Patents

Literature

207results about How to "Increase the angle of incidence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

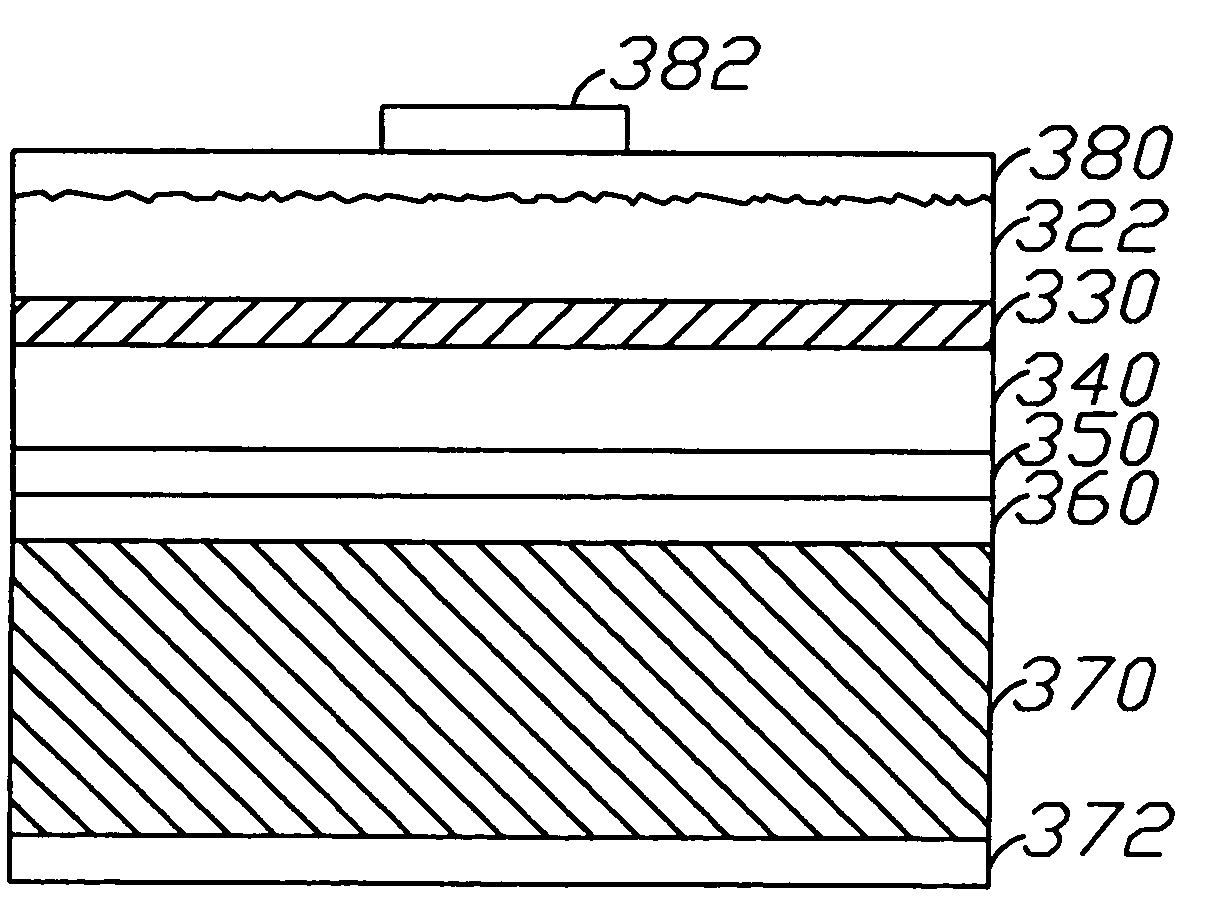

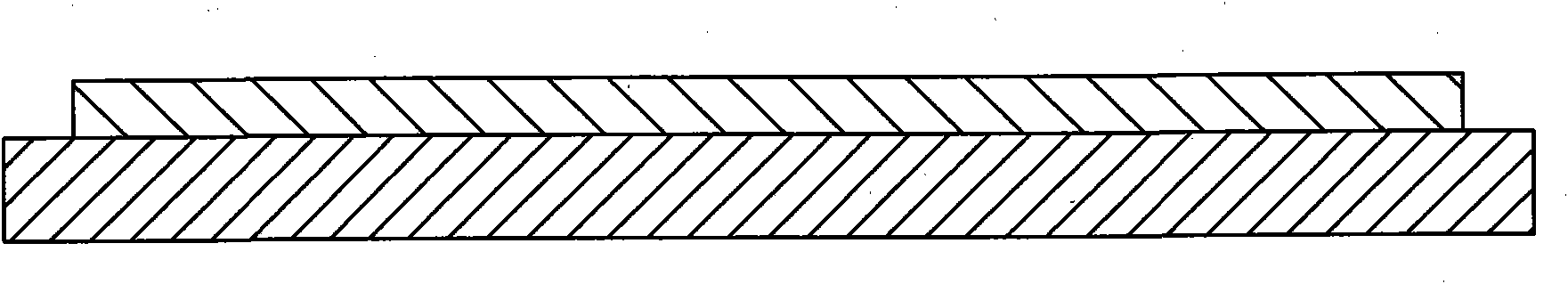

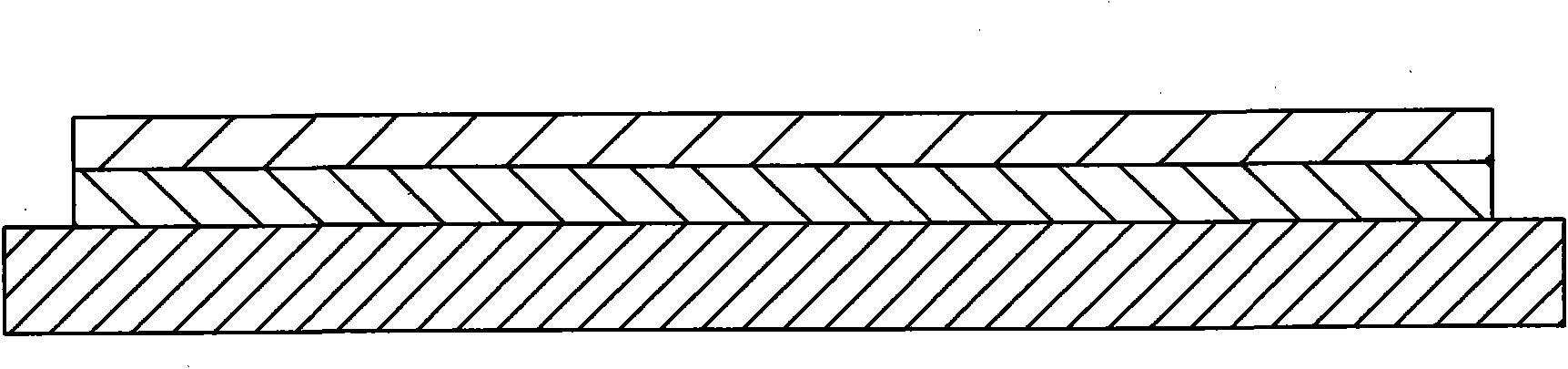

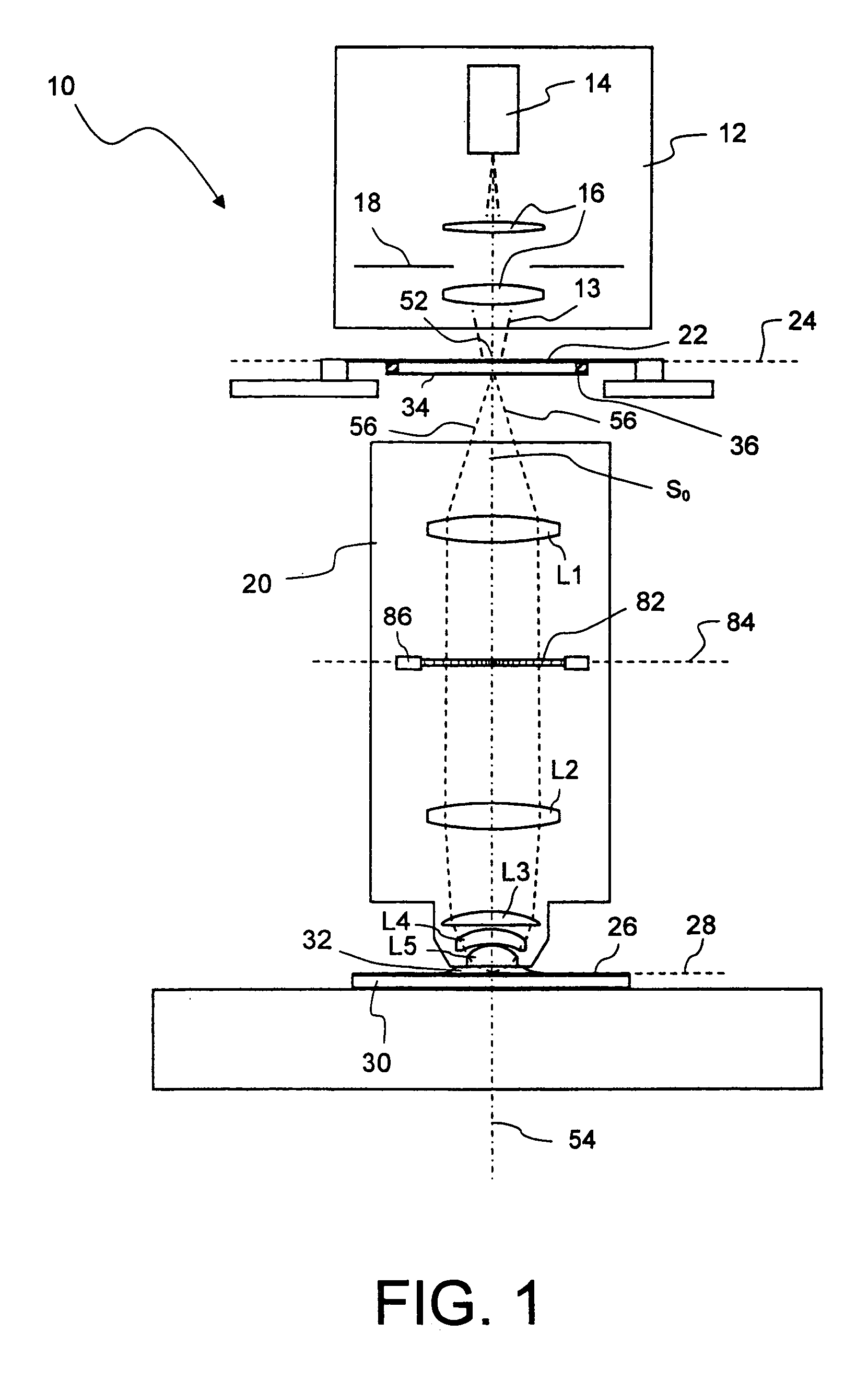

Gradient immersion lithography

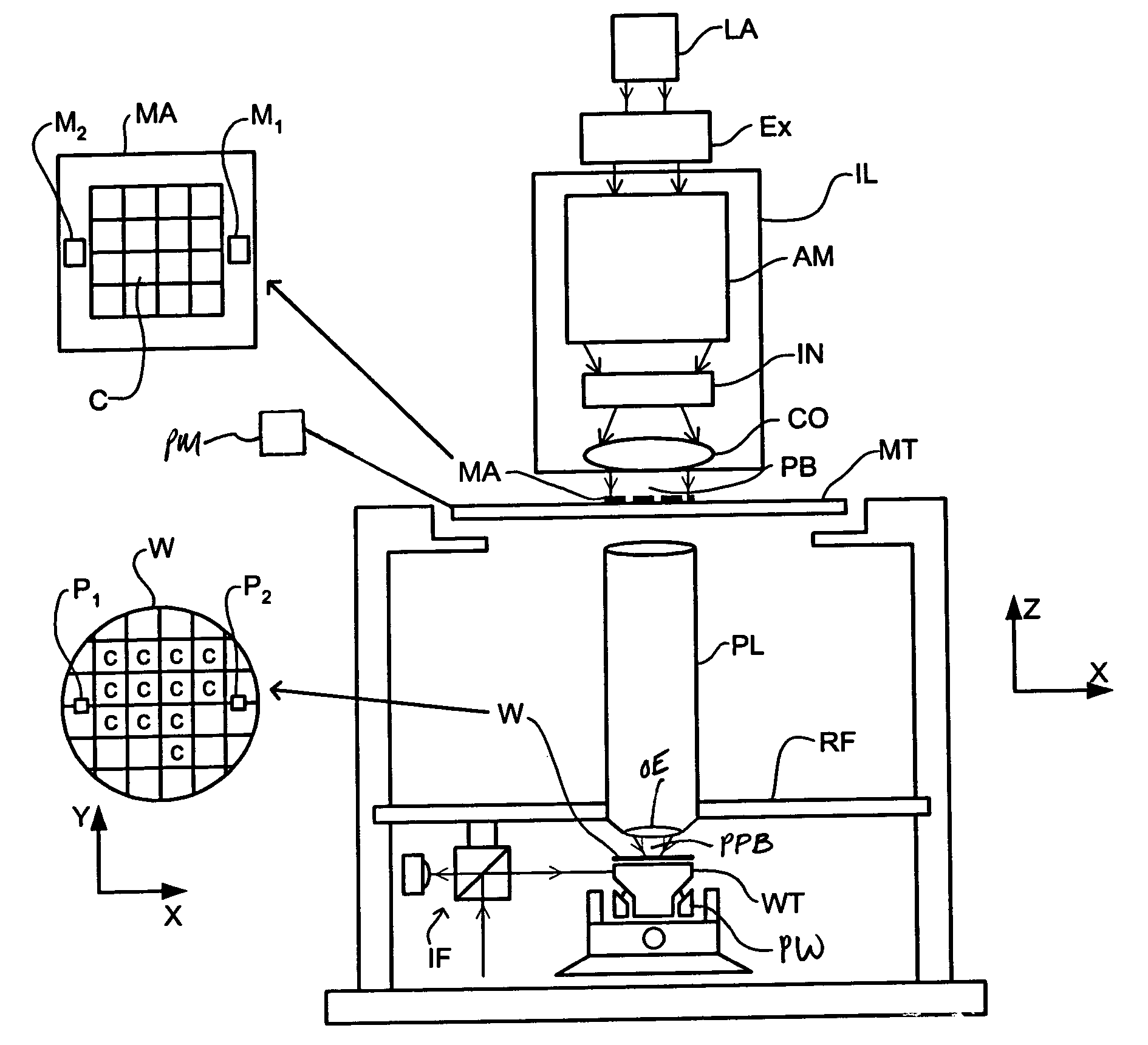

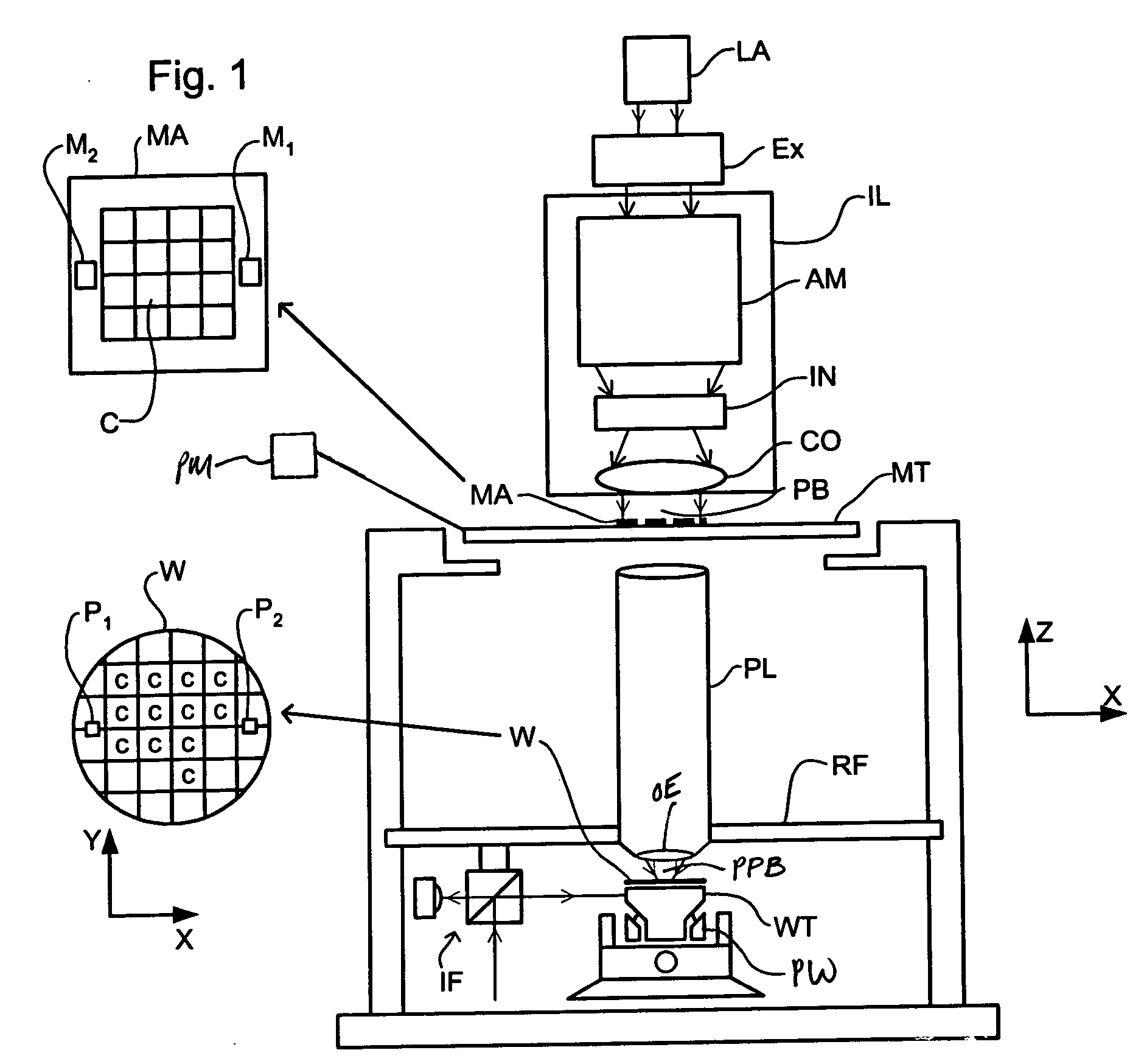

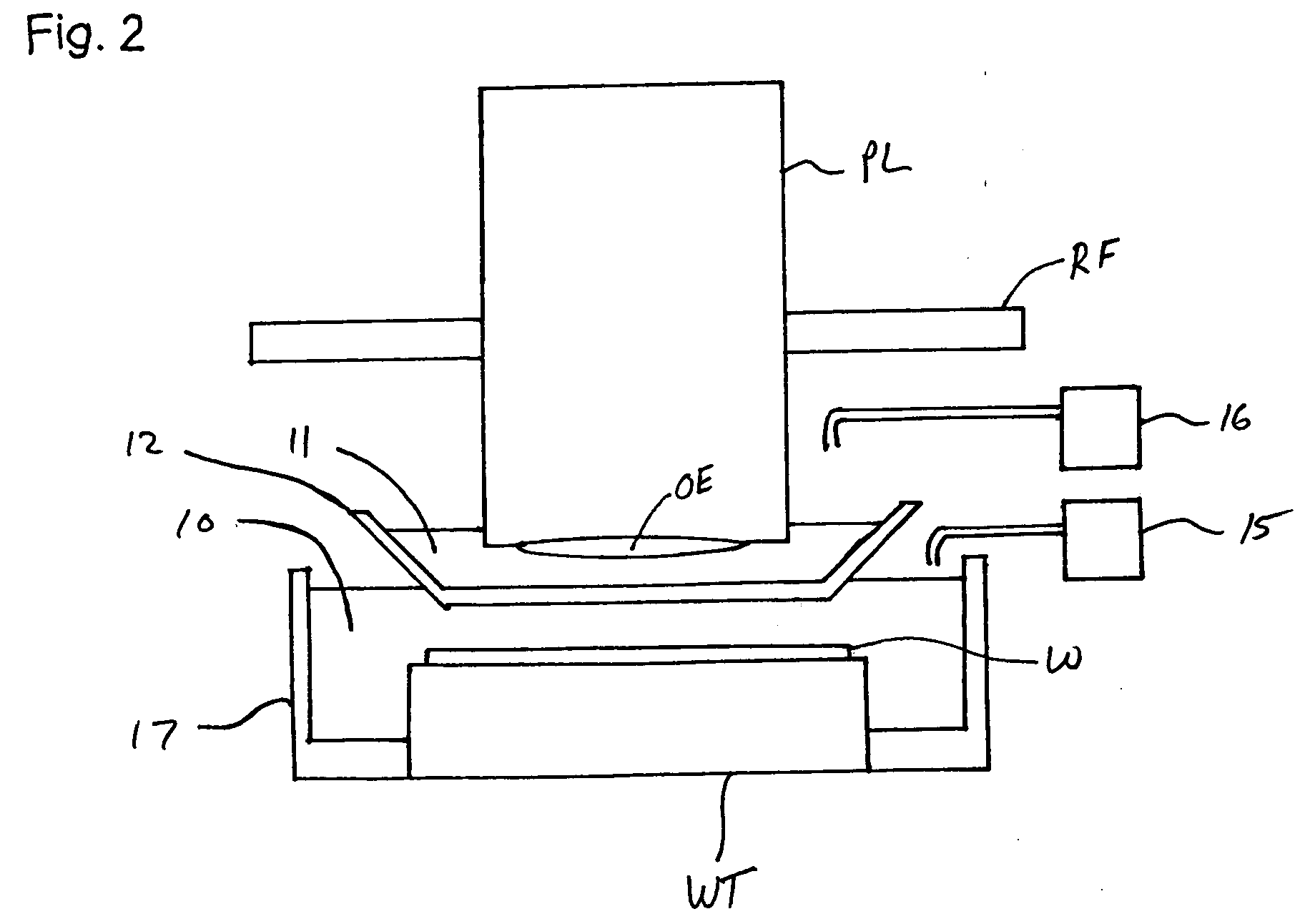

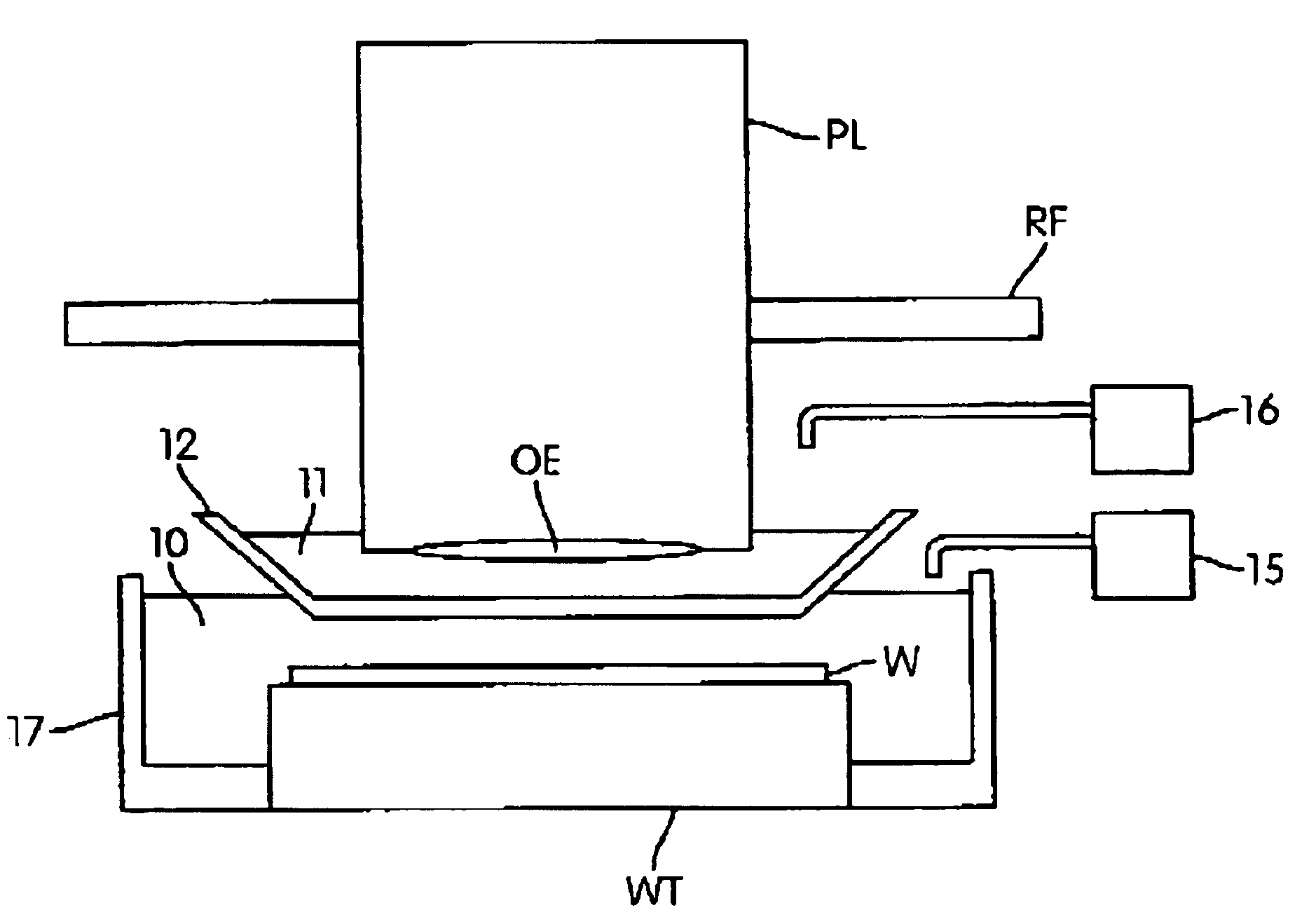

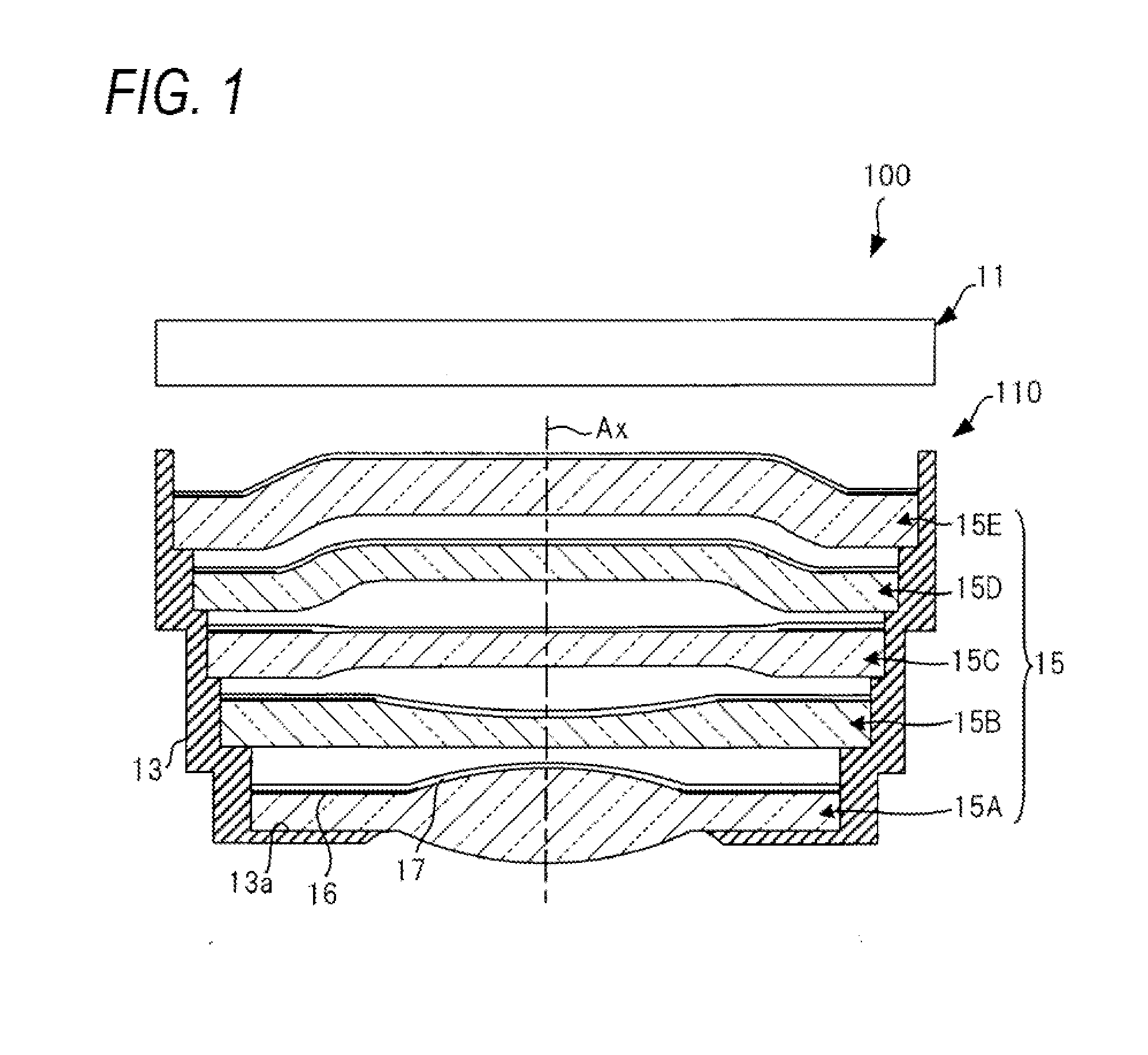

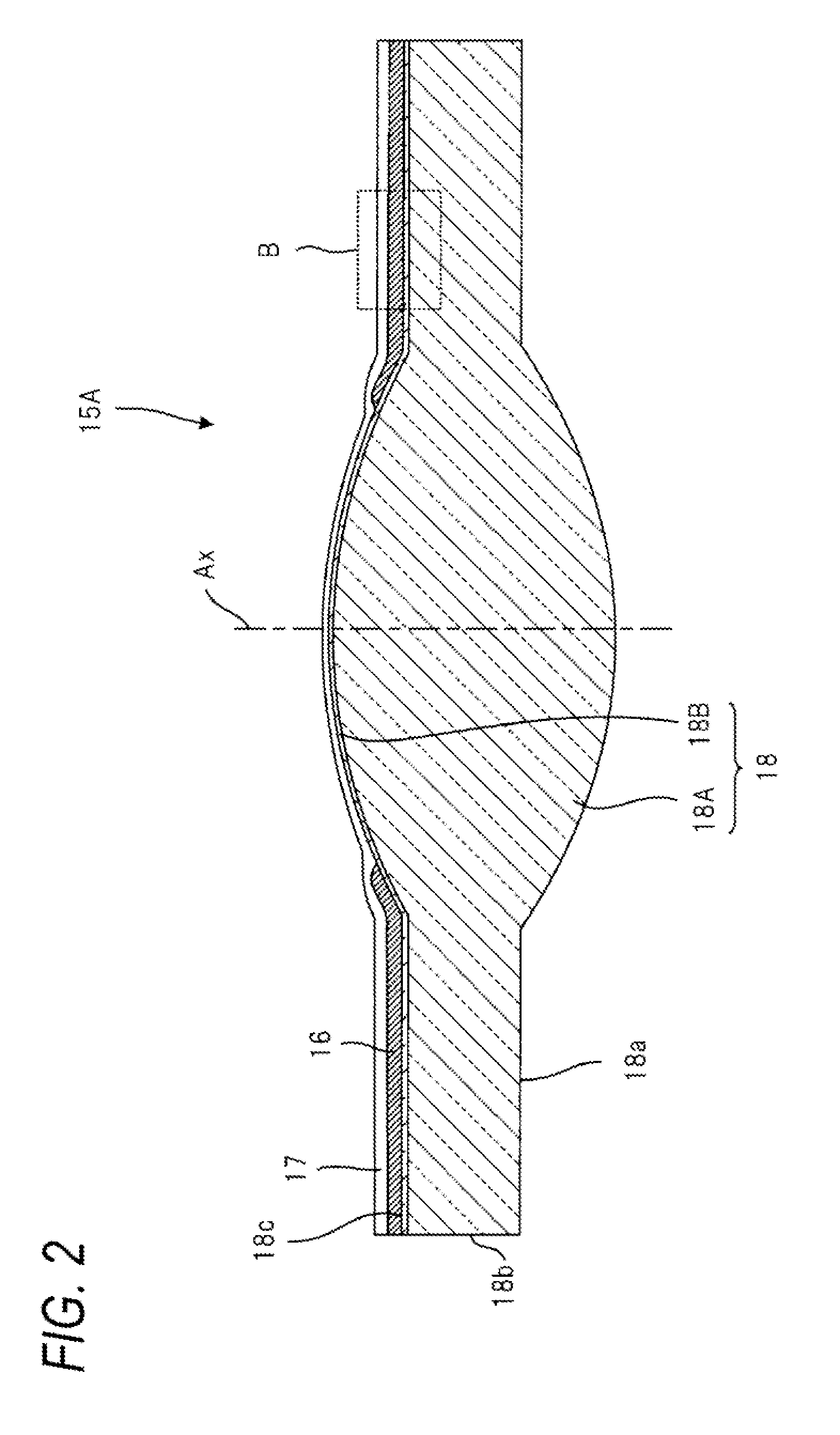

InactiveUS20050094116A1Increase the angle of incidenceReduce reflectionRadiation applicationsSemiconductor/solid-state device manufacturingRefractive indexProjection system

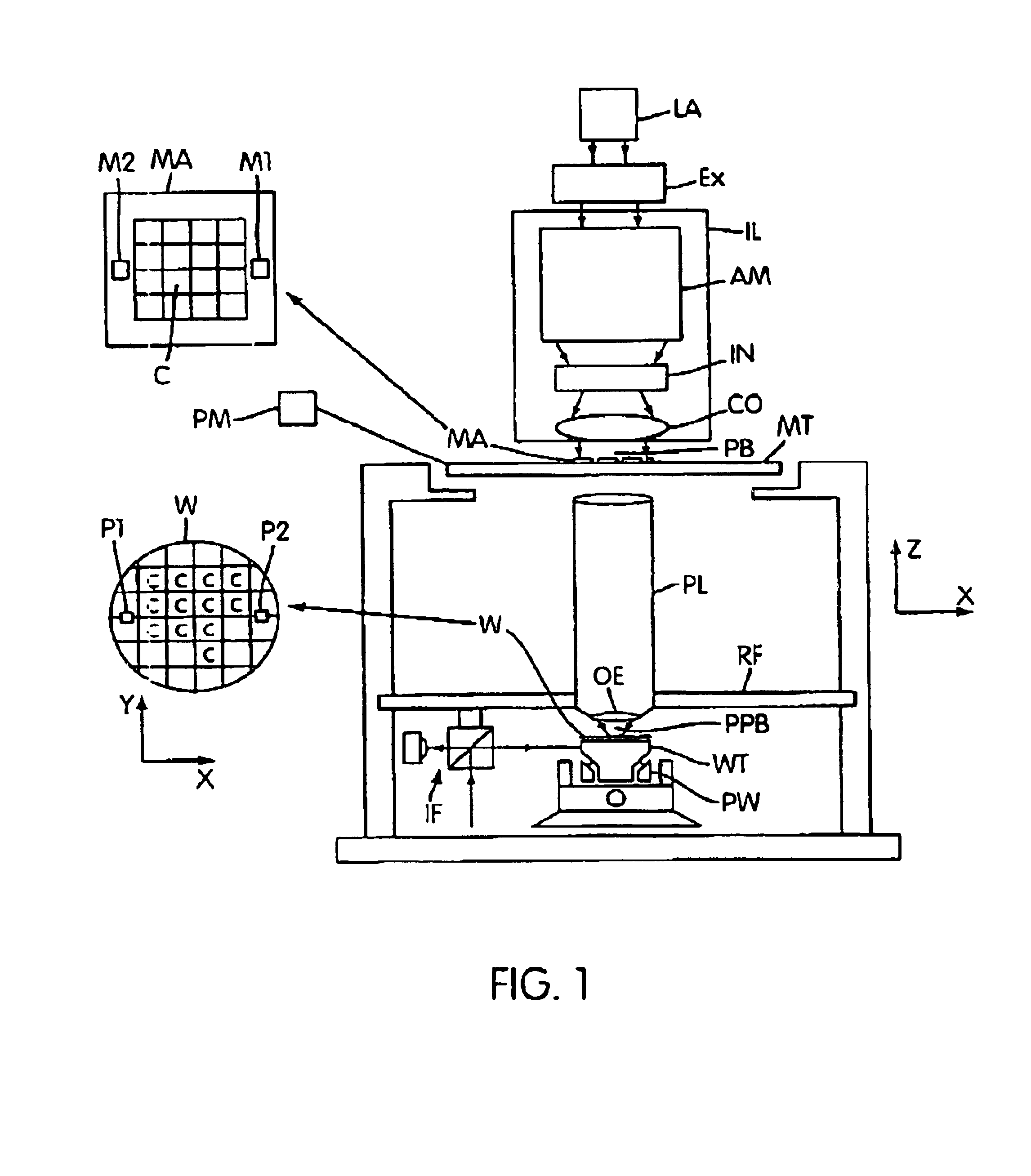

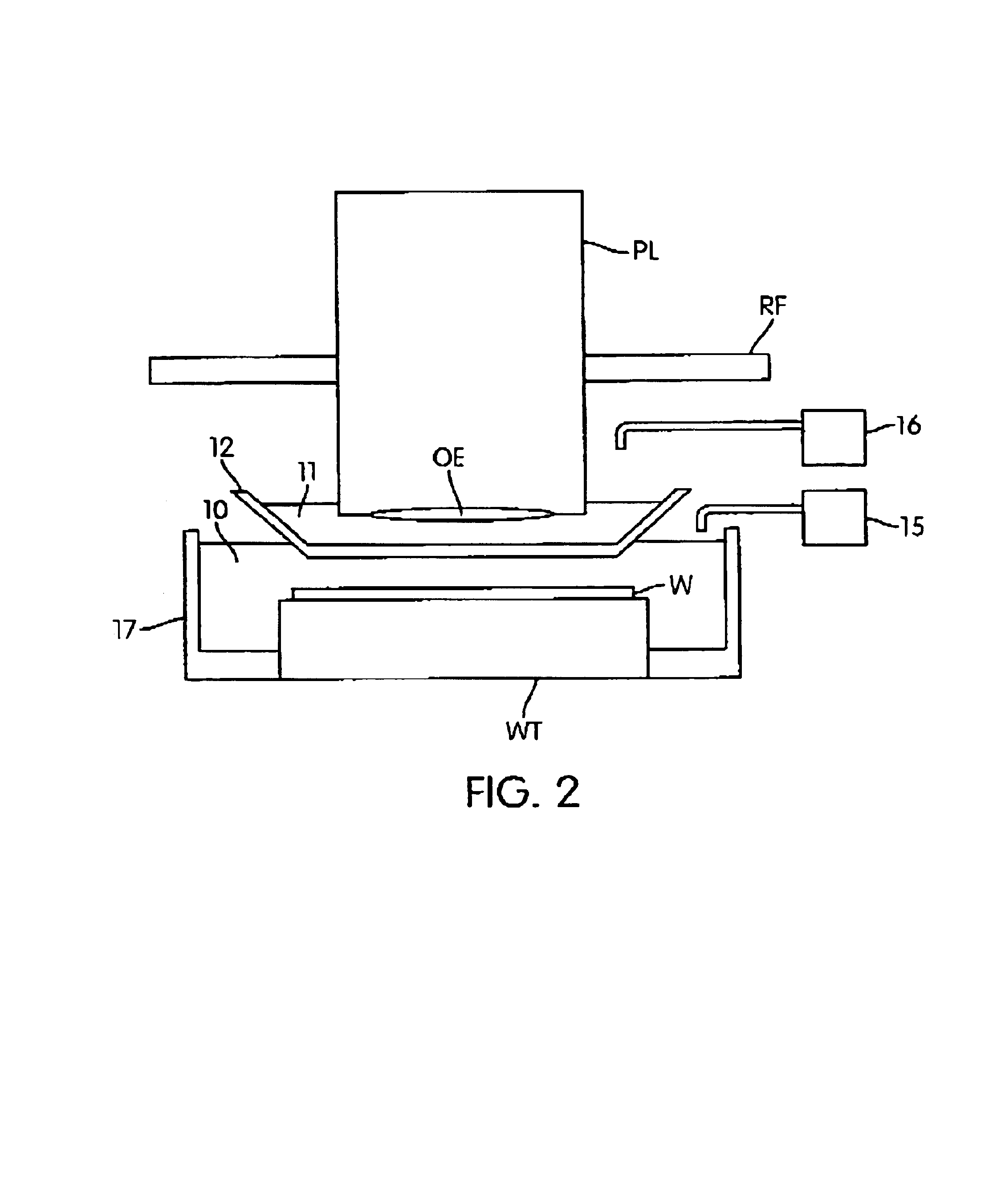

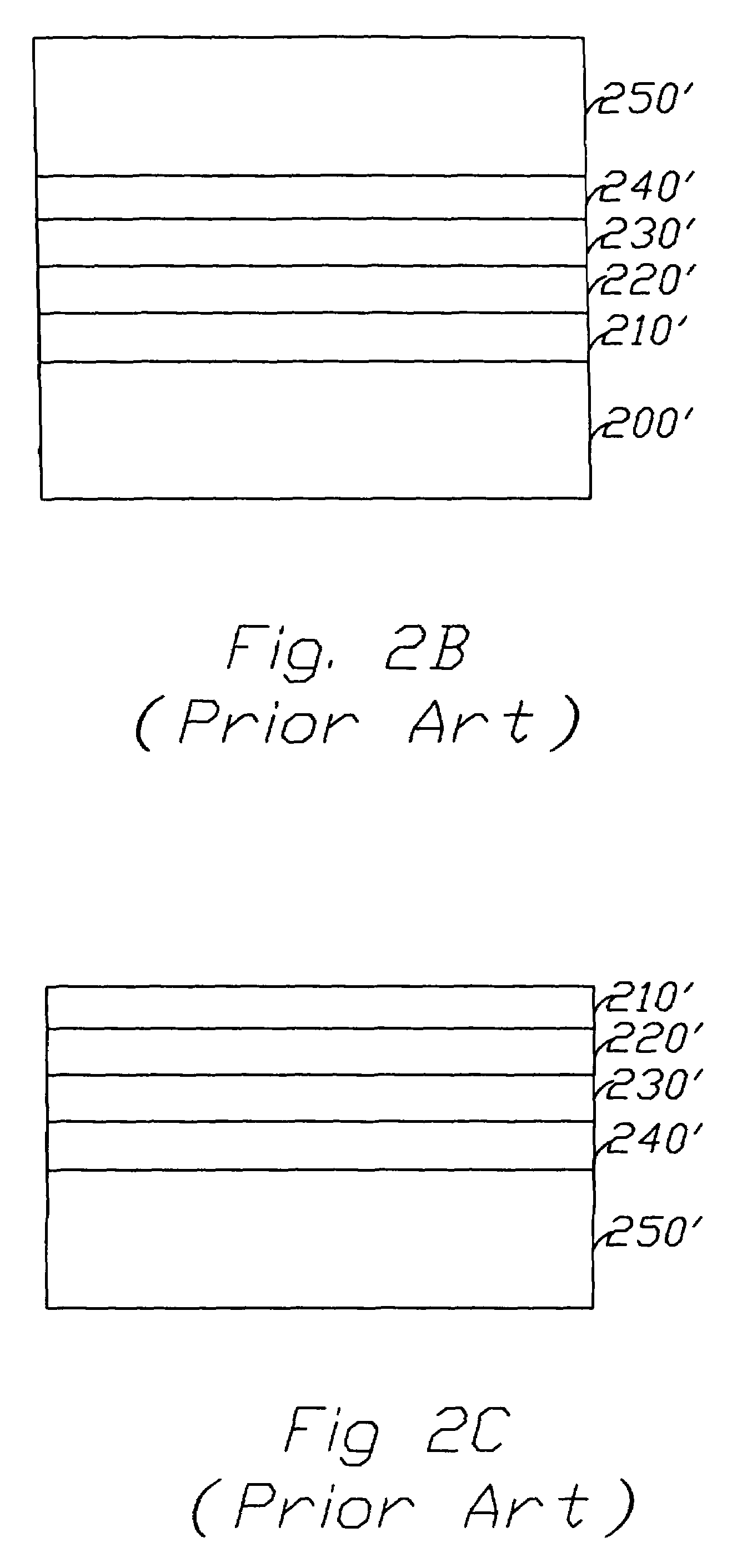

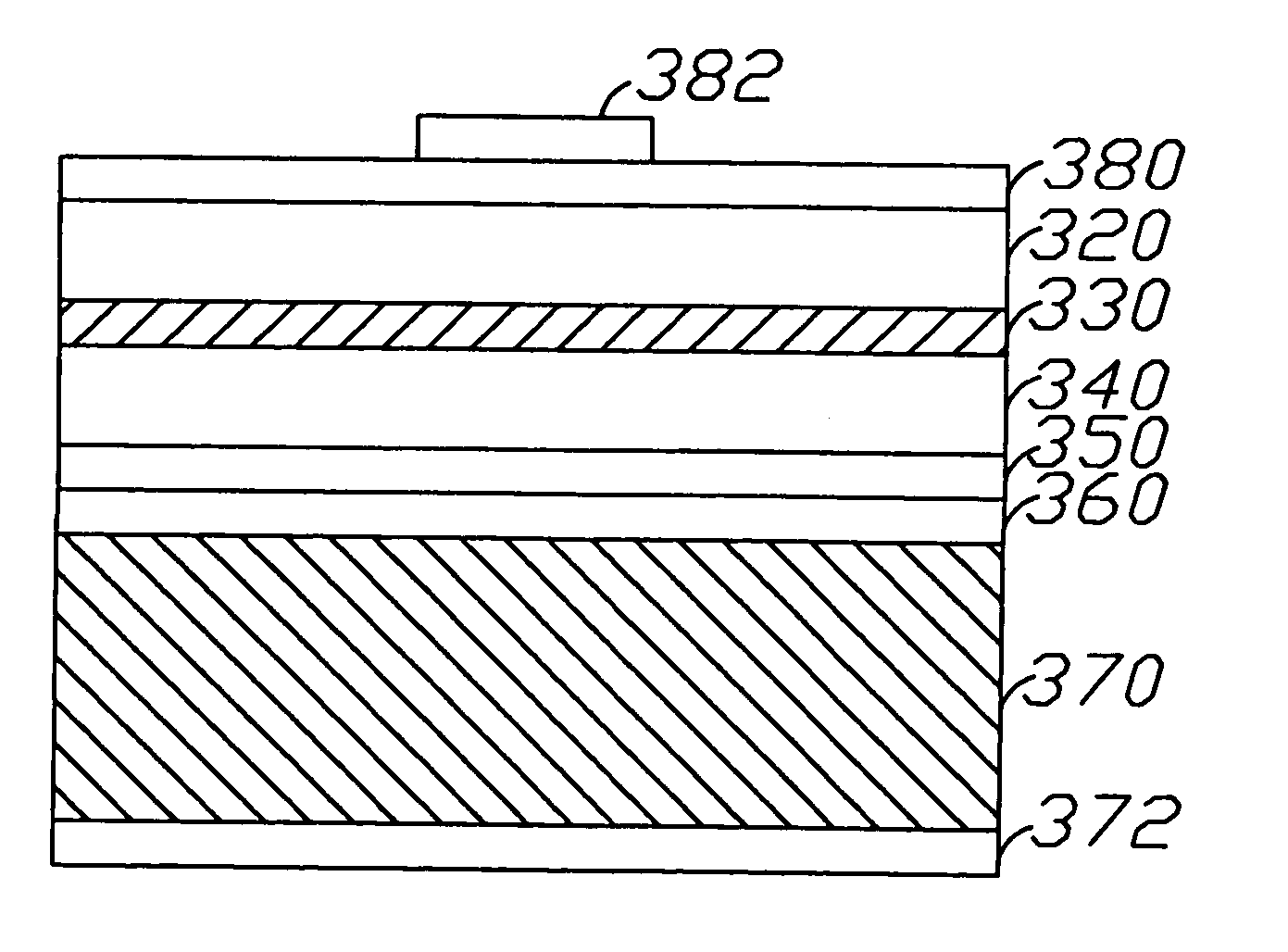

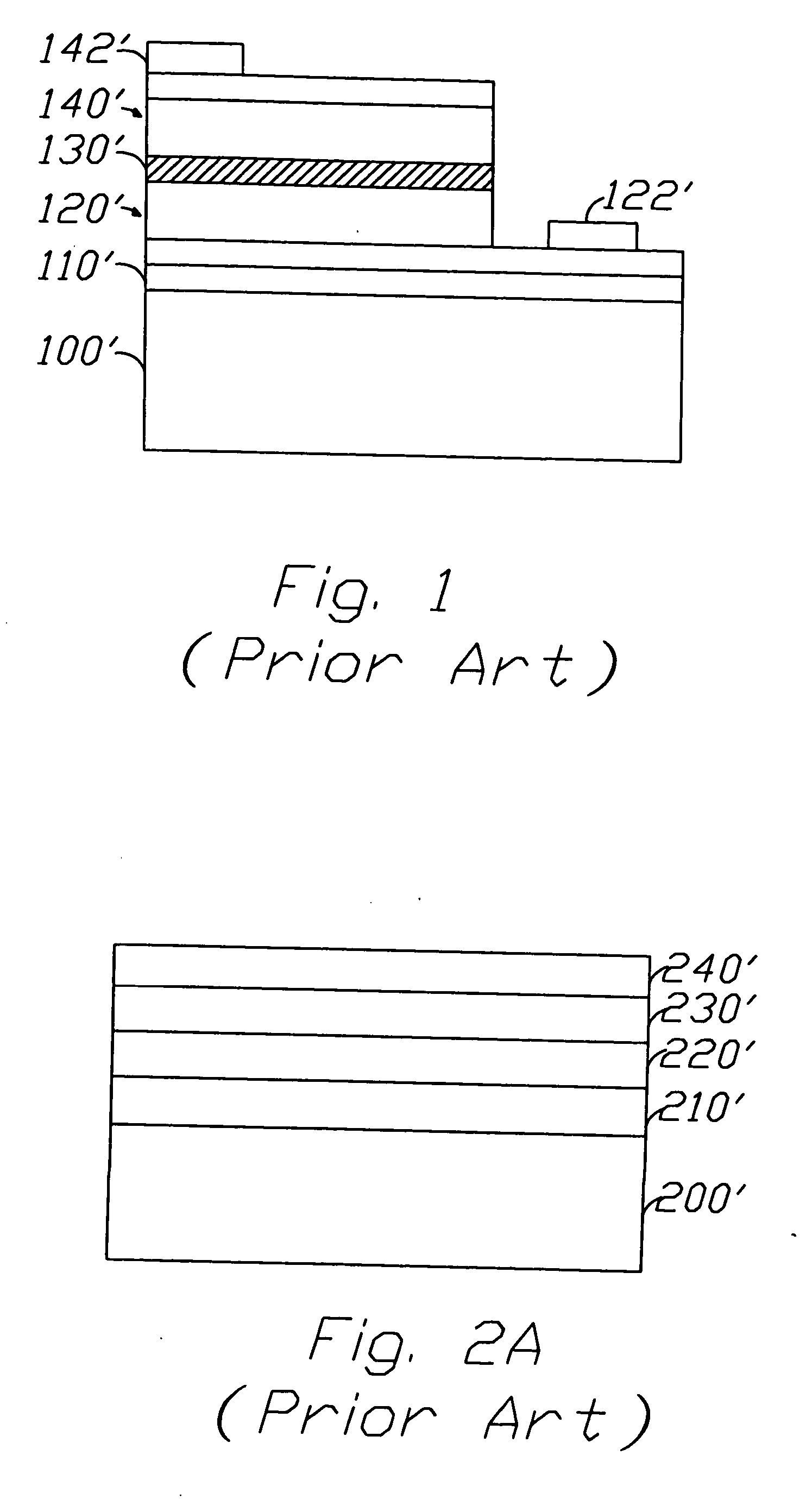

In a lithographic projection apparatus, a space between an optical element of a projection system is filled with a first fluid and a second fluid separated by a translucent plate. The first and second fluids have first and second indices of refraction, respectively, that are different from one another. The first fluid is provided in a space between a substrate and the translucent plate and preferably has an index of refraction similar to the index of refraction of the substrate. The second fluid is provided in a space between the translucent plate and the optical element and preferably has an index of refraction similar to the index of refraction of the optical element. The translucent plate has a third index of refraction between the first and second indices of refraction. The third index of refraction may be equal to the first index of refraction or the second index of refraction. A device manufacturing method includes filling a space between the optical element and the substrate with at least two fluids having different indices of refraction.

Owner:ASML NETHERLANDS BV

Gradient immersion lithography

InactiveUS6954256B2Increase the angle of incidenceReduce reflectionRadiation applicationsSemiconductor/solid-state device manufacturingRefractive indexImmersion lithography

In a lithographic projection apparatus, a space between an optical element is filled with a first fluid and a second fluid separated by a transparent plate. The first and second fluids have first and second indices of refraction, respectively, that are different from one another. The first fluid is provided between a substrate and the transparent plate and has an index of refraction similar to the index of refraction of the substrate. The second fluid is provided between the transparent plate and the optical element and has an index of refraction similar to the index of refraction of the optical element. The transparent plate has a third index of refraction between the first and second indices of refraction and may be equal to the first index of refraction or the second index of refraction. A device manufacturing method includes filling a space between the optical element and the substrate with at least two fluids having different indices of refraction.

Owner:ASML NETHERLANDS BV

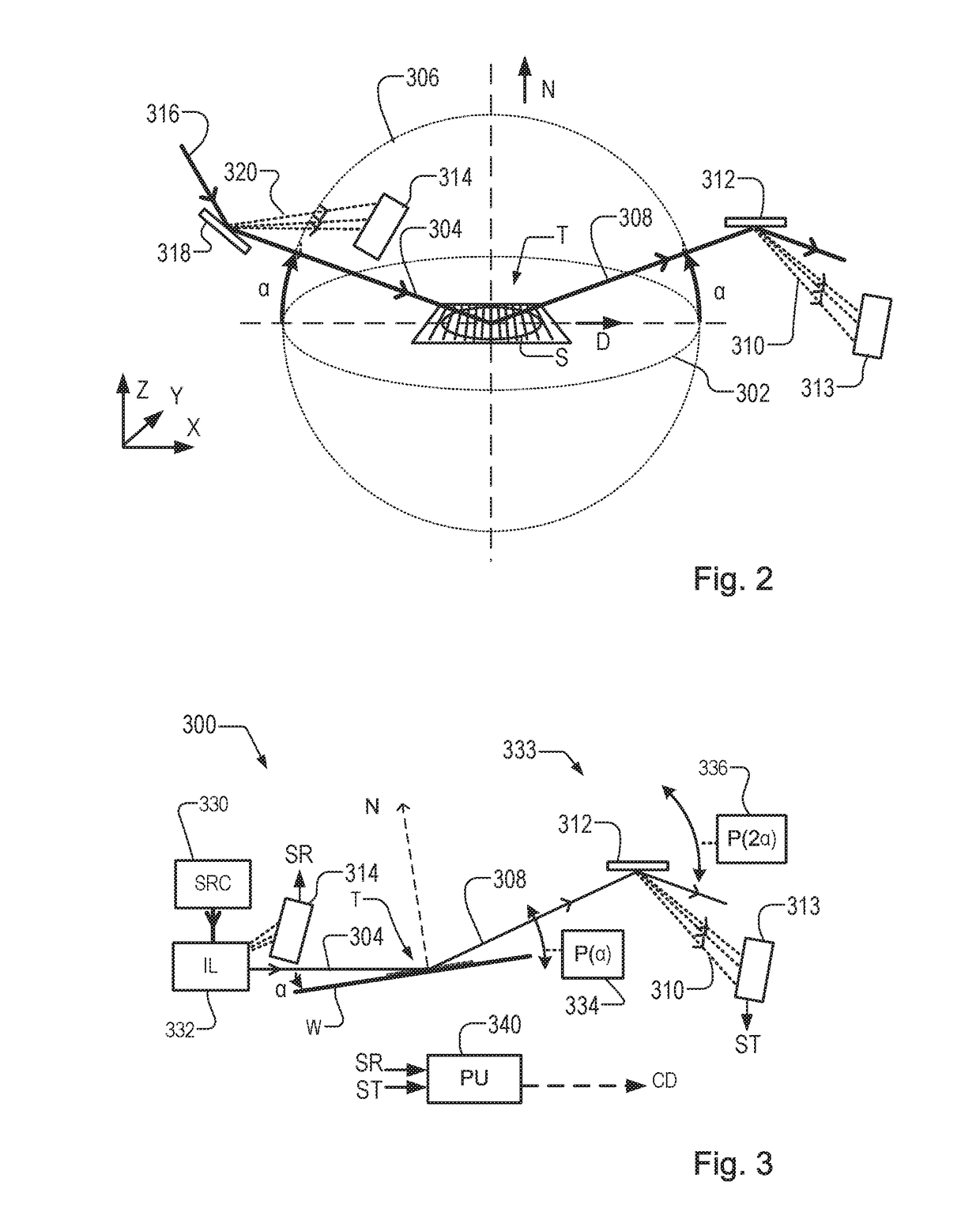

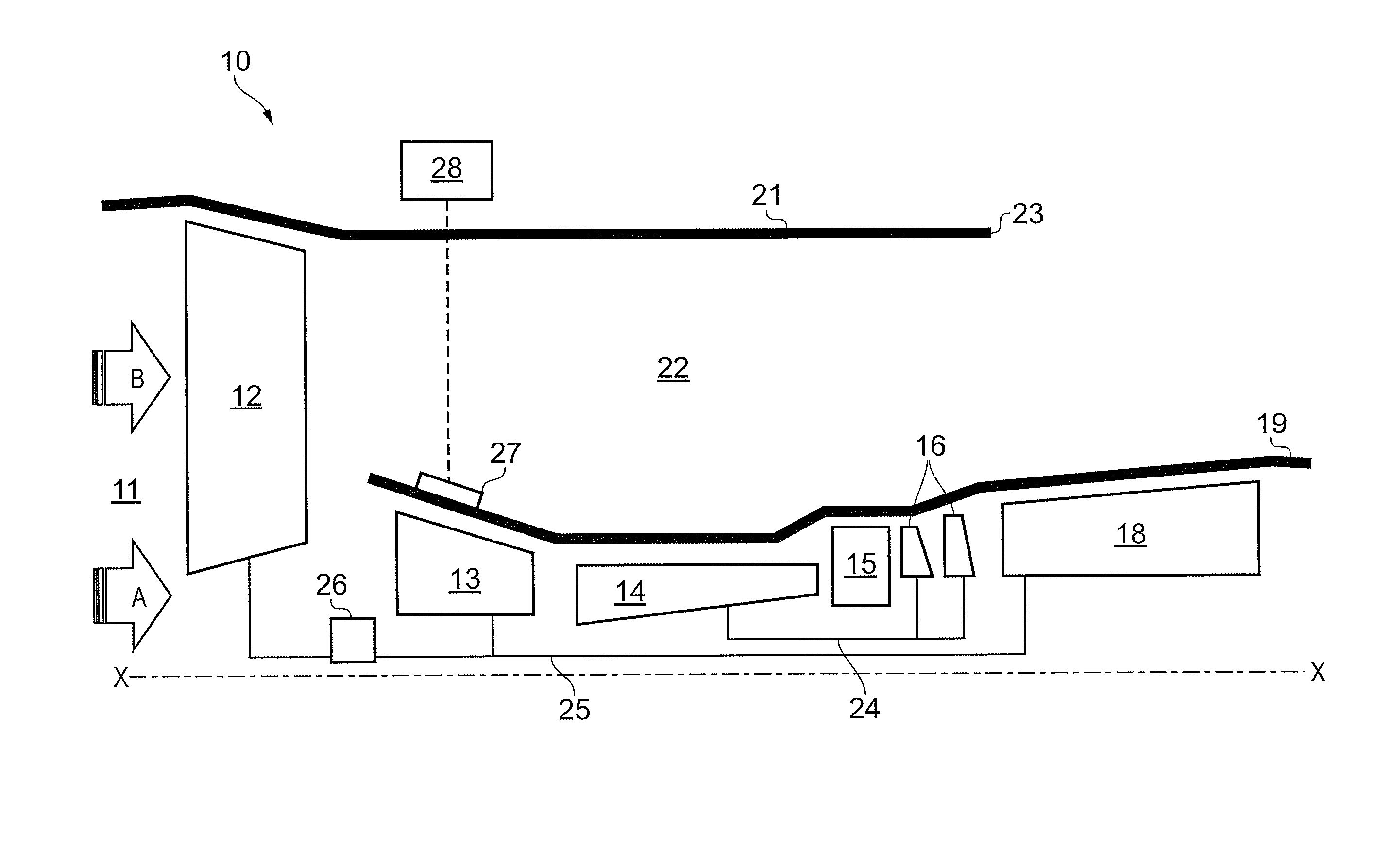

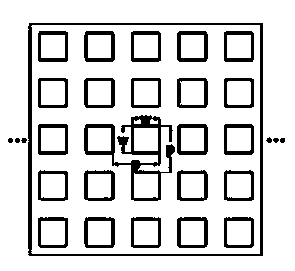

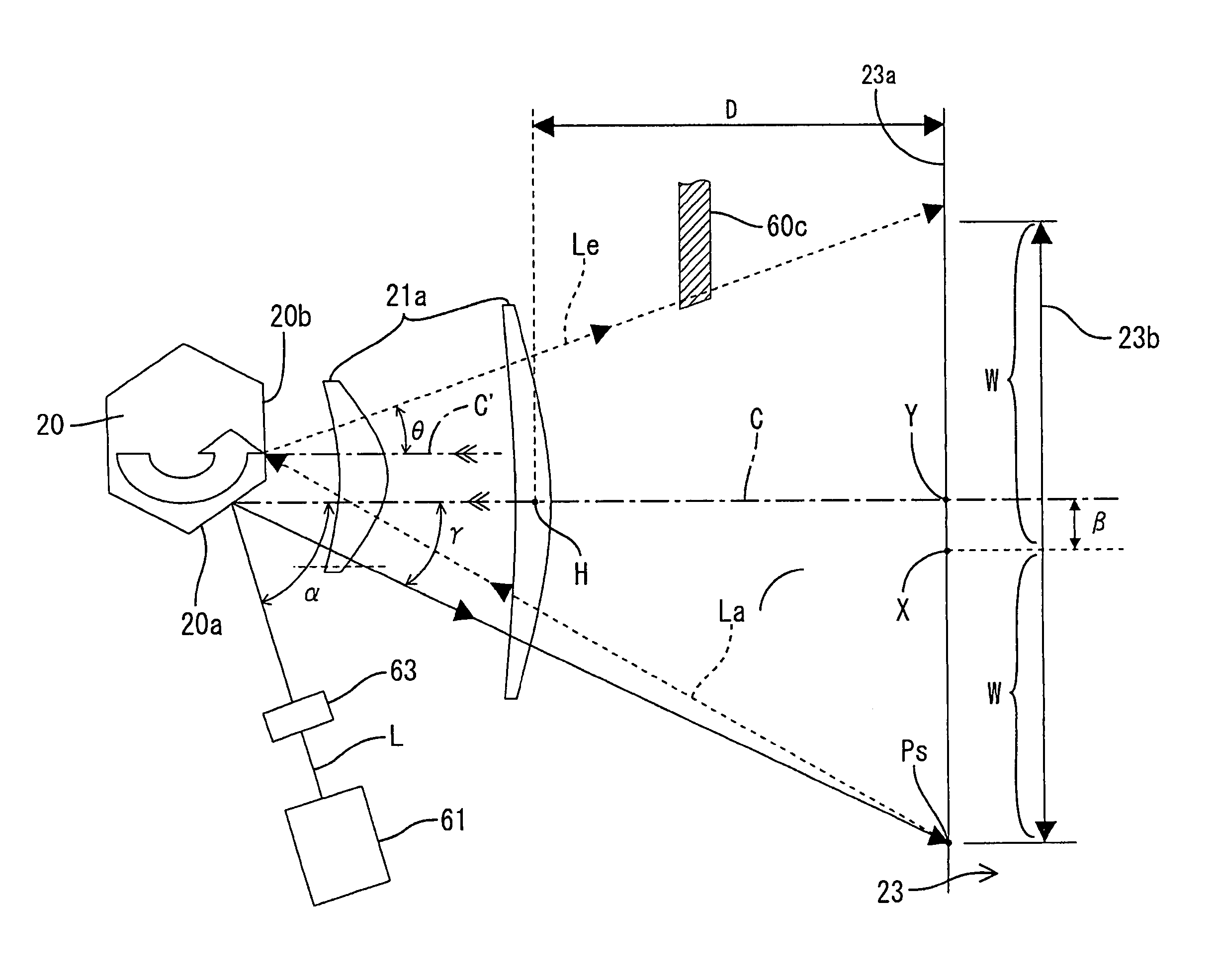

Metrology Methods, Metrology Apparatus and Device Manufacturing Method

ActiveUS20170184981A1Precise structureIncrease the angle of incidenceOptically investigating flaws/contaminationPhotomechanical exposure apparatusAction spectrumMetrology

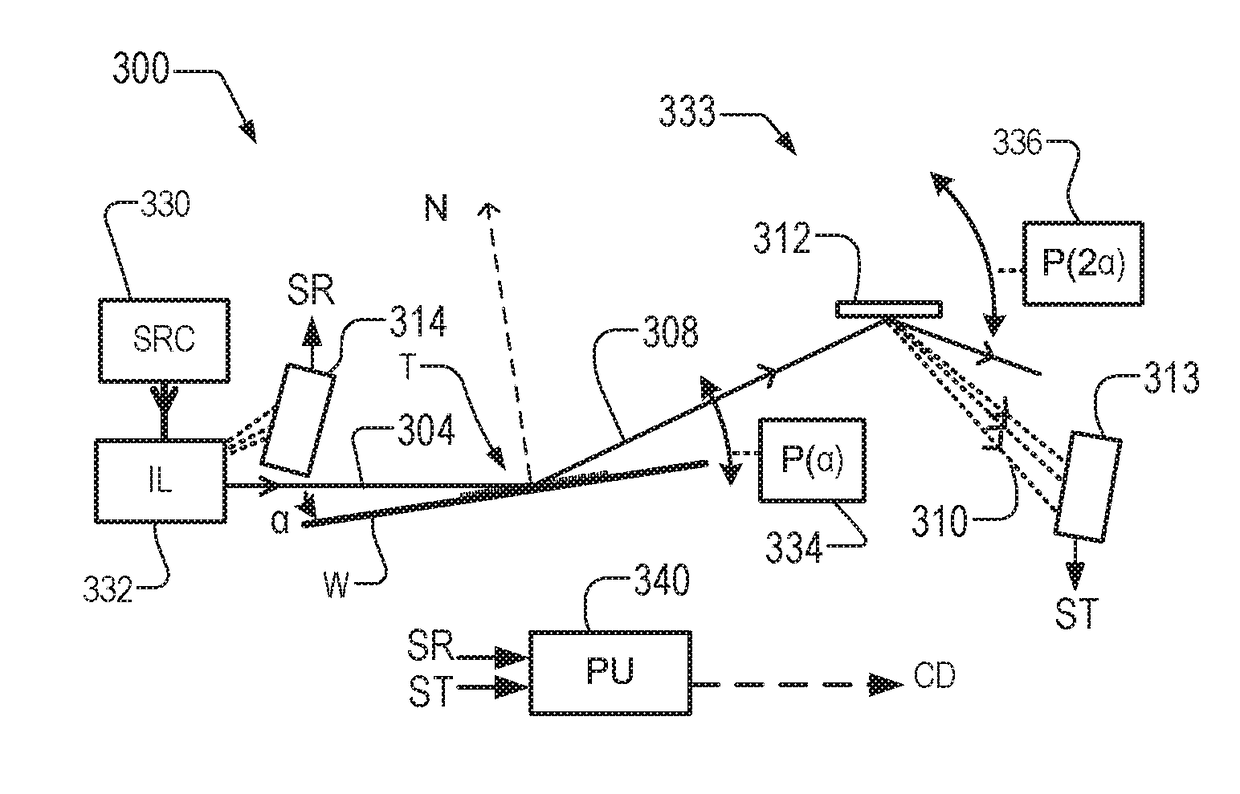

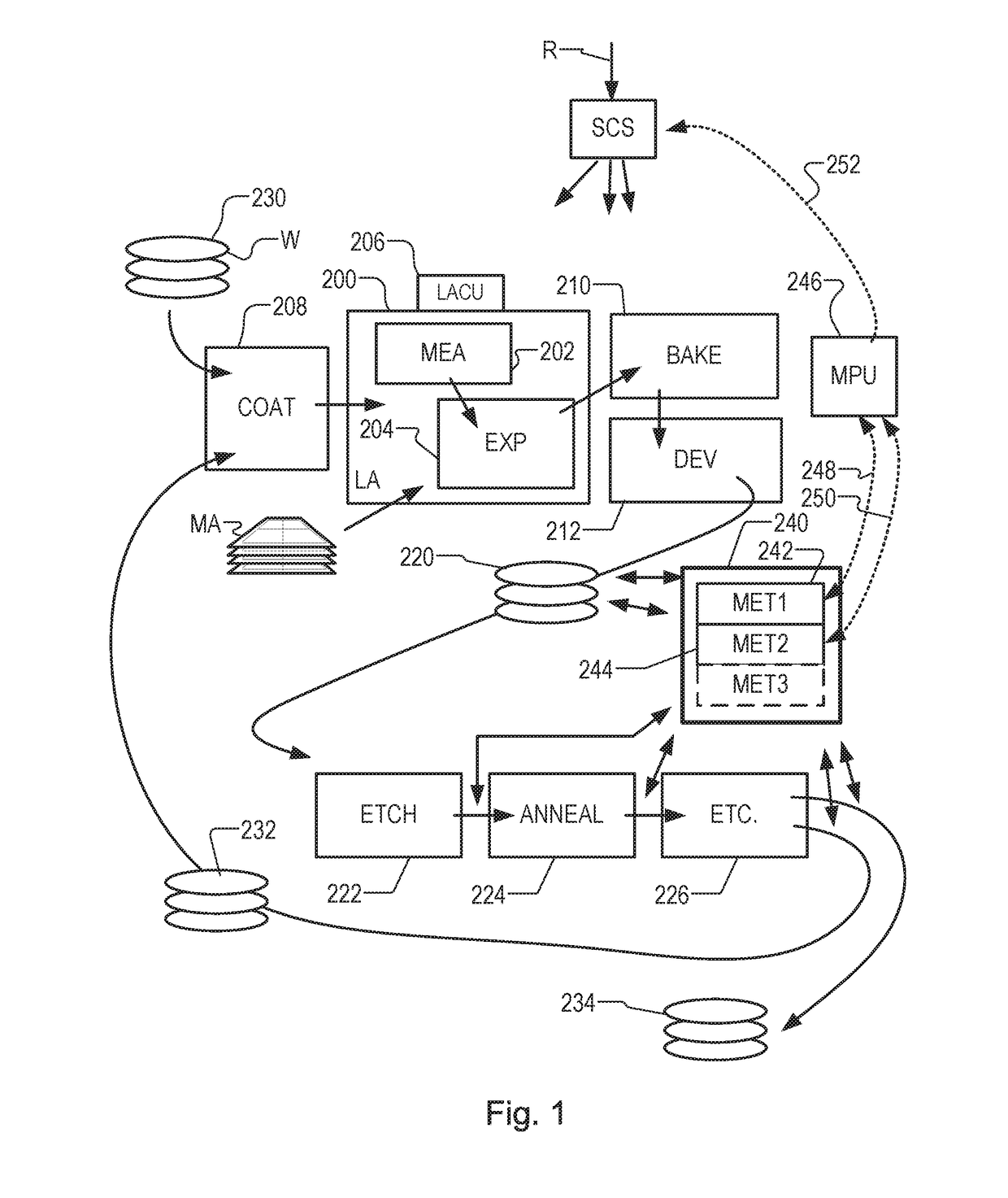

Hybrid metrology apparatus (1000, 1100, 1200, 1300, 1400) measures a structure (T) manufactured by lithography. An EUV metrology apparatus (244, IL1 / DET1) irradiates the structure with EUV radiation and detects a first spectrum from the structure. Another metrology apparatus (240, IL2 / DET2) irradiates the structure with second radiation comprising EUV radiation or longer-wavelength radiation and detects a second spectrum. Using the detected first spectrum and the detected second spectrum together, a processor (MPU) determines a property (CD / OV) of the structure. The spectra can be combined in various ways. For example, the first detected spectrum can be used to control one or more parameters of illumination and / or detection used to capture the second spectrum, or vice versa. The first spectrum can be used to distinguish properties of different layers (T1, T2) in the structure. First and second radiation sources (SRC1, SRC2) may share a common drive laser (LAS).

Owner:ASML NETHERLANDS BV

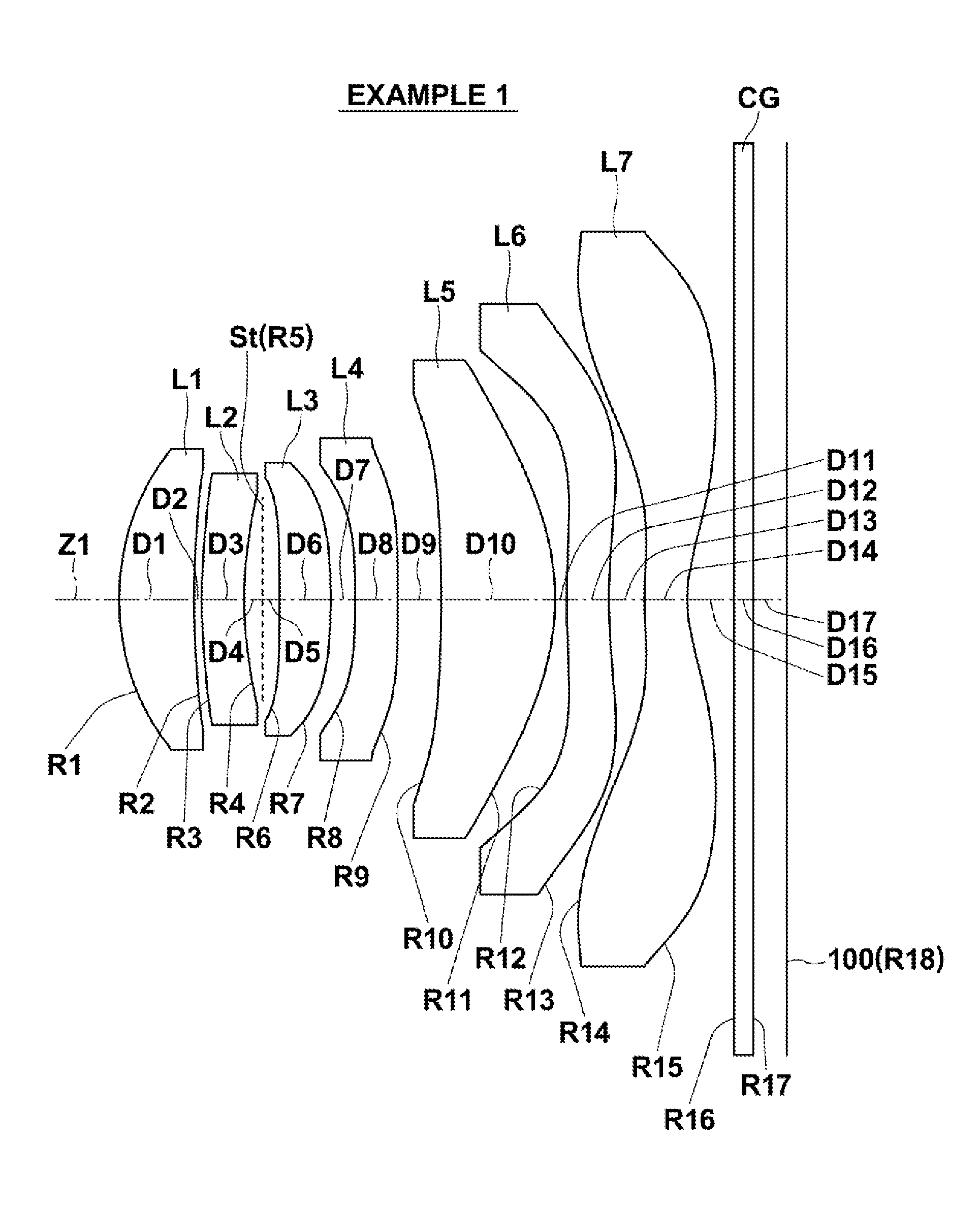

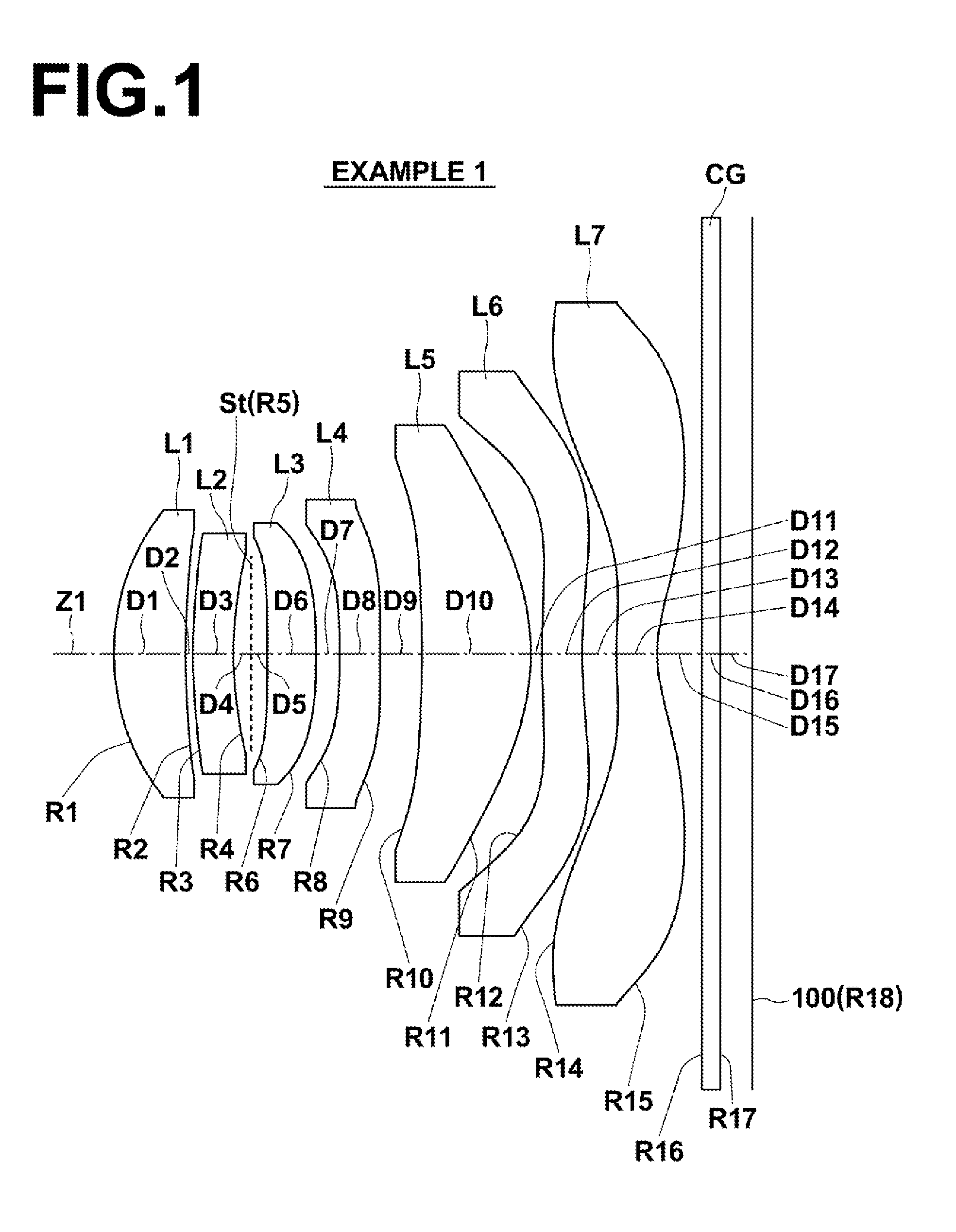

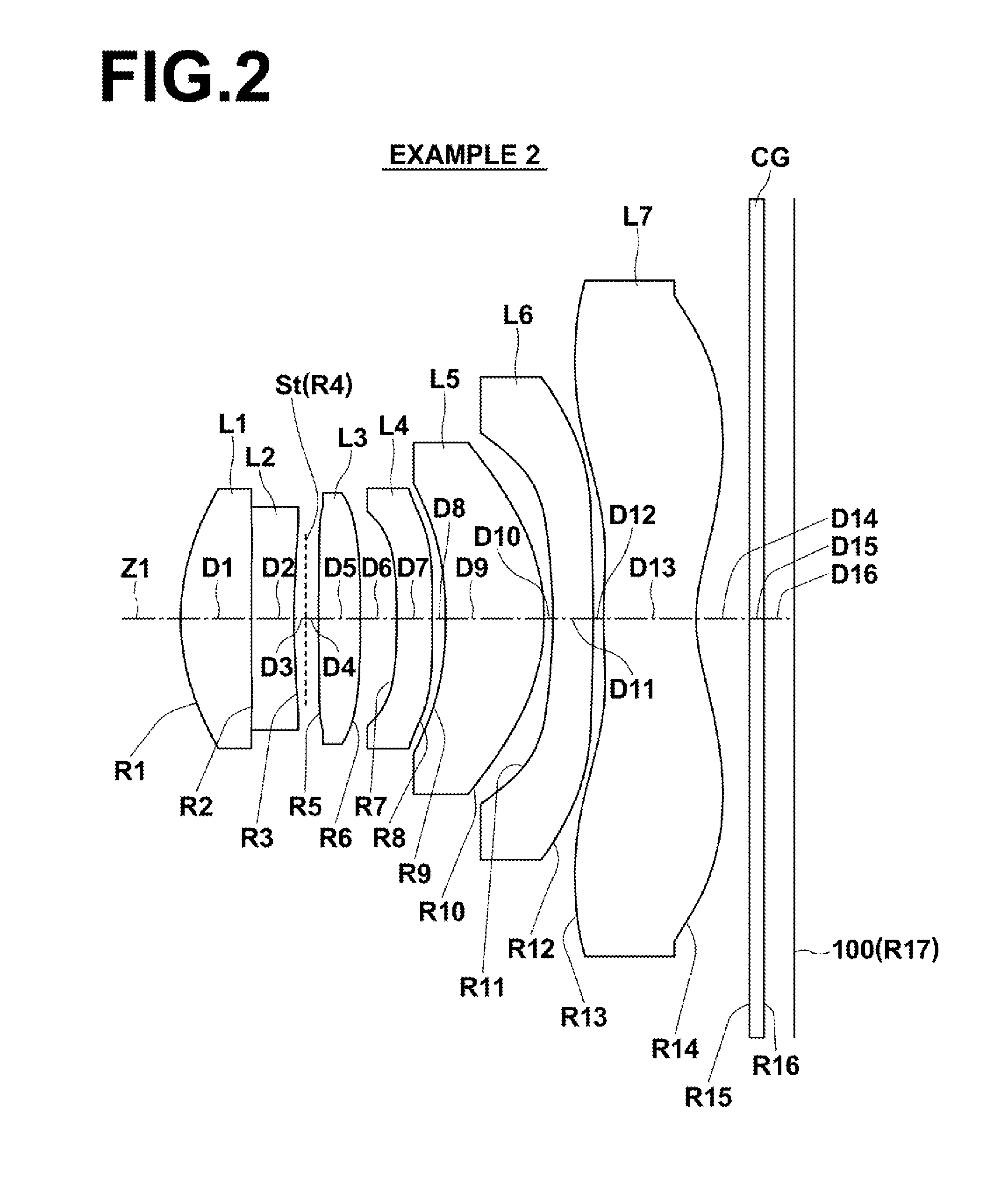

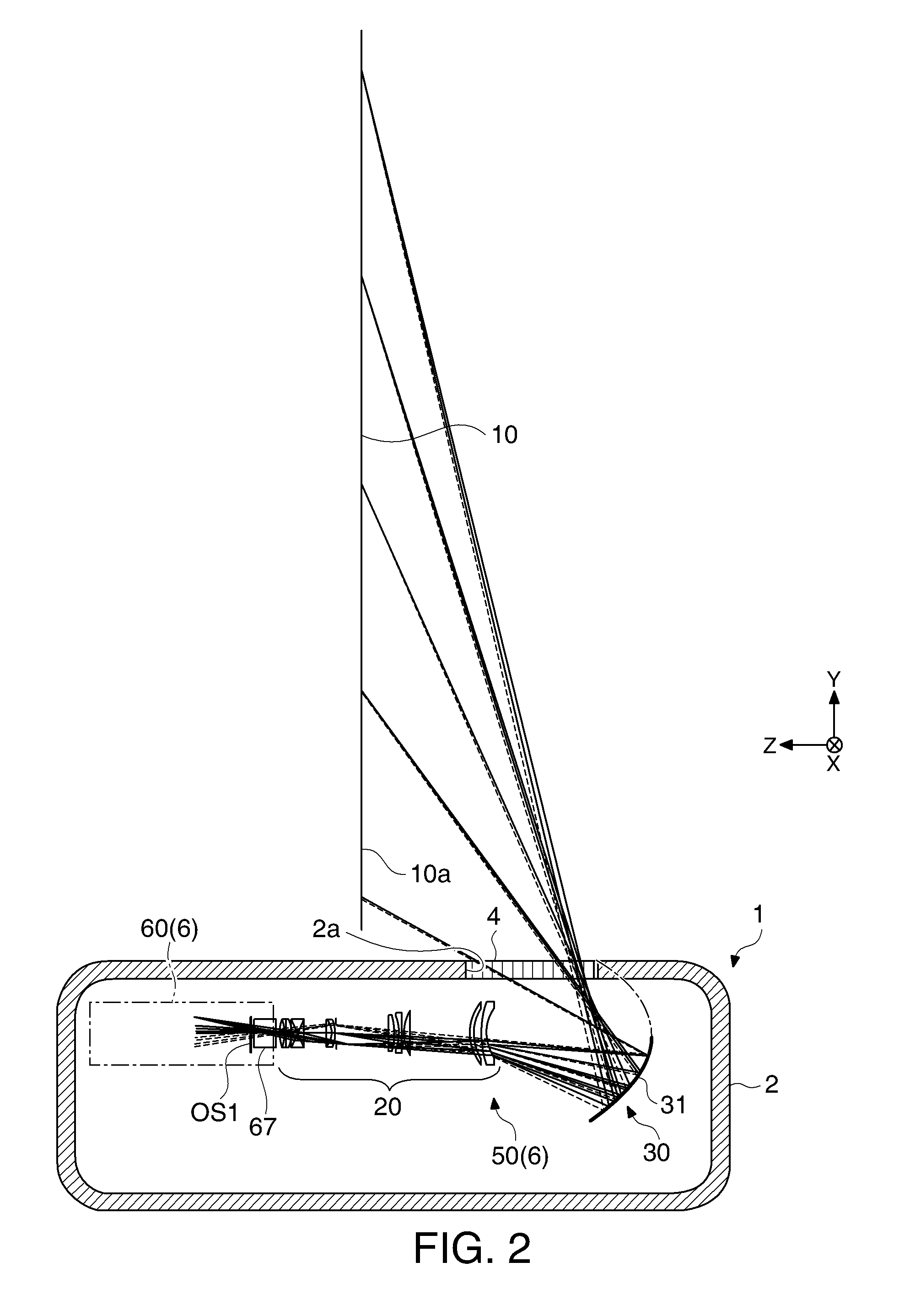

Imaging lens and imaging apparatus equipped with the imaging lens

ActiveUS20150212298A1Improve imaging effectShorten the lengthLensFocusing aidsImaging lensImaging equipment

An imaging lens is essentially constituted by seven lenses, including: a positive first lens having a convex surface toward the object side; a second lens, of which at least one surface is of an aspherical shape; a third lens, of which at least one surface is of an aspherical shape; a fourth lens, of which at least one surface is of an aspherical shape; a positive fifth lens of a meniscus shape with a convex surface toward the image side; a sixth lens, of which at least one surface is of an aspherical shape; and a negative seventh lens having a concave surface toward the image side, provided in this order from the object side. The imaging lens satisfies a predetermined conditional formula.

Owner:JIANGXI OFILM OPTICAL CO LTD

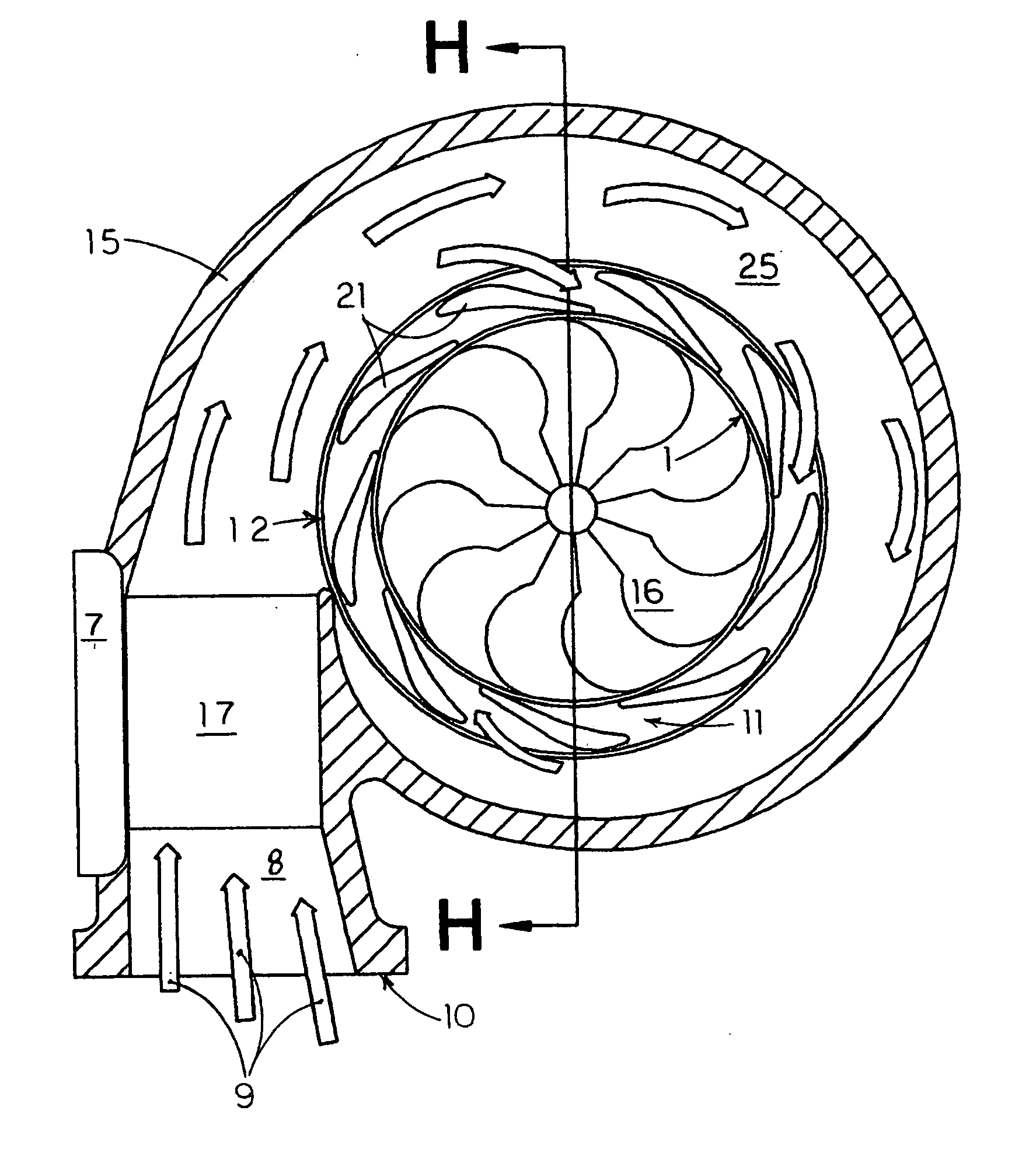

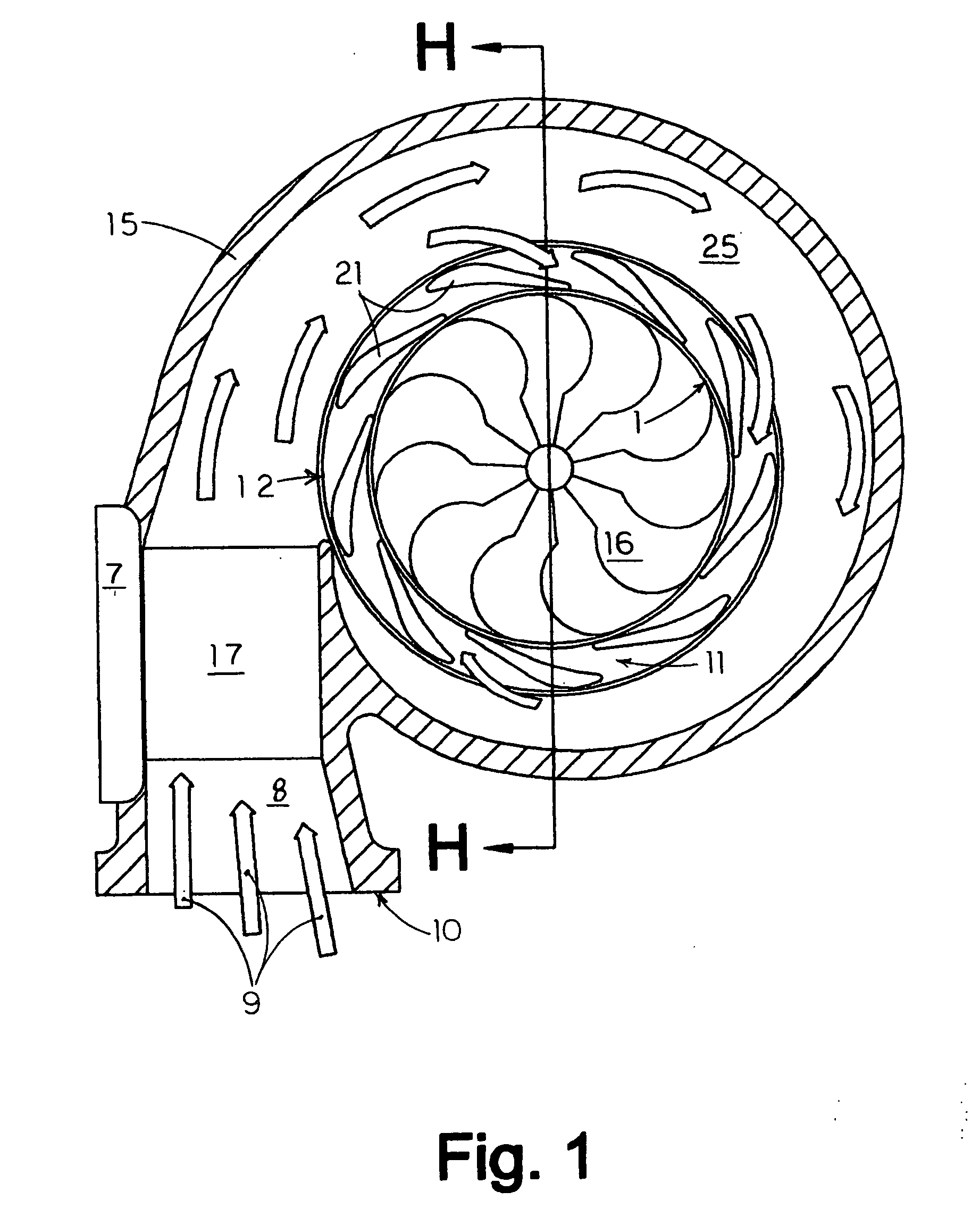

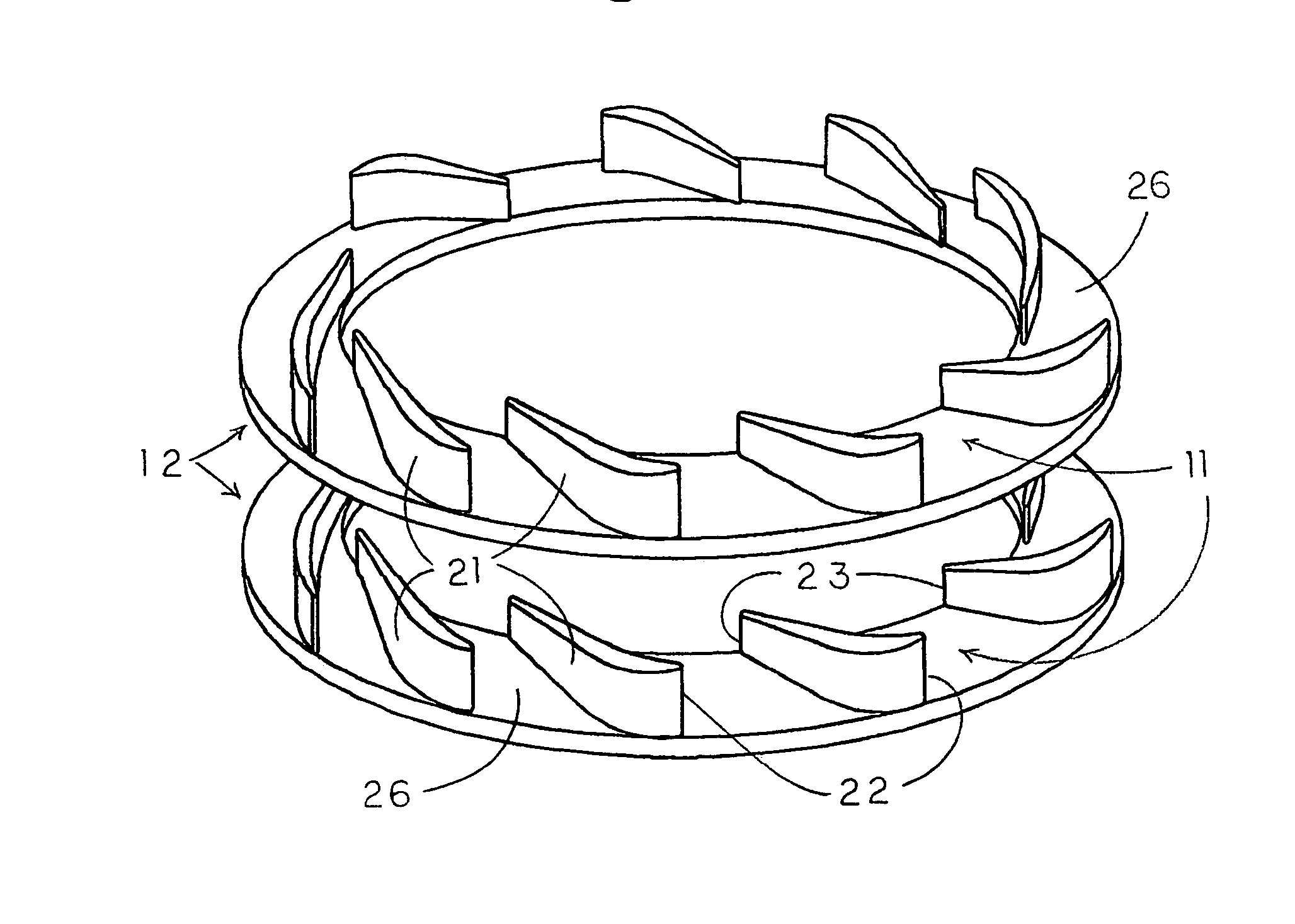

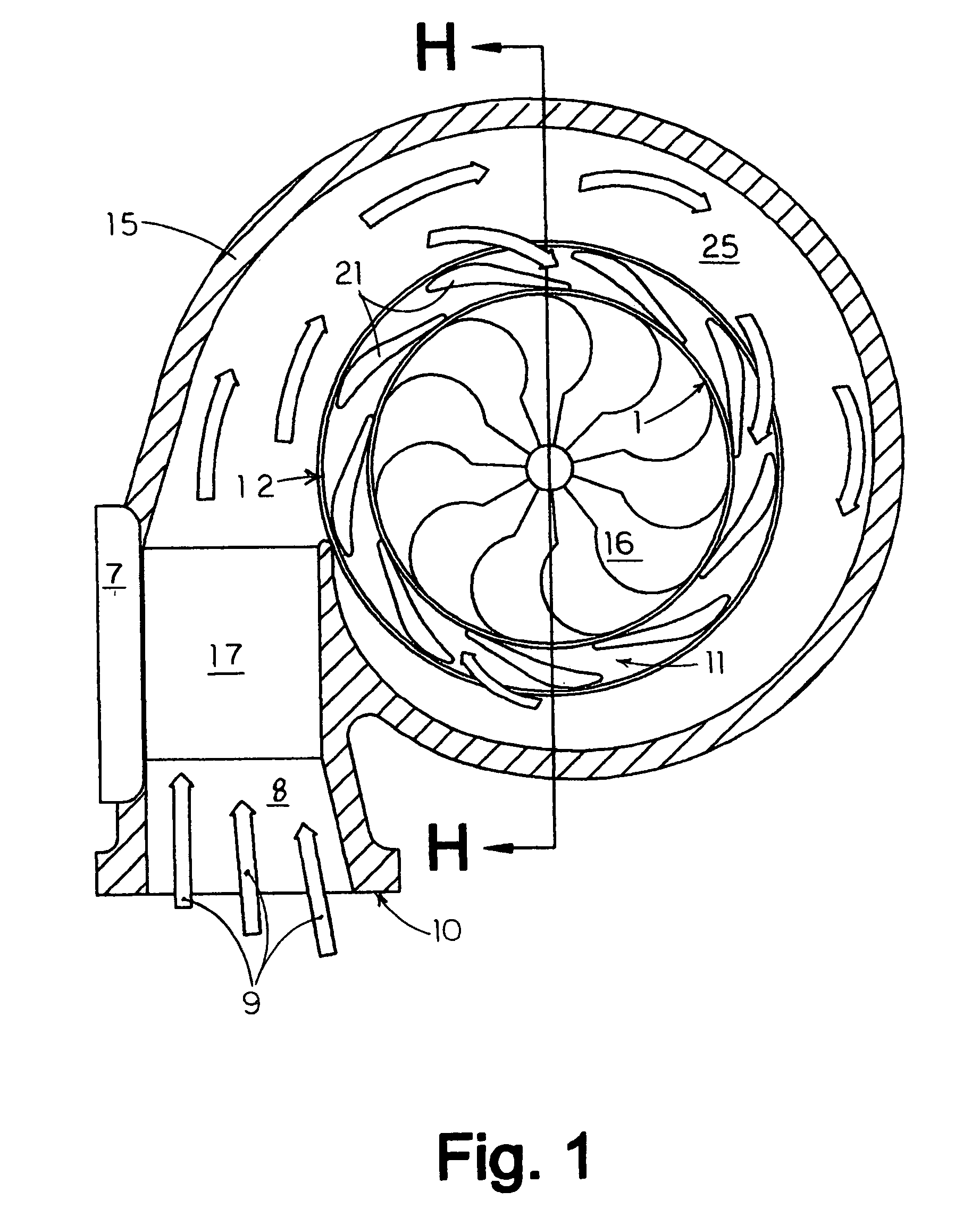

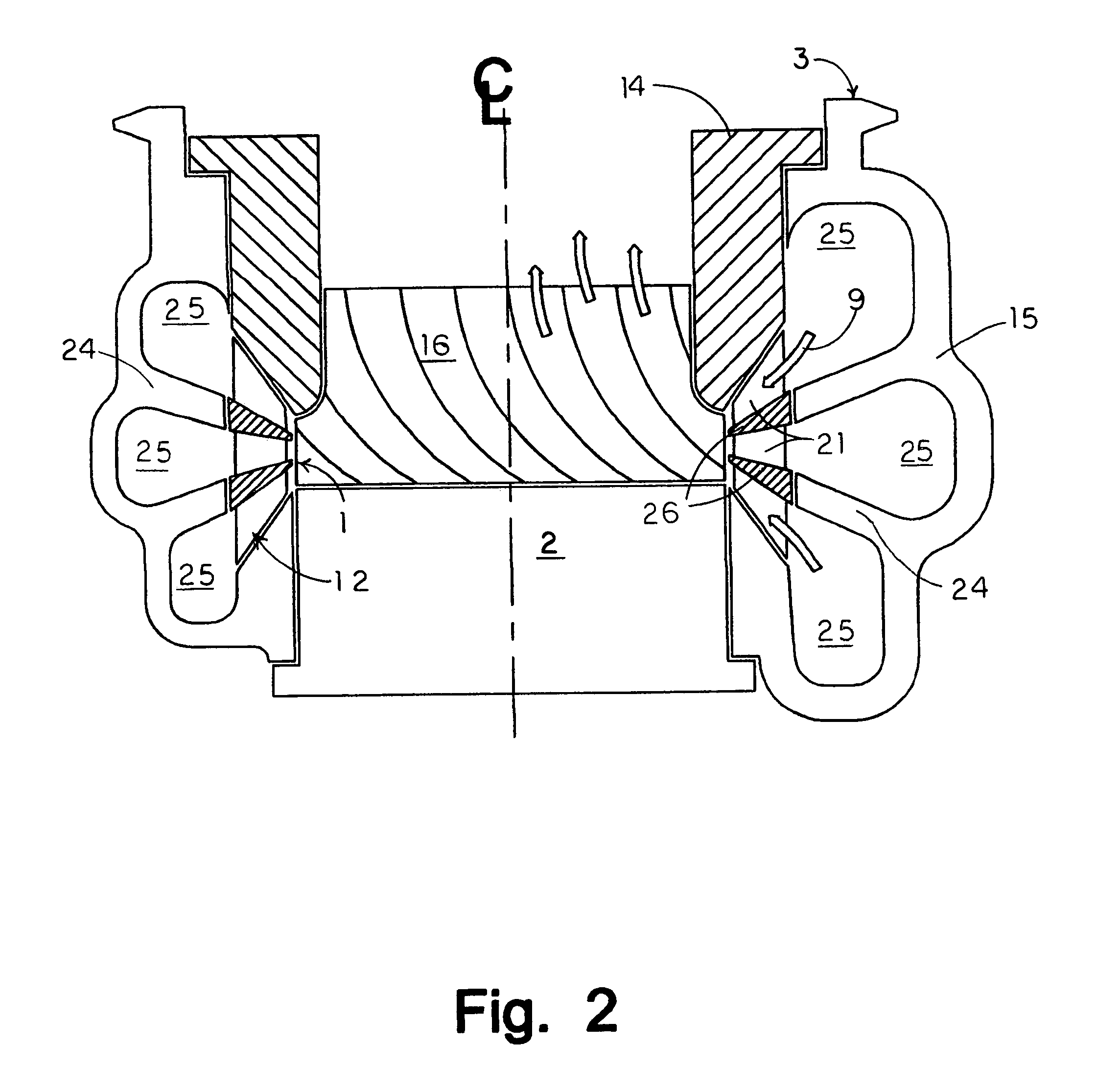

Multiple nozzle rings and a valve for a turbocharger

InactiveUS20070209361A1Increase impact speedReduce back pressureEngine manufactureInternal combustion piston enginesTurbochargerEngineering

A turbocharger turbine housing with at least two volutes utilizing multiple nozzle rings to optimize the turbocharger's proficiency per application, and a valve to control the exhaust flow to selected volutes in the turbine housing.

Owner:PEDERSEN MELVIN HESS +1

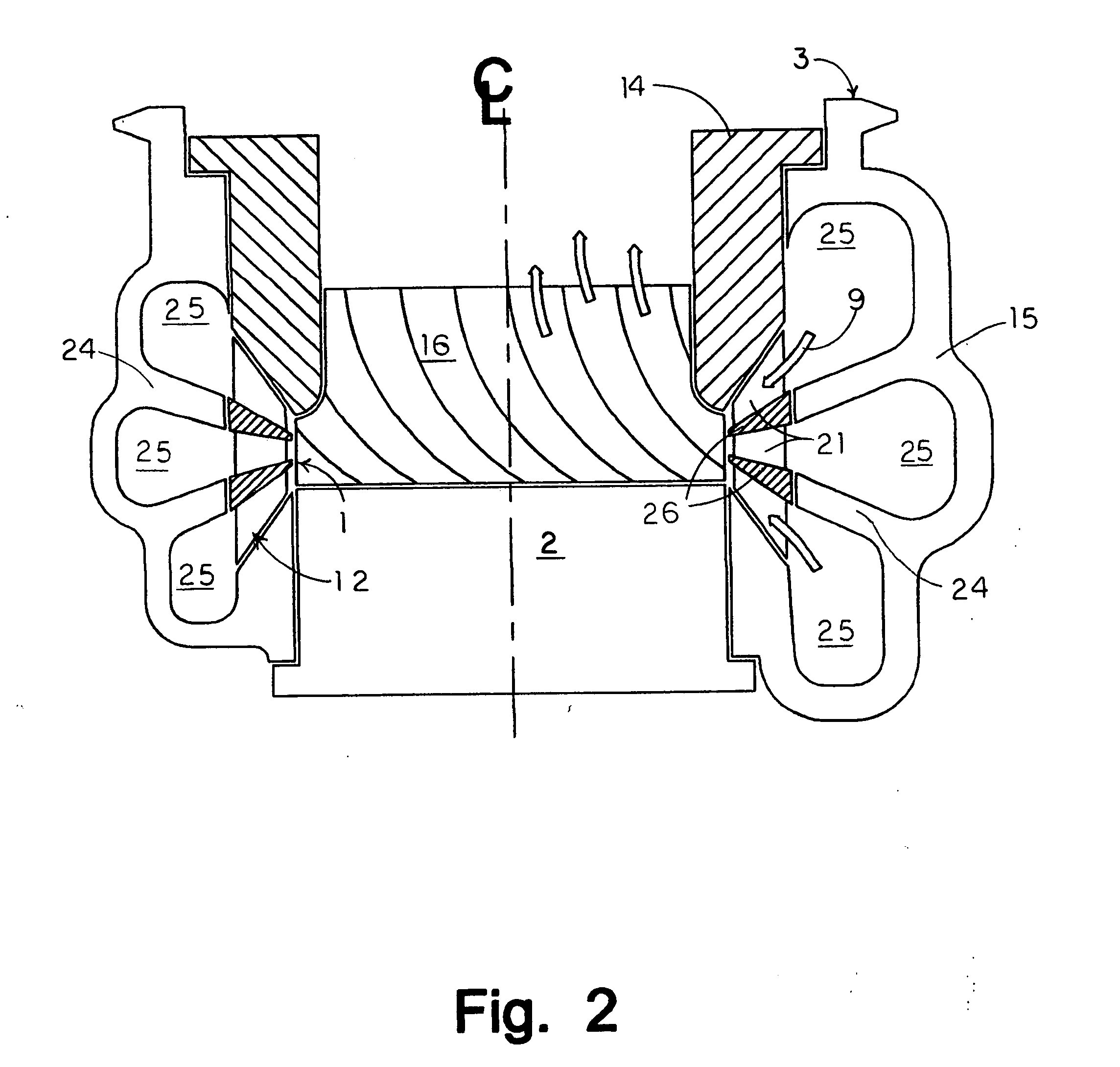

Skylight

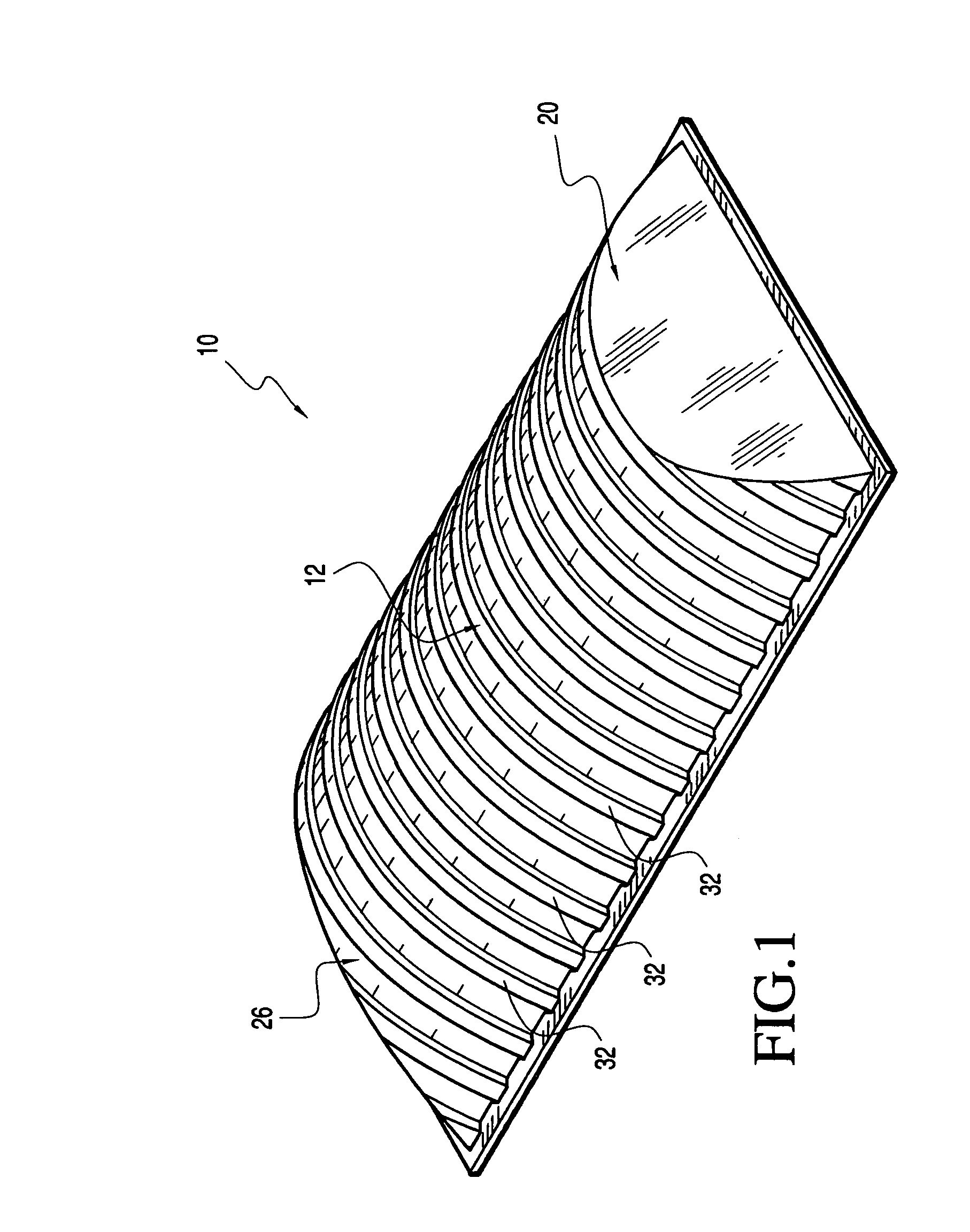

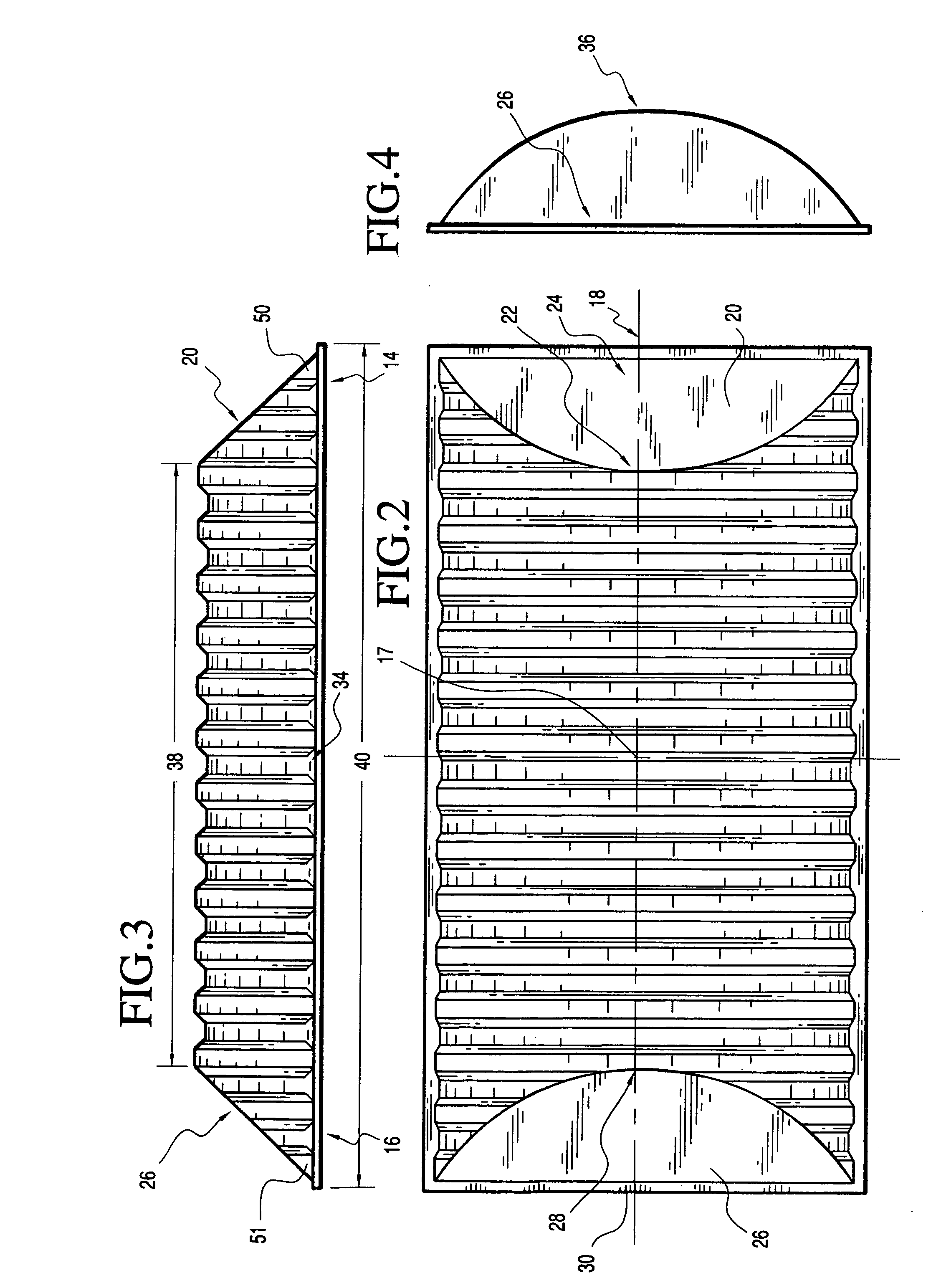

InactiveUS7395636B2Reduce light transmittanceIncrease costBuilding roofsSky-lights/domesEngineeringMechanical engineering

A skylight having an arched main body, an apex, a base, and corrugations is described. The main body has two lengths, the first being at substantially the apex and the second at the base wherein the first length is less than the second length. The skylight also has a first end portion and a second end portion at opposing ends of the main body, each of which has a top and bottom section. The distance between the top sections define the first length and the distance between the bottom sections defines the second length. The corrugations disposed on the main body vary by orientation, method of manufacture, number, and shape.

Owner:ABL IP HLDG

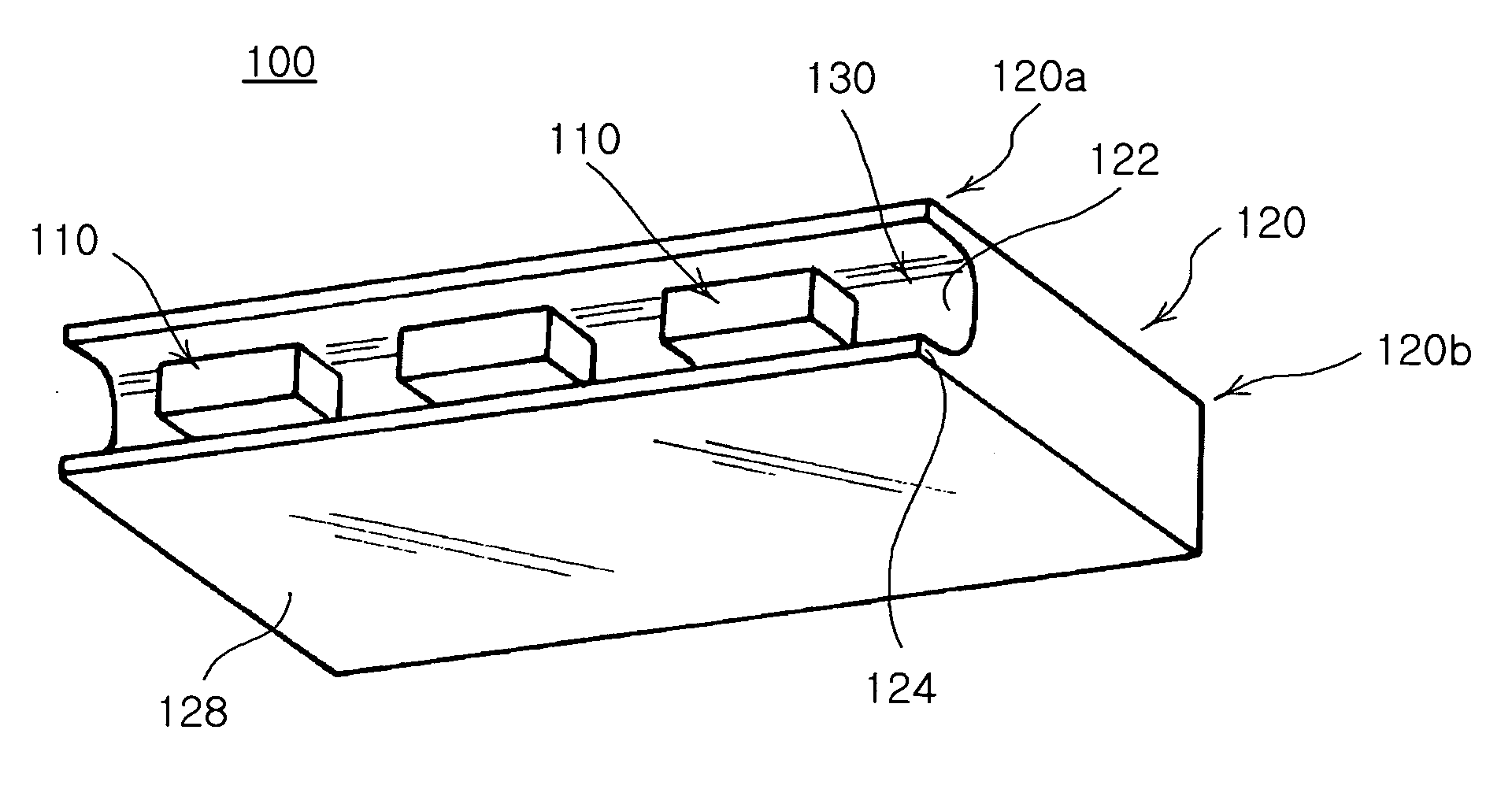

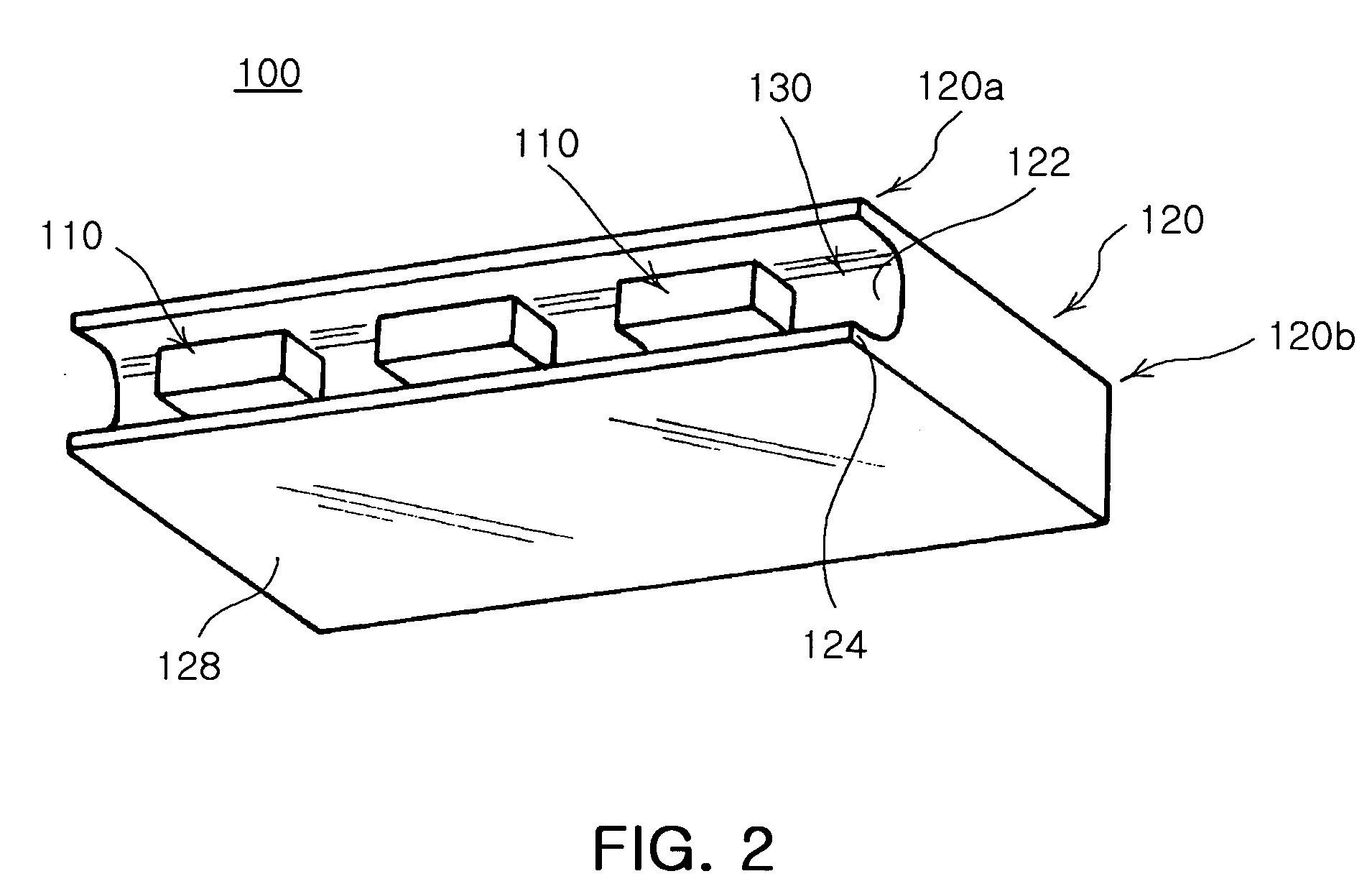

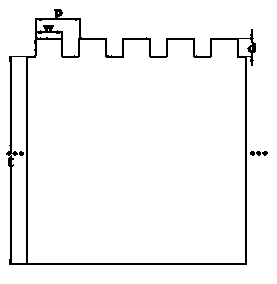

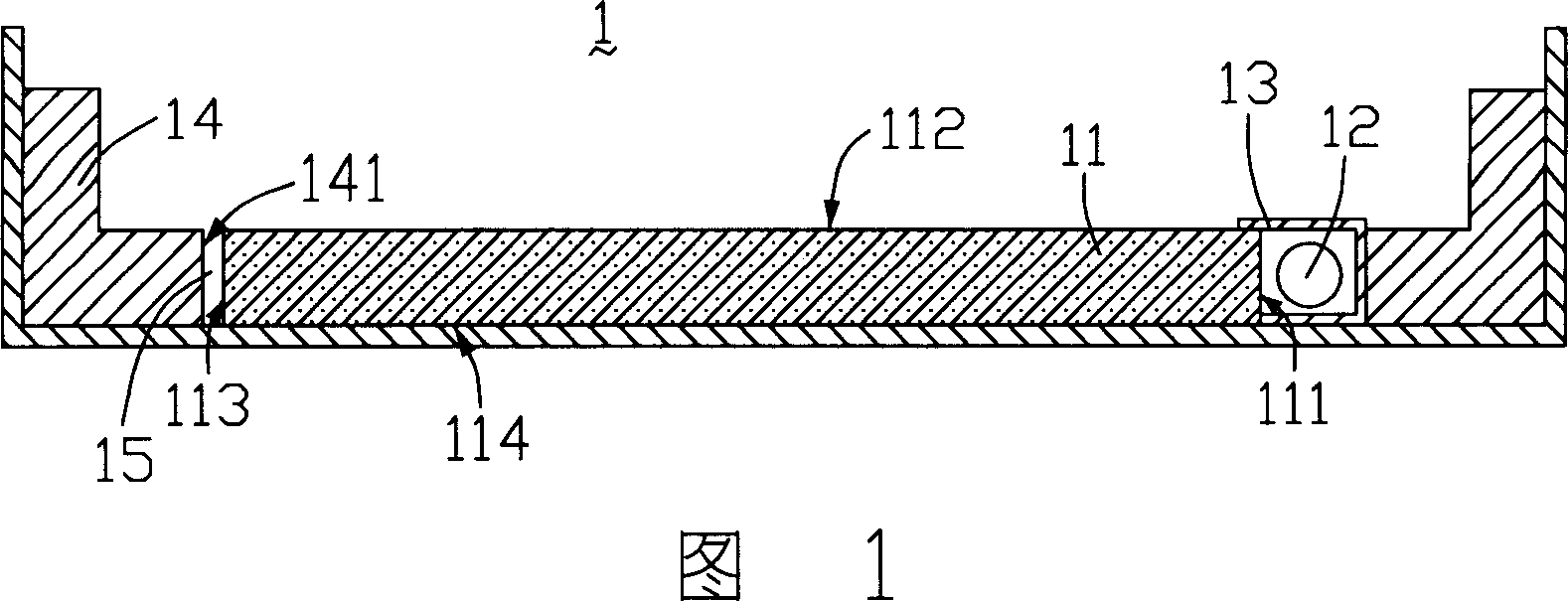

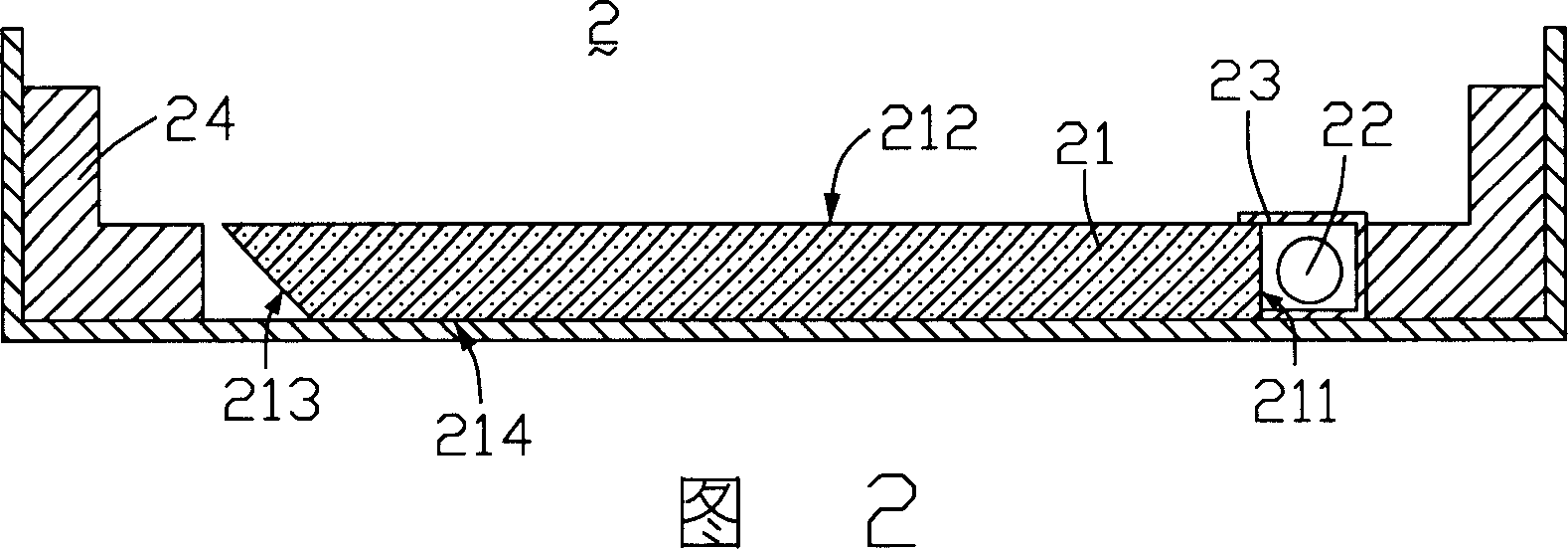

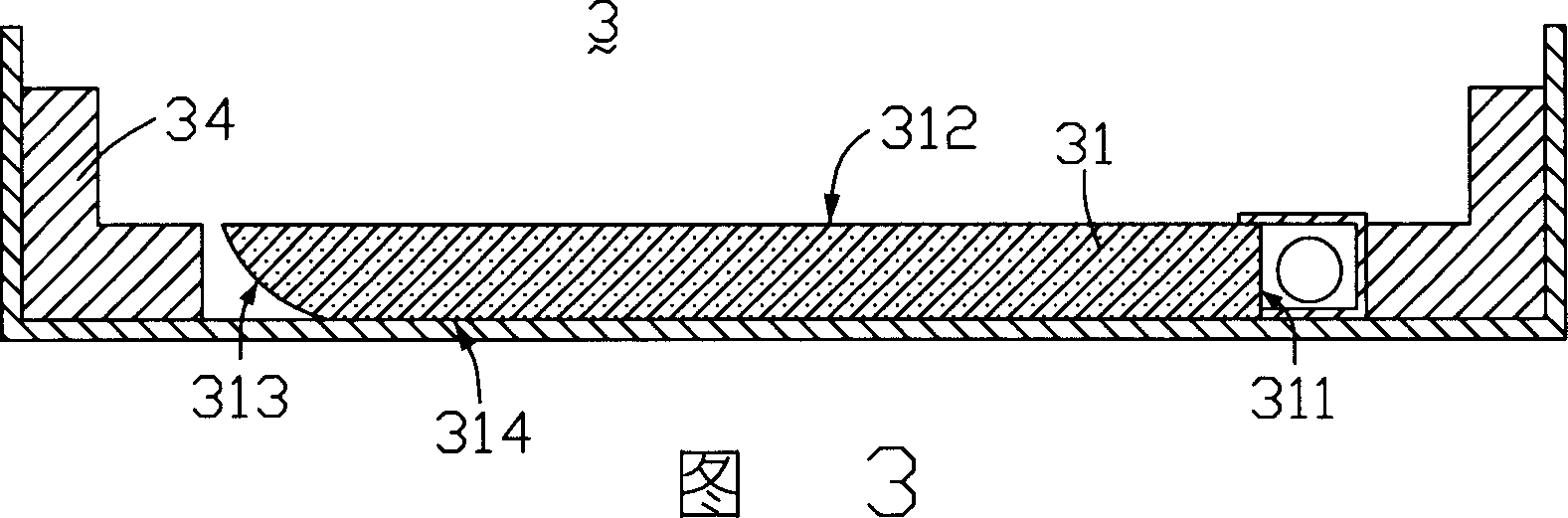

LED backlight device

InactiveUS20070127261A1Reduce lossesReduce distancePlanar/plate-like light guidesNon-linear opticsLed packagingEngineering

An LED backlight device is provided. A light guide plate has opposing edges of a width direction at a side thereof extended into a pair of opposing walls and a recess formed therebetween. A light emitting diode (LED) light source is accommodated in the recess to project light into the light guide plate. In this fashion, the light guide plate has the recess formed at one side of the light guide plate to seat the LED package therein. This minimizes loss of light incident from the LED package into the light guide plate and allows the LED package to be aligned securely with the light guide plate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Turbine assemblies and related systems for use with turbochargers

InactiveUS7428814B2Reduce back pressureHigh speedInternal combustion piston enginesEngine manufactureTurbochargerNozzle

A turbocharger turbine housing with at least two volutes utilizing multiple nozzle rings to optimize the turbocharger's proficiency per application, and a valve to control the exhaust flow to selected volutes in the turbine housing.

Owner:PEDERSEN MELVIN HESS +1

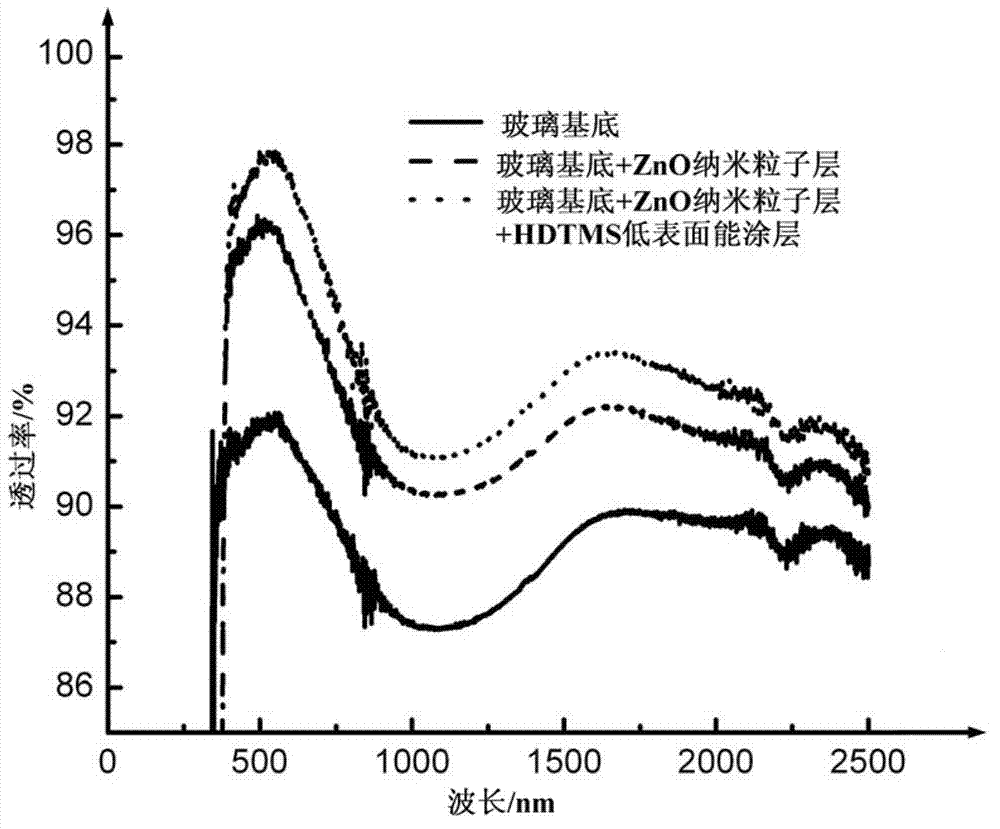

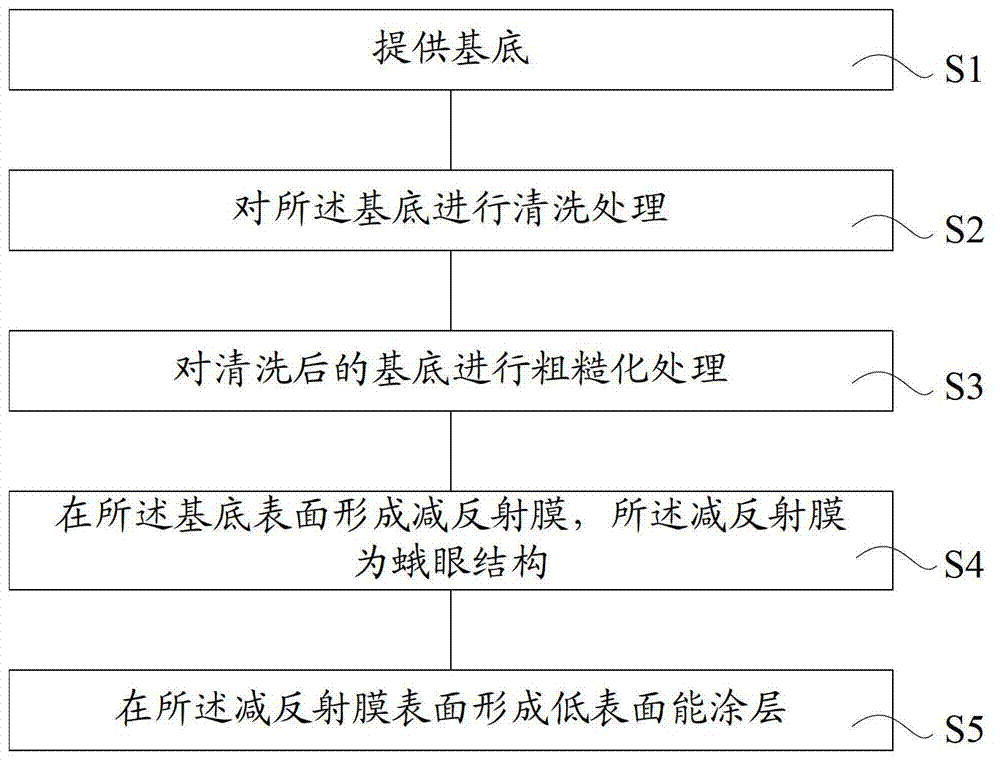

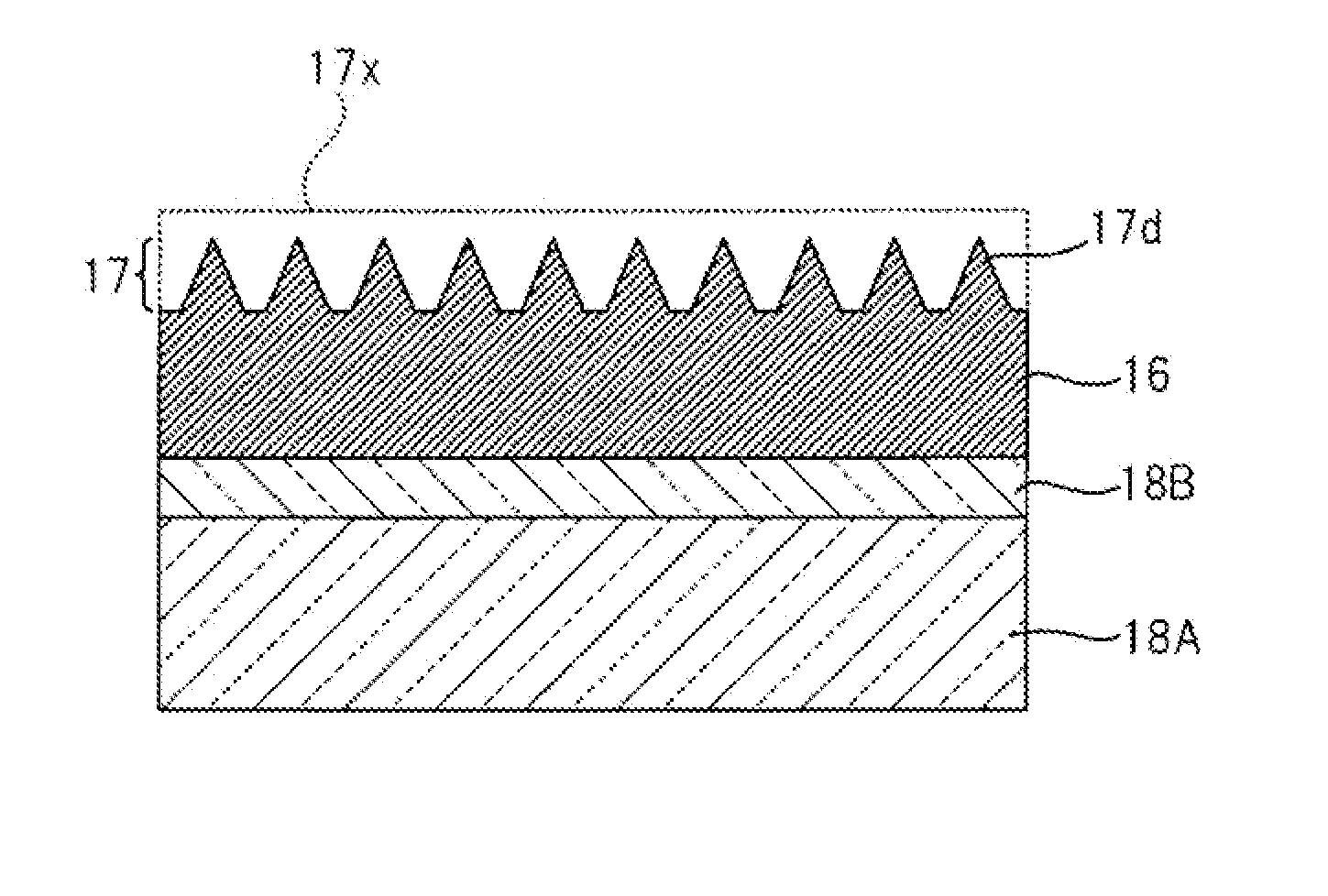

Super-hydrophobic anti-reflection substrate and its manufacturing method

InactiveCN102815052AIncrease the angle of incidenceAchieve superhydrophobic self-cleaningSynthetic resin layered productsCeramic layered productsSurface energyTransmittance

Disclosed are a super-hydrophobic anti-reflection substrate and its manufacturing method. The super-hydrophobic anti-reflection substrate comprises: a basement, an antireflective film positioned on the surface of the basement and a low surface energy coating positioned on the surface of the antireflective film, wherein the antireflective film has a moth eye structure. The manufacturing method of the super-hydrophobic anti-reflection substrate comprises the following steps of: providing the basement; forming the antireflective film having the moth eye structure on the surface of the basement; and forming the low surface energy coating on the surface of the antireflective film. Light transmittance of the antireflective film can be further raised through formation of the low surface energy coating on the surface of the antireflective film.

Owner:SAINT-GOBAIN GLASS FRANCE

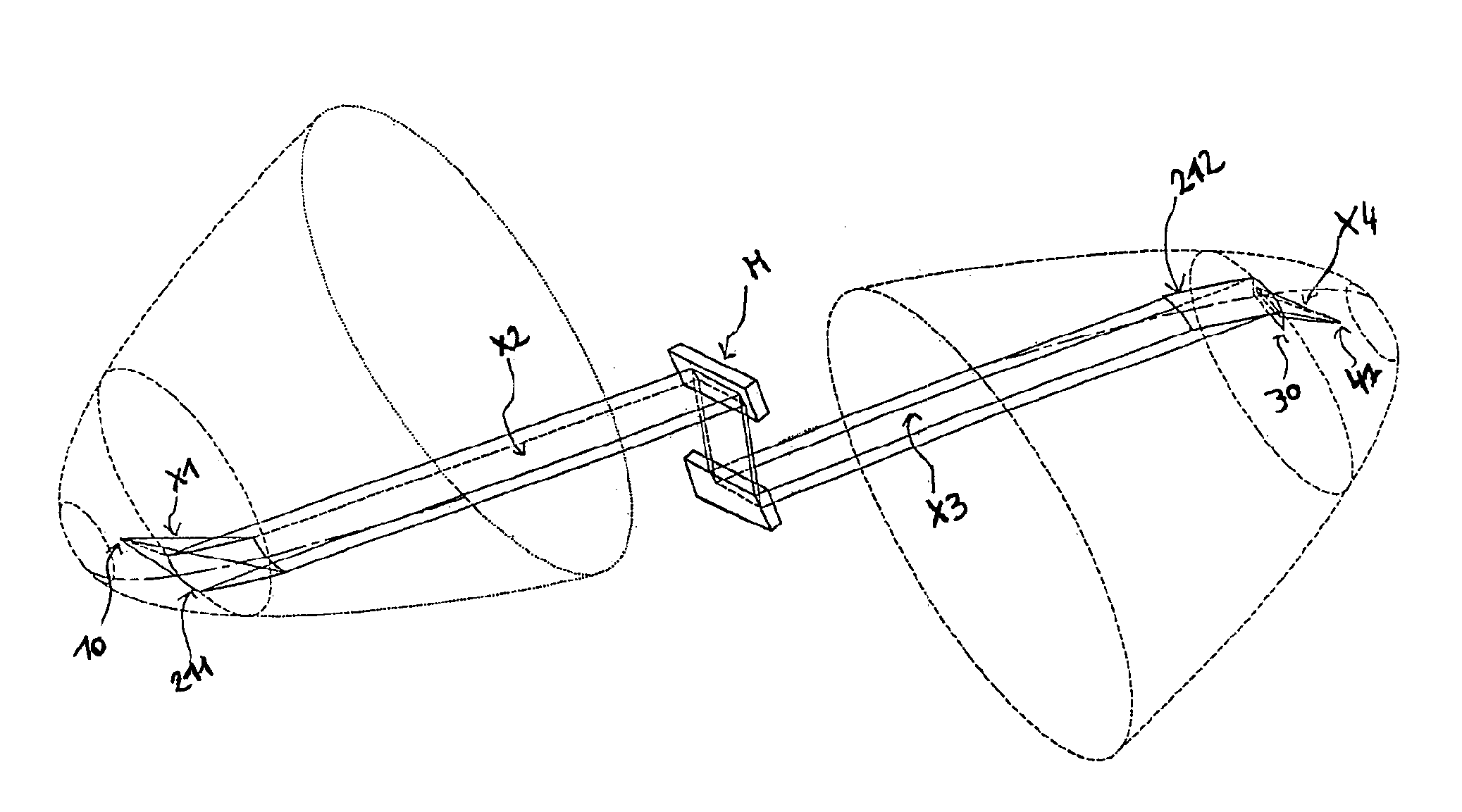

X-ray beam device

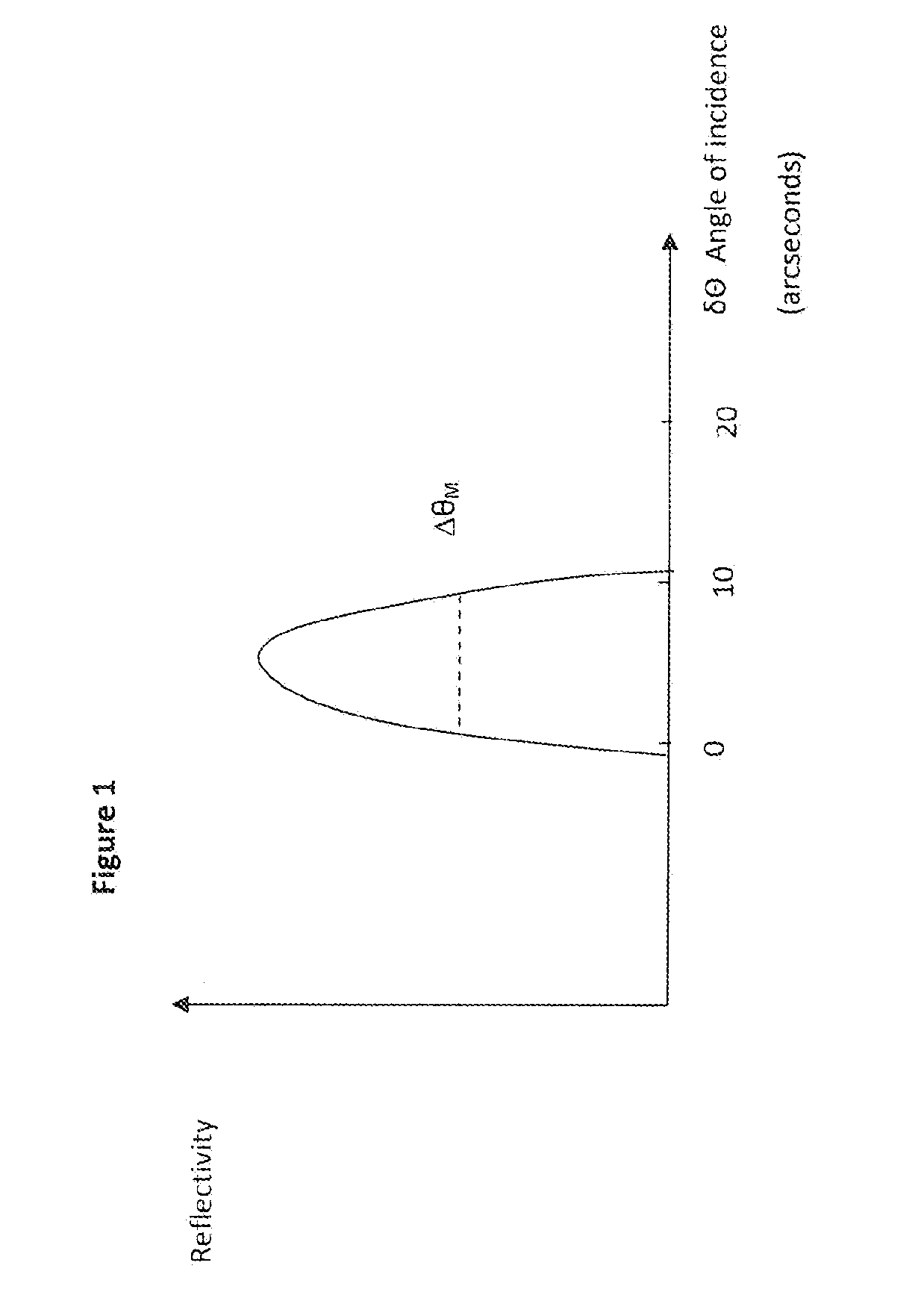

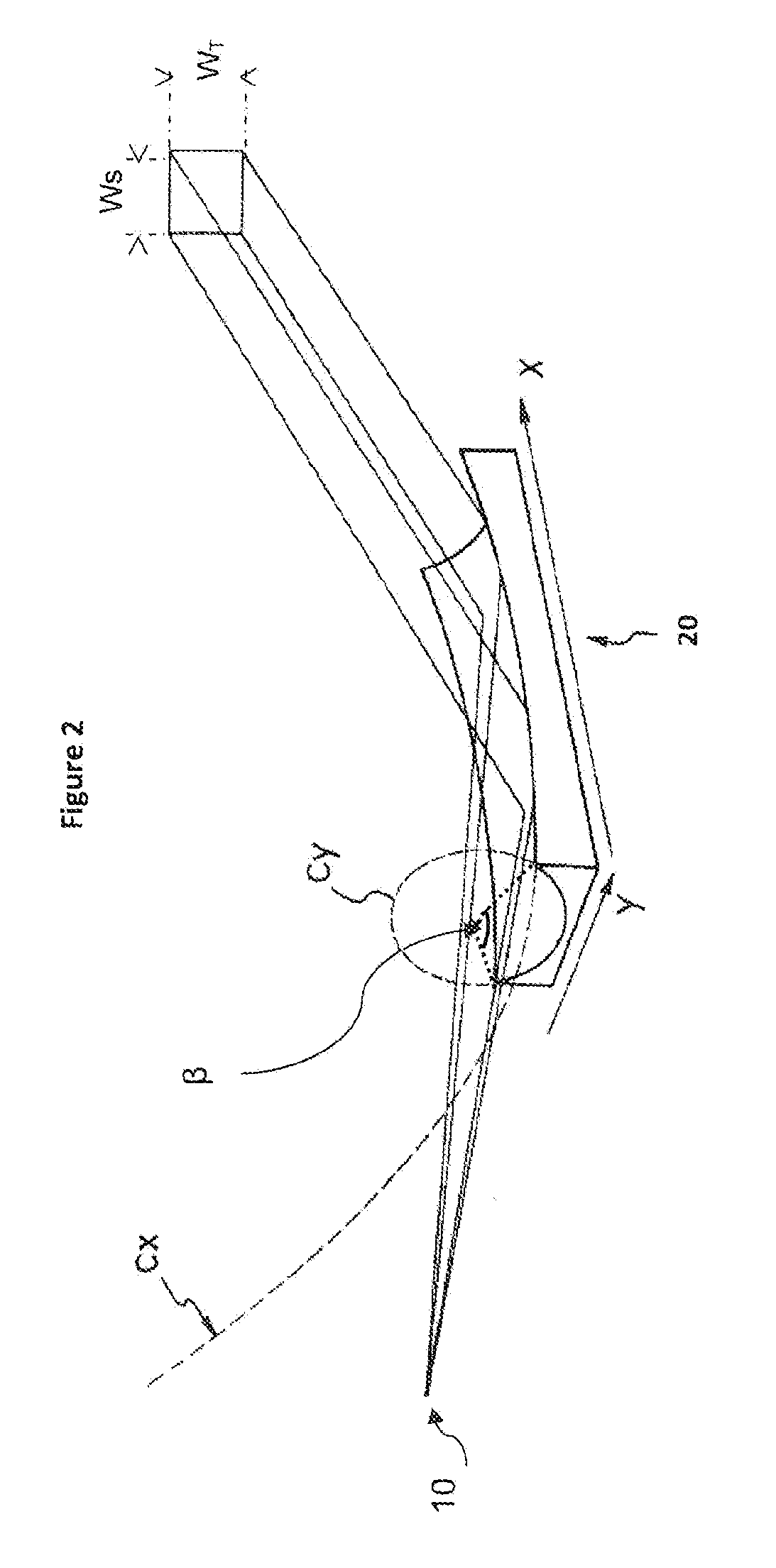

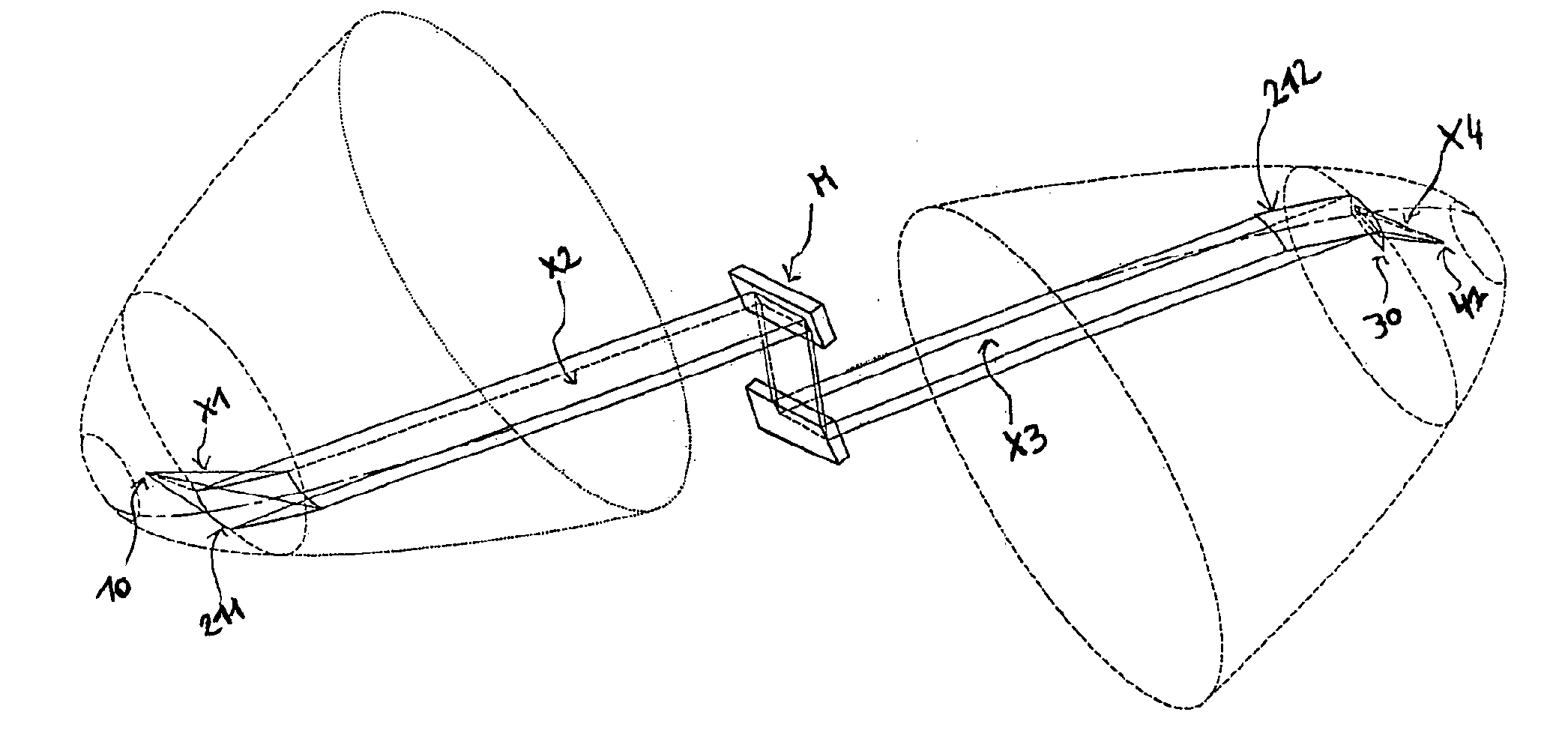

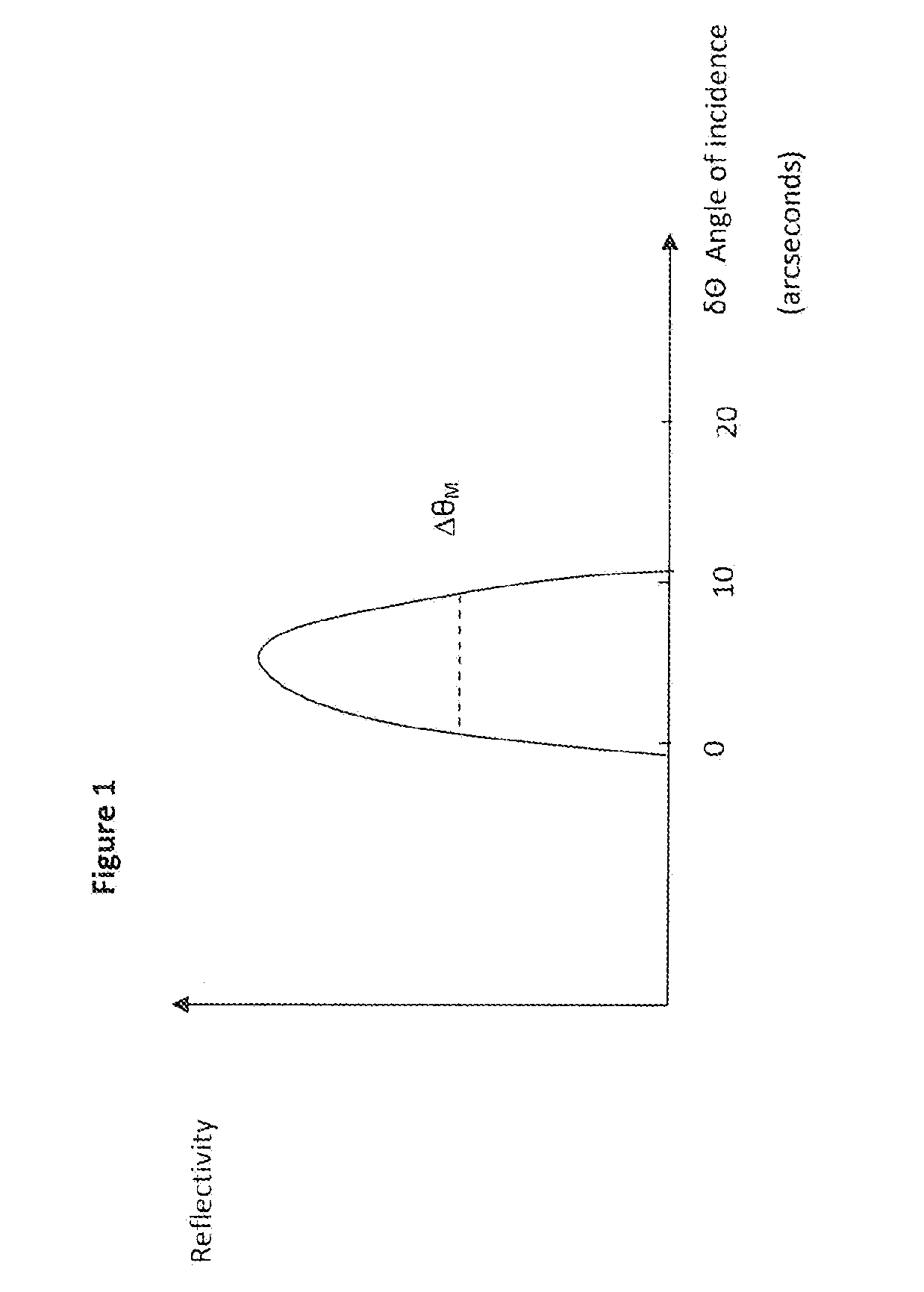

ActiveUS8422633B2Improve throughputIncreased collecting angleMaterial analysis using wave/particle radiationHandling using diffraction/refraction/reflectionSoft x rayCatoptrics

The invention refers to an X-ray beam device for X-ray analytical applications, comprising an X-ray source designed such as to emit a divergent beam of X-rays; and an optical assembly designed such as to focus said beam onto a focal spot, wherein said optical assembly comprises a first reflecting optical element, a monochromator device and a second reflecting optical element sequentially arranged between said source and said focal spot, wherein said first optical element is designed such as to collimate said beam in two dimensions towards said monochromator device, and wherein said second optical element is designed such as to focus the beam coming from said monochromator device in two dimensions onto said focal spot.

Owner:XENOCS

X-ray beam device

ActiveUS20100272239A1Reduce divergenceImprove throughputHandling using diffraction/refraction/reflectionMaterial analysis using radiation diffractionSoft x rayX-ray

The invention refers to an X-ray beam device for X-ray analytical applications, comprising an X-ray source designed such as to emit a divergent beam of X-rays; and an optical assembly designed such as to focus said beam onto a focal spot, wherein said optical assembly comprises a first reflecting optical element, a monochromator device and a second reflecting optical element sequentially arranged between said source and said focal spot, wherein said first optical element is designed such as to collimate said beam in two dimensions towards said monochromator device, and wherein said second optical element is designed such as to focus the beam coming from said monochromator device in two dimensions onto said focal spot.

Owner:XENOCS

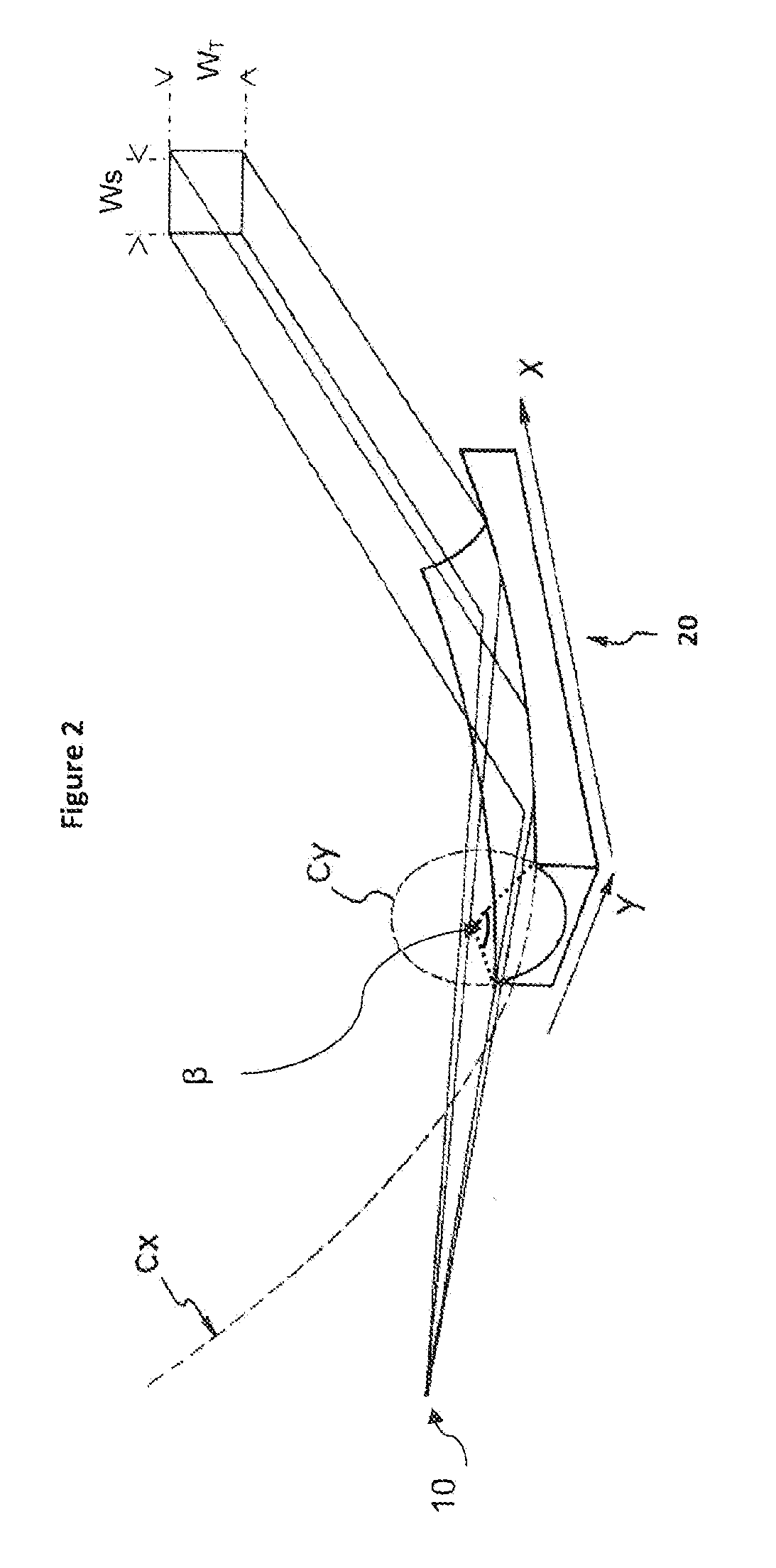

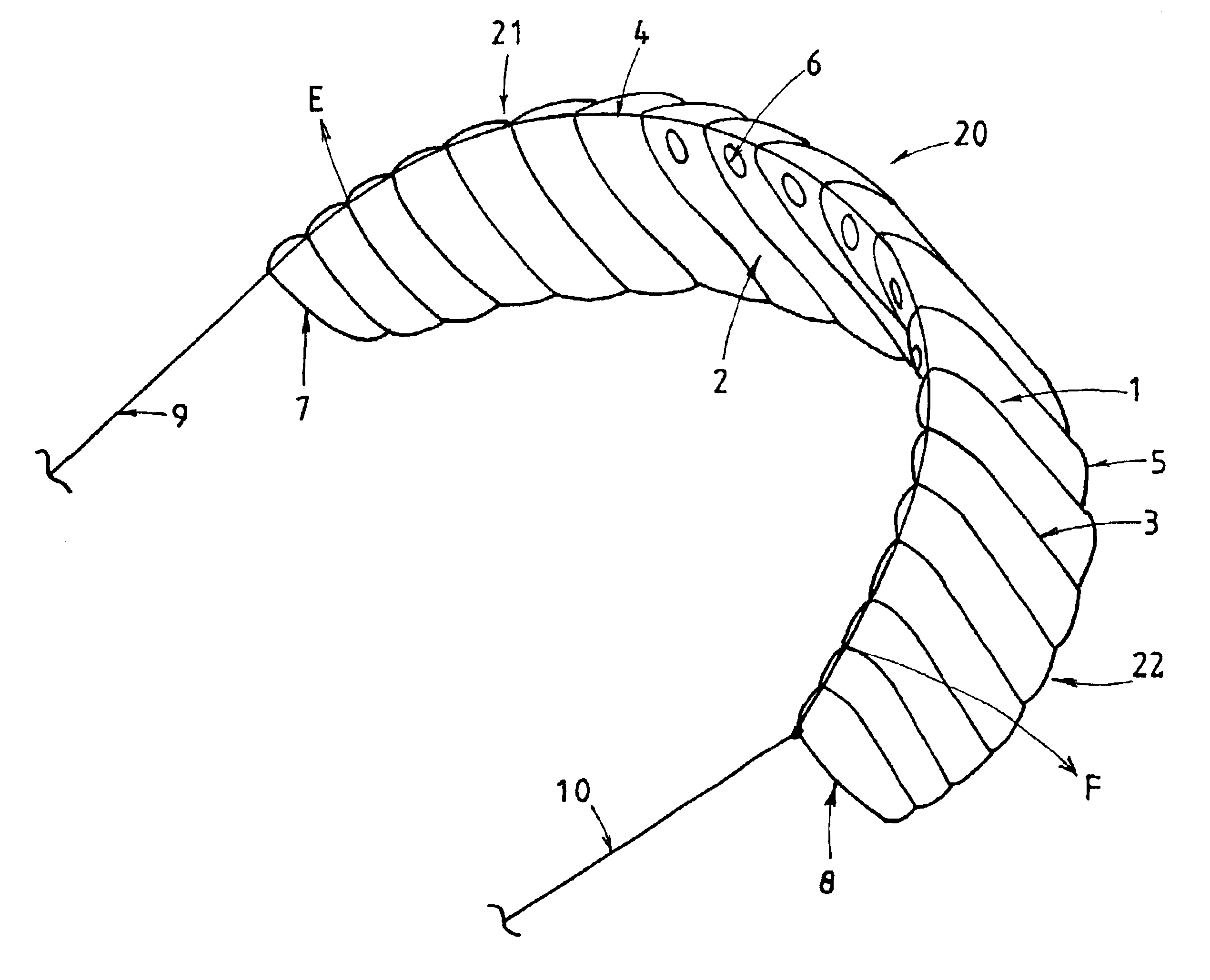

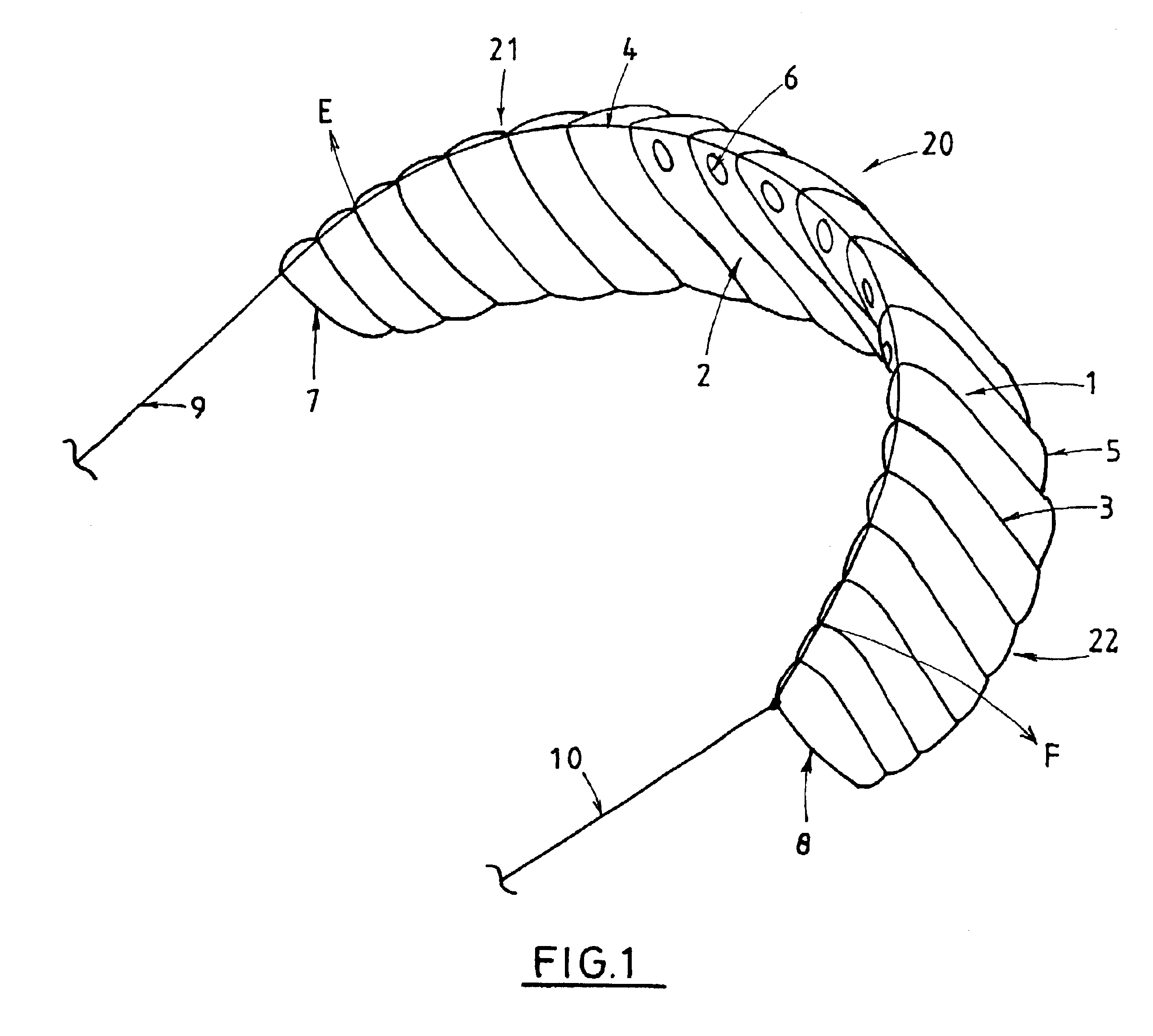

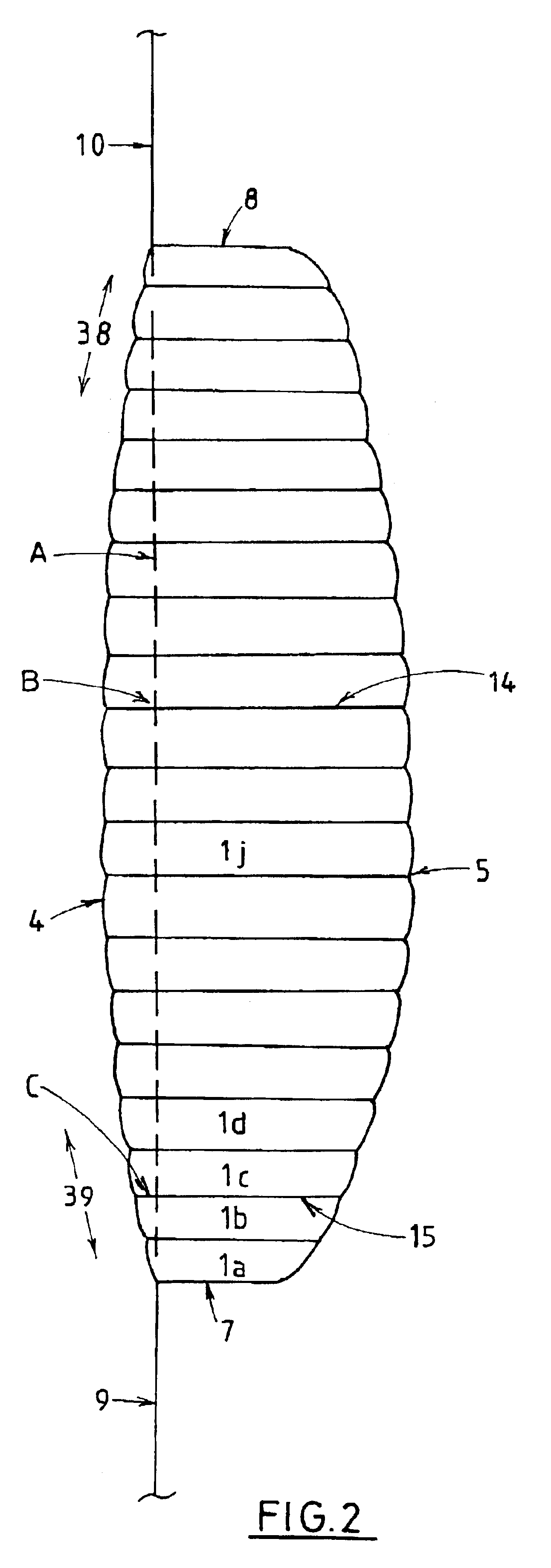

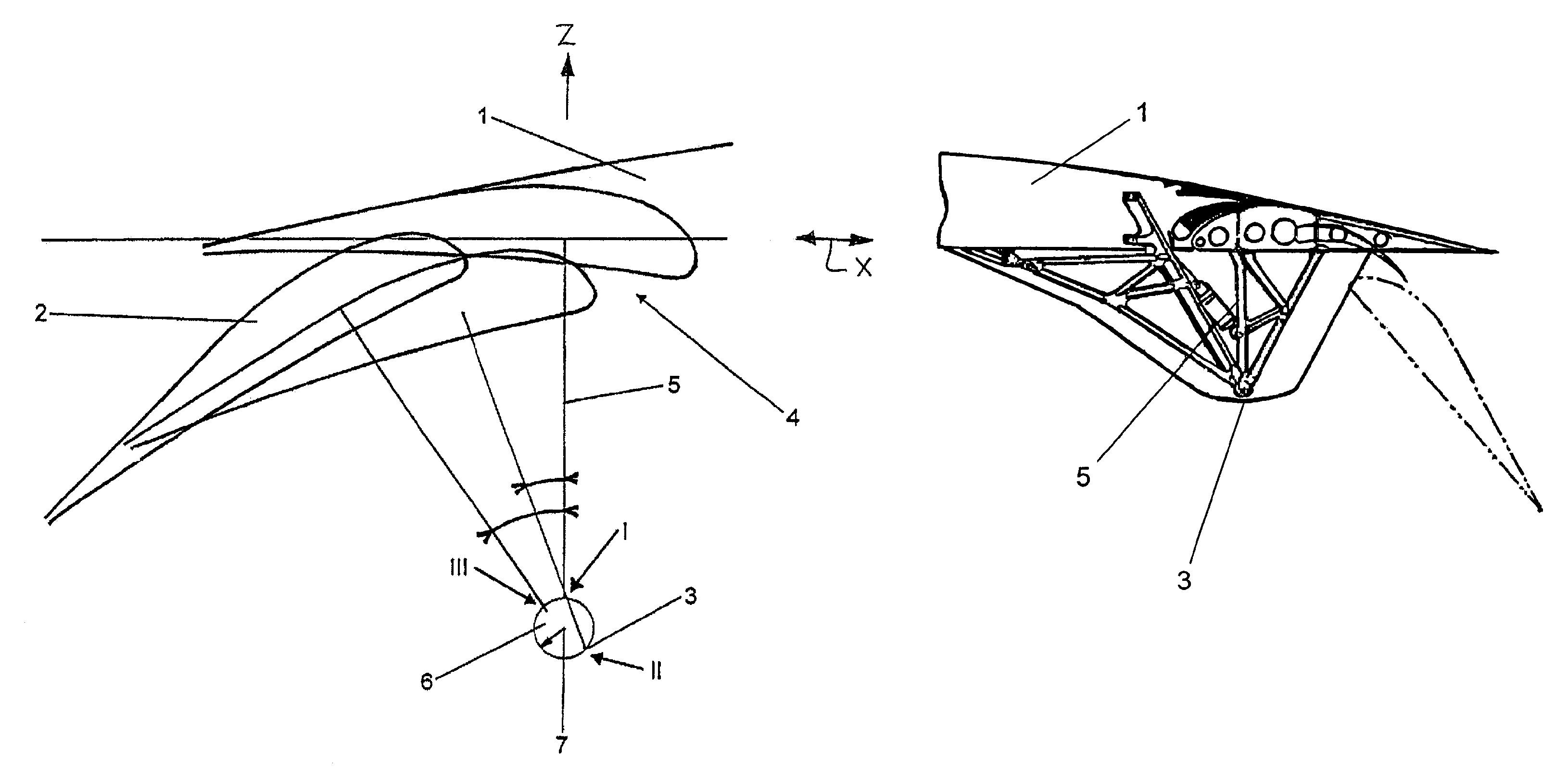

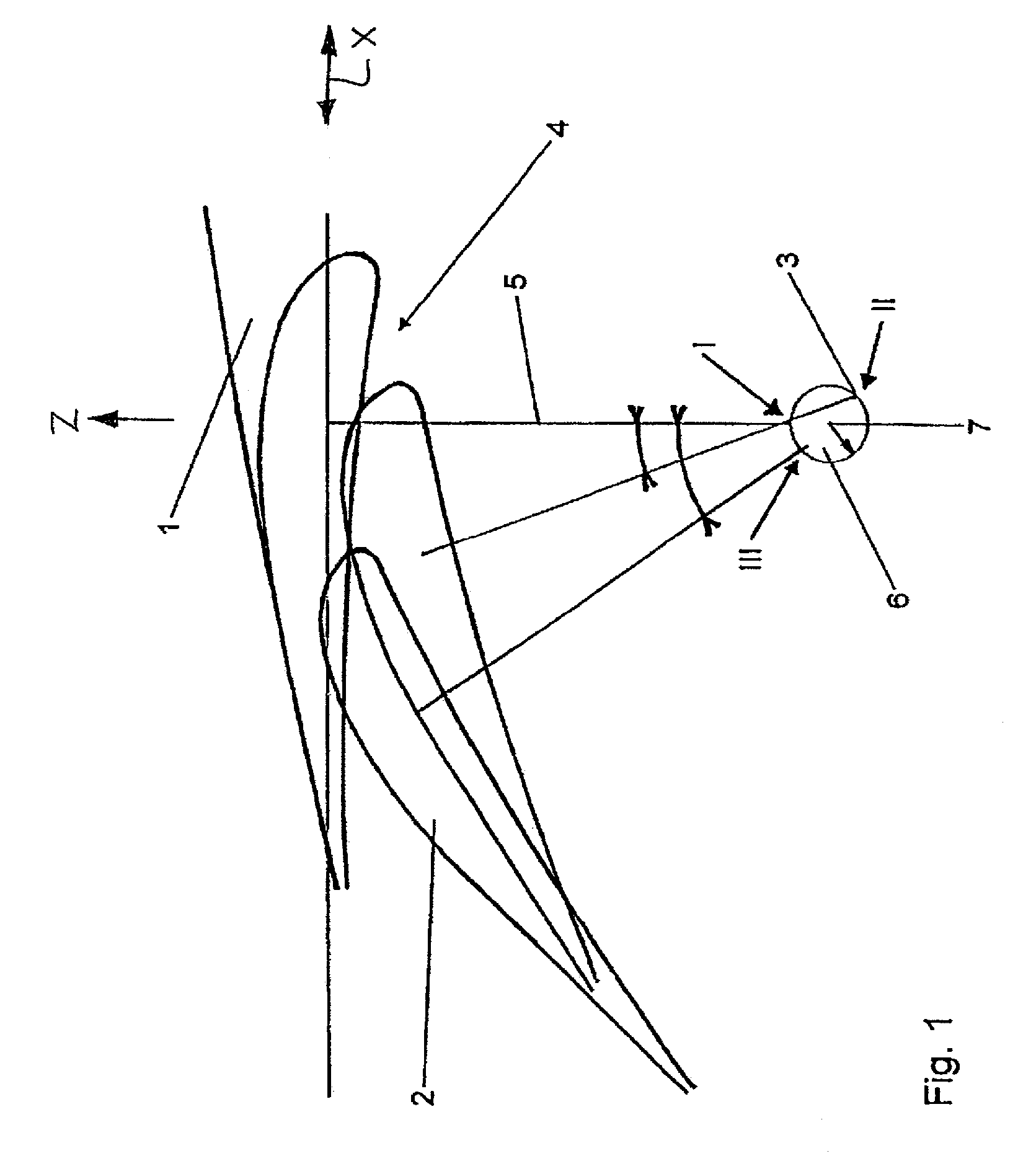

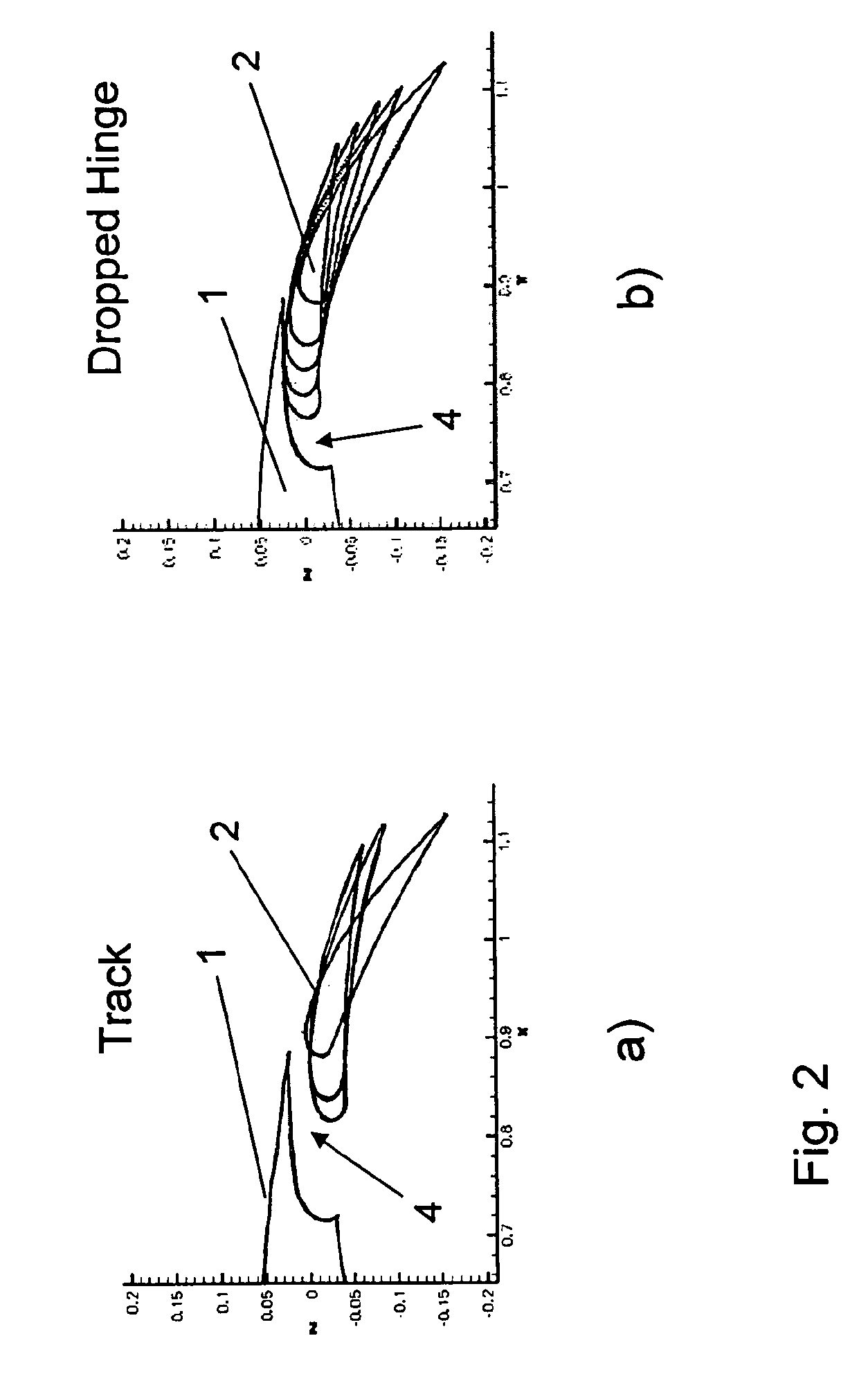

Ram air inflated wing

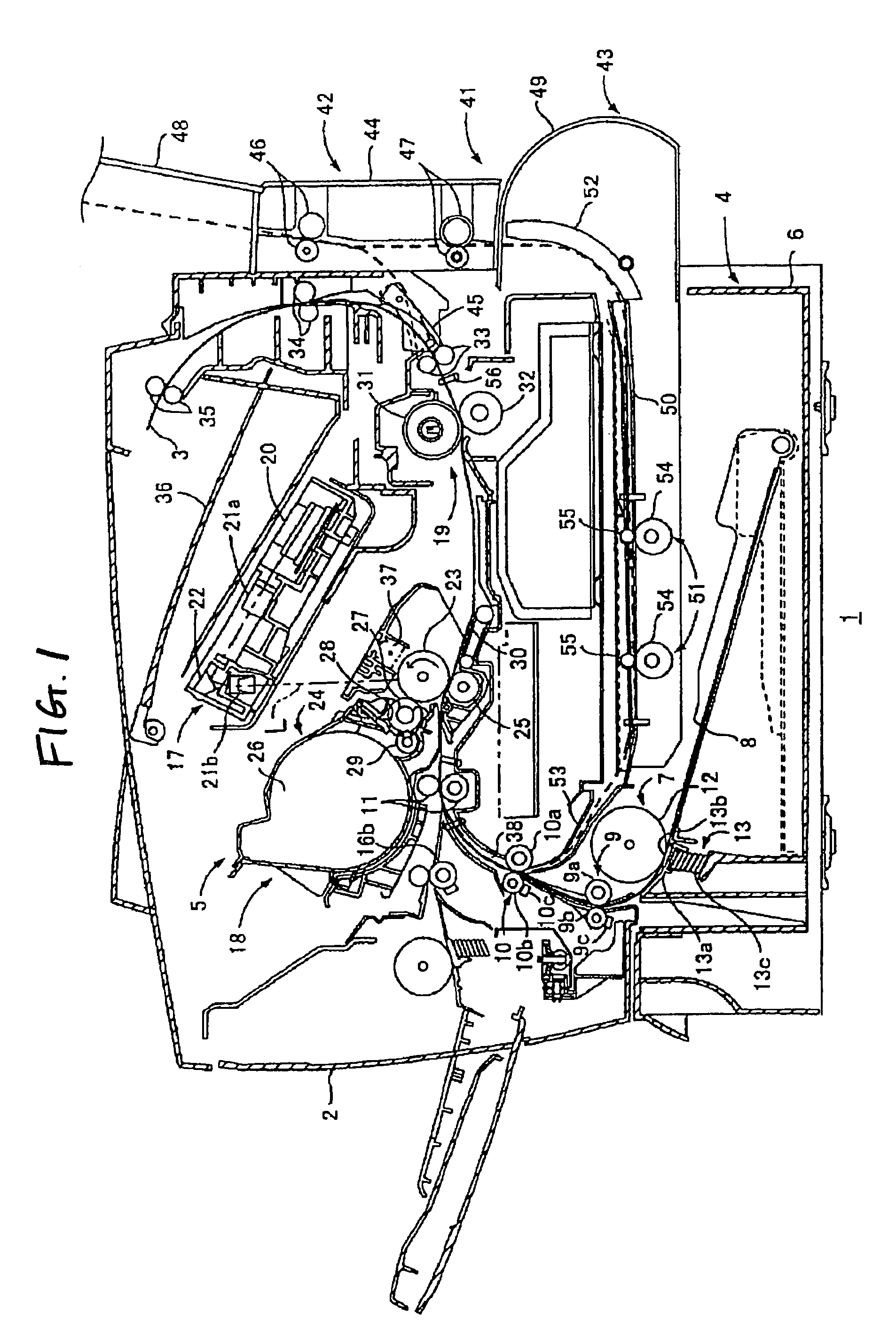

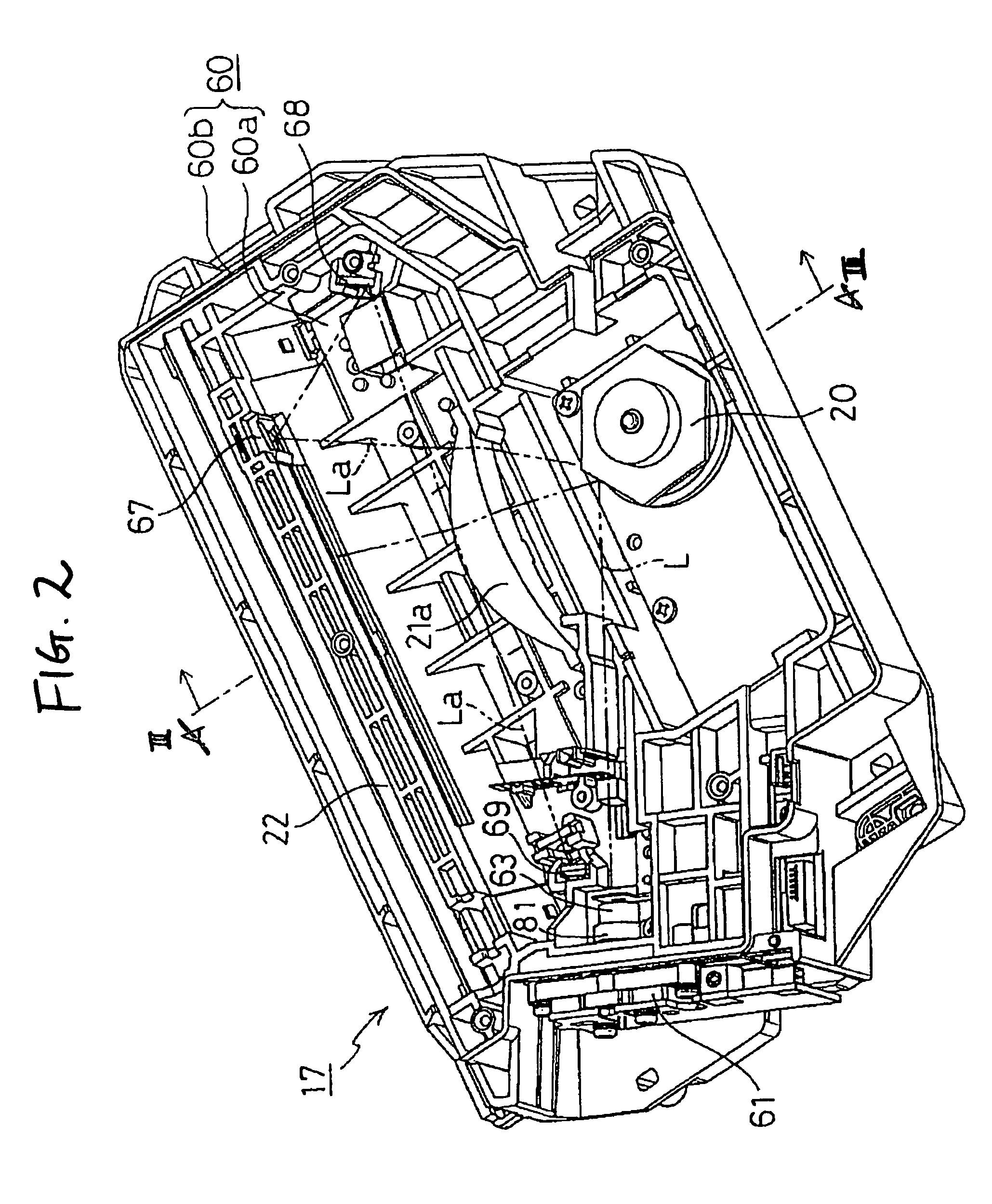

InactiveUS6837463B2Increase the angle of incidenceMarine propulsionParachutesCentre of pressureAngle of incidence

A wing for a traction kite, etc comprises a plurality of cells formed by chordwise-extending ribs (3), valved openings (6) to the cells allowing ram air to inflate the wing. By changing the initial cut-out of the material forming the cells near wing tips (7, 8), compared with that of the cells central to the wing, it is possible to alter the aerodynamic forces at wing tips (7, 8). This allows attachment of flying lines (9, 10) to wing tips (7, 8) only, despite the wing having no framing to maintain its spanwise shape under the loading of flying lines (9, 10). The increased aerodynamic forces at wing tips (7, 8) are achieved by making the aerofoil profiles of the cells progressively more reflexive towards wing tips (7, 8), by giving wing tips (7, 8) a residual twist increasing their angle of incidence, by placing the centres of pressure of the cells near wing tips (7, 8) somewhat forward of the pivot line of the wing, etc.

Owner:LYNN PETER ROBERT

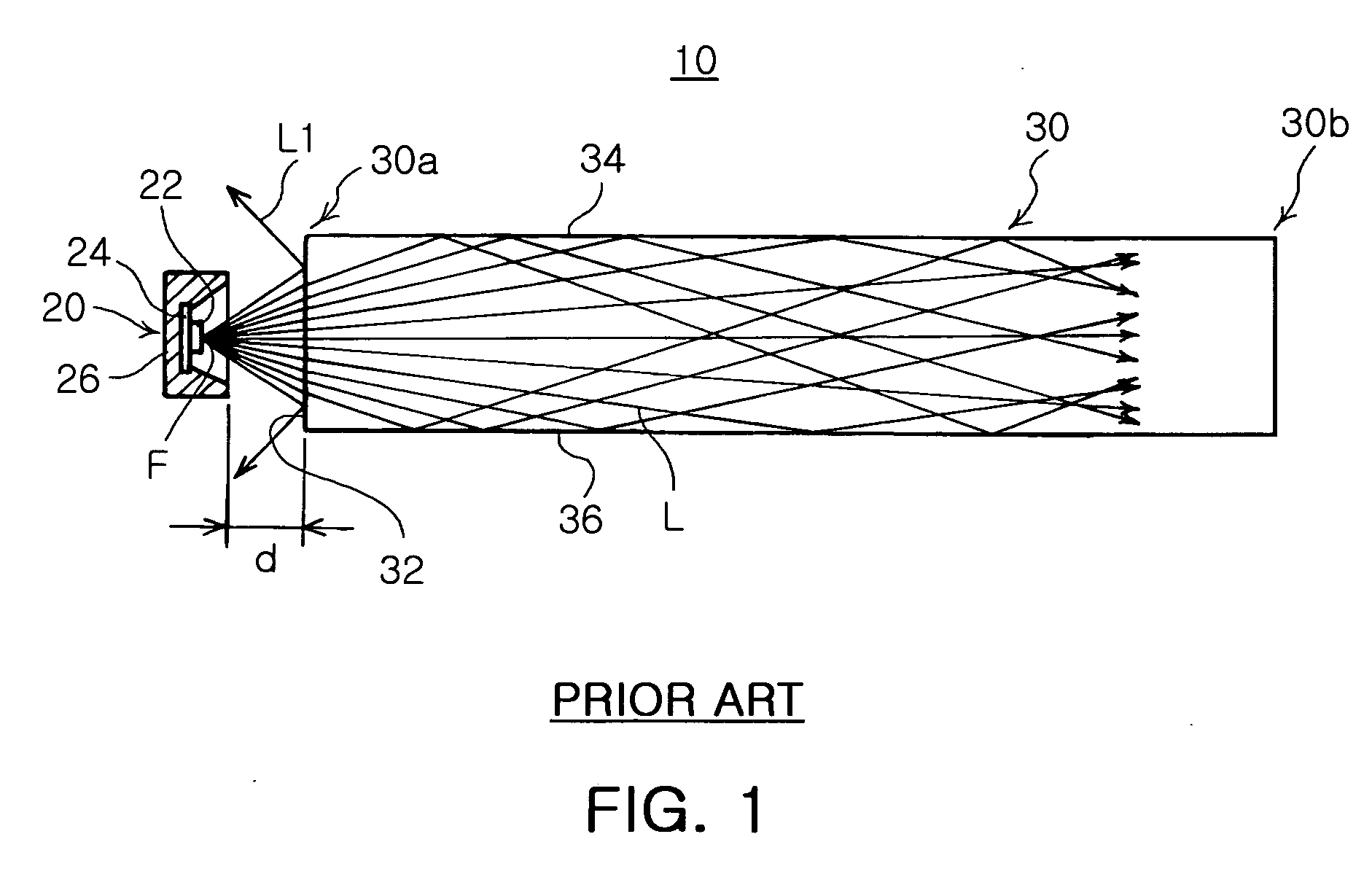

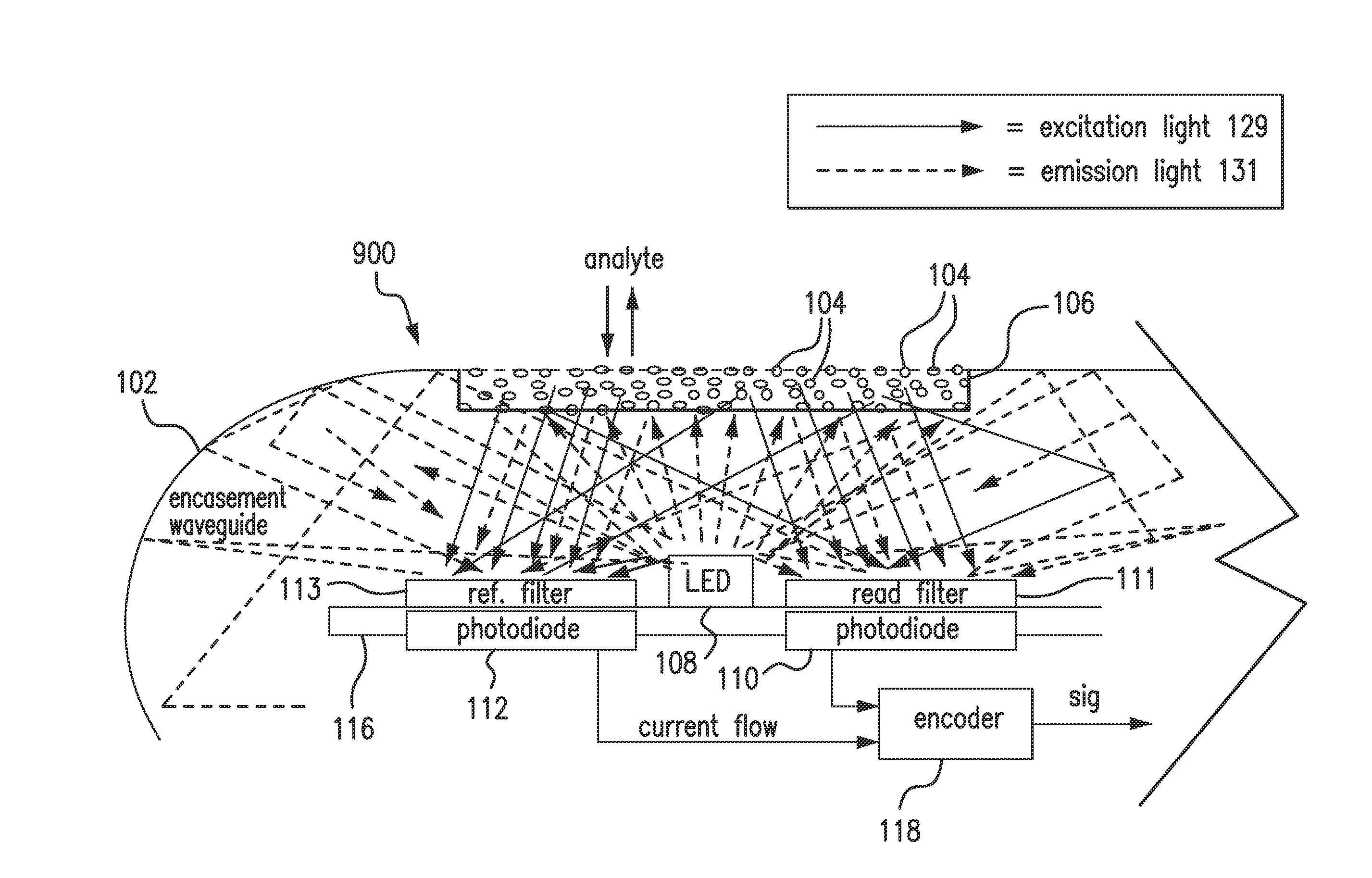

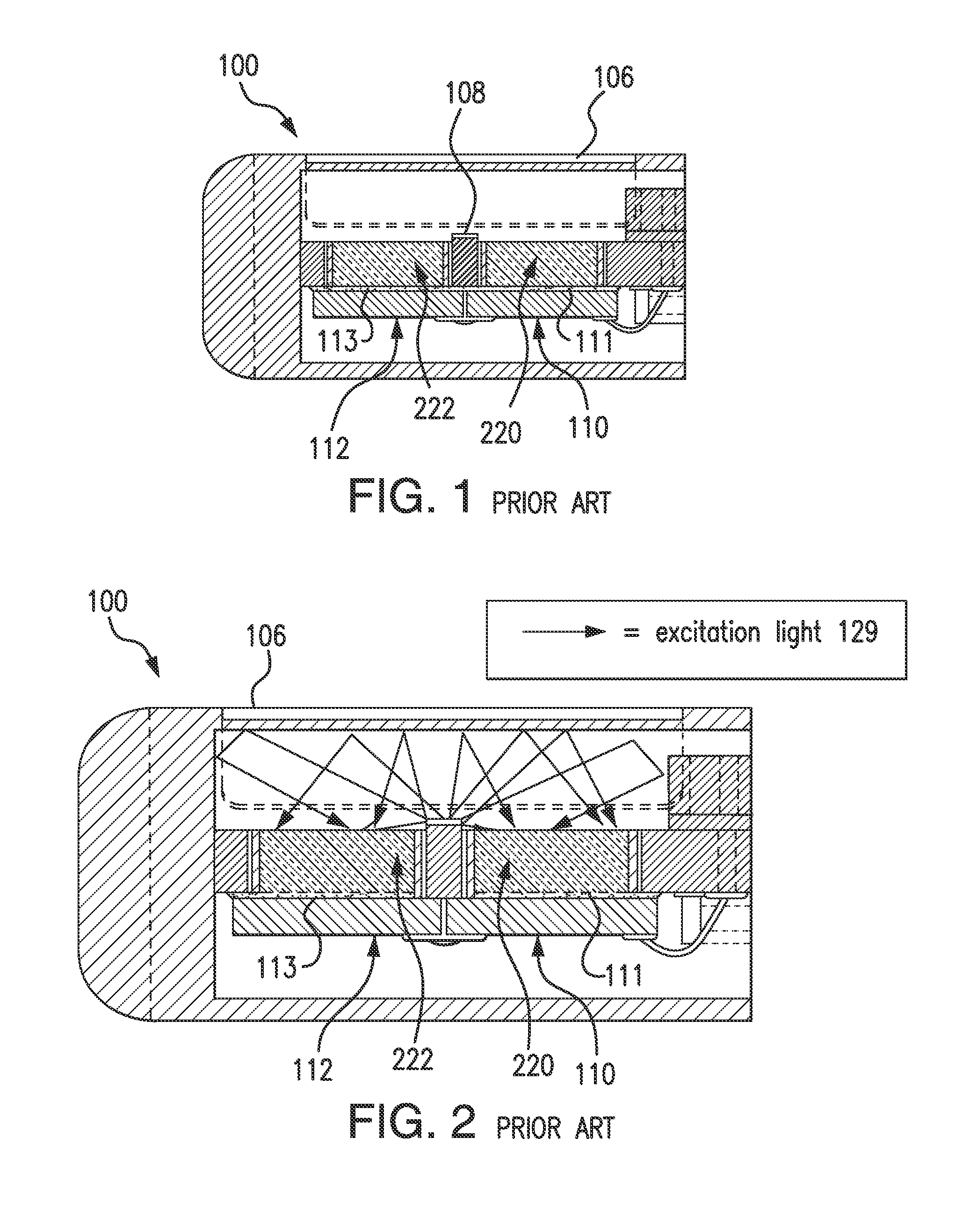

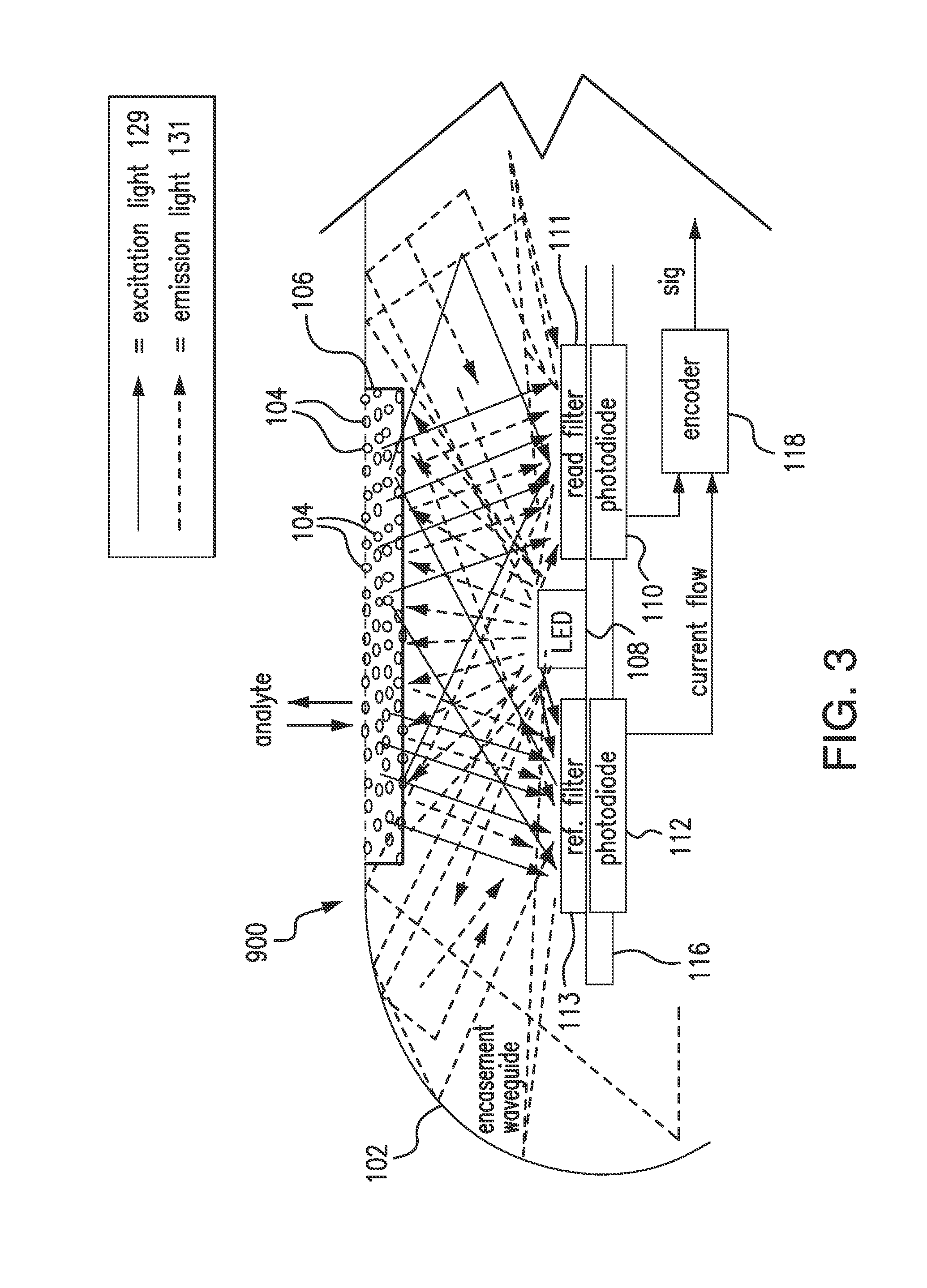

Angle of incidence selective band pass filter for implantable chemical sensor

InactiveUS20130324819A1Overcome disadvantagesIncrease the angle of incidenceLuminescent dosimetersCatheterAngle of incidencePhotovoltaic detectors

Apparatuses and methods for limiting the angle of incidence (AOI) of light reaching a dichroic filter. The apparatus may include an AOI filter element and the dichroic filter. The apparatus may be a sensor and may include a photodetector. The dichroic filter may be configured to prevent light having a wavelength outside a band pass region from reaching the photodetector and to pass light having a wavelength within the band pass. Physical limitations of the dichroic filter may preclude the dichroic filter from preventing high AOI light having a wavelength outside a band pass region from reaching the photodetector. The AOI filter element may be configured to prevent light having a high AOI from reaching the dichroic band pass filter and to propagate light having a low AOI to the dichroic band pass filter. The AOI filter element may be a fiber optic bundle comprising a plurality of optical fibers.

Owner:SENSEONICS INC

Optical lens, lens unit, imaging module, and electronic apparatus

InactiveUS20150103226A1Avoid it happening againIncrease brightnessTelevision system detailsBeam/ray focussing/reflecting arrangementsCamera lensComputer module

An optical element includes an optical base material and a light blocking portion. The optical base material transmits light therethrough. The light blocking portion is formed on part of a surface of the optical base material. The light blocking portion includes a light blocking layer and an antireflection layer that is formed on a non-adhesion surface with the optical base material in the light blocking layer. A refractive index of the antireflection layer is lower than a refractive index of the light blocking layer.

Owner:FUJIFILM CORP

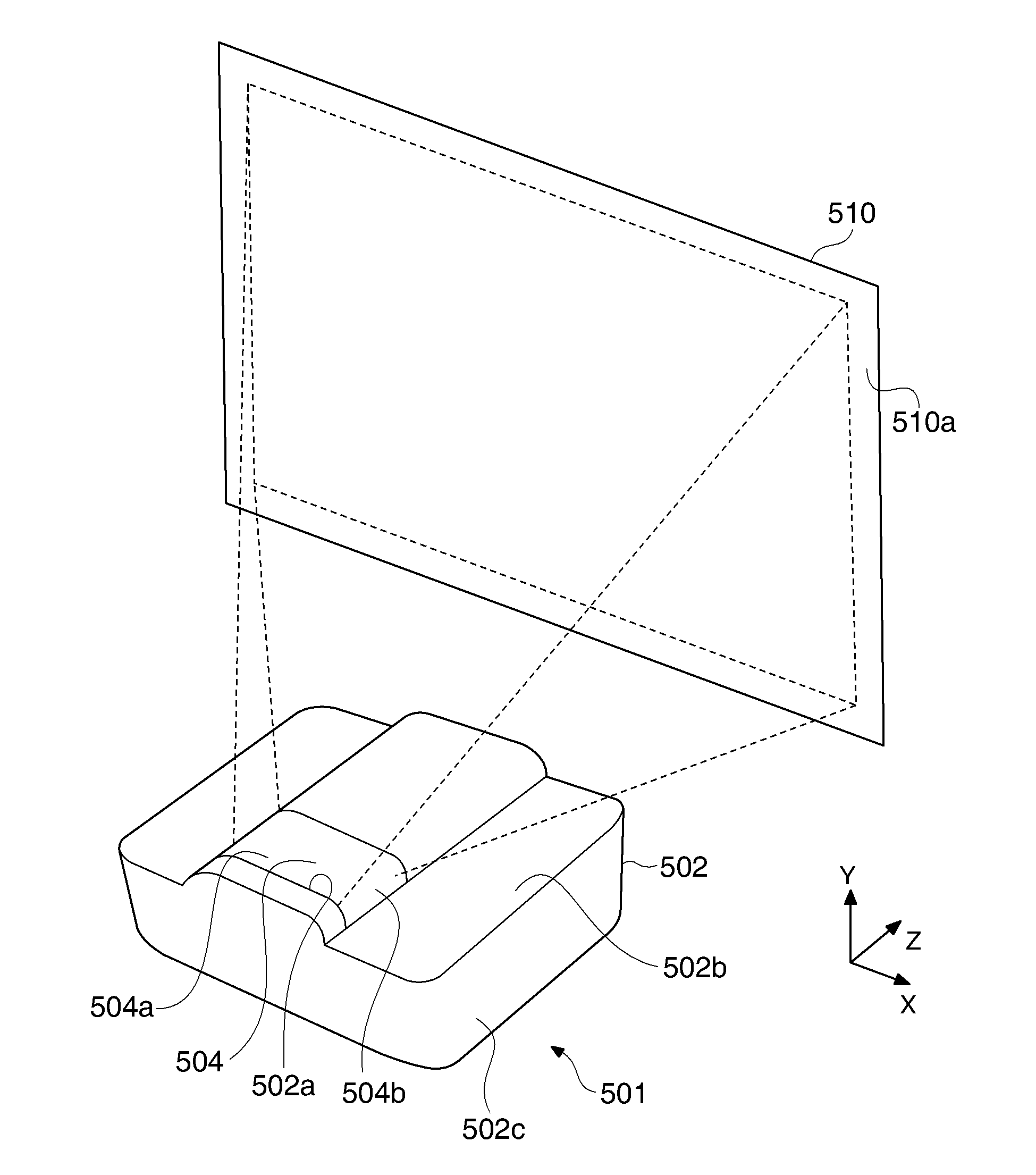

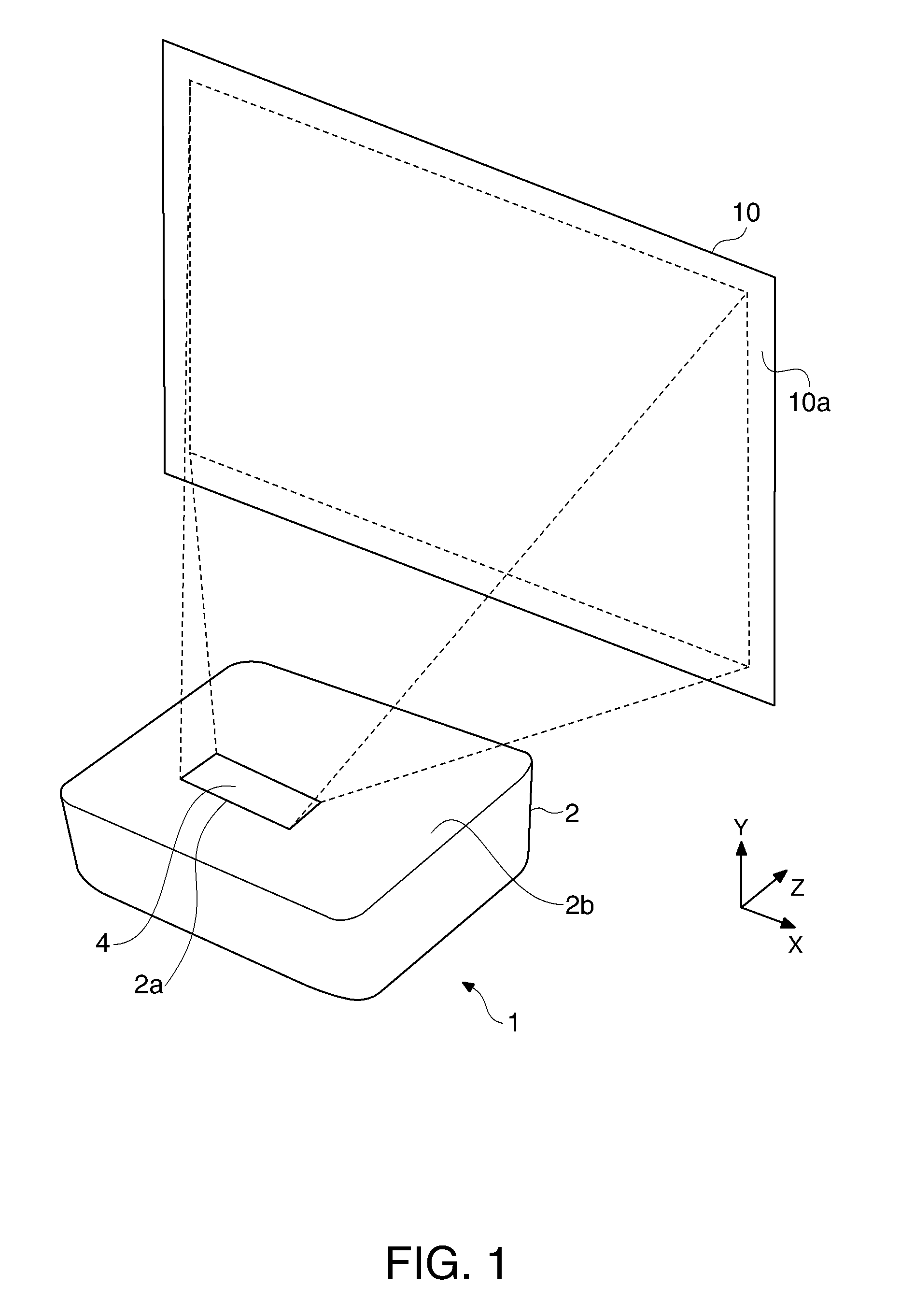

Projector

ActiveUS20100165308A1Reduce manufacturing costDegree of design can be increasedProjectorsReflectivityProcesses of change

A projector includes: a projection unit that projects projection light toward an illuminated surface; a housing that houses the projection unit and has an opening that allows the projection light to exit outward; and a cover portion that blocks the opening and transmits the projection light, wherein a plurality of areas is set in the cover portion relative to the projection unit, and a process of changing the reflectance of the light-incident surface of the cover portion at which the projection light is reflected is performed on each of the areas.

Owner:SEIKO EPSON CORP

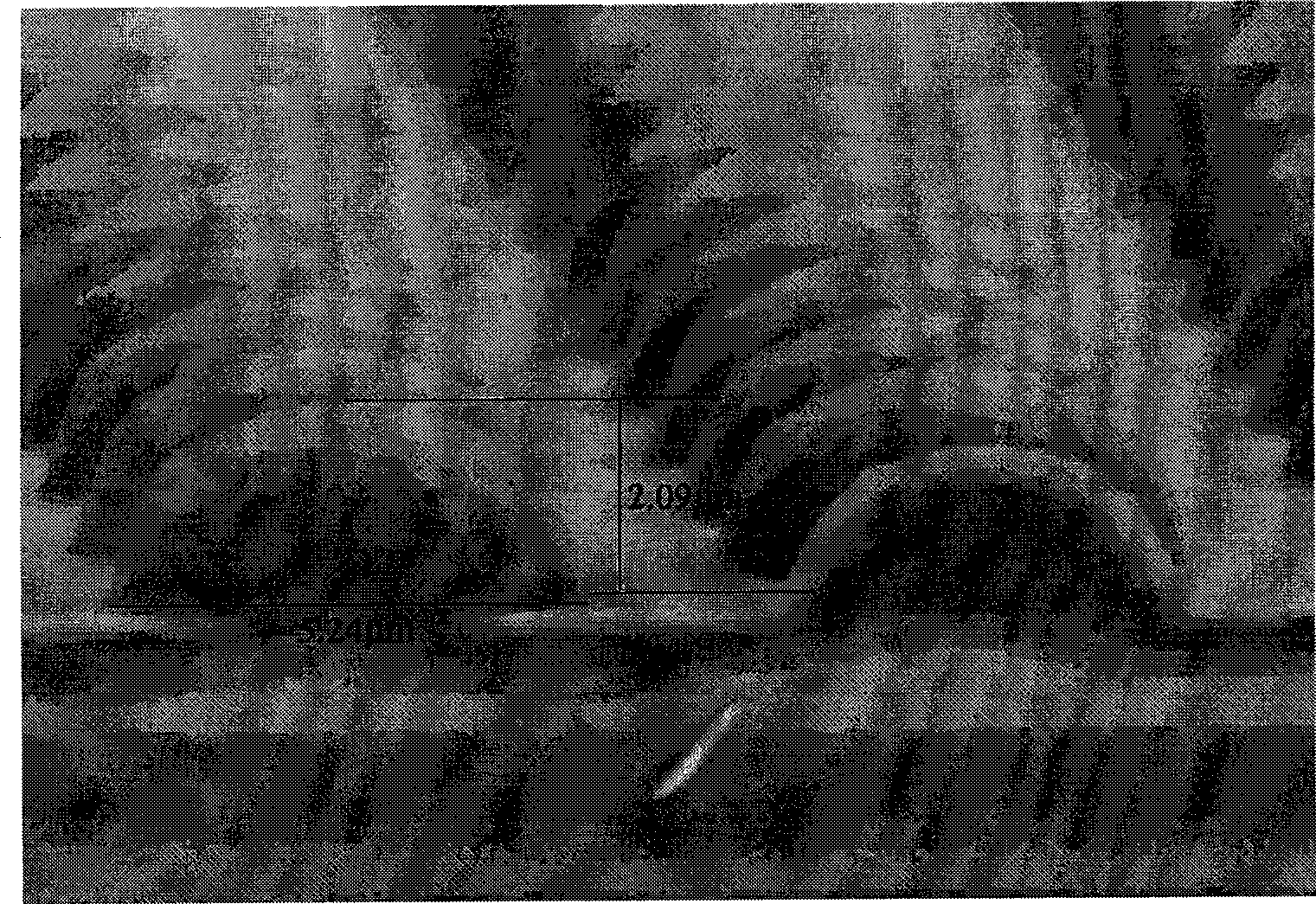

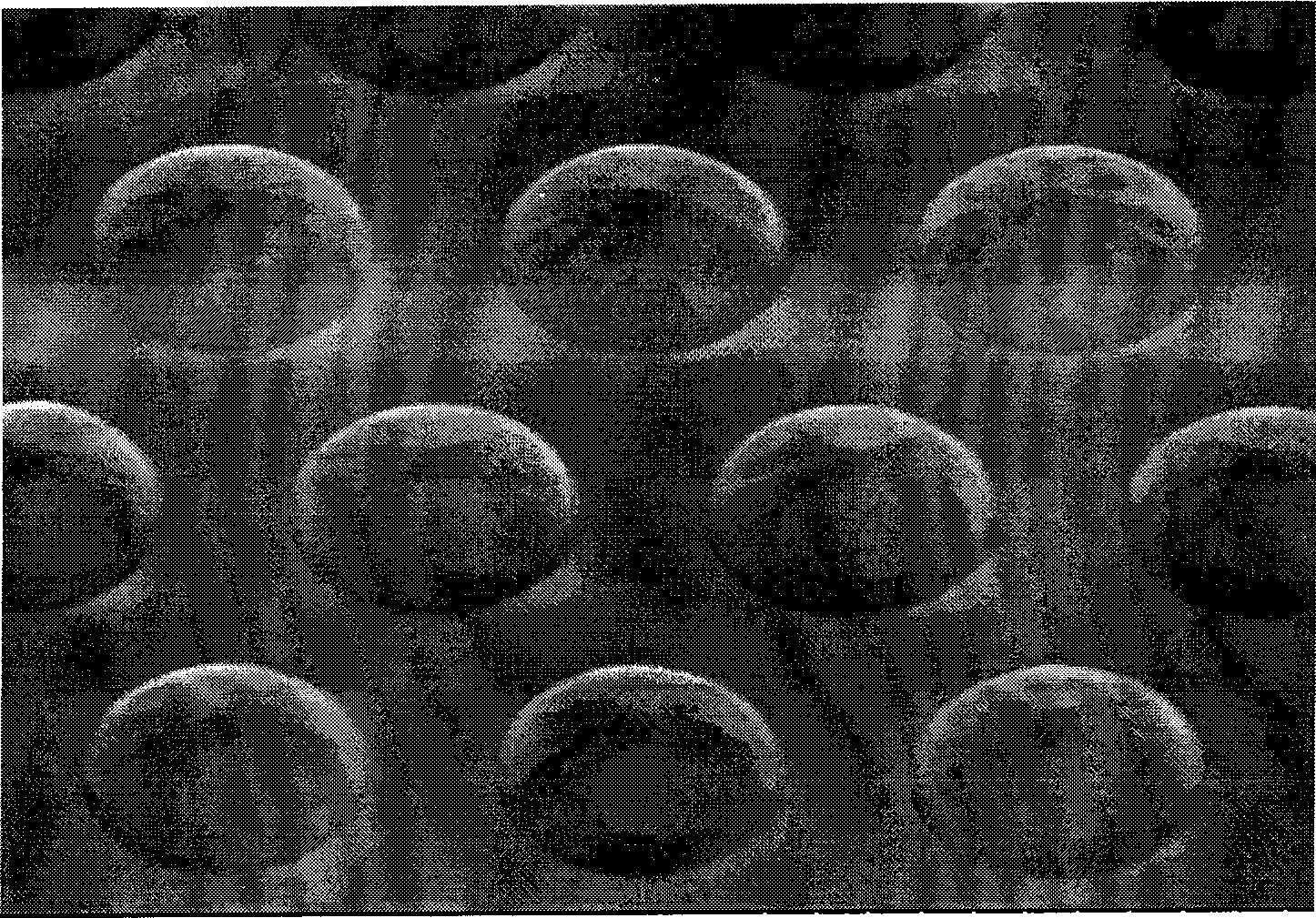

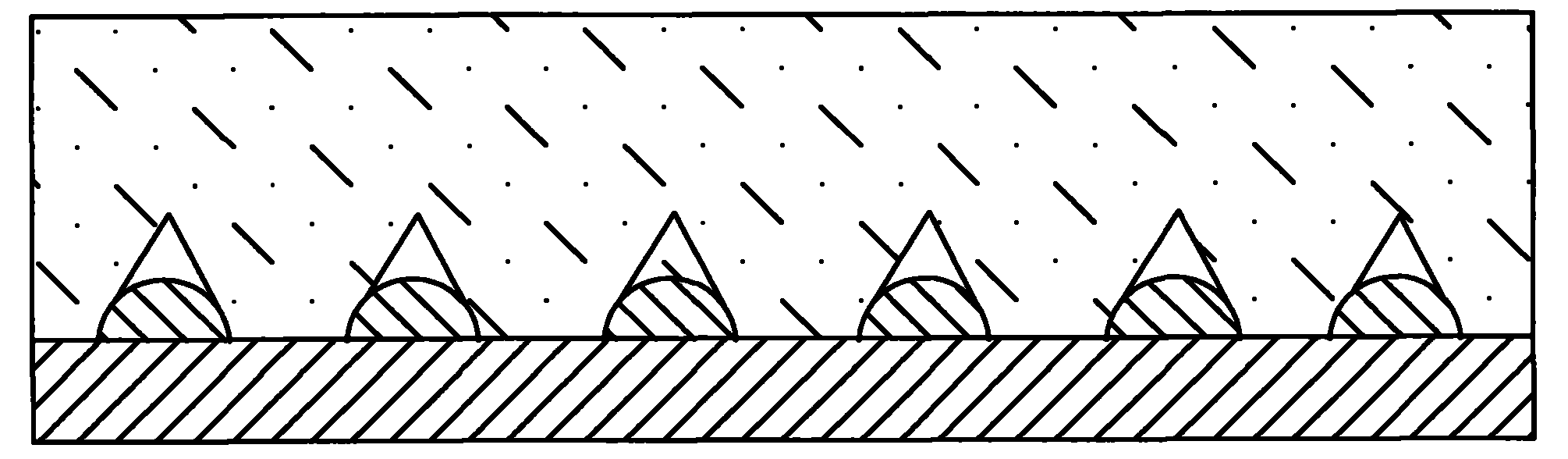

Gallium nitride based LED epitaxial substrate and preparing process thereof

InactiveCN101504964ALow refractive indexReduce hardnessSemiconductor devicesRefractive indexGallium nitride

The invention provides a gallium nitride based light-emitting diode epitaxial substrate and a method for preparing the same. The method comprises the following steps: (1) depositing a layer of film made of a low-refractive-index material; (2) preparing a mask graph on the film by using a photoresist; (3) transferring patterns of a photoresist mask to the film through etching; and (4) cleaning the substrate to remove the residual photoresist, wherein the substrate is one of sapphire, silicon, silicon carbide, gallium arsenide and zinc oxide, the film is one of the materials of silicon dioxide, silicon nitride, silicon oxynitride or titanium dioxide and the like, the thickness of the film is between 0.1 micro-millimeter and 3 micrometers, the refractive index of the film is less than 2.5, and the substrate pattern is approximately semispherical, conical or round platform shaped. By adopting the gallium nitride based light-emitting diode epitaxial substrate, the light-emitting efficiency of a diode can be improved, the preparation process is easy to control, the preparation method is simple and various, the yield is high, and the production cost is reduced.

Owner:HANGZHOU SILAN AZURE

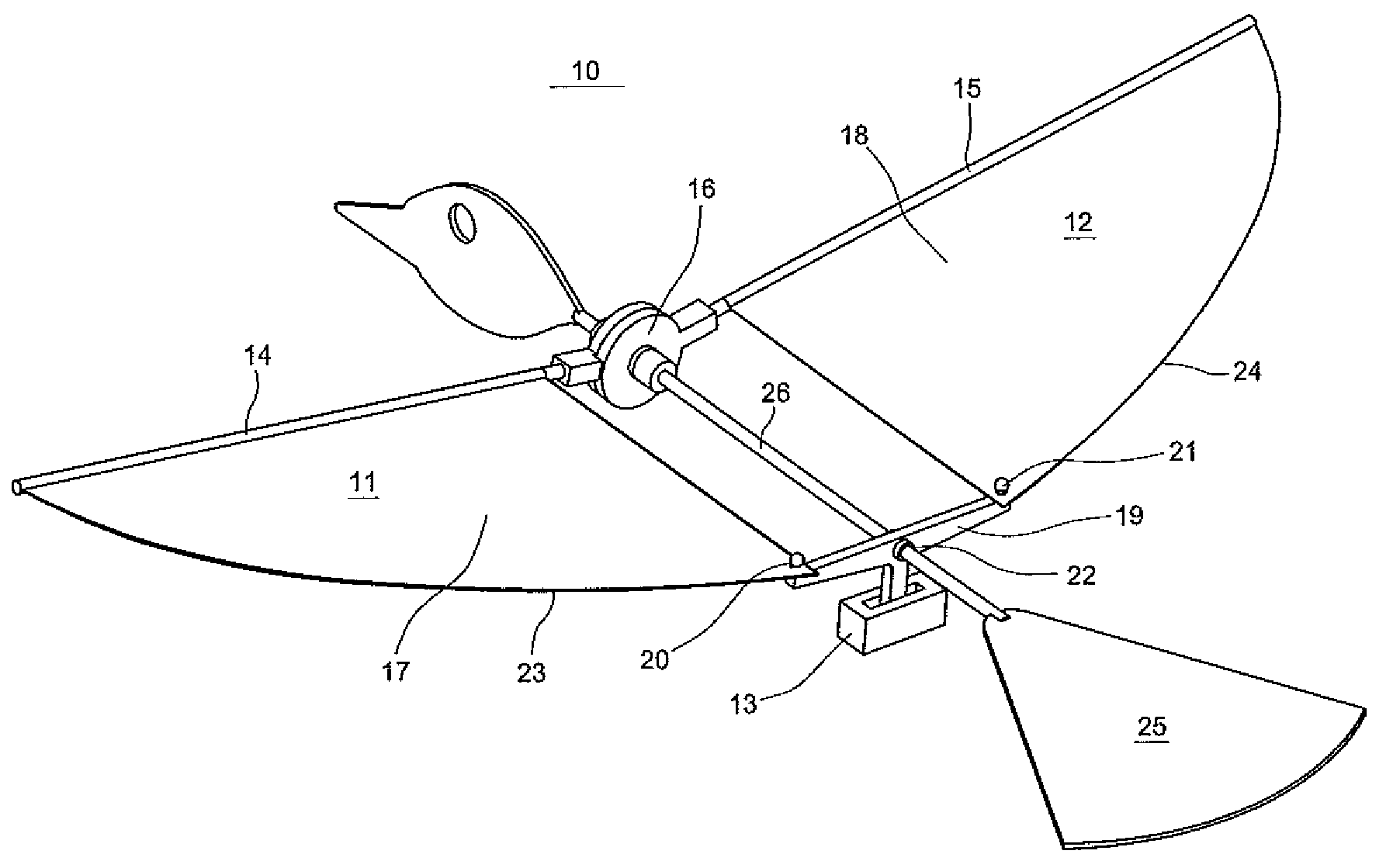

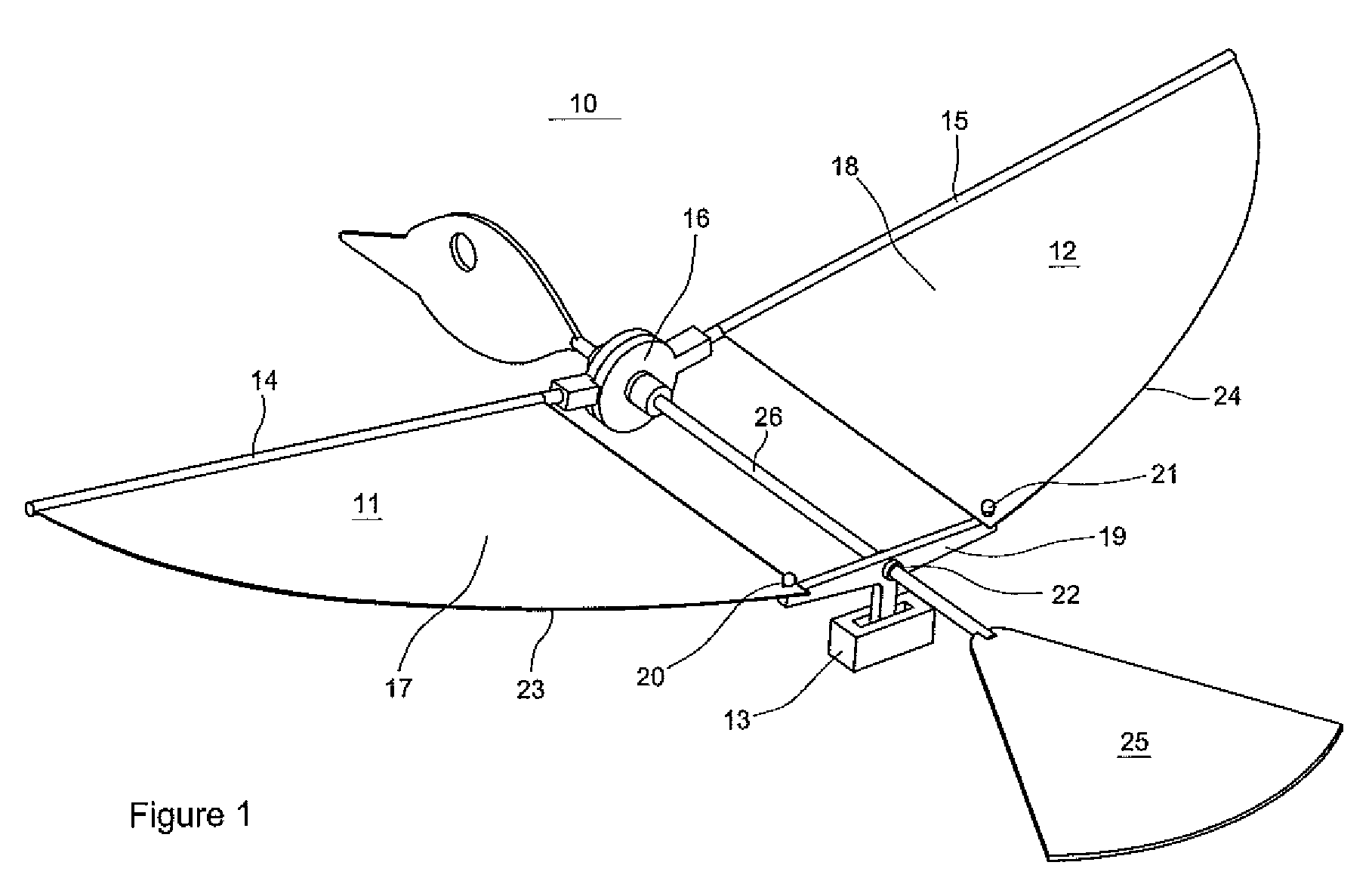

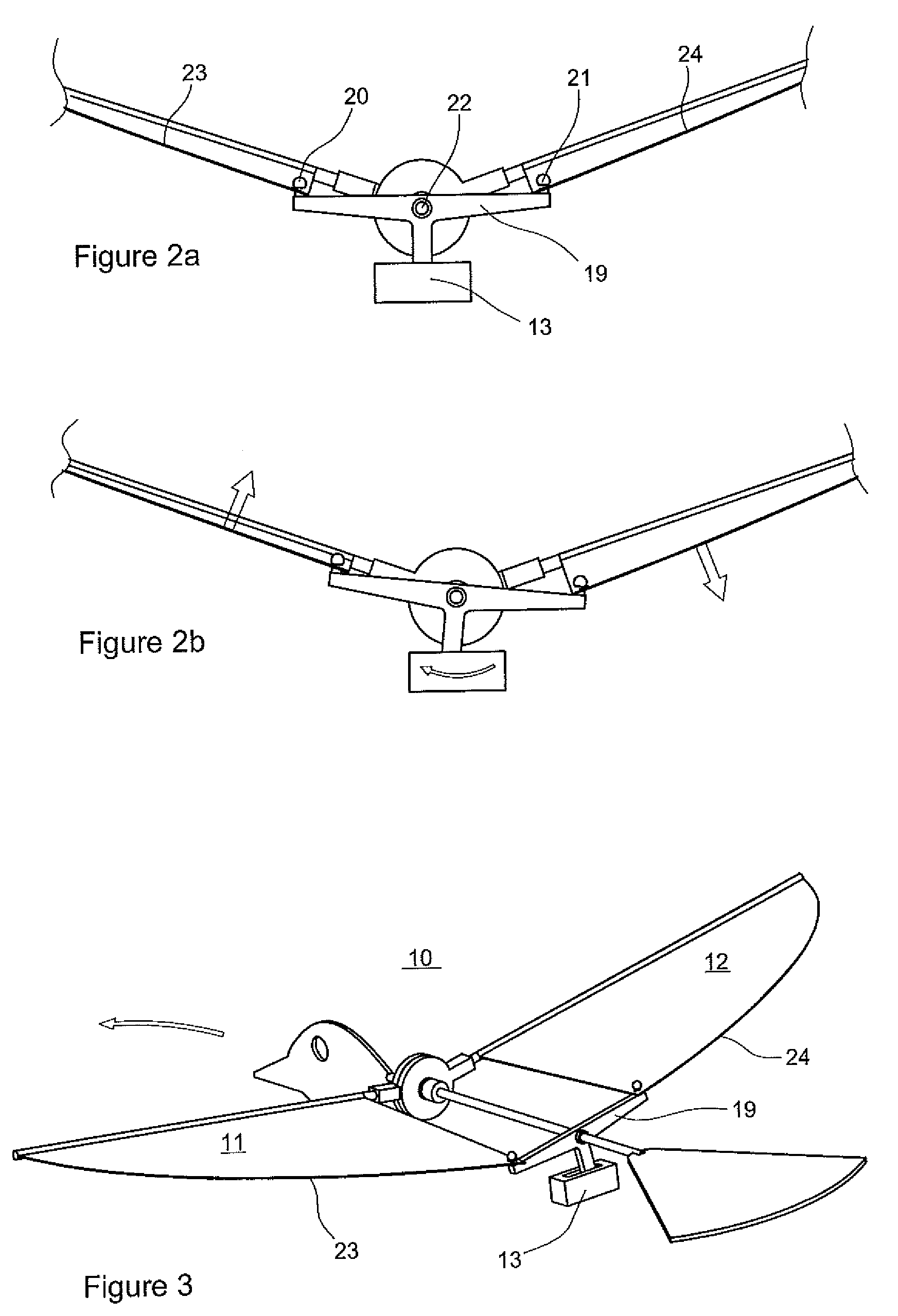

System for controlling flight direction

ActiveUS20080191100A1Low costIncrease the angle of incidenceAircraft controlWing adjustmentsFlight directionControl signal

An aircraft that is enable to turn in a desired direction, and a method for controlling the flight direction of an aircraft, by employing differential drag on the respective wings. A control means that receives a control signal indicating a left turn increases the incidence angle on the left wing and reduces it on the right wing. For a right turn the opposite action is performed. The aircraft comprises airfoils that have increased drag as the incidence angle increases but have a generally constant lift.

Owner:FLIR UNMANNED AERIAL SYST AS

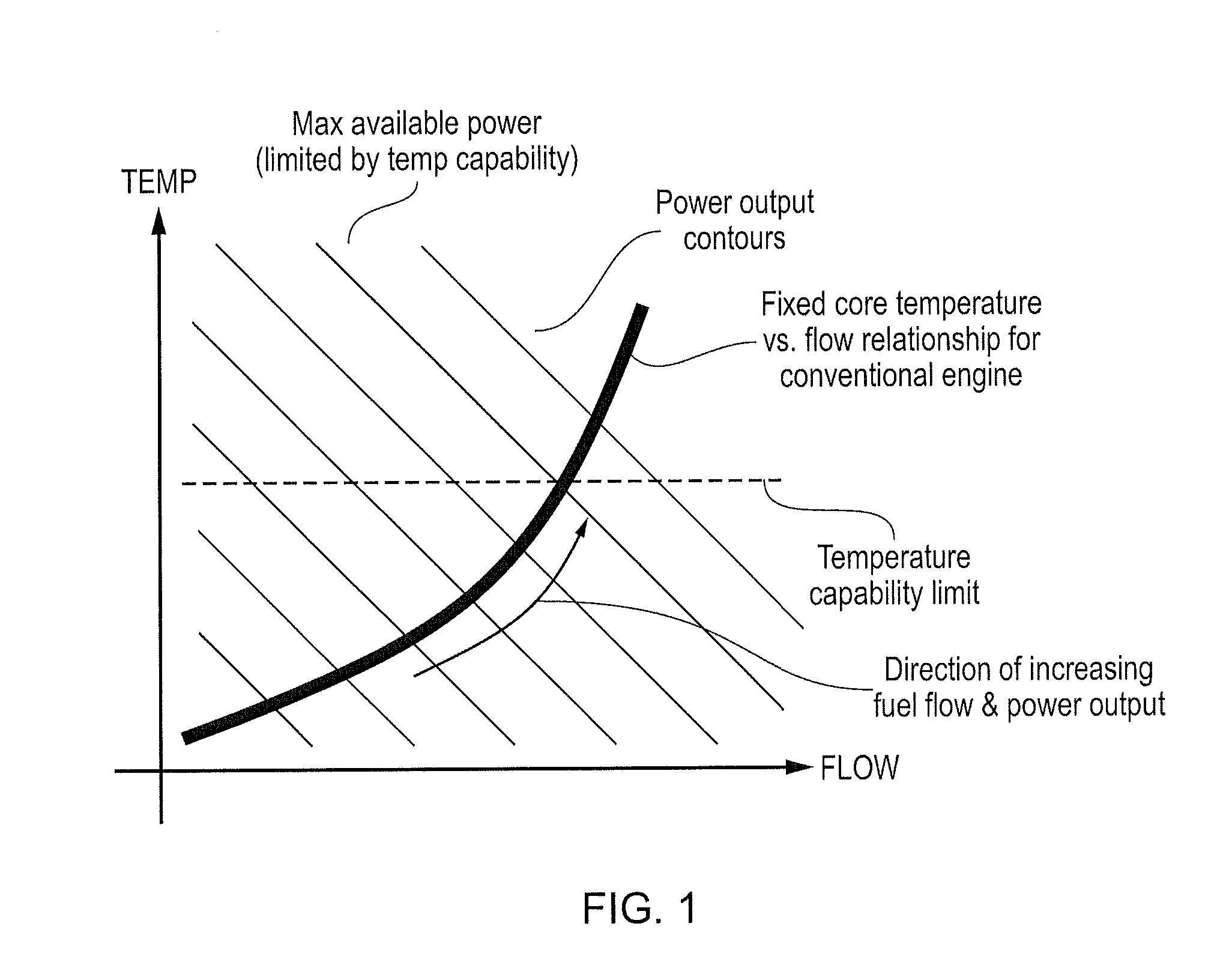

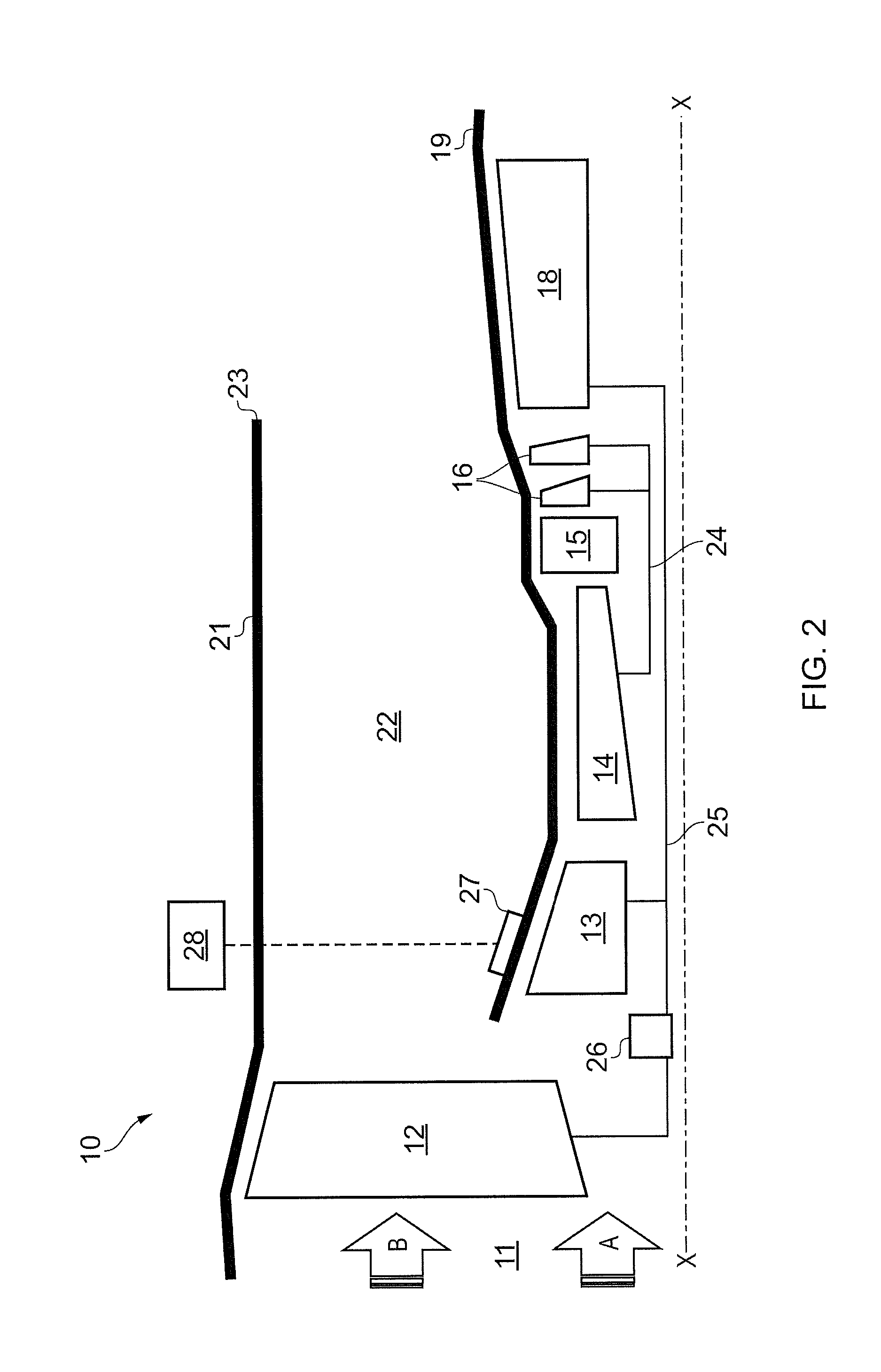

Control of a gas turbine engine

ActiveUS20150308353A1Temperature variationHigh power outputGas turbine plantsEfficient propulsion technologiesCombustionHigh pressure

An engine that has, in axial flow series, booster compressor, core compressor, combustion equipment, core turbine, and low-pressure turbine. Core turbine drives core compressor via an interconnecting high-pressure shaft. Low-pressure turbine drives booster compressor via an interconnecting low-pressure shaft. Low-pressure turbine also drives external load having a defined speed characteristic that dictates speed of the low-pressure turbine and booster compressor. Booster compressor has one or more rows of variable stator vanes. The method includes: scheduling variation in the angle of variable stator vanes as a function of speed of the booster compressor wherein the vanes open as booster compressor speed increases; measuring or setting one or more operational parameters which are determinative of temperature at entry to core turbine; and biasing scheduling of angle variation of variable stator vanes as a function of operational parameter(s) to reduce variation in temperature at entry to core turbine.

Owner:ROLLS ROYCE PLC

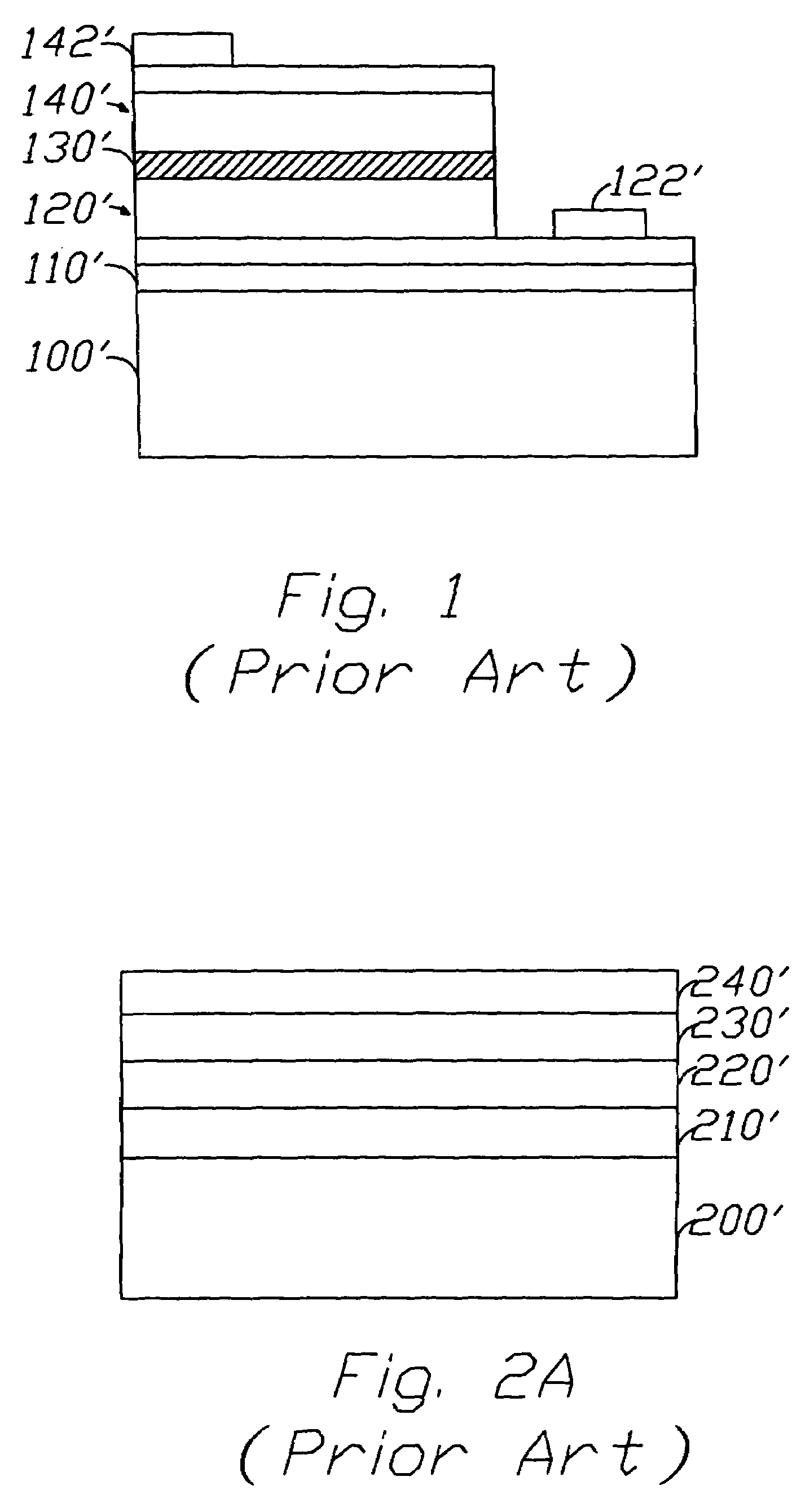

Vertical electrode structure of gallium nitride based light emitting diode

ActiveUS7453098B2Reduce refractionImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingReflection lossAngle of incidence

A vertical electrode structure of GaN-based light emitting diode discloses an oxide window layer constructing the GaN-based light emitting diode of vertical electrode structure, which effectively decreases the Fresnel reflection loss and total reflection, and further advances the luminous efficiency. Moreover, the further included metal reflecting layer causes the reflection without the selective angle of incidence, thus increasing the coverage of the reflecting angles and further reflecting the light emitted from a light emitting layer effectively. In addition, the invented structure can also advance the function of heat elimination and the electrostatic discharge (ESD) so as to the increase the operating life of the component and to be applicable to the using under the high current driving. Moreover, the vertical electrode structure of the present invention is able to lower down the manufacturing square of the chip and facilitate the post stage of the conventional wire bonding process.

Owner:LUMENS

Photovoltaic array maximum power point tracking servo system and control method

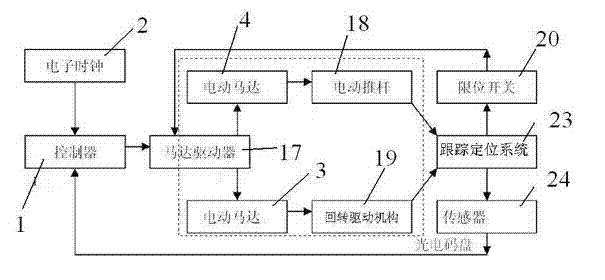

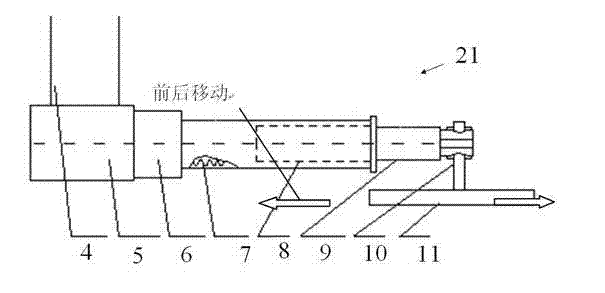

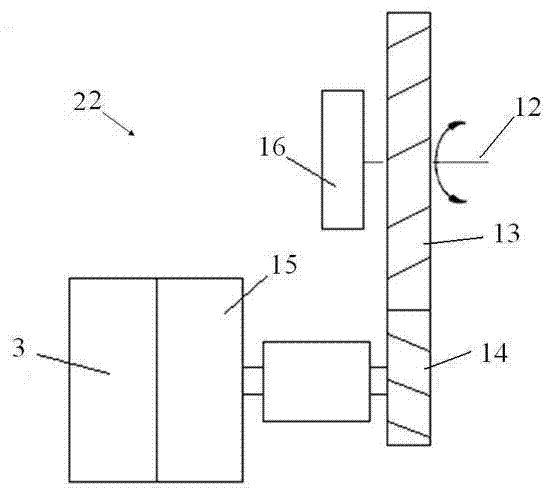

InactiveCN102447422AAvoid defectsIncrease the angle of incidencePV power plantsMultiple ac dynamo-electric motors controlControl systemActive solar

The invention discloses a photovoltaic array maximum power point tracking servo system comprising a clock circuit, a double-shaft mechanical tracking and locating system and a photovoltaic detecting device respectively connected with a singlechip control system. The double-shaft mechanical tracking and locating system comprises a first tracking component and a second tracking component connected with a battery panel bracket. A battery panel and the photovoltaic detecting device are provided on the battery panel bracket. The singlechip control system respectively controls and drives the first tracking component and the second tracking component to drive the battery panel and the photovoltaic detecting device to move in the vertical direction and the horizontal direction. The driving system adopted by the invention is a double-shaft active solar servo system which can realize the sun tracking under all weather conditions, has high precision, can always align the solar battery panel to the sun and maintain the maximum generating efficiency. Furthermore, the invention also discloses a control method of the system.

Owner:SHANGHAI YUEJIA ENERGY TECH

High-lift system for an aircraft

ActiveUS8302913B2Increase the angle of incidenceAircraft controlWing adjustmentsKinematicsFlight vehicle

An exemplary high-lift system for an aircraft includes a wing, a high-lift flap coupled to the wing, a kinematic element which is driven by a drive device, and a flap lever structured and arranged to rotate via an actuating drive between a retracted position in which the high-lift flap complements a wing profile and a plurality of extended positions in which a slot of a given width is formed between the wing and the high-lift flap. A first end of the flap lever is coupled to the high-lift flap. A second end of the flap lever is coupled to the kinematic element and is capable of rotating relative thereto via a first rotation point. The kinematic element is structured and arranged to rotate relative to a second rotation point that is fixed in position relative to the wing. The first rotation point is separated by a predetermined distance from the second rotation point.

Owner:AIRBUS OPERATIONS GMBH

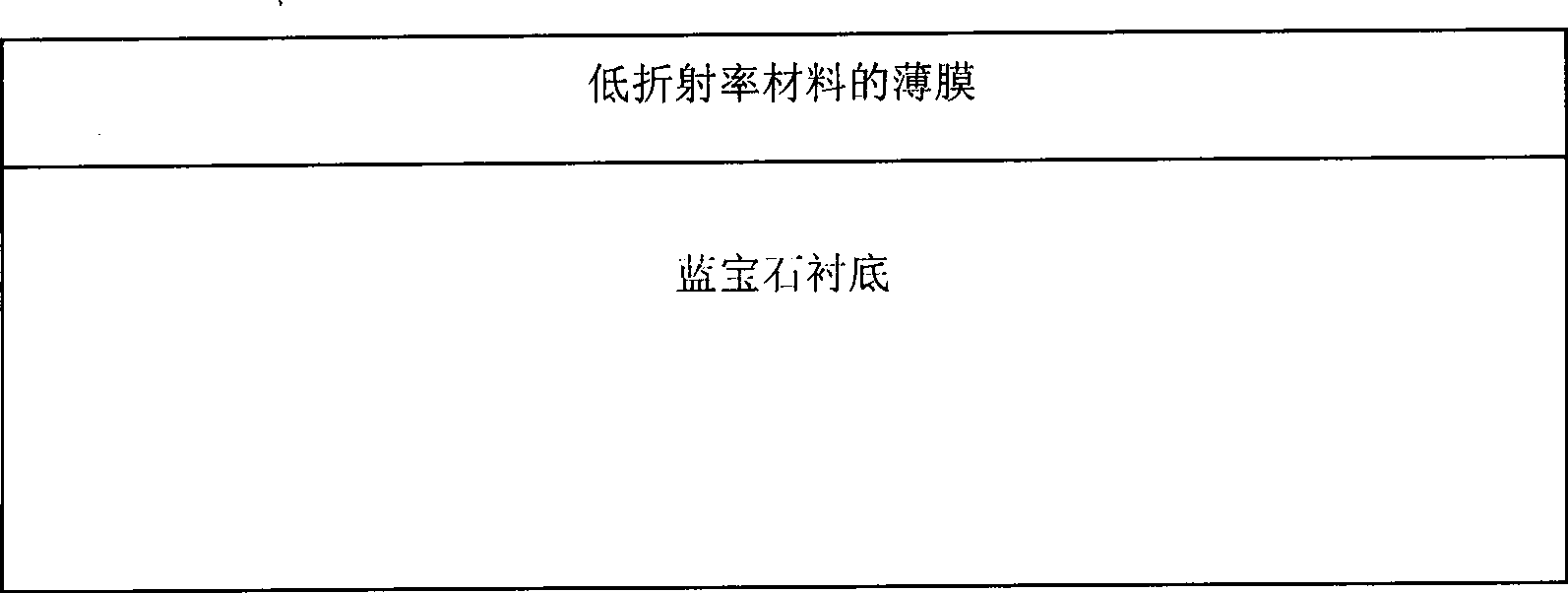

Production method for sapphire pattern substrate

InactiveCN101814426ALow refractive indexReduce hardnessSemiconductor/solid-state device manufacturingRefractive indexPhotoresist

The invention discloses a production method for a sapphire pattern substrate, comprising the following particular steps of (1) depositing a layer of thin film on the upper surface of a sapphire which has a low refractive index material and 1AA-999AA thickness; (2) preparing a mask pattern on the thin film with photoresistance; (3) transferring the pattern masked with photoresist to the thin film through etching to obtain a protuberance with the 1AA-999AA thickness, wherein the lower substrate of the pattern of the protuberance has a width of 0.5-3 mu m and a gap of 0.5-3 mu m; and (4) cleaning the sapphire to remove the residual photoresistance. The invention has the advantages that PSS cost can be greatly reduced and total reflection angles are increased for light, thereby being more favorable for emergent light, improving emergent light efficiency, being favor of laser peeling and increasing excellent rate of the finished product LED chip.

Owner:NANCHANG UNIV

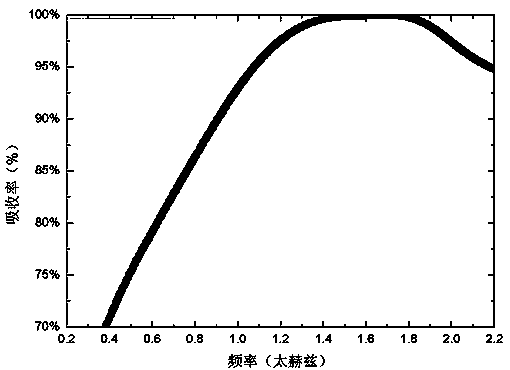

Manufacturing method for broadband THz wave absorber unrelated to wide-angle polarization

InactiveCN103969712AHigh absorption frequency bandIncrease the angle of incidenceAntennasOptical elementsHigh absorptionGrating

The invention relates to a manufacturing method for a broadband THz wave absorber unrelated to wide-angle polarization. The manufacturing method includes that semiconductor silicon with certain doping concentration is selected, a photolithography technique and an ICP (inductively coupled plasma) technique etching or a chemical corrosion technique are adopted on the surface of a silicon wafer to obtain periodically arranged grating layers with reduced reflectivity, and the rest part of the grating layers is a substrate layer with reduced transmissivity. By the arrangement, broadband absorber unrelated to the wide-angle polarization is realized in a THz band. Compared with a conventional metamaterial absorber, the high-doping silicon substrate absorber with the two-dimensional grating structure has the advantages of high absorption frequency band, unrelated to polarization, wide in incident angle and the like; the manufacturing method of the absorber is wide in material taking, simple and efficient, convenient to manufacture and wide in application range; the broadband THz absorber unrelated to the polarization can be manufactured according to actual application scenarios and demands, and absorption rate, absorption frequency band and absorption broadband can be regulated through regulation of structural parameters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vertical electrode structure of gallium nitride based light emitting diode

ActiveUS20070018180A1Reduce refractionImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingAngle of incidenceReflection loss

Owner:LUMENS

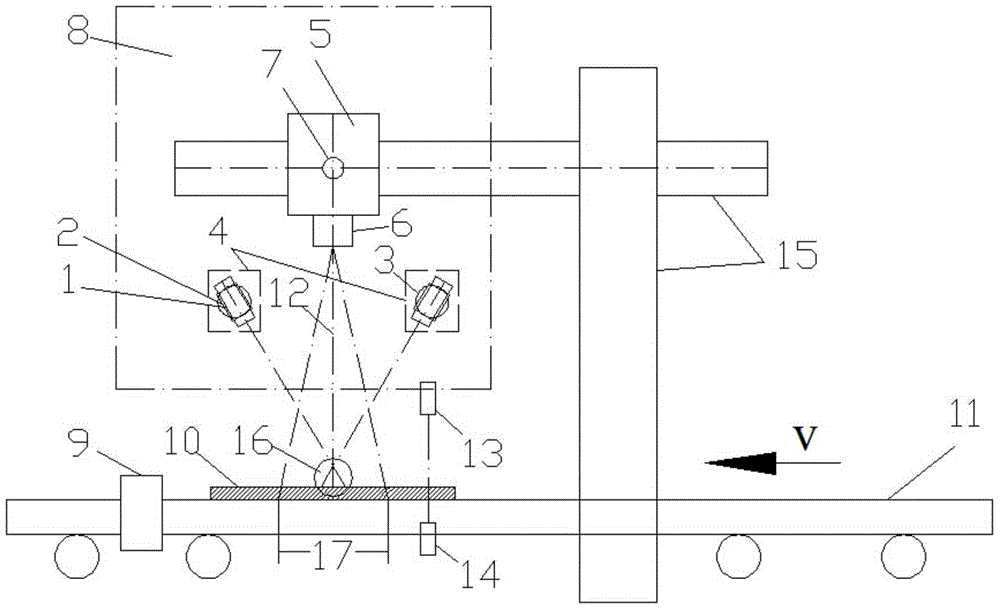

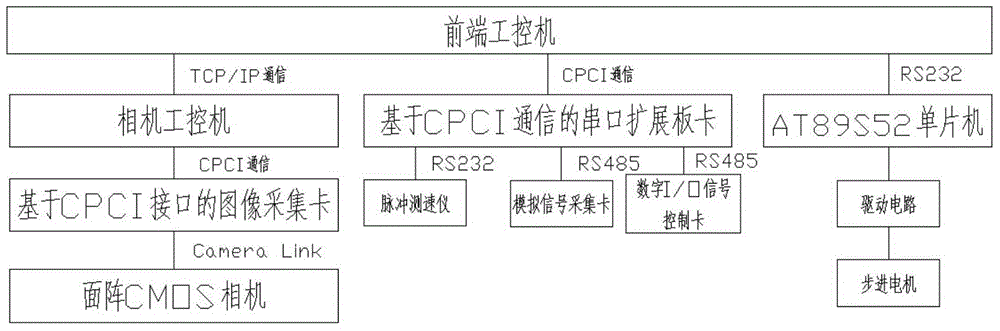

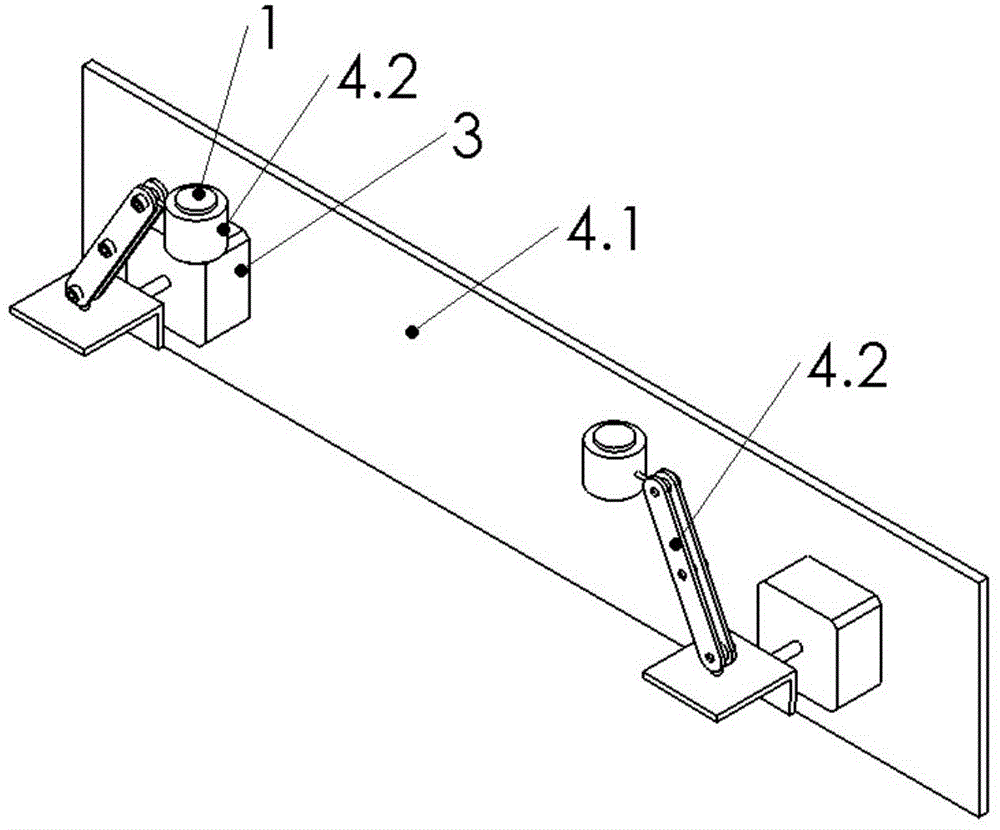

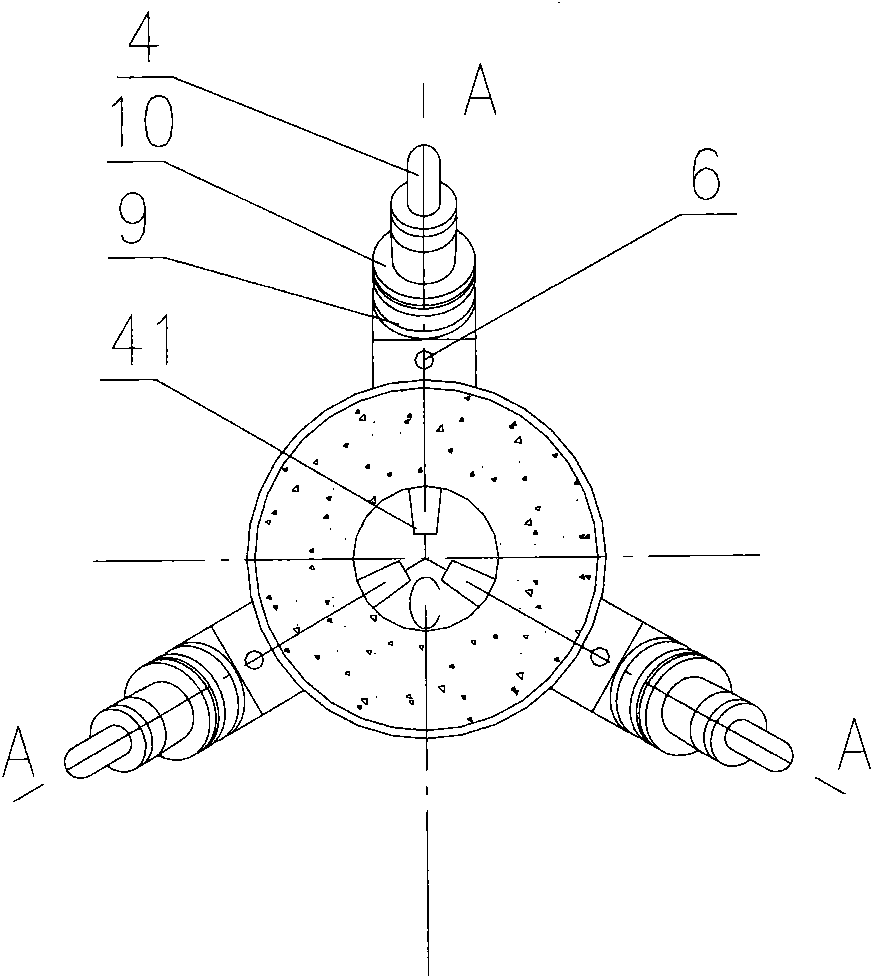

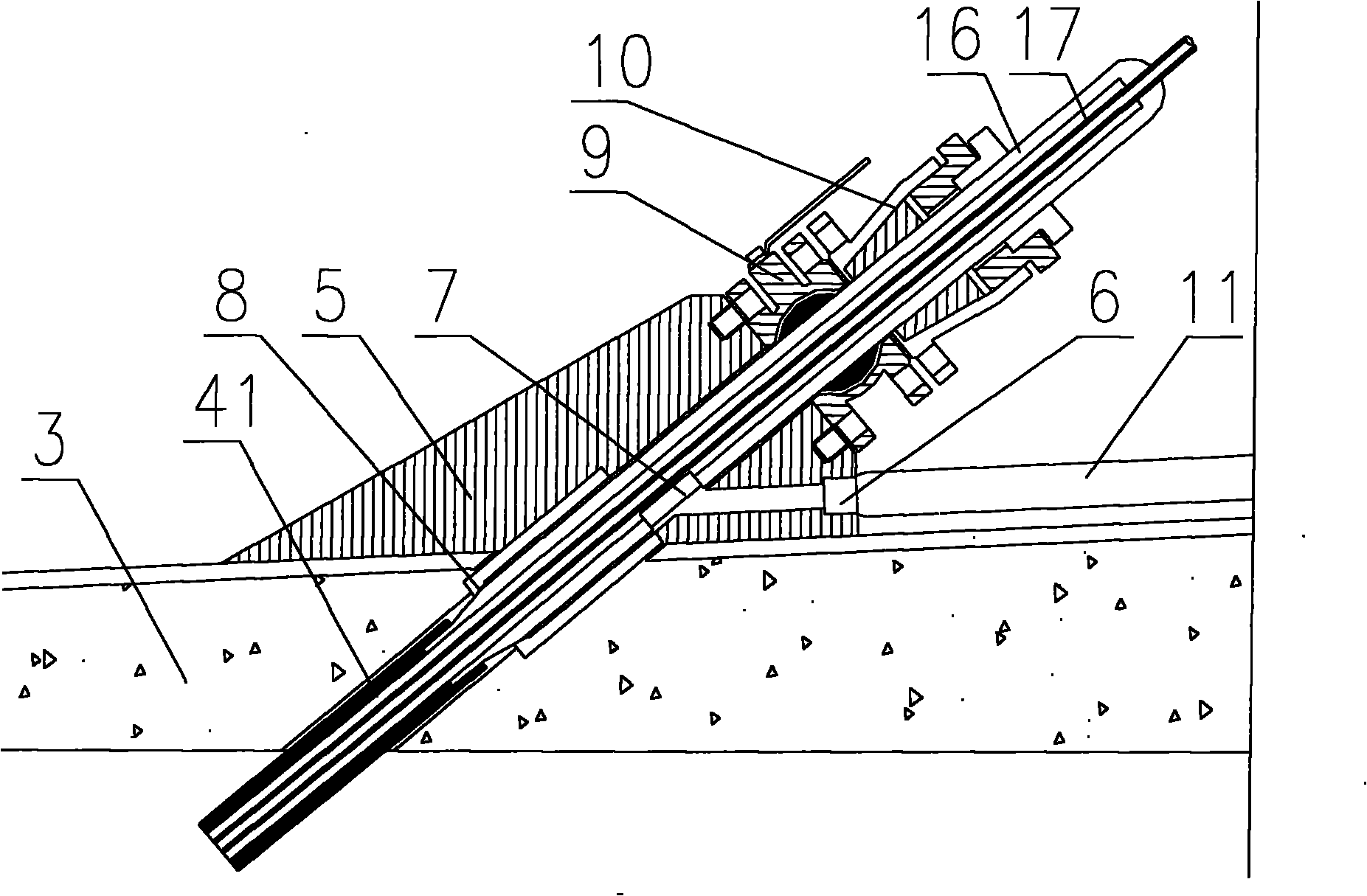

Medium or heavy steel plate morphology detection system based on controllable symmetrical double-line laser angle and method thereof

InactiveCN104833317ACalibration method is simpleImprove detection resolutionUsing optical meansCamera lensCMOS

The invention discloses a medium or heavy steel plate morphology detection system based on a controllable symmetrical double-line laser angle, and a method thereof. A sensor cabinet is internally provided with two planar array CMOS cameras in an equal-height plane. Each planar array CMOS camera is provided with a camera lens and furthermore is fixed on a bracket through a mounting device. Two sides of the planar array CMOS camera are respectively provided with a linear laser source. A pulse speed testing velocimeter is fixed at the side of a conveyor belt. The to-be-measured medium or heavy steel plate is placed on the conveyor belt. The to-be-measured medium or heavy steel plate is provided with the laser ray overlapping area of the symmetrical linear laser sources. Correlation is formed between a photoelectric switch transmitter and a photoelectric switch receiver. The sensor cabinet is placed on a bracket. A detecting device is controlled by a control device. According to the medium or heavy steel plate morphology detection system, simple calibration method is realized in detecting by two symmetrical linear laser sources, and furthermore high detection resolution and high precision are realized. The detecting system with two symmetrical linear laser sources is adopted, thereby realizing large incident angle of the linear laser, preventing detection inflection point failure, reducing drift and ensuring accurate and reliable result.

Owner:ZHEJIANG SCI-TECH UNIV

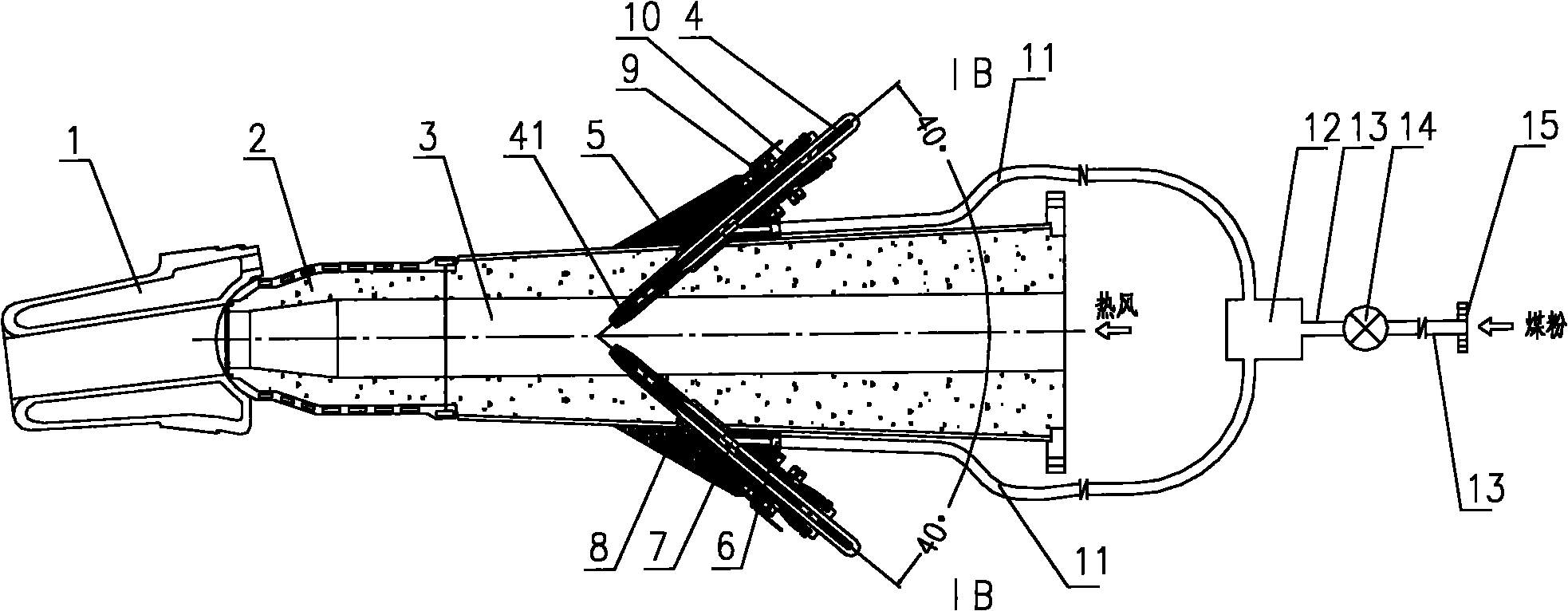

Method and device for blast furnace to blow coal powder

InactiveCN102485913AEnhance heat and mass transferExtended stayTuyeresBlast furnace detailsBall valveNew device

The invention puts forward a method and device for a blast furnace to blow coal powder. Characterized by employment of several short spray guns, a large incidence angle, accurate positioning of spray guns, small heat radiation and long life of blowpipes, and adoption of ceramic nozzles, the new method and new device of the invention aims to eliminate various defects in prior art, such as small coal powder incidence angle, restriction by high speed hot airflow, inadequate mixing with hot air, long length and long service life of spray guns, large heat radiation and short service life of blowpipes, and hard use of oxygen-coal lances, etc. According to the invention, on the blowpipes of each air ports, each short spray gun is inserted into each installation seat, and coal powder blown into a blast furnace enters from blowing inlets positioned on a lateral side of each installation seat, then reaches the inside of each short spray gun through coal spraying holes that are disposed on tube walls of the short spray guns and are over against the blowing inlets, and is finally blown into the furnace through each short spray gun. The device of the invention at least comprises: a blowpipe with a coal powder precombustion function, short spray guns, installation seats, ball valves, locking devices, coal conveying branch pipes, a distributor, a small ball valve, a coal conveying pipe, and an inlet connecting piece.

Owner:张昭贵

Back light module unit

InactiveCN1924664AIncrease the angle of incidenceOvercoming Bad Optical PhenomenaPlanar/plate-like light guidesNon-linear opticsLight guideOptoelectronics

This invention relates to one aphototropism module set, which comprises one light source, one light board and one back frame, wherein, the frame contains light source and light guide board with one incident surface and one emergent surface to guide the light crossing with incident surface and one bottom surface relative to the emergent surface and the side surface crossing with the emergent surface; the light source is in one side of the incident surface; the guide board side and its relative back frame side has anti-leakage structure to prevent leakage phenomena from the gap between the side surface and back frame.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

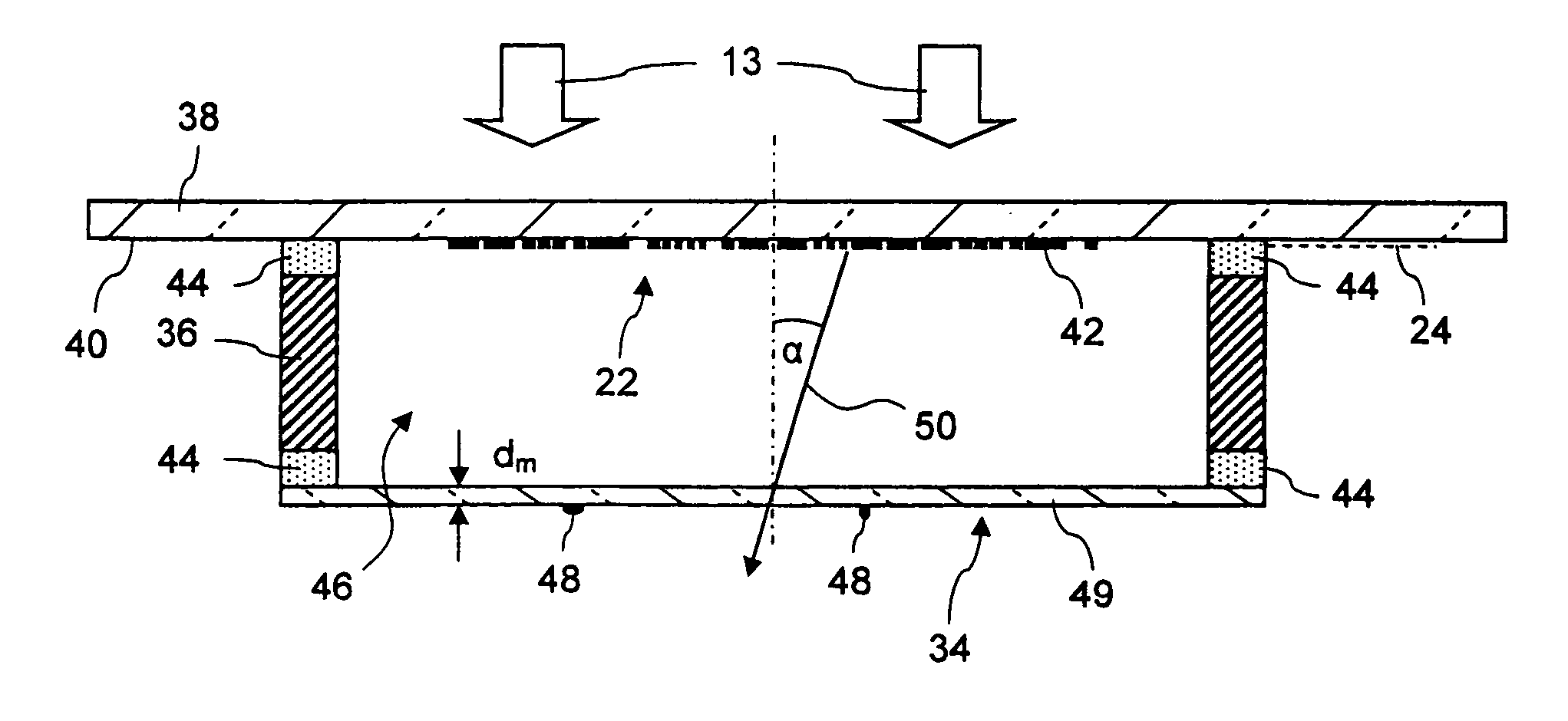

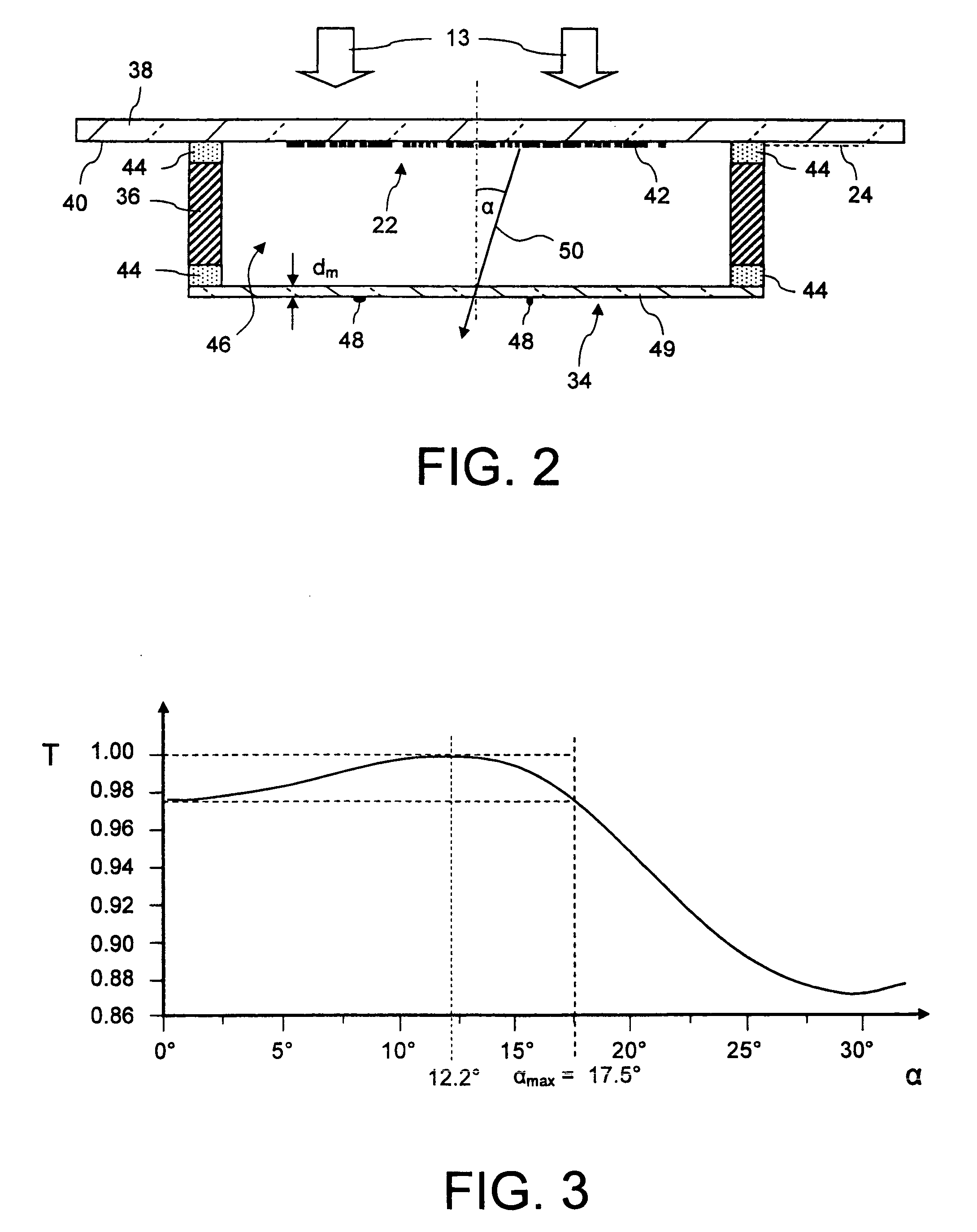

Pellicle for use in a microlithographic exposure apparatus

InactiveUS20090059189A1Easy to solveLimited lifetimeOptical filtersPhotomechanical apparatusAngle of incidenceHigh numerical aperture

A pellicle for use in microlithographic exposure apparatus (10) has, for an operating wavelength of the apparatus, a maximum transmittance for light rays (56) that obliquely impinge on the pellicle (34; 134; 234). This ensures smaller variations of the transmittance over a broad range of angles of incidence, as it occurs in very high numerical aperture projection lenses.

Owner:CARL ZEISS SMT GMBH

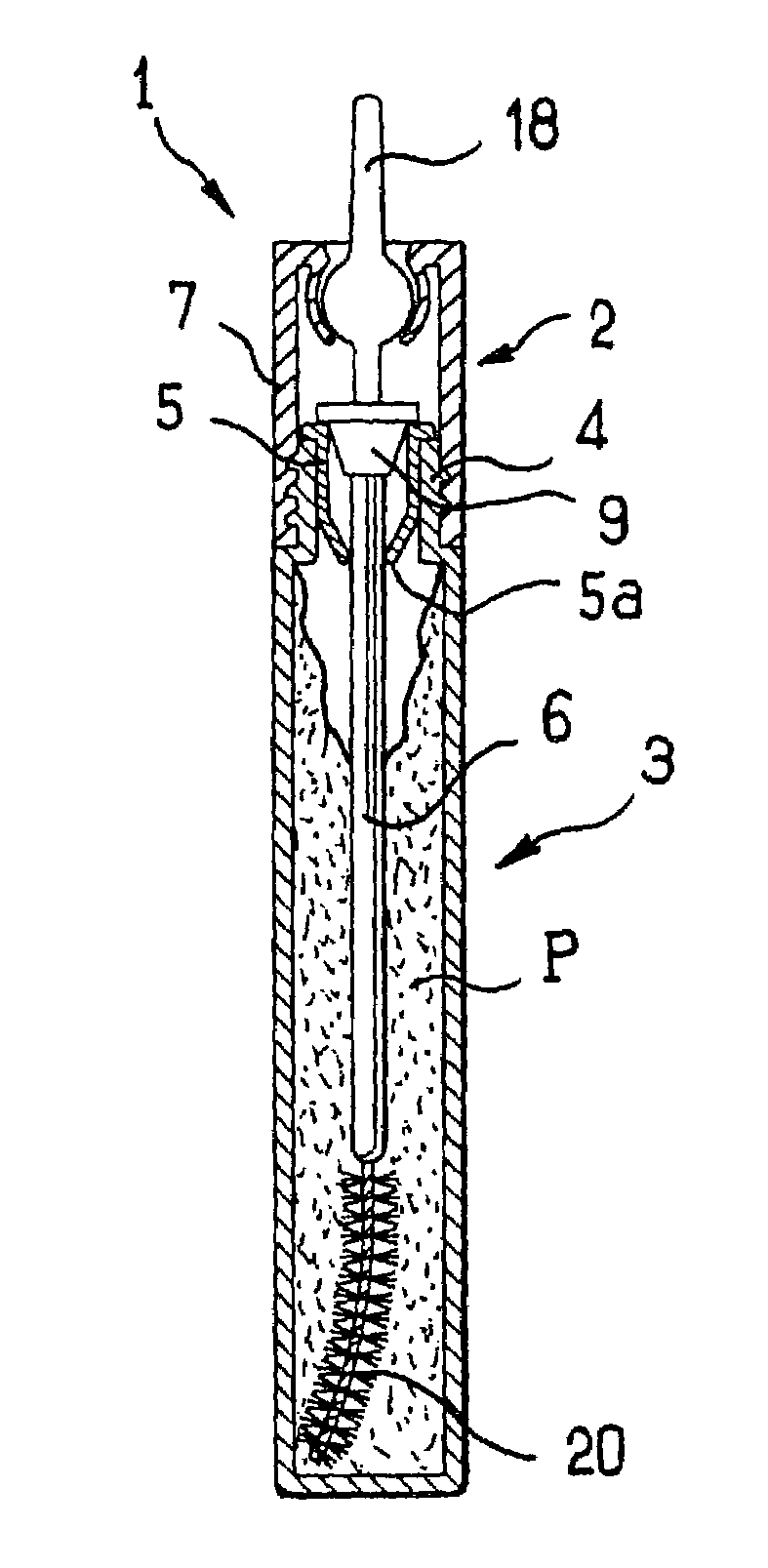

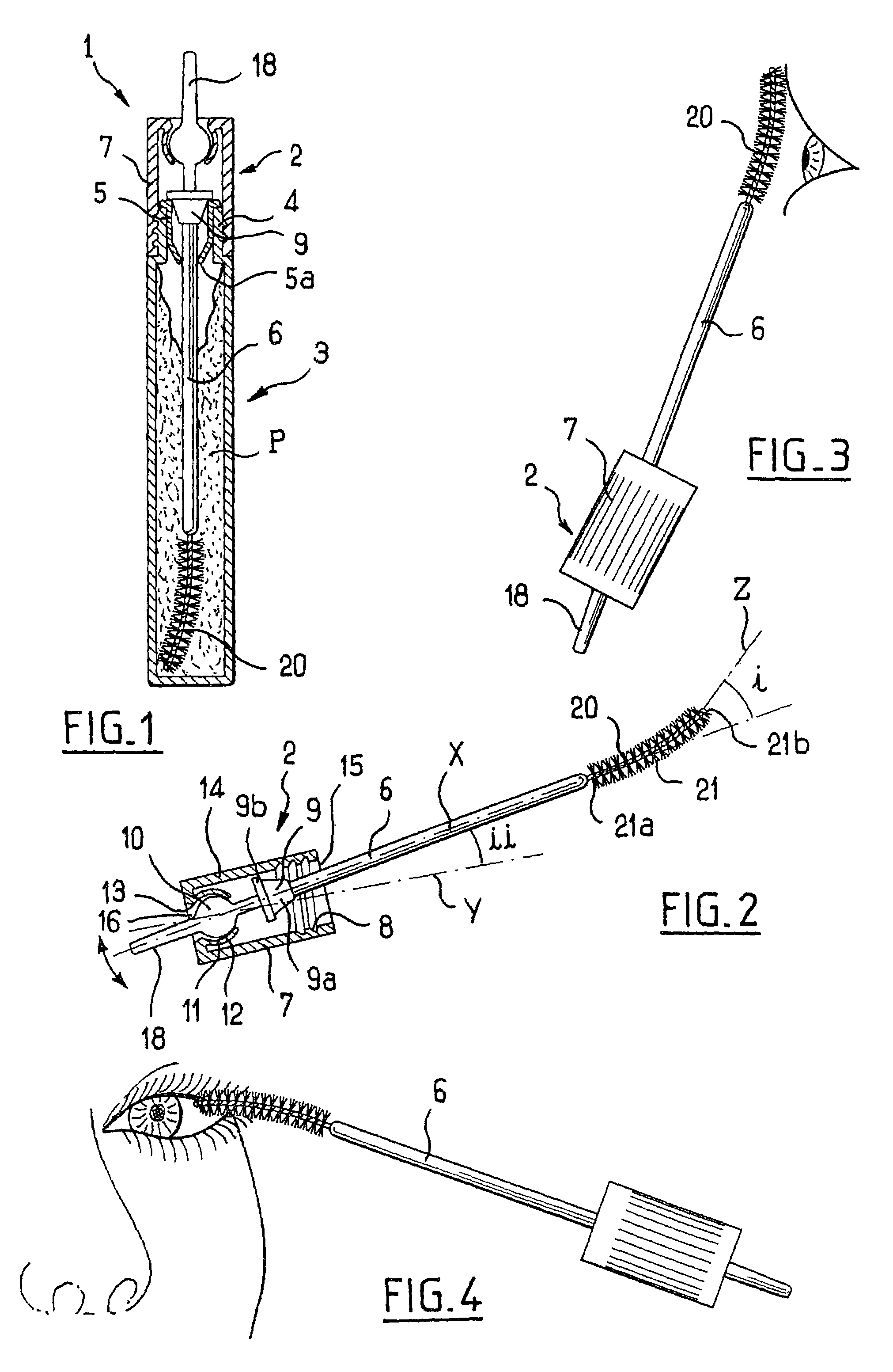

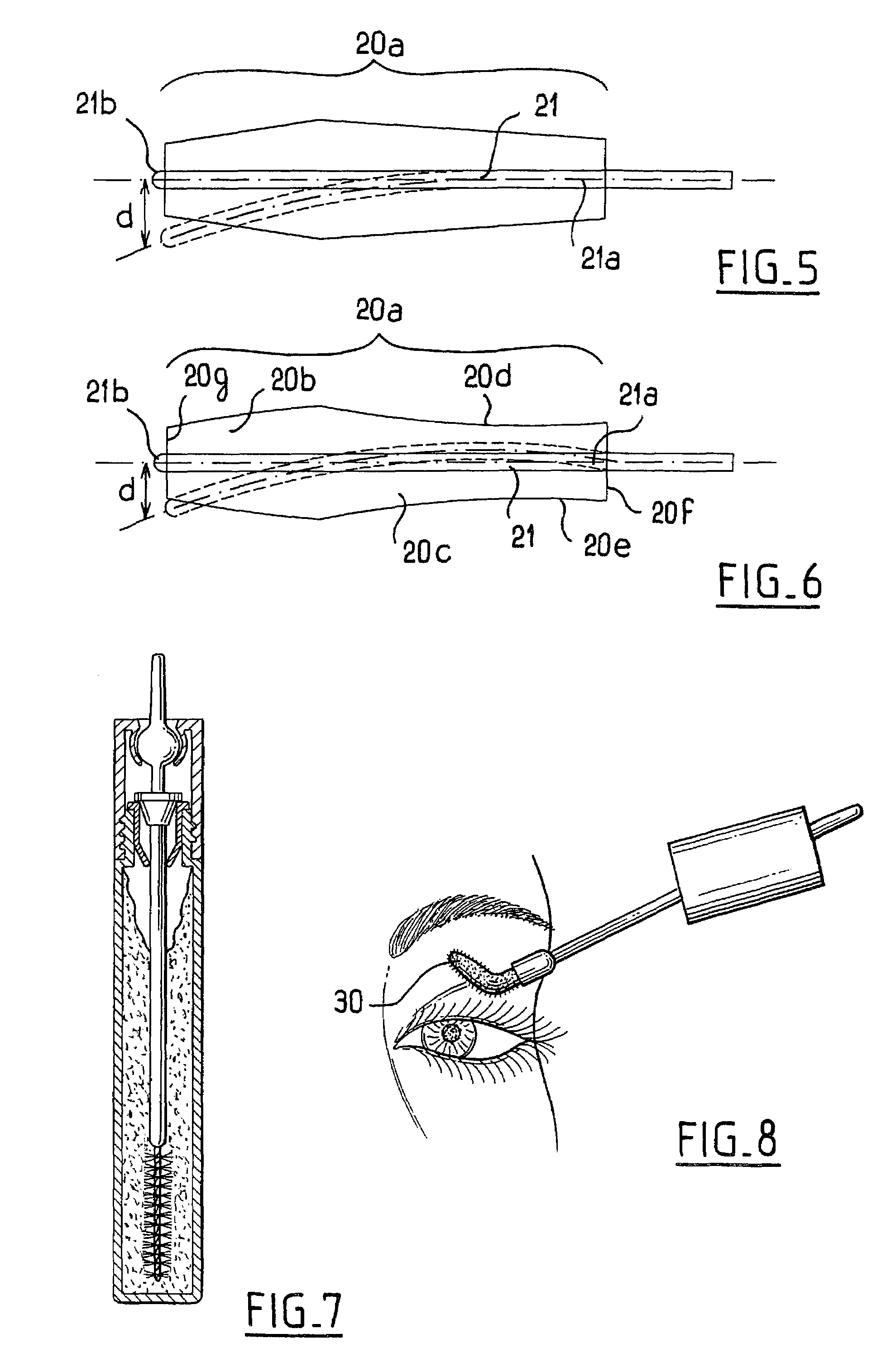

Applicator including a stem connected to a handle member via a hinge

InactiveUS7487784B2Efficient use ofIncrease the angle of incidencePackaging toiletriesPackaging cosmeticsEngineering

The present invention provides an applicator comprising:a handle member;a stem connected via a hinge to the handle member; andan applicator element disposed at a first end of the stem and configured to apply makeup on keratinous fibers;the stem including a maneuverable portion enabling the direction in which it points relative to the handle member to be modified, the maneuverable portion extending at least in part between the hinge and a second end of the stem opposite from its first end.

Owner:LOREAL SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com