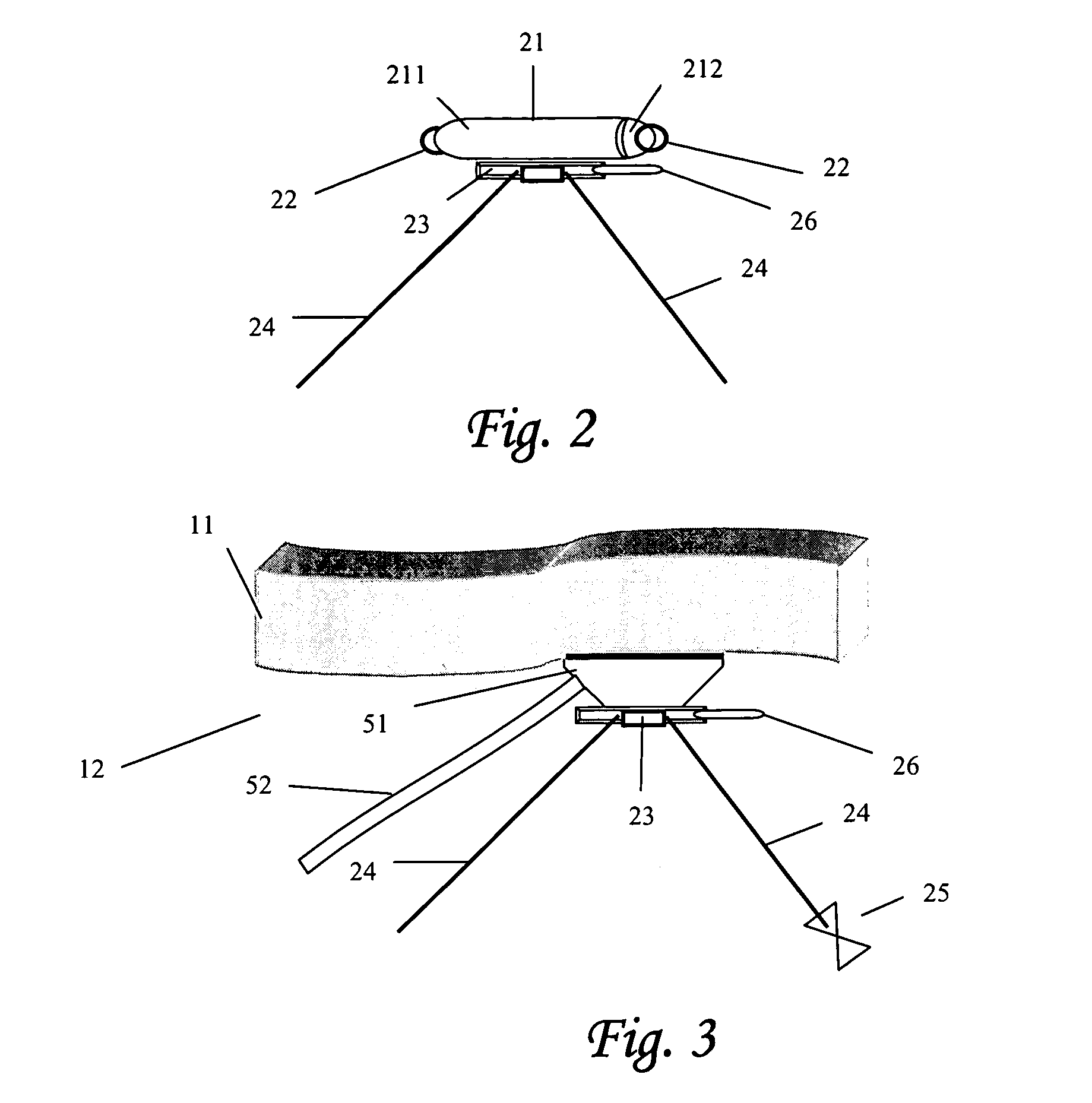

Insertion detector for medical probe

ActiveUS20110257521A1Reduce fluxUltrasonic/sonic/infrasonic diagnosticsThermometer detailsProximity sensorLight flux

An insertion detector for monitoring a position of a medical probe relative to a body cavity of a patient, the probe incorporates a proximity sensor that is responsive to a predetermined property of the patient's body. The proximity sensor may include a light emitter and a light detector. When the medical probe is inserted into the body cavity, a light flux between the light emitter and light detector is changed due to either obstruction by the cavity walls or reflection by the patient's skin. A response from the proximity sensor may be used to adjust a temperature measured from the body cavity to correct for errors due to non-insertion or partial insertion of the probe into the body cavity.

Owner:HELEN OF TROY LIMITED

Virtual ports devices and method

Owner:VIRTUAL PORTS

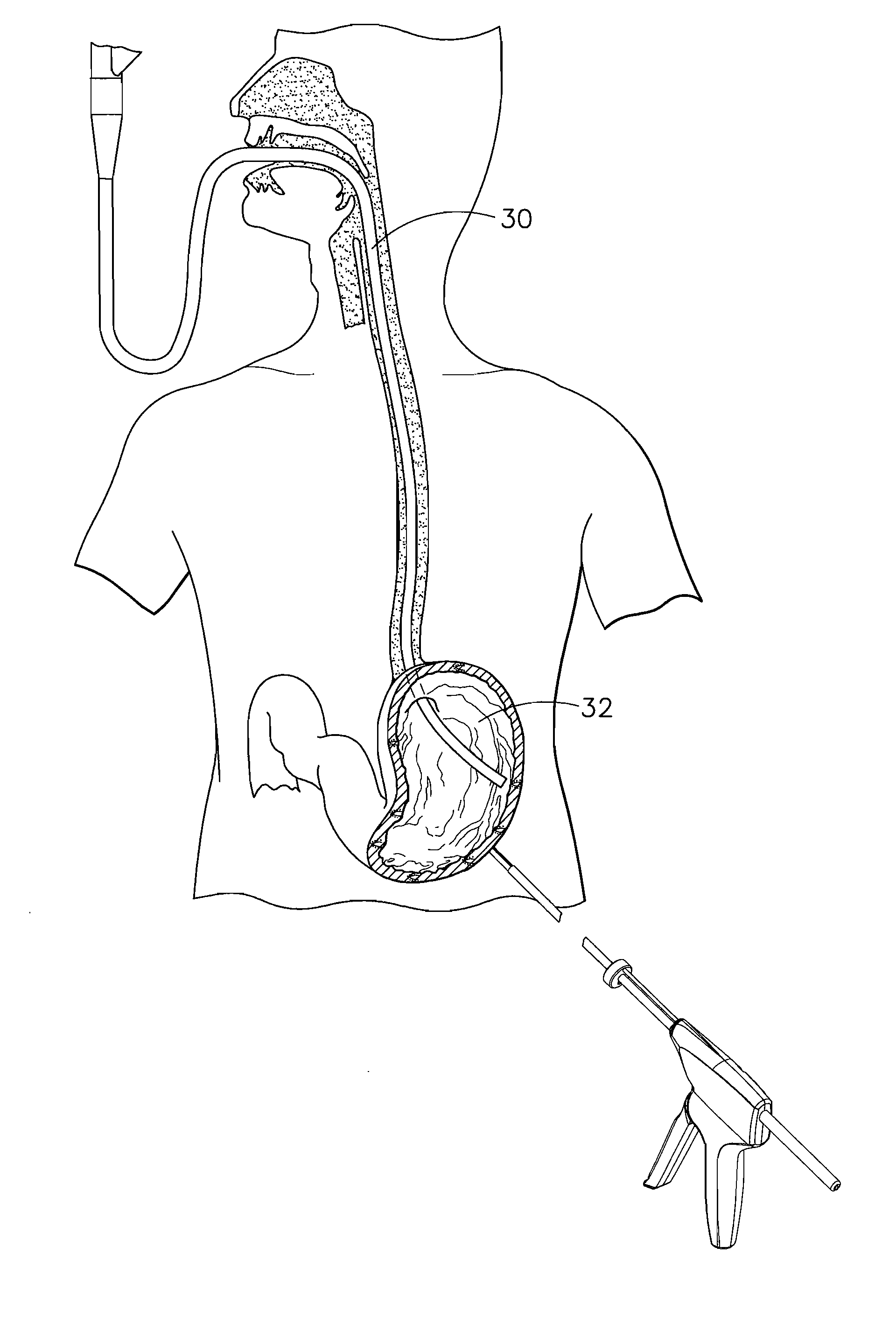

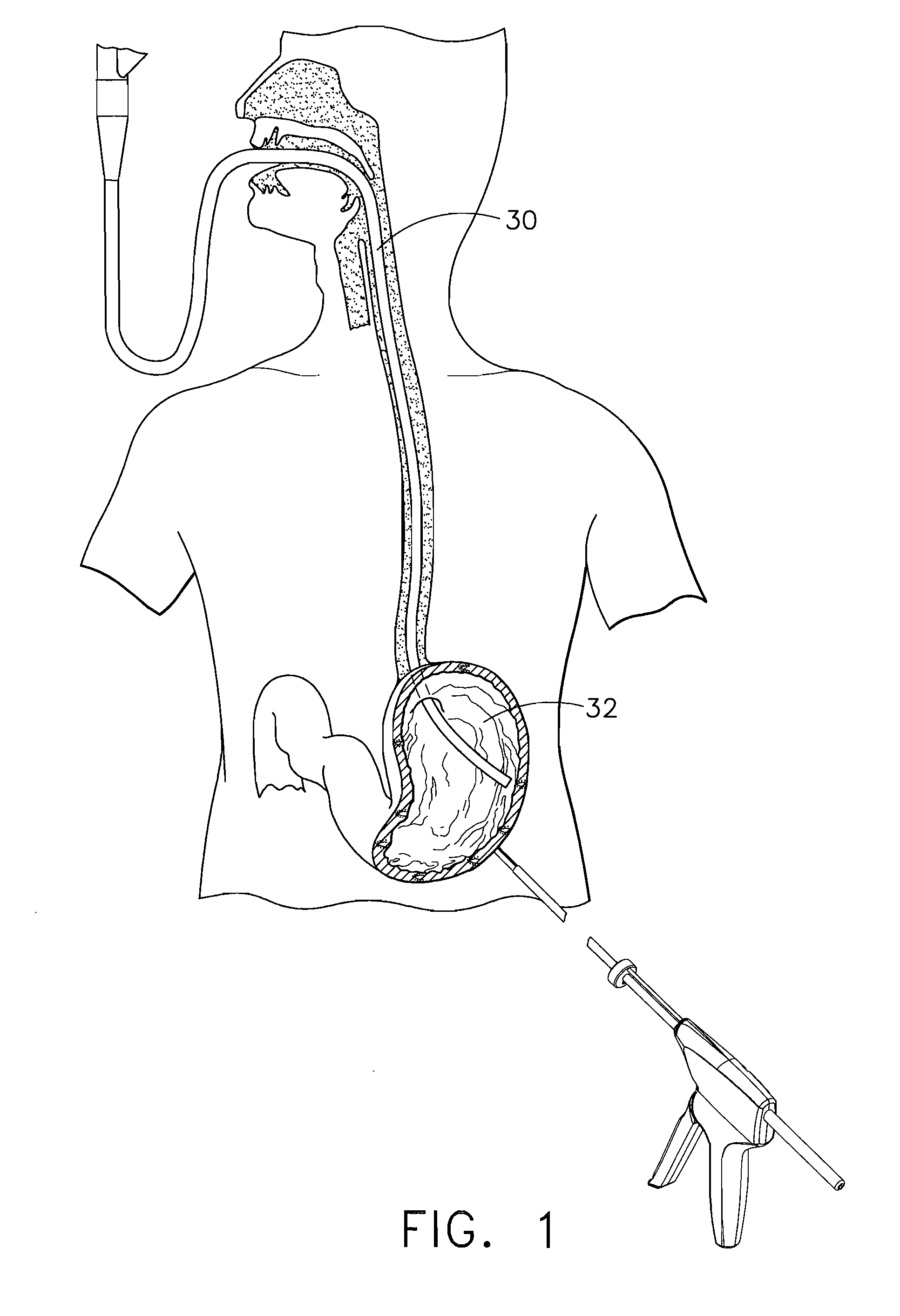

Hybrid endoscopic/laparoscopic method for forming serosa to serosa plications in a gastric cavity

ActiveUS20090024163A1Lower the volumeLimiting available food capacitySuture equipmentsCannulasVia incisionFood consumption

A method for treating obesity by reducing the volume and / or alter the functioning of the gastric cavity to limit food consumption and induce early satiety. The method includes accessing the cavity endoscopically to visualize the interior of the cavity. The peritoneal cavity is accessed through a small incision in the abdominal wall. Using endoscopic visualization, suture anchoring devices are introduced into the peritoneal cavity through the incision and deployed from the exterior surface through the gastric cavity wall. Suture from pairs of the anchoring devices is drawn through the gastric cavity wall and tightened outside of the cavity to form a serosa to serosa plication. Any number of plications may be formed in the cavity wall and the contacting tissue within a plication may be treated to promote healing and a more durable bond.

Owner:ETHICON ENDO SURGERY INC

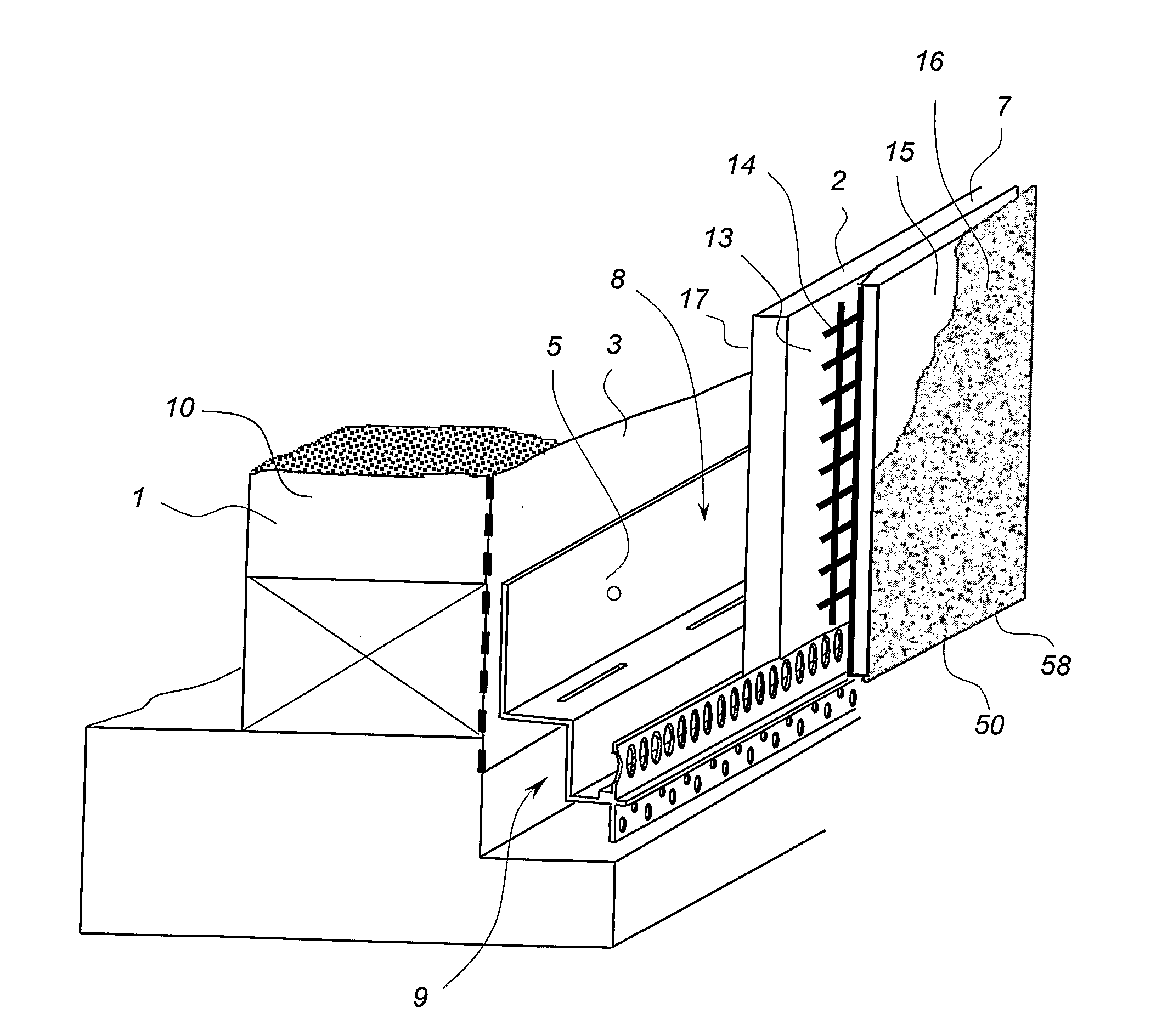

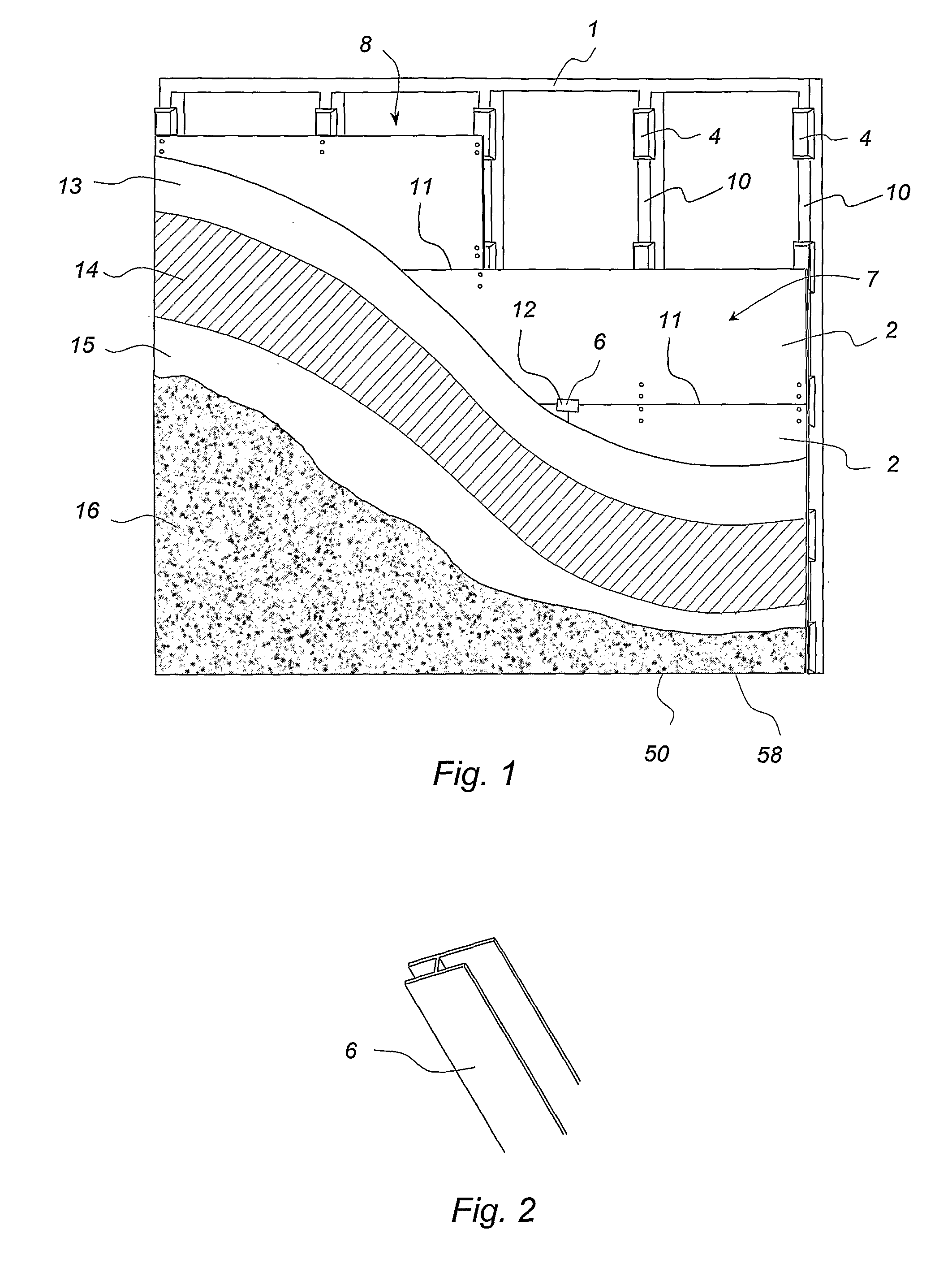

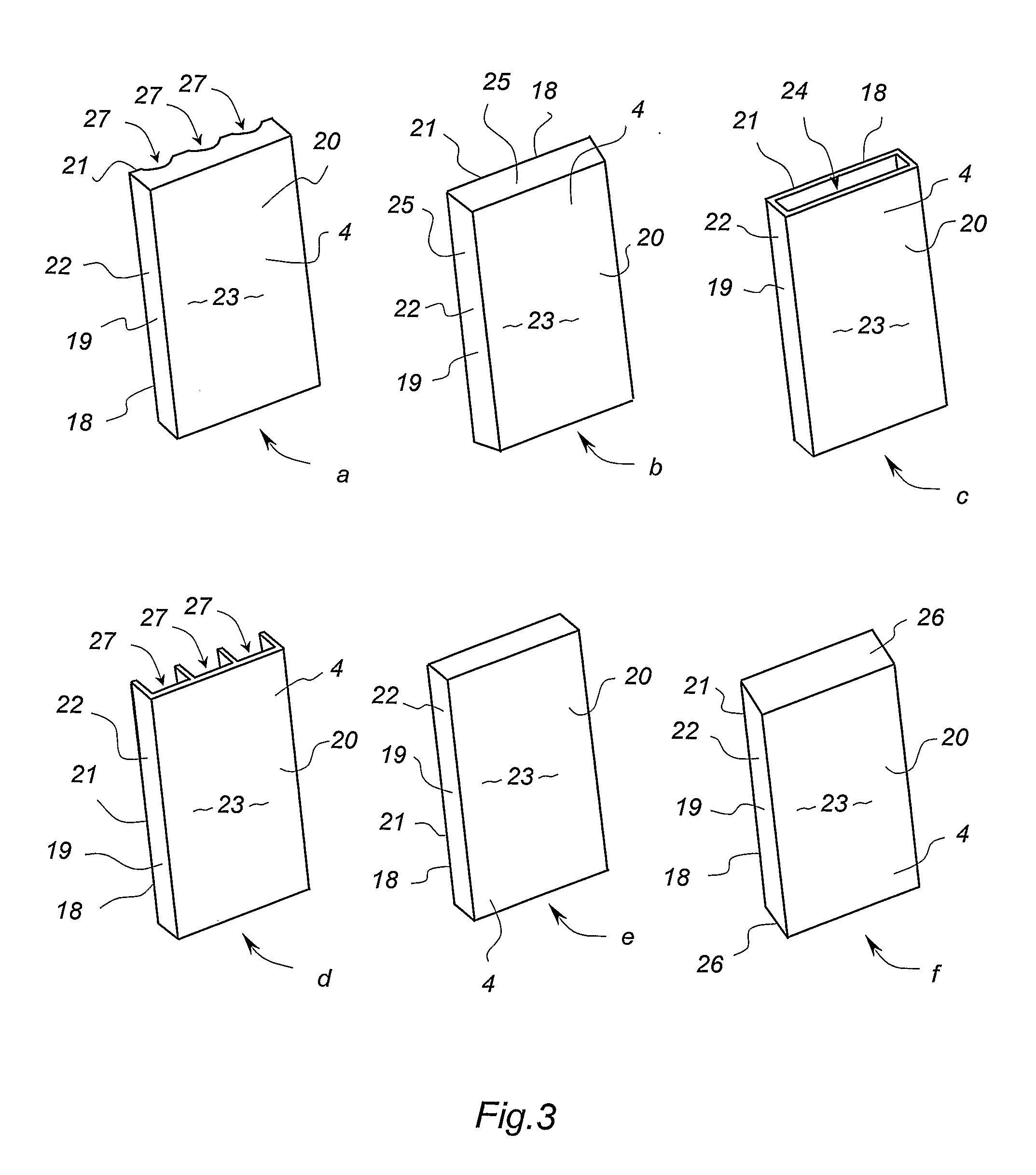

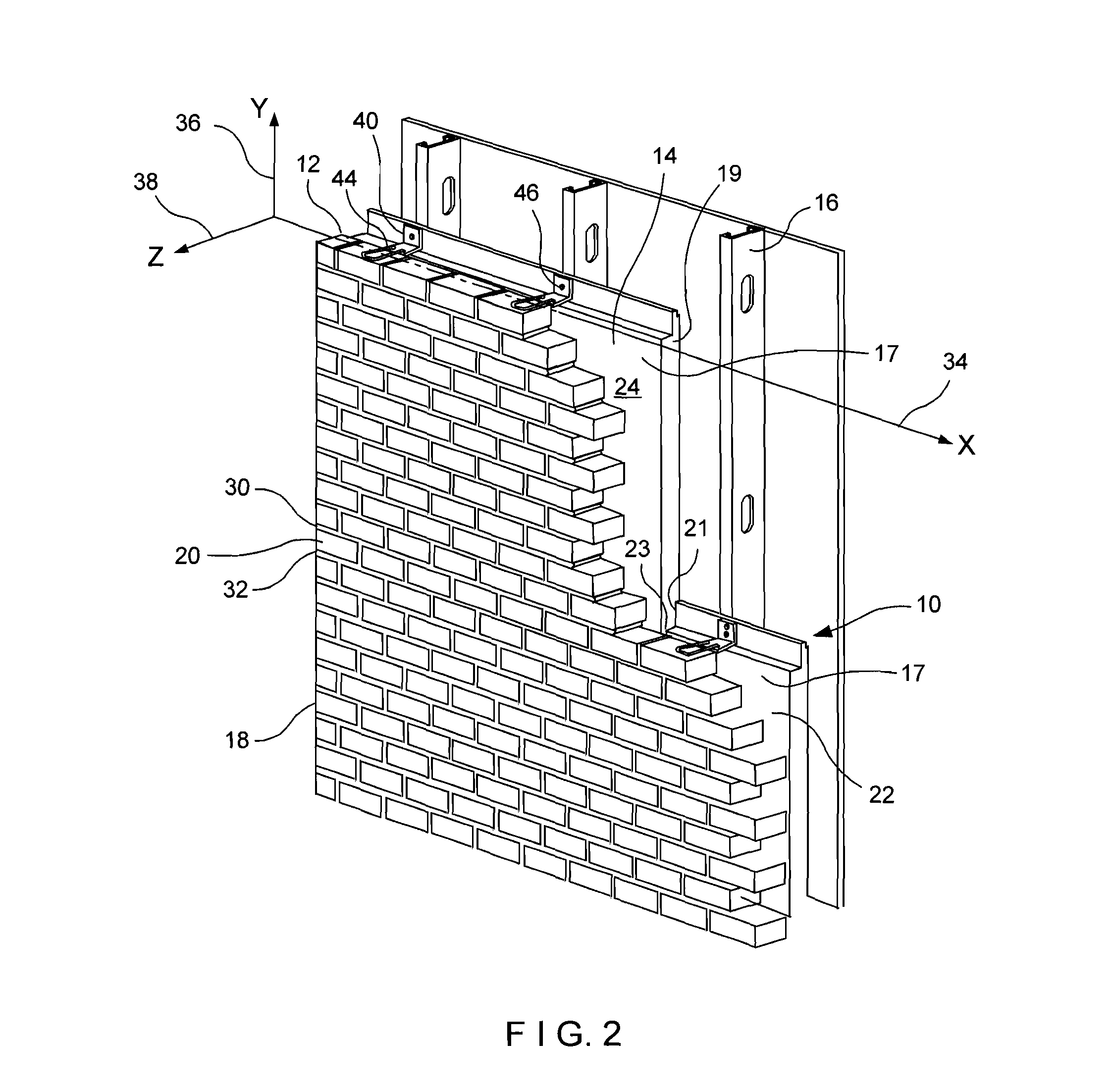

Cavity Wall System

InactiveUS20080104918A1Keep dryImprove thermal insulation propertiesCovering/liningsWallsStructural engineeringCavity wall

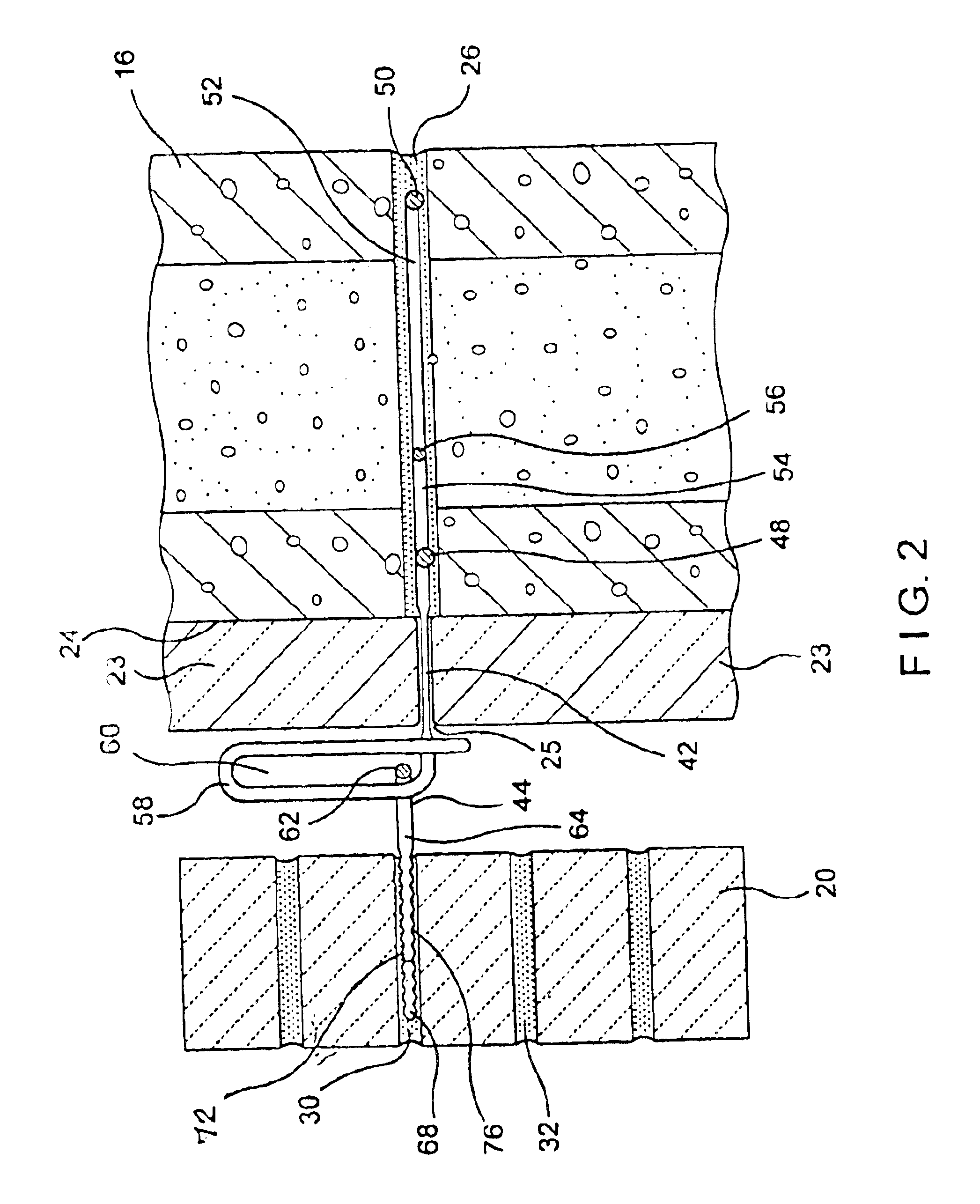

A cavity wall system and a method of forming a cavity wall including: a wall structure (1); a plurality of outer wall cladding panels (2); and a plurality of discrete mounting elements (4, 5, 6) for mounting the cladding panels a predetermined distance away from the wall structure (1) so as to form a substantially flat exterior wall surface (7) and a substantially uninterrupted internal wall cavity (8) between the cladding panels (2) and the wall structure (1); the mounting elements (4, 5, 6) being sized and arranged so as to allow substantially uninterrupted fluid flow throughout the cavity (8); and the system further including moisture control means defining a moisture control plane to minimise migration of liquid moisture from the cavity (8) into the wall structure (1). The invention also provides a mounting member (4) and a termination member (5) for use as mounting elements in the cavity wall system and method.

Owner:JAMES HARDIE TECH LTD

Snap-in wire tie

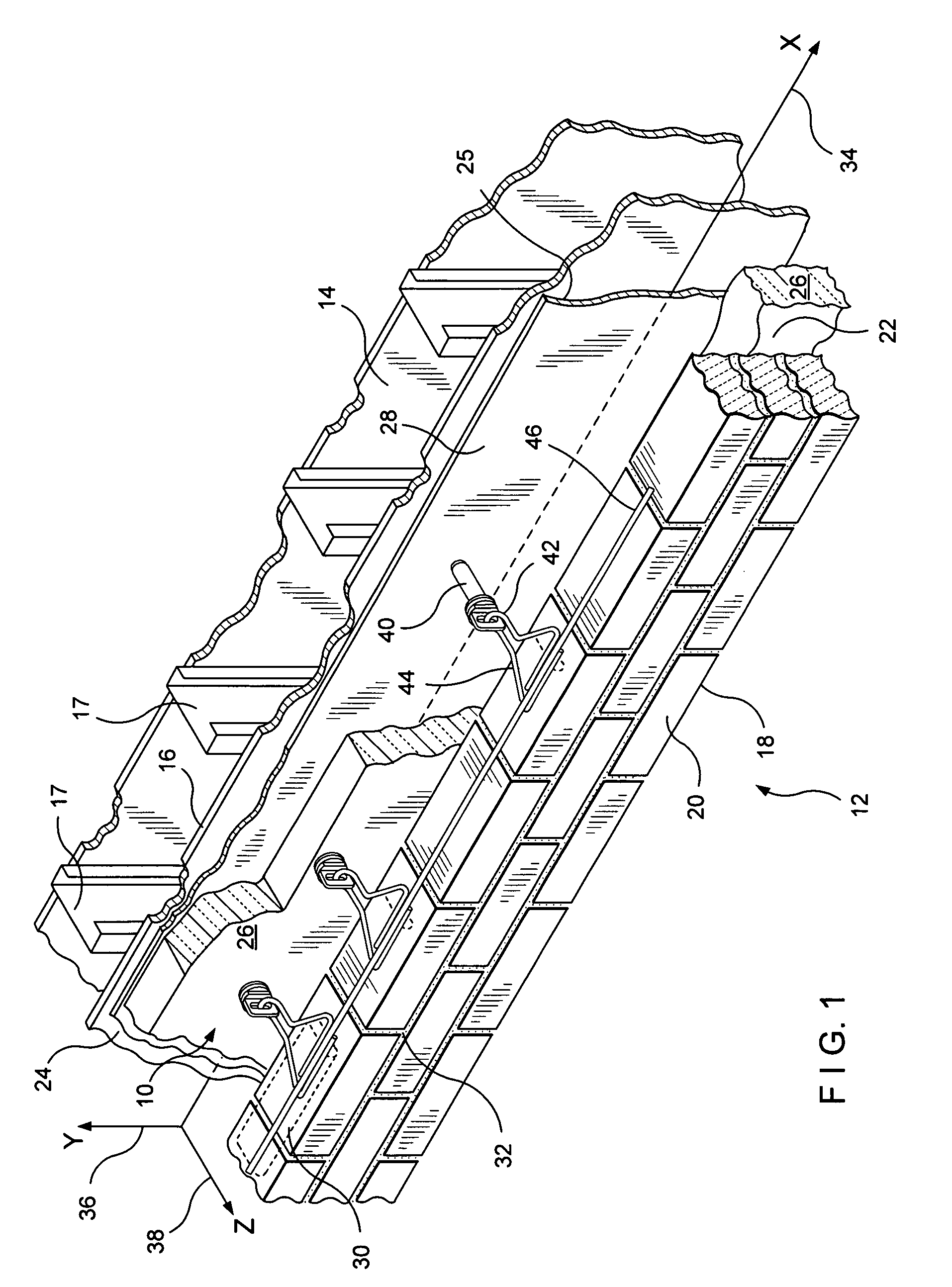

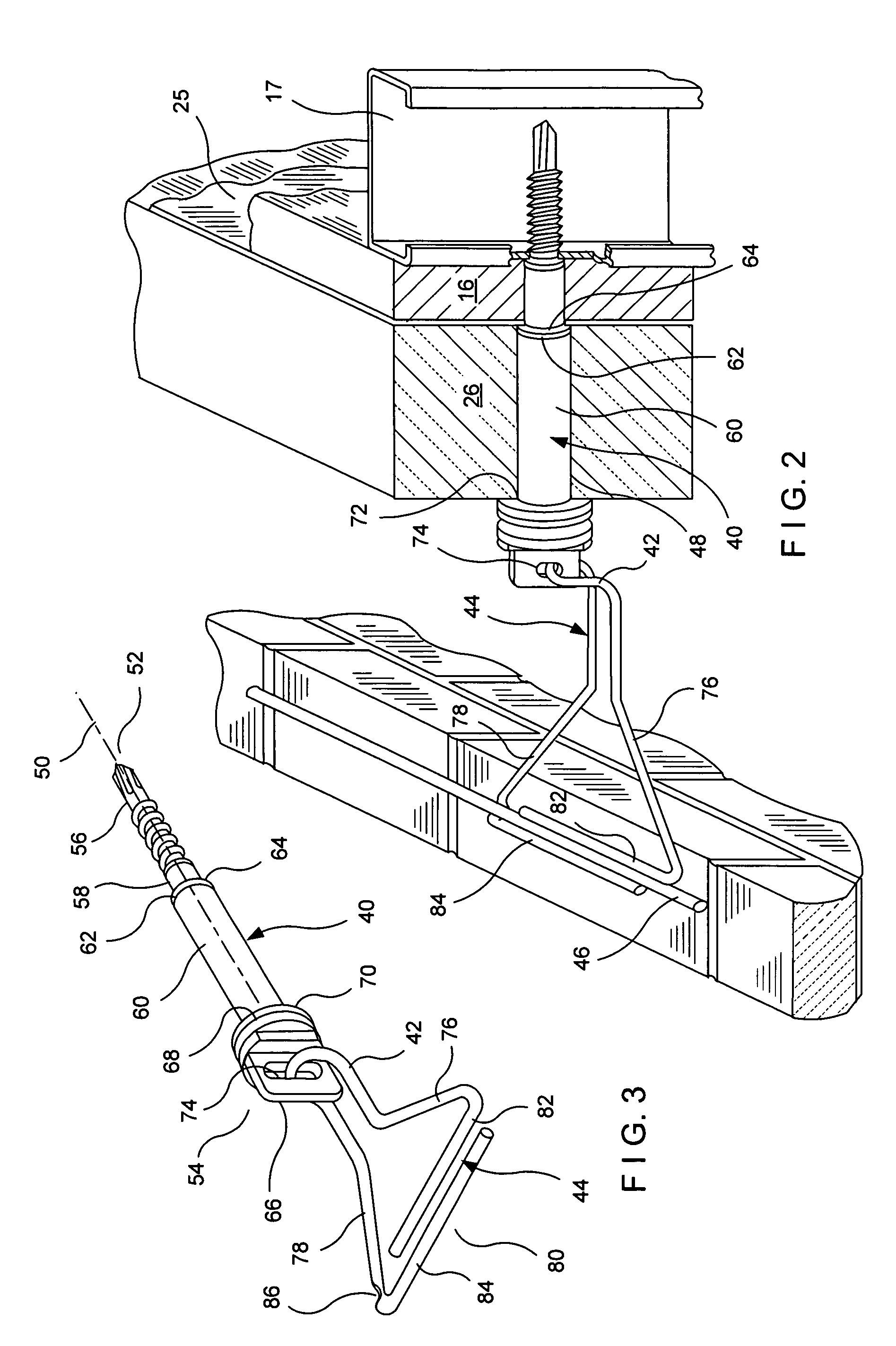

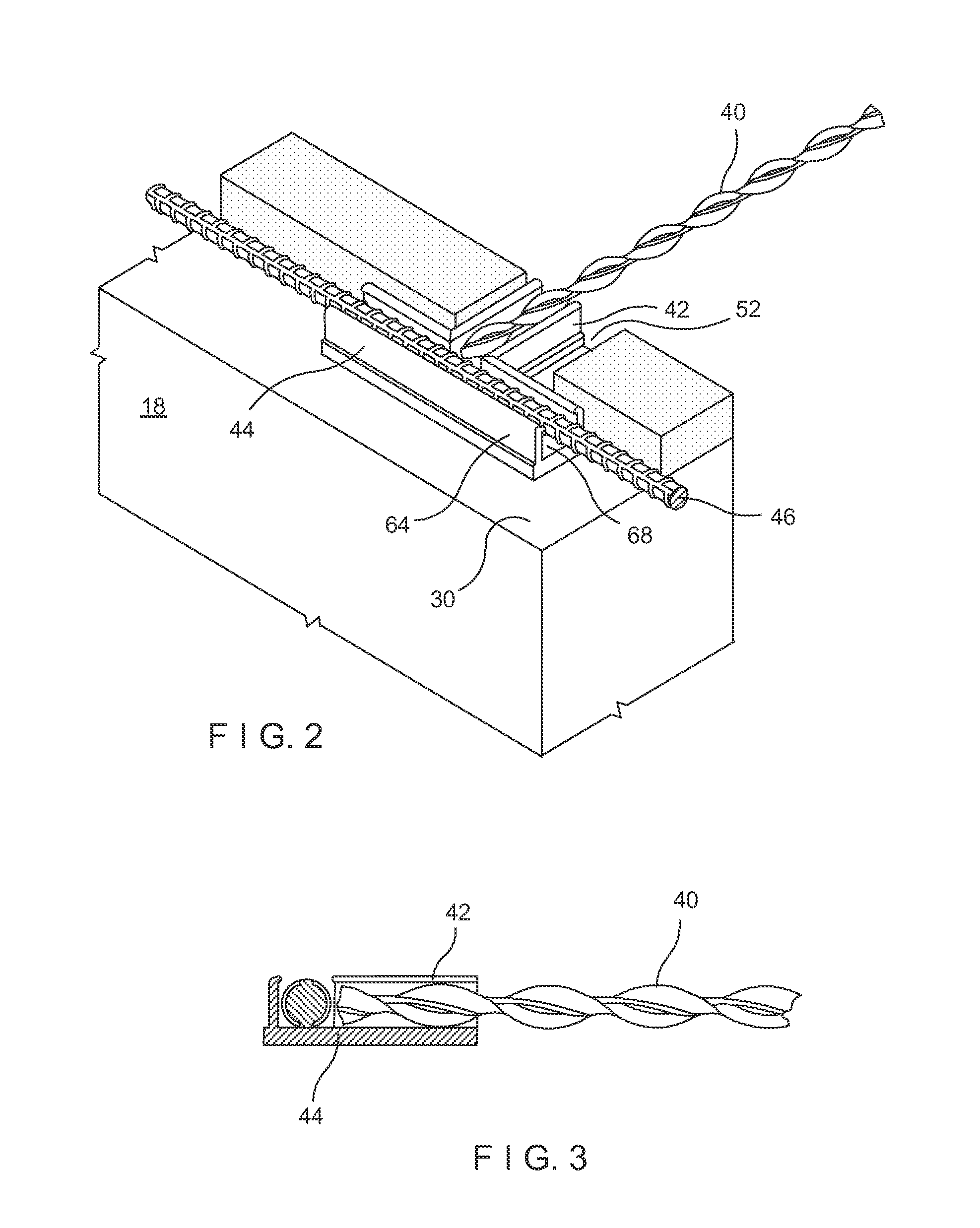

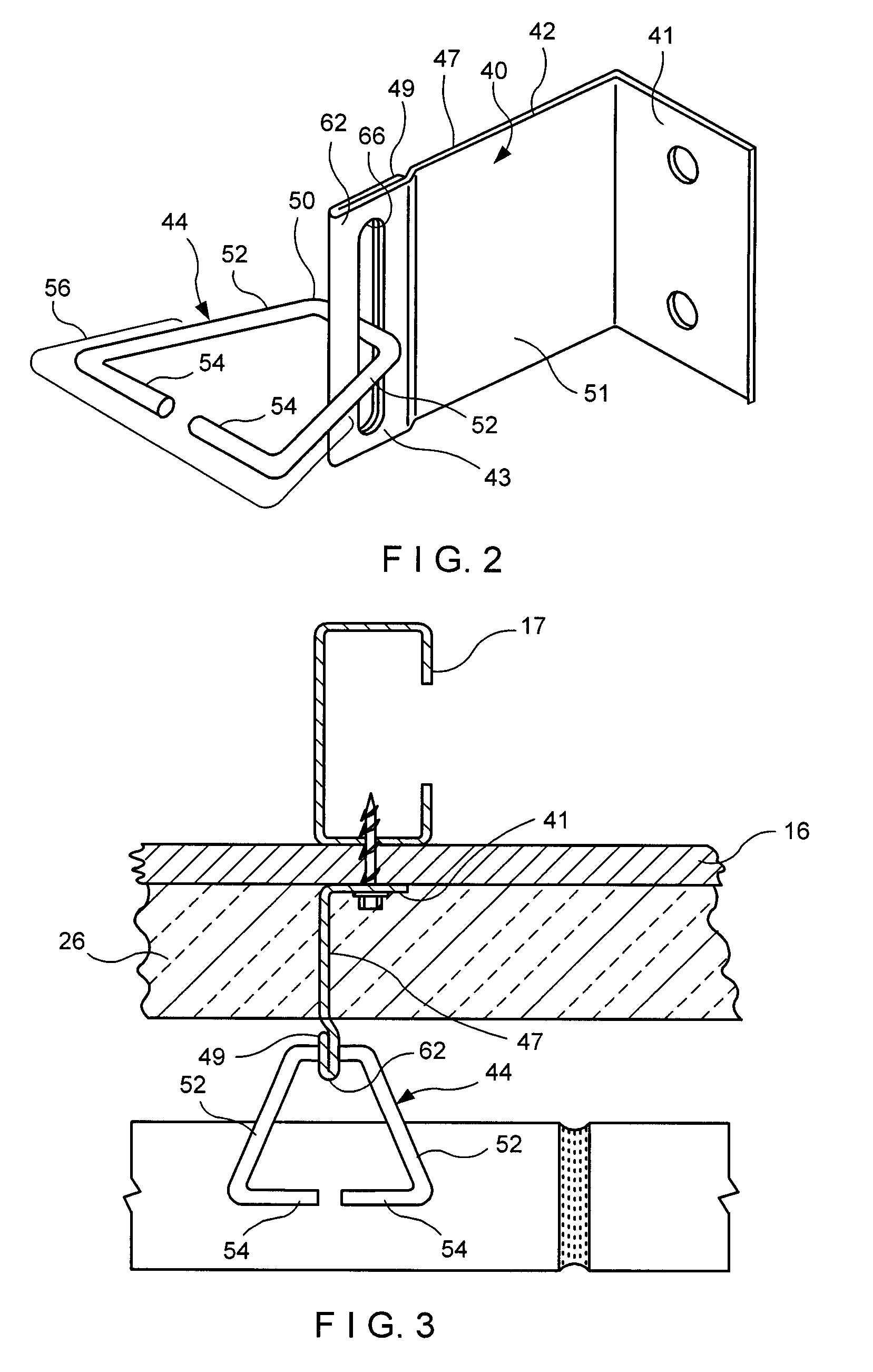

ActiveUS7325366B1Reduce manufacturing costLower unit costConstruction materialFloorsEngineeringCavity wall

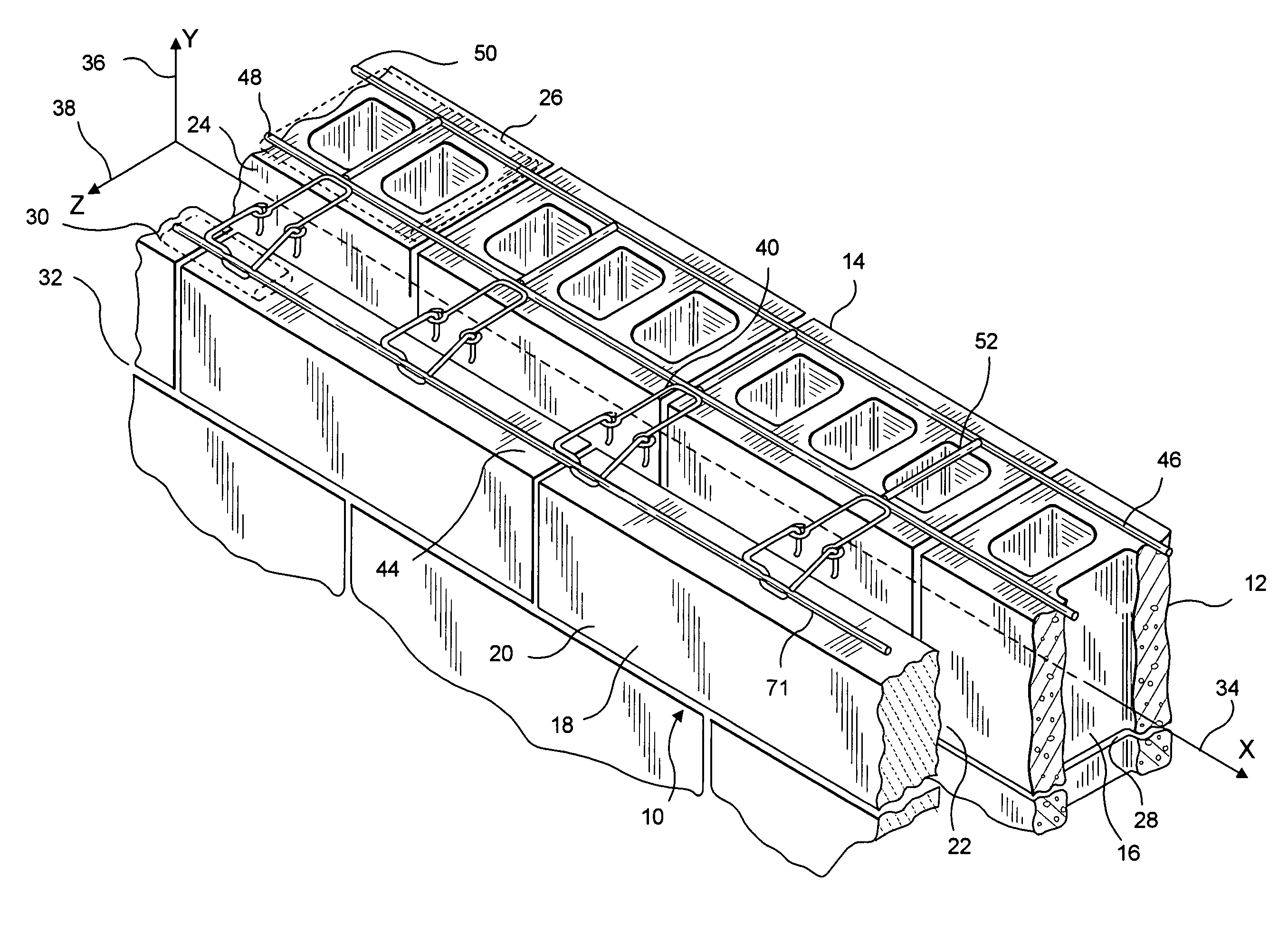

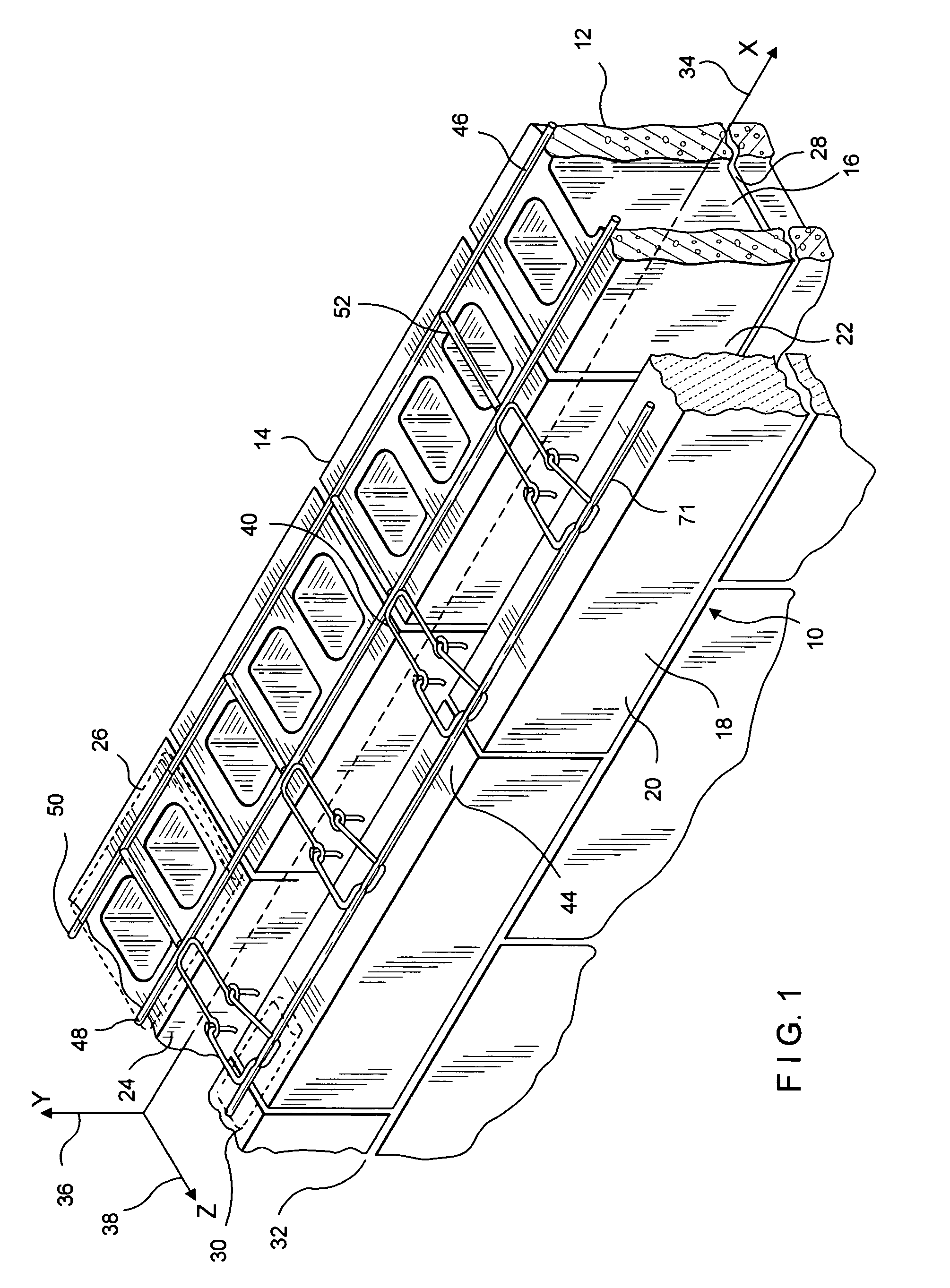

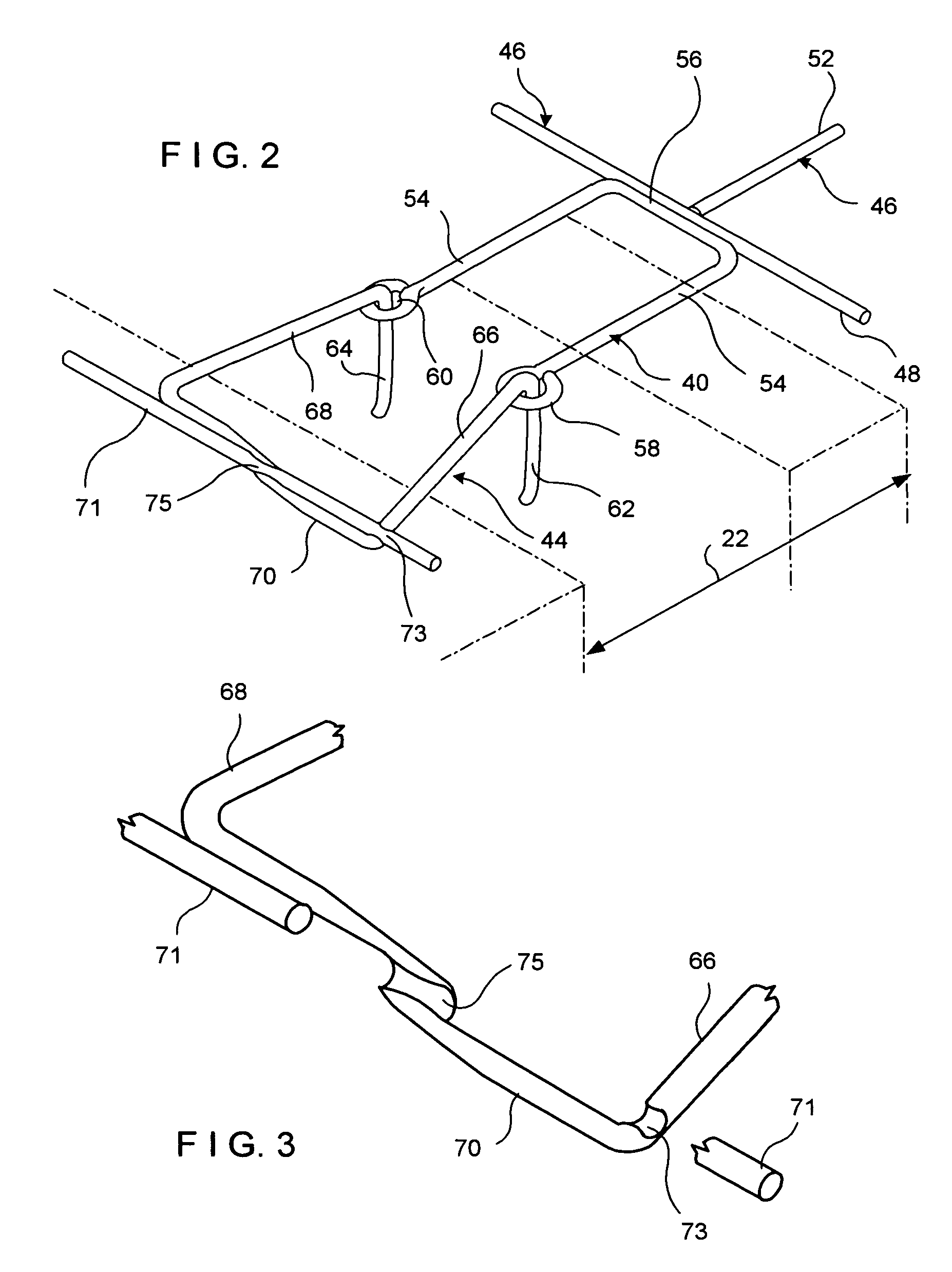

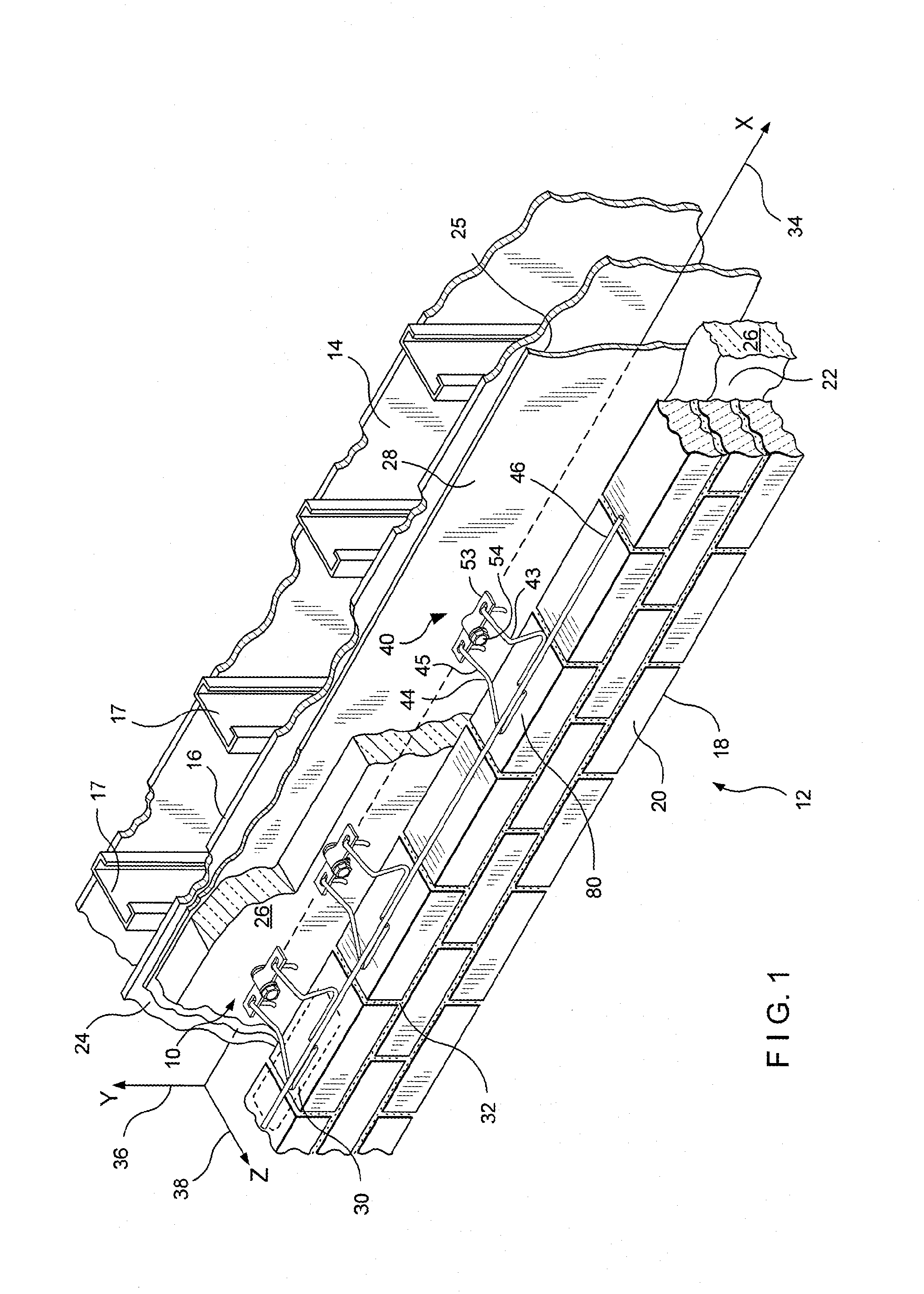

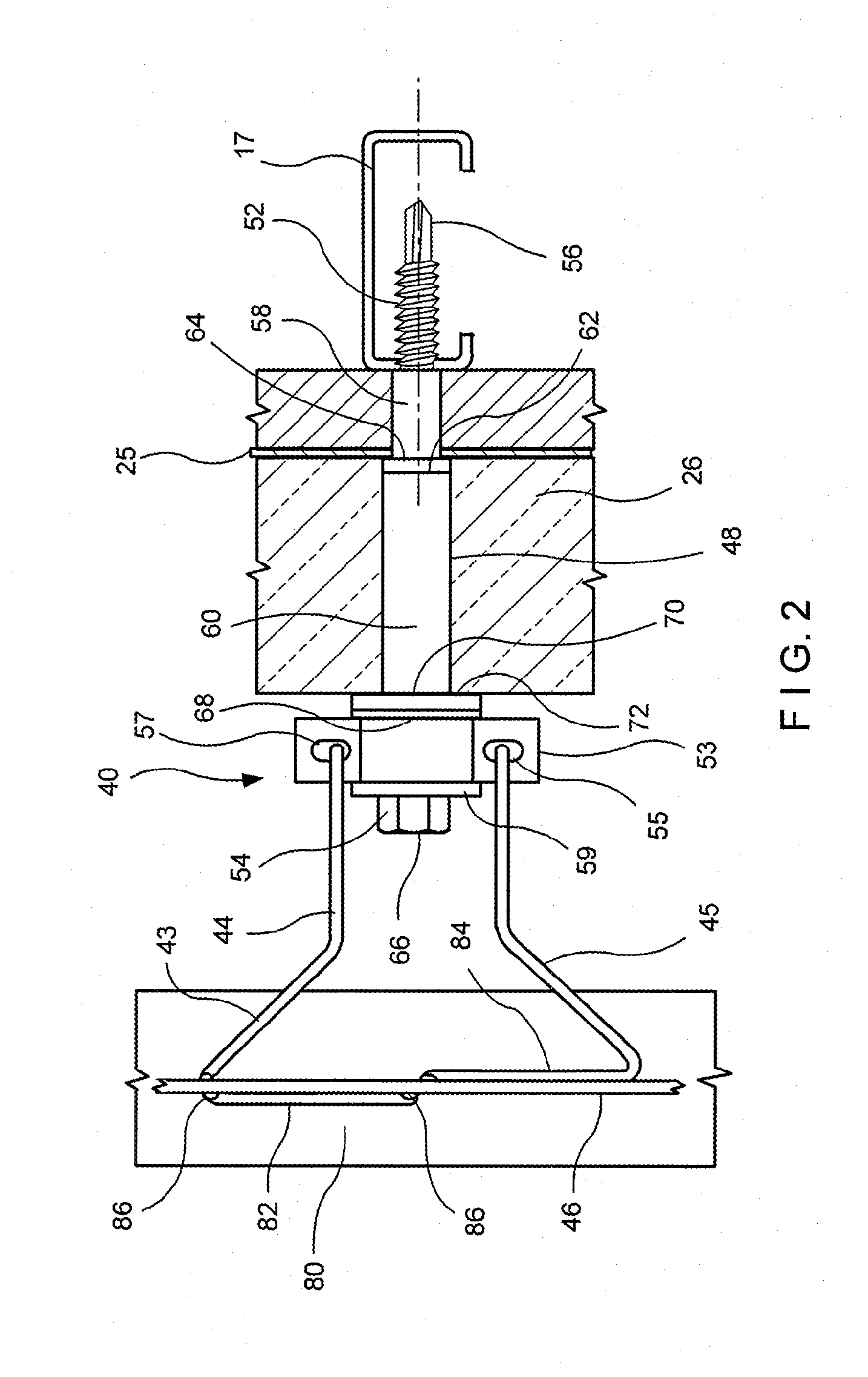

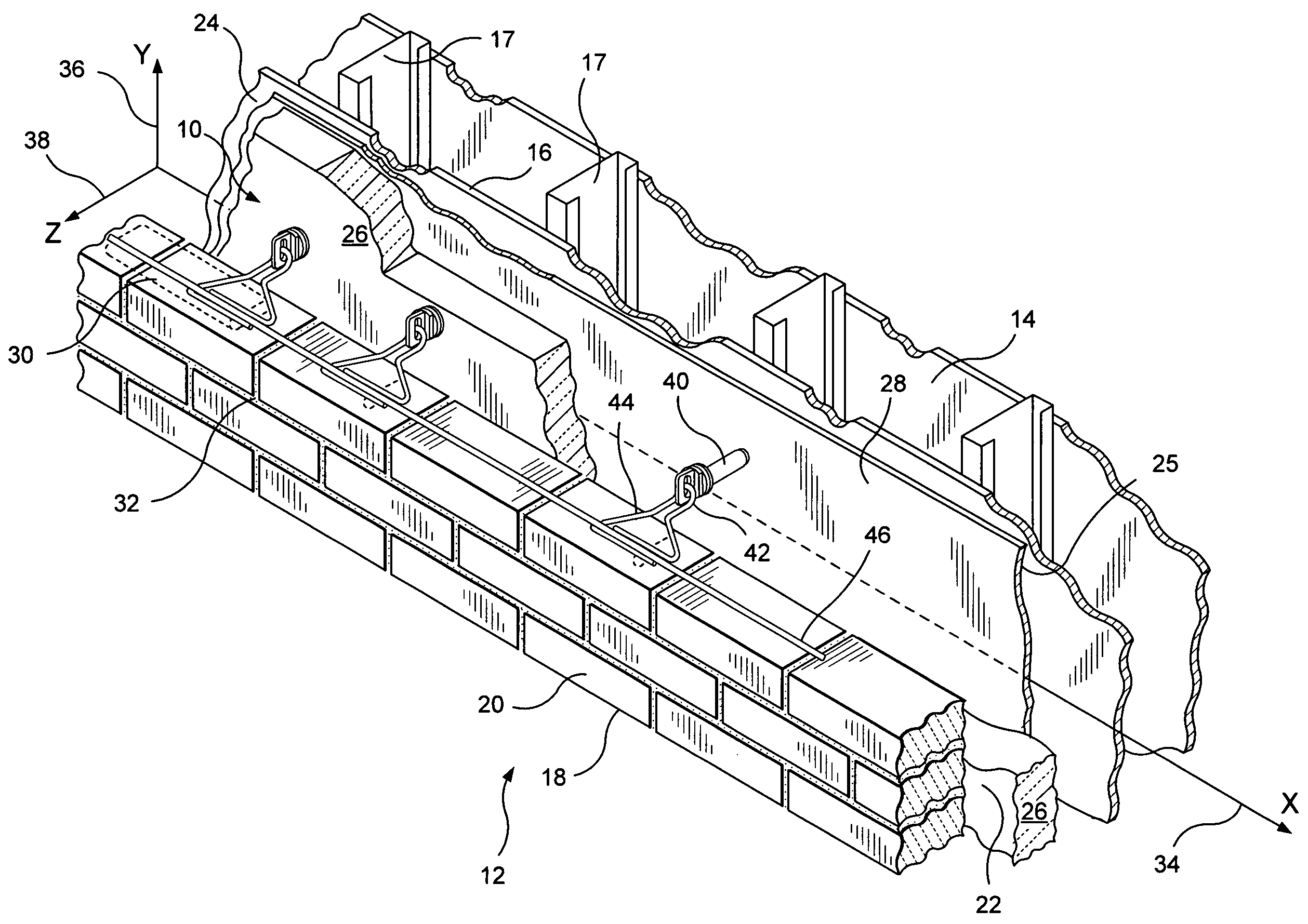

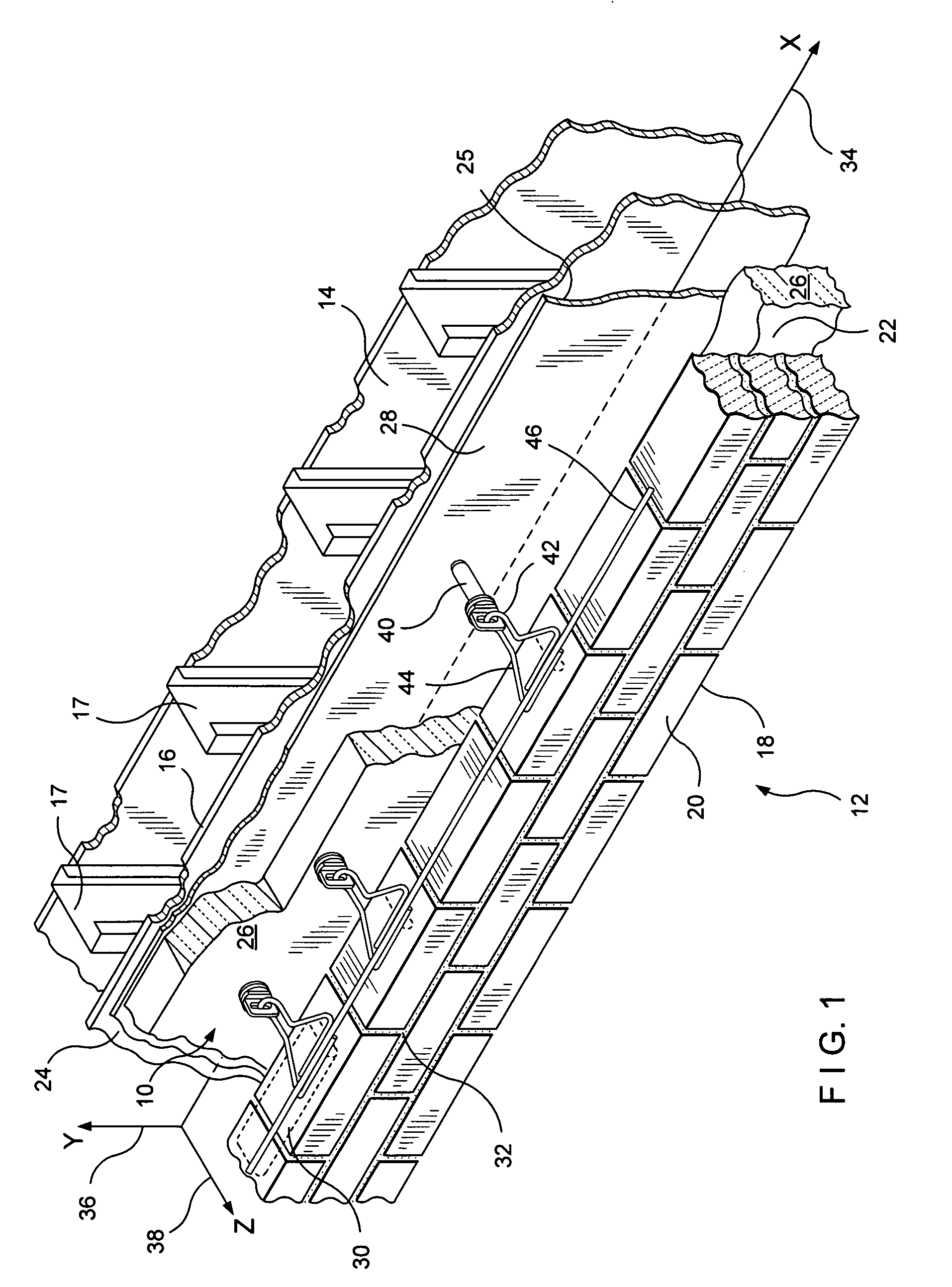

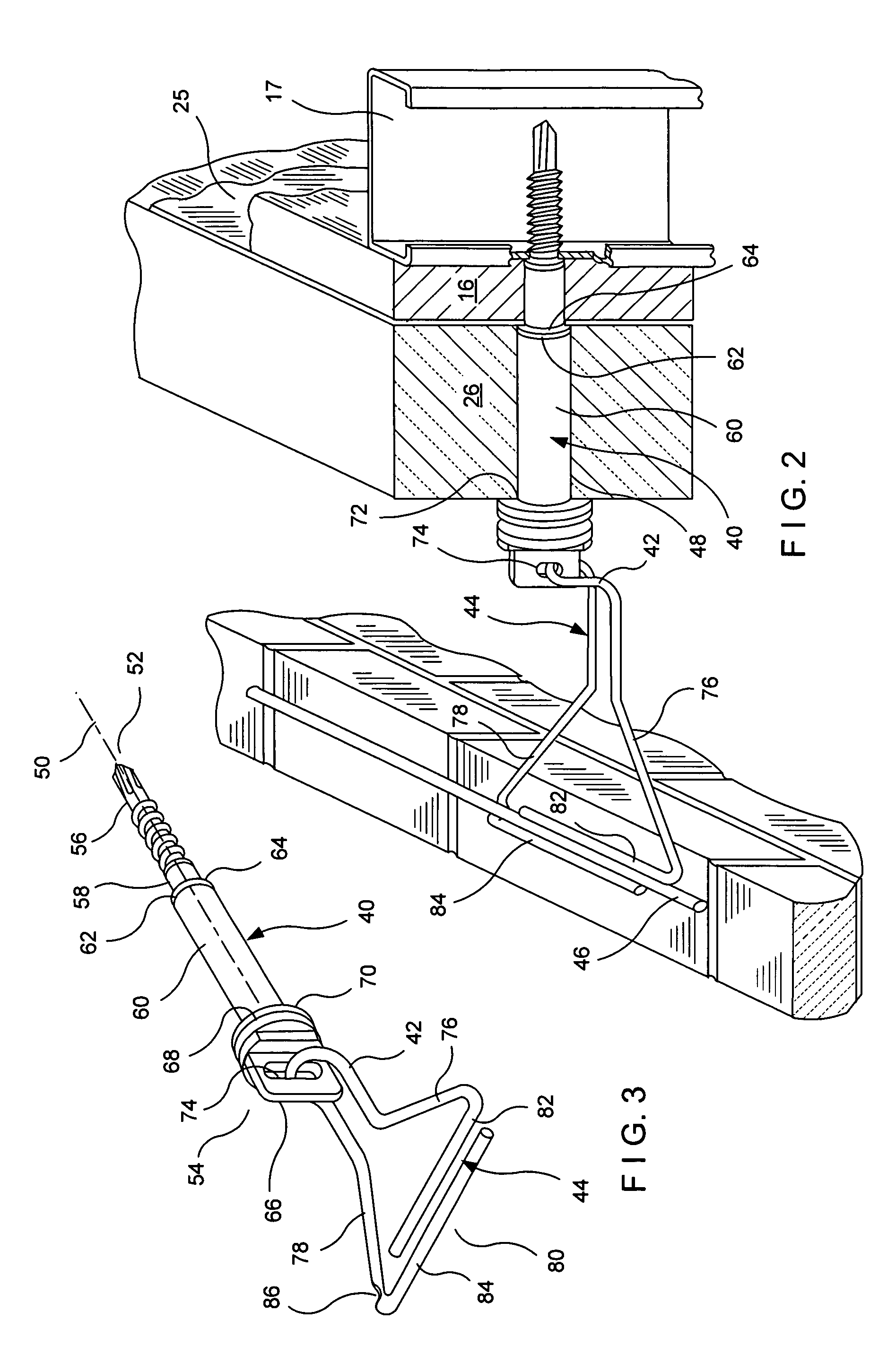

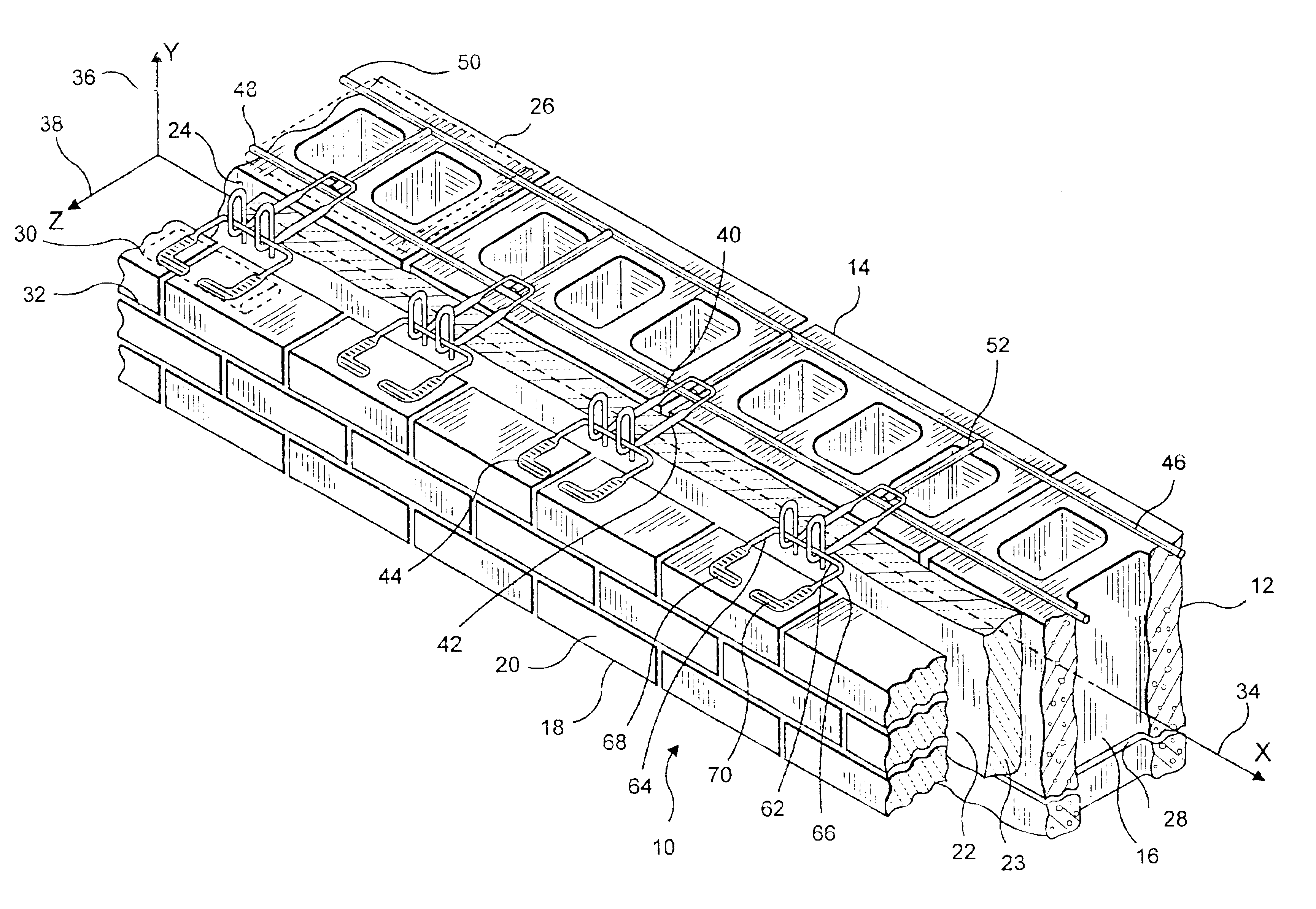

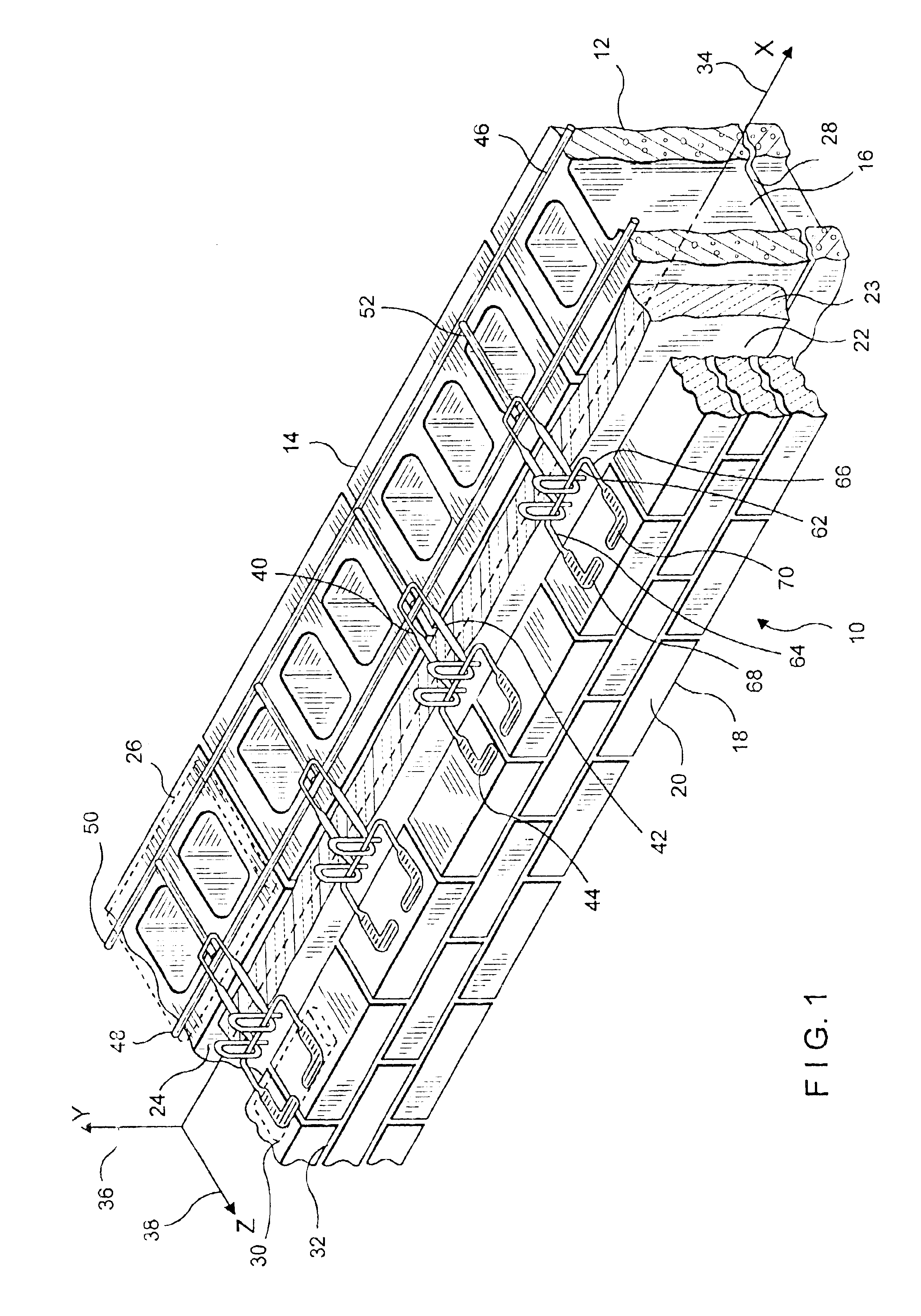

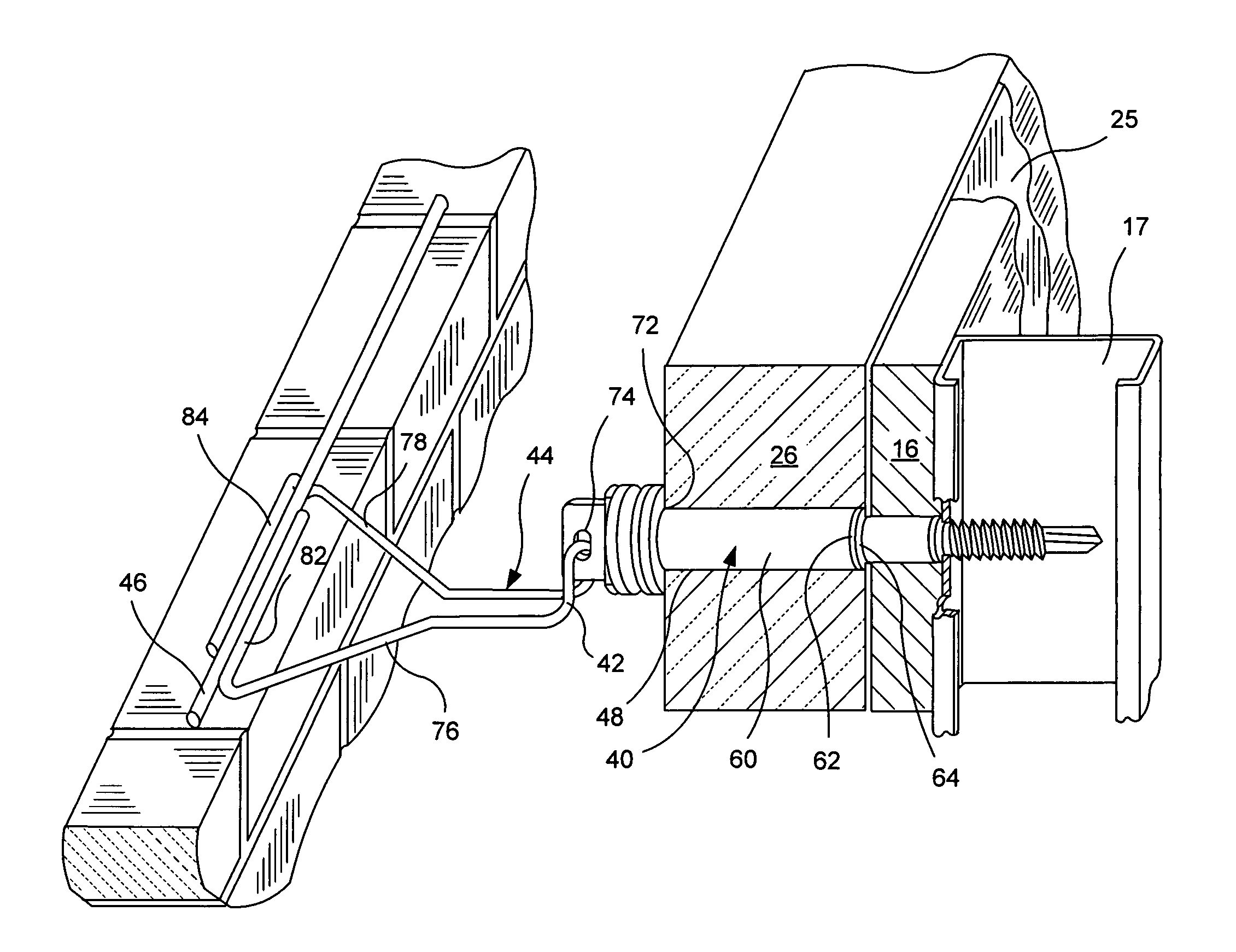

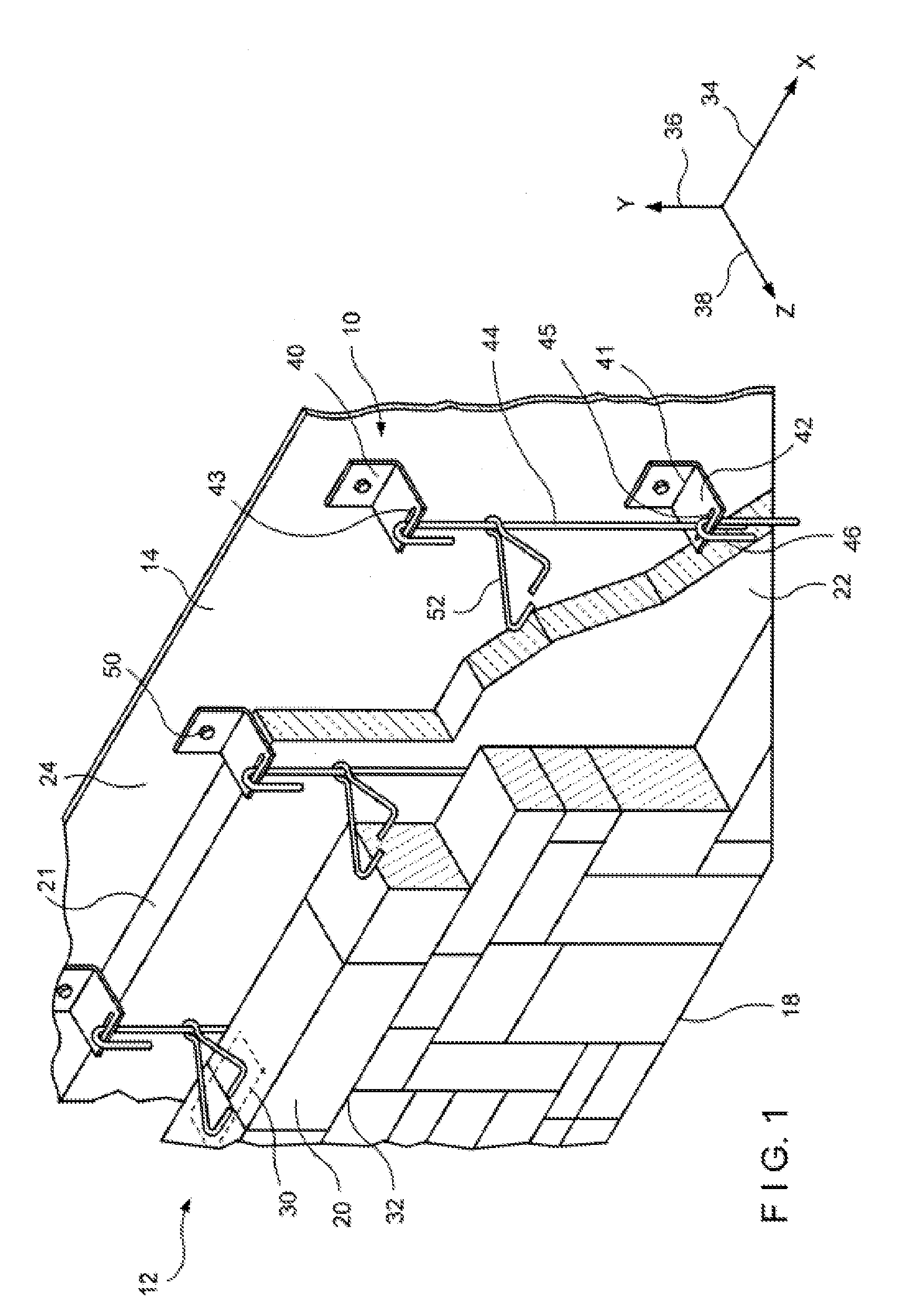

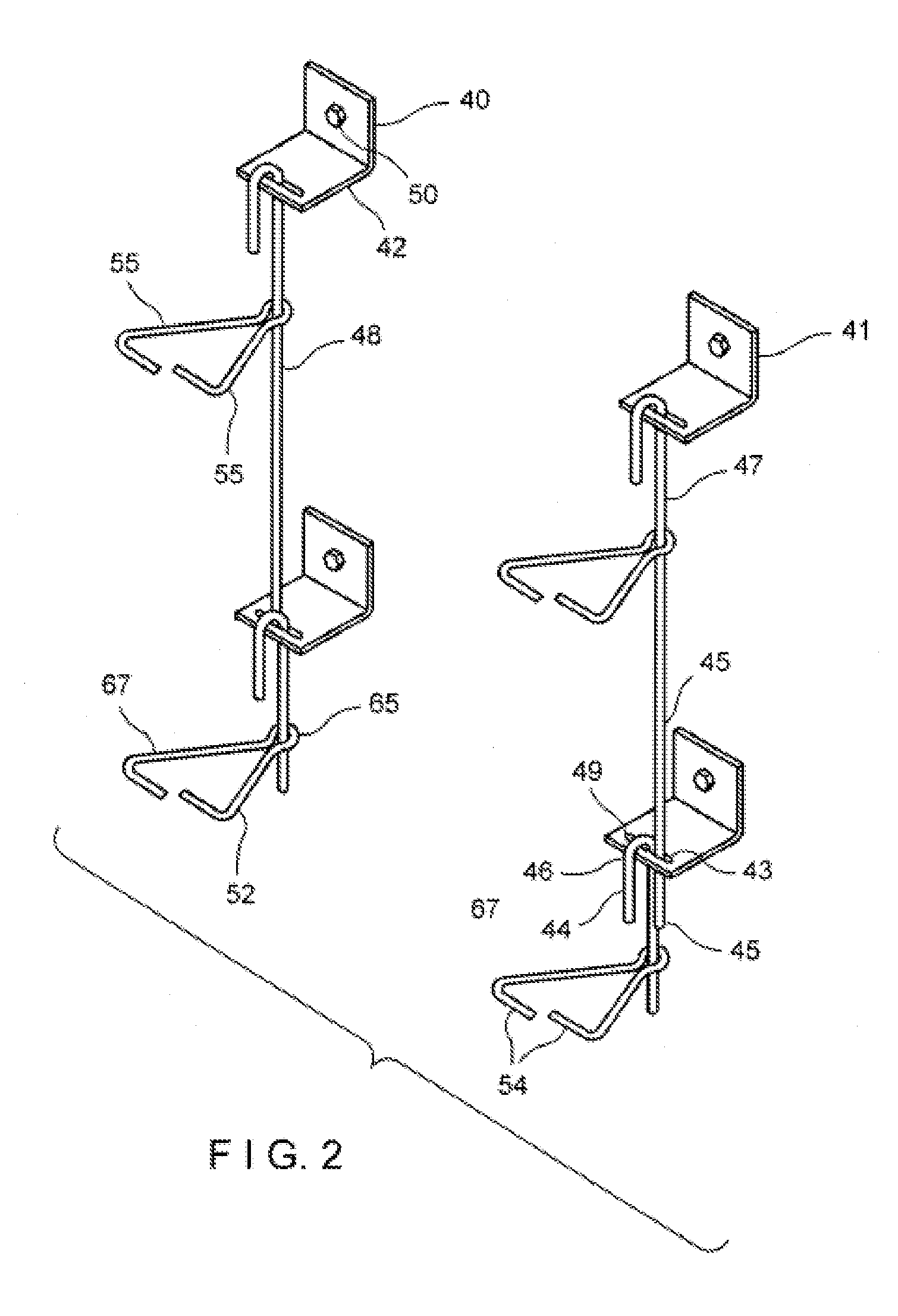

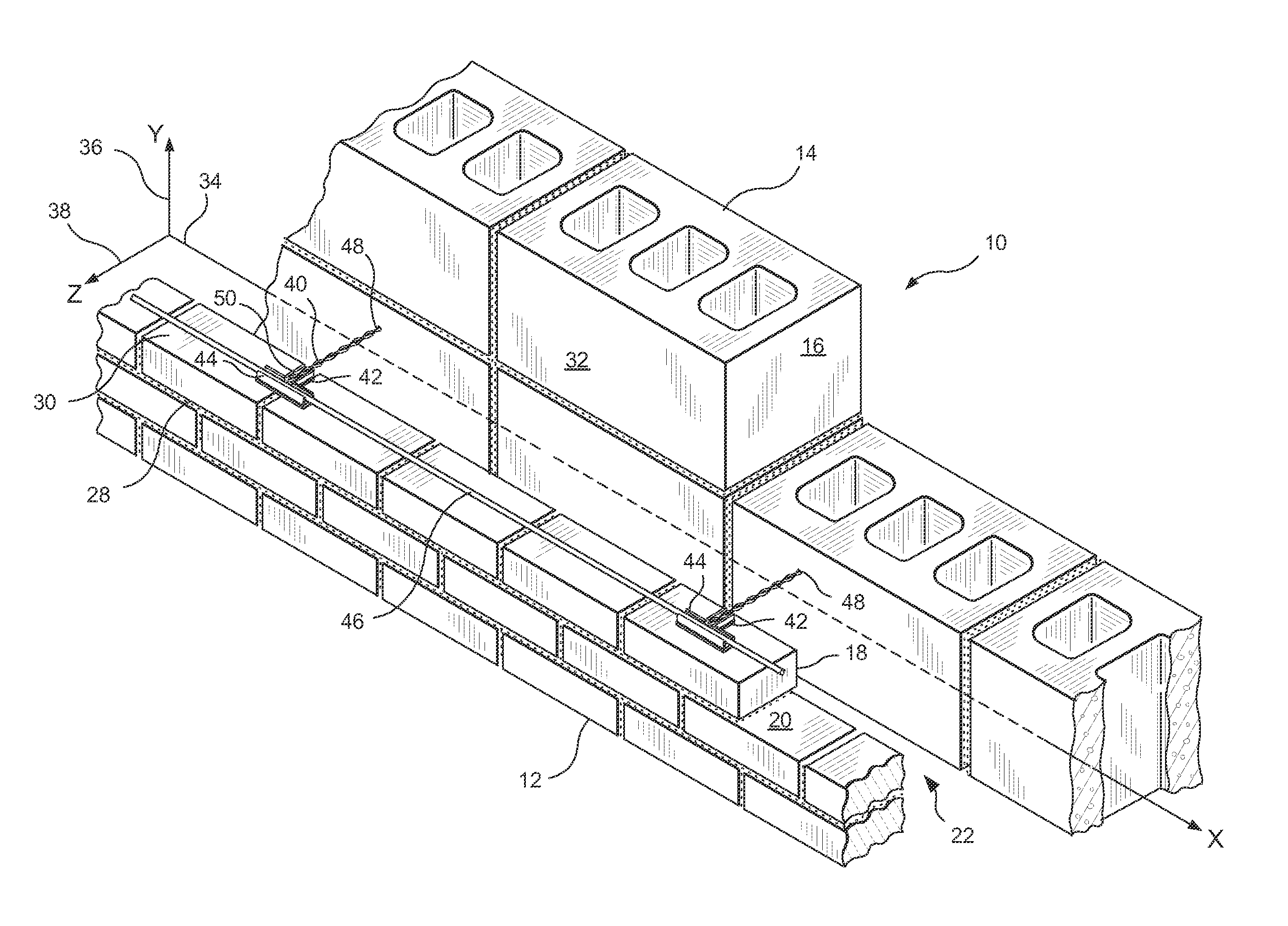

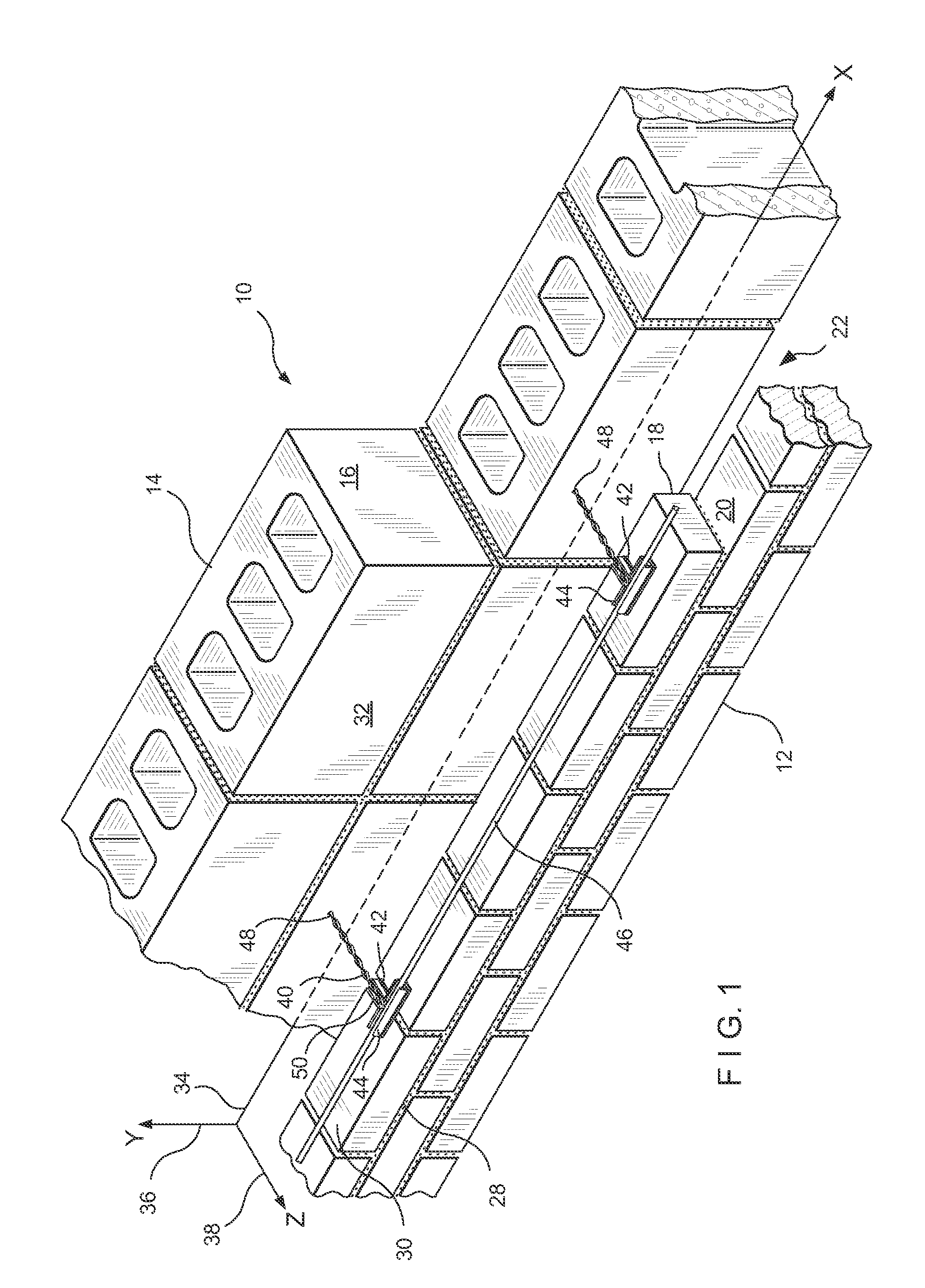

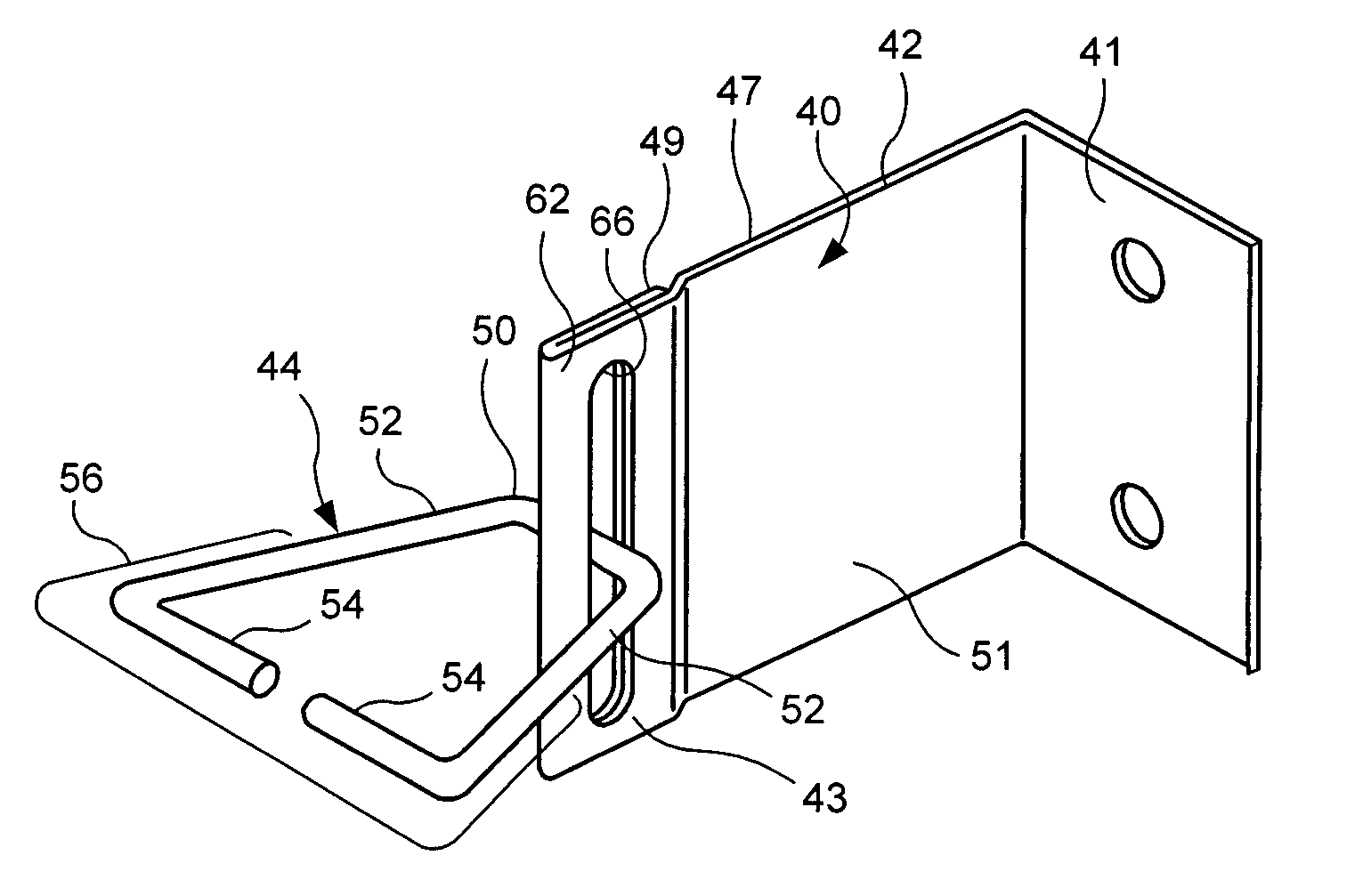

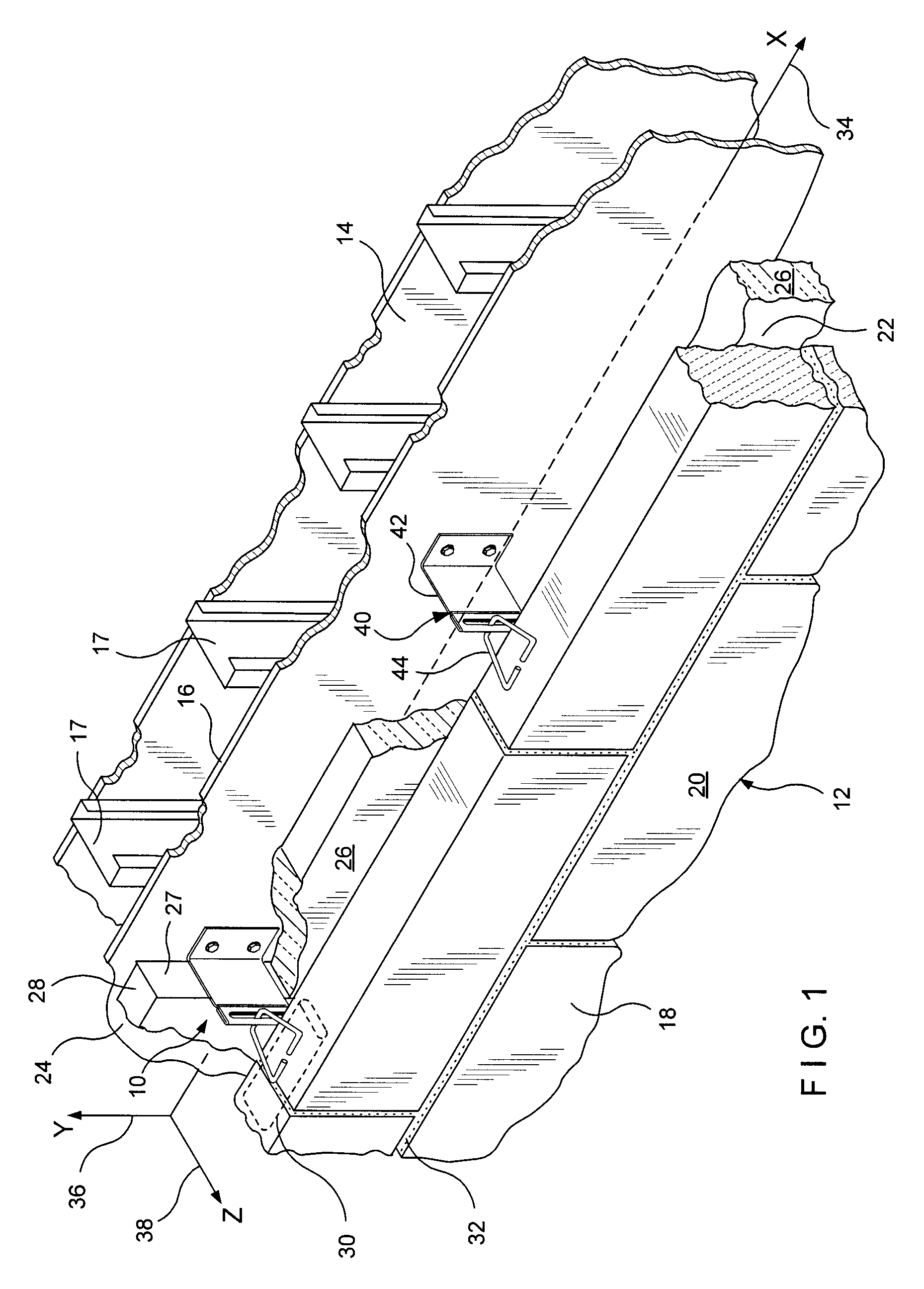

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder- or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder- or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

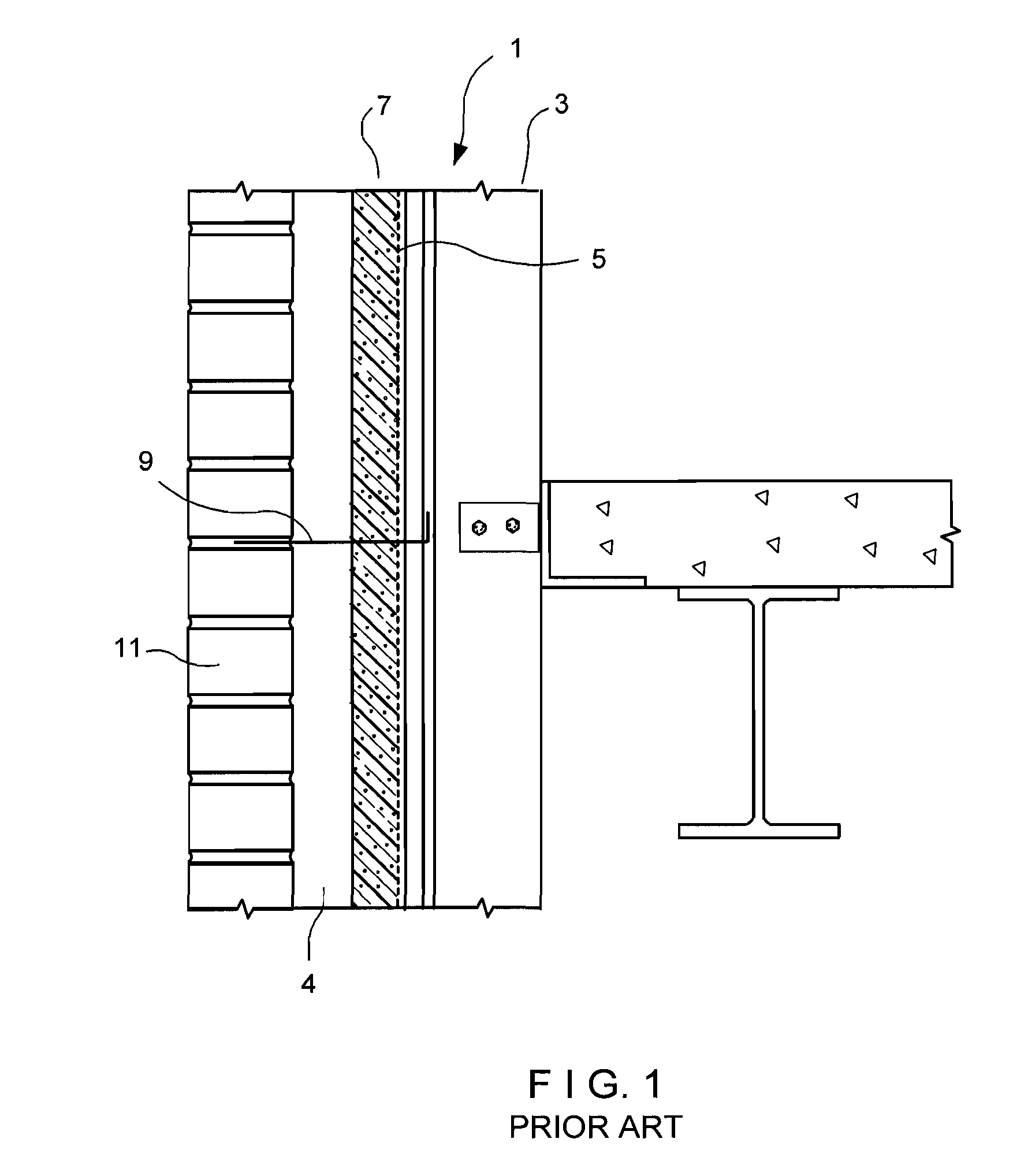

Thermally isolated anchoring system

InactiveUS20110047919A1Preserves the insulation integrityOvercome problemsConstruction materialBuilding reinforcementsHigh intensityEngineering

An anchoring system for cavity walls is disclosed and includes a stud-type wall anchor and veneer tie. The stud is comprised of high-strength, nonconductive thermally-isolating components that maintain the insulation R-values. The stud has a driver head, dual-diameter barrel, and driven tip. A flange at the juncture of the two barrels houses an interior seal; a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. The wall anchor is clamped in place by the seals. The anchor operates with various of veneer ties.

Owner:MITEK HLDG INC

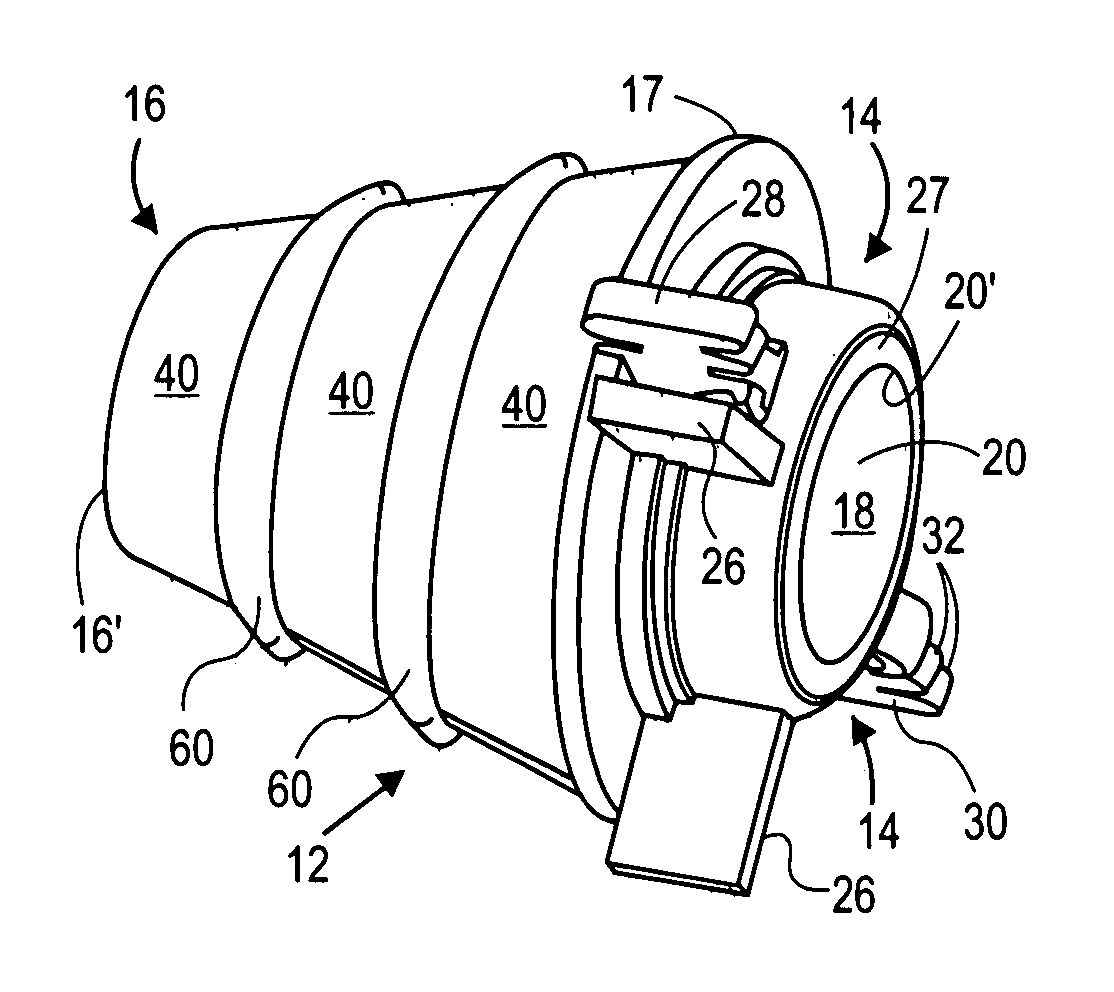

Dual seal anchoring systems for insulated cavity walls

ActiveUS20080141605A1Prevent air infiltrationPrevent water penetrationConstruction materialStrutsEngineeringCavity wall

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

True-joint anchoring systems for cavity walls

InactiveUS6851239B1Improve evenlyReadily maintained verticalityStrutsConstruction materialMetal alloySingle plate

A high-span anchoring system is described for a cavity wall incorporating a wall reinforcement combined with a wall tie which together serve a wall construct having a larger-than-normal cavity. Further the various embodiments combine wire formatives which are compressively reduced in height by the cold-working thereof. Among the embodiments is a veneer anchoring system with a low-profile wall tie for use in a heavily insulated wall. The compressively reduced in height wall anchors protrude into the cavity through the seams, between insulation strips, which seams seal thereabout and maintain the integrity of the insulation by minimizing air leakage. Further, the eye wires extend across the insulation into the cavity between the wythes, and each accommodates the threading thereinto of a wire facing anchor or wall tie with either a pintle inserted through the eye or the open end of the veneer tie. The veneer tie is then positioned so that the insertion end is embedded in the facing wall. The close control of overall heights permits the mortar of the bed joints to flow over and about the wall reinforcement and wall tie combination inserted in the inner wythe and insertion end of the wall in the outer wythe. Because the wire formatives hereof employ extra strong material and benefit from the cold-working of the metal alloys, the high-span anchoring system meets the unusual requirements demanded thereof.

Owner:HOHMANN & BARNARD INC

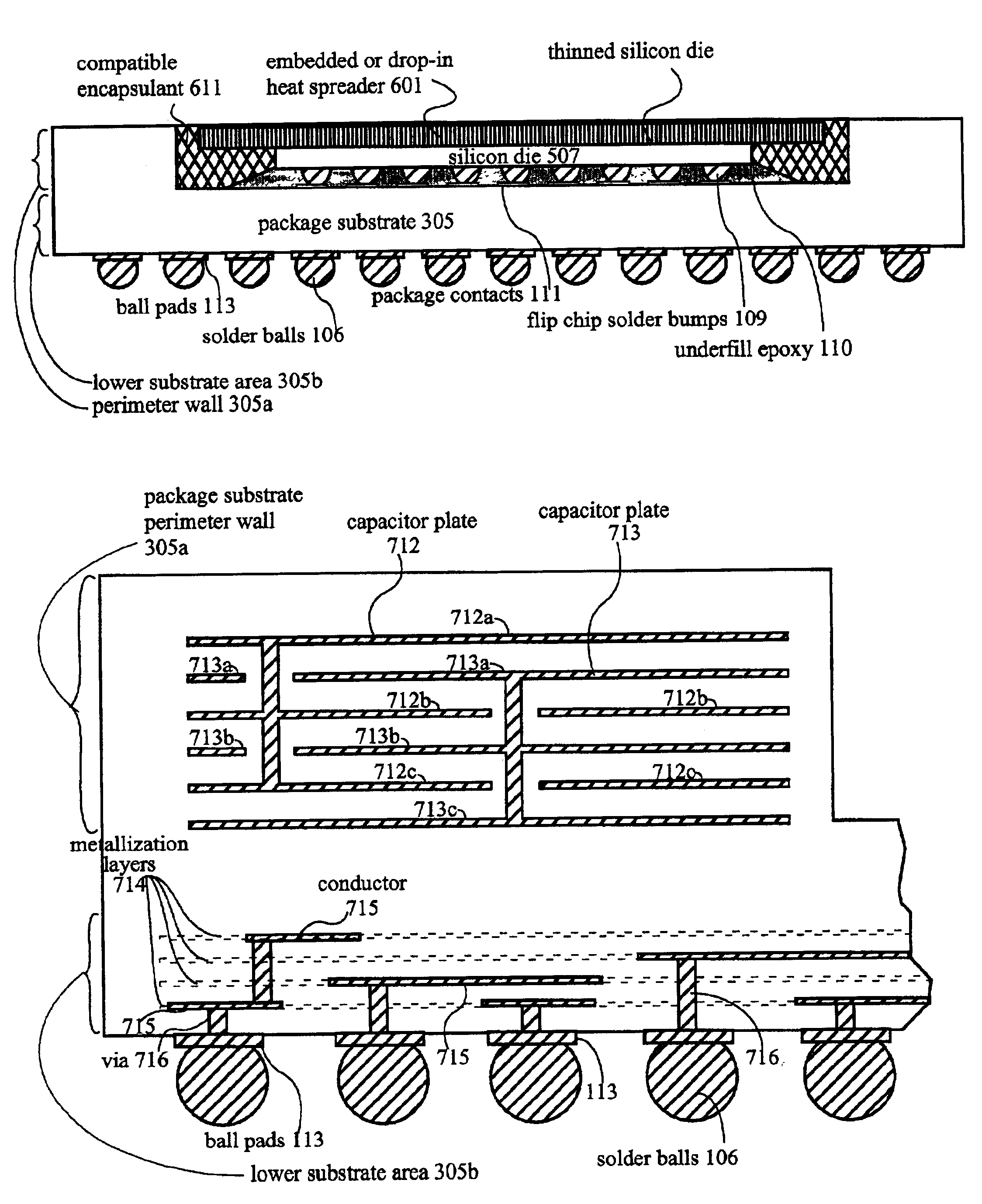

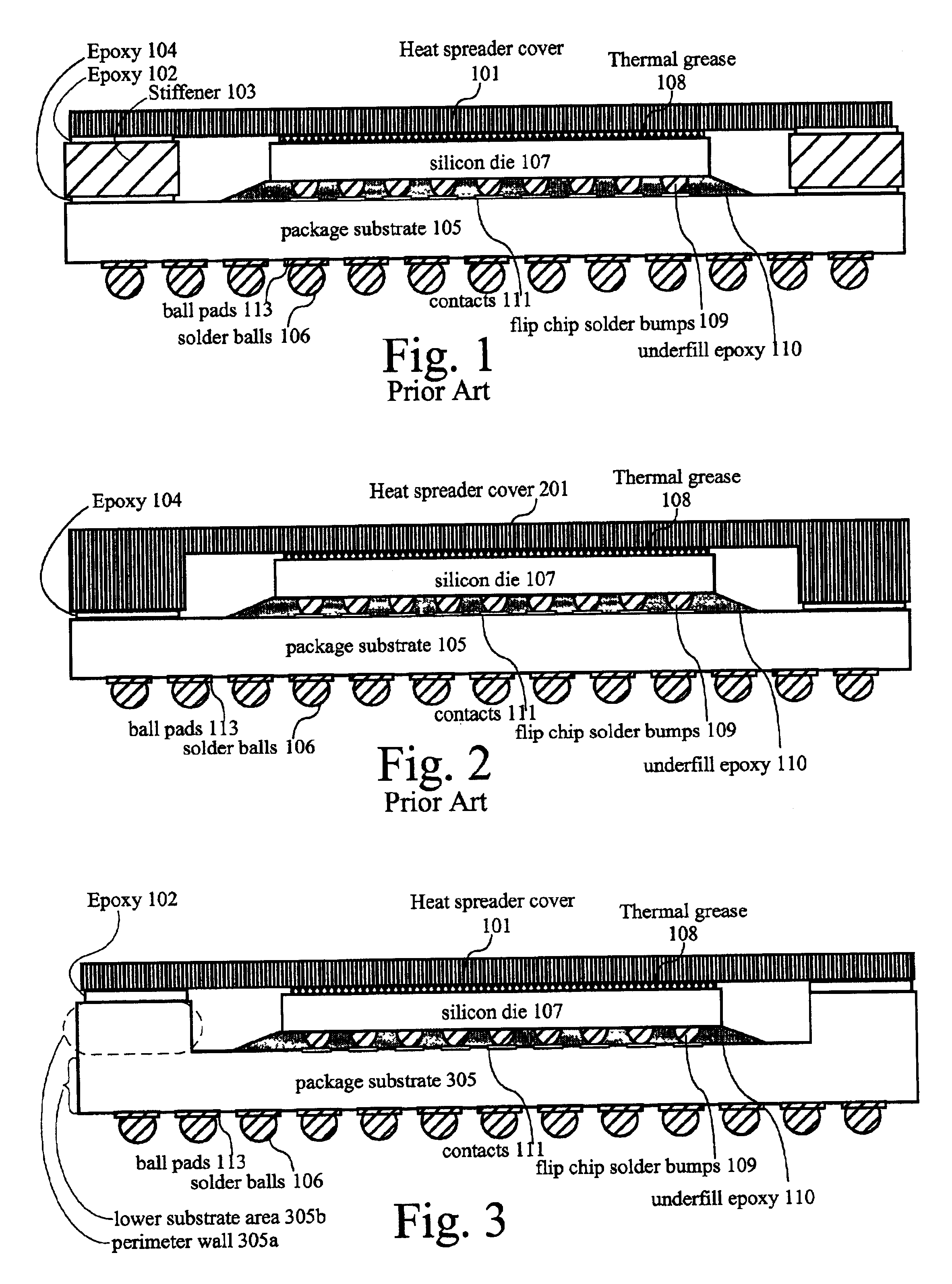

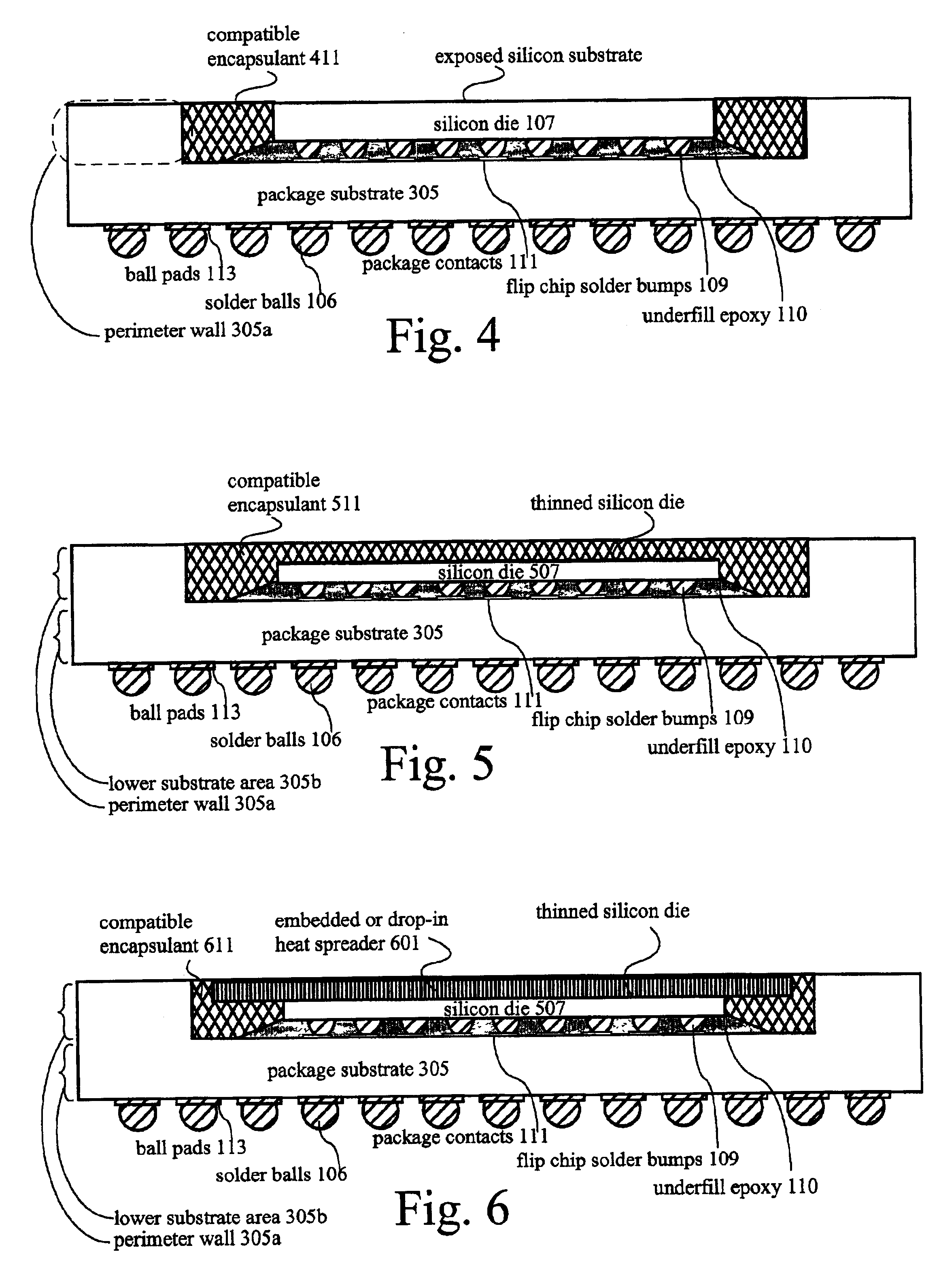

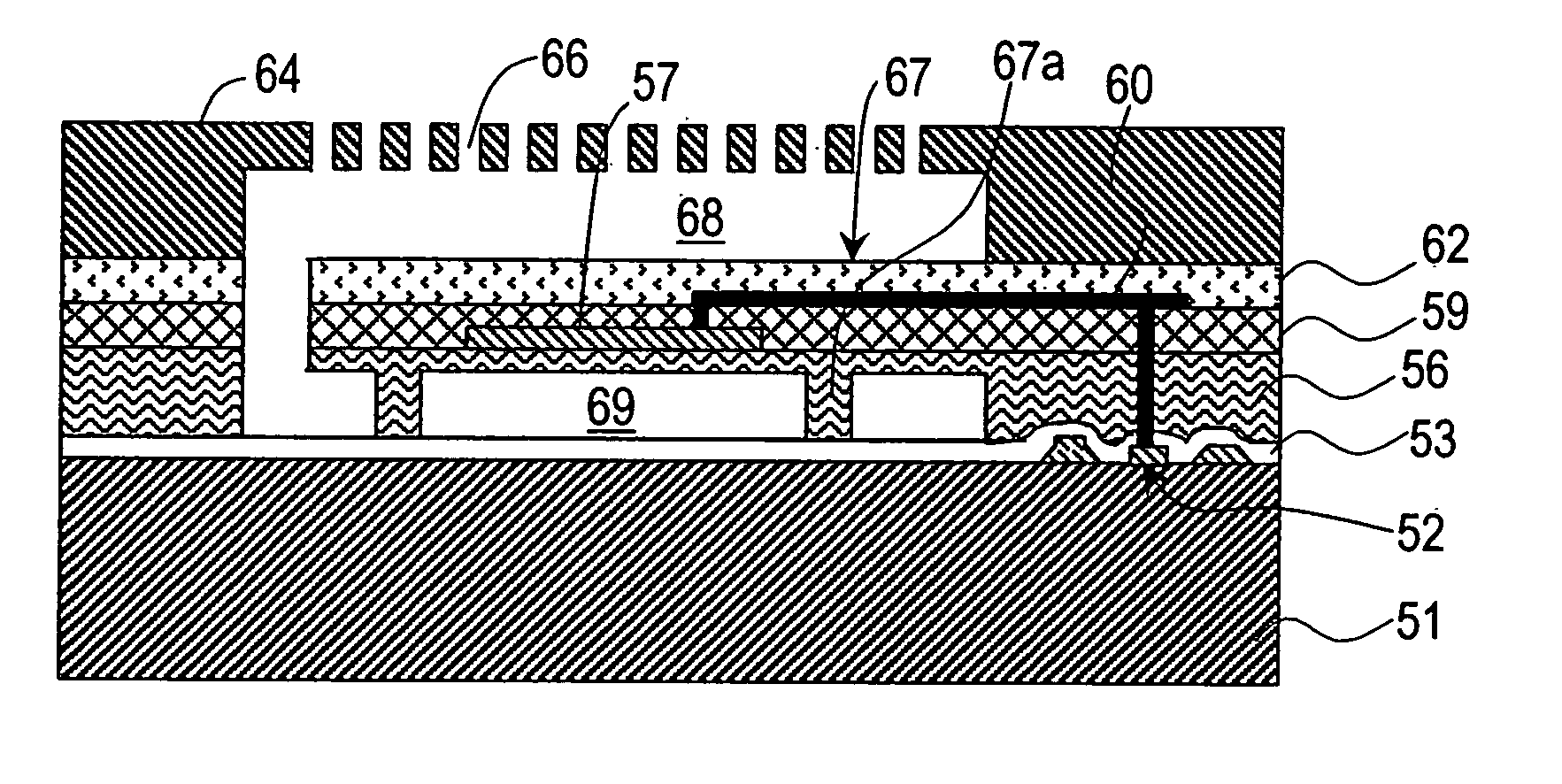

High performance flipchip package that incorporates heat removal with minimal thermal mismatch

InactiveUS7061102B2Reduce warpageMinimize interfacial stressSemiconductor/solid-state device detailsSolid-state devicesFlip chip interconnectSemiconductor package

A semiconductor flipchip package includes a central cavity area on the first major side for receiving a flipchip die therein. The package substrate is substantially made from a single material that serves as the support and stiffener and provides within the cavity floor all the connecting points for flipchip interconnection to the silicon die. The integral cavity wall serves as a stiffener member of the package and provides the required mechanical stability of the whole arrangement without the need for a separate stiffener material to be adhesively attached. The cavity walls may contain extra routing metallization to create bypass capacitors to enhance electrical performance. Optional methods to cover the silicon die enhance thermal performance of the package.

Owner:XILINX INC

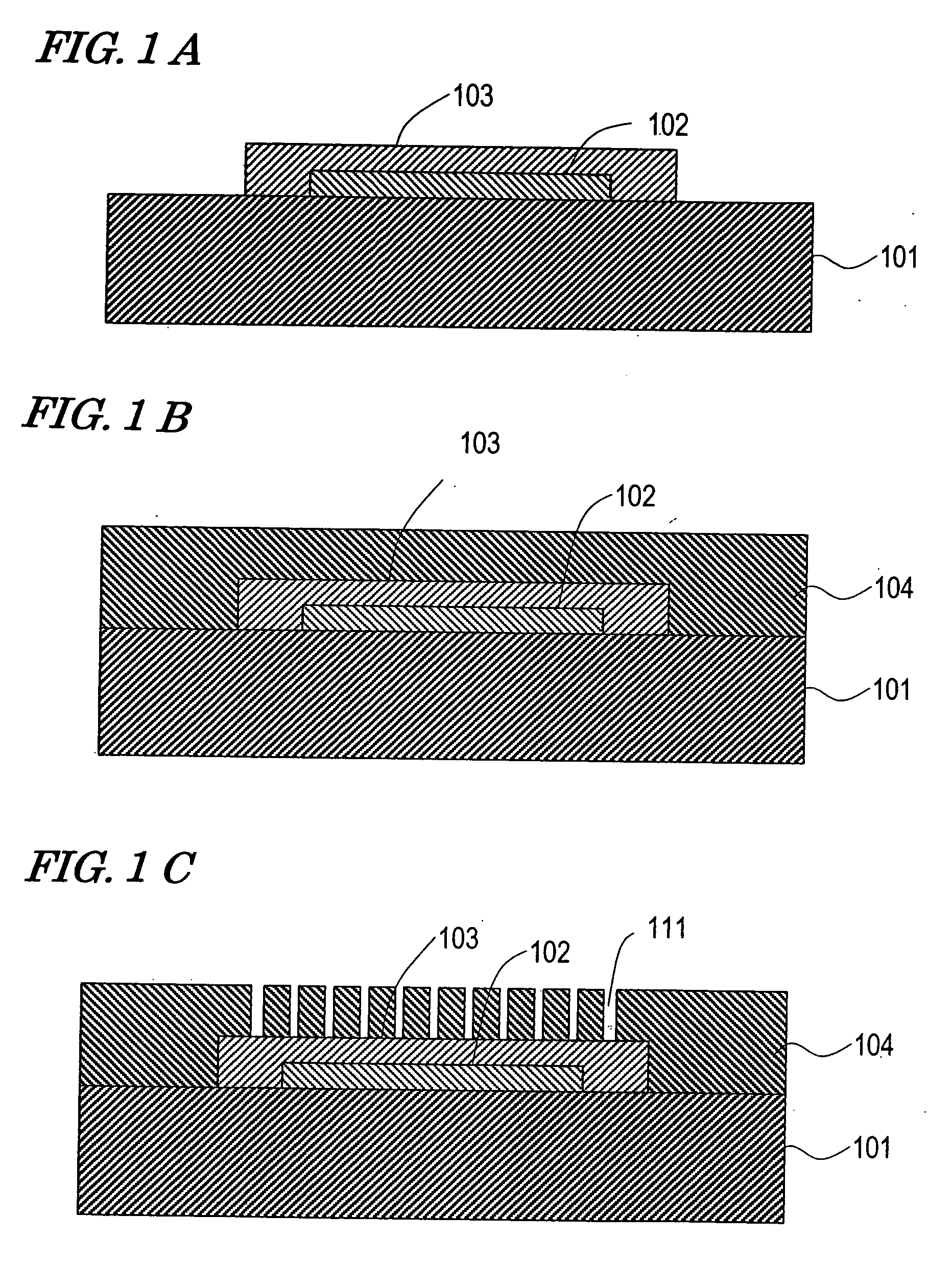

Electronic device and method of manufacturing the same

ActiveUS20050176179A1Small openingTelevision system detailsThermoelectric device with dielectric constant thermal changeSputteringHydrofluoric acid

In the present invention, an etching hole 21 is formed in a polysilicon film 14 as a cavity-wall member. Through the etching hole 21, hydrofluoric acid is injected, so as to dissolve a silicon oxide film 13, thereby forming a cavity 22. In the cavity 22, a detecting unit 12 of a sensor is in an exposed condition. Next, by sputtering, an Al film 16 is deposited in the etching hole 21 and on an upper face of a substrate. Thereafter, a portion of the Al film 16 positioned on the polysilicon film 14 is removed by etching back, thereby leaving only a metal closure 16a of Al which closes the etching hole. The sputtering step is performed under a pressure of 5 Pa or less, so that the pressure in the cavity can be held to be low.

Owner:PANASONIC CORP

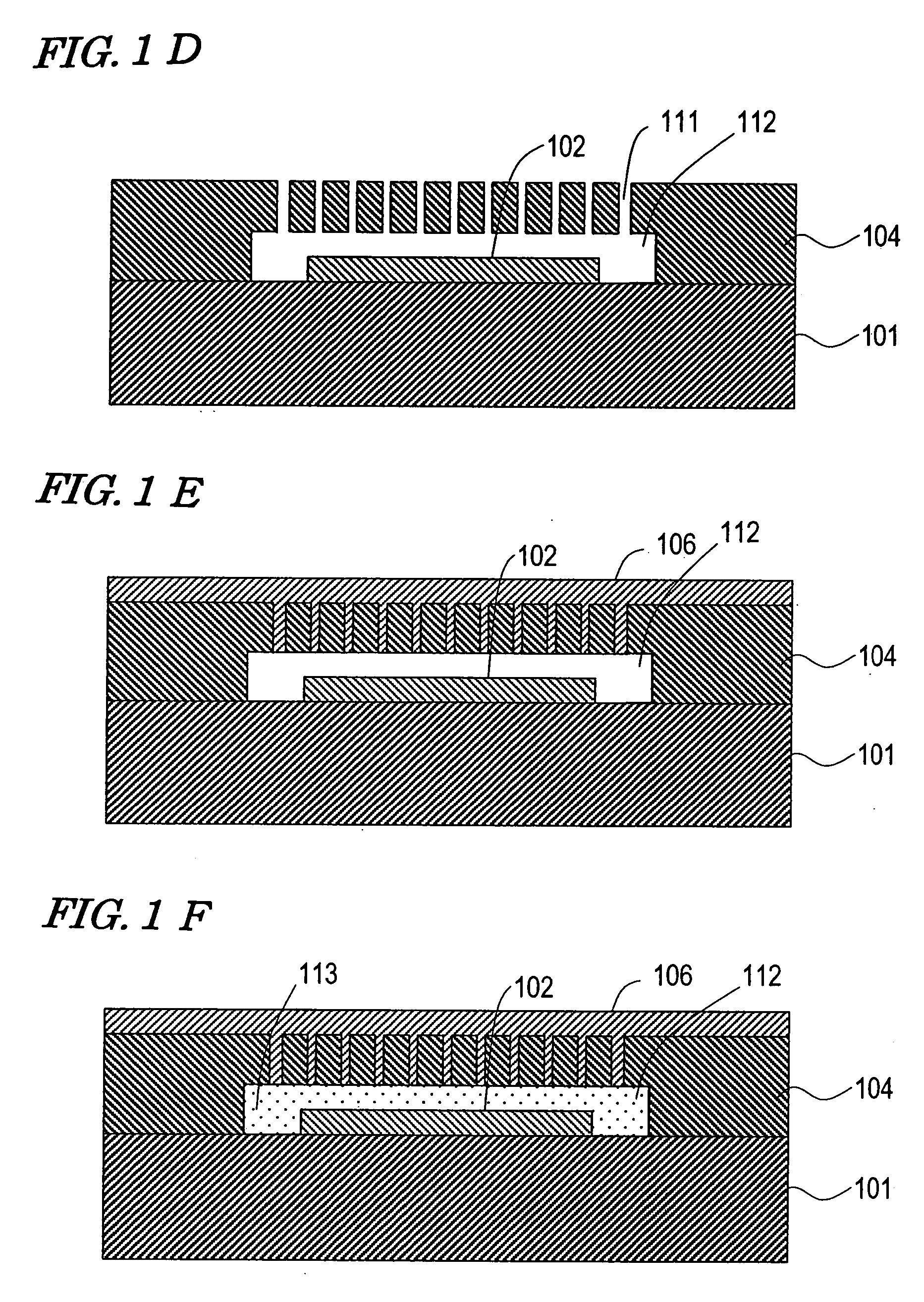

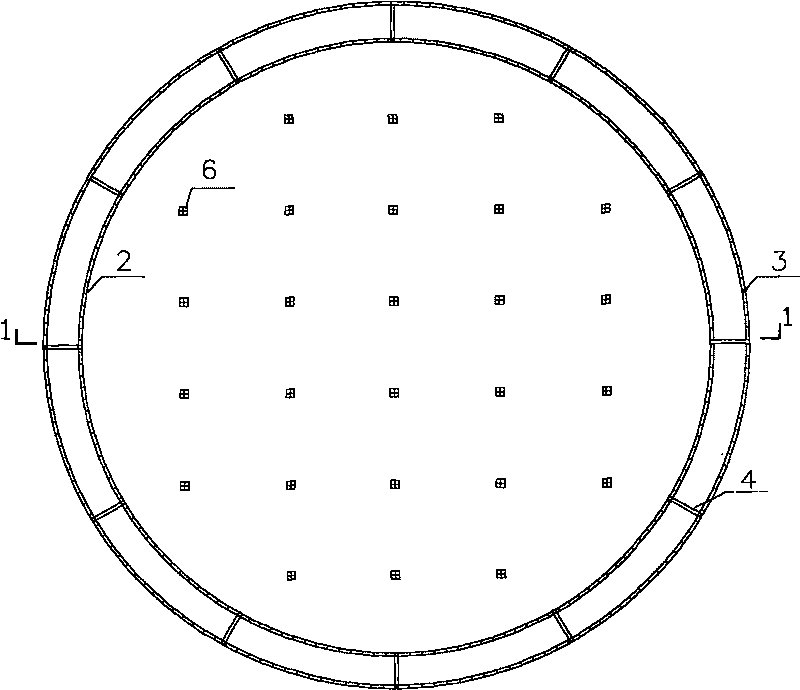

Underground barn with cavity barn wall

InactiveCN101709603AOvert target concealmentClimate change adaptationBulk storage containerLeaking waterStructural engineering

Owner:HENAN UNIVERSITY OF TECHNOLOGY

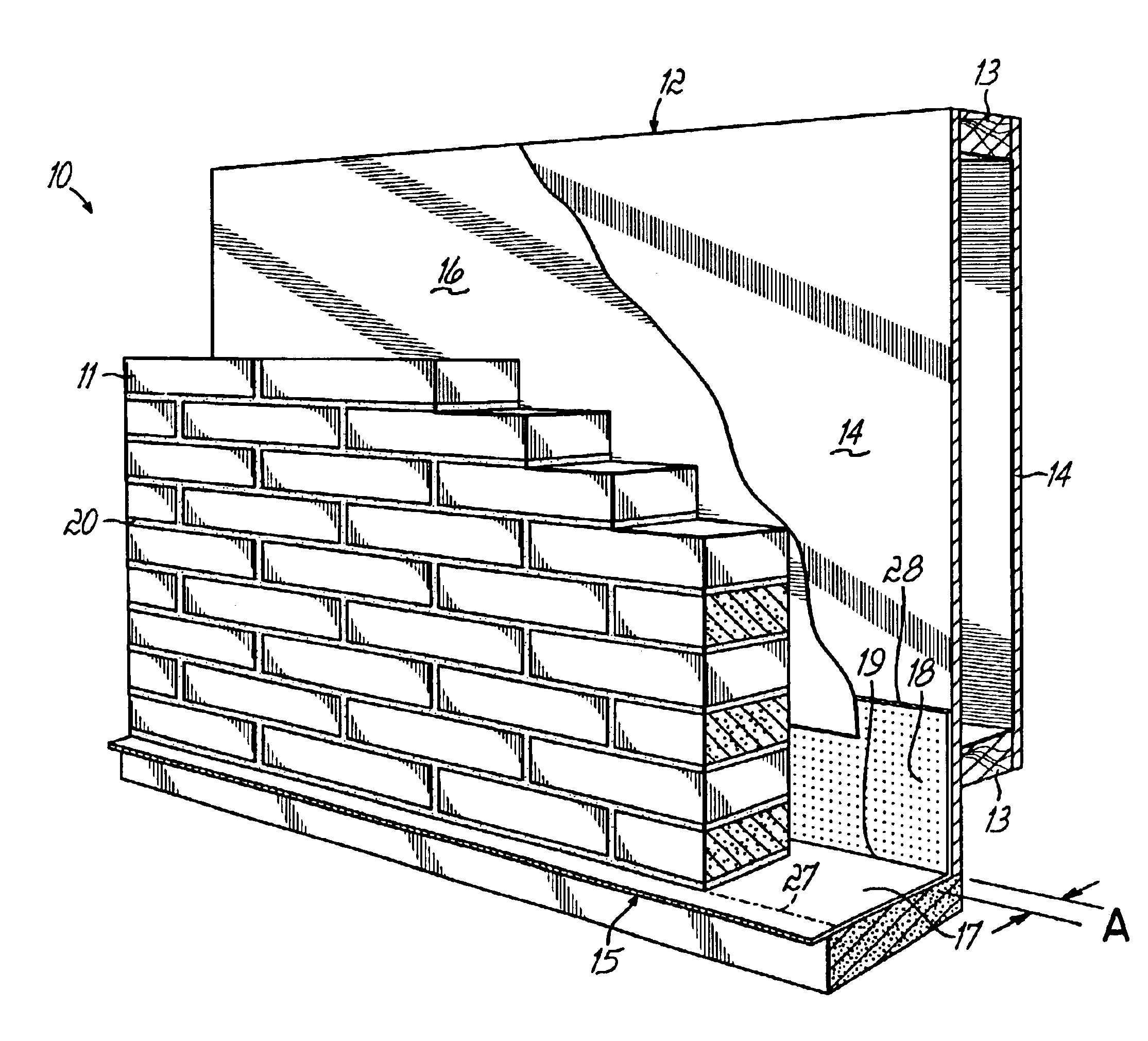

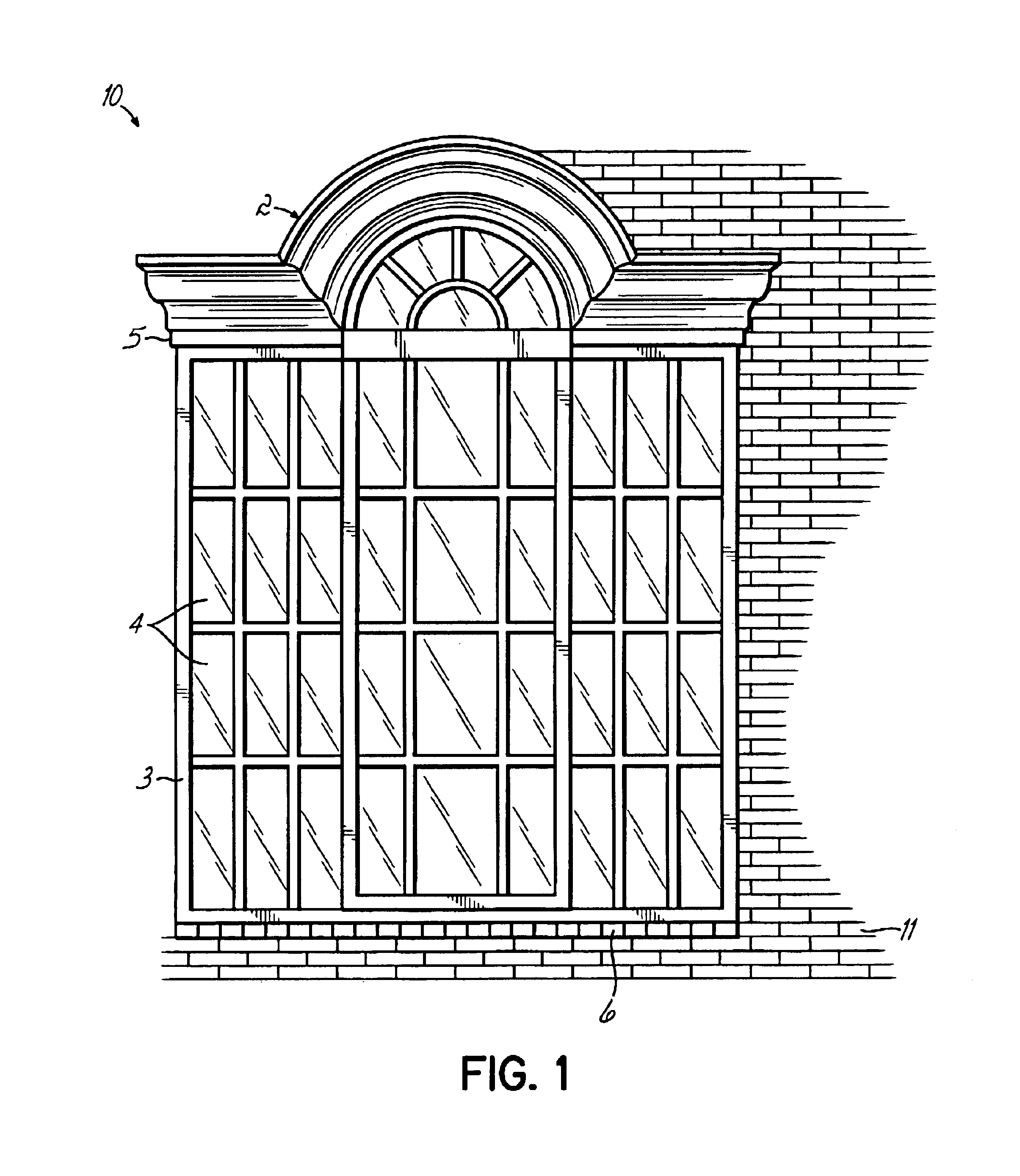

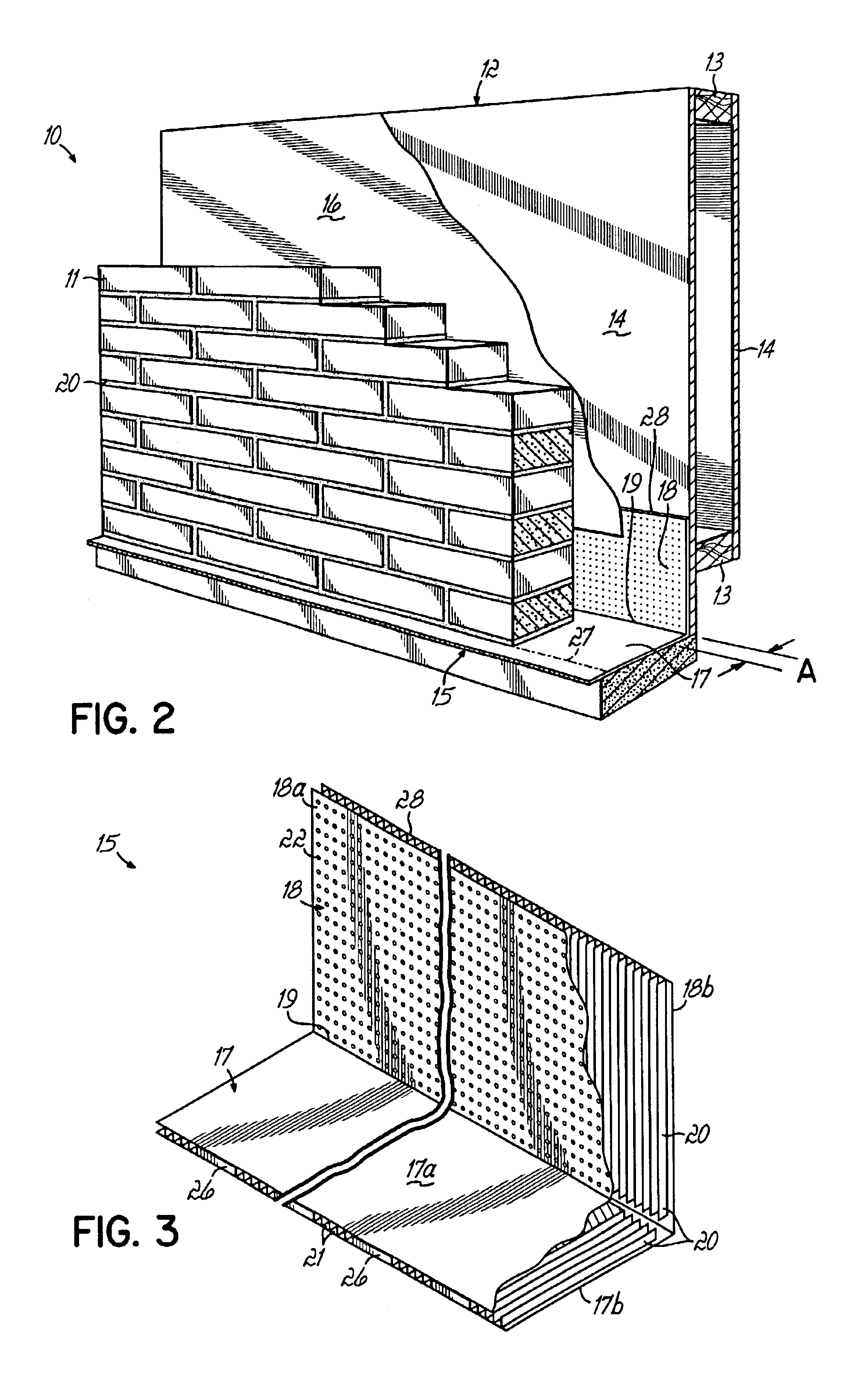

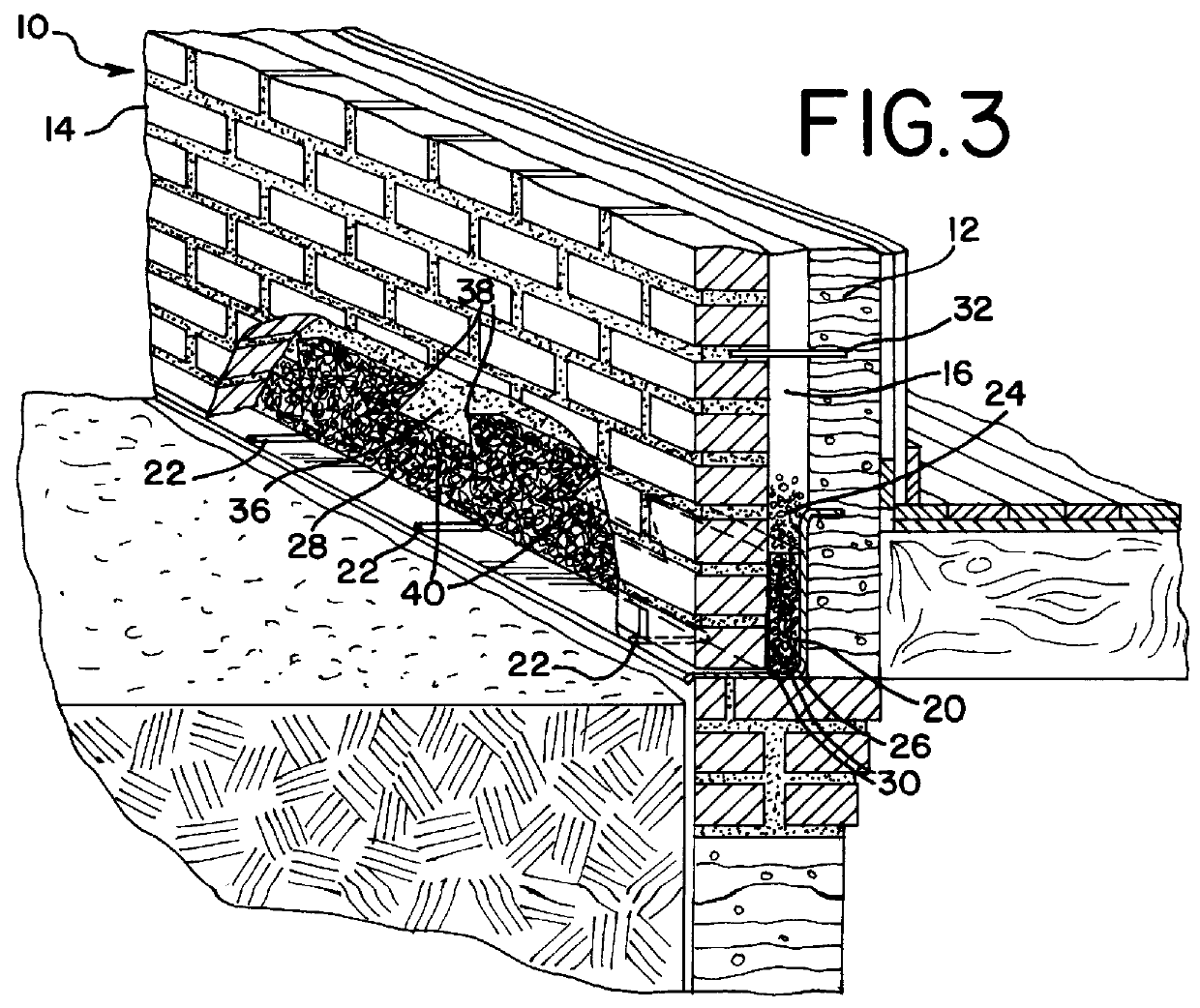

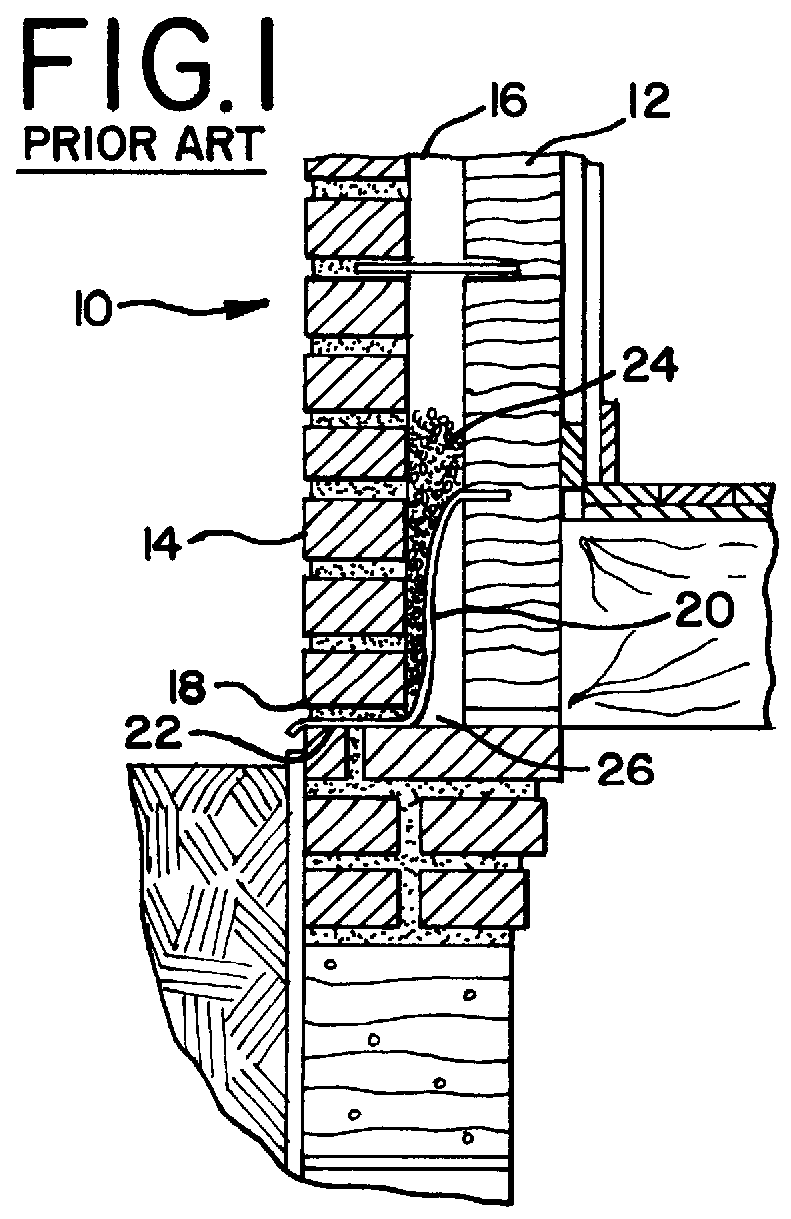

Flashing and weep apparatus for masonry wall window and door installations

ActiveUS6964136B2Easy to installEasy to implementRoof covering using slabs/sheetsRoof covering using tiles/slatesCavity wallMoisture

A flashing and weep apparatus allows for simple installation and accurate placement windows and doors in cavity wall construction. In a first embodiment, the flashing and weep apparatus is a two-panel extrusion that has a flashing panel that acts as a non-porous support for the masonry veneer. This embodiment also includes a second panel which is joined at a generally right angle to the first panel to be juxtaposed against the outer face of the inner wall in the cavity wall construction. Weep channels are formed between the two panels and allow for the drainage and dissipation of water and other moisture in the cavity wall system. In a second embodiment, membrane is initially attached to and draped along the lower portion of the inner wall immediately above the sill or lintel. The membrane extends across the cavity spacing between the walls to underlie the masonry components forming the outer veneer. Weep channels on the membrane communicate and transmit water and moisture from the cavity between the walls to the exterior of the veneer. The weep channels are positioned at the joint between adjacent bricks. The membrane extending beyond the mortar joint at the masonry veneer is trimmed during the installation process so as not to extend beyond the outer veneer wall while still providing an easily installed and implemented flash and weep system.

Owner:TY DAS BUILDING PROD LLC

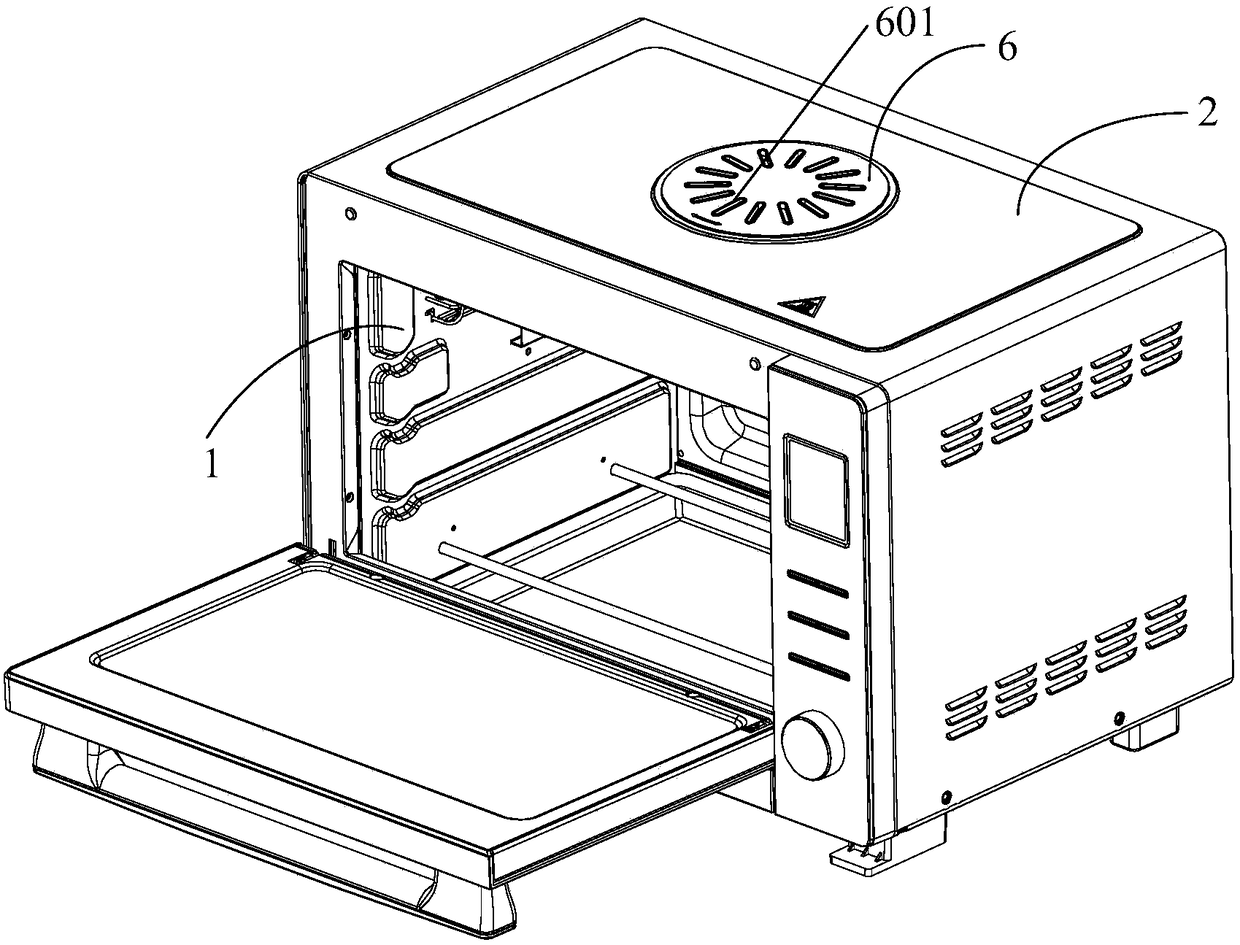

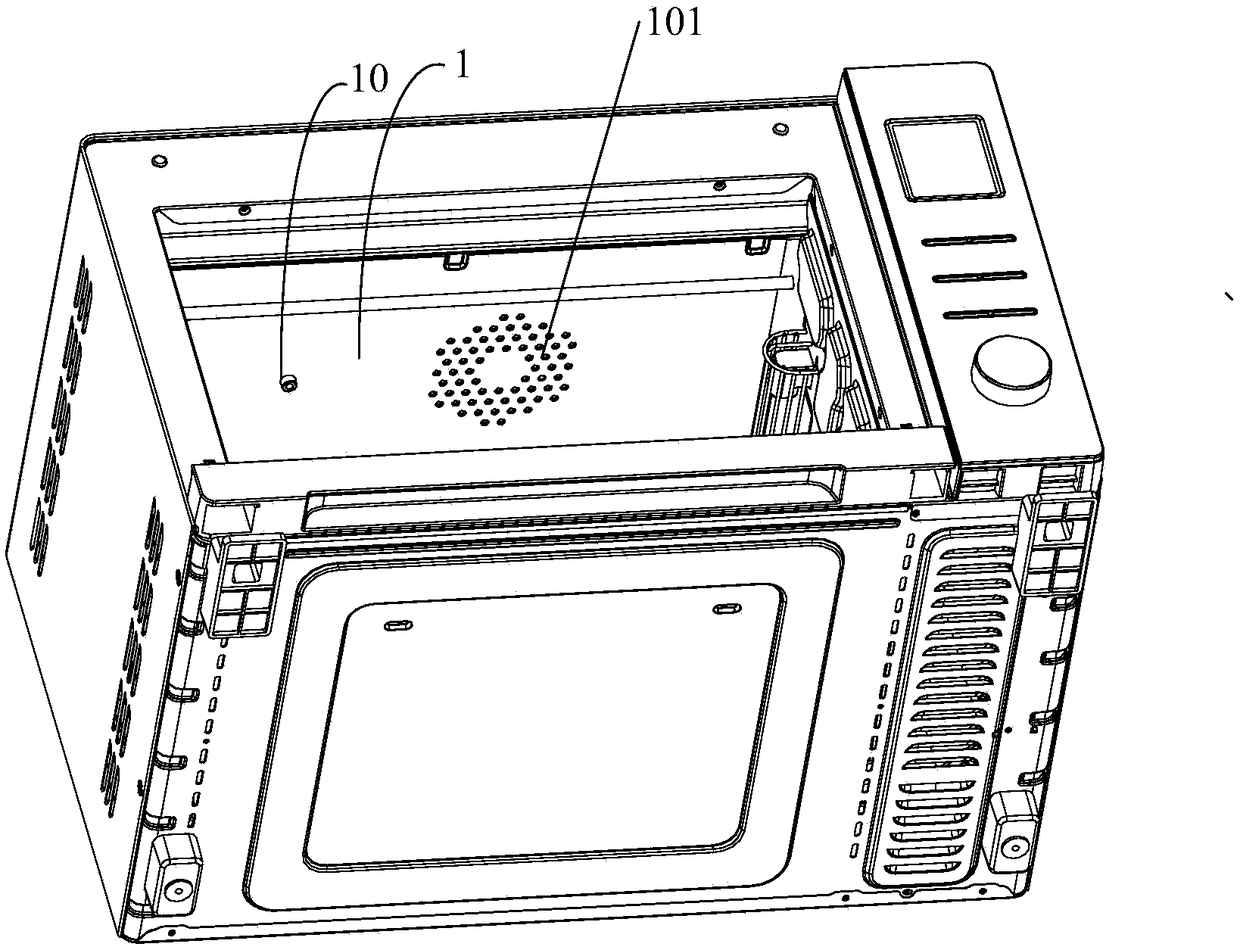

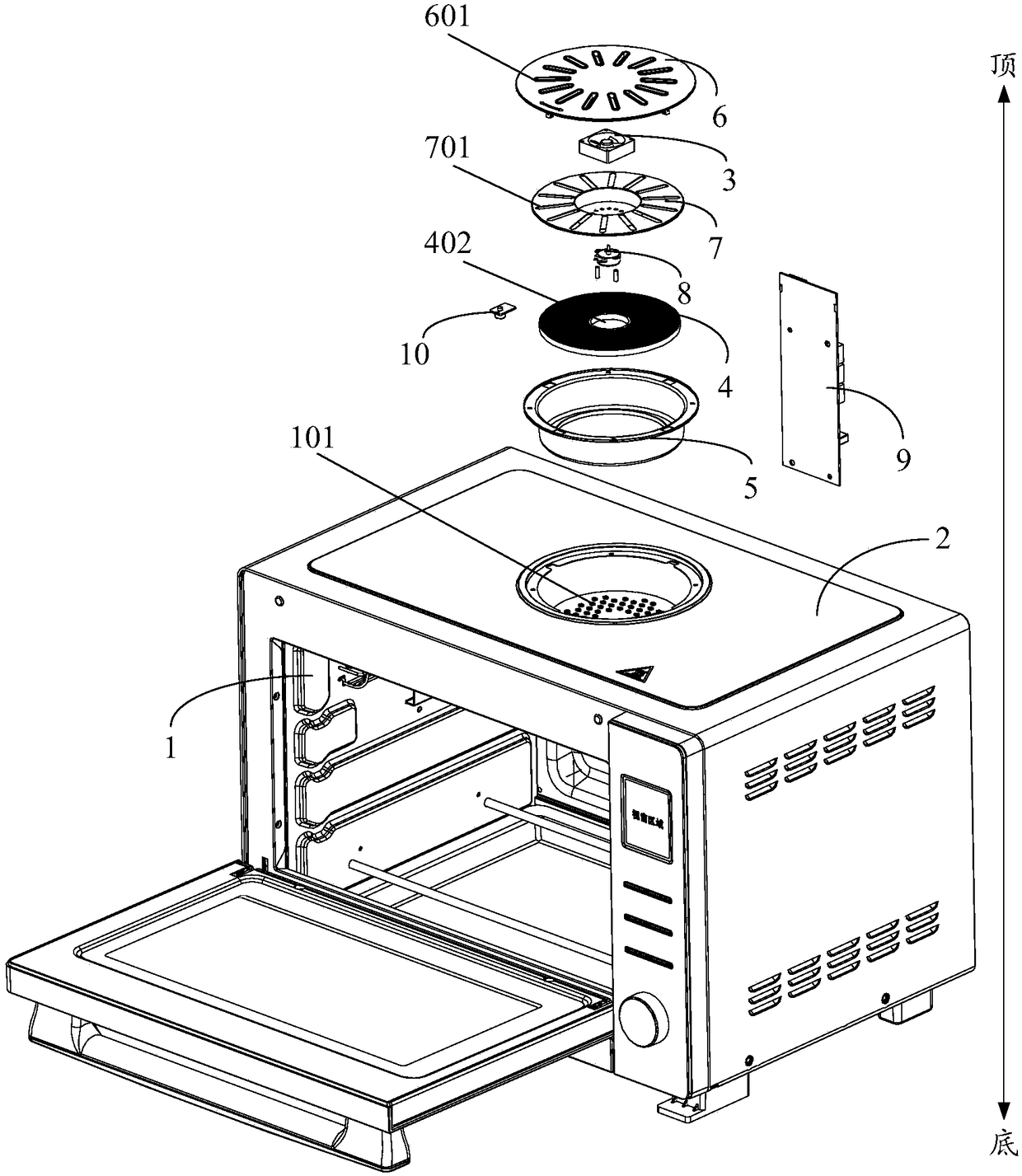

Electric oven and oil fume odor purification device control method

ActiveCN108497942ACompact structureSmall footprintDomestic stoves or rangesLighting and heating apparatusCavity wallScreen filter

The invention provides an electric oven and an oil fume odor purification device control method. The electric oven comprises a cavity and an oil fume odor purification device which comprises a draughtfan and a filter screen used for filtering oil fume and odor, an exhaust port is formed in the cavity wall of the cavity, the filter screen is installed at the exhaust port, and the draught fan is installed near the filter screen and used for discharging the oil fume in the cavity out of the cavity from the exhaust port and makes the oil fume flow through the filter screen. According to the screen, the oil fume odor purification device of the electric oven comprises the draught fan and the filter screen, the filter screen is installed at the exhaust port of the cavity, in the food heating process of the electric oven, the draught fan works to make gas in the cavity pass through the exhaust port and the filter screen, the filter screen filters out the oil fume and odor in the gas, and filtered gas enters a room and cannot pollute indoor air, so that bad feeling cannot be brought to a user, and the degree of satisfaction of the user on products can be improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

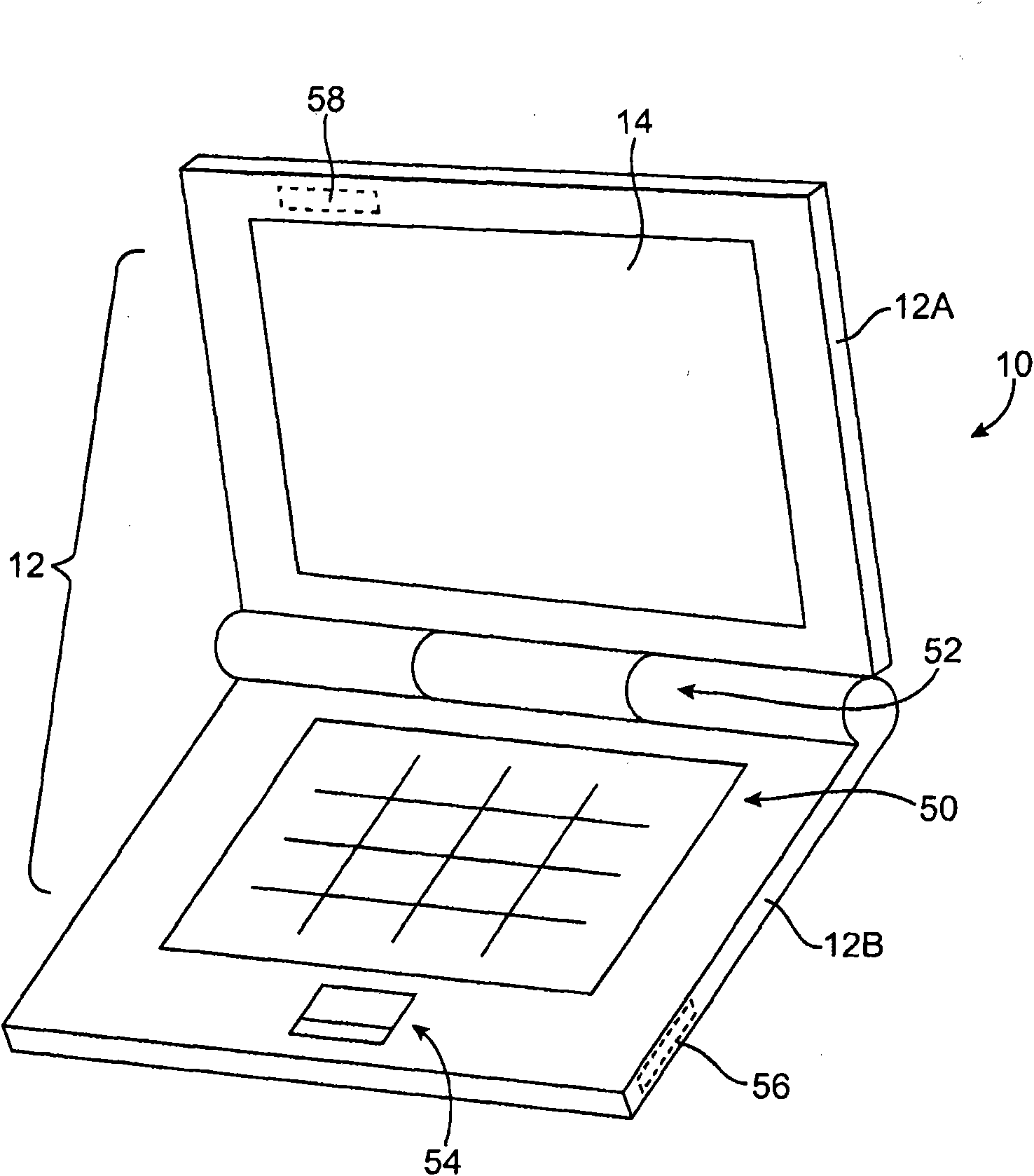

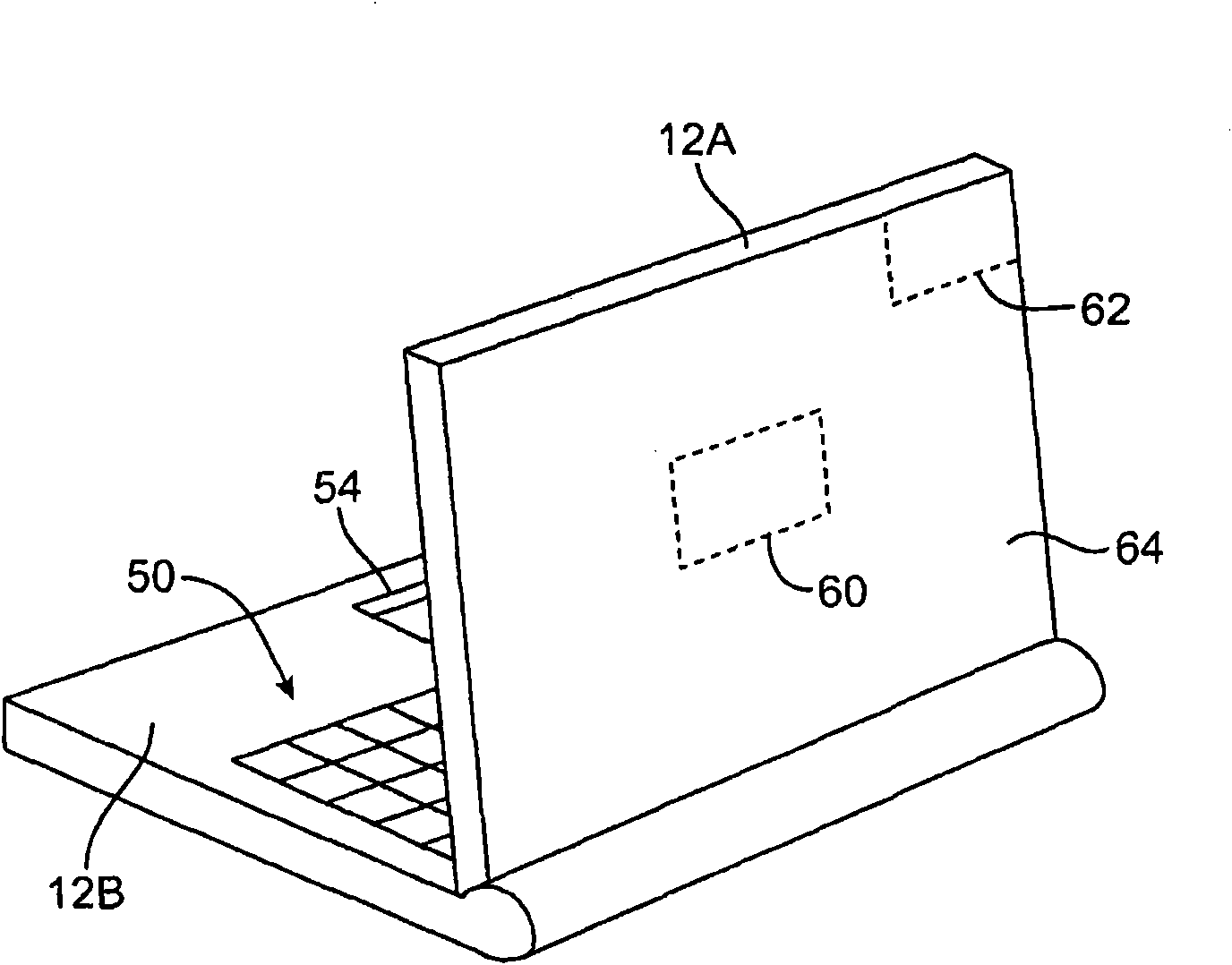

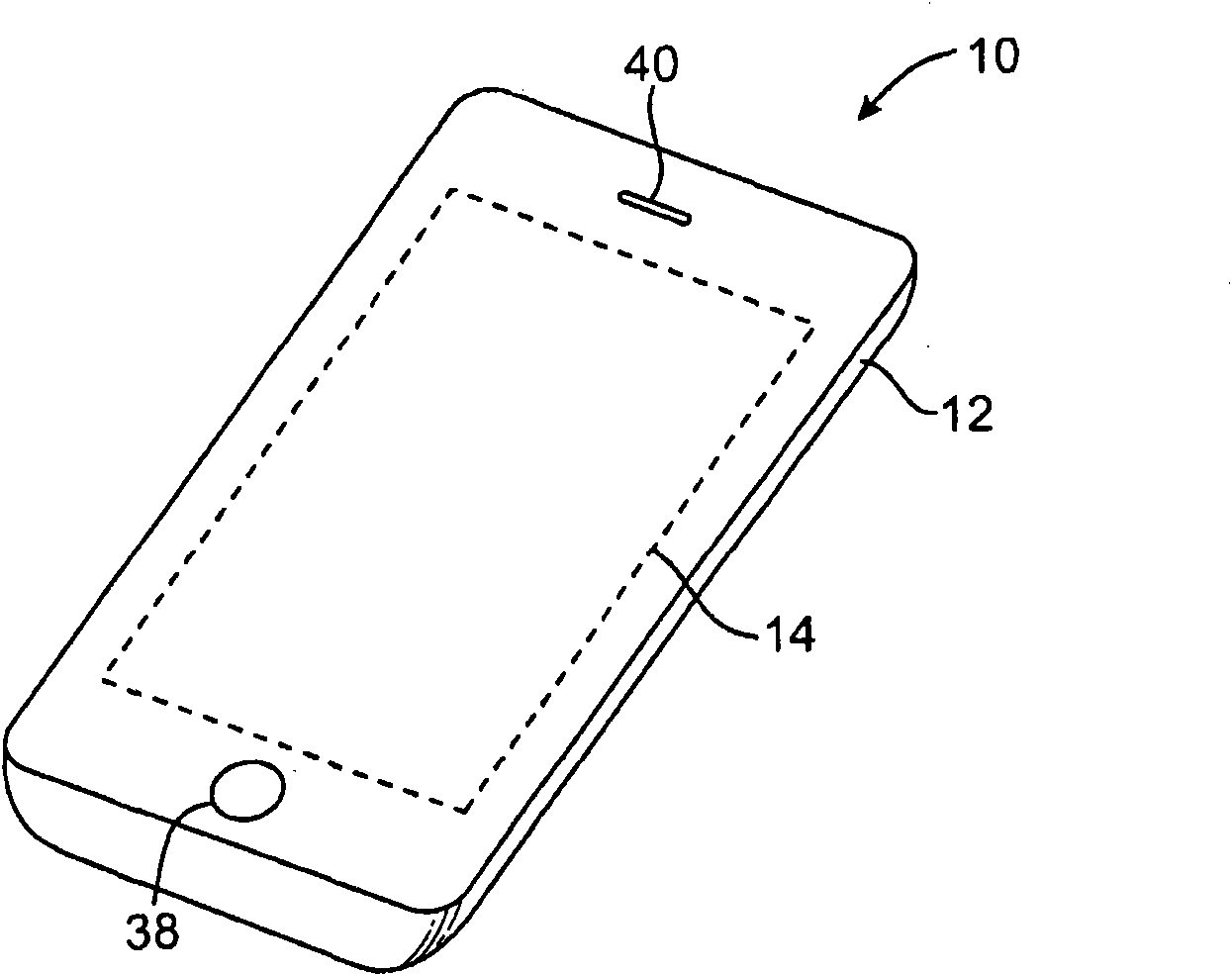

Cavity antennas for electronic device

Antennas are provided for electronic devices such as portable computers. An electronic device may have a housing in which an antenna is mounted. The housing may have an antenna window for the antenna. The antenna window may be formed from dielectric or from antenna window slots in a conductive member such as a conductive wall of the electronic device housing. An antenna may have an antenna resonating element that is backed by a conductive antenna cavity. The antenna resonating element may have antenna resonating element slots or may be formed using other antenna configurations such as inverted-F configurations. The antenna cavity may have conductive vertical sidewalls and a conductive rear wall. The antenna cavity walls may be formed from conductive layers on a dielectric antenna support structure.

Owner:APPLE INC

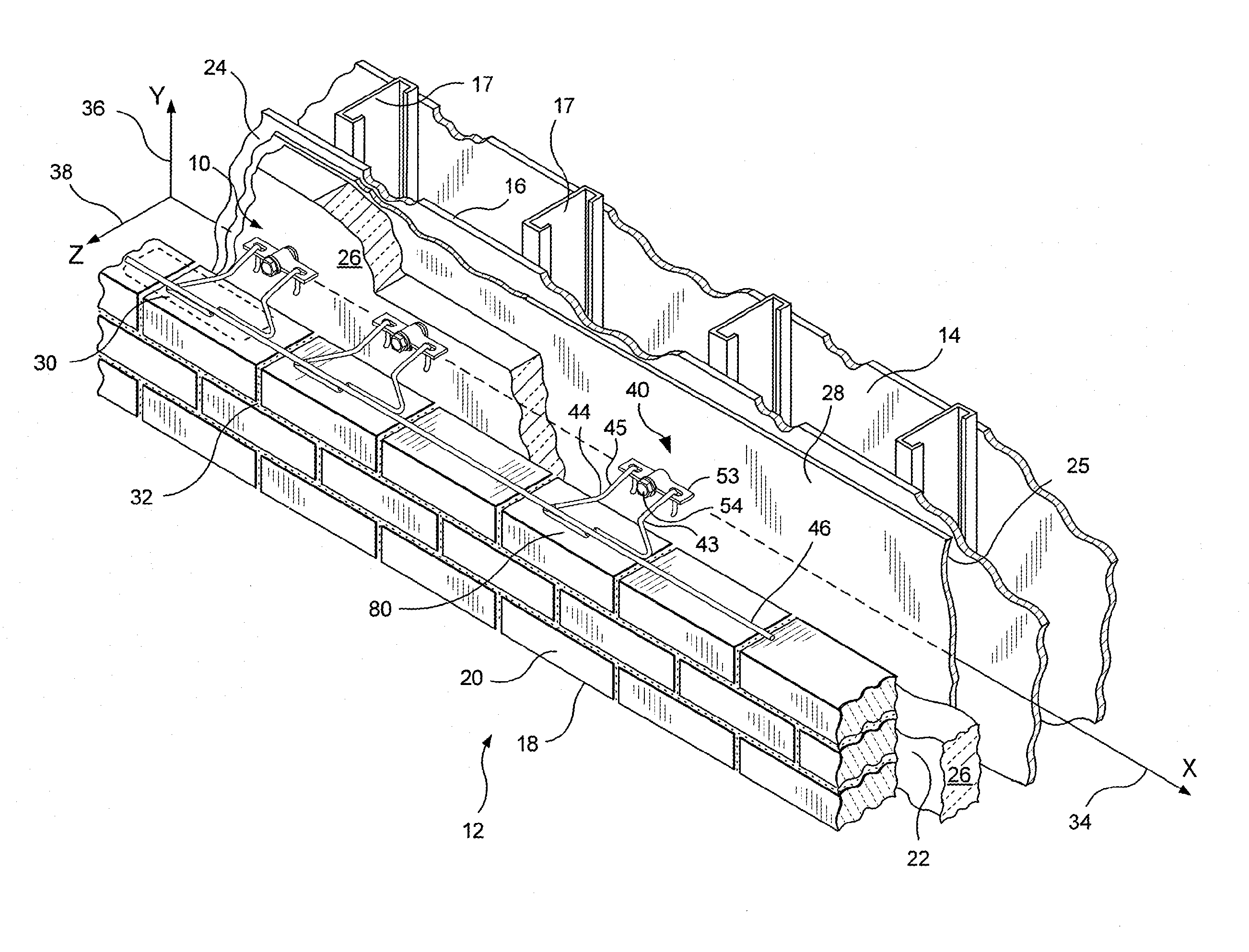

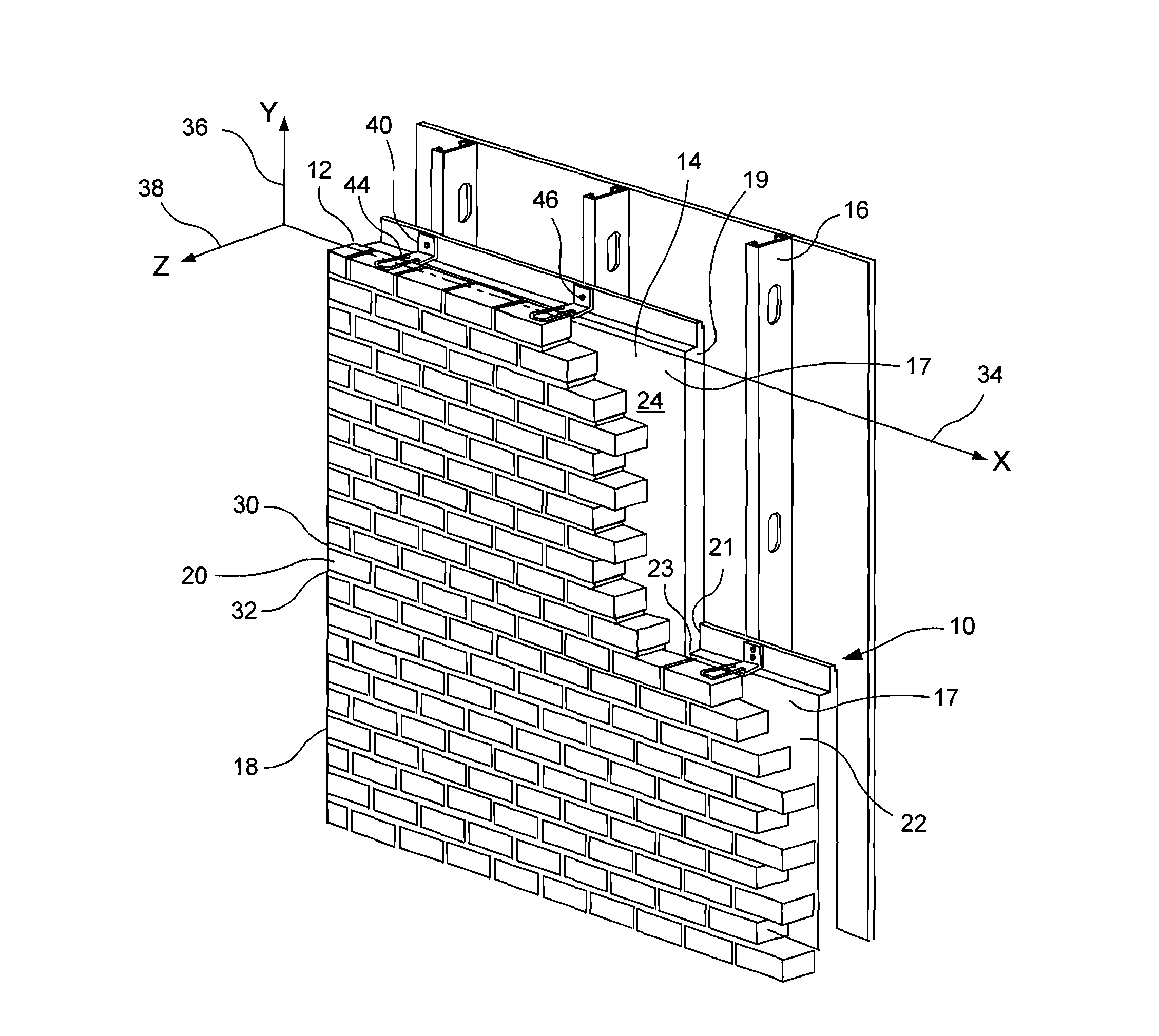

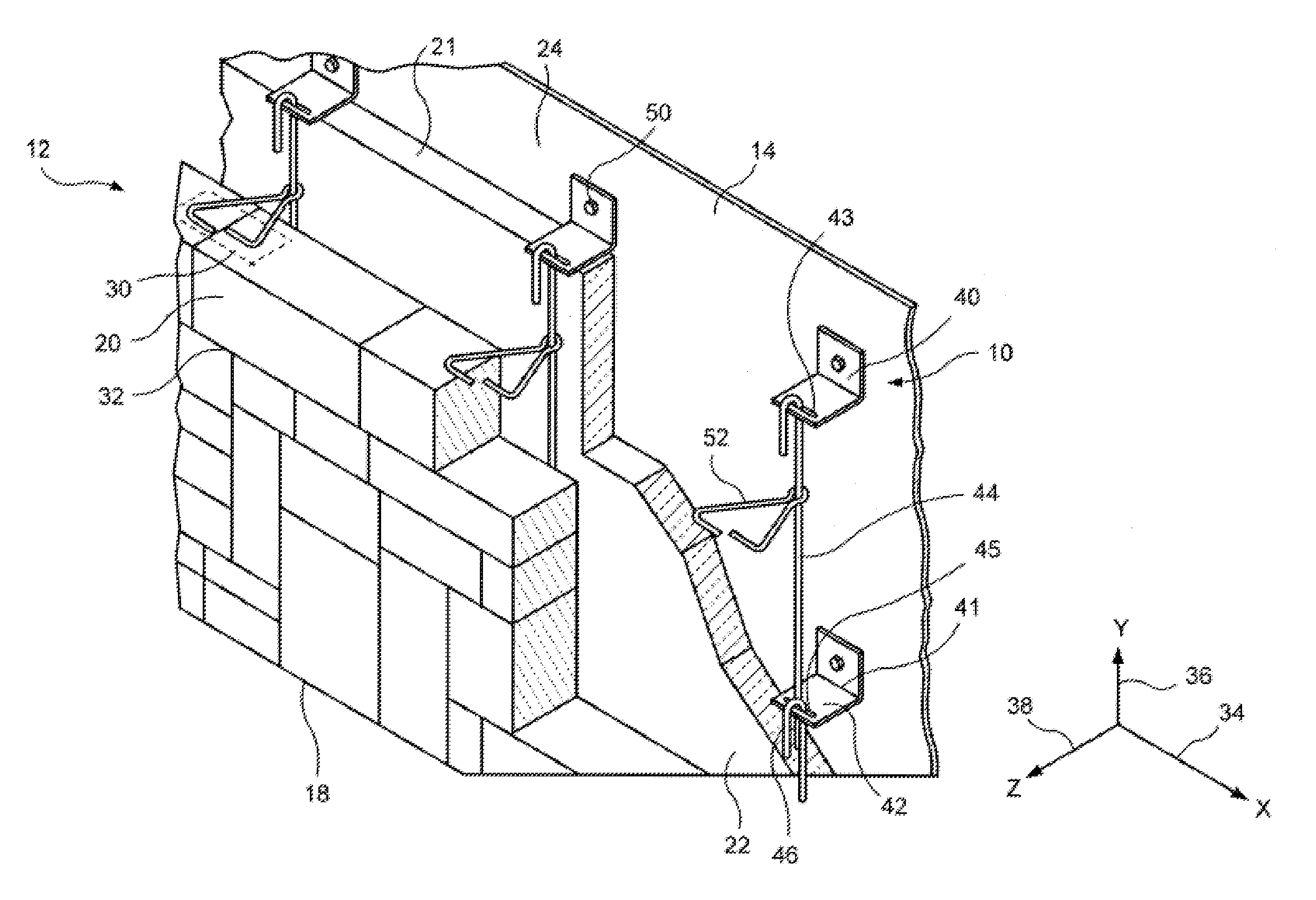

Anchor System for Composite Panel

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

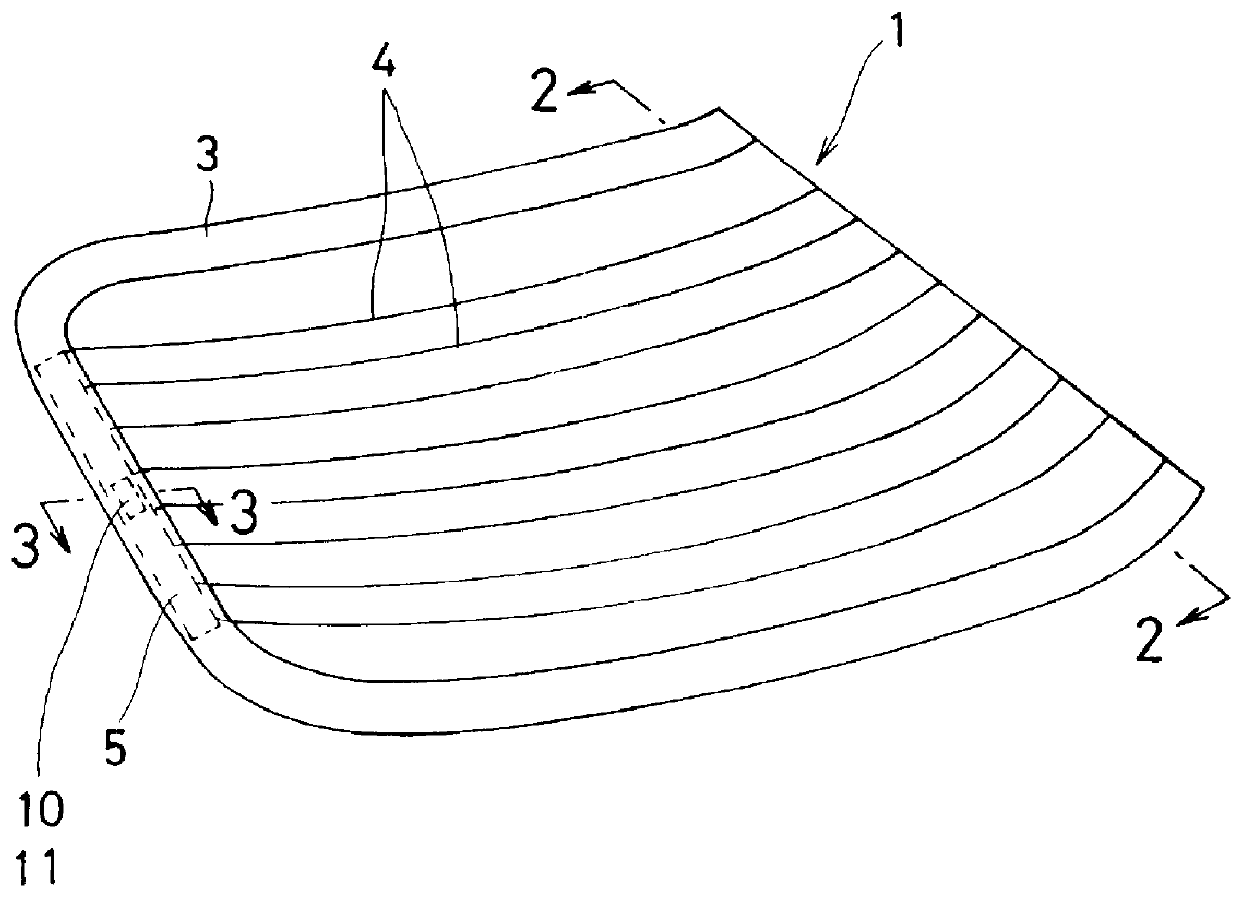

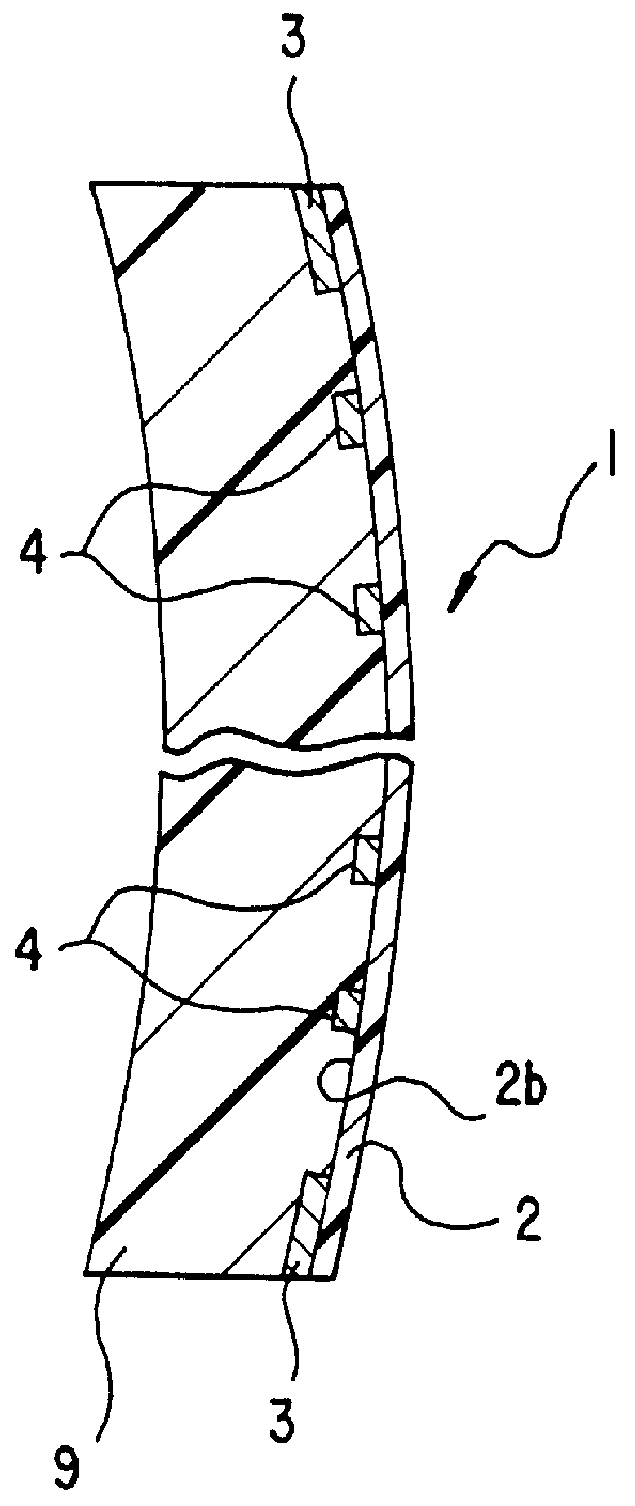

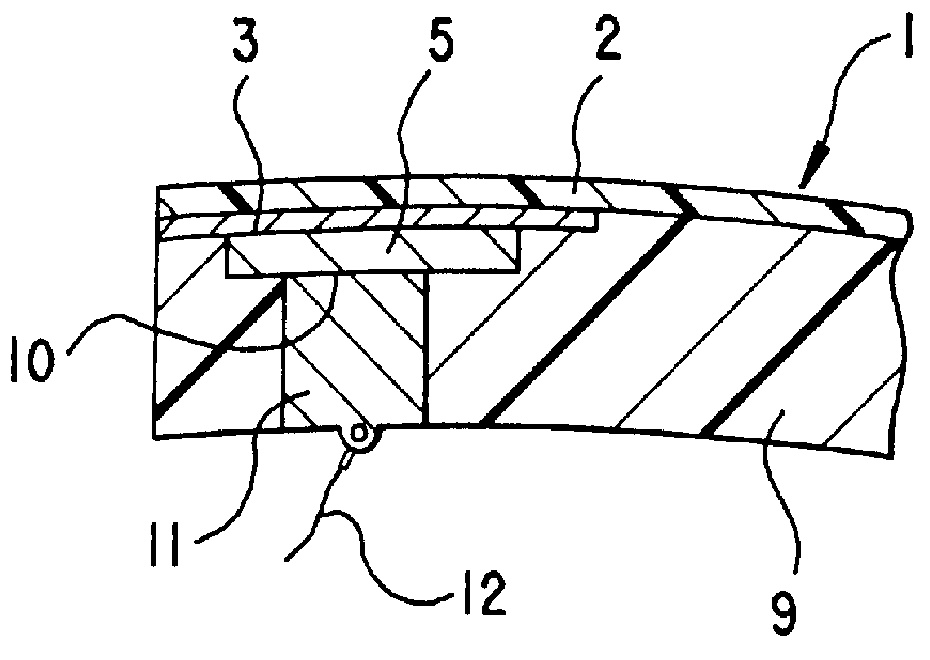

Method of making an antifogging window plate of synthetic resins

InactiveUS6024904AReduce the number of stepsFlat surfaceMouldsSynthetic resin layered productsConductive pasteEngineering

An antifogging window plate has a transparent film and a base both made of thermoplastic resins. Conductive lines and electrodes are printed using a conductive paste on one side of the film, which is then bonded to the base. One portion of each electrode is exposed as a terminal portion to be connected to an electric contact member. The window plate is made by injection molding with the surface of the film opposite from the printed surface being in contact with the cavity wall of the mold, so that the integration of the film with the base is effected simultaneously with the forming of base. Each contact member is subsequently fitted in an injection-molded void facing the terminal portion, or is secured in place at the same time as the injection molding.

Owner:TSUTSUNAKA PLASTIC IND

Dual seal anchoring systems for insulated cavity walls

ActiveUS8037653B2Increase profitHigh strength connectionConstruction materialStrutsEngineeringCavity wall

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

Rubble stone anchoring system

ActiveUS20110146195A1Minimized cavity sizeRestricting veneer tie lateral movementStrutsBuilding reinforcementsEngineeringCavity size

Anchoring systems for use in cavity wall structures having an inner wythe and an outer wythe constructed of rubble stone are disclosed. The anchoring system employs an anchor fastened to or set within the inner wythe that extends into the cavity and connects to a J-hook. A vertically adjustable veneer tie enwraps the J-hook, limiting lateral movement and front-to-back displacement, and is set within the bed joint of the outer wythe. The anchoring system minimizes cavity size and provides stability for an uncoursed outer wythe equivalent to that of anchoring systems for standards coursed bed joints.

Owner:HOHMANN & BARNARD INC

Mortar and debris collection device and system

InactiveUSRE36676E1Promote full dispersionAvoid Waterlogging ProblemsStrutsFoundation engineeringPorosityWater channel

A mortar and debris collection device for a cavity wall construction has a non-water absorbent body formed with circuitous paths therethrough making the body water-permeable. The collection device has a porosity sufficient to permit water to pass therethrough but insufficient to permit mortar and other debris to pass therethrough to weep holes or other water channels covered by the collection debris. The device may be freely placed on the wall base within the cavity to cover the opening of a weep hole, or may also be placed on existing wall ties within the cavity.

Owner:MORTAR NET USA

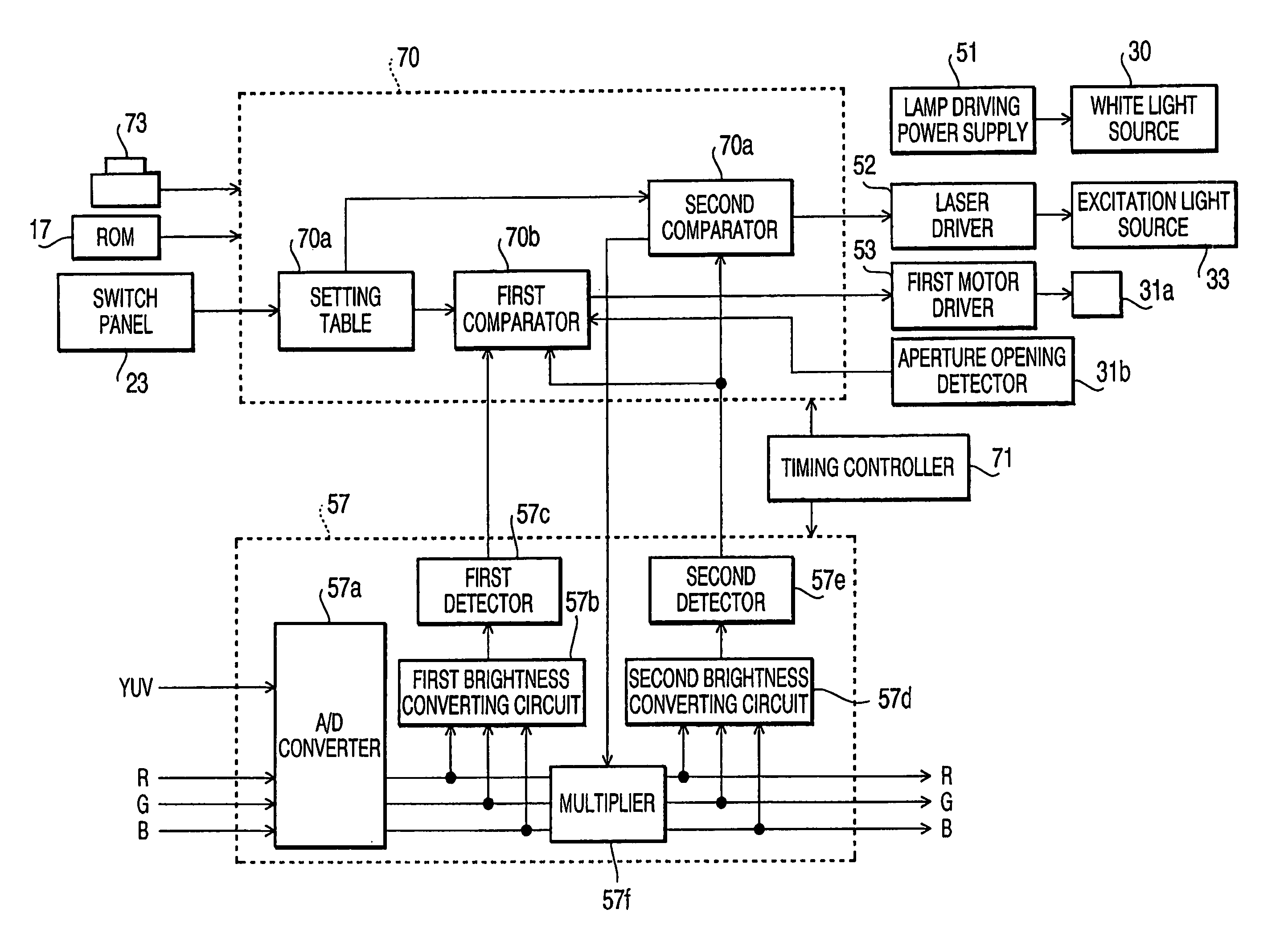

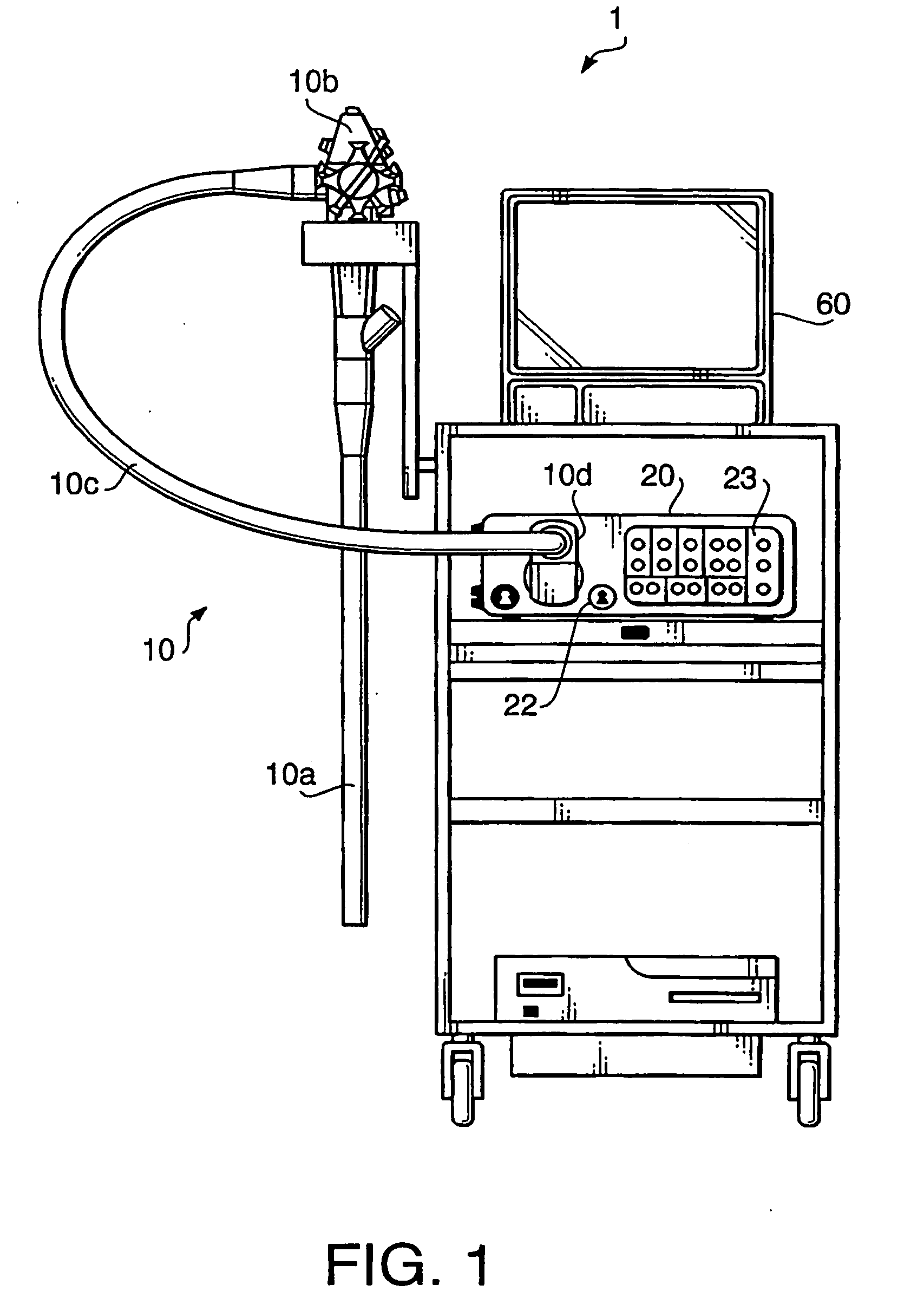

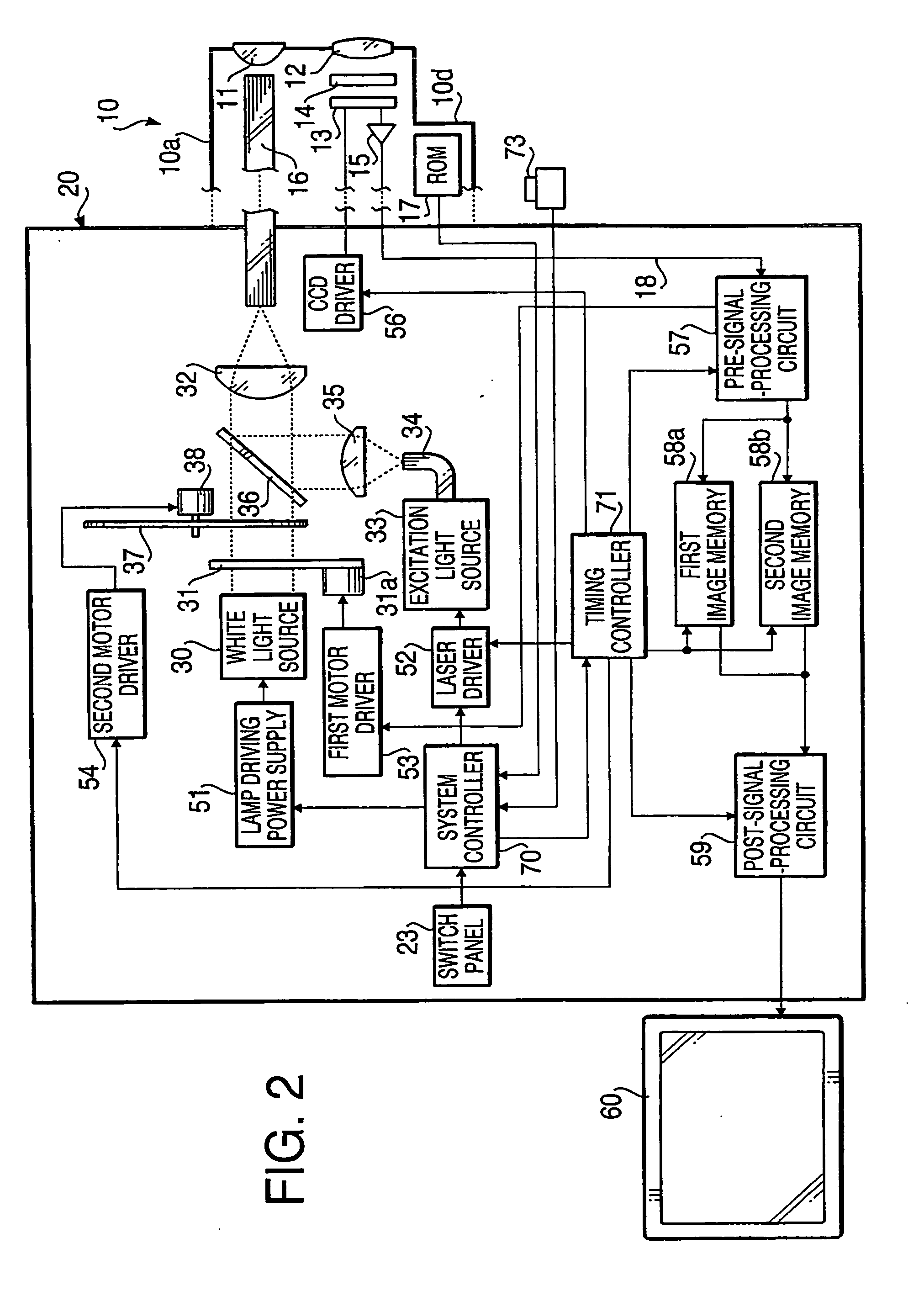

Electronic endoscope system for fluorescence observation

InactiveUS20060020169A1Reduce fatigueReduce brightness differenceSurgeryEndoscopesControl systemDisplay device

An electronic endoscope system, which is adapted to observe a fluorescence image of autofluorescence emitted from a body cavity wall irradiated with excitation light as well as a normal image of the body cavity wall illuminated with white light on a display device, includes a brightness control system configured to adjust brightness of at least one of the normal image and the fluorescence image to reduce brightness difference between the normal image and the fluorescence image to be displayed.

Owner:HOYA CORP

Restoration Anchoring System

ActiveUS20110277397A1Reduce manufacturing costLower unit costConstruction materialCovering/liningsEngineeringCavity wall

A restoration anchoring system for use in cavity wall structures having an inner wythe and an outer wythe that requires remediation or re-anchoring is disclosed. The anchoring system employs a three-part system that is installed within the existing bed joints of the outer wythe to reattach and re-anchor the outer wythe to the structural inner wythe. The three-part system includes a helical dowel, a seismic T-clip and a reinforcement member. The helical dowel is self-threading and self-drilling. When the three-part system is installed within the outer wythe and attached to the inner wythe, the system is captively embedded in the outer wythe thereby providing a seismic construct.

Owner:HOHMANN & BARNARD INC

Wind load anchors and high-wind anchoring systems for cavity walls

ActiveUS8201374B2Improve tensile propertiesHigh strengthCeilingsConstruction materialEngineeringCavity wall

High-wind load wall anchors and high-wind load wall anchoring systems for cavity walls are described which utilize double-walled anchor constructs with interengaging wire formative veneer ties. The high wind load anchors are mounted upon an interior cavity wall and the veneer ties are embedded within joints of an exterior cavity wall. The anchors have an aperture, for threading the veneer ties therethrough and restricting undesired movement, coupled with a double-walled wing structure to resist anchor deformation by high-wind forces. For resistance against seismic forces, the high-wind load wall anchoring system has a reinforcement wire which snaps into contoured veneer ties.

Owner:HOHMANN & BARNARD INC

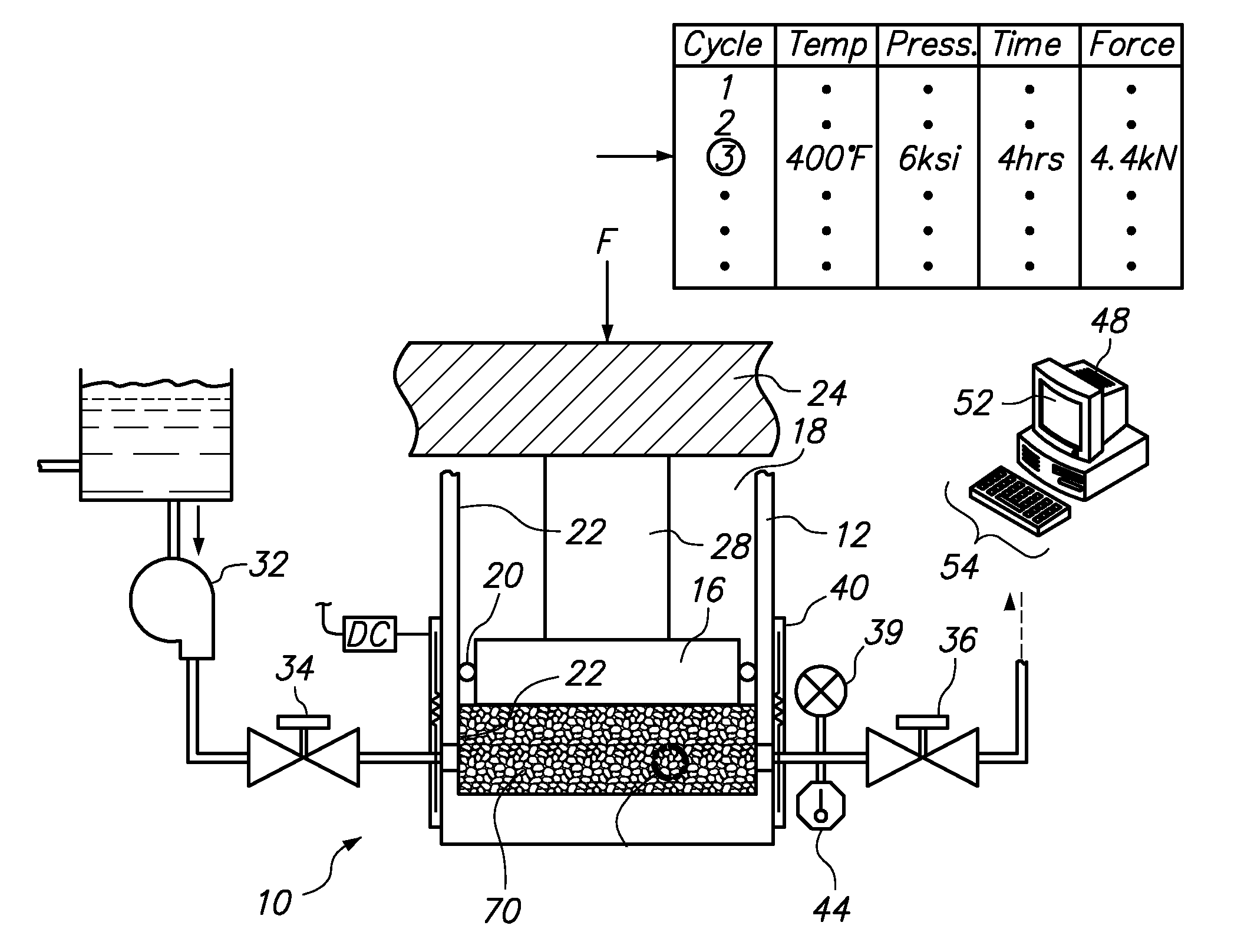

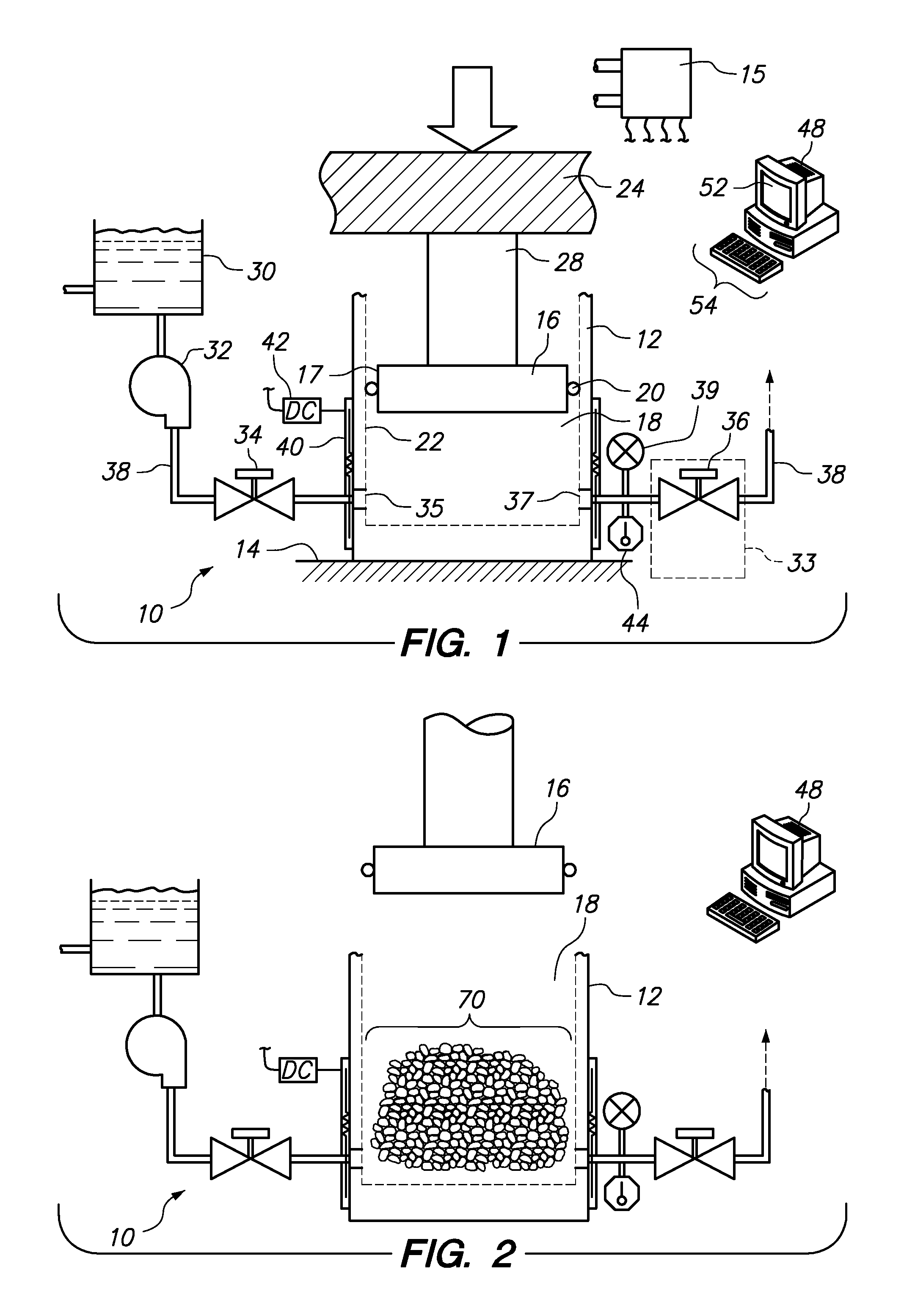

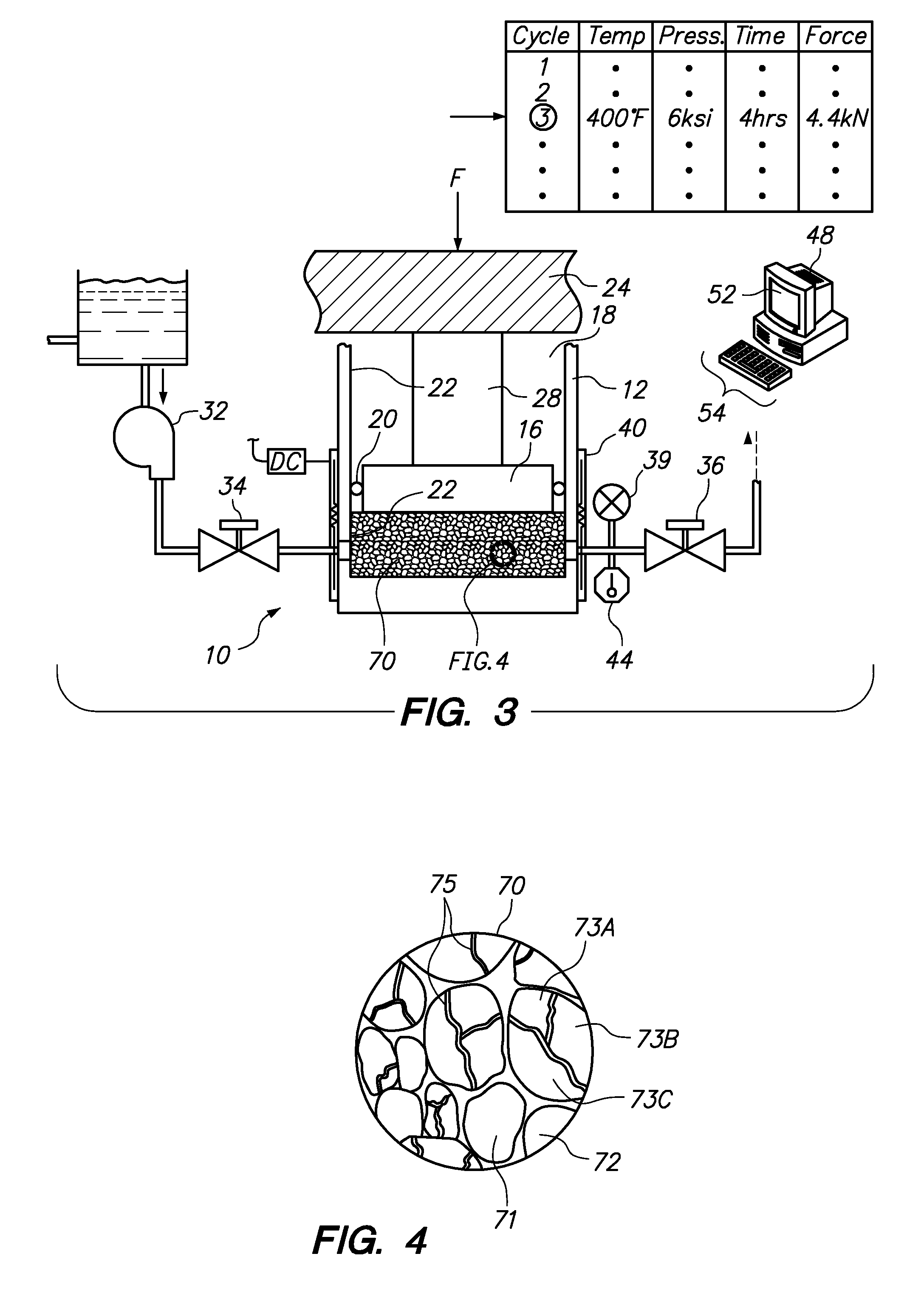

Testing Particulate Materials

InactiveUS20090306898A1Electric/magnetic detection for well-loggingMaterial strength using tensile/compressive forcesParticulatesAmbient pressure

Embodiments include an apparatus and method for testing a particulate material suitable for use as a proppant. According to one embodiment, a sample of the particulate material is captured in the cavity of a test vessel between a cavity wall and a piston sealed with the cavity wall. A fluid is flowed into the test vessel from a fluid inlet of the test vessel to wet the sample of particulate material. The fluid is pressurized to a target fluid pressure greater than ambient pressure and heated to a target temperature greater than ambient temperature. The piston is moved into direct contact with the particulate material with sufficient force to crush at least a portion of the particulate material while maintaining one or both of the target temperature and the target pressure for one or more test cycles. Each test cycle has a duration of at least about 120 seconds and as long as about 24 hours.

Owner:PROP TESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com