Patents

Literature

285results about How to "Small opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

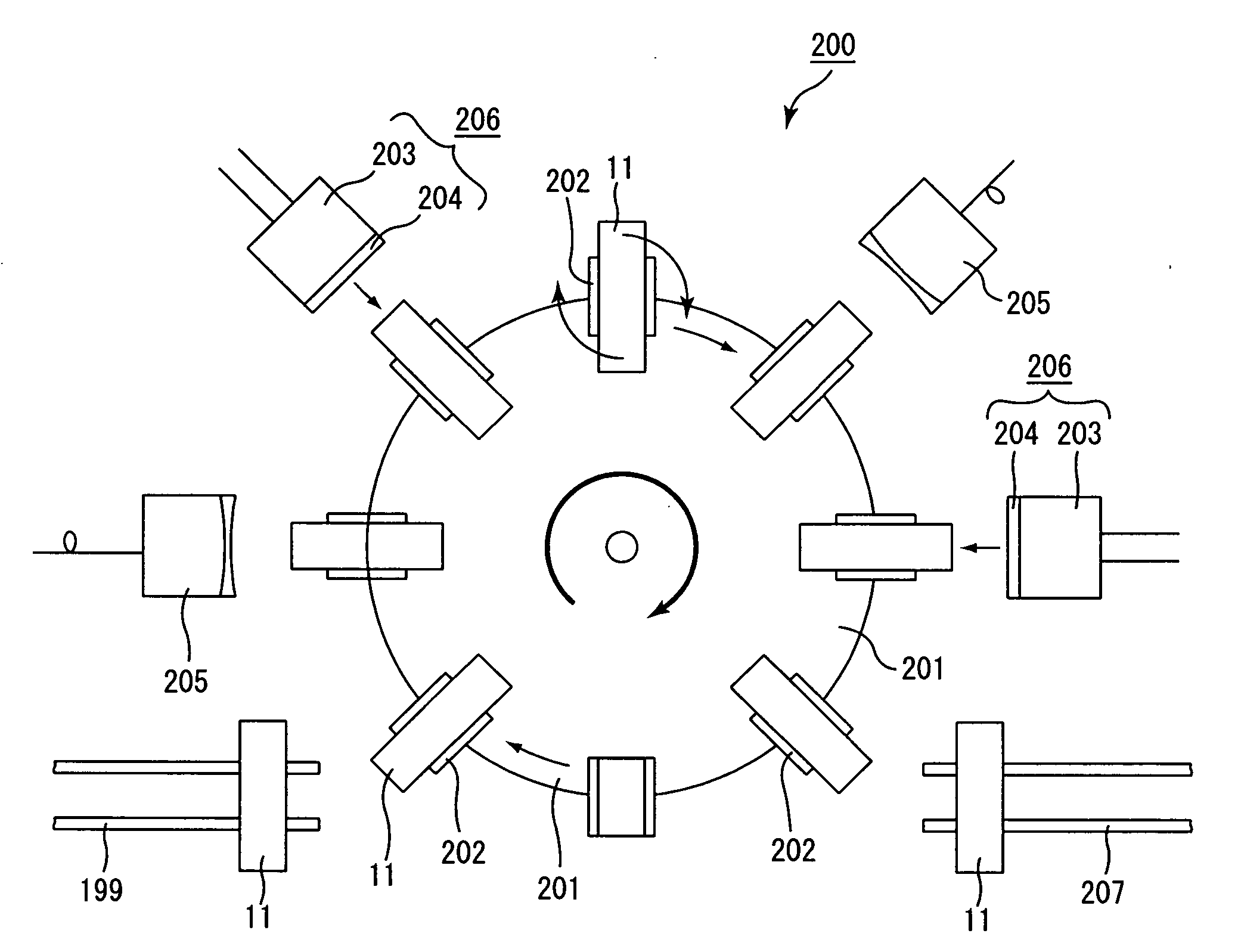

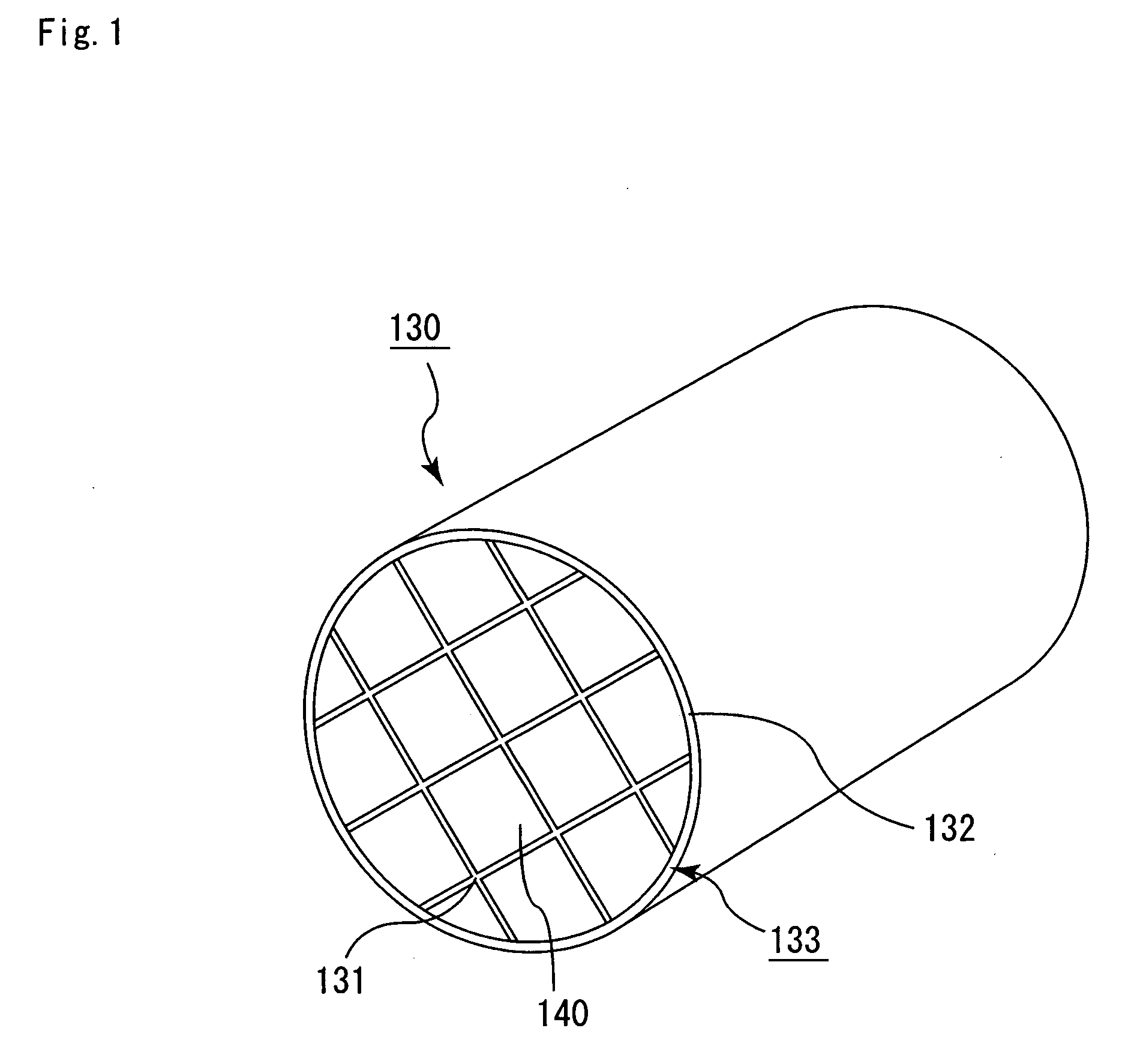

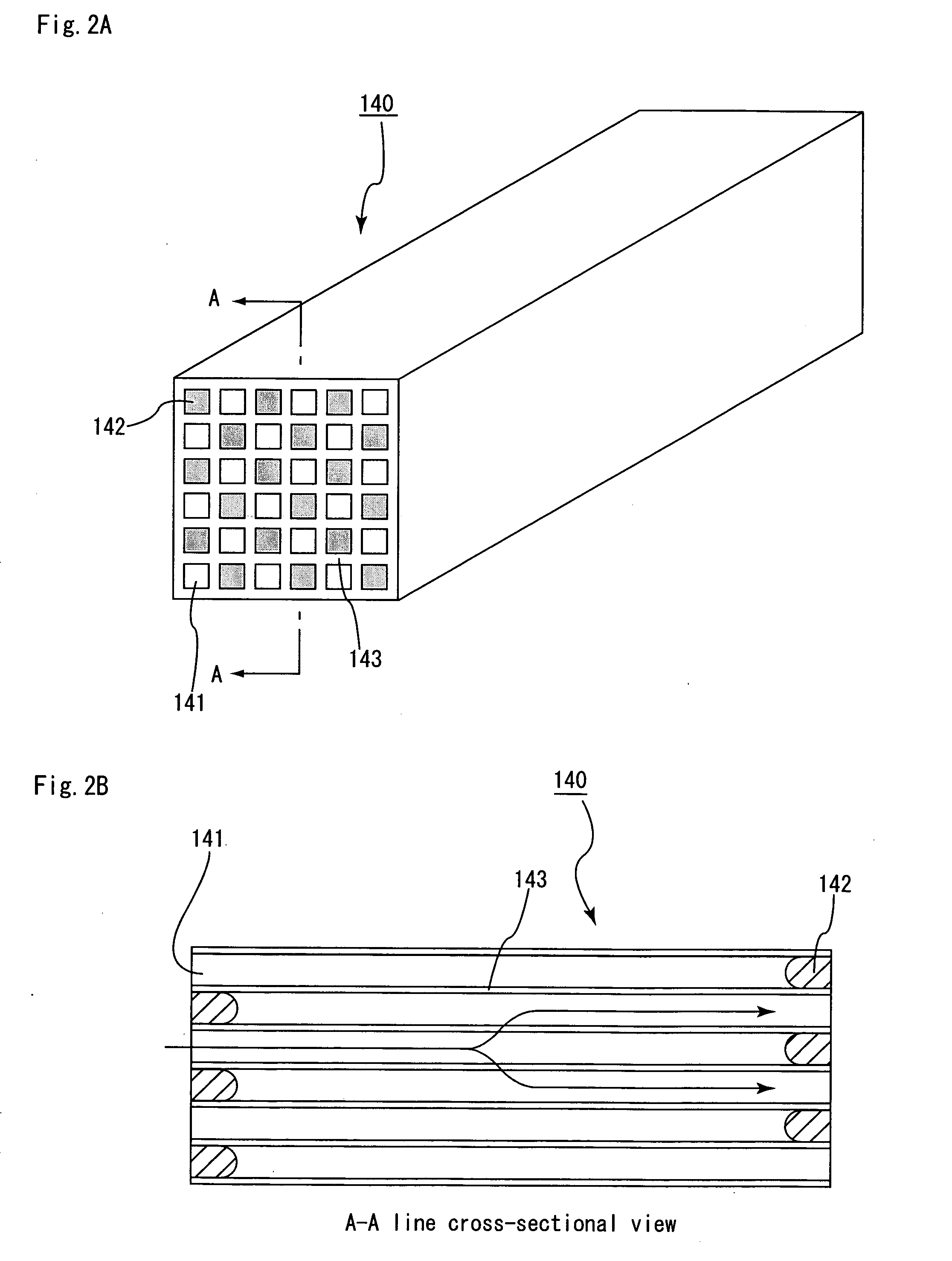

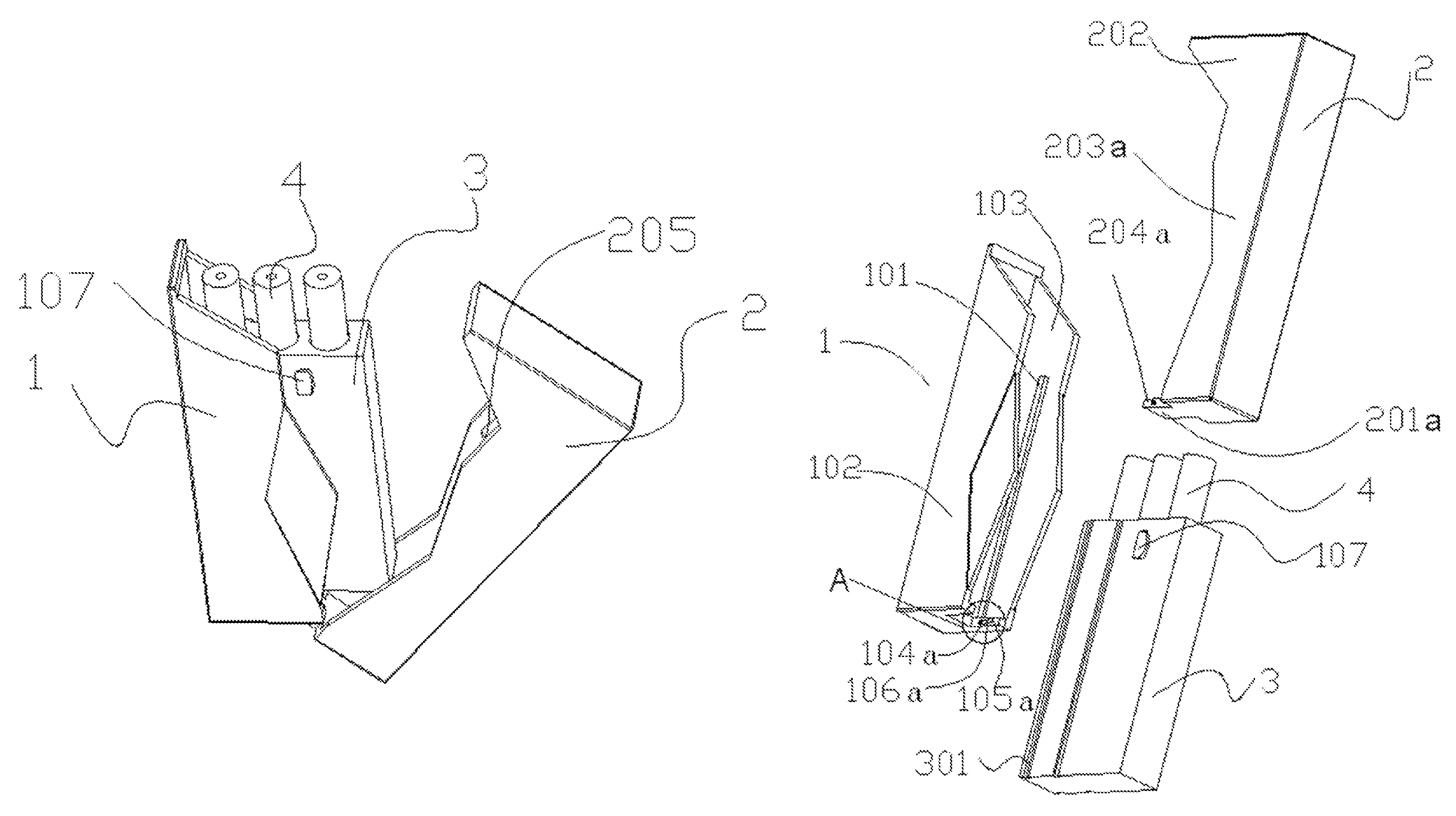

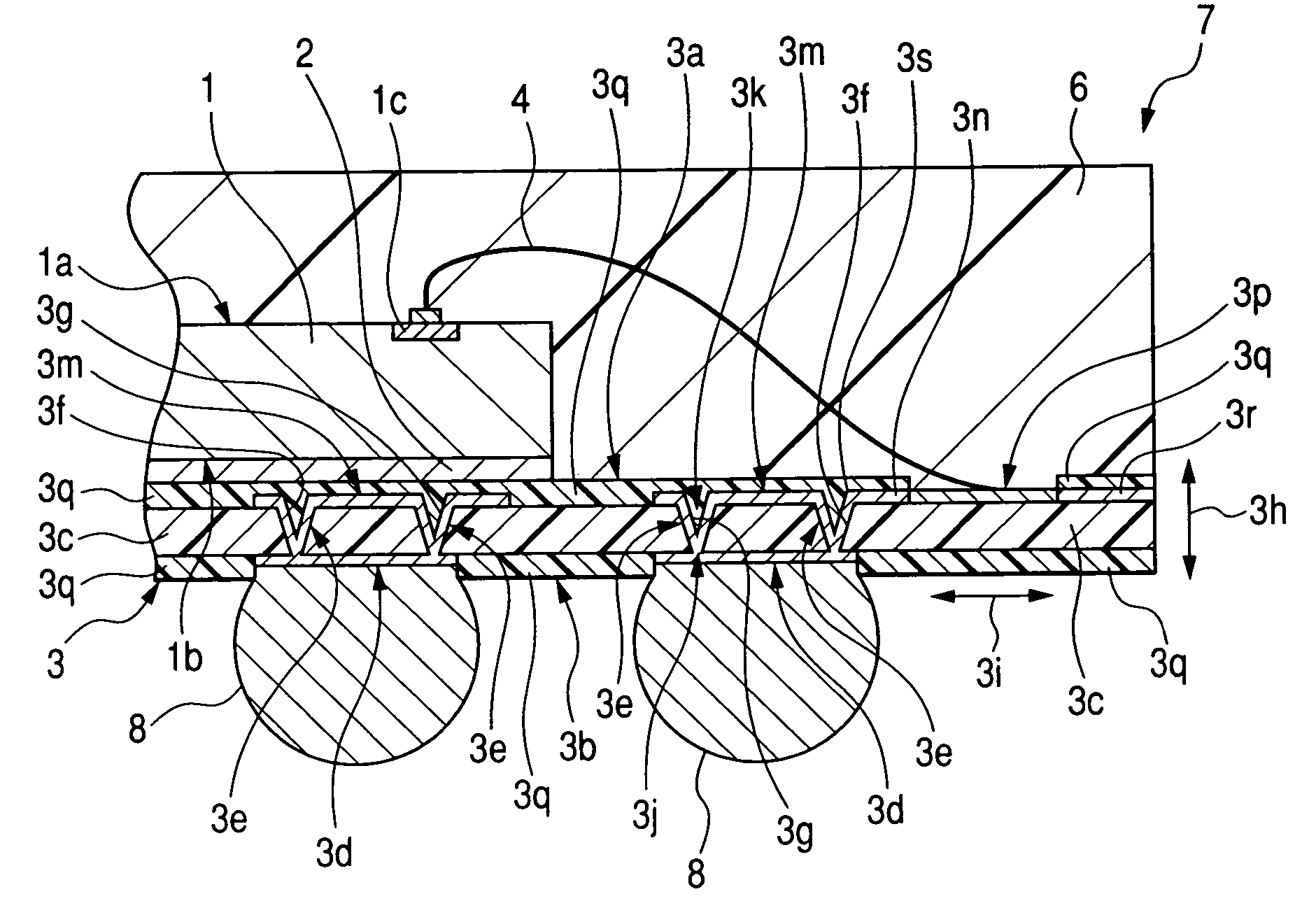

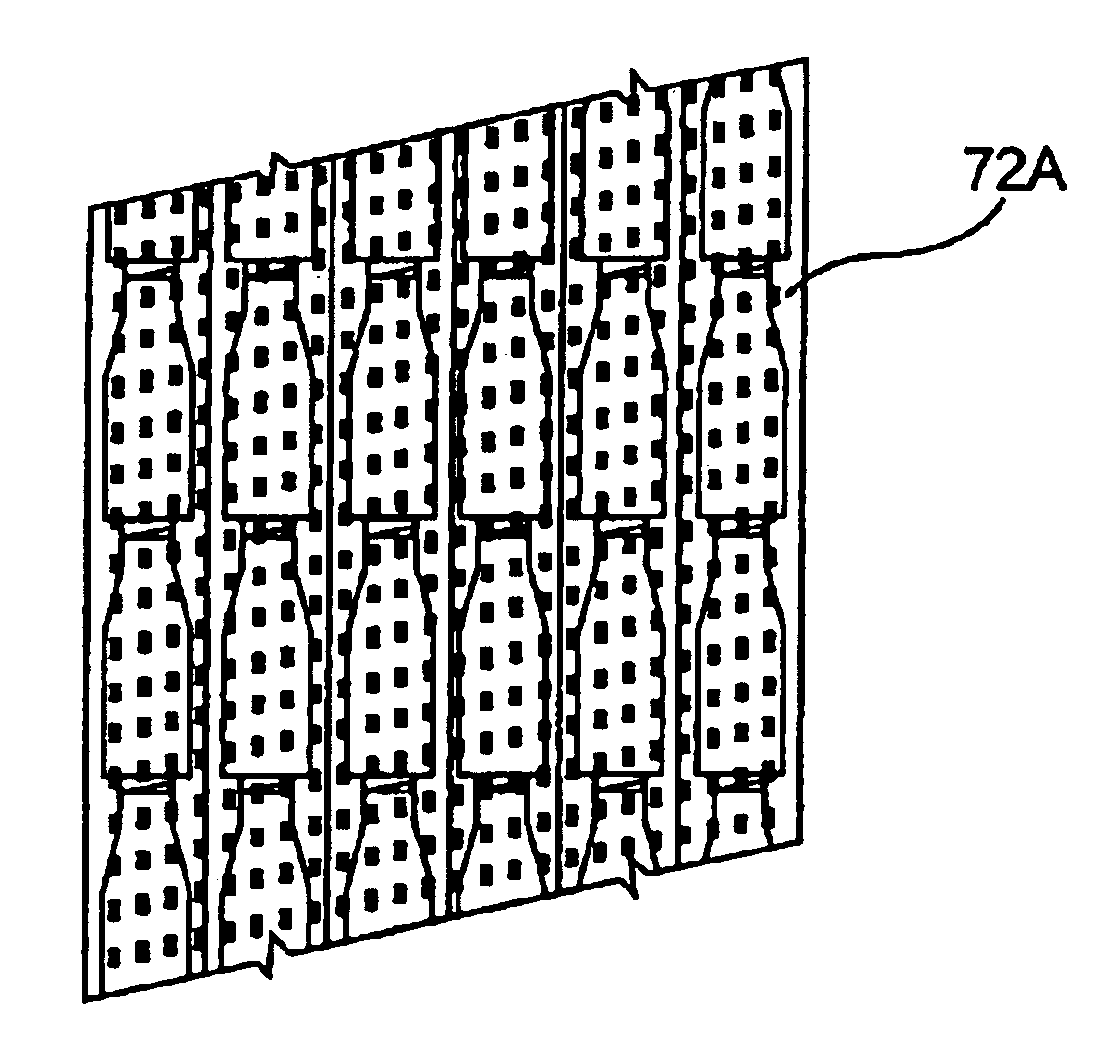

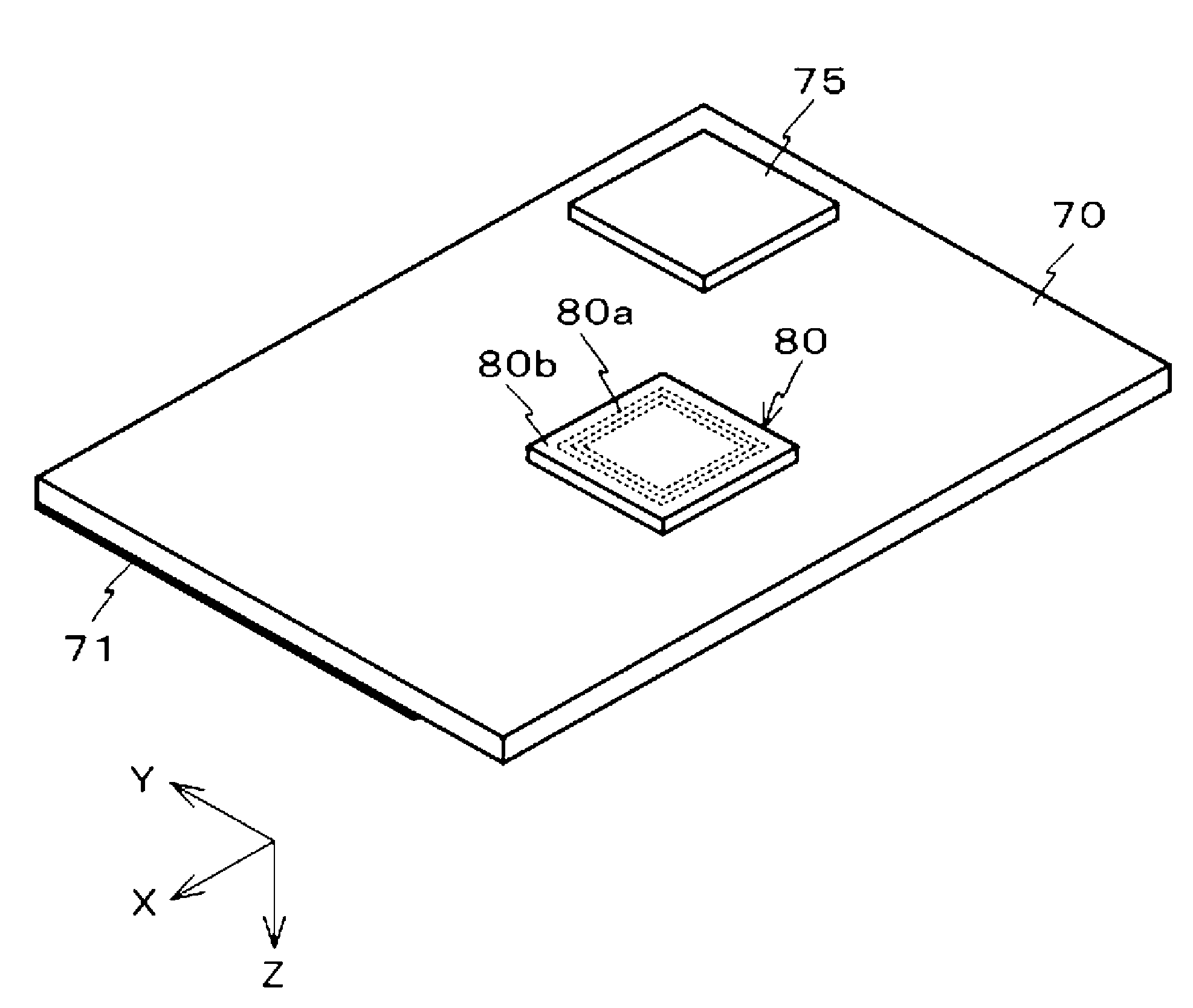

Opening-sealing apparatus for honeycomb molded body, opening-sealing apparatus for honeycomb fired body, method of filling plug material paste, and method of manufacturing honeycomb structured body

ActiveUS20070199643A1Small diameterSmall openingInternal combustion piston enginesSilencing apparatusCell basedPosition error

An opening-sealing apparatus for a honeycomb molded body comprising:a paste filling device equipped with a paste filling unit having an opening-sealing mask in which a number of openings are formed at predetermined positions and a paste supplying unit;an image pickup device for picking up an image of the end face of the honeycomb molded body; andan image analyzing device for analyzing the image obtained by the image pickup device, whereinthe image analyzing device analyzes the positions of the cells based upon the image of the end face picked up by the image pickup device; the opening-sealing mask is made in contact with the end face of the honeycomb molded body in such a manner that the positional error between the openings of the opening-sealing mask and the cells of the honeycomb molded body is reduced to a minimal level; and the plug material paste, which has been supplied from the paste supplying unit to the paste filling unit, is injected through the opening-sealing mask and filled in the end portion of the cells.

Owner:IBIDEN CO LTD

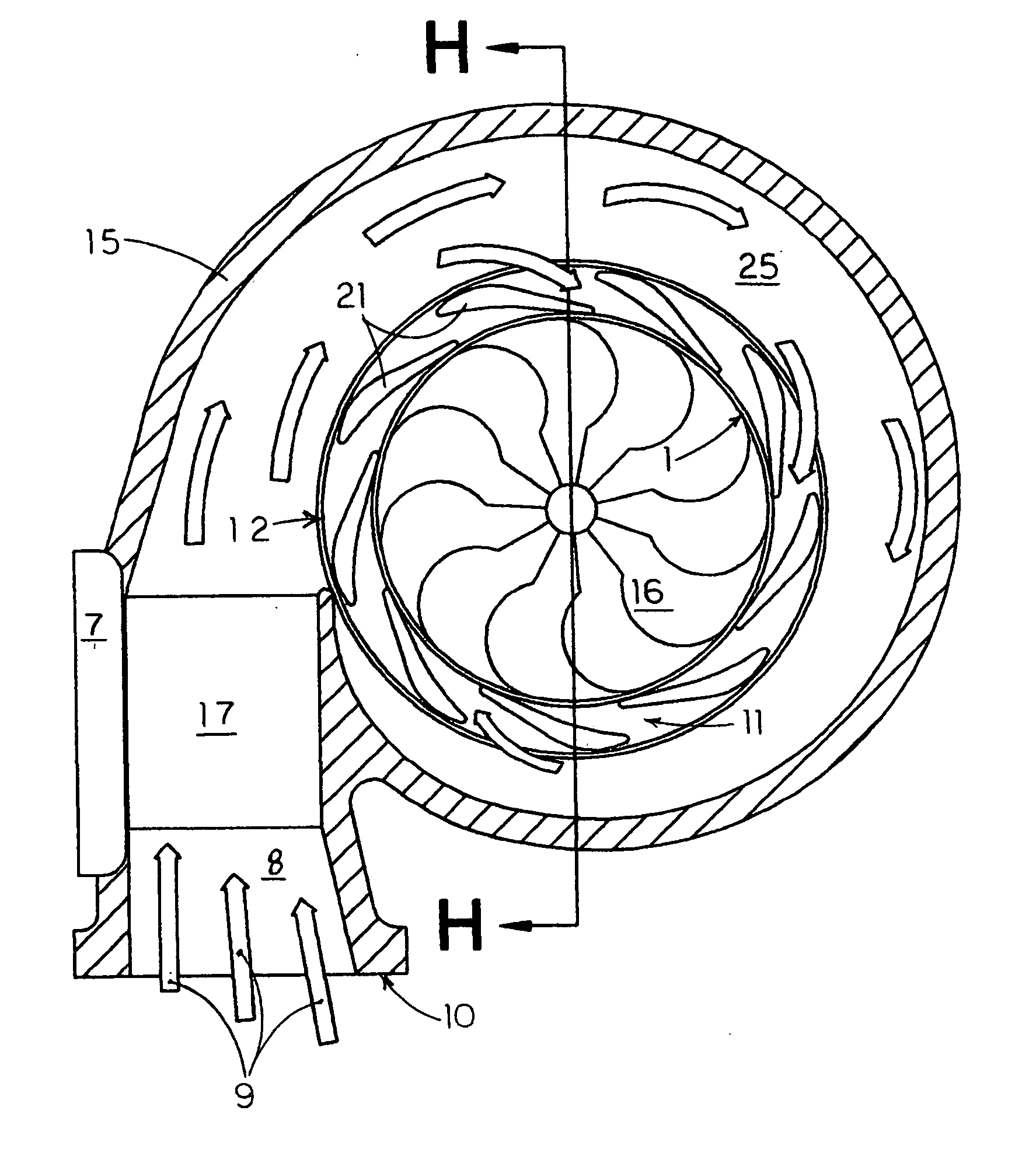

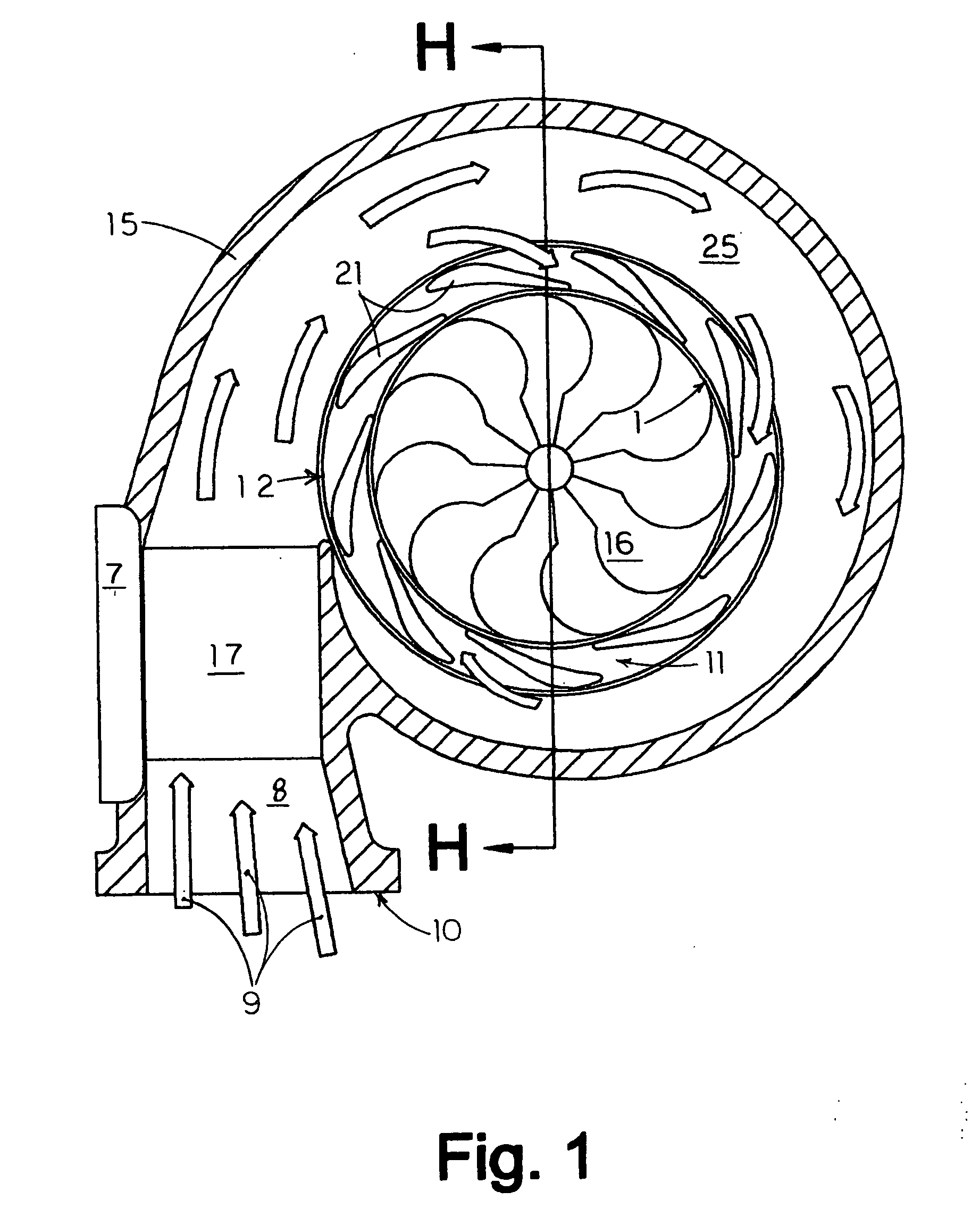

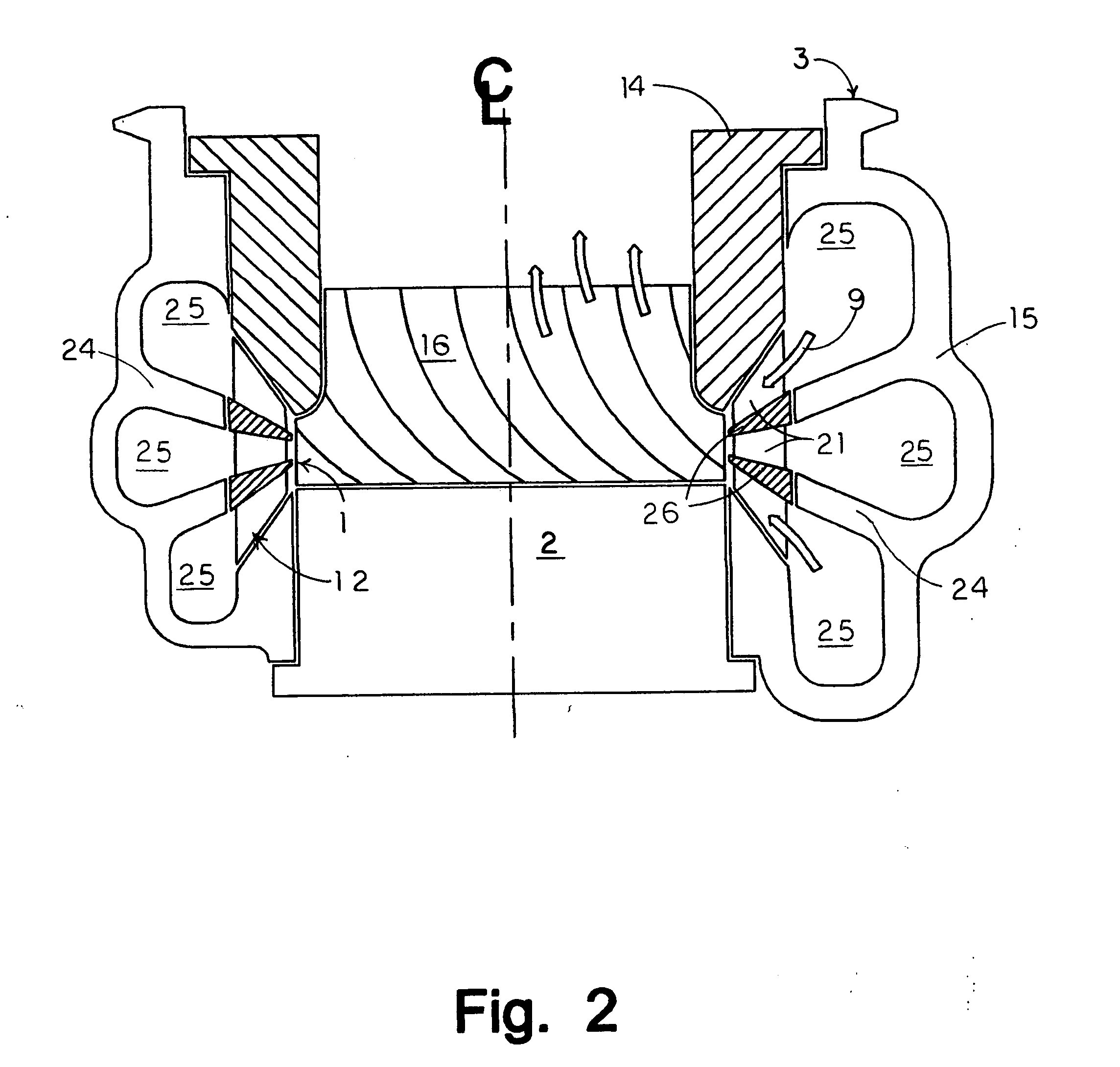

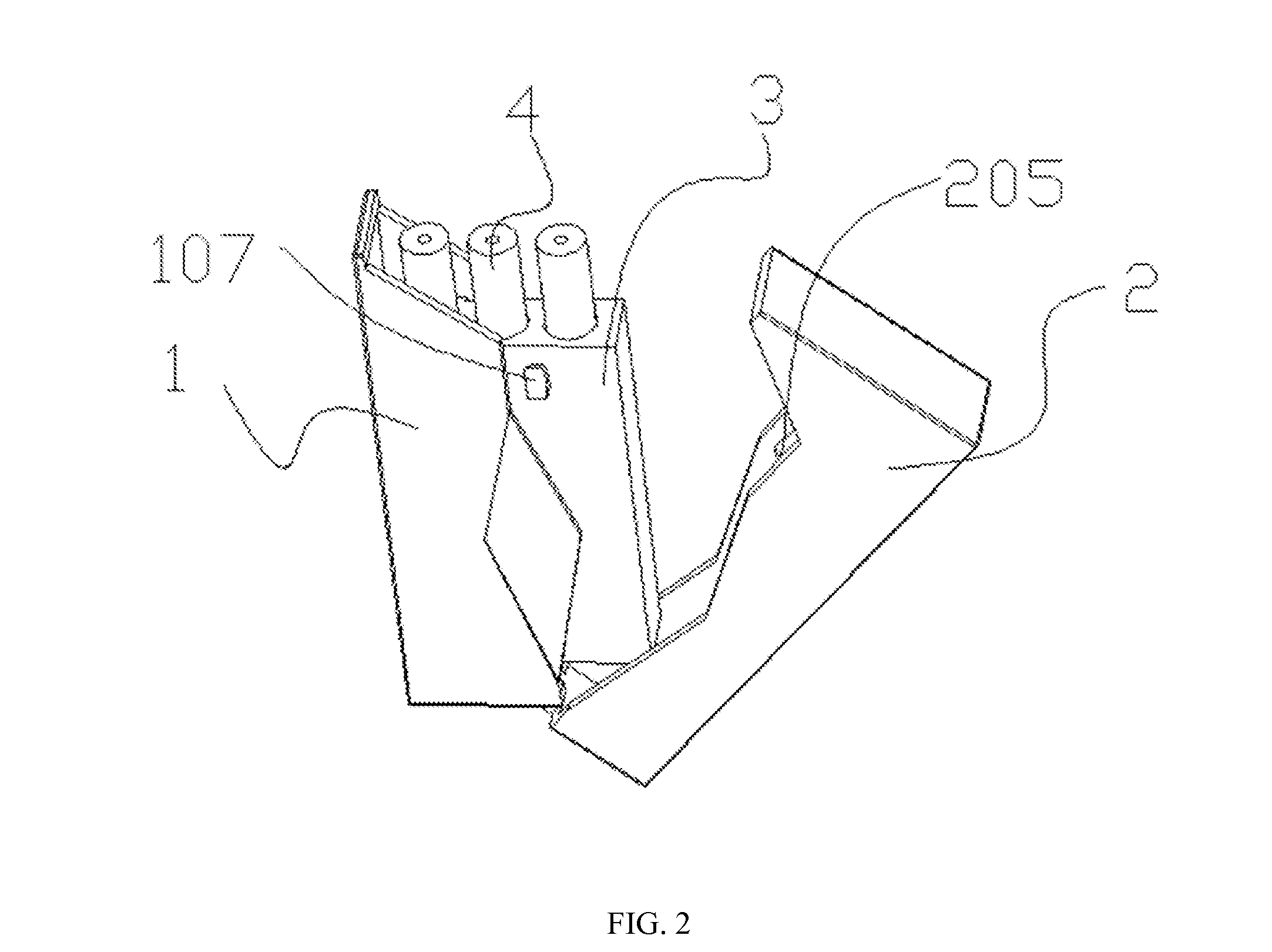

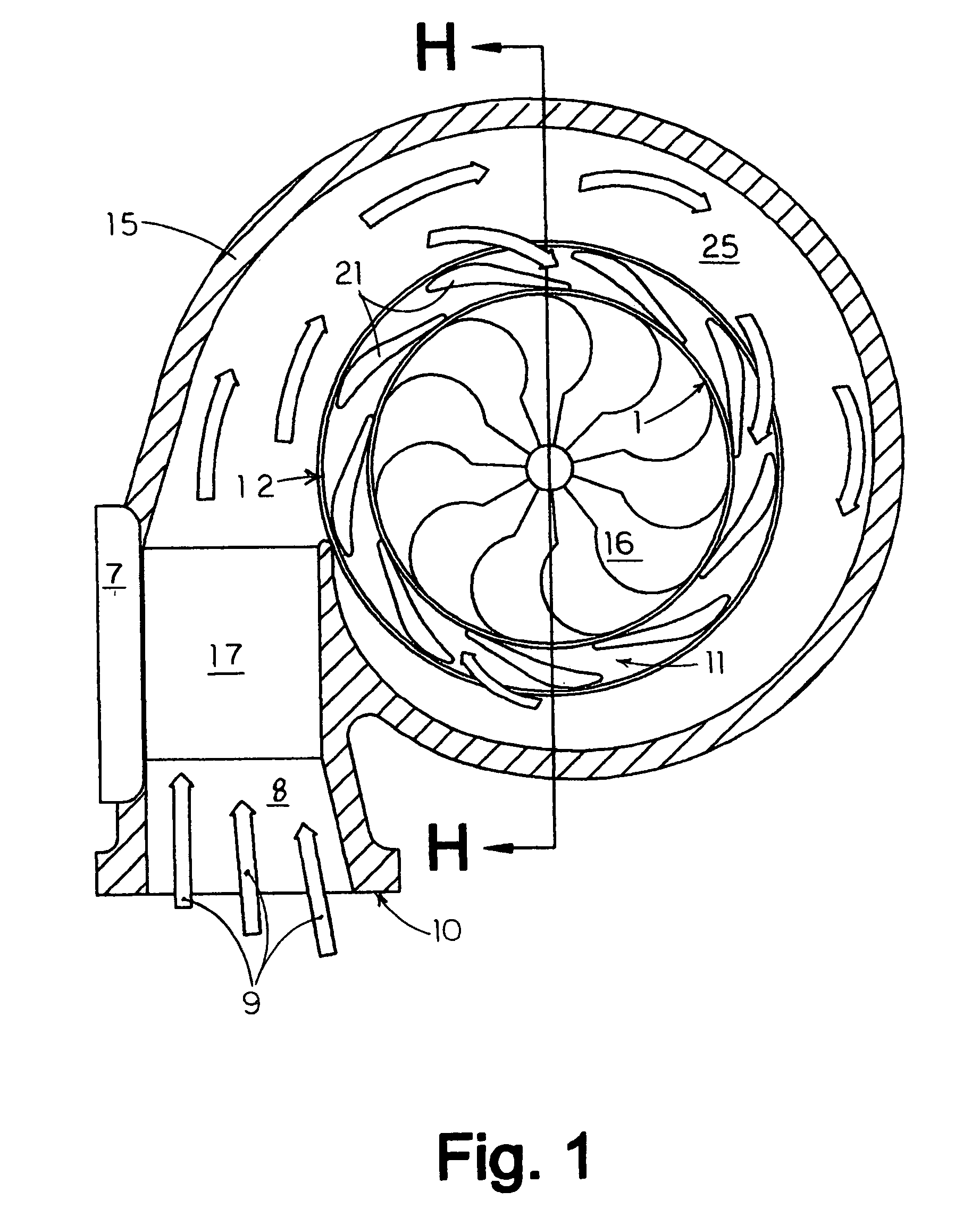

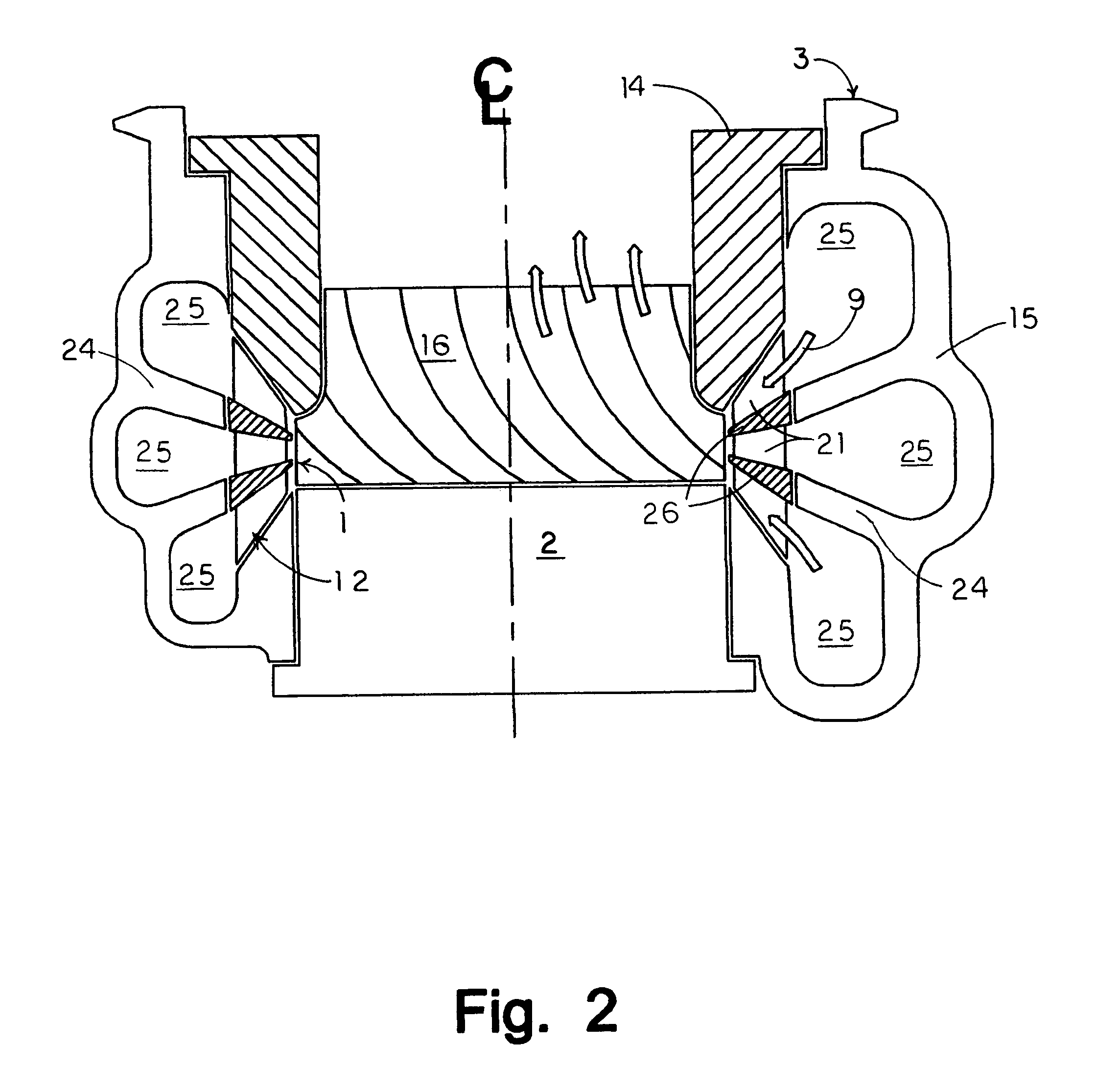

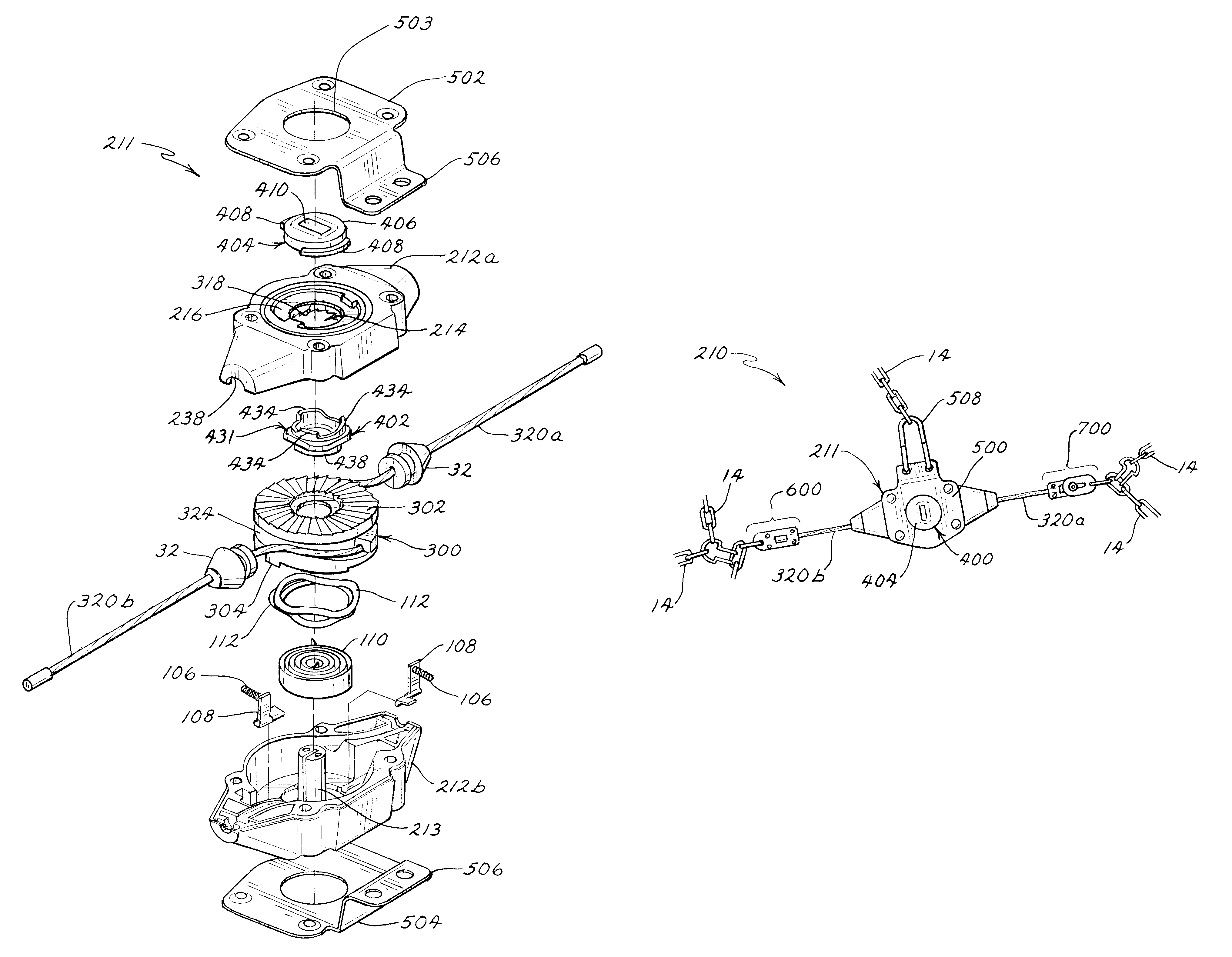

Multiple nozzle rings and a valve for a turbocharger

InactiveUS20070209361A1Increase impact speedReduce back pressureEngine manufactureInternal combustion piston enginesTurbochargerEngineering

A turbocharger turbine housing with at least two volutes utilizing multiple nozzle rings to optimize the turbocharger's proficiency per application, and a valve to control the exhaust flow to selected volutes in the turbine housing.

Owner:PEDERSEN MELVIN HESS +1

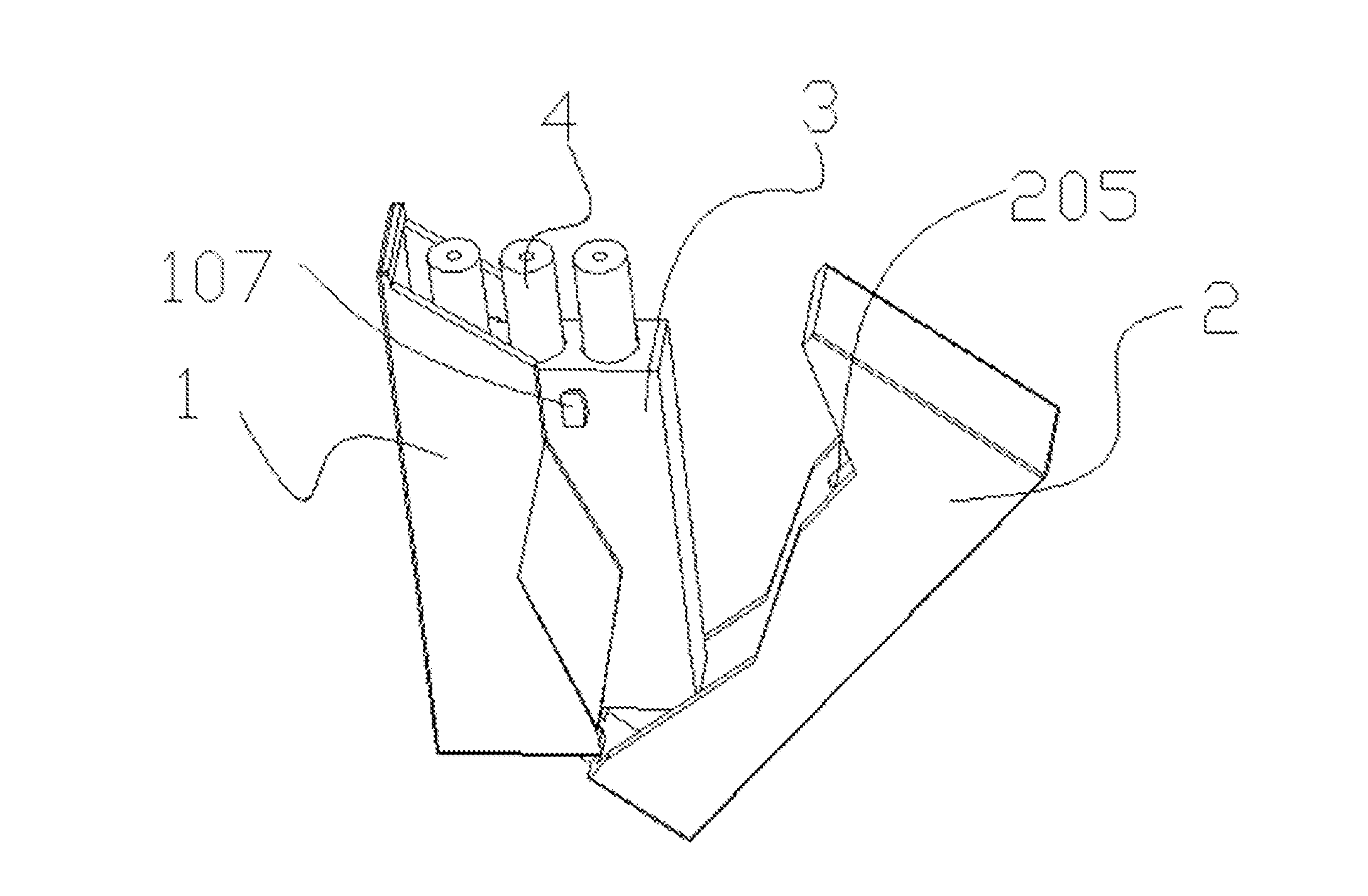

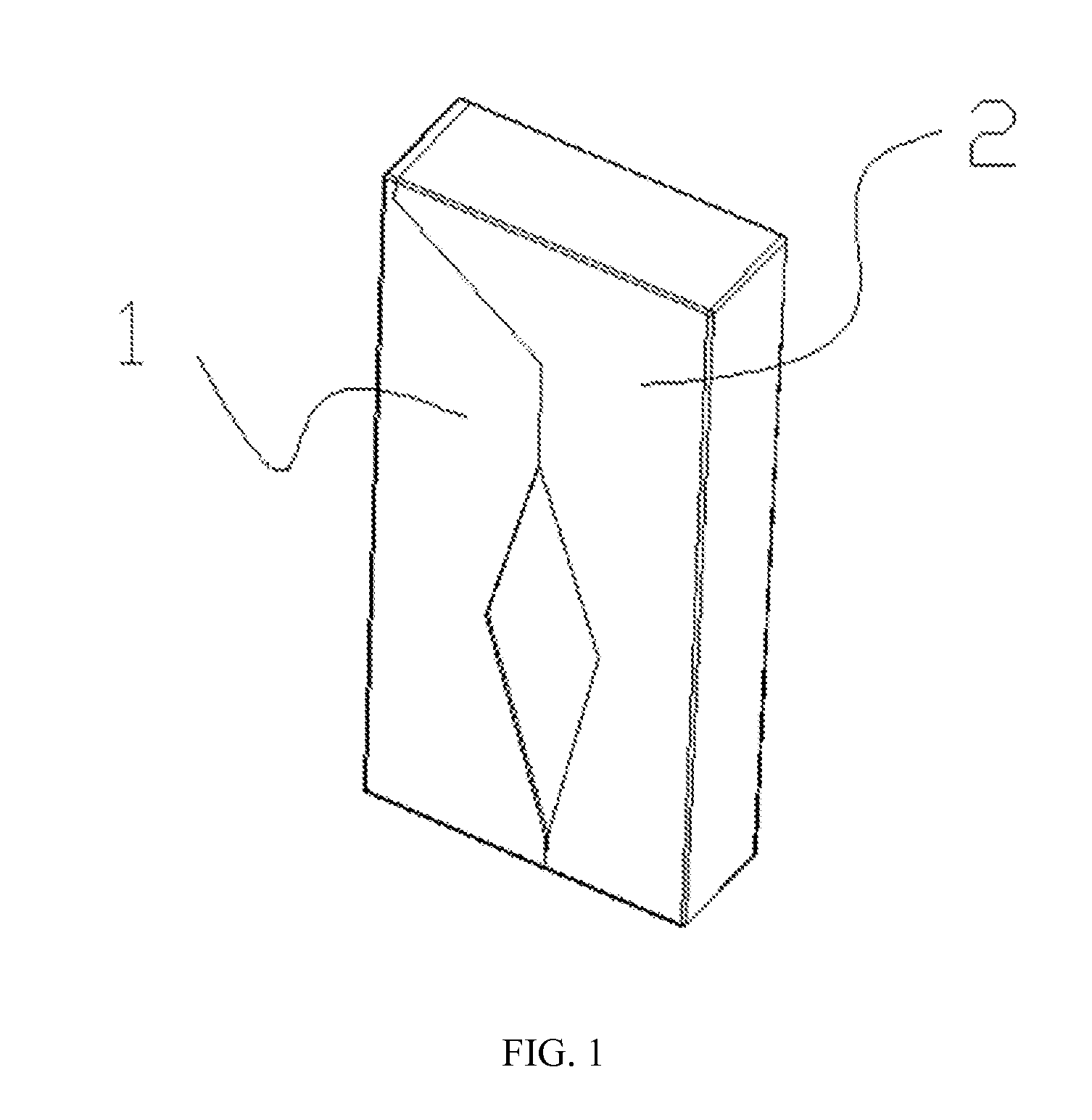

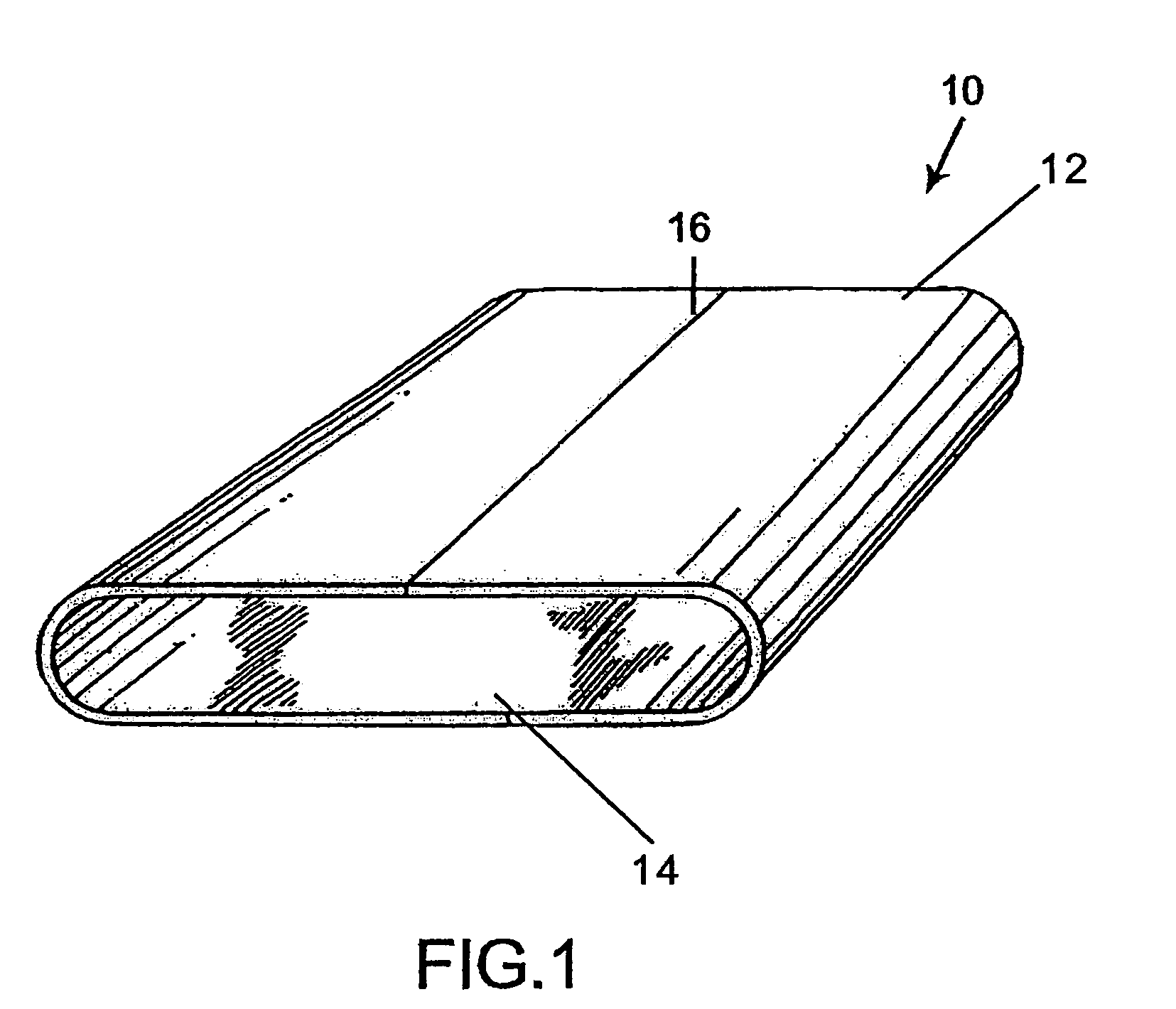

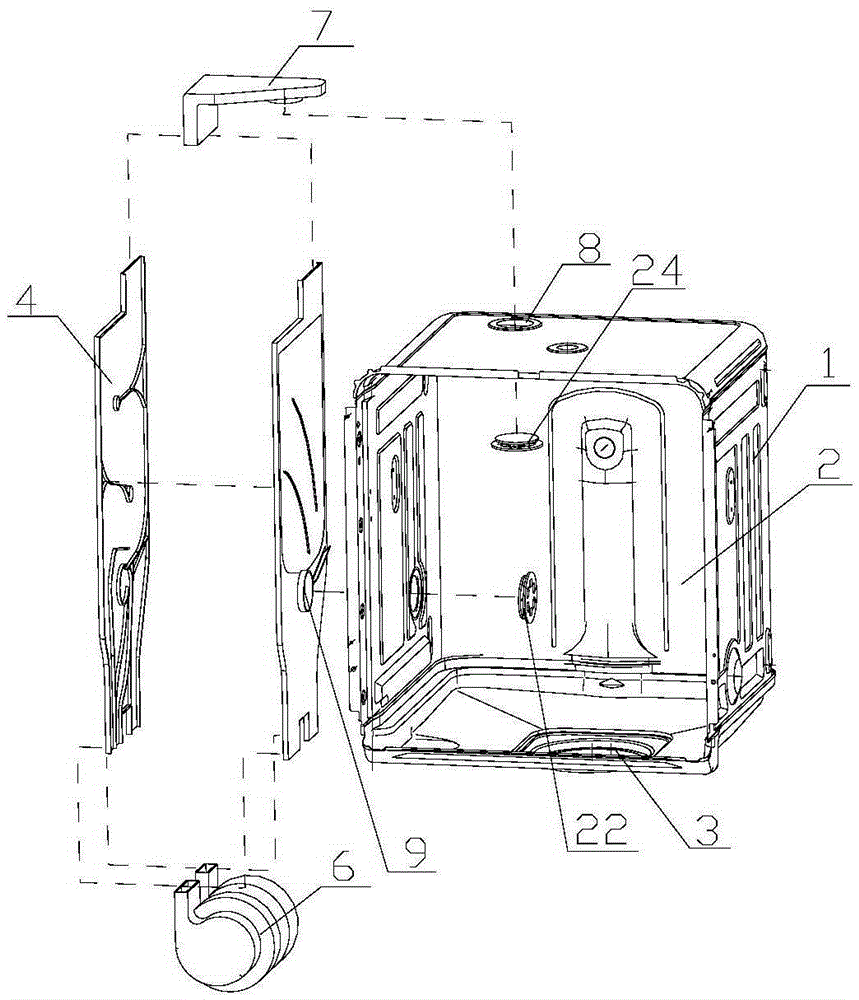

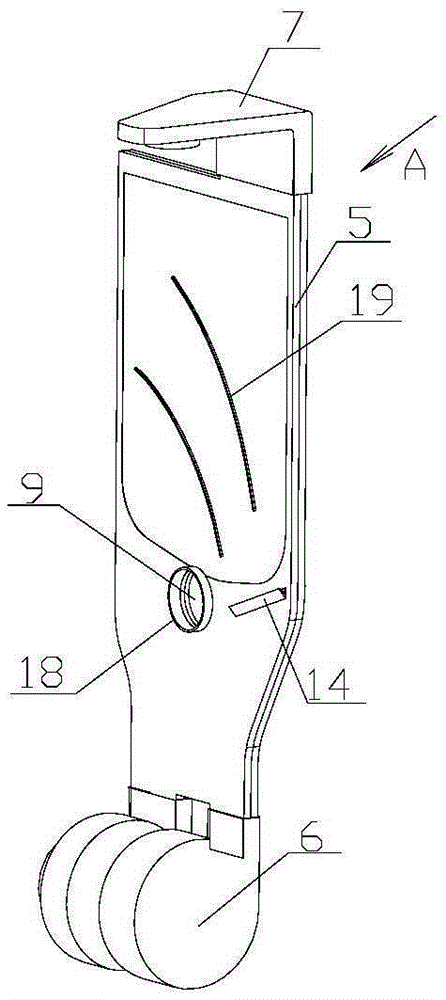

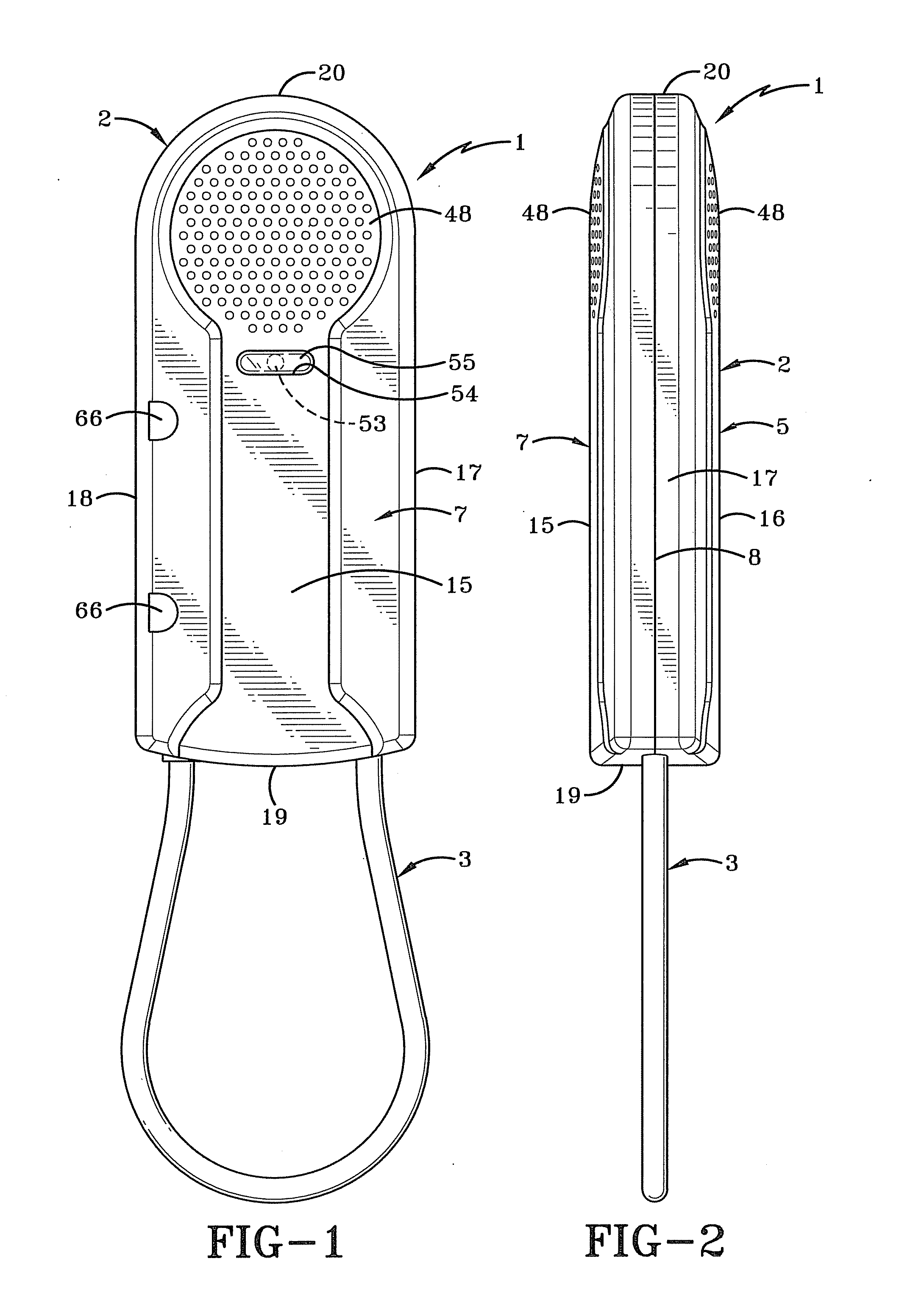

Electronic cigarette case

InactiveUS20150034507A1Wide rangeConveniently takenContainers for flexible articlesCigar manufactureElectronic cigaretteComputer engineering

The present application relates to an electronic cigarette case, comprising a case body with an opening defined on the top of the case body, and a case cover which covers the case body; the case cover includes a cover body and a connection portion which is extending from one side of the cover body to the bottom of the case body in the direction of far away from the top of the cover body; an notch corresponding to the position of the case cover is defined in the case body, the shape of the notch matches with the shape of the case cover, and the connection portion is connected to the case body rotationally. When implementing the electronic cigarette case of the present application, it is easy to take out the cigarettes, and the effect of user experience is well.

Owner:HUIZHOU KIMREE TECH

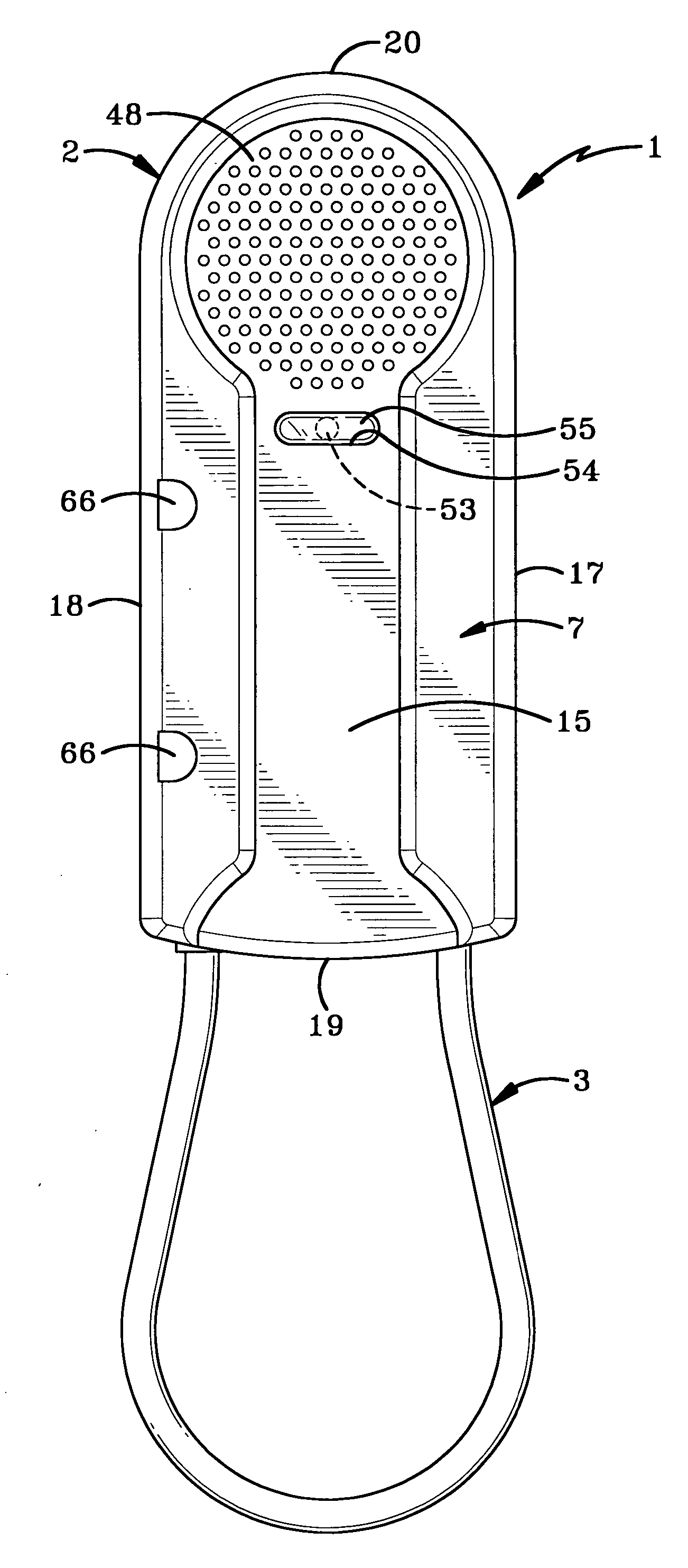

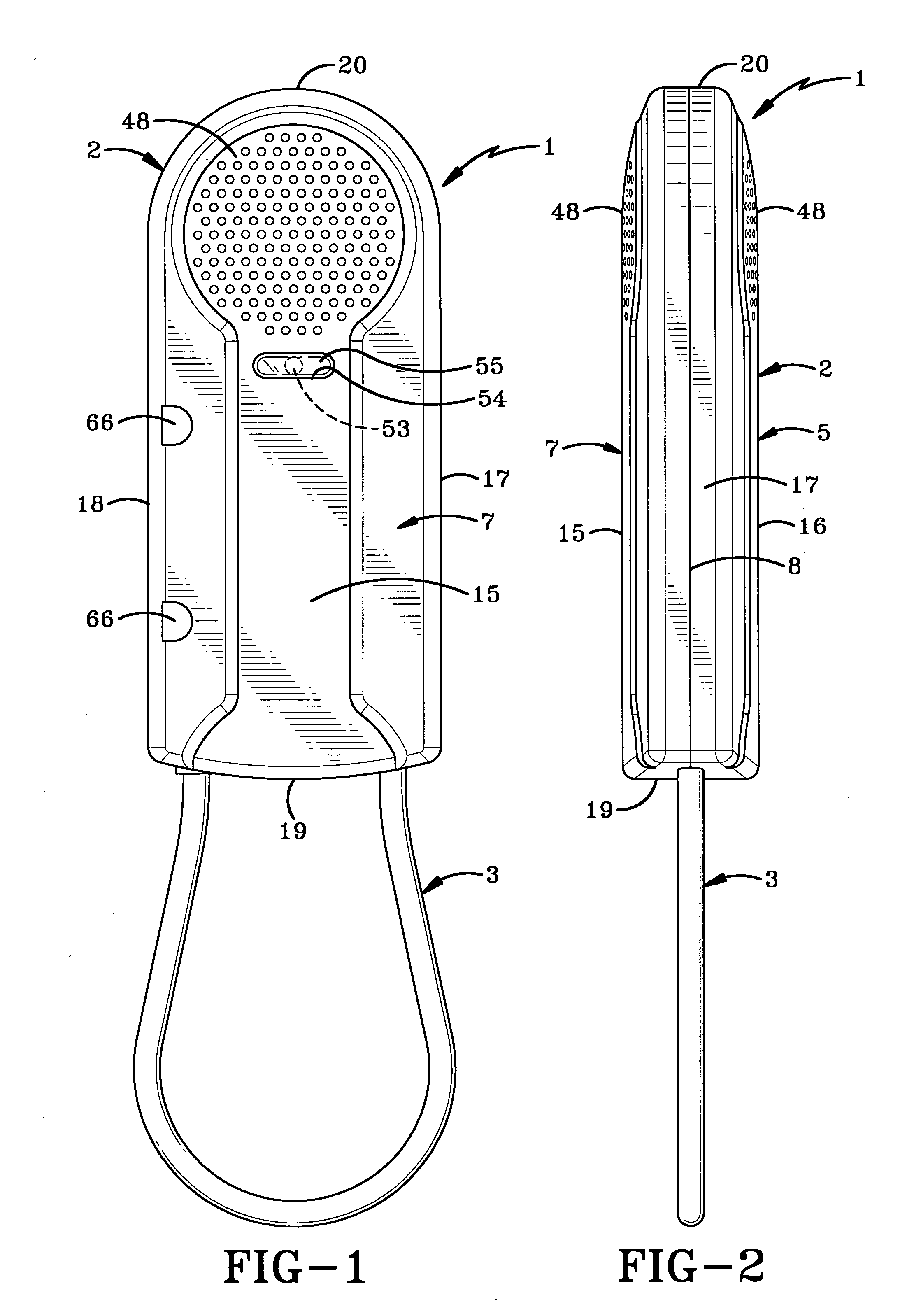

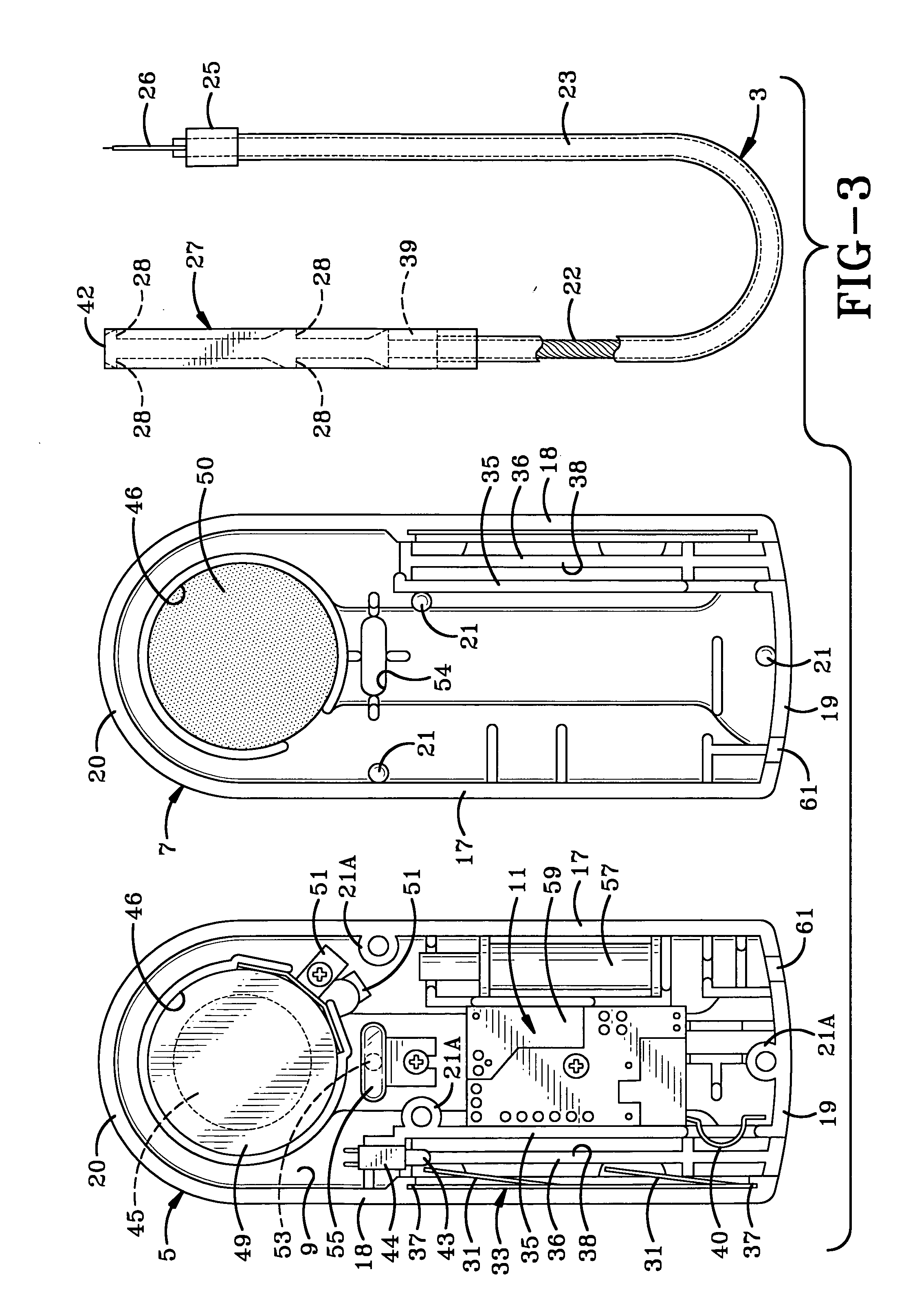

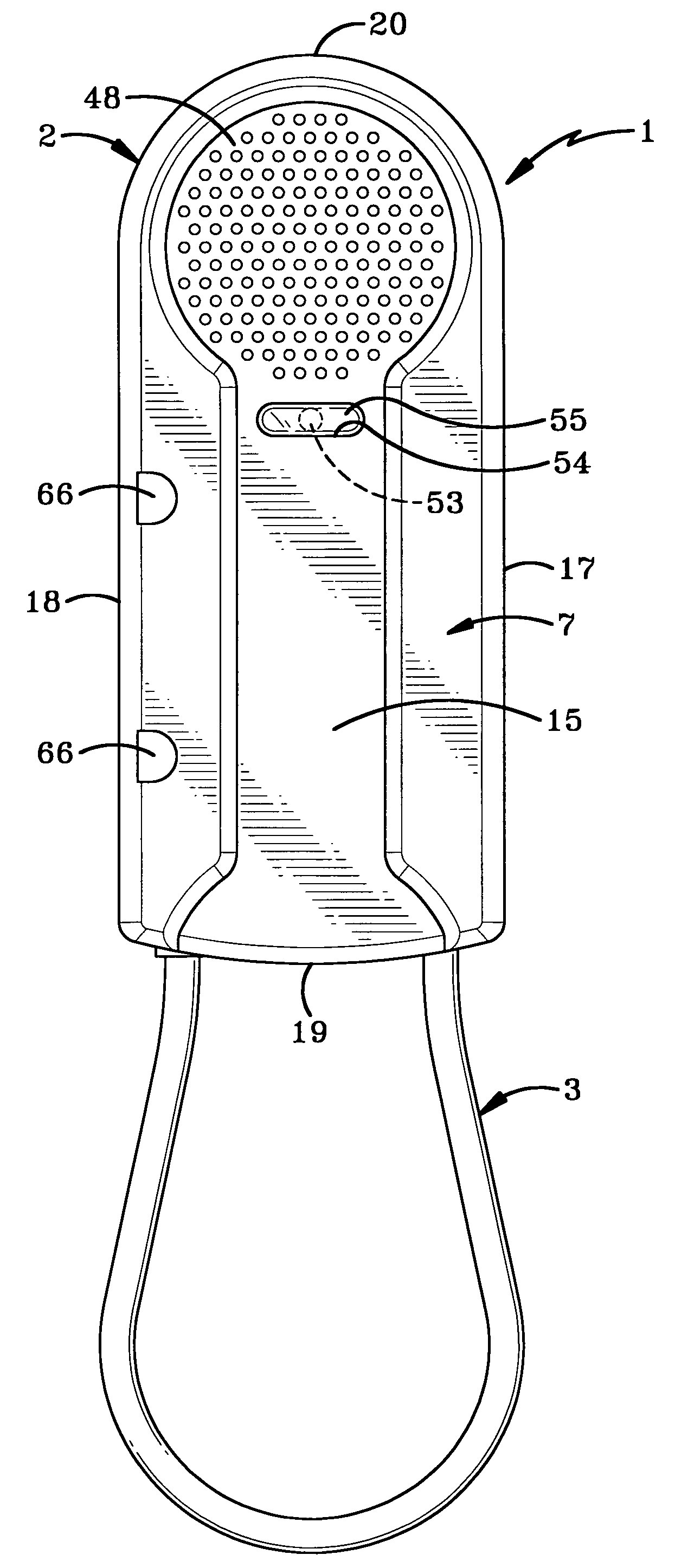

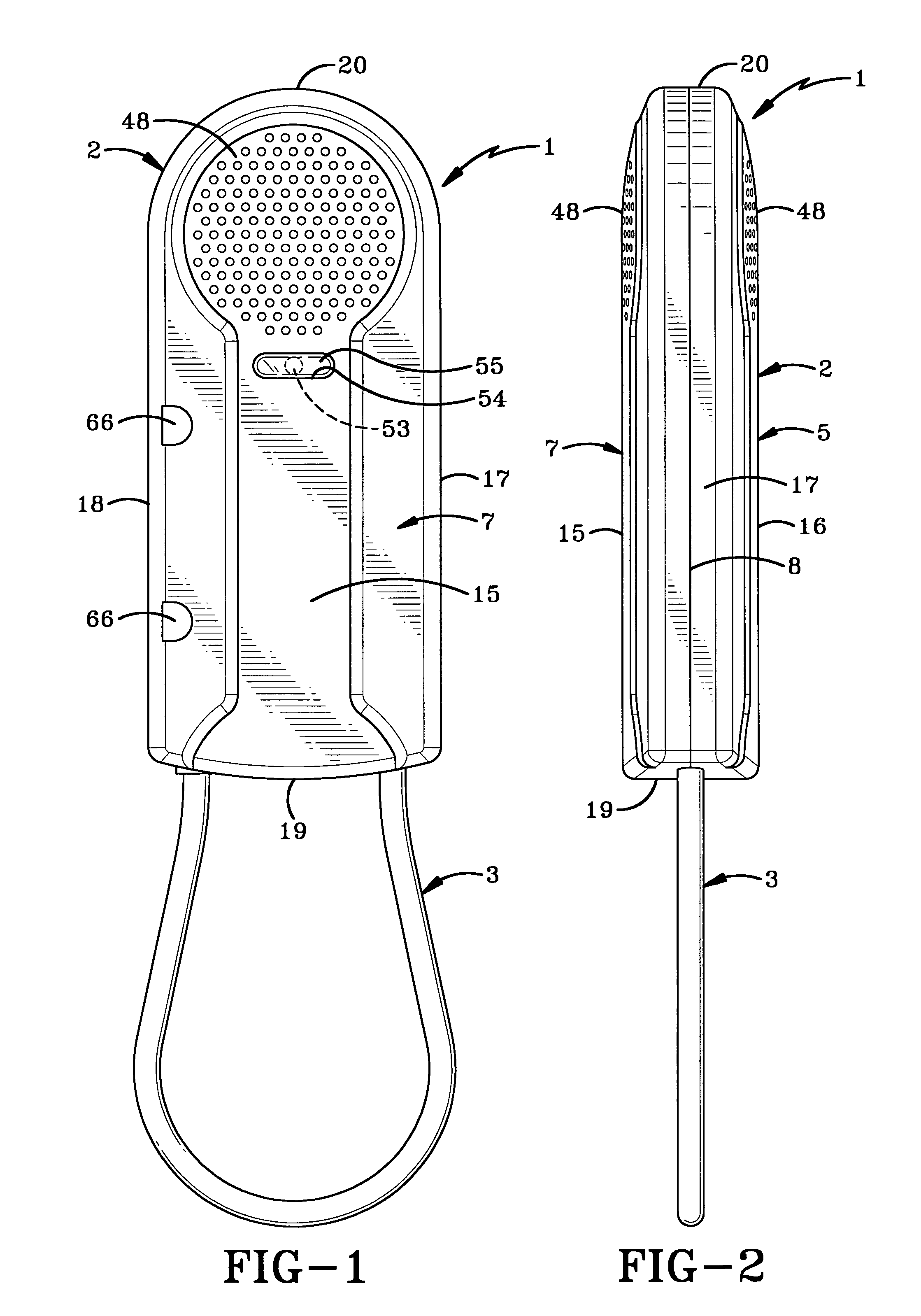

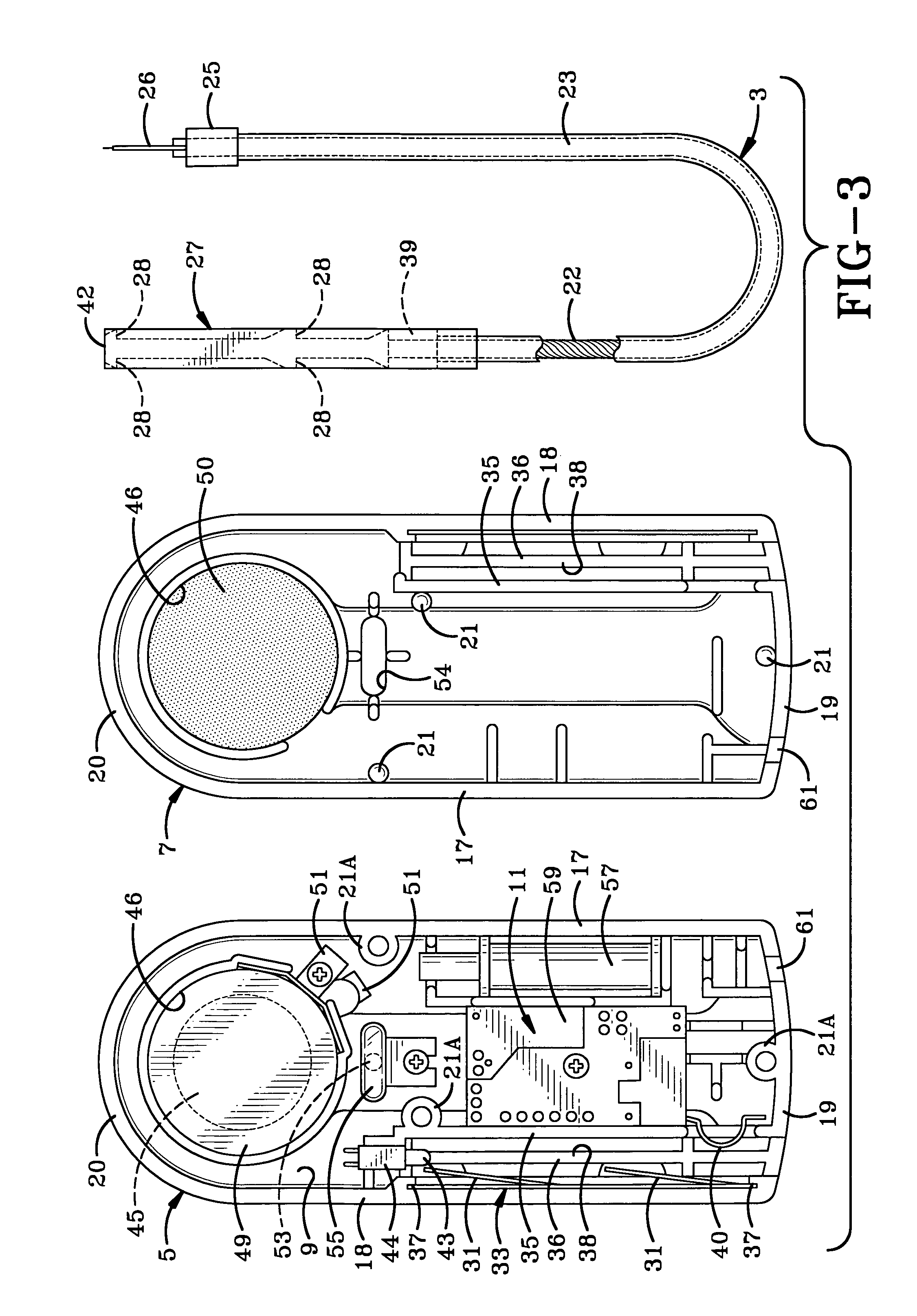

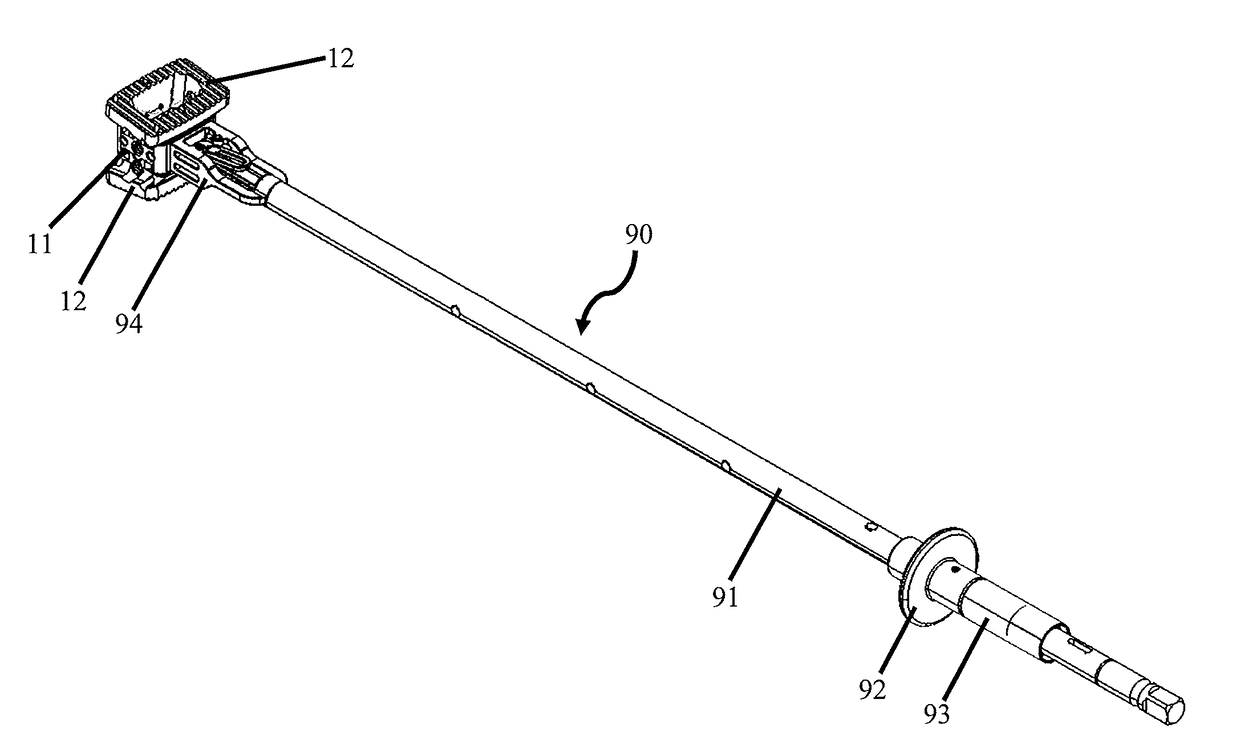

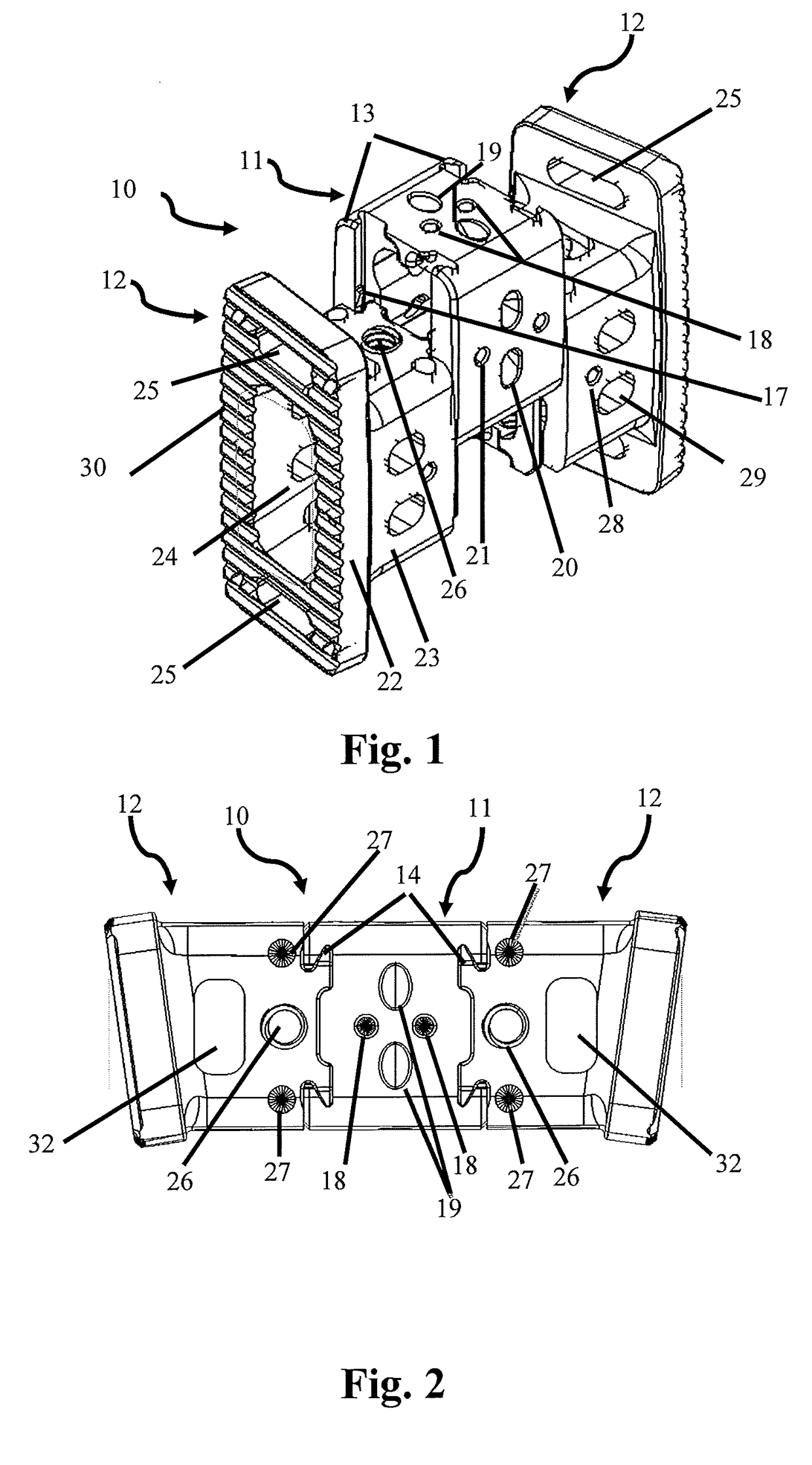

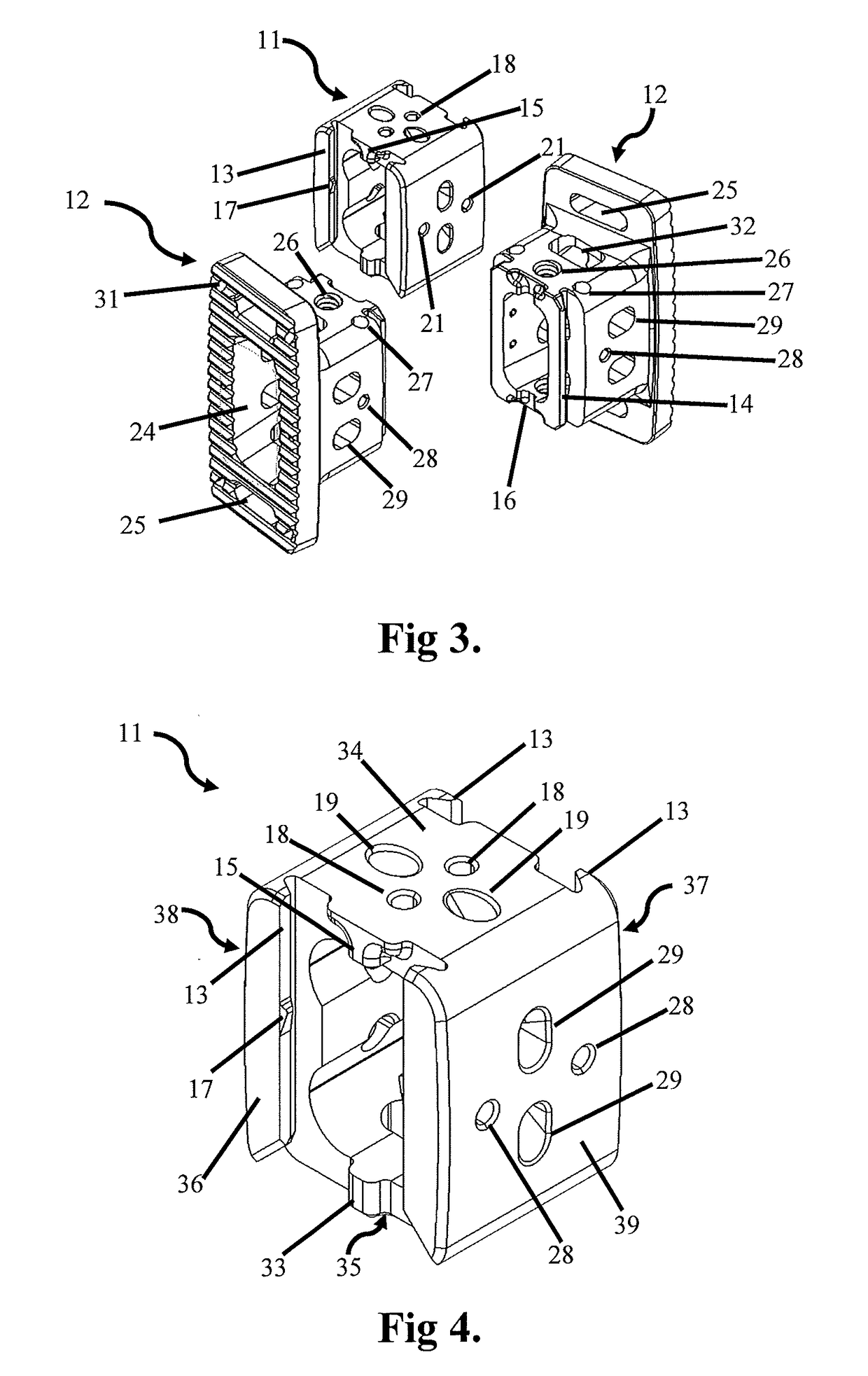

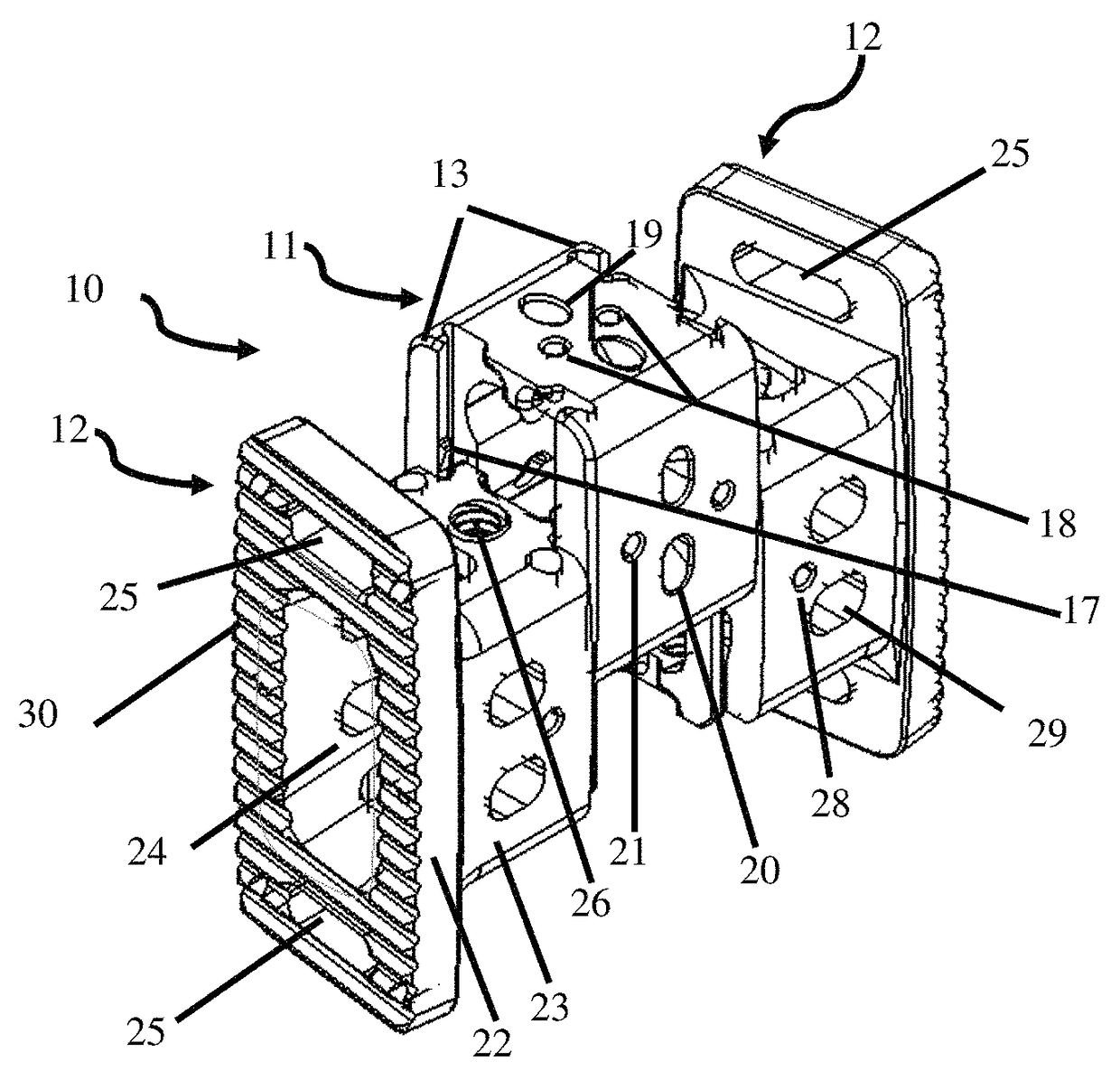

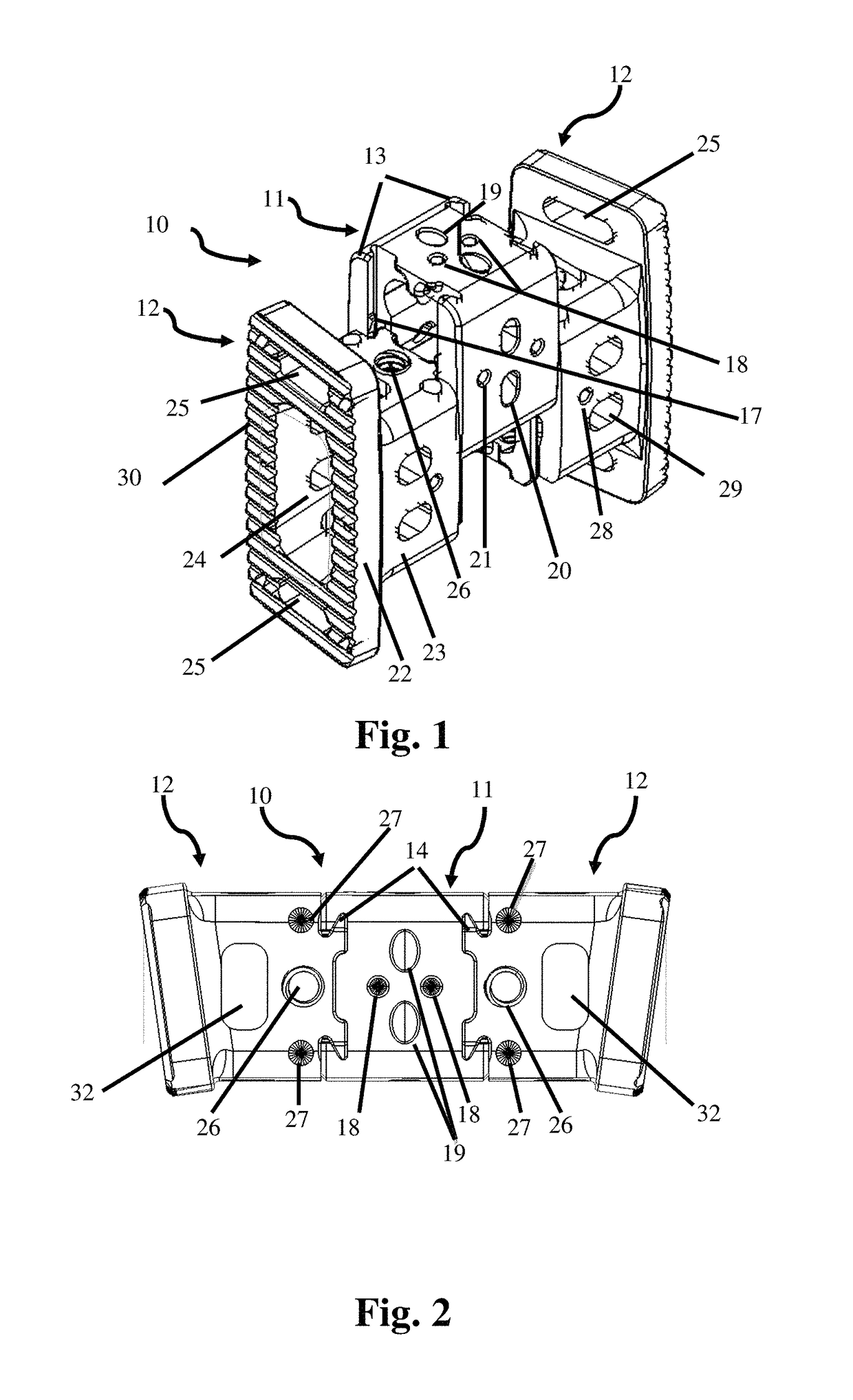

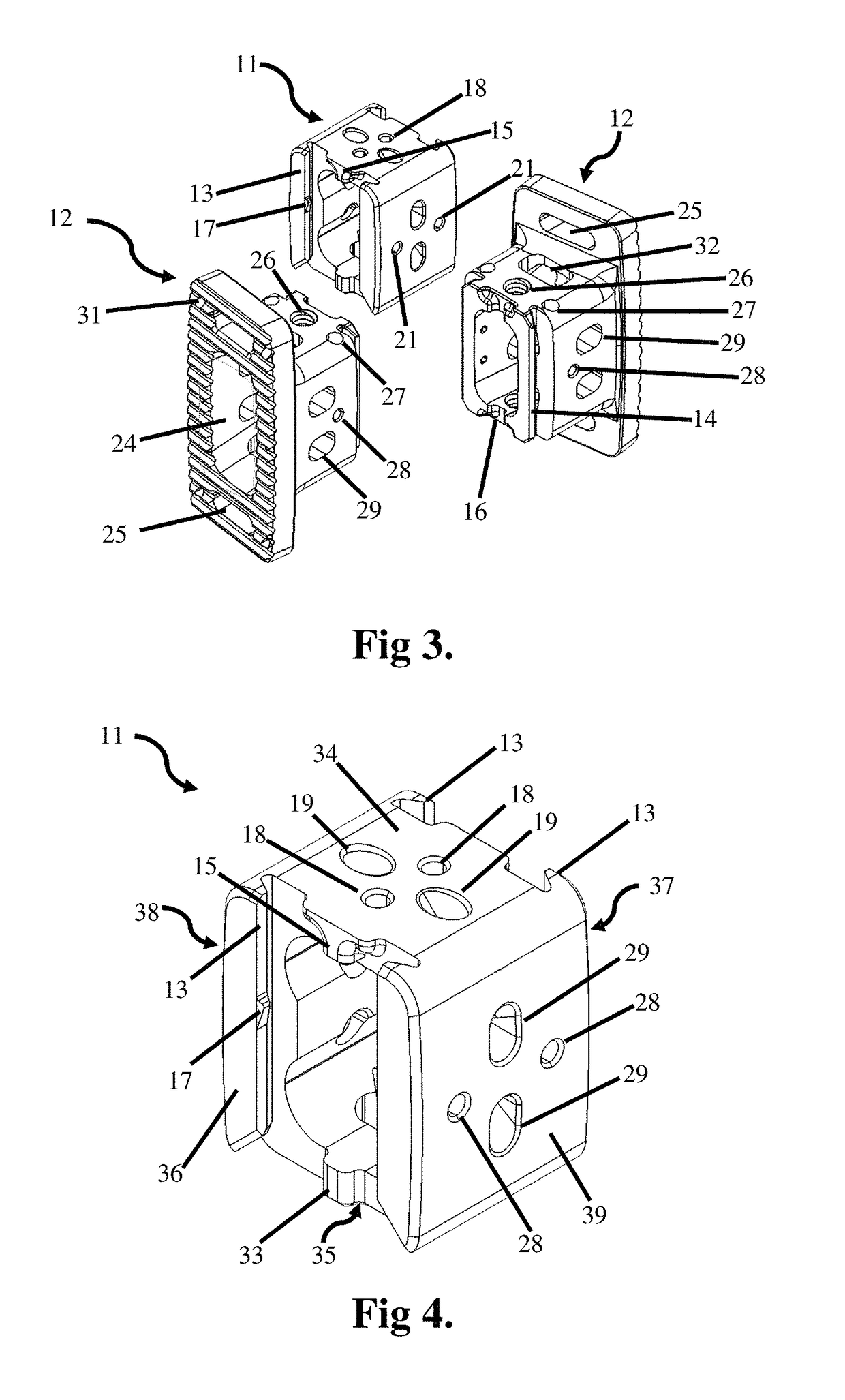

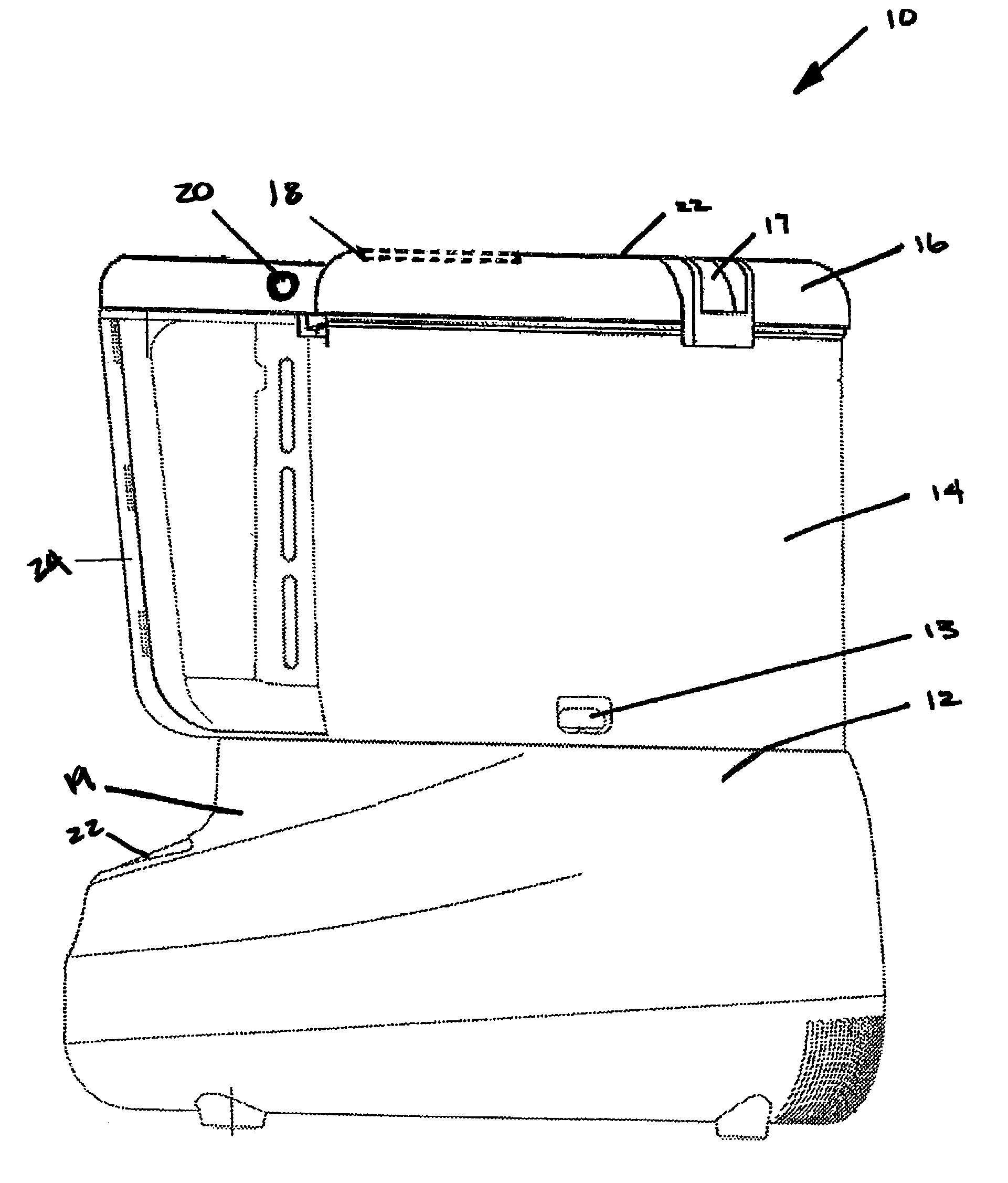

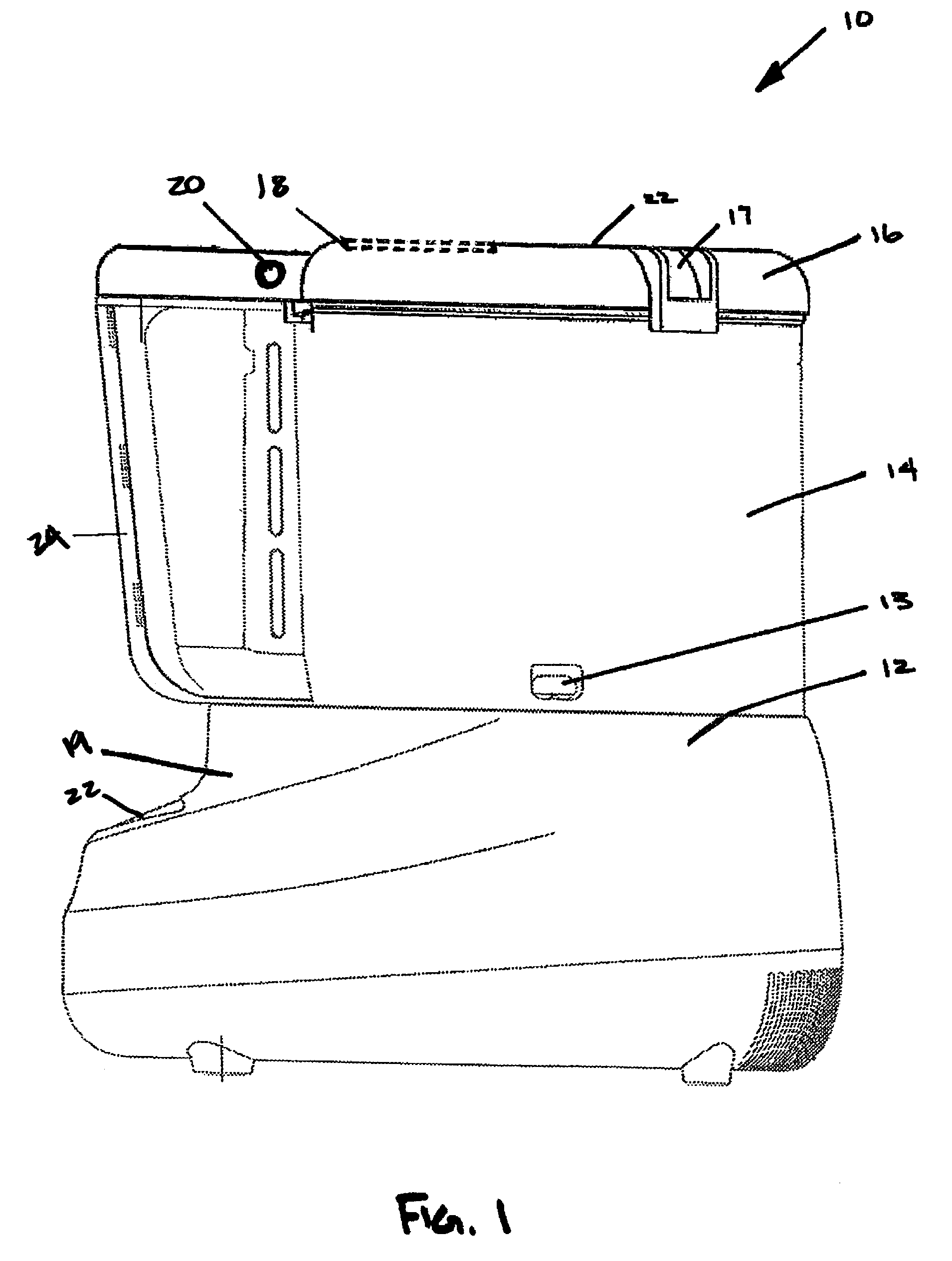

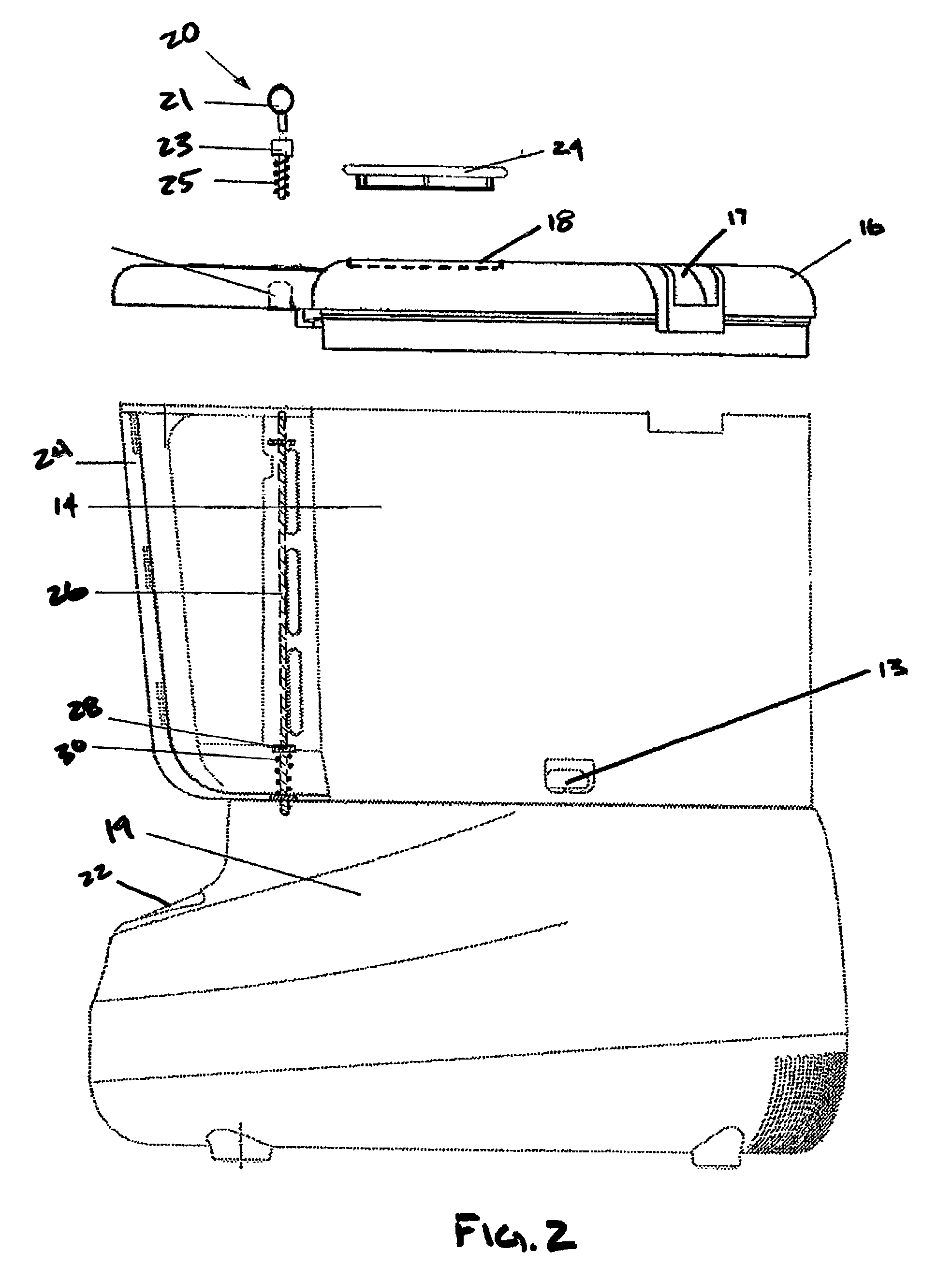

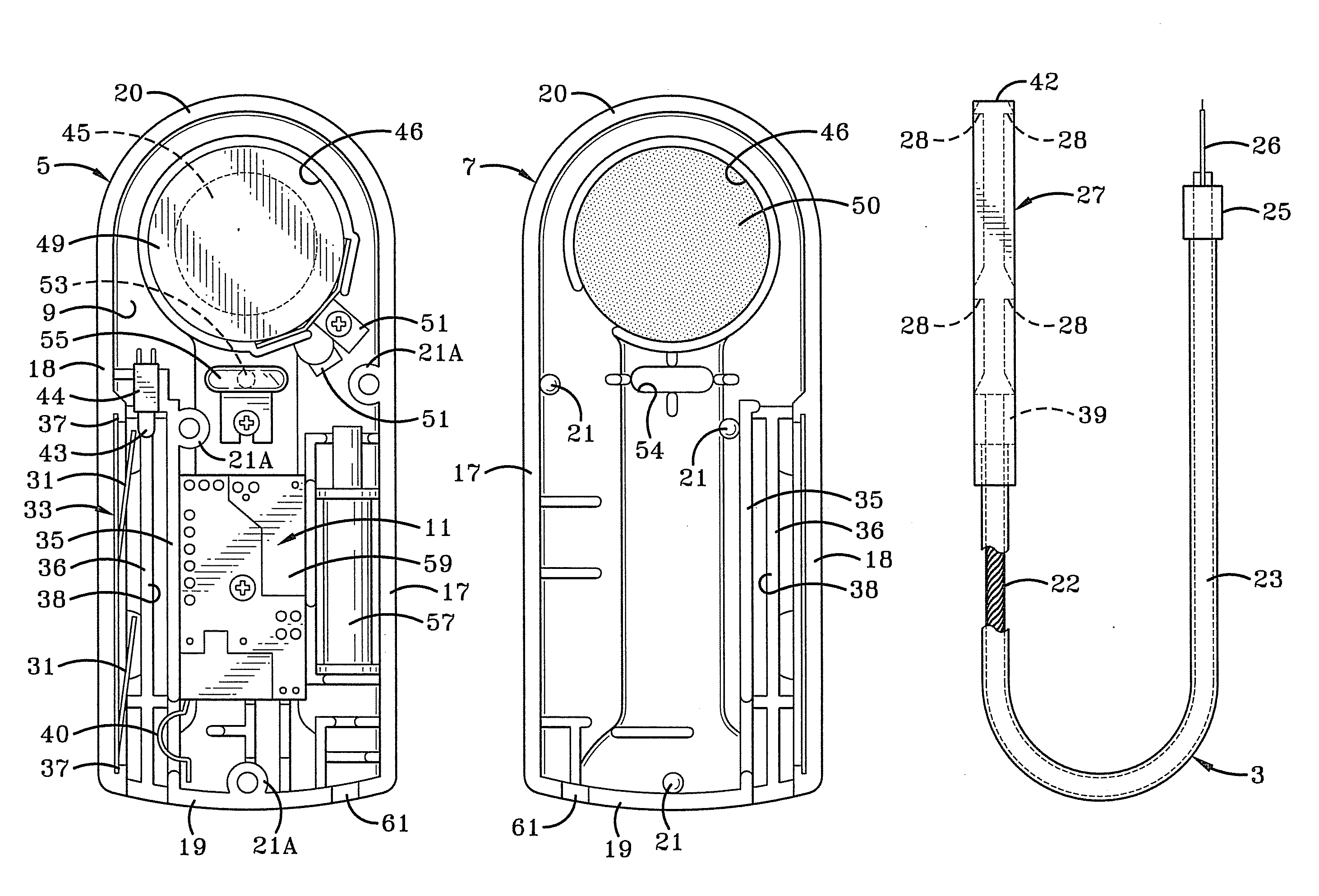

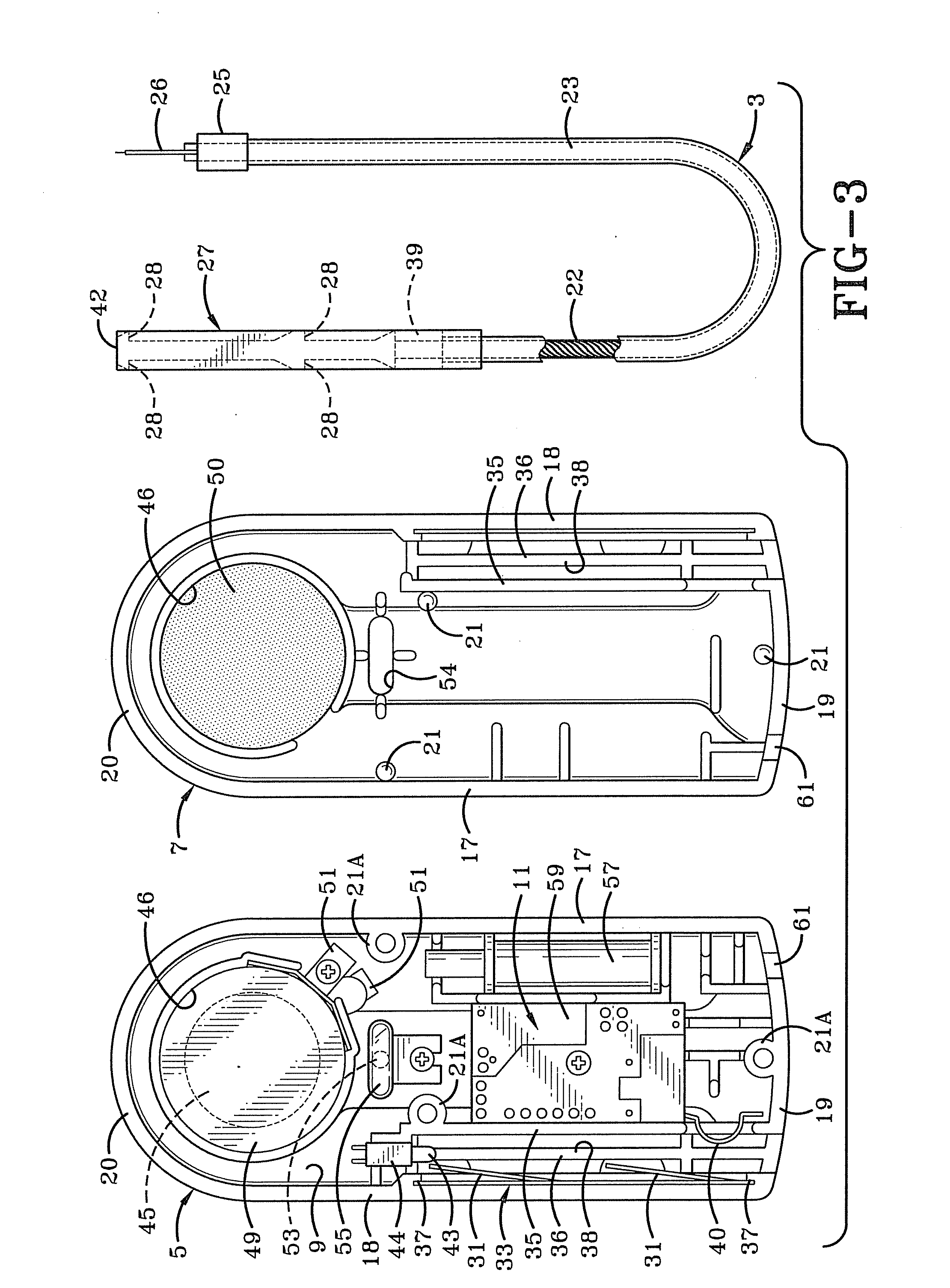

Cable alarm security device

InactiveUS20060170550A1Easy to disassembleMany timesLocks for portable objectsPadlocksElectricityElectrical conductor

A security device for attachment to an article to deter theft of the article has a housing containing an alarm system including an audible alarm and an LED. A cable has one end attached to the housing and a second end attached to a plug which is selectively inserted into and locked to the housing. The cable includes a conductor electrically connected to the alarm system when in the locked position. The audible alarm is activated if the integrity of the cable is compromised. An EAS tag located in the housing will actuate an alarm at a security gate and can actuate the audible alarm of the security device when the device is in proximity to a security gate. The LED is positioned in the housing to be visible from both sides of the housing. A magnetically attractable lock mechanism releasably secures the cable plug in the locked position.

Owner:CHECKPOINT SYST INC

Cable alarm security device

InactiveUS7474209B2Easy to disassembleMany timesLocks for portable objectsPadlocksElectricityElectrical conductor

A security device for attachment to an article to deter theft of the article has a housing containing an alarm system including an audible alarm and an LED. A cable has one end attached to the housing and a second end attached to a plug which is selectively inserted into and locked to the housing. The cable includes a conductor electrically connected to the alarm system when in the locked position. The audible alarm is activated if the integrity of the cable is compromised. An EAS tag located in the housing will actuate an alarm at a security gate and can actuate the audible alarm of the security device when the device is in proximity to a security gate. The LED is positioned in the housing to be visible from both sides of the housing. A magnetically attractable lock mechanism releasably secures the cable plug in the locked position.

Owner:CHECKPOINT SYST INC

Turbine assemblies and related systems for use with turbochargers

InactiveUS7428814B2Reduce back pressureHigh speedInternal combustion piston enginesEngine manufactureTurbochargerNozzle

A turbocharger turbine housing with at least two volutes utilizing multiple nozzle rings to optimize the turbocharger's proficiency per application, and a valve to control the exhaust flow to selected volutes in the turbine housing.

Owner:PEDERSEN MELVIN HESS +1

Electronic cigarette case

InactiveUS9415929B2Large openingEasy to take cigarette outContainers for flexible articlesPackaging cigaretteElectronic cigaretteComputer engineering

The present application relates to an electronic cigarette case, comprising a case body with an opening defined on the top of the case body, and a case cover which covers the case body; the case cover includes a cover body and a connection portion which is extending from one side of the cover body to the bottom of the case body in the direction of far away from the top of the cover body; an notch corresponding to the position of the case cover is defined in the case body, the shape of the notch matches with the shape of the case cover, and the connection portion is connected to the case body rotationally. When implementing the electronic cigarette case of the present application, it is easy to take out the cigarettes, and the effect of user experience is well.

Owner:HUIZHOU KIMREE TECH

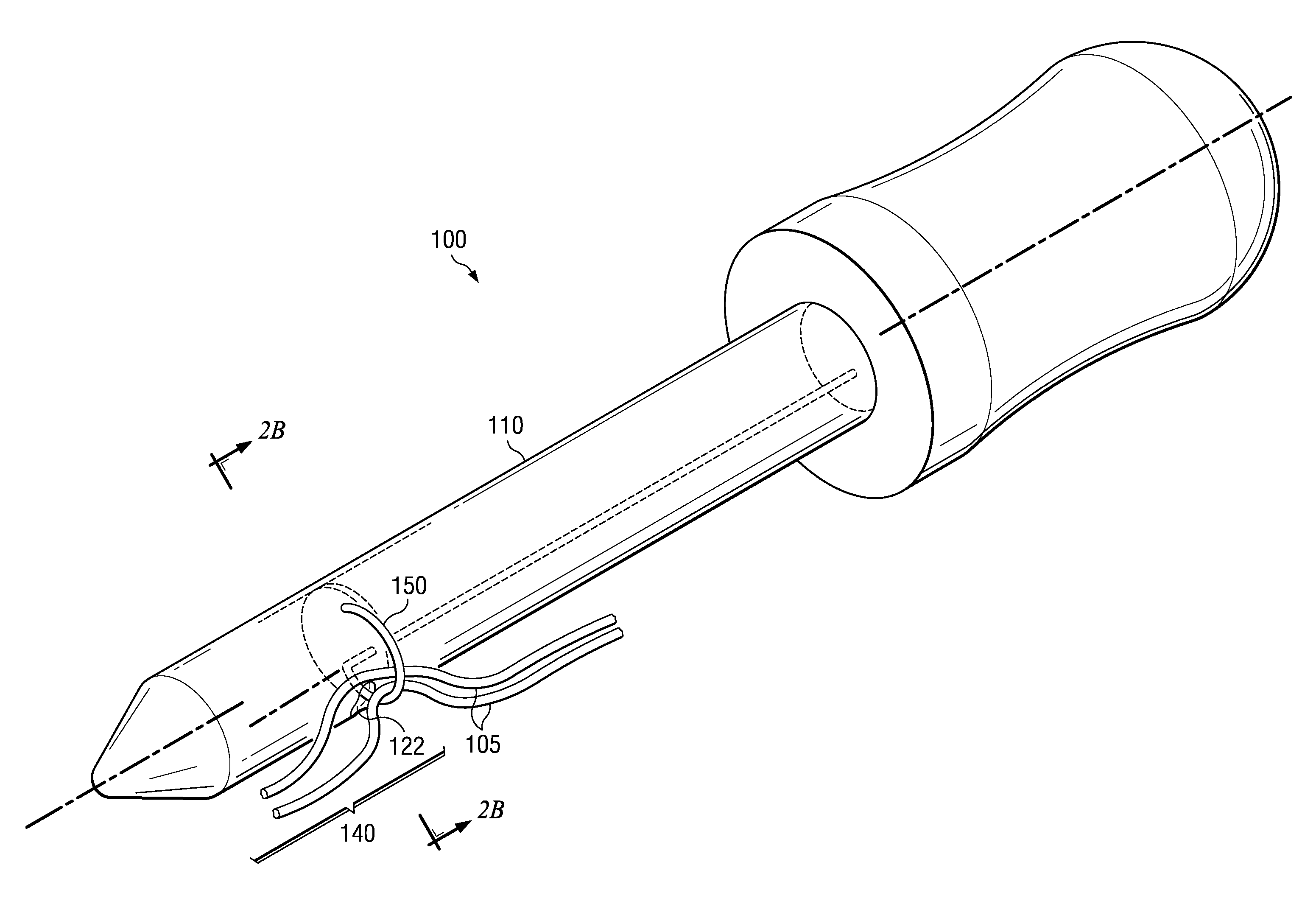

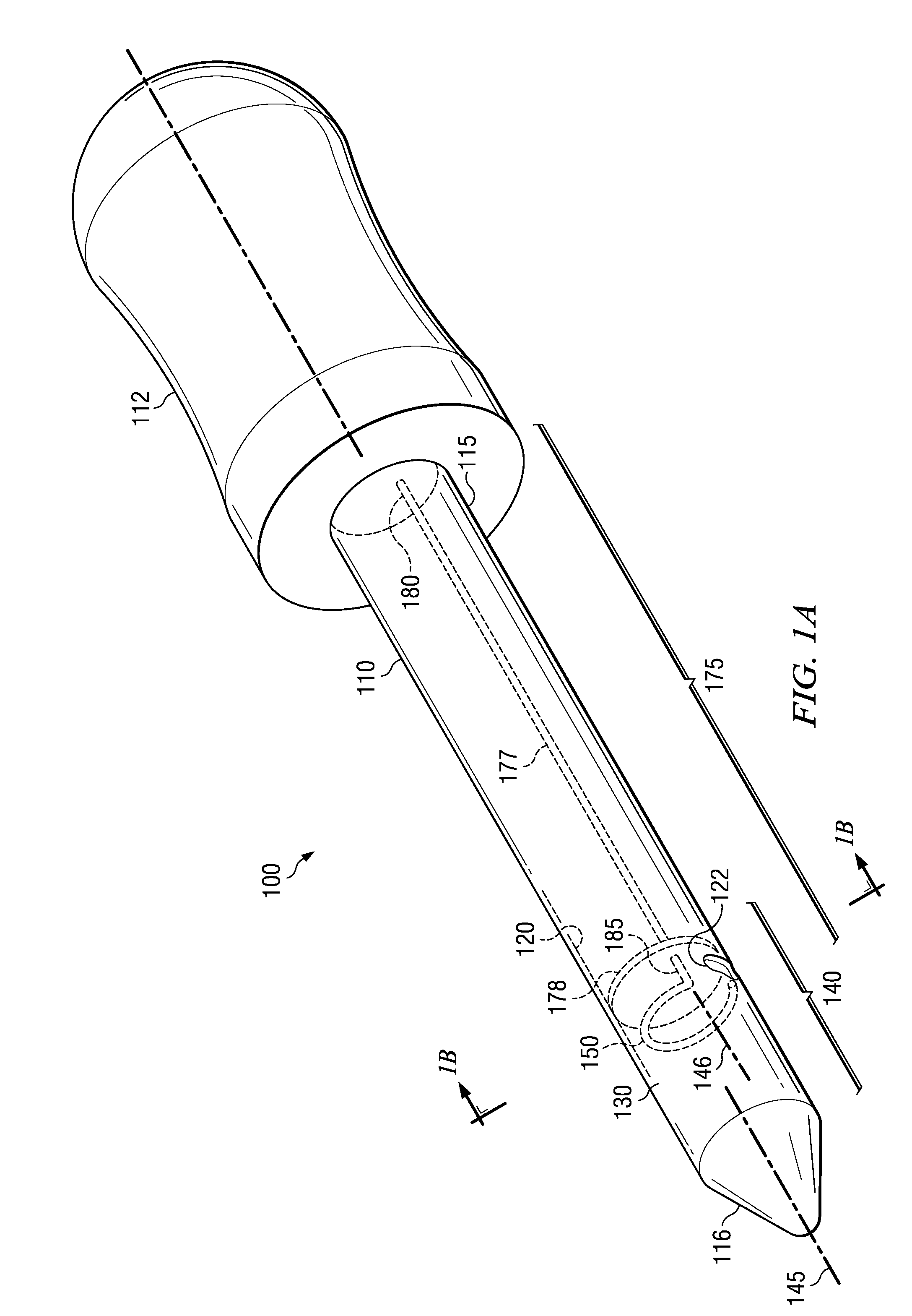

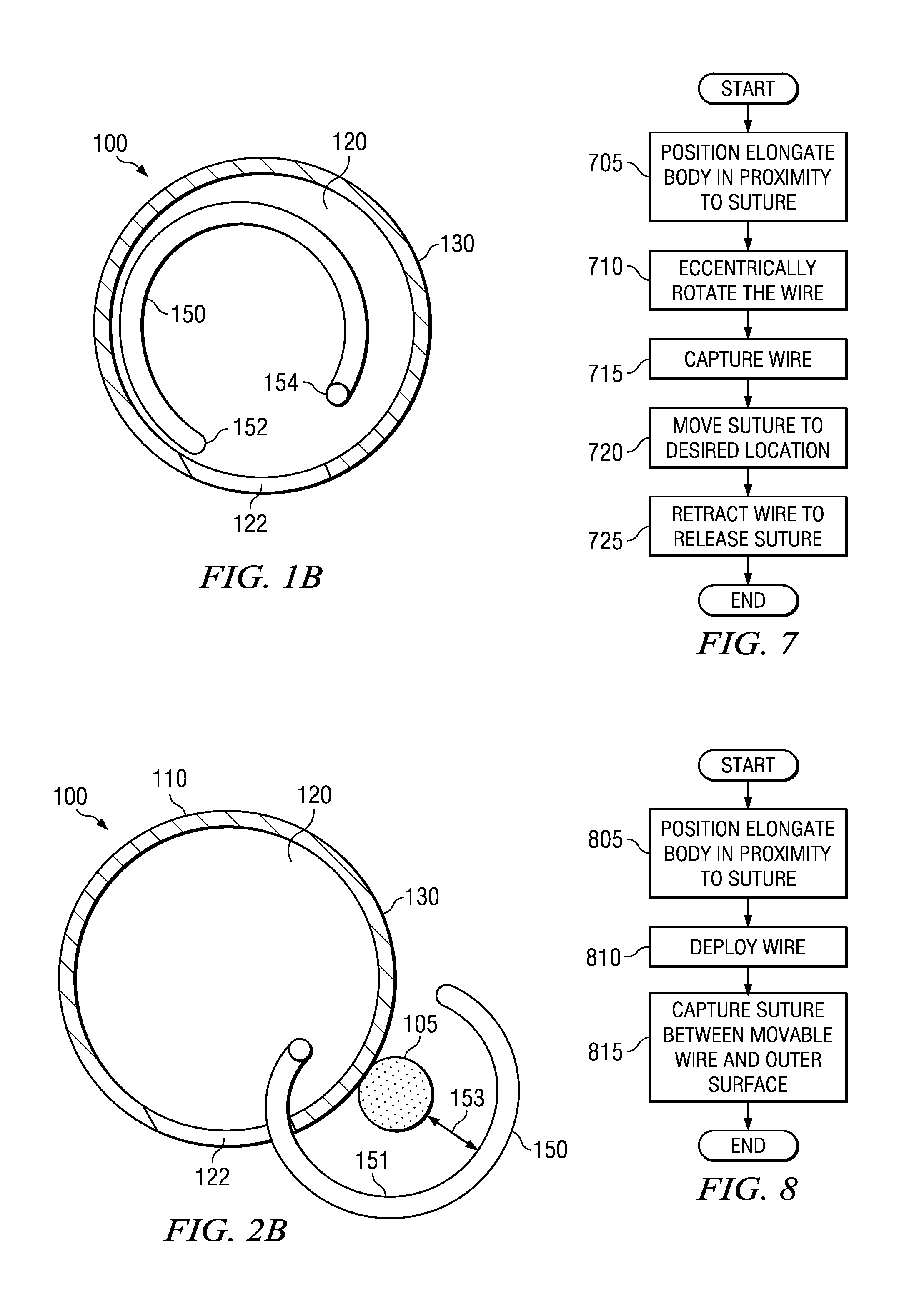

Surgical instrument for manipulating surgical suture and methods of use

InactiveUS8147505B2Small sizeReduce traumaSuture equipmentsSurgical forcepsSurgical instrumentationDistal portion

Owner:ARTHROCARE

Vertebral Body Replacement and Insertion Methods

ActiveUS20170304066A1Small openingShorten recovery timeDiagnosticsSurgeryAnterior approachVertebral bone

A vertebral body replacement device, dimensioned for implantation between a first and second vertebral bone is described. The vertebral body replacement device includes a superior endcap, an inferior endcap and a central core between the superior and inferior endcaps. The vertebral body replacement device further includes a fusion aperture extending through the superior and inferior endcaps and central core. The vertebral body replacement device is made of radiolucent material and can be implanted from a lateral or anterior approach to the spine.

Owner:NUVASIVE

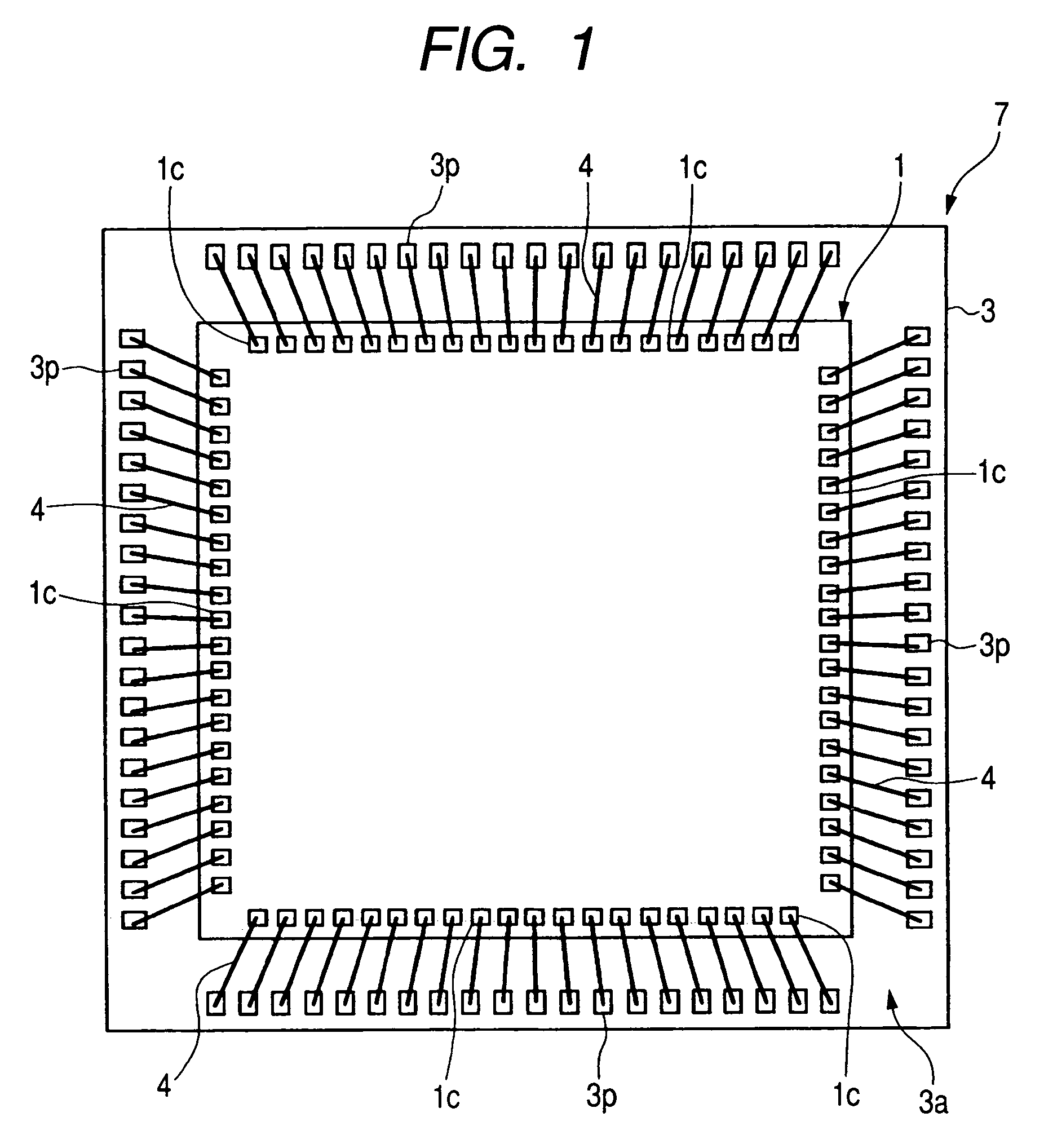

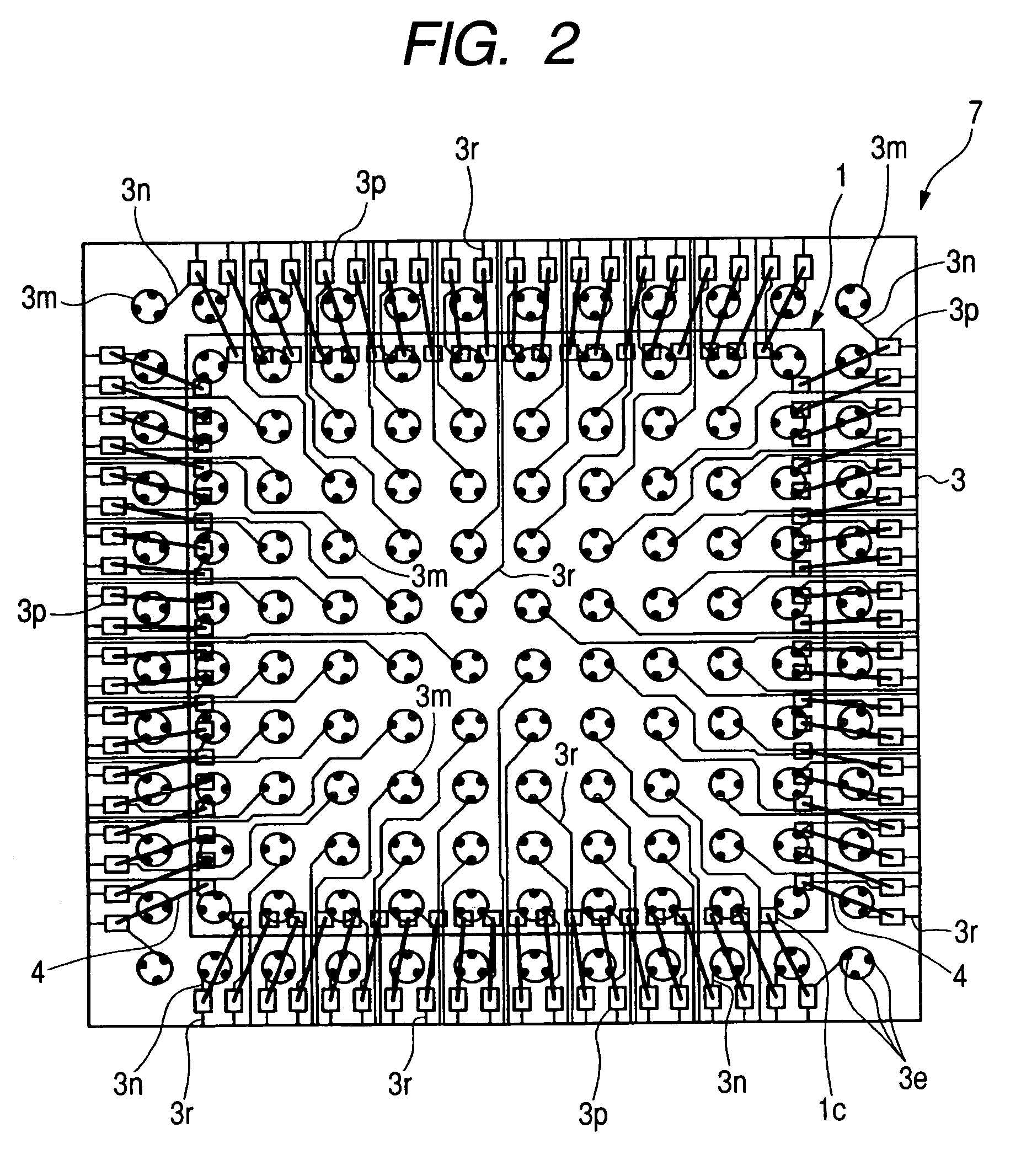

Semiconductor device with improved arrangement of a through-hole in a wiring substrate

InactiveUS7566969B2Raise countIncrease heatSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationSemiconductor chip

To miniaturize a semiconductor device, a package substrate is provided having terminals formed on the main surface, lands formed on the back surface, through holes formed by laser beam machining and arranged at the upper part of each of the lands, and plating films arranged in the through hole to connect the lands with the terminals electrically. A semiconductor chip is mounted on the main surface of the substrate, a conductive wire connects the pad of the chip and the substrate, and solder bumps are formed in the lands. Since the through holes are formed by laser beam machining, the openings of the through holes are small. Further, the through holes have a larger opening on the main surface of the package substrate than the opening on the back surface of the package substrate. Therefore, it becomes possible to arrange a solder bump directly under each of the through holes, and miniaturization can be realized.

Owner:RENESAS ELECTRONICS CORP

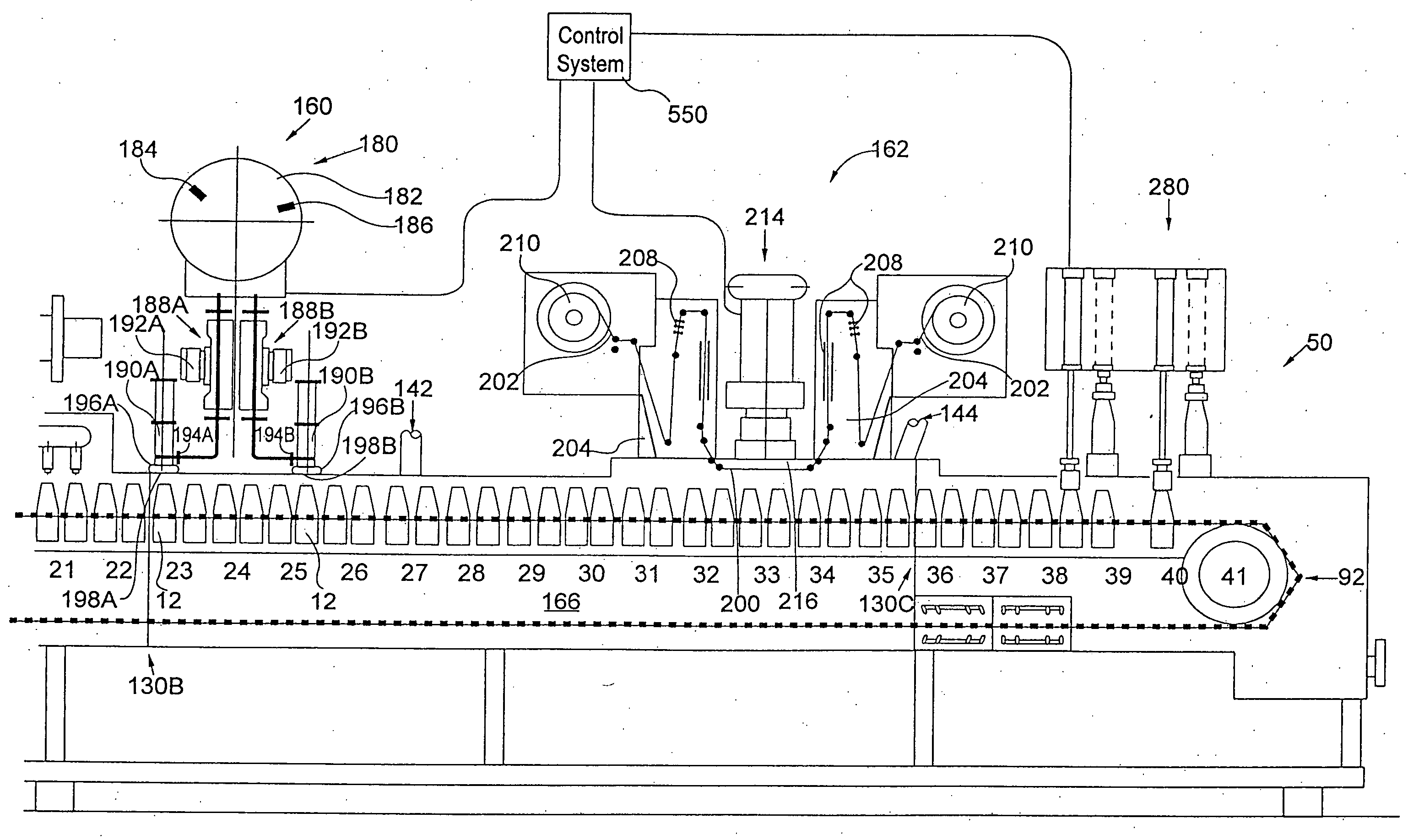

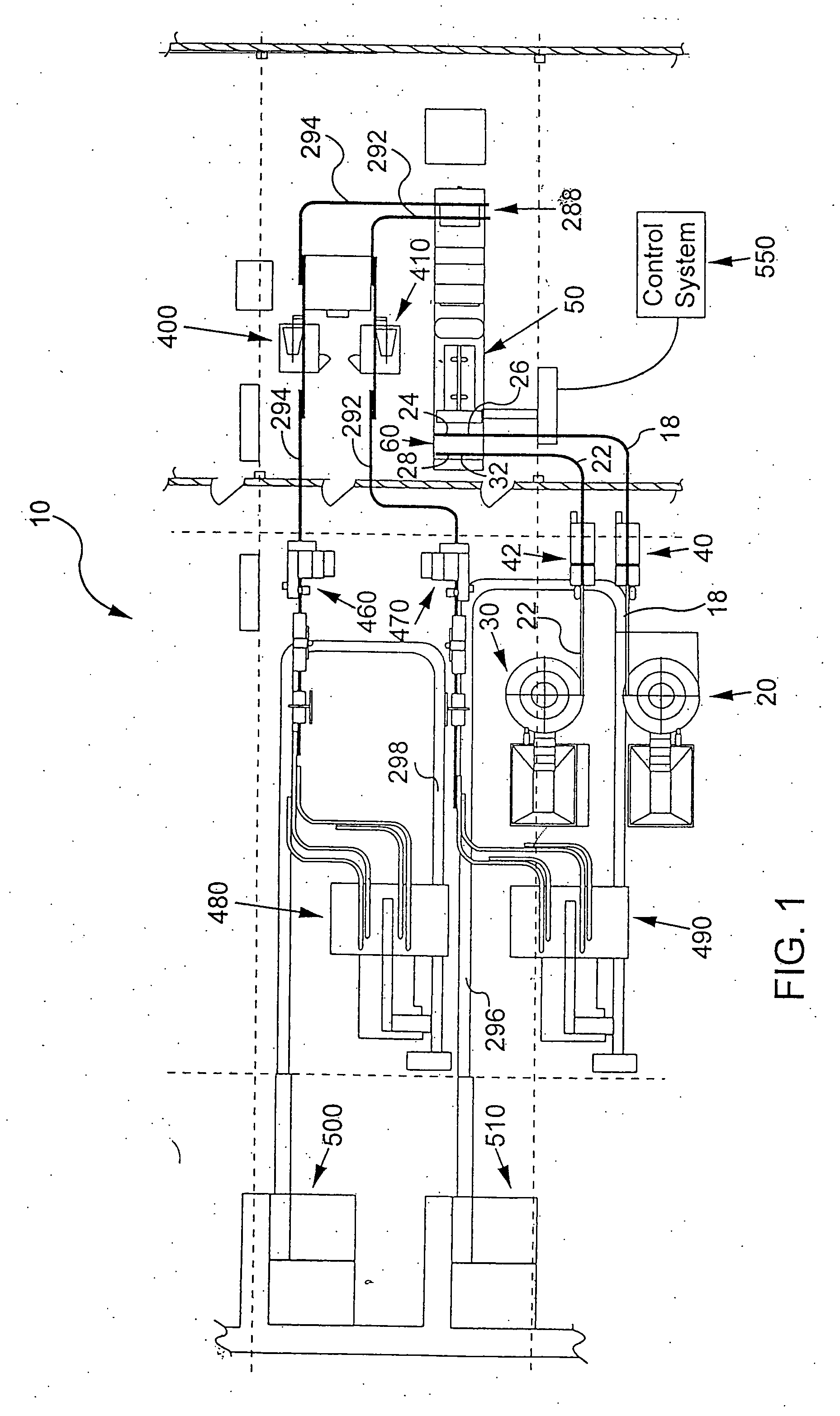

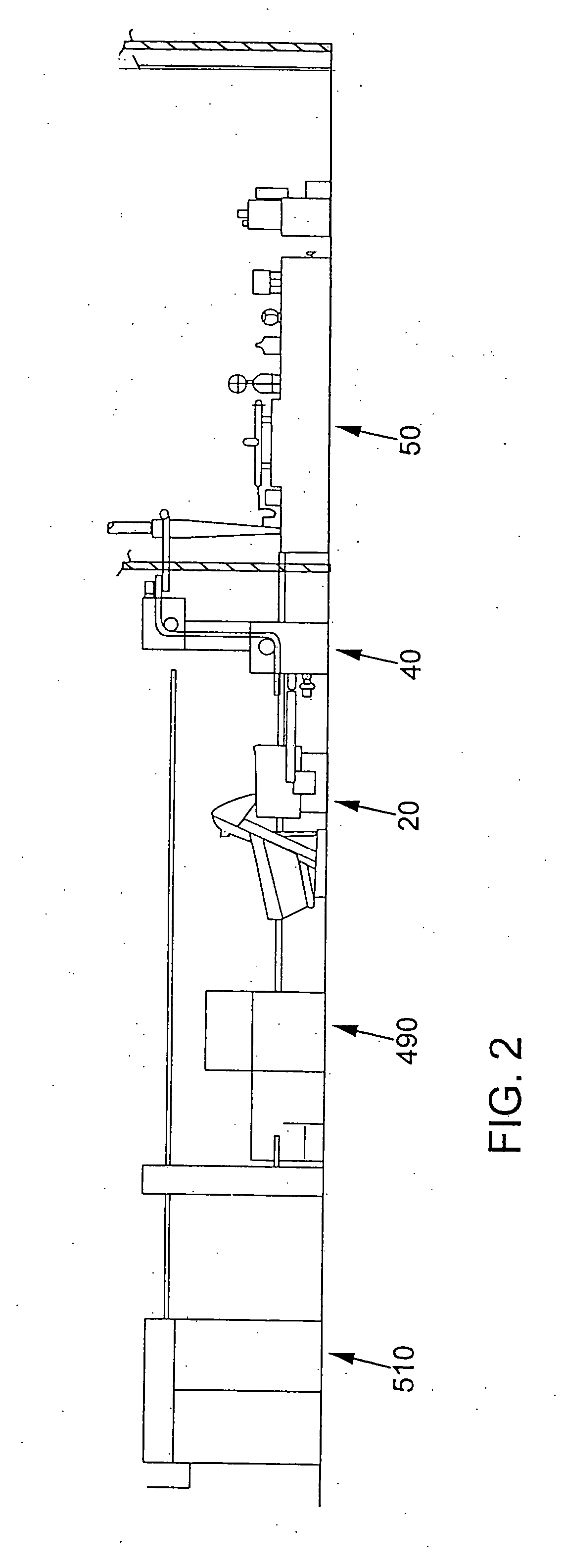

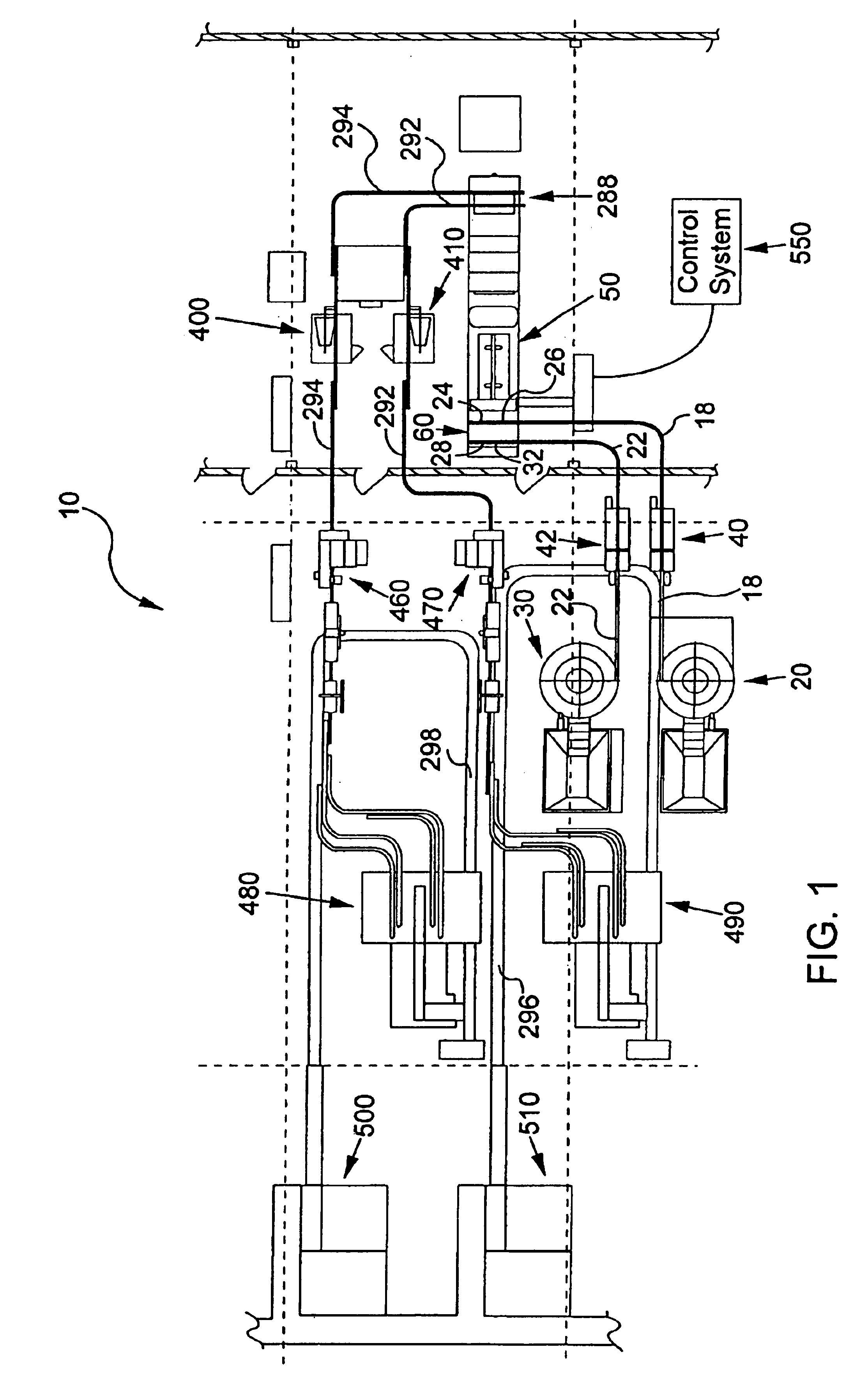

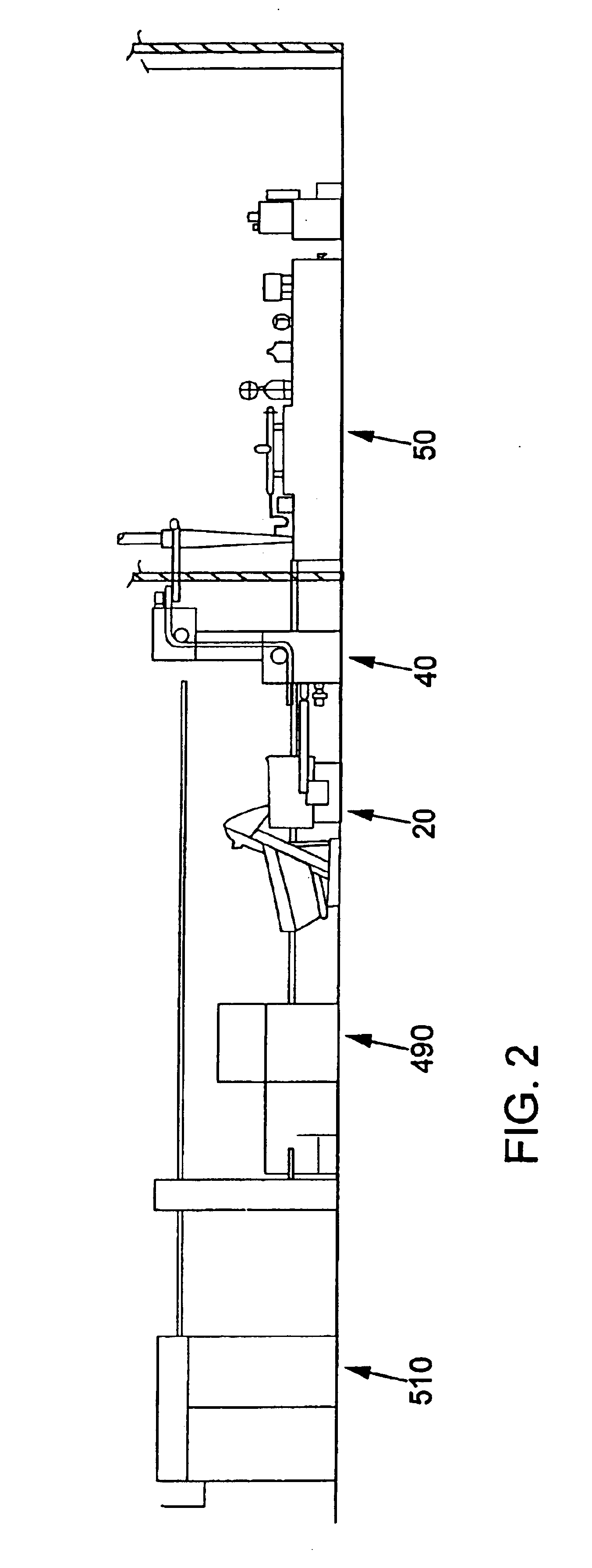

Apparatus for aseptic packaging

InactiveUS20050097863A1High output process speedFast processingSynchronising machinesPackage sterilisationAseptic processingEngineering

A method and apparatus for providing aseptically processed low acid products in a container having a small opening, such as a glass or plastic bottle or jar, at a high output processing speed.

Owner:TAGGART THOMAS D

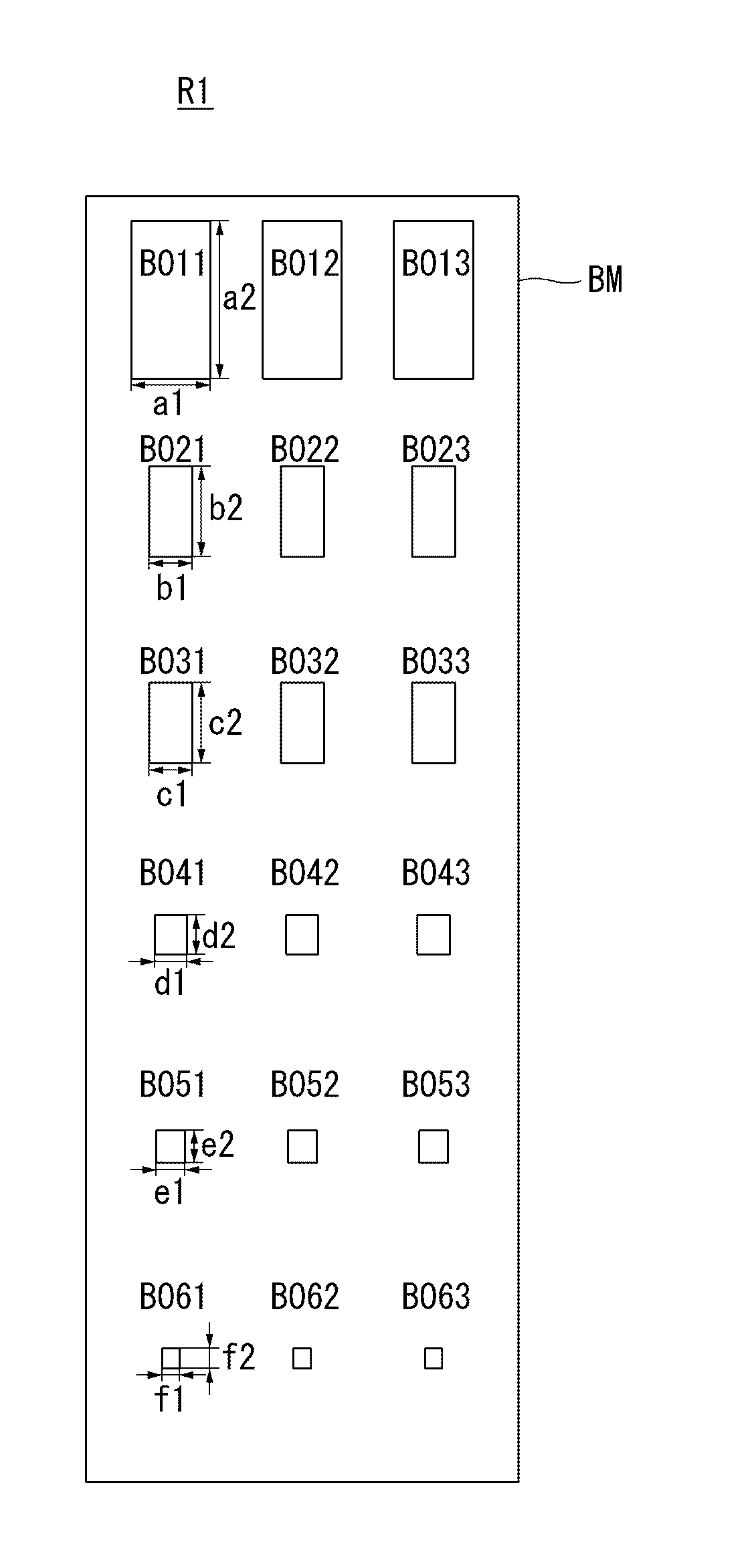

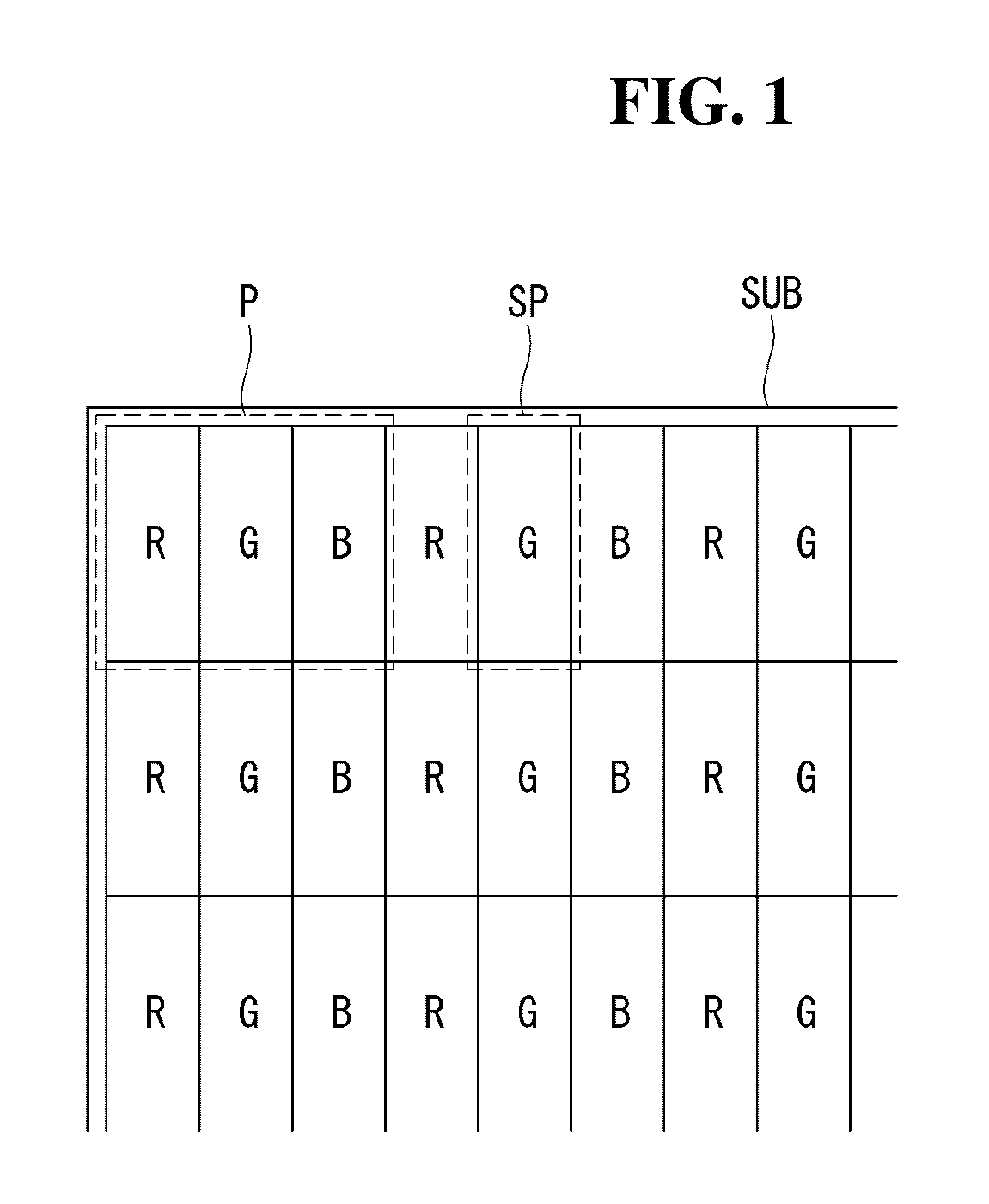

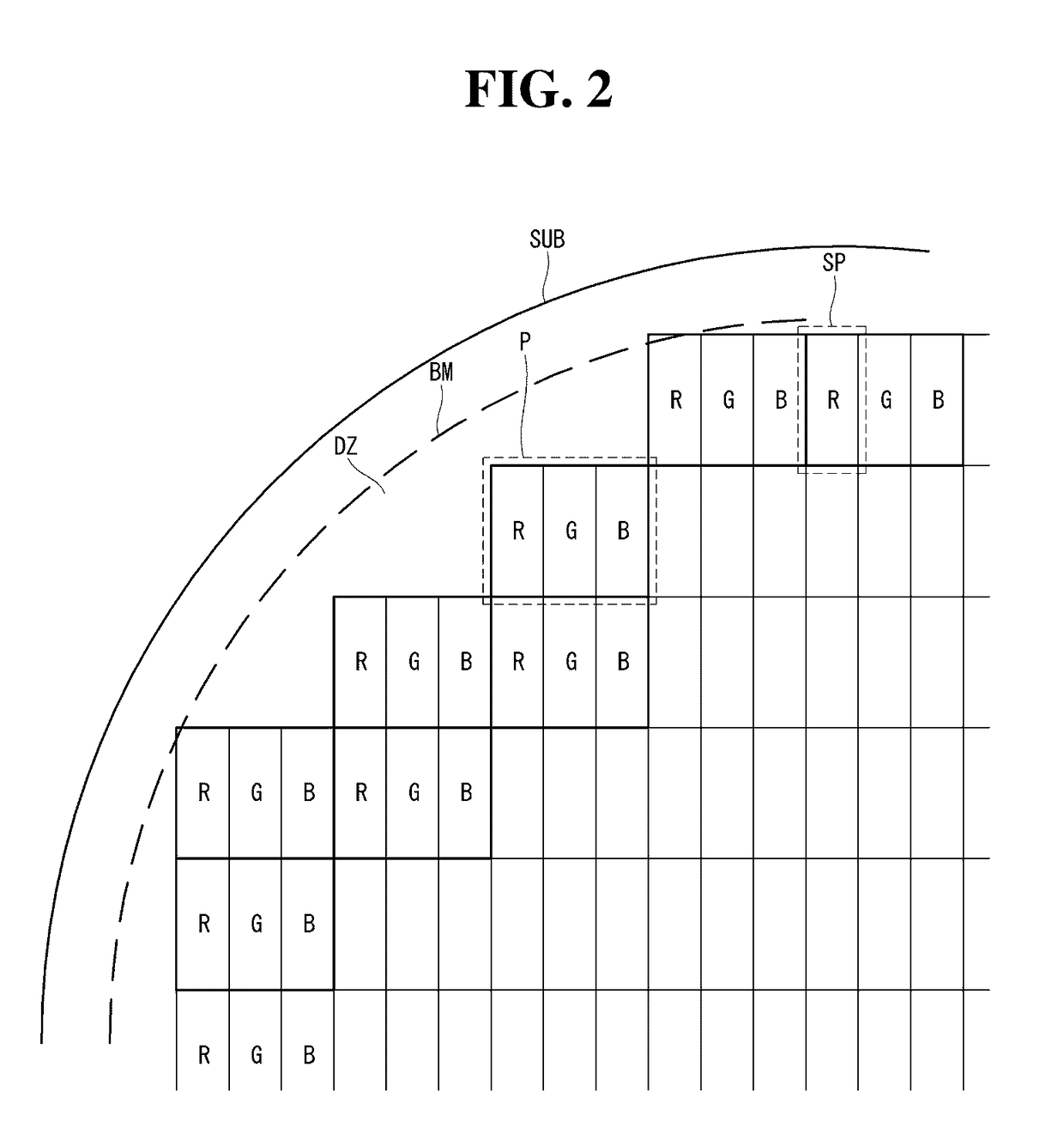

Free-form display

A free-form display is disclosed which makes a step-like pattern adjacent to a free-form portion less visible. The free-form display has an active area and a bezel area, and at least part of a boundary between the active area and the bezel area has a free-form portion. The free-form portion comprises subpixel electrodes and a light blocking portion. A plurality of subpixel electrodes are placed in areas defined by a plurality of gate lines and a plurality of data lines that intersect each other. A light blocking portion has openings exposing the subpixel electrodes, respectively, and is arranged to overlap the gate lines and the data lines. The active area comprises subpixel areas where the subpixel electrodes are placed, and a non-pixel area where no subpixel electrodes are placed. The openings of the light blocking portion adjacent to the non-pixel area, are made in different sizes.

Owner:LG DISPLAY CO LTD

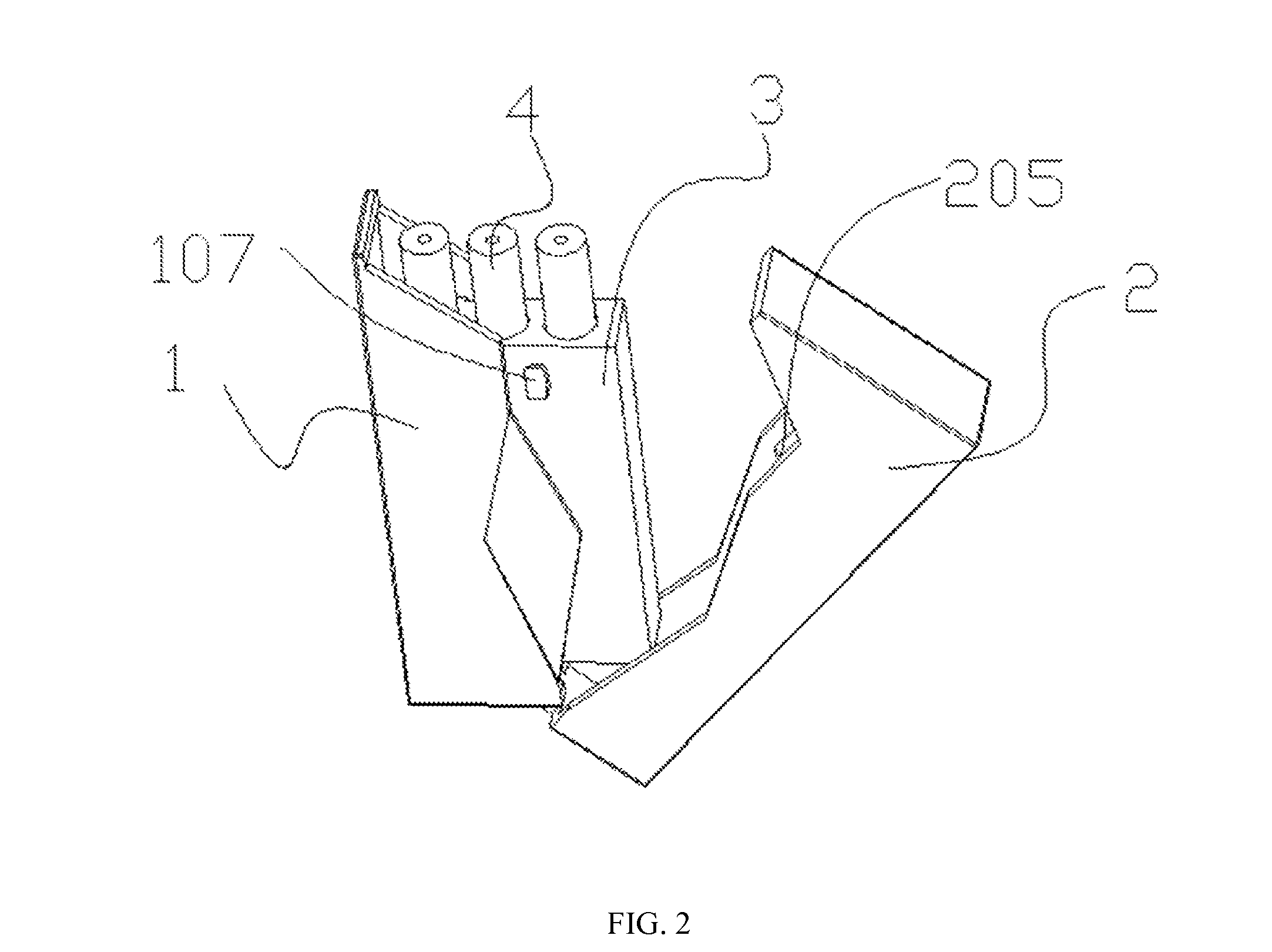

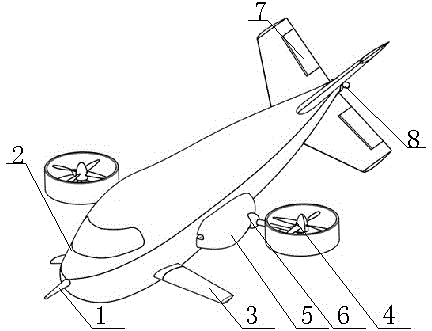

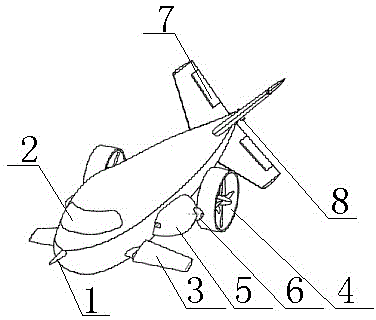

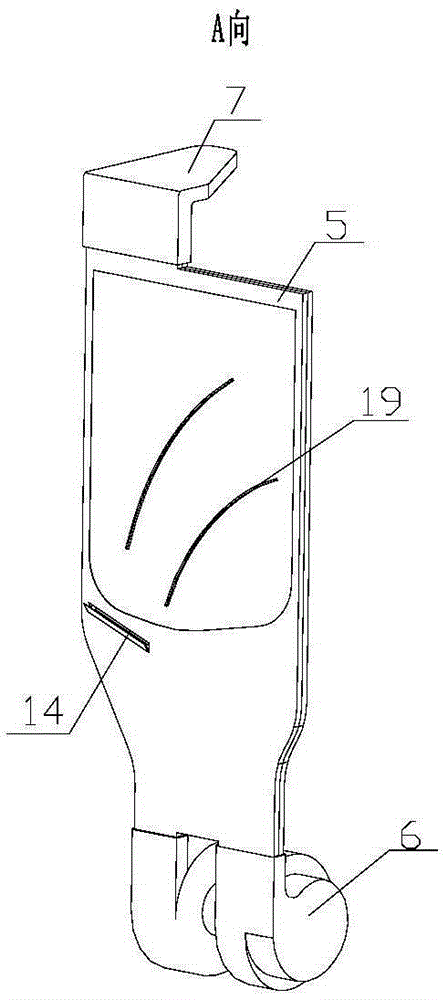

Cross-medium aircraft with changeable shape like sailfish

ActiveCN104589939AGood mobilityAbility to perform tasksAircraft convertible vehiclesPropellerFlight vehicle

Provided is a cross-medium aircraft with a changeable shape like a sailfish. The streamline type appearance of the sailfish is simulated by a machine body (2). A head pointed cone (1) is arranged at the head portion of the machine body (2) to divide water flow. A pair of angle-changeable water wings (3) are installed on the two sides of the front portion of the machine body (2) respectively. The aircraft is controlled to sink or float in water by adjusting the positive tapping angle and the negative tapping angle of the pair of angle-changeable water wings (3). A pair of scale-shaped rectifying covers are installed on the two sides of the middle of the machine body (2) respectively. A pair of self-adaption spiral paddles (4) capable of rotating in an inclined mode are installed on the scale-shaped rectifying covers (5) through a pair of spherical multi-freedom-degree linkage steering gears (6). An X-shaped tail wing (7) is arranged at the middle rear section of the machine body (2). An underwater-propulsion spiral paddle (8) is installed at the tail portion of the machine body (2). By means of the cross-medium aircraft, the design principles and bionics principles of the aircraft and an autonomous underwater vehicle are successfully applied, and the designed cross-medium aircraft has the good running capacity in fluid of two different types including air and water.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Vertebral body replacement and insertion methods

ActiveUS9700425B1Small openingShorten recovery timeDiagnosticsSurgeryAnterior approachVertebral bone

A vertebral body replacement device, dimensioned for implantation between a first and second vertebral bone is described. The vertebral body replacement device includes a superior endcap, an inferior endcap and a central core between the superior and inferior endcaps. The vertebral body replacement device further includes a fusion aperture extending through the superior and inferior endcaps and central core. The vertebral body replacement device is made of radiolucent material and can be implanted from a lateral or anterior approach to the spine.

Owner:NUVASIVE

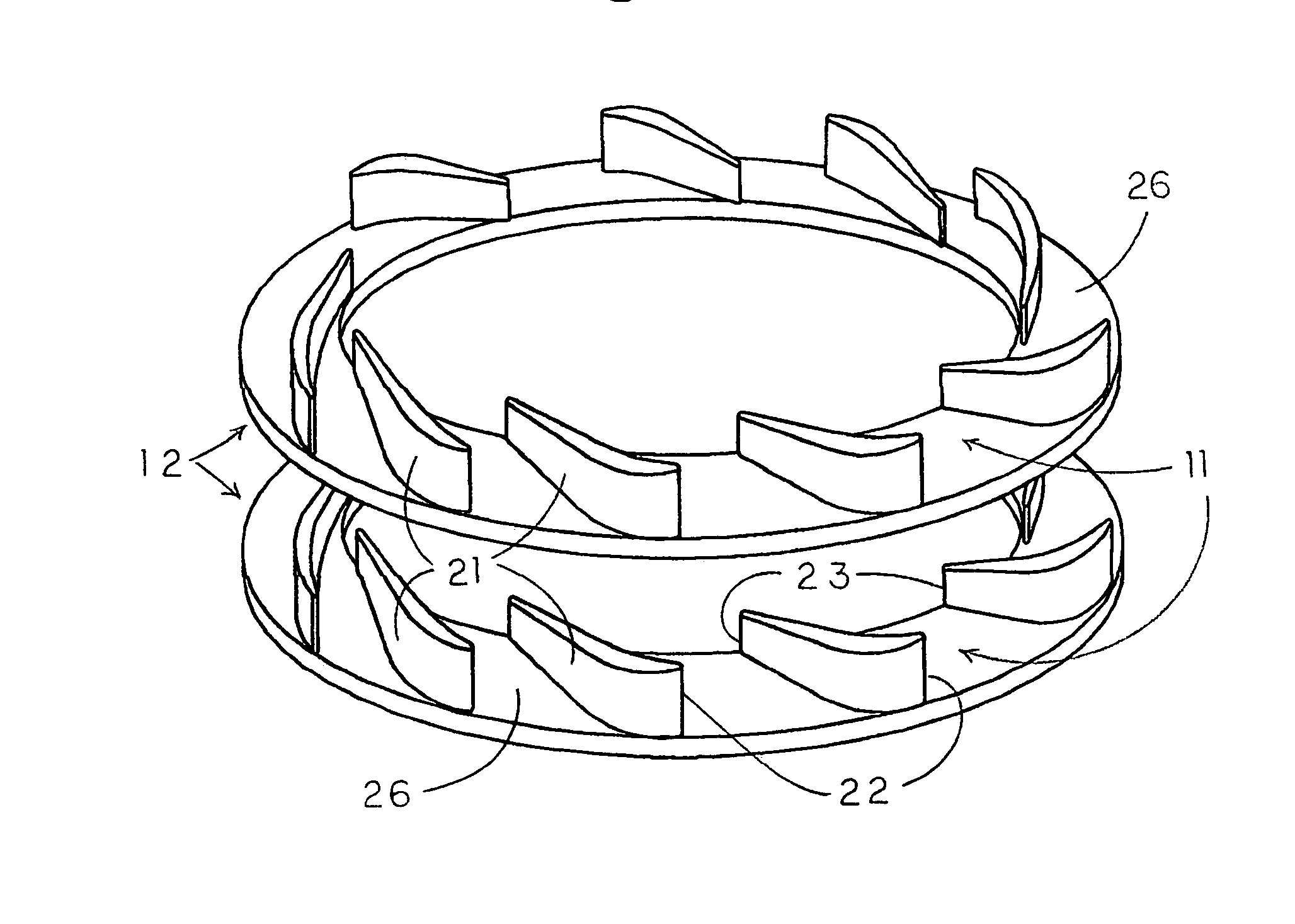

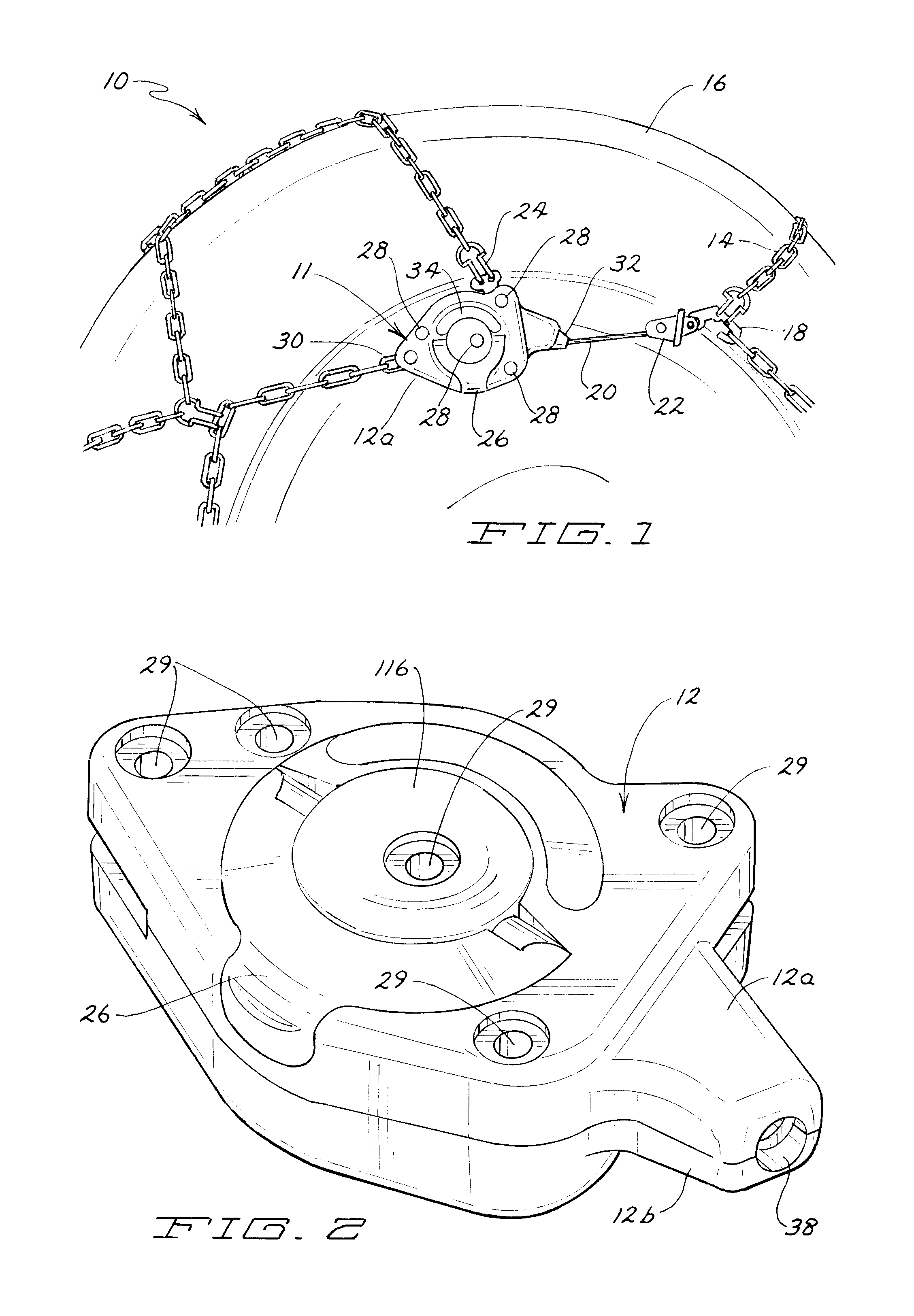

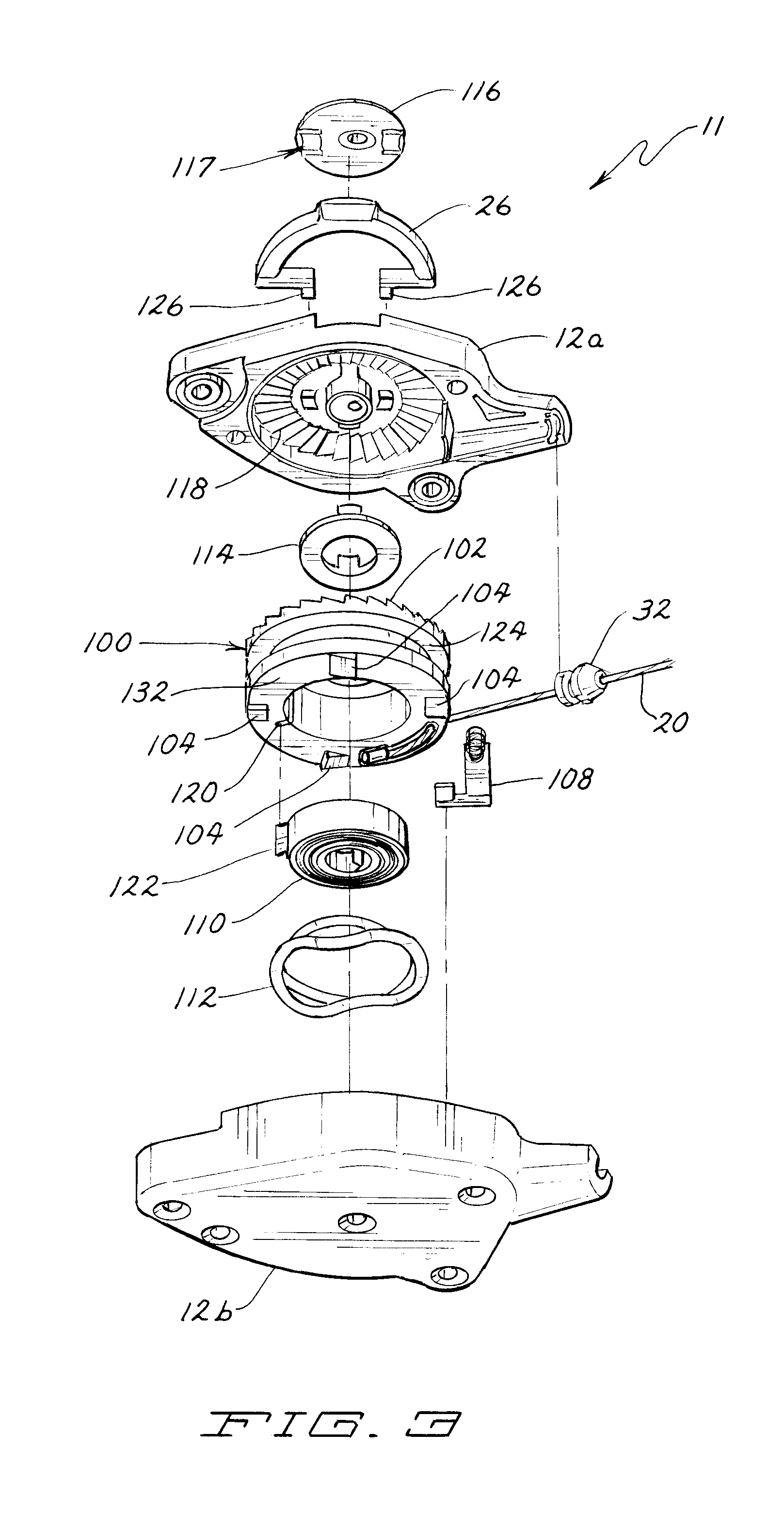

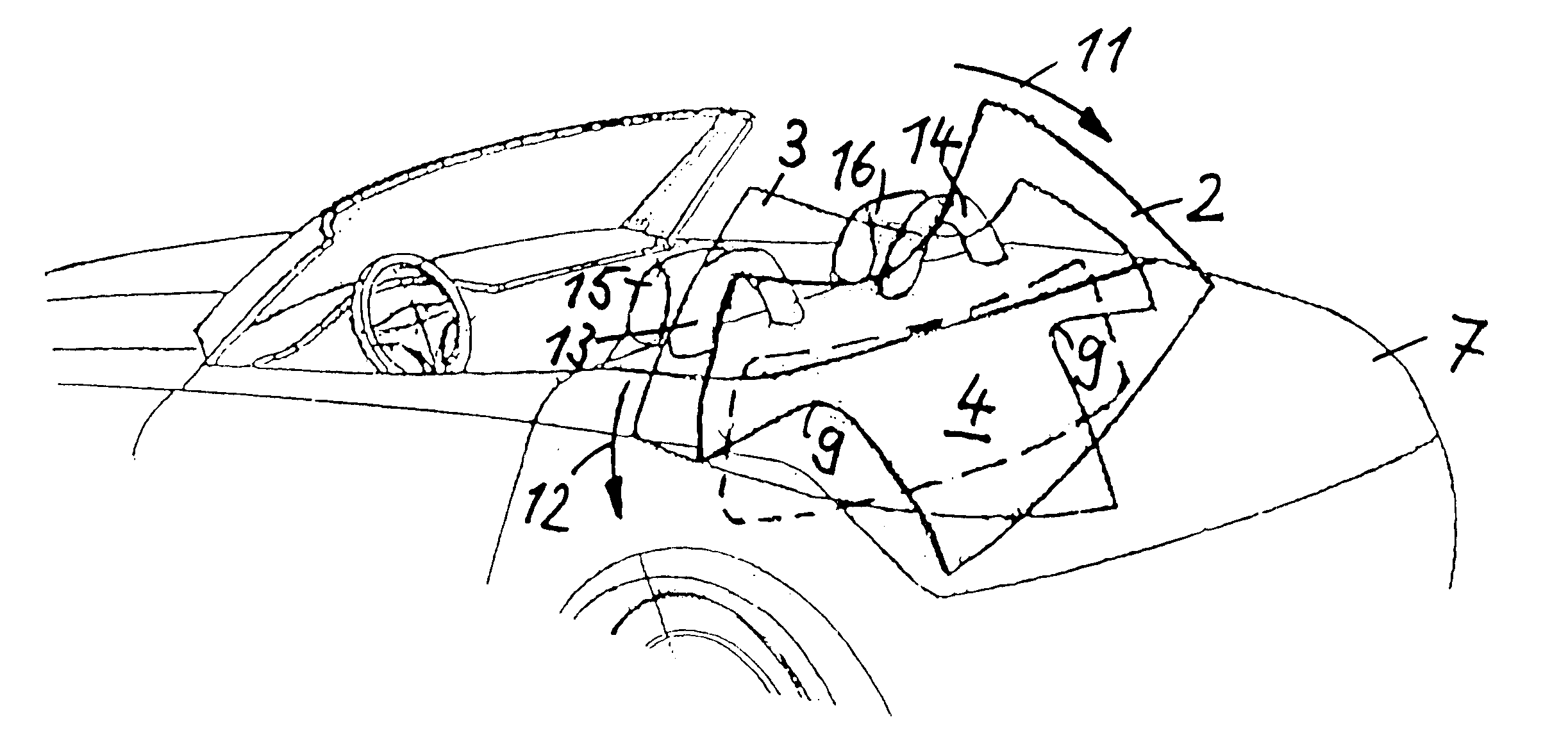

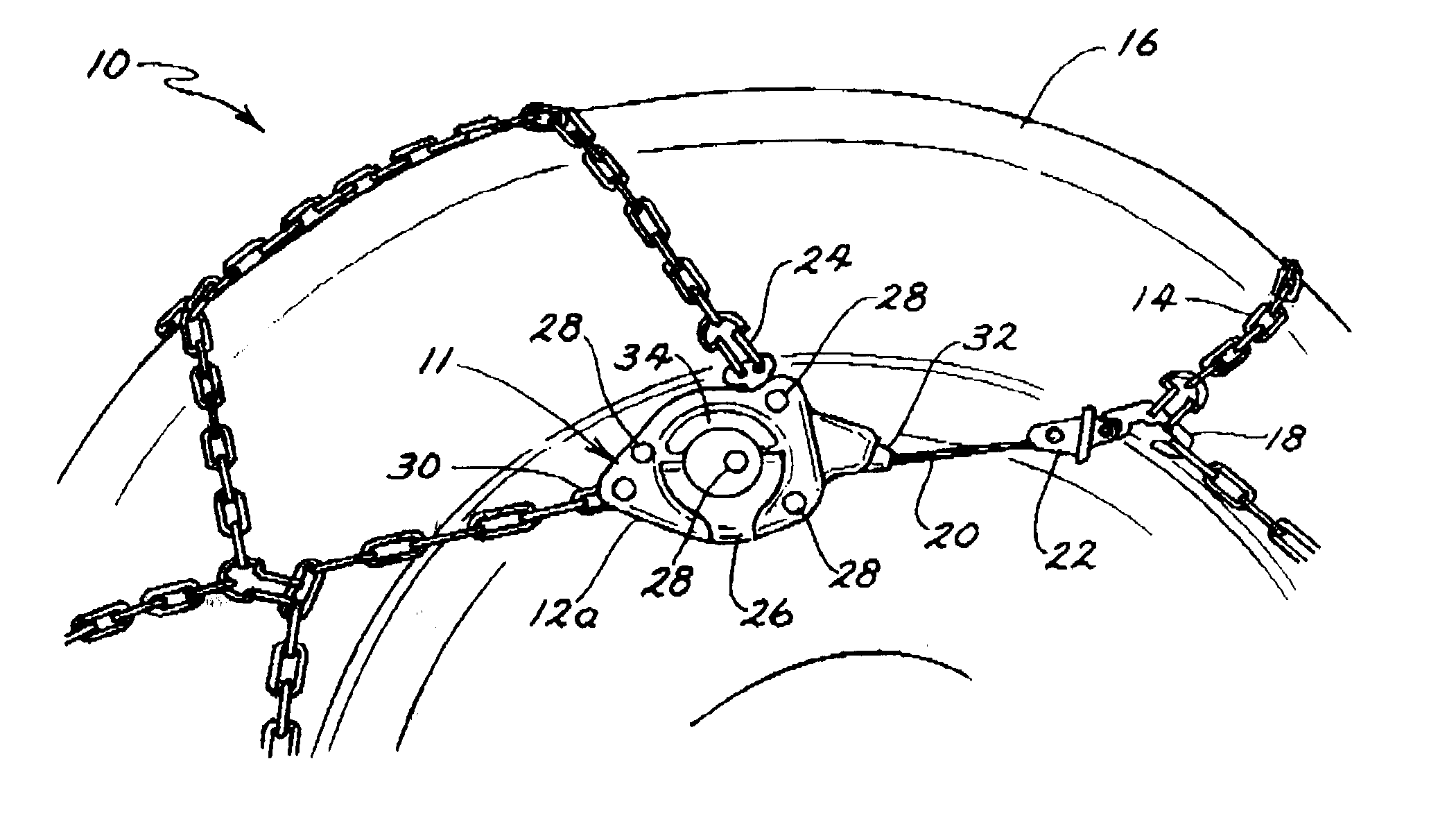

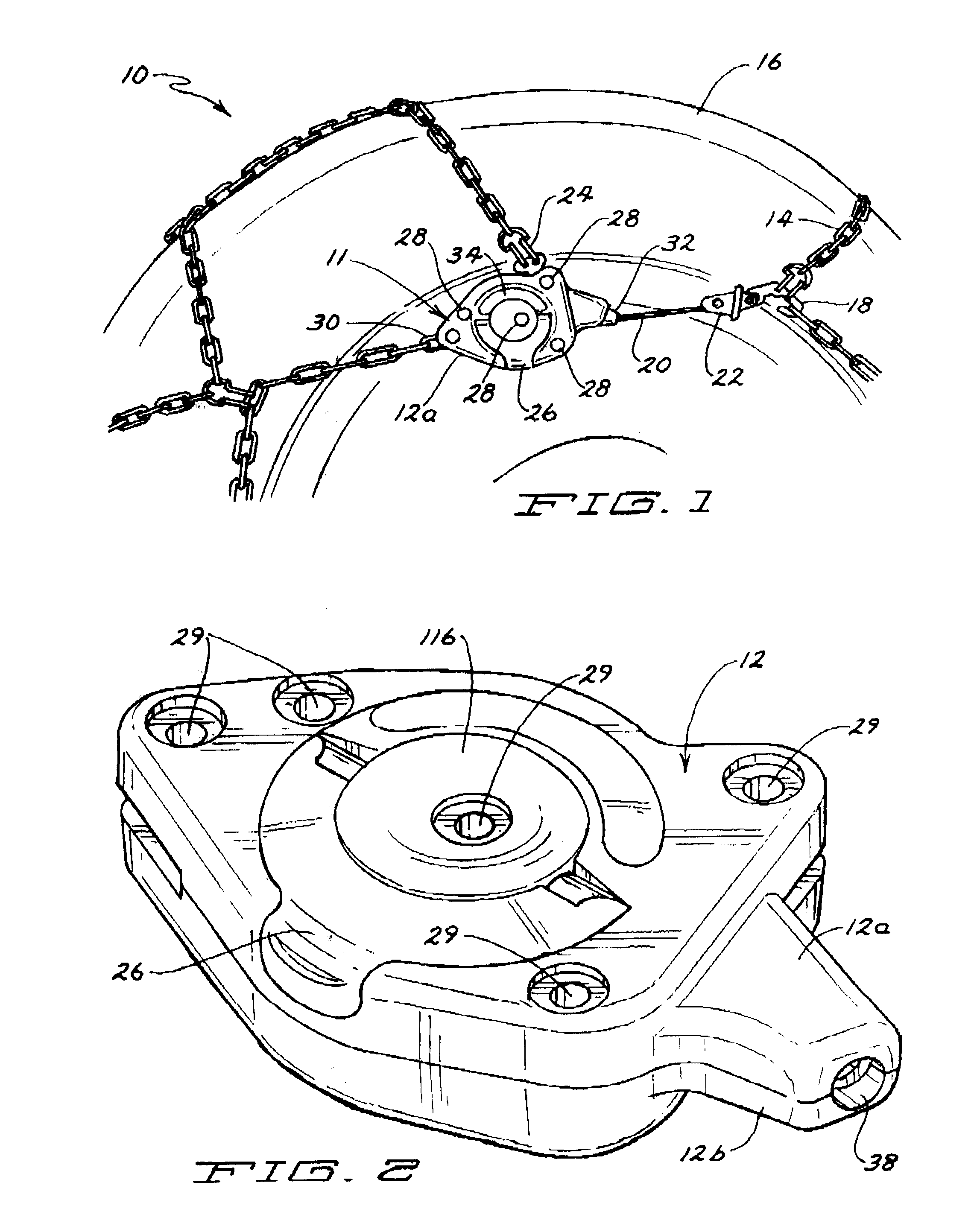

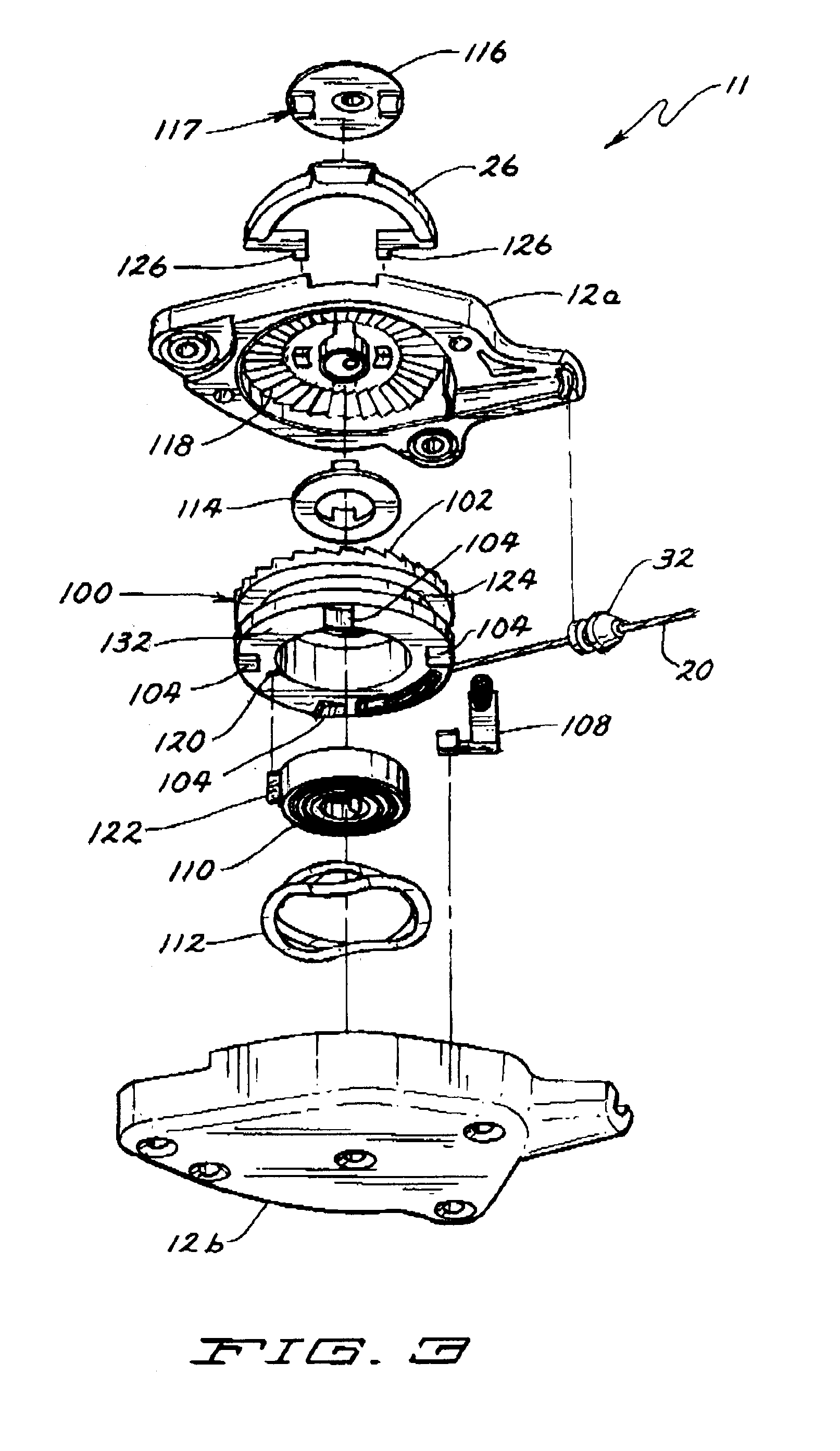

Self-tightening traction assembly having tensioning device

ActiveUS7900670B2Effectively tightensEasy to installSnap fastenersBelt retractorsActuatorControl theory

Self-tightening traction assemblies or snow chains having tensioning devices that can be used with snow chains for attachment to a vehicle wheel to provide traction. The preferred tensioning device including a housing having a top including a set of housing teeth, a bottom and at least one aperture; an actuator interconnected to the housing; a ratchet spool within the housing having a set of ratchet teeth that mate with the housing teeth and a channel between upper and under surfaces to receive at least one cord that is interconnected with the ratchet spool; a tension spring that places a bias on the ratchet spool toward a wind-up direction; and a wave spring. Preferred embodiments include a bracket that can secure the actuator to the housing and provide strength to the tensioning device. The tensioning devices of the present invention can be utilized in a variety of applications not limited to self-tightening snow chains.

Owner:PEERLESS CHAIN COMPANY

Enclosure for food processor

An enclosure for a food processor having a lower portion for cooperating with a control and / or operational base assembly of a food processor, a central portion for holding matter to be processed, an upper portion with one or more openings for receiving the matter into the central portion, and a safety actuator, is provided. The openings being relatively small to allow for the safe operation of the food processor without the need to close or cover said one or more openings. The openings is capable of cooperating with various accessories and / or of facilitating matter being introduced in a variety of different amounts and forms.

Owner:CONAIR CORP

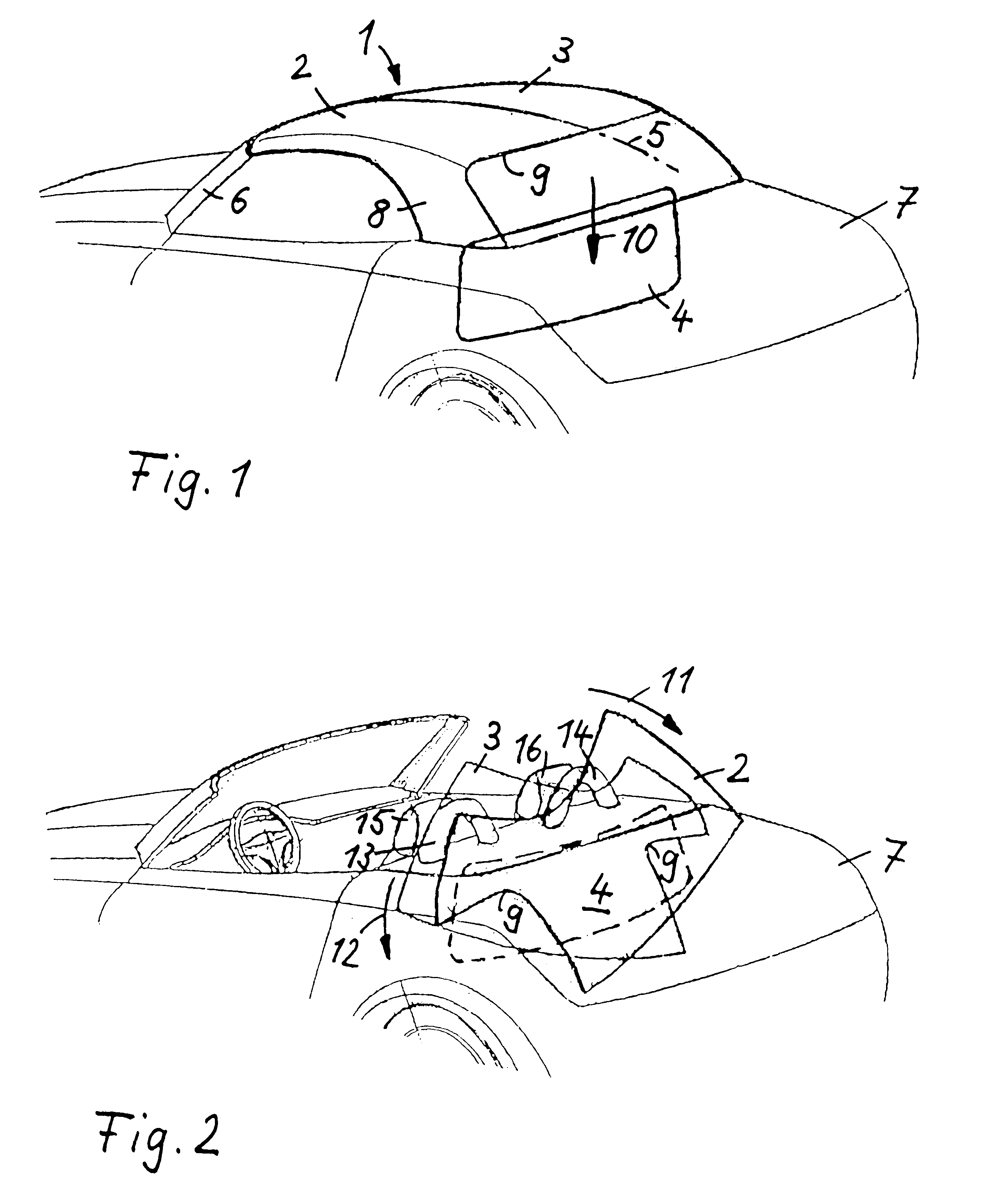

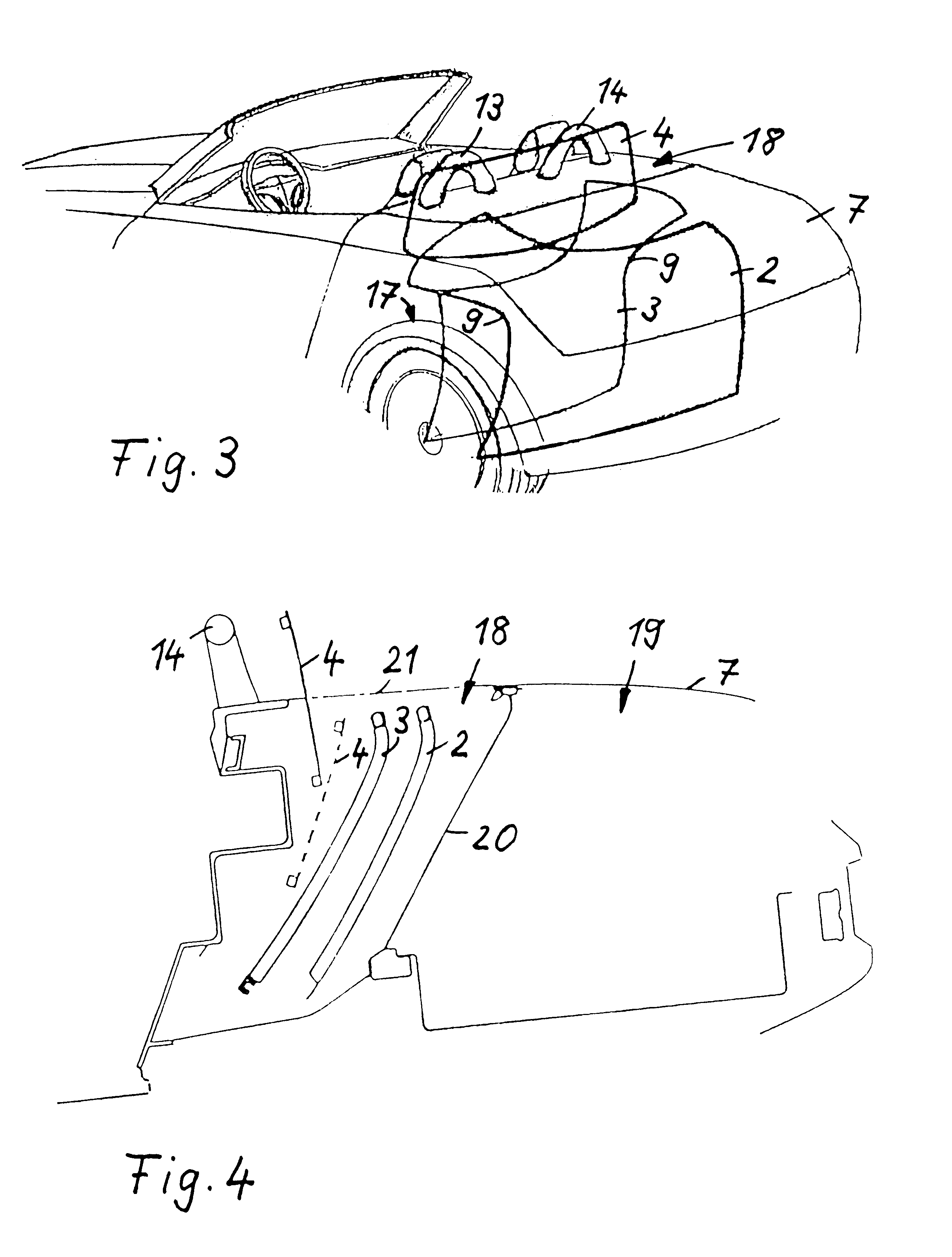

Hardtop vehicle roof movable between closed and open positions

InactiveUS6557921B2Convenient to accommodateSmall spacingWindowsWindscreensInterior spaceEngineering

In a hardtop vehicle roof comprising at least two roof parts which are movable between a closed position, in which the roof covers the interior space of the vehicle and an open position, in which the roof is in storage compartment behind the interior vehicle space, the roof parts are separated from each other along a separation line extending in the longitudinal direction of the vehicle and are fitted, when the roof is open, into the storage compartment behind the interior space in a position transverse to the longitudinal vehicle direction.

Owner:CTS FAHRZEUG DACHSYST

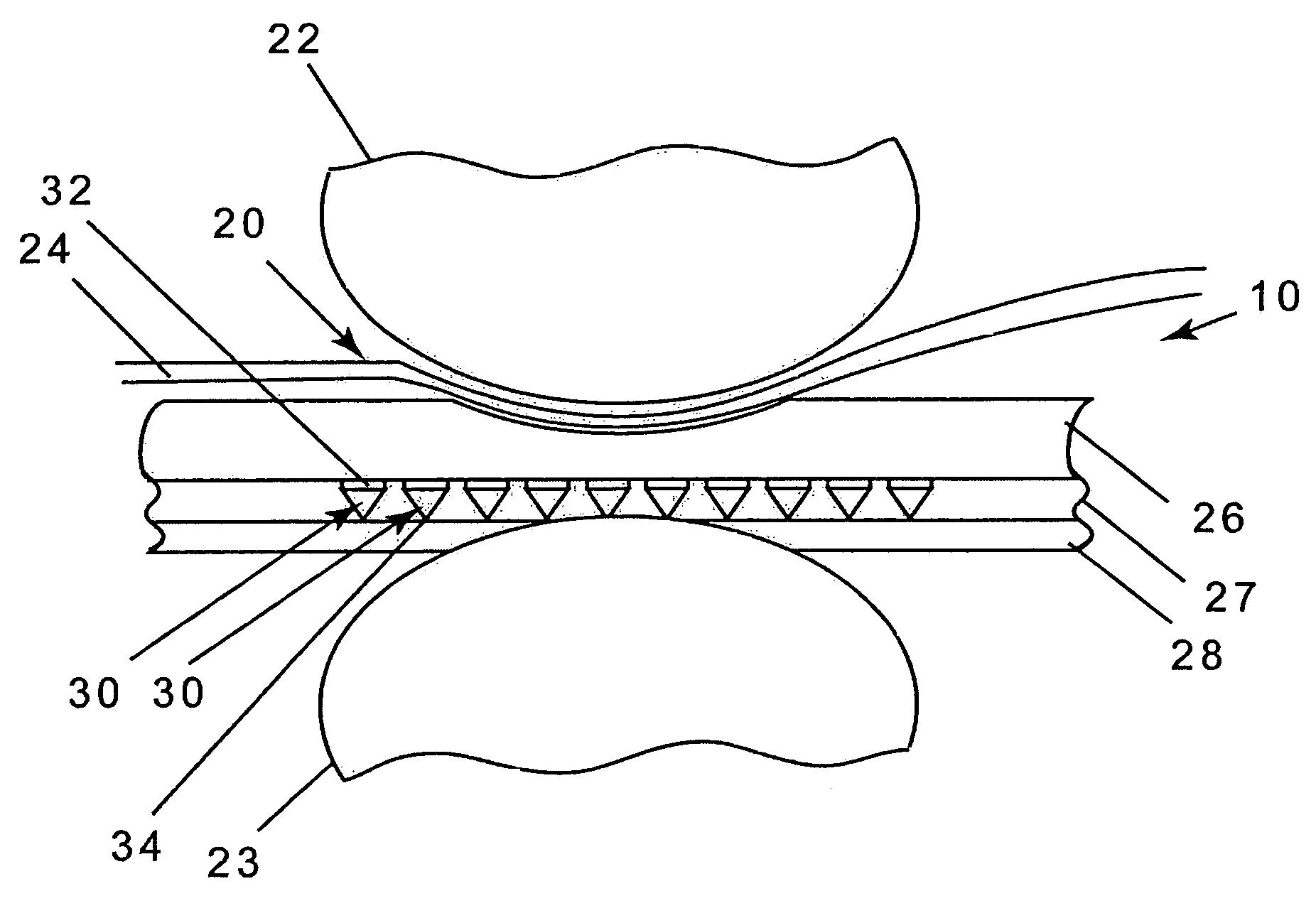

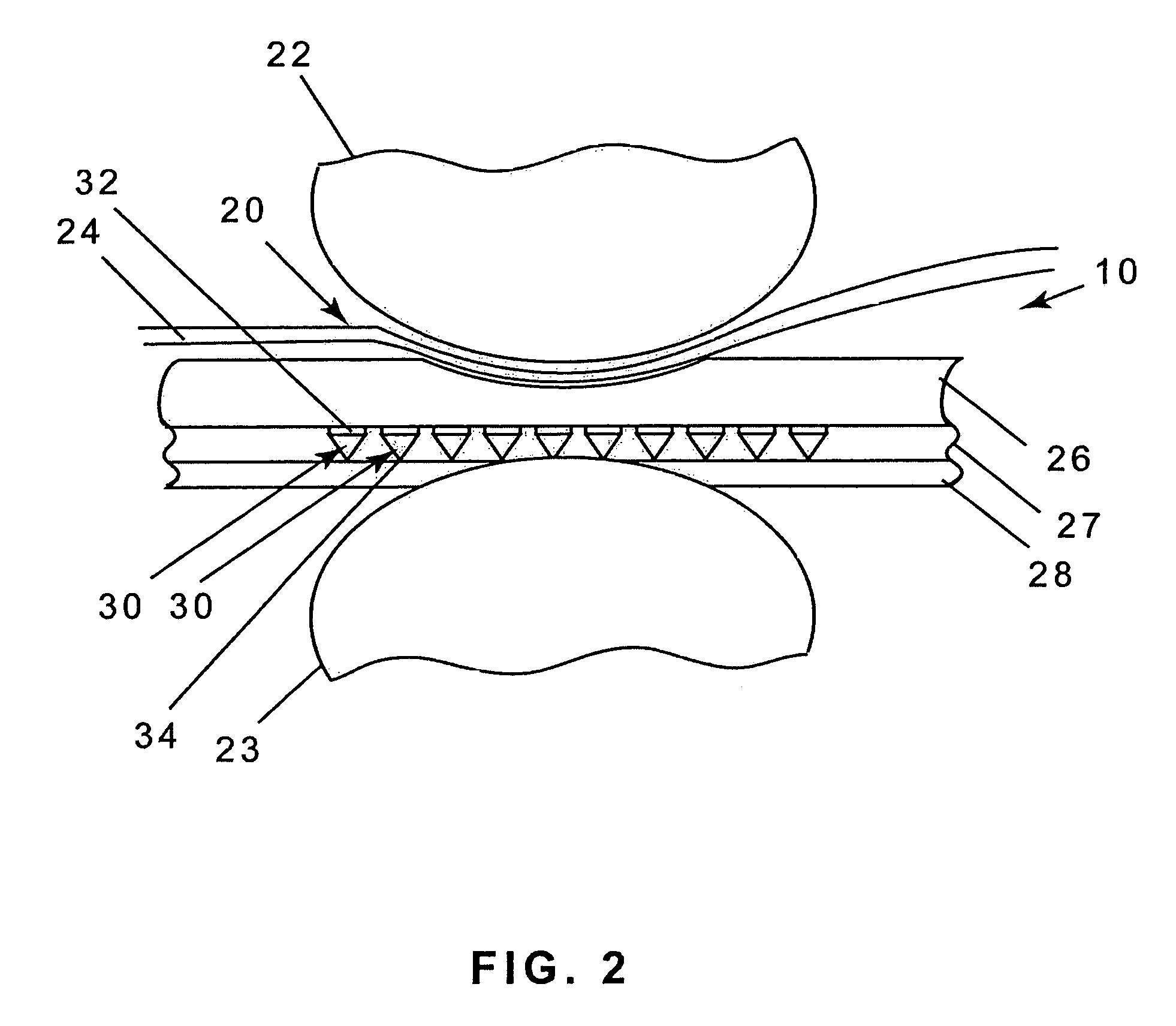

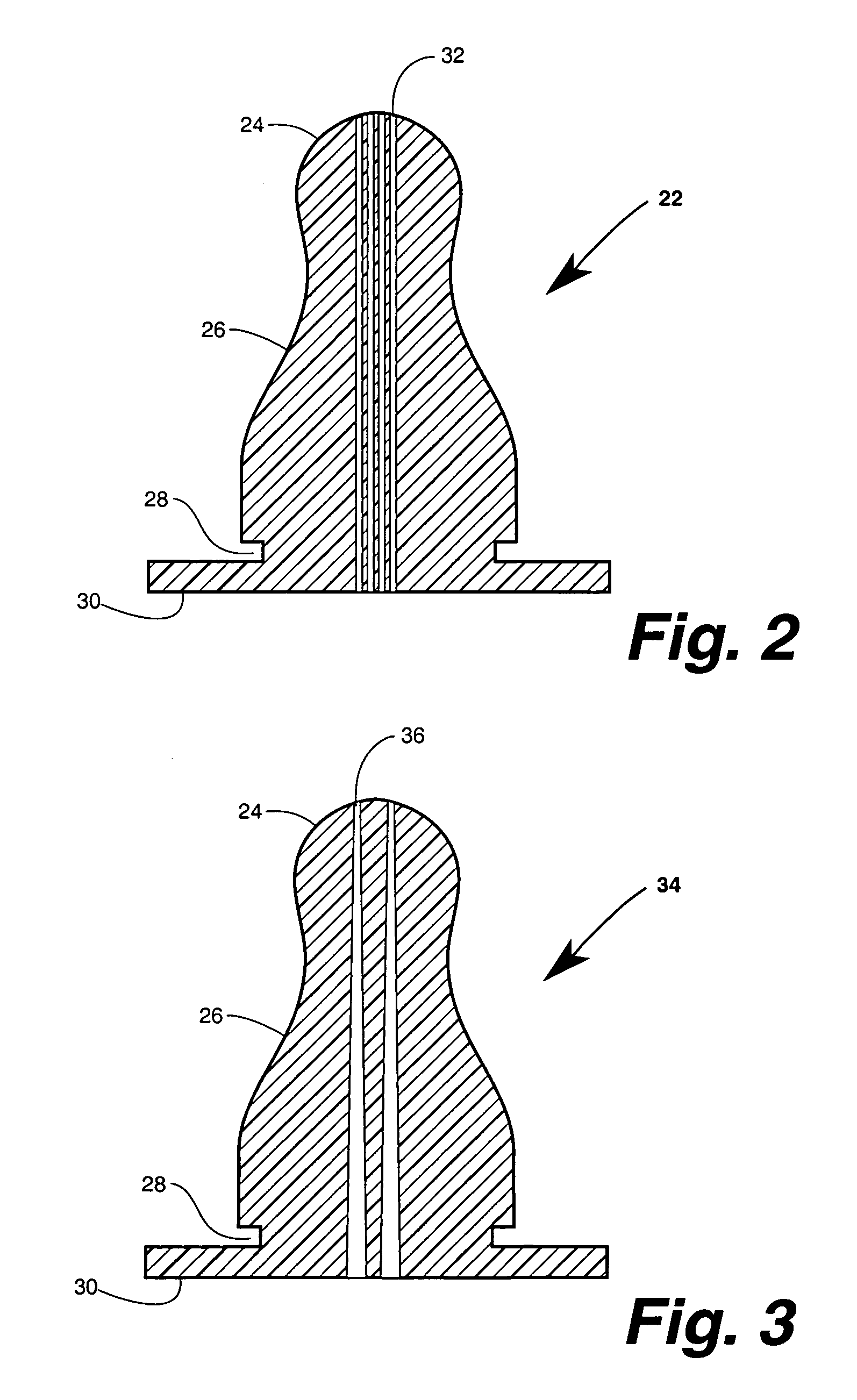

Anti-rewet press fabric

ActiveUS7128810B2Reduce openingIncrease pressureSynthetic resin layered productsPaper/cardboardWater flowEngineering

An anti-rewet press fabric for paper and board machines includes a barrier layer such that during compression in the press nip, the water is forced through the barrier layer, but is prevented from flowing back to the paper web during expansion. The barrier layer comprises a continuous material possessing, for example square, rectangular, tetrahedral, circular or oblong conical inclusions with a smaller opening on the bottom than on the top of the structure. Each of these “funnels” effectively constitutes a one-way valve and creates a vacuum to prevent re-absorption of water by the paper sheet. Under pressure, the structure of the barrier layer allows water to flow into the cones and out of the smaller opening in the bottom. Upon expansion, the smaller opening in the bottom of the structure restricts backward water flow and creates a vacuum on the other side. The vacuum increases water retention in the press fabric and prevents rewetting of the paper sheet. Another embodiment of the invention is described herein, wherein the barrier layer exists as a separate fabric fed through a press section. In this embodiment, the “separate fabric” can just be the “conical inclusion sheet” itself. That is, the sheet itself constitutes an inventive belt having anti-rewet properties.

Owner:ALBANY INT CORP

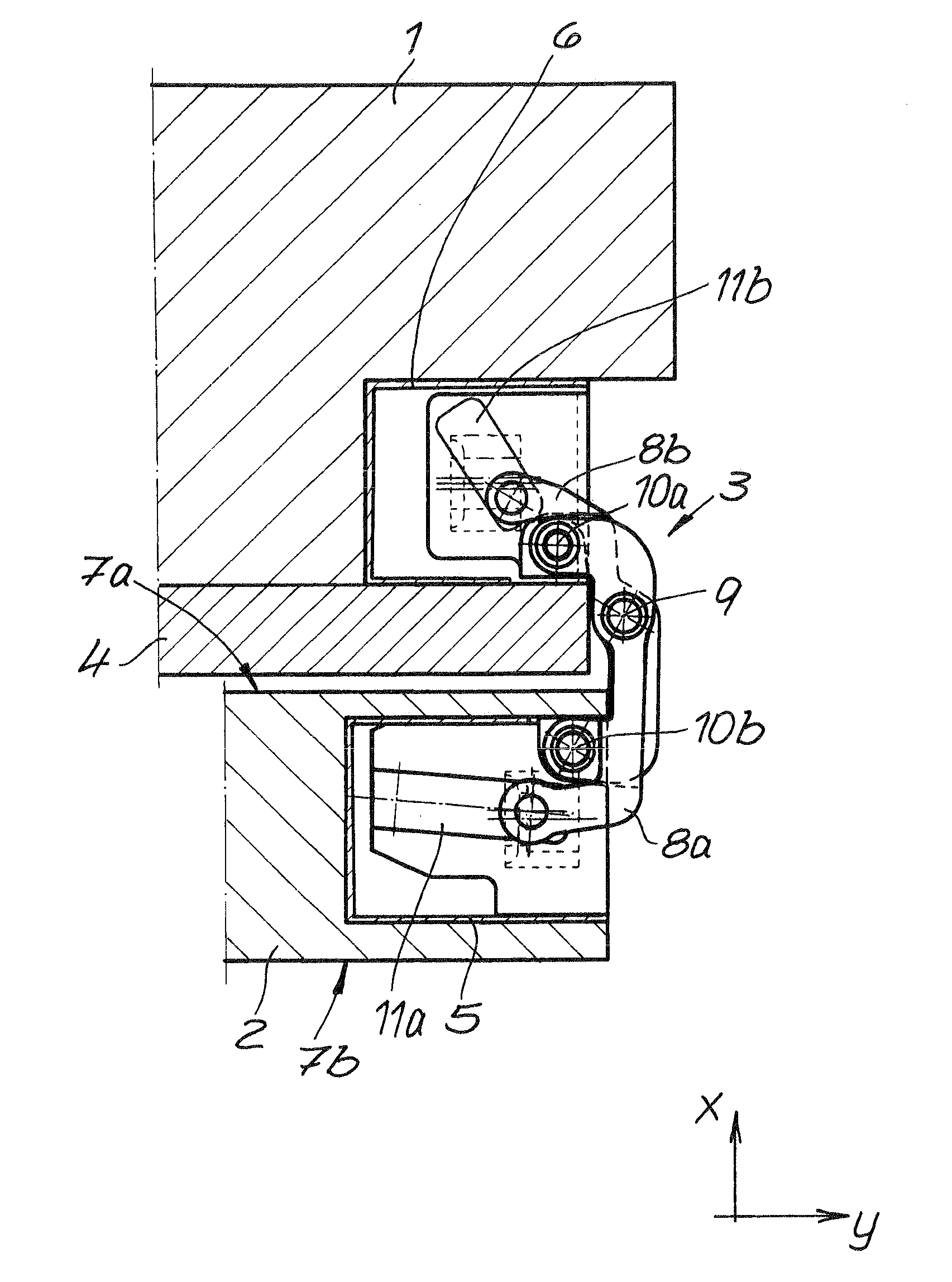

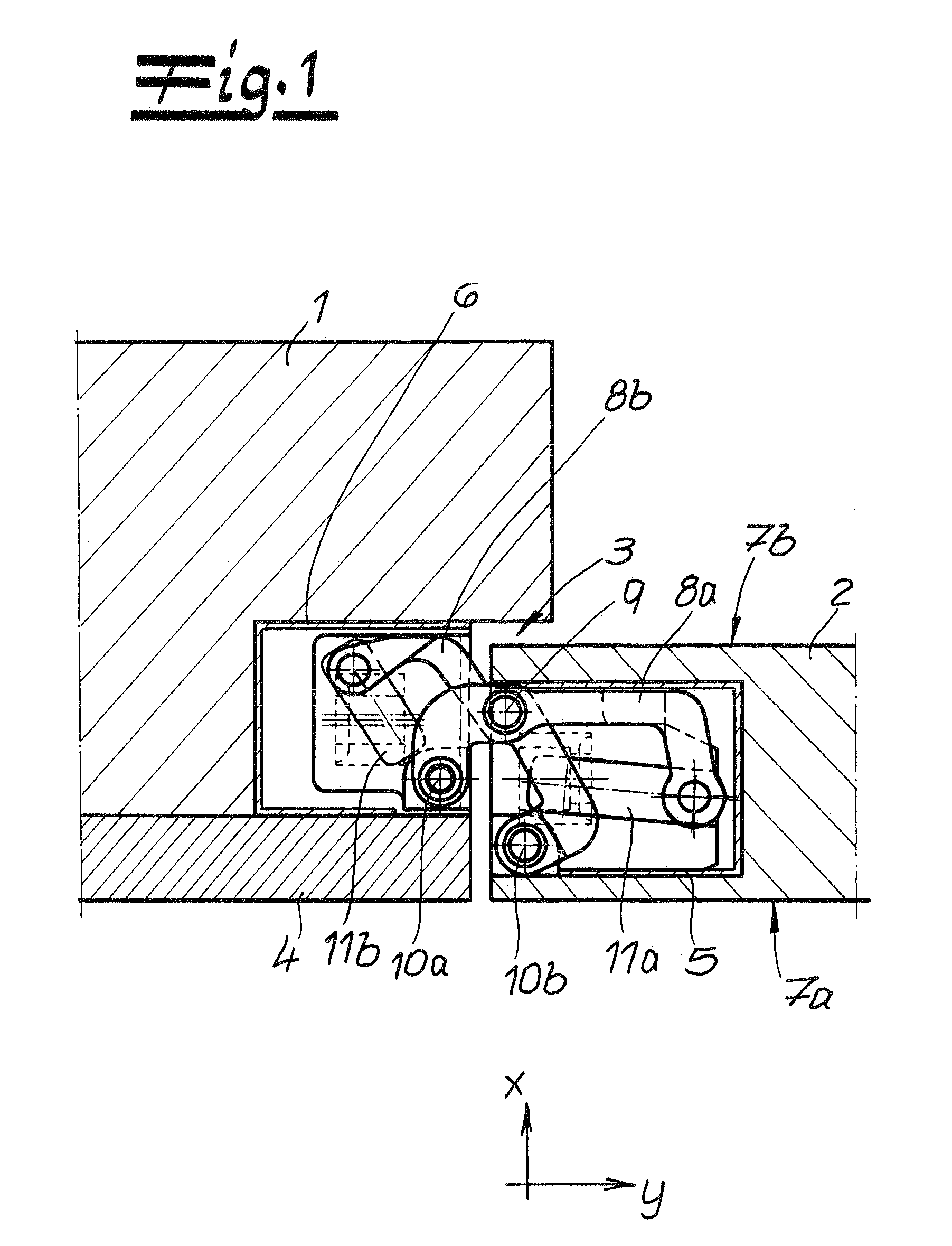

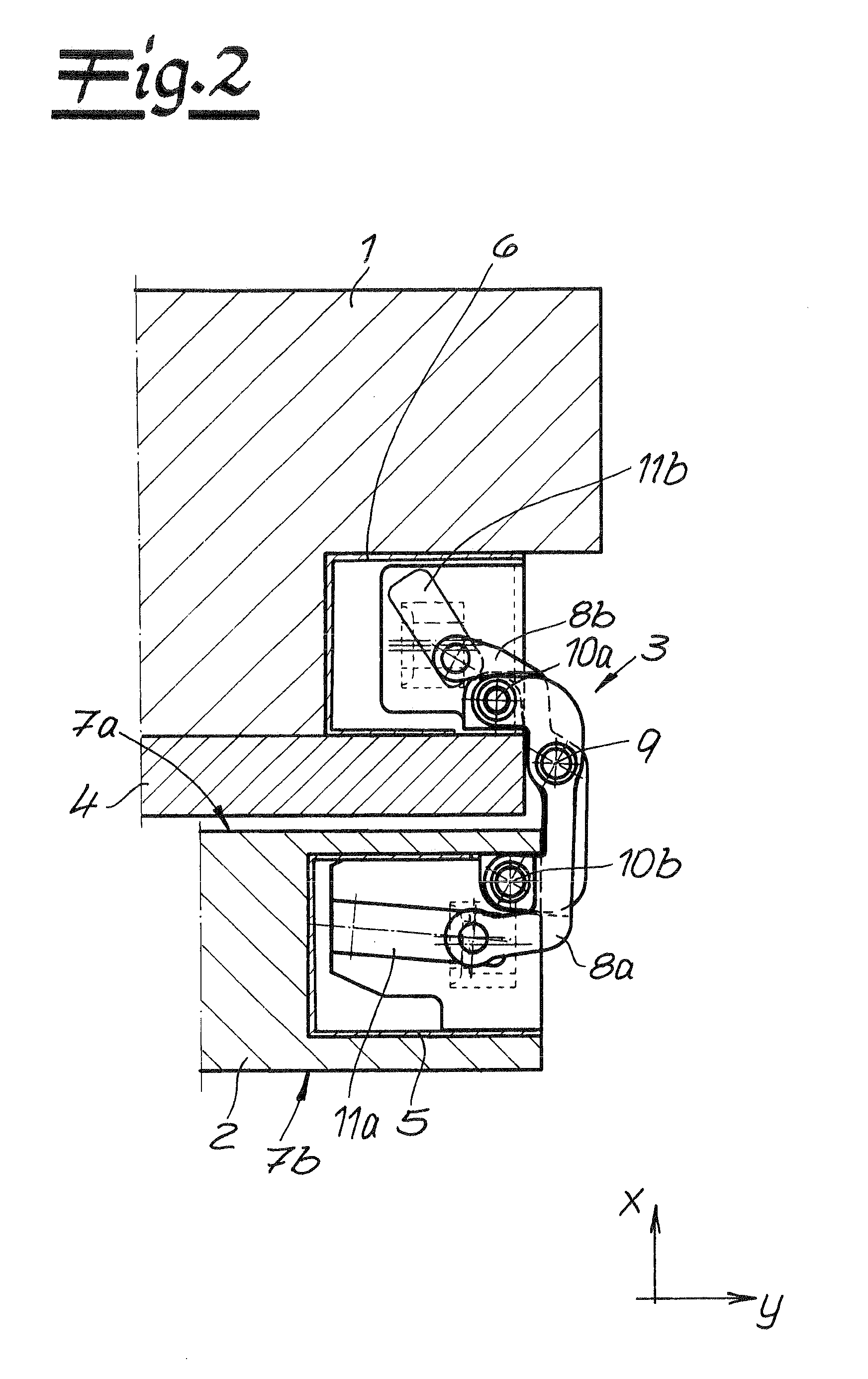

Door hinge for hidden placement between door frame and door leaf, and door provided with the door hinge

ActiveUS20120180396A1Avoid insufficient lengthSmall openingPin hingesWing arrangementsEngineeringMechanical engineering

Owner:SIMONSWERK

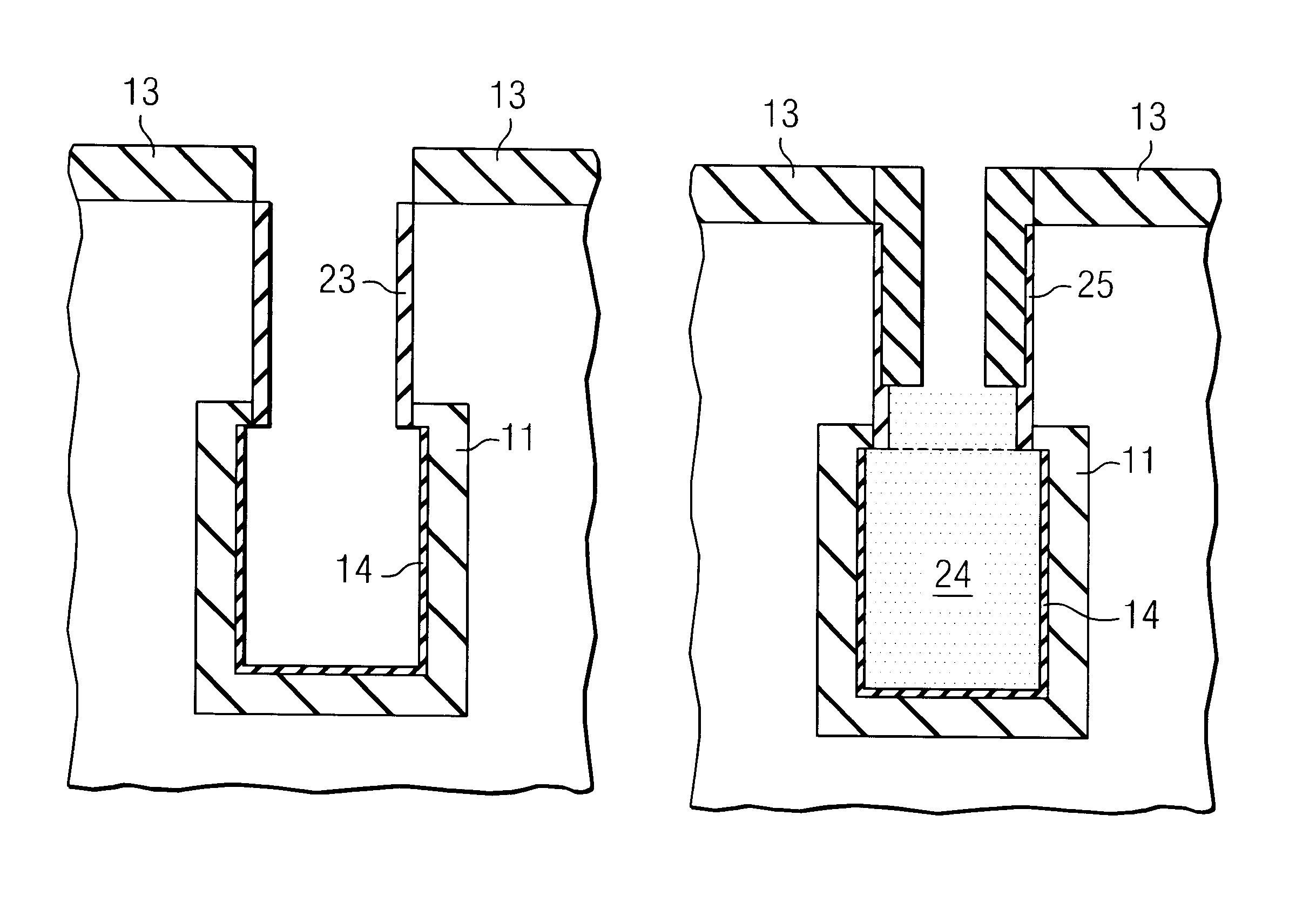

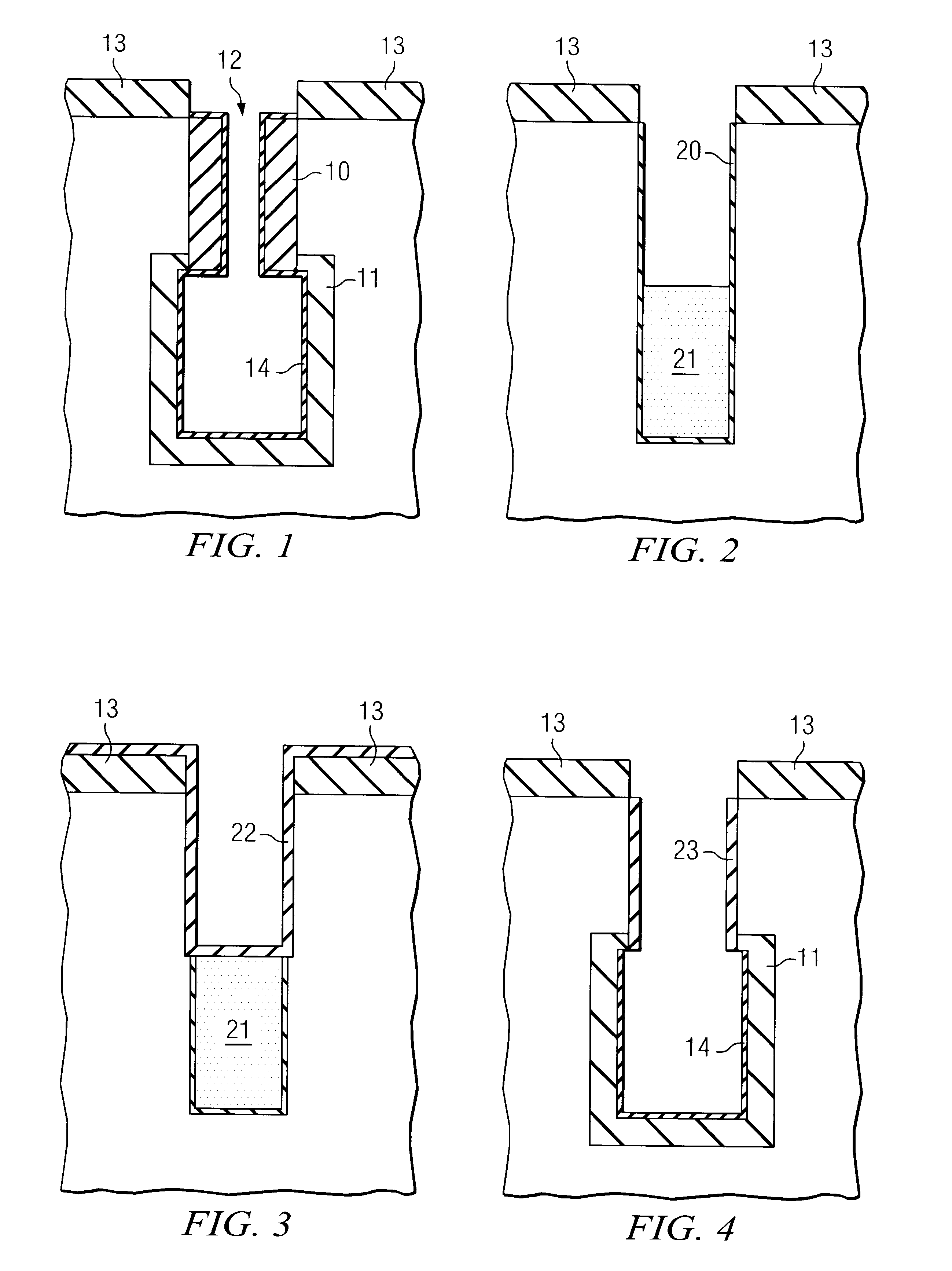

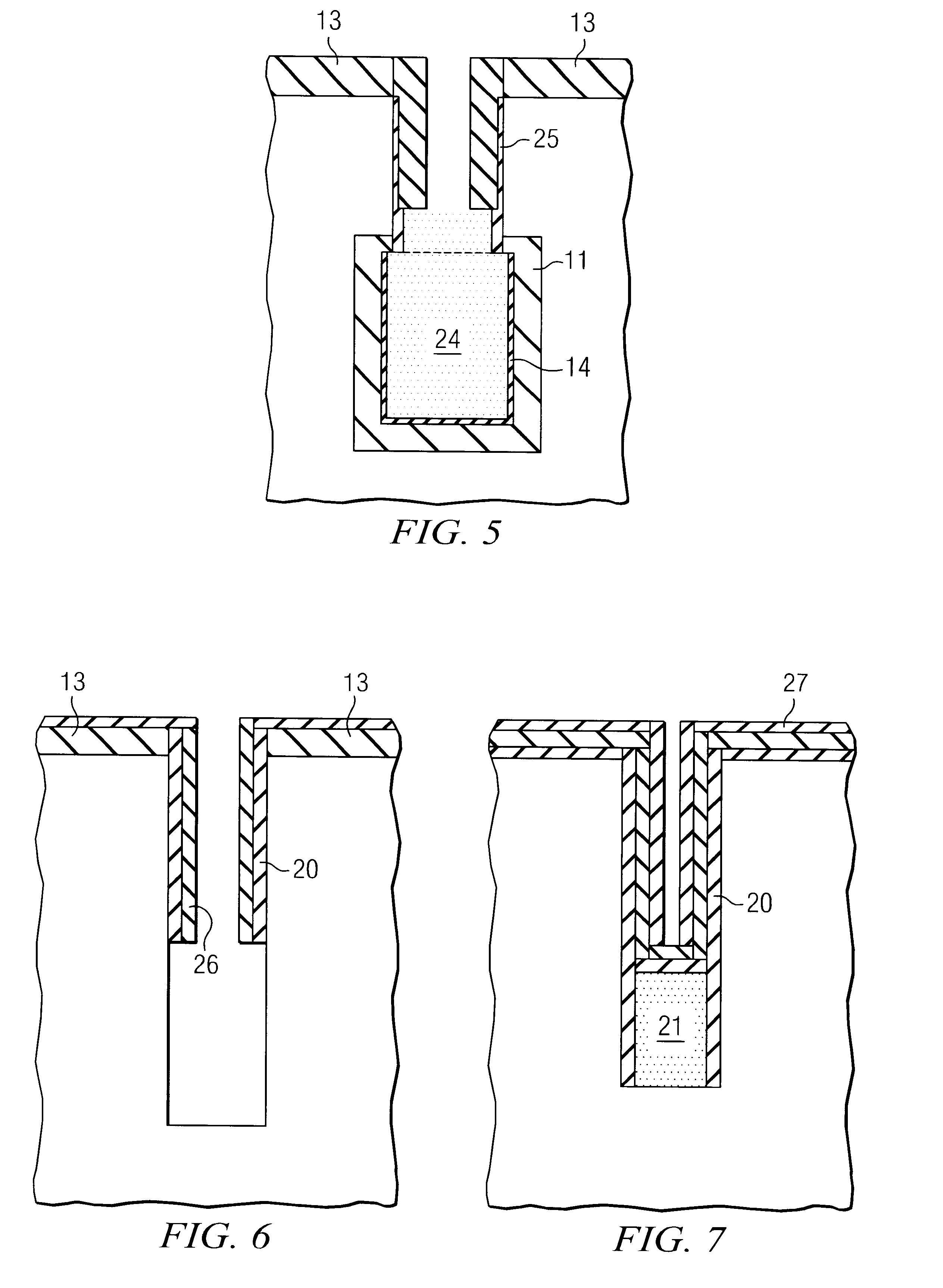

Process flow for two-step collar in DRAM preparation

InactiveUS6670235B1Small openingSolid-state devicesSemiconductor/solid-state device manufacturingDielectricReactive-ion etching

In a method of forming a DRAM cell in a semiconductor substrate, the improvement of maintaining a substantially full trench opening during trench processing comprising: a) forming a pad nitride on the surface of the substrate and reactive ion etching (RIE) a trench vertically to a first depth; b) depositing a nitride layer in the trench; c) filling the trench with a poly silicon fill; d) recess etching the fill to the collar depth; e) oxidizing to transform the exposed nitride layer into a nitrided oxide collar or depositing an oxide on the layer of nitride; f) reactive ion etching to open the bottom oxide; g) stripping the poly fill trench, and performing a nitride etch selective to oxide; h) expanding the trench horizontally by etching lower trench sidewalls and bottom while masking the upper sidewalls; i) forming a buried plate at the bottom of the trench sidewalls; j) forming the node dielectric in the deep trench to grow a collar oxide that consists of a nitrided oxide and a layer of node nitride; k) filling the trench with a poly fill; l) recess etching the poly fill approximately to the collar bottom; m) depositing a collar oxide; n) reactive ion etching to open the bottom; o) filling the trench with a poly fill; and p) chemically mechanically polishing the semiconductor substrate.

Owner:POLARIS INNOVATIONS

Method and apparatus for aseptic packaging

InactiveUS6945013B2Fast processingRule out the possibilitySynchronising machinesPackage sterilisationEngineeringProcess rate

A method and apparatus for providing aseptically processed low acid products in a container having a small opening, such as a glass or plastic bottle or jar, at a high output processing speed.

Owner:STEUBEN FOODS

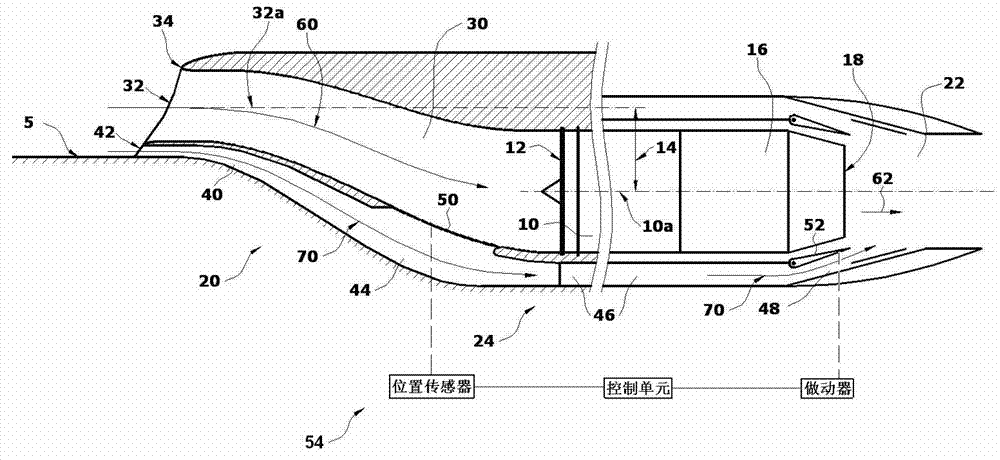

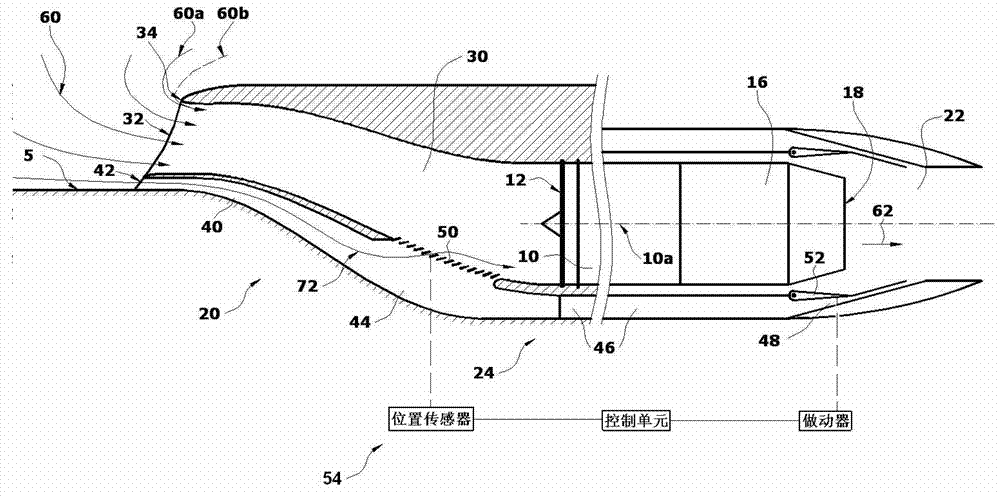

Invisible air intake system

InactiveCN102923309AImprove stealth performanceReduce intake air lossPower plant air intake arrangementsRam-air intakeExhaust valve

The invention relates to an air intake system which is used in an aircraft, and particularly relates to an invisible air intake system. A total main air intake channel of the invisible air intake system is designed into a bent S-like shape; an air intake bypass, an air accumulation cabin, an air path and an exhaust bypass are connected in sequence so as to form into an auxiliary air flow path; an air intake controller is installed on the air accumulation cabin; an exhaust valve is positioned at an outlet of the exhaust valve at the rear part of the auxiliary air flow path; when the air intake controller is at the opened state, the exhaust valve is at the closed state; and when the air intake controller is at the closed state, the exhaust valve is at the opened state. With the adoption of the air intake system, the influence of a boundary layer generated by a wing / body to an engine, and the requirements of the engine on the quantity and the quality of the air intake at different velocities / different engine states are met; and meanwhile, with the adoption of the air intake system, openings in the surface of the wing / body can be reduced with good invisibility performance.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Self-Tightening Snow Chain and Methods of Use

ActiveUS20070199635A1Effectively tightensEasy to installBelt retractorsTyre tread bands/patternsEngineeringGrommet

Self-tightening snow chain for attachment to a vehicle wheel to provide traction. The preferred self-tightening snow chain includes a traction cable and a tensioning device including a housing having a top including a set of housing teeth, a bottom and at least one aperture; a lever interconnected to the housing; a ratchet spool within the housing having a set of ratchet teeth that mate with the housing teeth and a channel between upper and under surfaces to receive a cord that is interconnected with the ratchet spool; a tension spring that places a bias on the ratchet spool toward a wind-up direction; and a wave spring. A preferred tensioning device includes a cord sub-unit having two knobs, one on each end, and a grommet encircling the cord. A method of assembling the tensioning device is also disclosed.

Owner:PEERLESS CHAIN COMPANY

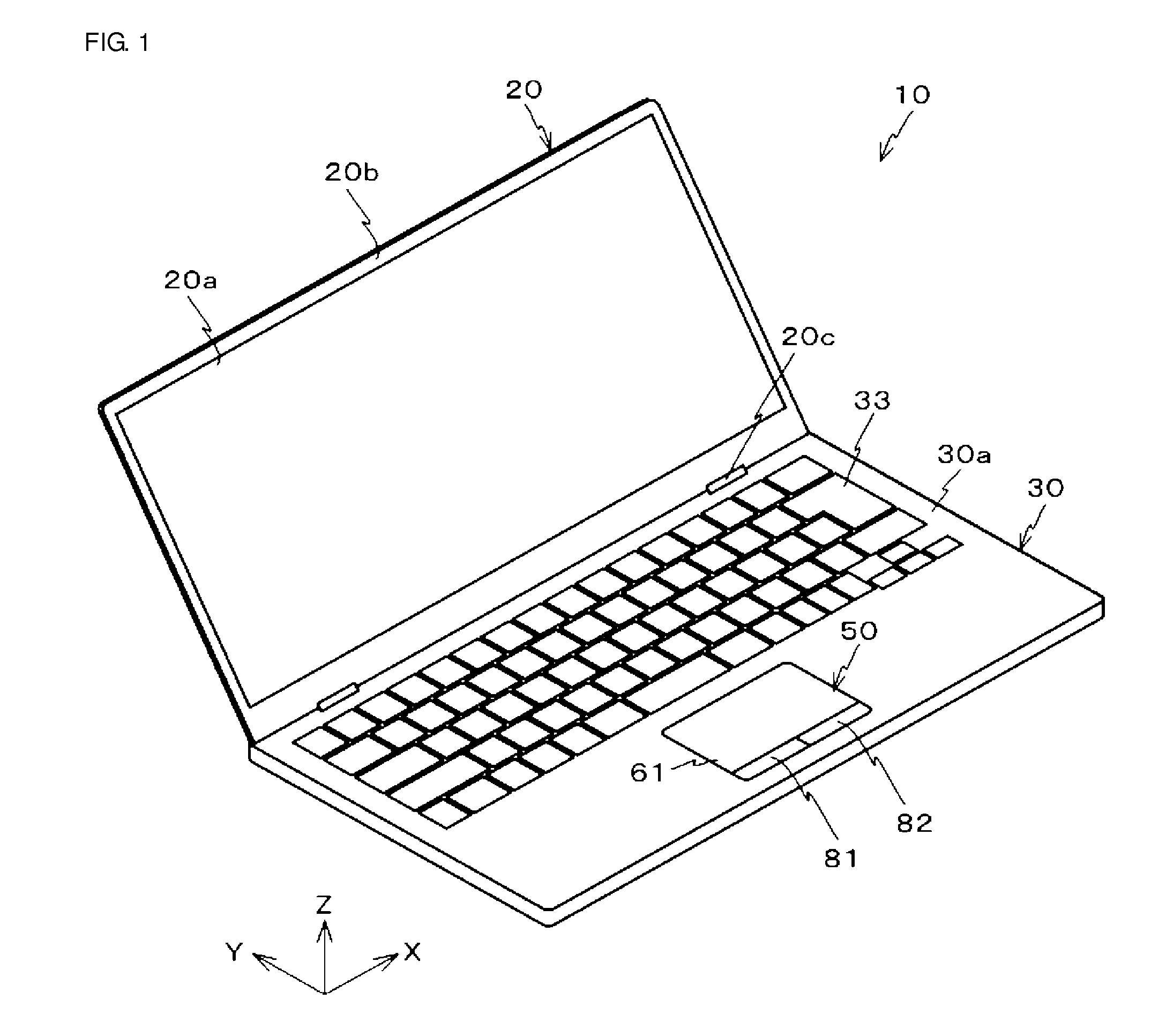

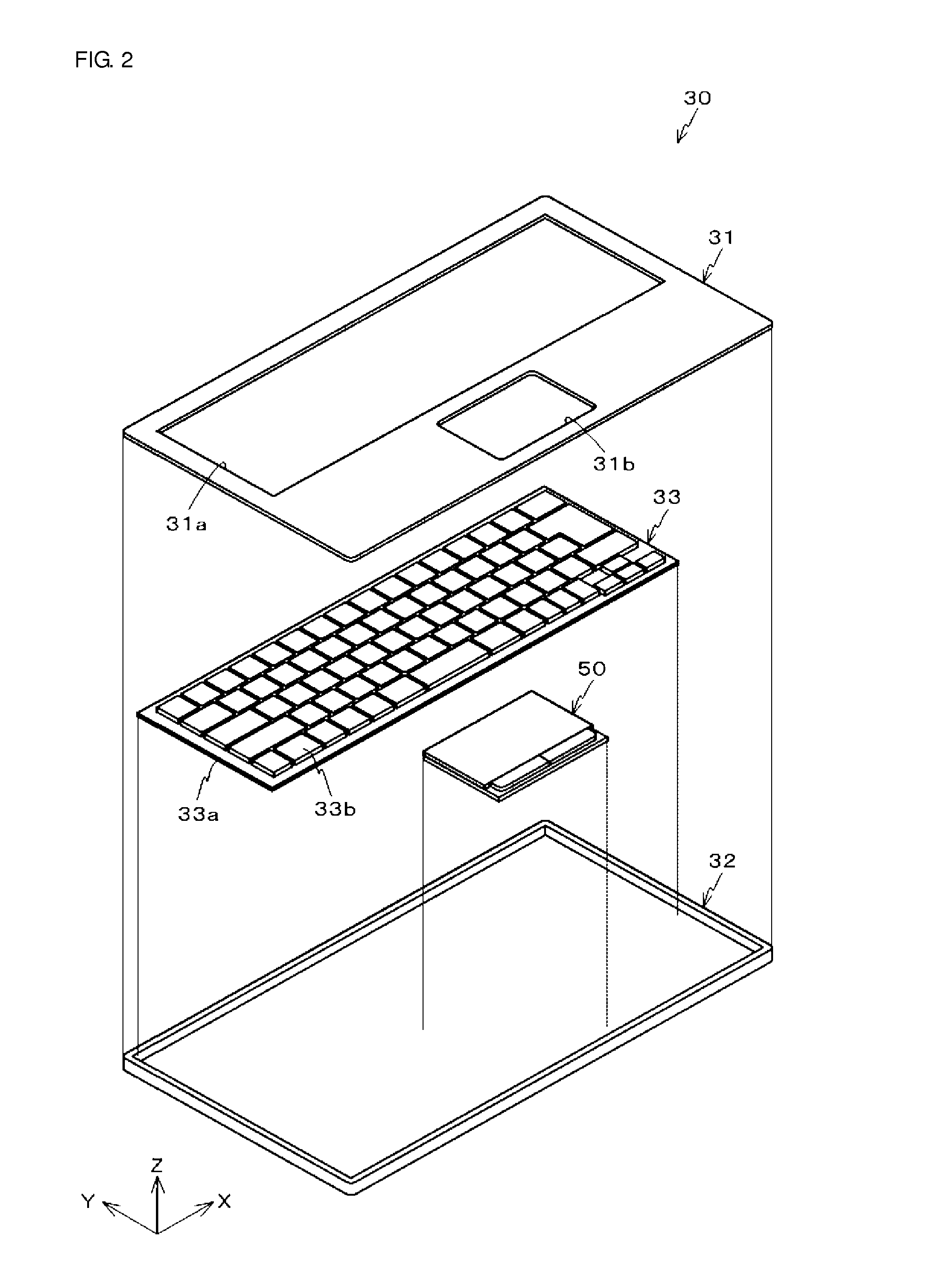

Interface unit and computer

ActiveUS20140335785A1Ensure correct executionAccurate communicationNear-field transmissionDigital data processing detailsElectromagnetic couplingMagnetic flux

In an interface unit, a shield layer includes an aperture through which magnetic flux generated by a power feeding coil of an antenna passes. Since the antenna is smaller than the shield layer, the aperture is much smaller than the shield layer. Thus, noise constituted by electromagnetic waves that travel from inside to outside of a computer via an aperture provided in an upper surface cover is blocked. During communication, the antenna and the shield layer are electromagnetically coupled to each other, and the shield layer defines and functions as an antenna. This allows proper communication with a communication target.

Owner:MURATA MFG CO LTD

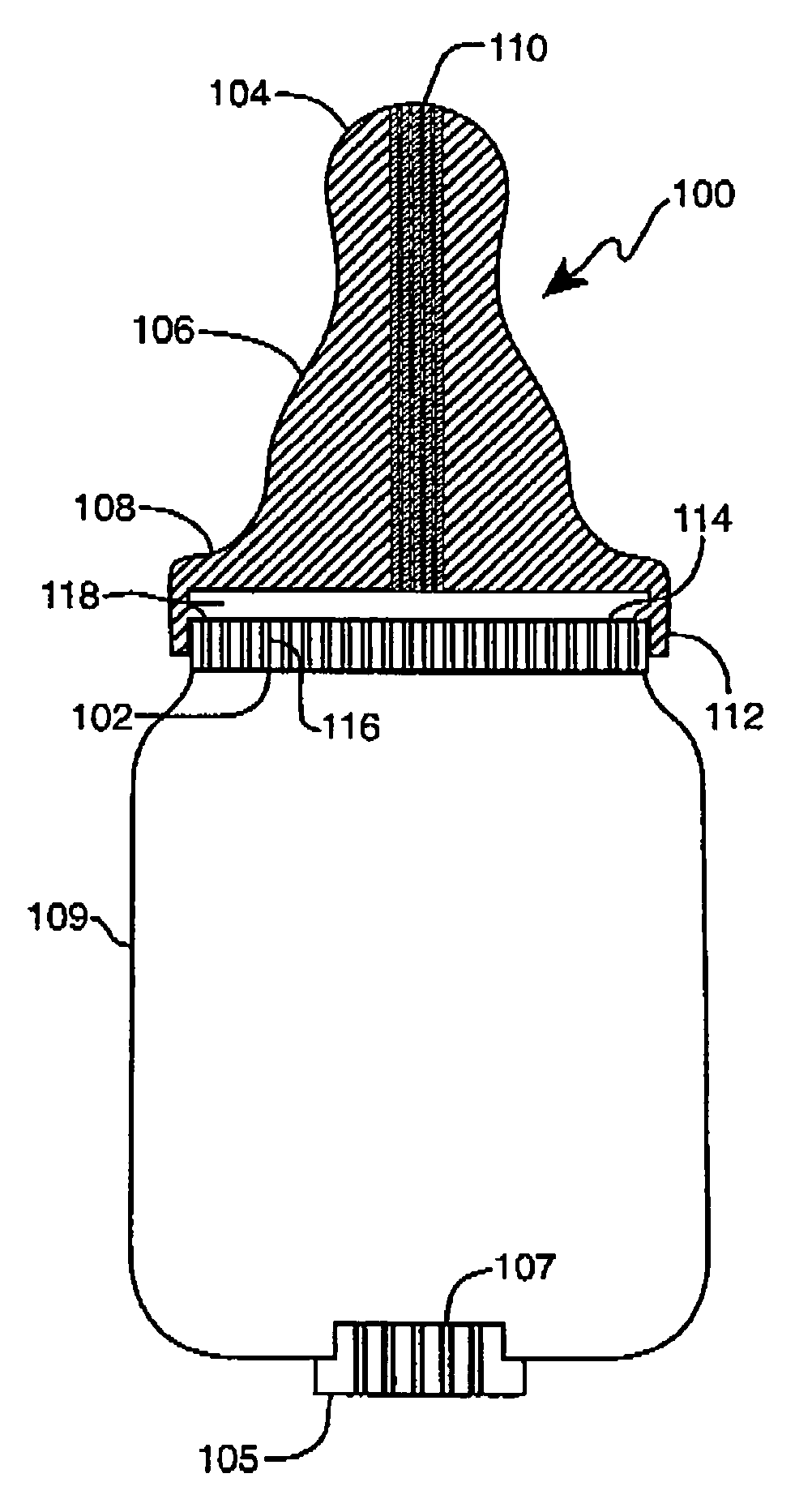

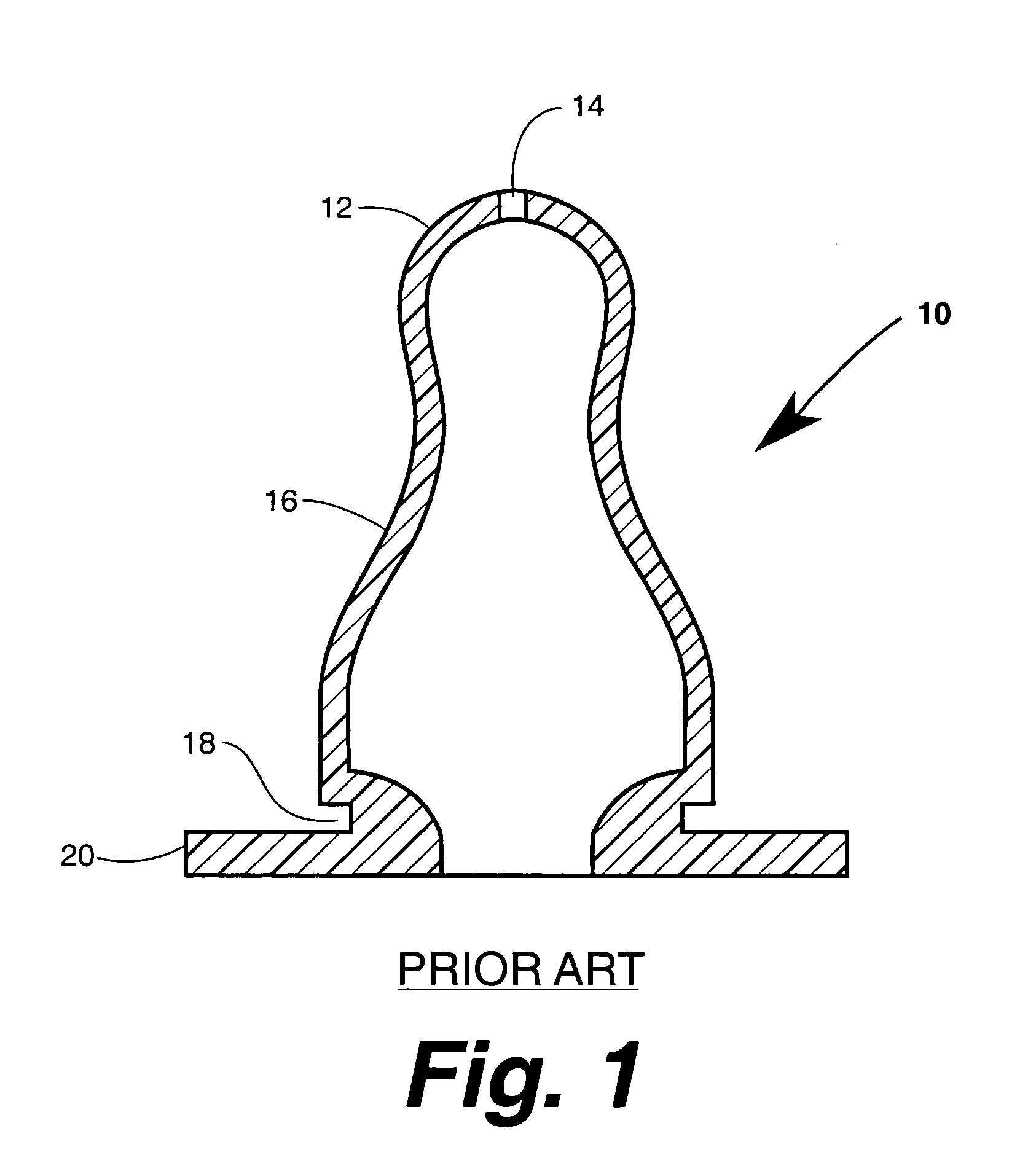

Air-admittance device and method for making same

InactiveUS7503461B1Easy to cleanImprove the bactericidal effectBottlesLarge containersWater basedMicroporous material

There are provided methods for fabricating devices for admitting air to a closed container while preventing passage of a water-based fluid therethrough. These devices comprise a plurality of hydrophobic capillaries or a hydrophobic reticulated microporous material. The devices comprising hydrophobic capillaries are fabricated by a variety of techniques, such as those employing extrusion, pultrusion, fugitive mandrel removal or a combination of these techniques. The devices comprising hydrophobic reticulated microporous material are fabricated by techniques such as foaming, sintering, template replication, incorporation of sacrificial particles or a combination of these techniques.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

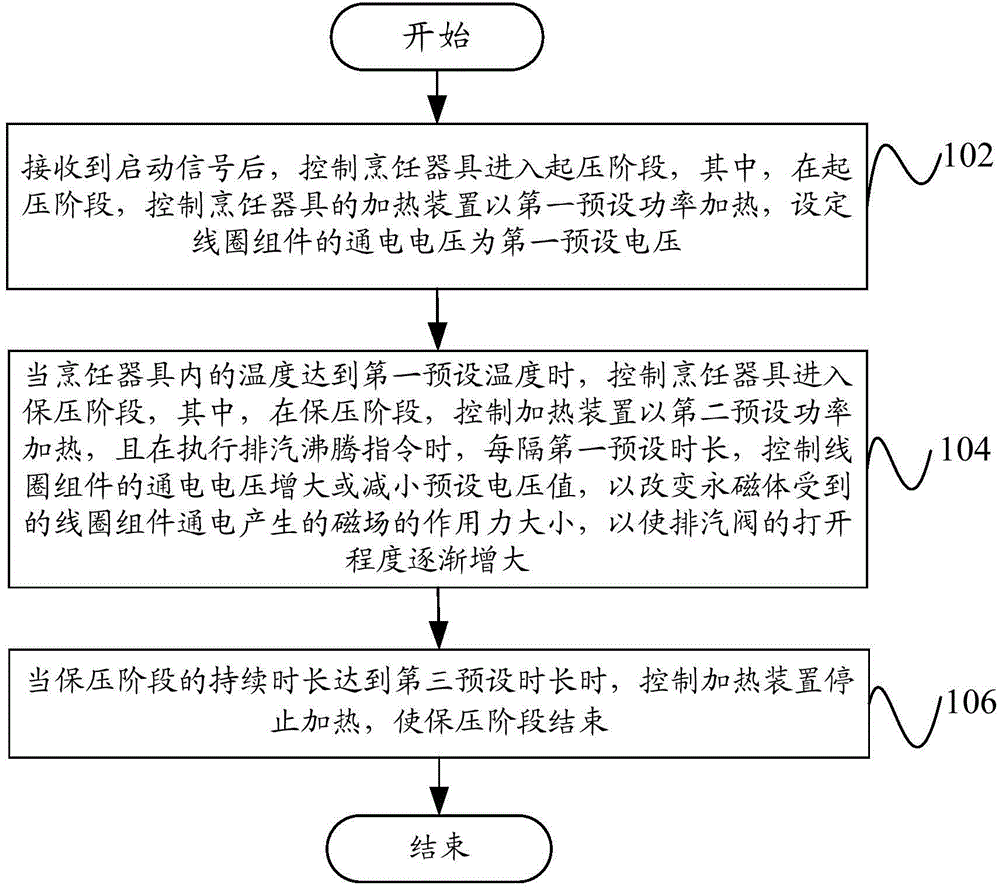

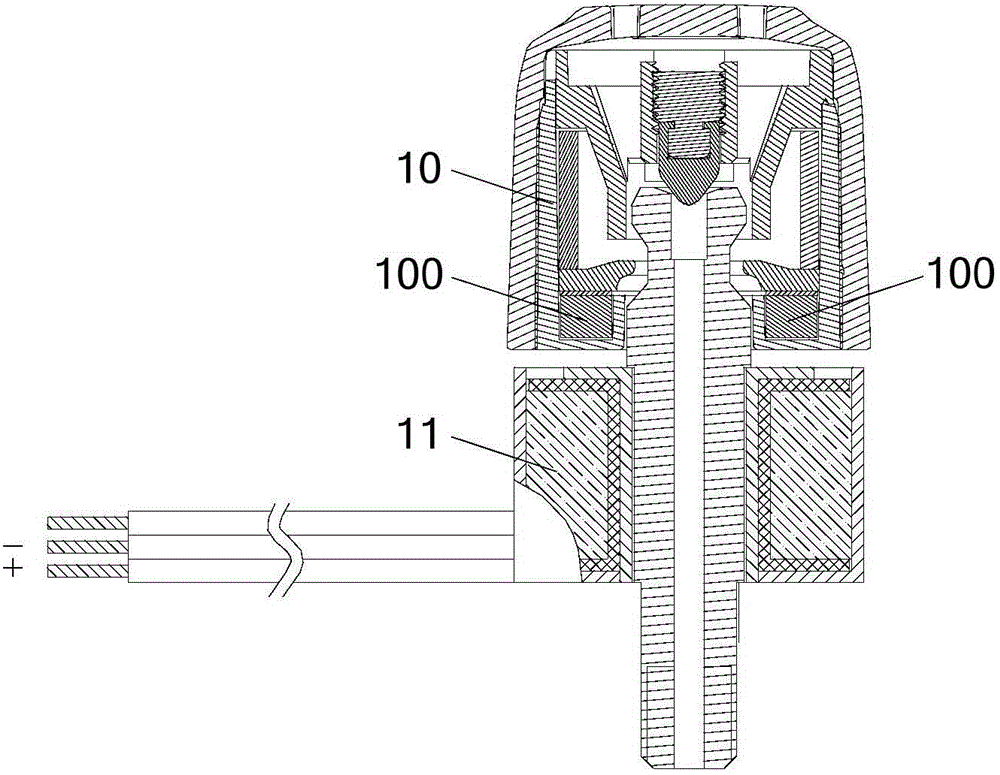

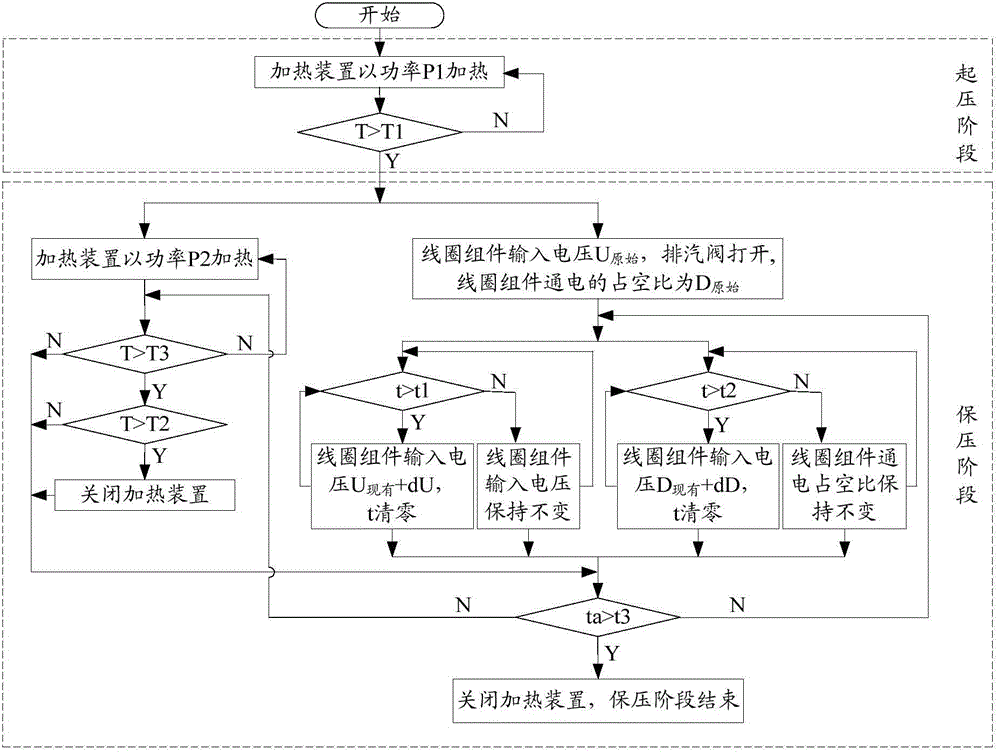

Control method, control device and cooking appliance

ActiveCN106136874AEffectively control the degree of openingRealize the boiling and tumbling effectPressure-cookersPressure riseExhaust valve

The invention provides a control method, a control device and a cooking appliance. The control method comprises the following steps: after a start signal is received, the cooking appliance is controlled to enter a pressure rising stage, a heating device of the cooking appliance is controlled for heating with first preset power, and the power-on voltage of a coil assembly is set as first preset voltage; when the temperature in the cooking appliance reaches a first preset temperature, the cooking appliance enters a pressure maintaining stage, the heating device is controlled for heating with second preset power, and third preset duration is lasted; moreover, when an exhaust and boiling order is executed, the power-on voltage of the coil assembly is controlled to increase or decrease a preset voltage value at an interval of first preset duration, so that the opening degree of an exhaust steam valve is gradually enlarged. The control method provided by the invention dynamically adjusts the magnitude of the power-on voltage of the coil assembly when the cooking appliance enters the pressure maintaining stage, so as to control the opening degree of the exhaust steam valve, effectively improve the intensity of food boiling and rolling, and improve the food cooking taste.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

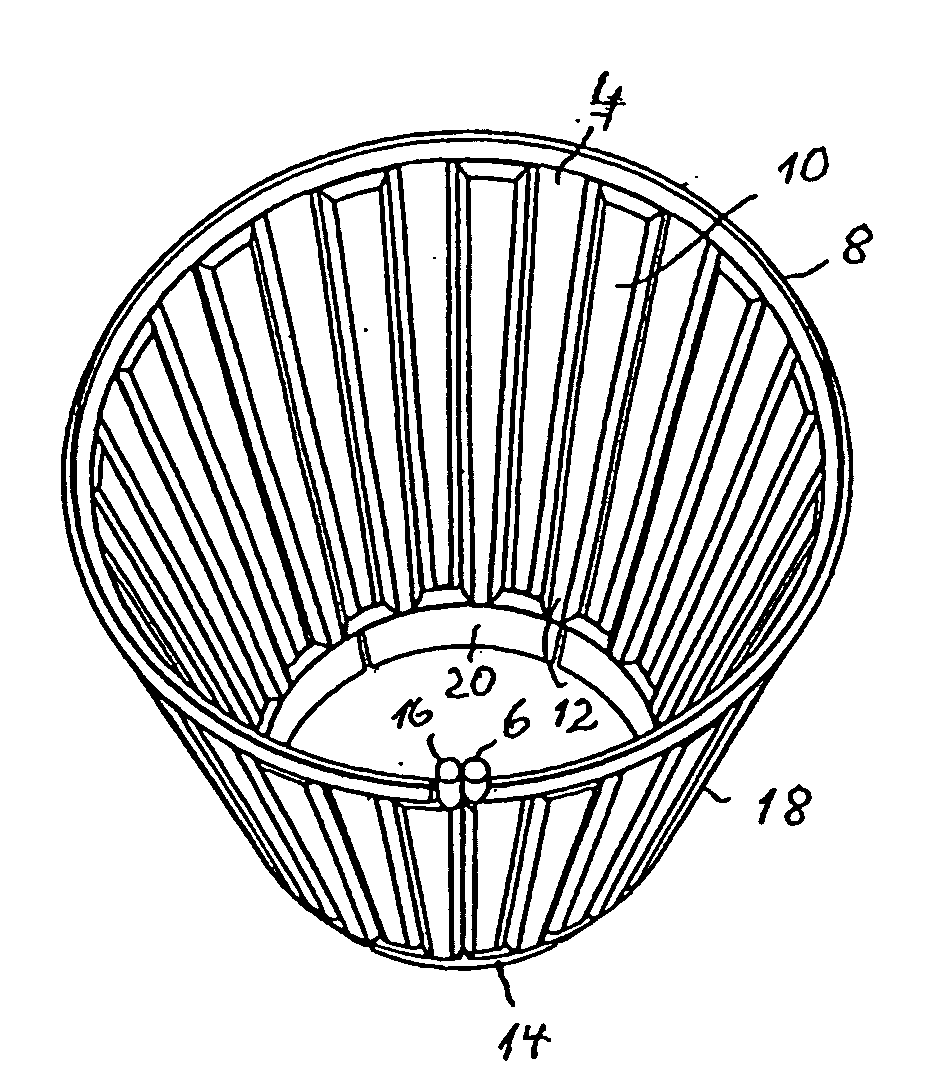

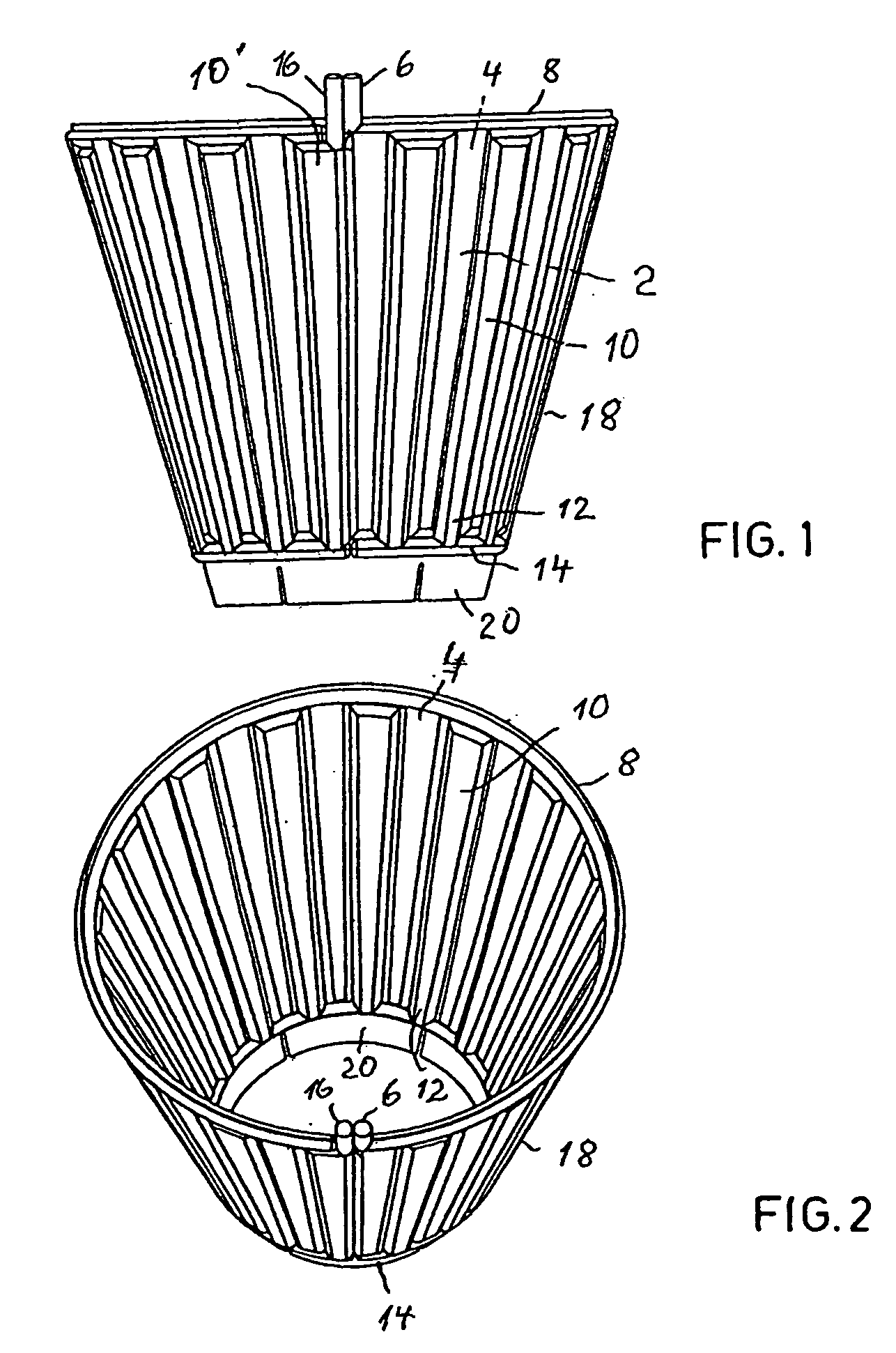

Device for supporting the abdominal wall relative to underlying organs during minimally invasive surgery

InactiveUS20090069627A1Easy to produceKeeping the surgery site freeSurgeryProsthesisLess invasive surgeryAbdominal wall

Device for supporting the abdominal wall away from organs positioned thereunder for freeing up a surgical space in minimally invasive surgery, having multiple tube-shaped hollow bodies, which are fillable via a hose line (6, 16), and which are connected to each other in circumferential direction to form a preferably conical toroidal shape. The elongated hollow bodies (2, 10) are each supported at their ends (4, 12) on a tube-shaped, thin-walled, foldable hollow body (8, 14), which forms a ring, and which can be filled via a hose line (6, 16), extending along the two edges of the toroidal shape. The diameters of the two annular hollow bodies (8, 14) may be the same, or different, thus forming a cylindrical or frustoconical wall (18) serving for support.

Owner:HAINDL HANS

Condensing device for dish-washing machine and dish-washing machine provided with condensing device

ActiveCN106551666ARapid condensationSpeed up the flowTableware washing/rinsing machine detailsWater vaporEngineering

The invention relates to a condensing device for a dish-washing machine and the dish-washing machine provided with the condensing device. The condensing device comprises an inner container, a condenser and draught fans. One end of the condenser communicates with the inner container through an air inlet, and the other end of the condenser is connected with the draught fans. An air supply opening communicating with the inner container is formed in one side plate of the condenser. Airflow is conveyed into the condenser and supplied into the inner container through the air supply opening so that water vapor can enter the condenser through the air inlet to form inner airflow circulation, meanwhile, cooling airflow is conveyed to the outer surface of the condenser to form outer airflow circulation, and power is provided for inner airflow circulation and outer airflow circulation through the two draught fans correspondingly or through one draught fan at the same time. The condensing device has inner airflow circulation and outer airflow circulation at the same time, the flowing speed of airflow on the outer surfaces of the side plates of the condenser can be increased, the surface temperature of the condenser can be reduced, fast condensation of the water vapor in the condenser can be facilitated, and the condensation efficiency can be greatly improved.

Owner:QINGDAO HAIER DISHWASHER +1

Cable lock with integral connected metal sheath

InactiveUS20130098122A1Easy to disassembleMany timesLocks for portable objectsBurglar alarmElectricityElectrical conductor

A security device for attachment to an article to deter theft of the article has a housing containing an alarm system including. A cable has one end attached to the housing and a second end attached to a plug which is selectively inserted into and locked to the housing. The cable formed with an outer braided jacket that is difficult to cut and includes a conductor electrically connected to the alarm system when in the locked position. The audible alarm is activated if the integrity of the cable is compromised. An EAS tag located in the housing will actuate an alarm at a security gate and can actuate the audible alarm of the security device when the device is in proximity to a security gate. A magnetically attractable lock mechanism releasably secures the cable plug in the locked position.

Owner:CHECKPOINT SYST INC

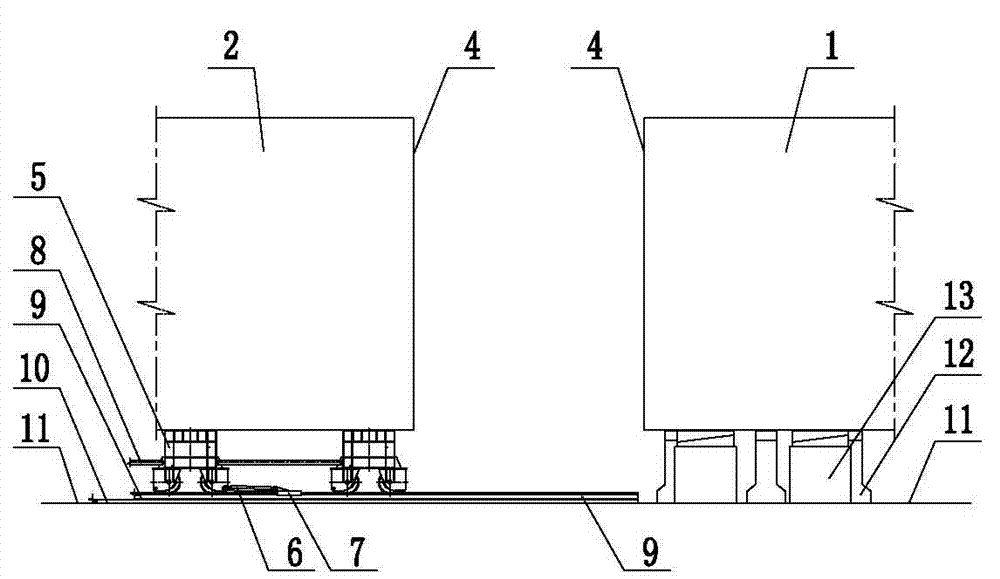

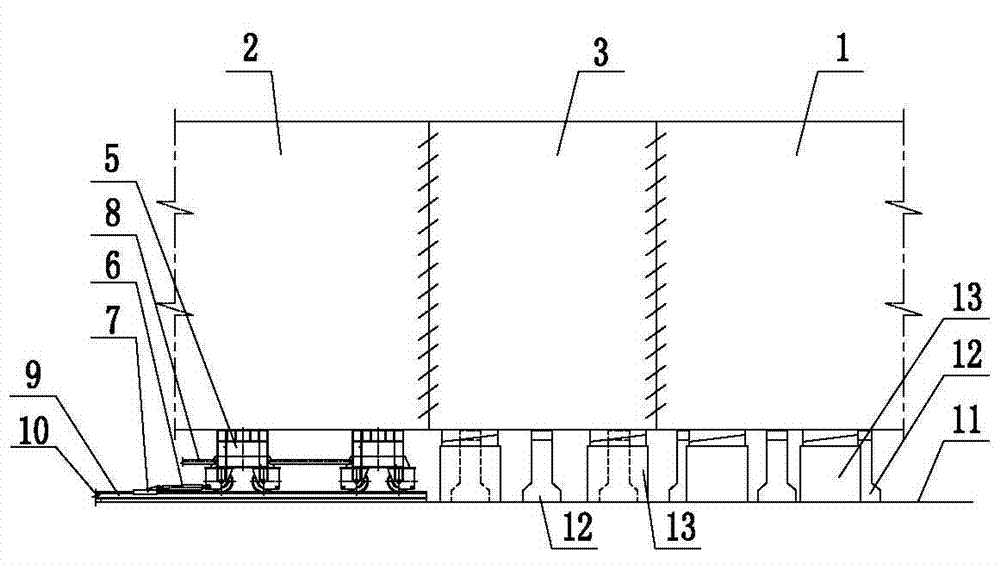

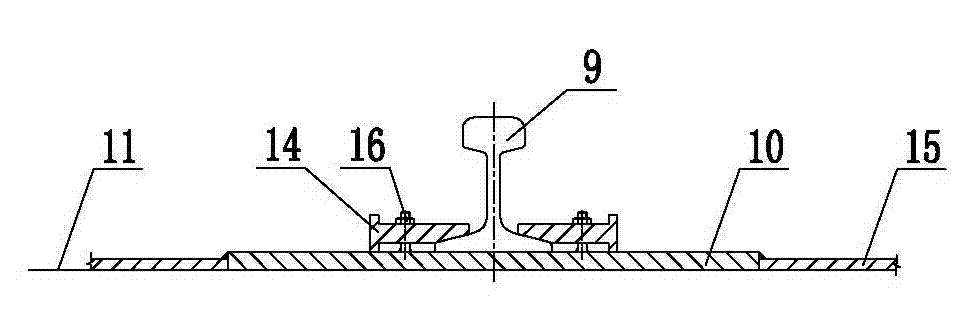

Retrofit technology for cutting and lengthening ships via dry-type trolley method

ActiveCN102923254AImprove securityEasy to fixVessel partsRecycling waterborne vesselsKeelMarine engineering

The invention discloses a retrofit technology for cutting and lengthening ships via a dry-type trolley method. The technology is carried out by prefabricating newly-added sections by sectioning, arranging docking blocks, drawing lines on a ship body, strengthening the structure of the ship body, and cutting by sectioning. The technology comprises the following main steps of: controlling the docking precision of the ship; paving a combined-type rail, connecting and putting a combined trolley; precisely lying the ship on a keel block after the ship docks; arranging a thrust device; adding supports at the front end of a bow section and the rear end of a stern section of the ship; displacing the bow section; assembling the newly-added sections and folding the newly-added sections with the stern section; and precisely aligning, locating and folding the bow section with the newly-added sections. The technology is suitable for cutting and lengthening ships in any mold lines and tonnages and has the advantages of rapid folding speed, high firmness safety, simple and reliable process operation, short retrofit period and low cost. The folding and locating precisions are high, so that the precise displacement and aligned location of the bow section are effectively guaranteed and the folding precision reaches the level of a newly-constructed ship. On the other hand, the technology is less affected by the change of exterior environment factors such as weather, which is beneficial to the control of the docking period in enterprises.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com