Medium or heavy steel plate morphology detection system based on controllable symmetrical double-line laser angle and method thereof

A detection system and line laser technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to measure the surface phase height information of strip steel, limit the application range of contour detectors, and inability to accurately contour information, etc. The effect of high precision, accurate and reliable results, and simple calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

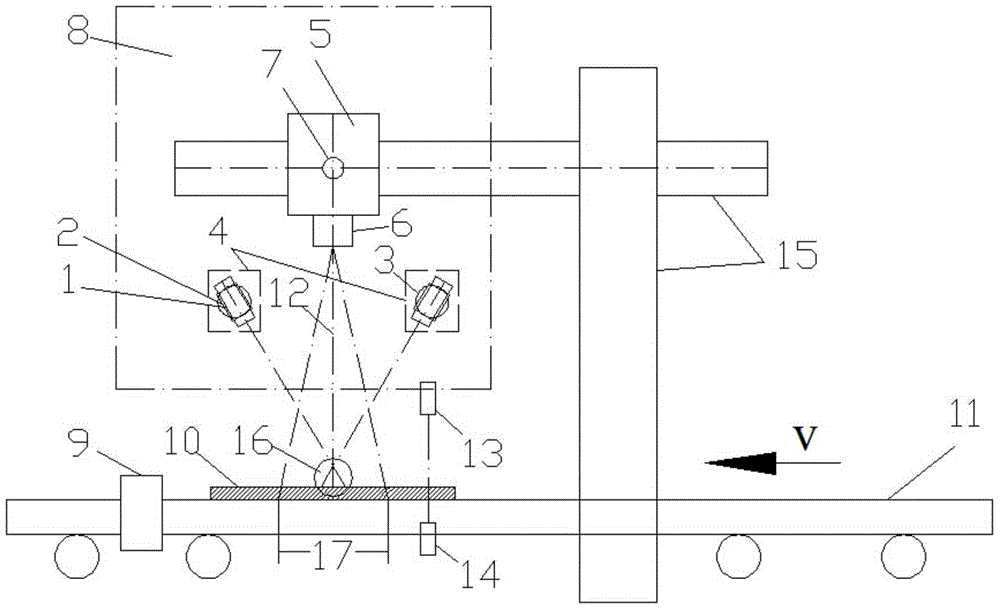

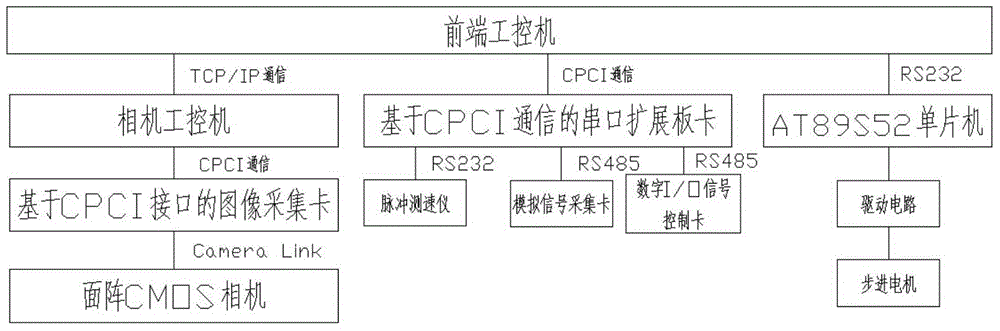

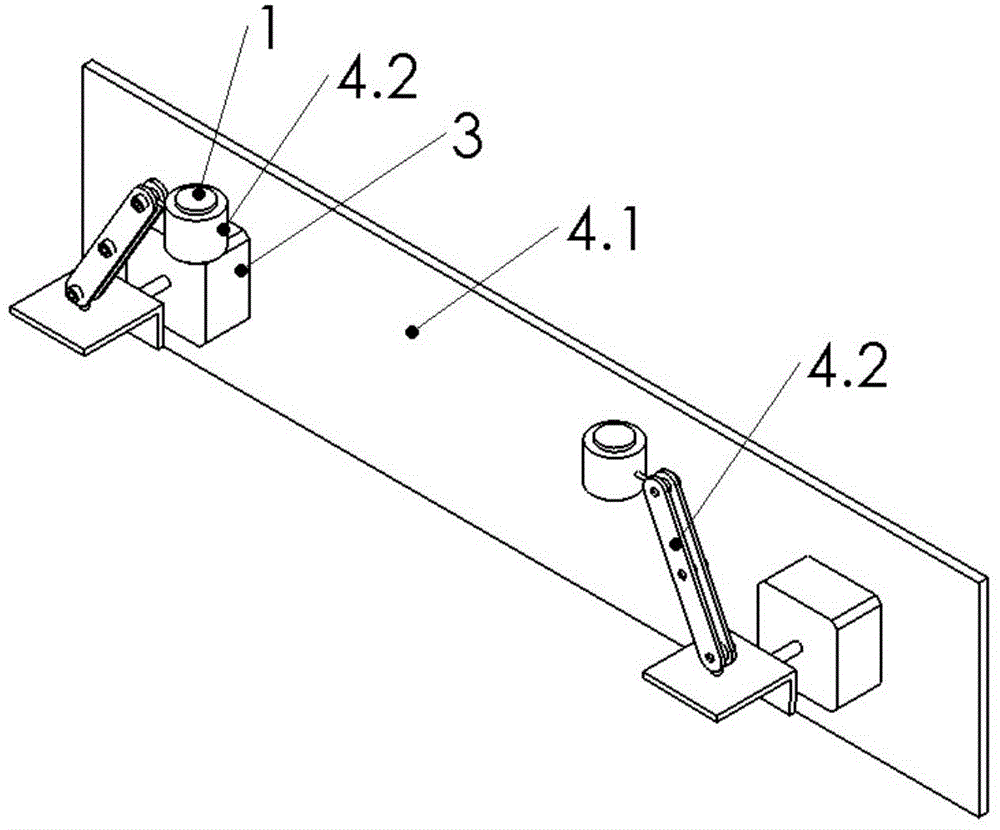

[0045] Such as figure 1 As shown, the shape detection system of medium-thick steel plate based on symmetrical double-line laser angle controllable includes a detection device and a control device. The detection device includes a line laser source 1, a line laser fixing device 2, a stepping motor 3, a single-chip microcomputer control unit 4, Area array CMOS camera 5, camera lens 6, area array CMOS camera installation device 7, sensor cabinet 8, pulse velocimeter 9, medium and thick steel plate to be tested 10, conveyor belt 11, axis 12 of area array CMOS camera, photoelectric switch receiver 13. Photoelectric switch transmitter 14, bracket 15, laser line overlapping area 16, camera detection area 17; sensor cabinet 8 is provided with two area array CMOS cameras 5 on the contour plane, and camera lenses are installed on the area array CMOS cameras 5 6, and fixed on the bracket 15 by the installation device 7, the two sides of the area array CMOS camera 5 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com