Back light module unit

A backlight module and back frame technology, applied in light guides, optics, optical components, etc., can solve problems such as bad optical phenomena of backlight modules, achieve the effect of improving display quality and overcoming bad optical phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

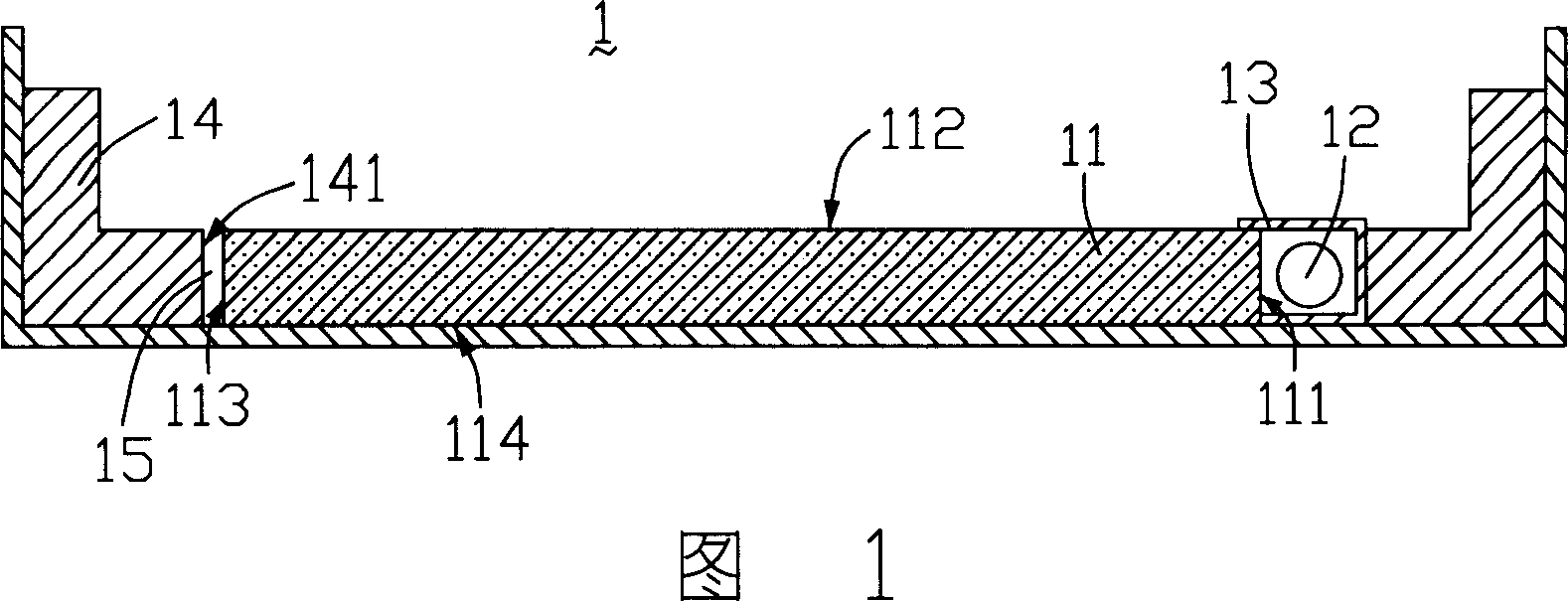

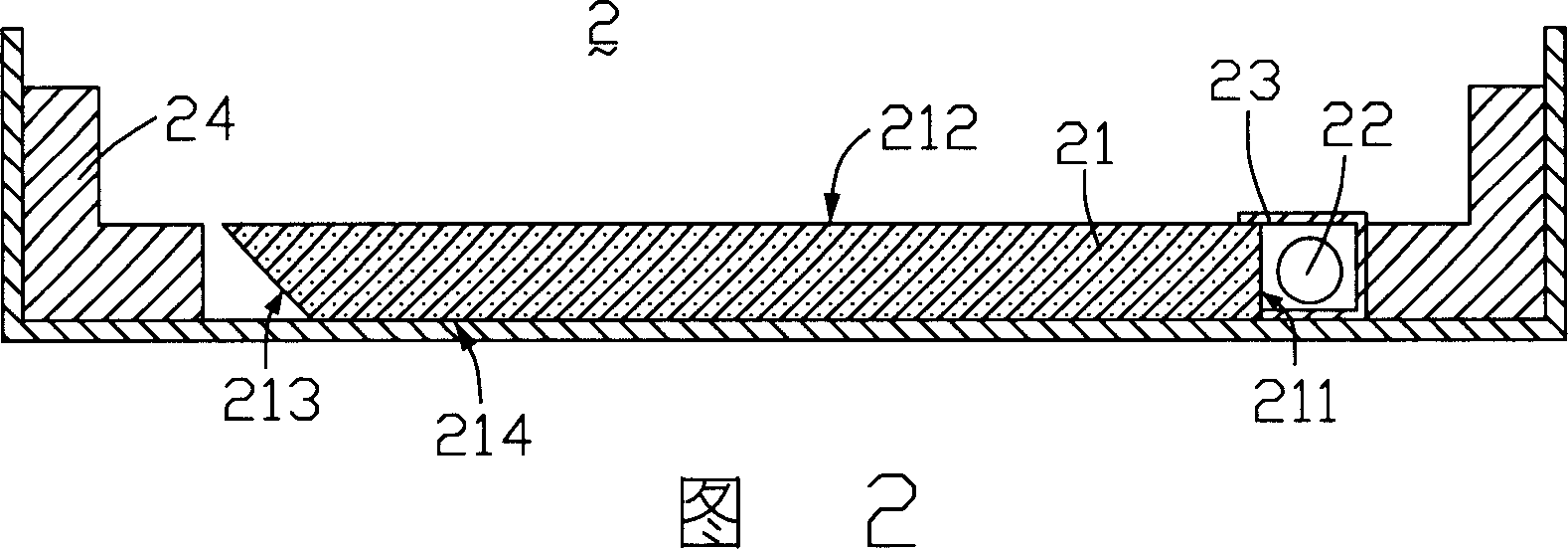

[0018] Please refer to FIG. 2 , which is a schematic cross-sectional view of the first embodiment of the backlight module of the present invention. The backlight module 2 includes a light guide plate 21, a light source 22, a light source cover 23 and a back frame 24, the light source 22 is located on one side of the light guide plate 21, the light source cover 23 is arranged around the light source 22, and the back frame 24 fixes the light guide plate 21 and light source 22 .

[0019] The light guide plate 21 includes a light incident surface 211 for receiving light, a light exit surface 212 intersecting with the light incident surface 211 for guiding the light to exit, a bottom surface 214 opposite to the light exit surface 212, three intersecting the light exit surface and the bottom surface The side surfaces 213 of the light guide plate 21 are inclined.

[0020] The light emitted by the light source 22 enters the light guide plate 21 through the light incident surface 211,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com